Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1157results about How to "Precise thickness control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

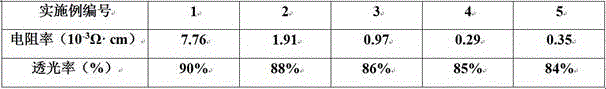

Method for preparing high-uniformity Nb-doped TiO2 transparent conducting thin film through atomic layer deposition

ActiveCN106011785ALow resistivityDisplacemental dopingChemical vapor deposition coatingThin membraneTransmittance

The invention relates to a method for preparing a high-uniformity Nb-doped TiO2 transparent conducting thin film through atomic layer deposition in the technical field of semiconductor photoelectric materials. According to the method, a substrate which is subjected to ultrasonic cleaning and nitrogen blowing-drying is heated; titanium tetrachloride, niobium tris(ethylmethylamido)-tert-butylimino and high purity water serve as precursor sources; and deposition combination is cycled for multiple times, so that the high-uniformity Nb-doped TiO2 transparent conducting thin film is prepared. The transparent conducting thin film prepared through the method is excellent in performance; the refractive index is 2.3 or above; the electrical resistivity can reach 2.9*10<4> omega.cm at a minimum; and at this moment, the light transmittance is still 85% or above.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

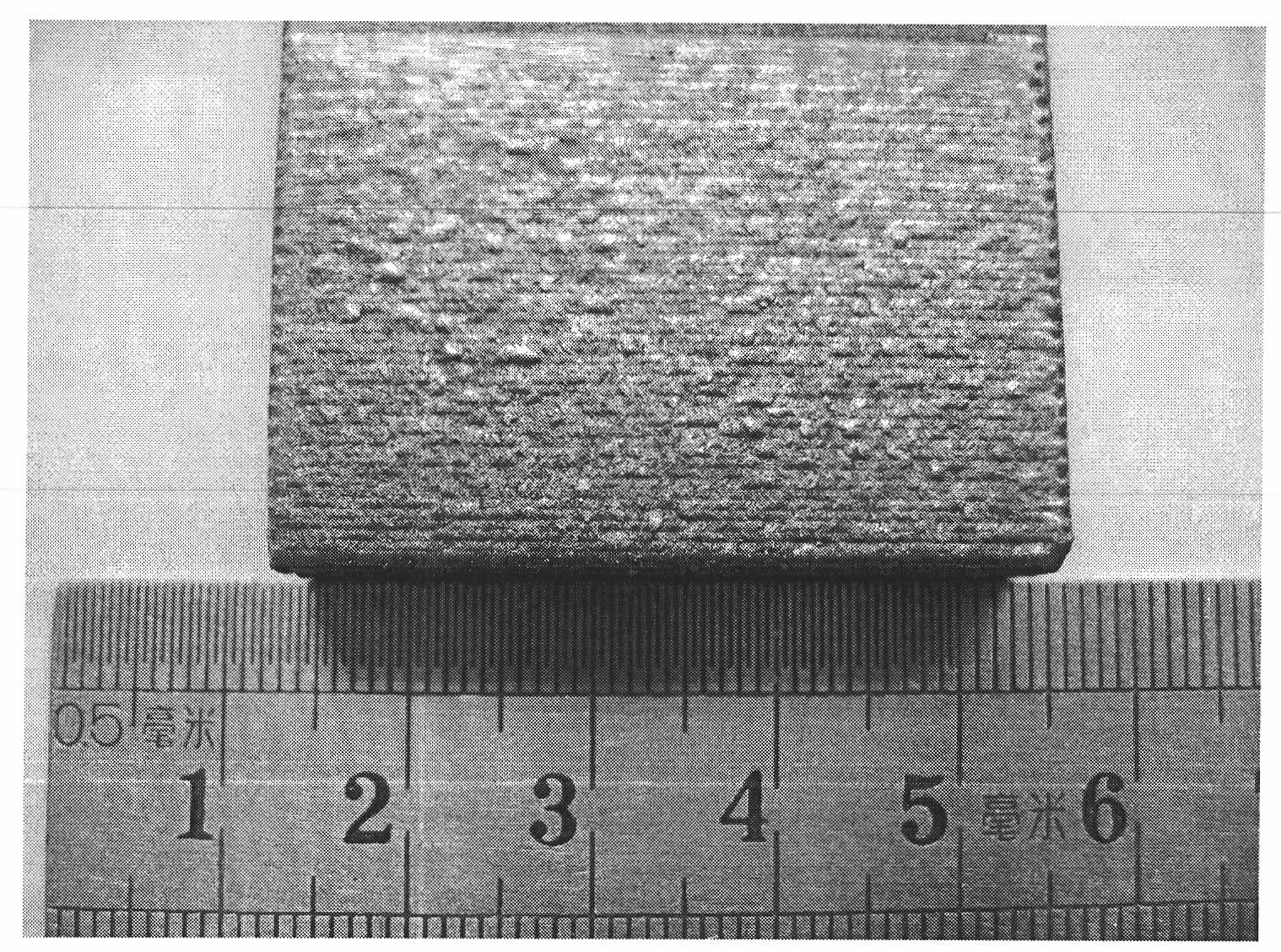

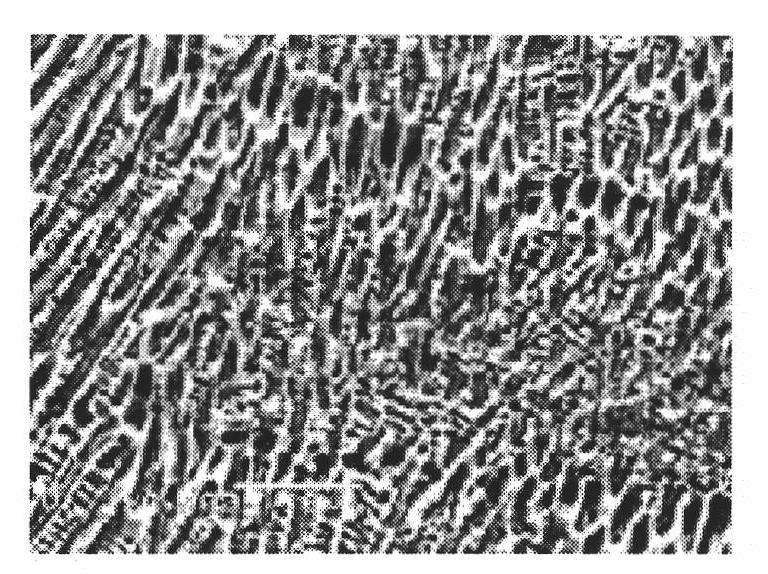

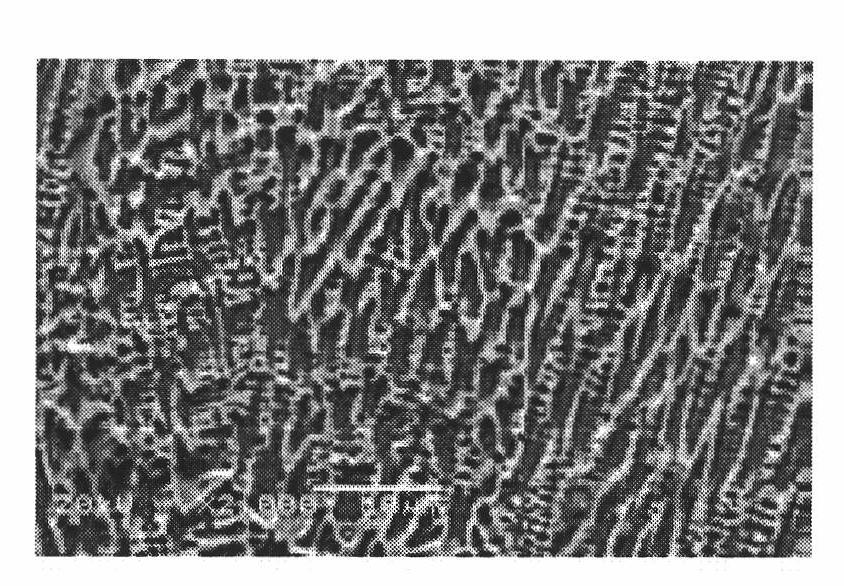

Laser-cladded composite wear-resisting layer on surfaces of copper and copper alloys and preparation method

InactiveCN102041503ADense tissueReduce energy consumptionMetallic material coating processesCobalt based alloyCopper alloy

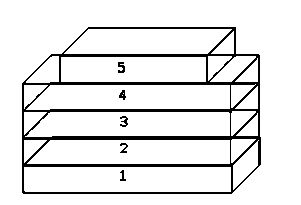

The invention relates to a laser-cladded composite wear-resisting layer on the surfaces of copper and copper alloys and a preparation method. The composite wearing layer is a multi-layered laser cladding layer comprising at least two or more than two layers, wherein the coating connected with a substrate is the first layer, which is also called as a transition layer and is a copper-based alloy prepared from the following components in percentage by weight: 20.0-30.0 percent of Cu, 6.0-8.0 percent of Al, 0.3-0.6 percent of Si, 1.7-2.4 percent of Zr and the balance of Ni; and the rest layer is a cobalt-based alloy prepared from the following components in percentage by weight: 1.0-1.5 percent of C, 25-30 percent of Cr, 2-4 percent of Fe, 10-15 percent of W, 0.8-1.2 percent of Si, 3-4 percent of B, 8-12 percent of Ti, 10-12 percent of Ni and the balance of Co. The composite wear-resisting layer provided by the invention has compact tissues without cracks or pores and forms favorable metallurgy combination with the surfaces of copper and copper alloys. The preparation method provided by the invention can be used for accurately controlling the thickness of the composite wear-resisting layer and automatically controlling the whole process, and has the advantages of low energy consumption, no pollution, high efficiency and low cost.

