Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

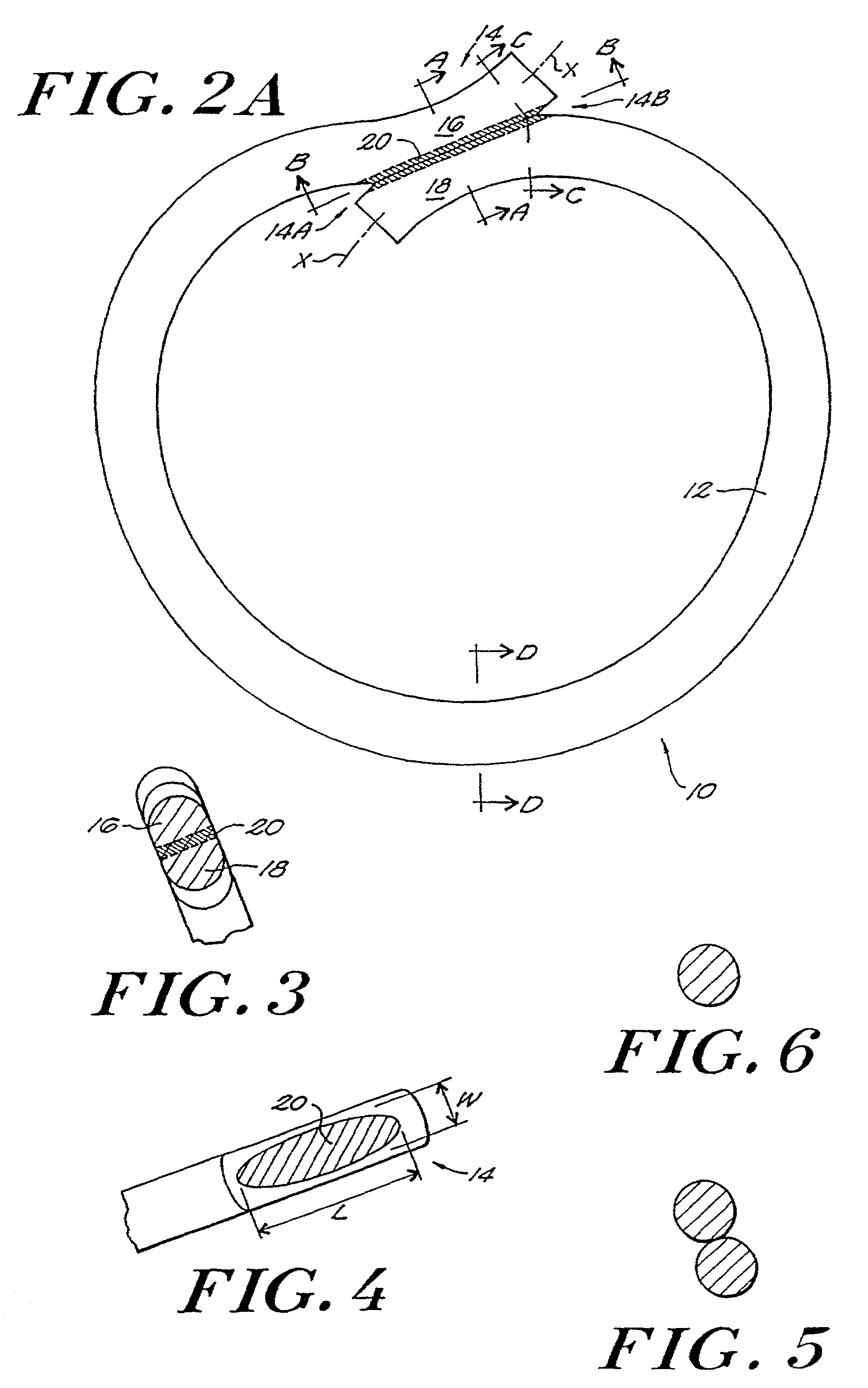

13624results about "Non-electric welding apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

