Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

219results about How to "Combine accurately" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

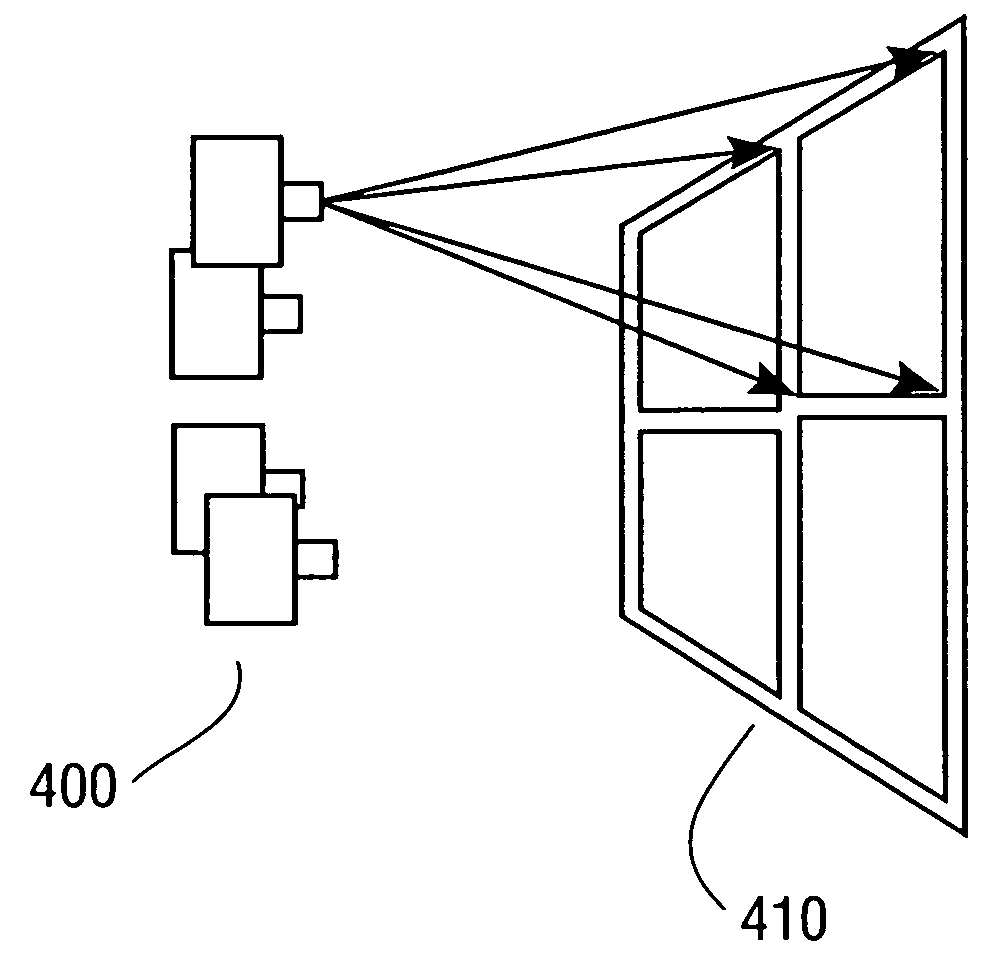

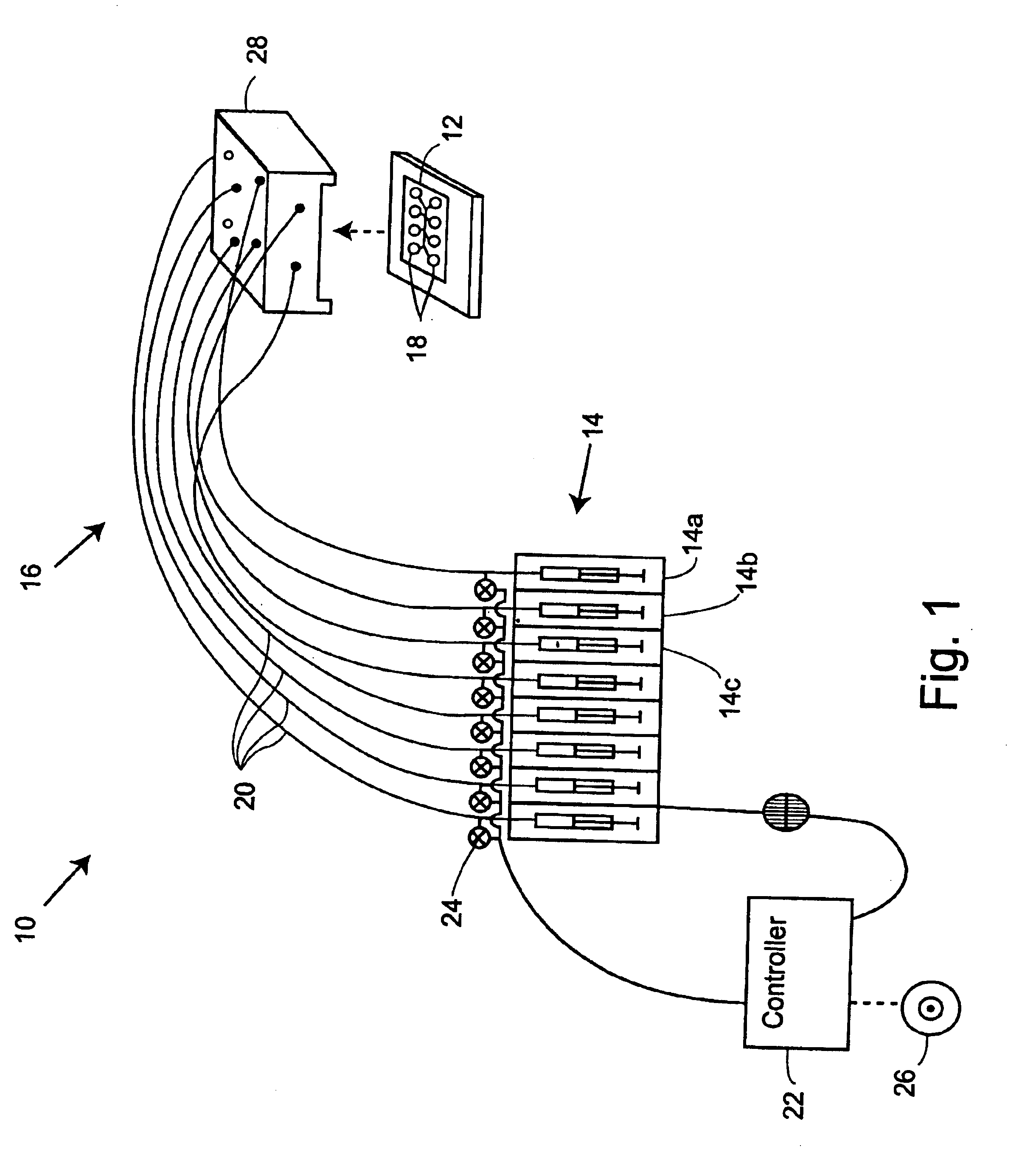

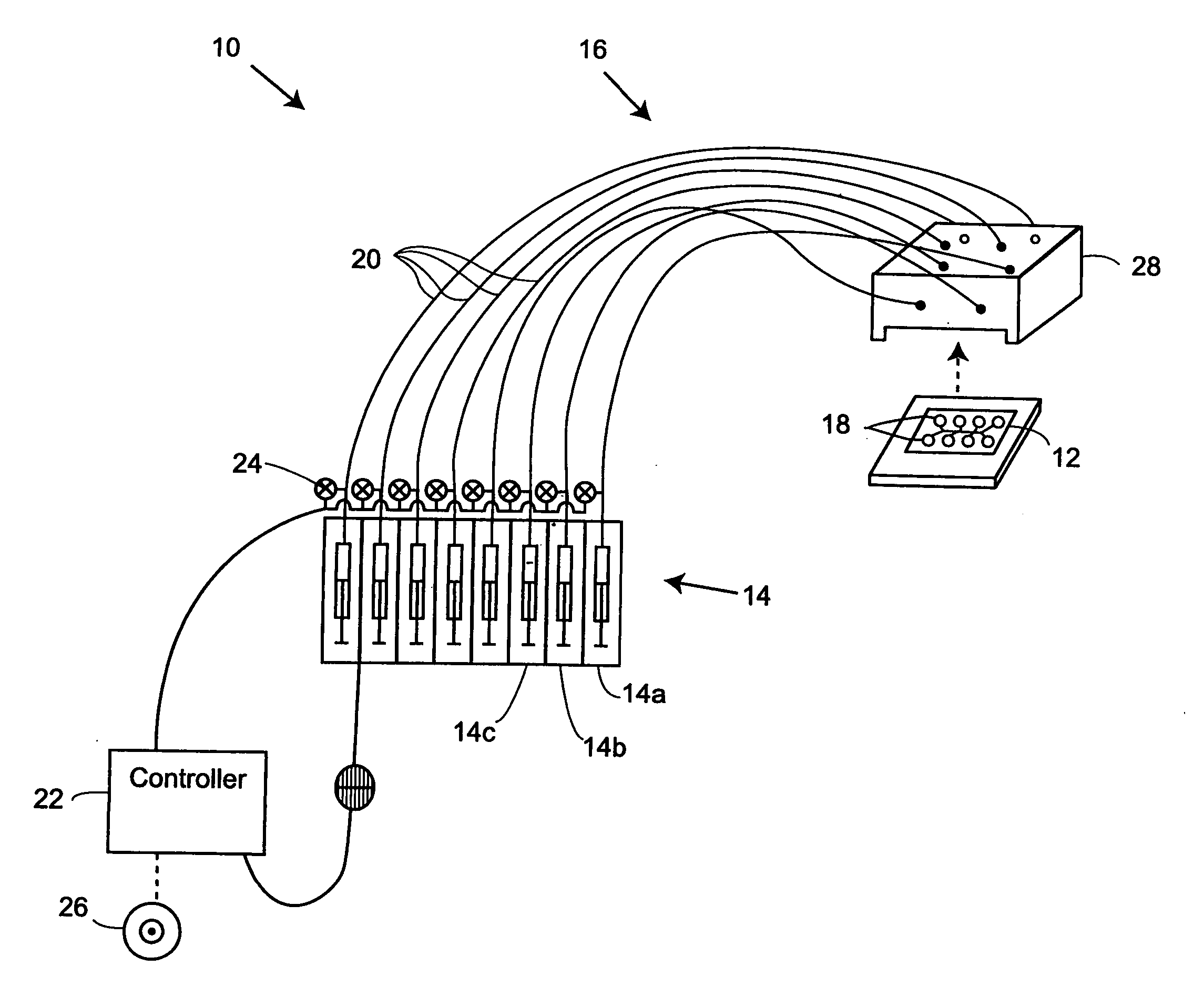

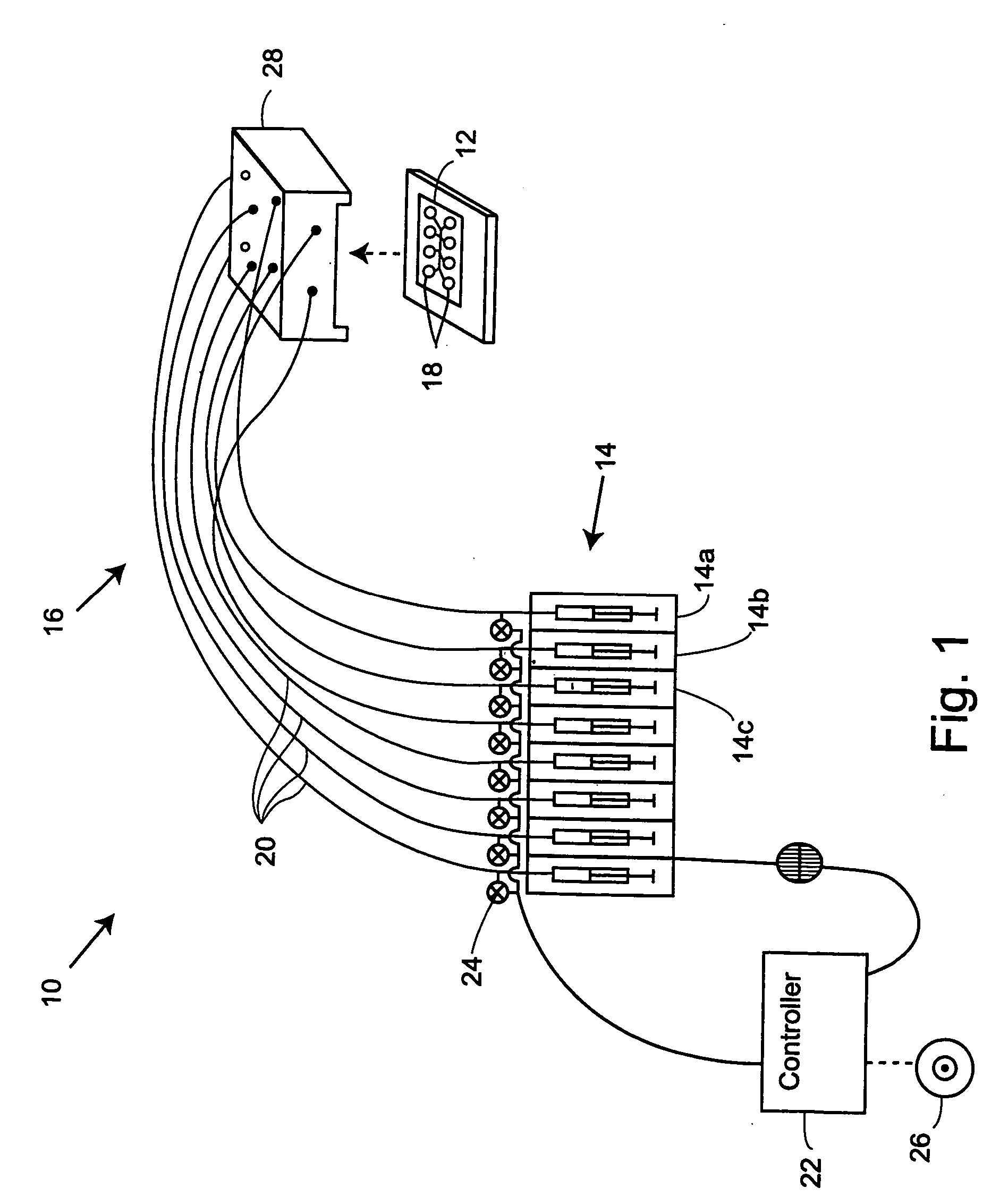

Automatic video system using multiple cameras

InactiveUS7015954B1Reduce manufacturing costCombine accuratelyImage enhancementTelevision system detailsDynamic equationCombined use

A camera array captures plural component images which are combined into a single scene from which “panning” and “zooming” within the scene are performed. In one embodiment, each camera of the array is a fixed digital camera. The images from each camera are warped and blended such that the combined image is seamless with respect to each of the component images. Warping of the digital images is performed via pre-calculated non-dynamic equations that are calculated based on a registration of the camera array. The process of registering each camera in the arrays is performed either manually, by selecting corresponding points or sets of points in two or more images, or automatically, by presenting a source object (laser light source, for example) into a scene being captured by the camera array and registering positions of the source object as it appears in each of the images. The warping equations are calculated based on the registration data and each scene captured by the camera array is warped and combined using the same equations determined therefrom. A scene captured by the camera array is zoomed, or selectively steered to an area of interest. This zooming- or steering, being done in the digital domain is performed nearly instantaneously when compared to cameras with mechanical zoom and steering functions.

Owner:FUJIFILM BUSINESS INNOVATION CORP

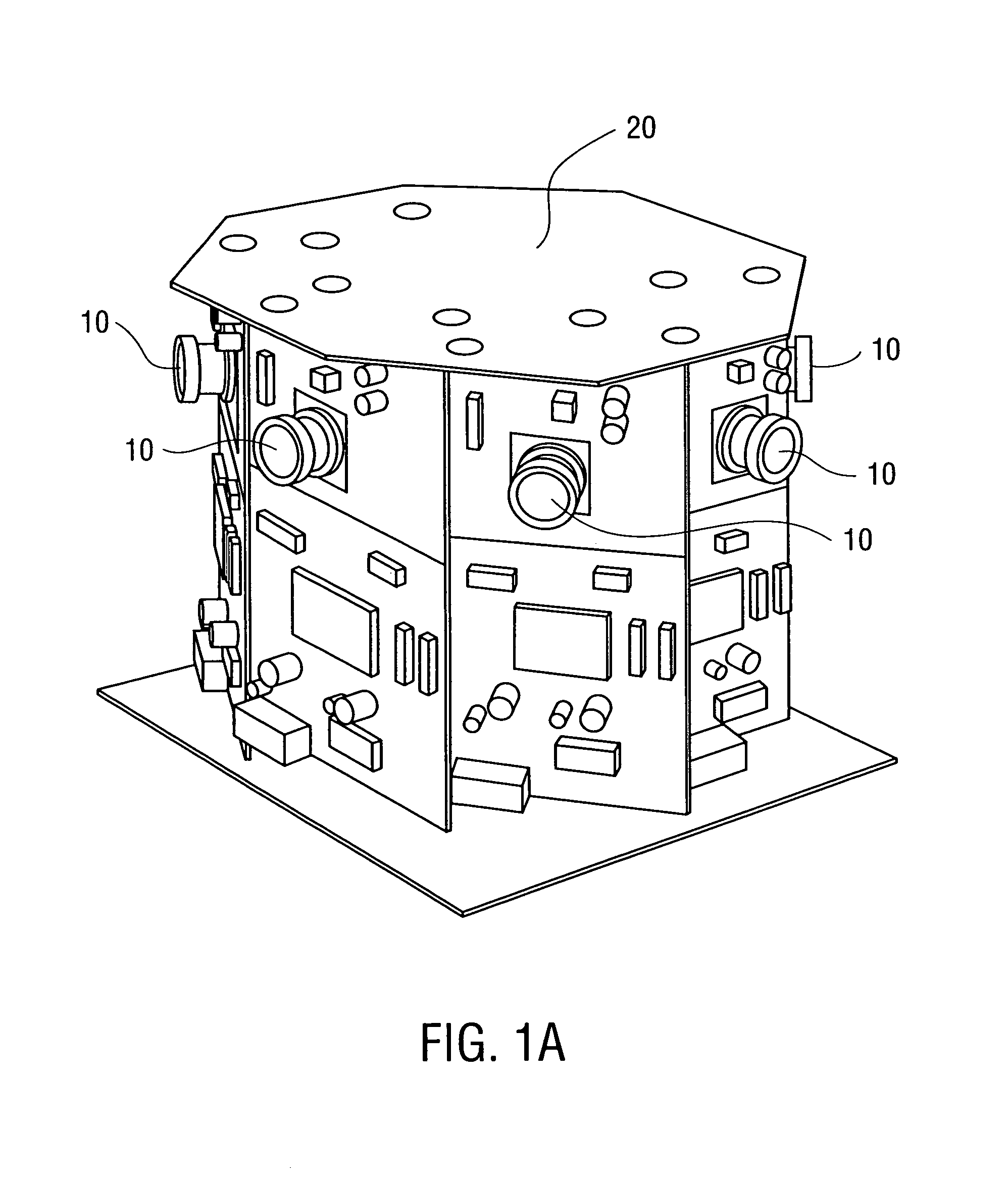

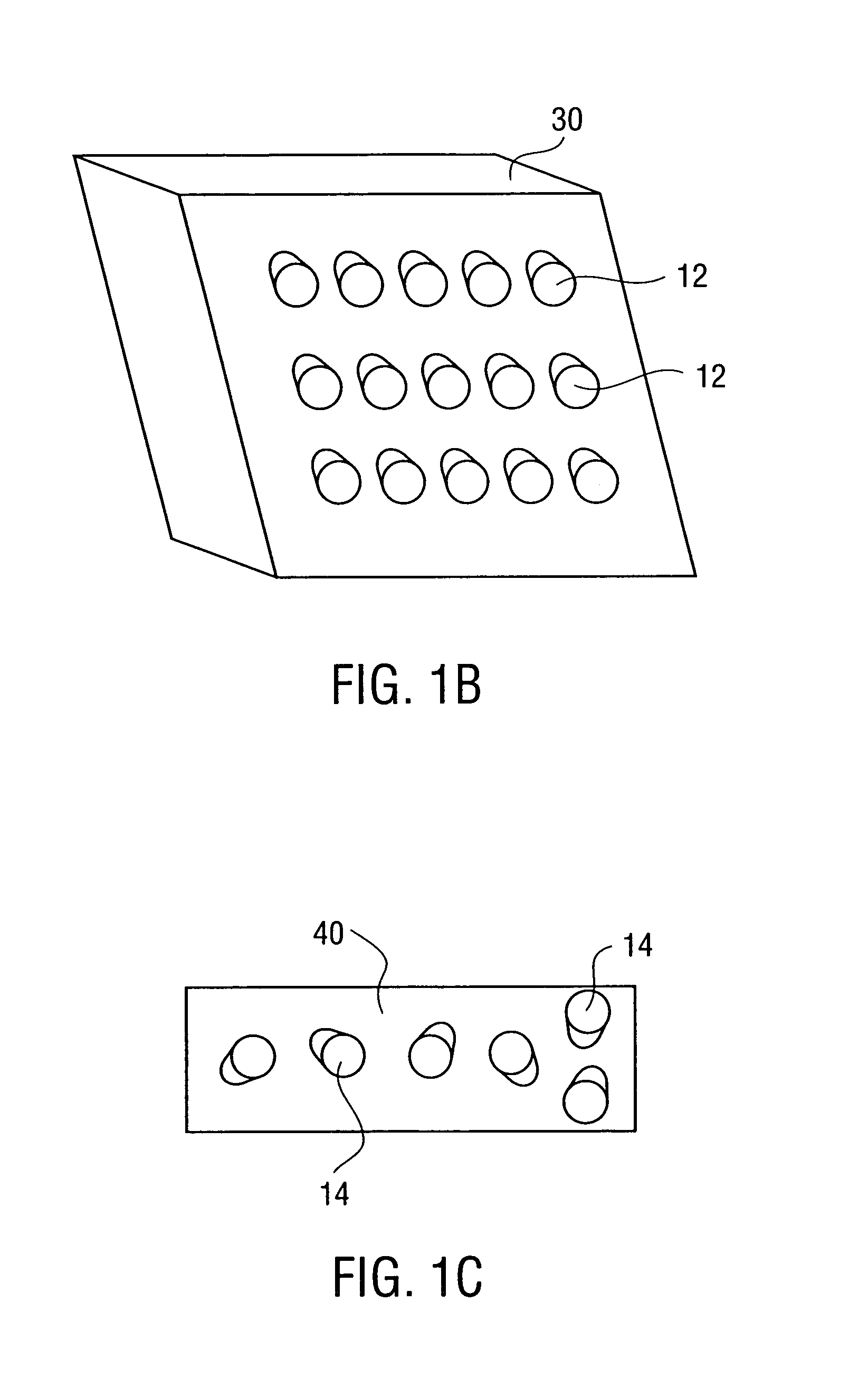

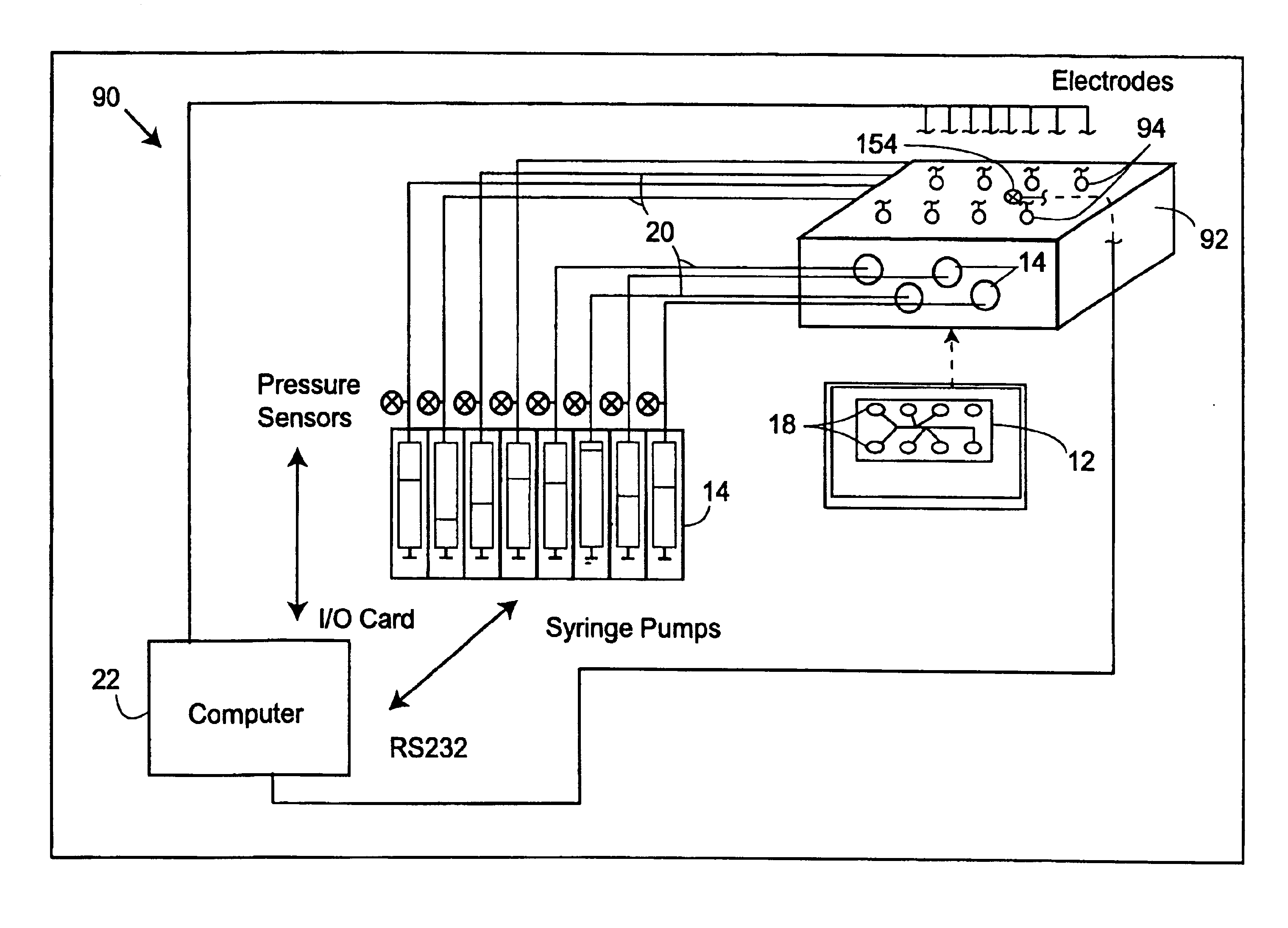

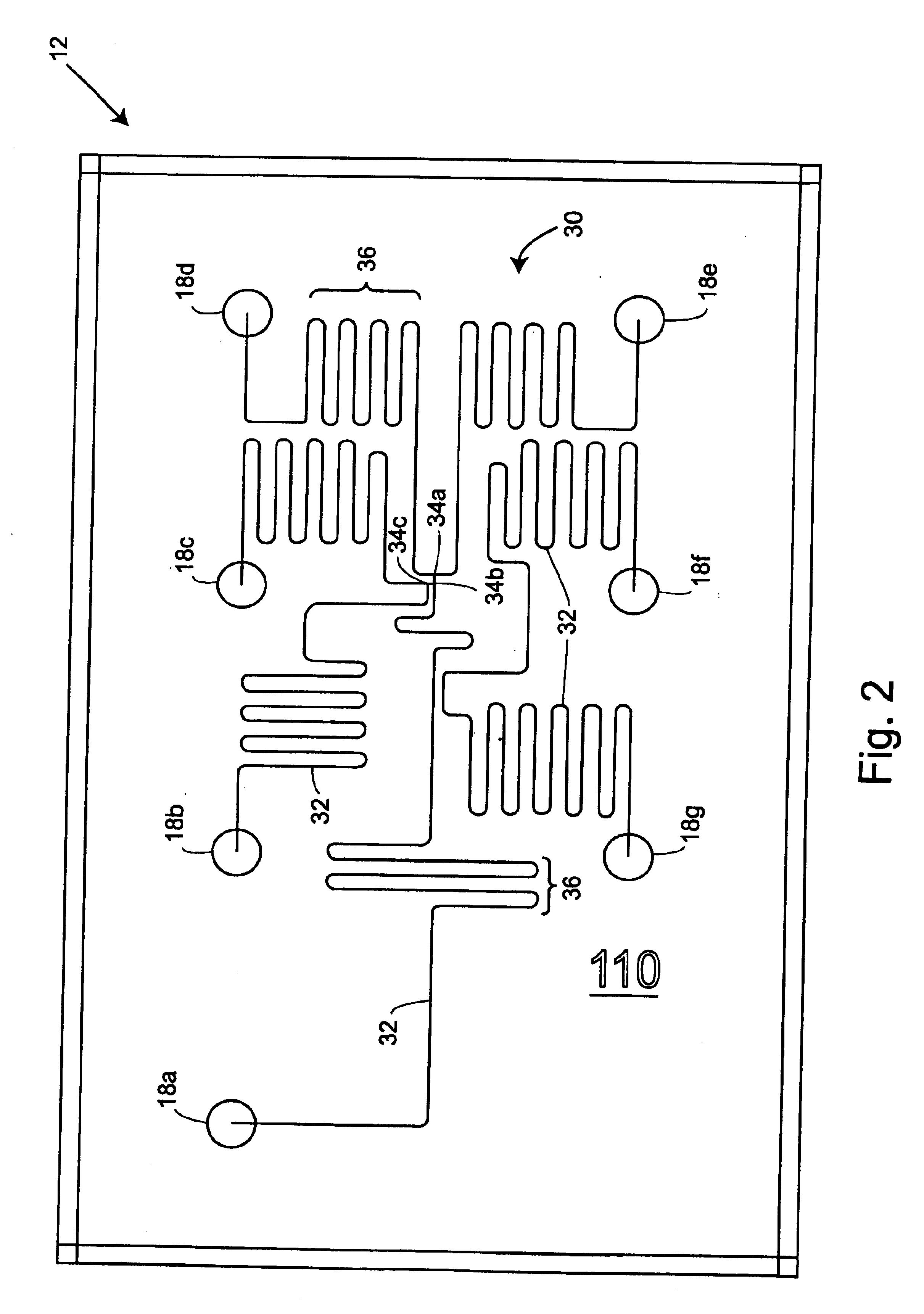

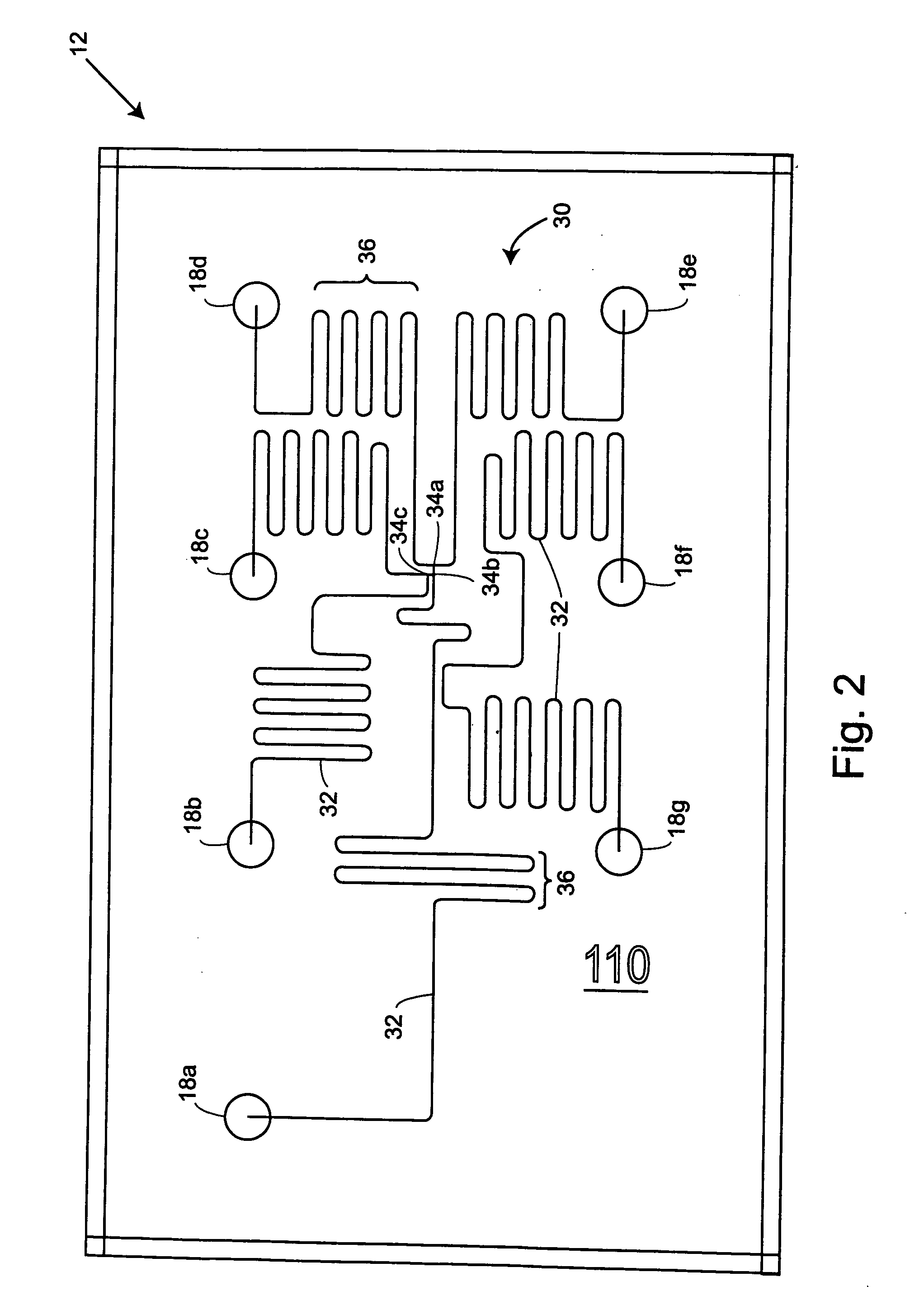

Multi-reservoir pressure control system

InactiveUS6915679B2Sufficient oscillationAccurate and stable and reliable assayAnalysis by electrical excitationLaboratory glasswaresFluid transportFlow resistivity

Improved microfluidic devices, systems, and methods allow selective transportation of fluids within microfluidic channels of a microfluidic network by applying, controlling, and varying pressures at a plurality of reservoirs. Modeling the microfluidic network as a series of nodes connected together by channel segments and determining the flow resistance characteristics of the channel segments may allow calculation of fluid flows through the channel segments resulting from a given pressure configuration at the reservoirs. To effect a desired flow within a particular channel or series of channels, reservoir pressures may be identified using the network model. Viscometers or other flow sensors may measure flow characteristics within the channels, and the measured flow characteristics can be used to calculate pressures to generate a desired flow. Multi-reservoir pressure modulator and pressure controller systems can optionally be used in conjunction with electrokinetic or other fluid transport mechanisms.

