Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1721 results about "Composite substrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

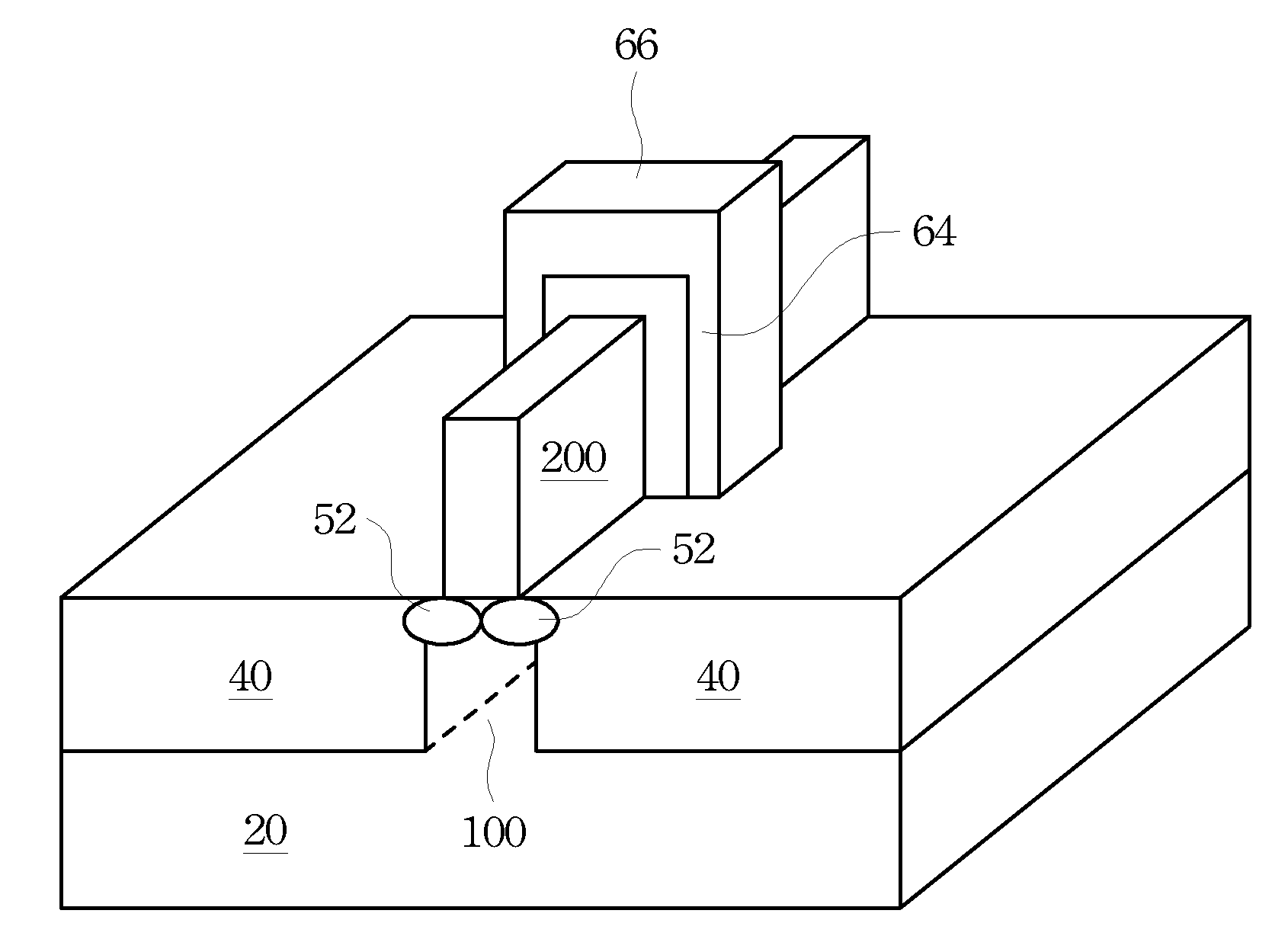

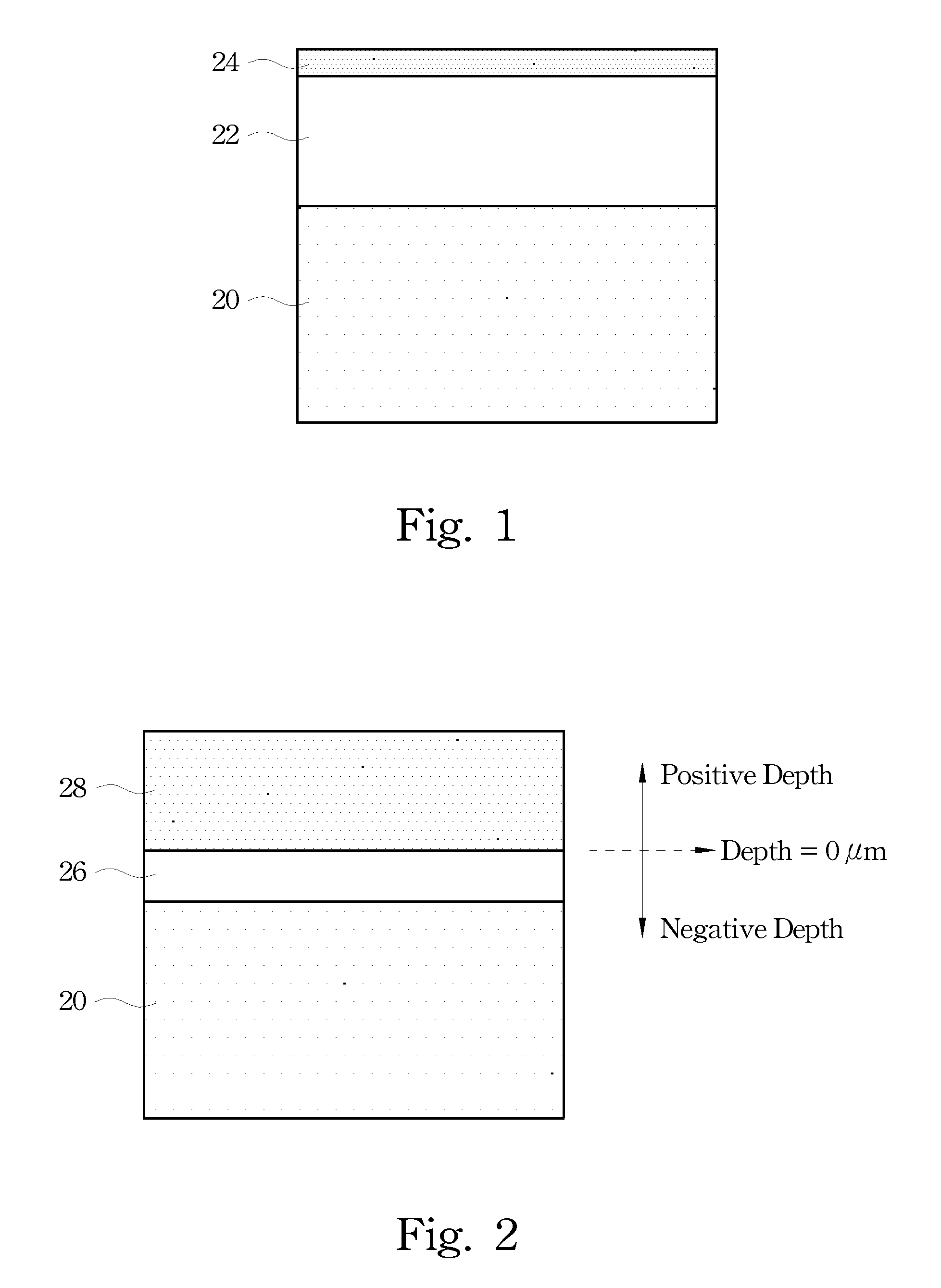

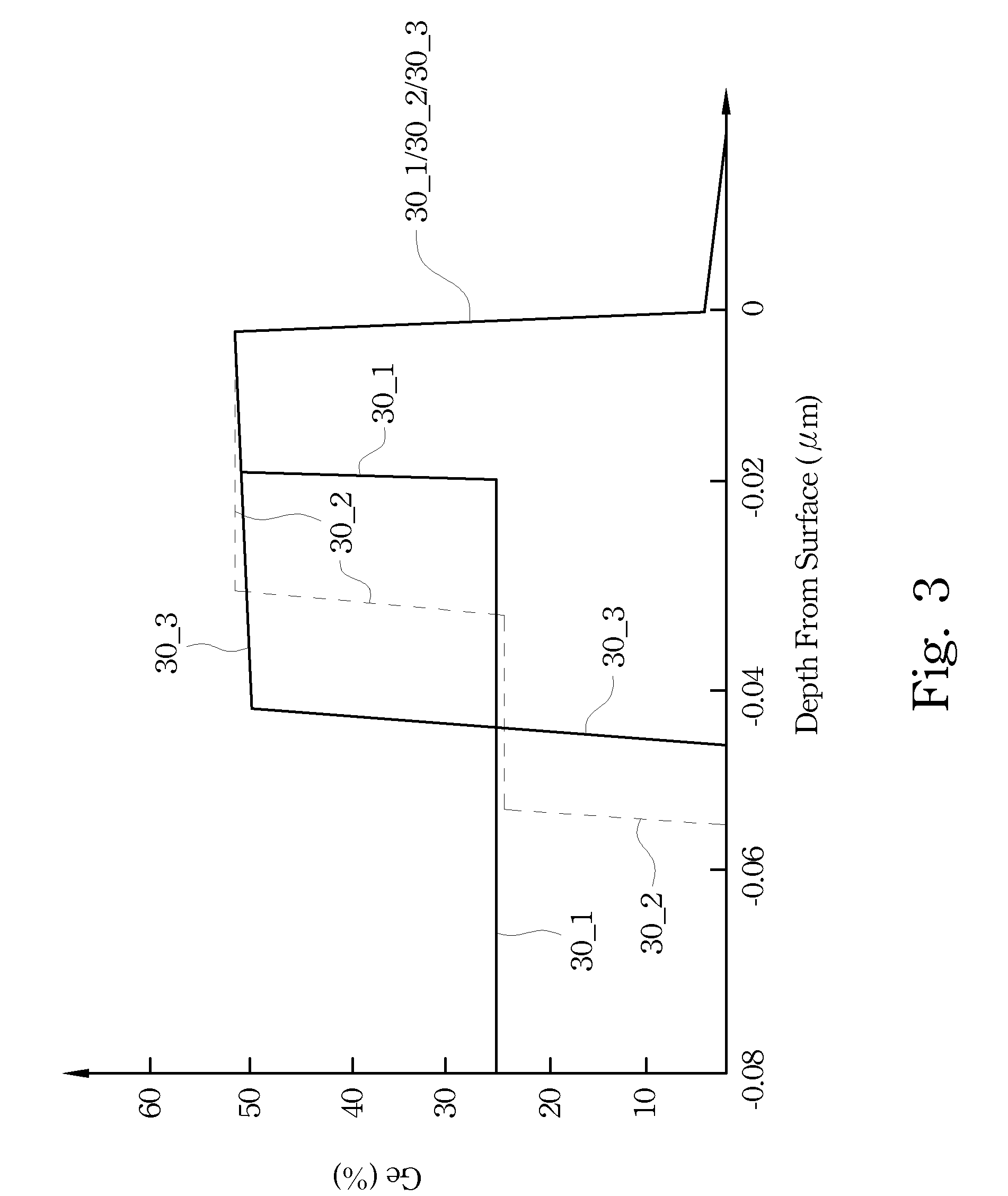

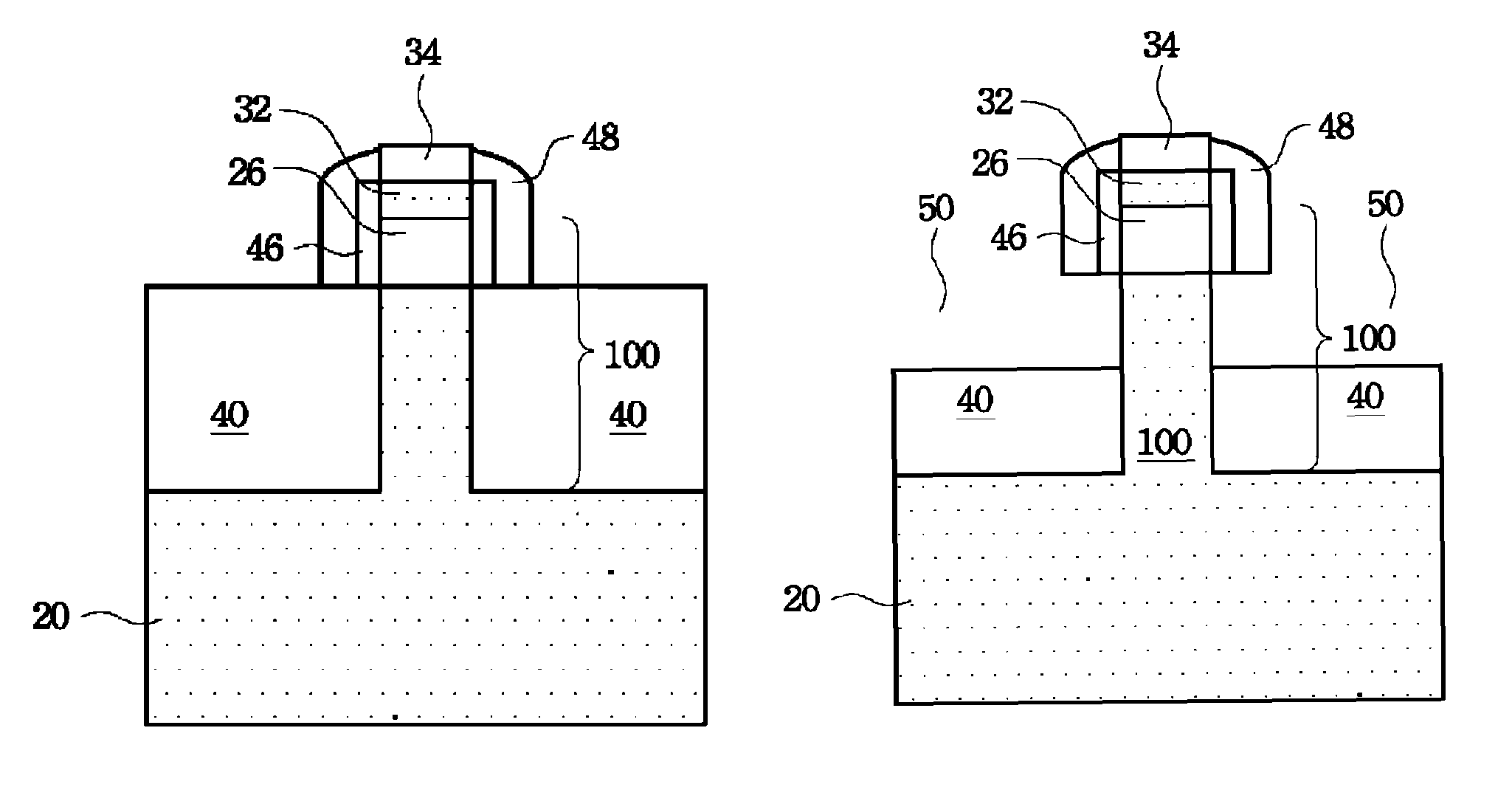

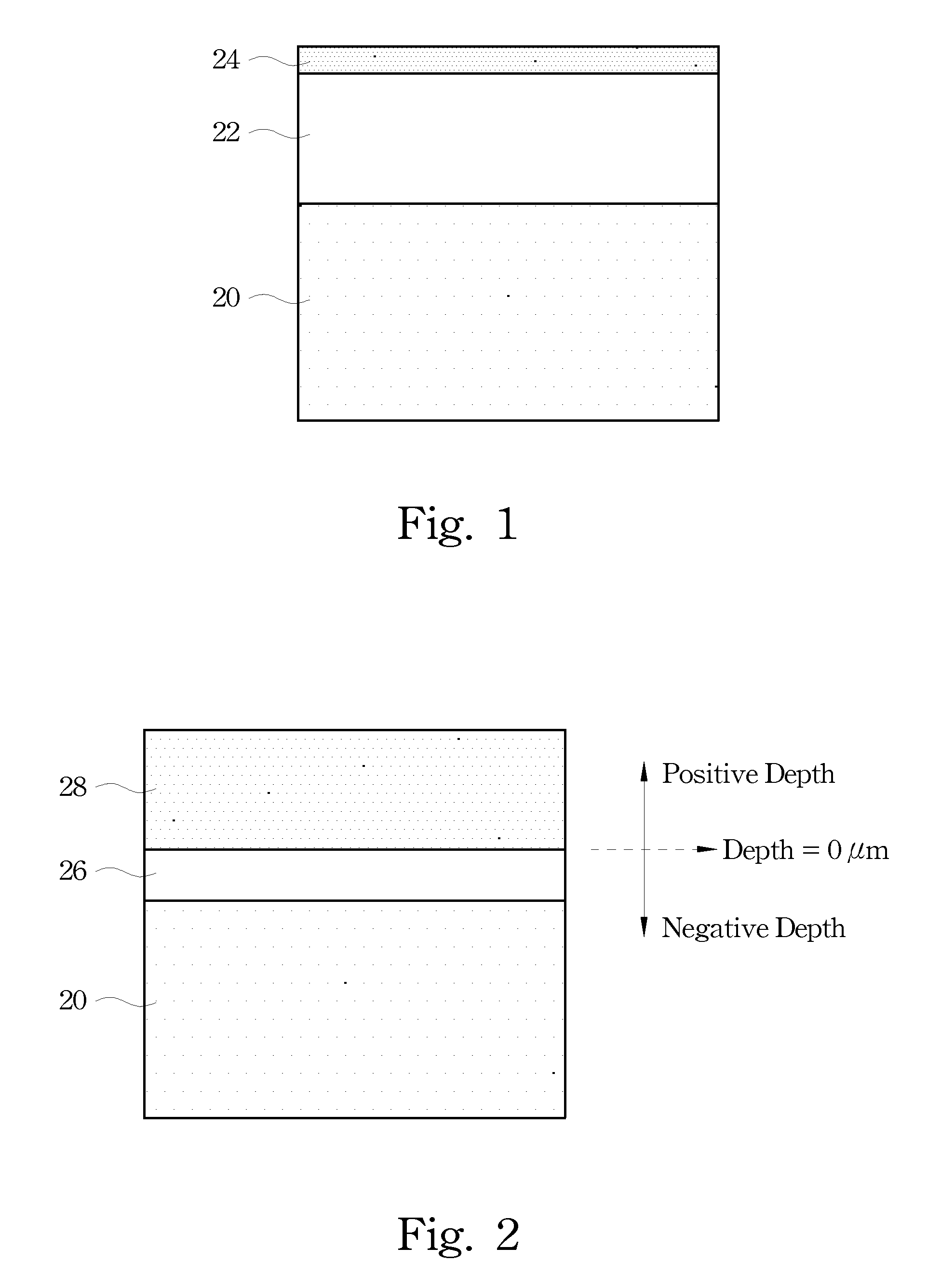

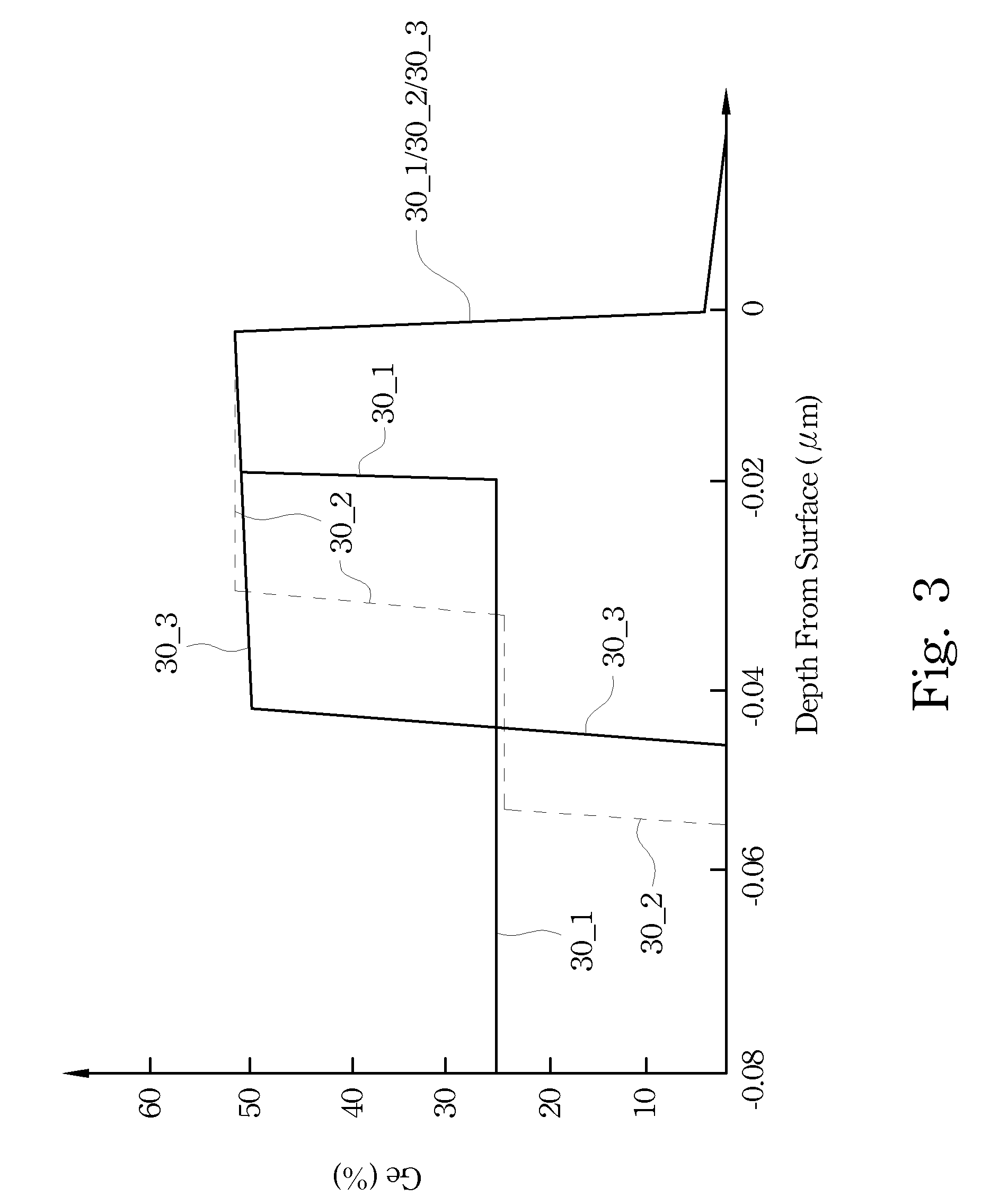

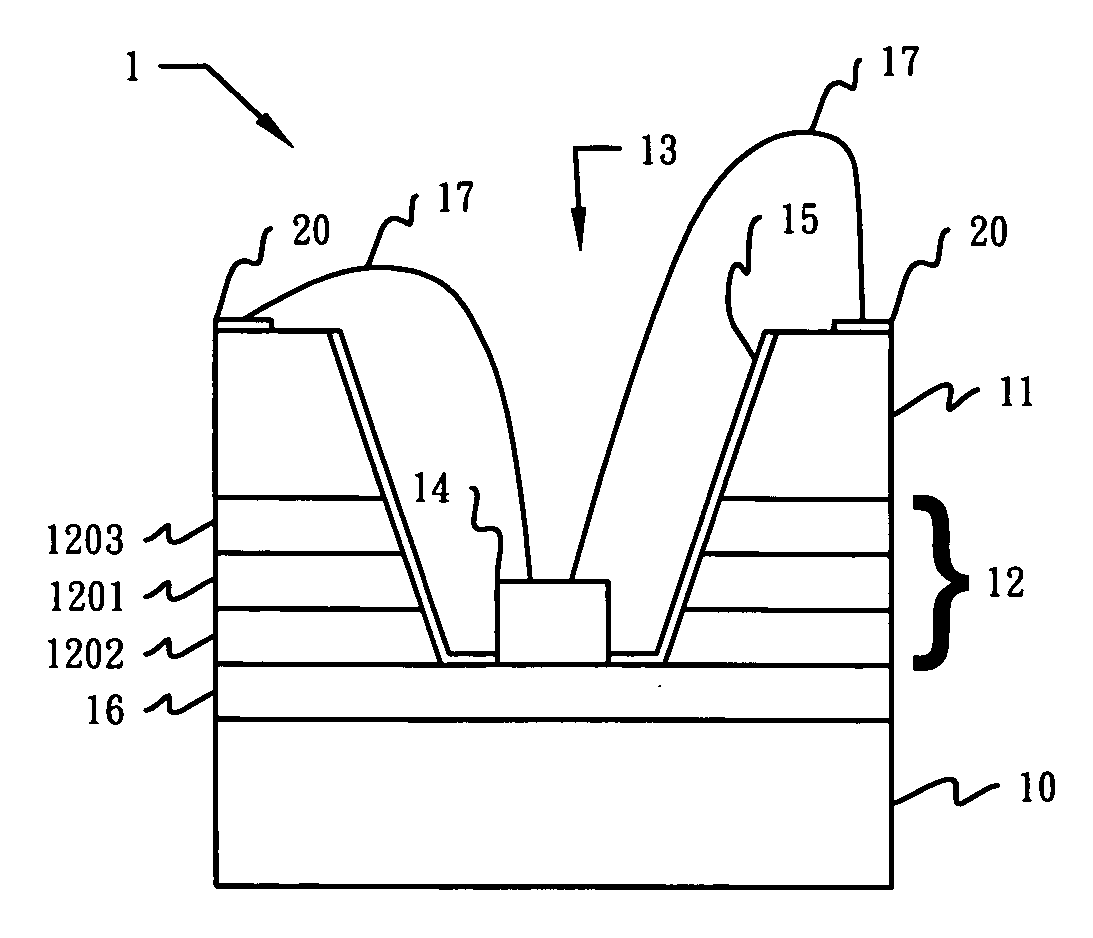

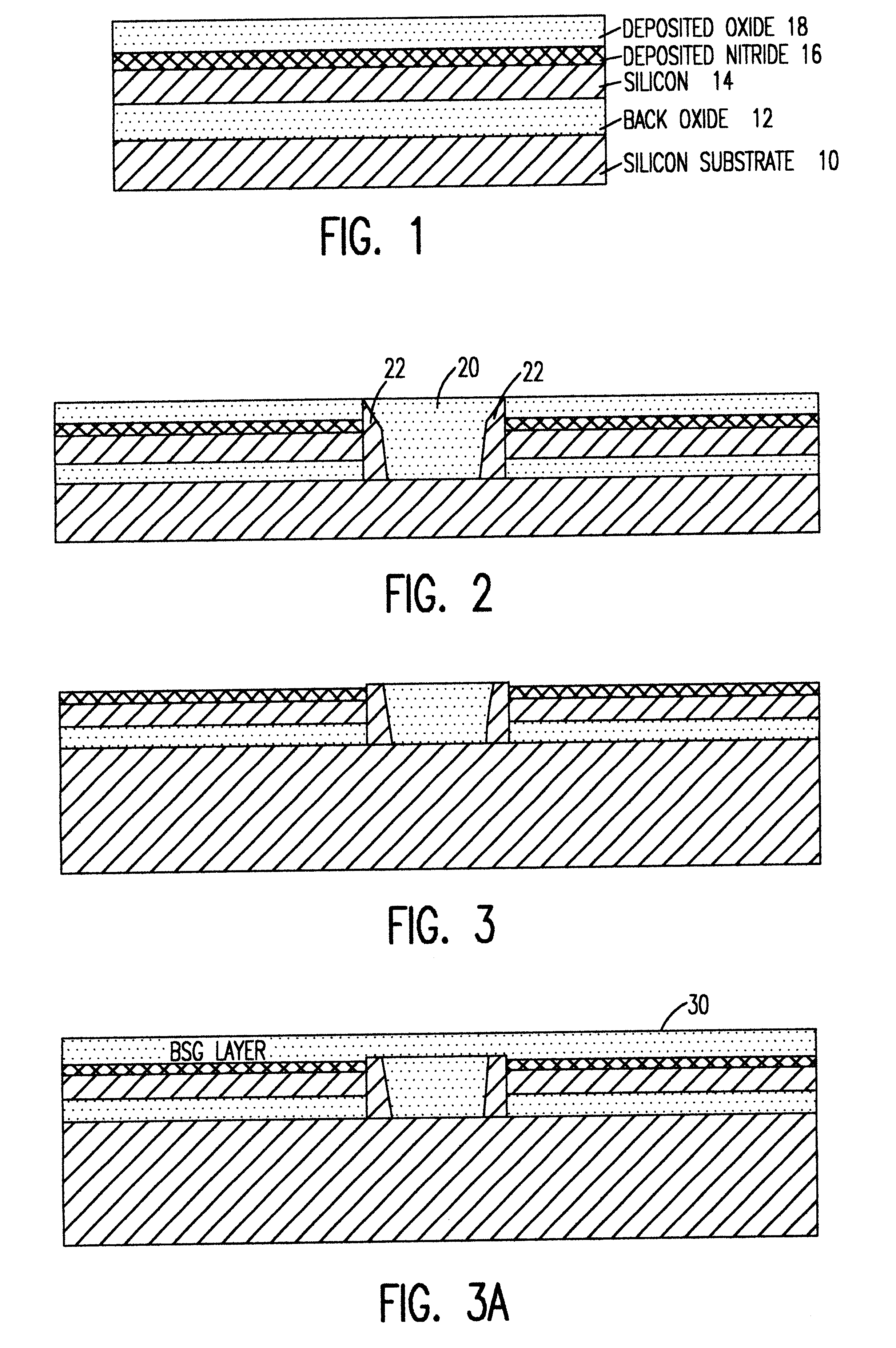

Germanium FinFETs Having Dielectric Punch-Through Stoppers

ActiveUS20100144121A1Total current dropHigh carrier mobilitySemiconductor/solid-state device manufacturingSemiconductor devicesComposite substrateSemiconductor structure

A method of forming a semiconductor structure includes providing a composite substrate, which includes a bulk silicon substrate and a silicon germanium (SiGe) layer over and adjoining the bulk silicon substrate. A first condensation is performed to the SiGe layer to form a condensed SiGe layer, so that the condensed SiGe layer has a substantially uniform germanium concentration. The condensed SiGe layer and a top portion of the bulk silicon substrate are etched to form a composite fin including a silicon fin and a condensed SiGe fin over the silicon fine. The method further includes oxidizing a portion of the silicon fin; and performing a second condensation to the condensed SiGe fin.

Owner:TAIWAN SEMICON MFG CO LTD

Germanium FinFETs having dielectric punch-through stoppers

InactiveUS8048723B2High carrier mobilityTotal current dropSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureComposite substrate

A method of forming a semiconductor structure includes providing a composite substrate, which includes a bulk silicon substrate and a silicon germanium (SiGe) layer over and adjoining the bulk silicon substrate. A first condensation is performed to the SiGe layer to form a condensed SiGe layer, so that the condensed SiGe layer has a substantially uniform germanium concentration. The condensed SiGe layer and a top portion of the bulk silicon substrate are etched to form a composite fin including a silicon fin and a condensed SiGe fin over the silicon fine. The method further includes oxidizing a portion of the silicon fin; and performing a second condensation to the condensed SiGe fin.

