Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3070 results about "Thick plate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

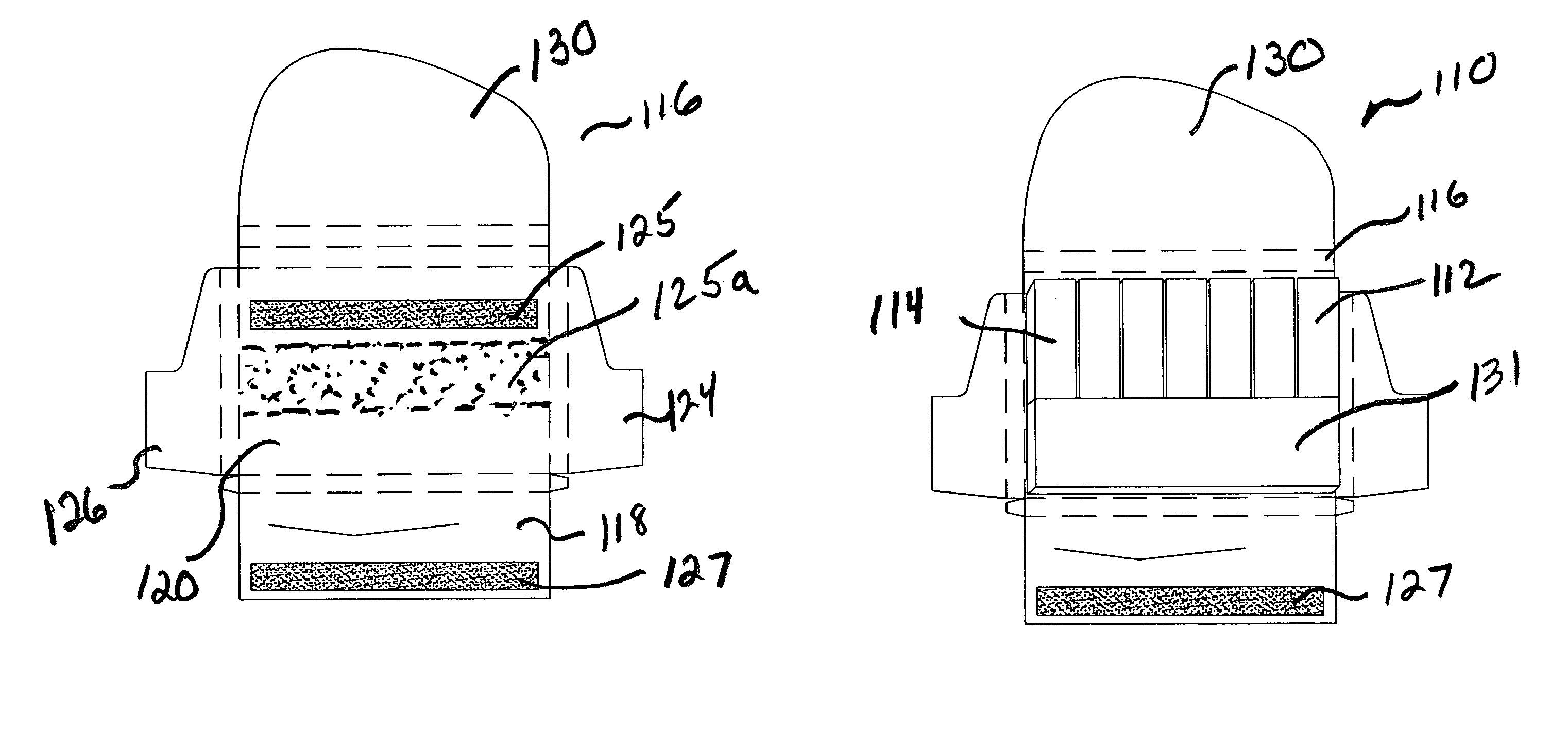

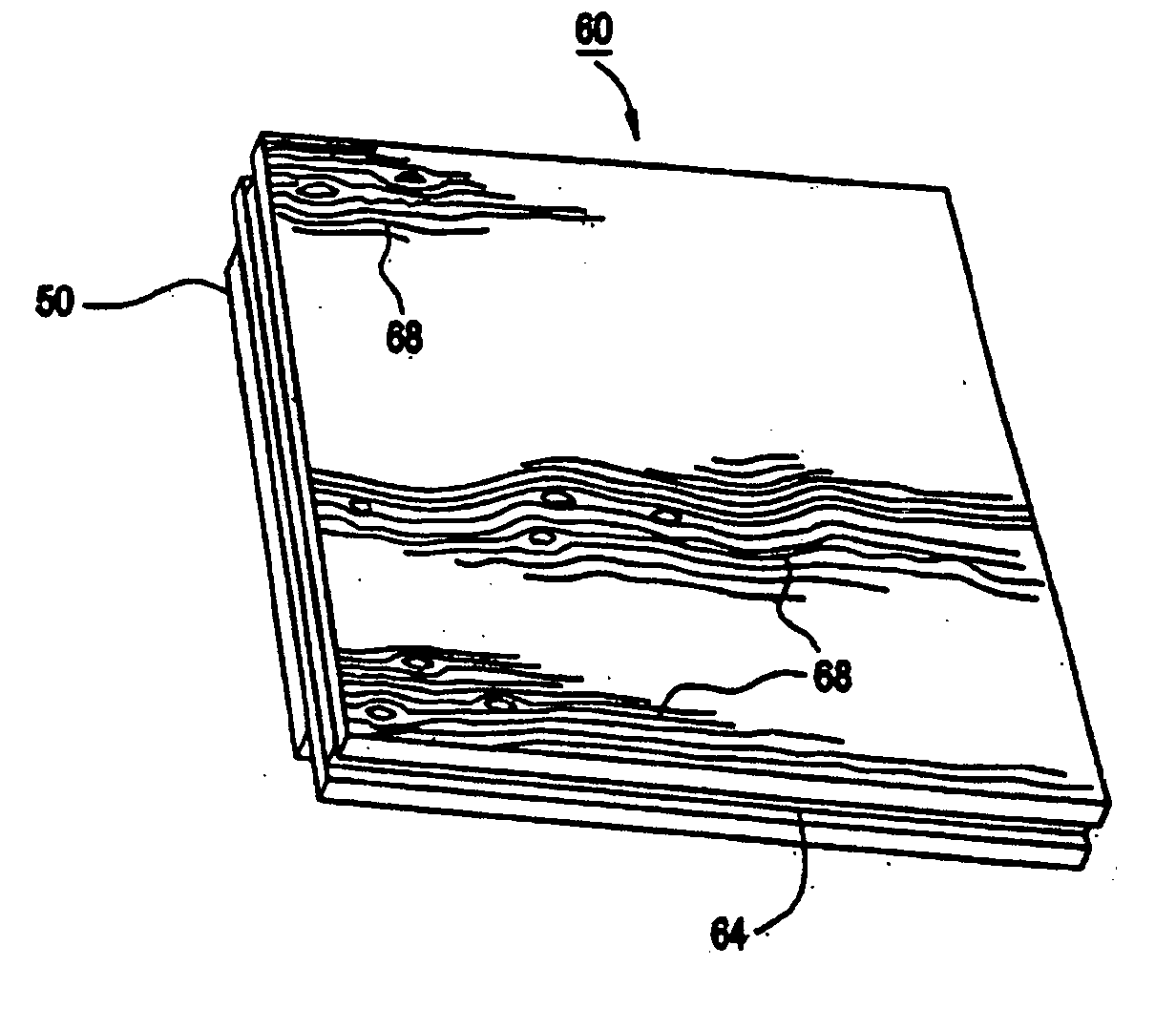

Flooring products and methods of making the same

InactiveUS20060032175A1Improve moisture resistanceStrutsSynthetic resin layered productsThick plateNatural fiber

A plank is described wherein the plank comprises a core, and optionally, a print layer, and optionally an overlay. The core includes from about 30 wt % to about 95 wt % at least one polymeric material, by weight of the core, and from about 5 wt % to about 70 wt % of least one natural fiber or flour, by weight of the core, wherein the core includes a top surface and a bottom surface, and opposing sides, wherein said plank is substantially moisture resistant, having a swelling property of from about 0.5% to about 5% by NALFA Thickness Test Section 3.2 LF 01-2003 standard, and wherein said plank includes a bow of from about 0.5% to about 4%. In addition, a method of making the plank is further described.

Owner:MANNINGTON MILLS

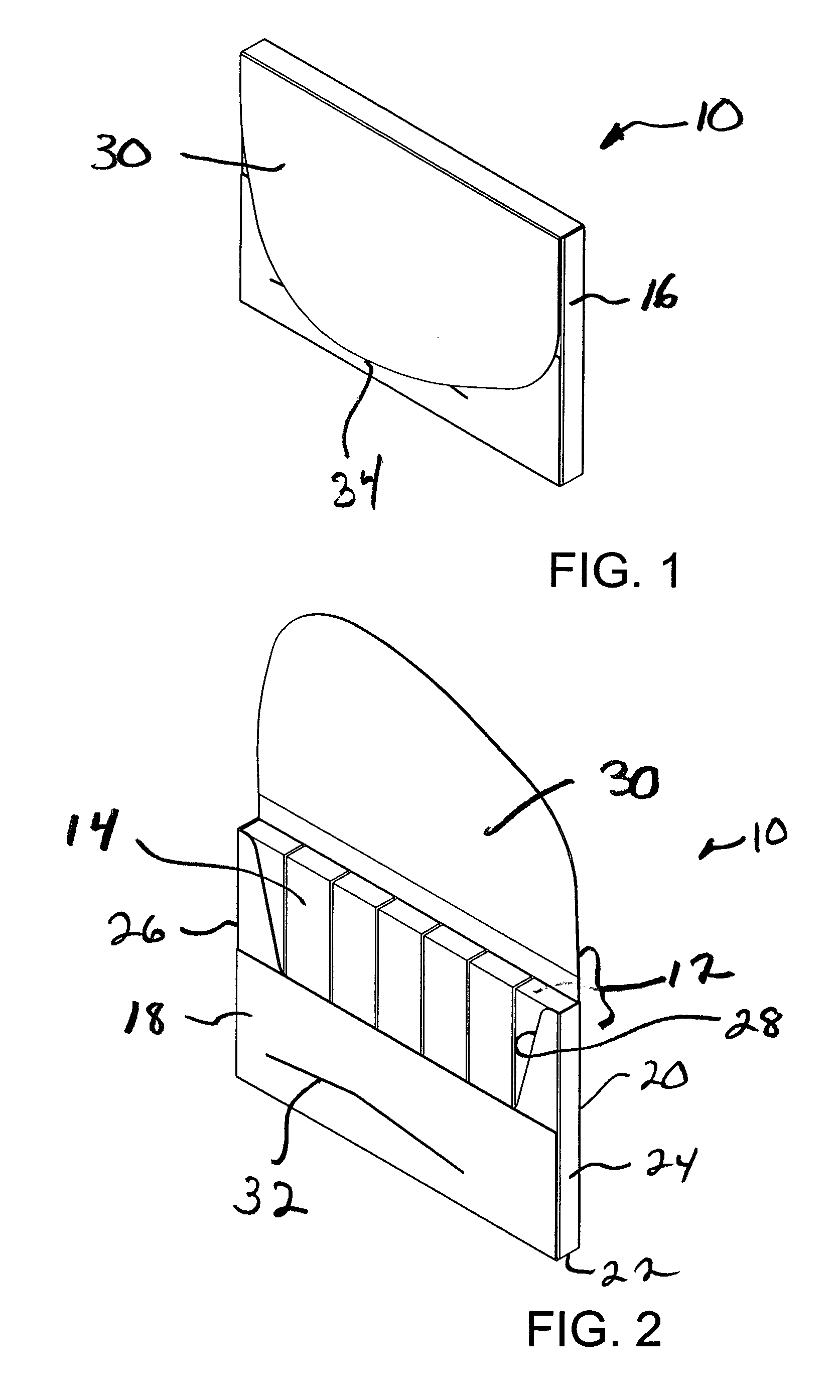

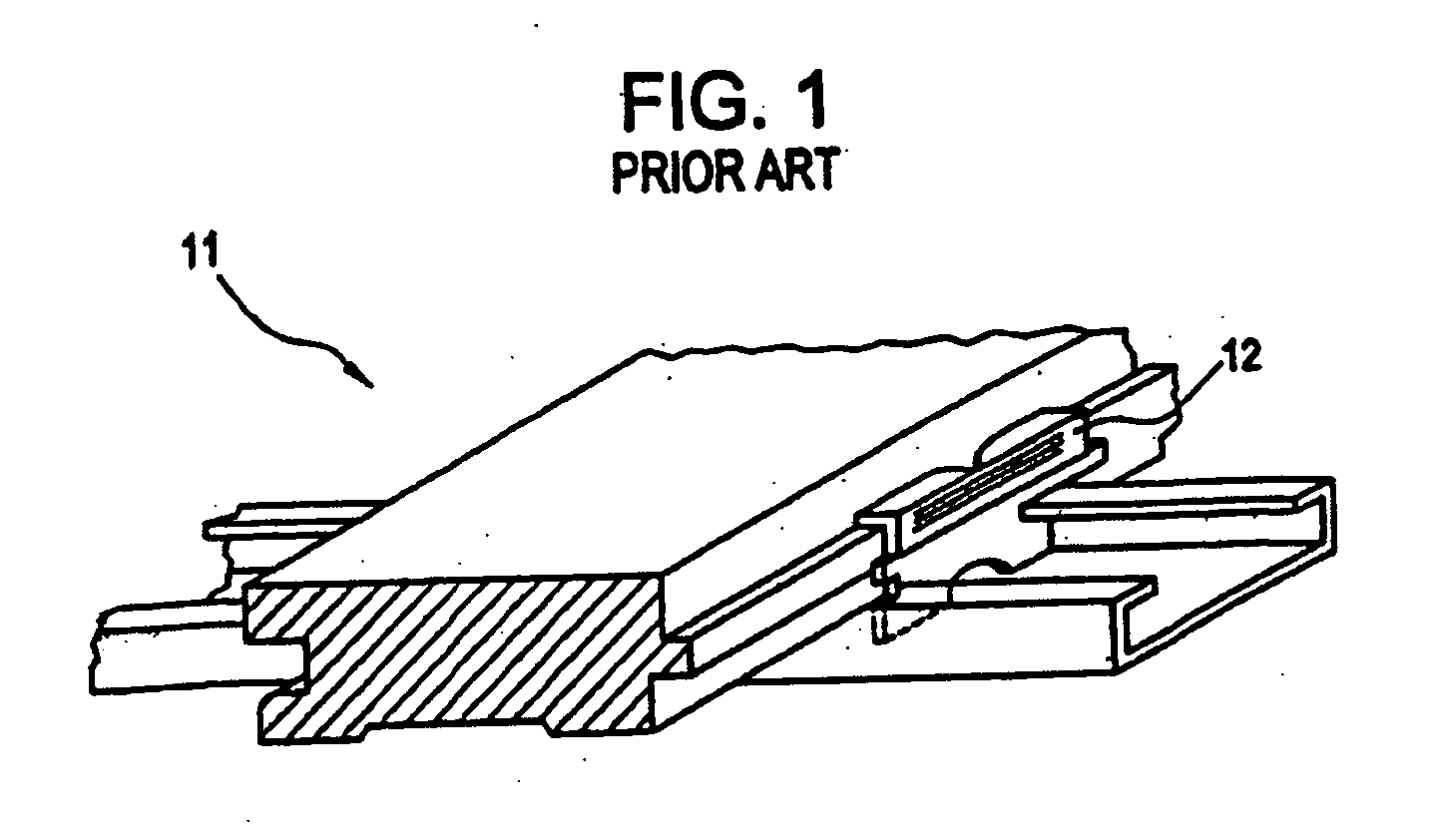

Thermoplastic planks and methods for making the same

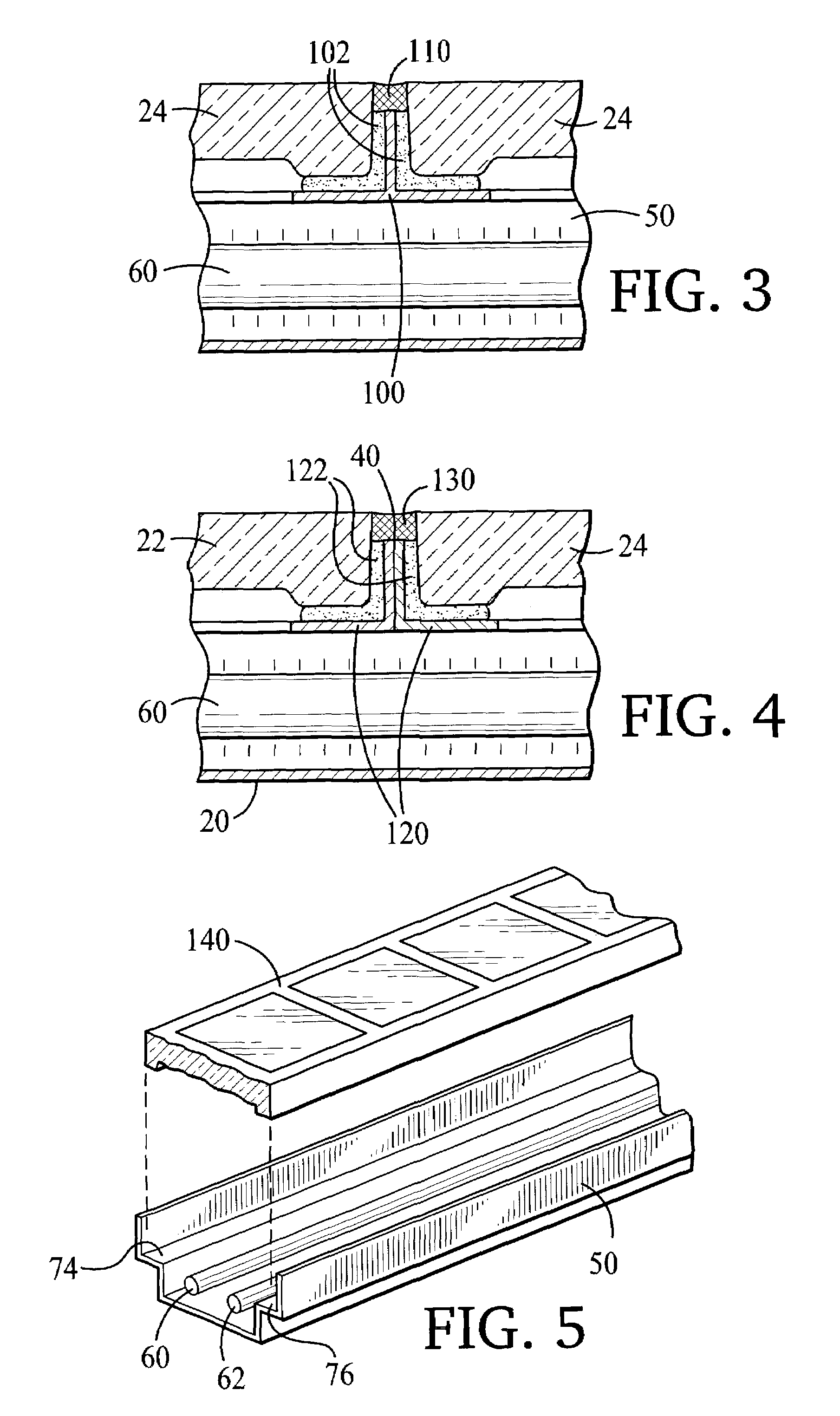

InactiveUS7763345B2Improve moisture resistanceEasy flexibilityCovering/liningsDecorative surface effectsThick plateEngineering

A thermoplastic laminate plank is described wherein the thermoplastic laminate plank comprises a core, a print layer, and optionally an overlay. The core comprises at least one thermoplastic material and has a top surface and bottom surface wherein a print layer is affixed to the top surface of the core and an overlay layer is affixed to the top surface of the print layer. Optionally, an underlay layer can be located and affixed between the bottom surface of the print layer and the top surface of the core. In addition, a method of making the thermoplastic laminate plank is further described which involves extruding at least one thermoplastic material into the shape of the core and affixing a laminate on the core, wherein the laminate comprises an overlay affixed to the top surface of the print layer and optionally an underlay layer affixed to the bottom surface of the print layer.

Owner:VÄLINGE INNOVATION AB

Thermoplastic planks and methods for making the same

InactiveUS7211310B2Improve moisture resistanceEasy flexibilityCovering/liningsTraffic signalsThick plateEngineering

A thermoplastic laminate plank is described wherein the thermoplastic laminate plank comprises a core, a print layer, and optionally an overlay. The core comprises at least one thermoplastic material and has a top surface and bottom surface wherein a print layer is affixed to the top surface of the core and an overlay layer is affixed to the top surface of the print layer. Optionally, an underlay layer can be located and affixed between the bottom surface of the print layer and the top surface of the core. In addition, a method of making the thermoplastic laminate plank is further described which involves extruding at least one thermoplastic material into the shape of the core and affixing a laminate on the core, wherein the laminate comprises an overlay affixed to the top surface of the print layer and optionally an underlay layer affixed to the bottom surface of the print layer.