Owner:HUAZHONG UNIV OF SCI & TECH

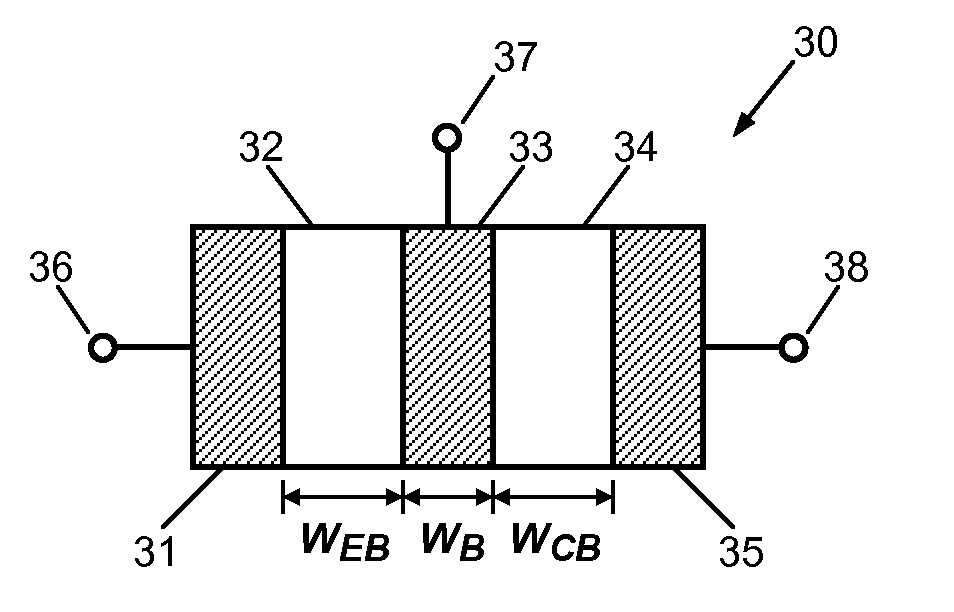

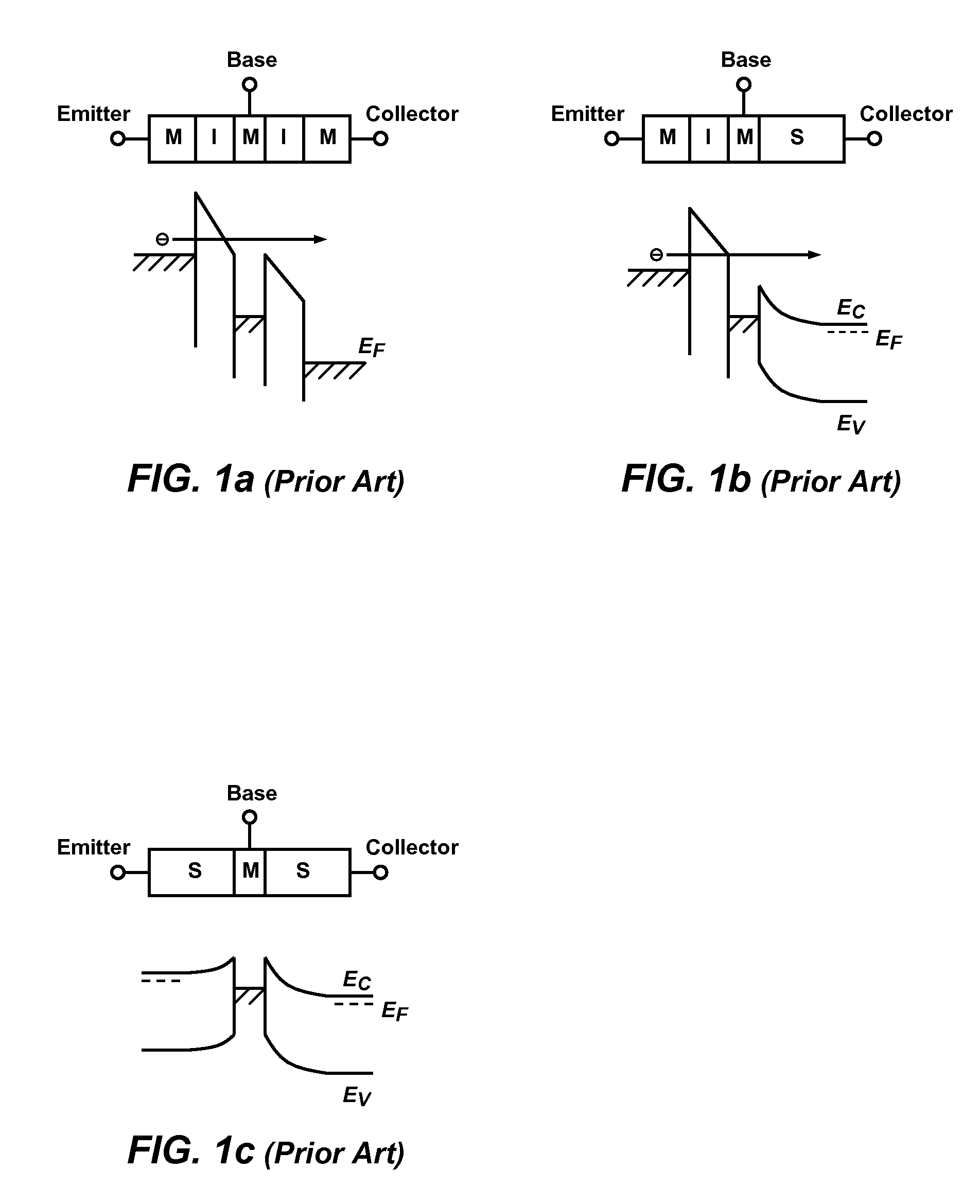

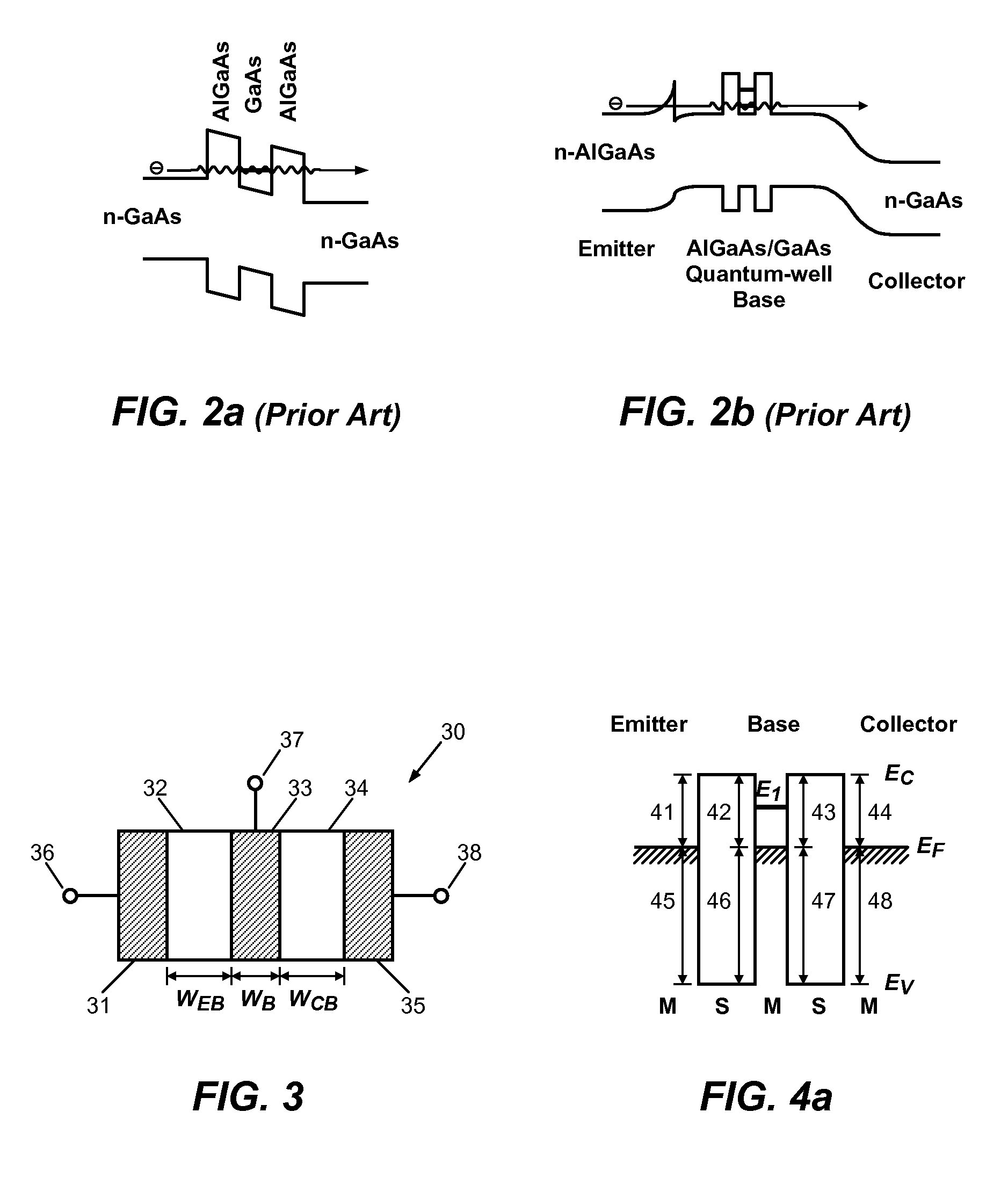

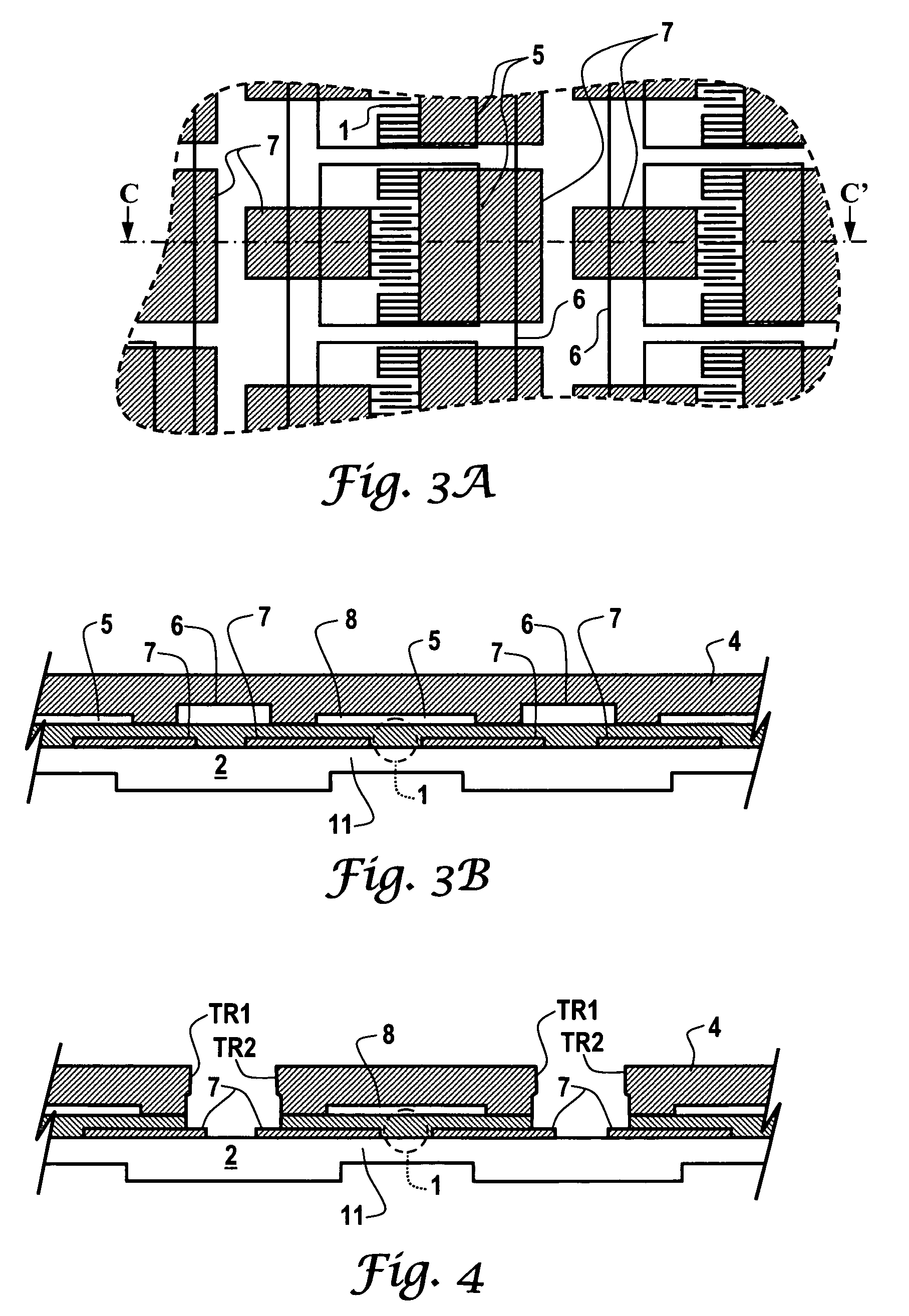

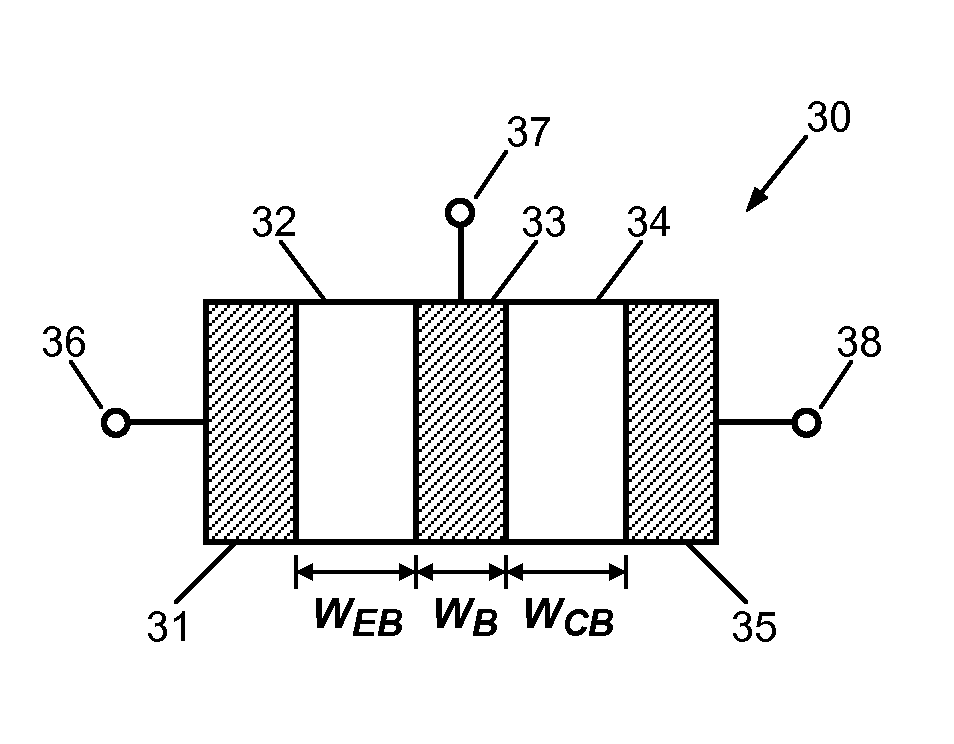

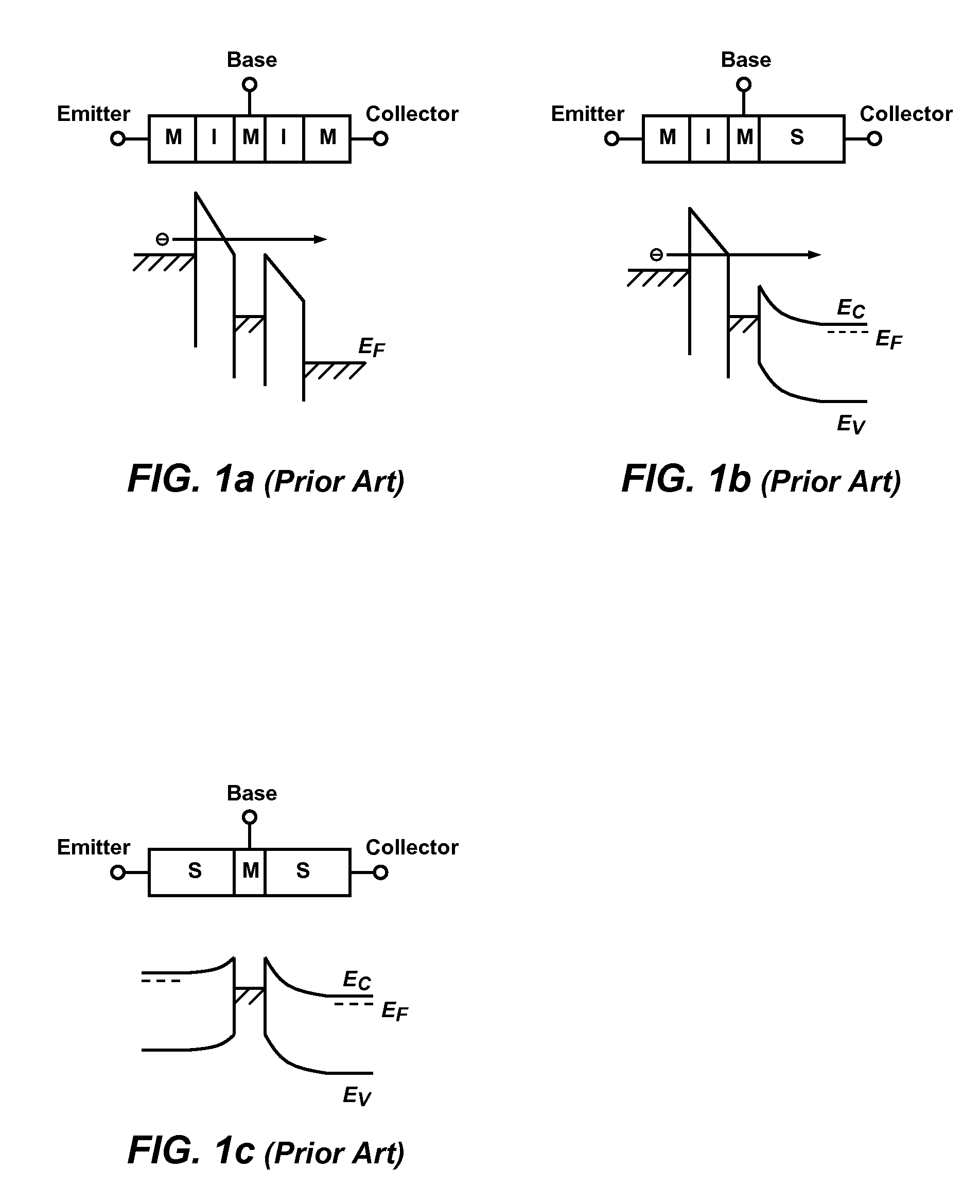

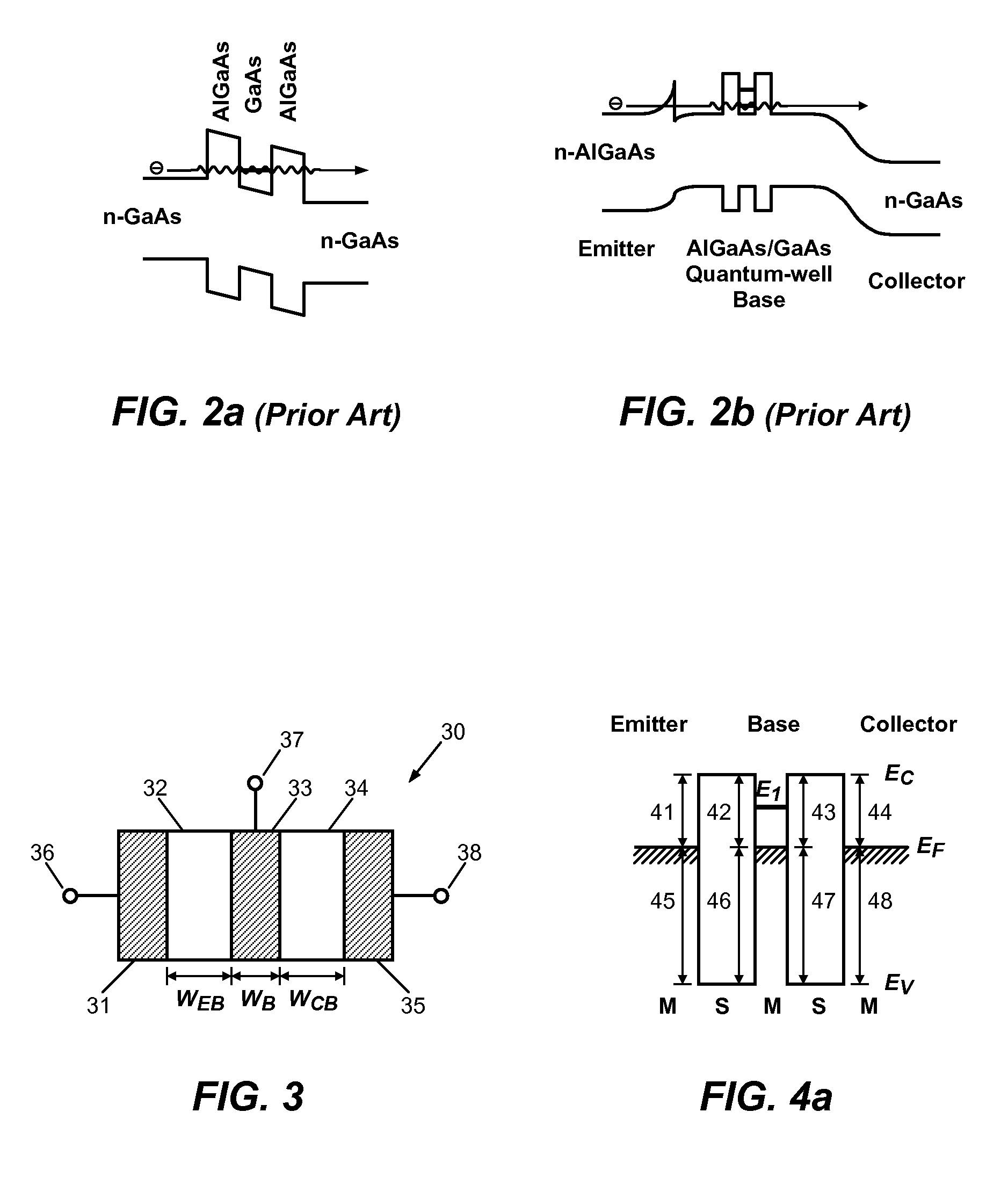

Schottky barrier quantum well resonant tunneling transistor

InactiveUS20100102298A1High speedReduce series resistanceTransistorSolid-state devicesQuantum wellSchottky barrier

A semiconductor transistor device includes one or more conductive base regions, a first semiconductor barrier region, a second semiconductor barrier region, a conductive emitter region, and a conductive collector region. The first semiconductor barrier region or the second semiconductor barrier region has a dimension smaller than 100 Å. A first Schottky barrier junction is formed at the interface of the first semiconductor barrier region and the one or more conductive base regions. A second Schottky barrier junction is formed at the interface of the second semiconductor barrier region and the one or more conductive base regions. A third Schottky barrier junction is formed at the interface of the conductive emitter region and the first semiconductor barrier region. A fourth Schottky barrier junction is formed at the interface of the conductive collector region and the second semiconductor barrier region.

Owner:WU KOUCHENG

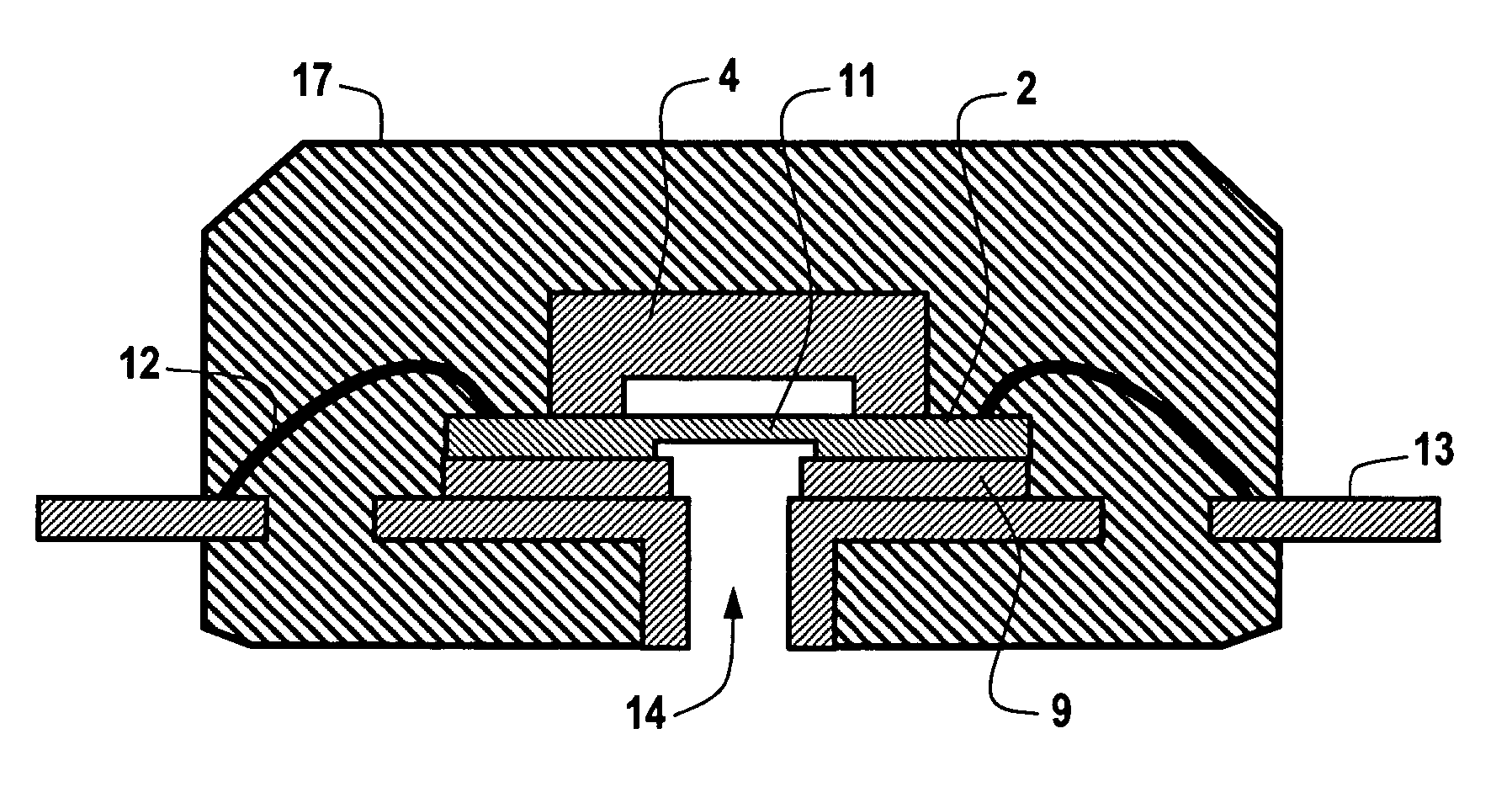

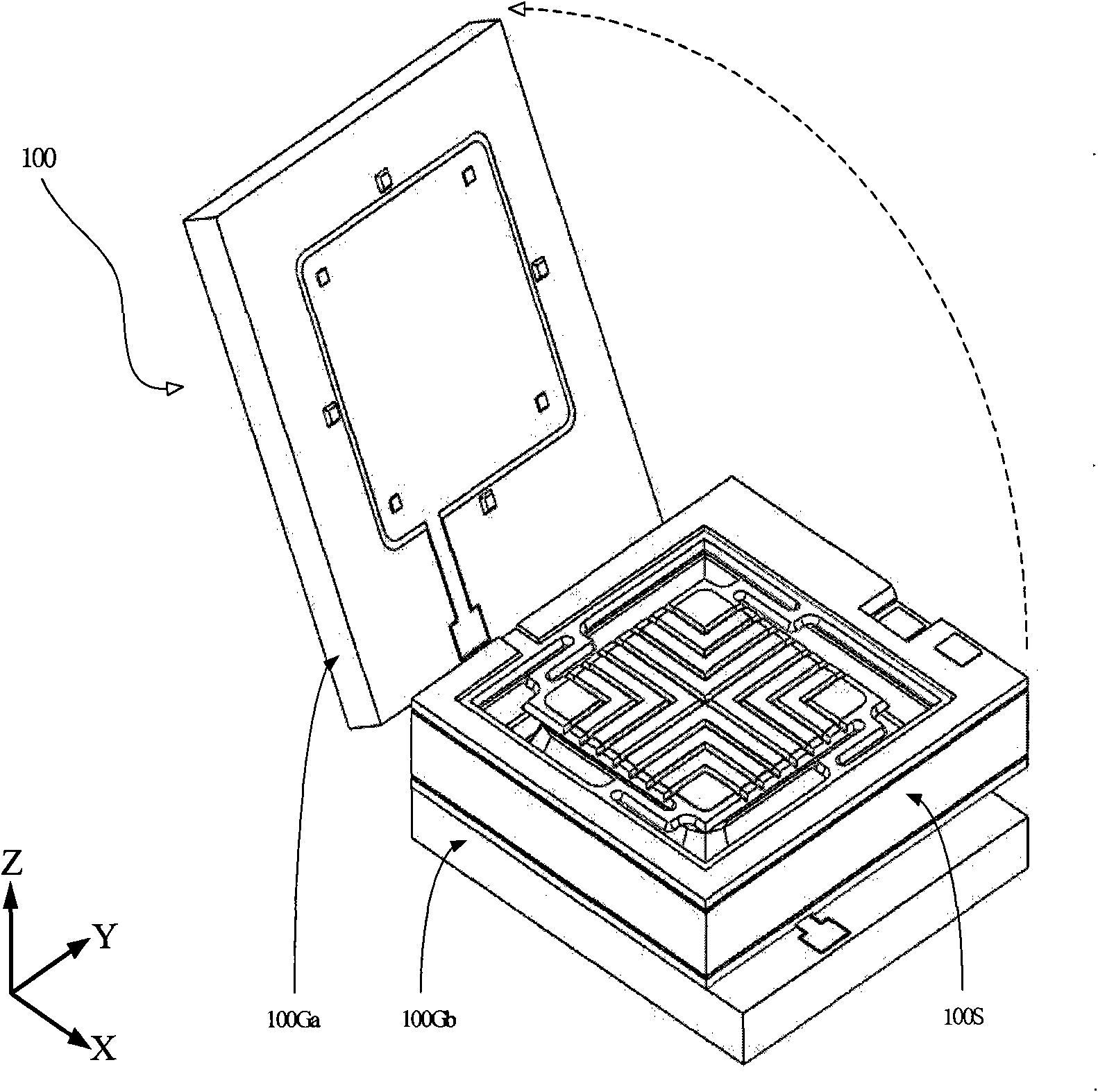

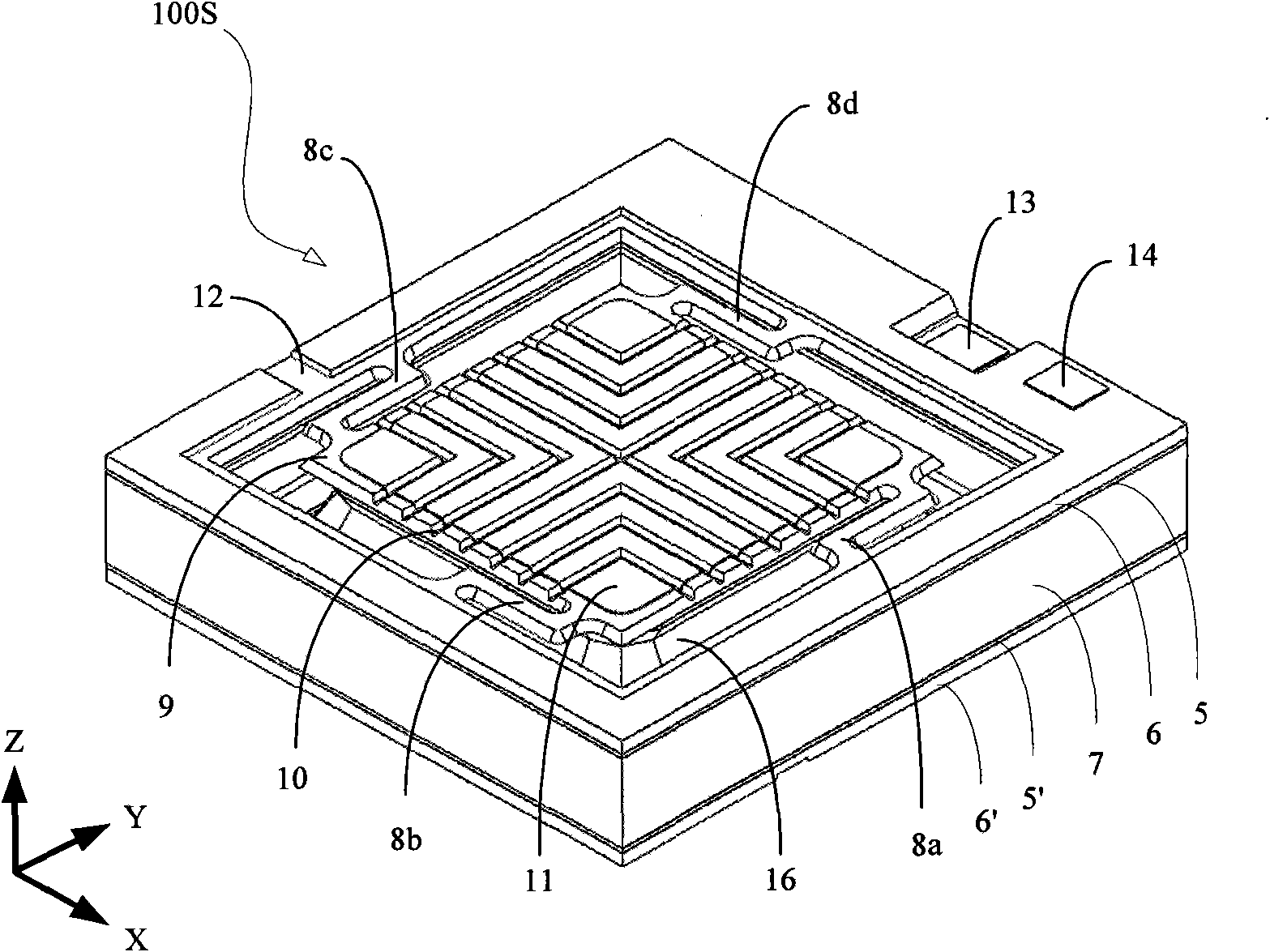

Vacuum sealed surface acoustic wave pressure sensor

InactiveUS20060086188A1Simple structureLow costFluid pressure measurement by electric/magnetic elementsSolid-state devicesEngineeringSurface acoustic wave sensor

A vacuum sealed SAW pressure sensor is disclosed herein, which includes a sensing element configured as a SAW device (e.g., SAW resonator or SAW delay line) supported by a thin diaphragm. The substrate material can be implemented as a quartz wafer (i.e., a “base” wafer). The SAW device can be configured on one side of the wafer and the diaphragm etched on the opposite side. A quartz micromachined pressure sensor can thus be realized, which operates based on a variation of the surface wave velocity of a SAW device situated on the thin diaphragm. The SAW sensor is generally sealed in a vacuum and diaphragm sustains the sensor, thereby implementing a sensor on a wafer scale while allowing for a cost reduction per chip.

Owner:HONEYWELL INT INC

Processing method of differential type high-precision accelerometer

ActiveCN101786593AReduce process difficultyLow process temperatureTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesStress ProblemMonocrystalline silicon

The invention discloses a processing method of a differential type high-precision accelerometer. The accelerometer comprises an upper electrode cover plate, a movable silicon structural assembly with a beam-mass block structure and a lower electrode cover plate which are sequentially connected from top to bottom. The method comprises the following steps of: processing the upper electrode plate and the lower electrode plate by using a glass sheet or a monocrystalline silicon wafer as a substrate; processing the movable silicon structural assembly with the beam-mass block structure by using a double-device-layer SOI (Silicon-On-Insulator) monocrystalline silicon wafer as a substrate; and connecting the upper electrode plate and the lower electrode plate which are processed by using the substrates with the movable silicon structural assembly based on a bonding mode. In the invention, only one monocrystalline silicon wafer is adopted to process the movable silicon structural assembly, thereby avoiding the condition that a frequently used high-temperature silicon-silicon bonding process is used for preparing the movable silicon structural assembly, reducing the process difficulty, lowering the highest process temperature and eliminating bonding stress problems introduced by silicon-silicon bonding; and moreover, the beam-mass block structure has generality.

Owner:PEKING UNIV

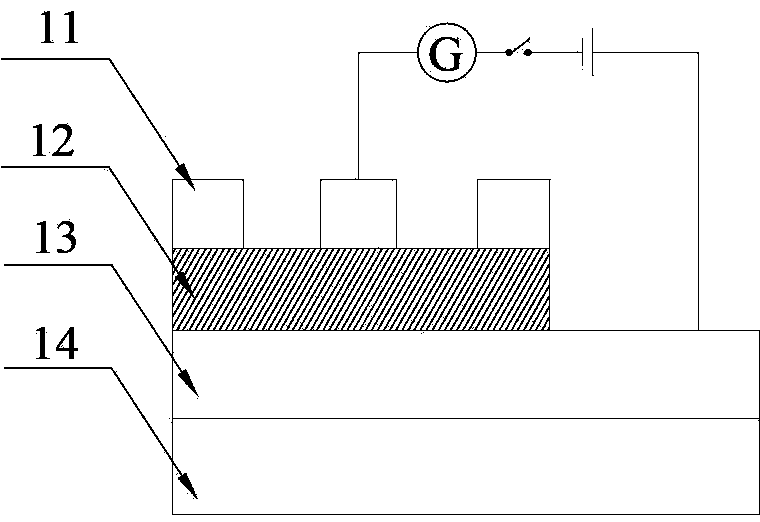

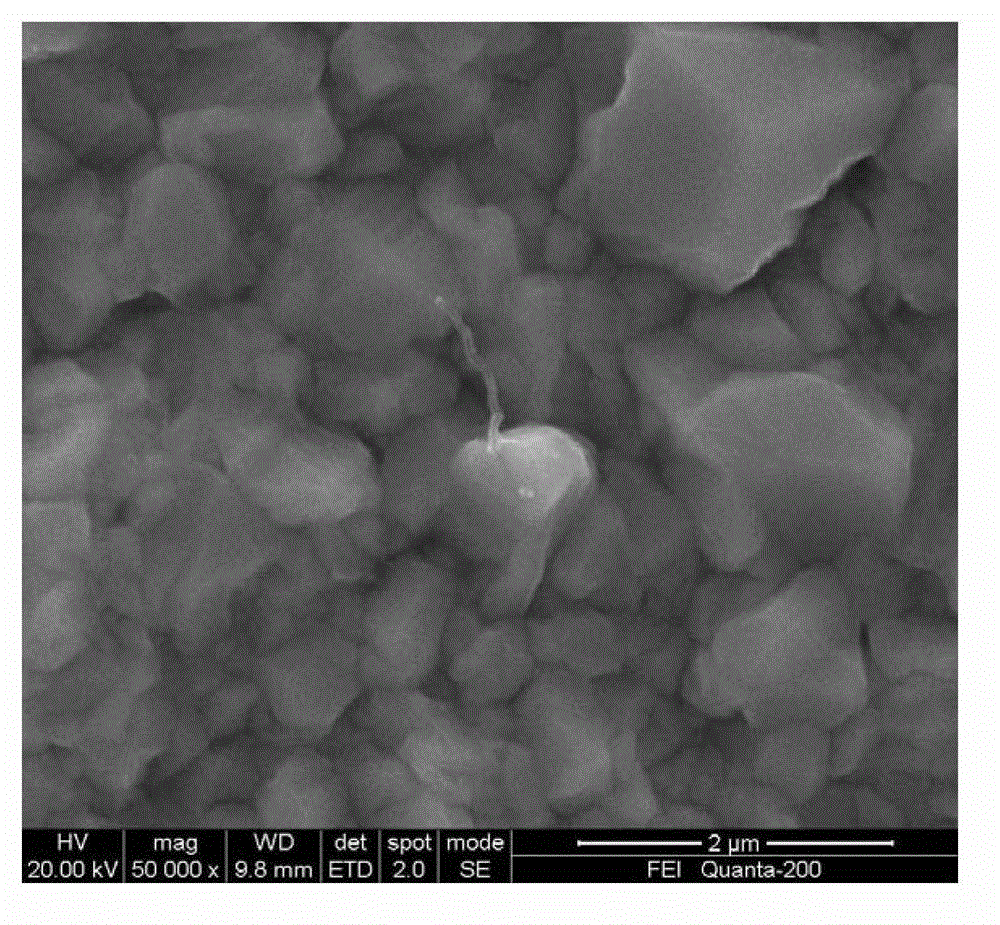

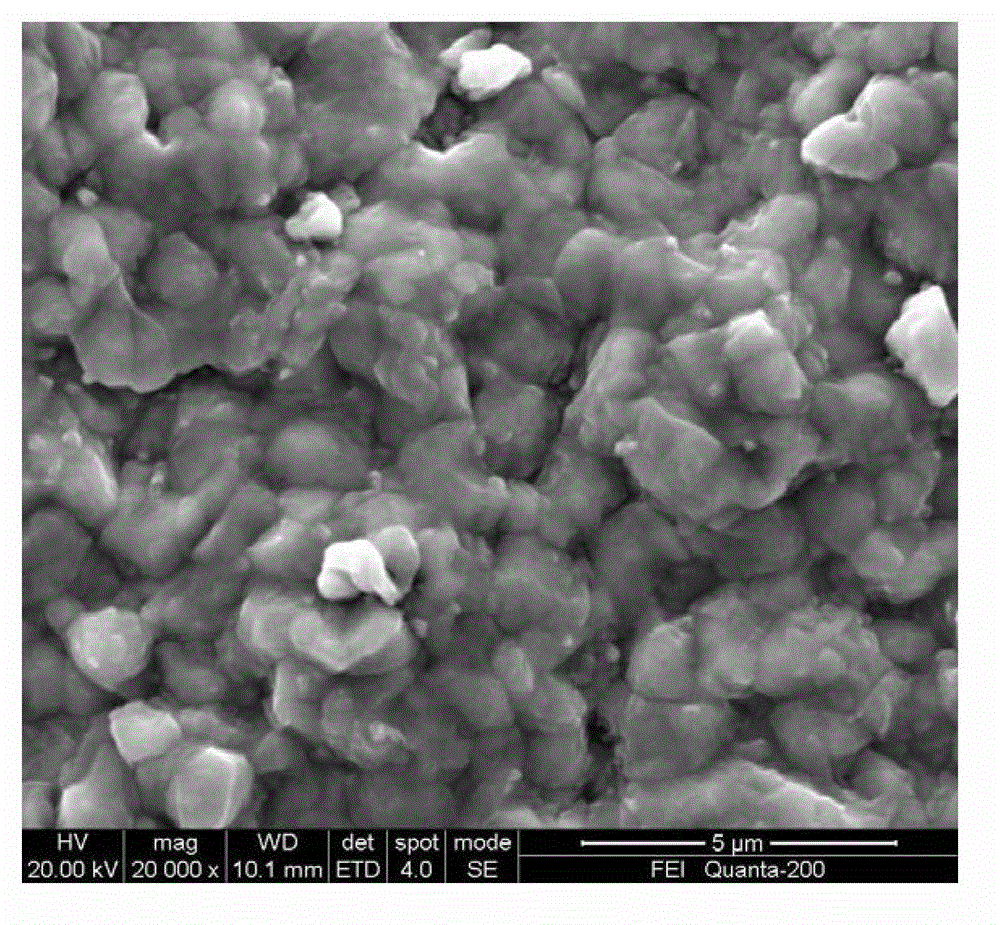

Noble metal doped particles and metallic oxide film integrated gas sensor and preparation method thereof

