Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49 results about "Saw (device)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

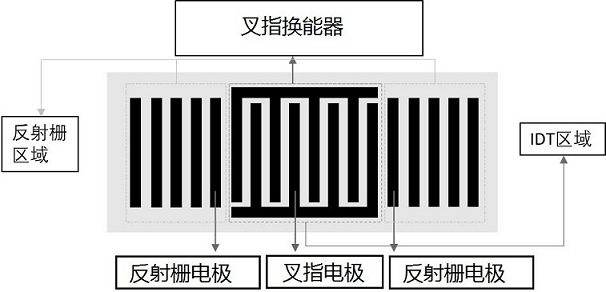

SAW devices. SAW devices use SAWs in electronic components to provide a number of different functions, including delay lines, filters, correlators and DC to DC converters. Application in electronic components. This kind of wave is commonly used in devices called SAW devices in electronic circuits.

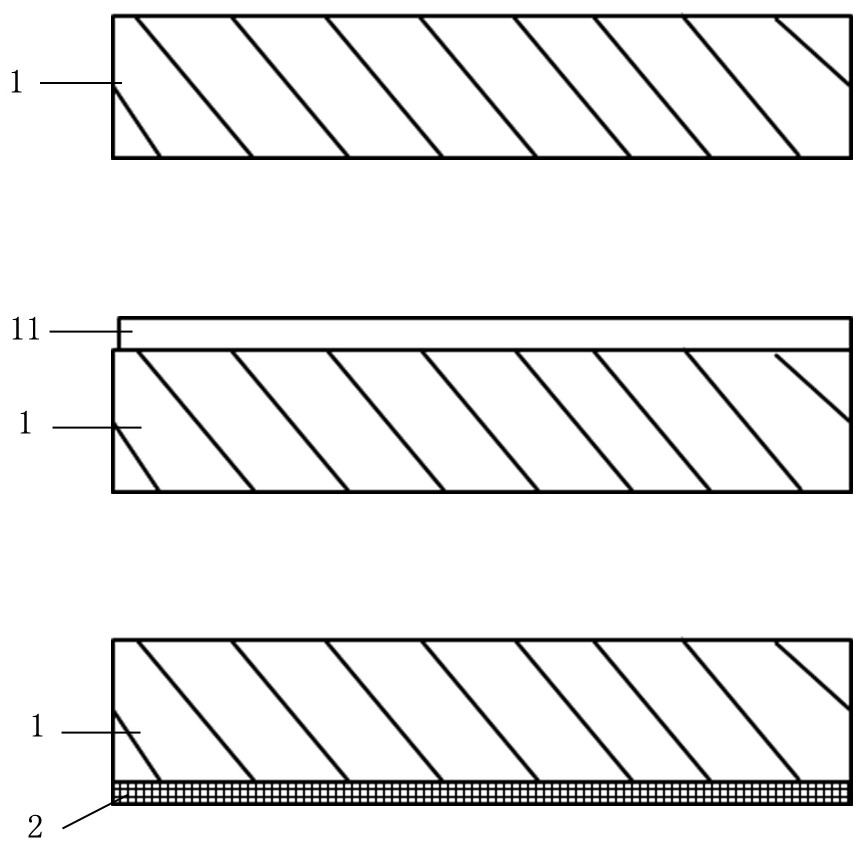

Structure of surface acoustic wave device on basis of flexible substrate and manufacturing method of surface acoustic wave device

InactiveCN102420582ARaise the resonant frequencyNo drop in Q valueImpedence networksEngineeringAcoustic wave

Owner:ZHEJIANG UNIV +1

Surface acoustic wave device, electronic apparatus, and sensor apparatus

InactiveUS20120068573A1Improve Q valueSmall frequency fluctuationPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesEngineeringAcoustic wave

