Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3235 results about "Bimetal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bimetal refers to an object that is composed of two separate metals joined together. Instead of being a mixture of two or more metals, like alloys, bimetallic objects consist of layers of different metals. Trimetal and tetrametal refer to objects composed of three and four separate metals respectively. A bimetal bar is usually made of brass and iron.

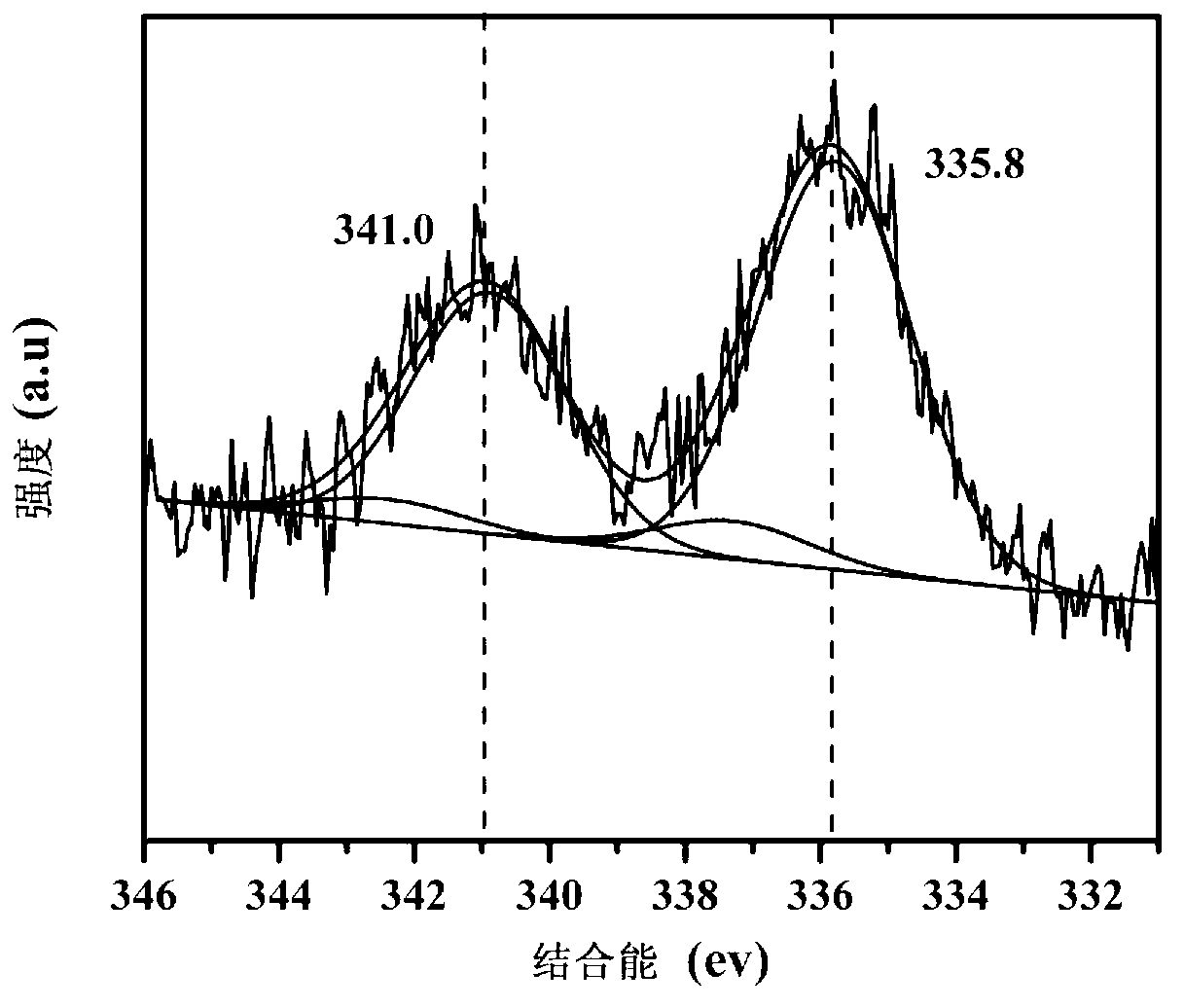

Catalyst propane using aluminium oxide modified mesonore molecular sieve as carrier for dehydrogenation producing propylene

InactiveCN101125298AHigh propane conversionGood dehydrogenation stabilityMolecular sieve catalystsHydrocarbonsMolecular sievePlatinum

The invention relates to a catalyst to make the propene by dehydrogenation propane which takes the modifying alumina medium molecular sieve as the carrier. The catalyst takes the modifying medium molecular sieve by the Al2O3 as the carrier; the platinum and tin double metal catalyst has an alumina weight proportion of 5.0 to 30.0 percent. The active component of the catalyst is the platinum; the weight proportion of the platinum is 0.4 percent; and the weight proportion of the accessory ingredient Sn is 0.1 to 2.0 percent.