Owner:VÄLINGE INNOVATION AB

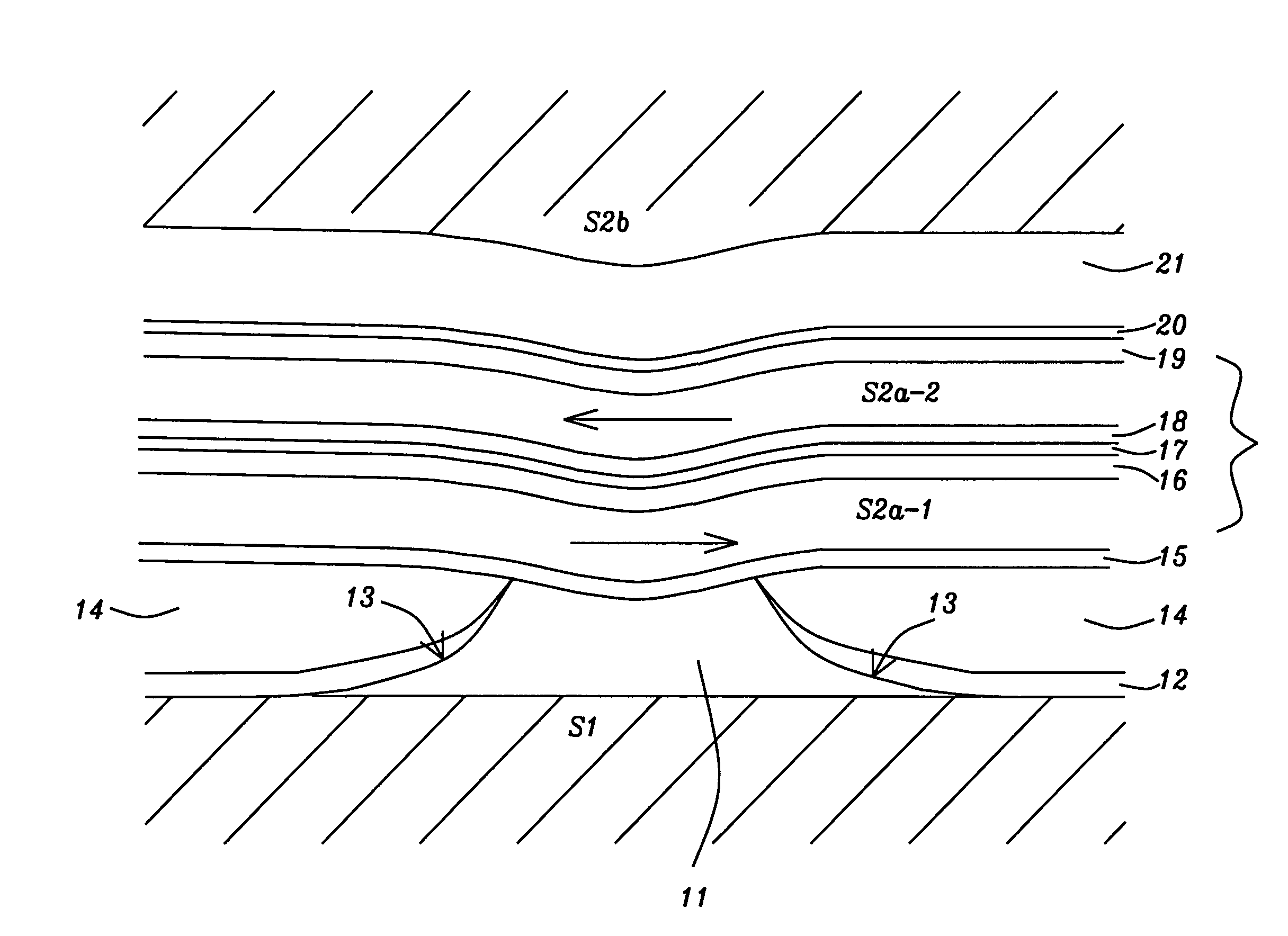

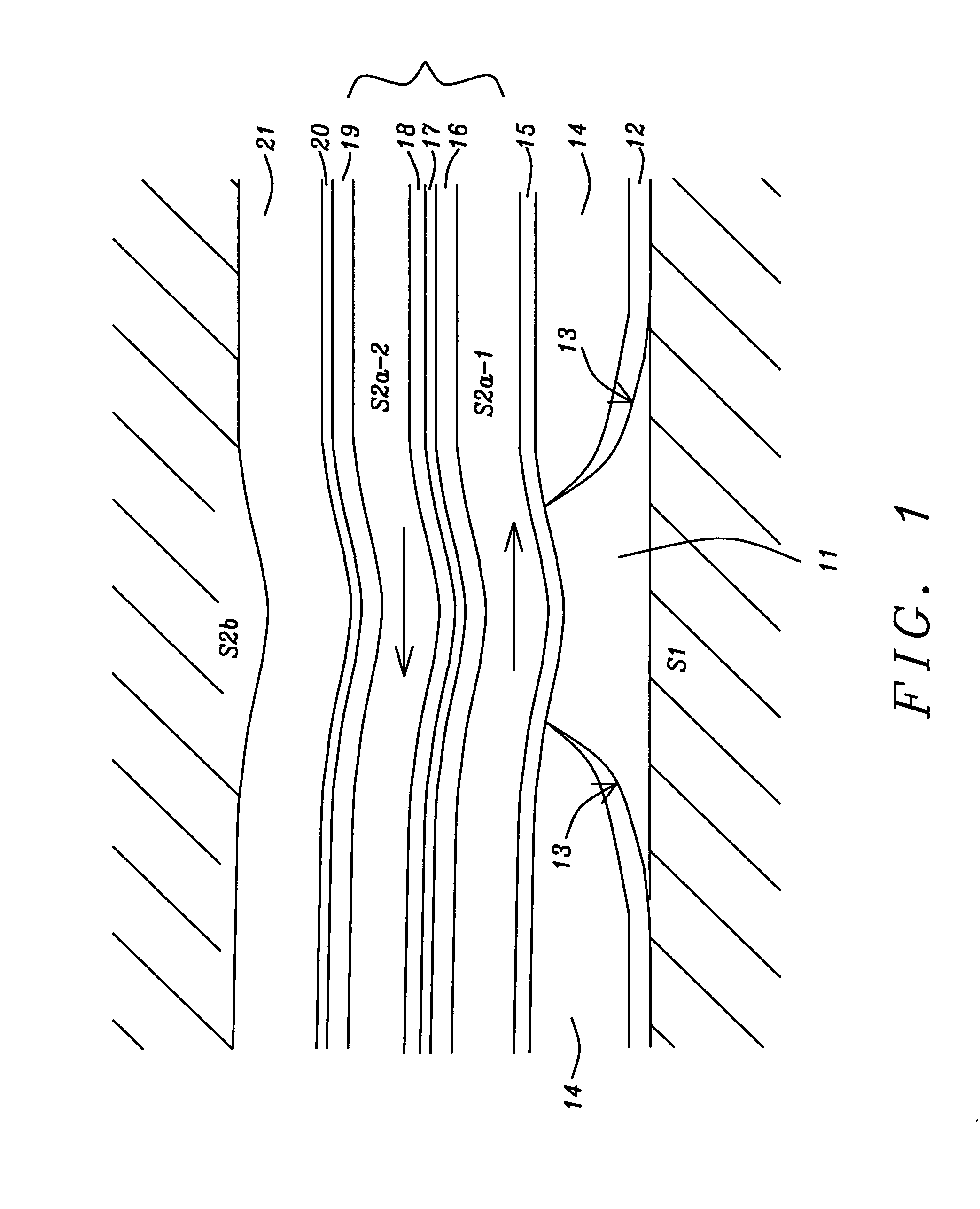

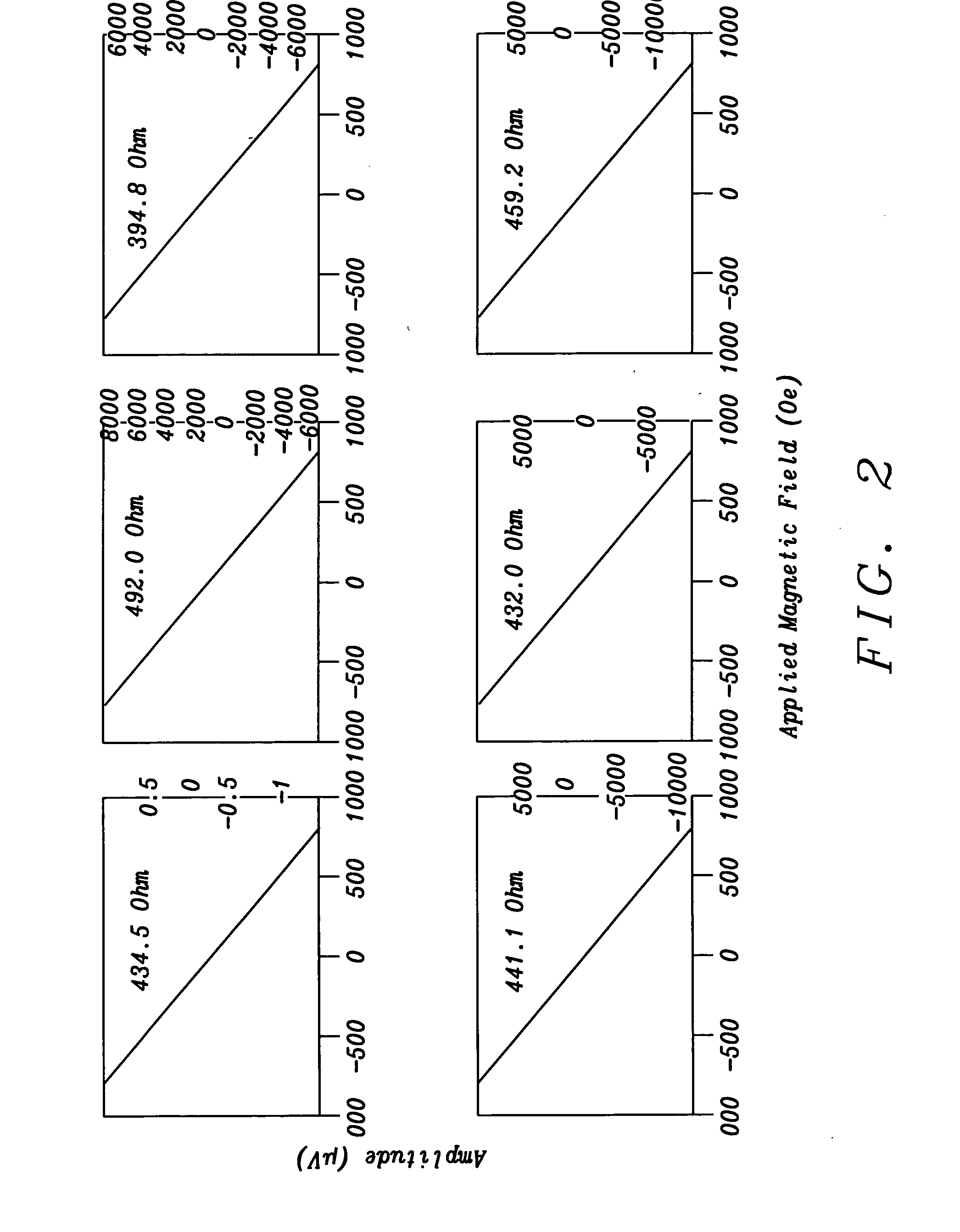

Stabilized shields for magnetic recording heads

ActiveUS20090279213A1Large reductions (or elimination) of the shield net momentGood pinningRecord information storageManufacture of flux-sensitive headsThick plateAntiferromagnetic coupling

Owner:HEADWAY TECH INC

Thermoplastic planks and methods for making the same

InactiveUS20070196624A1Improve moisture resistanceEasy flexibilityCovering/liningsDecorative surface effectsThick plateEngineering

Owner:VÄLINGE INNOVATION AB

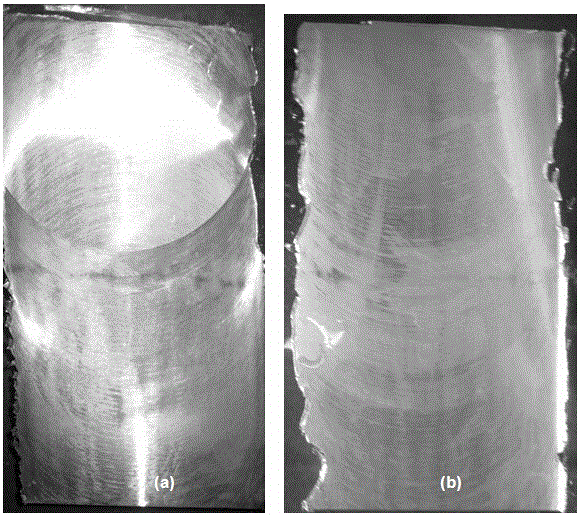

Technological process for producing super-thick plate

InactiveCN101439348AQuality improvementLow costTemperature control deviceElectron beam welding apparatusElectro-slag remeltingVacuum chamber

The invention relates to a process for producing an ultra-thick plate and belongs to the field of rolling and producing an ultra-thick steel plate in the metallurgical industry. The invention mainly overcome the defect of producing the ultra-thick steel plate by a traditional model casting manufacturing blank and an electro-slag remelting manufacturing blank. The method comprises the following steps: cutting and fixing lengths of the blanks, mechanically conditioning the blanks (eliminating, leveling and cleaning a single-surface oxide layer of a casting blank with a milling machine, a planer or a shot blast); clamping an assembly (relatively superposing the cleaning surfaces of the two blanks after processing, placing the two blanks oppositely and clamping the blanks); mounting the blanks in a vacuum chamber of an electronic beam welding machine for purpose of vacuuming; sewing the assembly on the electronic beam welding seal edge, heating the assembly in a furnace and rolling the assembly through temperature control; and then producing the ultra-thick steel plate. Compared with the traditional electro-slag remelting production process, the process has the advantages of high production efficiency, reduced electric power consumption, less investment of production devices and low production cost. Compared with the traditional die casting production process, the process solves the problem of segregation and looseness of a large-scale die casting ingot center part; the finished product ratio is high; and the finished product ratio of blank assembly is over 90 %.

Owner:SHANDONG IRON & STEEL CO LTD

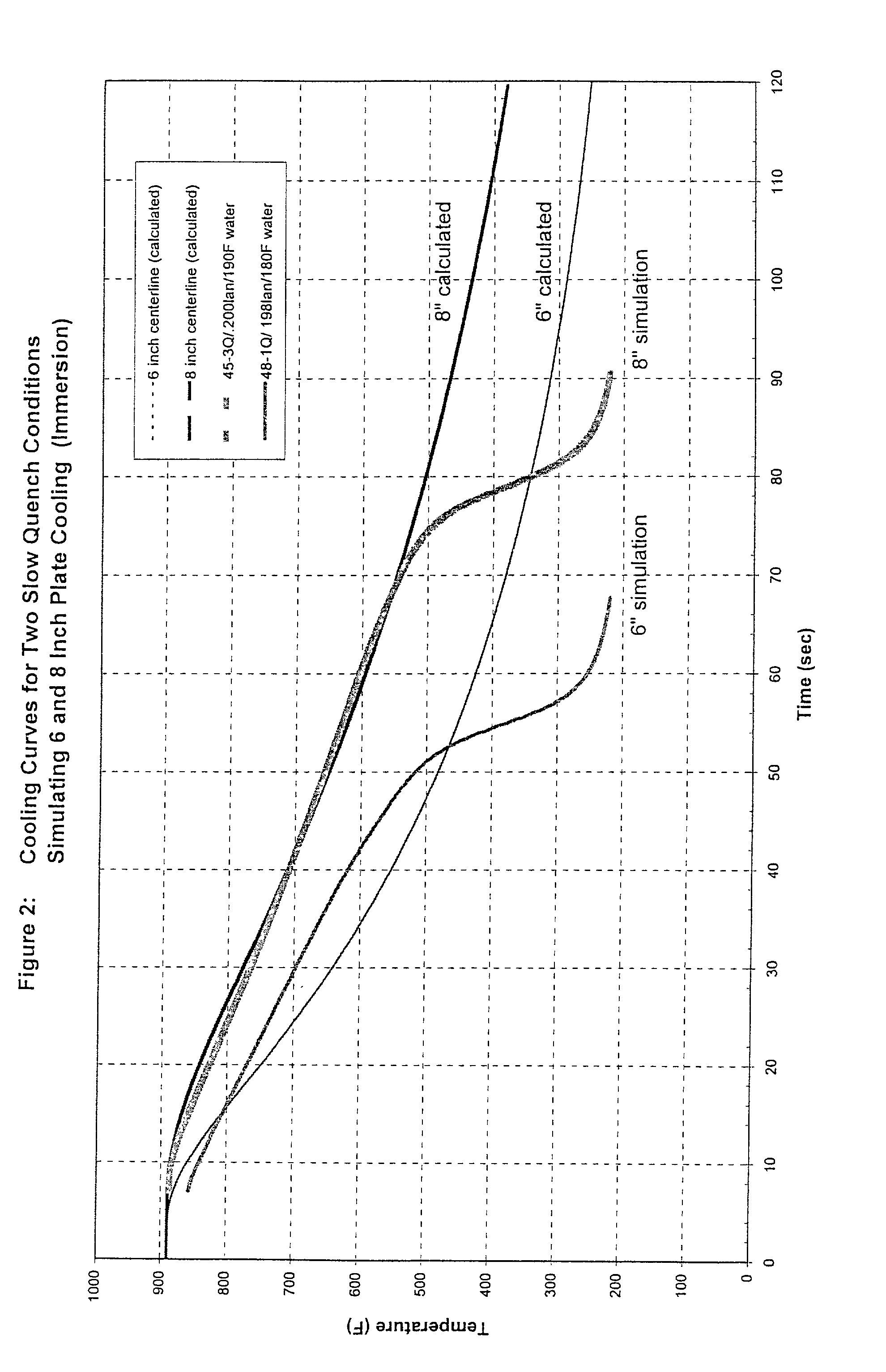

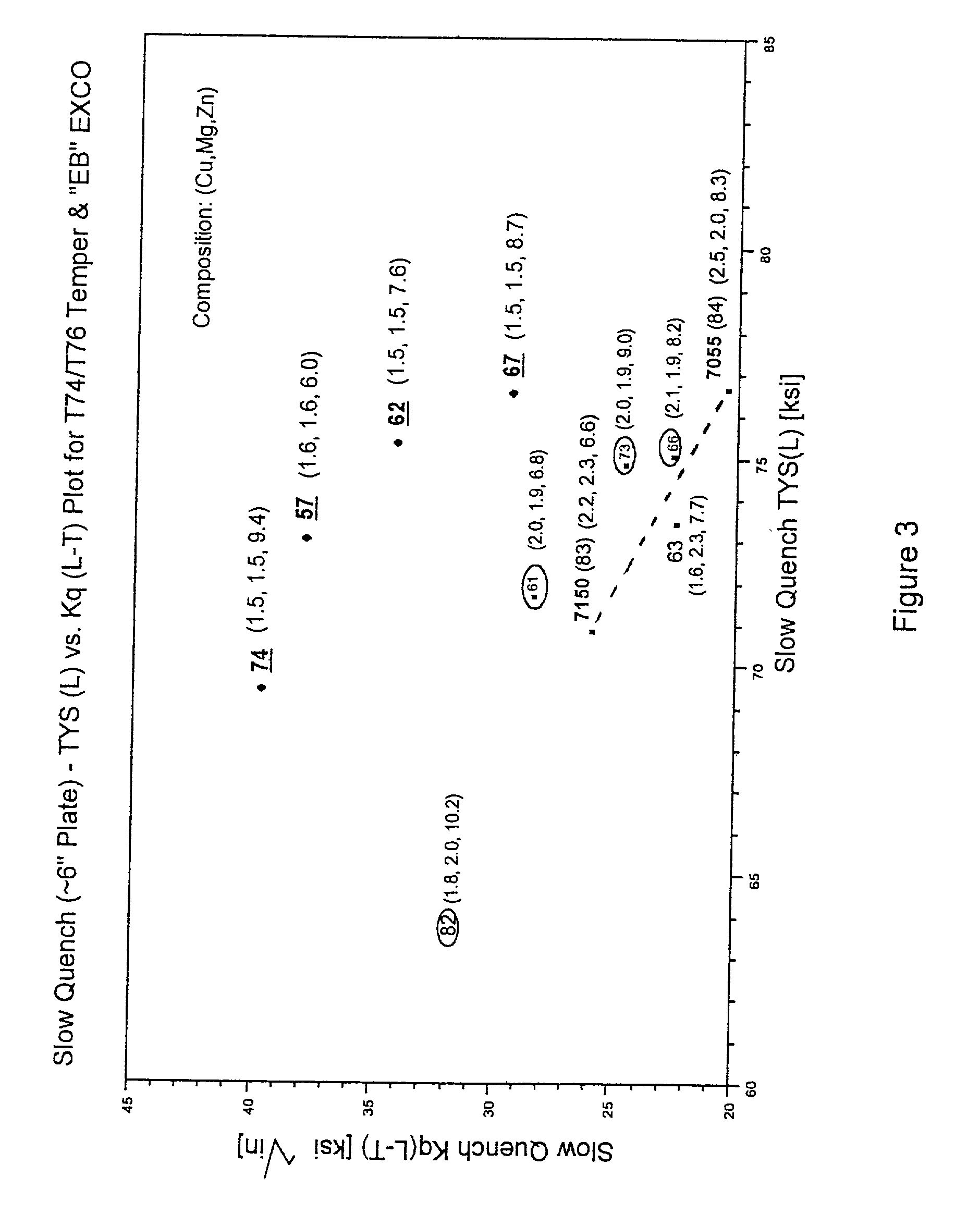

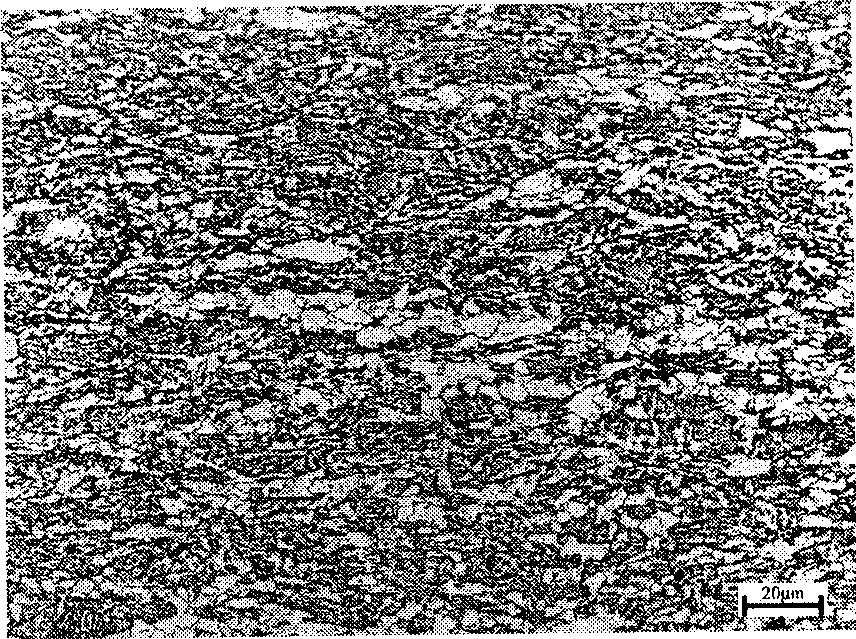

Aluminum alloy having superior strength-toughness combinations in thick gauges

A 7XXX series aluminum alloy having reduced quench sensitivity suitable for use in aerospace structural components, such as integral wing spars, ribs, extrusions and forgings comprises, in weight %: 6 to 10 Zn, 1.3 to 1.9 Mg, 1.4 to 2.2 Cu, wherein Mg<=Cu+0.3, one or more of 0 to 0.4 Zr, up to 0.4 Sc, up to 0.2 Hf, up to 0.4 Cr, up to 1.0 Mn and the balance Al plus incidental additions including Si, Fe, Ti and the like plus impurities. By controlling the Mg content to 1.3 to 1.7 wt. %, limiting Mg<=Cu+0.3 and 6.5<=Zn<=8.5, the alloy provides significantly improved combined strength and fracture toughness in heavy gauges. For example, in a six-inch thick plate there is provided a combination of about 75 ksi quarter-plane tensile yield strength (L) with a fracture toughness (L-T) of about 33 ksi{square root}in which progresses by artificial aging / tempering to a combined strength and fracture toughness of about 67 ksi tensile yield strength (L) and a fracture toughness (L-T) of about 40 ksi{square root}in. The alloy product possesses equally attractive combinations of strength and fracture toughness when intentionally quenched slowly following solution heat treatment so as to lessen dimensional distortion, particularly in shapes of varying cross section.

