Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9379results about "Special ornamental structures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

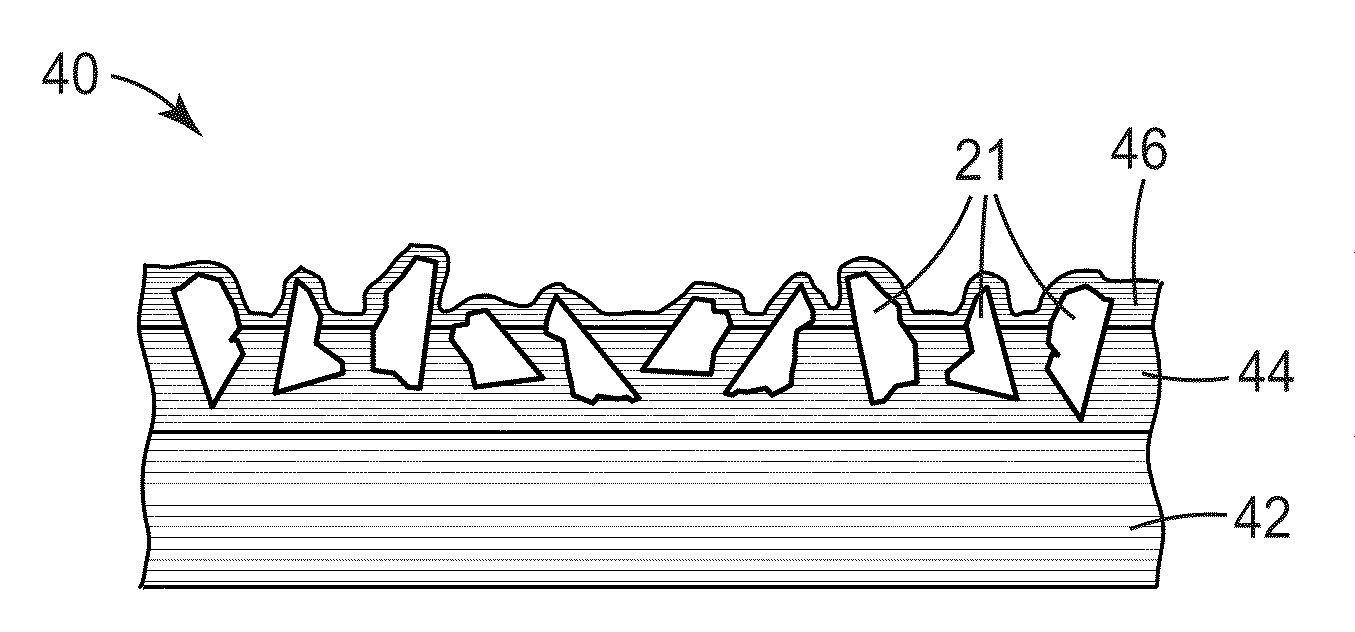

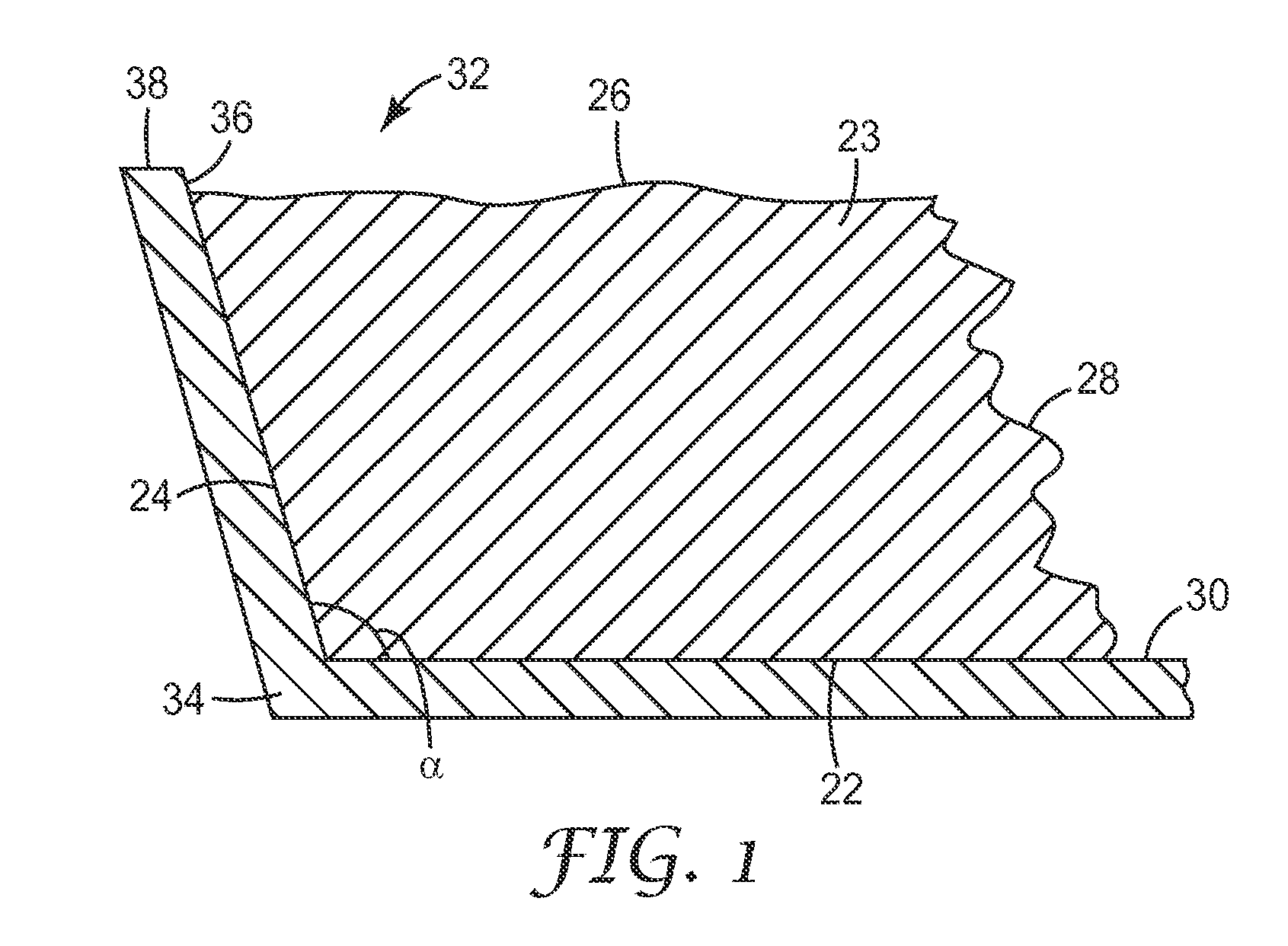

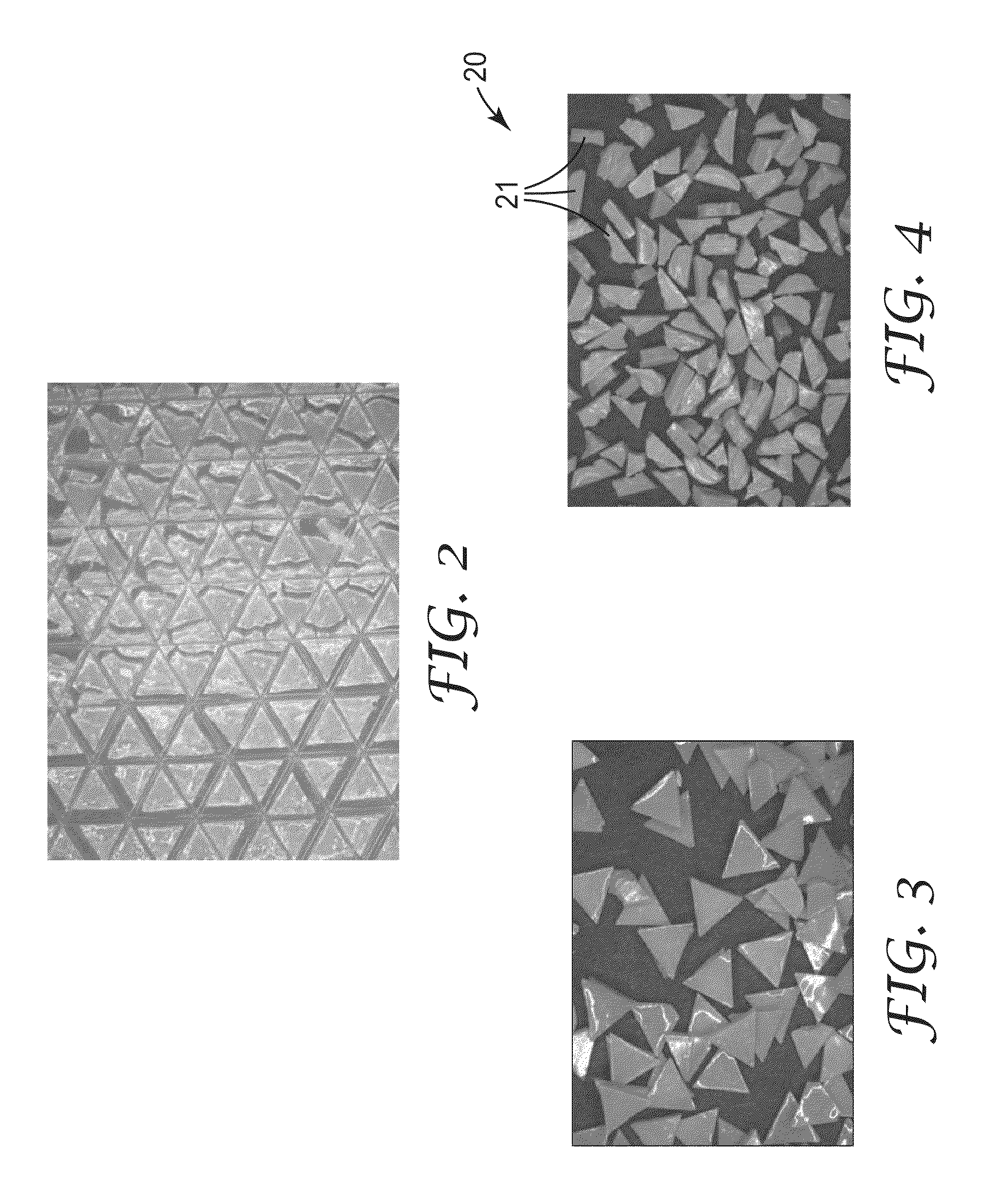

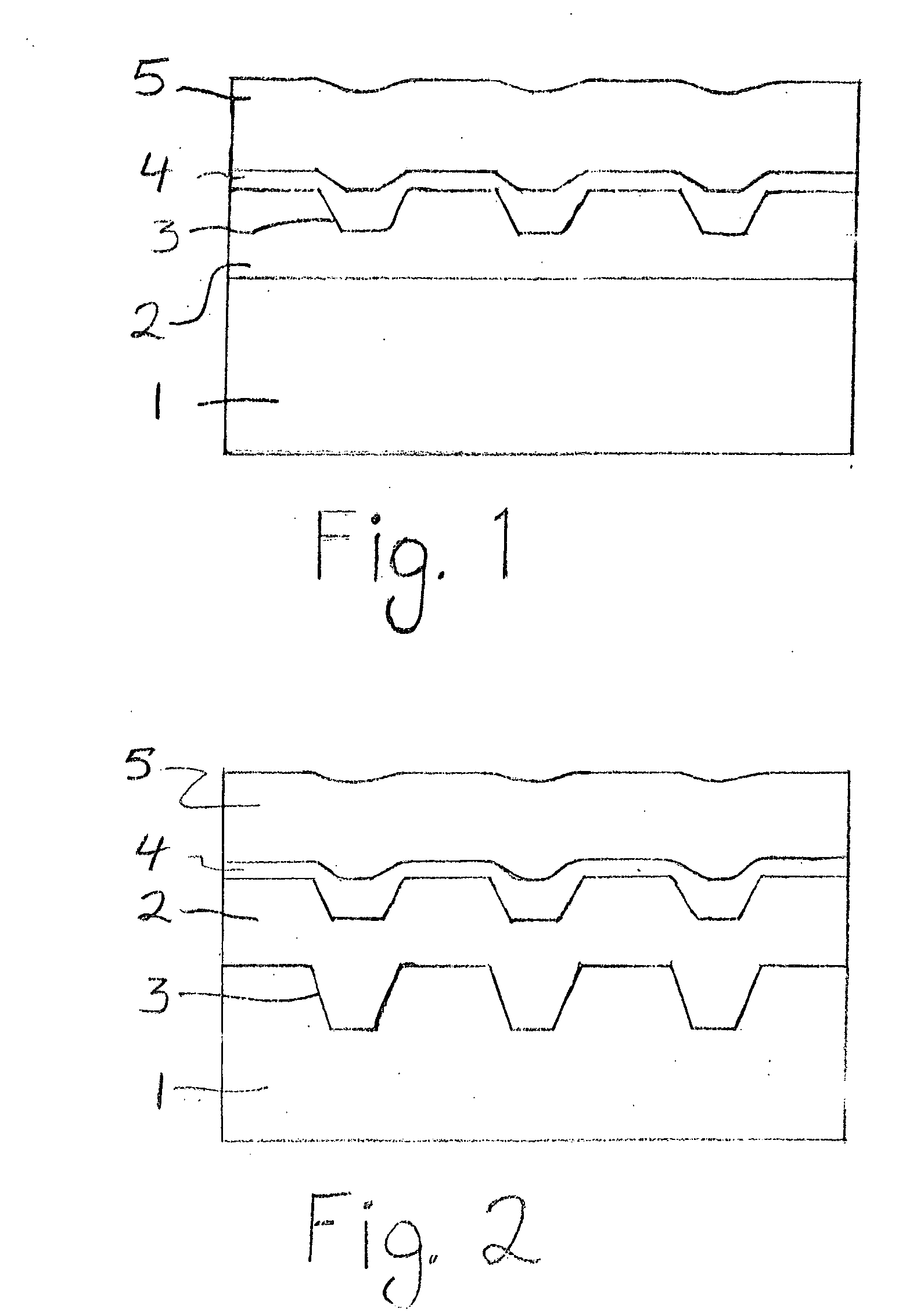

Shaped, fractured abrasive particle, abrasive article using same and method of making

ActiveUS20090169816A1Improve performanceLarge distributionPigmenting treatmentSpecial ornamental structuresPolymer chemistryAbrasive

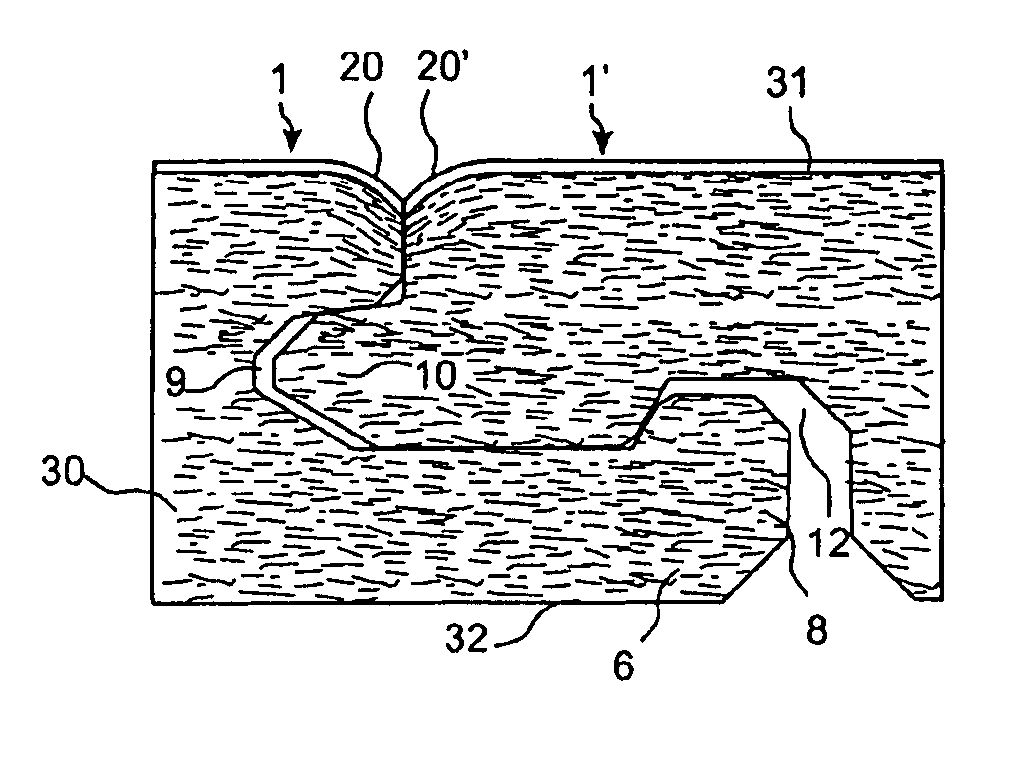

Precursor alpha alumina abrasive particles in a mold are subjected to a drying process that cracks or fractures at least a majority of the precursor abrasive particles into at least two pieces thereby producing abrasive shards having a smaller size than the mold cavity from which they were made. The smaller abrasive shards, once formed, could be reassembled like jigsaw puzzle pieces to reproduce the original cavity shape of the mold from which they were made. The cracking or fracturing of the precursor abrasive particles is believed to occur by ensuring that the surface tension of the abrasive dispersion to the walls of the mold is greater than the internal attractive forces of the abrasive dispersion as the abrasive dispersion is dried within the mold cavity.

Owner:3M INNOVATIVE PROPERTIES CO

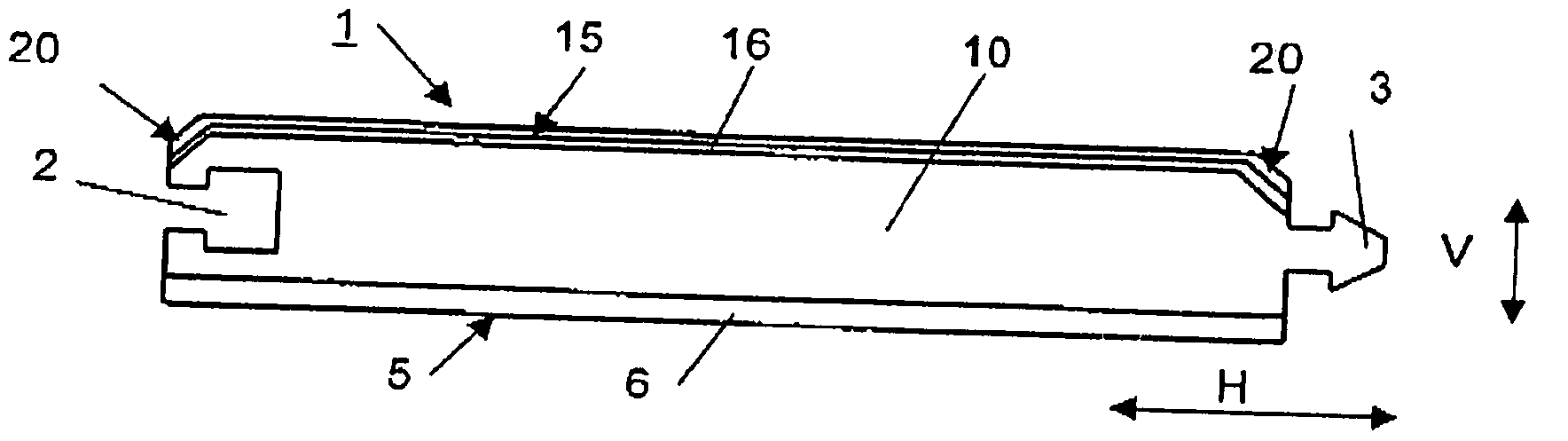

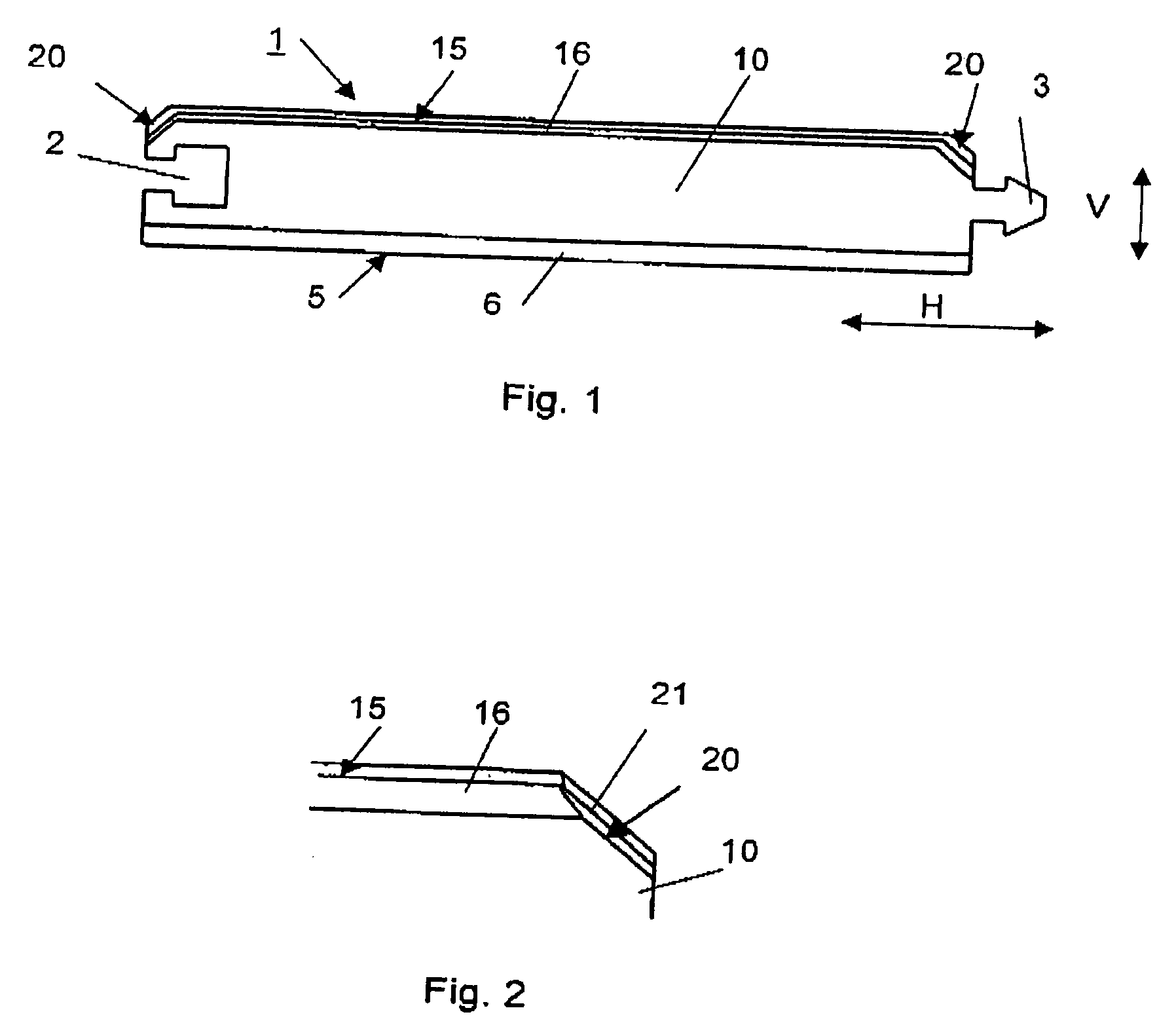

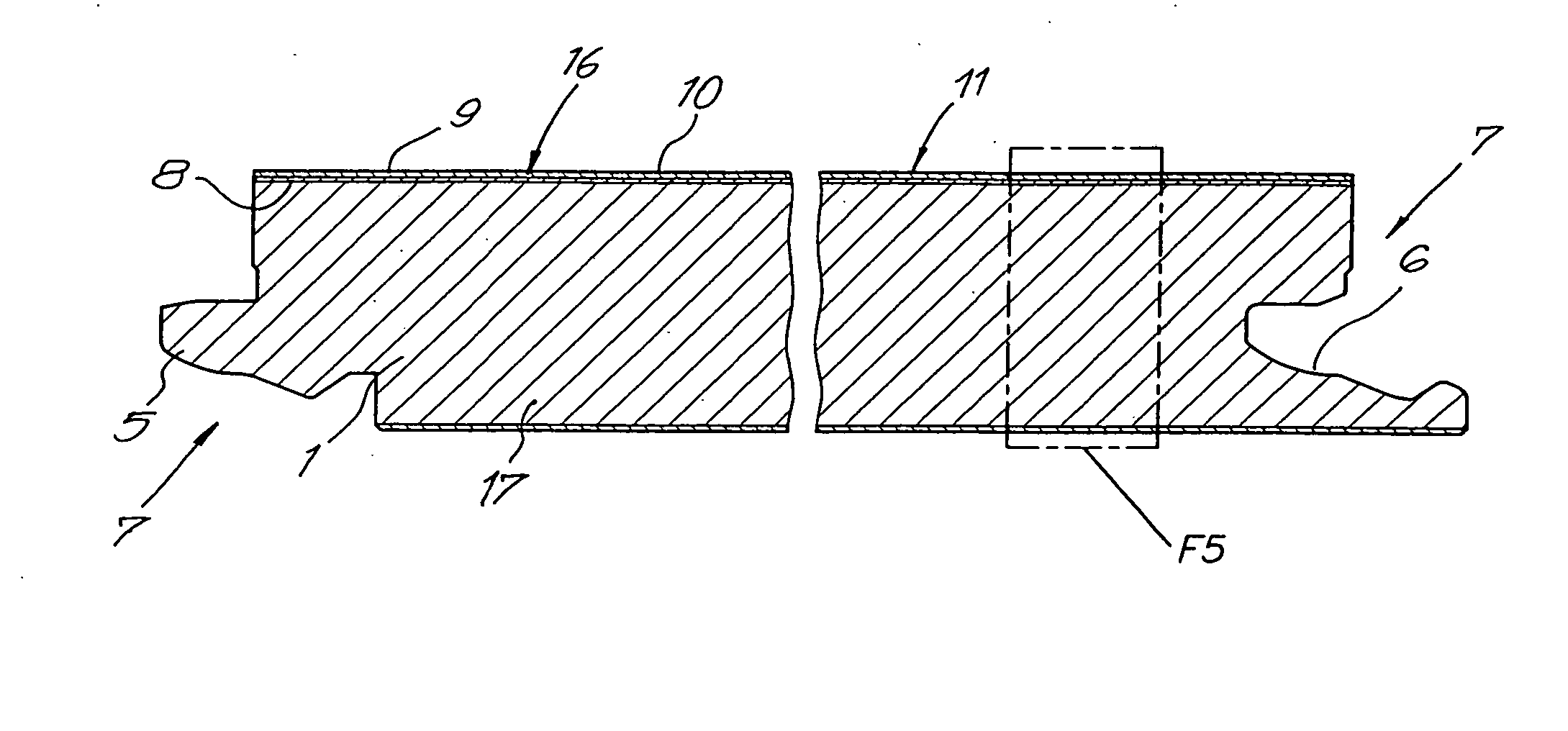

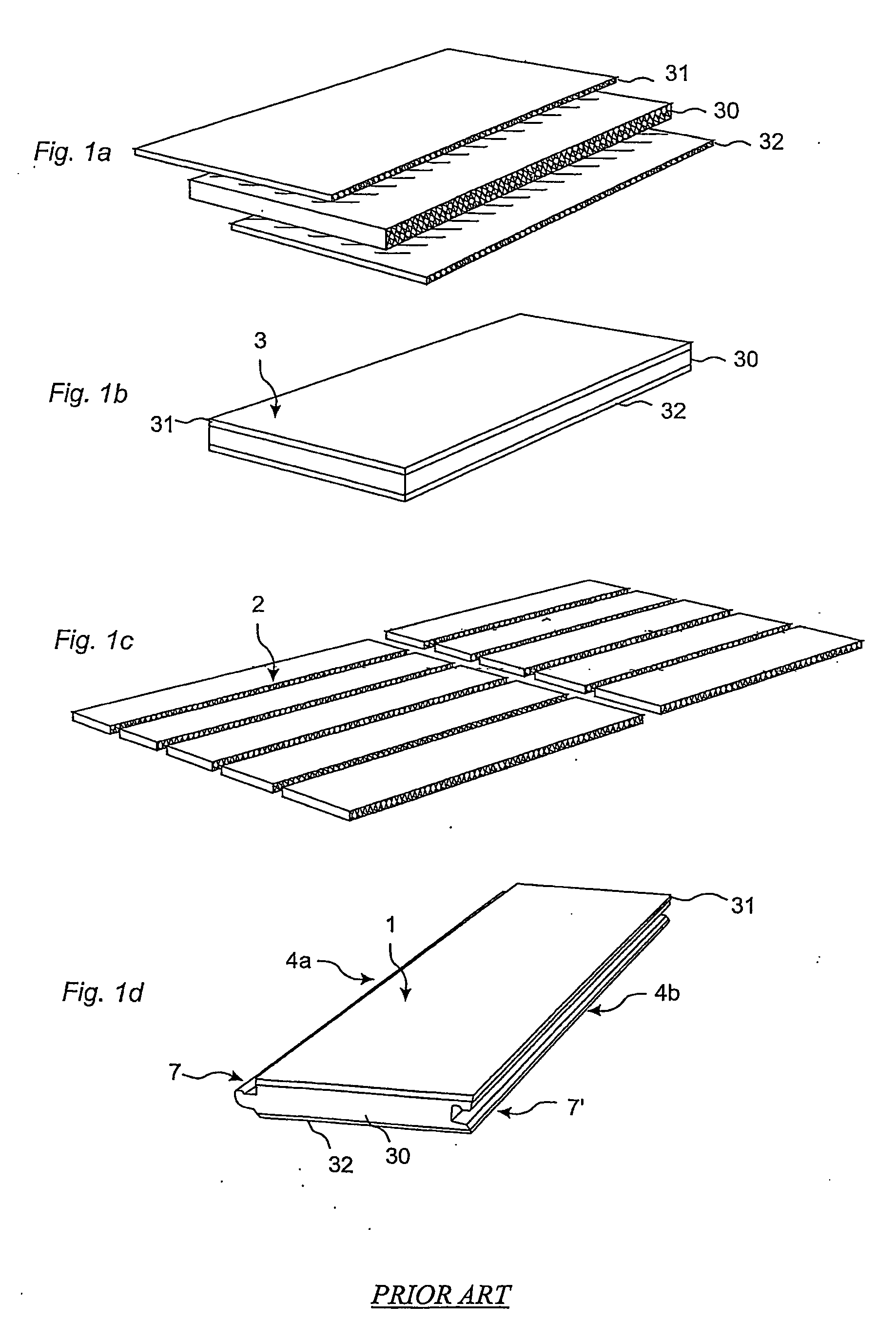

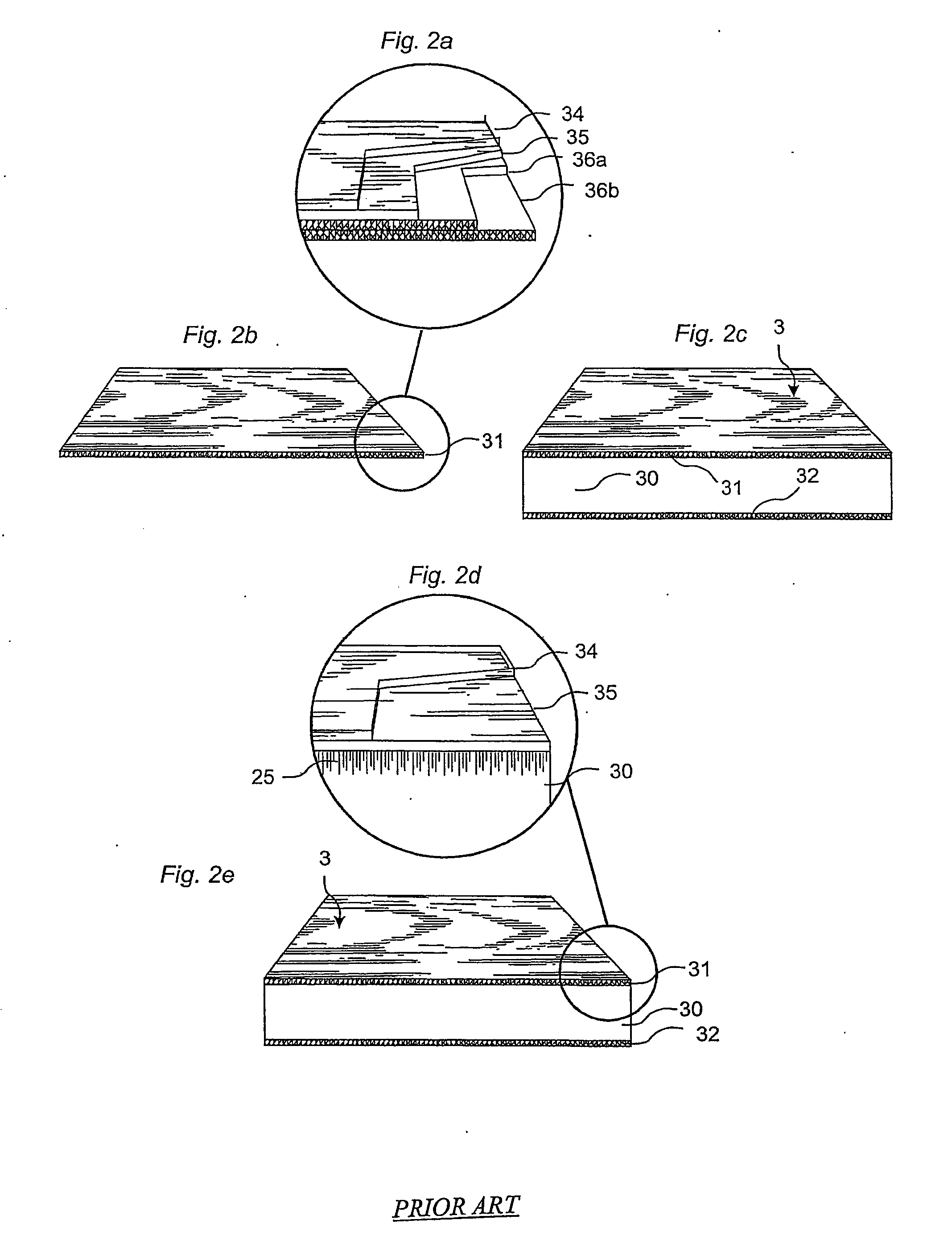

Flooring panel

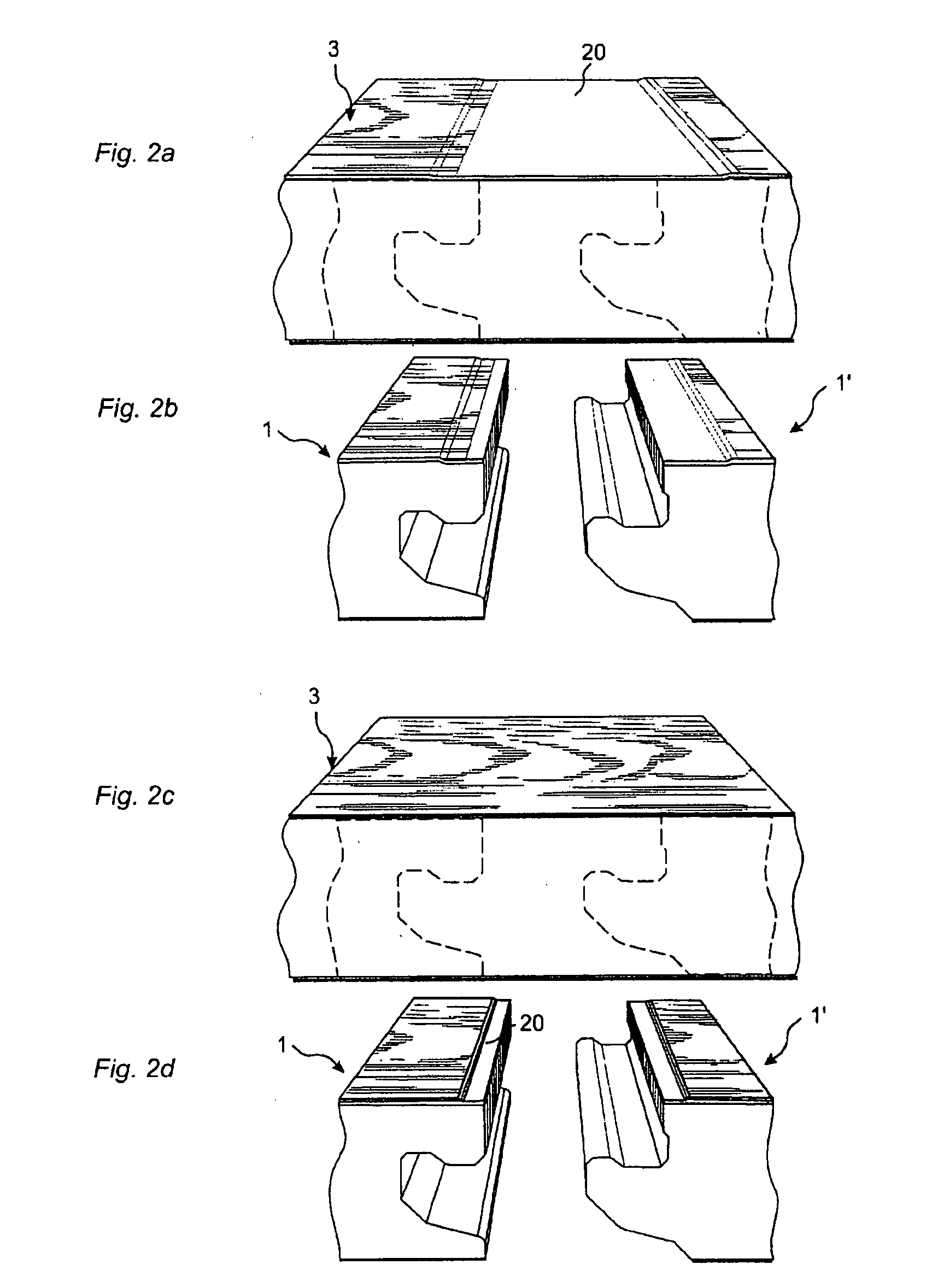

A panel, in particular a flooring panel, of a wood material which is provided with a mechanism for the detachable connection of a least two panels, whereby form-fitting elements for locking in the vertical direction and in the horizontal direction with another panel are embodied on at least one lateral edge of a first panel, whereby a chamfer is embodied on at least one lateral edge starting from an upper side. The chamfer or the form-fitting elements are coated or impregnated with at least one melamine layer.

