Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

103results about How to "Avoid back pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

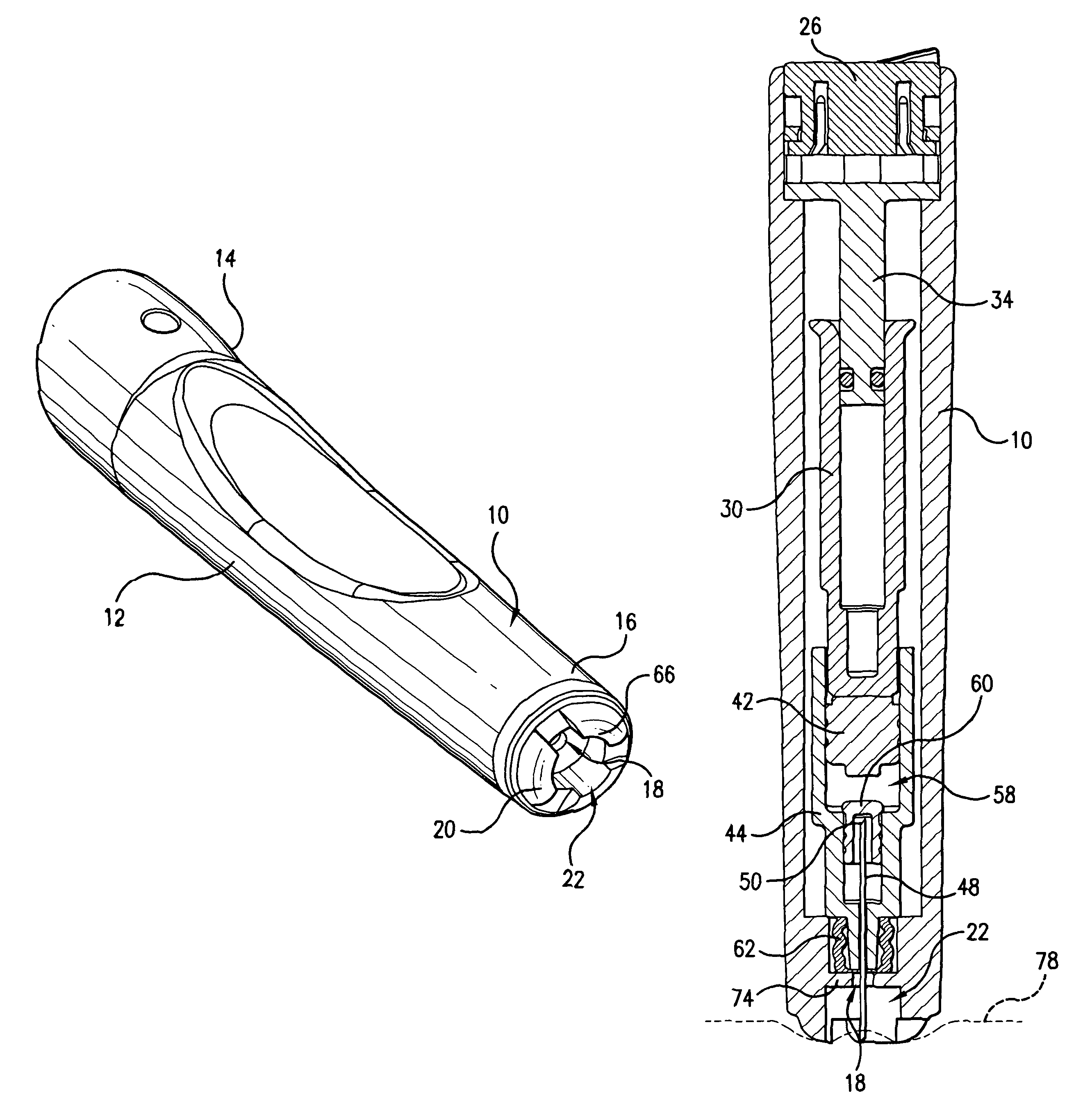

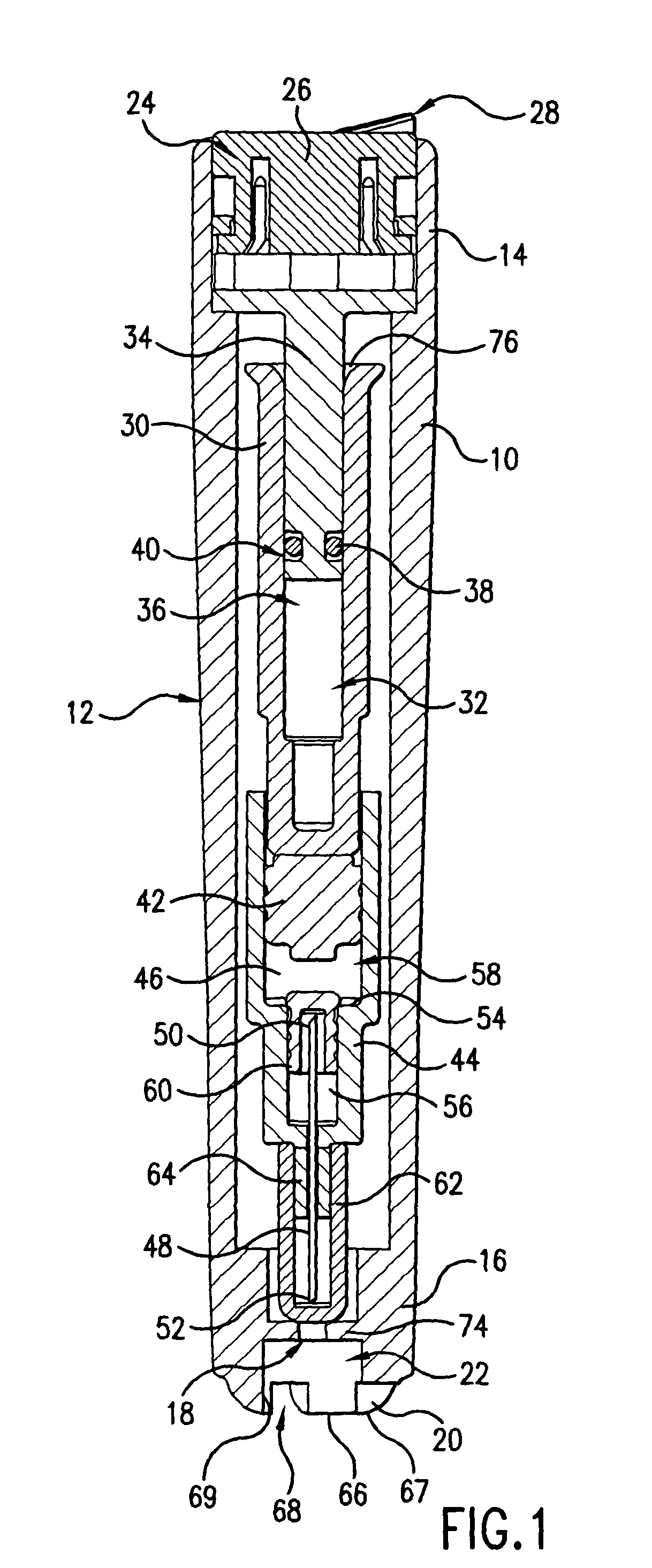

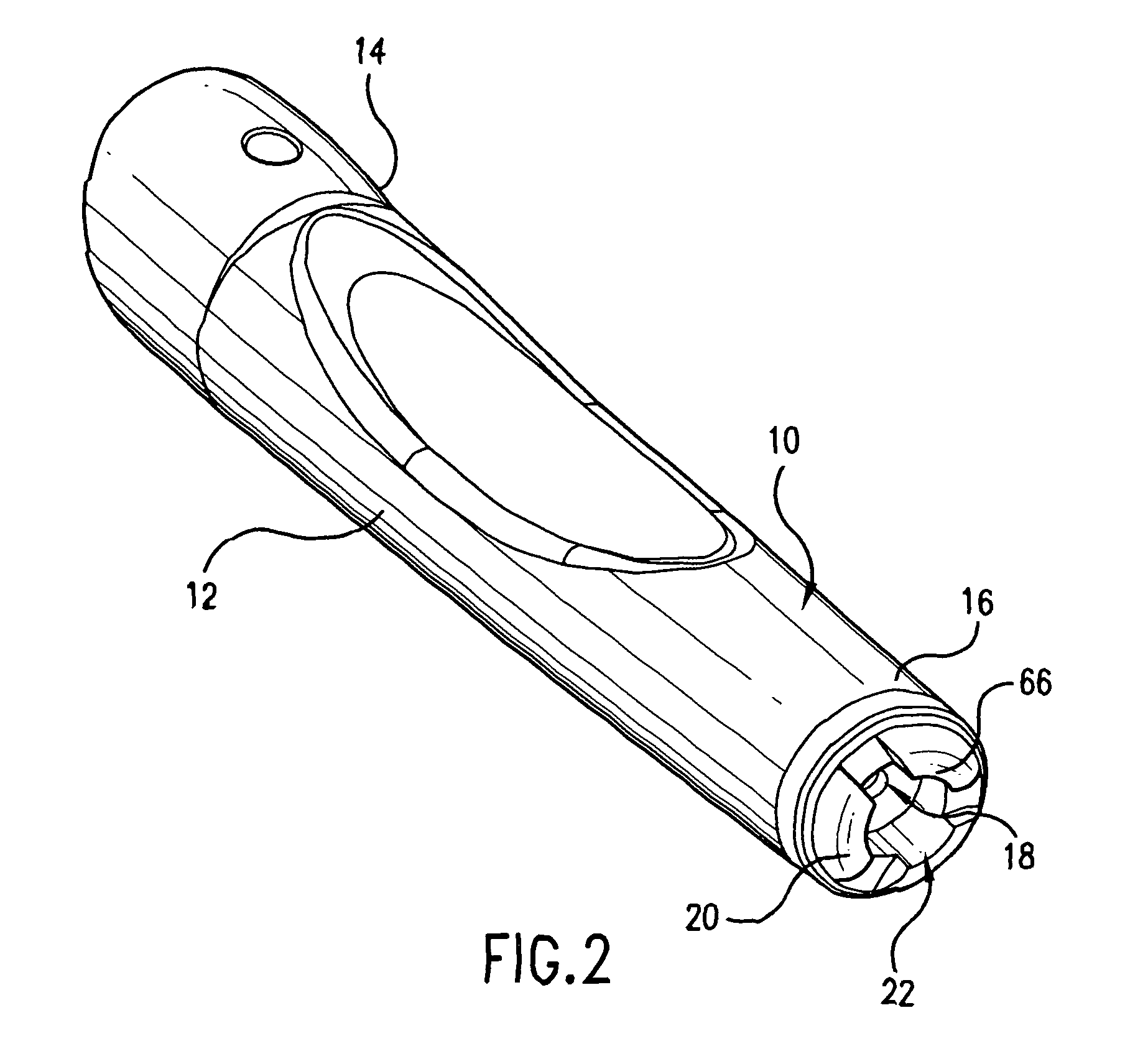

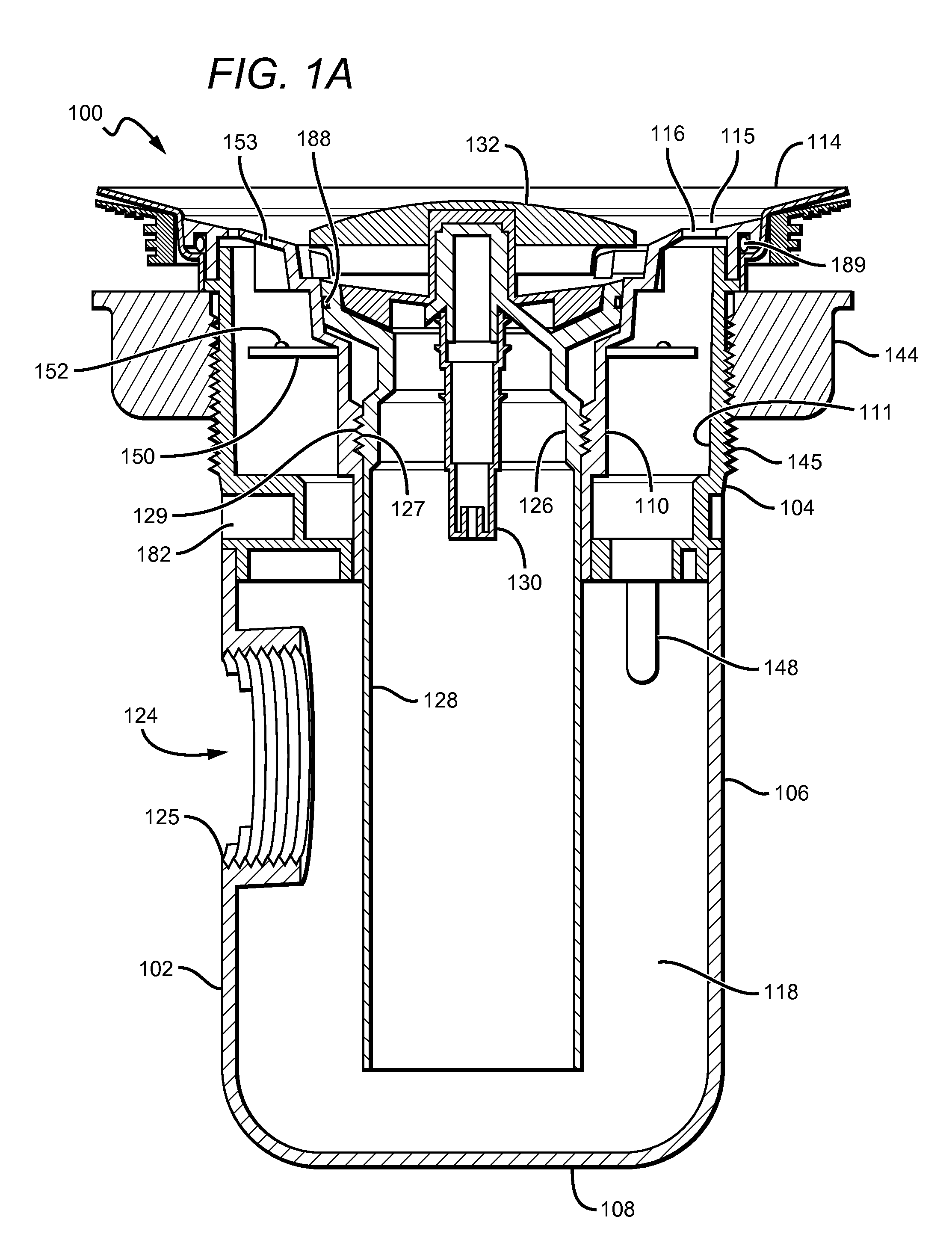

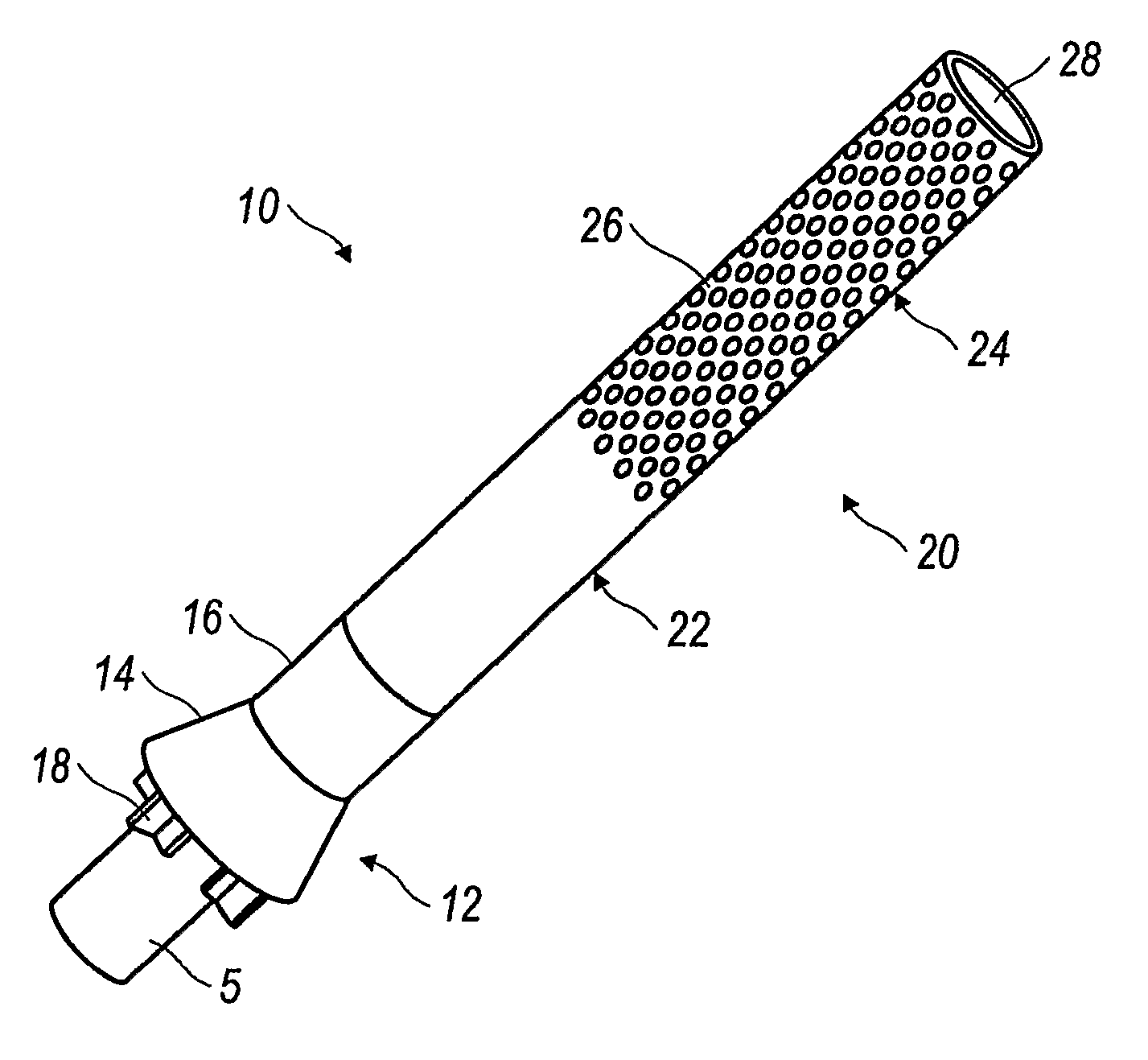

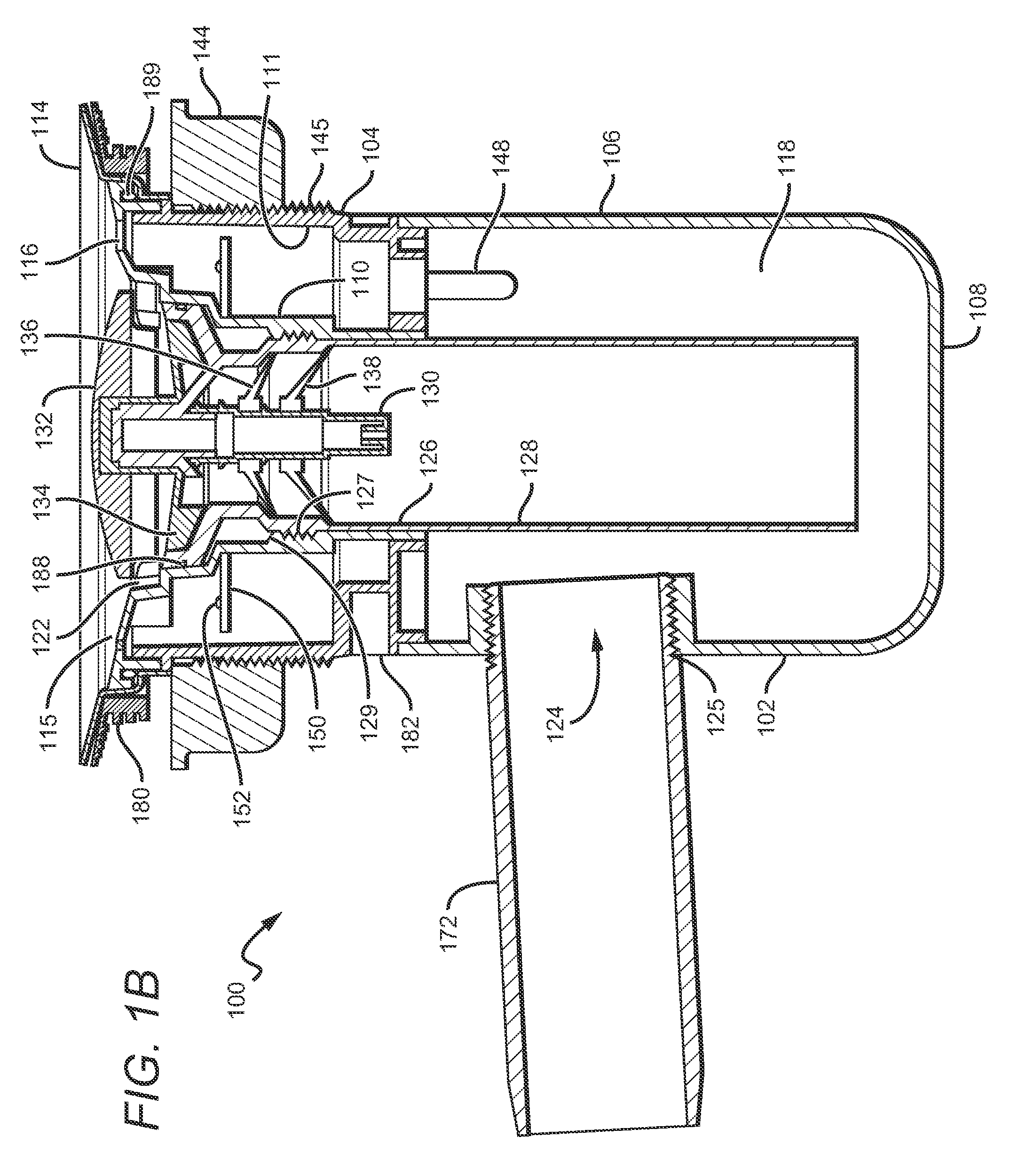

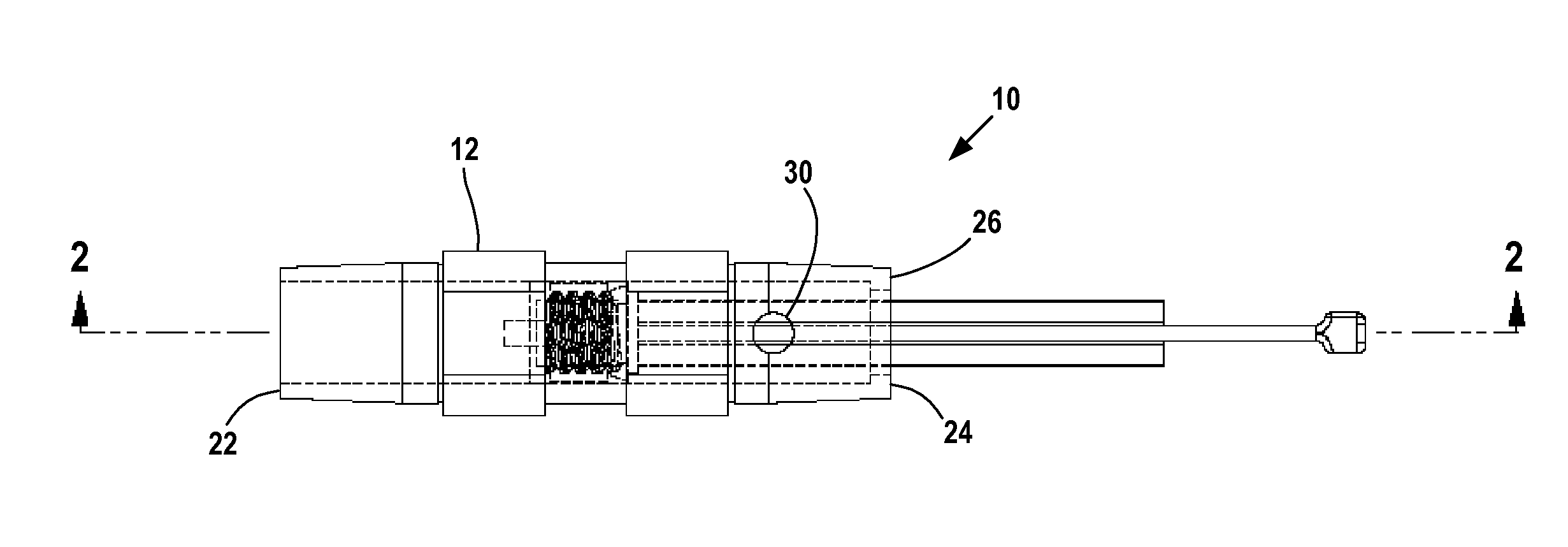

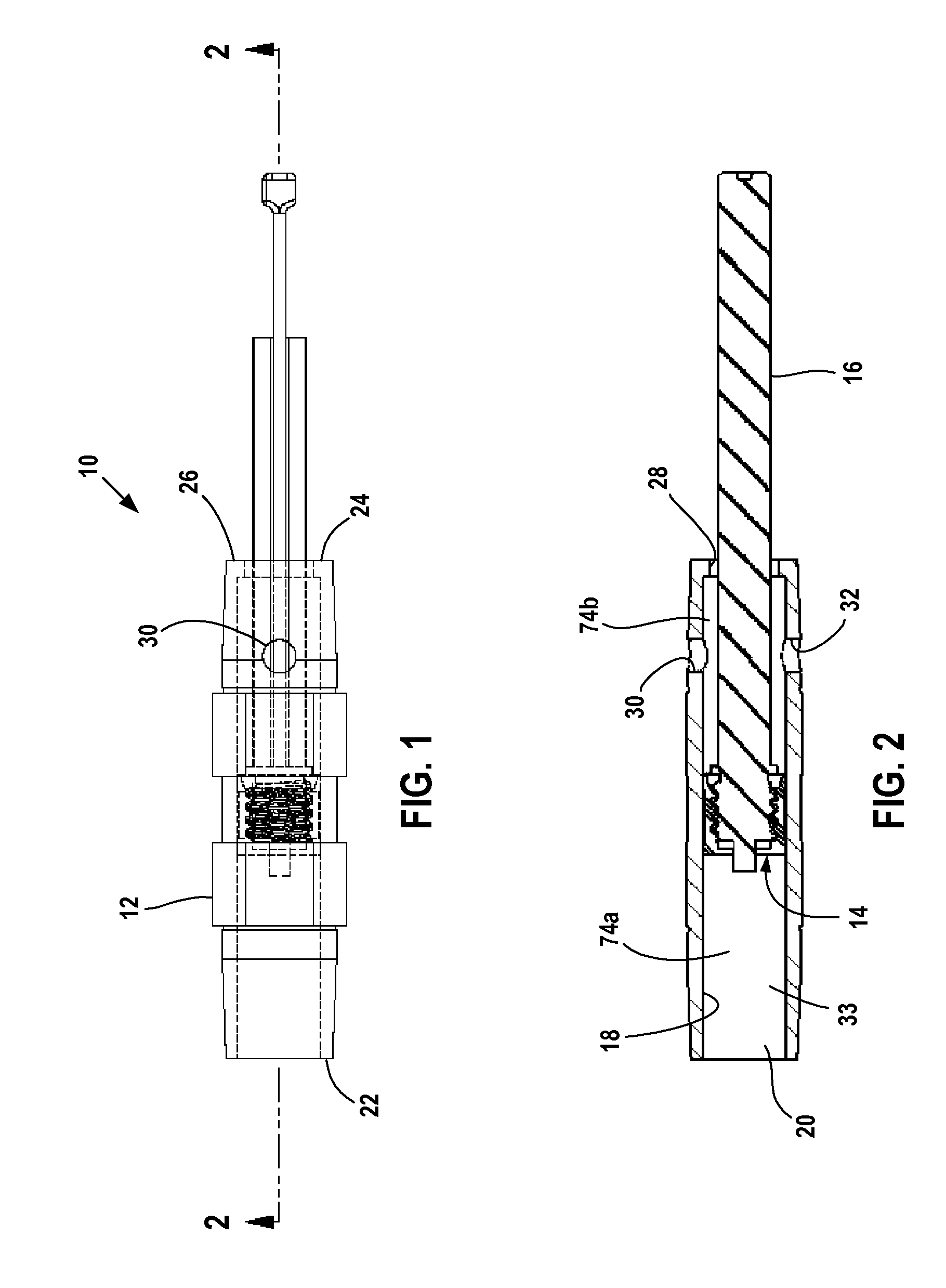

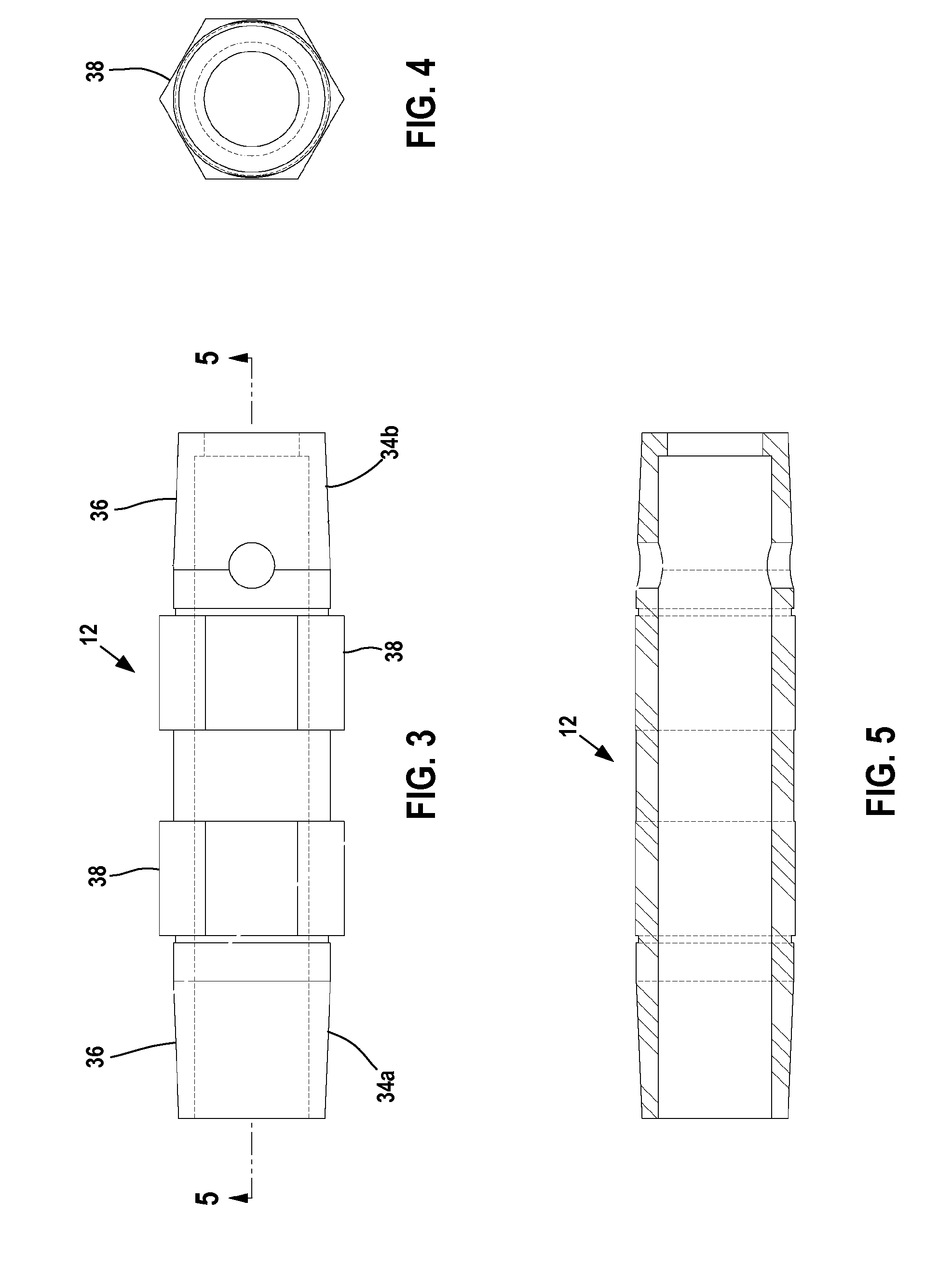

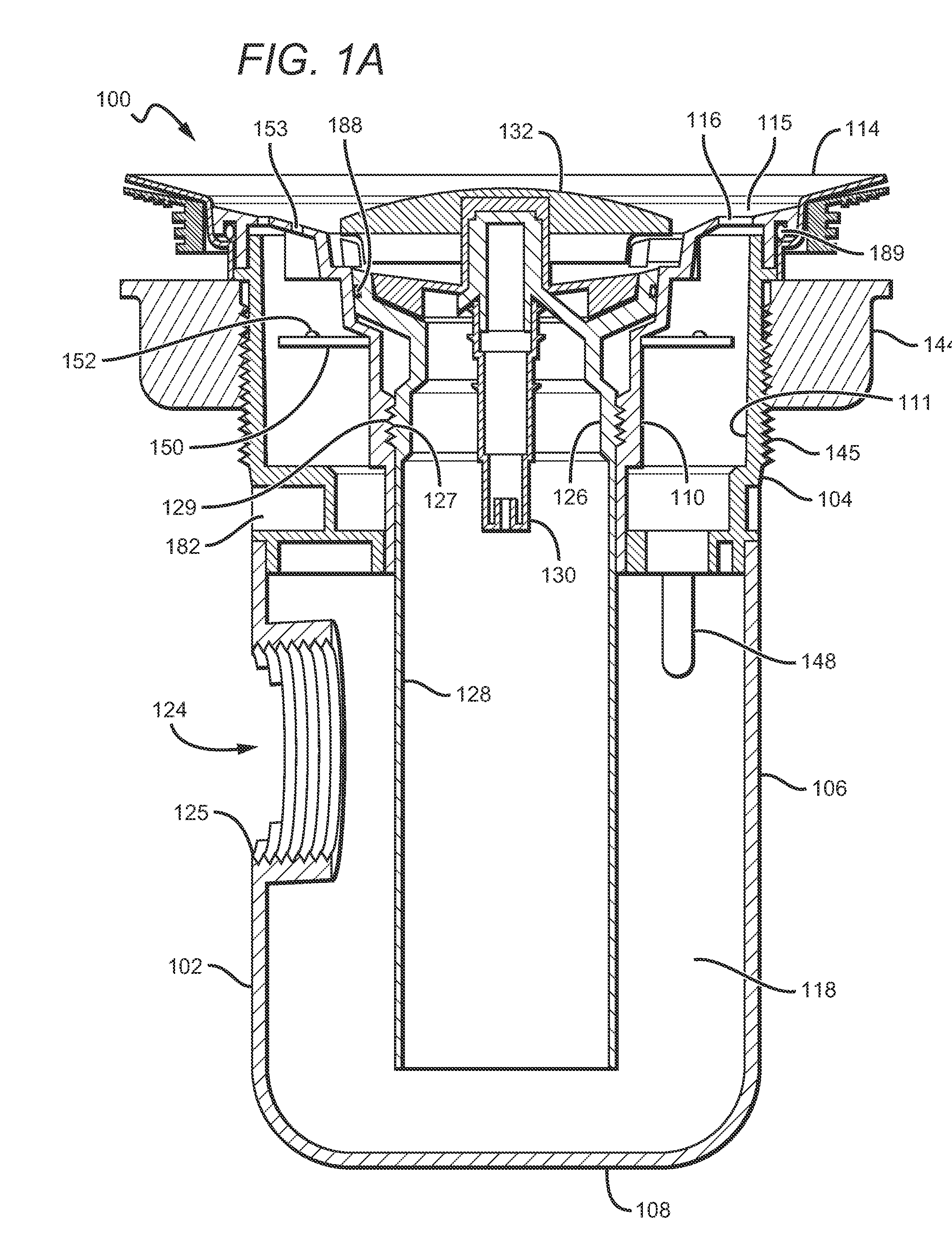

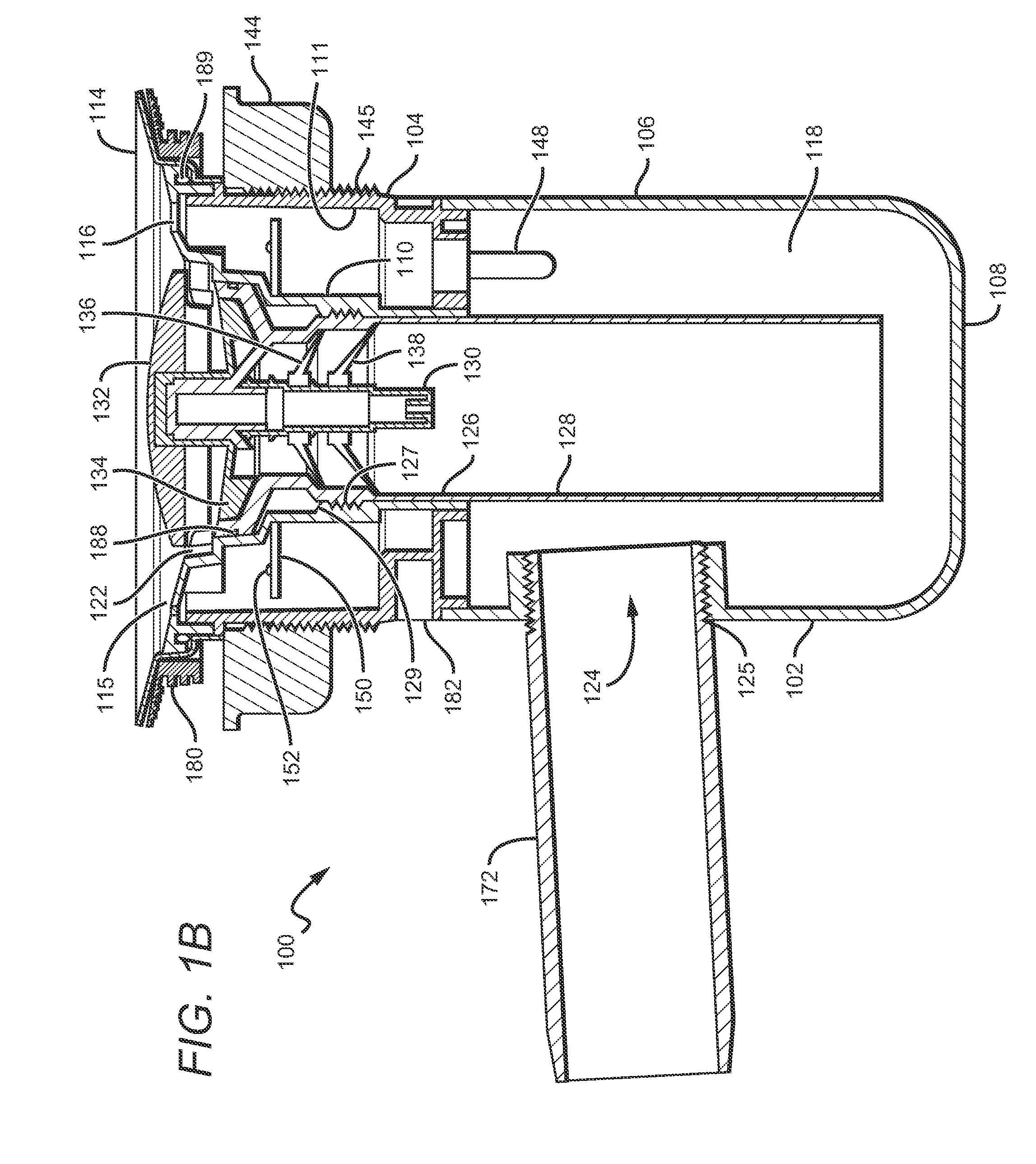

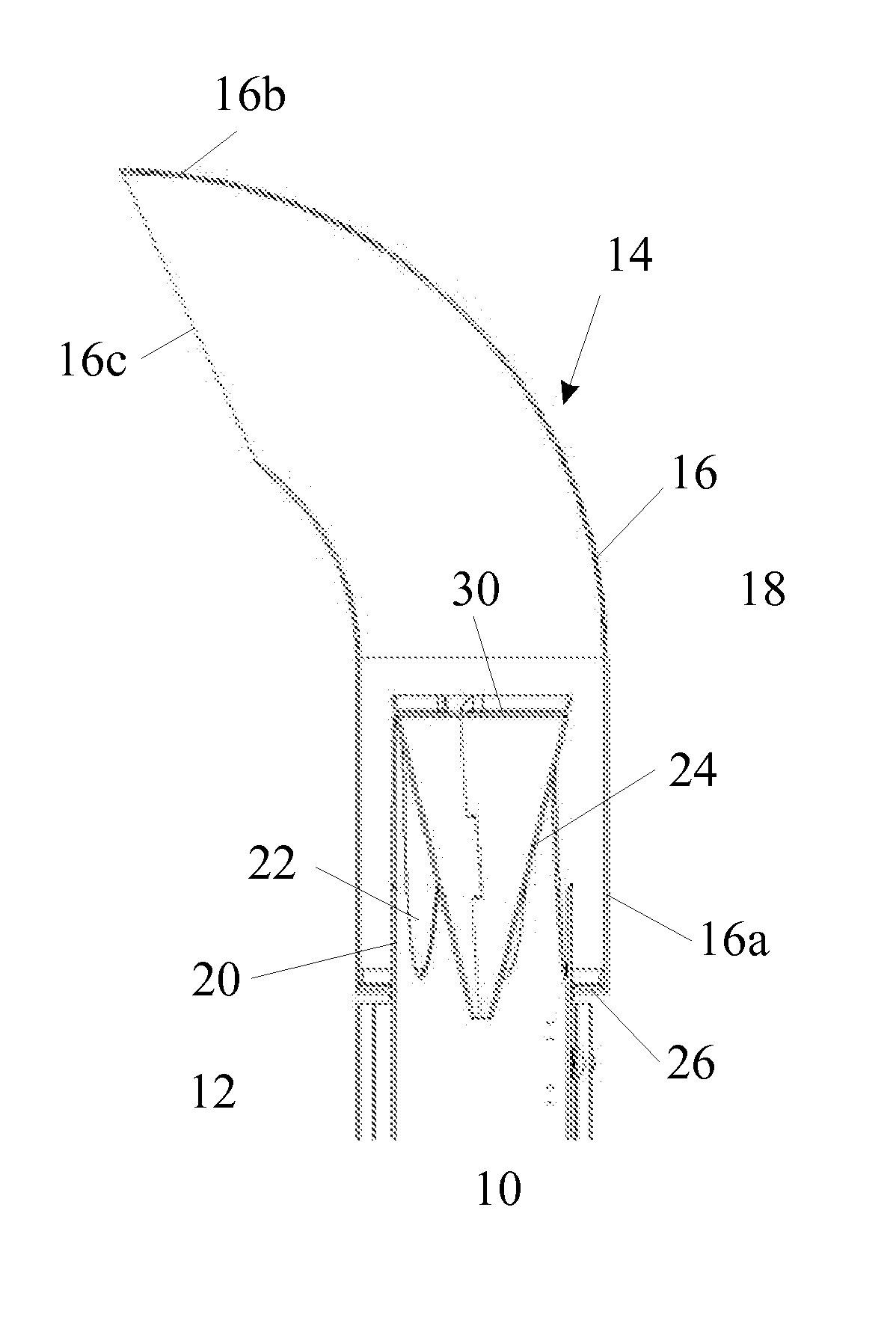

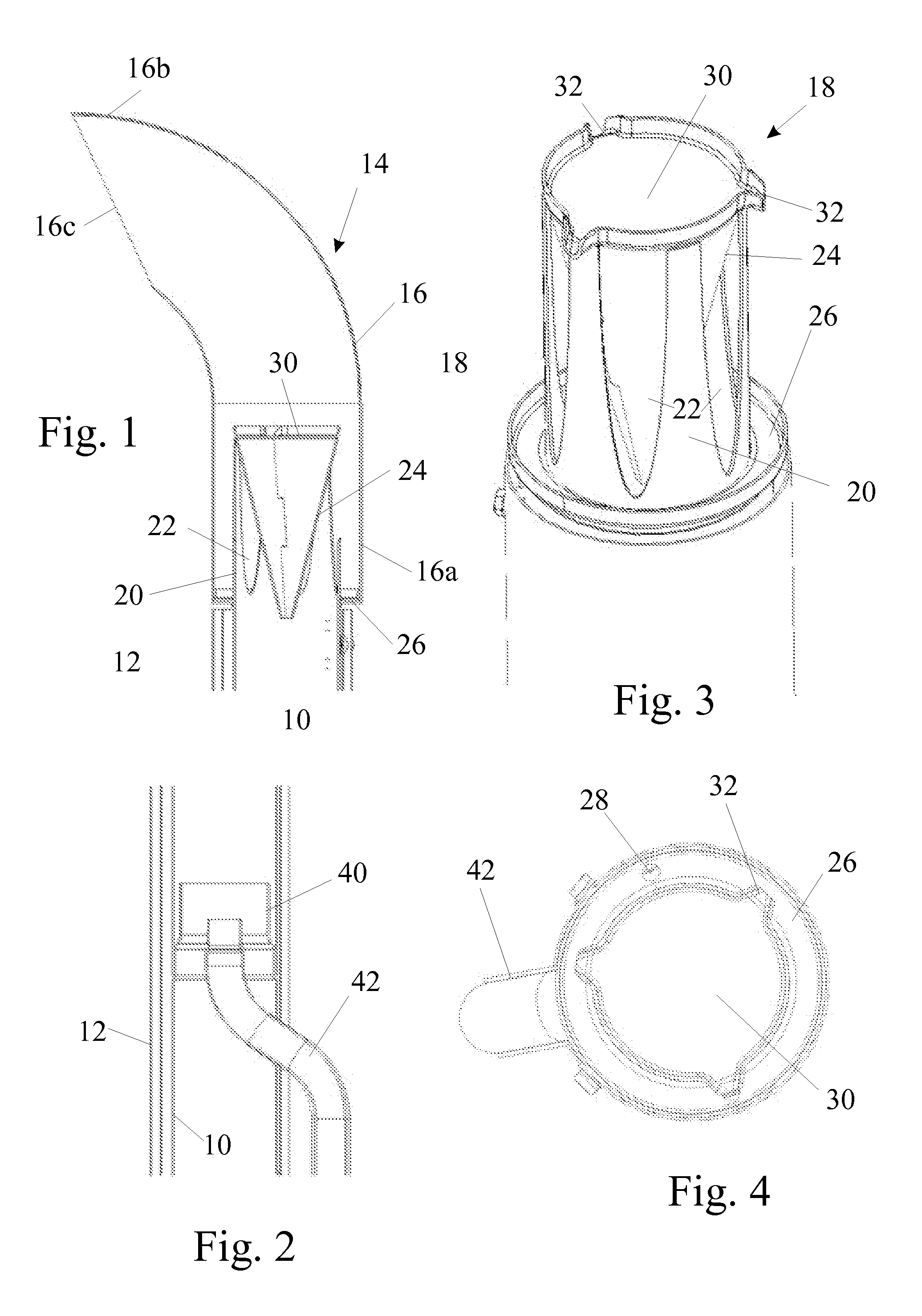

Intradermal injector

InactiveUS8162886B2Avoid back pressureAvoid insufficient lengthAmpoule syringesAutomatic syringesInjection siteSkin contact

An injection device that comprises a chamber configured for containing a substance to be injected and a needle operatively associated with the chamber and having a length sufficient to deliver the substance to an intradermal injection site. A collar surrounds the needle, defining a collar cavity. The collar also has a peripheral forward skin-contacting surface that surrounds and is radially spaced from the needle and injection site by an area that is sufficiently large to allow a patient's