InactiveCN104034763AGuaranteed surface catalytic effectMaximize surface catalytic effectDecorative surface effectsChemical vapor deposition coatingMaterials scienceMetal oxide thin films

The invention relates to a noble metal doped particles and metallic oxide film integrated gas sensor and a preparation method thereof. The integrated gas sensor comprises a substrate, a heating electrode, a heat-conductive insulating layer, a detecting electrode and a metallic oxide film, wherein the heating electrode is prepared on the substrate, the heat-conductive insulating layer is arranged between the heating electrode and the detecting electrode, and the metallic oxide film is covered on the detecting electrode; the integrated gas sensor is characterized in that noble metal particles are deposited on the metallic oxide film, and the noble metal particles are monatomically covered on the metallic oxide film, the coverage degree of the noble metal particles is 0.05-10% of the surface area of the metallic oxide film and the particle size is 0.2-0.4nm. The integrated gas sensor can effectively improve the gas sensitivity and the gas stability of the metallic oxide film; the metallic oxide film doped with noble metal particles can achieve the sensitivity improved to 9.46 of the noble metal and metallic oxide film from 1.51 of the pure metallic oxide film when used for testing 200ppm ethyl alcohol gas; furthermorethe gas sensitivity reaction temperature of the metallic oxide film is only 150 DEG C.

Owner:NANJING UNIV OF TECH +1

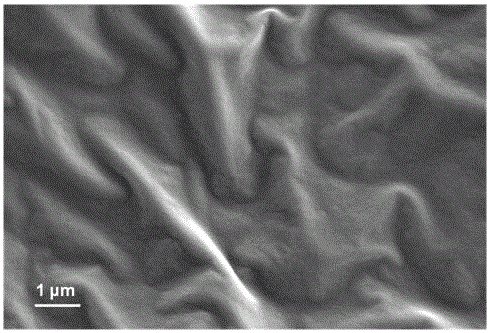

Preparation method of two-dimensional laminar covalent organic framework membrane

ActiveCN106512754APrecise thickness controlSimple film making processSemi-permeable membranesWater bathsOrganic solvent

The invention discloses a preparation method of a two-dimensional laminar covalent organic framework membrane. The method comprises the specific steps: (1) mixing a two-dimensional laminar covalent organic framework powder material with an organic solvent, uniformly mixing the mixture after discharging air in a bottle with nitrogen and sealing the bottle, then putting the bottle in an ultrasonic water bath for treatment, and peeling off the covalent organic framework material layer by layer to obtain a dispersion liquid of single atom layer sheets; and (2) depositing the dispersion liquid of the peeled covalent organic framework sheets to the surface of a vector, and after a solvent is fully evaporated, repeating the depositing process many times to obtain a continuous covalent organic framework membrane layer. Compared with an existing membrane forming technology of the covalent organic framework material, the preparation method is simple in process and easy to control, continuous to form membrane and relatively good in repeatability.

Owner:SOUTH CHINA UNIV OF TECH

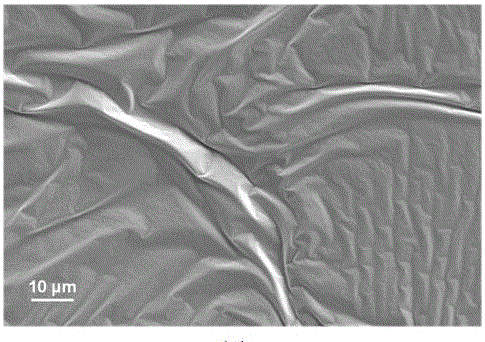

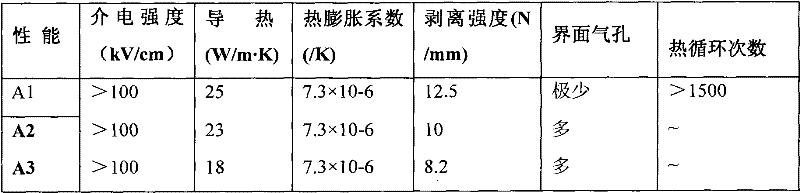

Ceramic copper-clad substrate and preparation method thereof

ActiveCN102206098AReduce post-processingImprove welding effectSemiconductor/solid-state device detailsSolid-state devicesBonding processCopper foil

The invention provides a preparation method for a ceramic copper-clad substrate. The preparation method comprises the following steps: carrying out a pre-processing for copper foil, wherein one side of the copper foil is a bonding surface for bonding with a ceramic substrate, the other side is a non-bonding surface; forming an organic protection layer on the non-bonding surface of the copper foil; carrying out a electrochemical deposition process for the copper foil to form a cuprous oxide layer on the bonding surface of the copper foil in a Cu<2+> electrolyte solution; removing the organic protection layer on the non-bonding surface of the copper foil; superimposing the bonding surface with the cuprous oxide layer and the preprocessed ceramic substrate, followed by a bonding process. In addition, the invention further provides a ceramic copper-clad substrate. With the present invention, the uniform and dense cuprous oxide layer on the bonding surface of the copper foil is formed through the electrochemical deposition method, and the cuprous oxide layer does not contain copper oxide causing generation of tiny bubbles, such that the bonding surface of the copper foil and the ceramic can forms a good bonding during a bonding process so as to great improve bond strength of the copper foil and the ceramic substrate.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

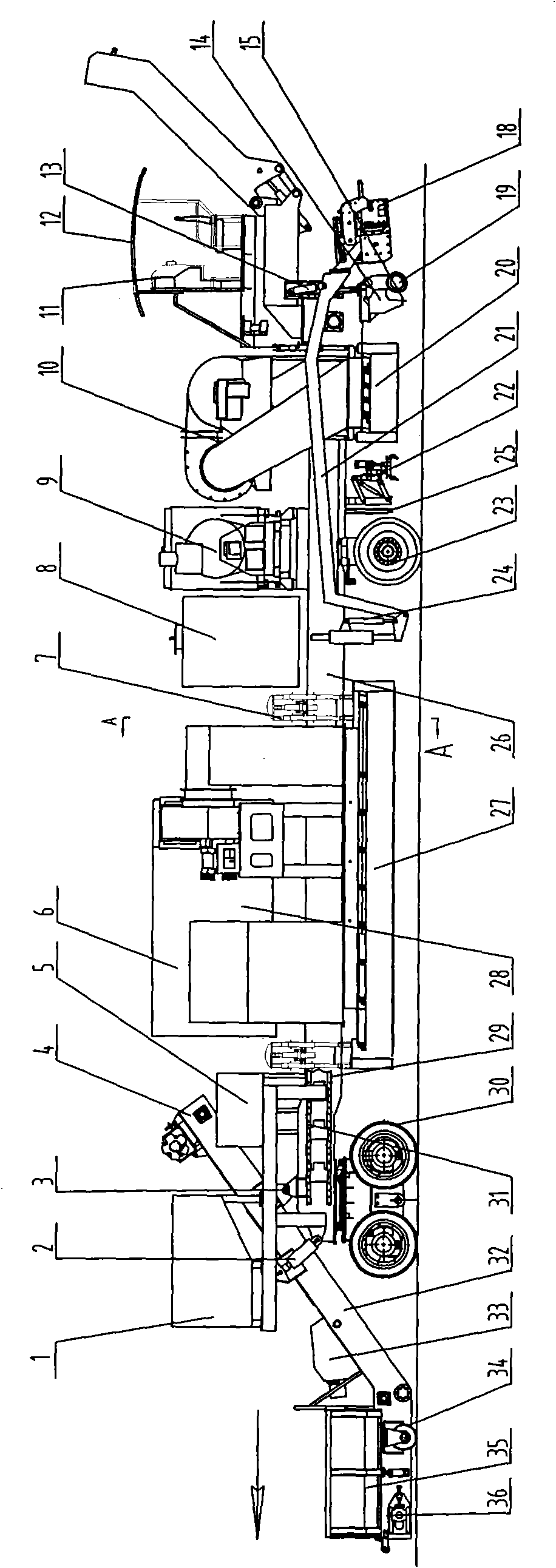

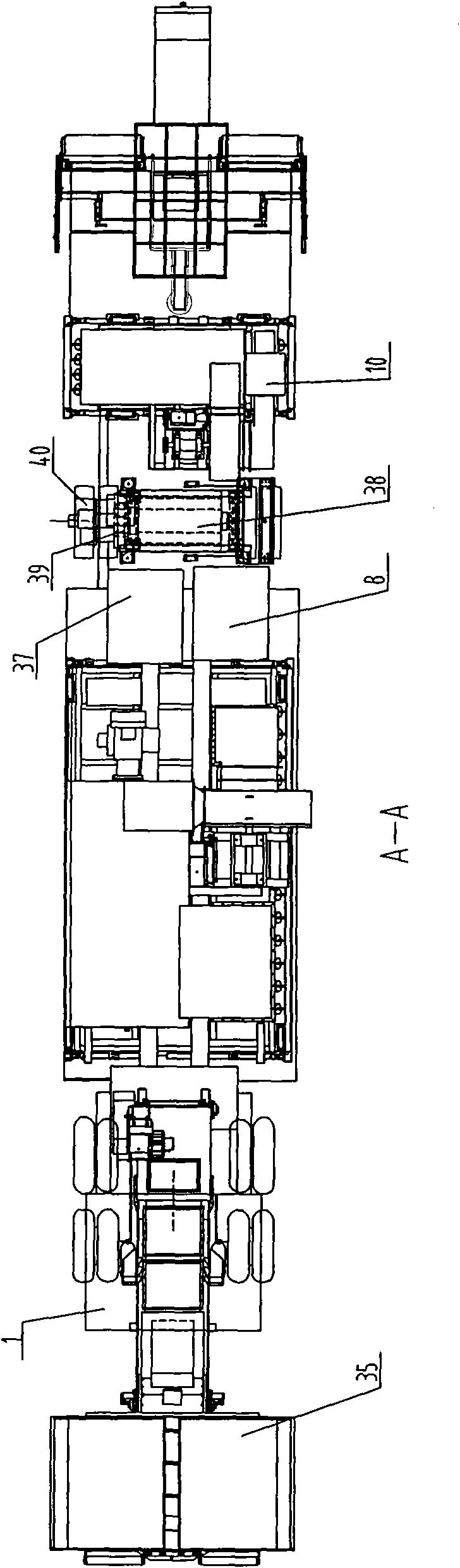

Hot in-place recycling ultrathin overlaying machine of bituminous pavement and construction method thereof

InactiveCN102011362ARestoration of slip resistanceGood lookingIn situ pavingsRoads maintainenceTraffic noiseScreed

The invention provides a hot in-place recycling ultrathin overlaying machine of a bituminous pavement and a construction method thereof. The hot in-place recycling ultrathin overlaying machine of the bituminous pavement comprises an automobile chassis, an integral power device, an electric control system, a diesel tank, a receiving and transporting device, a material transfer hopper, a horizontal transporting device, a heating device, a hydraulic system, a recycling agent spraying system, a harrowing device, a distributing spiral device, a paving screed device, a cab, and an electric control operating floor, wherein the automobile chassis is a special automobile chassis. The hot in-place recycling ultrathin overlaying machine of the bituminous pavement finishes the continuous overlay repair work of the pavement through a series of processes such as receiving the materials, feeding the materials quantitatively, transporting the materials horizontally, spraying the recycling agent, harrowing, heating, distributing and paving the materials, ironing, and grinding and the like, and has the advantage of carrying out one-time maintenance on the defects such as loose, shallow vertical and horizontal cracks, track, slight crack, bituminous aging, pavement seepage and the like of a functional layer of the pavement. By adopting the invention, the antiskid resistance of the pavement is restored, the profile of the pavement is corrected, the appearance and the evenness of the pavement are improved, the pavement strength of the pavement is increased, the traffic noise is reduced, and the service life of the pavement is prolonged.

Owner:ANSHAN SENYUAN ROAD & BRIDGE

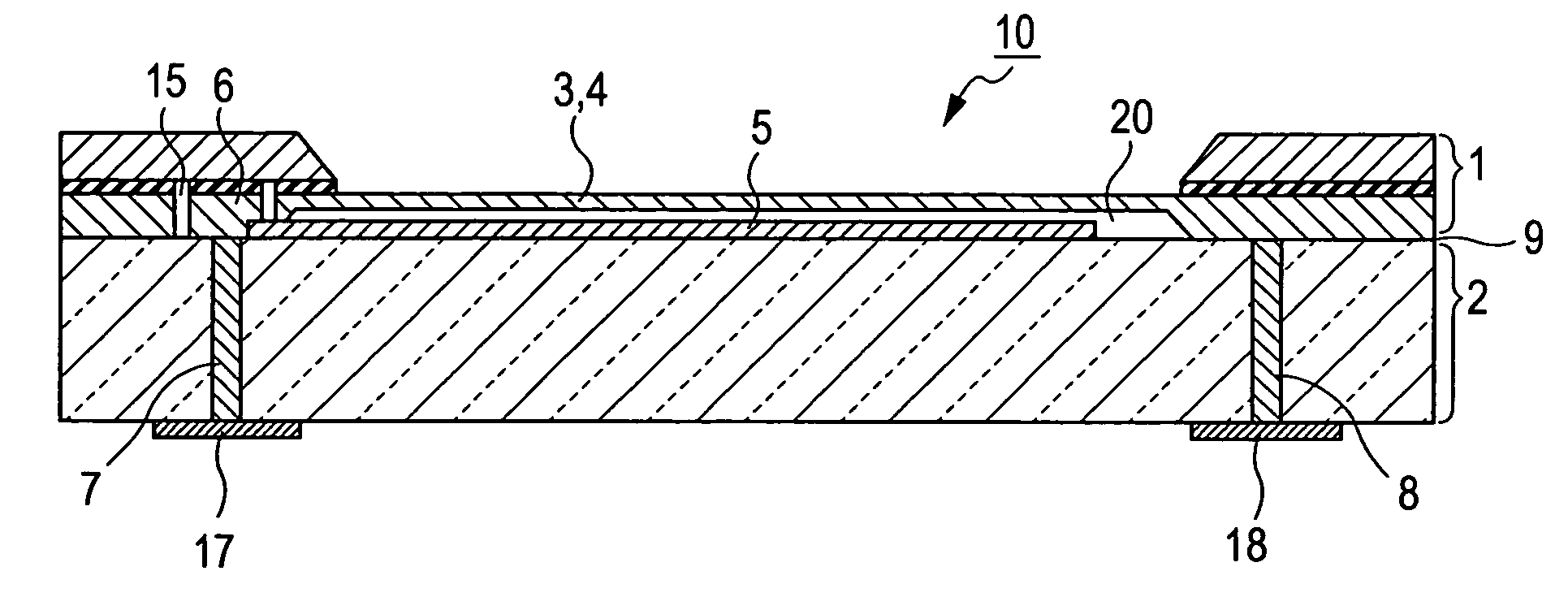

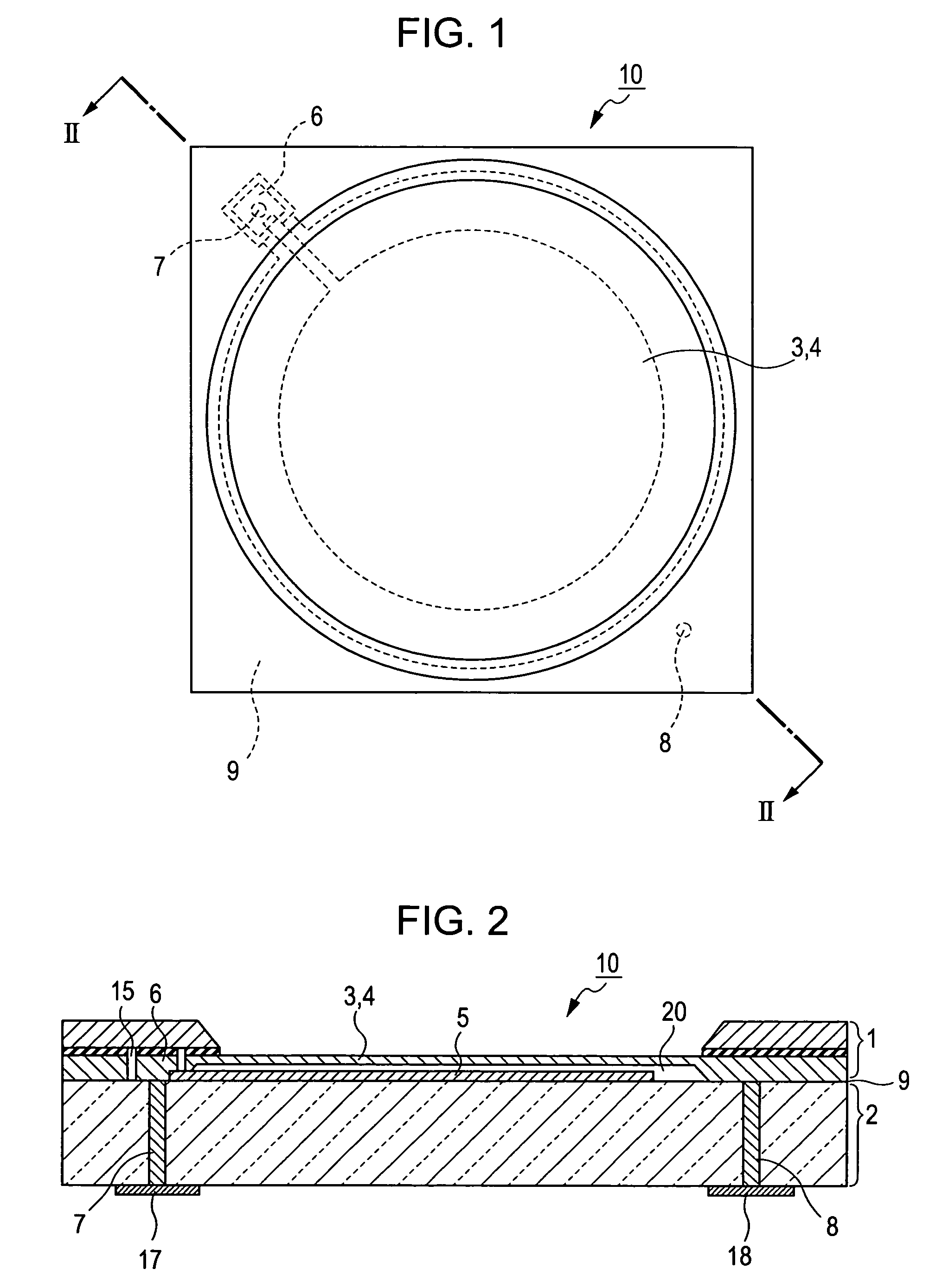

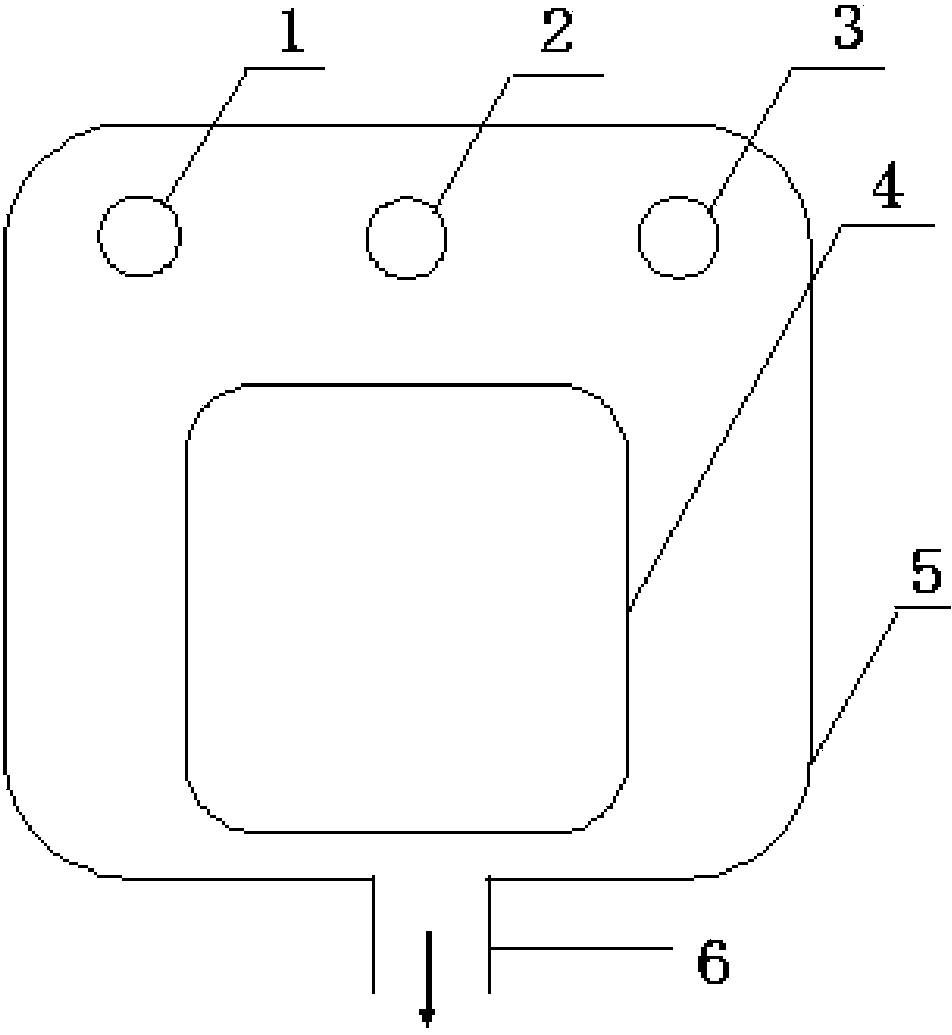

Pressure sensor

InactiveUS7135749B2Precise thickness controlLittle changeTransducer detailsSolid-state devicesSoi substrateConductive materials

A pressure sensor includes a silicon-on-insulator (SOI) substrate, a glass substrate bonded to the SOI substrate by anode bonding, a silicon island formed on a part of a silicon layer of the SOI substrate and surrounded by a groove extending to an insulating layer of the SOI substrate, a through hole formed in the glass substrate, and an output electrode that is made of a conductive material, is disposed inside the through hole, and is electrically connected to an electrode formed on the glass substrate via the silicon island.