Owner:KRONOTEC

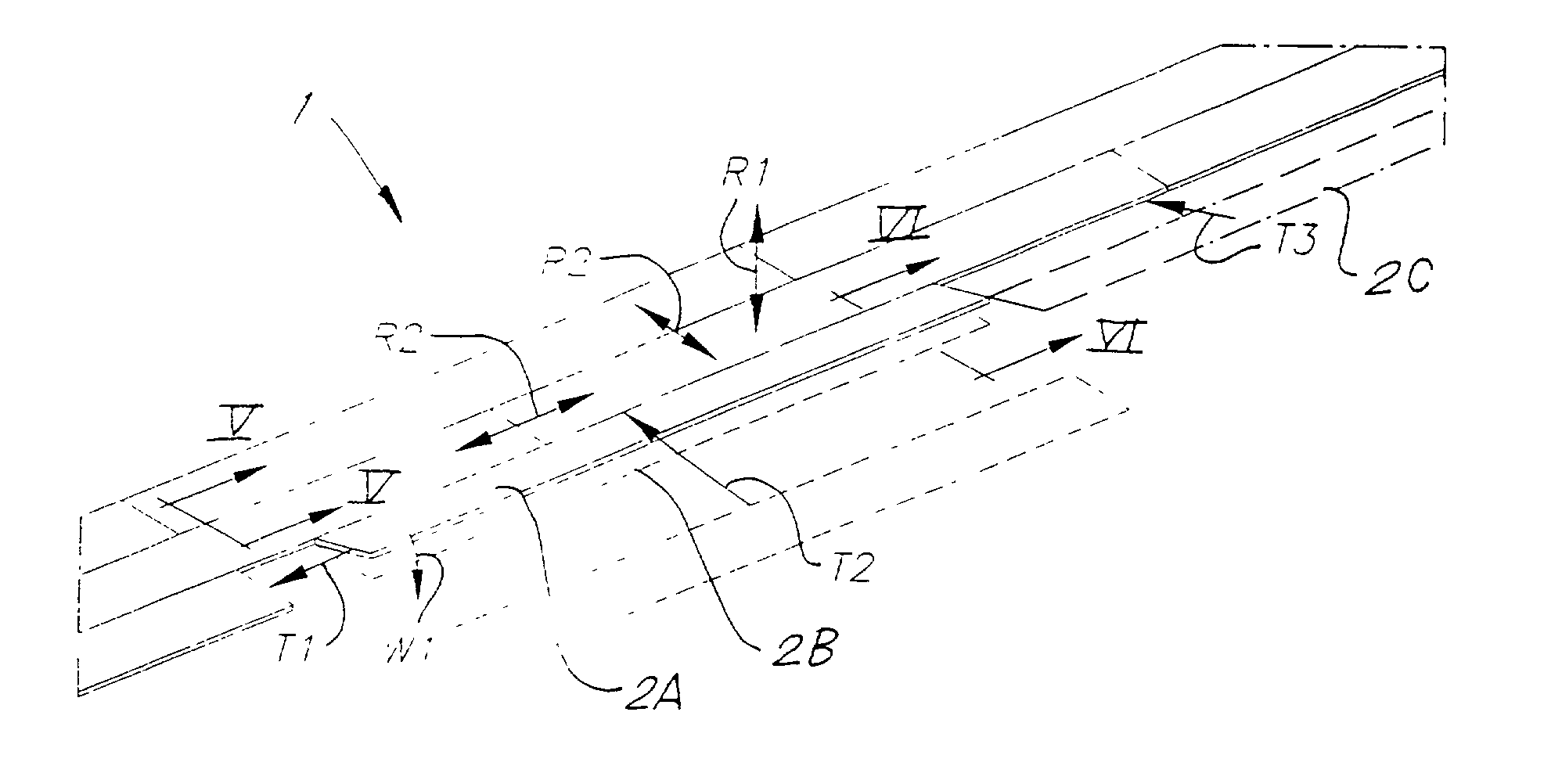

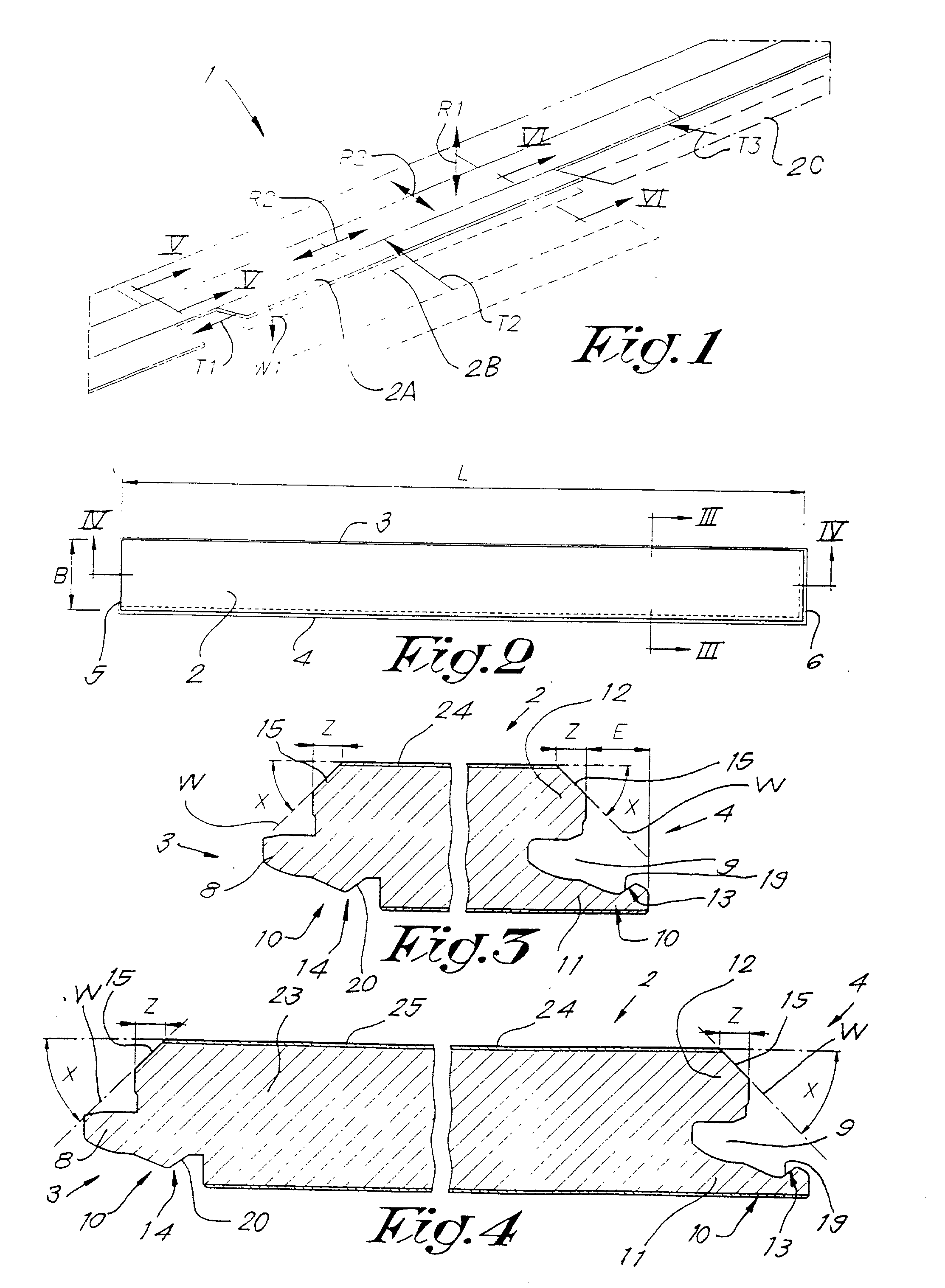

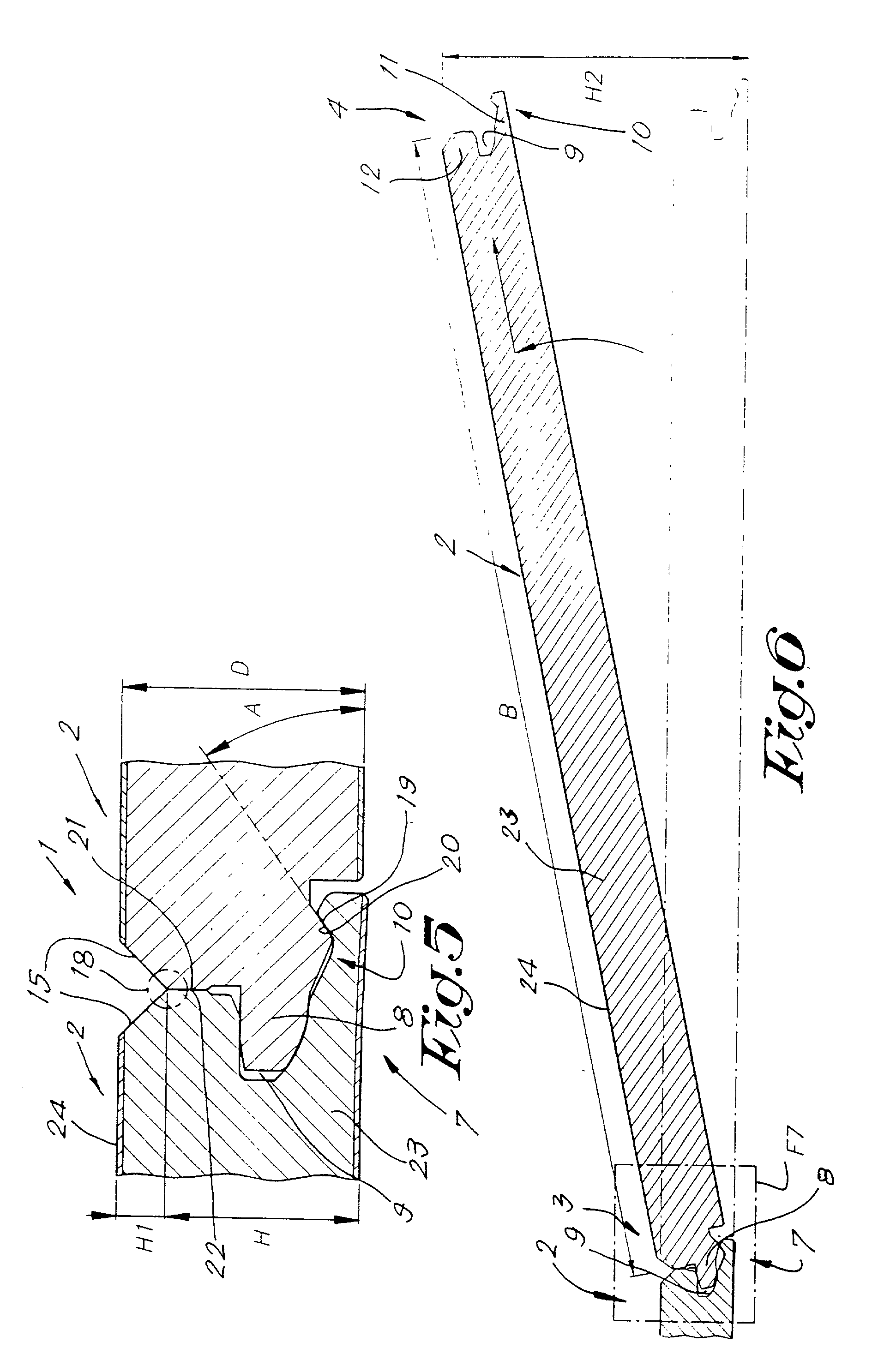

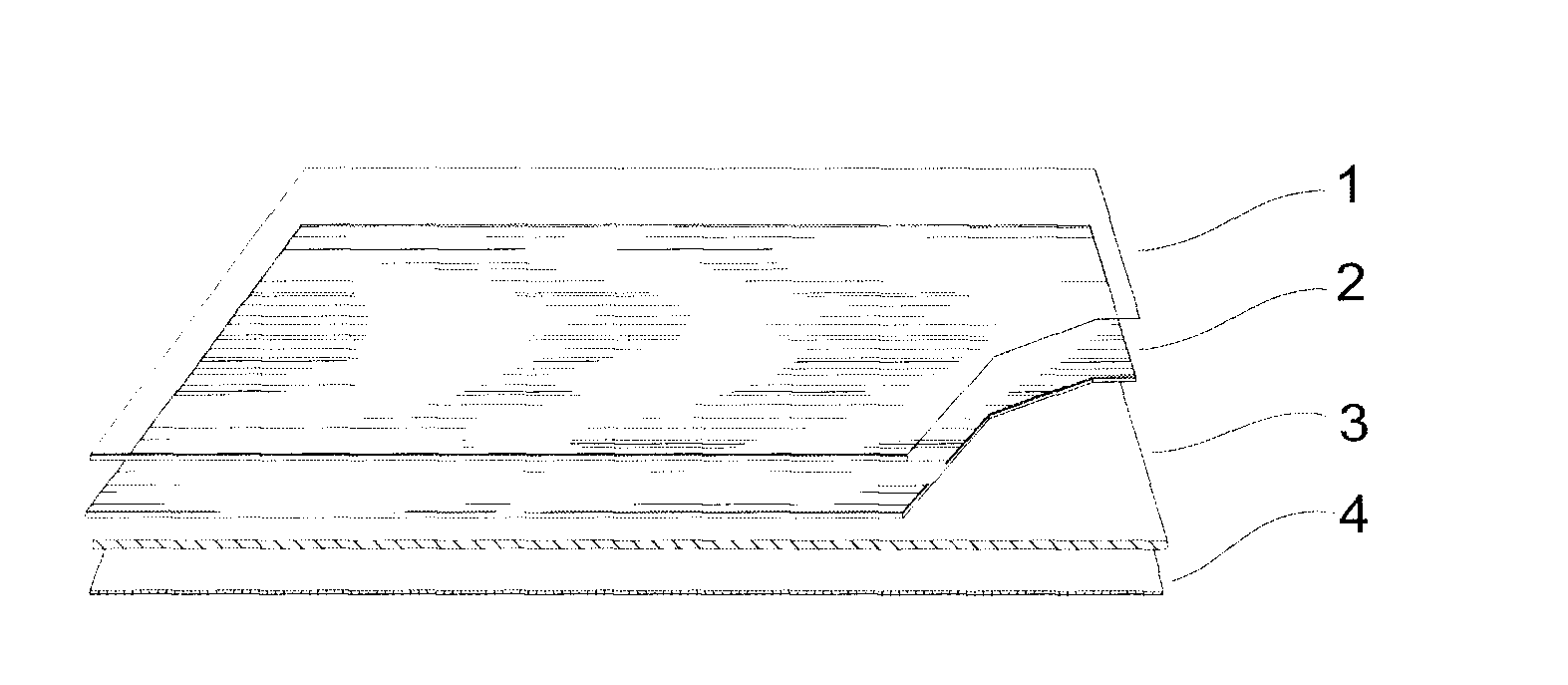

Floor covering

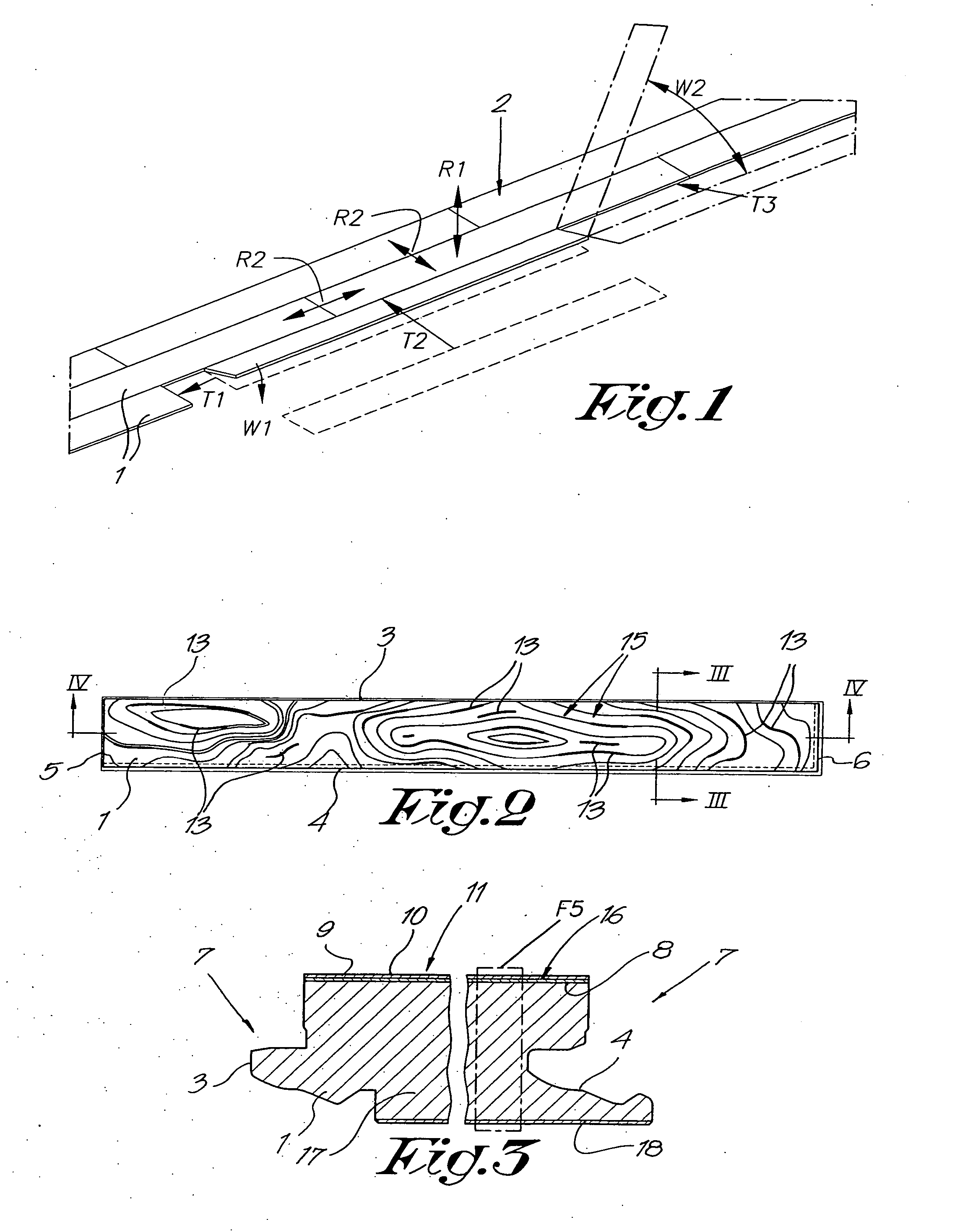

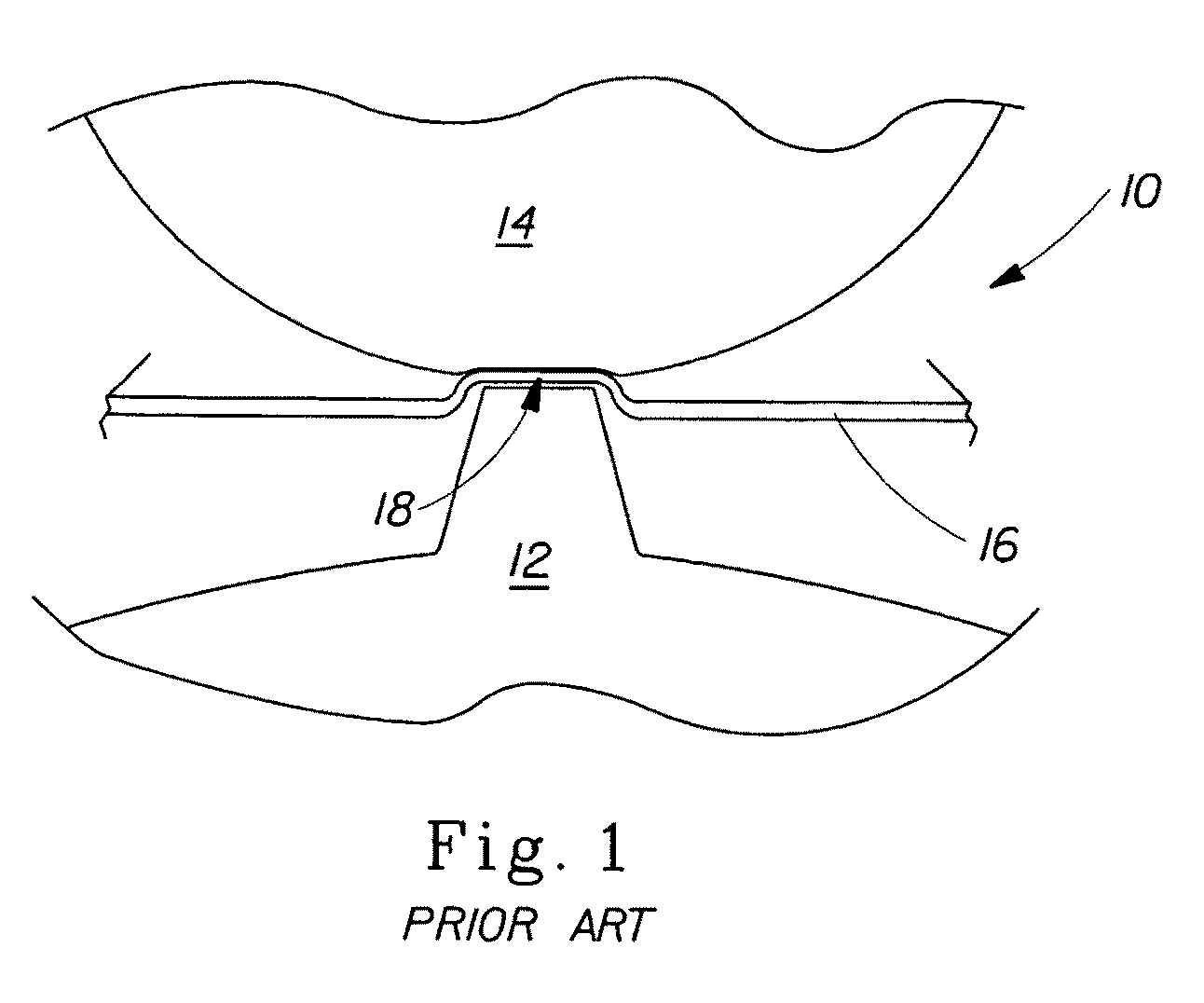

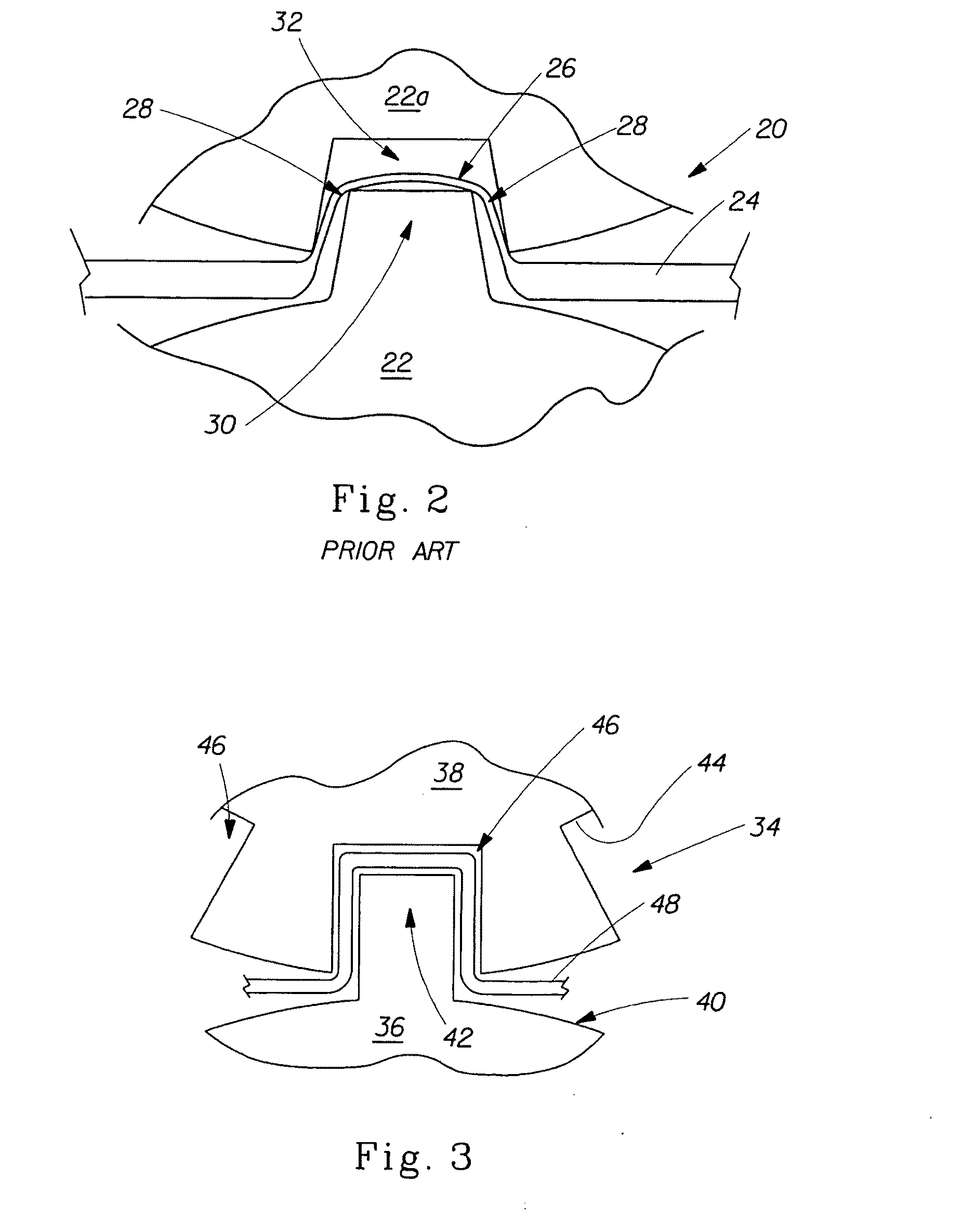

InactiveUS20020056245A1Easy to movePrevent mutual rotationCovering/liningsNatural patternsEngineeringMechanical engineering

A floor covering of hard panels (2) having at least on two opposite edges (3-4; 5-6), coupling elements (7) made in one piece with the panels (2), so that several of such panels (2) can be mutually coupled, whereby these coupling elements (7) provide for an interlocking in a direction (R1) perpendicular to the plane of the floor covering (1), as well as in a direction (R2) perpendicular to the edges (3-4; 5-6) and parallel to the plane of the floor covering (1), and whereby these coupling elements (7) are made such that the panels (2) can be rotated into and / or out of one another at least along the above-mentioned edges (3-4; 5-6). The panels (2) are provided, at least on the above-mentioned edges (3-4; 5-6), near the top side, with a part from which has been removed an amount of material such as by a level.