Owner:CAPLIPER LIFE SCI INC

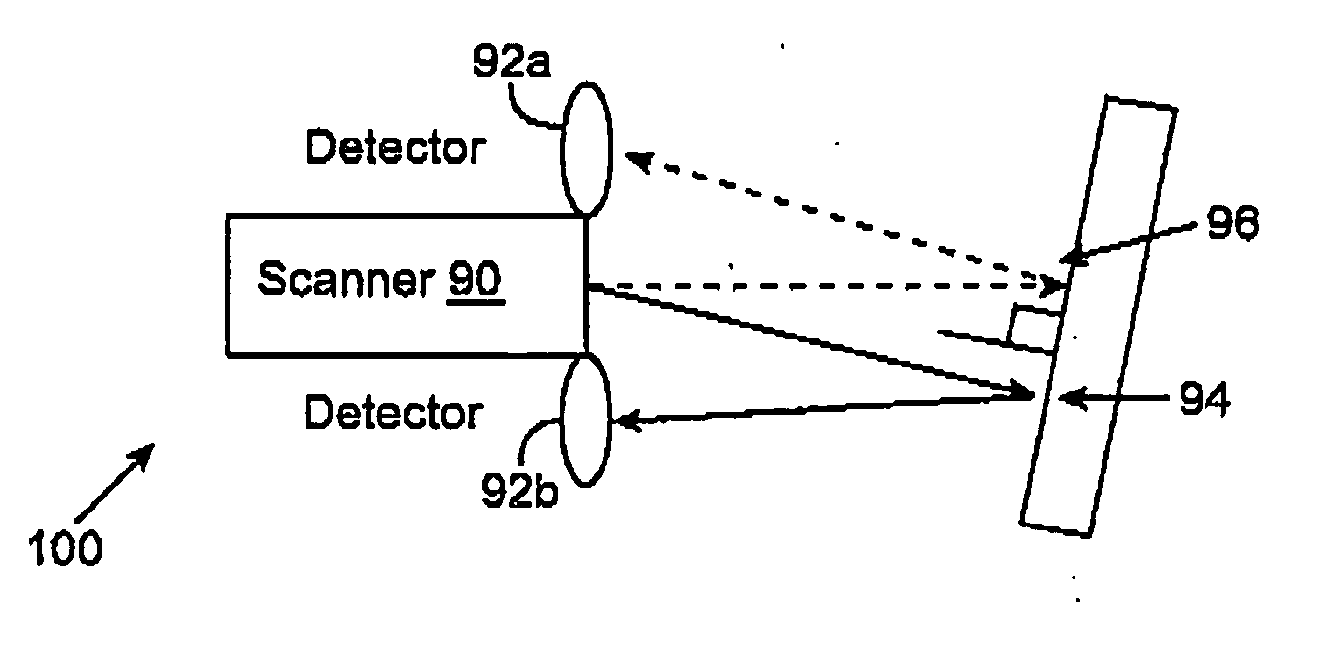

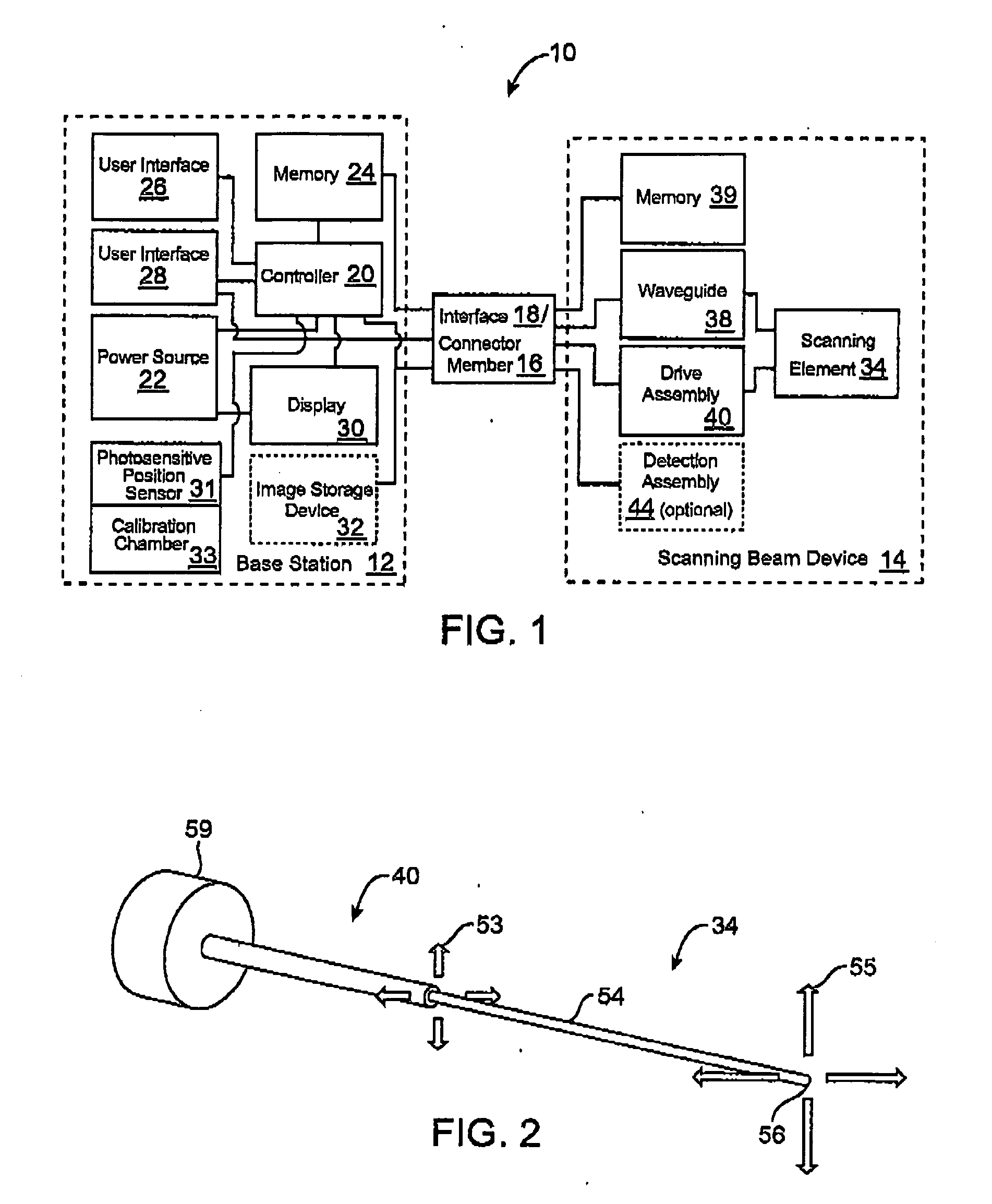

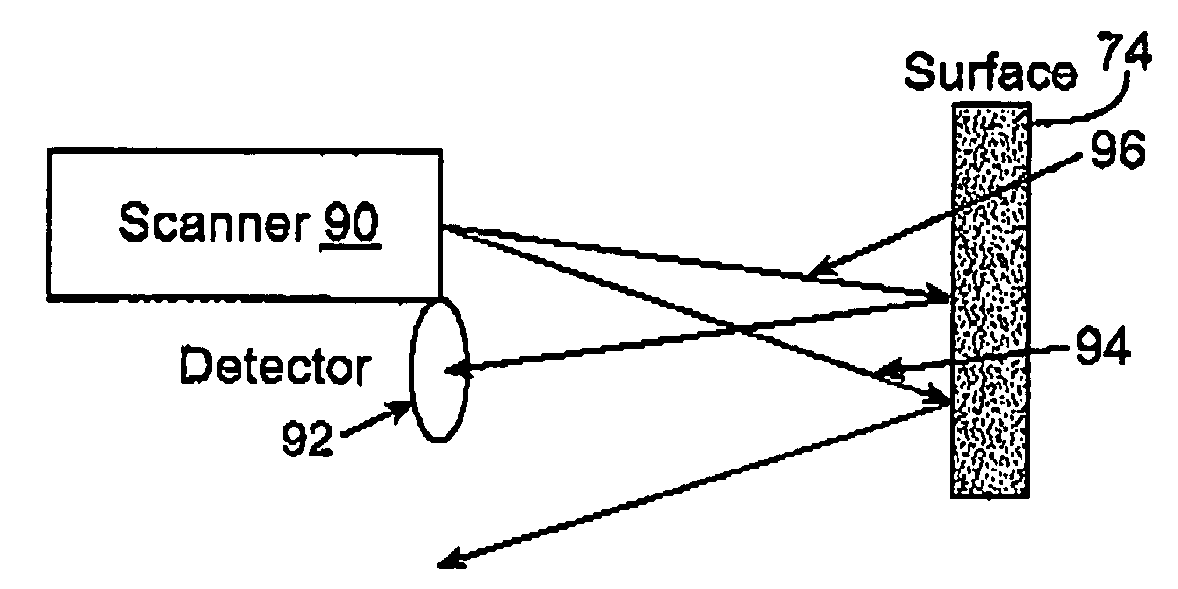

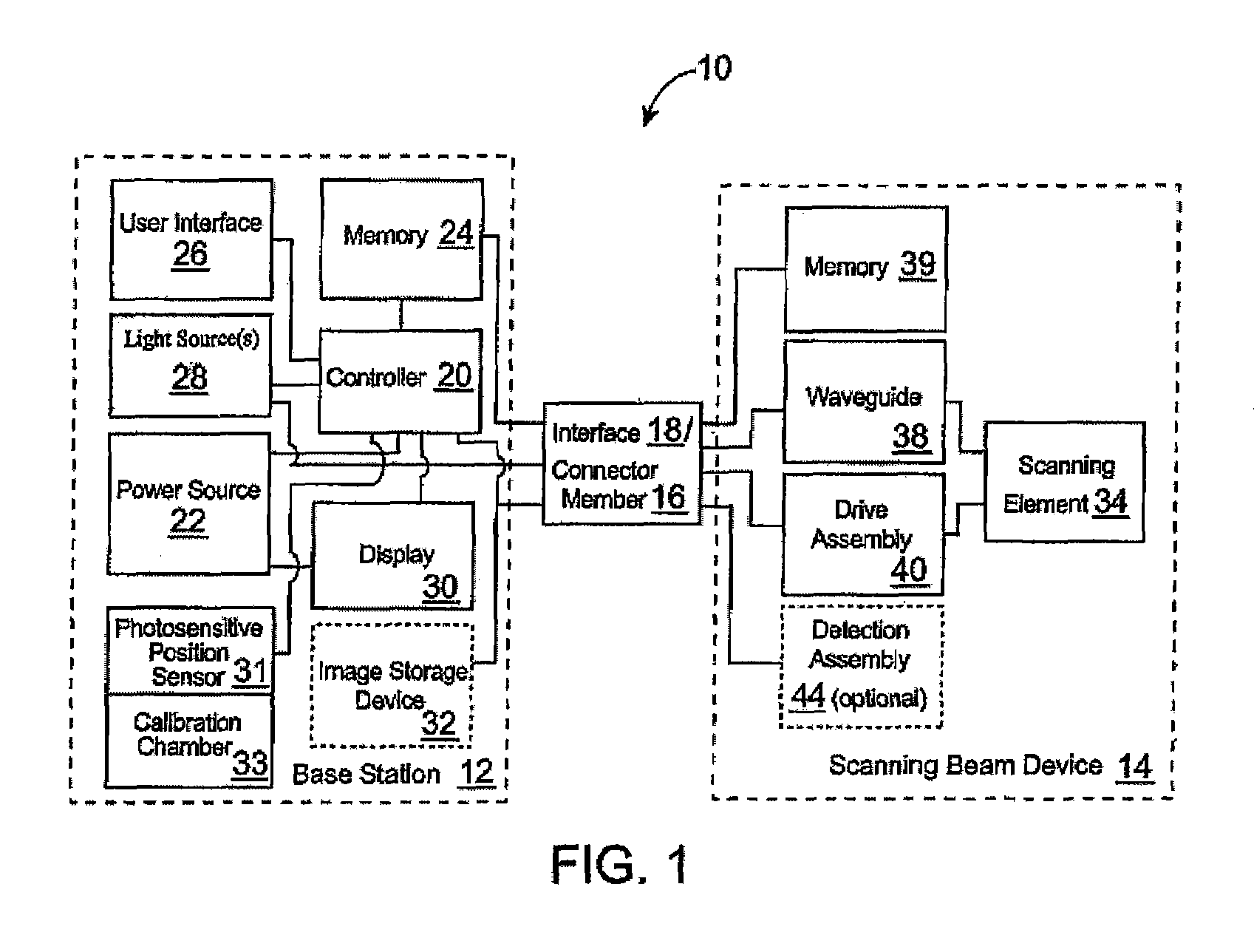

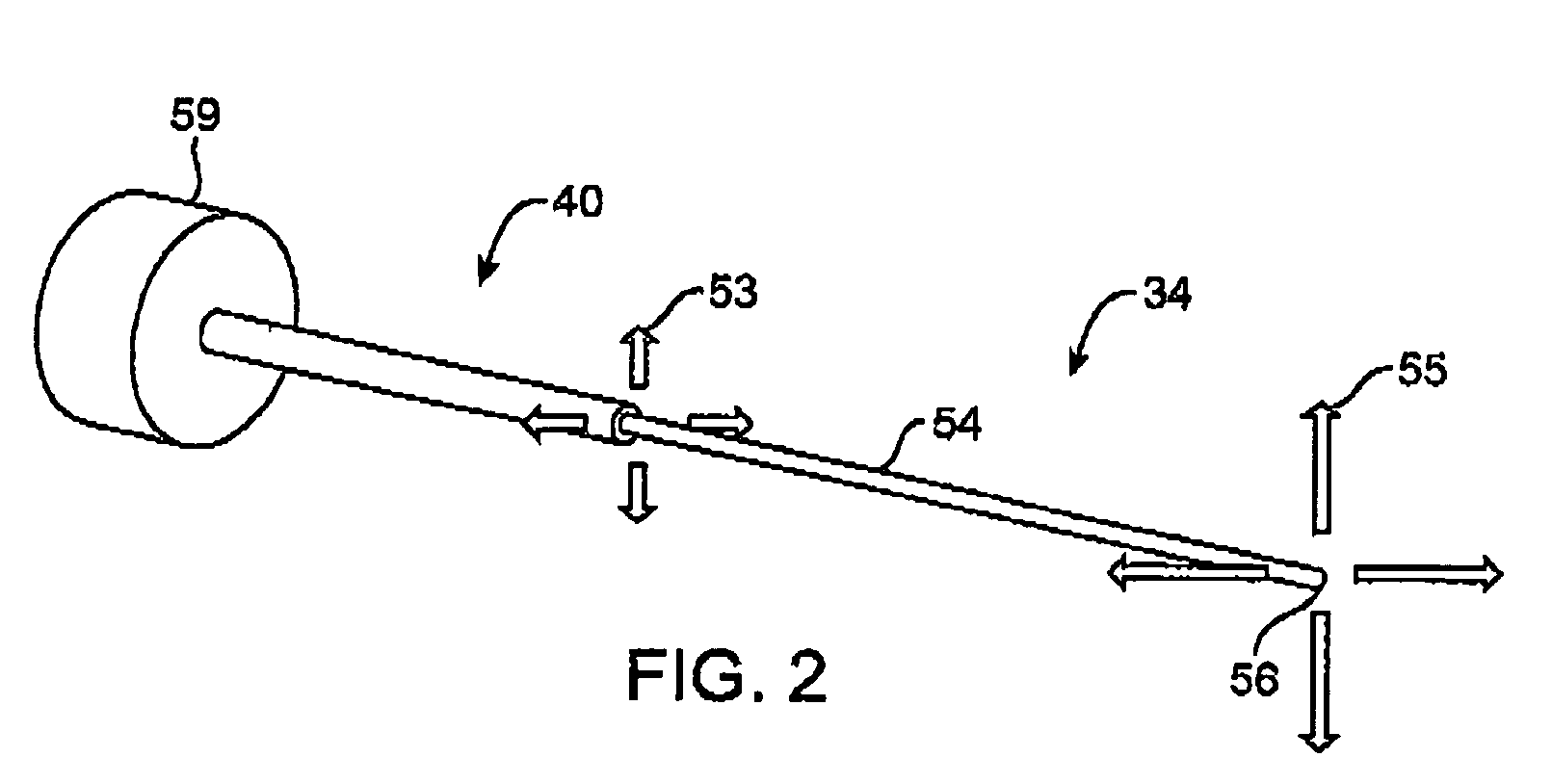

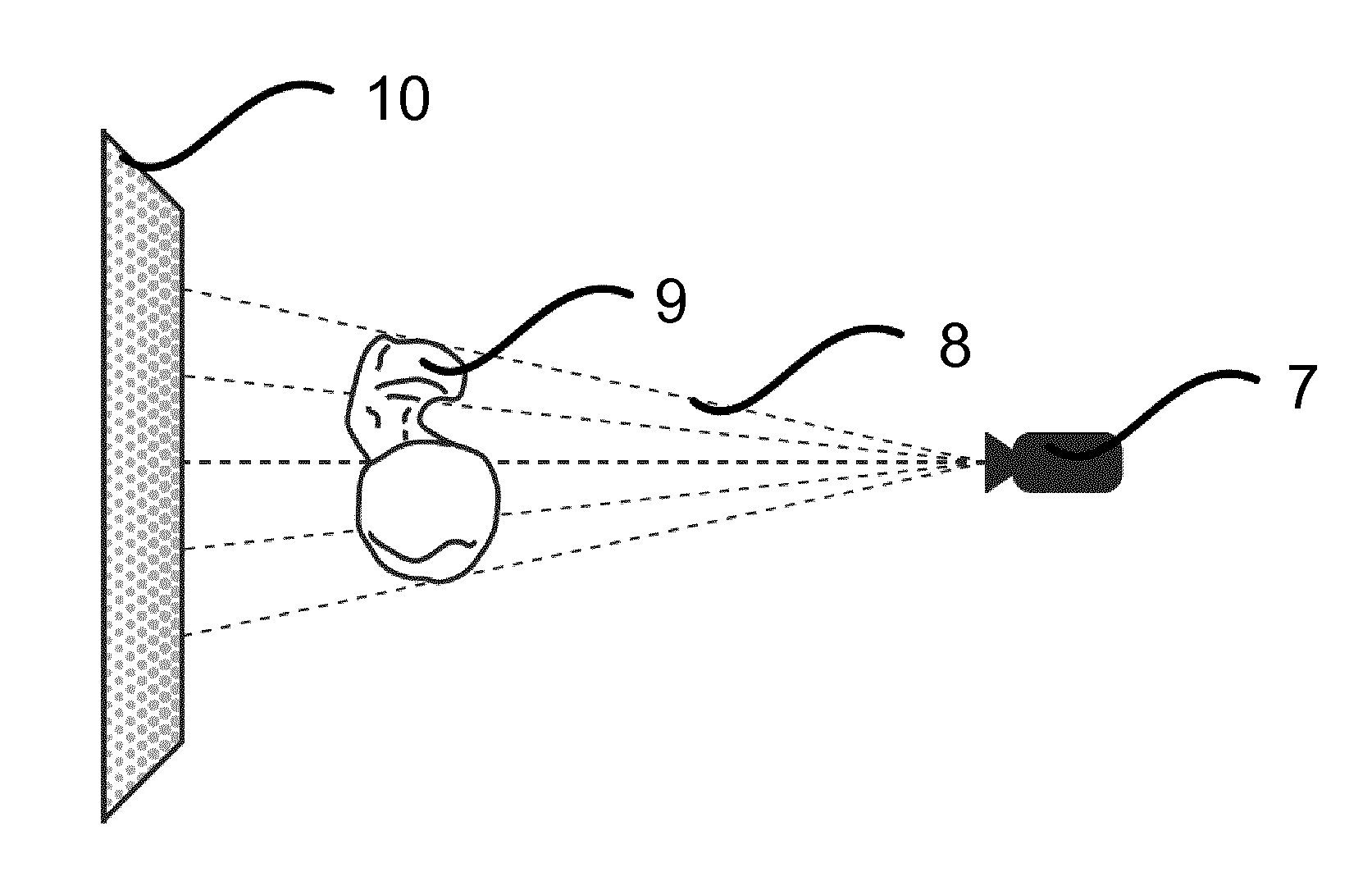

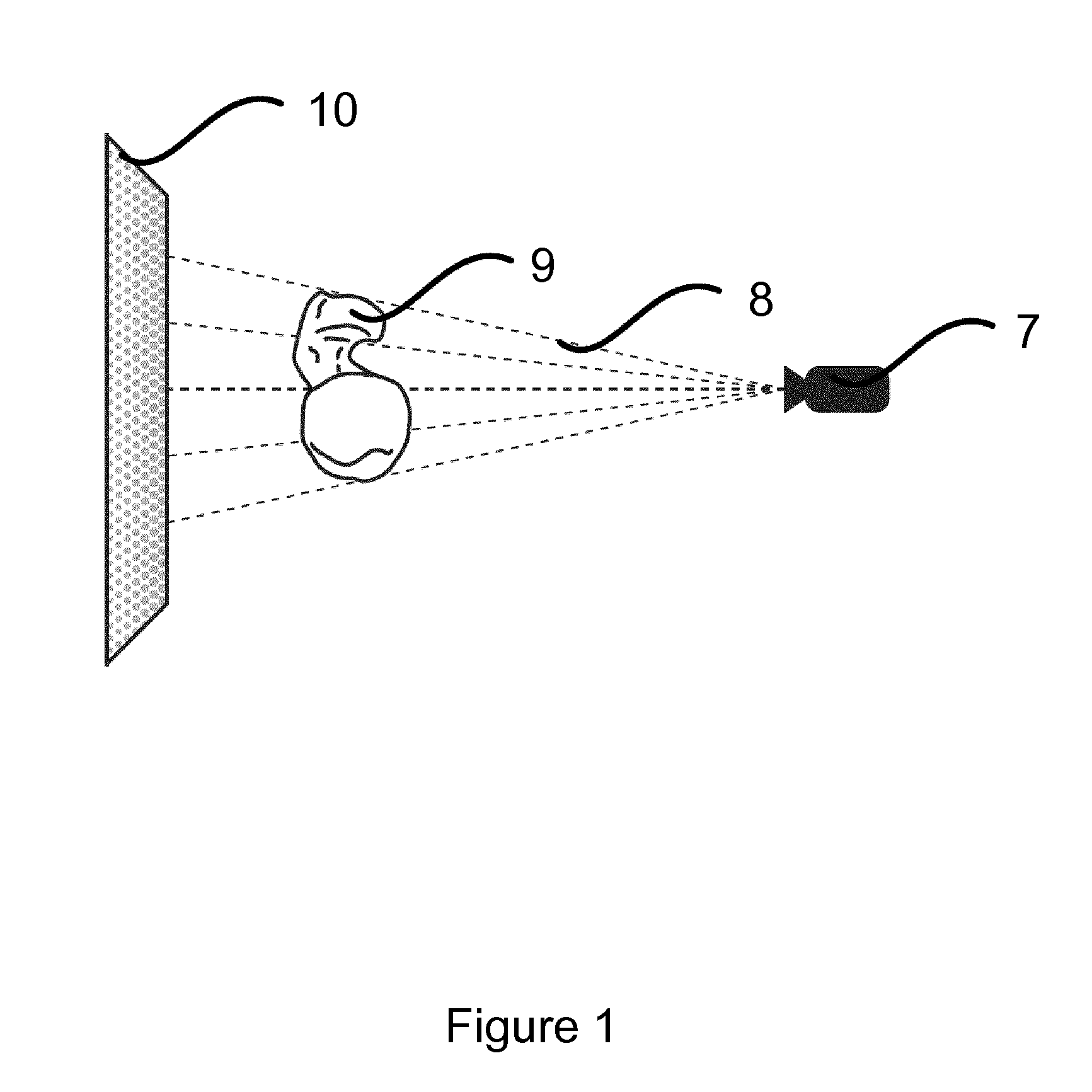

Distance determination in a scanned beam image capture device

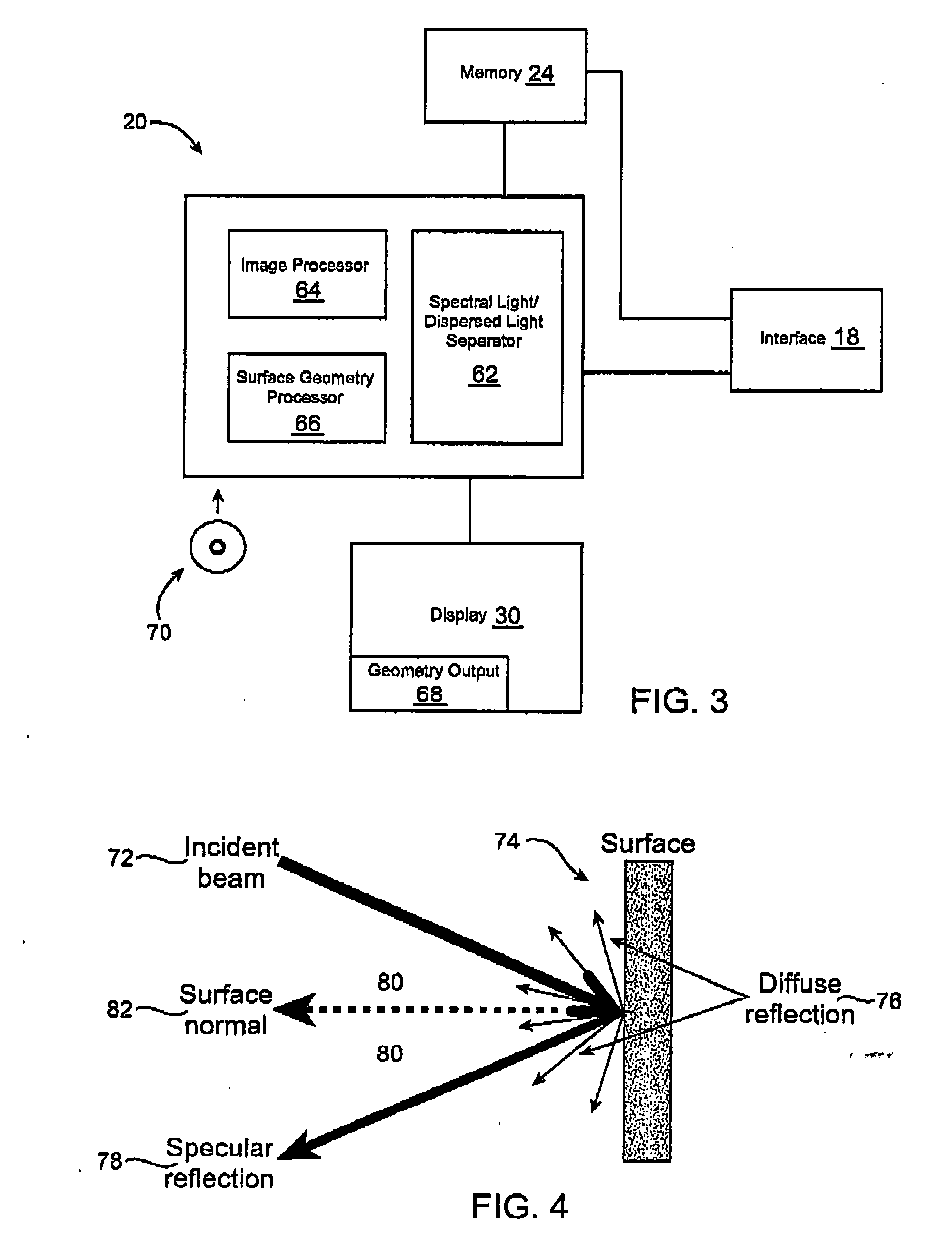

ActiveUS20070081168A1Readily separateEasy to separate and identifyUltrasonic/sonic/infrasonic diagnosticsSurgeryPhysicsSpecular reflection

Methods, systems, and devices can determine spatial relationships between a probe and a target surface. Specular reflections from the target surface vary dramatically with small changes in angle between the scanning beam and the target surface, and as the geometry of the beam scanner and light detector of the probe are often known, and as the angle of the light beam projected from a scanner for accurately generating an image, the pattern of spectral light reflected from the light beam directly back to the detector allows the distance between the probe and the target surface, and / or the angular relationship between the probe and the target surface, to be calculated.

Owner:UNIV OF WASHINGTON

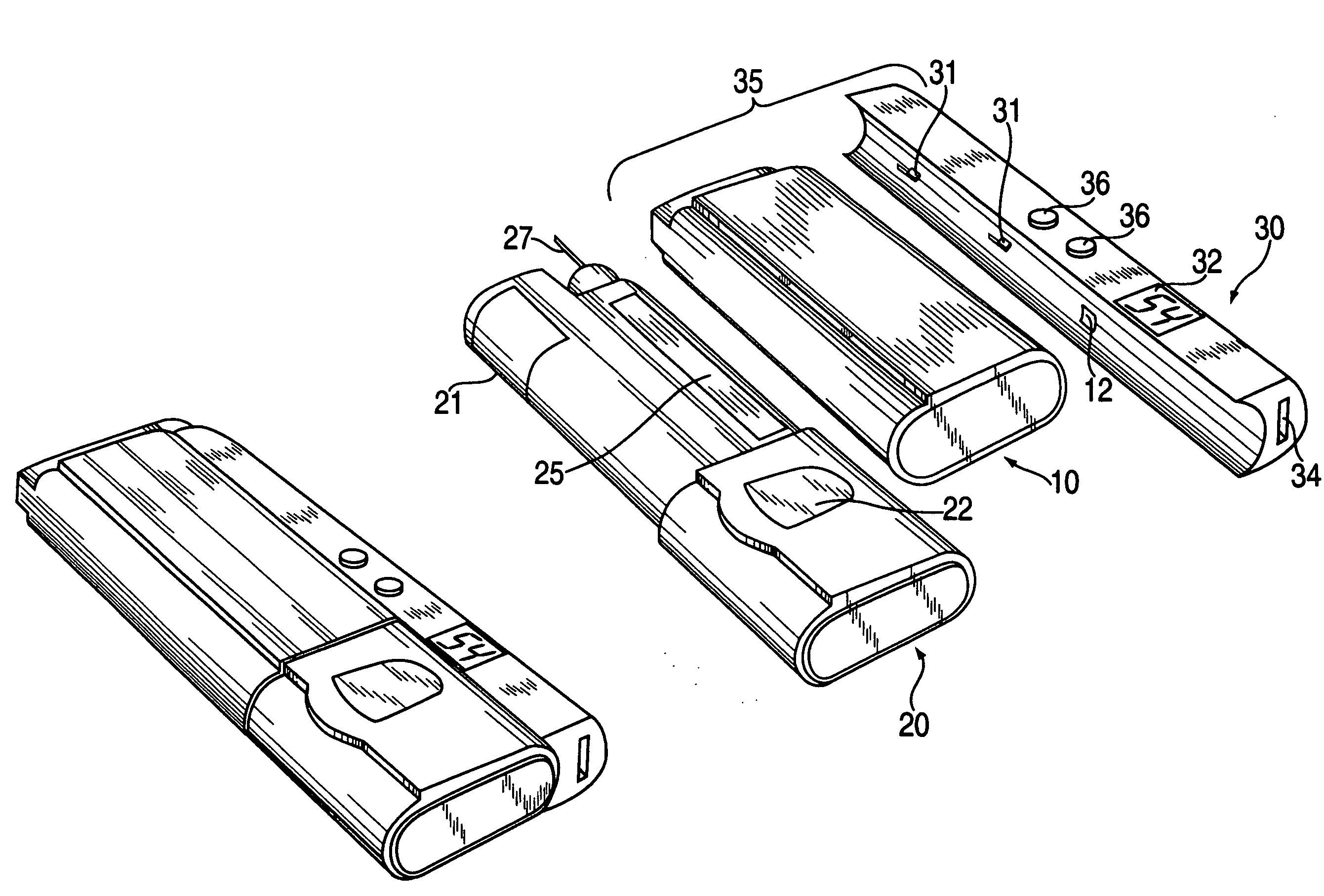

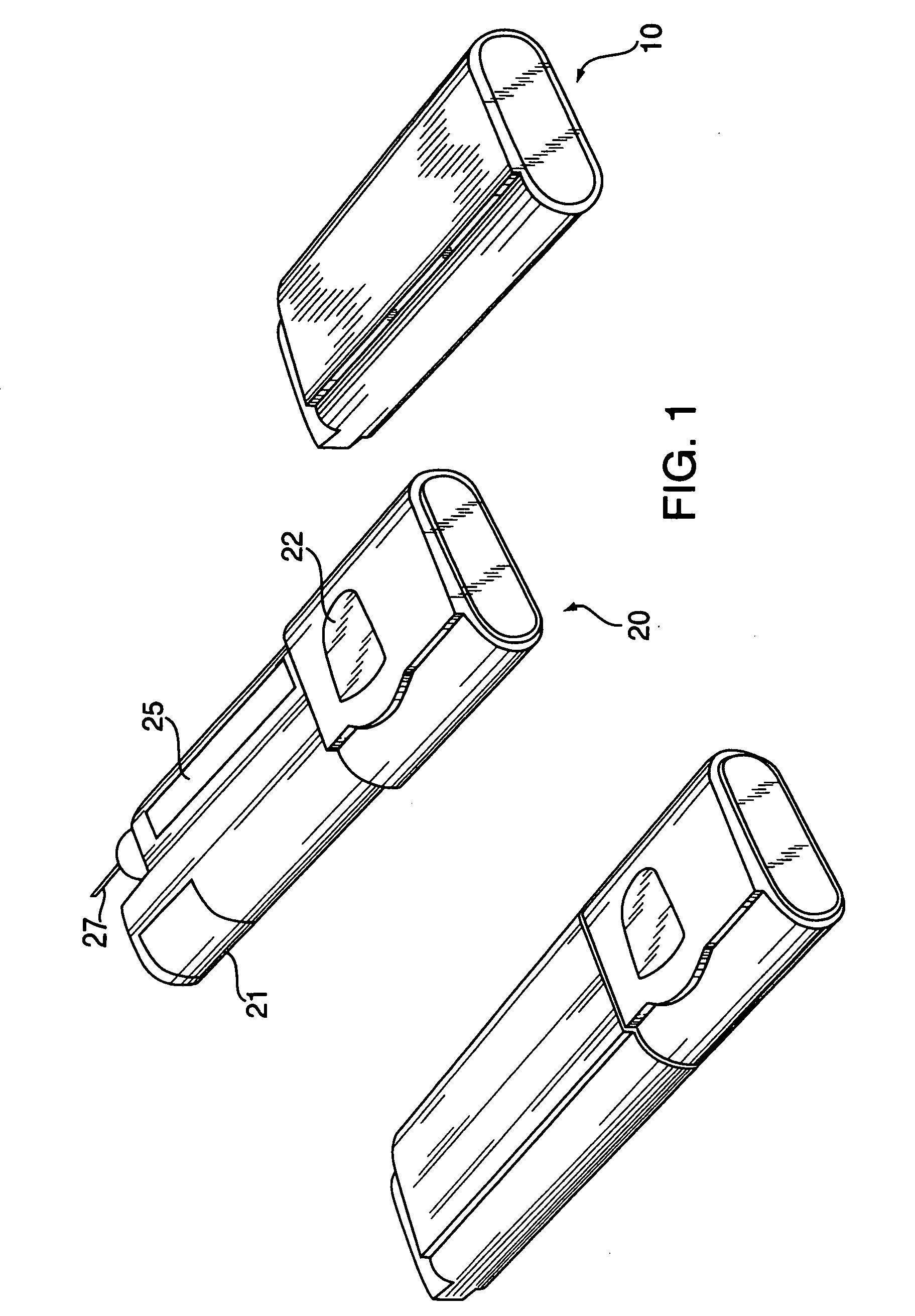

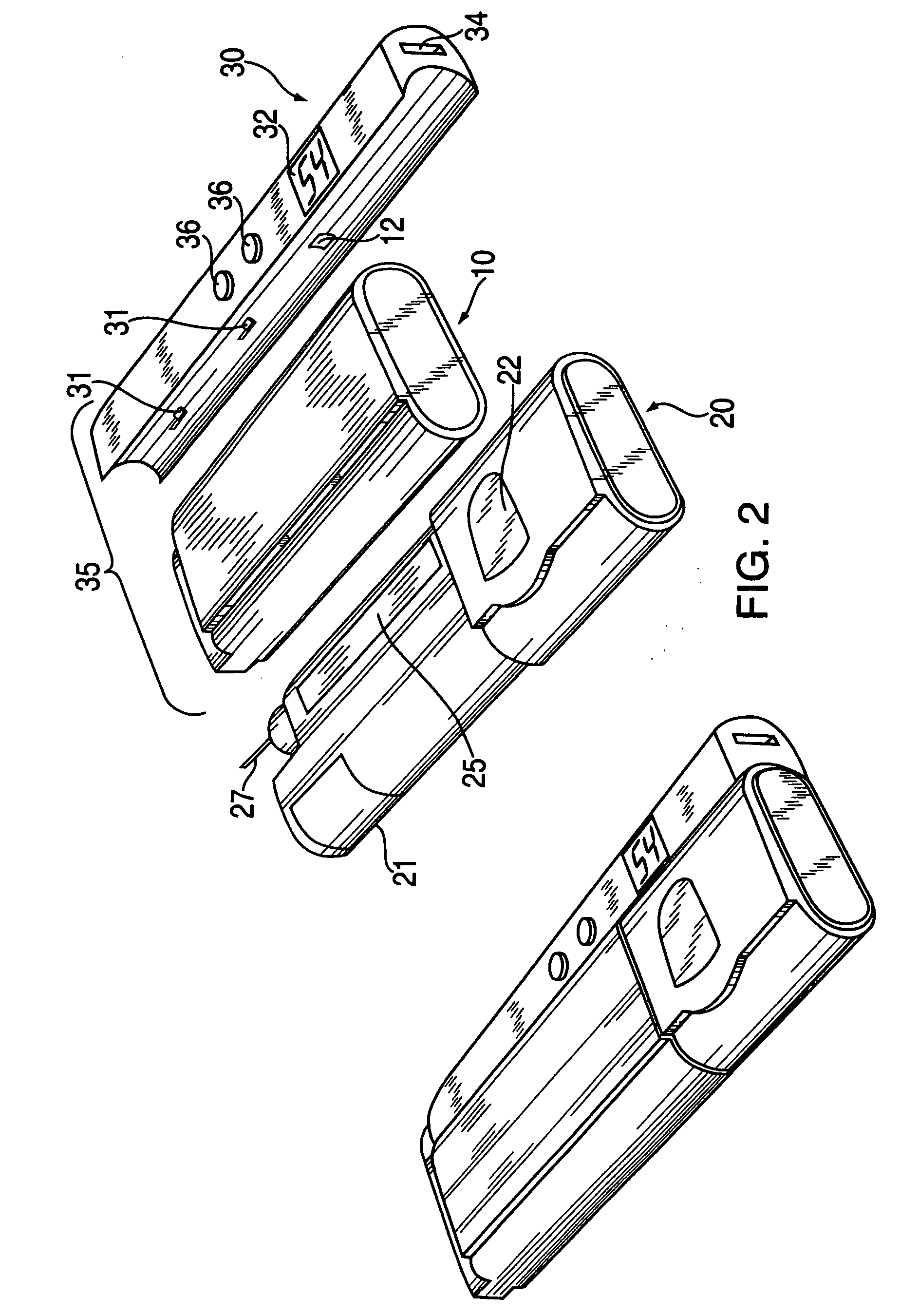

Medical apparatus for use by a patient for medical self treatment of diabetes

InactiveUS20070244412A1Better self-treatmentConfidenceAmpoule syringesAutomatic syringesMedical equipmentSelf-treatment

The invention relates to an apparatus for self-treatment of diabetes. The apparatus is particularly advantageous by comprising a plurality of devices each of which has its own dedicated function corresponding to a number of acts which a diabetic must perform on himself. The individual devices are mutually interconnectible, and the combination comprises at least a body fluid analyser and a dosing apparatus for administering a predetermined dose of insulin to the patient. Each of the devices may be provided in several sizes so that the user himself may combine the relevant devices of the relevant size with respect to the current need. This reduces the risk of forgetting parts of the equipment, and the confidence of using the equipment is enhanced because it is evident to the user that it is a complete apparatus consisting of unified parts.