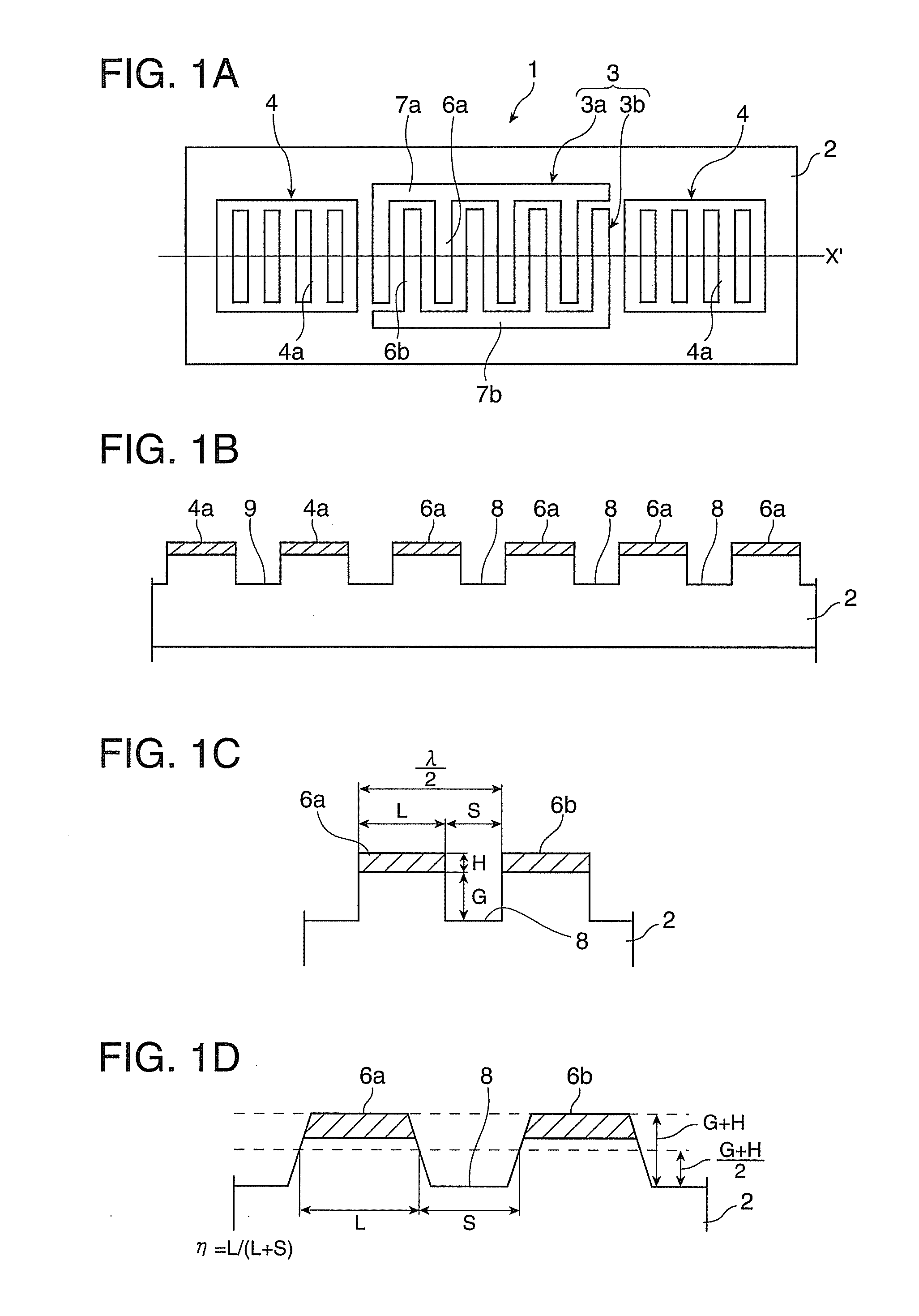

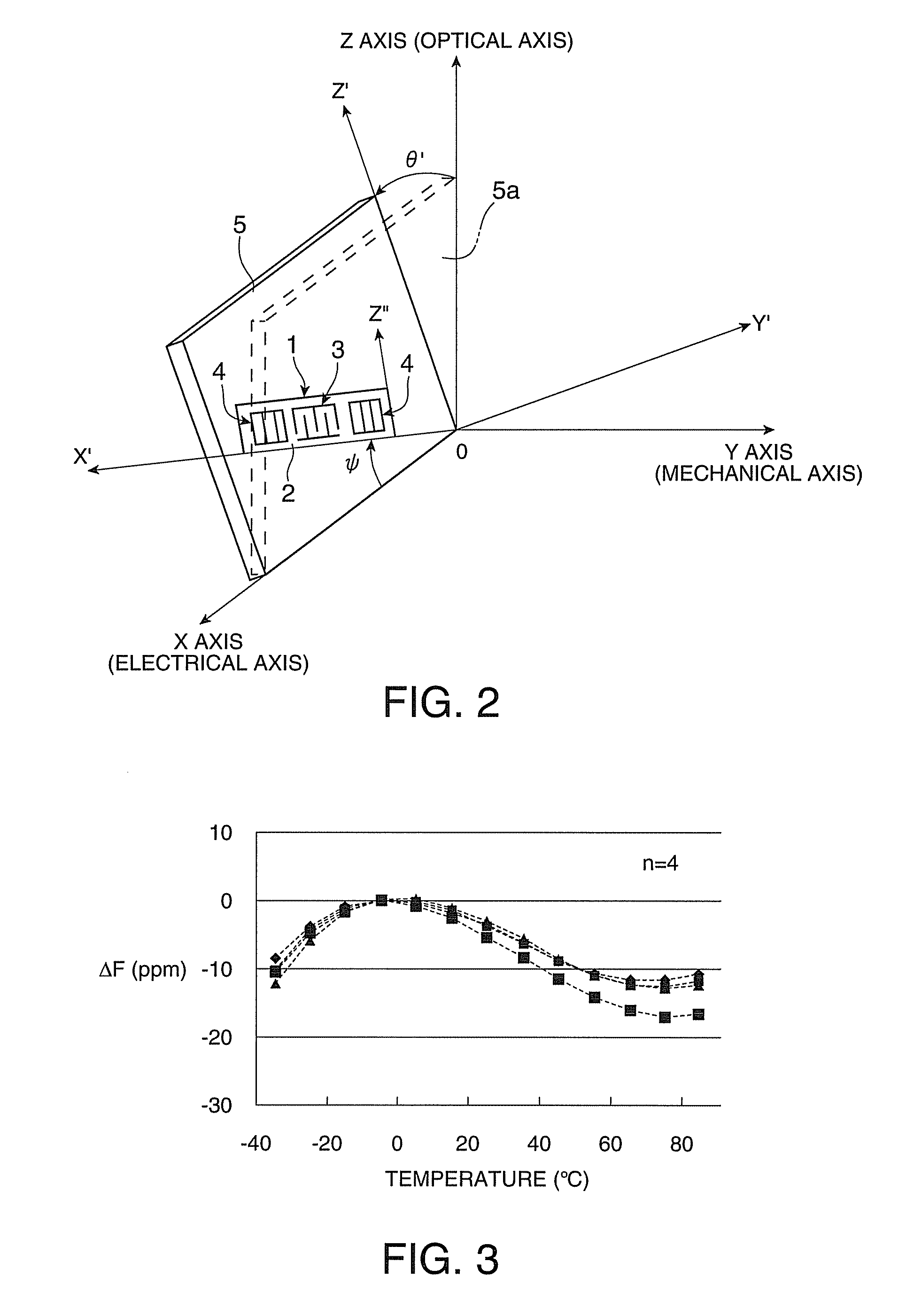

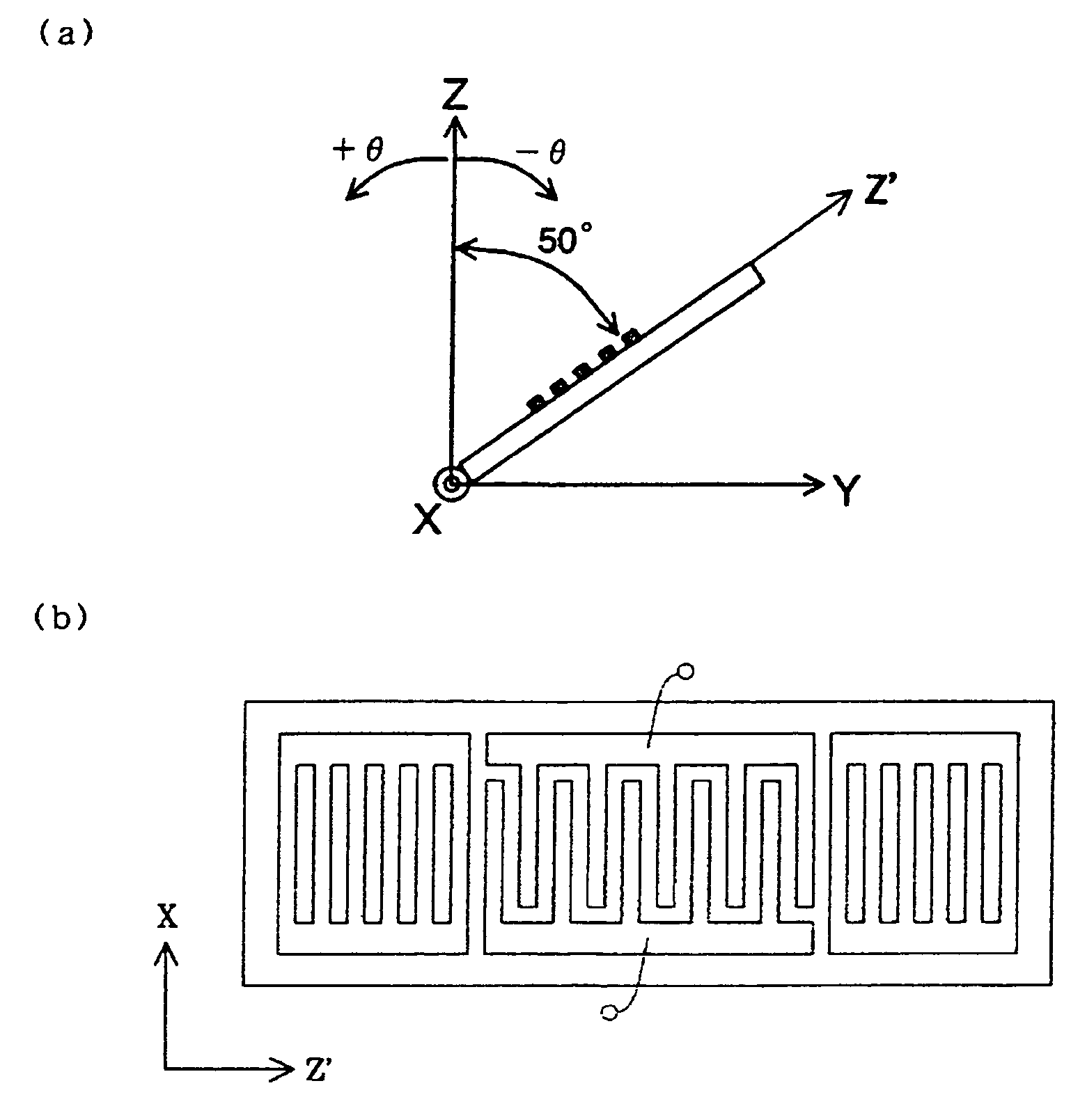

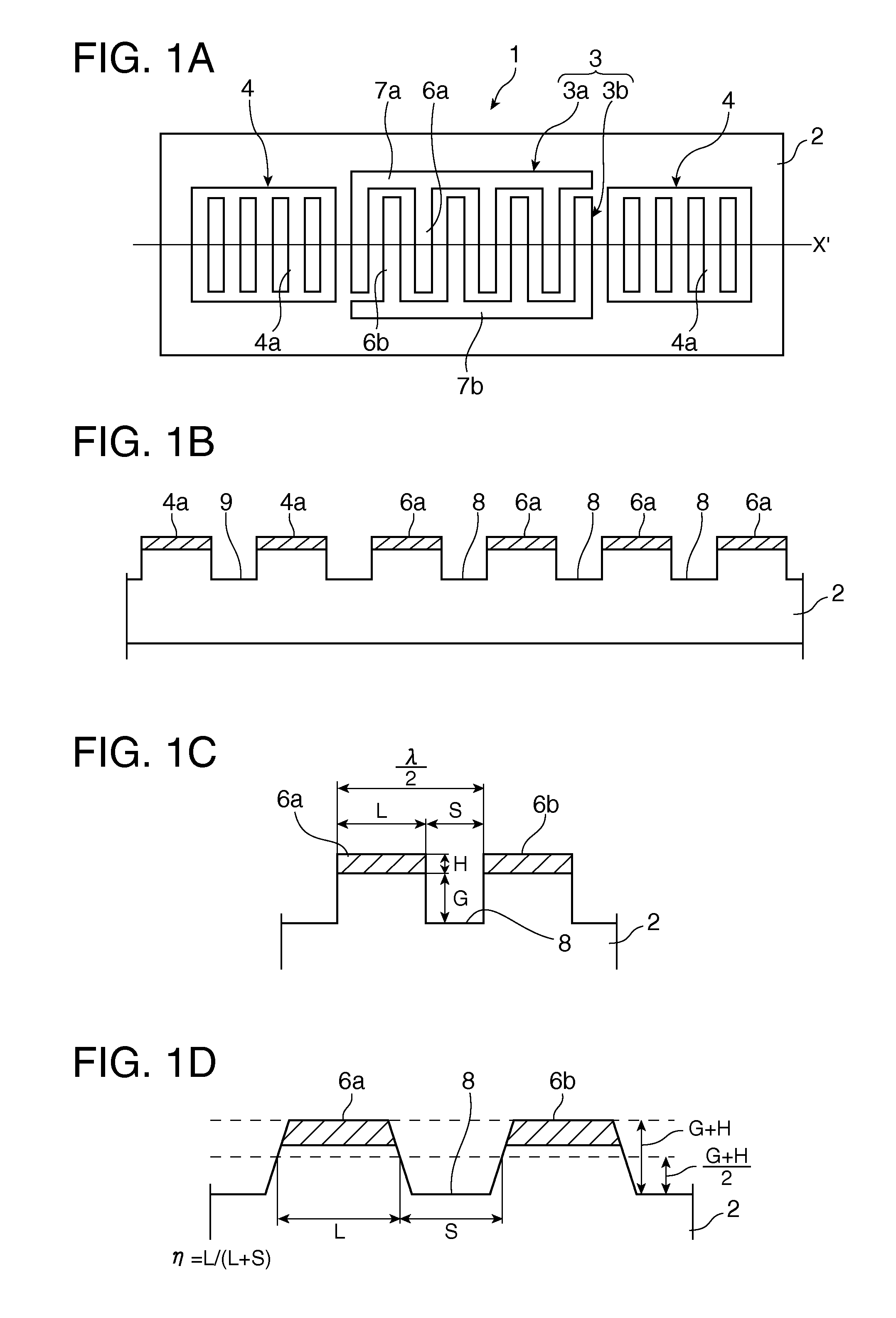

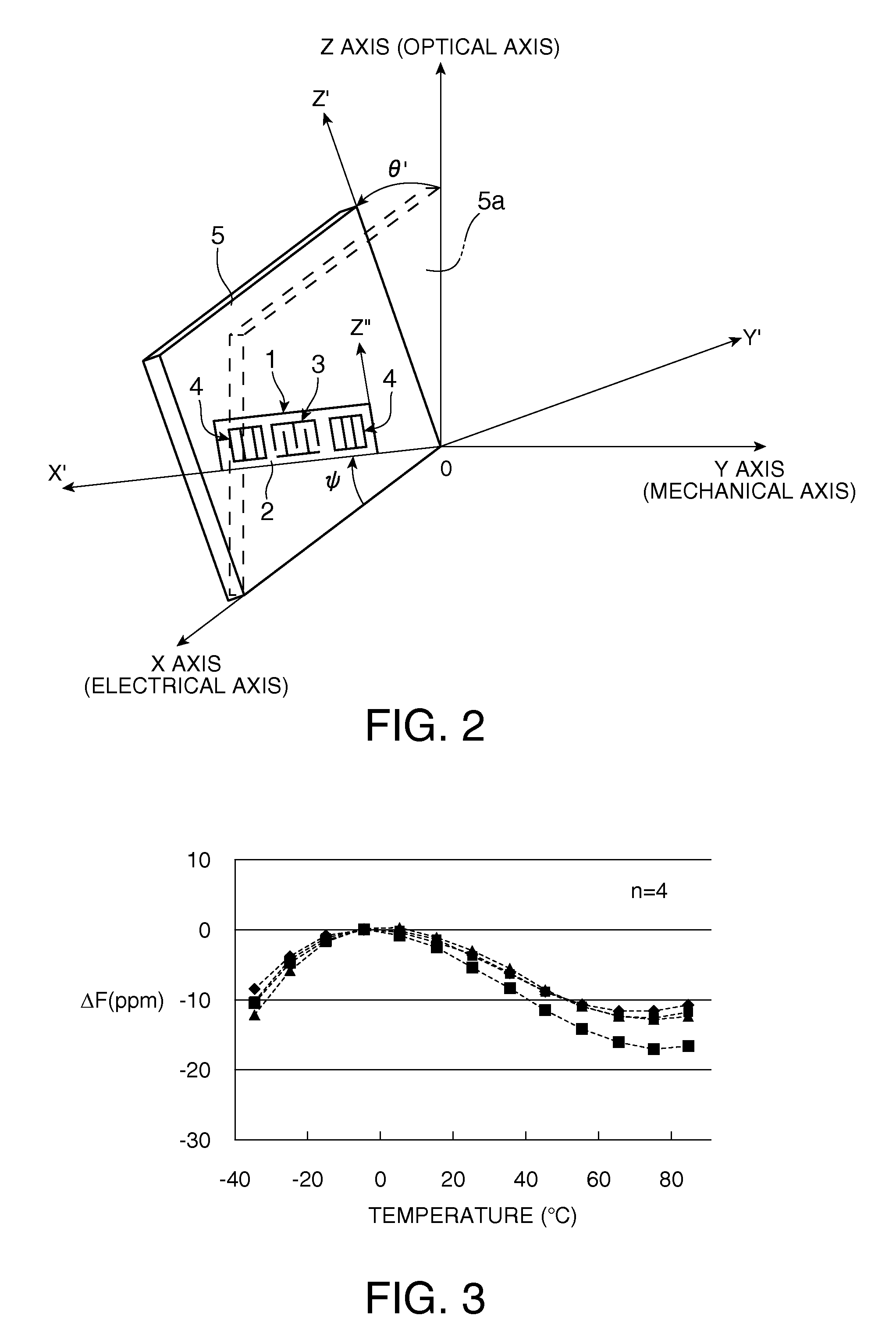

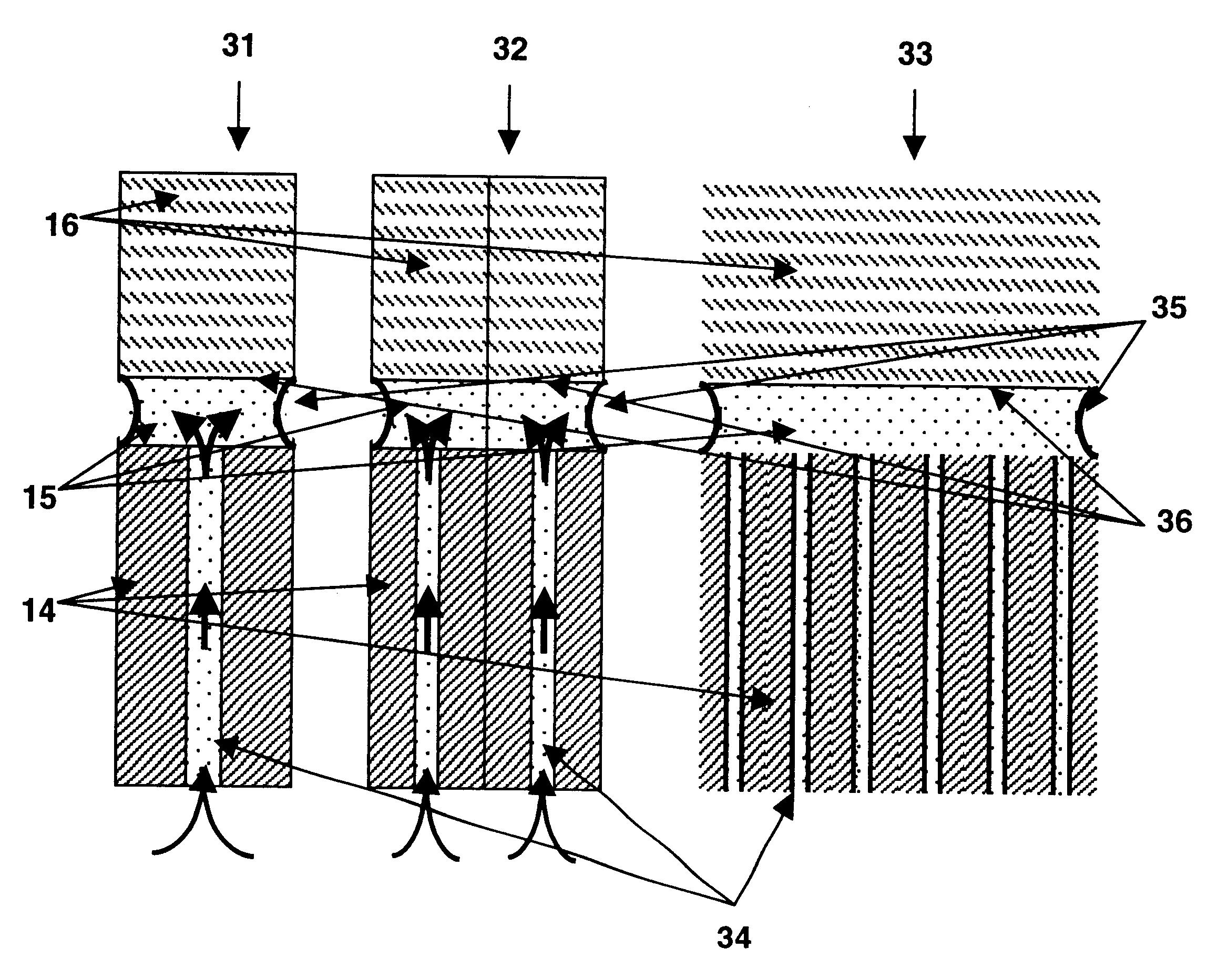

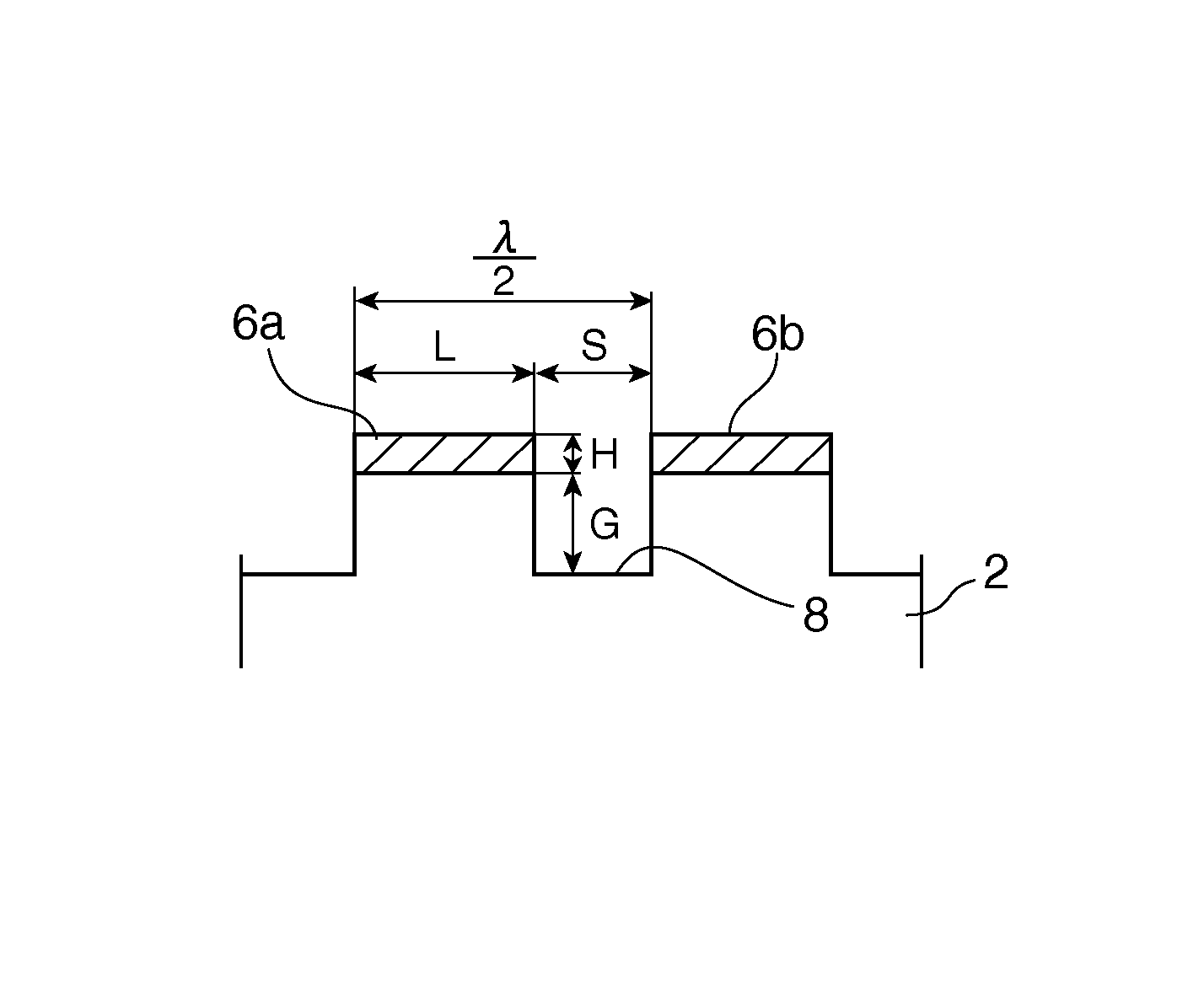

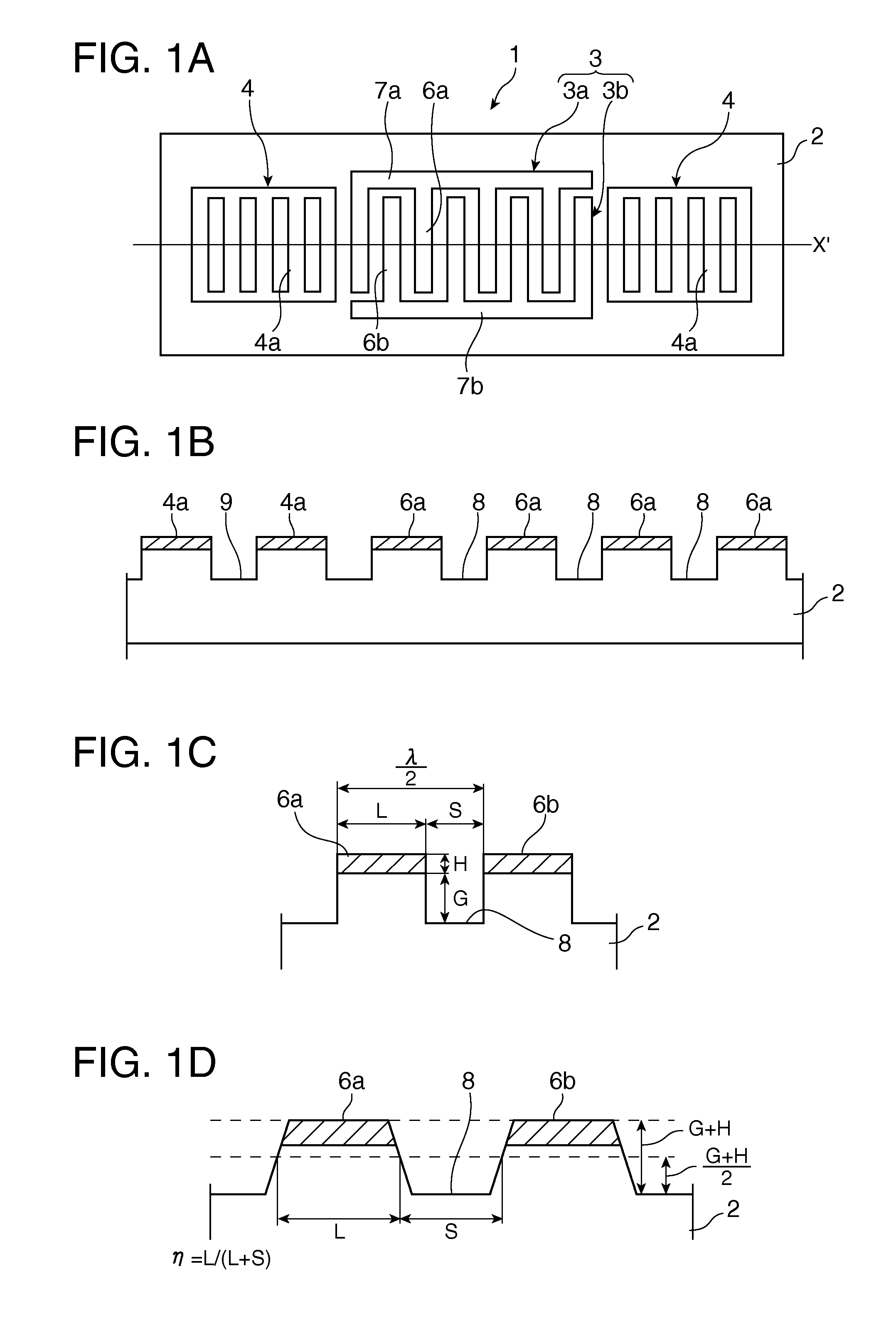

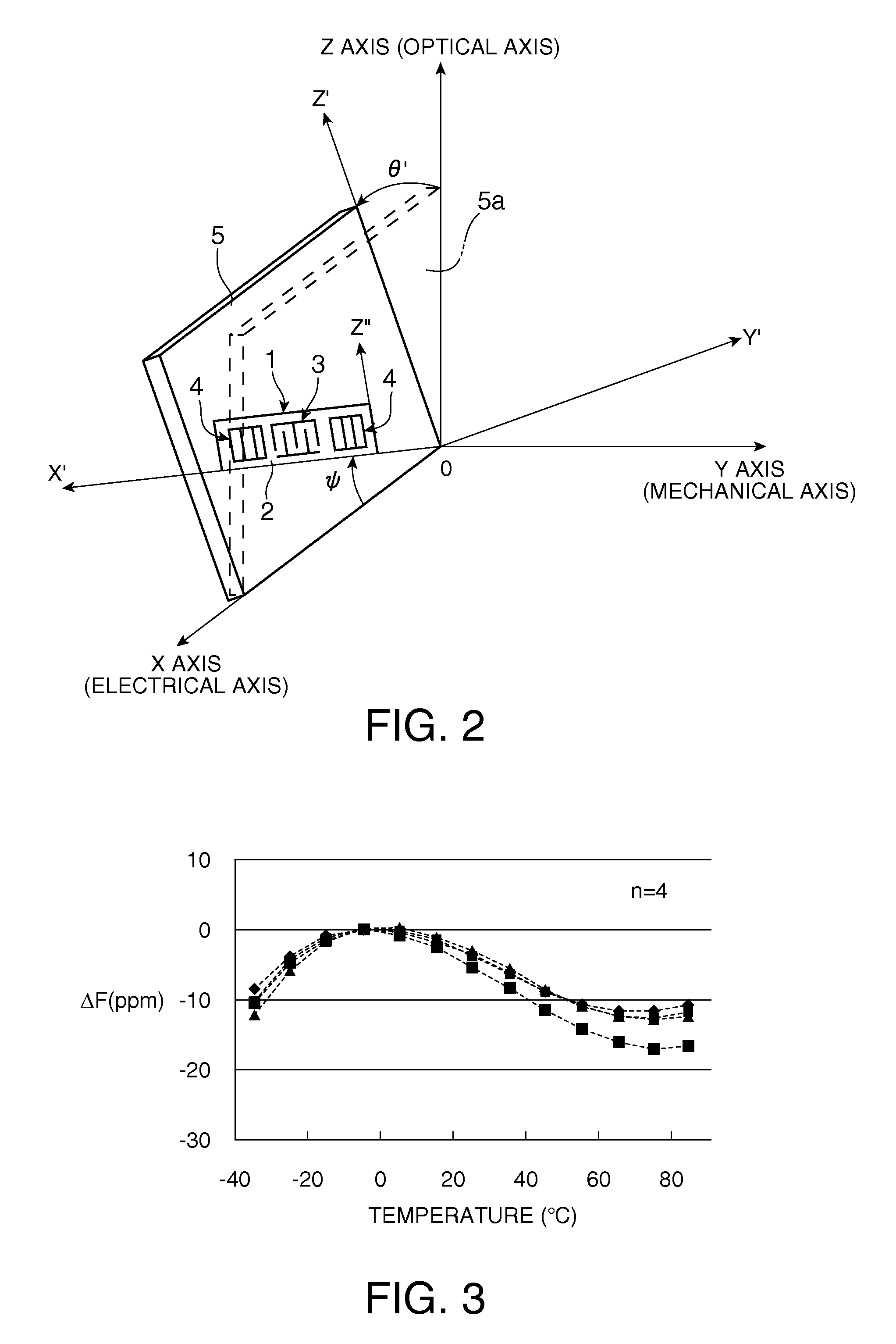

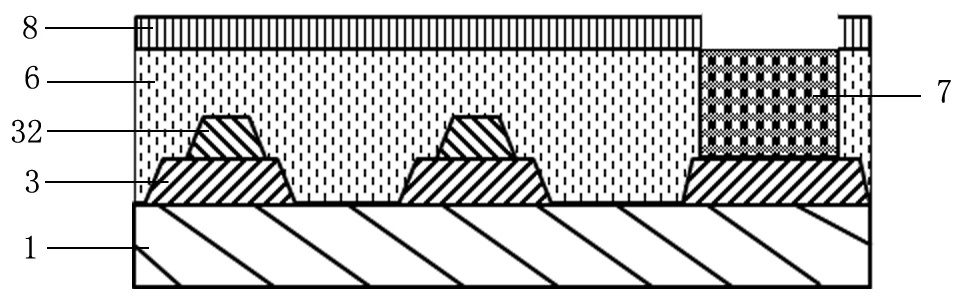

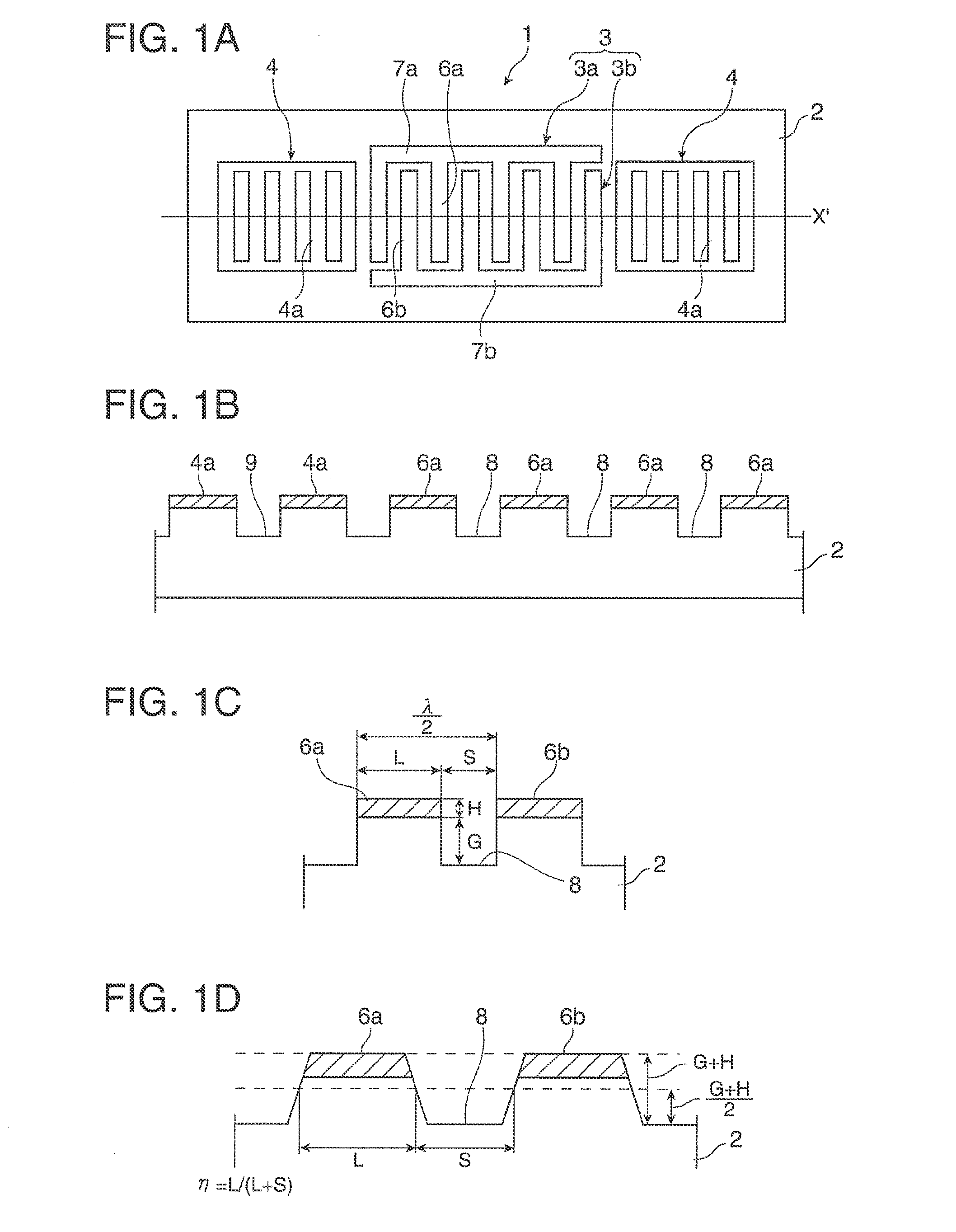

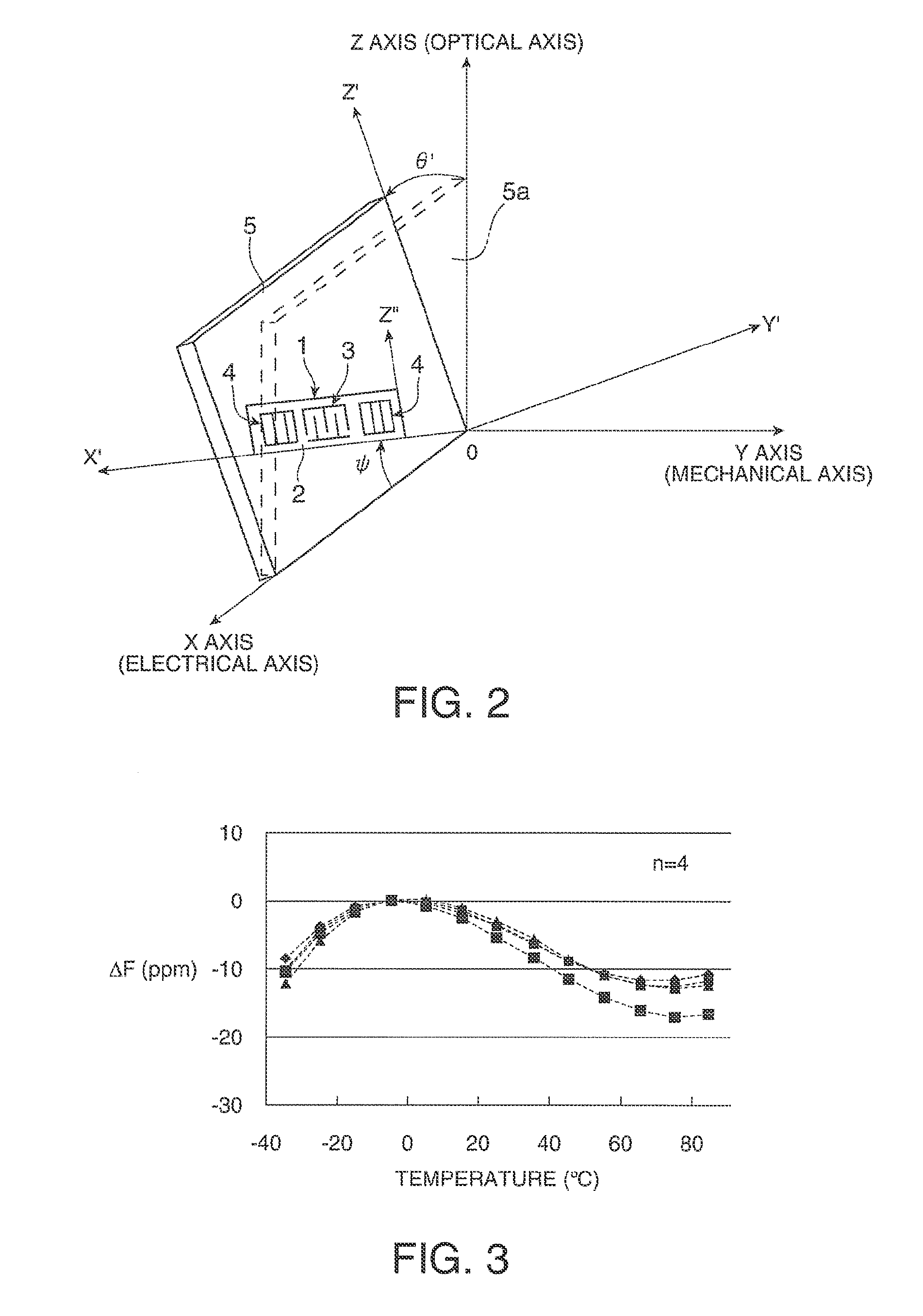

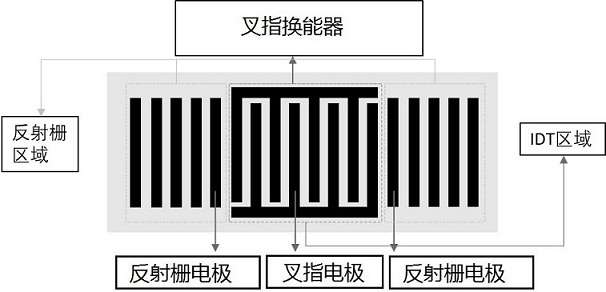

A SAW device includes an IDT which is provided on the principal surface of a quartz crystal substrate having Euler angles (−1.5°≦φ≦1.5°, 117°≦θ≦142°, |ψ|≠90°×n (where n=0, 1, 2, 3)) and excites a Rayleigh wave (wavelength: λ) in a stopband upper end mode. Inter-electrode-finger grooves are recessed between electrode fingers of the IDT. An IDT line occupancy η and an inter-electrode-finger groove depth G satisfy a predetermined relationship in terms of the wavelength λ, such that the SAW device has a frequency-temperature characteristic of a cubic curve having an inflection point between a maximum value and a minimum value in an operation temperature range. The inflection point is adjustable to a desired temperature or a desired temperature range depending on the IDT line occupancy η within an operation temperature range.

Owner:SEIKO EPSON CORP

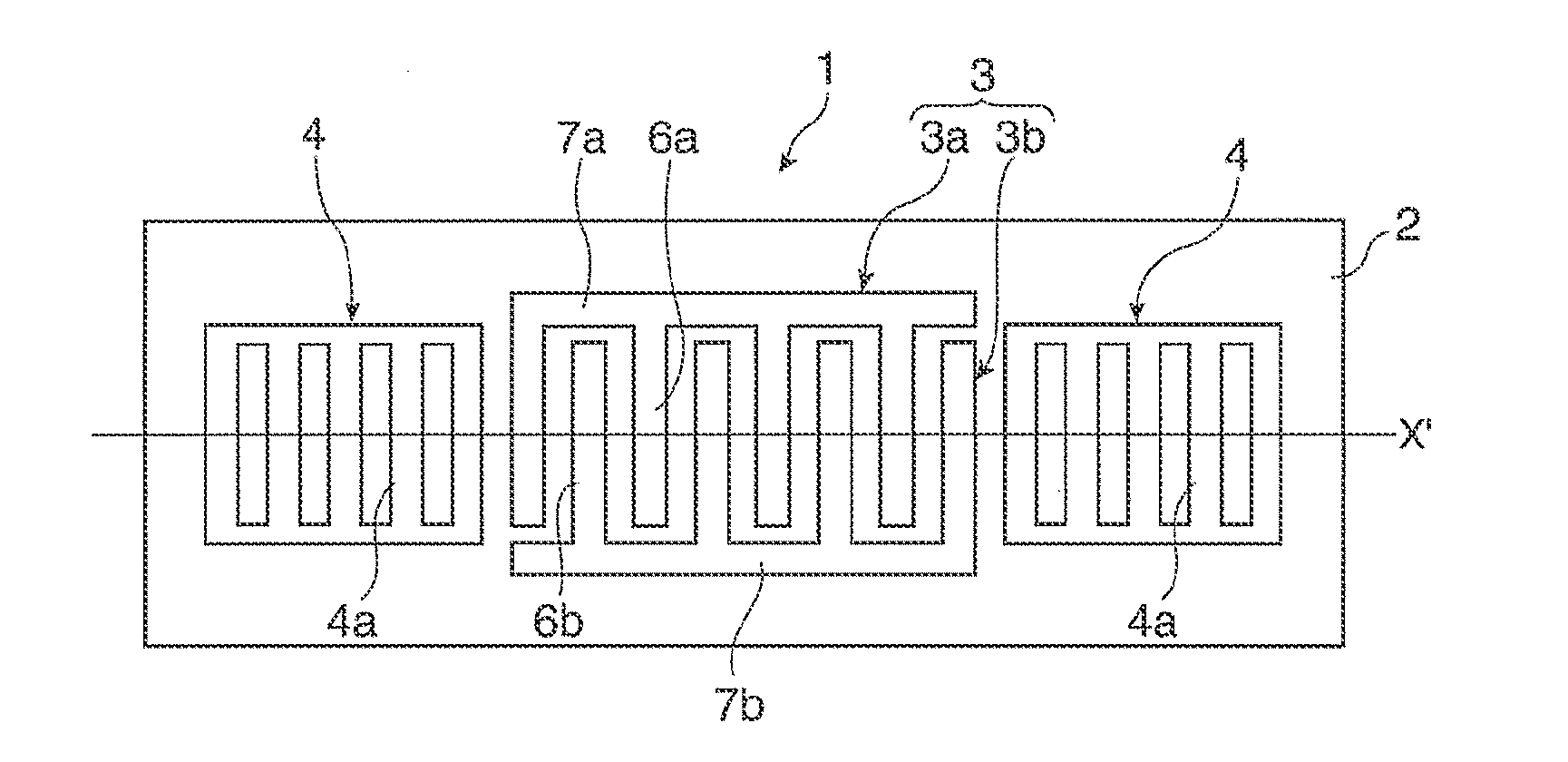

Surface acoustic wave device

ActiveUS7589451B2Small sizeHigh Q-valuePiezoelectric/electrostriction/magnetostriction machinesImpedence networksGratingAlloy

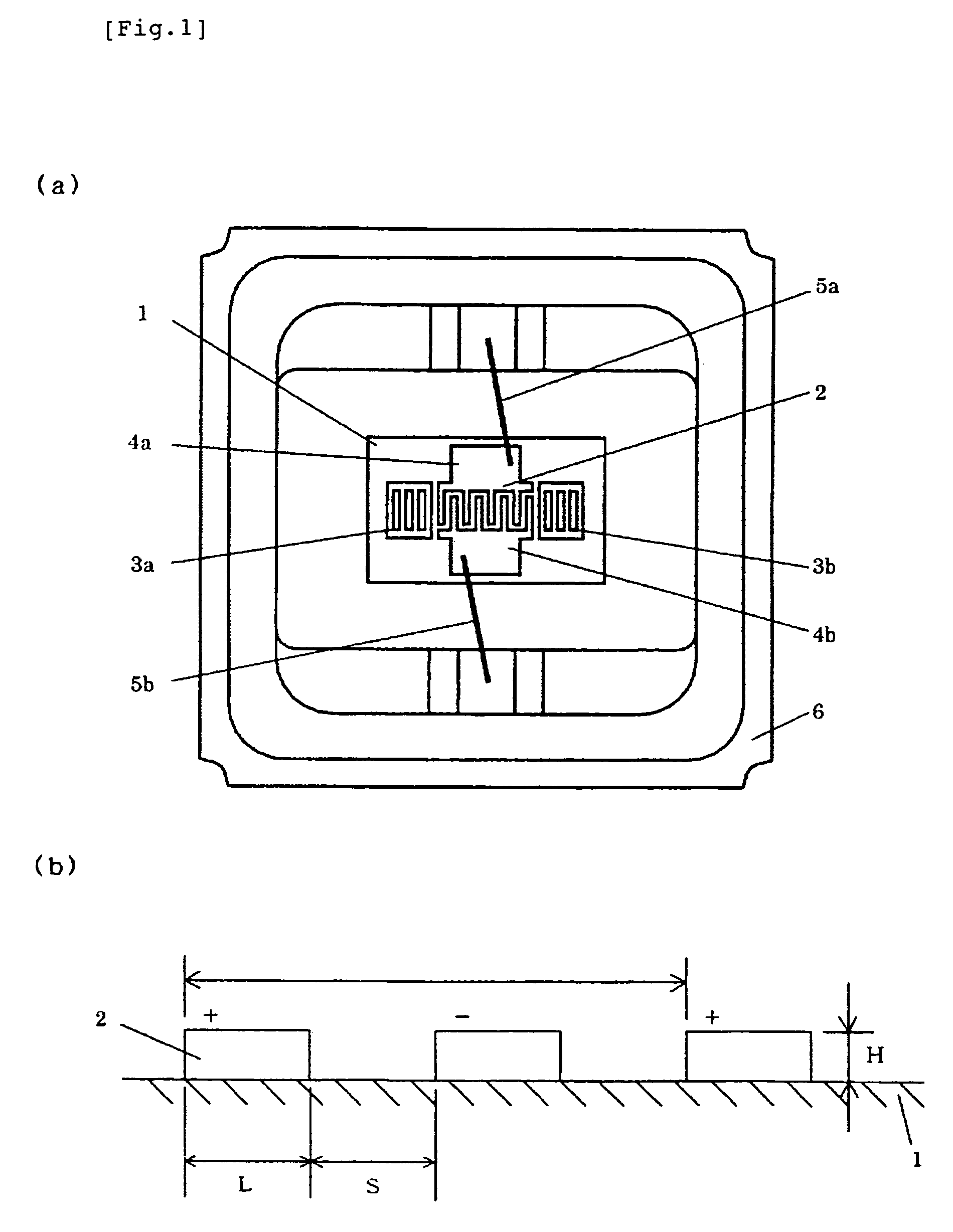

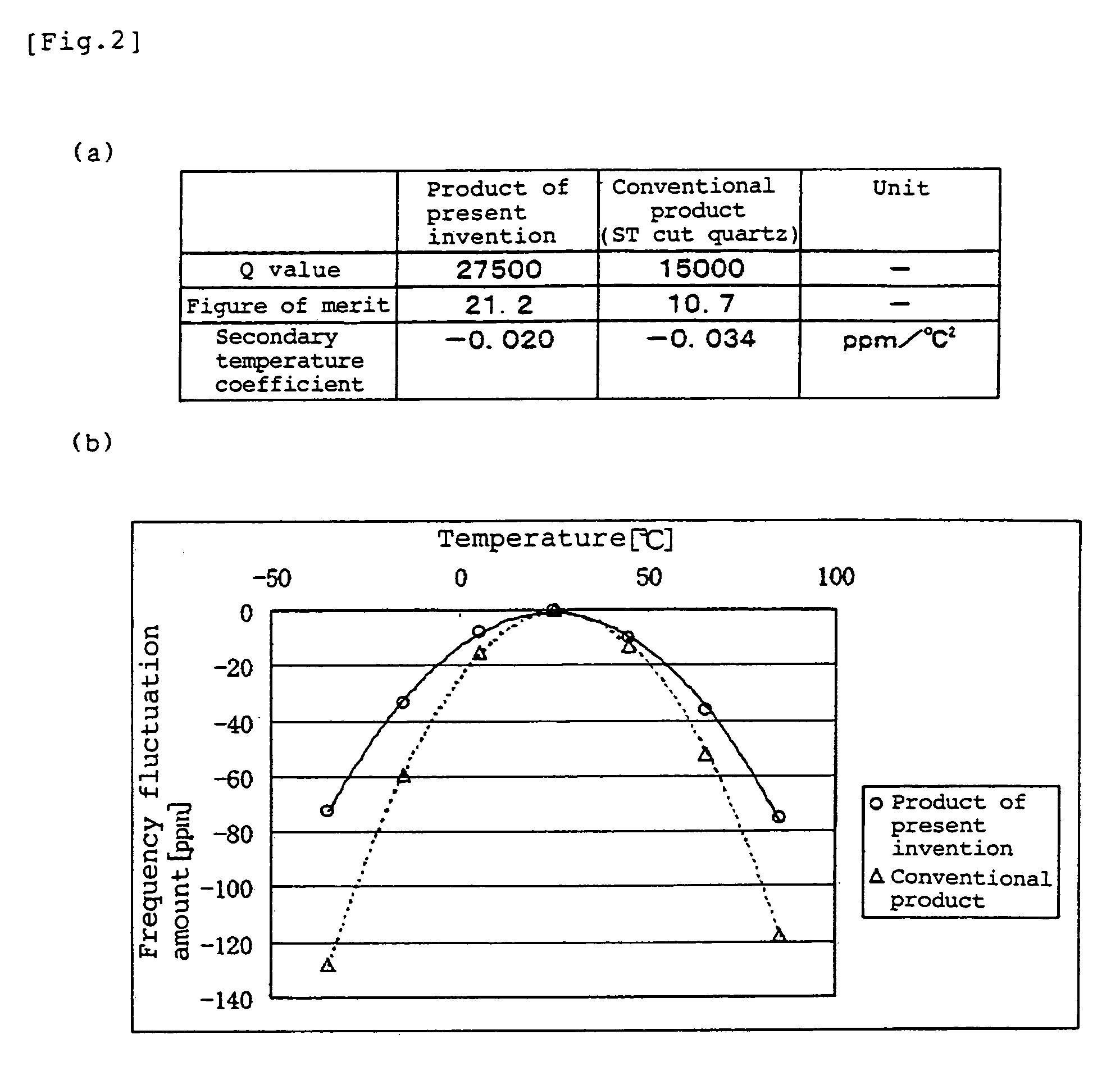

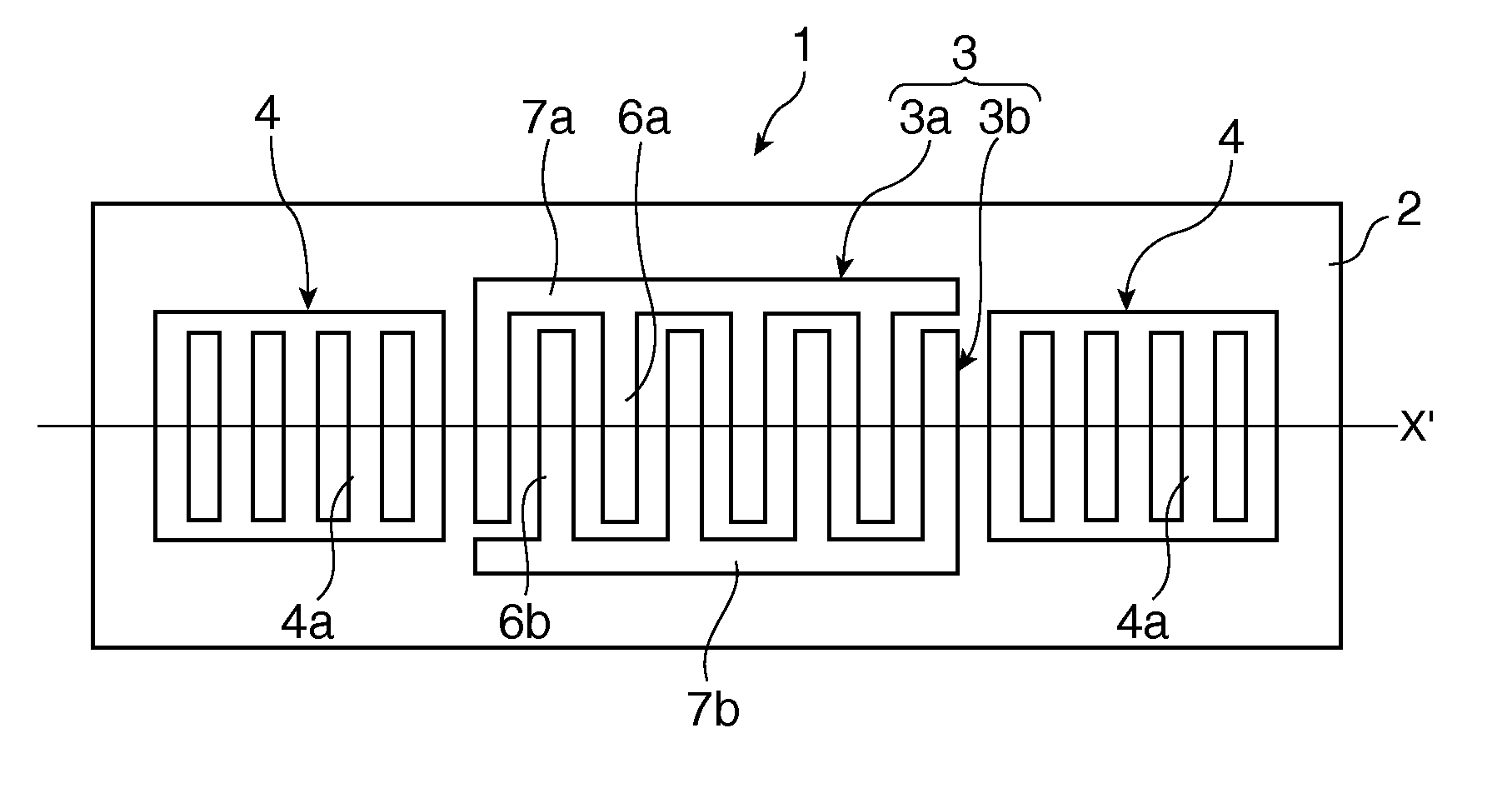

An object of the invention is to provide a SAW device where a device size is made smaller than that of a conventional structure, has a high Q value, and is excellent in a frequency temperature characteristic in a SAW device using a quartz substrate. Therefore, IDTs 2 including pluralities of electrode fingers mutually inserted and grating reflectors 3a and 3b positioned on both sides of the IDTs 2 are disposed on a piezoelectric substrate 1. The piezoelectric substrate 1 is a quartz flat plate where a cut angle θ of a rotation Y cut quartz substrate is set to satisfy a range of −64.0°<θ<−49.3° in a counterclockwise direction from a crystal Z-axis and a propagation direction of a surface acoustic wave is set to 90°±5° to a crystal X-axis, and a surface acoustic wave to be excited is an SH wave. The IDTs 2 and the grating reflectors 3a and 3b are made from Al or alloy including Al as a main component, and when a wavelength of a surface acoustic wave is represented as λ, an electrode film thickness H / λ standardized by the wavelength is set to satisfy 0.04<H / λ<0.12.