Owner:TAIWAN SEMICON MFG CO LTD

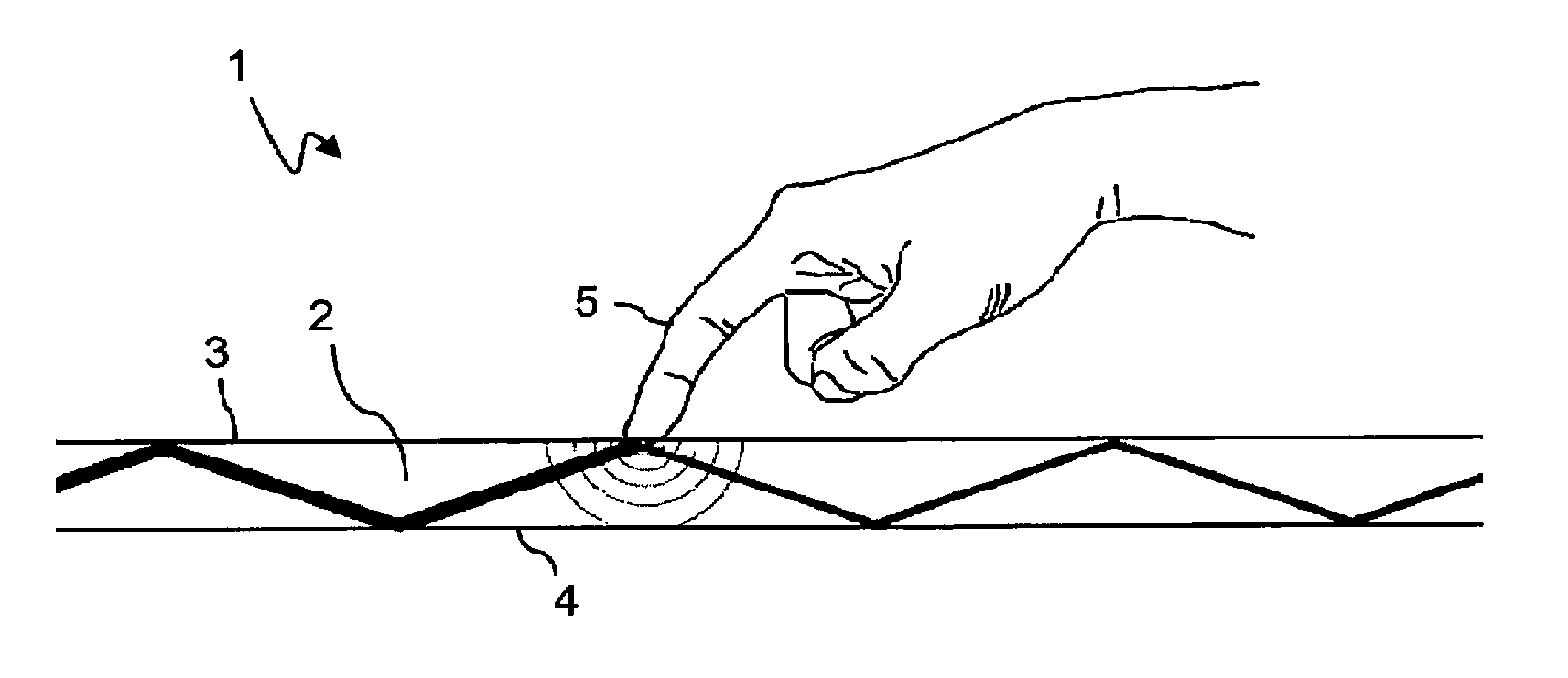

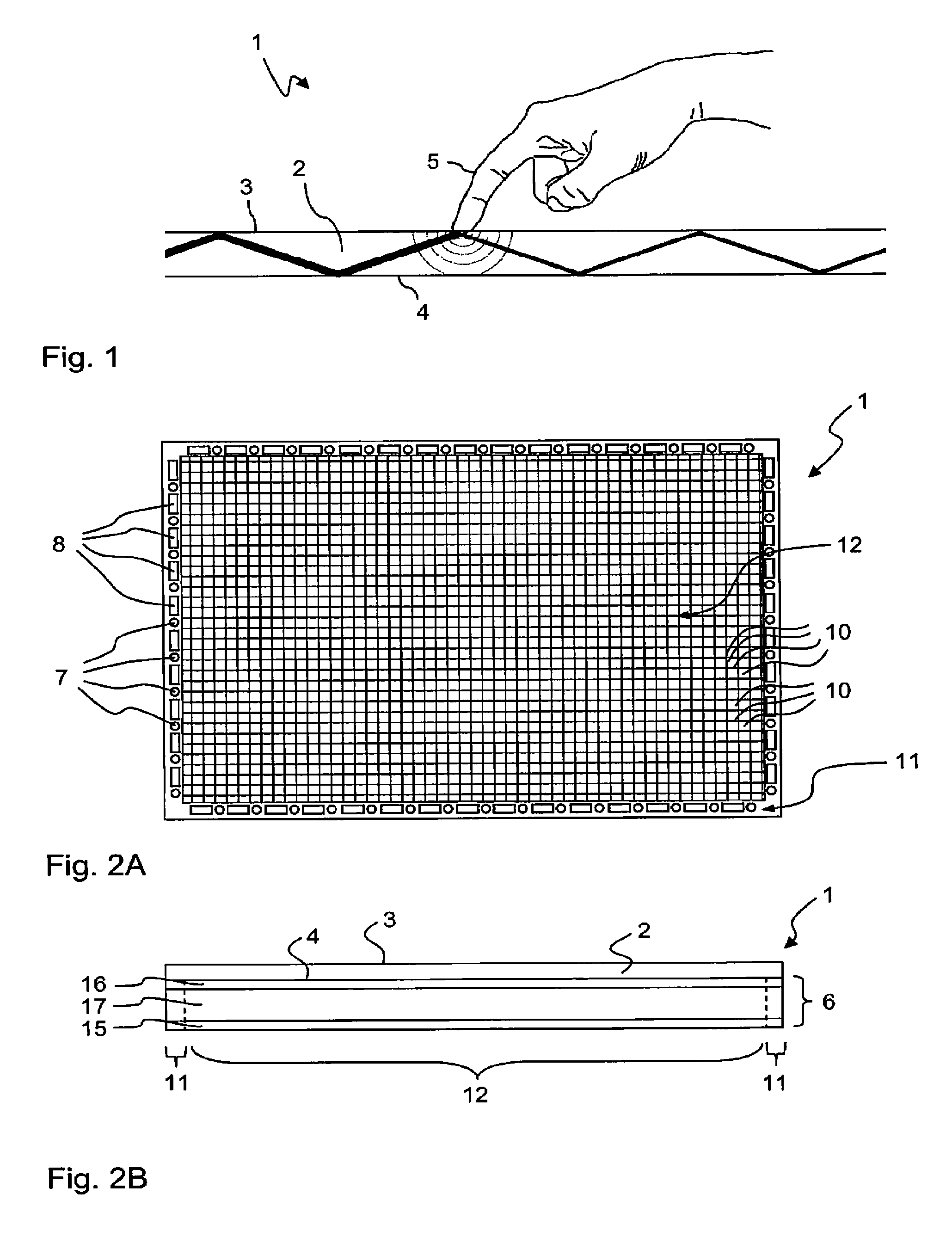

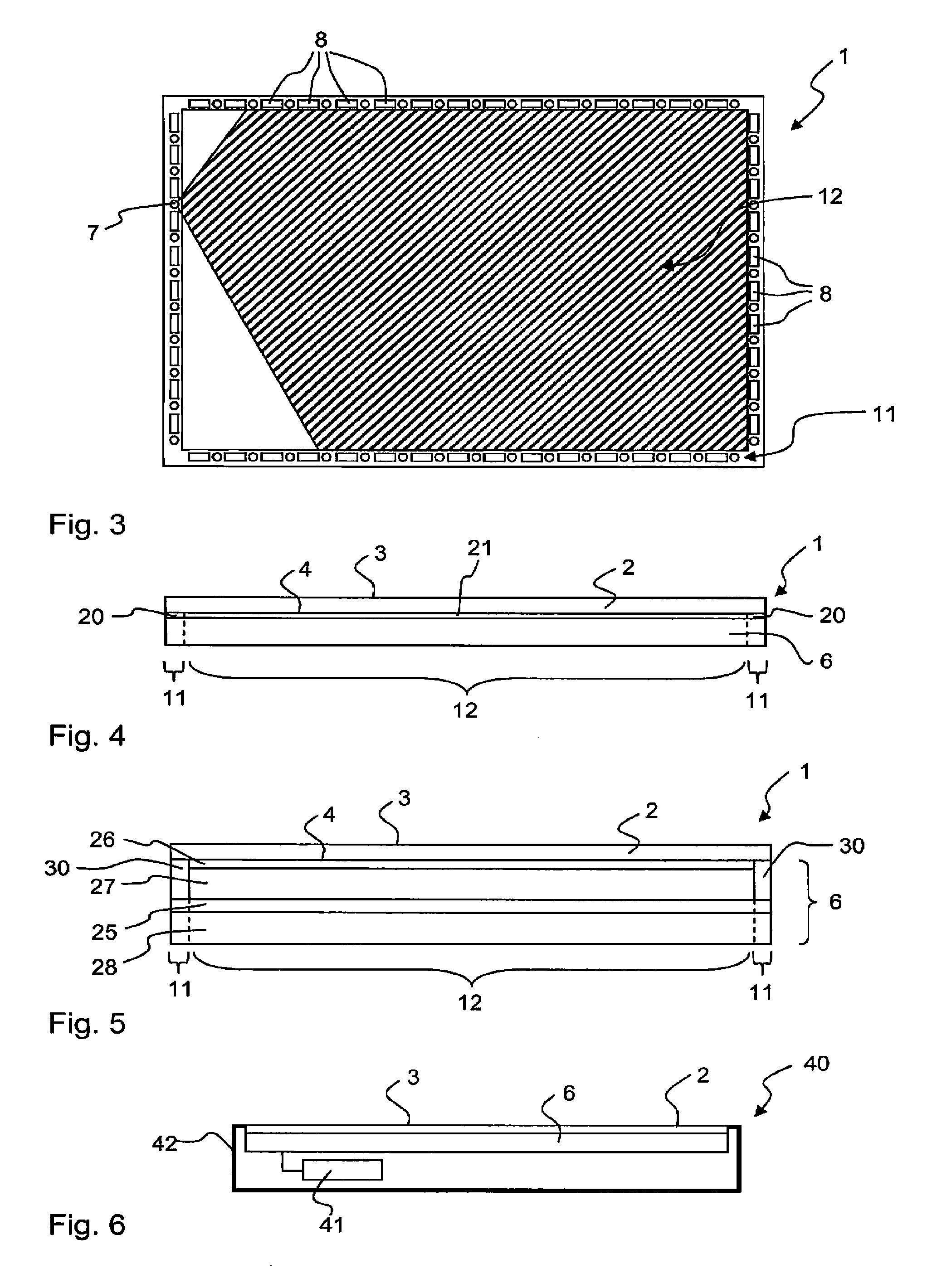

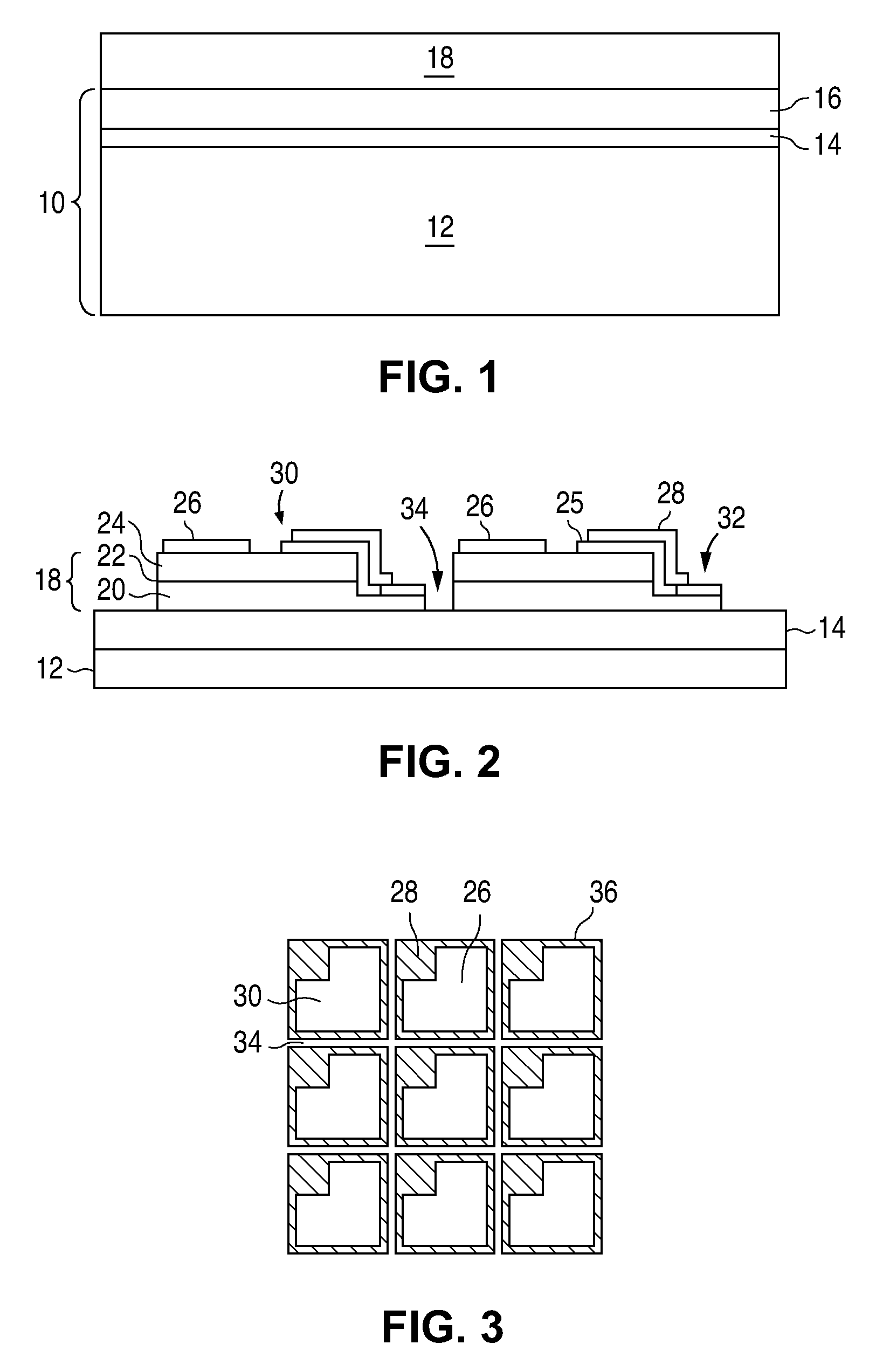

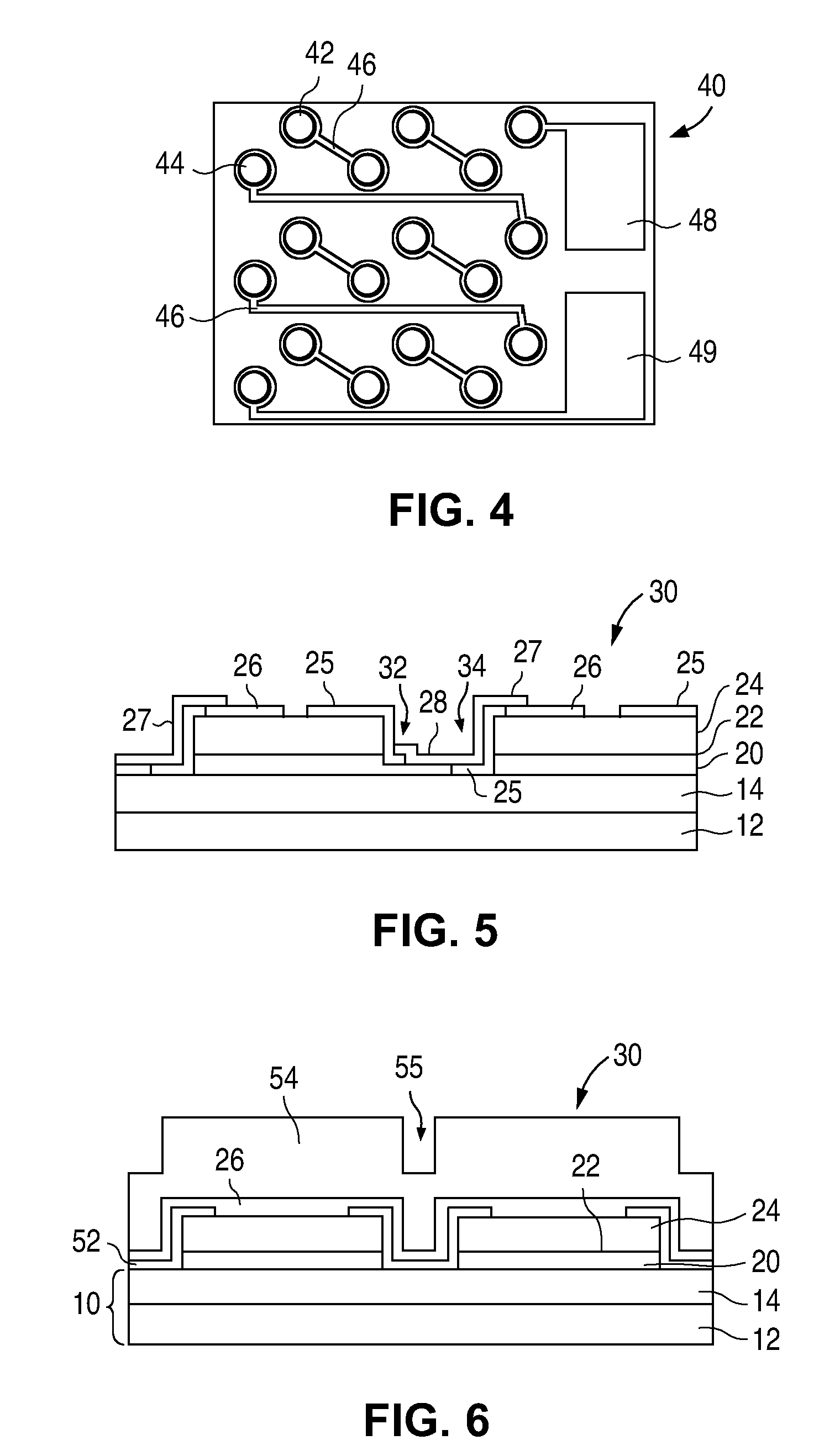

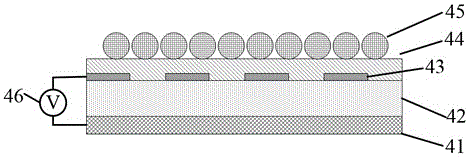

Touch-sensing display apparatus and electronic device therewith

InactiveUS20130021300A1Reduce thicknessInput/output processes for data processingTotal internal reflectionTouch Senses

A touch-sensing display apparatus comprises a display unit with integrated elements, and a planar light guide located in front of the display unit so as to define a touch surface. At least one light emitter is arranged to emit light into the light guide for propagation by total internal reflection inside the light guide, and at least one light detector is arranged to receive at least part of the light propagating inside the light guide. The integrated elements are designed as image-forming elements and touch-sensor elements, wherein the touch-sensor elements comprise the emitter(s) and / or the detector(s) and are arranged along a periphery region of the display unit. The image-forming elements and the touch-sensor elements may be integrated in one and the same composite substrate within the display unit.

Owner:FLATFROG LAB

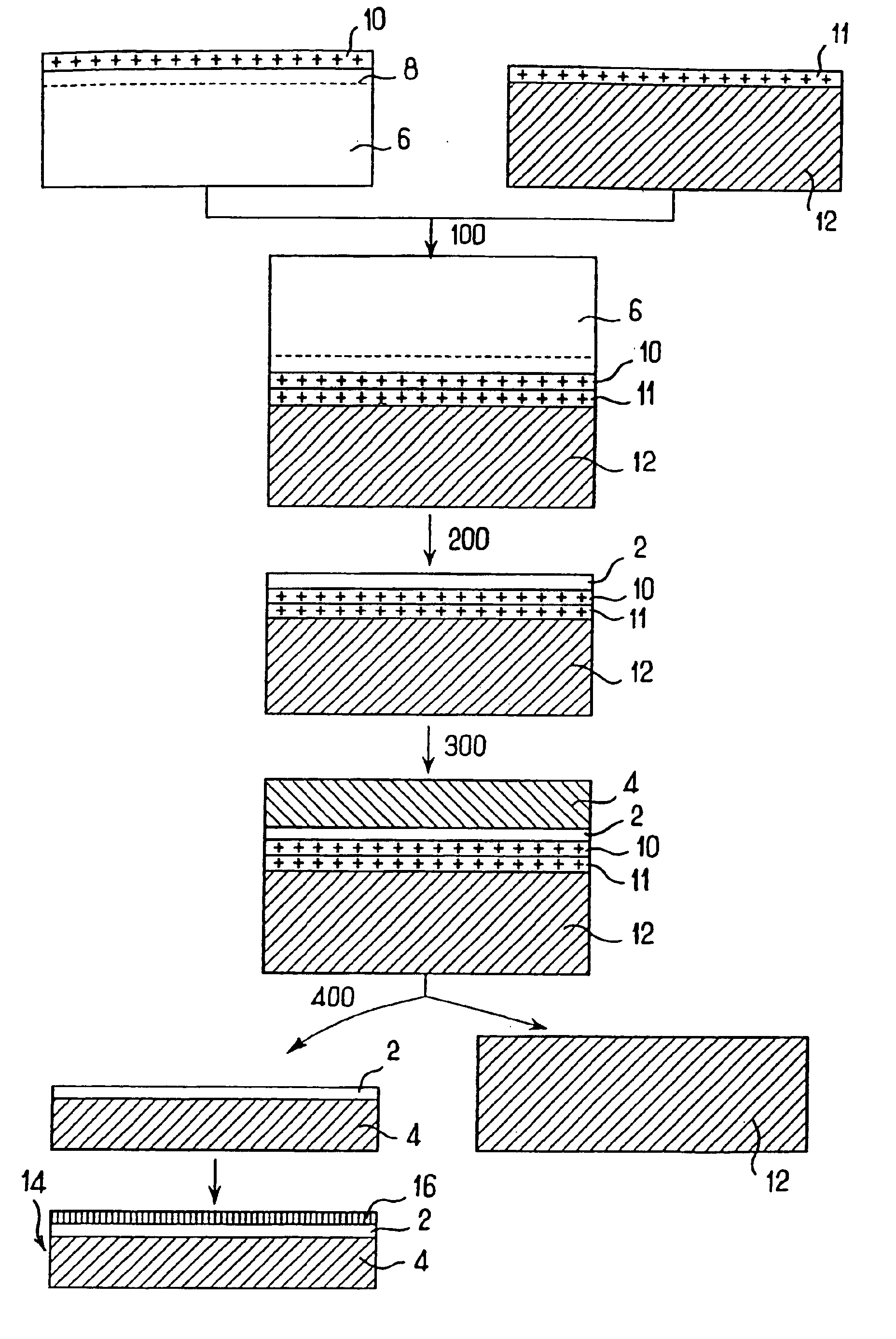

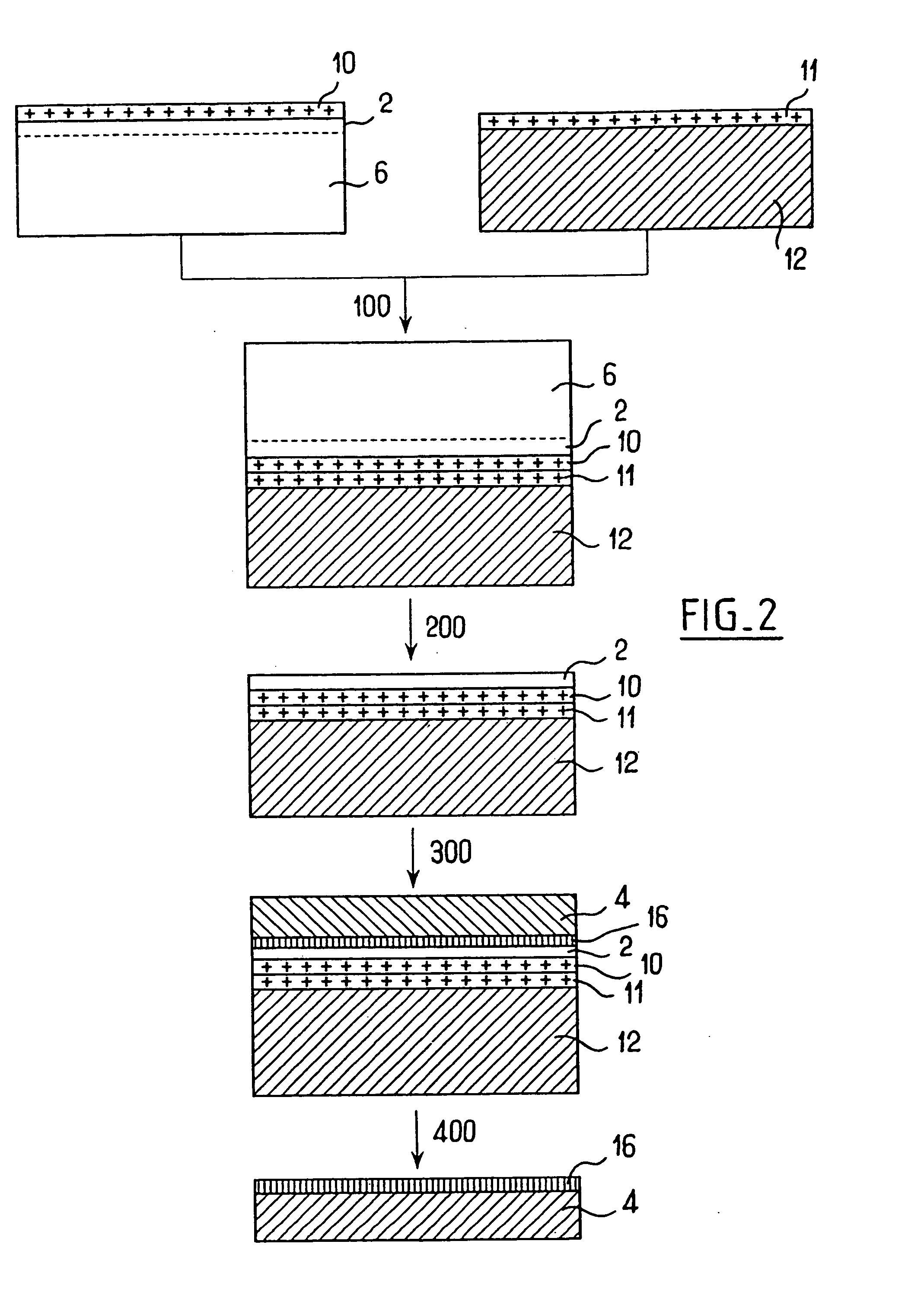

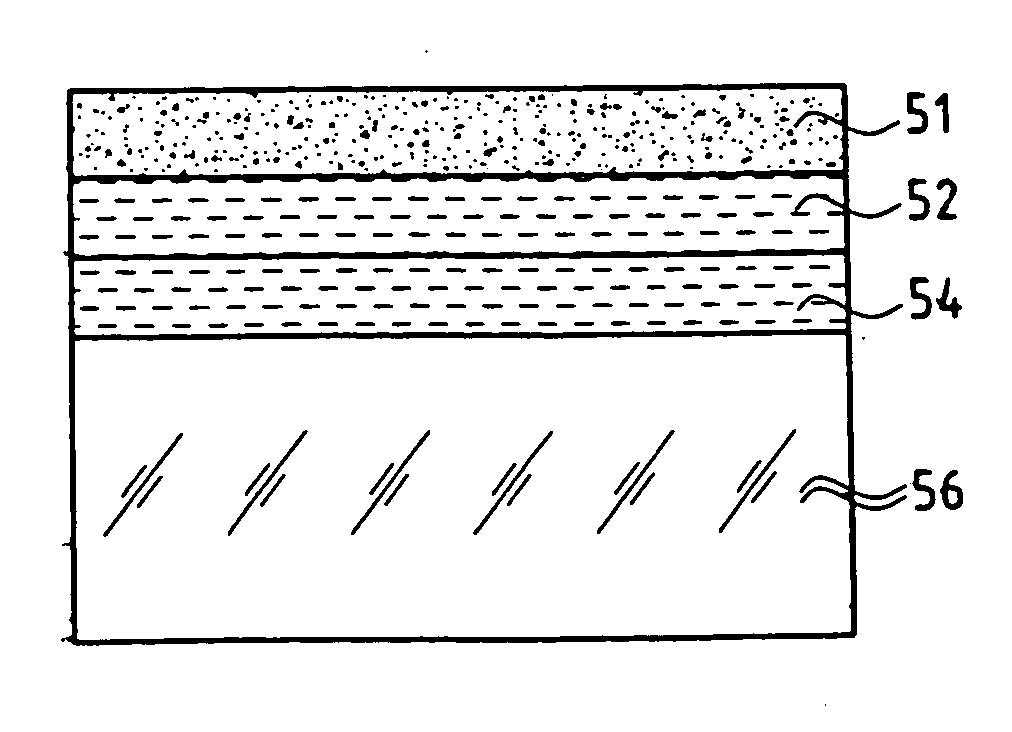

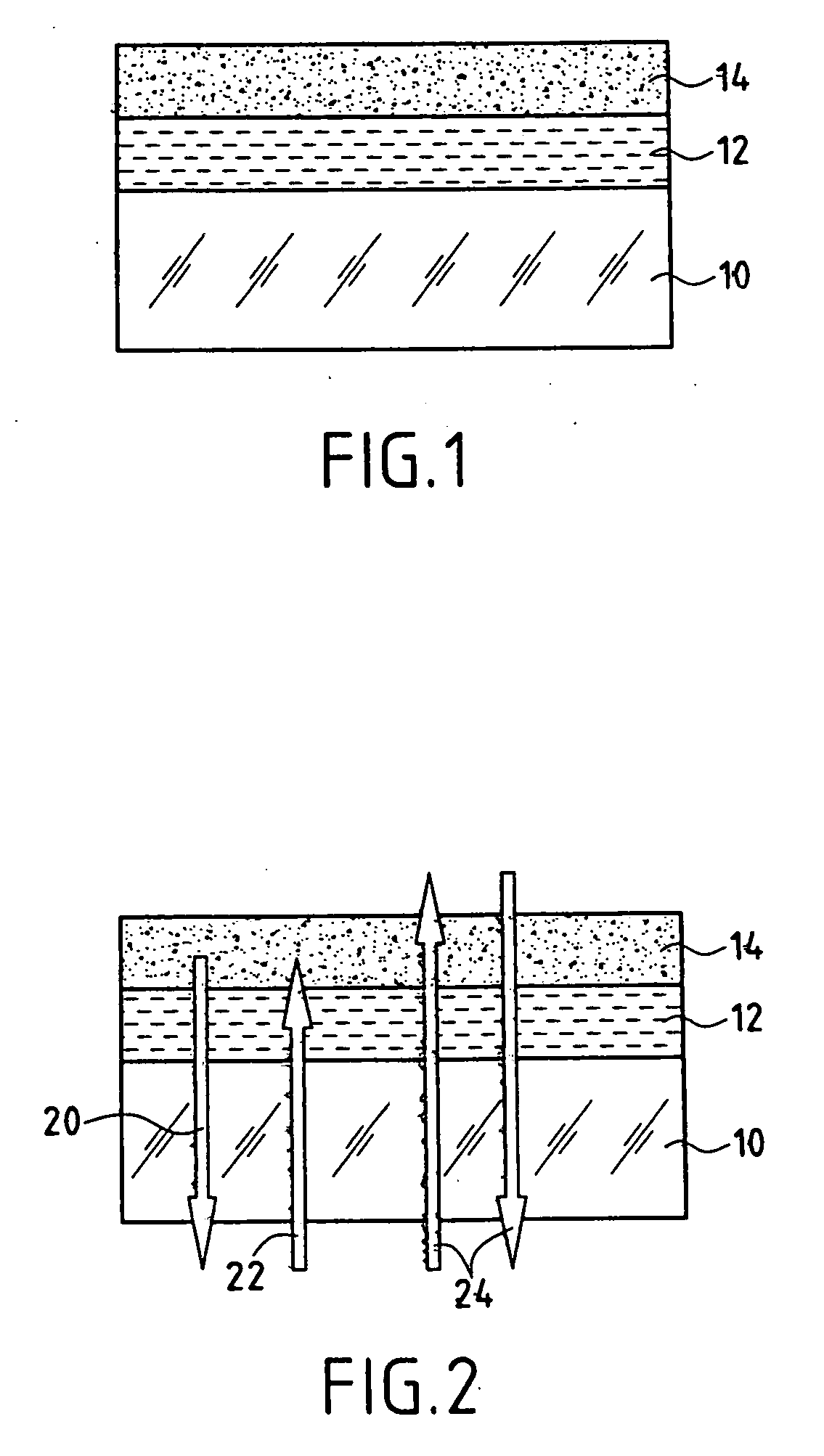

Methods for fabricating final substrates

InactiveUS6867067B2Solid-state devicesSemiconductor/solid-state device manufacturingComposite substrateOptoelectronics

Methods for fabricating final substrates for use in optics, electronics, or optoelectronics are described. In an embodiment, the method includes forming a zone of weakness beneath a surface of a source substrate to define a transfer layer, and forming a first bonding layer on the source substrate surface. A second bonding layer may be formed on a surface of an intermediate support, and the exposed surfaces of the first and second bonding layers joined to form a composite substrate. Next, the source substrate is detached from the composite substrate along the zone of weakness to expose a surface of the transfer layer, and a support material is deposited onto the exposed surface of the transfer layer. The transfer layer and support material are then separated from the composite substrate by elimination of at least the first bonding layer to form the final substrate. The zone of weakness may advantageously be formed by implanting atomic species into the source substrate.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