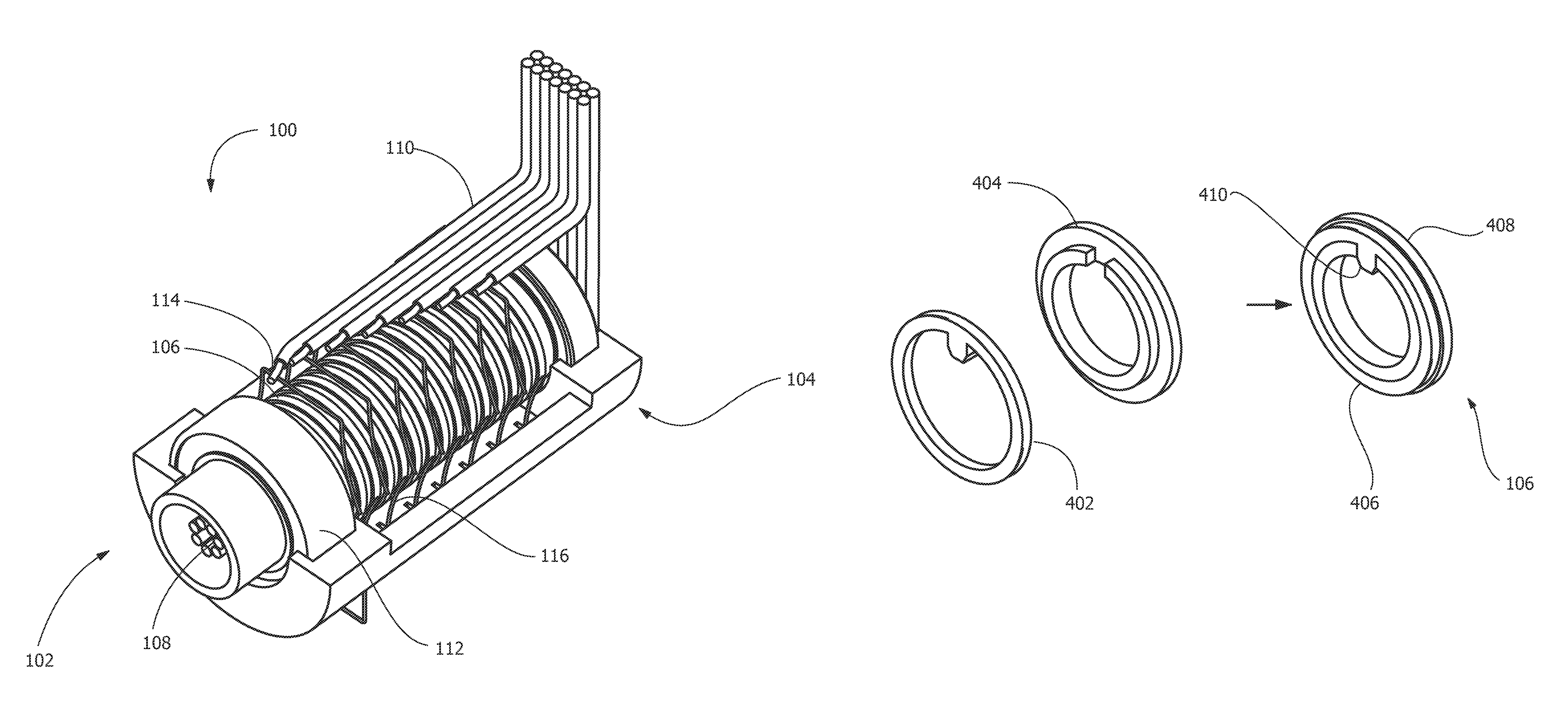

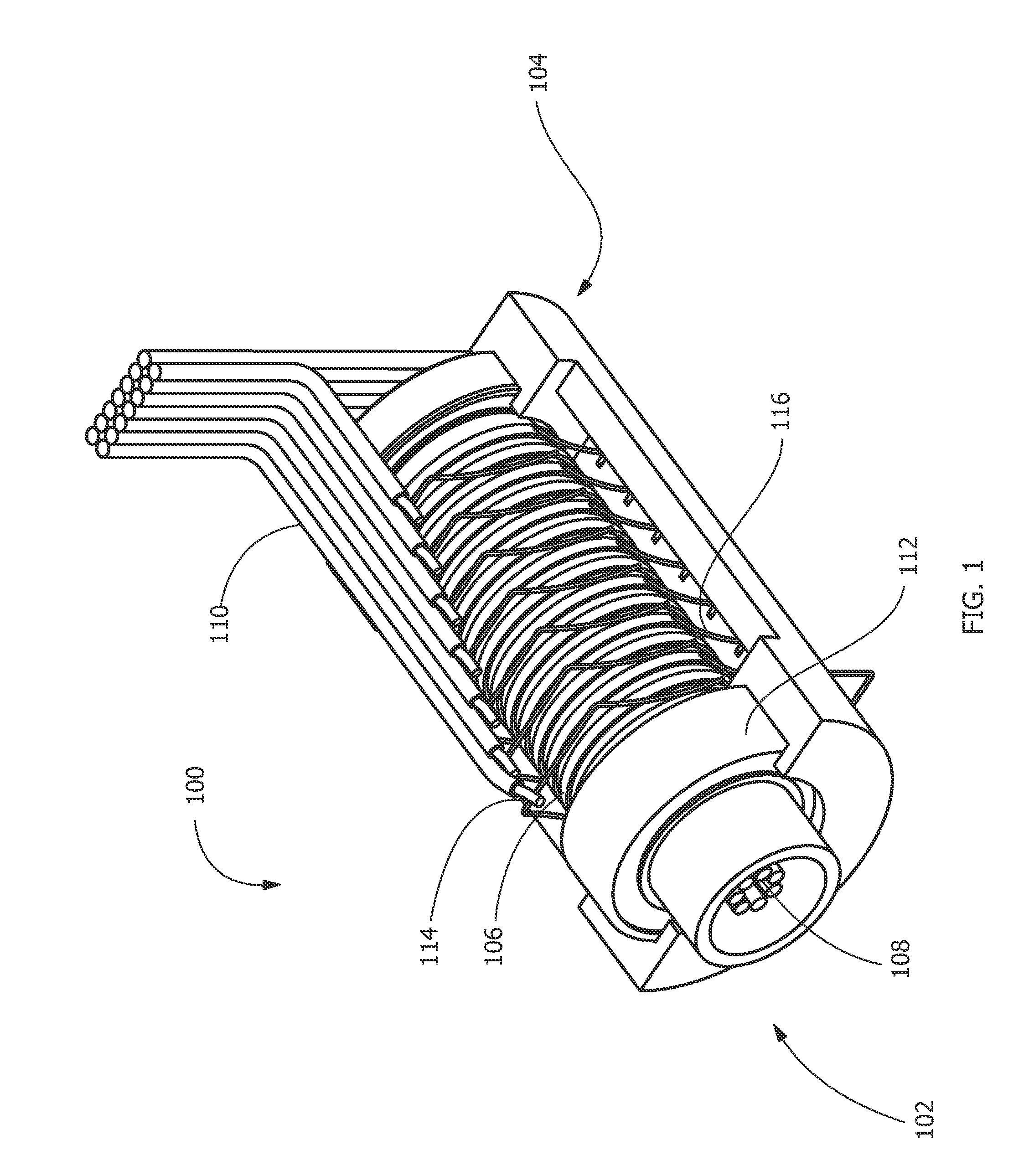

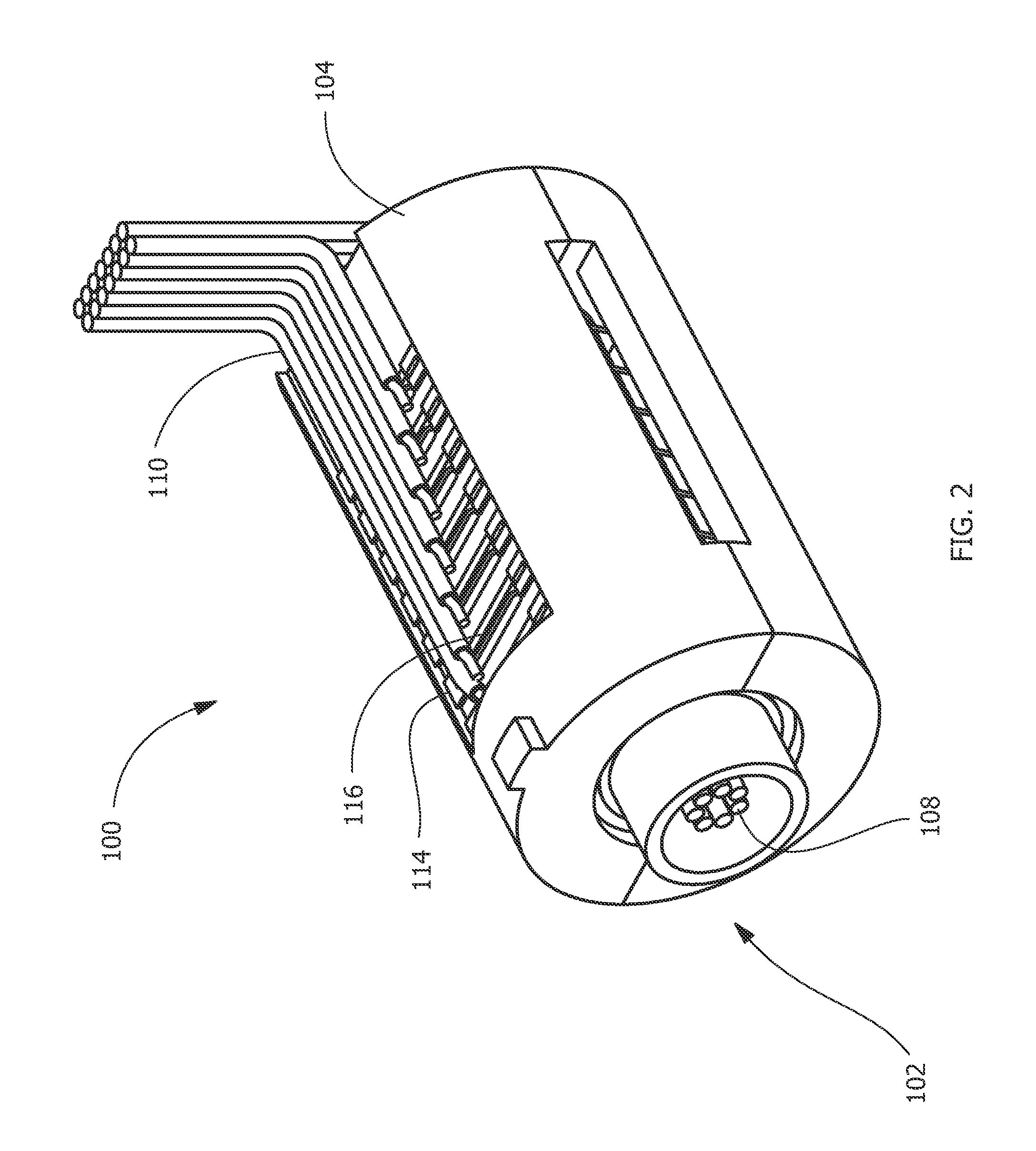

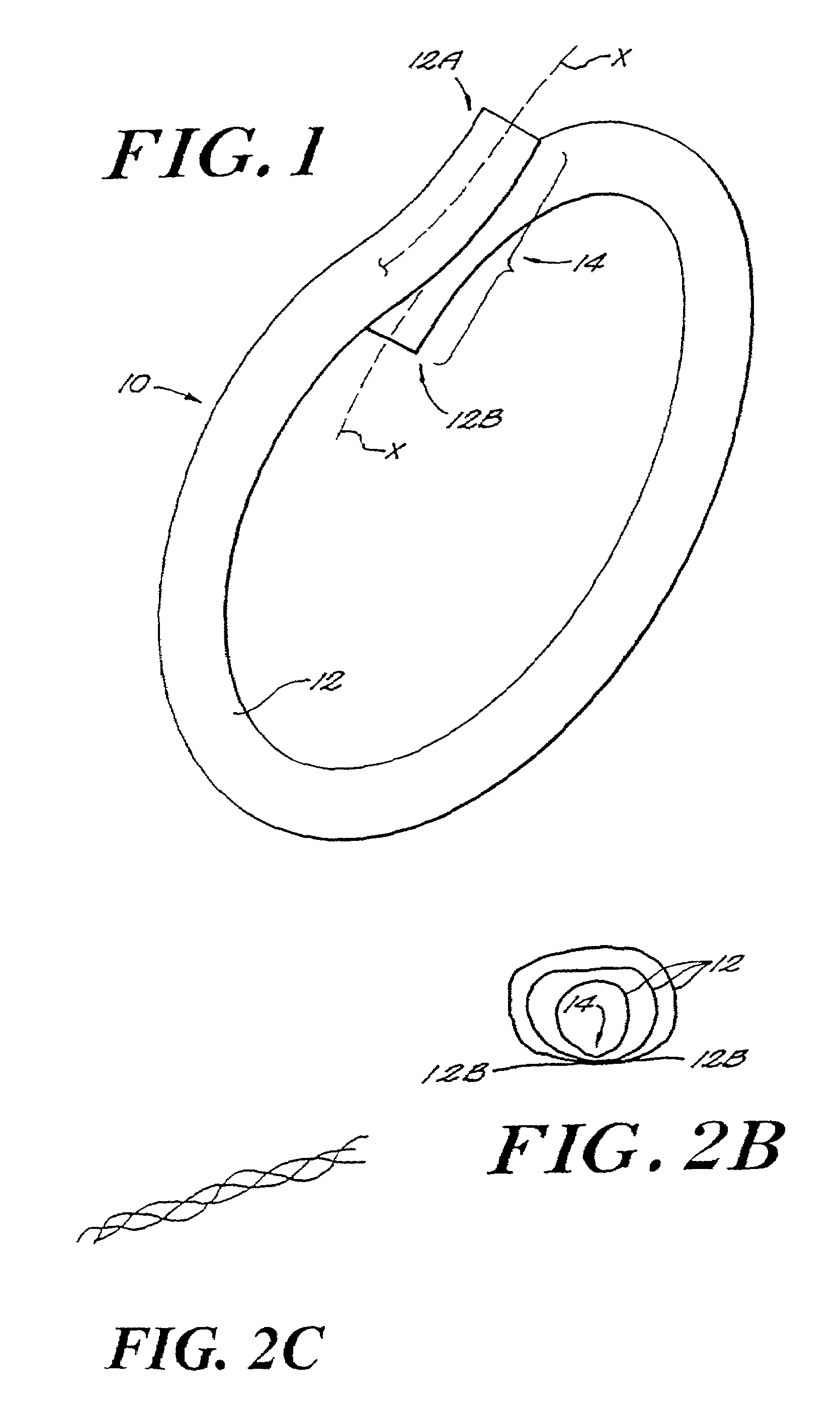

Method of fabricating a slip ring component

A process of fabricating a slip ring component, a slip ring component, and a slip ring assembly are disclosed. The process includes forming a first shot, forming a second shot, and immersion bathing the first shot and the second shot. The immersion bathing applies an electrically conductive plating to exposed surfaces of the second shot.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