Owner:FLOORING IND LTD

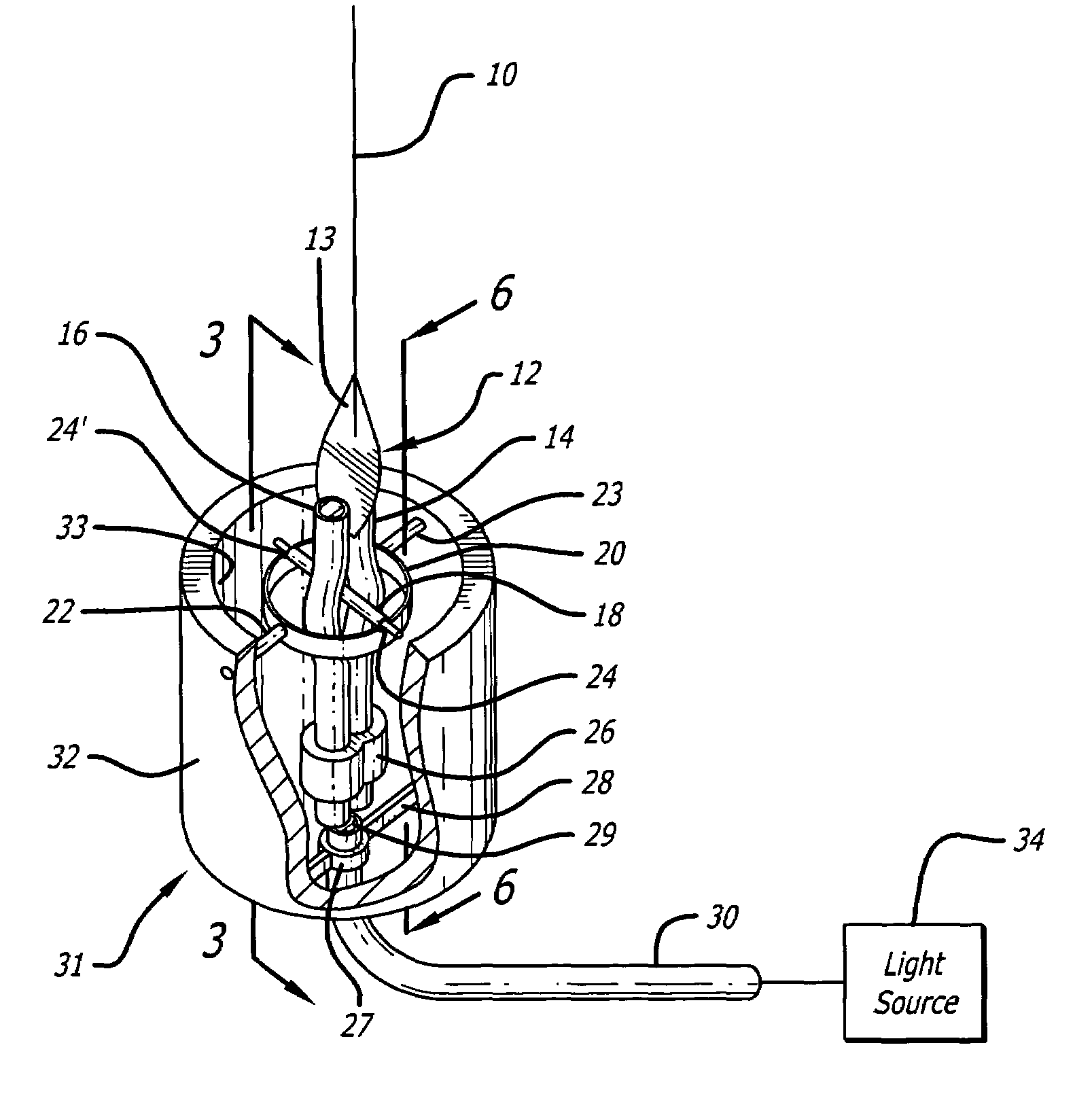

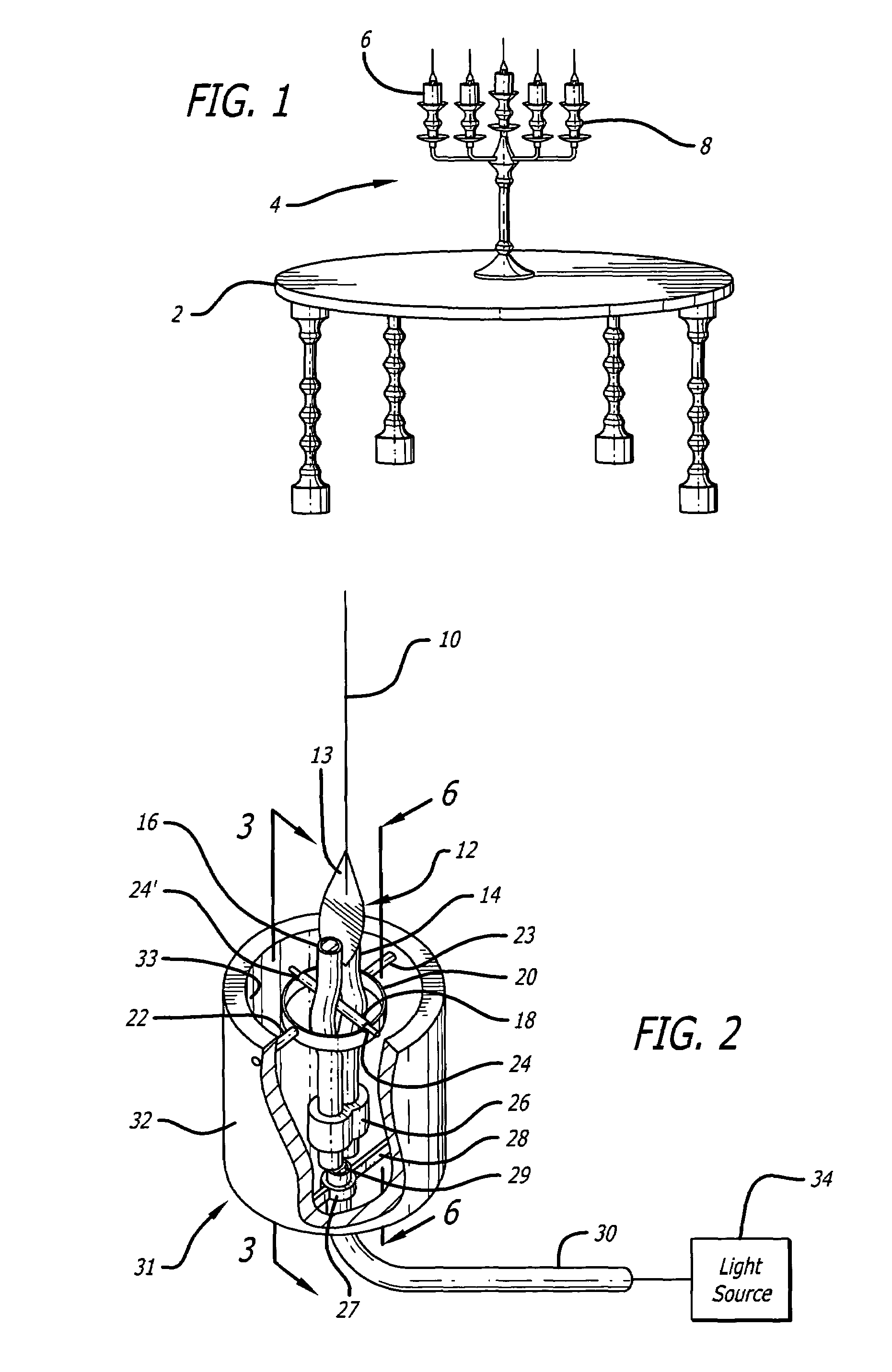

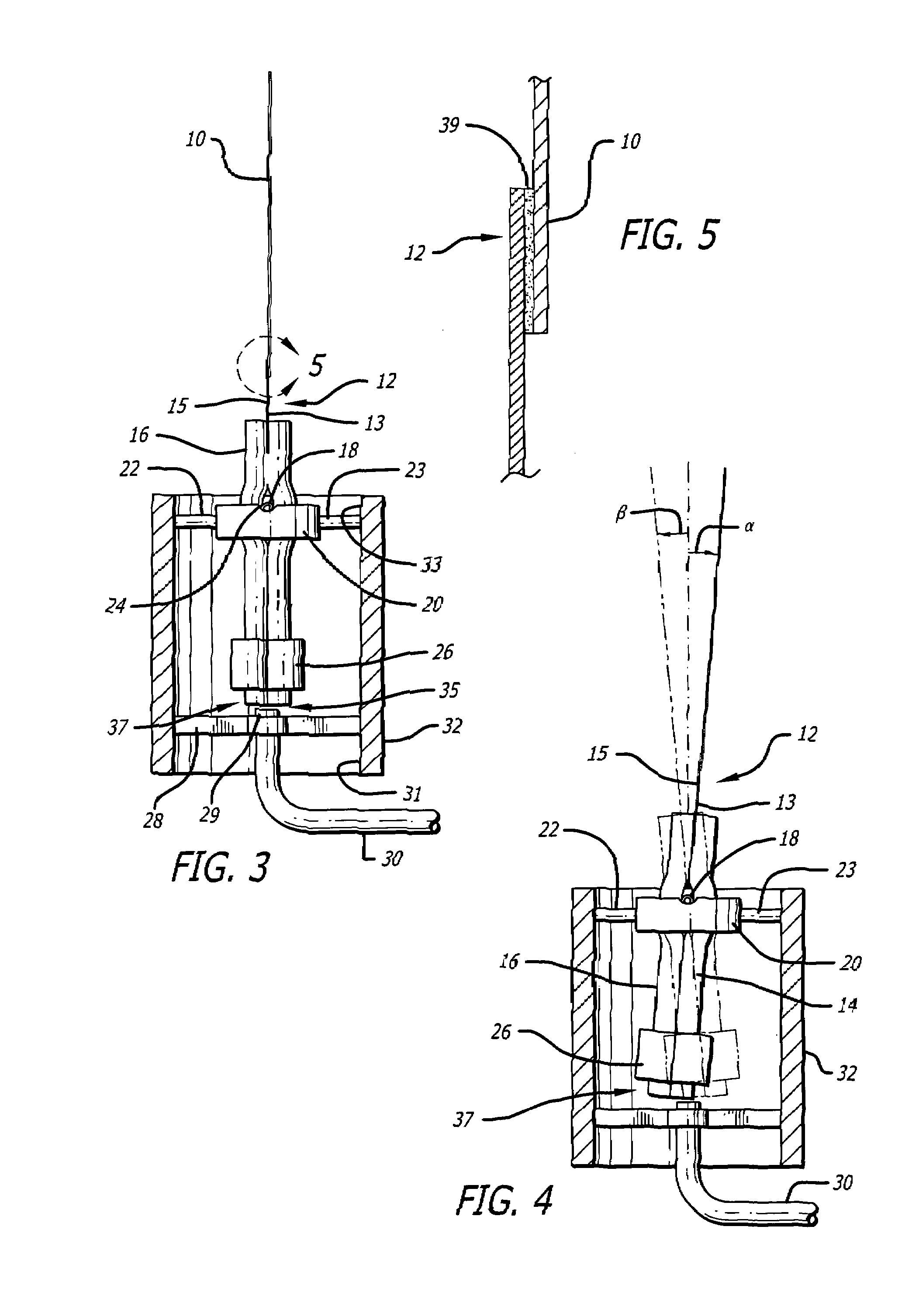

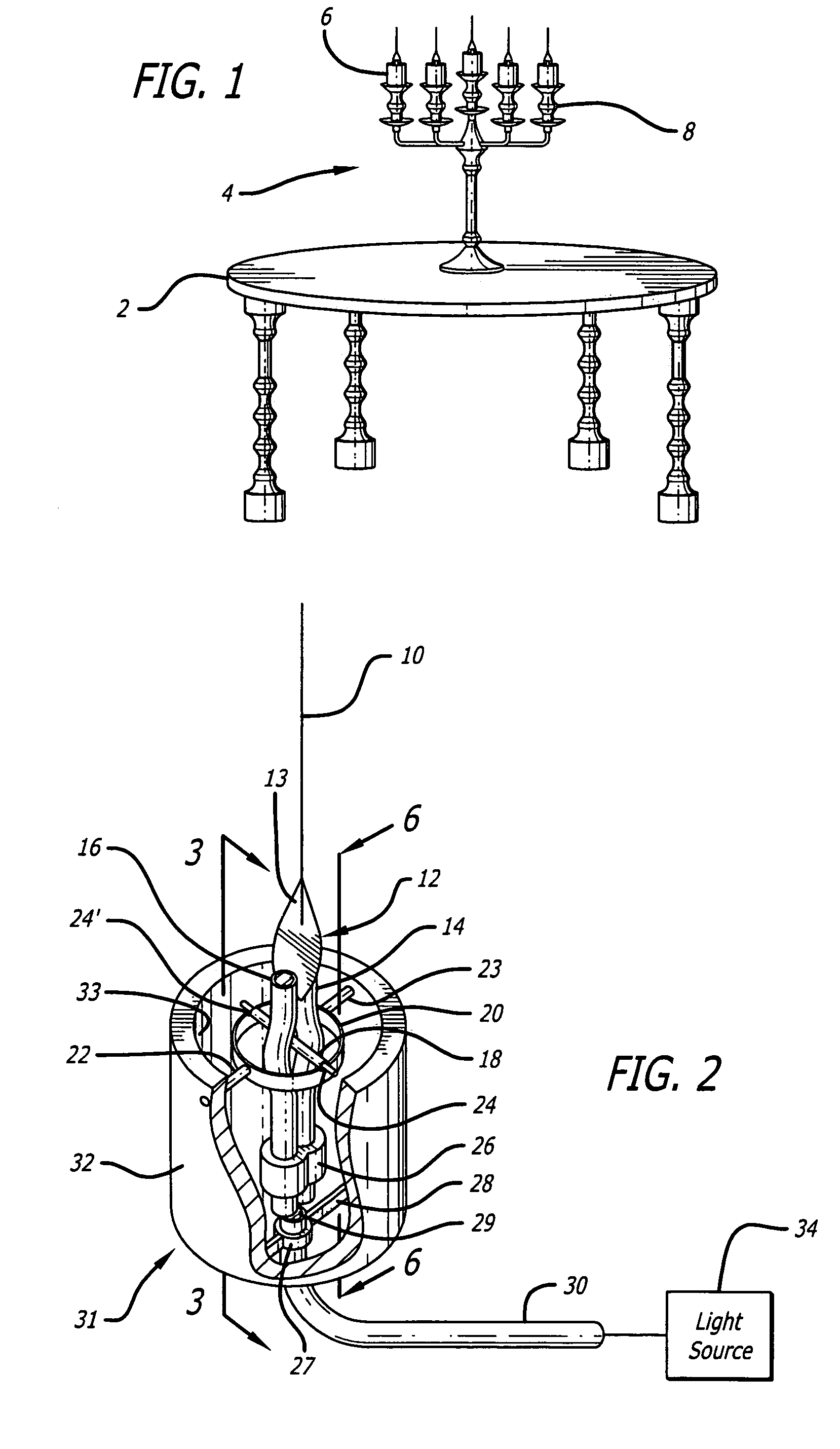

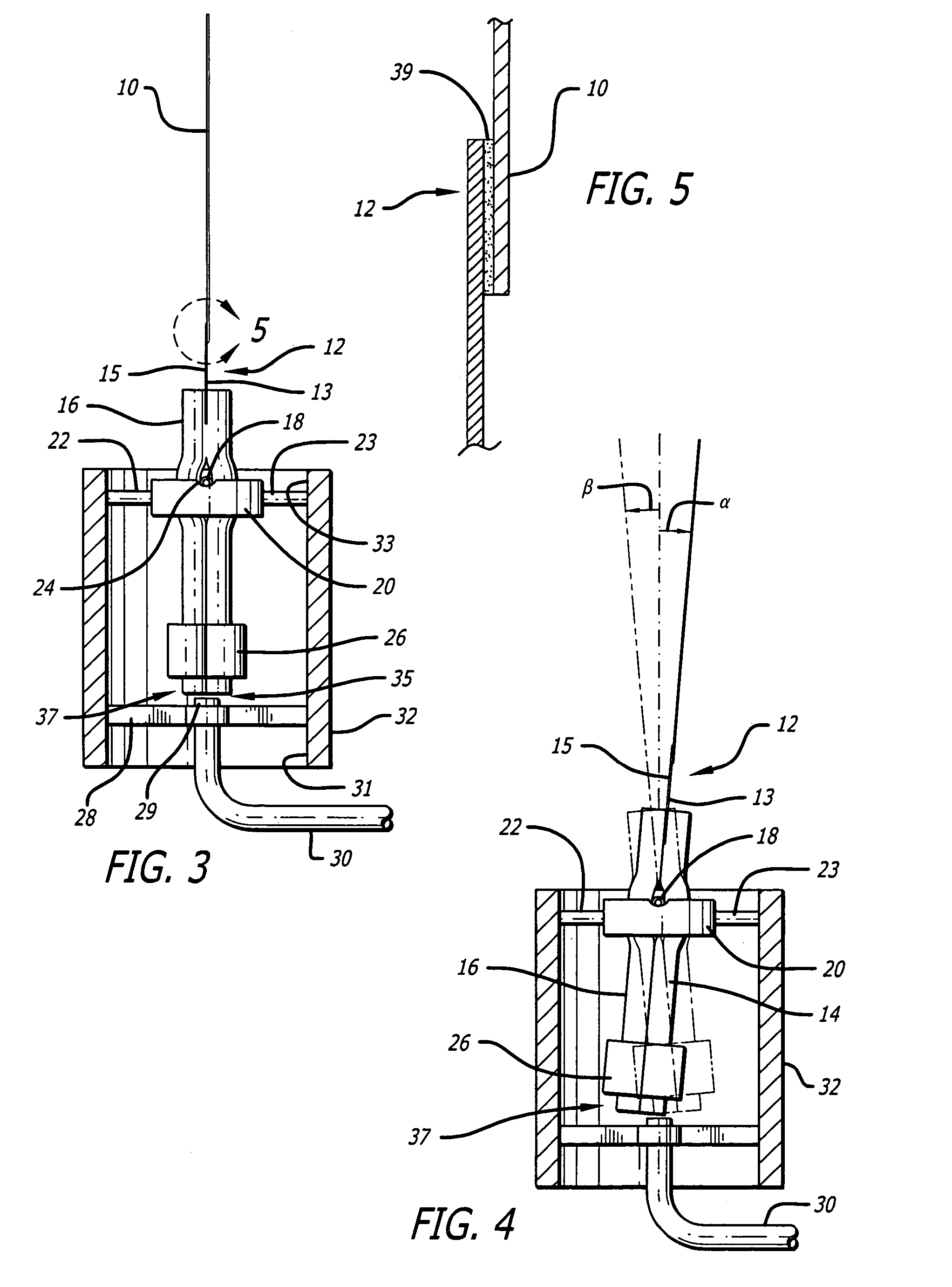

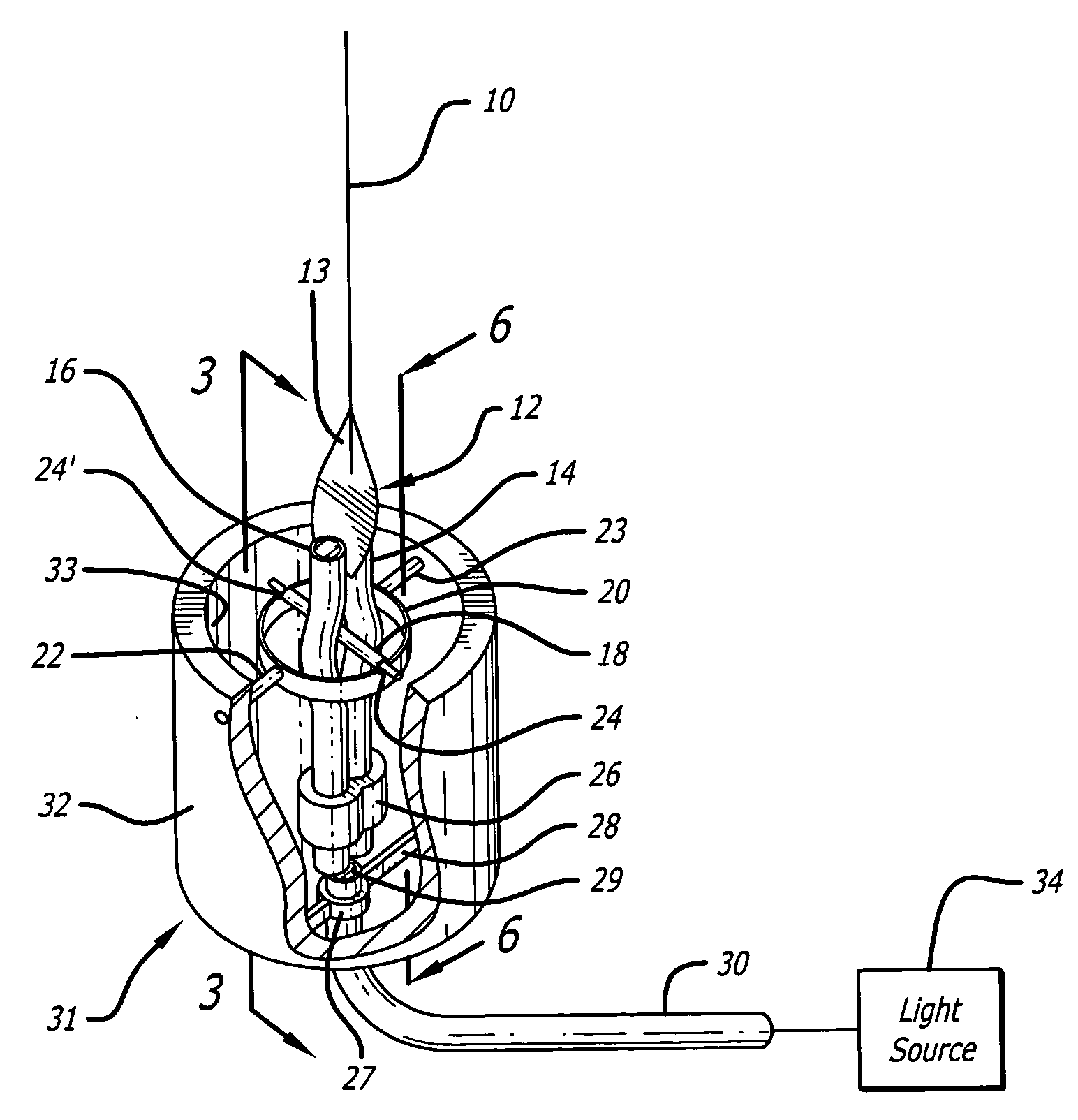

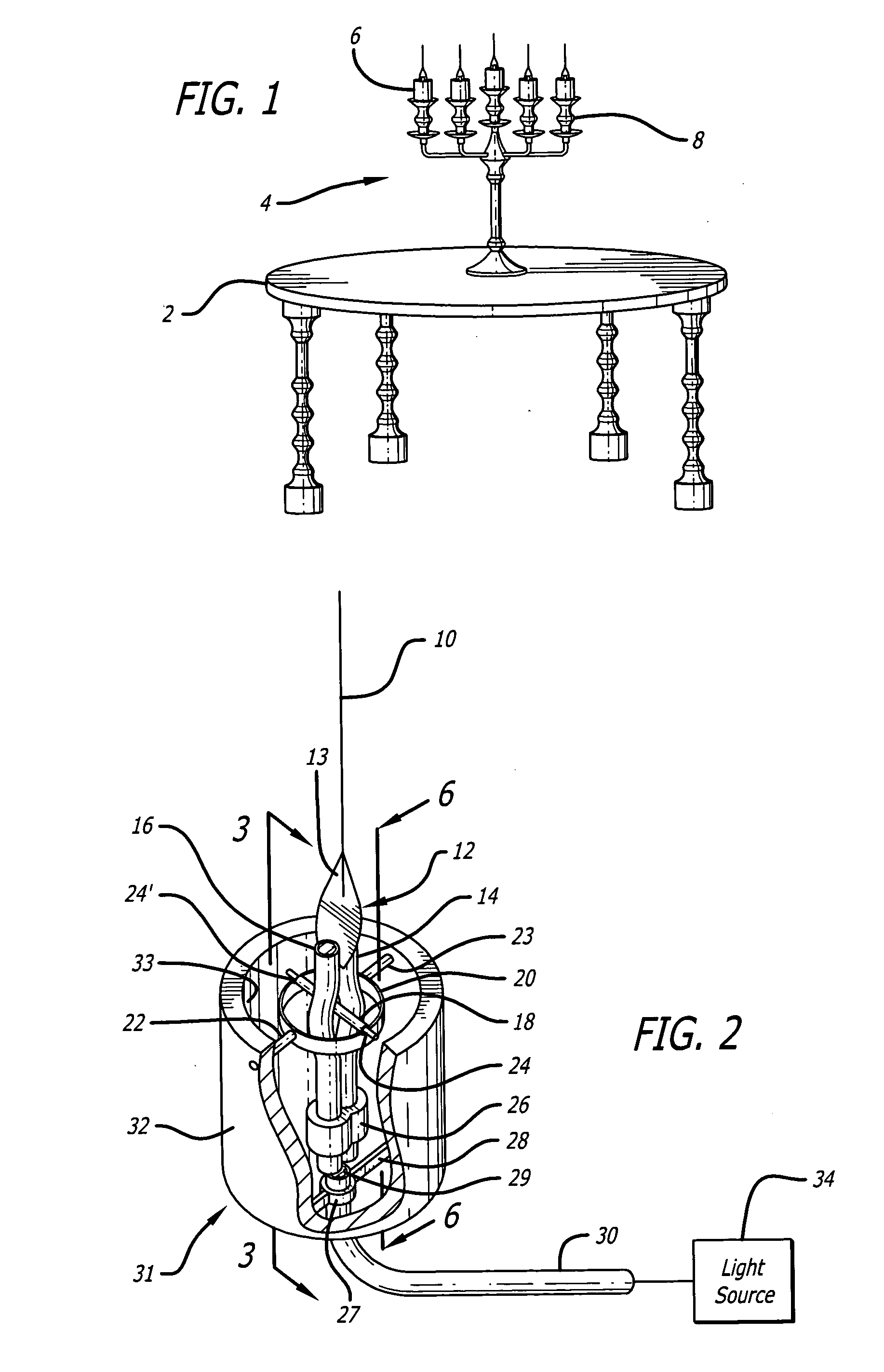

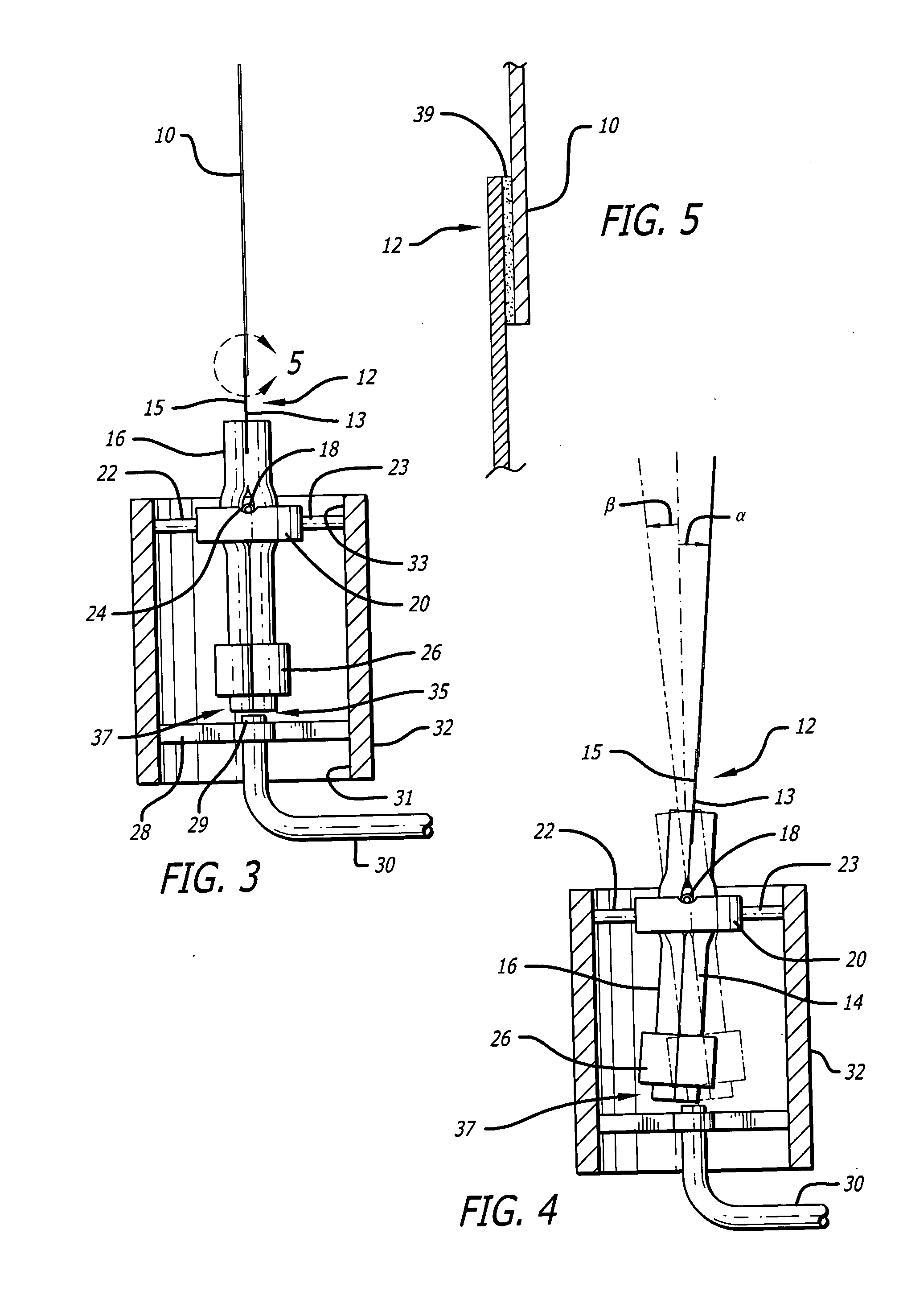

System and method for generating a flickering flame effect

ActiveUS7261455B2Safe and easy to manufactureCandle holdersPoint-like light sourceUltraviolet lightsEngineering

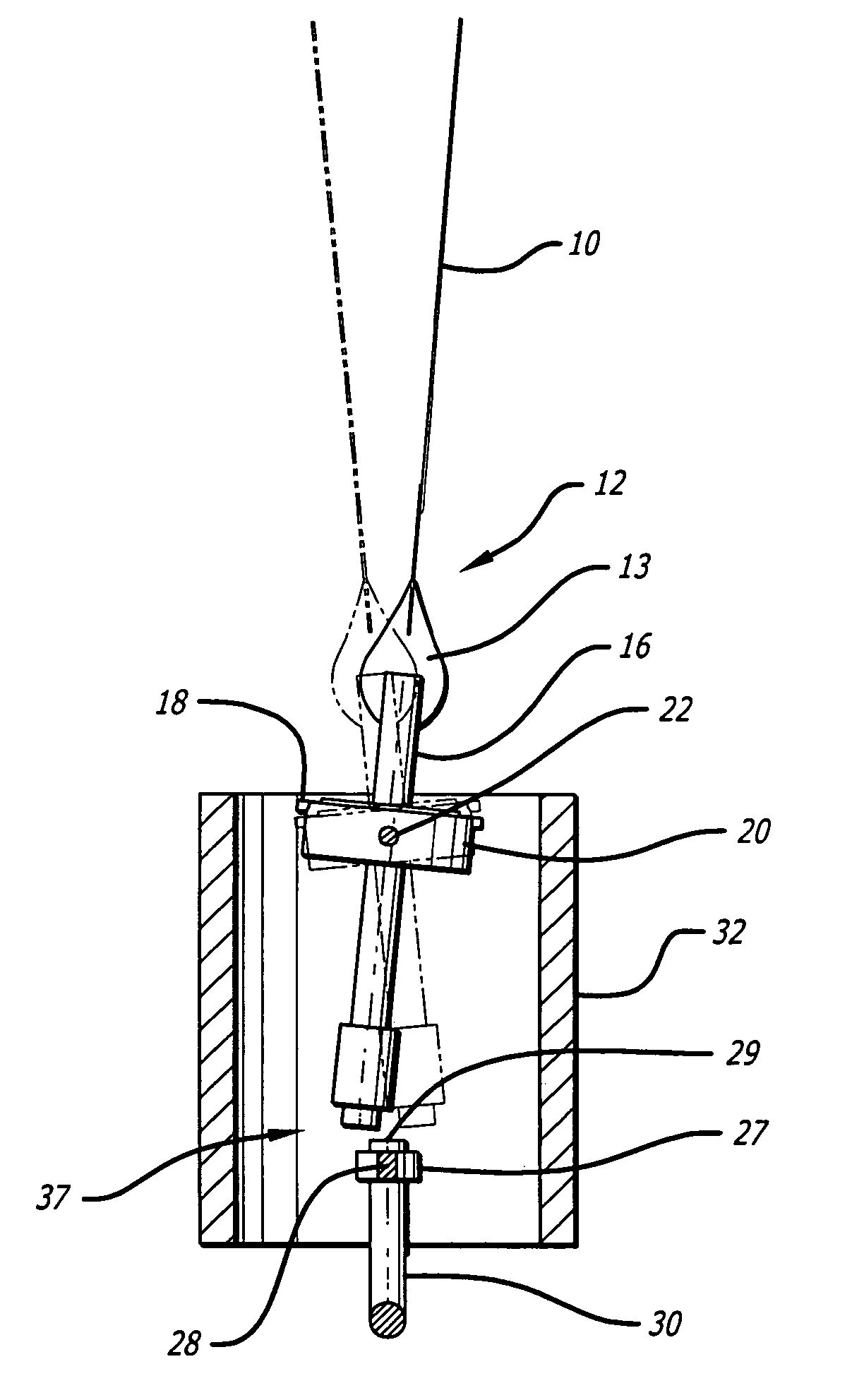

A system for creating a flickering effect comprising a simulated candle housing, a light communicating channel on the housing, a source of ultraviolet light disposed in the channel, and a simulated flame having ultraviolet material thereon movable back and forth from its vertical axis mounted in the housing, the light focused on the simulated flame simulating a flickering flame.

Owner:L&L CANDLE CO LLC

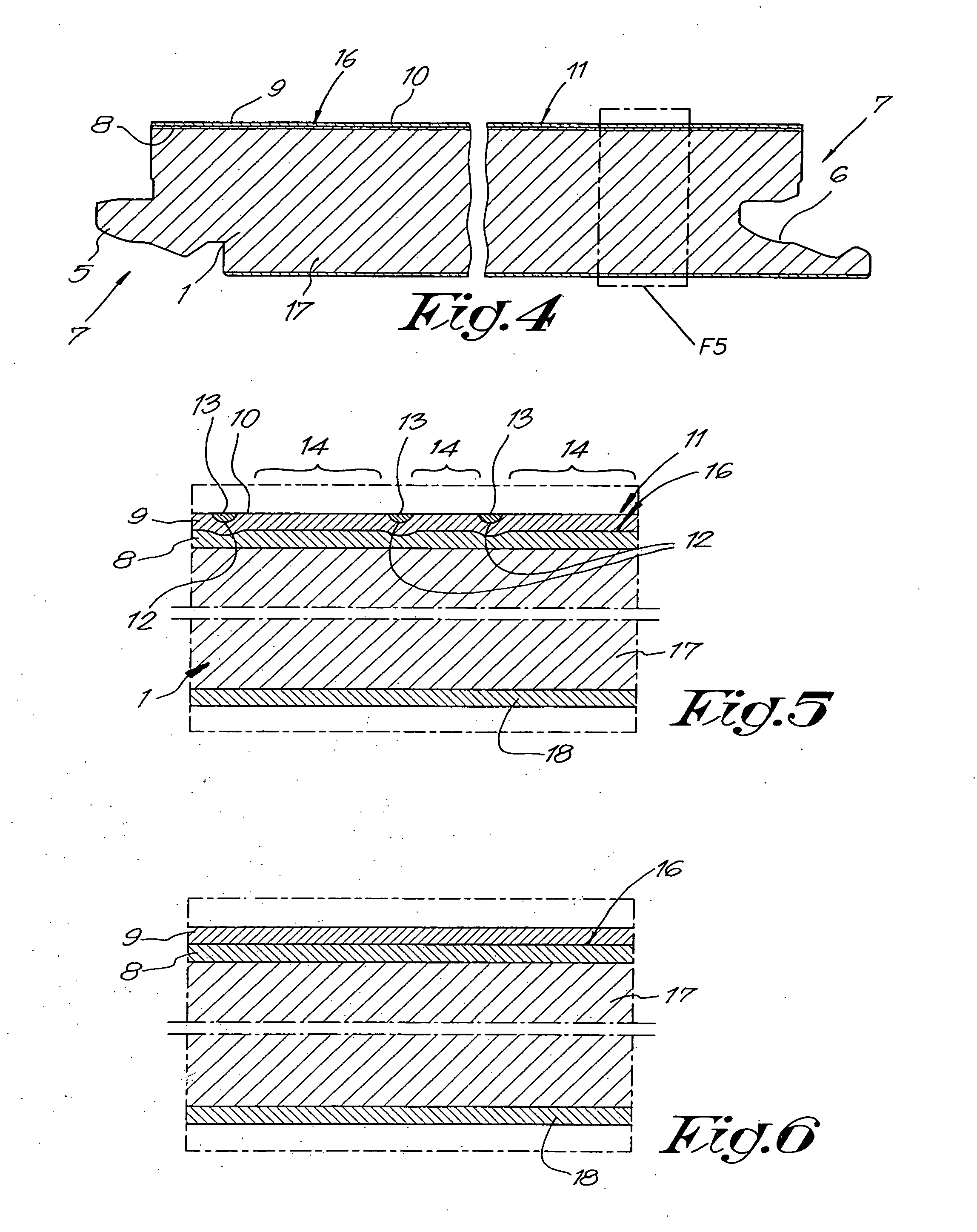

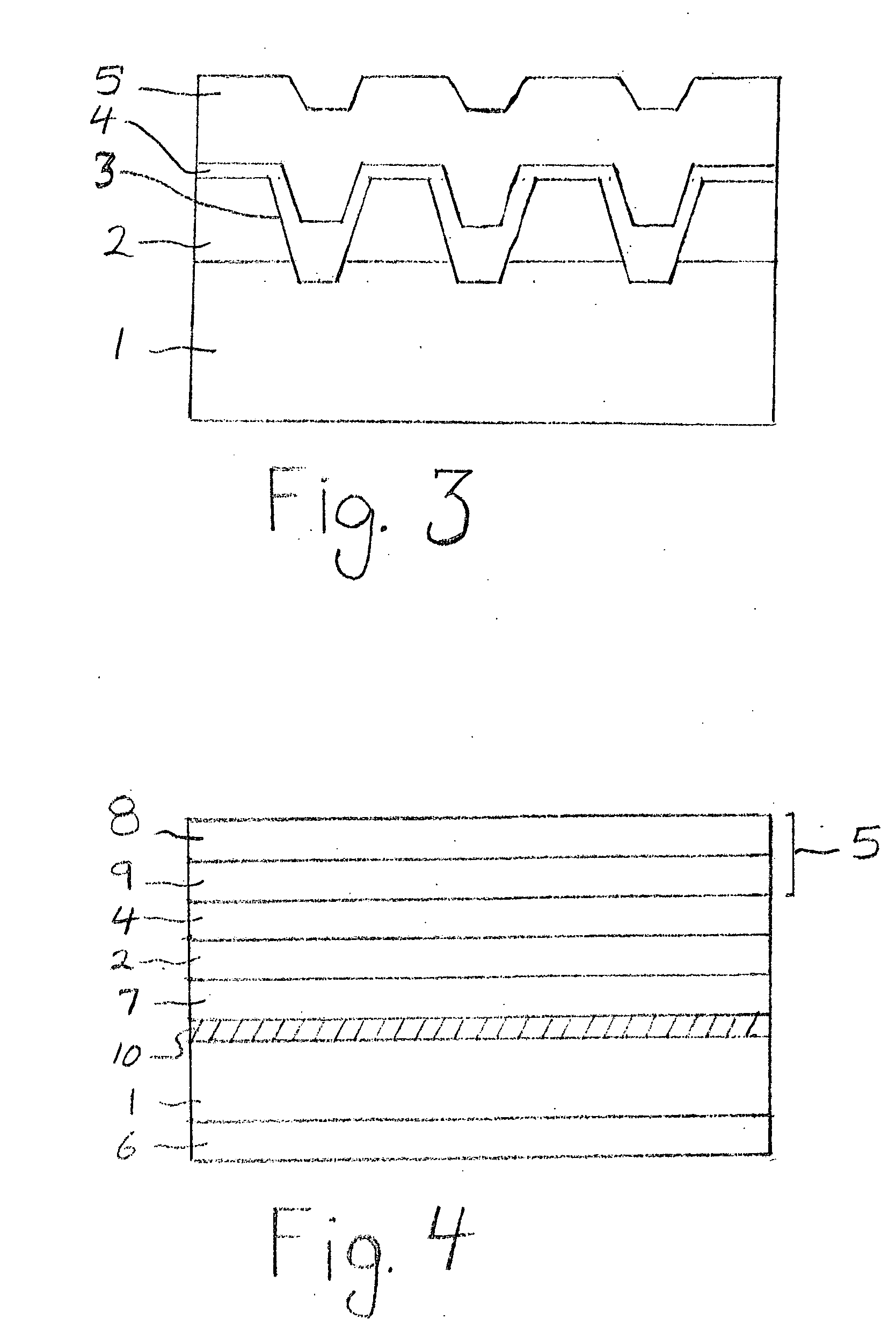

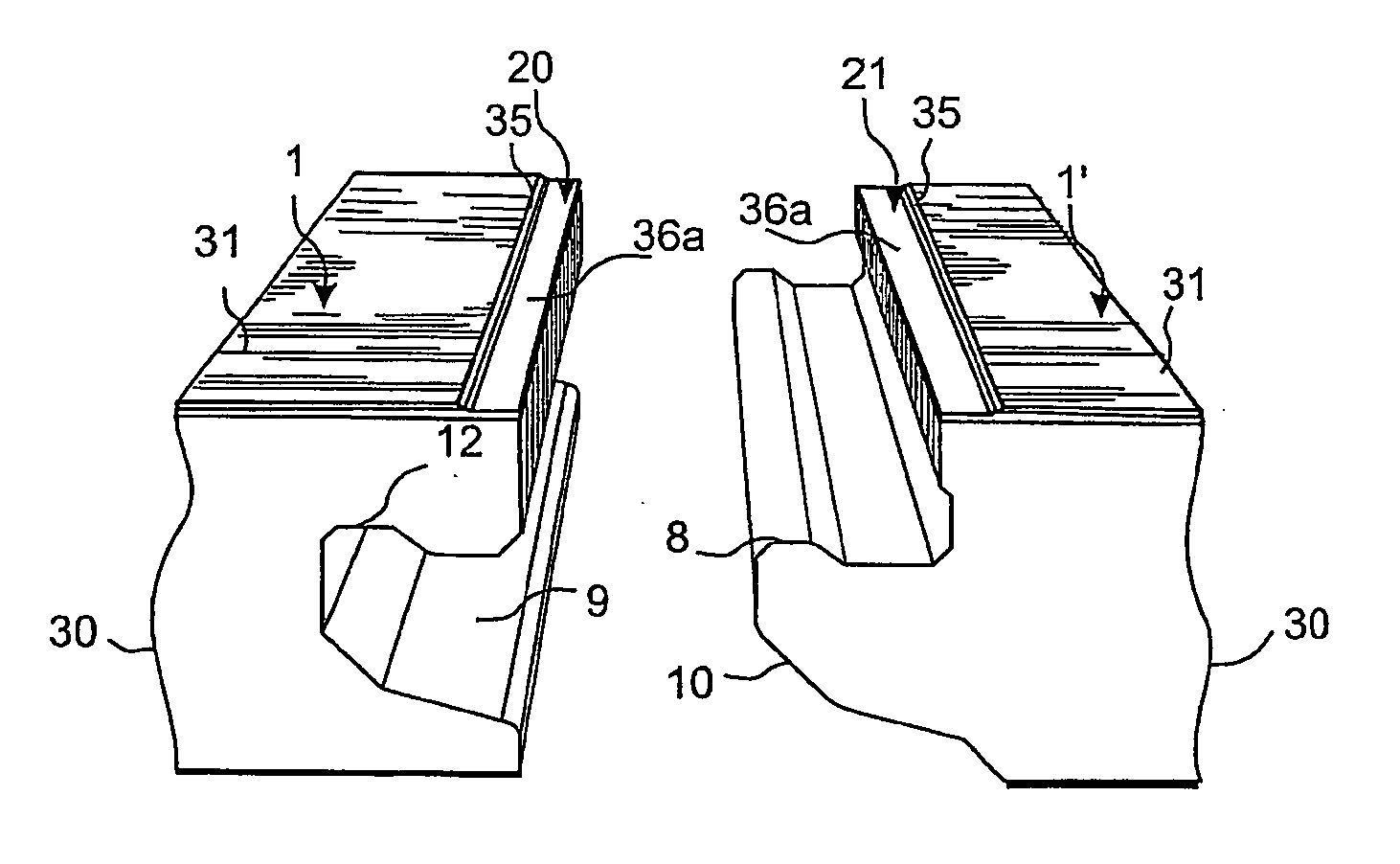

Floor panel and method for manufacturing such floor panels

Floor panel, of the type consisting of a laminate panel which comprises at least a printed decorative layer (8) and a top layer (9) forming the upper surface (10) of the floor panel (1), more particularly a so-called overlay, whereby this top layer (9), or, thus, overlay, is realized on the basis of a thermosetting resin, characterized in that in the upper side (11) of the floor panel (1), indentations (12) are formed and in that at last in a number of these indentations (12), a component (13) is provided, which is obtained in that it has been provided in those indentations (12) after the provision of the indentations (12).

Owner:FLOORING IND LTD

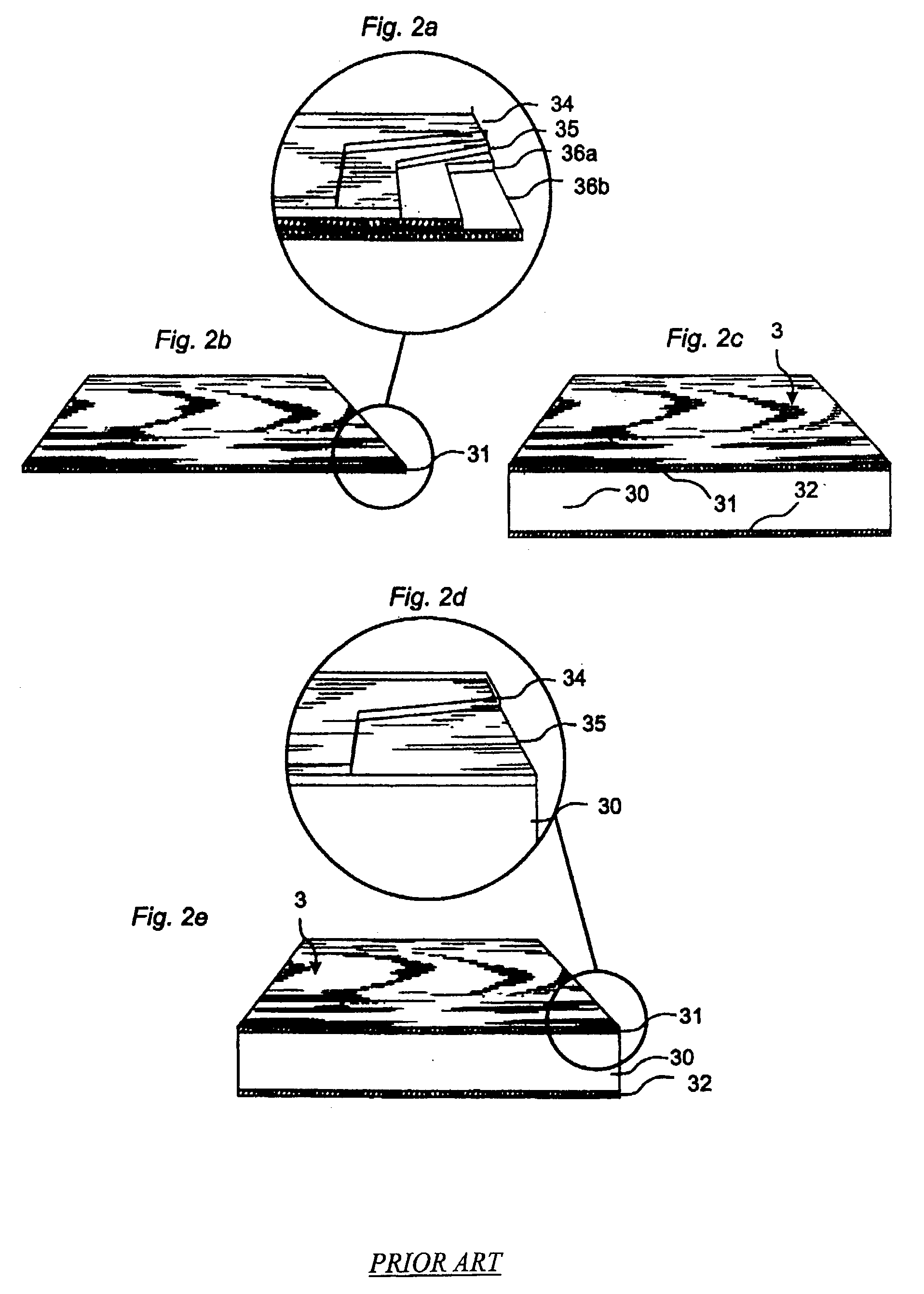

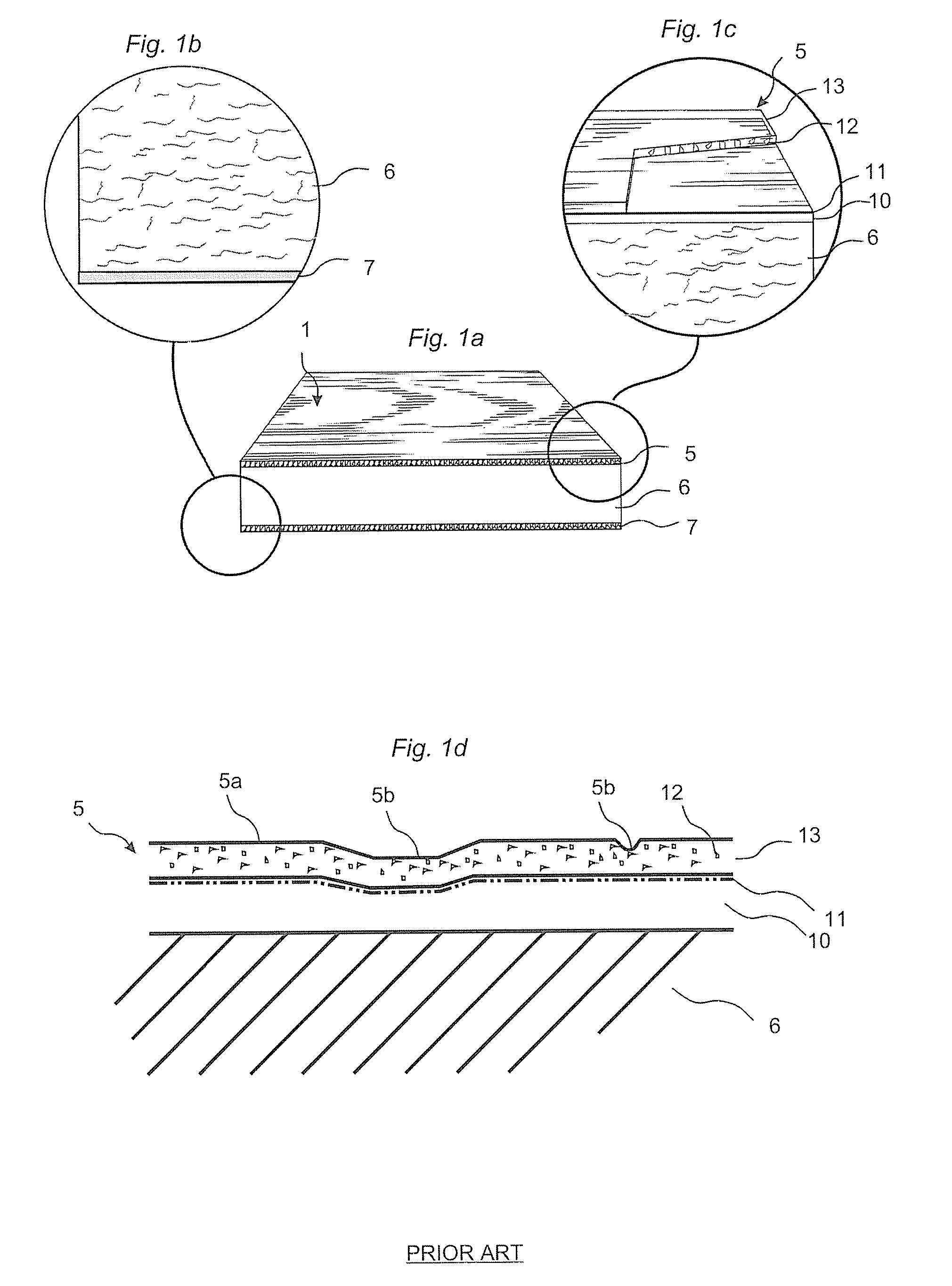

Floorboards with decorative grooves

InactiveUS20040035078A1Provides appearance and durabilityNatural appearanceCovering/liningsTongue/grooves making apparatusSurface layerEngineering

Floorboards consisting of a core and a surface layer with decorative joint edge portions which are formed by removing the surface layer.

