Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

19614results about "Rotary piston pumps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

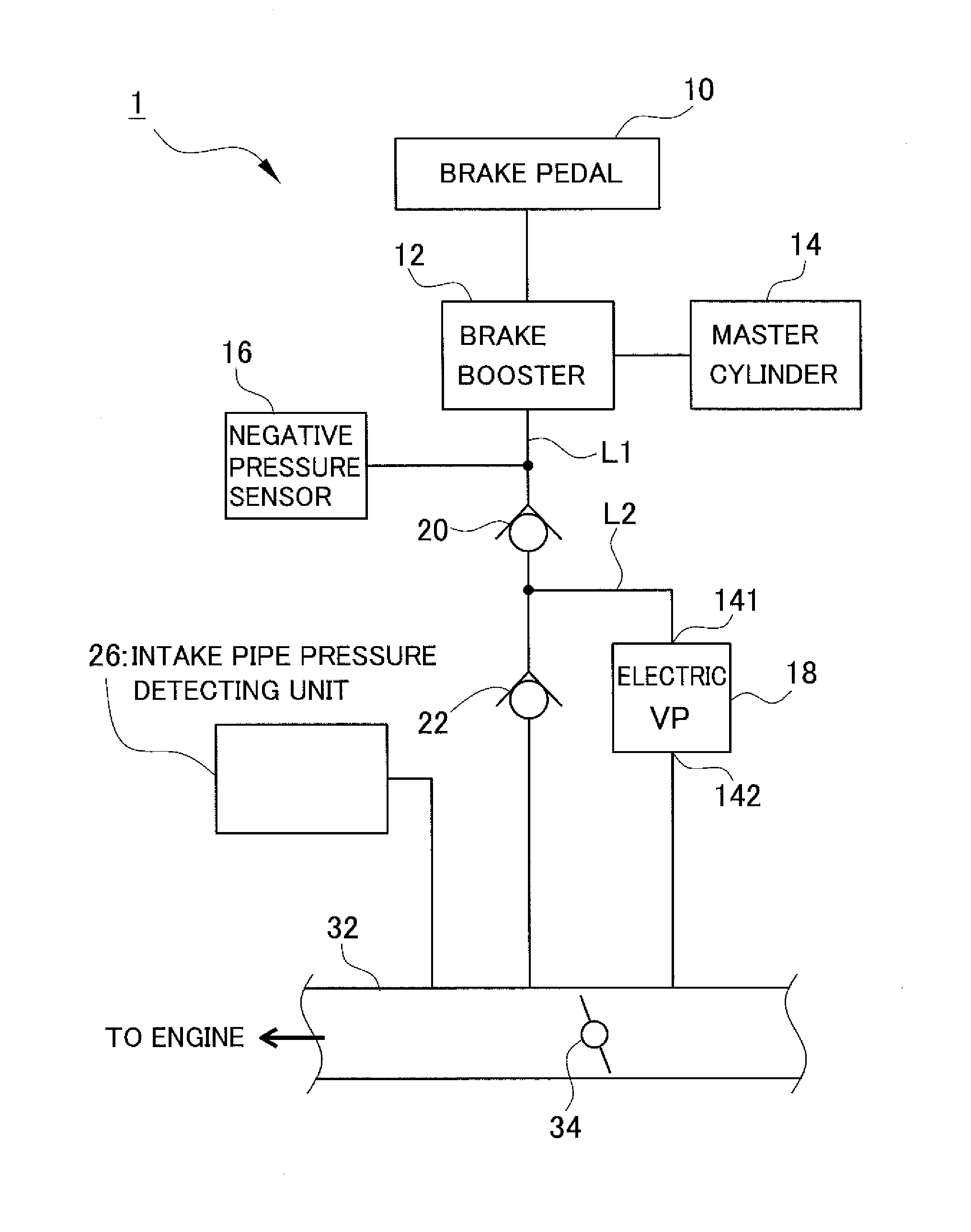

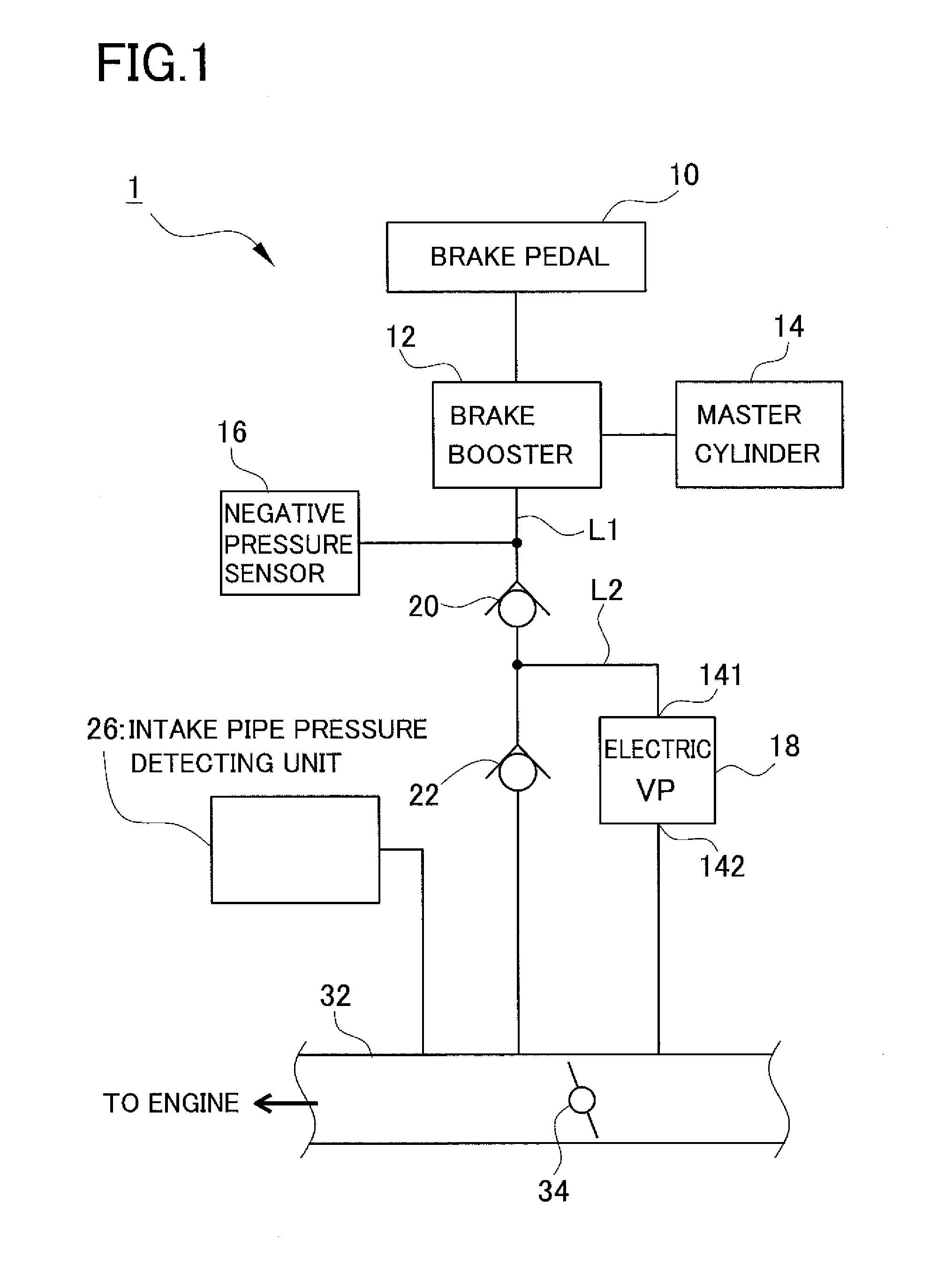

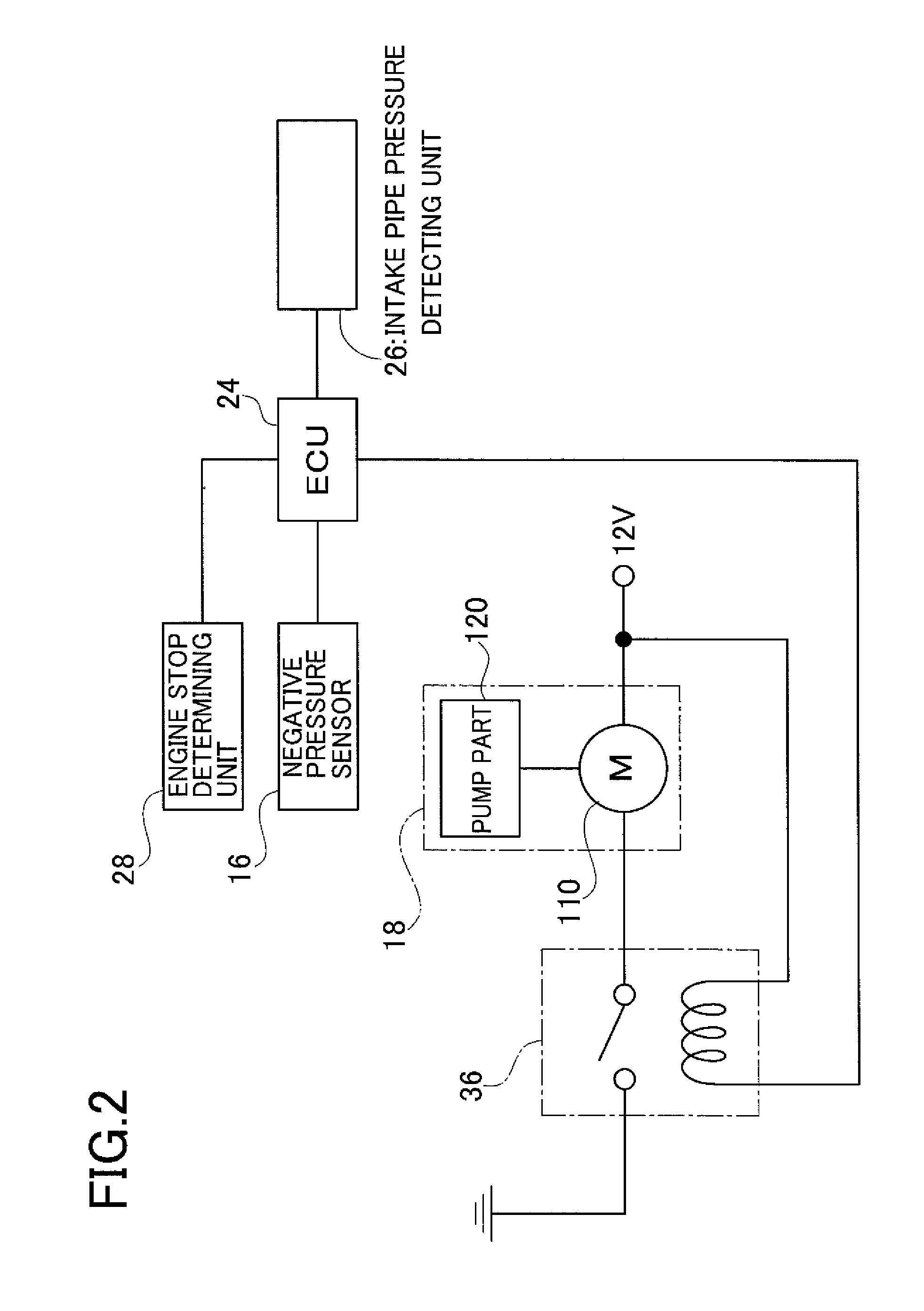

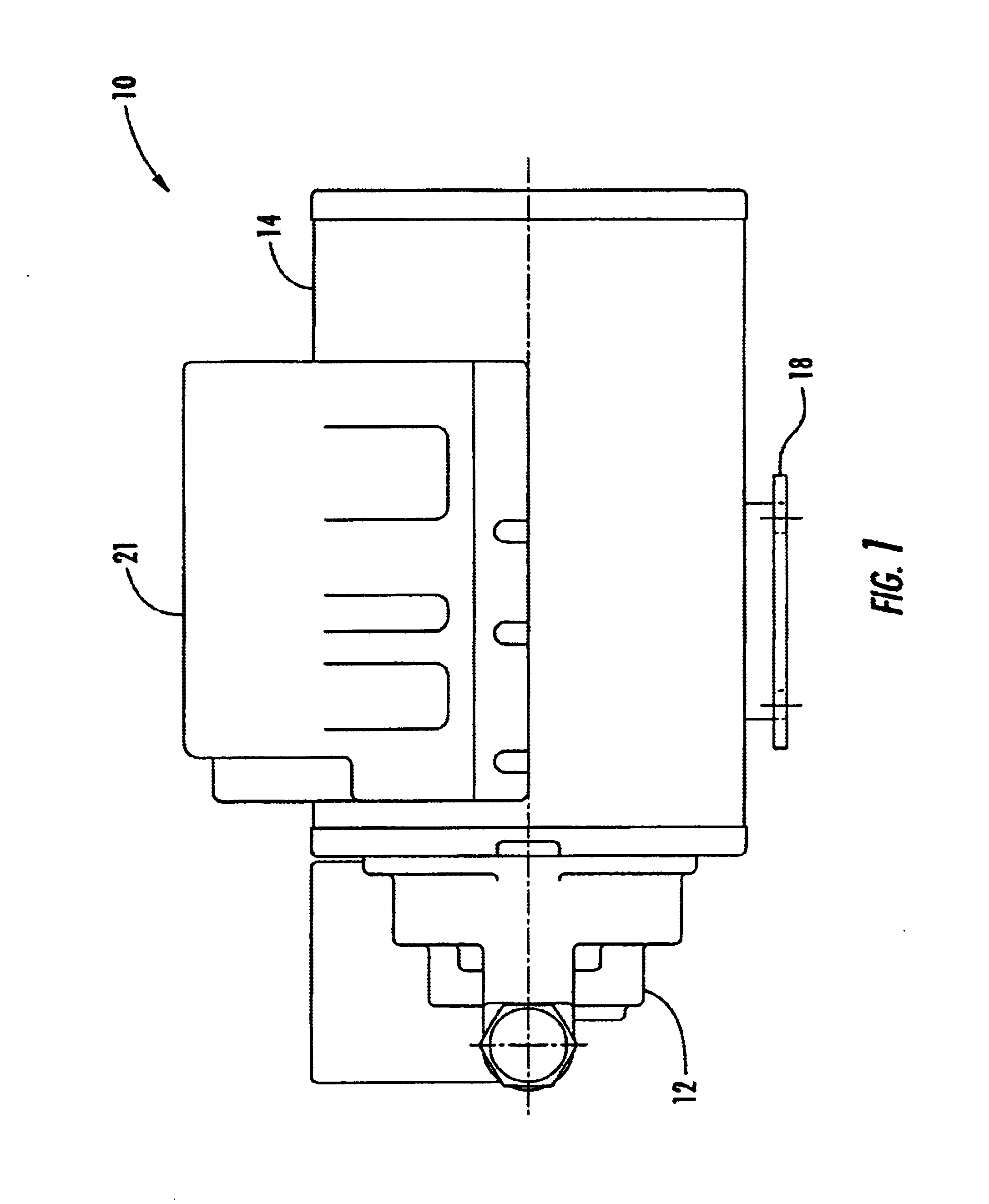

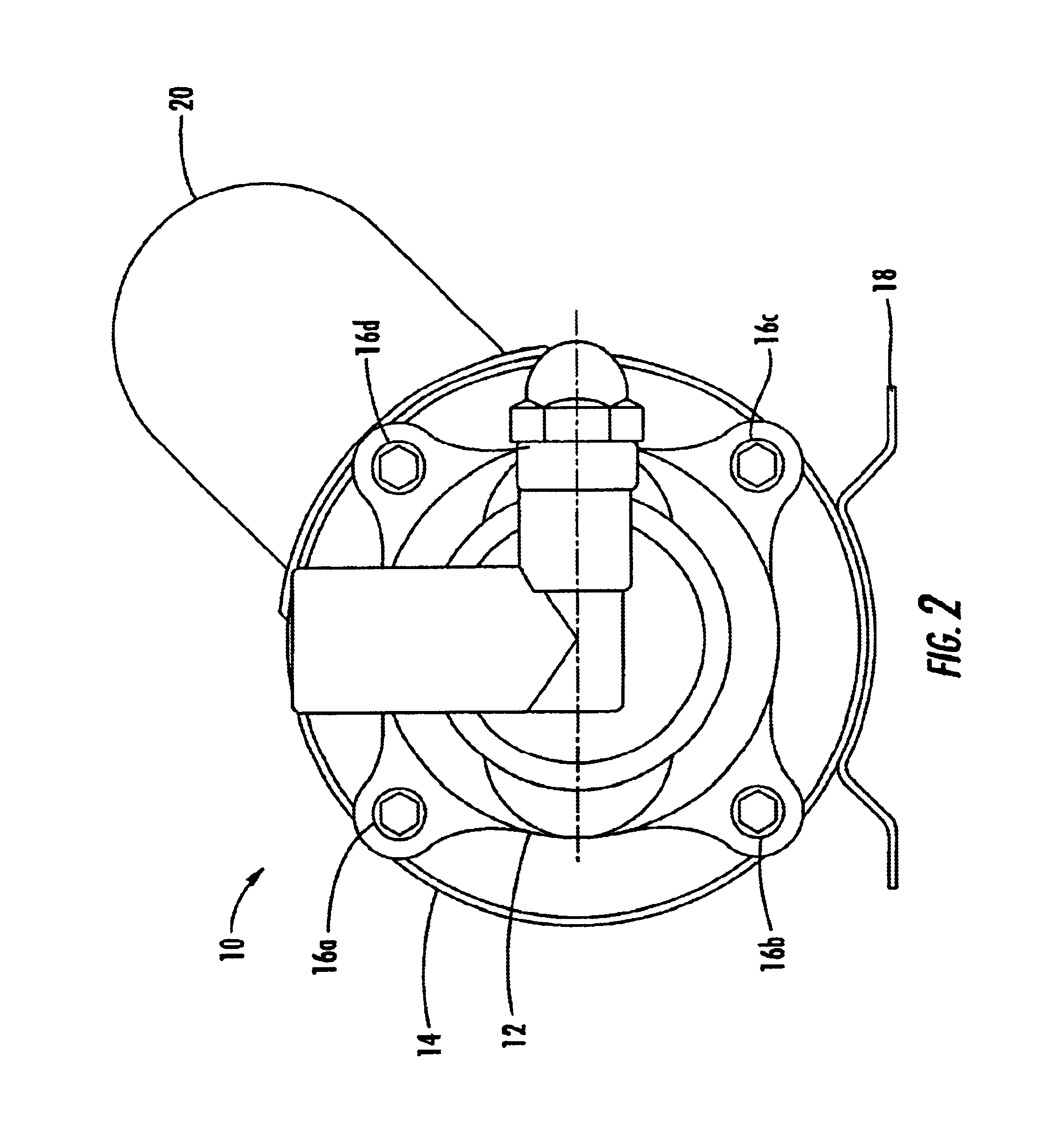

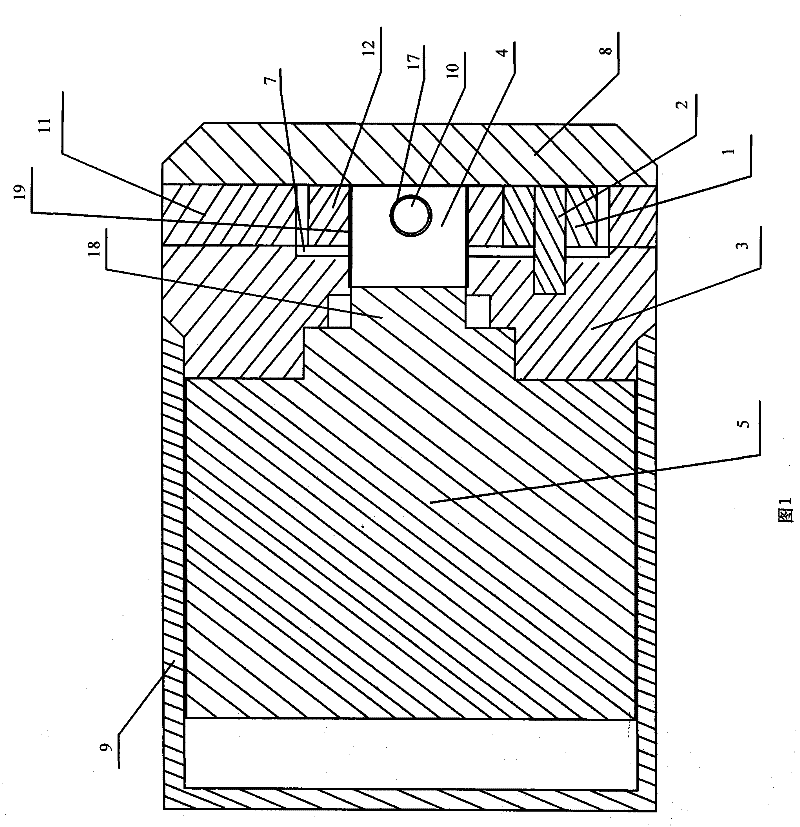

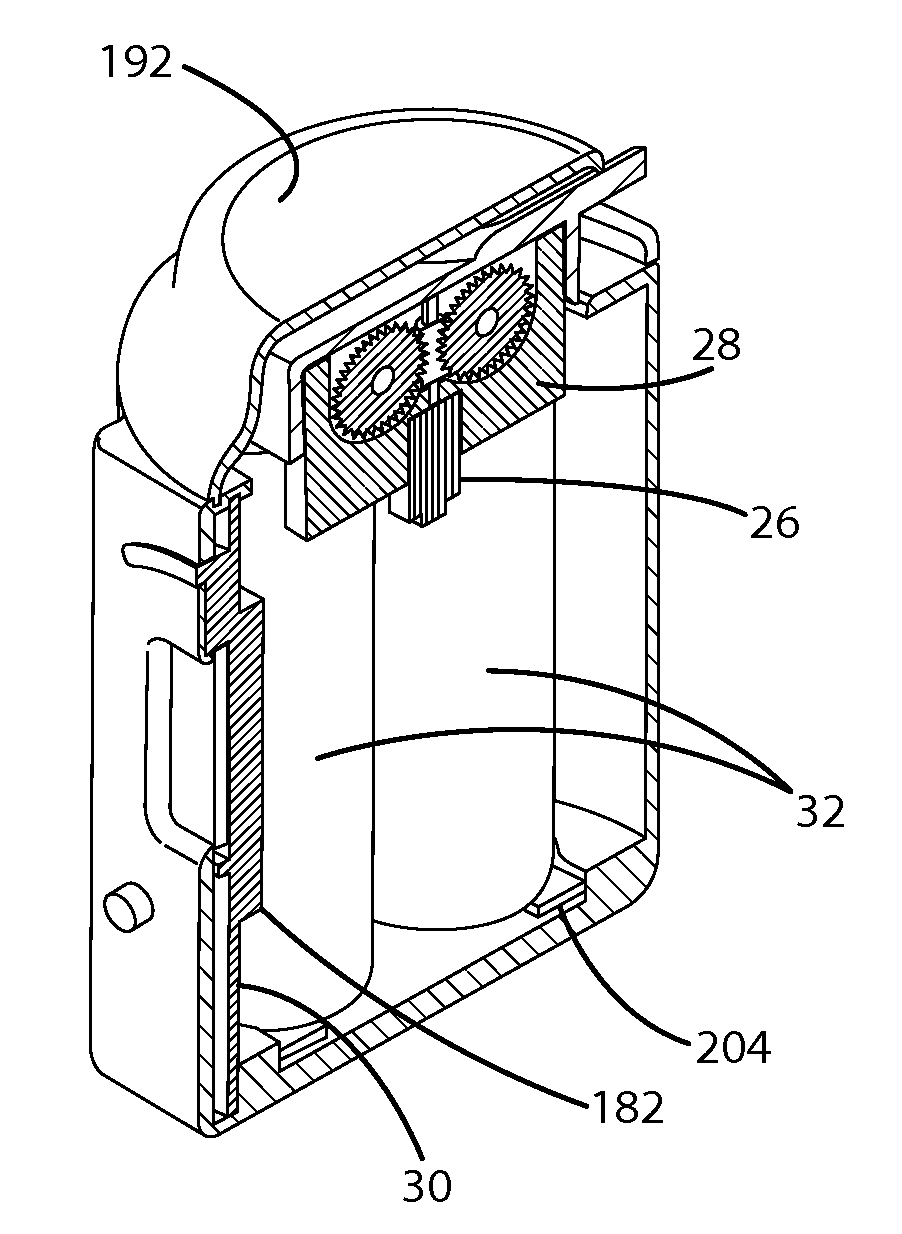

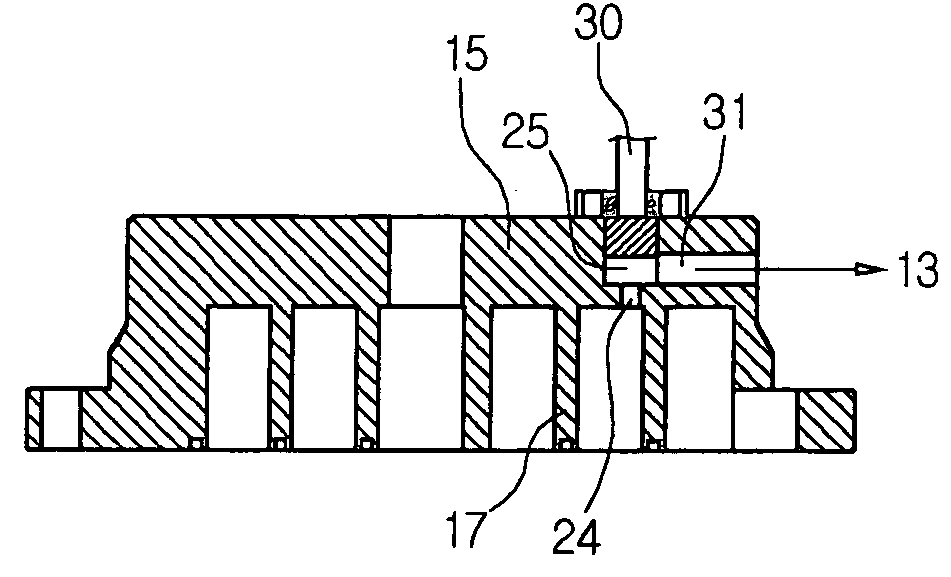

Electric vacuum pump

InactiveUS20140248167A1Small sizeImprove accuracyRotary piston pumpsRotary piston liquid enginesEngineeringVacuum pump

In an electric vacuum pump, a pump housing and a lower-end cover member respectively include positioning retainers respectively formed on outer peripheries of the pump housing and the lower-end cover member. A case includes positioning retainers each protruding inward from an inner peripheral surface of the case. The positioning retainers are in contact with the positioning protrusions, thereby positioning the pump housing and the lower-end cover member with respect to the case. The positioning protrusions are formed with screw holes.