Owner:NANJING UNIV

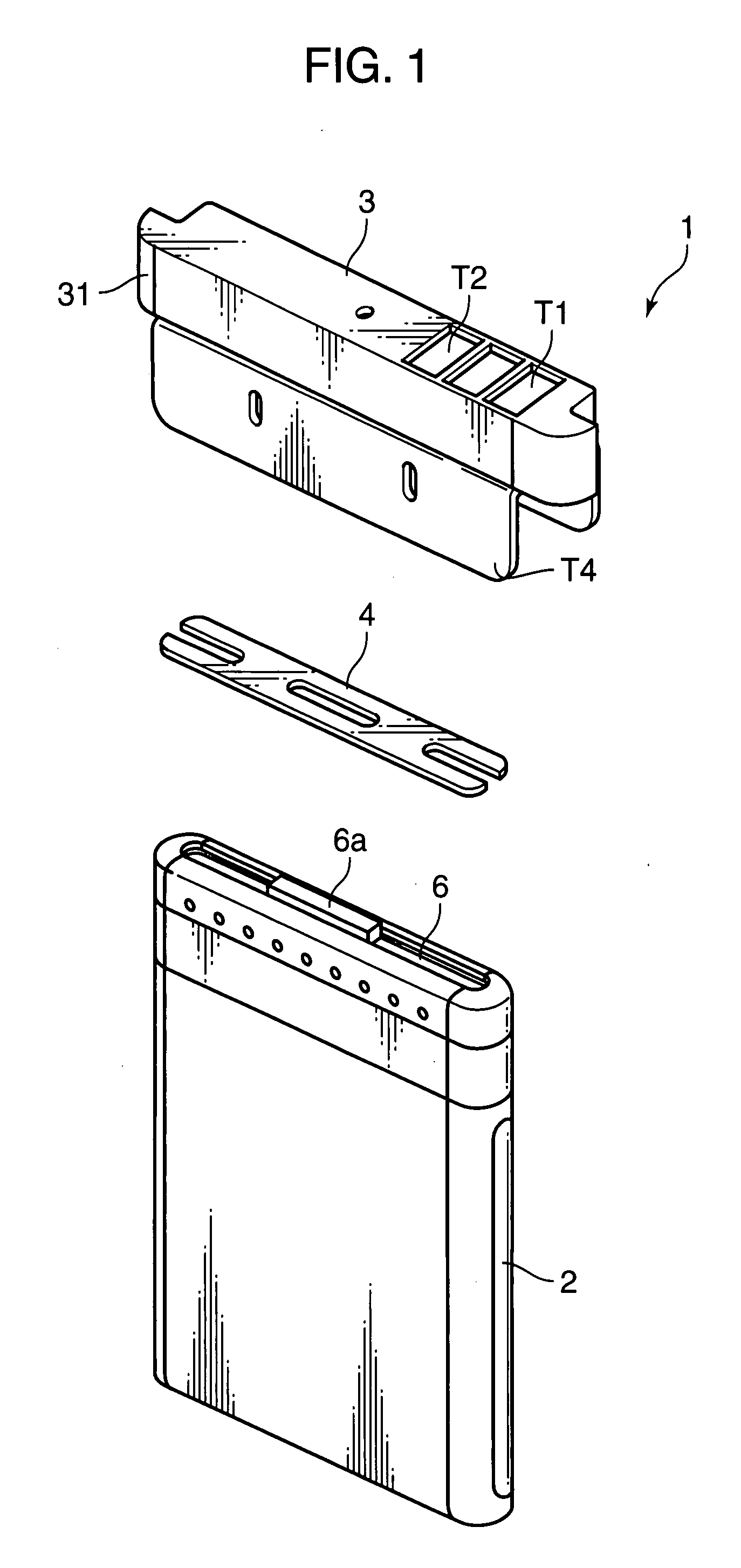

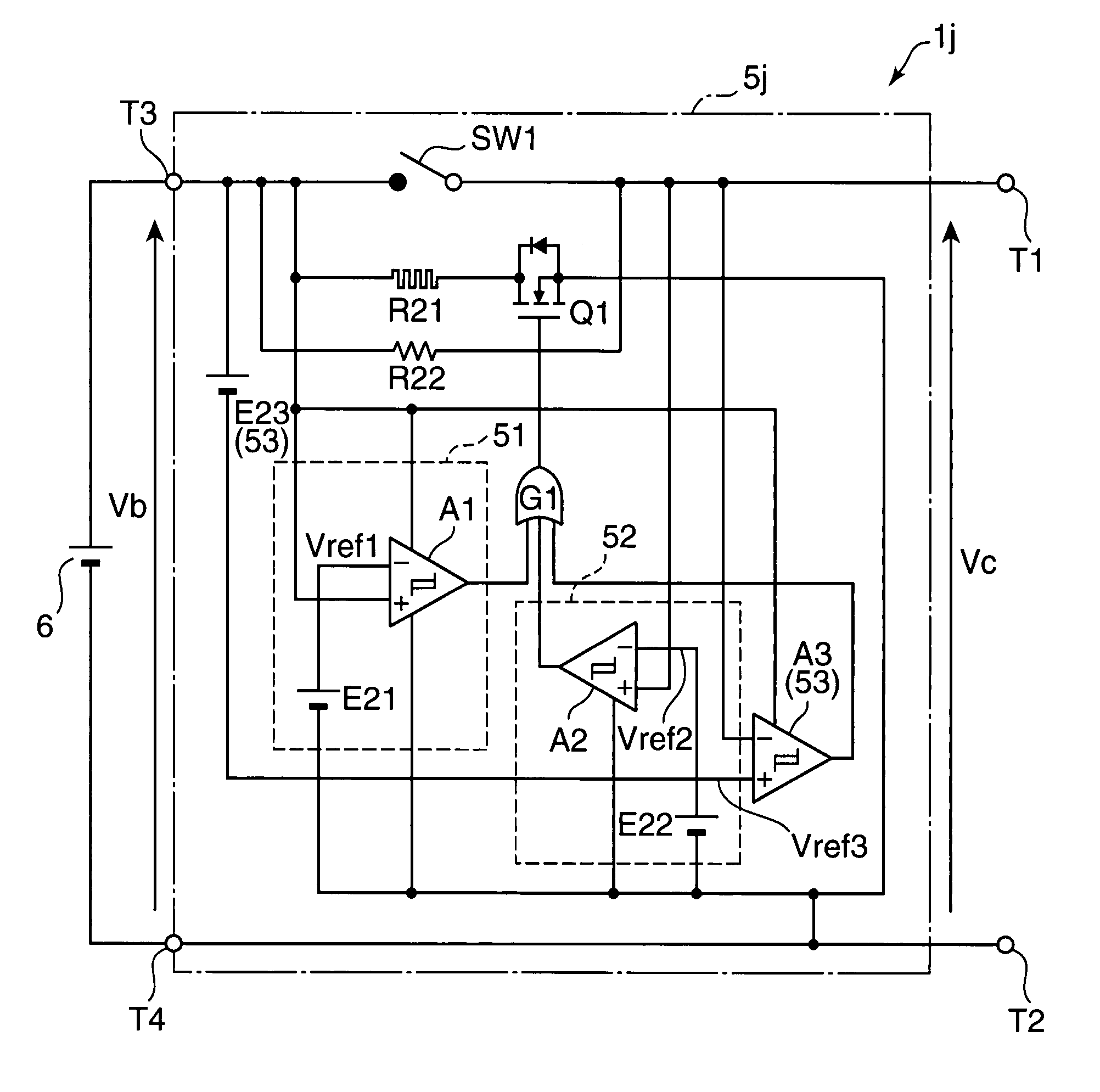

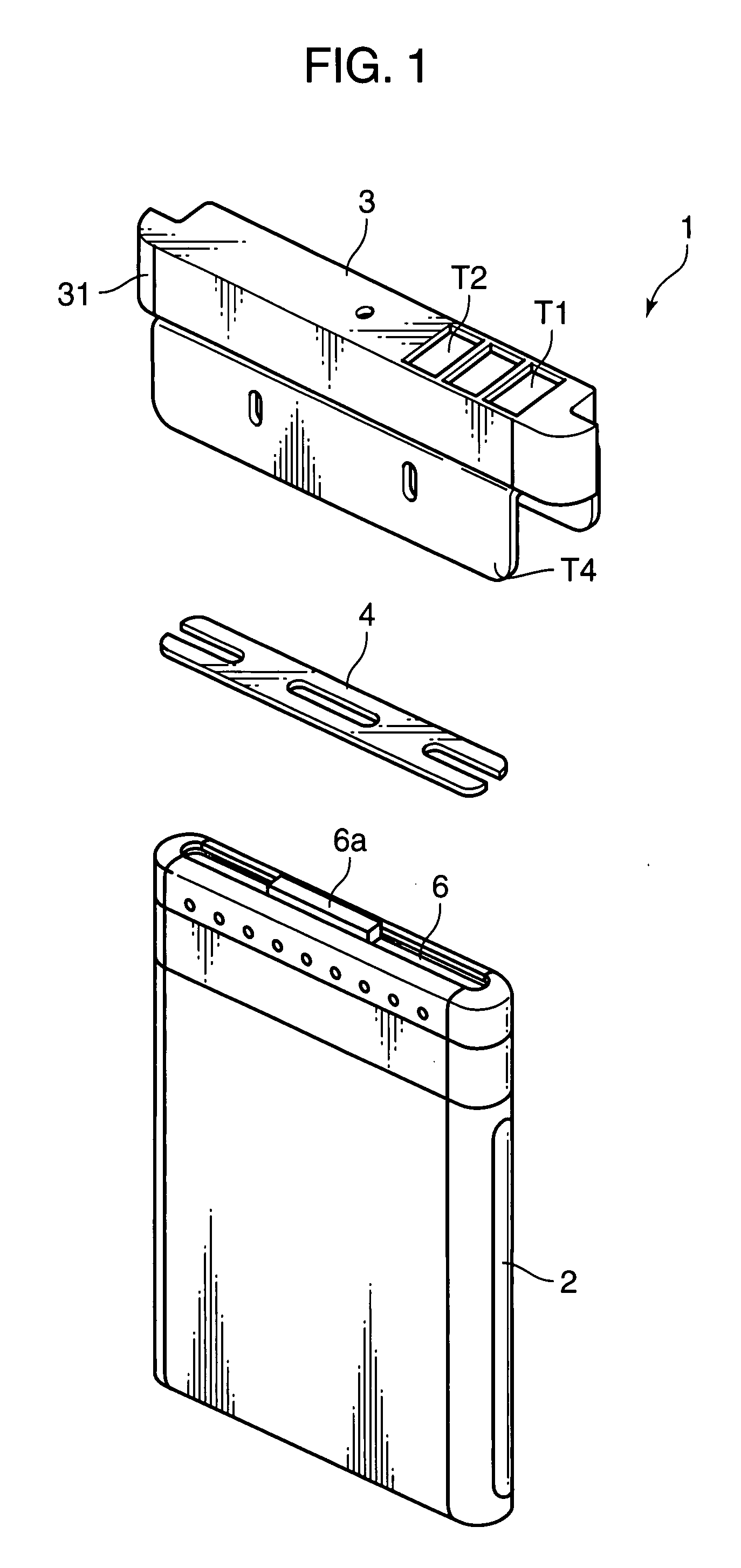

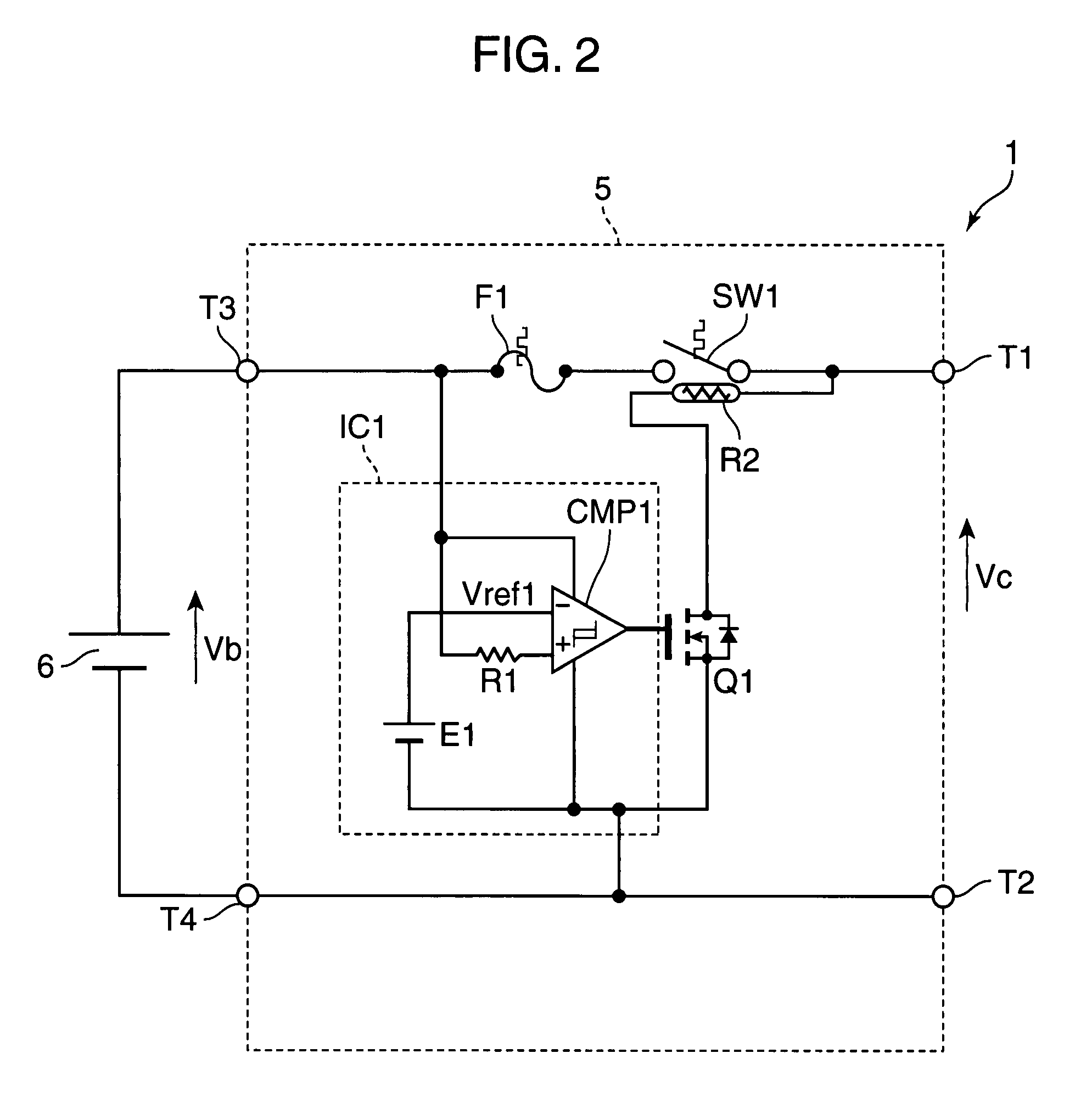

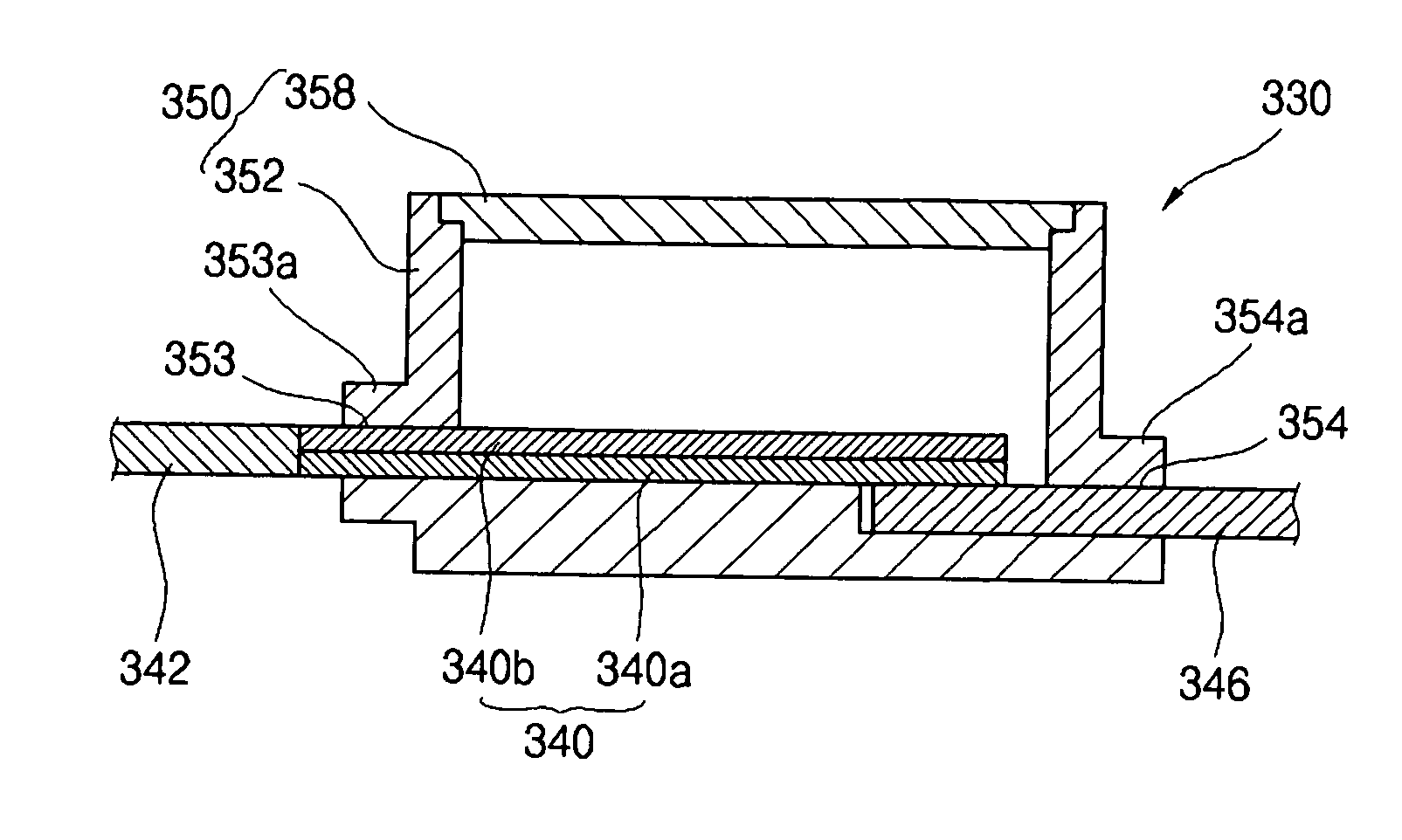

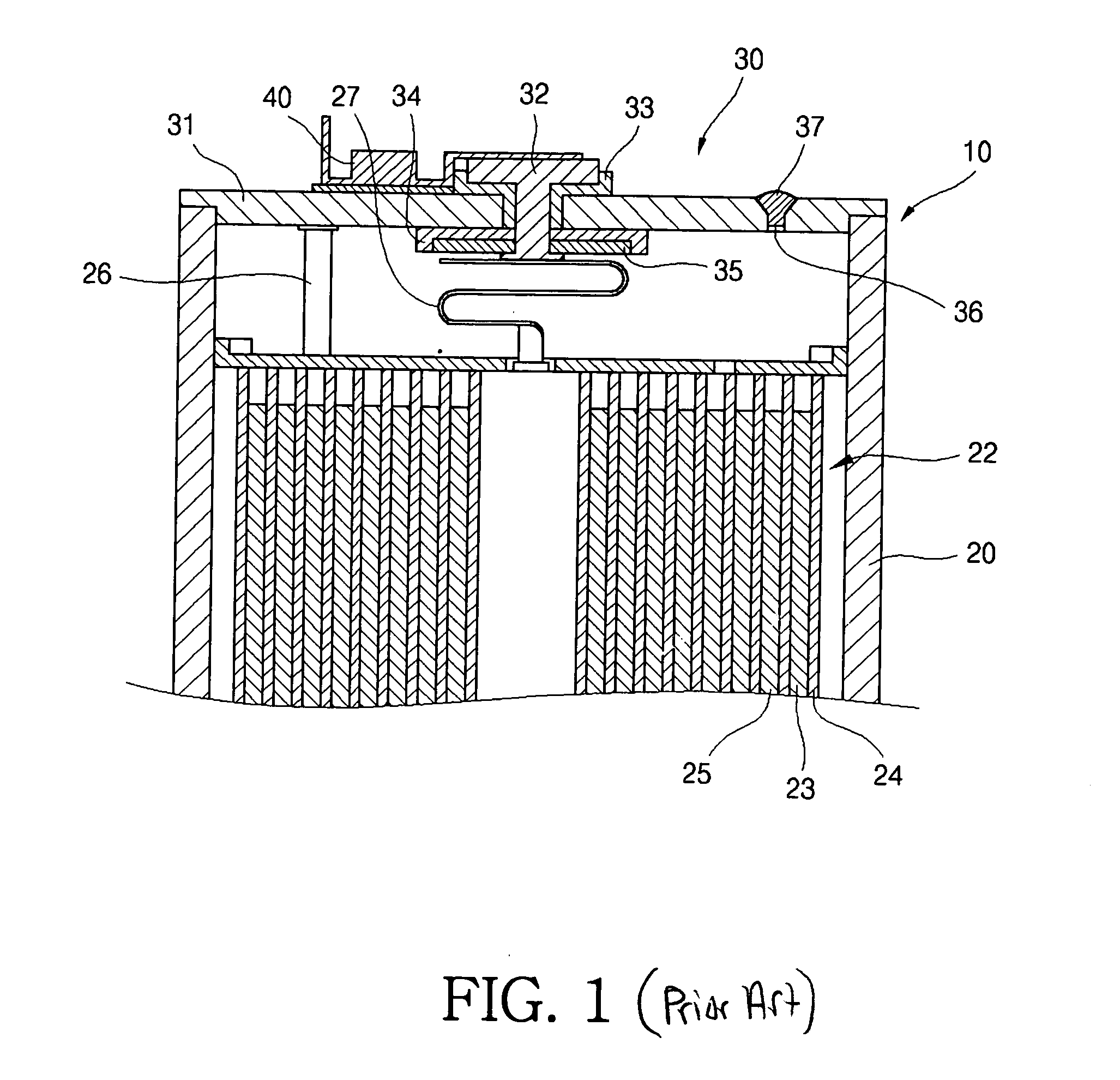

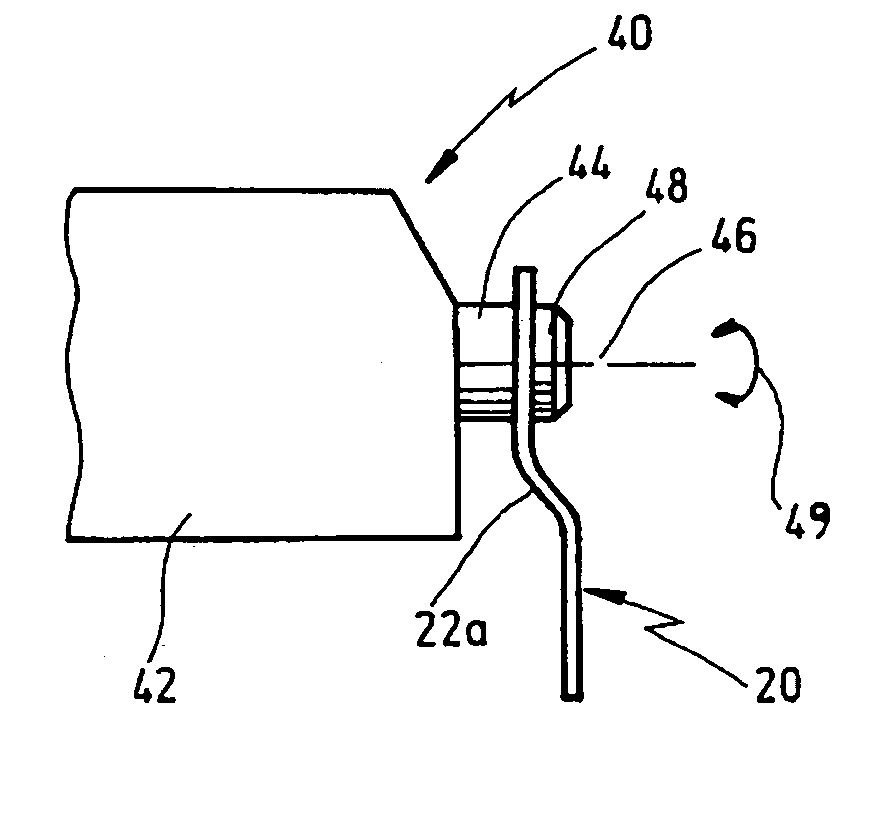

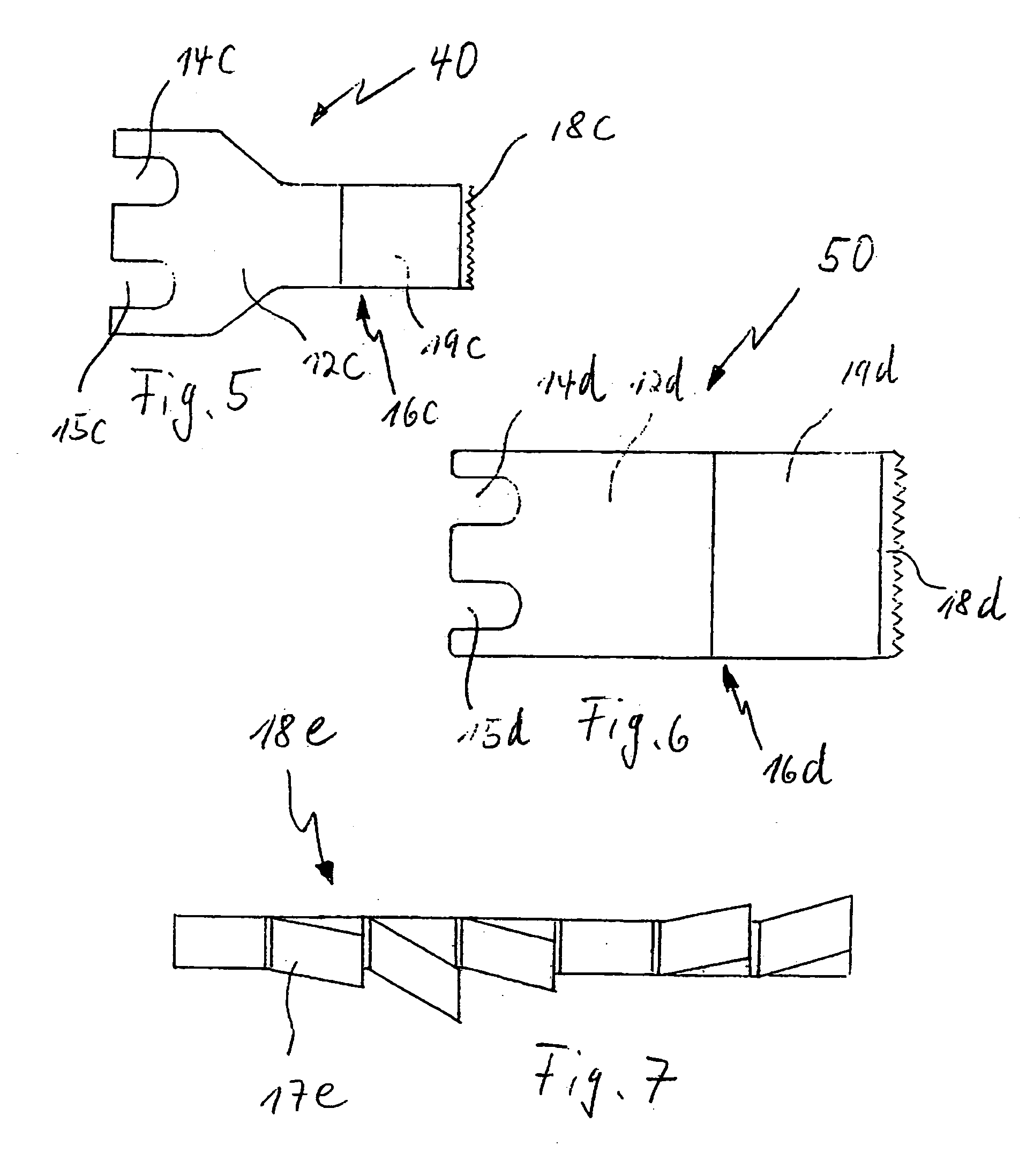

Secondary Battery Protection Circuit, Battery Pack and Thermosensitive Protection Switch Device

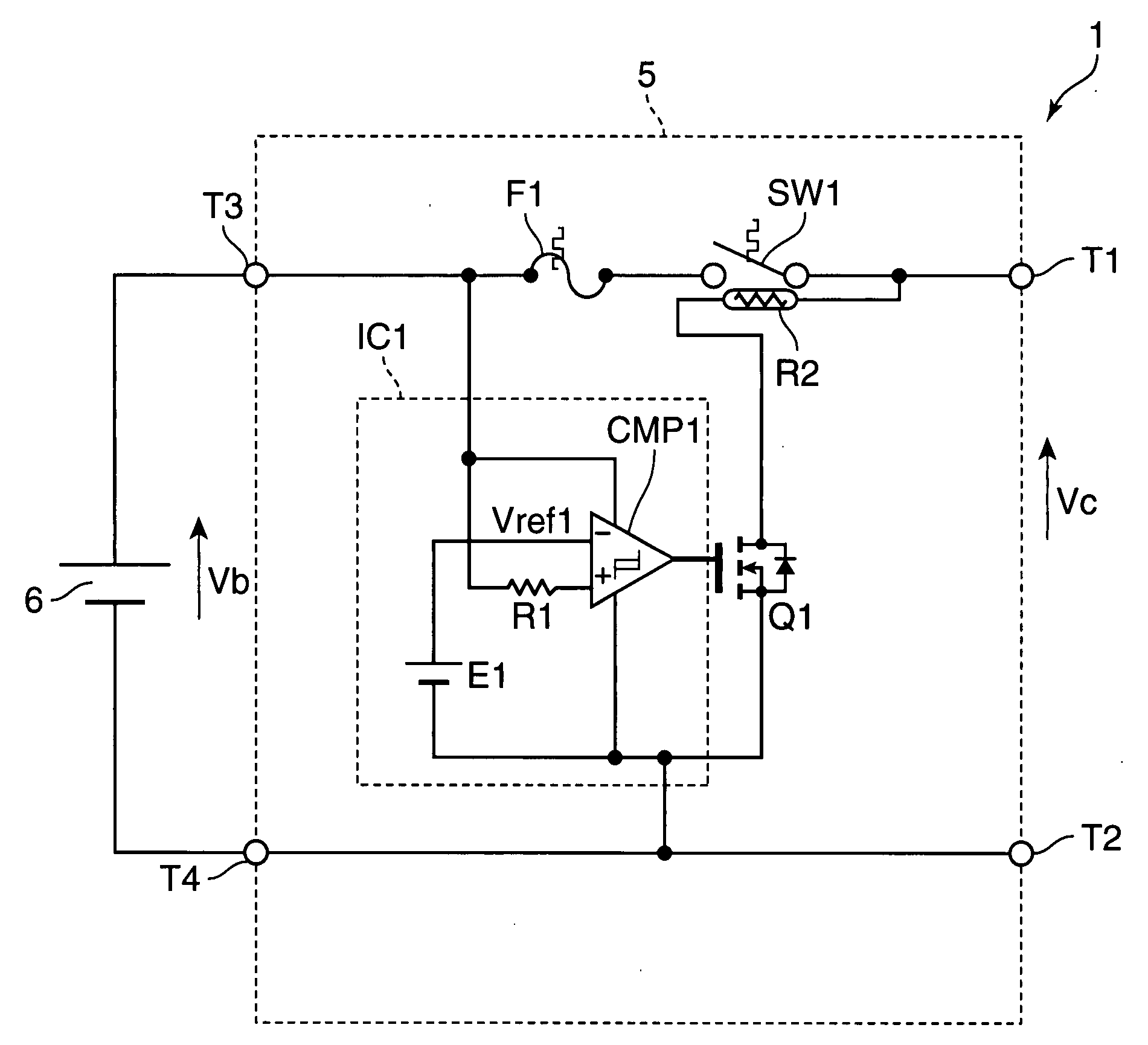

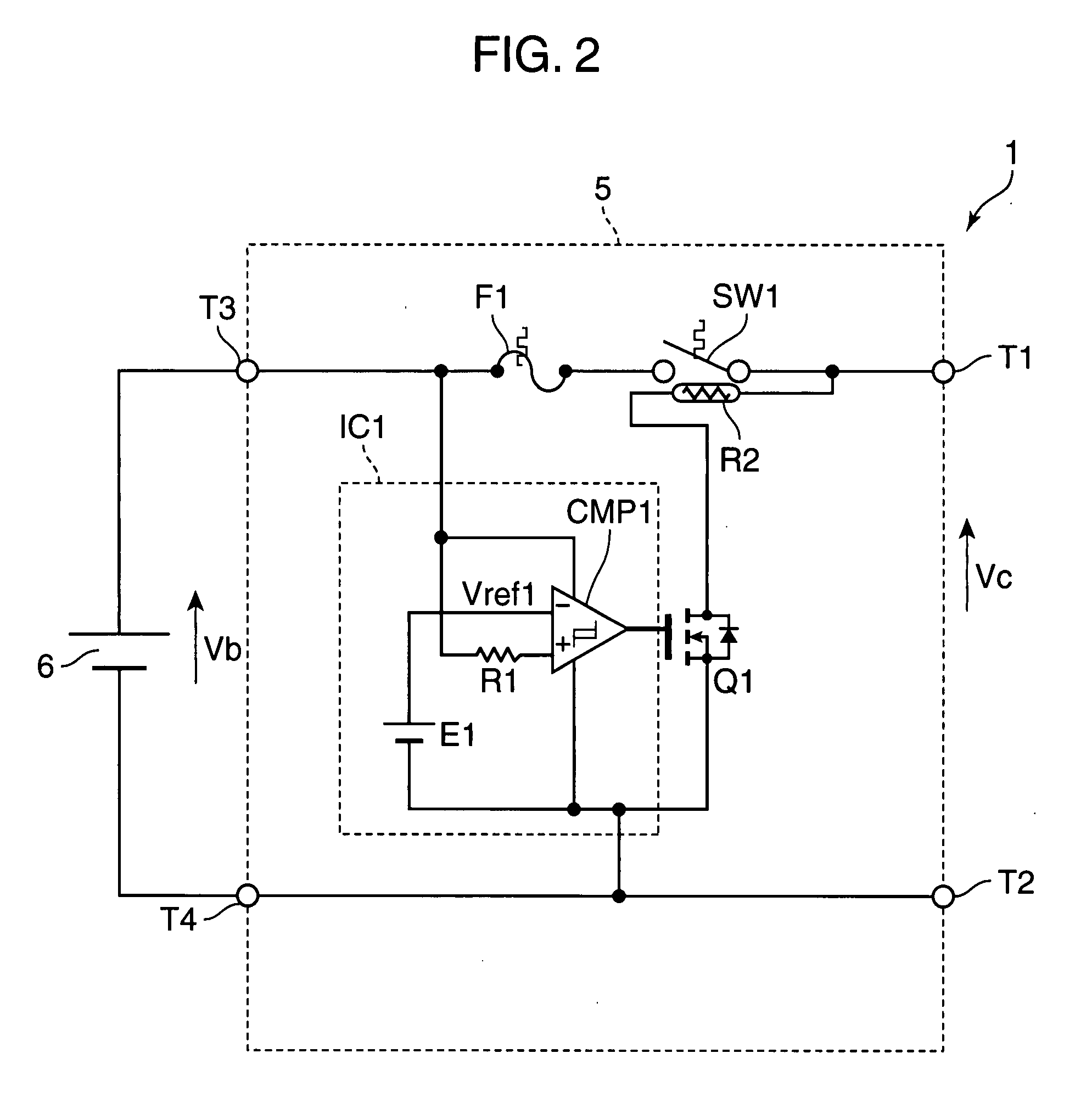

InactiveUS20080116851A1Reduced characteristicsReduce degradationElectrothermal relaysEmergency protective circuit arrangementsEngineeringDischarge current

A protection circuit is provided for protecting a secondary battery from overcharging and excessive discharge current by a simple circuit. The protection circuit is provided with a connection terminal (T3) for connecting the secondary battery (6); a connection terminal (T1) for connecting a charging device for charging the secondary battery (6) and / or a load device driven by a discharge current from the secondary battery (6); a bimetal switch (SW1) that is provided between the connection terminals (T1, T3) and turned off in the case of exceeding a specified temperature set beforehand; a heater (R2) for heating the bimetal switch (SW1); and an integrated circuit (IC1) for turning the bimetal switch (SW1) off by causing the heater (R2) to generate heat if a voltage applied to the connection terminal (T3) by the secondary battery (6) exceeds a preset reference voltage.