Electronic device with composite substrate

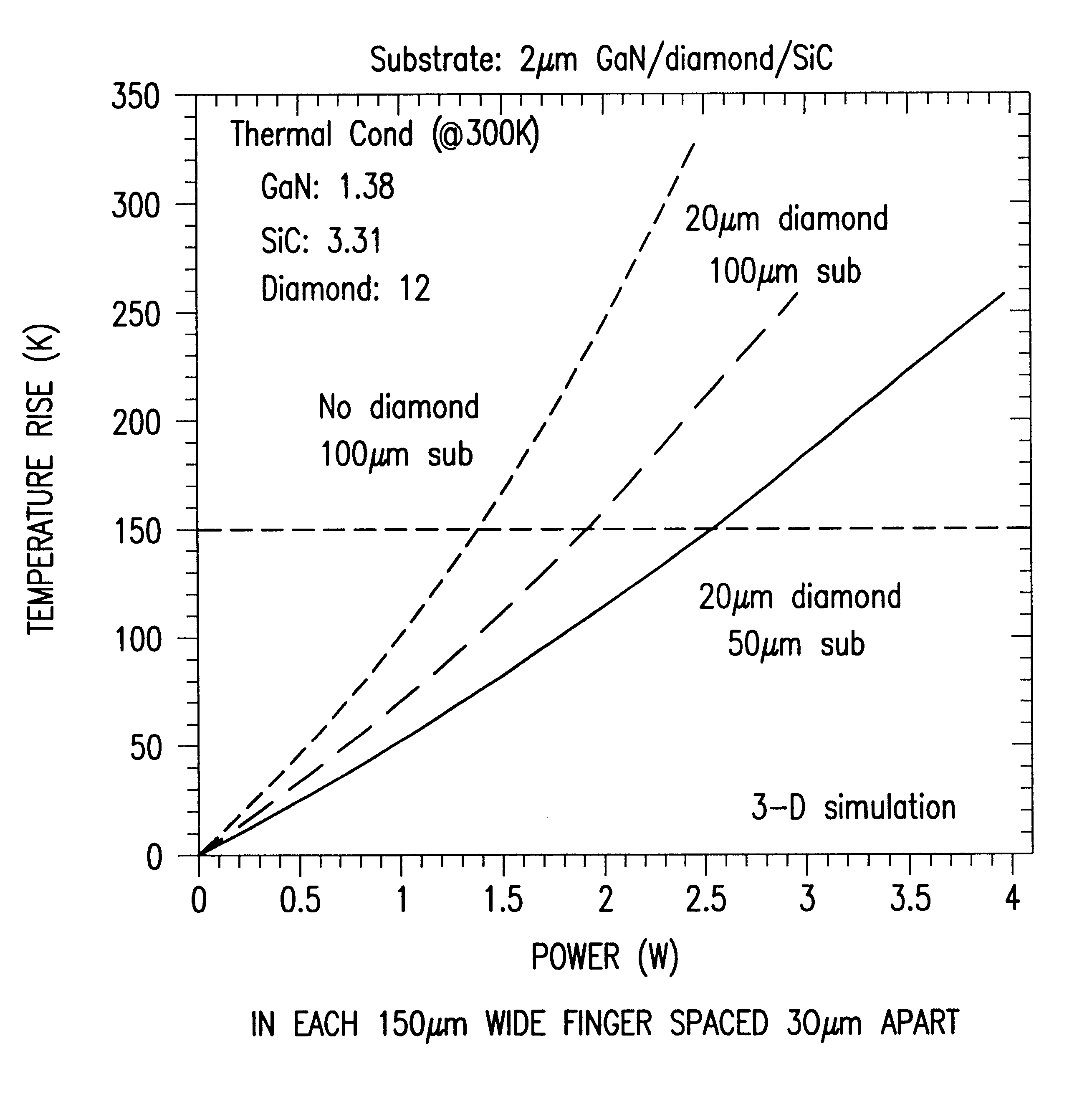

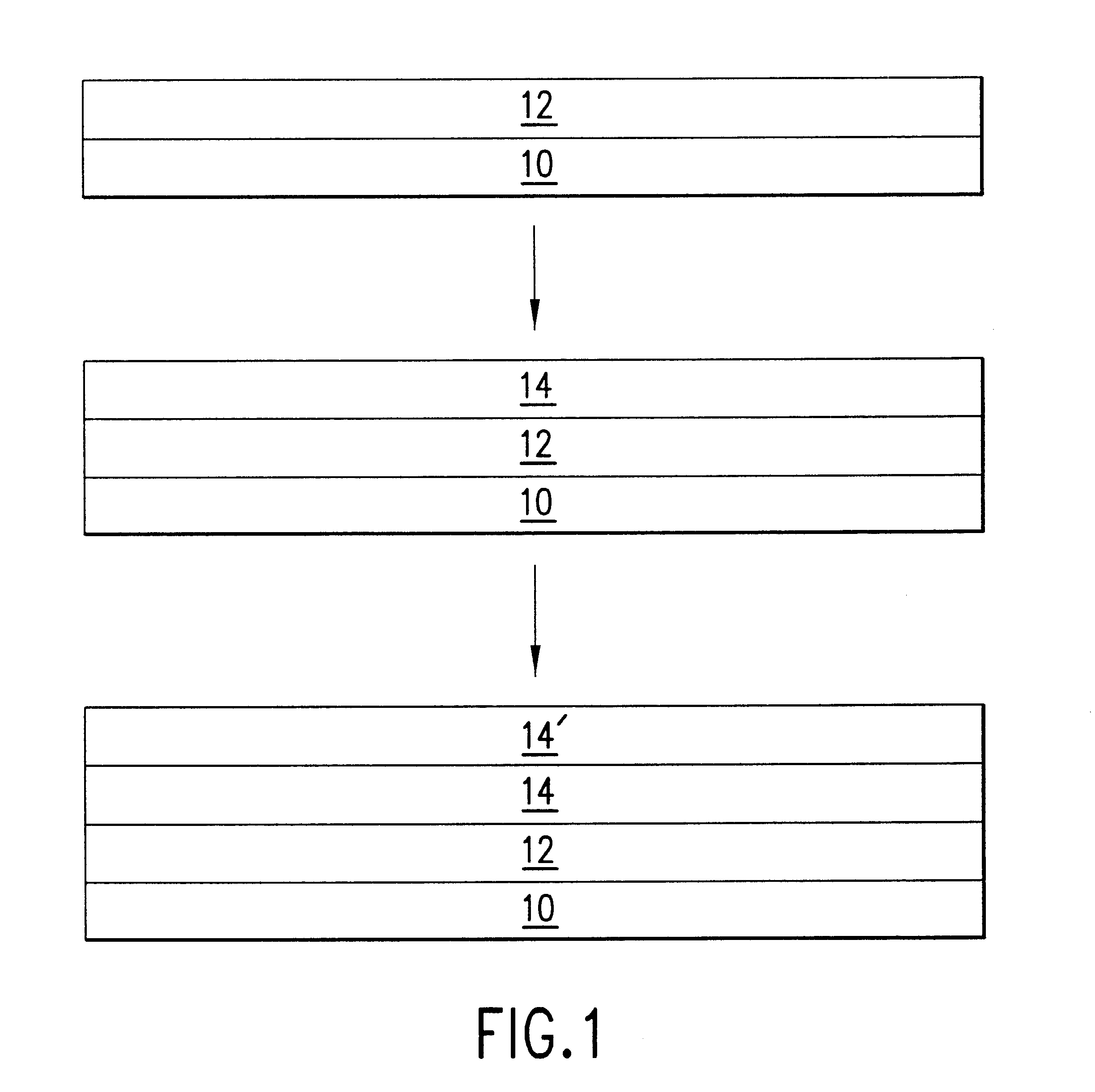

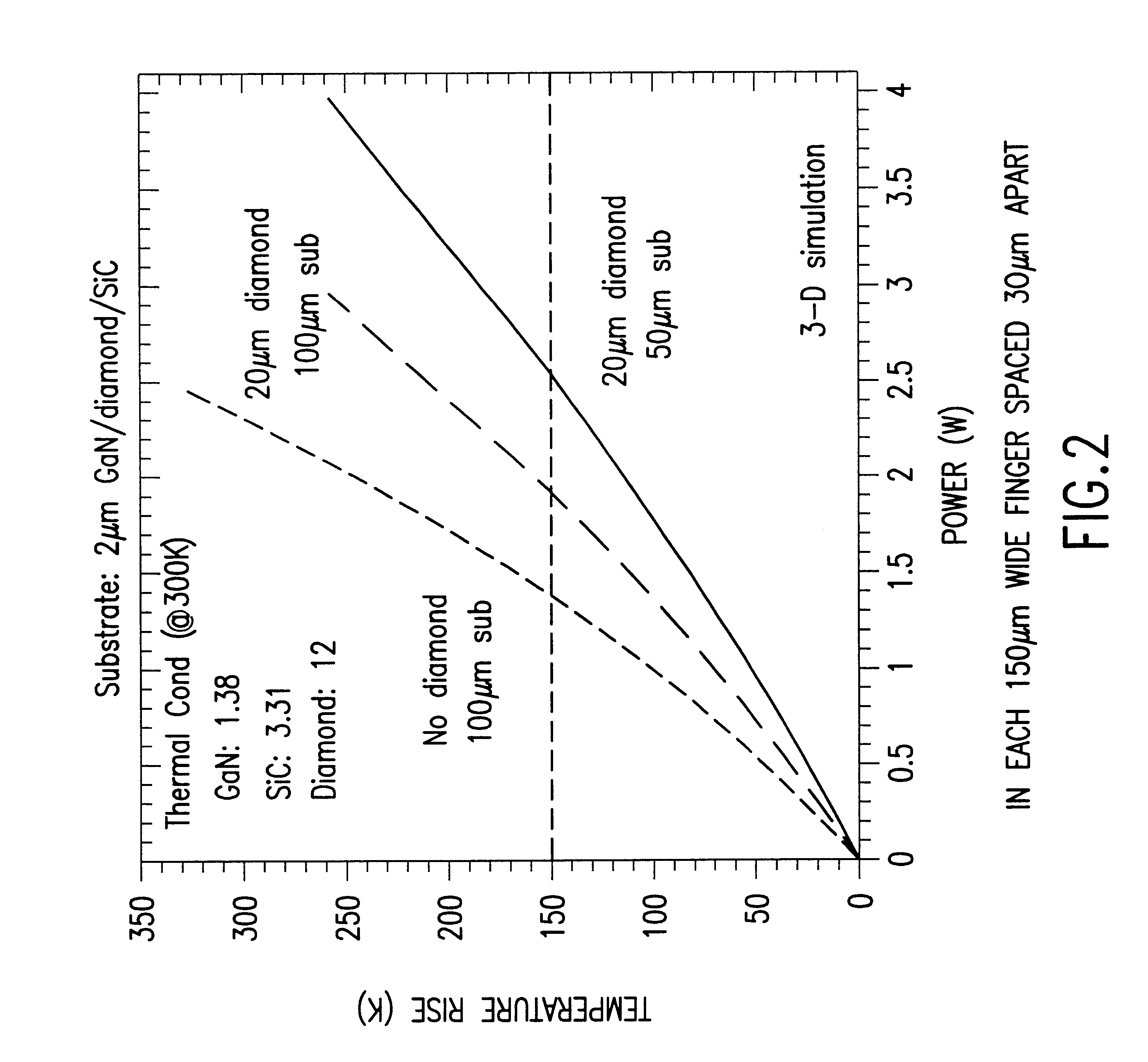

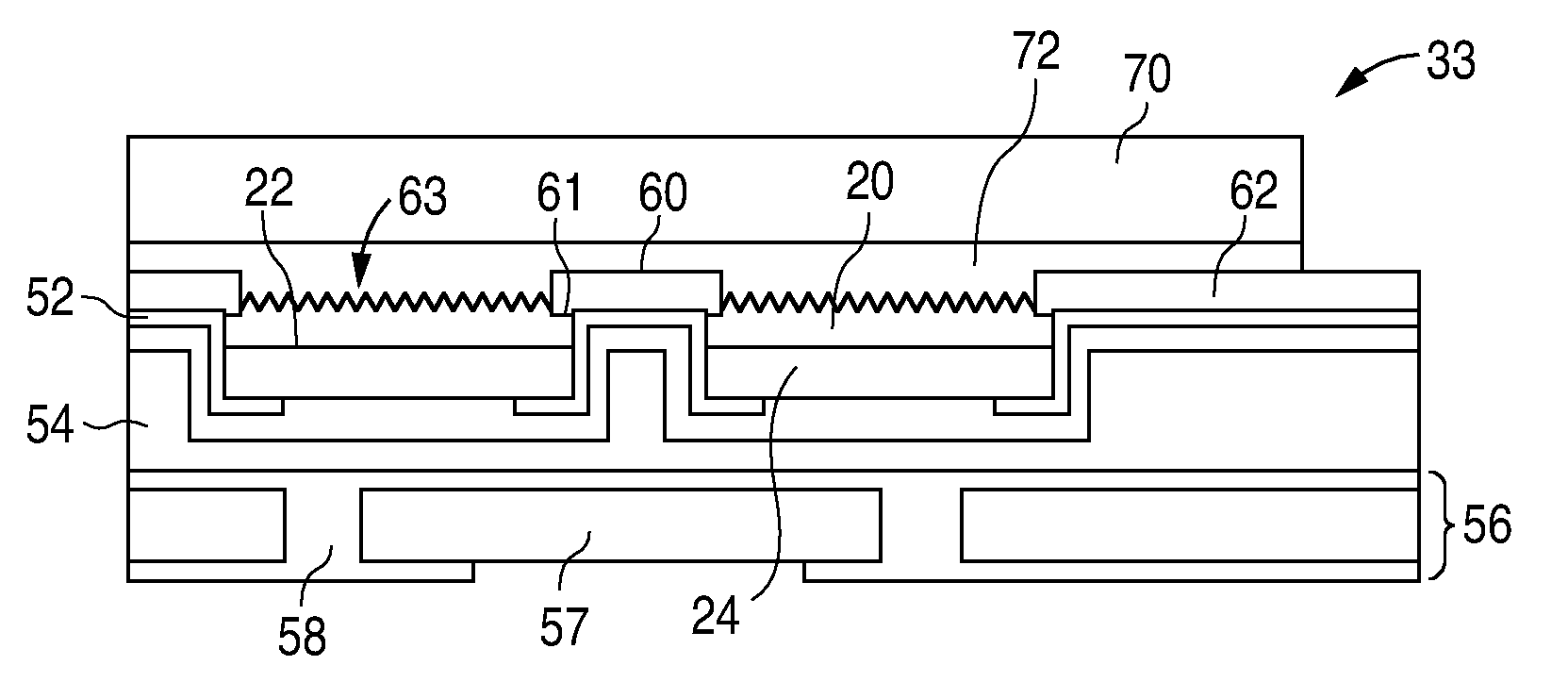

InactiveUS6497763B2Improve scalabilityImprove electronic performancePolycrystalline material growthSemiconductor/solid-state device manufacturingThermal coefficientComposite substrate

A method for making a multilayered electronic device with at least one epitaxial layer grown on a single-crystal film bonded to a composite wherein at least one layer is polycrystalline, the method includes the step of bonding a single-crystal film at least one of the epitaxial layers on the single-crystal film wherein thermal coefficients of expansion for the substrate and the epitaxial layer are closely matched.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

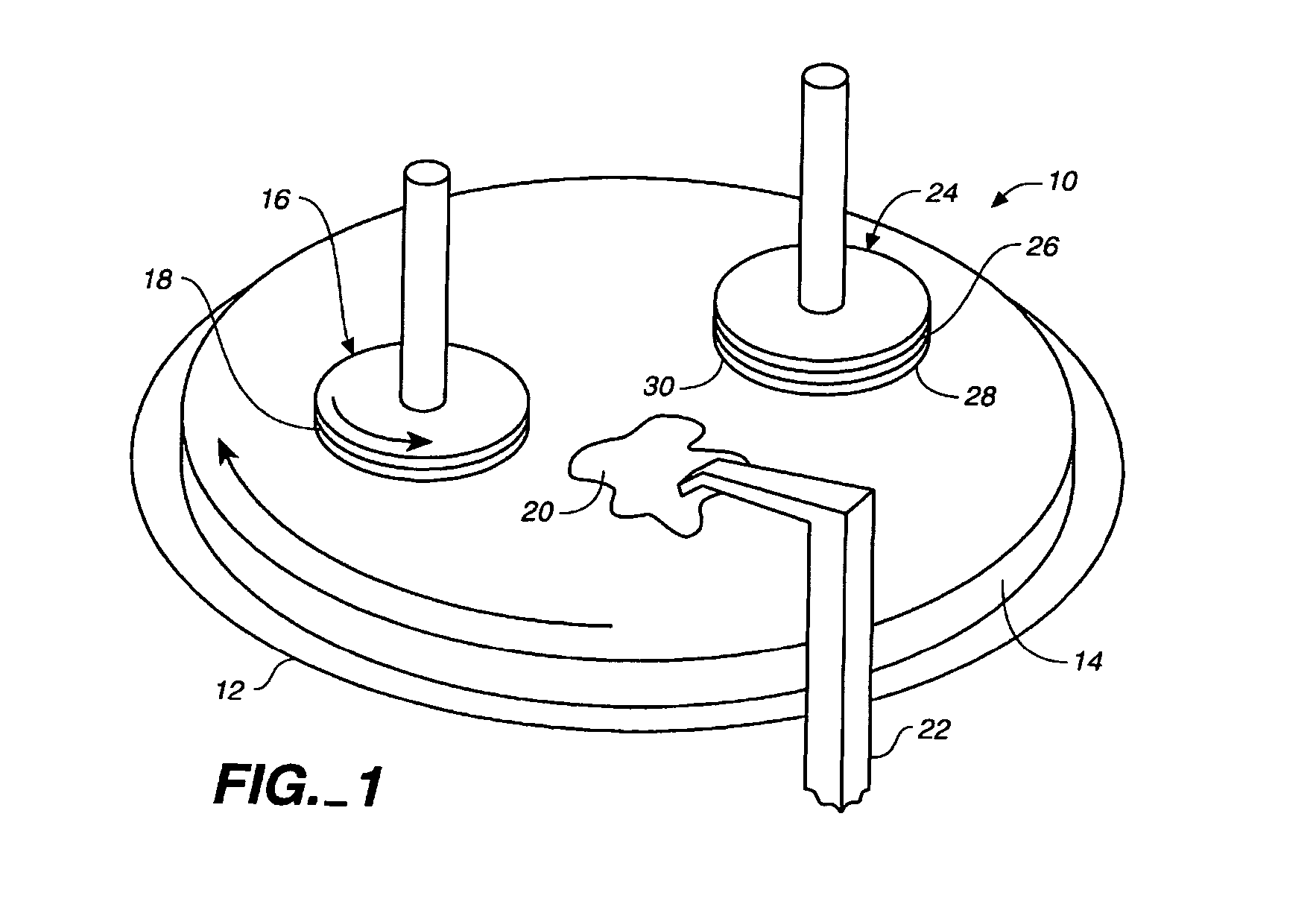

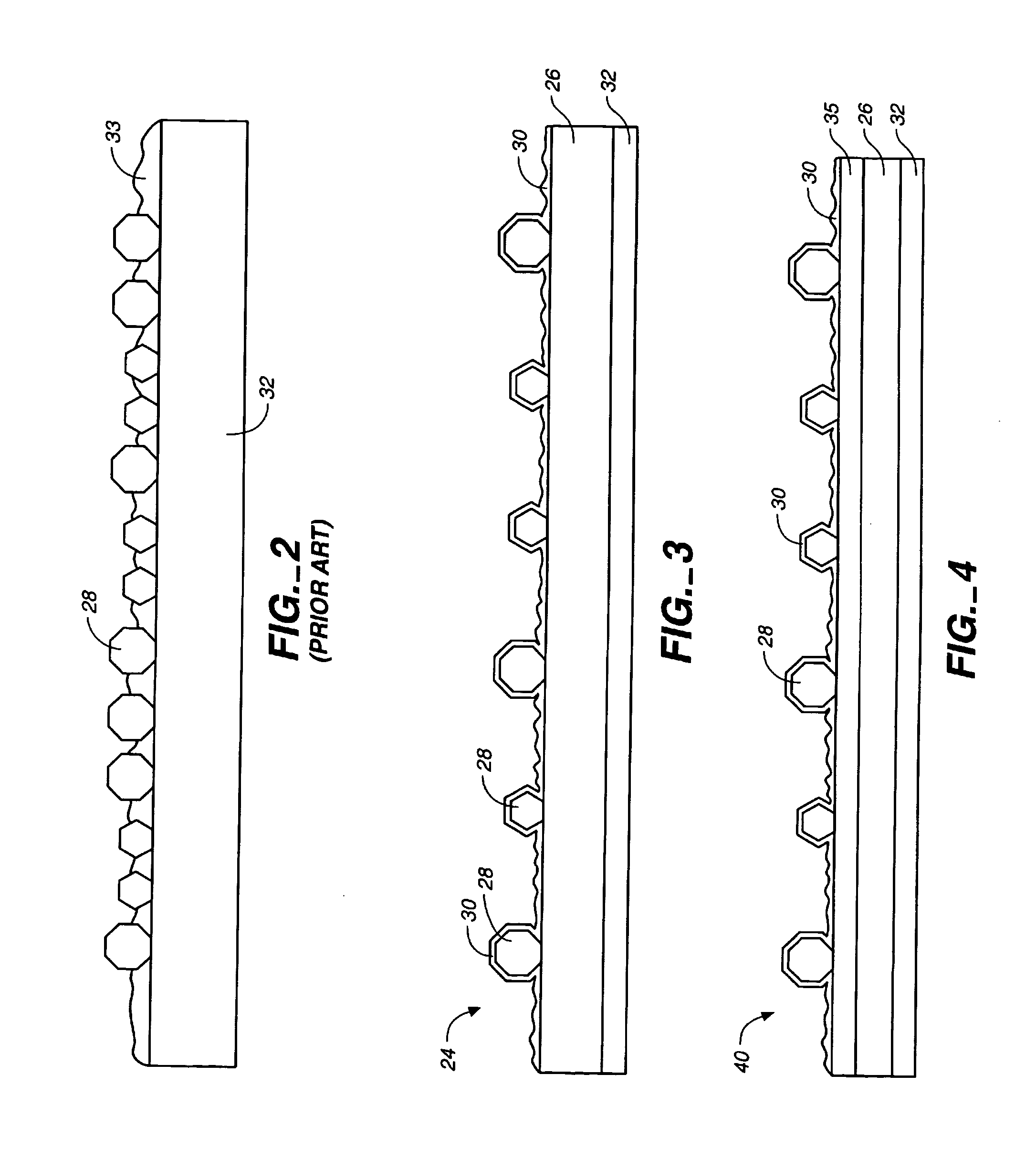

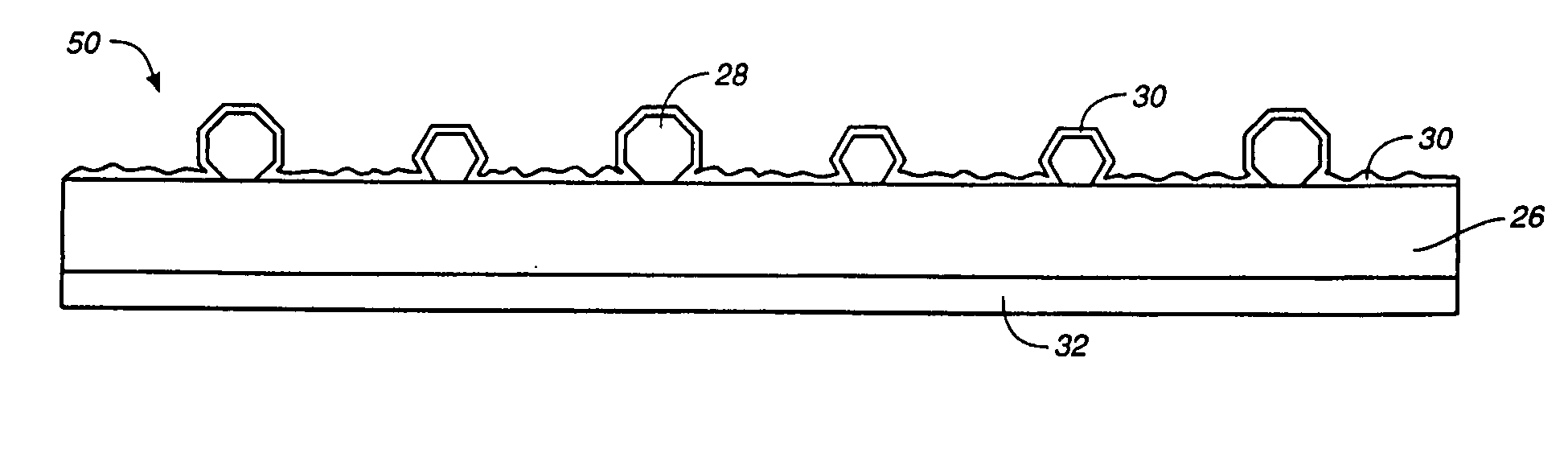

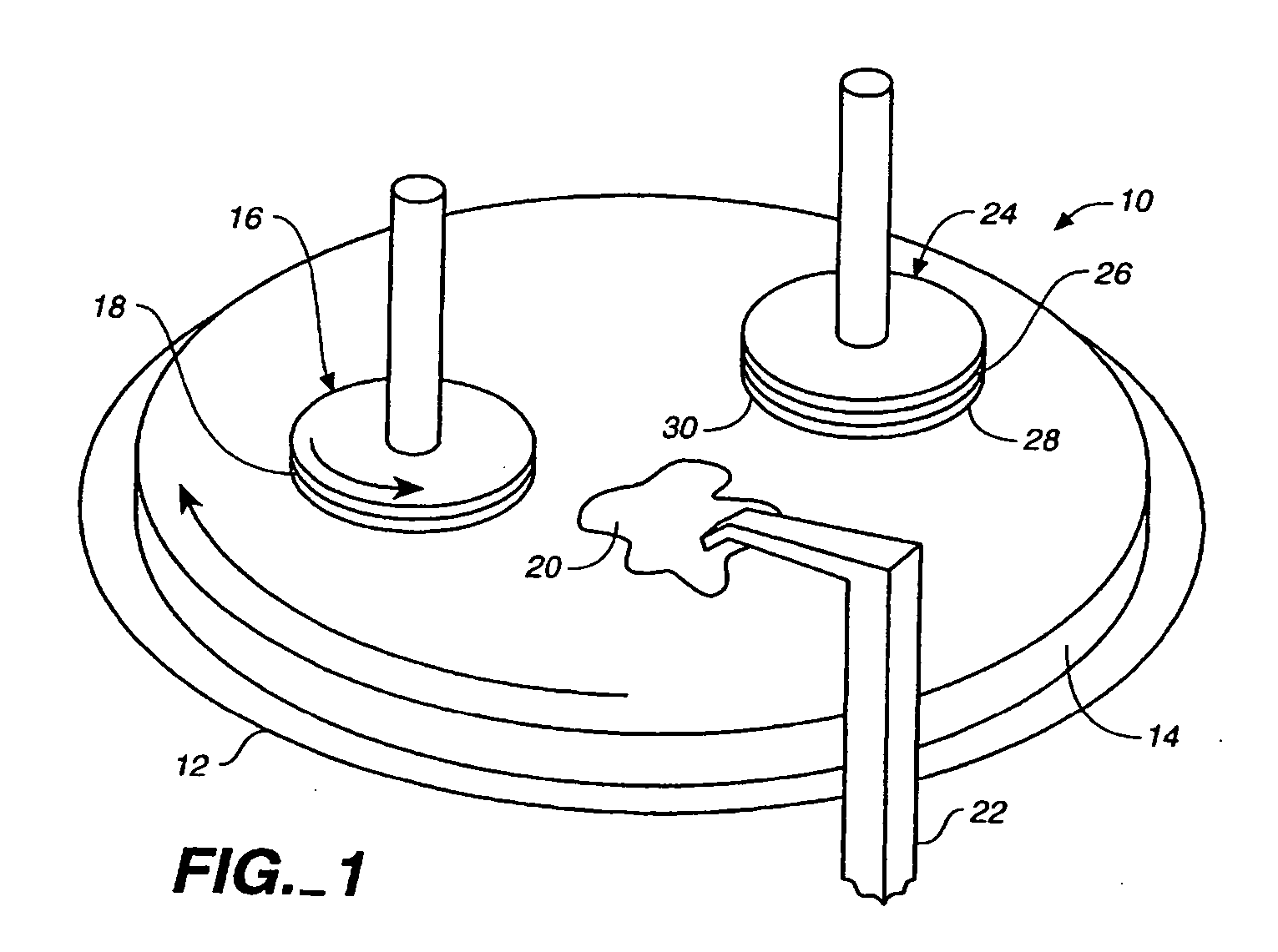

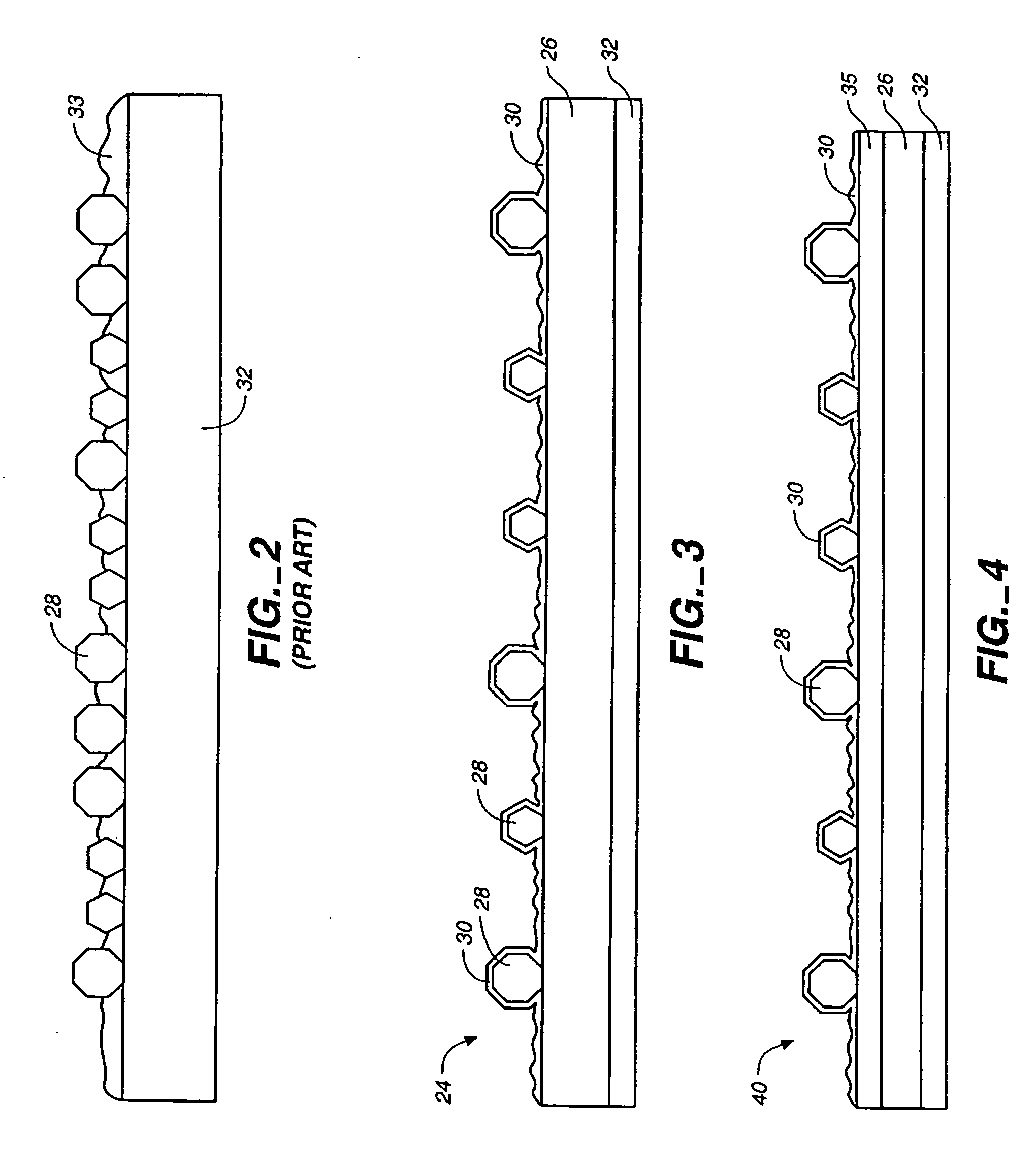

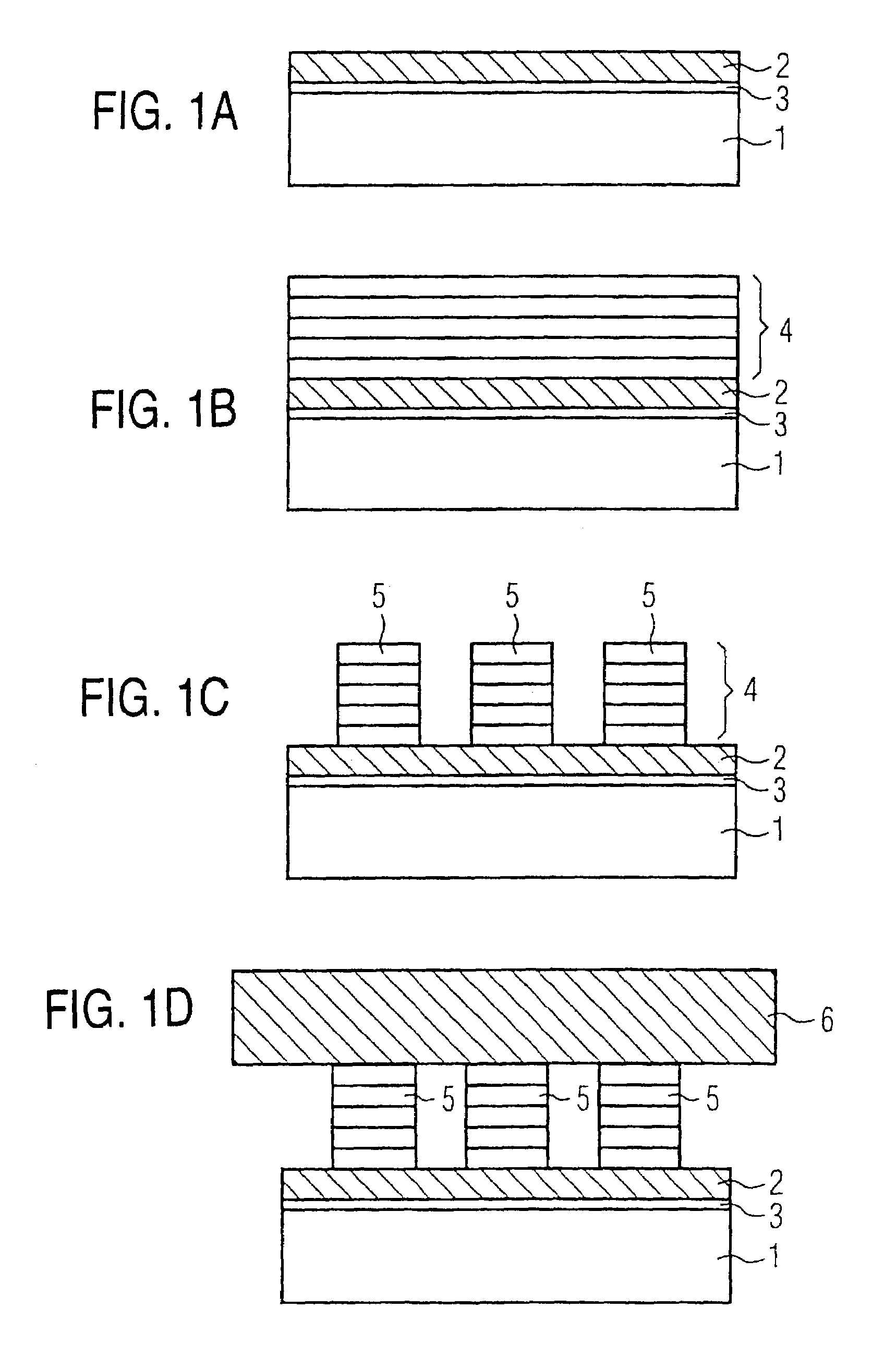

Semiconductor light emitting devices grown on composite substrates

ActiveUS20100072489A1Relieve pressureSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor structureComposite substrate

A plurality of III-nitride semiconductor structures, each comprising a light emitting layer disposed between an n-type region and a p-type region, are grown on a composite substrate. The composite substrate includes a plurality of islands of III-nitride material connected to a host by a bonding layer. The plurality of III-nitride semiconductor structures are grown on the III-nitride islands. The composite substrate may be formed such that each island of III-nitride material is at least partially relaxed. As a result, the light emitting layer of each semiconductor structure has an a-lattice constant greater than 3.19 angstroms.

