Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1636results about "Work cooling devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

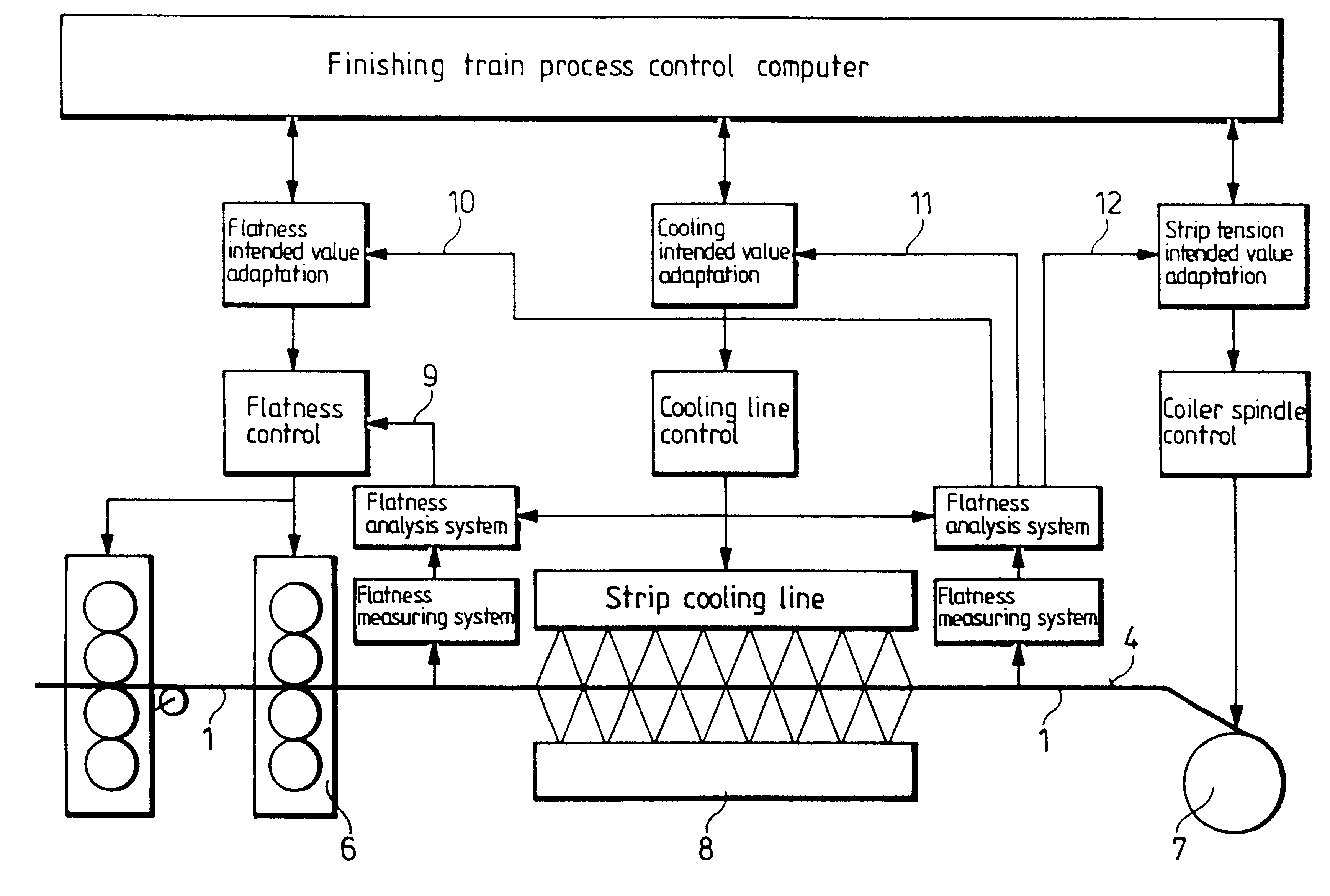

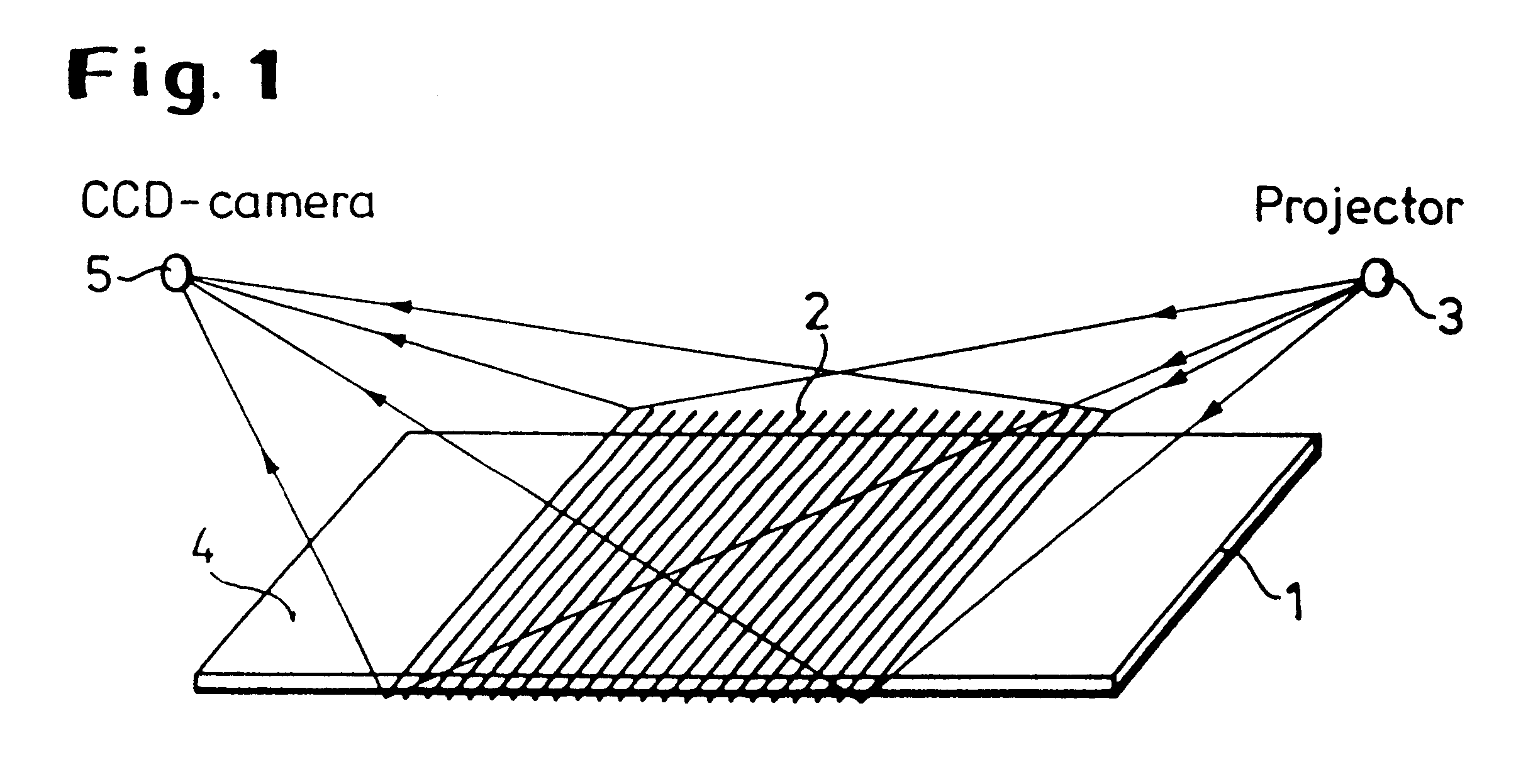

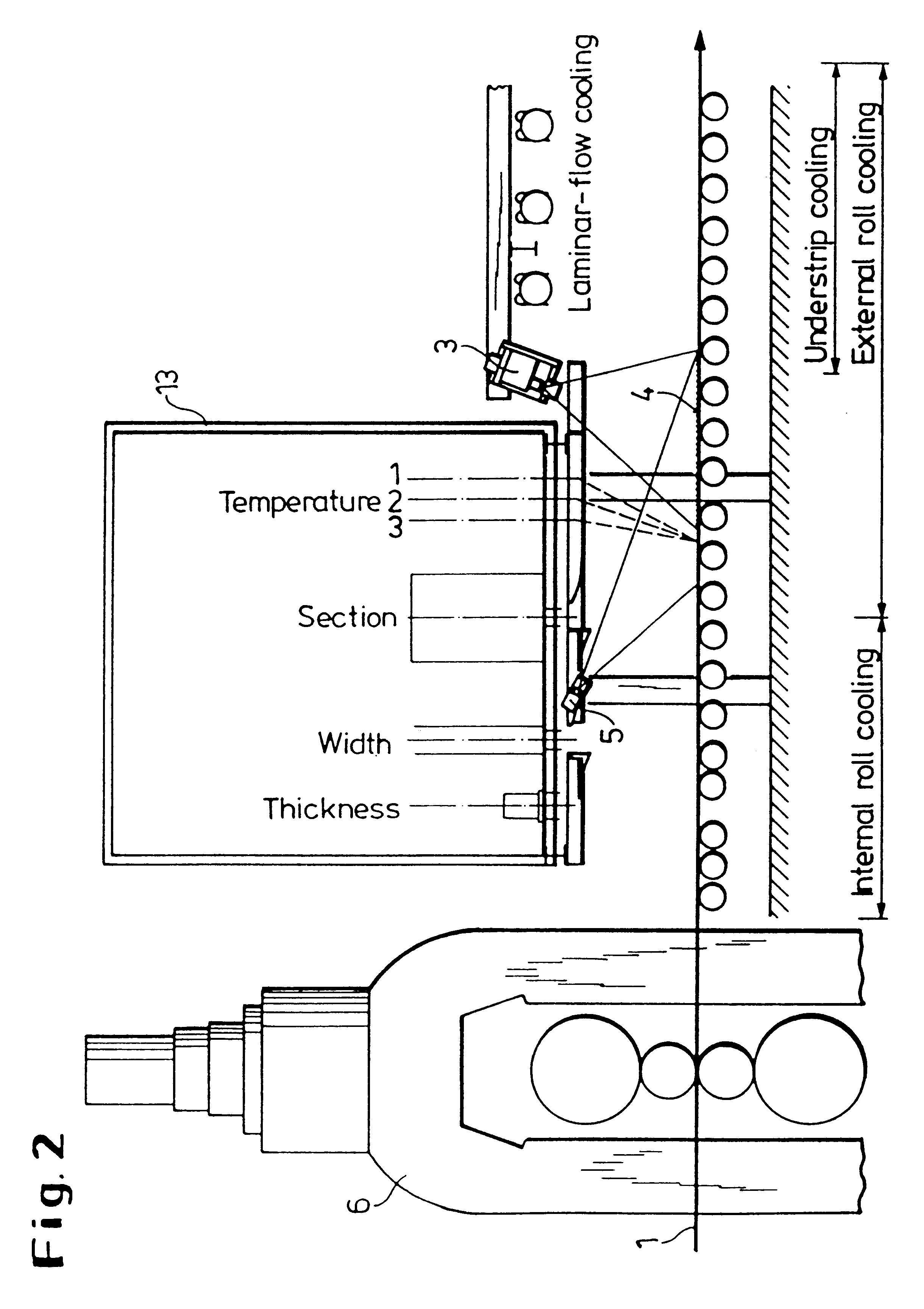

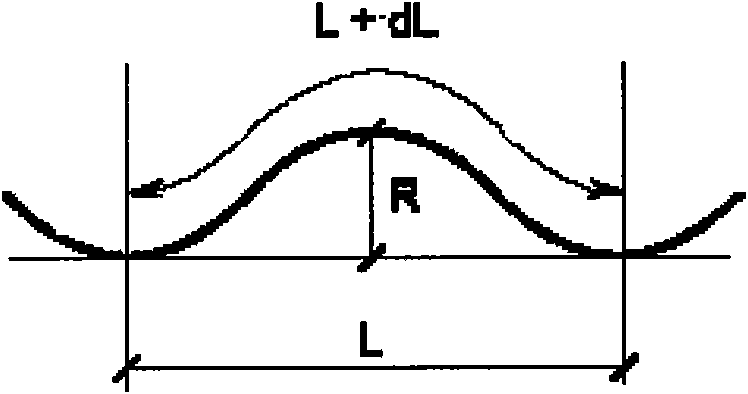

Flatness measurement system for metal strip

InactiveUS6286349B1Easy to measurePermit fine controlTemperature control deviceMeasuring devicesMetal stripsControl system

Owner:THYSSEN KRUPP STAHL AG +1

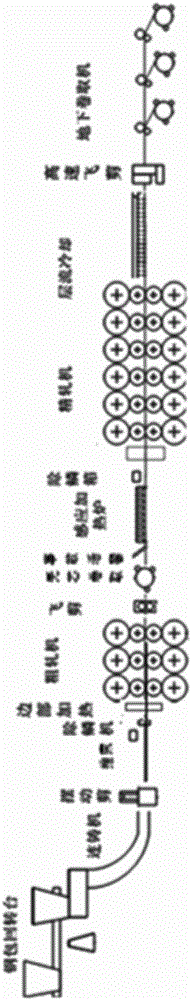

Production process of continuous-casting tandem-rolling coiled sheet of medium thick plate

InactiveCN1840252ASave shipping timeImprove work rateMetal rolling stand detailsWork cooling devicesComputer control systemThree level

The invention discloses a cut deal blank joint continuous casting and rolling coil manufacturing technique, which is characterized by the following: the conticaster is fillet-bevel crystallizer; the conticaster adopts double-machine four-flow, four-flow in one technique, straight-rolling heat-feed heat-transfer technique and straight-rolling technique; the big mill adopts fore-and-aft edger roll device; the form is adhesion-upper drive-roller; the finishing mill group adopts work roller trending-running and bend bar device; the fine rolling uses raising speed rolling, which has maximum speed at 22.8m / s and roller way speed at 5.89m / s; the front of finishing mill group installs edge-part calorifier, multistage coarse, fine adjusting-valve group, which adopts cool three-stage laminar flow chilling control technique, adds heat cover on delivery roll table, reduces the temperature dropping of intermediate area blank and head-to-tail temperature difference; the automatic system is three-level computer-controlled system. The invention improves the device, manufacturing technique, which improves the product quality.