Owner:PANASONIC CORP

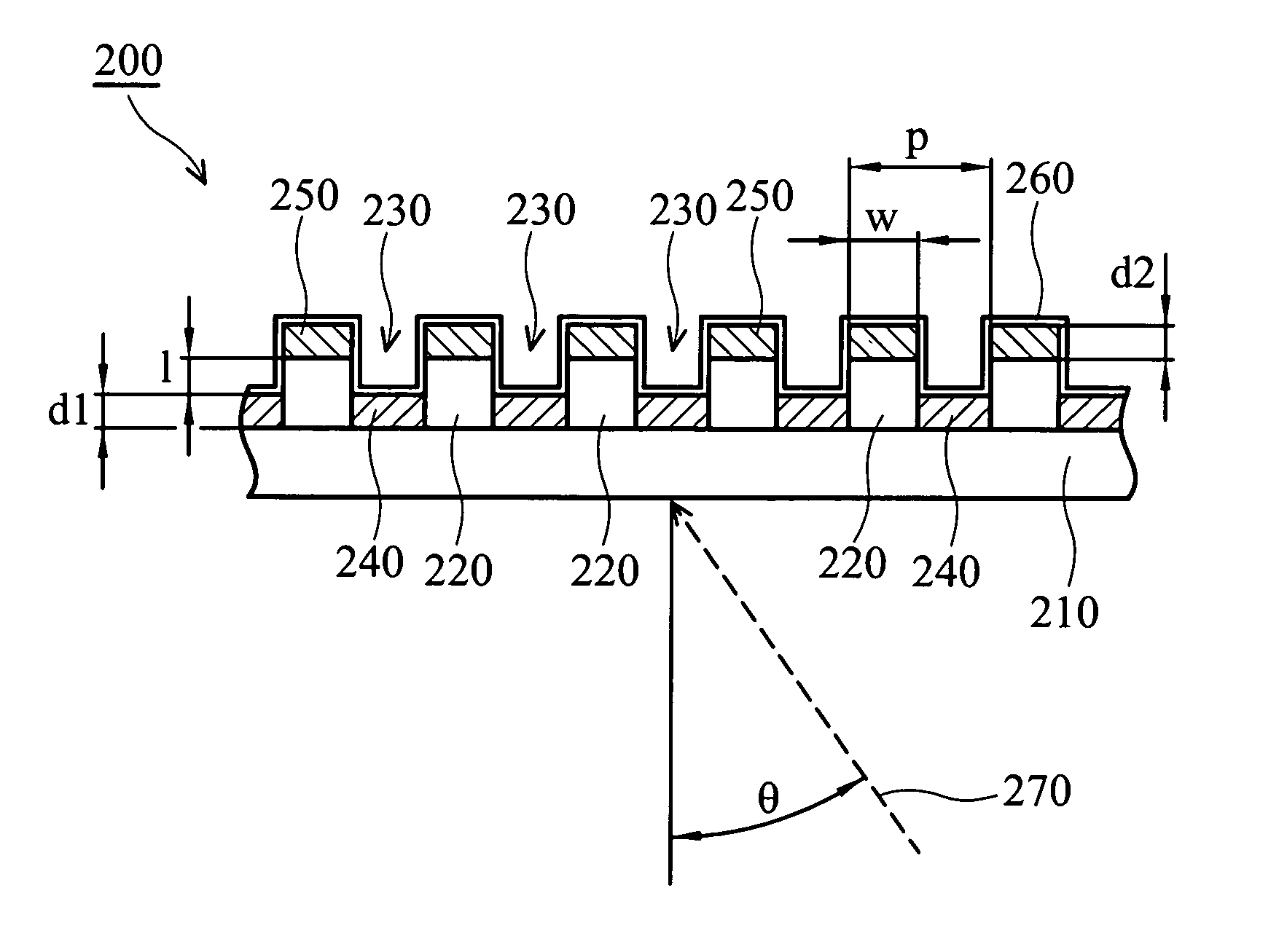

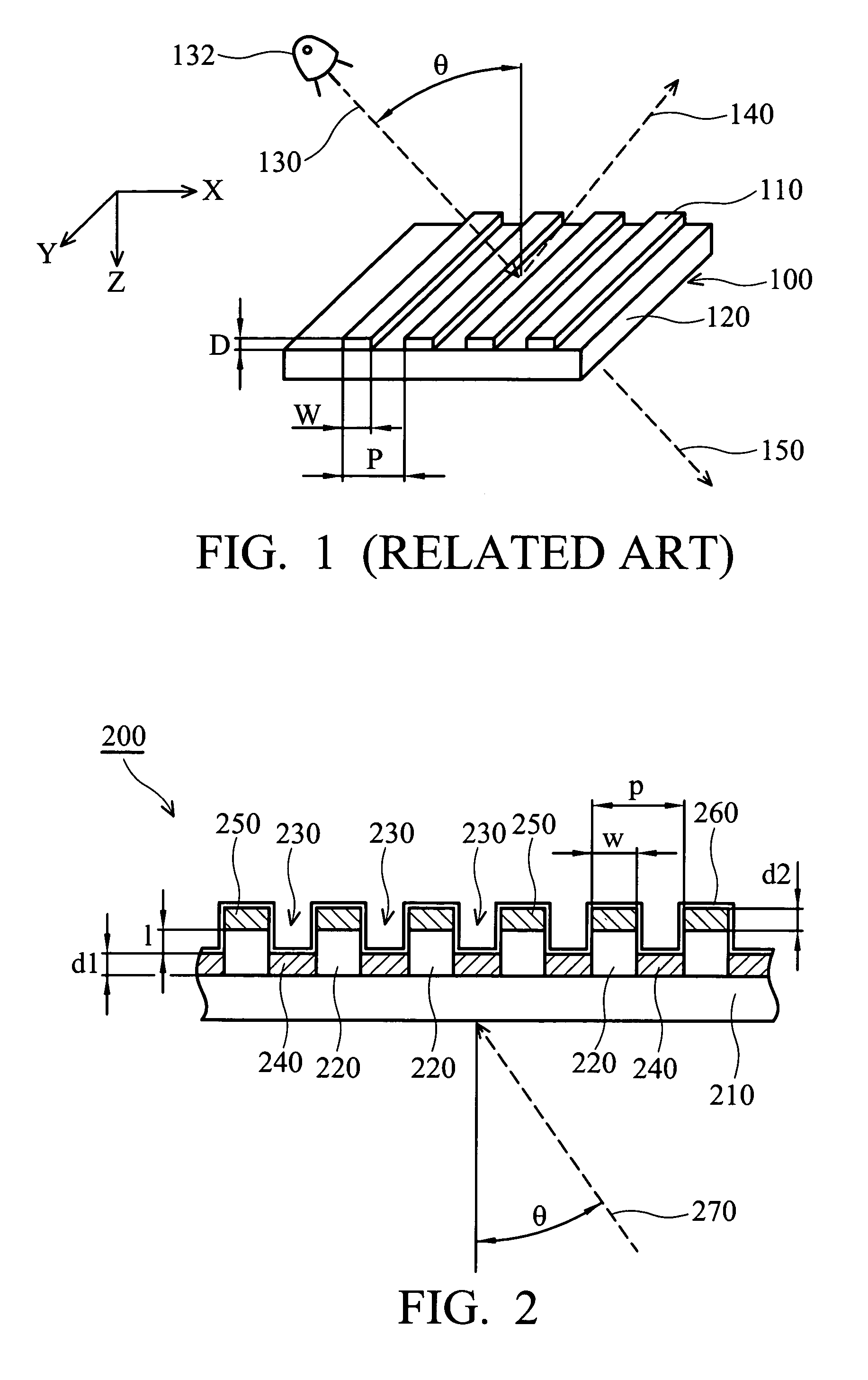

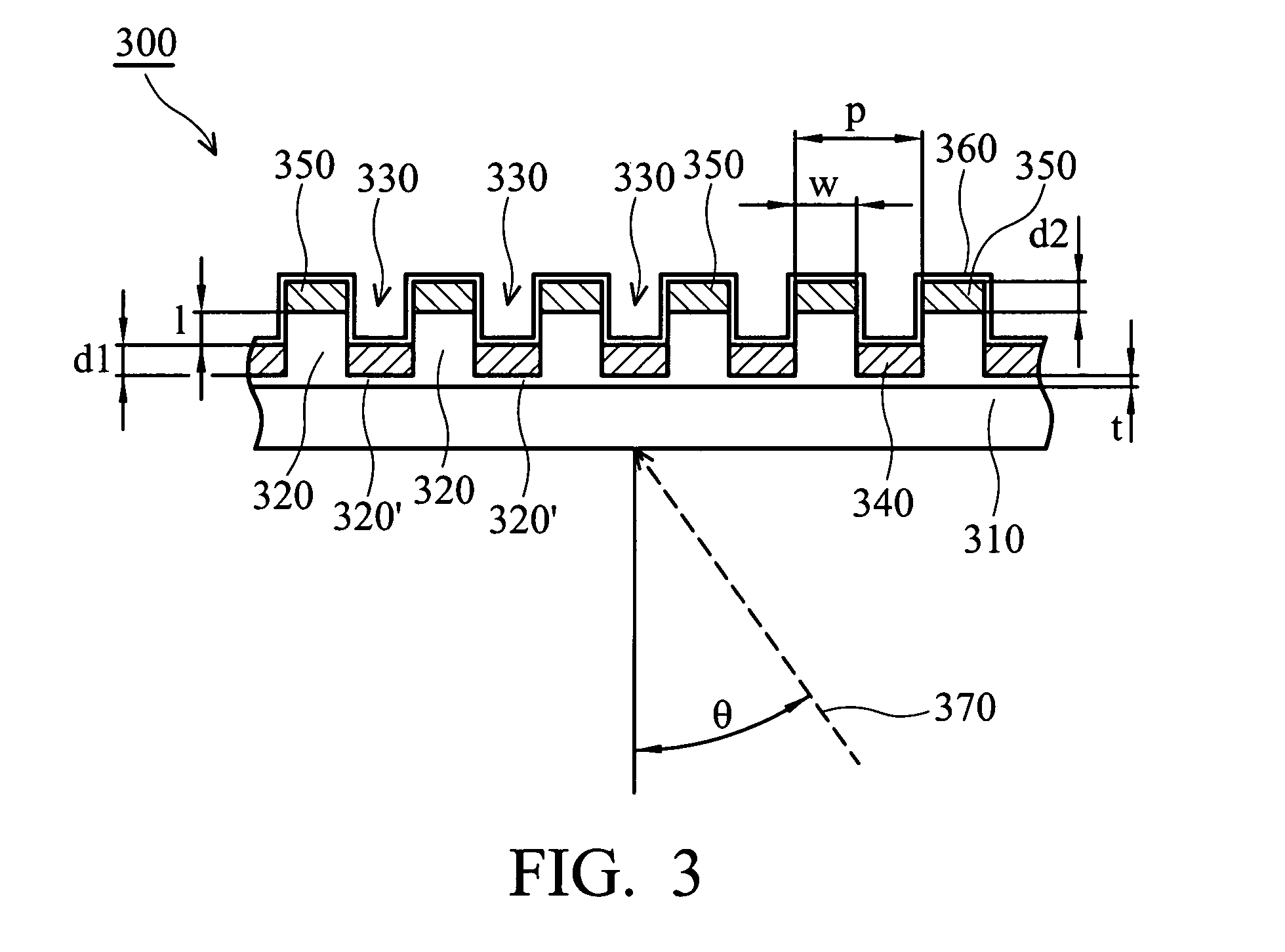

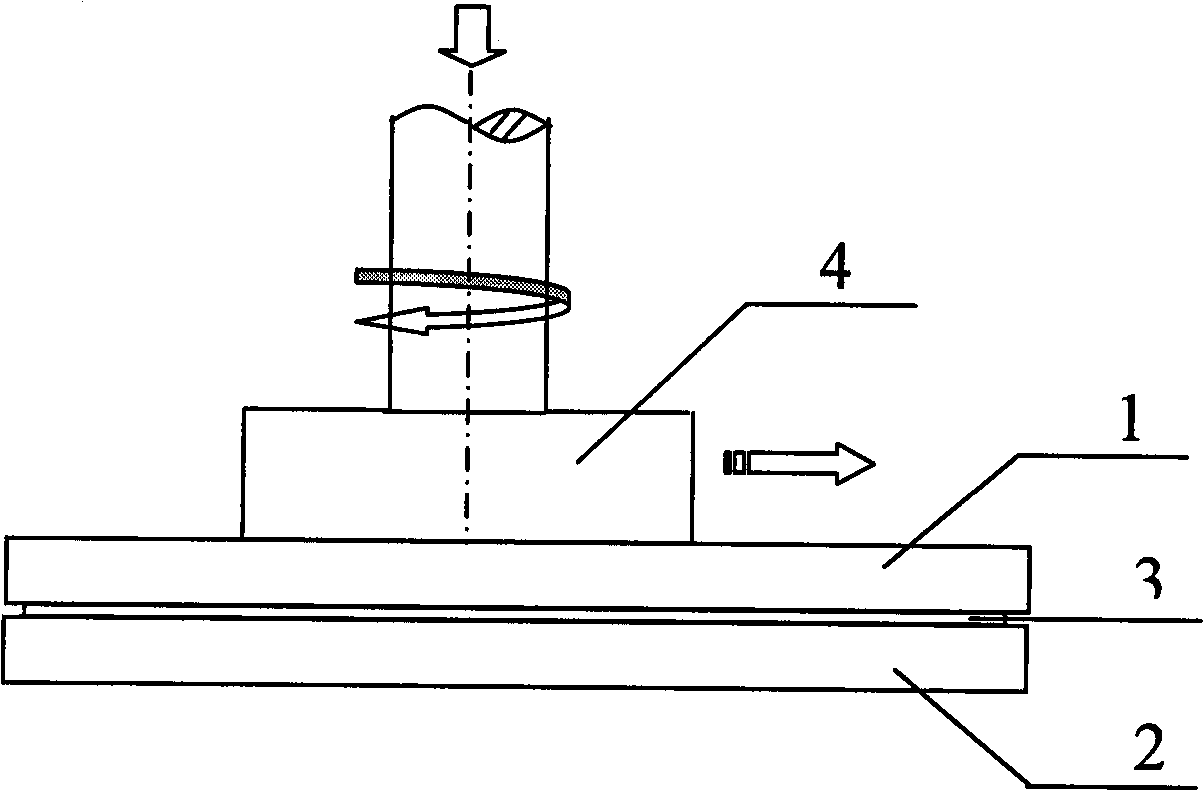

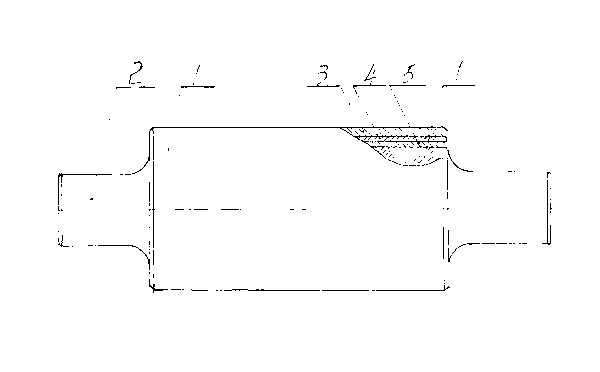

Wire grid polarizer with double metal layers

ActiveUS7158302B2High extinction ratioImprove disadvantagesPolarising elementsDiffraction gratingsWire gridDielectric layer

A wire grid polarizer with double metal layers for the visible spectrum. Parallel dielectric layers having a period (p) of 10˜250 nm and a trench between adjacent dielectric layers overlie a transparent substrate. A first metal layer having a first thickness (d1) of 30˜150 nm is disposed in the trench. A second metal layer having a second thickness (d2) of 30˜150 nm and a width (w) overlies on the top surface of each dielectric layer. The first and second metal layers are separated by a vertical distance (l) of 10˜100 nm. The first thickness (d1) is the same as the second thickness (d2). A ratio of the width (w) to the period (p) is 25˜75%.

Owner:IND TECH RES INST

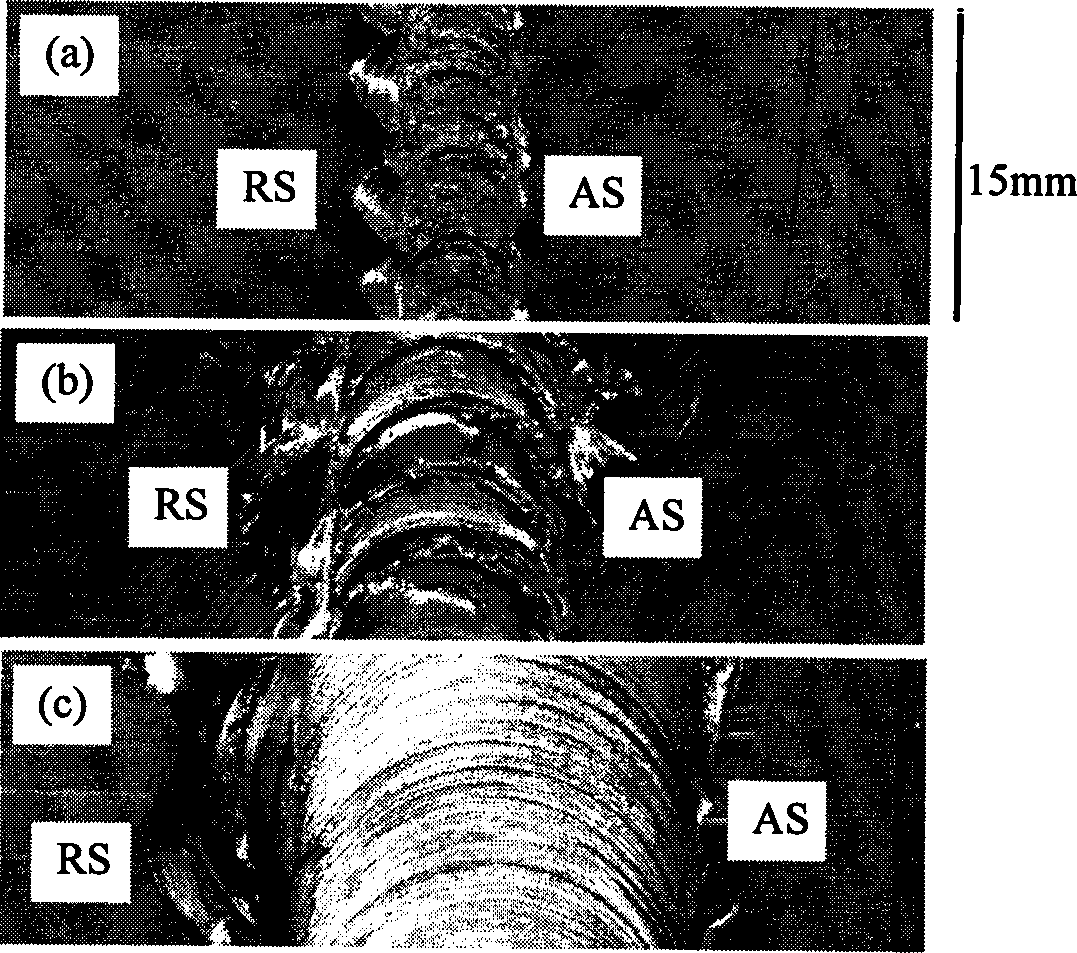

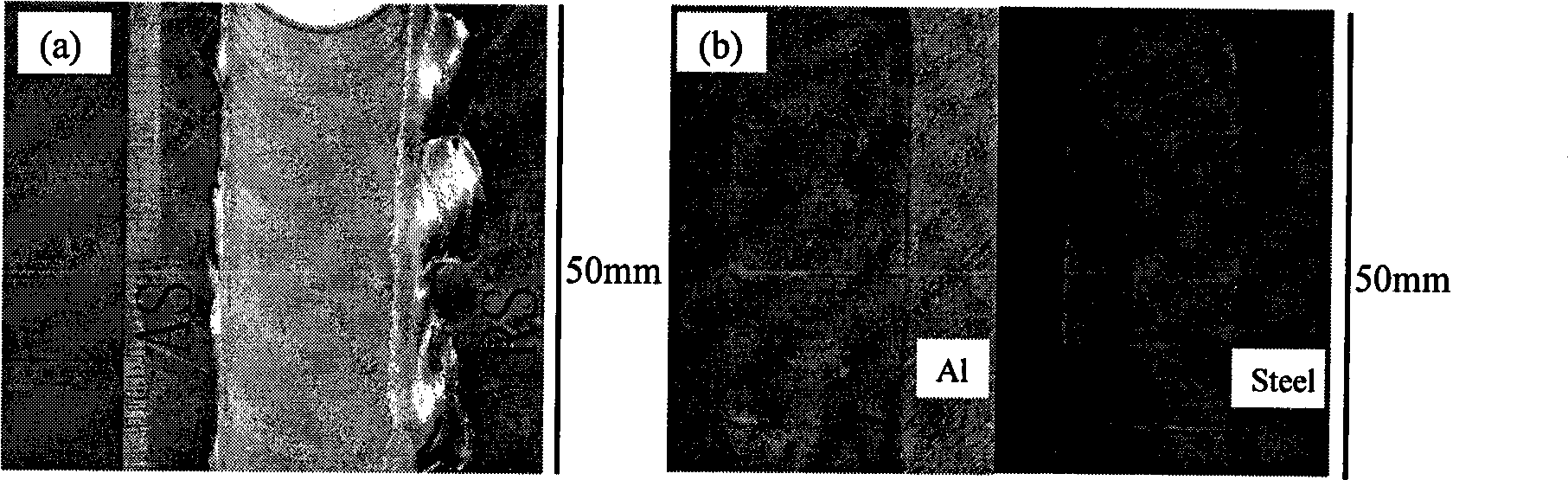

Method for preparing bimetal composite plate by stirring friction braze welding

InactiveCN101530947APrevent thinningAvoid direct contactNon-electric welding apparatusSurface layerShielding gas

The invention discloses a method for preparing a bimetal composite plate by stirring friction braze welding. The method comprises that: a plate with small hardness is used as a covering layer metal plate; a plate with high hardness is used as a base layer metal plate; the covering layer metal plate and the base layer metal plate are horizontally fixed on a working platform surface in a lap joint mode; solders which can generate eutectic reaction with one of the upper / base layer metal plates are preset between the upper / base layer metal plates; a non-needle type cylinder friction device is arranged over the covering layer metal plate; the non-needle type cylindrical friction device is made to rotate and be pressed to be closely contacted with the surface layer of the covering layer metal plate, but not penetrate the covering layer metal plate, and the non-needle type cylindrical friction device rotates in the original position or moves forward along the surface of the covering layer metal plate while rotating; by utilizing frictional heat to melt the solders, the upper / base layer metal plates are both quickly melted in the solders, thereby achieving excellent interface combination; and the excessive solders are squeezed out, and a thin and dense soldering seam is formed, so that the bimetal composite plate is prepared. Compared with the braze welding in a furnace, the method has the advantages of high efficiency, energy conservation, pressure lead-in, unnecessary soldering flux and gas protection and short holding time at a high temperature.

Owner:XI AN JIAOTONG UNIV

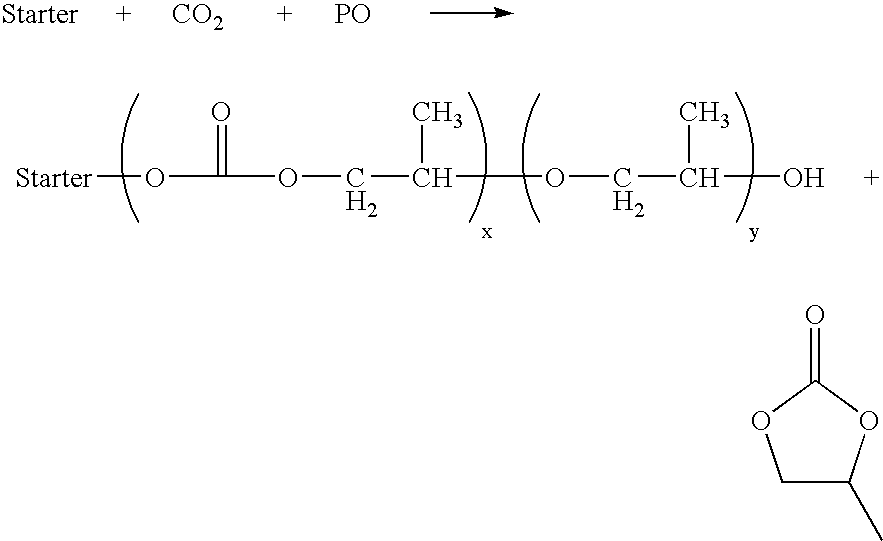

Polyether carbonate polyols made via double metal cyanide (DMC) catalysis

ActiveUS20080021154A1Lower Level RequirementsOrganic chemistryPharmaceutical non-active ingredientsElastomerAdhesive

The present invention relates to a polyether carbonate polyol made by copolymerizing a starter molecule with carbon dioxide, at a pressure ranging from about 10 psia to about 2,000 psia, and an alkylene oxide, at a temperature ranging from about 50° C. to about 190° C. and in the presence of from about 0.001 wt. % to about 0.2 wt. % of a substantially non-crystalline double metal cyanide (DMC) catalyst, wherein the polyol has an incorporated carbon dioxide content of from about 1 wt. % to about 40 wt. %, wherein the ratio of cyclic carbonate by-product to total carbonate is less than about 0.3 and wherein the weight percentages are based on the weight of the polyol. The inventive polyether carbonate polyols may find use in producing polyurethane foams, elastomers, coatings, sealants and adhesives with improved properties.