Owner:SEIKO EPSON CORP

Surface acoustic wave device, electronic apparatus, and sensor apparatus

InactiveUS20120086308A1Improve Q valueSmall frequency fluctuationPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksEngineeringAcoustic wave

A SAW device has an IDT which is provided in the principal surface of a quartz crystal substrate having Euler angles (−1.5°≦φ≦1.5°, 117°≦θ≦142°, |ψ|≠90°×n (where n=0, 1, 2, 3)) and excites a Rayleigh wave (wavelength: λ) in a stopband upper end mode. Inter-electrode-finger grooves are recessed between the electrode fingers of the IDT. The depth G of the inter-electrode-finger grooves is 0.01λ≦G≦0.07λ, and an electrode finger thickness H and an IDT line occupancy η satisfy a predetermined relationship. Thus, a frequency-temperature characteristic constantly has an inflection point between a maximum value and a minimum value in an operation temperature range, thereby suppressing a fluctuation in an inflection-point temperature due to a manufacturing variation in the IDT line occupancy η.

Owner:SEIKO EPSON CORP

Method of growing piezoelectric lanthanide gallium crystals

InactiveUS6514336B1Minimal loss of materialImprove temperature stabilityPolycrystalline material growthBy pulling from meltLanthanideSingle crystal

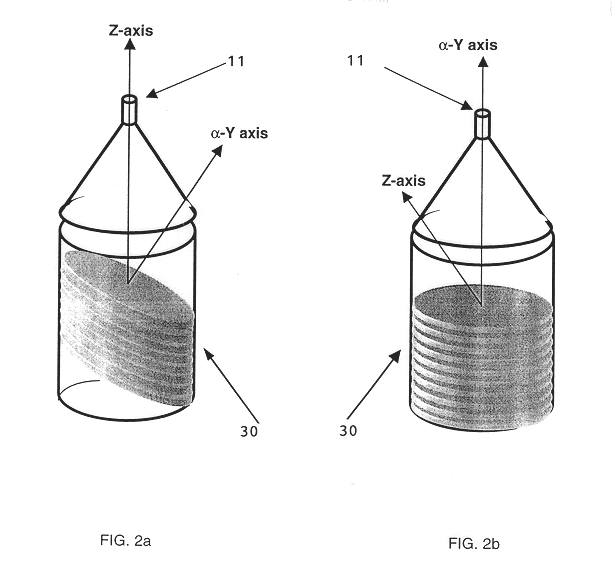

A method for producing piezoelectric lanthanide gallium crystals includes pulling a crystal through a forming mould dipped into a crucible containing a melt, which controls a heat and mass transfer, as the crystal is grown. While a lanthanide gallium single crystal is growing, a charge of mixed oxides, having a composition of the melt may be continuously added to the melt such that the quantity of melt is maintained substantially stable. Crystals produced by this method exhibit less variability in piezoelectric properties. The growth direction of the crystal is aligned along an axis perpendicular to such a crystallographic plane of lanthanide gallium crystal that an improved temperature stability, lowered power flow angle, and reduced diffraction would be present in surface acoustic wave (SAW) devices made in this crystallographic plane. Such crystals are more suitable for the mass-production slicing wafers, for example over 2 inches in diameter, for SAW devices.

Owner:SOUTHBOURNE INVESTMENTS

Wafer level package for surface acoustic wave device and fabrication method thereof

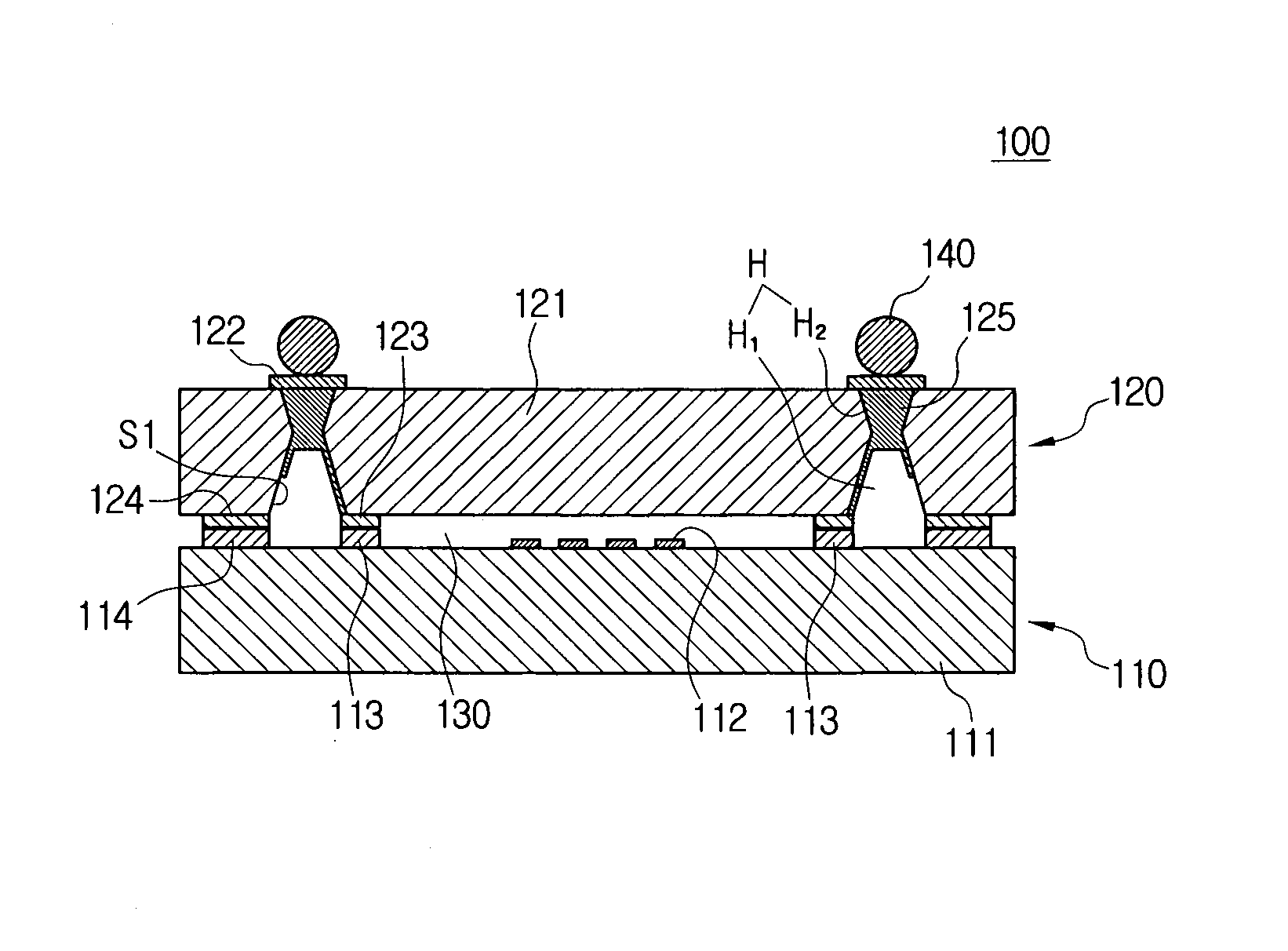

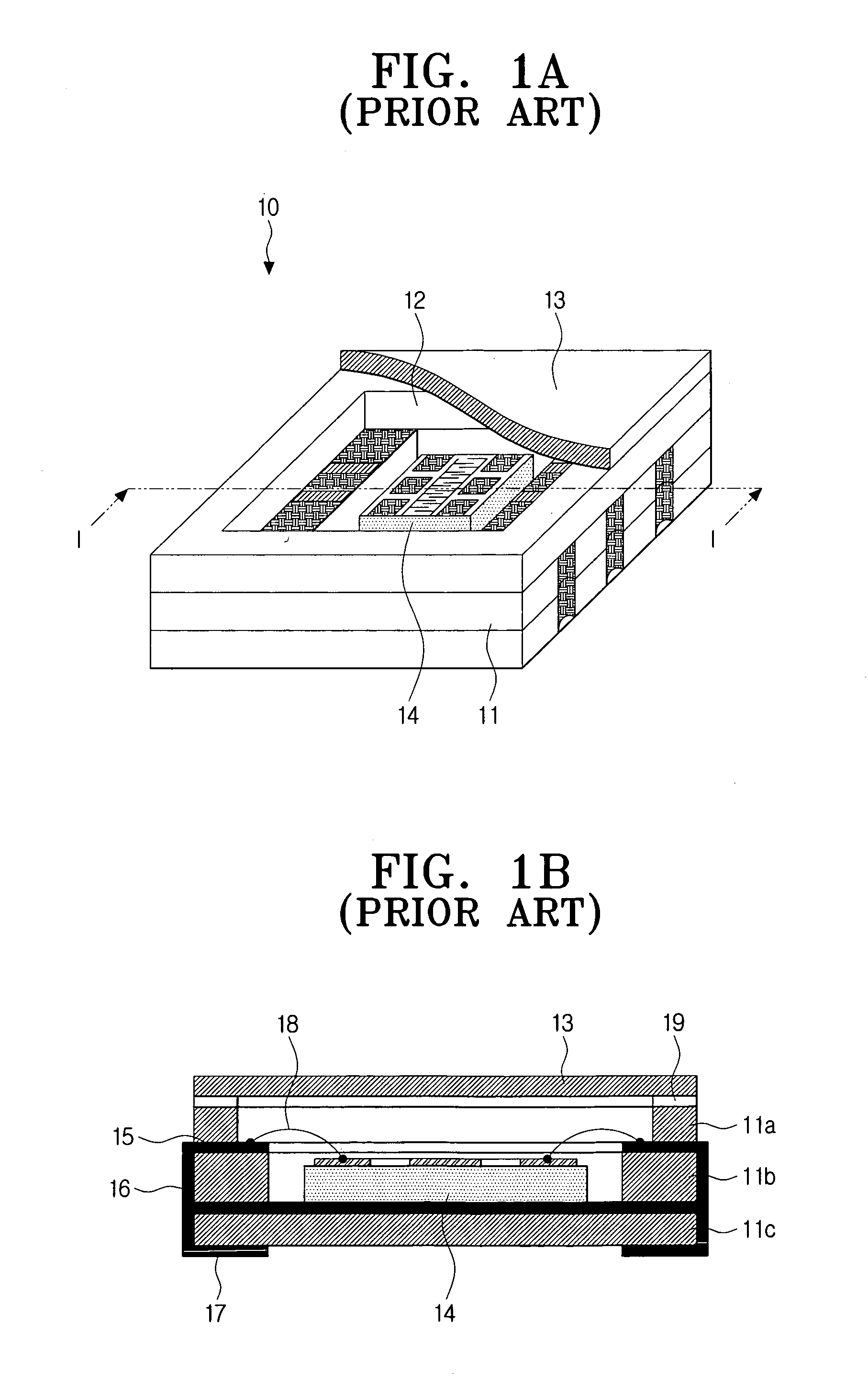

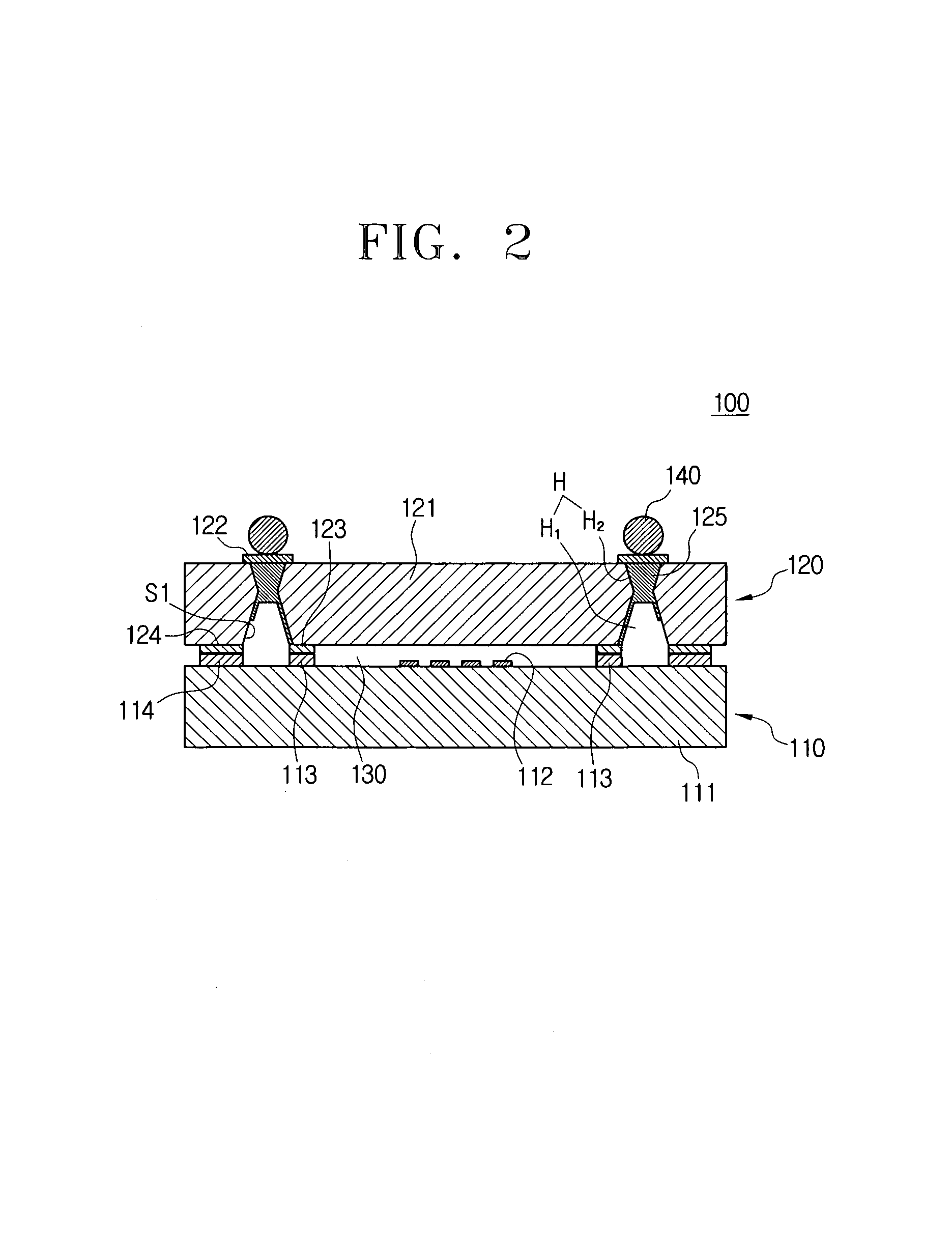

A wafer level package for a surface acoustic wave (SAW) device and a fabrication method thereof. The SAW device wafer level package includes a SAW device in which a SAW element is formed on a top surface of a device wafer, a cap wafer which is bonded with a top surface of the SAW device and has a viahole penetrating the cap wafer, and a conductive member to fill a part of the viahole. The viahole has a first via portion and a second via portion, the first via portion has a gradually smaller diameter from a bottom surface of the cap wafer until a certain depth, and the second via portion has a gradually greater diameter from the first via portion until a top surface of the cap wafer.