Owner:LAV STEFFEN +2

Distance determination in a scanned beam image capture device

ActiveUS7312879B2Easy to separate and identifyWeakening rangeUltrasonic/sonic/infrasonic diagnosticsSurgeryTarget surfaceLight beam

Owner:UNIV OF WASHINGTON

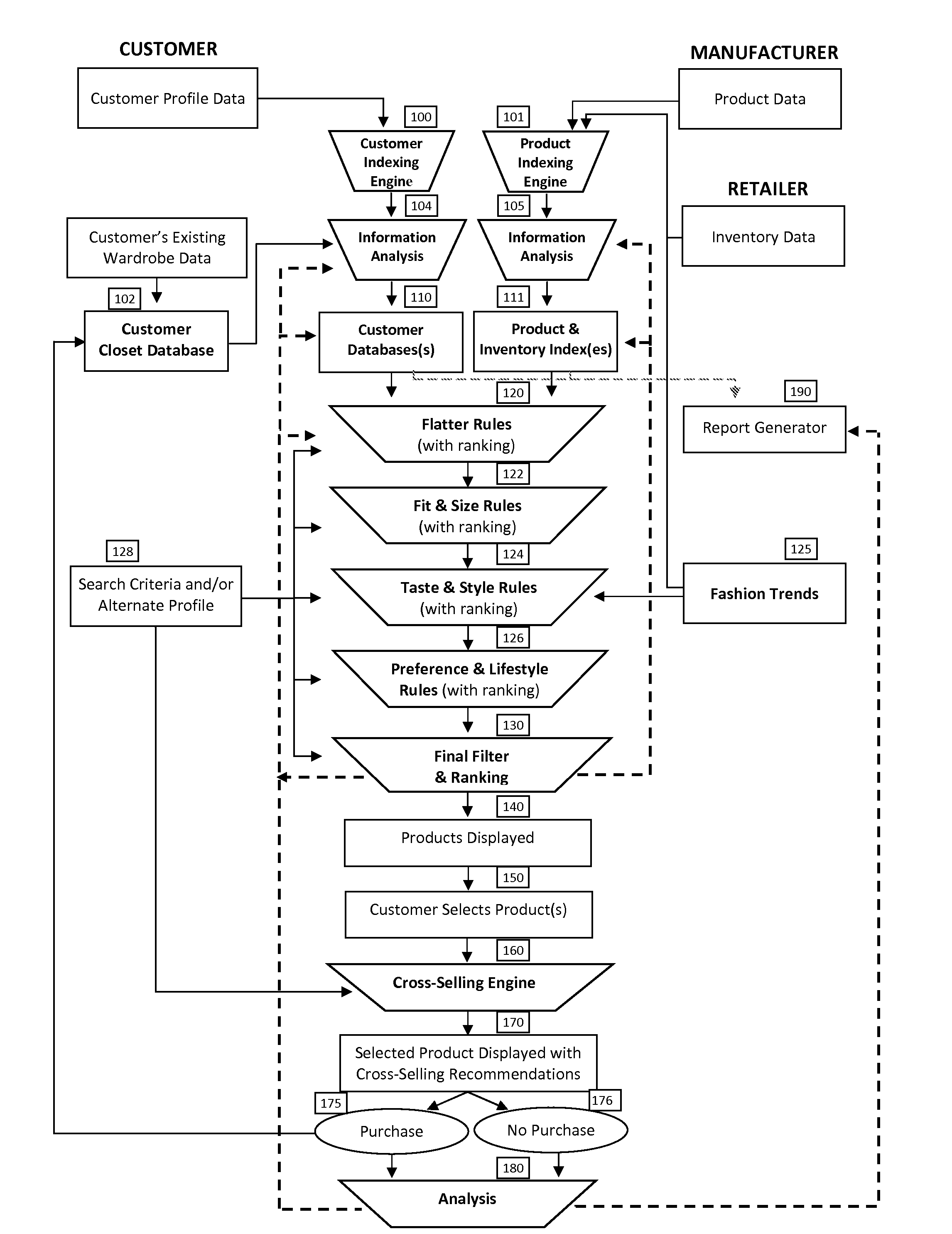

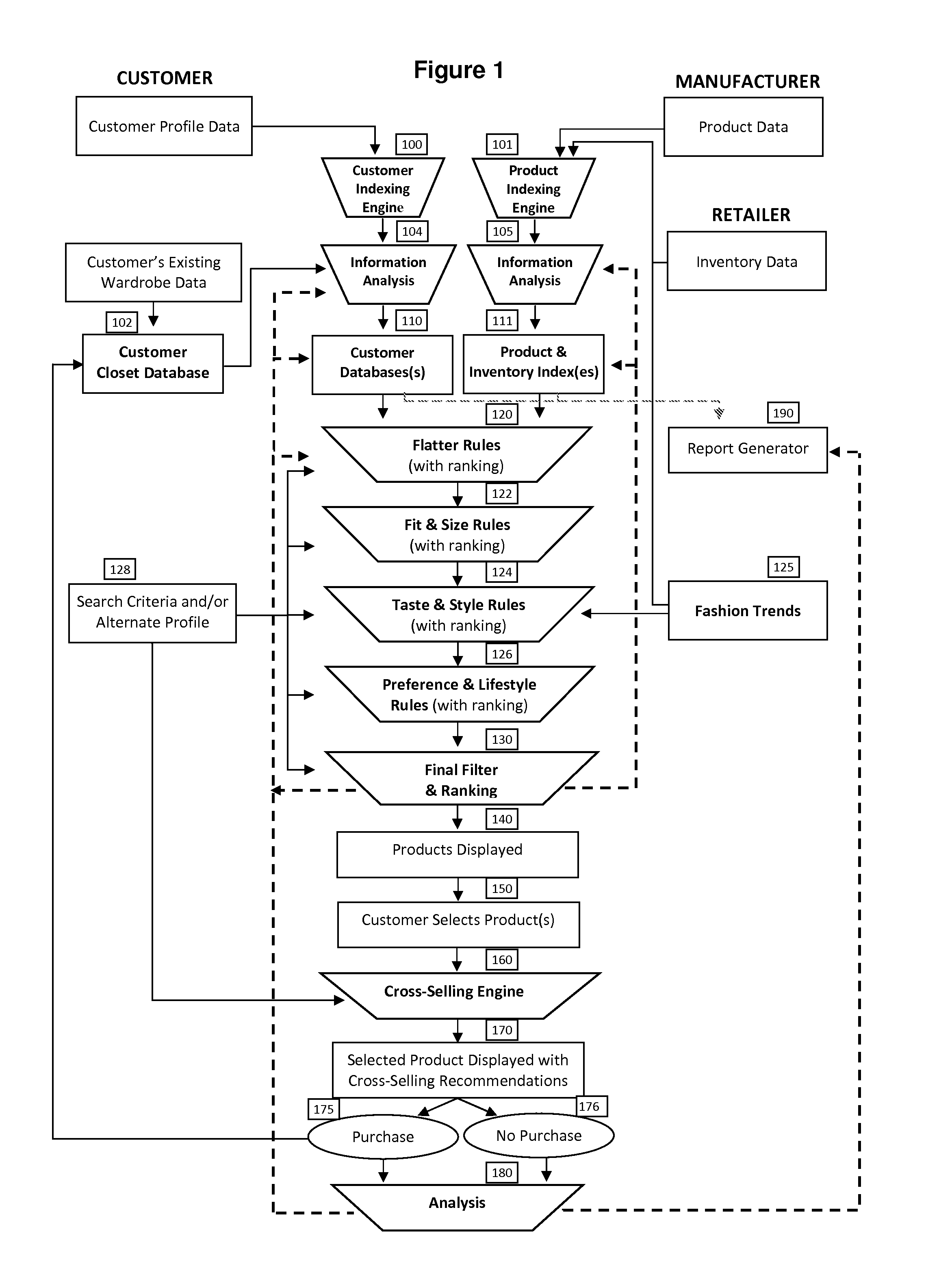

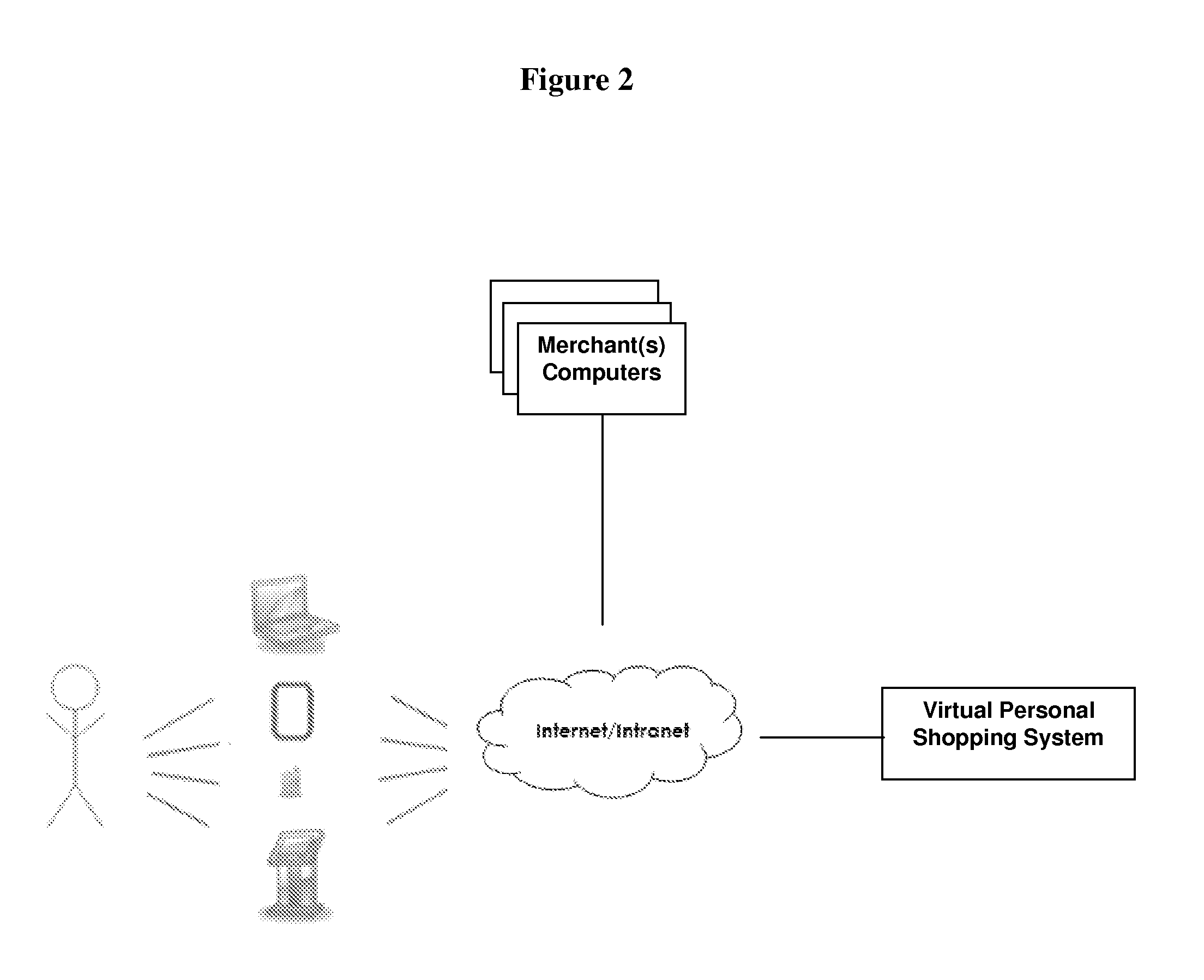

Virtual Personal Shopping System

InactiveUS20140344102A1Significantly increases sales, profit margins and customer loyaltyChoose accuratelyBuying/selling/leasing transactionsComputer scienceAutomated method

The invention relates to selecting products and / or services that meet a customer's needs. In particular, the invention relates to an automated method and system for recommending relevant products and / or services utilizing expert knowledge.

Owner:COOPER CHAYA

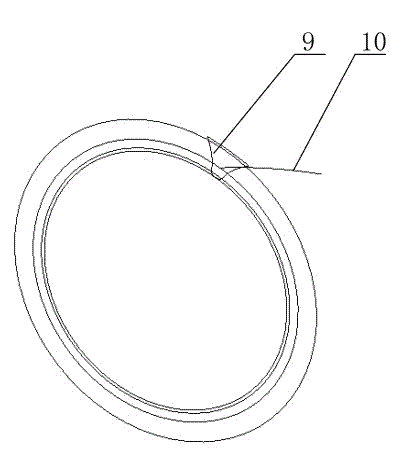

High precision modeling method of involute helical gear

ActiveCN102289534ACombine accuratelyAvoid errorsSpecial data processing applicationsInvoluteEngineering

A method for modeling an involute helical gear accurately comprises the following steps: first step: setting related parameters; second step: establishing an involute and a transition curve by a curve equation, setting a toothspace center line and drawing a dimensional tooth profile; third step: inputting a spiral line equation and establishing a spiral line; fourth step: generating a toothspace by mixed scanning and an array, and cutting a gear blank by Boolean operation to form a gear model; and fifth step: applying a gear model to practical gear machining or simulation analysis. According to the method, a formula suitable for three-dimensional software is deduced based on the basic principle of the involute helical gear and the engagement of a rack and a gear, the original fussy programming computation is saved; besides, the formation of the entity can be highly fitted to provide technical support for the subsequent manufacture and analysis of the helical gear; and the method is not only suitable for a standard profile gear but also a non-standard gear profile, and has remarkable scientific research value and economic efficiency.

Owner:WUXI YONGKAIDA GEAR

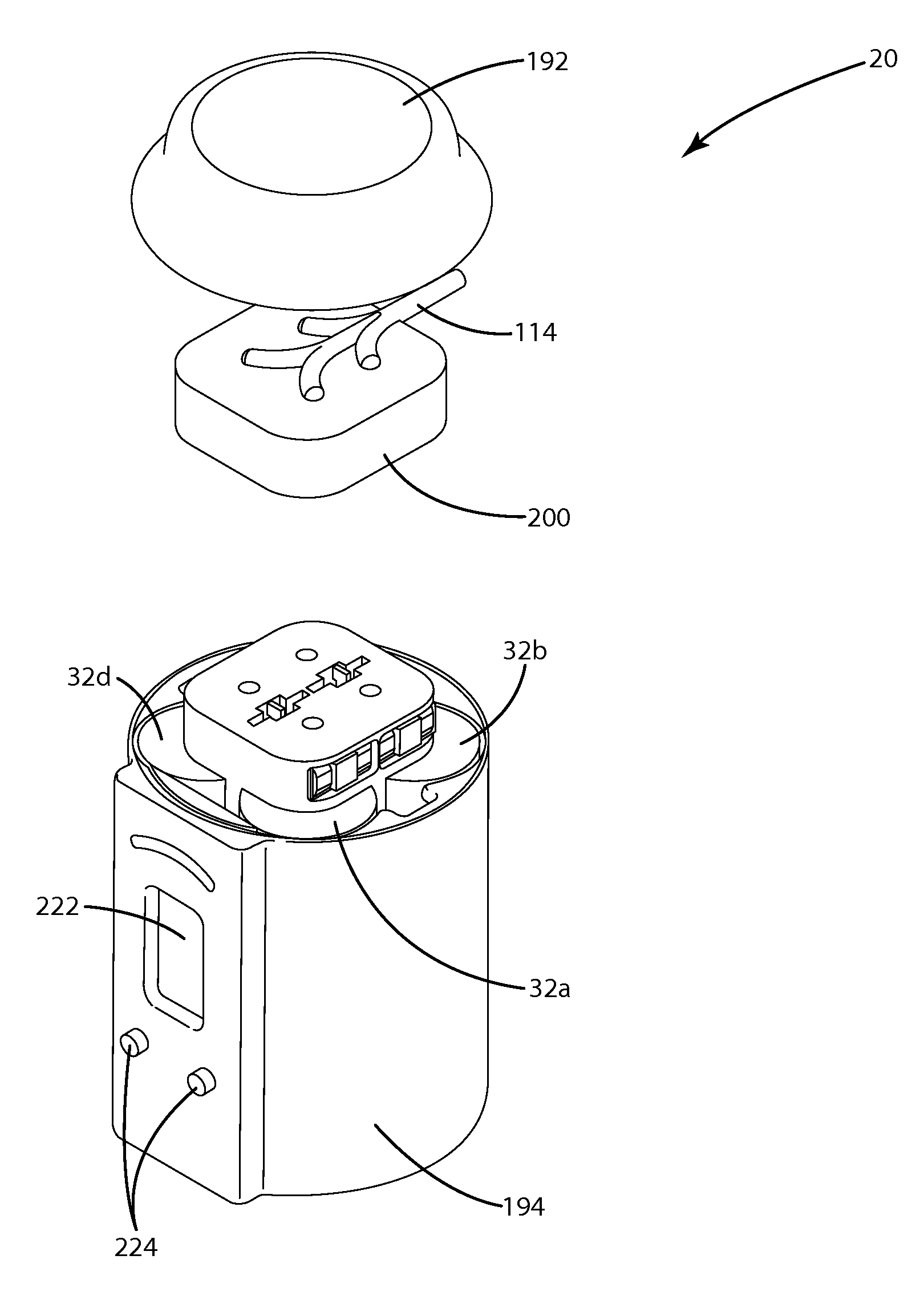

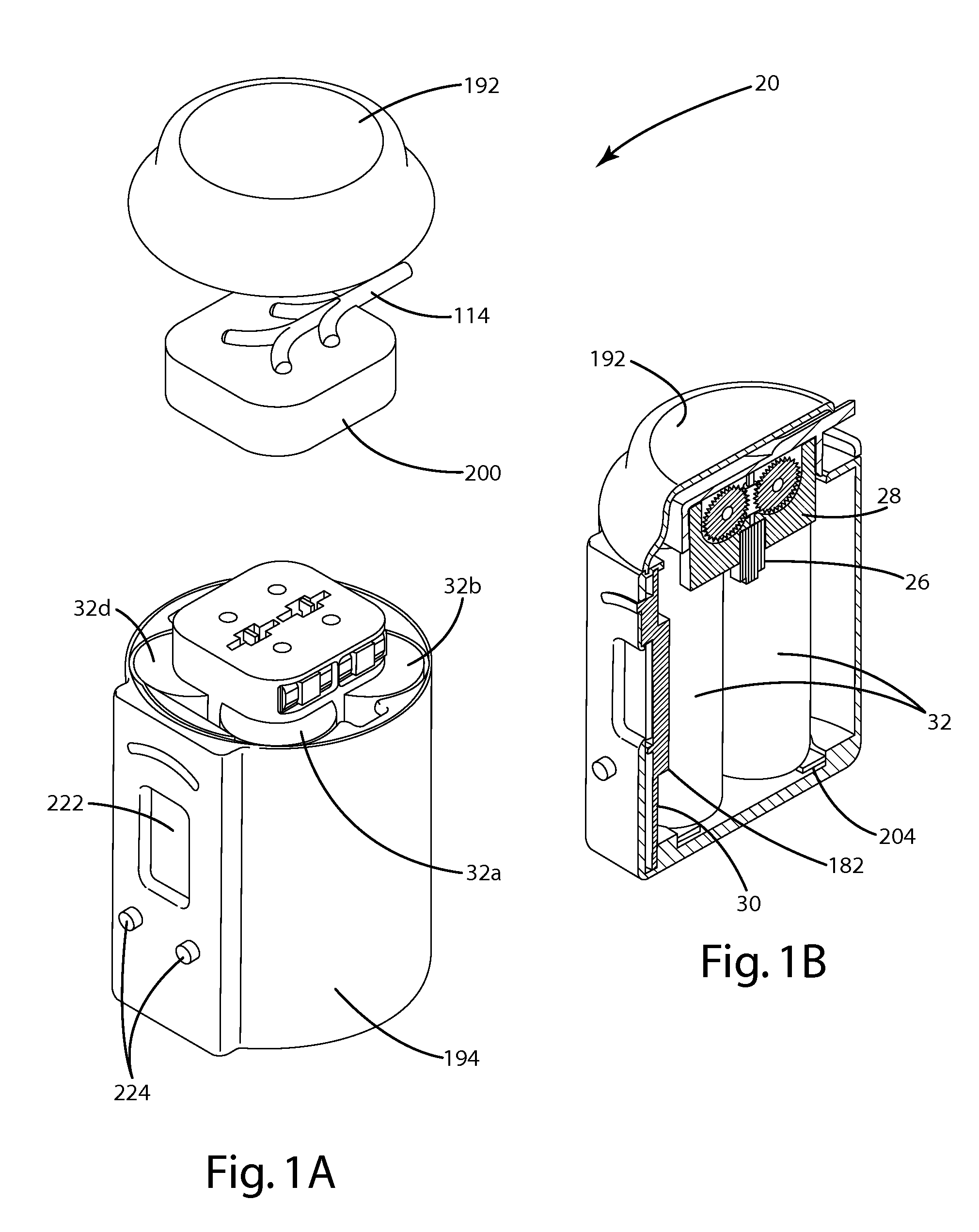

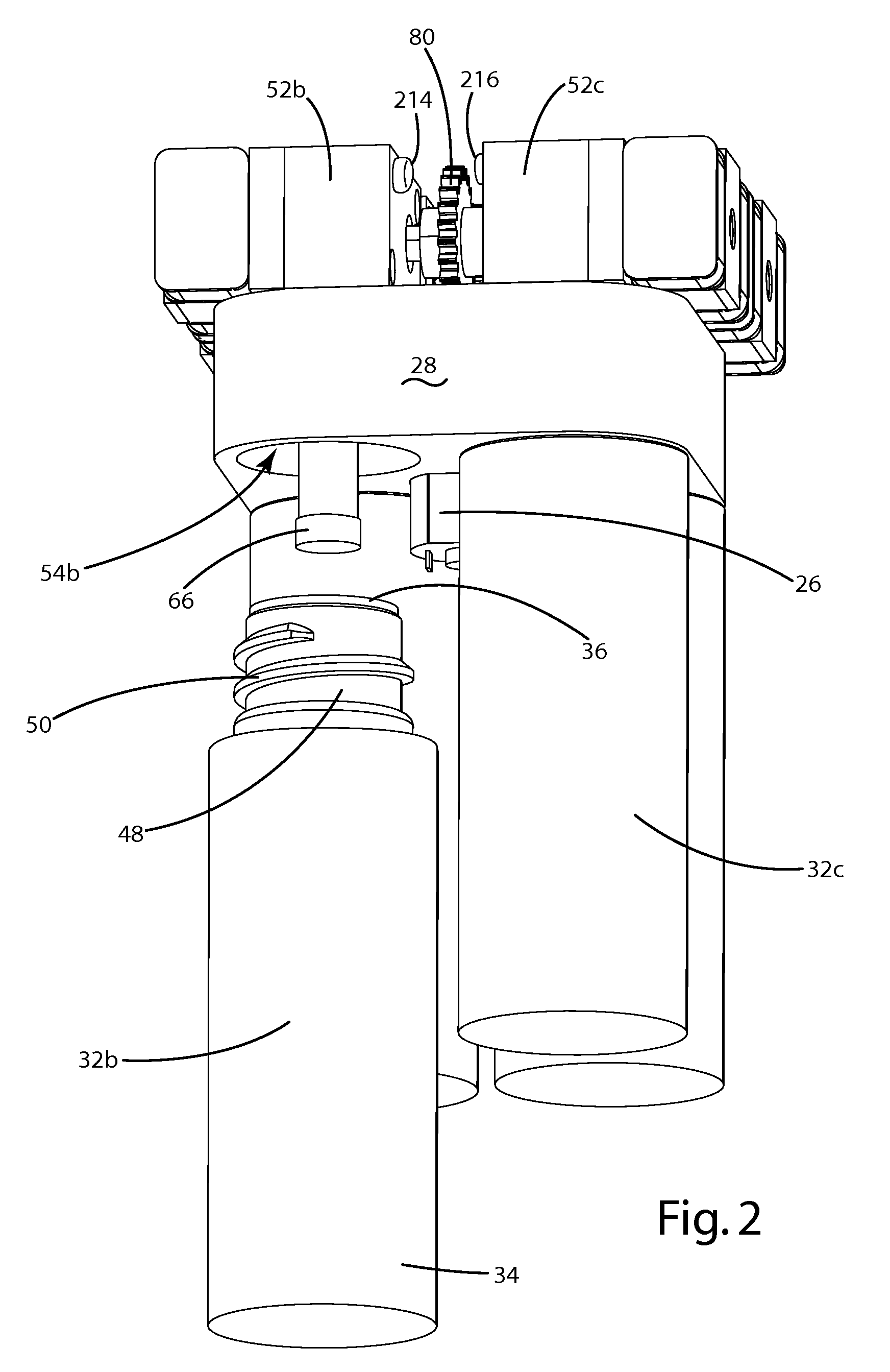

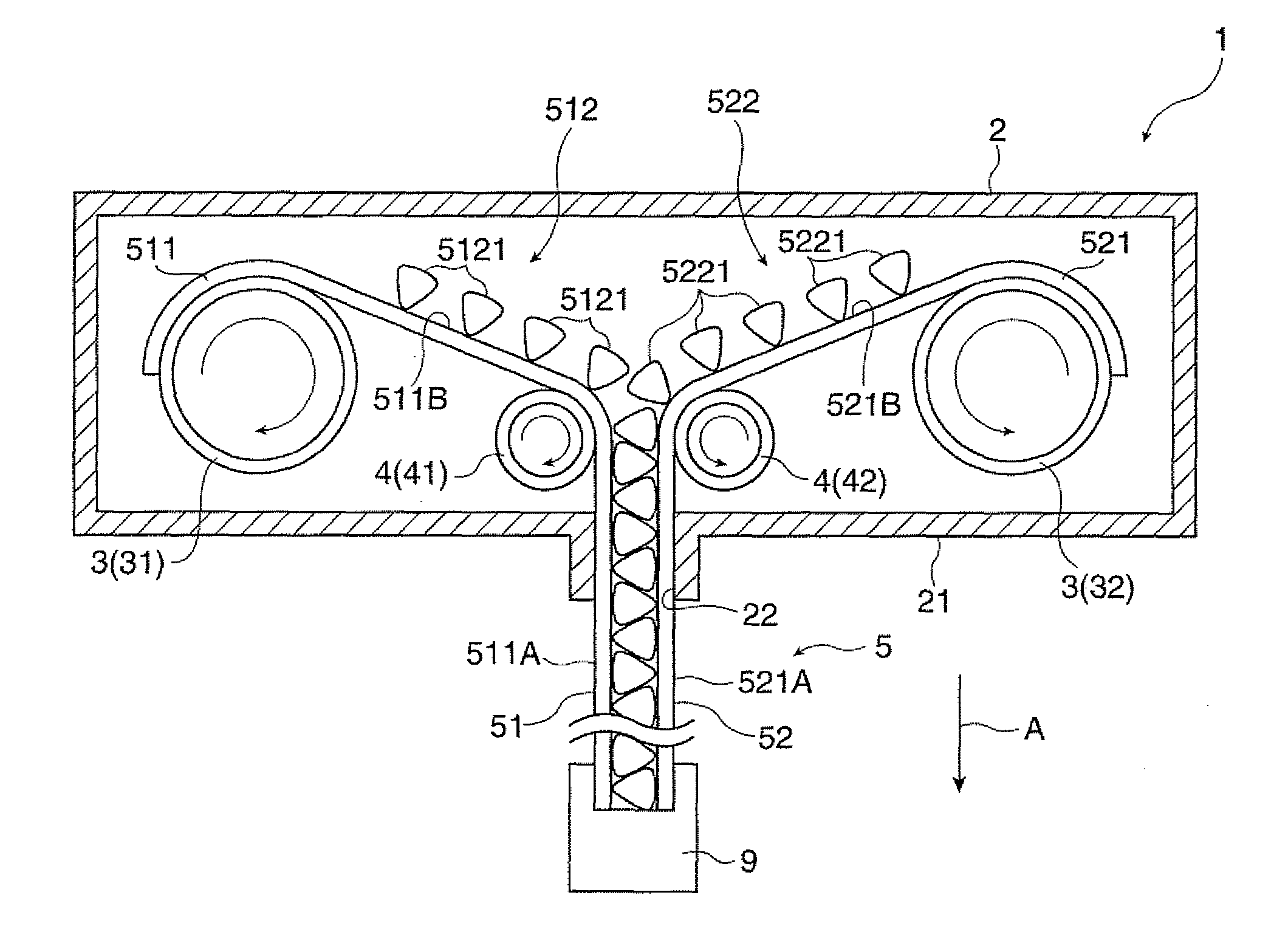

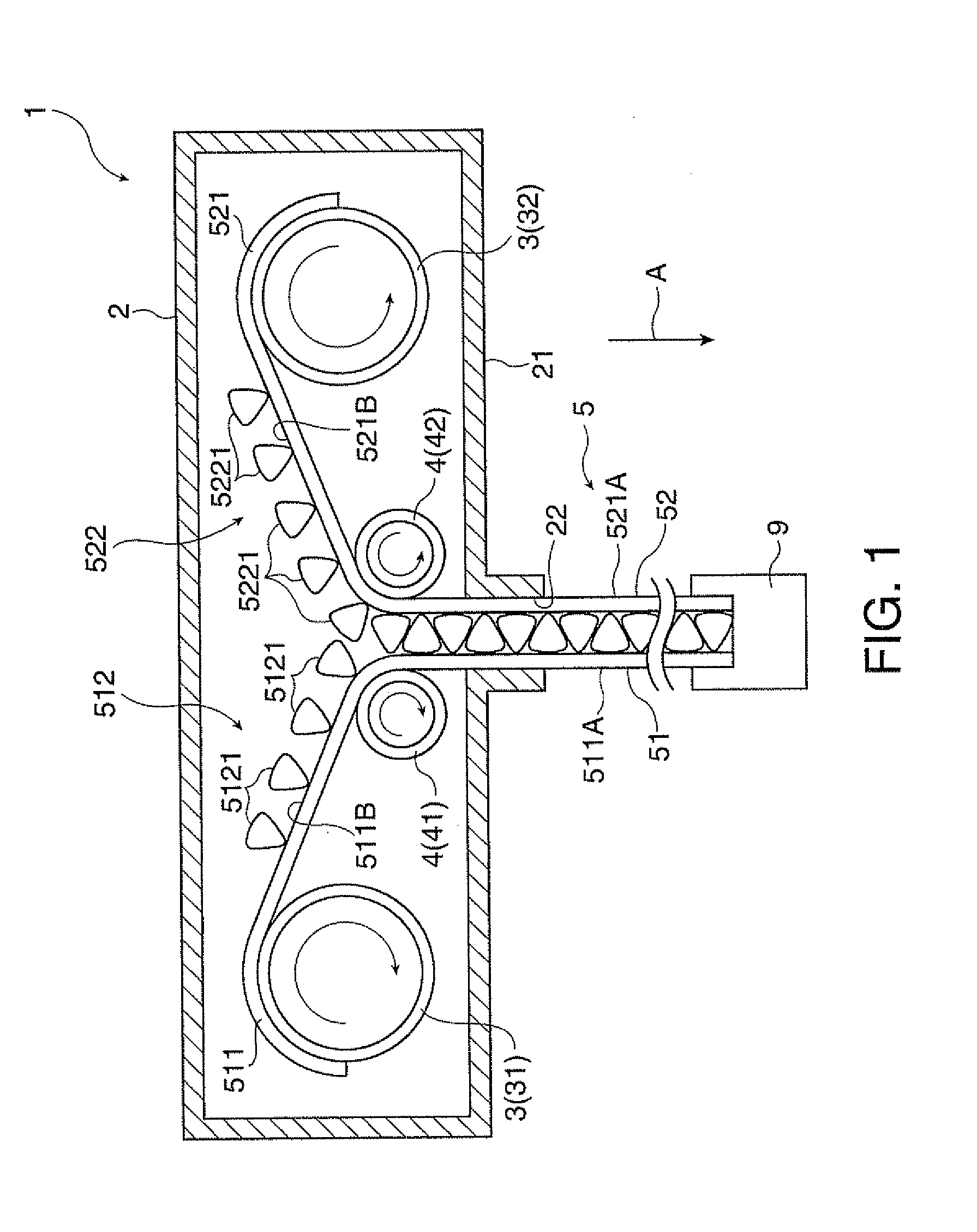

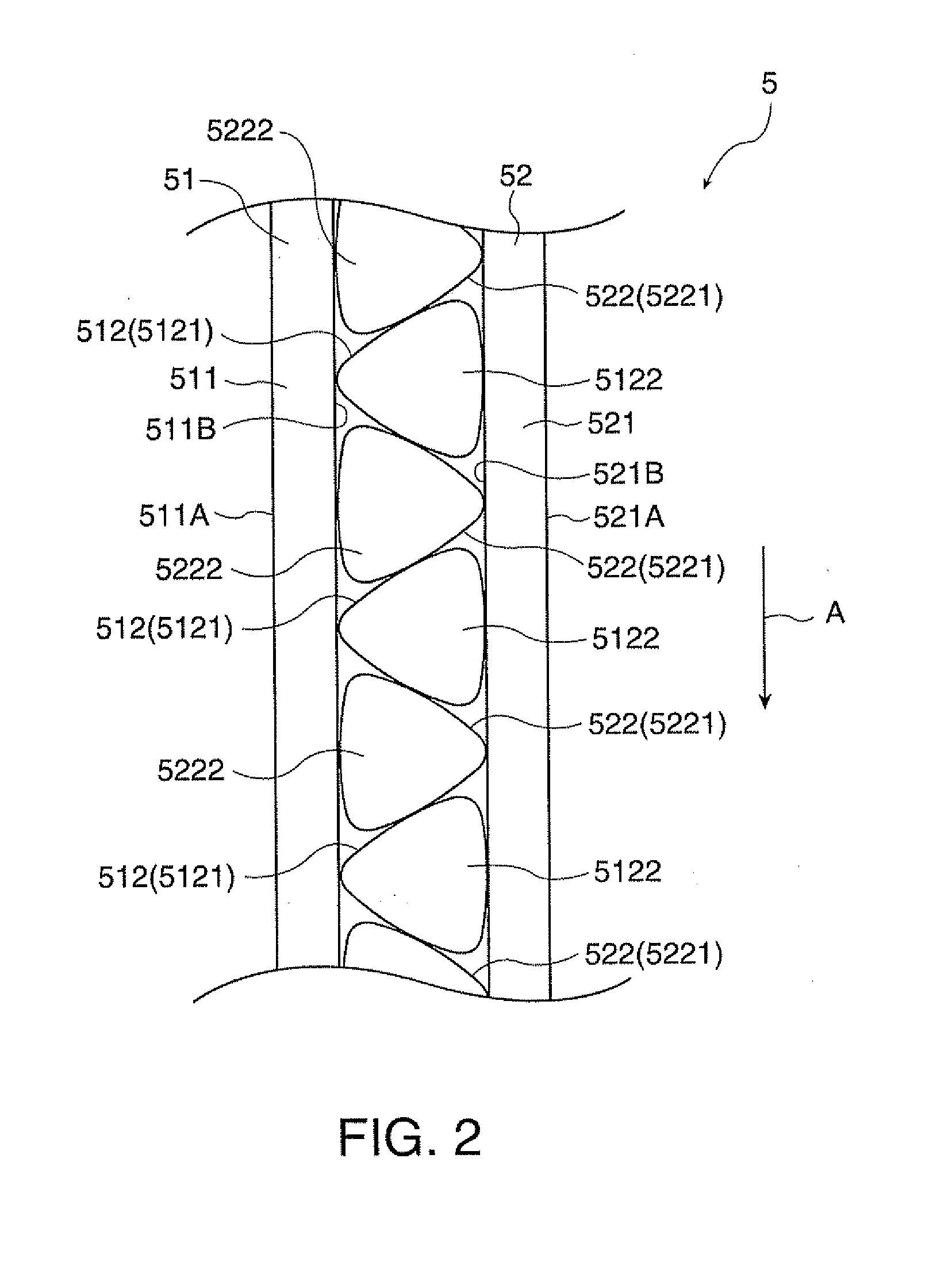

Method and apparatus for dispensing fluid compositions

ActiveUS8224481B2Combine accuratelySmall sizePump componentsRotary piston pumpsRegimenControl system

A miniaturized fluid dispensing system for dispensing customized fluids. The dispenser may include first and second reservoirs containing constituent fluids; a drive motor; at least two pump assemblies commonly driven by the drive motor and in communication with the first and second reservoirs; first and second valve assembly in communication with the first and second pump assemblies; and a control system for selectively controlling the valve assemblies to blend and discharge a composition from the constituent fluids. The system may include a dispensing header to house the valves and to define ‘discharge’ and ‘recirculation’ flow paths for each constituent fluid. The present invention also provides a method for dispensing a fluid regimen (e.g. a plurality of compositions) by periodically blending and discharging varying compositions over time.