Owner:AISAN IND CO LTD

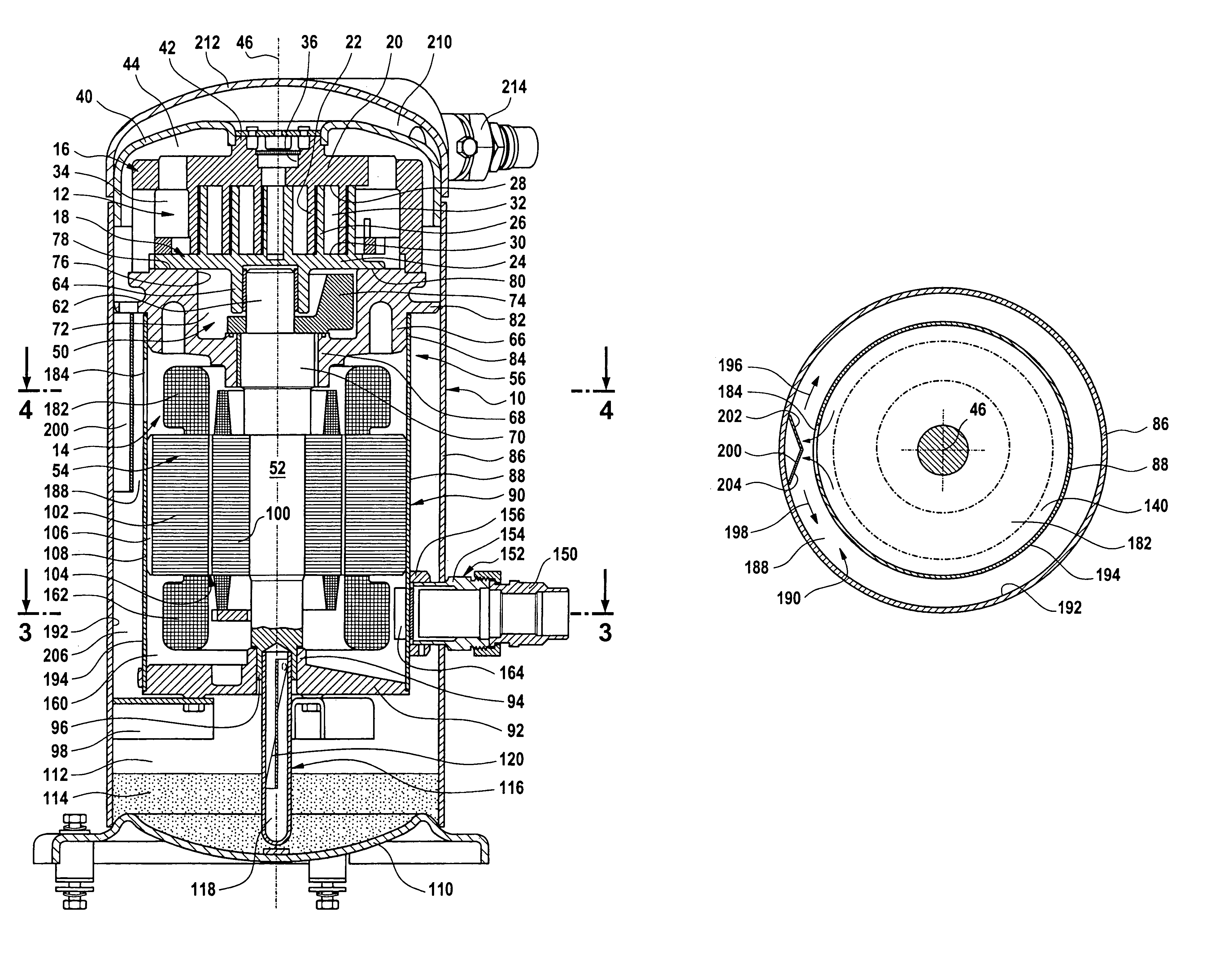

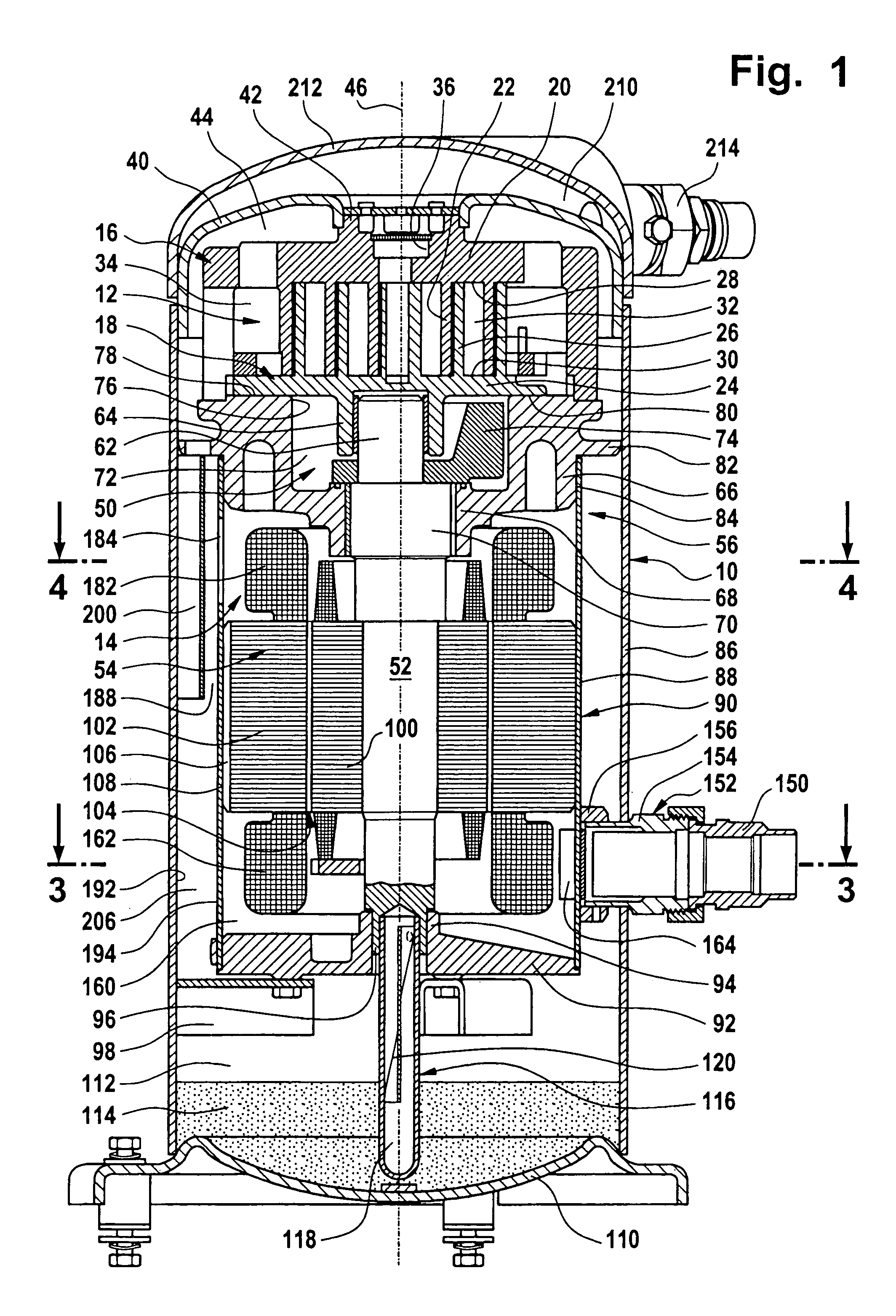

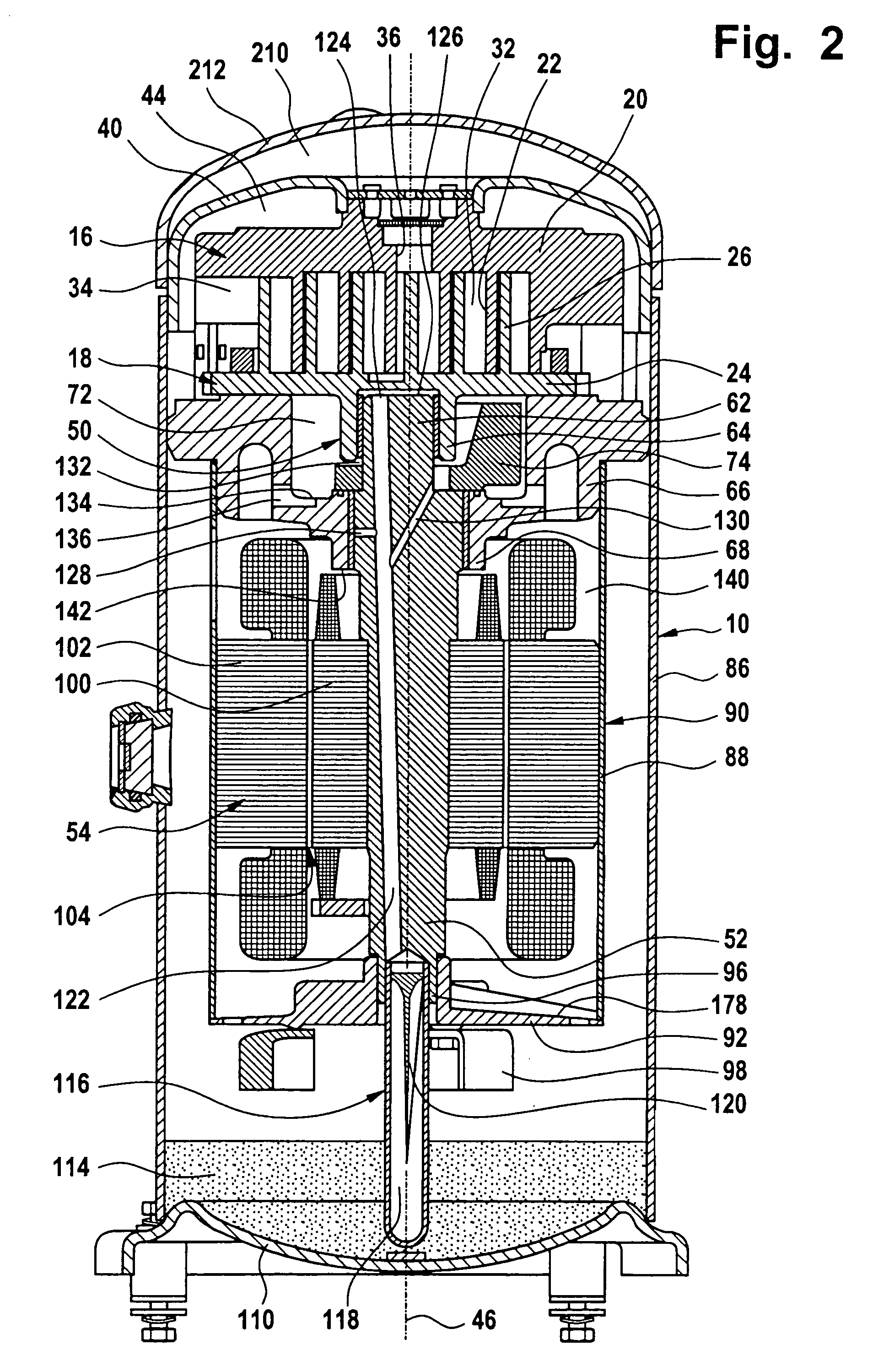

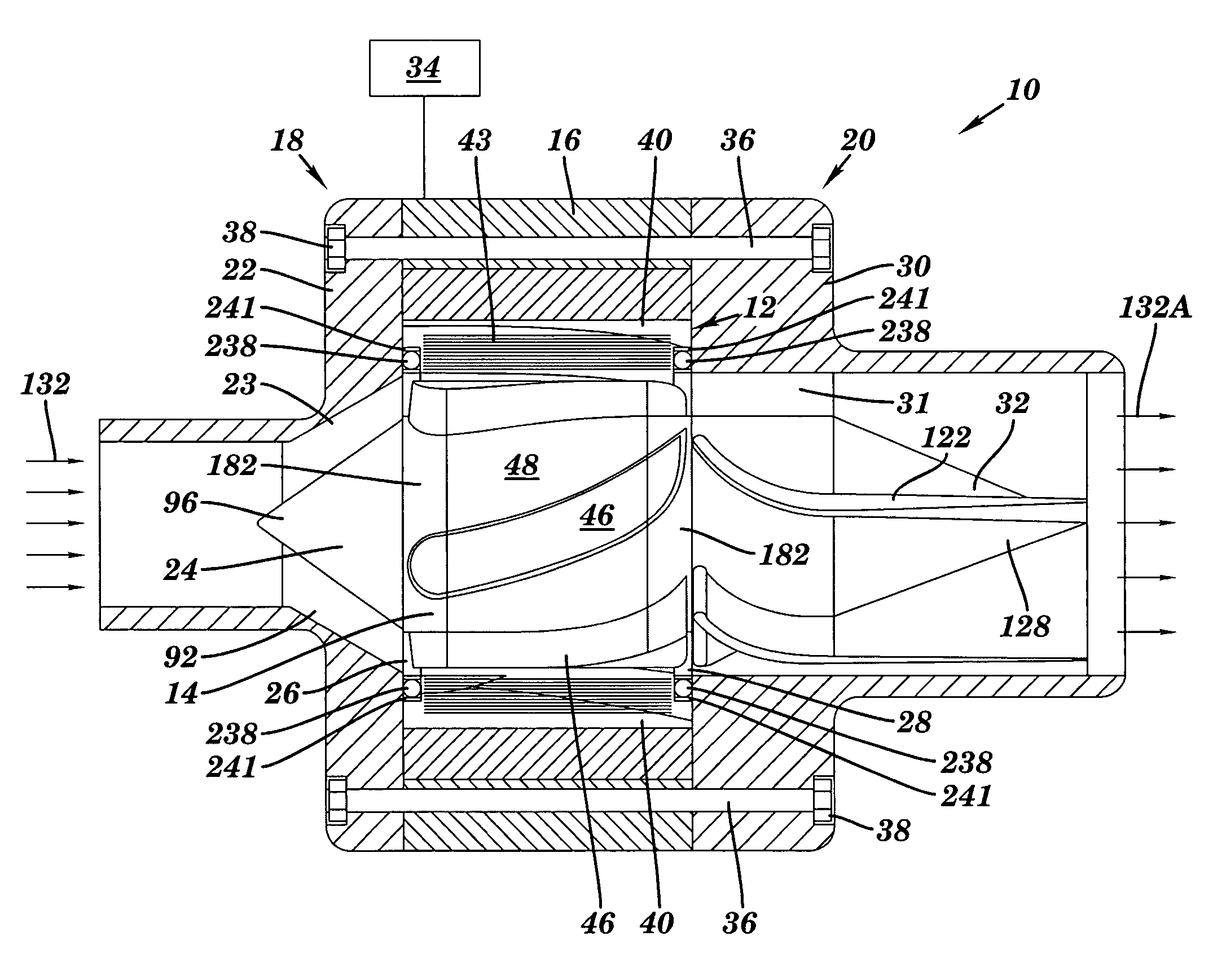

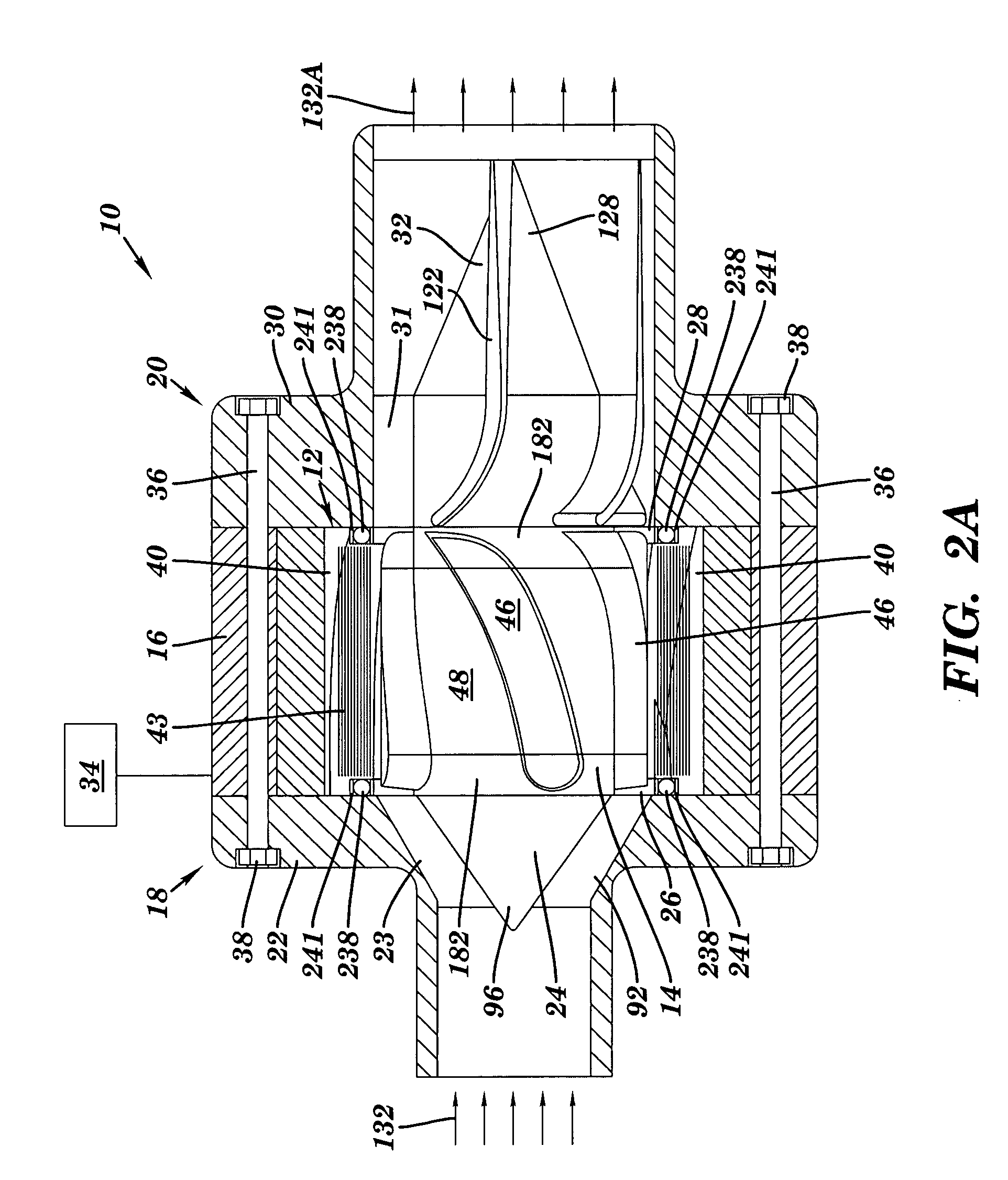

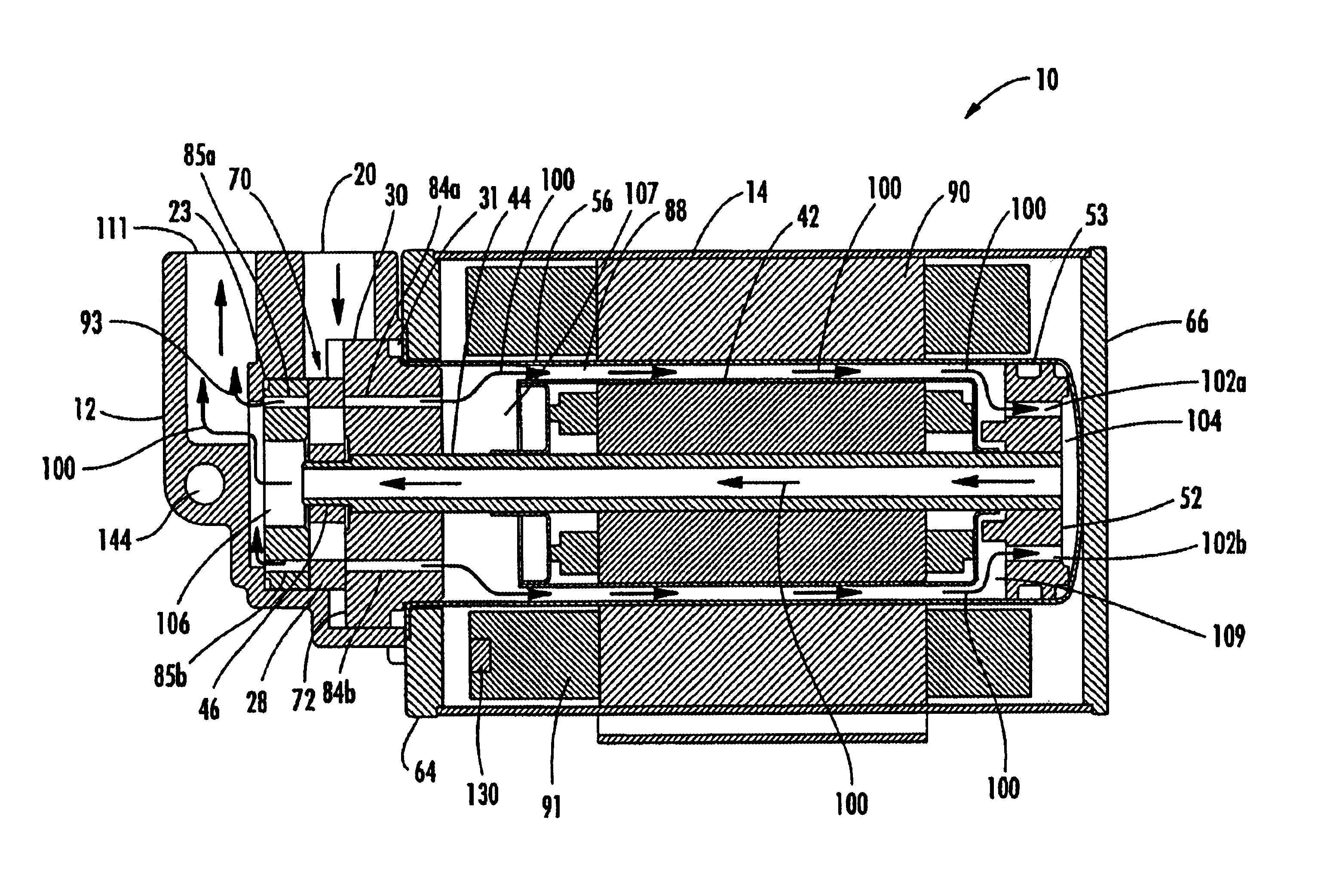

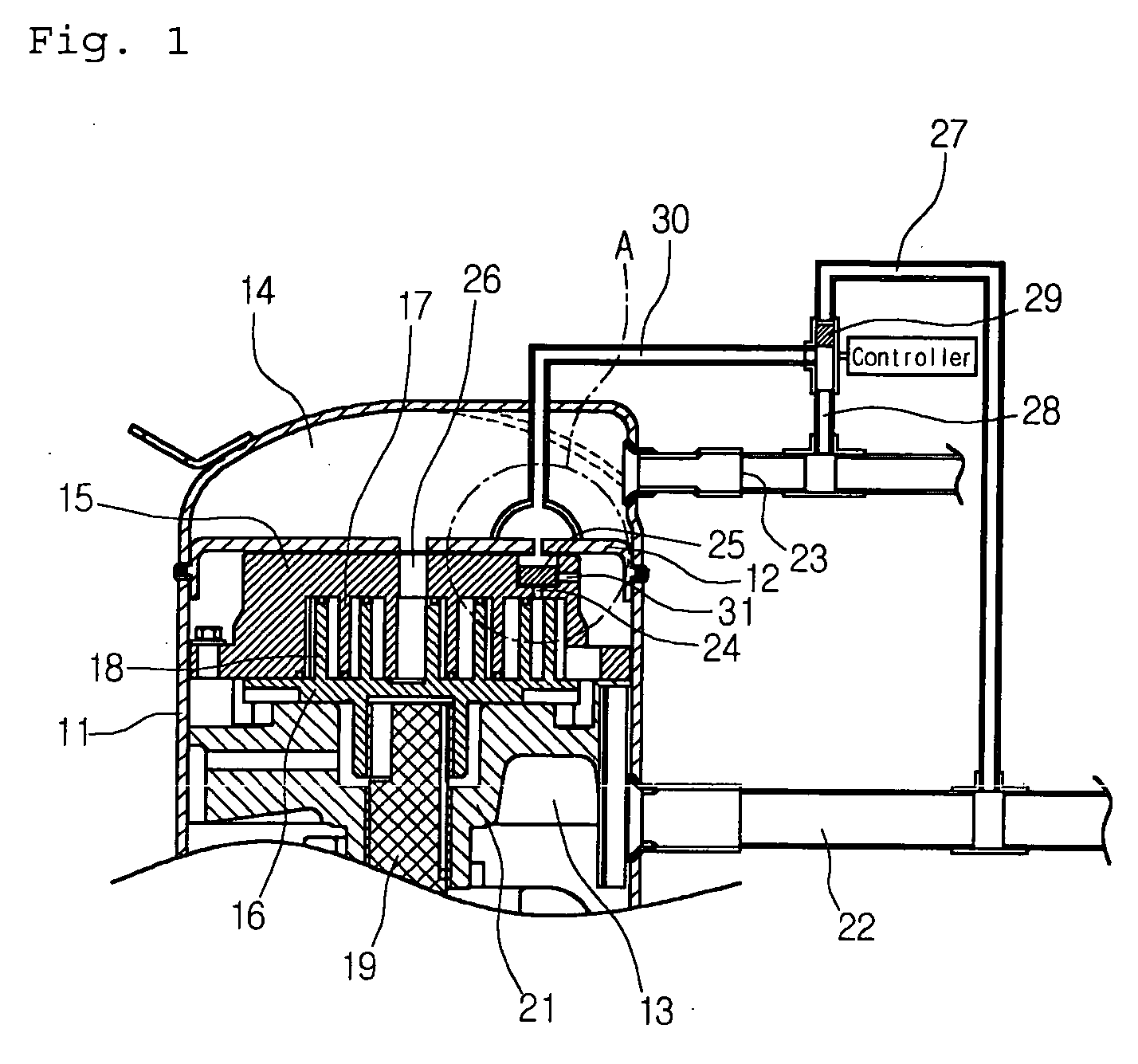

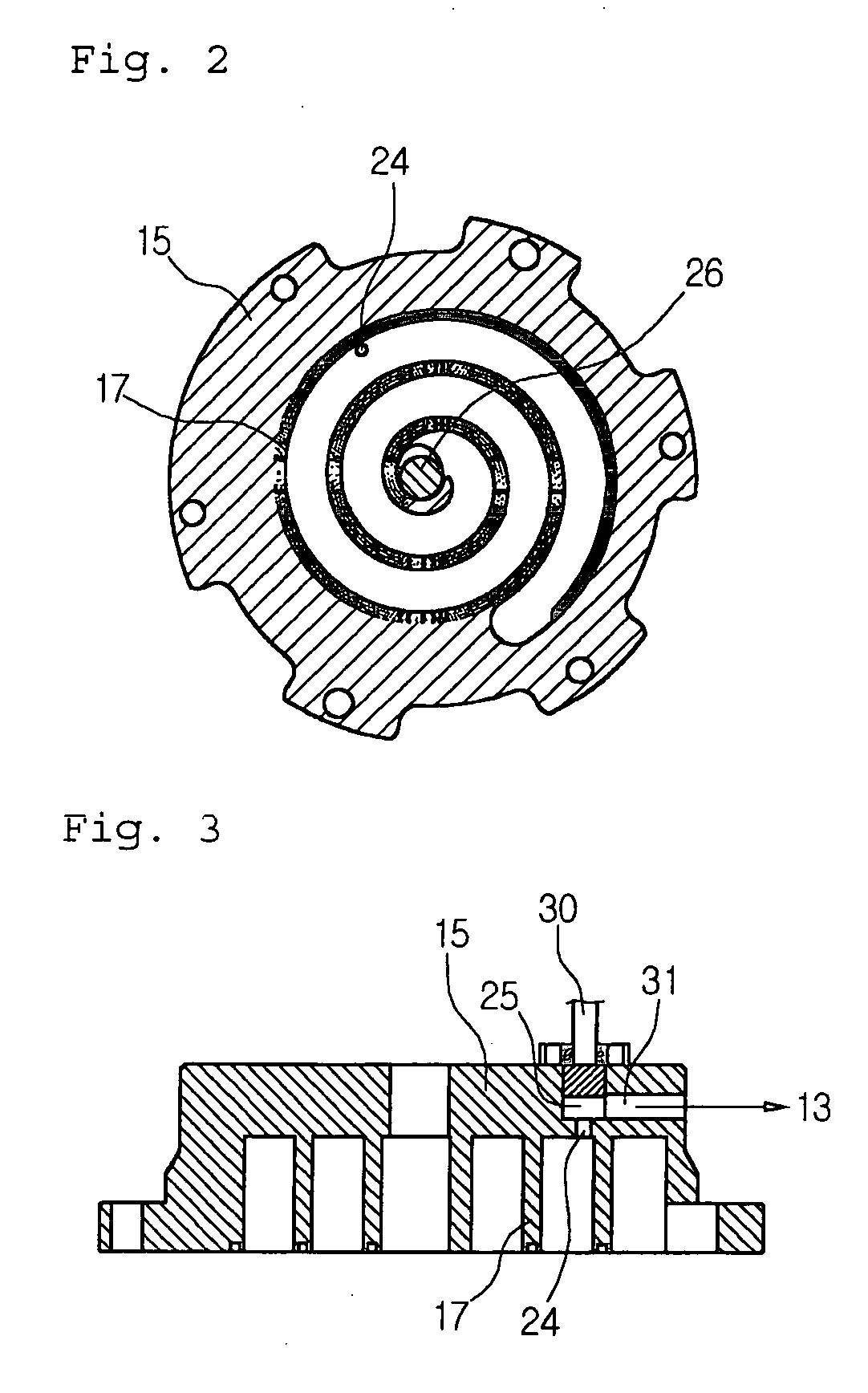

Compressor

ActiveUS6960070B2Easy to fixPrecise alignmentRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeDrive shaftEngineering

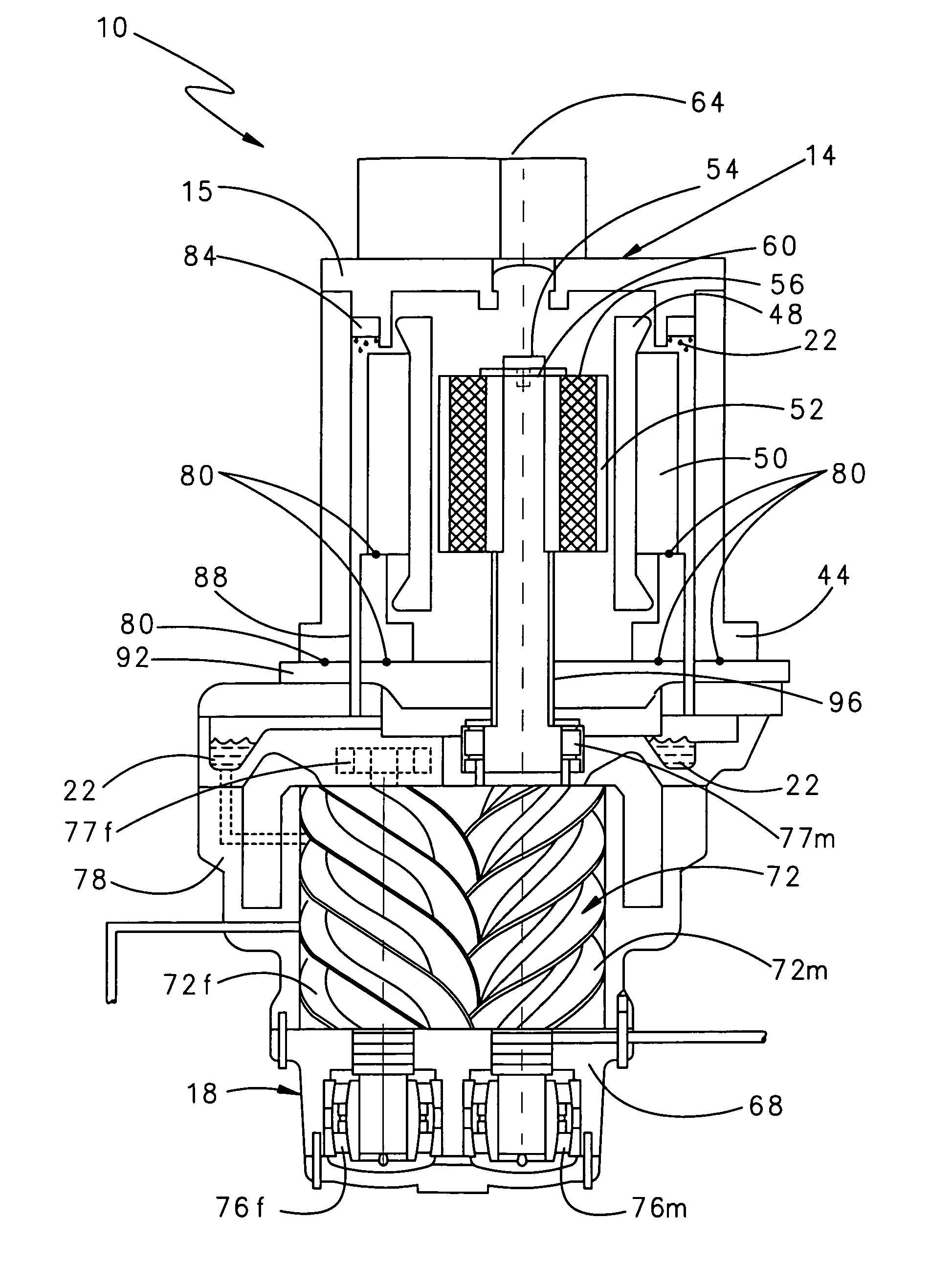

In order to improve a compressor for refrigerant, comprising an outer housing, a scroll compressor arranged in the outer housing and having a first compressor member arranged stationarily in the outer housing and a second compressor member which is movable relative to the first compressor member, the compressor members each having a base and first and second scroll ribs, respectively, which rise above the respective base and engage in one another such that the second compressor member is movable relative to the first compressor member on an orbital path about a central axis for the purpose of compressing the refrigerant, a drive unit for the second compressor member having an eccentric drive, a drive shaft, a drive motor arranged in a motor housing and having drawn-in refrigerant flowing around it as well as a bearing unit for the drive shaft which comprises a first bearing member connected to the outer housing, in such a manner that the refrigerant drawn in by the scroll compressor is free from lubricating oil to as great an extent as possible it is suggested that the refrigerant flow through an oil separator, which is arranged in the outer housing between this and the drive unit, after flowing around the drive motor and prior to entering the scroll compressor.

Owner:BITZER KUEHLMASCHINENBAU GMBH

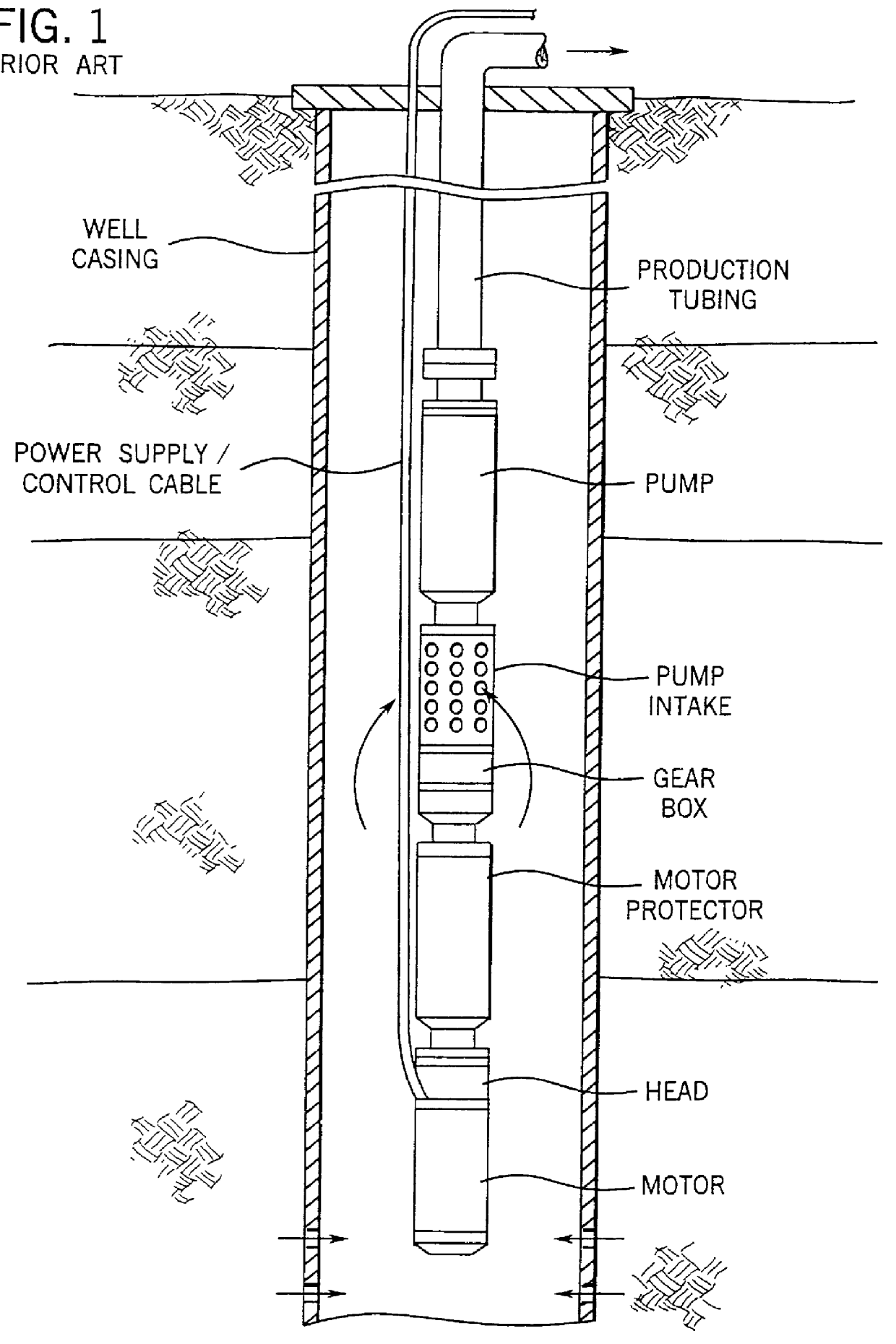

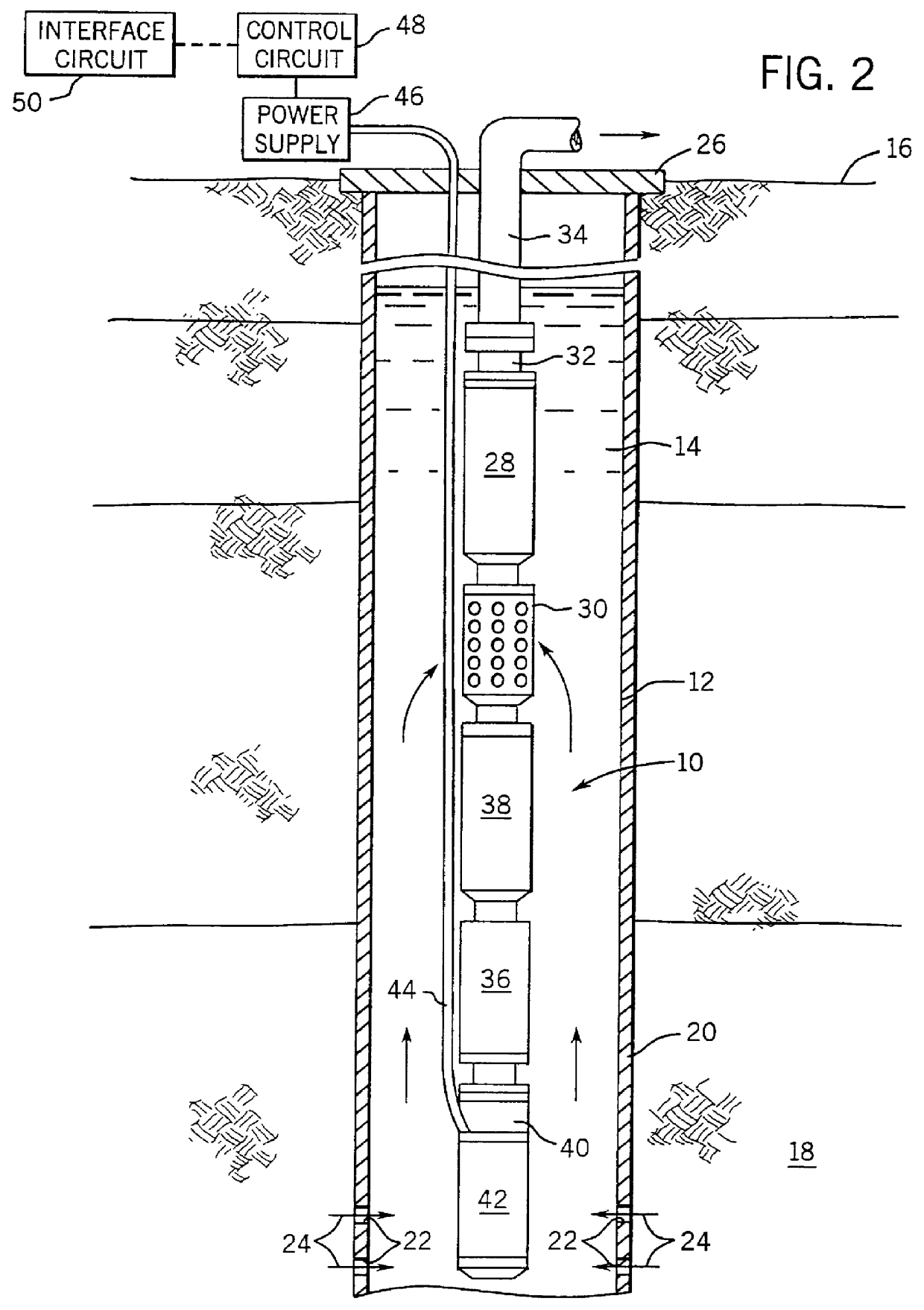

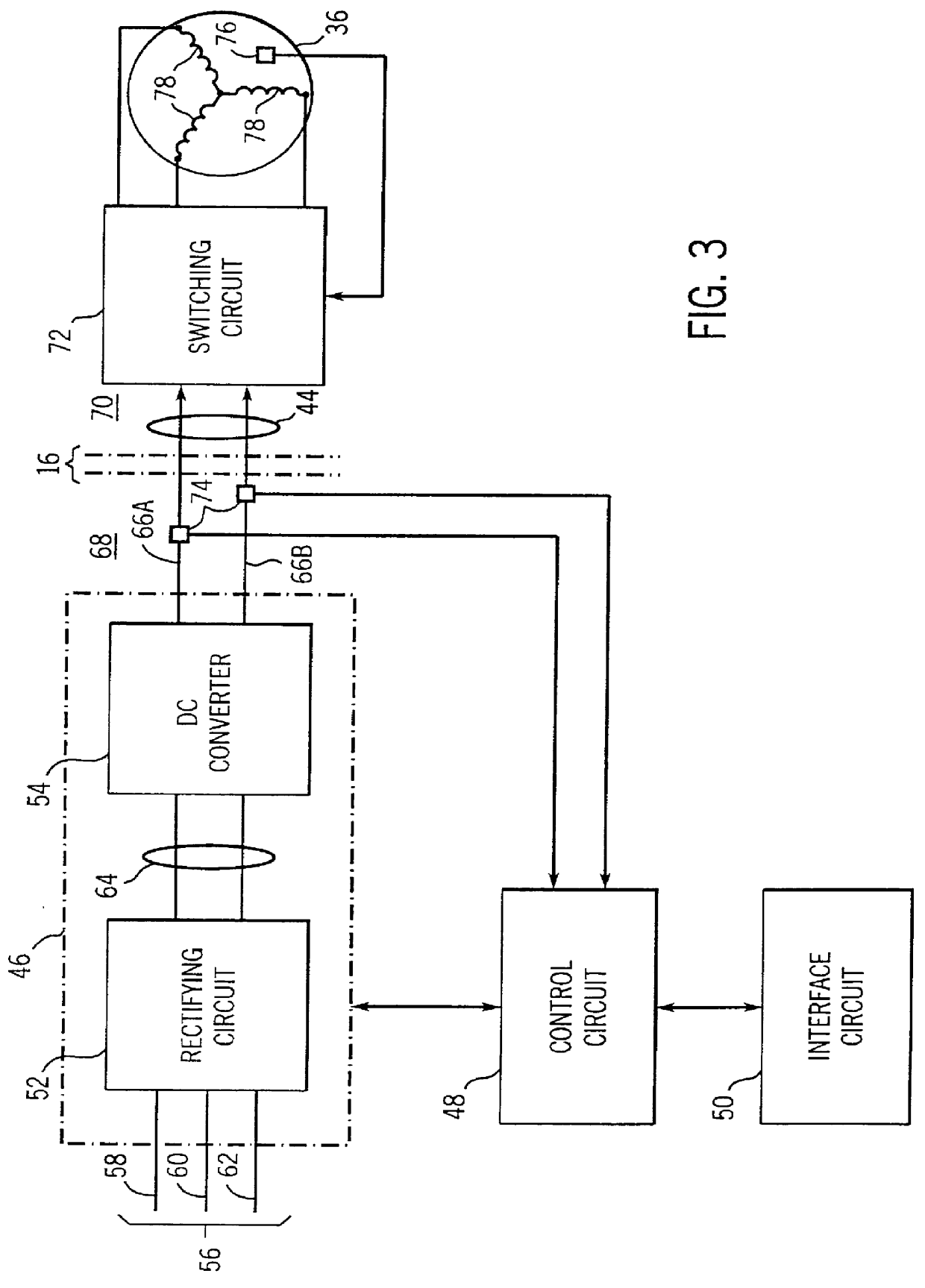

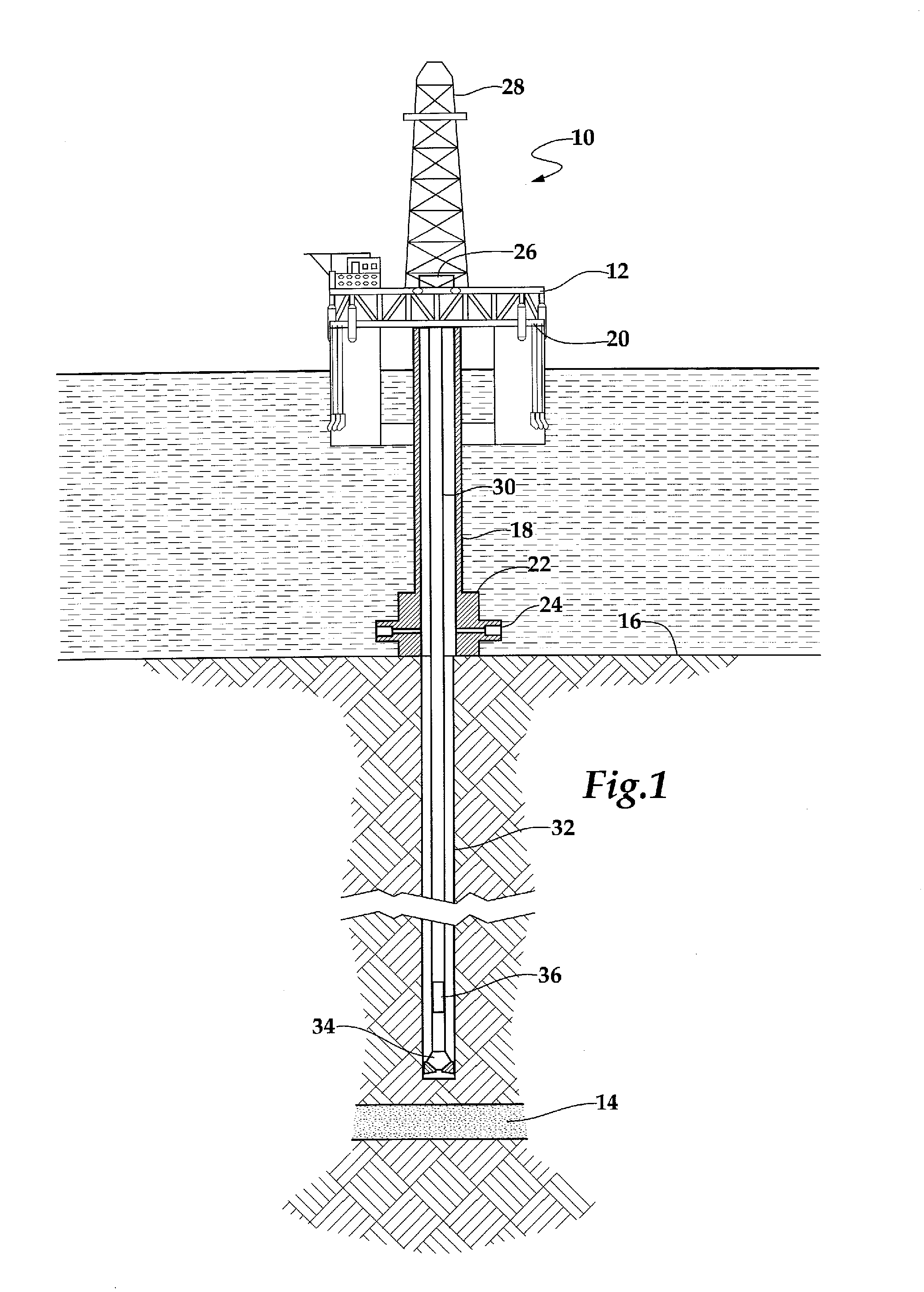

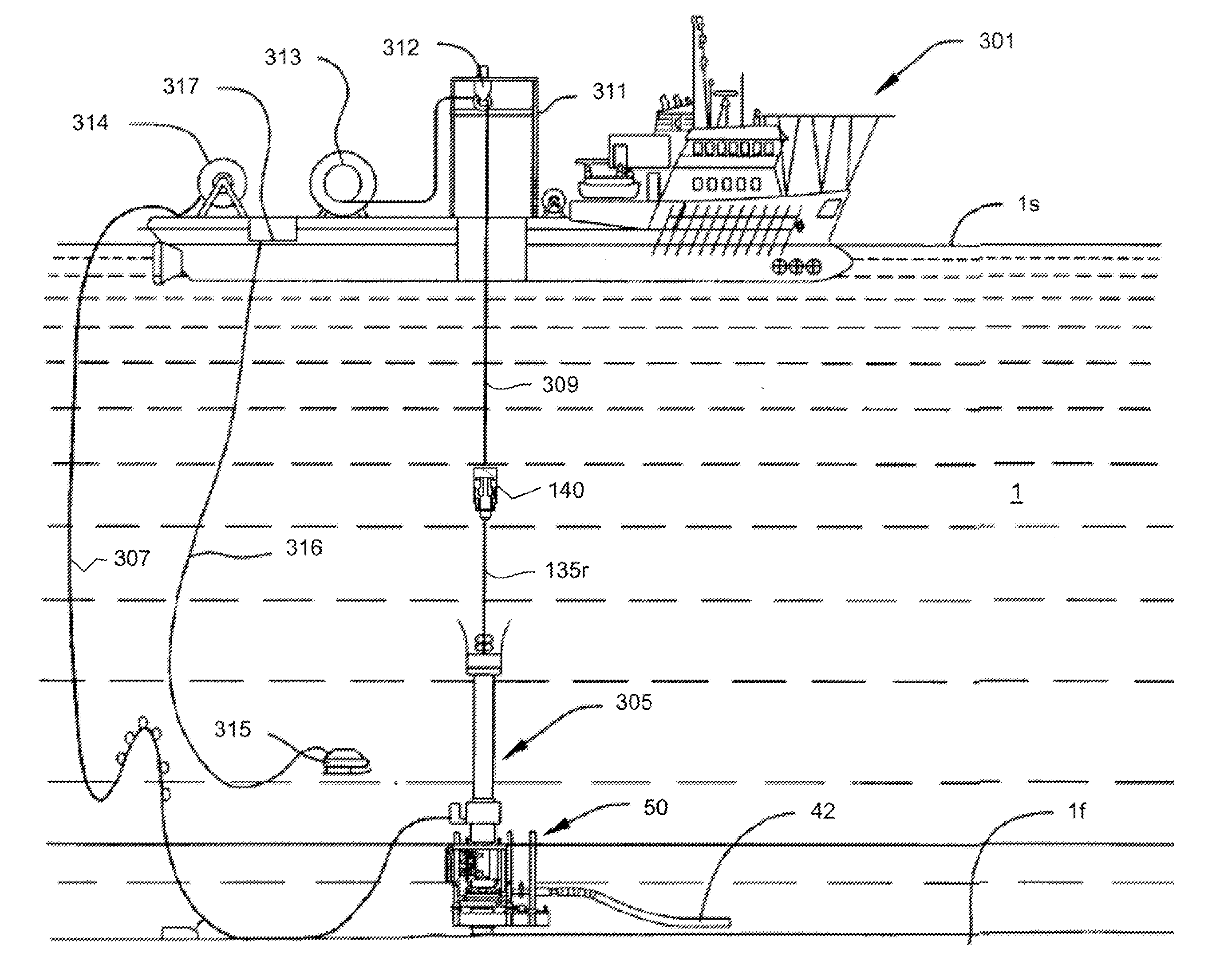

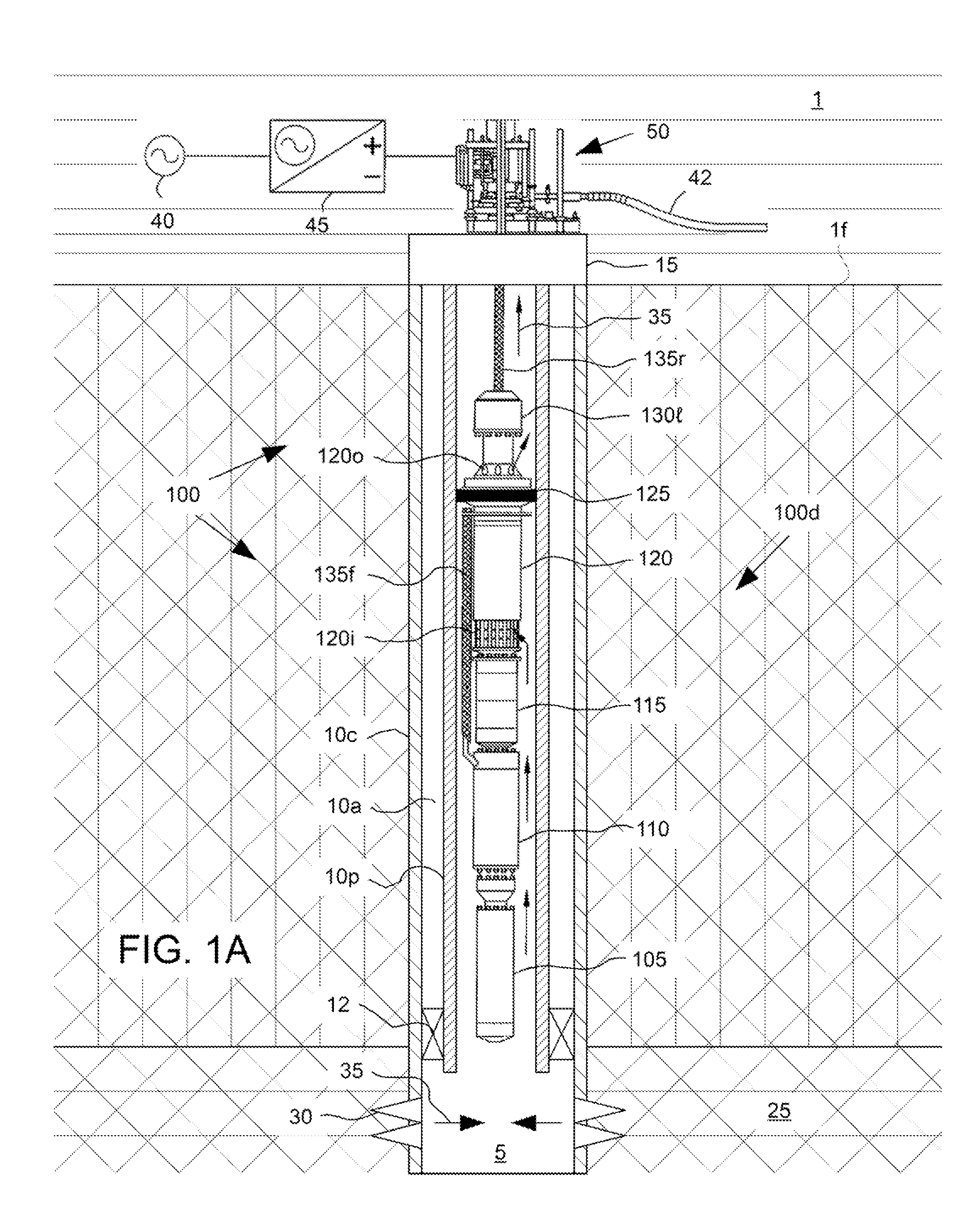

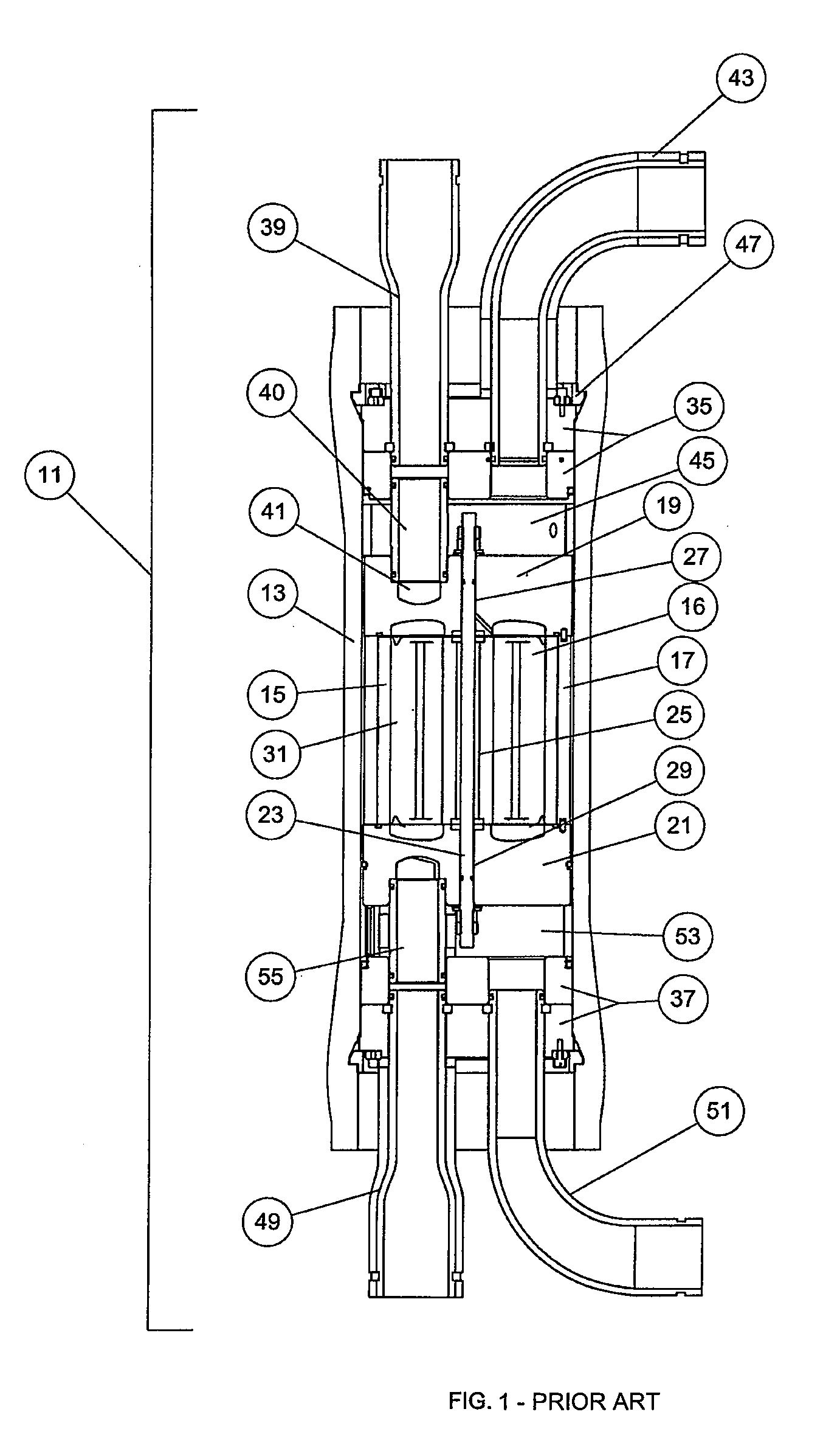

Method and apparatus for controlling a submergible pumping system

A submergible pumping unit for raising viscous fluids from a well is driven by an electronic drive and control system, a first portion of which is located above the well, and a second portion of which is coupled to the submergible pumping unit. The drive and control system includes a power supply circuit located above the well for converting AC power from a source to DC power having current and voltage levels. The DC power is transmitted to the pumping unit via a two-conductor DC bus cable. The pumping unit includes a switching circuit which receives the DC power for driving a submergible motor, such as a permanent magnet brushless motor. The speed of the motor, and of a pump coupled thereto, is proportional to the voltage of the DC power applied to the pumping unit. The pump is preferably a progressive cavity pump, and the drive and control circuitry provides sufficient torque to start the pump from a static condition. A control circuit is provided for transmitting configuration and desired flow rate and speed data to the power supply.