Owner:LUMILEDS

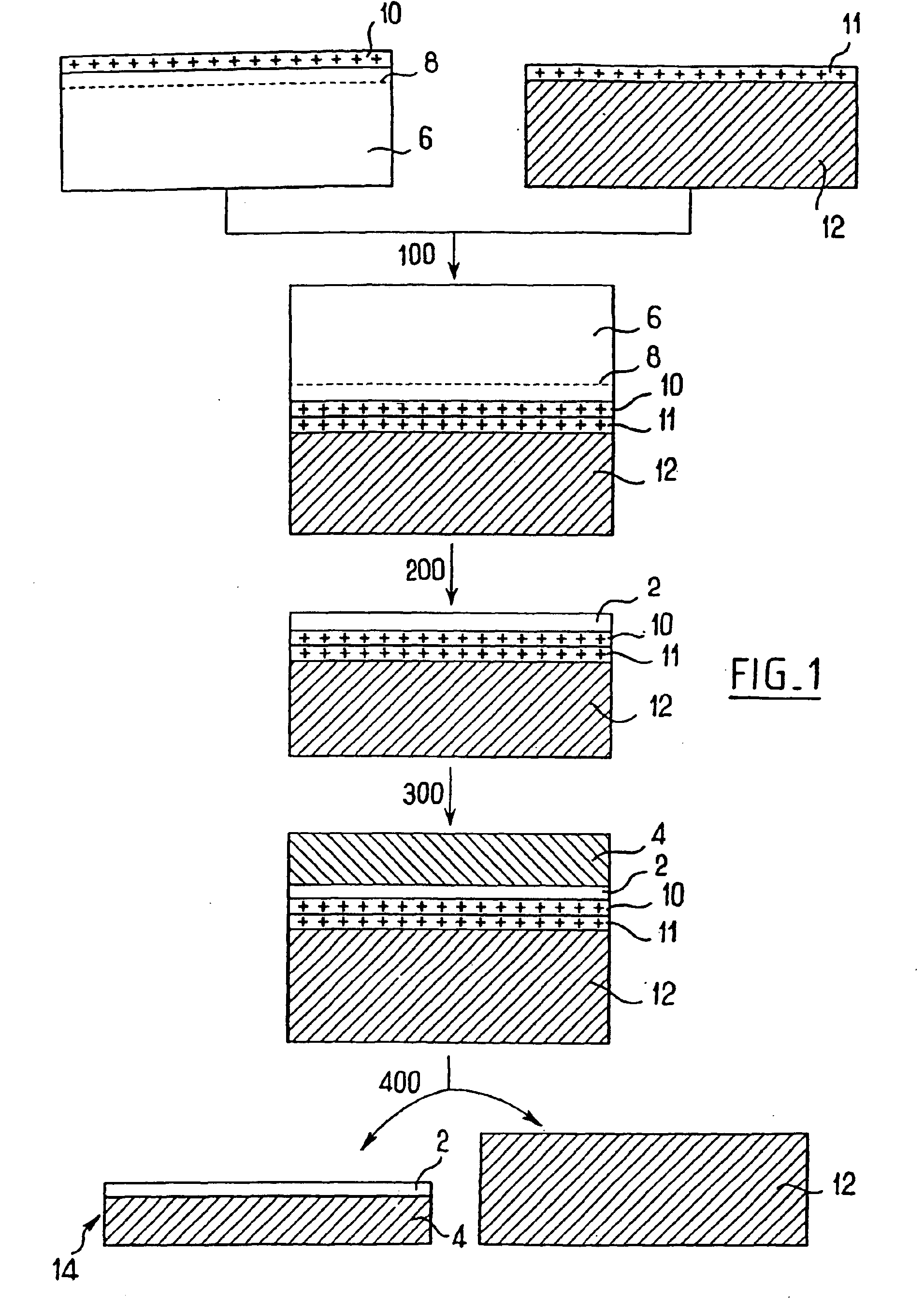

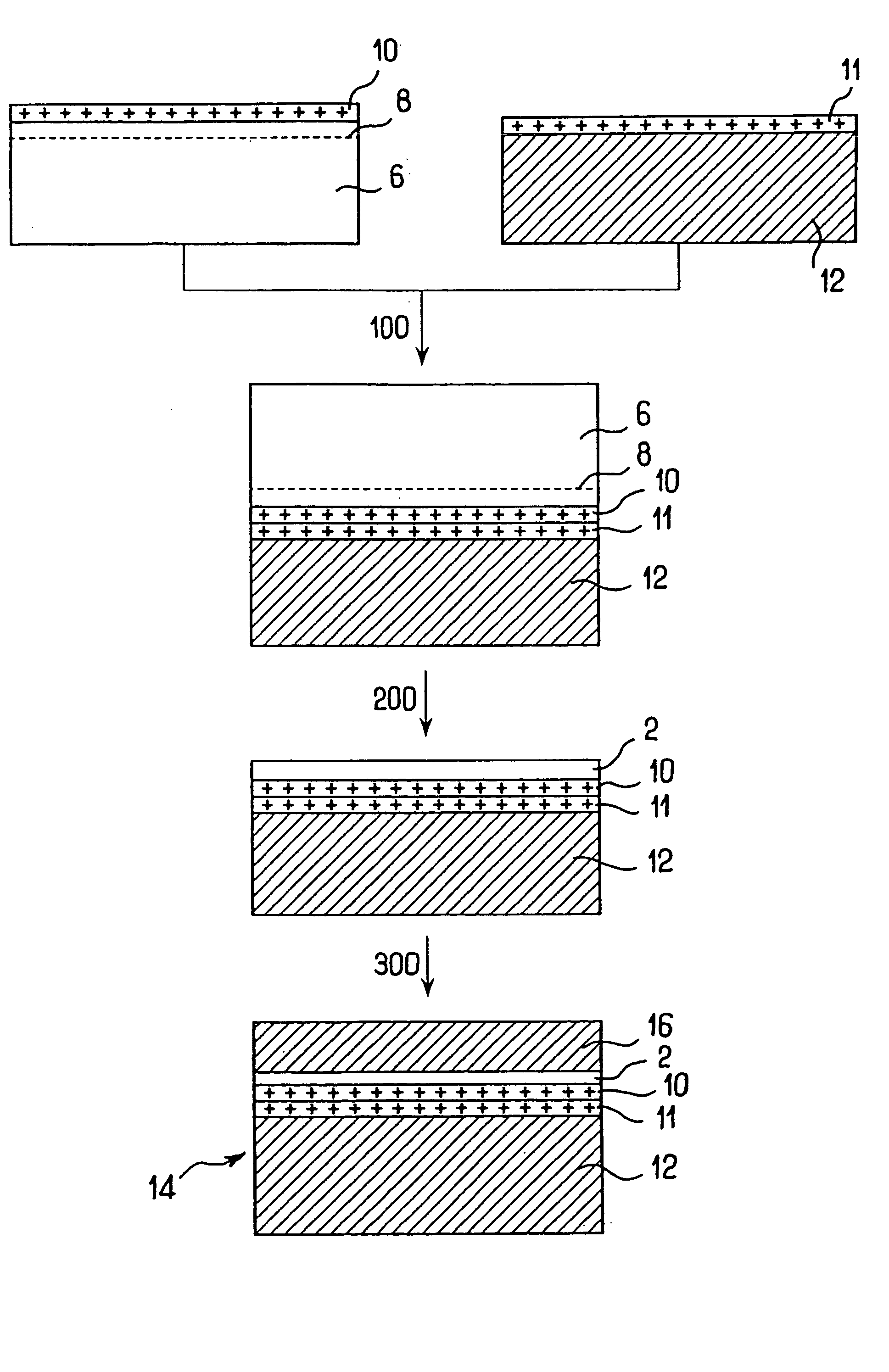

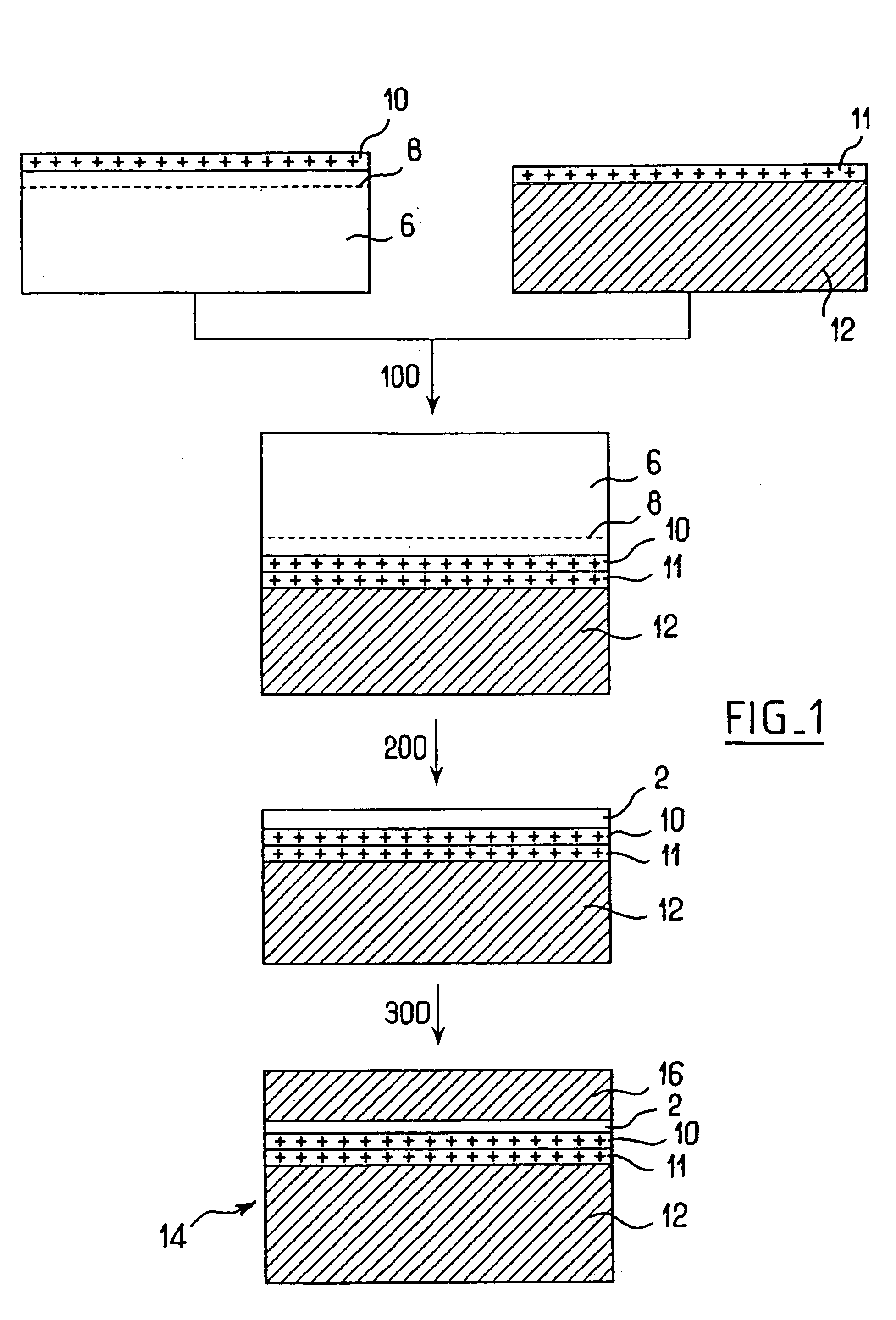

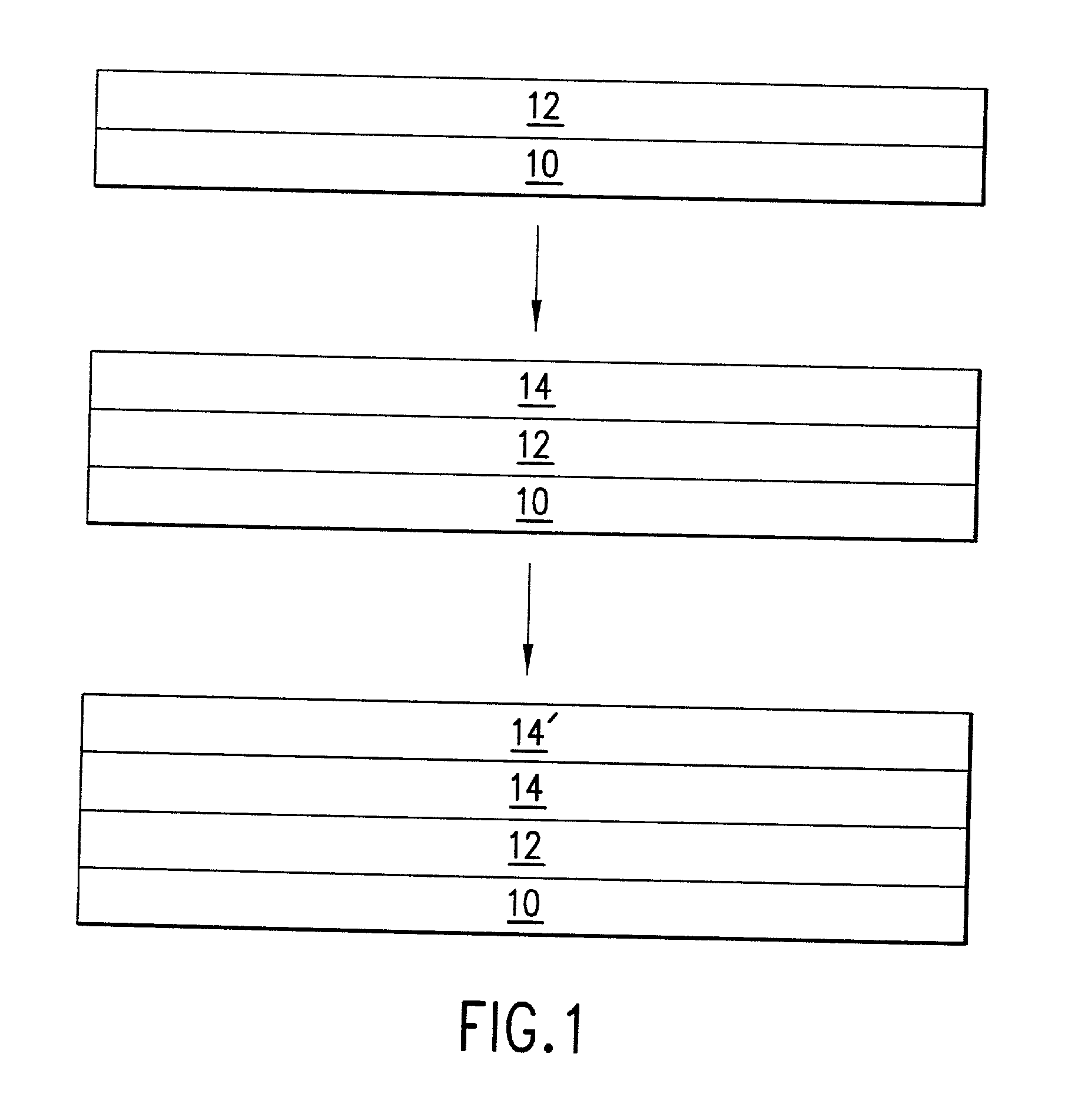

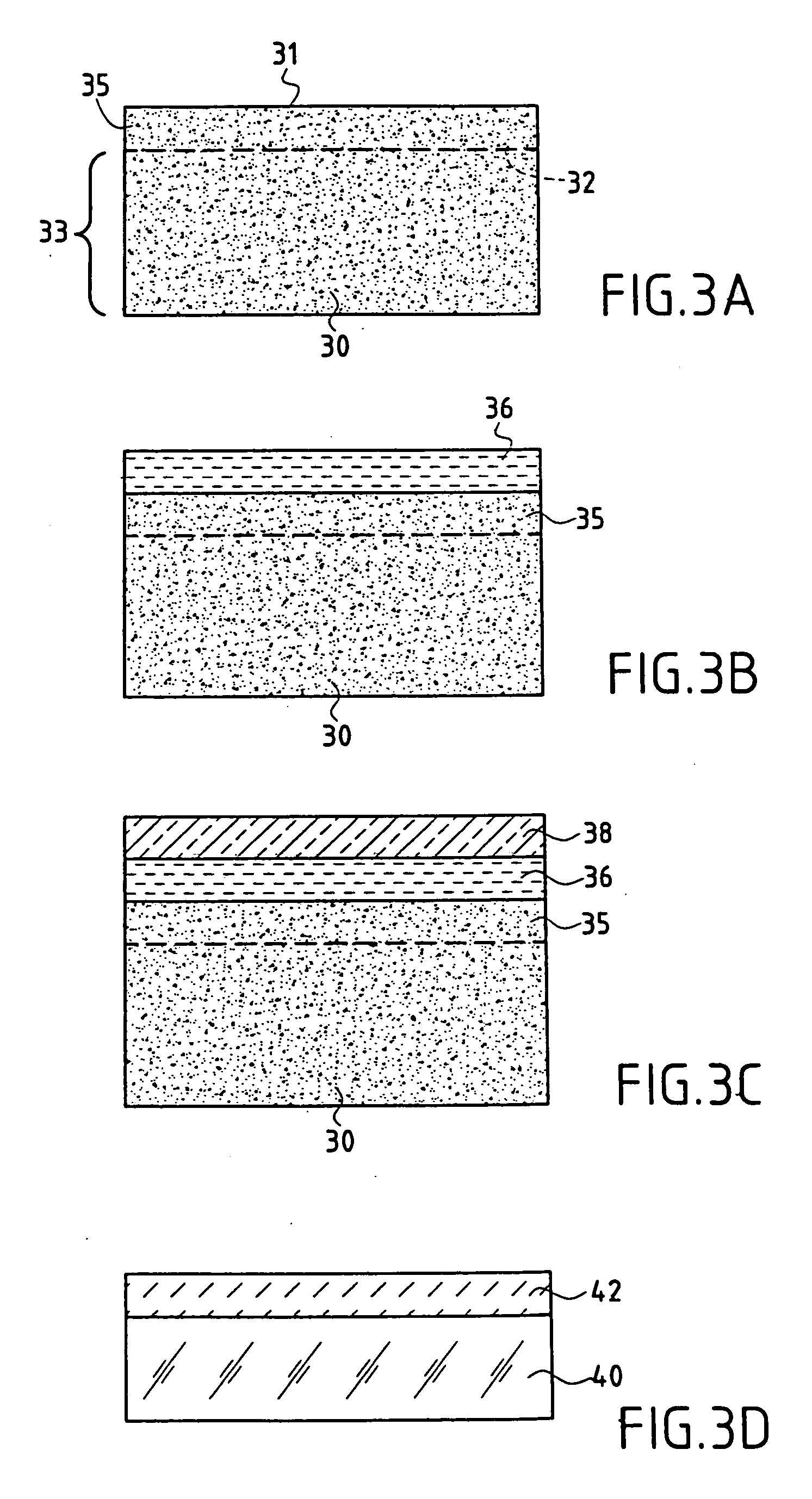

Methods for fabricating a substrate

InactiveUS20050026394A1Simple methodOvercome difficultiesPolycrystalline material growthSemiconductor/solid-state device manufacturingComposite substrateEngineering

A method is provided for fabricating a substrate for optics, electronics, or opto-electronics. This method includes the steps of implanting atomic species into a face of a source substrate to form a weakened zone therein corresponding to the depth of penetration of the atomic species; transferring the seed layer on to a support substrate by bonding a face of the support substrate to the face of the source substrate and detaching the seed layer from the source substrate; depositing a working layer on the seed layer to form a composite substrate comprising the support substrate, seed layer and working layer; and detaching the seed layer and the working layer from the support substrate to form a substrate. Advantageously, the support substrate comprises a material having a thermal expansion value of about 0.7 to 3 times the coefficient value of the working layer, and the seed layer includes a crystal lattice parameter sufficient for the epitaxial growth of the working layer onto the seed layer such that the working layer has a dislocation concentration of less than about 107 / cm2.

Owner:SOITEC SA

Electronic device with composite substrate

InactiveUS20020096106A1Fast heat conductionGood thermal expansionPolycrystalline material growthSemiconductor/solid-state device manufacturingThermal dilatationComposite substrate

A method for making a multilayered electronic device with at least one epitaxial layer grown on a single-crystal film bonded to a composite wherein at least one layer is polycrystalline, the method includes the step of bonding a single-crystal film at least one of the epitaxial layers on the single-crystal film wherein thermal coefficients of expansion for the substrate and the epitaxial layer are closely matched.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

CVD diamond-coated composite substrate containing a carbide-forming material and ceramic phases and method for making same

InactiveUS20050025973A1Improve adhesionLow costPigmenting treatmentEngine sealsReaction bonded silicon carbideComposite substrate

The present invention relates to a composite material and the method of making same, which comprises a CVD diamond coating applied to a composite substrate of ceramic material and an unreacted carbide-forming material of various configurations and for a variety of applications. One example of the composite material is a composite of SiC and free silicon metal known as Reaction-Bonded Silicon Carbide. Several examples of applications of the invention include: 1) heads or disks for conditioning polishing pads, including pads used in Chemical-Mechanical-Planarization, 2) cutting and dressing tool inserts and tips, 3) heat spreaders for electronic devices, and 4) wear components including mechanical seals and pump seals.

Owner:MORGAN ADVANCED CERAMICS

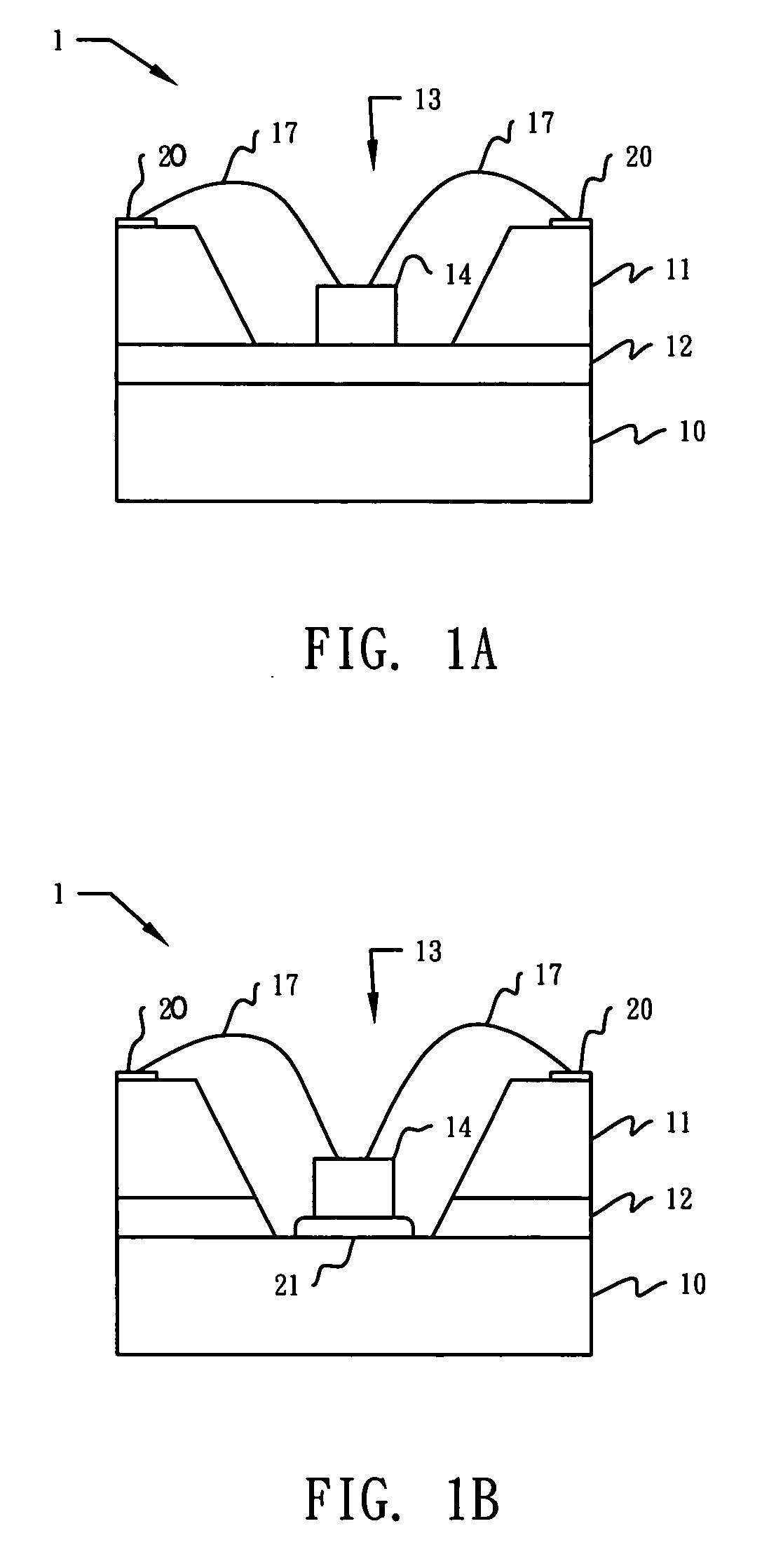

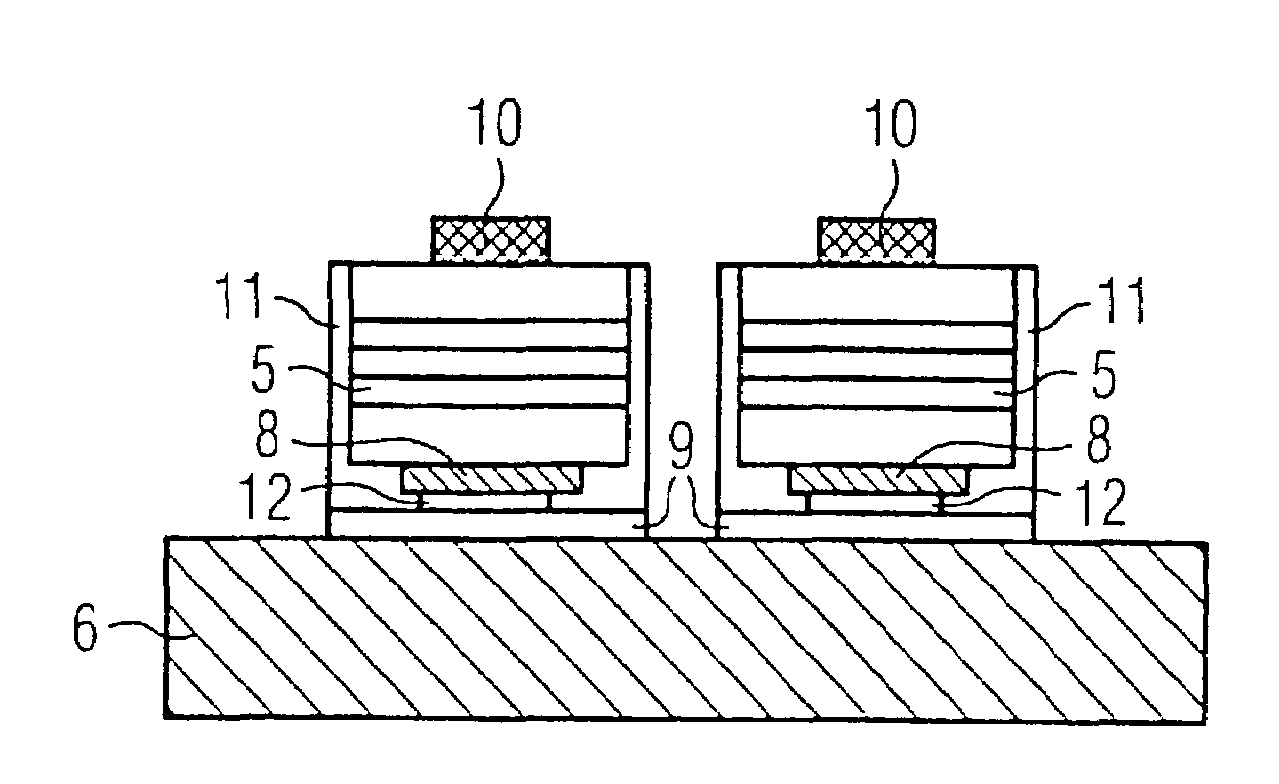

Semiconductor light-emitting element assembly

ActiveUS20060076571A1Improve cooling effectReduce adverse effectsSemiconductor/solid-state device detailsSolid-state devicesComposite substrateEngineering

A semiconductor light-emitting element assembly, comprising a composite substrate, a circuit layout carrier, a connecting structure, a recess, and a semiconductor light-emitting element, is disclosed. The connecting structure is used for bonding the composite substrate with the circuit layout carrier. The recess is formed by the circuit layout carrier and extends toward the composite substrate. The semiconductor light-emitting element is deposited in the recess and electrically connected to the circuit layout carrier.