Owner:ACCESS BUSINESS GRP INT LLC

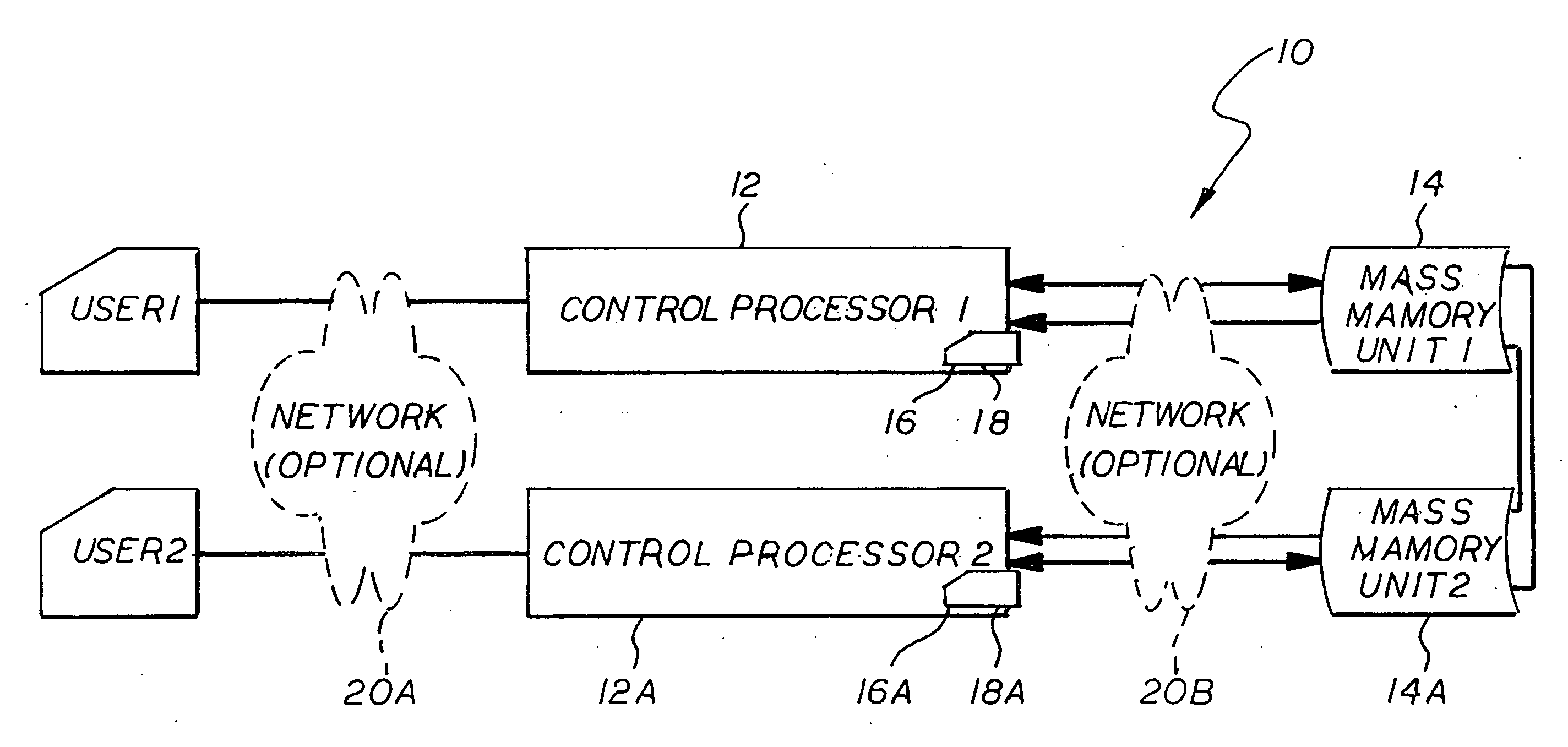

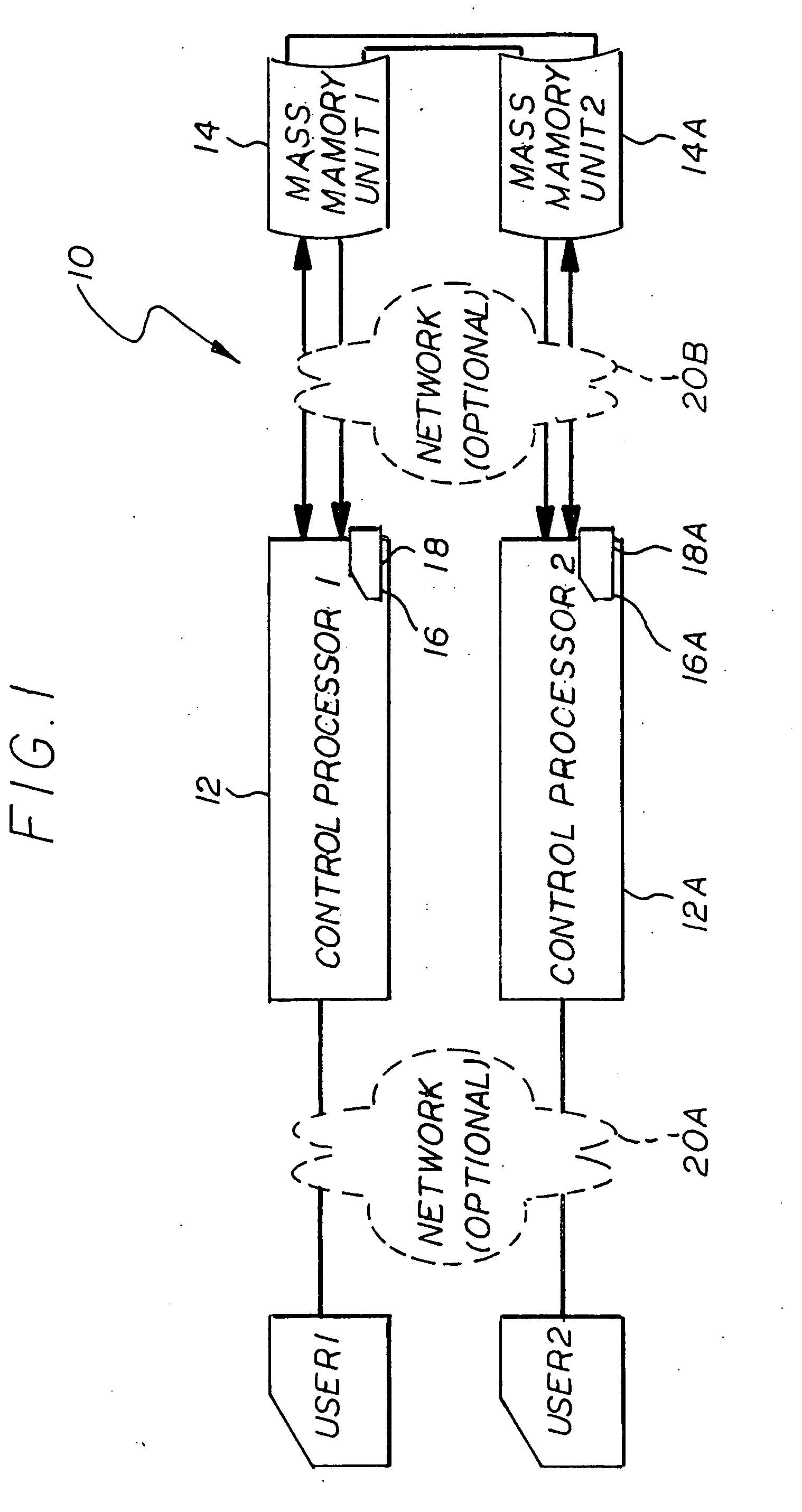

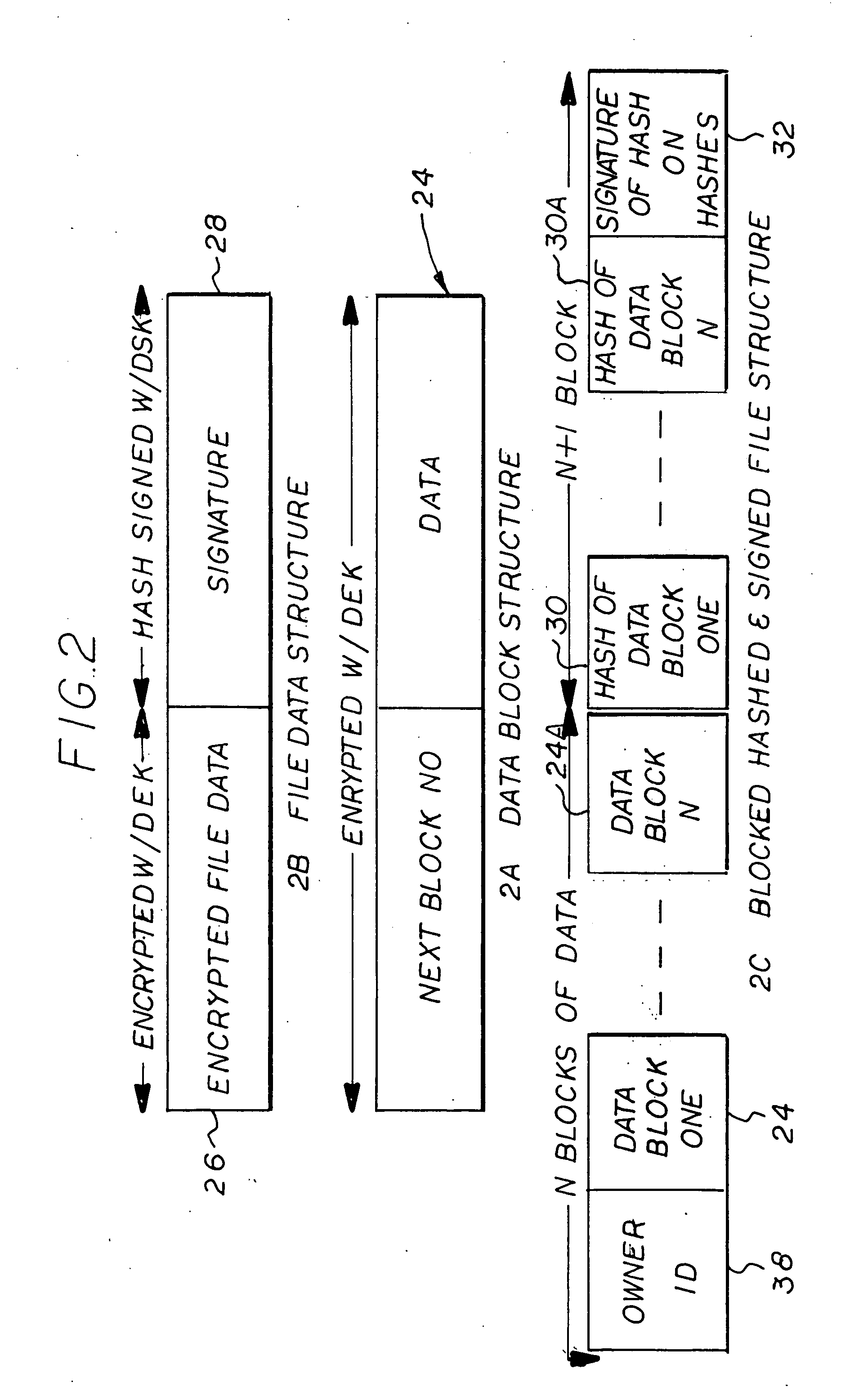

Process for securing data in a storage unit

InactiveUS20100005318A1Avoid performanceCombine accuratelyEncryption apparatus with shift registers/memoriesDigital data processing detailsEncryption

The invention is a process for securing data in a storage unit using public and private key encryption and symmetrical encryption techniques by a owner of the data for use by multiple users. The process including the steps of: 1) encrypting the data; 2) attaching encrypted meta data to the encrypted data providing access at a selected level to the data by each of the multiple users, the access level to each of the multiple users being the ability to read and change the data, or the ability to only read the data, or no access to the data; 3) storing the encrypted data and meta data in the storage unit; and 4) providing each of the multiple users with de-encryption means such that the encrypted data can be de-encrypted at the selected level granted to each of the multiple users.

Owner:NORTHROP GRUMAN CORP

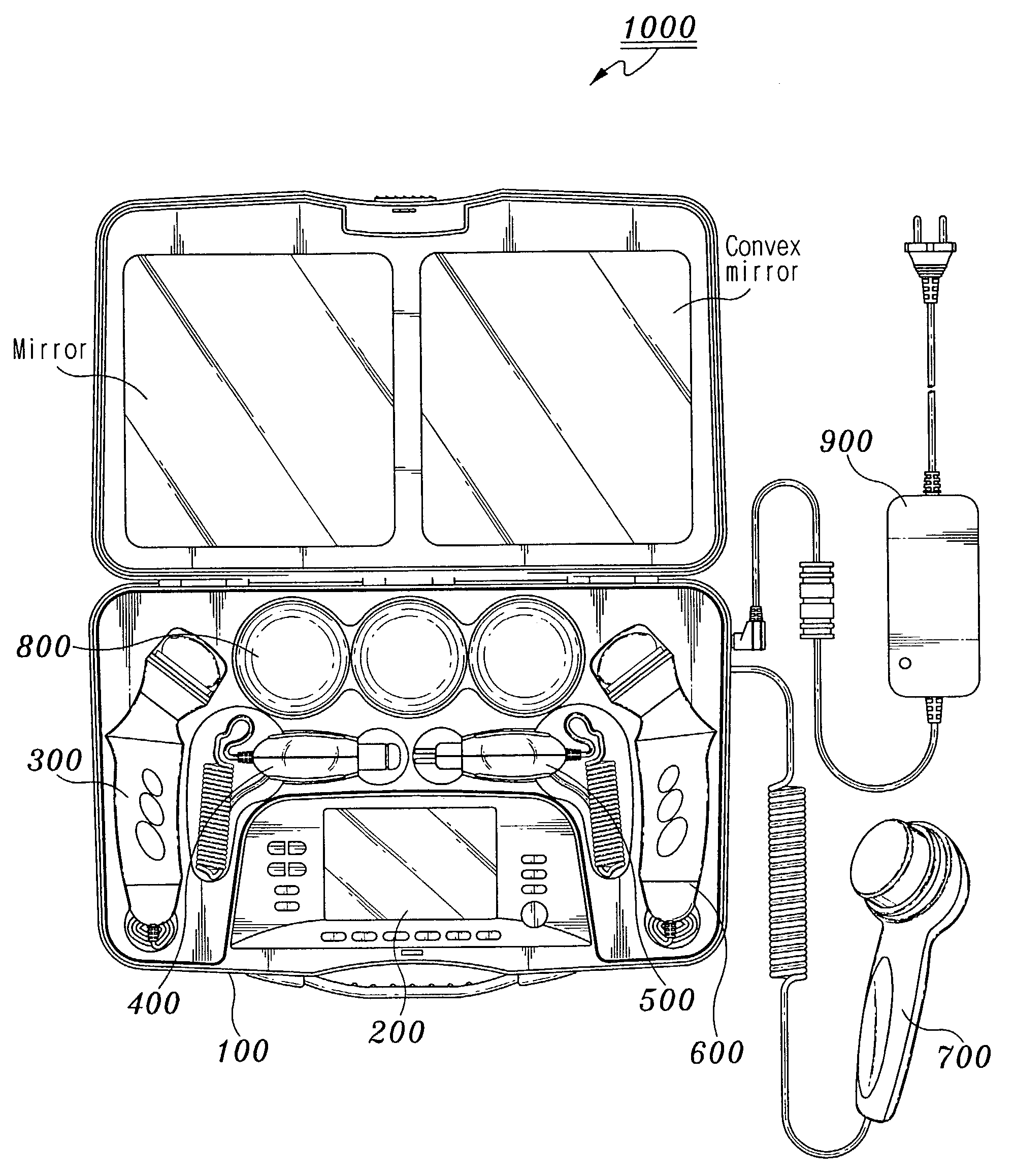

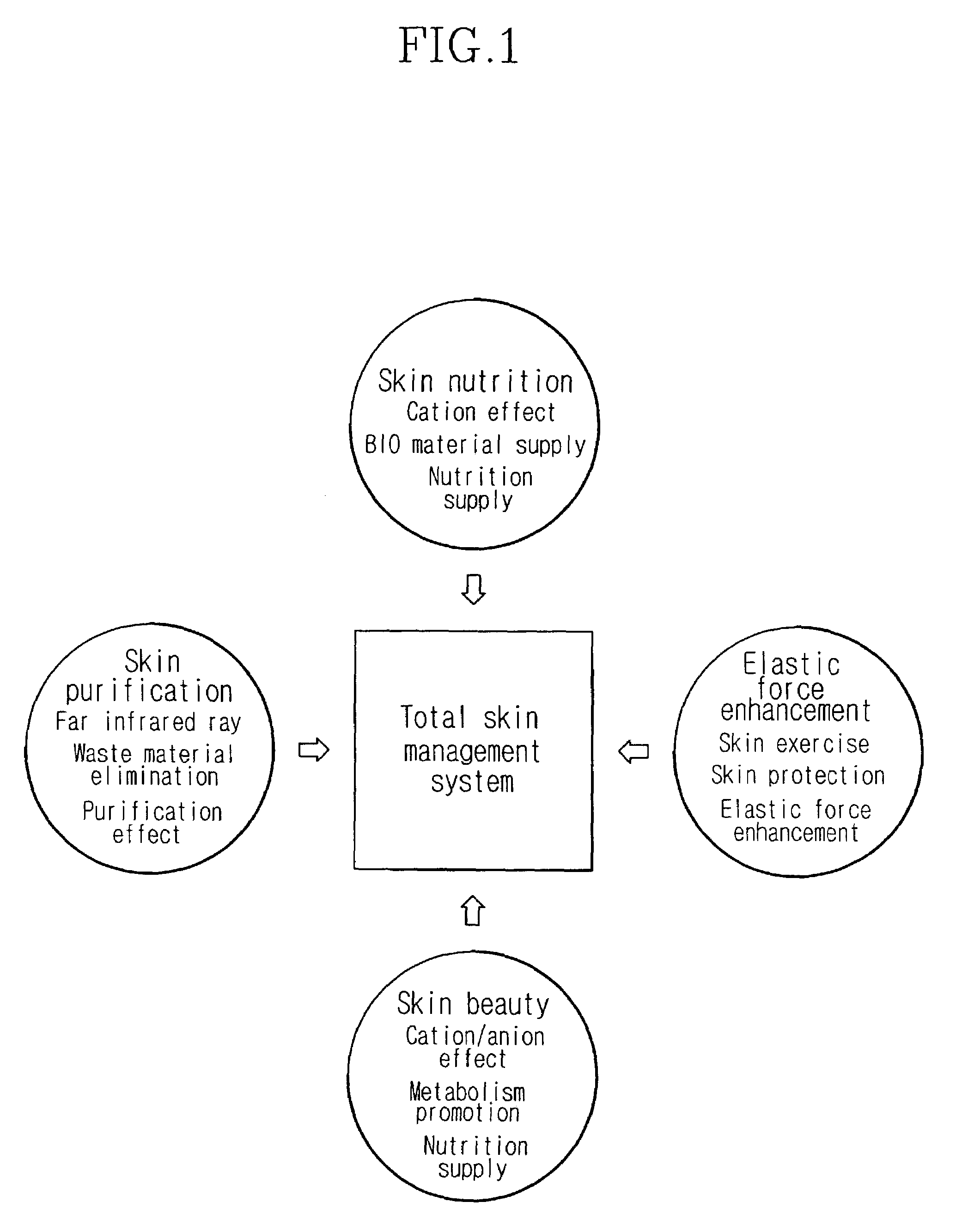

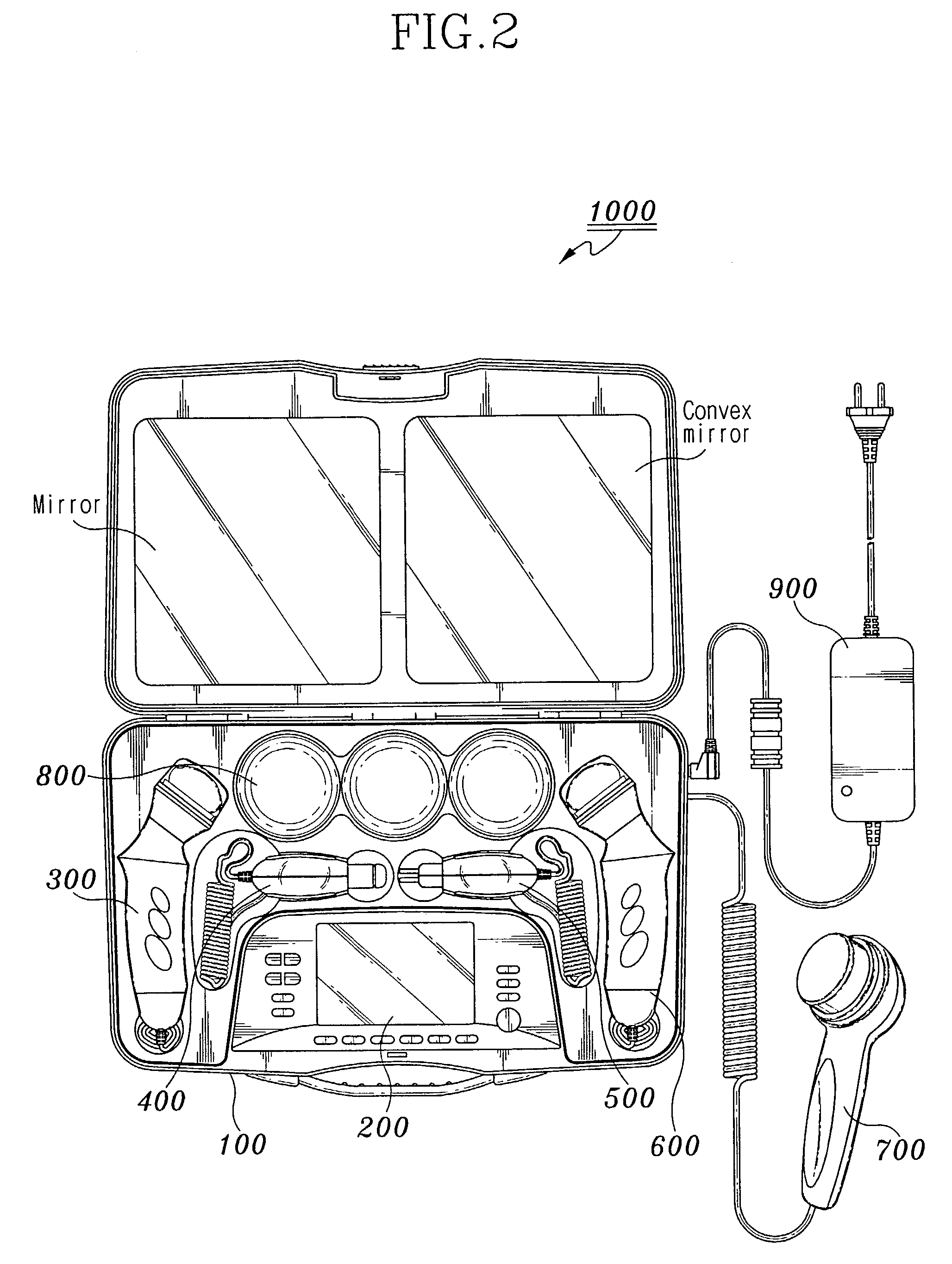

Total skin management system and total skin management method using the same

InactiveUS7090649B2Easy to checkEasy to adjustCosmetic preparationsElectrotherapyInfraredExamination skin

The present invention relates to a skin management system, and in particular to a total skin management system and a total skin management method using the same which are capable of checking a state of skin and comprehensively managing a skin based on a type of skin. In addition, the present invention relates to a total skin management system and a total skin management method using the same which are capable of checking a state of skin and classifying the skin into numerous types by integrating and controlling the functions of a skin check, far infrared ray massage, ozone massage, low frequency massage, low frequency vibration massage and ultrasonic wave massage and comprehensively managing the functions of a skin cleansing, skin management, skin nutrition and skin elastic force increase through a certain skin exercise corresponding to a structure of skin based on a skin cell activity and metabolism in a proper combination with the functions of an infrared ray massage, ozone massage, low frequency wave massage, low frequency vibration massage and ultrasonic wave massage based on the checked type of skin.

Owner:AEGIS HWAJIN COSMETICS

Multi-reservoir pressure control system

InactiveUS20050005684A1Sufficient oscillationAccurate and stable and reliable assayFlow control using electric meansLaboratory glasswaresFluid transportFlow resistivity

Improved microfluidic devices, systems, and methods allow selective transportation of fluids within microfluidic channels of a microfluidic network by applying, controlling, and varying pressures at a plurality of reservoirs. Modeling the microfluidic network as a series of nodes connected together by channel segments and determining the flow resistance characteristics of the channel segments may allow calculation of fluid flows through the channel segments resulting from a given pressure configuration at the reservoirs. To effect a desired flow within a particular channel or series of channels, reservoir pressures may be identified using the network model. Viscometers or other flow sensors may measure flow characteristics within the channels, and the measured flow characteristics can be used to calculate pressures to generate a desired flow. Multi-reservoir pressure modulator and pressure controller systems can optionally be used in conjunction with electrokinetic or other fluid transport mechanisms.

Owner:CAPLIPER LIFE SCI INC

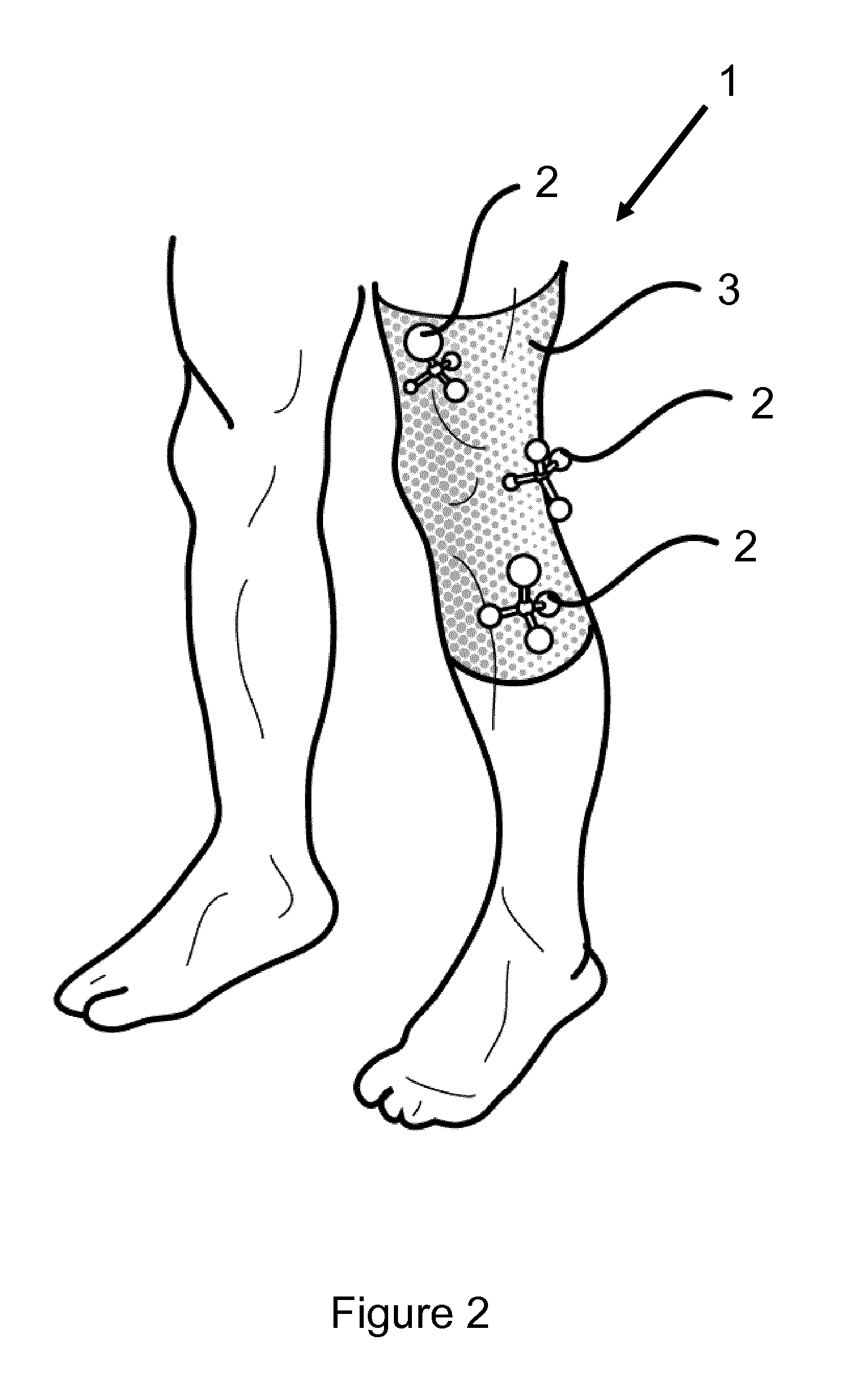

Imaging calibration device

InactiveUS20140056495A1Help positioningImprove image qualityImage enhancementCharacter and pattern recognitionImage calibrationComputer science

The present invention relates to calibration devices, the use thereof and methods for the in-line geometric and grey-value correction of data obtained from imagingN devices such as x-ray radiography. The calibration devices according to the invention comprise a set of two or more interconnected calibration components and a means for mounting the set of calibration components on the body.

Owner:MATERIALISE NV

Screen

ActiveUS20110011542A1Well formedCombine accuratelyScreensShutters/ movable grillesEngineeringMechanical engineering

Owner:SEIKO EPSON CORP

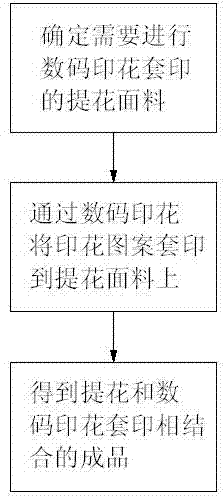

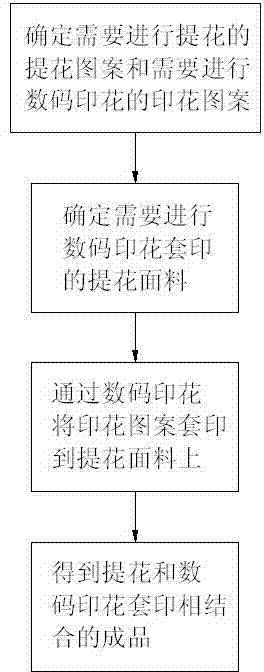

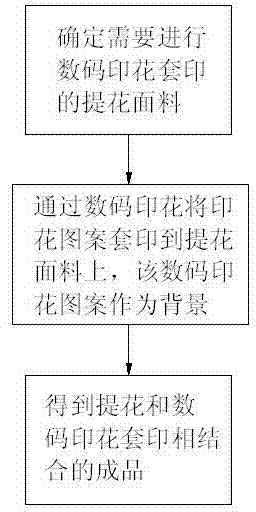

Digital printing overprinting method of jacquard fabric

ActiveCN102756581AThree-dimensionalImprove qualityTypewritersOther printing apparatusEngineeringDigital printing

The invention relates to a digital printing overprinting method of jacquard fabric. At present, a manufacturing method for organically combining the jacquard weaving and the digital printing of the fabric does not exist. The digital printing and overprinting method is characterized by comprising the steps of 1) determining the jacquard fabric needing to be subjected to digital printing overprinting; 2) overprinting printing patterns on the jacquard fabric by digital printing so as to match the digital printing patterns on the jacquard fabric with jacquard patterns and form combined patterns combining the jacquard patterns and the digital printing patterns on the jacquard fabric. According to the digital printing overprinting method, the process design is scientific, the operation is simple and convenient, the complicated positioning is not needed, the jacquard of the fabric and the digital printing can be combined organically, a product with the jacquard patterns and digital printing patterns can be produced, has a strong three-dimensional effect, is layered, colorful and strong in expression.

Owner:HANGZHOU HONGHUA DIGITAL TECH

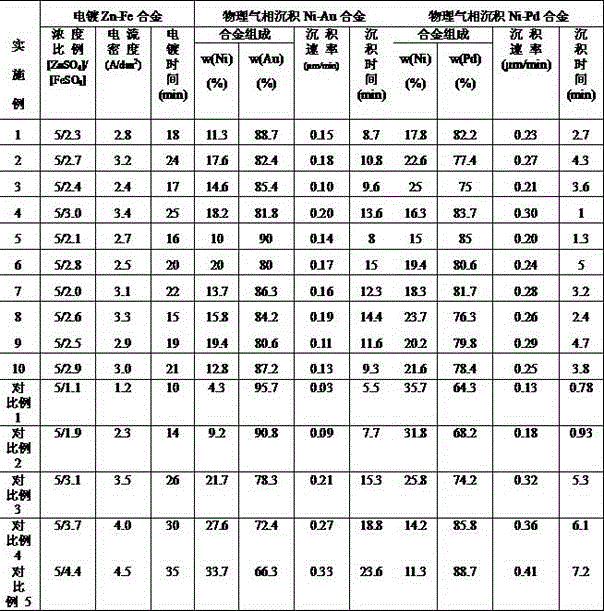

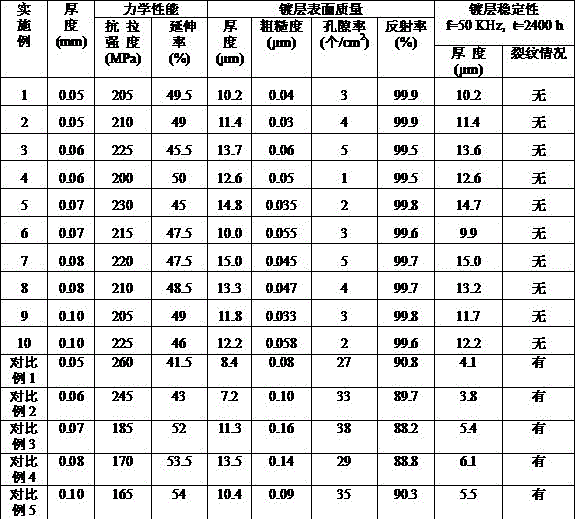

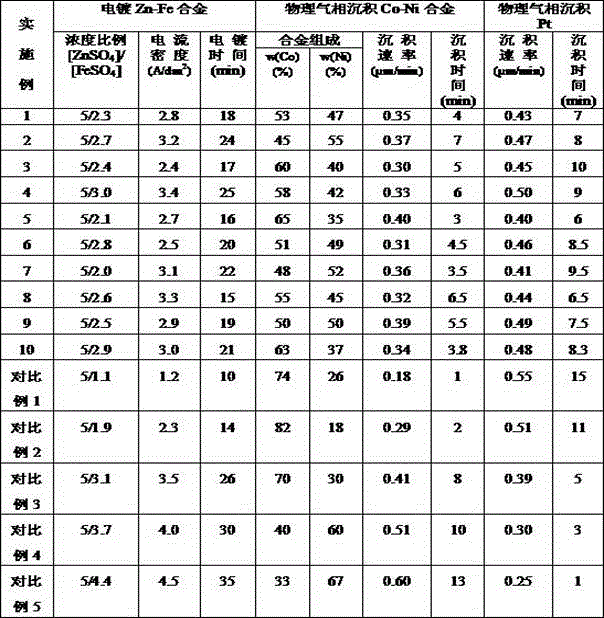

Production method of ultra-thin steel belt plated with precious metal

InactiveCN105887085APrecise thickness controlImprove stabilityVacuum evaporation coatingSputtering coatingLoss ratePorosity

Provided is a production method of an ultra-thin steel belt plated with precious metal. The production method includes the steps that a DC01 cold-rolled steel plate is used as a raw material, and conventional degreasing is conducted after the steel plate is cold-rolled repeatedly; annealing is conducted; the belt is prepared, specifically, uncoiling, striping and burr removal are carried out; Zn / Fe electroplating, primary water-washing and drying, primary physical vapor deposition, secondary water-washing and drying and secondary physical vapor deposition are carried out sequentially; and the belt is rolled after being naturally cooled to be at the room temperature. According to the steel belt, the Rm is 200-230 MPa, the percentage of elongation is 45%-50%, the surface roughness of an Au-plated or Ag-plated coating is 0.05-0.10 micron, and the specular reflection is 99%-99.9%; after the coating is stored on the indoor atmospheric condition for 1800 days, the specular reflection of the coating is 98.7%-99.7%, the gloss loss rate is not higher than 0.5%, and the rate of the corroded area is not higher than 0.05%; after the coating is exposed in air containing 30 ppmH2S for 1200 days, the specular reflection of the coating is 98.5%-99.5%, the gloss loss rate is not higher than 0.6%, and the rate of the corroded area is not higher than 0.08%; for a Pt-plated steel belt, the surface roughness is 0.03-0.06 micron, the porosity is not higher than five each square centimeter, and the specular reflection is 99.5%-99.9%; and after the coating is stored in the 50-KHz ultrasonic environment continuously for 2400 hours, the thickness of the coating is not changed, and the surface has no crack.