Owner:SAMSUNG ELECTRONICS CO LTD

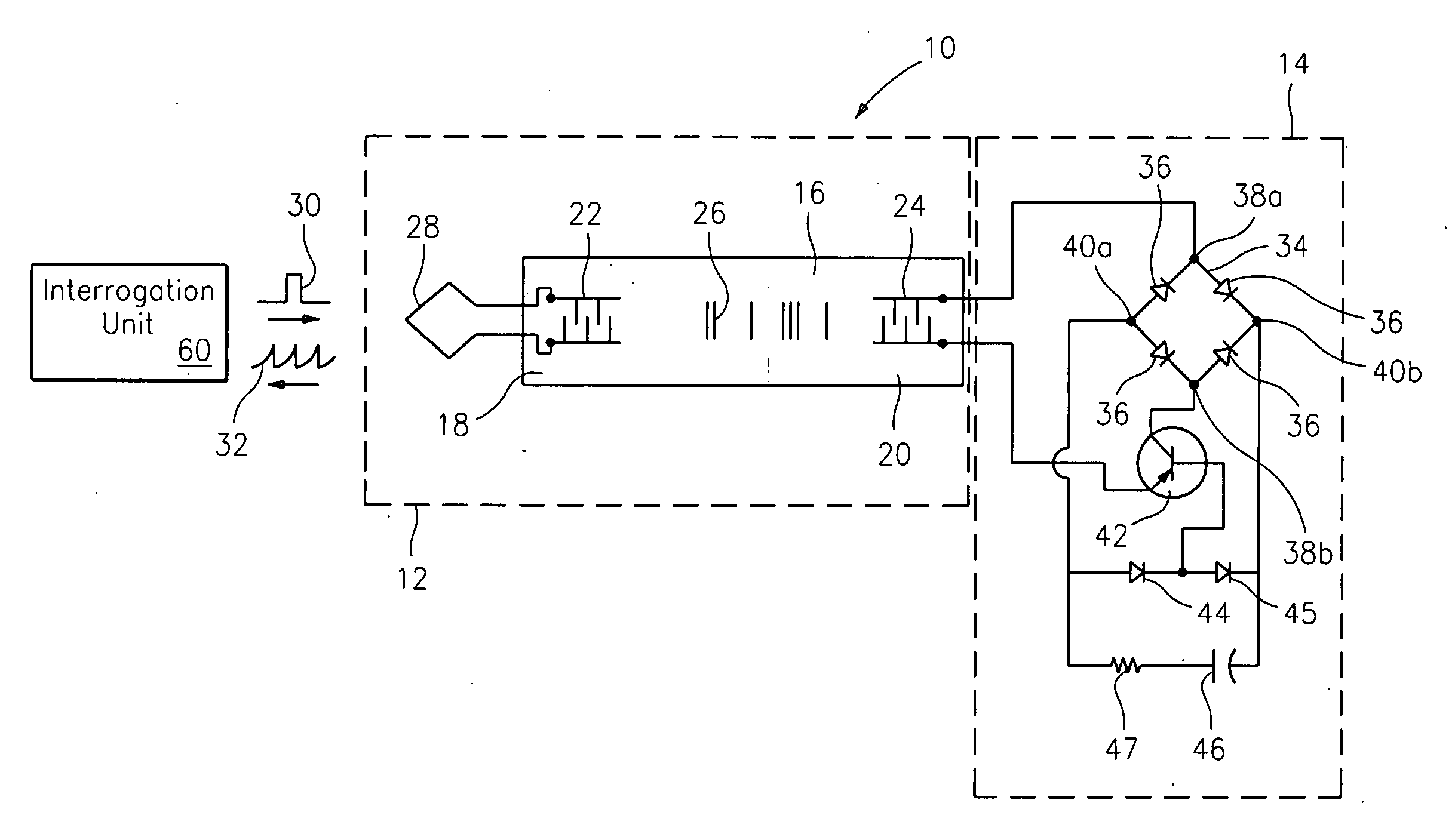

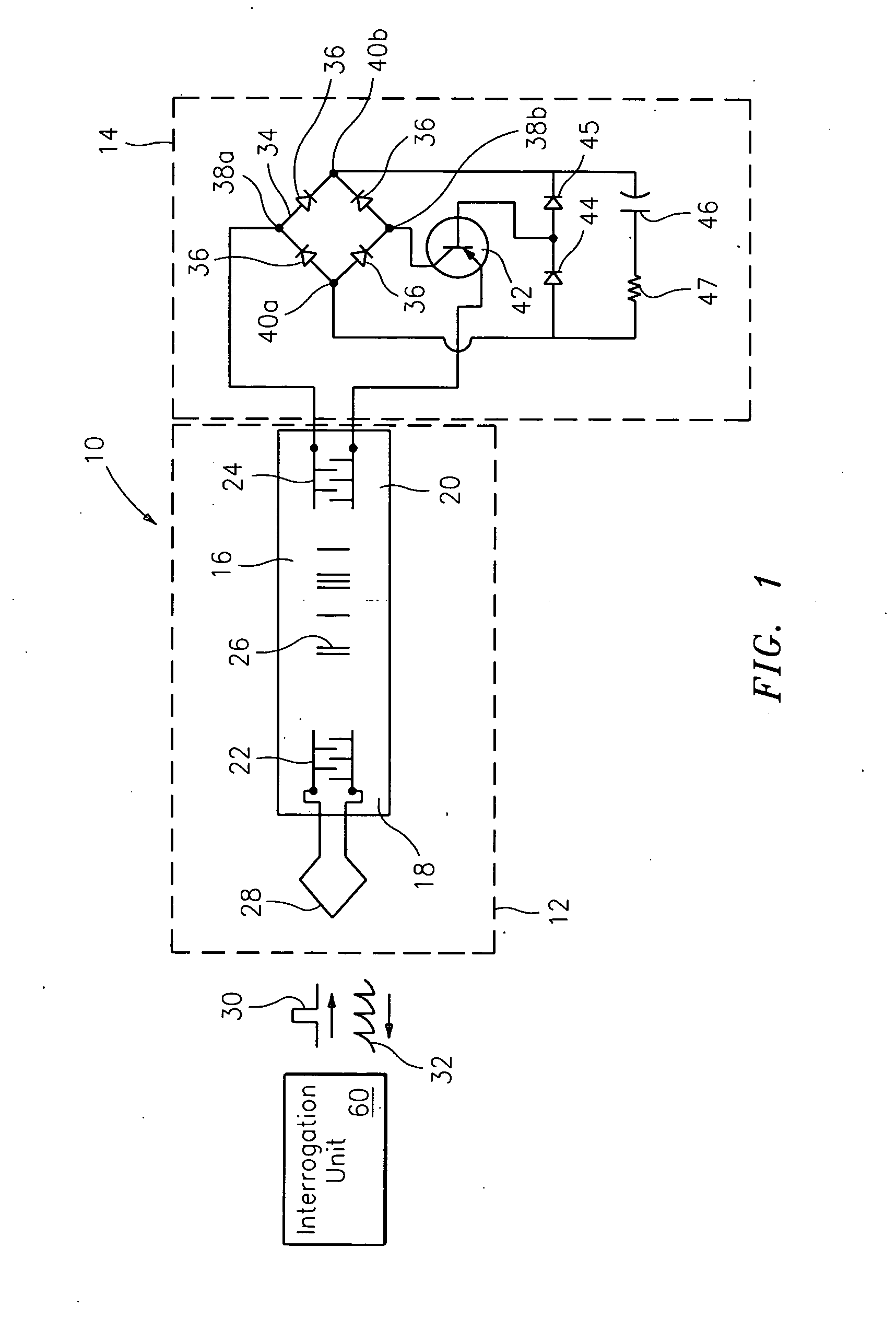

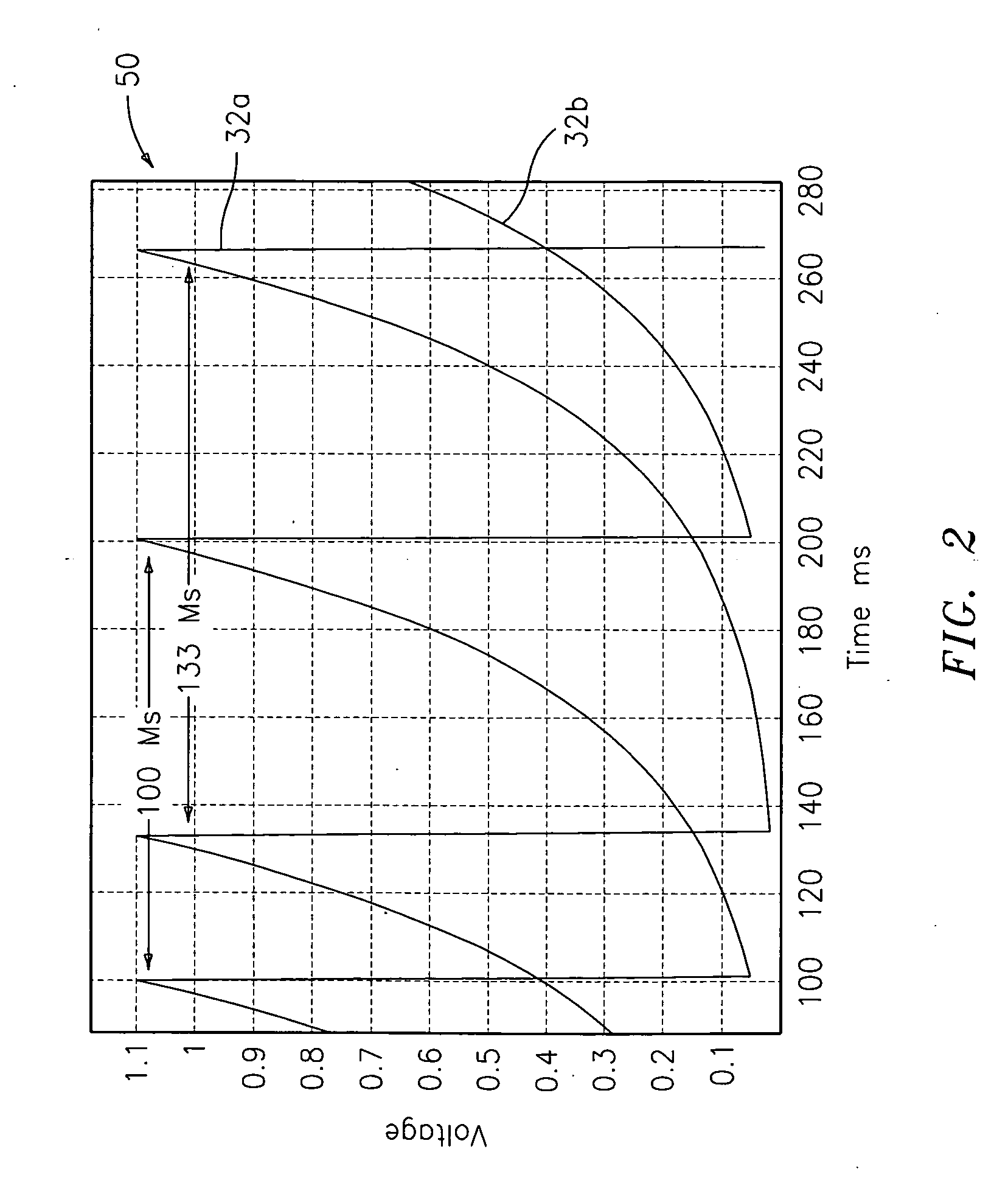

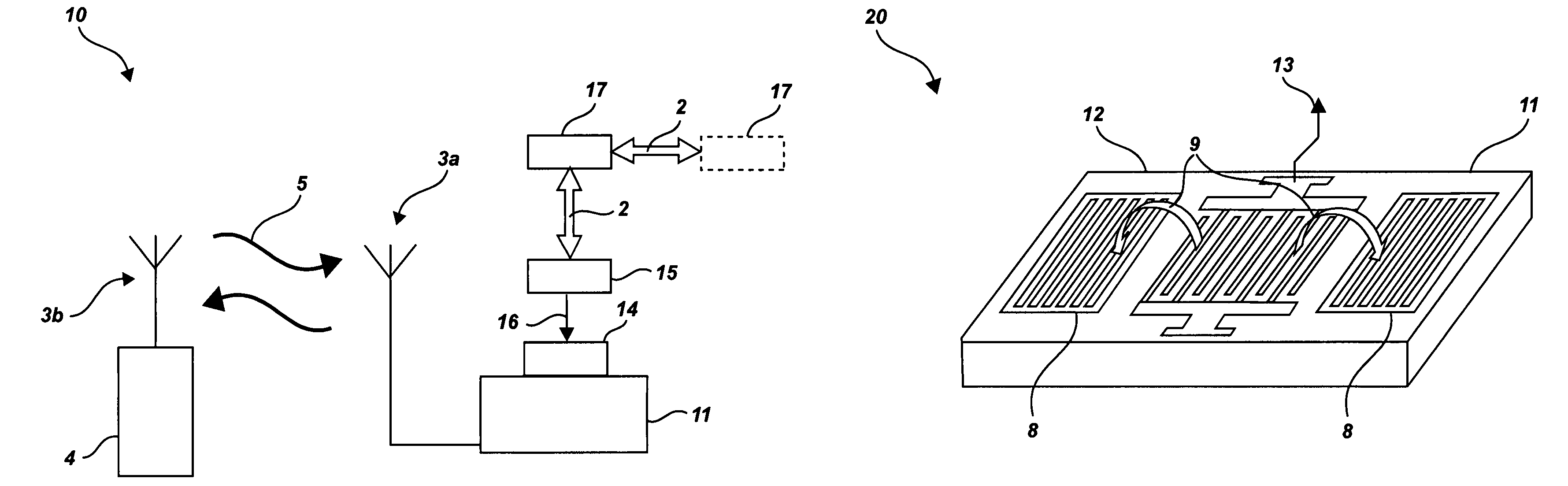

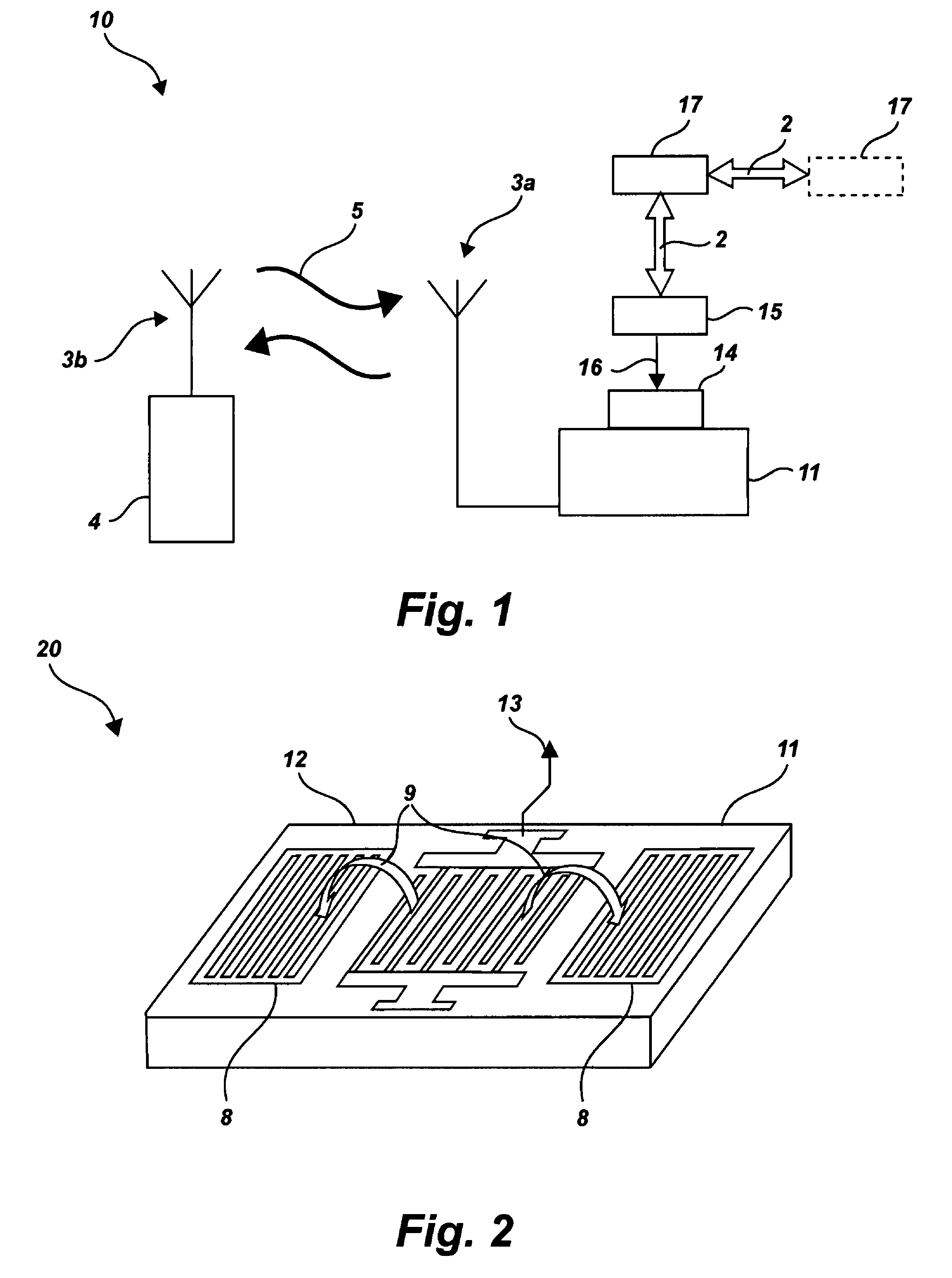

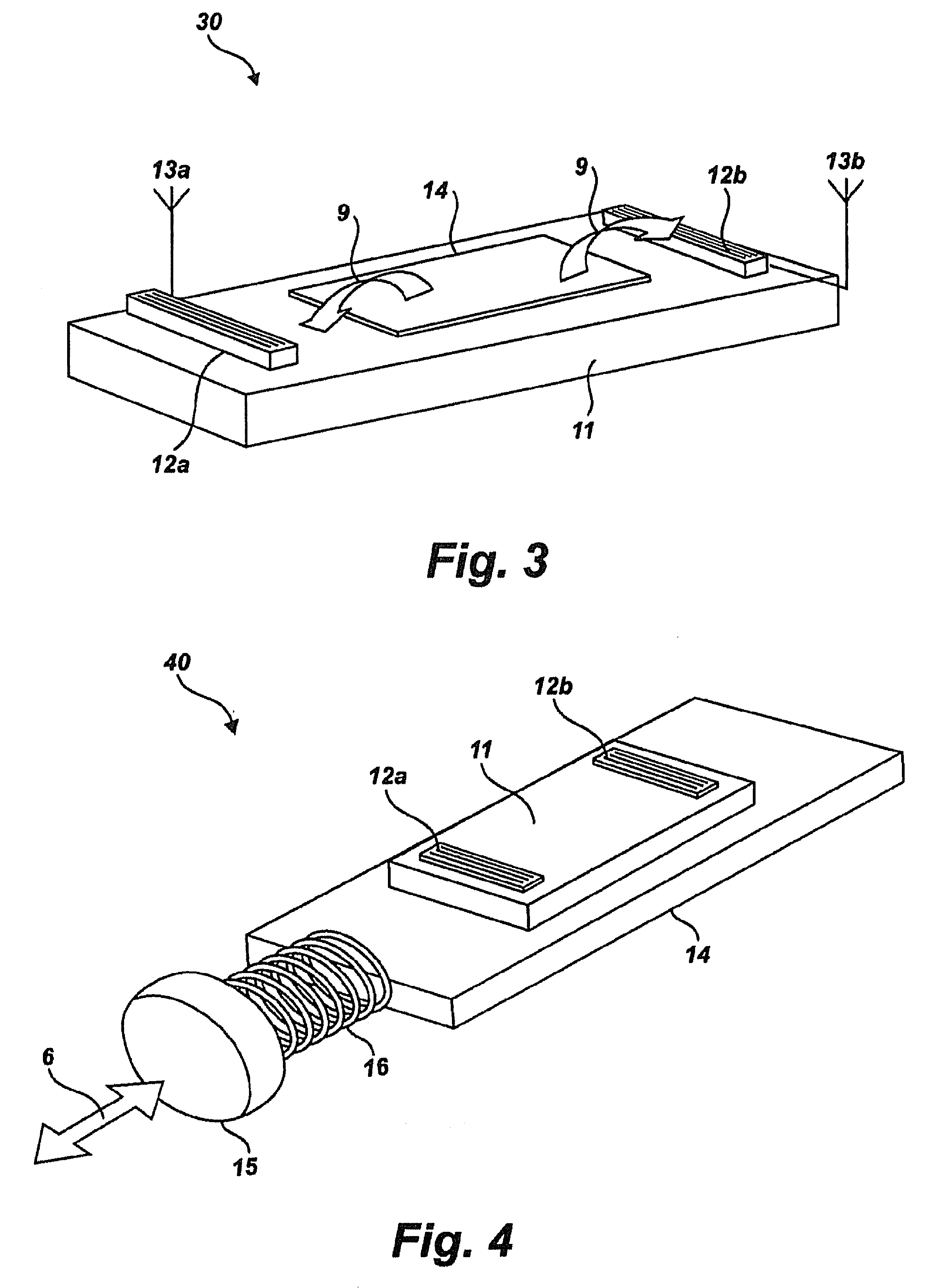

Radio frequency surface acoustic wave proximity detector

ActiveUS20080129144A1Analysing solids using sonic/ultrasonic/infrasonic wavesImpedence networksProximity sensorAcoustic wave

A proximity sensor for determining a position of an object. The proximity sensor includes a SAW device having a load end and an input end for receiving an input pulse. A sensing section connects to the load end of the SAW device. When the object is in a first position, the sensing section provides a first response indicative of the first position and, when the object is in a second position, the sensing section provides a second response indicative of the second position such that the position of the object can be determined based upon the response to the input pulse.

Owner:SIMMONDS PRECISION PRODS

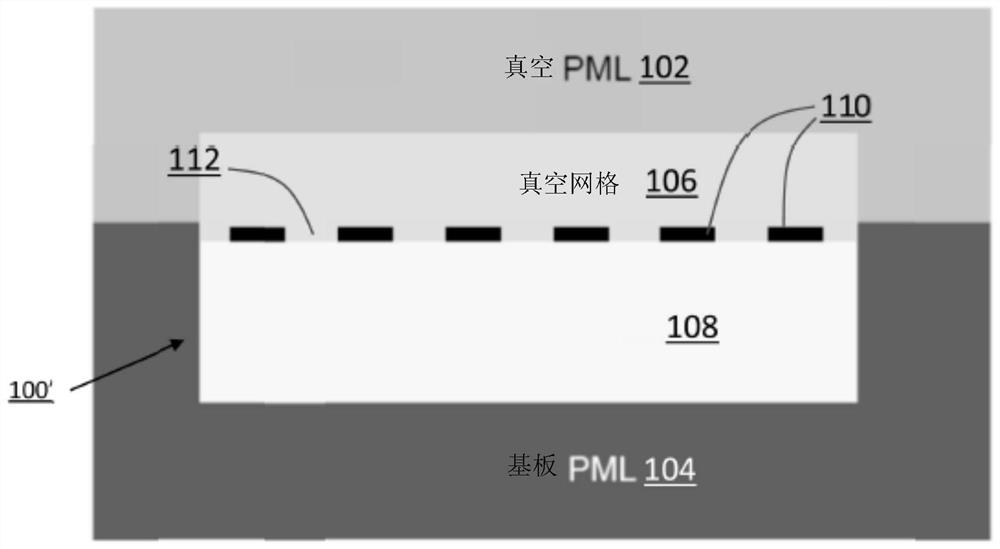

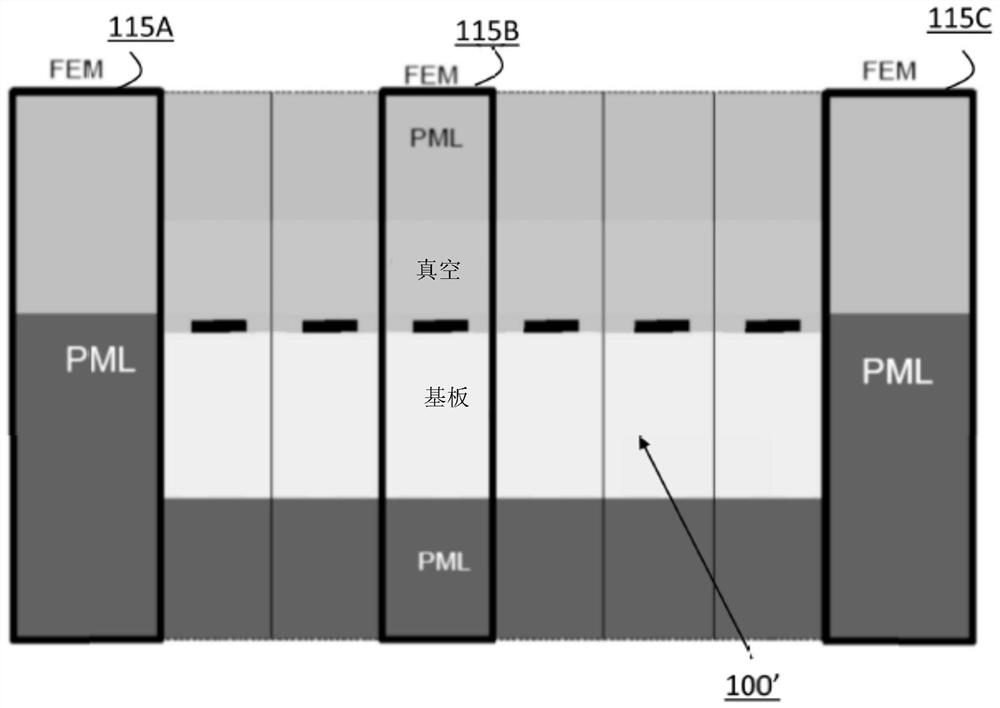

Fast, highly accurate, full-FEM surface acoustic wave simulation

PendingCN113544687ADesign optimisation/simulationCAD circuit designComputational scienceConcurrent computation

The present disclosure provides systems and methods for scalable and parallel computation of hierarchical cascading in finite element method (FEM) simulations of surface acoustic wave (SAW) devices. Different computing units of a cluster or cloud service may be assigned to independently model different core blocks or combinations of core blocks for iterative cascading to generate a model of the SAW devices. Similarly, frequency ranges may independently be assigned to computing units for modeling and analysis of devices, drastically speeding up computation.

Owner:MURATA MFG CO LTD

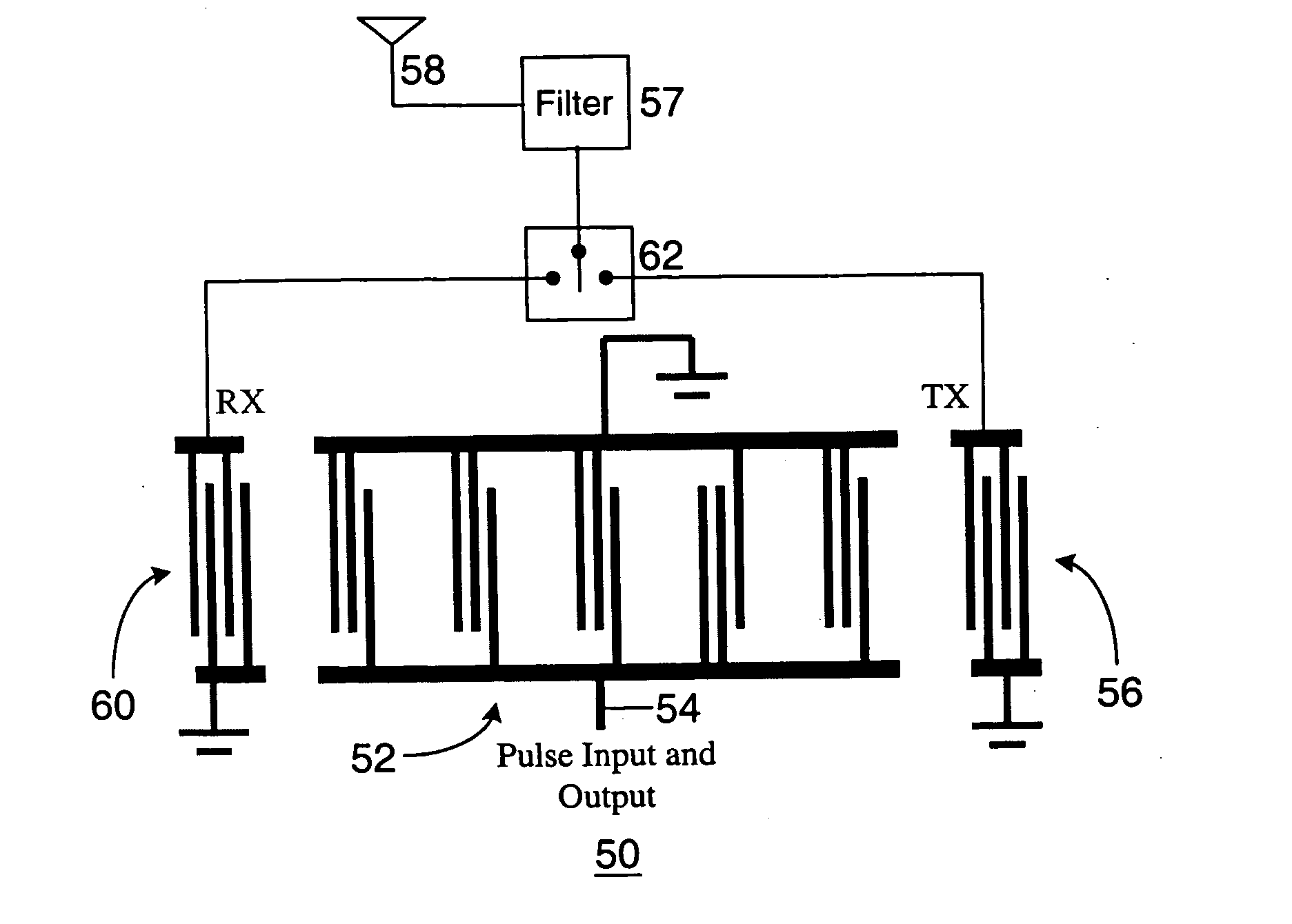

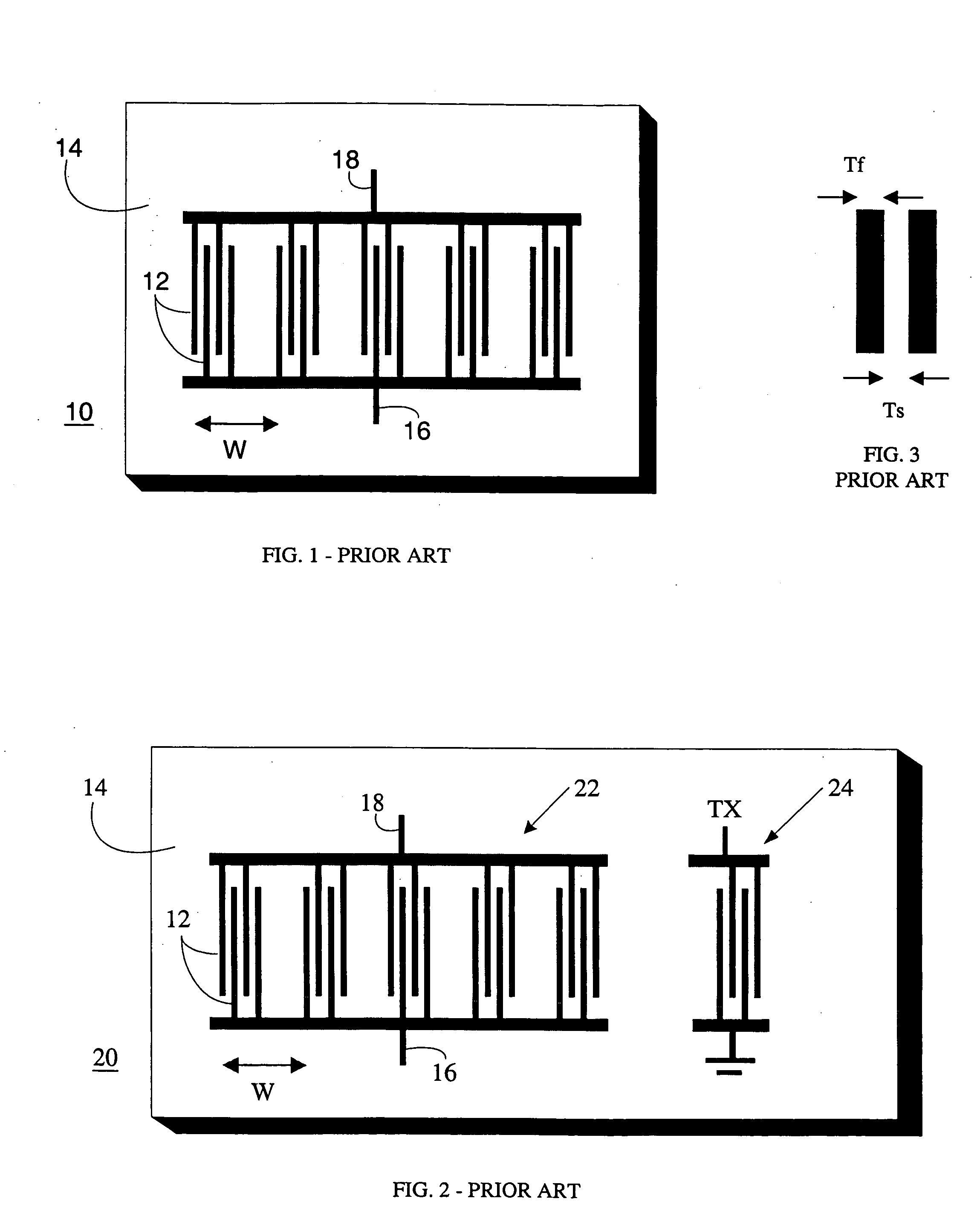

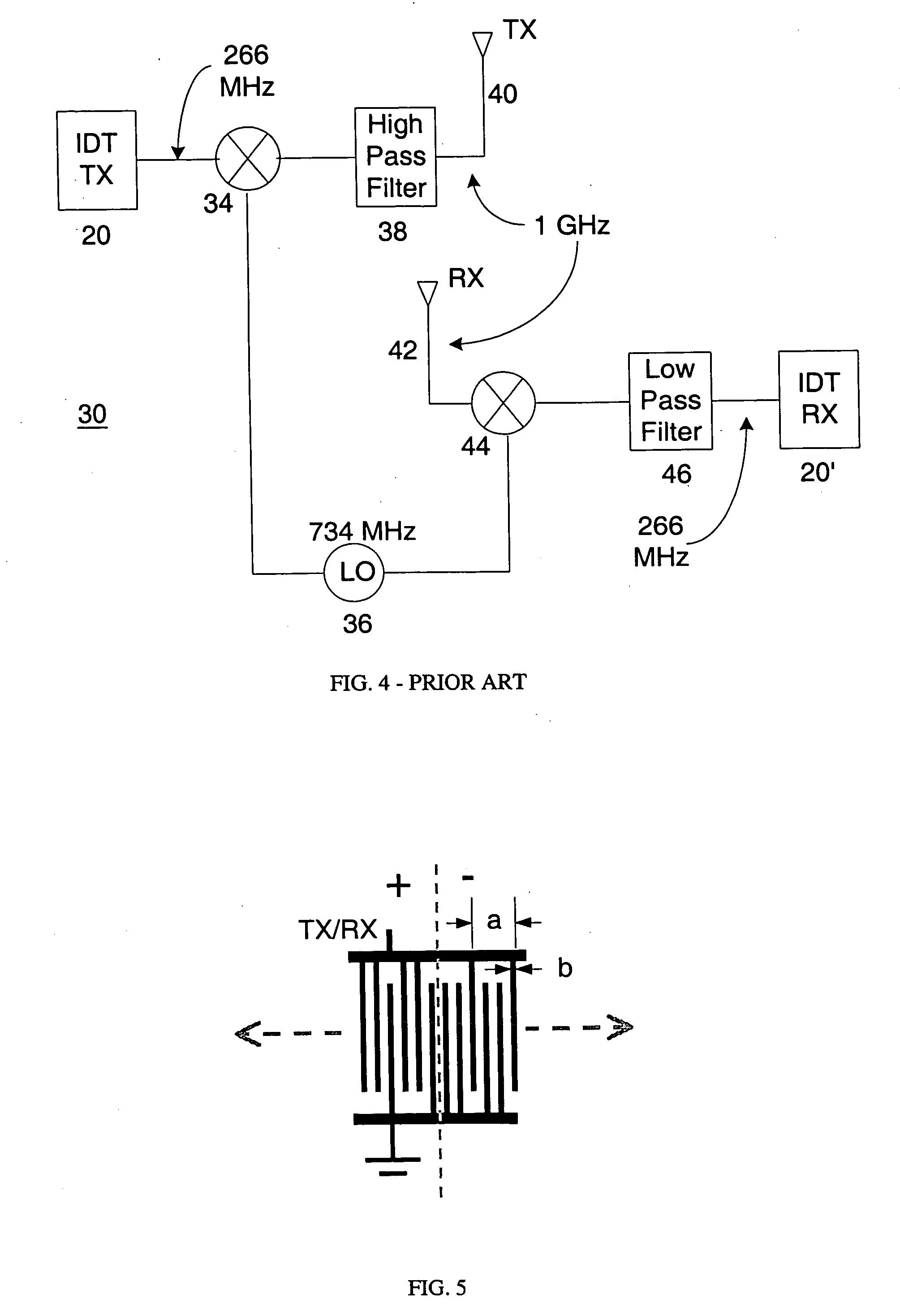

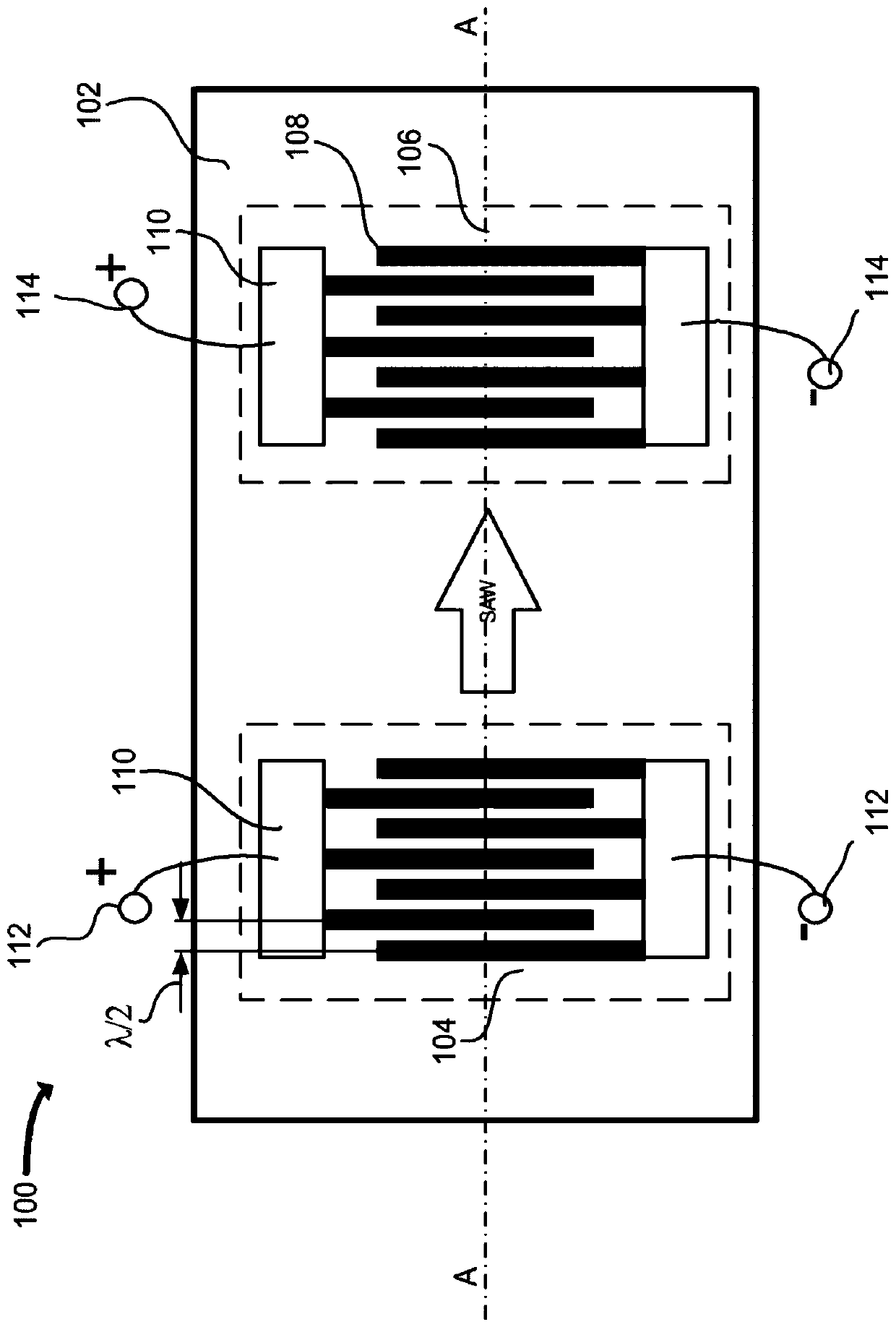

Wireless communication system using surface acoustic wave (SAW) second harmonic techniques

InactiveUS20050059357A1Low costEasy to manufactureMultiple-port networksPiezoelectric/electrostriction/magnetostriction machinesElectrical impulseFundamental frequency

SAW devices such as interdigital transducers (IDTs) have been widely used in RADAR applications and as filters. An IDT produces a SAW when excited by a single electrical pulse and can be fabricated to embody a code, which code provides for a passive autocorrelation of a SAW input to the IDT and thereby lends itself to further application as a signal generator in a communication device. However, internal dimensions of IDTs are inversely proportional to operating frequency, such that high frequency IDTs present significant manufacturing difficulties. Fabrication of IDTs for high frequency applications is simplified by exploiting a harmonic frequency SAW generated by IDTs. An IDT may therefore be designed according to fundamental frequency internal dimension criteria but can operate at a multiple of the fundamental frequency, thereby providing much higher frequency operation than conventional SAW systems. A communication system based on SAW harmonic techniques would be low-cost, low-power, small and simple alternative to known short range communications schemes, including for example the Bluetooth™ solution. Operation of a second harmonic SAW system at 2.4 GHz based on a fundamental frequency of 1.2 GHz is contemplated.