Owner:COVESTRO LLC

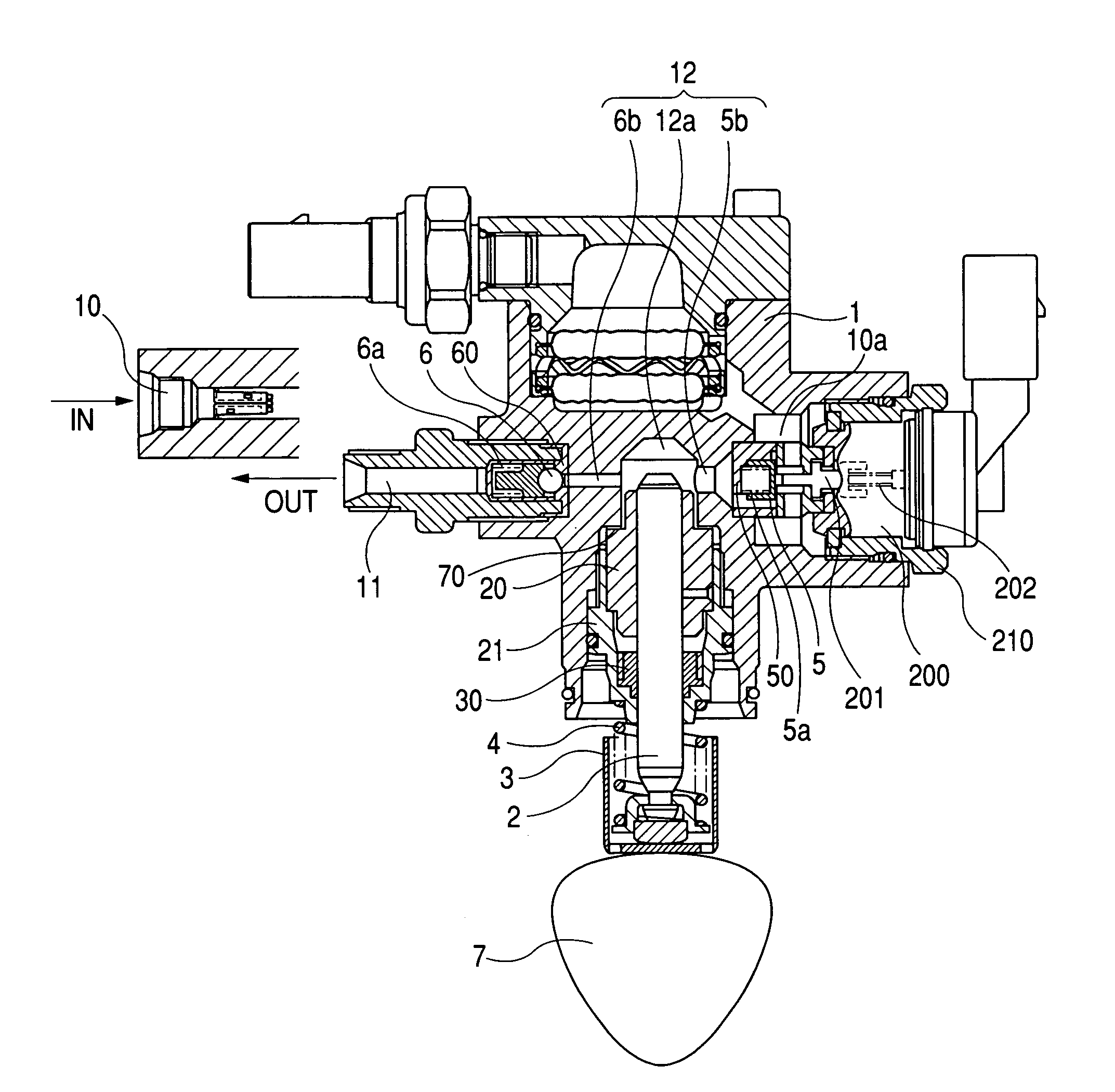

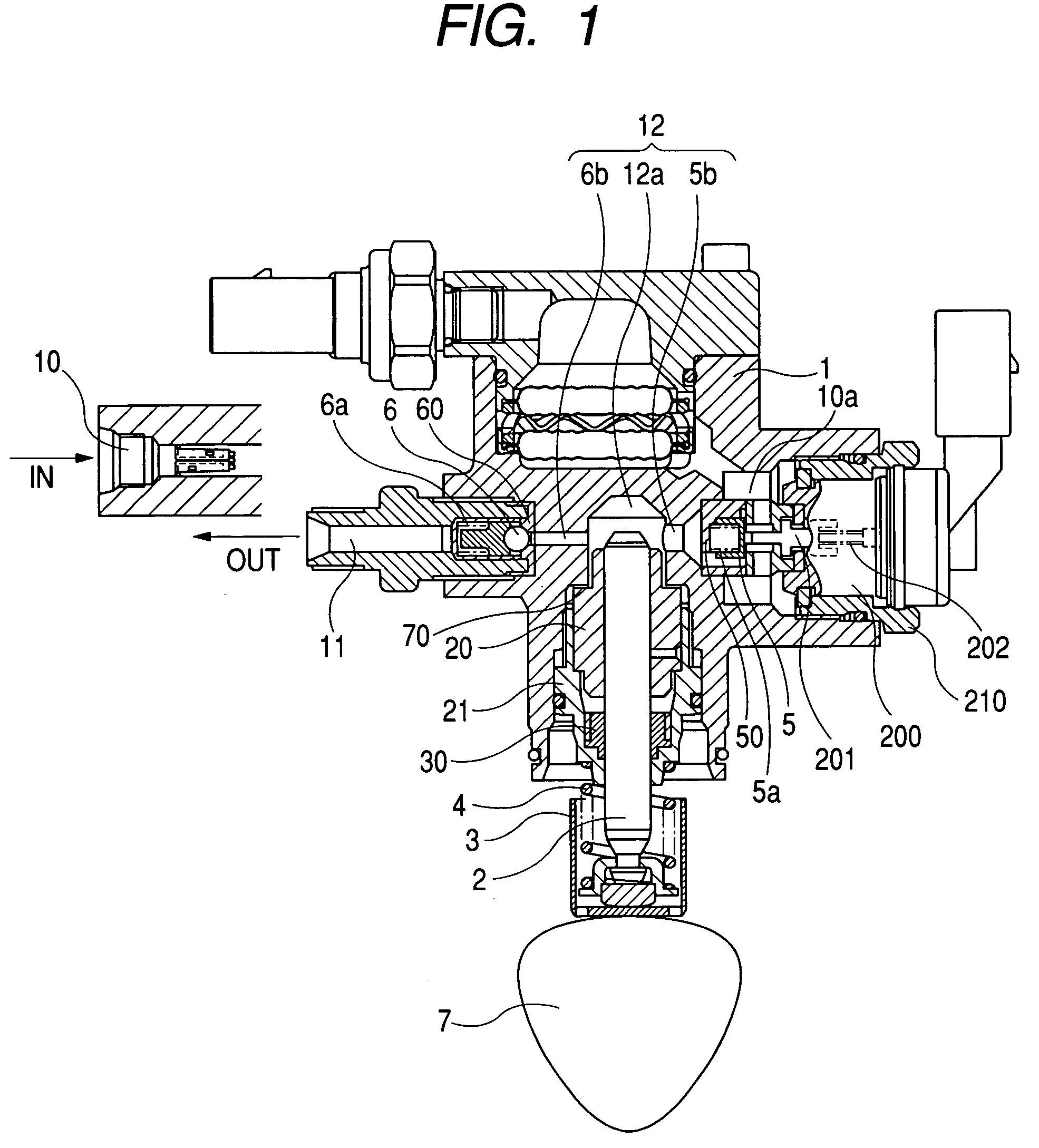

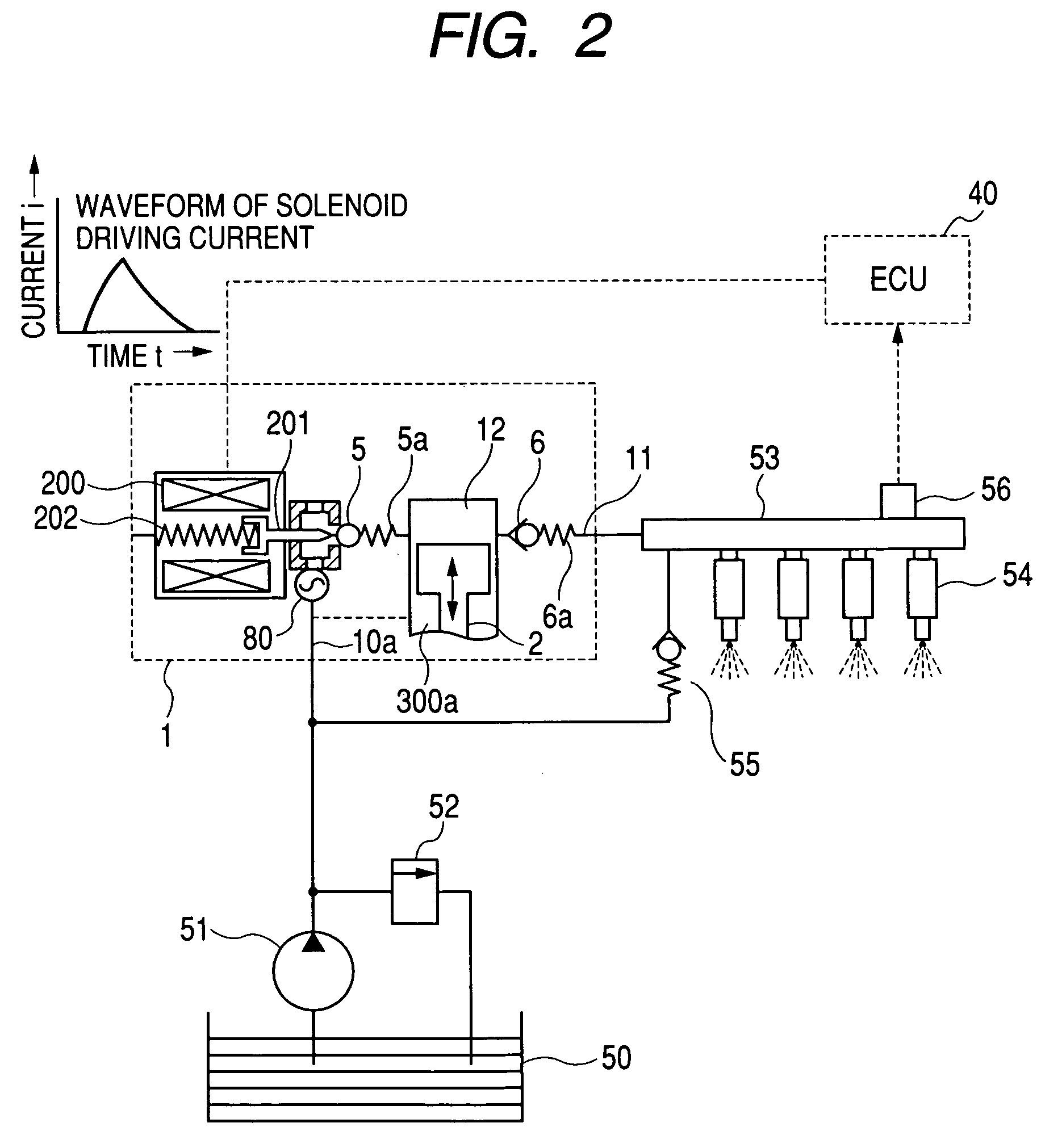

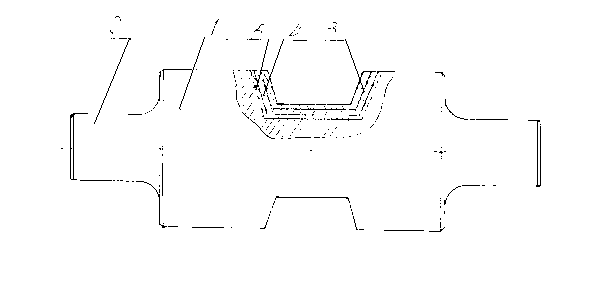

Damper mechanism and high pressure fuel pump

ActiveUS7124738B2Increase in sizeReduce pressure pulsationFuel injecting pumpsFuel injection with sensorsEngineeringHigh pressure

To obtain a small and high performance damper mechanism which reduces pressure pulsation in low pressure-side fuel in the high pressure fuel pump in a high pressure fuel supply system or a high pressure fuel pump provided with the small and high performance damper mechanism.Two metal diaphragms are welded together over the entire circumference to obtain a metal diaphragm assembly (also referred to as “double metal diaphragm damper”). The whole or part of the portion of the metal diaphragm assembly other than the weld (for example, the portion inside the weld) is clamped by a pressing member and thereby the assembly is secured in a housing enclosure. The housing enclosure may be formed integrally with the body of a high pressure pump.

Owner:HITACHI ASTEMO LTD

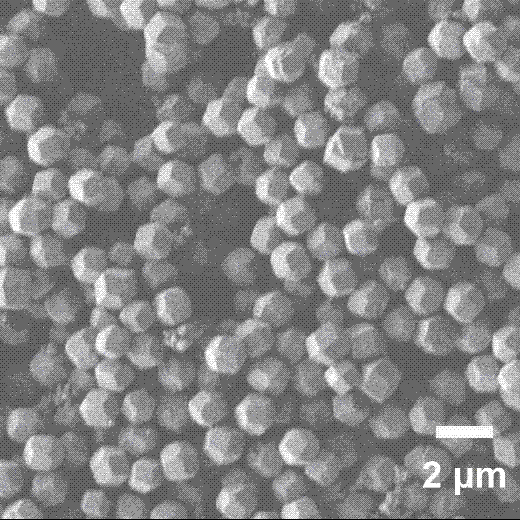

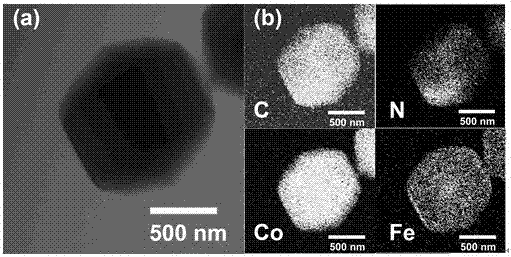

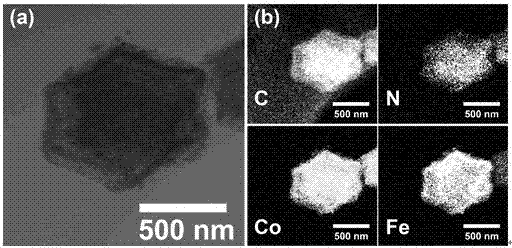

Iron, cobalt and nitrogen codoped carbon catalyst and preparation method and application thereof

The invention relates to an iron, cobalt and nitrogen codoped carbon catalyst and a preparation method and application thereof. An iron / cobalt double-metal zeolite imidazate framework material is adopted as a precursor, and the iron, cobalt and nitrogen codoped carbon catalyst is prepared and obtained through high-temperature pyrolysis, wherein the iron / cobalt double-metal zeolite imidazate framework material is prepared by adopting ferrous sulfate, cobalt nitrate and 2-methylimidazole to carry out a self-assembly reaction in a solvent under an oxygen-free environment. The iron, cobalt and nitrogen codoped carbon catalyst prepared in the invention has the advantages that the oxygen reduction catalytic activity, electrochemical stability and methanol poisoning resistance is superior to those of commercial Pt / C, the cost is low, the preparation method is simple and volume production can be realized. The catalyst disclosed by the invention can be widely applied to the fields of fuel batteries, metal-air batteries and the like.