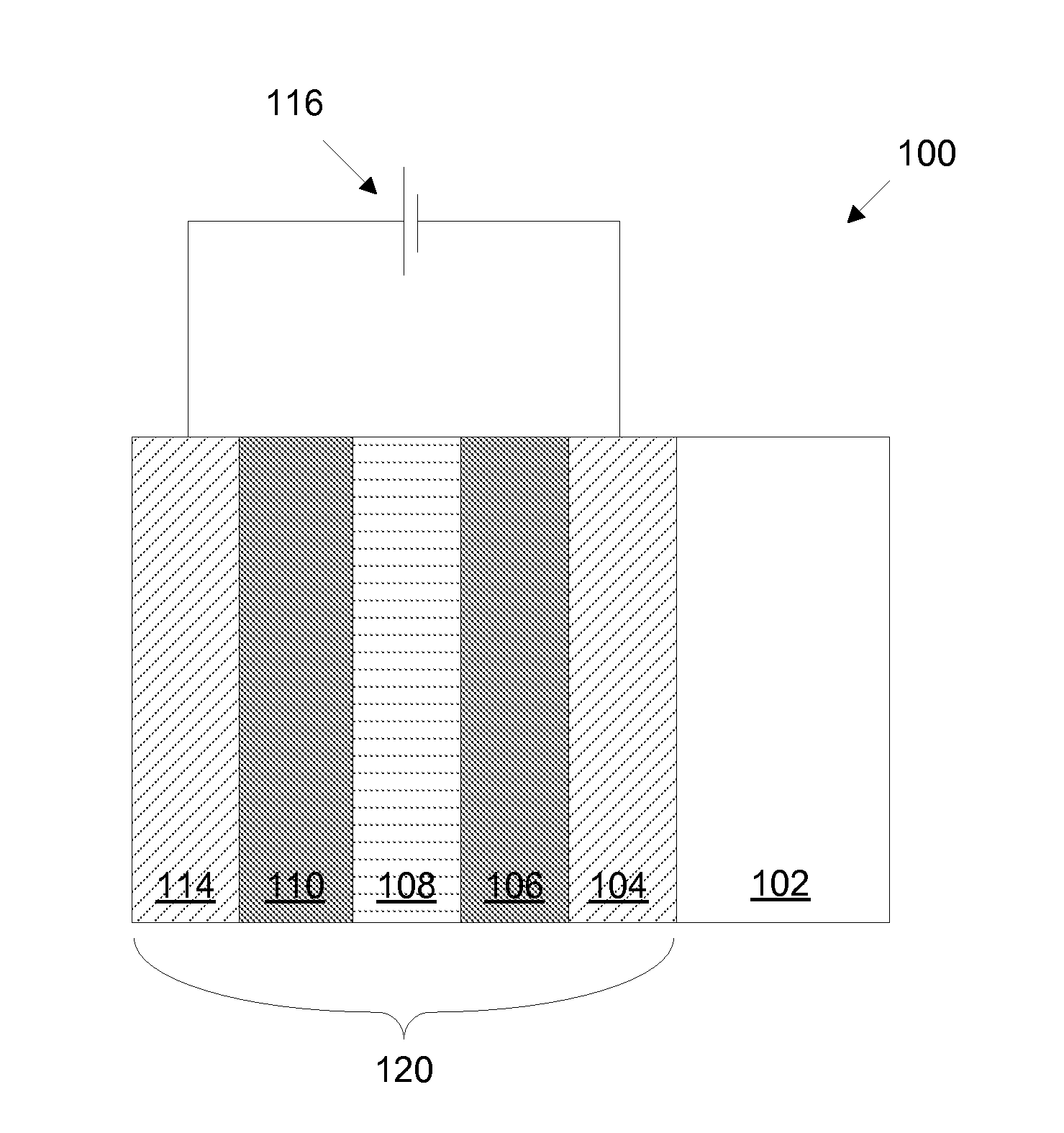

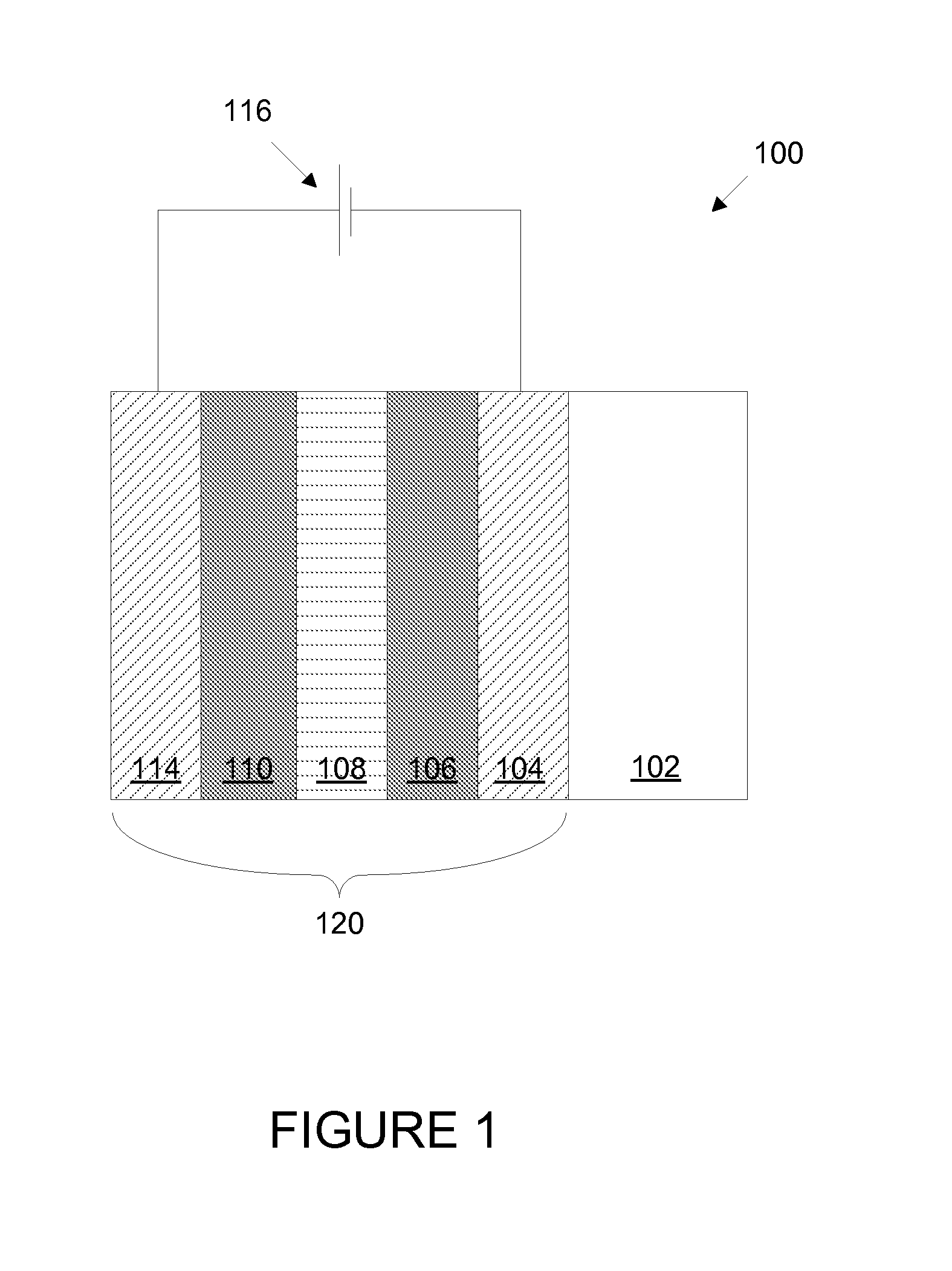

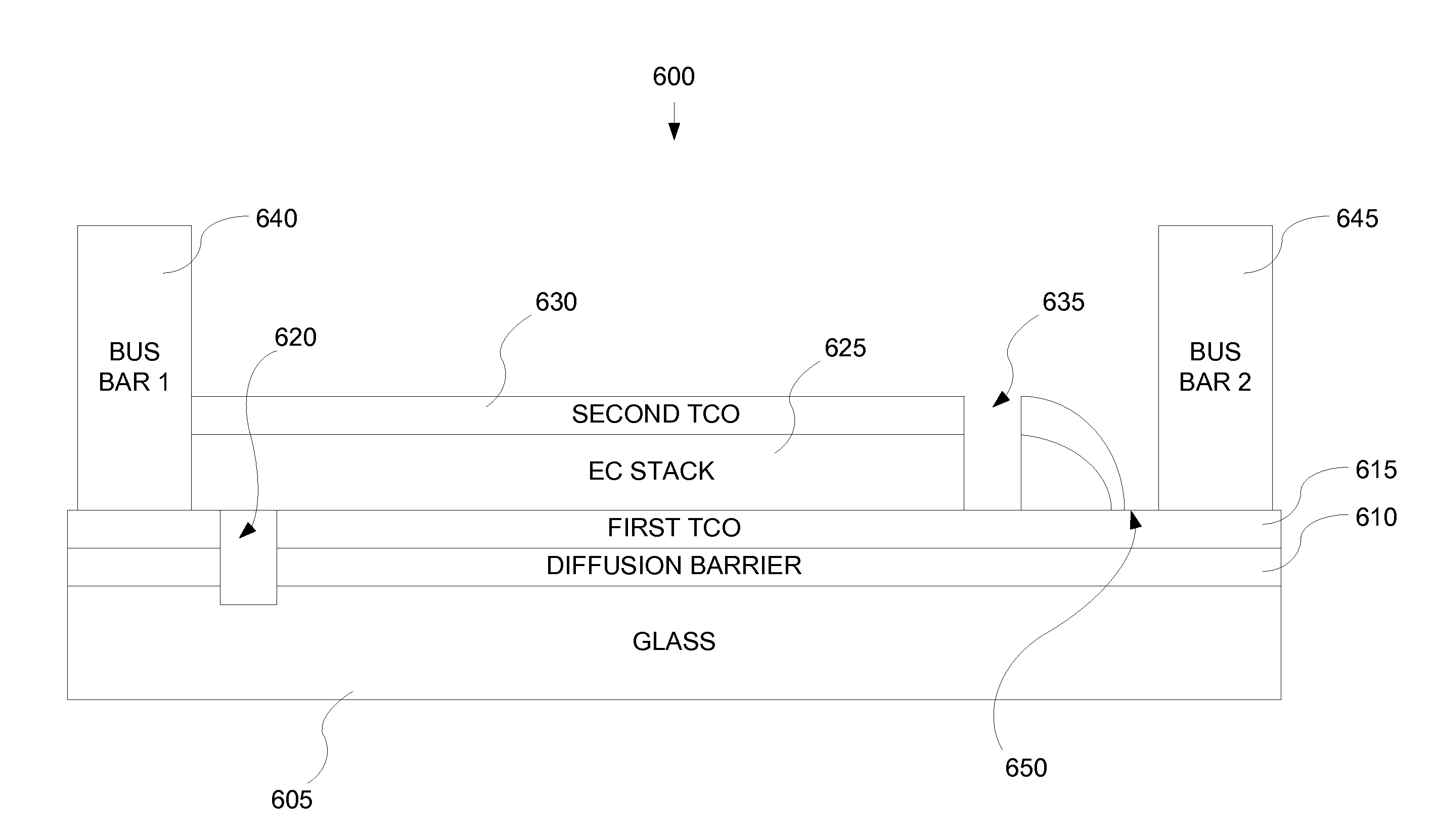

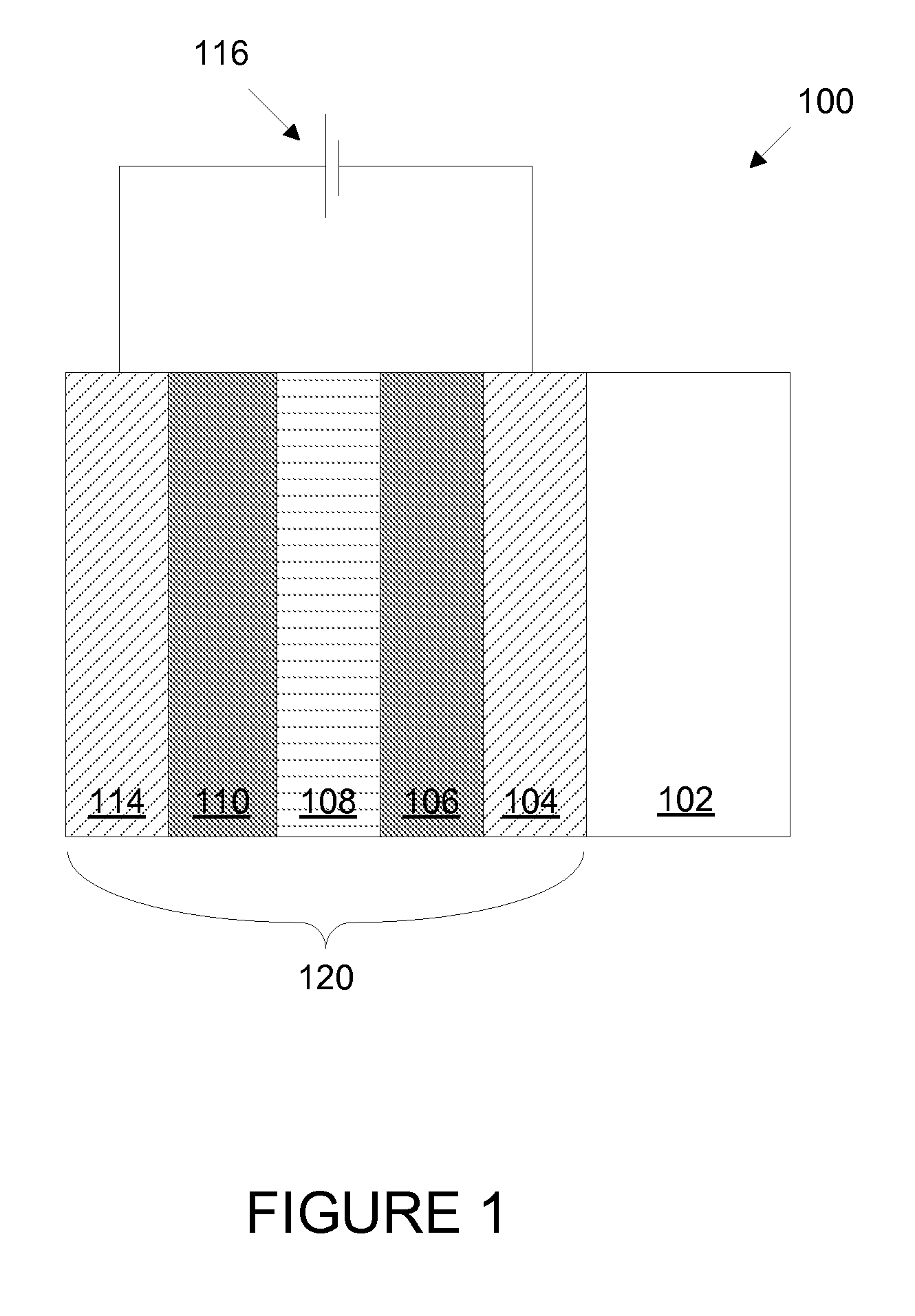

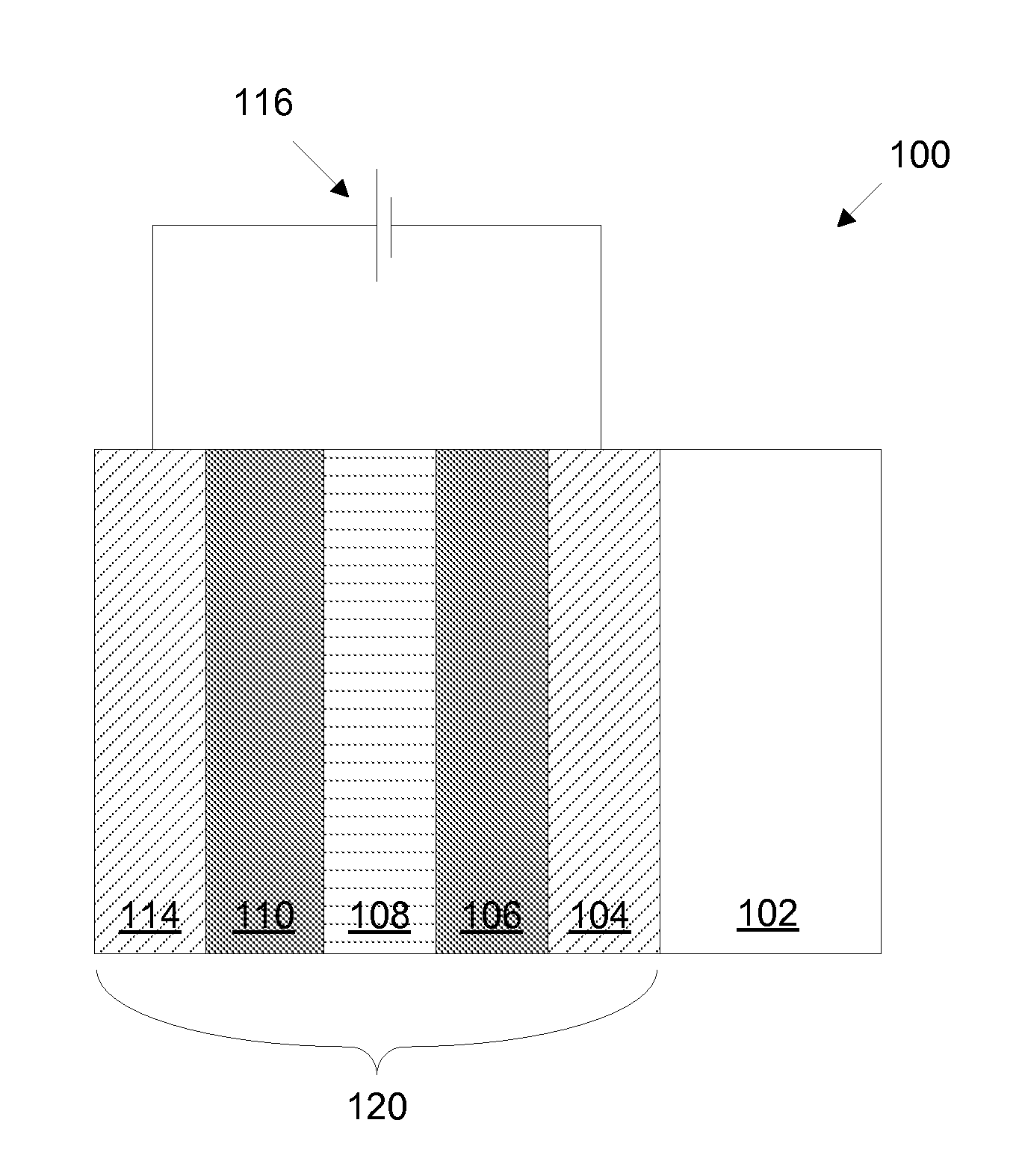

Fabrication of low defectivity electrochromic devices

ActiveUS20100243427A1High level of defectivityVacuum evaporation coatingSputtering coatingArchitectural glassGas phase

Prior electrochromic devices frequently suffer from high levels of defectivity. The defects may be manifest as pin holes or spots where the electrochromic transition is impaired. This is unacceptable for many applications such as electrochromic architectural glass. Improved electrochromic devices with low defectivity can be fabricated by depositing certain layered components of the electrochromic device in a single integrated deposition system. While these layers are being deposited and / or treated on a substrate, for example a glass window, the substrate never leaves a controlled ambient environment, for example a low pressure controlled atmosphere having very low levels of particles. These layers may be deposited using physical vapor deposition.