Owner:CAMCO INT

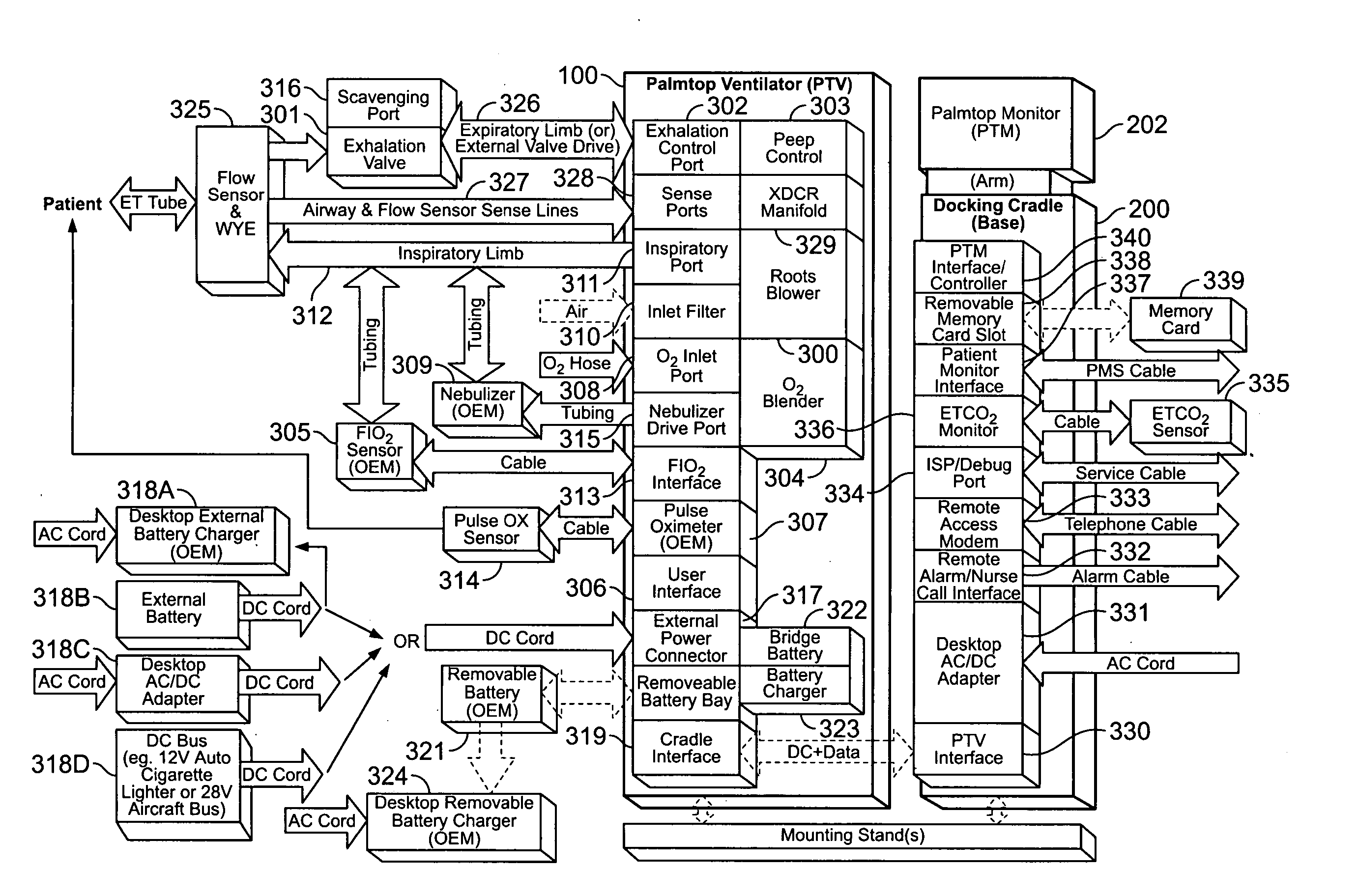

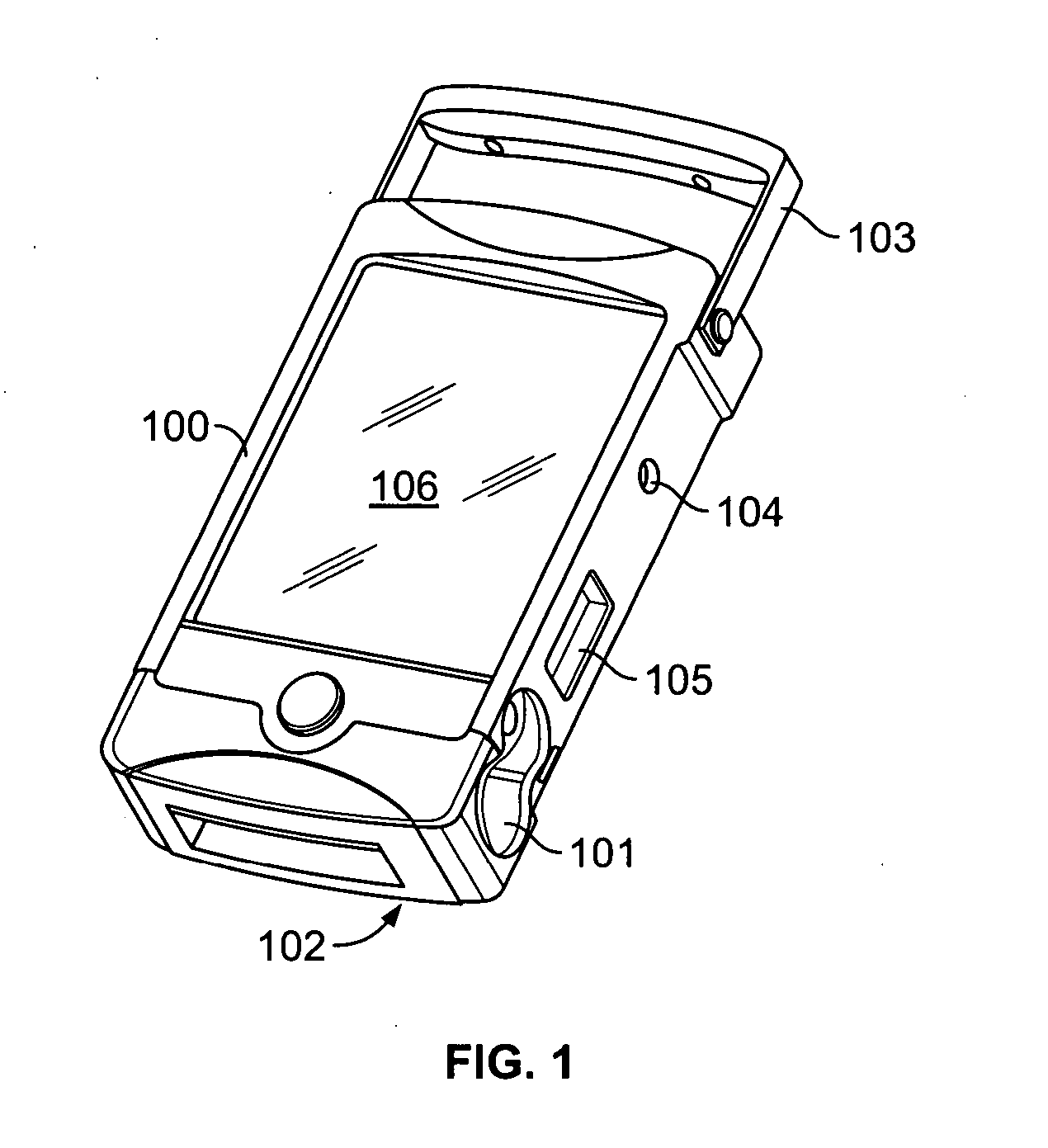

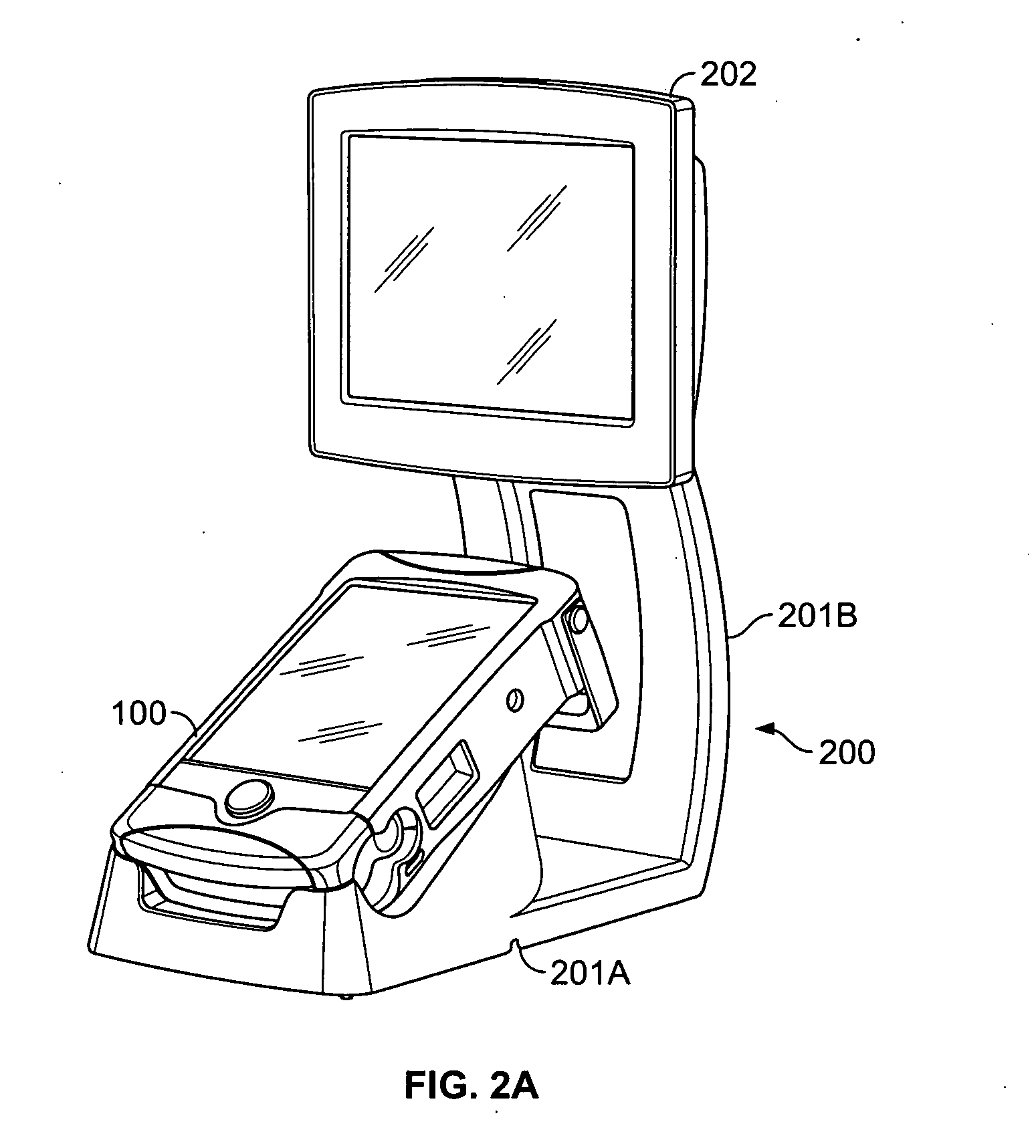

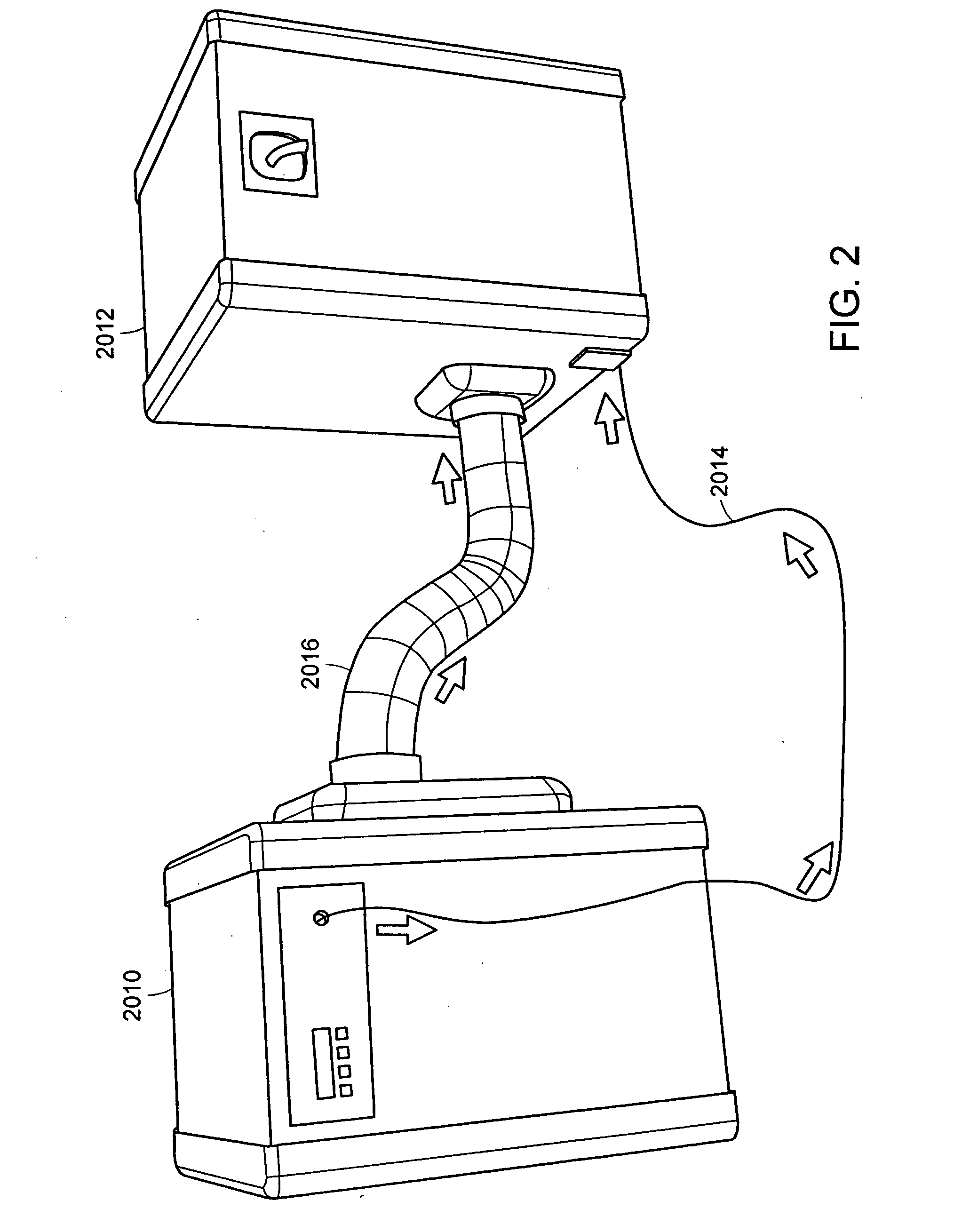

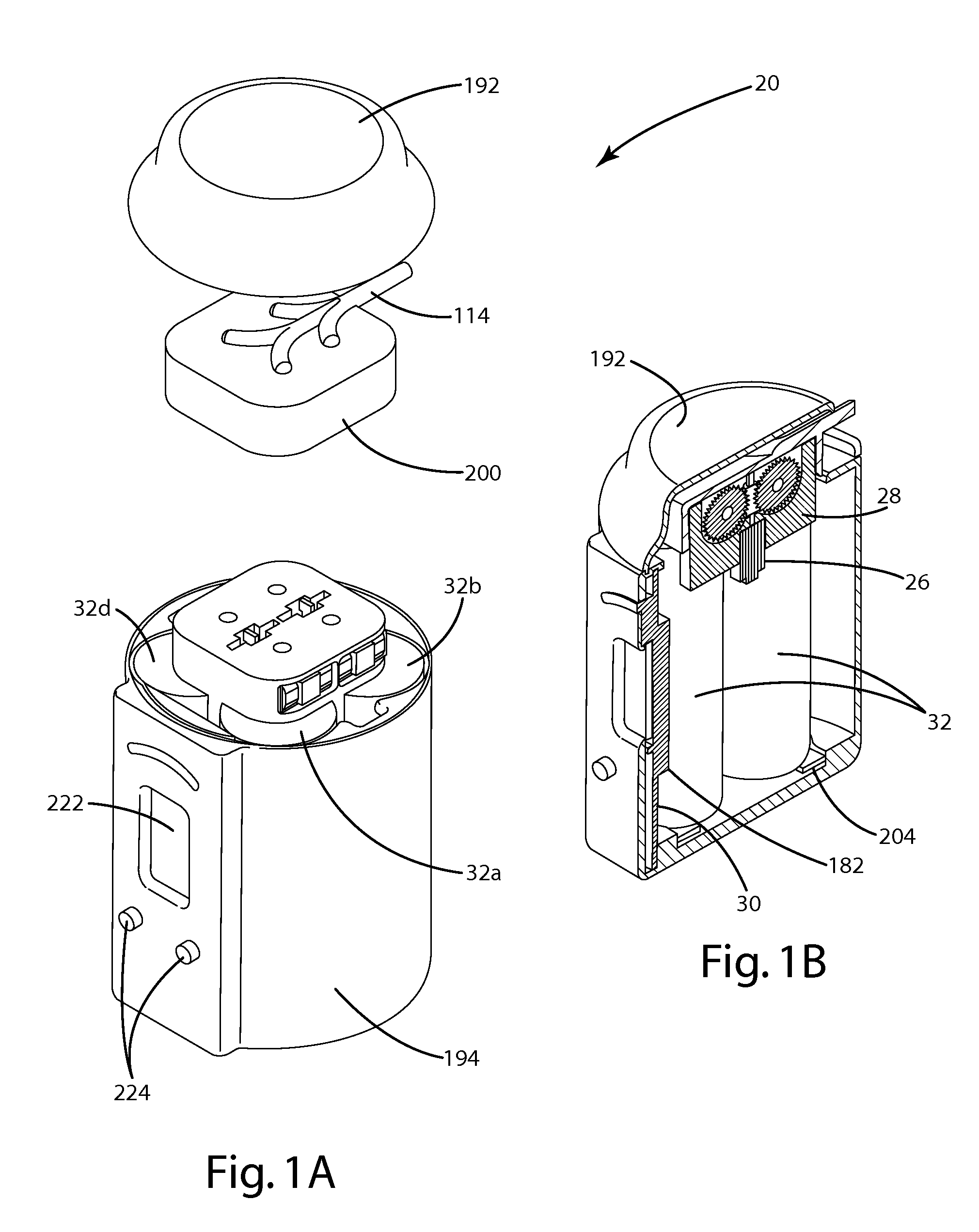

Portable ventilator system

ActiveUS20050051168A1Reduce power consumptionSmall sizeMechanical/radiation/invasive therapiesPhysical therapyPortable ventilatorsEngineering

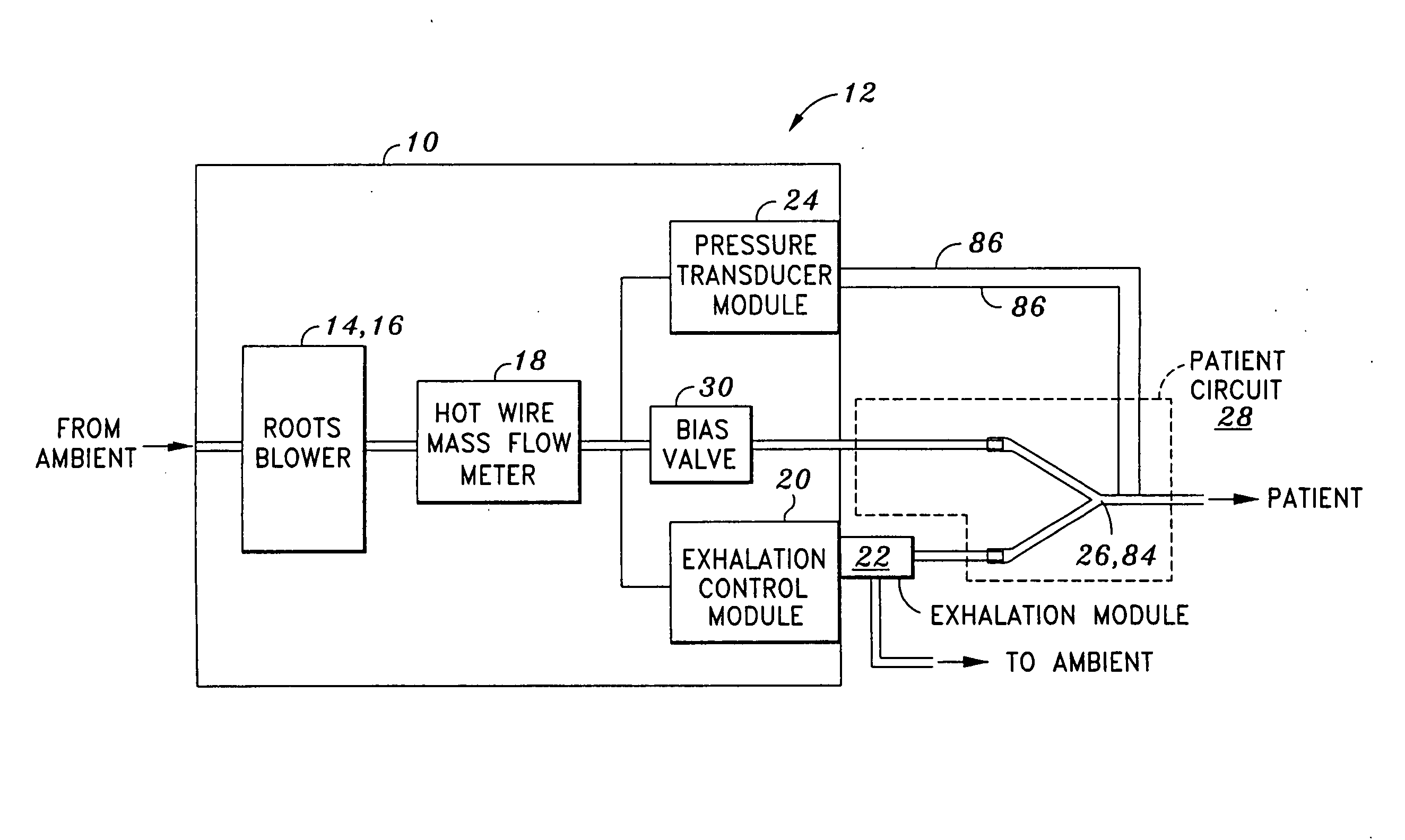

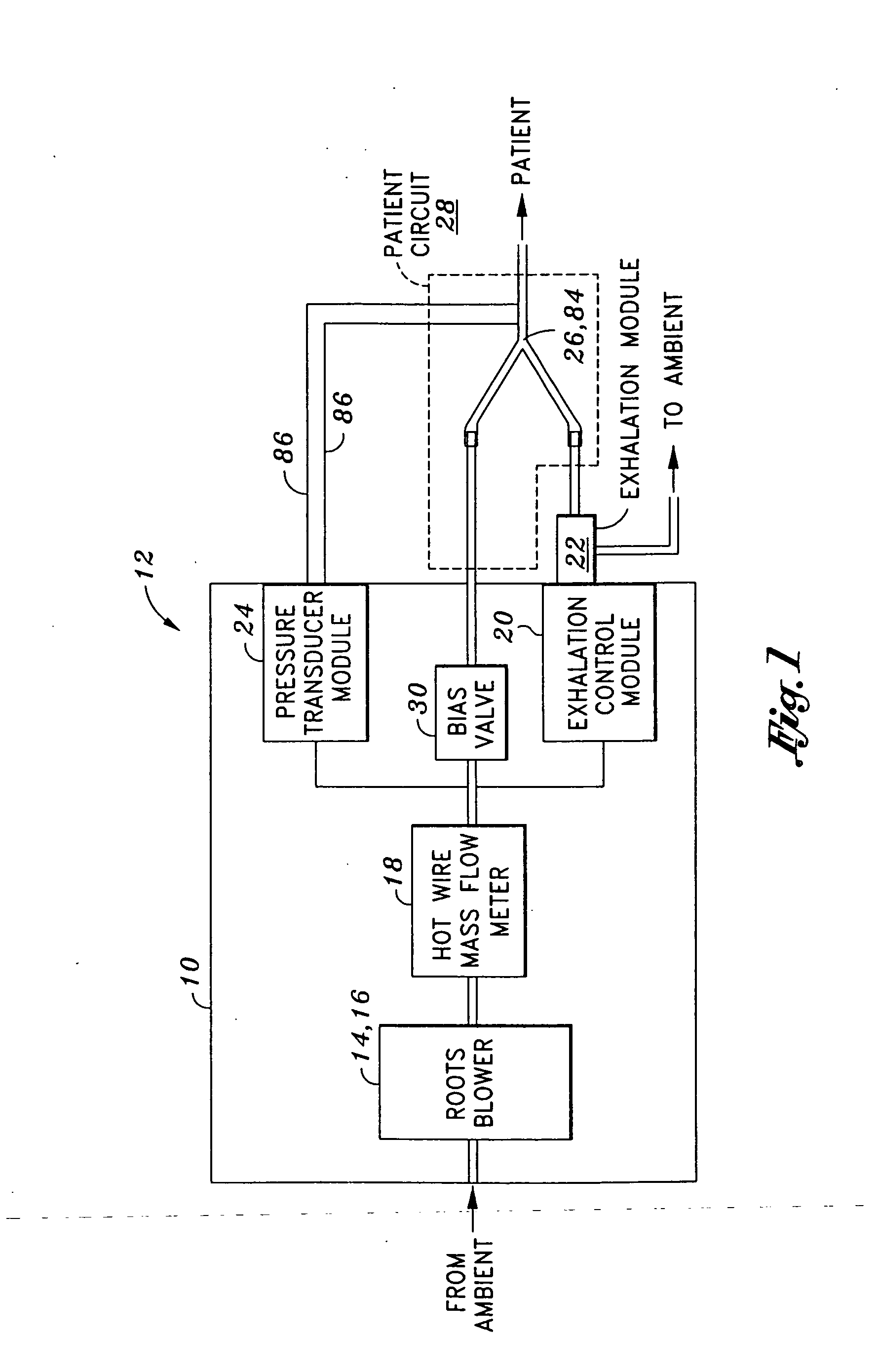

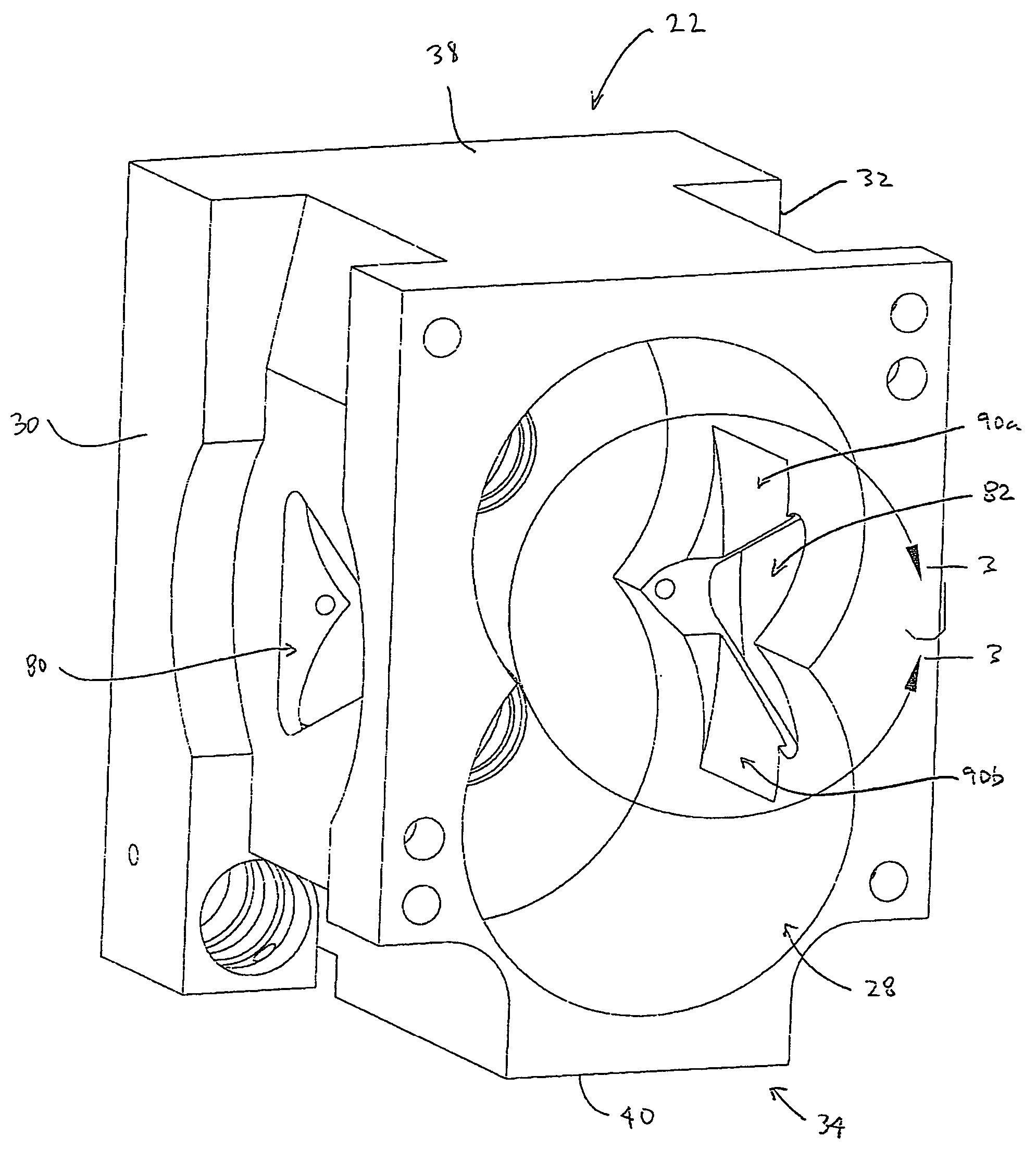

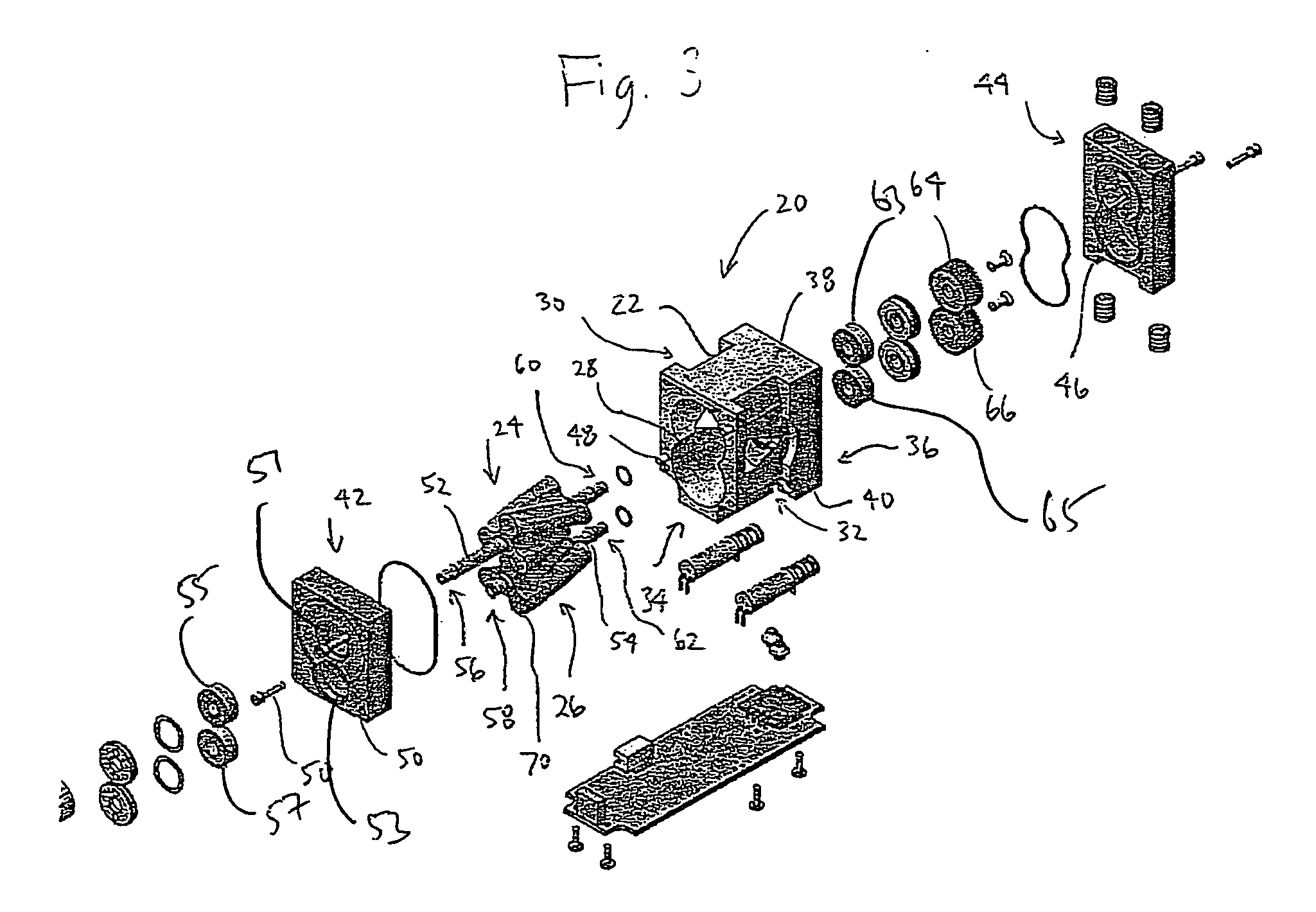

A portable ventilator uses a Roots-type blower as a compressor to reduce both the size and power consumption of the ventilator. Various functional aspects of the ventilator are delegated to multiple subassemblies having dedicated controllers and software that interact with a ventilator processor to provide user interface functions, exhalation control and flow control servos, and monitoring of patient status. The ventilator overcomes noise problems through the use of noise reducing pressure compensating orifices on the Roots blower housing and multiple baffling chambers. The ventilator is configured with a highly portable form factor, and may be used as a stand-alone device or as a docked device having a docking cradle with enhanced interface and monitoring capabilities.