Owner:ANGANG STEEL CO LTD

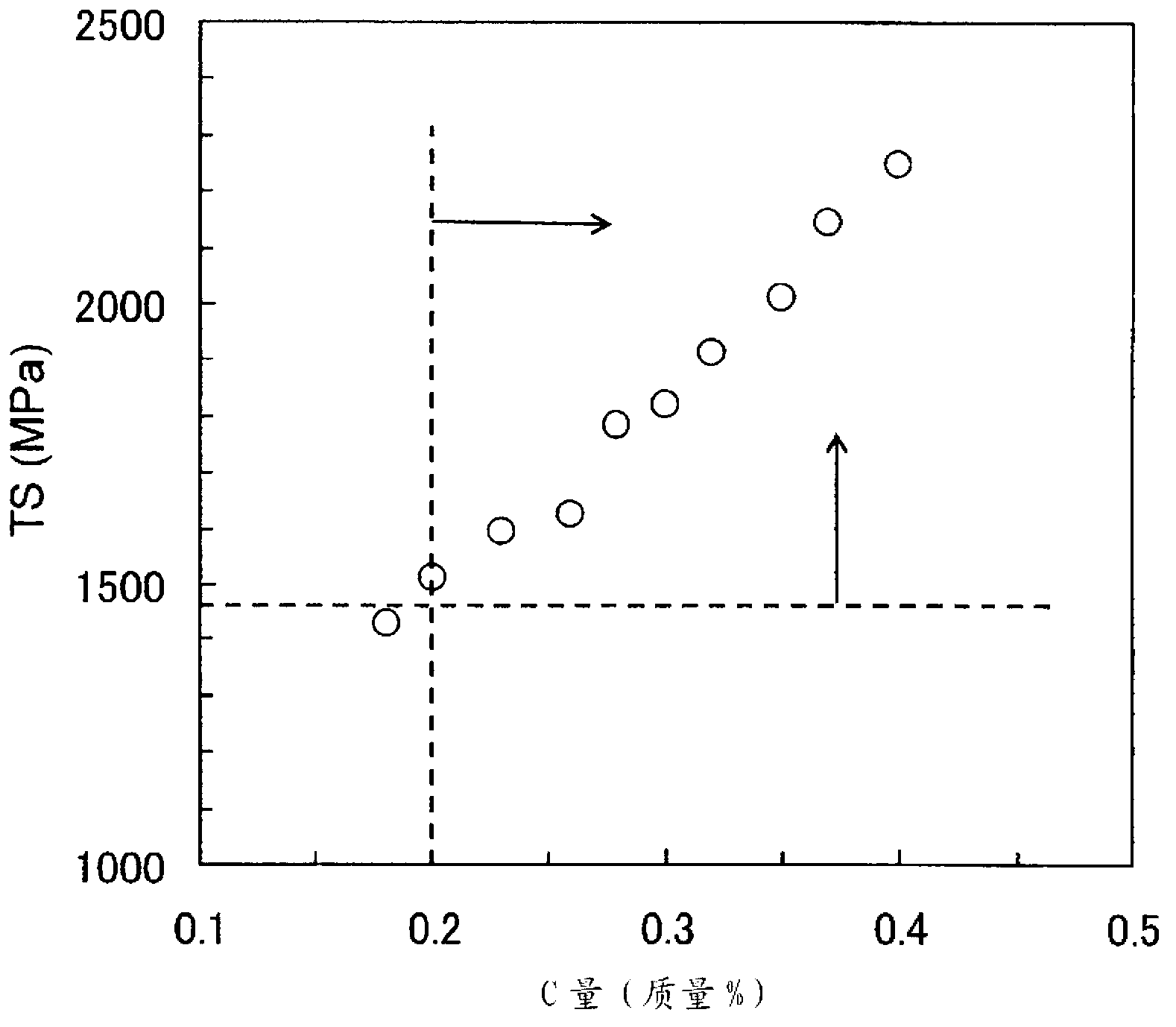

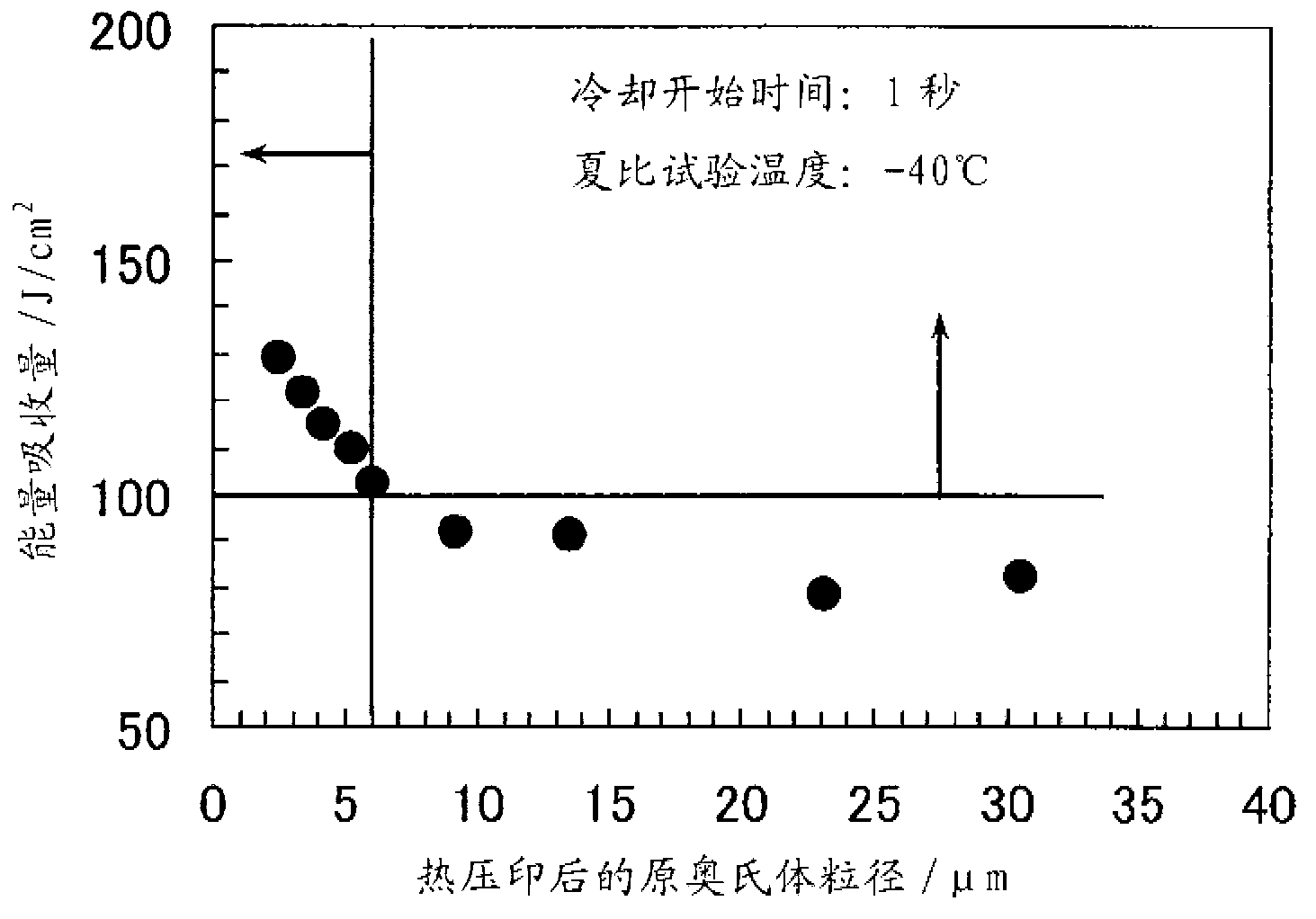

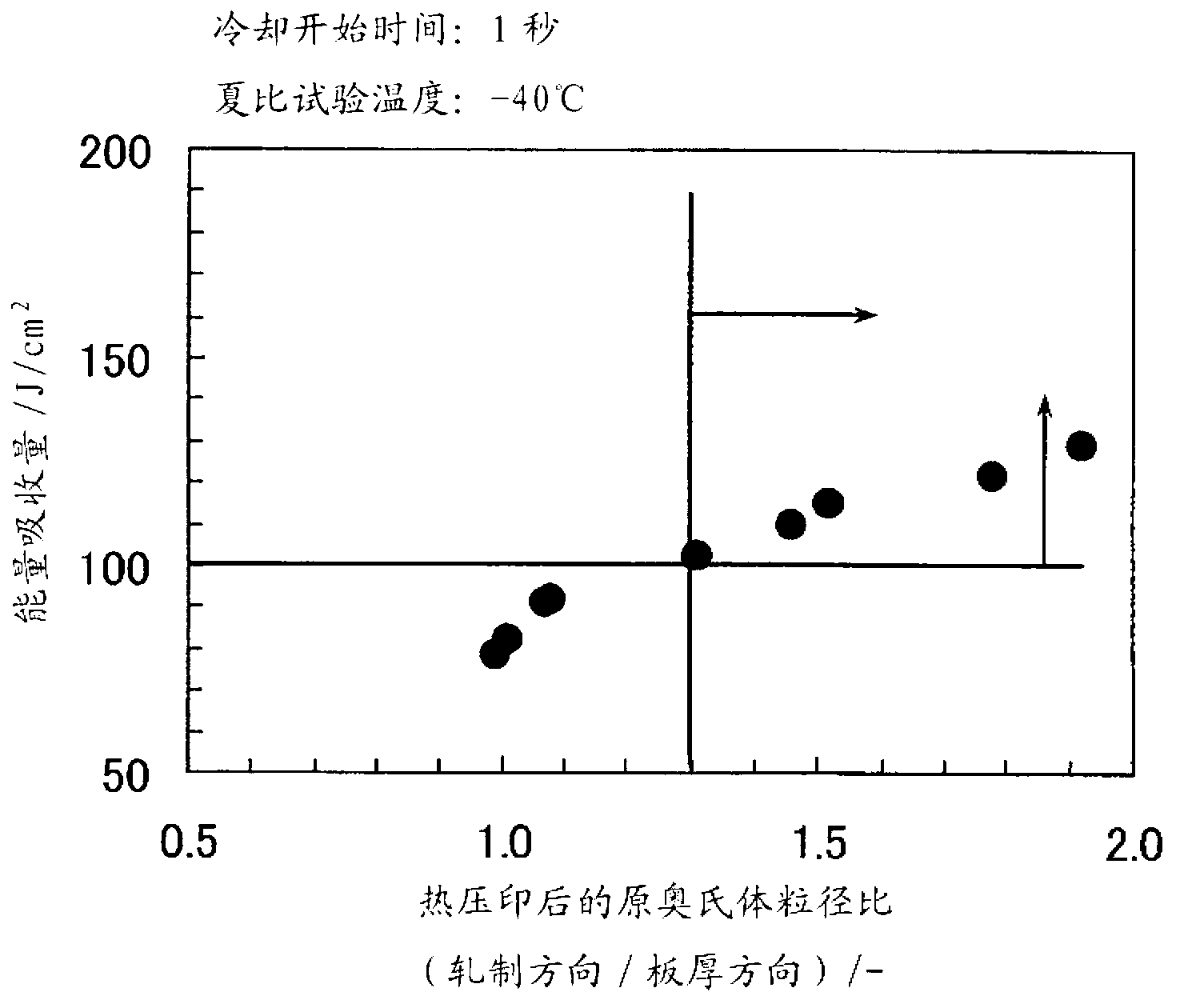

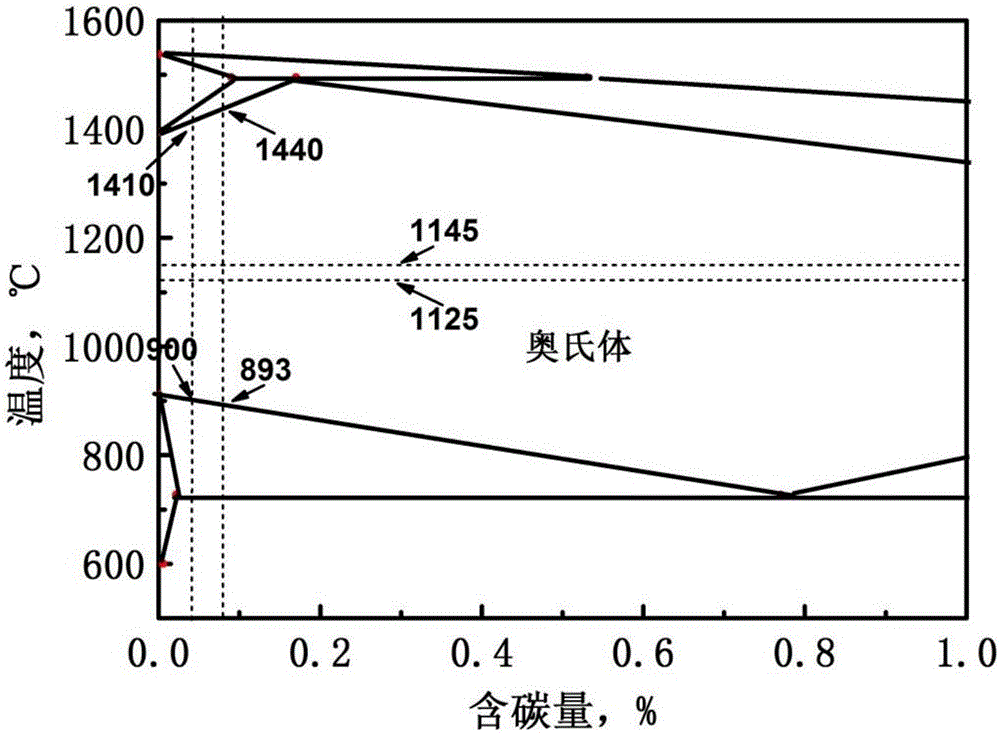

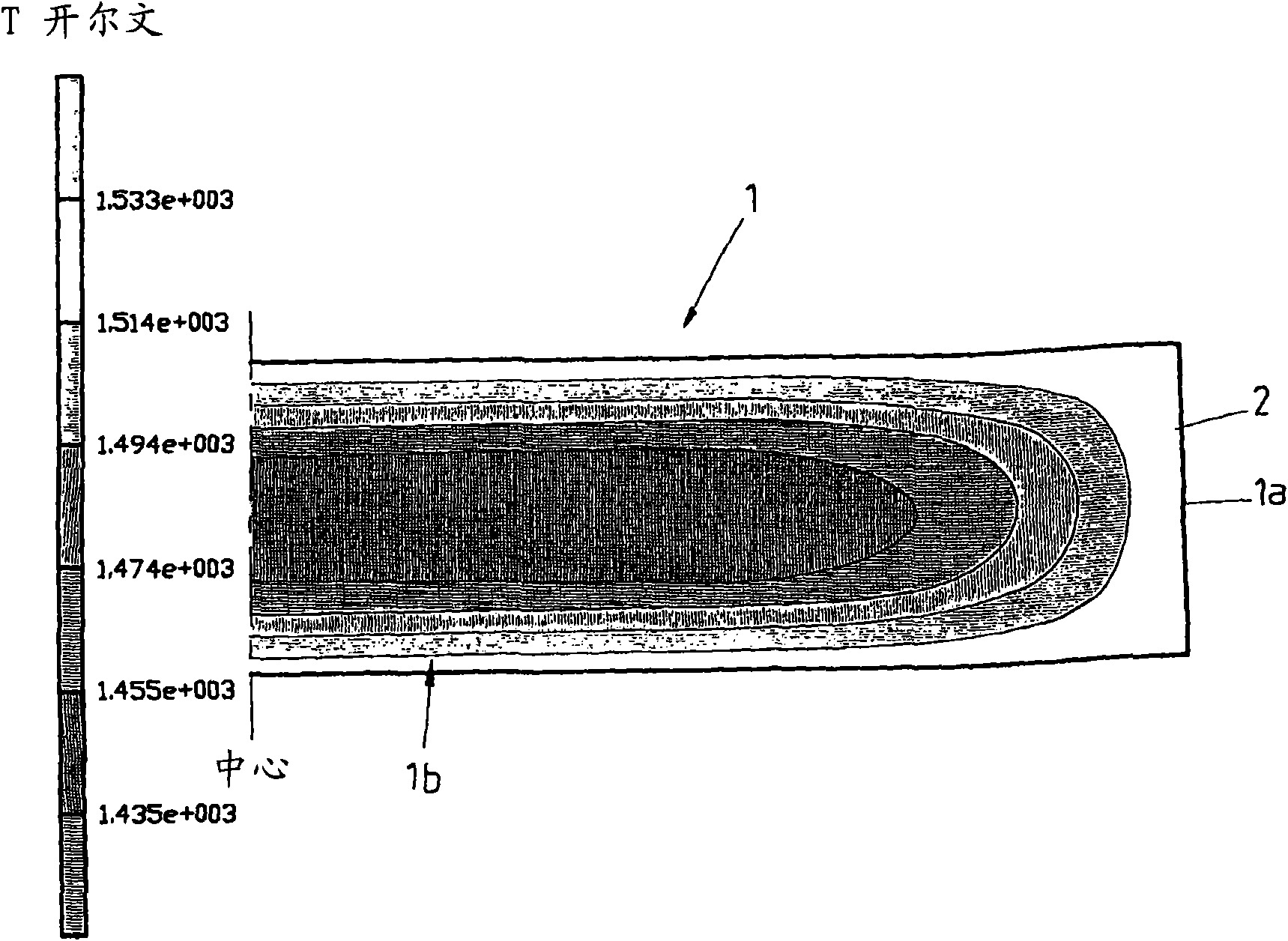

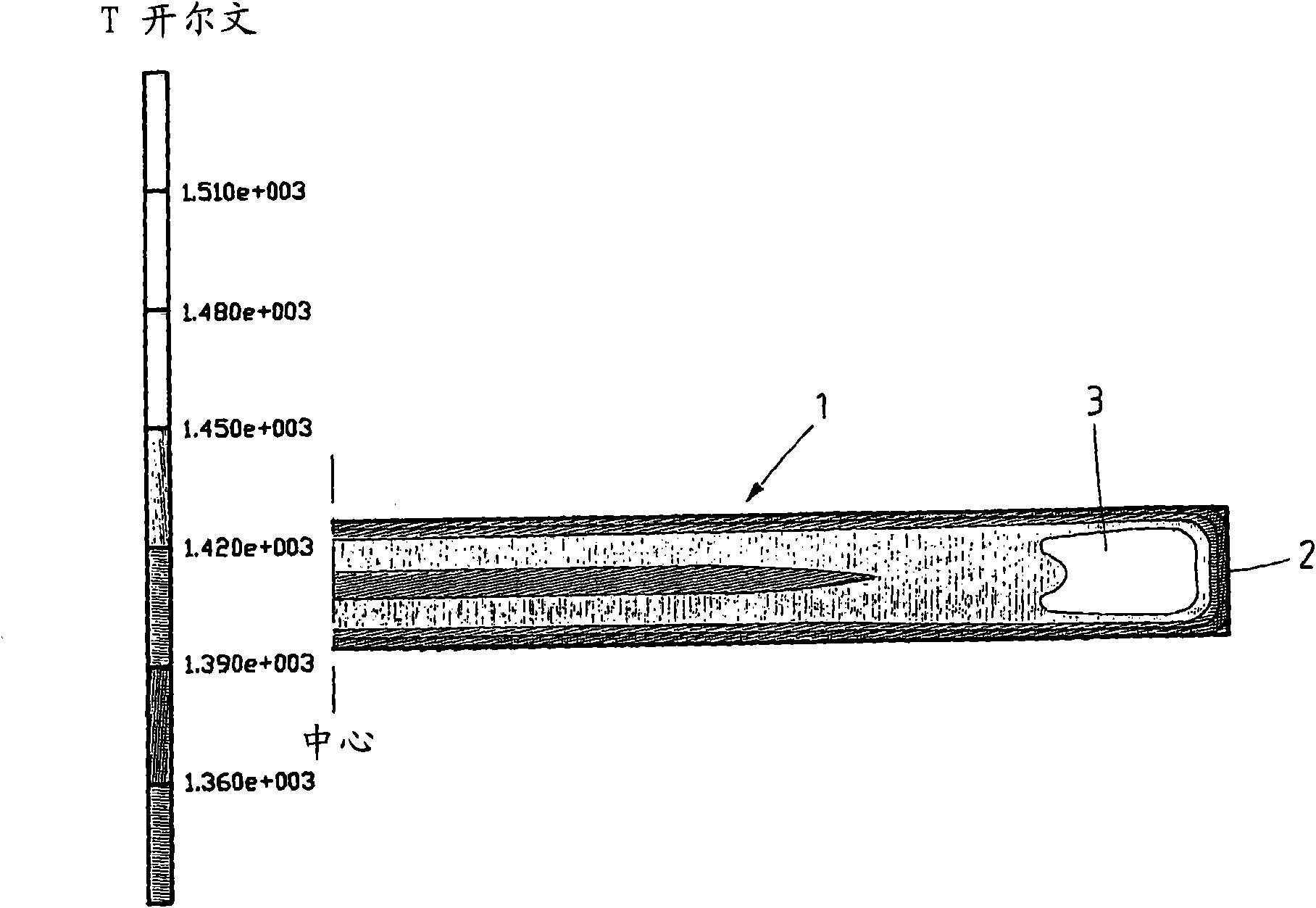

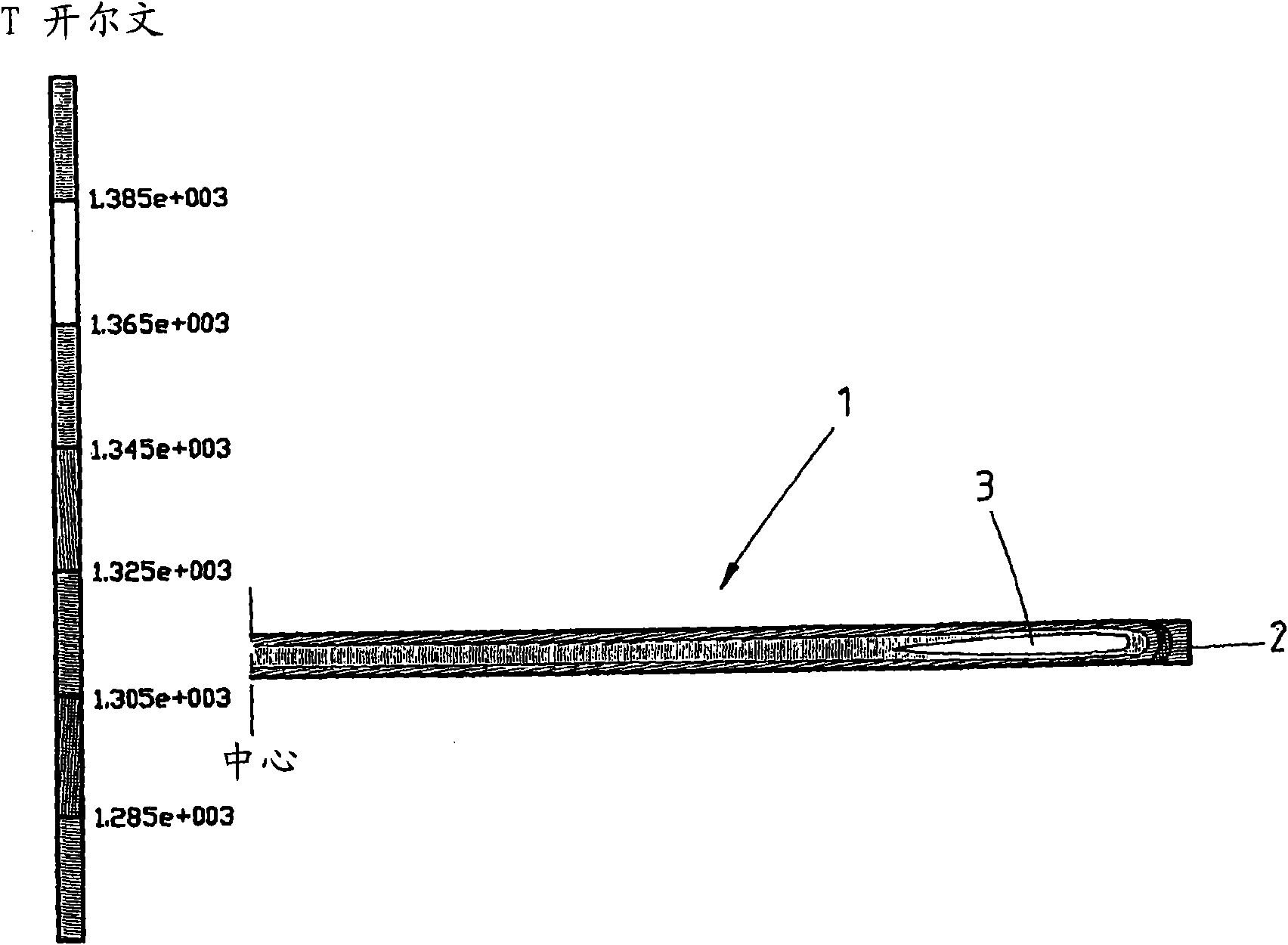

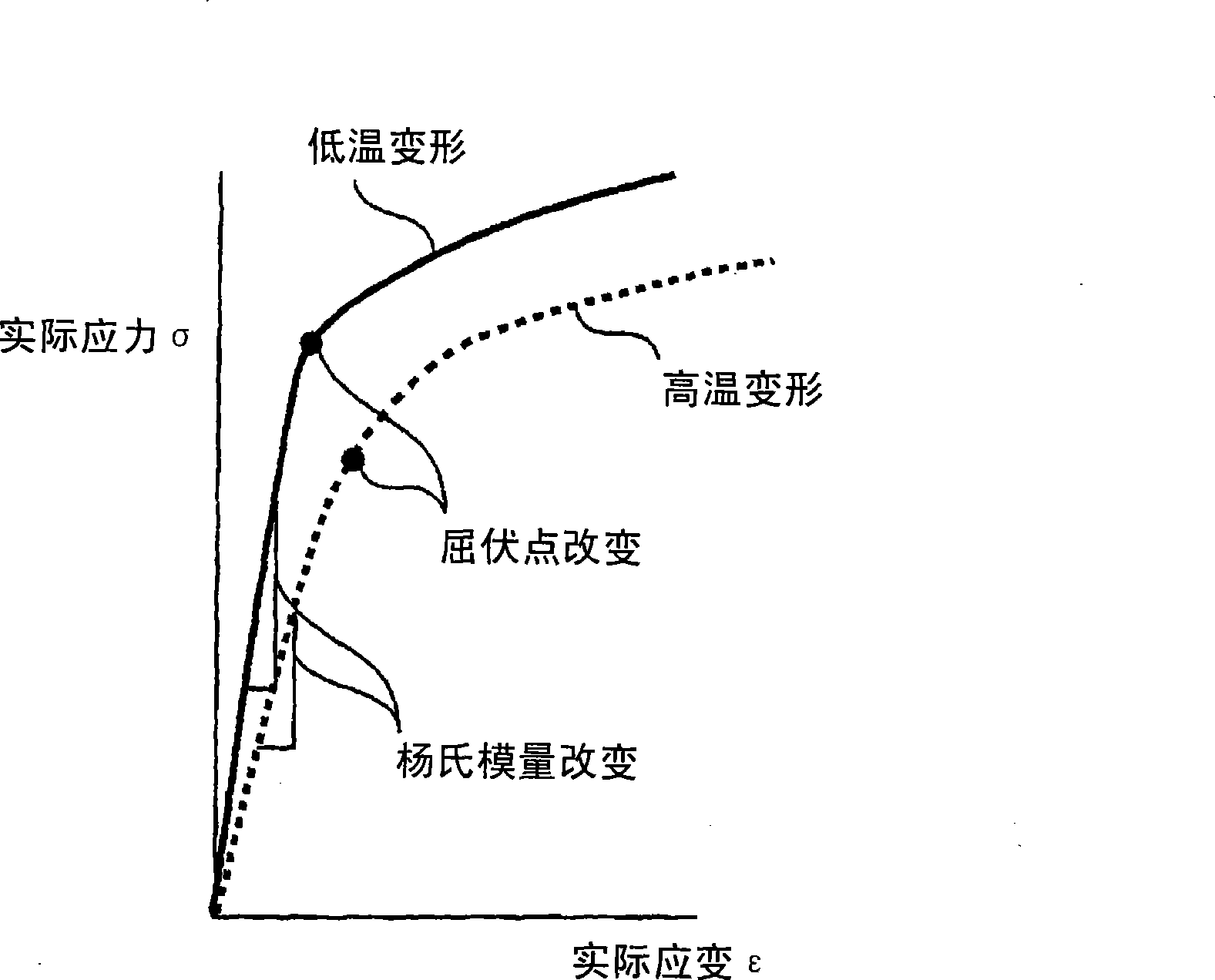

Hot-stamp-molded article, process for production of steel sheet for hot stamping, and process for production of hot-stamp-molded article

ActiveCN102939399AAchieve lightweightHigh strengthHot-dipping/immersion processesFurnace typesHot stampingAustenite grain

A hot-stamp-molded article comprises, in mass%, 0.20 to 0.35% of C, 0.1 to 0.5% of Si, at least one element selected from Mn and Cr in the total amount of 1 to 3%, 0.005 to 0.06% of Al, 0.002 to 0.1% of Ti, 0.002 to 0.1% of Nb, 0.003 to 0.007% of O, 0.015% or less of P, 0.01% or less of S, 0.004% or less of N, and a remainder made up by Fe and unavoidable impurities, wherein the dimensional ratio of the length of a prior austenite grain in the rolling direction to that in the thicknesswise direction is 1.3 to 2.5 inclusive, the prior austenite grain has an average particle diameter of 6 [mu]m or less, martensite is contained at a proportion of 98% or more, and the tensile strength is 1470 MPa or more.

Owner:NIPPON STEEL CORP

Manufacturing method for thin-specification hot-rolled strip steel

ActiveCN106552831AIncrease profitReduce energy consumptionMetal rolling stand detailsWork cooling devicesProduction lineThin slab

Owner:NORTHEASTERN UNIV

Method and device for controlling strip shape and precision of hot rolling steel strips and plates

InactiveCN101780478AHigh thickness accuracyChange the temperature distributionWork cooling devicesWork heating devicesSheet steelNonferrous metal

The invention belongs to hot rolling equipment and a hot rolling method, and particularly relates to a method and a device for controlling the strip shape and the precision of hot rolling steel strips and plates. The invention regulates the deformation capacity of the metal by changing the temperature distribution in the width direction of rolled pieces so as to reach ideal strip shape control, i.e. an aerial fog cooling medium is accurately sprayed on the rolled pieces to change the temperature distribution in the width direction of the rolled pieces; the cooling parameters for spraying along the width of the rolled pieces are regulated according to the set and feedback information to realize the open-loop or closed-loop strip shape control; aerial fog cooling devices are arranged in front of and at the back of a reversing mill; and the aerial fog cooling devices in front of rolling mills and among the standers of the rolling mills in series-type hot steel strip rolled pieces and simultaneously spray the aerial fog on the upper and lower surfaces of the rolled pieces. The invention has simple structure and strong applicability, can be used for the strip shape control of the newly-built hot rolling mill or be used for carrying out improvement of the strip shape control on the rolling mill, is also suitable to roll the hot rolling steel strips and plates of the nonferrous metals and has wide popularization value.

Owner:CISDI ENG CO LTD

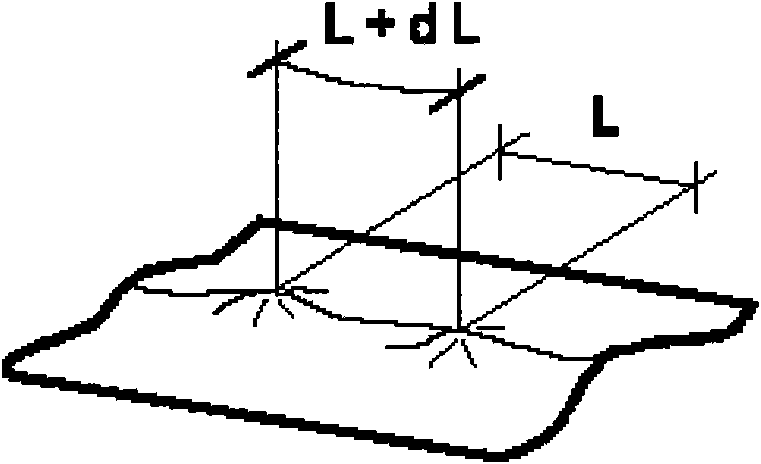

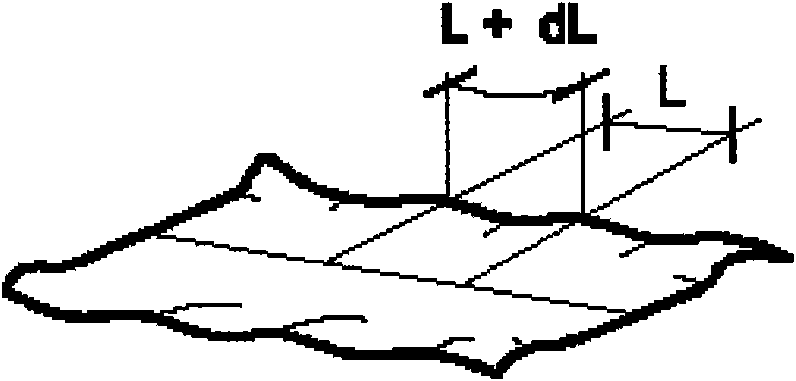

Deep cooling asynchronous rolling method for preparing lamellar copper/lithium composite foil

ActiveCN108435791AImprove plasticityAchieve hypoplastic deformationWork cooling devicesMetal rolling arrangementsLithiumCopper foil

Provided is a deep cooling asynchronous rolling method for preparing lamellar copper / lithium composite foil. Copper foil and lithium foil are shorn into a rectangle size, the thickness of the copper foil is 1 / 2 that of the lithium foil, the width of the copper foil is equal to that of the lithium foil, and the length of the copper foil is twice that of the lithium foil; the copper foil is oppositely folded in the length direction, the lithium foil is completely wrapped, and the copper foil and the lithium foil are placed into a deep cooling box to be cooled; then deep cooling rolling is performed; then folding and deep cooling rolling are performed, operation is repeated for 5-10 times, and the high-performance lamellar copper / lithium bimetal composite foil is produced; the lamellar copper / lithium bimetal composite foil is folded, and is placed into the deep cooling box to be cooled again; and then deep cooling asynchronous rolling is performed till the thickness of a rolled piece is rolled to 10-50 microns. According to the deep cooling asynchronous rolling method for preparing the lamellar copper / lithium composite foil, ultra-low temperature plastic deformation is utilized, the binding force between metal lithium and metal copper is relatively weak, and therefore it is difficult to form intermetallic compounds. In the meantime, under the condition of ultra-low temperature, the metal lithium and the metal copper both have good plasticity, and therefore multi-pass plastic deformation is achieved. An obtained material is of a nanometer lamellar composite structure, and goodbattery properties are achieved.

Owner:CENT SOUTH UNIV

Method for manufacturing seamless steel tube

A method for manufacturing a seamless steel tube, wherein a tubing material for the seamless steel tube is produced by a hot working process from a material having less workability, such as a high Cr-high Ni-high C alloy steel including Cr at a content not less than 15 weight % and Ni at a content not less than 20 weight % or a ferritic stainless steel including Cr at a content not less than 16 weight %, and then cold drawn at a reduction rate of not less than 15% and further cold rolled after applying an appropriate heat treatment, so that a round or an inner grooved steel tube is obtained. It is preferable that the hot extrusion process is employed for the hot working process and a cold Pilger mill is employed for the cold rolling process. In the cold rolling process, the crackings or damage resulting from the reduced toughness of the tubing material as well as the breakage of a mandrel in producing the round or the inner grooved tube can be suppressed.

Owner:NIPPON STEEL CORP

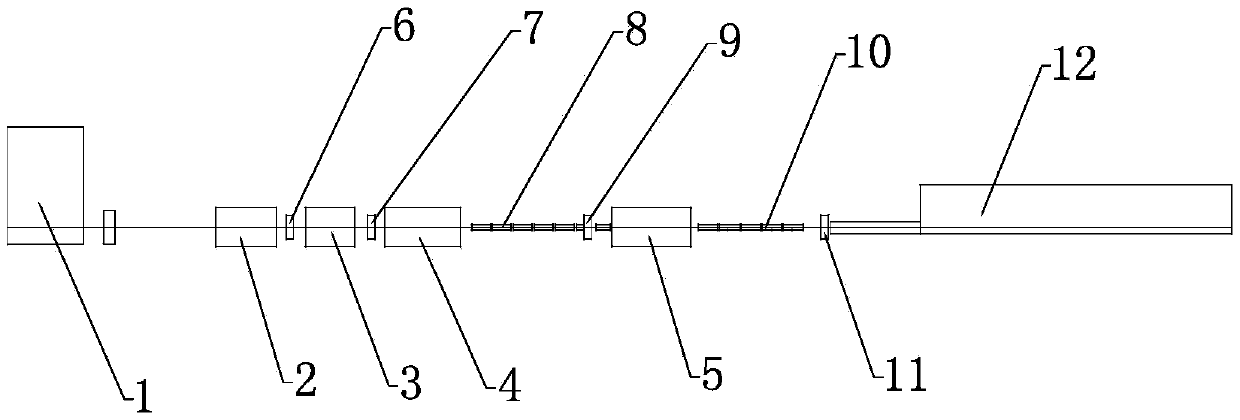

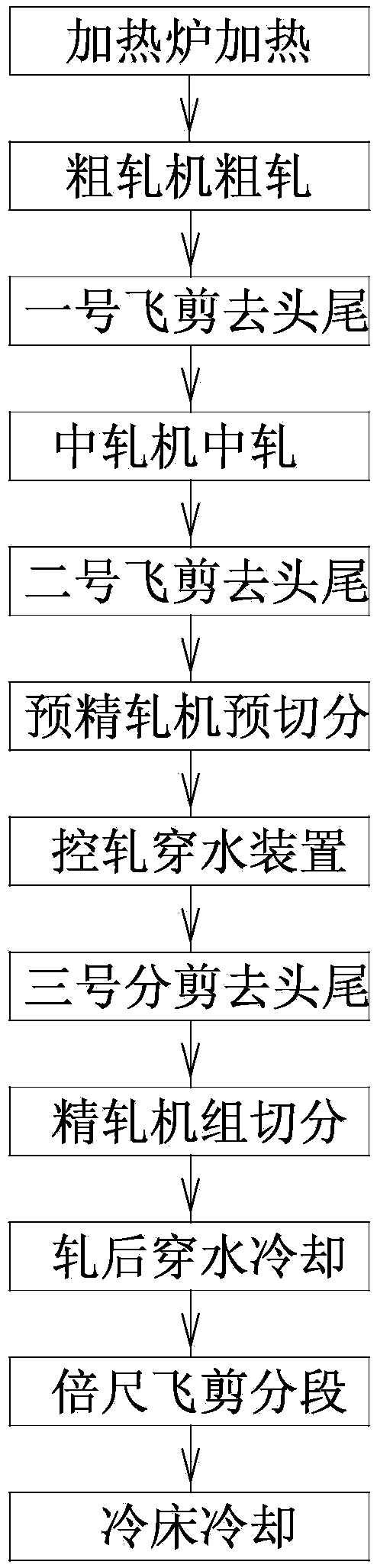

Low-temperature control rolling and splitting process method and device for ribbed steel bars

ActiveCN105290106AReduce the amount addedNot easy to collapseTemperature control deviceWork cooling devicesSocial benefitsEconomic benefits

The invention discloses a low-temperature control rolling and splitting process method for ribbed steel bars. The method comprises the steps of (1), heating square billets to 960-1000 DEG C; (2), conveying the square billets to a rough rolling unit for rolling and rolling the square billets to form round bars; (3), after a first flying shear shears the heads and the tails of the round bars, conveying the round bars to an intermediate rolling unit to form rectangular bars; (4), after a second flying shear shears the heads and the tails of the rectangular bars, conveying the rectangular bars to a finish rolling unit for pre-splitting and rolling the rectangular bars to form rolled pieces shape like dog bones; (5), conveying the rolled pieces to a control rolling and through water cooling device for through water cooling; (6), after a third flying shear shears the heads and the tails of the rolled pieces, rolling the rolled pieces in the finish rolling unit to form a plurality of the independent ribbed steel bars; (7), conveying the ribbed steel bars to a post-rolling control cooling and through water cooling device for cooling; (8) conveying the ribbed steel bars to a multi-length flying shear for multi-length sectioning and then conveying the sectioned steel bars to a cooling bed. According to the invention, the production efficiency is greatly improved, and the economic benefits and social benefits are great because the rolling energy consumption is greatly lowered, the addition amount of alloy is greatly lowered and mine exploitation is greatly reduced.