Owner:ARCONIC INC

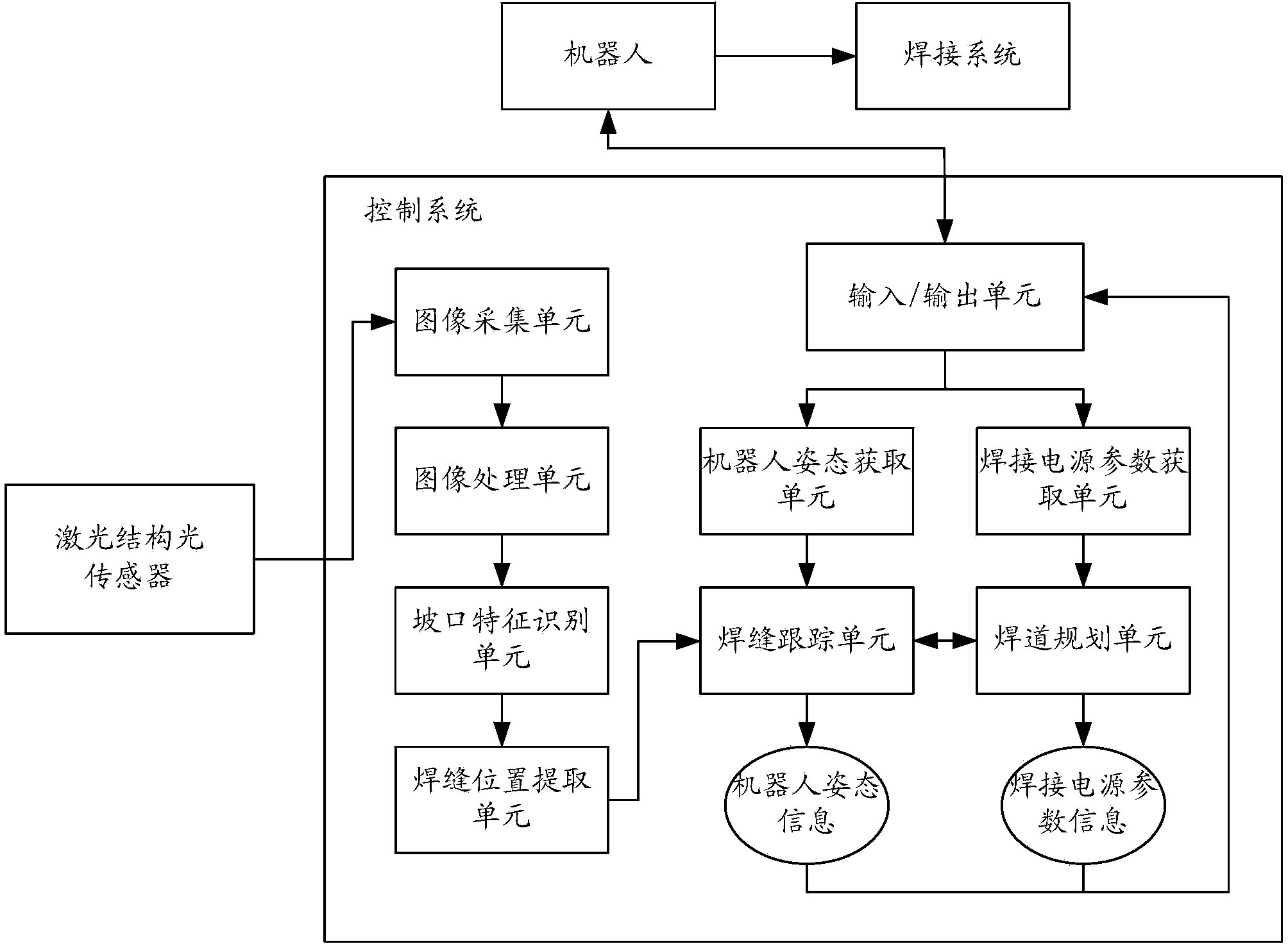

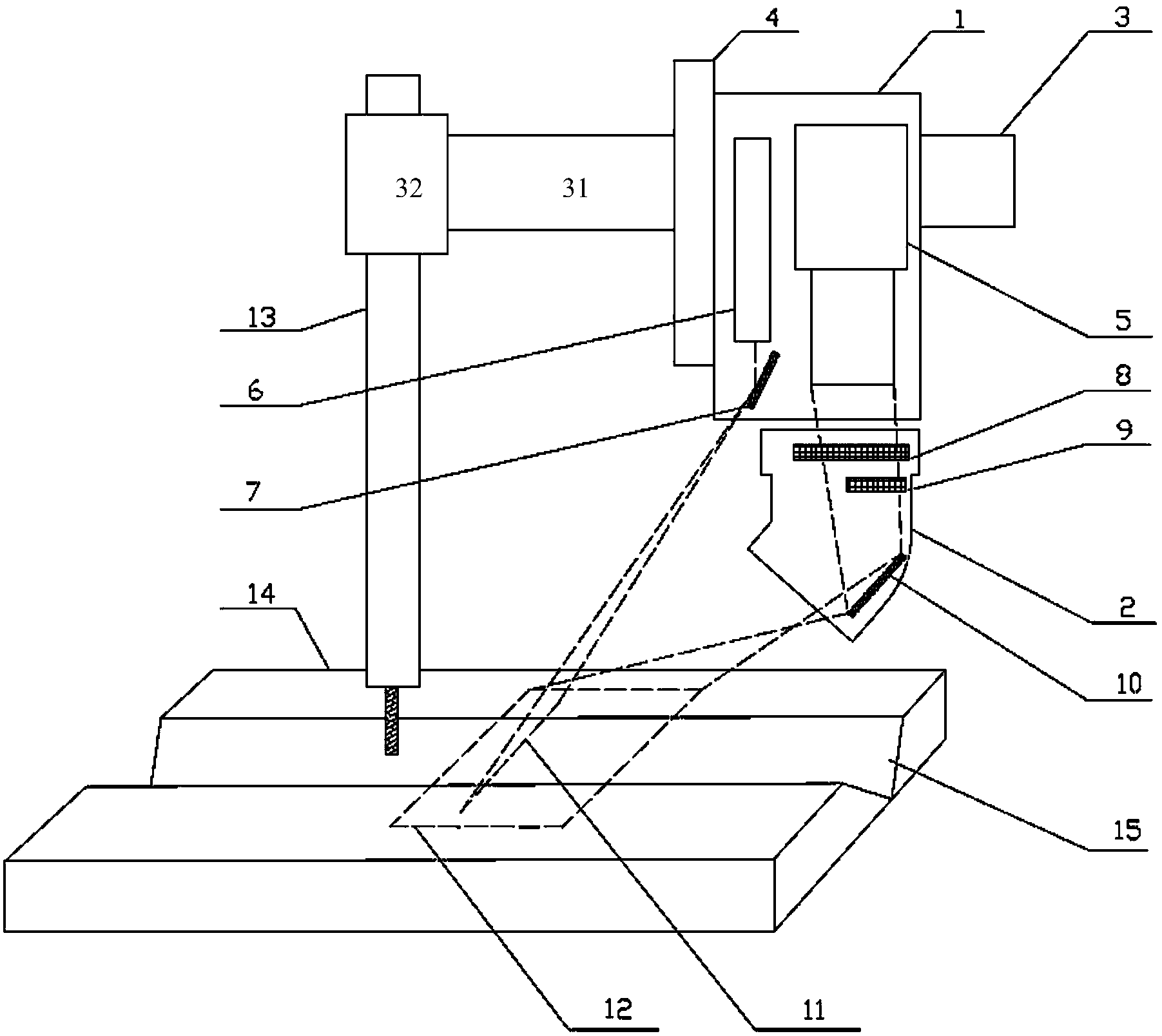

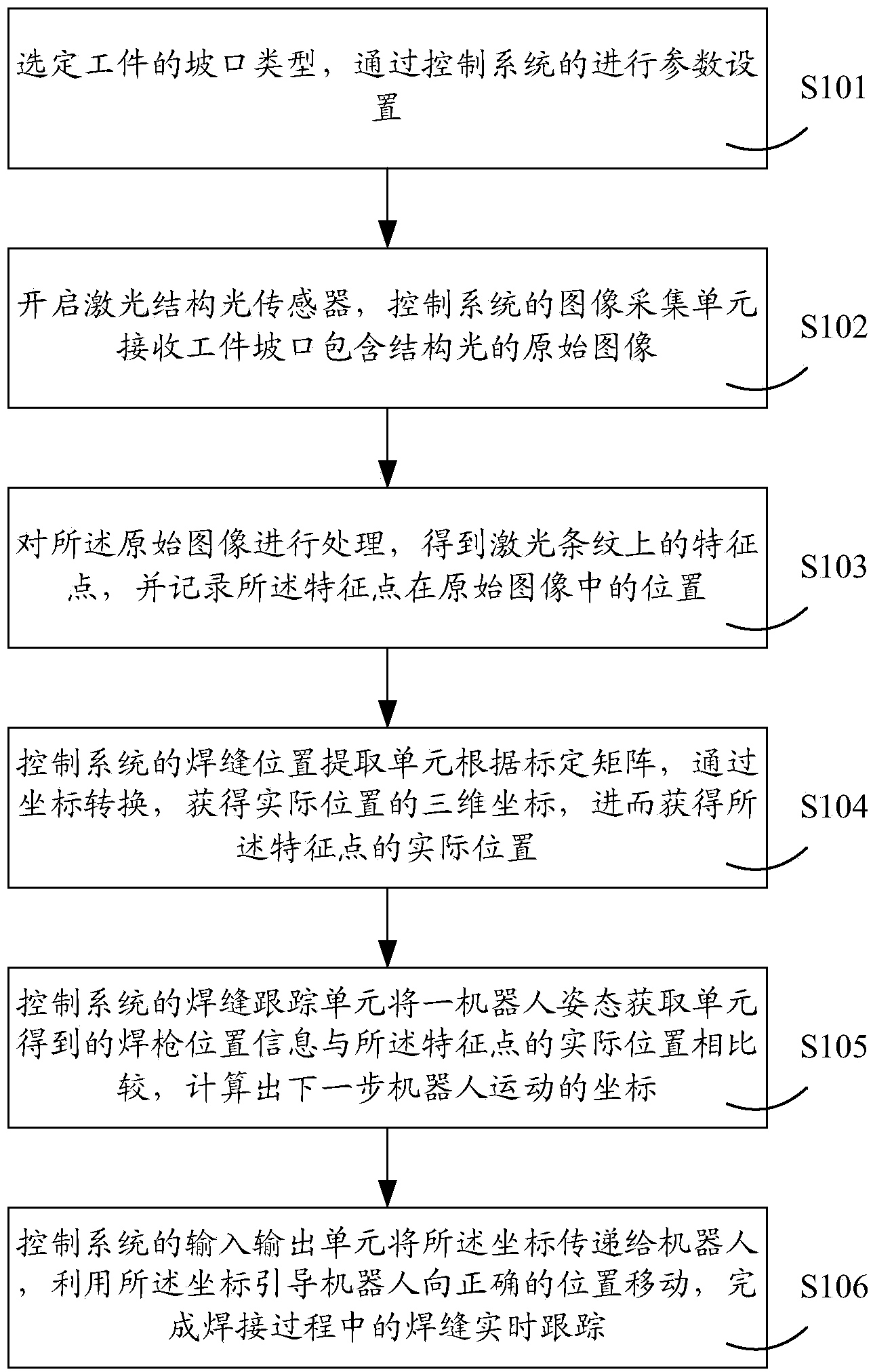

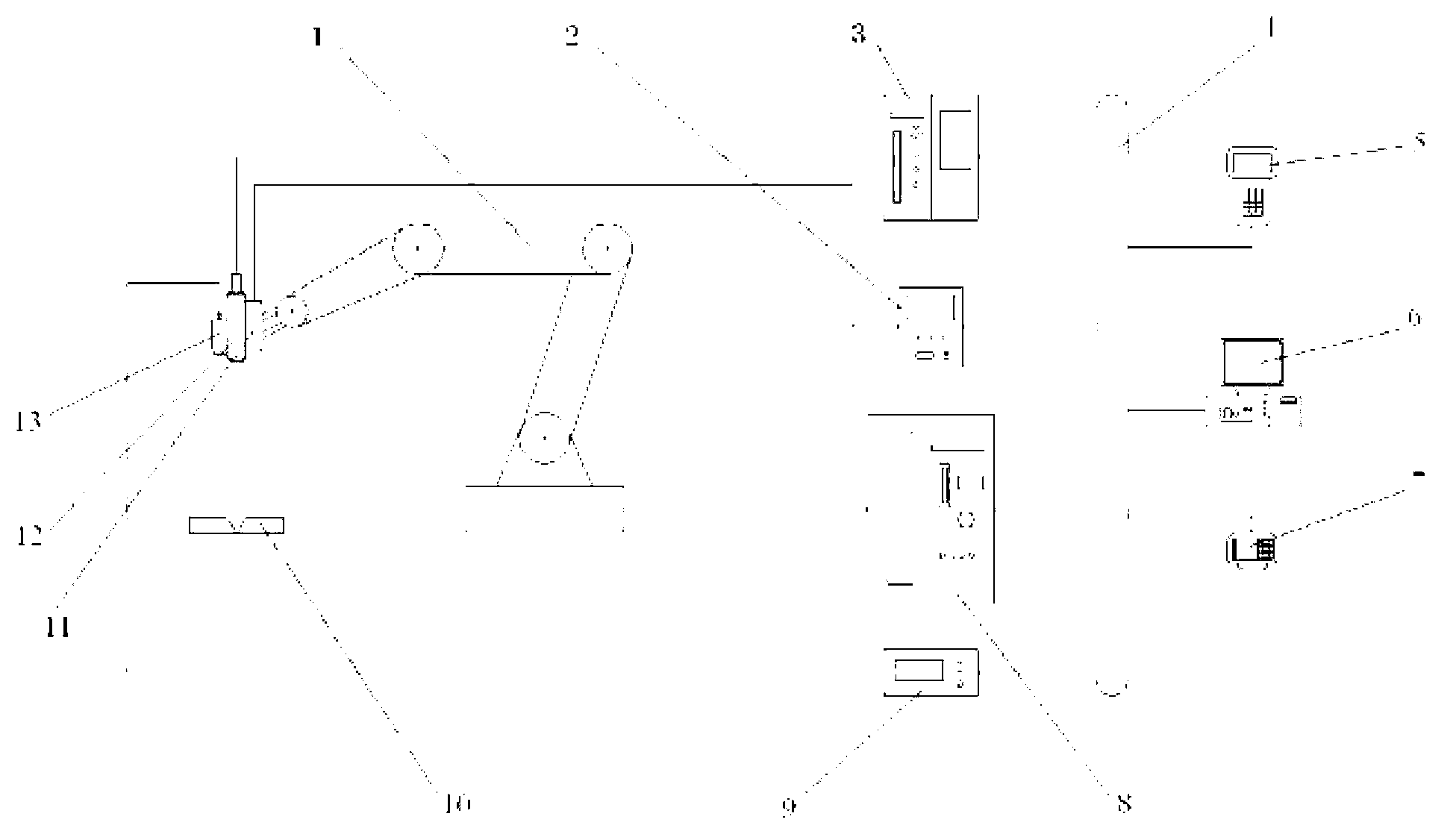

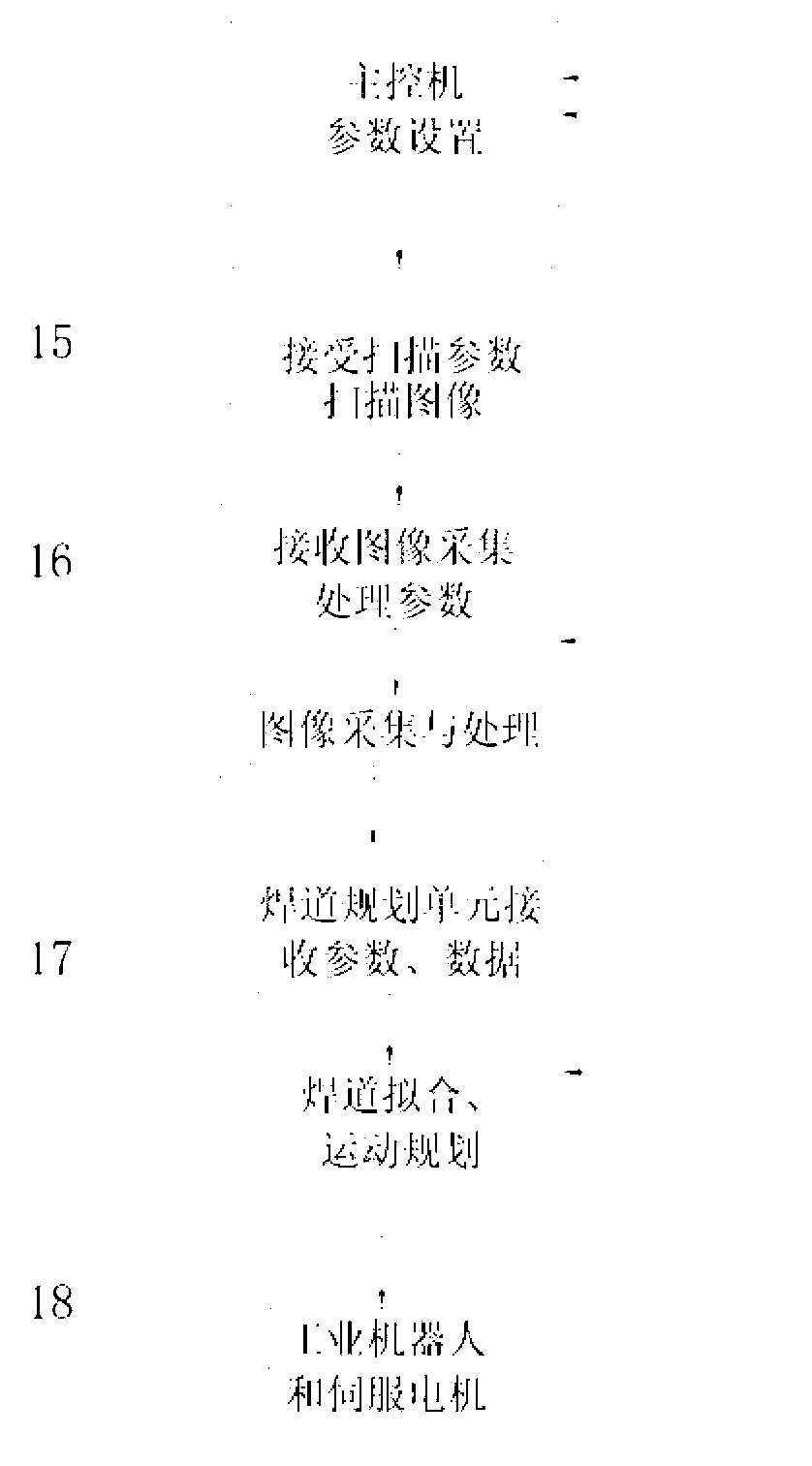

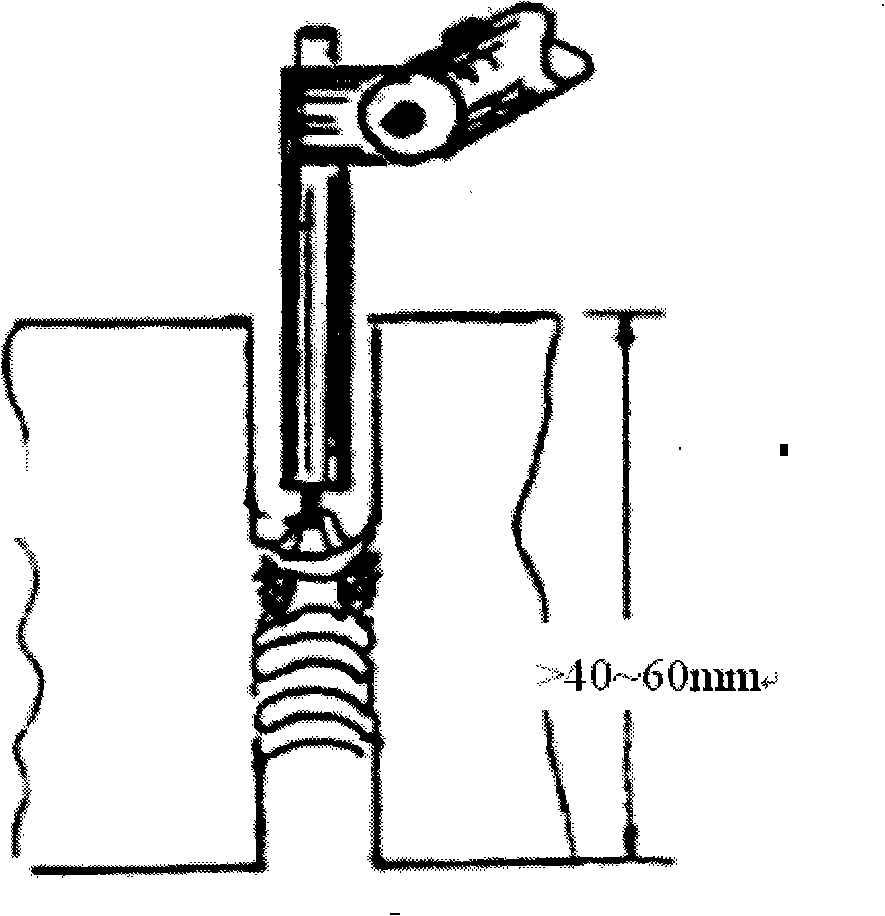

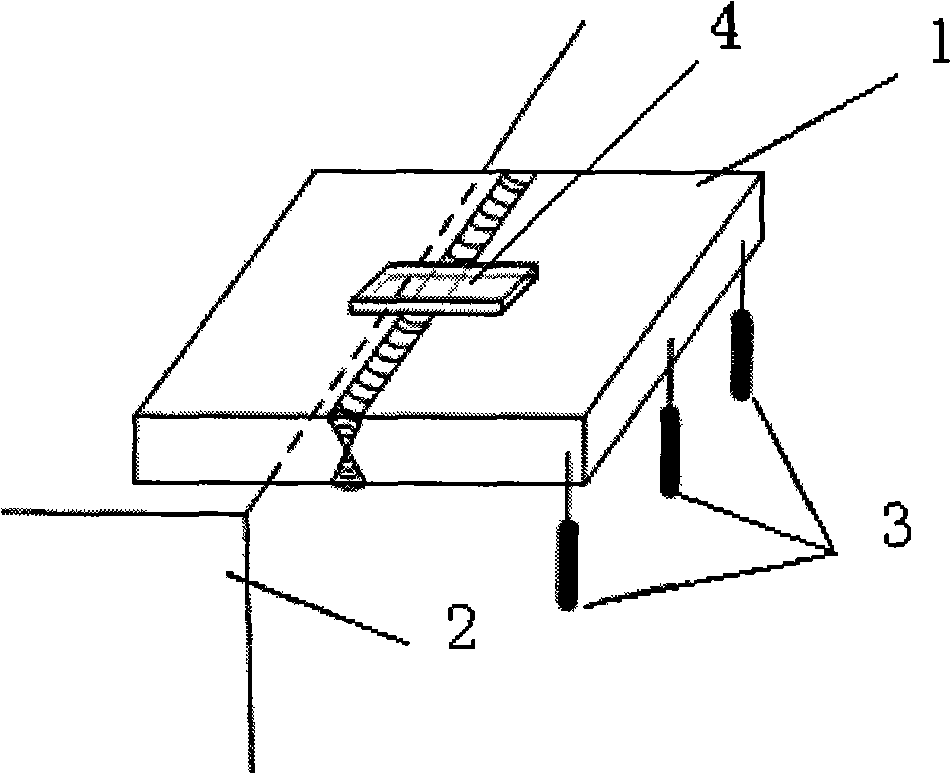

Thick plate robot welding system and multilayer multiple-pass weld real-time tracking and planning method

InactiveCN103934571AEnable real-time planningImprove flexibilityWelding/cutting auxillary devicesArc welding apparatusThick plateControl system

The invention discloses a thick plate robot welding system and a multilayer multiple-pass weld real-time tracking and planning method. The thick plate robot welding system comprises a robot, a laser structure optical sensor, a welding system and a control system. The laser structure optical sensor comprises a main system, an optical system, a clamping system and a cooling system. In the welding process, images containing weld groove feature information can be obtained in real time and transmitted to the control system; the control system obtains the groove information from the images and controls the robot to constantly correct the position of a welding gun in the welding system; meanwhile, the control system adjusts a weld pass track and welding parameters so that multilayer multiple-pass real-time planning can be achieved, and labor efficiency and production quality can be improved.

Owner:SHANGHAI JIAO TONG UNIV +1

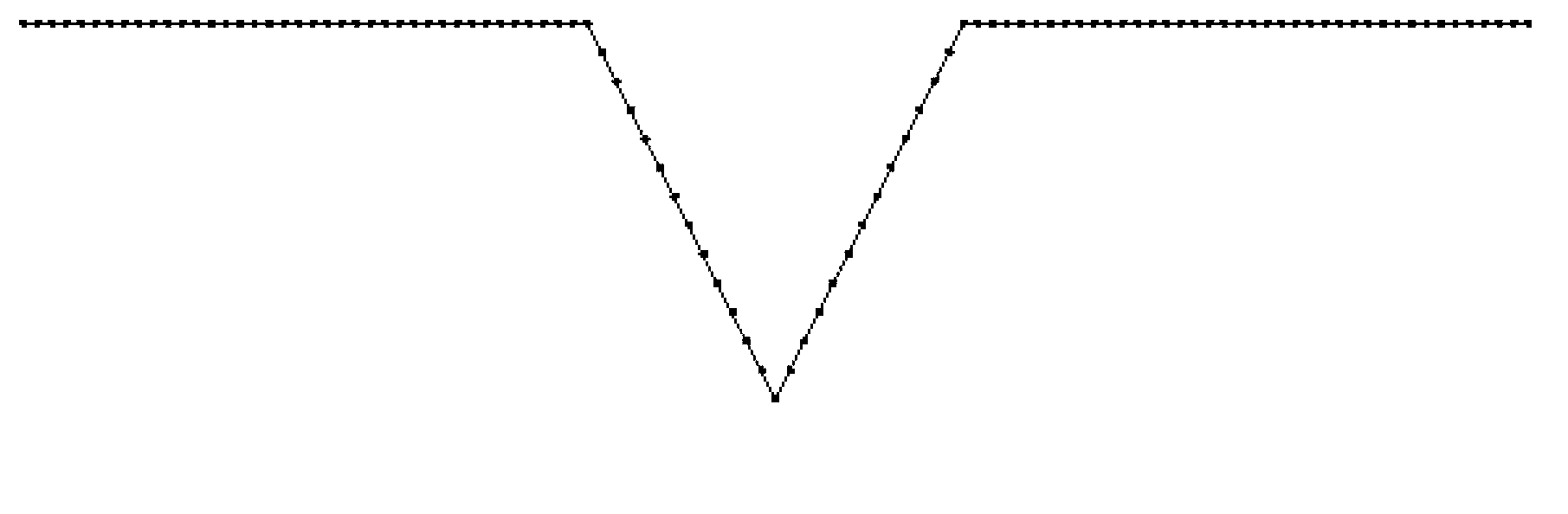

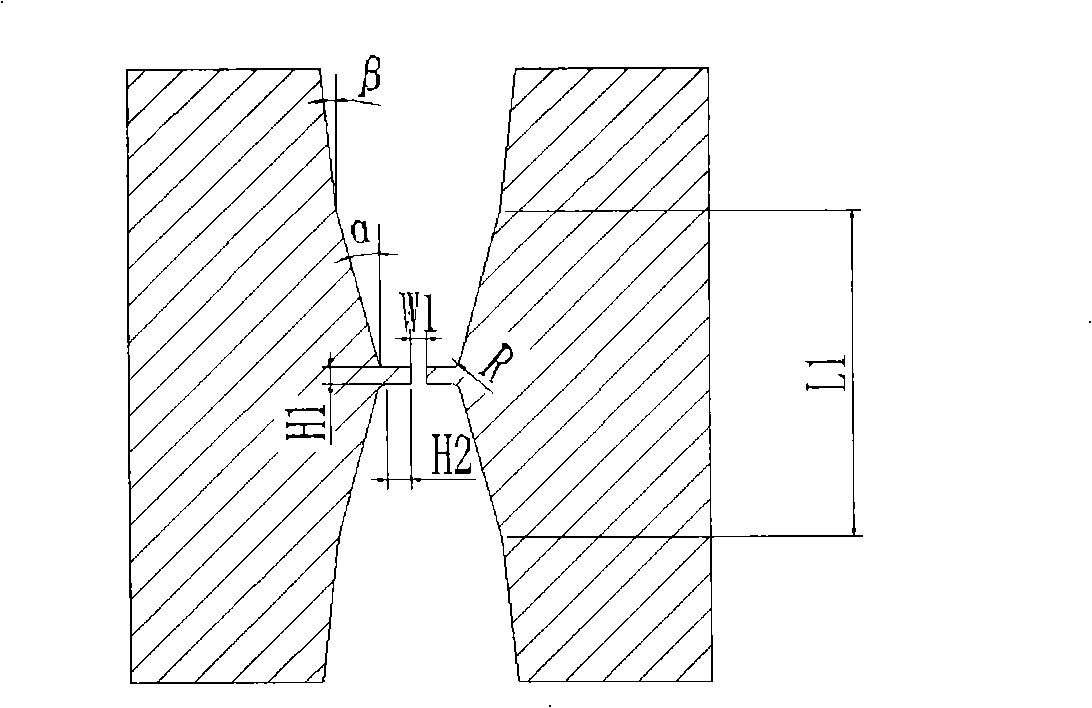

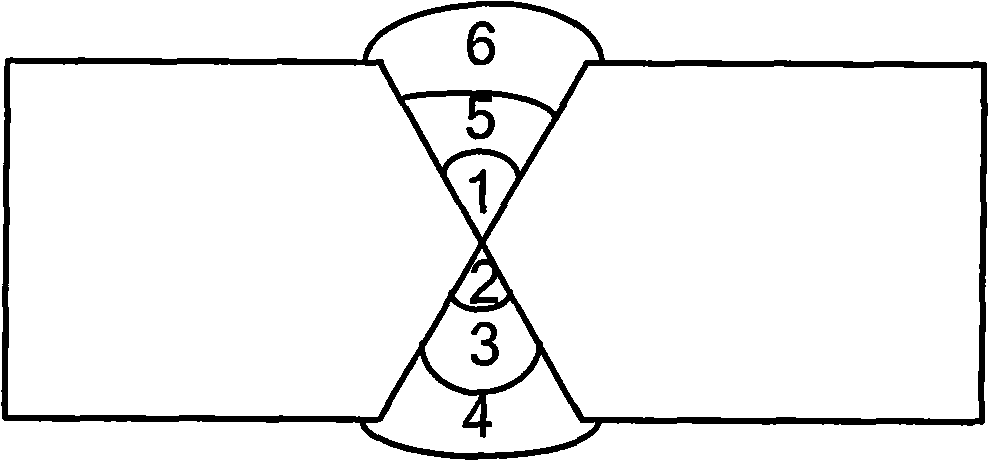

Scanning type laser vision sensing-based narrow-gap deep-groove automatic laser multilayer welding method for thick plate

InactiveCN102699534AImprove portabilityIncrease flexibilityLaser beam welding apparatusThick plateImaging algorithm

The invention discloses a scanning type laser vision sensing-based narrow-gap deep-groove automatic laser multilayer welding method for a thick plate, relates to a welding method, and aims to solve the problems that the conventional structured light vision sensing-based welding method can only be used for a simple shallow-groove laser weld seam tracking task and that when the conventional structured light vision sensing-based welding method is used for the narrow-gap deep-groove weld seam welding of the thick plate, a covering phenomenon is easily produced, the groove identification accuracy is lower, only real-time weld seam alignment calibration can be realized and narrow-gap deep-groove laser multilayer welding bead planning and welding cannot be realized. The method specifically comprises the following steps of: 1, selecting a groove form; 2, scanning a groove section image of a thick plate workpiece to be welded by using an image scanning unit; 3, processing the acquired groove section image by using an image algorithm to obtain weld seam image data; 4, performing fitting calculation; and 5, finishing the welding of welding beads layer by layer. The method is used for the deep-groove weld seam welding of the thick plate.

Owner:HARBIN INST OF TECH

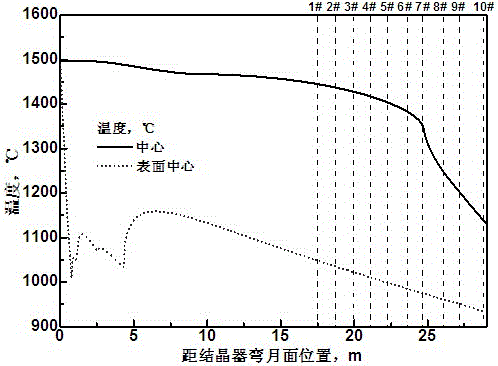

Method for continuous casting billet two-stage continuous and dynamic heavy downward pressing

The invention belongs to the field of continuous casting production, and particularly relates to a method for continuous casting billet two-stage continuous and dynamic heavy downward pressing. The method for the c two-stage continuous and dynamic heavy downward pressing is provided for the characteristics of a bloom caster and a wide and thick plate continuous casting machine. A specific process parameter design method of heavy downward pressing process implementation is given and includes downward pressing interval section and division and downward pressing amount design. The casting billet segregation defect is overcome in the first stage of downward pressing, the looseness defect of casting billets is overcome in the second stage of continuous downward pressing, and therefore the synchronous improvement of casting billet segregation and looseness is achieved.