Owner:VYAIRE MEDICAL 203 INC

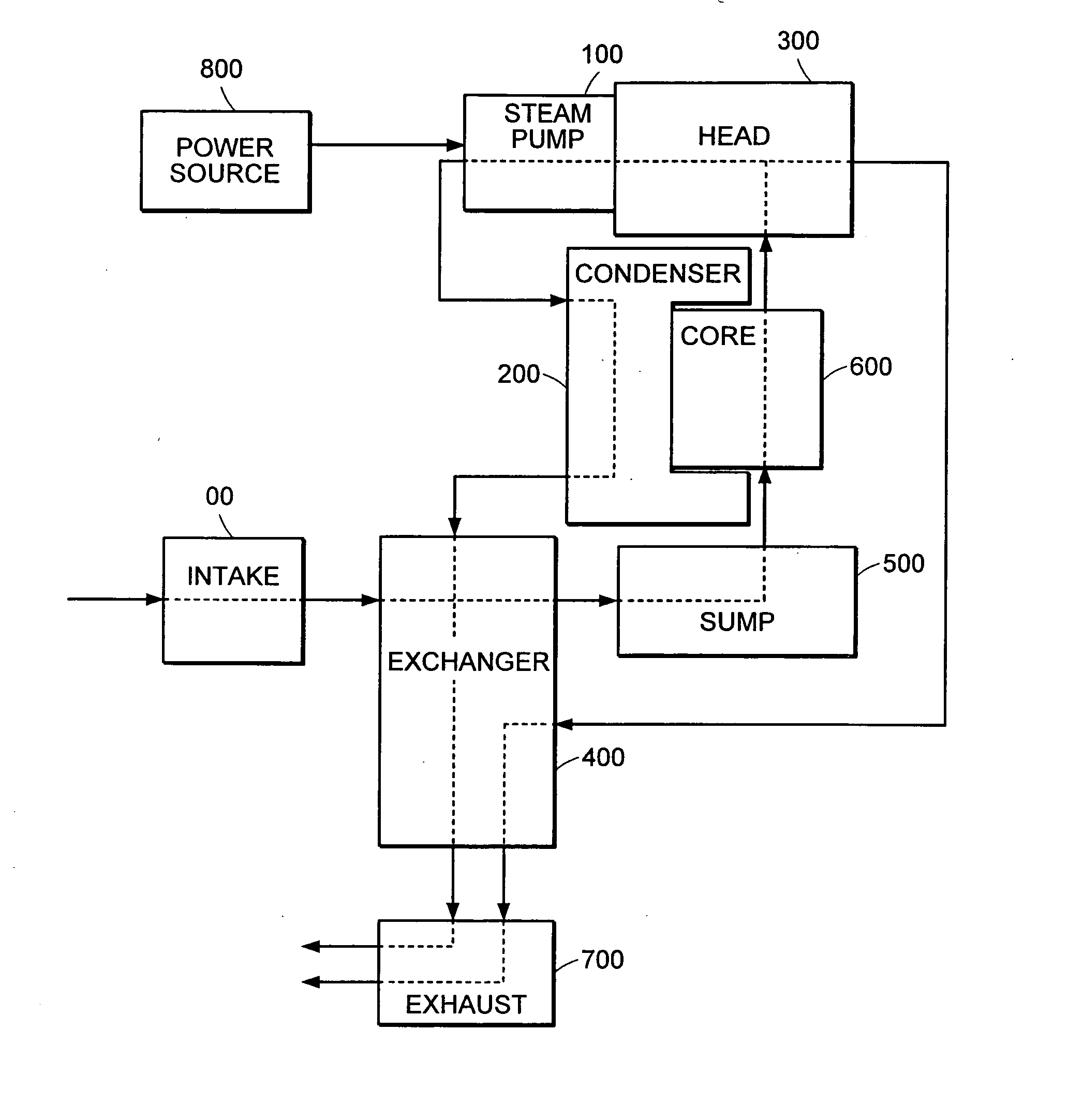

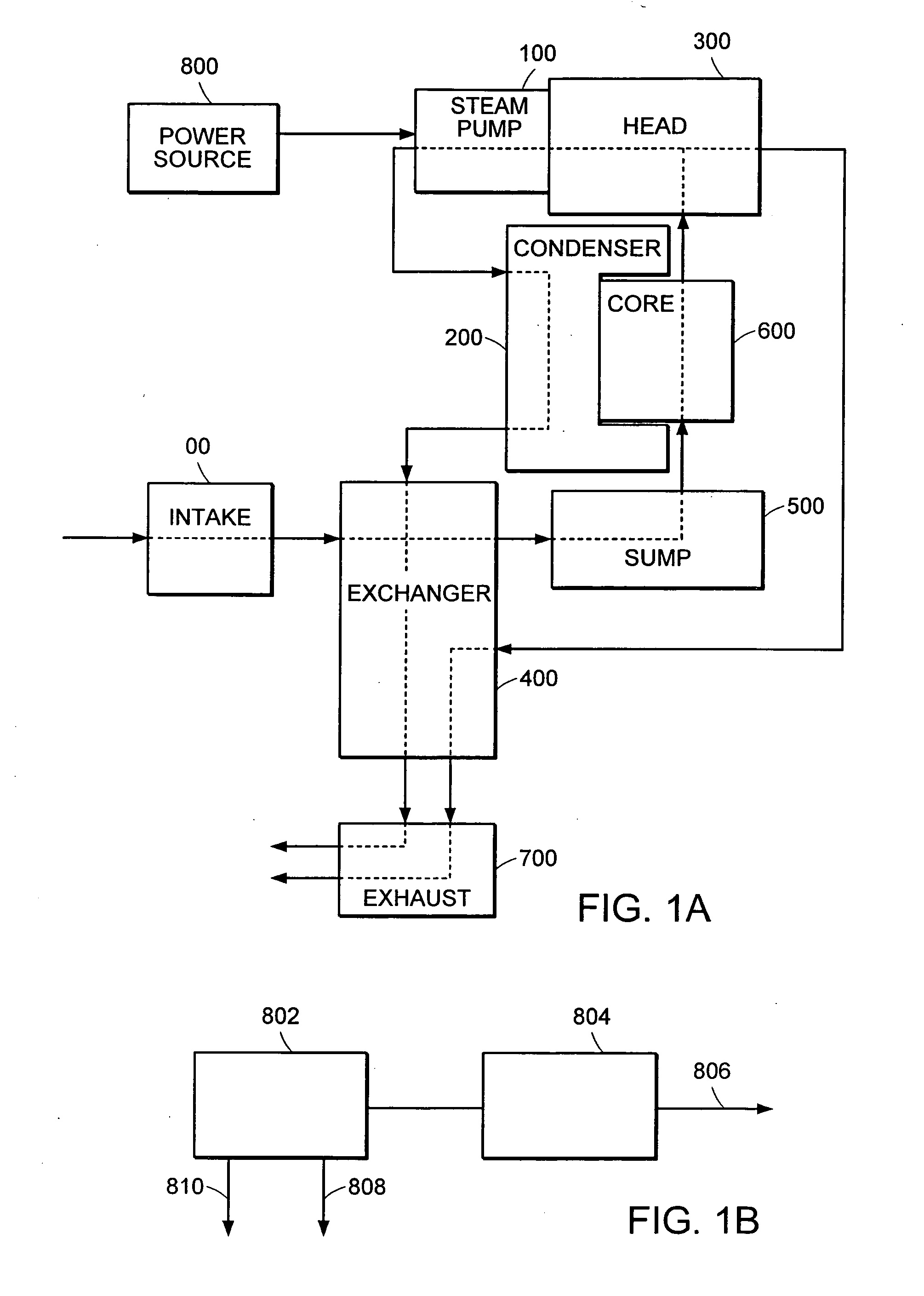

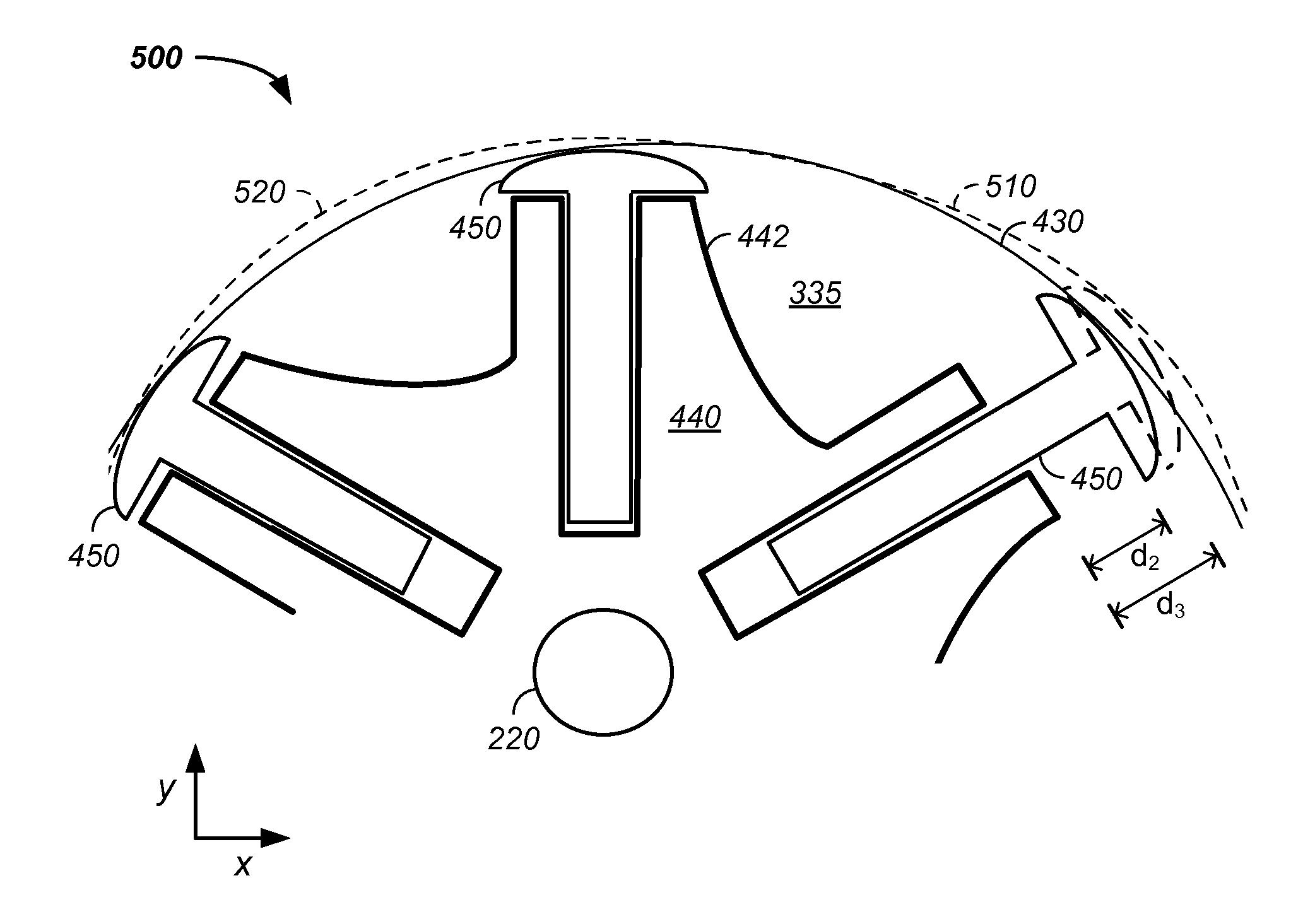

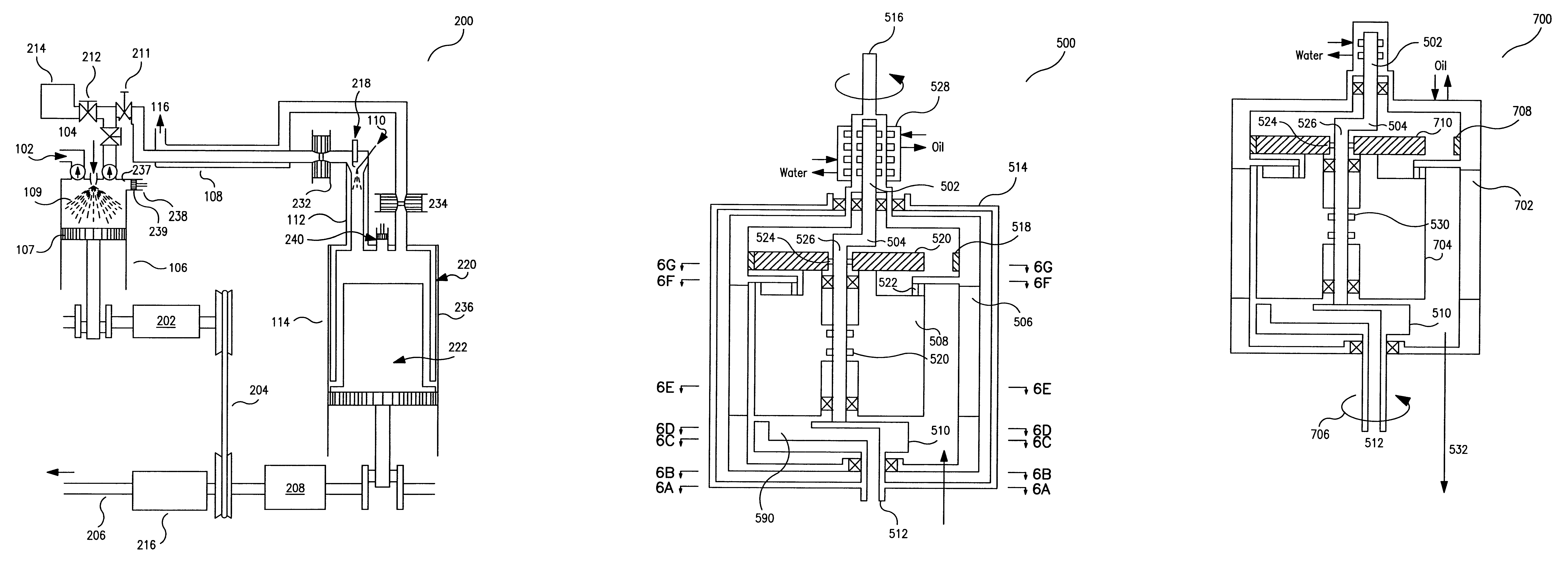

Pressurized vapor cycle liquid distillation

ActiveUS20050016828A1Easy maintenanceMaximize energy efficiencyDistillation regulation/controlUsing liquid separation agentHeat managementDrive shaft

Embodiments of the invention are directed toward a novel pressurized vapor cycle for distilling liquids. In some embodiments of the invention, a liquid purification system is revealed, including the elements of an input for receiving untreated liquid, a vaporizer coupled to the input for transforming the liquid to vapor, a head chamber for collecting the vapor, a vapor pump with an internal drive shaft and an eccentric rotor with a rotatable housing for compressing vapor, and a condenser in communication with the vapor pump for transforming the compressed vapor into a distilled product. Other embodiments of the invention are directed toward heat management, and other process enhancements for making the system especially efficient.

Owner:DEKA PROD LLP

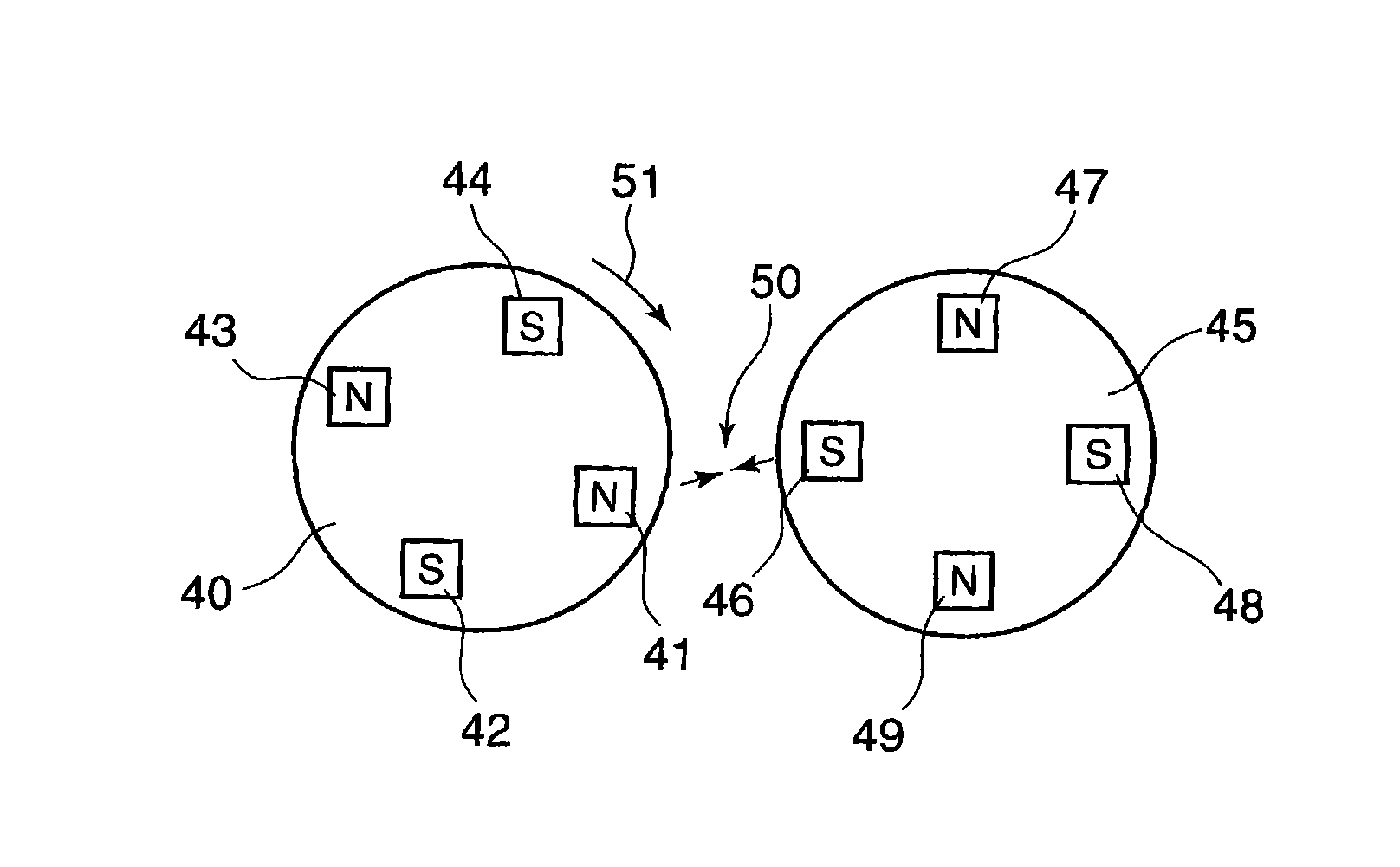

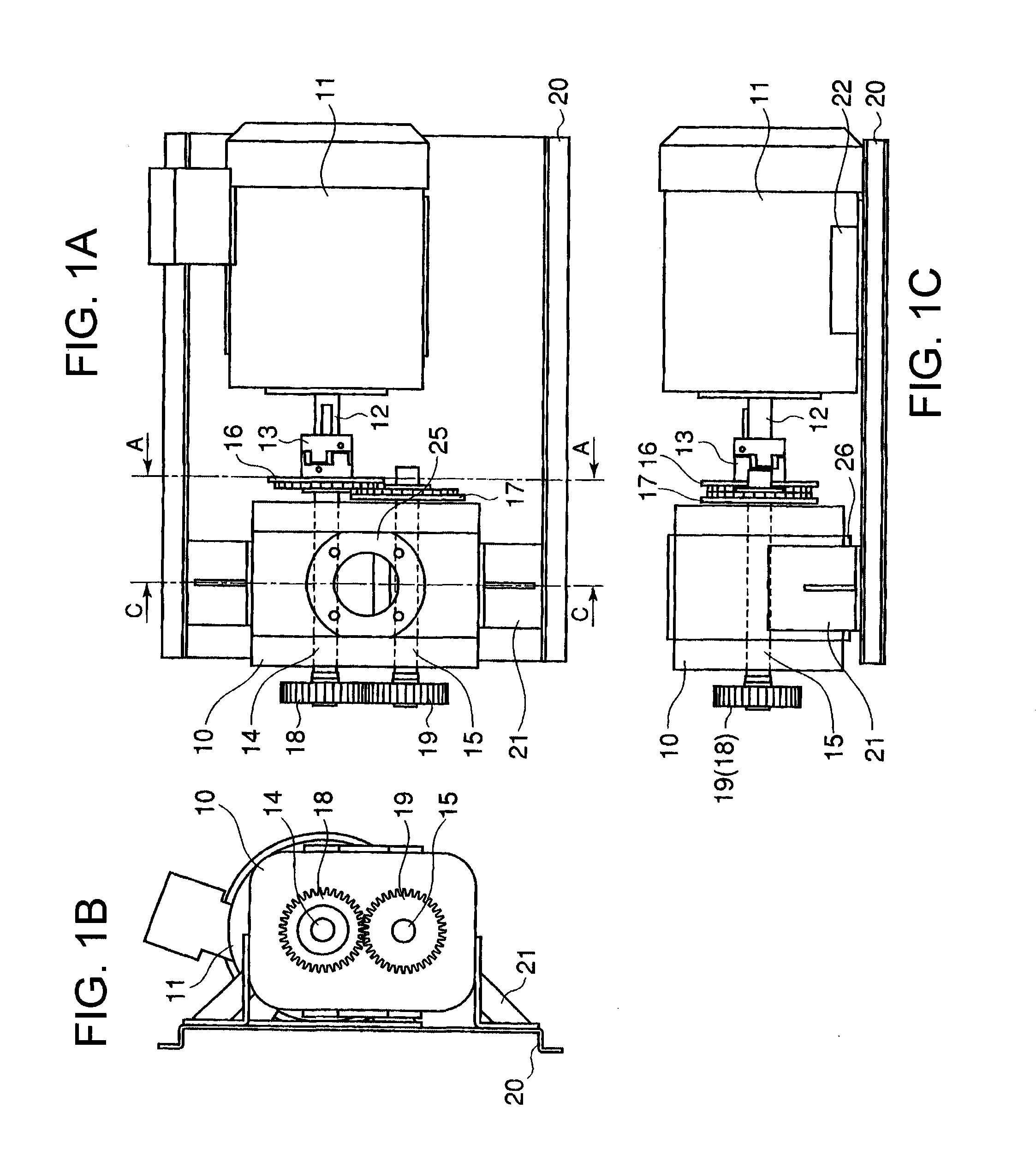

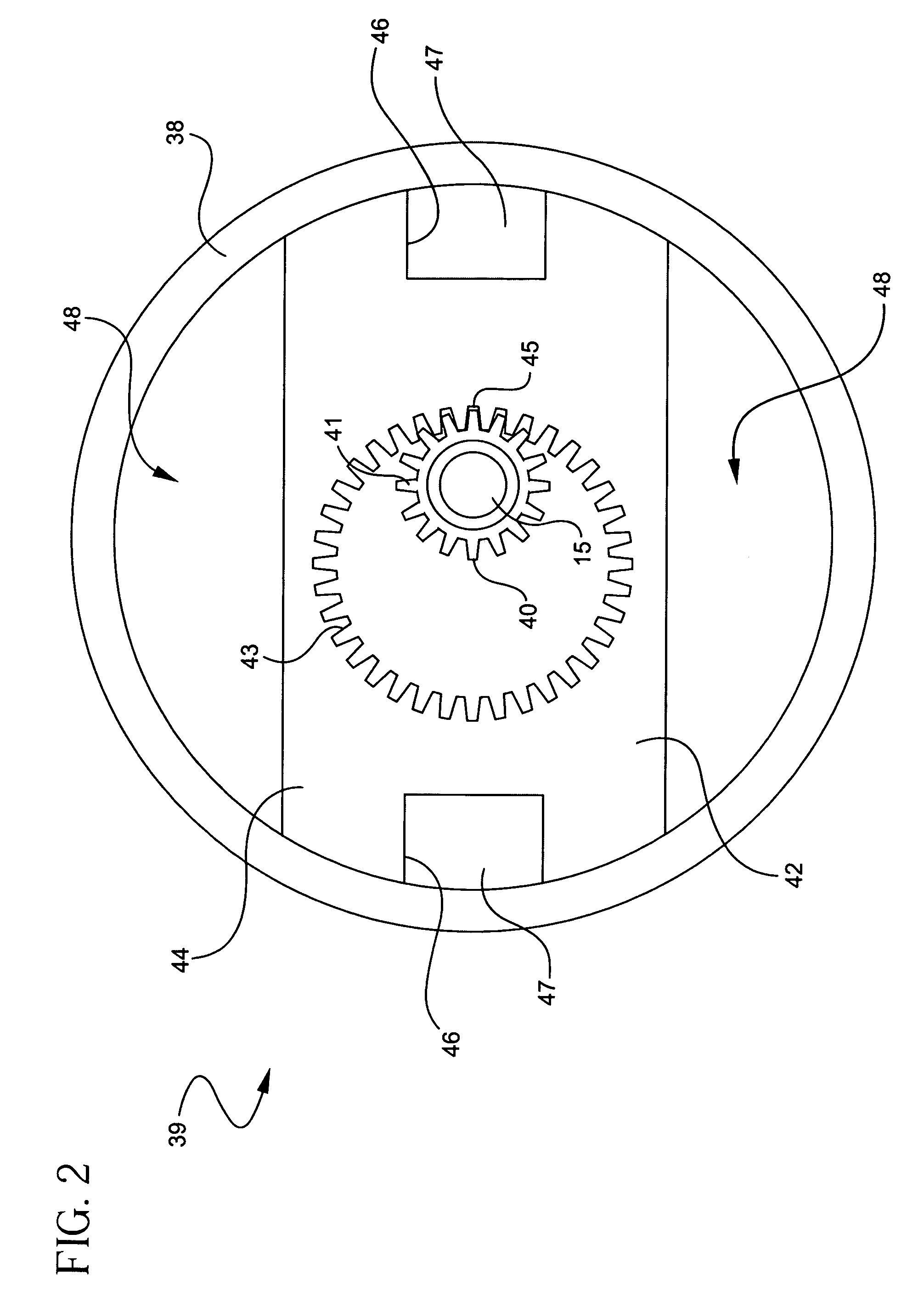

Drive transmission mechanism between two or more rotary shafts and oil-free fluid machine equipped with the mechanism

InactiveUS20080181804A1Reduced service lifeEliminate pollutionDynamo-electric brakes/clutchesEngine of counter-engagement typePlastic materialsOil free

A drive transmission mechanism for transmitting torque between two or more rotary shafts in synchronization with one another without need for lubrication thereby eliminating occurrence of oil contamination, and an oil-free fluid machine equipped with the mechanism, are provided. A magnetic drive disk 16 and a synchronization gear 18 are attached to a rotary shaft 14 connected to a drive motor 11, a magnetic drive disk 17 and a synchronization gear 19 is attached to a rotary shaft 15, torque transmission from the rotary shaft 14 to the rotary shaft 15 is carried out in two ways, via the magnetic drive disks 16, 17 and via the synchronization gears 18, 19, and at least one of the synchronization gears is made of plastic material. With the construction, torque transmit load between the rotary shafts via the synchronization gears is decreased, and a plastic gear or gears can be adopted for synchronization gears without reducing life of the gears without need for lubrication oil.

Owner:ANEST IWATA CORP

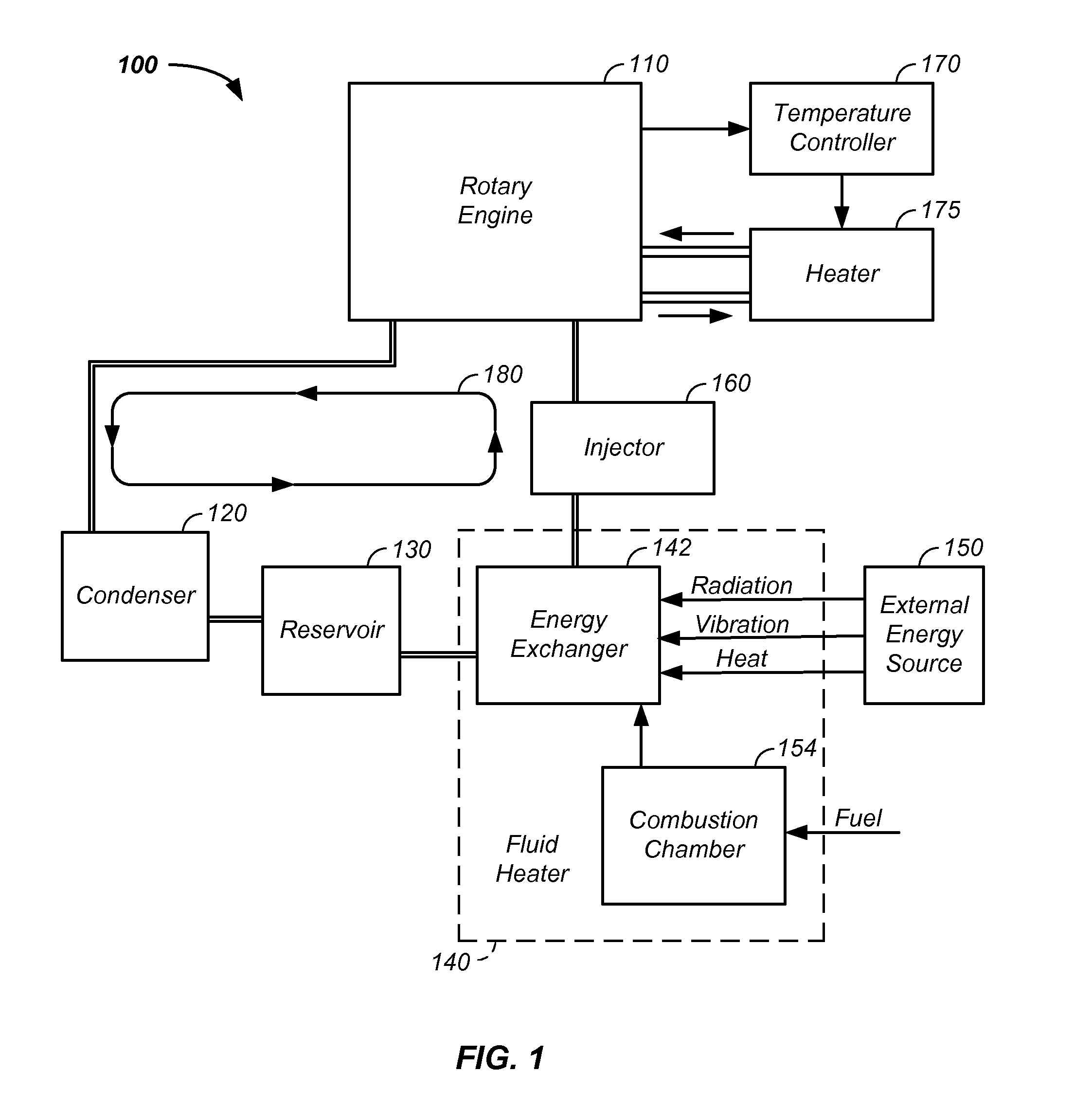

Rotary engine expansion chamber apparatus and method of operation therefor

ActiveUS8523547B2Internal combustion piston enginesOscillating piston enginesRotary engineExpansion chamber

Owner:PEKRUL MERTON W

Fluid pump/generator with integrated motor and related stator and rotor and method of pumping fluid

InactiveUS7021905B2Small sizeReduce the number of partsGas turbine plantsRotary piston pumpsImpellerElectric machine

Owner:ADVANCED ENERGY CONVERSION

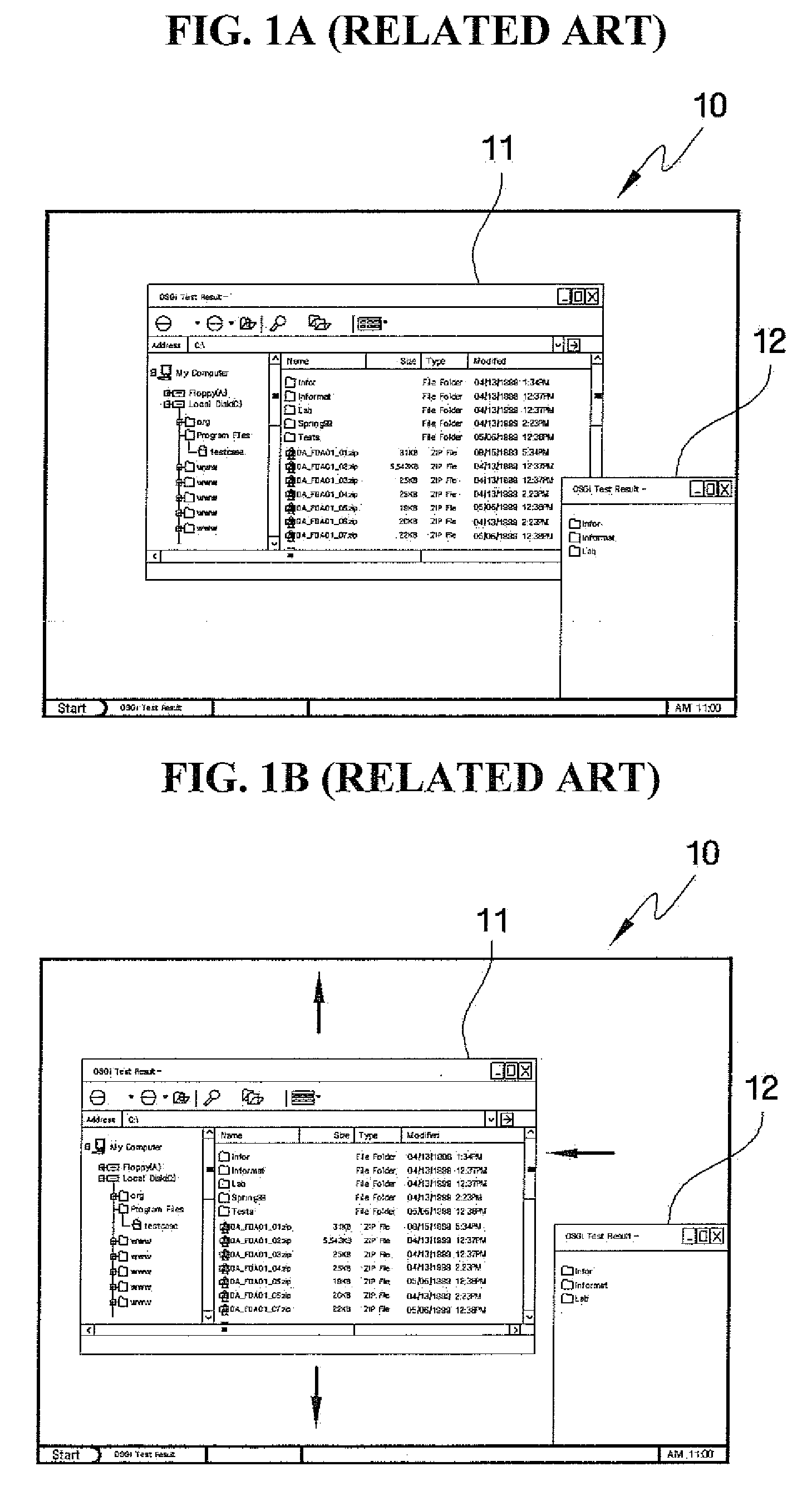

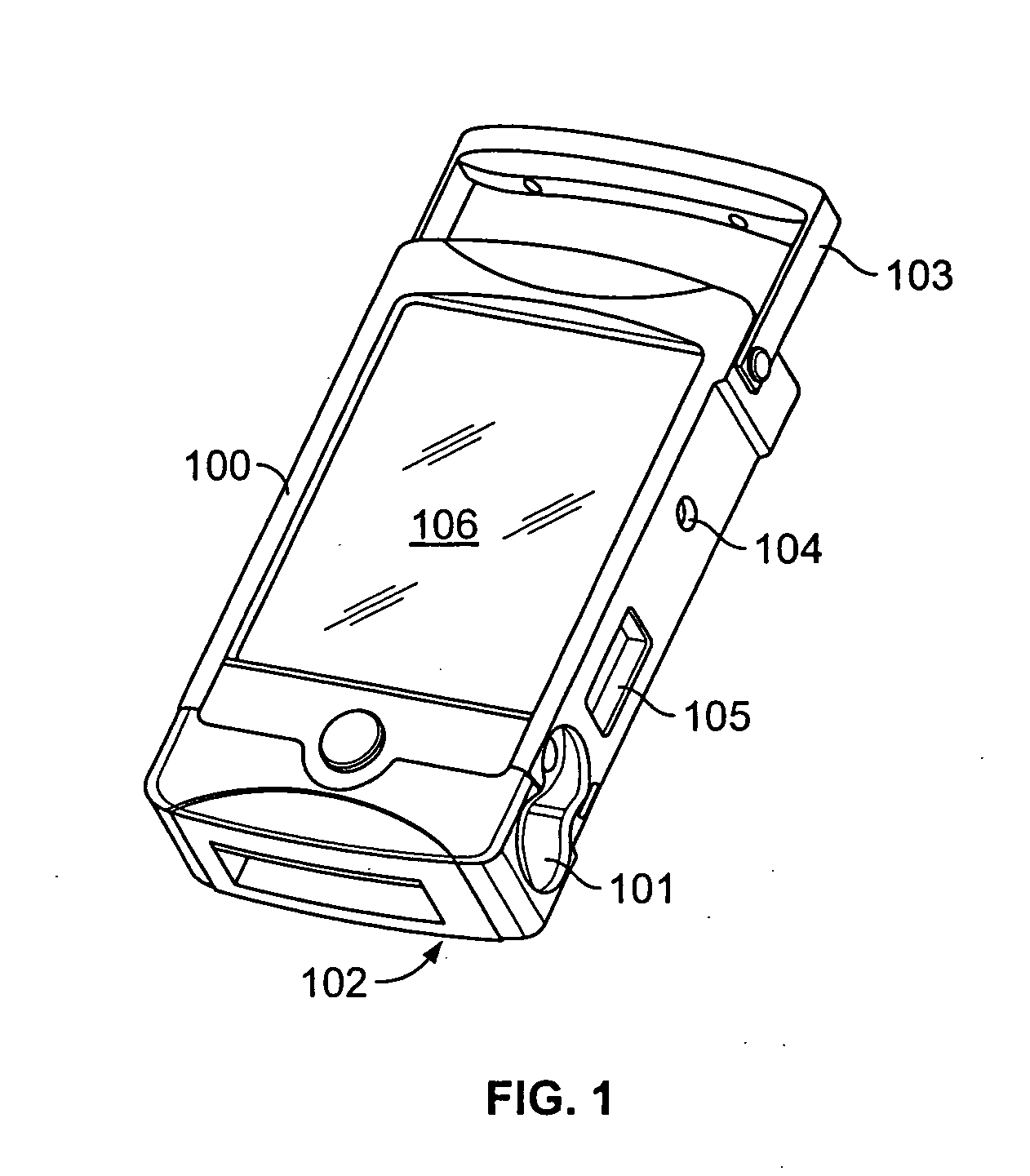

Apparatus and method for managing layout of a window

InactiveUS20070192726A1Easy to useRotary piston pumpsCathode-ray tube indicatorsComputer graphics (images)

An apparatus and method for managing the layout of a window is provided. The apparatus includes a display unit that displays the window on a screen; the screen is divided into a plurality of display areas; a pointer-position-checking unit that checks the coordinate position of a pointer moved by a user and determines the one display area corresponding to the position of the checked pointer; and a window-size-adjusting unit that moves the window to the one display area where the pointer is positioned and adjusts the size of the window in proportion to the size of the one display area.

Owner:SAMSUNG ELECTRONICS CO LTD

Overheat protection for fluid pump

InactiveUS6837688B2Avoid damageReduce stepsRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsPump headThreshold temperature

An apparatus for detecting the presence of an overheat condition in a fluid pump includes a pump head for receiving a fluid at a first pressure and outputting the fluid at a second pressure that is greater than the first pressure. A motor is positioned adjacent the pump head to drive the pump head to pressurize the fluid. A single overheat sensor senses an overheat condition in the pump head and an overheat condition in the motor. When a threshold temperature is sensed by the overheat sensor, a switch is activated to prevent operation of the motor. In one embodiment, the overheat sensor and switch are integral and may, for example, take the form of a bi-metal switch formed in the stator windings of the motor. In alternate embodiments, the overheat sensor and switch are separate.

Owner:STANDEX INT CORP

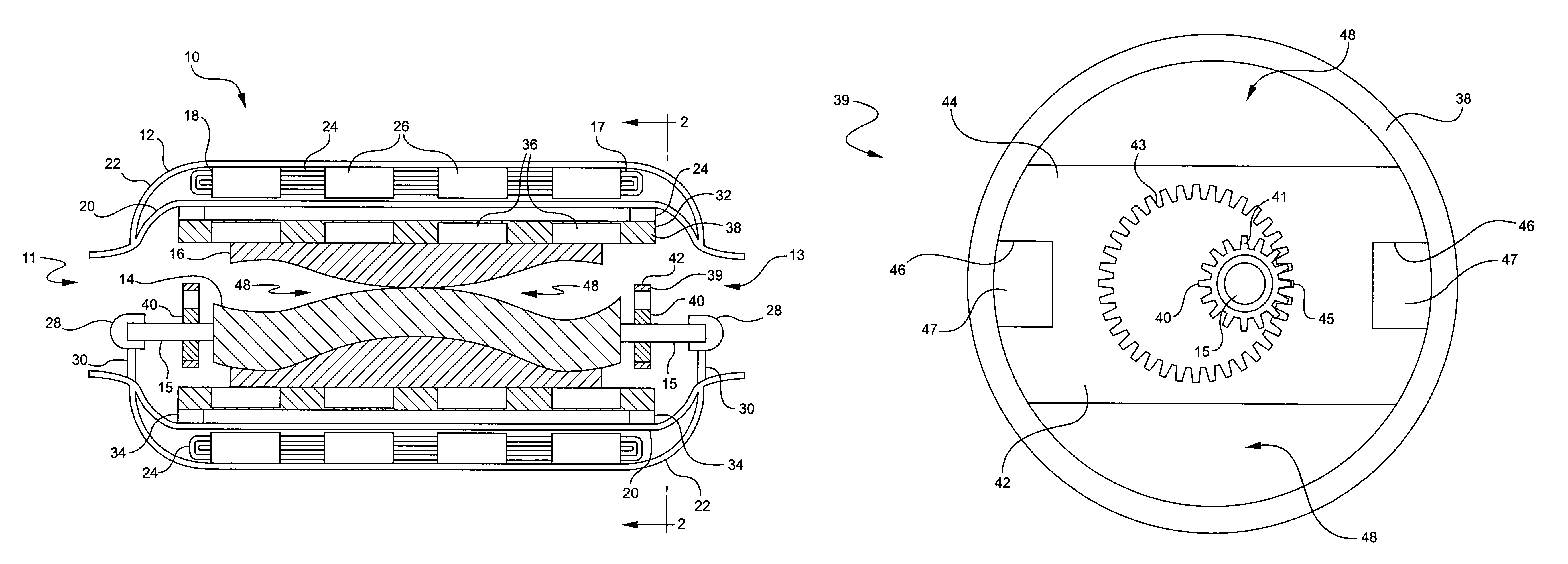

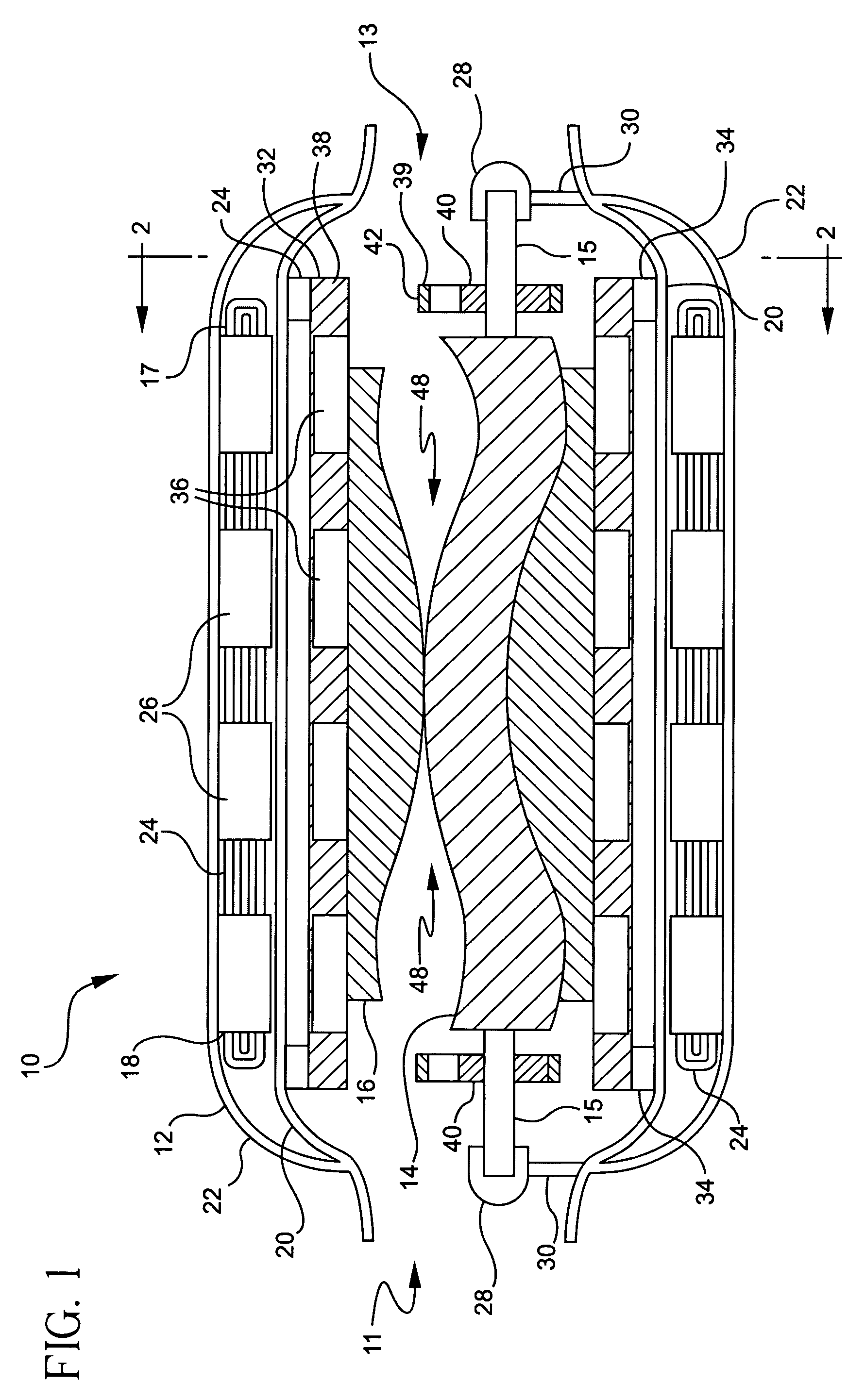

Direct drive linear flow blood pump

A ventricular assistive device (VAD) based on a progressive cavity pump includes a pump housing having an inlet and an outlet, a pump stator contained within the pump housing, a pump rotor rotatably disposed within the pump stator, a motor including a motor rotor contained within the pump housing and a direct drive means connected between the motor rotor and an axial shaft of the pump rotor for rotating the pump rotor. The motor rotates the motor rotor, which in turn rotates the pump rotor through the direct drive means. The rotation of the pump rotor within the pump stator forms a plurality of cavities that carry blood forward through the pump housing from the inlet to the outlet as the motor drives the direct drive means.