Owner:EPISTAR CORP

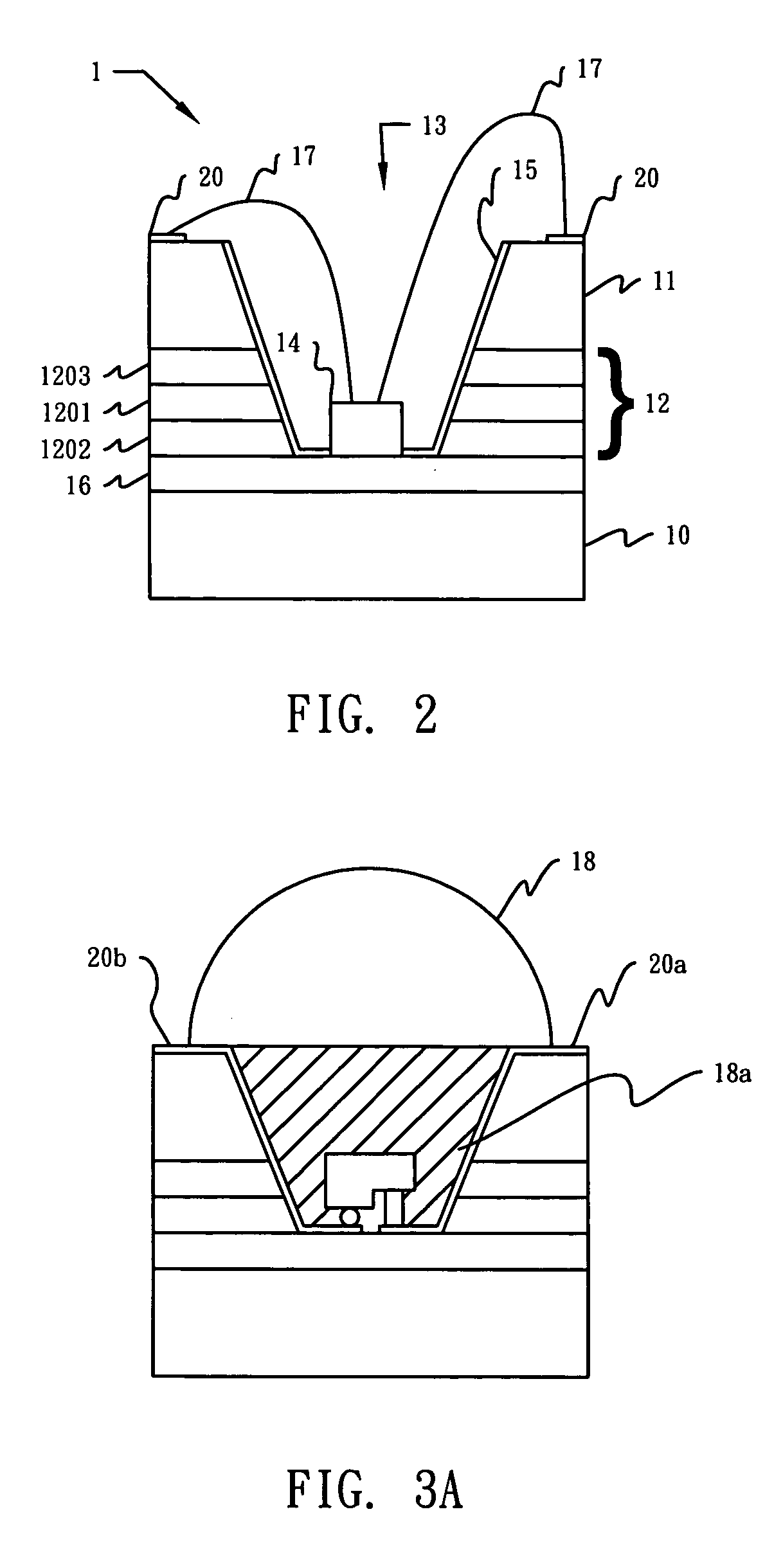

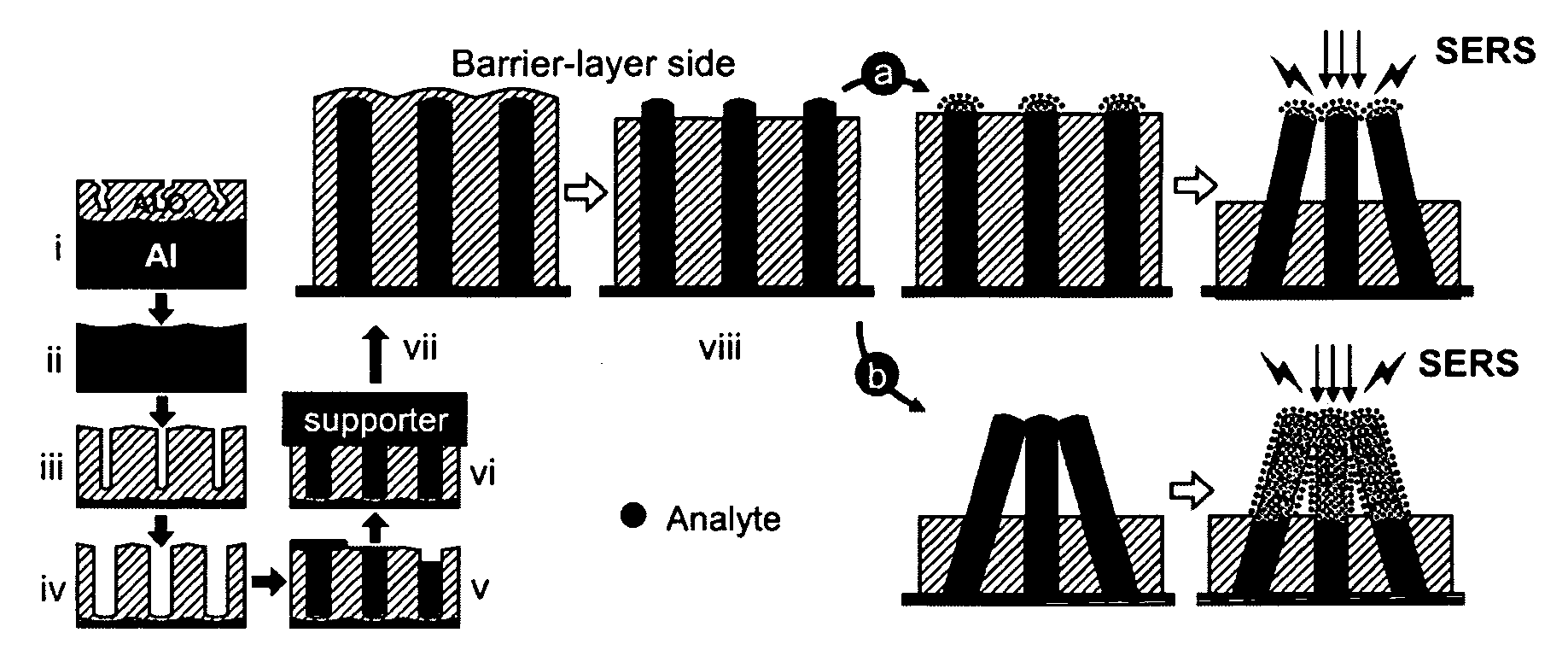

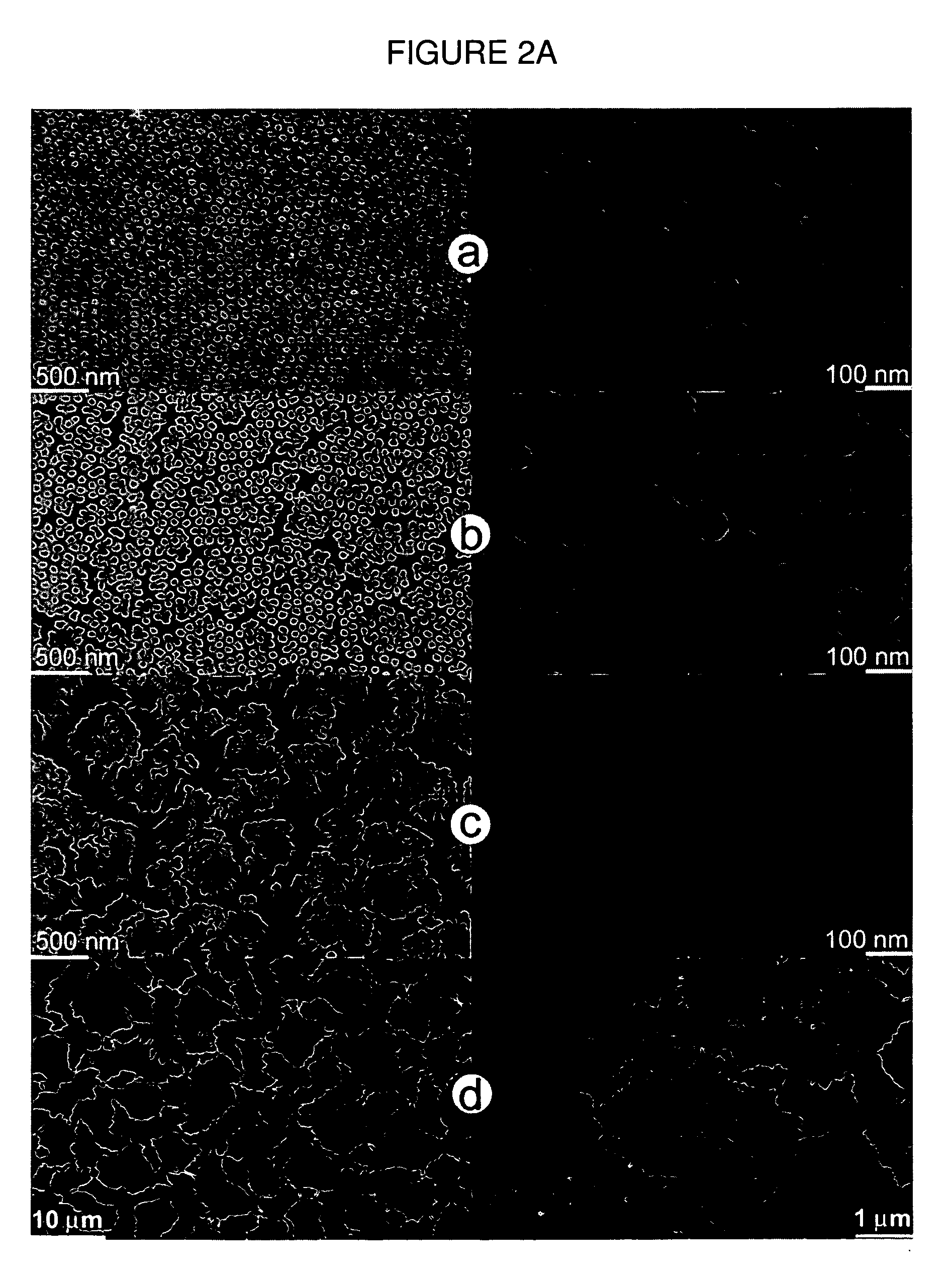

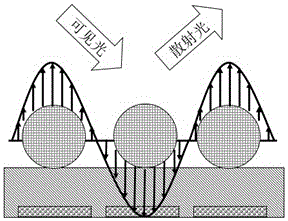

Platform for chemical and biological sensing by surface-enhanced raman spectroscopy

InactiveUS20080174775A1High strengthWell formedRadiation pyrometryPaper/cardboard articlesAnalyteSurface-enhanced Raman spectroscopy

Methods of analysis, and compositions relating to such, to determine the presence or absence of an analyte in a sample utilizing a composite substrate which facilitates surface enhanced Raman spectroscopy through the use of ‘hot spots’ of the form ‘metal / analyte / metal’ are presented. Additionally, substrates which contain ‘hot spots’ of the form ‘metal / analyte / metal’ and substrates which facilitate the formation of ‘hot spots’ of the form ‘metal / analyte / metal’ are presented as well as methods for making these substrates.

Owner:RGT UNIV OF CALIFORNIA

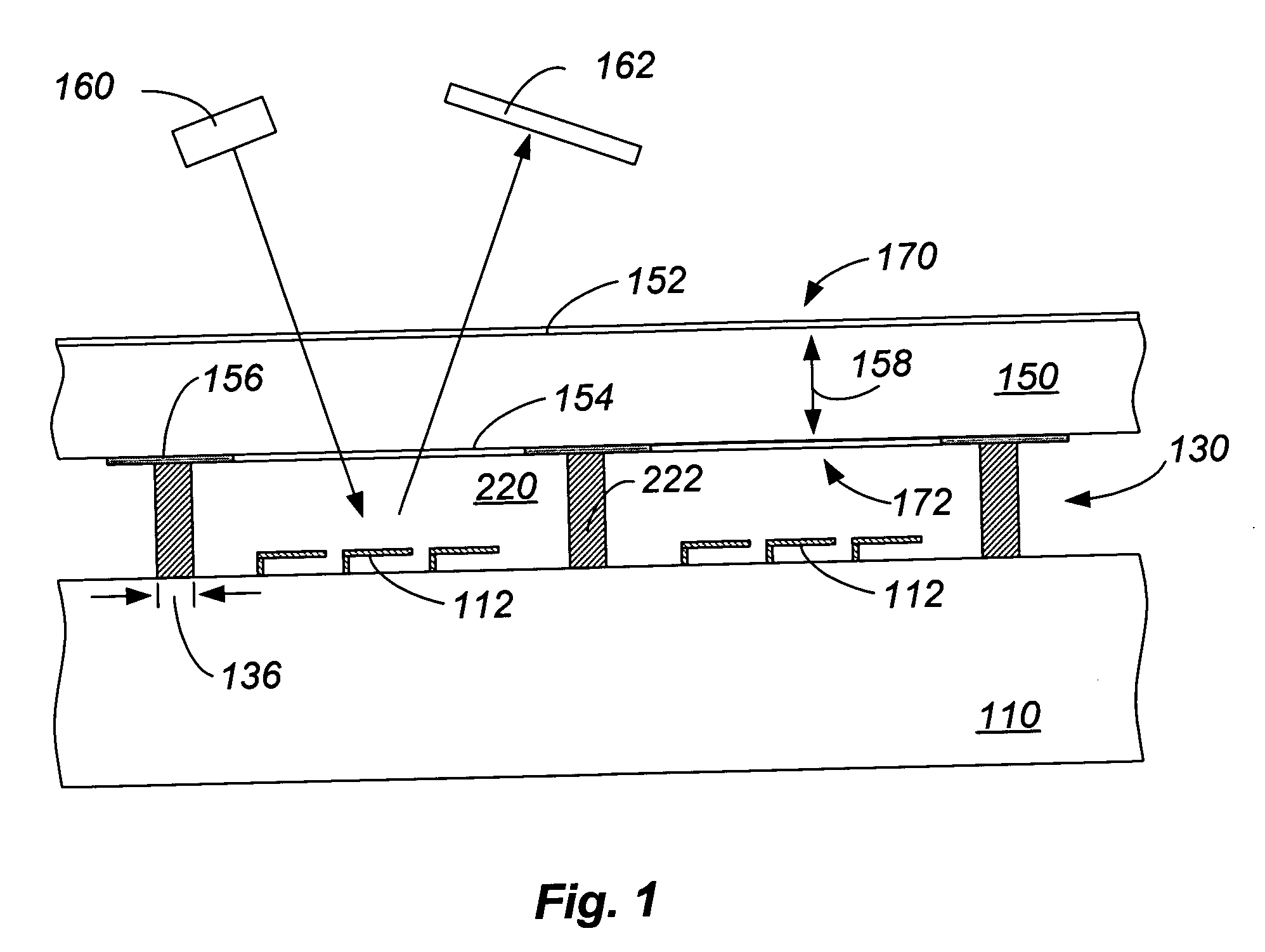

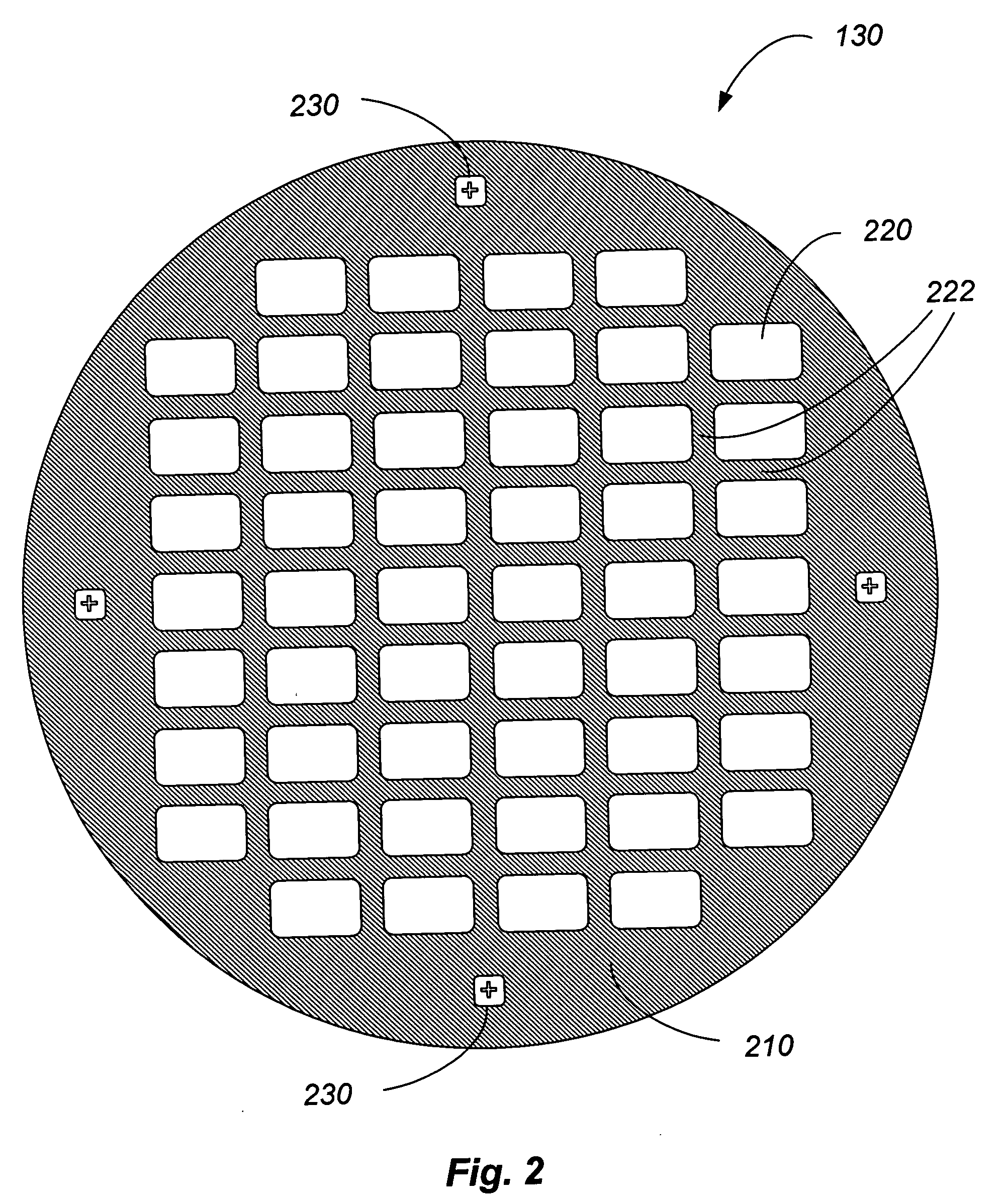

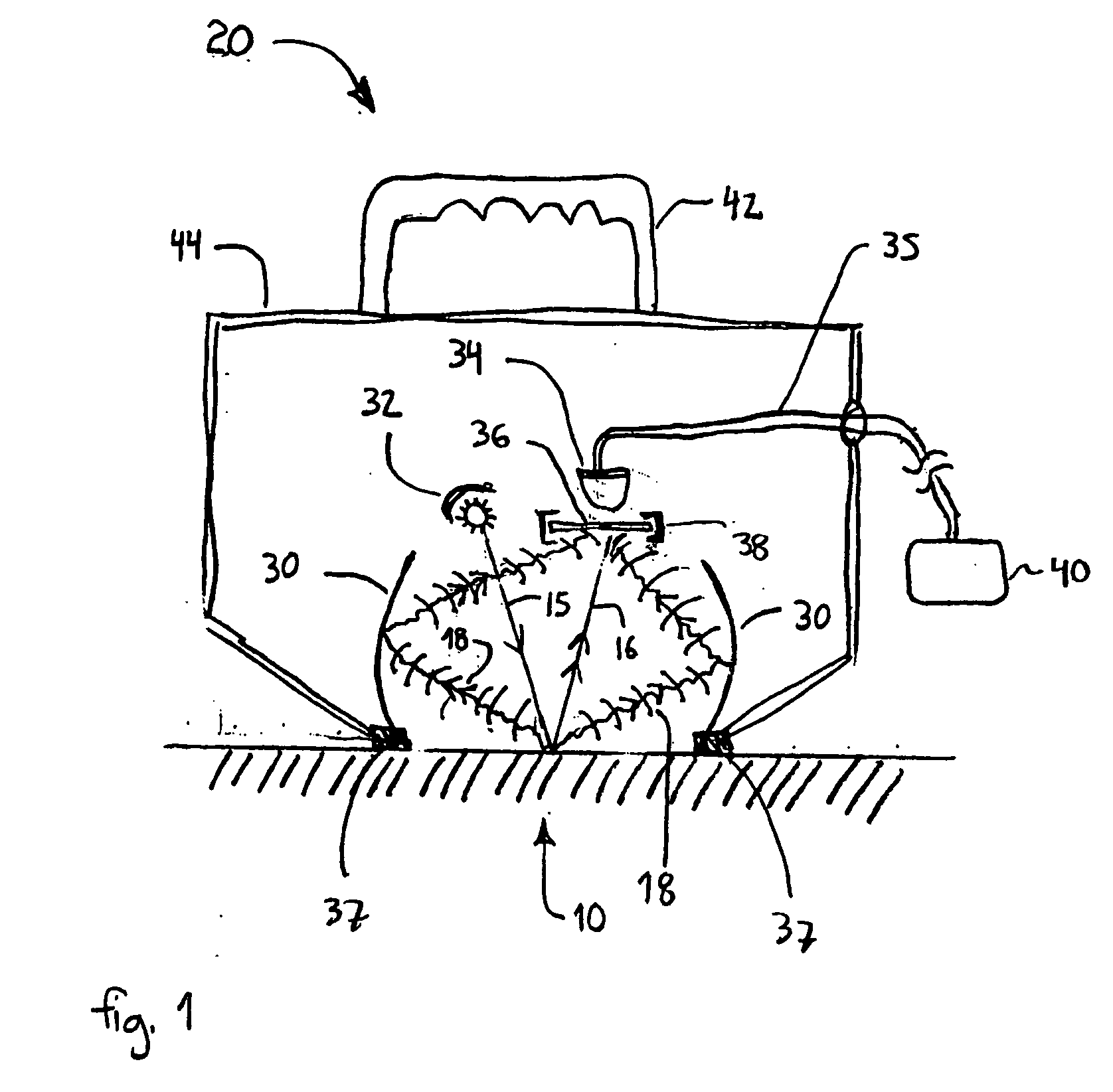

Triple alignment substrate method and structure for packaging devices

ActiveUS20060270179A1Easy to useHigh device yieldSemiconductor/solid-state device detailsSolid-state devicesSelf limitingEtching

A method for aligning multiple substrates. The method includes providing a handle substrate, providing a spacer substrate, and forming a plurality of first alignment marks on a first surface of the handle substrate. The method also includes forming a plurality of self-limiting alignment marks on a first surface of the spacer substrate and forming a plurality of openings in the spacer substrate, each of the plurality of openings surrounded by standoff regions. The method further includes aligning the first surface of the handle substrate and the first surface of the spacer substrate using the first alignment marks and the self-limiting alignment marks and bonding the handle substrate to the spacer substrate to form a composite substrate structure. In a specific embodiment, the plurality of self-limiting alignment marks and the plurality of openings are formed using an anisotropic wet etching process that preferentially etches the spacer substrate.

Owner:MIRADIA INC

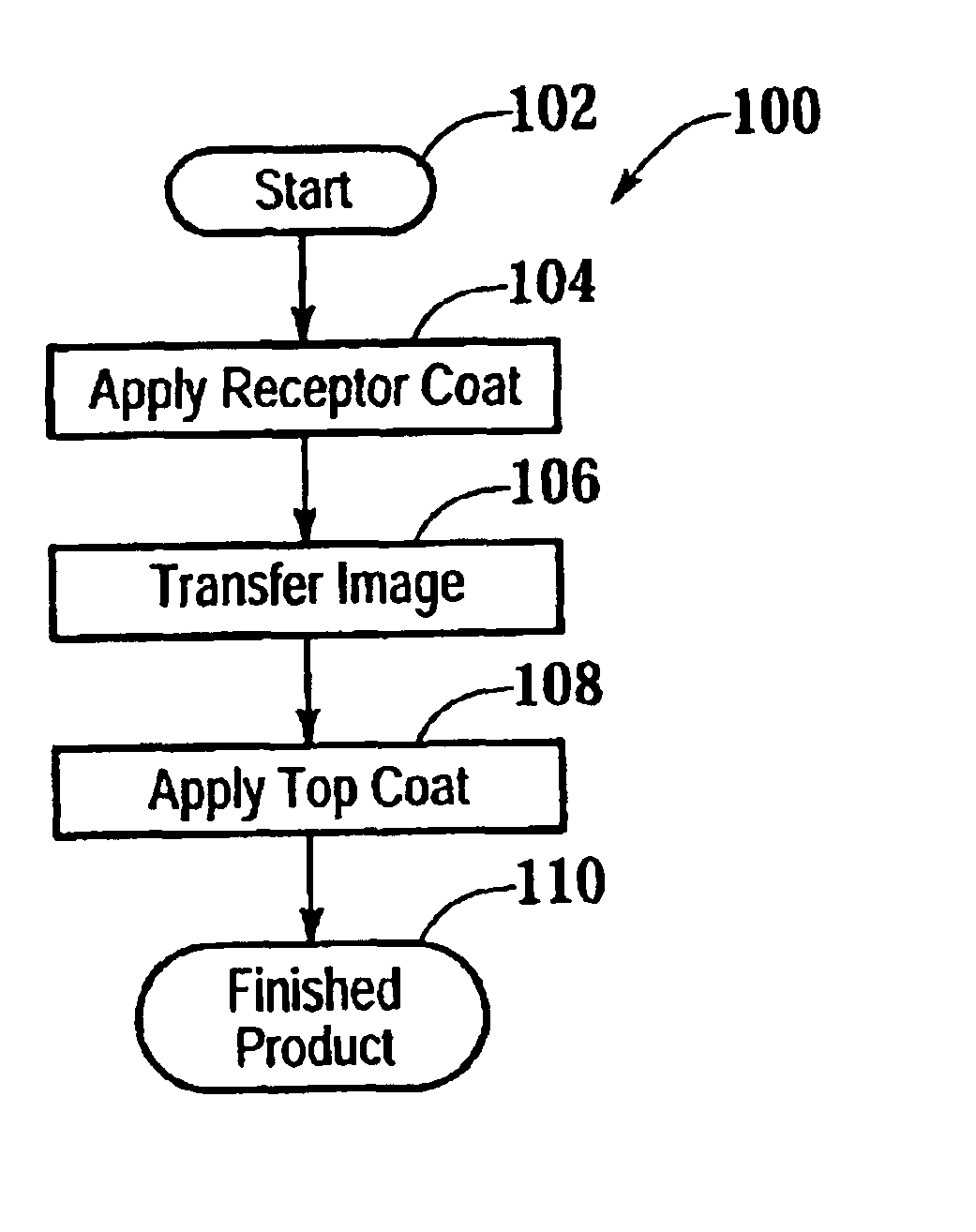

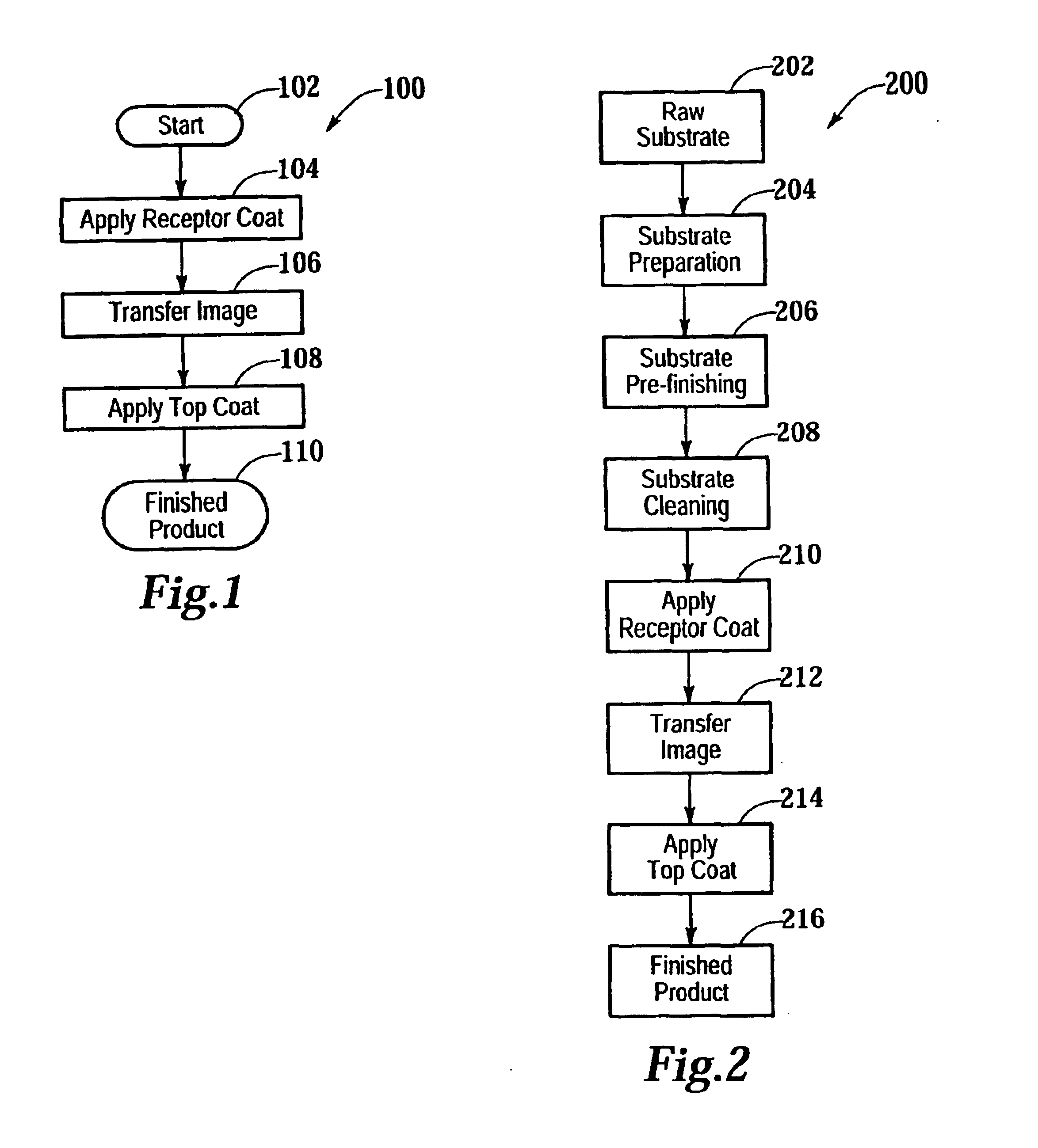

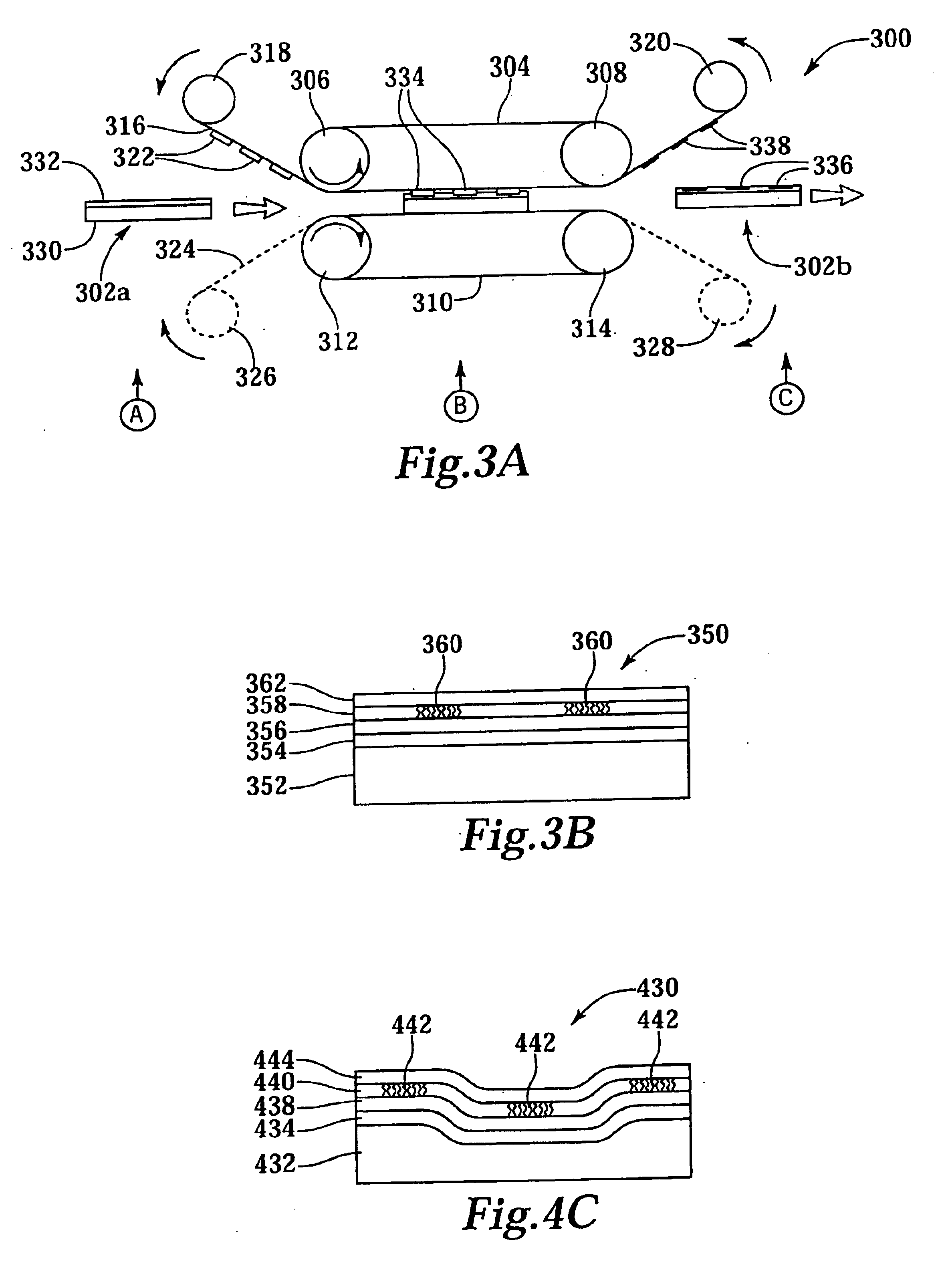

Method for producing a wood substrate having an image on at least one surface

InactiveUS6964722B2Quality improvementImprove reliabilityDecorative surface effectsSpecial ornamental structuresComposite substrateEngineering

A method and system is provided for producing an image on one or more surfaces of a wood or wood composite substrate by applying a receptor coat to at least the one or more surfaces of the substrate, transferring the image to the receptor coat using a variety of image transfer processes and applying a topcoat to the image and receptor coat. The system implements the above method using a series of stations and includes a series of platens connected together by a chain and a set of rollers that allow the substrate to travel through the stations on the platens. The resulting wood or wood composite product includes a substrate, a receptor coat disposed on one or more surfaces of the substrate, an image disposed on or within the one or more surfaces of the receptor coat and a top coat disposed on the image and receptor coat.