Owner:SHANDONG SHIHENG SPECIAL STEEL GROUP

Deposit removing device

Owner:KOBE STEEL LTD

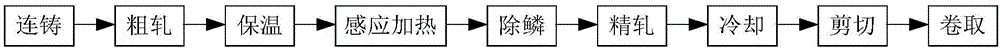

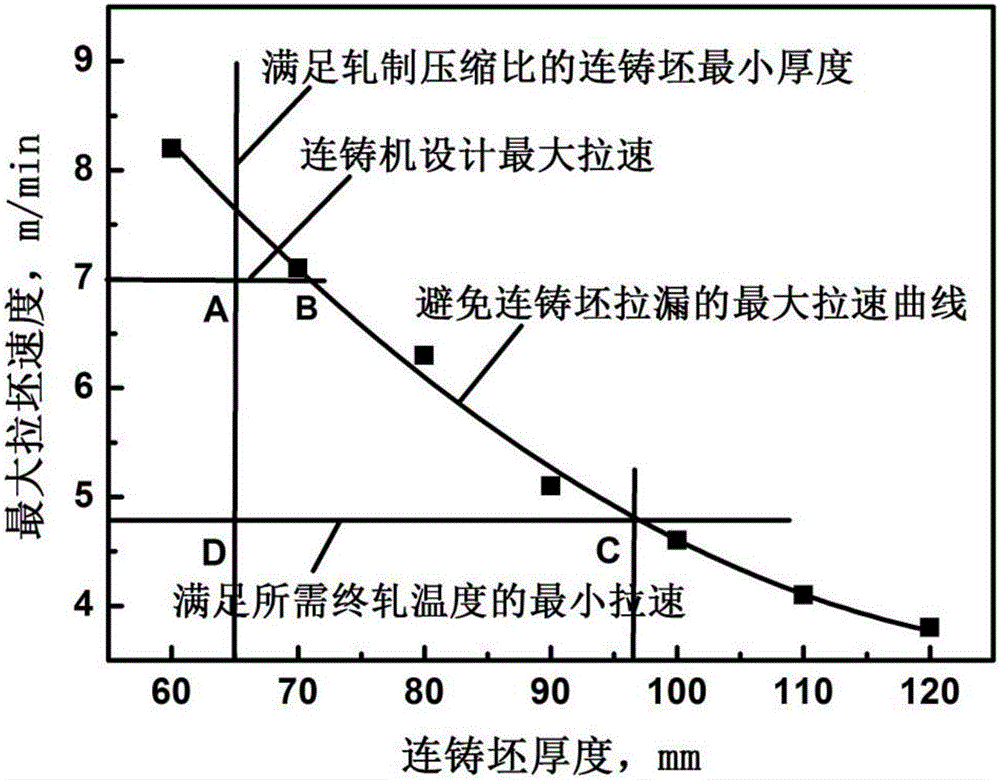

Method for producing ultrathin low-carbon steel by use of thin slab casting and rolling process

ActiveCN106583453AStable productionRealize the demand of "replacing cold with heat"Roll force/gap control deviceTemperature control deviceThin slabHigh pressure water

The invention relates to a method for producing ultrathin low-carbon steel by use of a thin slab casting and rolling process. The method comprises the following steps: continuously casting molten steel into a continuous cast billet with the width of 1,300-1,600 mm and the thickness of 60-100 mm; then sequentially conducting rough rolling, heat preservation by a heat holding cover, induction heating, high-pressure water phosphorus removal and finish rolling to obtain ultrathin strip steel with the width of 1,300-1,600 mm and the thickness of 0.8-1 mm; and finally, performing controlled cooling, roll-dividing cutting and roll take-up. A produced ultrathin low-carbon steel end product has the yield strength of 250-310 MPa, the tensile strength of 350-400 MPa and the ductility of larger than or equal to 35%. By adoption of the method, stable production of hot-rolled ultrathin low-carbon steel with the thickness of 0.8-1 mm can be realized, the dimensional accuracy, the flatness accuracy and the comprehensive mechanical property can be improved, the demand for 'replacement of cold product by hot product' is met and the production cost is lowered.

Owner:WISDRI ENG & RES INC LTD

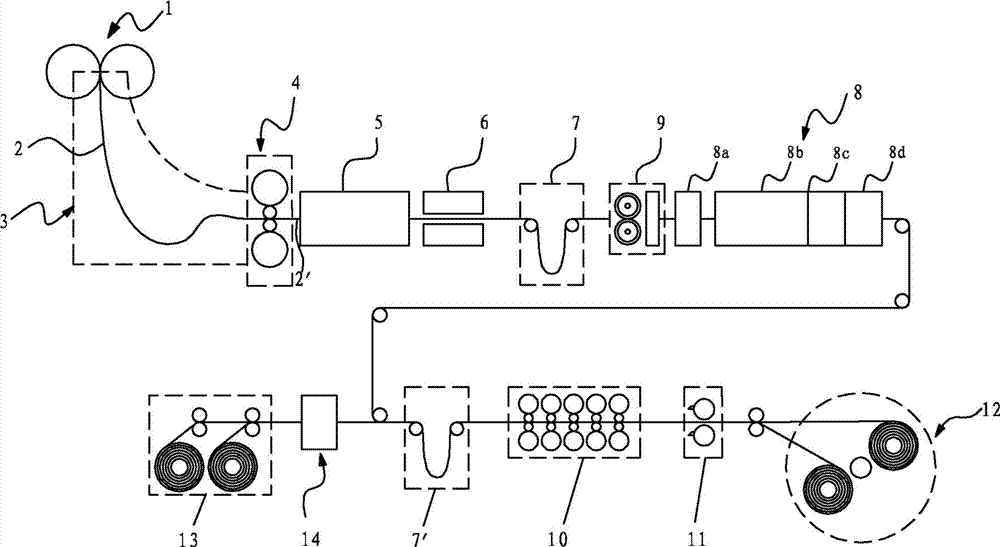

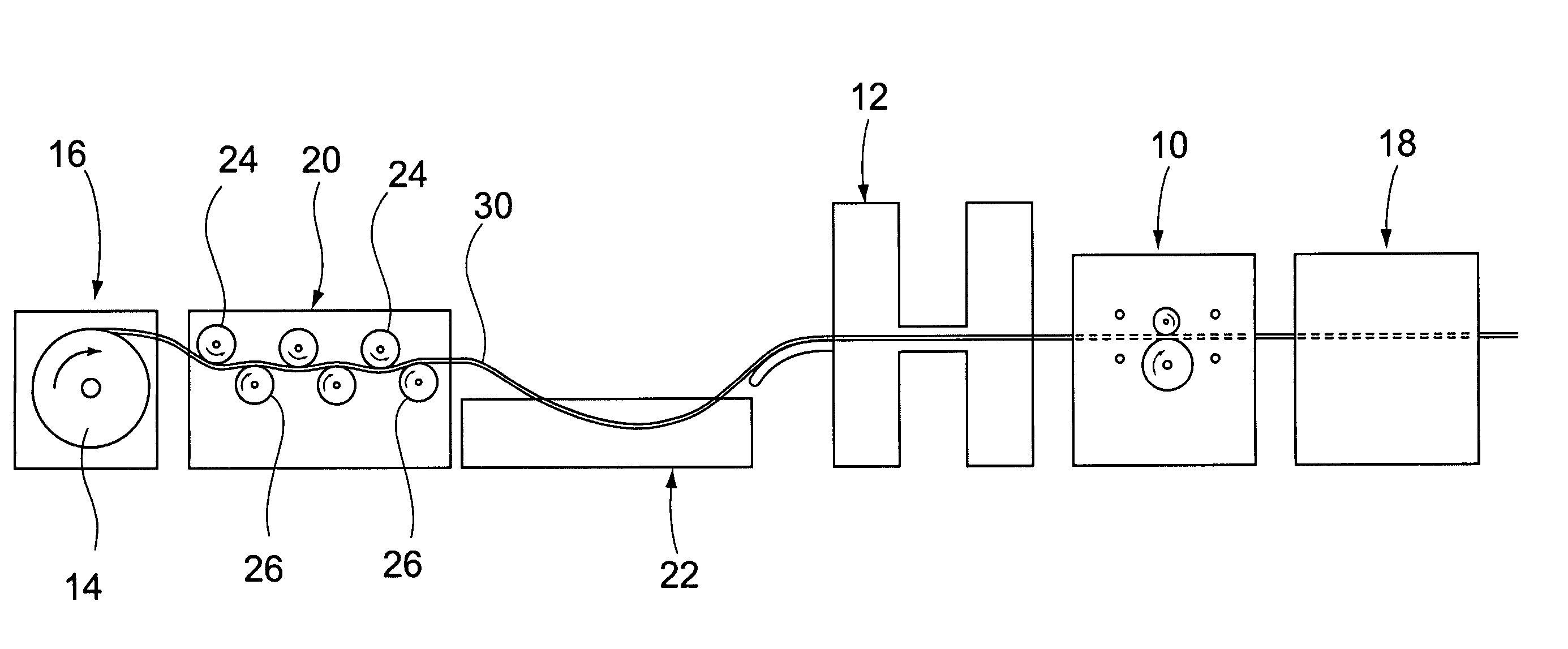

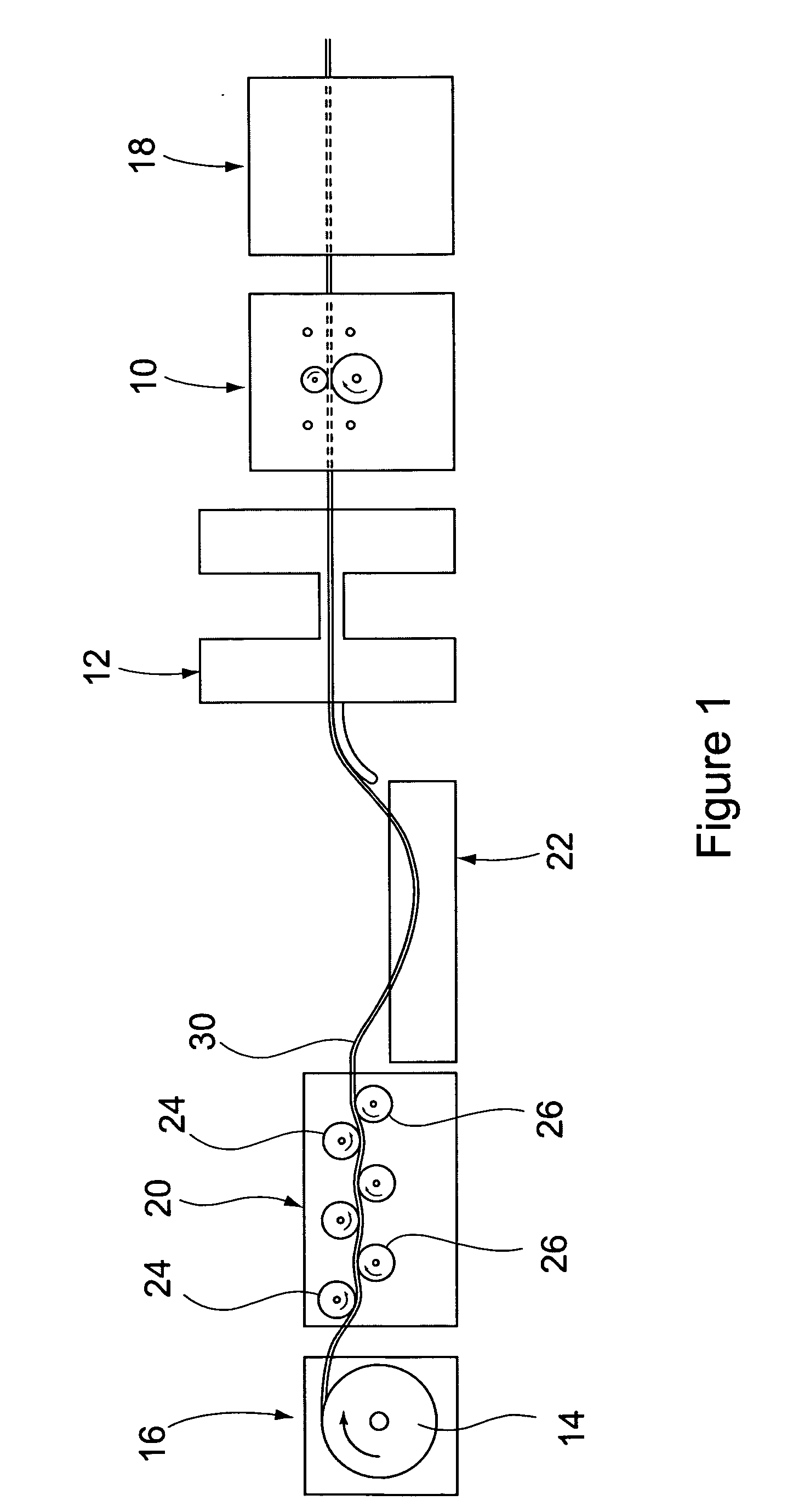

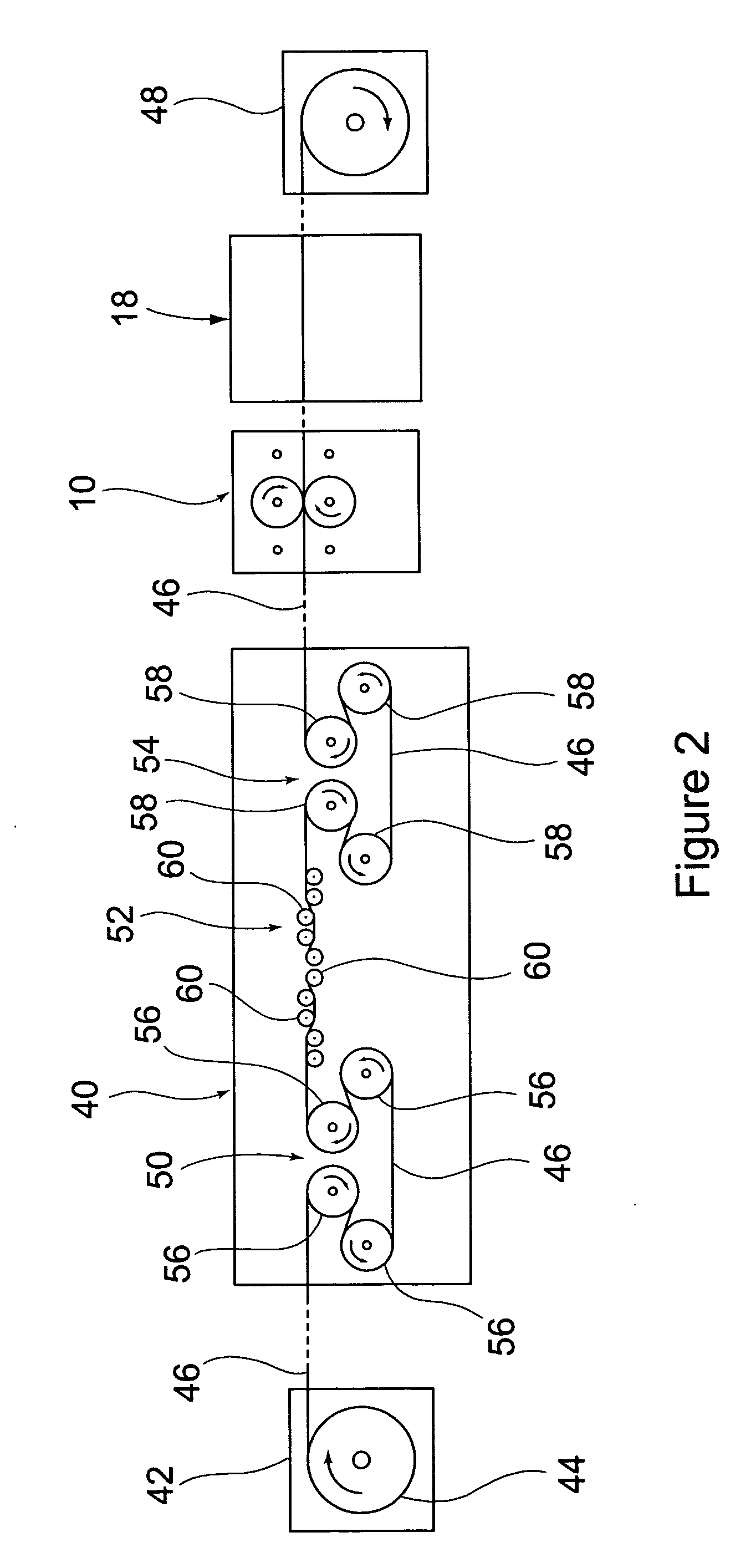

Continuous rolling production process and process arrangement

InactiveCN104722577AReduce the temperatureSatisfy the protective effectWork cooling devicesMetal rolling arrangementsBand shapeLiquid metal

The invention discloses a continuous rolling production process and process arrangement. The continuous rolling production process includes the steps: 1) adopting liquid metal for casting of hot strip billet materials according to a thin-strip continuous casting and rolling process, subjecting the cast strip billets to hot rolling, and subjecting the strip billets to stipulated-curve heat treatment including heating and cooling after casting and hot rolling of the strip billets are finished; 2) enabling the cold hot-rolled strip billets to enter a side cutting unit to realize fixed-width cutting of side materials of the cold hot-rolled strip billets; 3) subjecting the cold strip billets to scale removal by means of jet mixing flow; 4) subjecting metal strips to continuous rolling in a cold-state continuous rolling unit; 5) enabling the metal strips to enter a shearing unit and a rolling unit sequentially. The continuous rolling production process and process arrangement have the advantages that intensified metallurgical production process arrangement is realized, one-time investment cost is remarkably reduced while the technical process is greatly simplified, carbon emission and acid liquid pollution are remarkably reduced, and processing cost of metal strip products is directly reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