Owner:武汉钢铁有限公司

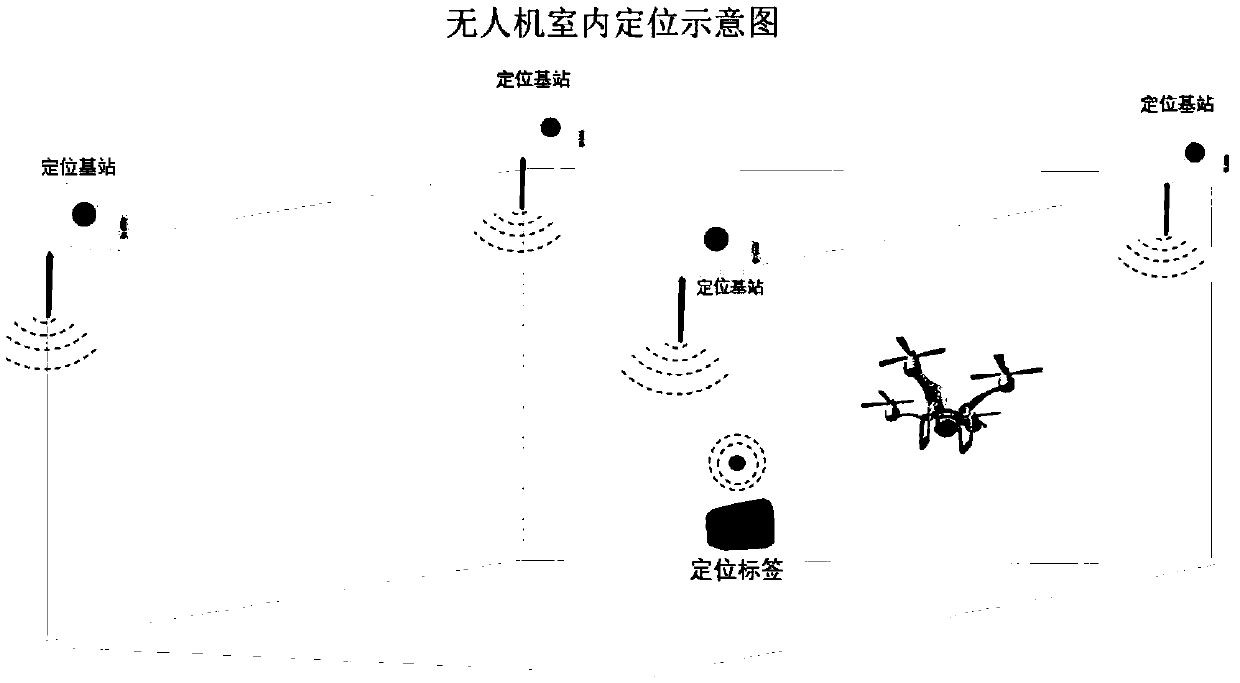

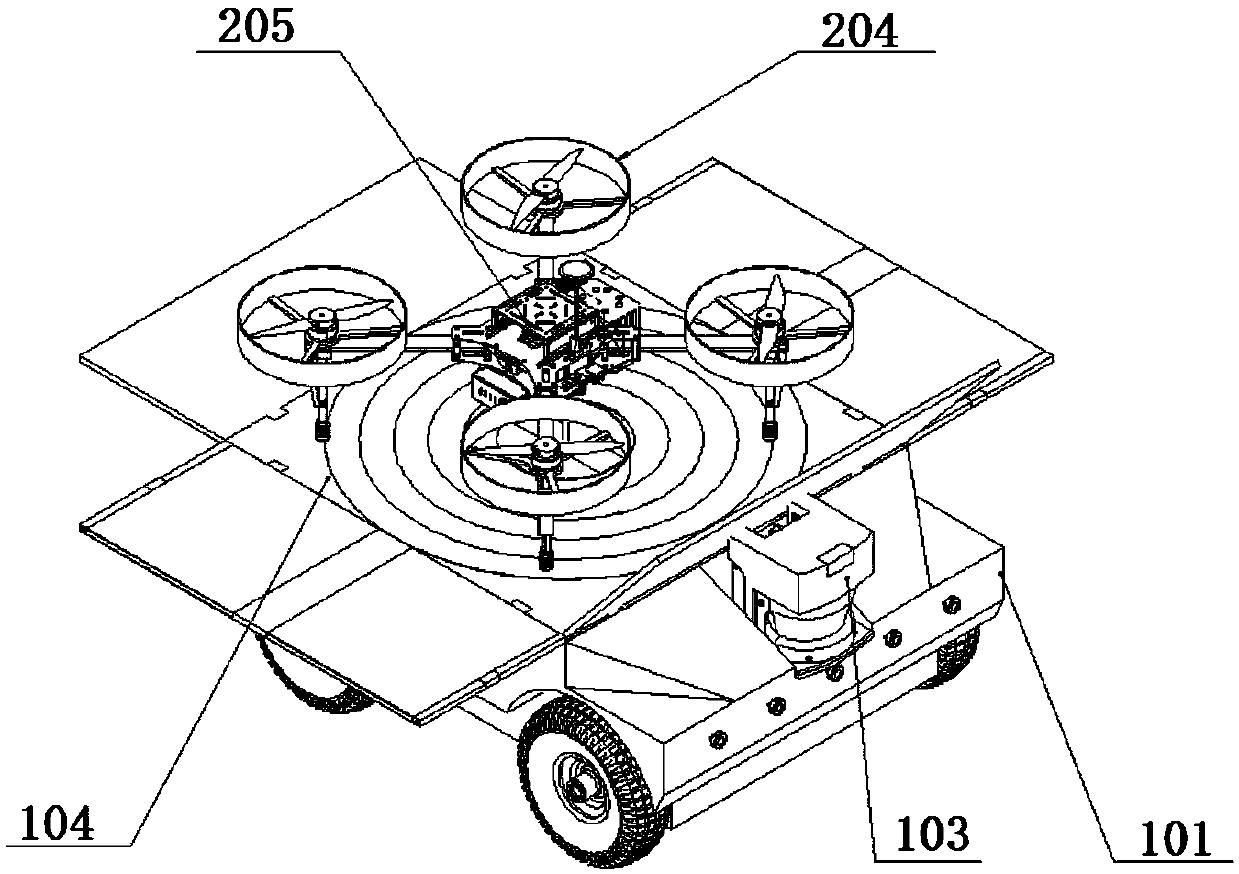

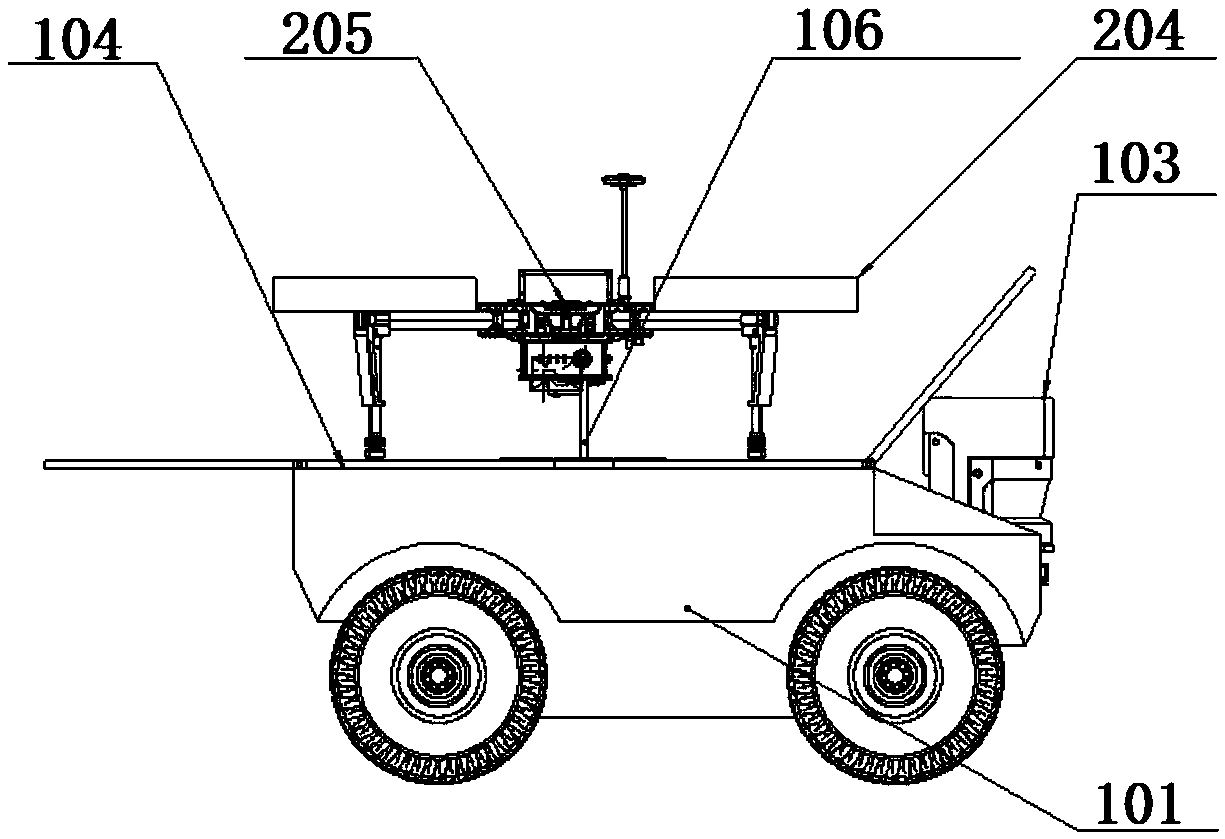

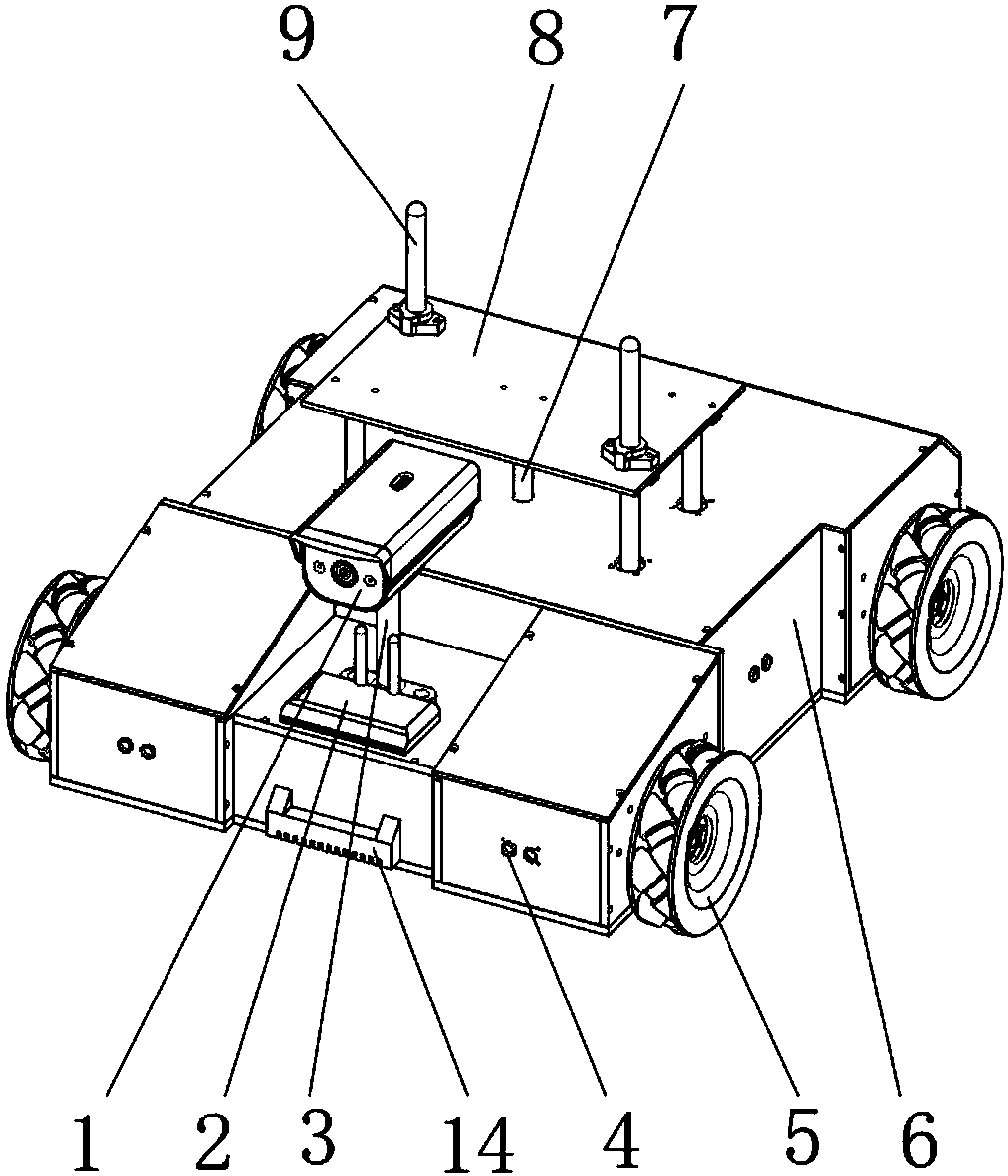

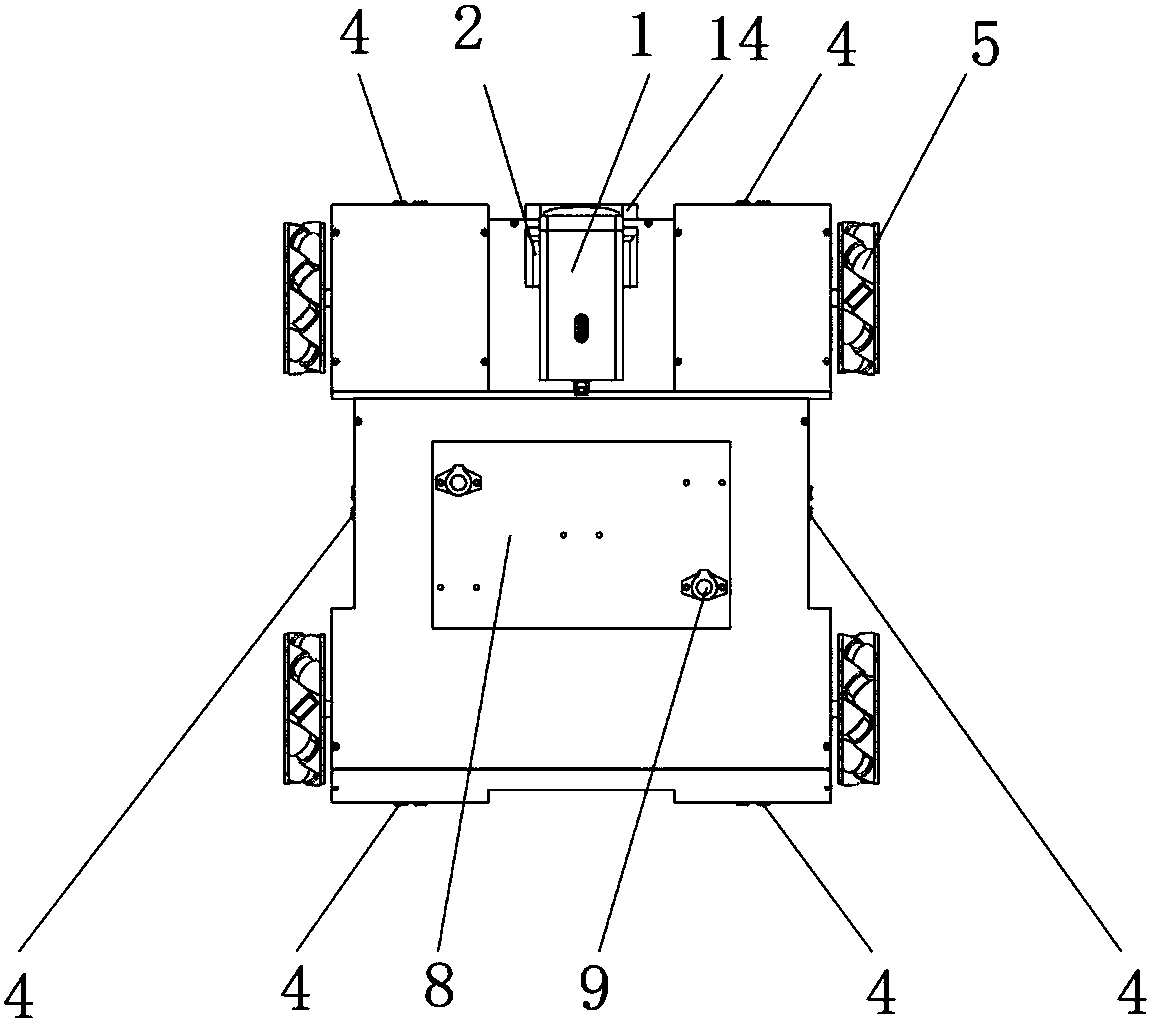

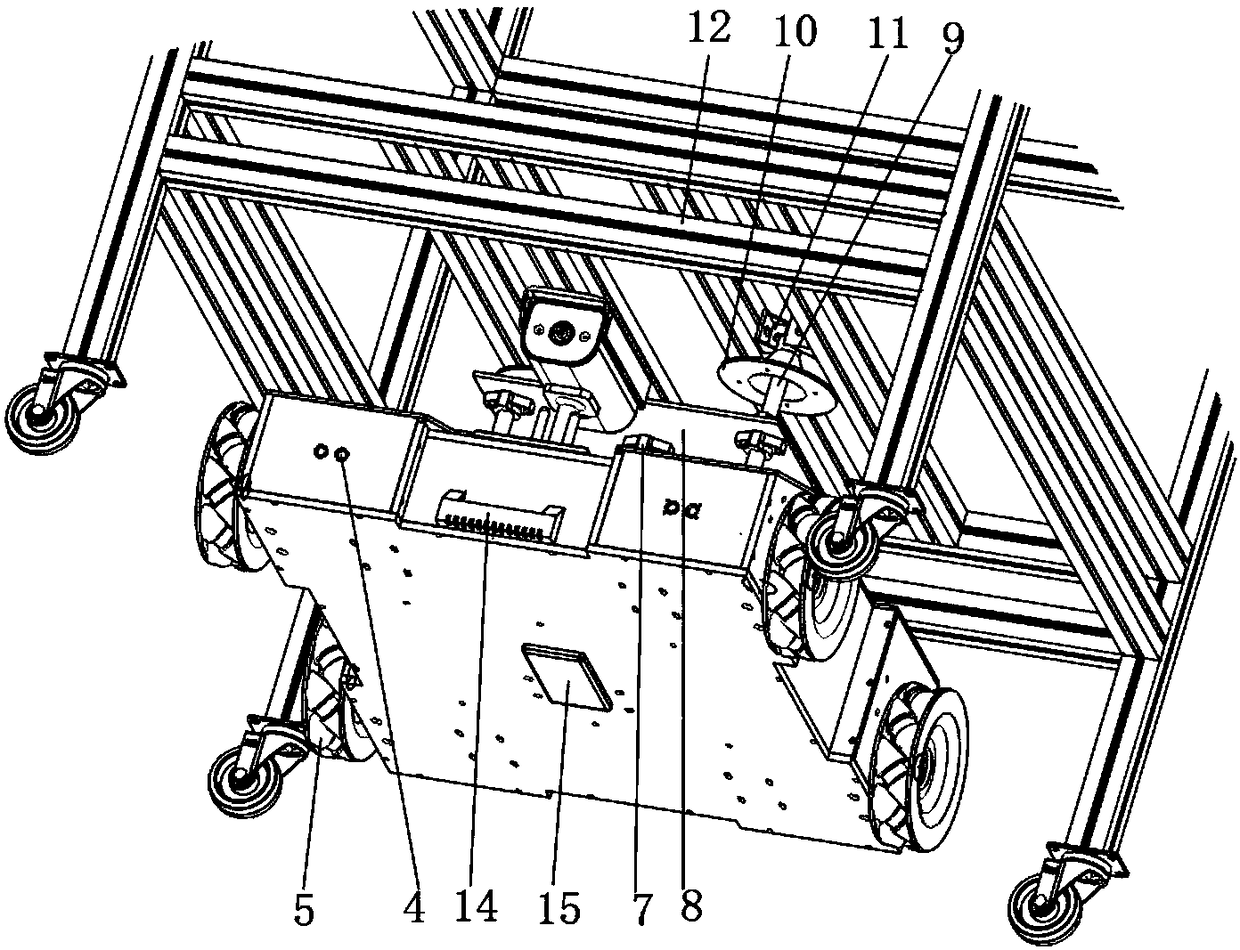

Power distribution station indoor equipment floor space collaborative routing inspection device and routing inspection method thereof

InactiveCN109623839ACombine accuratelySolve battery lifeCharging stationsElectric vehicle charging technologyUltrasonic sensorEngineering

The invention provides a power distribution station indoor equipment floor space collaborative routing inspection device and a routing inspection method thereof. The top of a four-wheel walking robotbody is provided with a parking apron allowing an unmanned aerial vehicle to take off and stop, a positioning mark for determining the position of the unmanned aerial vehicle is arranged on the parking apron, and the front part of the robot body is provided with an ultrasonic sensor and a laser sensor; four rotor wings of the four-rotor unmanned aerial vehicle are provided with rotor wing protection shells correspondingly, a UWB positioning label is arranged at the top of the four-rotor unmanned aerial vehicle, and a landing gear is arranged at the lower part of the four-motor unmanned aerialvehicle; the routing inspection device is installed on the unmanned aerial vehicle; a robot is connected with the unmanned aerial vehicle through a telescopic cable, the collecting and releasing of the telescopic cable is controlled by an electric winder installed on the robot, and the cable is composed of an unmanned aerial vehicle power line powered by the unmanned aerial vehicle and a communication line between the cable and the unmanned aerial vehicle power line. According to the power distribution station indoor equipment floor space collaborative routing inspection device, high-precisionpositioning is realized by utilizing the robot, the unmanned aerial vehicle can detect the vertical direction of a power distribution station large-scale frame machine, and the power distribution station indoor equipment floor space collaborative routing inspection device has the characteristics that the routing inspection is free of dead corners, the detection precision is high, and the detection efficiency is high.

Owner:SOUTHWEST JIAOTONG UNIV

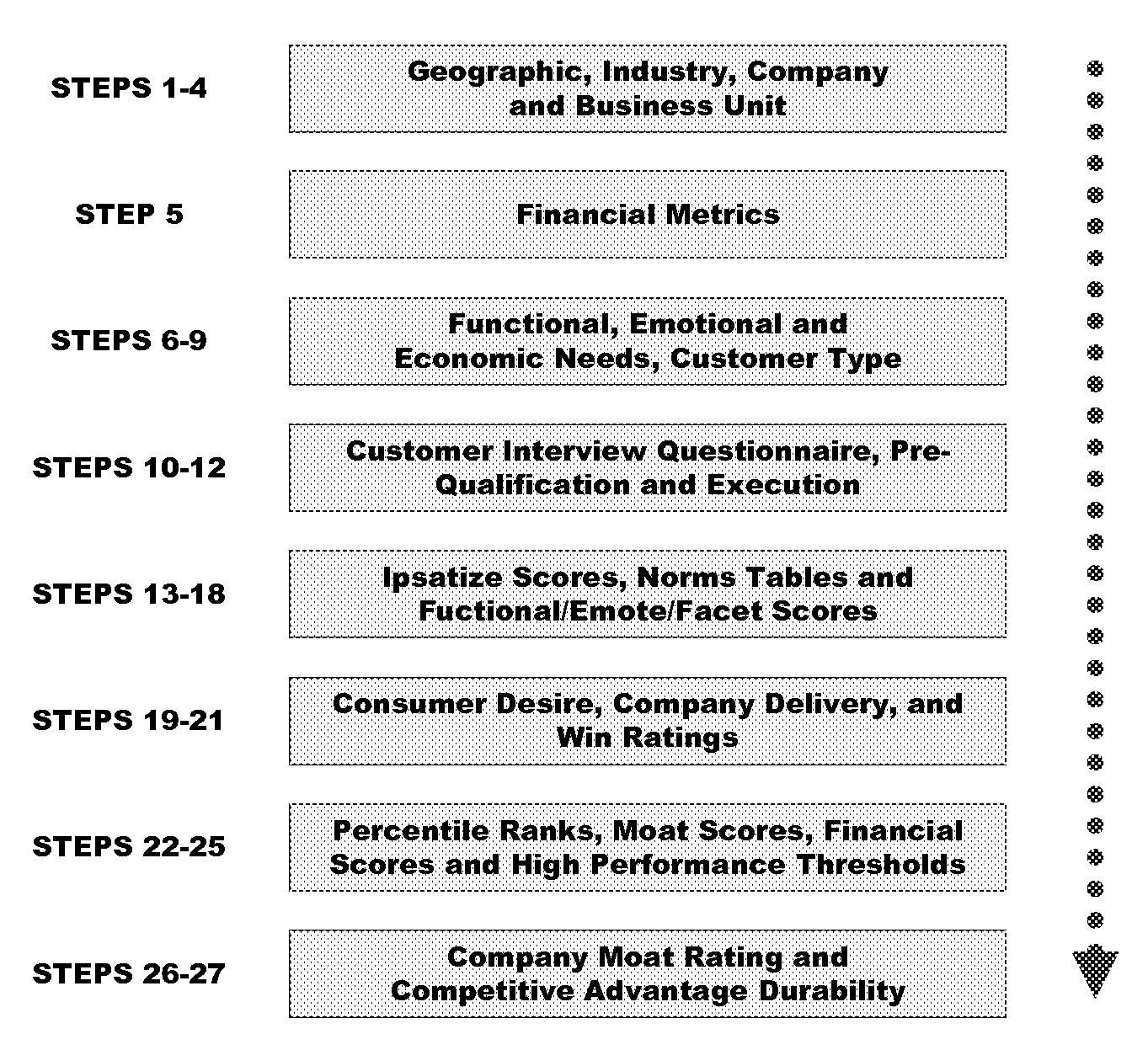

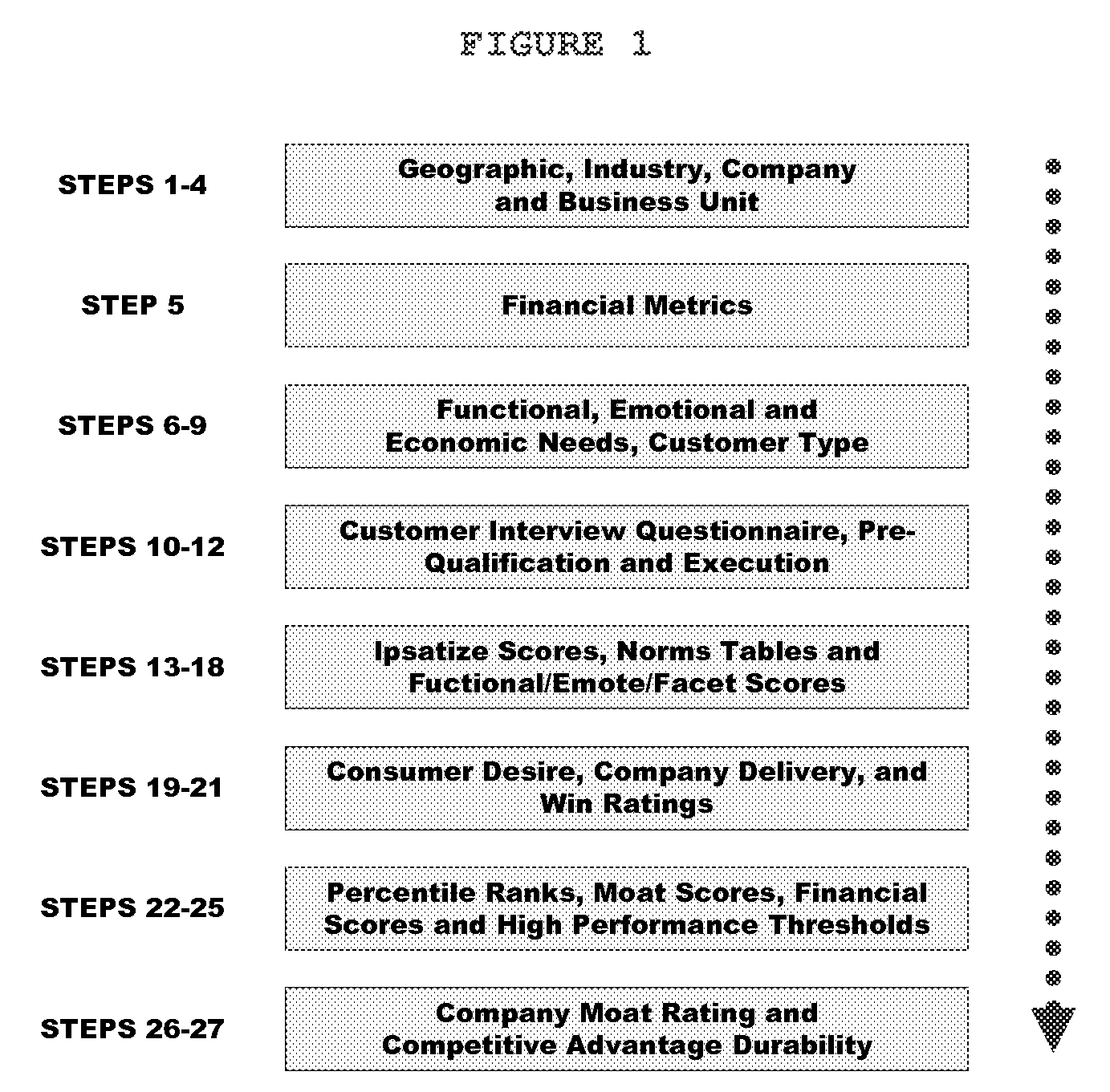

Competitive advantage rating method and apparatus

InactiveUS20080300960A1Improve product qualityEasily voiced and understoodMarket predictionsResourcesData miningDawn

This invention relates to a rating method and apparatus that quantifies competitive advantage based on measurements of how well companies are delivering on consumer desires when benchmarked against their industry peers. More specifically, the method measures the existence of one or more barriers to entry, referred to herein as barriers, which companies build in order to protect their superior financial performance from competitors. The ratings further quantify the company's strength of their performance on the individual attributes that define each barrier. To begin analyzing competitive advantage in an industry, the Competitive Advantage rating method and apparatus starts by examining a company's past financial records. Using standard factor analysis, three sources of competitive advantage exist: Supply Chain, Products and Delivery Chain. Each source has three barriers for a total of 9 barriers common to every industry. While the sources of advantage have been around for centuries, since the dawn of business, this method identifies the drivers behind consumer desires and company delivery for each barrier.