Owner:NORTHEASTERN UNIV

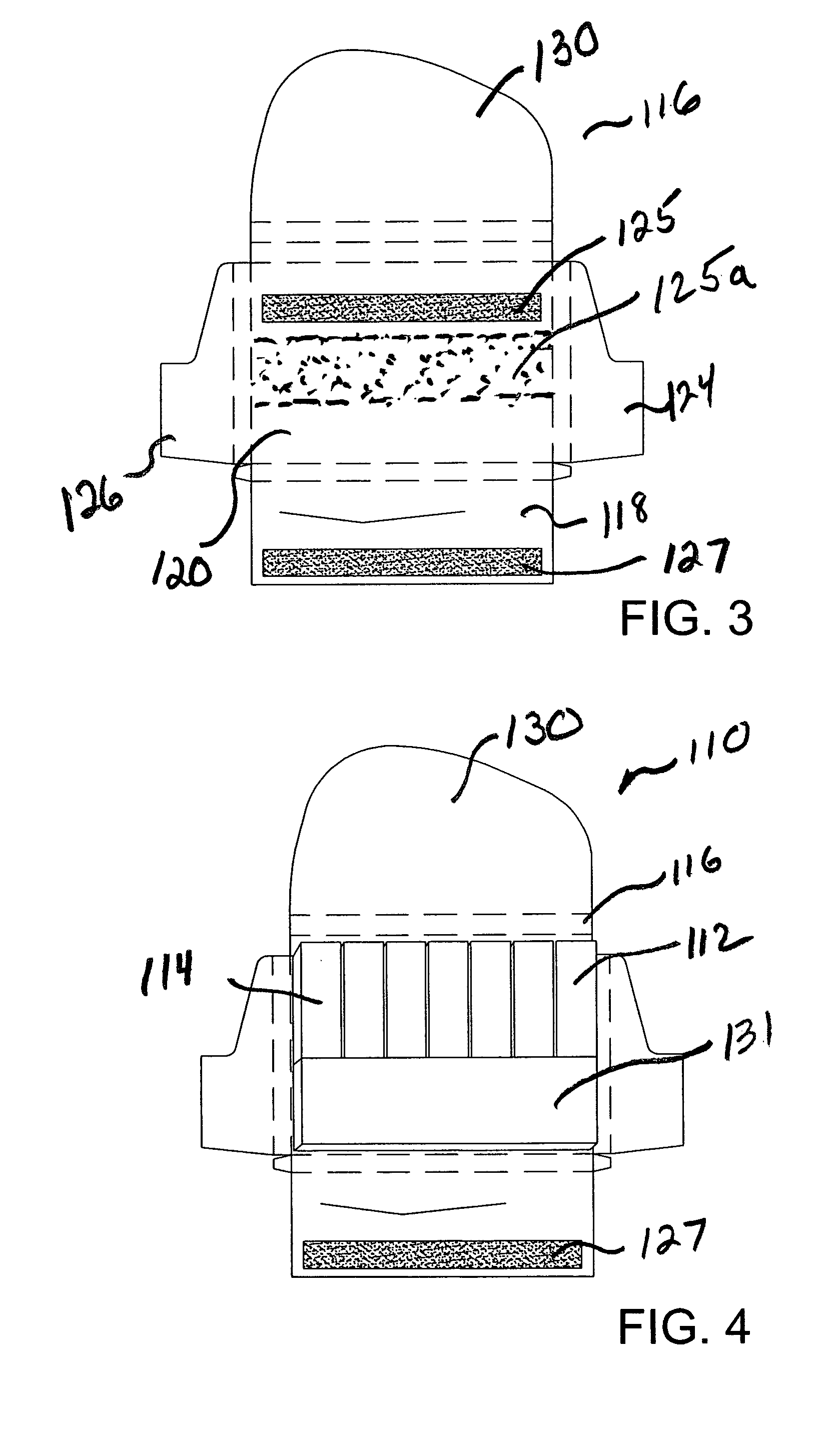

Package for dispensing and retaining gum slabs with adhesive securement

Owner:INTERCONTINENTAL GREAT BRANDS LLC

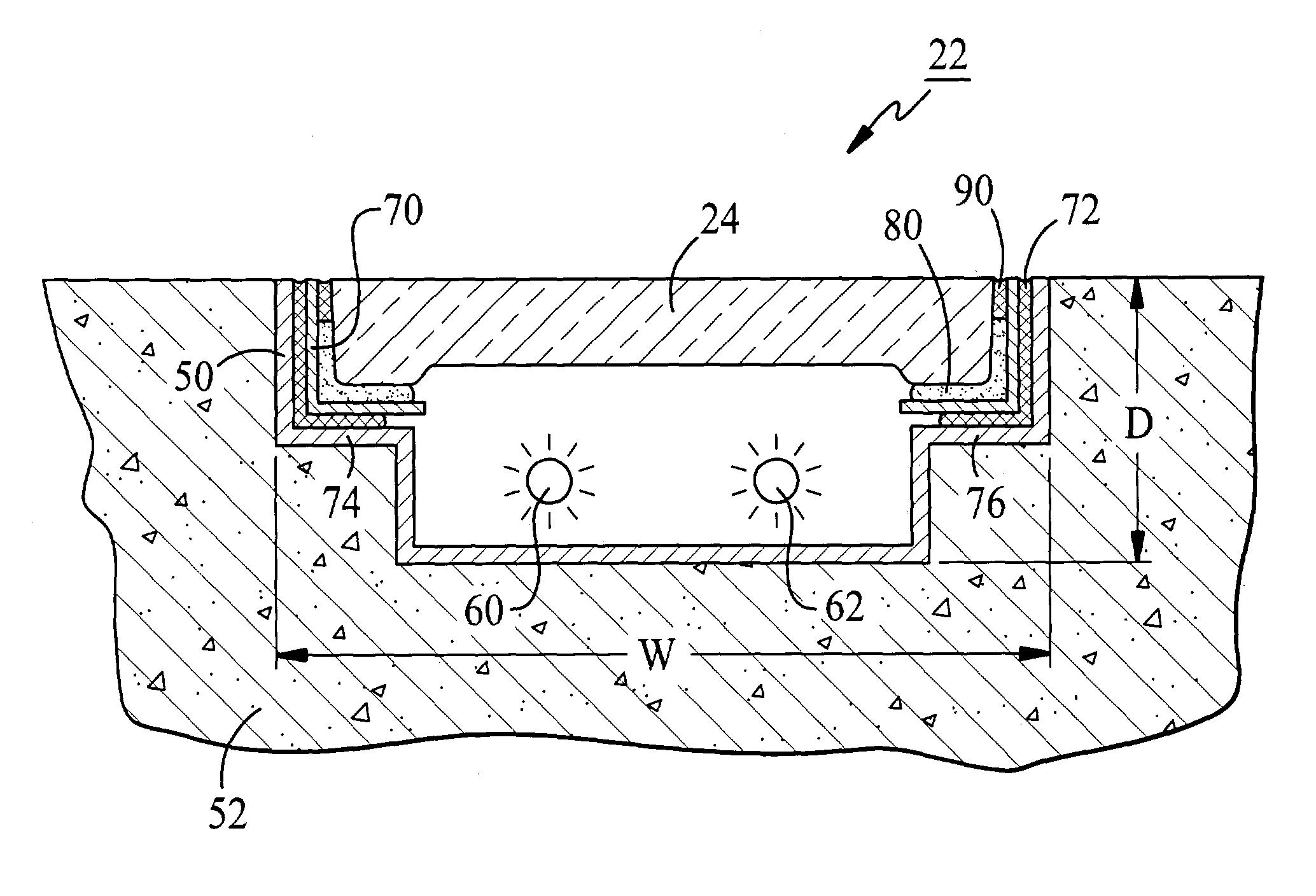

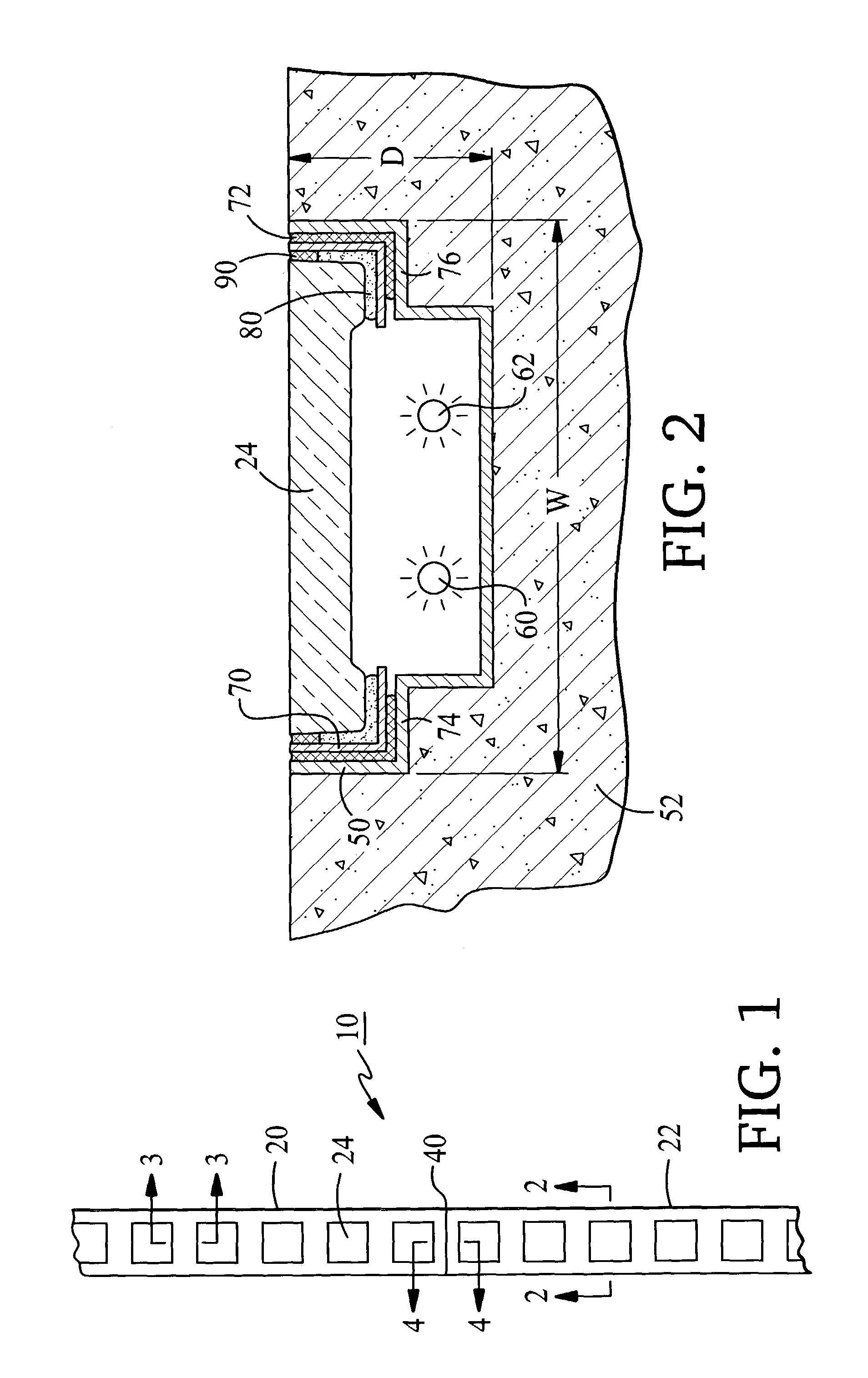

Illuminated glass deck light panel and method of installation

In a preferred embodiment, an illuminated glass deck light panel, including: a plurality of glass pavers, structural plank glass elements, or other structural lenses; a longitudinally extending support pan for embedding in a supporting substrate; the plurality of glass pavers, structural plank glass elements, or other structural lenses resting on ledges formed in the support pan; a sealing material disposed between the glass pavers, structural plank glass elements, or other structural lenses and the support pan; a plurality of illumination sources disposed in the support pan underneath the plurality of glass pavers, structural plank glass elements, or other structural lenses; and the plurality of illumination sources being at all times illuminated whenever one of the plurality of illumination sources is illuminated. The plurality of illumination sources may also be selected from the group consisting of: pulsed illumination sources, blinking illumination sources, and progressive illumination sources to direct persons in a certain direction.

Owner:SANDOR FREDERICK J SR

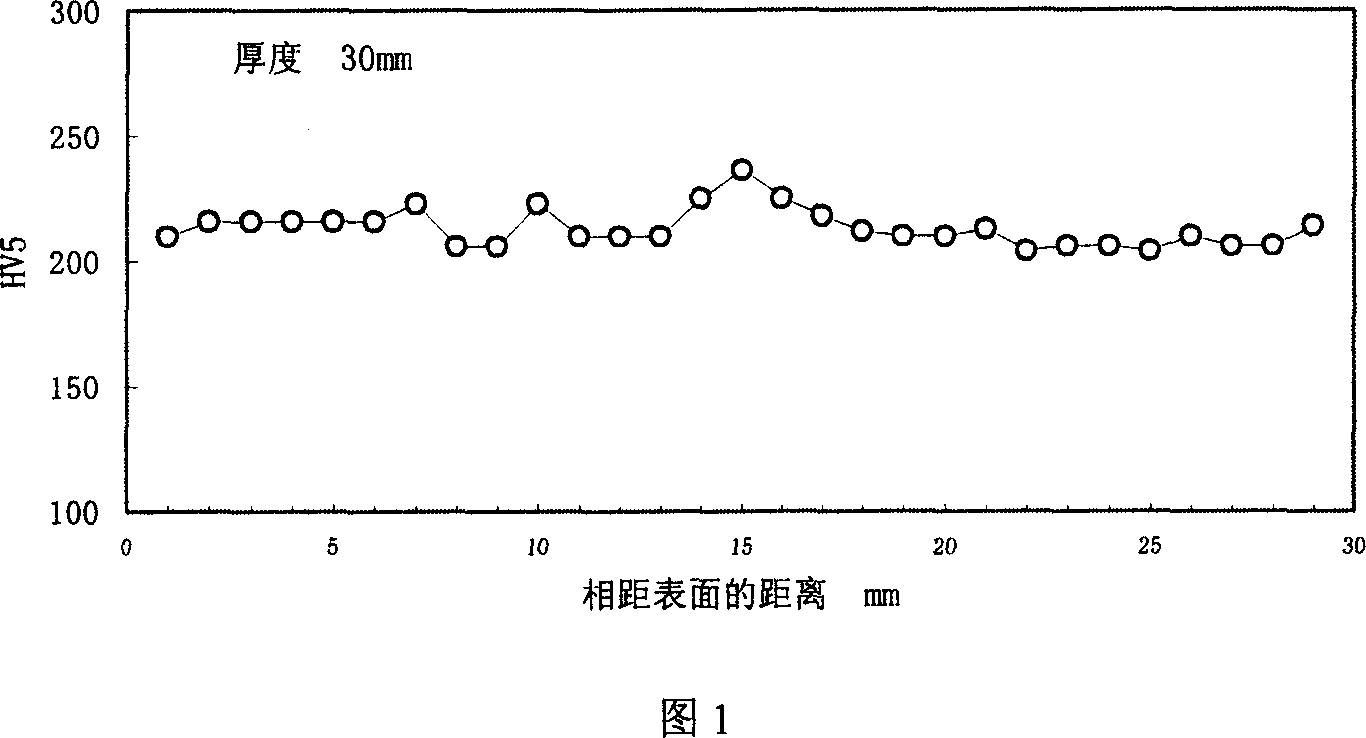

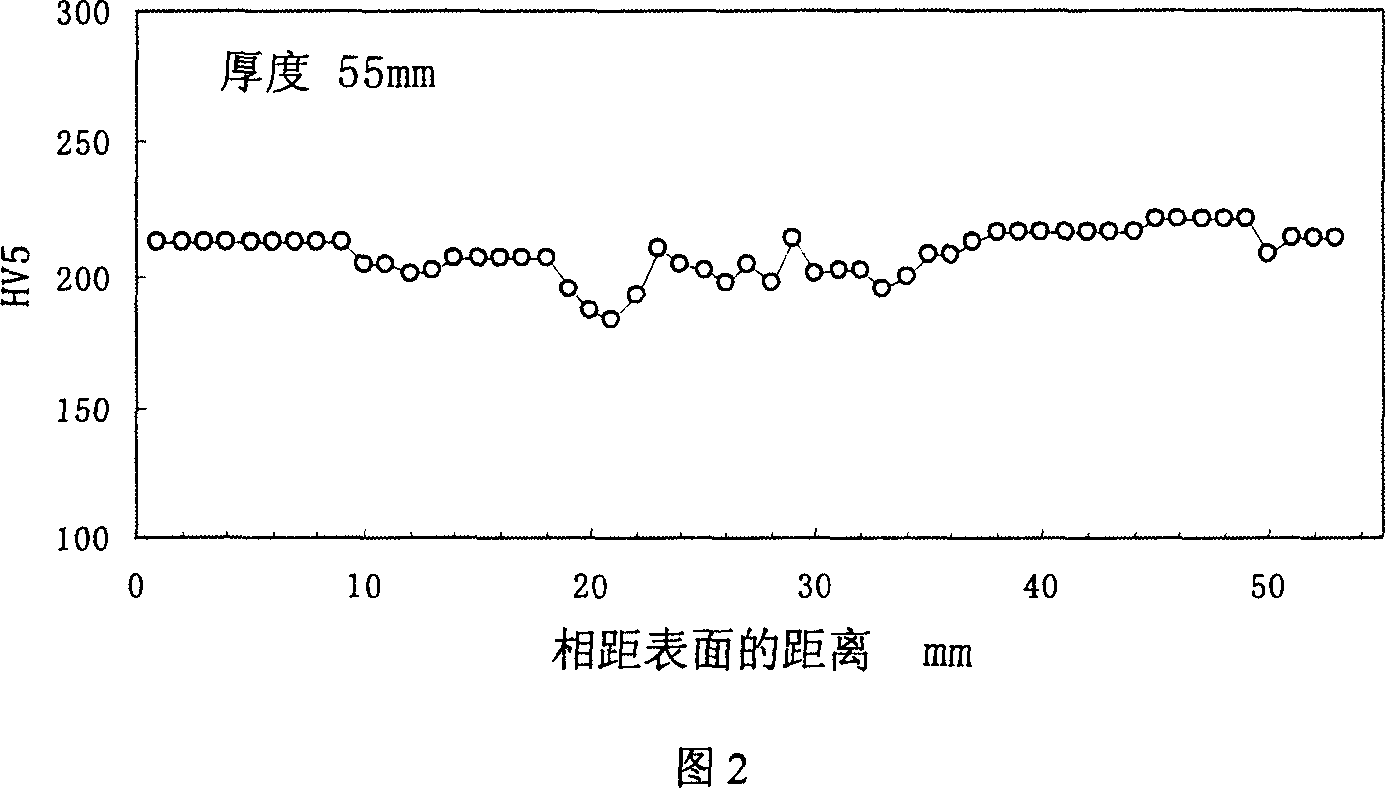

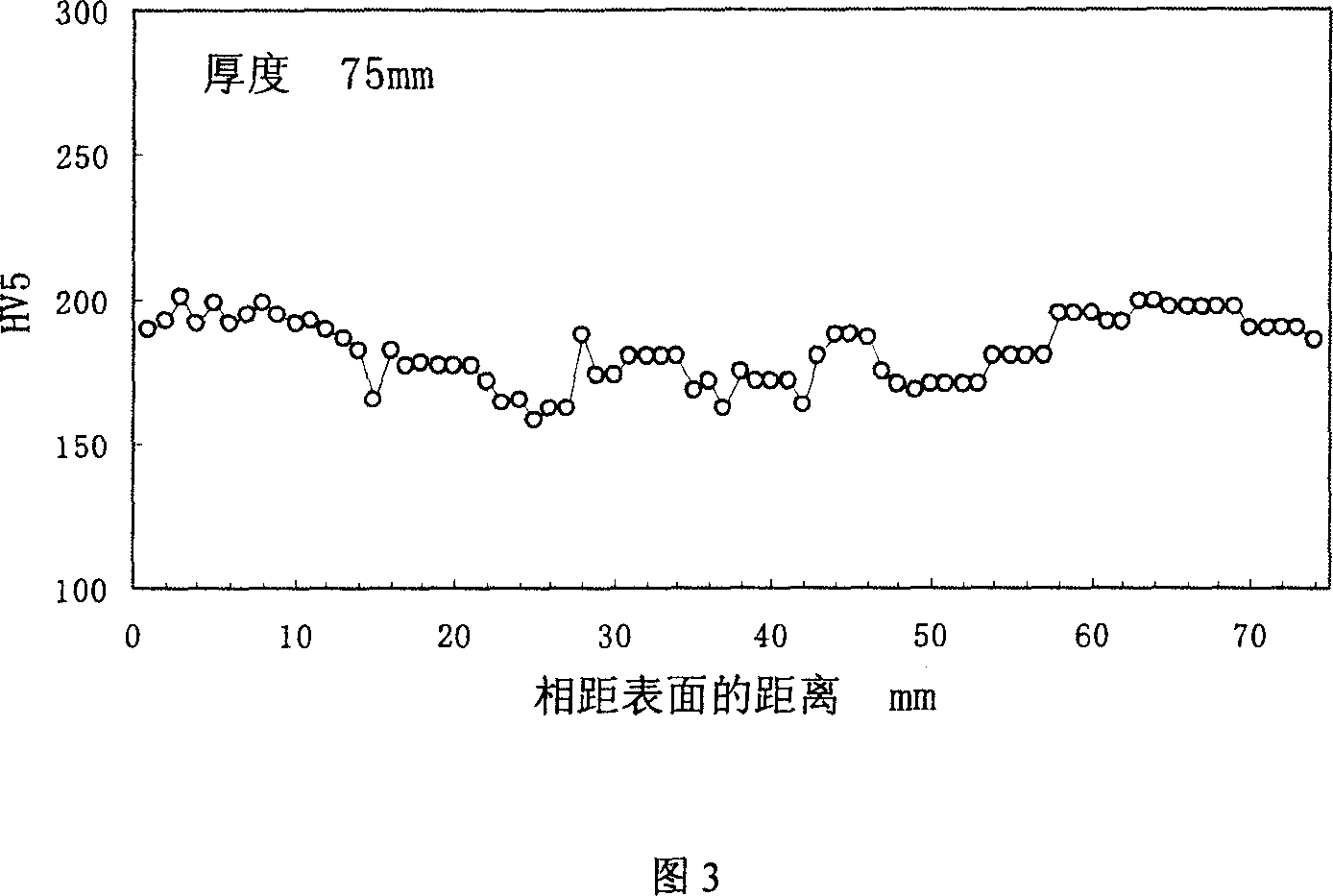

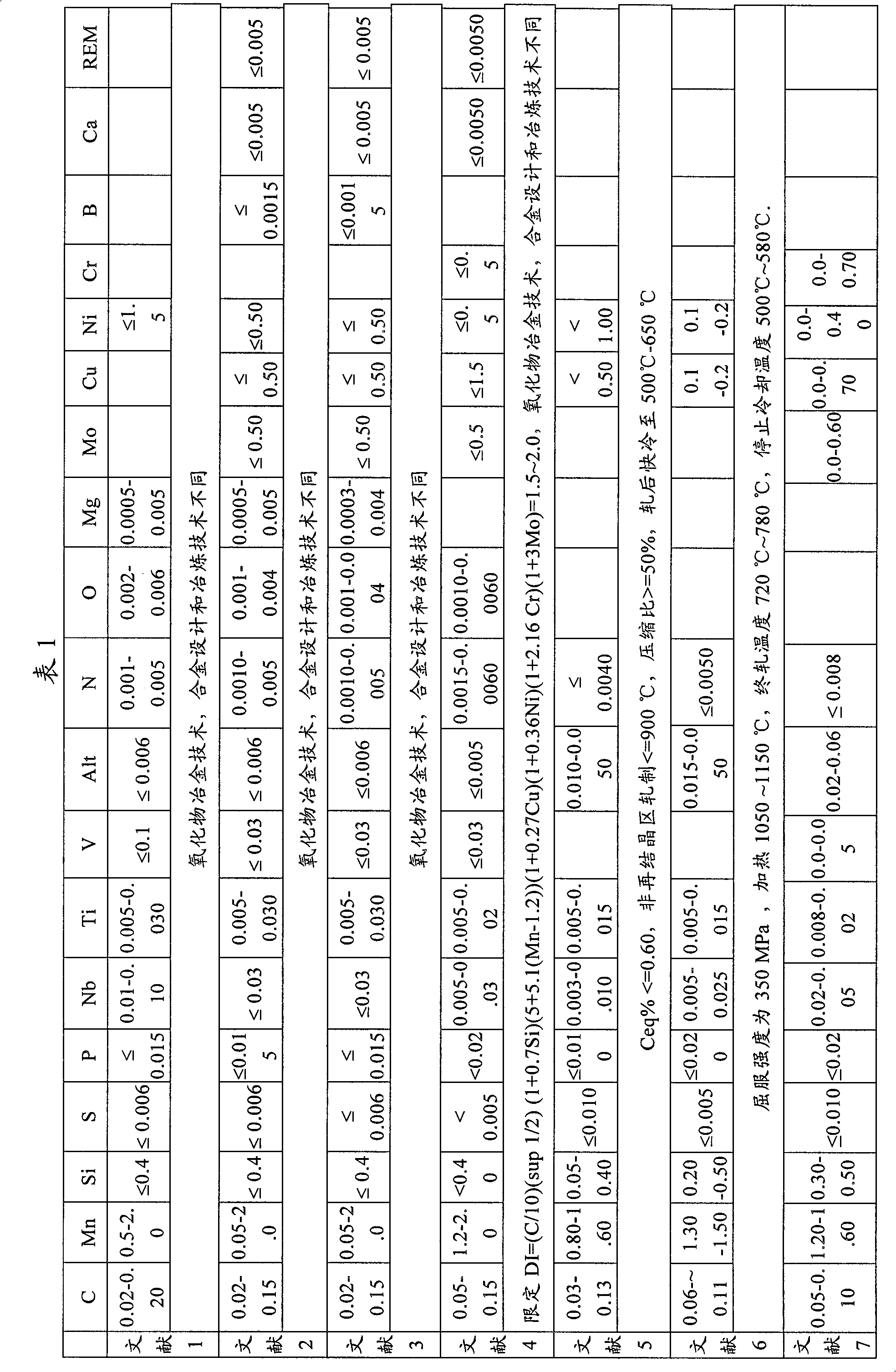

Thick steel plate with high strength and low welding crack sensitivity and its production process

InactiveCN1932063ASimple designGuaranteed performanceTemperature control deviceSheet steelChemical composition

The present invention discloses one kind of thick steel plate with high strength and low welding crack sensitivity and its production process. The chemical composition includes C 0.06-0.09 wt%, Si 0.15-0.55 wt%, Mn 1.00-1.60 wt%, P not more than 0.015 wt%, S not more than 0.006 wt%, Ni 0.15-0.40 wt%, Cr not more than 0.30 wt%, Mo not more than 0.30 wt%, Cu not more than 0.30 wt%, V 0.02-0.06 wt%, Nb 0.005-0.05 wt% and Als 0.010-0.04 wt%, except Fe and inevitable impurities; and meets Pcm not higher than 0.20 % and Ceq not higher than 0.42 %. The production process includes two stage controlled rolling, on-line laminar flow cooling, off-line tempering and other steps. The produced steel plate has thickness up to 75mm, tensile strength not lower than 610 MPa and very low welding crack sensitivity.

Owner:ANGANG STEEL CO LTD

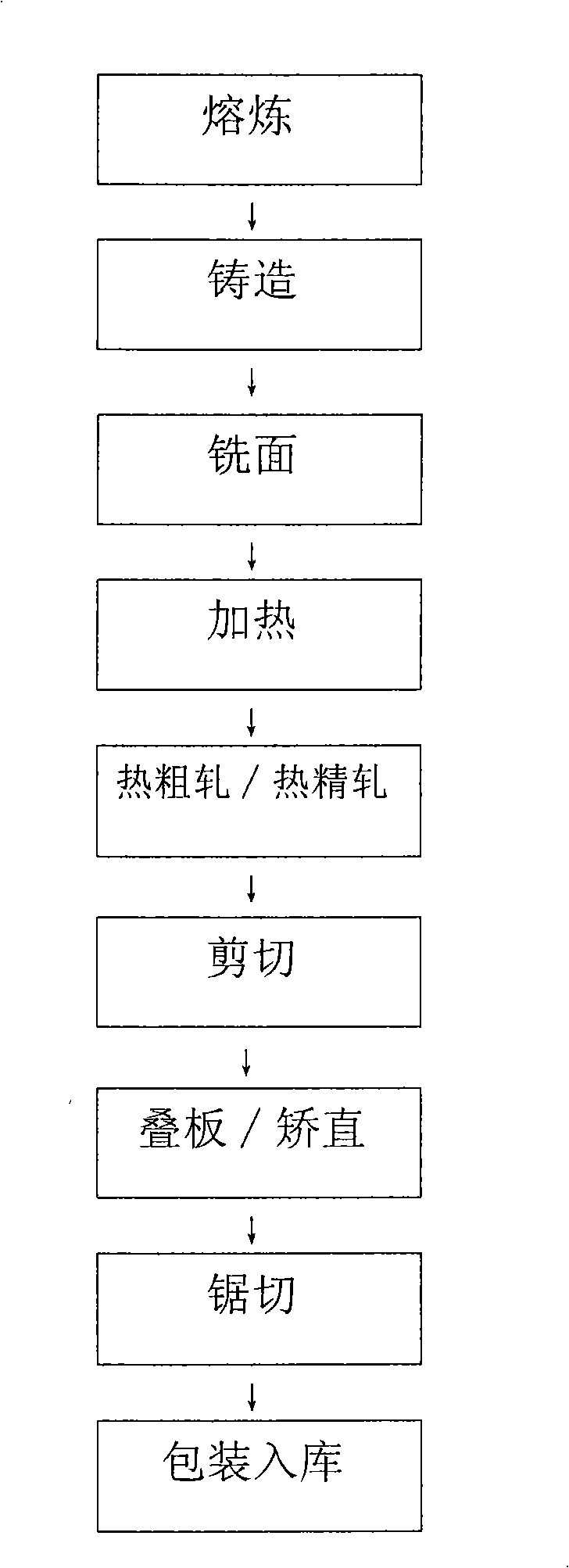

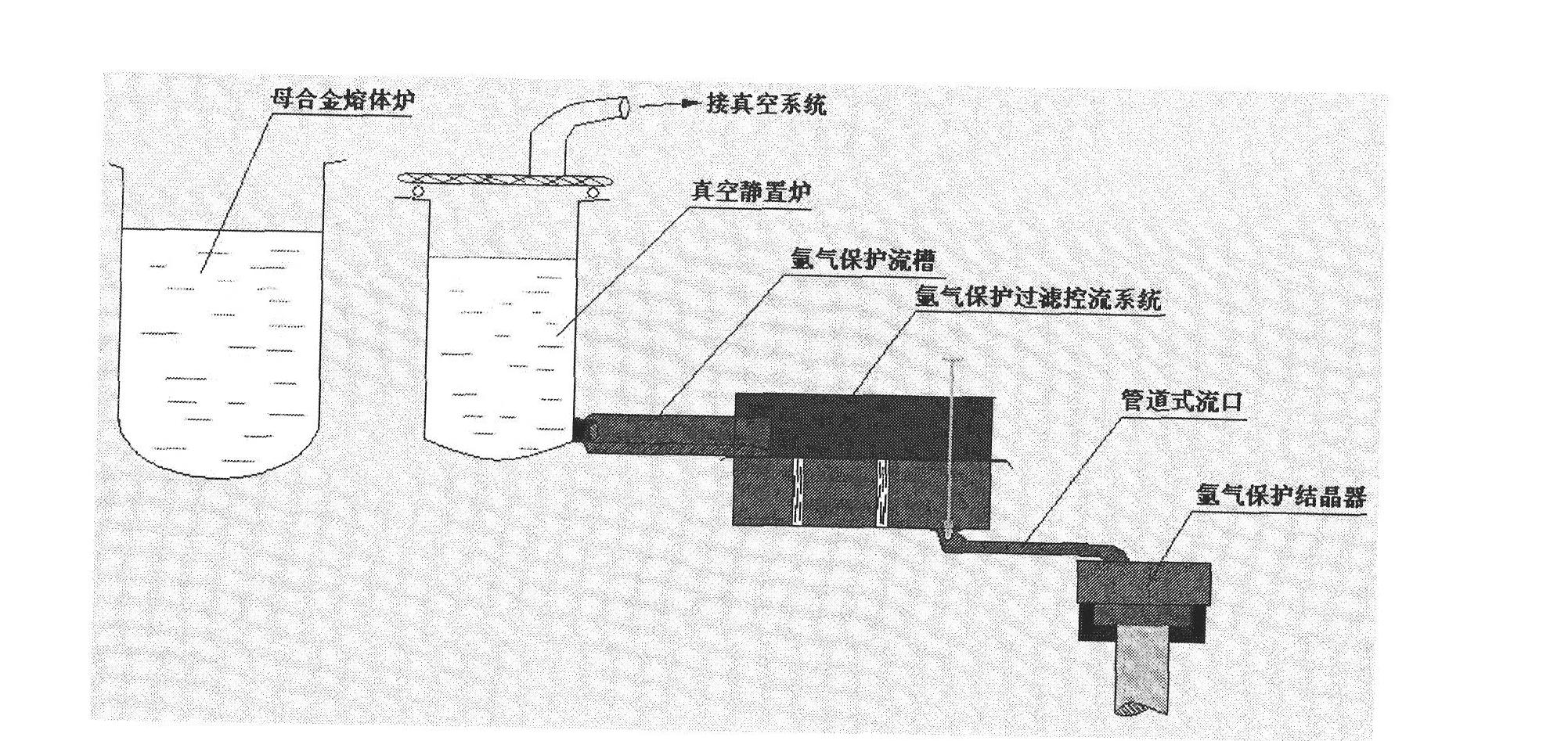

Production process of aluminum alloy hot rolling medium plate

The invention relates to a production process for hot-rolling medium plate by adopting aluminum alloy. The aluminum alloy materials are as follows according to the weight percentage: Fe is less than or equal to 0.35, Si is less than or equal to 0.25, Cu is less than or equal to 0.10, Mn is 0.70-0.90, Mg is 4.50-4.80, Cr is 0.10-0.20, Zn is less than or equal to 0.20, Ti is less than or equal to 0.10, other impurities are less than or equal to 0.15 in total, Na is less than or equal to 5pp,, Ca is less than or equal to 5ppm, and Al is the balance; and the sum of all components is 100. The main process comprises the following steps of melting, milling, heating, hot rough rolling or fine rolling. The invention adopts a soaking process during the processing of the aluminum alloy, mainly adopts two measures of milling sides and rolling the sides to solve the edge crack problem, controls the thickness difference and the plate form as well as oil spot and scuffing, and develops the production process for hot-rolling the medium plate by adopting the 5083 aluminum alloy.