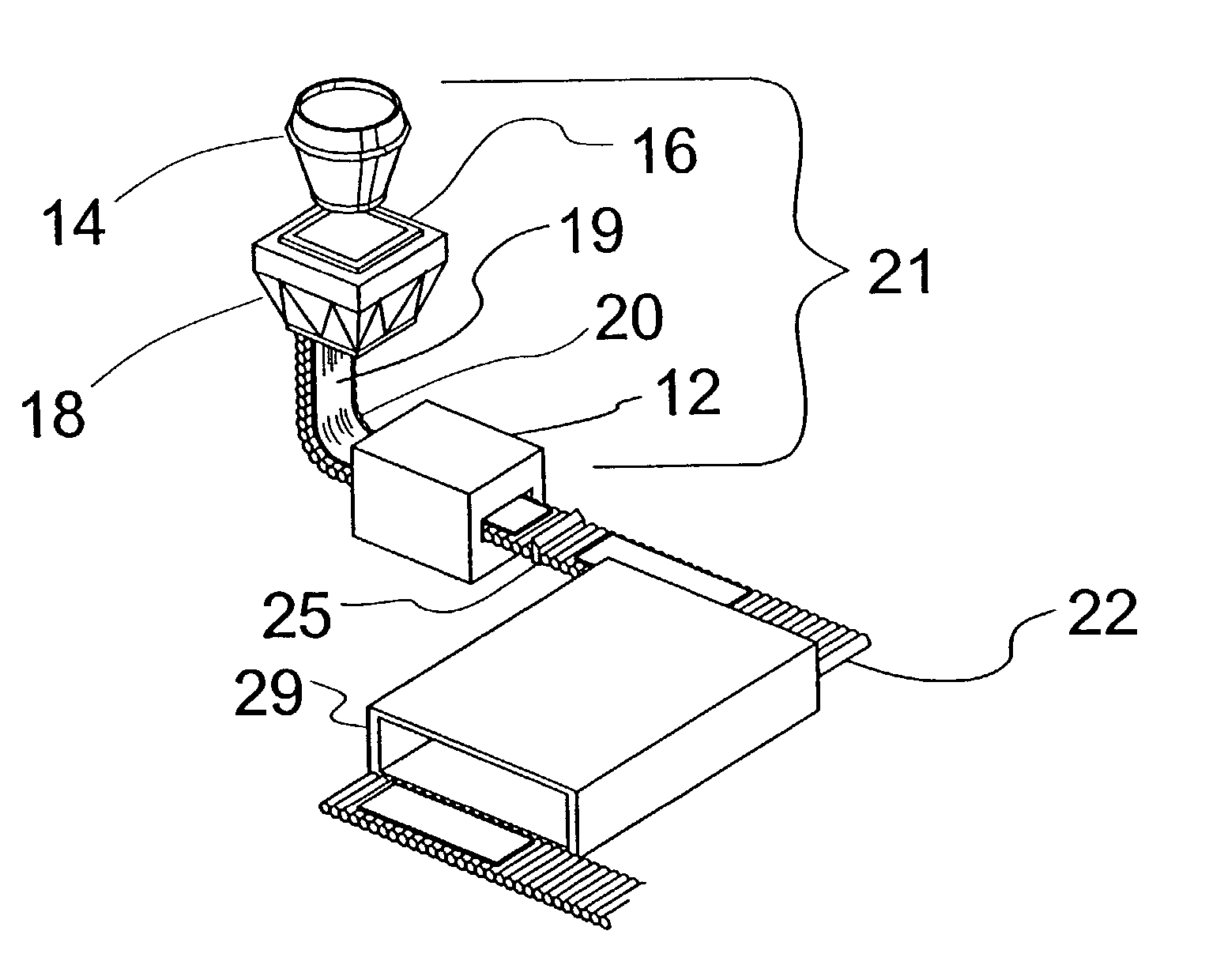

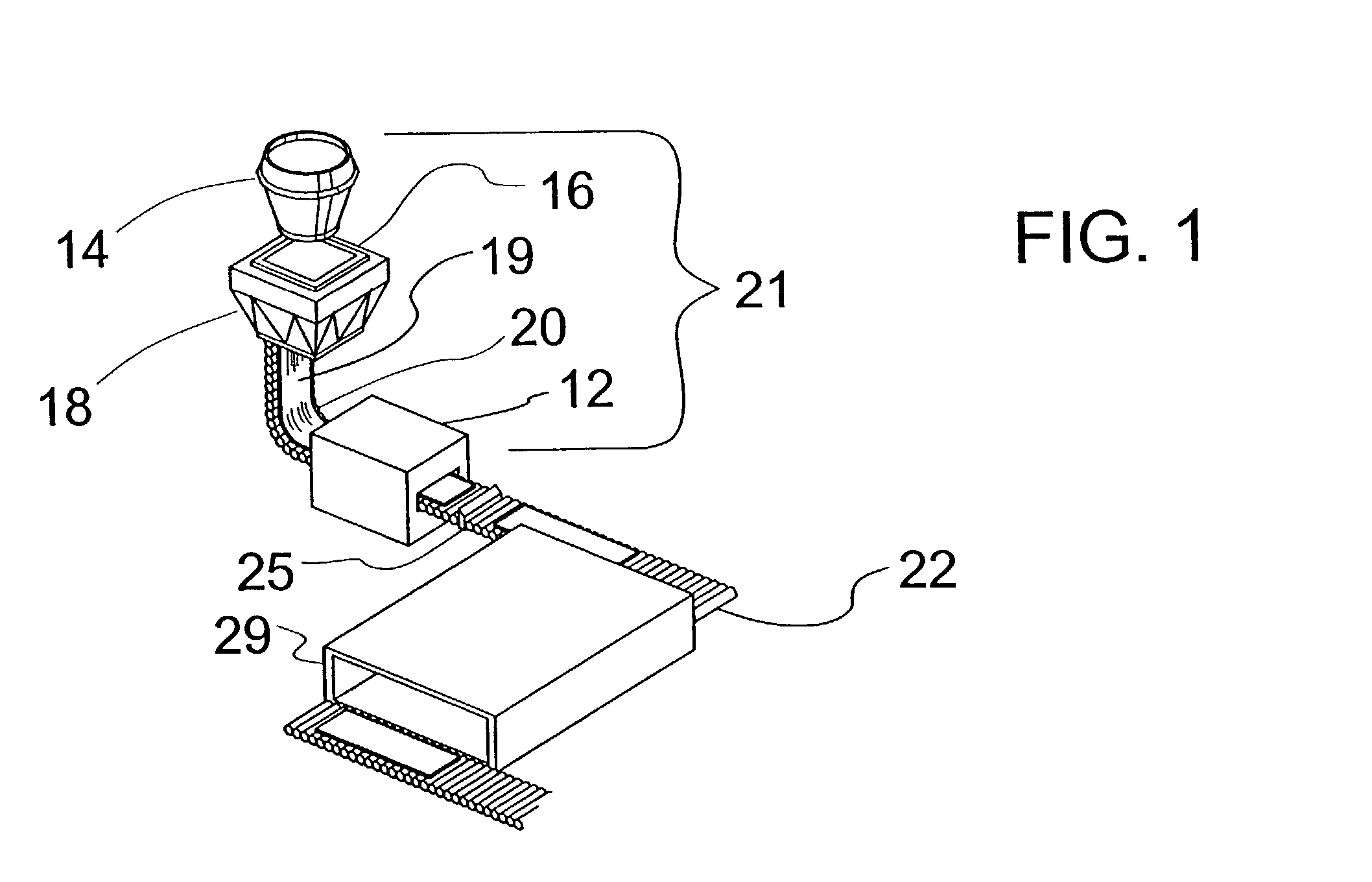

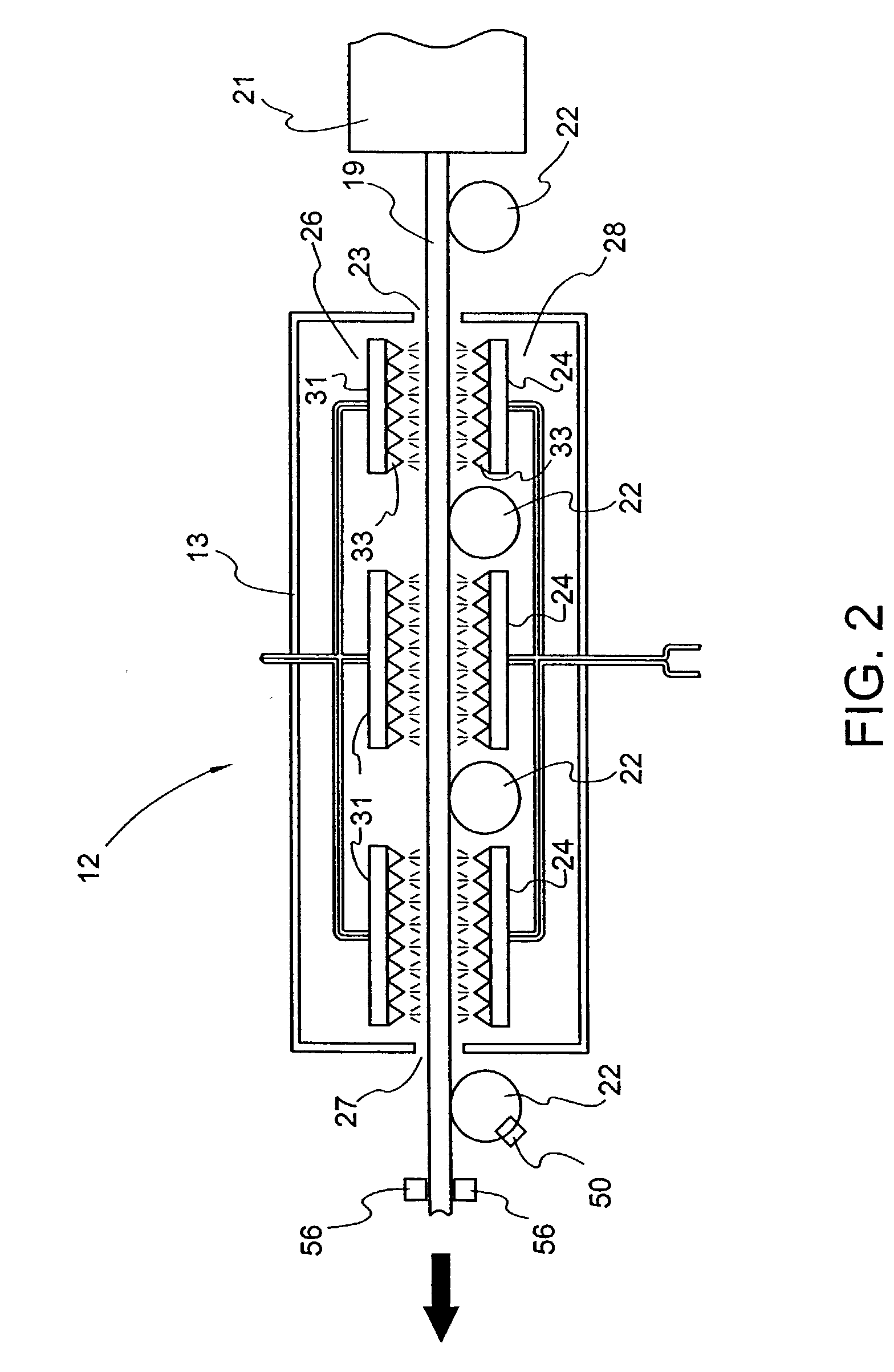

Differential quench method and apparatus

InactiveUS20020129921A1Facilitate transverse temperature equalizationReduce surface temperatureTemperature control deviceCasting safety devicesSurface layerMetallurgy

Surface defects in rolled steel are remedied by quenching a surface layer of the steel product downstream of the caster and upstream of the reheat furnace by transversely differentiated quenching to match the transverse temperature profile of the steel product. The flow rate of the quench spray is differentially adjustable across the width and optionally the length of the steel product. An array of spray nozzles controlled in transversely or longitudinally arranged groups provides the quench spray.

Owner:UNTRA PREMIUM OILFIELD SERVICES LTD

Cold rolling method for preventing high-silicon strip steel from being broken

InactiveCN102476131AImprovement of strip breakage in cold rollingGood effectTemperature control deviceMetal rolling stand detailsEmulsionEconomic benefits

The invention discloses a cold rolling method for preventing high-silicon strip steel from being broken. The Si content of the high-silicon strip steel is more than or equal to 2.3 percent by weight; when cold rolling is started, the temperature of strip steel at an inlet is higher than 45 DEG C; and in a cold rolling process, an emulsion is sprayed onto the strip steel, the emulsion flow at the inlet along a rolling direction is smaller than or equal to 3,500 liters per minute, and the emulsion flow at an outlet along the rolling direction is 1,500-4,000 liters percent minute, so that the temperature of the strip steel is over 45 DEG C on the premise of ensuring process lubricating. The cold rolling method disclosed by the invention has remarkable effects of reducing strip breakage on a head and a tail, increasing rolled piece yield, increasing production efficiency, and the like, and has a remarkable economic benefit.

Owner:BAOSHAN IRON & STEEL CO LTD

30CrMo steel strip and production method thereof

InactiveCN107419192AControl surface decarburizationControl decarbonizationRoll force/gap control deviceTemperature control deviceChemical compositionThin slab

The invention discloses a 30CrMo steel strip and a production method thereof. The steel strip comprises the chemical compositions of, by mass, 0.26-0.34% of C, 0.17-0.30% of Si, 0.40-0.70% of Mn, less than or equal to 0.025% of P, less than or equal to 0.025% of S, more than or equal to 0.010% of Als, 0.80-1.10% of Cr, 0.15-0.25% of Mo, less than or equal to 0.30% of Ni, less than or equal to 0.30% of Cu, and the balance Fe and unavoidable impurities. The production method comprises the process of converter smelting, LF refining, thin slab continuous casting, heating, hot continuous rolling and coiling. The 30CrMo steel strip and the production method thereof start from the point of full process technology, the center shrinkage, the center segregation and the surface decarburization of the slab are eliminated, and the hot-rolled thin gauge steel strips with the thickness of 2.5-4.0mm are produced, so that the low-cost production of 30CrMo steel strip is realized.

Owner:TANGSHAN IRON & STEEL GROUP +1

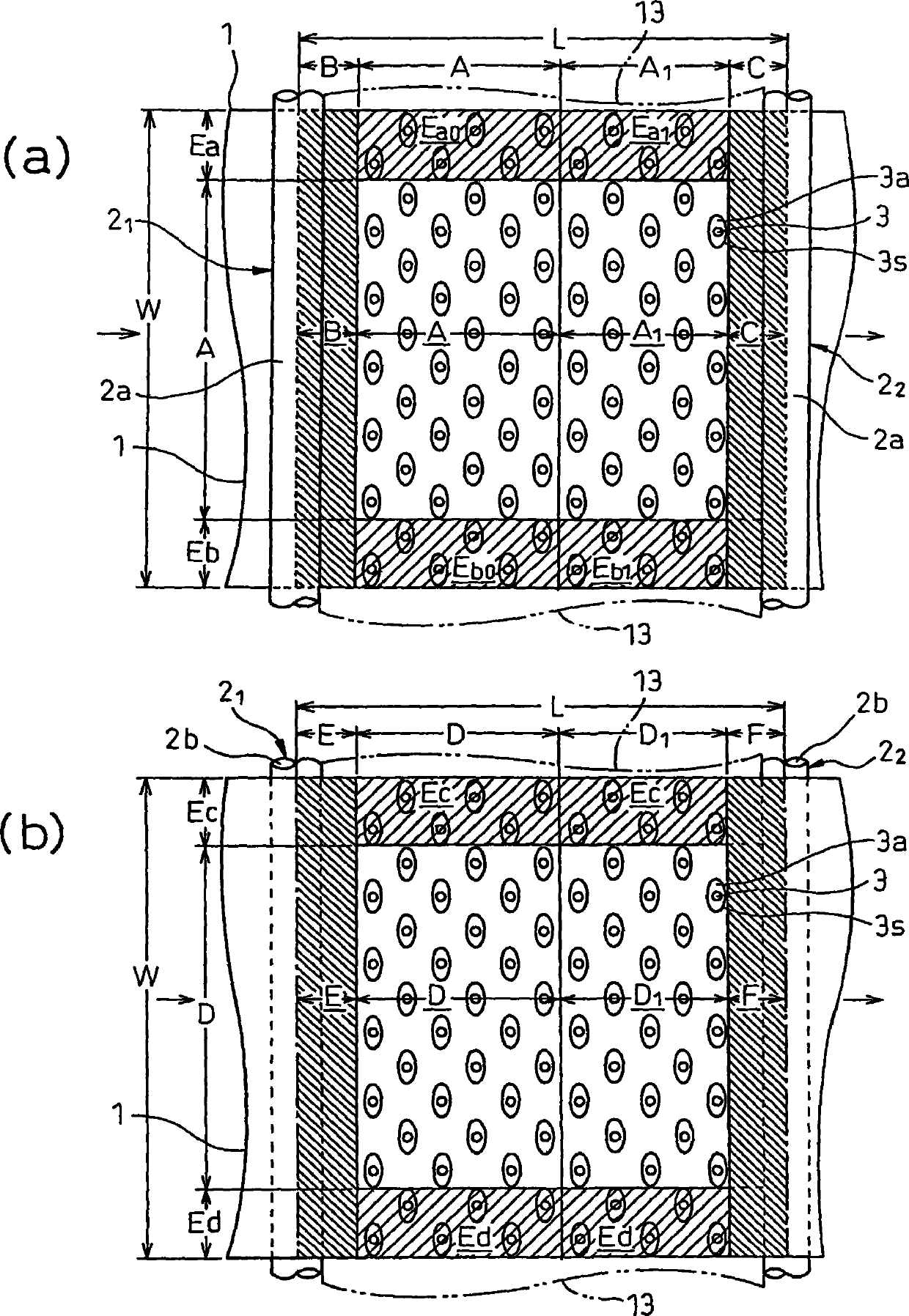

Cooling method of steel plate

ActiveCN101374613ATemperature control deviceWork cooling devicesSheet steelHeat transfer coefficient

A method for cooling the opposite surfaces of a steel plate under clamp conveyance between a clamp roll pair with refrigerant jet flow from the upper / lower surface nozzle groups between the clamp roll pair in which the upper and lower surfaces of a steel plate is cooled uniformly and precisely down to a target temperature while the quality of steel material is stably ensured by ensuring cooling control precision stably from start of cooling to end of cooling in the steel plate cooling region between the clamp roll pair. The steel plate cooling region between each clamp roll pair in which the upper / lower surface nozzle group is arranged is divided into at least a jet flow collision region and a jet flow non-collision region in the steel plate conveyance direction or in the steel plate conveyance direction and the width direction, heat transfer coefficient is predicted previously for each divided region, prediction temperature history of the steel plate is operated based on the prediction value, and then the quantity of refrigerant being jetted to the jet flow collision region of the upper / lower surface nozzle group is set and controlled.

Owner:NIPPON STEEL CORP

Method for using thin slab continuous casting and rolling technology for producing thin-specification, low-alloy and high-strength steel

ActiveCN106734201AIncreasing the thicknessIncrease pulling speedRoll force/gap control deviceTemperature control deviceDouble phaseThin slab

The invention relates to a method for using a thin slab continuous casting and rolling technology for producing thin-specification, low-alloy and high-strength steel. Molten steel is continuously cast into a continuous casting blank with the width being 1300 mm to 1600 mm and the thickness being 65 mm to 96 mm; then rough rolling, heat insulation cover heat insulation, induction heating, high-pressure water scale removing and finish rolling are conducted in sequence, and ultrathin strip steel with the width being 1300 mm to 1600 mm and the thickness being 1.3 mm to 1.6 mm is obtained; and finally the strip steel is controlled to be cooled, shorn in different rolled and are coiled into rolls. The yield strength of the thin-specification double-phase steel finished product ranges from 380 MPa to 430 MPa, the tensile strength ranges from 530 MPa to 610 MPa, and the elongation is larger than or equal to 25%. By means of the method, stable production of hot rolled thin-specification, low-alloy and high-strength steel with the thickness being 1.3 mm to 1.6 mm can be achieved, the size precision, the plate shape precision and the comprehensive mechanical performance are improved, the requirement for replacing cold with hot is met, and the production cost is reduced.

Owner:WISDRI ENG & RES INC LTD

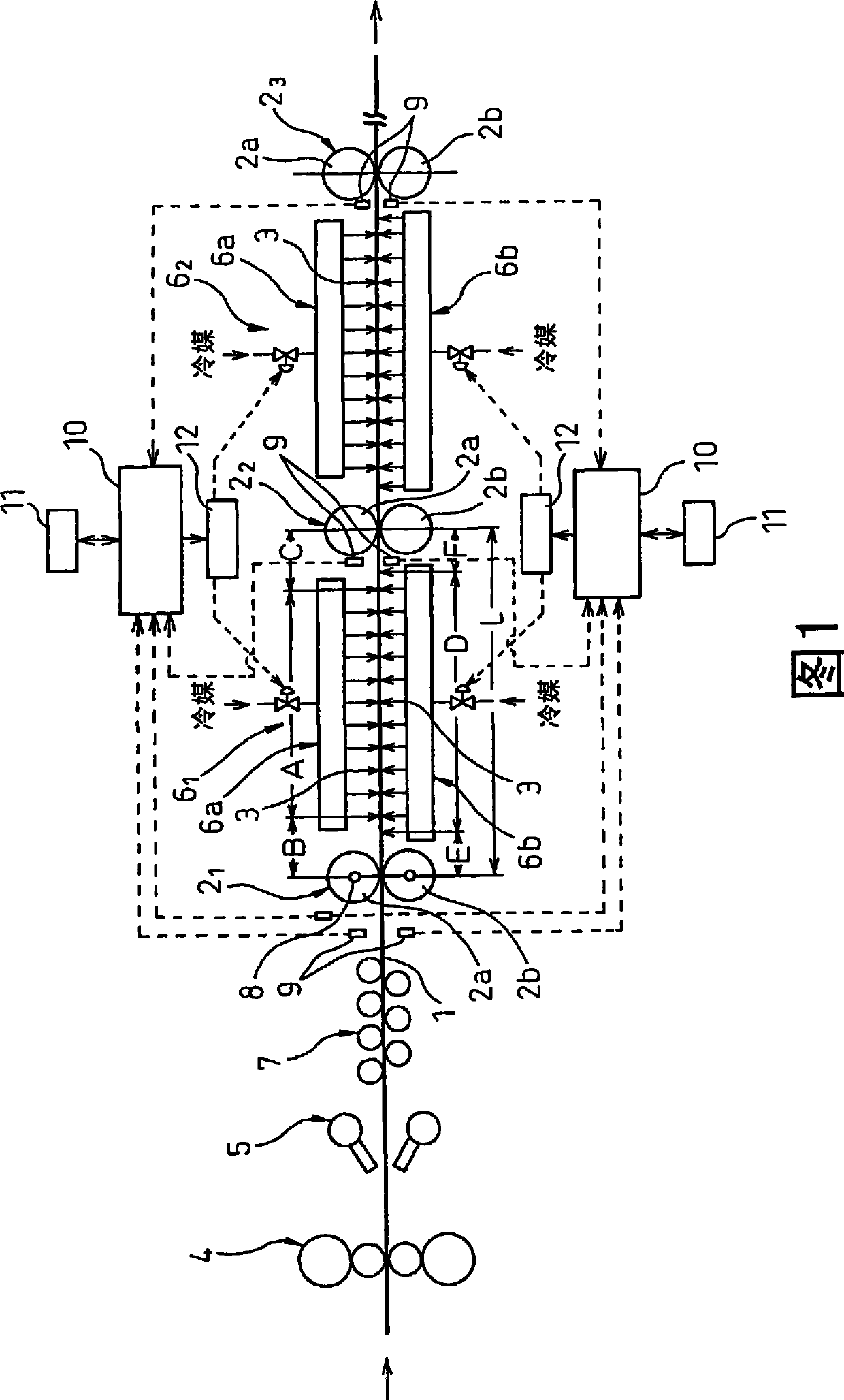

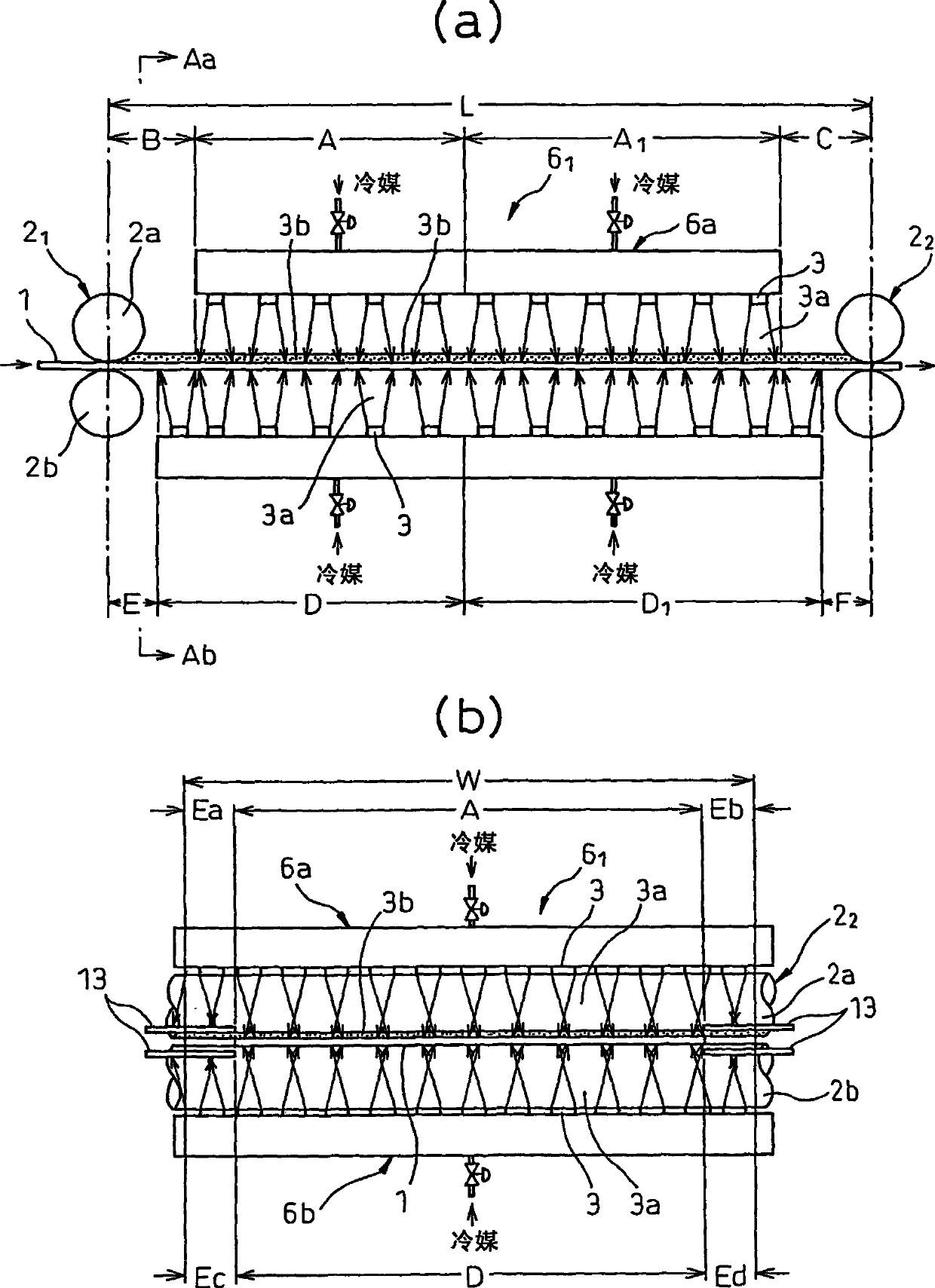

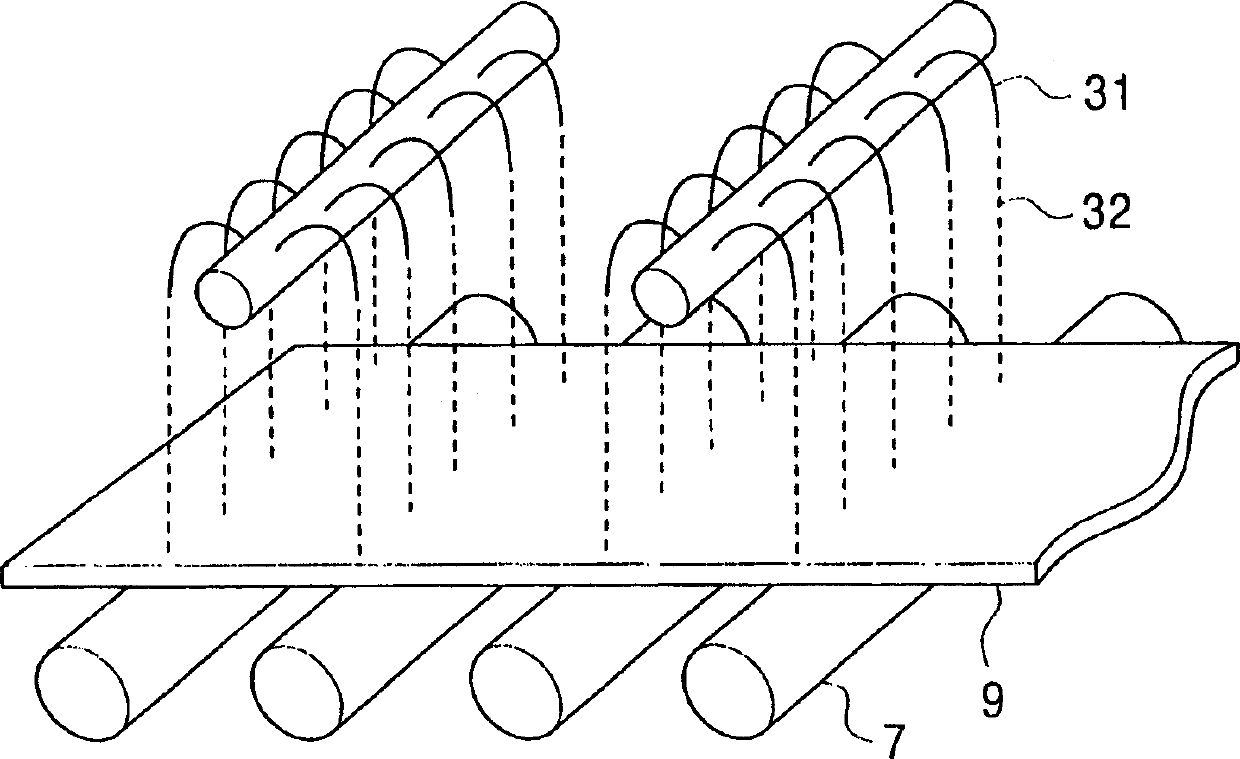

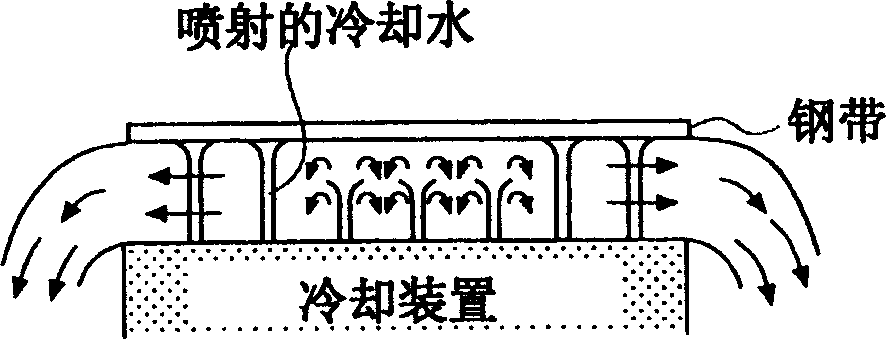

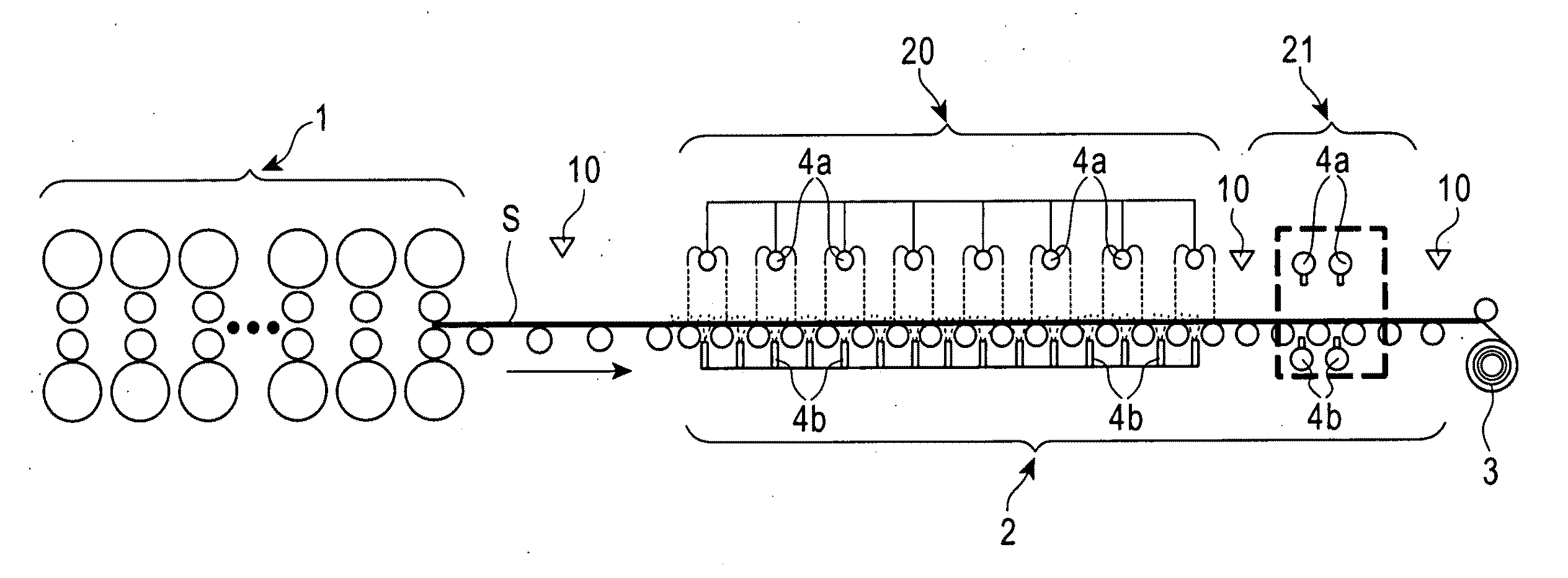

Cooling device, manufacturing method, and manufacturing line for hot rolled steel band

The present invention relates to a cooling apparatus for hot rolled steel strip comprising: an upper means for cooling an upper side of a steel strip transported by transporting rolls after hot rolling, located above the upper side of the steel strip; and a bottom means for cooling the bottom side of the steel strip, located under the bottom side of the steel strip, each means for cooling including: a protecting member having at least one cooling water hole slotted thereon, located near the surface of the steel strip; at least one cooling water header, located across the steel strip from the protecting member; and cooling water injection nozzles for injecting cooling water vertically onto the surface of the steel strip through the cooling water hole, projected on the cooling water header, wherein the top of the cooling water injection nozzle is positioned at a longer distance from the surface of the steel strip than the surface of the protecting member facing to the surface of the steel strip. The present invention allows to constantly transport the steel strip after hot rolling and to rapidly and homogeneously cool it.