Owner:CHANG SHELDON

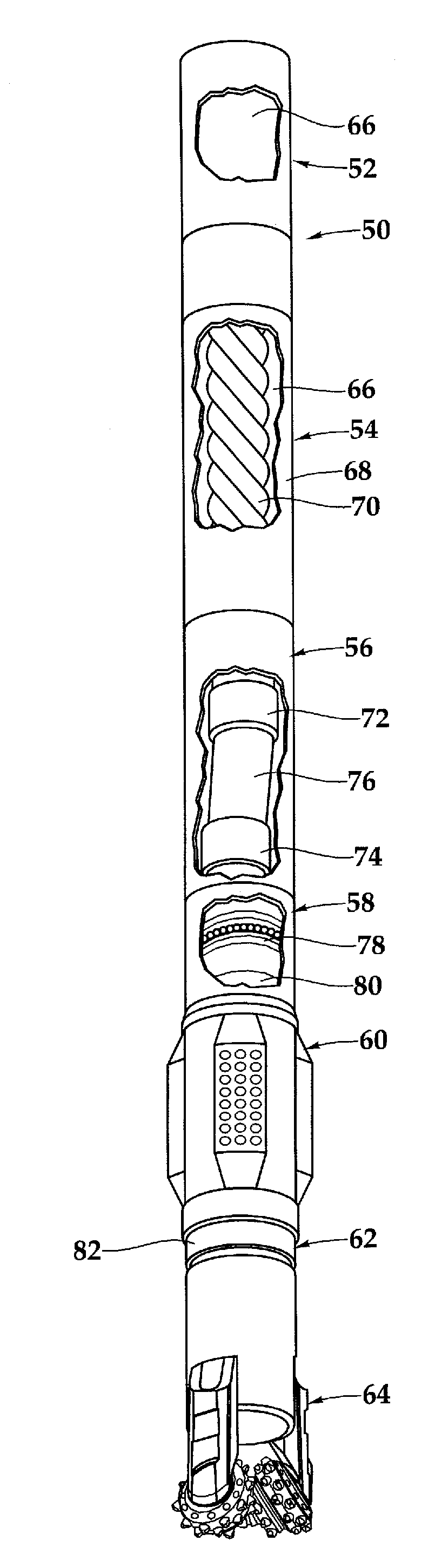

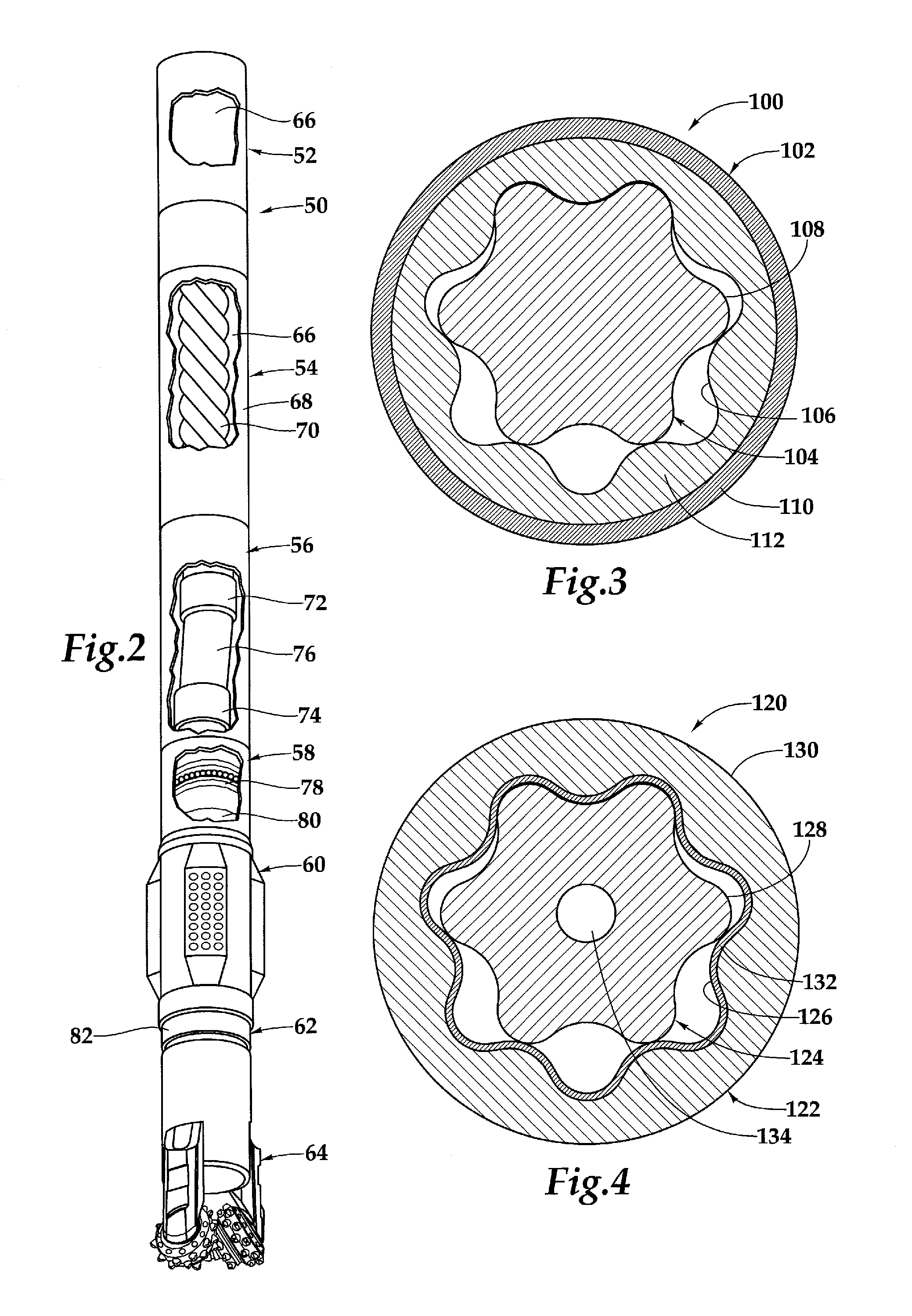

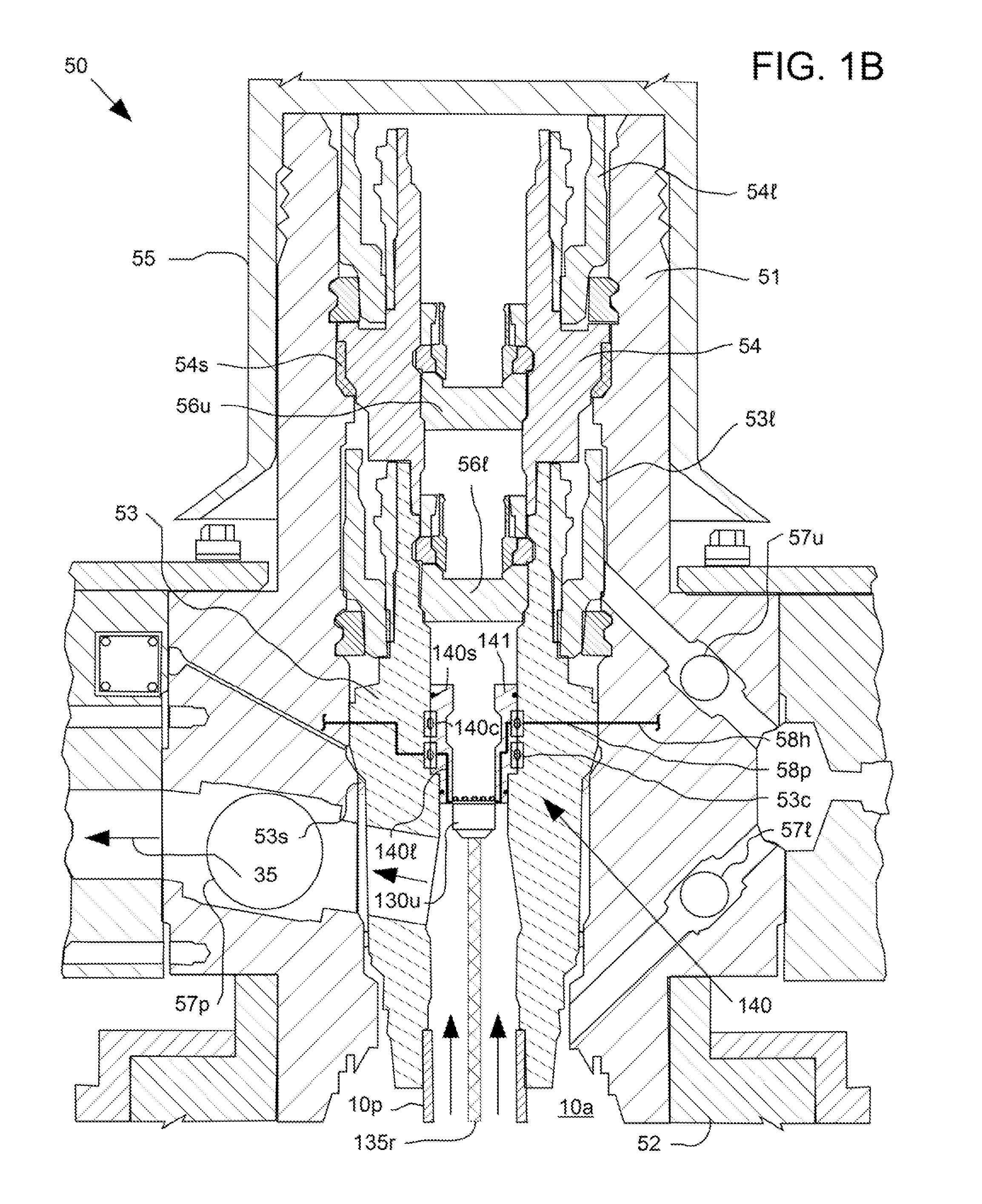

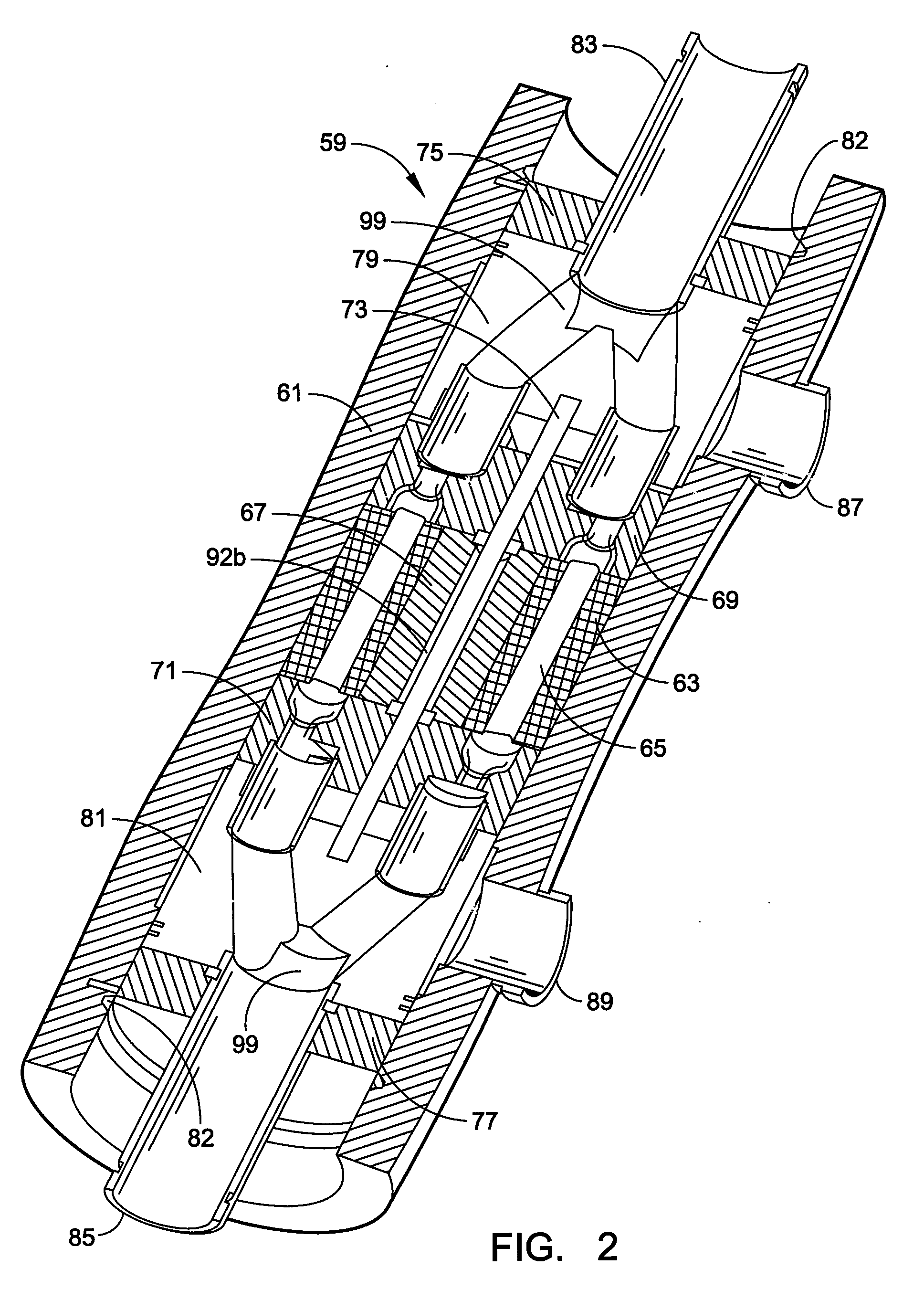

Apparatus and method for high temperature drilling operations

InactiveUS20100038142A1High mechanical loadPump componentsOscillating piston enginesEngineeringWellbore

An apparatus (50) for drilling a wellbore that transverses a subterranean hydrocarbon bearing formation. The apparatus (50) includes a drill string (52) having an inner fluid passageway (66). A drill bit (64) is disposed at a distal end of the drill string (52) and is operable to rotate relative to at least a portion of the drill string (52). A fluid motor (54) is disposed within the drill string (52) and is operable to rotate the drill bit (64) in response to a circulating fluid received via the inner fluid passageway (66) of the drill string (52). The fluid motor (54) has a stator (68) with (n) lobes and a rotor (70) with (n−1) lobes. The stator (68) includes an inner surface formed from a first material and the rotor (70) includes an outer surface formed from a second material that is dissimilar to the first material.

Owner:HALLIBURTON ENERGY SERVICES INC

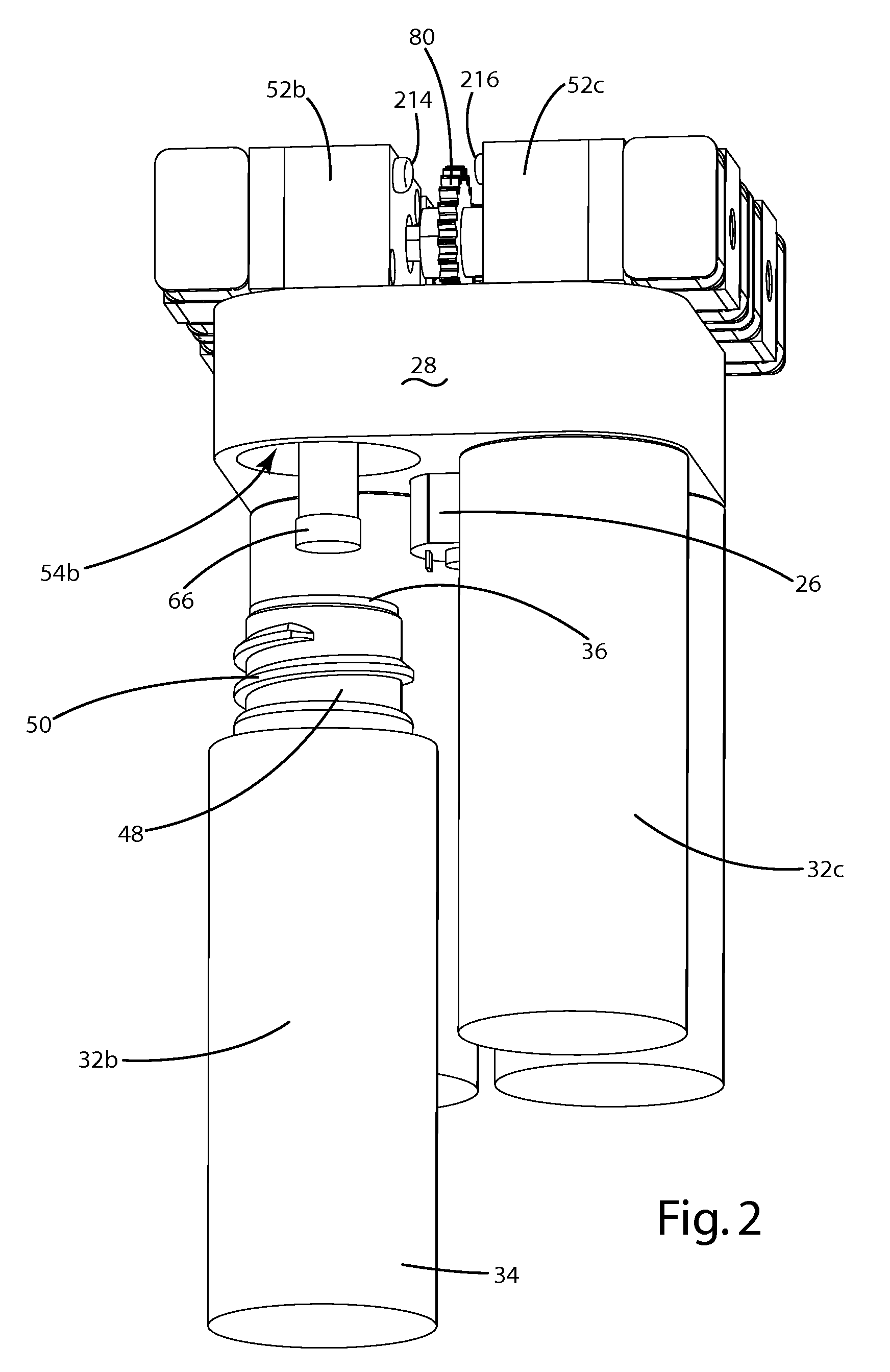

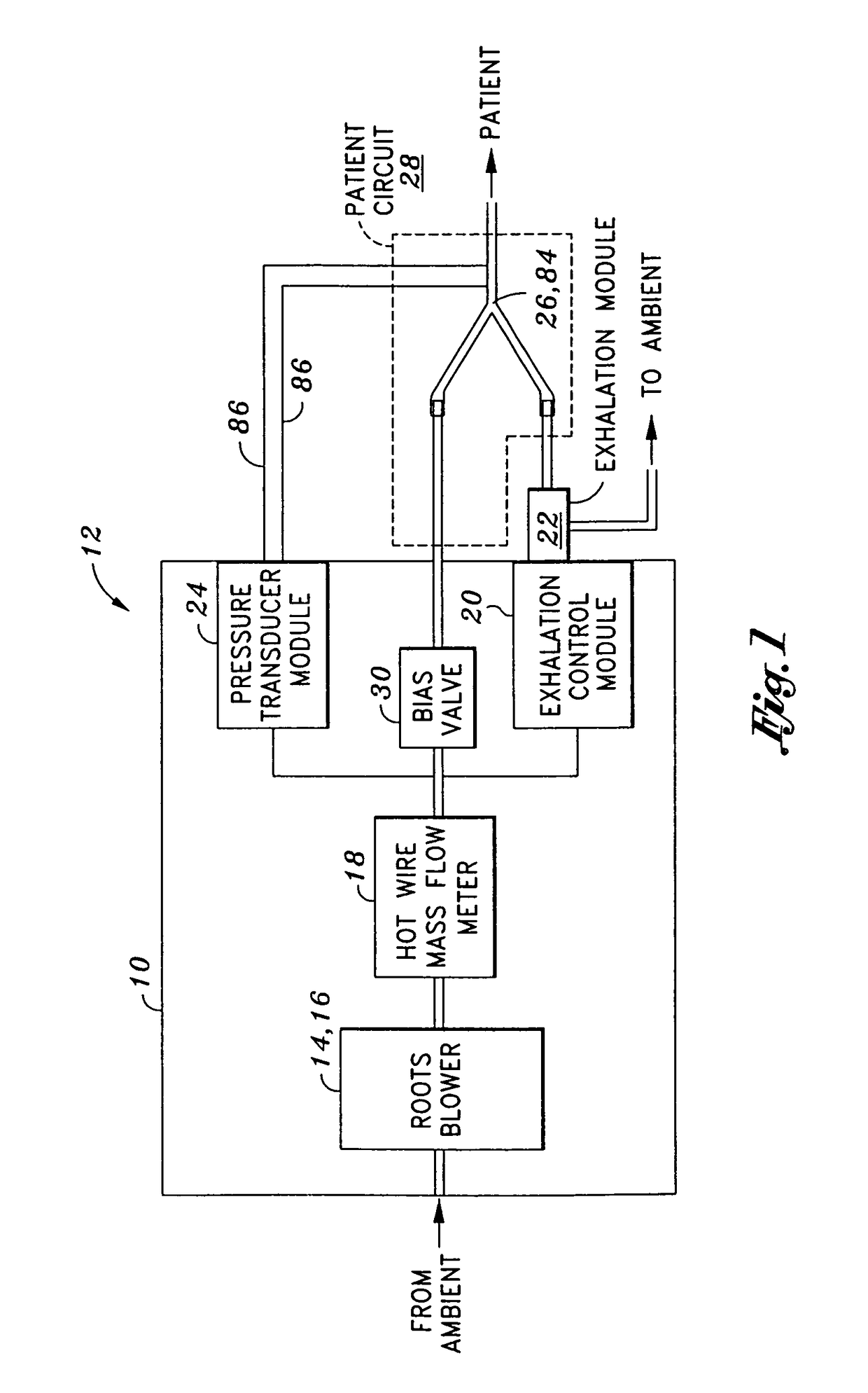

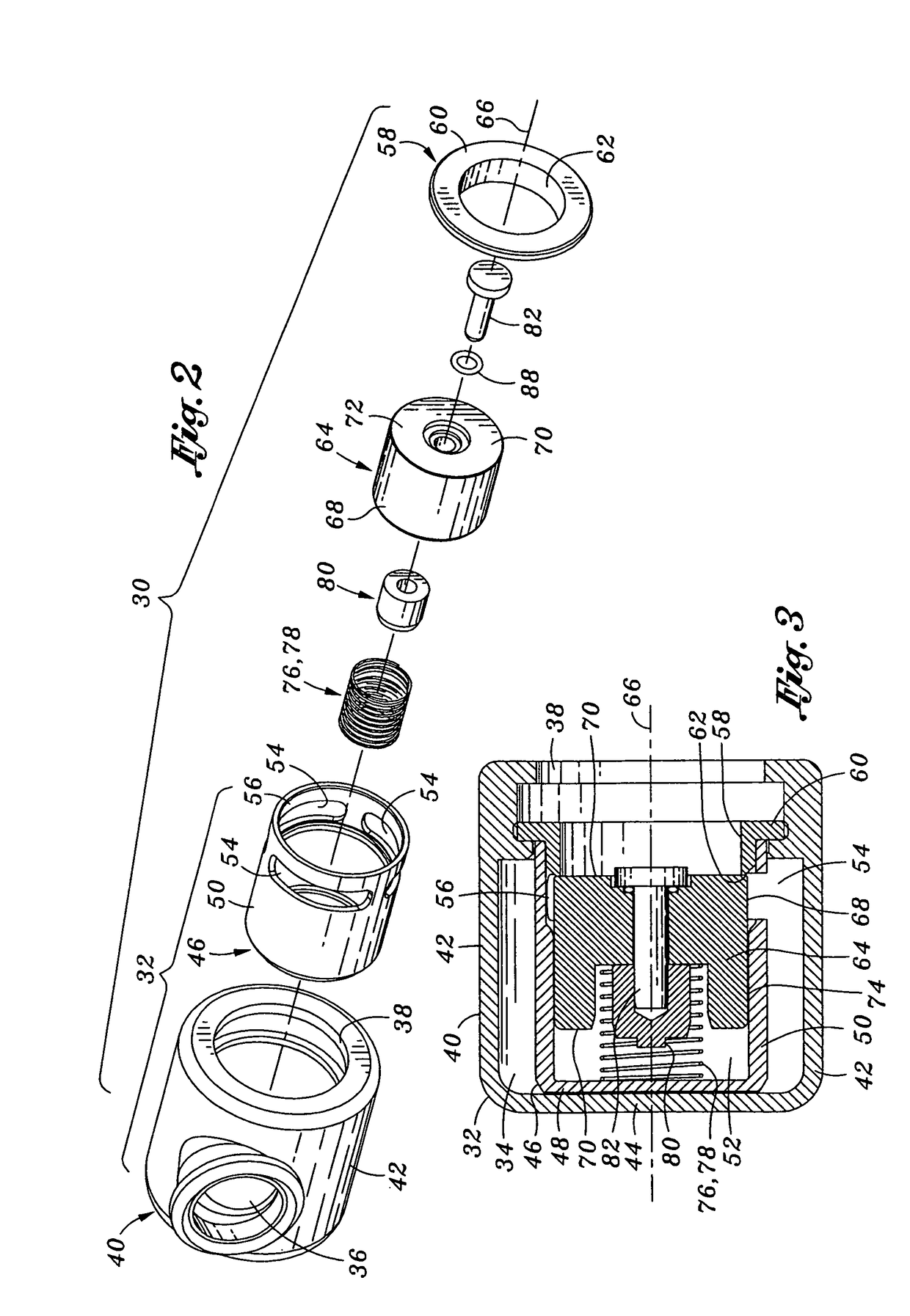

Mechanical ventilation system utilizing bias valve

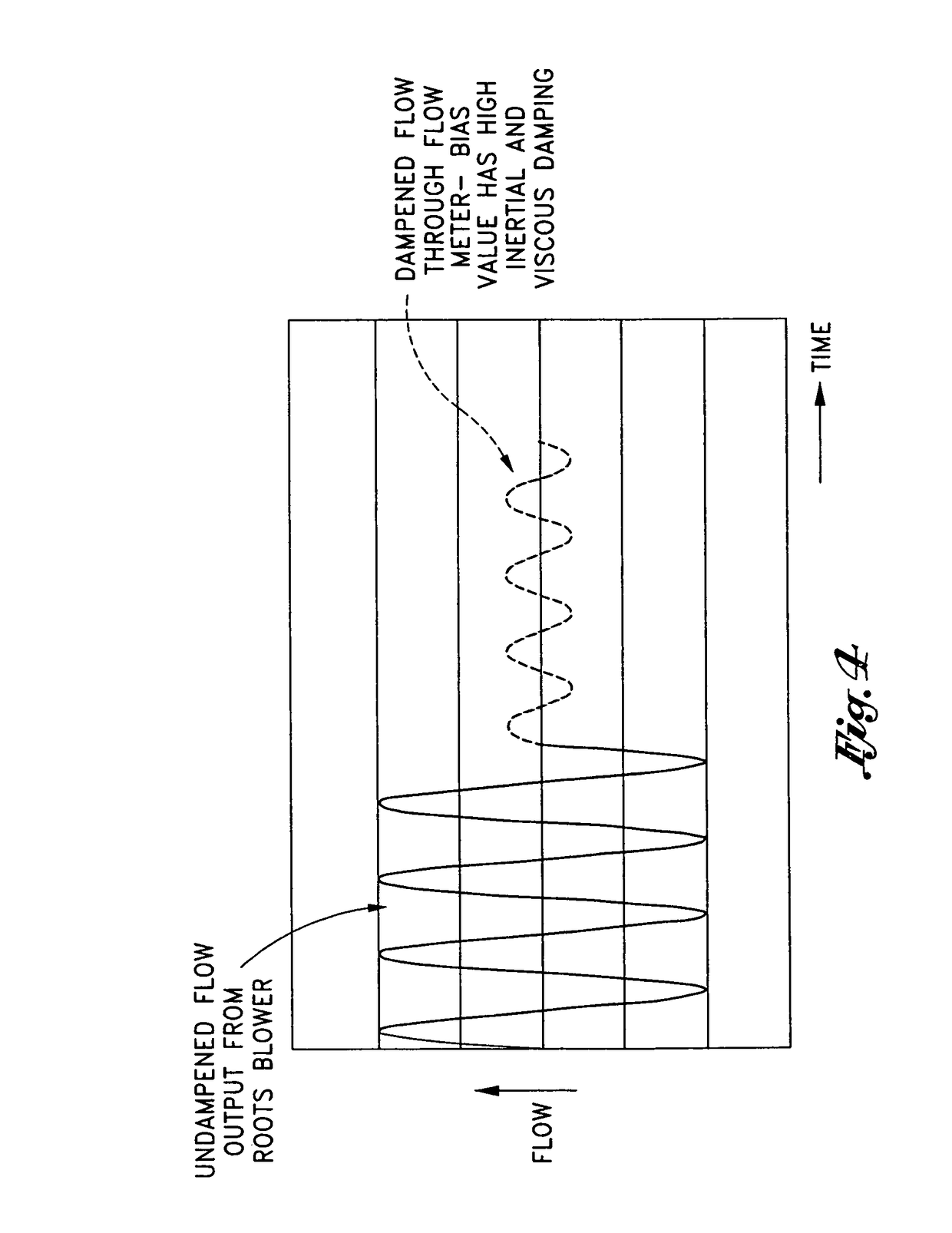

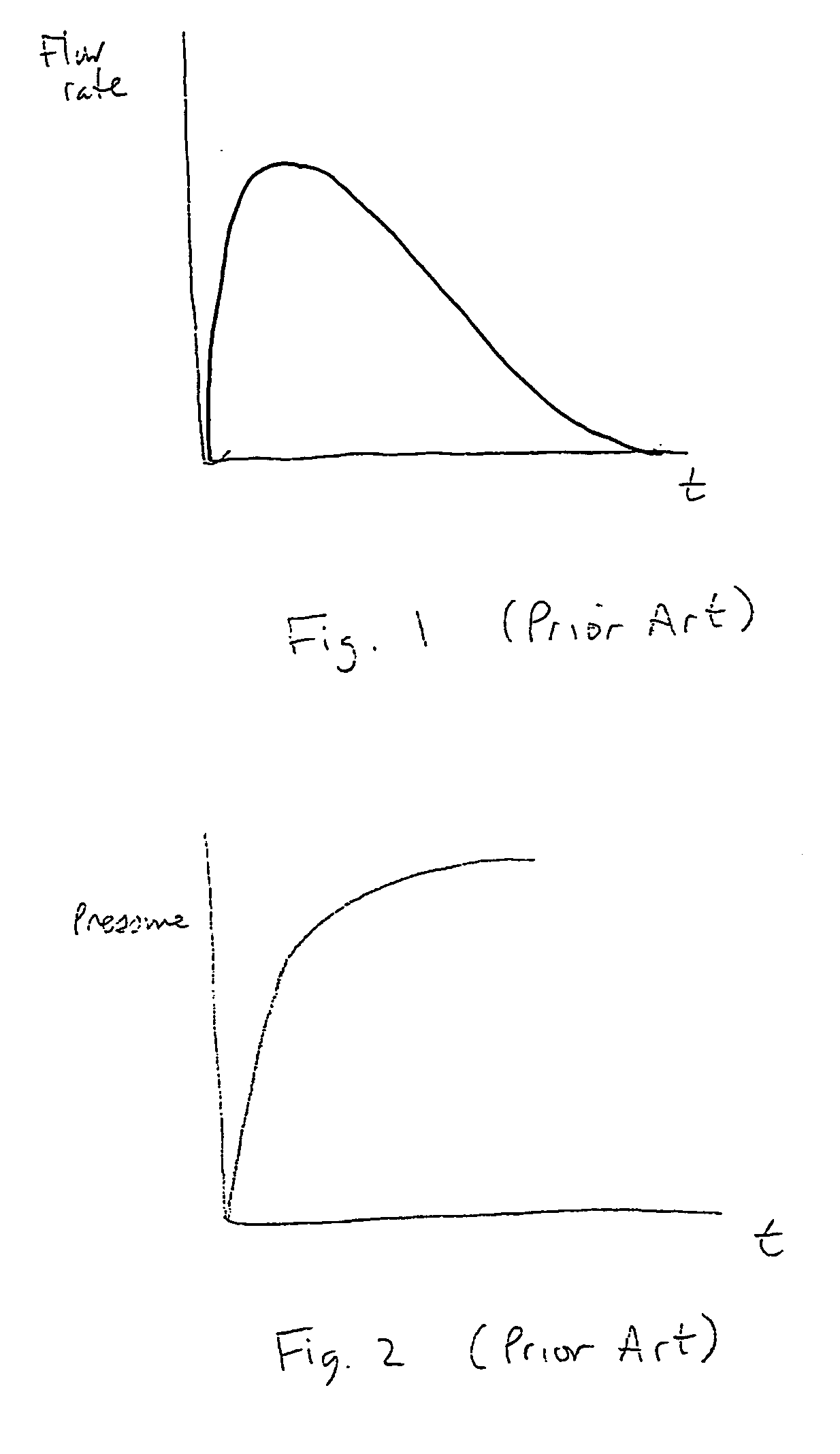

ActiveUS20060249153A1Accurate measurementViscous dampingRespiratorsOperating means/releasing devices for valvesPositive pressureEngineering

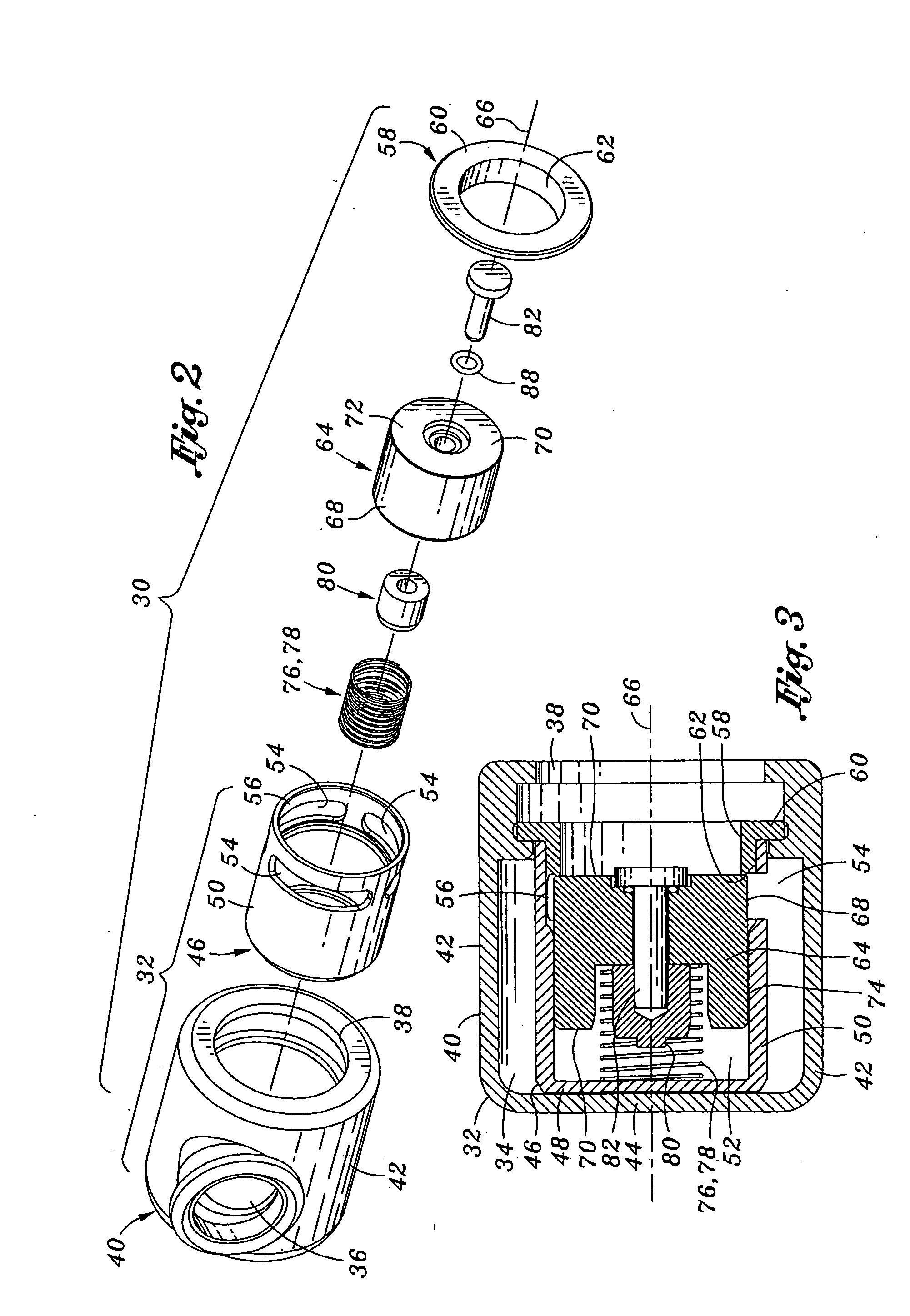

A portable mechanical ventilator having a Roots blower is configured to provide a desired gas flow and pressure to a patient circuit. The mechanical ventilator includes a flow meter operative to measure gas flow produced by the Roots blower and an exhalation control module configured to operate an exhalation valve connected to the patient circuit. A bias valve connected between the Roots blower and the patient circuit is specifically configured to generate a bias pressure relative to the patient circuit pressure at the exhalation control module. The bias valve is further configured to attenuate pulsating gas flow produced by the Roots blower such that gas flowing to the mass flow meter exhibits a substantially constant pressure characteristic. The bias pressure facilitates closing of the exhalation valve at the start of inspiration, regulates positive end expiratory pressure during exhalation, and purges sense lines via a pressure transducer module.