Owner:ALPS ALPINE CO LTD

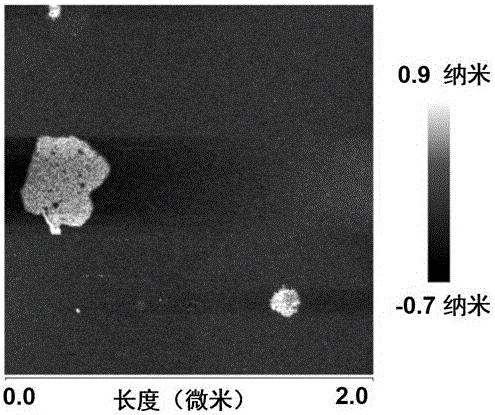

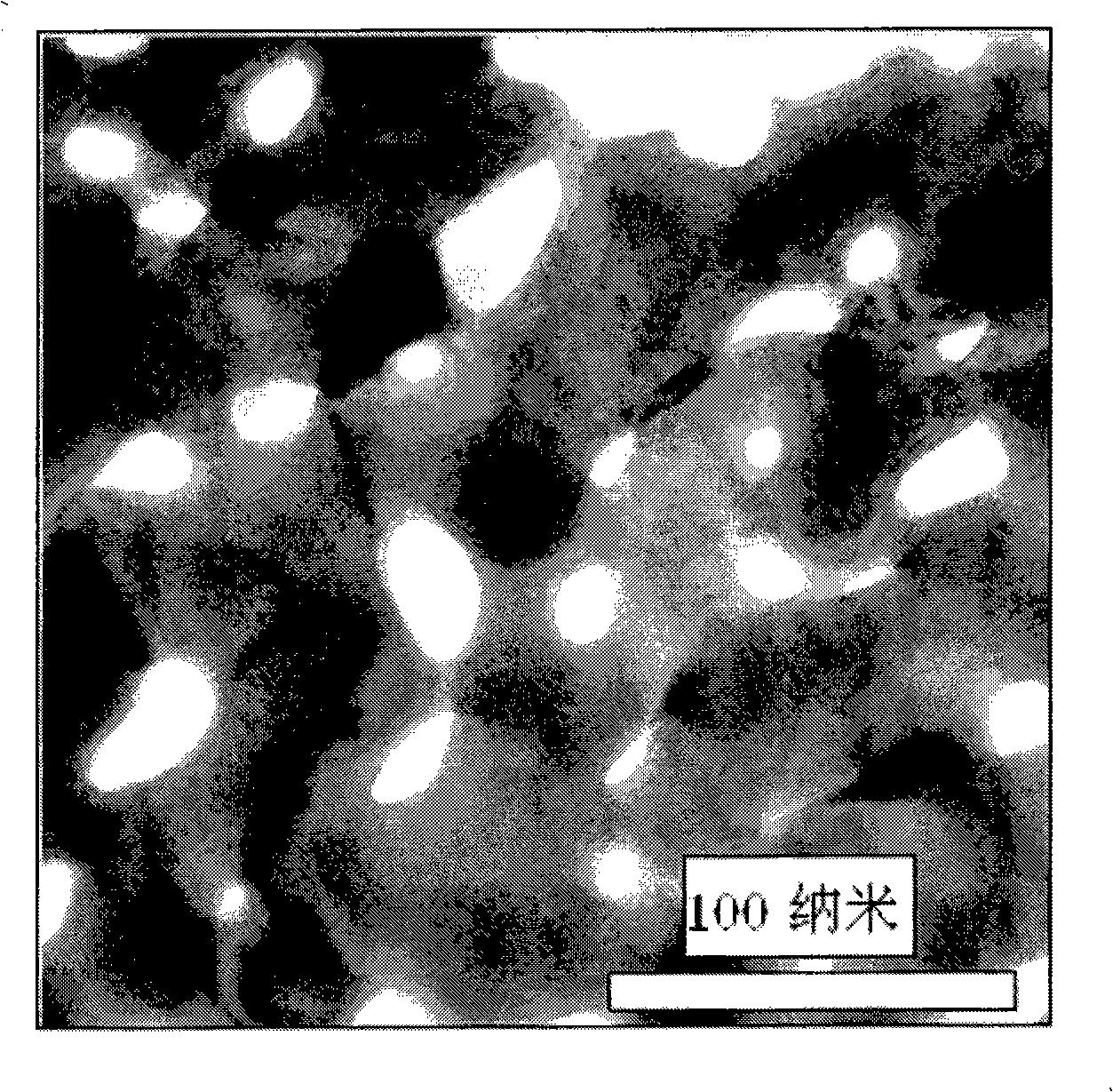

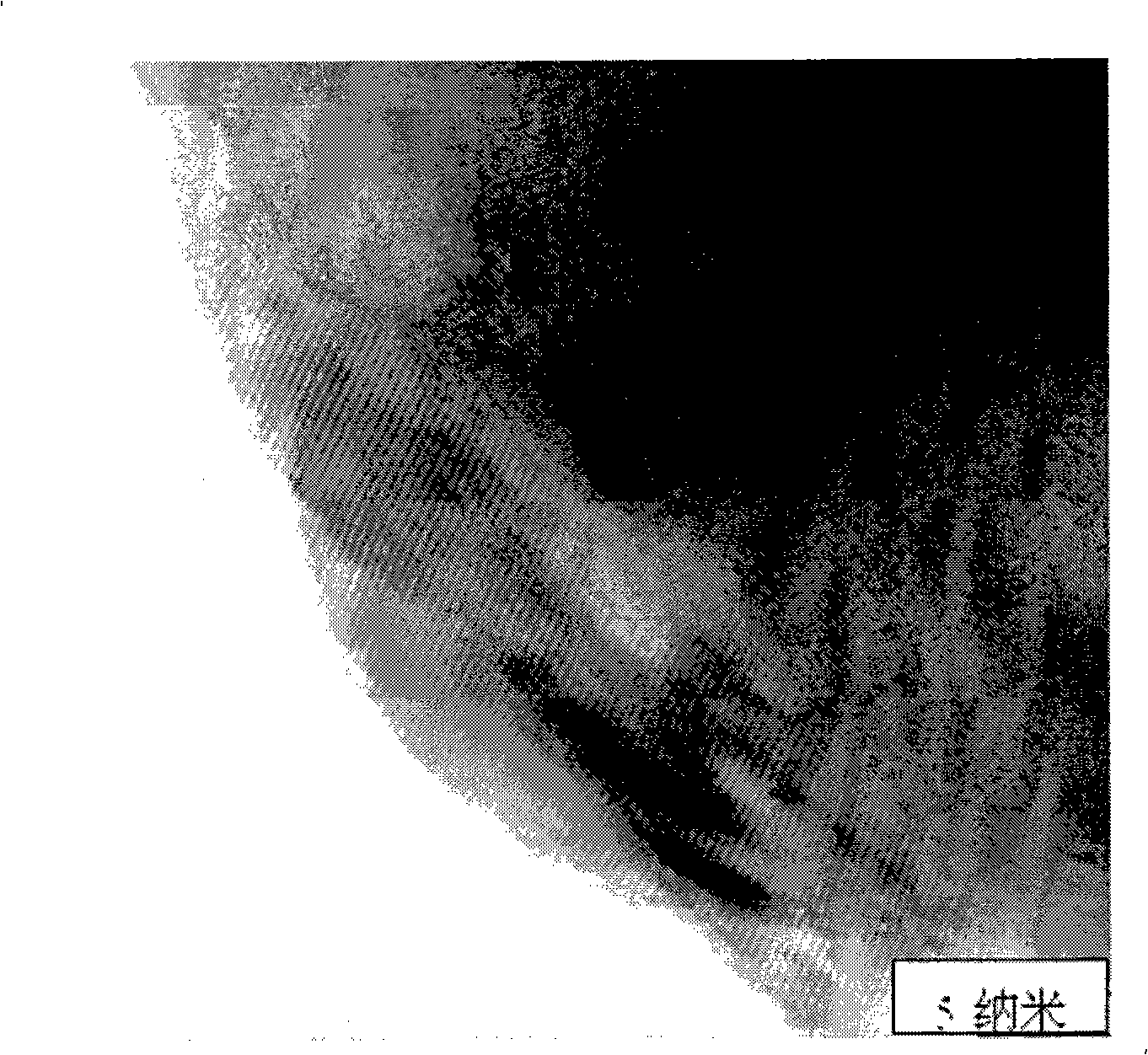

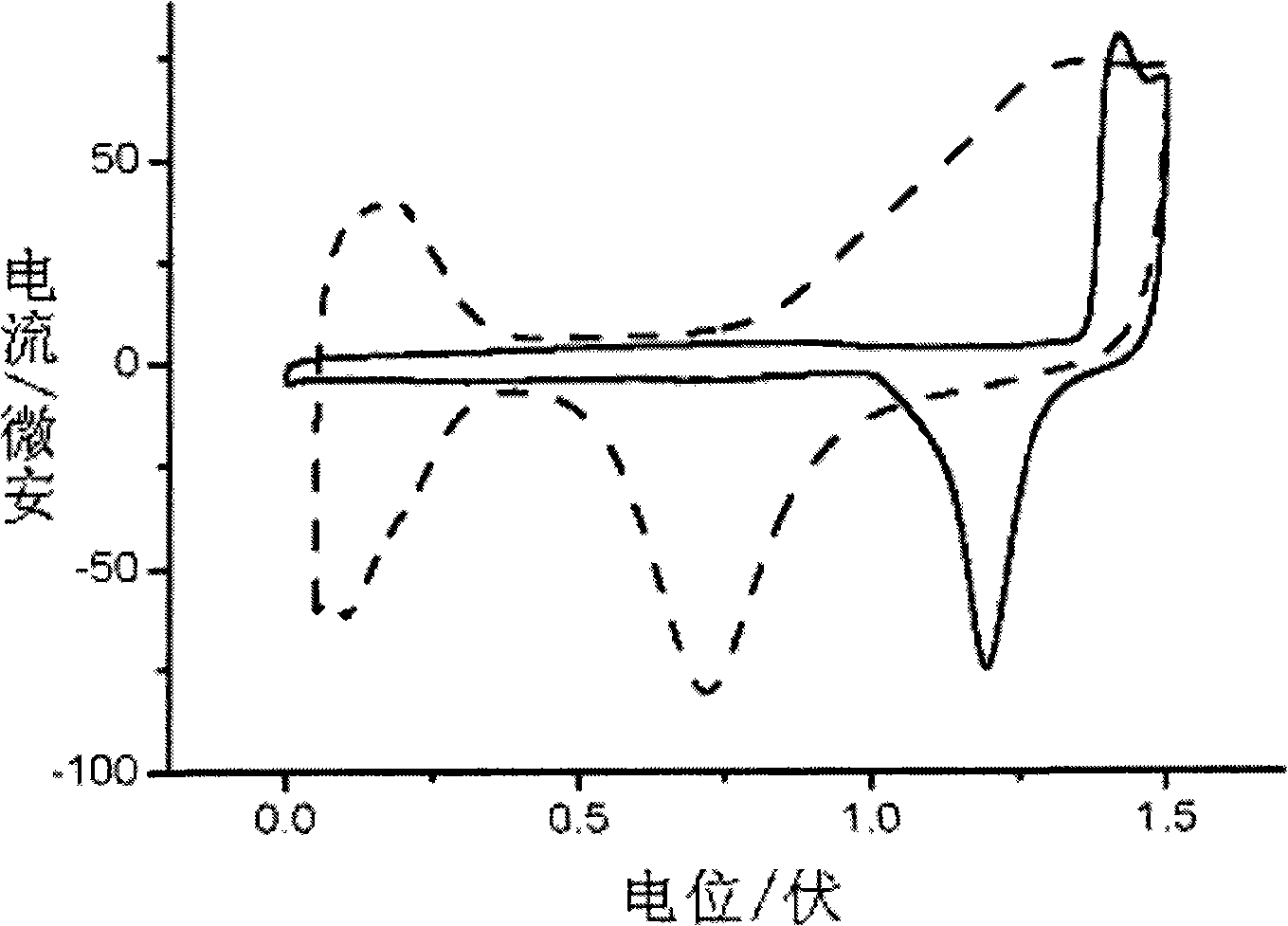

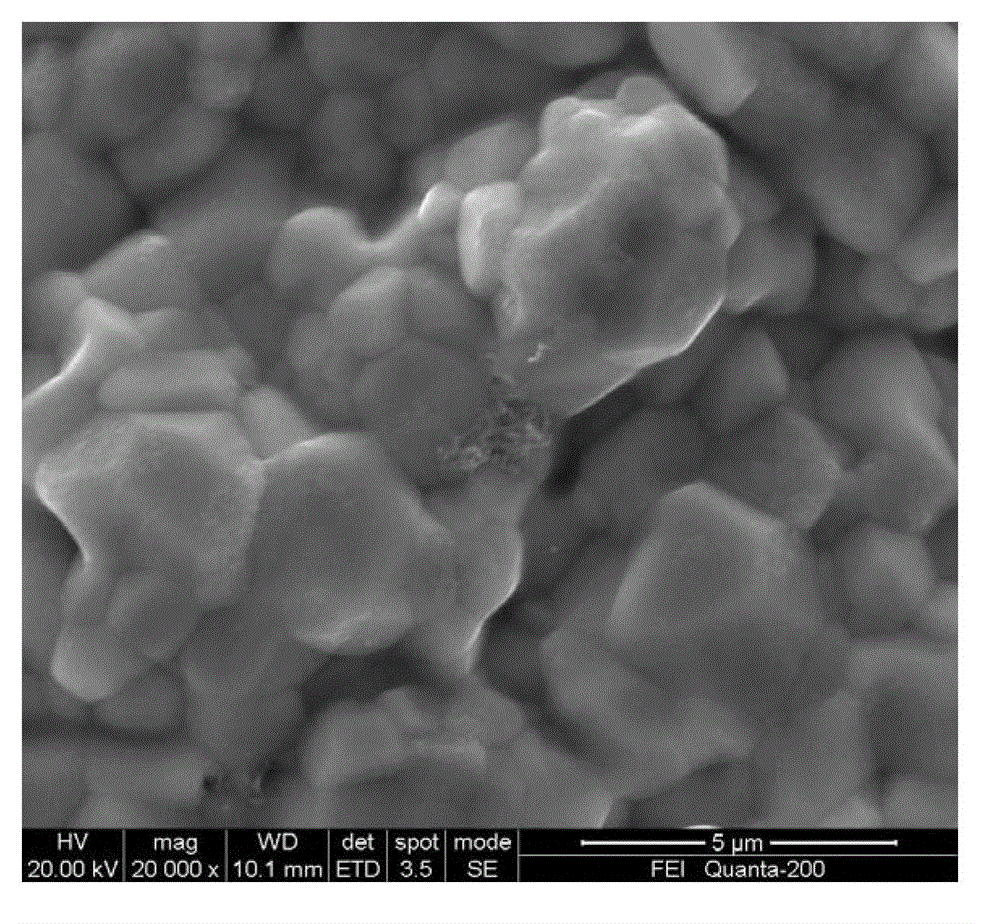

Nano porous gold-loaded ultrathin platinum metallic film catalyst and preparation method thereof

InactiveCN101332425AReduce loadPrecise thickness controlMetal/metal-oxides/metal-hydroxide catalystsMicrometerAlloy

The invention discloses a nanoporous gold supported ultrathin platinum metal film catalyst; the catalyst is an alloy sheet which is 0.1 - 100 micrometer thick, 0.1 - 10cm wide, and 0.1 - 20cm long, and is uniformly covered with a platinum metal atom layer on the surface thereof; the invention takes the method of under-potential depositing copper, silver or lead on the nanoporous gold and then performing exchange with the platinum metal cations to deposit the platinum metal film on the surface of the porous gold, thus obtaining the nanoporous gold supported ultrathin platinum metal film catalyst. The catalyst material prepared by the method of the invention can be easily controlled with regards to the aperture size, pore wall thickness and the platinum metal film thickness; and the catalyst is characterized by high specific surface area, high utilization ratio of the platinum metal, good catalytic activity and high anti-poisoning property.

Owner:SHANDONG UNIV

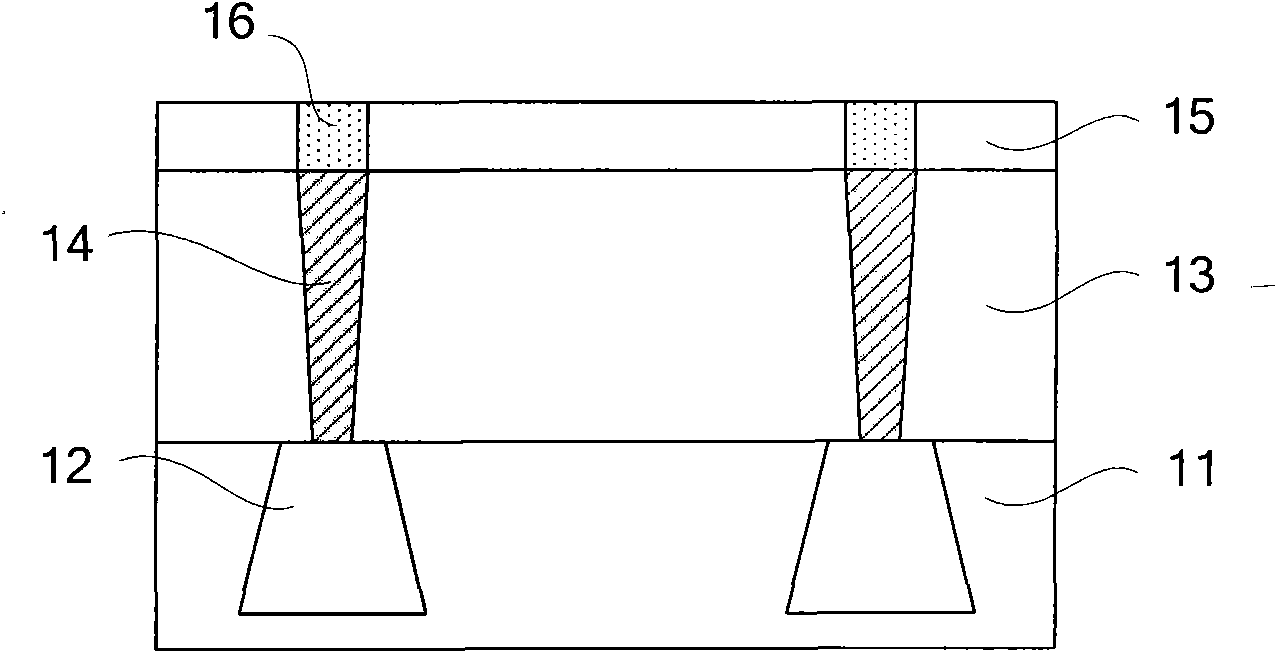

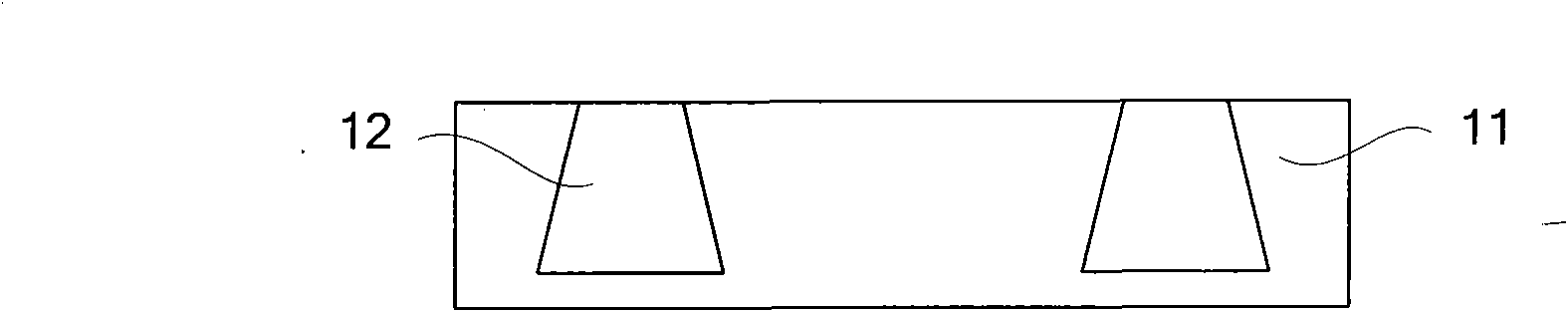

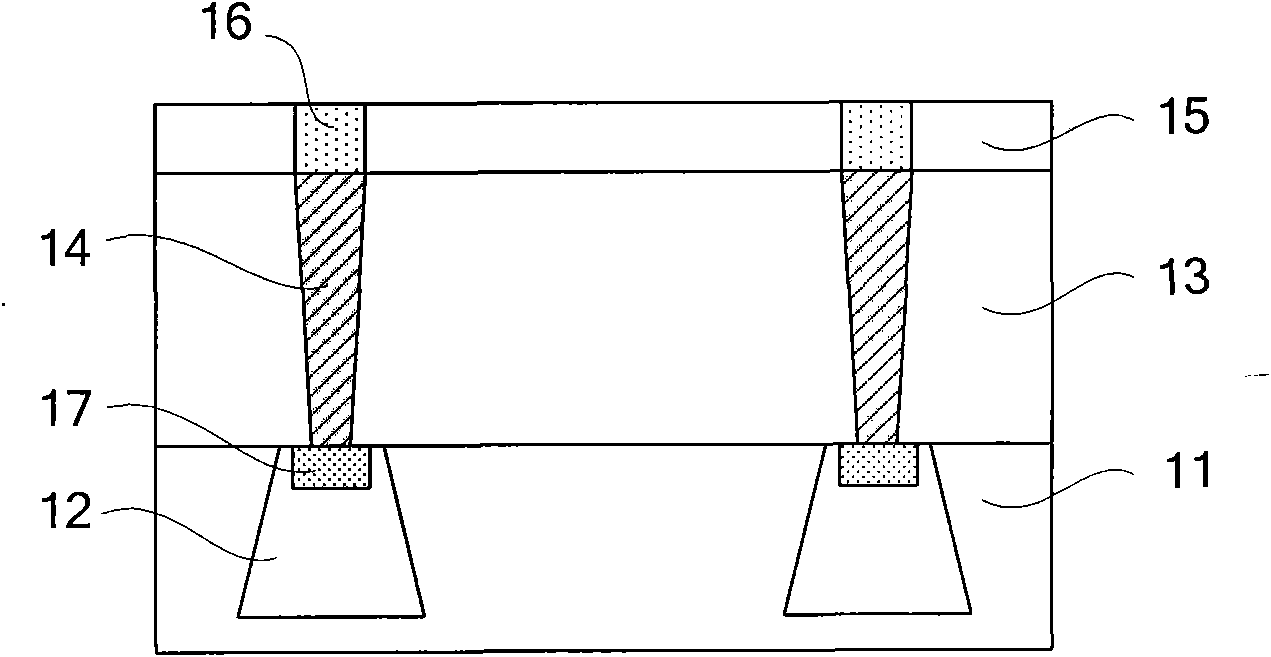

Schottky barrier quantum well resonant tunneling transistor

InactiveUS7936040B2Simple device structureImprove good performanceTransistorSolid-state devicesSchottky barrierQuantum well

A semiconductor transistor device includes one or more conductive base regions, a first semiconductor barrier region, a second semiconductor barrier region, a conductive emitter region, and a conductive collector region. The first semiconductor barrier region or the second semiconductor barrier region has a dimension smaller than 100 Å. A first Schottky barrier junction is formed at the interface of the first semiconductor barrier region and the one or more conductive base regions. A second Schottky barrier junction is formed at the interface of the second semiconductor barrier region and the one or more conductive base regions. A third Schottky barrier junction is formed at the interface of the conductive emitter region and the first semiconductor barrier region. A fourth Schottky barrier junction is formed at the interface of the conductive collector region and the second semiconductor barrier region.

Owner:WU KOUCHENG

Novel electrode lead capacitive screen manufacturing method and its product and touch screen terminal

ActiveCN102279684AThere will be no disconnectionPrecise thickness controlInput/output processes for data processingPolyesterCapacitance

The invention is applicable to the technical field of touch screen production and provides a method for manufacturing a novel electrode lead capacitive screen, the novel electrode lead capacitive screen and a touch screen terminal. The method comprises the following steps of: (1) preparing an indium tin oxide (ITO) conductive film on a polyester (PET) base film; (2) preparing a copper film on the ITO conductive film by using a magnetically-controlled splutter coating method; (3) manufacturing ITO patterns, and forming an edge copper electrode lead at one time; (4) selectively etching the copper film on the middle ITO pattern, and reserving the ITO pattern to obtain PET thin film structures; and (5) sequentially adhering two PET thin film structures which are obtained in the step (4) and a piece of panel glass by using an optical adhesive to obtain the novel electrode lead capacitive screen. In the method for manufacturing the novel electrode lead capacitive screen provided by the invention, the magnetically-controlled splutter coating method is adopted to replace a silk-screening silver paste process to manufacture an electrode lead of a capacitive screen with mature technical means; and by the method, the good rate for manufacturing the capacitive screen having a film-film structure can be greatly improved, so that the manufacturing cost of the capacitive screen is saved.