Owner:BEIJING UNIV OF CHEM TECH

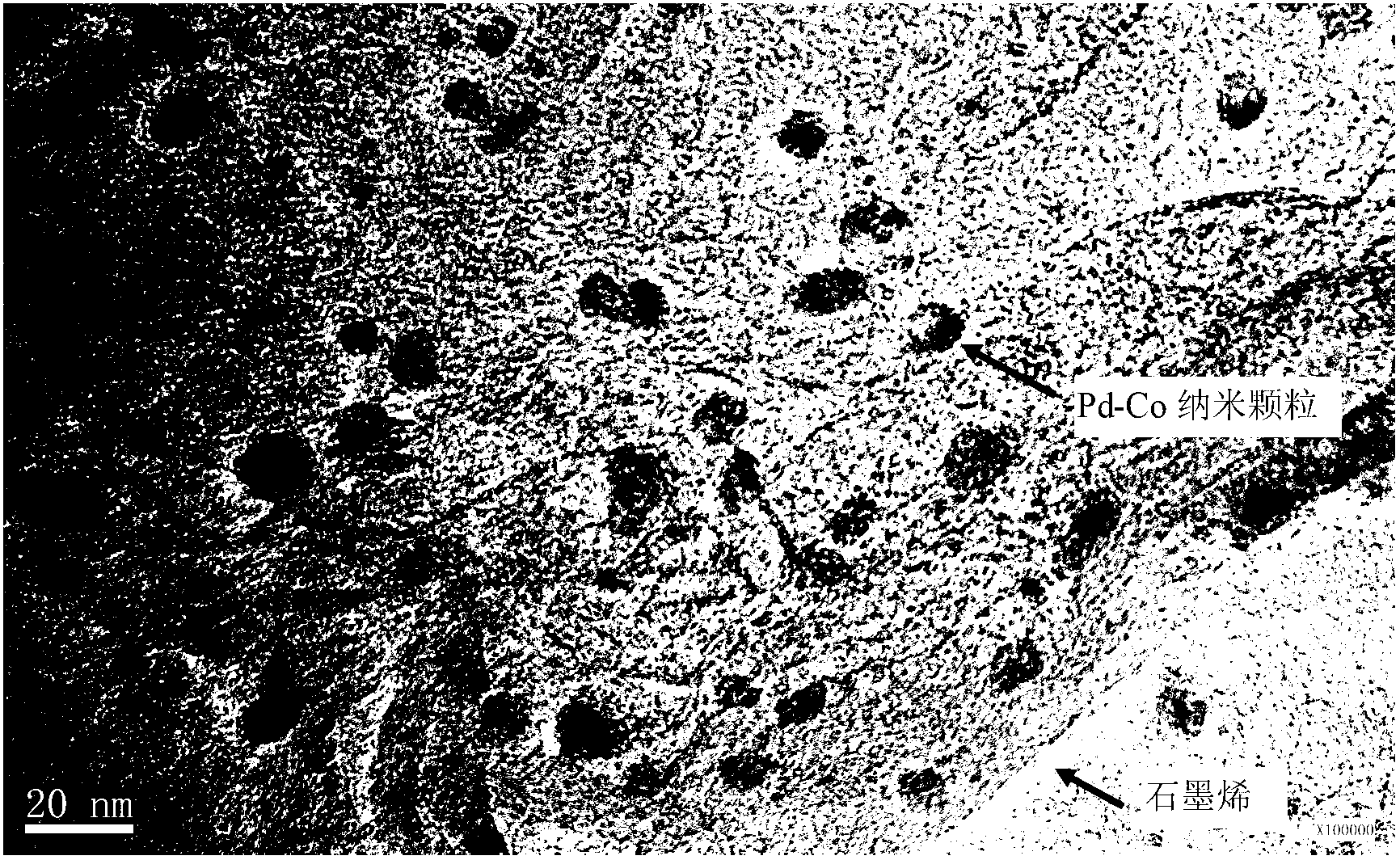

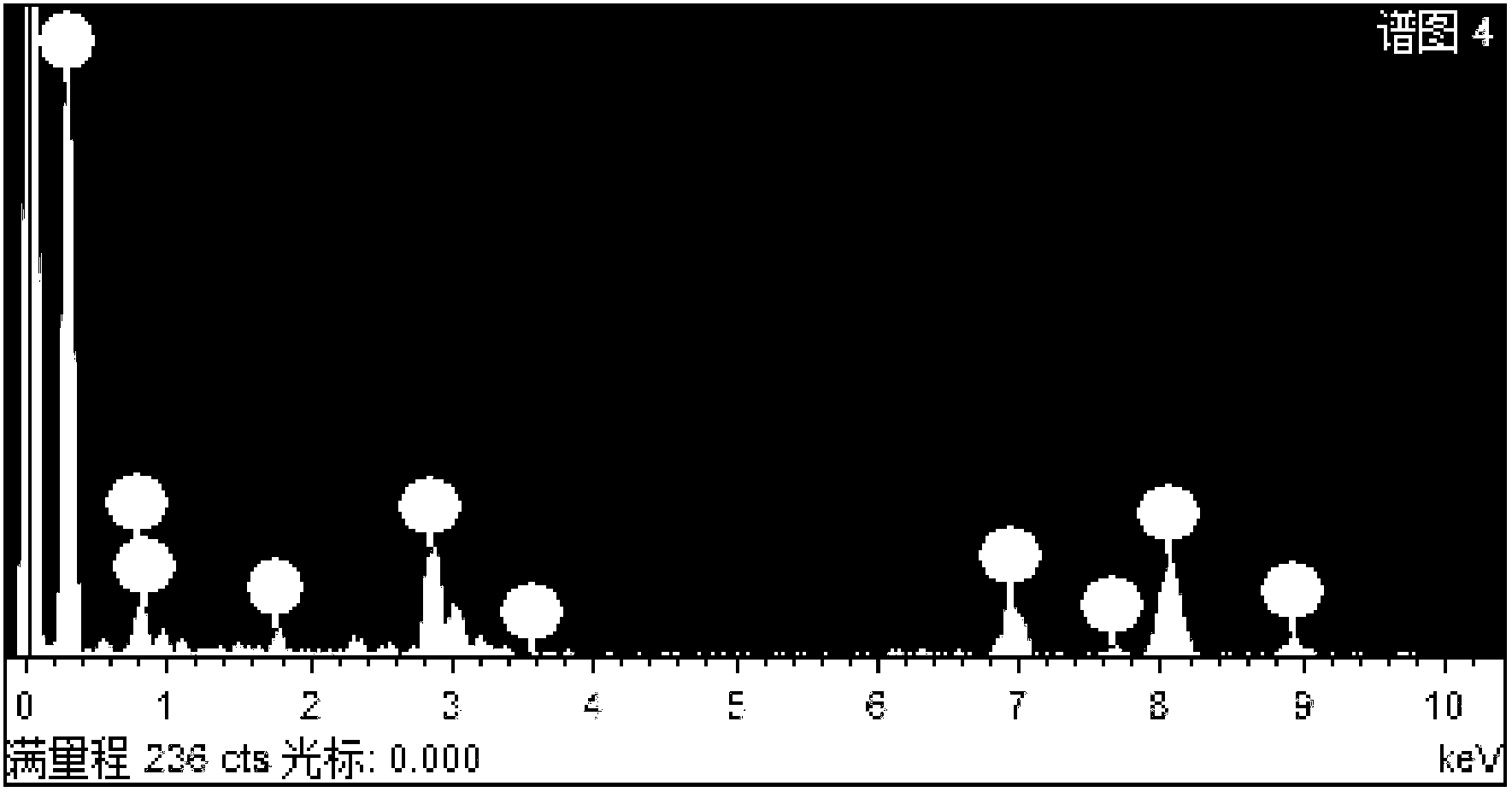

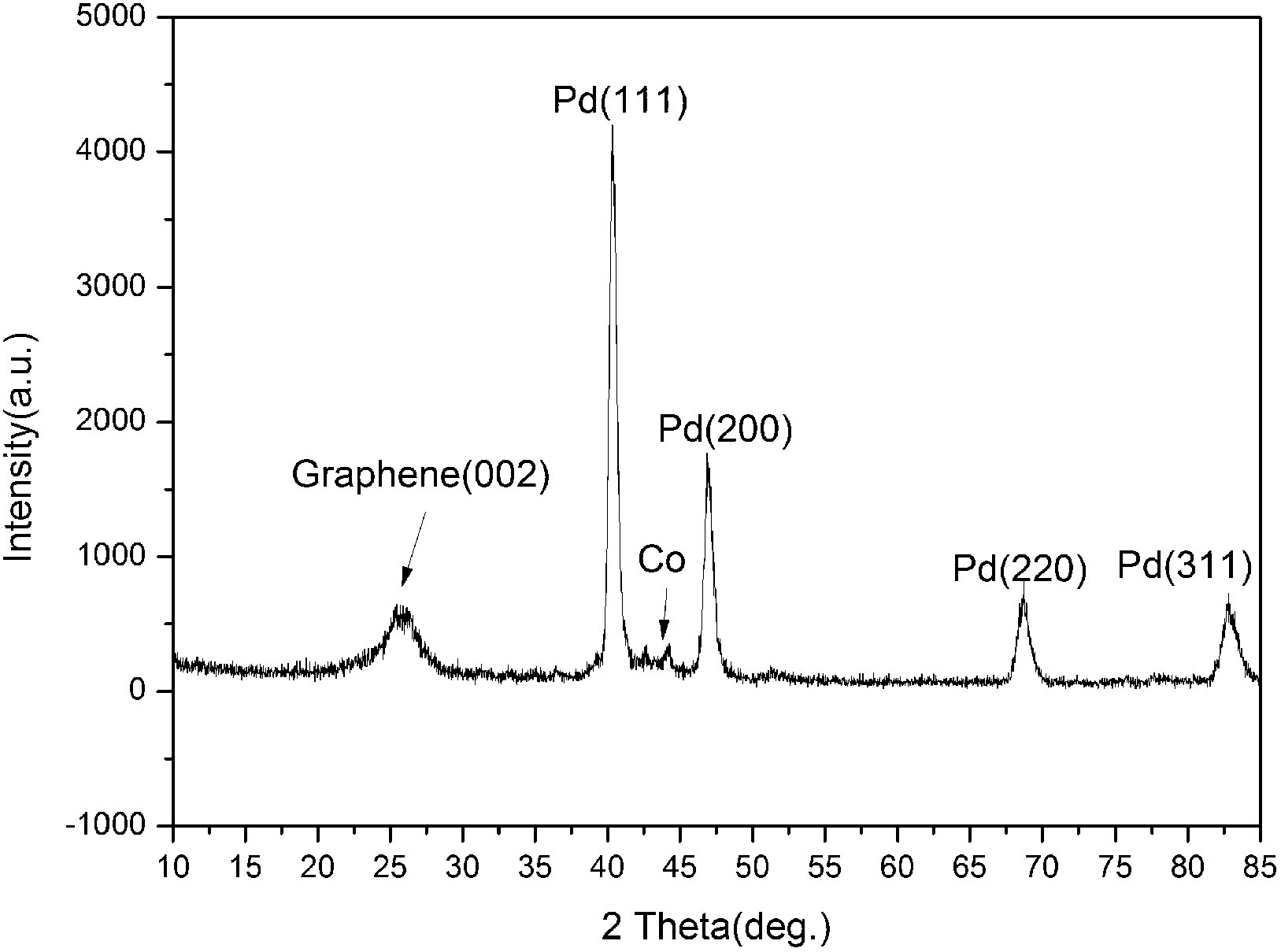

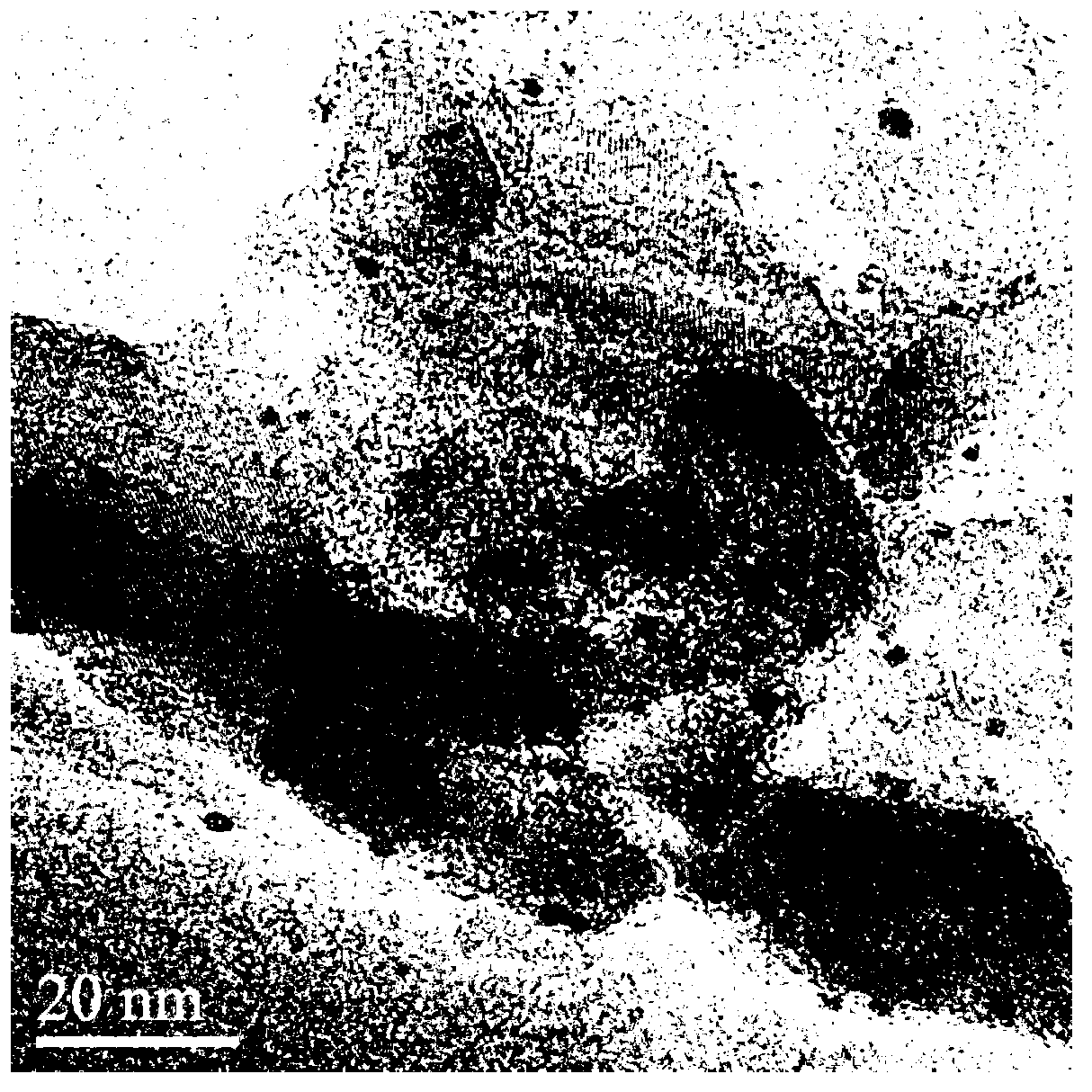

Method for preparing bimetallic nanometer alloy composite material by taking graphene as carrier

ActiveCN103007963AEvenly dispersedLow impurity contentMetal/metal-oxides/metal-hydroxide catalystsElectromagnetic shieldingAlloy composite

The invention discloses a method for preparing a bimetallic nanometer alloy composite material by taking graphene as a carrier. The method comprises the following steps of: by taking a precious metal N salt (N=Pd, Pt) and a transition metal M salt (M=Co, Ni and Cu) as precursors and taking graphene oxide as a matrix, reducing the components by employing a reducing agent; and finally, washing, filtering, drying, grinding and roasting to obtain the high-purity graphene bimetallic nanometer composite material. The composite material has high nanoparticle load capacity, stable structure, high uniformity and high dispersing property, has high binding force with the graphene and is high-efficiency in preparation method, low in cost, simple in process and suitable for industrial production. The composite material can be widely applied to the fields of magnetic targeting materials, various catalysts, electromagnetic shielding wave-absorbing materials, super-capacitor electrode materials and other related function materials.

Owner:安徽皖瑞能源科技有限公司

Secondary battery protection circuit, battery pack and thermosensitive protection switch device

InactiveUS7952330B2Avoid feature degradationReduced characteristicsSecondary cellsElectric powerSimple circuitBattery pack

A protection circuit is provided for protecting a secondary battery from overcharging and excessive discharge current by a simple circuit. The protection circuit is provided with a connection terminal (T3) for connecting the secondary battery (6); a connection terminal (T1) for connecting a charging device for charging the secondary battery (6) and / or a load device driven by a discharge current from the secondary battery (6); a bimetal switch (SW1) that is provided between the connection terminals (T1, T3) and turned off in the case of exceeding a specified temperature set beforehand; a heater (R2) for heating the bimetal switch (SW1); and an integrated circuit (IC1) for turning the bimetal switch (SW1) off by causing the heater (R2) to generate heat if a voltage applied to the connection terminal (T3) by the secondary battery (6) exceeds a preset reference voltage.

Owner:PANASONIC CORP

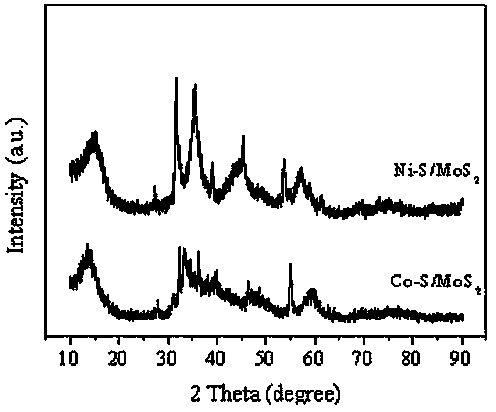

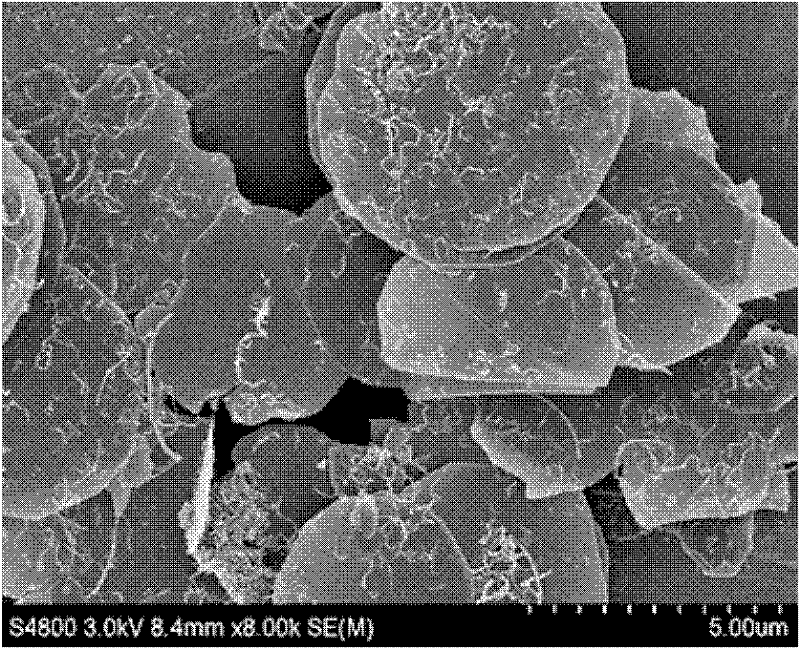

Double-metal-sulfide catalyst with high hydrodeoxygenation activity and preparation method thereof

InactiveCN103920506ALarge specific surface areaHigh catalytic activityPhysical/chemical process catalystsRefining to eliminate hetero atomsNickel saltVulcanization

The invention relates to a preparation method for a double-metal-sulfide catalyst. Soluble molybdate and nickel salt or cobalt salt serves as a raw material, thiourea or thioacetamide serves as a sulfur source, and a Ni(Co)-S / MoS2 catalyst is prepared through a two-step hydrothermal method. The method particularly comprises the following steps: MoS2 is prepared in a high pressure reactor through the hydrothermal method first, then the nickel salt or cobalt salt and the sulfur source are added into the reactor of the obtained MoS2 to be evenly mixed, the reactor is sealed and heated, a reaction is conducted for a certain period of time, and Ni-S or Co-S is deposited on the MoS2, so that the Ni(Co)-S / MoS2 catalyst is prepared. The preparation method is characterized in that the specific area of the Ni(Co)-S / MoS2 catalyst prepared through the two-step hydrothermal method is large, high temperature vulcanization is not required in the preparation process, the preparation condition is mild, the catalyst is used for hydrodeoxygenation, a target product has high yield and good repeatability, and hydrodeoxygenation activity of the catalyst is high.

Owner:XIANGTAN UNIV

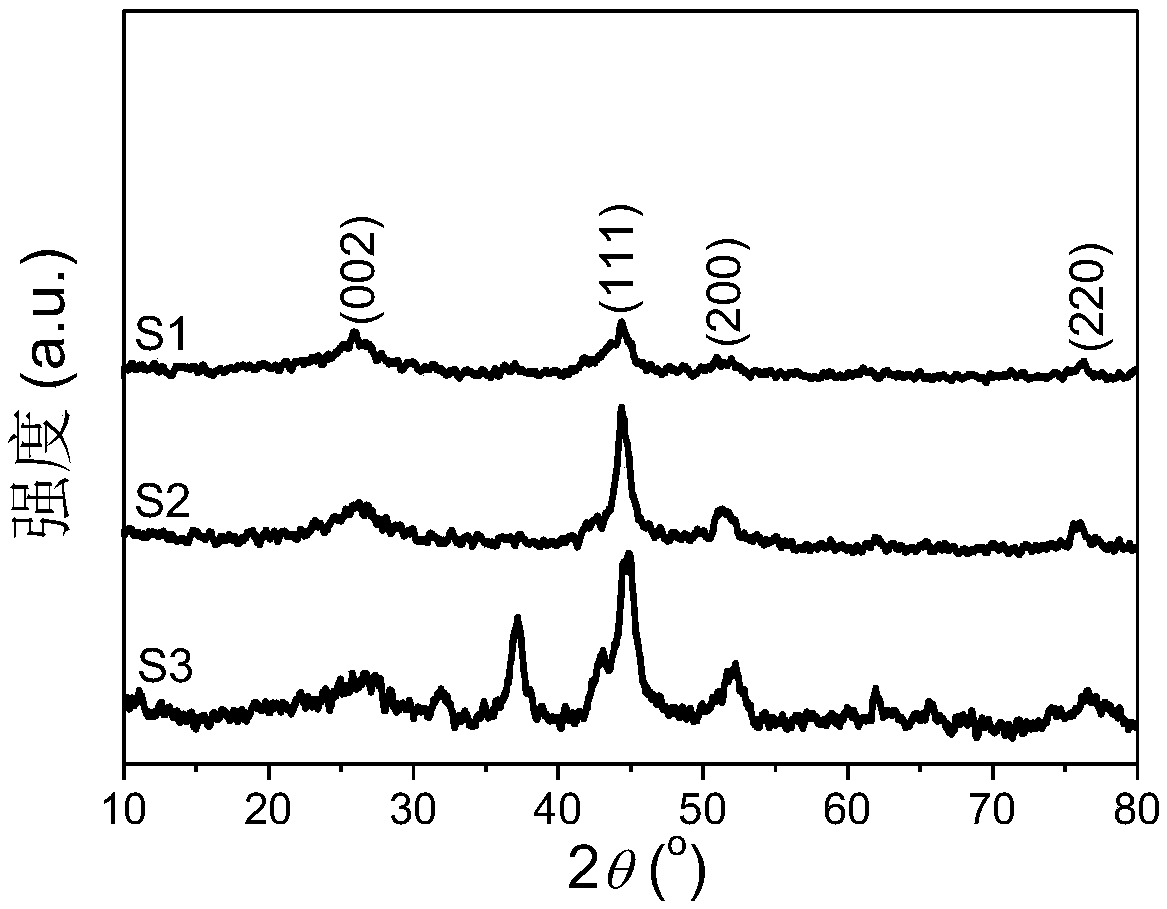

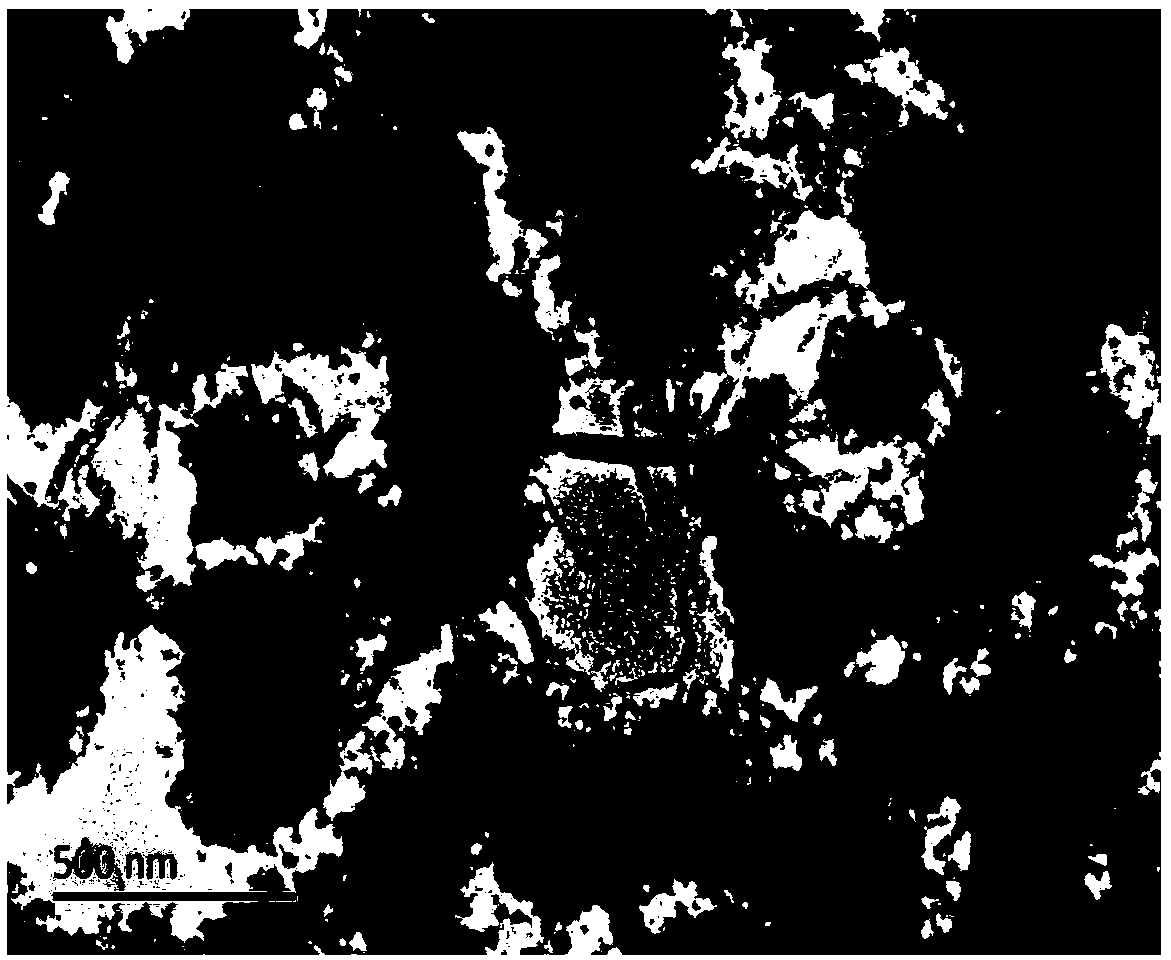

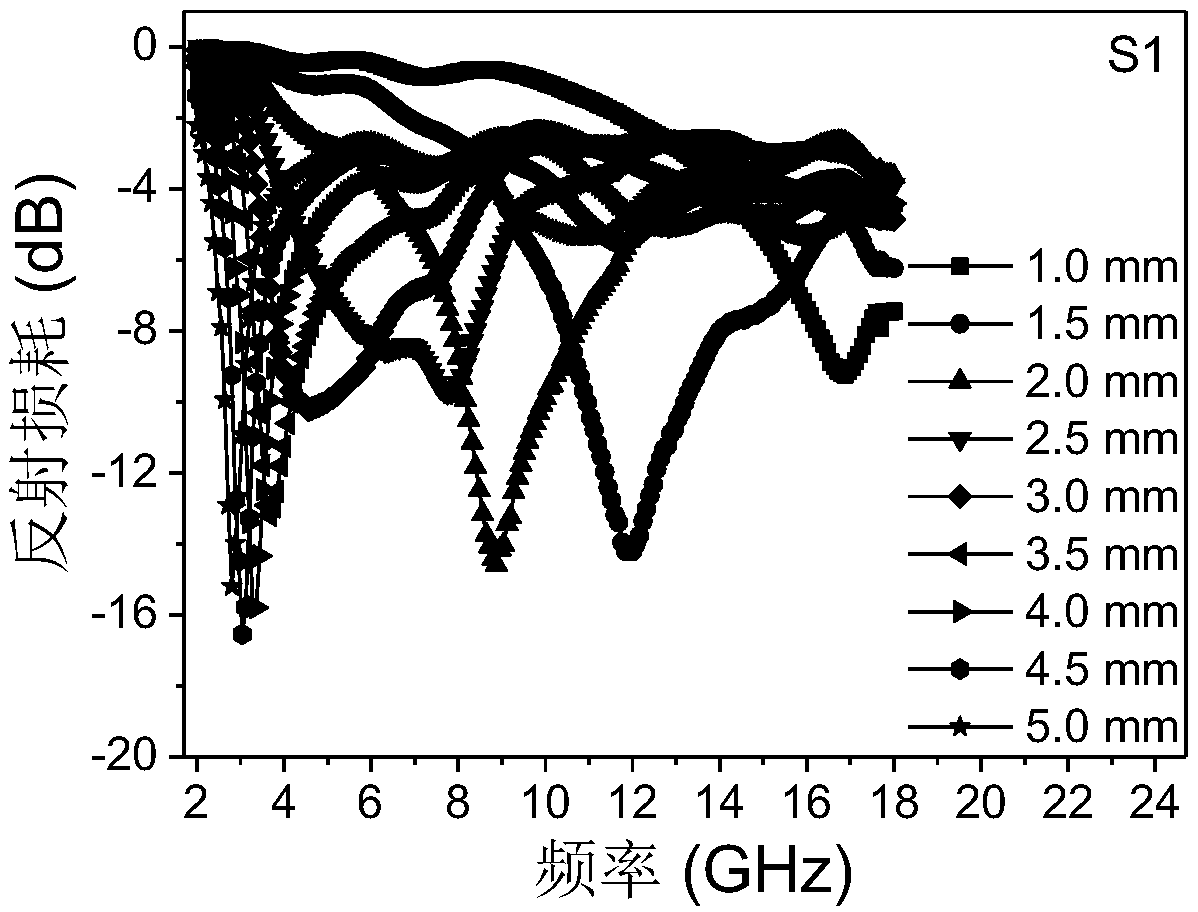

Bimetallic-organic-framework-based derived porous carbon/multi-wall carbon nanotube nano composite absorbing material and preparation method thereof

ActiveCN108834389ASimple and fast operationImprove absorbing performanceMaterial nanotechnologyMagnetic/electric field screeningPorous carbonCarbon nanotube

The invention discloses a bimetallic-organic-framework-based derived porous carbon / multi-wall carbon nanotube nano composite absorbing material and a preparation method thereof. On the basis of a hightemperature pyrolysis method, the porous carbon / multi-wall carbon nanotube nano composite material is prepared by using a multi-wall carbon nano tube as a carrier, cobaltous nitrate hexahydrate and zinc nitrate hexahydrate as metal salt precursors, 2-methylimidazole as an organic ligand, and methanol and ethanol as mixed solvents. The preparation method has good green and environment-friendly effects; no hazardous by products are generated; and the preparation process is simple. The prepared nano composite material has advantages of high electromagnetic wave absorption capacity, large absorption frequency bandwidth and low density. Electromagnetic wave with different wavebands can be absorbed effectively by adjusting the additive amount of the multi-wall carbon nano tube and the coating thickness. The bimetallic-organic-framework-based derived porous carbon / multi-wall carbon nanotube nano composite absorbing material and the preparation method thereof have the great application valuein the electromagnetic absorption and electromagnetic shielding fields.