Owner:POLYMER WOOD TECH

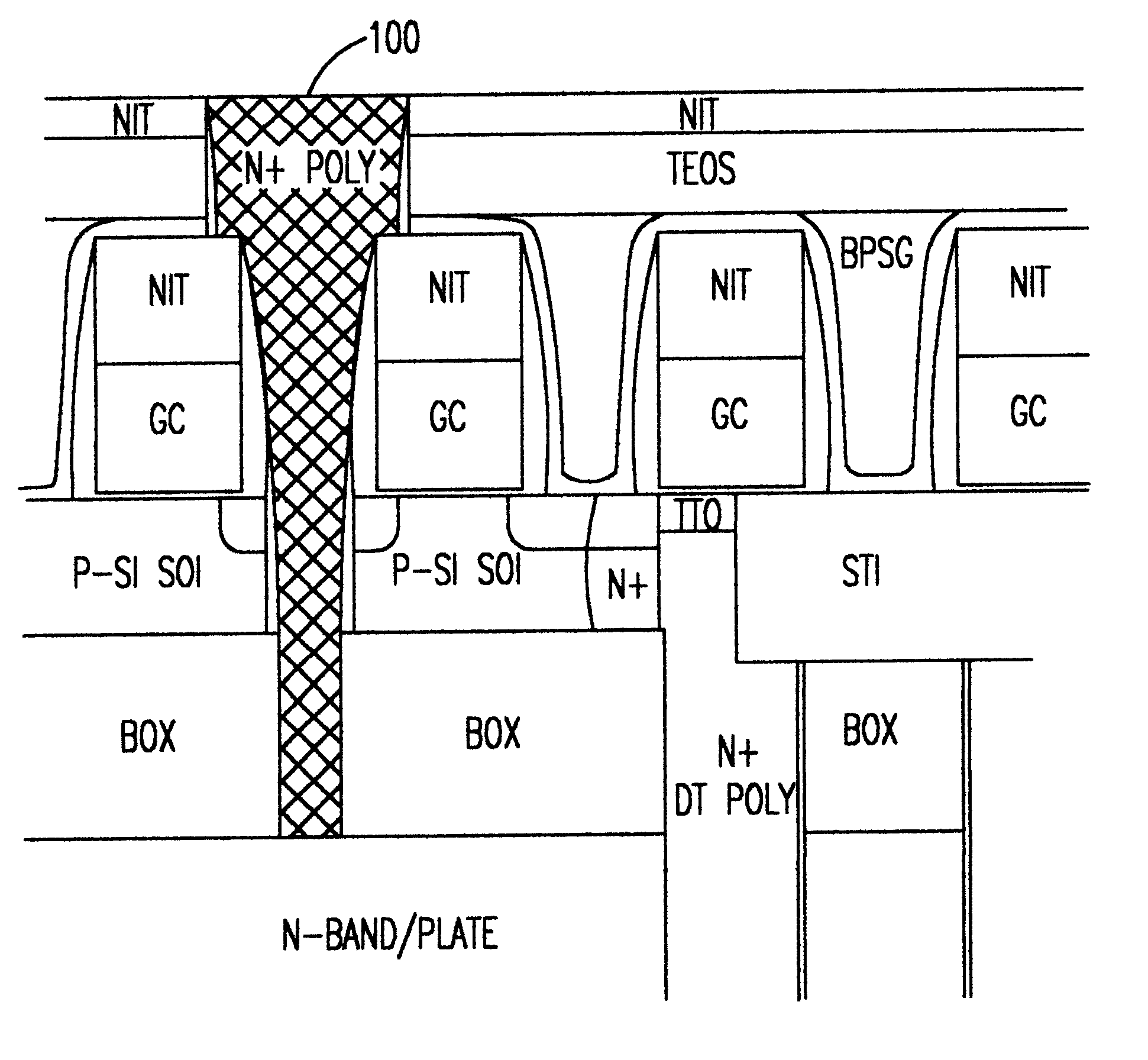

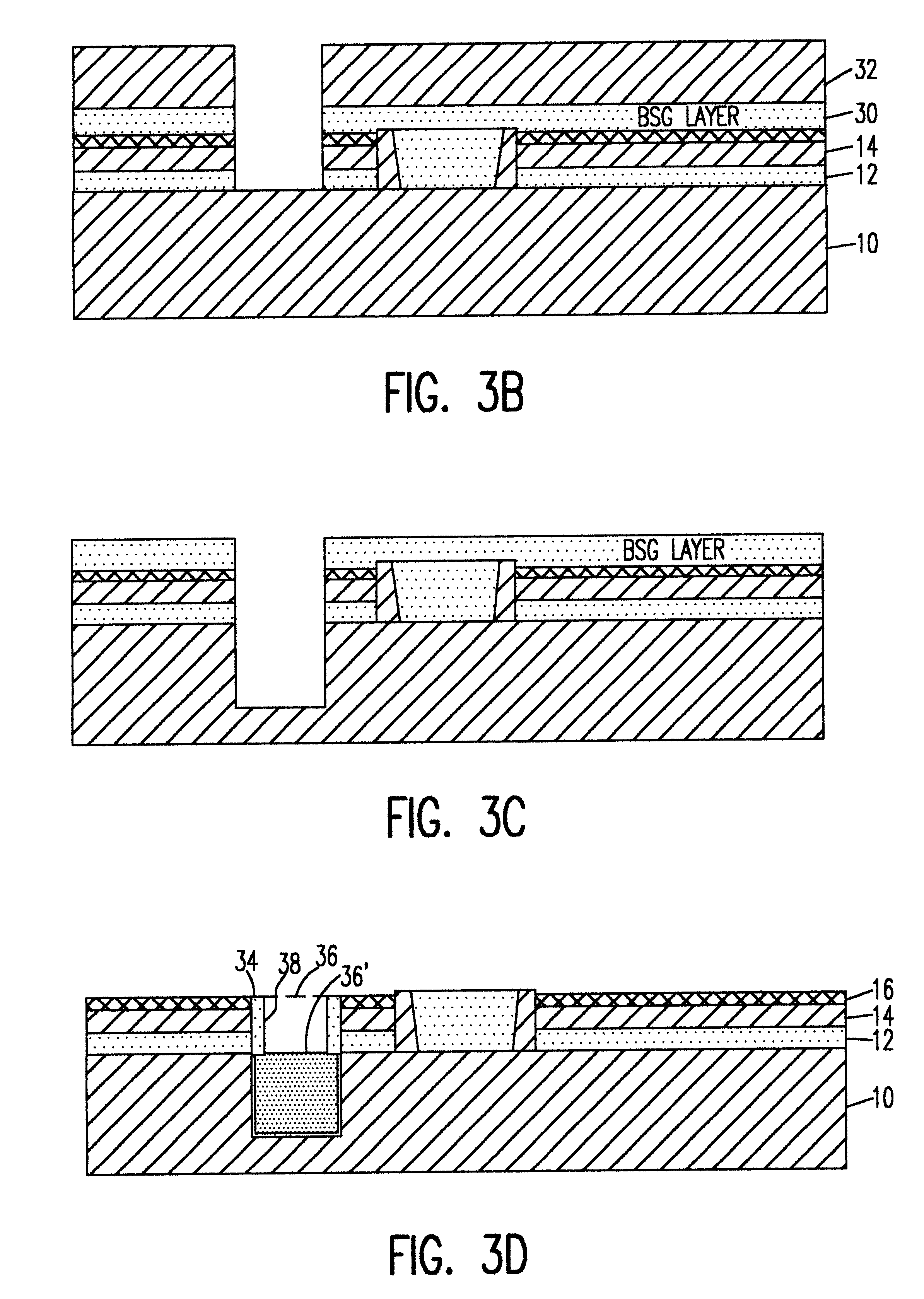

Structures and methods of anti-fuse formation in SOI

InactiveUS6396121B1Low programming voltage and currentReduce thermal effectsTransistorSemiconductor/solid-state device detailsDielectricElement space

An anti-fuse structure that can be programmed at low voltage and current and which potentially consumes very little chip spaces and can be formed interstitially between elements spaced by a minimum lithographic feature size is formed on a composite substrate such as a silicon-on-insulator wafer by etching a contact through an insulator to a support semiconductor layer, preferably in combination with formation of a capacitor-like structure reaching to or into the support layer. The anti-fuse may be programmed either by the selected location of conductor formation and / or damaging a dielectric of the capacitor-like structure. An insulating collar is used to surround a portion of either the conductor or the capacitor-like structure to confine damage to the desired location. Heating effects voltage and noise due to programming currents are effectively isolated to the bulk silicon layer, permitting programming during normal operation of the device. Thus the potential for self-repair without interruption of operation is realized.

Owner:IBM CORP

CVD diamond-coated composite substrate containing a carbide-forming material and ceramic phases and method for making same

InactiveUS20050276979A1Improve adhesionLow costLiquid surface applicatorsEngine sealsReaction bonded silicon carbideComposite substrate

The present invention relates to a composite material and the method of making same ,which comprises a CVD diamond coating applied to a composite substrate of ceramic material and an unreacted carbide-forming material of various configurations and for a variety of applications. One example of the composite material is a composite of SiC and free silicon metal known as Reaction-Bonded Silicon Carbide. Several examples of applications of the invention include: 1) heads or disks for conditioning polishing pads, including pads used in Cheniical-Mechanical-Planarization, 2) cutting and dressing tool inserts and tips, 3) heat spreaders for electronic devices, and 4) wear components including mechanical seals and pump seals.

Owner:BEST ENGINEERED SURFACE TECH LLC

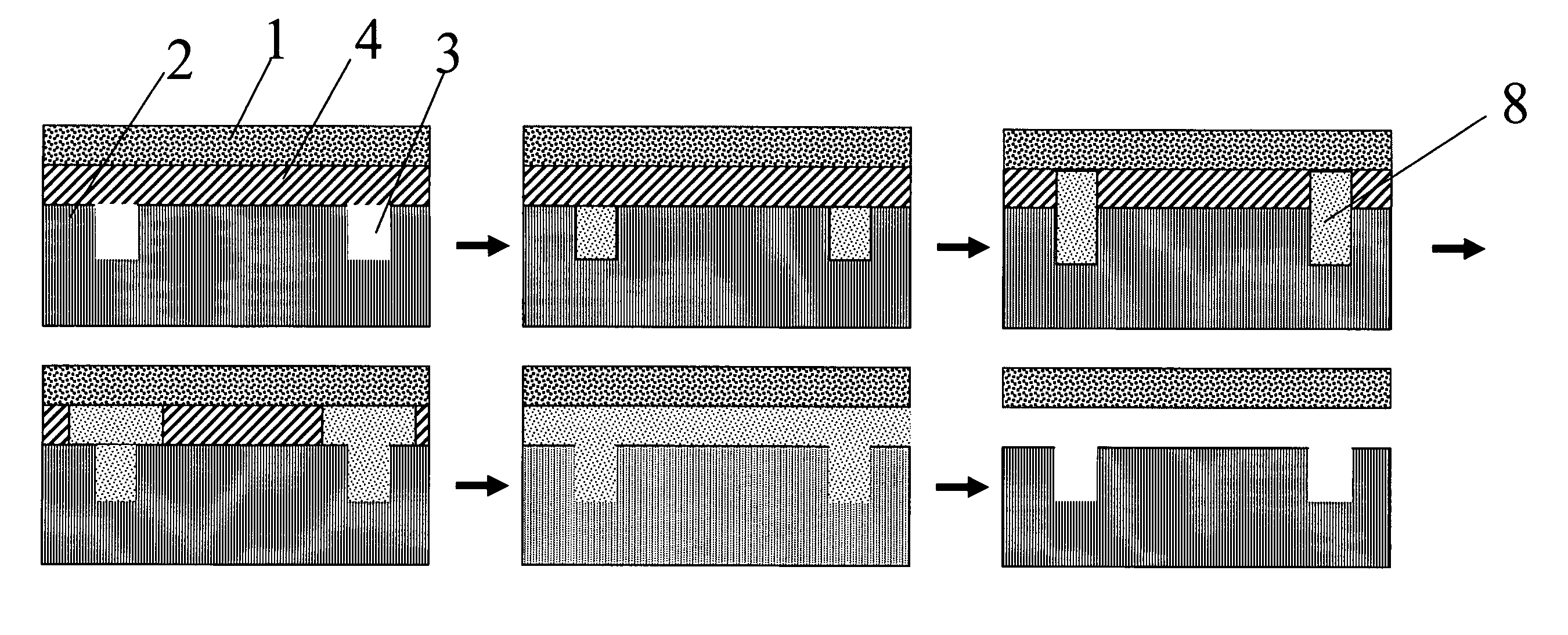

Method for the manufacture of electronic devices on substrates and devices related thereto

Methods for manufacturing electronic devices and devices produced by those methods are disclosed. One such method includes releasably bonding a first surface of a device substrate to a face of a first carrier substrate using a first bonding agent to produce a first composite substrate, where the face of the first carrier substrate includes a pattern of trenches. The method also includes processing the device substrate to manufacture an electronic device on a second surface of the device substrate. The method further includes releasing the device substrate from the first carrier substrate by a releasing agent.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW) +1

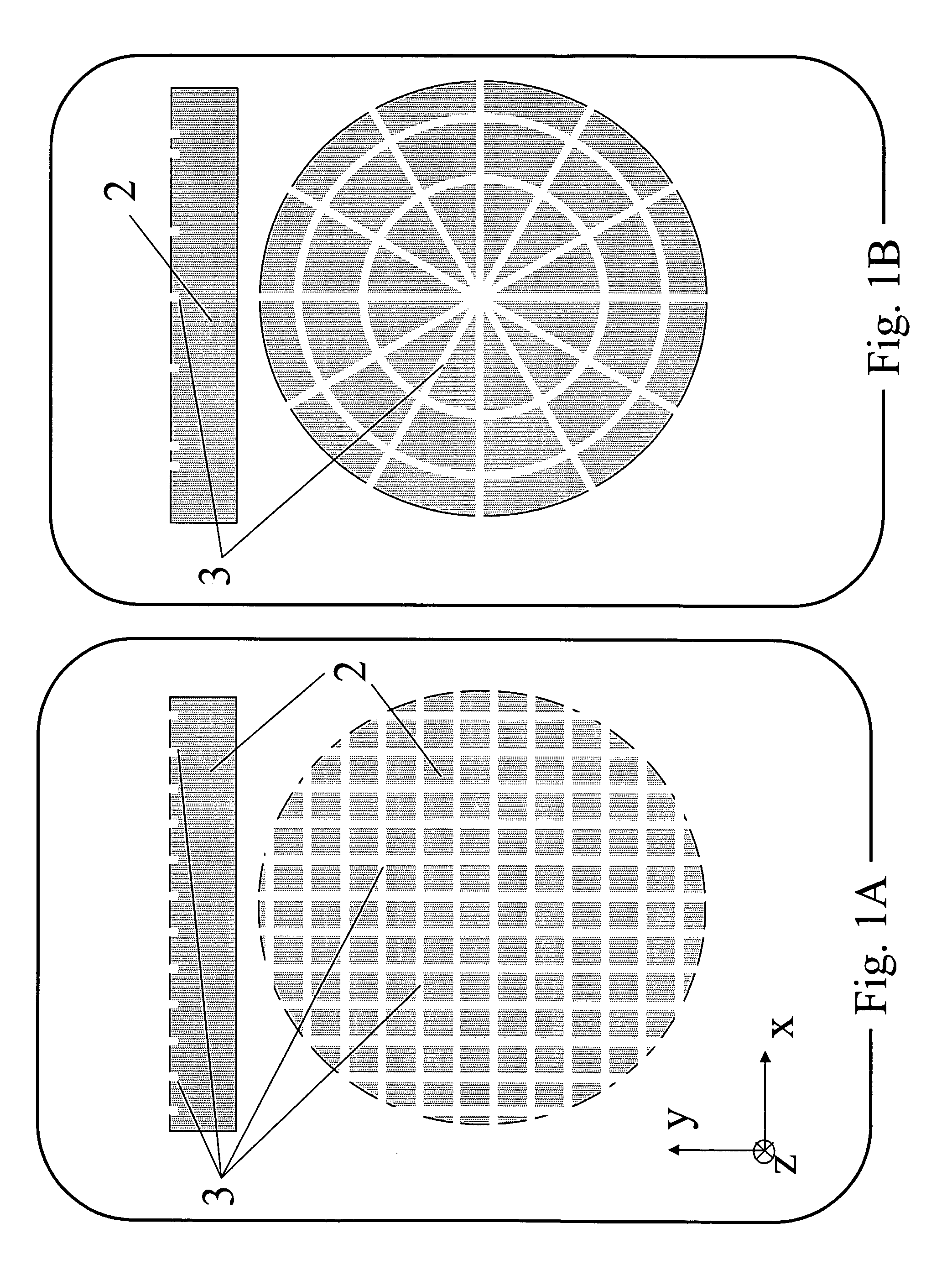

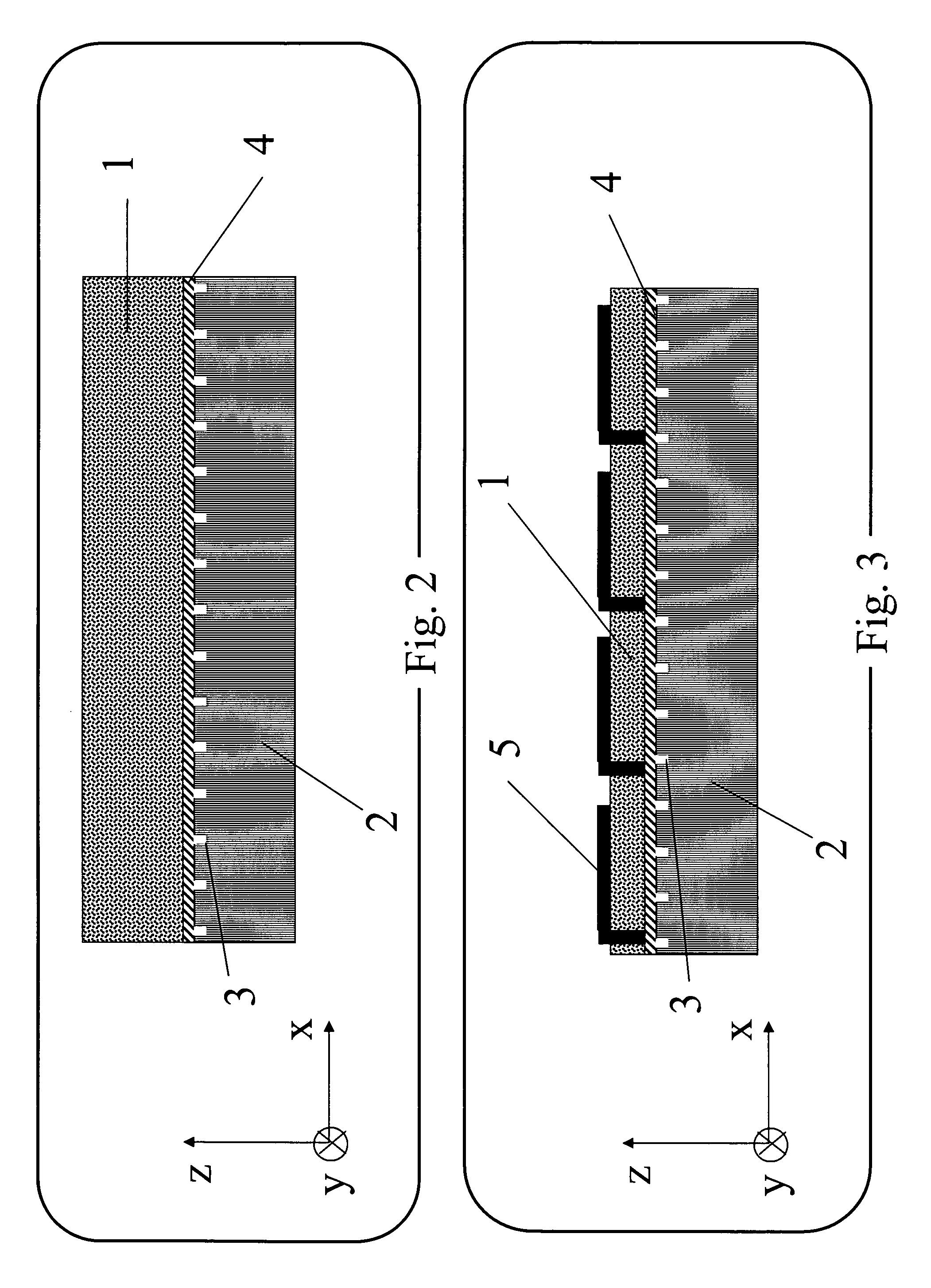

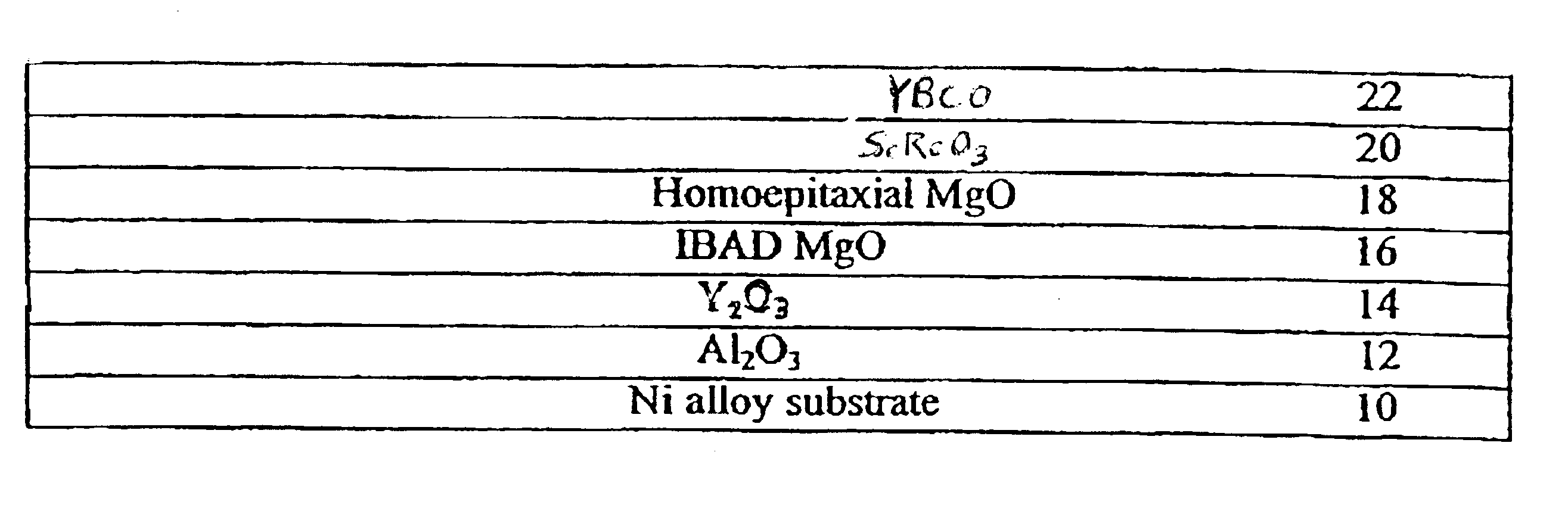

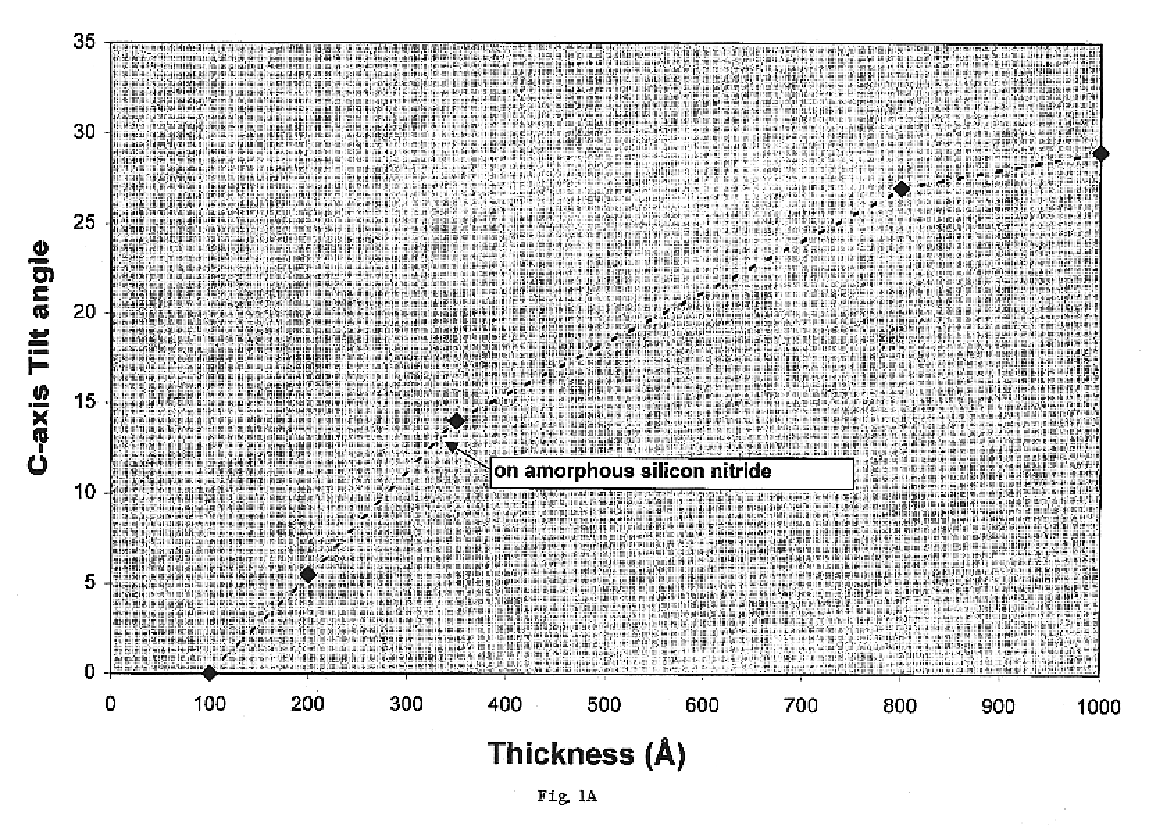

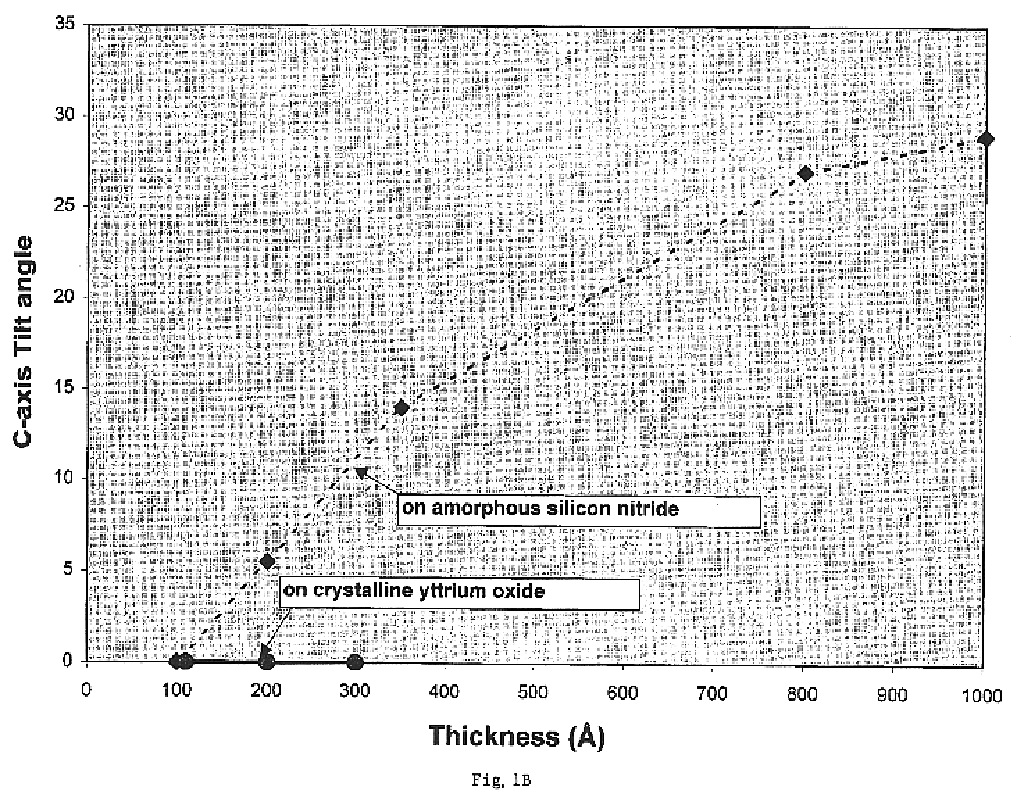

Substrate structure for growth of highly oriented and/or epitaxial layers thereon

InactiveUS6921741B2Polycrystalline material growthSuperconductors/hyperconductorsHigh temperature superconductingComposite substrate

A composite substrate structure including a substrate, a layer of a crystalline metal oxide or crystalline metal oxynitride material upon the substrate, a layer of an oriented cubic oxide material having a rock-salt-like structure upon the crystalline metal oxide or crystalline metal oxynitride material layer is provided together with additional layers such as one or more layers of a buffer material upon the oriented cubic oxide material layer.Jc′s of 2.3×106 A / cm2 have been demonstrated with projected Ic′s of 320 Amperes across a sample 1 cm wide for a superconducting article including a flexible polycrystalline metallic substrate, an inert oxide material layer upon the surface of the flexible polycrystalline metallic substrate, a layer of a crystalline metal oxide or crystalline metal oxynitride material upon the layer of the inert oxide material, a layer of an oriented cubic oxide material having a rock-salt-like structure upon the crystalline metal oxide or crystalline metal oxynitride material layer, a layer of a buffer material upon the oriented cubic oxide material layer, and, a top-layer of a high temperature superconducting material upon the layer of a buffer material.