Owner:W RATINGS CORP

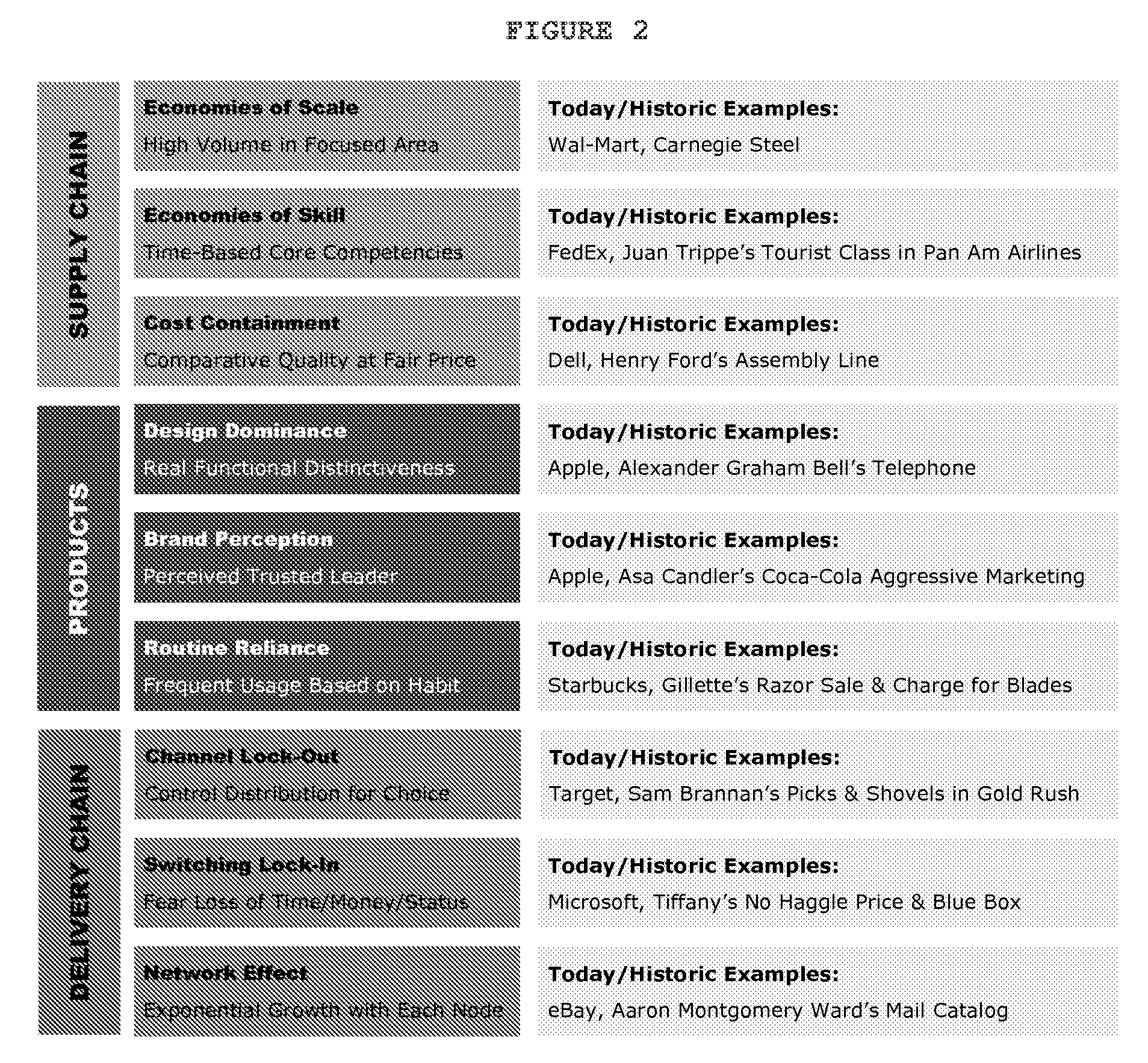

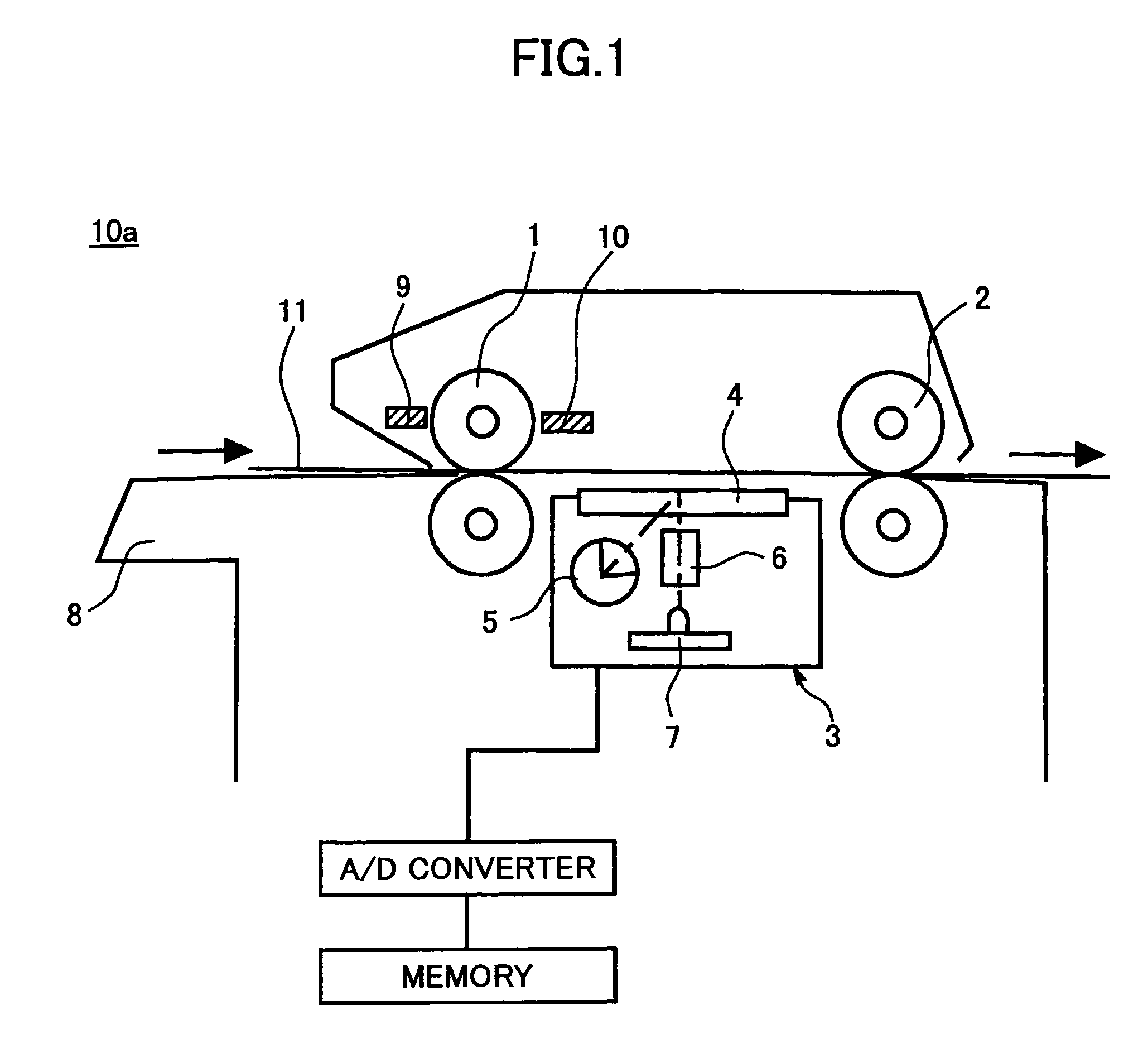

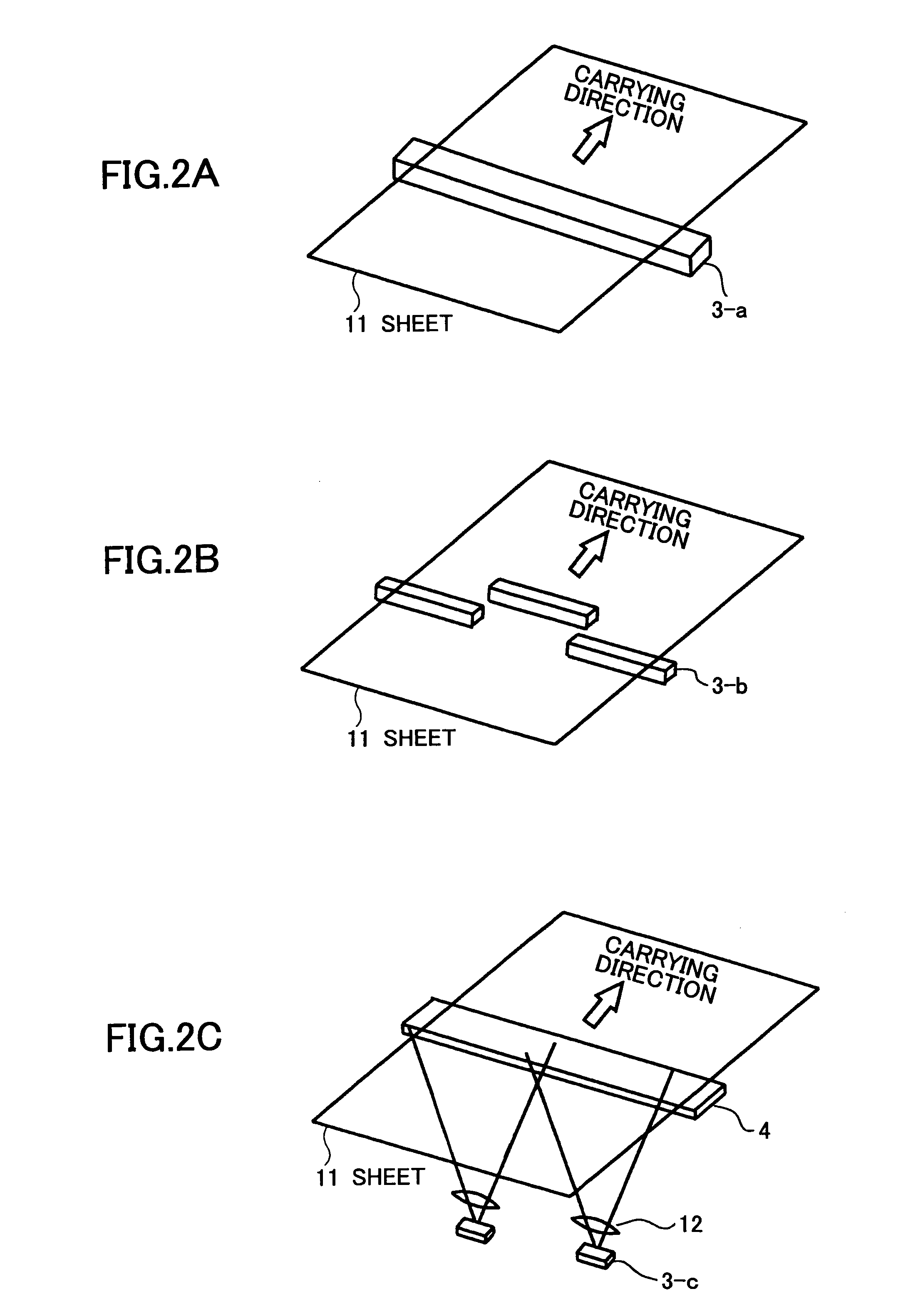

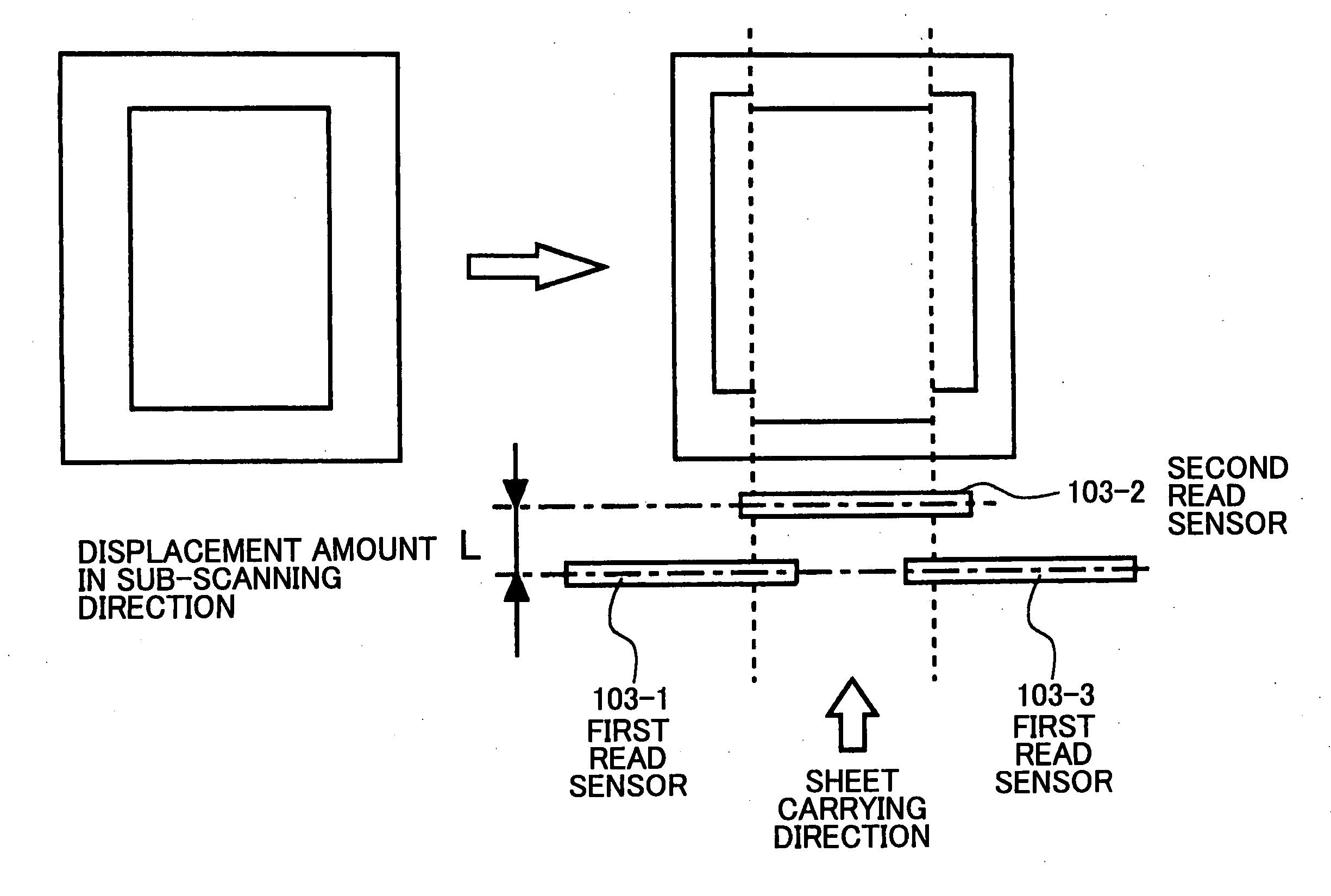

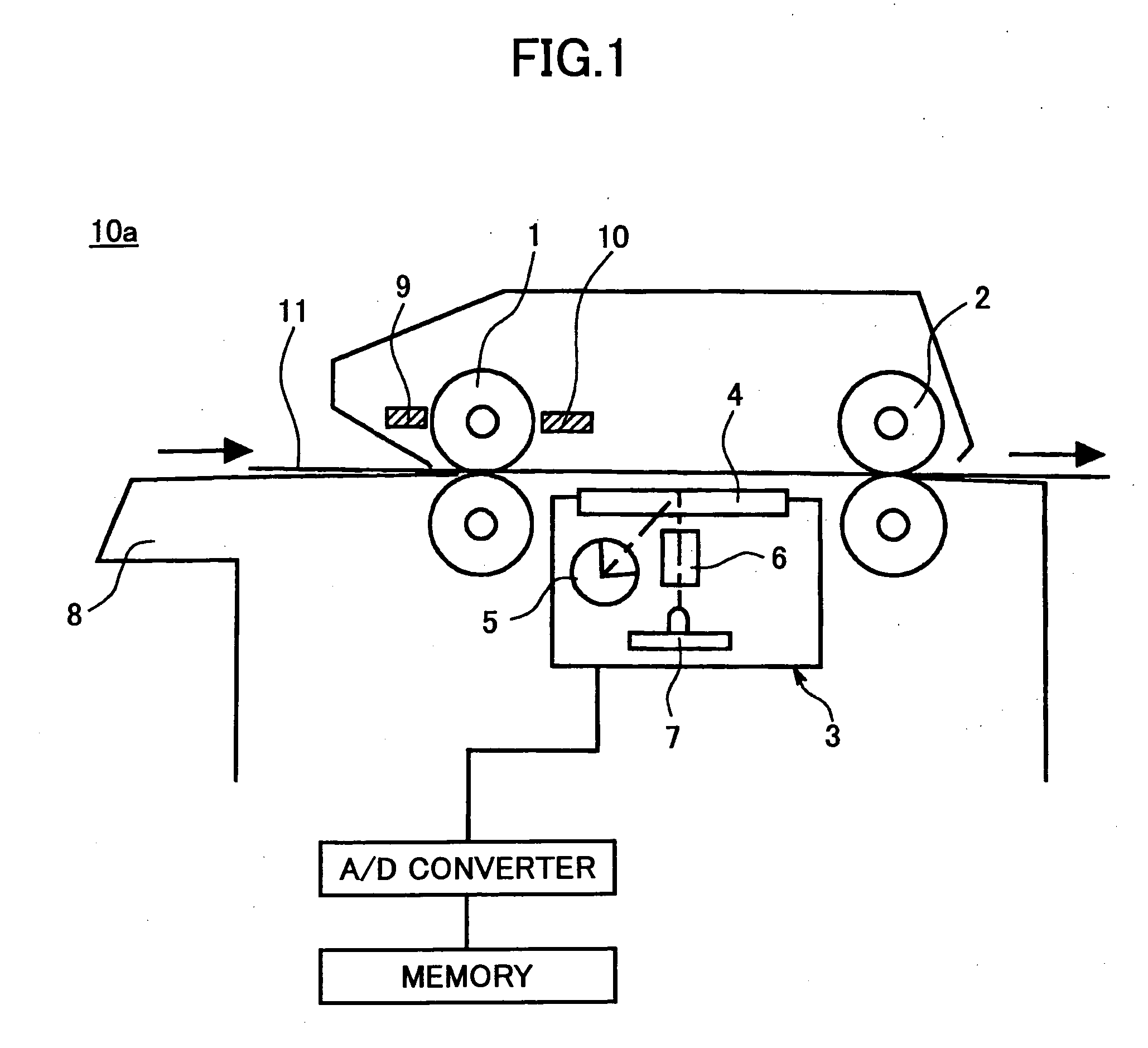

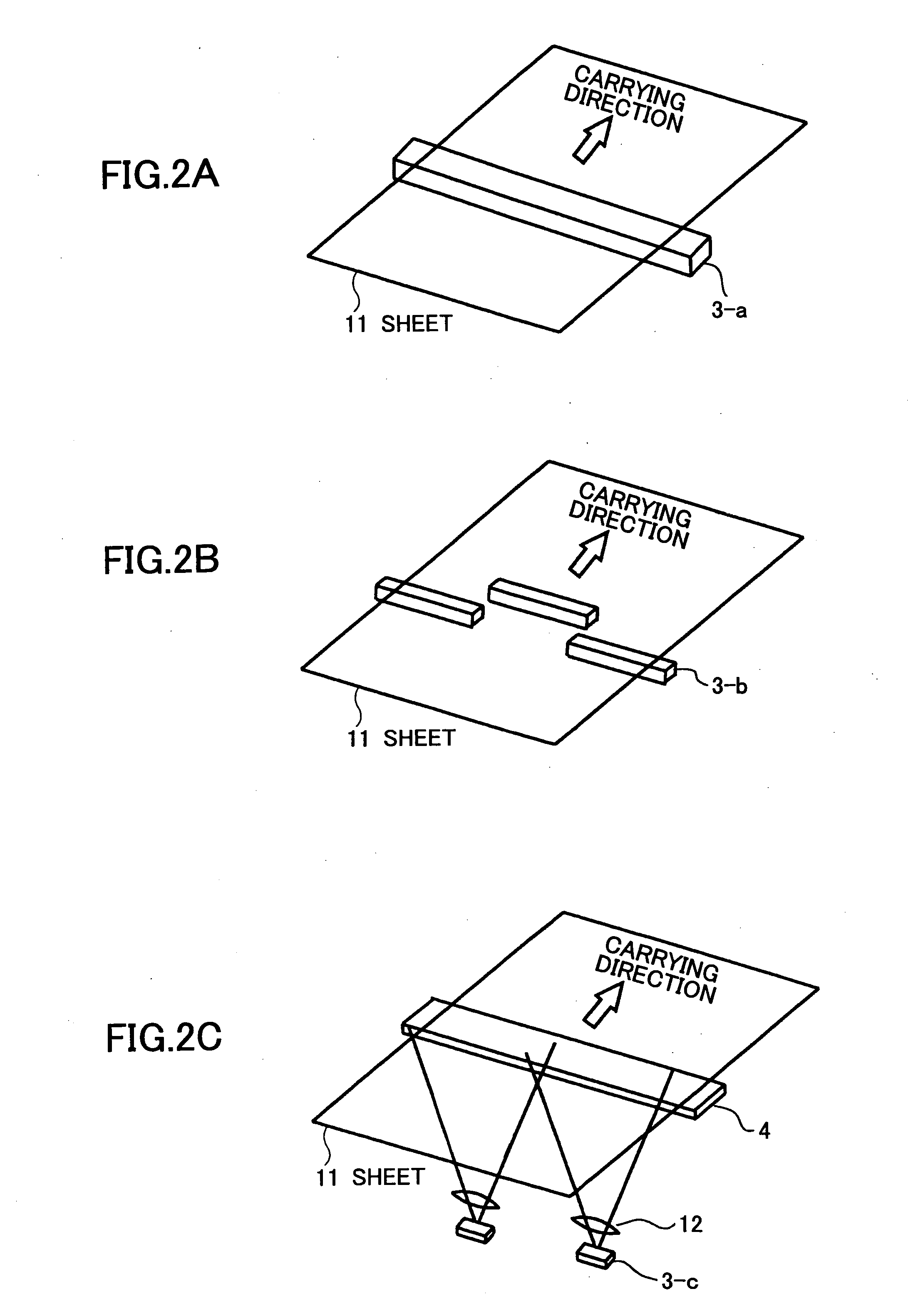

Adjustment method, image reading device, and image forming apparatus for adjusting read sensors

ActiveUS7460279B2Easy to measureAccurate displacementCharacter and pattern recognitionPictoral communicationRelative displacementDelayed time

The adjustment method is disclosed in that a predetermined reference interval in a main scanning direction is compared with each interval in the main scanning direction obtained by reading a sheet so that each joint of image is located between two parallel lines, a start pixel and an end pixel to read image data at each joint are determined and adjusted by calculating each interval difference, a reference straight line extending along the main scanning direction is compared with each of the plurality of straight line images extending along the main scanning direction at joints of images, and a delay time for reading sensors is adjusted by calculating an average value of relative displacement amounts.

Owner:RICOH KK

All-dimensional mobile robot applied to intelligent warehouse

InactiveCN108177147AReduce walkingImprove efficiencyProgramme-controlled manipulatorVehicle position/course/altitude controlSimulationNetwork management

The invention discloses an all-dimensional mobile robot applied to an intelligent warehouse. A movable platform, a traction mechanism, an ultrasonic obstacle avoidance system, a visual module and a remote maintenance module are included; an auxiliary positioning mechanism matched with the mobile robot is further included, it is achieved that the robot automatically carries a goods shelf to a target area in a traction mode, and the work state and the warehousing environment of the robot are monitored; and the robot can be managed and maintained through a network. Besides, the all-dimensional mobile robot applied to the intelligent warehouse is designed into the Mecanum wheel type movable platform, can move all dimensionally and is high in flexibility.

Owner:DONGGUAN UNIV OF TECH +1

Adjustment method, image reading device, and image forming apparatus for adjusting read sensors

ActiveUS20060050951A1Easy maintenanceShort timeCharacter and pattern recognitionPictoral communicationRelative displacementImage formation

The adjustment method is disclosed in that a predetermined reference interval in a main scanning direction is compared with each interval in the main scanning direction obtained by reading a sheet so that each joint of image is located between two parallel lines, a start pixel and an end pixel to read image data at each joint are determined and adjusted by calculating each interval difference, a reference straight line extending along the main scanning direction is compared with each of the plurality of straight line images extending along the main scanning direction at joints of images, and a delay time for reading sensors is adjusted by calculating an average value of relative displacement amounts.

Owner:RICOH KK

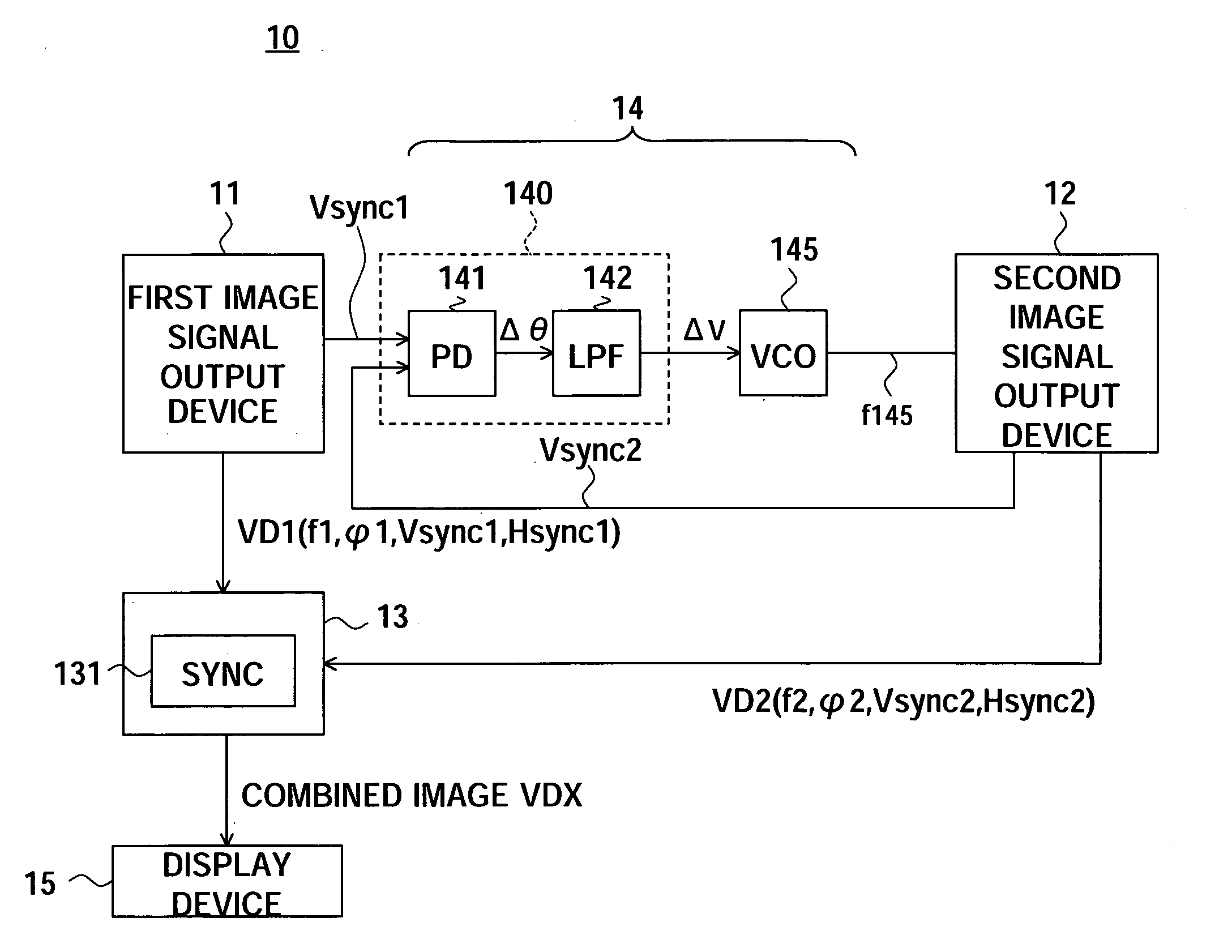

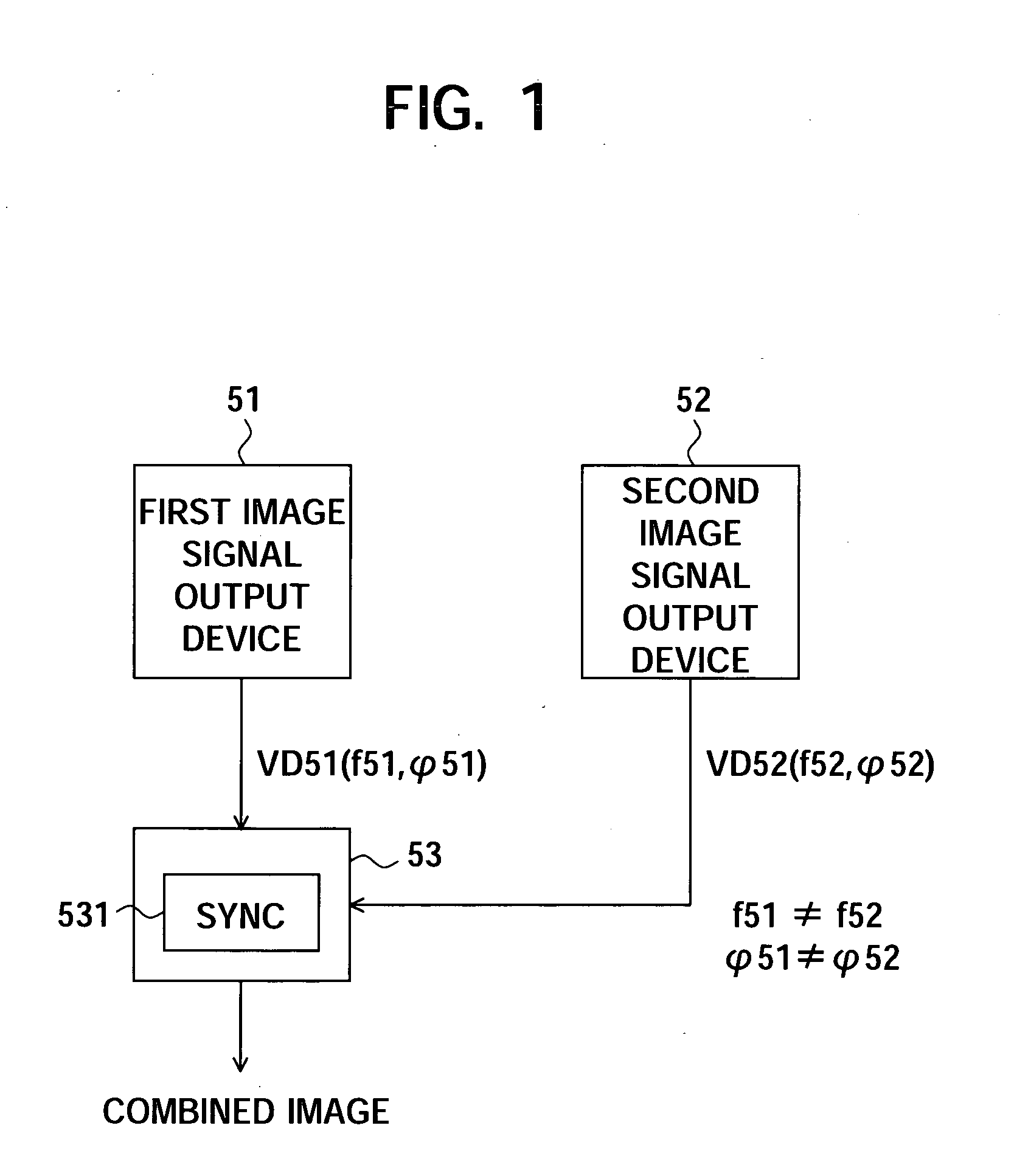

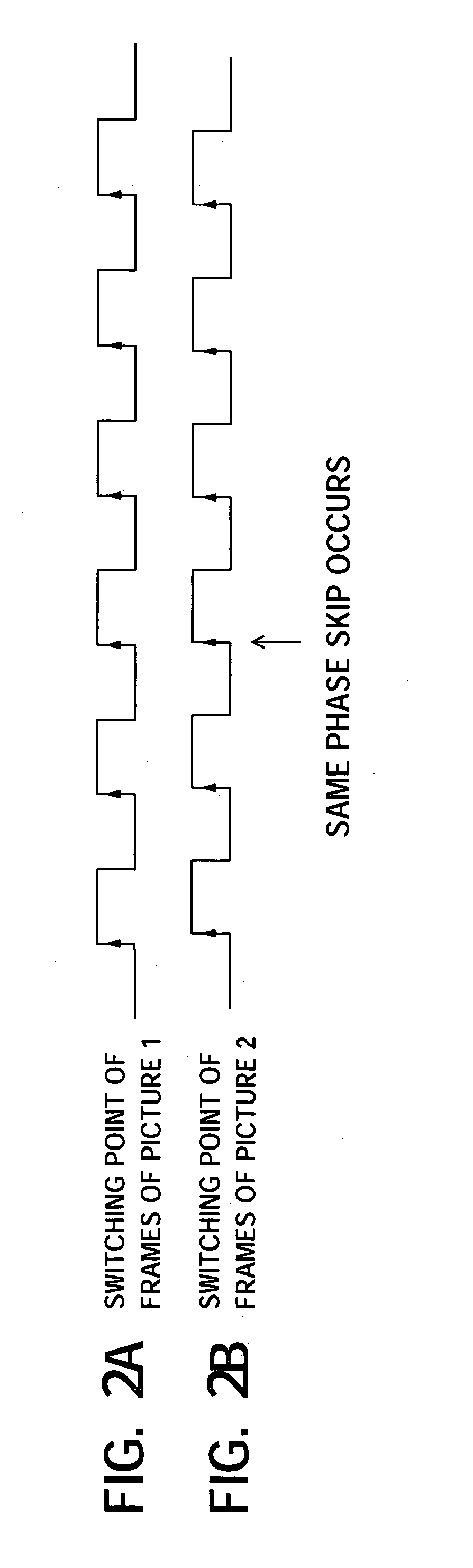

Image signal processing apparatus and phase synchronization method

InactiveUS20060038810A1Reduce image qualityCombine accuratelyTelevision system detailsCathode-ray tube indicatorsImage signalImaging Signal

An image signal processing apparatus provided with a plurality of image signal output units for outputting image signals, an image signal combining unit for combining a plurality of image signals output from the plurality of image signal output units, and a phase synchronization signal generation unit for synchronizing with a first reference signal of a first image signal output from a first image signal output unit among the plurality of image signal output units the phase of another reference signal of another image signal output from another image signal output unit other than the first image signal output unit so as to generate a signal, wherein the first image signal output unit outputs the first image signal based on the first reference signal to the image signal combining unit, the other image signal output units output image signals using clock signals based on their own phase synchronized oscillation signals to the image signal combining unit, and the image signal combining unit combines the plurality of image signals output from the plurality of image signal output units.

Owner:SONY CORP

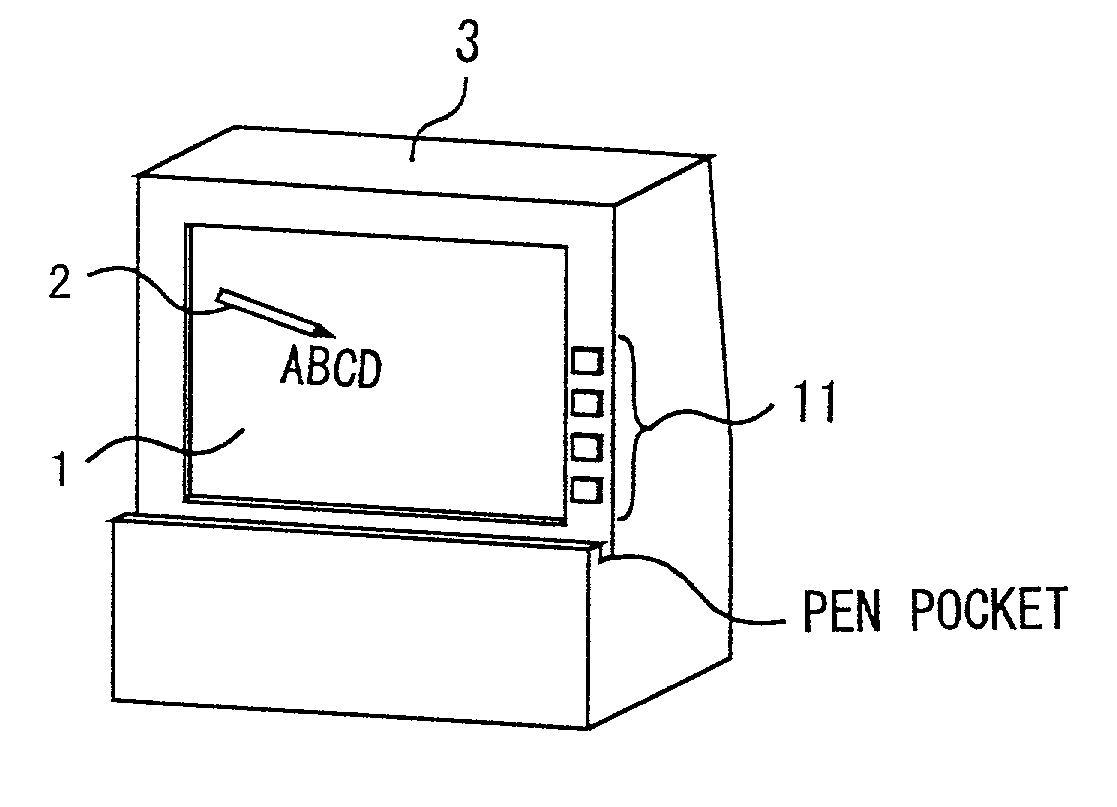

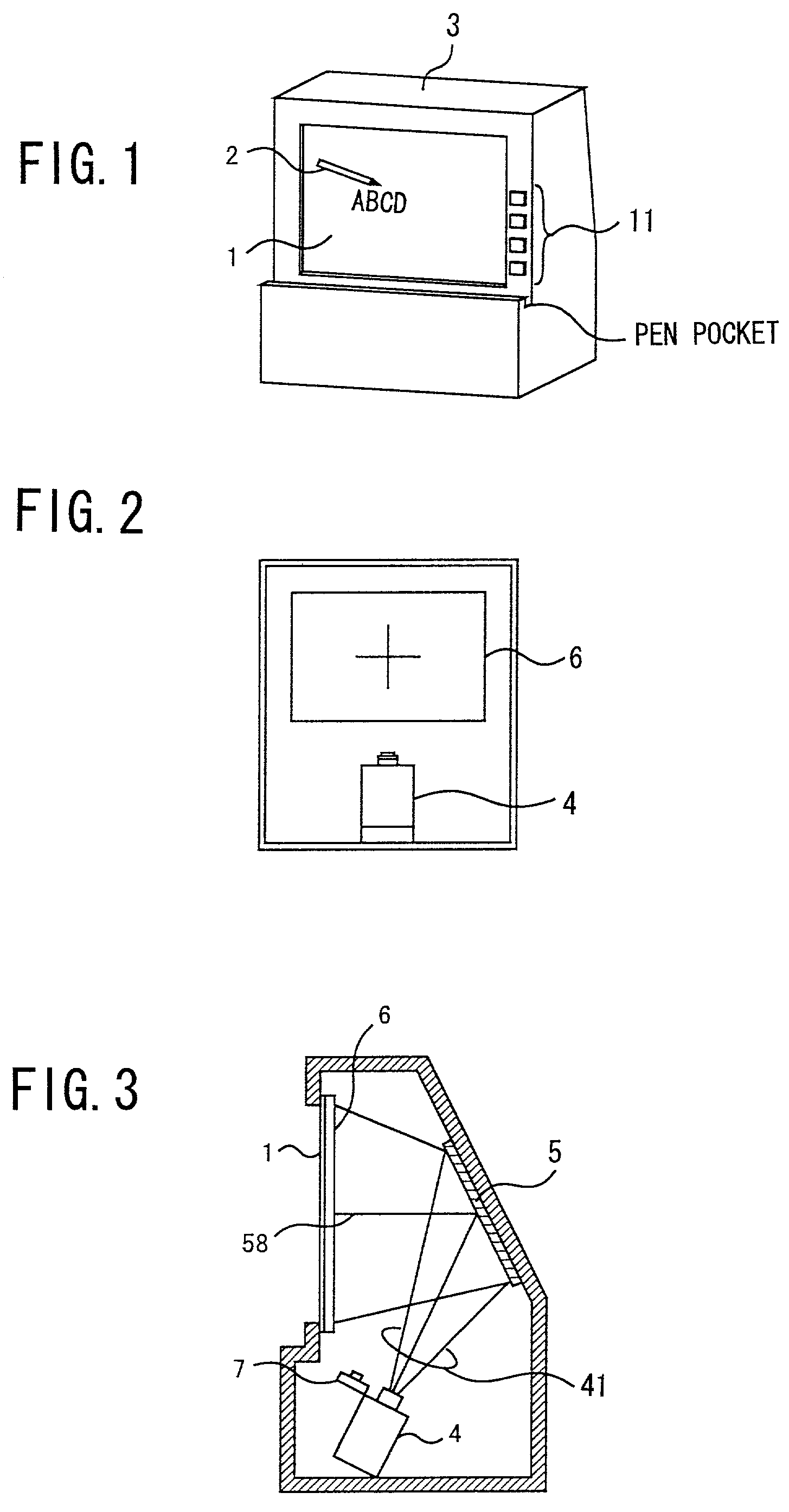

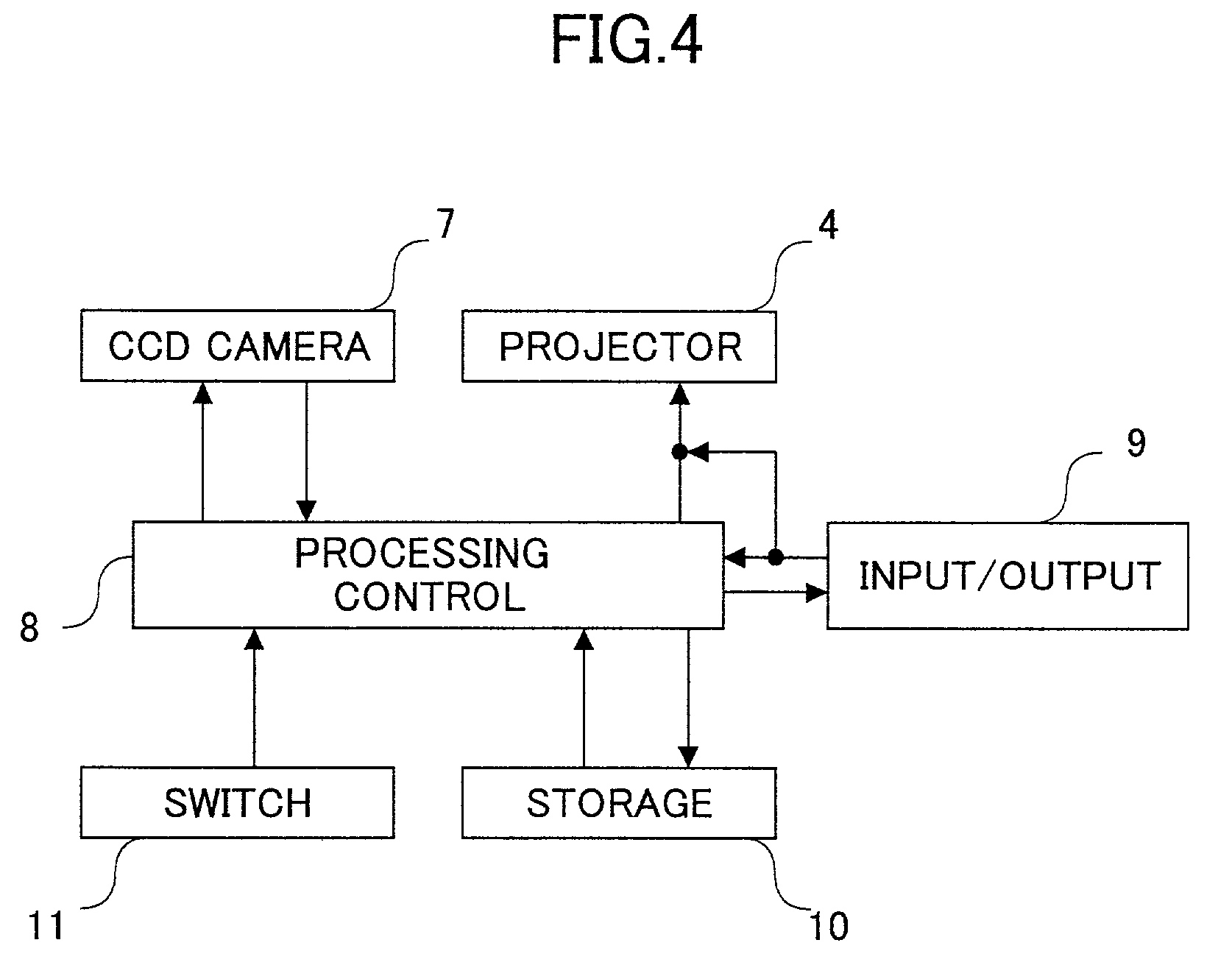

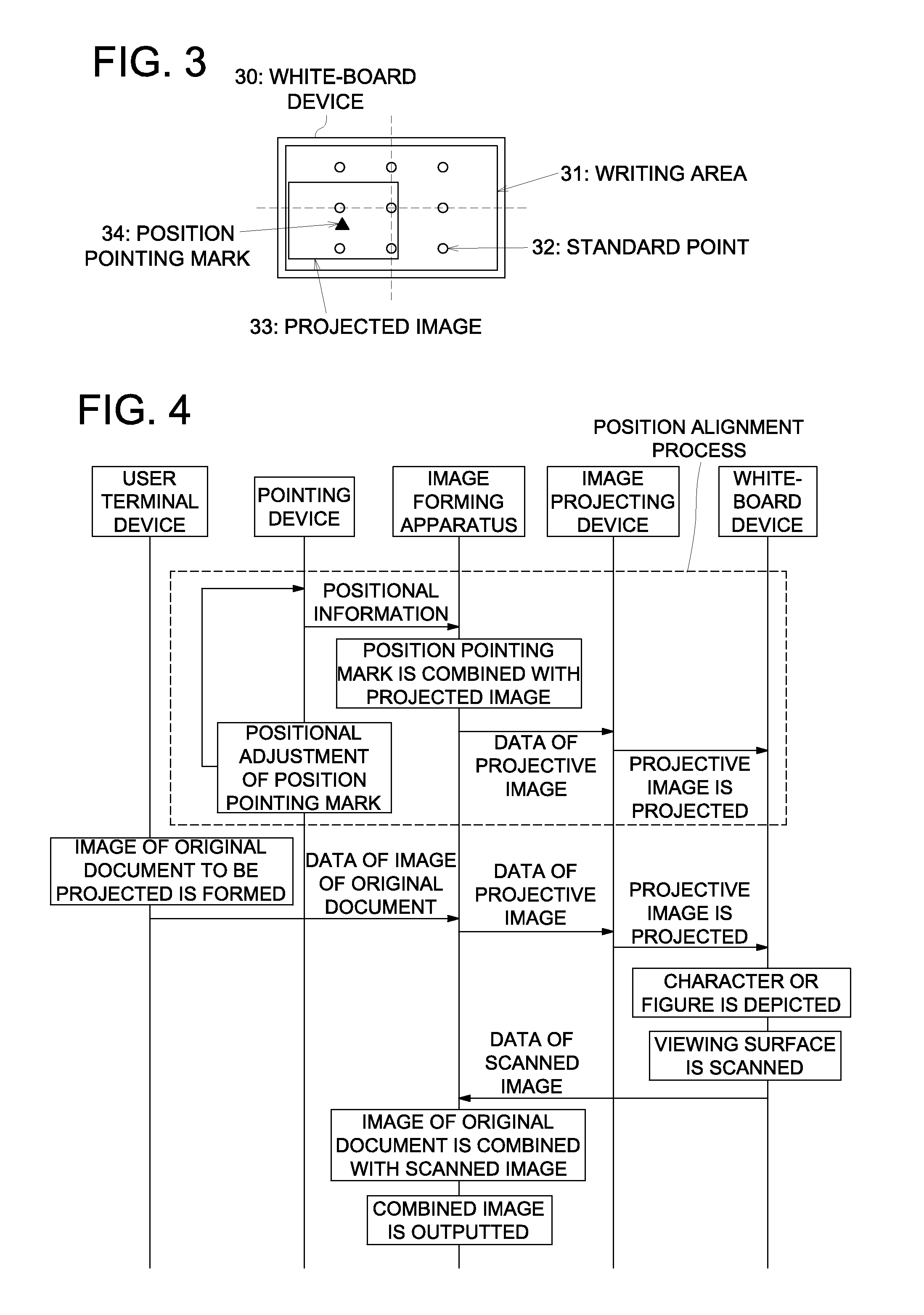

Projection-type display device and software program

InactiveUS7176890B2Easy to operateWhole system is simplifiedTelevision system detailsDigital data processing detailsComputer graphics (images)Projection image

A projection surface on which a predetermined projection image is projected is provided; a writing surface on which an image can be drawn directly in a superimposing manner with a projection image displayed on the projection surface is provided; and a photography part photographing an image drawn on the writing surface by means of an image-pickup part comprising two-dimensionally-disposed pixels is provided.