Owner:MALIKIE INNOVATIONS LTD

LiNbO3/SiO2/diamond multilayer piezoelectric film and preparation method thereof

InactiveCN101777622AAddress temperature stabilityIncrease working frequencyPiezoelectric/electrostrictive device manufacture/assemblyTO-18Surface acoustic wave

The invention relates to a LiNbO3 / SiO2 / diamond multilayer piezoelectric film and a preparation method thereof, efficiently solving the problems of the temperature stability of surface acoustic wave (SAW) devices and preparation of high c-axis orientated LiNbO3 thin film. The technical scheme of the invention is as follows: an amorphous SiO2 buffering layer is introduced between a diamond substrate and a LiNbO3 piezoelectric thin film. The preparation method comprises the following steps of: firstly, taking silicon as a target material on the diamond substrate, and depositing the amorphous SiO2 on the diamond substrate by a pulse laser deposition method to form an amorphous SiO2 buffering layer; secondly, heating the prepared amorphous SiO2 / diamond substrate, taking the LiNbO3 as the target material, and depositing the LiNbO3 on the amorphous SiO2 buffering layer by the pulse lasers to form a composite piezoelectric thin film having the amorphous SiO2 buffering layer between the LiNbO3 piezoelectric thin film layer and the diamond substrate; and cooling down the layer to 18-25 DEG C after the LiNbO3 piezoelectric thin film layer is deposited. The invention has simple structure, advanced and scientific method and high temperature stability, and improves the working frequency of the SAW devices.

Owner:ZHENGZHOU UNIV

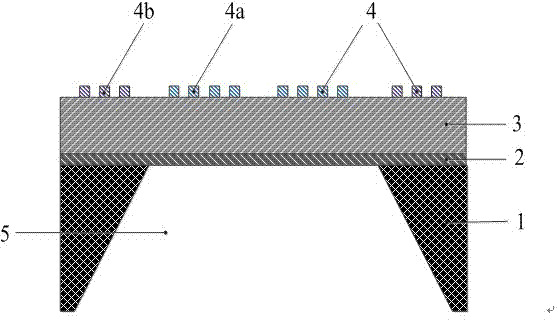

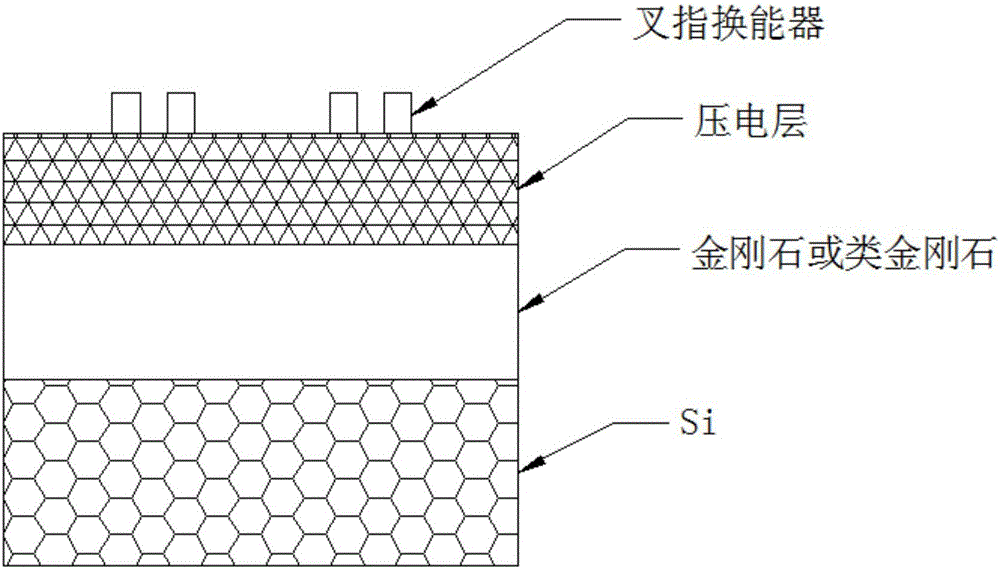

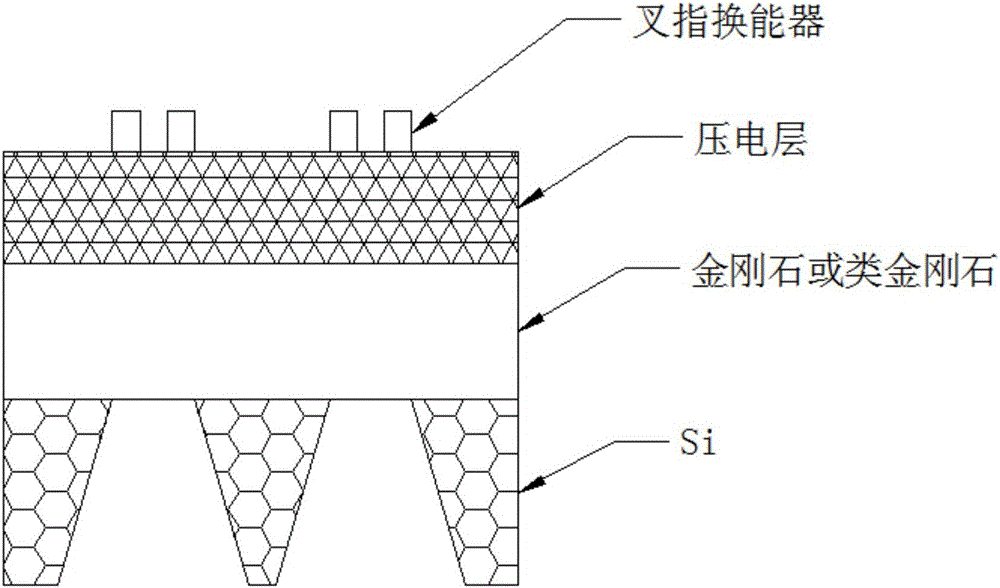

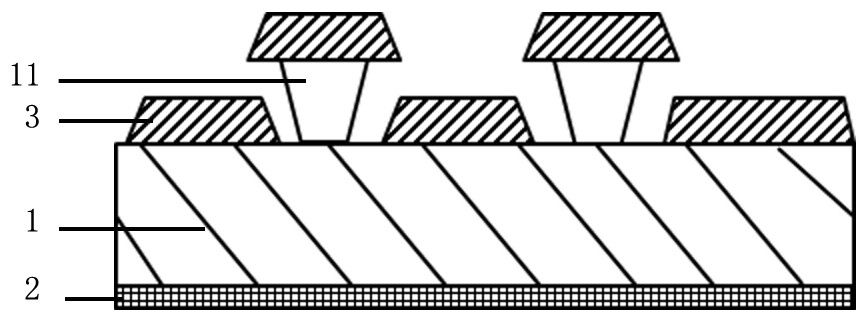

High-frequency SAW (Surface Acoustic Wave) device based on Si substrate and manufacturing method thereof

The invention relates to the field of manufacturing of SAW (Surface Acoustic Wave) devices, in particular to a high-frequency SAW device based on a Si substrate and a manufacturing method thereof. The high-frequency SAW device has a multilayer membrane structure, and comprises the Si substrate, a high-acoustic-speed layer, a piezoelectric layer and interdigital transducers in sequence from bottom to top. A back side of the Si substrate is provided with slots, so that transmission of surface acoustic waves is limited in the high-acoustic-speed layer in order to increase the center frequency of the device. The SAW device with the multi-membrane structure can satisfy high-frequency and high electromechanical coupling coefficients and meet the application demands in the field of integrated circuits. Compared with a piezoelectric single-crystal material, a piezoelectric membrane adopted in the piezoelectric layer is easy to integrate, and can be applied to the semiconductor industry.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

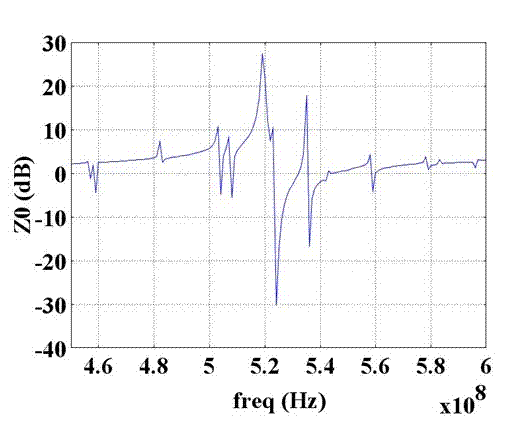

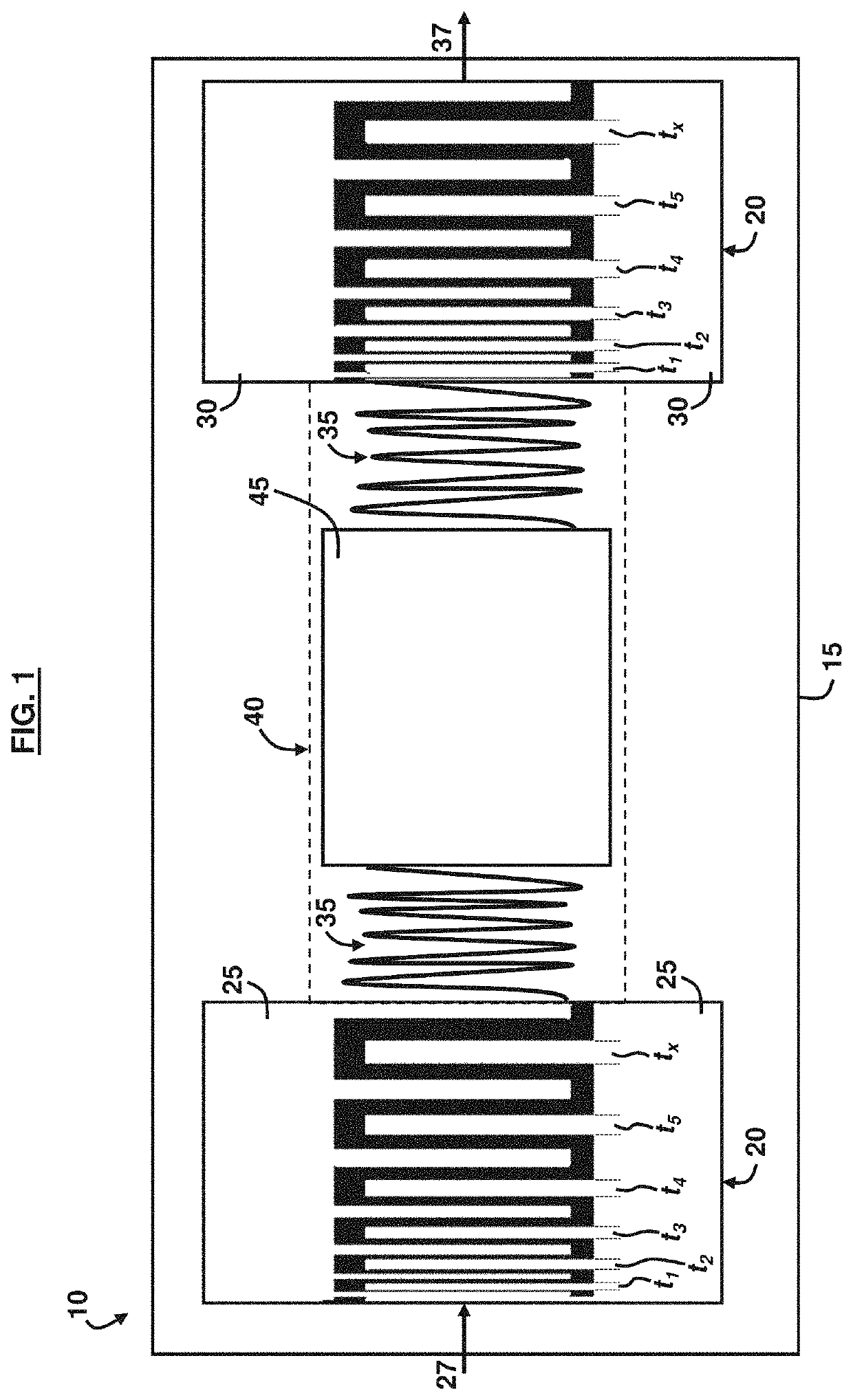

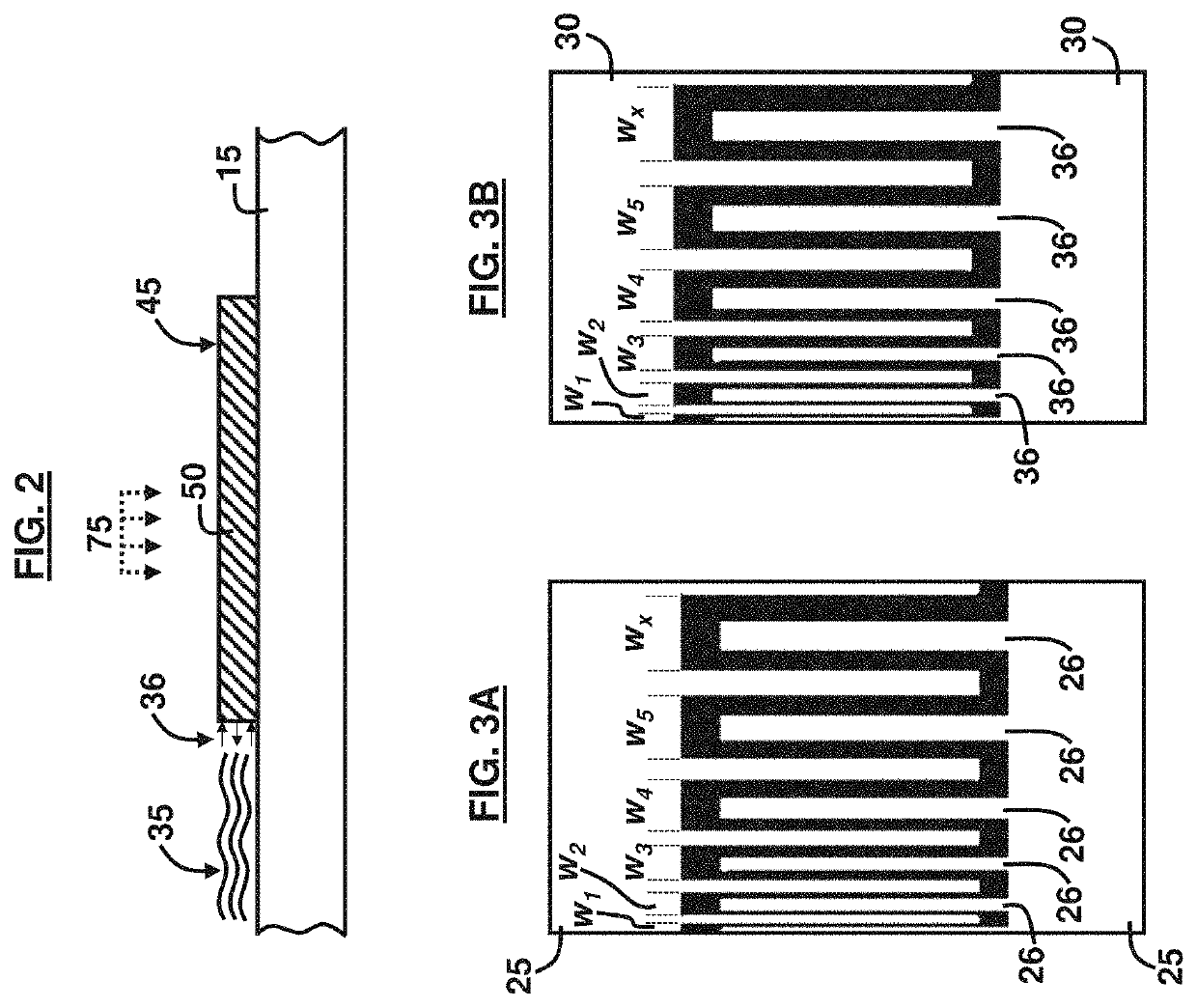

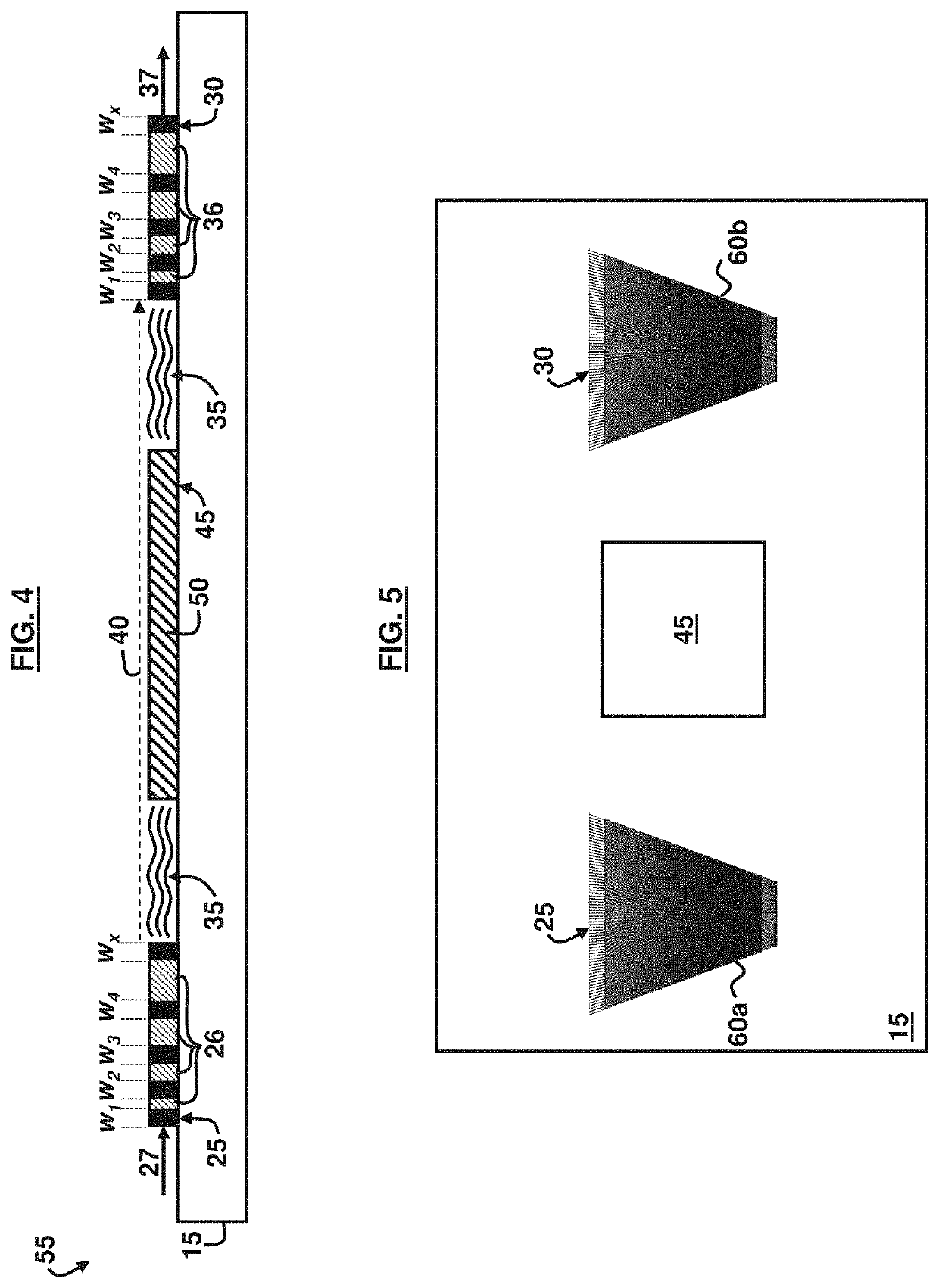

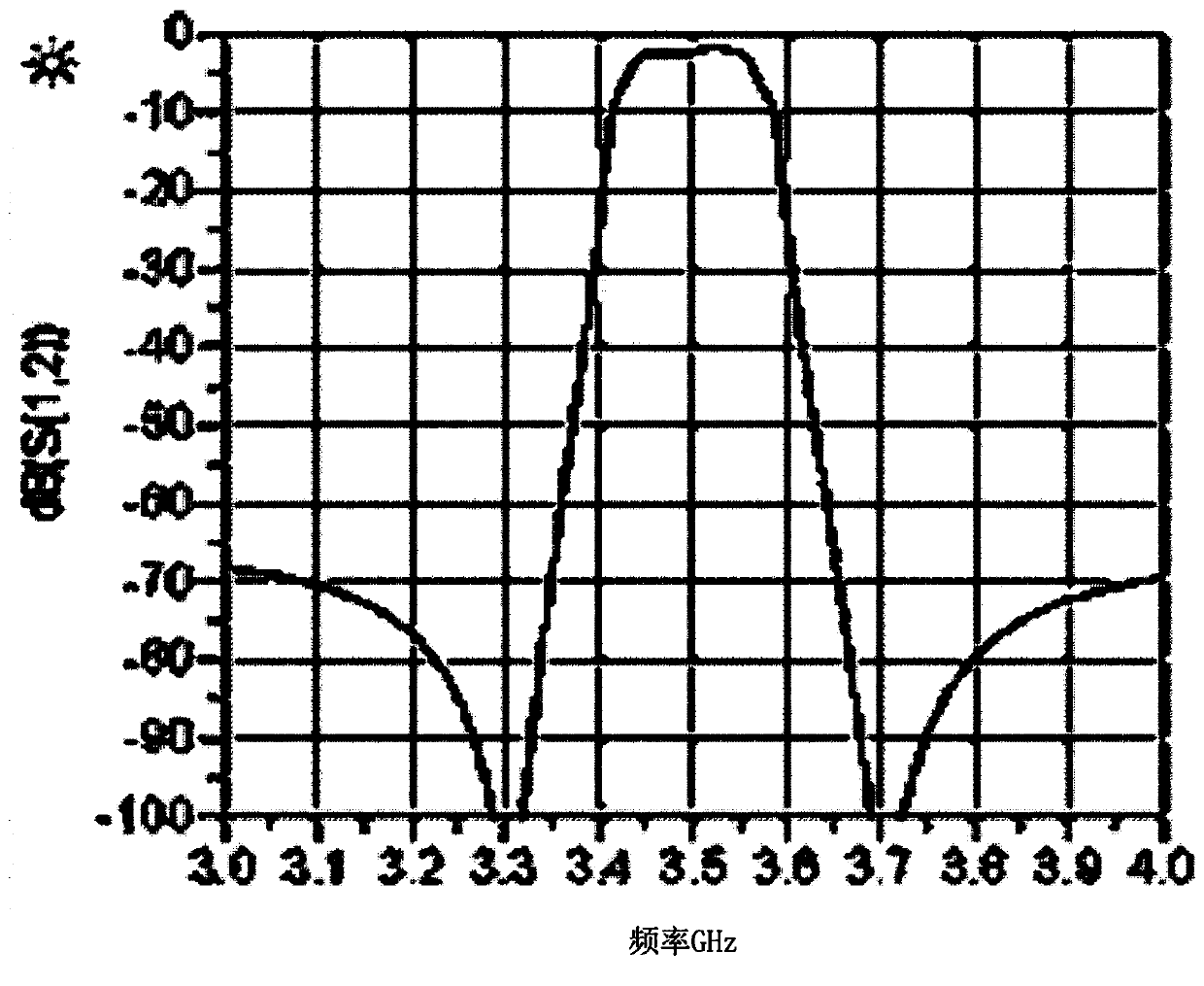

Frequency tunable RF filters via a wide-band SAW-multiferroic hybrid device

A filter including a piezoelectric substrate; a surface acoustic wave (SAW) device on the piezoelectric substrate and including unequally spaced interdigitated input and output transducer electrodes of unequal widths, wherein the input transducer electrodes are to convert an incoming radio frequency (RF) electrical signal into surface acoustic waves; a SAW propagation path between the input and output transducer electrodes; and a magnetostrictive film in the SAW propagation path to filter the surface acoustic waves that are at a ferromagnetic resonance frequency of the magnetostrictive film, wherein the output transducer electrodes are to convert the filtered surface acoustic waves into an outgoing electrical RF signal. The SAW device may operate in a wide-band pass configuration. The wide-band pass configuration result in a transmission of frequencies up to −60 dB. The magnetostrictive film may include a ferromagnetic material. The interdigitated input and output transducer electrodes may include unequal widths between adjacent electrodes.