Owner:VÄLINGE INNOVATION AB

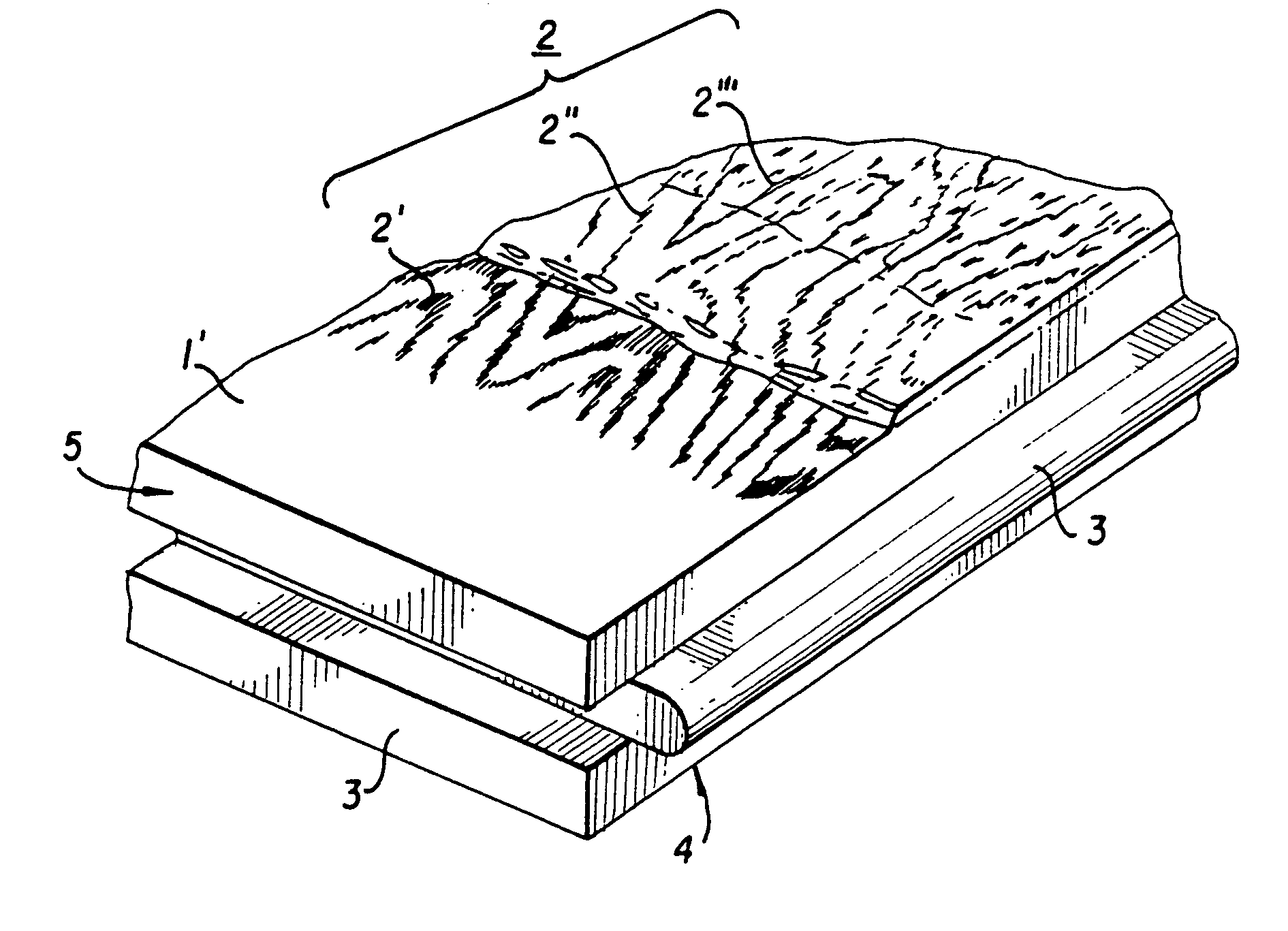

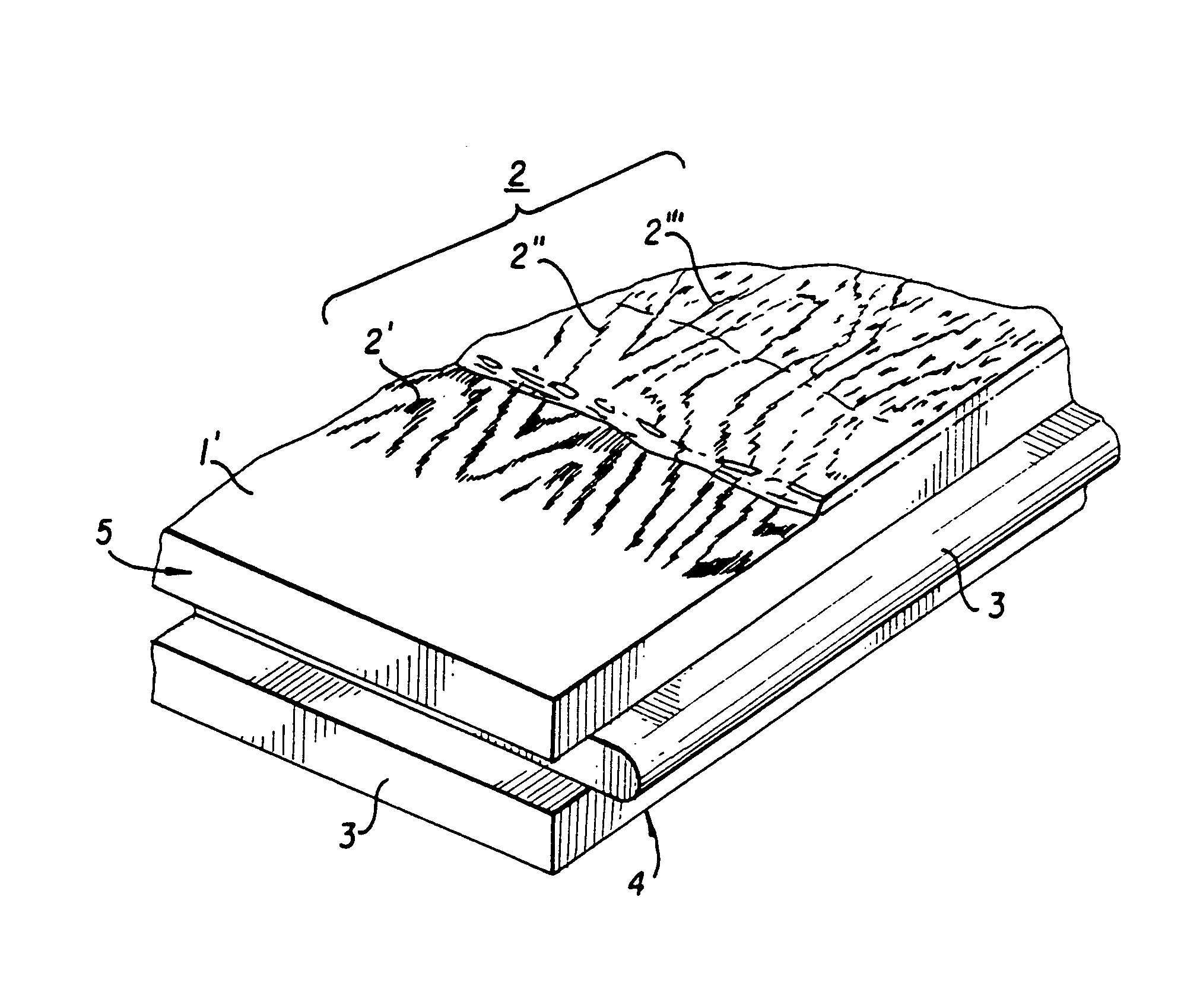

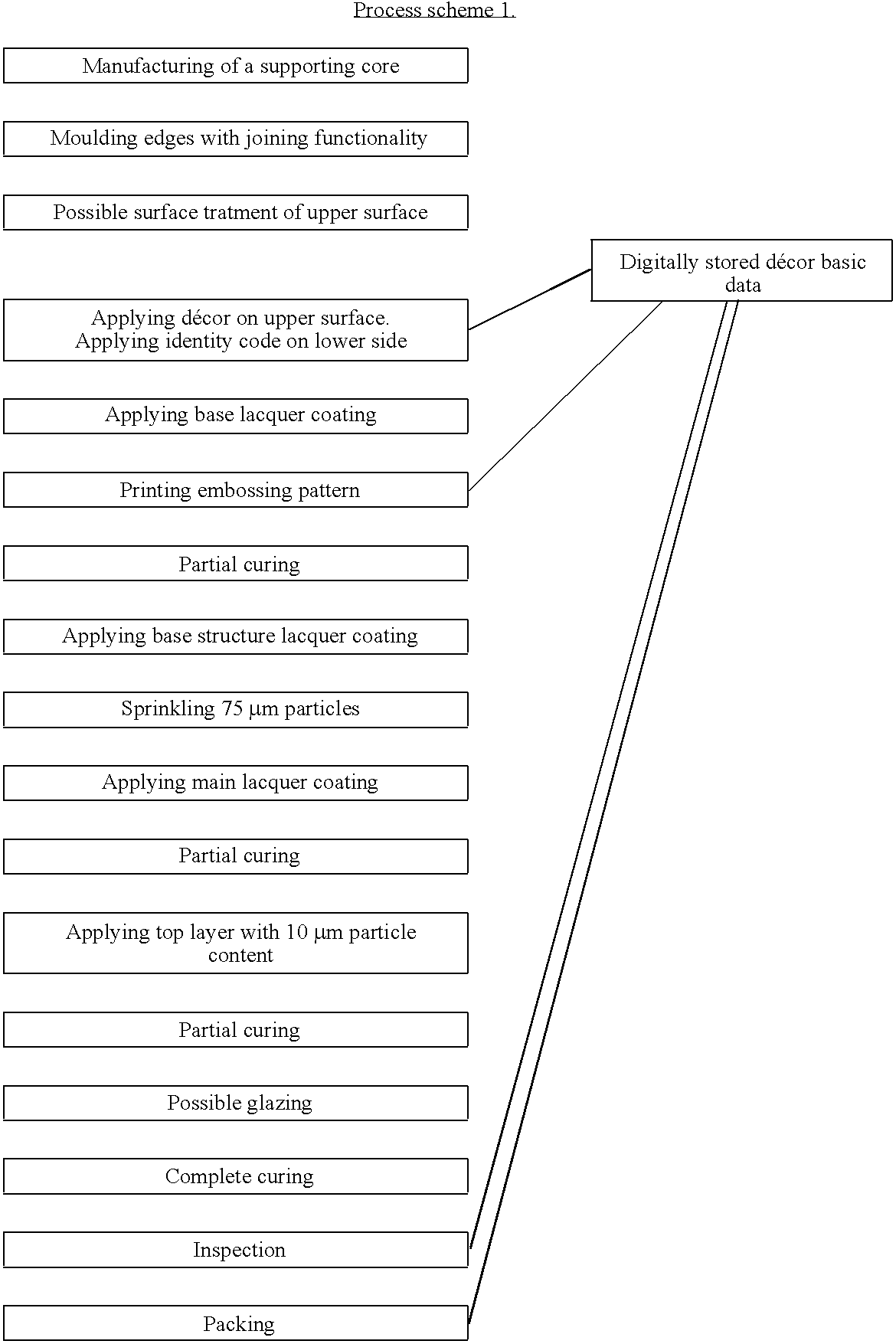

Process for the manufacturing of surface elements with a structured upper surface

InactiveUS6991830B1High resolutionRearrange décorCovering/liningsOrnamental structuresLacquerEngineering

A process for the manufacturing of a decorative surface element, which element comprises a base layer and a decorative upper surface. A wetting repellent lacquer is printed in a predetermined pattern on the decorative upper surface. The wetting repellent lacquer covers only parts of the decorative upper surface. A wear layer of a UV or electron beam curing lacquer is then applied on top of the decorative upper surface which UV or electron beam curing lacquer is repelled from the parts of the surface being covered by the wetting repellent lacquer whereby a surface structure is achieved.

Owner:UNILIN NORDIC AB

Building panel with compressed edges and method of making same

ActiveUS20080034701A1Efficient productionImproved abrasionWallsSpecial ornamental structuresSurface layerEngineering

Floorboards comprising a core and a surface layer with curved edge portions, which are formed by a compression of the core.

Owner:VÄLINGE INNOVATION AB

System and method for generating a flickering flame effect

ActiveUS7159994B2Safe and easy to manufactureCandle holdersPoint-like light sourceHorizontal axisEngineering

A system for creating a flickering effect comprises a light communicating cable, at least one light receiving cable secured on a rotatable mount rotatable about a horizontal axis, a light diffuser element in communication with the at least one light receiving cable and a rod connected to the diffuser element for causing rotary motion of the light diffuser surface about the horizontal axis.

Owner:L&L CANDLE CO LLC

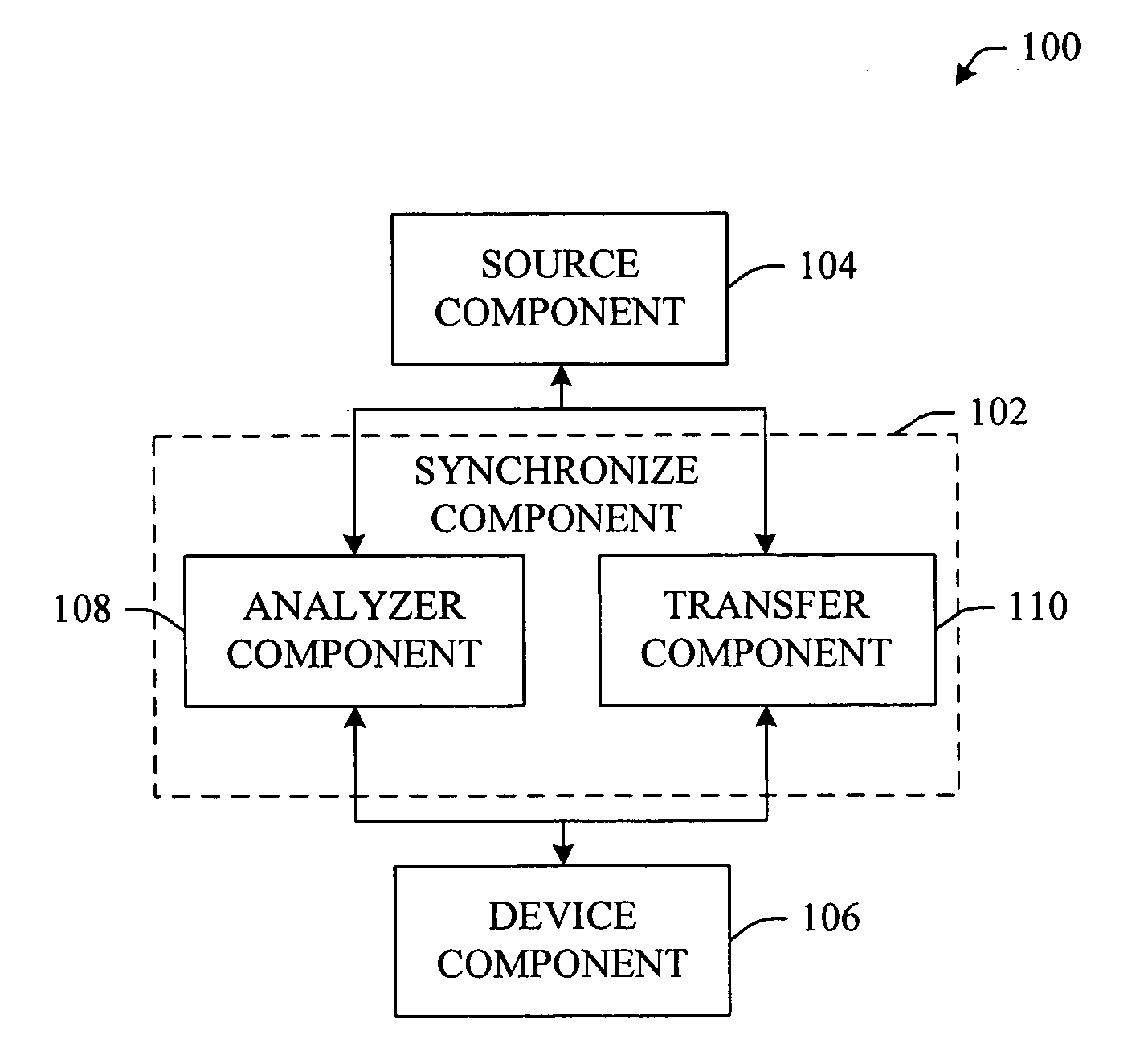

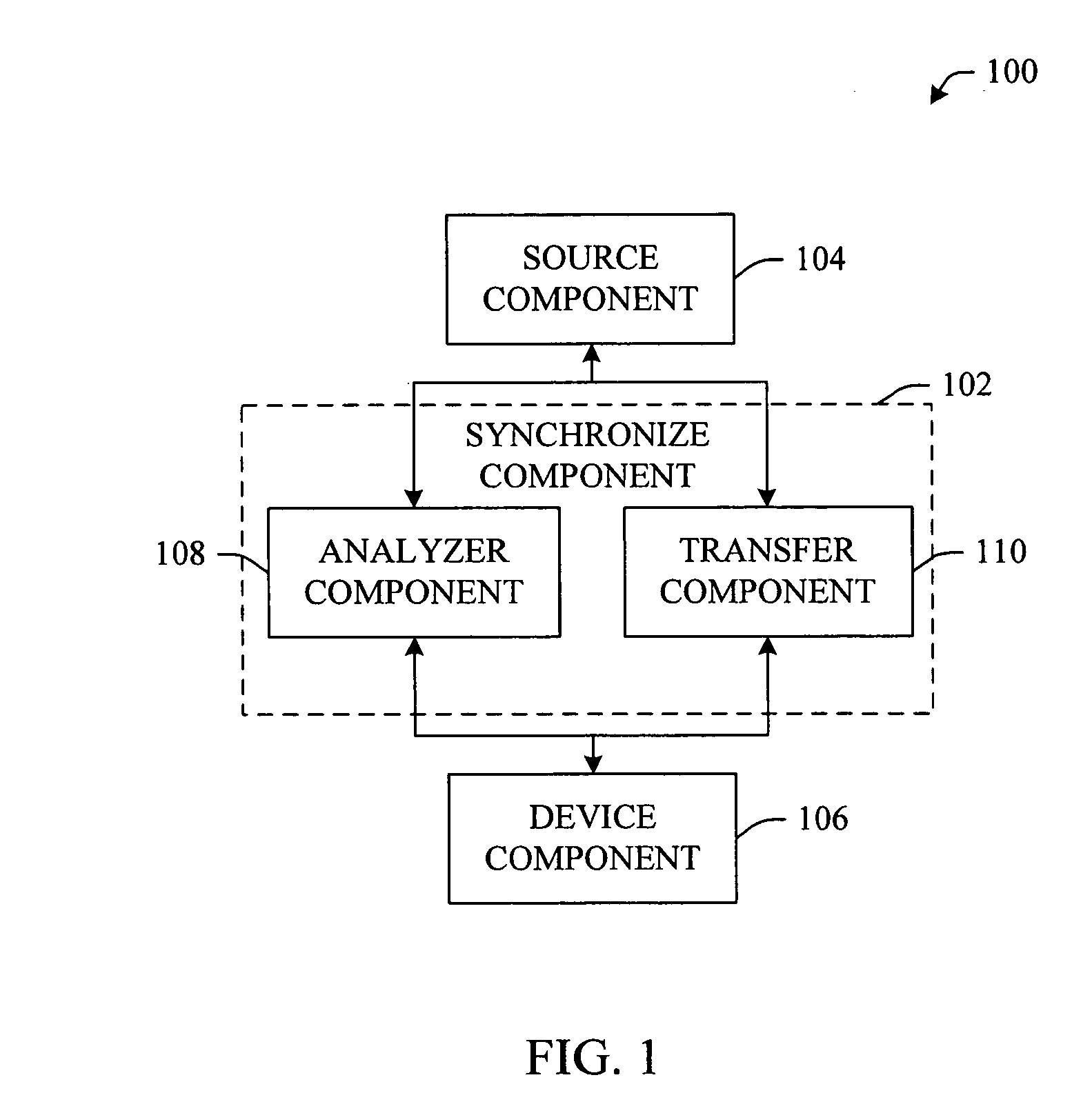

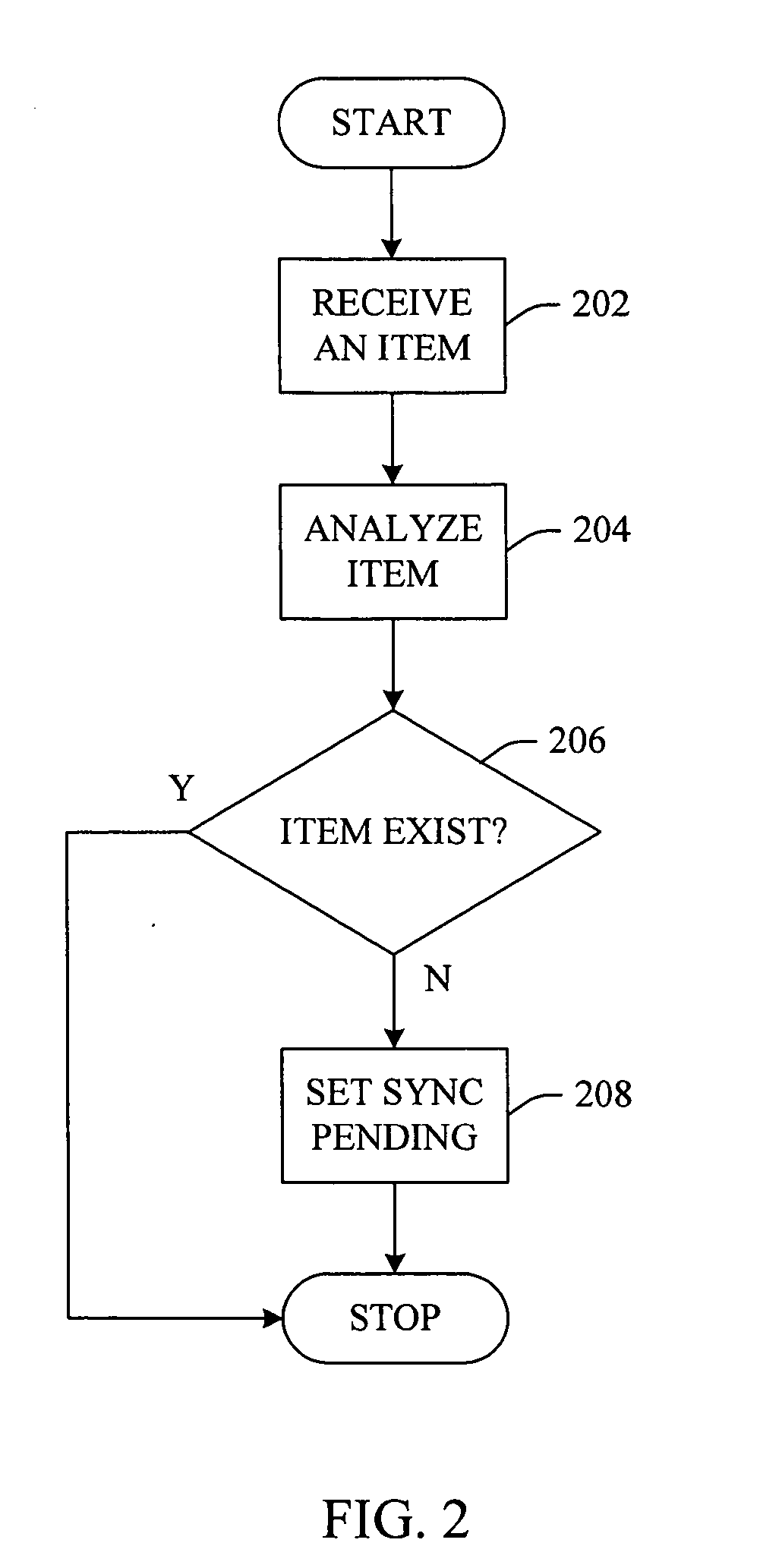

Cross-pollination synchronization of data

ActiveUS20060020804A1Duplicative entries can be eliminatedData processing applicationsUser identity/authority verificationPollinationPersonal computer

Owner:MICROSOFT TECH LICENSING LLC

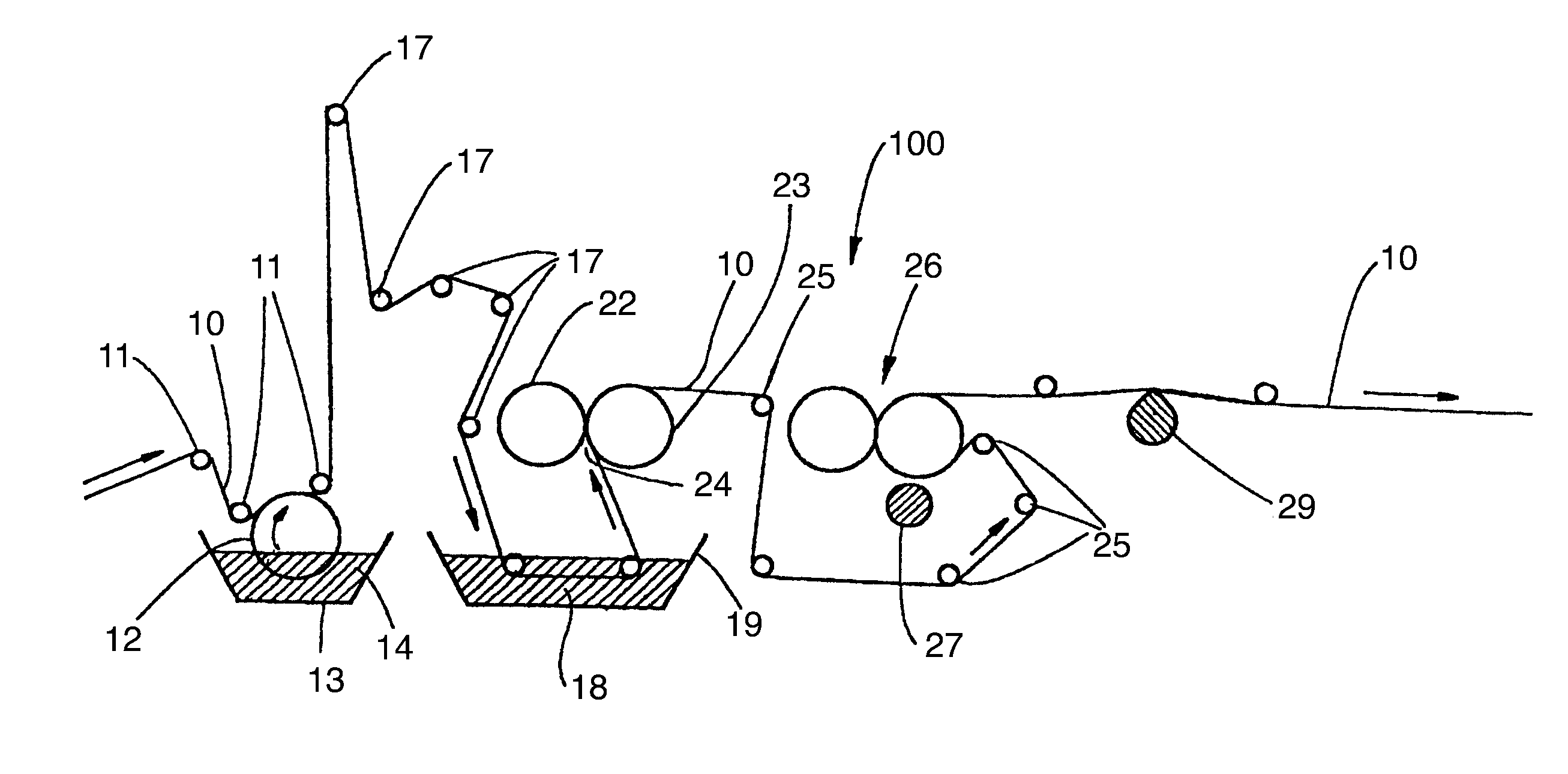

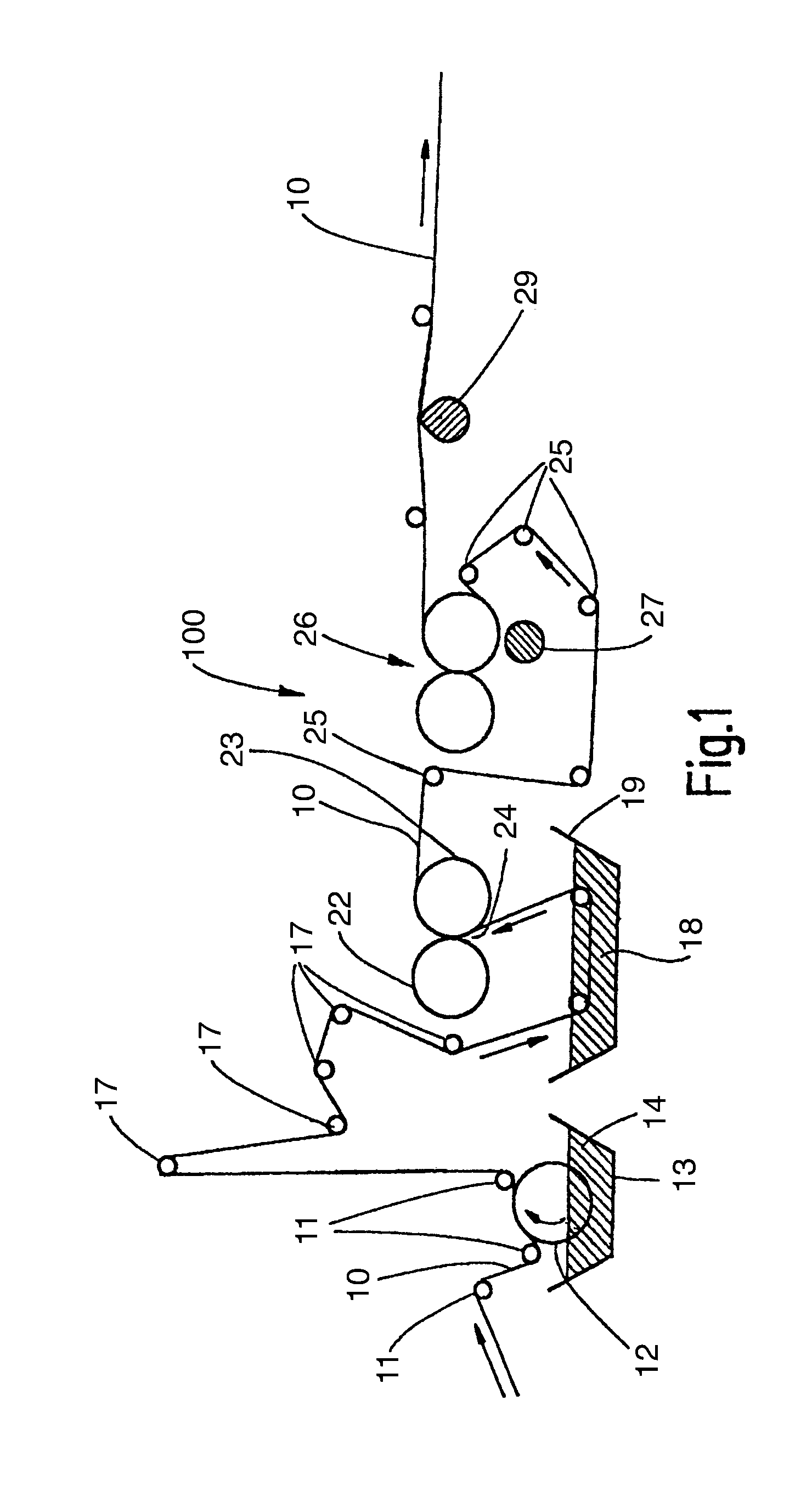

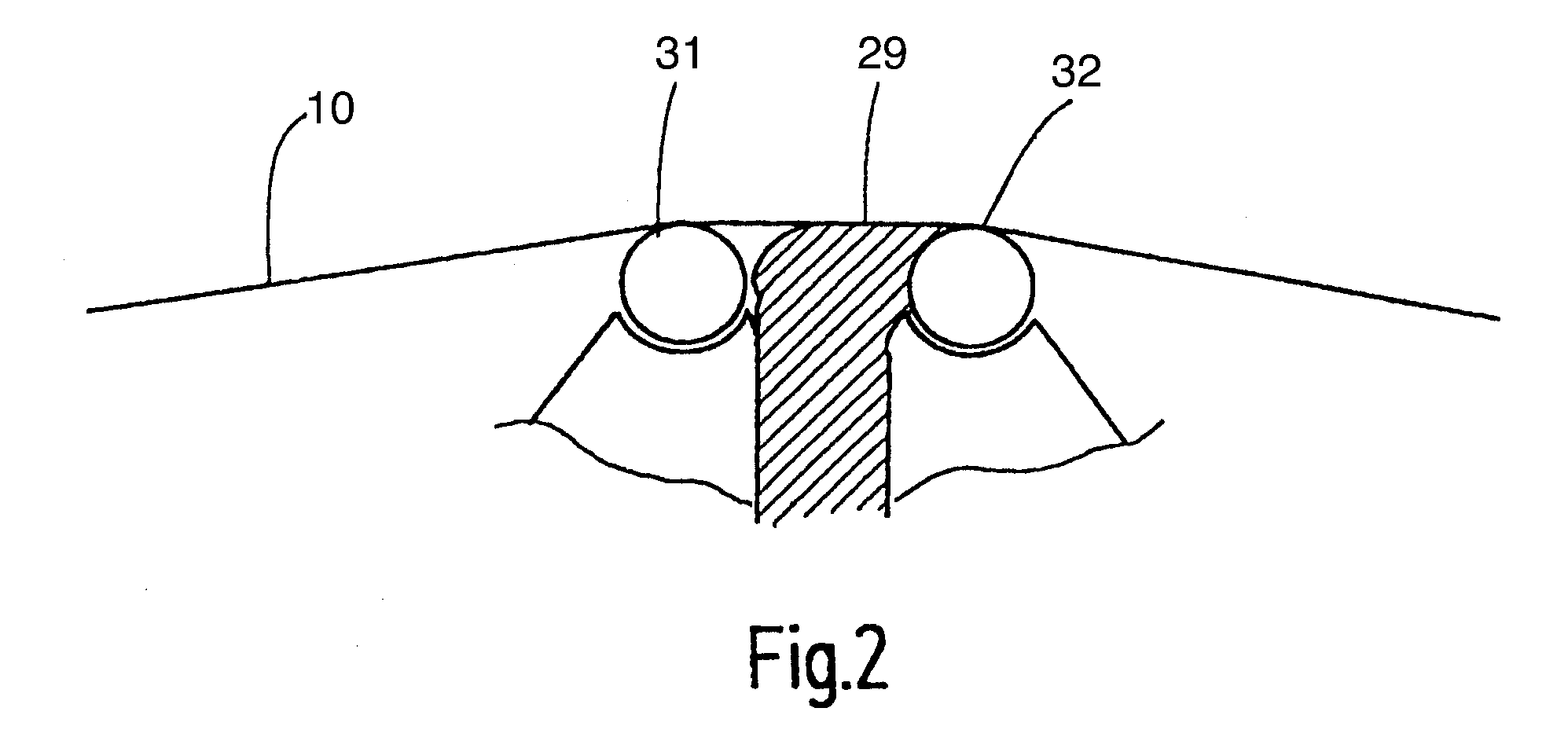

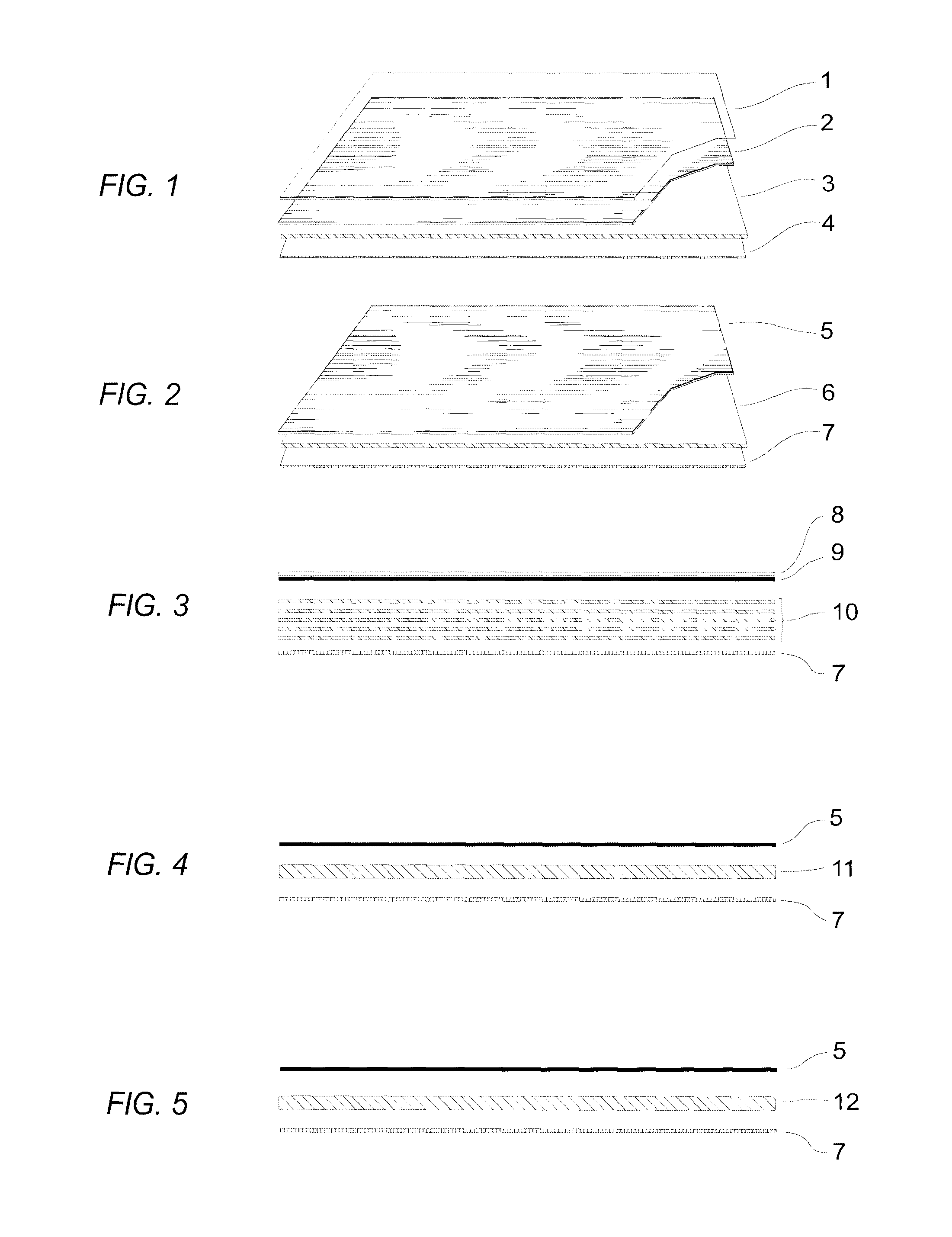

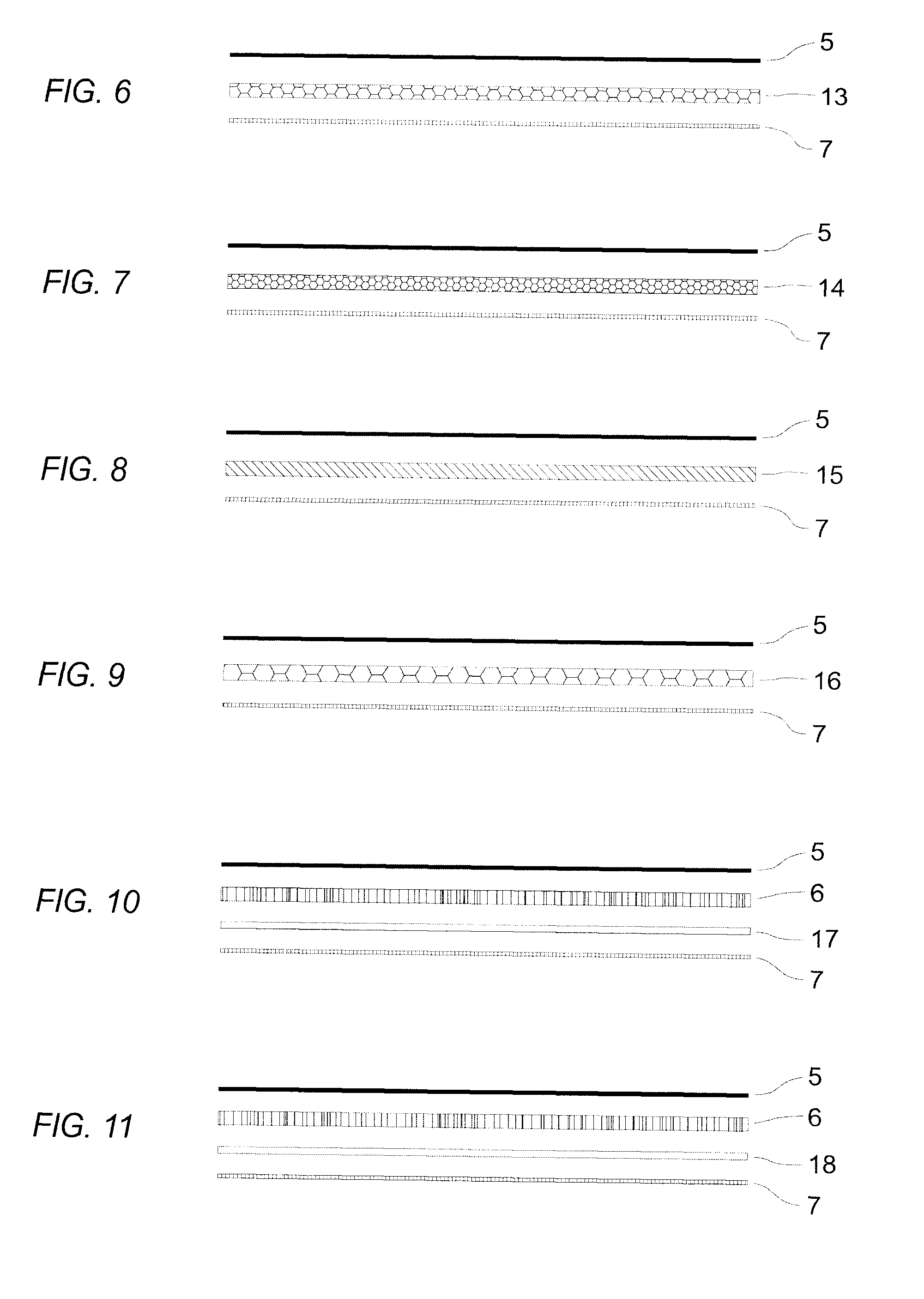

Method for the production of a chafe resistant overlay

InactiveUS20090208646A1Avoid large quantitiesSpecial paperSpecial ornamental structuresBiochemical engineeringCorundum