skin to move into the collar cavity to properly position the needle for intradermal delivery of the substance to the injection site to allow spread of the injected substance under the skin while inhibiting or preventing backpressure within the skin from forcing the substance out through the injection site.

Owner:ANTARES PHARMA INC

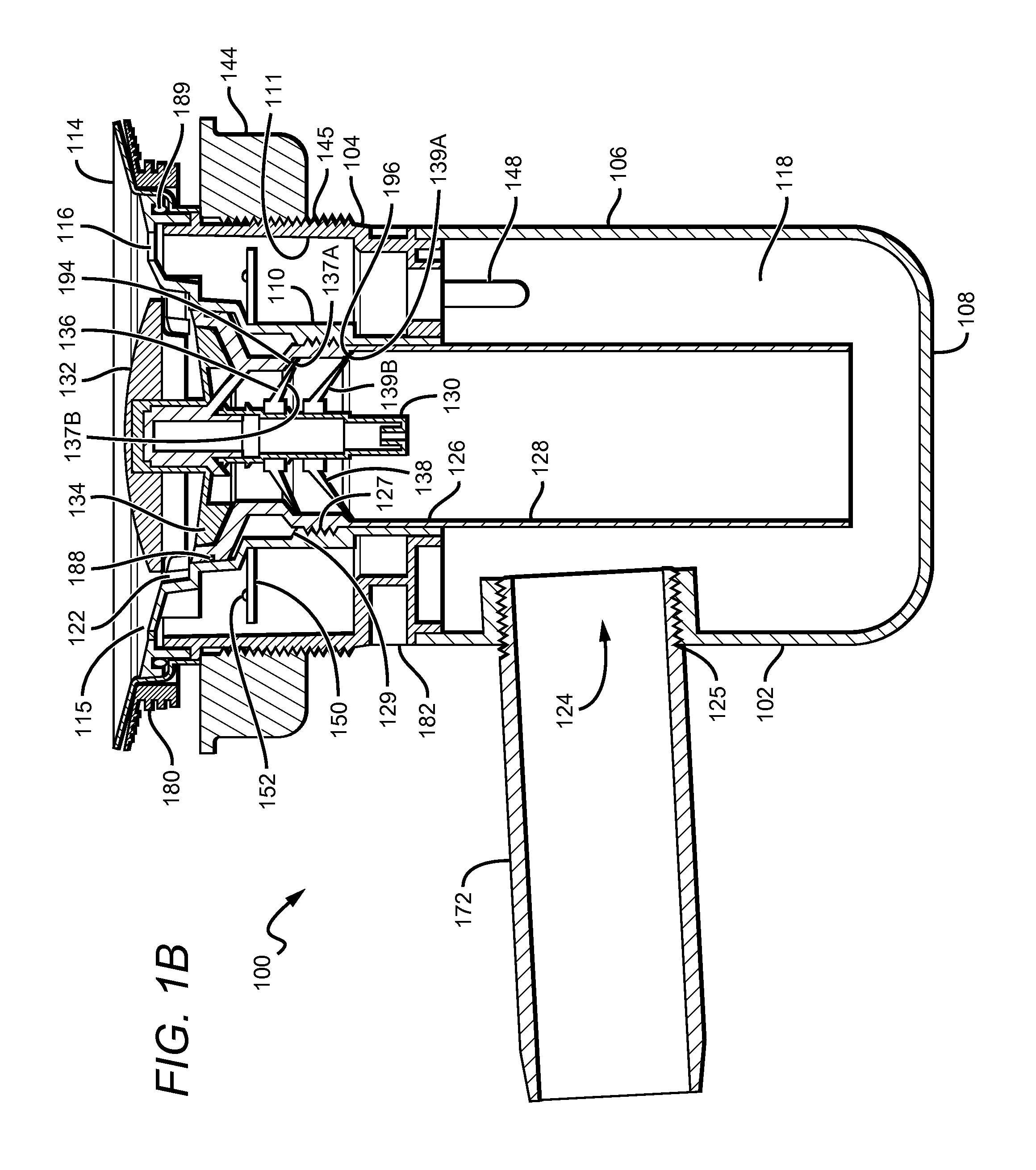

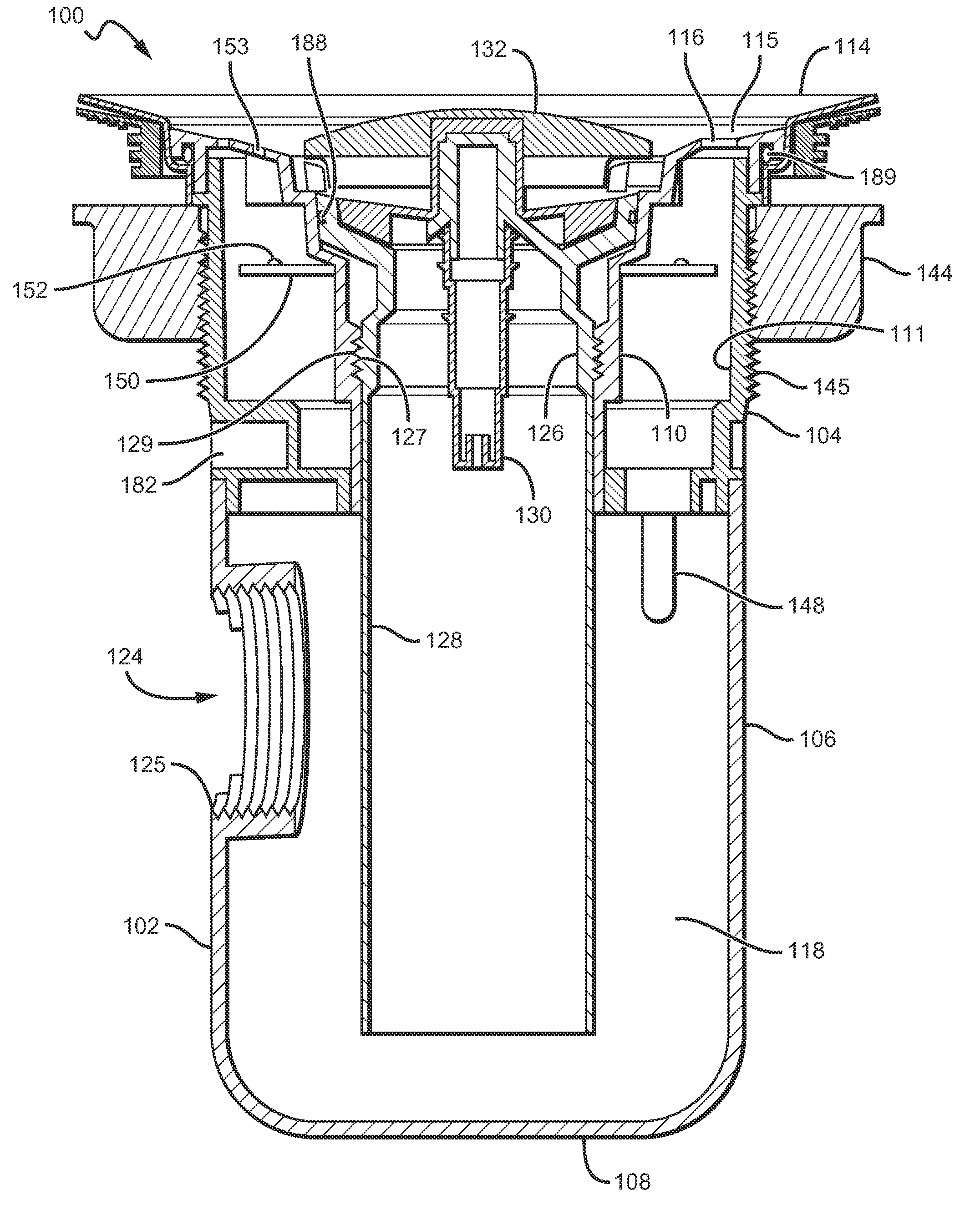

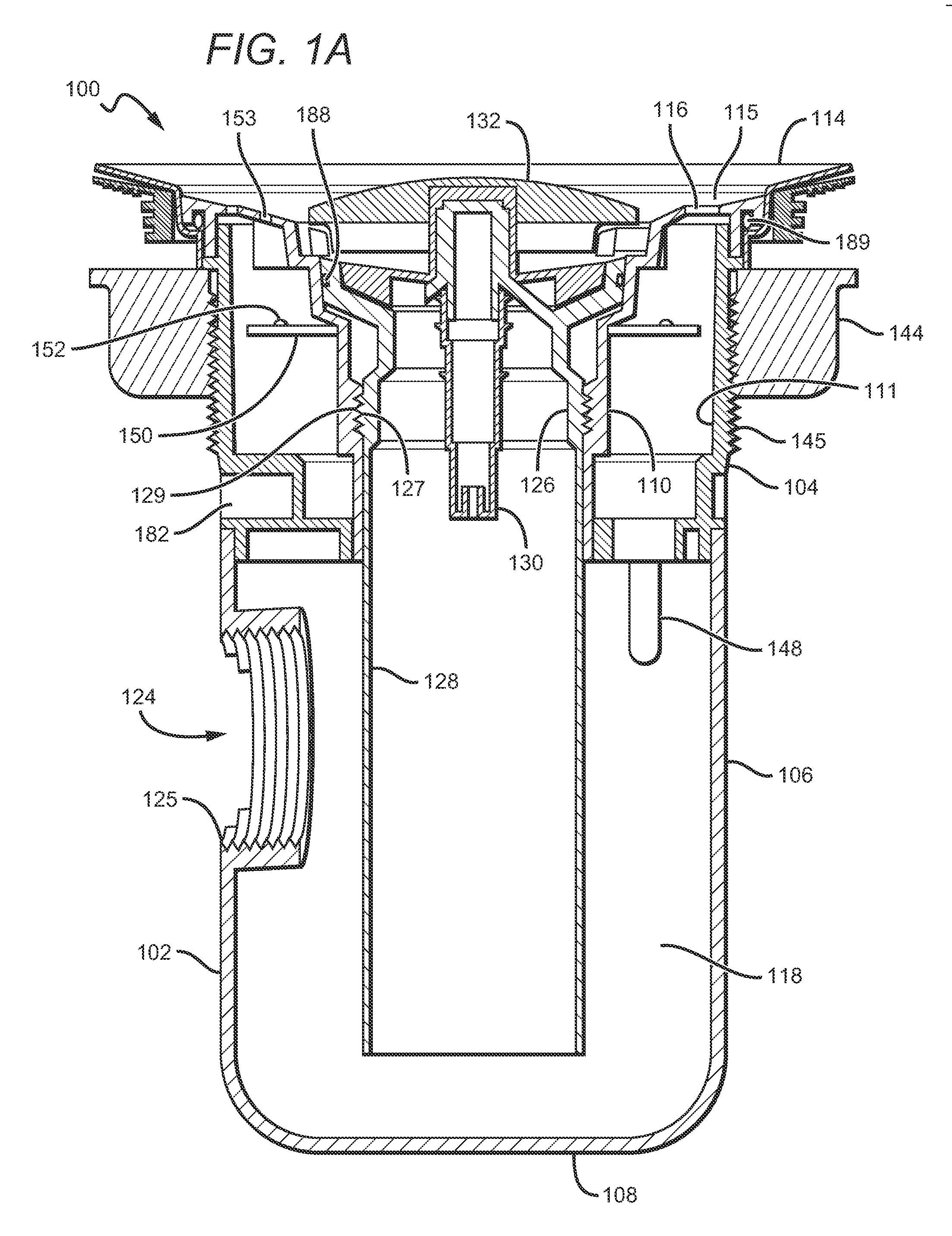

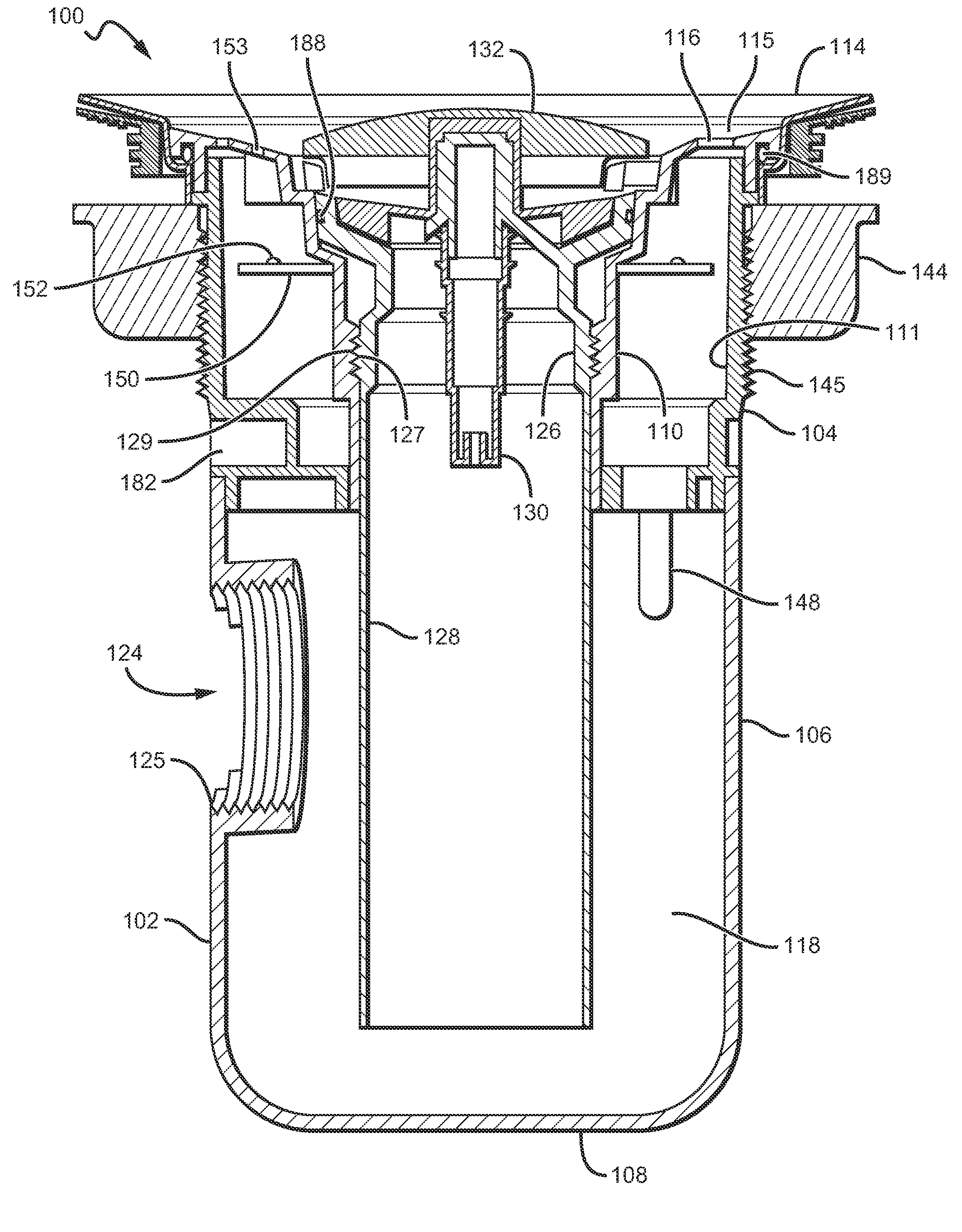

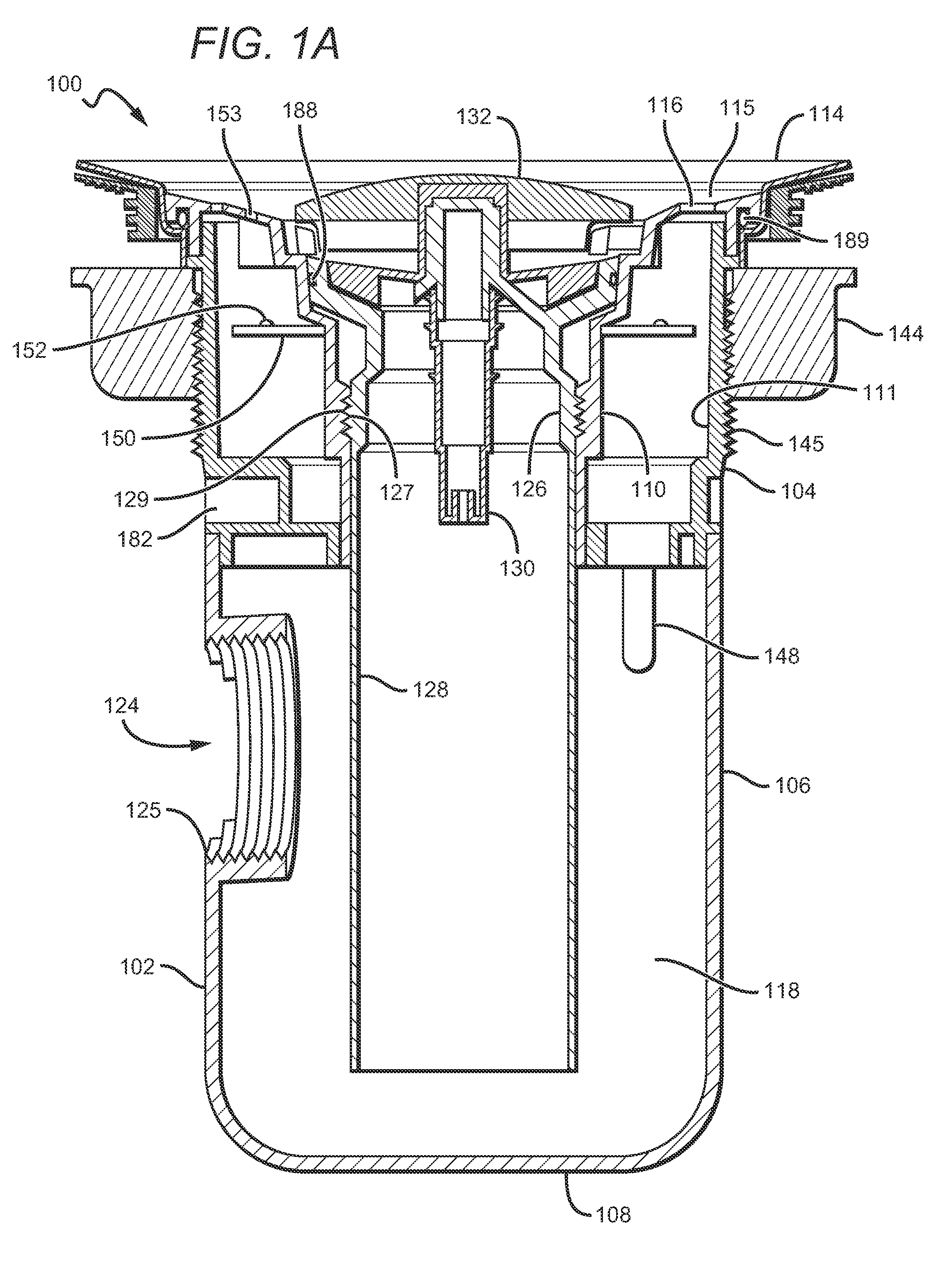

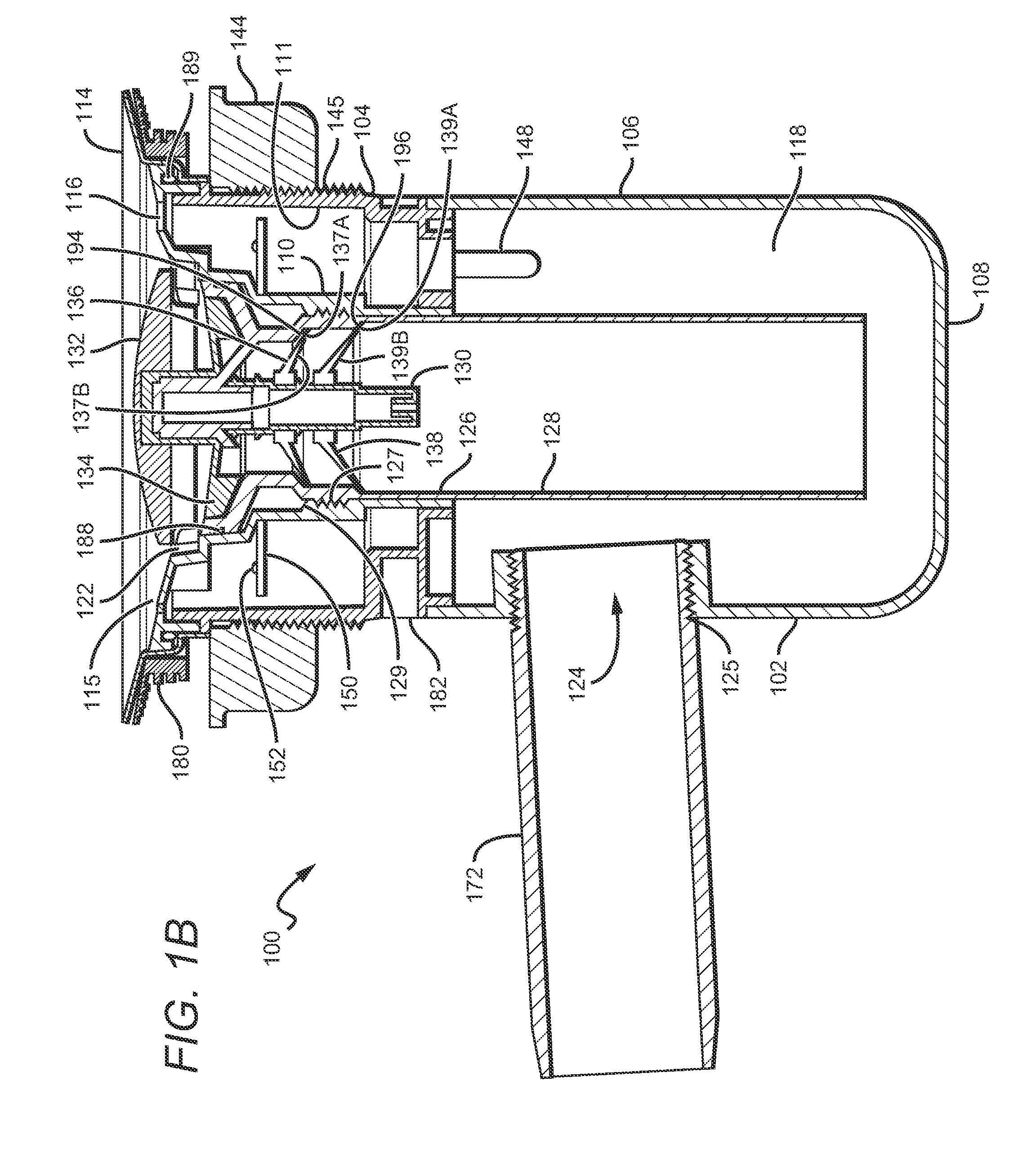

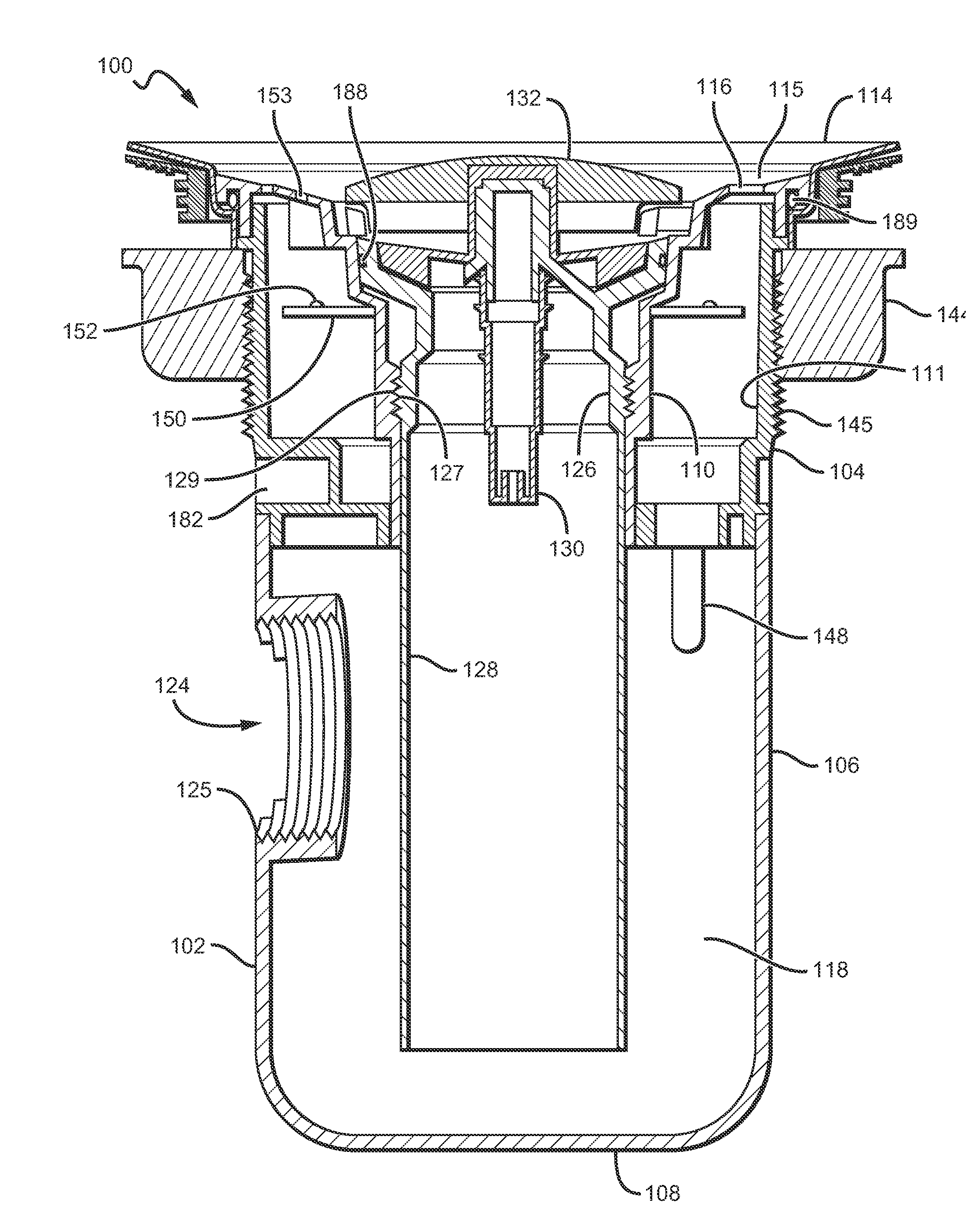

Drain cartridge having removable valved system

ActiveUS7900288B2Eliminate needEasy to replaceUrinalsWater treatment parameter controlUltraviolet lightsEngineering

Various embodiments of a cartridge for regulating a fluid flow are described that include an upper housing, and an insert that is user-removable from the upper housing. The cartridge can include one or more valves that are biased in a closed position to prevent odors from escaping the cartridge. The cartridge can also include a fluid trap that is at least partially disposed within the cartridge or fluidly coupled thereto. An ultraviolet light can be inserted within the cartridge to disinfect a fluid passageway of the cartridge.