Owner:中铝河南铝业有限公司

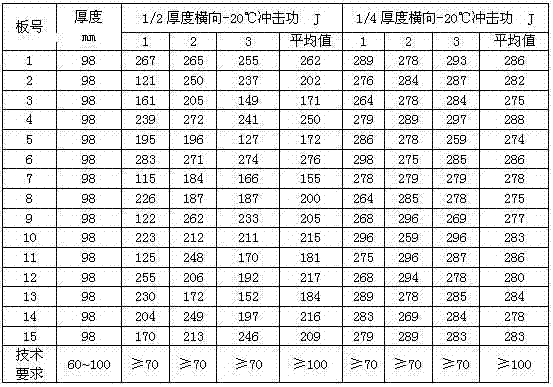

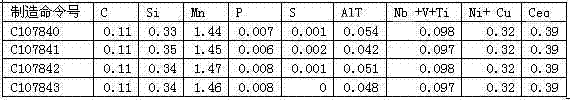

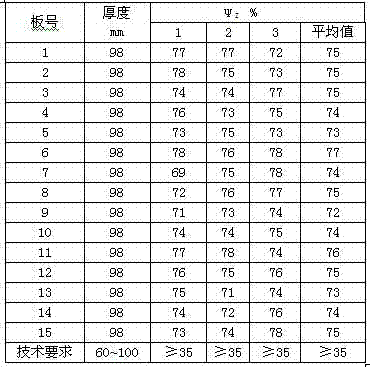

Method for producing super-thick steel plate

ActiveCN102409236AMeet manufacturing requirementsReduce manufacturing costRoll mill control devicesFurnace typesThick plateContinuous casting

The invention discloses a method for producing a super-thick steel plate. The method comprises the following production process steps of: performing pretreatment on molten iron; making steel by using a convertor; performing external refining; continuously casting; heating; rolling; cooling in an accelerated way; normalizing; controlling a cold condition; finishing; inspecting performance; and performing ultrasonic flaw detection. In the method, a low-C high-Mn component system is utilized, and Ni and Cu alloy elements are added into the steel in combination with micro-alloying treatment of Nb, V and Ti. The steel comprises the following chemical components in percentage by weight: less than or equal to 0.12 percent of C, 0.20 to 0.40 percent of Si, 1.20 to 1.50 percent of Mn, less than orequal to 0.008 percent of P, less than or equal to 0.003 percent of S, 0.03 to 0.06 percent of AlT, less than or equal to 0.10 percent of Nb, Ti and V, less than or equal to 0.80 percent of Cu and Ni, less than or equal to 0.40 percent of Ceq and the balance of Fe and inevitable impurities. By the method, a continuous casting blank is used for producing high-performance Q345R steel plates with the thickness of 60 to 100mm, so that production cost is reduced, and the requirement of manufacturing containers with high parameter pressure is met; the low-C high-Mn component system is used for a component design, so that the requirement that the material Ceq is less than or equal to 0.40 percent is met; and the continuous casting blank is used for producing a high-performance Q345R super-thick plate, so that the method has a simple process, the process is easy to realize, and the plate can be produced by a common wide and thick plate factory.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

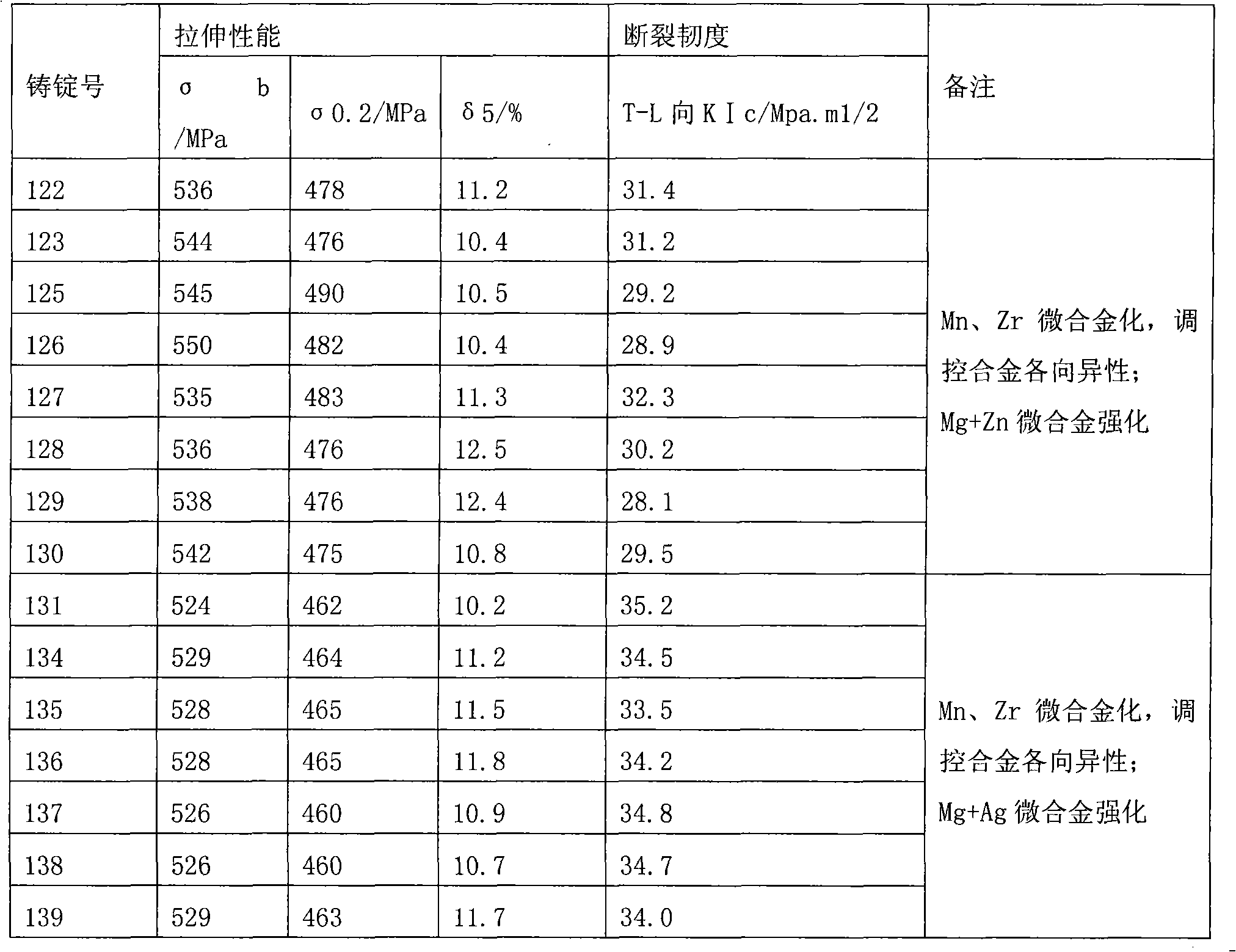

High-toughness aluminum lithium alloy and preparation method thereof

The invention discloses a high-toughness aluminum lithium alloy and a preparation method thereof. The alloy comprises the following chemical components in percentage by weight: 3.2 to 4.2 percent of Cu, 0.7 to 1.8 percent of Li, 0.20 to 0.60 percent of Mn, 0.20 to 0.60 percent of Zn, 0.06 to 0.20 percent of Zr, 0.20 to 0.80 percent of Mg, 0.2 to 0.7 percent of Ag, less than or equal to 0.10 percent of Si, less than or equal to 0.10 percent of Fe, less than or equal to 0.12 percent of Ti, less than or equal to 0.15 percent of other impurities (single impurity is less than or equal to 0.05 percent) and the balance of Al. One or five of alloy elements Mn, Zn, Mg, Ag and Zr can be selectively added. Proportioning is performed according to the alloy components, the raw materials are melted, then furnace refining and standing are performed, and alloy ingots with required specifications are cast. The alloy ingots are preferably homogenized and then molded by any process of hot extruding, hot rolling and the like, and the alloy ingots thermally treated by the preferable process can be used for processing parts. The high-toughness aluminum lithium alloy material has uniform microscopic structure and stable performance, and is suitable for manufacturing thick plates and extruded materials. The ultimate tensile strength can reach over 510MPa, and meanwhile, the elongation rate is more than 8 percent and the KIc can reach over 30MPam1 / 2. The material product can be used for structural elements of the fields of aerospace, nuclear industry, traffic and transportation, sports goods, weapons and the like.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

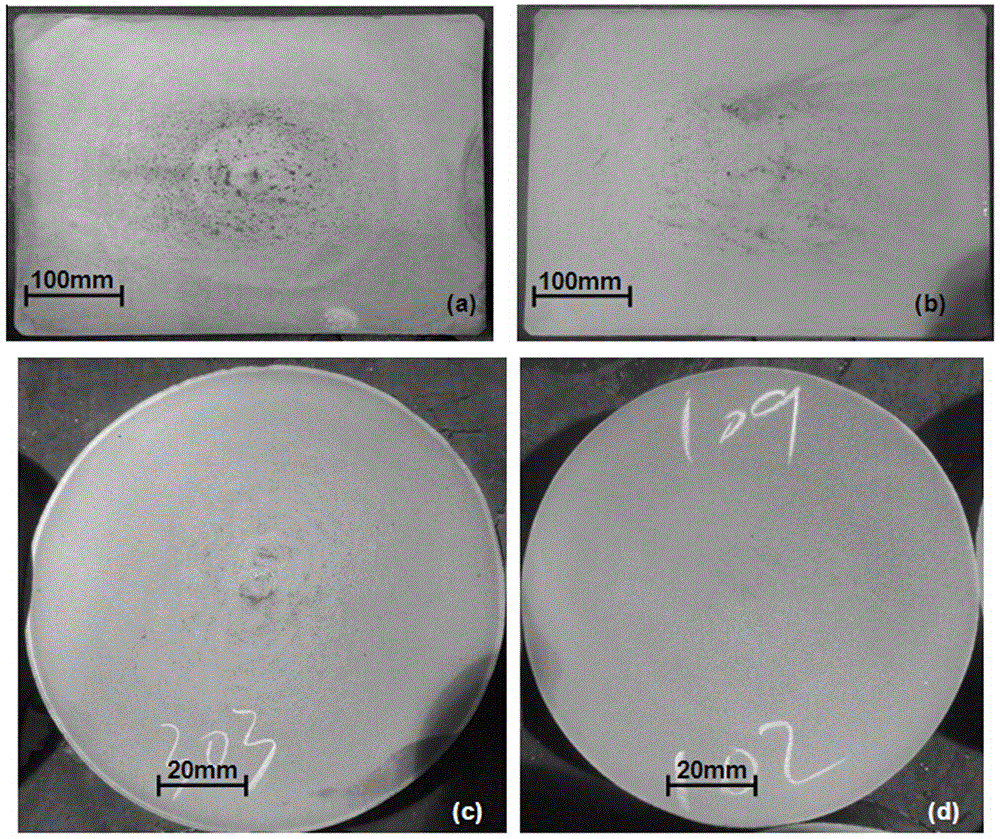

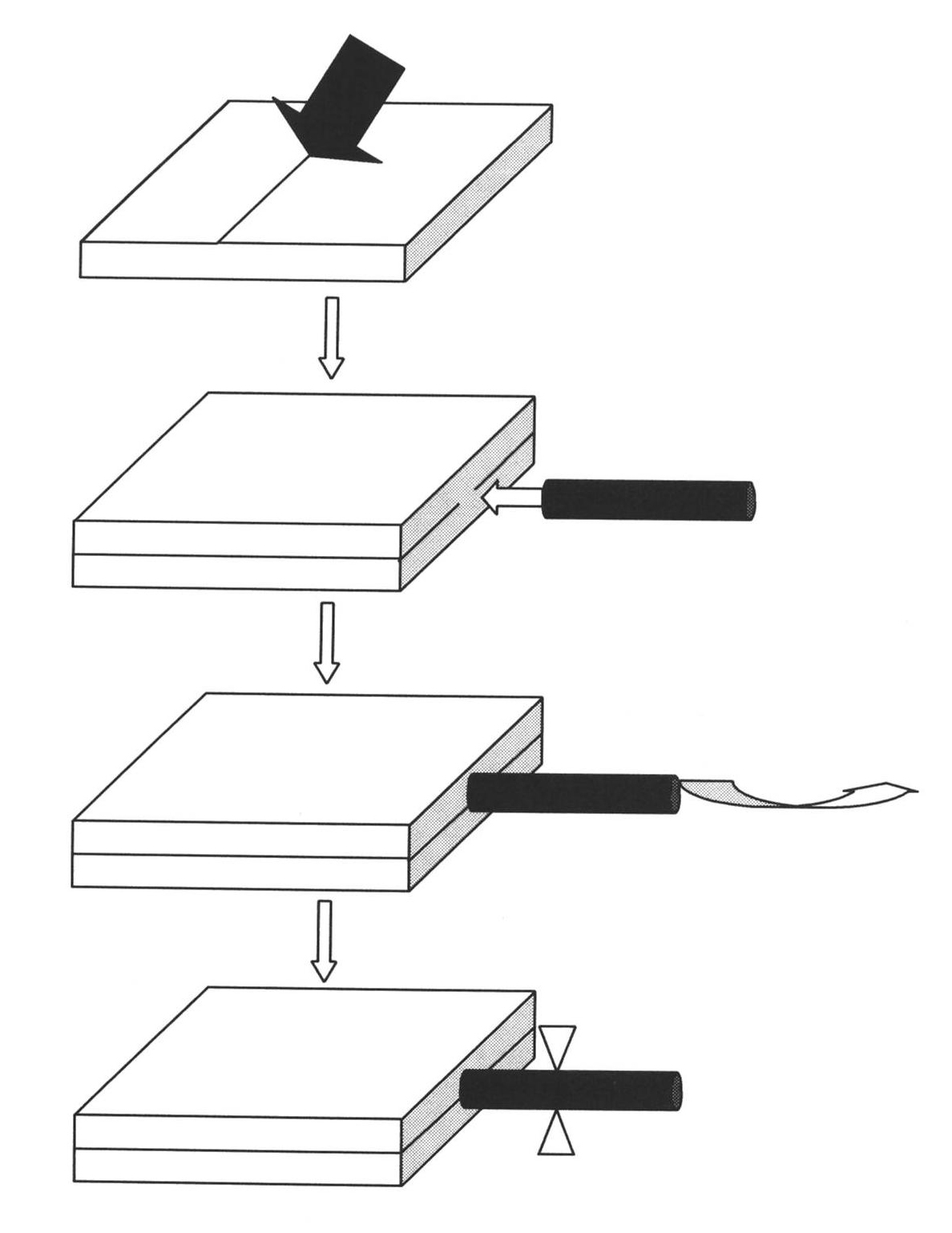

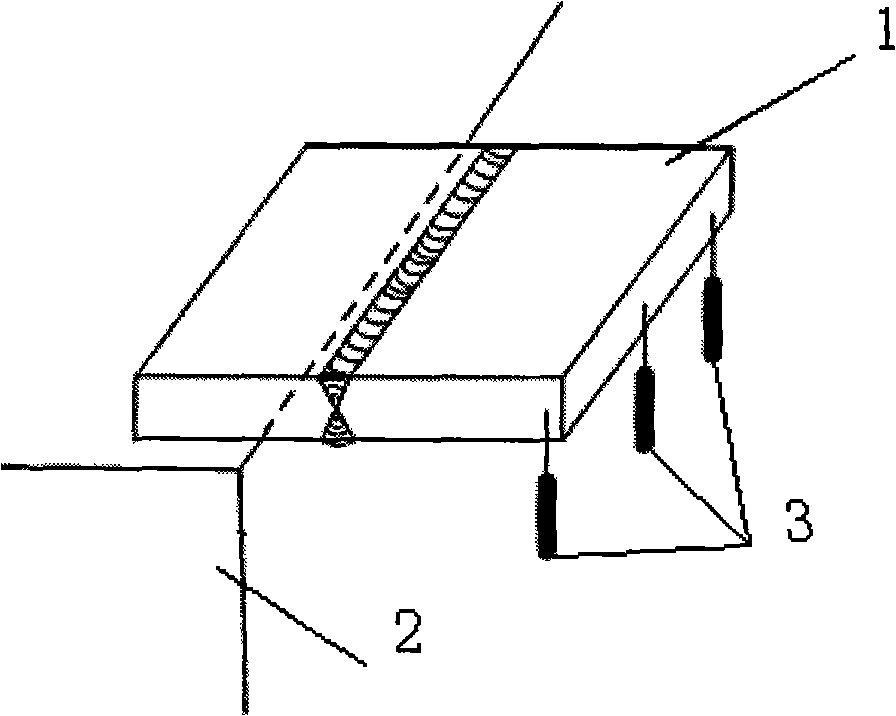

Method for producing super-thick plate by packrolling welding process

InactiveCN102009332AAvoid difficultiesImprove internal qualityNon-electric welding apparatusThick plateEngineering

The invention discloses a method for producing a super-thick plate by a packrolling welding process, which mainly comprises the steps of: cutting the continuously cast blank, cleaning surface of the blank blocks, aligning and overlaying the blank blocks in same size, welding the surrounding of the combined surface after the blank blocks are fastened, vacuumizing the combined gaps, sealing and finally hot rolling. The hot rolling accumulation rolling reduction is controlled within 40% to 70%. Compared with the traditional super-thick plate production method, the invention has the advantages that the blank blocks are from the continuously cast blank so that the quality of the blank is better than a mould ingot and the production efficiency is better than that of the blank produced by electroslag remelting, the processing cost is low, and the production efficiency is high; and the invention has low requirements on the equipment and is suitable for industrial production.