Owner:VIEW INC

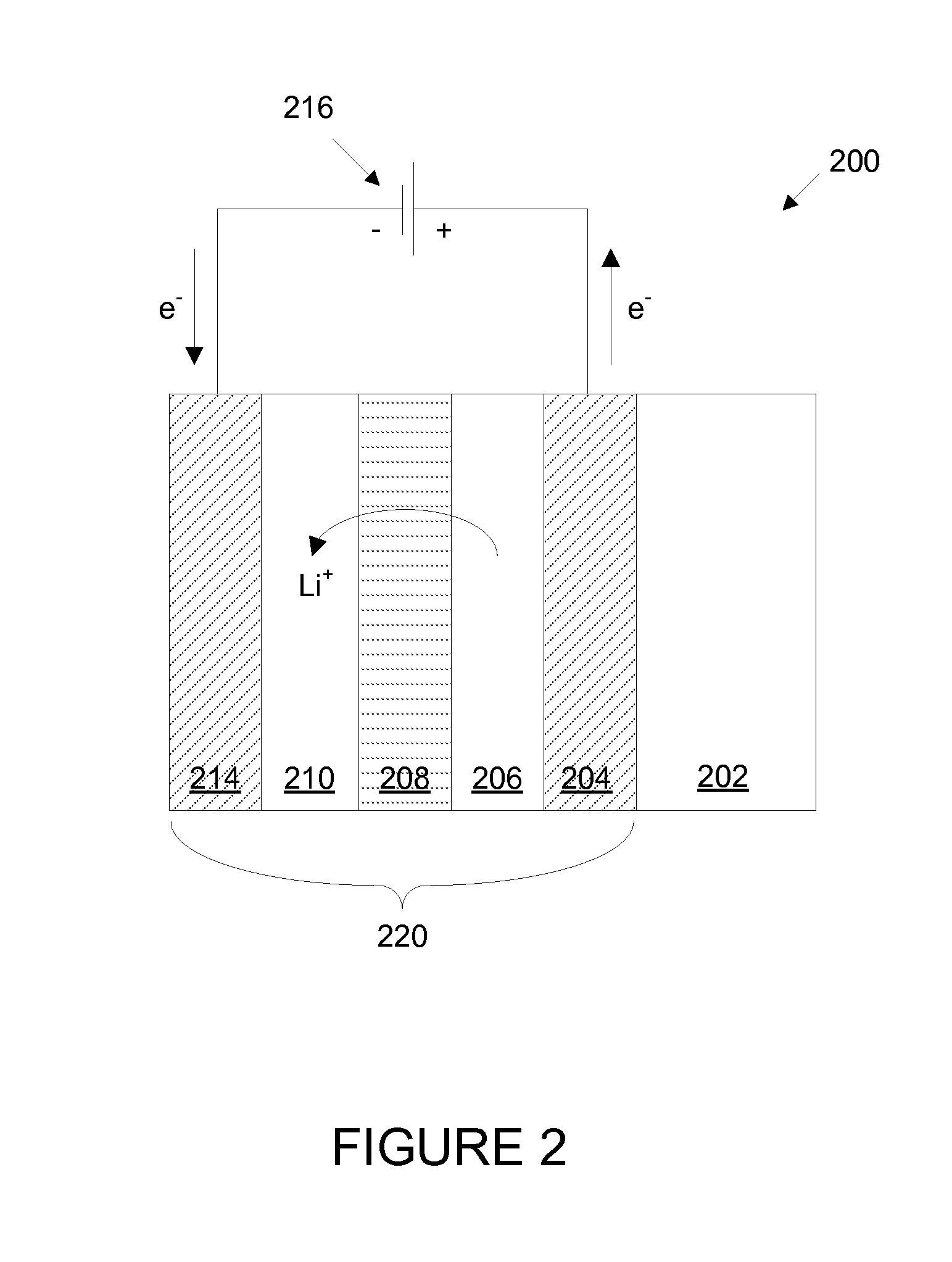

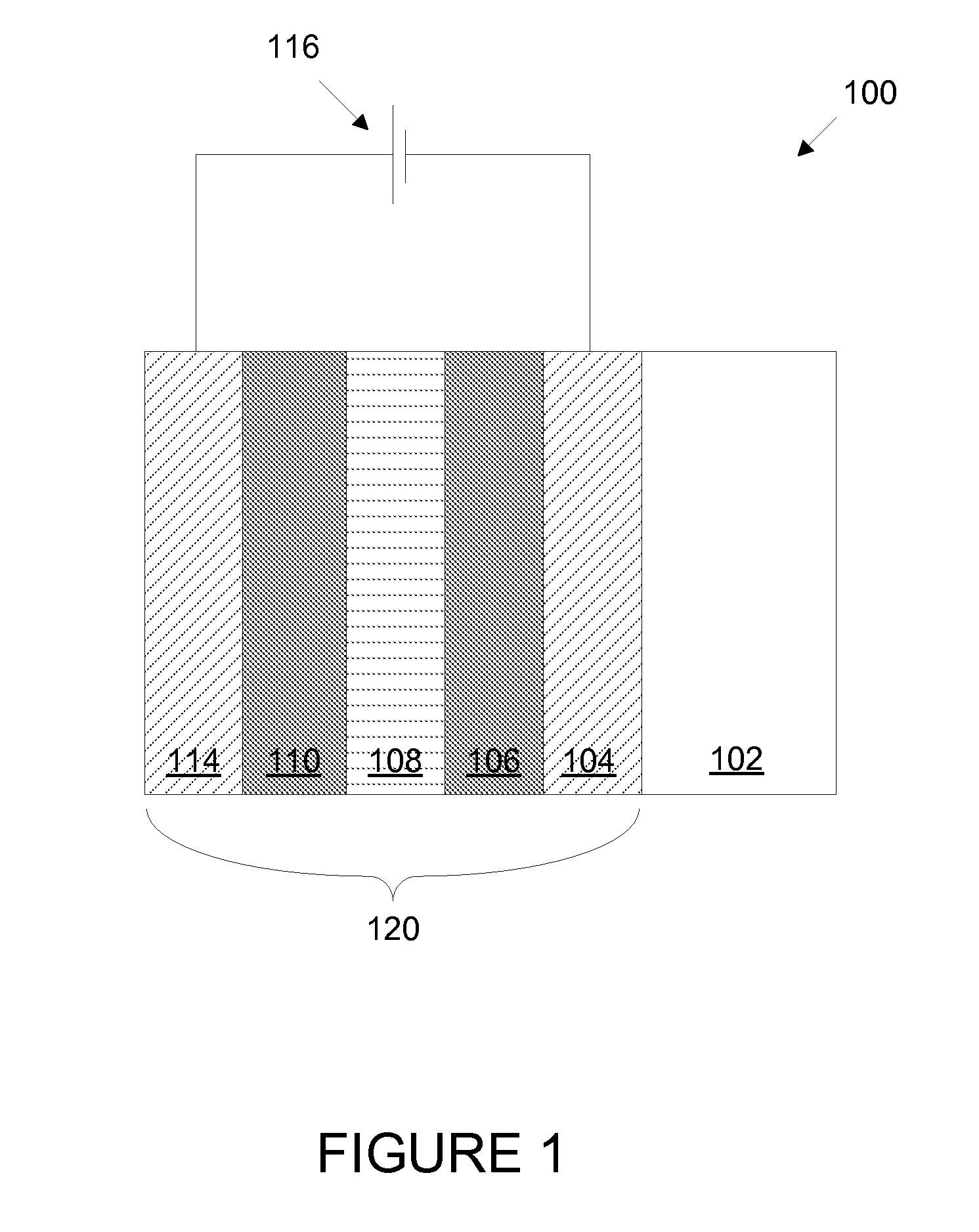

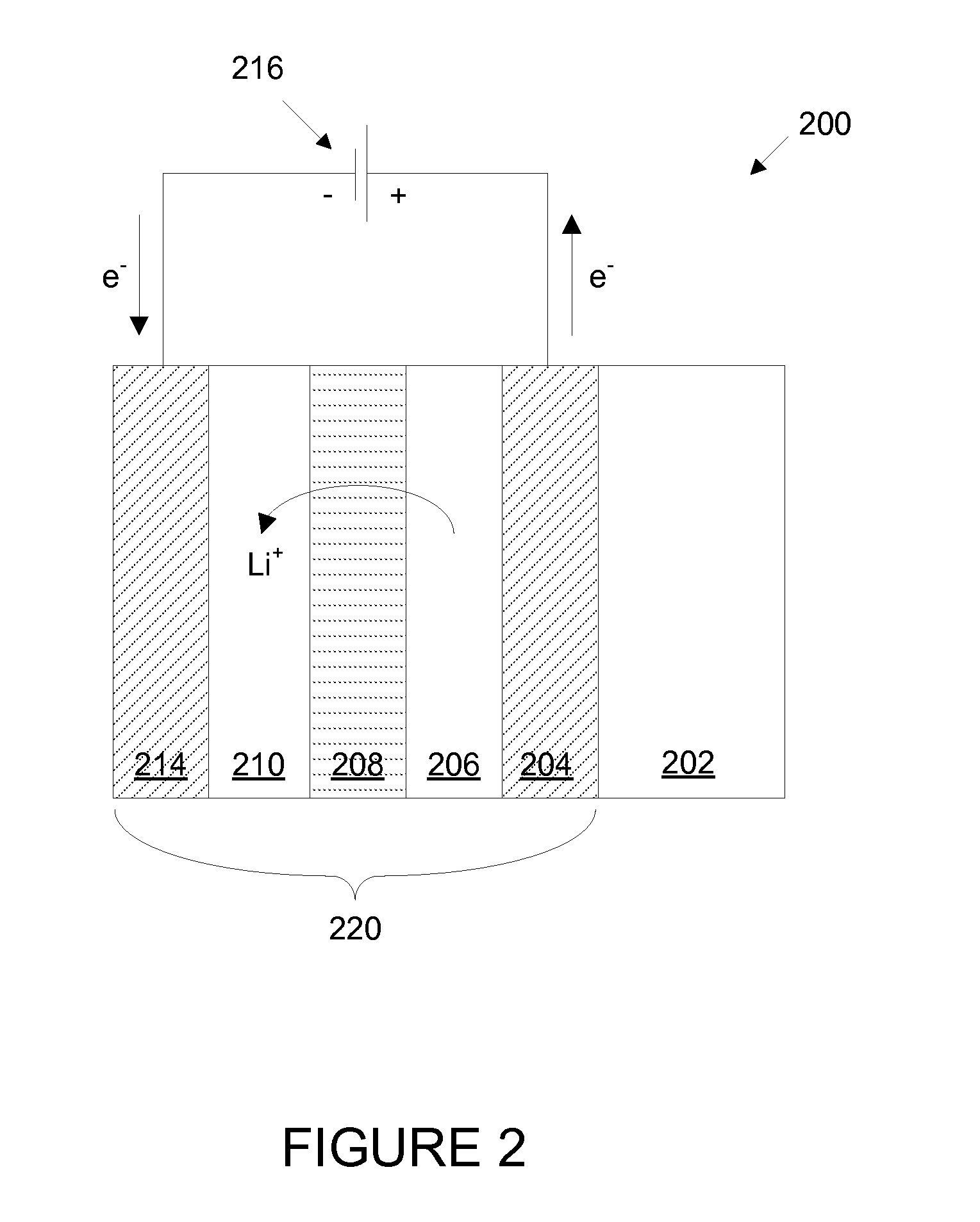

Electrochromic devices

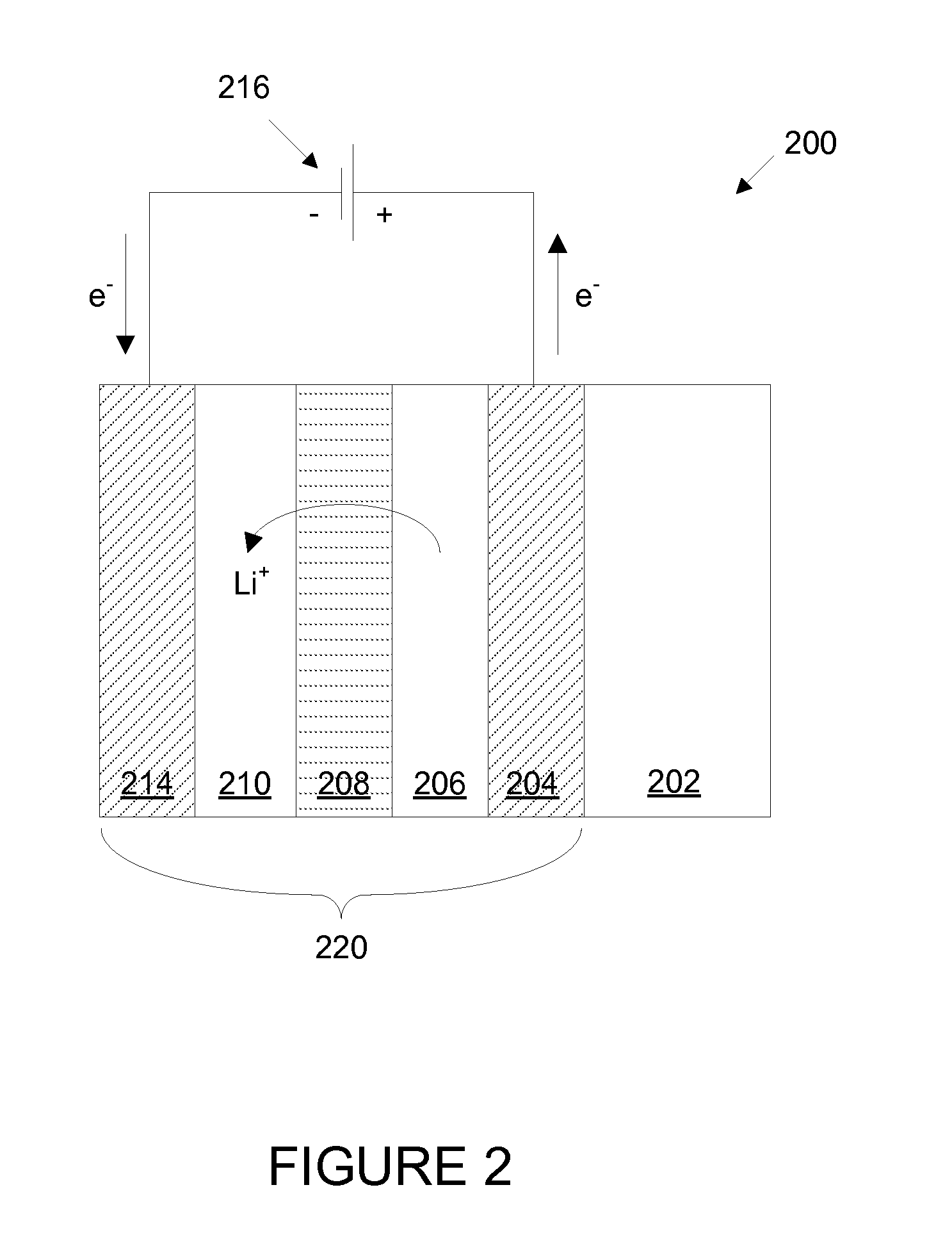

ActiveUS20100245973A1Improve equipment reliabilityImprove performanceVacuum evaporation coatingSputtering coatingElectricityLithium

Prior electrochromic devices frequently suffer from poor reliability and poor performance. Some of the difficulties result from inappropriate design and construction of the devices. In order to improve device reliability two layers of an electrochromic device, the counter electrode layer and the electrochromic layer, can each be fabricated to include defined amounts of lithium. Further, the electrochromic device may be subjected to a multistep thermochemical conditioning operation to improve performance. Additionally, careful choice of the materials and morphology of some components of the electrochromic device provides improvements in performance and reliability. In some devices, all layers of the device are entirely solid and inorganic.