Owner:JFE STEEL CORP

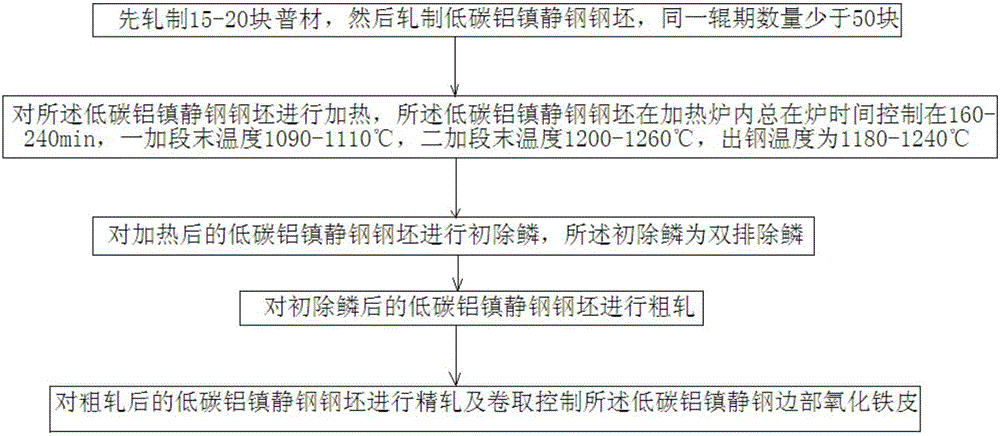

Hot rolling control method for scale on edges of low-carbon aluminum killed steel

InactiveCN105689408AAchieve the effect of easy picklingImprove surface qualityTemperature control deviceWork cooling devicesStrip steelHeating furnace

The invention discloses a hot rolling control method for scale on edges of low-carbon aluminum killed steel, and belongs to the technical field of steel rolling. The hot rolling control method comprises the following steps: first, rolling 15 to 20 pieces of common steel, and carrying out rolling to obtain low-carbon aluminum killed steel billets, wherein the piece number of the low-carbon aluminum killed steel billets in the same roller period is lower than 50; heating the low-carbon aluminum killed steel billets, wherein the total time when the low-carbon aluminum killed steel billets are in a heating furnace is controlled to be 160 to 240 min, the temperature at the end of the first heating period is 1090 to 1110 DEG C, the temperature at the end of the second heating period is 1200 to 1260 DEG C, and the steel discharging temperature is 1180 to 1240 DEG C; conducting primary descaling on the heated low-carbon aluminum killed steel billets, wherein the primary descaling adopts double-row descaling; conducting rough rolling on the primarily descaled low-carbon aluminum killed steel billets; conducting finish rolling on the low-carbon aluminum killed steel billets suffered to rough rolling, and controlling the scale on edges of the low-carbon aluminum killed steel billets suffered to finish rolling. The hot rolling control method has the advantages that the surface quality of edges of strip steel can be improved effectively; the production efficiency is improved; and a foundation is laid for energy consumption and cost reduction in a pickling process.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

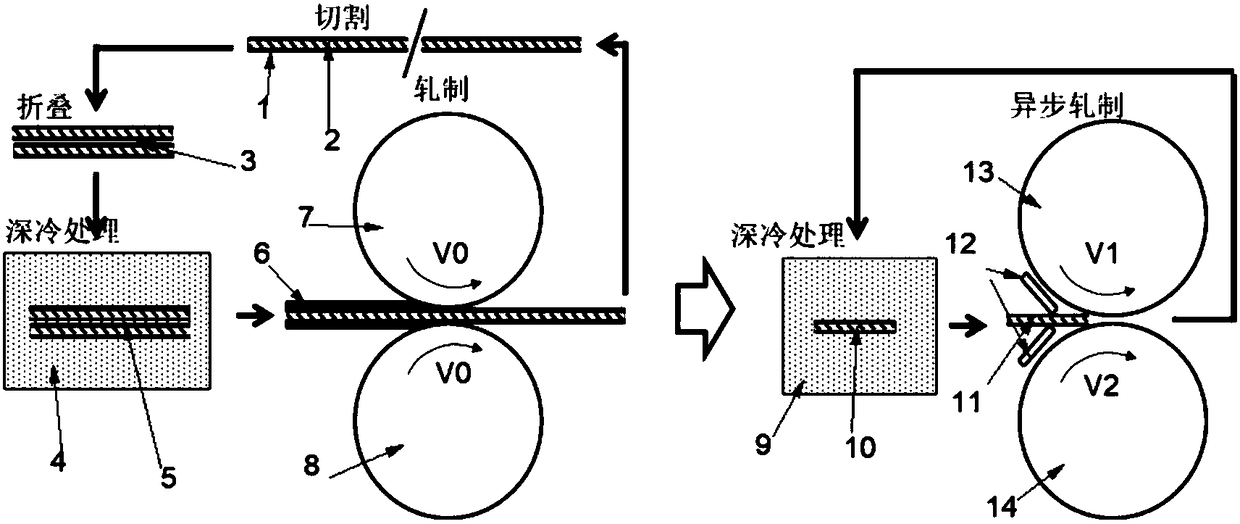

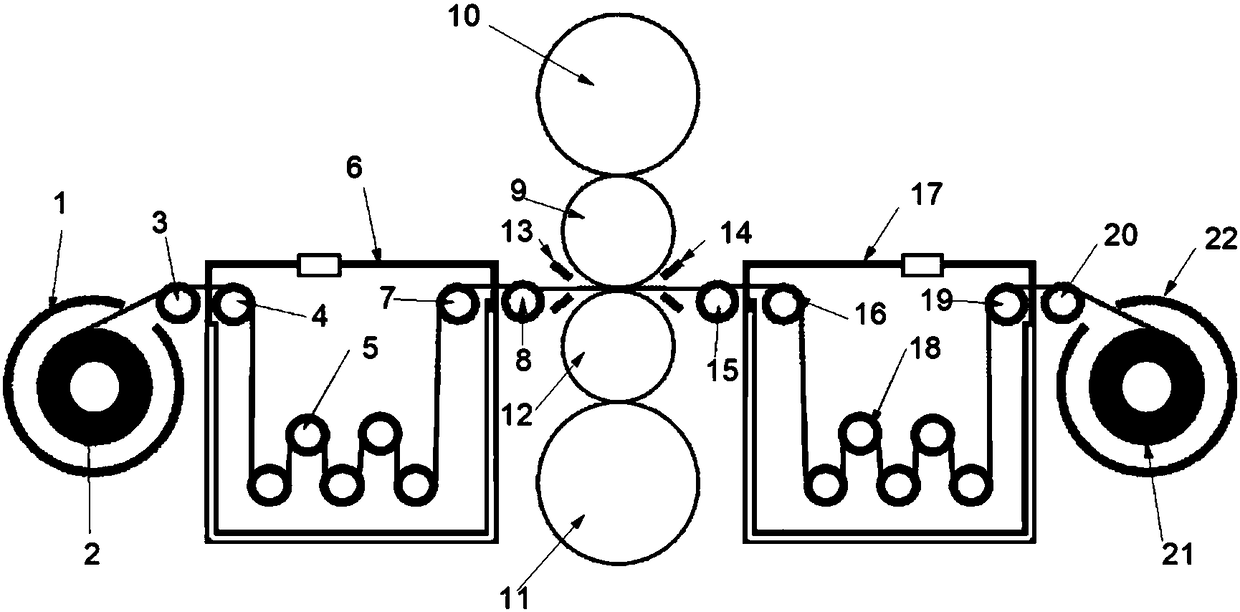

Continuous and reversible copious cooling rolling process and equipment for preparing high-performance aluminum alloy strip for car

InactiveCN108296286AHigh strengthImprove toughnessWork cooling devicesMetal rolling arrangementsNew energyUltimate tensile strength

Provided is a continuous and reversible copious cooling rolling process for preparing a high-performance aluminum alloy strip for a car. A copious cooling box and a coiling machine are additionally arranged on the two sides of a reversible rolling mill, the aluminum alloy strip is kept under an ultralow-temperature condition all the time through the copious cooling box, the coiling direction of the coiling machine is adjusted, and continuous rolling preparation of the aluminum alloy strip is achieved. The invention further provides continuous and reversible copious cooling rolling process forpreparing the high-performance aluminum alloy strip for the car. Compared with a steel material, aluminum alloy has very excellent deformability. Meanwhile, in the ultralow-temperature plastic deformation process of the aluminum alloy, plastic strain promotes grains to be refined, dislocation motion is restrained by ultralow temperature, and the strength and toughness of the aluminum alloy are greatly improved. Compared with the prior art, the aluminum strip prepared through the method has higher strength and toughness compared with an aluminum alloy strip prepared through traditional cold rolling, the aluminum alloy is likely to be applied to the fields of car weight reducing and the like, especially light reducing of new energy cars.

Owner:CENT SOUTH UNIV

Method of removing scale and inhibiting oxidation and galvanizing sheet metal

InactiveUS20050136184A1Prevent oxidationLess-expensive and troublesomePretreated surfacesCleaning using toolsSurface conditionsZinc

A method of removing iron oxide scale and galvanizing sheet metal bonds galvanizing zinc to a wustite layer of the sheet metal. The iron oxide scale on the sheet metal generally comprises three layers prior to surface conditioning: a wustite layer, a magnetite layer, and a hematite layer. The wustite layer is bonded to a base metal substrate of the sheet metal. The magnetite layer is bonded to the wustite layer, and the hematite layer is bonded to the magnetite layer. Conditioning the surface of the sheet metal includes bringing a surface conditioning member into engagement with the surface of the sheet metal in a manner to remove substantially all of the hematite and magnetite layers from the surface, and in a manner to remove some but not all of the wustite layer from the surface. The portion of the wustite layer that remains bonded to the base metal substrate of the sheet metal protects the surface from oxidation until the surface is galvanized.

Owner:THE MATERIAL WORKS

Device for influencing the temperature distribution over a width

InactiveCN101678419ARare end control deviceTemperature control deviceStrip steelIncrease temperature

The invention relates to a device (10) for influencing the temperature distribution over the width of a rolled material and / or a strip (11) or a slab, particularly in a hot strip mill, wherein at least one cooling device is provided and has nozzles (14) for applying a cooling means, wherein the nozzles (14) are arranged in such a manner or are controlled such that a cooling means is applied particularly to positions at which an increased temperature is detected. Furthermore, the invention relates to a device (10) for influencing the strip surface evenness by strip cooling, wherein according tothe surface evenness of the strip (11), the cooling device is controlled in such a manner that the uneven areas are reduced or removed. In addition, with this invention the strip contour can be influenced in a specific manner, wherein the strip (11) or the slab is cooled over the width thereof in such a manner that the strip contour better approximates a desired target contour.

Owner:SMS GRP GMBH

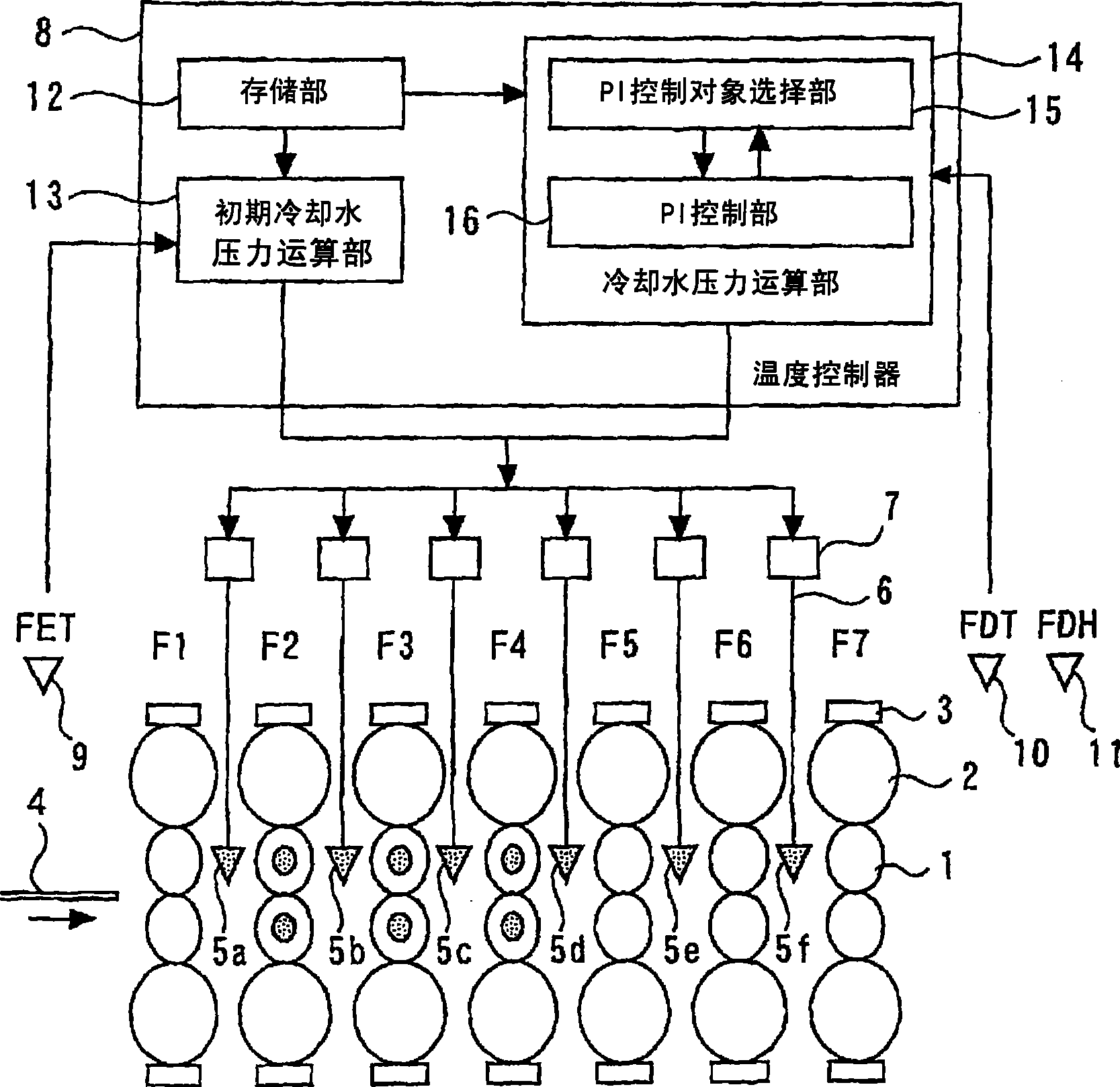

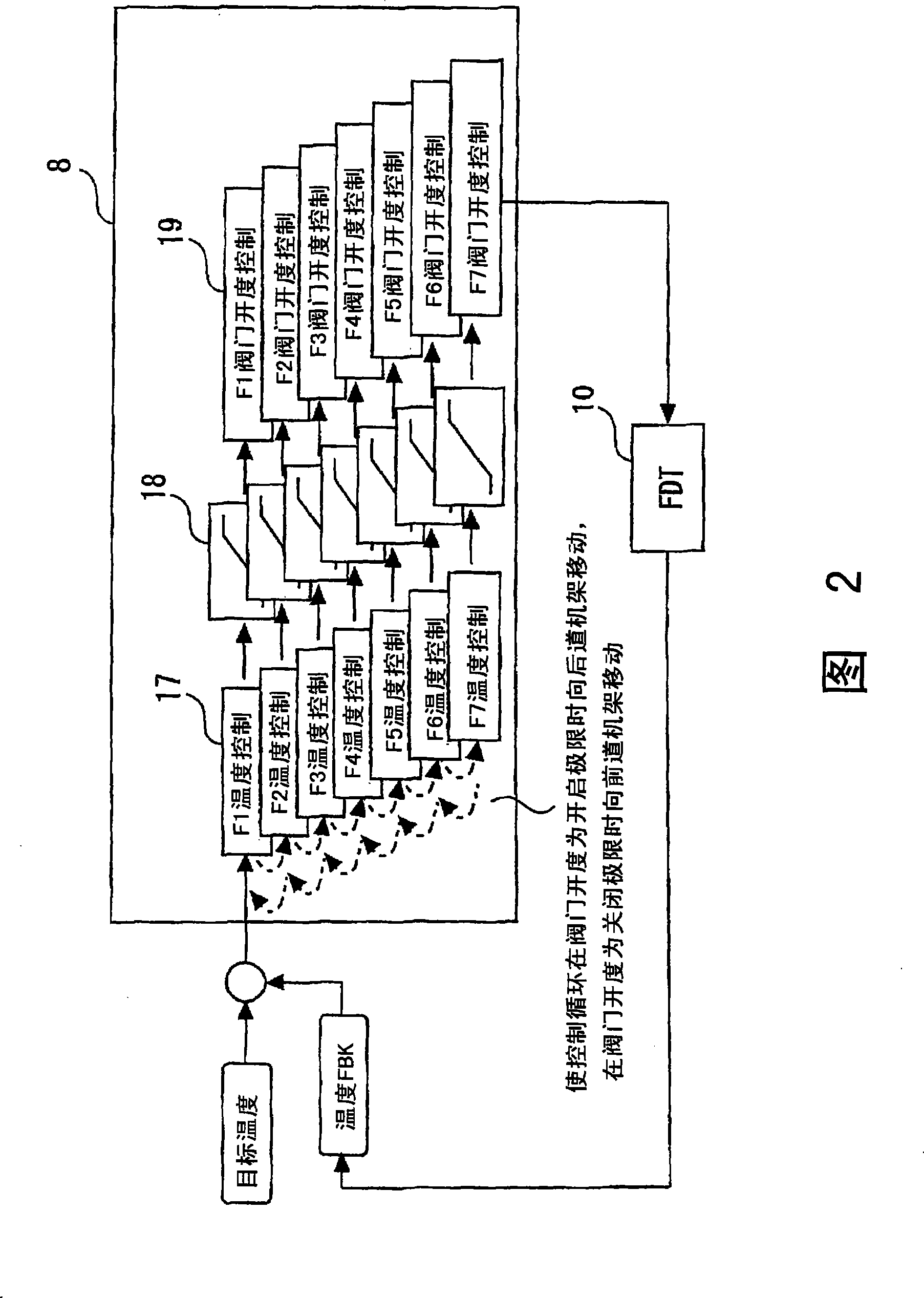

Temperature control device for hot rolling mill

ActiveCN101394945AReduce biasAvoid drastic changesTemperature control deviceWork cooling devicesLower limitTemperature control

A temperature control unit of hot rolling machine that avoids any sharp temperature change of rolling material at a place near the outlet of the rolling machine to thereby realize a high-precision control of sheet thickness. Accordingly, in a hot rolling machine equipped with multiple rolling stands continually disposed and further with multiple cooling units for cooling of rolling material, first, the cooling water pressure of each of the cooling units is computed using up to the upper limit pressure preferentially from one of the multiple cooling units disposed on the inlet side of the rolling machine on the basis of the target temperature and inlet actual temperature of the rolling material. Subsequently, on the basis of the target temperature and outlet actual temperature of the rolling material, so as to reduce any deviation between the target temperature and the outlet actual temperature, there is computed the cooling water pressure of one of the cooling units in operation disposed nearest the outlet of the rolling machine. At that stage, when the cooling water pressure of the cooling unit under control reaches the upper limit pressure, the control object is changed to the cooling unit disposed adjacent to the outlet of the rolling machine. On the other hand, when the cooling water pressure reaches the lower limit pressure, the control object is changed to the cooling unit disposed adjacent to the inlet of the rolling machine.