Owner:UNIV OF SCI & TECH BEIJING

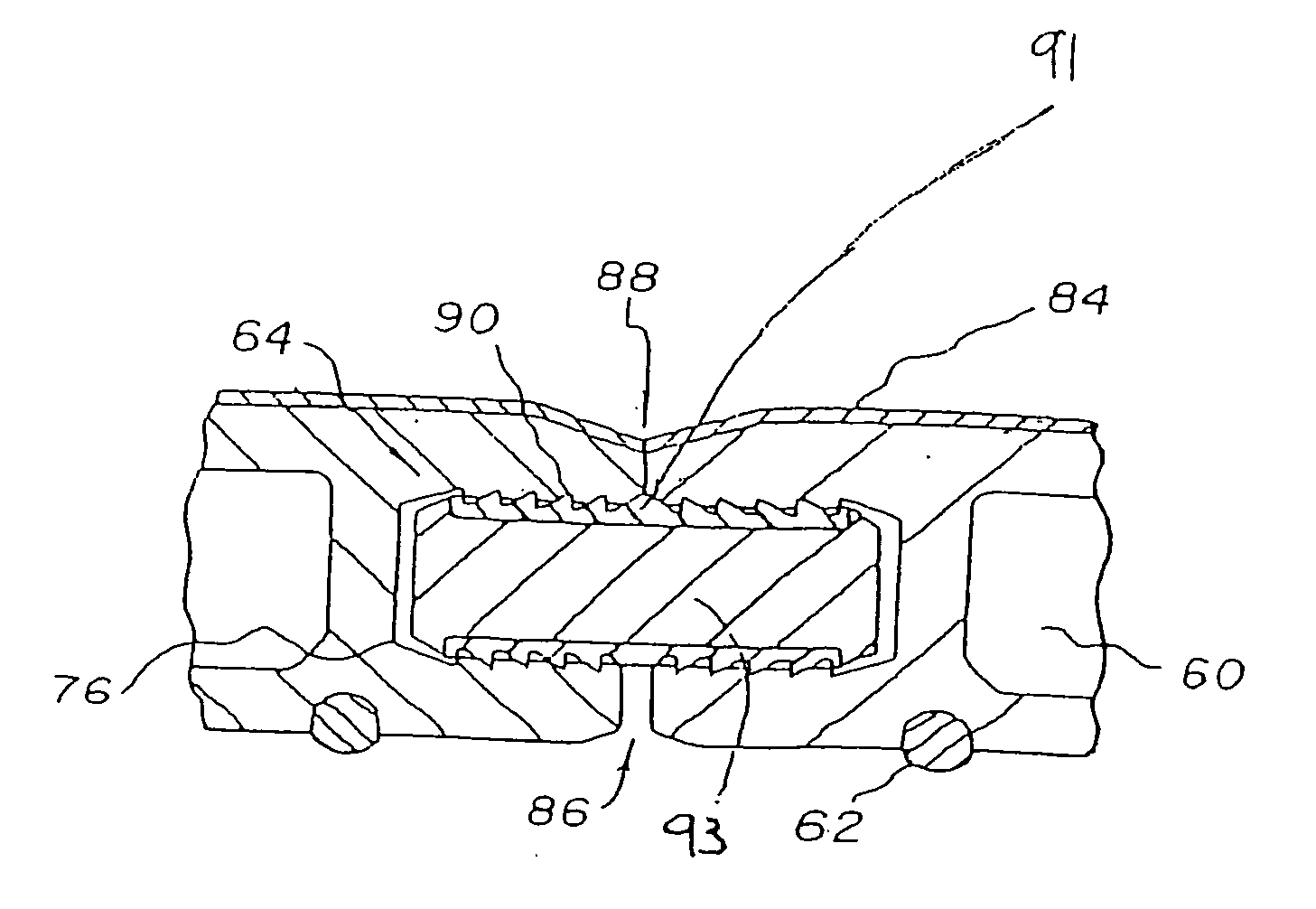

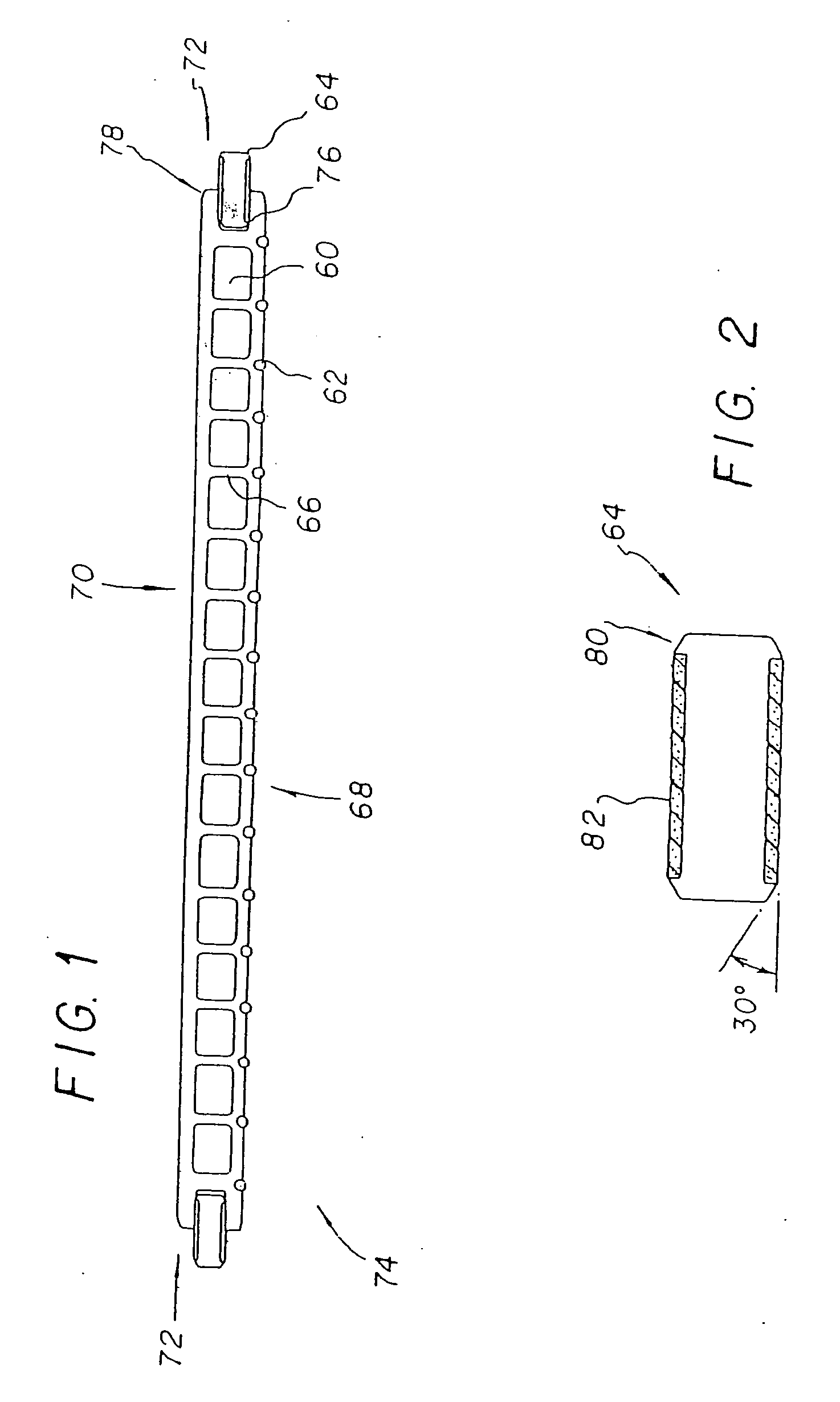

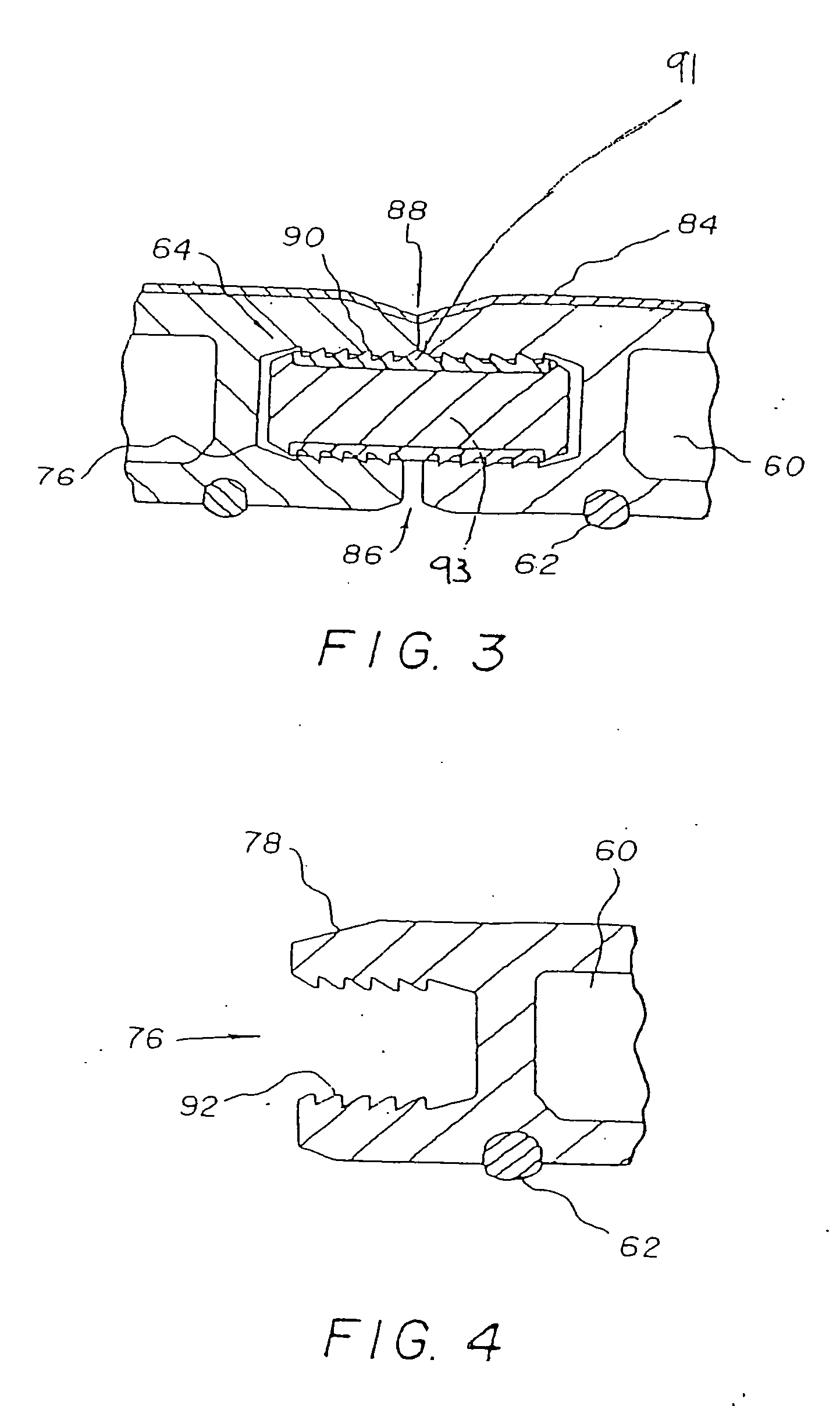

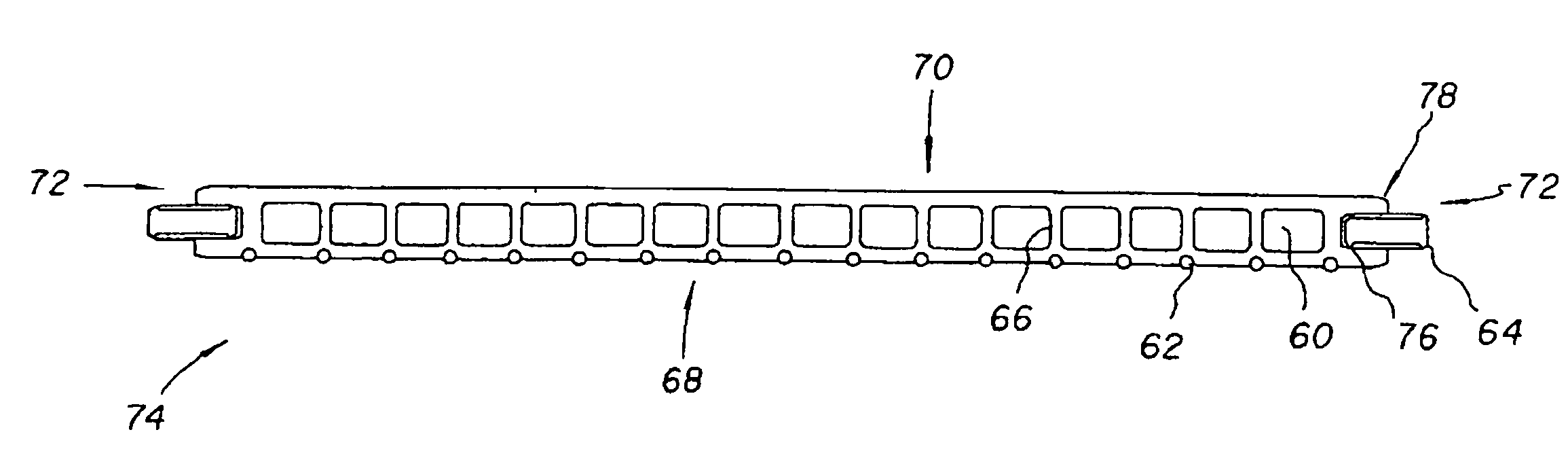

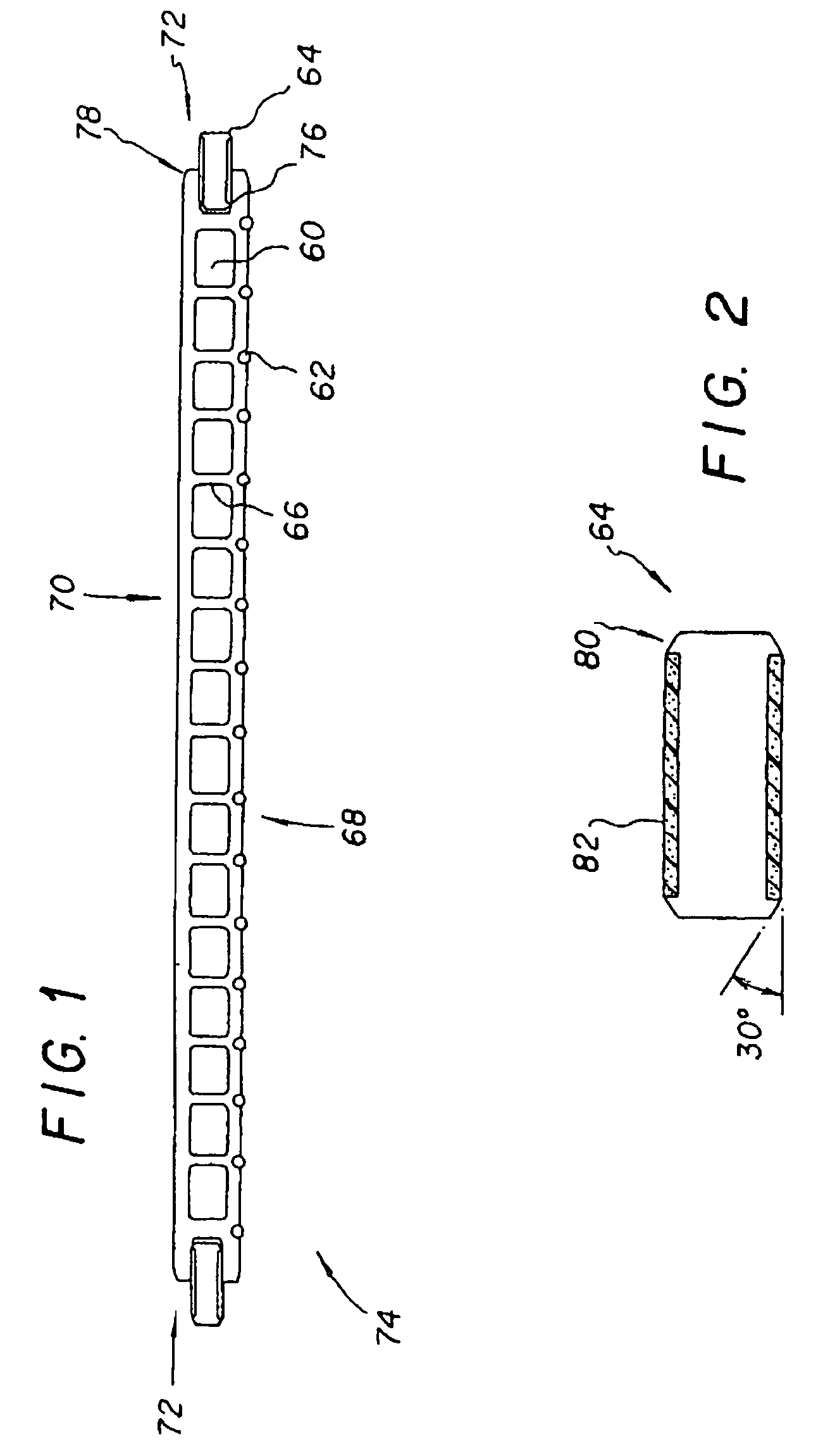

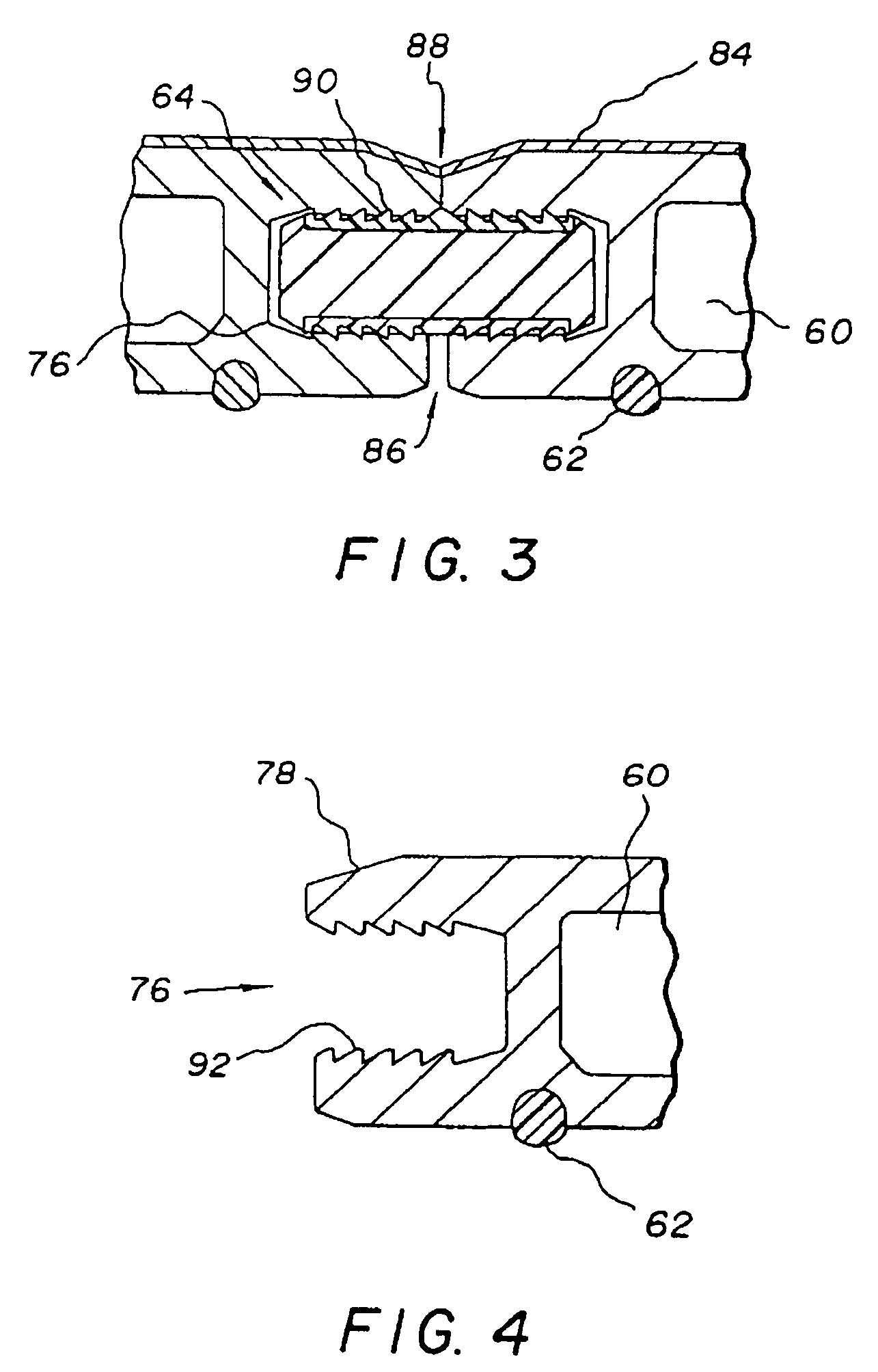

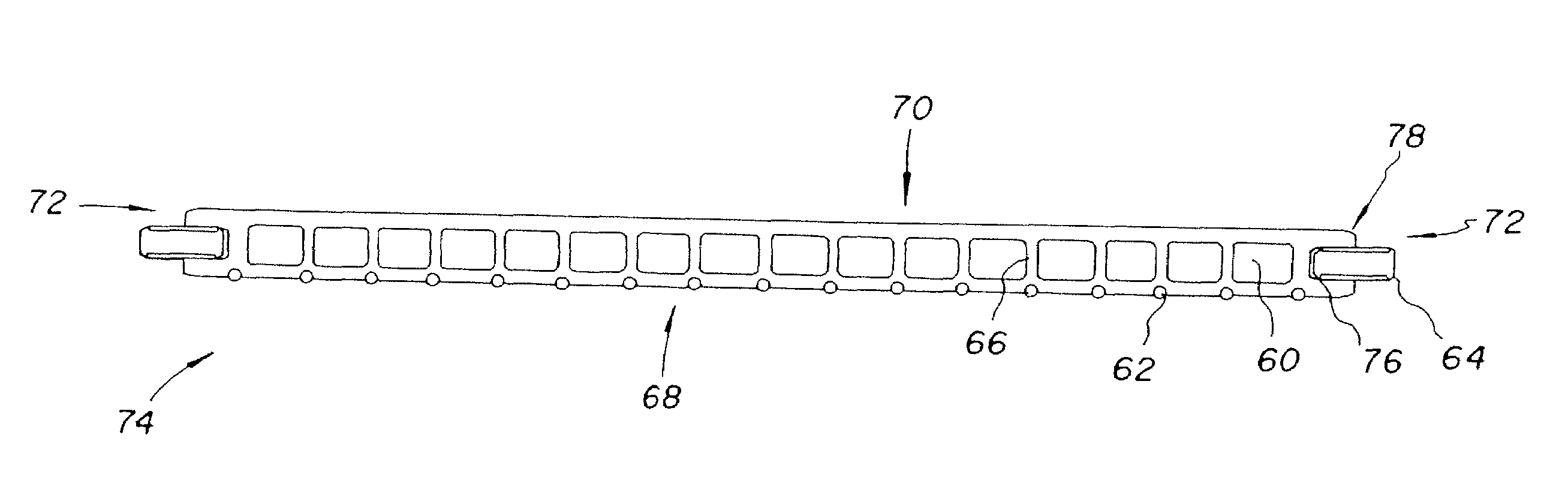

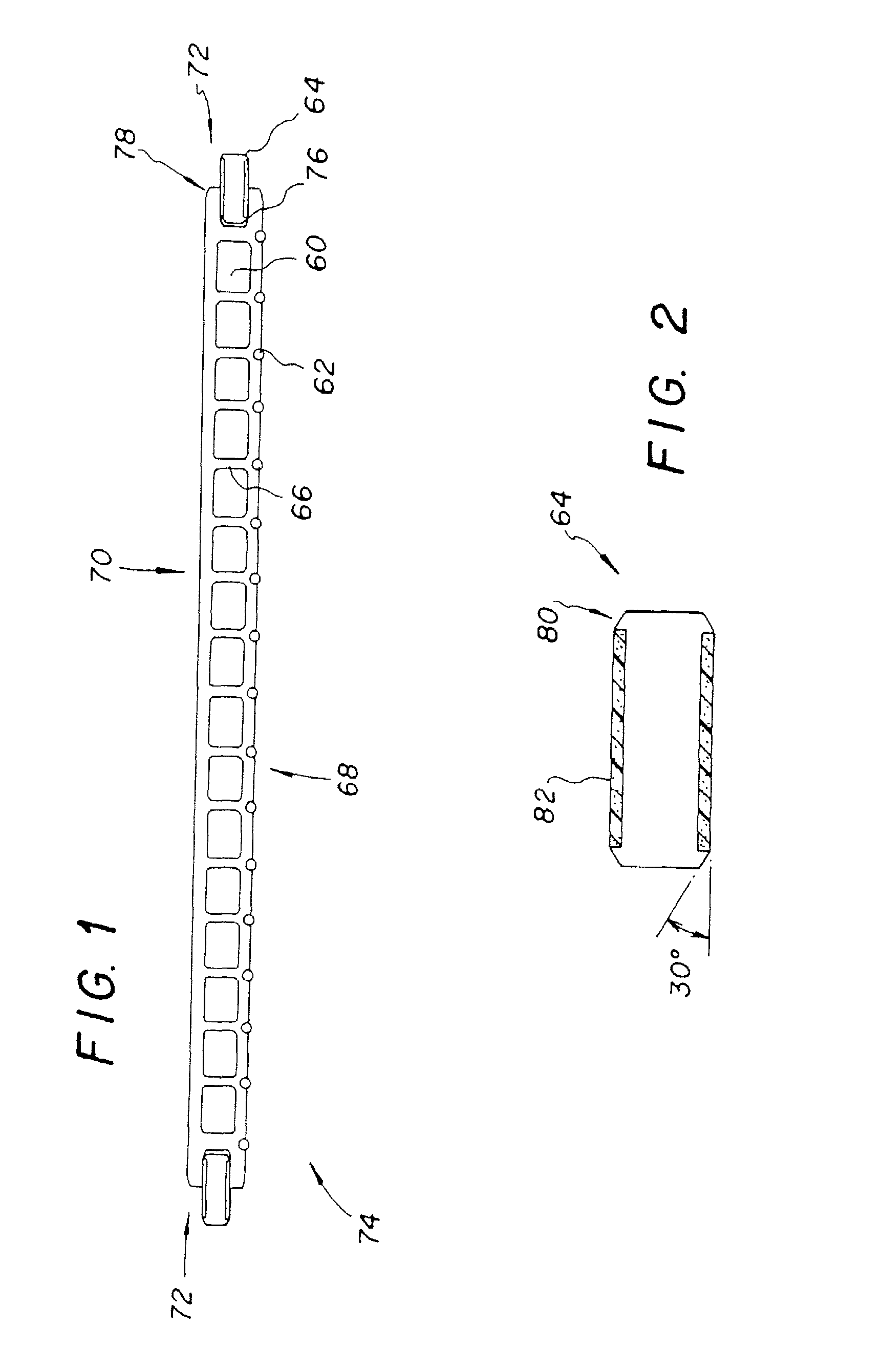

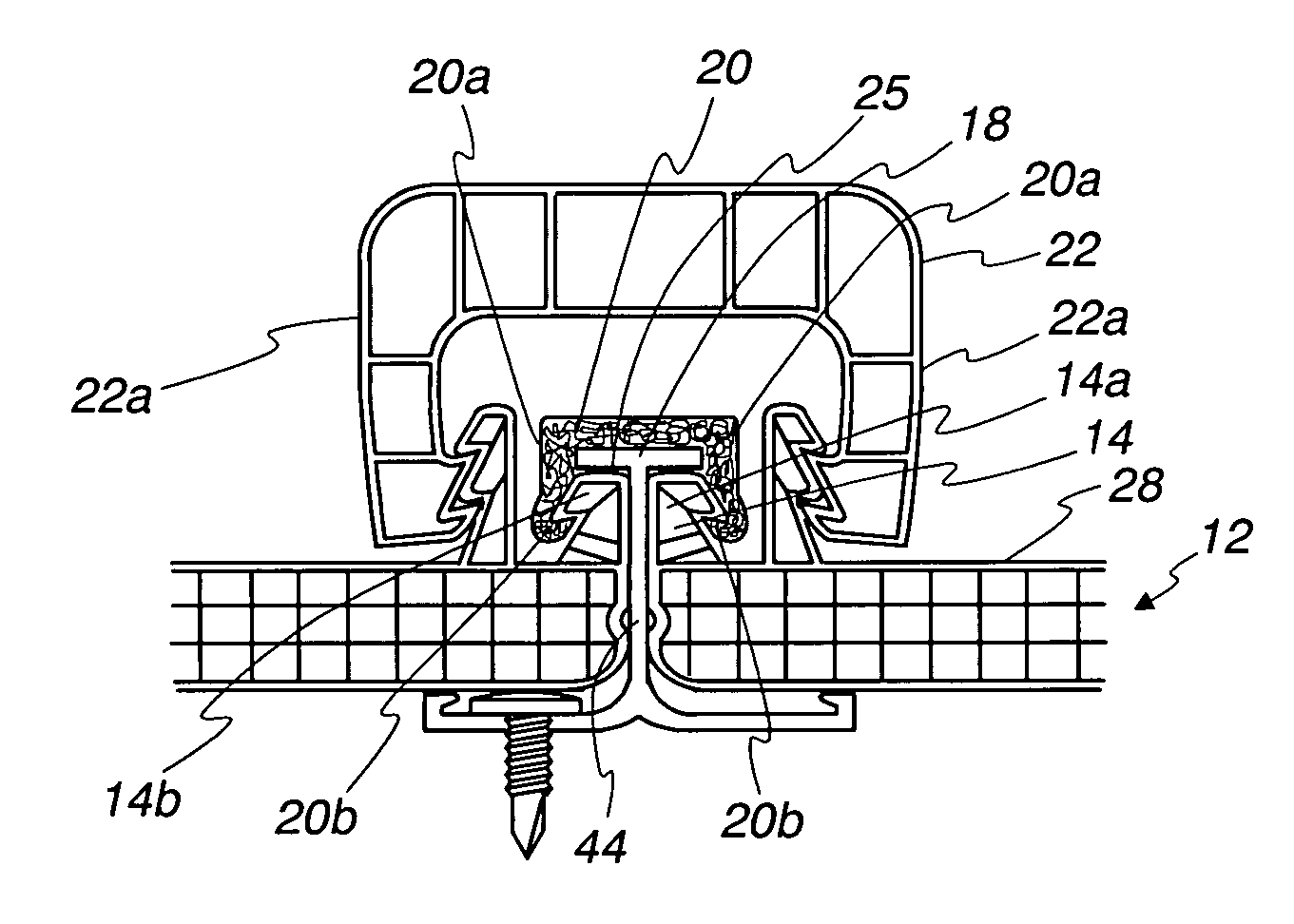

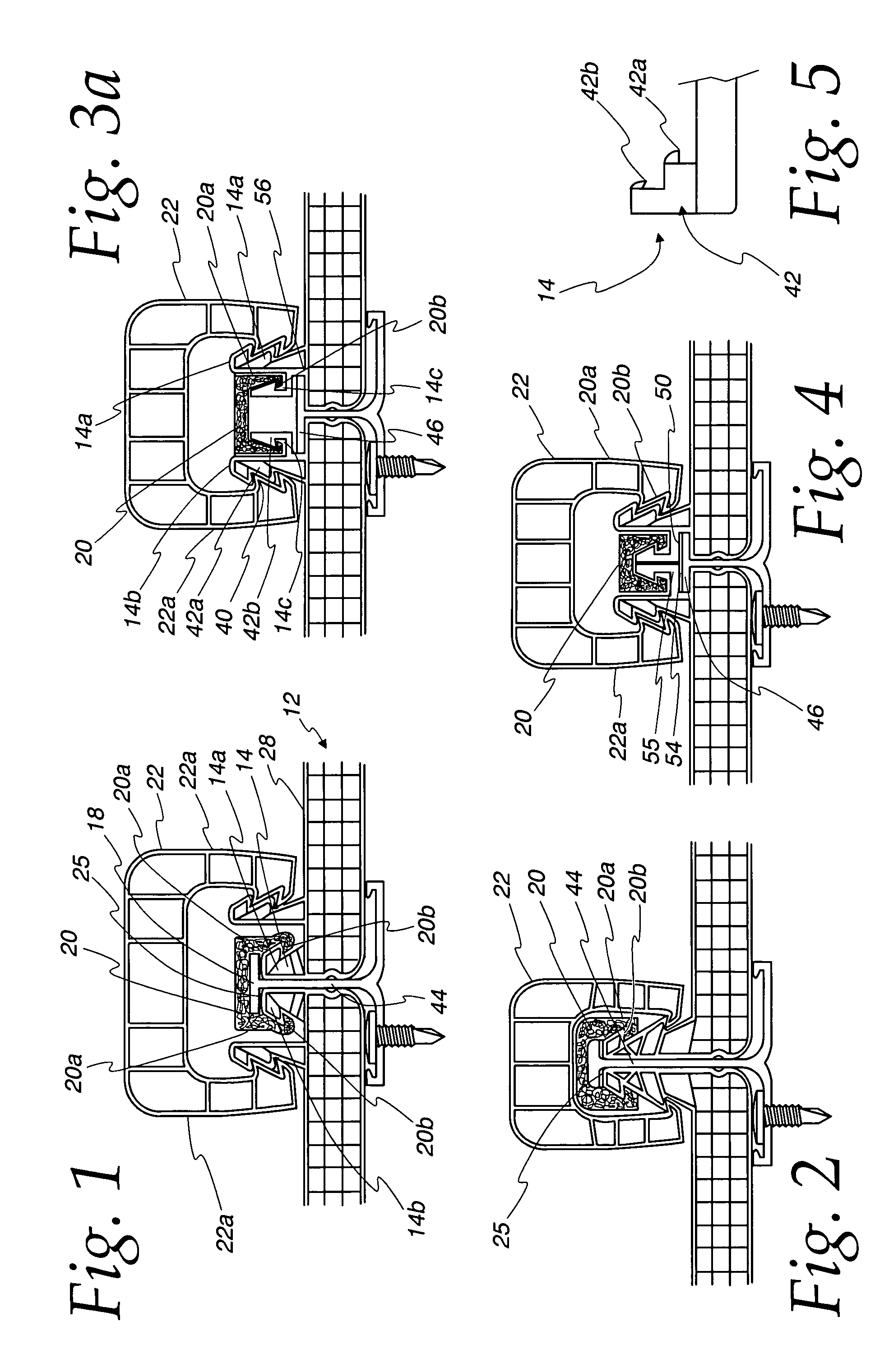

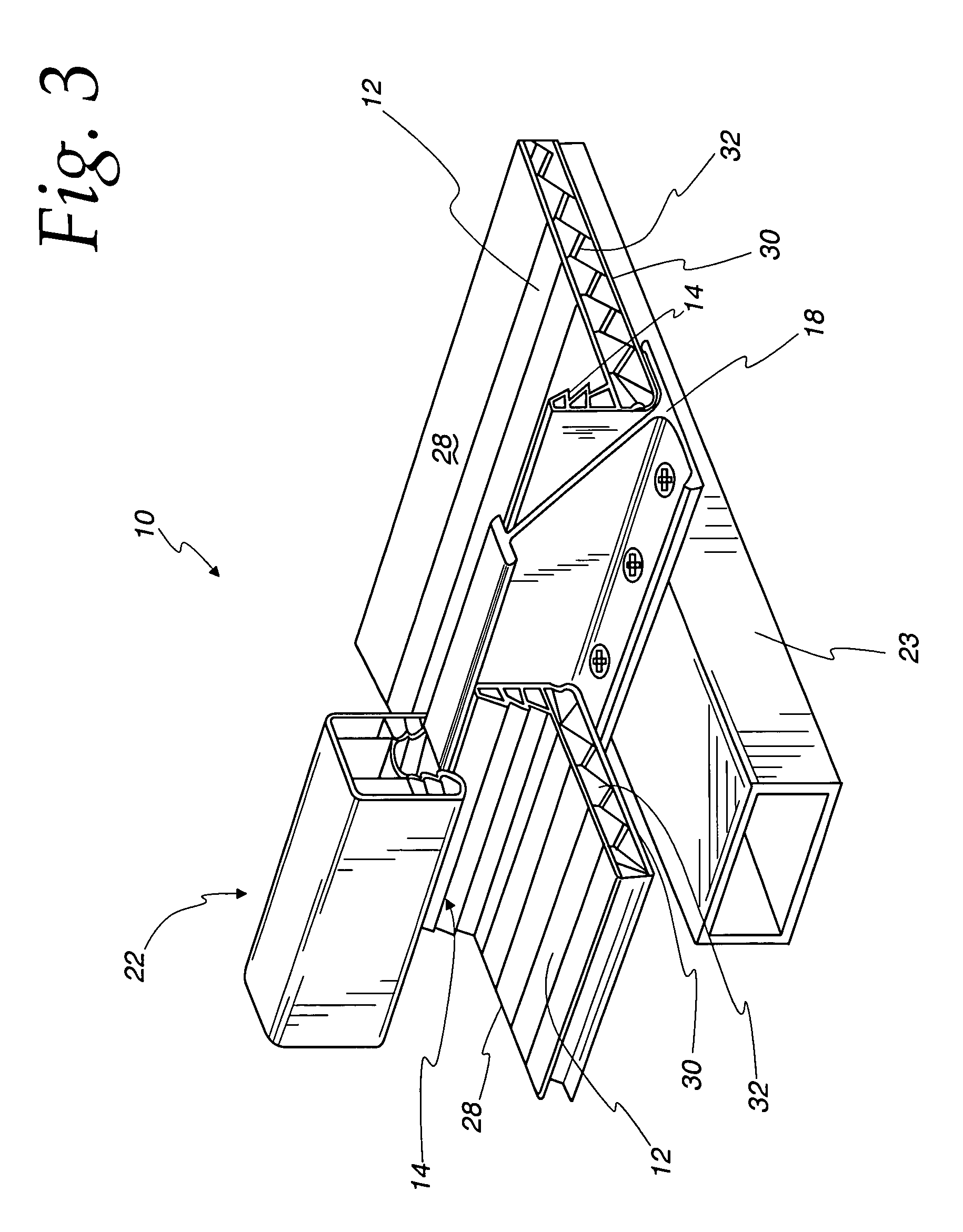

Light transmission panels, retaining clip and a combination thereof

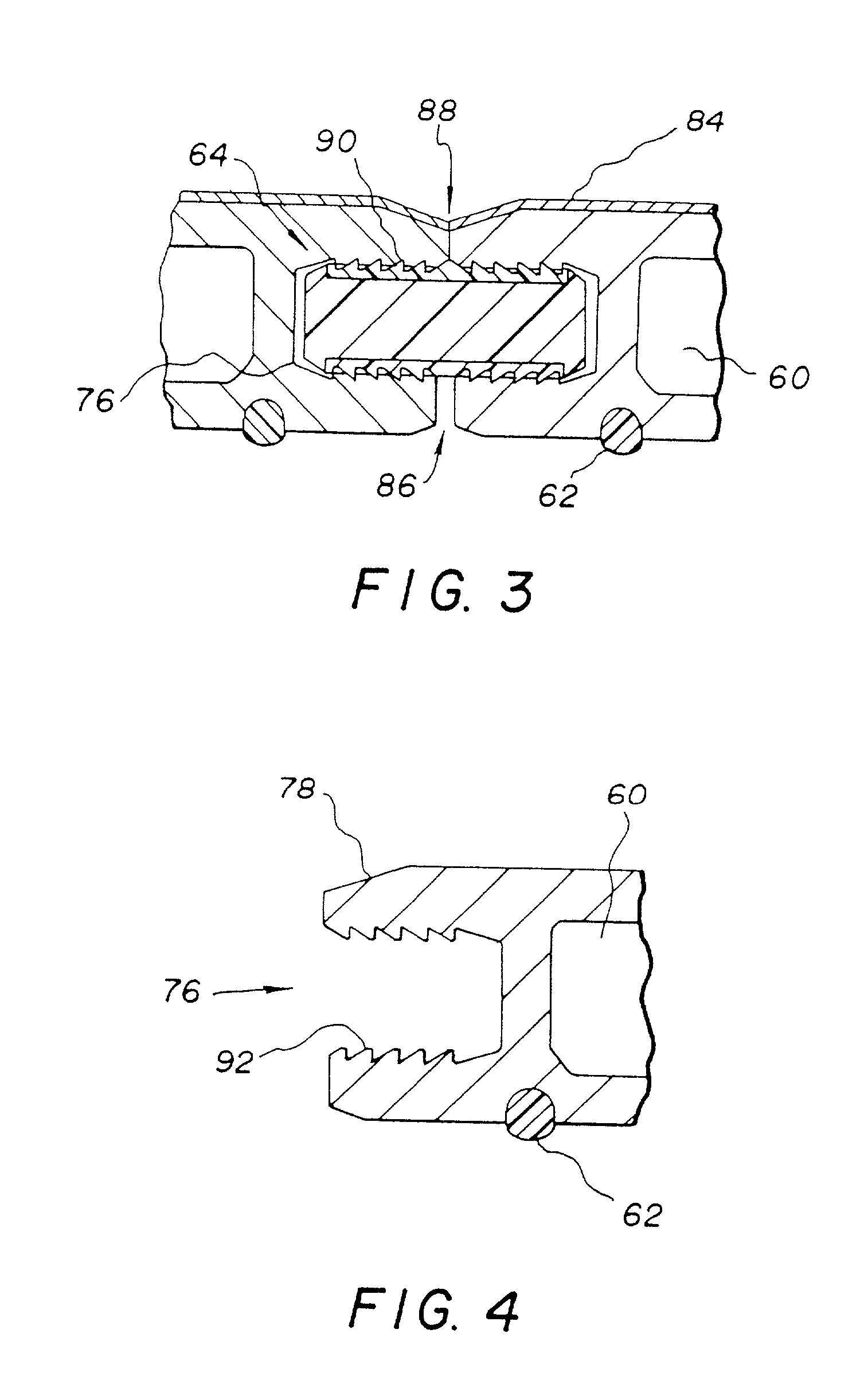

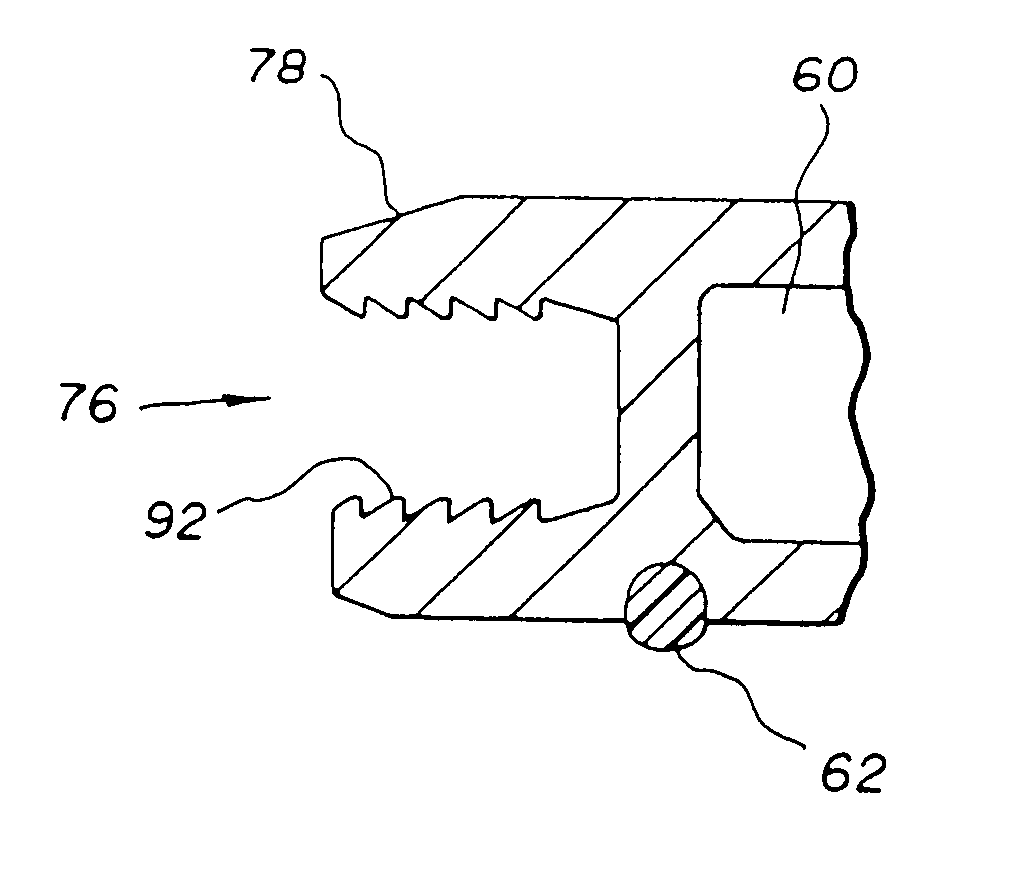

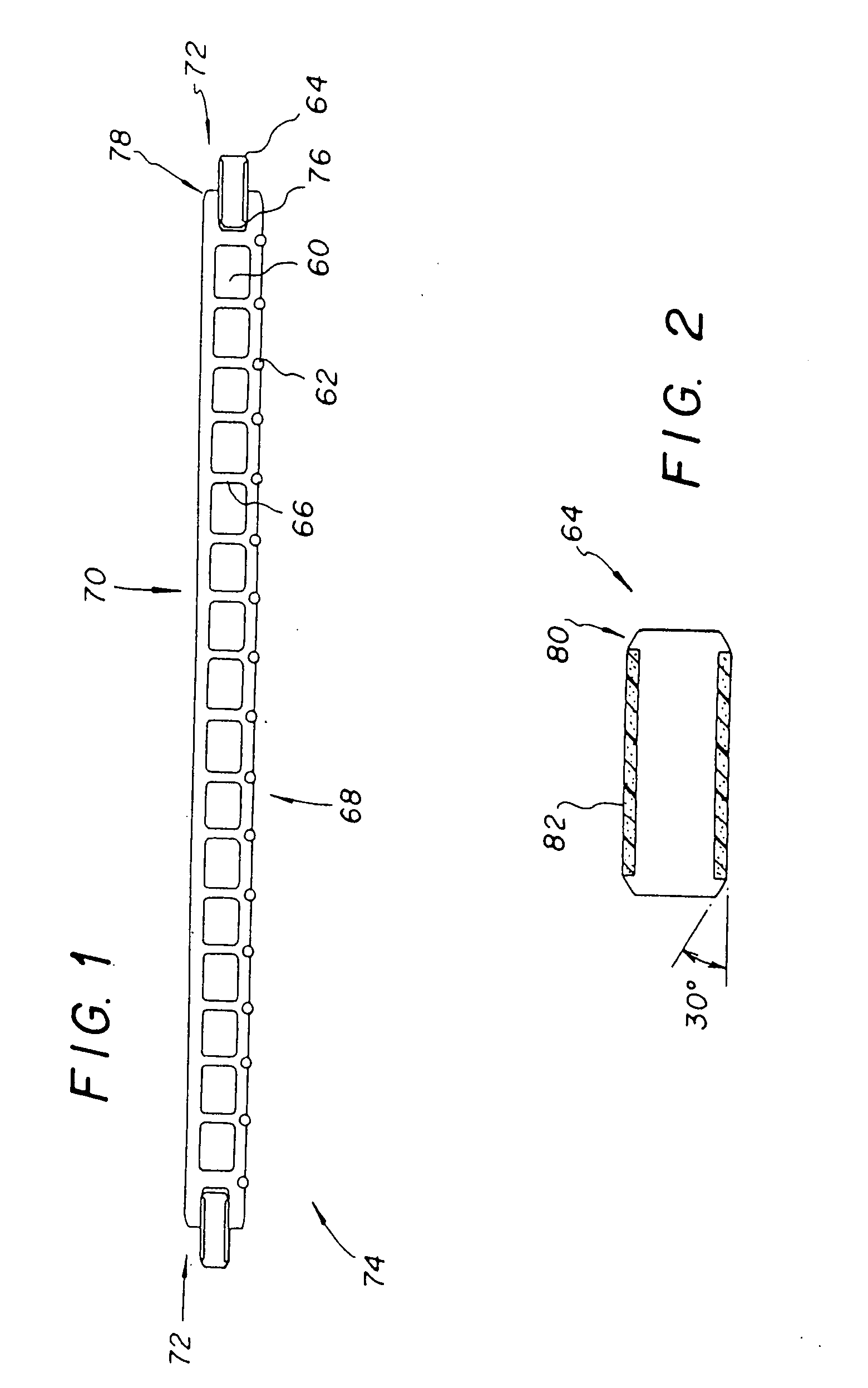

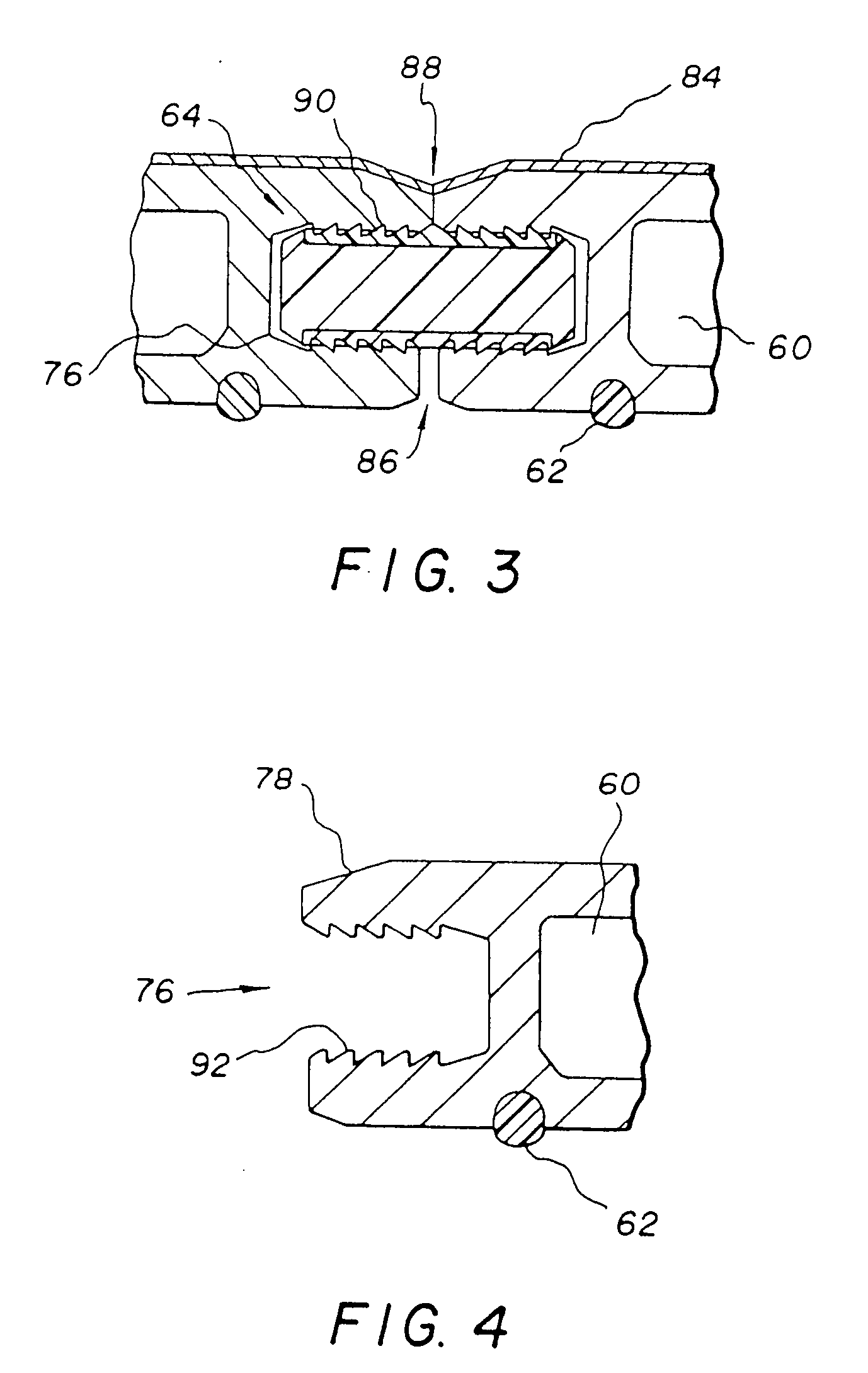

ActiveUS7441379B2High retention rateEasy loadingRoof covering using slabs/sheetsBuilding roofsThick plateAdded resistance

A glazing panel system is provided with improved glazing panels, retention clips and / or U-shaped connectors. The retention clip may engage the glazing panels at locations lower than top ends of the upstanding seam flanges. In one embodiment, an internal U-shaped connector is positioned to engage the seam flanges while an external U-shaped connector covers the internal connector and the seam between adjacent glazing panels. The retention clips may be formed with an upper transverse portion that is movable relative to the base portion of the clip to accommodate panel expansion and contraction. Also, a thicker plate or portion may be provided at a top flange for the retention clip to provide increased resistance to uplift loads trying to bend the flange.

Owner:VIKON LLC

X80 level large-deformation resistance pipe line steel medium and heavy plate production method

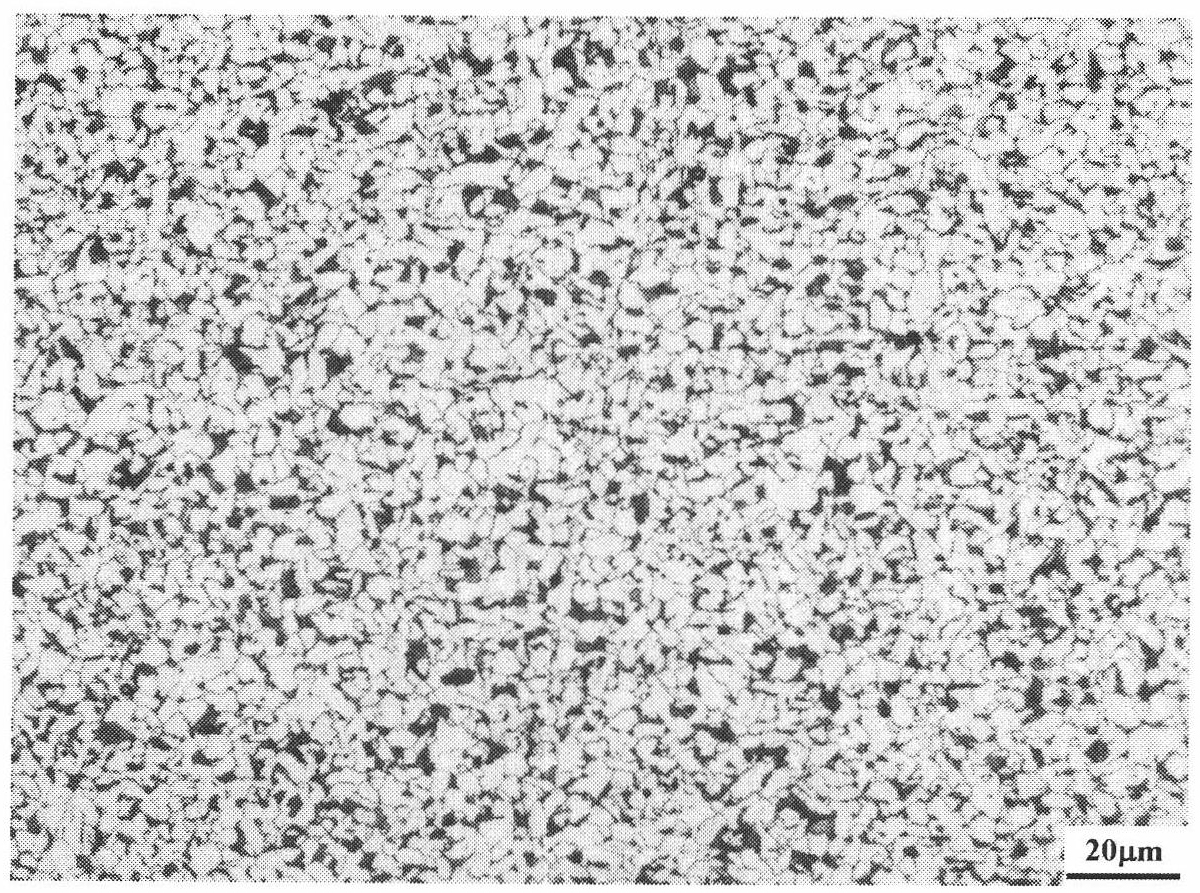

InactiveCN101456034AReduce manufacturing costGrain refinementTemperature control deviceWork treatment devicesDouble phaseYield ratio

The invention relates to a method for producing an X80 grade large deformation resistant pipeline steel medium plate. The economic component design with low carbon is adopted to perform controlling and rolling stages on ingot, namely rolling the grain refined zone and the non grain refined zone. The method comprises: firstly, air cooling and relaxing after finished rolling is performed so that the temperature of a steel plate before entering water and cooled is reduced below the phase change point Ar3 between 30 and 50 DEG C, and 50 to 70 percent of austenite in the relaxing process is converted into proeutectoid ferrite; and secondly, laminar flow cooling is performed on the steel plate within the range of the cooling speed between 20 and 35 DEG C per second, the finished cooling temperature is controlled within the range of between 250 and 400 DEG C; and in the water cooling process, the remaining austenite is converted into bainite structure, and proeutectoid ferrite + bainite double-phase structure is obtained. The intensity and the plasticity index of the finished product satisfy the following requirements: the yield strength Rt0.5 is 530 to 630MPa, the intensity of tension Rm is 625 to 825 MPa, the yield ratio Rt0.5 / Rm is less than or equal to 0.80, and the homogeneous deformation tensile stretch UEL is more than or equal to 10 percent.

Owner:UNIV OF SCI & TECH BEIJING

Bridge structural steel and production method thereof

ActiveCN102199725ATemperature control deviceProcess efficiency improvementThick plateChemical composition