Owner:VIEW INC

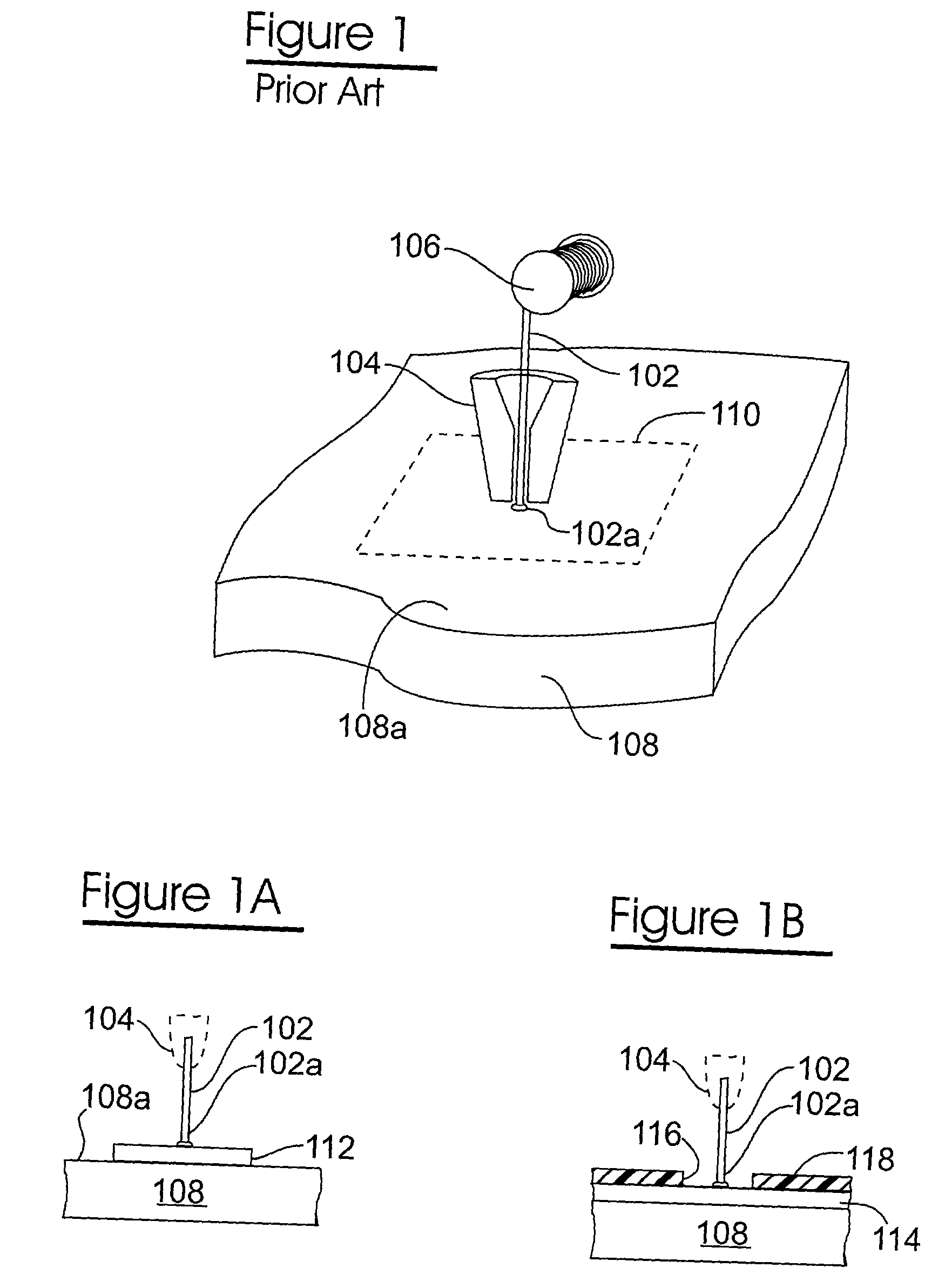

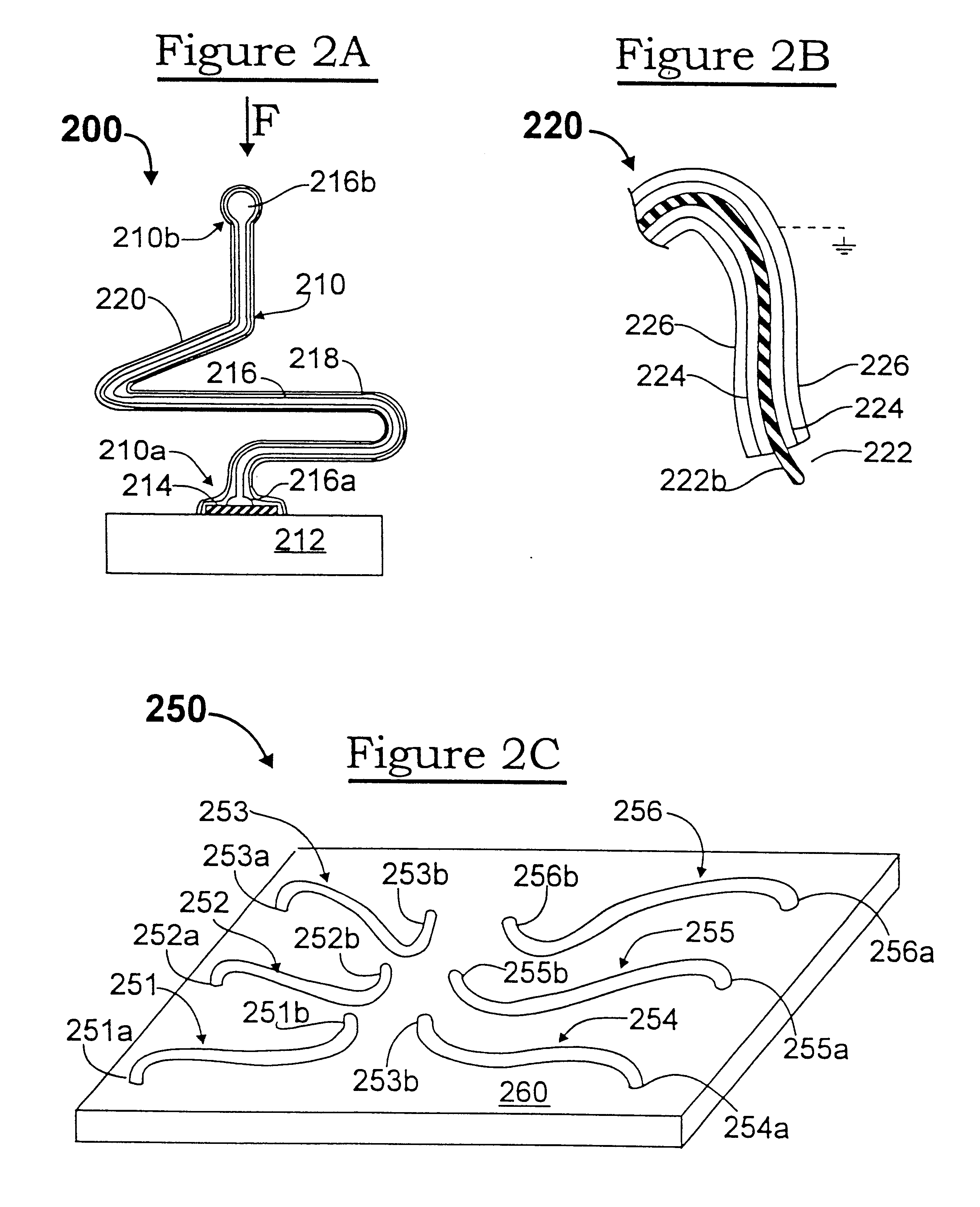

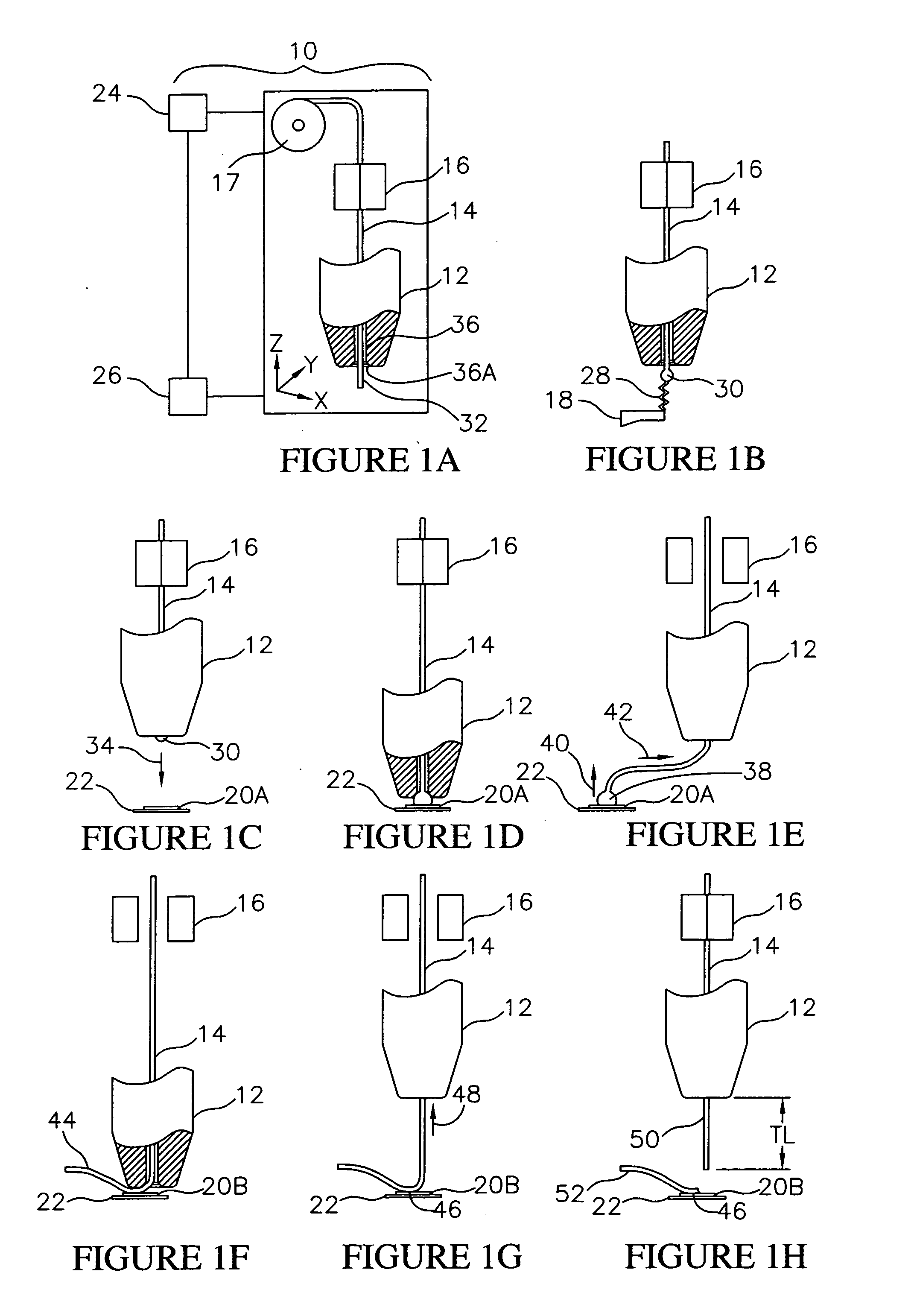

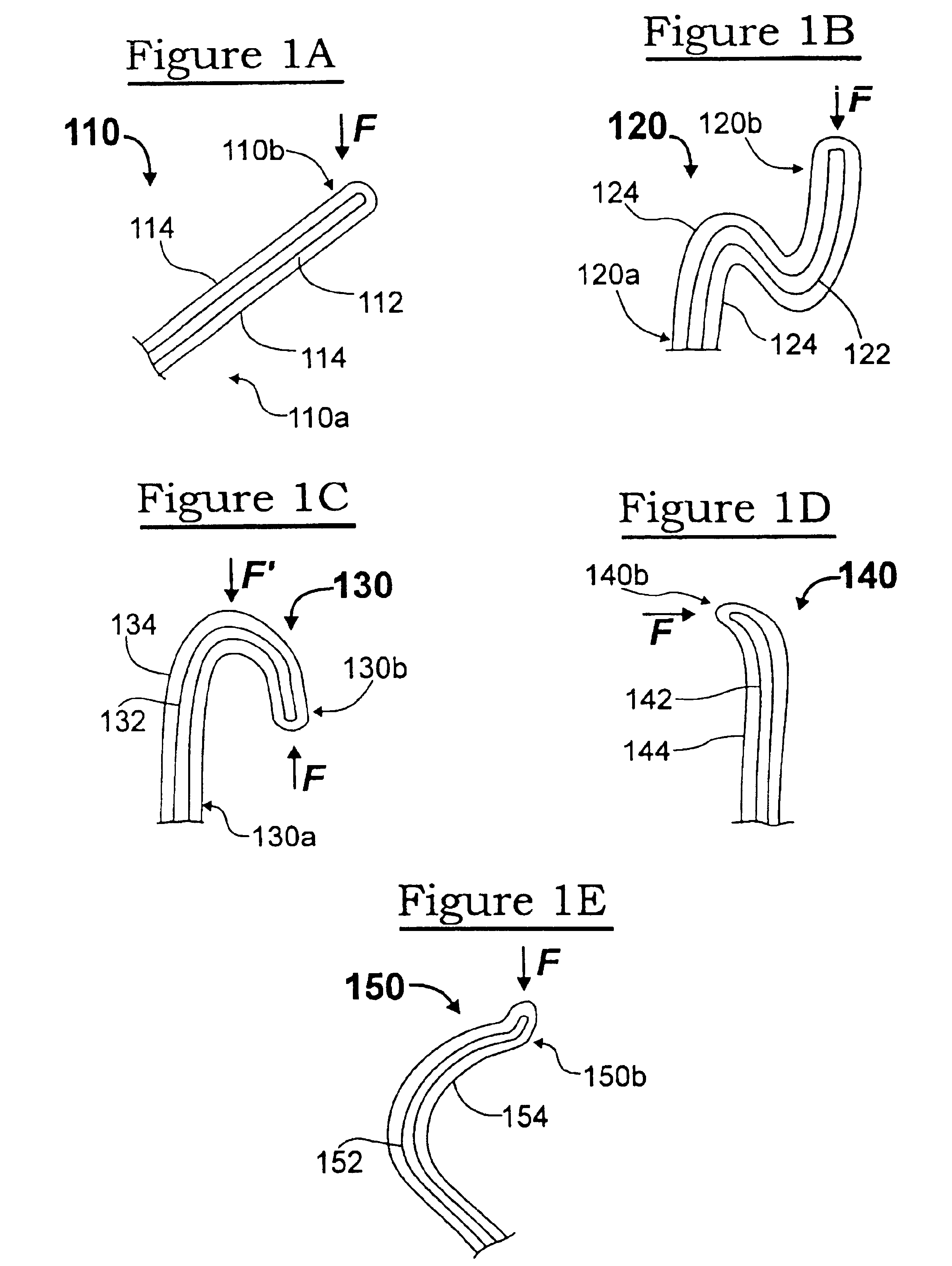

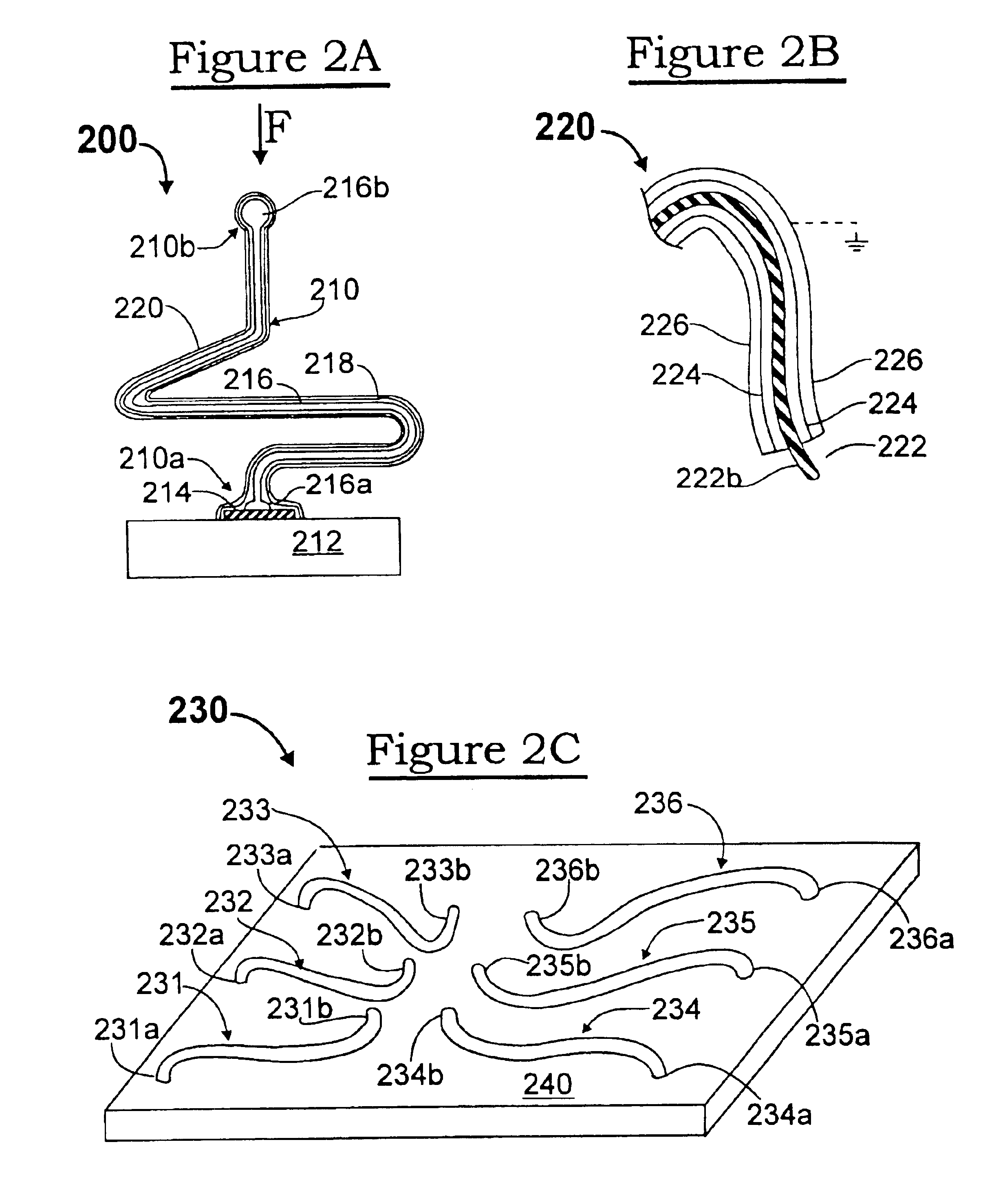