Owner:RICOH KK

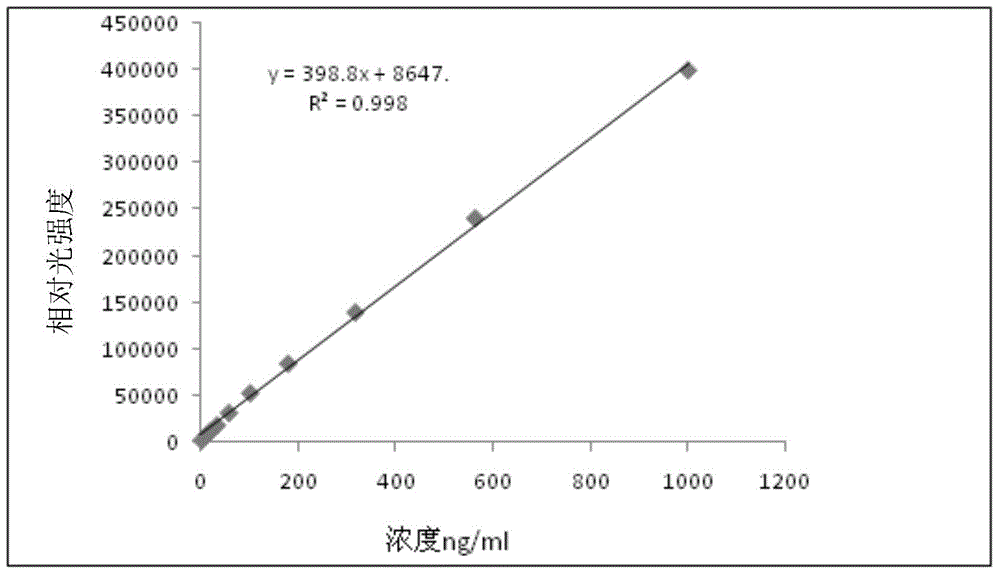

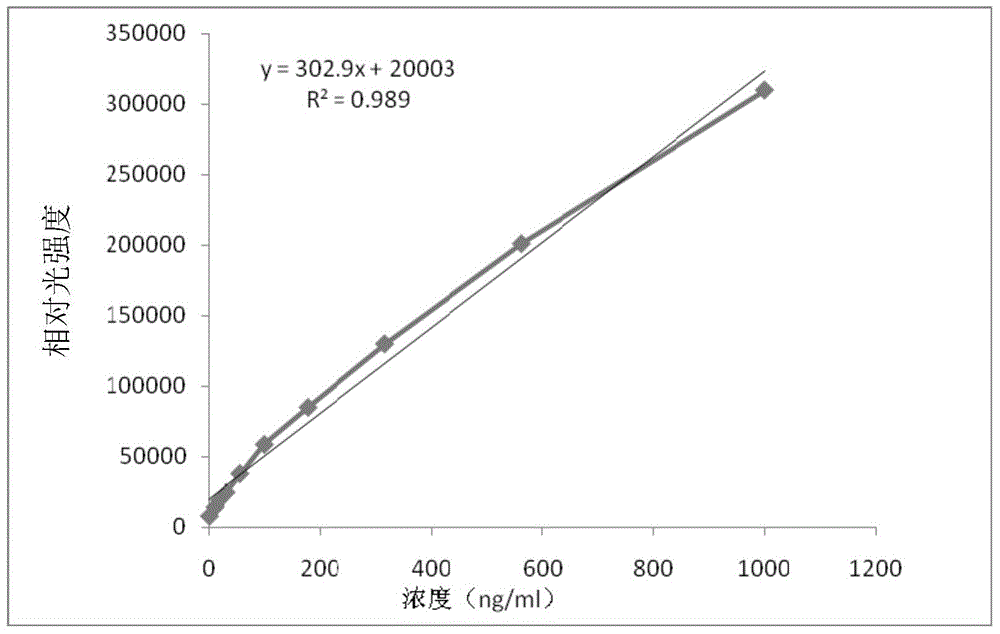

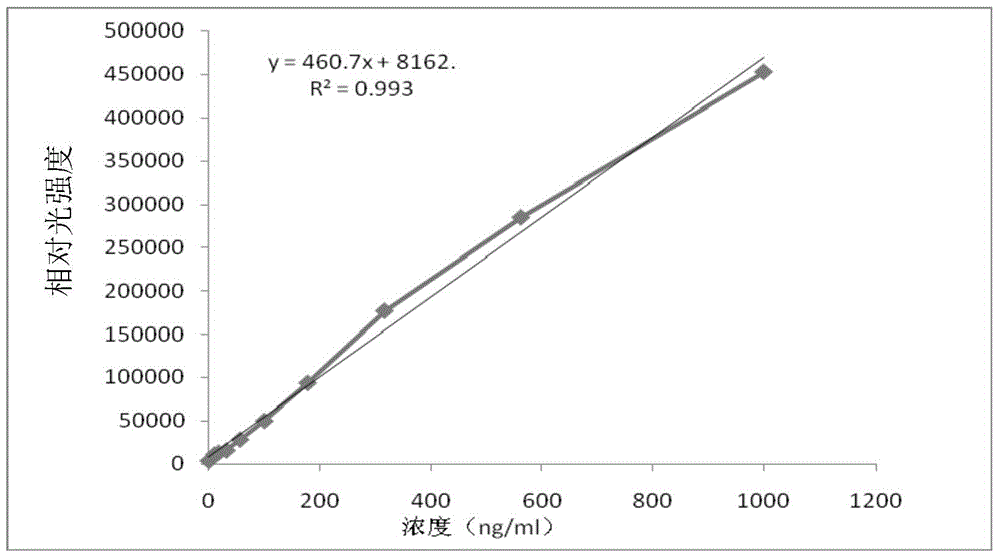

Kit for detecting lipoprotein-associated phospholipase A2 and preparation method and application of kit

ActiveCN104634970AEliminate distracting factorsEliminate preprocessing timeDisease diagnosisMagnetic sphereAntibody

The invention provides a kit for detecting lipoprotein-associated phospholipase A2 and a preparation method of the kit. The kit comprises one or more first antibodies for resisting the lipoprotein-associated phospholipase A2, and one or more second antibodies for resisting the lipoprotein-associated phospholipase A2, wherein the first antibodies are used for being combined with enveloped magnetic spheres of to-be-tested lipoprotein-associated phospholipase A2; the second antibodies are combined with the to-be-tested lipoprotein-associated phospholipase A2 on other sites which are different from the combined site of the to-be-tested lipoprotein-associated phospholipase A2 and the first antibodies for resisting the lipoprotein-associated phospholipase A2 and are marked with tracer markers. In a preferred scheme, the kit also comprises a displacing agent; and the detection accuracy of the kit can be further improved. The invention further provides a method for detecting the lipoprotein-associated phospholipase A2 by virtue of the kit. The concentration of the lipoprotein-associated phospholipase A2 in the sample can be determined by adopting serum as a detection sample at high repeatability, high accuracy and high sensitivity.

Owner:SHENZHEN NEW INDS BIOMEDICAL ENG

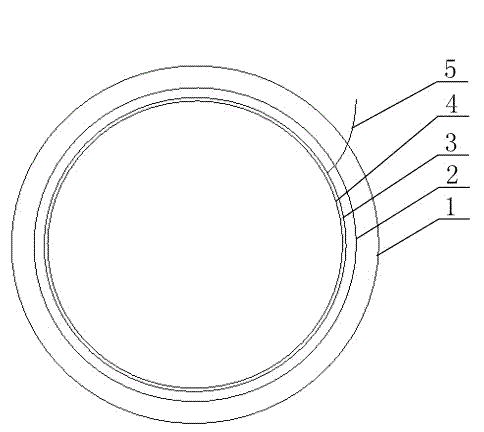

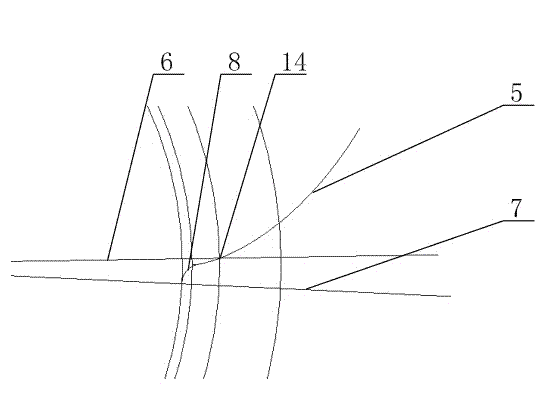

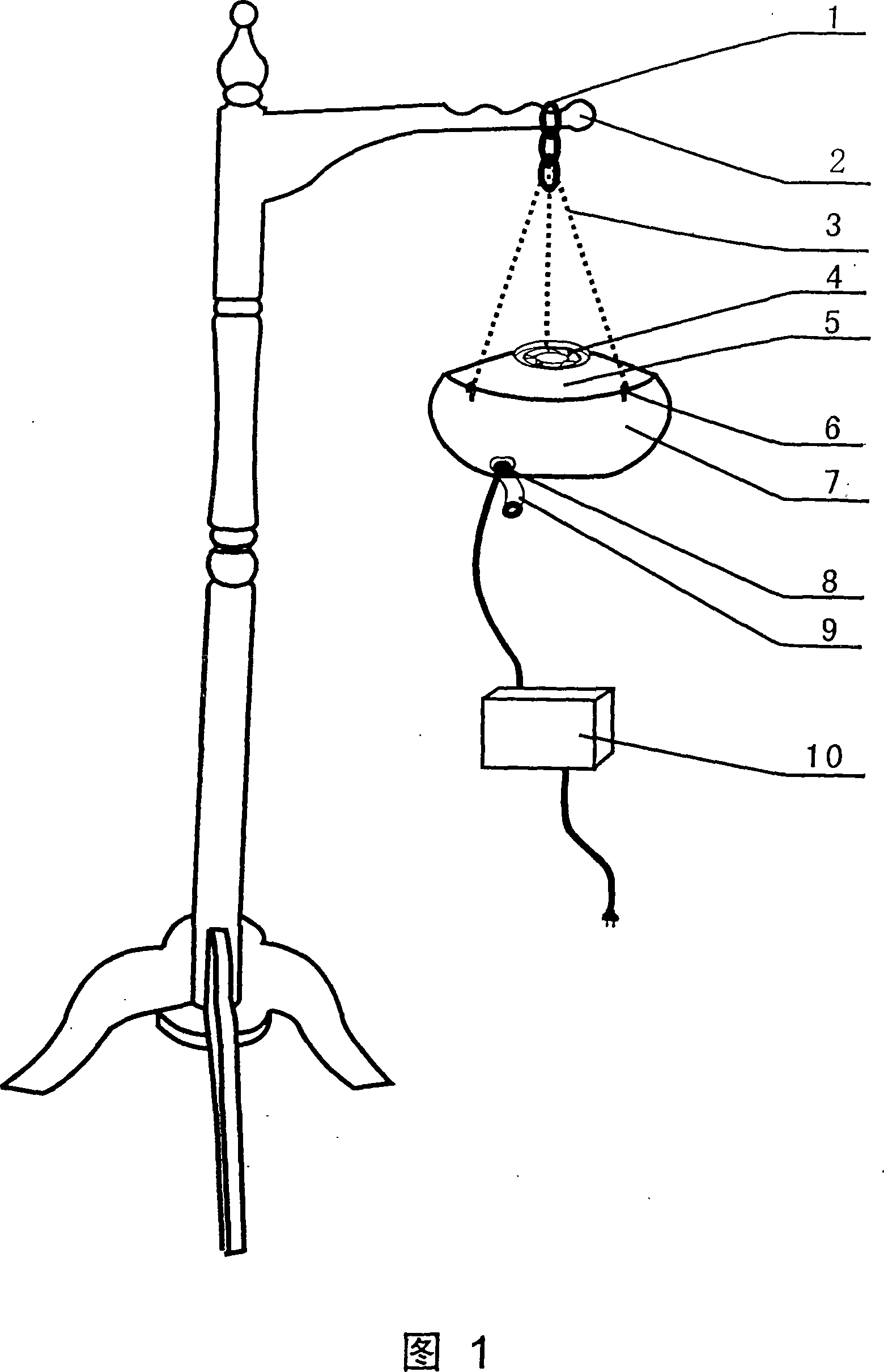

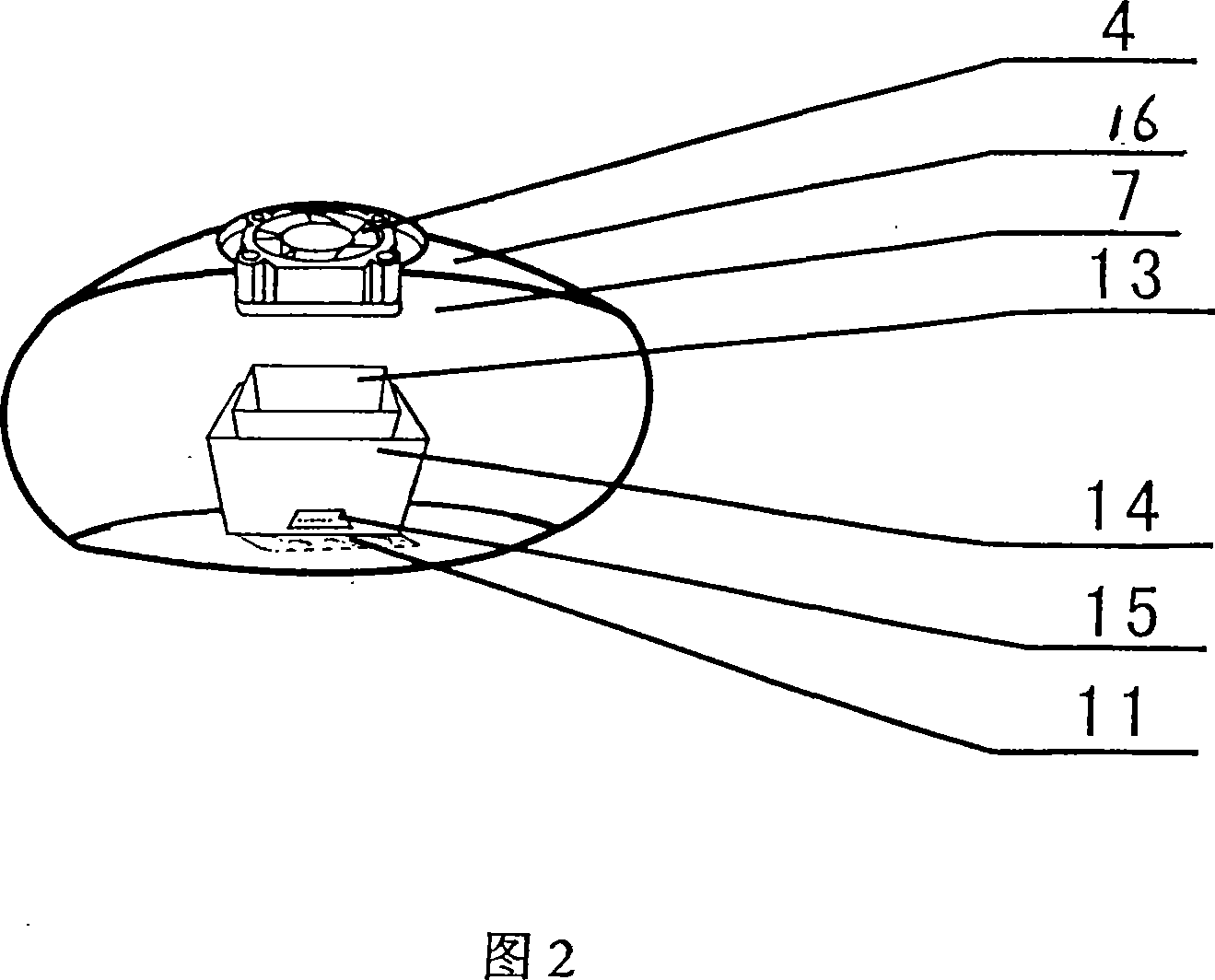

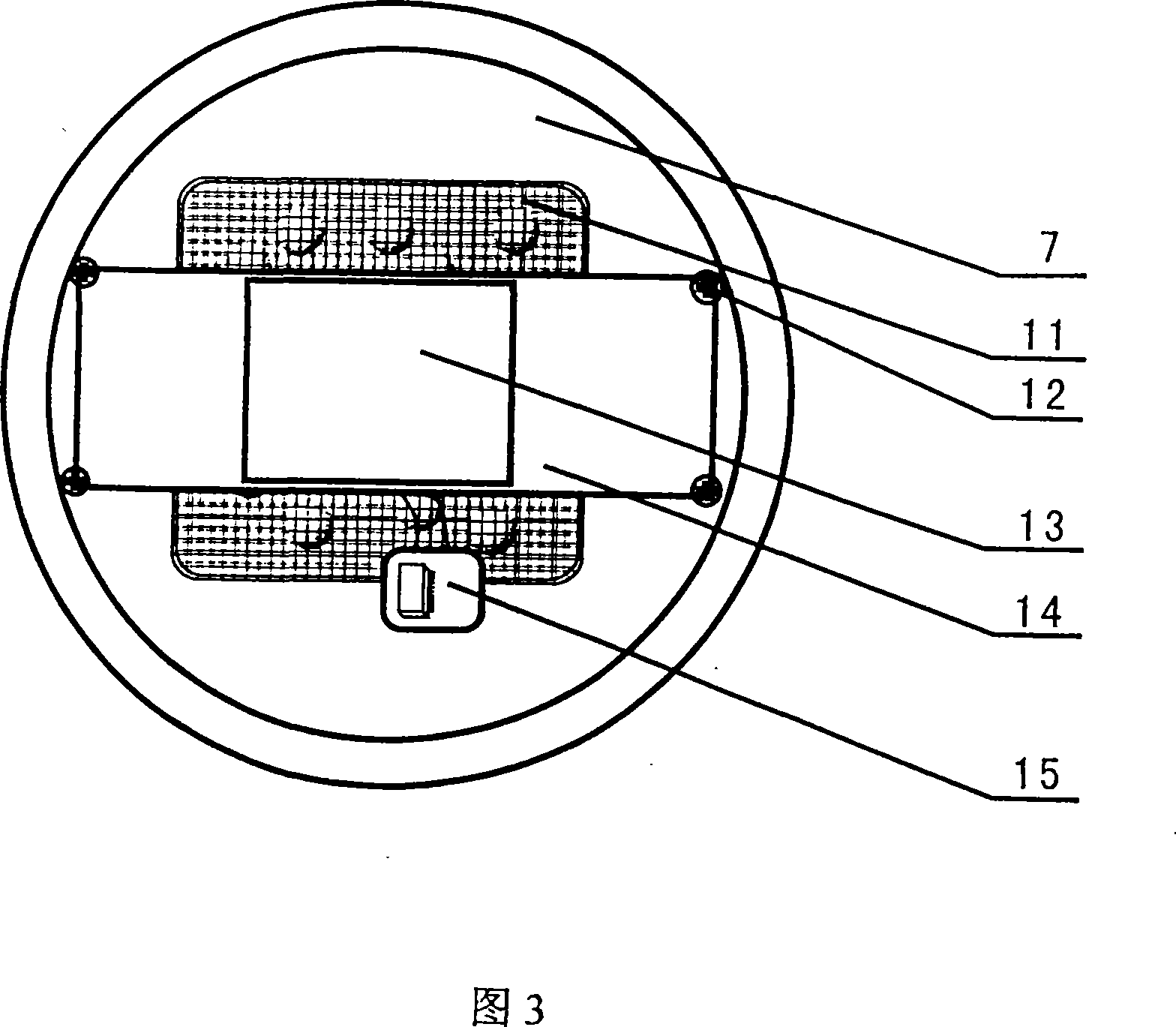

Laser moxibustion instrument

InactiveCN101134128AReduce pollutionControllableMedical devicesSurgical instrument detailsInvasive treatmentsLaser beams

The laser moxibustion apparatus consists of one circular metal chain, one movable support, at least three locating chains, one fan, one box with one power socket, one box cover, 1-6 semiconductor helium-neon laser irradiating probes and one power source control box. The present invention has the advantages including the combination of no-invasion acupuncture and no-burning moxibustion, and the combination of laser and moxibustion to warm needle with laser beam.

Owner:上海采逸生物科技有限公司

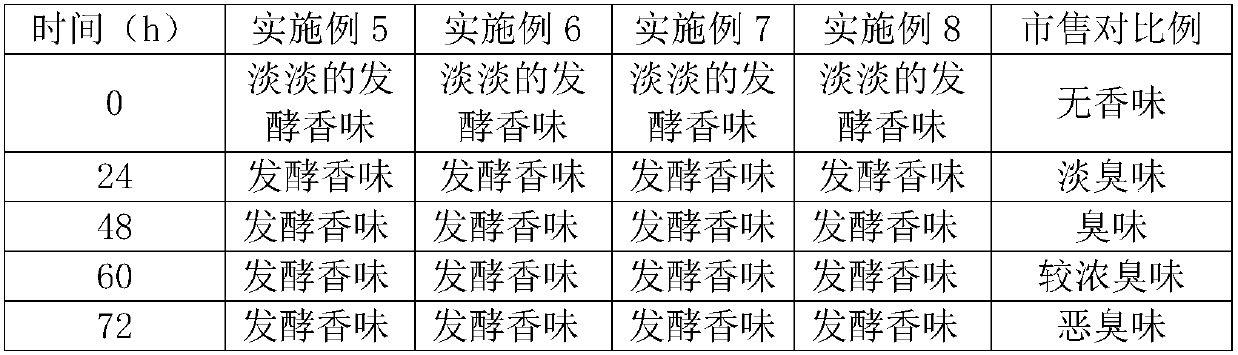

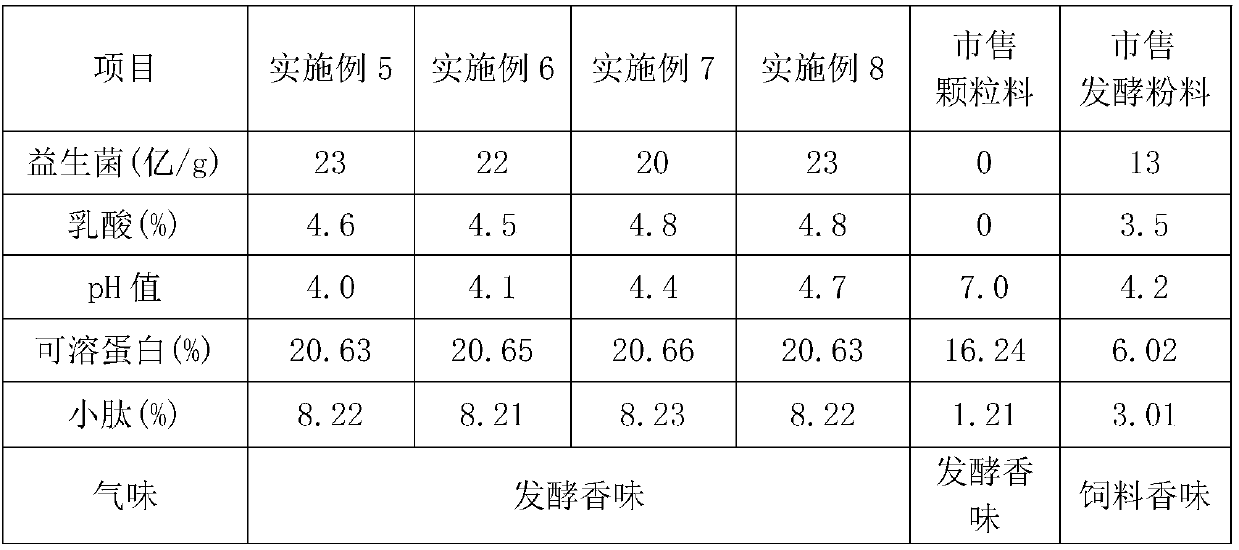

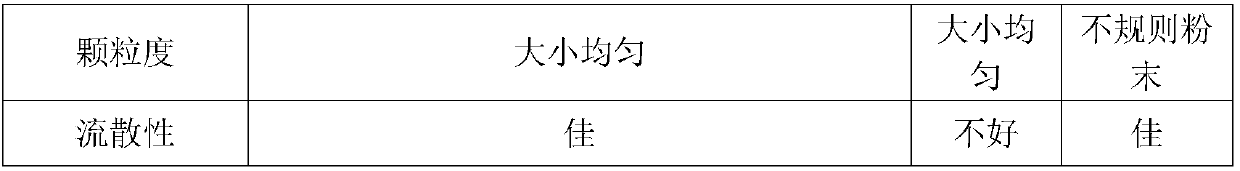

Wet granular microorganism fermented feed for aquatic animals and preparation method of wet granular microorganism fermented feed

InactiveCN108013213AAdd lessLow costFood processingClimate change adaptationMacromolecular SubstancesBacteriocin

The invention discloses a wet granular microorganism fermented feed for aquatic animals and a preparation method of the wet granular microorganism fermented feed. The wet granular microorganism fermented feed is prepared by virtue of an improved feed formula through the following steps: pretreatment, expansion treatment, granulation treatment, fermentation treatment and packaging. The wet granularmicroorganism fermented feed has the advantages that (1) the feed is soft and good in elasticity and taste, has strong stability after being fed into a water body and is not dispersed, so that the ingestion probability is increased; (2) the feed contains a large number of beneficial microorganisms, and macromolecular substances in the feed raw materials are decomposed into micromolecular amino acid, sugar, active peptide, vitamin, bacteriocin and the like, so that the digestive absorption is promoted; (3) the emission of nitrogen in animal waste is reduced, the decomposition of substrate organic matters is promoted, and an environment with purified water quality is maintained; and (4) the feed is sequentially expanded and granulated, the components are relatively precisely bonded, and fermentation liquid is added and is soaked to generate aerobic and anaerobic fermentation in a fermentation bag, so that the macromolecular substances in the feed raw materials are decomposed into micromolecular amino acid, sugar, active peptide, vitamin, bacteriocin and the like by virtue of the beneficial bacteria.

Owner:高嘉泰

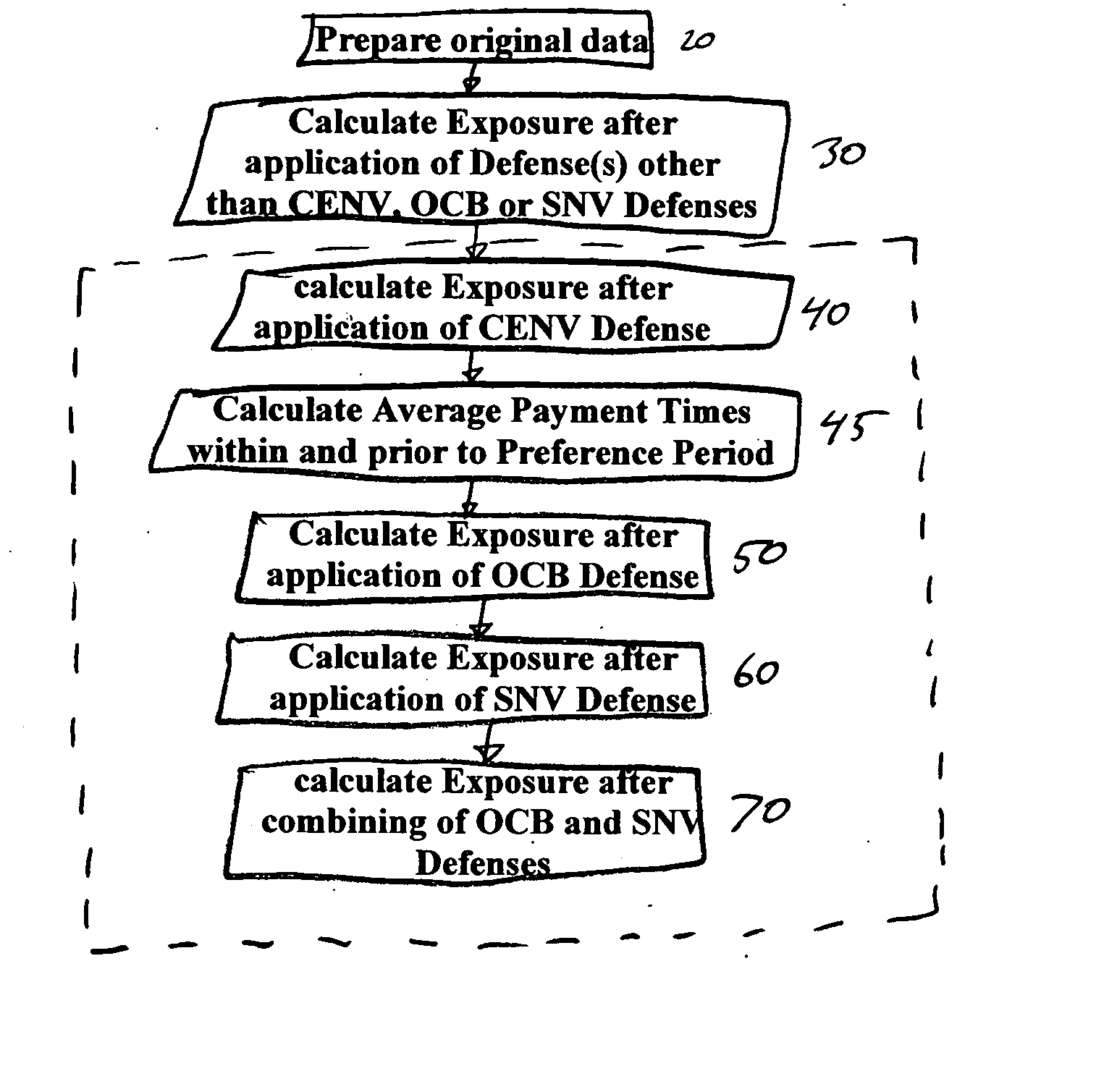

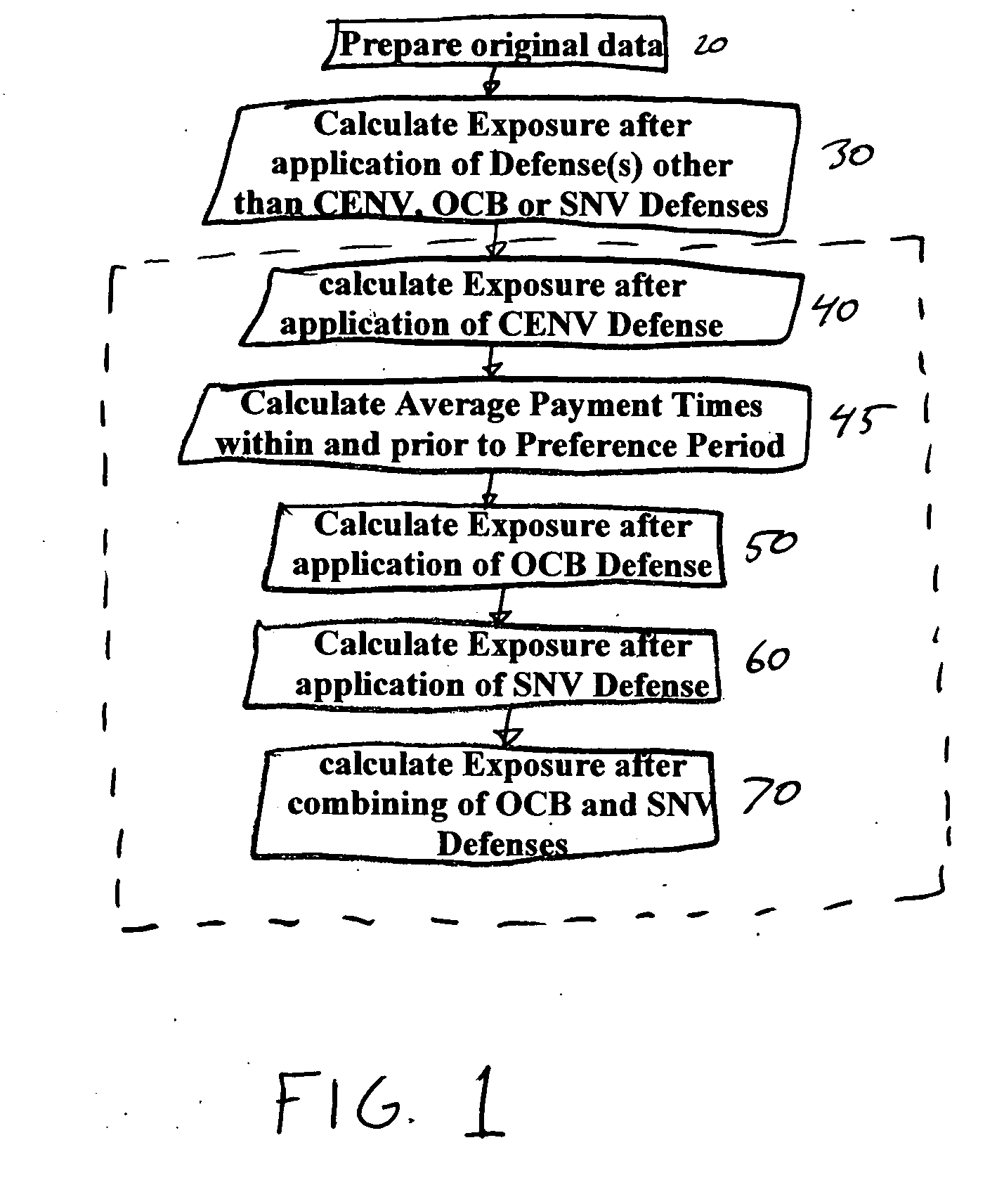

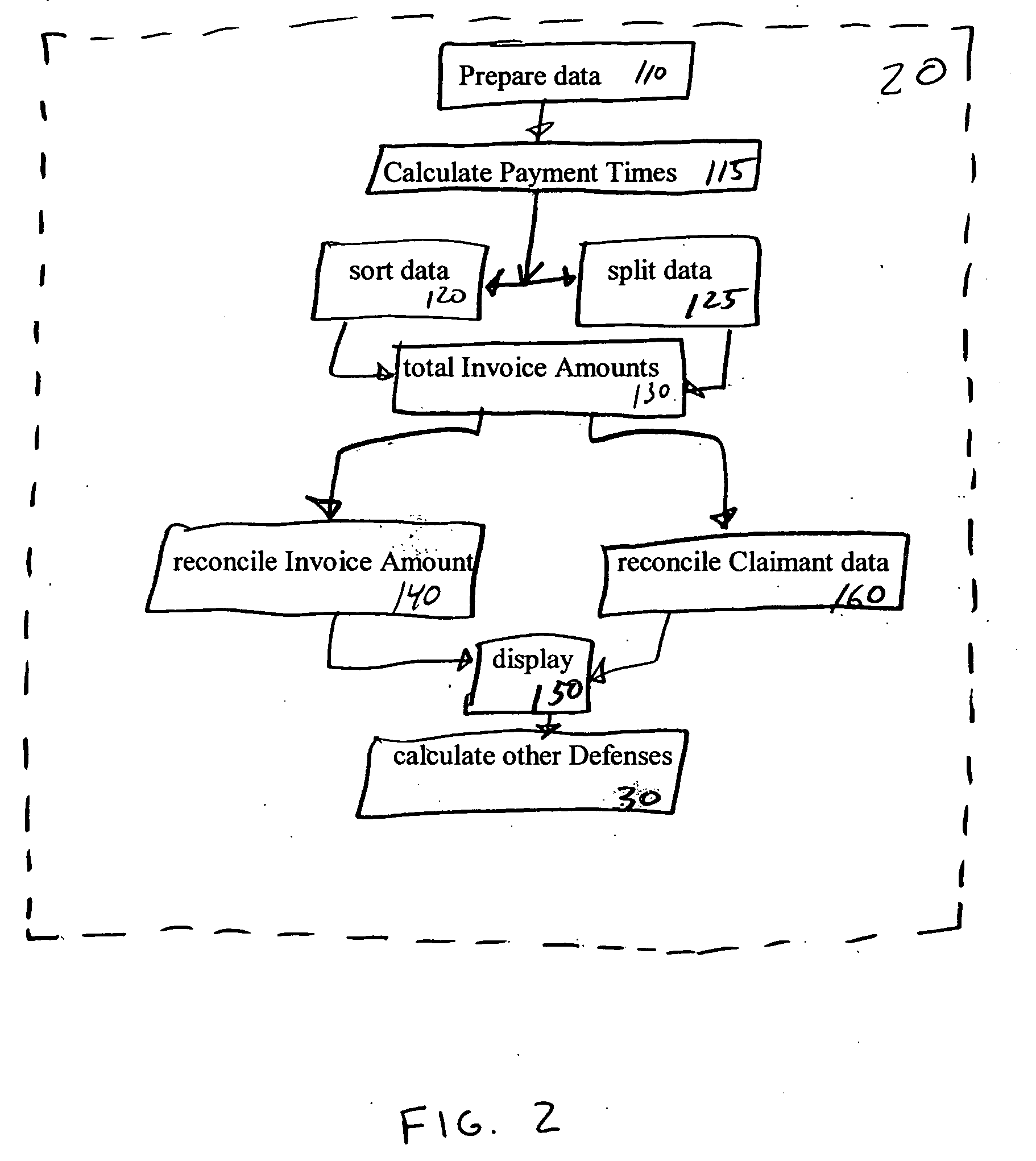

Method and system for calculating and presenting bankruptcy preference payment defenses