The invention discloses bridge structure steel and a production method thereof. The production method comprises: pretreating molten iron; smelting in a top and bottom combined blown converter; refining in a ladle furnace (LF); performing Ruhrstahl Heraeus (RH) refining; continuously casting plate blanks; rolling wide and thick plates; and performing normalizing heat treatment. The produced bridge structural steel comprises the following chemical components in percentage by weight: 0.11 to 0.16 percent of C, 0.10 to 0.45 percent of Si, 1.35 to 1.70 percent of Mn, less than or equal to 0.010 percent of S, less than or equal to 0.020 percent of P, 0.025 to 0.060 percent of Nb, 0.008 to 0.030 percent of Ti, 0.025 to 0.080 percent of V, 0.10 to 0.50 percent of Ni, 0.015 to 0.060 percent of Als, less than or equal to 40*10<-6> of N, less than or equal to 40*10<-6> of O, less than or equal to 2*10<-6> of H and the balance of iron and inevitable impurities, wherein Als represents Alsol. The lower yield strength of the steel plates produced by the method is not less than 370MPa, the tensile strength of the steel plates is not less than 510MPa, the yield to strength ratio of the steel plates is not more than 0.75, the percentage elongation after fracture of the steel plates is not less than 30 percent, the longitudinal AKv of the steel plates at -40 DEG C is not less than 240J, and the steel plates meet the requirements for manufacturing high-speed multi-track railway bridges and can be promoted to be used in engineering structures such as building, transport and ocean platforms.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

TIG automatic welding technique for titanium alloy thick plate narrow interstice

InactiveCN101293303AEnables narrow gap weldingWeld firmlyElectrode supporting devicesWorkpiece edge portionsEngineeringTitanium alloy

The invention discloses a narrow clearance TIC automatic welding technique for a thick plate of titanium alloy. The welding technique comprises six items of a welding torch form, a welding line spreading form, a bevel for welding form, selecting the parameters of the welding process, selecting the protection atmosphere of the welding process and eliminating a welding stress adopted by welding process. The welding technique of the invention realizes the narrow clearance welding for the large thick plate of the titanium alloy, has stable welding process, can obtain the welding lines which have no defects, qualified properties and 10mm to 16mm of widths of the welding lines on a cover surface layer, thus solving the key technical problems of the narrow clearance TIC automatic welding for the large thick plate of the titanium alloy, realizing the narrow clearance TIC automatic welding for the thick plate of the titanium alloy and having the advantages of high manufacture efficiency, low manufacture cost, small residual stress and residual deformation of joints, relatively thin and small welding line tissues and good mechanical property of the joints.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

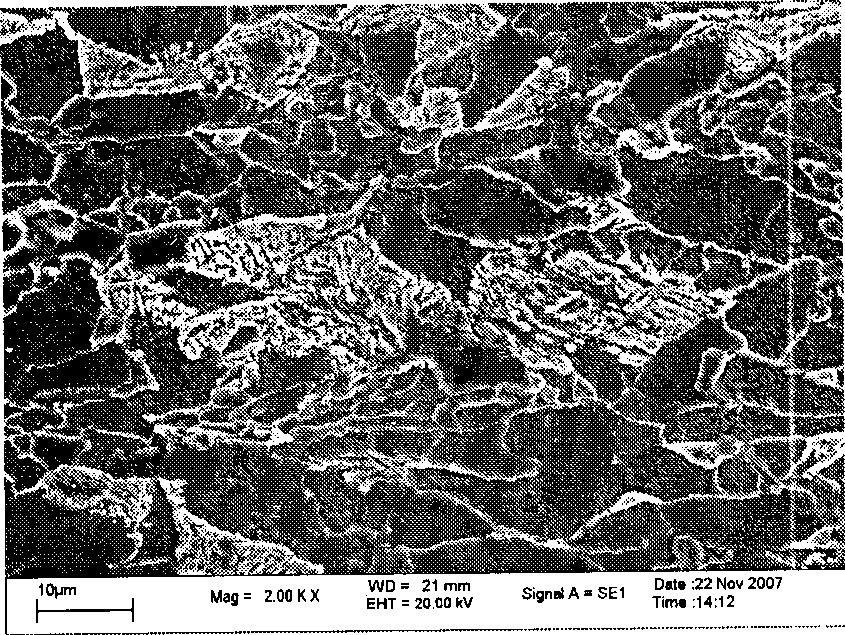

High-strength high-toughness aluminum alloy pre-tensioned thick plate and preparation method thereof

A high-strength high-toughness aluminum alloy pre-tensioned thick plate and a preparation method thereof relate to an aluminum alloy pre-tensioned thick plate and a preparation method thereof and aim at solving problems that due to a poorly soluble compound which is formed by Fe, Si and other elements in 7A04 aluminum alloy or due to a eutectic compound generated during casting, aluminum alloy structural materials have bad toughness and low strength so that long-time safe and reliable work in bad working environment cannot be realized. The thick plate consists of the following components according to percentage by weight: 1.40-2.00% of Cu, 1.80-2.80% of Mg, 0.20-0.60% of Mn, 0.10-0.25% of Cr, 5.00-6.50% of Zn, 0-0.10% of Si, 0.05-0.25% of Fe, 0-0.05% of Ti, 0-0.10% of Ni, 0.01-0.05% of single impurity, 0.01-0.10% of aggregate impurity and the balance of Al. The preparation method is as follows: fusing and casting a flat aluminum alloy cast ingot; and carrying out homogenizing annealing, hot rolling, quenching pre-tensioning and single and double aging treatment. The higher stress corrosion resistance capability, the anti-fatigue strength and the fracture toughness property of the aluminum alloy pre-tensioned thick plate prepared according to the method are obviously improved so as to satisfy the requirement of the long-time safe and reliable work in bad working environment.