Owner:ANHUI UNIV OF SCI & TECH

Method for atmospheric catalytic oxidation of cyclohexane by metalloporphyrin

InactiveCN1405131APreparation by oxidation reactionsOxygen compounds preparation by hydrocarbon oxidationCyclohexanoneReaction temperature

The invention relates to a new process in which under the catalytic action of metal porphyrin the cyclohexane can be selectively oxdated by air and made into cyclohexanol and cyclohexanone. Under the condition of 2-10 atm air, reaction temp. is 125-150 deg.C, it selects and uses micro-oxo double metal porphyrin and single metal porphyrin or their solid carrier as main catalyst, and uses transition metal salt or oxide as co-catalyst, the metal porphyrin can high-effectively and high-selectively catalyze oxidation of cyclohexane by using air in the biological concentratino as biological enzyme. The dose of metal porphyrin is small and said metal porphyrin can be repeatedly used, and said catalyst dose also is small, its catalystic effect is good, said catalyst can be used for making homogeneous catalysis, and after it is solid-carried, it also can be used for making heterogeneous catalysis.

Owner:HUNAN UNIV

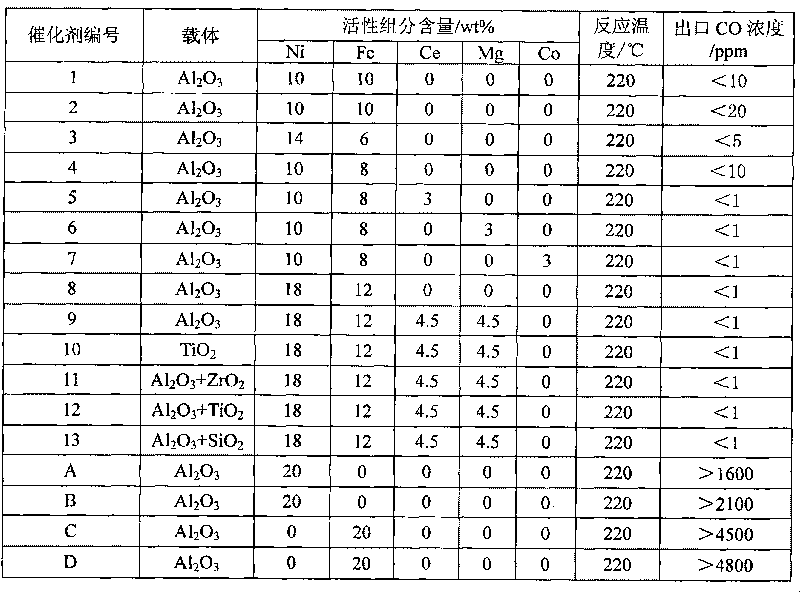

Bimetal methanation catalyst and preparation method thereof

InactiveCN101703933ARestoredGood dispersionHydrogen separation using solid contactCatalyst activation/preparationLow loadMethanation

The invention discloses a bimetal methanation catalyst for the removal of micro carbon monoxide from a hydrogen-rich gas and a preparation method thereof. The bimetal methanation catalyst contains active components, namely nickel oxide and ferric oxide, loaded on an oxide carrier and an assistant, wherein the assistant is at least one element selected from the main group I, the main group II, the subgroup I, the subgroup III, the subgroup VI and the subgroup VIII of the periodic table, and the oxide carrier is alumina, titanium dioxide, zirconium dioxide and silicon dioxide or a mixture thereof. The catalyst of the invention can allow the micro carbon monoxide to be removed from the hydrogen-rich gas at a relatively low temperature and has the advantages of low load, high activity, relatively low cost and wide application prospect.

Owner:SHANXI UNIV

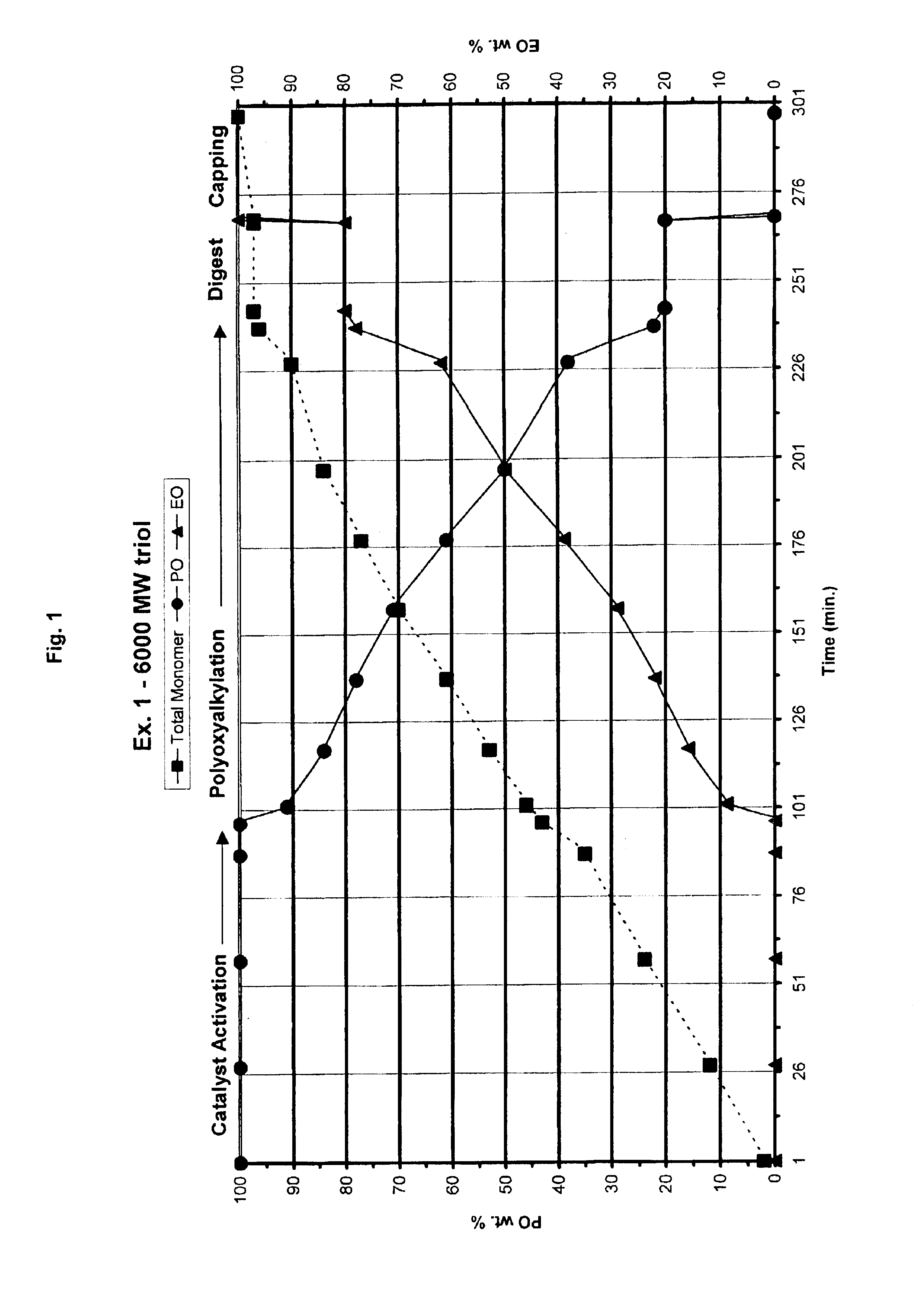

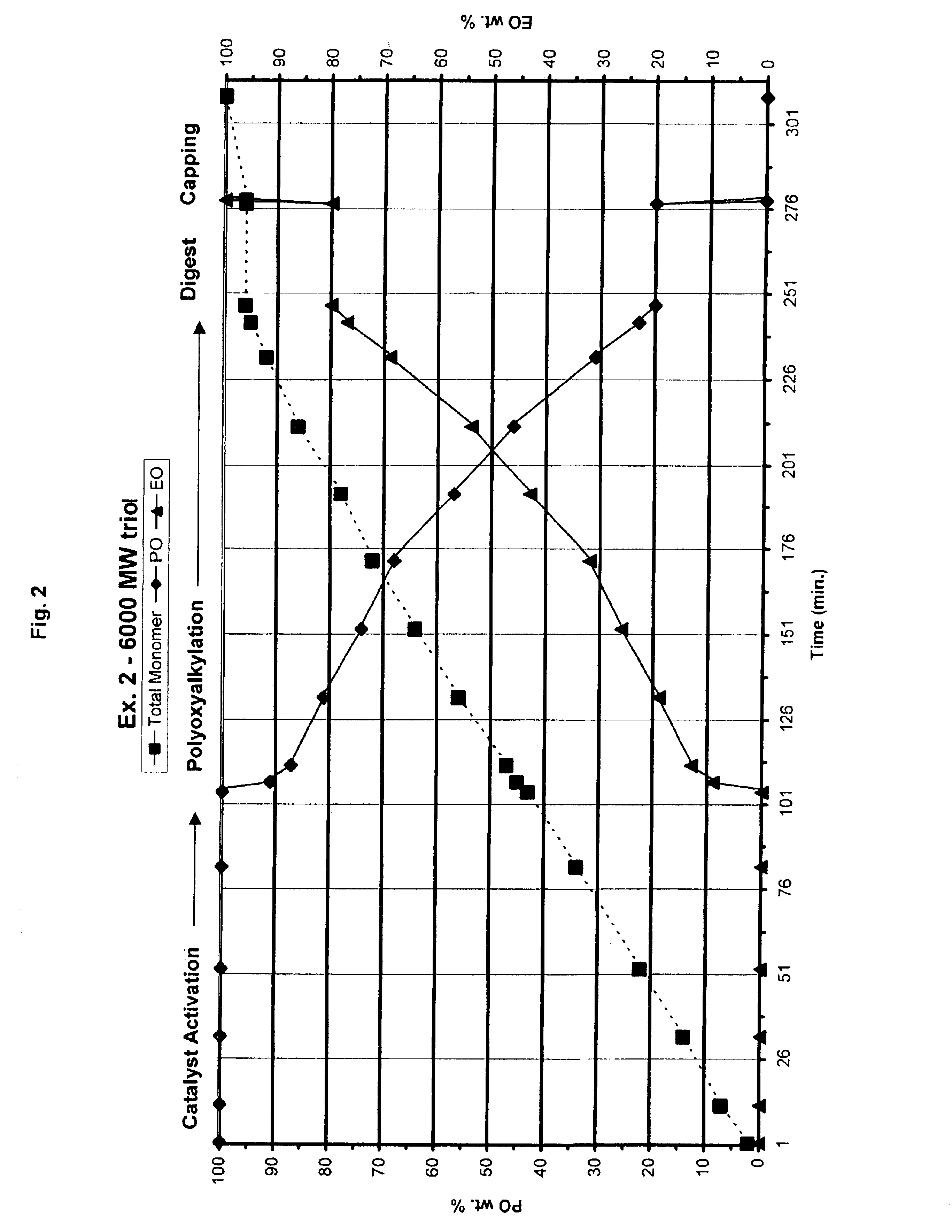

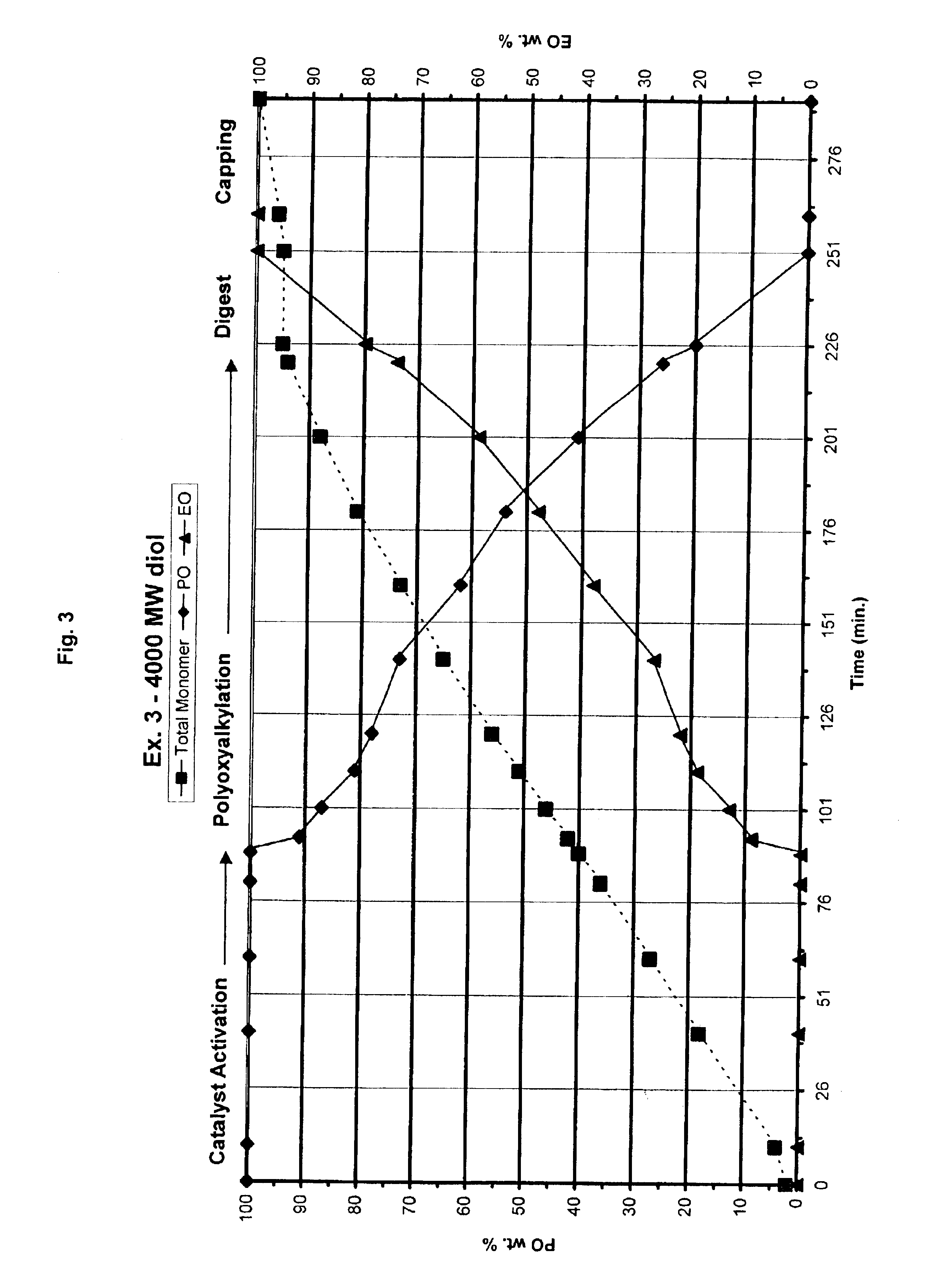

Process for preparing double metal cyanide catalyzed polyols

The present invention provides a process for preparing a polyoxyalkylene polyol by polyoxyalklating a starter compound with a mixture of two different alkylene oxide monomers in which the first alkylene oxide monomer content of the mixture decreases as the content of the second alkylene oxide monomer increases over the course of the polyoxyalkylation, digesting unreacted monomers of the alkylene oxides and capping the polyol.

Owner:BAYER ANTWERPEN NV

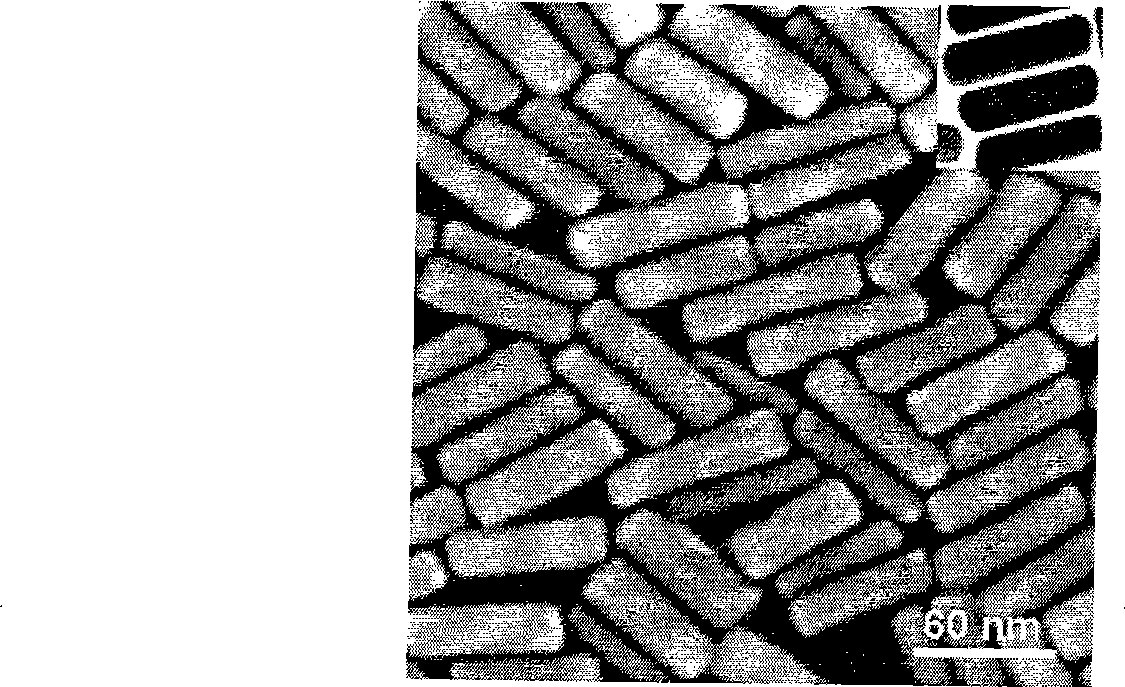

Bimetal nano rod of branched gold core/platinum shell structure and preparation method thereof

InactiveCN101450380AImprovement of poisoningLarge specific surface areaCoatingsPlatinumOptical property

The invention provides a dendritic gold-core / platinum-shell bimetal nanometer rod and a preparation method thereof. The dendritic gold-core / platinum-shell bimetal nanometer rod comprises a cylindrical gold nanometer-rod core and a porous platinum-shell layer covering the outer surface of the cylindrical gold nanometer-rod core; the diameter of the cylindrical gold nanometer-rod core is 10 to 15 nanometers; the length of the cylindrical gold nanometer-rod core is 55 to 60 nanometers; the thickness of the porous platinum-shell layer is 0.4 to 8 nanometers; and the length of platinum grains covering the outside of a nanometer rod is 2 to 4 nanometers. The preparation method provided by the invention has the advantages of simplicity, flexibility, environmental protection, green chemistry and low energy consumption. In addition, the obtained bimetal nanometer rod with a gold-core / platinum-shell structure has the characteristics of high yield, narrow size distribution, stable structure and adjustable optical properties.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

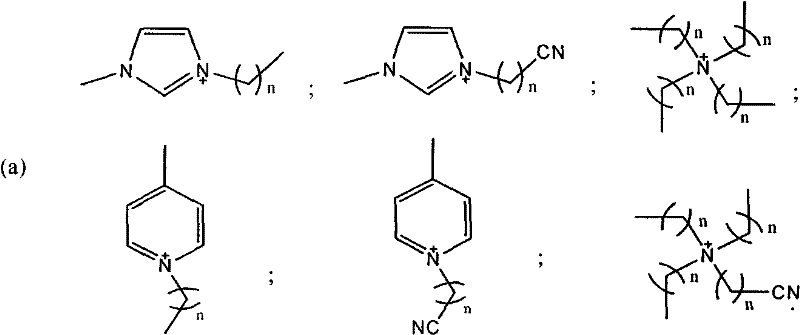

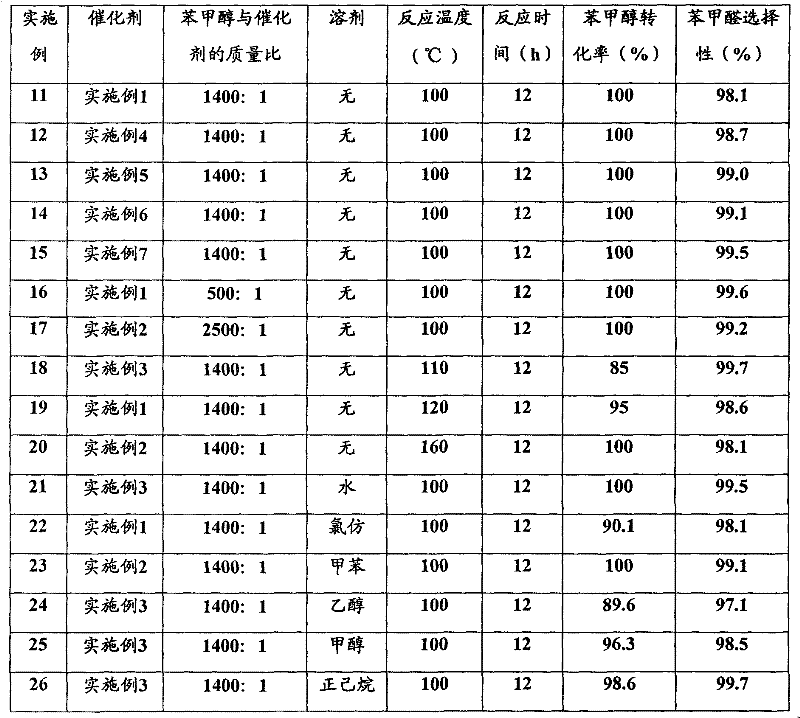

Preparation method of benzaldehydes compound and novel double-metal catalyst loaded by mesoporous carbon for preparation method

ActiveCN102513104AHigh catalytic activityGood synergyCatalyst carriersOrganic compound preparationBenzeneBenzaldehyde

The invention relates to a preparation method of a benzaldehydes compound and a catalyst for the preparation method. The catalyst is composed of 0.01-90 wt% of metal grains and 10-99.99 wt% of mesoporous carbon carrier; the metal grains are selected from any two of Pd, Au, Ag, Pt, Ru, Rh, Ni, Cu, Fe, Co, Cr, W, Mo, Ti and Ta; the weight ratio of two types of the metal is 1: (0.01-100) and the average grain diameter of the metal grains is 1-100 nm; and the mesoporous carbon carrier is prepared from a heteroatom-doped mesoporous carbon material. The content of heteroatoms in the mesoporous carbon material is 0.01-80 wt%. The catalyst provided by the invention is stable for water, air and heat and has an excellent catalytic activity; particularly, the catalyst has a high selectivity when being used for catalyzing an alcohol oxidation reaction to prepare aldehyde or ketone. The preparation method of the benzaldehydes compound provided by the invention has the advantages of high conversion rate of raw materials and good selectivity of a target product.