Owner:GREEN DRAIN

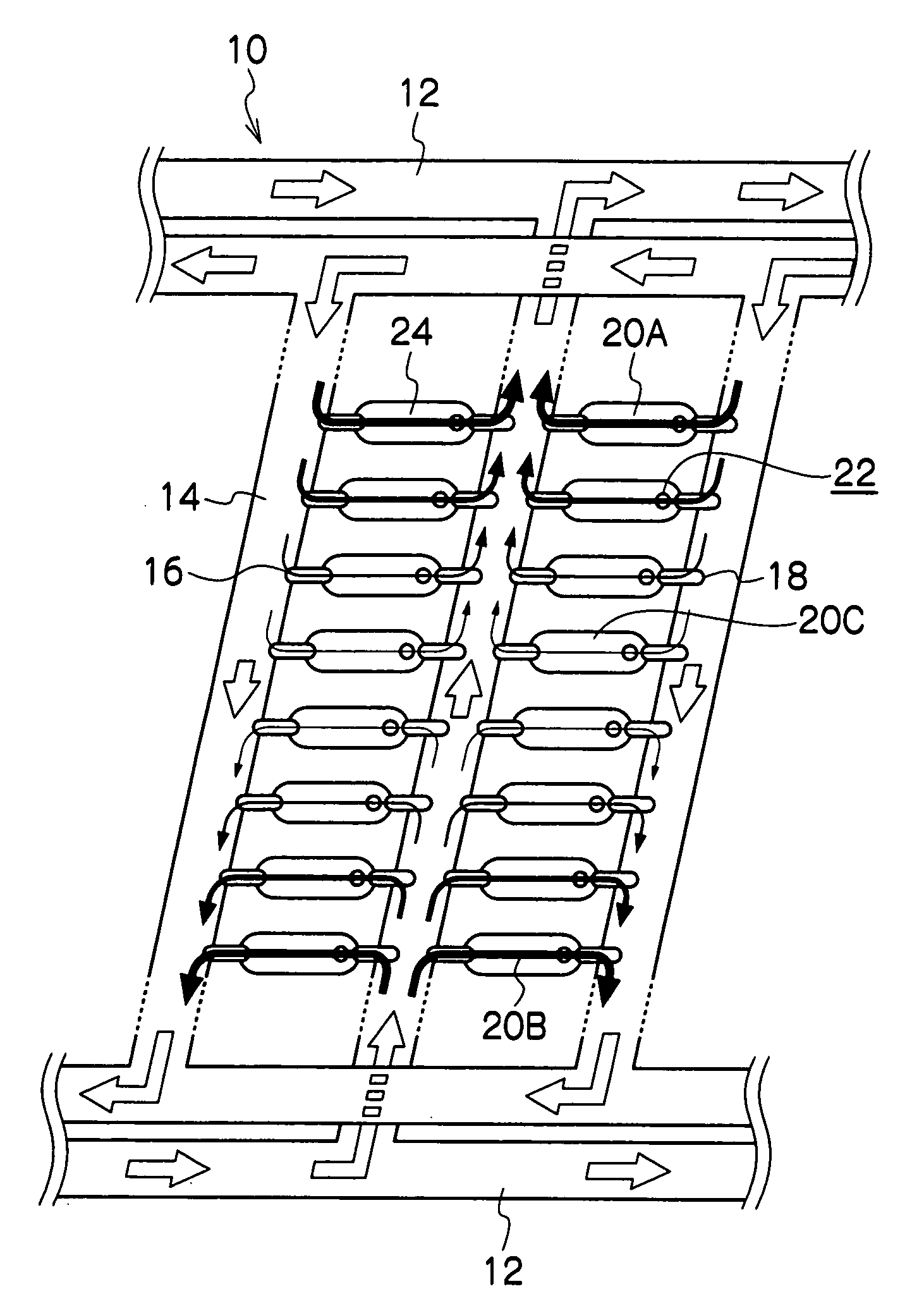

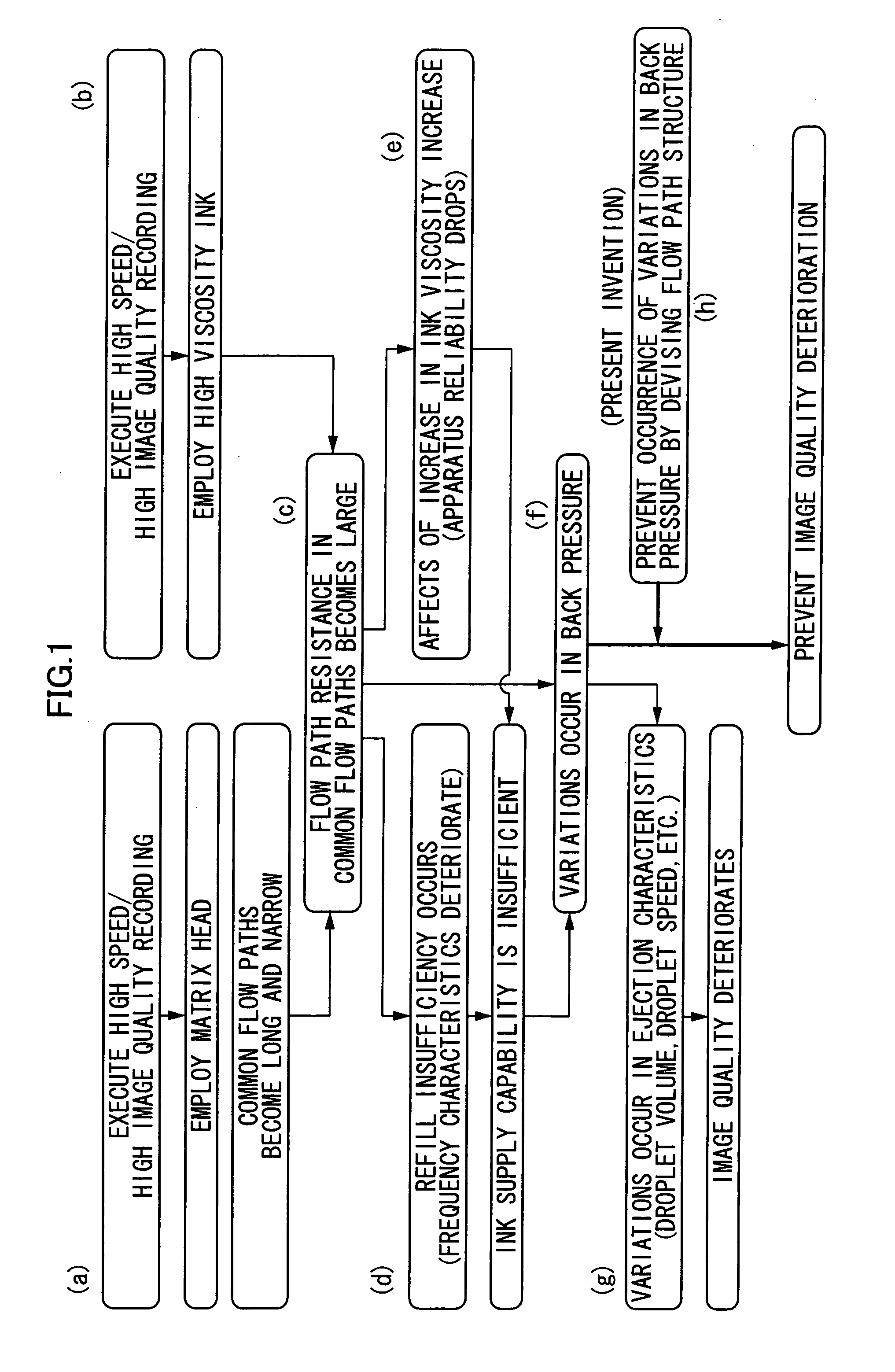

Liquid droplet ejecting head and liquid droplet ejecting apparatus

InactiveUS20080143793A1Avoid back pressureImage quality can be hinderedInking apparatusEngineeringLiquid drop

Owner:FUJIFILM BUSINESS INNOVATION CORP

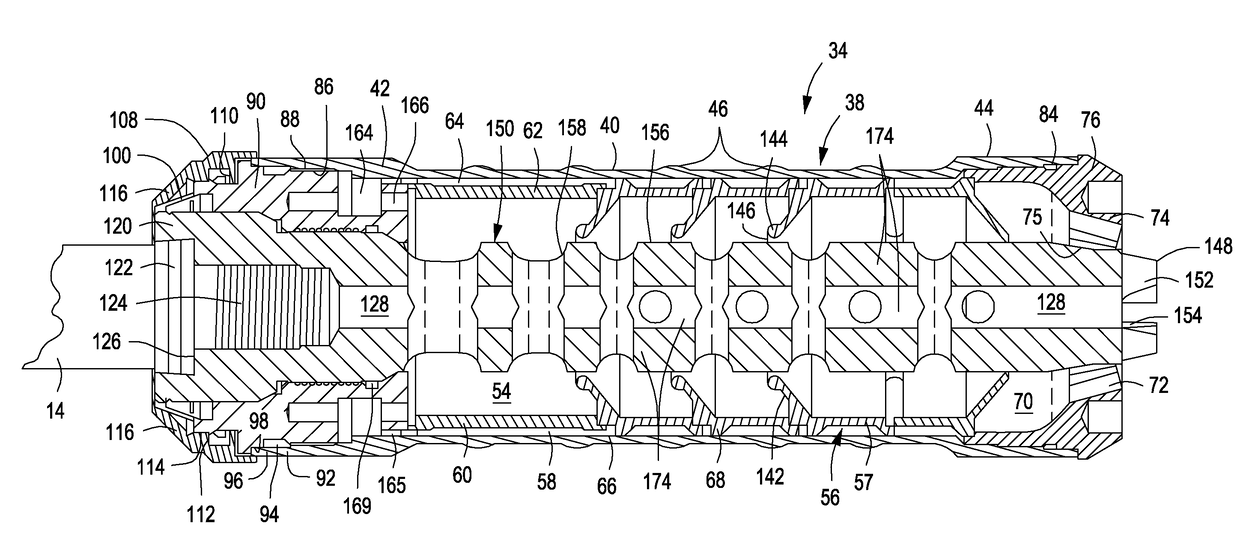

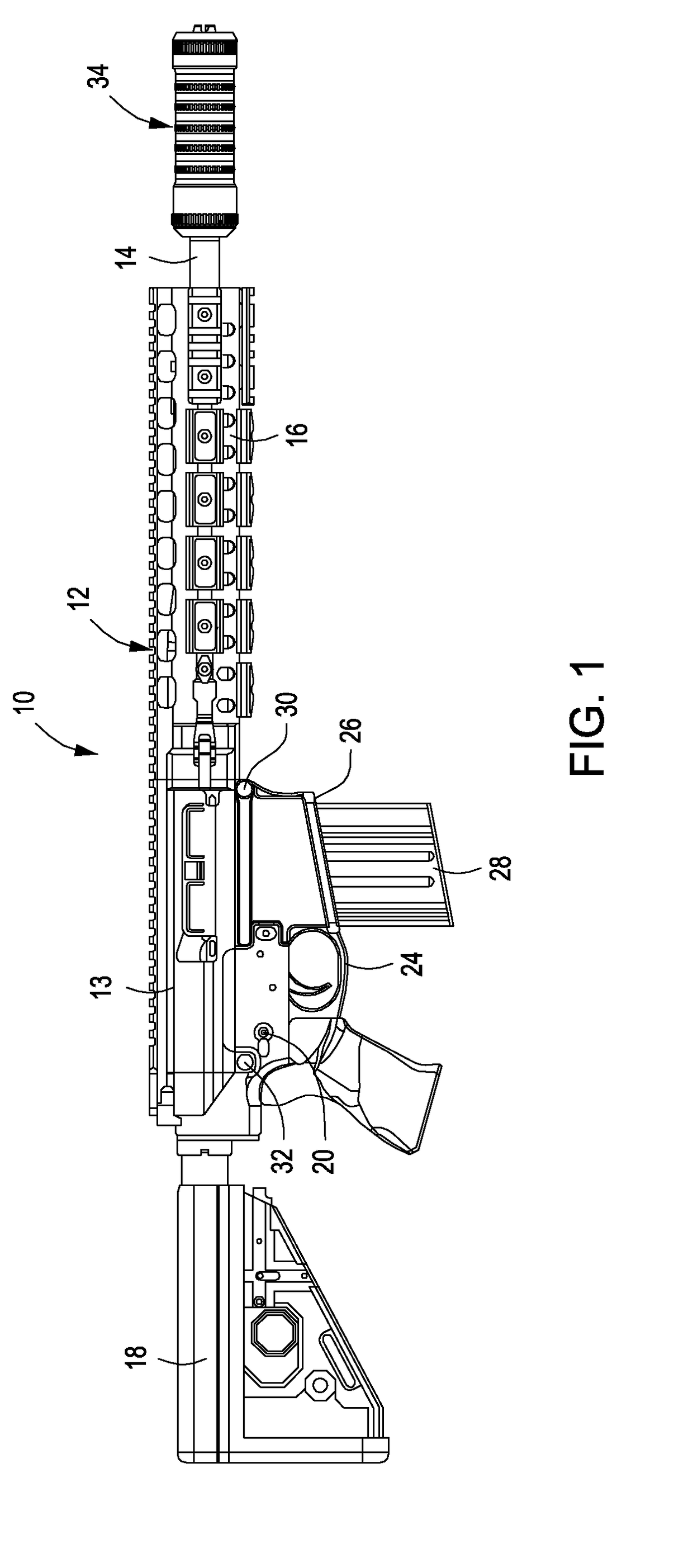

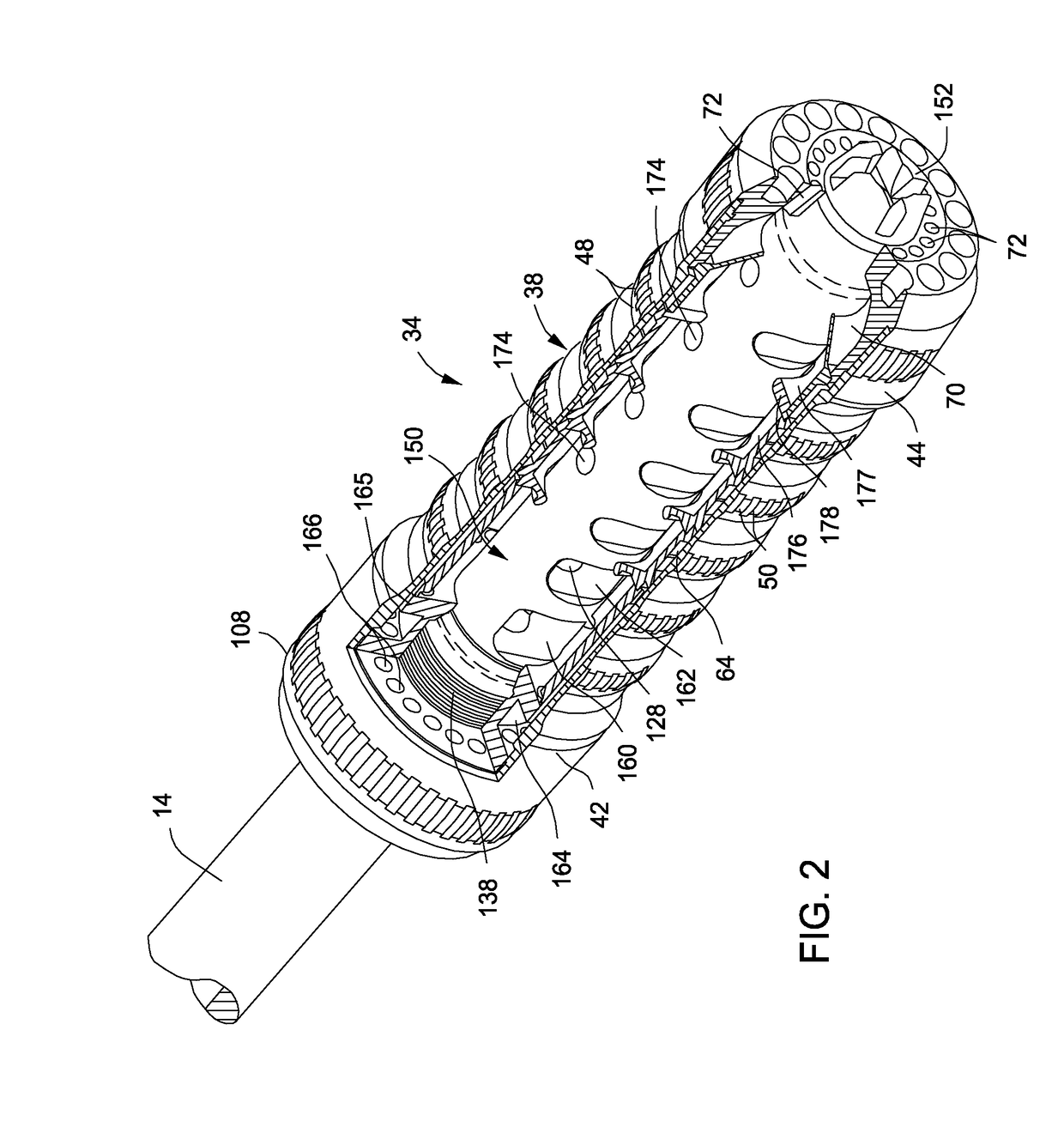

Suppressed upper receiver group having locking suppressor with through brake

InactiveUS20180038663A1Prevent excessive back pressureEasy dischargeBreech mechanismsMuzzle attachmentSuppressorMajor and minor

A suppressed upper receiver group for a firearm having a suppressor mounted to the barrel thereof. The suppressor has a tubular housing defining primary and secondary flow paths for propellant gas processing, diverting a portion of the propellant gas to the secondary flow path for pressure control. A number of baffle members are arranged in spaced relation within the housing and define serially arranged propellant gas processing chambers. A suppressor mounting adapter is connected with the barrel and has a propellant gas processing section having a propellant flow bore and extends completely through the housing and has a flash retarding tip projecting through a discharge opening of the housing.

Owner:LARUE MARK C

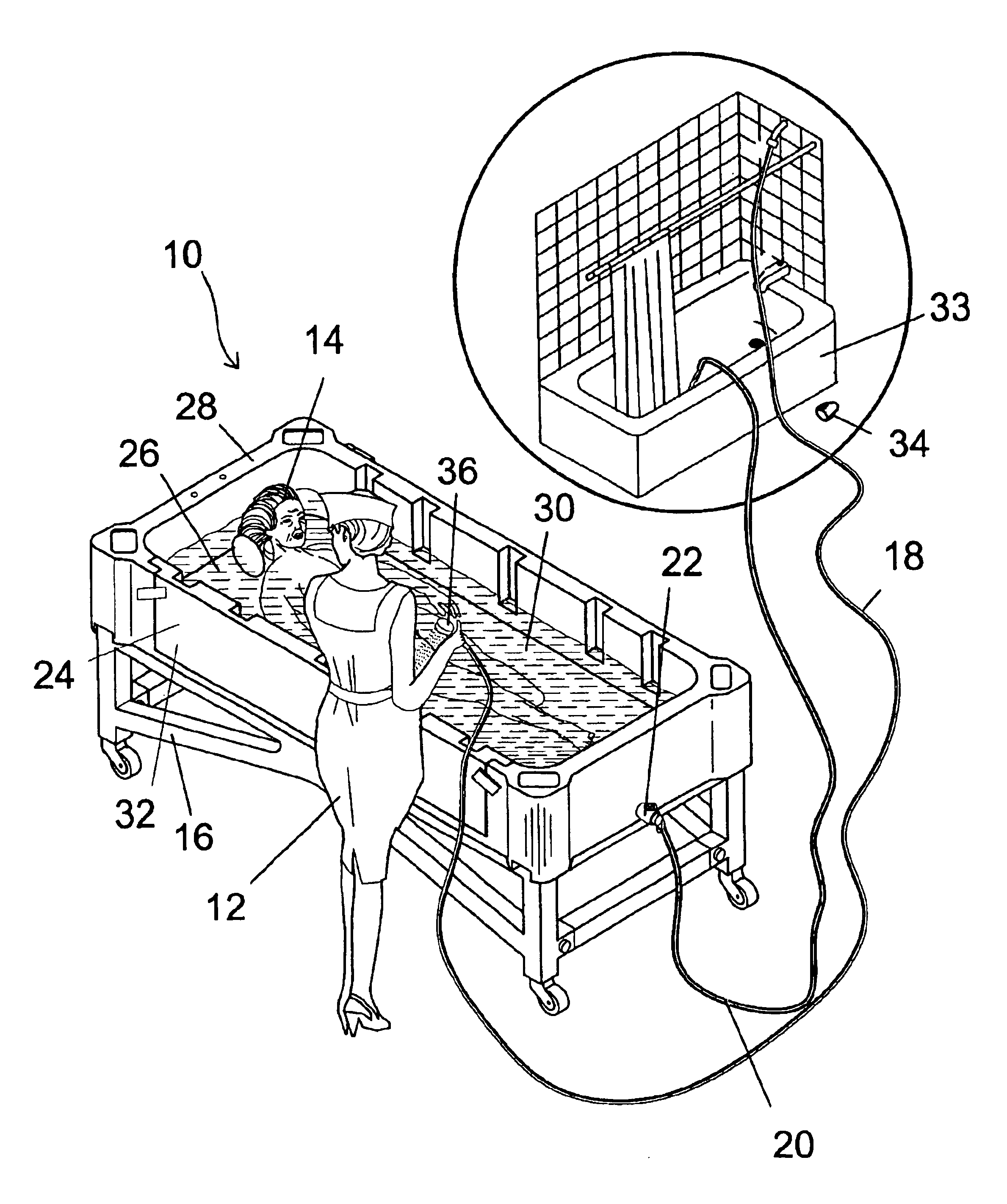

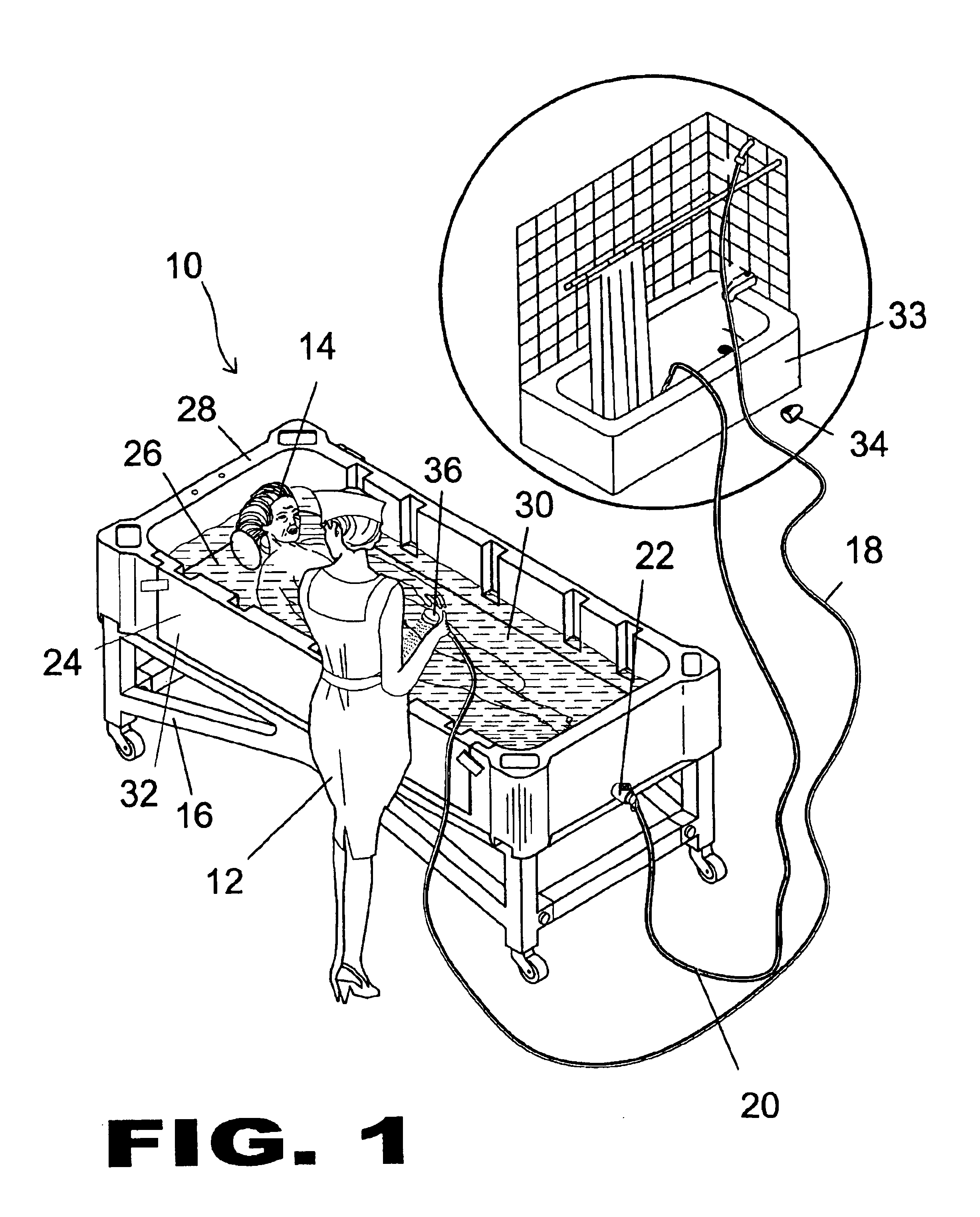

Comfort bed bath

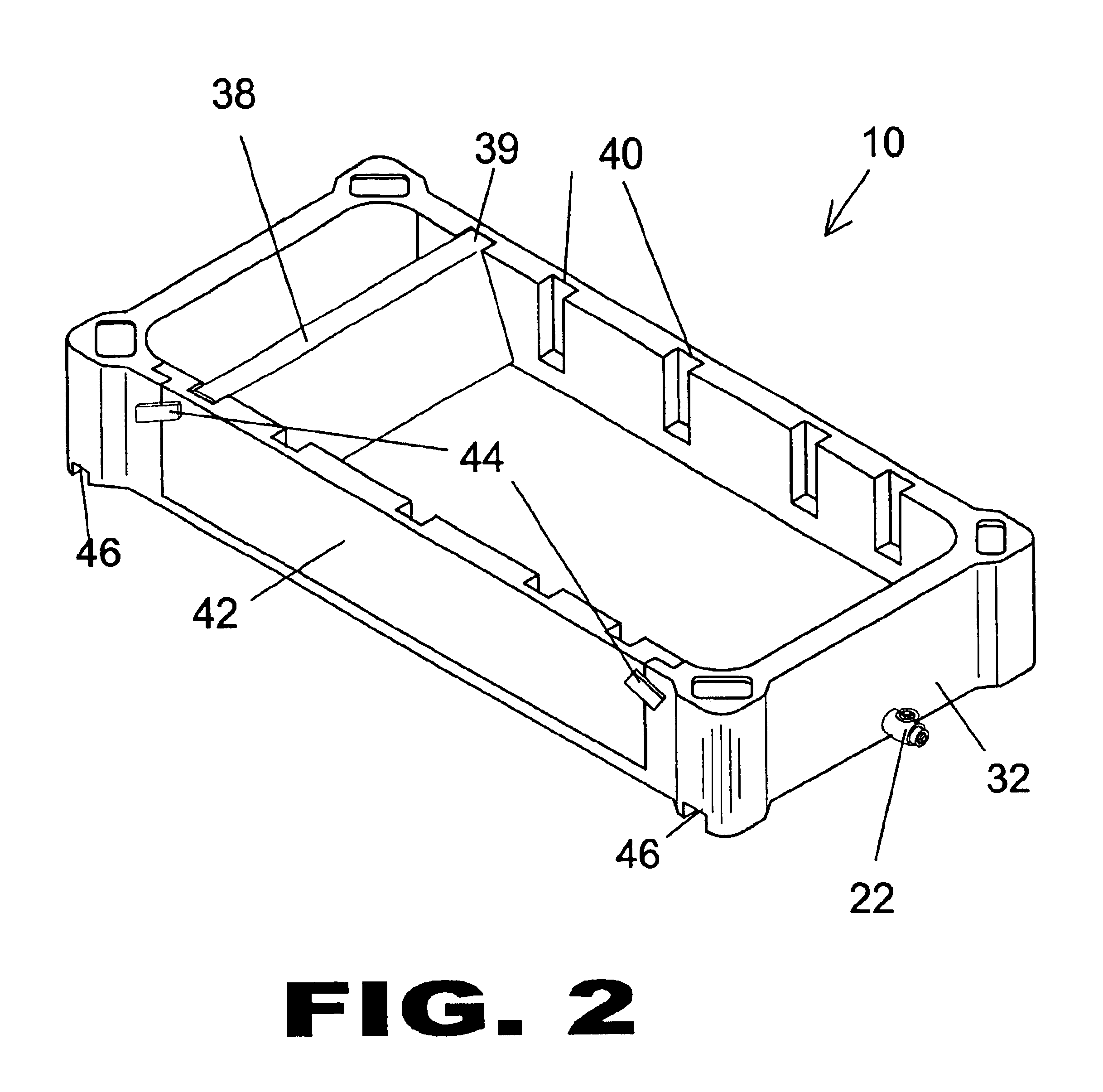

InactiveUS6802088B1Cheap manufacturingGuaranteed economical operationBathsDouchesEngineeringGuide tube

The present invention 10 discloses a portable bed device comprising a horizontal bottom 26 surrounded by vertical walls 28 with an open top forming a tub 32 for holding water therein in order to wash a person. The tub 32 has a removable side panel 42 incorporated into at least one sidewall wherein a latching mechanism 44 is used to attach the removable side panel to the tub 32. An adjustable backrest / footrest 38 is provided in order to rest the patient's head thereon wherein the backrest / footrest element is attached by tongue 39 and groove 40 fastening means to the sidewalls of the tub 32. A headrest 48 may also be removably attached to the backrest / footrest element. A means for introducing water into the tub 32 comprises a flexible inlet conduit 18 and a flexible outlet conduit 20 wherein water may be supplied from a conventional household showerhead and diverted back for discharge into, for example, the shower or tub 33 itself The patient may be washed using the showerhead 36 attached to the end of the inlet line 18. The tub 32 may be placed onto a gurney 16 when it is not feasible to bathe the patient in the bed.

Owner:GRUNER MARK

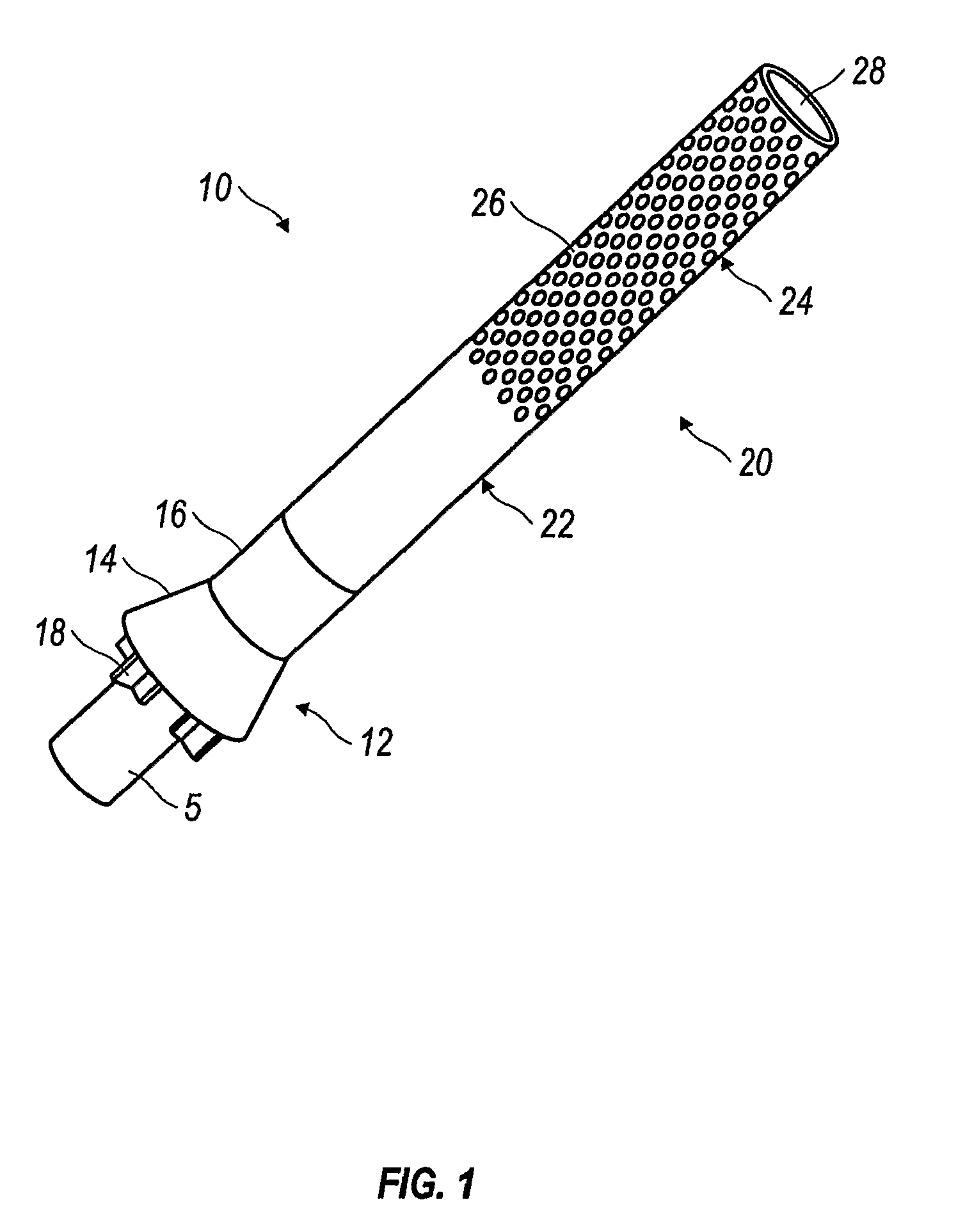

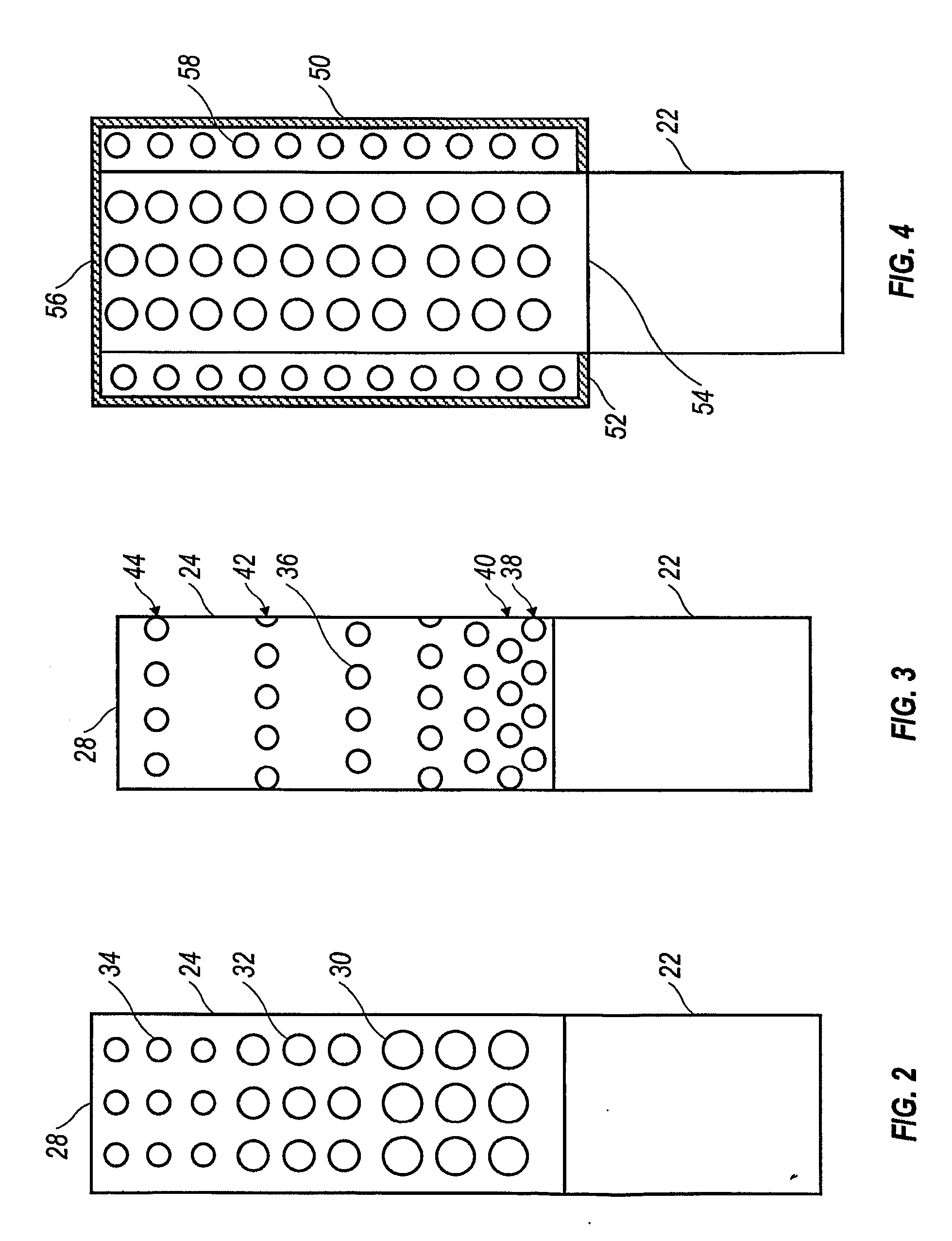

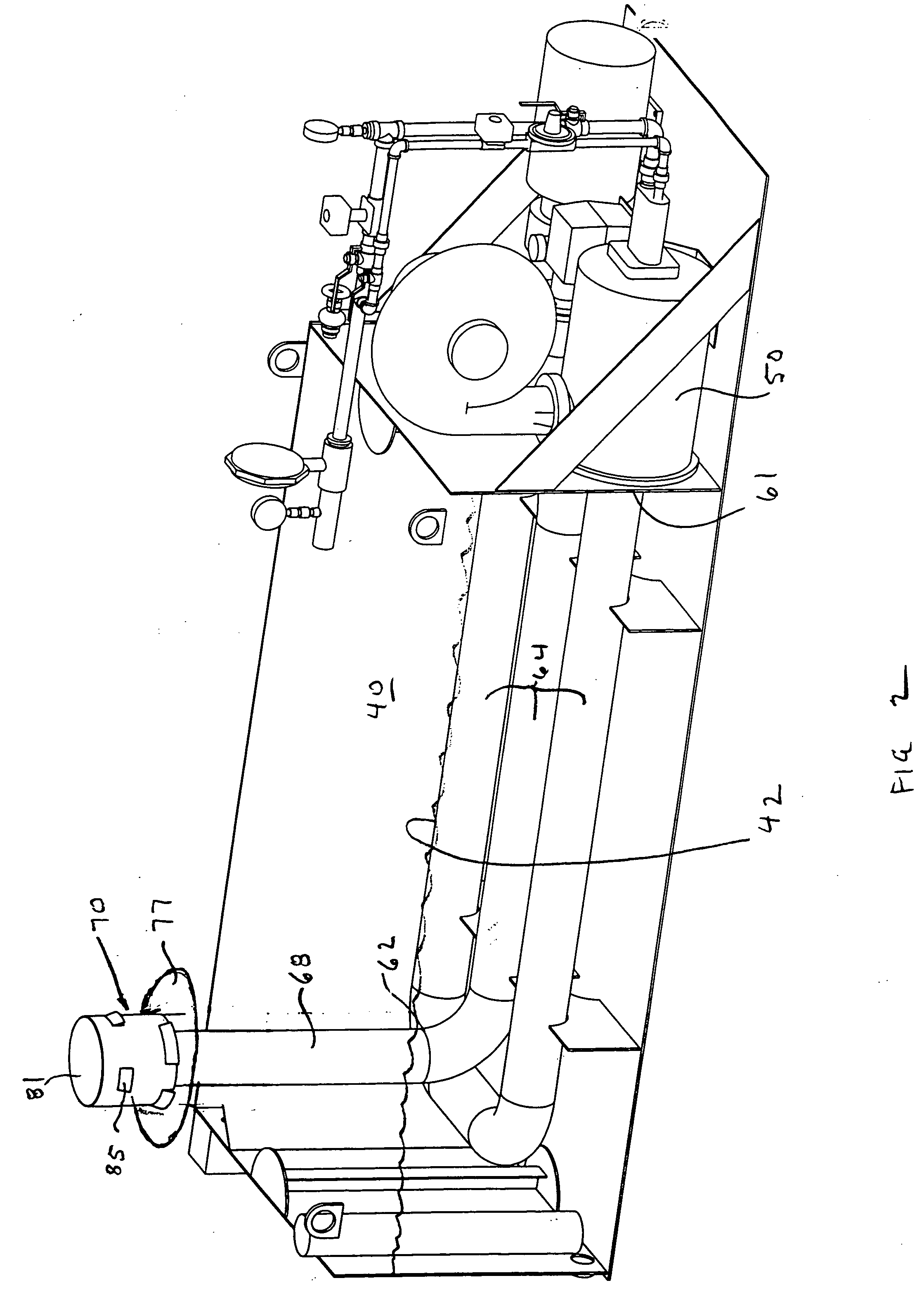

Exhaust diffuser for a truck

ActiveUS20100043412A1Avoid back pressureEliminate back pressureSilencing apparatusMachines/enginesEngineeringTruck

An exhaust diluting and diffusing apparatus includes a pipe mountable on a exhaust stack pipe, and having a flared skirt inlet to define an annular inlet, a mixing section adjacent the inlet, and an exhaust section formed as a pipe section with a multiplicity of holes. The apparatus pipe has a diameter greater than the diameter of the exhaust stack on which it is mounted.

