Deep cooling asynchronous rolling method for preparing lamellar copper/lithium composite foil

A technology of asynchronous rolling and composite foil, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of pure lithium material oxidation, inability to prepare copper/lithium composite foil, material combustion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

application example 1

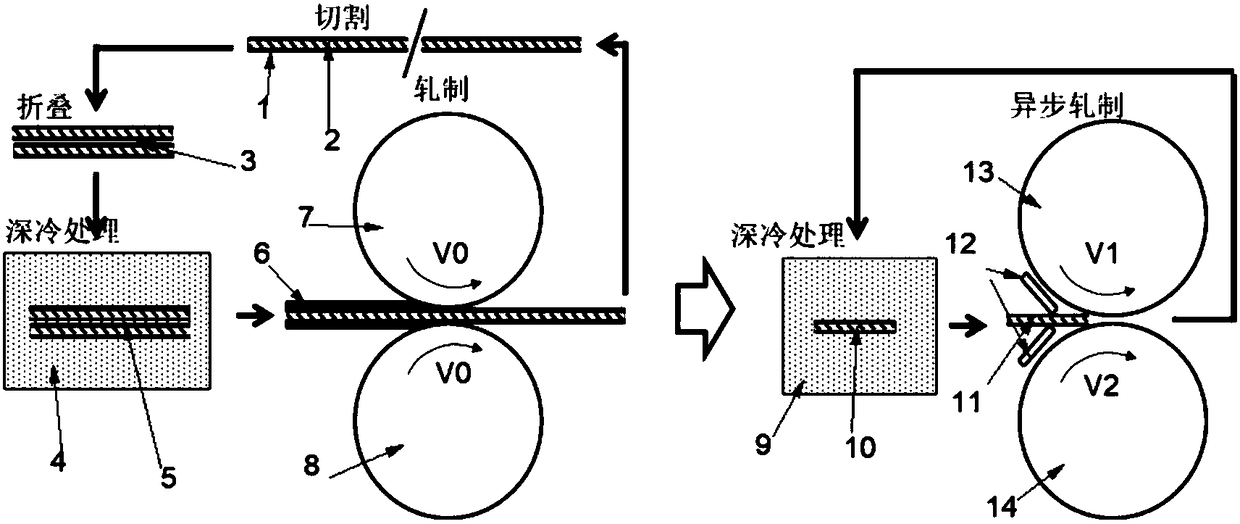

[0039] The 50 μm thick layered copper / lithium composite foil is prepared by cryogenic asynchronous rolling, and the steps are as follows:

[0040] The first step: using pure lithium and pure copper metal foils as raw materials, the thickness before lithium rolling is 100 μm, and the thickness before copper rolling is 50 μm.

[0041] Step 2: Metal copper foil and metal lithium foil are cut into rectangular sizes. The width of the copper foil is the same as that of the lithium foil, but the length of the copper foil is twice that of the lithium foil.

[0042] Step 3: Fold the copper foil in half along the length direction to completely cover the lithium foil.

[0043] Step 4: Put the material into a deep freezer for cooling for 10 minutes to achieve uniform cooling of the material temperature. The cryogenic box is cooled with nitrogen, and the cooling temperature range is -190°C.

[0044] Step 5: Take the material out and perform cryogenic rolling at a reduction ratio ((H-h) / H...

application example 2

[0052] The 30 μm thick layered copper / lithium composite foil is prepared by cryogenic asynchronous rolling, and the steps are as follows:

[0053] The first step: using pure lithium and pure copper metal foils as raw materials, the thickness before lithium rolling is 50 μm, and the thickness before copper rolling is 25 μm.

[0054] Step 2: Metal copper foil and metal lithium foil are cut into rectangular sizes. The width of the copper foil is the same as that of the lithium foil, but the length of the copper foil is twice that of the lithium foil.

[0055] Step 3: Fold the copper foil in half along the length direction to completely cover the lithium foil.

[0056] Step 4: Put the material into a deep freezer for cooling for 10 minutes to achieve uniform cooling of the material temperature. The cryogenic box is cooled with nitrogen, and the cooling temperature range is -150°C.

[0057] Step 5: Take the material out and perform cryogenic rolling at a reduction ratio ((H-h) / H)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com