The invention relates to a method (100) for the production of an overlay, in particular for laminates. For this, firstly an overlay base paper (10) is impregnated in the usual manner and is coated on one side with a resin / coarse corundum application. In order to endow the overlay with additional characteristics, such as for example chafe resistance on the surface, in a further wet-in-wet application step a coating substance (29) is applied on the opposite side and is dosaged by a wiper (31).

Owner:DEKOR KUNSTE

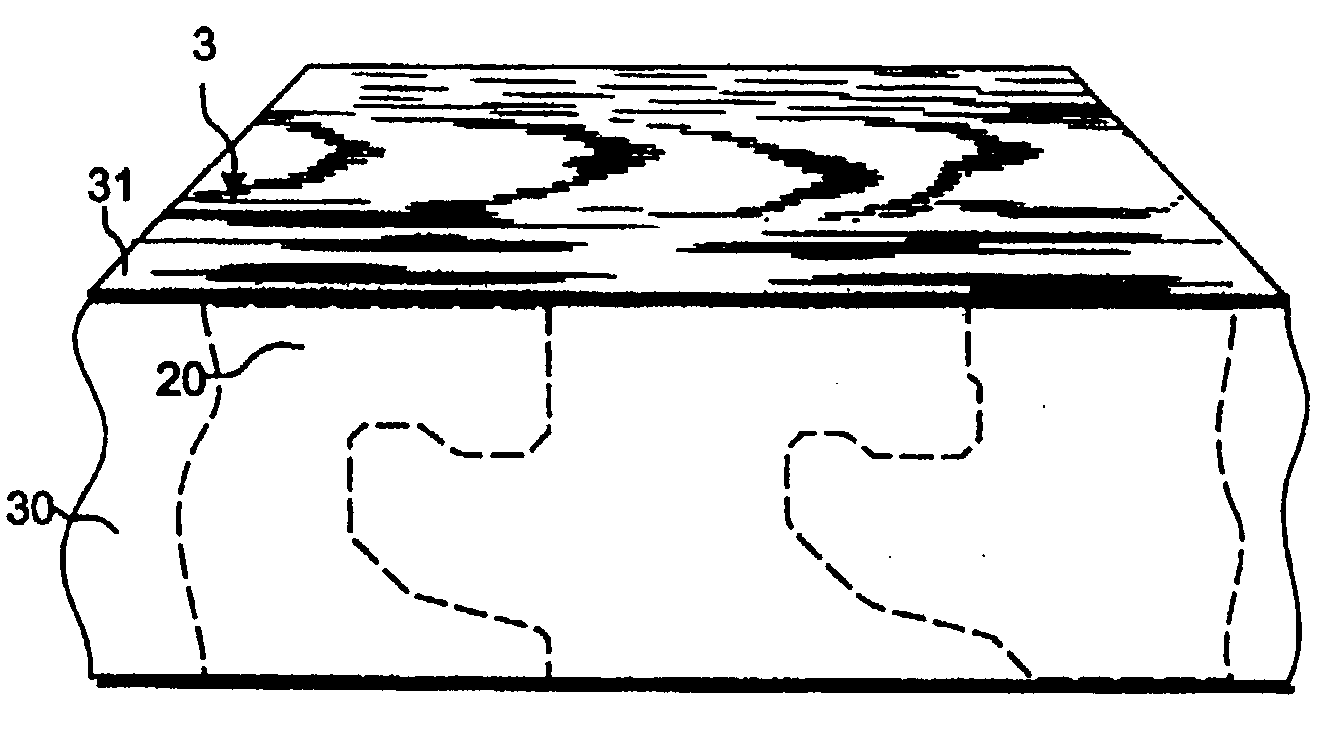

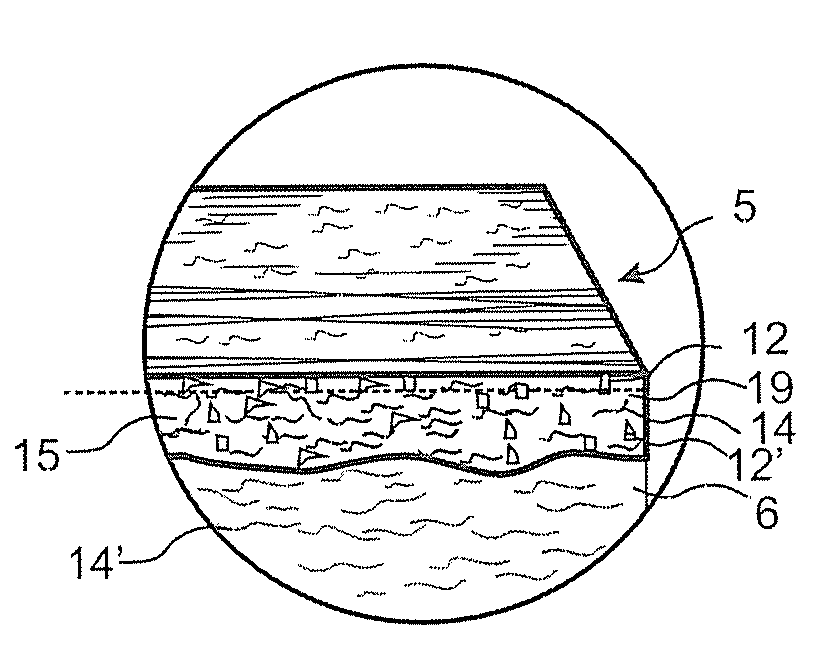

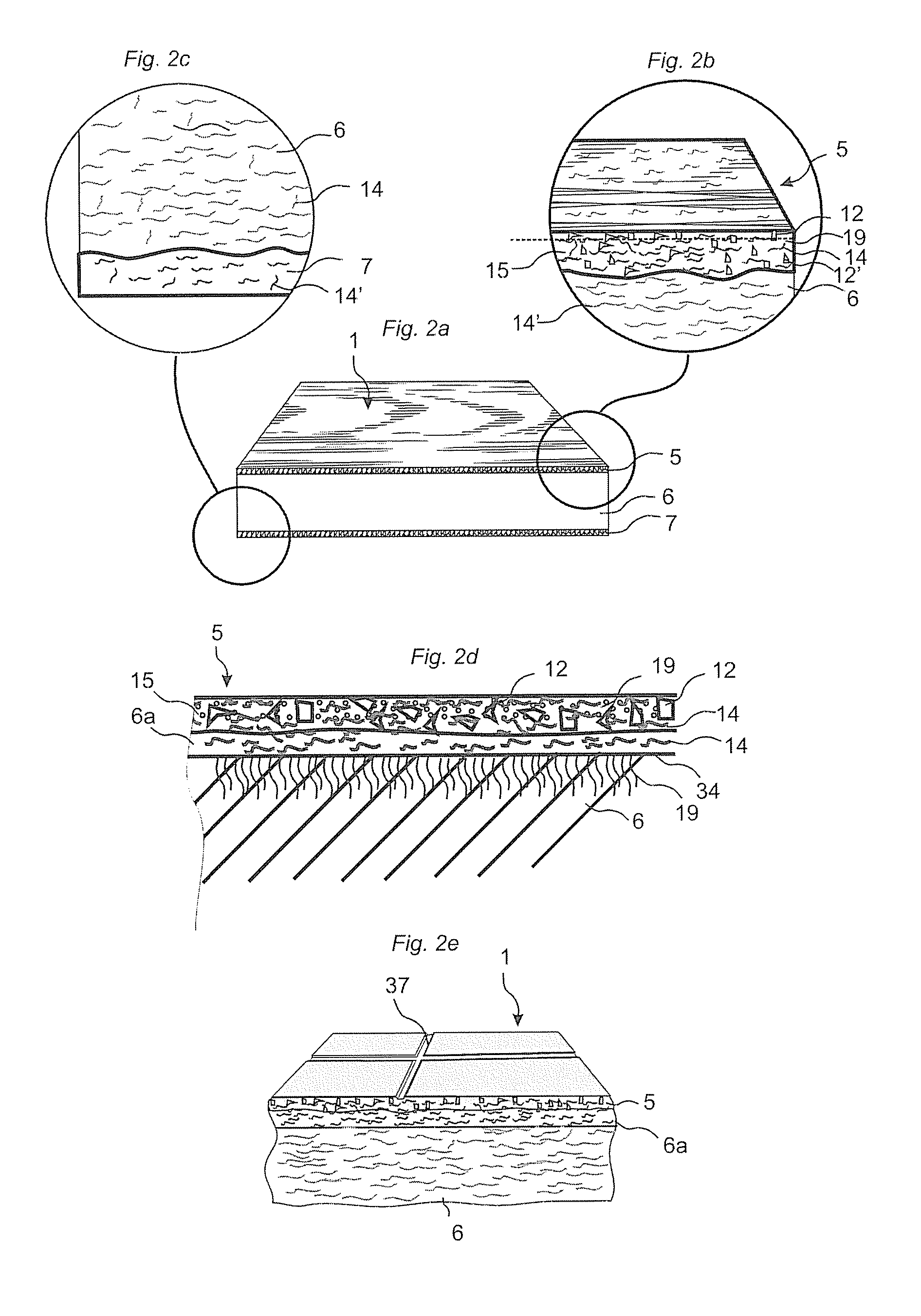

Wood fibre based panels with a thin surface layer

ActiveUS20100092731A1Large market shareImprove impact resistanceLiquid surface applicatorsCovering/liningsSurface layerWood fibre

Building panels with a thin and embossed surface layer and a sub layer between a surface layer and a core.

Owner:VÄLINGE INNOVATION AB

Surface covering panel

InactiveUS20040086678A1Sophisticated and delicateLamination ancillary operationsCovering/liningsBiomedical engineeringSupport surface

A surface covering is described wherein the surface covering includes at least one support surface, such as a core, with at least one base coating located on the support surface. The support surface preferably has a textured top surface. A printed pattern is located on the base coating and preferably the printed pattern is in register with the textured surface. At least one protective layer is located on the printed pattern. Methods of making the surface covering are further described.

Owner:MANNINGTON MILLS

System and method for generating a flickering flame effect

ActiveUS20060034100A1Safe and easy to manufactureRealistic flame effectCandle holdersPoint-like light sourceUltraviolet lightsEngineering

A system for creating a flickering effect comprising a simulated candle housing, a light communicating channel on the housing, a source of ultraviolet light disposed in the channel, and a simulated flame having ultraviolet material thereon movable back and forth from its vertical axis mounted in the housing, the light focused on the simulated flame simulating a flickering flame.

Owner:L&L CANDLE CO LLC

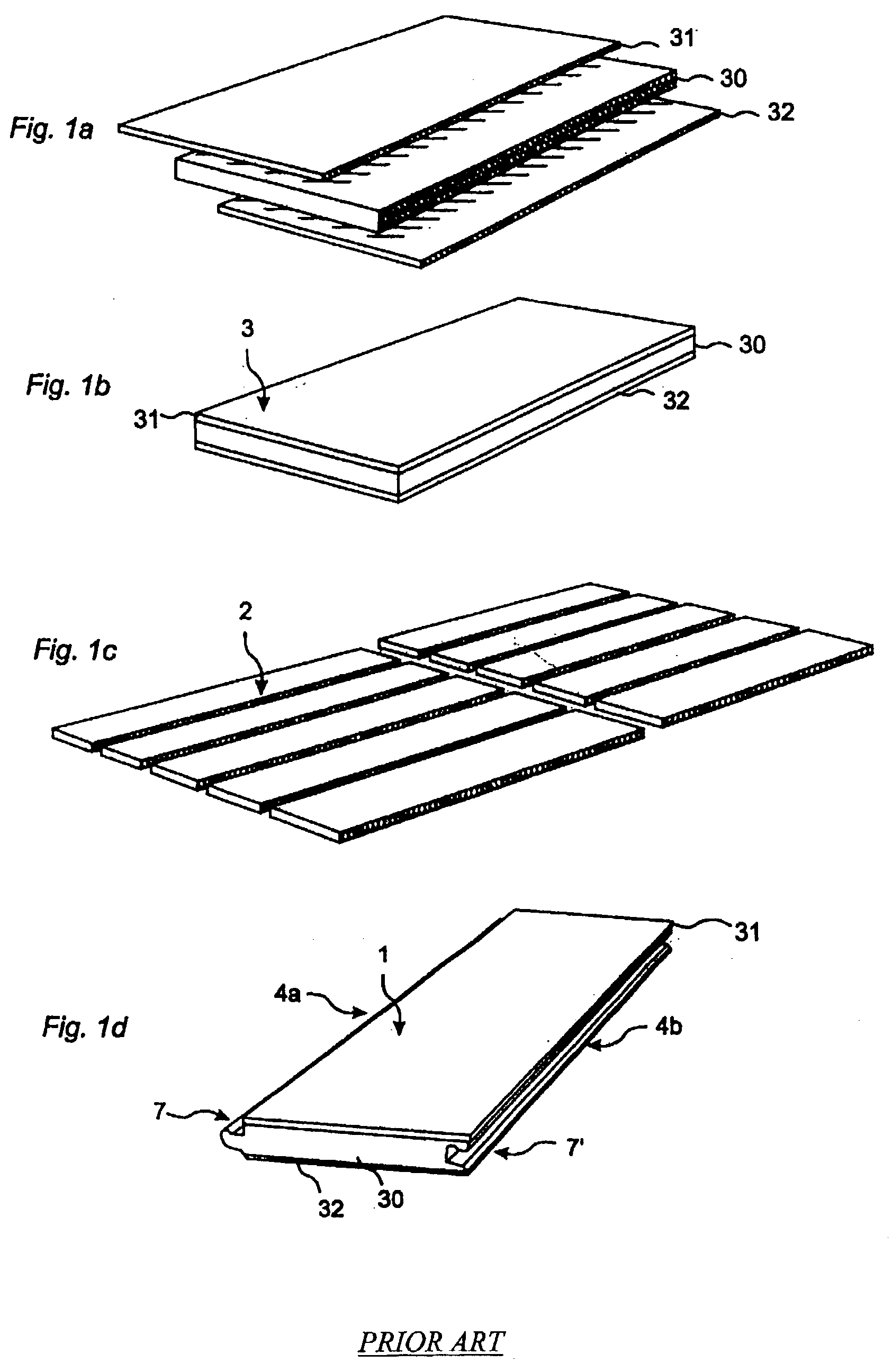

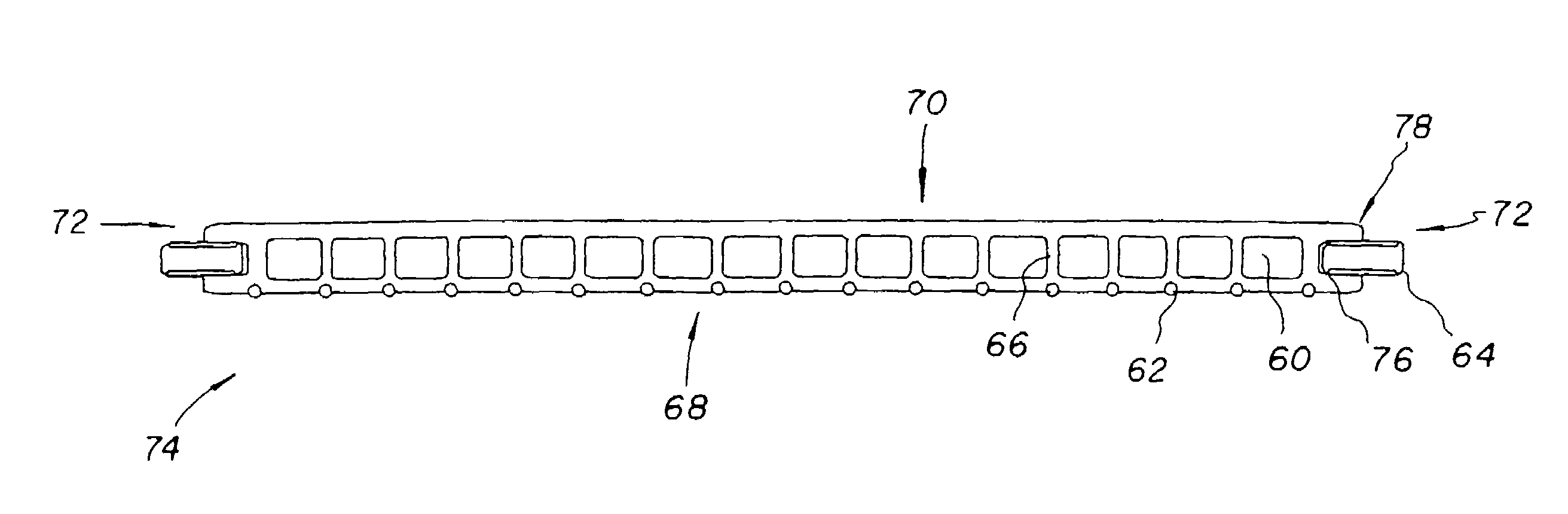

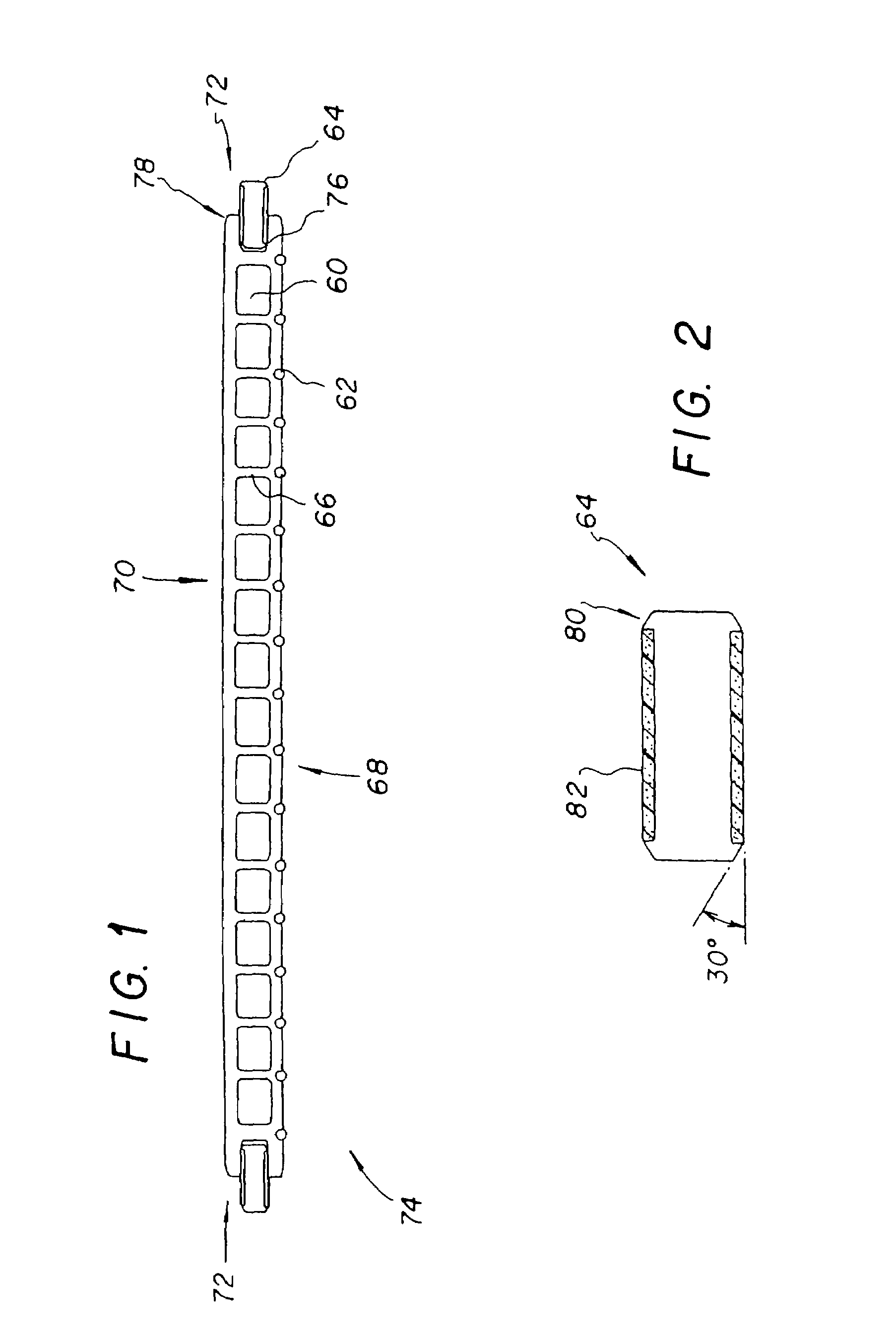

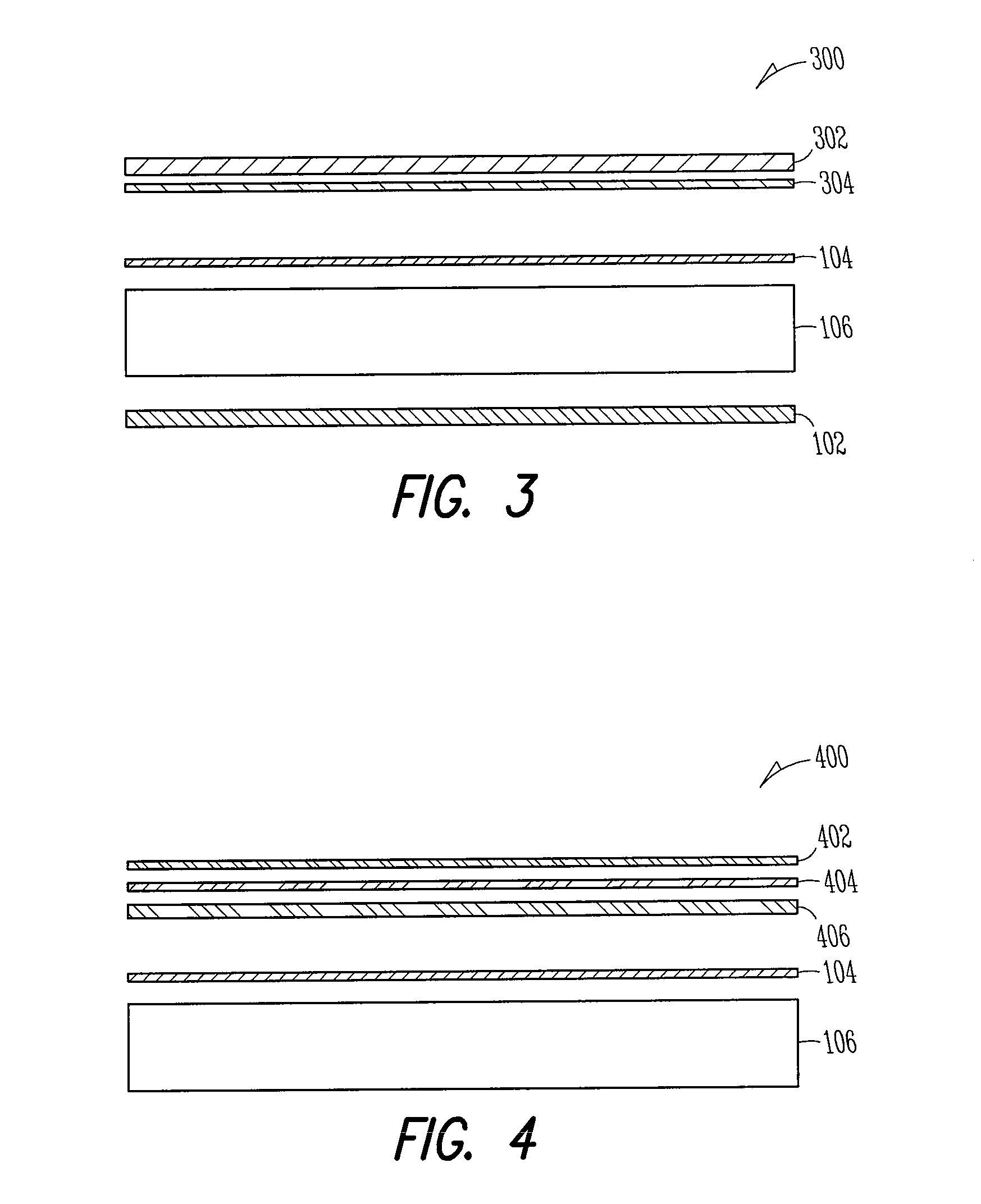

Thermoplastic planks and methods for making the same

InactiveUS6986934B2Improve moisture resistanceEasy flexibilityDecorative surface effectsSpecial ornamental structuresEngineeringThermoplastic materials

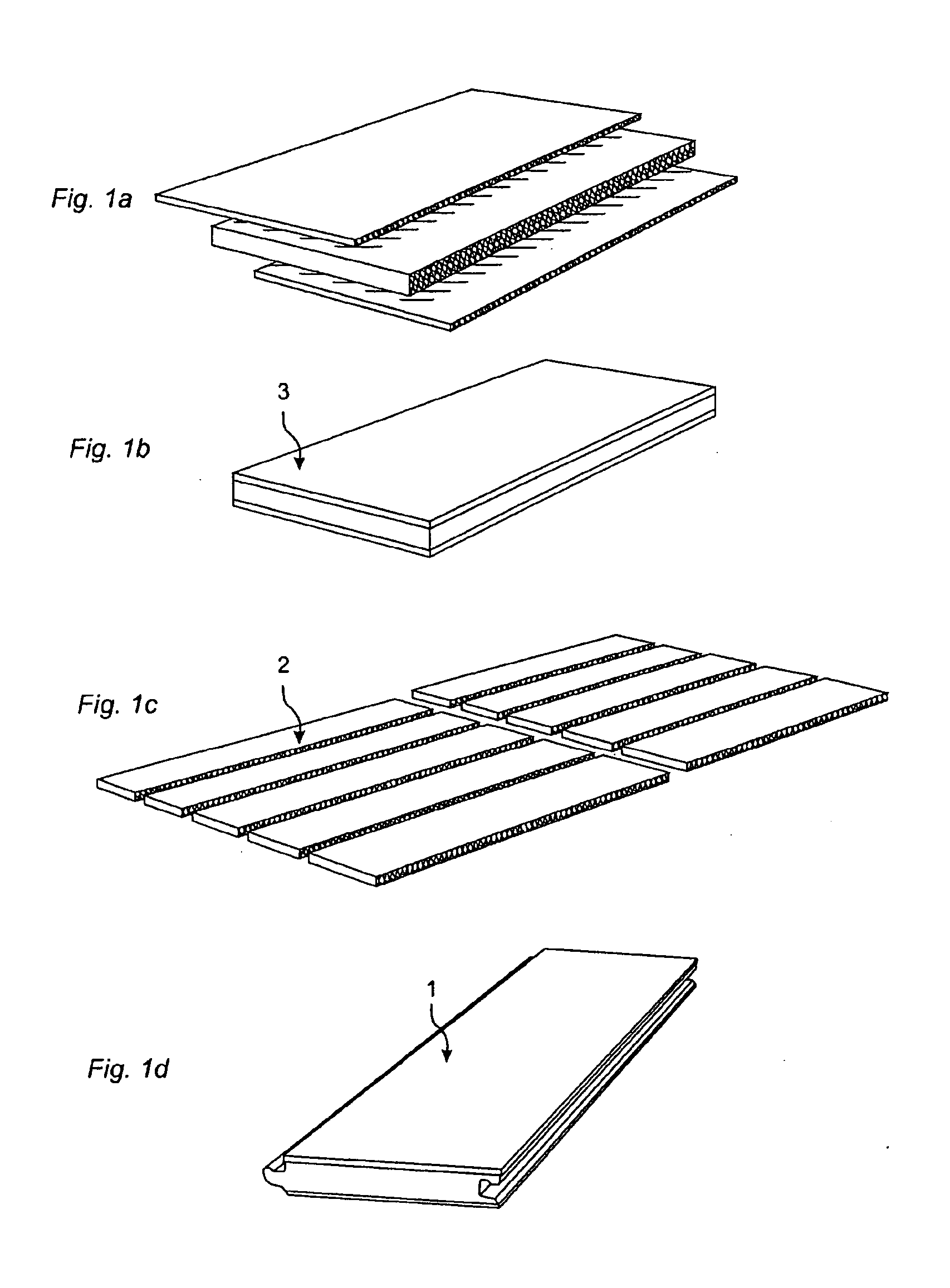

A thermoplastic laminate plank is described wherein the thermoplastic laminate plank comprises a core, a print layer, and optionally an overlay. The core comprises at least one thermoplastic material and has a top surface and bottom surface wherein a print layer is affixed to the top surface of the core and an overlay layer is affixed to the top surface of the print layer. Optionally, an underlay layer can be located and affixed between the bottom surface of the print layer and the top surface of the core. In addition, a method of making the thermoplastic laminate plank is further described which involves extruding at least one thermoplastic material into the shape of the core and affixing a laminate on the core, wherein the laminate comprises an overlay affixed to the top surface of the print layer and optionally an underlay layer affixed to the bottom surface of the print layer.

Owner:VÄLINGE INNOVATION AB

Thermoplastic planks and methods for making the same

InactiveUS7763345B2Improve moisture resistanceEasy flexibilityCovering/liningsDecorative surface effectsThick plateEngineering

A thermoplastic laminate plank is described wherein the thermoplastic laminate plank comprises a core, a print layer, and optionally an overlay. The core comprises at least one thermoplastic material and has a top surface and bottom surface wherein a print layer is affixed to the top surface of the core and an overlay layer is affixed to the top surface of the print layer. Optionally, an underlay layer can be located and affixed between the bottom surface of the print layer and the top surface of the core. In addition, a method of making the thermoplastic laminate plank is further described which involves extruding at least one thermoplastic material into the shape of the core and affixing a laminate on the core, wherein the laminate comprises an overlay affixed to the top surface of the print layer and optionally an underlay layer affixed to the bottom surface of the print layer.