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

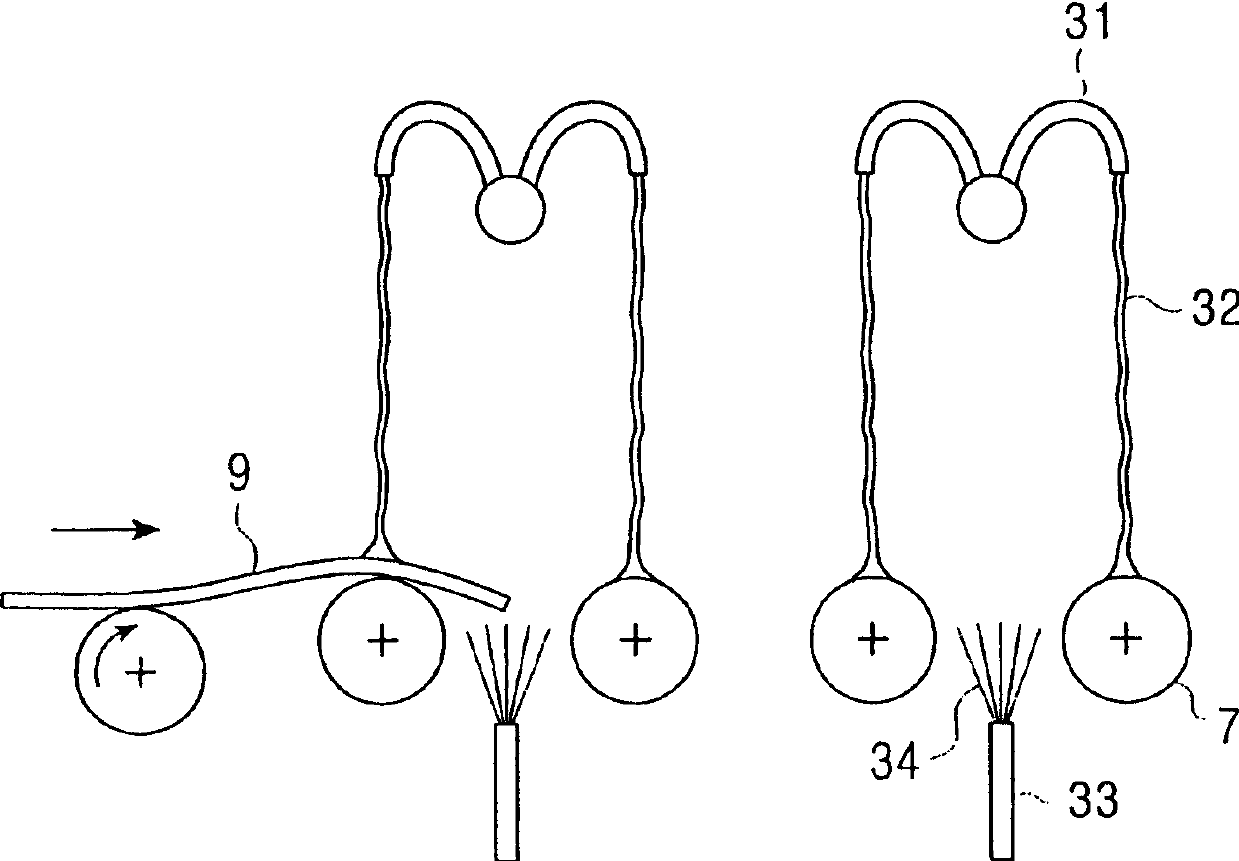

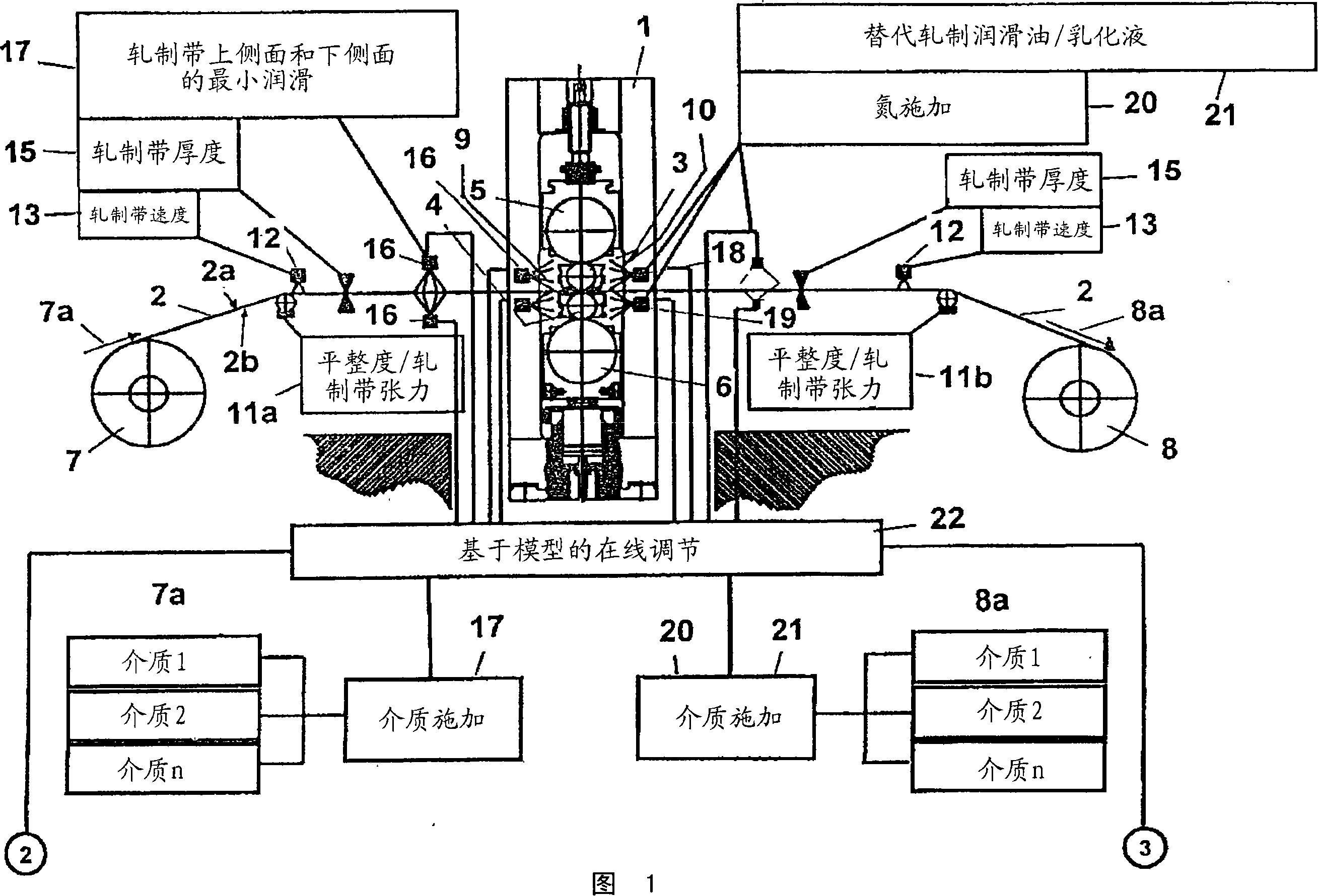

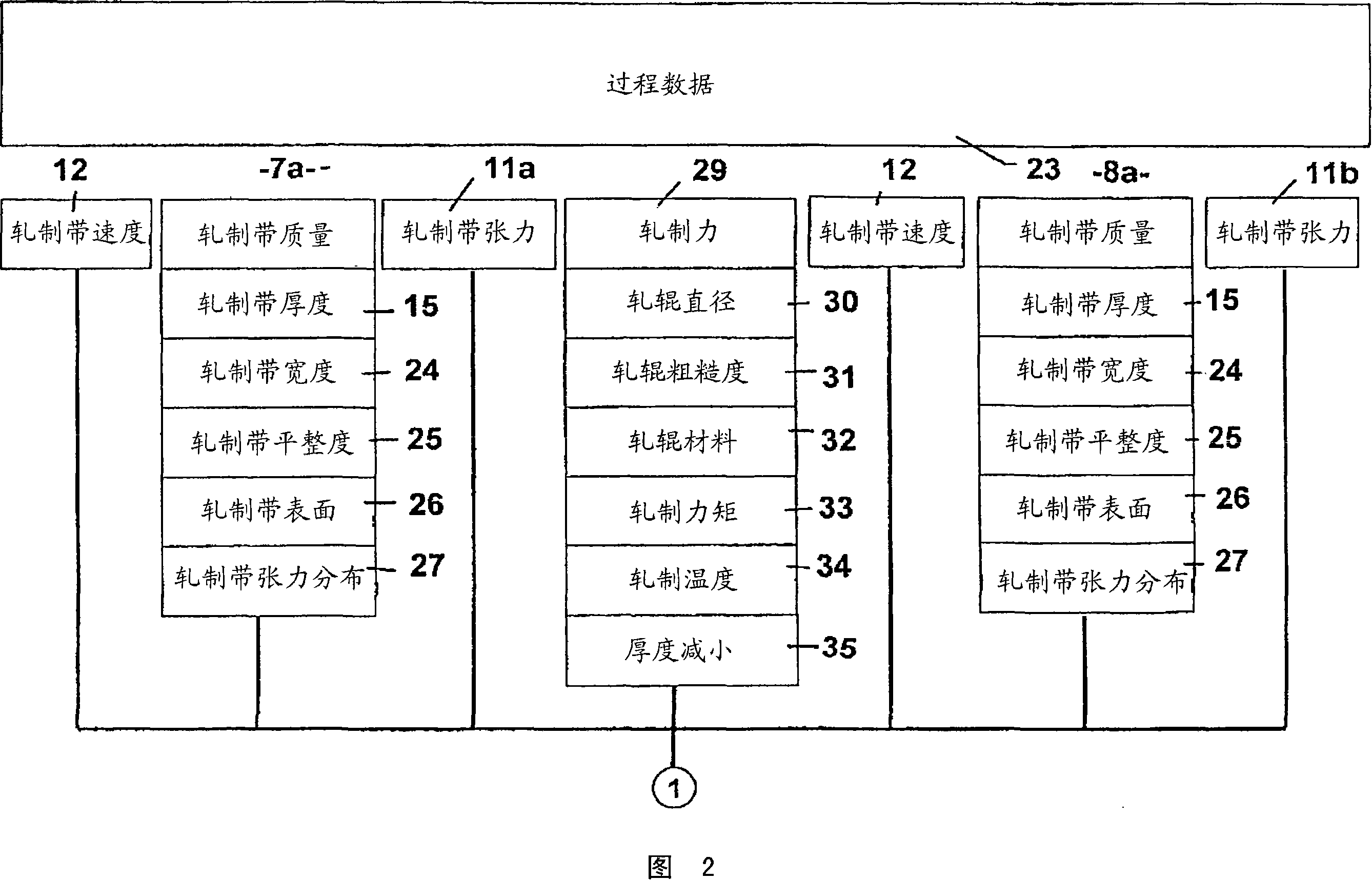

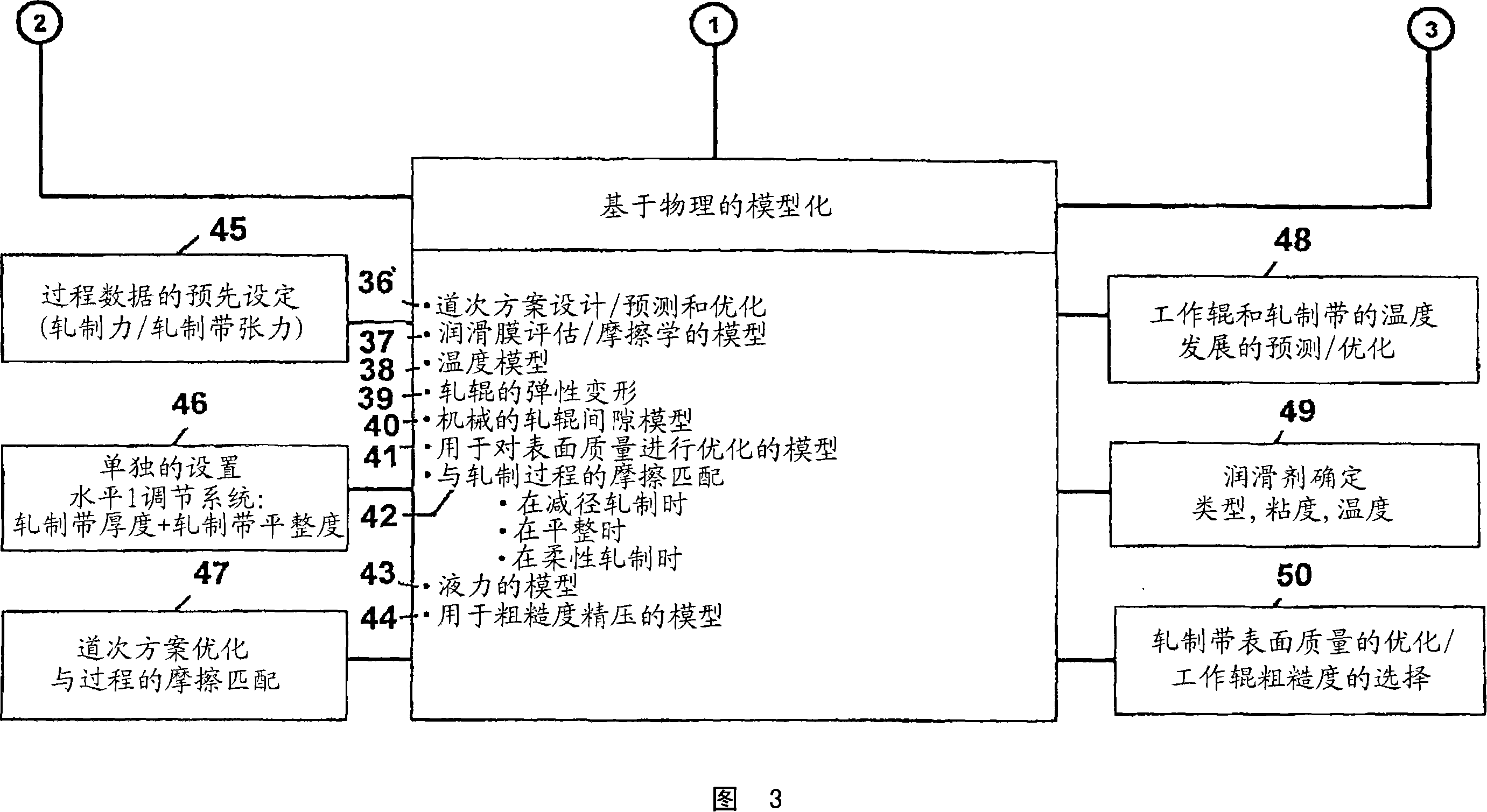

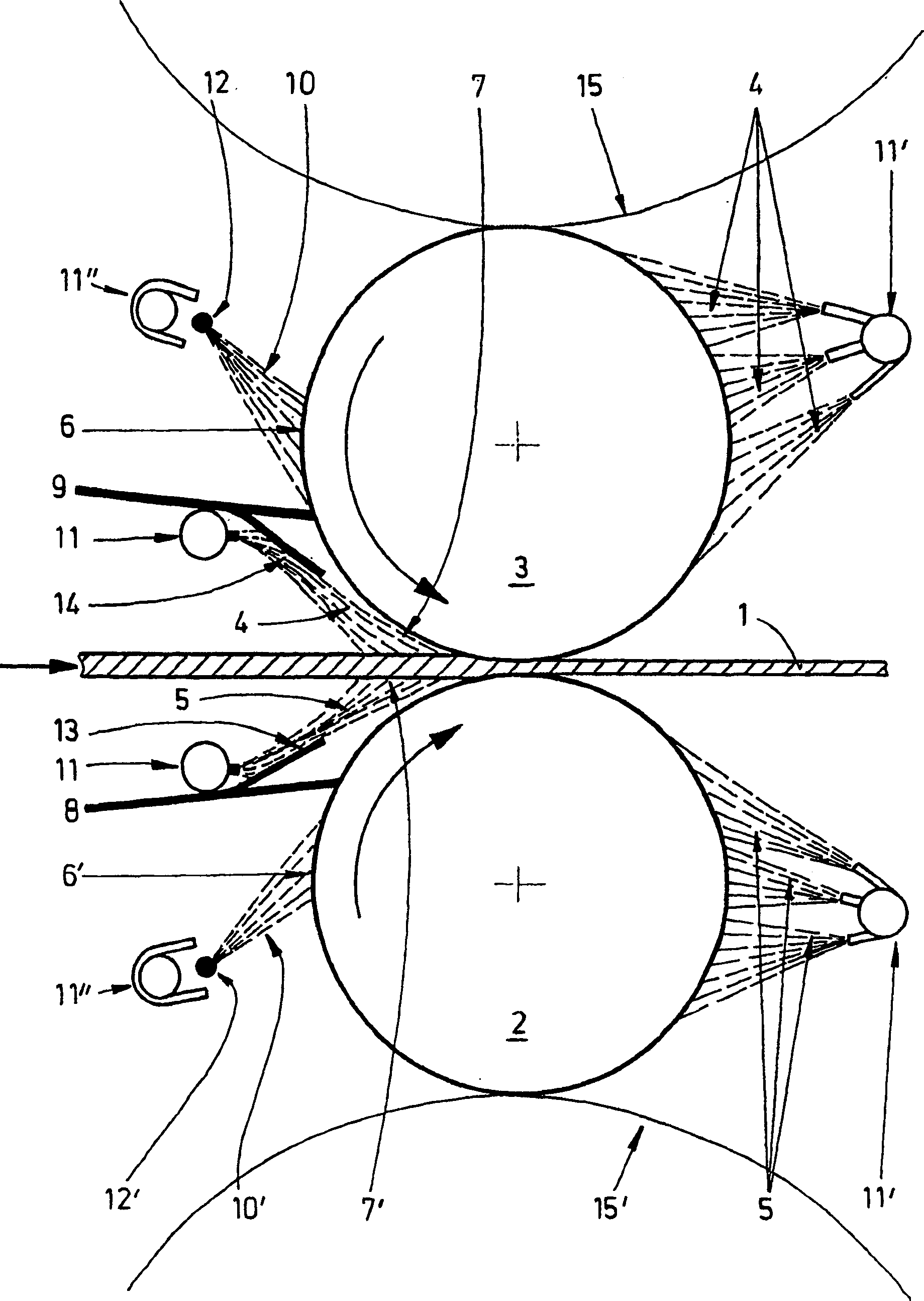

Method for lubricating and cooling rollers and metal strips on rolling in particular on cold rolling of metal strips

InactiveCN101253007ARolled strip of good qualityAchieving Friction MatchingRollsWork cooling devicesMetal stripsControl manner

The invention relates to a method for lubricating and cooling rollers (3,4,5,6) and metal strips (2) on rolling in particular, on cold rolling of metal strips (2), wherein, on the inlet side (7a) a minimal amount of pure lubricant (9) without a high water content is continuously supplied in an online controlled manner with a controlled viscosity and lubricity depending on a number of process data measurements (23) by means of a physical computer model (22) and the equivalent process data measurements (23) from the outlet side (8a) are also used online by the physical computer model (22).

Owner:SMS DEMAG AG

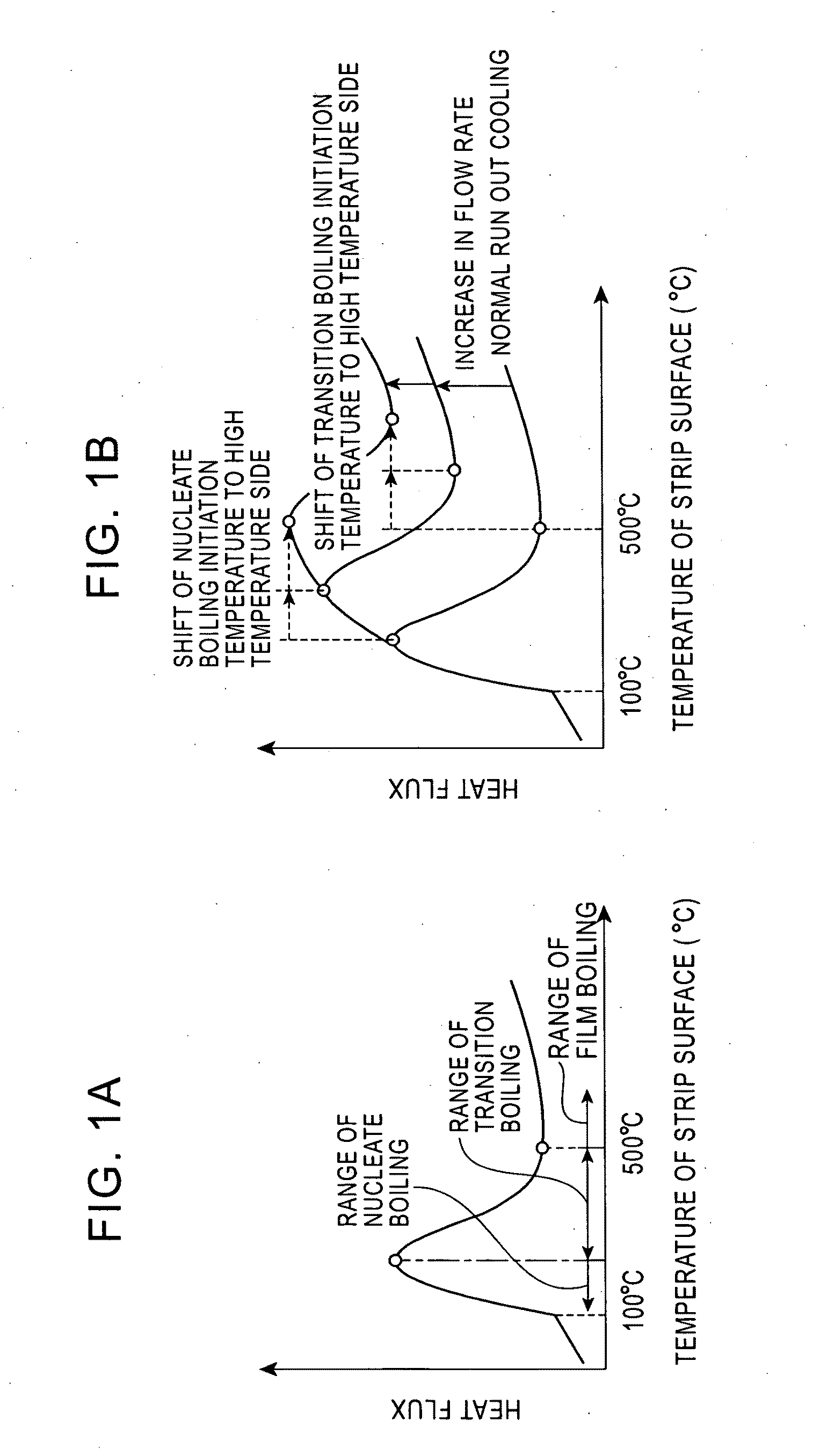

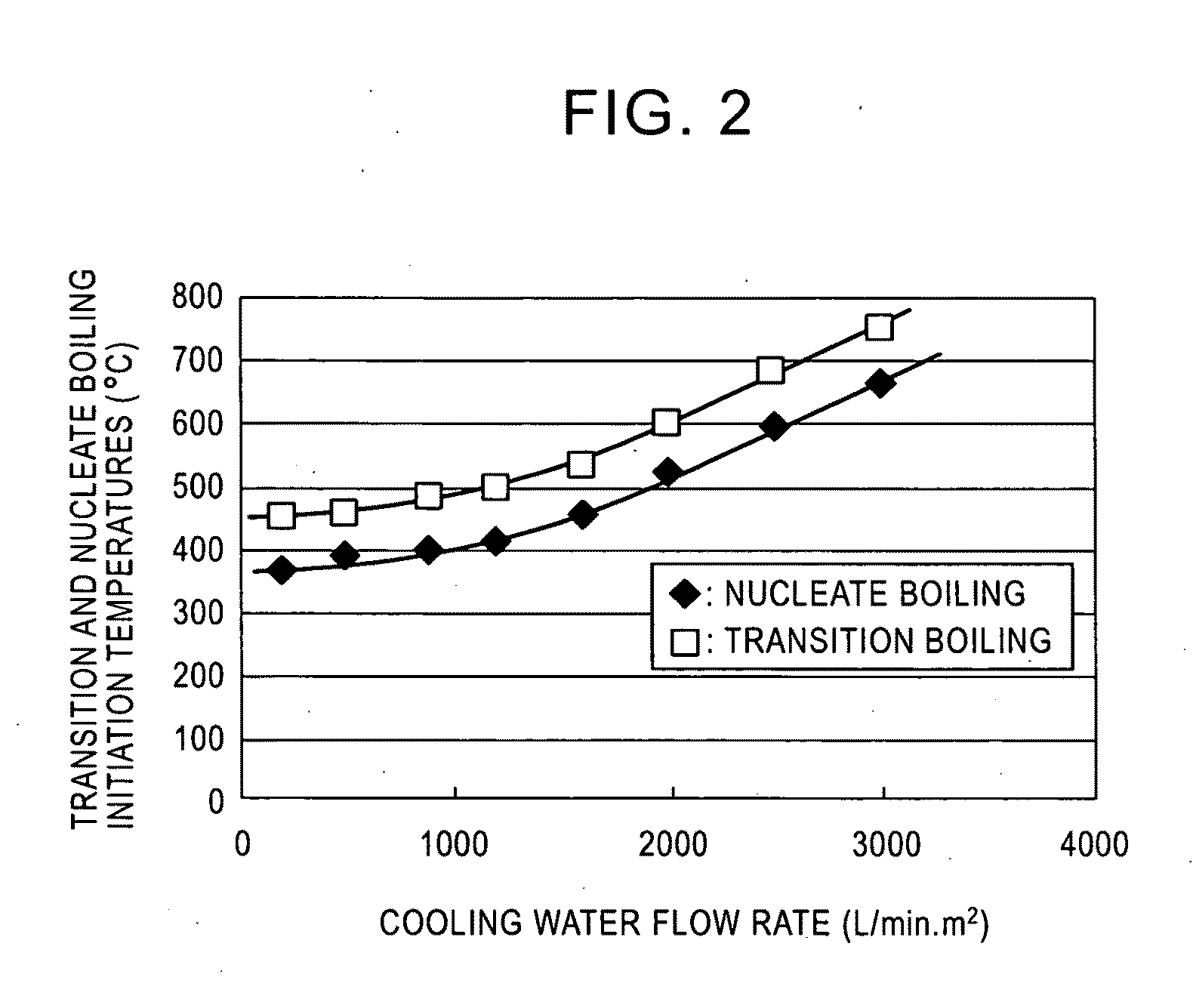

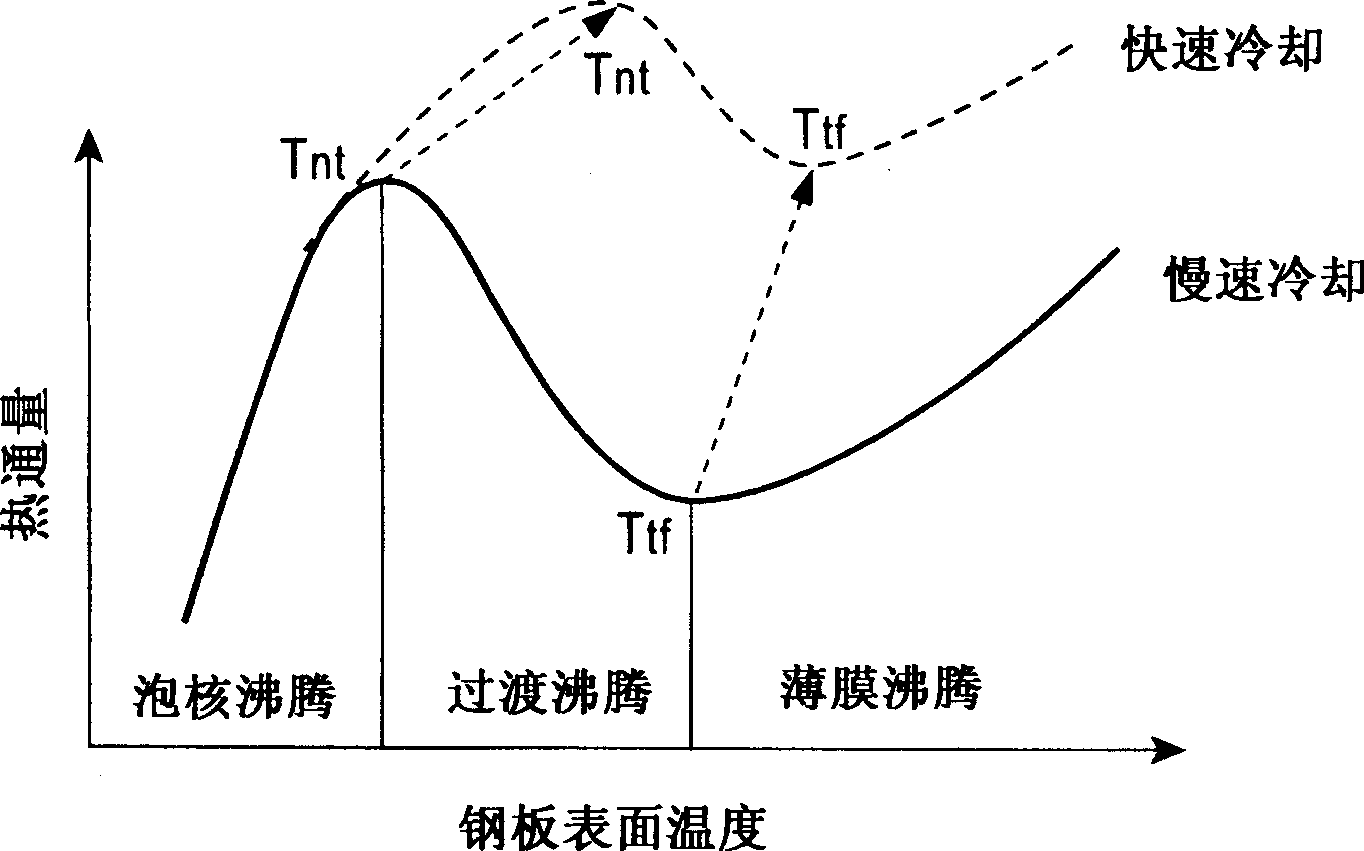

Method for cooling hot strip

ActiveUS20100192658A1Reduce temperature changesAvoid instabilityShaping toolsTemperature control deviceThermal instabilityWater flow

A method for cooling a hot strip with less facilities and processing costs in which the temperature variation of a strip after cooling is controlled to be small and a cooling end temperature can be precisely controlled particularly when the hot strip is cooled to the temperature range of 500° C. or less is provided. The method for cooling a hot strip, which is obtained after a hot rolling process, by bringing cooling water into contact with the hot strip, includes a first cooling step and a subsequent second cooling step. In this method, cooling is stopped at a strip temperature that is higher than a transition boiling initiation temperature in the first cooling step, and the cooling is conducted using the cooling water having a water flow rate that causes nucleate boiling in the subsequent second cooling step. Entering the temperature range of transition boiling can be completely prevented to avoid thermal instability in cooling resulting from the transition boiling, and the temperature variation of the strip after cooling is controlled to be small while the cooling end temperature can be precisely controlled.