Owner:ZHEJIANG UNIV

Vulcanized hydrogenation catalyst, and preparation method and application thereof

InactiveCN105521799AReduce manufacturing costImprove hydrogenation performancePhysical/chemical process catalystsRefining to eliminate hetero atomsDispersityHydrodesulfurization

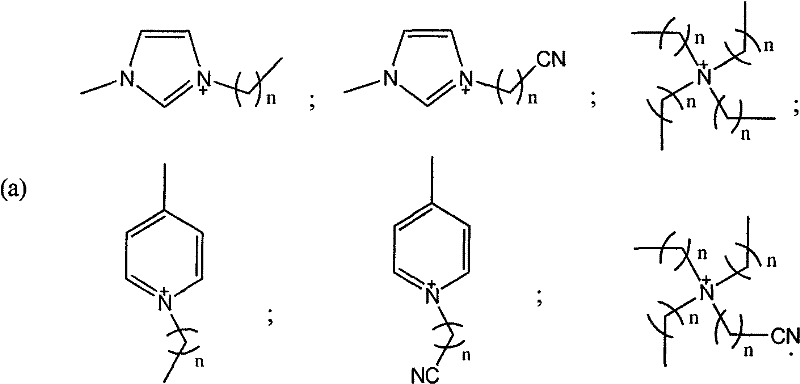

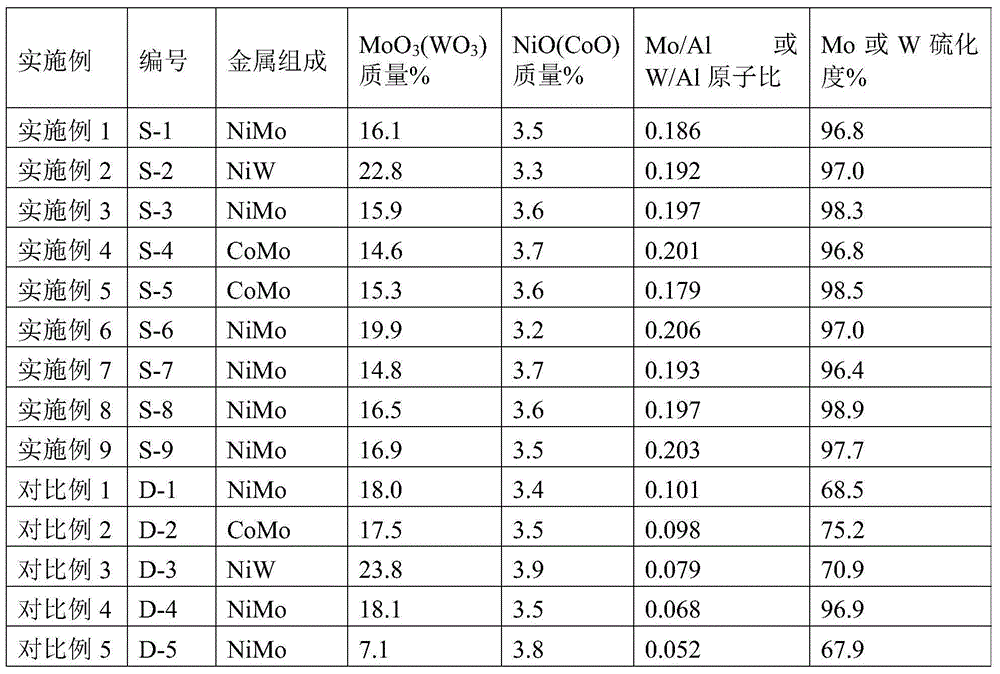

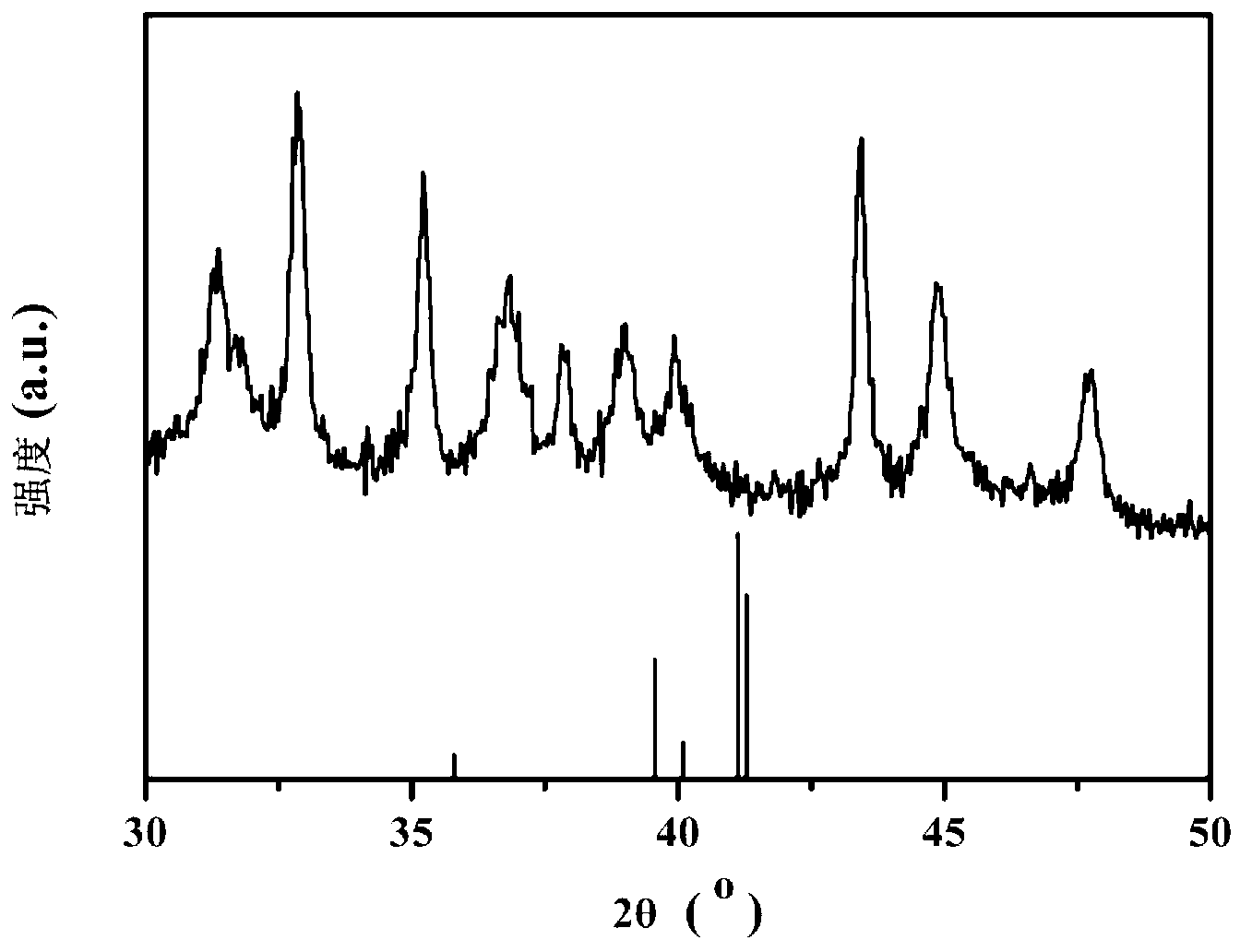

The invention provides a single-metal vulcanized hydrogenation catalyst and a double-metal vulcanized hydrogenation catalyst, and a preparation method and application thereof. The preparation method for the single-metal vulcanized hydrogenation catalyst comprises the following steps: (1) subjecting a dispersant and a solution A containing group-VIB metal salt and a sulfur source to contacting, wherein the solution A is acidic; the dispersant is a water-soluble organic solvent with a boiling point of 15 DEG to 90 DEG C; and the sulfur source is a sulfur-contained substance capable of hydrolyzing at 50 to 100 DEG C under the condition of acidity; (2) subjecting the product obtained by contacting in the step (1) and a catalyst carrier to contacting at 60 to 150 DEG C under a sealed condition for 5 to 30 hours; and (3) subjecting a solid material obtained by contacting in the step (2) to calcinating in an inert or reducing atmosphere. The invention also provides the single-metal vulcanized hydrogenation catalyst prepared by using the above-mentioned method, and application of the single-metal vulcanized hydrogenation catalyst in hydrodesulfurization and / or hydrodenitrification. Compared with the prior art, the hydrogenation catalyst provided by the invention has the characteristics of high metal activation grade, high active metal dispersity, high activity, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

Aromatic saturated hydrogenation catalyst and its preparing process

ActiveCN101099934AHigh catalytic activityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsBimetalChemistry

The present invention relates to one kind of arene saturation hydrogenating metal nitride catalyst, which consists of gamma-Al2O3 carrier and supported bimetal Ni-Mo nitride. Of the active components, Ni accounts for 2.5-10 wt%, Mo accounts for 6-25 wt%, and Ni and Mo co-exist as Ni2Mo3N, Ni, Mo2N and small amount of oxides. The catalyst is prepared through the following steps: roasting gamma-Al2O3 powder at 500-550 deg.c for 4-5 hr; dissolving nickel acetate, ammonium molybdenum and HMT in the molar ratio of 14 to 3 to 17.2-27 in 13 % ammonia water solution to form immersion solution; soaking the gamma-Al2O3 powder in the solution via stirring for 2-4 hr, filtering, air drying, vacuum drying at 60-100 deg.c for 5-8 hr, tabletting and sieving; roasting first in Ar flow to 650-680 deg.c for 2 hr and then in H2 flow for 2 hr, and cooling to room temperature in H2; and final deactivating in N2 containing O2 in 1 % for 4 hr. It has high catalytic activity and other features.

Owner:PETROCHINA CO LTD

Supported bimetal nanocrystal catalyst and preparation method thereof

InactiveCN103157469AEvenly dispersedIncrease profitMetal/metal-oxides/metal-hydroxide catalystsLayered double hydroxidesMetal salts

The invention provides a supported bimetal nanocrystal catalyst which is a binary bimetal catalyst taking aluminum oxide as a supporter and is abbreviated to P-M / MgO-AlO3, wherein P represents noble metal such as Pd, Au, Pt, Ag and the like, and M represents one or two of metal cations such as Cu<2+>, Zn<2+>, Ni<2+>, Ga<3+> and Fe<3+>. The particle size of the P-M bimetal nanocrystal is 2-10 nm, the dimension distribution is narrow, the nanocrystal particles are highly dispersed on the surface of the supporter uniformly and stably, and the crystal form is complete. The preparation method of the catalyst comprises the following steps: preparing soluble Mg<2+> salt for MgMAl-LDH (layered double hydroxide) preparation and an endogenous active metal salt solution into a mixed solution; then simultaneously adding precipitant and the aluminum oxide supporter into the reaction system; enabling hydrotalcite to grow on the surface of the aluminum oxide supporter through an in-situ growth method; supporting exogenous active metal through a wet impregnation method; and performing high-temperature reduction on the obtained catalyst precursor under a reducing atmosphere, thus obtaining the supported bimetal nanocrystal catalyst which is stably and highly dispersed.

Owner:BEIJING UNIV OF CHEM TECH

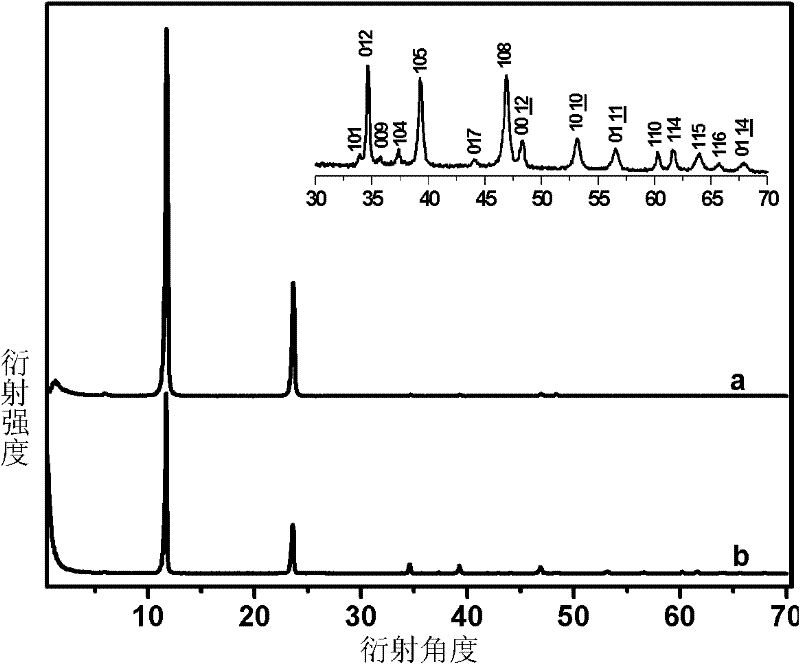

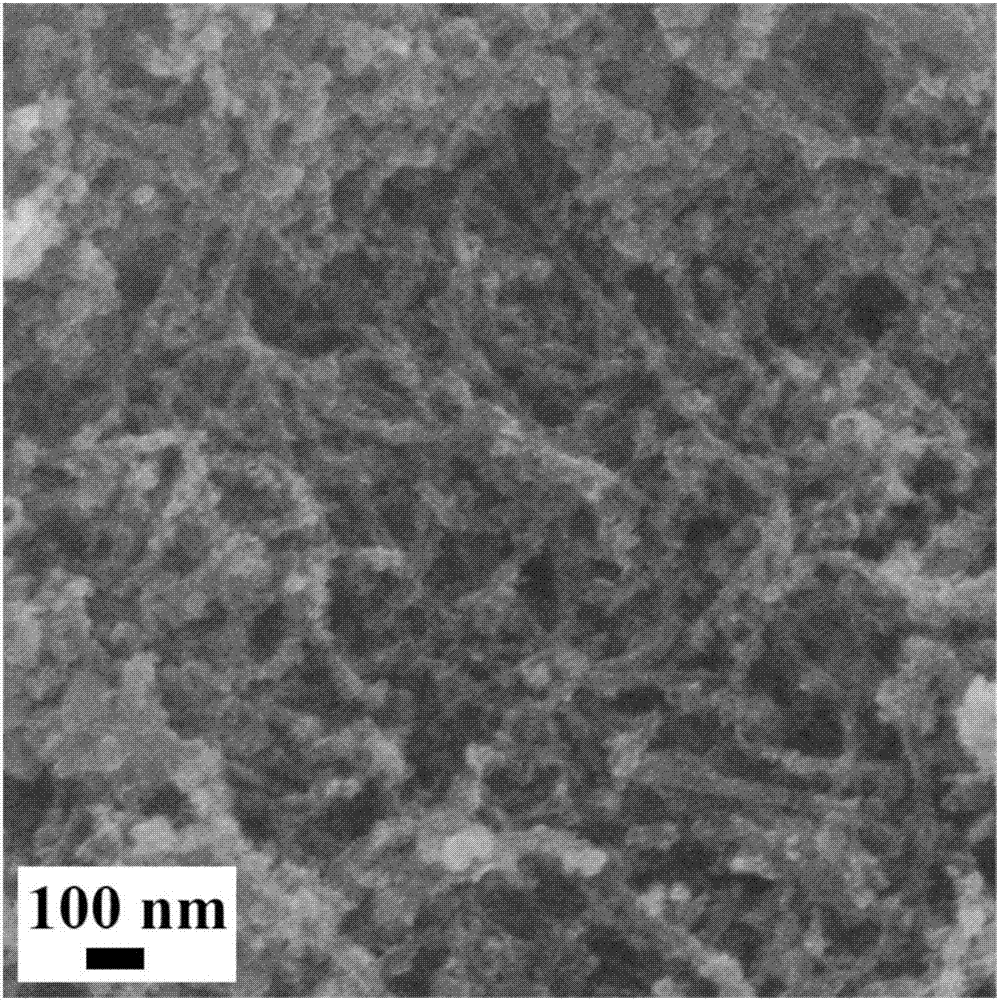

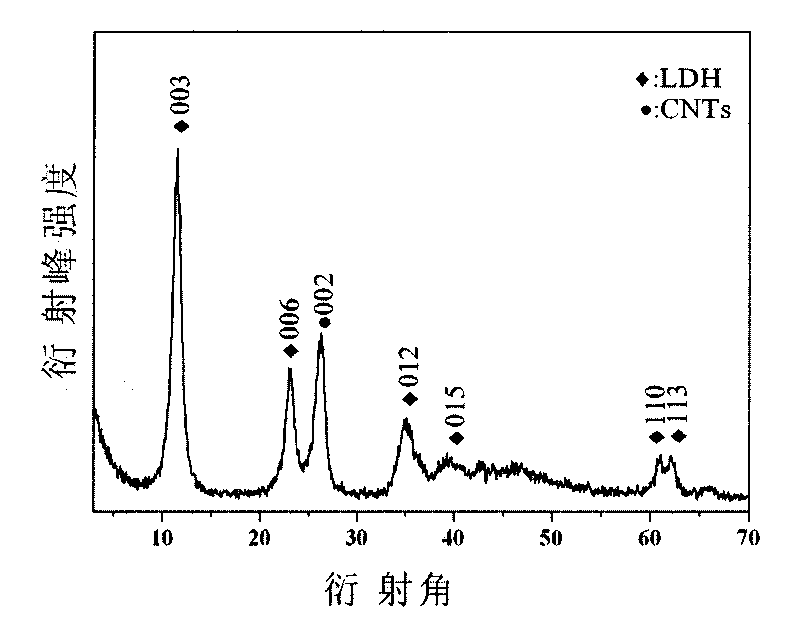

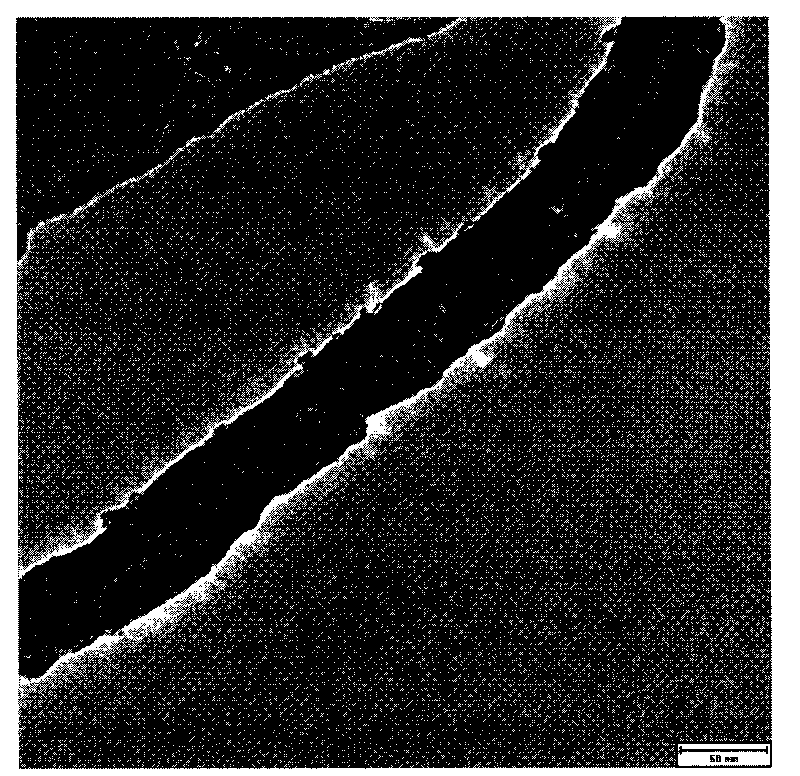

Method for preparing carbon nanotube (CNT)/layered double-metal hydroxide (LDH) compound

InactiveCN102350279AFacilitate ion exchangeExcellent peelabilityMicroballoon preparationMicrocapsule preparationCarbon nanotubeOxide composite

The invention discloses a method for preparing a CNT / LDH compound. The CNT / LDH compound is obtained through connecting hydroxy groups and carboxylic groups to the surface of CNTs through acidifying, adding metal salts and an alkaline substance to an aqueous dispersion of the CNTs, and forming an LDH in an in situ mode. The method of the invention has the advantages of simplicity, no need of a high temperature and low cost; and in the prepared CNT / LDH compound, the CNTs are uniformly dispersed in the LDH, and the composition and the structure are controllable. The prepared CNT / LDH compound which well preserves the layered structure of the LDH and effectively improves the dispersibility of the CNTs allows the sheet peeling of the LDH and the uniform dispersion of the CNTs to be easily realized when the CNT / LDH compound is applied to a polymer matrix.