Owner:VYAIRE MEDICAL 203 INC

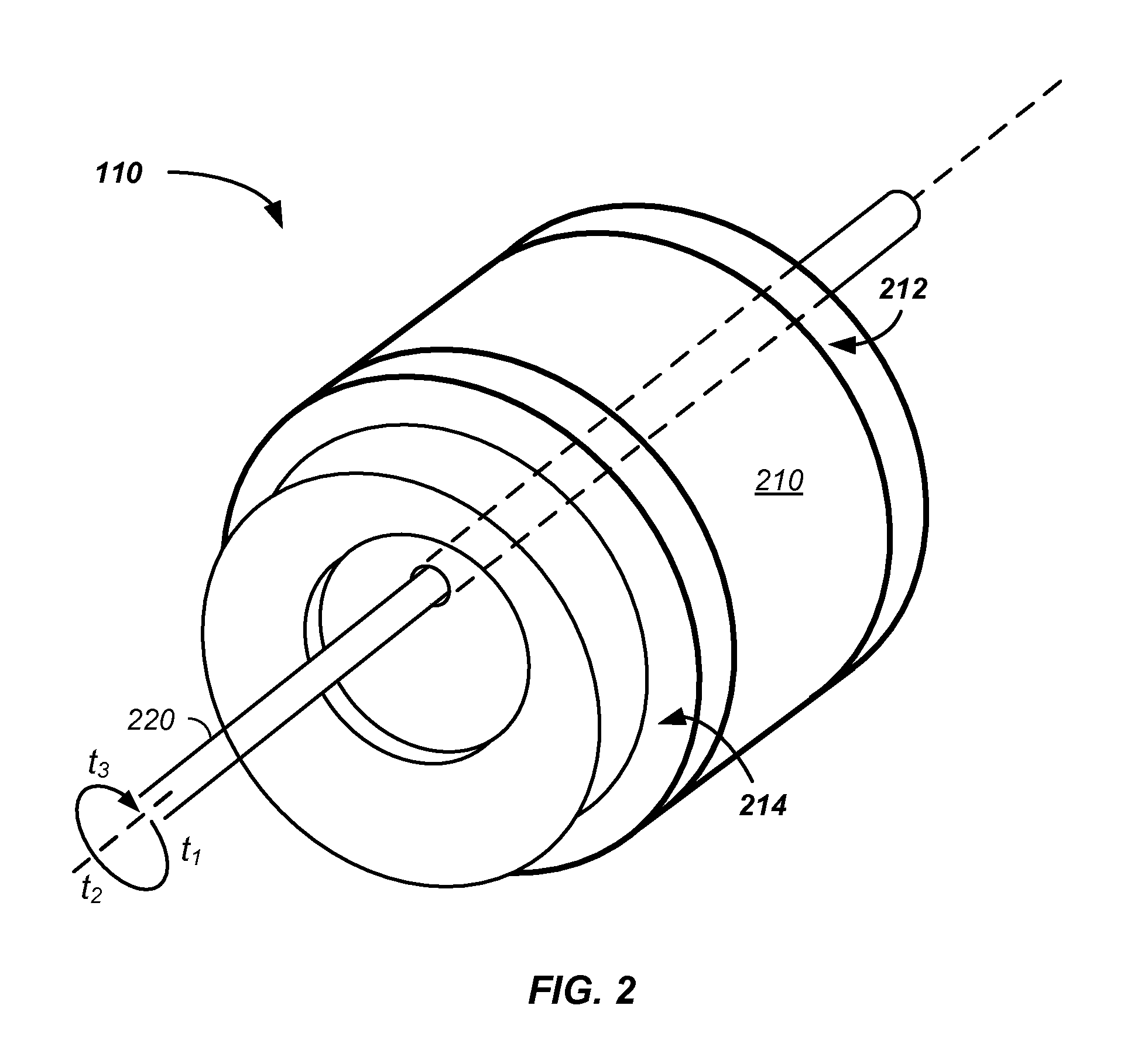

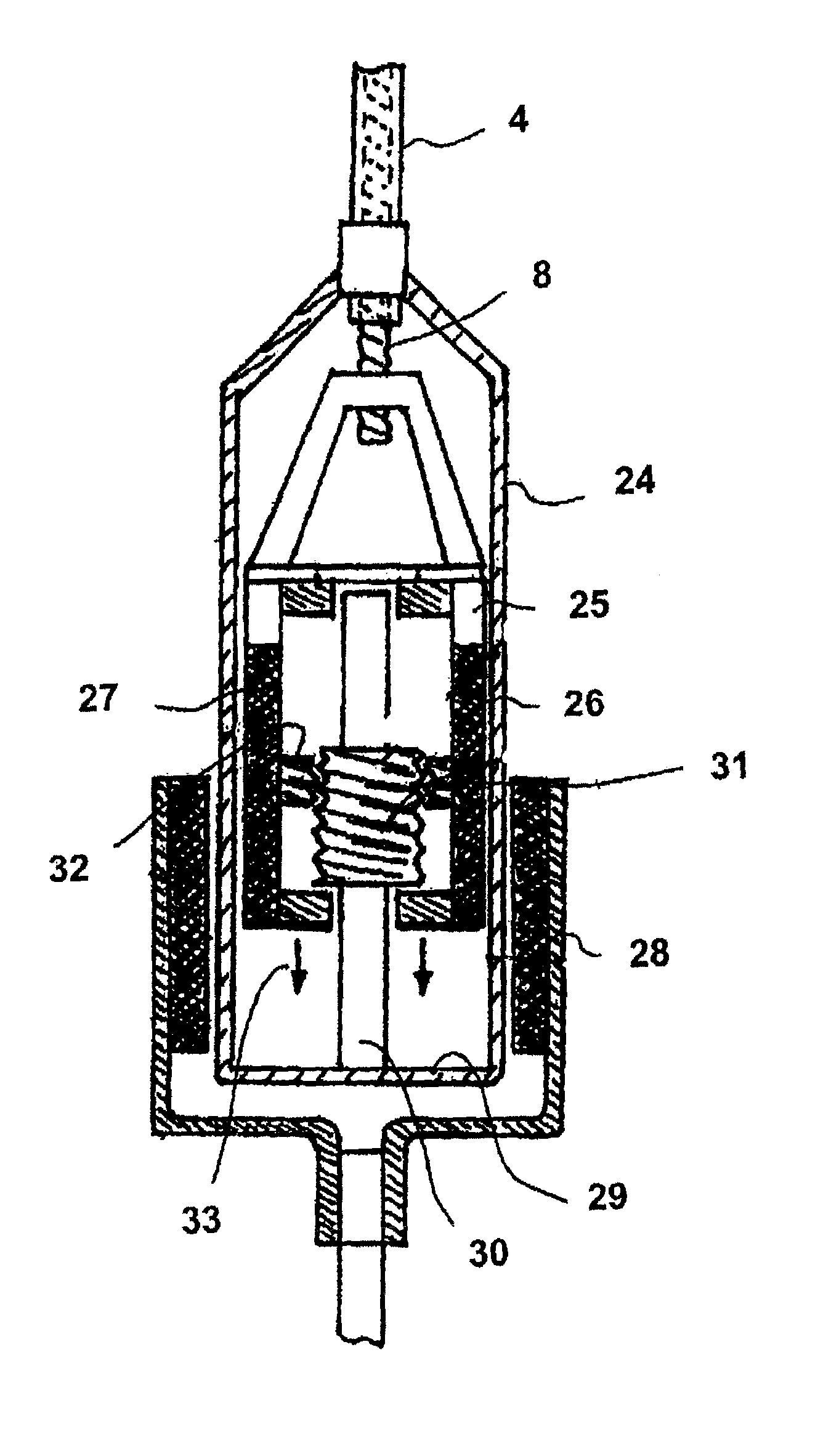

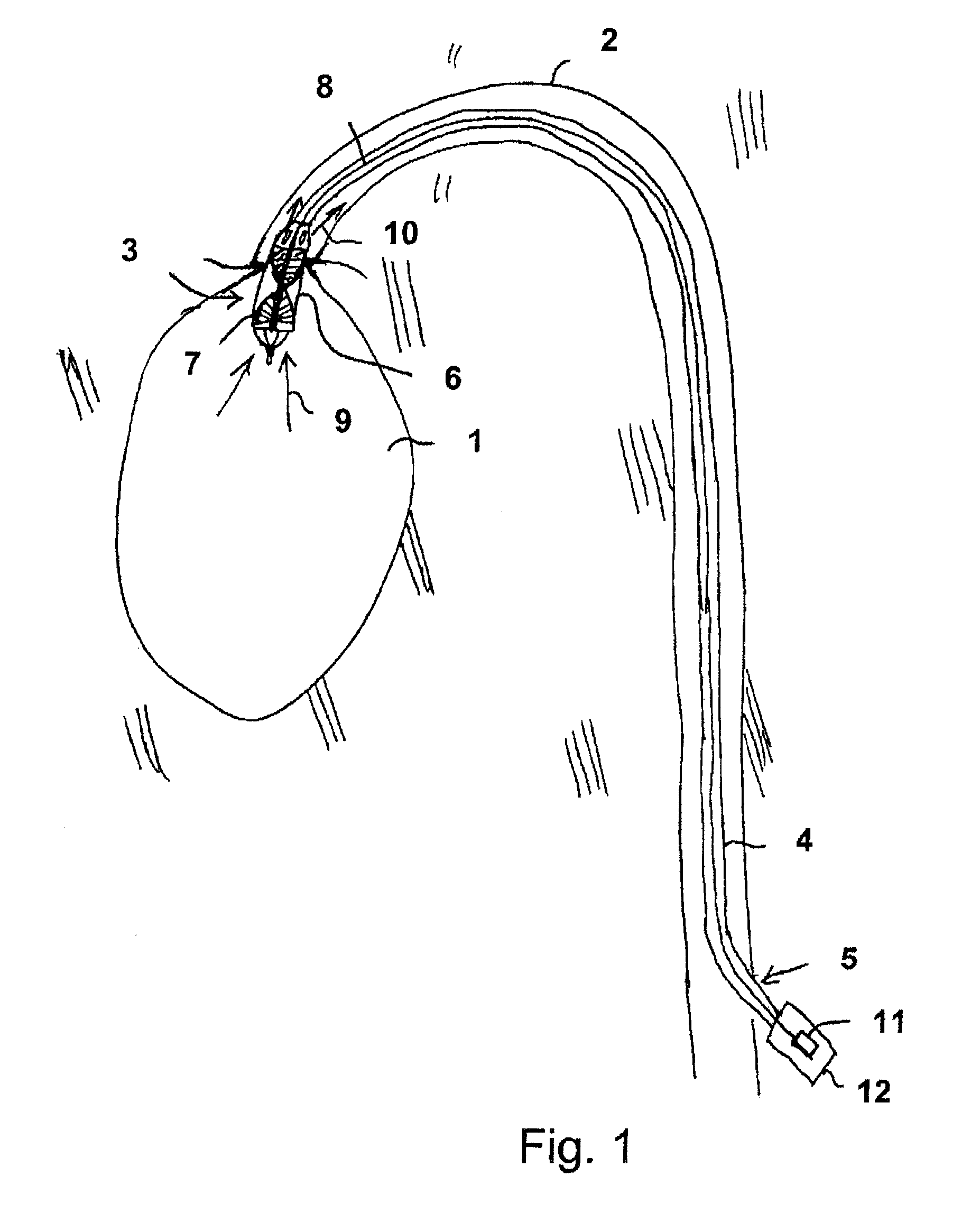

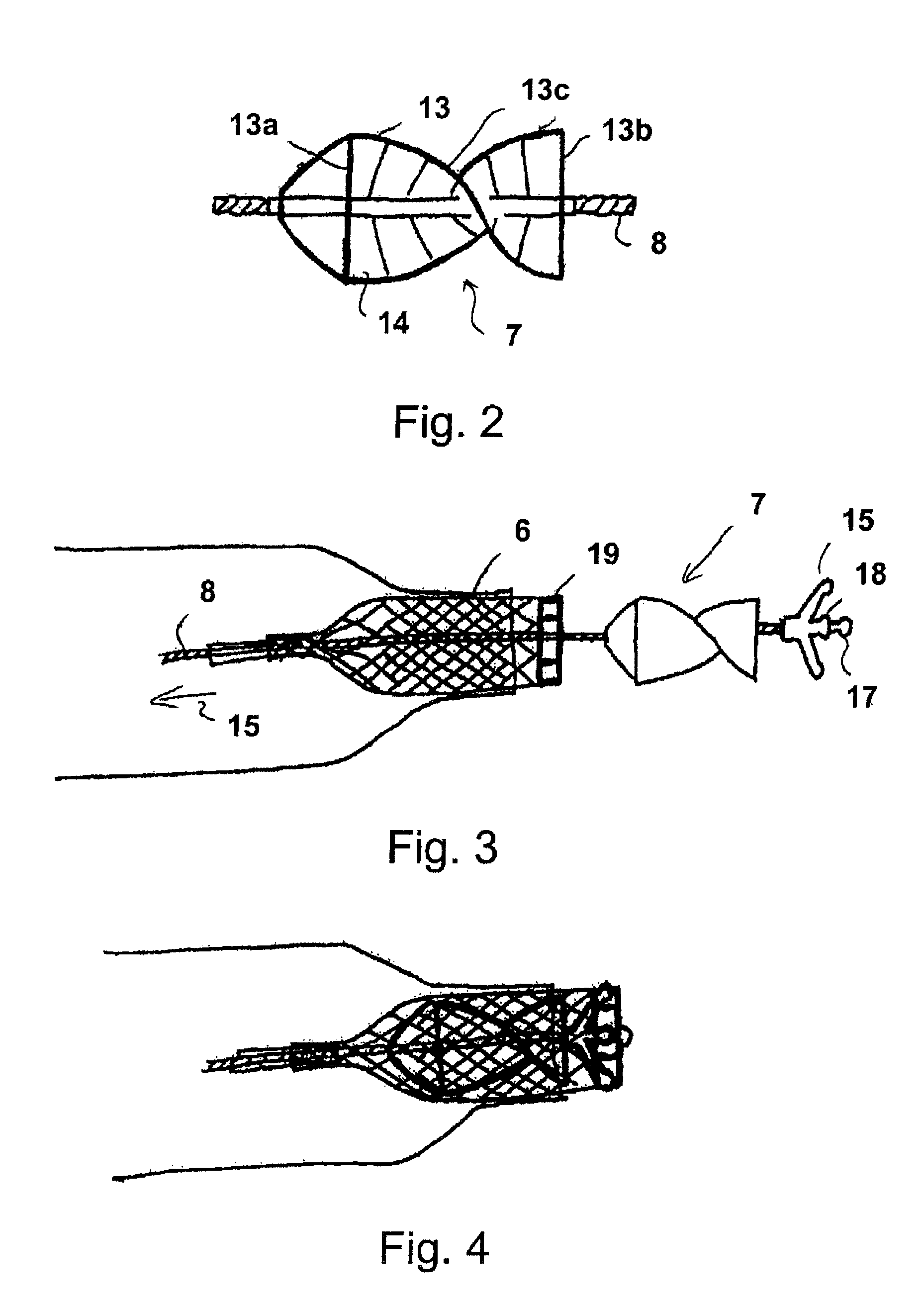

Fluid pump changeable in diameter, in particular for medical application

ActiveUS8944748B2Quiet and smooth operationPrevent penetrationPropellersRotary piston pumpsDrive shaftMedical treatment

A fluid pump device, in particular for a medical application, is described having a compressible pump housing and rotor, as well as with a drive shaft which runs in a sleeve and on whose end the fluid pump is arranged. In order to utilize all possibilities of a space-saving arrangement of the respective pump housing of the rotor, which is compressible per se, and as the case a bearing arrangement, the mentioned elements are displaceable to one another in the axial direction compared to an operation position. In particular these elements may be end-configured by way of an axial movement of the drive shaft after the assembly.

Owner:ECP ENTWICKLUNGSGMBH

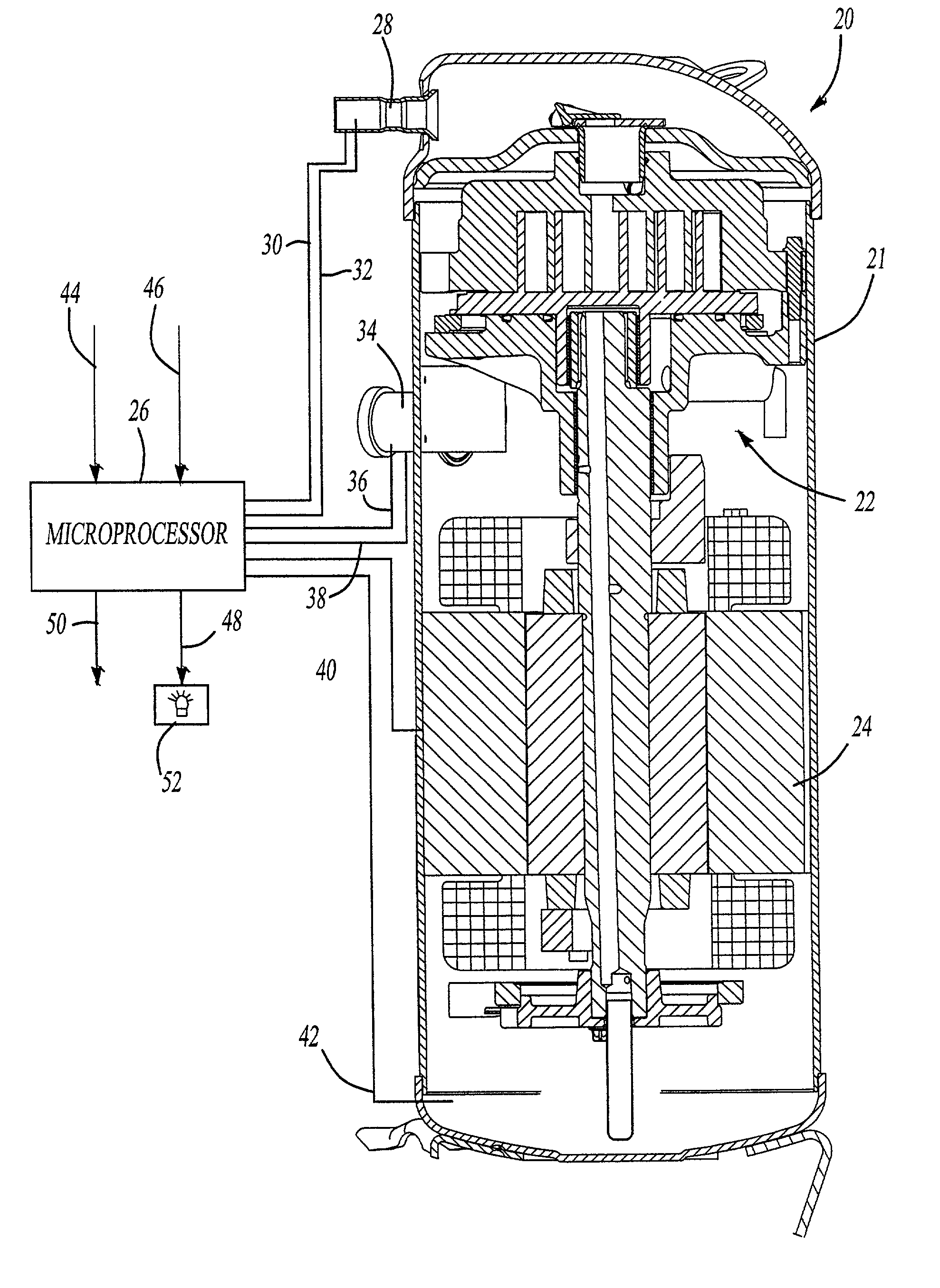

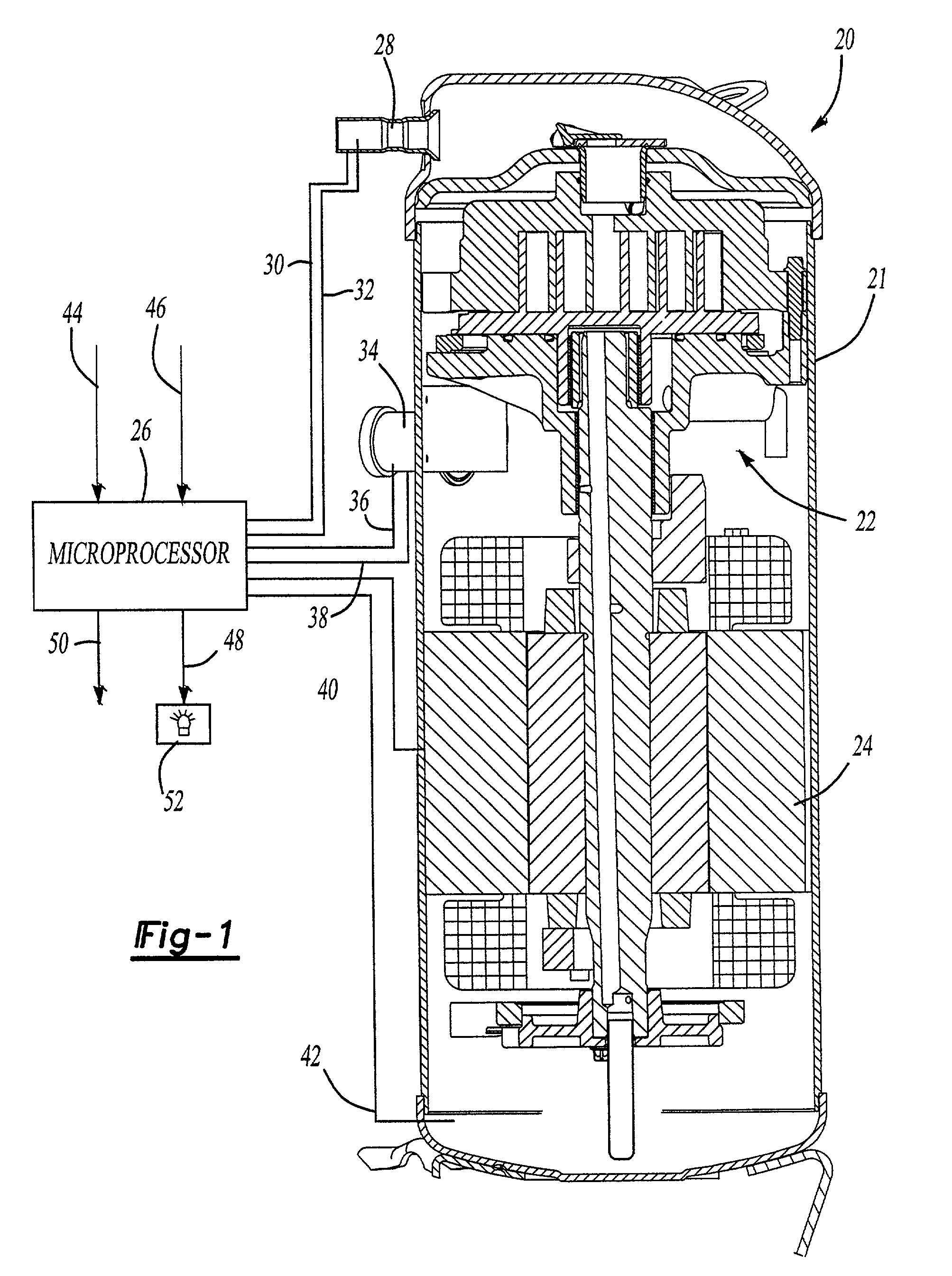

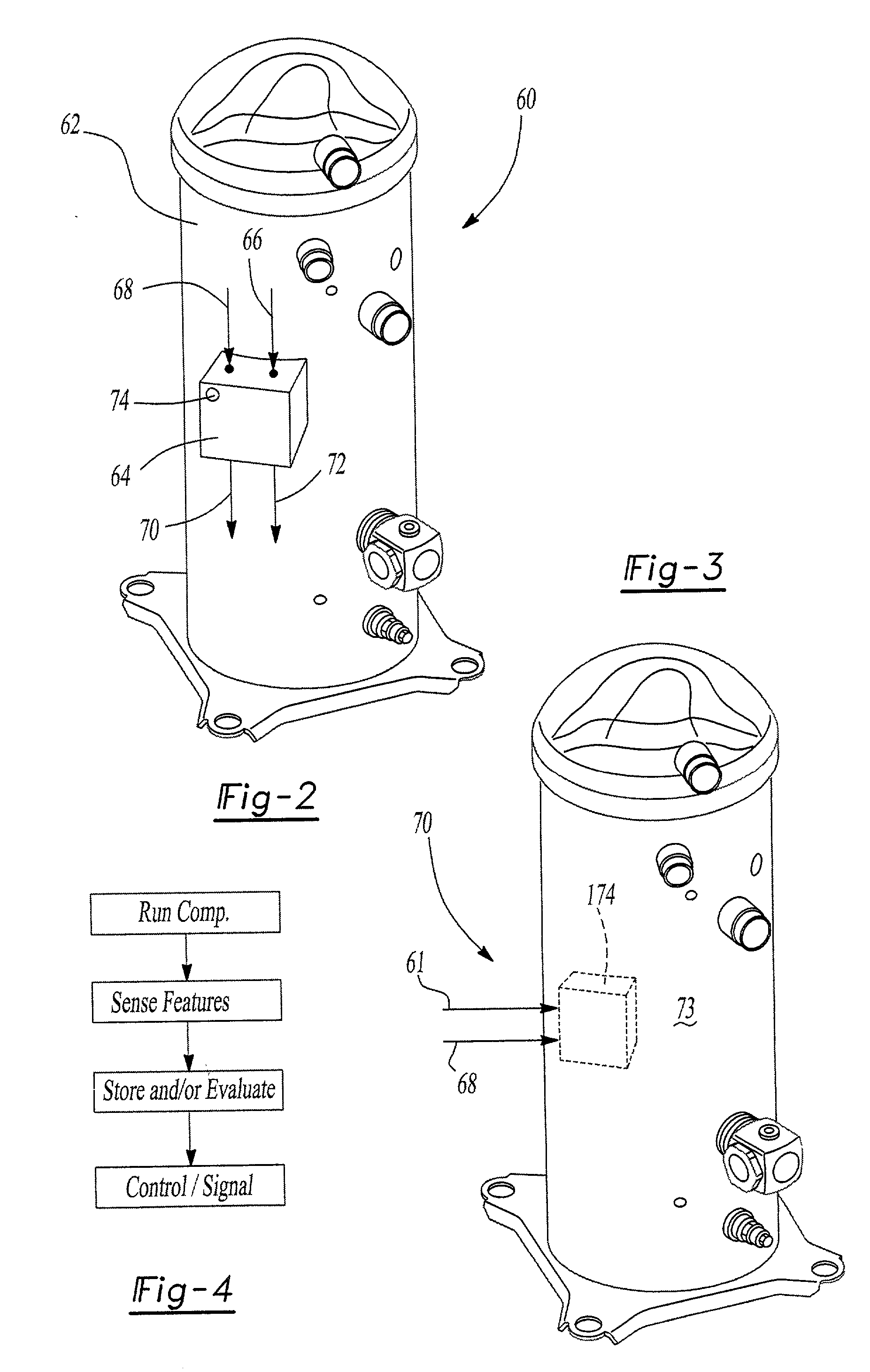

Compressor diagnostic and recording system

InactiveUS20020127120A1Rotary/oscillating piston combinations for elastic fluidsPump componentsData streamEngineering

A compressor diagnostic system incorporates a control which receives a plurality of data streams about various operational features of the compressor. As an example, both temperature and pressure of the suction and discharge refrigerant are taken and sent to the control. Moreover, information with regard to the power being supplied to the motor is taken and stored. All of this information is utilized at a control which compares the information to expected values and determines a fault based upon the evaluation. Moreover, in another feature of this invention, much of this data is stored, and maintained at the compressor. In the event of a compressor failure, this stored information will provide a maintenance worker with a good indication of why the compressor failed.

Owner:HAHN GREG +7

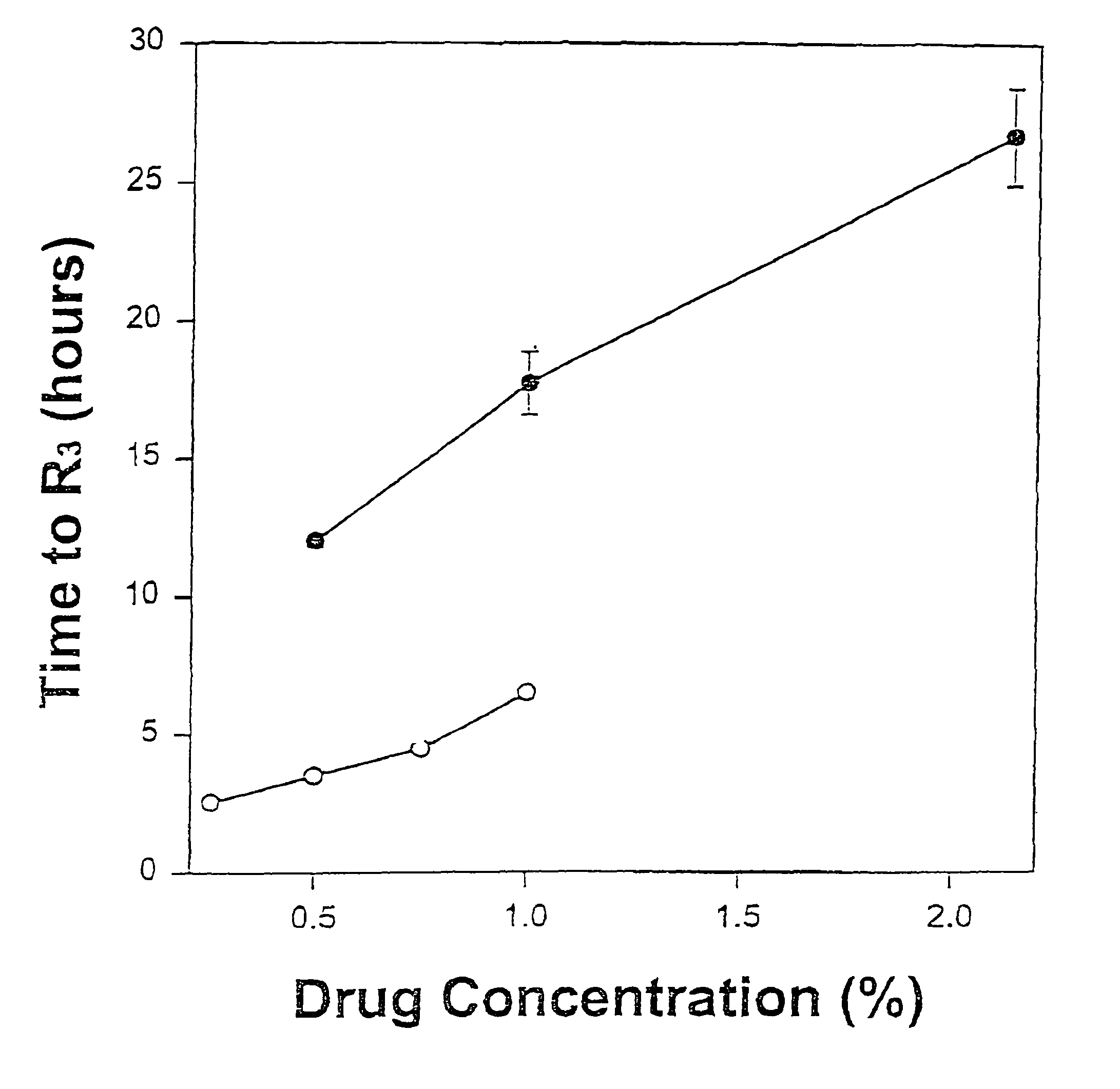

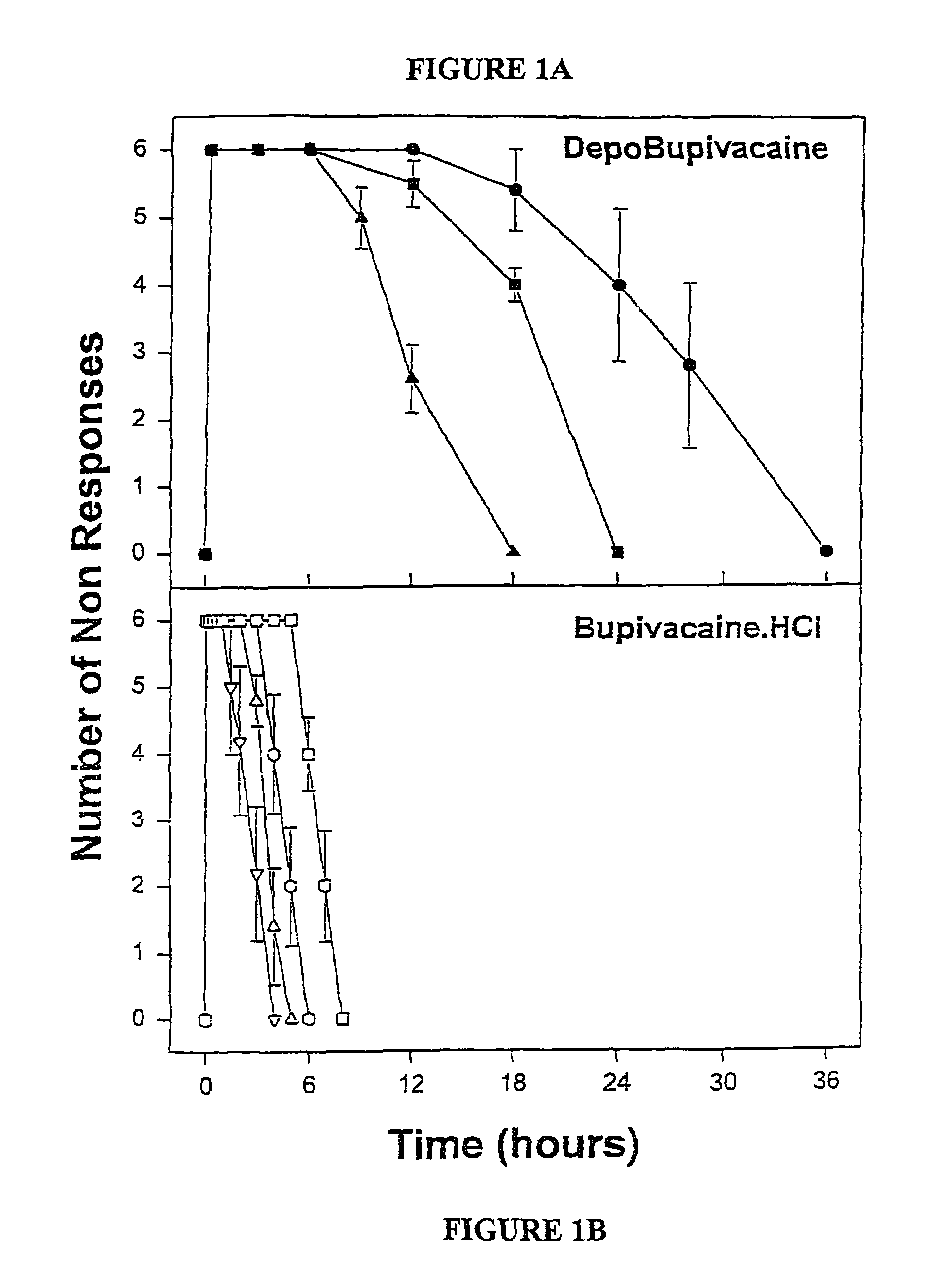

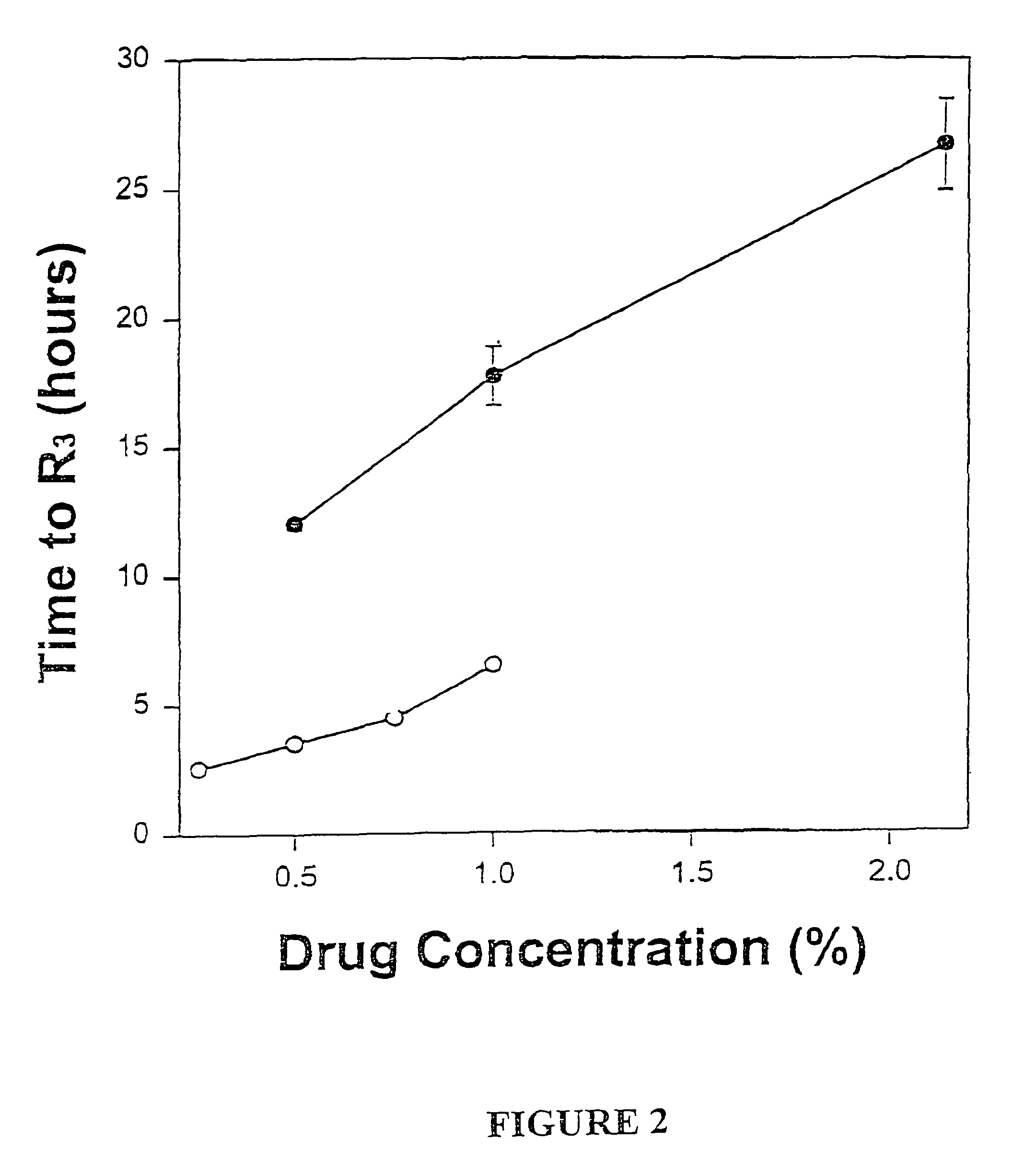

Sustained-release liposomal anesthetic compositions

InactiveUS8182835B2High acceptabilityImprove encapsulationInorganic non-active ingredientsAnaestheticsHalf-lifeMaximum tolerated dose

Owner:PACIRA PHARMA INC

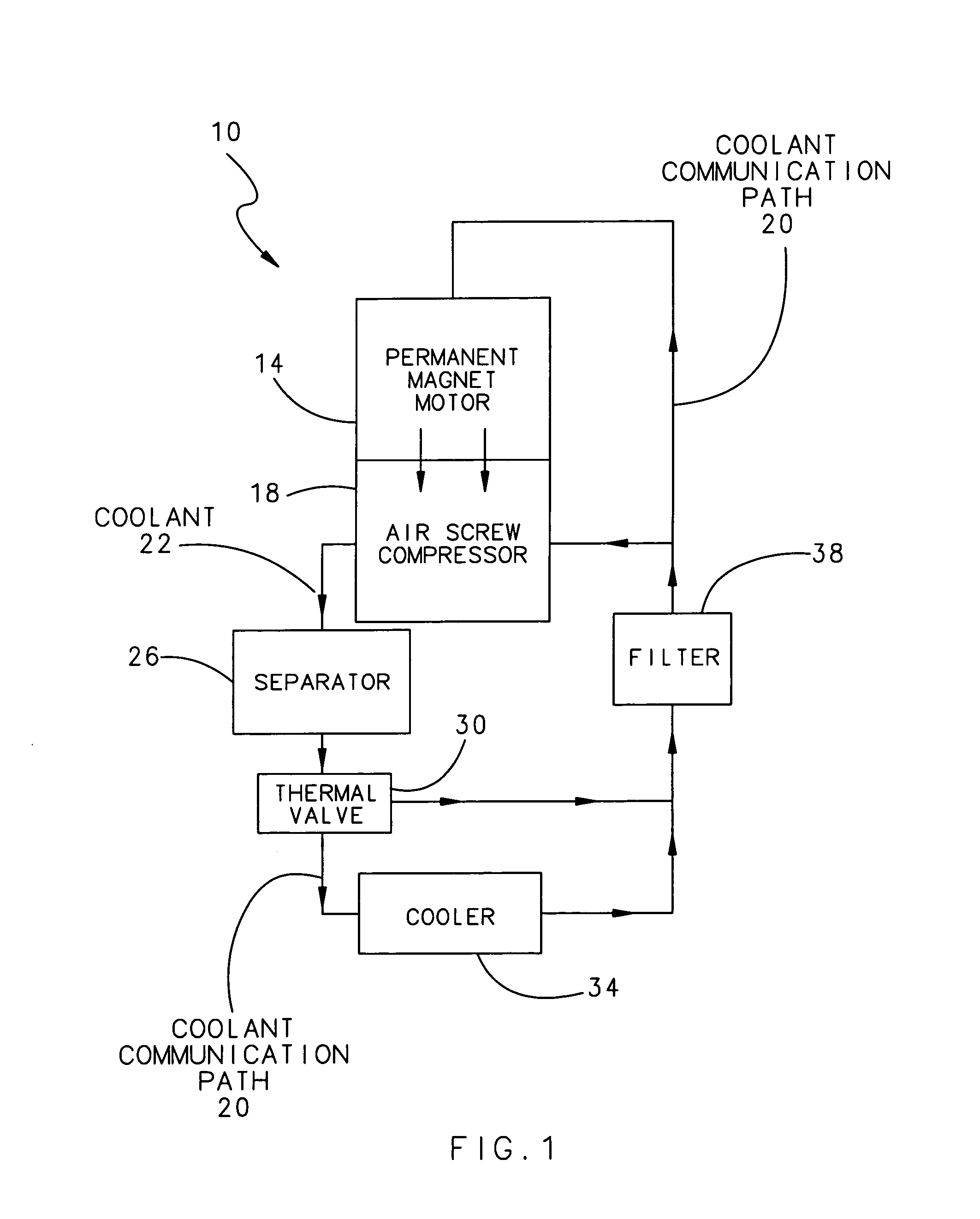

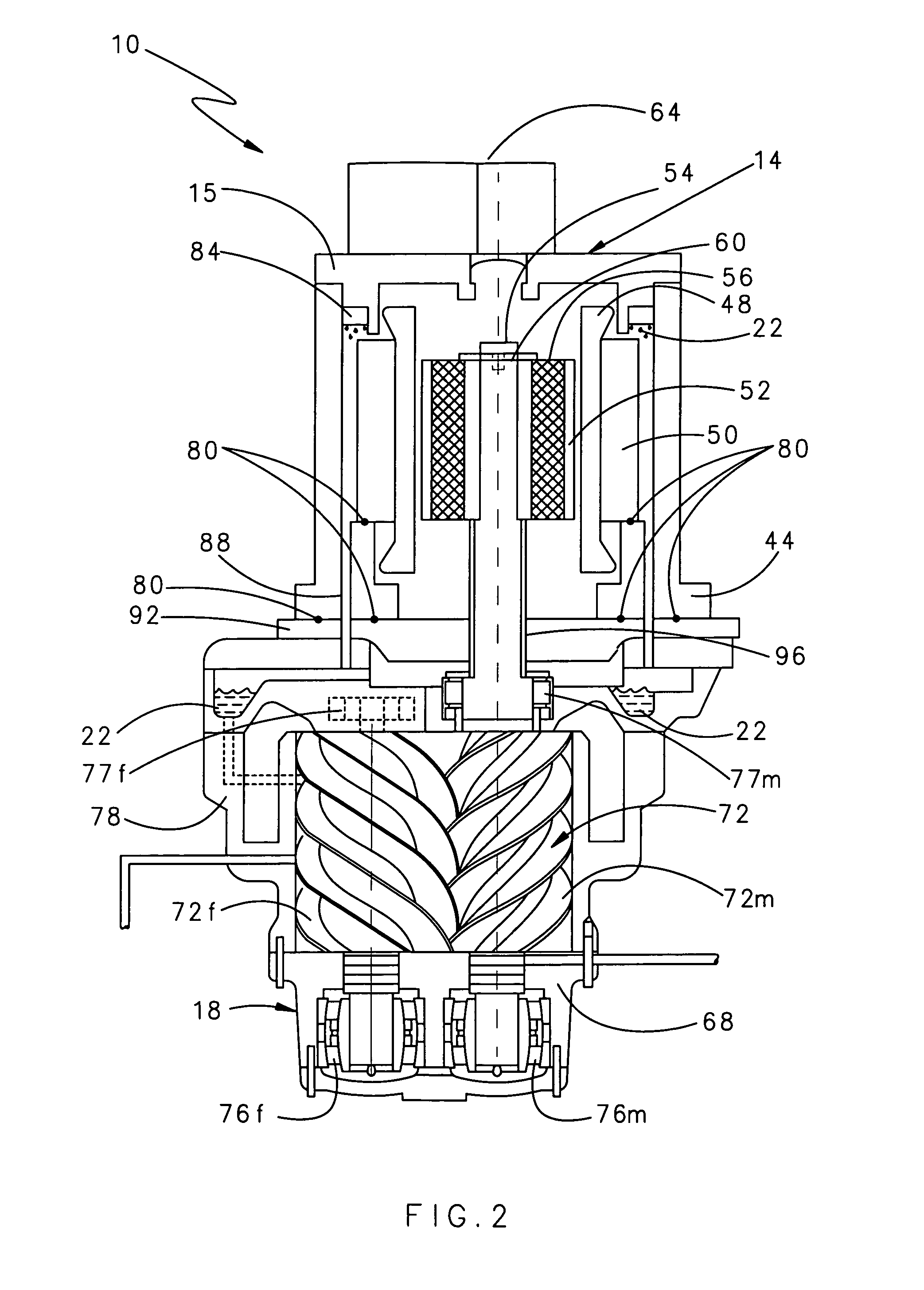

Lubricant cooled integrated motor/compressor design

InactiveUS20070241627A1Prevent overboard leakageThe process is compact and efficientRotary/oscillating piston combinations for elastic fluidsEngine of counter-engagement typePermanent magnet motorGear train

A compressor system according to the present invention utilizes direct rotational input from a permanent magnet motor to generate compressed air. The permanent magnet motor is mounted directly to an air screw compressor. The rotational input is provided by the permanent magnet motor to the air screw compressor without a gear train. The permanent magnet motor and associated variable speed drive controls the rotational speed of the permanent magnet motor and hence the screw compressor. Differing motors may selectively mount, and provide rotational input to, the air screw compressor.