Owner:深圳豪威显示科技有限公司

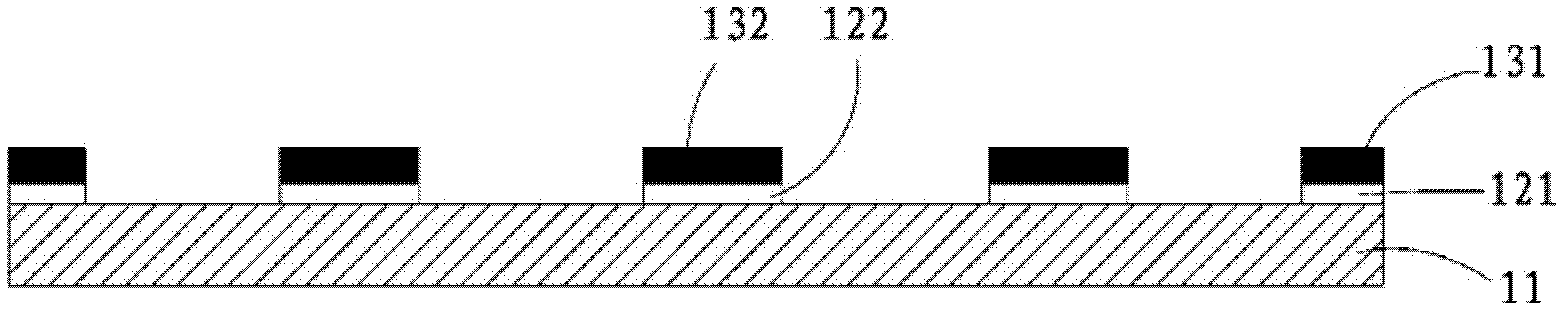

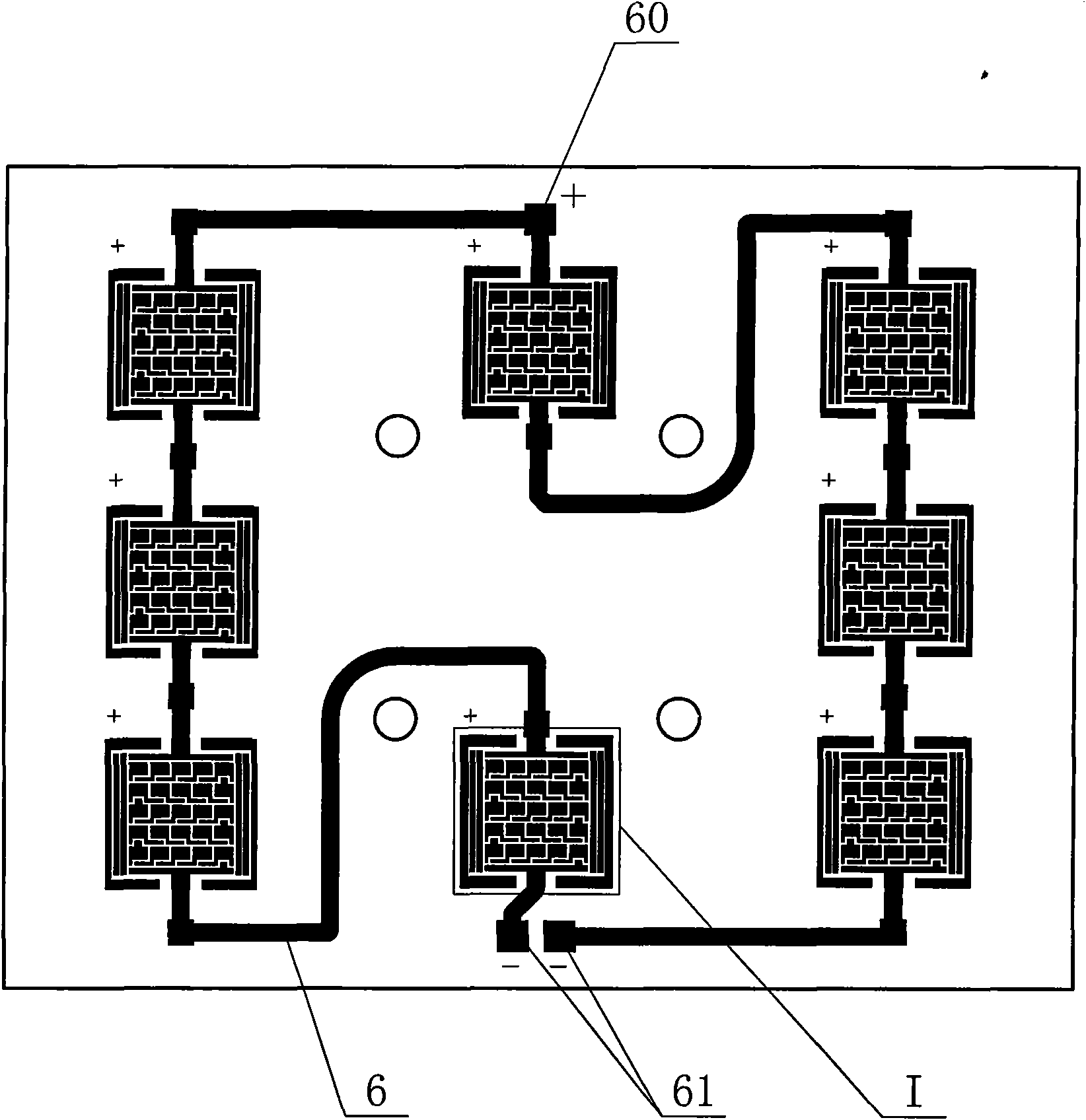

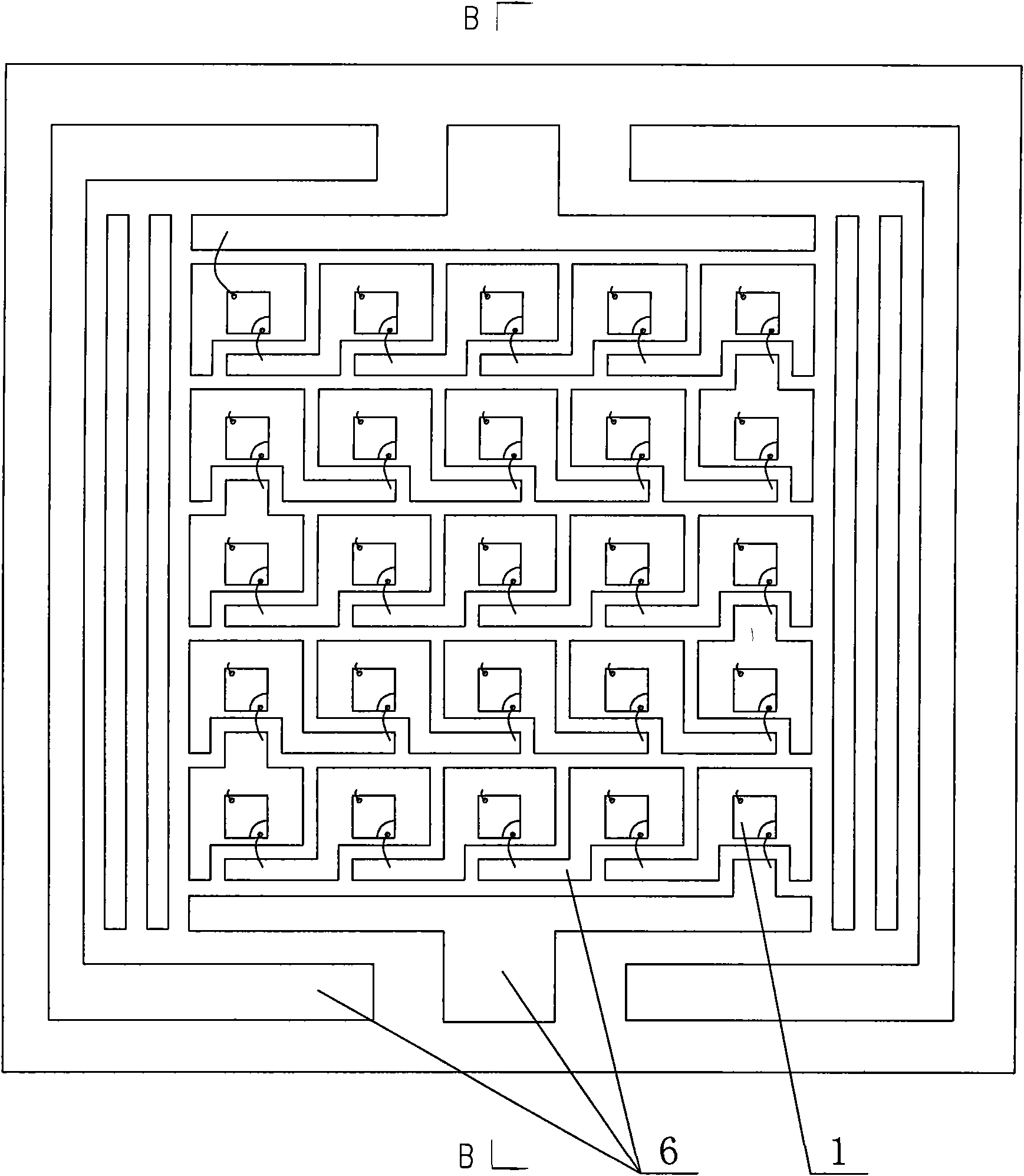

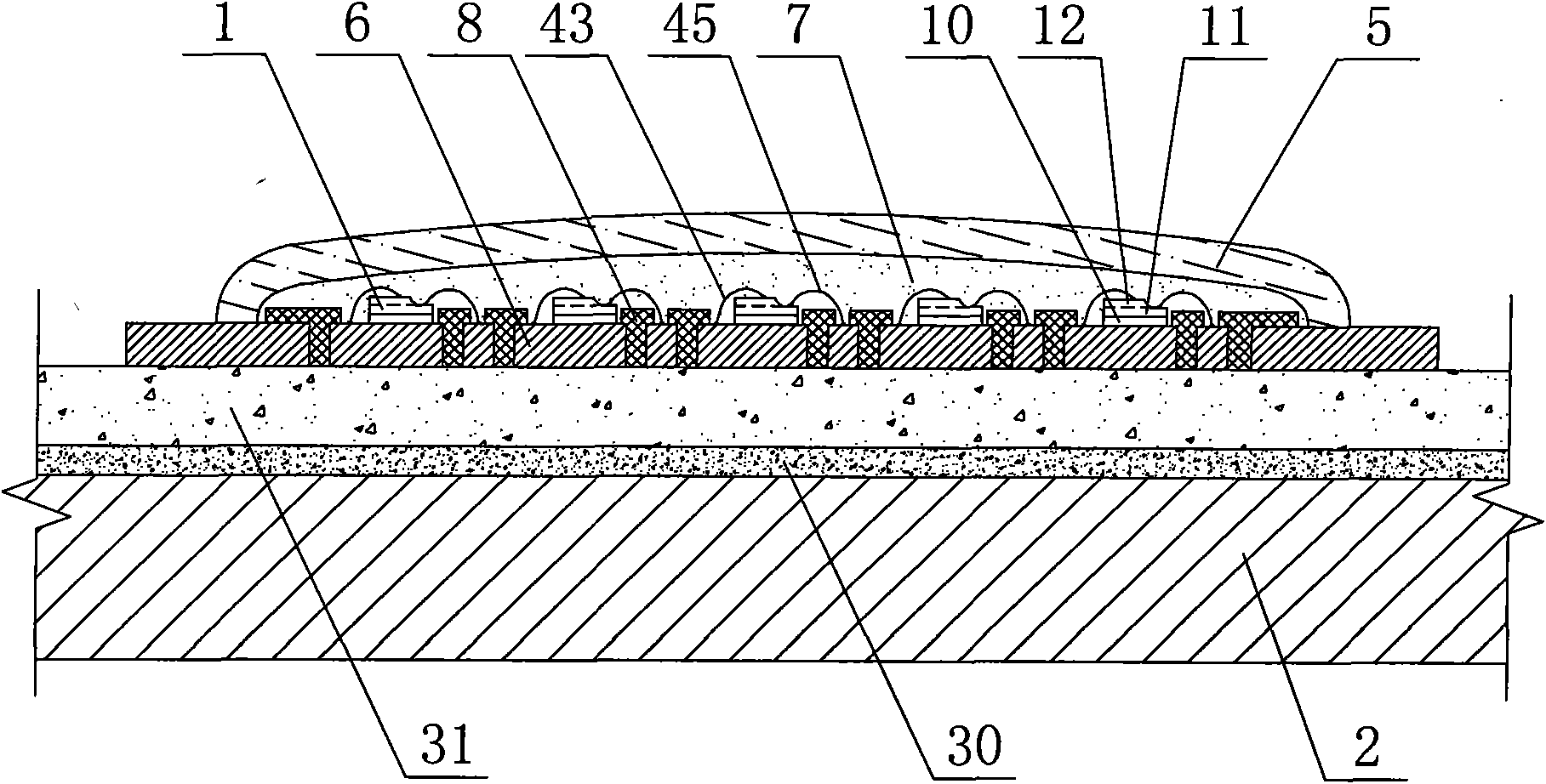

High-efficiency radiating LED illumination light source and manufacture method

InactiveCN101614333AImprove thermal conductivityPrecise thickness controlPoint-like light sourceElectric circuit arrangementsOptoelectronicsSilicon dioxide

The invention discloses a high-efficiency radiating LED illumination light source with low cost, good radiating effect, high production efficiency and high manufacture precision and a manufacture method. The high-efficiency radiating LED illumination light source comprises LED bare chips (1) and a metal substrate (2), wherein a heat conduction insulating layer is deposited on the metal substrate (2); metal layers (6) are deposited on the heat conduction insulating layer; the metal layers (6)are covered by a welding prevention layer (8); the heat conduction insulating layer is combined by a silicon dioxide layer (30) or a silicon nitride (31) or the combination of the silicon dioxide layer (30) and the silicon nitride (31); a preset circuit connection and a preset figure are formed on each metal layer (6) according to the serial connection and parallel connection relation of the LED bare chip (1); the LED bare chips (1) are divided into a plurality of groups and are mounted on each metal layer (6) normally or inversely; and the LED bare chips (1) in each group and the LED bare chips in the plurality of groups are connected through the metal layers (6) to form circuits. The manufacture method comprises the steps of pretreatment of the metal substrate, formation of the heat conduction insulating layer, the metal layers and the welding prevention layer as well as the encapsulation of the LED bare chips.

Owner:NANKER GUANGZHOU SEMICON MFG

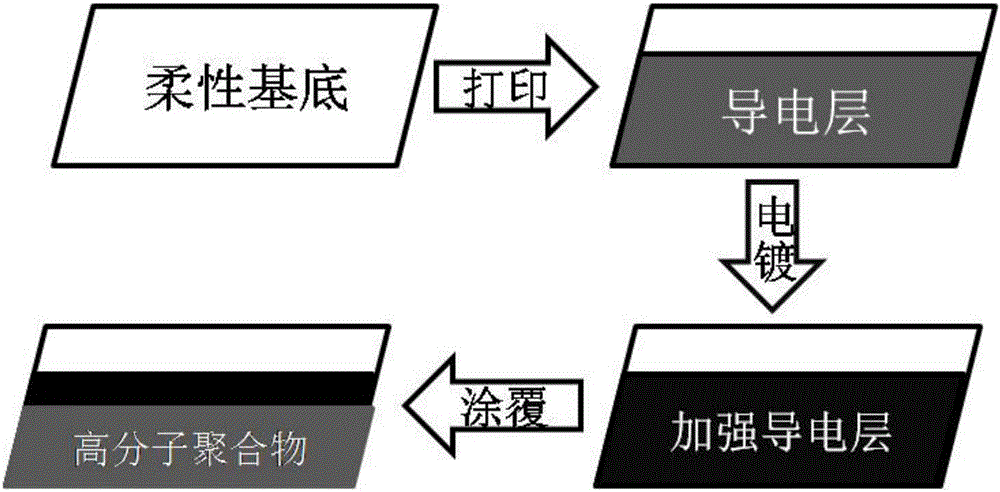

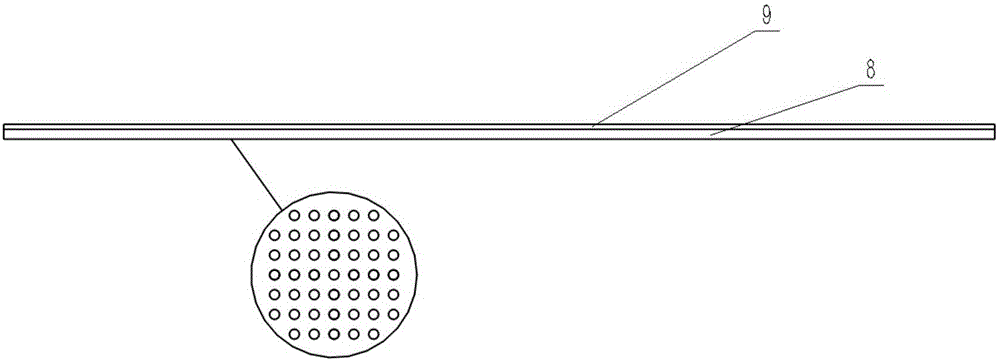

Flexible power generation thin-film and preparation method thereof

InactiveCN106230306AImprove conductivityAchieve film thicknessAdditive manufacturing apparatusConductive layers on insulating-supportsThree dimensional shapeEngineering

The invention discloses a flexible power generation thin-film and a preparation method thereof. The flexible power generation thin-film comprises a non-conductive flexible substrate, a conductive thin-film, a metal film and a polymer layer. The preparation method of the flexible power generation thin-film comprises the steps that 1) a layer of conductive thin-film is printed on the flexible substrate; 2) a layer of metal film is deposited on the conductive thin-film through electroplating; 3) a layer of polymer layer is coated on the metal film; and 4) the flexible power generation thin-film can be obtained after the polymer layer is dried. The conductive thin-film is prepared by using the printing technology so that the conductive effect can be realized on the surface of any flexible thin-film. Besides, accurate control of the three-dimensional shape of the conductive thin-film can be realized so that the thin-film having a microscopic lattice structure can be easily manufactured. A layer of metal film is deposited on the conductive thin-film through electroplating so that the conductivity of the conductive layer can be greatly enhanced. Concentration, coating time and other factors of the polymer can be adjusted so that accurate control of the film thickness can be realized.