Owner:ZHEJIANG UNIV

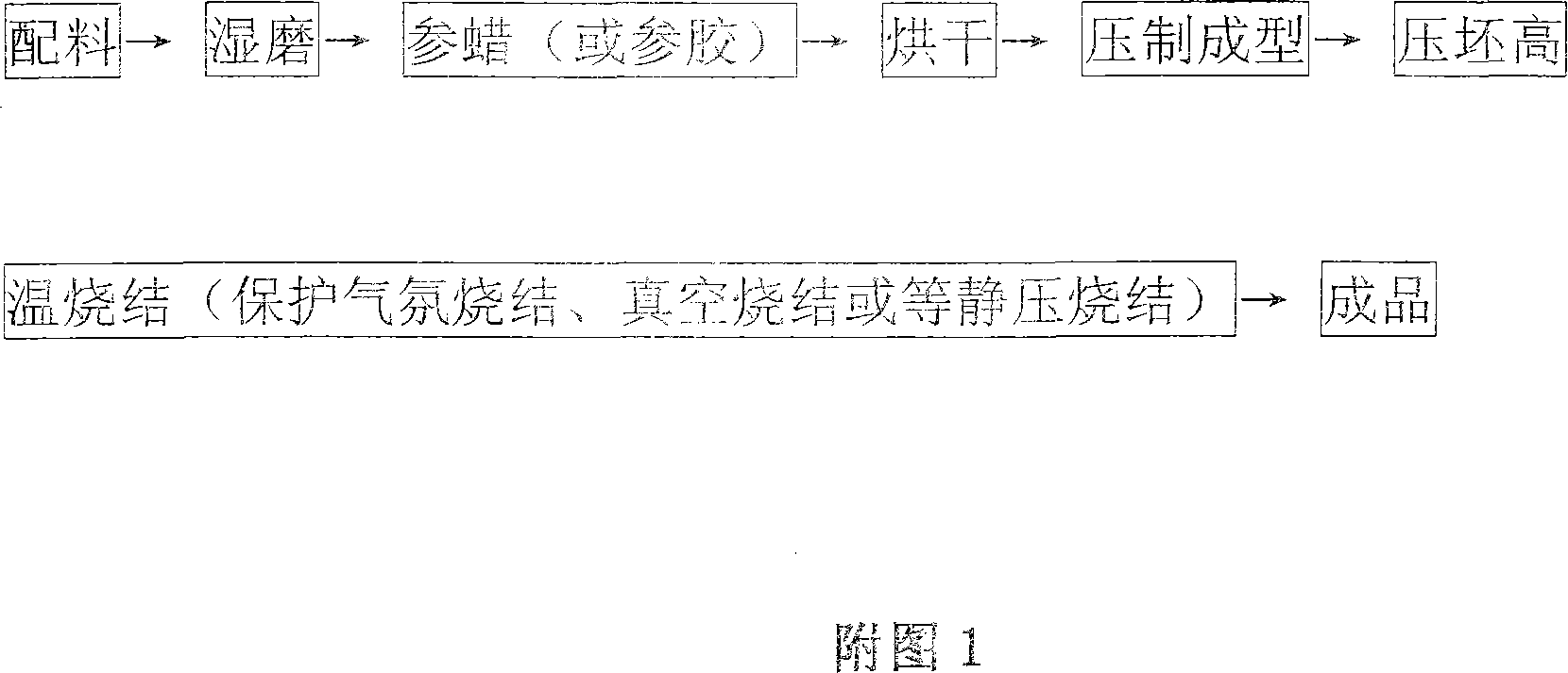

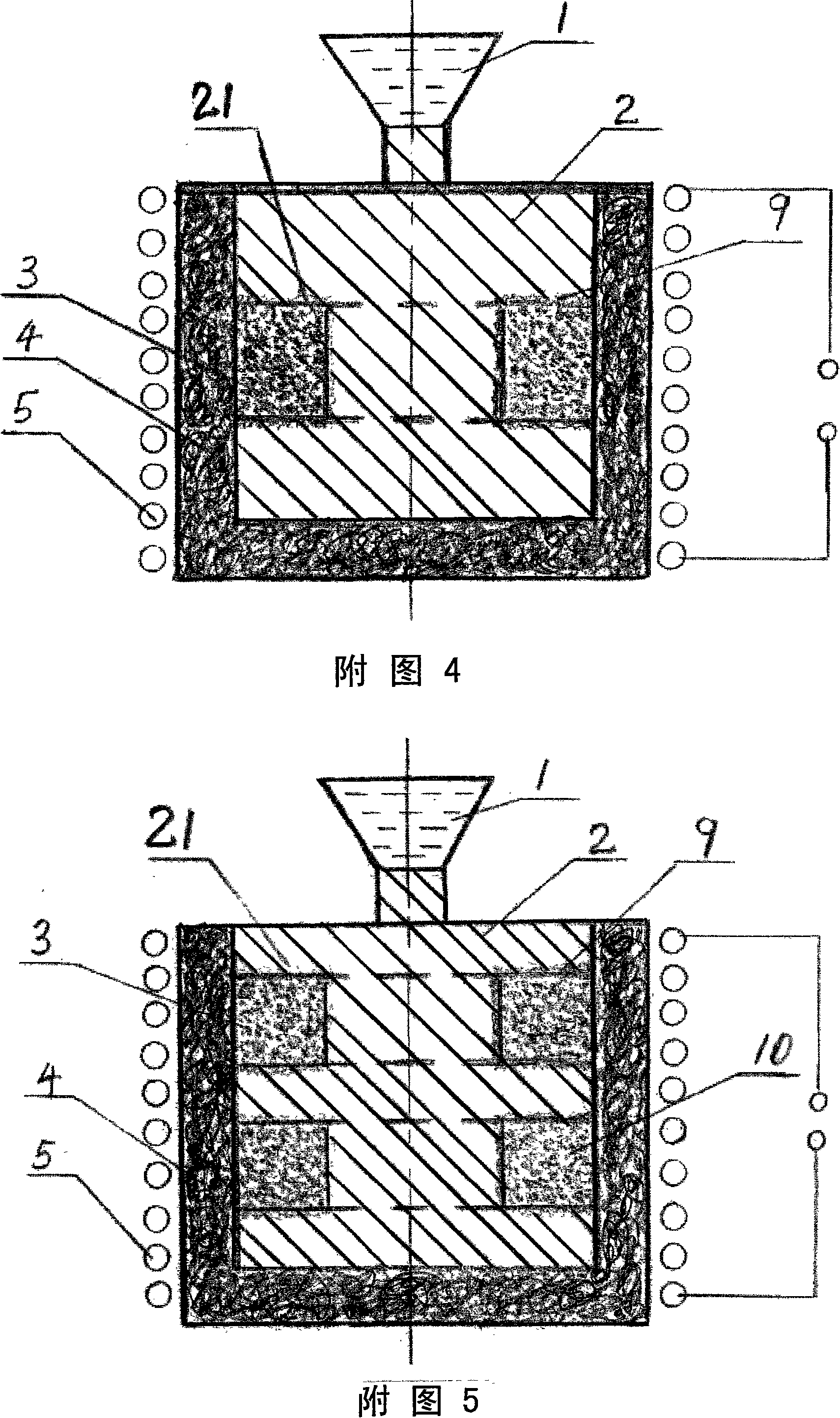

Hard alloy and double-metal composite technique and device

The utility model relates to a composite art and apparatus for hard alloy and bimetal, wherein the hard alloy is made of C with the content from 1.5 to 3.8 percent, Cr with the content from 15 to 27 percent, high chromium foundry iron with the content Fe used as binder, WC or TIC particles by the powder metallurgy technique, wherein the C and Cr are both accounted for 10-40 percent, the rest is the high chromium foundry iron, the WC or the TIC has the content from 90 to 60 percent. The hard alloy proceed composite casting with the C with the content from 1.5 to 3.8 percent, the Cr with the content from 15 to 25 percent, the rest high chromium foundry iron and spheroidal graphite cast iron in the mould provided with an electro-magnetism induction heater outside. The recombination of two materials is achieved by directly heating to the hard alloy and base metal liquid via the induction heater in the process of casting. The hard alloy produced by the invention has better wetting property and less bulking difference to the base metal, and is capable of achieving good recombination with the base metal. The invention has the advantages of simple recombination technique, easy achievement of technique, good property of the recombination products and low manufacturing costs.

Owner:丁家伟 +1

Secondary battery

ActiveUS20050266302A1Improve stabilityReduce spacingPrimary cell maintainance/servicingFinal product manufactureElectrical connectionElectrical current

A secondary battery having an improved electrical connection structure of a secondary protective device by positioning a thermo-breaker in a protective device groove, in order to improve the stability of the secondary battery while minimizing the occupation of the inner space of the can. The secondary battery includes an electrode assembly having positive and negative electrode tabs. A can contains the electrode assembly therein. A cap assembly has an insulated electrode terminal and a cap plate for sealing the top opening of the can. A protective device groove is formed on the bottom surface of the cap plate. A thermo-breaker is seated in the protective device groove while being connected between the first electrode tab and the electrode terminal. When the temperature inside the battery reaches a predetermined value, the bimetal loses contact and the electrical current inside the battery is interrupted, avoiding overcharge / over-discharge or explosion of the battery.

Owner:SAMSUNG SDI CO LTD

Carbon material-supported copper-cobalt bimetallic sulfide composite material and its preparation method and application in waste water treatment

ActiveCN106944098ARegulatory TopographyPromote degradationPhysical/chemical process catalystsWater contaminantsMetallic sulfideCobalt

The invention discloses a carbon material-supported copper-cobalt bimetallic sulfide composite material and its preparation method and application in water treatment. In the composite material, the copper-cobalt bimetallic sulfide (CuCo2S4) micrometer or nanometer particles are loaded on the carbon material. Through a one-step method or a multi-step method, the composite material is prepared. In water treatment or waste water treatment, through synergistic effects between the copper-cobalt bimetals and synergistic effects between the sulfide and carbon material, the composite material has good catalytic degradation and degradation pollutant adsorption performances.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI +1

Double metal hydroxide-composited porous bismuth vanadate photo-electrode and preparation method thereof

The invention provides a double metal hydroxide-composited porous bismuth vanadate photo-electrode and a preparation method thereof, wherein a composite of Co-Al double metal hydroxide and bismuth vanadate is grown on the surface of an electric-conductive glass substrate. The pore size of the bismuth vanadate is 50-120 nm and the particle size of the bismuth vanadate is 200-300 nm. The Co-Al double metal hydroxide is grown on the bismuth vanadate particles with the thickness being 10-100 nm. The preparation method includes following steps: 1) preparing a porous bismuth vanadate electrode through an electro-deposition precursor method; and 2) growing the Co-Al double metal hydroxide on the porous bismuth vanadate electrode. The method is simple in operation and is mild in reaction conditions. With zinc ion as an electro-deposition additive for controlling the size and appearance of the bismuth vanadate electrode, the method is more green and environment-friendly compared with a method in the prior art with an organic template agent or organic additives, so that the method is suitable for large-scale production. The photo-electrode can be directly used in photo-electro-chemical water oxidizing catalytic reaction. Because of excellent catalytic performance and visible light absorption capability of the Co-Al double metal hydroxide, the photo-electrode is significantly improved in water oxidizing performance.

Owner:BEIJING UNIV OF CHEM TECH

NiAl-laminated type bimetal hydroxide/carbon nano-tube compound electrode as well as preparation method and application thereof

InactiveCN101718738AEasy to prepareLow costMaterial electrochemical variablesSynthesis methodsCarbon nanotube

The invention provides a NiAl-laminated type bimetal hydroxide / carbon nano-tube compound electrode, a preparation method thereof, and an application of the electrode to the electro-catalytic oxidation of glucose. In the electrode, a glassy carbon electrode is taken as a substrate electrode and coated with a layer of film of a NiAl-laminated type bimetal hydroxide / carbon nano-tube compound. The preparation method comprises the following steps of: enabling laminated type bimetal hydroxide to grow in-situ on the surface of carbon nano-tubes by adopting a coprecipitation method to obtain the laminated type bimetal hydroxide / carbon nano-tube compound; then dispersing the compound into a water solution to prepare a solution; dispensing the solution on the surface of the clean glassy carbon electrode; drying at room temperature to volatilize the solvent and obtain the electrode modified by the laminated type bimetal hydroxide / carbon nano-tube compound. The electrode can be used for the electro-catalytic oxidation of the glucose under an alkaline condition and has favorable electro-catalysis performance and stability with simple synthesis method, low cost and wide application prospect.

Owner:BEIJING UNIV OF CHEM TECH

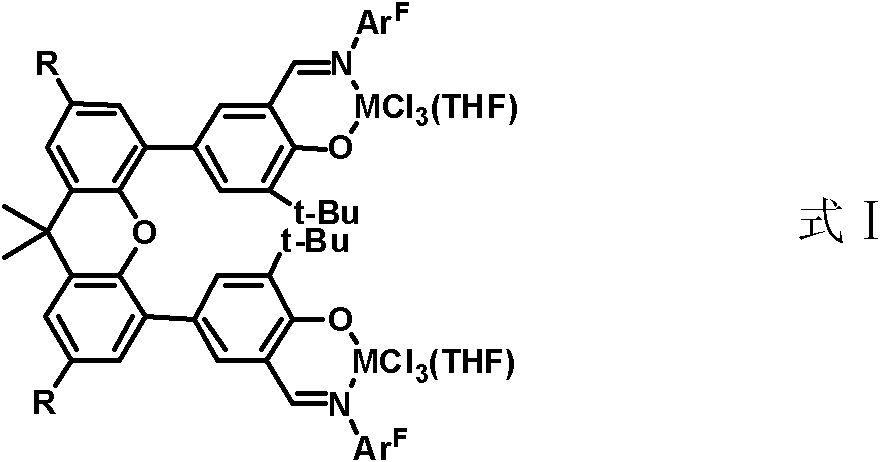

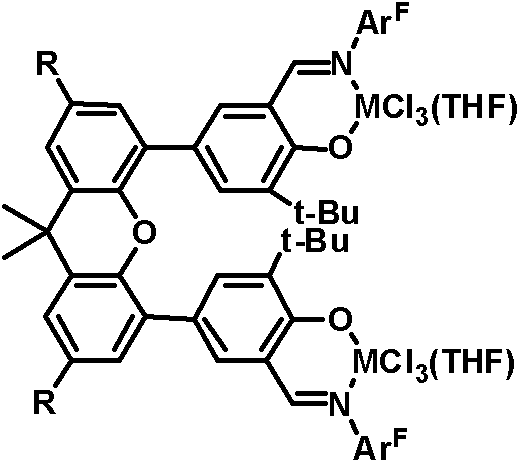

Bimetallic catalyst precursor and application thereof to olefin polymerization or copolymerization

ActiveCN101864010AHigh catalytic efficiencyHigh polymerization activityAluminoxaneCoordination polymerization

The invention discloses a bimetallic catalyst precursor for catalyzing olefin to polymerize or copolymerize and belongs to the field of olefin coordination polymerization. The catalyst precursor is based on a salicvlaldimine ligand and an IV group transition metal. Compared with a monometallic catalyst, with the synergistic effect of bimetals, a catalyst consisting of the precursor and alkyl aluminum has higher activity when used for catalyzing the olefin to homopolymerize or copolymerize; particularly, the activity of the catalyst can reach 5.2*104g / mol<-1>h<-1> at the ethylene pressure of 1atm when used for catalyzing 1,5-hexadiene to be copolymerized with the ethylene; and in addition, the catalyst has higher ratio of inducing a comonomer into a polymer.

Owner:PEKING UNIV

Saw blade and saw having an oscillatory drive

InactiveUS20050178261A1Wide applicationLong lastingPower driven reciprocating sawsMetal working apparatusDrive shaftEngineering

A saw comprising an oscillatory drive for oscillatingly driving a drive shaft about its longitudinal axis is disclosed. The saw comprises a saw blade being driven oscillatingly by the drive shaft and further comprises a mounting section comprising a mounting opening for engaging the drive shaft of the oscillatory drive positively or non-positively. The working section has a cutting edge comprising a series of cutting teeth, wherein at least the cutting edge is made of bimetal. Also preferably there is provided on both sides of the saw blade adjoining the cutting edge a coating comprising diamond grinding particles.

Owner:C & E FEIN

Method for manufacturing double metal composite wear-resistant metallurgical rollers

ActiveCN103009015AIncrease the amount of steelAvoid Roll Breaking AccidentsArc welding apparatusWear resistantHardness

A method for manufacturing double metal composite wear-resistant metallurgical rollers includes steps of roller core processing, preheating, surfacing of a composite layer, finish machining and thermal treatment. The roller core processing step includes subjecting steel good in tensile strength, yield strength and impact resistance to forging, pressing and tempering, manufacturing roller core blanks, subjecting the roller core blanks to rough machining to reserve size for a surfaced composite layer. The preheating step includes preheating the roller cores to the optimum surfacing temperature of 380 DEG C + / - 5 DEG C. The surfacing step of the composite layer includes surfacing and filling the reserved surfaced composite layer by flux-cored wires on the surface of the preheated roller cores by means of submerged-arc welding process. The finish machining step includes processing the surfaced double metal composite wear-resistant metallurgical roller blanks into design size. The thermal treatment step includes quenching and tempering the double metal composite wear-resistant metallurgical rollers subjected to finish machining, so that the surfaces of the double metal composite wear-resistant metallurgical rollers can meet the requirements for good anti-sticking abrasion, grain abrading resistance, red hardness, resistance to cold and hot fatigue, and peeling resistance.

Owner:邯郸市永固冶金备件有限公司

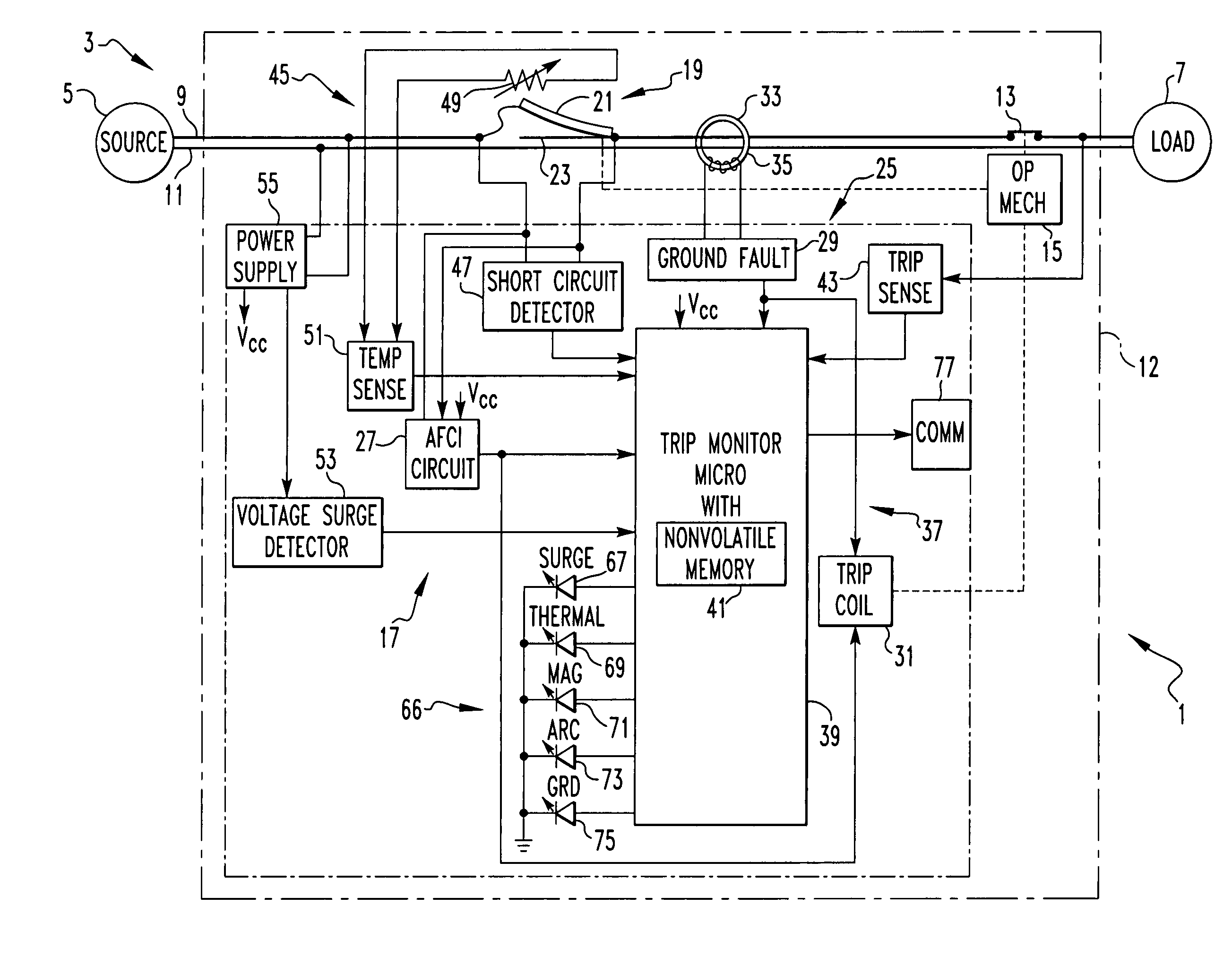

Monitor providing cause of trip indication and circuit breaker incorporating the same

ActiveUS7030769B2Emergency protective circuit arrangementsSnap-action arrangementsDistribution systemEngineering

Owner:EATON INTELLIGENT POWER LTD

High water content tolerant process for the production of polyethers

The present invention provides a process for the production of a polyether involving establishing oxyalkylation conditions in an oxyalkylation reactor in the presence of from about 5 ppm to about 1,000 ppm, based on the final polyether weight, of a double metal cyanide (DMC) catalyst, continuously introducing into the reactor at least one alkylene oxide and a low molecular weight starter having a number average molecular weight of less than about 300 Daltons (Da) containing from about 200 ppm to about 5,000 ppm water and acidified with from about 10 ppm to about 2,000 ppm of at least one of an inorganic protic mineral acid and an organic acid, and recovering a polyether product having a number average molecular weight of from about 200 Da to about 4,000 Da, wherein the ppm (parts per million) of water and acid are based on the weight of the low molecular weight starter. The inventive process may allow for the use of low molecular weight starters containing higher levels of water at lower DMC catalyst levels than current processes.

Owner:BAYER MATERIALSCIENCE AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com