Owner:VÄLINGE INNOVATION AB

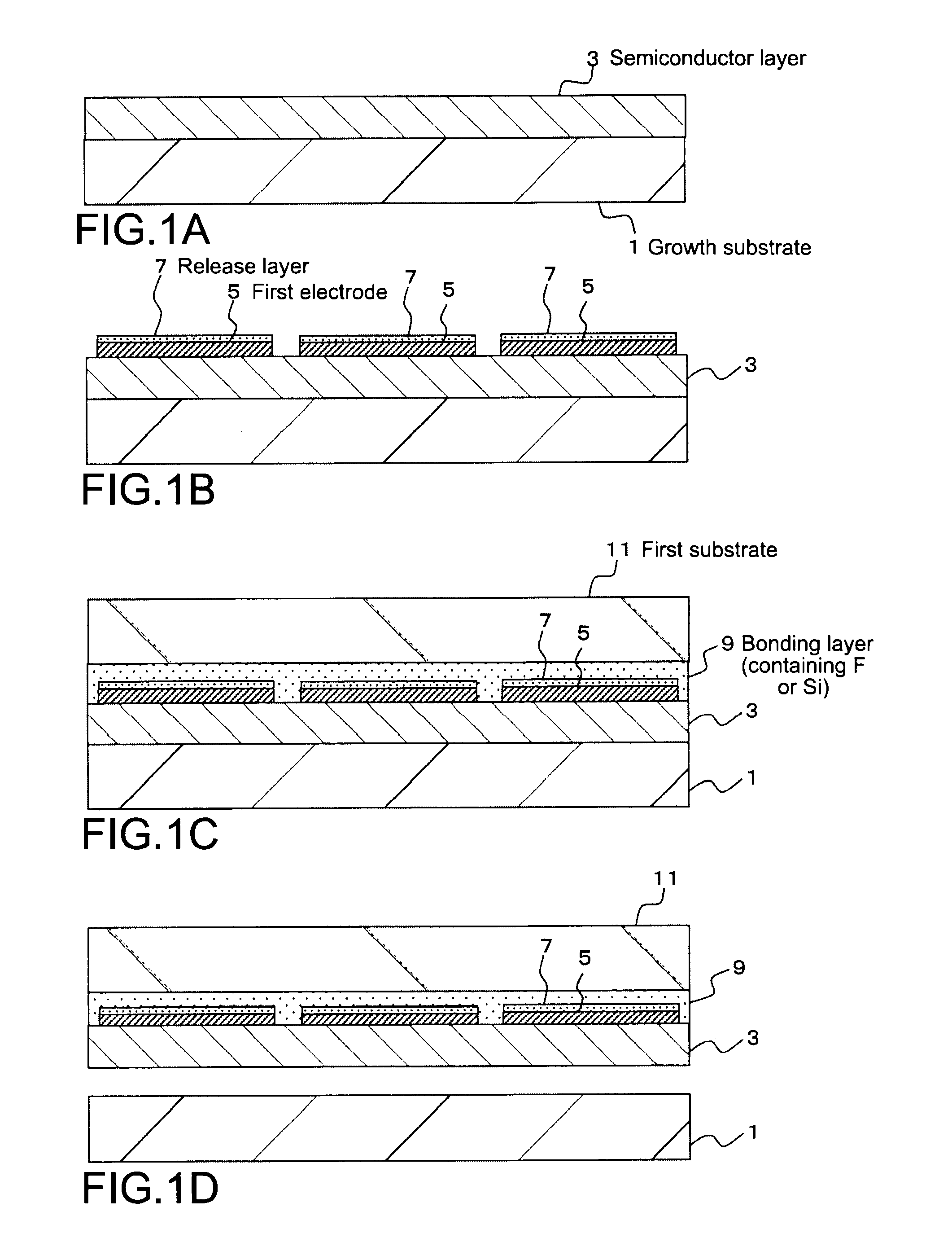

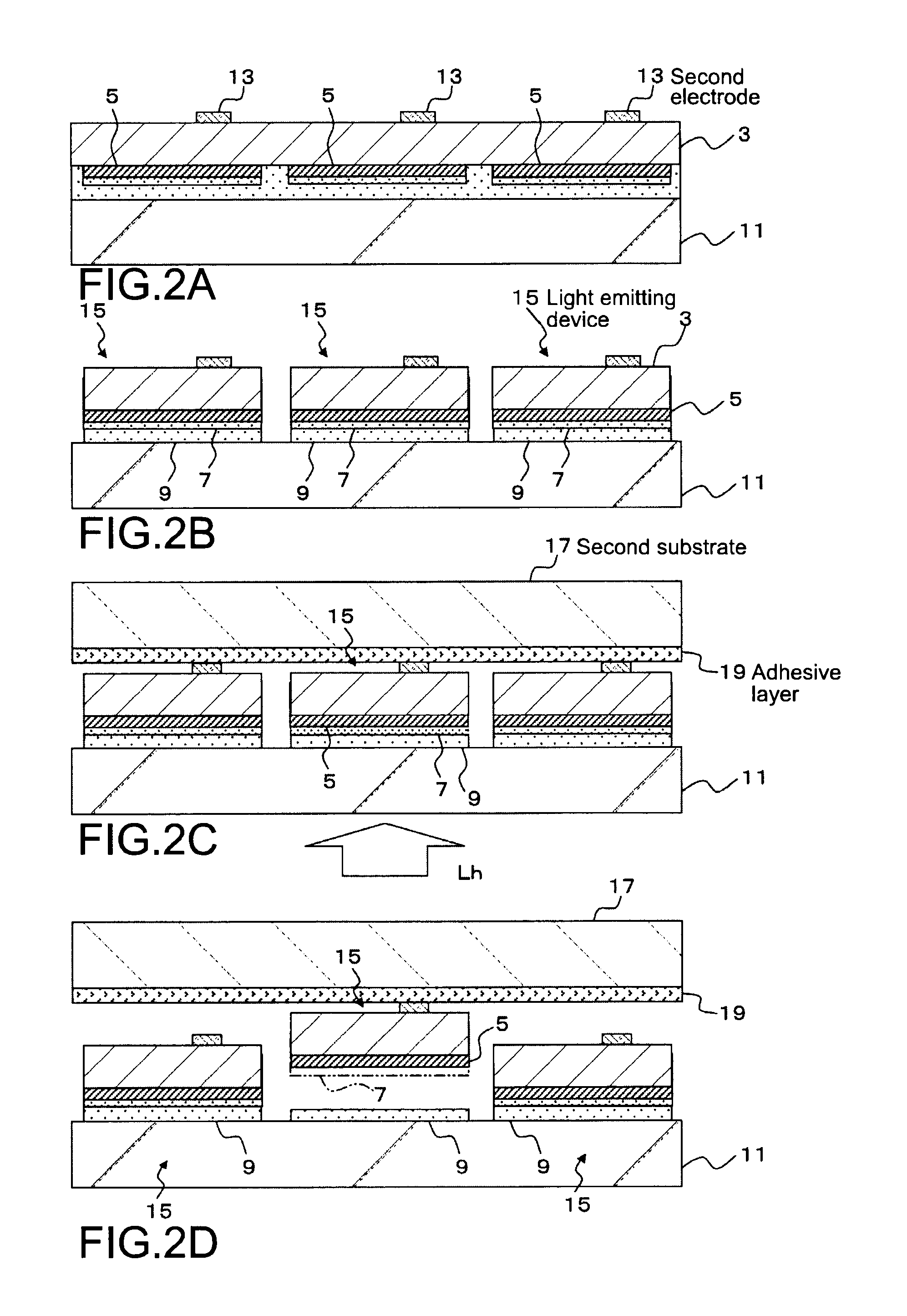

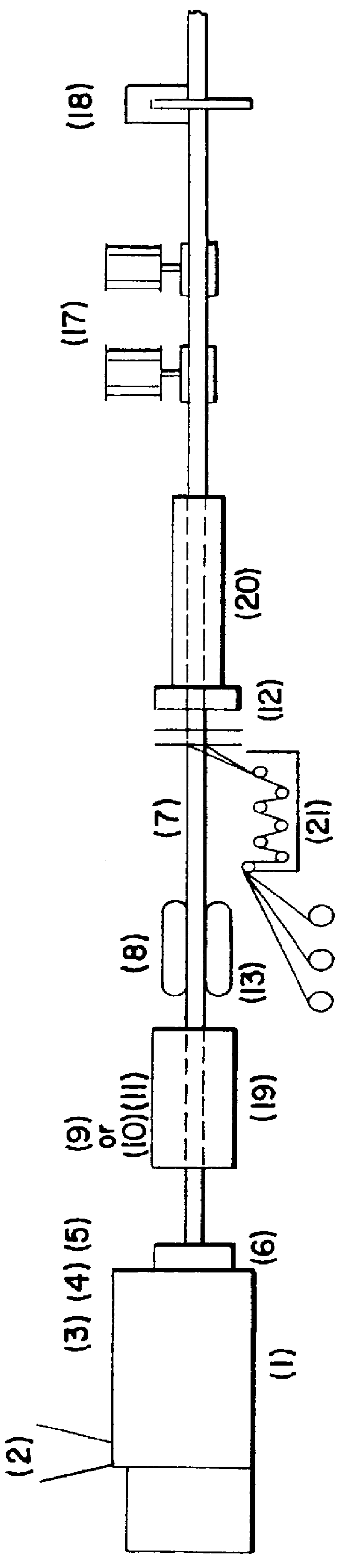

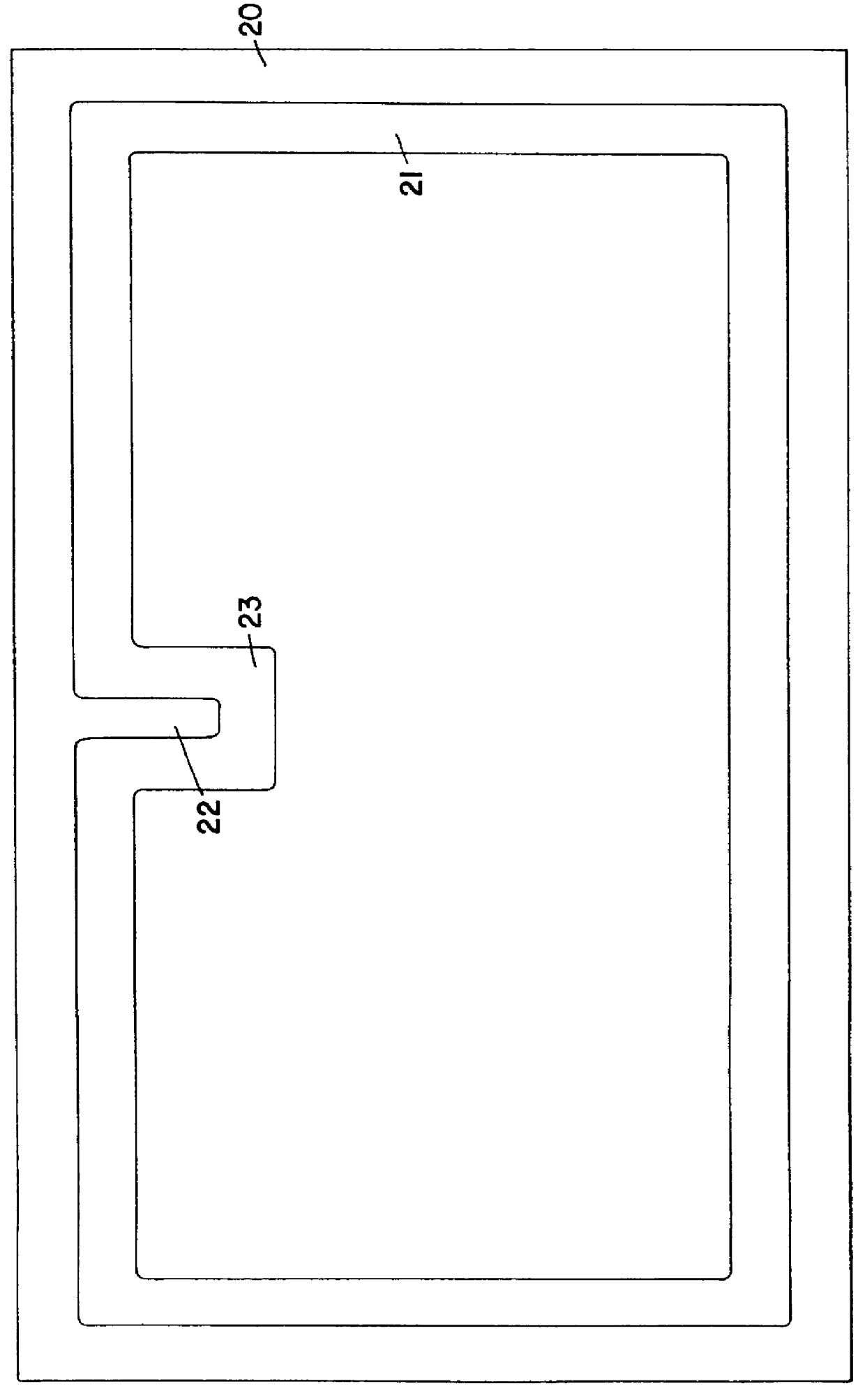

Method of transferring a device and method of manufacturing a display apparatus

InactiveUS20100186883A1Easily ablatedSufficient bonding propertyOrnamental structuresSolid-state devicesLight irradiationOptoelectronics

A method of transferring a device includes: arranging a release layer and a device in the stated lamination order on a first substrate having light transmitting property via a bonding layer having light transmitting property; arranging an adhesive layer formed on a second substrate so that the adhesive layer is opposed to a surface of the first substrate on which the device is arranged; and ablating the release layer by performing light irradiation on the release layer from the first substrate side and transferring the device onto the second substrate with the bonding layer being left on the first substrate.

Owner:SONY CORP

Panel and methods for manufacturing panels

InactiveUS20130062006A1Realized more smoothly and/or economicallyAcceptable soundCovering/liningsDecorative surface effectsSynthetic materialsEngineering

Owner:FLOORING IND LTD

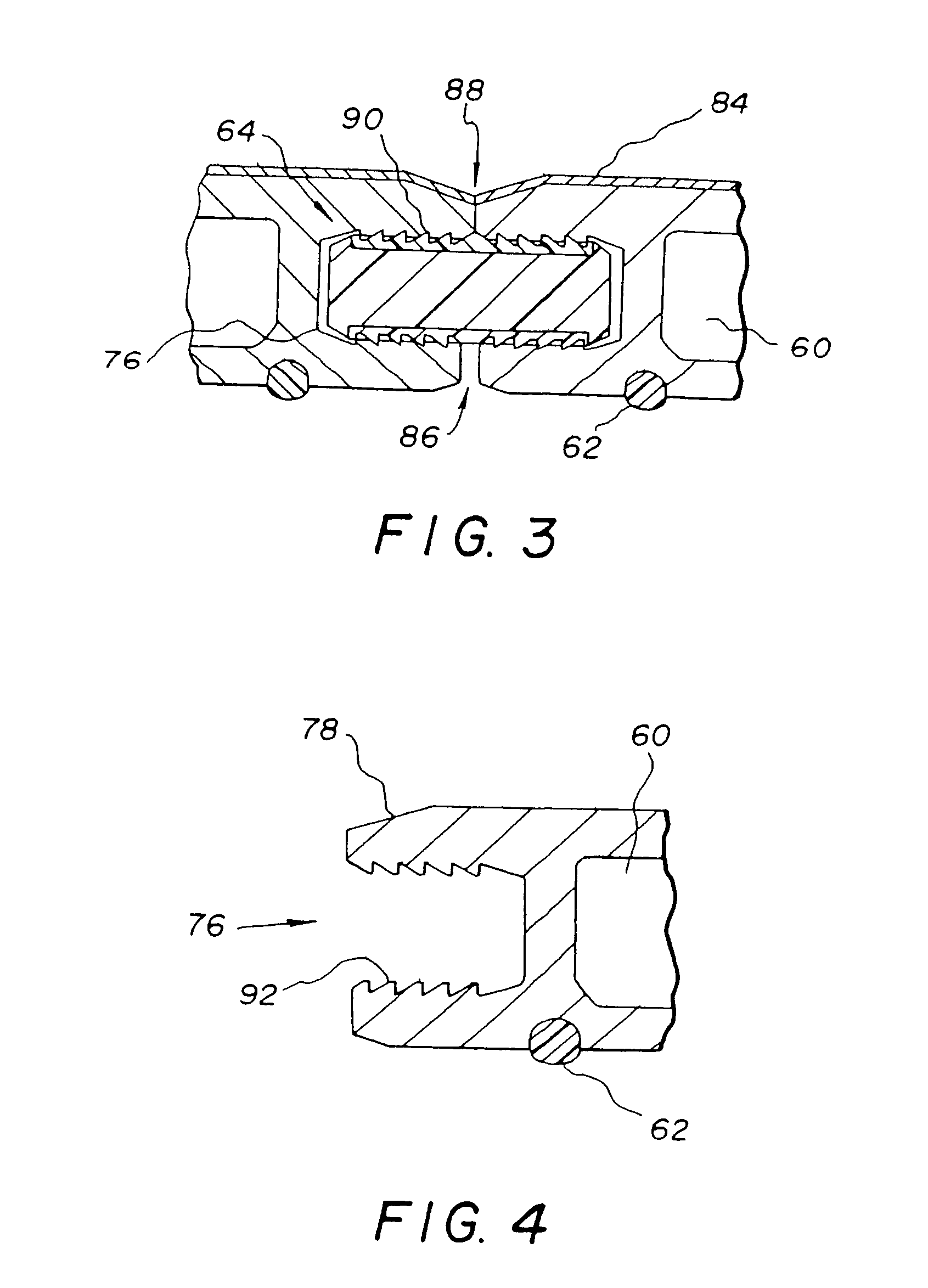

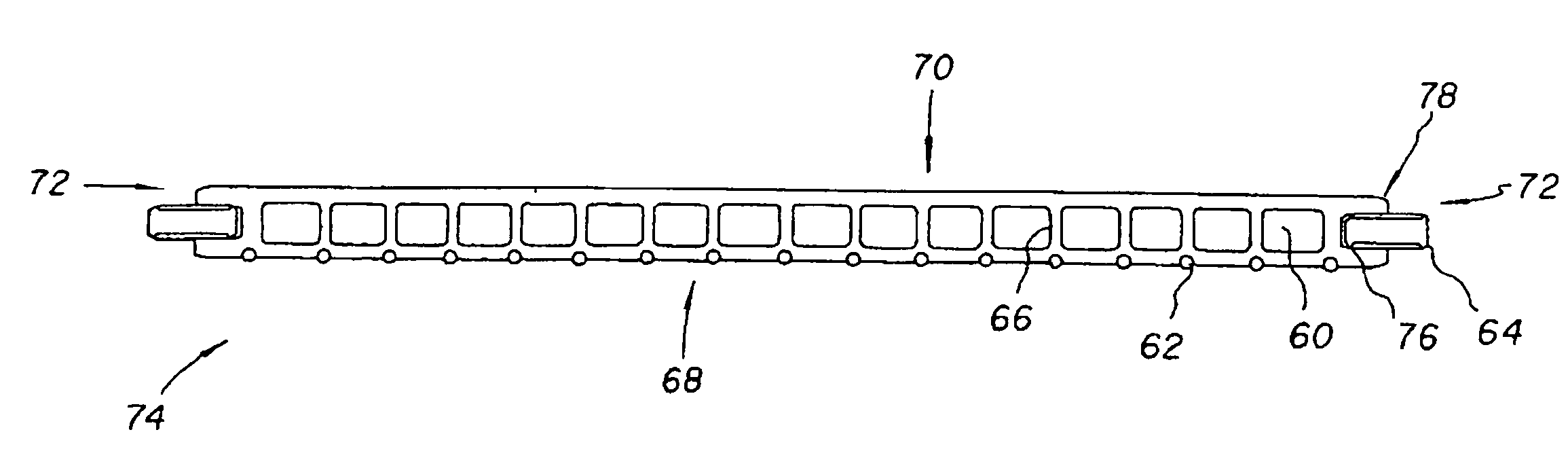

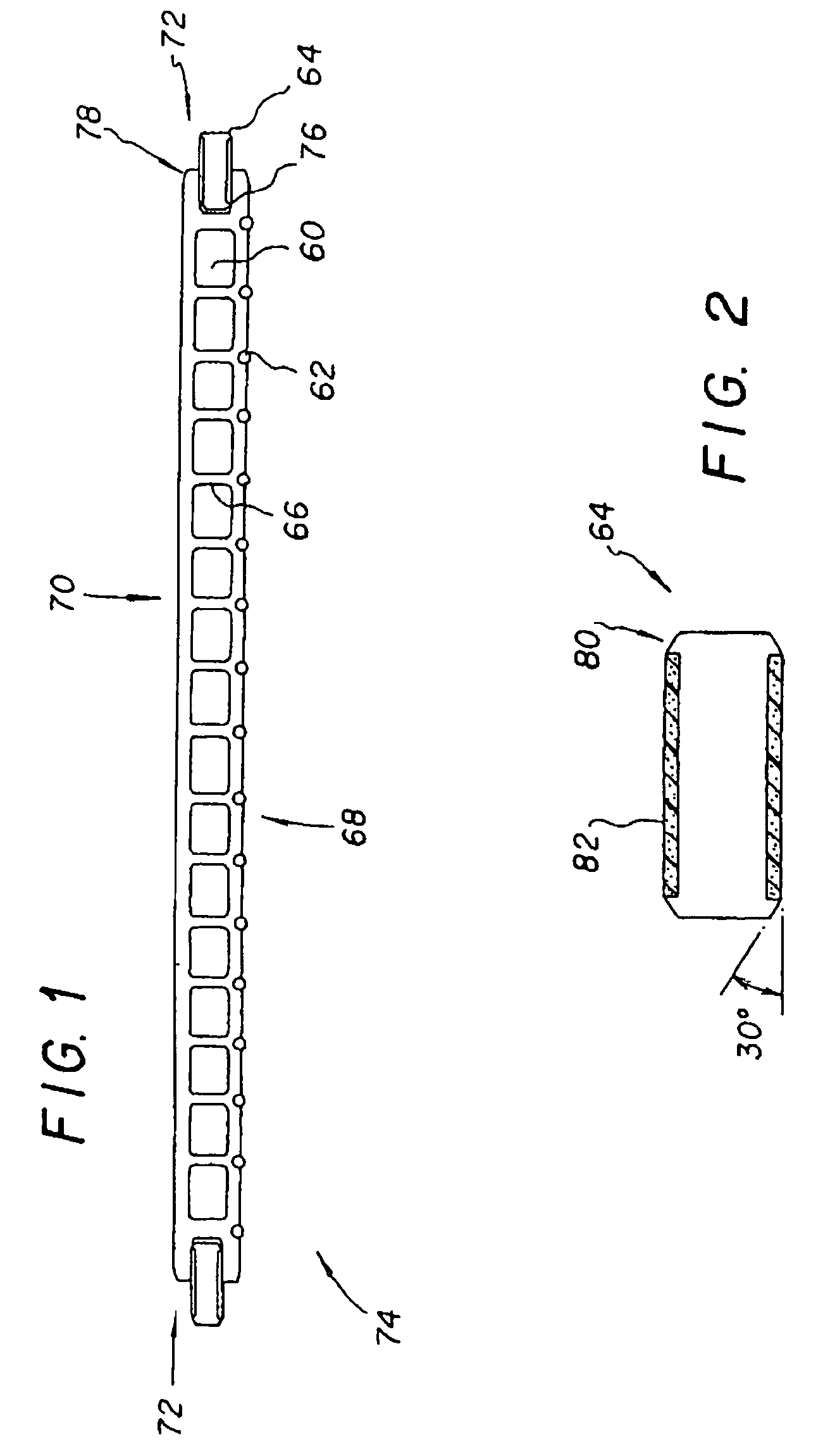

Fiber thermoset reinforced thermoplastic structural member

InactiveUS6106944AHigh strengthImprove mechanical propertiesLayered productsSpecial ornamental structuresYoung's modulusEngineering

In the manufacture of a structural member comprising a thermoplastic composite core with an exterior reinforcing layer, the core member is initially extruded in the shape of a profile. The profile is then contacted with reinforcing fiber and resin to form the exterior reinforcing layer. The exterior thermosetting layer is cured to form a reinforcing layer. The structural member is preferably manufactured using a pultrusion method in which a tractor device is used to provide linear movement of the profile from the extrusion head to the exterior coating operation. The fiber-reinforced thermoset is coated on the entirety of the exterior of the profile or is applied only on a portion of the profile requiring reinforcement in a defined load-bearing direction. A preferred thermoplastic core comprises a polymer-fiber composite material. A structural member of the invention has significantly improved Young's modulus providing strength for applications such as telephone poles, electric poles, electric lighting poles, boat mast or keel applications, lumber replacements, structural members used in window and door manufacture, etc.

Owner:ANDERSEN CORPORATION

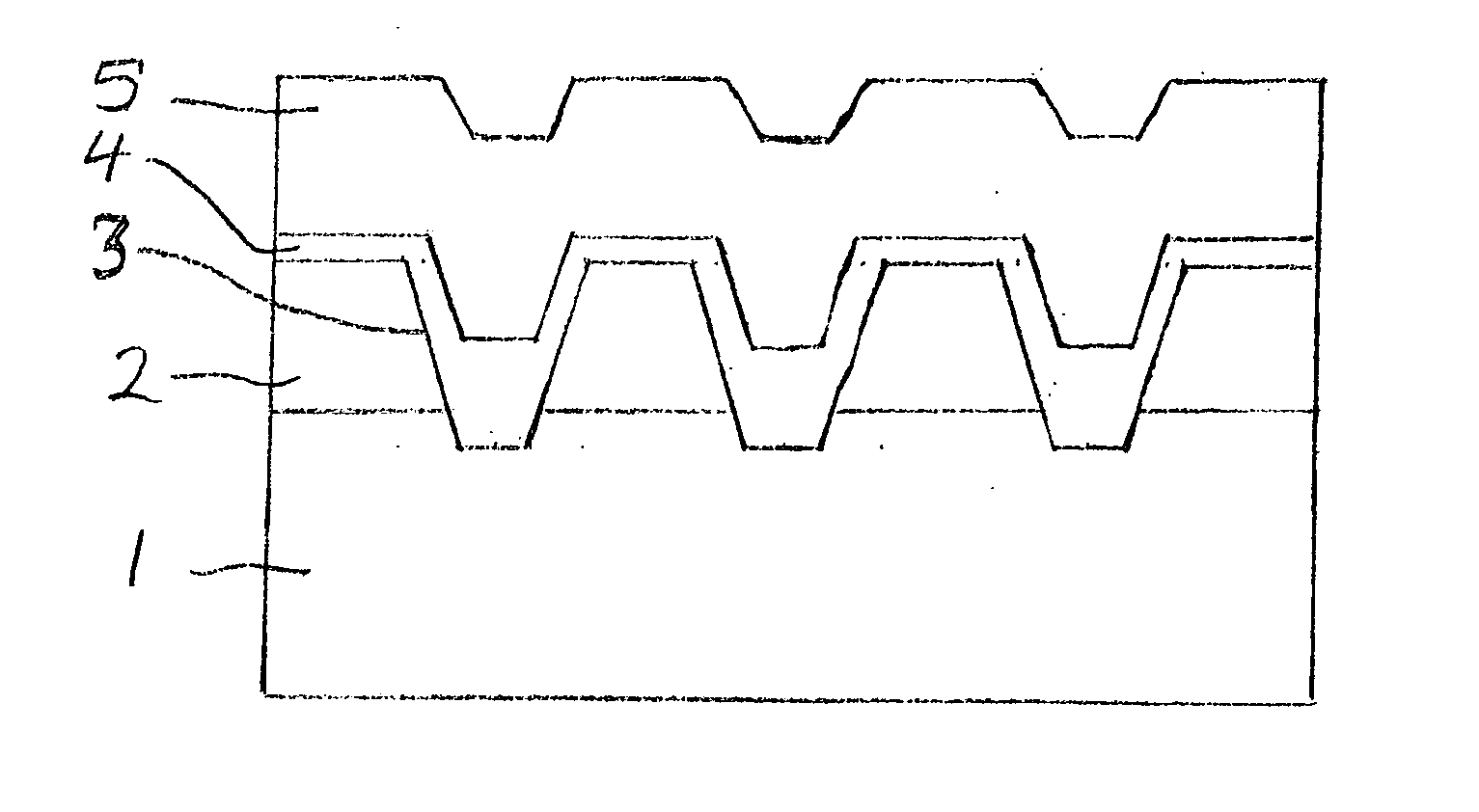

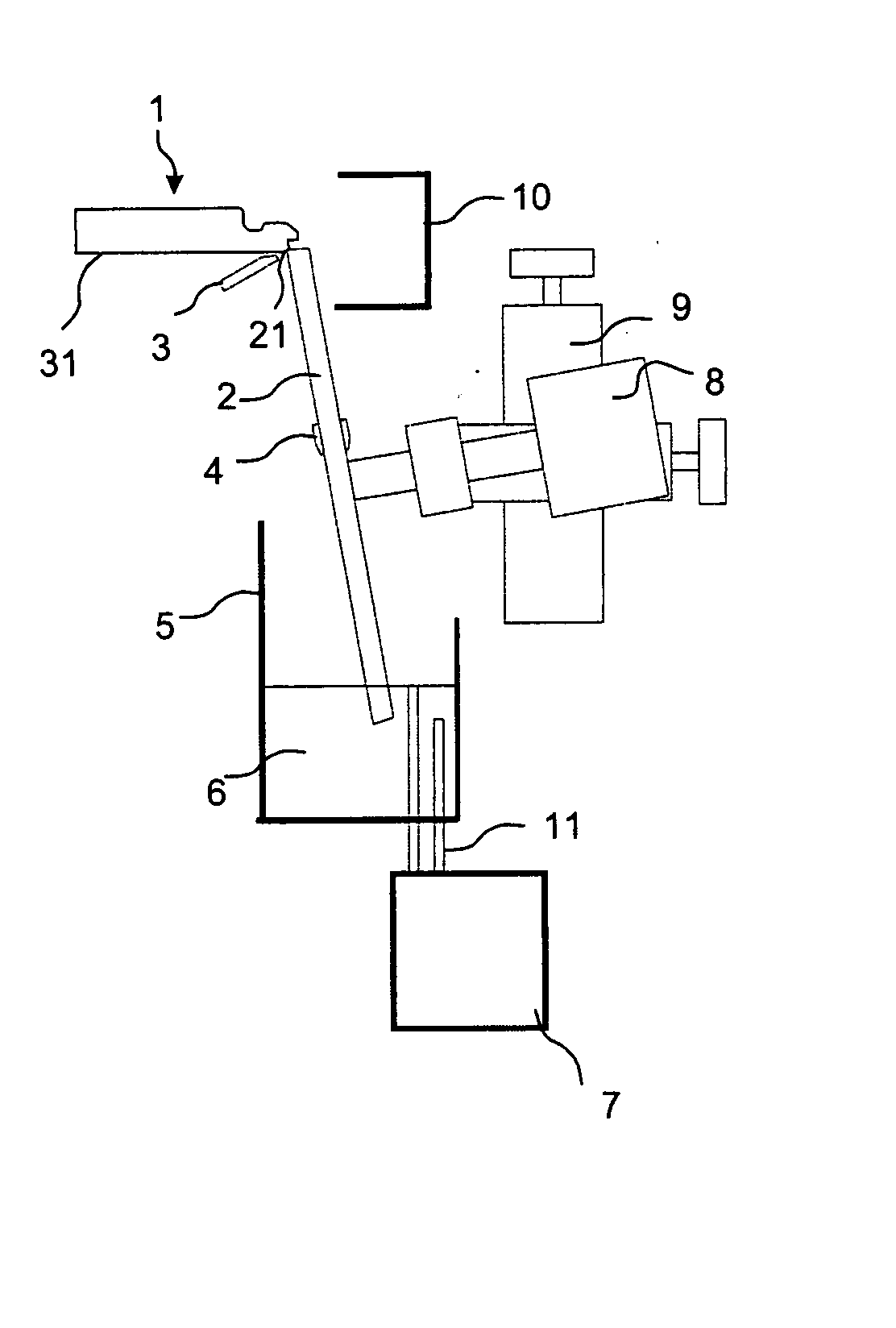

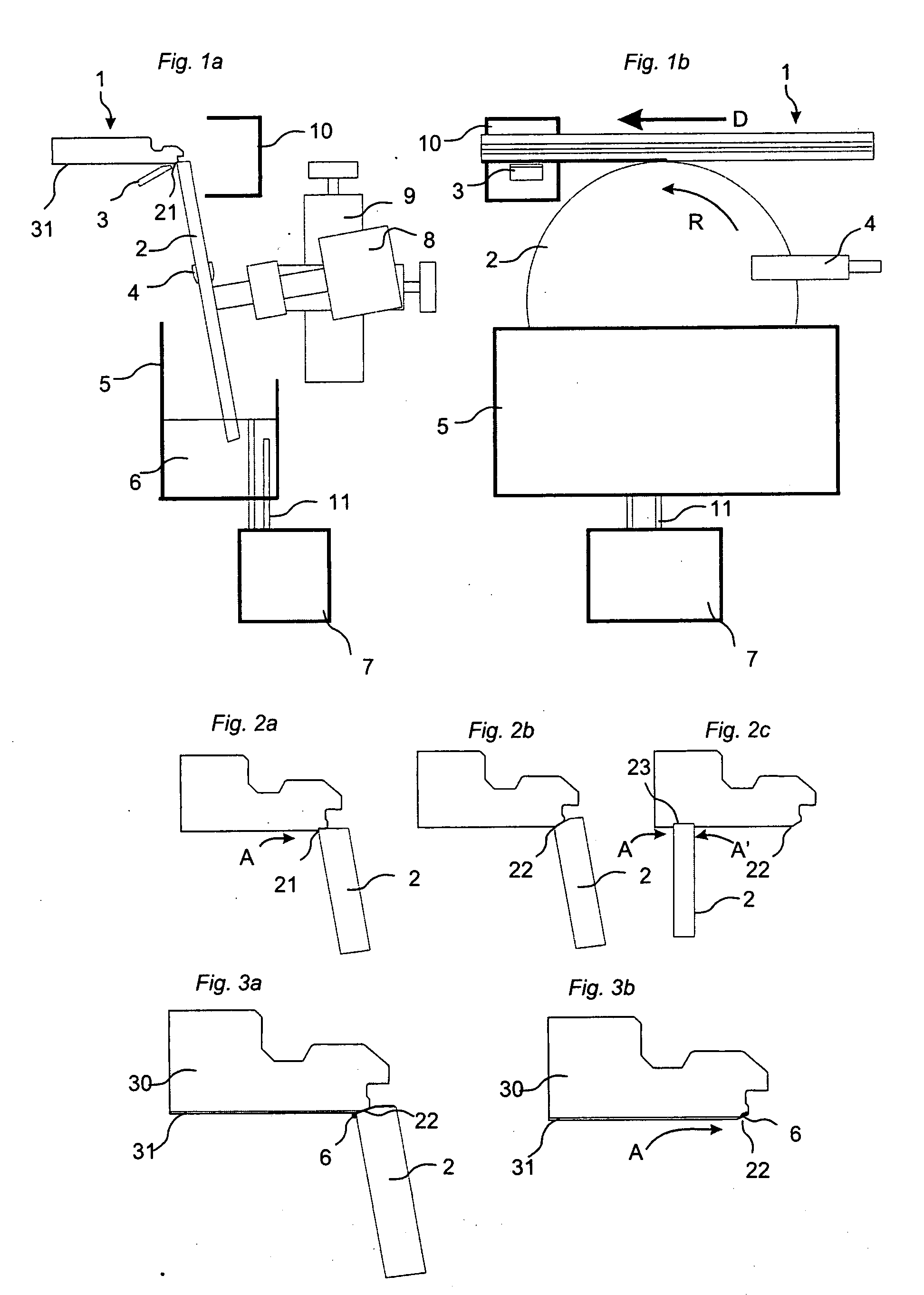

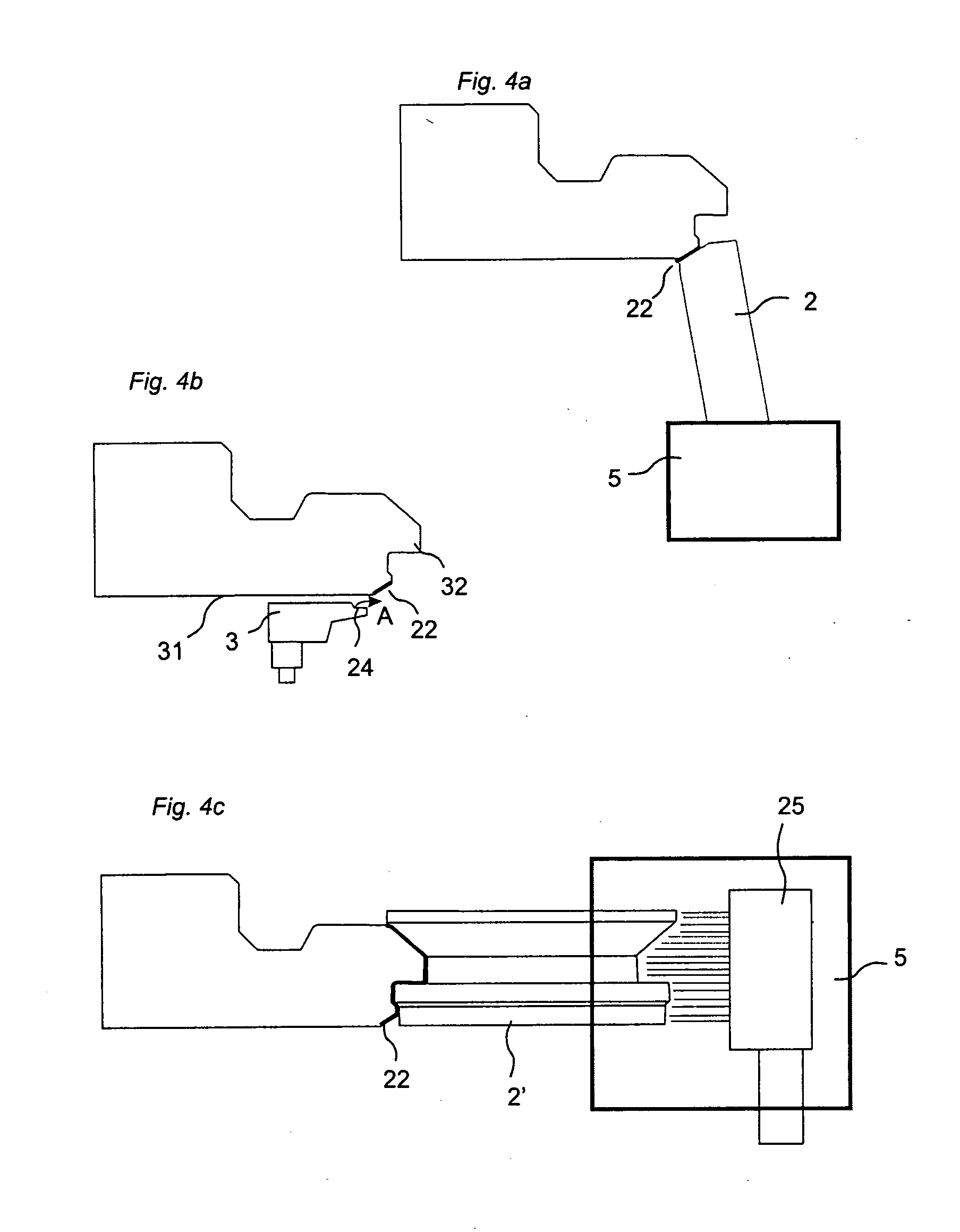

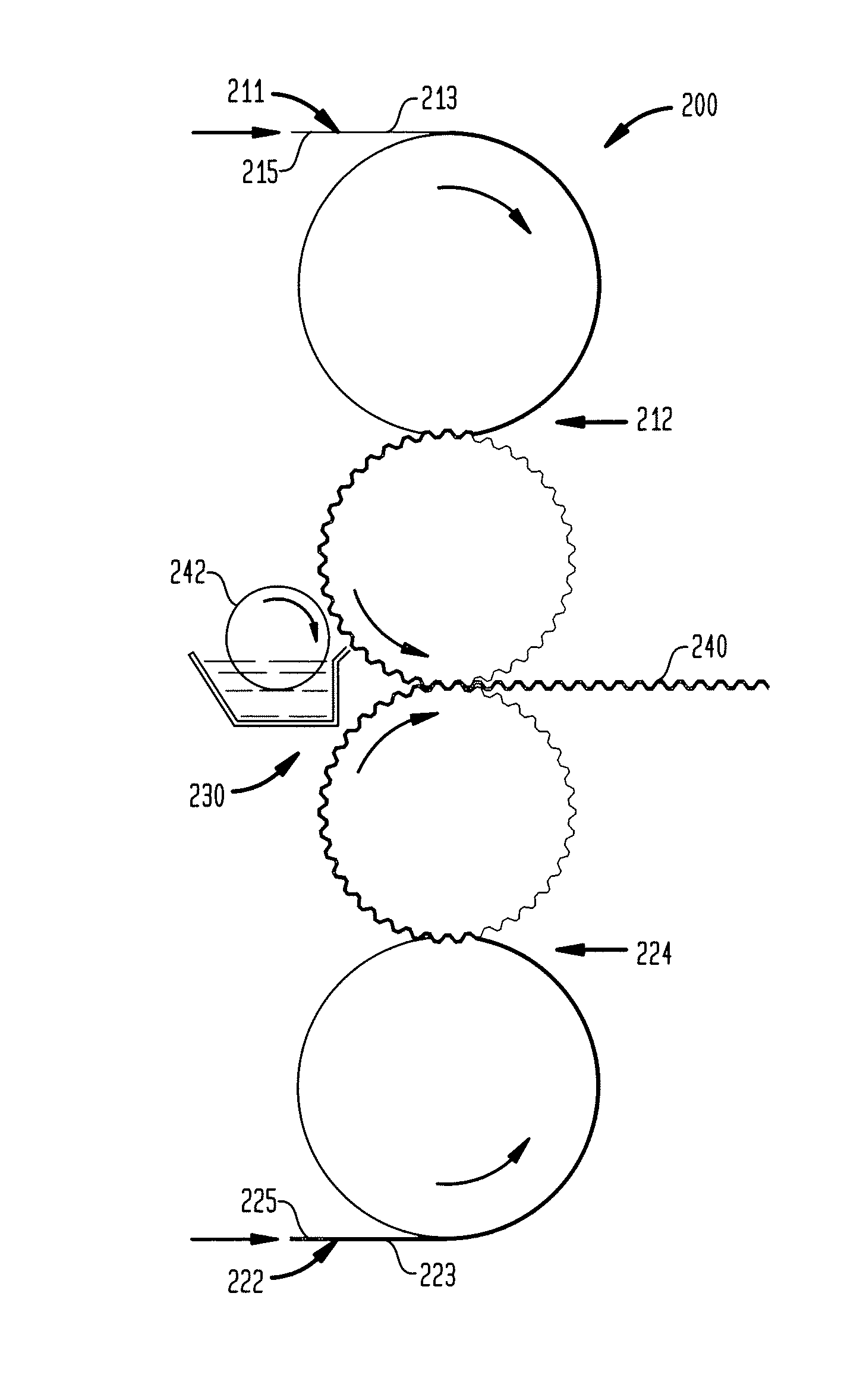

Appliance and method for surface treatment of a board shaped material and floorboard

InactiveUS20080000417A1Improve accuracyCovering/liningsSpecial ornamental structuresMaterials scienceSurface coating

A device for coating surface portions of a board material with a liquid material. The device includes a wheel which transfers the coating material and compressed air which positions the coating material. A method for surface coating and a floorboard with a finished surface portion.