Owner:SULLAIR CORP

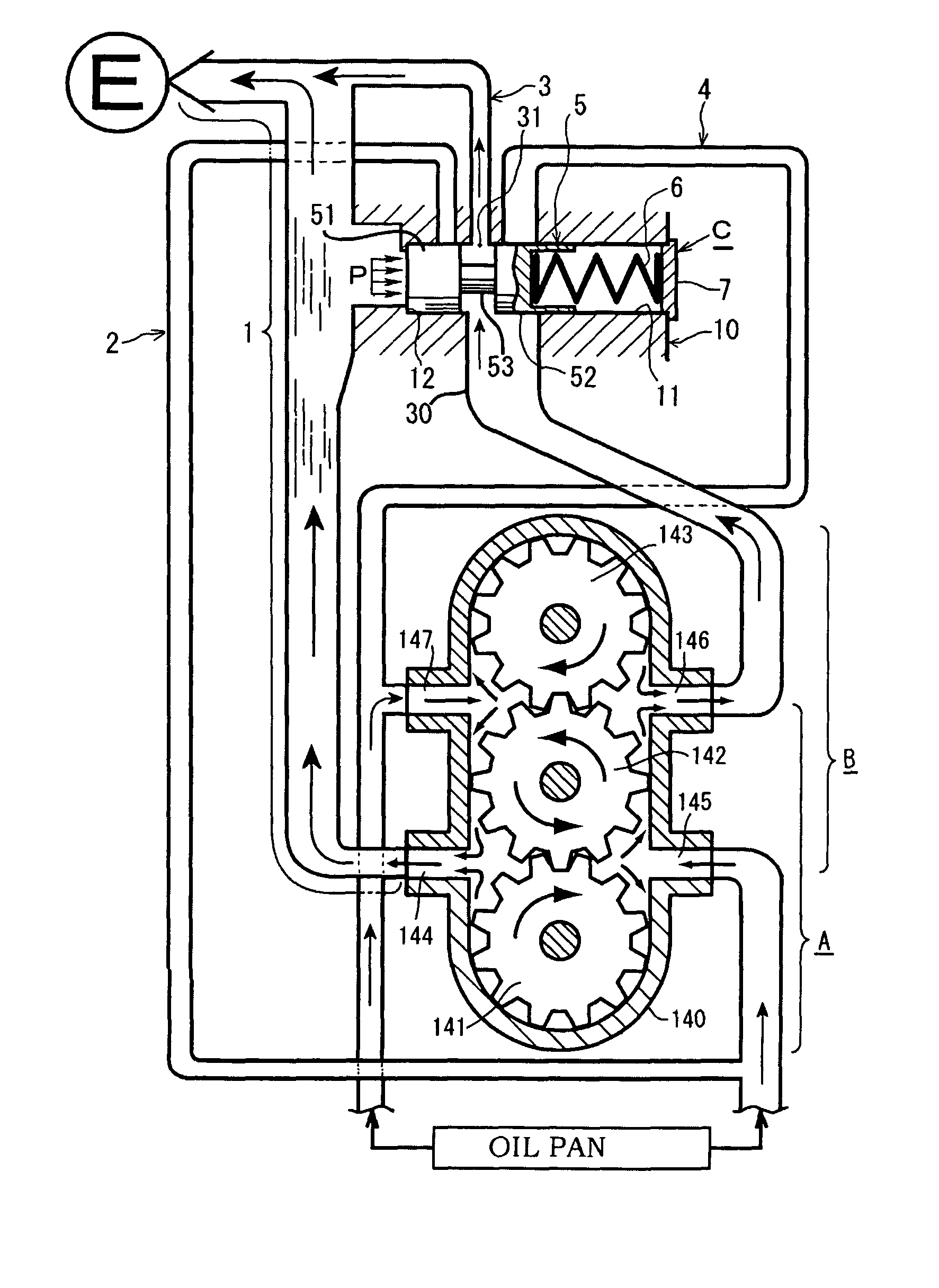

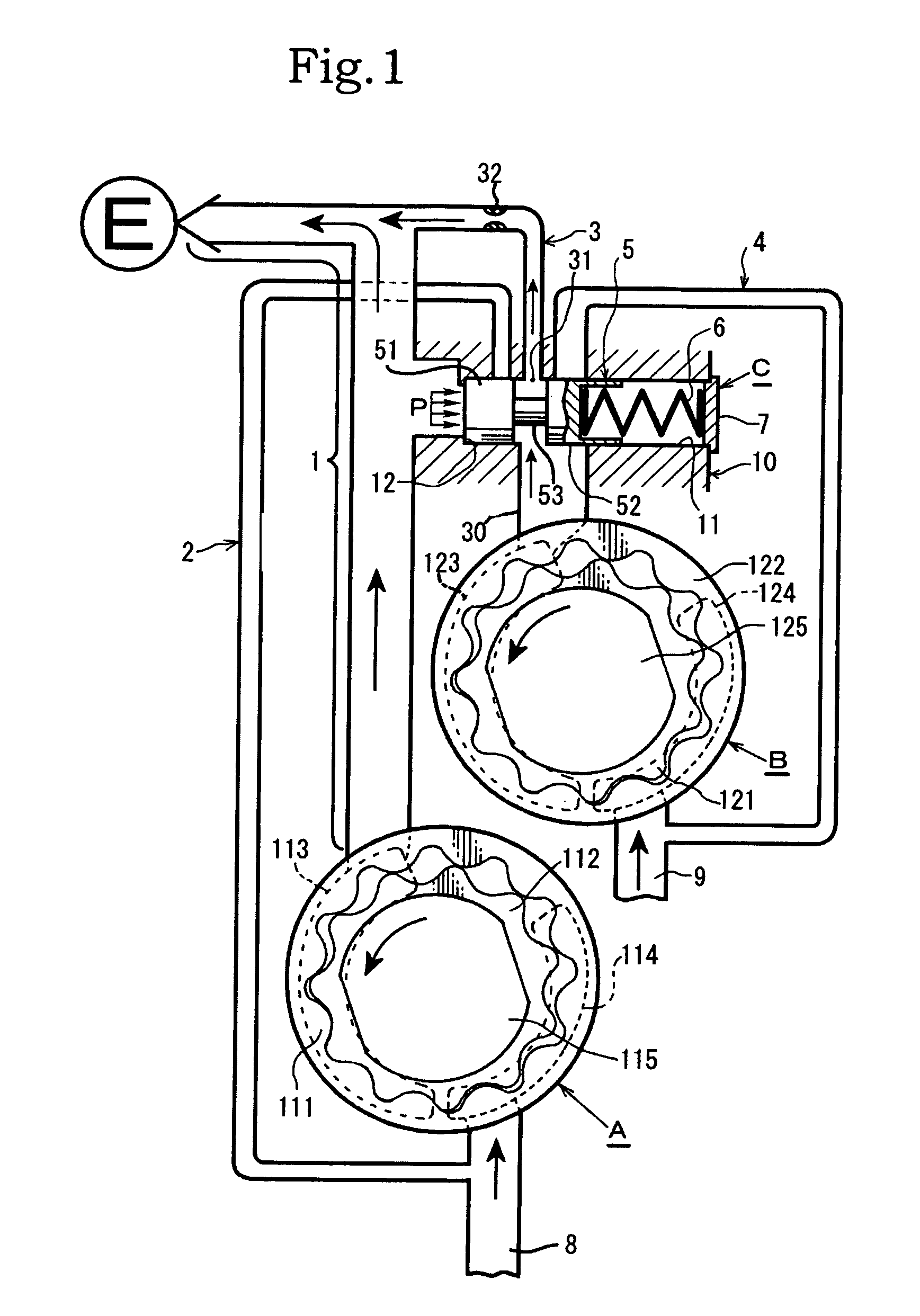

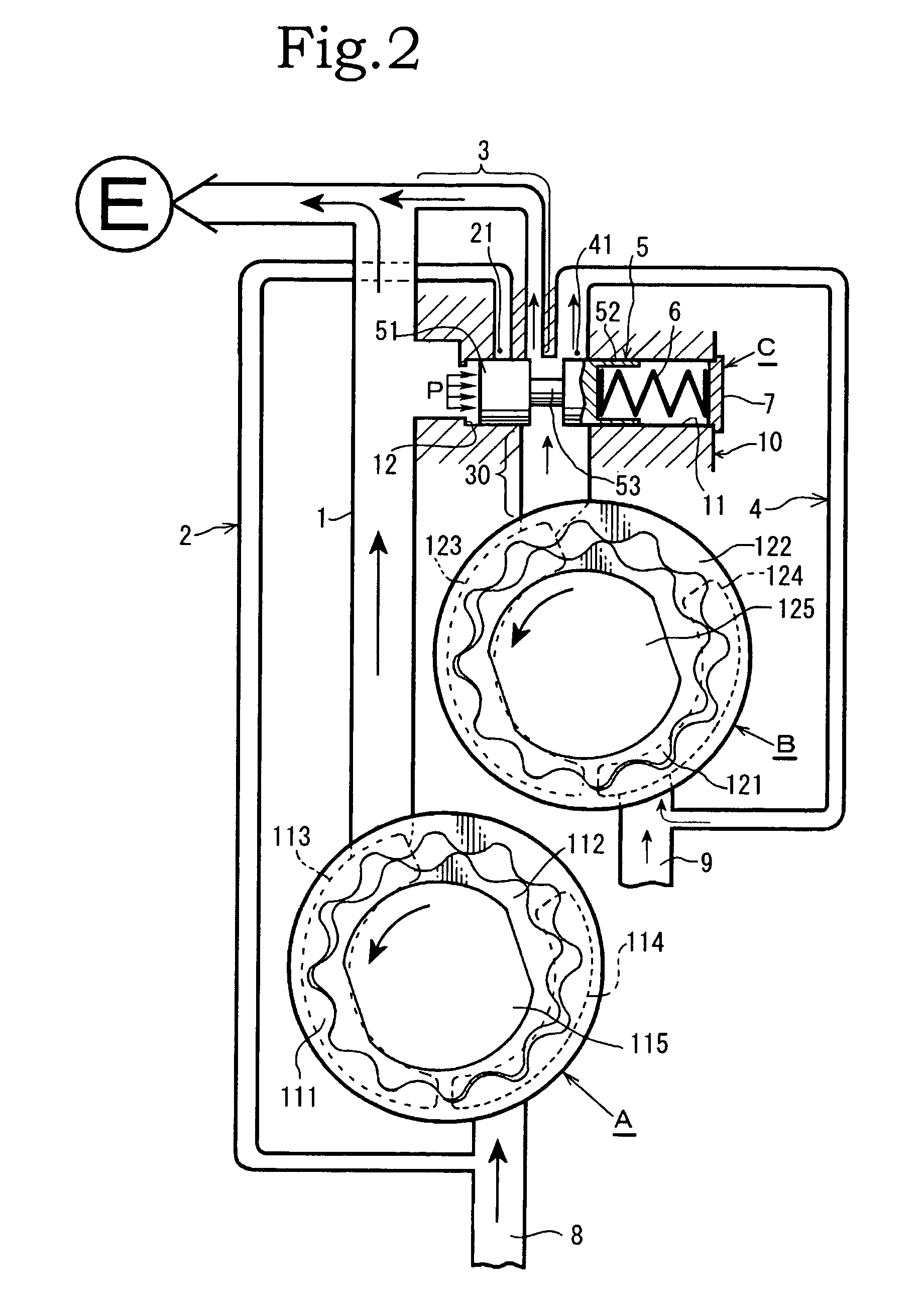

Oil pump pressure control device

InactiveUS8038416B2Drop in overall pump pressureWork moreOscillating piston enginesEngine of counter-engagement typeControl valvesReturn channel

A device including a first discharge passage from a first rotor assembly to an engine, a first return passage that returns to an intake side of the first rotor assembly, a second discharge passage from a second rotor assembly to the engine, a second return passage that returns to an intake side of the second rotor assembly, and a pressure control valve whose valve main body is provided between a discharge port from the second rotor assembly and the first discharge passage. The first discharge passage and the second discharge passage are coupled, and a flow passage control is executed in each of: a low revolution range; an intermediate revolution range; and a high revolution range.

Owner:YAMADA MANUFACTURING CO LTD

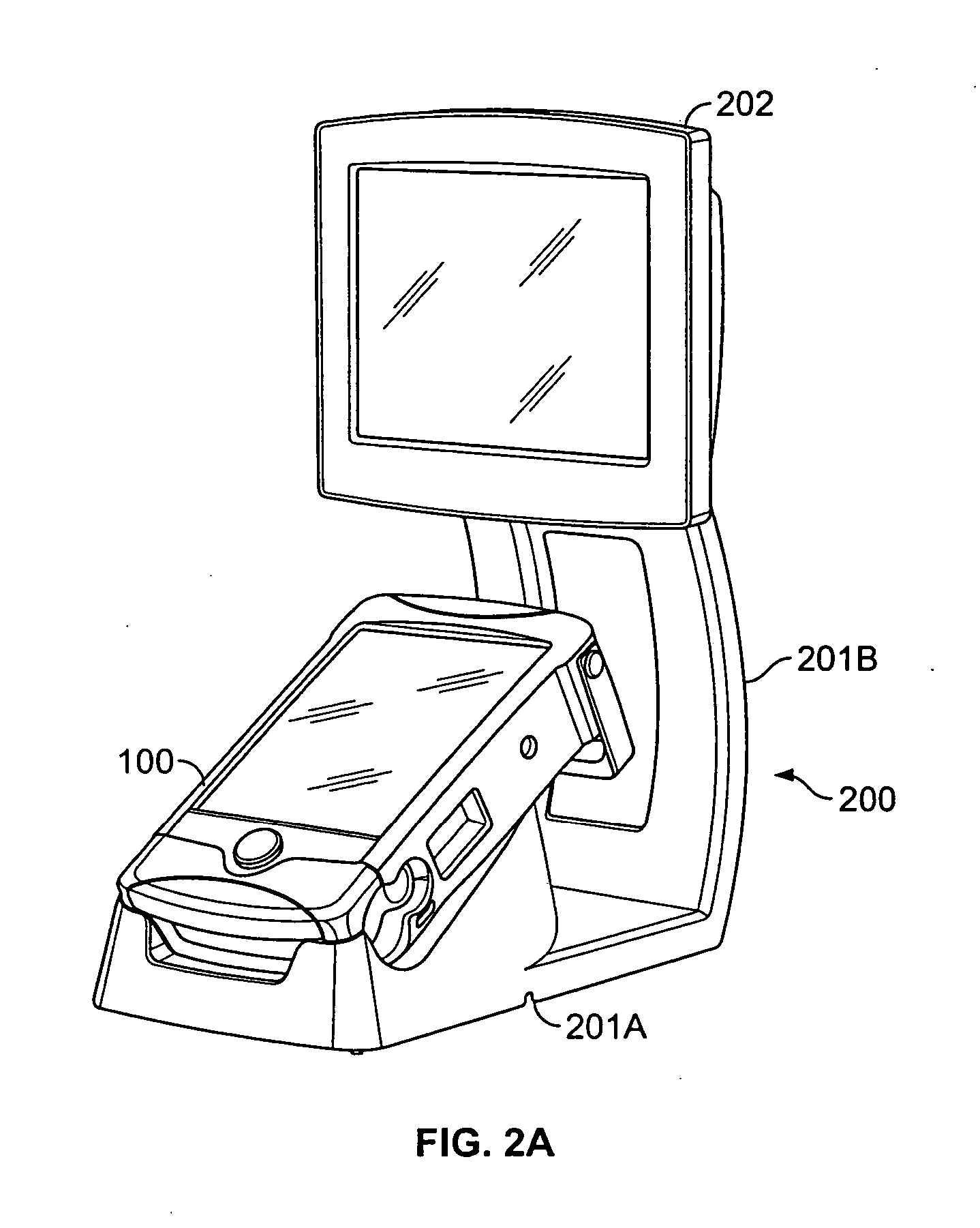

Portable ventilator system

InactiveUS20060213518A1Small sizeReduce power consumptionMechanical/radiation/invasive therapiesPhysical therapyPortable ventilatorsEngineering

A portable ventilator uses a Roots-type blower as a compressor to reduce both the size and power consumption of the ventilator. Various functional aspects of the ventilator are delegated to multiple subassemblies having dedicated controllers and software that interact with a ventilator processor to provide user interface functions, exhalation control and flow control servos, and monitoring of patient status. The ventilator overcomes noise problems through the use of noise reducing pressure compensating orifices on the Roots blower housing and multiple baffling chambers. The ventilator is configured with a highly portable form factor, and may be used as a stand-alone device or as a docked device having a docking cradle with enhanced interface and monitoring capabilities.

Owner:VYAIRE MEDICAL 203 INC

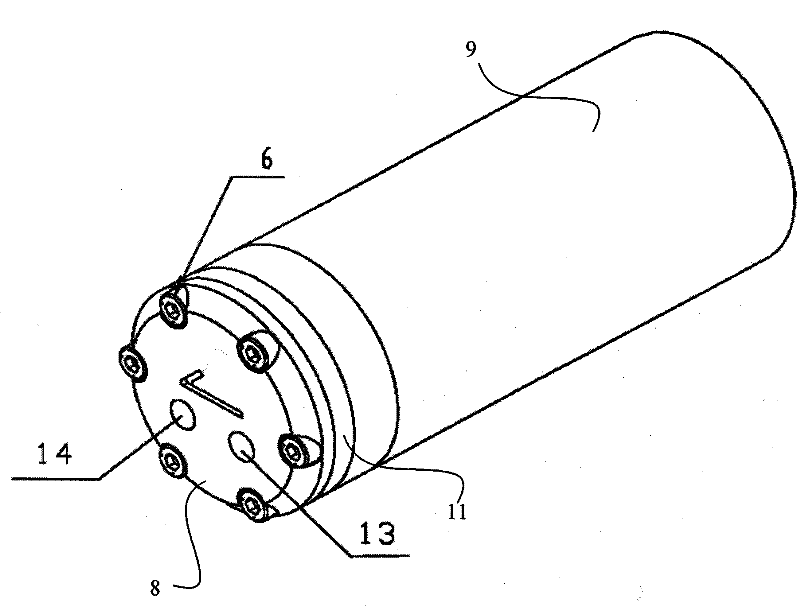

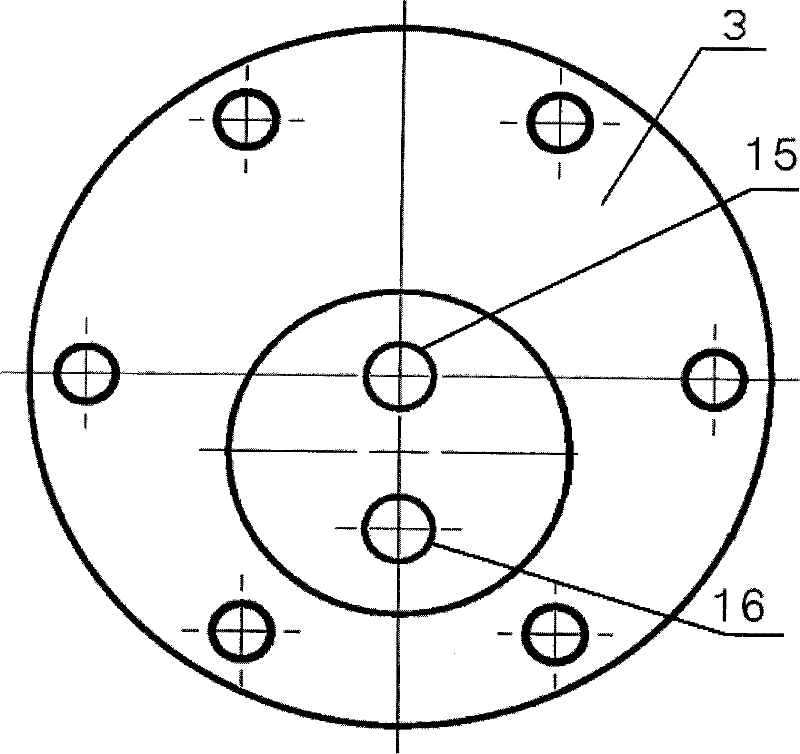

Gear pump for micro-miniature turbojet engine

ActiveCN101403382BReduce weightReduce leakageRotary piston pumpsRotary piston liquid enginesMicrocontrollerJet engine

The invention discloses a gear pump used for a microminiature turbo-jet engine, comprising a direct current motor, a pump body, an upper pump cover, a lower pump cover, a shell, a pair of driving and driven gears which are meshed and a driving shaft and a driven shaft. The driving gear is arranged on the driving shaft; the driven gear is arranged on the driven shaft and is aligned and meshed withthe driving gear; the lower pump cover is fixed on the direct current motor, the upper pump cover is connected to the lower pump cover and the plane of the pump body is pressed tightly and sealed so as to lead the structure to be simple; the shell is sleeved at the outside of the lower pump cover; the driving gear and the driving shaft adopt a method of combining clearance fit and a transmission pin to eliminate the installation error of an output shaft of the direct current motor; and an antifriction material is embedded at the positions on the lower pump cover and the upper pump cover corresponding to the driving gear and the driven gear so as to increase the reliability and durability of the gear pump. Most parts of the gear pump adopt aluminium alloy so as to reduce the weight furthest. The gear pump can control the rotating speed of the direct current motor by pulse-width modulation of a single-chip microcontroller and control the flow rate of the gear pump precisely.

Owner:北京领动国创科技有限公司

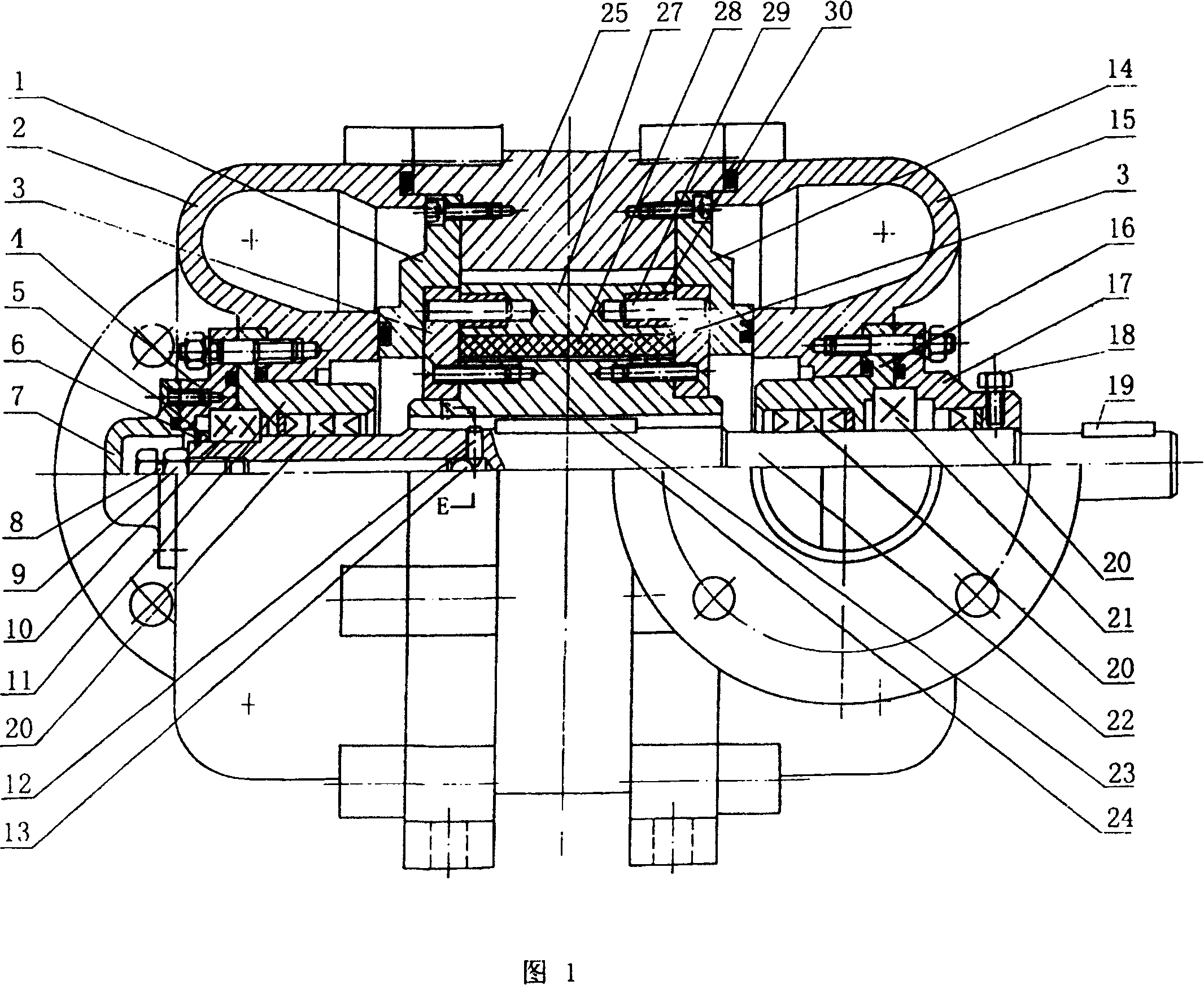

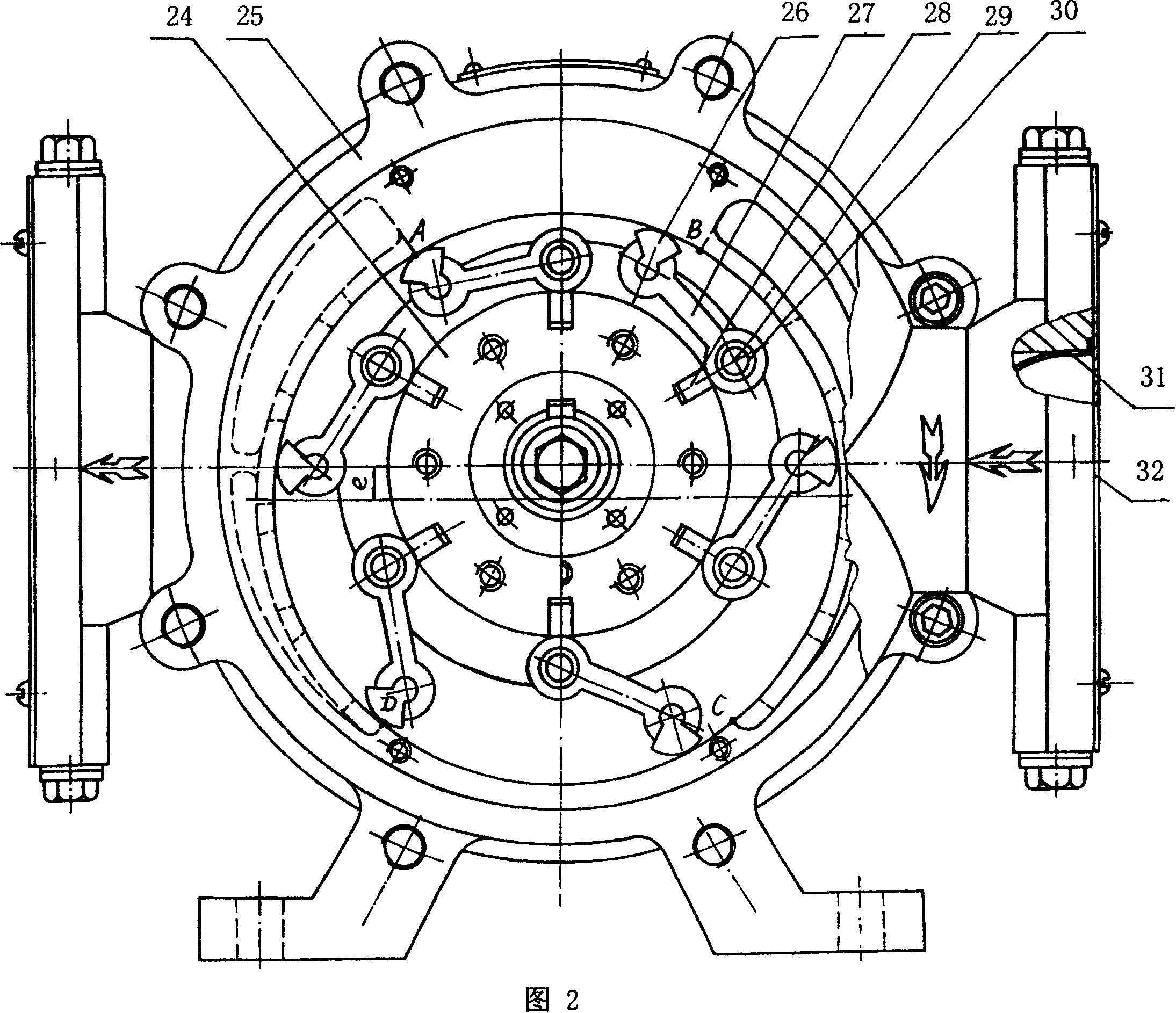

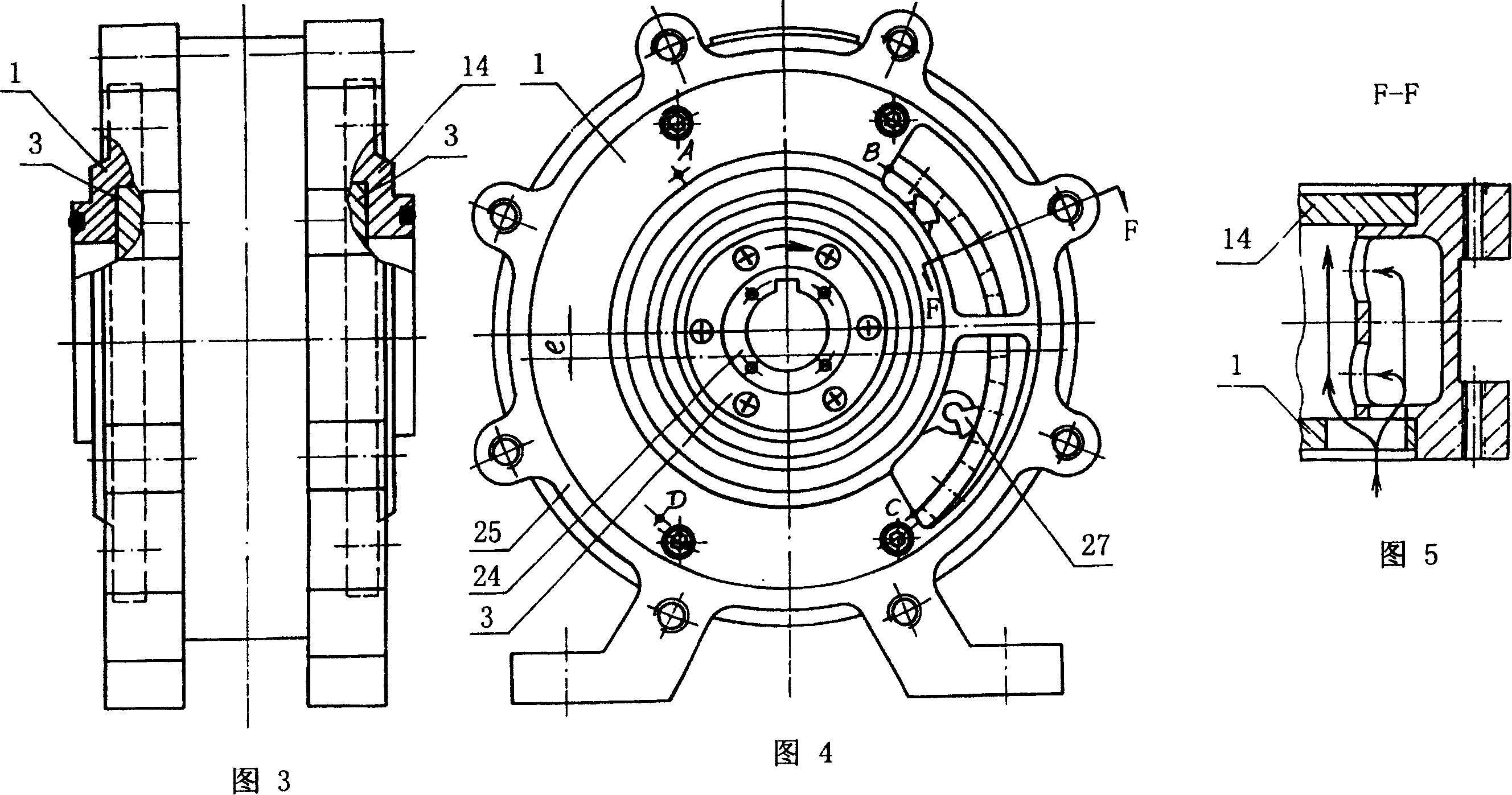

Rotary blade pump

InactiveCN100374725CReduce line speedEliminate cavitationRotary piston pumpsRotary piston liquid enginesClassical mechanicsEngineering

In the invention, an inlet-outlet oil flow plate is fixed at two ends of a pump case stator. A radial inlet-outlet runner is built-up on the pump case stator to realize axial and radial inlet and outlet oil at the same time. A rotor is mounted in the internal cavity of the pump case stator and there is an offsetting e between the rotor and the ID of the pump case stator. Rotary vanes are mounted on a rotating board fixed on the two end faces of the rotor. The rotor is mounted on the pump spindle via a rotor key. A rotor locking device is assembled on the front part of the pump spindle. The inlet-outlet oil pump covers are fixed at two ends of the pump stator separately. A ring inlet-outlet oil passageway is disposed in inlet-outlet oil pump. A bearing support and sealing device is assembled on the central of the inlet-outlet oil pump cover.

Owner:王振忠 +1

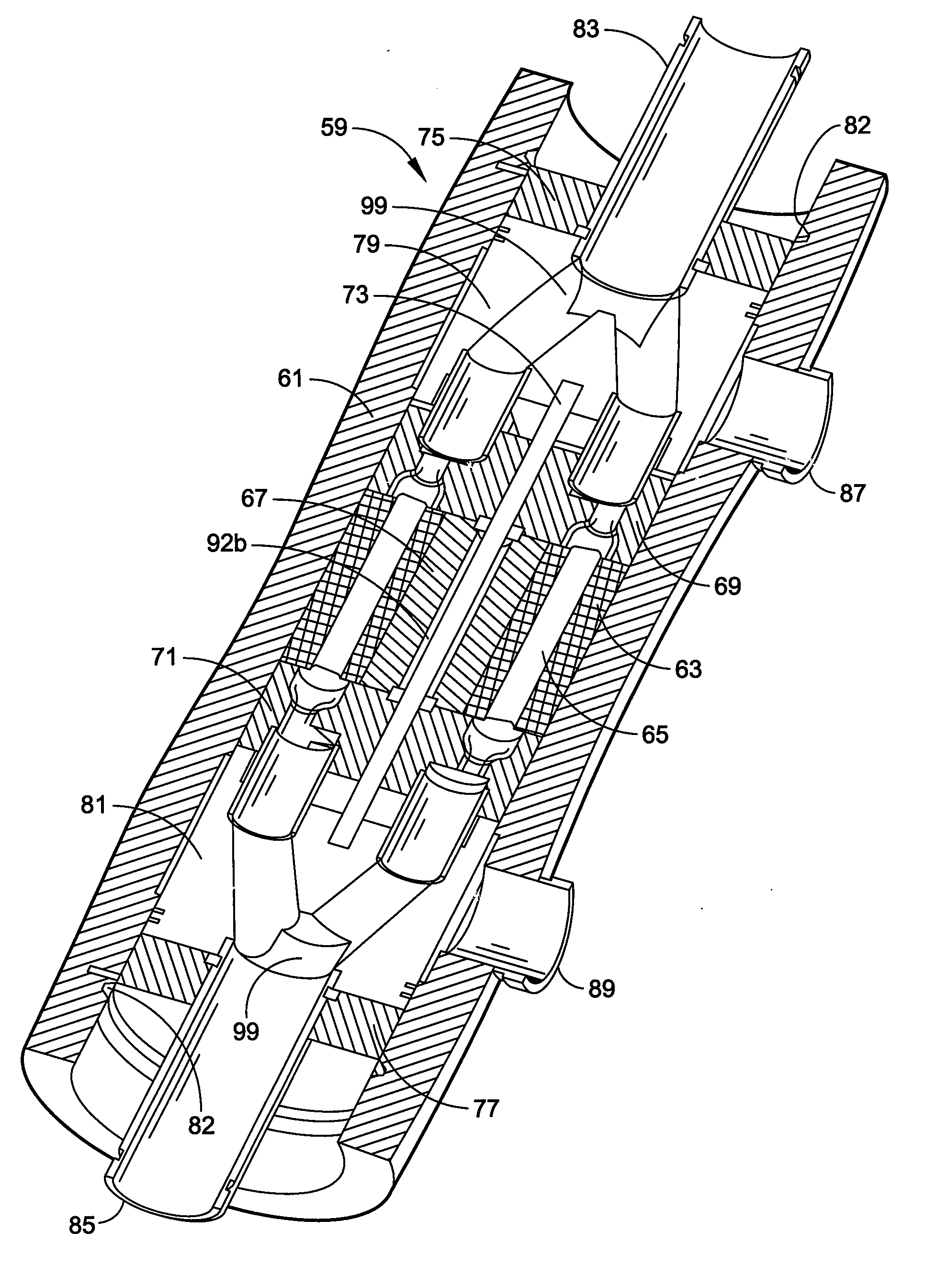

Rotary pressure transfer device

ActiveUS20090180903A1Pump pressureIncrease pressureMembranesPump componentsEngineeringMechanical engineering

A pressure transfer device for the transfer of pressure energy from a high pressure fluid stream to a lower pressure fluid stream wherein a generally cylindrical housing (61) contains a rotor (63) having a plurality of channels (65) extending axially therethrough that revolves about a central stator (67) or within a surrounding sleeve (73) and a pair of end covers (69, 71) which slidingly and sealingly interface with respective planar end faces (68) of the rotor. The end covers (69, 71) and the accompanying components of the device are constructed so as to allow the channels to be at least twice filled with a high pressure first liquid during each revolution of the rotor and thus discharge twice the volume of a pressurized second liquid than if they were filled only one with high pressure liquid.