Owner:JFE STEEL CORP

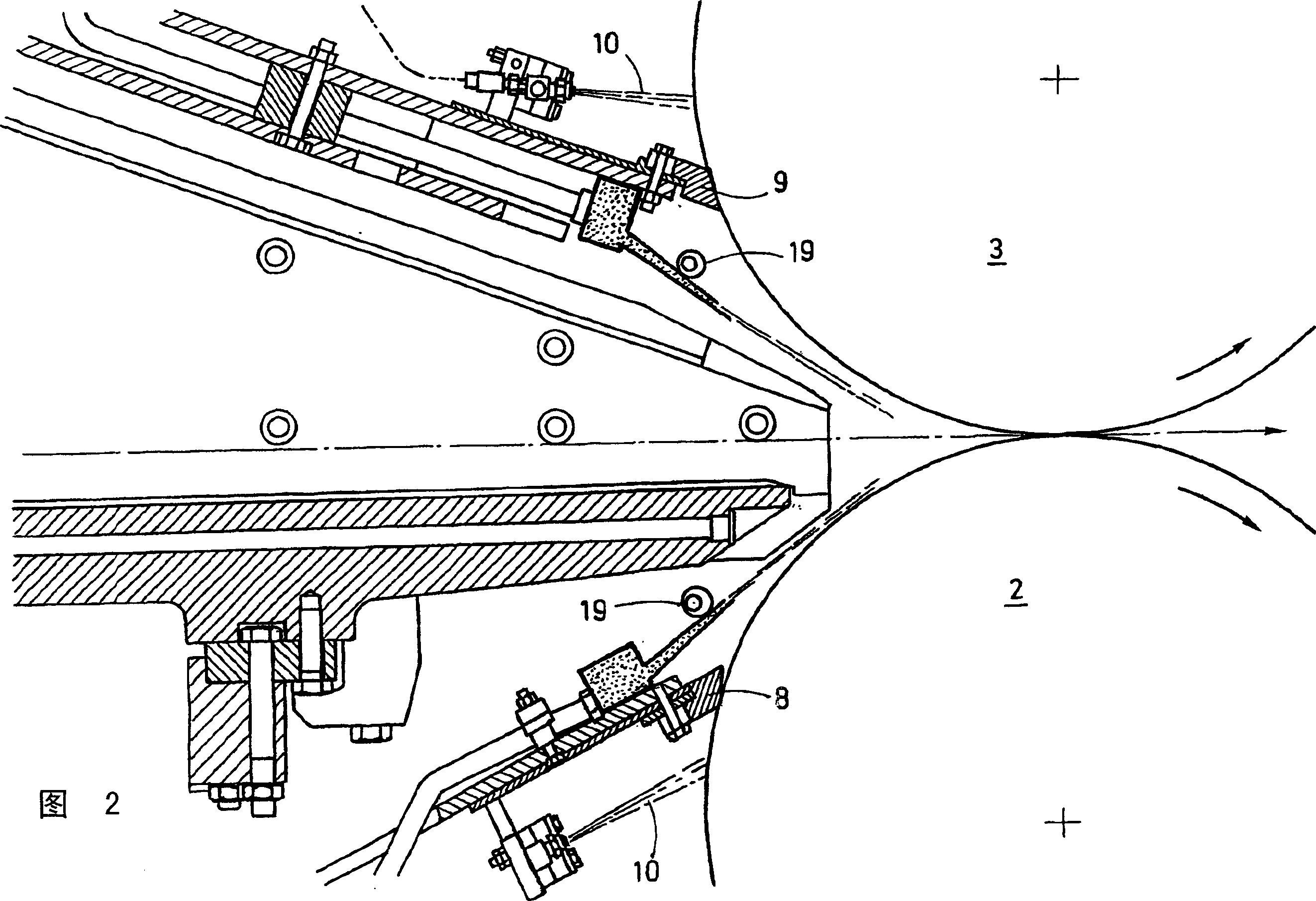

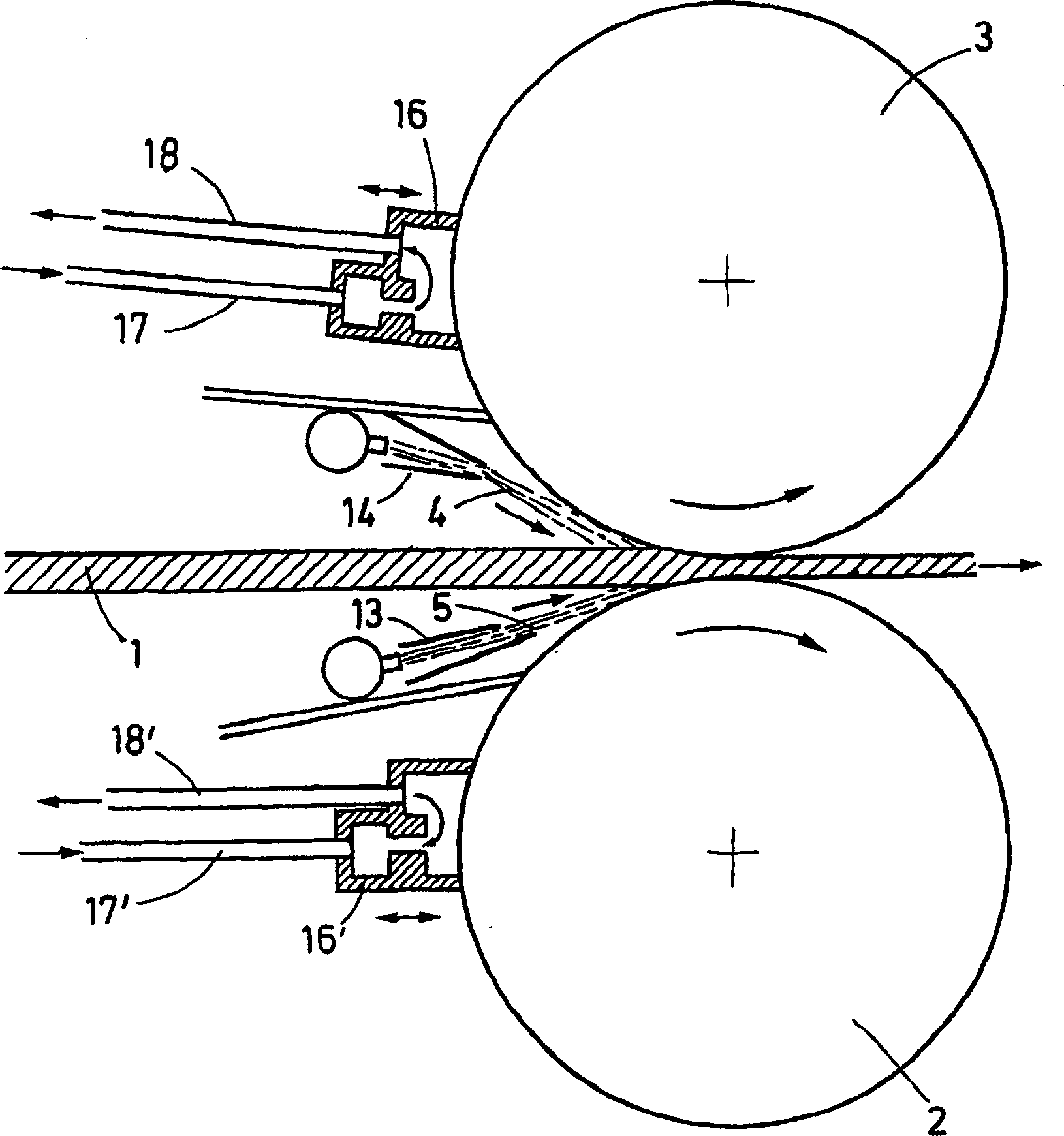

Method for cooling and lubricating rollers on rolling stand

InactiveCN1537035AIncrease stressPeeling suppressionRollsWork cooling devicesOil and greaseSuper cooling

The invention relates to a method and a device for cooling and / or lubricating rollers, in particular the working rollers (2, 3) on a rolling stand and a rolled strip (1), rolled between the above rollers and transported onwards, using water in the form of spray jets (4, 5) as cooling medium and oil, oil / air mix, oil / water mix, oil / air / water mix or grease mixtures as lubricant. In order to improve the lubricating and cooling effects, a combined application of super-cooling the strip and roller surfaces and roller lubrication on the input side of the stand is disclosed, in which both media, water and lubricant, are separately fed to the rollers (2, 3) and the rolled strip and applied to the roller surface at different application points. Separate reservoirs for water and lubricant and separate lines to the spraying bar (11) for water and the spraying bar (12) for the lubricant are provided.

Owner:SMS DEMAG AG

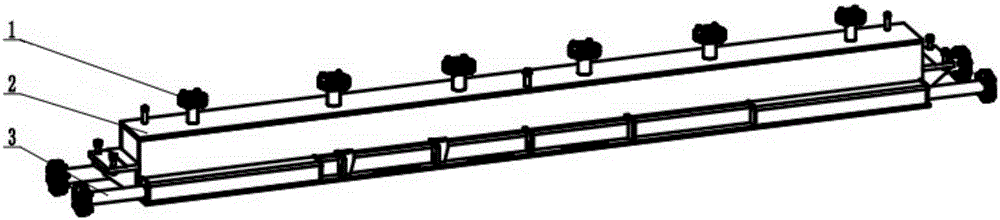

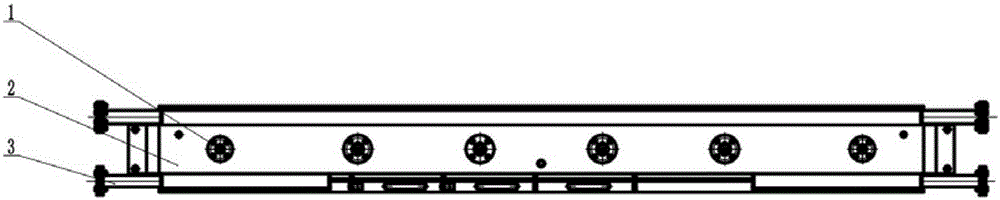

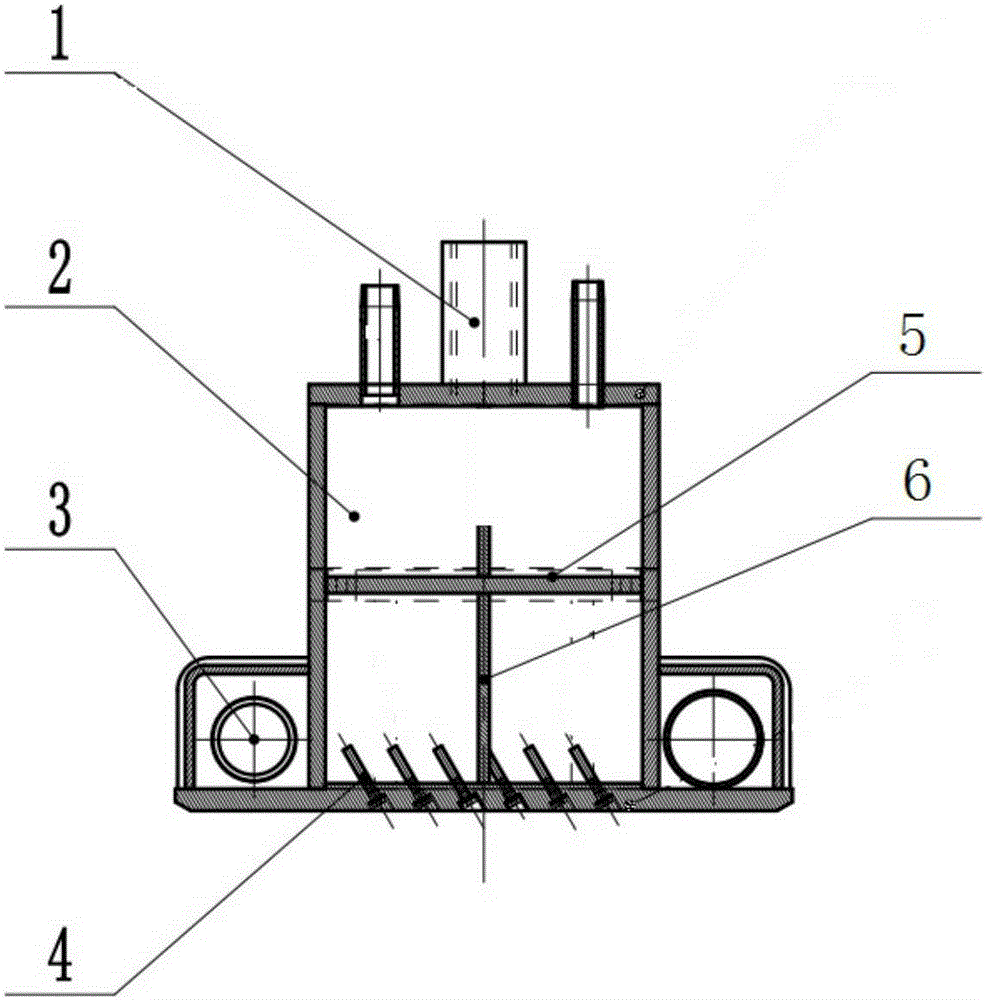

Multi-cavity flow-controllable spray header

ActiveCN105170662AAccurate and controllable flowAdjust the spray effectFurnace typesWork cooling devicesStrip steelEngineering

The invention relates to the technical field of controlled rolling and controlled cooling of hot rolled strips, in particular to a multi-cavity flow-controllable spray header. The spray header comprises a hole damping plate transversely arranged in a water spraying cavity, a nozzle arranged on the lower surface of the spray header, a long partition plate vertically arranged in the length direction of the water spraying cavity, and a plurality of short partition plates arranged in the water spraying cavity; the water spraying cavity is divided into a plurality of independent chambers in different shapes through the hole damping plate, the long partition plate and the short partition plates, and the flows of the chambers are independently controlled; and the good jet fluid shape can be kept under the condition of large-range pressure and flow adjusting. Large-range stepless adjustment of the instant cooling speed of a steel plate can be achieved, the steel plate cooling process has the extremely high uniformity, and fine and uniform cooling of the rolled steel plate can be achieved under the high-strength cooling condition; and the internal texture of the steel plate is uniform, small in stress and good in plate shape, and plate deformation appearing in the production process can be effectively avoided.