Owner:GOVERNMENT OF THE UNITED STATES AS REPRESENTED BY THE SEC OF THE AIR FORCE

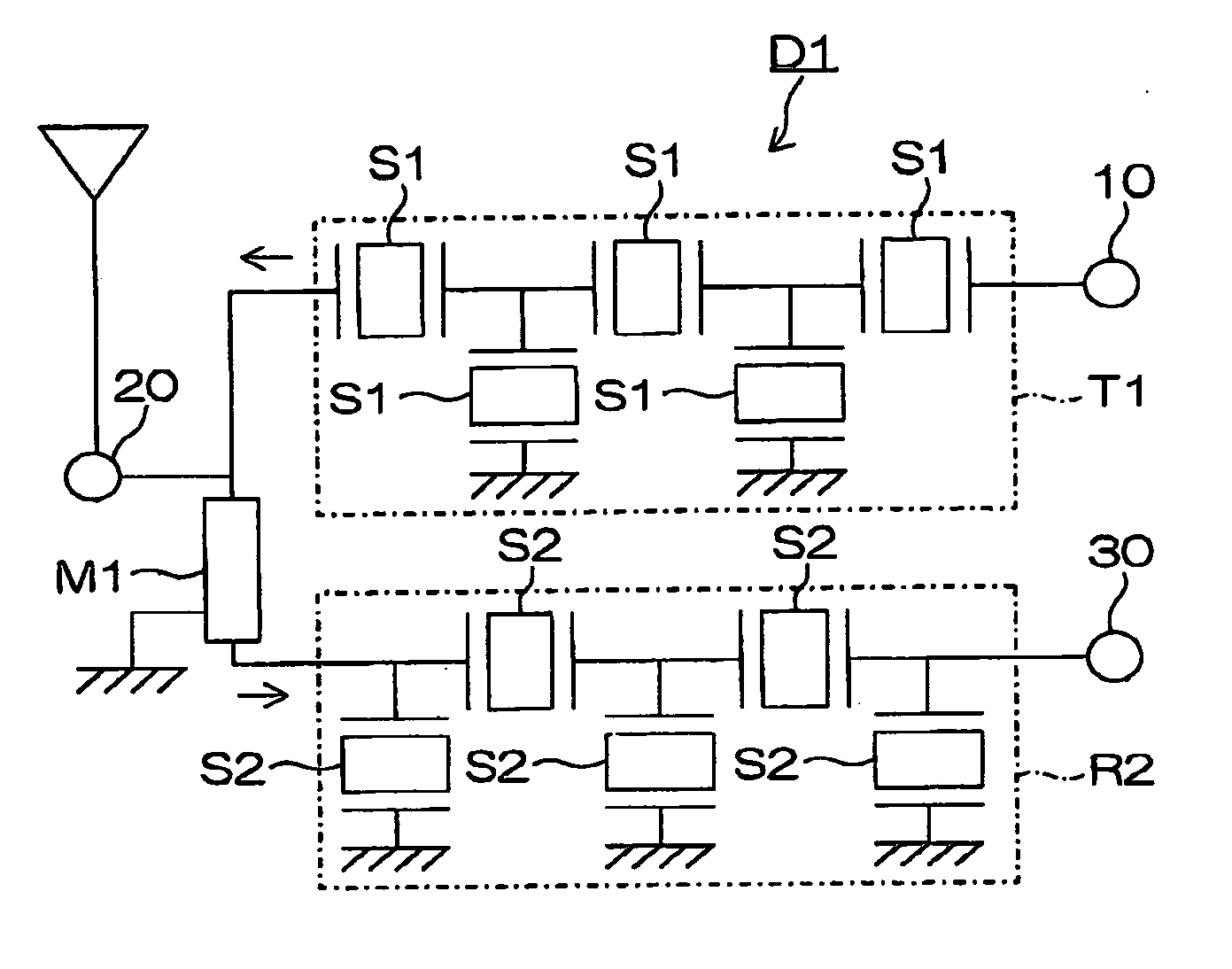

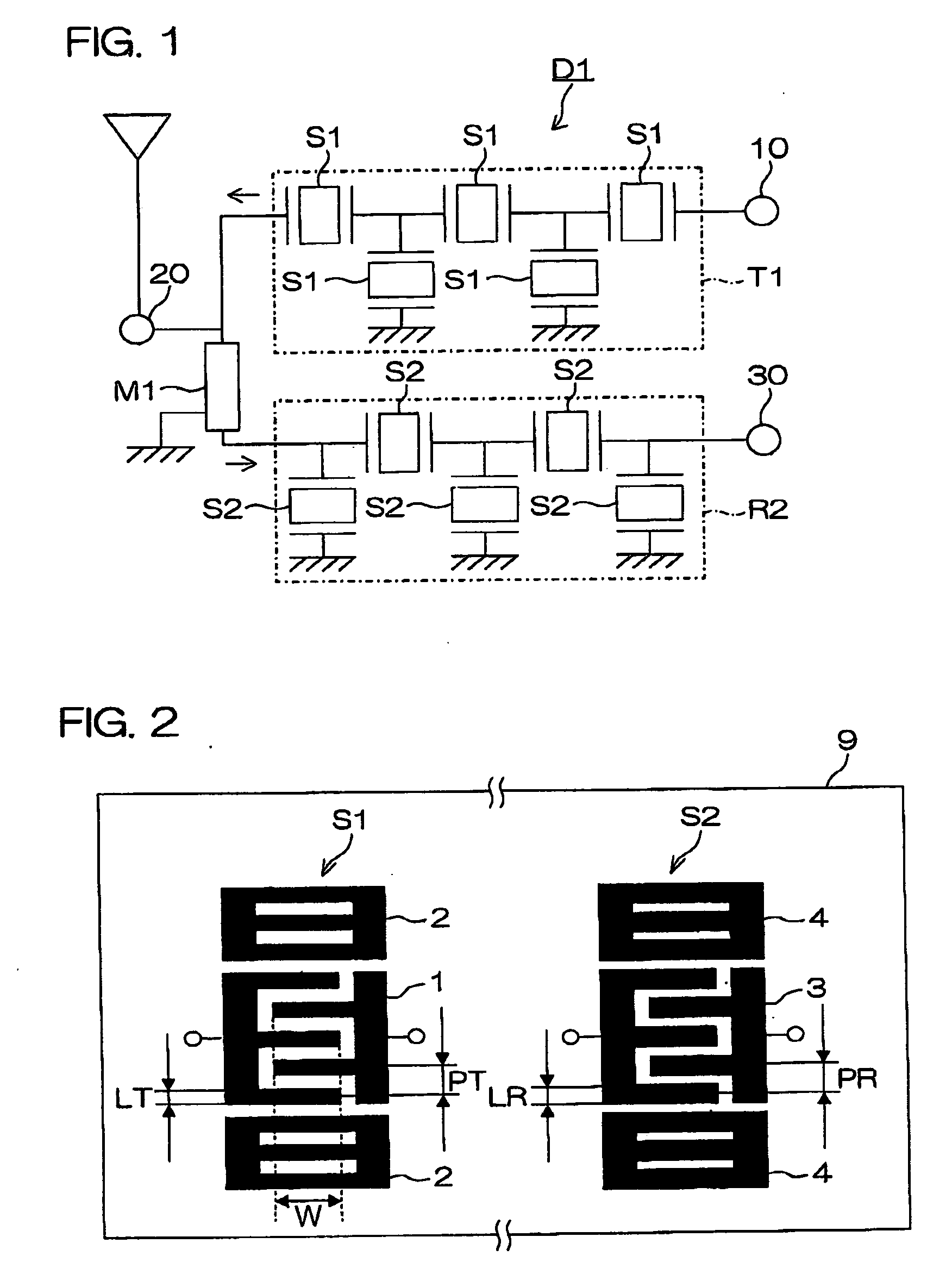

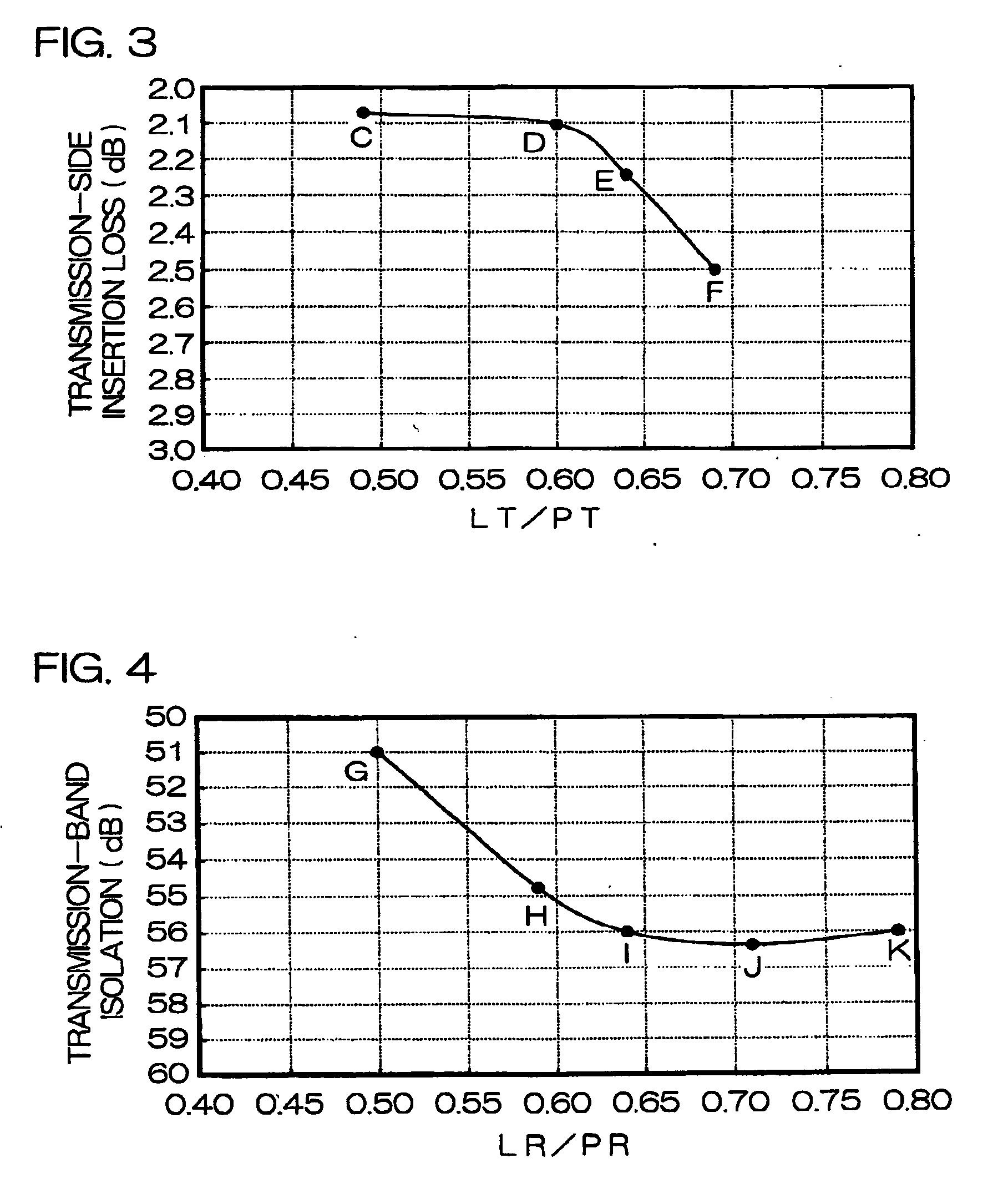

Surface acoustic wave device, duplexer, and communications equipment

ActiveUS20060186968A1Improve featuresImprove isolation characteristicsImpedence networksPiezoelectric/electrostrictive/magnetostrictive devicesUltrasound attenuationEngineering

A SAW device D1 according to the present invention comprises a ladder-type SAW device T1 for transmission and a ladder-type SAW device R2 for receiving on a main surface of a piezoelectric substrate. The ratio (LT / PT) of the width LT of electrode fingers to the pitch PT between the electrode fingers in a SAW resonator S1 in the ladder-type SAW device T1 for transmission is made lower than the ratio (LR / PR) of the width LR of electrode fingers to the pitch PR between the electrode fingers in a SAW resonator S2 in the ladder-type SAW device R2 for receiving. As a result, the SAW device D1 has a low loss within a band and has steep attenuation characteristics outside the band, and is miniaturized.

Owner:KYOCERA CORP

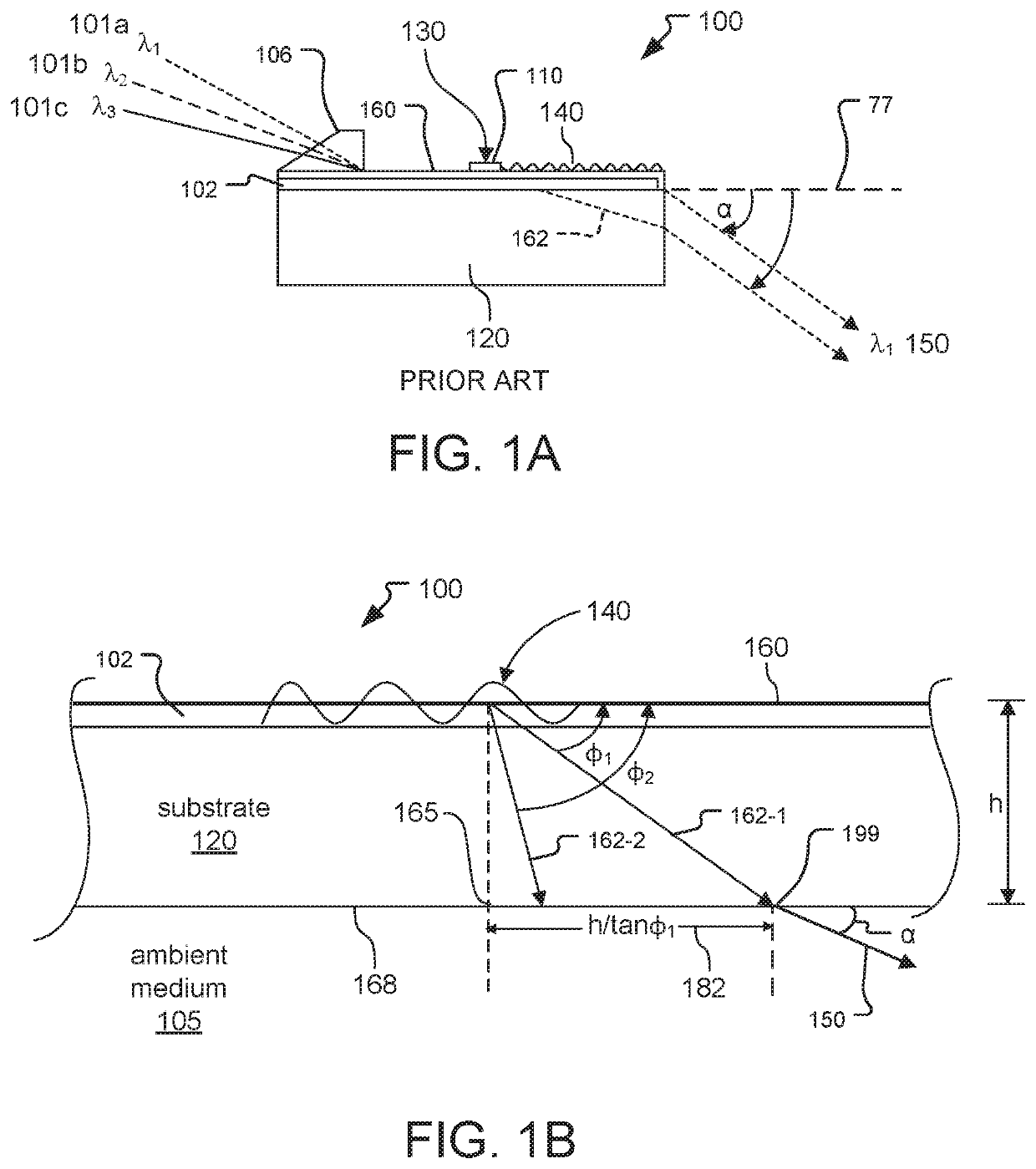

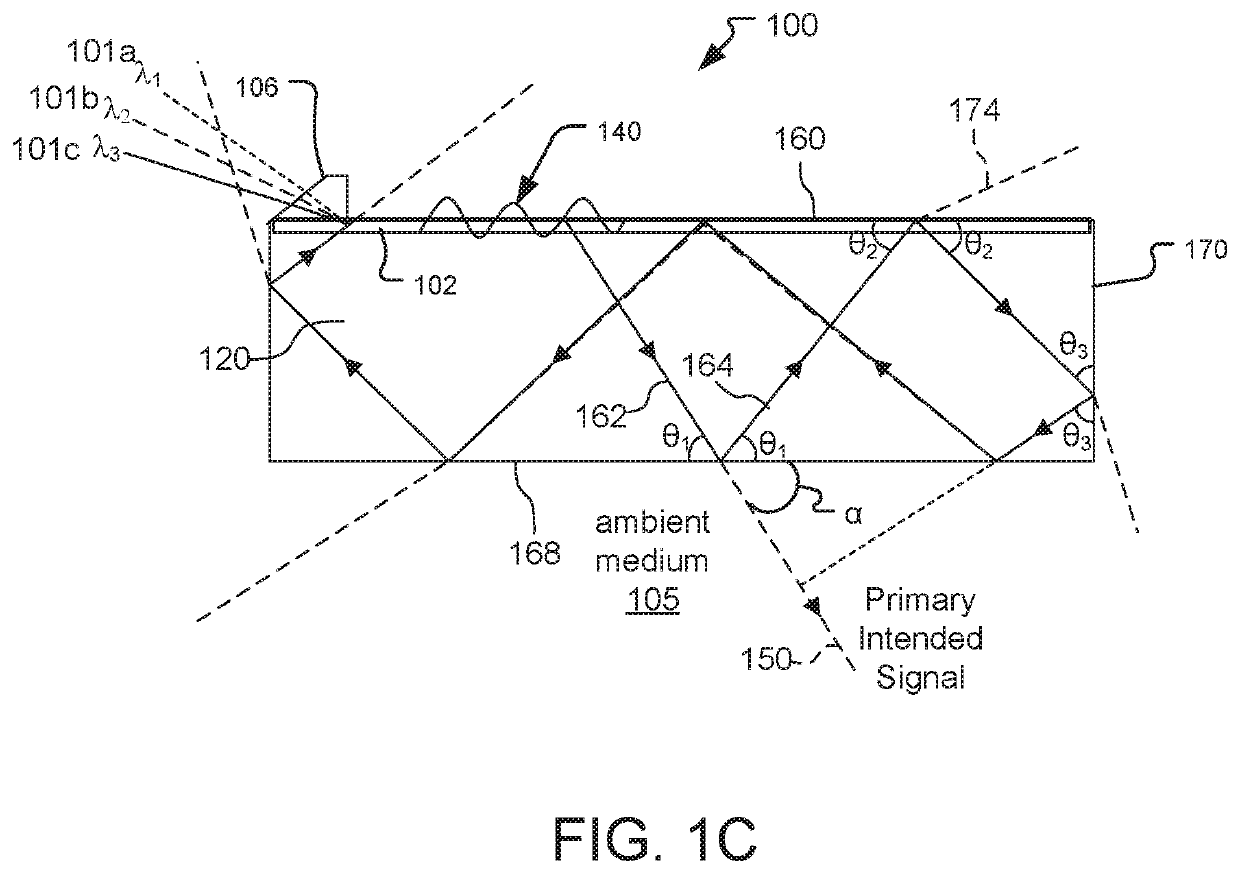

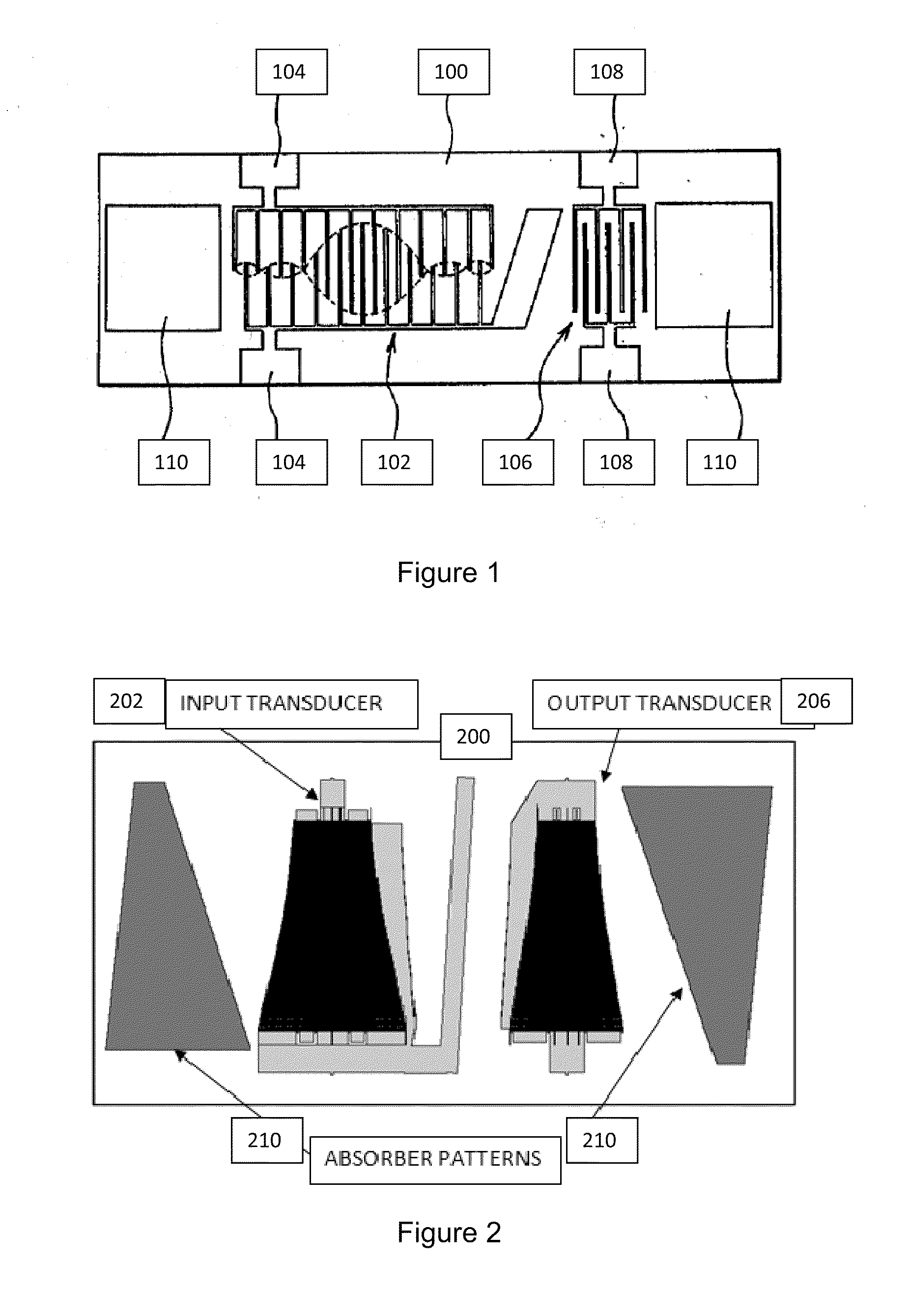

SAW modulators and light steering methods

ActiveUS10795235B2Piezoelectric/electrostrictive device manufacture/assemblyImpedence networksTransducerEngineering

An electro-holographic light field generator device is disclosed. The light field generator device has an optical substrate with a waveguide face and an exit face. One or more surface acoustic wave (SAW) optical modulator devices are included within each light field generator device. The SAW devices each include a light input, a waveguide, and a SAW transducer, all configured for guided mode confinement of input light within the waveguide. A leaky mode deflection of a portion of the waveguided light, or diffractive light, impinges upon the exit face. Multiple output optics at the exit face are configured for developing from each of the output optics a radiated exit light from the diffracted light for at least one of the waveguides. An RF controller is configured to control the SAW devices to develop the radiated exit light as a three-dimensional output light field with horizontal parallax and compatible with observer vertical motion.

Owner:CHARLES STARK DRAPER LABORATORY

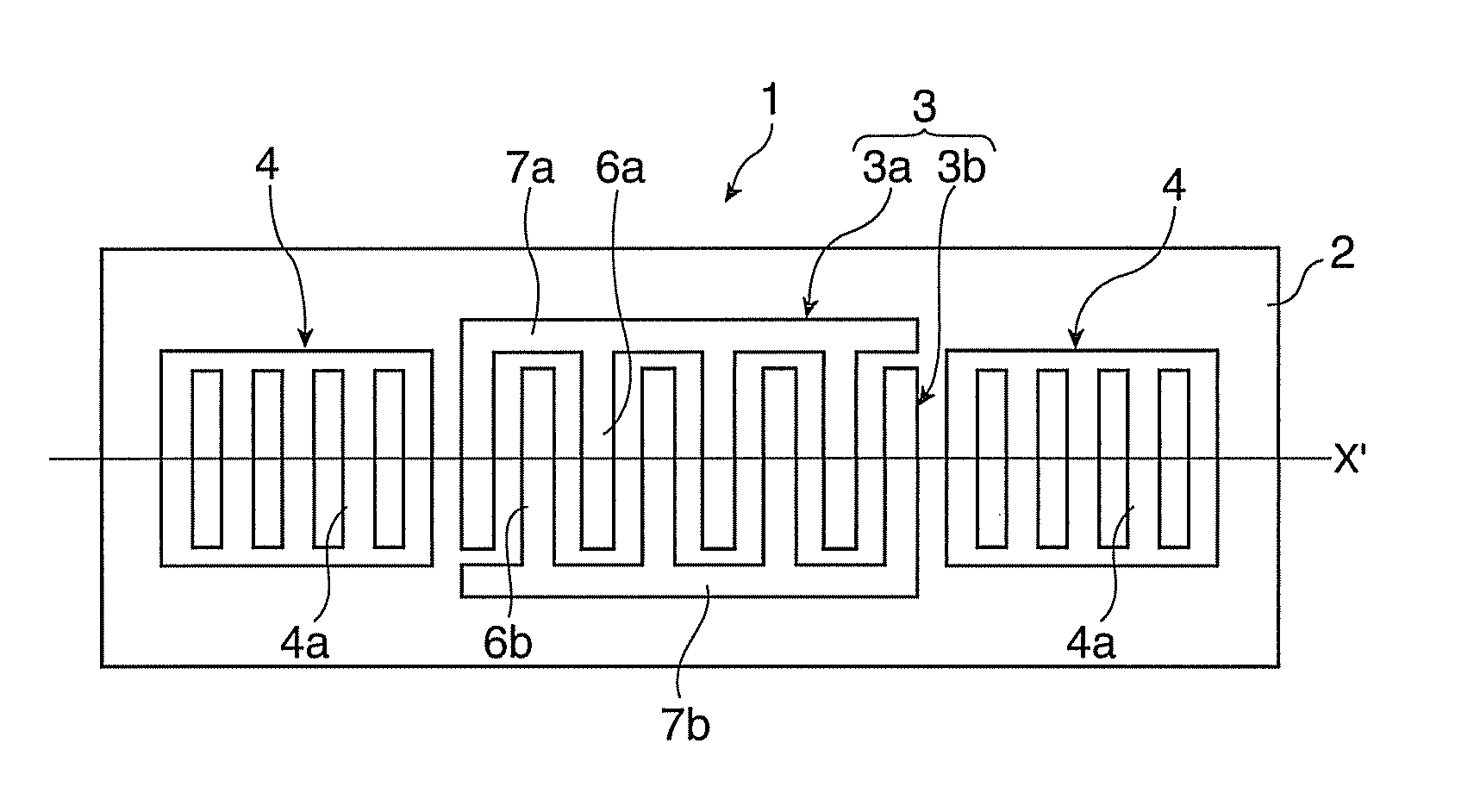

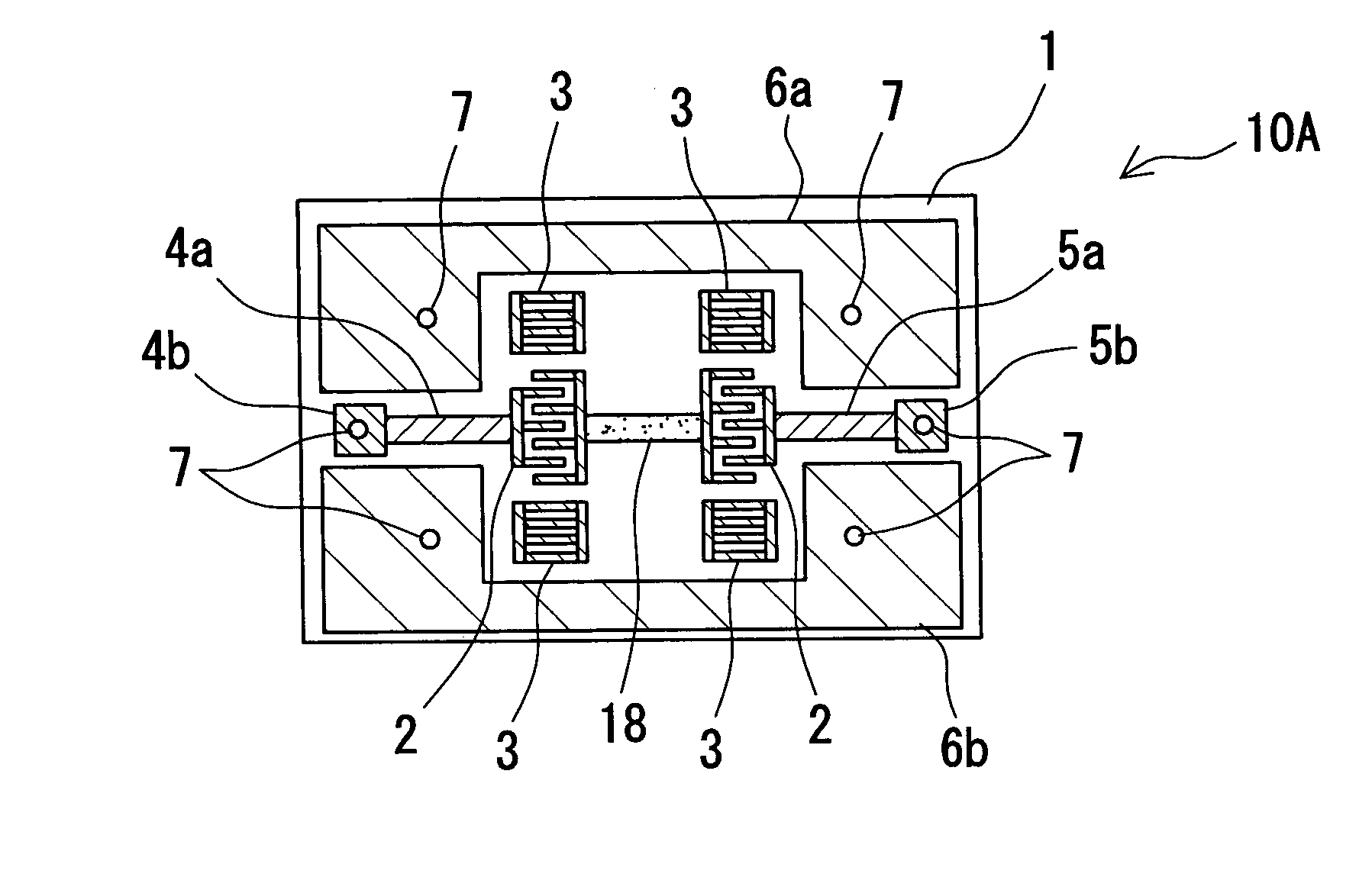

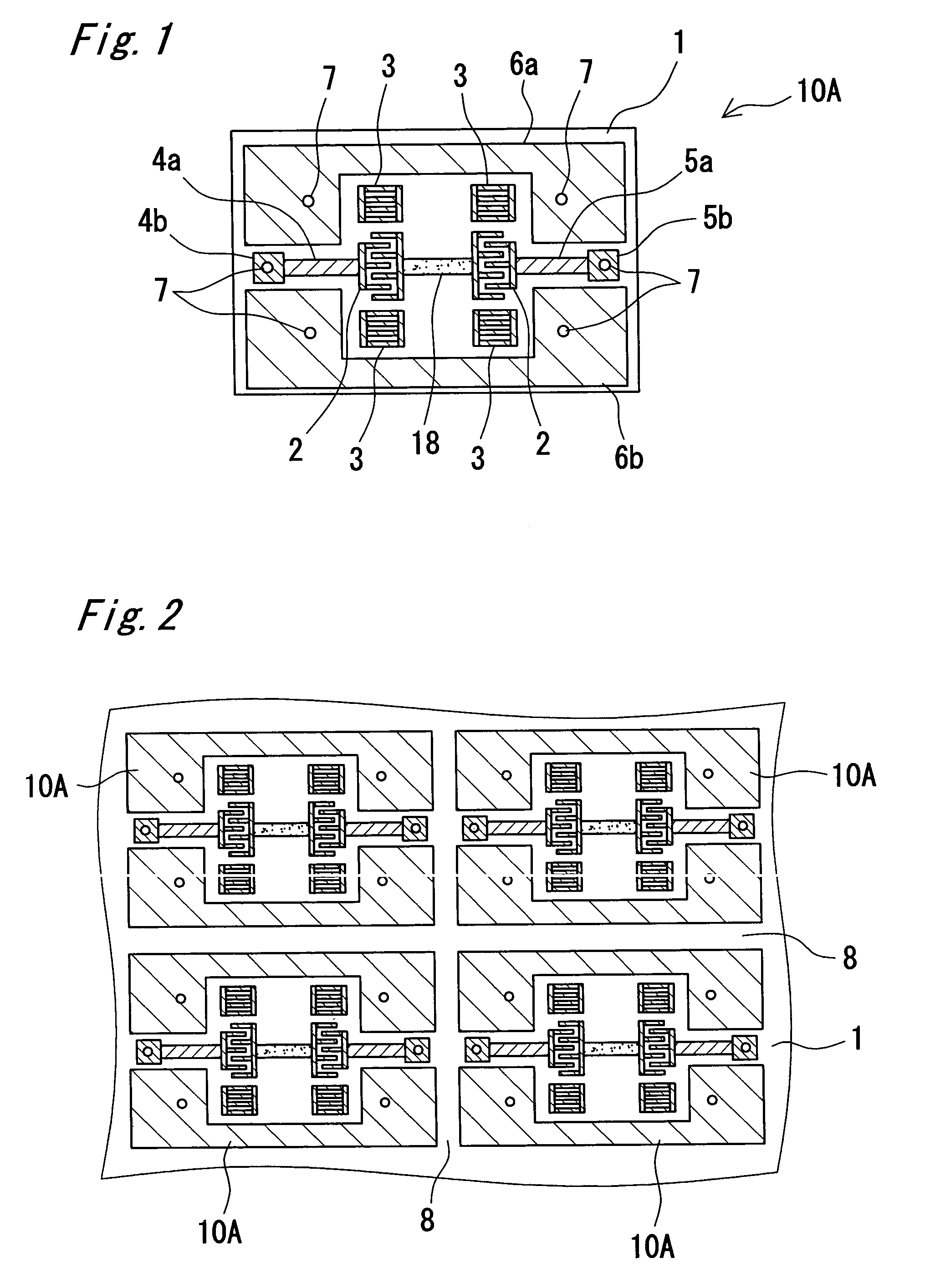

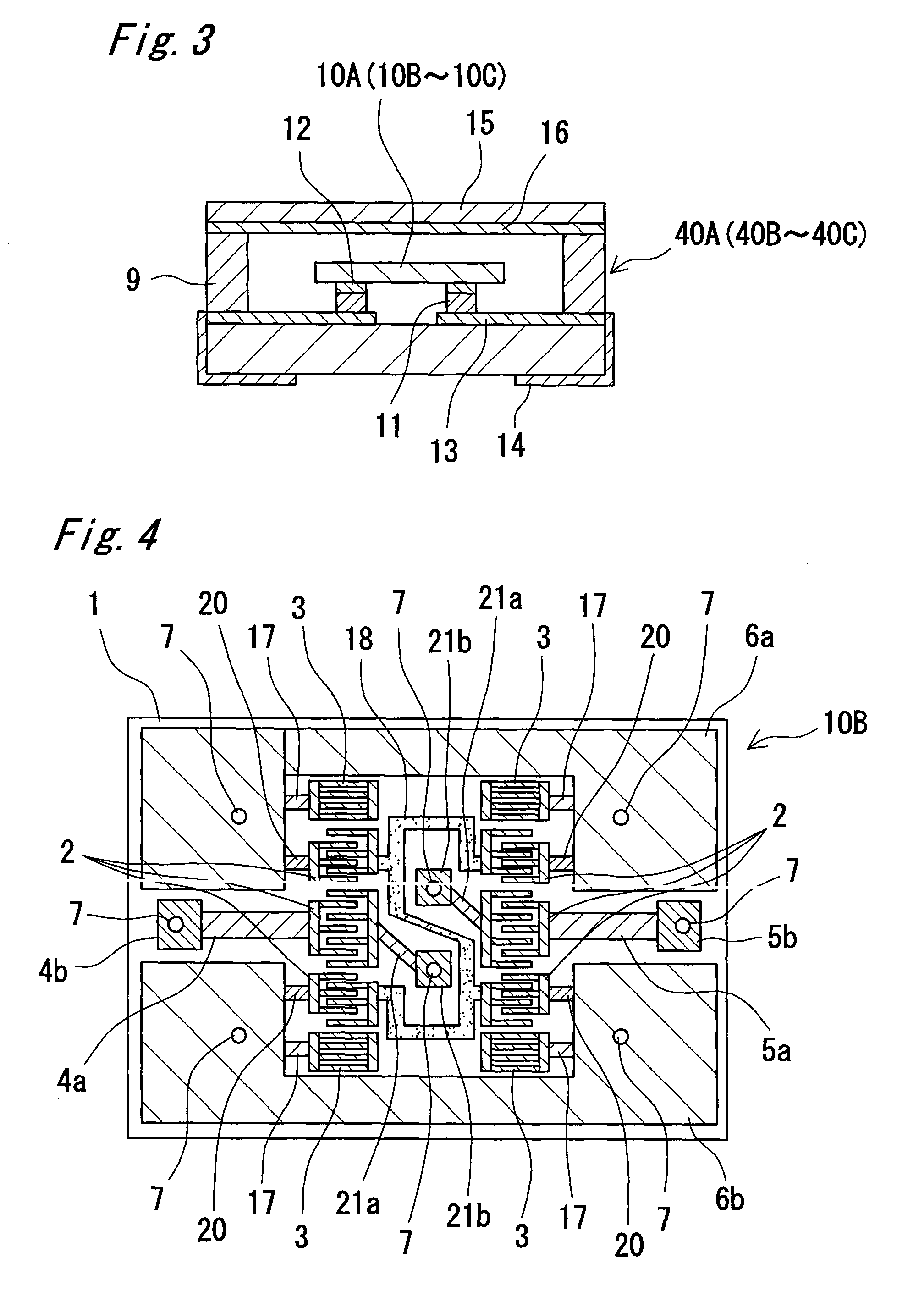

Surface acoustic wave device, method of manufacturing the device, and electronic component using the device and method