Owner:TRIAD NAT SECURITY LLC

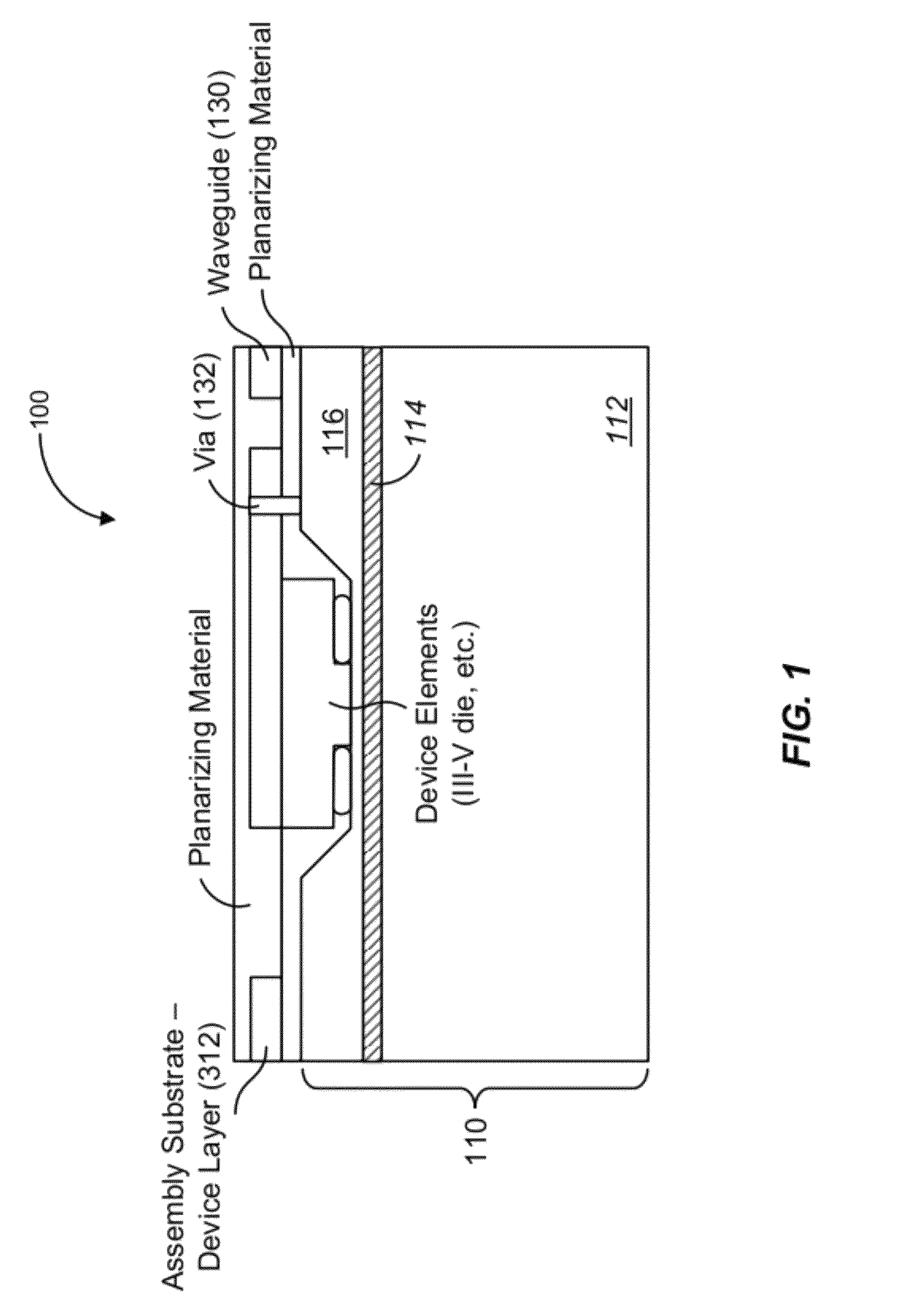

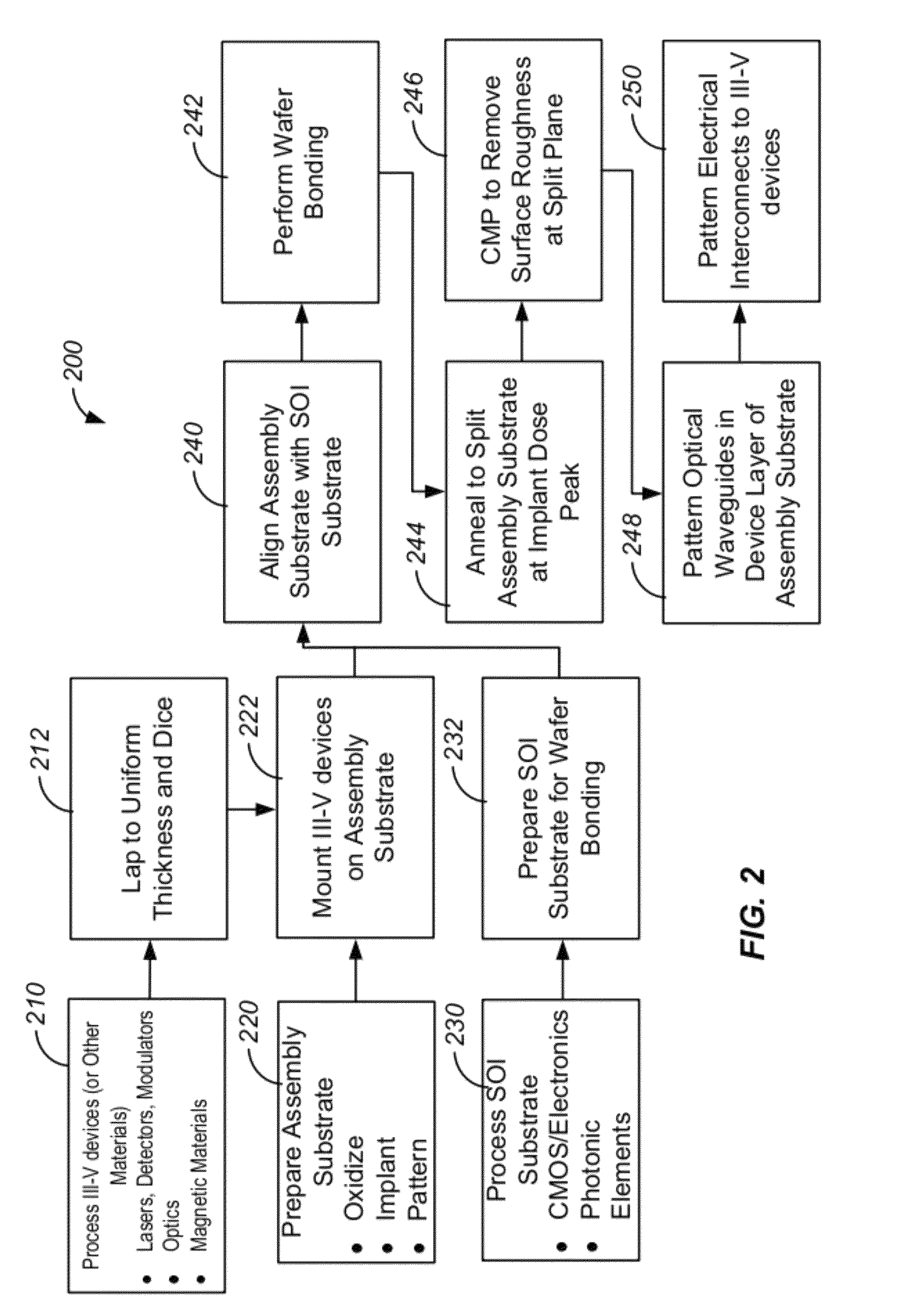

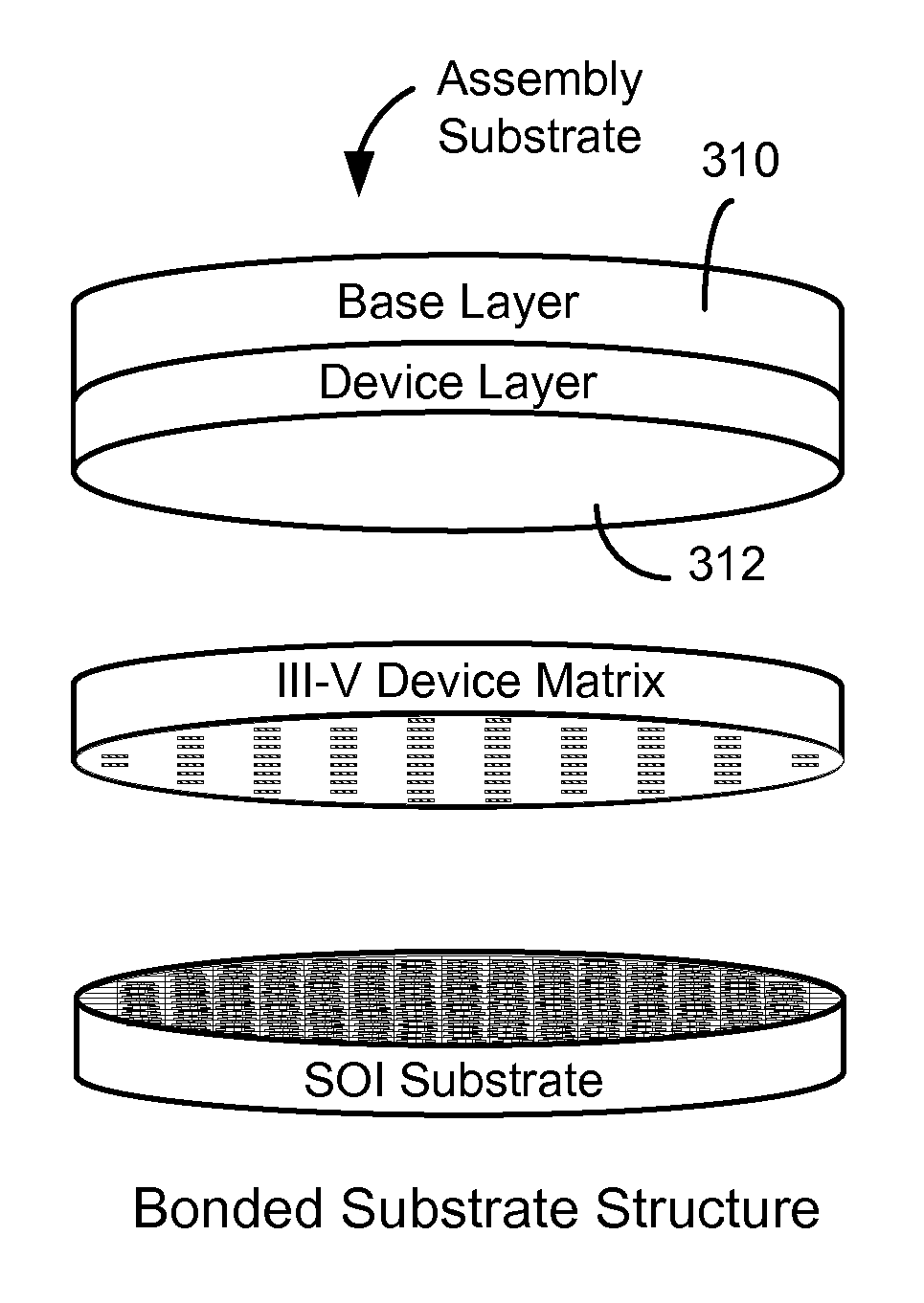

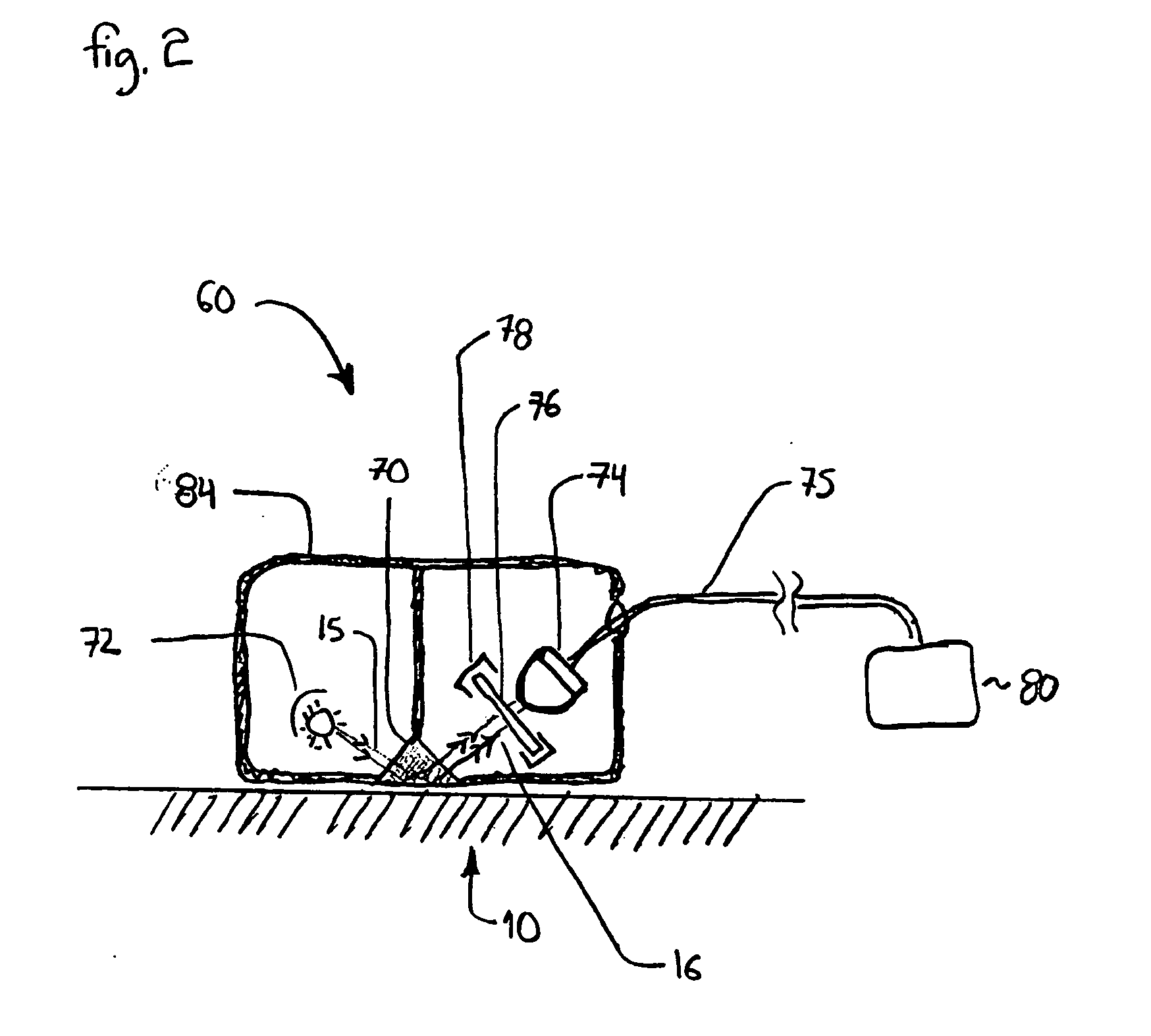

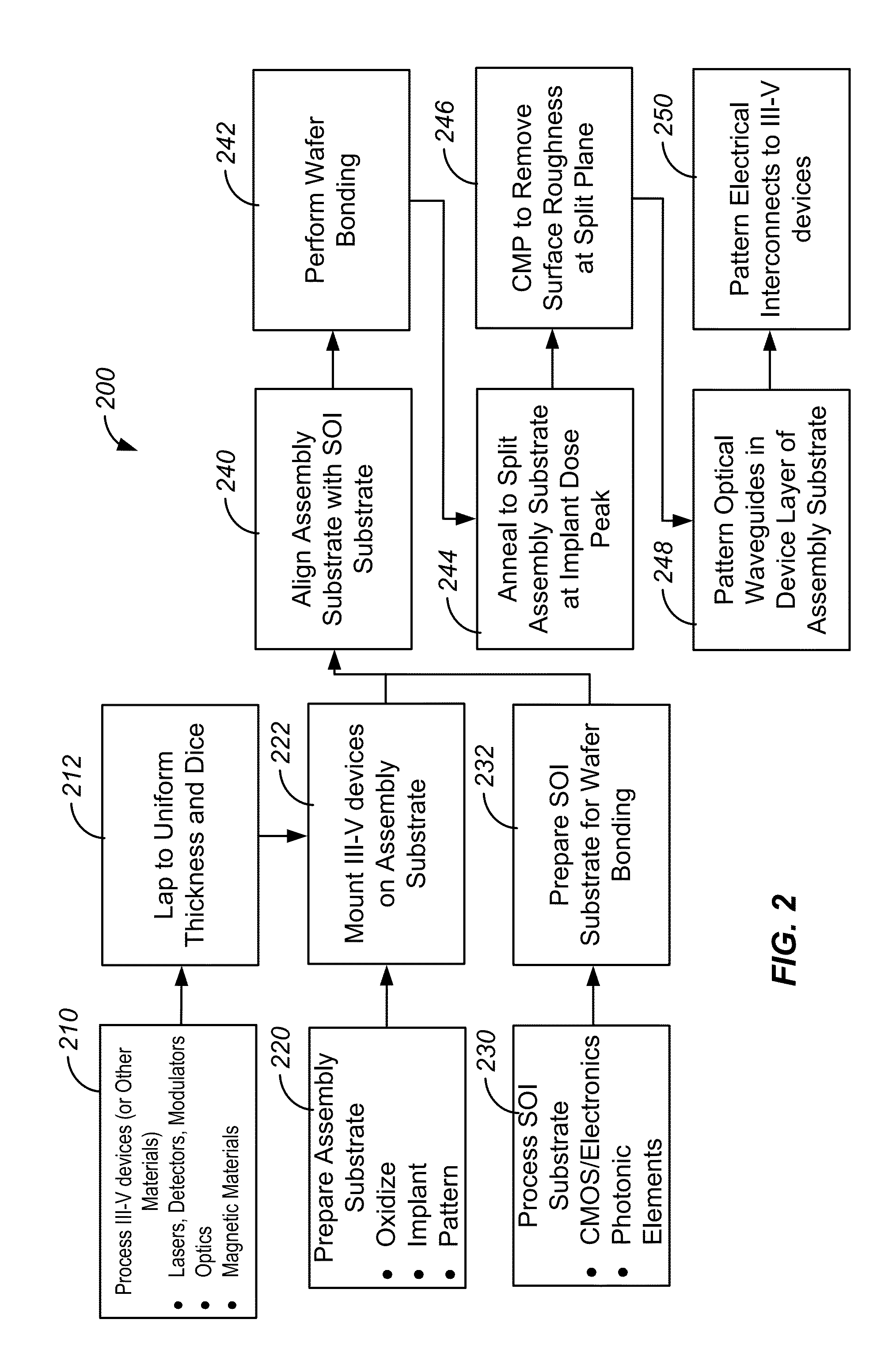

Method and system for template assisted wafer bonding

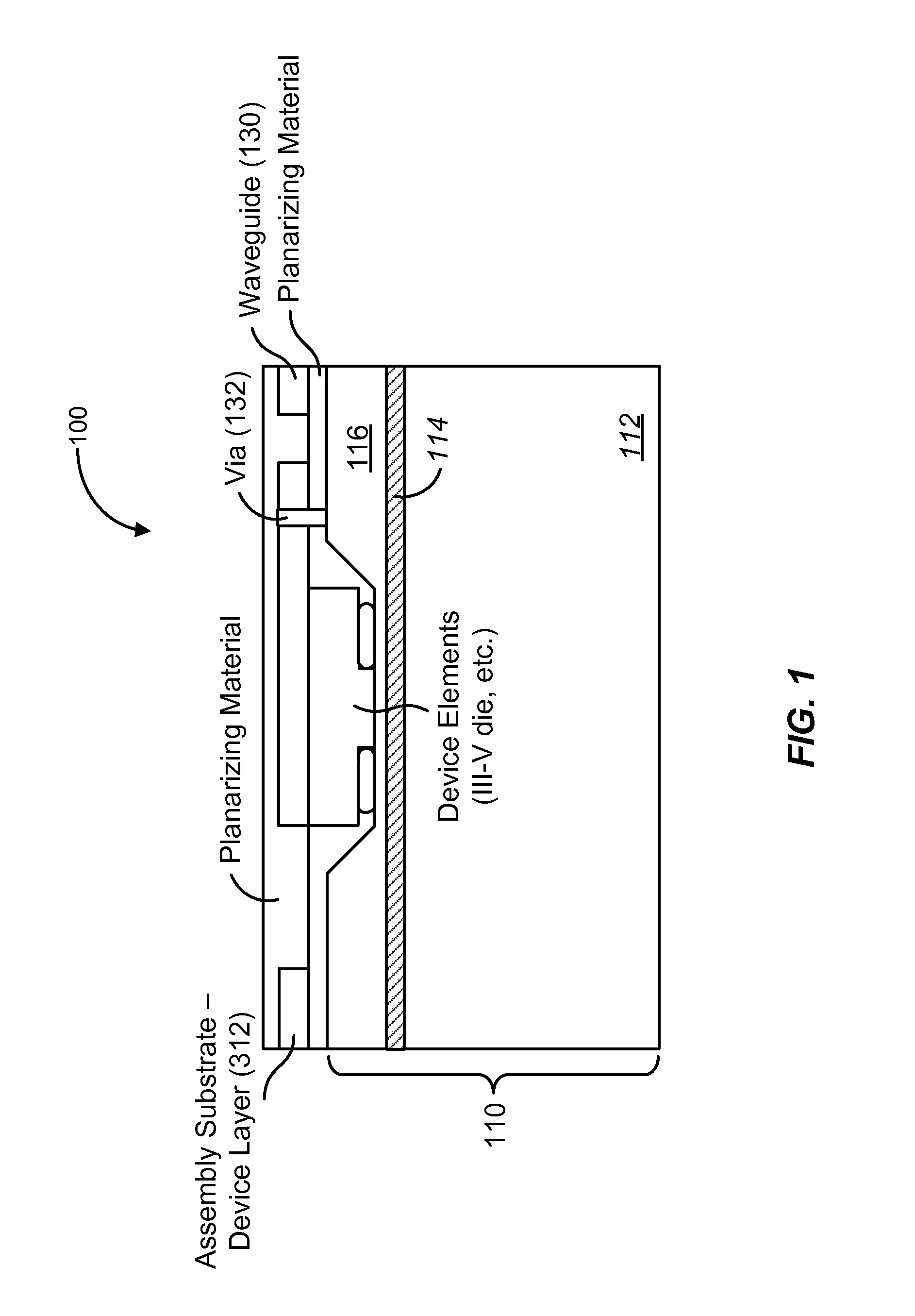

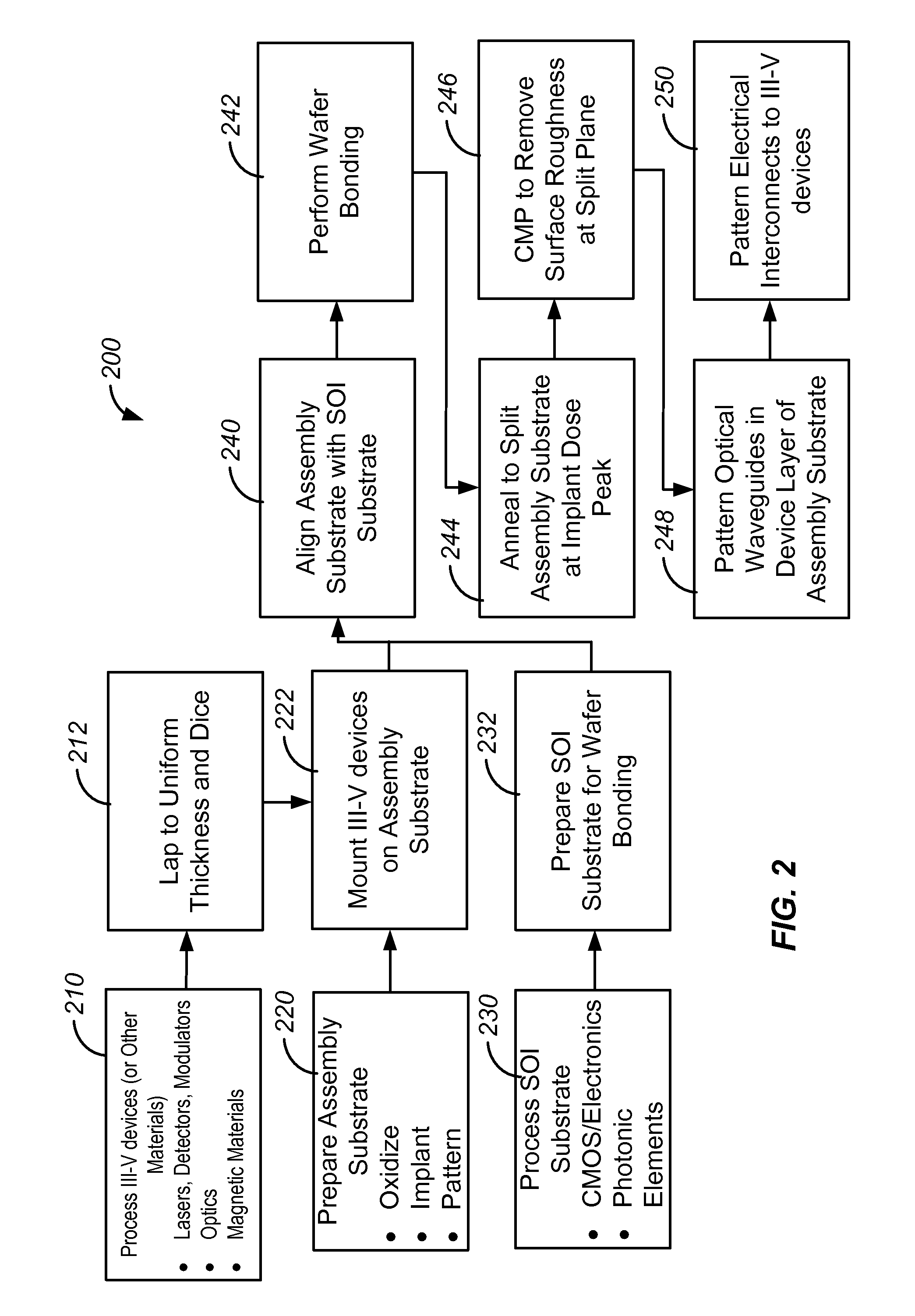

ActiveUS8222084B2Alignment toleranceSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureWafer dicing

A method of fabricating a composite semiconductor structure includes providing an SOI substrate including a plurality of silicon-based devices and providing a compound semiconductor substrate including a plurality of photonic devices. The method also includes dicing the compound semiconductor substrate to provide a plurality of photonic dies. Each die includes one or more of the plurality of photonics devices. The method further includes providing an assembly substrate, mounting the plurality of photonic dies on predetermined portions of the assembly substrate, aligning the SOI substrate and the assembly substrate, joining the SOI substrate and the assembly substrate to form a composite substrate structure, and removing at least a portion of the assembly substrate from the composite substrate structure.

Owner:SKORPIOS TECH

Substrate with refractive index matching

InactiveUS20060197096A1Solid-state devicesSemiconductor/solid-state device manufacturingThin layerComposite substrate

This invention provides a composite substrate that has a transparent mechanical support, for example of glass or quartz, a film or thin layer of monocrystalline semi-conductive material and an intermediate antireflective layer located between the thin layer or the semi-conductive film and the support. The composition of the intermediate antireflective layer varies between the support and the semi-conductive film, so that the refractive index similarly varies.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

Method and system for template assisted wafer bonding

ActiveUS20120149148A1Increase costRelaxing alignment toleranceSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureWafer dicing

A method of fabricating a composite semiconductor structure includes providing an SOI substrate including a plurality of silicon-based devices and providing a compound semiconductor substrate including a plurality of photonic devices. The method also includes dicing the compound semiconductor substrate to provide a plurality of photonic dies. Each die includes one or more of the plurality of photonics devices. The method further includes providing an assembly substrate, mounting the plurality of photonic dies on predetermined portions of the assembly substrate, aligning the SOI substrate and the assembly substrate, joining the SOI substrate and the assembly substrate to form a composite substrate structure, and removing at least a portion of the assembly substrate from the composite substrate structure.

Owner:SKORPIOS TECH

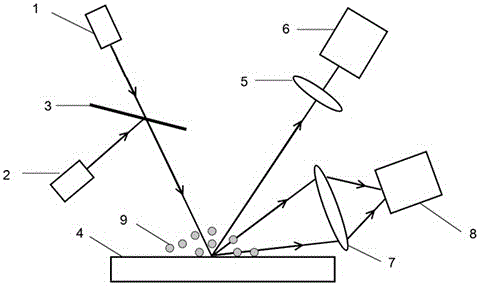

Surface Raman and infrared spectroscopy double-enhanced detecting method based on graphene and nanogold compounding

ActiveCN105699358ARealize measurementComplete measurementMaterial nanotechnologyRaman scatteringPlasma effectComposite substrate

Provided is a surface Raman and infrared spectroscopy double-enhanced detecting method based on graphene and nanogold compounding.According to the method, light sources, a lens, a graphene nanobelt and gold nanoparticle composite substrate, an infrared Fourier spectrograph and a Raman spectrometer are included.Infrared light waves and visible light waves emitted by the infrared light source and the laser light source respectively pass through a beam combiner and then irradiate the graphene nanobelt and gold nanoparticle composite substrate, after the light waves and trace molecules adsorbed on the substrate interact, reflected light is gathered by the focusing lens to enter the infrared Fourier spectrograph, and meanwhile scattered light is gathered into the Raman spectrometer.Raman scattering signals of the trace molecules can be enhanced through the local area plasma effect of the gold nanoparticles, and meanwhile infrared absorption spectrum signals of the trace molecules can be dynamically enhanced through the graphene surface plasma effect within the broadband range.According to the method, double enhancement of surface Raman and broadband infrared spectroscopy signals is achieved on the same substrate, and the advantages of being wide in enhancement wave band, high in detecting sensitivity, wide in detected matter variety range, good in stability and the like are achieved.