Owner:VOLVO LASTVAGNAR AB

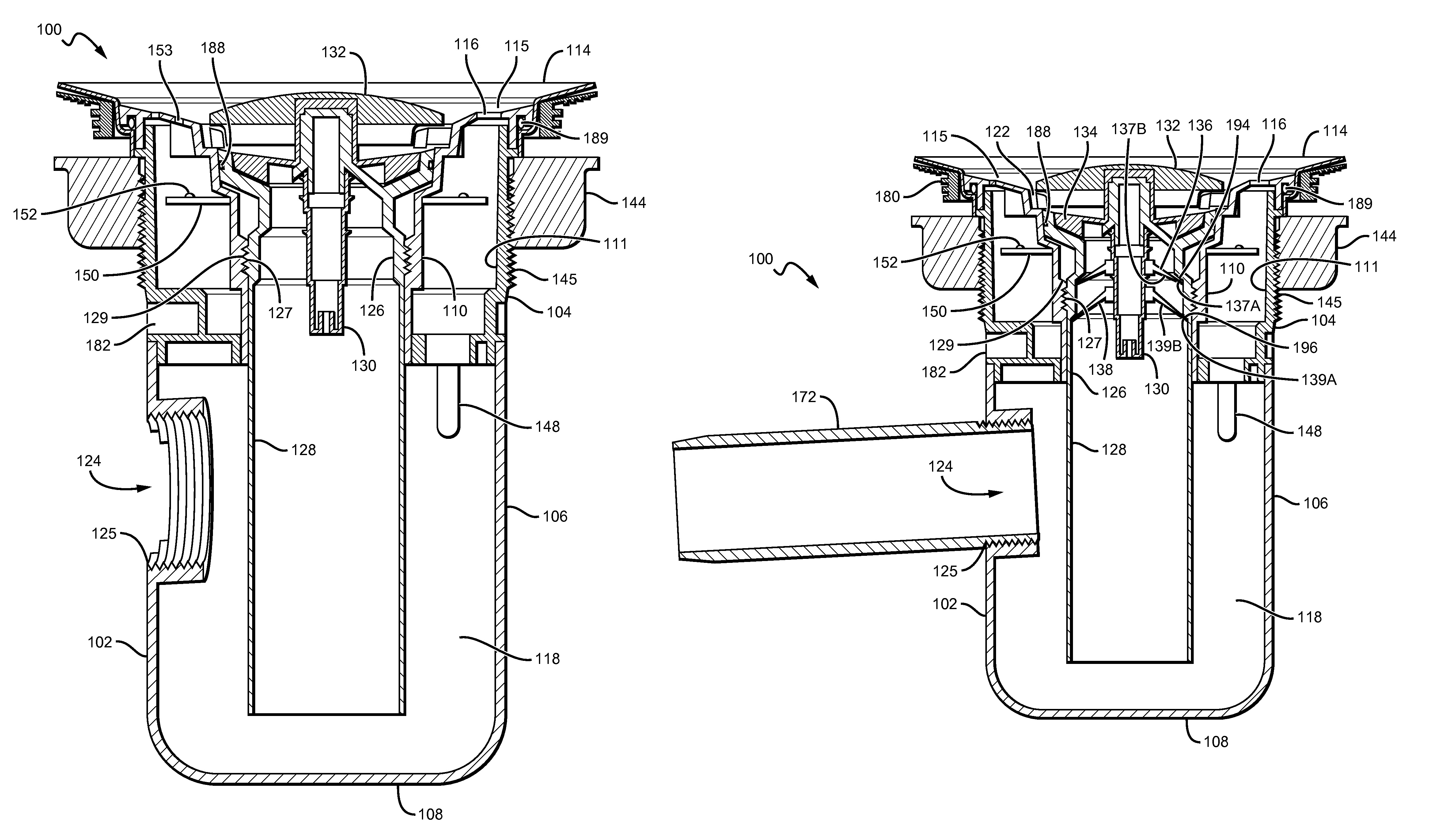

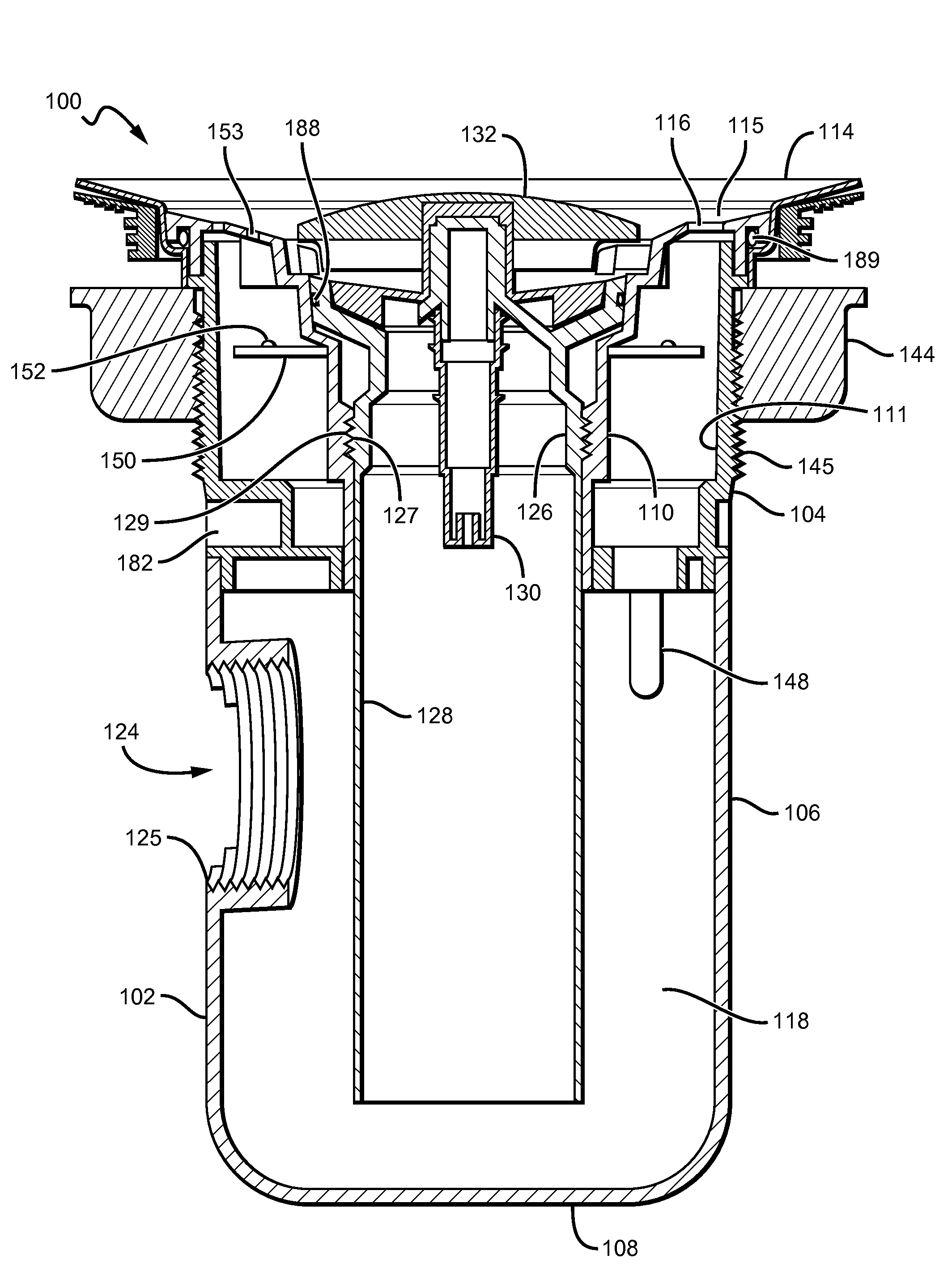

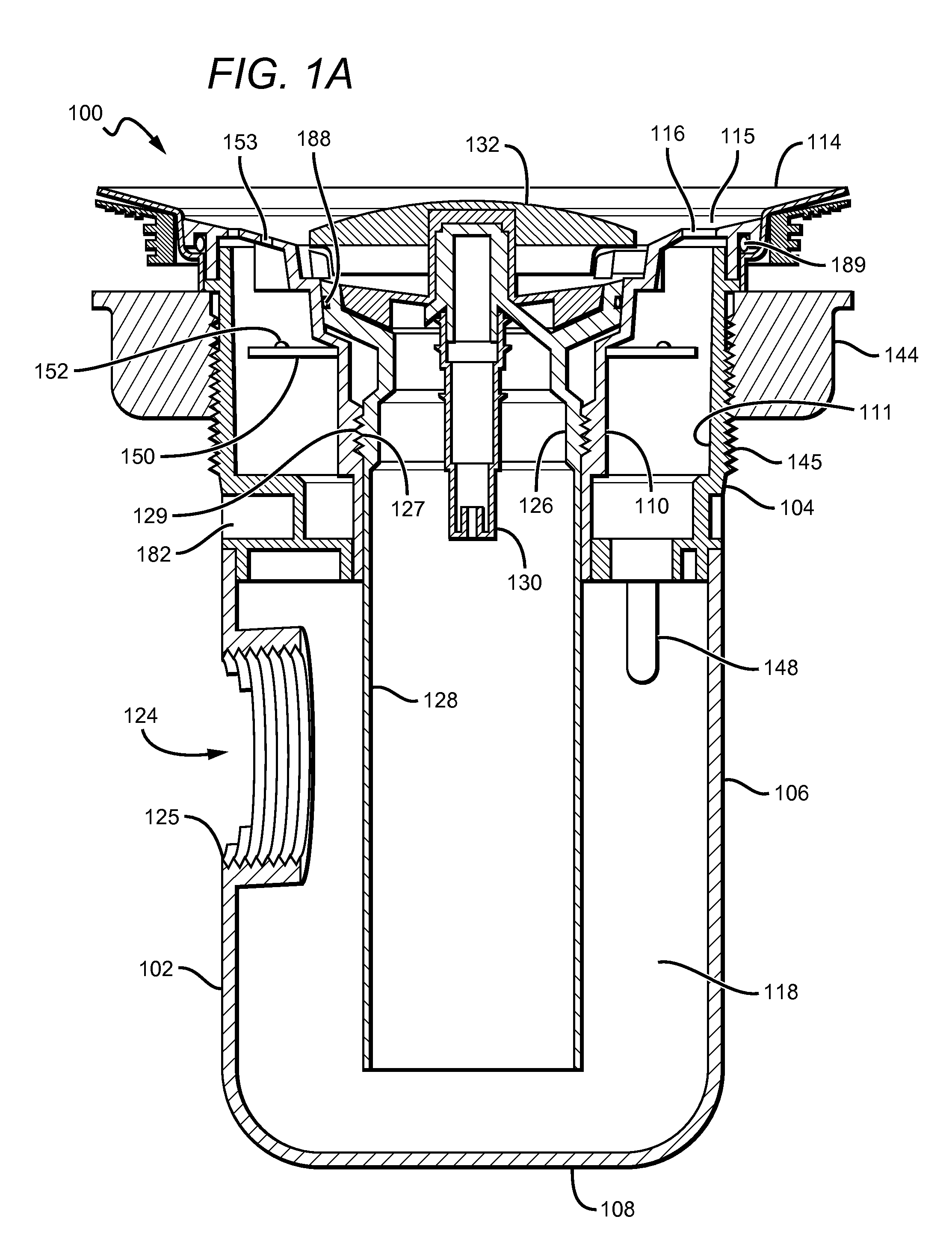

Drain Cartridge Having Removable Valved System

InactiveUS20100192295A1Eliminate needEasy to replaceUrinalsDomestic plumbingEngineeringUltraviolet light

Various embodiments of a cartridge for regulating a fluid flow are described that include an upper housing, and an insert that is user-removable from the upper housing. The cartridge can include one or more valves that are biased in a closed position to prevent odors from escaping the cartridge. The cartridge can also include a fluid trap that is at least partially disposed within the cartridge or fluidly coupled thereto. An ultraviolet light can be inserted within the cartridge to disinfect a fluid passageway of the cartridge.

Owner:LIQUIDBREAKER

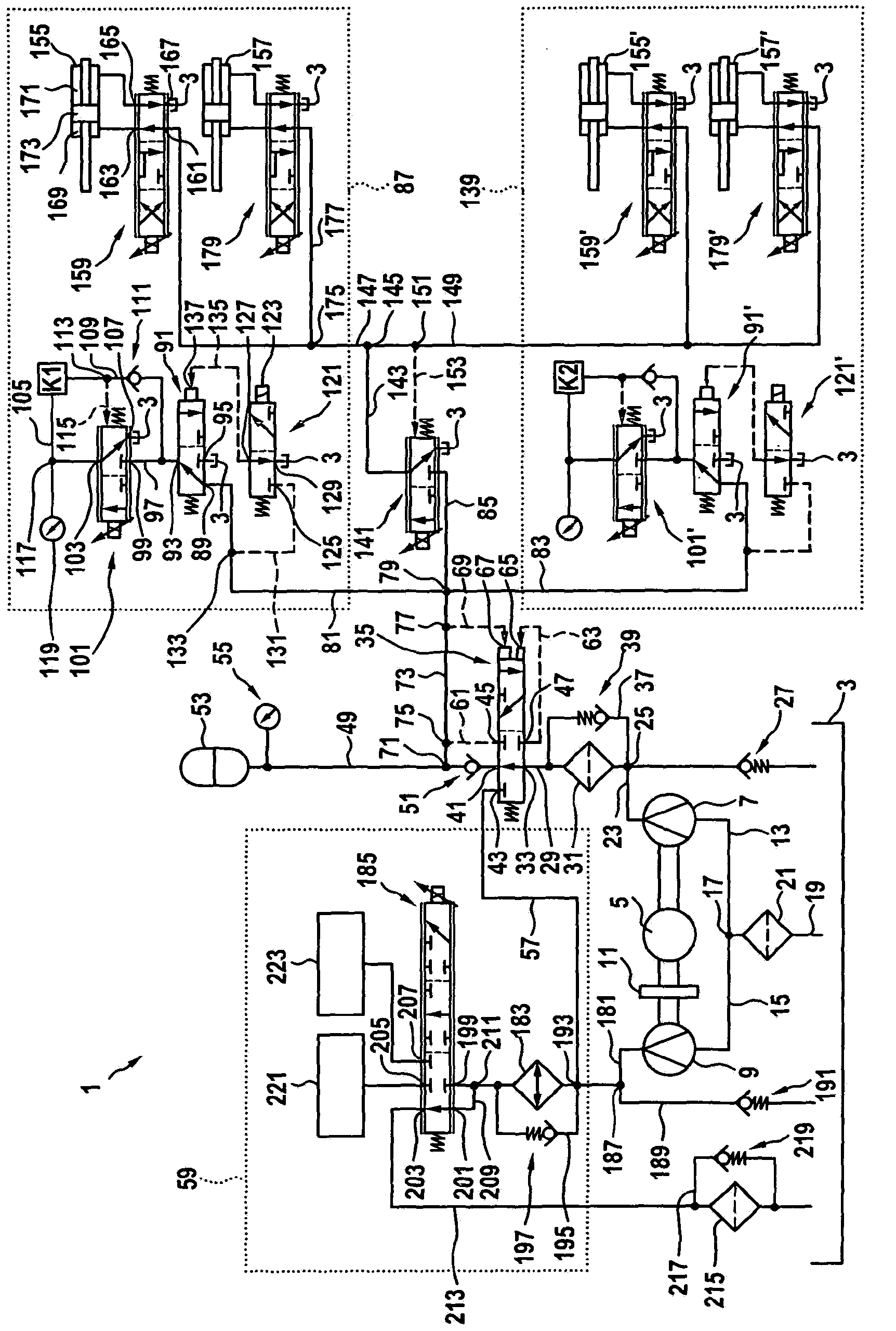

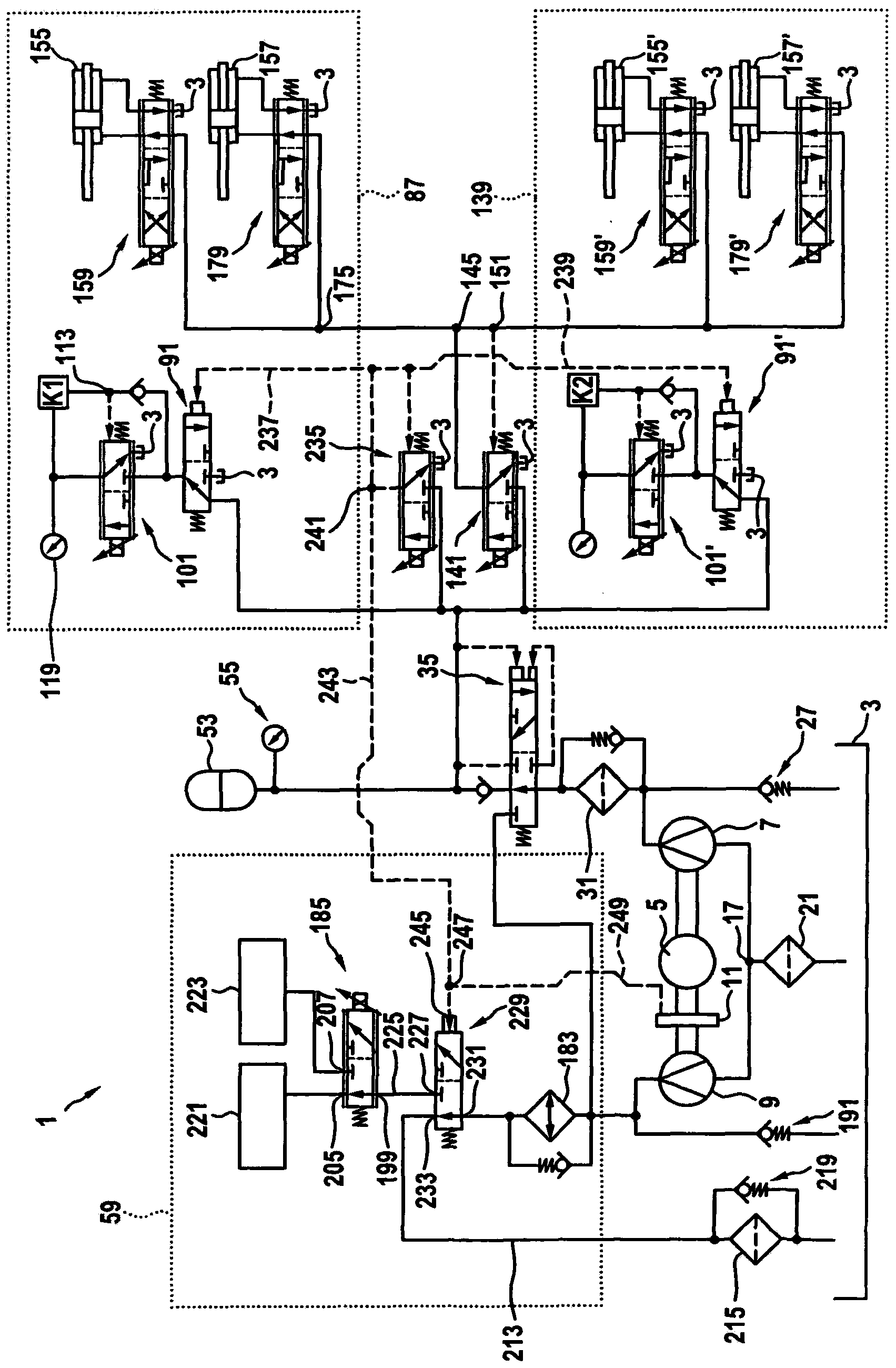

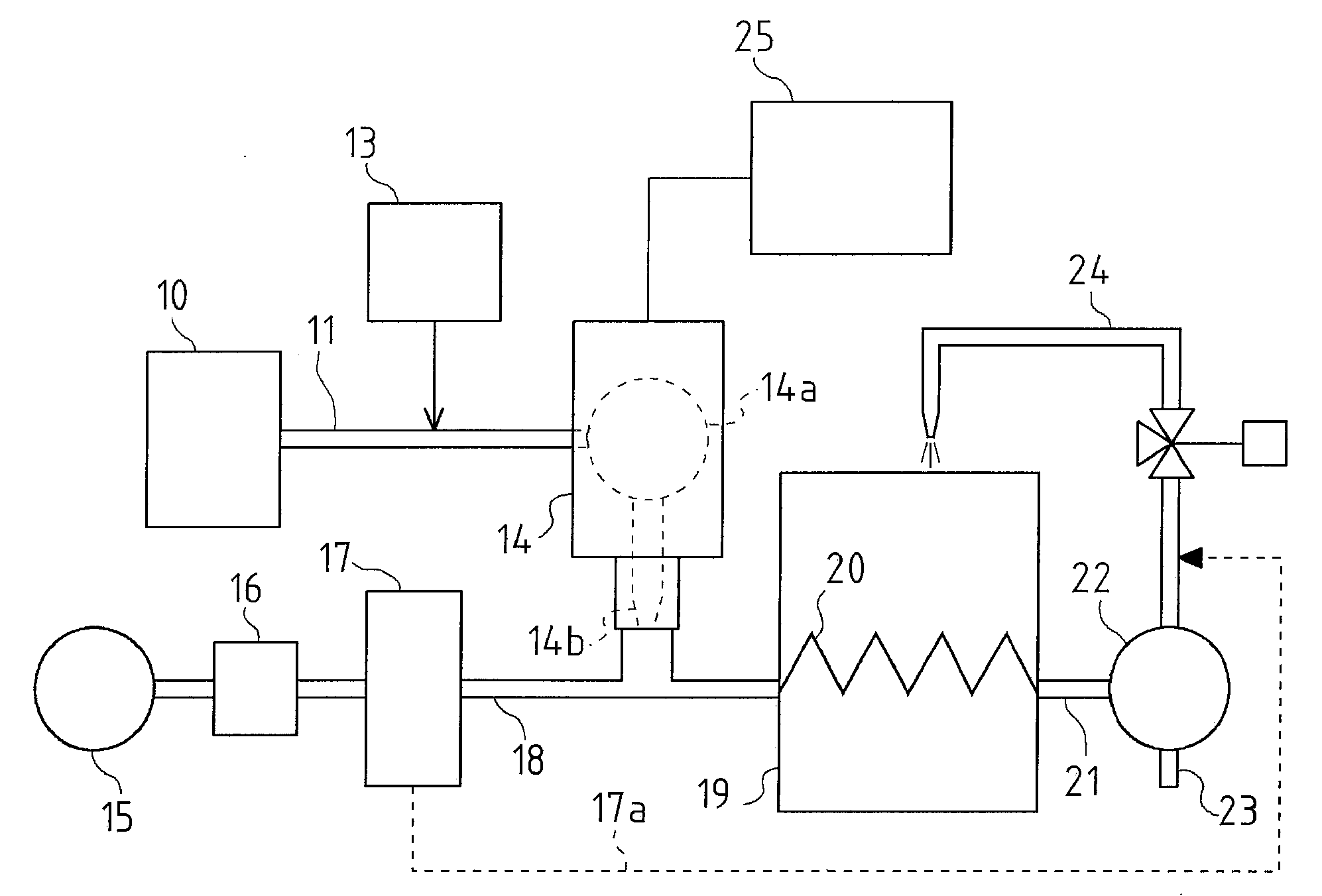

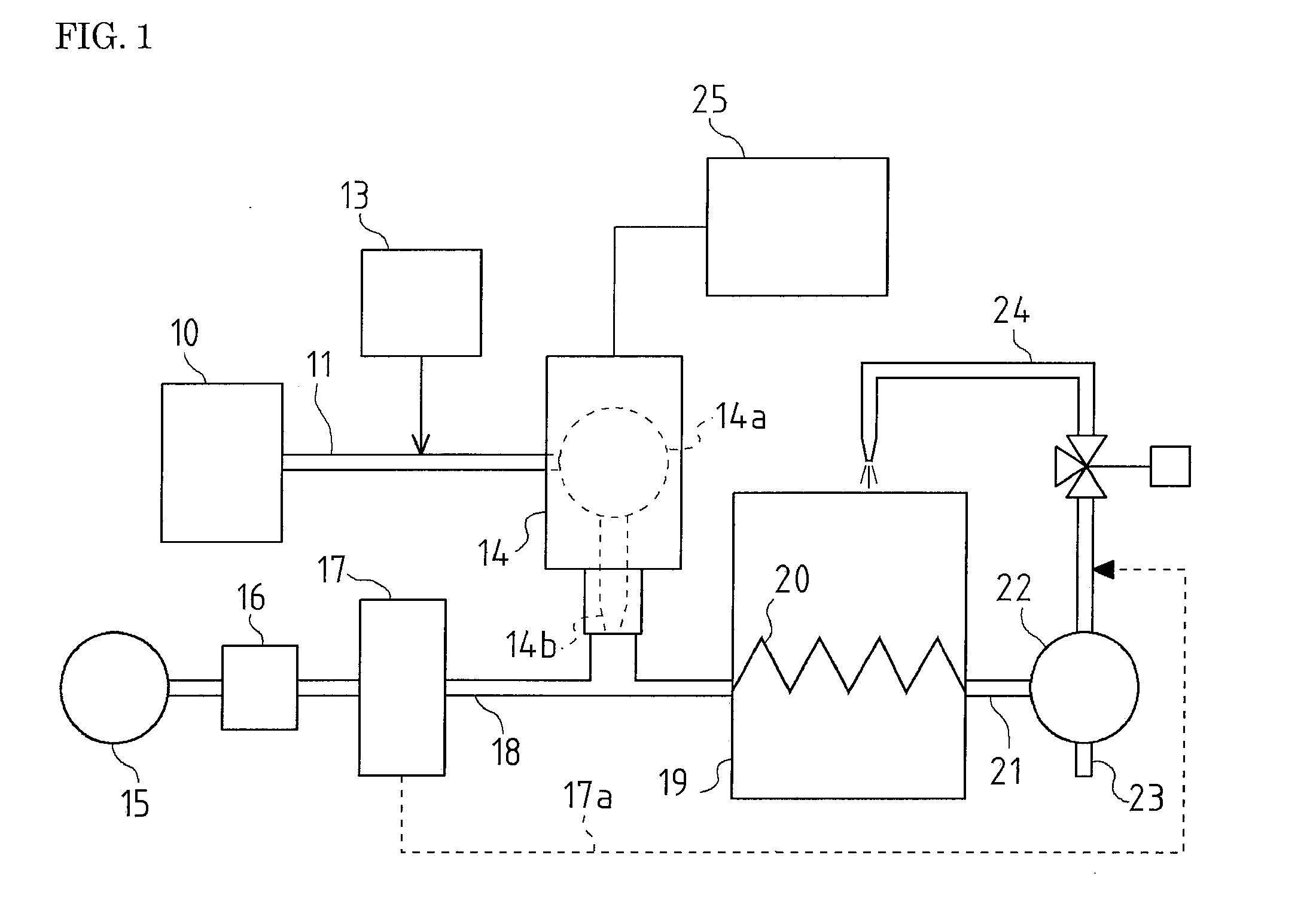

Hydraulic circuit, method for operating same

ActiveCN103562598AImprove cooling effectImprove adjustment qualityFluid actuated clutchesGearing controlHydraulic circuitEngineering

The invention relates to a dual clutch transmission, especially of a motor vehicle, comprising a hydraulic circuit (1) for cooling the dual clutch transmission, said hydraulic circuit (1) comprising at least one pump (7, 9) for delivering a hydraulic fluid flow, at least one cooler (183) for cooling the hydraulic fluid flow, and a volume control valve (185) for adjusting the hydraulic fluid flow for at least one cooling system (221, 229) which is associated with clutches (K1, K2) of the dual clutch transmission. Said volume control valve (185) is designed such that it supplies the hydraulic fluid flow to a first cooling system (221), which is associated with a first one of the clutches (K1), in a first switching state and to a second cooling system (229), which is associated with a second one of the clutches (K2), in at least one second switching state.

Owner:AUDI AG

Drain Cartridge Having Removable Valved System

InactiveUS20110203048A1Eliminate needEasy to replaceUrinalsPipe supportsEngineeringUltraviolet light

Various embodiments of a cartridge for regulating a fluid flow are described that include an upper housing, and an insert that is user-removable from the upper housing. The cartridge can include one or more valves that are biased in a closed position to prevent odors from escaping the cartridge. The cartridge can also include a fluid trap that is at least partially disposed within the cartridge or fluidly coupled thereto. An ultraviolet light can be inserted within the cartridge to disinfect a fluid passageway of the cartridge.