Owner:广西先进铝加工创新中心有限责任公司

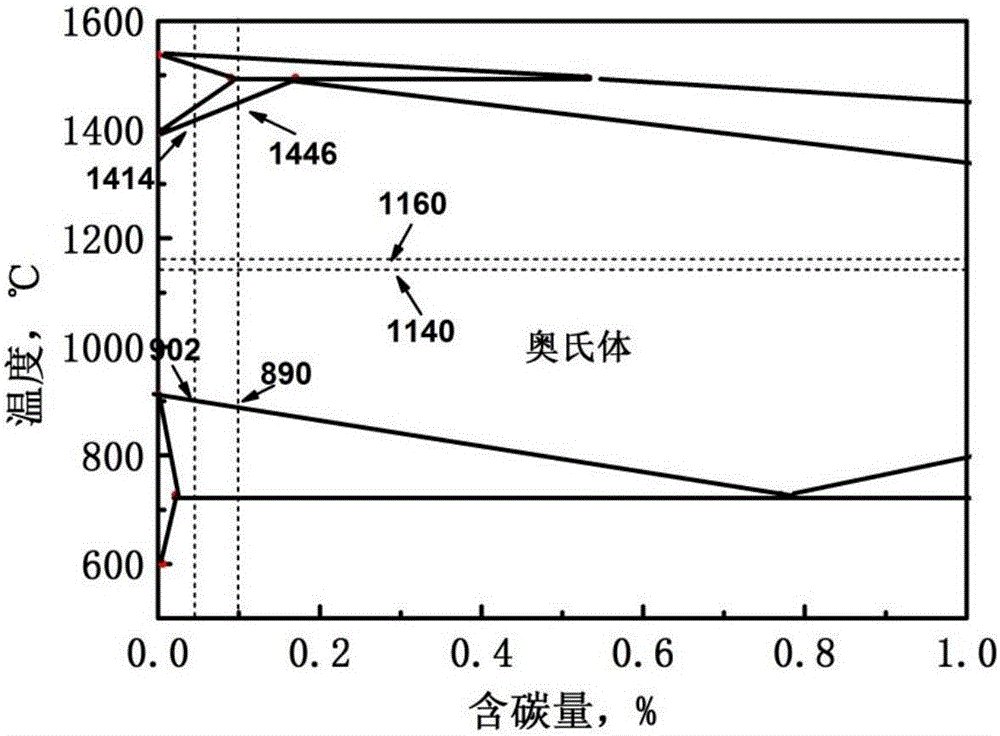

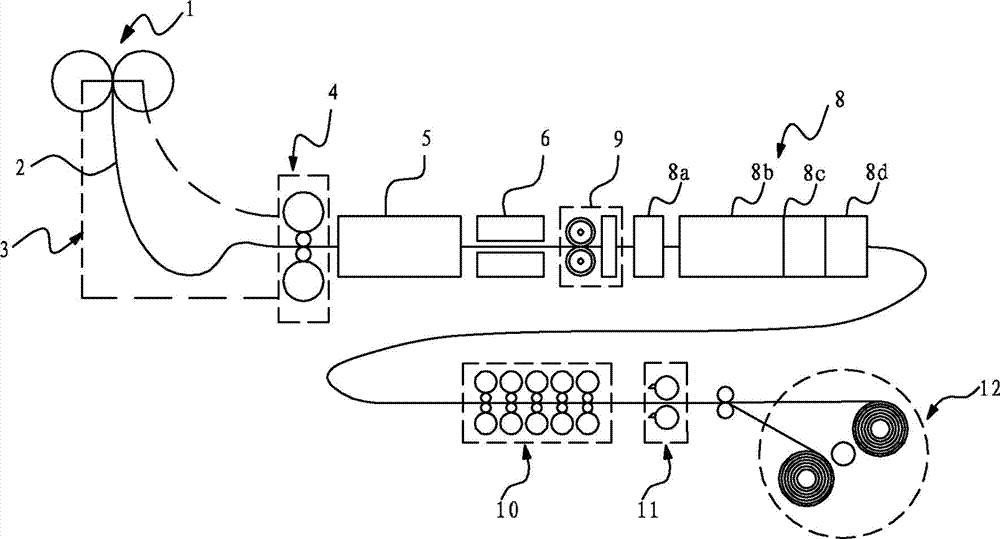

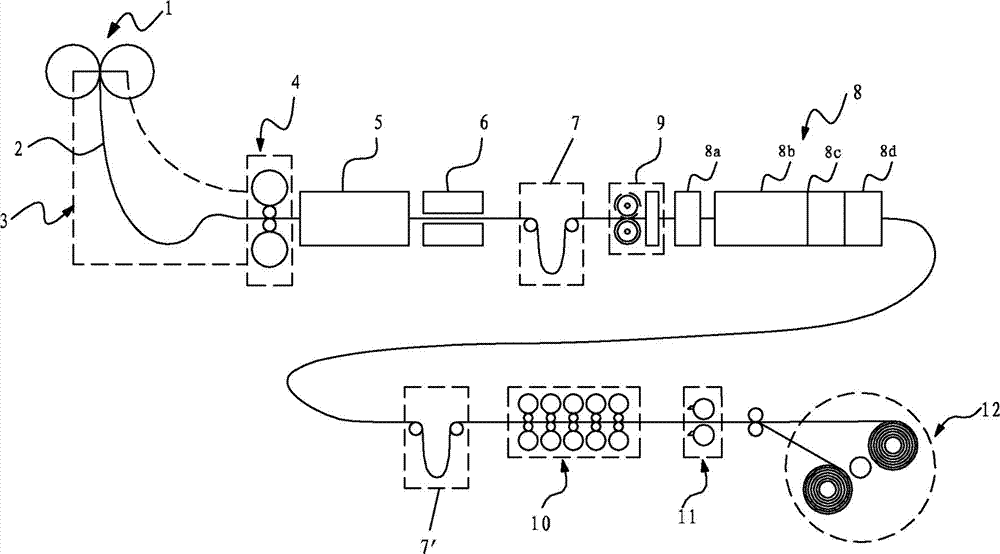

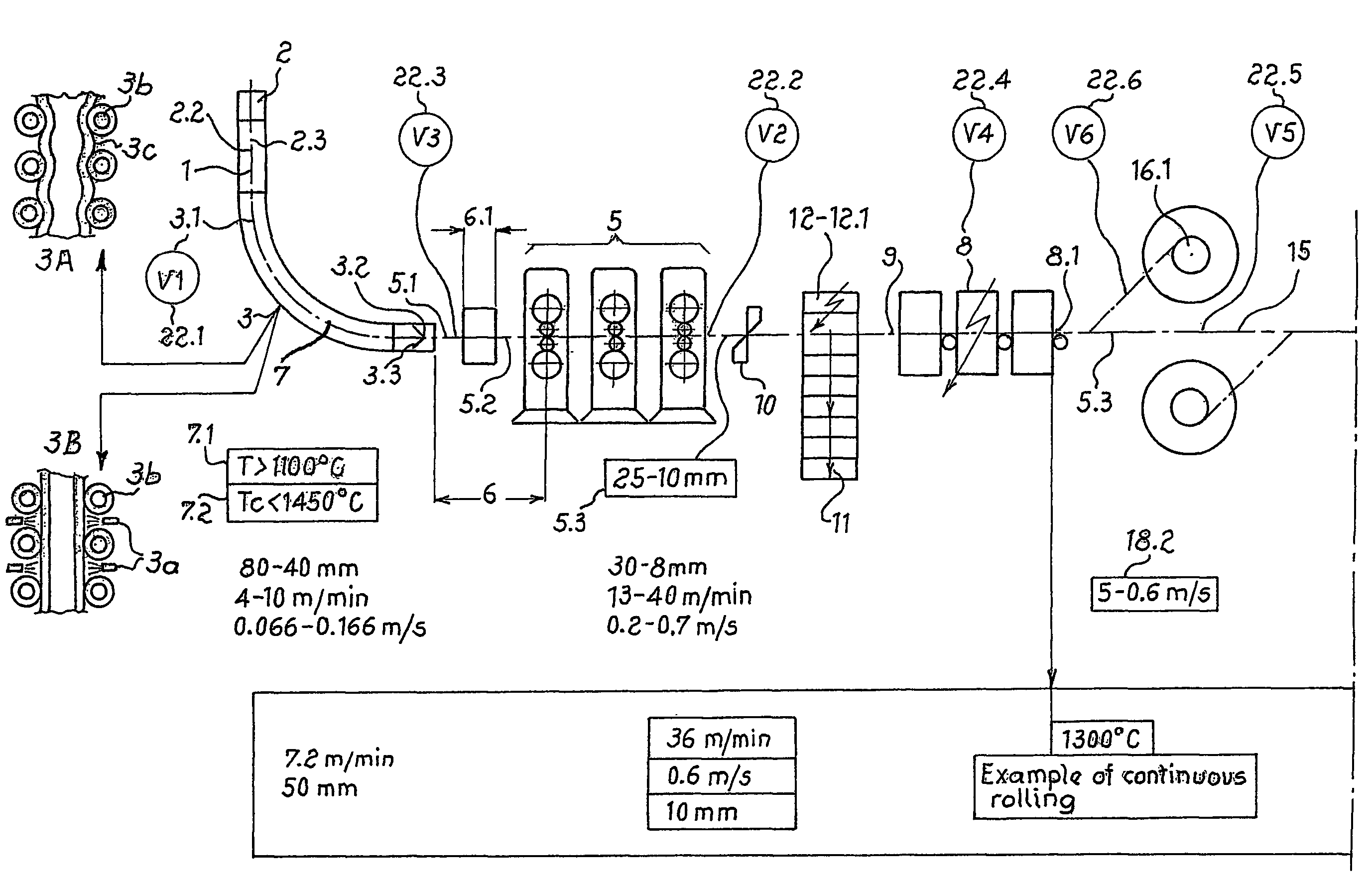

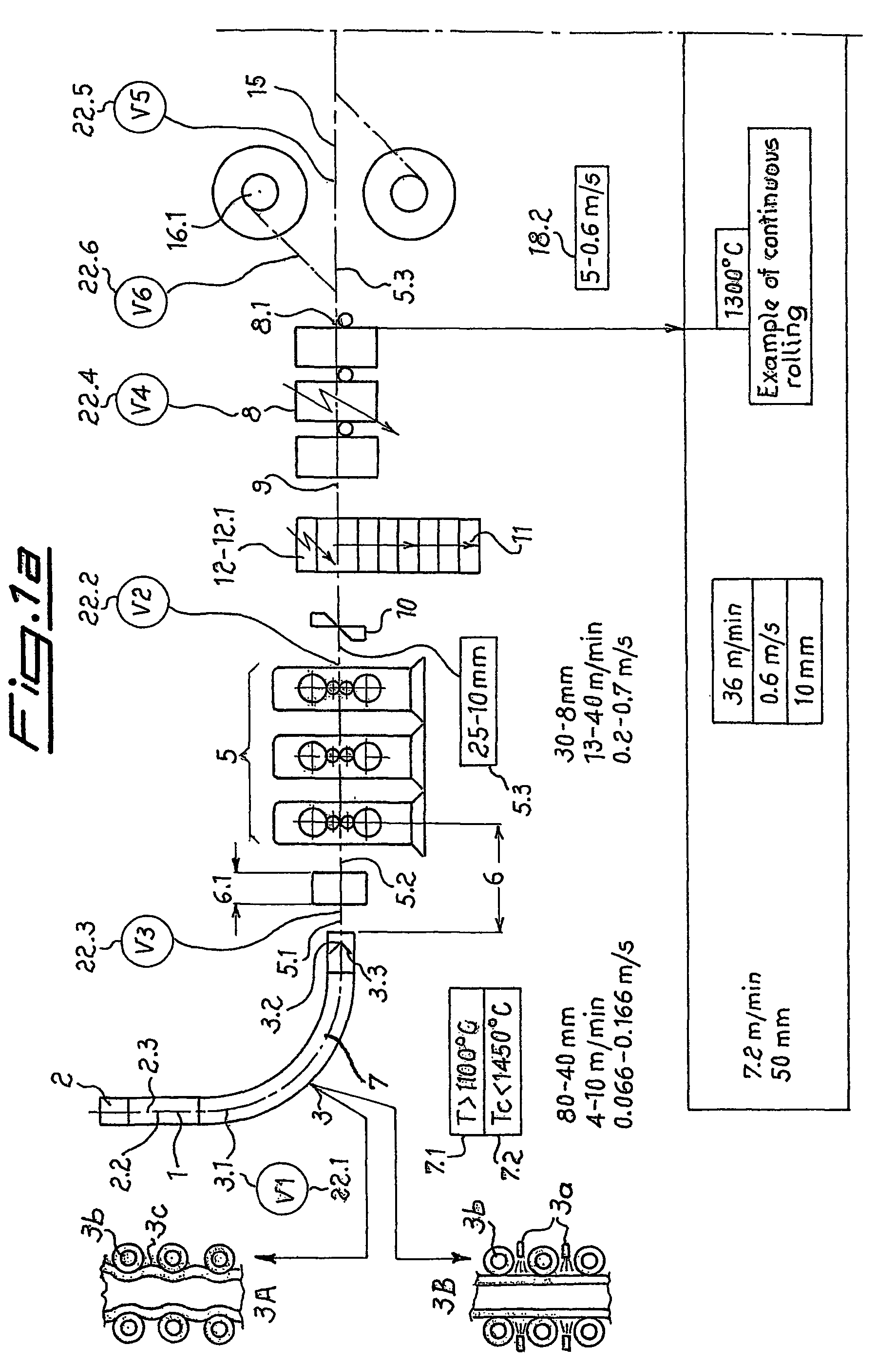

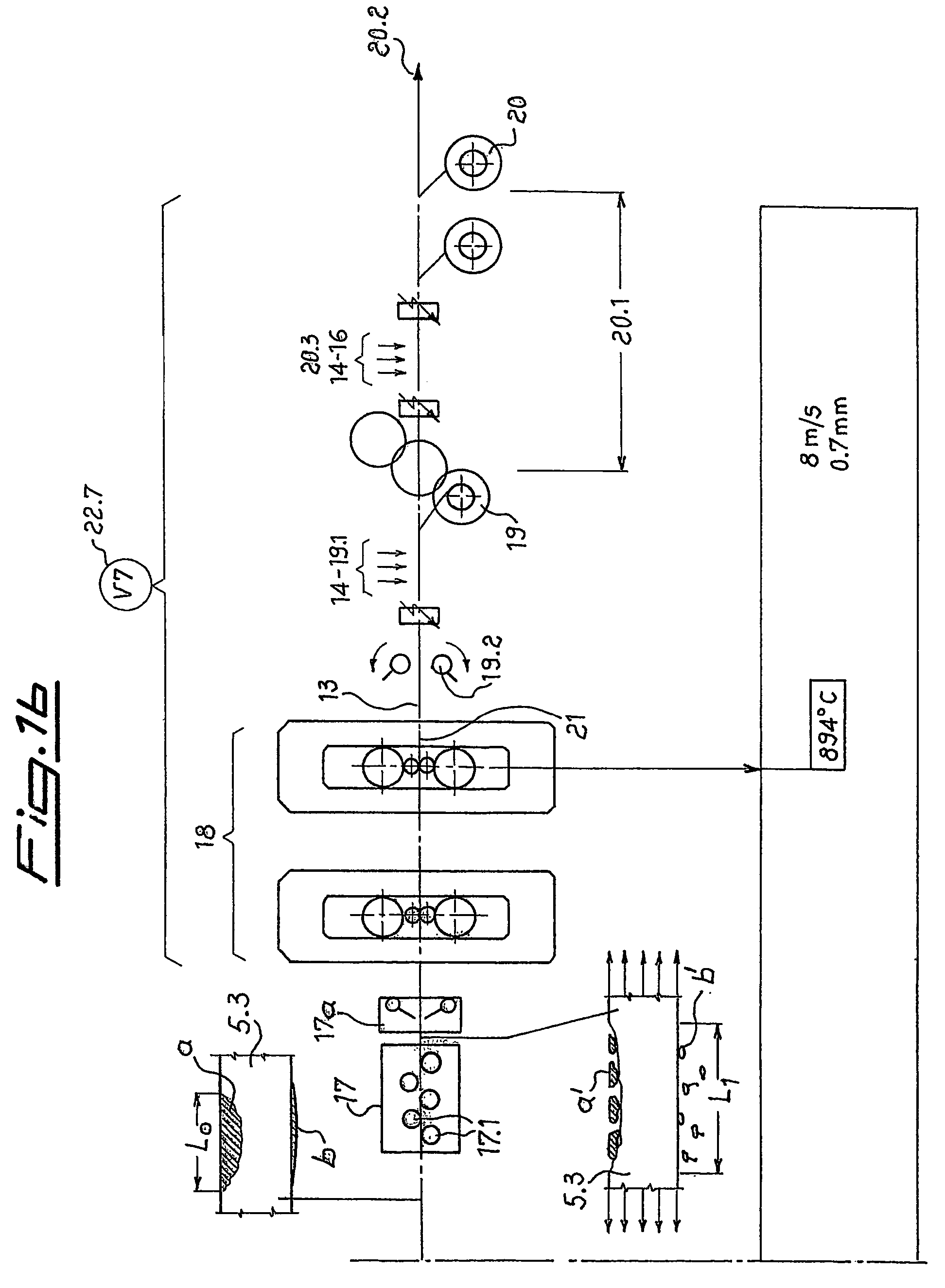

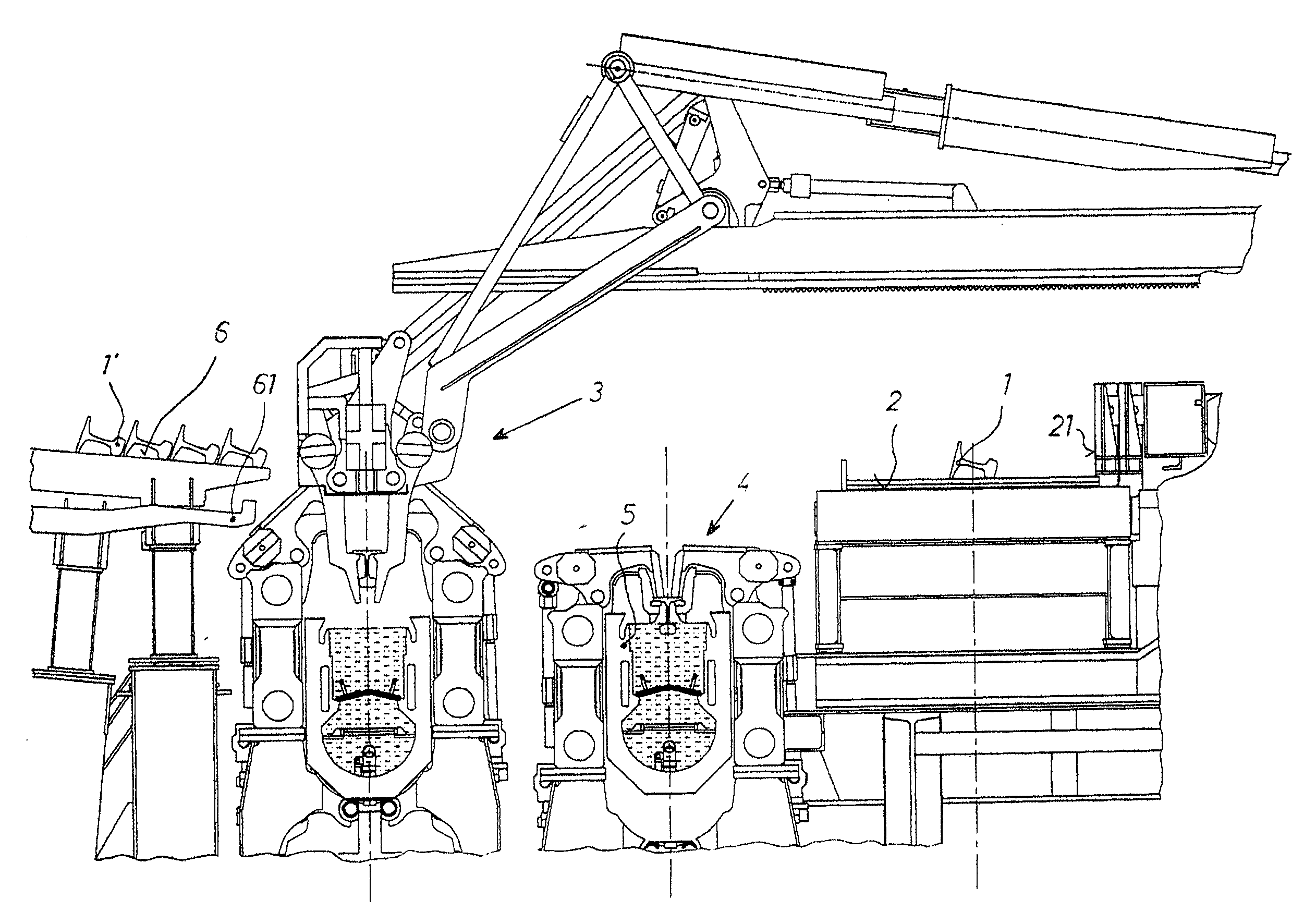

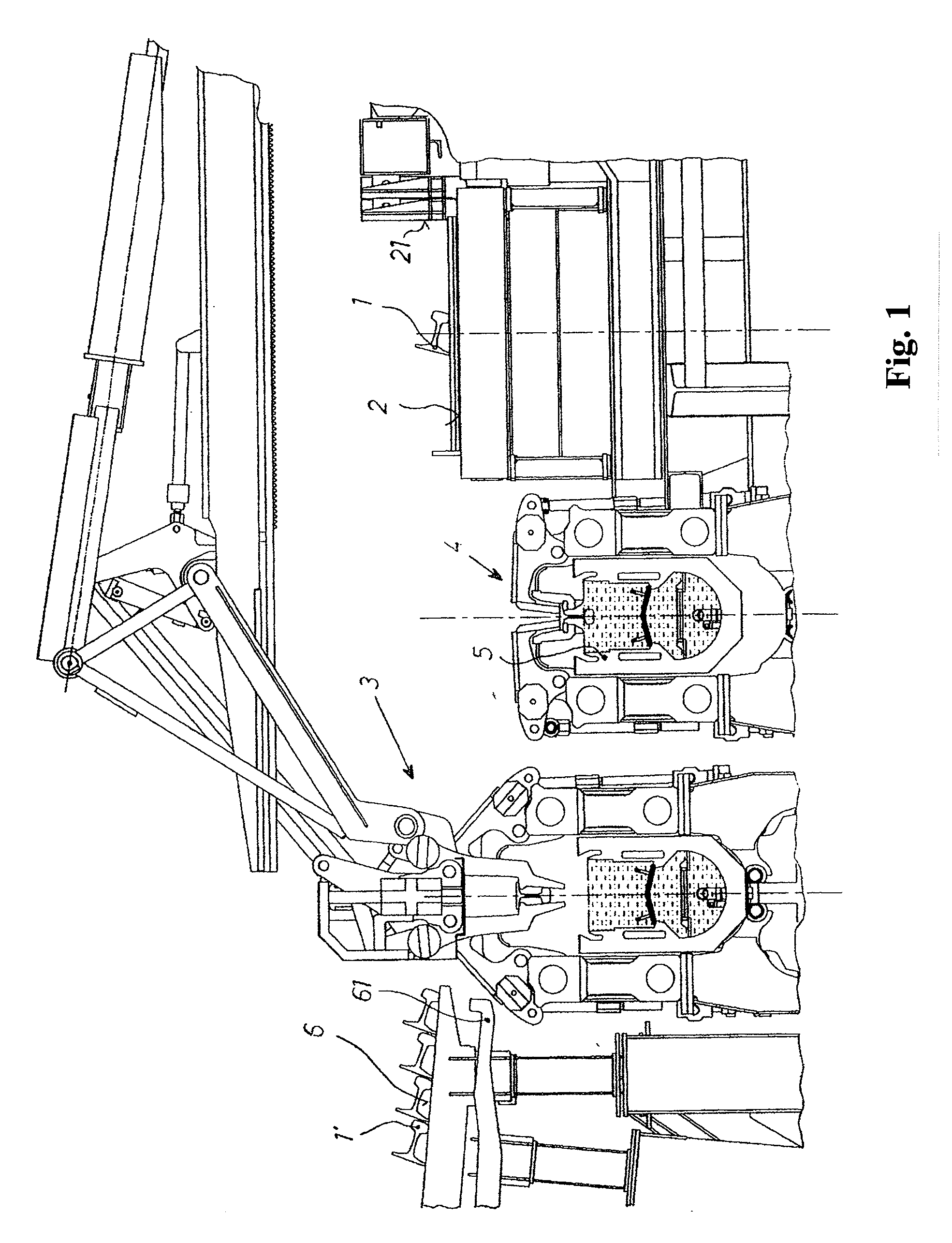

Process and production line for manufacturing ultrathin hot rolled strips based on the thin slab technique

ActiveUS7343961B2Temperature control deviceHeat treatment process controlProduction lineControl system

Ultrathin hot rolled steel strips are obtained from thin slabs using a continuous casting process and production line. The process and production line includes a secondary cooling system, a roughing mill, an induction heating zone to fix temperatures of the intermediate strip chosen between 1000 and 1400° C., a final rolling zone to reduce the thickness of the hot finished strip while keeping a controlled temperature of the hot rolled strip from the last stand of the finishing rolling mill higher than 750° C. The strip is cooled between the last stand of the finishing rolling mill and the coiling station using a specific T.T.T diagram (time-temperature-transformation) for steel quality and strip thickness. A control system is also provided with a master system and six further peripheric sub-systems.

Owner:ARVEDI GIOVANNI

System and method for hardening rails

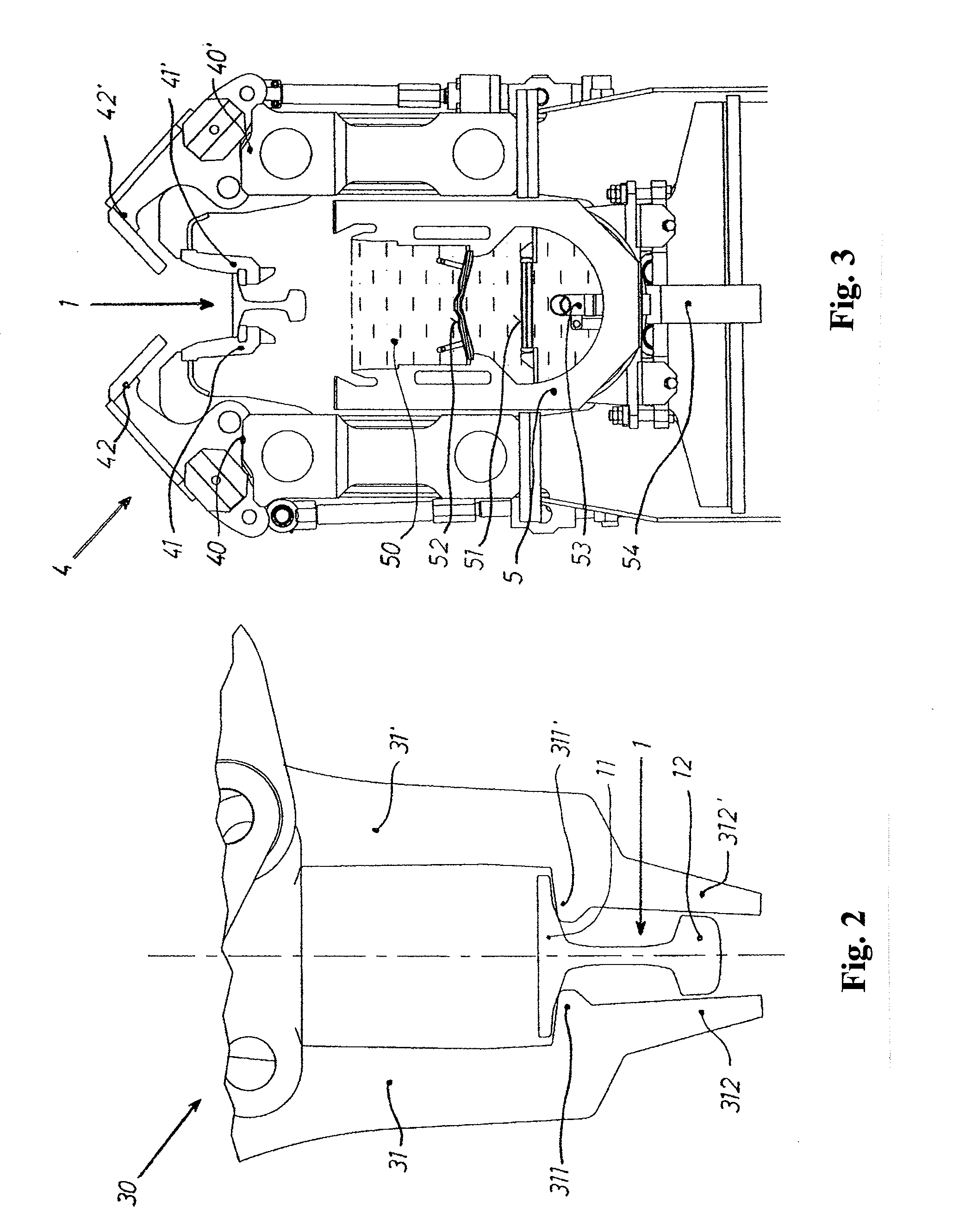

ActiveUS20090200713A1High-quality railProduced very safely and economicallyFurnace typesWork cooling devicesEngineeringLateral displacement

System and method for hardening rails by cooling, in a cooling medium, at least one part of a respective rail cross-section of a rail over an entire length of the rail. The system includes a cross displacement device arranged in an area of a roller table, at least one positioning device, at least one coolant container containing the cooling medium, a manipulation gripper comprising a plurality of pincers and being structured and arranged to move the rail. The method includes at least one of moving the rail from the roller table to the at least one coolant container positioning the rail into the at least one positioning device via the manipulation gripper, as well as moving the rail into the coolant medium with the at least one positioning device.

Owner:VOEST ALPINE SCHIENEN GMBH

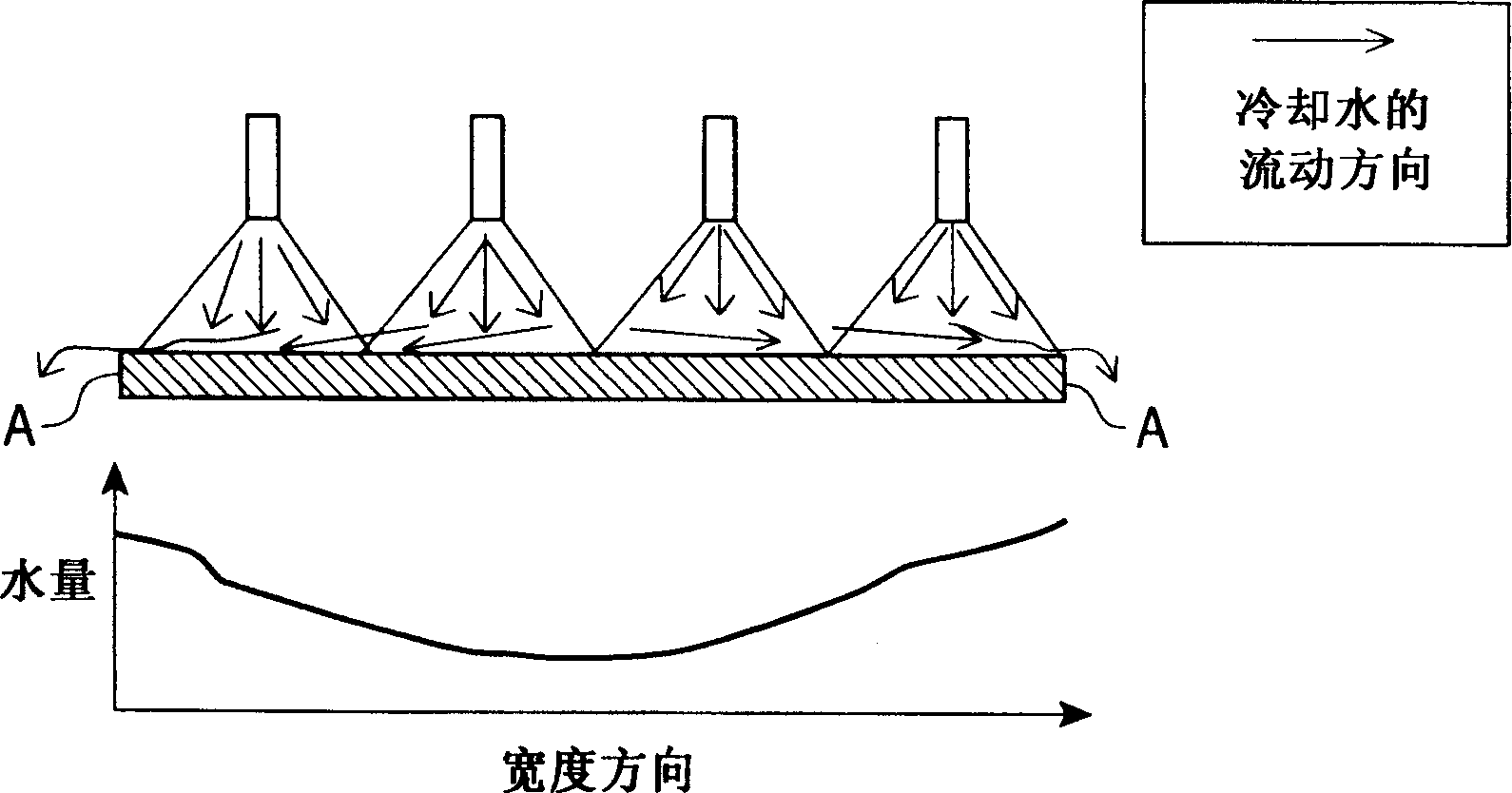

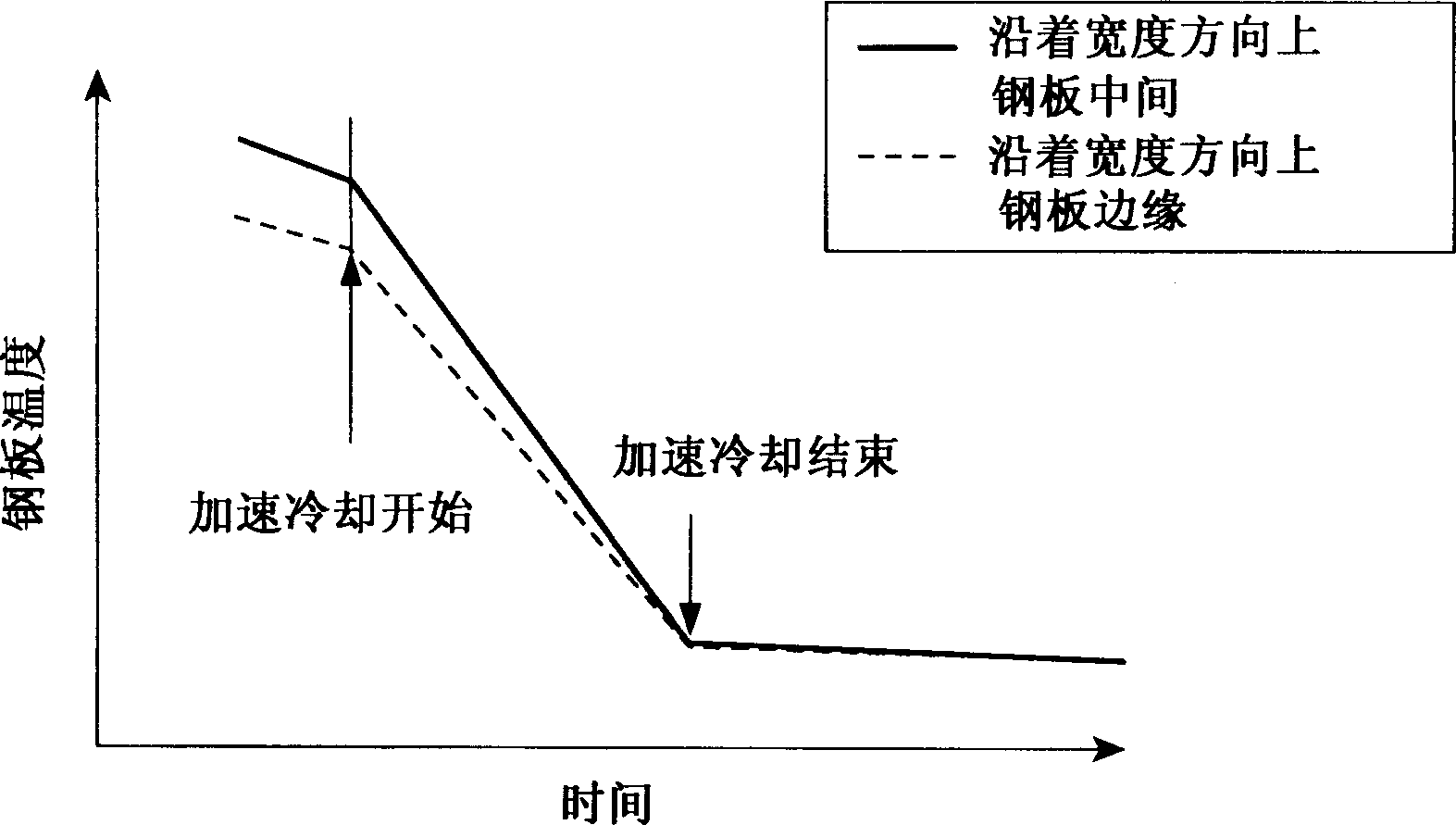

Controllable cooling method for thick steel plate, thick steel plate manufactured by the controllable cooling method, and cooling device for the thick steel plate

A controllable cooling method for a hot rolled thick steel plate, a thick steel plate manufactured by the controllable cooling method, and a cooling device for the thick steel plate. Specifically, the controllable cooling method for the thick steel plate, the method wherein the temperature distribution of the thick steel plate in the lateral direction is uniformized before or at the beginning of the controllable cooling, and the entire part of the thick steel plate in the lateral direction is cooled by the controllable cooling device at a same cooling rate.

Owner:JFE STEEL CORP

Wide thick titanium alloy plate rolling method

InactiveCN104874604ASolve the practical problems of high rolling tonnage and large deformation resistanceRealize industrial productionWork cooling devicesMetal rolling arrangementsSolution treatmentTemperature control

The invention relates to a wide thick titanium alloy plate rolling method. The wide thick titanium alloy plate rolling method comprises the following steps: 1) placing a wide thick titanium alloy plate blank in a heating furnace, controlling heating temperature to be 10-50DEG C below an alpha plus beta / beta phase transformation point and preserving heat for 150-600min; 2) feeding the heated plate blank obtained in step 1 into a rolling mill to perform unidirectional rolling, keeping rolling deformation to be 40-75 percent and keeping final rolling temperature to be no less than 200DEG C below the alpha plus beta / beta phase transformation point to obtain a finished thick titanium alloy plate; 3) cooling the finished plate obtained in step 2 to be below 300DEG C by adopting a quick cooling method; 4) performing solid solution treatment to the finished plate after being quickly cooled, wherein the solid solution treatment temperature is controlled to be within a range of 890-970DEG C and the heat preserving time is controlled to be 1-3h. The wide thick titanium alloy plate rolling method thoroughly solves the realistic problems that the rolling tonnage of the wide thick TC4 ELI titanium alloy plate is high and the deformation resistance is large, realizes the industrial production of the wide titanium alloy plates, reduces the production cost and improves the production efficiency.

Owner:BAOJI TITANIUM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com