Owner:CHONGQING UNIV

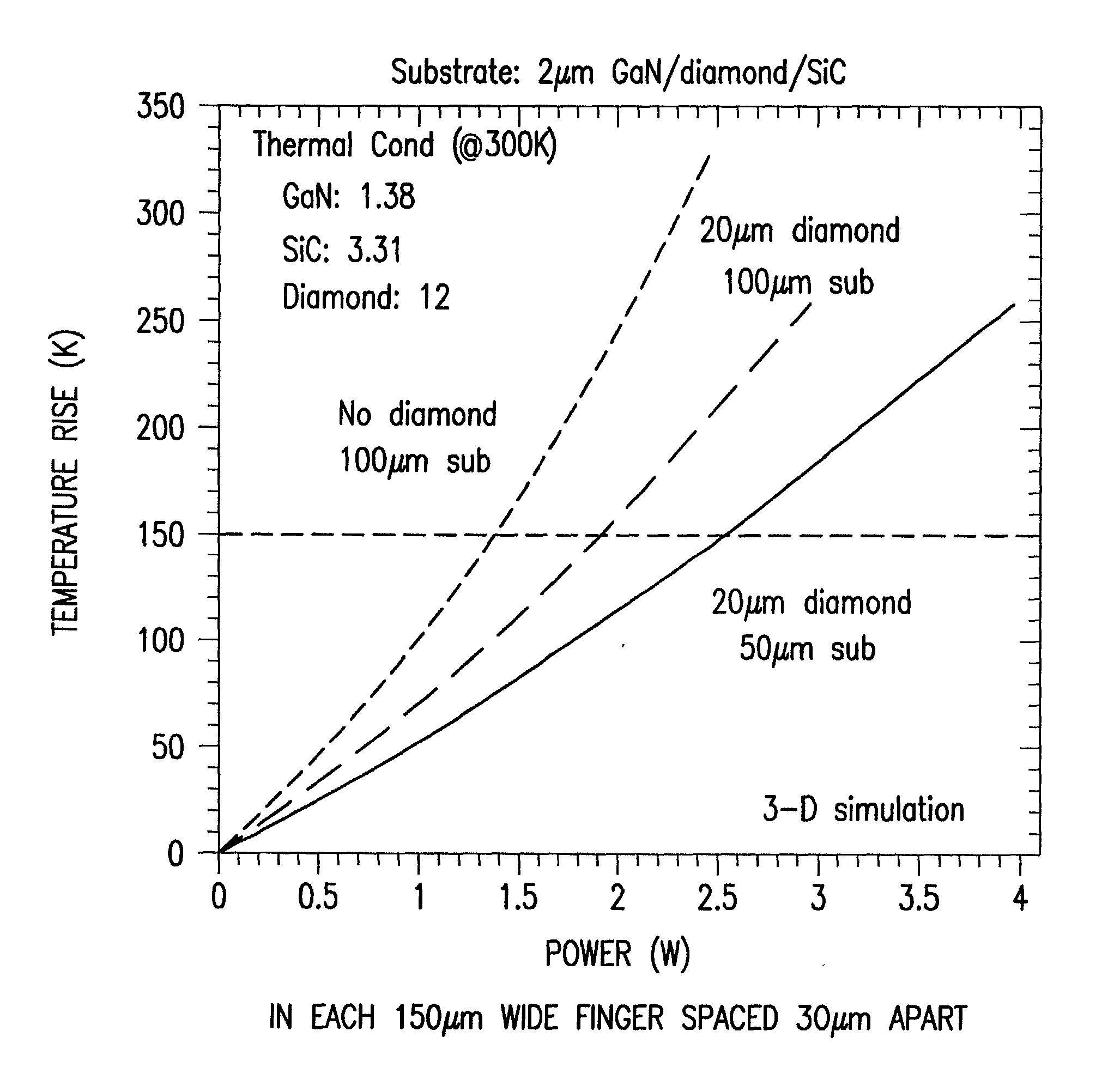

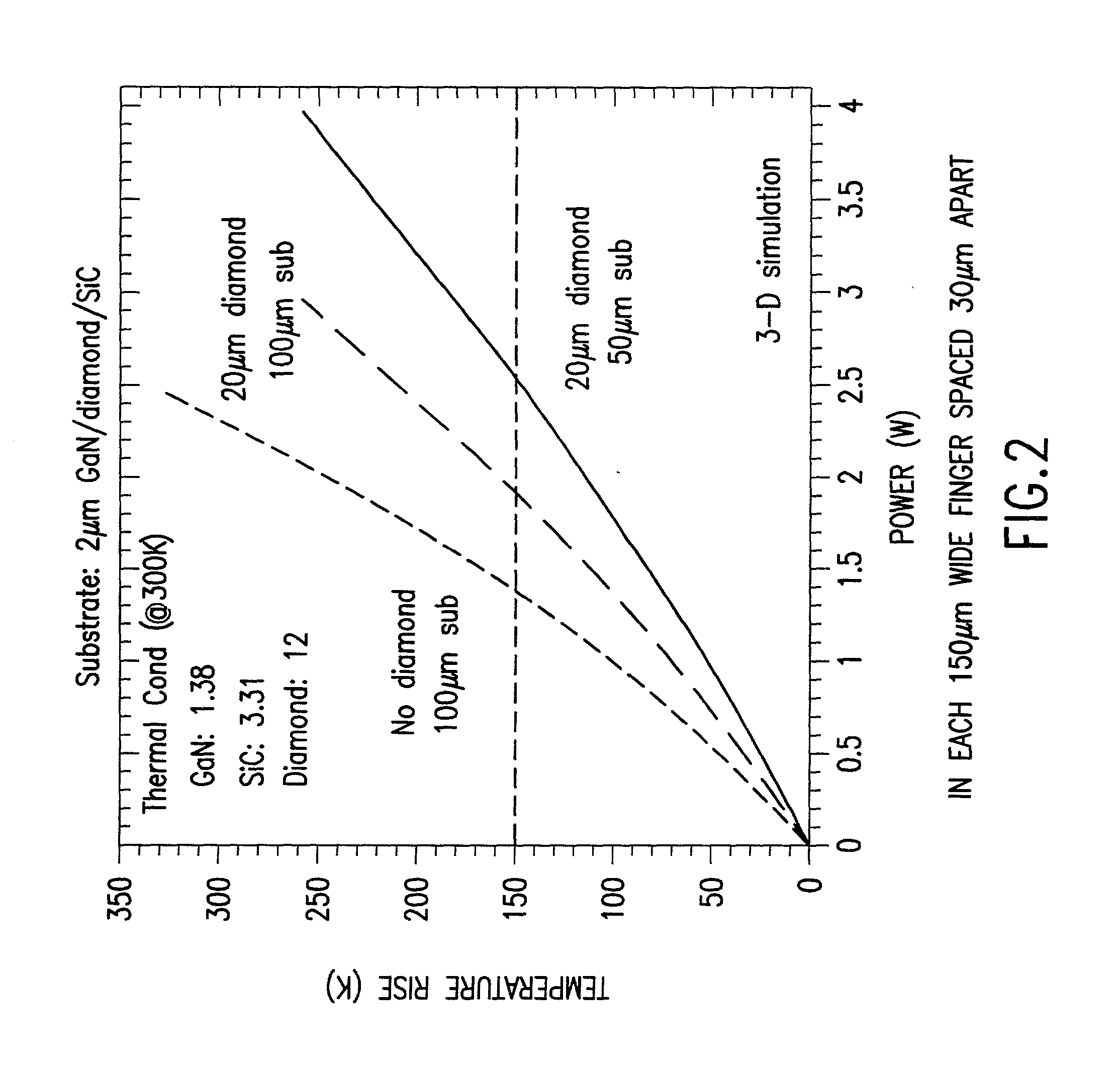

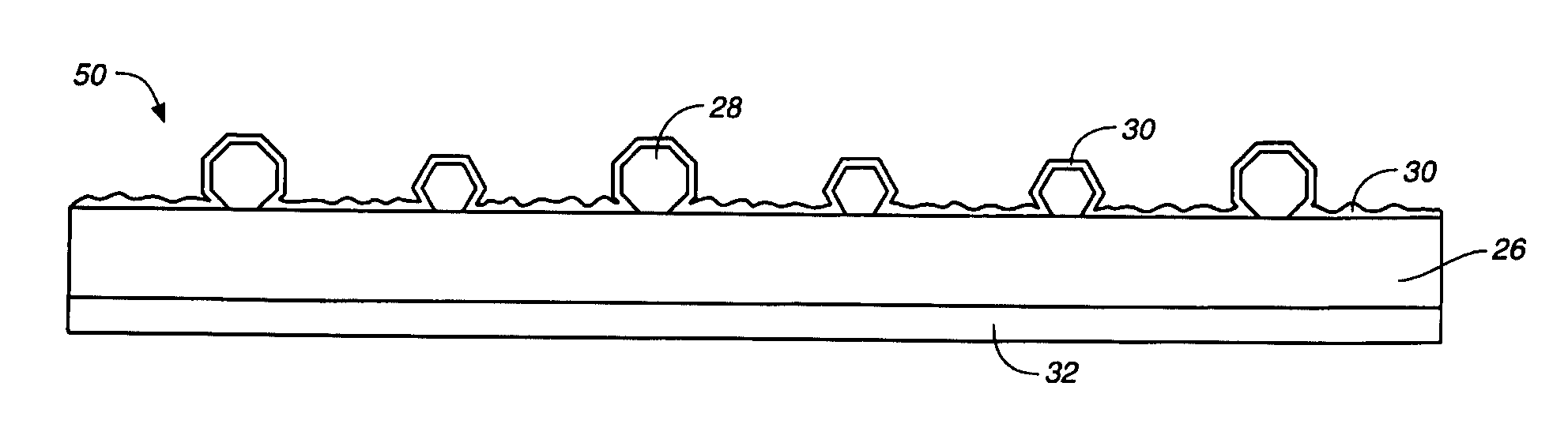

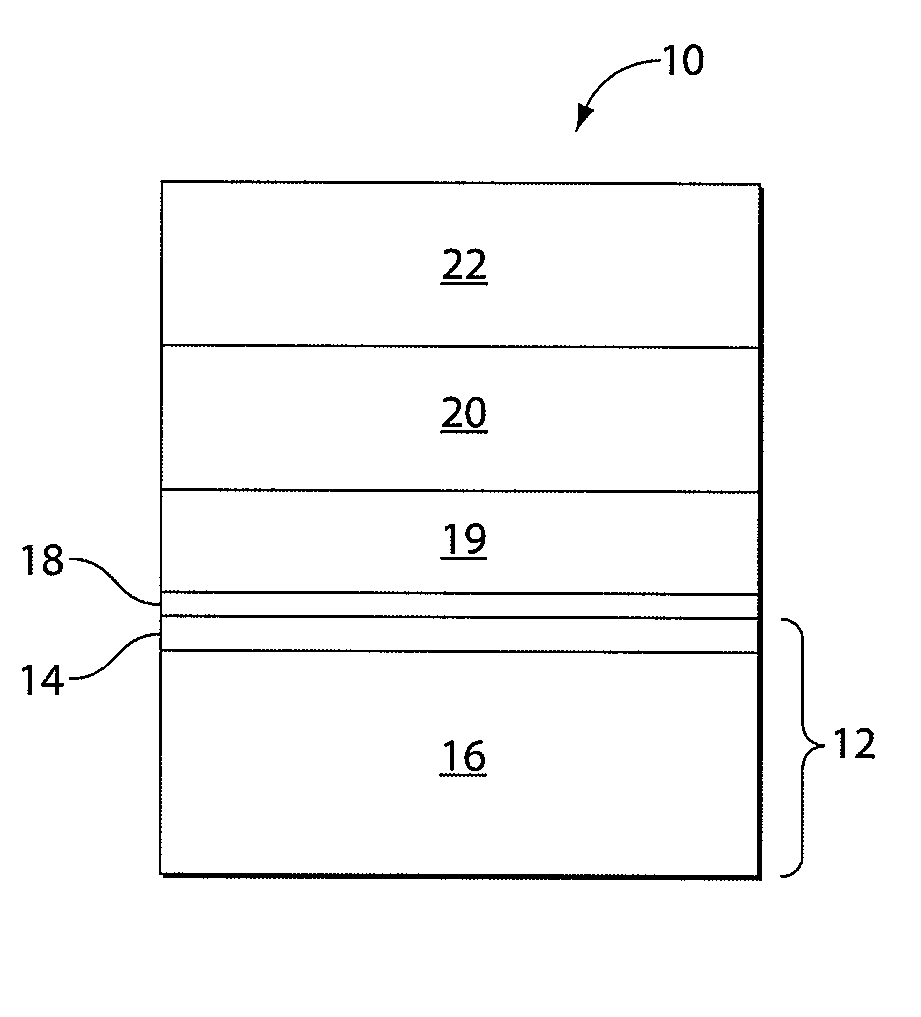

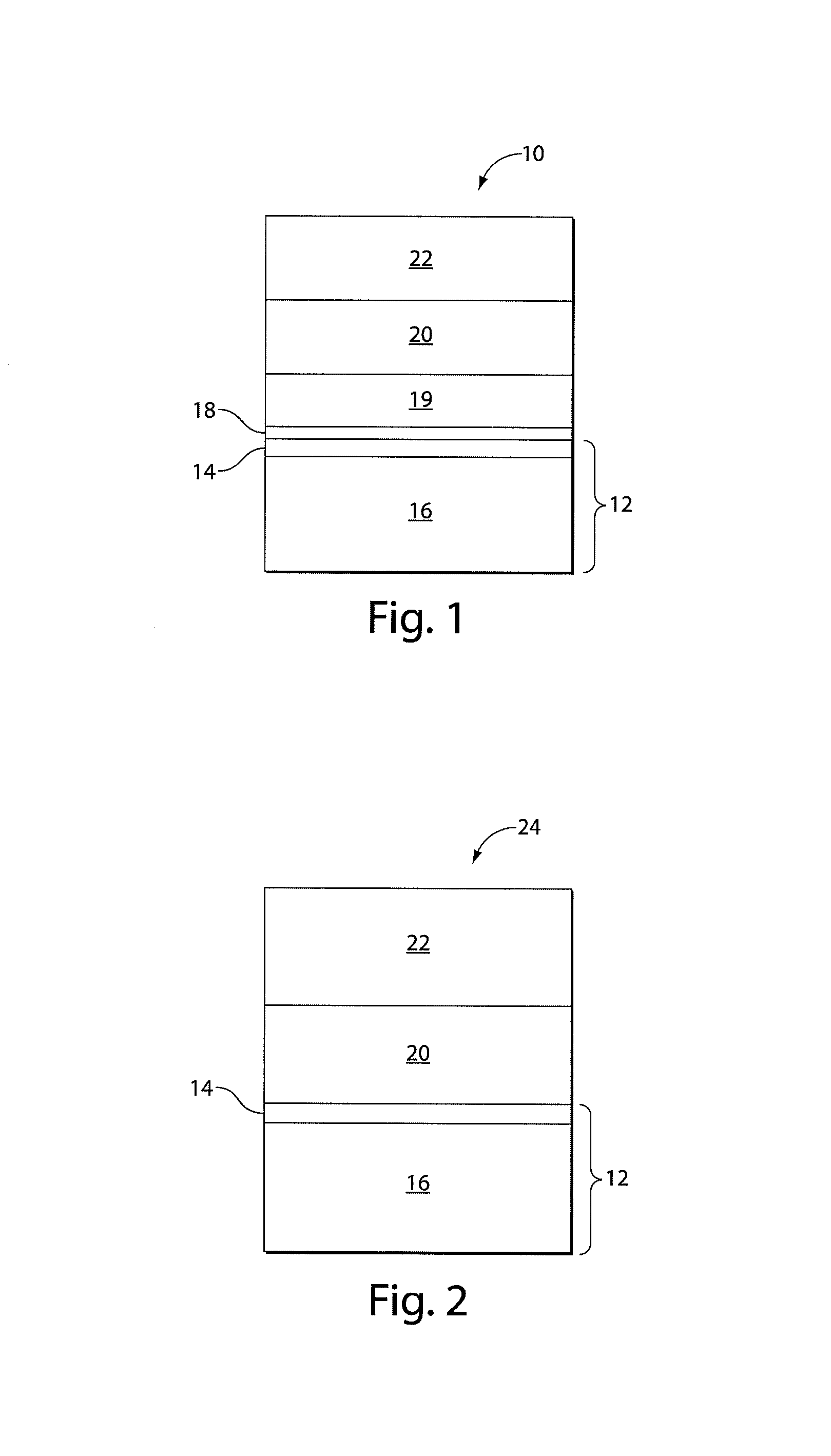

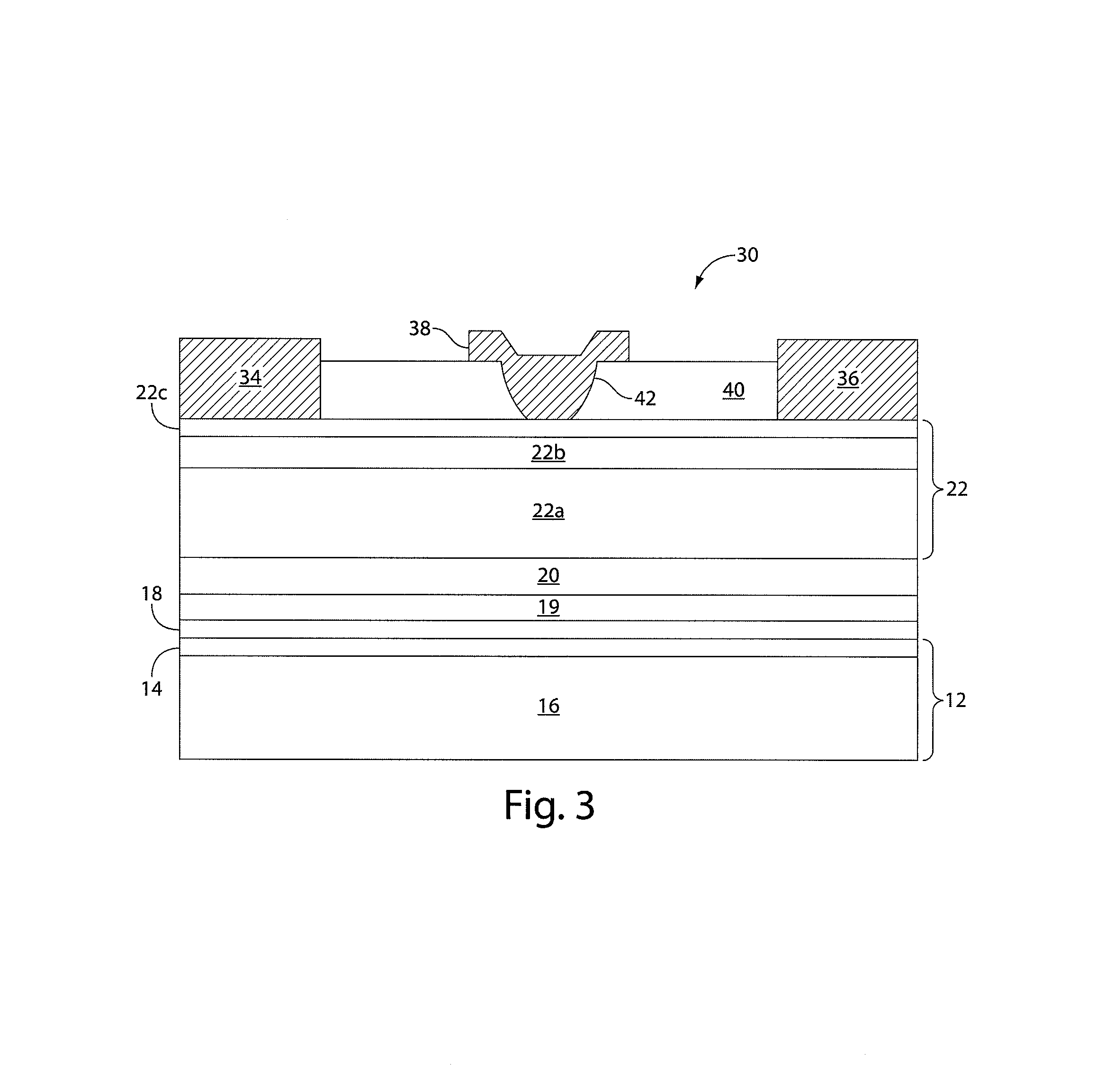

Gallium nitride material structures including substrates and methods associated with the same

ActiveUS7365374B2Semiconductor/solid-state device manufacturingSemiconductor devicesStress conditionsSemiconductor structure

Gallium nitride material-based semiconductor structures are provided. In some embodiments, the structures include a composite substrate over which a gallium nitride material region is formed. The gallium nitride material structures may include additional features, such as strain-absorbing layers and / or transition layers, which also promote favorable stress conditions. The reduction in stresses may reduce defect formation and cracking in the gallium nitride material region, as well as reducing warpage of the overall structure. The gallium nitride material-based semiconductor structures may be used in a variety of applications such as transistors (e.g. FETs) Schottky diodes, light emitting diodes, laser diodes, SAW devices, and sensors, amongst others devices.

Owner:MACOM TECH SOLUTIONS HLDG INC

Catalytic cracking catalyst and preparing method thereof

InactiveCN1552801AHigh activityGood activity and stabilityCatalytic crackingRare earthComposite substrate

A catalytic cracking catalyst and its production are disclosed. The catalyst consists of clay 20 - 80m%, silica sol 5 - 30m%, pseudodiaspore 0 - 30%, faujusite with cell parameters of (2.432 - 2.472nm) 5 - 40%, and balanced of ZSM-5 zeolite, beta zeolite and their mixture, oxide selected from Sb, rare earths, Ti, Mg, Zn, P, Sr or their mixture. It uses silica sol as substrate or silica sol and pseudodiaspore as composite substrate to increase macromolecular cracking ability and to improve wearproof performance. It can be produced by non-continuous process or multi-stream continuous process with easy mass production.

Owner:中国石油化工集团公司长岭炼油化工有限责任公司

Method for measurement of composite heat damage with infrared spectroscopy

ActiveUS7115869B2Efficiently and objectively determiningRadiation pyrometryScattering properties measurementsFiberNon destructive

Owner:THE BOEING CO

Aqueous acrylic emulsion, aqueous adhesive for plastic-plastic composite materials and preparation method thereof

InactiveCN101717468AGood adhesionHigh molecular weightEster polymer adhesivesFunctional monomerMetal foil

The invention discloses an aqueous acrylic emulsion, an aqueous adhesive for plastic-plastic composite materials and a preparation method thereof, and belongs to the field of preparation of adhesive. The acrylic emulsion is polymerized from 30-50 wt% of acrylic acid hard monomer, 40-60 wt% of acrylic acid soft monomer and 5-10 wt% of acrylic acid functional monomer under the action of water, an emulsifying agent, an initiator, a buffering agent and a pH regulator. The invention also provides an aqueous adhesive and a preparation method thereof. The molecule segment of the film forming matter (acrylate copolymer) in the aqueous acrylic emulsion has various chemical groups, such as -OH, -COOH, -NH and the like; and the chemical groups can form various chemical bonds and hydrogen bonding acting force, and thereby having favorable adhering force for various composite substrates (plastic films, aluminum plating films, metal foils and the like). By properly matching the soft monomer and the hard monomer and adopting the corresponding functional monomer to participate in the copolymerization, the invention enhances the adhesive affinity to the plastic films with low surface tension, thereby enhancing the wetting property of the adhesive on the surface of the plastic films and the combined strength.

Owner:BEIJING COMENS NEW MATERIALS

Aqueous acrylic emulsion, aqueous adhesive for pearlized film composite materials and preparation method thereof

InactiveCN101717467AGood adhesionImprove the level ofEster polymer adhesivesFunctional monomerMetal foil

The invention discloses an aqueous acrylic emulsion, an aqueous adhesive for pearlized film composite materials and a preparation method thereof, and belongs to the field of preparation of adhesive. The acrylic emulsion is polymerized from 20-40 wt% of acrylic acid hard monomer and 55-70 wt% of acrylic acid soft monomer and 1-5 wt% of acrylic acid functional monomer under the action of water, an emulsifying agent, an initiator, a buffering agent and a pH regulator. The invention also provides an aqueous adhesive and a preparation method thereof. The molecule segment of the film forming matter (acrylate copolymer) in the aqueous acrylic emulsion has various chemical groups, such as -OH, -COOH, -NH and the like; and the chemical groups can form various chemical bonds and hydrogen bonding acting force, and thereby having favorable adhering force for various composite substrates (plastic films, aluminum plating films, metal foils and the like). The polymer obtained by polymerization has higher molecular weight, lower coating viscosity and favorable levelling property; and thus, the polymer has high shear strength and initial strength and can achieve the best bonding strength without curing for a long time.

Owner:BEIJING COMENS NEW MATERIALS

Method for measurement of composite heat damage with infrared spectroscopy

ActiveUS20050067569A1Efficiently and objectively determiningRadiation pyrometryScattering properties measurementsNon destructiveFiber

A non-destructive method determines an amount of heat exposure to a resin-fiber composite substrate. A value of infrared energy reflected by a composite substrate is determined. The value of infrared energy reflected, or conversely absorbed, is correlated to a degree or amount of heat exposure. According to an aspect of the present invention, one method utilizes an infrared spectrometer to determine infrared absorbance of a composite substrate. The infrared energy of the reflected beam is then compared with the pre-determined value of infrared energy reflected off a reference heat damaged composite substrate to determine the amount of heat exposure.

Owner:THE BOEING CO

Fire-retardant paint with steel structure

ActiveCN101857756AExtend fire resistance timeImprove fire resistanceFireproof paintsPolyurea/polyurethane coatingsPhosphoric acidComposite substrate

The invention relates to fire-retardant paint with a steel structure, which is prepared from the following raw materials proportioning by weight: 45 to 60 of composite substrate resin, 6 to 8 of melamine, 6 to 8 of pentaerythritol, 16 to 20 of ammonium polyphosphate, 4 to 10 of expansible graphite, 2 to 5 of nano magnesium hydroxide, 1 to 3 of zinc phosphate, 1 to 3 of zinc borate, 2 to 5 of aluminum hydroxide, 3 to 5 of aluminum polyphosphate, 6 to 9 of titanium dioxide, 0.5 to 0.8 of flatting agent and 15 to 20 of acetone. The paint has excellent capabilities of fire prevention and corrosion prevention.

Owner:INNER MONGOLIA XINGTAI CONSTRAL GRP CO LTD

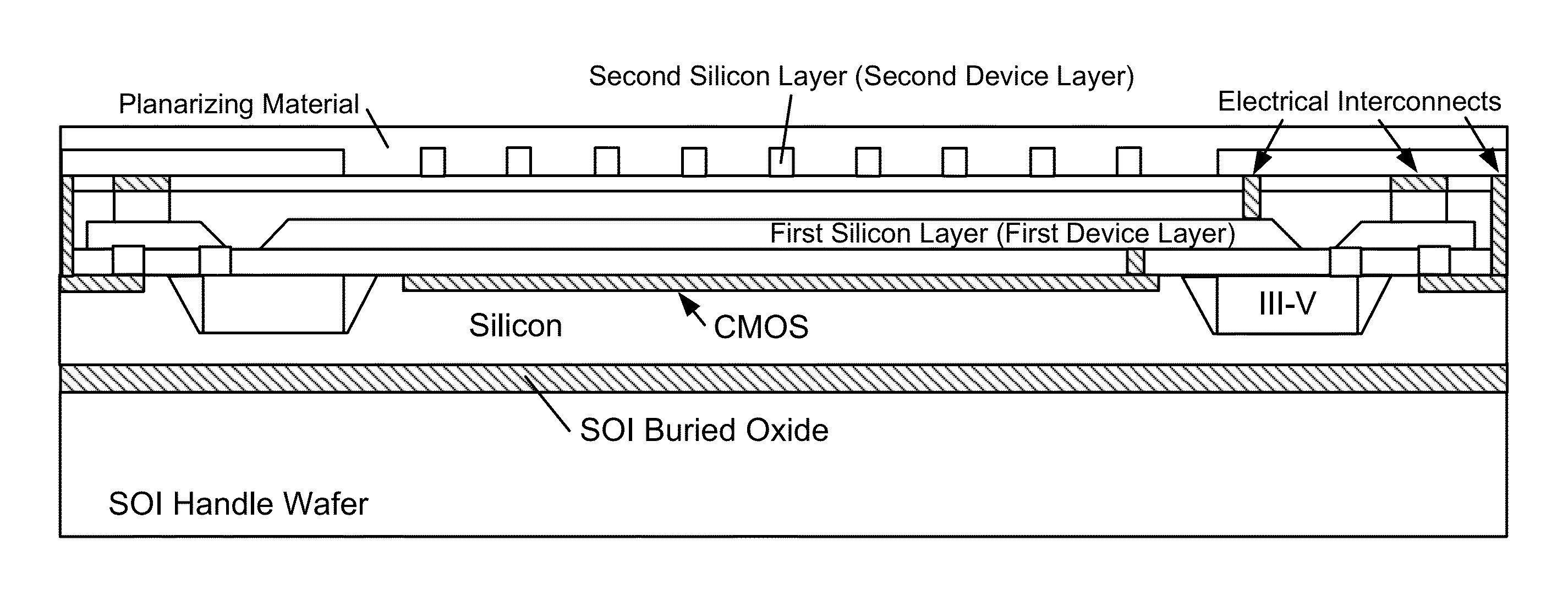

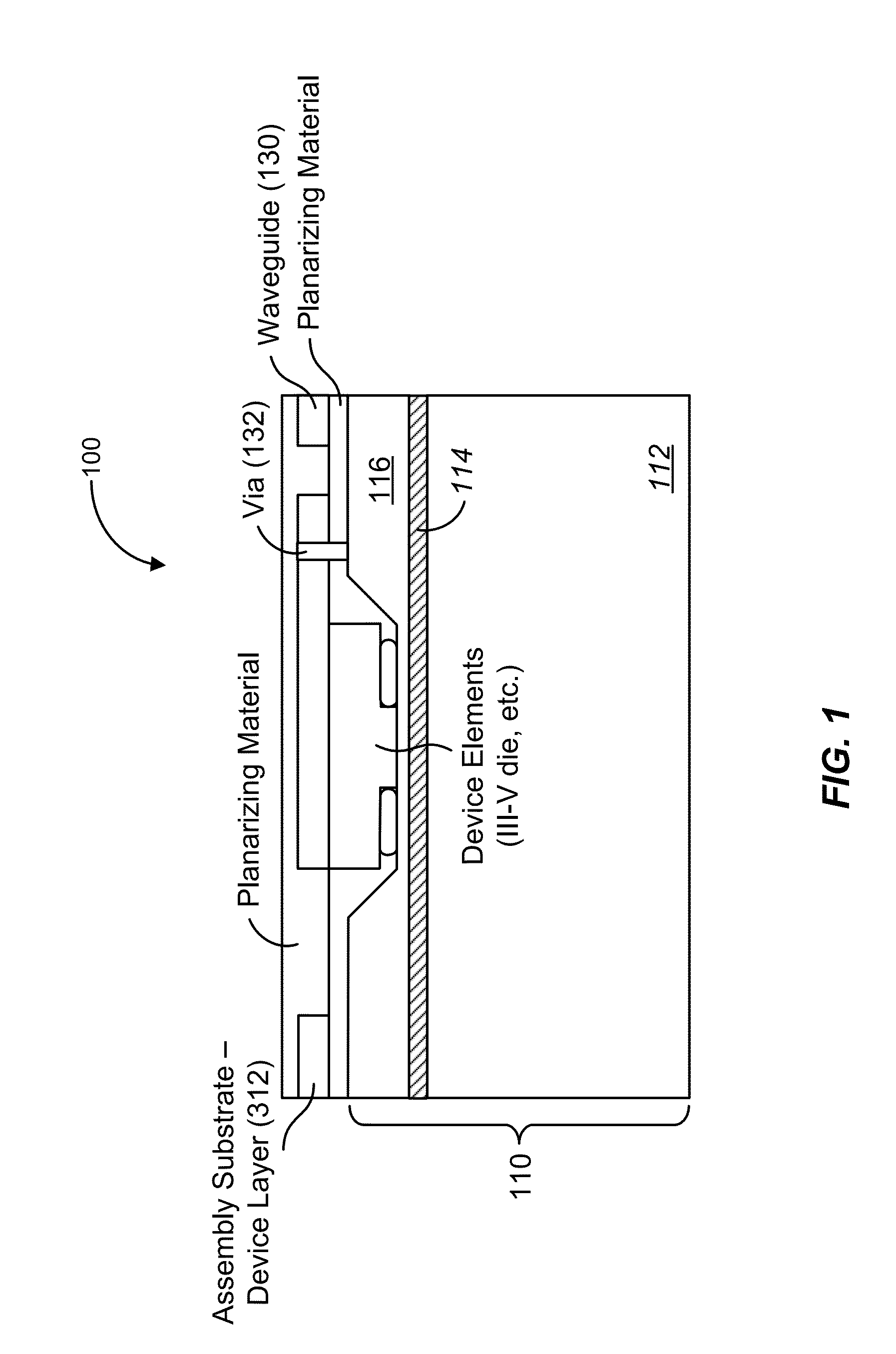

Vertical integration of CMOS electronics with photonic devices

ActiveUS20130210214A1Increase costRelaxing alignment toleranceSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor structureCmos electronics

A method of fabricating a composite semiconductor structure includes providing an SOI substrate including a plurality of silicon-based devices, providing a compound semiconductor substrate including a plurality of photonic devices, and dicing the compound semiconductor substrate to provide a plurality of photonic dies. Each die includes one or more of the plurality of photonics devices. The method also includes providing an assembly substrate having a base layer and a device layer including a plurality of CMOS devices, mounting the plurality of photonic dies on predetermined portions of the assembly substrate, and aligning the SOI substrate and the assembly substrate. The method further includes joining the SOI substrate and the assembly substrate to form a composite substrate structure and removing at least the base layer of the assembly substrate from the composite substrate structure.

Owner:SKORPIOS TECH

Method for fabricating a semiconductor component based on GaN

InactiveUS7691656B2Increased radiation outputTechnically simpleSolid-state devicesSemiconductor/solid-state device manufacturingInter layerComposite substrate

A semiconductor component has a plurality of GaN-based layers, which are preferably used to generate radiation, produced in a fabrication process. In the process, the plurality of GaN-based layers are applied to a composite substrate that includes a substrate body and an interlayer. A coefficient of thermal expansion of the substrate body is similar to or preferably greater than the coefficient of thermal expansion of the GaN-based layers, and the GaN-based layers are deposited on the interlayer. The interlayer and the substrate body are preferably joined by a wafer bonding process.

Owner:OSRAM OLED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com