Owner:NORTHEAST LIGHT ALLOY CO LTD

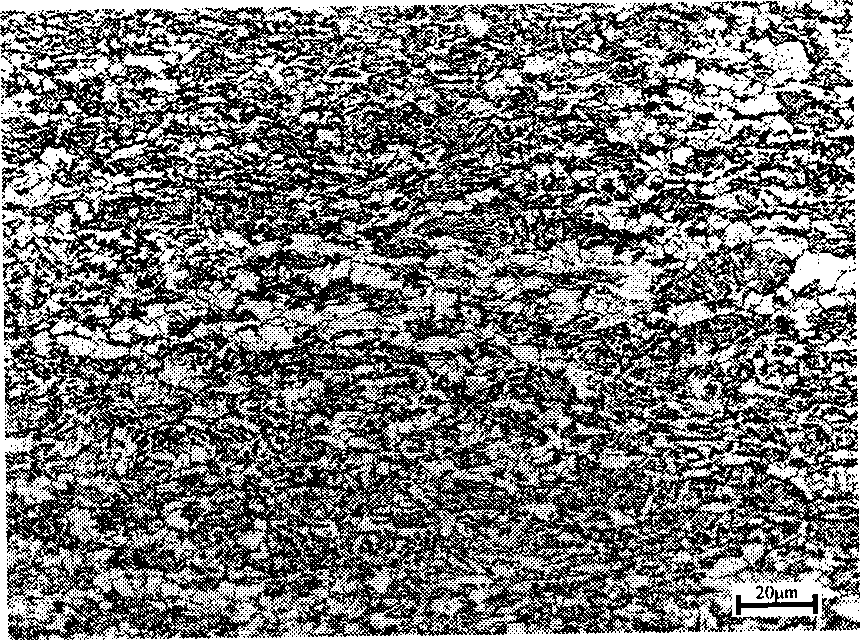

High-plasticity magnesium alloy and preparation method thereof

The invention relates to the field of metal materials, in particular to a high-plasticity magnesium alloy and a preparation method thereof. The alloy comprises the following chemical components in percentage by mass: 0.1 to 6.0 percent of aluminum, 0.1 to 3.0 percent of tin, 0.01 to 2.0 percent of manganese, 0.01 to 2.0 percent of strontium and the balance of magnesium and other inevitable impurities; simultaneously, the magnesium alloy can also contain one or more of additional elements such as zinc and stibium and rare earth elements. The preparation method comprises the following steps of: melting the magnesium and the aluminum, adding the tin, the additional elements, the rare earth elements and the strontium in turn, stirring and refining, and preparing a melt into a plate by a cast-rolling and rolling process; or directly pouring the melt into a cast ingot; or pouring the melt into the cast ingot, extruding the cast ingot into a section or a thick plate and rolling the thick plate into a thin plate. The preparation method enhances the intensity and toughness of the alloy and overcomes the defects that a cast magnesium alloy is difficult to adapt to a deformation condition and a deformed magnesium alloy is difficult to adapt to a casting condition.

Owner:JILIN UNIV

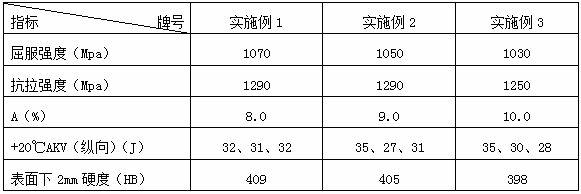

Hardening and tempering high-strength steel plate for wood based panel equipment and production method of tempering high-strength steel plate

The invention relates to a hardening and tempering high-strength steel plate for wood based panel equipment and a production method of the steel plate, and belongs to the field of manufacturing low-alloy high-strength structural steel. The steel plate consists of the following chemical components in percentage by weight: 0.18 to 0.24 percent of C, 0.20 to 0.50 percent of Si, 0.80 to 1.20 percent of Mn, more than or equal to 0.02 percent of P, more than or equal to 0.01 percent of S, 0.20 to 0.50 percent of Mo, 0.20 to 0.50 percent of Ni, 0.70 to 1.00 percent of Cr, more than or equal to 0.003percent of B, 0.017 to 0.030 percent of Nb, 0.040 to 0.050 percent of V, 0.017 to 0.026 percent of Ti, and the balance of Fe and inevitable impurities. The production method of the steel plate comprises the following steps of: electric furnace smelting, vacuum decarburization / vacuum arc decarburization (VD / VOD) furnace vacuum decarburization, ladle furnace (LF) furnace refining, continuous casting (die casting), billet steel (ingot) clearing, heating, plate rolling, hardening and tempering, steel plate checking and polishing, tempering, sampling inspection, and warehousing. The hardening andtempering high-strength steel plate for the wood based panel equipment adopts Cr-Ni-Mo-B system micro-alloy elements for composite strengthening, and acquires good obdurability matching through a reasonable heat treatment process, and simultaneously the welding performance of a thick plate is not reduced.

Owner:WUYANG IRON & STEEL +1

Method for measuring welding residual stress

InactiveCN101539506AReduce additional stressIntegrity guaranteedUsing mechanical meansMaterial analysisThick plateWelding residual stress

The invention relates to a method for measuring welding residual stress-a partial layer-by-layer blind hole removing method for measuring the residual stress on the basis of a blind hole method, which proposes to measure the residual stress in a component by using the partial layer-by-layer blind hole removing method. After materials of certain depth on both the front side and the opposite side of a component to be measured are partially removed, the blind hole method is used for measuring the residual stress. The method is a semi-destructive residual stress measuring method, can be used for carrying out multi-point measurement and measuring the residual stress in the component with severe stress change and has convenient operation and high measuring efficiency. Proved by a thick plate carbon steel welding residual stress measuring test, the method has more accurate measuring results.

Owner:XI AN JIAOTONG UNIV

Production process of continuous-casting tandem-rolling coiled sheet of medium thick plate

InactiveCN1840252ASave shipping timeImprove work rateMetal rolling stand detailsWork cooling devicesComputer control systemThree level

The invention discloses a cut deal blank joint continuous casting and rolling coil manufacturing technique, which is characterized by the following: the conticaster is fillet-bevel crystallizer; the conticaster adopts double-machine four-flow, four-flow in one technique, straight-rolling heat-feed heat-transfer technique and straight-rolling technique; the big mill adopts fore-and-aft edger roll device; the form is adhesion-upper drive-roller; the finishing mill group adopts work roller trending-running and bend bar device; the fine rolling uses raising speed rolling, which has maximum speed at 22.8m / s and roller way speed at 5.89m / s; the front of finishing mill group installs edge-part calorifier, multistage coarse, fine adjusting-valve group, which adopts cool three-stage laminar flow chilling control technique, adds heat cover on delivery roll table, reduces the temperature dropping of intermediate area blank and head-to-tail temperature difference; the automatic system is three-level computer-controlled system. The invention improves the device, manufacturing technique, which improves the product quality.

Owner:ANGANG STEEL CO LTD

Flooring system with slant pattern

Laminated flooring planks include decorative motifs, mechanically embossed-in-registration surface textures, recessed perimeters, and locking mechanisms. Adjacent planks substantially aligned allow embossed-in-registration patterns to be substantially continuous across adjacent flooring panels. The recessed perimeter prevents the edges of the flooring panel from prematurely wearing. Individual planks within the flooring system may comprise at least one partial sub-panel having a decorative motif and / or embossed surface texture (i.e., pattern) that is complementary with a pattern of a neighboring partial sub-panel or plank. Each plank may include edge patterns adjacent a portion of an edge of the plank and at least one bulk pattern adjacent the edge patterns. The decorative motif may include stripes or slanted strips of wood, the strips aligning across adjacent planks to from a continuous, uninterrupted strip pattern.

Owner:FAUS GRP INC

TMCP ocean structure thick plate and method for manufacturing same

InactiveCN101514424ASimple ingredientsReduce manufacturing costMetal rolling arrangementsHull structureChemical composition

Owner:BAOSHAN IRON & STEEL CO LTD

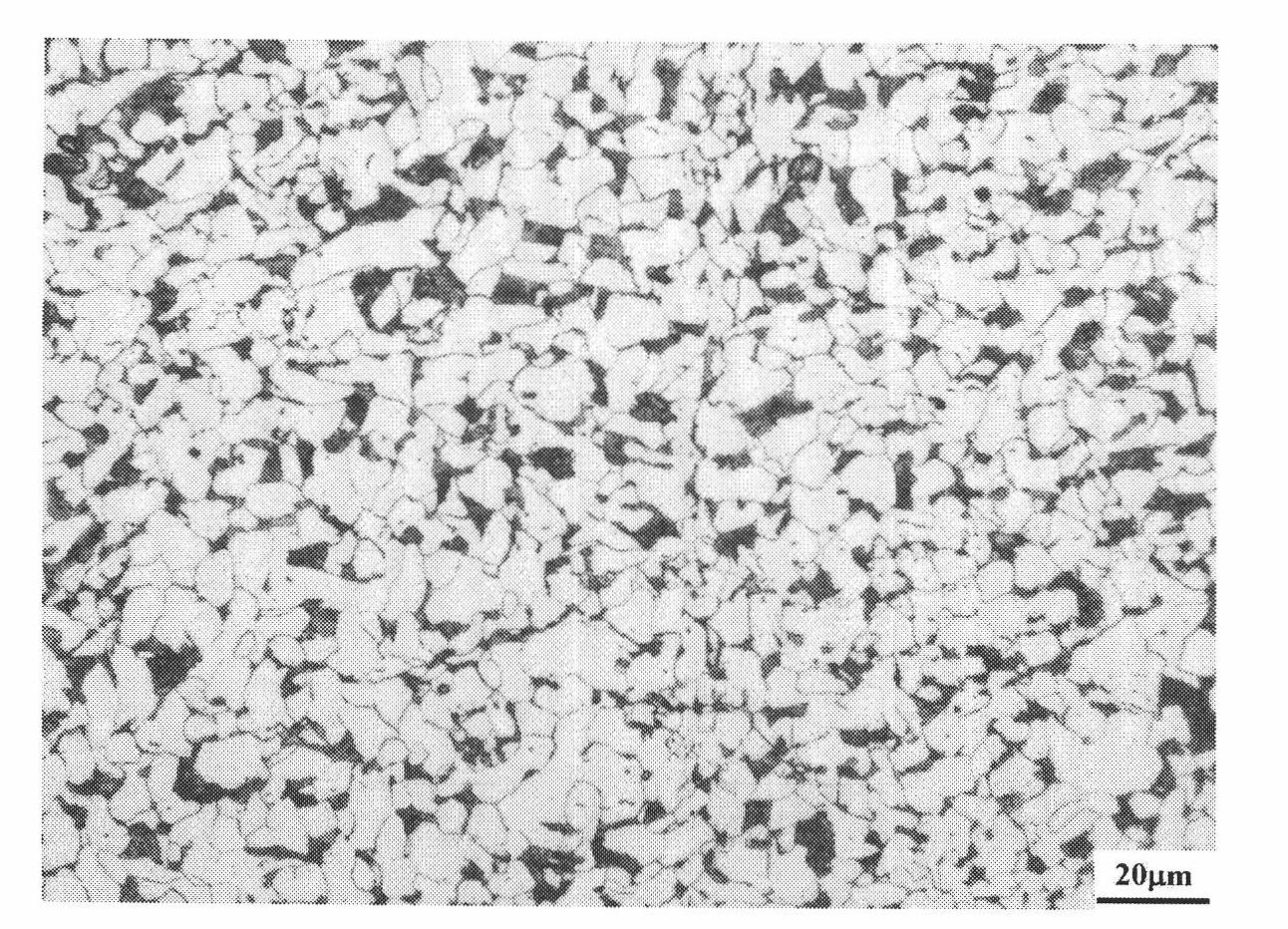

A non-modulated production process of plastic mold steel thick plate

The invention discloses a production technology of a non-modulated plastic die steel thick plate. The production technology comprises the following steps: converter smelting and ladle furnace (LF) and Ruhrstahl Heraeus (RH) refining are adopted to pour a continuous cast billet; the heating temperature is 1150-1200 DEG C, the precision rolling temperature is 900-950 DEG C, the finish rolling temperature is 860-900 DEG C; the cooling control of the steel plate is performed after the steel plate is rolled, the phase transformation strengthening and the precipitation strengthening of the microalloyed carbon nitride are utilized to ensure that when the section of the steel plate is not modulated, the structure and performance are uniform along the section, the plastic die steel of which section hardness is 300-340 is obtained; the rolled steel plate is tempered to eliminate the stress and avoid sawing crack, the hardness of the steel plate is uniform after tempering, and the section has granular bainite structure. In the production technology, the alloy component is controlled, Ni is not added, a small amount of Mo, B and V are added and the Cr content is increased properly, thus the steel plate has higher hardenability; and the cooling control of the rolled steel plate is performed to ensure that the large-section steel plate has bainite structure. The production technology is suitable for the production of the non-modulated plastic die steel thick plate, which is prepared from the 320mm continuous cast billet and of which thickness is less than 120mm.

Owner:NANJING IRON & STEEL CO LTD

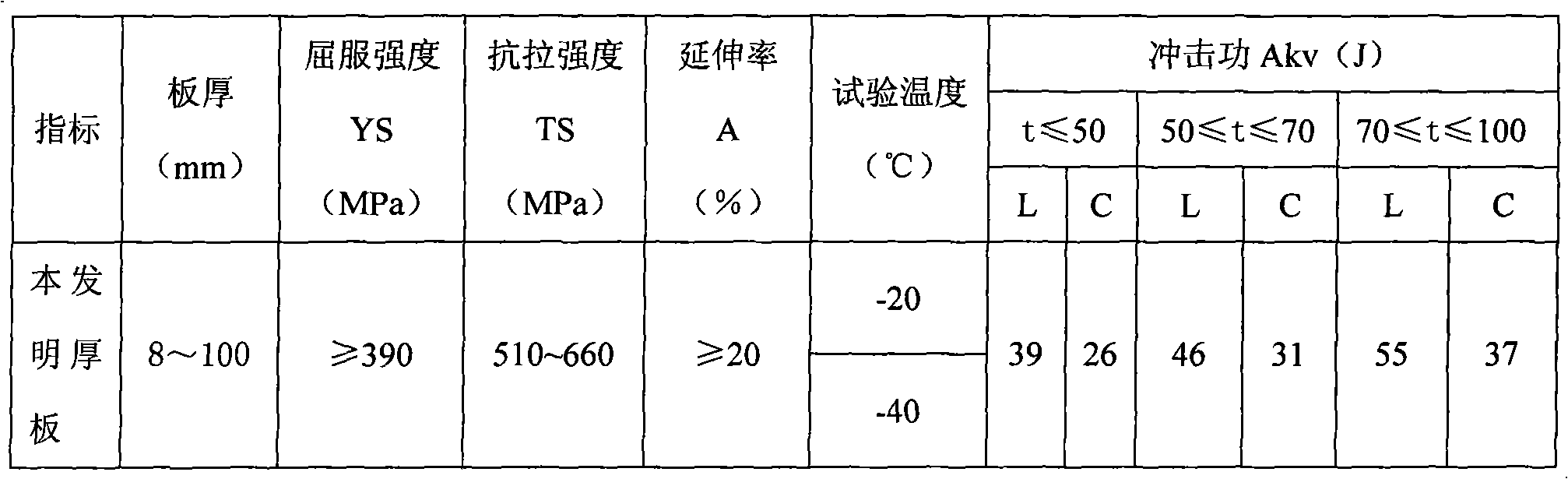

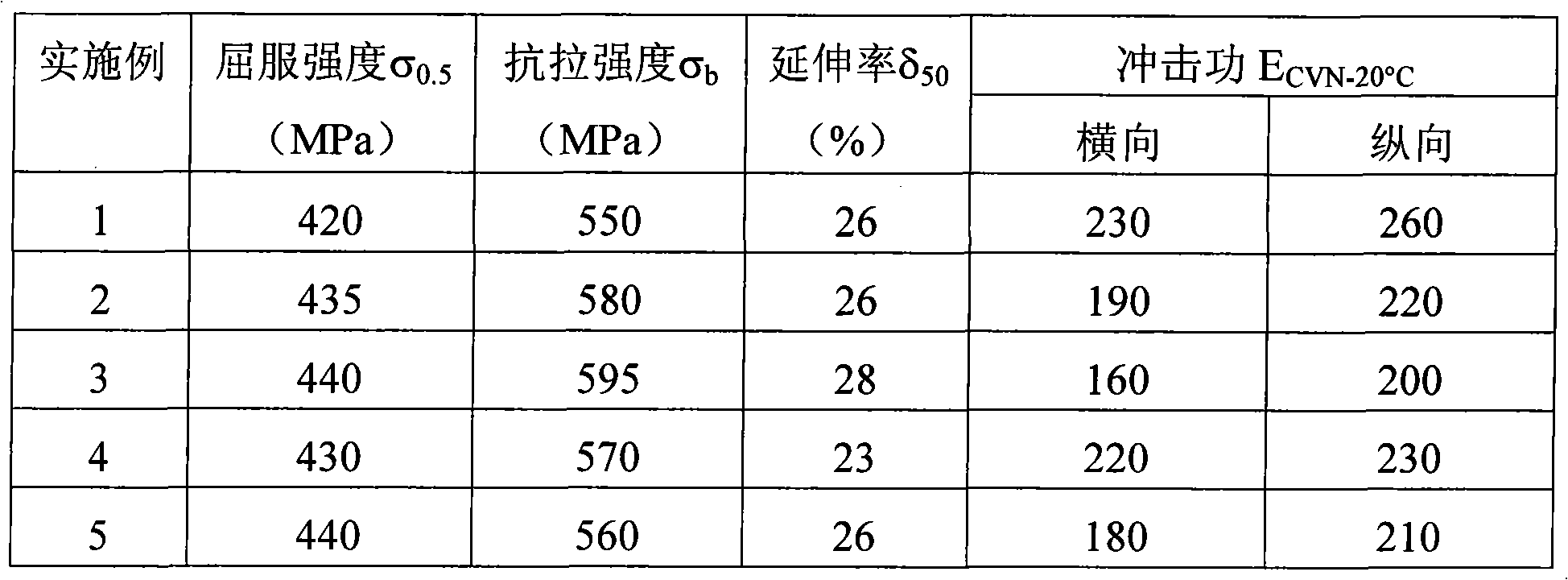

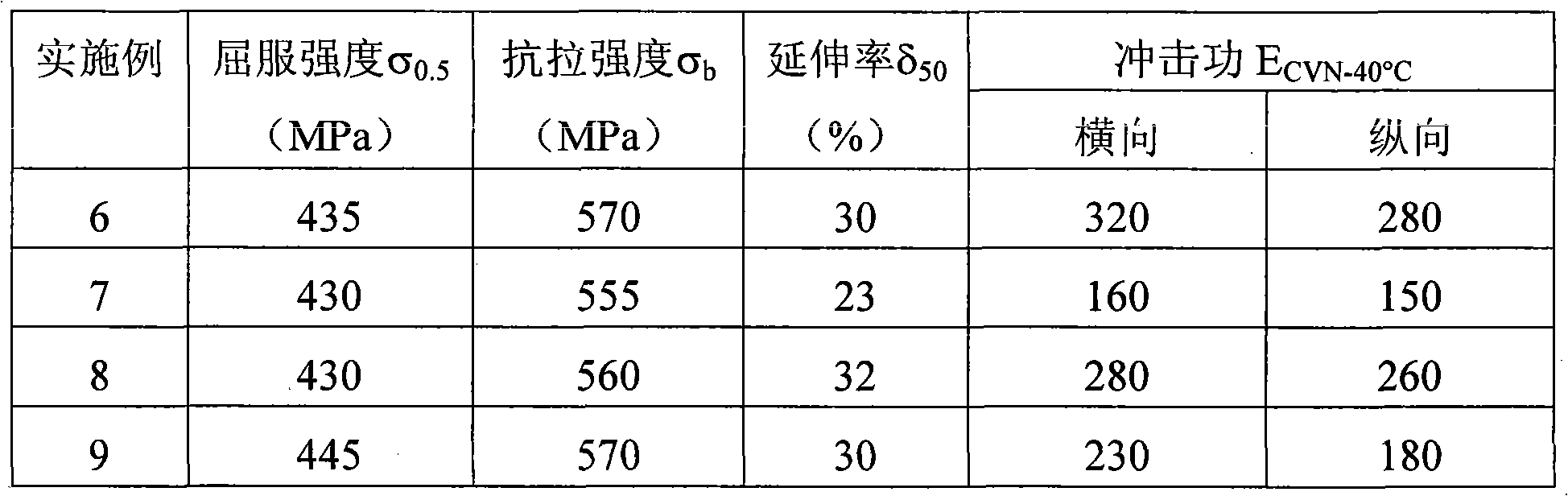

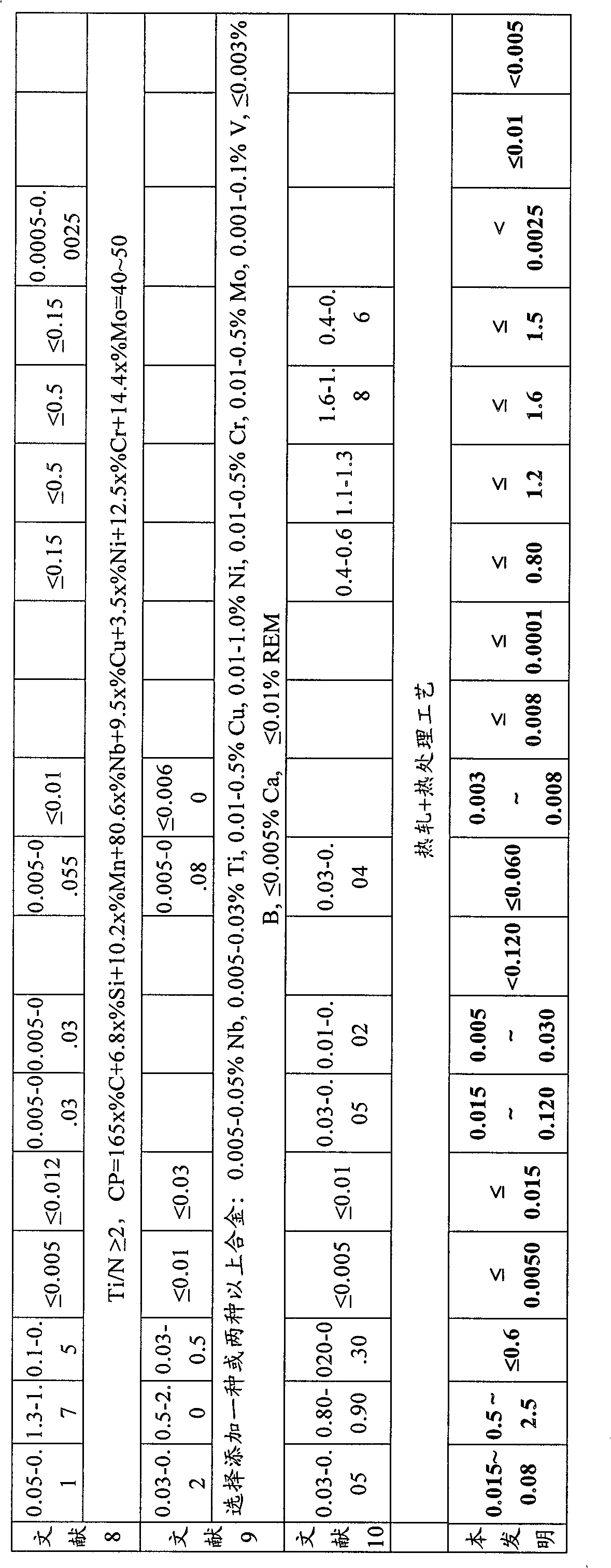

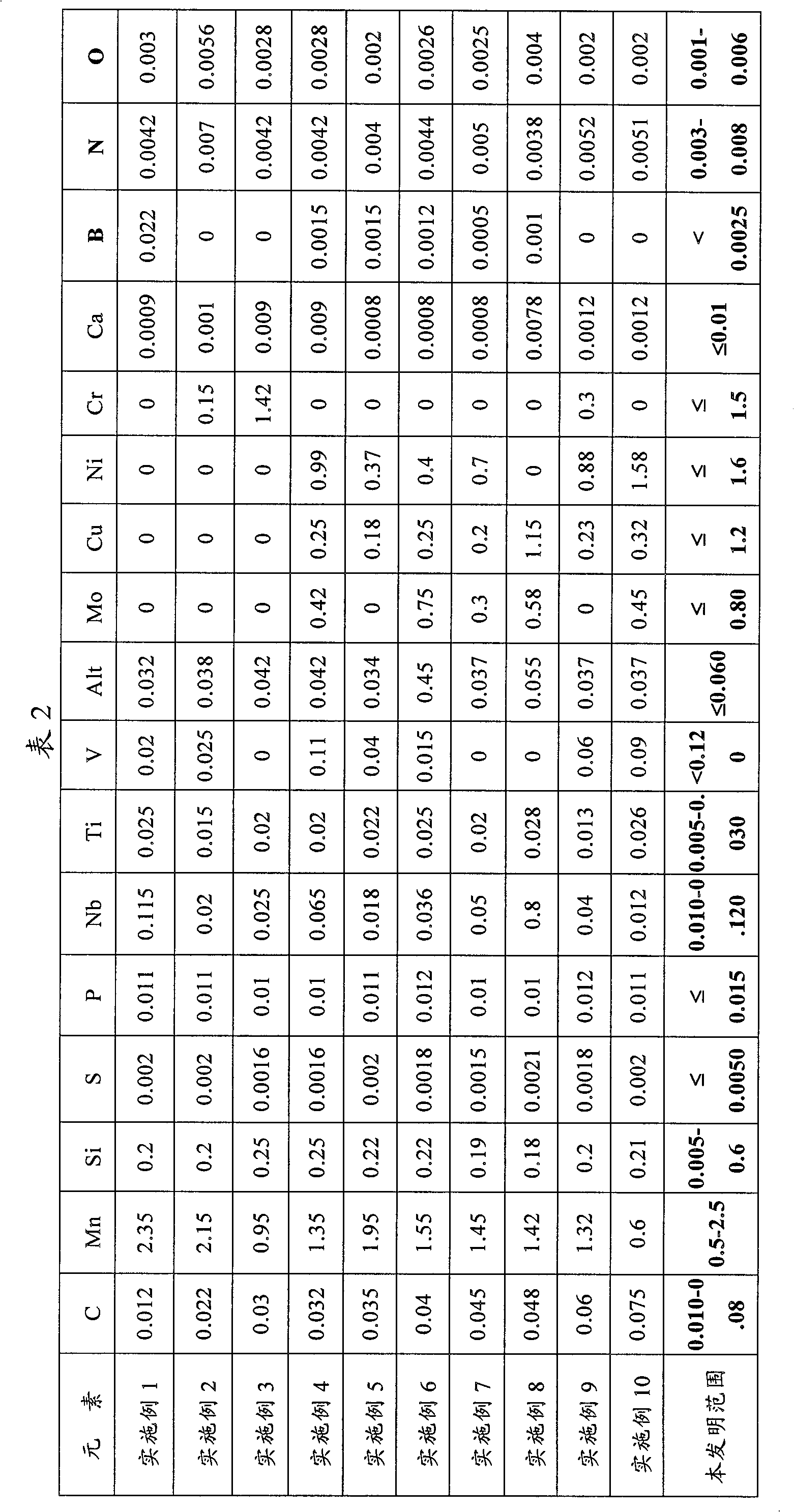

YP500MPa-level thick steel plate with excellent low-temperature toughness and manufacturing method thereof

InactiveCN102691015AImprove low temperature toughnessTemperature control deviceMetal rolling arrangementsCompound (substance)Toughness

The invention relates to a TMCP-type YP500MPa-level thick steel plate with excellent low-temperature toughness which comprises the following chemical components by weight: 0.010-0.08% of C, 0.005-0.6% of Si, 0.5-2.50% of Mn, not more than 0.015% of P, not more than 0.005% of S, 0.010-0.12% of Nb, 0.005-0.03% of Ti, less than 0.120% of V, not more than 1.50% of Cr, not more than 0.80% of Mo, not more than 1.2% of Cu, not more than 1.60% of Ni, not more than 0.06% of Al, not more than 0.01% of Ca, 0.003-0.008% of N, not more than 0.0025% of B, not more than 0.008% of O, and the balance of Fe and inevitable impurity elements. In the manufacturing process, a heating temperature of a continuous casting blank is 1100-1250 DEG C; a rolling temperature of a recrystallization zone is 920-1170 DEG C; a rolling temperature of a non-recrystallization zone is 680-910 DEG C; a finish rolling compression ratio is not less than 2 T, wherein T is a finished product thickness; a cooling speed is not less than 5 DEG C / s, and a finally cooling temperature is 300-600 DEG C. A TMCP-type YP500MPa-level thick steel plate with excellent low-temperature toughness is obtained.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com