Owner:VÄLINGE INNOVATION AB

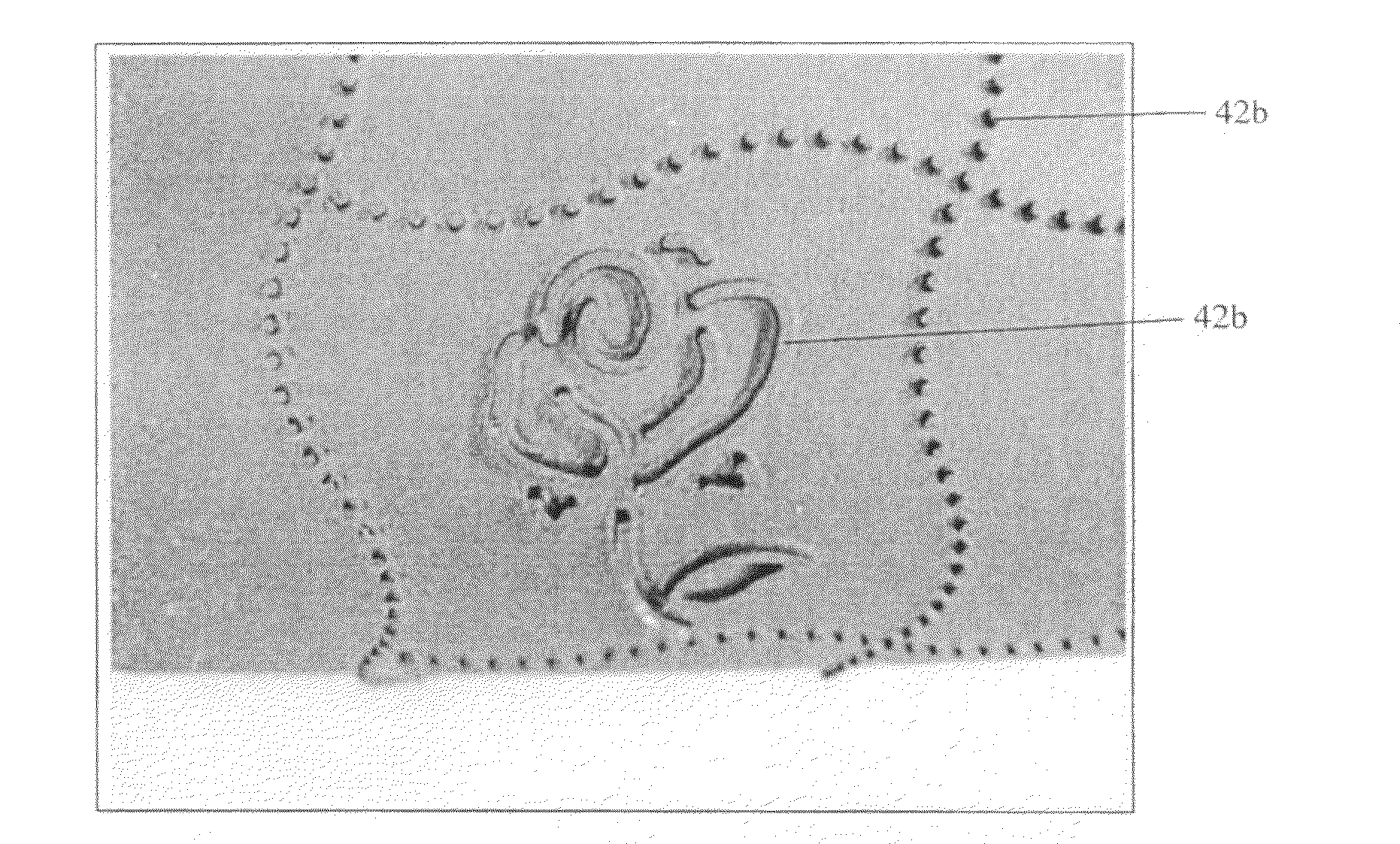

Embossed fibrous structures and methods for making same

InactiveUS20100028621A1Good flexibilityHigh strengthMechanical working/deformationLayered productsFiberEngineering

Owner:THE PROCTER & GAMBLE COMPANY

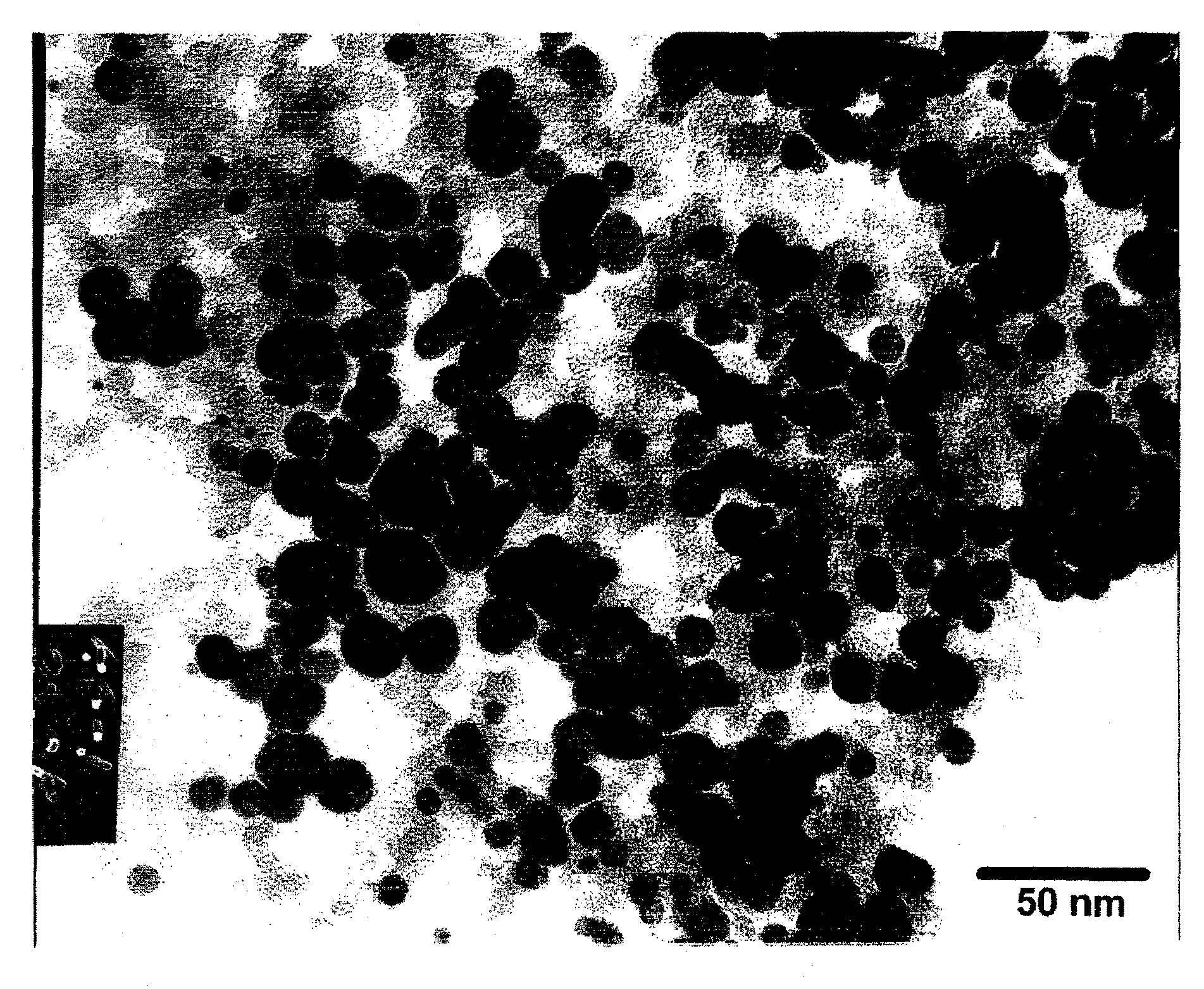

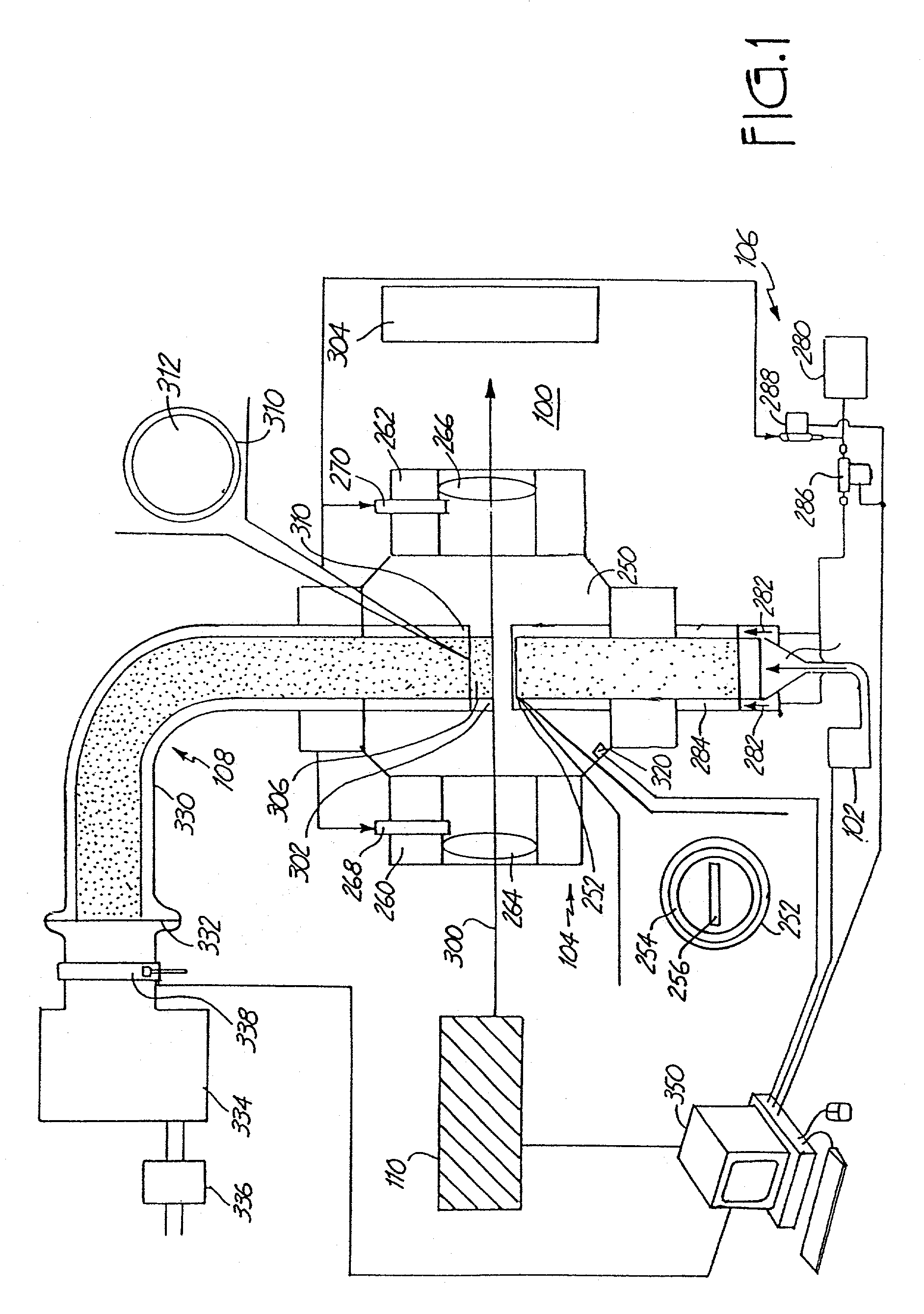

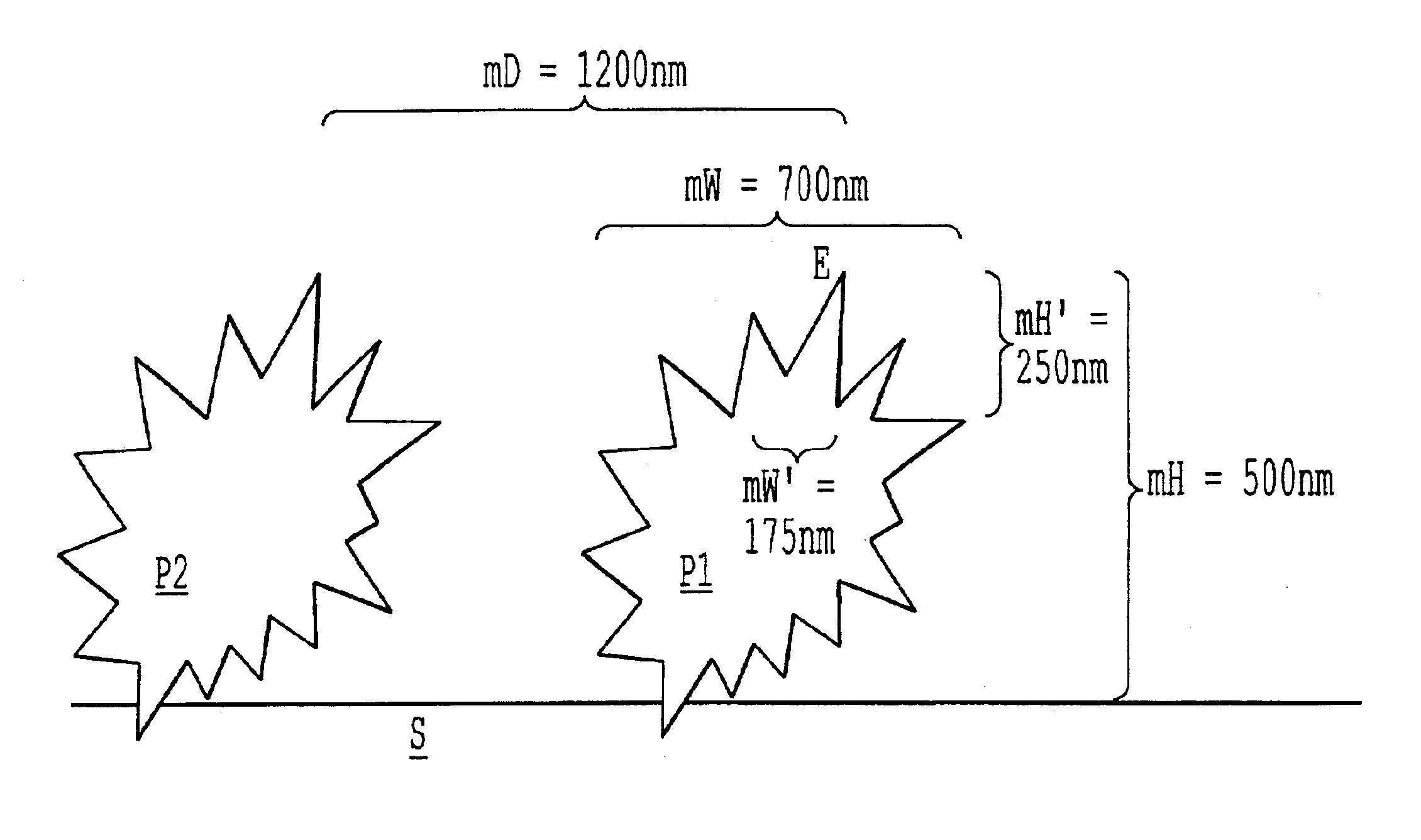

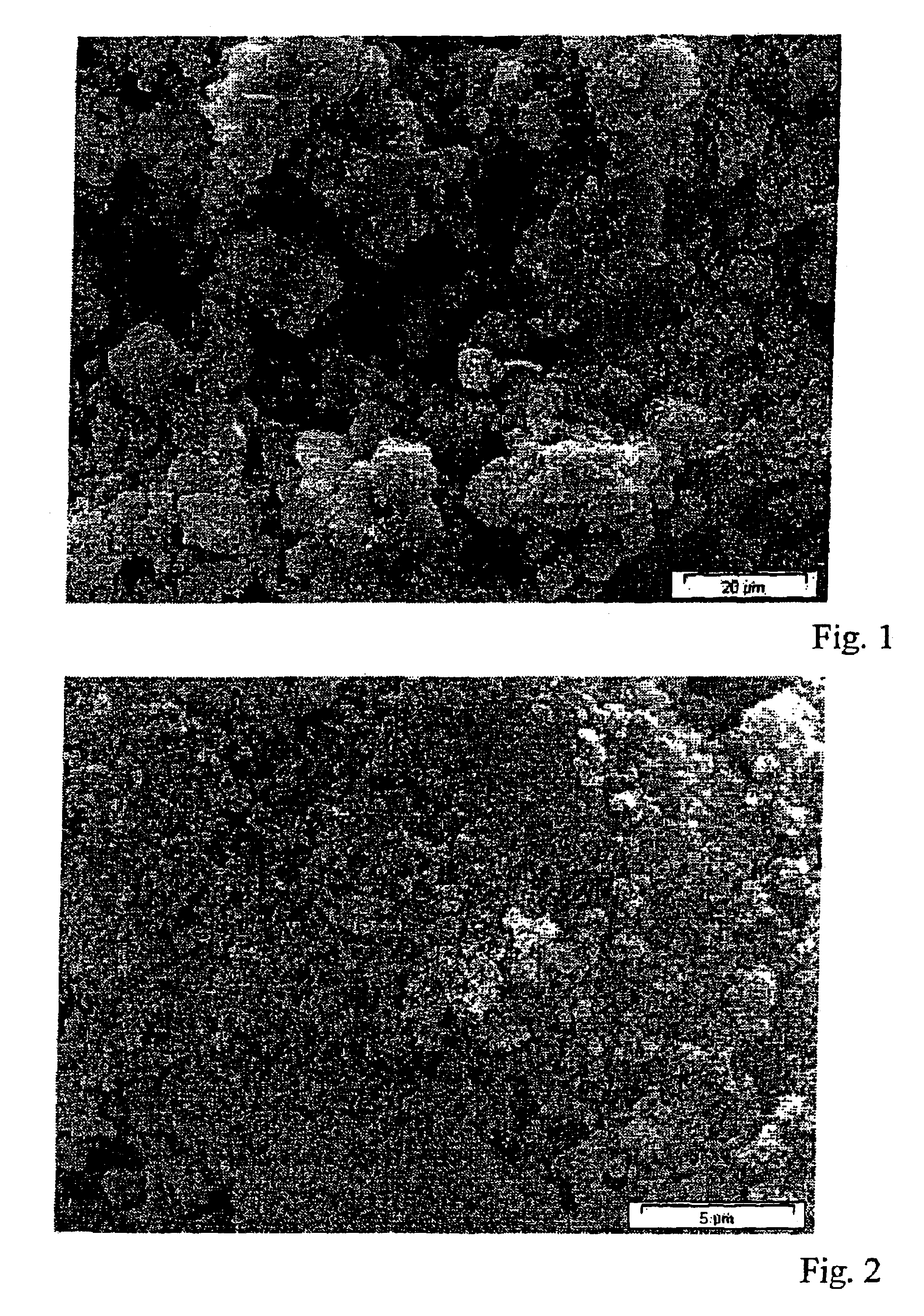

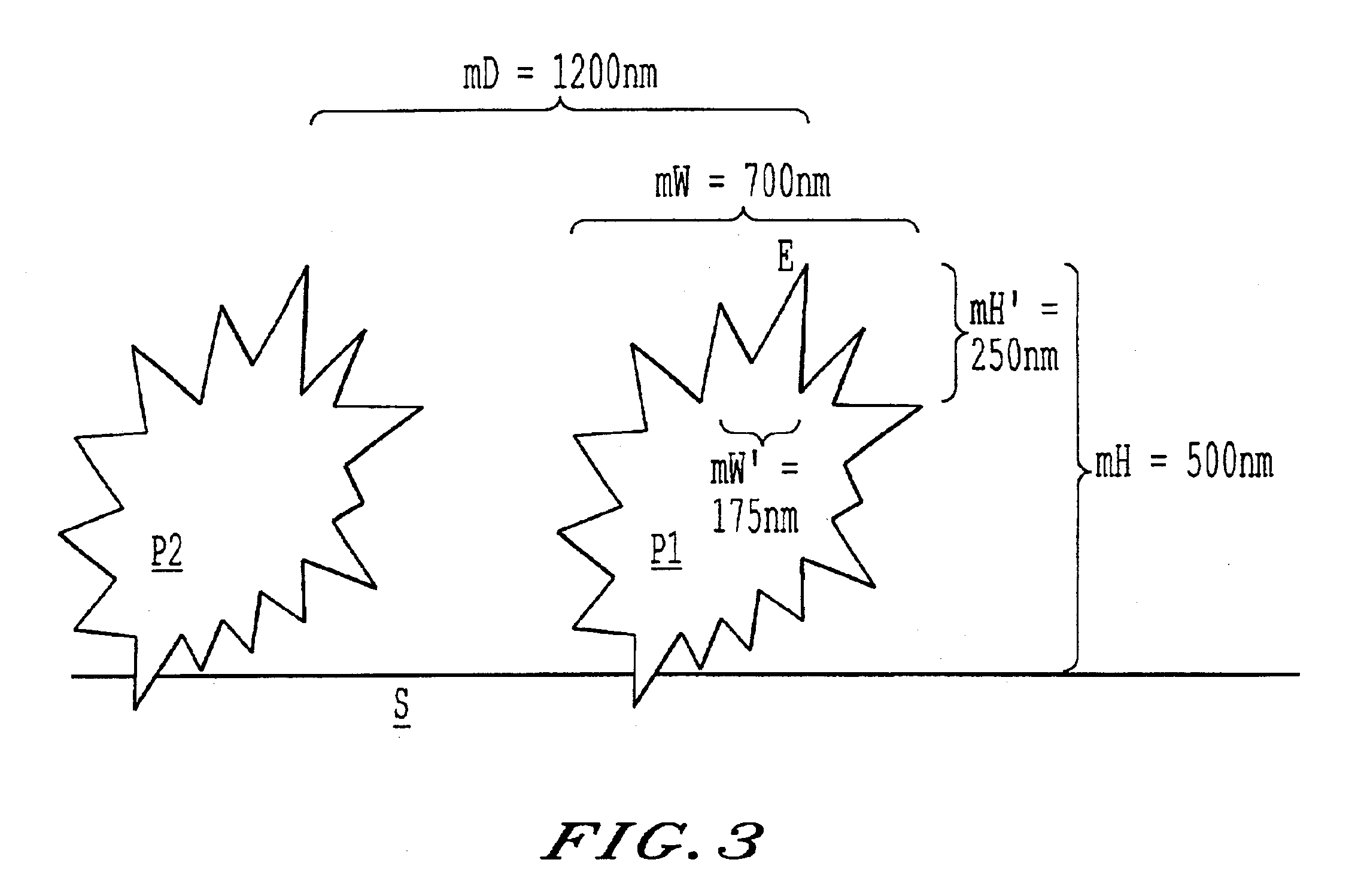

Nanoparticle-based power coatings and corresponding structures

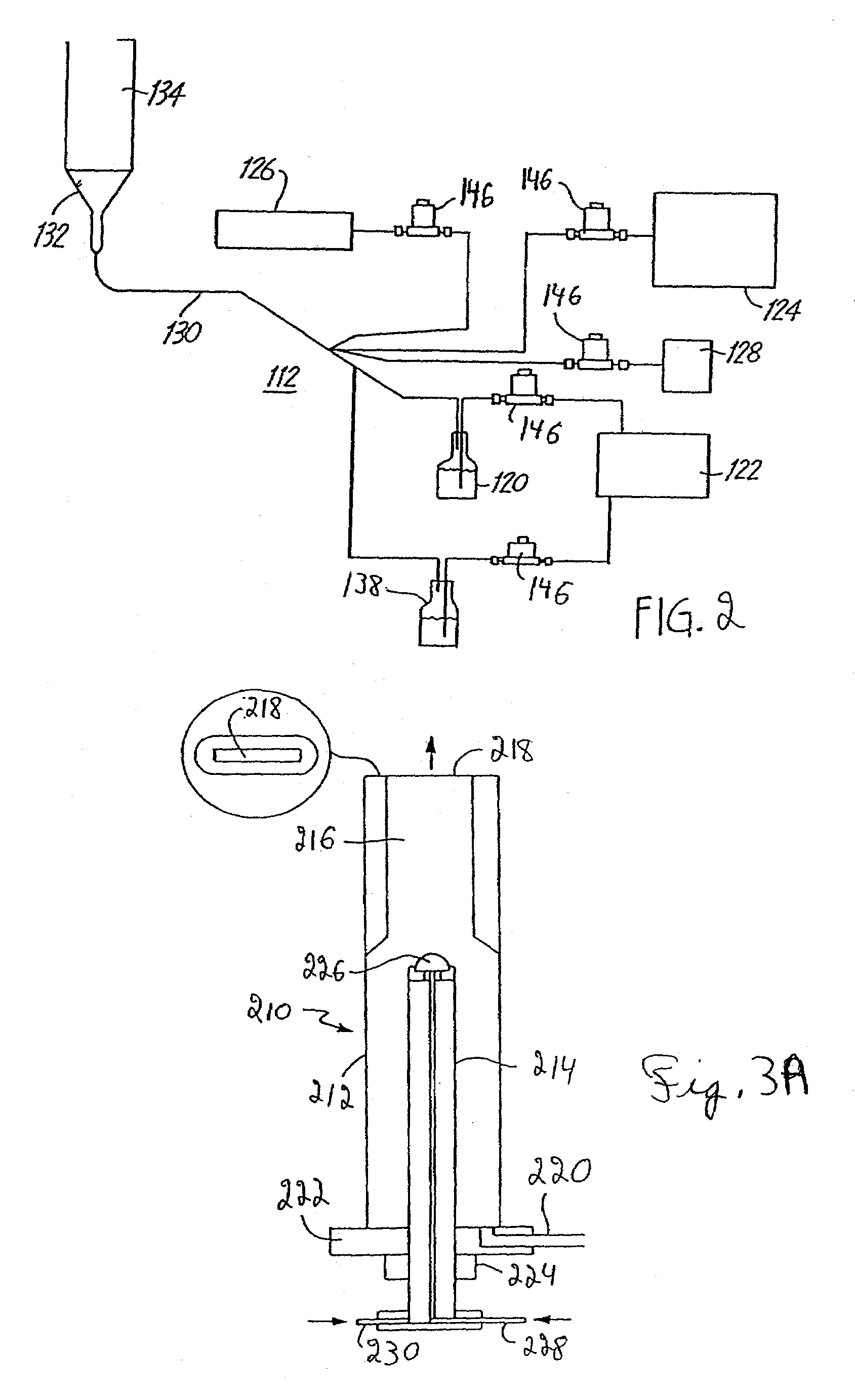

Methods are described that have the capability of producing submicron / nanoscale particles, in some embodiments dispersible, at high production rates. In some embodiments, the methods result in the production of particles with an average diameter less than about 75 nanometers that are produced at a rate of at least about 35 grams per hour. In other embodiments, the particles are highly uniform. These methods can be used to form particle collections and / or powder coatings. Powder coatings and corresponding methods are described based on the deposition of highly uniform submicron / nanoscale particles.

Owner:NANOGRAM

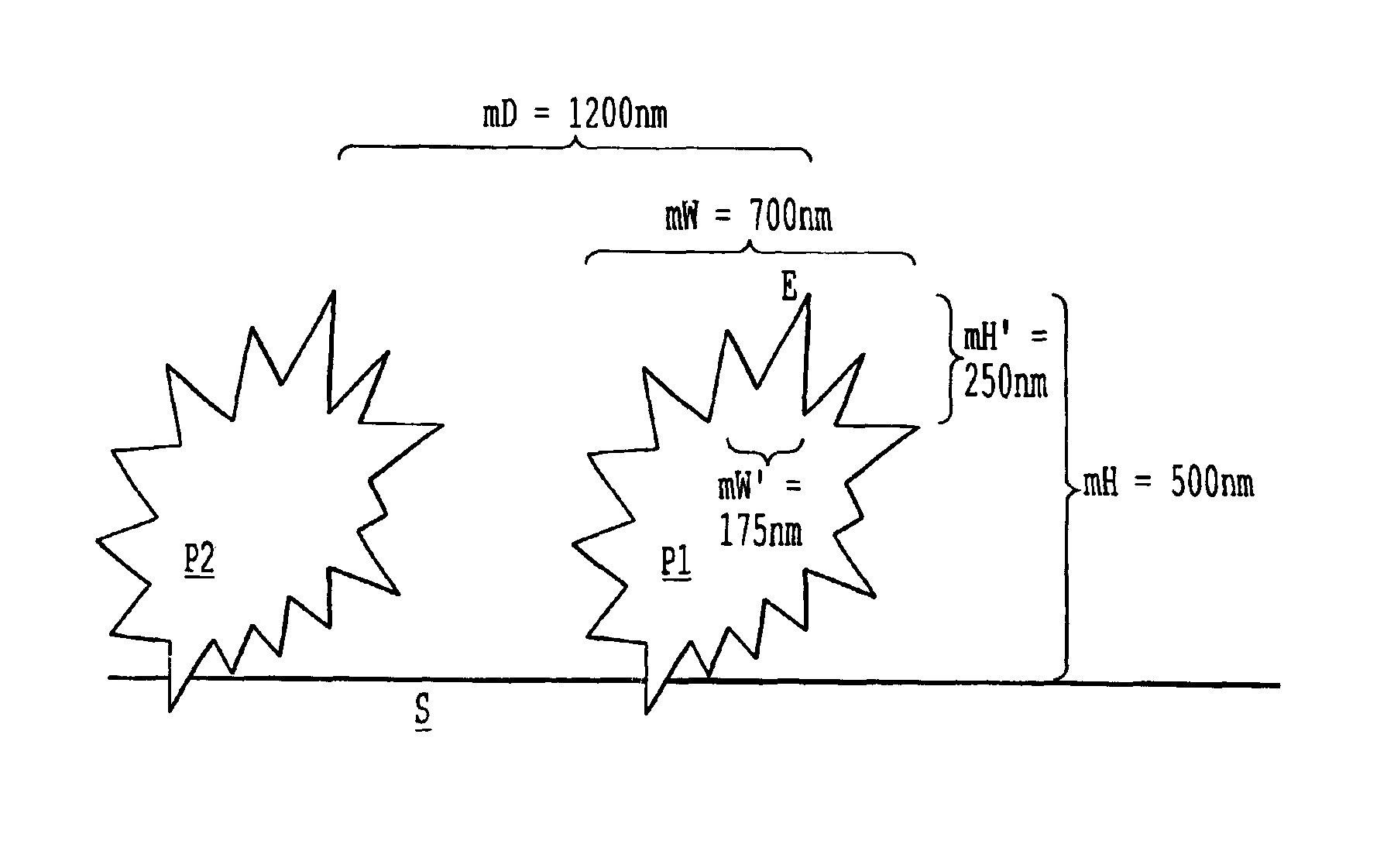

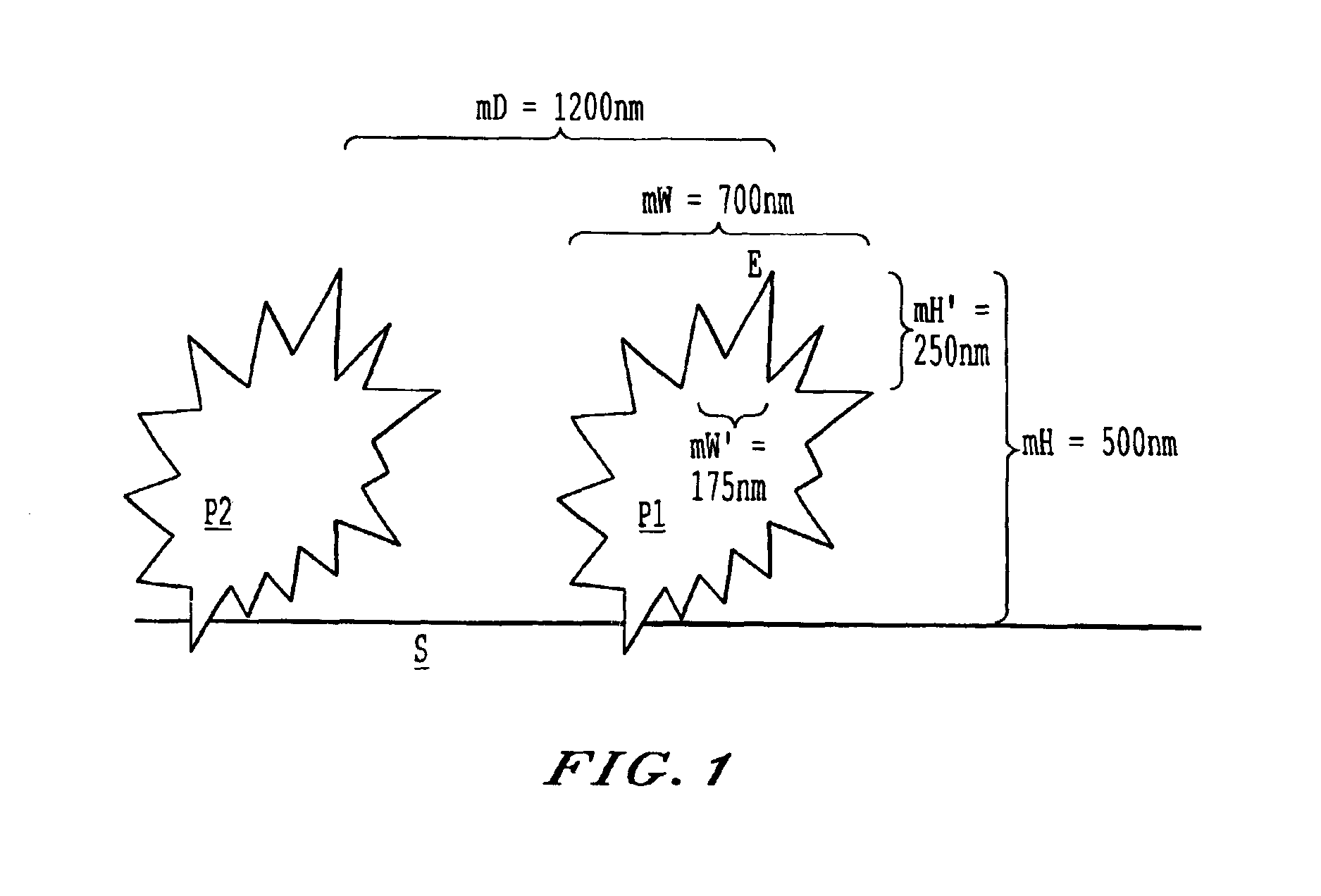

Surfaces rendered self-cleaning by hydrophobic structures, and process for their production

InactiveUS6852389B2Effectively self-cleaningSimple processNanotechSpecial ornamental structuresFissured structureFumed silica

A self-cleaning surface which has an artificial, at least partially hydrophobic, surface structure containing elevations and depressions, which comprises a surface having structure-forming particles, which are formed of hydrophobic, fumed silica, adhered thereto by way of fixative particles applied to the surface, whereby the structure-forming particles and the fixative particles have elevations and depressions ranging in dimensions of 1 to 1000 nm and the particles themselves having an average size of less than 50 μm, the particles providing said surface structure of elevations and depressions, wherein, by incipient melting of the fixative particles, only partial melting of the fixative particles occurs which is sufficient to bond the structure forming particles without substantial wetting of the particles by the fixative particles to said surface while retaining, the fissured structure of the structure-forming particles in the nanometer range.

