Structure of surface acoustic wave device on basis of flexible substrate and manufacturing method of surface acoustic wave device

A technology of surface acoustic wave devices and flexible substrates, applied in the direction of electrical components, impedance networks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

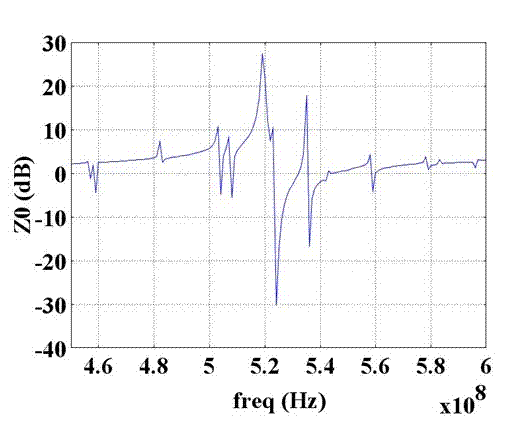

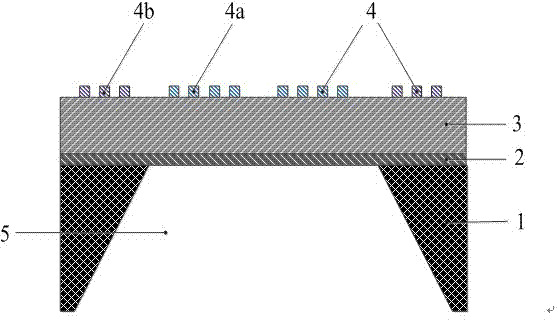

[0041] A polyimide substrate is used as a flexible substrate, the bottom electrode layer is an aluminum metal layer, the piezoelectric layer is a single-layer aluminum nitride piezoelectric film, and the electrode layer is only equipped with an interdigital transducer, which is one input and output Fork-value electrode pairs, no reflection grid is set, because the reflection grid only enhances the detection signal of the surface acoustic wave, and will not affect the excitation of the surface acoustic wave. No reflection grid is set in the simulation. Comsol multiphysics software was used to carry out finite element simulation analysis on the embodiment. The flexible substrate material used was polyimide with a thickness of 100 μm, which was placed under the left and right sides of the bottom electrode layer, each with a width of 2 μm; the bottom electrode layer used It is a 100 nm aluminum metal layer with a width of 20 μm in a suspended voltage state; the piezoelectric layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com