Owner:FIMA GIOVANNI

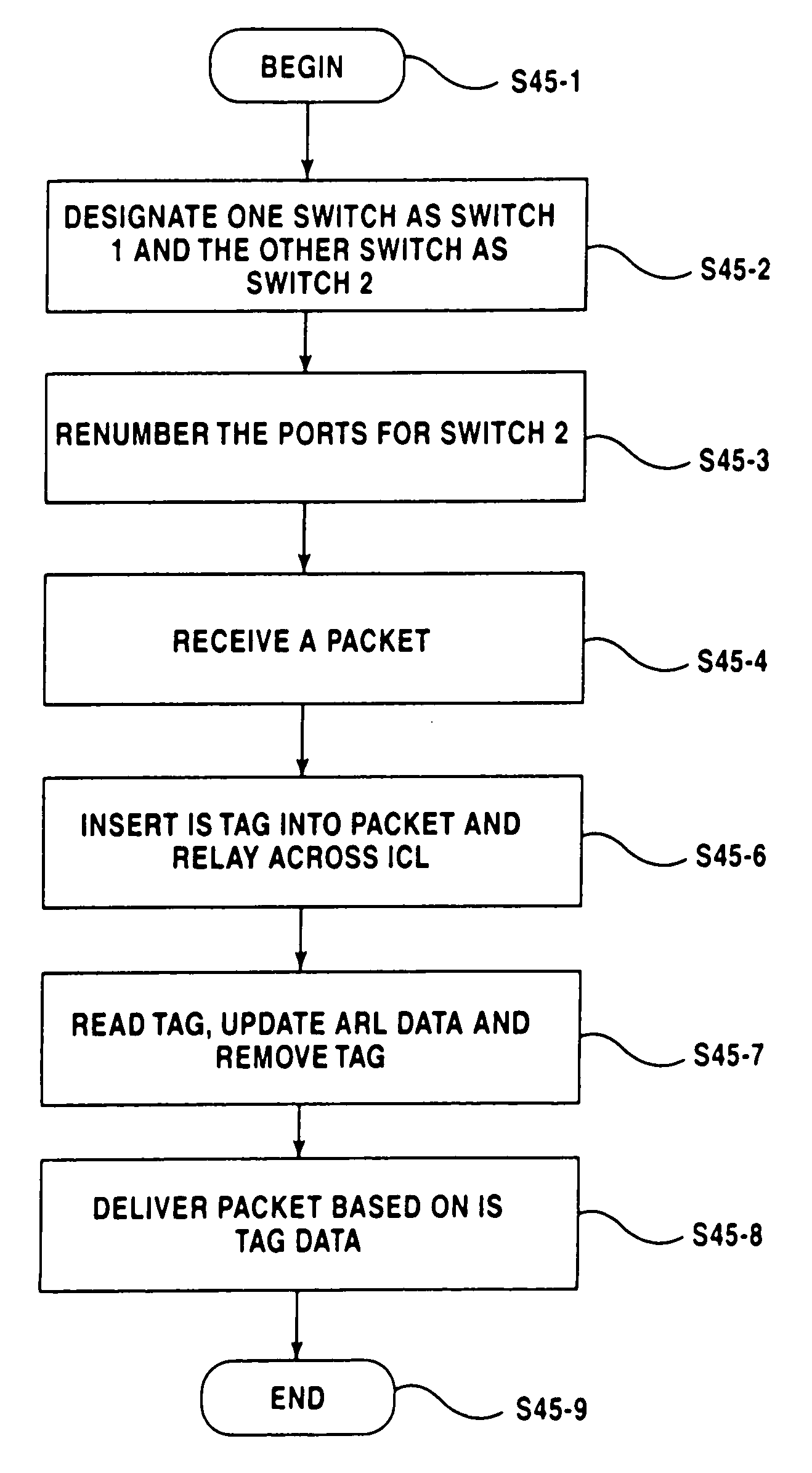

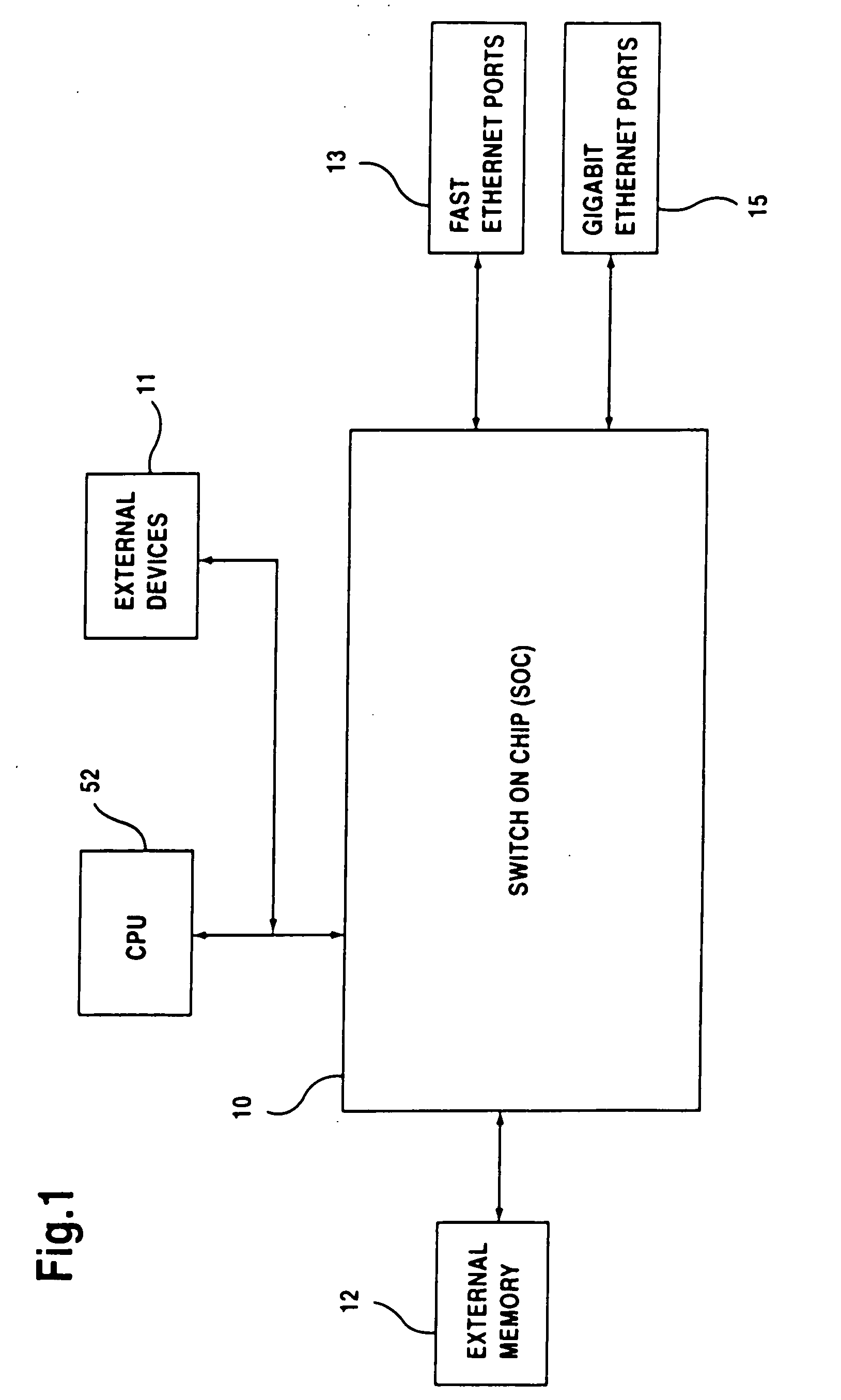

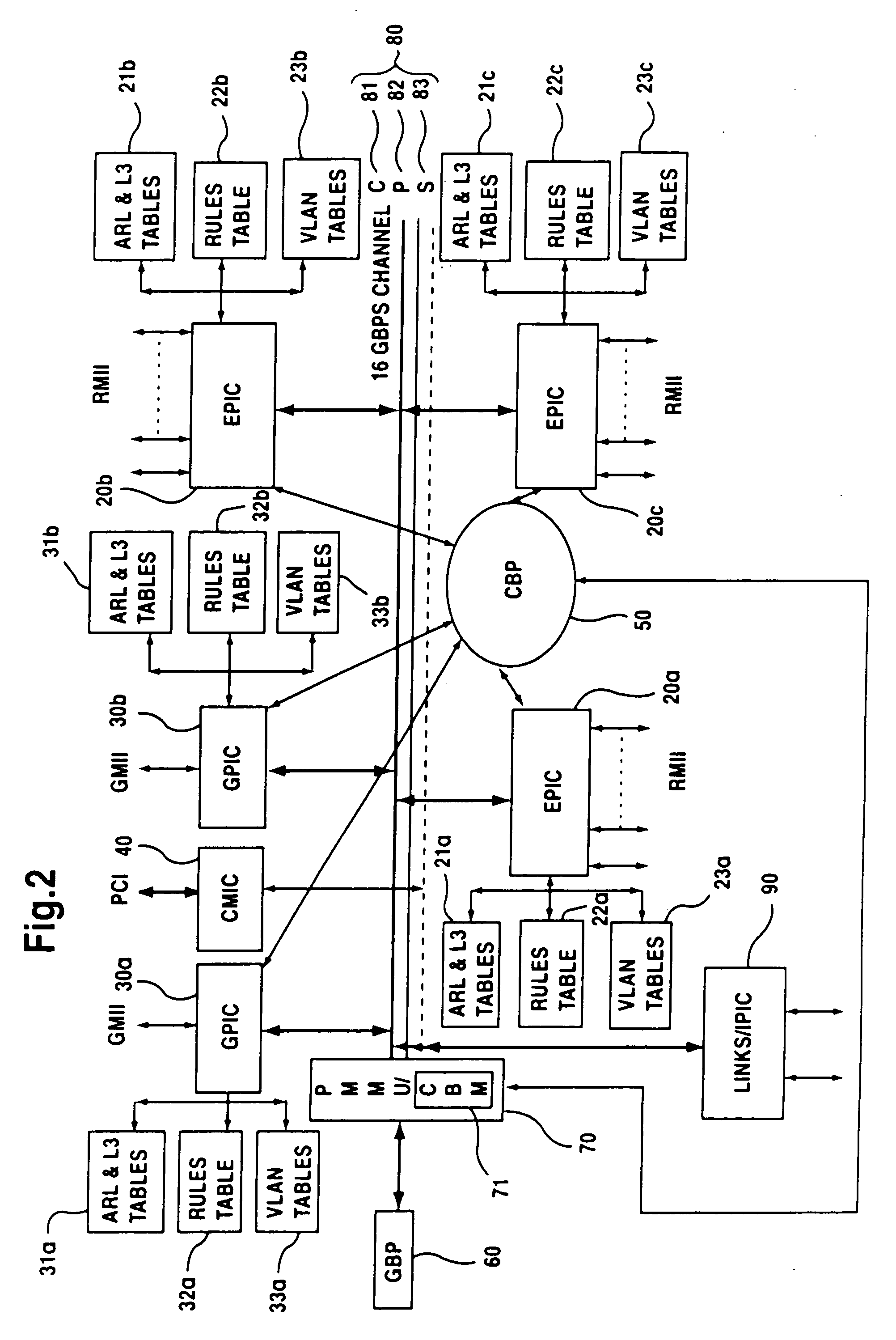

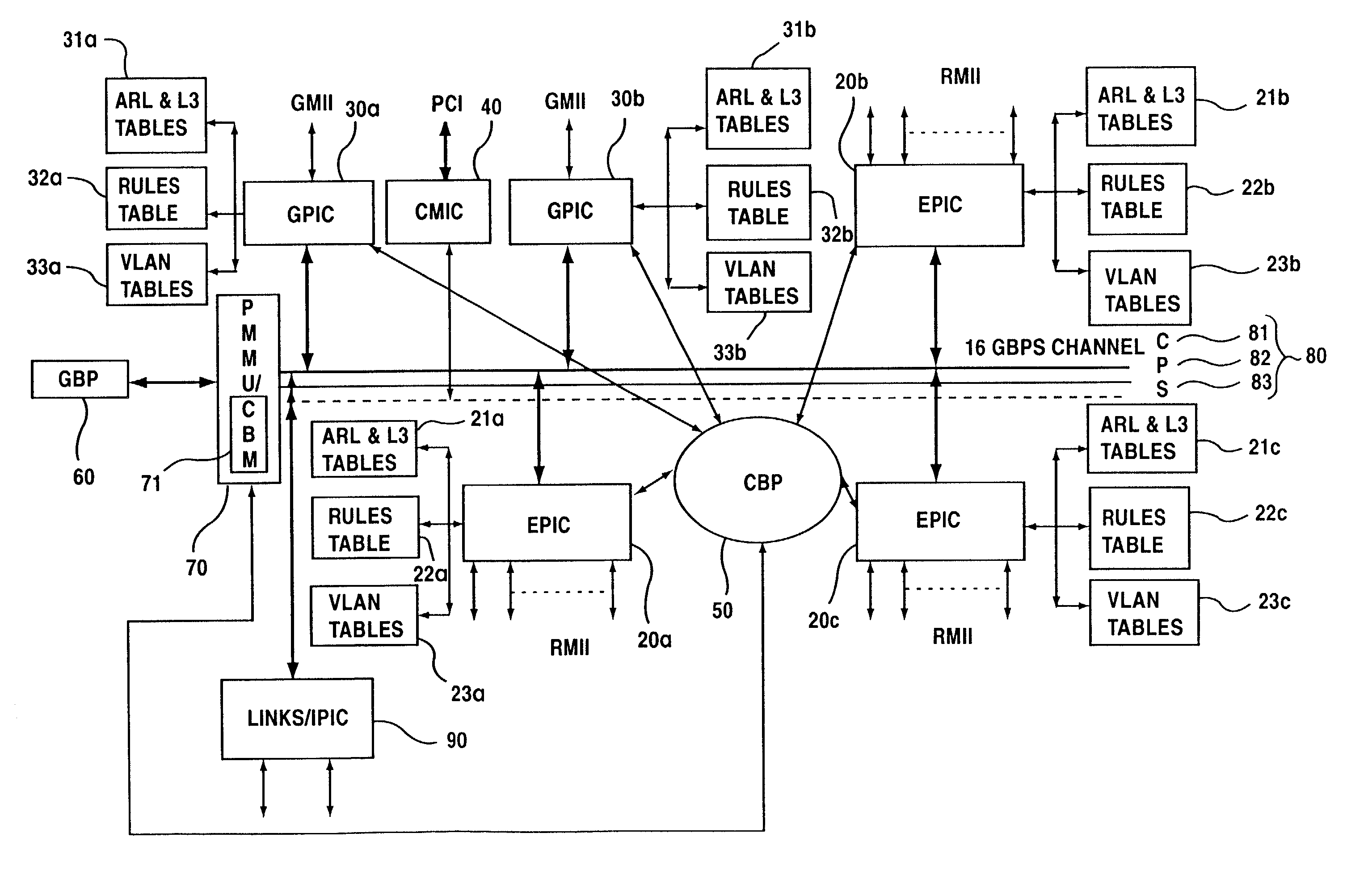

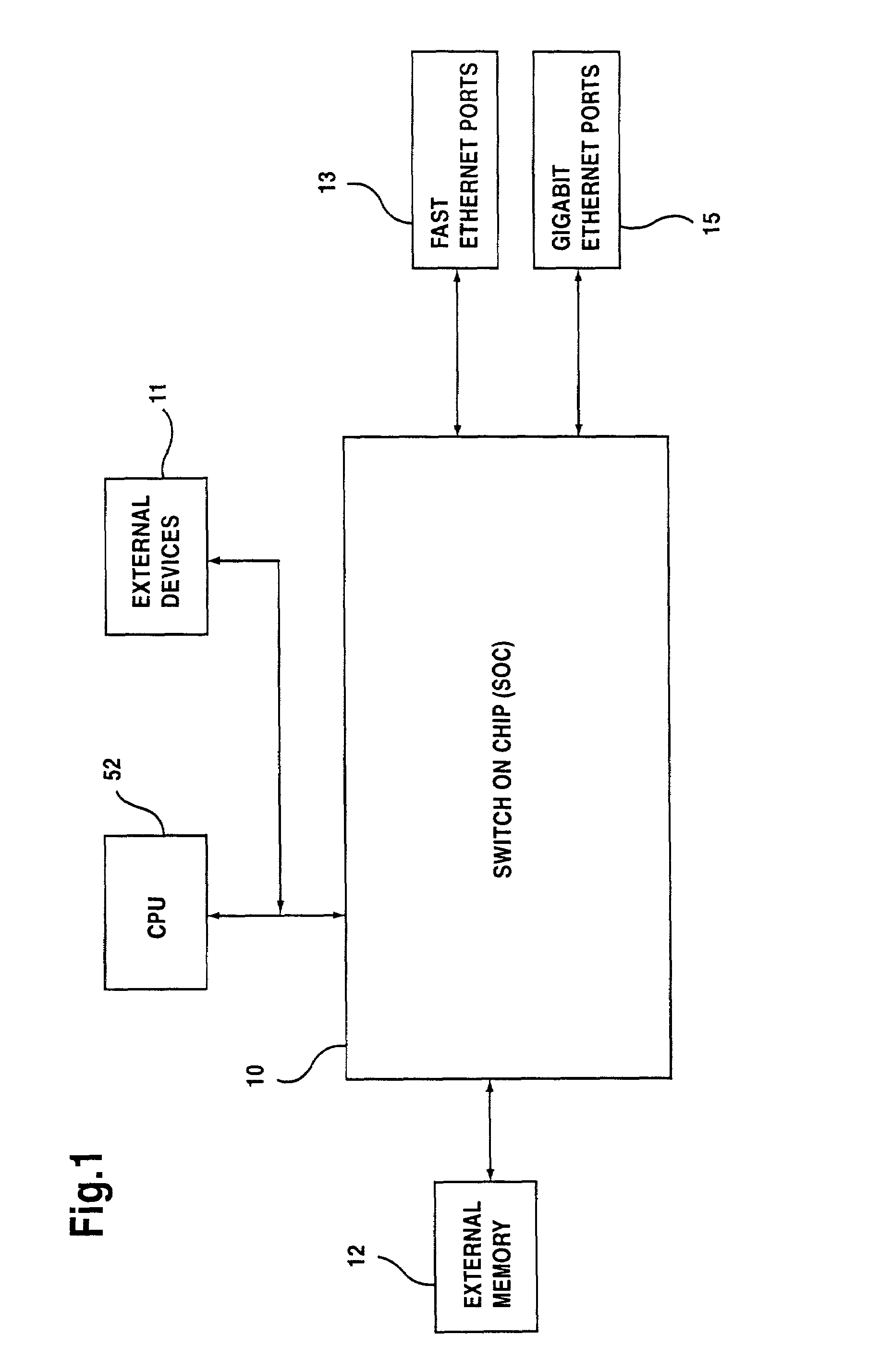

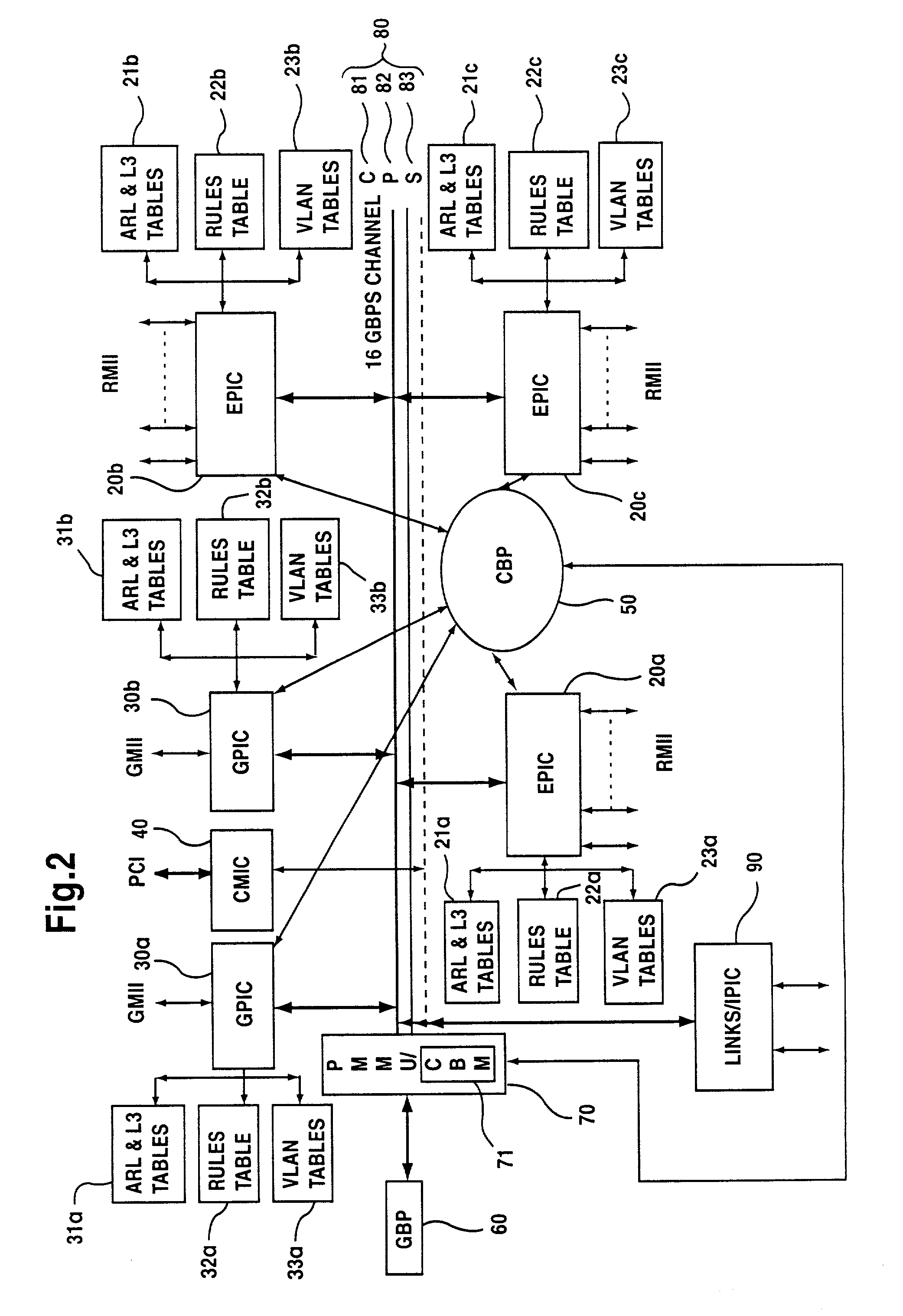

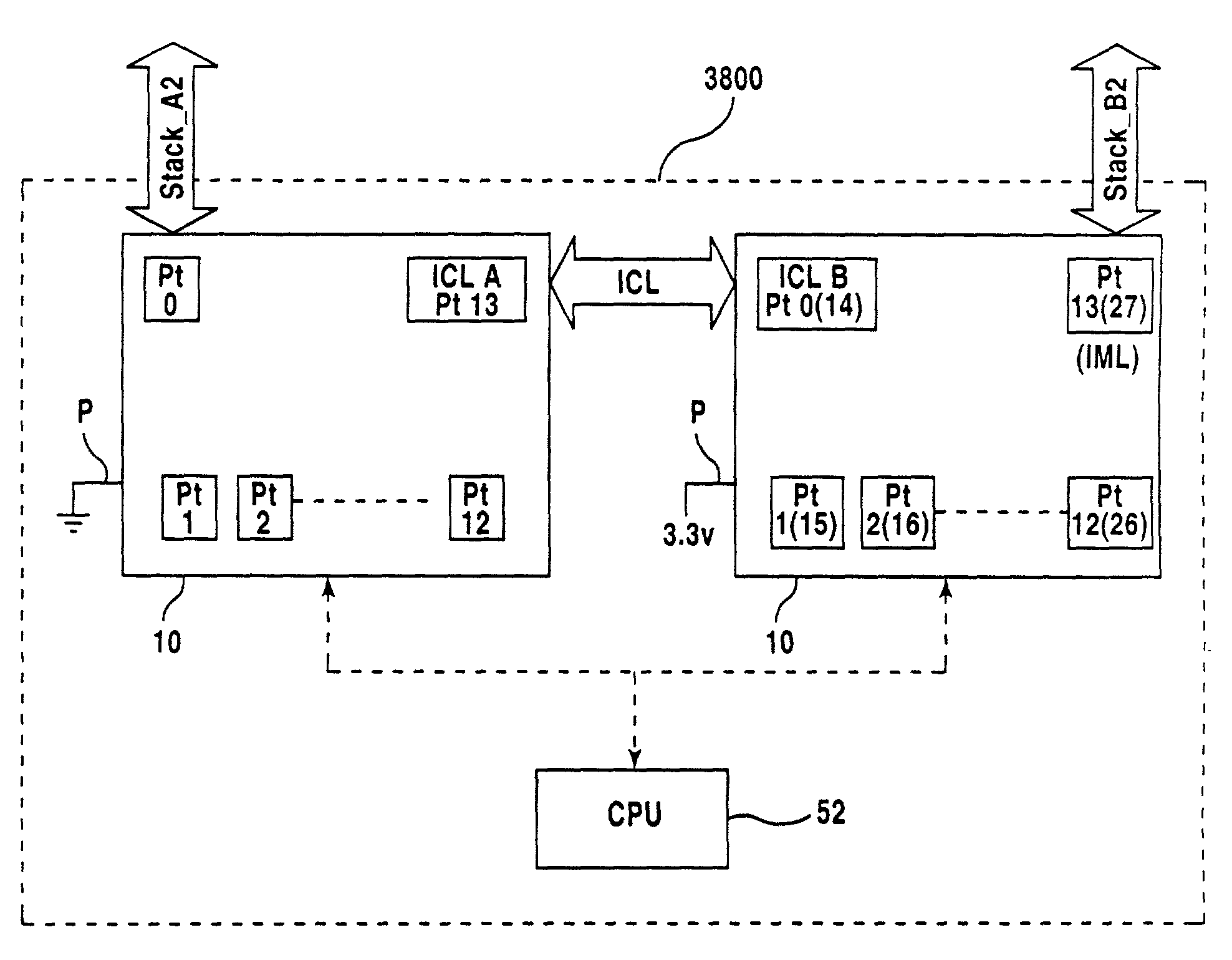

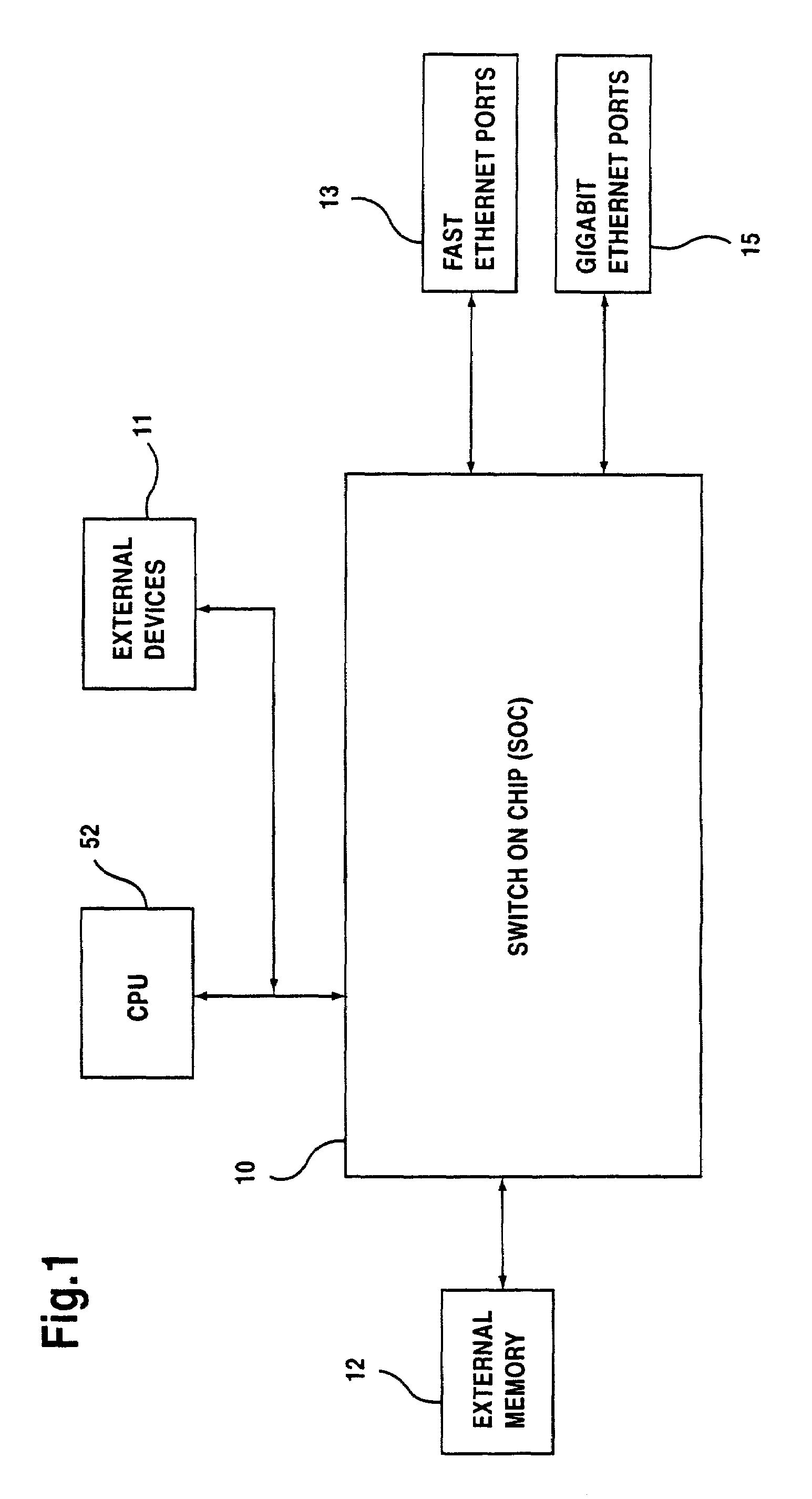

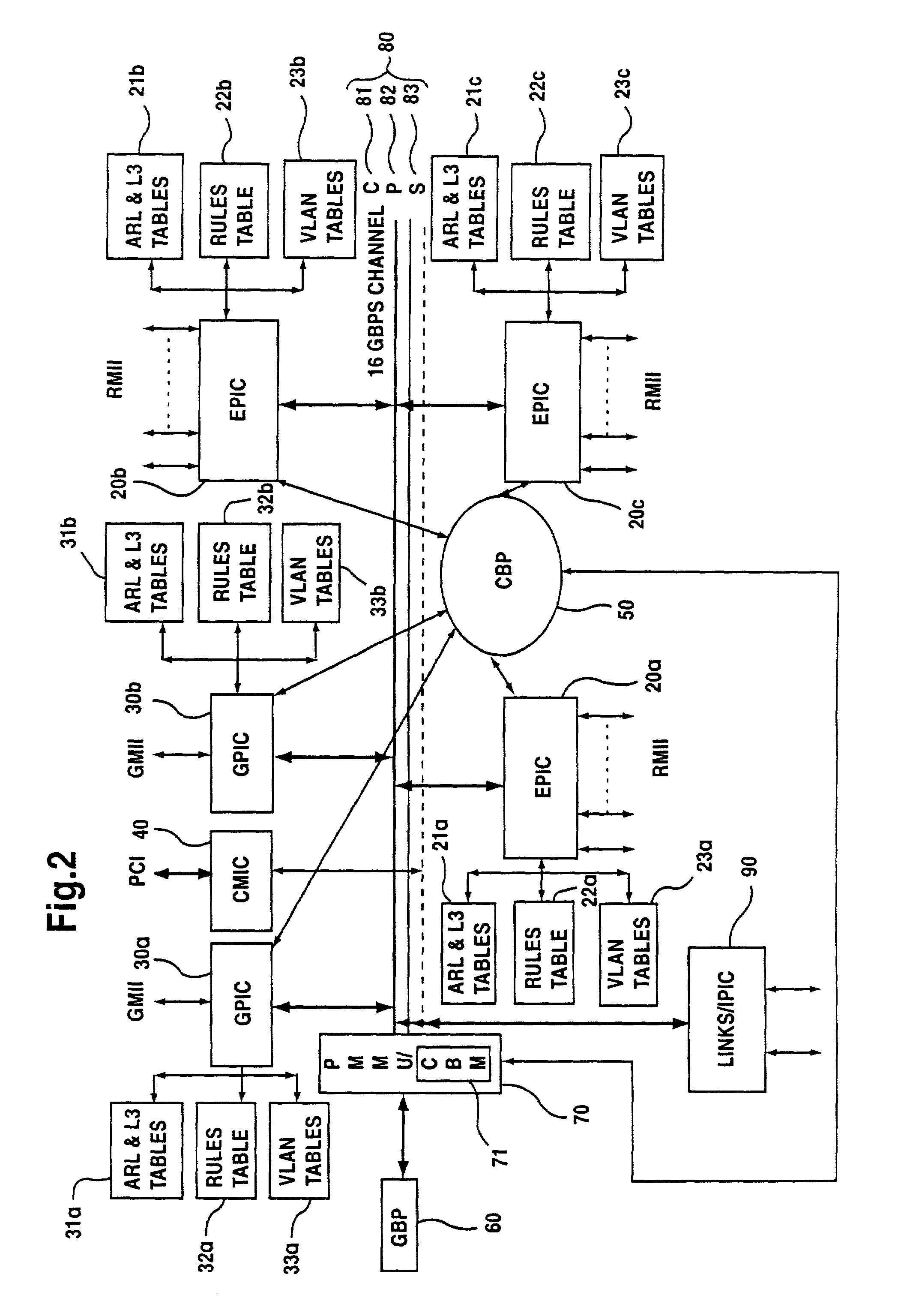

Linked network switch configuration

InactiveUS20090003213A1Avoid back pressureData switching detailsError preventionAddress resolutionNetwork switch

A network device having a plurality of ports including address resolution logic (ARL), a first switch, a second switch, and a CPU. The first and second switches include groups of ports which are a subset of the plurality of ports and are numbered by different numbering schemes, rate control logic for performing rate control functions related to switching data packets between the network ports, and local communications channels for transmitting messages between the groups of ports and the rate control logic. The first switch is configured to generate a rate control message and relay the rate control message to the second switch, and the second switch is configured to generate a second rate control message based on the first rate control message, where the second rate control message is different than the first message.

Owner:AVAGO TECH INT SALES PTE LTD

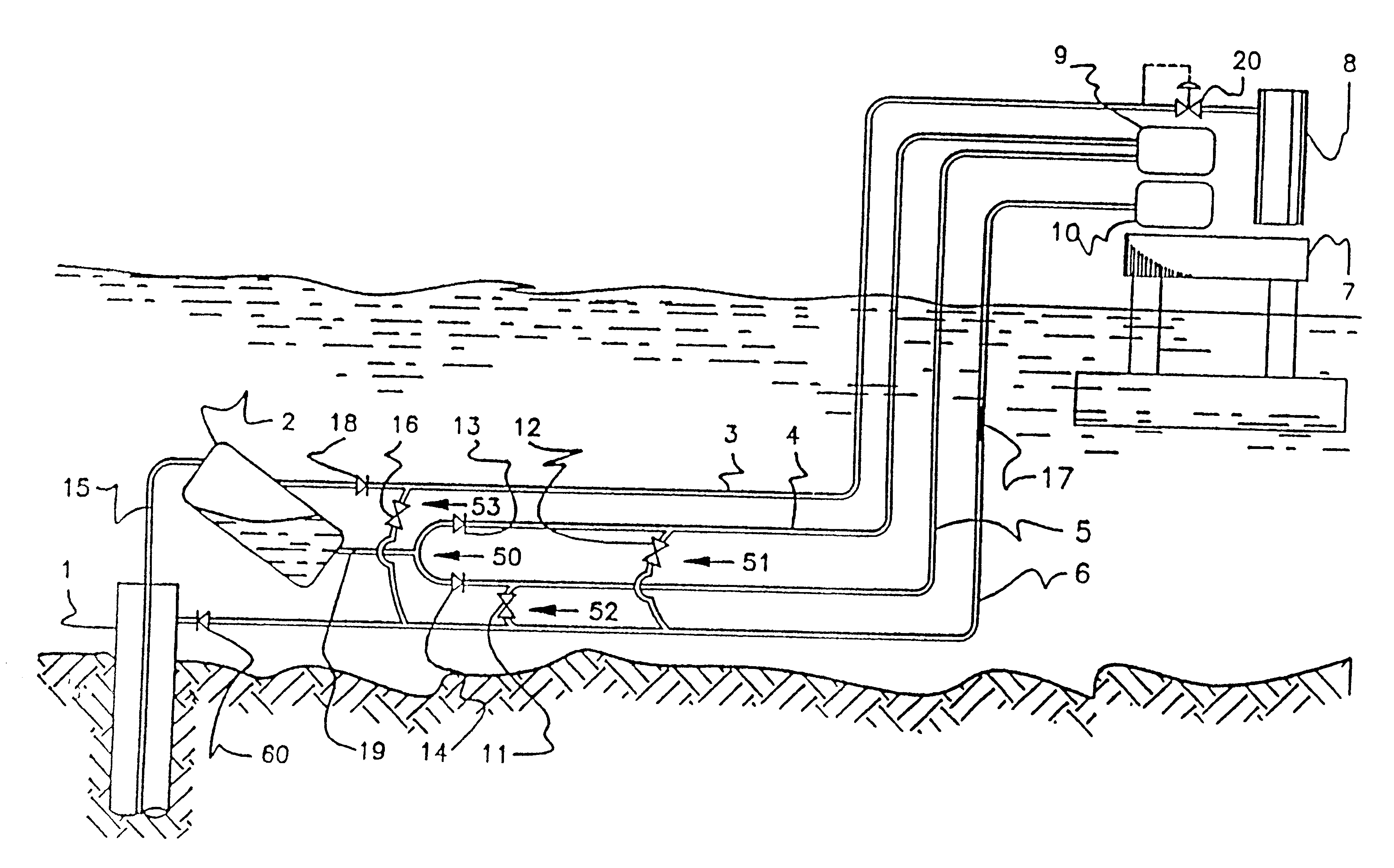

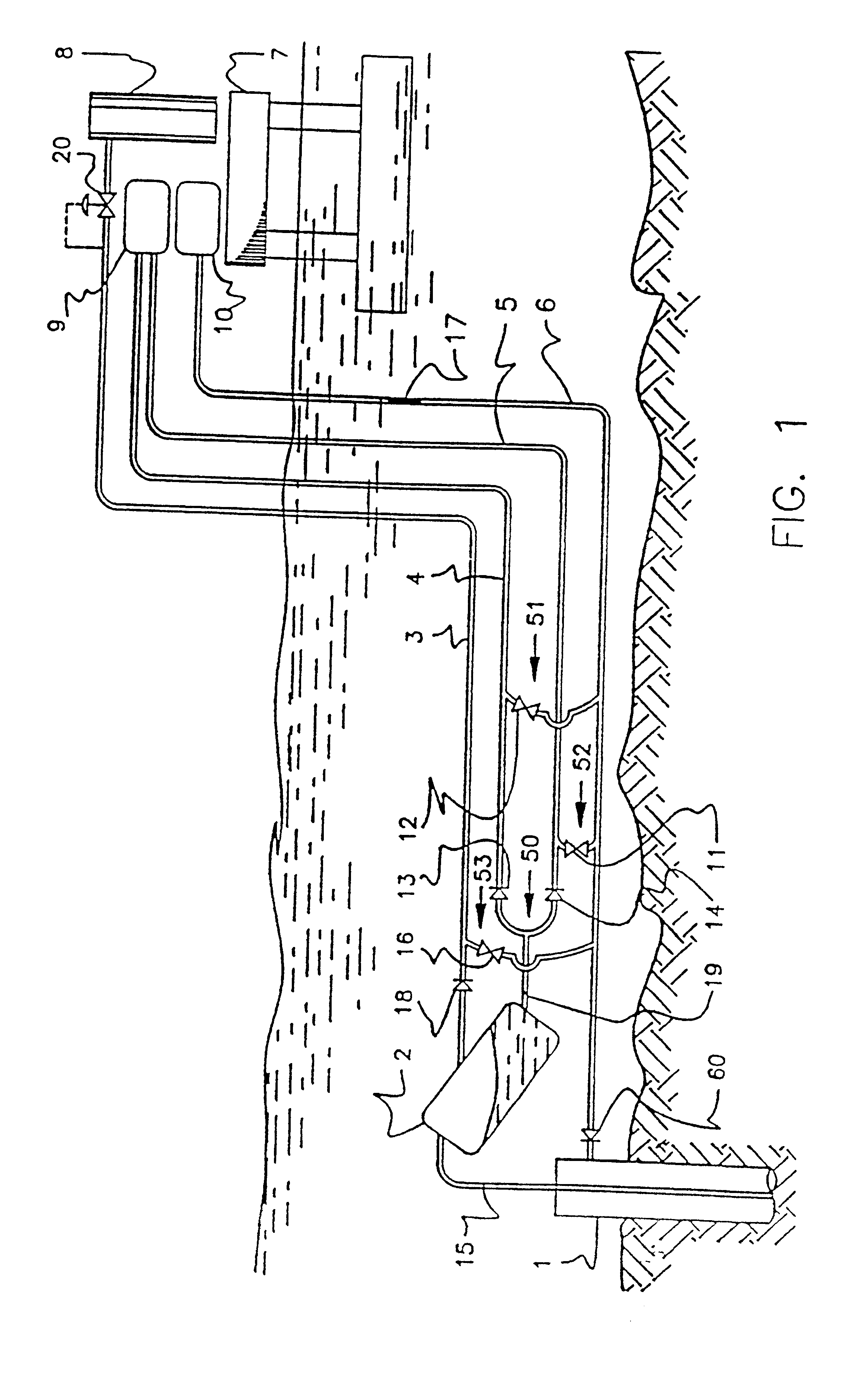

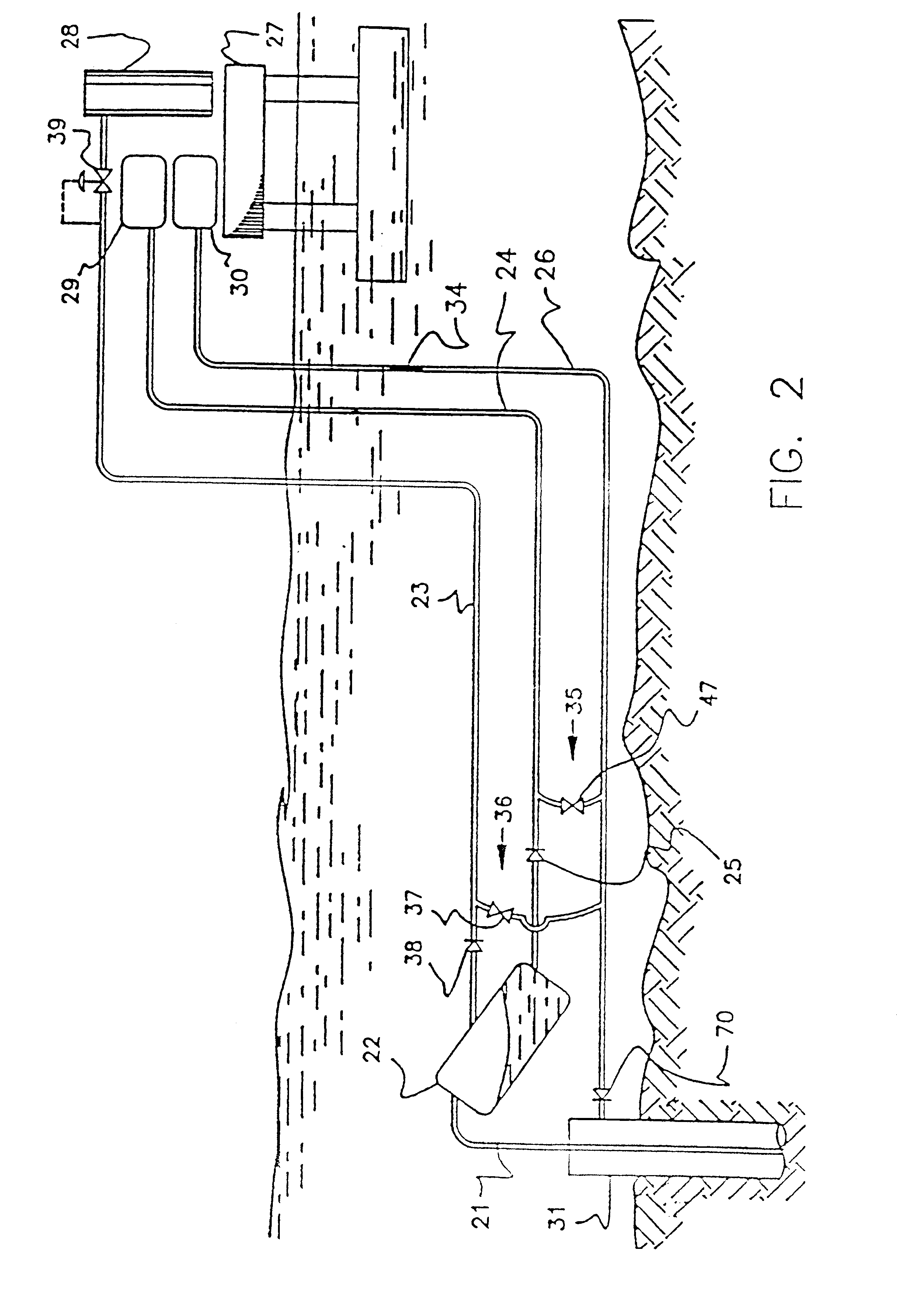

Method and equipment for offshore oil production with primary gas separation and flow using the injection of high pressure gas

InactiveUS6267182B1Promote primary separationAvoid separationFluid removalUnderwater drillingOil productionPetroleum

A subsea primary separating vessel (2,22) is installed close to the wellhead (1,31) of an oil producing well to effect primary separation of the liquid and gas phases of the fluids produced. A line (3,23) connected to the top of the separating vessel allows separated gas to flow to a gathering vessel (8,28) located at any gathering center. At least one flow line (4,5,24) connects the lower part of the separating vessel to a vessel (9,29) located at any gathering center. When the volume of liquid phase which separates out within the at least one flow line begins to exert a back pressure which adversely affects production from the well, pressurized gas can be injected into the flow line(s) for a specific period of time in order to promote the flow of liquid gas to the vessel (9,29). If it is desired that flow efficiency should be increased a mechanical interface driven by the pressurized gas may be used to encourage flow of the liquid phase.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

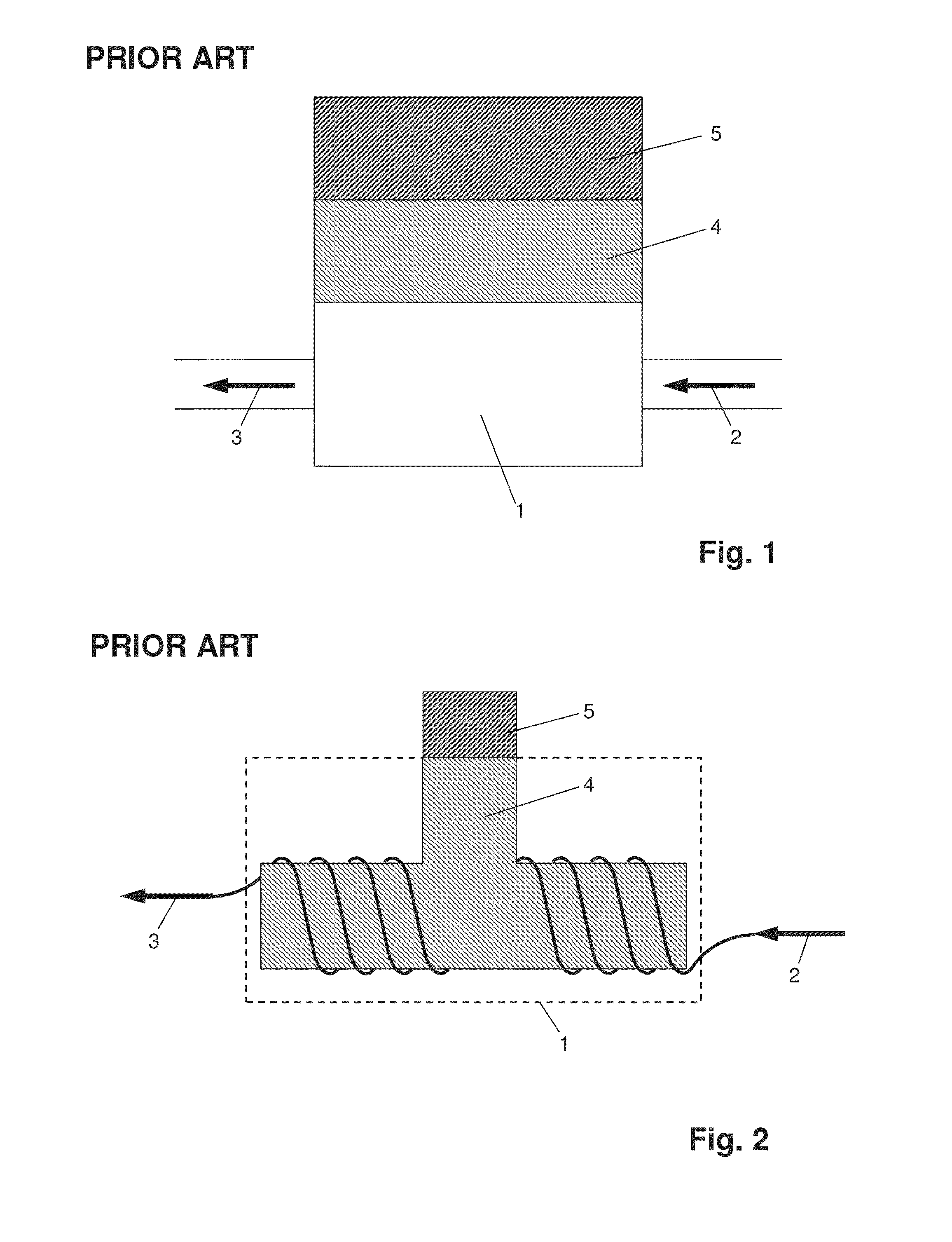

Cooling system for forming mold and method of cooling forming mold

InactiveUS20090315231A1Increase back pressureImprove cooling effectMelt-holding vesselsFoundry mouldsEvaporationEngineering

In a forming mold equipped with a cooling channel for circulation of a refrigerant composed of a cooling gas and a atomized cooling liquid, any increase of back pressure attributed to evaporation of the refrigerant fed to the cooling channel is inhibited to thereby attain cooling acceleration, and further any occurrence of rust or scale by the refrigerant circulated through the cooling channel is prevented. Accordingly, a channel for supply of the refrigerant to the cooling channel of the forming mold is provided with air pressure source for trapping of air in the supply channel and pressure feeding of the same; oxygen separation means for separation removal of oxygen from the pressure fed air to thereby lower the oxygen concentration of the air; and atomizing means for spraying of the cooling liquid into the air with oxygen concentration lowered. The oxygen separated from the air by the oxygen separation means is returned to the refrigerant forcedly emitted from the cooling channel by means of forced exhaust means.