Owner:DEGUSSA AG

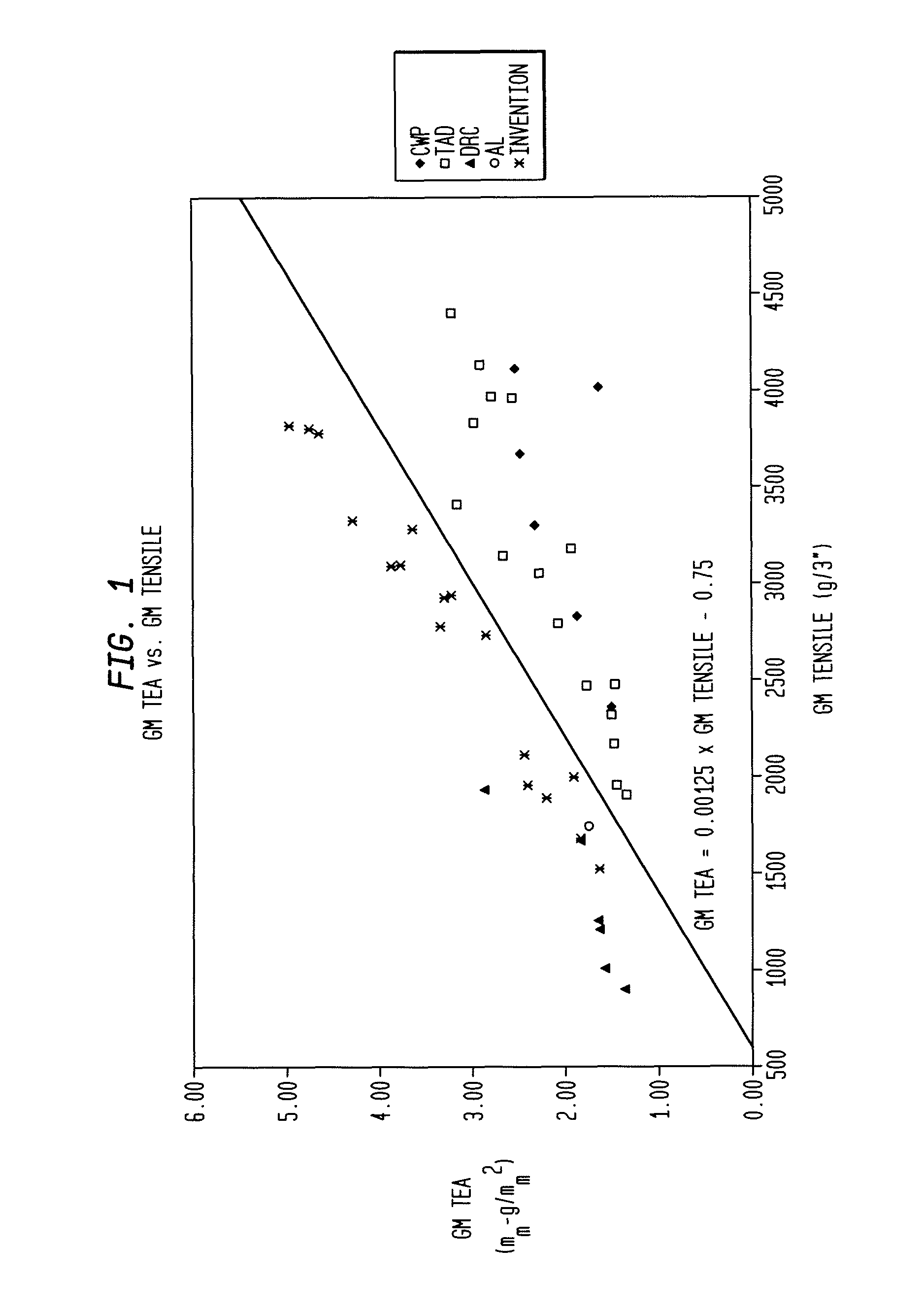

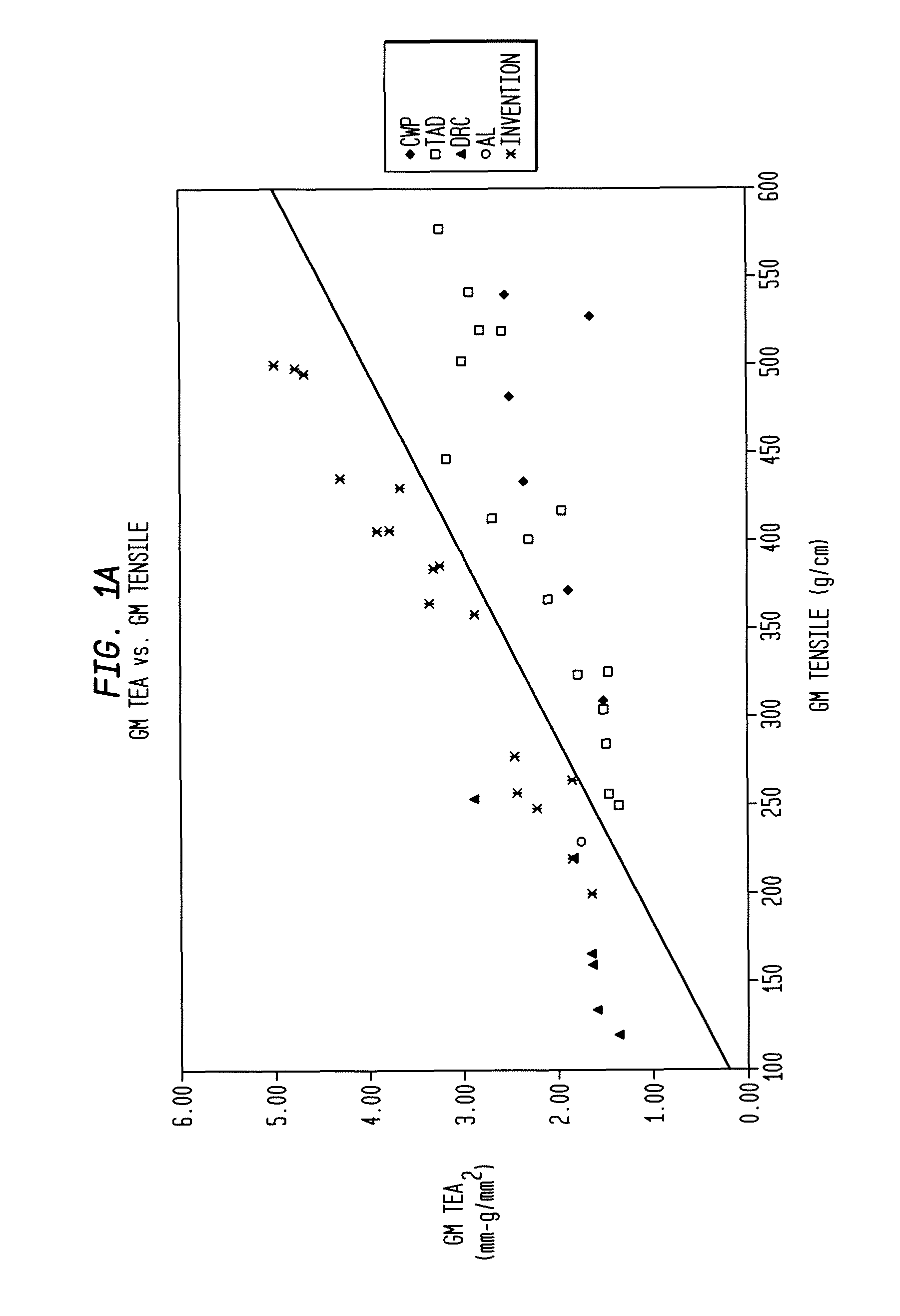

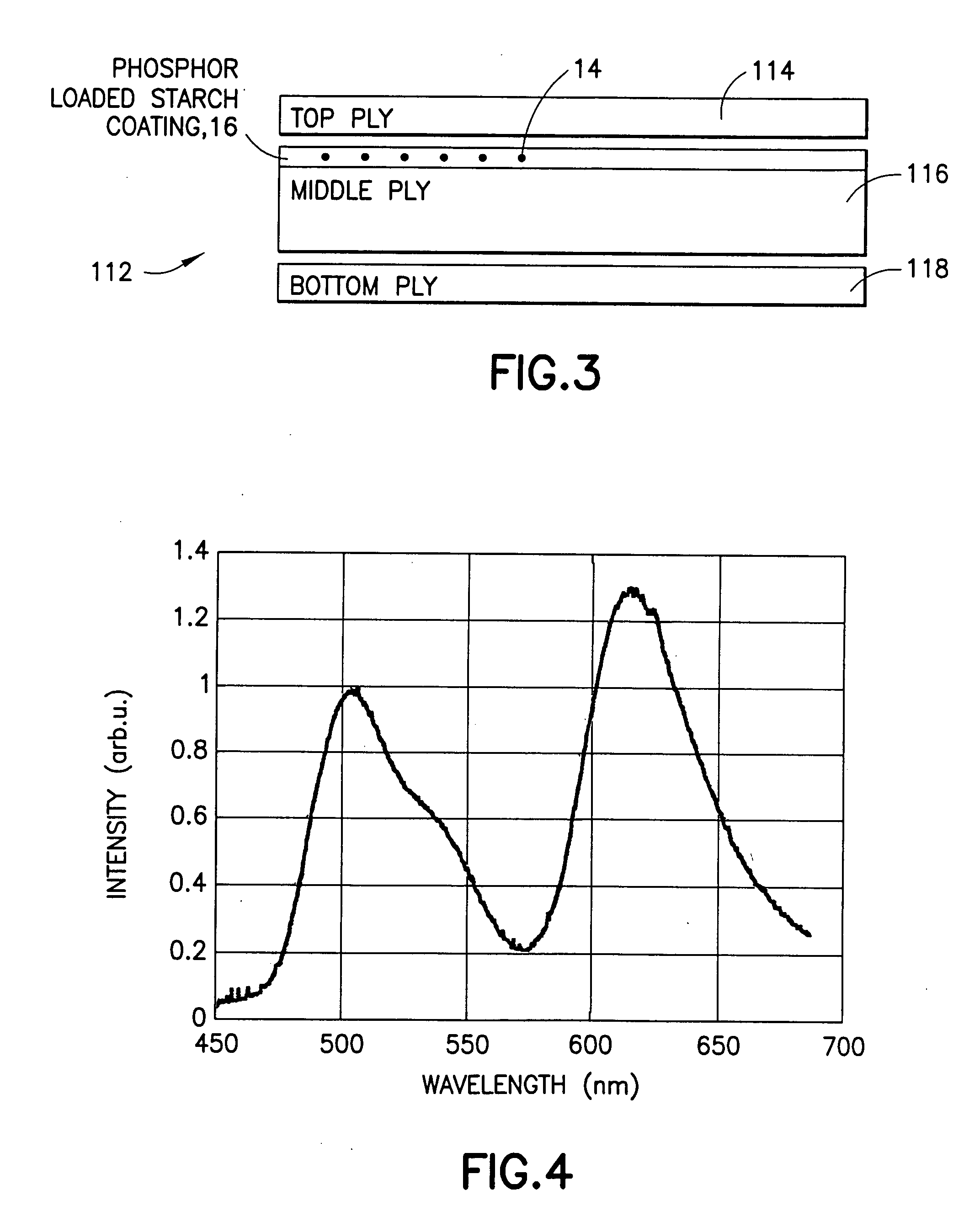

Multi-ply paper towel with creped plies

ActiveUS8409404B2Improve toughnessHigh strengthNon-fibrous pulp additionNatural cellulose pulp/paperFiberPaper towel

A multi-ply absorbent towel made from papermaking fiber comprising at least a first ply and a second ply bonded together, the towel having a basis weight of greater than 30 lbs per 3000 ft2 ream (48.8 gsm) and less than 50 lbs per 3000 ft2 ream (81.4 gsm), wherein the plies are selected and adhered together such that the towel typically exhibits (i) a GM TEA, mm-g / mm2 of greater than [0.00125 (GM Tensile, g / 3″)−0.75] and (ii) a GM Tensile Modulus, g / in / %, less than [0.0083 (GM Tensile Strength, g / 3″)+15.4] {(i) a GM TEA, mm g / mm2, of greater than [0.00952 (GM Tensile, g / cm)−0.75] and (ii) a GM Tensile Modulus, g / cm / %, less than [0.0249 (GM Tensile Strength, g / cm)+6.06}.

Owner:GPCP IP HLDG LLC

Surfaces rendered self-cleaning by hydrophobic structures, and process for their production

InactiveUS6858284B2Effectively self-cleaningSimple processNanotechSpecial ornamental structuresMeth-Gas phase

A self-cleaning surface which has an artificial, at least partially hydrophobic, surface structure containing elevations and depressions, which comprises an at least partially hydrophobic surface formed from structure-forming particles of hydrophobic fumed silica having elevations and depressions ranging in dimensions of 1 to 1000 nm and the particles themselves having an average size of less than 50 μm adhered to the surface by way of a viscous, curable carrier material selected from the group consisting of polyurethane, polyurethane acrylates, silicone acrylates and singly and / or multiply unsaturated (meth)acrylates applied to the surface, which is sufficient to bond the structure forming particles without substantial wetting of the particles by the carrier material while retaining the fissured structure of elevations and depressions of the structure-forming particles in the nanometer range.

Owner:DEGUSSA AG

Floorboards with decorative grooves

ActiveUS20060048474A1Rational and cost-efficientEasy to cleanTongue/grooves making apparatusWallsSurface layerEngineering

Floorboards are shown, which consist of a core and a surface layer and are provided with decorative joint edges which are formed by removing the surface layer.

Owner:VÄLINGE INNOVATION AB

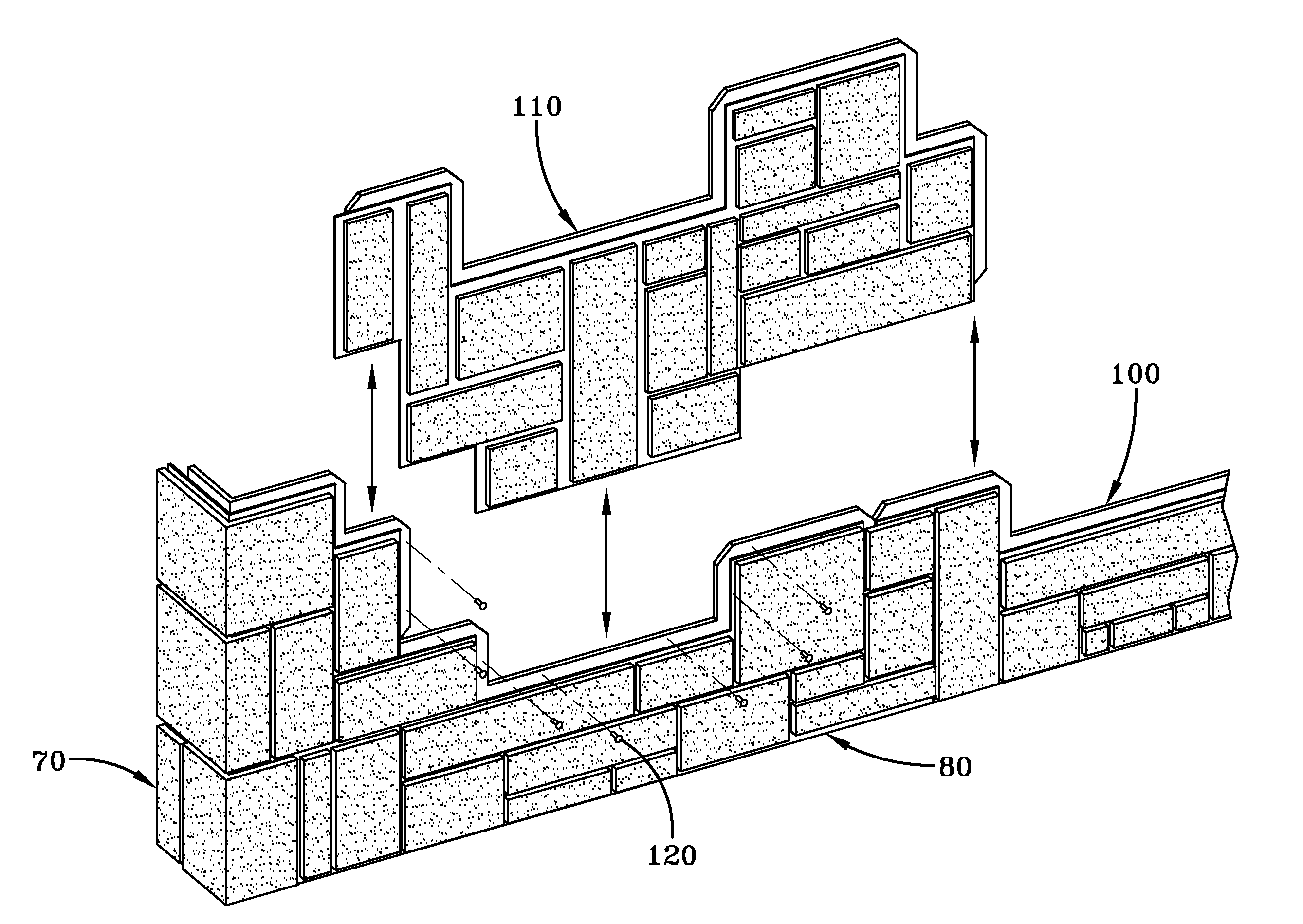

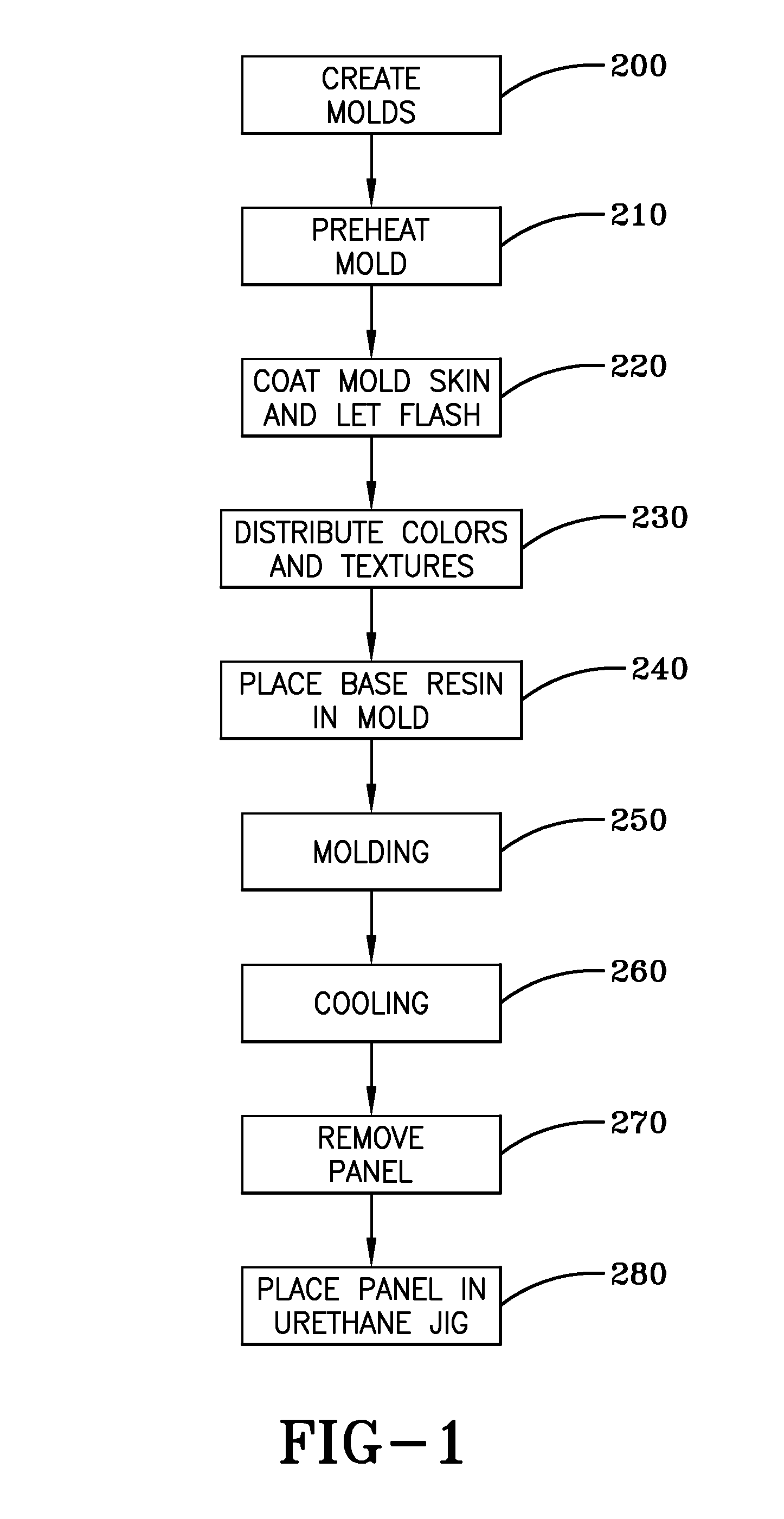

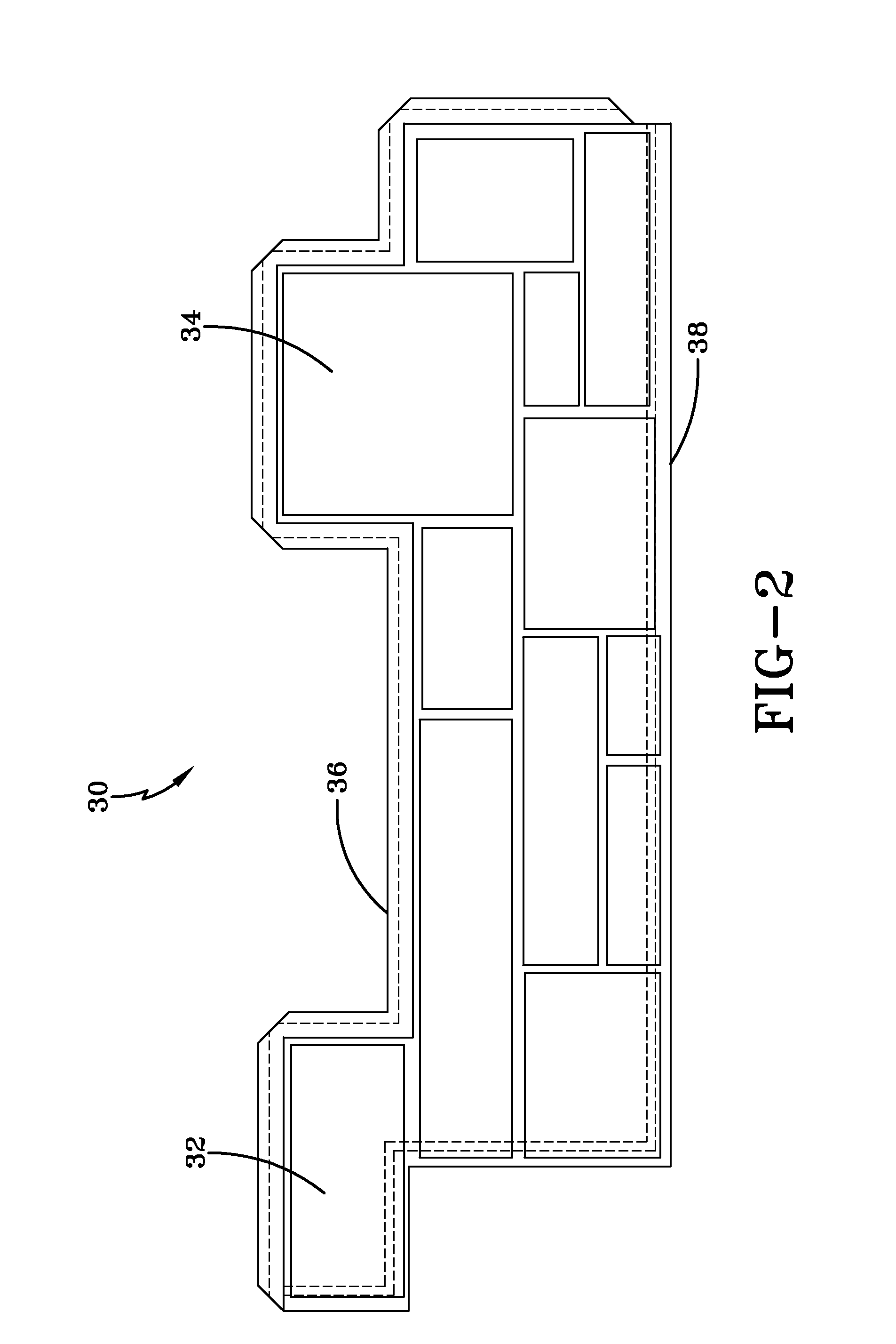

Foaming of simulated stone structures

InactiveUS20090056257A1Improve insulation performanceImprove sound insulationConstruction materialCovering/liningsBrickThermal insulation

Simulated stone, masonry, and brick textured products such as siding having a foam backing or with the hollow parts injected with foam or molded with foam in one or more steps, obtained when specially selected materials are properly admixed and formed via molding techniques. The foam backing is applied to the product in either a one or two step process. The foam backing may be used on panels, wall structures, and other products that may have contoured and textured surfaces and may simulate the appearance of conventional building and construction materials including, but not limited to, stone, brick, masonry, concrete, stucco, wood, other conventional building materials, and combinations of any of these materials are disclosed. The foam backing provides improves thermal insulation, improved sound reduction, improved rigidity, and improved dimensional stability. The disclosed invention is not limited to products in the building or construction industries and may be applied in the manufacture of a wide variety of products in other industries.

Owner:EXTERIOR PORTFOLIO

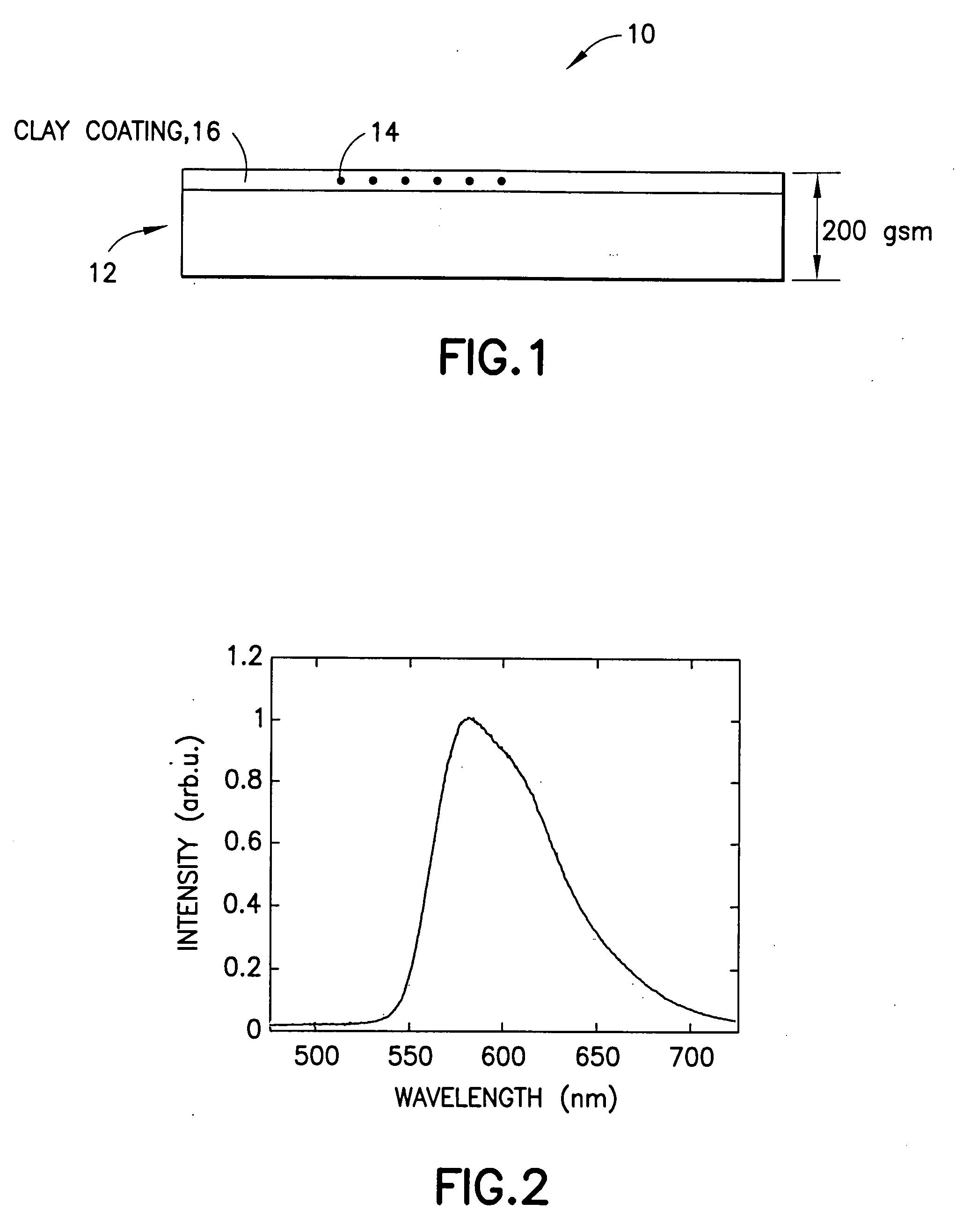

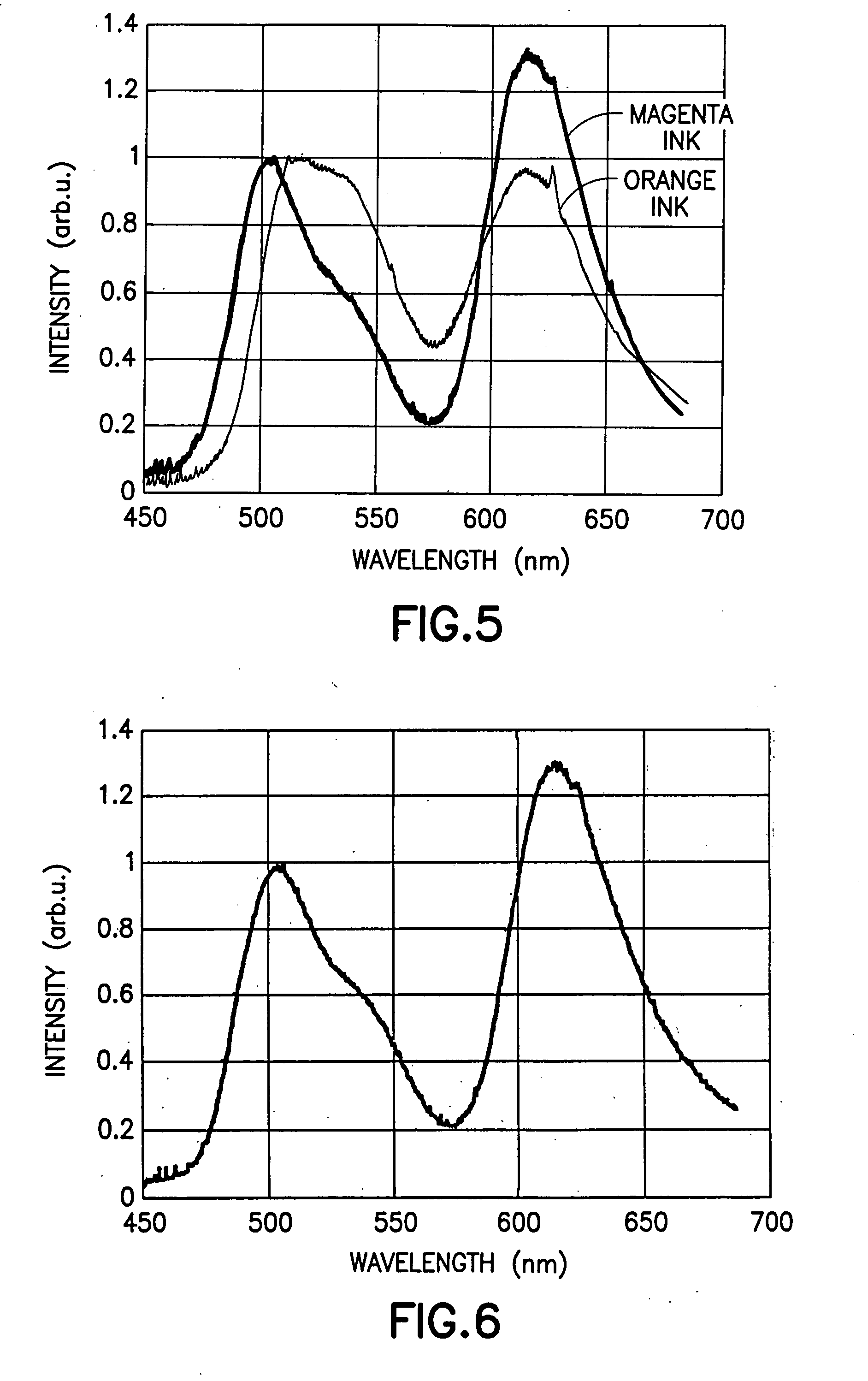

Taggant security system for paper products as a deterrent to counterfeiting

InactiveUS20050031838A1Difficult to duplicateNot easy to counterfeitNon-fibrous pulp additionOther printing matterPulp and paper industrySecurity system

A taggant security system for preventing the counterfeiting of goods associated with a paper product is provided. The taggant security system includes a paper product coating located on a paper product. The paper product coating is preferably one which is commonly used in the paper making industry. The taggant security system further includes one or more taggants incorporated within said paper product coating for authenticating said paper product. In preferred embodiments, the paper product coating is either a clay or starch coating. In addition, in preferred embodiments, the paper product is either a single or multi-ply packaging board or a label stock.

Owner:SPECTRA SYST CORP

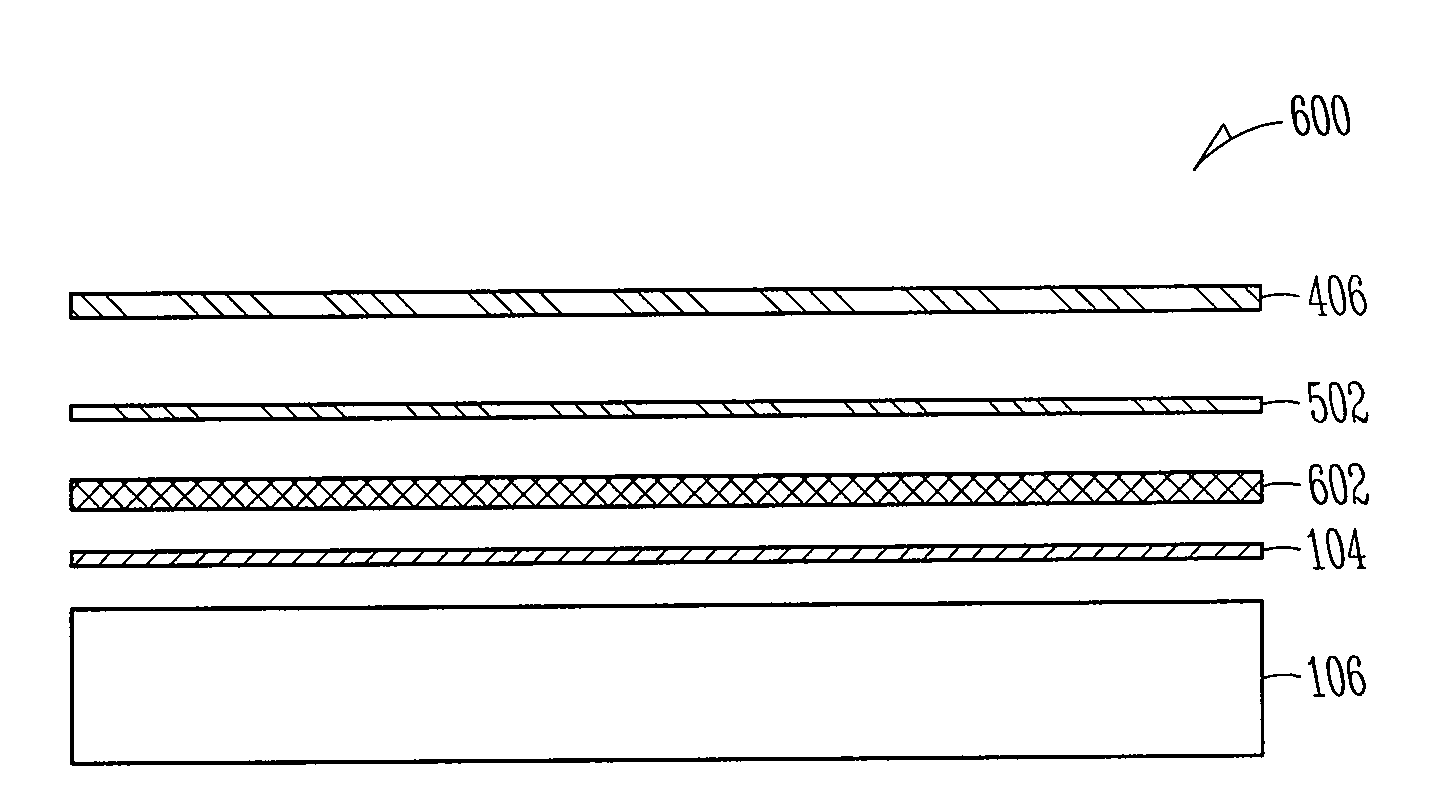

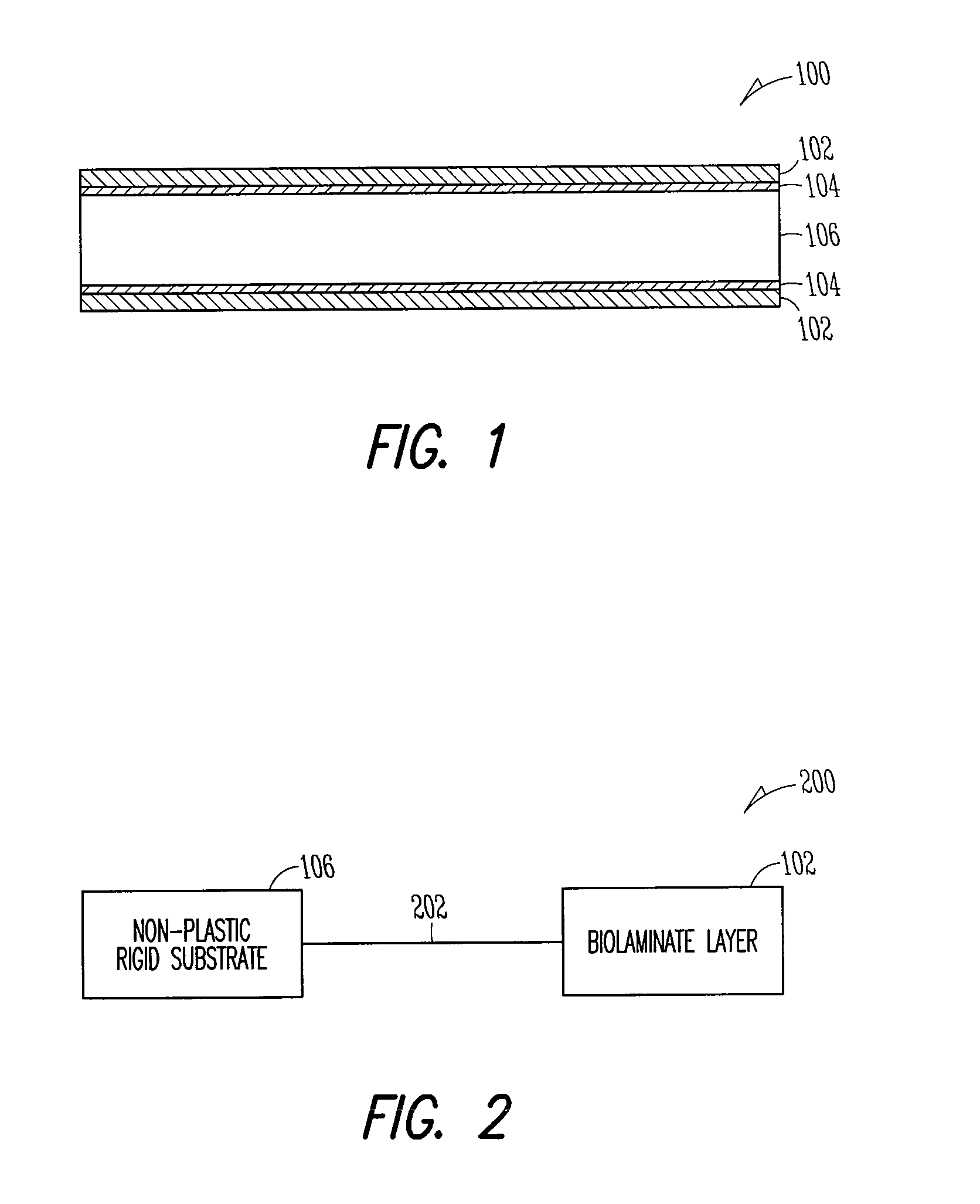

Biolaminate composite assembly and related methods

Embodiments of the invention relate to a biolaminate composite assembly, including one or more biolaminate layers, a non-plastic rigid substrate and an adhesive layer in contact with the substrate and the one or more biolaminate layers. The one or more biolaminate layers is laminated or formed to the substrate.

Owner:BIOVATION LLC

Resilient flooring compositions

InactiveUS20120276348A1Improve wear resistanceReduce the possibilityCovering/liningsSpecial ornamental structuresWood veneerNatural fiber

Resilient flooring materials made from impregnated papers or foils and core materials are provided. As well, the methods for producing such products are provided. In particular, panels, with a layered structure, created by forming an assembly which consists of laminating a heat-activated resin impregnated decorative layer with printed graphics or a wood veneer decorative layer, a core material made up of one or more heat-activated resin-impregnated papers or other materials including linoleum, natural or synthetic rubber, cork, flexible natural fiber composites or other core materials, and a heat-activated resin impregnated paper backing layer. The heat-activated resin also acts to waterproof each of the layers and abrasion particles may be incorporated to improve wear properties. The panels may also be formed into three-dimensional products.

Owner:CLAUSI ROBERT N +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com