Owner:中山市天美能源科技有限公司

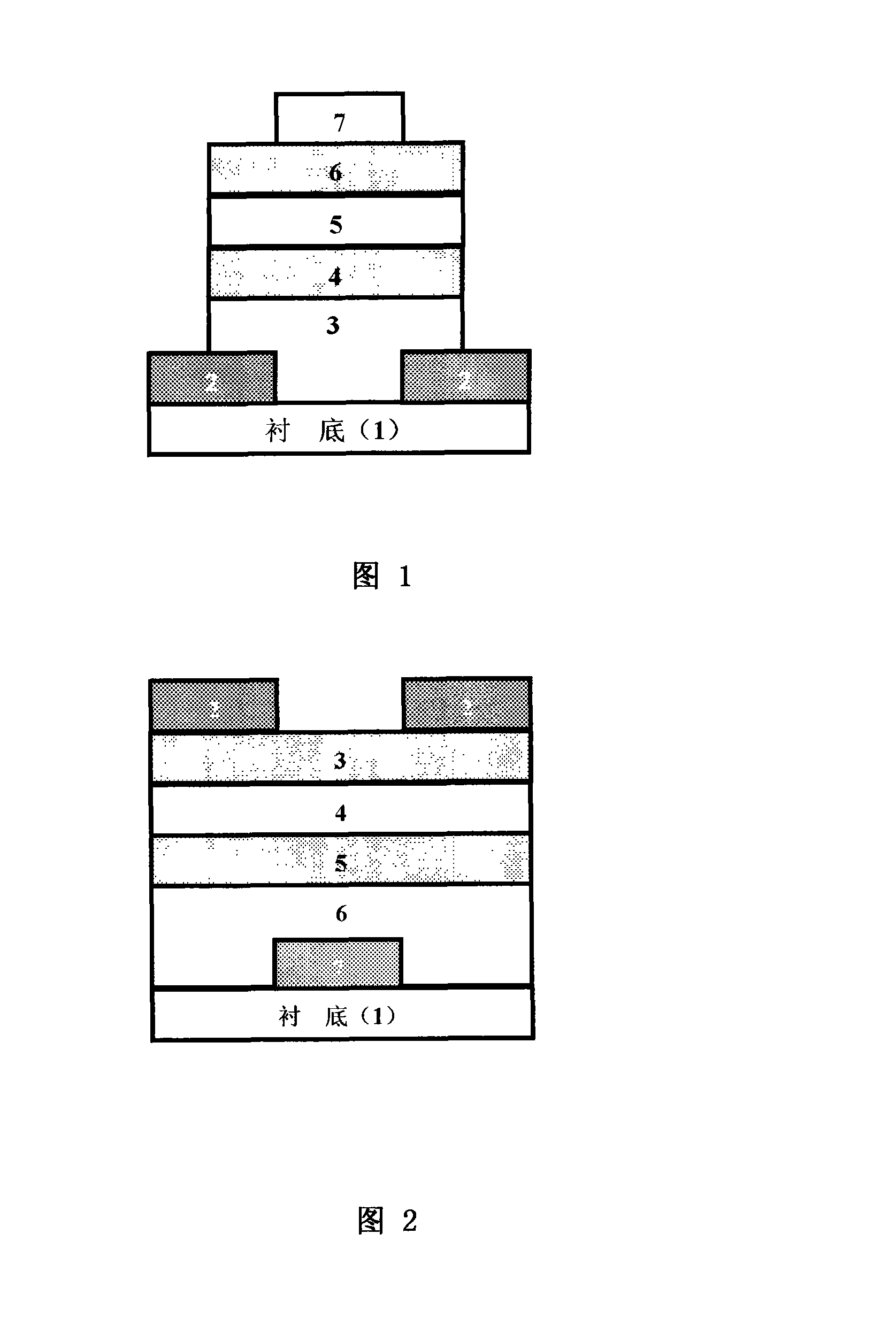

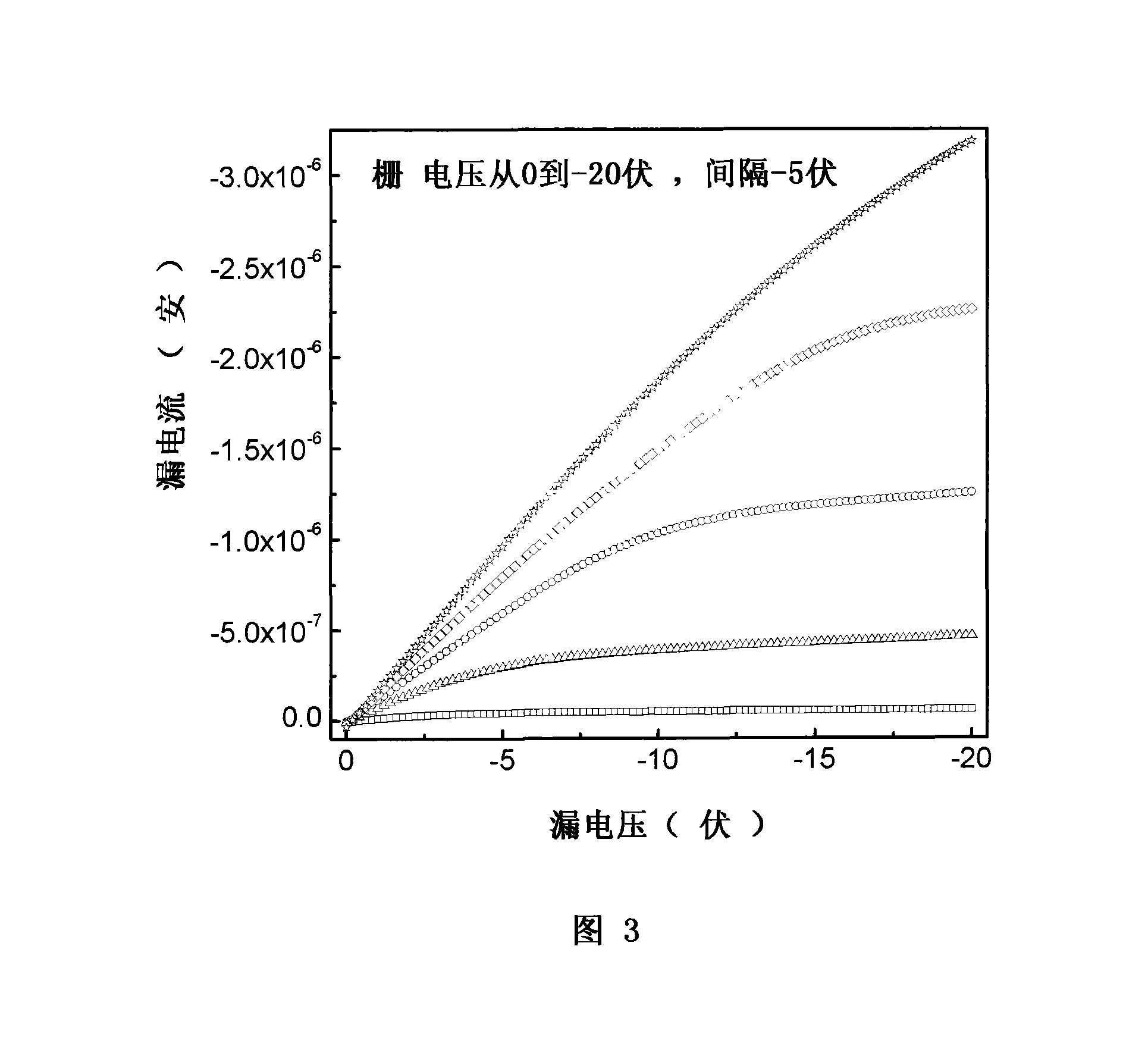

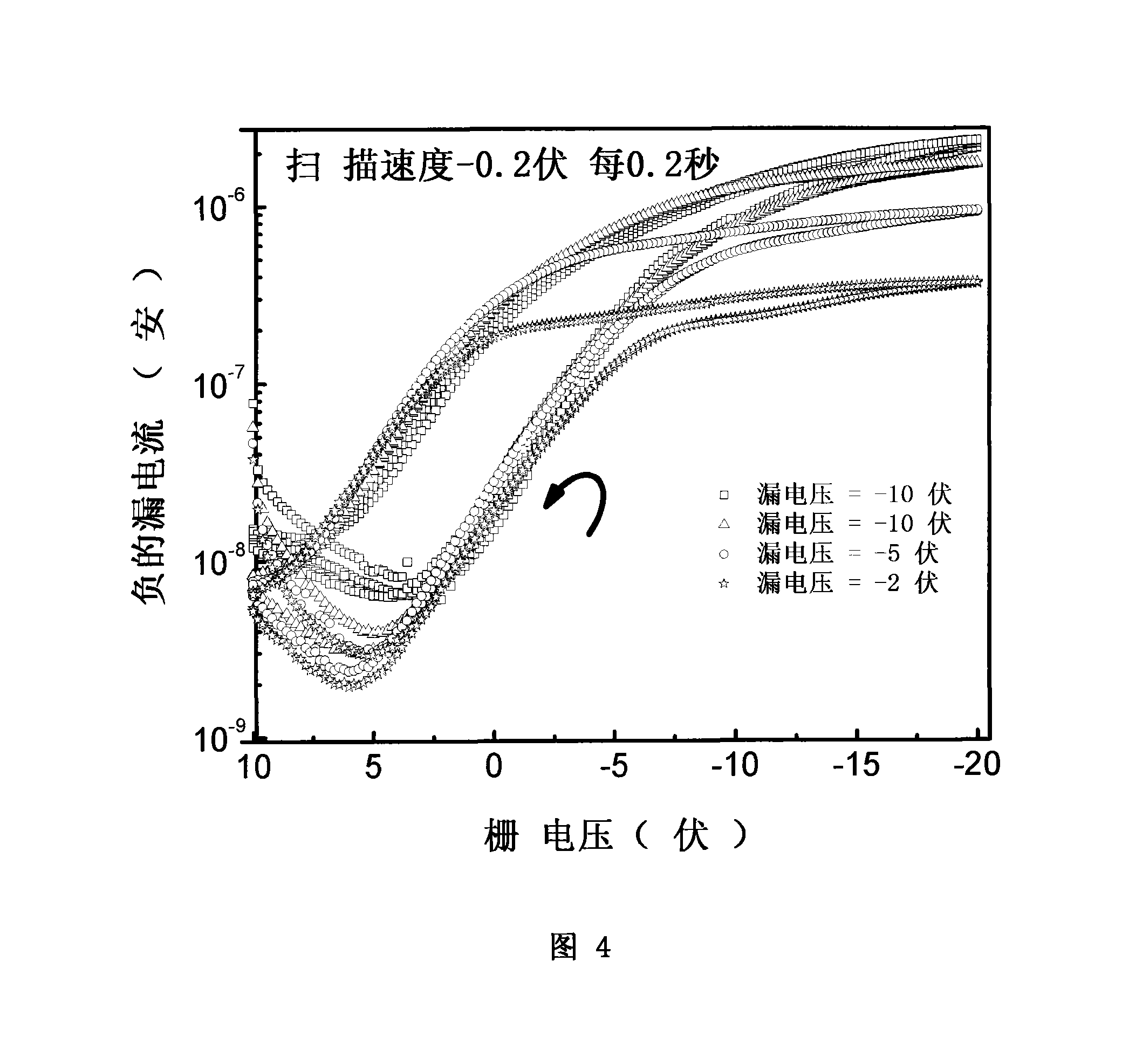

Non-volatile organic thin-film transistor memory based on floating gate structure and manufacturing method therefor

InactiveCN101179108AEasy to storeHigh Field Effect MobilitySolid-state devicesSemiconductor/solid-state device manufacturingBottom gateEngineering

The invention pertains to organic thin film transistorized memory based on floating gate structure. The manufacturing method adopts the top and bottom gate structures and the matched preparation process art respectively and introduces floating gate into medium layers between floating gate and control gate and realizes the nonvolatile memory of organic thin- film transistor. The invention has the advantages of simple process, low cost, small volume, low power dissipation and well stability.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

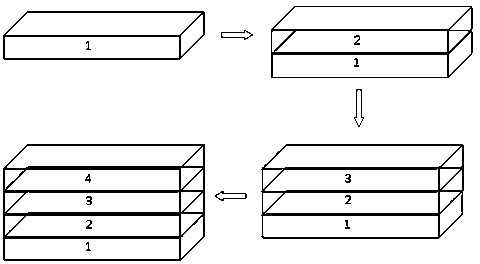

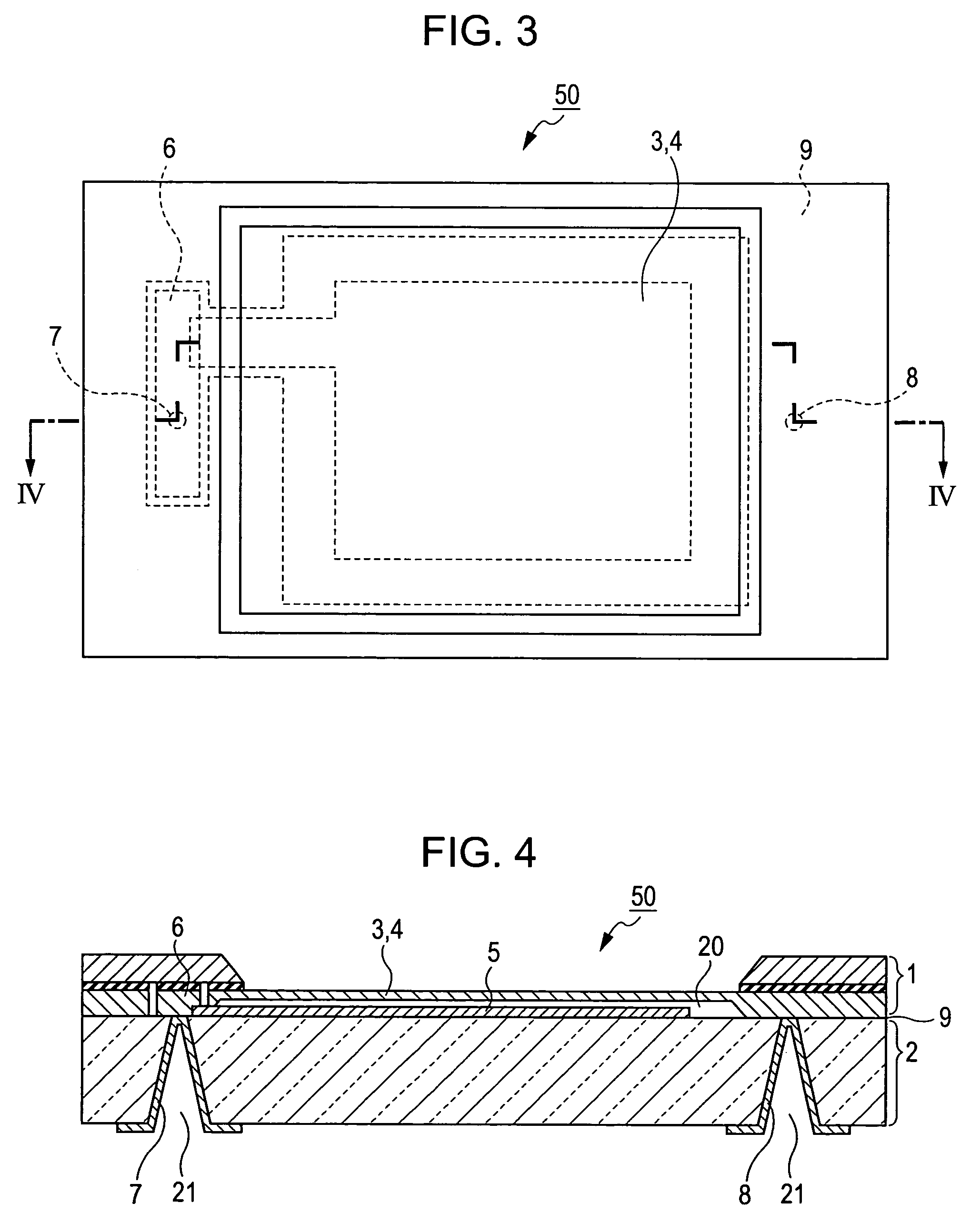

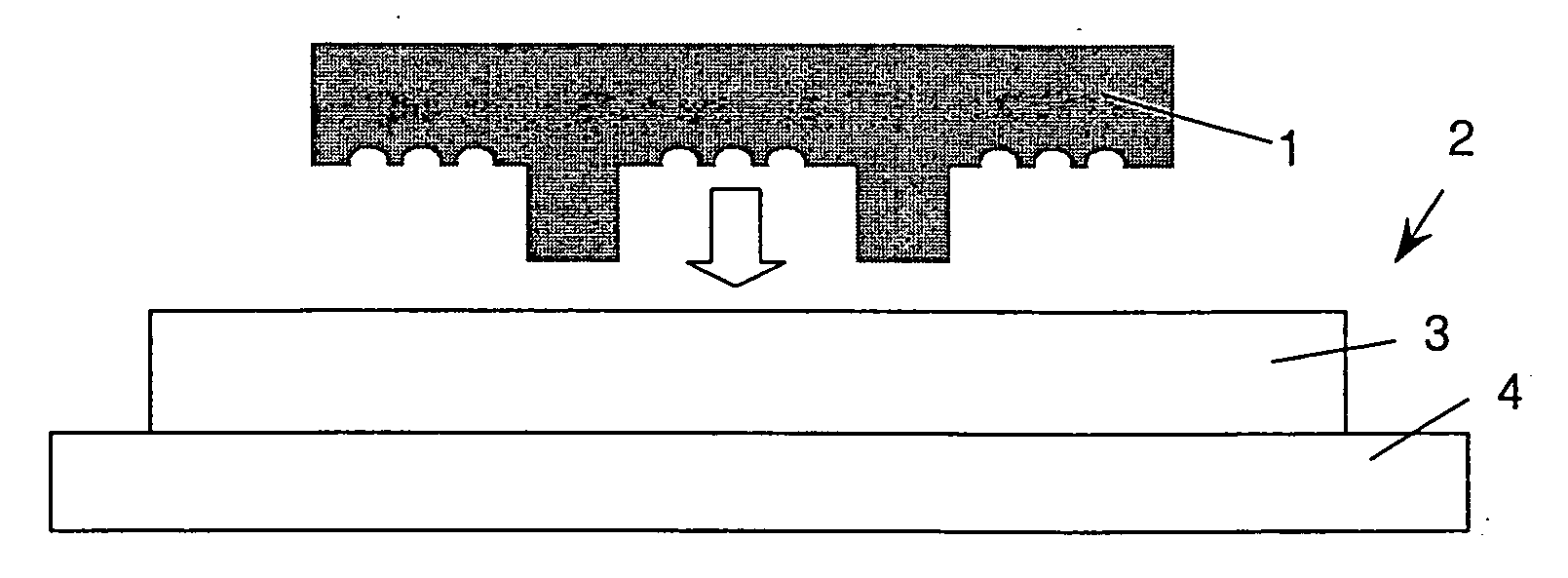

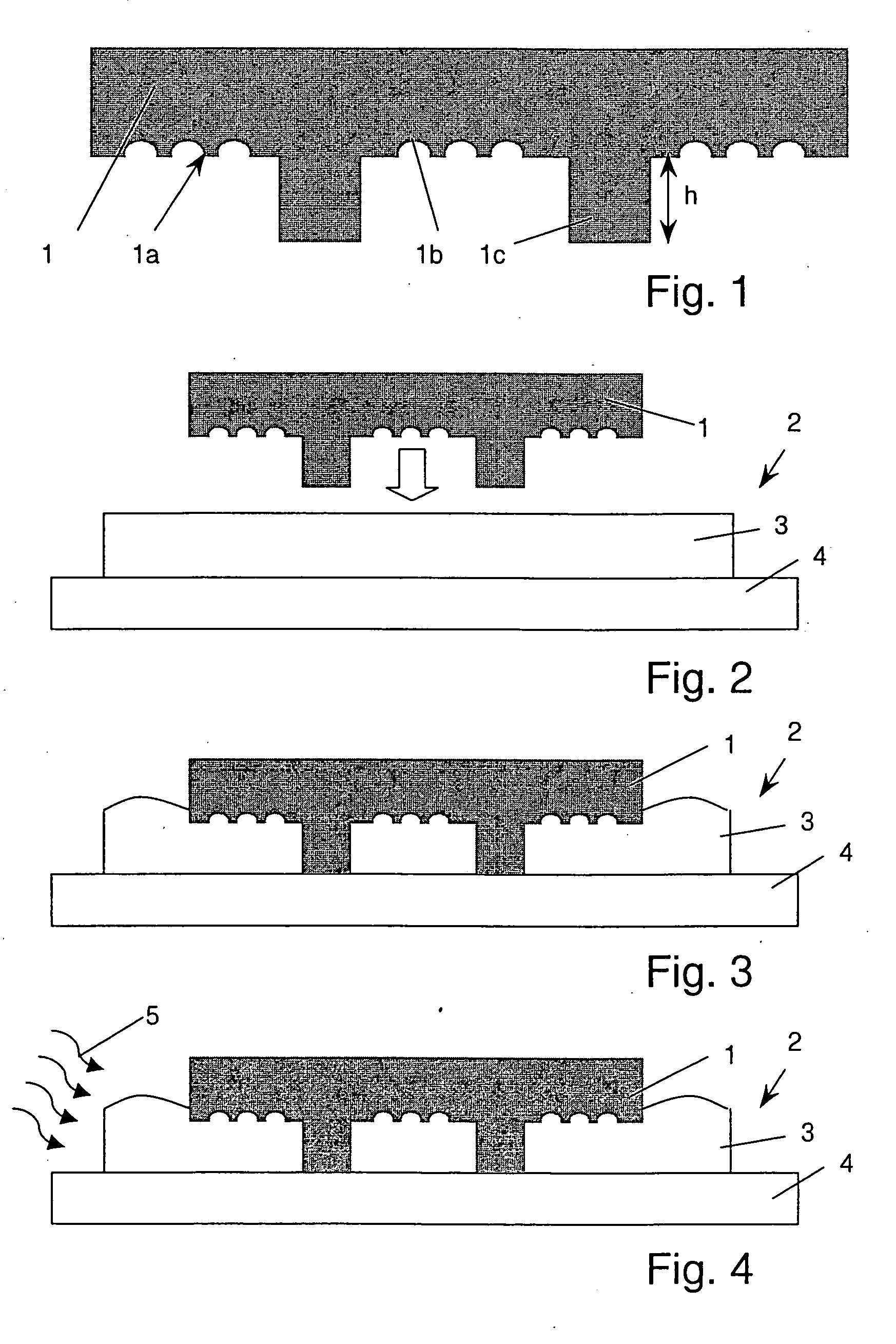

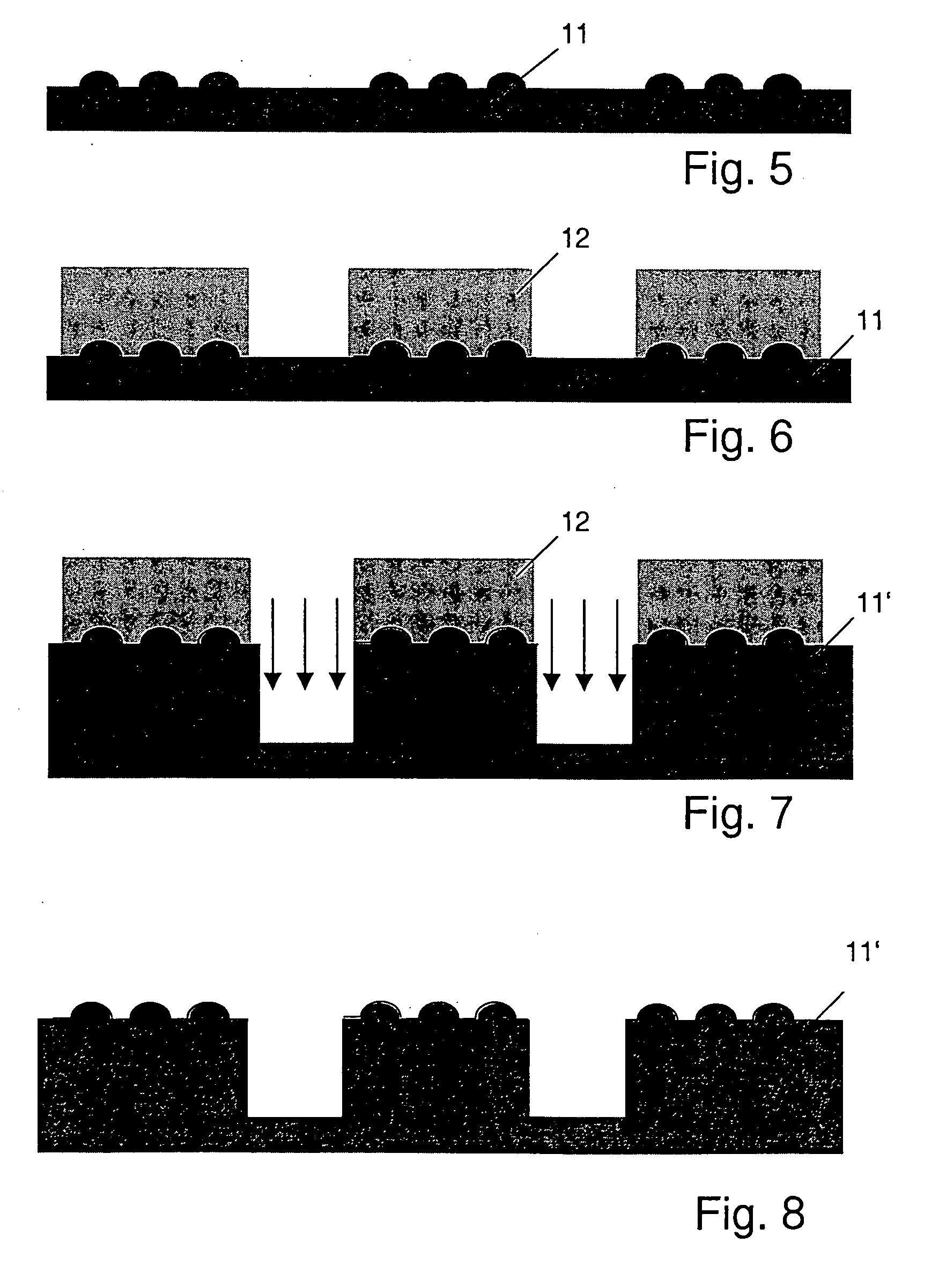

Manufacturing micro-structured elements

ActiveUS20060113701A1Automate and accurate thickness controlPrevent deformationOptical articlesCeramic shaping apparatusManufacturing engineeringReplication Process

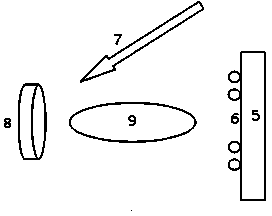

According to the invention, a micro-structured element is manufactured by replicating / shaping (molding or embossing or the like) a 3D-structure in a preliminary product using an replication tool (1). The replication tool comprises a spacer portion (1c) protruding from a replication surface (1a). The replica (the micro-structured element, for example the micro-optical element or micro-optical element component) may be made of epoxy, which is cured—for example UV cured—while the replication tool is still in place. The replication process may be an embossing process, where the deformable or viscous or liquid component of the preliminary product to be shaped is placed on a surface and then the replication tool is pressed against this surface. As an alternative, the replication process may be a molding process.

Owner:AMS SENSORS SINGAPORE PTE LTD

Atomic layer deposition preparation method for aluminum oxide thin film

ActiveCN103531658APrecise thickness controlImprove photoelectric conversion efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingOxygenDeposition process

The invention belongs to the field of semiconductor parts, and provides an atomic layer deposition preparation method for an aluminum oxide thin film. The method comprises the following steps of (1) loading a silicon substrate in an atomic layer deposition reaction chamber, and vacuumizing the reaction chamber; (2) performing atomic layer deposition by taking TMA (trimethylaluminum) as an aluminum source and taking H2O as an oxygen source; (3) performing atomic layer deposition by taking TMA as the aluminum source and taking O3 as the oxygen source. According to the method, an H2O and O3 combination Al2O3 diatomic layer deposition process is provided for solving the problem of bubbles after the sintering of an Al2O3 / SiNx laminated thin film, and compared with an H2O-based Al2O3 thin film, the Al2O3 thin film prepared from reaction sources TMA and O3 is looser, and the accumulation of H2 is effectively avoided; an atomic layer deposition technology is utilized, the thickness of an Al2O3 diatomic layer is accurately controlled, and prepared crystalline silicon with an Al2O3 passive film has high photoelectric conversion efficiency, and is free of hydrogen bubbles.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Lithium battery and electrode for same, and preparation method of solid electrolyte film

ActiveCN103268930ASimple equipmentReduce manufacturing costFinal product manufactureCell electrodesLaser printingCurrent collector

The invention relates to a lithium battery and an electrode for the same, and a preparation method of a solid electrolyte film, and belongs to the technical field of materials, and solves the problems of the film electrode prepared by the traditional method that the requirement on equipment is high, the process is complicated, the energy consumption is high and the pollution of organic solvent exists. A computer laser printing technology is used for preparing the electrode, the solid electrolyte film, the lithium battery and a full-solid lithium battery on a printing substrate or a current collector through electrode active substances and solid electrolyte materials. The method not only can conveniently and precisely control the shape, the size and the thickness of the electrode and the battery and can be environment-friendly and simple in equipment, but also can realize the mass production, can greatly reduce the production cost of the battery and can reduce the environmental pollution of the organic solvent.