Owner:TOYOTA JIDOSHA KK

Linked network switch configuration

InactiveUS7035286B2Avoid back pressureTime-division multiplexData switching by path configurationAddress resolutionNetwork switch

A network device having a plurality of ports including address resolution logic (ARL), a first switch, a second switch, and a CPU. The first and second switches include groups of ports which are a subset of the plurality of ports and are numbered by different numbering schemes, rate control logic for performing rate control functions related to switching data packets between the network ports, and local communications channels for transmitting messages between the groups of ports and the rate control logic. The first switch is configured to generate a rate control message and relay the rate control message to the second switch, and a first link port of the first switch is configured to generate a second rate control message based on the first rate control message, relay the second rate control message to the second switch, where the second rate control message is different than the first message.

Owner:AVAGO TECH INT SALES PTE LTD

Drain Cartridge Having Removable Valved System

ActiveUS20110010833A1Eliminate needEasy to replaceUrinalsWater treatment parameter controlEngineeringUltraviolet light

Various embodiments of a cartridge for regulating a fluid flow are described that include an upper housing, and an insert that is user-removable from the upper housing. The cartridge can include one or more valves that are biased in a closed position to prevent odors from escaping the cartridge. The cartridge can also include a fluid trap that is at least partially disposed within the cartridge or fluidly coupled thereto. An ultraviolet light can be inserted within the cartridge to disinfect a fluid passageway of the cartridge.

Owner:GREEN DRAIN

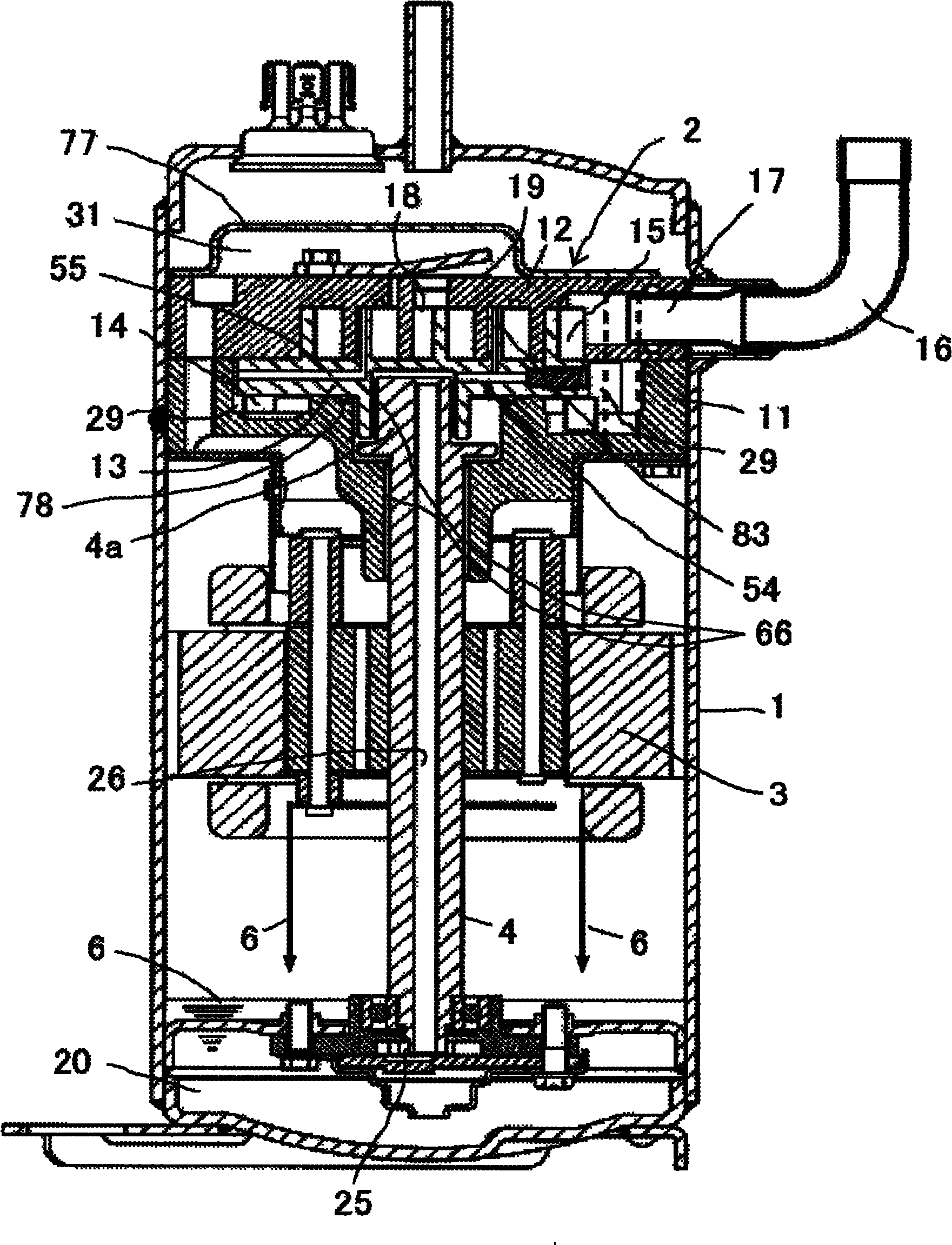

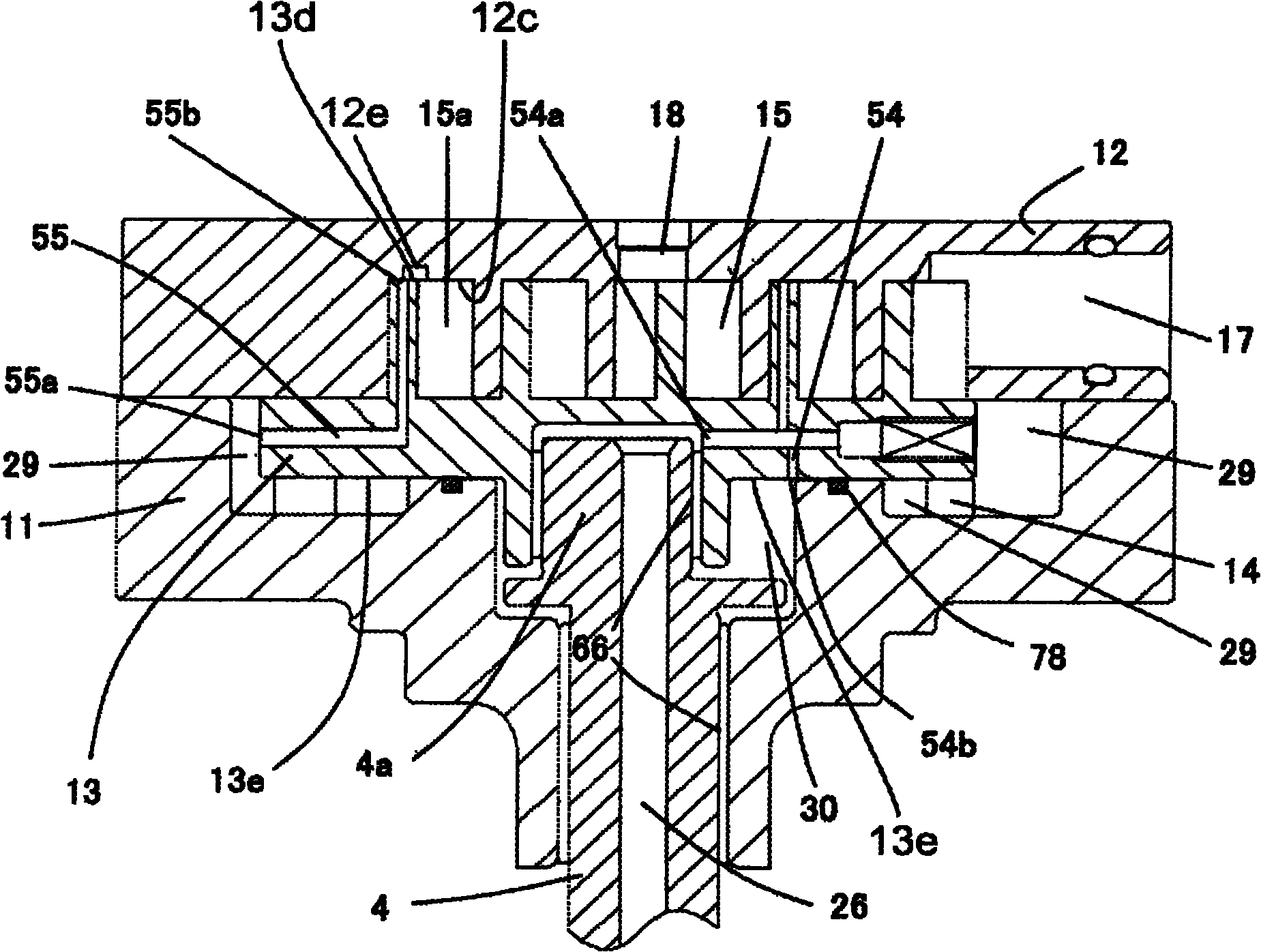

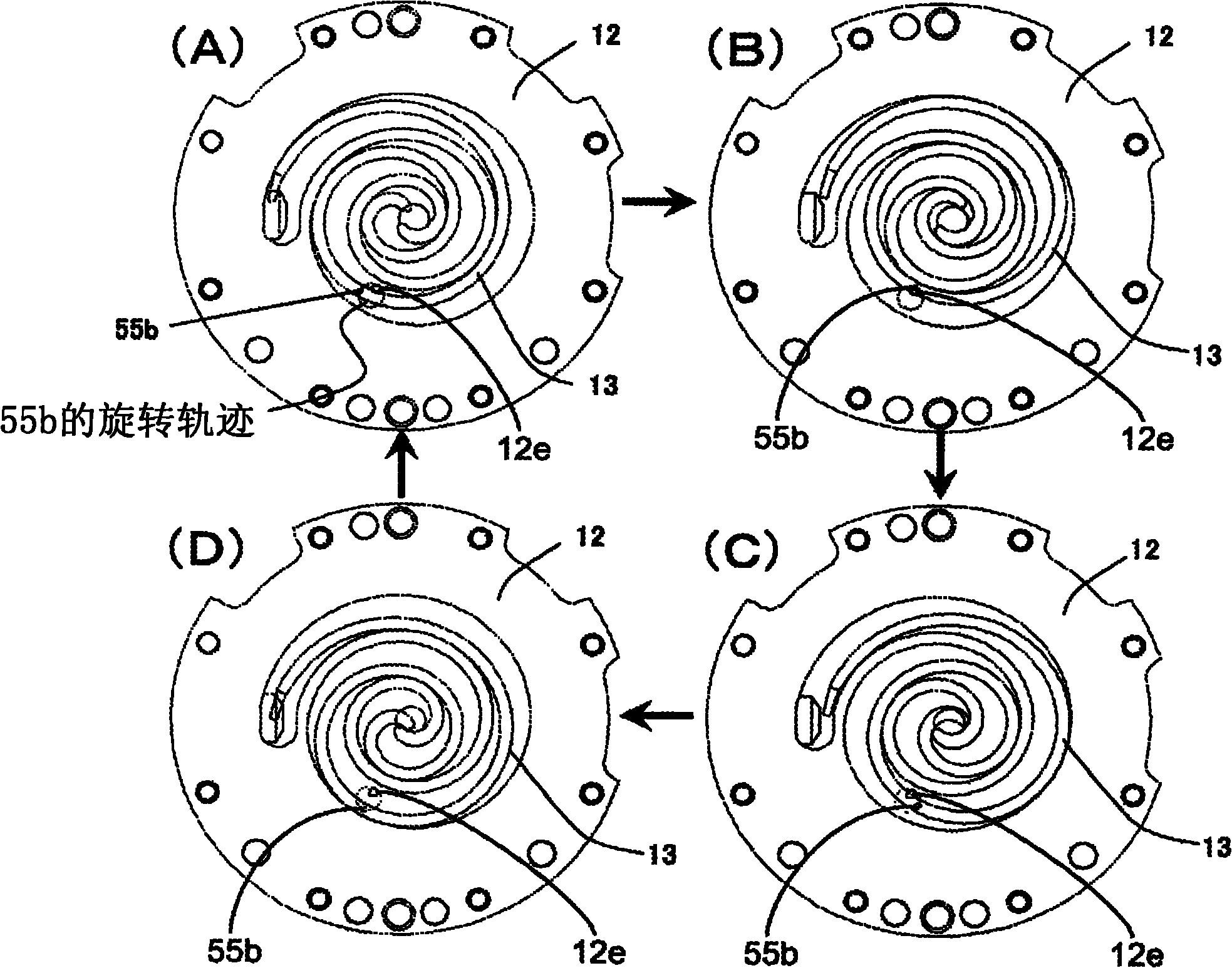

Scroll compressor

ActiveCN102016319AAvoid back pressureStable back pressureRotary piston pumpsRotary piston liquid enginesBack pressureEngineering

A scroll compressor in which timing of communication between a high-pressure region and a back pressure chamber and timing of communication between the back pressure chamber and a compression chamber are controlled to prevent excessive back pressure, allowing application of stable back pressure. As a result, the scroll compressor has high efficiency and high reliability. The scroll compressor has a first route (54) for intermittently interconnecting a high-pressure region (30) and a back pressure chamber (29), and also has a second route (55) for intermittently interconnecting the back pressure chamber (29) and a compression chamber (15).

Owner:PANASONIC CORP

Grease Sampling Kit, Grease Sampling Devices Made from the Kit, and Related Methods

ActiveUS20090183580A1Easy to assembleEfficiently obtainedWithdrawing sample devicesBurettes/pipettesOil and greaseEngineering

A kit of component parts for forming at least first and second grease sampling devices includes a number of housings, piston bodies, and piston shafts. A first grease sampling device has a piston movable in the barrel and vent holes that resists the buildup of back pressure when the device is filled with a grease sample. A second grease sampling device includes a push rod extending from the piston that enables a representative grease sample to be obtained from a bearing, gear or other lubricated part that is not easily accessible.

Owner:WURZBACH RICHARD N

Linked network switch configuration

InactiveUS7424012B2Avoid back pressureError preventionFrequency-division multiplex detailsAddress resolutionNetwork switch

A network device having a plurality of ports including address resolution logic (ARL), a first switch, a second switch, and a CPU. The first and second switches include groups of ports which are a subset of the plurality of ports and are numbered by different numbering schemes, rate control logic for performing rate control functions related to switching data packets between the network ports, and local communications channels for transmitting messages between the groups of ports and the rate control logic. The first switch is configured to generate a rate control message and relay the rate control message to the second switch, and the second switch is configured to generate a second rate control message based on the first rate control message, where the second rate control message is different than the first message.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

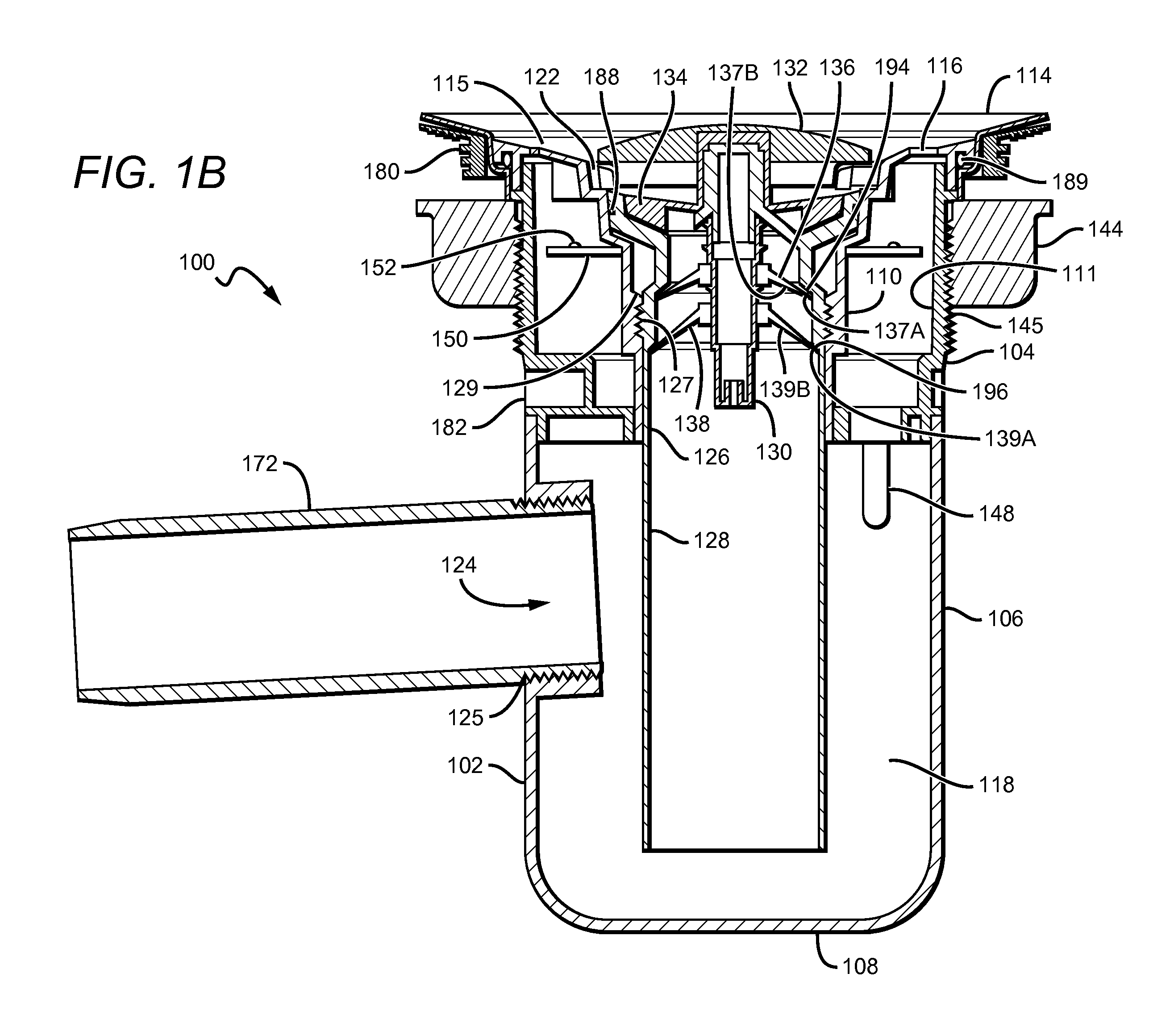

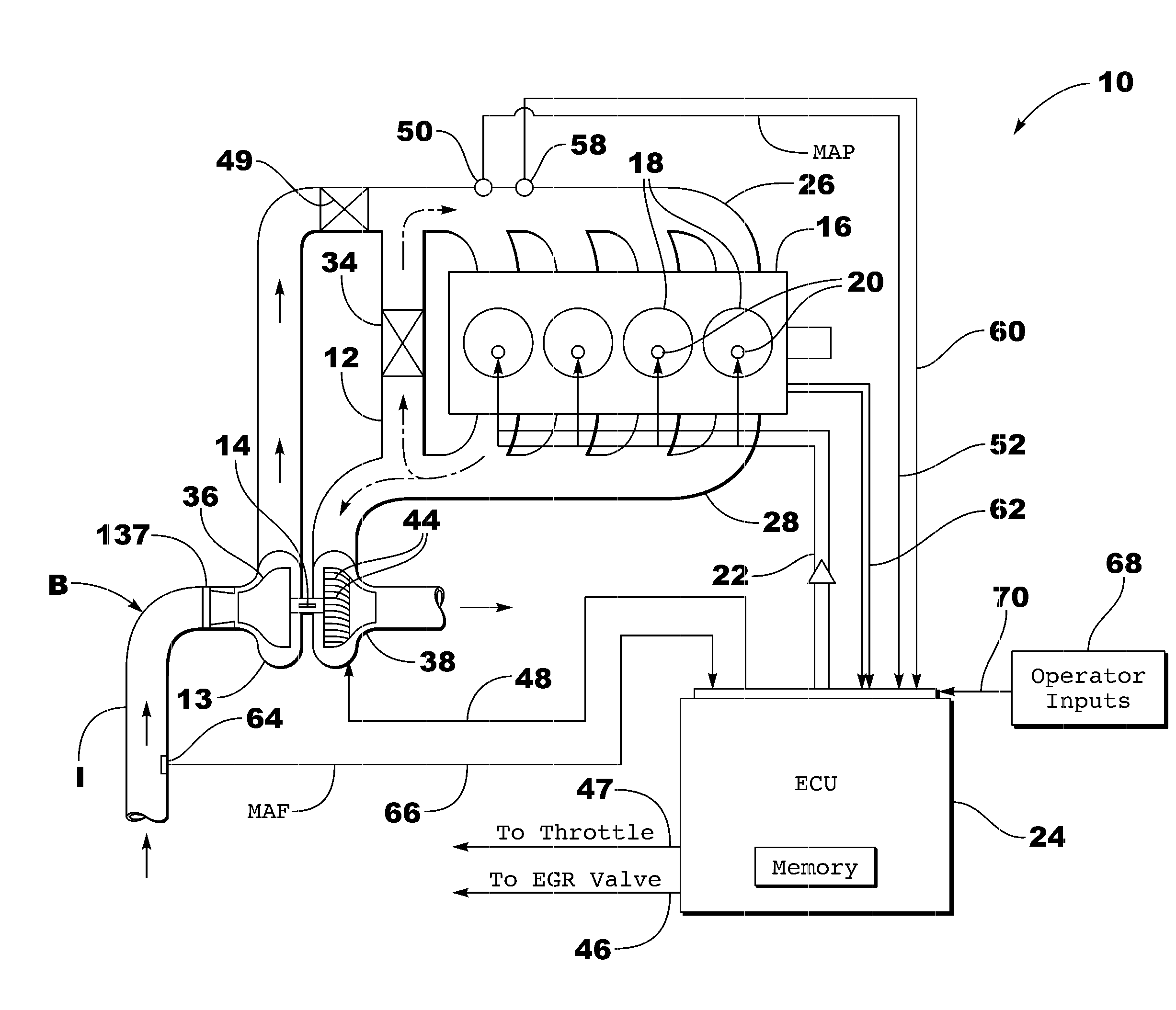

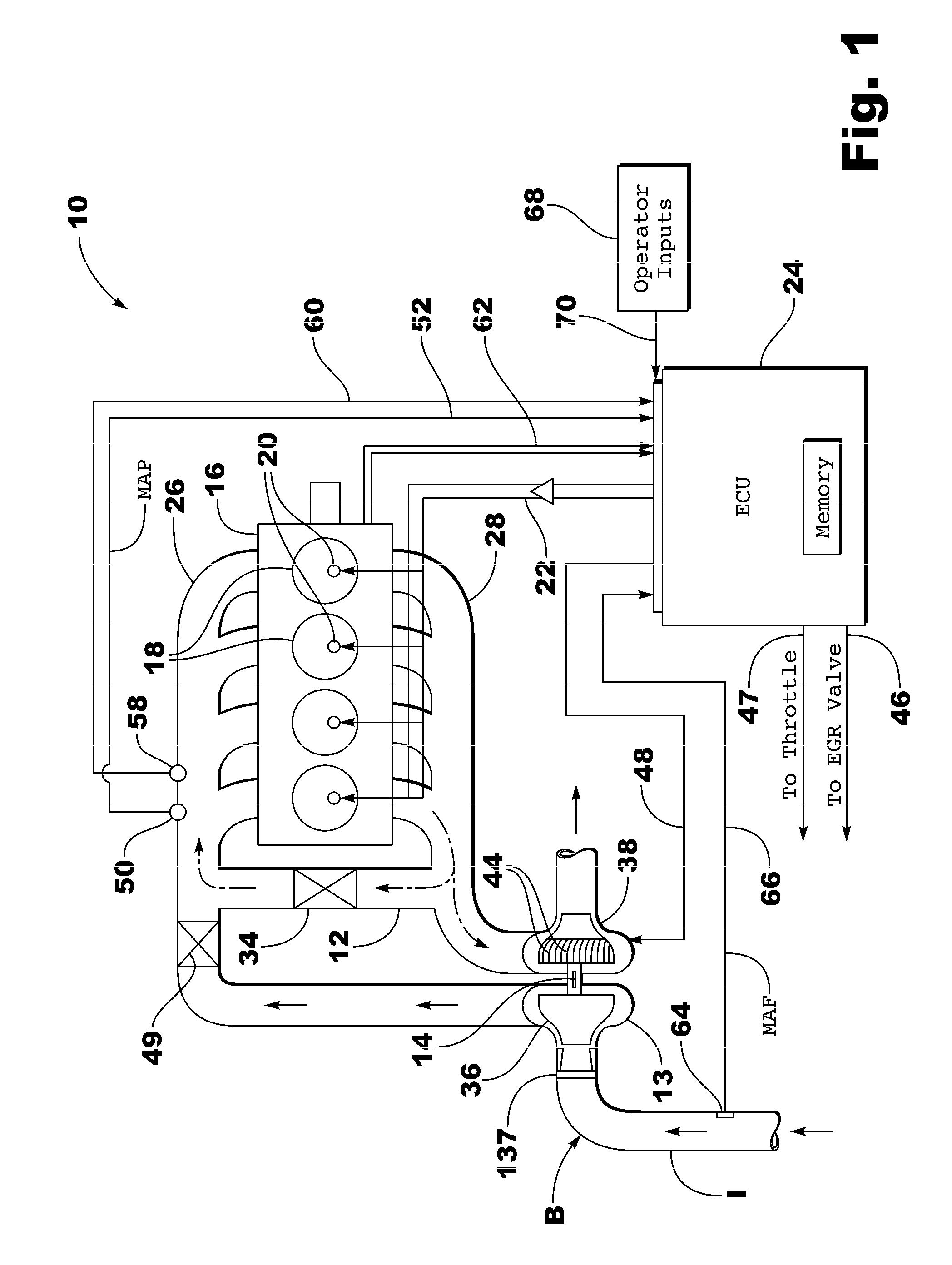

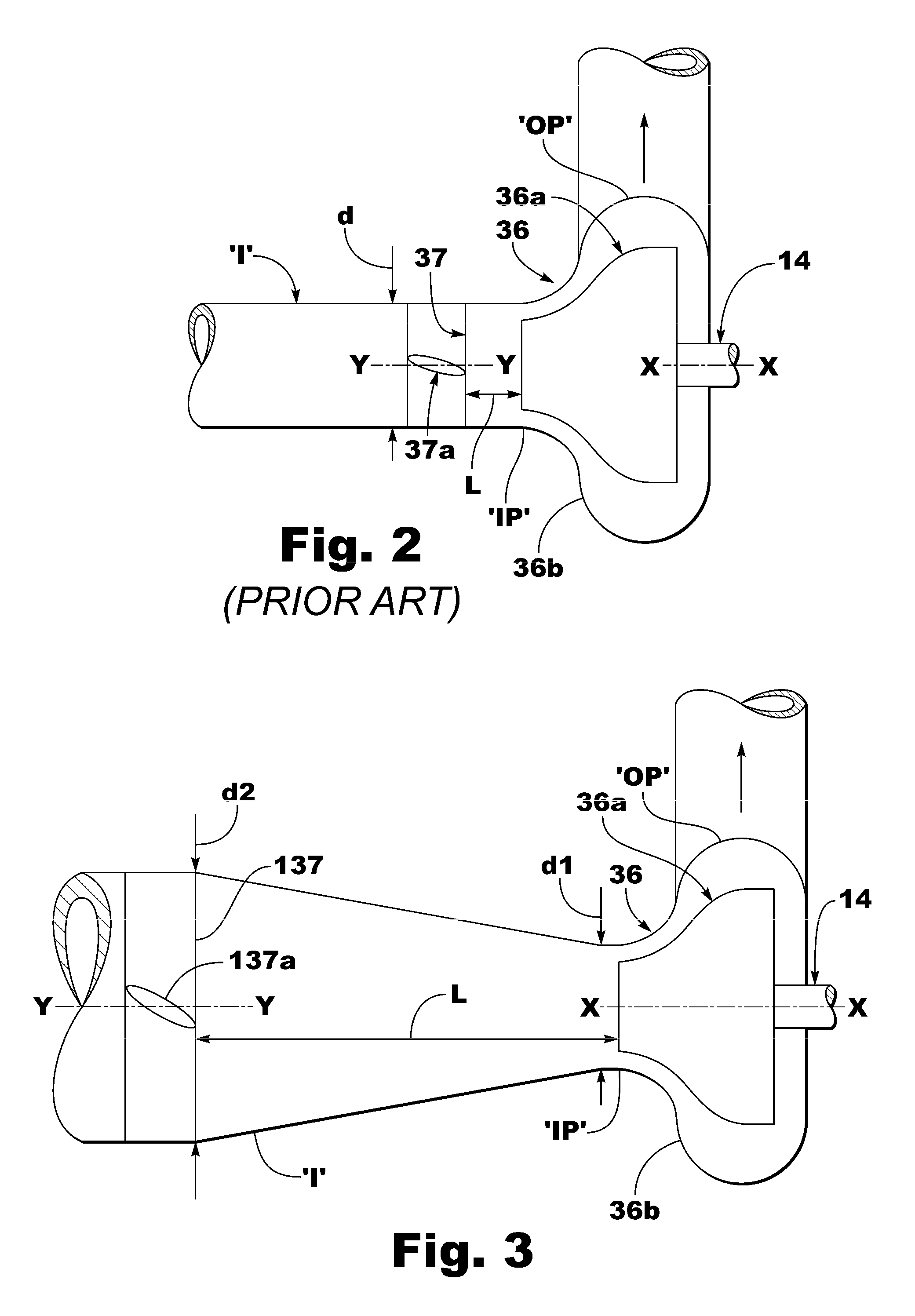

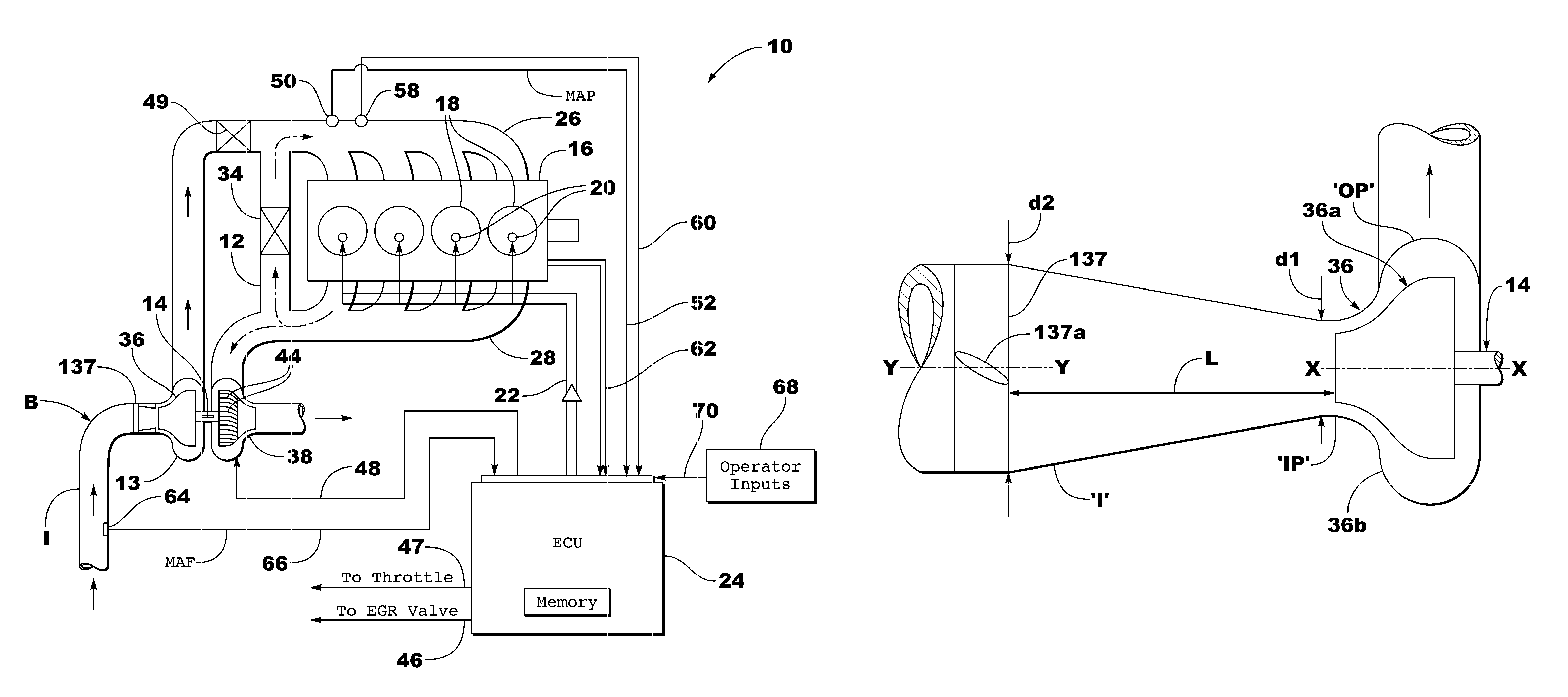

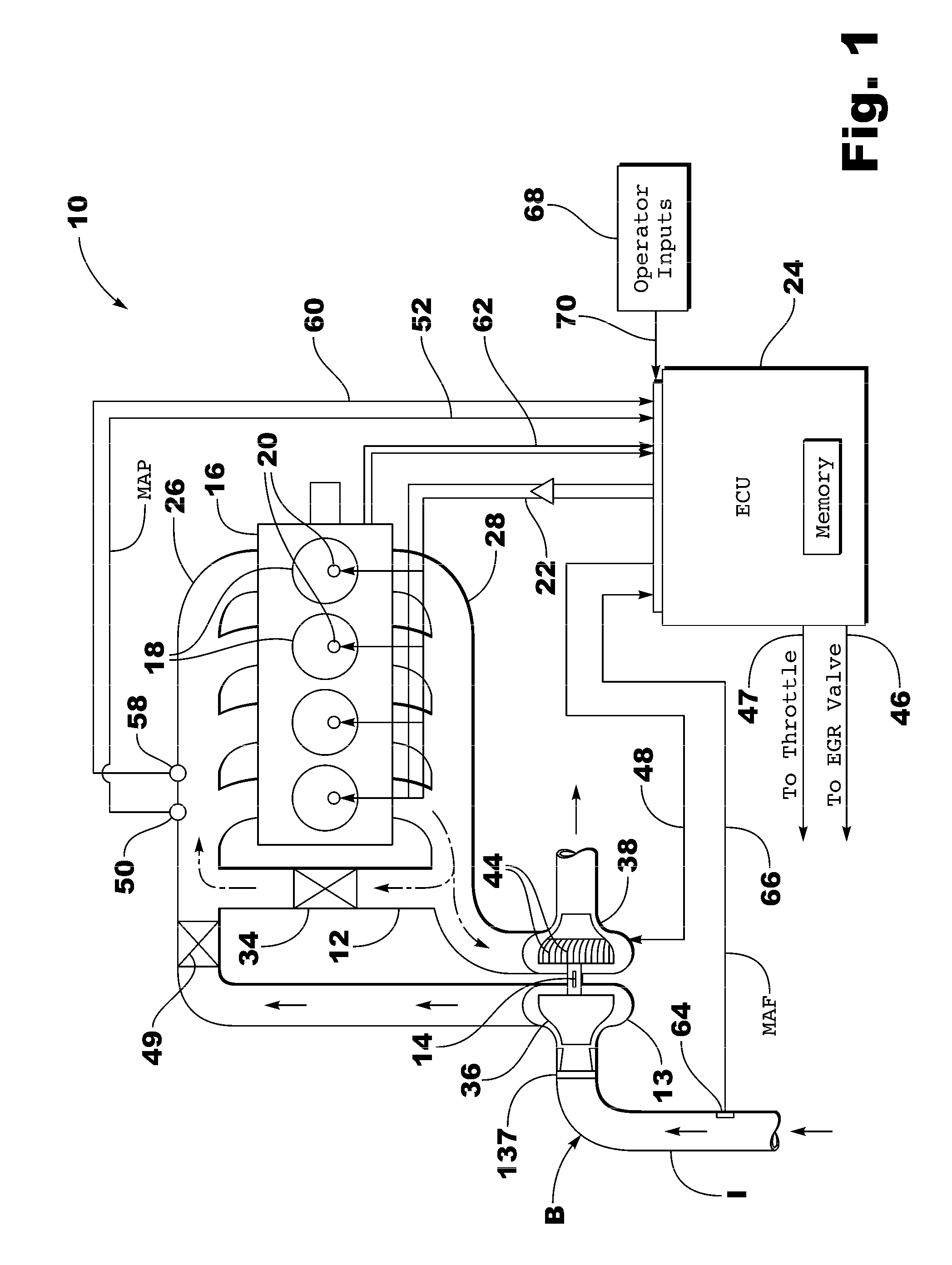

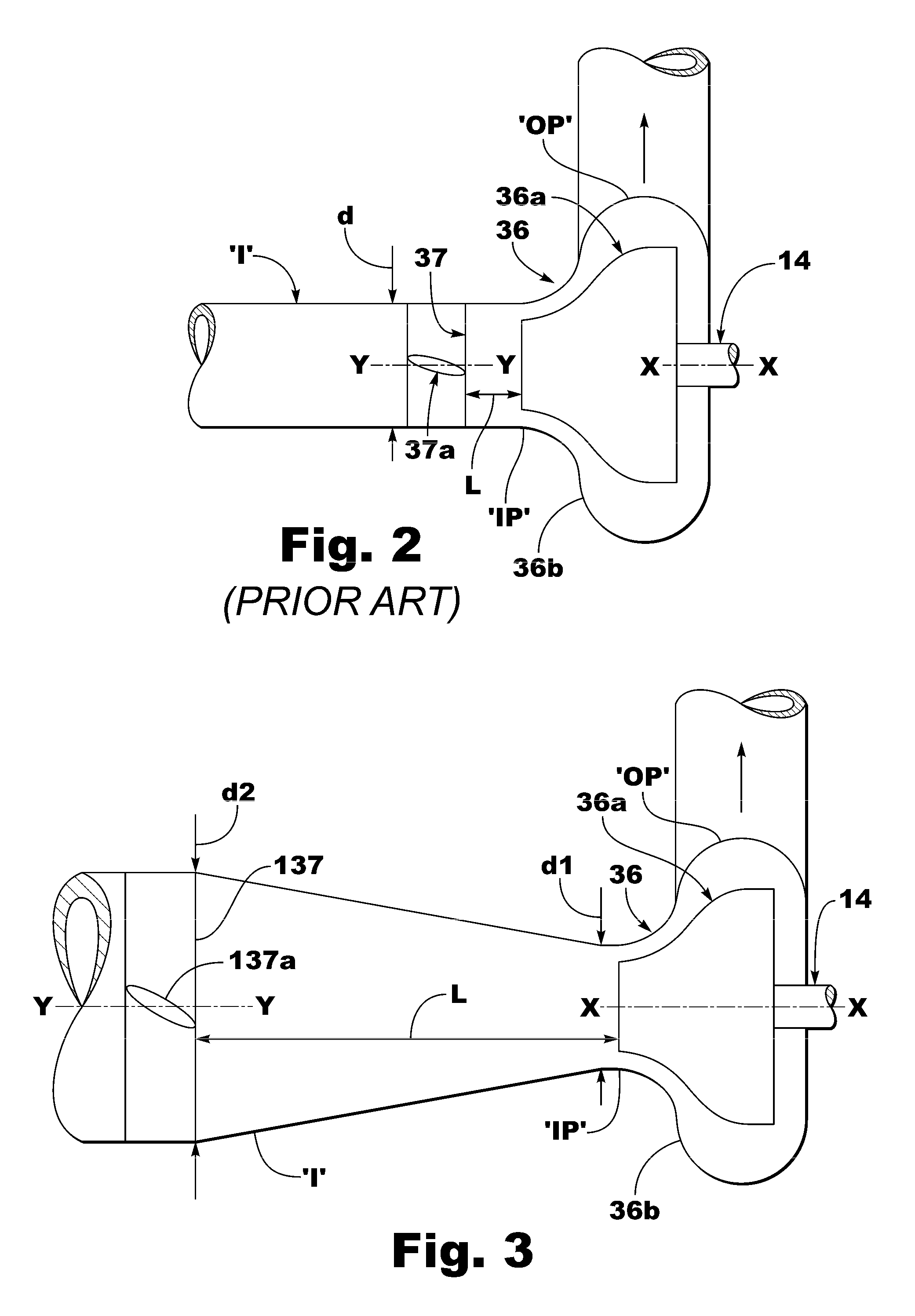

Inlet system for an engine

ActiveUS20100122531A1Prevent excessive back pressureReducing inlet areaInternal combustion piston enginesEngine manufactureFlow managementMechanical engineering

An apparatus for improving the performance of a radial compressor 36 forming part of an inlet system of an engine 10 is disclosed in which the configuration and positioning of a flow management device 137 used to generate pre-whirl is optimized so as to produce a pressure drop below a maximum acceptable level. An inlet duct ‘I’ connected to the radial compressor 36 has a tapered end portion so that a flow management device 137 of a larger diameter d2 can be accommodated than the diameter d1 of an inlet port ‘IP’ to the radial compressor 36.