InactiveUS20050125346A1Elimination of manipulation of dataEliminate calculationsFinancePayment architecturePaymentComputer science

Owner:WINIECKI KURT A

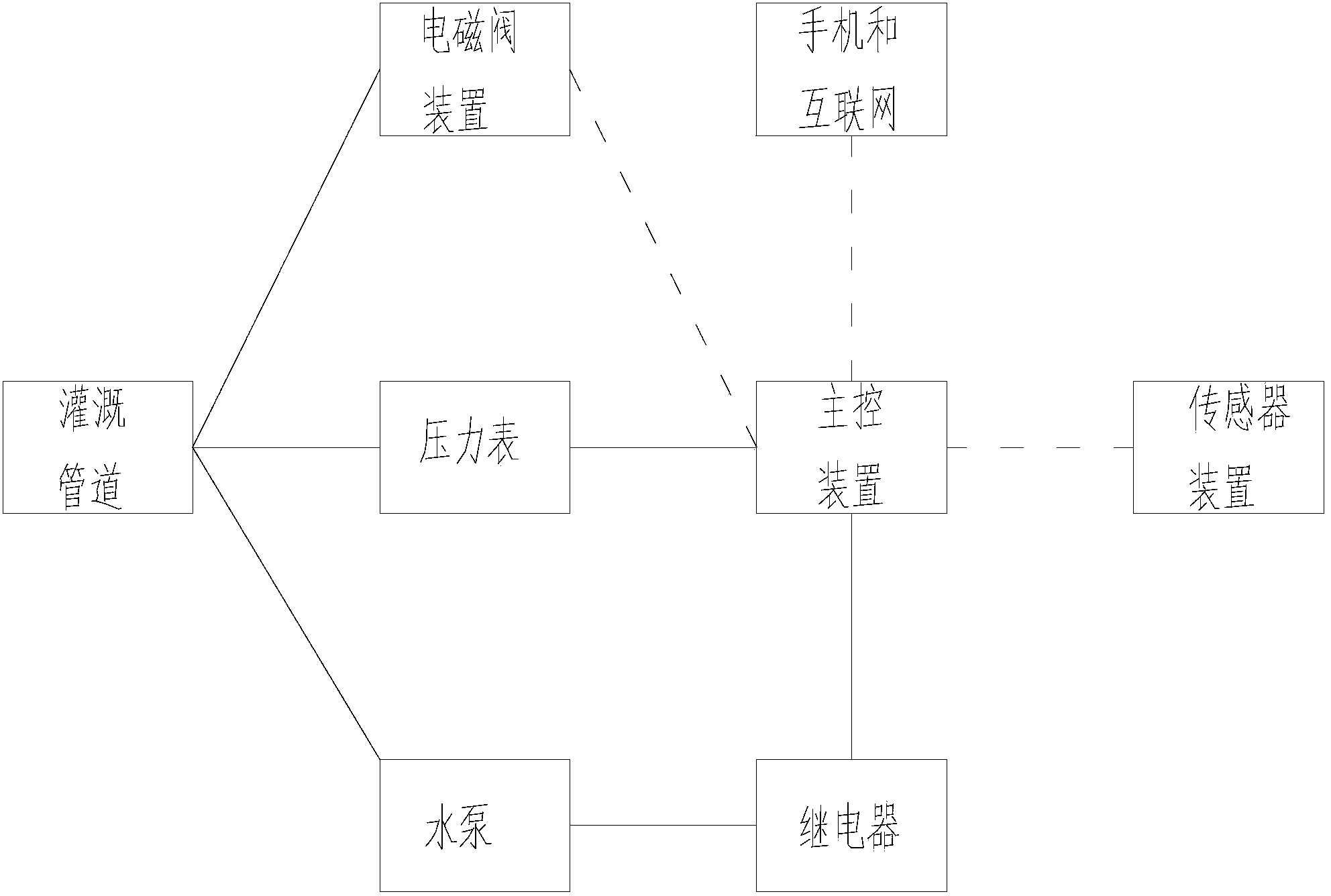

Automatic irrigation system

InactiveCN103380715AReduce shockCombine accuratelyClimate change adaptationWatering devicesControl mannerWater source

The invention relates to an automatic irrigation system, which comprises a main control device, multiple irrigation pipelines, an electromagnetic valve device, a sensor device and a wireless communication device, wherein the sensor device is arranged on a piece of land requiring irrigation; a water pump is arranged on each irrigation pipeline, and is positioned at one end close to a water source; a pressure gauge is arranged in each irrigation pipeline, and is positioned at one end close to an irrigation sprayer; the pressure gauges are connected with the main control device; the main control device controls the water pumps to open or close as per high and low water pressure values from the pressure gauges; the main control device is in wireless communication with a control mobile phone and the internet. The automatic irrigation system has the benefits as follows: the system can be controlled manually or automatically, and a more accurate effect can be obtained through combination of the two control manners; the manner that one water pressure control device is matched with one irrigation pipeline is adopted, so that the energy is saved on one hand, and the impact on the pipelines by high water pressure can be reduced and the pipelines are protected on the other hand.

Owner:周劼

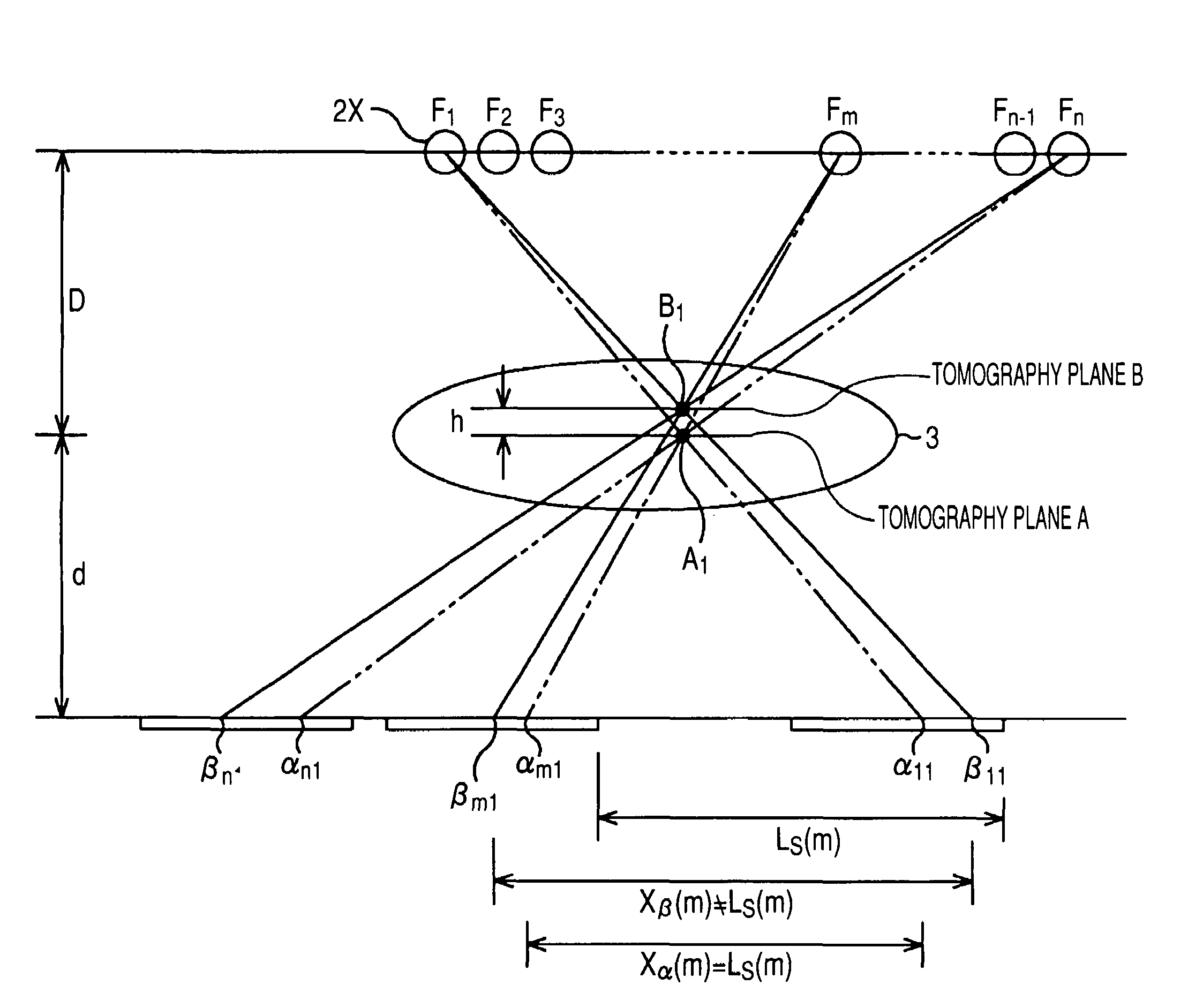

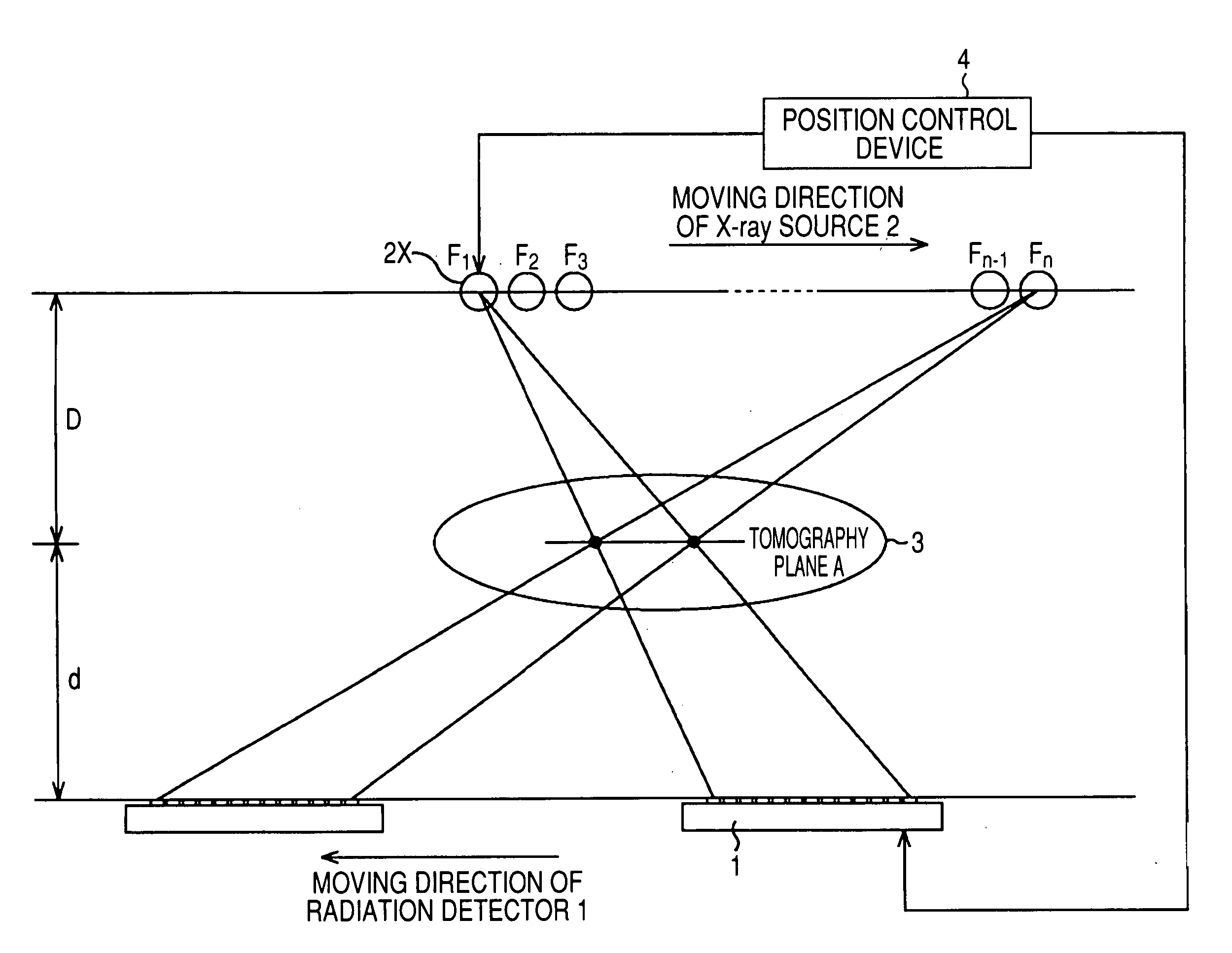

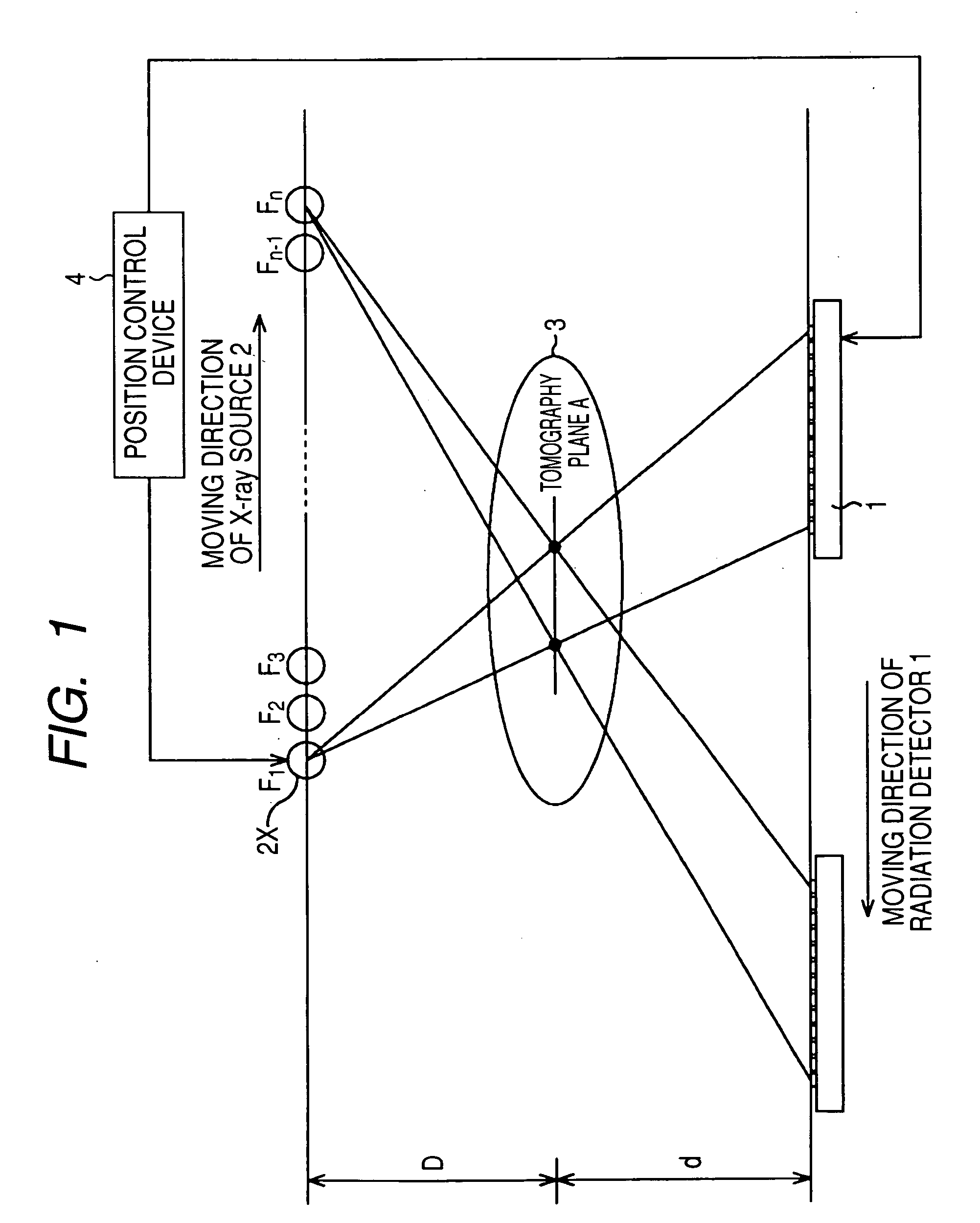

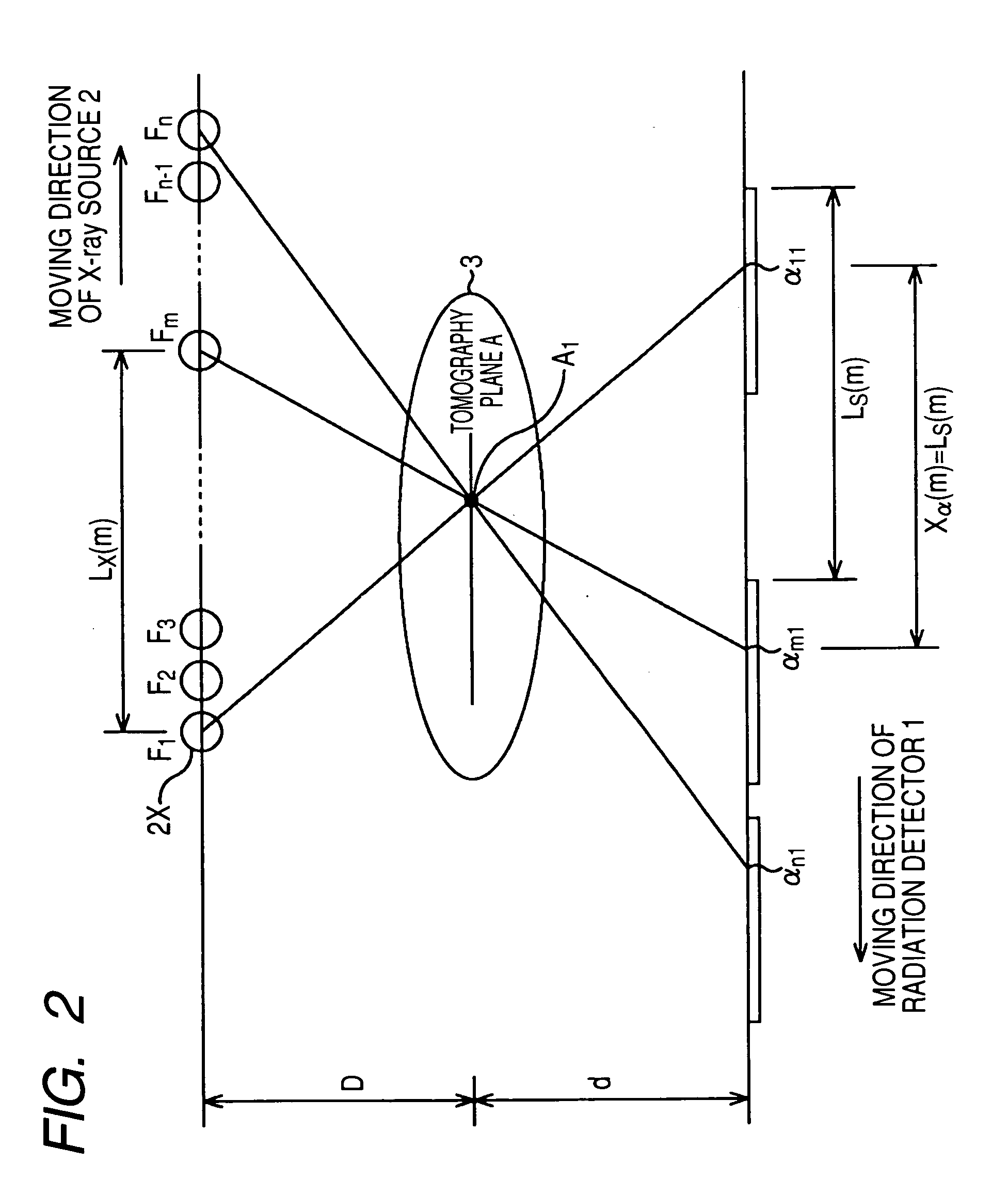

Radiation image pick-up device, radiation image pick-up method and program

InactiveUS7313219B2Reduce frequencyAvoid exposureTelevision system detailsRadiation/particle handlingX-rayTomography

Owner:CANON KK

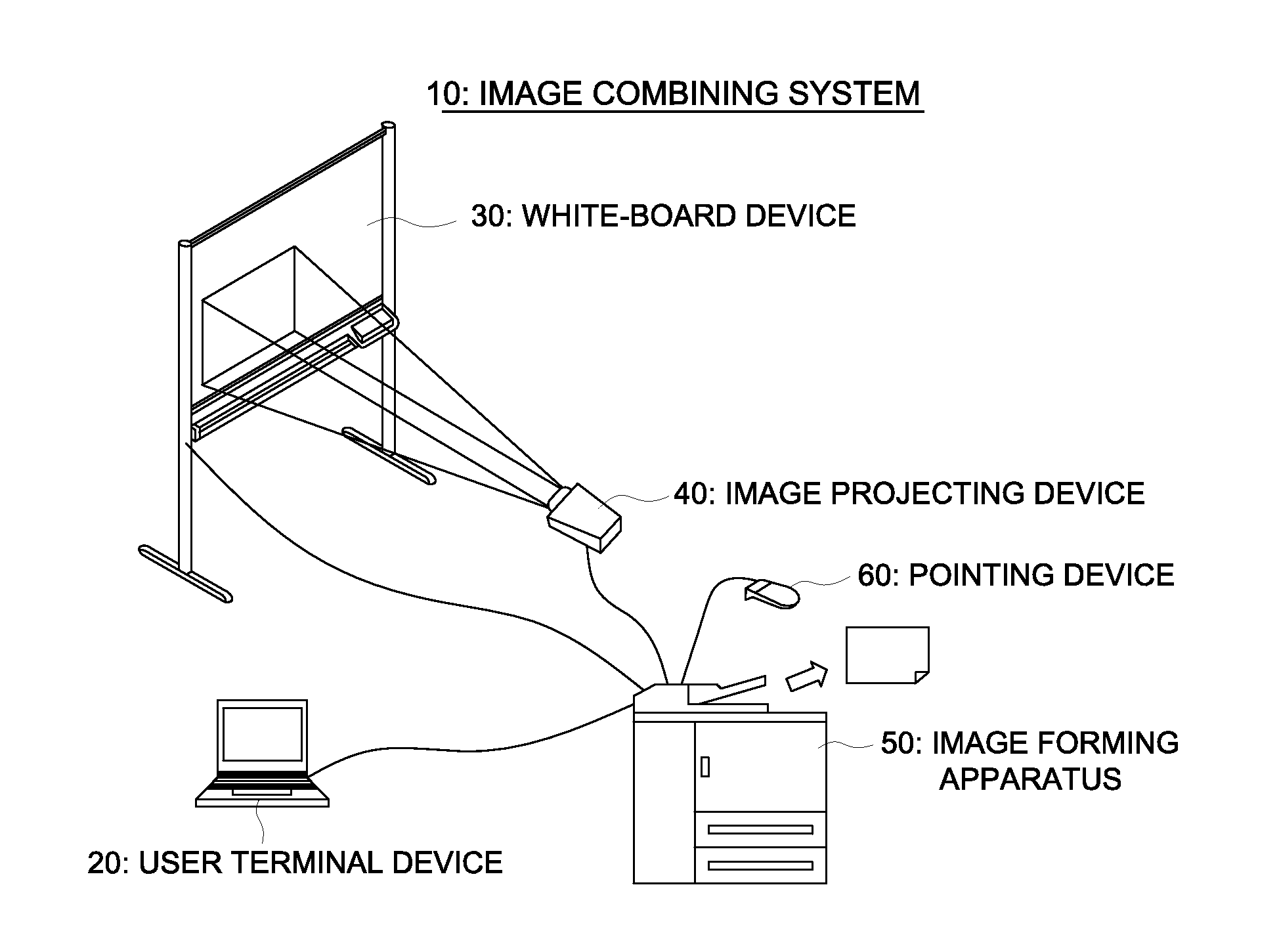

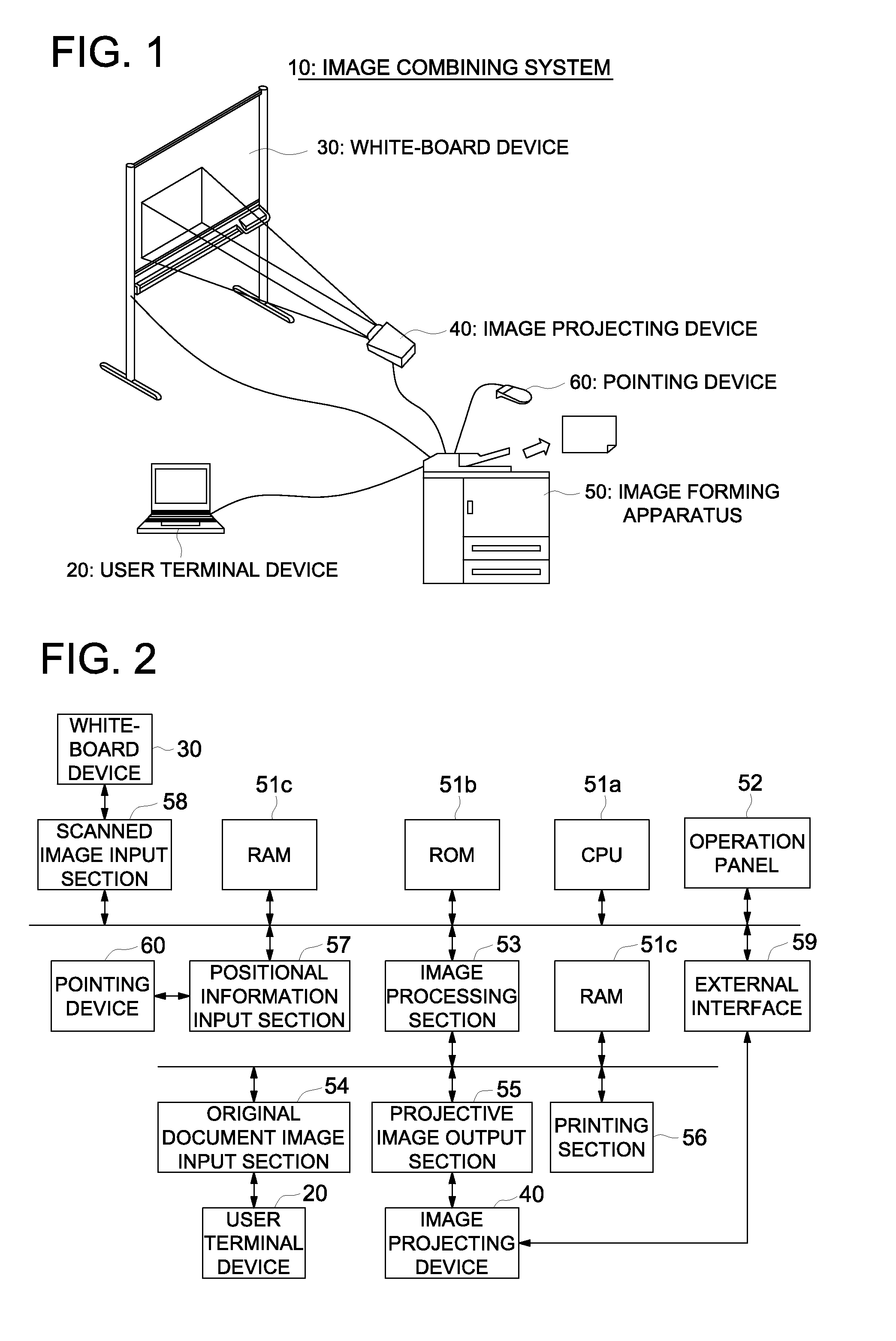

Image combining apparatus and method for aligning positions of images

InactiveUS20110199636A1Combine accuratelyEasy to identifyBuilt-on/built-in screen projectorsCathode-ray tube indicatorsProjection imageImage synthesis

An image combining apparatus, which is connected with a white-board device, and an image projecting device, includes an image outputting section for outputting the projective image data to the image projecting device, an operation section for designating any position on a projected image, an image processing section for generating projective image data for displaying a mark, a memory section for memorizing the coordinate positions of two or more standard points, and an image inputting section for receiving the scanned image data from the white-board device, wherein the image processing section obtains the coordinate positions of the certain marks when the two or more standard points have been designated, the image processing section makes correspondence with the coordinate positions of the certain marks and the coordinate positions of the two or more standard points respectively, whereby the image processing position recognizes the position of the projected image on the viewing surface.

Owner:KONICA MINOLTA BUSINESS TECH INC

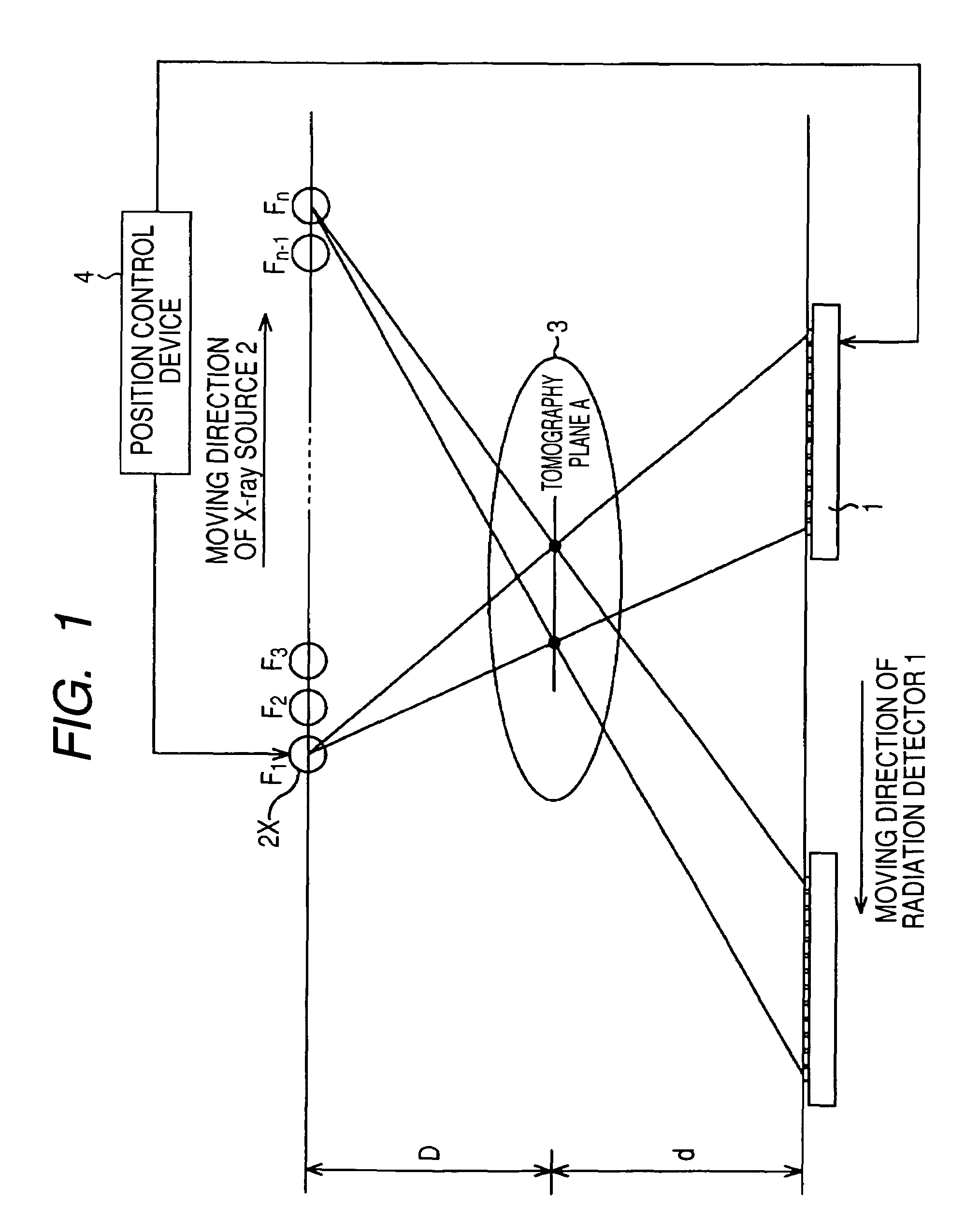

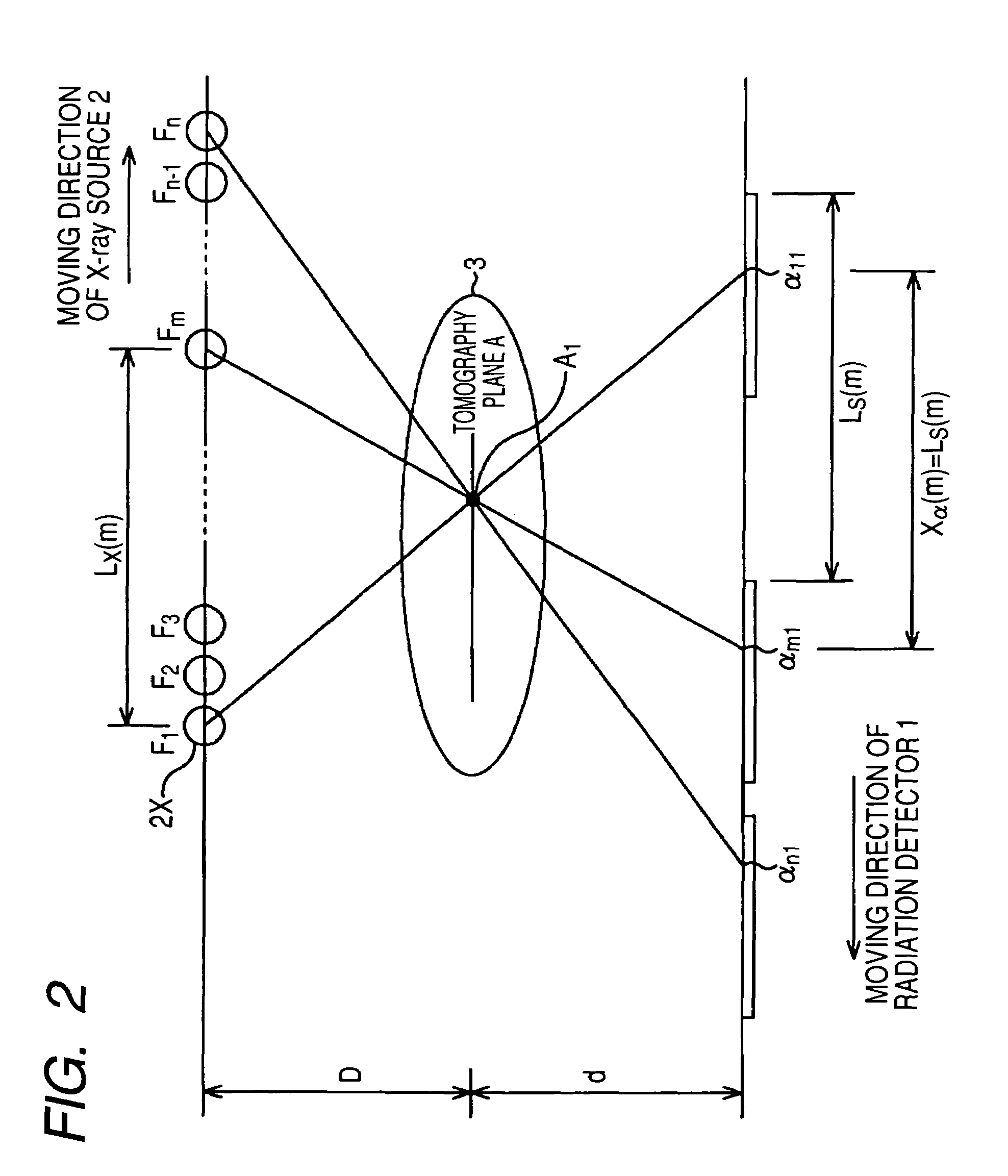

Radiation image pick-up device, radiation image pick-up method and program

InactiveUS20050078785A1Reduce frequencyAvoid exposureTelevision system detailsRadiation/particle handlingX-rayTomography

To provide a radiation image pick-up device capable of obtaining a plurality of tomography images through single-time image pick-up, a radiation image pick-up method and a program. When a position controller moves an X-ray source to an optional tomography plane in an object to be detected in parallel and the X-ray source is present at geometric focuses set at equal interval, X rays are pulsatively generated by the X-ray source and detection of X rays by a radiation detector is performed by the total of n times. Moreover, a position controller moves the radiation detector in accordance with the movement of the X-ray source.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com