InactiveUS7064471B2Lessens any nonuniformityLocal nonuniformity be lessenPiezoelectric/electrostriction/magnetostriction machinesImpedence networksAuxiliary electrodePiezoelectric substrate

A surface acoustic wave (SAW) device includes a comb-shaped electrode 2, a reflector 3 and a plurality of auxiliary electrodes 6a and 6b for surrounding the comb-shaped electrode 2 and the reflector 3, which are electrically independent of each other and have different widths locally. The SAW device is capable of efficiently and electrically uniformizing electric charge generated by pyroelectric property of a piezoelectric substrate 1.

Owner:PANASONIC CORP

Surface acoustic wave device, electronic apparatus, and sensor apparatus

InactiveUS8723394B2Improve featuresSmall fluctuationPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesEngineeringSurface acoustic wave

A SAW device has an IDT which is provided in the principal surface of a quartz crystal substrate having Euler angles (−1.5°≦φ≦1.5°, 117°≦θ≦142°, |ψ|≠90°×n (where n=0, 1, 2, 3)) and excites a Rayleigh wave (wavelength: λ) in a stopband upper end mode. Inter-electrode-finger grooves are recessed between the electrode fingers of the IDT. The depth G of the inter-electrode-finger grooves is 0.01λ≦G≦0.07λ, and an electrode finger thickness H and an IDT line occupancy η satisfy a predetermined relationship. Thus, a frequency-temperature characteristic constantly has an inflection point between a maximum value and a minimum value in an operation temperature range, thereby suppressing a fluctuation in an inflection-point temperature due to a manufacturing variation in the IDT line occupancy η.

Owner:SEIKO EPSON CORP

TC-SAW device and manufacturing method thereof

The invention relates to the field of surface acoustic wave devices. A conventional STD-SAW device is very sensitive to temperature change, and performance change is relatively obvious. Therefore, theinvention provides a TC-SAW device, which comprises a piezoelectric material substrate, an interdigital electrode arranged on the piezoelectric material substrate, a temperature compensation layer covering the interdigital electrode, a third metal PAD layer on the piezoelectric material substrate and a passivation layer on the outermost layer. A manufacturing method comprises the following steps:coating a photoresist layer, depositing a metal film, depositing a first layer of interdigital electrode layer, depositing a second layer of electrode, depositing a temperature compensation material,and depositing a passivation layer for isolating air and the like. The temperature coefficient of the TC-SAW device can reach 0 ppm / K to-25 ppm / K, frequency stability is improved, the Q value is improved, and high requirement of mobile communication equipment can be met; the manufacturing method can be used for manufacturing resonators, filters, duplexers and other elements and is wide in application.

Owner:SHENZHEN MICROGATE TECH

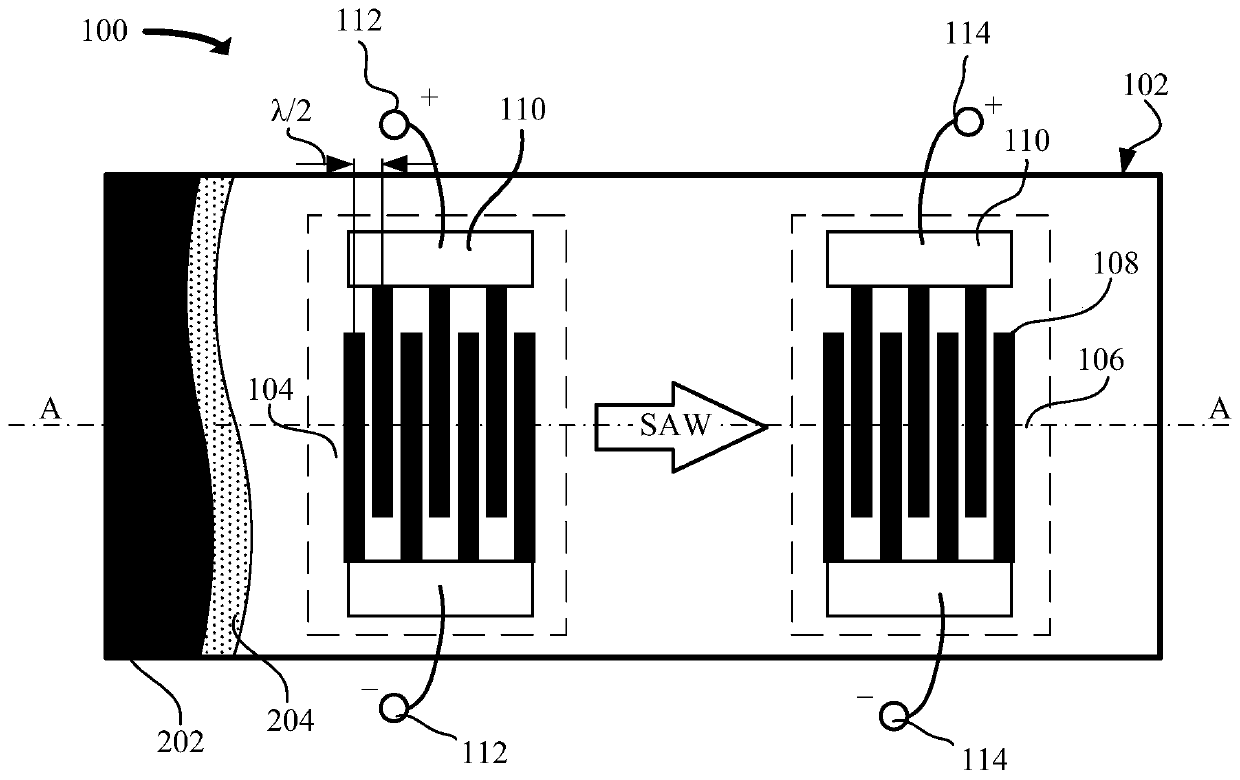

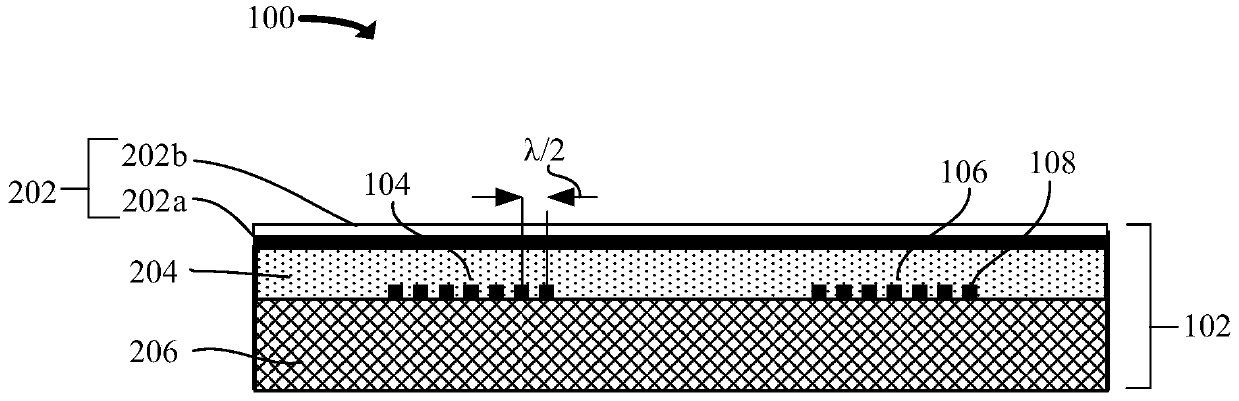

Surface acoustic wave device

The embodiments herein relate to surface acoustic wave (SAW) devices, such as filters and duplexers. The SAW device may have a high acoustic velocity layer and a piezoelectric layer coupled to the high acoustic velocity layer. At least one transducer is coupled at least to the piezoelectric layer, where the transducer propagates a surface acoustic wave having an operating wavelength along a surface of the piezoelectric layer. A metallic layer may be coupled to the surface of the piezoelectric layer and electrically isolated from the transducer.

Owner:HUAWEI TECH CO LTD

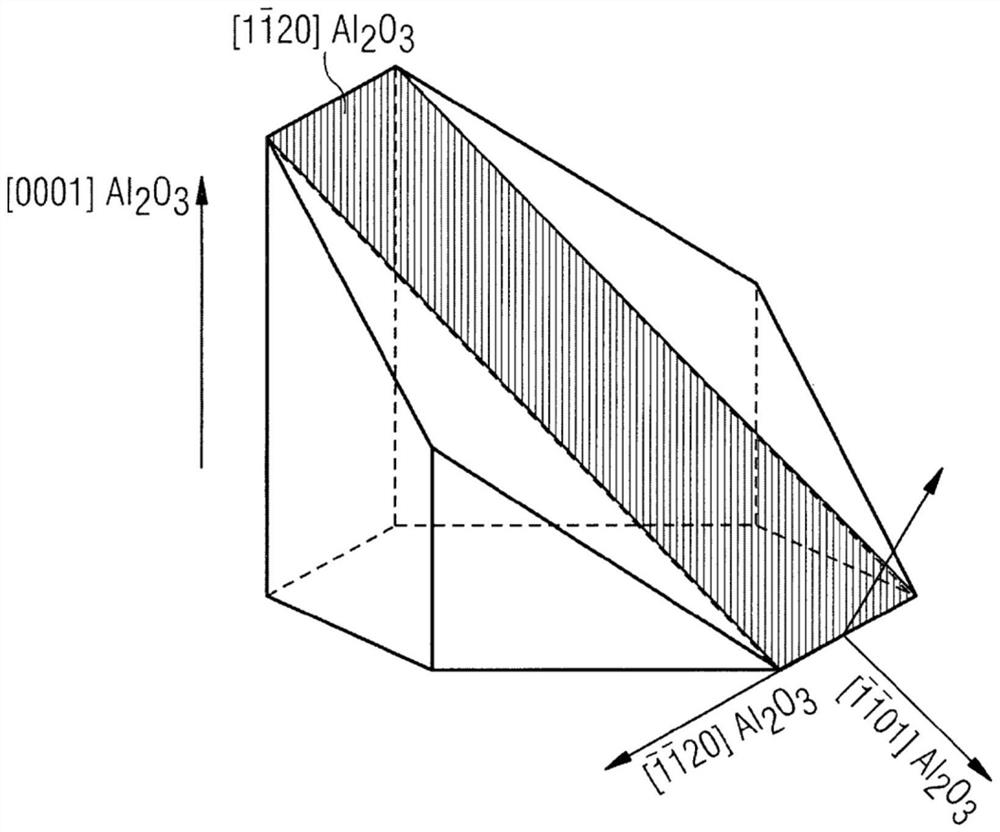

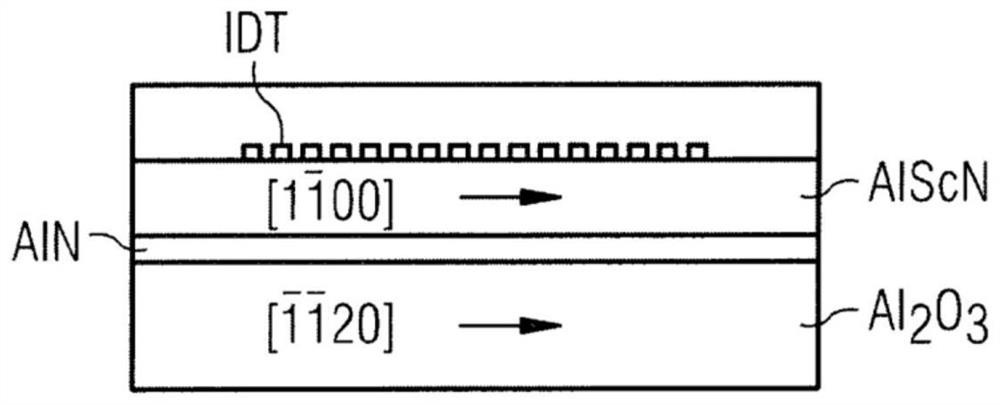

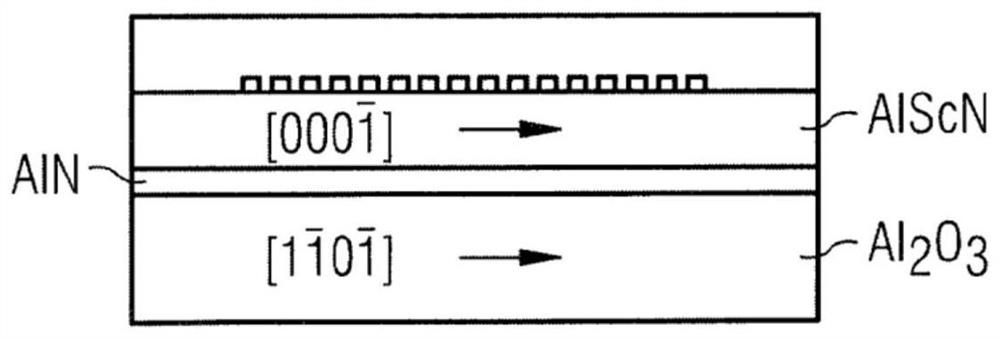

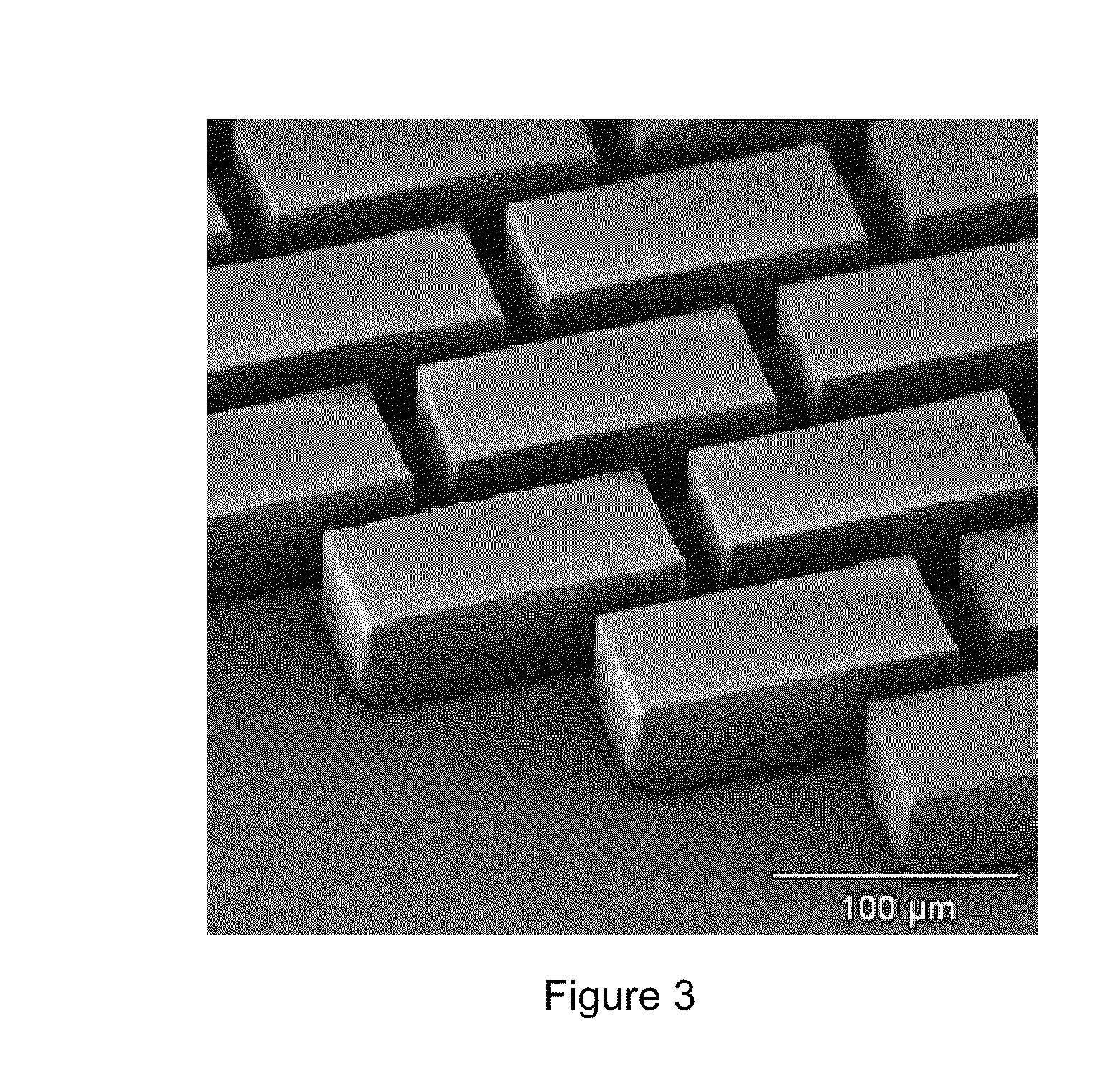

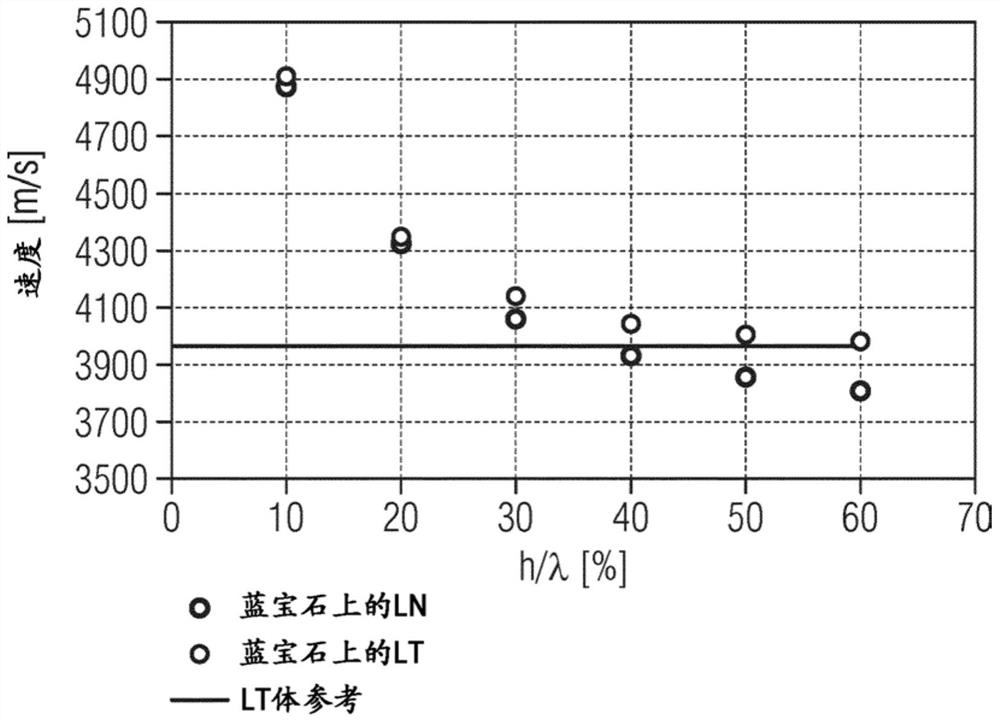

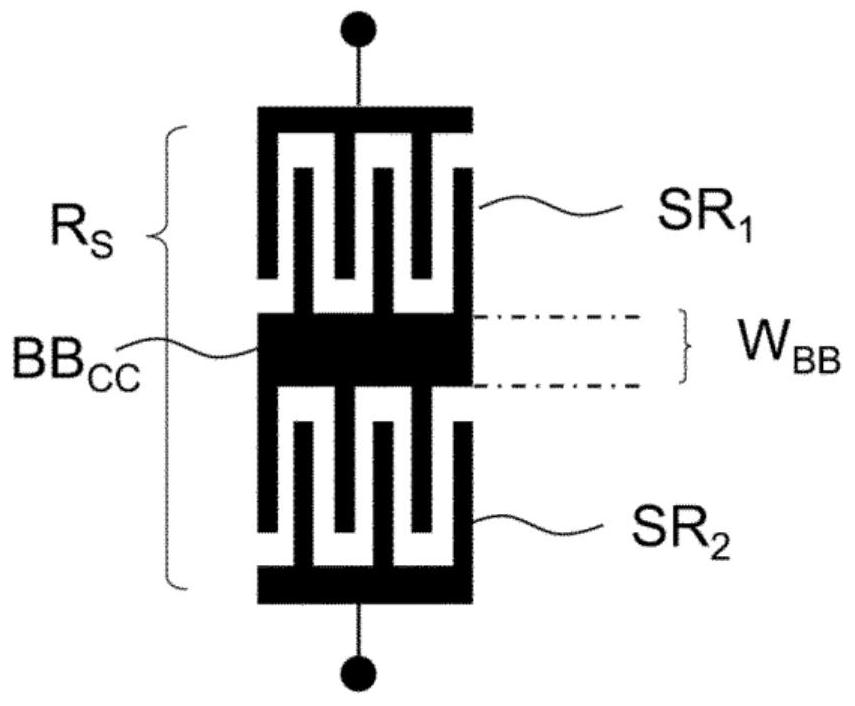

Multiple layer system, method of manufacture and saw device formed on the multiple layer system

A layer system especially for forming SAW devices thereon is proposed comprising a monocrystalline sapphire substrate having a first surface and a crystalline piezoelectric layer comprising A1N, deposited onto the first surface, and having a second surface. As a first surface a crystallographic R-plane of sapphire is used enabling an orientation of c-axis of the piezoelectric layer parallel to thefirst and second surfaces.

Owner:RF360新加坡私人有限公司

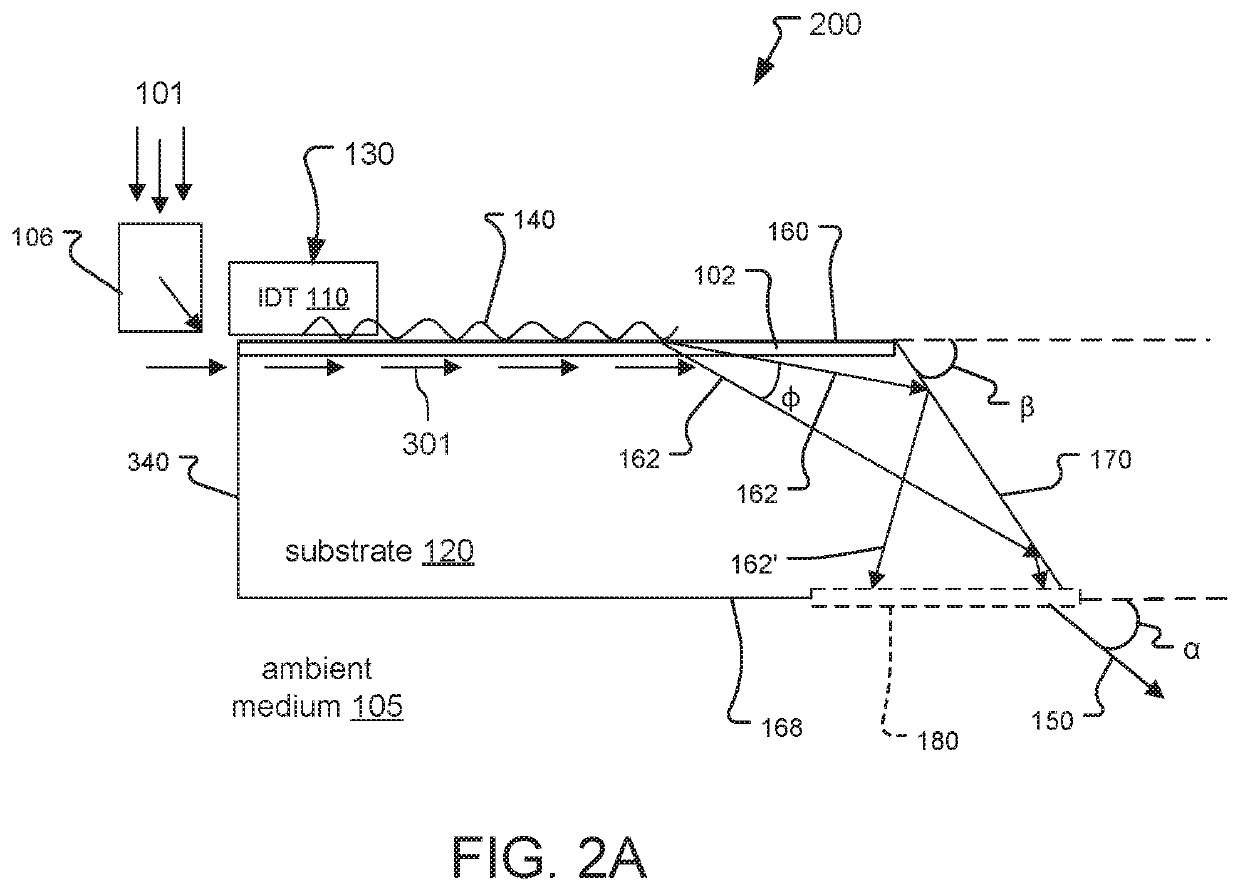

Surface Acoustic Wave Diverter

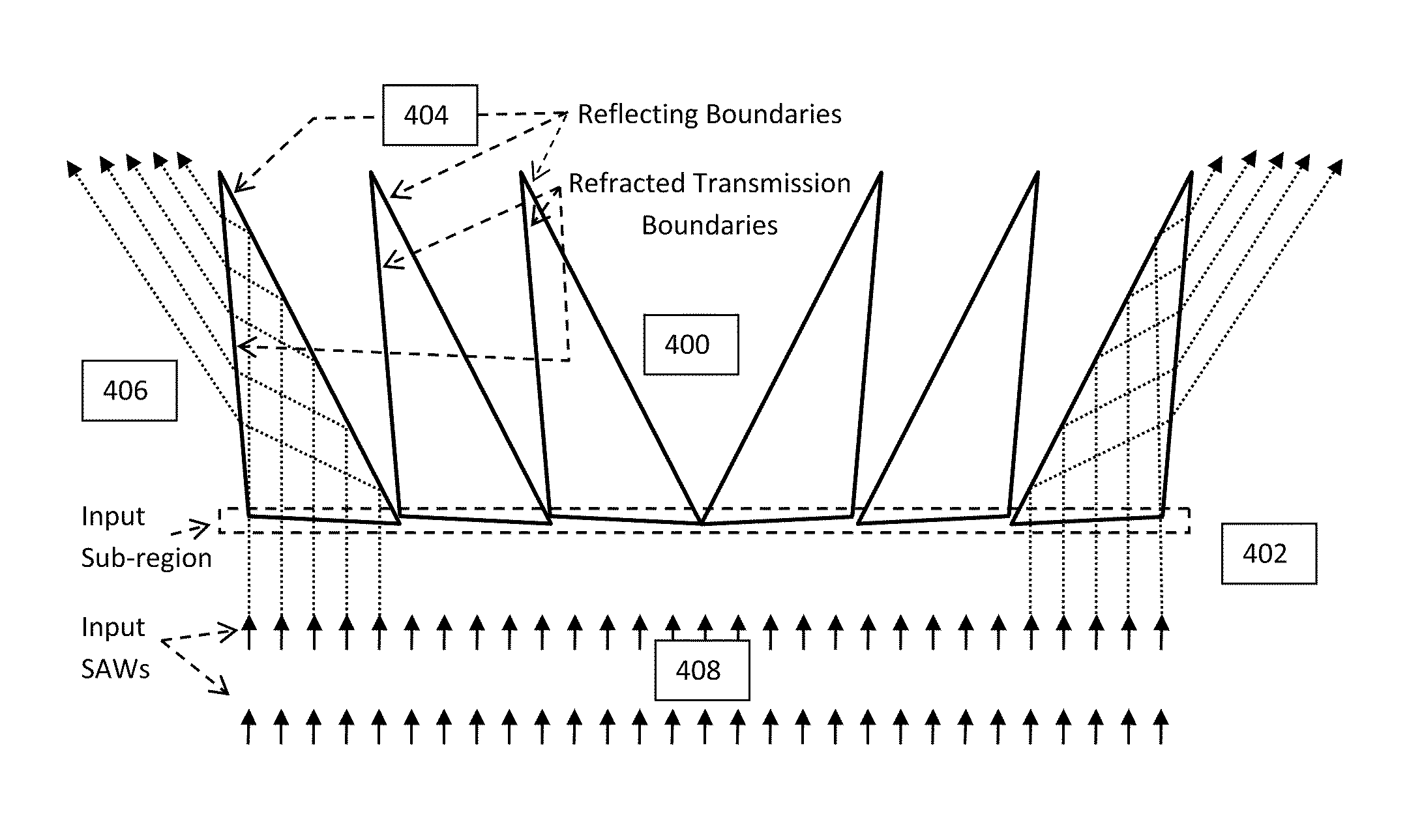

InactiveUS20100225421A1Increase the angle of incidenceImprove reflectivityImpedence networksRecord carriers used with machinesNarrow rangeTotal internal reflection

The present invention is directed to using the uniquely high reflectivity that occurs at high angles of incidence at a boundary between two SAW propagation regions for which the incident wave region has a lower SAW phase velocity. In optical systems, this region is known as the region of total internal reflection. Use of total internal reflection for SAW devices is not well known because it usually only occurs over a narrow range of angles and which are high incidence angles.