Owner:FORD GLOBAL TECH LLC

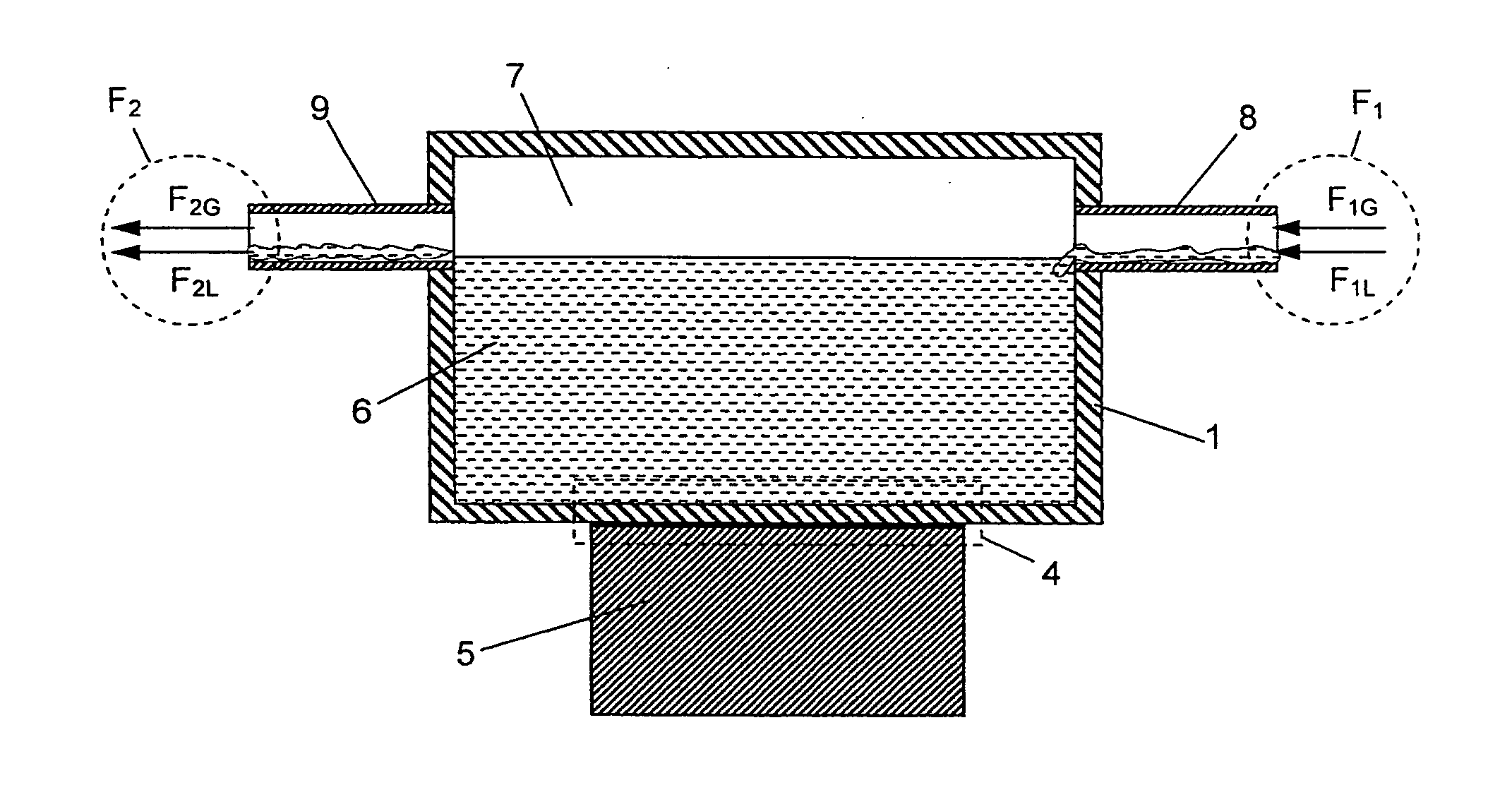

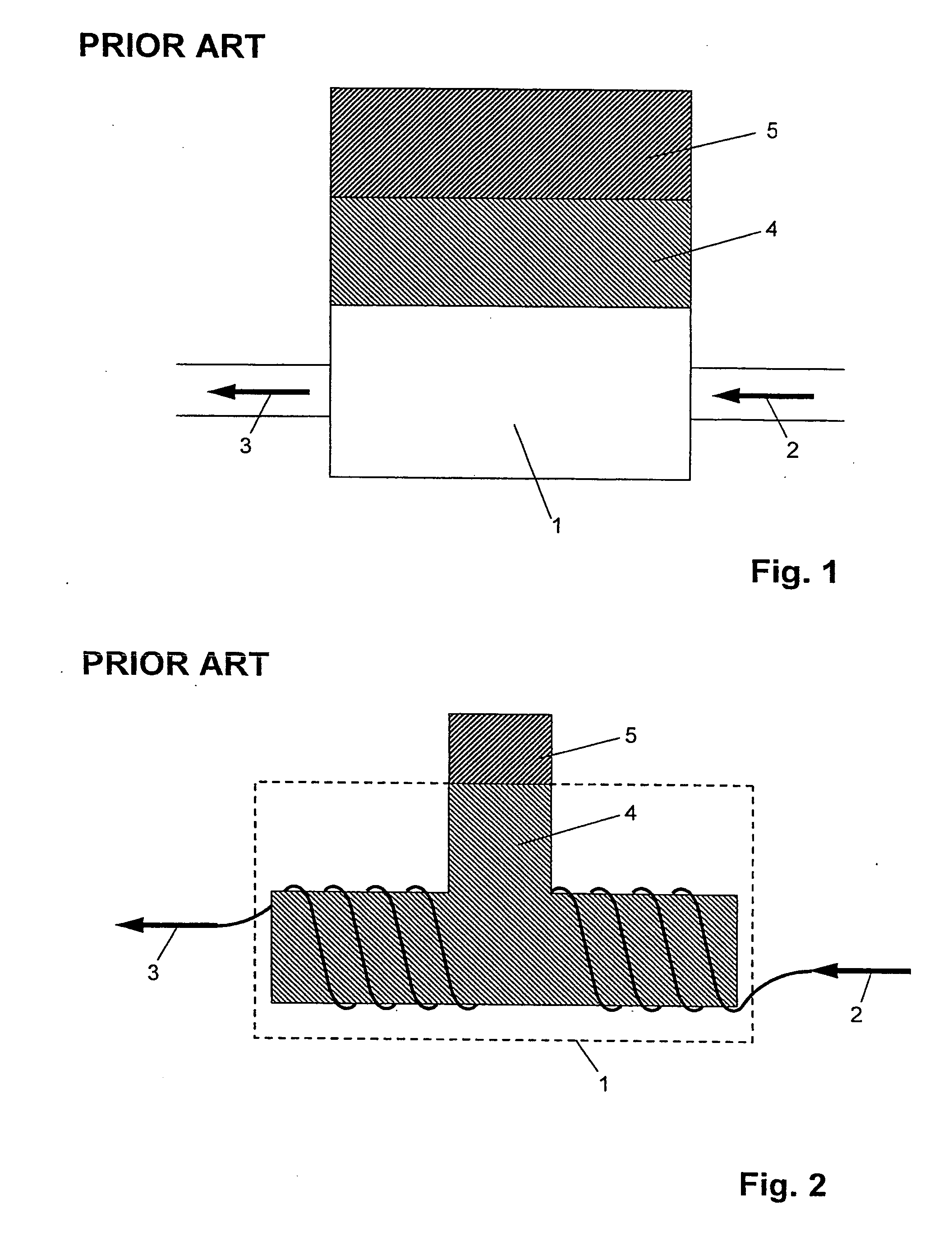

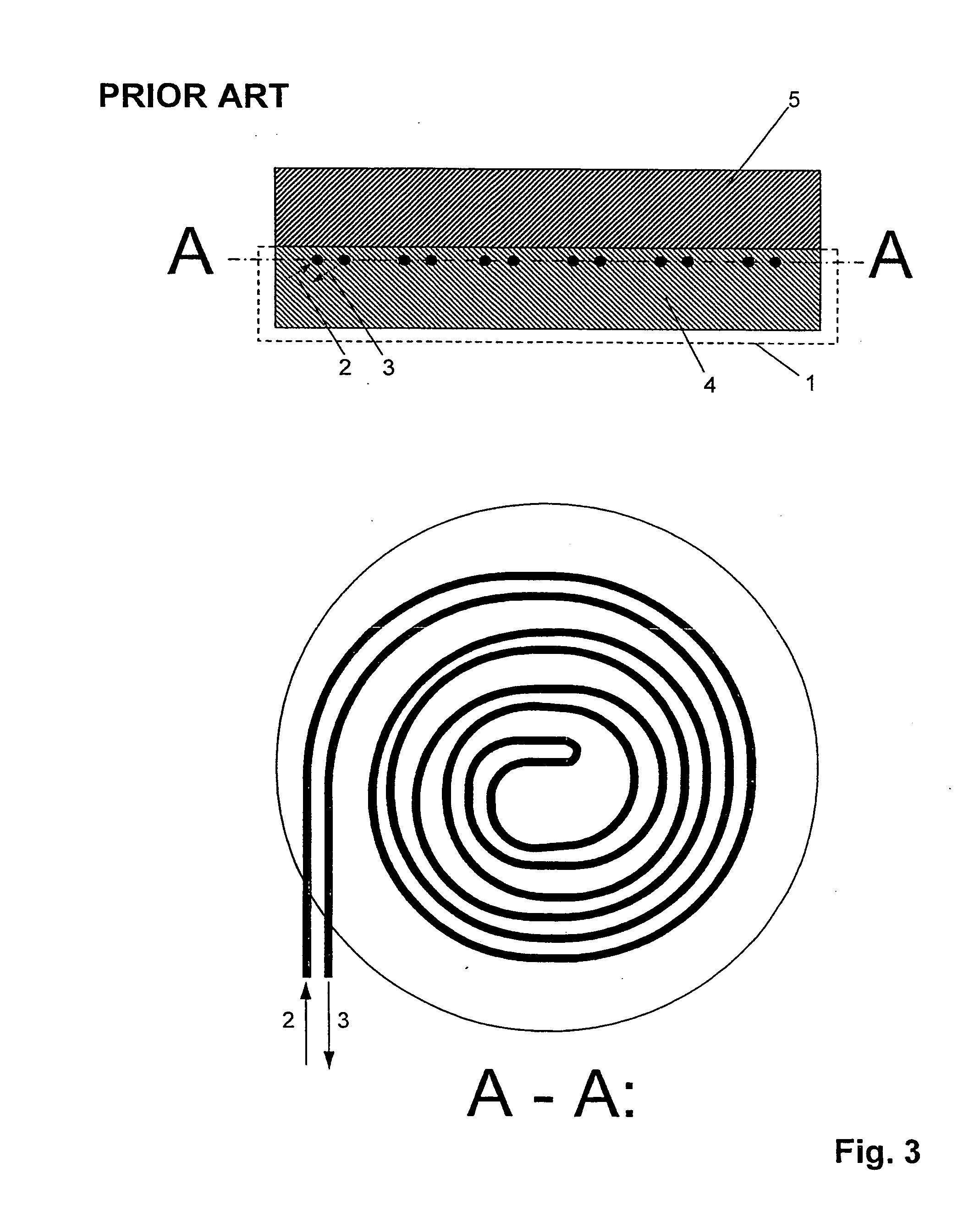

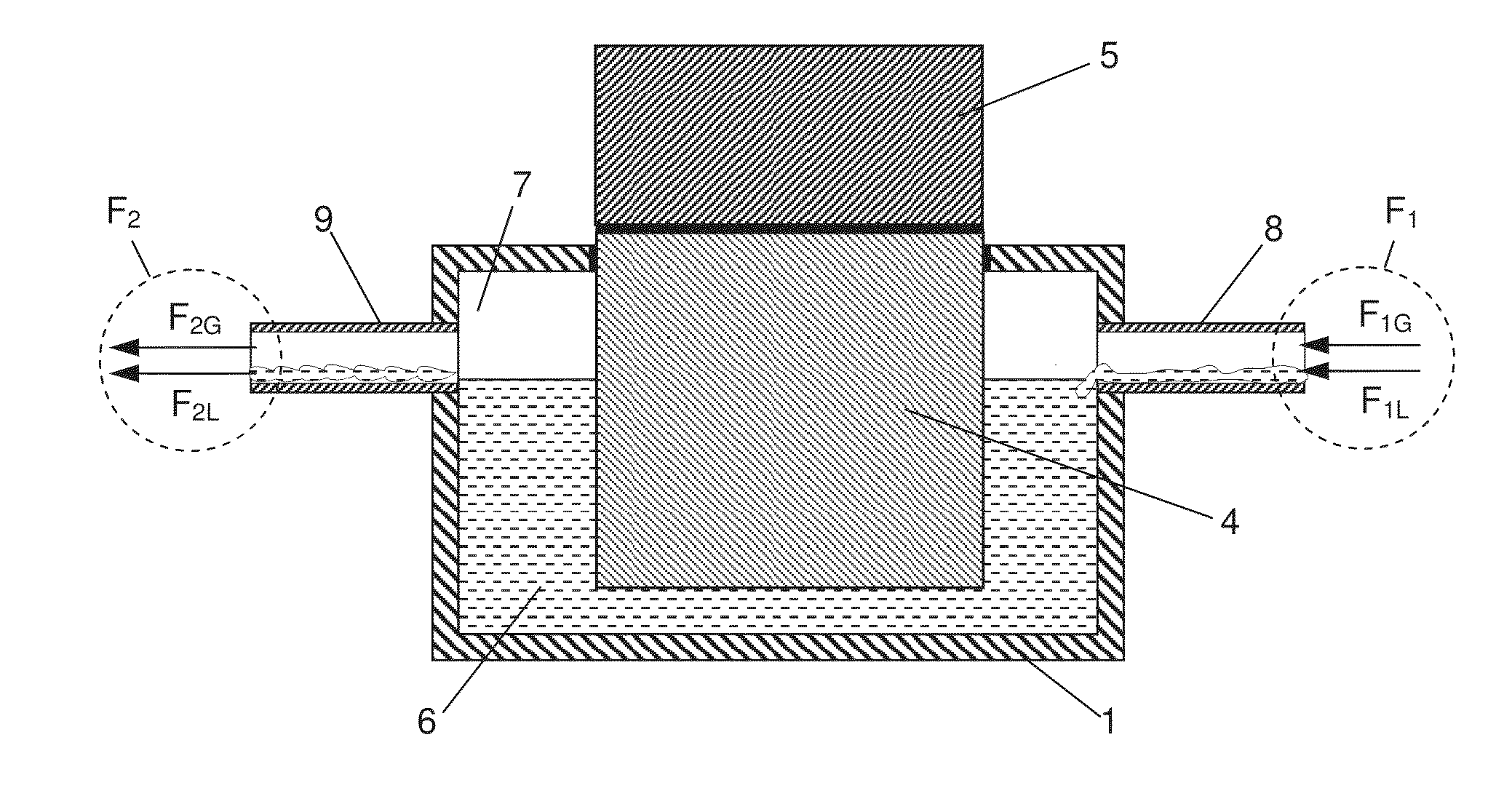

Cooling device for cryogenic cooling of an NMR detection system with the assistance of a container filled with a cryogenic fluid

InactiveUS20110100027A1Undesirable influenceReduce consumptionLevel controlTemperatue controlProcess engineeringThermal contact

A cryo probe head for the transmission / reception of RF signals for NMR measurements with a heat exchanger (1) for cooling heat sources (5), the heat exchanger having a contact element (4.2) for thermal connection between a cryogenic fluid and the heat source, is characterized in that the heat exchanger comprises a container having an interior volume VB into which a first cryogenic fluid F1 that has a liquid component F1L and a gaseous component F1G flows through an inflow conduit (8) and from which a second cryogenic fluid F2 that has liquid component F2L and a gaseous component F2G flows out through an outflow conduit (9). The inflow conduit has a flow cross-section QZ and a circumference UZ from which a characteristic conduit volume VZ=4·Q2Z / UZ results, wherein VB>10·VZ, and the outflow conduit has a flow diameter QA wherein QA≧QZ. The contact element is in close thermal contact with both the liquid volume component VL of the cryogenic fluid and with the heat source. A device for setting the inflow quantity of the first cryogenic fluid F1 into the container is provided that ensures a state F1L / F1G>F2L / F2G during operation. In this way, vibrations due to the cooling process can be largely reduced and the consumption of cryogenic fluid minimized.

Owner:BRUKER BIOSPIN

Drain Cartridge Having Removable Valved System

InactiveUS20100199415A1Eliminate needEasy to replaceServomotor componentsMachines/enginesEngineeringUltraviolet light

Various embodiments of a cartridge for regulating a fluid flow are described that include an upper housing, and an insert that is user-removable from the upper housing. The cartridge can include one or more valves that are biased in a closed position to prevent odors from escaping the cartridge. The cartridge can also include a fluid trap that is at least partially disposed within the cartridge or fluidly coupled thereto. An ultraviolet light can be inserted within the cartridge to disinfect a fluid passageway of the cartridge.

Owner:LIQUIDBREAKER

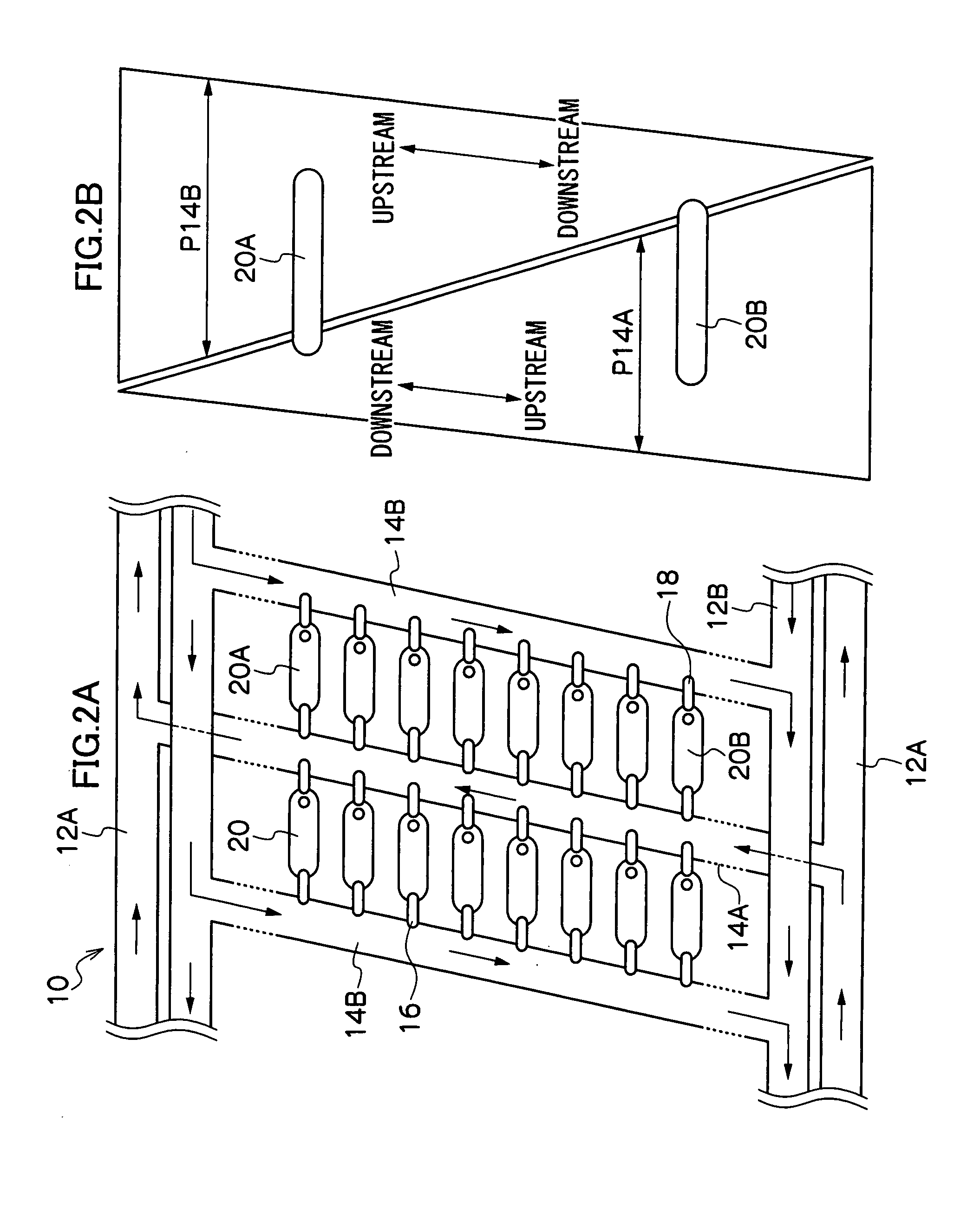

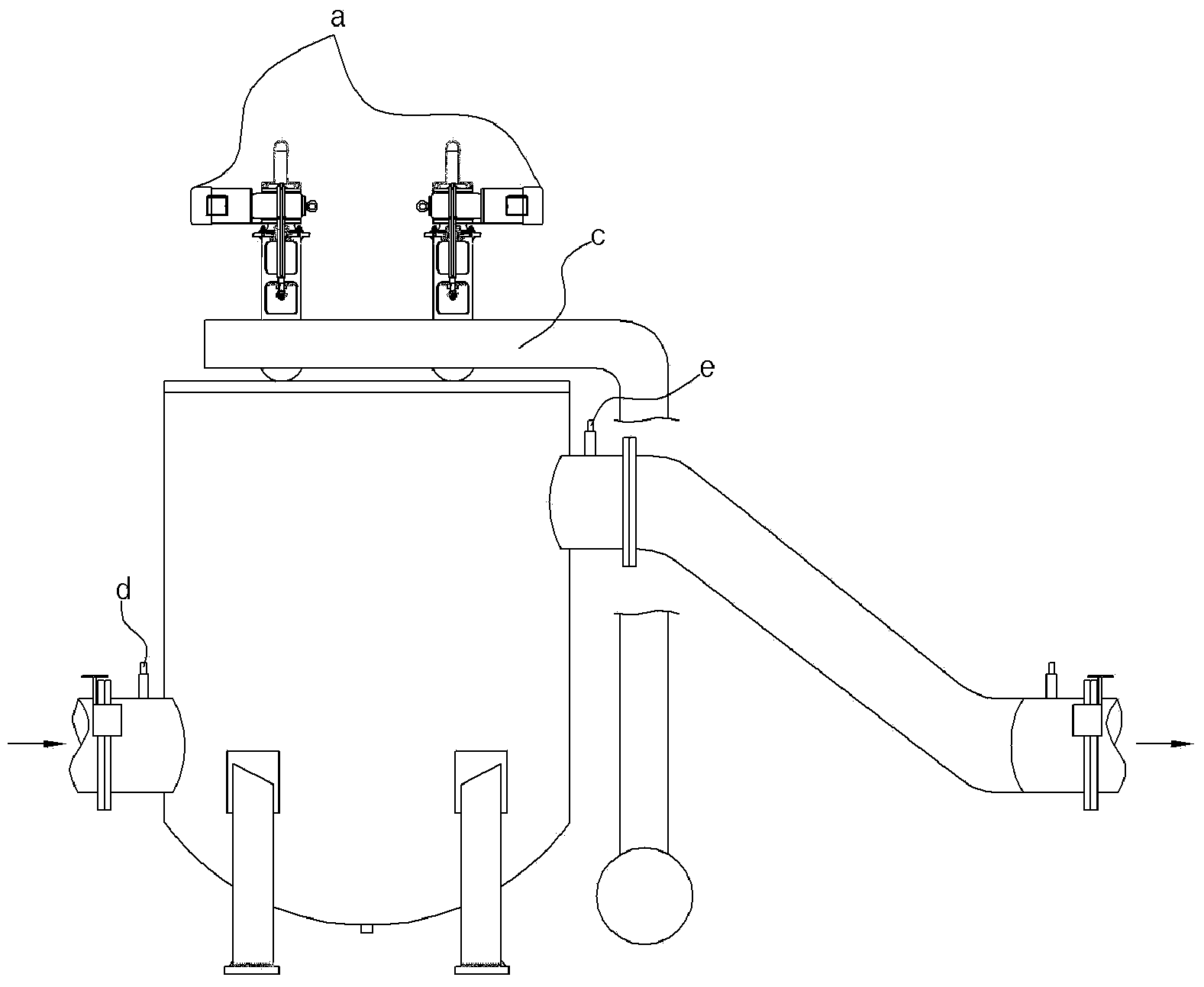

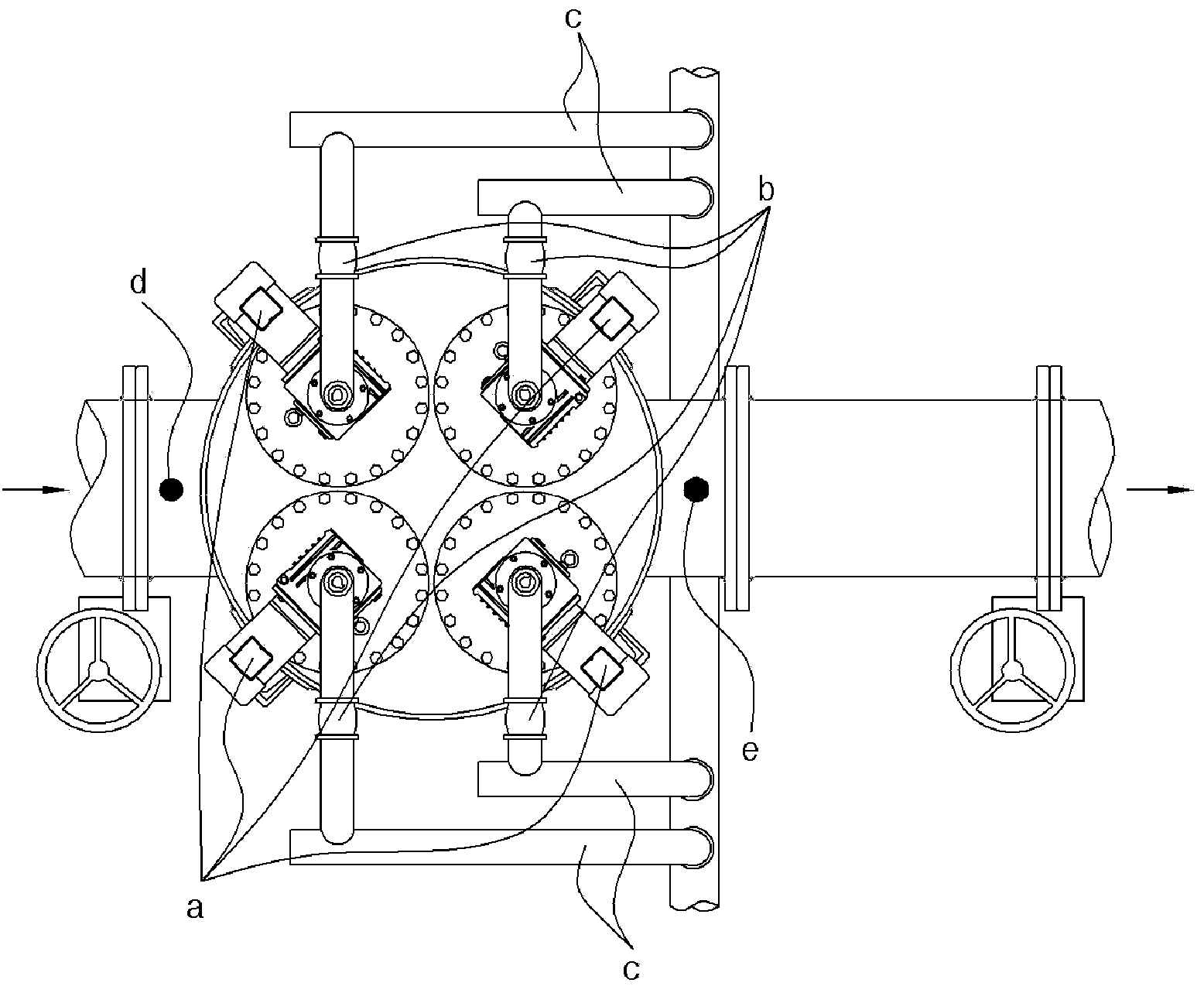

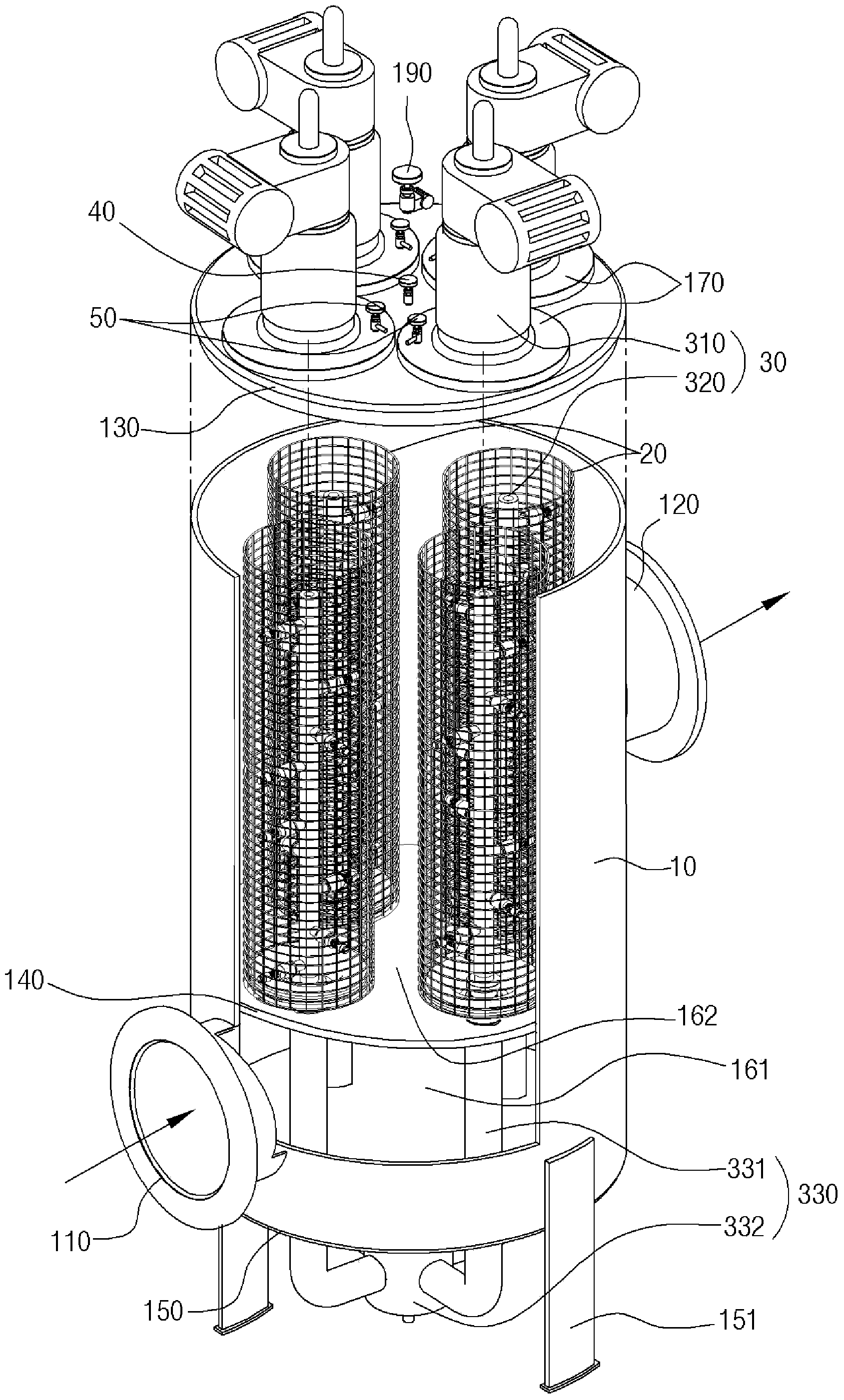

Multicage-type device for filtering ballast water for automatically controlling sequential backwashing and method for same

InactiveCN104039414APrevent back pressure build-upContinuous cleaningWater treatment parameter controlAuxillariesAutomatic controlDifferential pressure

The present invention relates to a device for filtering for treating ballast water by means of a filtering method, and to a method for controlling same, and more particularly, to a multicage-type device for filtering ballast water which automatically controls sequential backwashing and a method for same. In the multicage-type device for filtering ballast water, an automatic cleaning portion in each filtering device, in which differential pressure of at least a specific range with respect to pressure inside a body is generated, from a plurality of filtering units in the device for filtering, is sequentially actuated under the control of a control portion, thereby allowing smooth backwashing by preventing increase of back pressure during backwashing of foreign substances, and increasing repair / maintenance efficiency by installing a second pressure sensor for measuring pressure inside a filter in each of the filtering units via a pressure measurement aperture that penetrates an upper portion cover plate that covers a filter inlet aperture on an upper portion of the body.