Owner:ENERGY RECOVERY INC

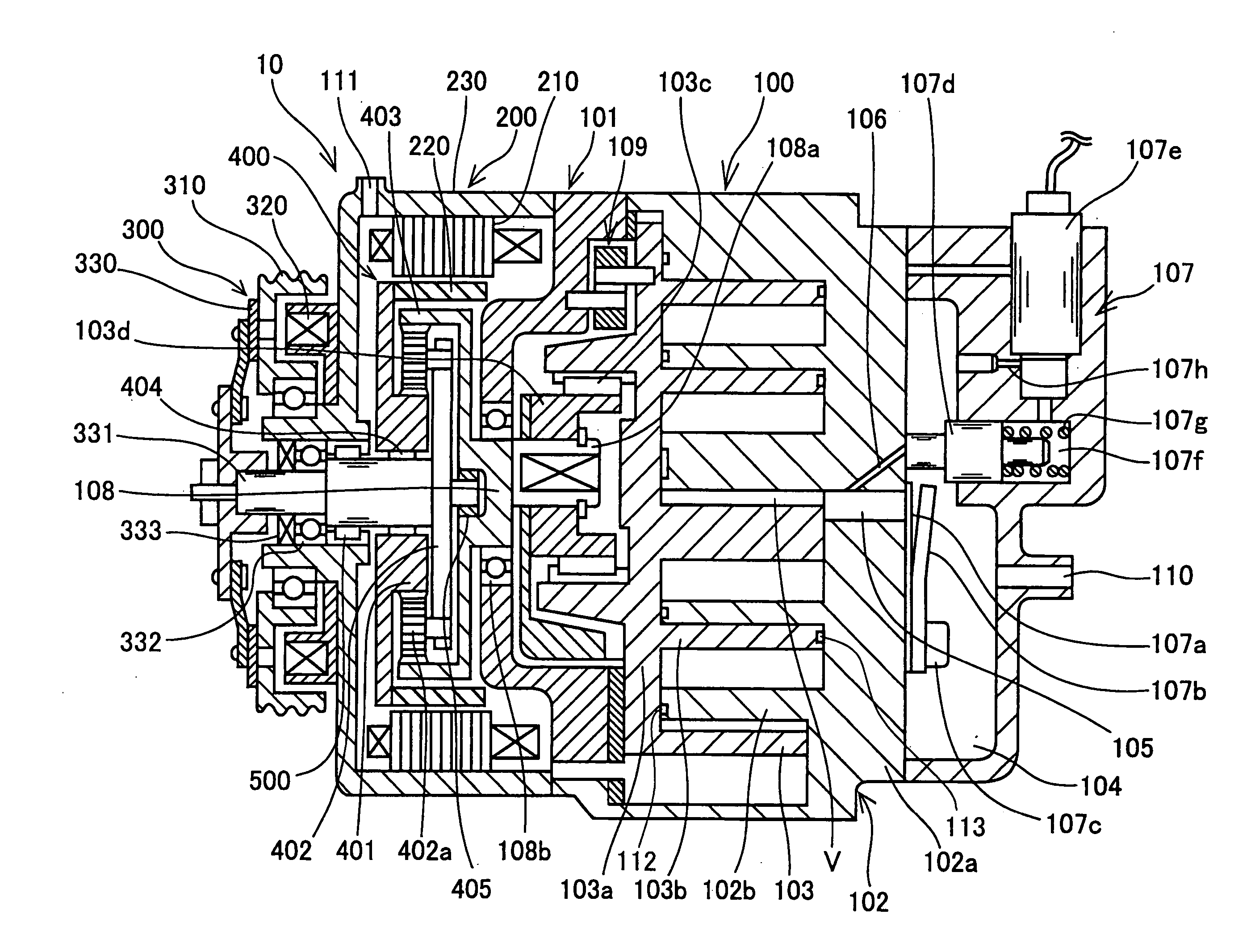

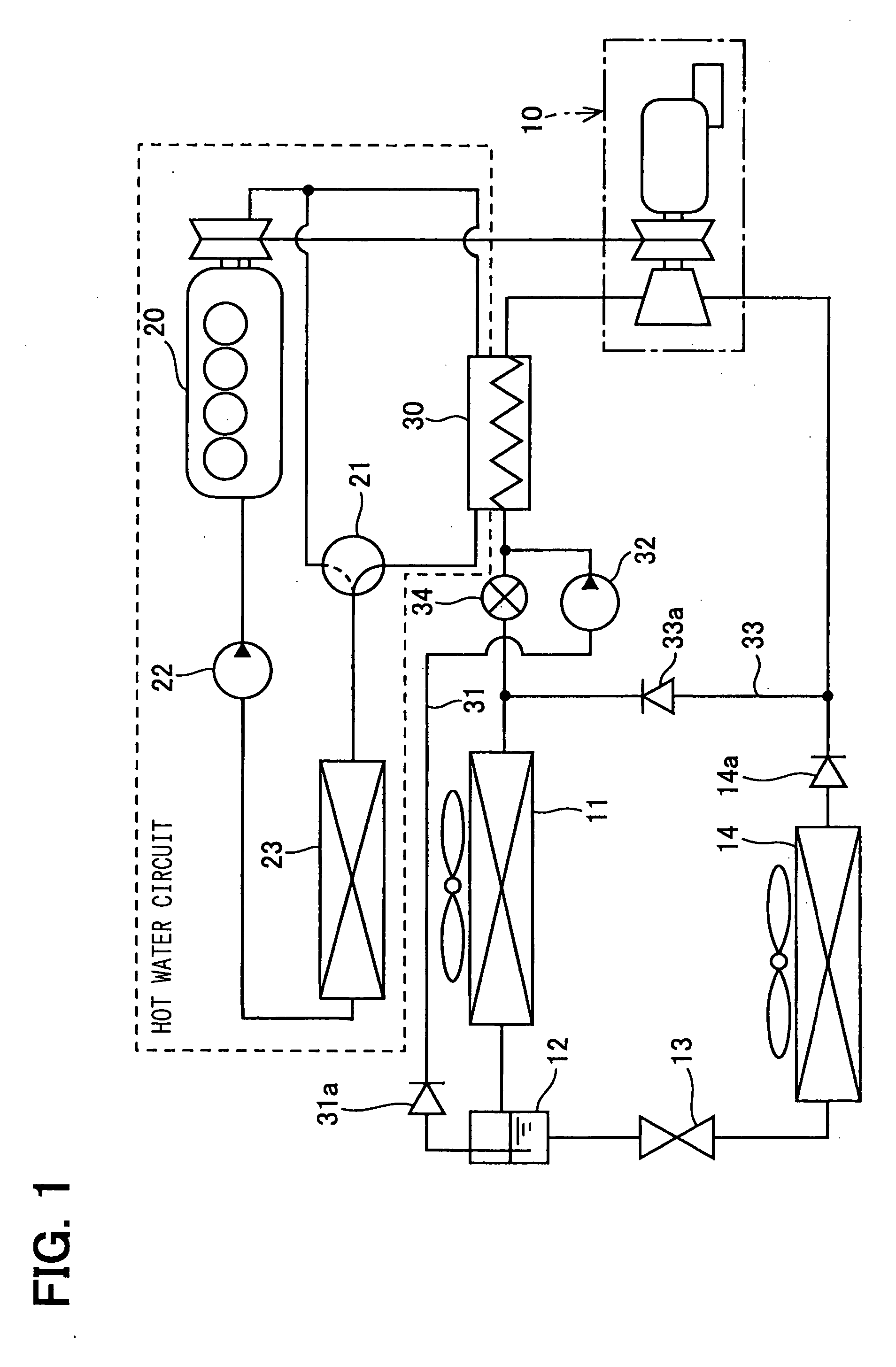

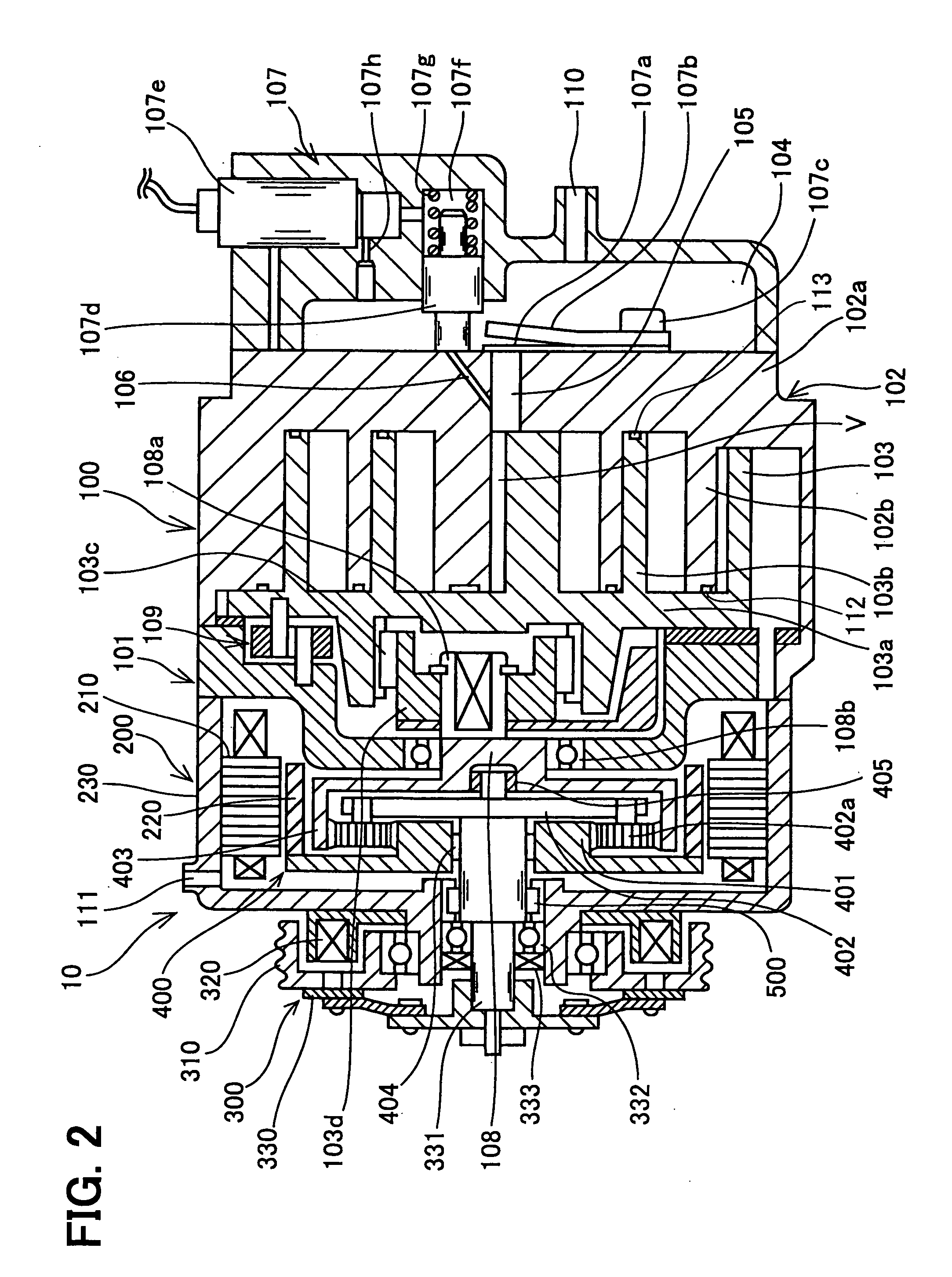

Fluid machine

InactiveUS20050214148A1Improve sealingSmall sizeCompressorEngine of arcuate-engagement typeEngineeringSliding contact

An outer end of a seal element for a fixed scroll is extended to a position close to an end of an inside spiral wall of the fixed scroll, and an outwardly extended portion is formed at an outer periphery of a disc-shaped base plate of a movable scroll, so that a bottom surface of the movable scroll is always kept in a sliding contact entirely with the seal element during the orbital movement of the movable scroll. A thickness of the outwardly extended portion formed at the outer periphery of the disc-shaped base plate is made smaller than that of the disc-shaped base plate, so that the weight of the fluid machine can be smaller.

Owner:NIPPON SOKEN +1

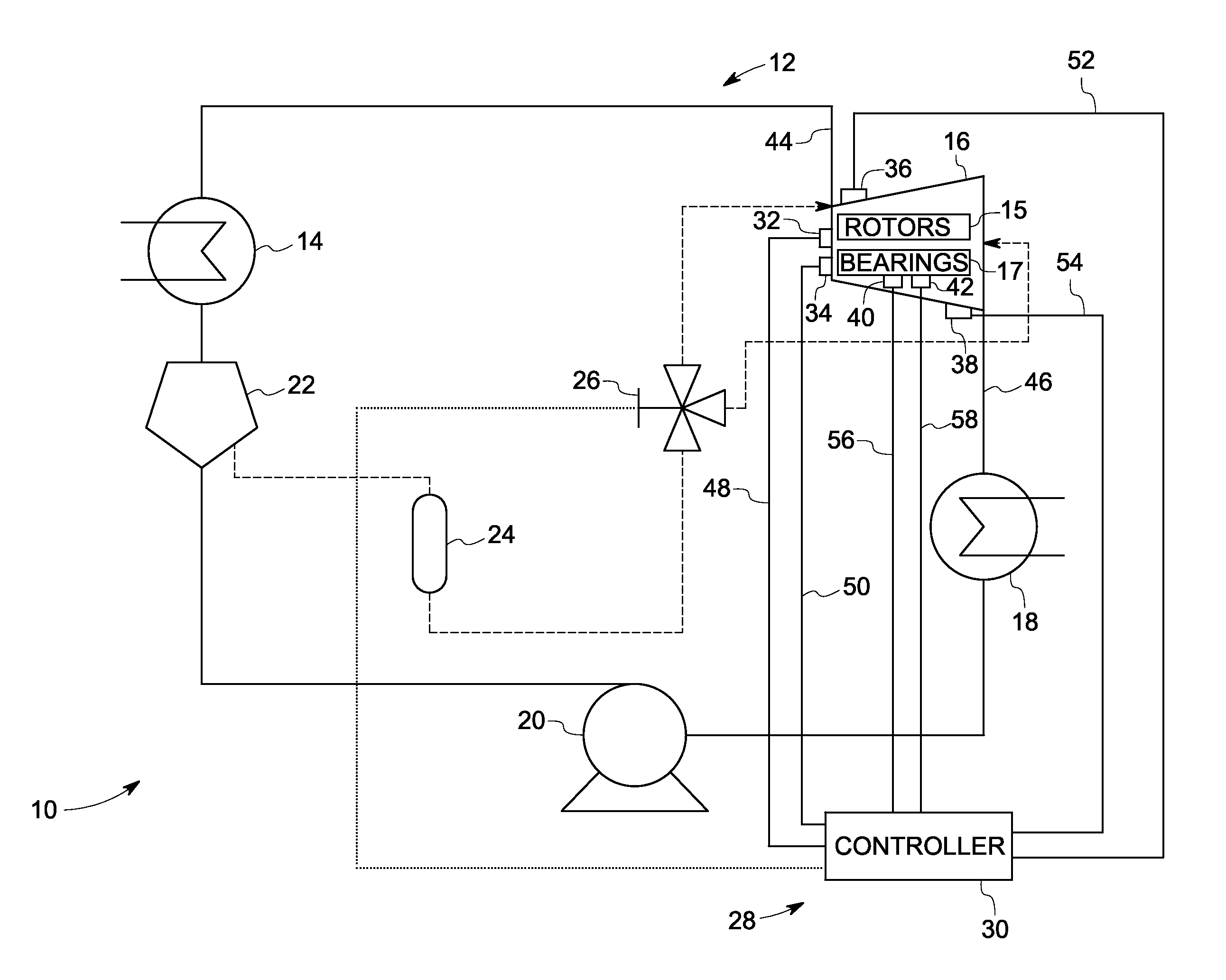

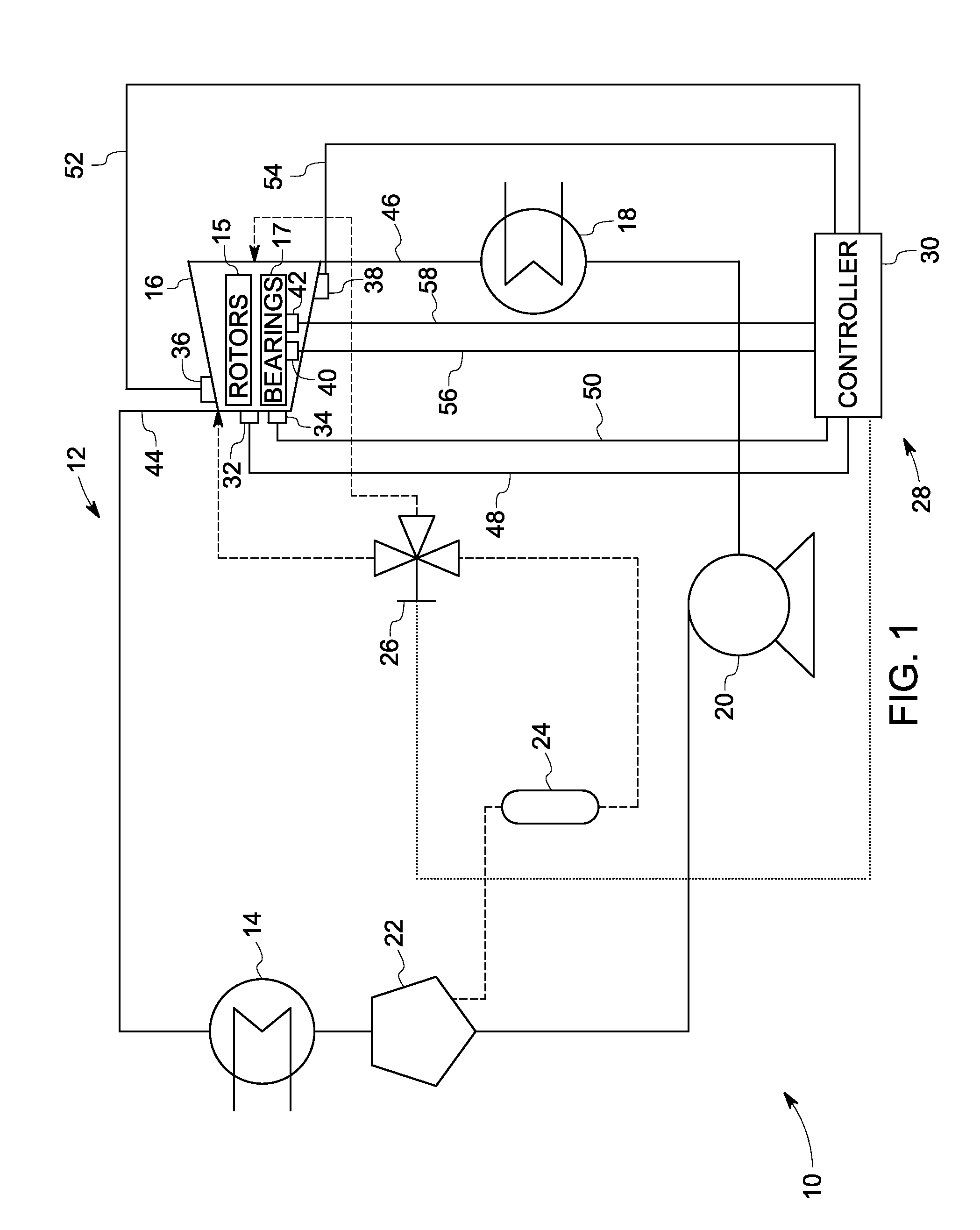

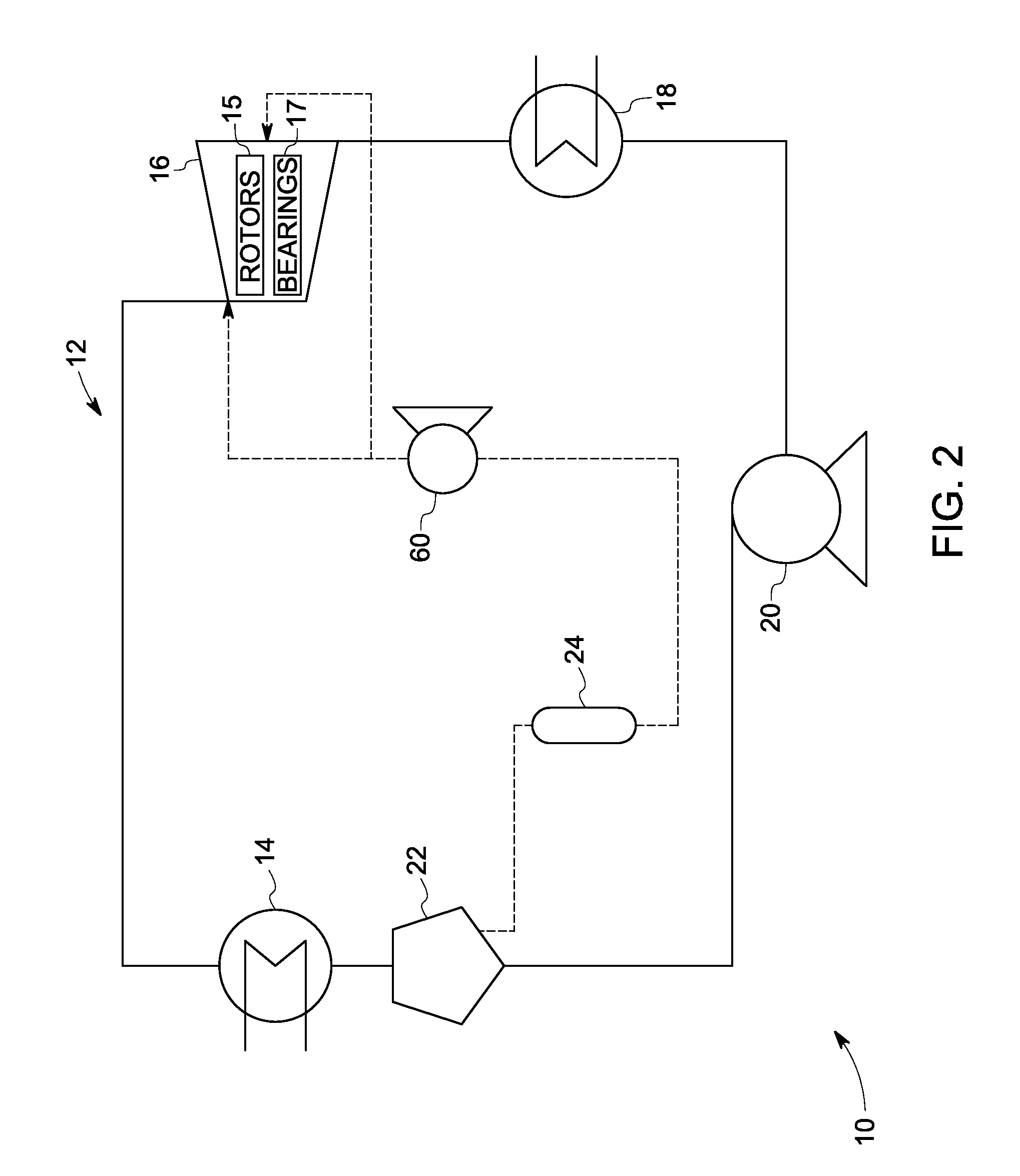

Method for lubricating screw expanders and system for controlling lubrication

A method for lubricating a screw expander includes condensing a mixture of working fluid and lubricant fed from the screw expander, through a condenser. At least a portion of the mixture of working fluid and lubricant fed from the condenser is pressurized from a first pressure to a second pressure through a pump. The method also includes separating the lubricant from the condensed working fluid of the at least portion of the mixture via a separator and feeding the lubricant to the screw expander; or separating the lubricant from the working fluid of the at least portion of the mixture via an evaporator and feeding the lubricant to the screw expander; or feeding the at least portion of the mixture of condensed working fluid and lubricant to the screw expander; or combinations thereof.

Owner:GENERAL ELECTRIC CO

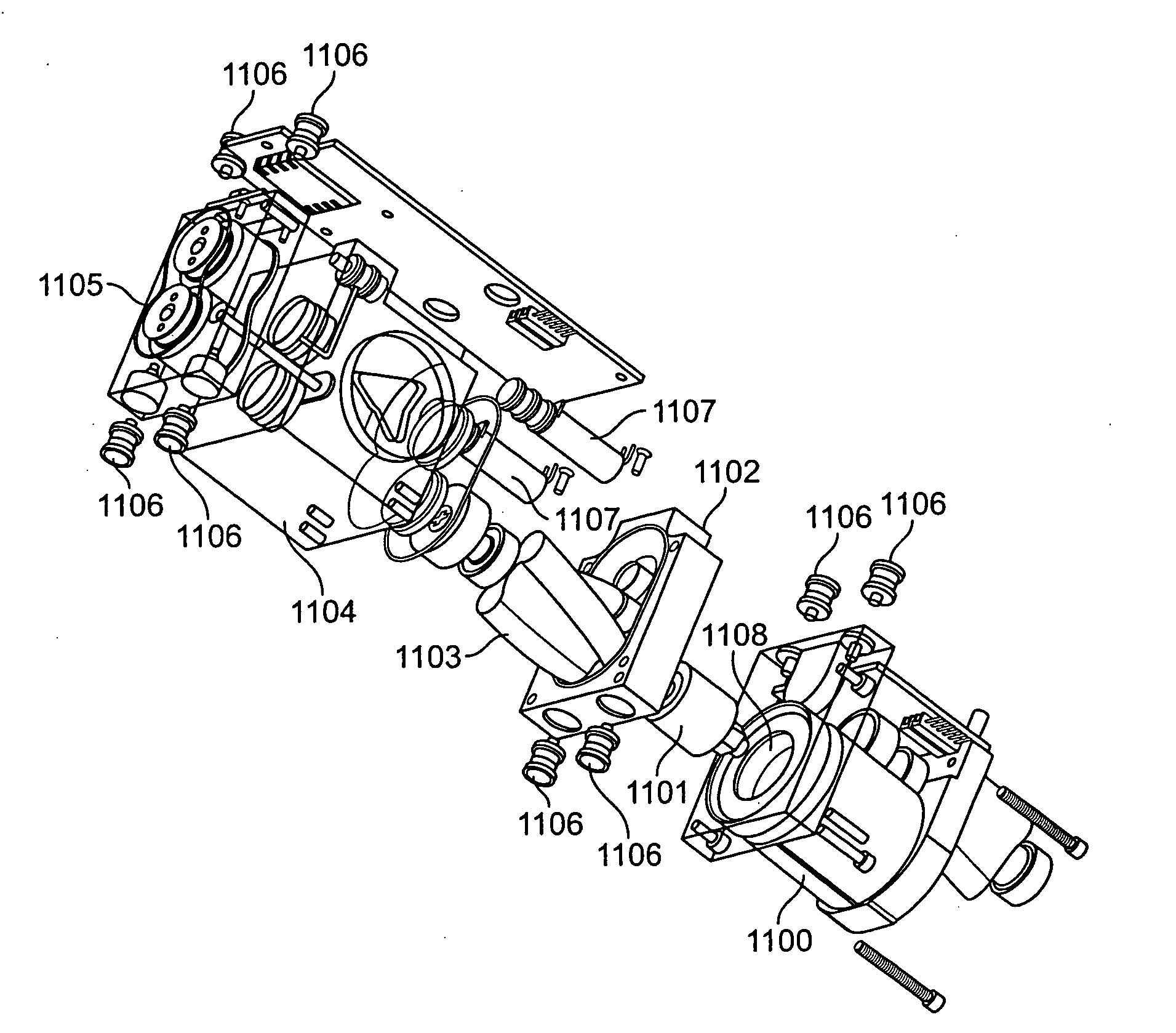

Method and apparatus for dispensing fluid compositions

ActiveUS20100185322A1Combine accuratelySmall sizePump componentsMixer accessoriesRegimenControl system

A miniaturized fluid dispensing system for dispensing customized fluids. The dispenser may include first and second reservoirs containing constituent fluids; a drive motor; at least two pump assemblies commonly driven by the drive motor and in communication with the first and second reservoirs; first and second valve assembly in communication with the first and second pump assemblies; and a control system for selectively controlling the valve assemblies to blend and discharge a composition from the constituent fluids. The system may include a dispensing header to house the valves and to define ‘discharge’ and ‘recirculation’ flow paths for each constituent fluid. The present invention also provides a method for dispensing a fluid regimen (e.g. a plurality of compositions) by periodically blending and discharging varying compositions over time.

Owner:ACCESS BUSINESS GRP INT LLC

Mechanical ventilation system utilizing bias valve

ActiveUS8118024B2Small powerSmall sizeRespiratorsOperating means/releasing devices for valvesTransducerEngineering

A portable mechanical ventilator having a ROOTS® blower is configured to provide a desired gas flow and pressure to a patient circuit. The mechanical ventilator includes a flow meter operative to measure gas flow produced by the ROOTS® blower and an exhalation control module configured to operate an exhalation valve connected to the patient circuit. A bias valve connected between the ROOTS® blower and the patient circuit is specifically configured to generate a bias pressure relative to the patient circuit pressure at the exhalation control module. The bias valve is further configured to attenuate pulsating gas flow produced by the ROOTS® blower such that gas flowing to the mass flow meter exhibits a substantially constant pressure characteristic. The bias pressure facilitates closing of the exhalation valve at the start of inspiration, regulates positive end expiratory pressure during exhalation, and purges sense lines via a pressure transducer module.

Owner:VYAIRE MEDICAL 203 INC

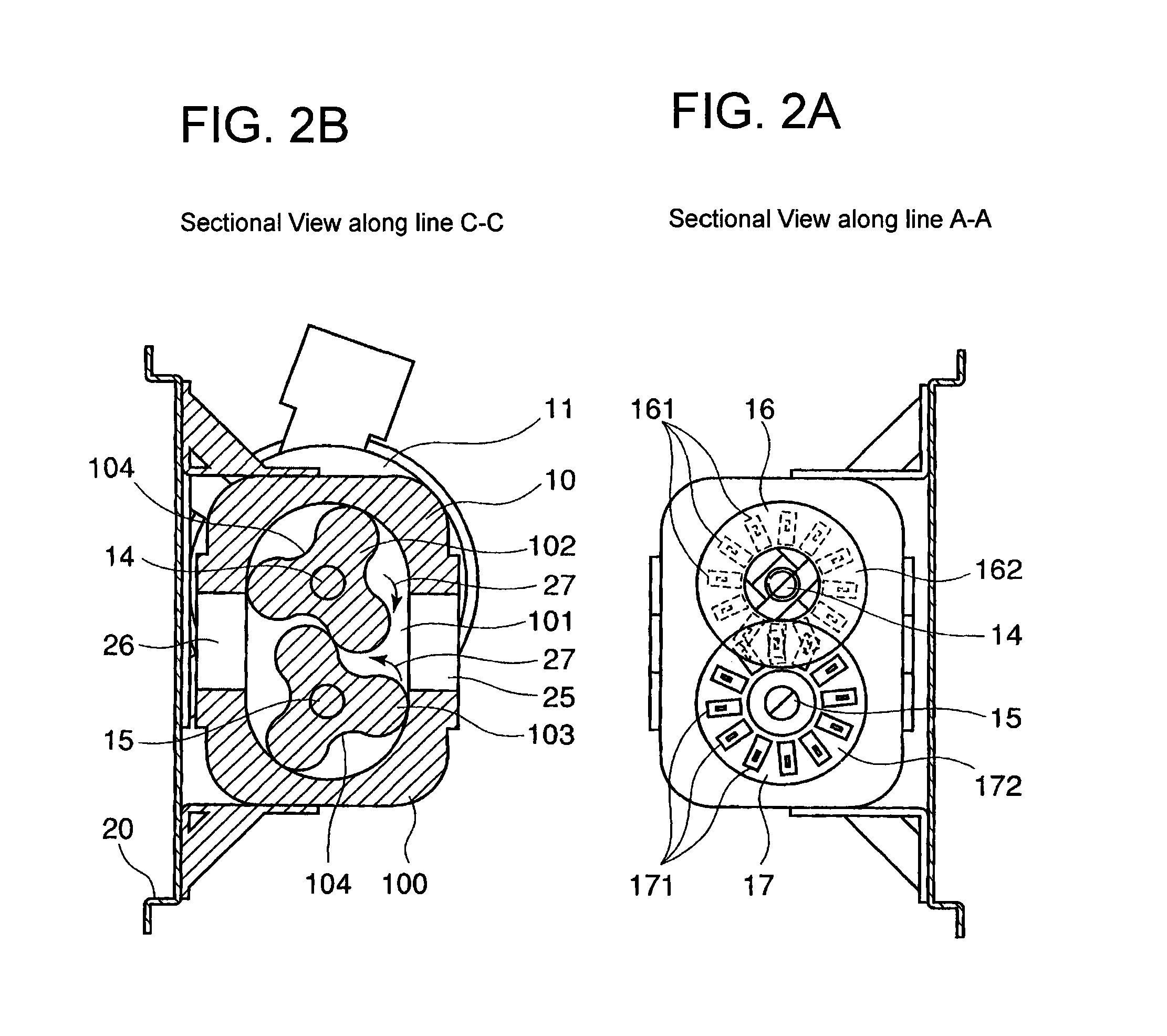

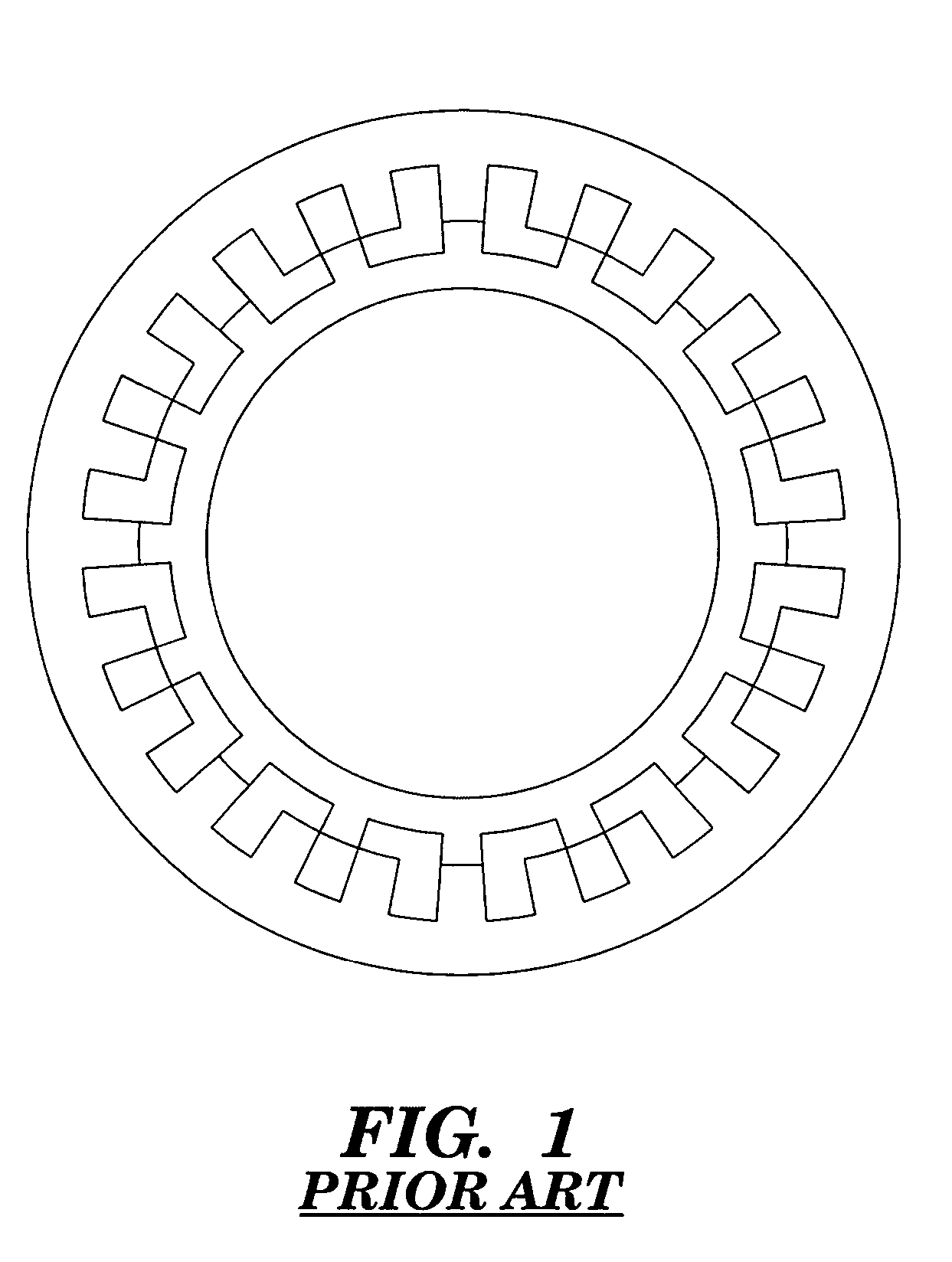

Method and apparatus for reducing noise in a roots-type blower

InactiveUS20050112013A1Reduce noisePhysical therapyEngine of counter-engagement typeNoise levelEngineering

A Roots-type blower comprises a housing defining a rotor chamber and an inlet and outlet to the rotor chamber. First and second rotors are mounted in the rotor chamber, each rotor defining a plurality of lobes, adjacent lobes and the housing cooperating to define gas transport chambers. The blower is configured so that a net flow rate of gas into a gas transport chamber is generally or approximately constant, whereby a change in gas pressure in the gas transport chamber is generally or approximately linear, as the gas transport chamber approaches the outlet. In one embodiment, this is accomplished by providing flow channels extending from the outlet towards the inlet, and from the inlet towards the outlet, corresponding to each rotor. The flow channels permit gas to flow from the high pressure outlet to a gas transport chamber and from the gas transport chamber to the low pressure inlet. The resulting amelioration of pressure spikes associated with flow back substantially reduces the operational noise level of the blower.

Owner:PULMONETIC SYST

Variable capacity scroll compressor

InactiveUS20050019177A1Easy to changeRotary piston pumpsRotary piston liquid enginesEngineeringMechanical engineering

Disclosed is a variable capacity scroll compressor including one or more bypass ports formed in a compression space, the bypass port being manipulated by intake / exhaust pressure of the compressor to control compression volume in multi-stages.

Owner:LG ELECTRONICS INC

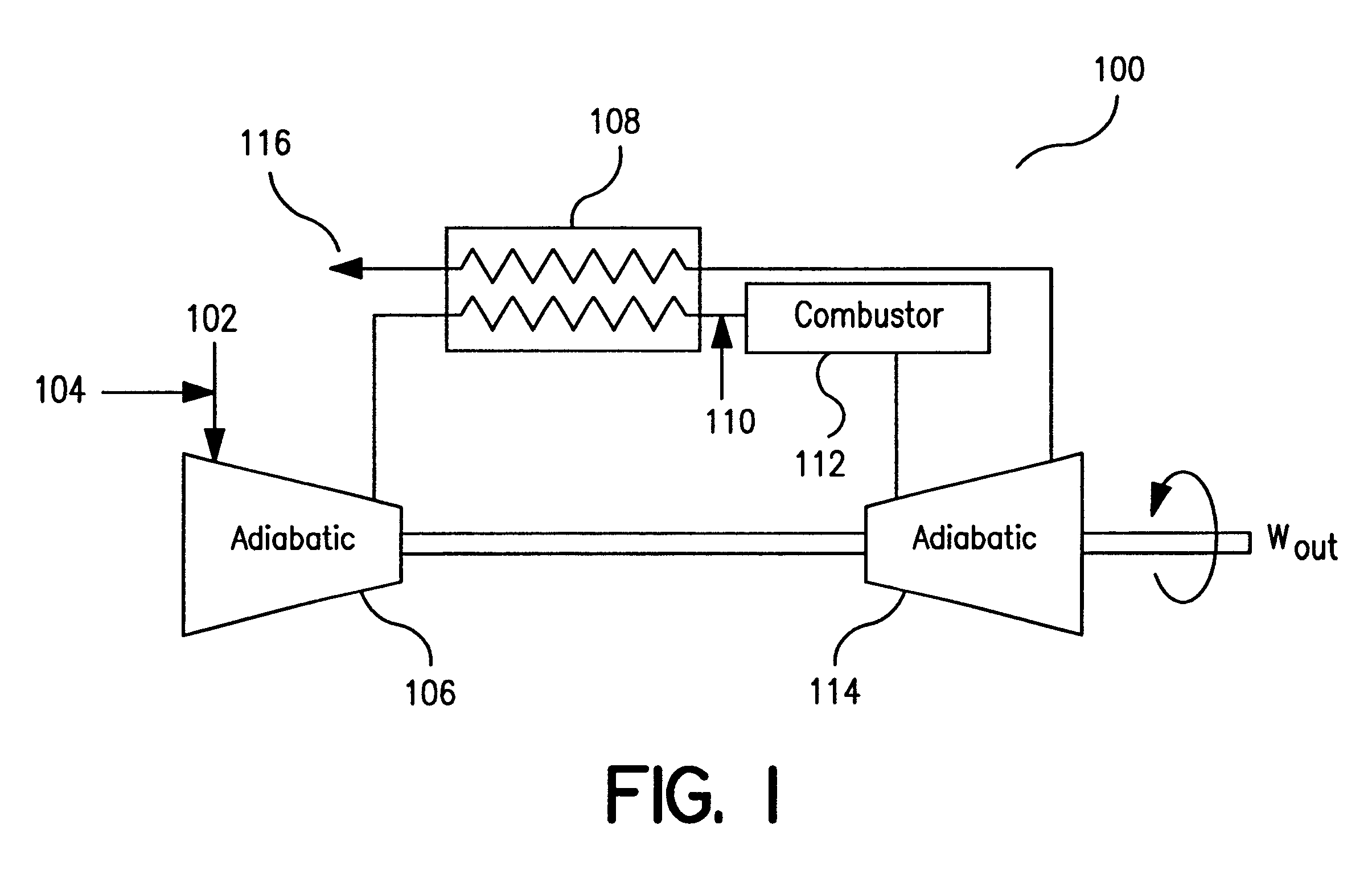

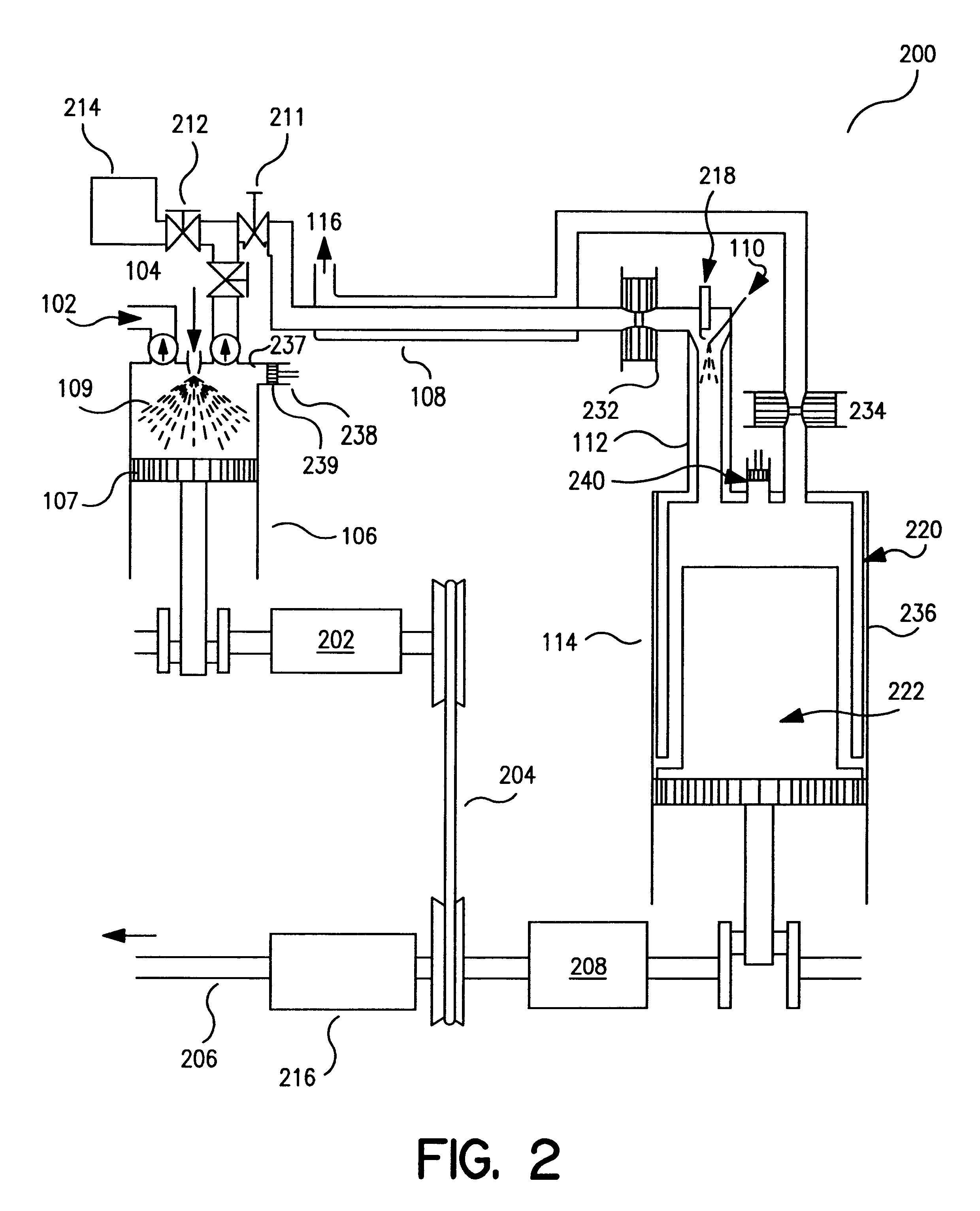

Quasi-isothermal Brayton Cycle engine

InactiveUS6530211B2Increase the turndown ratioHigh operating requirementsInternal combustion piston enginesEngine of arcuate-engagement typeBrayton cycleCombustor

Owner:HOLTZAPPLE MARK T +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com