Owner:RF SAW INC

Long-life anti-counterfeiting method

InactiveCN102346837AGood anti-counterfeiting effectLong anti-counterfeiting periodSensing record carriersCommerceTemperature resistanceEngineering

The invention discloses a long-life anti-counterfeiting method, which comprises an anti-counterfeiting establishment step and an anti-counterfeiting detection step, wherein the anti-counterfeiting establishment step comprises: preparing at least one of SAW (surface acoustic wave) devices and microwave ceramic devices, storing the data of the device, and fixing the device with a product or product packing together; and the anti-counterfeiting detection step comprises: sending a testing wave to the product or product packing to obtain and record a feedback wave, and judging when the feedback wave is corresponding to the stored data, if so, determining that the product is a genuine product, otherwise, determining that the product is a counterfeiting product. The applicant cleverly applies SAW devices and microwave ceramic devices to the anti-counterfeiting method, and through using the characteristics (such as complicated and diversified waveforms, long life and high temperature resistance) of the devices, the following technical effects are generated: the anti-counterfeiting effect is good, and the anti-counterfeiting period is long even up to hundreds or thousands of years, and the like; and the device is high-temperature-resistant, and can be embedded into products or product packing through sinter molding.

Owner:刘述江

Surface acoustic wave device, electronic apparatus, and sensor apparatus

InactiveUS20140285063A1Prevent movementSuppresses frequency fluctuationsPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksEngineeringAcoustic wave

Owner:SEIKO EPSON CORP

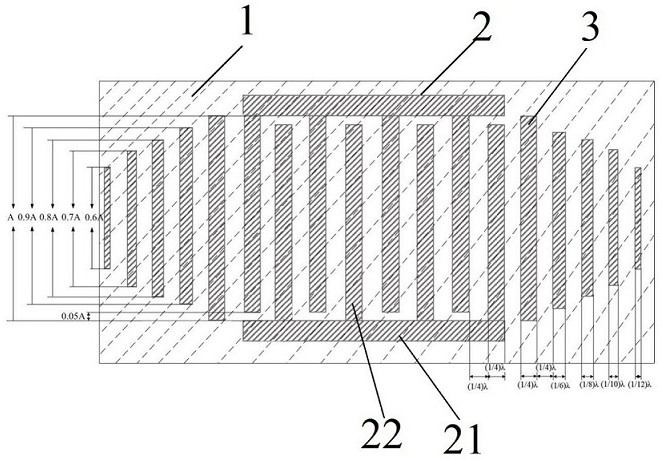

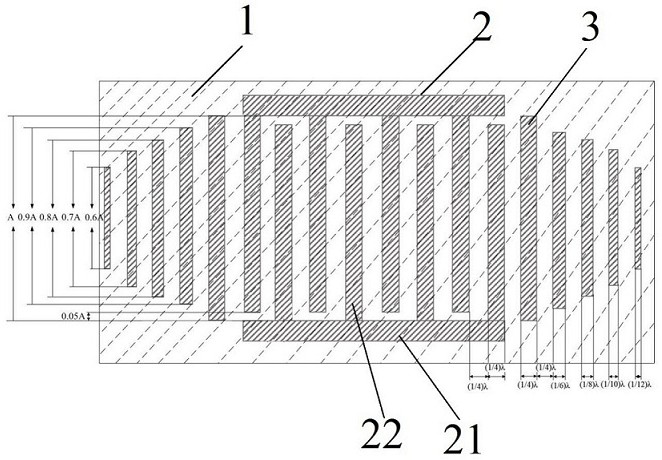

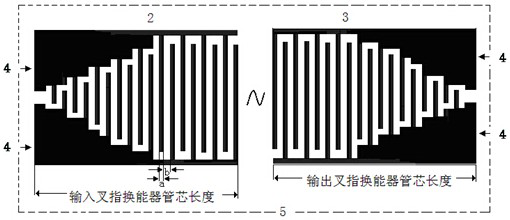

SAW device comprising mixed weighted reflecting grating and mixed weighted reflecting grating

ActiveCN114268294ASuppress lateral clutterImprove frequency response characteristicsImpedence networksGratingEngineering

The invention relates to an SAW device comprising mixed weighted reflecting gratings and the mixed weighted reflecting gratings, and belongs to the technical field of radio frequency filtering, the SAW device comprises a piezoelectric substrate, an interdigital transducer and two mixed weighted reflecting gratings, the interdigital transducer and the two mixed weighted reflecting gratings are arranged on the piezoelectric substrate, each mixed weighted reflecting grating comprises a plurality of reflecting grating electrodes which are distributed at equal intervals, and the reflecting grating electrodes are arranged on the piezoelectric substrate. The lengths and the widths of the plurality of reflecting gate electrodes are gradually reduced in a preset direction, and the preset direction is a direction far away from the interdigital transducer. Therefore, according to the invention, the mixed weighted reflecting grating is arranged to be a plurality of reflecting grating electrodes which are distributed at equal intervals, and the lengths and the widths of the plurality of reflecting grating electrodes are gradually reduced in the direction far away from the interdigital transducer, so that a mixed weighted structure combining width gradual-change weighting and apodization weighting is formed; the transverse clutter generated in the SAW device can be suppressed under a more compact structure, the clutter suppression performance is improved, the frequency response characteristic of the SAW device is improved, and then the Q value of the SAW device is improved.

Owner:深圳新声半导体有限公司

Wireless surface acoustic wave-based proximity sensor, sensing system and method

InactiveUS7834514B2Device fabrication is simplifiedFew stepsPiezoelectric/electrostriction/magnetostriction machinesUsing electrical meansProximity sensorTransceiver

Owner:ROSEMOUNT AEROSPACE

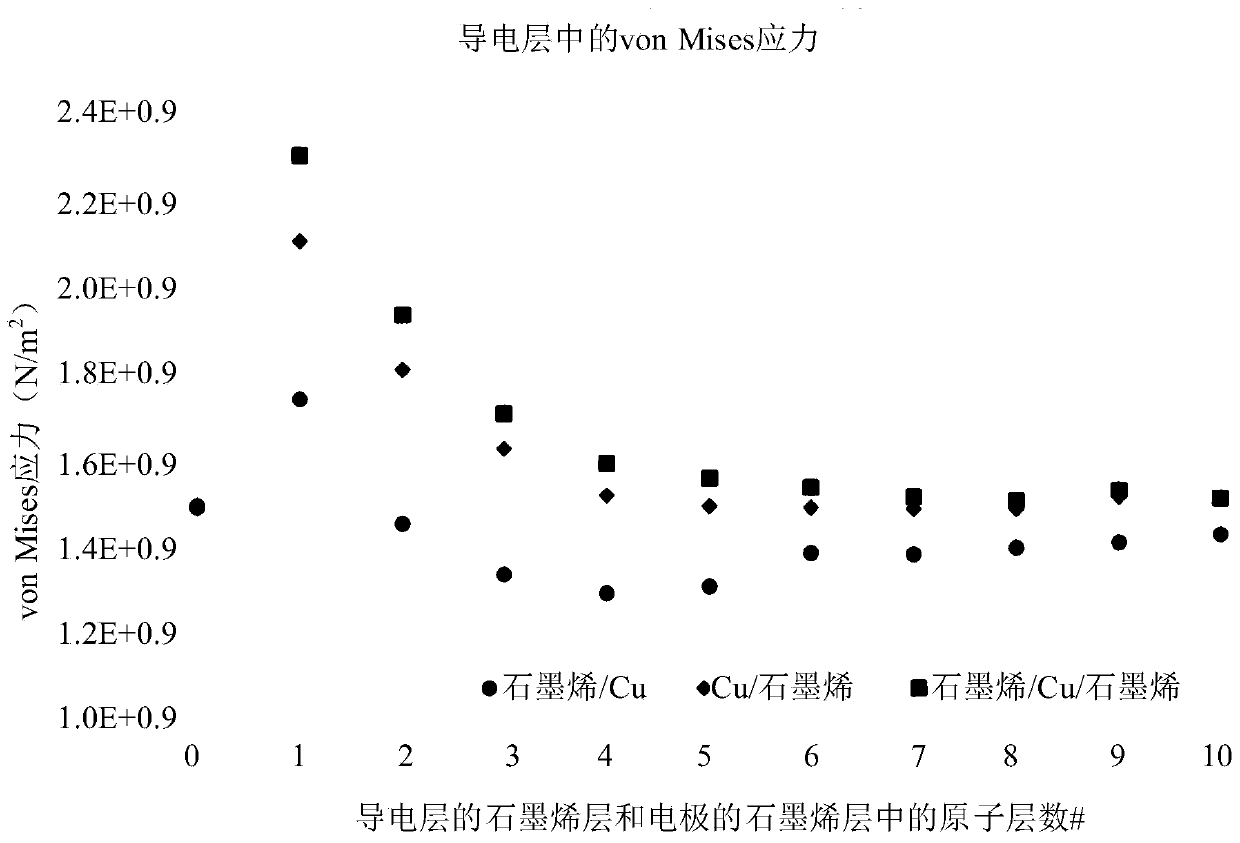

Surface acoustic wave device

A surface acoustic wave (SAW) device including a piezoelectric layer, a high acoustic velocity layer coupled to the piezoelectric layer, and at least one transducer. The SAW device may include a multi-layer graphene layer in the electrodes of at least one of the transducer and in a conductive layer that is coupled to the piezoelectric layer.

Owner:HUAWEI TECH CO LTD

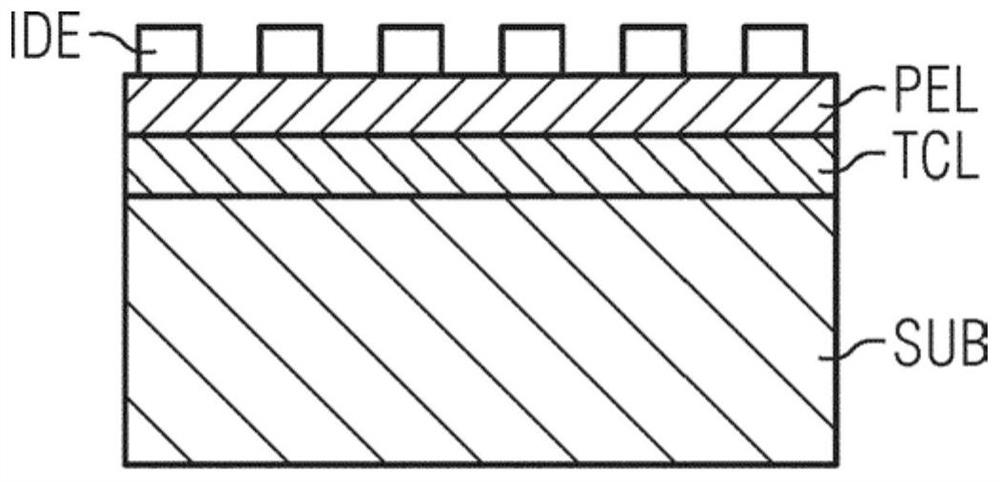

Saw device with composite substrate for ultra high frequencies

A SAW device having a stacked design of functional layers is proposed that is build up on a carrier substrate (SUB) that is chosen to provide a high acoustic velocity. The stack further comprises a thin TCF compensation layer (TCL), a thin film piezoelectric layer (PEL) and a set of interdigital electrodes (IDE) on top of the piezoelectric layer. Energy of the desired mode mainly in the high acoustic velocity material. Despite the high possible operating frequencies the SAW device can reliably be manufactured with present lithographic techniques.

Owner:RF360新加坡私人有限公司

A kind of blackening processing method of lithium tantalate crystal substrate

ActiveCN106521633BHigh precisionReduce bulk resistivityPolycrystalline material growthAfter-treatment detailsReduction treatmentLithography process

A method for blackening treatment of lithium tantalate crystal substrates. In a chemically reducing atmosphere, roughen the surfaces of metal sheets and lithium tantalate crystal substrates, and then alternately stack them in a contact manner, and place them in a temperature lower than the Curie temperature. In the environment, the lithium tantalate crystal substrate is reduced to make the lithium tantalate crystal substrate change from white or light yellow to colored and opaque, and still maintain its original piezoelectric material characteristics. The reduction treatment of lithium tantalate crystal substrate can reduce its volume resistivity, improve the discharge phenomenon caused by pyroelectric effect caused by temperature difference in the manufacturing process of surface acoustic wave filter (SAW filter), and improve the interdigitated electrode lines in The precision of the photolithography process helps to improve the yield of SAW device manufacturing and reduce production costs.

Owner:FUJIAN JING AN OPTOELECTRONICS CO LTD

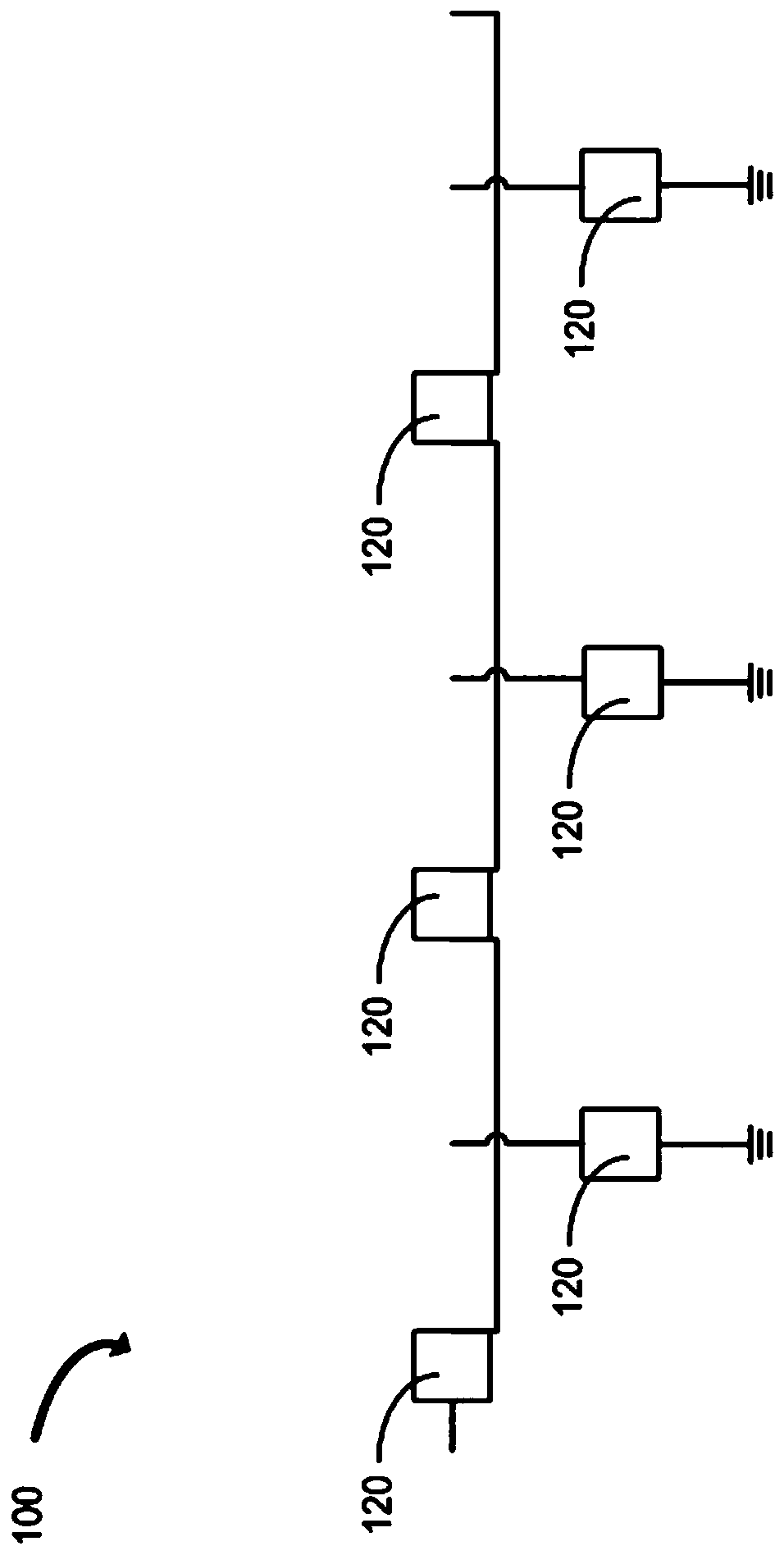

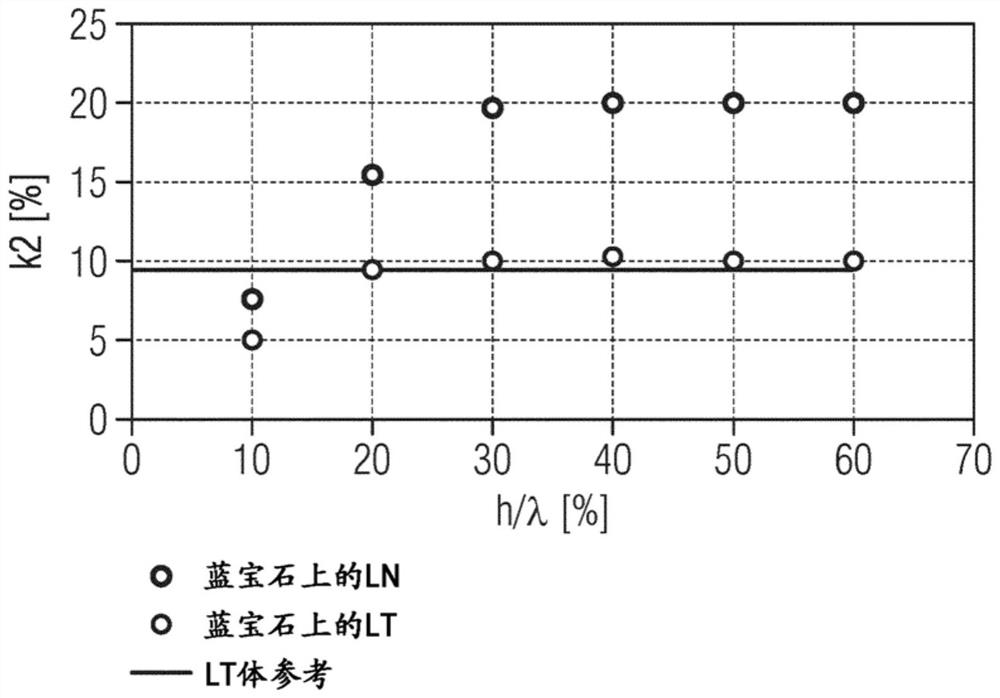

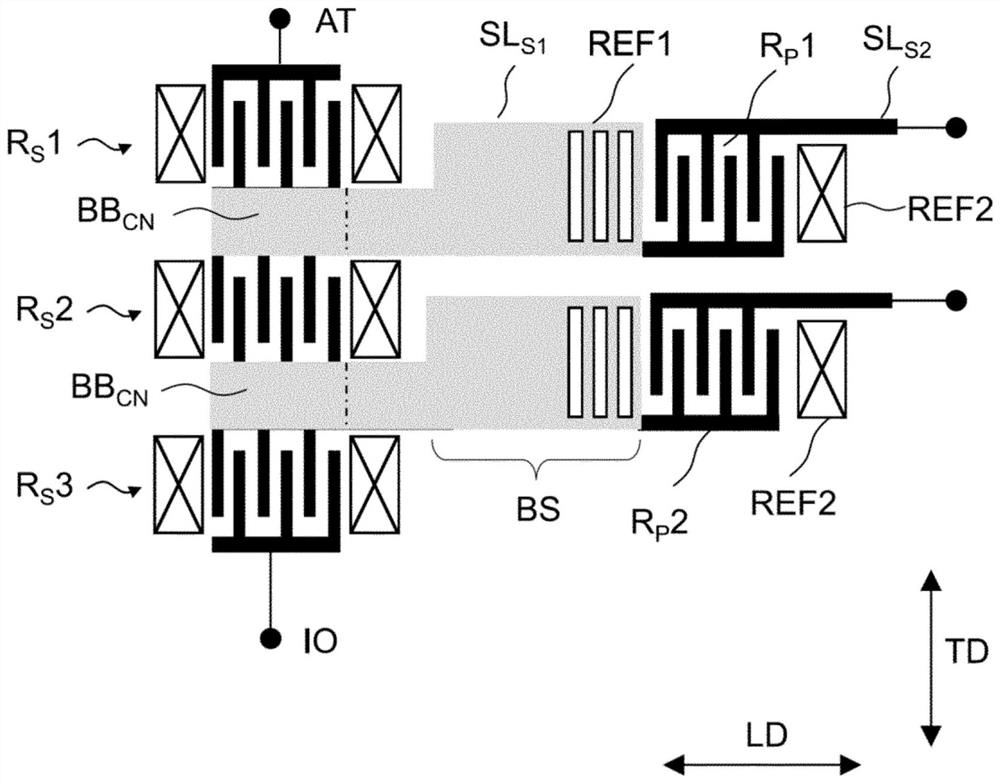

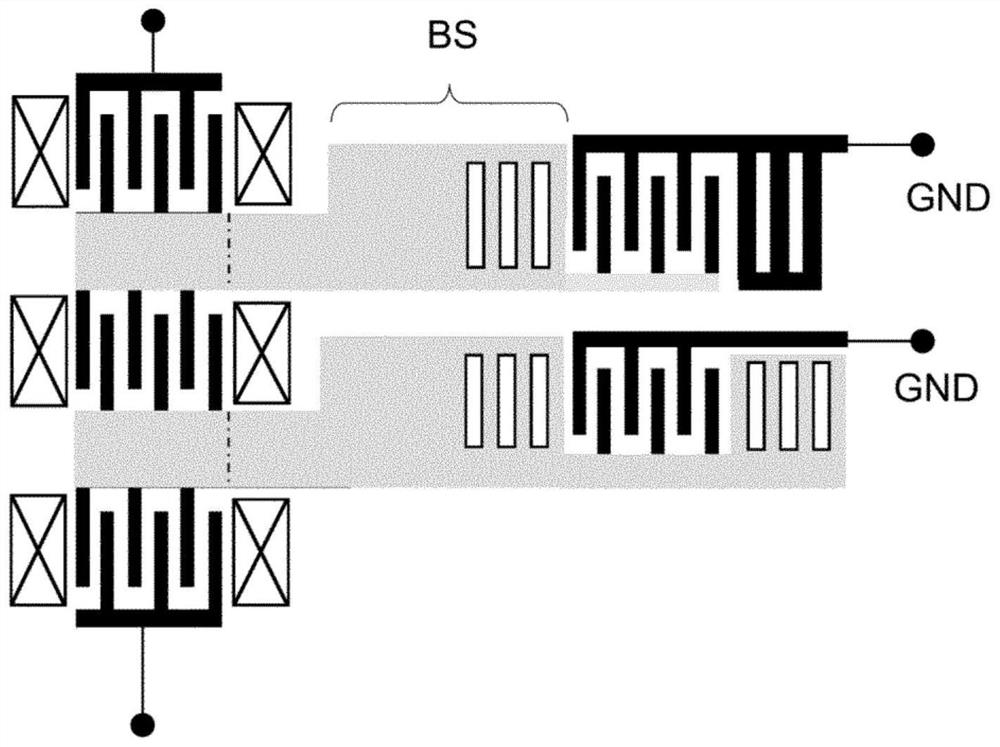

Saw device with improved thermal management

This invention focuses on minimizing the hot spots on a filter chip by creating thermal radiators using the mechano-acoustic structures and connection circuitry. A gradual increase of metal to wafer relation is made to provide better heat dissipation and heat sinking. Preferably the shunt lines of the ladder type arrangement of SAW resonators (RS1, RS2, RS3) comprise a broadened section (BBCN). Each two series resonators (RS1, RS2, RS3) that are subsequent to each other in the series signal line are connected via a common busbar (BBCN) extending over a whole length of that subsequent series resonators, a lateral extension of the common busbars represents a first section of a respective shunt line each, each first shunt line section between a node and the parallel resonator (RP1, RP2) of a shunt line (SLS1) comprises a broadened section (BS) that is broader than the common busbar, the broadened section extends over the whole width of the parallel resonator (RP1), the first reflector (REF1) of the parallel resonator that faces the laterally adjacent series resonator is formed from the broadened section (BS).

Owner:RF360新加坡私人有限公司

Saw device including hybrid weighted reflective grating and hybrid weighted reflective grating

ActiveCN114268294BSuppress lateral clutterImprove frequency response characteristicsImpedence networksGratingEngineering

The invention relates to a SAW device including a hybrid weighted reflection grid and a hybrid weighted reflection grid, belonging to the technical field of radio frequency filtering, including a piezoelectric substrate, an interdigital transducer arranged on the piezoelectric substrate and two A hybrid weighted reflective grating, the hybrid weighted reflective grating includes a plurality of reflective grid electrodes distributed at equal intervals, and the length and width of the multiple reflective grid electrodes are all decreasing in a preset direction, and the preset direction is away from the interdigitated fingers The orientation of the transducer. It can be seen that in the present invention, the hybrid weighted reflective grid is set as a plurality of reflective grid electrodes distributed at equal intervals, and the length and width of the multiple reflective grid electrodes decrease gradually in the direction away from the interdigital transducer, thereby forming a width The hybrid weighting structure combining gradual weighting and apodization weighting can suppress the lateral clutter generated in the SAW device in a more compact structure, improve the clutter suppression performance, and improve the frequency response characteristics of the SAW device, thereby improving its Q value .

Owner:深圳新声半导体有限公司

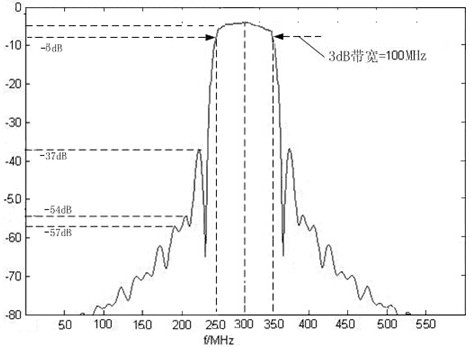

A kind of three-dimensional structure gain compensation type saw device and its preparation method

ActiveCN106100603BSolve the disadvantages of large insertion lossReduce volumeImpedence networksHemt circuitsGain

The invention discloses a stereoscopic structured gain compensation type SAW device and a preparation method. The stereoscopic structured gain compensation type SAW device comprises an input interdigital transducer and an output interdigital transducer, and is characterized in that both the input interdigital transducer and the output interdigital transducer are attached onto the surface of a piezoelectric material; the input interdigital transducer and the output interdigital transducer are in coupled connection through SAW; the output interdigital transducer and a matched compensation amplifying circuit are in conductor line connection; the disadvantage that the insertion loss of a SAW filter or a SAW resonator or a SAW delay line is high in prior art can be solved; and thus, the problems of poor consistency, repeatability and reliability, difficult debugging and the like due to external circuit compensation of devices traditionally can be solved.

Owner:GUIZHOU MINZU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com