Owner:PANASIA

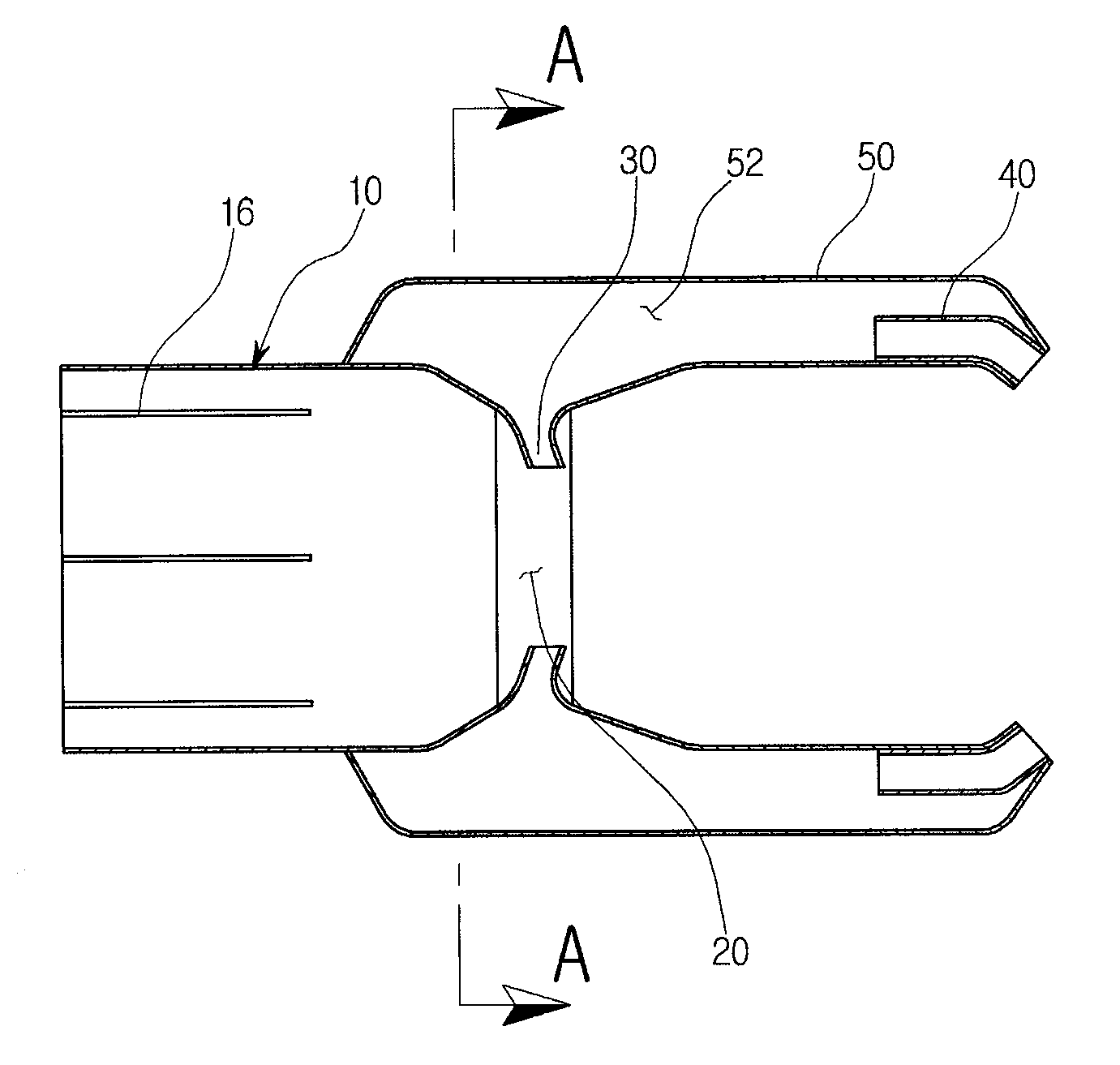

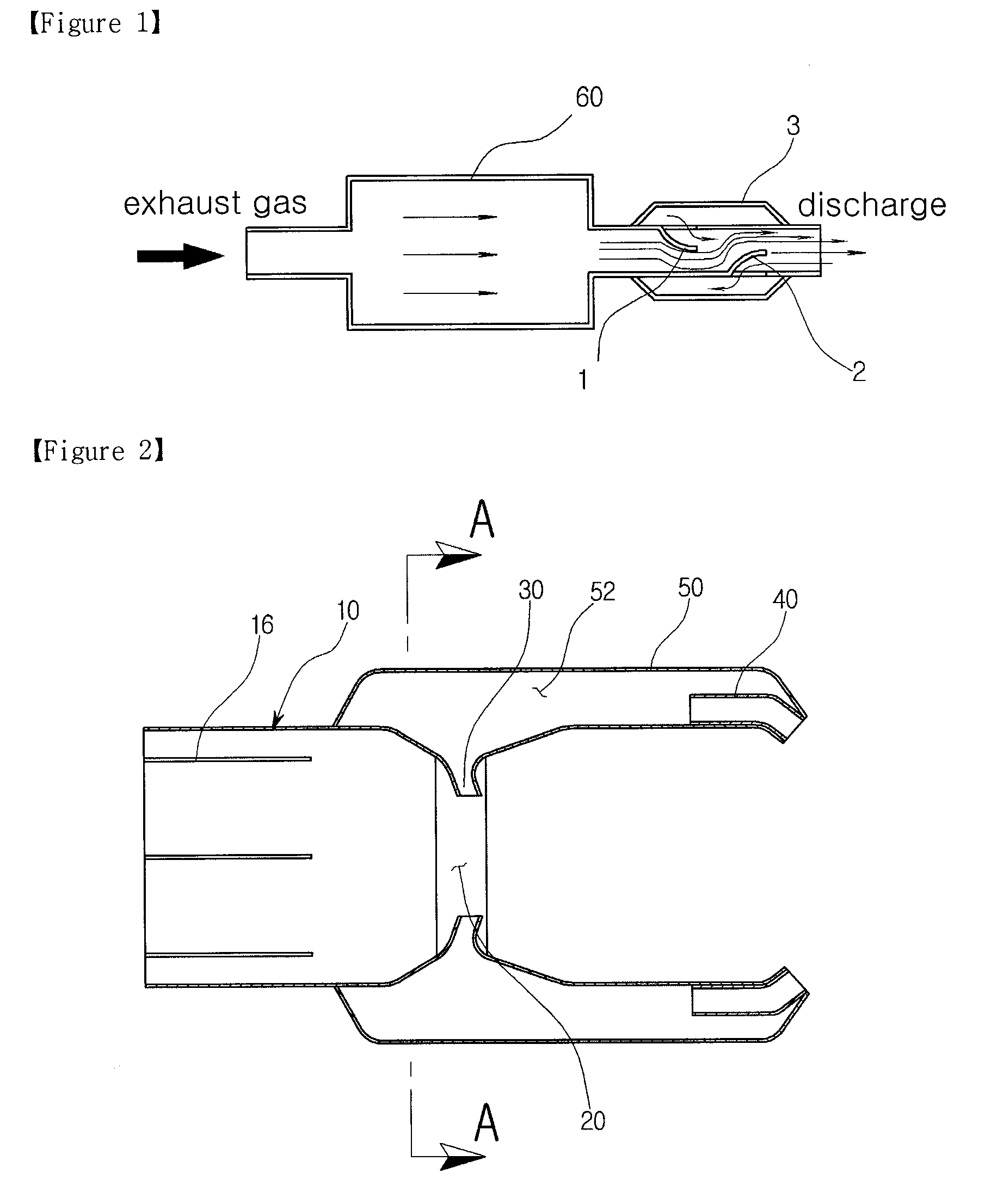

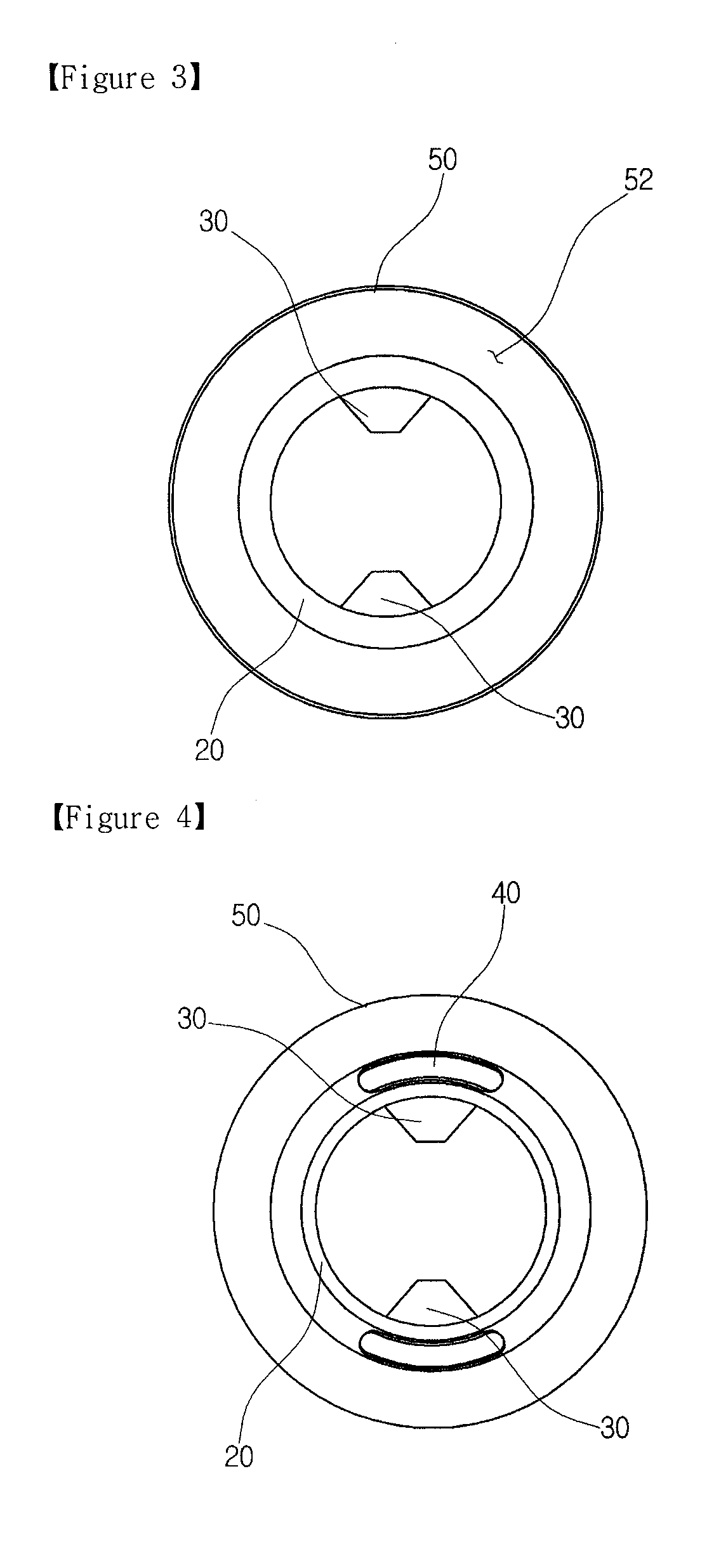

Exhaust Gas-Discharging Device of Vehicle

InactiveUS20090090101A1Efficient use ofImprove exhaust efficiencyBatteries circuit arrangementsExhaust apparatusExhaust gas emissionsExhaust fumes

An exhaust gas discharge device for vehicles is disclosed. The exhaust gas discharge device of the present invention includes an extension pipe (10), which is fitted over a tail pipe of a silencer of a vehicle. A venturi passage (20) is defined in an exhaust gas inlet end of the extension pipe to increase a flow speed of the exhaust gas. The exhaust gas discharge device further includes an outside air discharge nozzle (30), which extends into the venturi passage, a backflow inlet port (40), which is provided in an exhaust gas outlet end of the extension pipe to guide outside air, and a cover (50), which defines therein a chamber, through which the backflow inlet port communicates with the outside air discharge nozzle. Thus, the present invention restrains backflow of exhaust gas using the flow of outside air, thus preventing back pressure, and rapidly discharging the exhaust gas, thereby enhancing the output of the engine.

Owner:KIM SOO WON

Inlet system for an engine

ActiveUS8286428B2Reduce areaReduce distanceEngine manufactureInternal combustion piston enginesEngineeringFlow management

An apparatus for improving the performance of a radial compressor 36 forming part of an inlet system of an engine 10 is disclosed in which the configuration and positioning of a flow management device 137 used to generate pre-whirl is optimized so as to produce a pressure drop below a maximum acceptable level. An inlet duct ‘I’ connected to the radial compressor 36 has a tapered end portion so that a flow management device 137 of a larger diameter d2 can be accommodated than the diameter d1 of an inlet port ‘IP’ to the radial compressor 36.

Owner:FORD GLOBAL TECH LLC

Exhaust stack pipe cover

ActiveUS20140182718A1Effectively prevents ingress of waterMinimizing backpressureSilencing apparatusMachines/enginesFlow diverterExhaust gas

A cover for the upper end of an exhaust stack pipe comprises a curved cover pipe of greater diameter than the stack pipe. The curved cover pipe has a proximal end to fit over the end of the stack pipe and a distal end from which exhaust gases are discharged. The cover pipe is shaped to prevent rain from falling directly onto the end of the stack pipe. A flow diverter of lesser diameter than the cover pipe is mounted within the proximal end of the cover pipe to overlie the end of the stack pipe. The flow diverter comprises an extension tube for mounting onto the end of the stack pipe having lateral openings and a tapering deflector extending into the extension tube to divert exhaust gases to flow into the cover pipe through the lateral openings in the extension tube.

Owner:BLUE LEAF I P INC

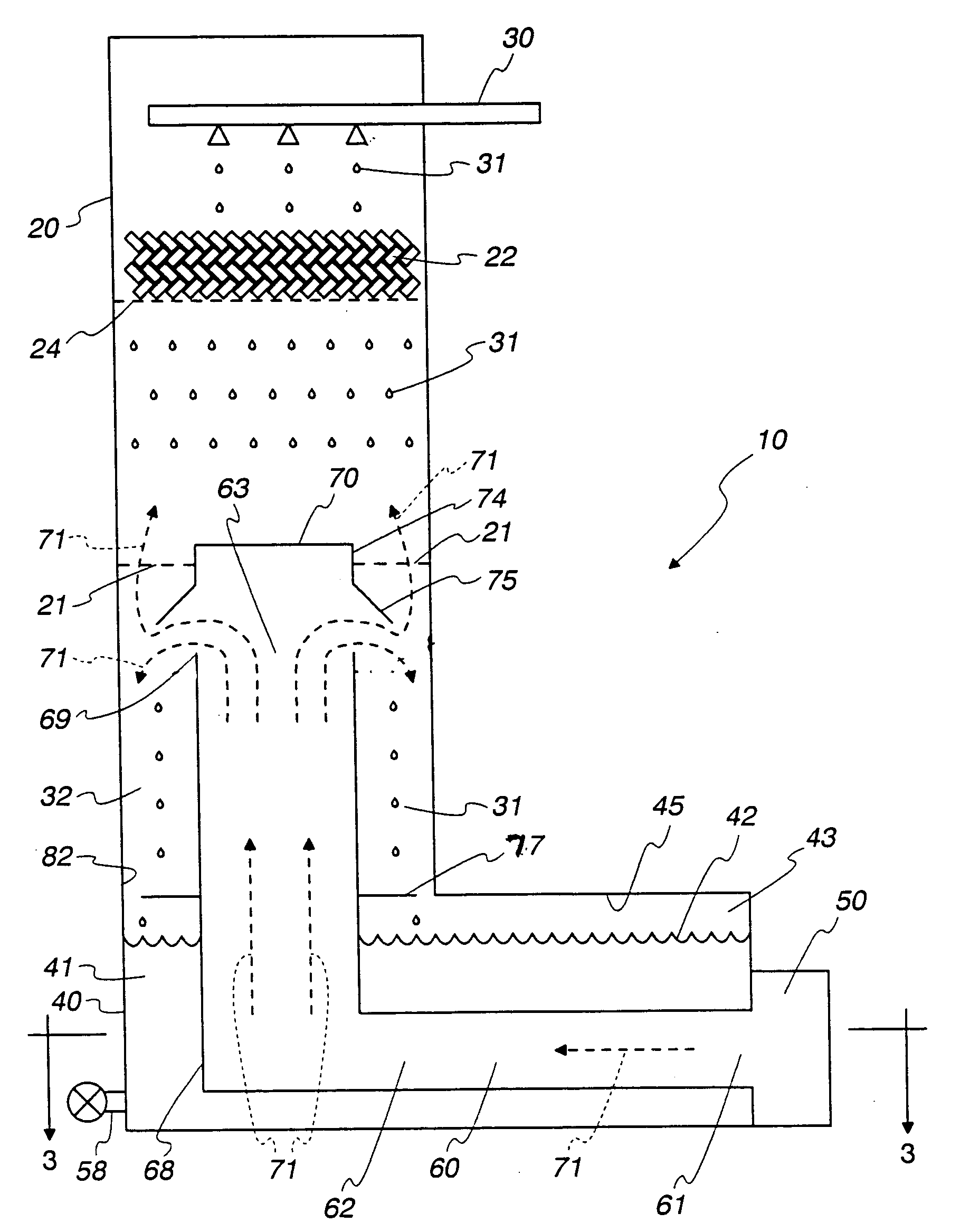

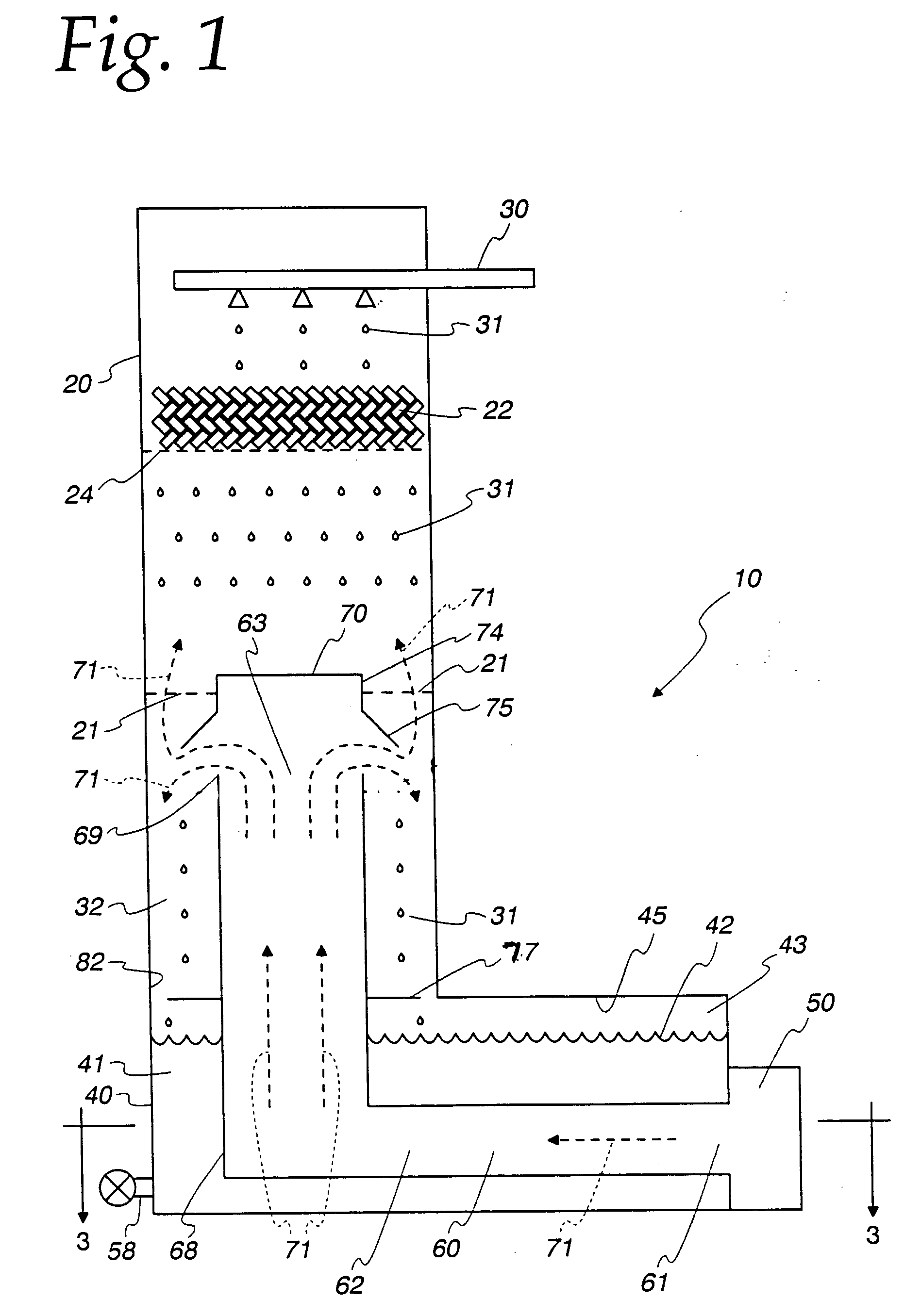

High efficiency combination direct/indirect water heater

InactiveUS20050072378A1Improve efficiencyImprove heat transfer performanceStationary conduit assembliesDirect contact heat exchangersWater flowEngineering

A combination direct / indirect liquid heating heater comprises a tower, a cold water inlet conduit causing water to fall in said tower, a hot water reservoir in communication with said tower, a gas burner, a hot gas inlet manifold encased in the reservoir and, by means of a vertical section, directing the gas into the tower. The hot gas manifold vertical section is capped by a cap impeding water flow into the manifold. Also, the vertical section comprises a baffle impeding gas flow from the tower into the reservoir.

Owner:QUIKWATER

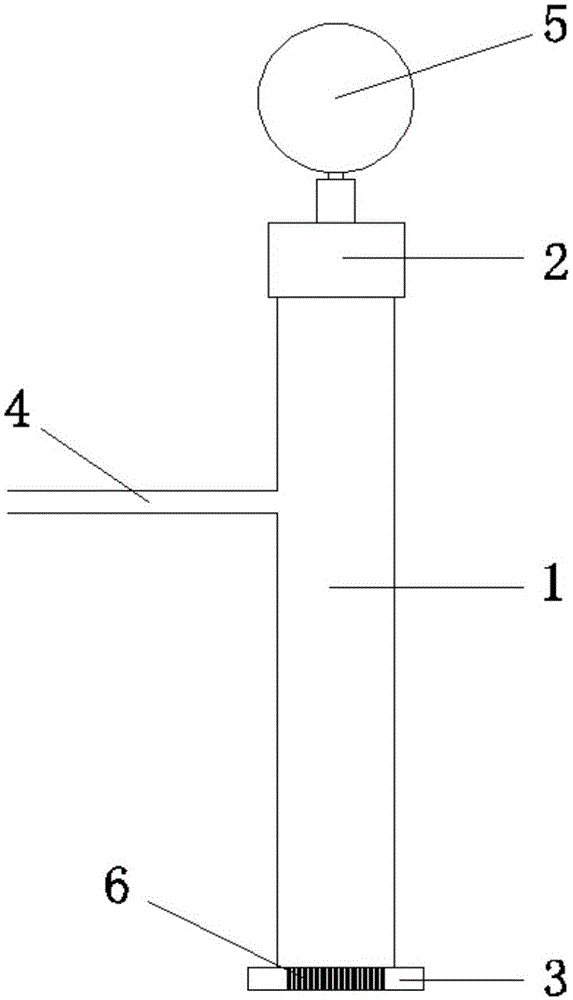

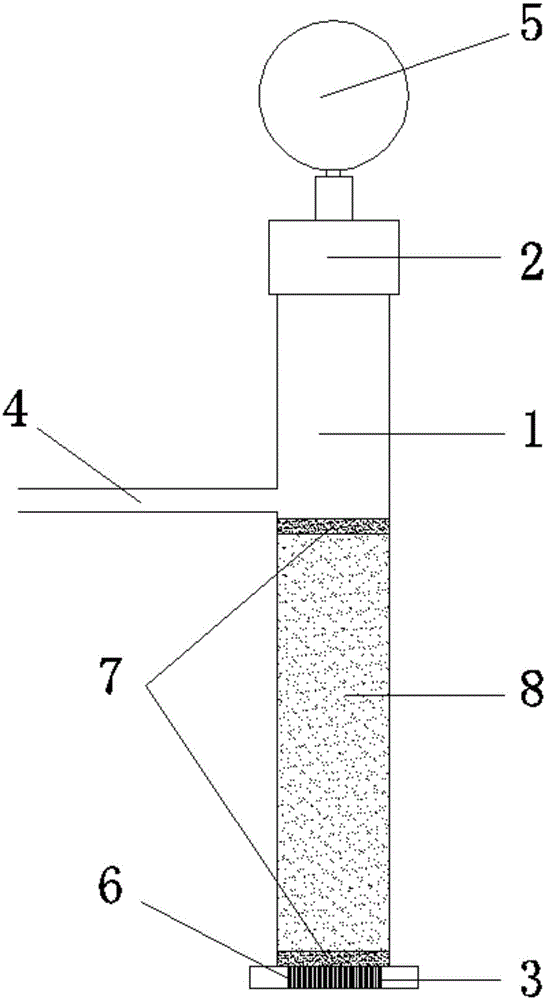

Grouting material pressure filter testing device and method

The invention provides a grouting material pressure filter testing device and method. The device comprises a grouting module and a testing module. The grouting module provides grout for the testing module through a grouting pipeline. The testing module comprises a testing cylinder. A testing cylinder base is arranged at the bottom end of the testing cylinder. A sealing cover connected with a pressure gauge is arranged at the top end of the testing cylinder. A grouting pipe for being connected with the grouting pipeline is arranged on the side wall of the testing cylinder. A filling medium is distributed in the portion, below the grouting pipe, of the testing cylinder. The upper end and the lower end of the filling medium are provided with water filter stone. The grout is pressed into the testing module through the grouting module and infiltrates the filling medium in the testing module so that testing can be completed. The testing device is small in size, easy and convenient to operate, recyclable and capable of reducing testing cost.

Owner:SHANDONG UNIV

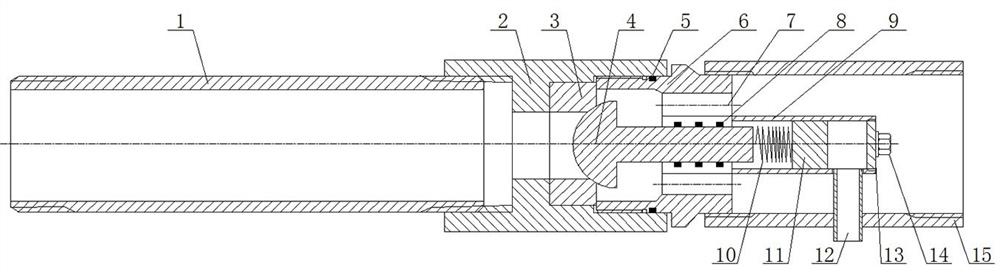

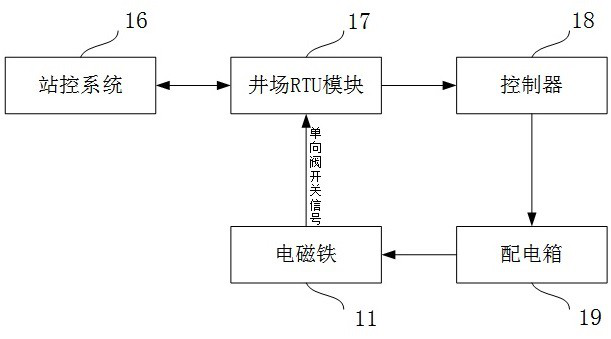

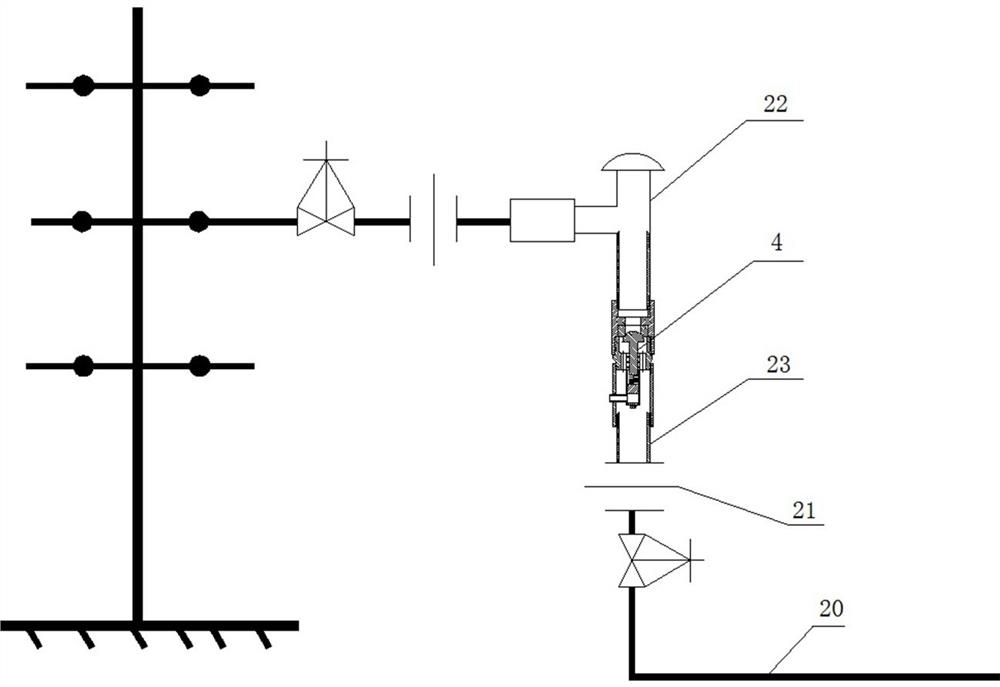

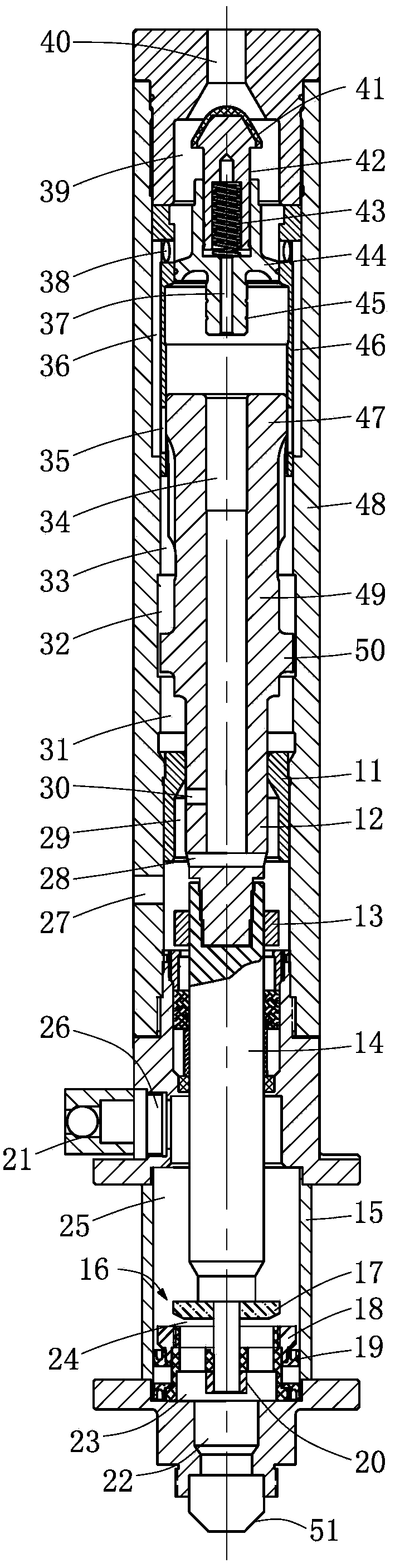

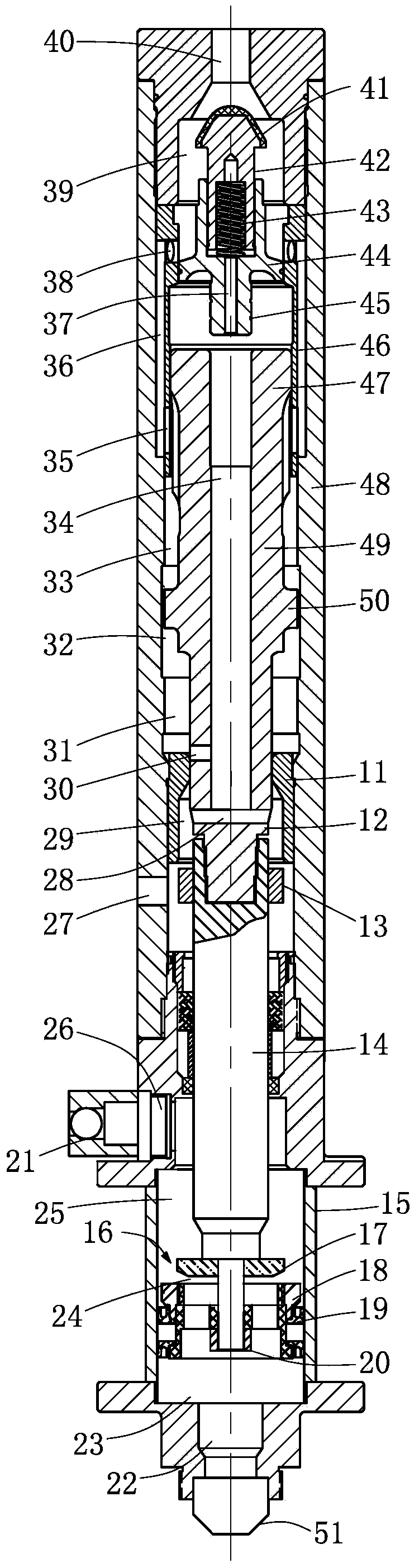

One-way valve and automatic intermittent pumping system and method with one-way valve

ActiveCN112282696AAvoid traffic changesSimplify the installation processWell/borehole valve arrangementsSealing/packingPhysicsEngineering

The invention provides a one-way valve and an automatic intermittent pumping system and method with the one-way valve. The one-way valve comprises an upper connector, a valve cover, a middle connectorand a lower connector which are coaxially connected in a screwed mode in sequence. The upper connector, the valve cover, the middle connector and the lower connector are coaxially connected in a screwed mode to form a revolving body structure with an axial hollow channel, and oil liquid flows through the axial hollow channel of the hollow revolving body. A valve seat, a valve element and a protective sleeve are arranged in the axial hollow channel, wherein the head of the valve element can be in contact with the valve seat in a setting mode, the tail of the valve element is fixedly connectedto one end of a reset spring, the other end of the reset spring is fixedly connected with an electromagnet, and the electromagnet is arranged in the protective sleeve. The electrified electromagnet slides in the protective sleeve and drives the valve element to be set or away from the valve seat through the reset spring, so that the axial hollow channel is in a blocked state or a smooth state. Thereset spring can control the opening pressure of the one-way valve, so that the opening pressure is kept within a small range, and flow change and even back pressure backflow caused by overlarge opening pressure are avoided.

Owner:PETROCHINA CO LTD

High-pressure washer

ActiveCN103480527AWill not stick to each otherOvercoming the disadvantages of relying on powerSingle-unit apparatusViscous liquidEngineering

The invention discloses a high-pressure washer, and belongs to the technical field of washing equipment. The high-pressure washer comprises a cabinet. A piston cavity, an air storage cavity and a material storage cavity are formed in the cabinet. The air storage cavity is positioned below the material storage cavity. The piston cavity is positioned on one side of the air storage cavity and communicated with the same through a single-way valve. A manual piston is slidably mounted in the piston cavity. The air storage cavity and the material storage cavity are both connected to a handheld pneumatic nebulizer. An air inlet of the handheld pneumatic nebulizer is communicated with the air storage cavity through an air pipe. A feed port of the handheld pneumatic nebulizer is connected with the material storage cavity through a rubber pipe. By the high-pressure washer, the problems that conventional high-pressure washers have poor effect in extracting viscous liquid and are greatly influenced by power sources are solved; the high-pressure washer is widely applied to manufacture of high-pressure washers.

Owner:NINGBO FUSLE MECHANICAL MFG

Method for cryogenic cooling of an NMR detection system with the assistance of a container filled with a cryogenic fluid

ActiveUS20140283530A1Constant heating temperatureMinimize signalingFluid transferredMachines using refrigerant evaporationCatheterProcess engineering

A method for the transmission / reception of RF signals for NMR measurements uses a heat exchanger (1) for cooling heat sources (5), the heat exchanger having a contact element (4.2) for thermal connection between a cryogenic fluid and the heat source, is characterized in that the heat exchanger comprises a container having an interior volume V.sub.B into which a first cryogenic fluid F.sub.1 that has a liquid component F.sub.1L and a gaseous component F.sub.1G flows through an inflow conduit (8) and from which a second cryogenic fluid F.sub.2 that has liquid component F.sub.2L and a gaseous component F.sub.2G flows out through an outflow conduit (9). The inflow conduit has a flow cross-section Q.sub.Z and a circumference U.sub.Z from which an associated parameter V.sub.Z=4Q.sup.2.sub.Z / U.sub.Z results, wherein V.sub.B>10V.sub.Z, and the outflow conduit has a flow diameter Q.sub.A wherein Q.sub.A.gtoreq.Q.sub.Z. The contact element is in close thermal contact with both the liquid volume component V.sub.L of the cryogenic fluid and with the heat source. A device for setting the inflow quantity of the first cryogenic fluid F.sub.1 into the container is provided that ensures a state F.sub.1L / F.sub.1G>F.sub.2L / F.sub.2G during operation. In this way, vibrations due to the cooling process can be largely reduced and the consumption of cryogenic fluid minimized.

Owner:BRUKER SWITZERLAND AG

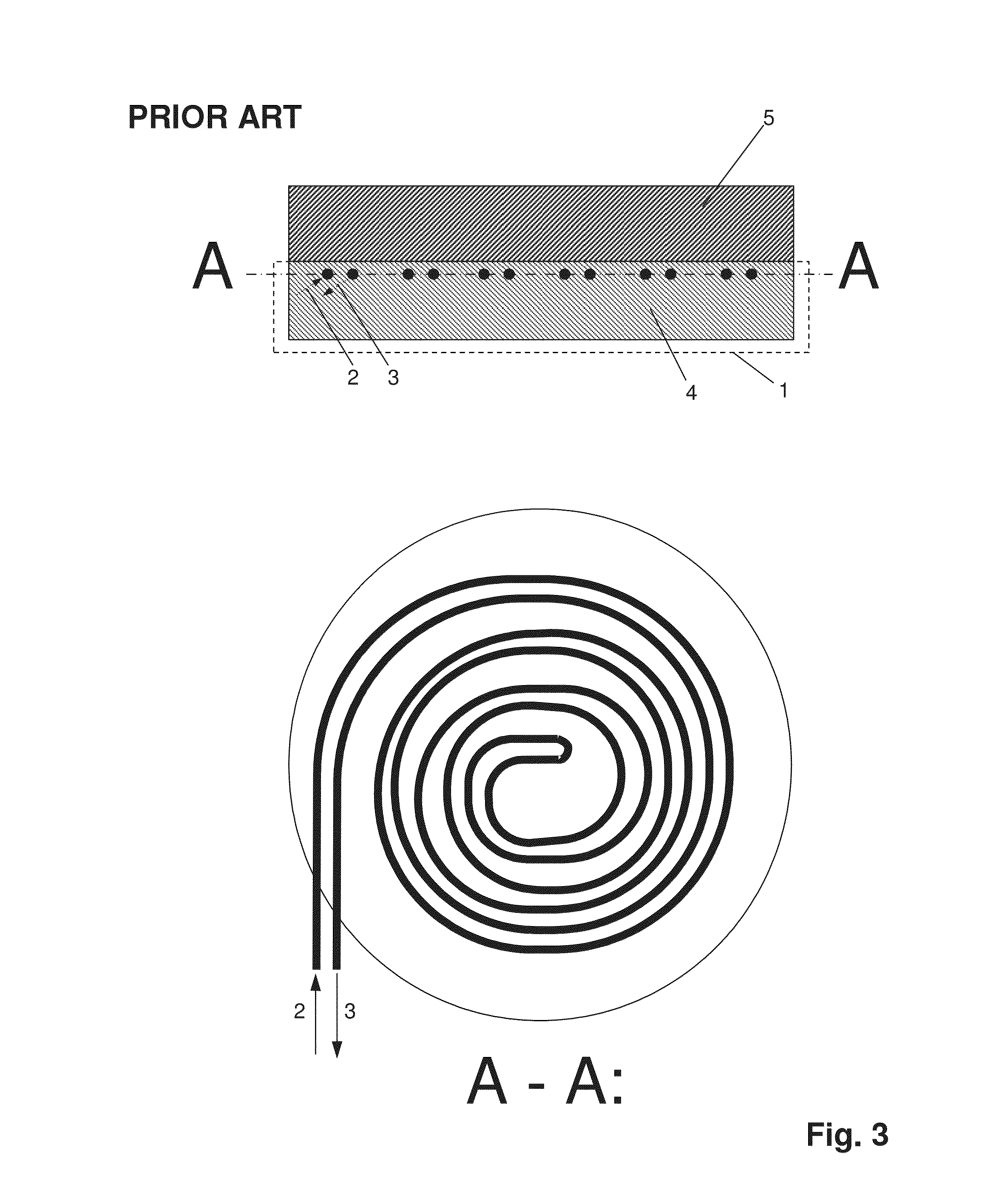

Safety relief valve having a low blow-down value and spring therefore

InactiveUS20080017257A1Lower emission valueImprove flow coefficientCheck valvesValve members for absorbing fluid energyCircular discInlet valve

A safety relief valve is provided that comprises a body comprising a chamber therein and an inlet and an outlet, the inlet comprising an inlet valve seat; a disk member closable on the inlet valve seat; and a mechanism in the body biasing the disk member to rest on the inlet valve seat with a set force such that when the pressure in the inlet exceeds a set pressure resulting from the set force, the disk member is lifted from the inlet valve seat, the mechanism comprising a combination of a coil spring and one or more disk springs stacked in series with the coil spring. A method of preparing a coil spring for use in a pressure relief valve comprises measuring the spring rate of the coil spring and; modifying the spring so as to modify its spring rate to be within ±2% of a desired spring rate.

Owner:MERCER VALVE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com