Owner:HARBIN INST OF TECH

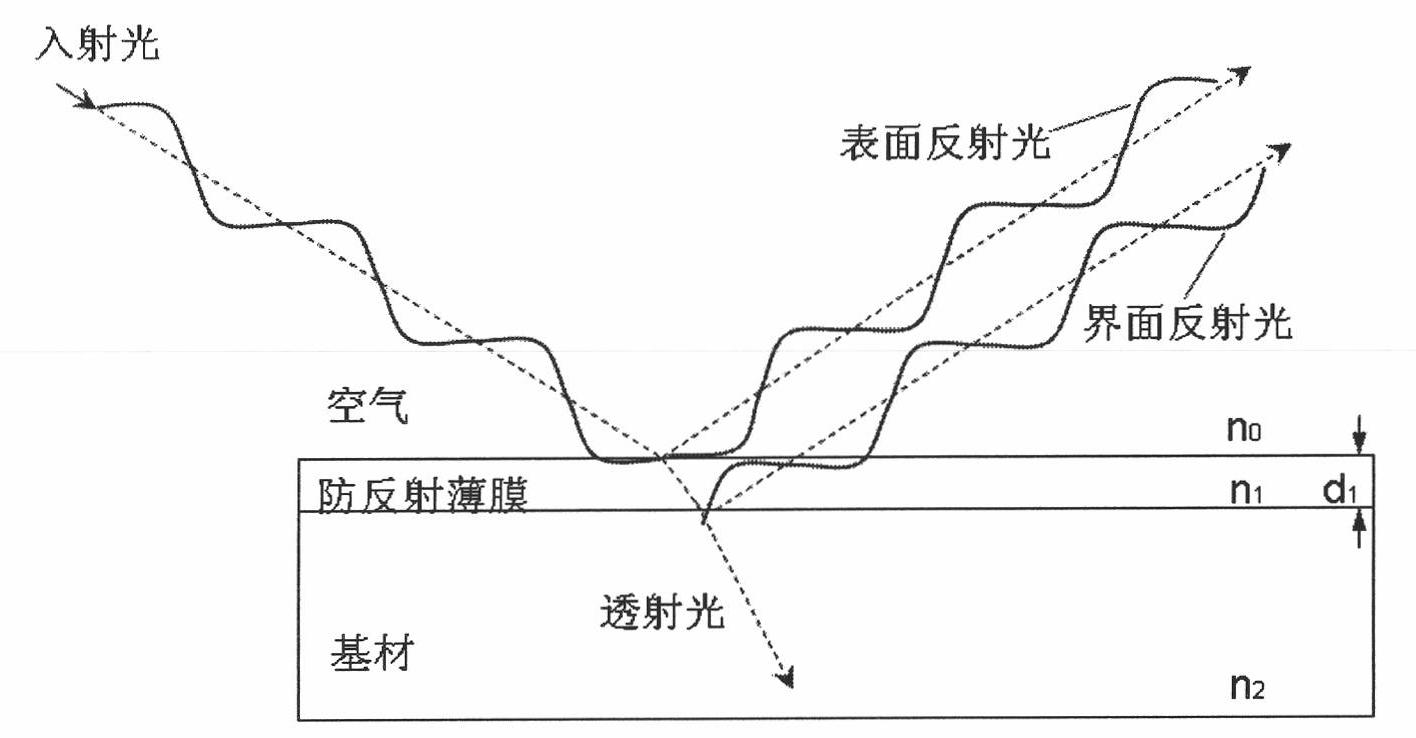

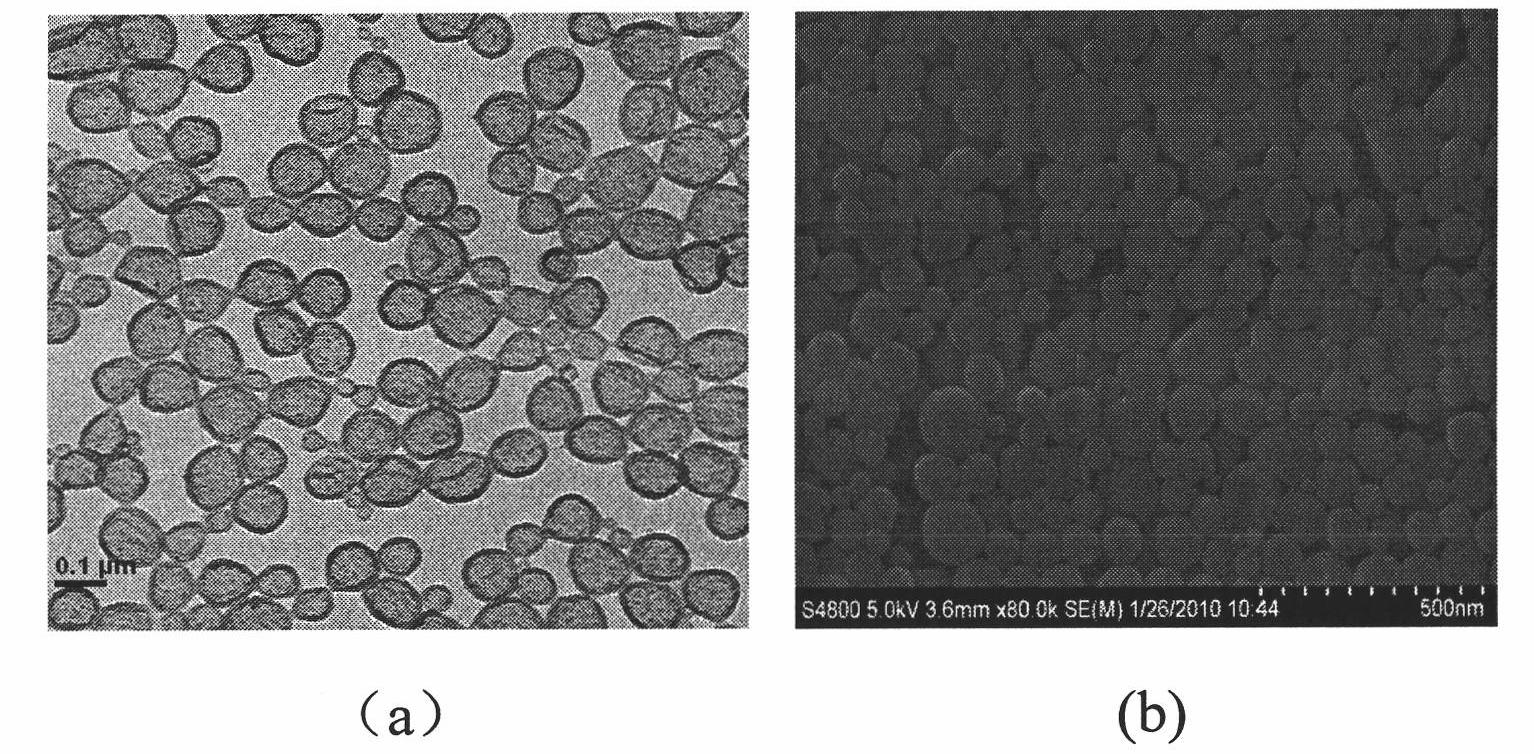

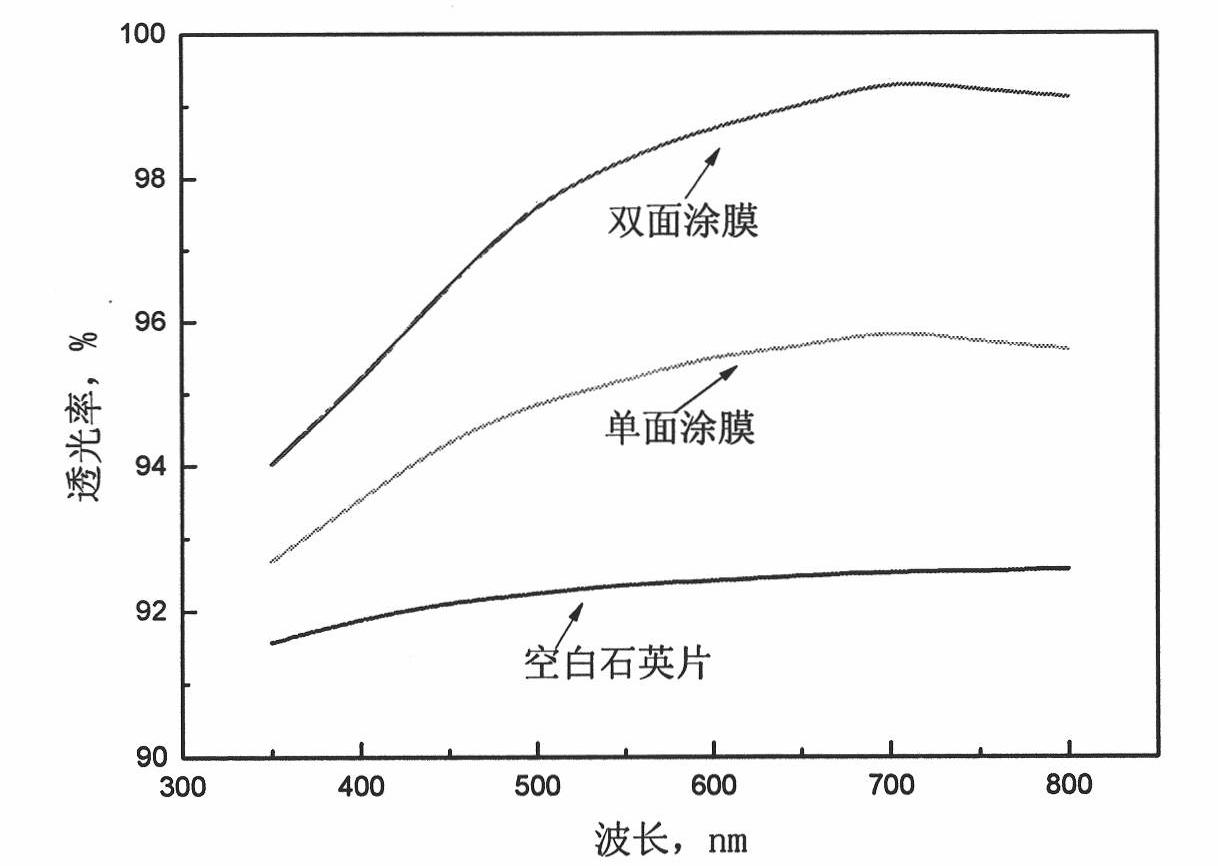

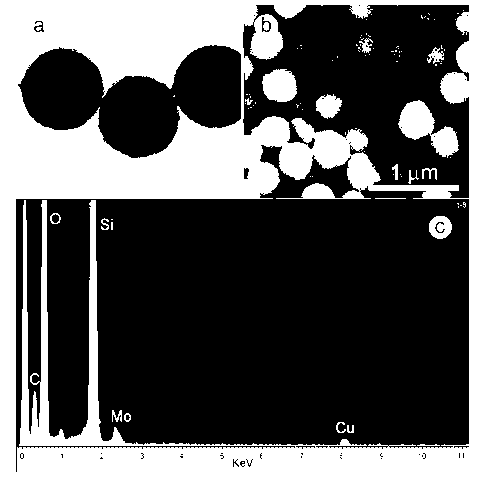

Preparation method of porous antireflection film formed by nanopolymer hollow particles

InactiveCN102030483APrecise thickness controlUniform thicknessMaterial nanotechnologyNanoopticsPolymer sciencePolymer adhesive

The invention discloses a preparation method of a porous antireflection film formed by nanopolymer hollow particles, comprising the following steps of: (1) preparing nanopolymer capsules into an aqueous dispersion with the concentration in mass percent of 3-7, carrying out spin coating on single or double surfaces of a base material through a spin coater to form a film containing the nanopolymer capsules; and (2) carrying out vacuum drying on the film containing nanopolymer capsules at high temperature to obtain the porous antireflection film formed by nanopolymer hollow particles after the core materials of the nanopolymer capsules in the film are completely volatilized and the nanopolymer capsules become nanopolymer hollow particles. The preparation method is simple, the thickness and the refractive index of the porous antireflection film can be conveniently and effectively adjusted by changing the concentration of the aqueous dispersion of the nanopolymer capsules and the cavity volume fraction of the nanopolymer hollow particles, in addition, the prepared porous antireflection film has higher mechanical strength and crocking resistance.

Owner:ZHEJIANG UNIV

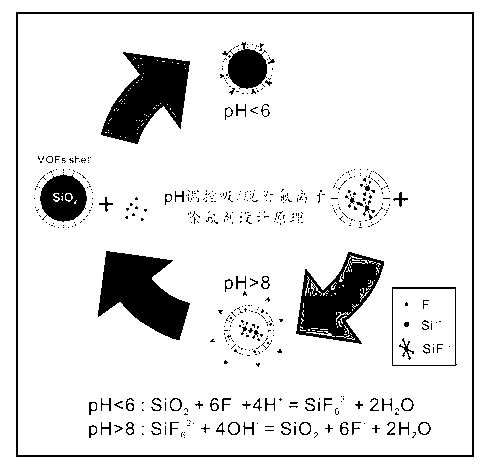

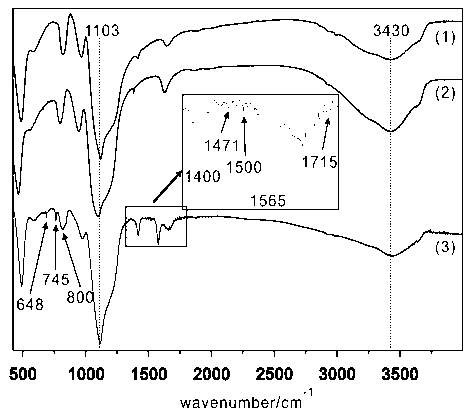

Fluorine removal agent with fluorine ion absorption/desorption function through pH value regulation and control and preparation method thereof

InactiveCN103157441APrecise thickness controlPrecise control of structure sizeOther chemical processesAlkali metal oxides/hydroxidesSilica particleHexafluoride

The invention discloses a fluorine removal agent with a fluorine ion absorption / desorption function through pH value regulation and control. The agent is of a core-shell structure. The agent mainly comprises a silica core and a metal organic framework shell layer which covers a silica surface and is provided with pore paths, wherein silica particles are spherical or irregular in shape, and the particle size is 100-5000 nanometers; and the pore size of the pore paths of the shell layer is between the diameters of a hydrated fluorine ion and a hydrated silicon hexafluoride ion. The invention further discloses a preparation method of the fluorine removal agent. The fluorine removal agent has the fluorine ion absorption / desorption function through pH value regulation and control. The fluorine removal agent can greatly absorb the fluorine ions in the water under the acid condition, and the fluorine ions which are greatly absorbed by the fluorine removal agent can be greatly desorbed under the alkaline condition. The method has the characteristics of accurately controlled thickness, pore path structure and pore size of the metal organic framework shell layer, and is low in preparation equipment investment, simple in technology and easy to operate.

Owner:CILIN & CAS ENVIRONMENTAL TECH ANHUIINC

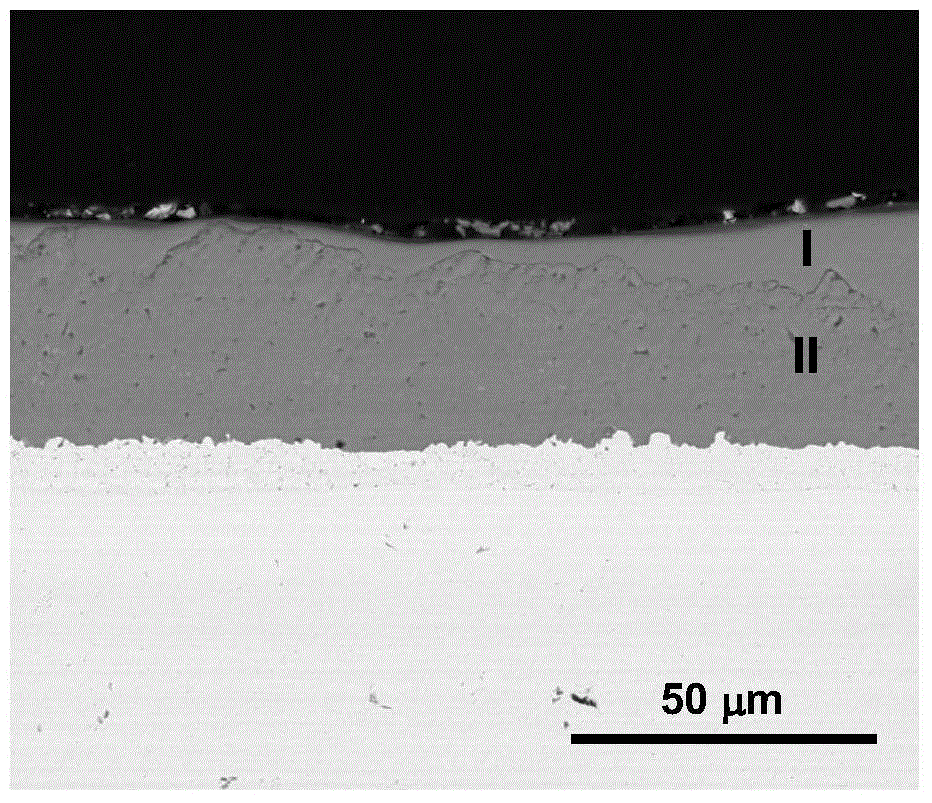

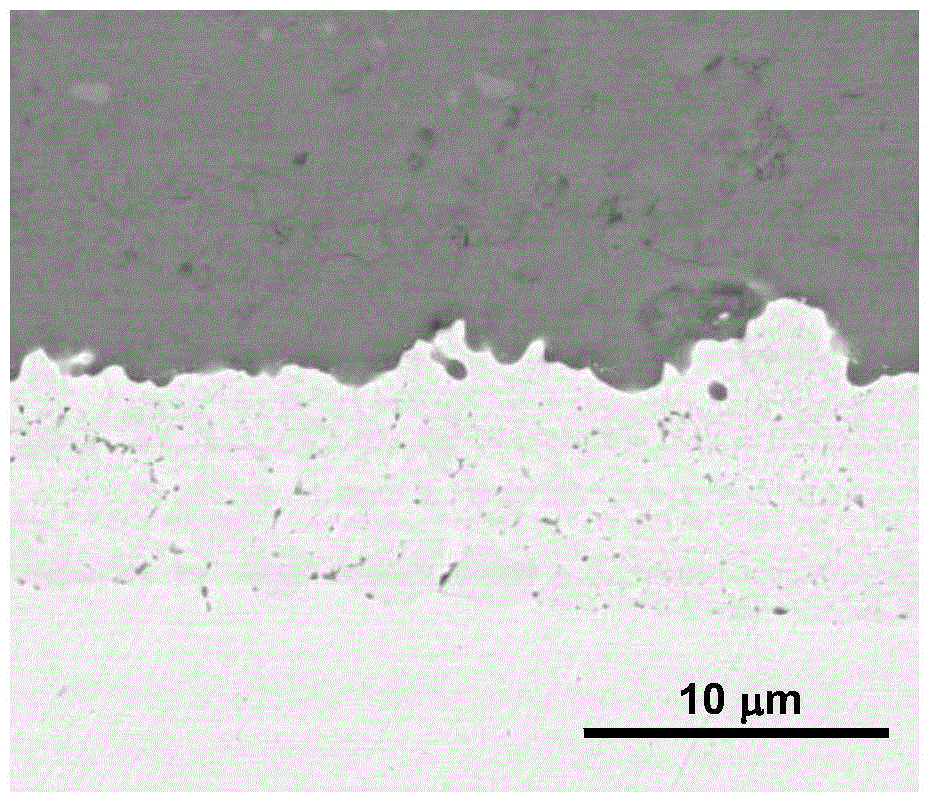

Zr-based ceramic coating protection method for surface of refractory metal material

ActiveCN104562154AImproves ablation resistancePrecise thickness controlElectrophoretic coatingsMetallic material coating processesCeramic coatingMetal

The invention relates to an ablation-resistant protection technology for refractory metal materials and particularly relates to a Zr-based ceramic coating protection method for the surface of a refractory metal material. The method comprises the following steps of firstly, degreasing a refractory metal and grinding with sand paper; secondly, depositing Zr-based ceramic powder on the surface of the refractory metal to form a Zr-based ceramic powder pre-coated layer by virtue of an electrophoretic technology; and finally, cladding the Zr-based ceramic powder pre-coated layer on the surface of the refractory metal to obtain the Zr-based ceramic coating by virtue of a laser cladding technology. According to the method, in order to solve the problem of relatively low application temperature of the silicide protective coating applied in the refractory metal, the Zr-based ceramic coating is adopted to solve the application limitation of the refractory metal so that the ablation resistance of the refractory metal matrix at above 2000 DEG C is effectively increased.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

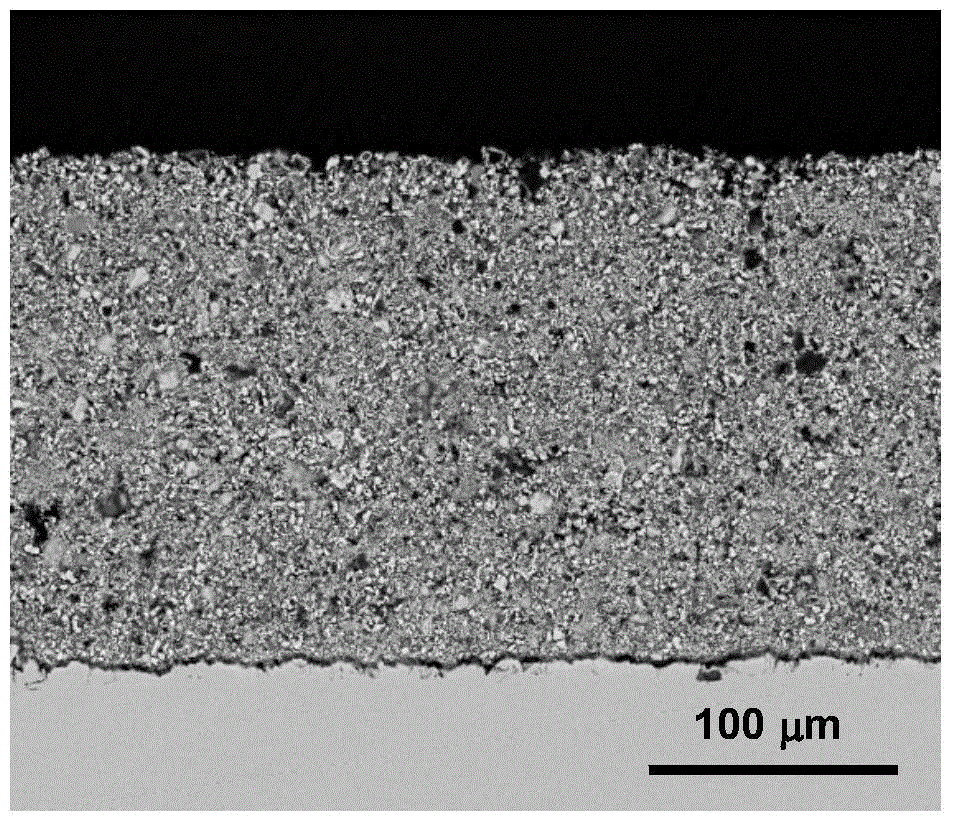

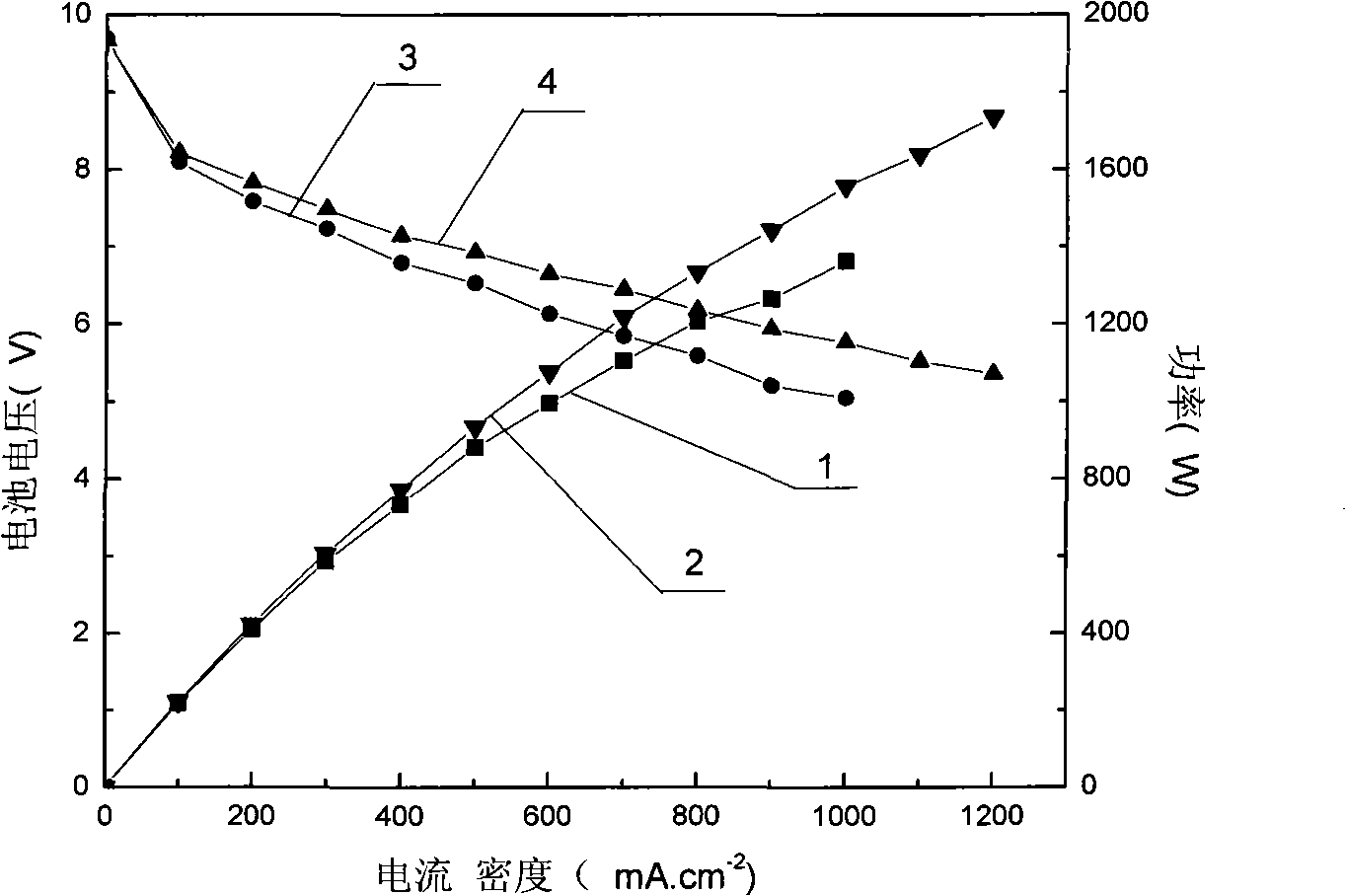

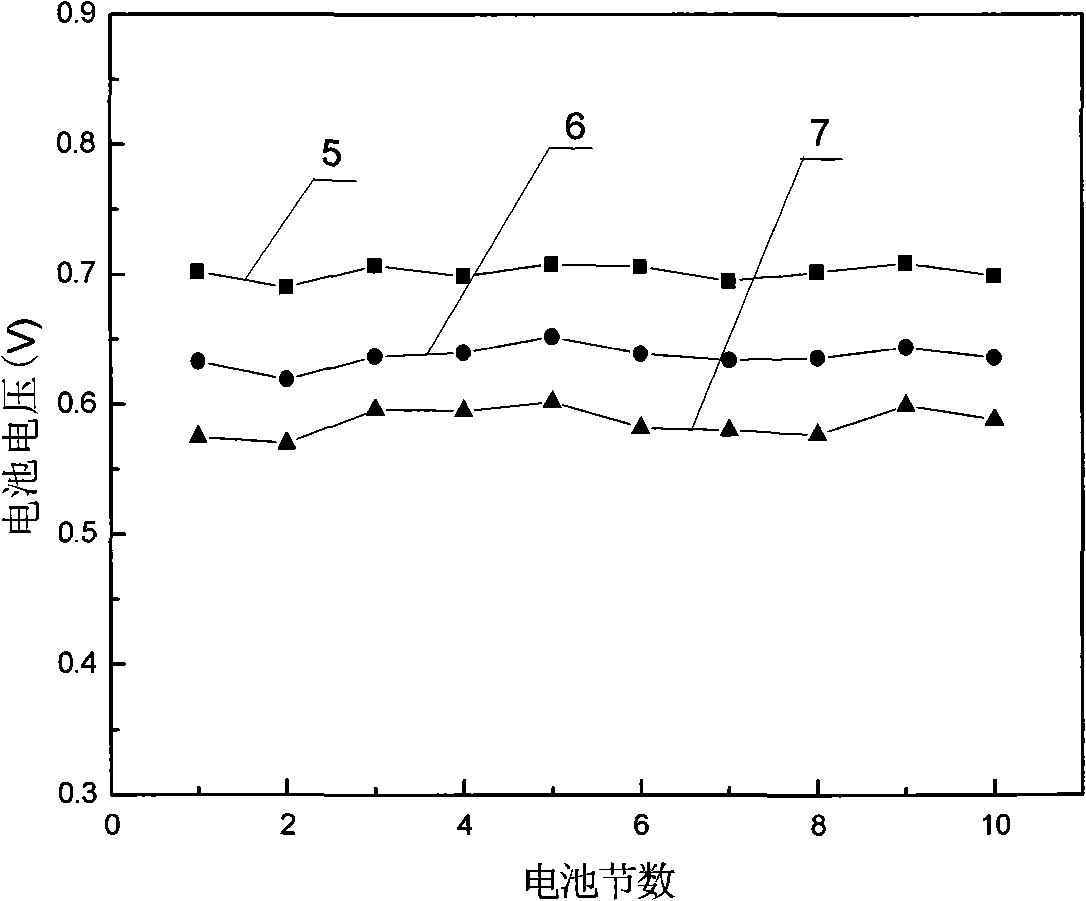

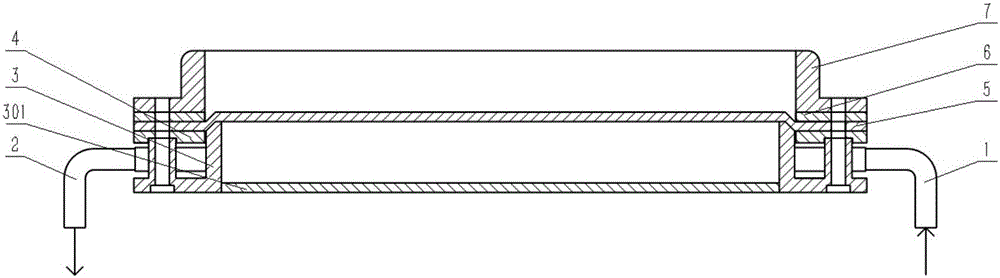

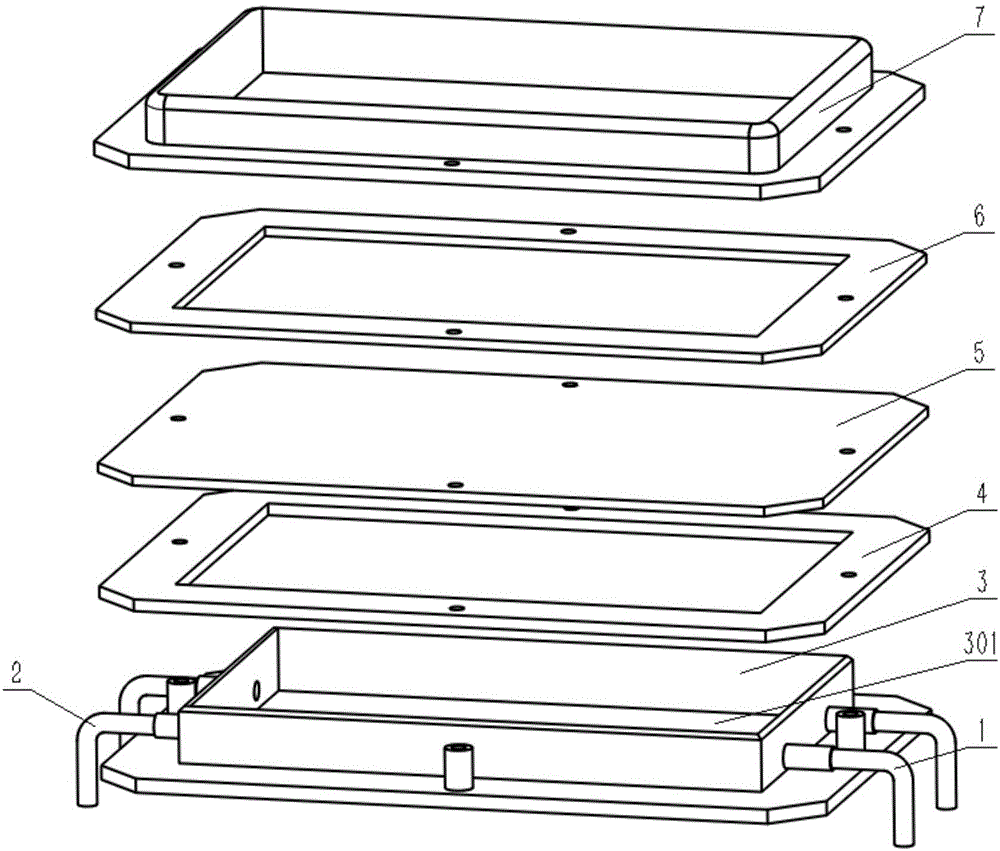

Preparation method of water retention type proton exchange membrane for fuel cell

ActiveCN101667648AEfficient fillingReduce air permeabilityFinal product manufactureCell component detailsTetrafluoroethyleneHigh humidity

The invention discloses a preparation method of a water retention type proton exchange membrane for a fuel cell, including spraying a perfluorinated sulfonic acid resin solution on the surface of an expanded polytetrafluoroethylene micropore film; the method comprises the following steps: filling a perfluorinated sulfonic acid resin component and a silicon dioxide component into micropores of theexpanded polytetrafluoroethylene micropore film in an impregnating way; and controlling the exchanging thickness of a compound proton in a way of spraying the perfluorinated sulfonic acid resin component and the silicon dioxide component. The compound proton exchange membrane prepared by the method not only ensures the absorption capability of water but also reduces the total resistance of the compound proton exchange membrane because water retention components of silicon dioxide is distributed in a gradient way, has a water retention function, reduces the dependency of the proton exchange membrane fuel cell on a humidification system, can ensure the compound proton exchange membrane to normally work under a low-humidification environment, is easy to realize the large-scale production andhas uniform thickness, high humidity strength and good size stability.

Owner:SUNRISE POWER CO LTD

Method for producing crease-resisting fabric

InactiveCN102535172AExtended service lifeImprove wrinkle resistanceVacuum evaporation coatingSputtering coatingRadio frequencyFiber

The invention relates to a method for producing crease-resisting fabric, which is characterized in that waterborne polyurethane crease-resisting finishing agent is coated on an ordinary fiber fabric by adopting the radio-frequency reactive magnetron sputtering technique to obtain the crease-resisting fiber fabric, a thin film formed by the waterborne polyurethane crease-resisting finishing agent covers the fiber uniformly and is well combined with the fiber so that the service life of the crease-resisting fiber fabric is prolonged, and the thickness of the thin film formed by the waterborne polyurethane crease-resisting finishing agent can be regulated precisely according to the differences of the use fields of the crease-resisting fiber fabric. The method is easy to realize the industrialization.

Owner:JIANGNAN UNIV

Forming window for high-speed continuous photocuring 3D printing

ActiveCN106273516AEfficient printingTroubleshoot quick fixesAdditive manufacturing apparatusCooling chamberEngineering

The invention discloses a forming window for high-speed continuous photocuring 3D printing. The forming window applied to a photocuring 3D printer comprises a window box and an oxygen supply cooling module. The photocuring 3D printer is divided into an upper cavity and a lower cavity through a middle partition. The window box and the oxygen supply cooling module are arranged in the upper cavity of the case of the photocuring 3D printer. The window box and the oxygen supply cooling module are fixedly mounted on the middle partition in a combined manner. Two ends of an oxygen supply cooling chamber are respectively connected with a cooling gas inlet pipeline and a cooling gas outlet pipeline, and the oxygen supply cooling chamber, the o cooling gas inlet pipeline and the cooling gas outlet pipeline form the oxygen supply cooling module. The forming window has the advantages that low-cost and efficient continuous printing of large-size optional-shape parts can be achieved, the forming window is wide in applicable materials, the precision and quality of the printed parts are high, the printed parts are good in consistency, and process stability and reliability are achieved. In addition, the forming window is high in industrial application value and applicable to a desktop-level 3D printer and industrial 3D printing.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

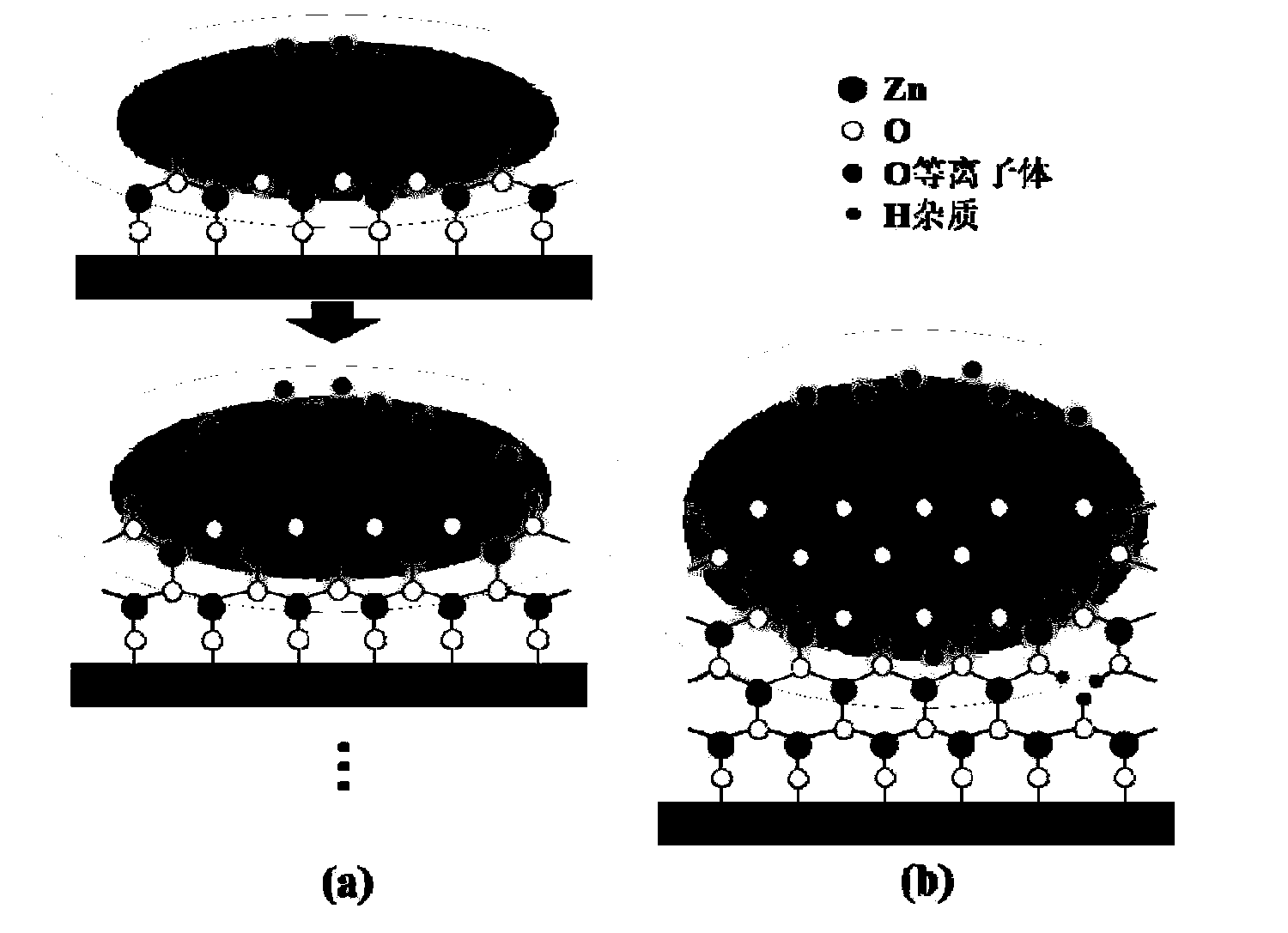

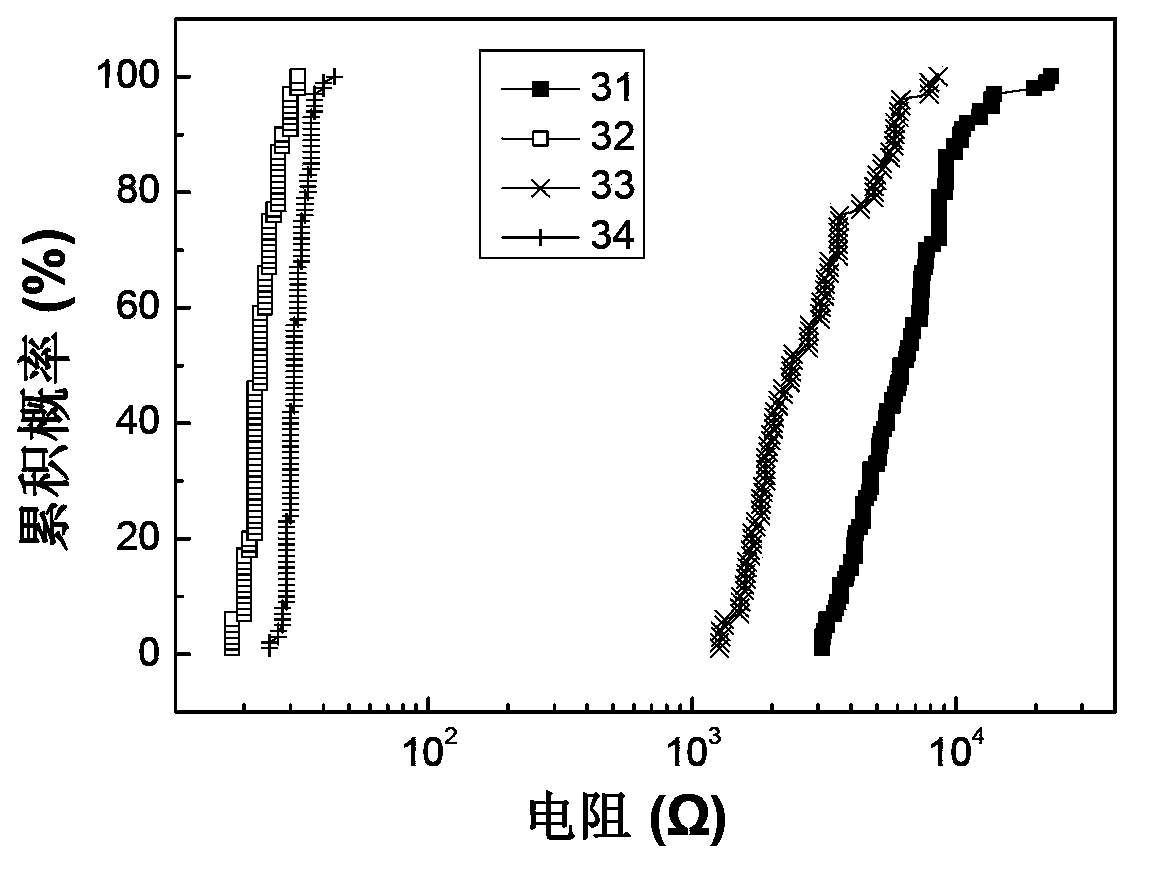

Preparation method for resistive random access memory

ActiveCN103441214AEfficient removalHigh on/off ratioElectrical apparatusElectrical resistance and conductanceStatic random-access memory

The invention discloses a preparation method for a resistive random access memory. The resistive random access memory comprises a bottom electrode, a resistance change dielectric layer material and a top electrode which are assembled in sequence. Preparation of the resistance change dielectric layer material includes the following steps that firstly, a first precursor, first inert gas, a second precursor and second inert gas are fed into a reactor in order, and a monolayer metallic oxide film is deposited on the bottom electrode through a cycle of hot atomic layer deposition; secondly, a plasma enhancement process is carried out on the film; finally, the steps are carried out circularly and alternately. In the preparation process of a resistance change dielectric layer, a brand new in-situ plasma enhancement hot atomic layer deposition technology is brought in, so the surface appearance and defects of the metallic oxide film can be adjusted on a large scale; the resistive random access memory obtained through the preparation method can achieve precision control over device resistance switching characteristics to enable the device switch ratio and erase / write voltage to be adjusted, and has excellent resistance change stability.

Owner:ZHEJIANG UNIV

Method for detecting bottom outline of contact plug

ActiveCN102254845AReduce mistakesReduce charge trapping effectSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingComputational physicsScanning electron microscope

The invention provides a method for detecting the bottom outline of a contact plug, comprising the following steps of: providing a wafer, wherein the wafer comprises a semiconductor substrate with an active region, a first dielectric layer on the semiconductor substrate, the contact plug passing through the first dielectric layer and electrically connected with the active region, a second dielectric layer formed on the first dielectric layer and the contact plug, and a metal layer passing through the second dielectric layer and electrically connected with the contact plug; removing the metal layer and the second dielectric layer; removing a part of the first dielectric layer in a manner of dry etching; removing the contact plug so as to form a detection sample wafer; and using a scanning electron microscope to detect the detection sample wafer. In the invention, a clear picture of the bottom outline of the contact plug can be obtained by using the scanning electron microscope, and a precise detection result is obtained.

Owner:WUHAN XINXIN SEMICON MFG CO LTD +1

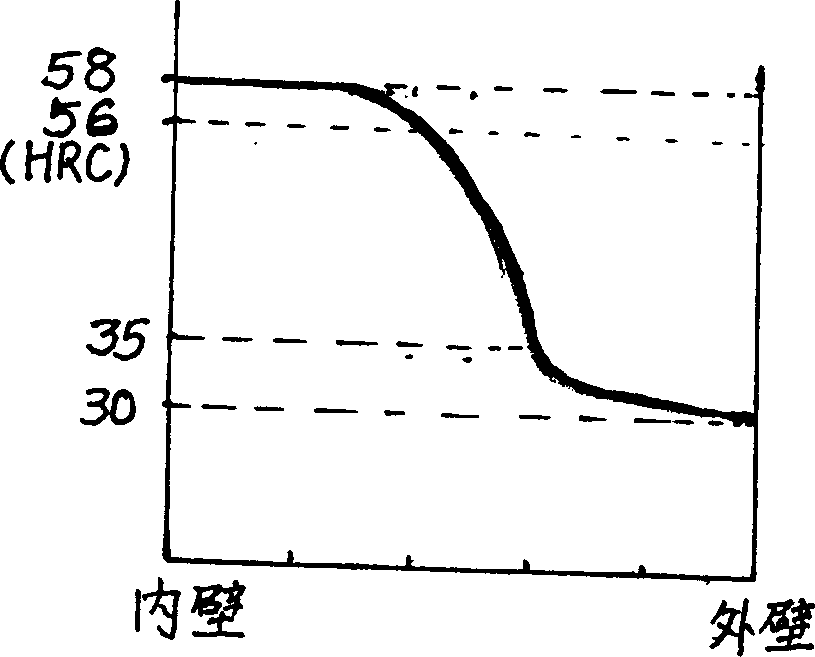

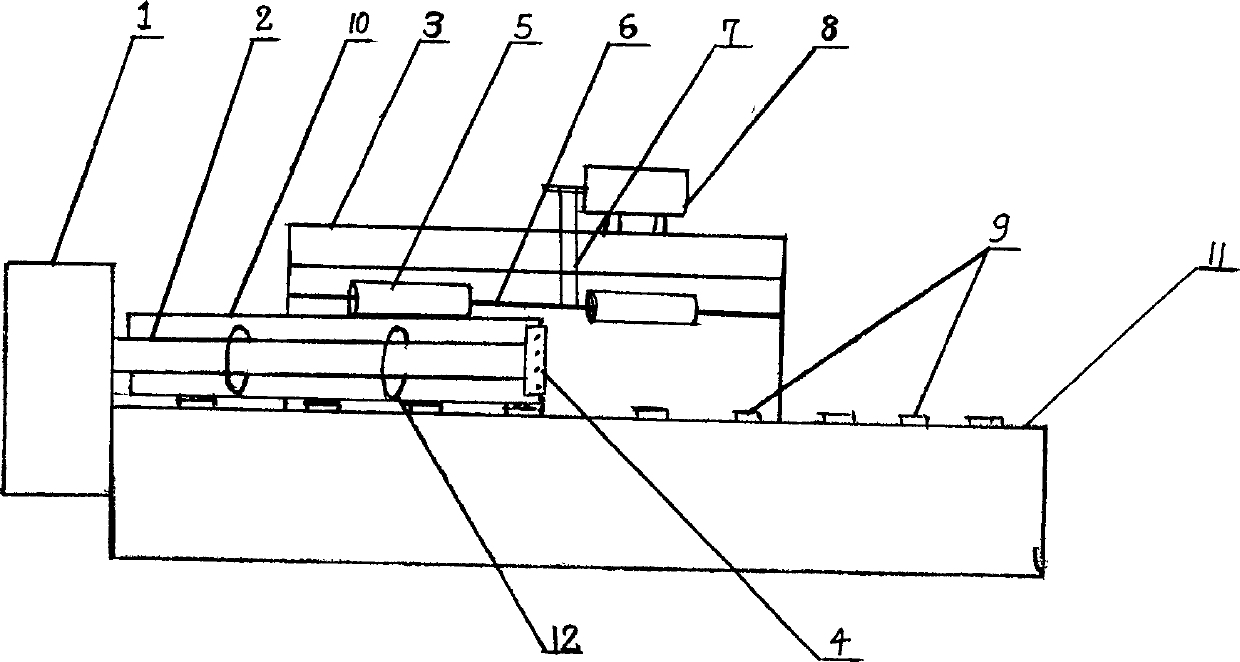

Cylinder shape pipe piece with inner harden layer and production method and equipment

InactiveCN1433942ALarge caliberSave materialIncreasing energy efficiencyFurnace typesFrictional coefficientEngineering

The present invention relates to a cylindrical pipe with internal hardened layer, its production method and special-purpose equipment. Said cylindrical pipe has small wall thickness and long length, its pipe wall has internal layer and external layer with different hardness, the hardness of its internal layer is greater than that of external layer, and said pipe is applicable for conveying material with high frictional coefficient. Its production method adopts the mode utilizing frequency to control pipe movement and proper hardening temp. range, and is special-purpose equipment is simple in structure, stable in operation, and can accurately control hardening temp., pipe moving speed nad depth of hardened layer.

Owner:王克发 +1

Carbon-Cu6Sn5 alloy negative electrode materials and preparation method thereof

InactiveCN103066252AReduce the likelihood of sheddingIncrease migration rateElectrolytic coatingsCell electrodesCarbon nanotubeAlloy

The invention discloses carbon-Cu6Sn5 alloy negative electrode materials and a preparation method thereof. The carbon-Cu6Sn5 alloy negative electrode materials and the preparation method thereof combine carbon nanometer tubes and graphene into electrodes and add a Cu-CNTs connecting layer between active materials and current collectors. Therefore, cyclic perforce of an alloy negative electrode is improved greatly. The carbon-Cu6Sn5 alloy negative electrode materials and the preparation method thereof use copper foils as the current collectors (electroplating substrates). The copper foils are plated by a Cu-CNTs composite plating and a composite plating of stannum-carbon nanometer tubes or stannum- graphene or stannum-carbon nanometer tubes- graphenes in sequence, wherein the thickness of the Cu-CNTs composite plating is 1-5 micrometers and the thickness of the composite plating of the stannum-carbon nanometer tubes or the stannum- graphene or the stannum-carbon nanometer tubes- graphene is 1-4 micrometers. The carbon-Cu6Sn5 alloy negative electrode materials can be obtained finally through thermal treatments. First specific discharge capacity of lithium ion battery alloy cathodes prepared by the method can achieve 613 m AH / g and specific capacity attenuation of the lithium ion battery alloy cathodes is only 4%-6% after 100 cycles. The carbon-Cu6Sn5 alloy negative electrode materials and the preparation method thereof are simple in technique, good in prepared alloy cathode performance and suitable for large-scale industrial production.

Owner:XIANGTAN UNIV

Method for compounding functional nanoparticles on surfaces of polymer filaments

ActiveCN103556451ADoes not affect mechanical propertiesRetain mechanical propertiesVegetal fibresFiberPolymer science

The invention relates to a method for compounding functional nanoparticles on surfaces of polymer filaments, belonging to the technical field of new fiber materials. The method comprises the steps of protein-based modification on surfaces of functional nanoparticles, preparation of a blended solution, formation of polymer filaments with surfaces compounded with the blended solution and control of thickness, phase inversion primary formation of the polymer filaments with surfaces compounded with the blended solution and thermosetting formation of the polymer filaments with surfaces compounded with the blended solution, thus obtaining the polymer filaments with surfaces compounded with the functional nanoparticles. In the preparation method, carbon nano tubes, graphene, carbon black, titanium dioxide, zinc dioxide, iron particles, iron oxide, aluminium oxide, silver particles and other nanoparticles can be compounded on the surfaces of the polymer filaments. The polymer filaments after compounding have good mechanical properties and functionality. The preparation method is simple to operate, dispenses with special equipment and achieves industrial production easily.

Owner:JIANGSU YIMAO FILTER MEDIA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com