Resilient contact structures formed and then attached to a substrate

InactiveUS20020117330A1Simple technologyCoupling device connectionsSemiconductor/solid-state device testing/measurementEngineeringTopography

Owner:FORMFACTOR INC

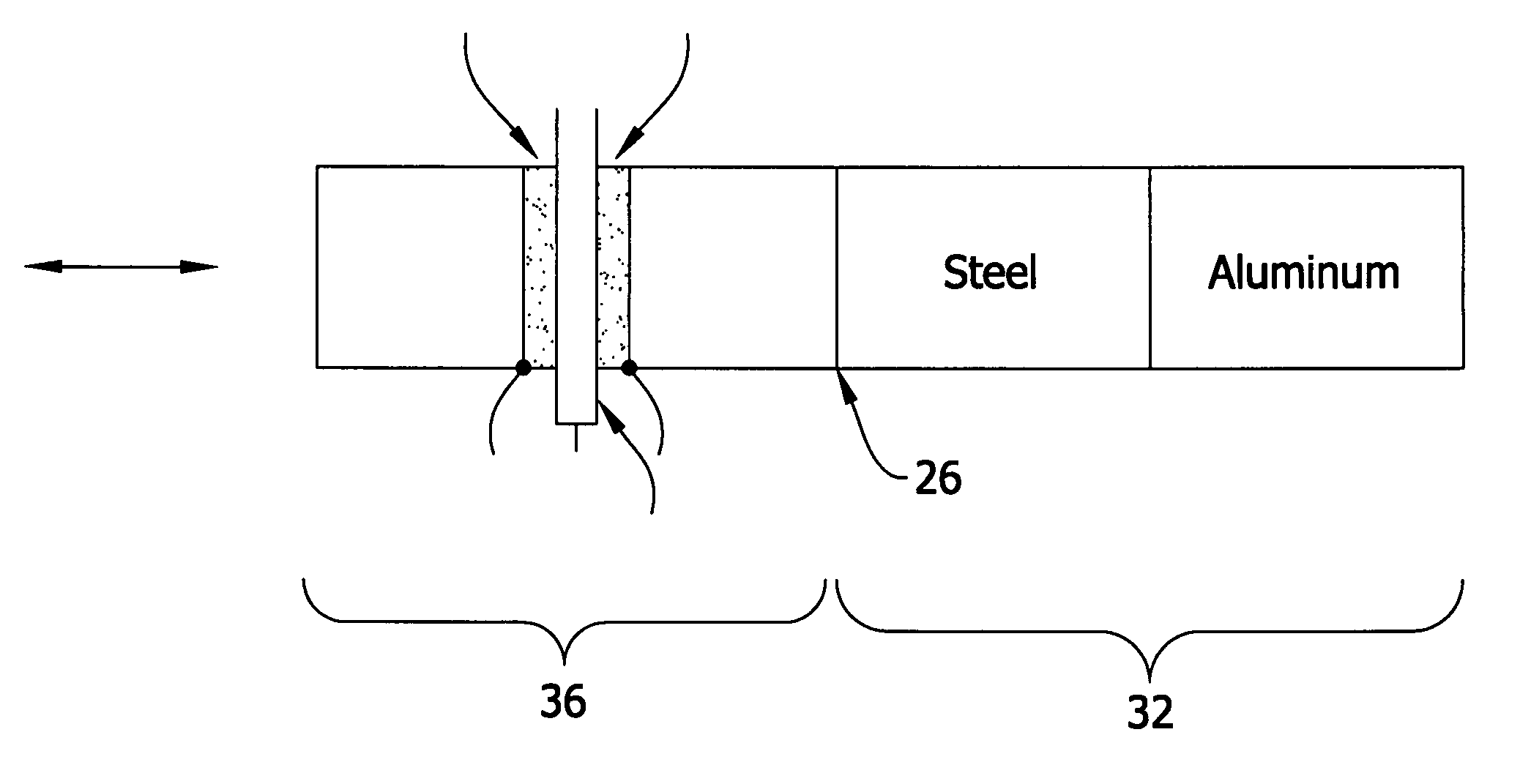

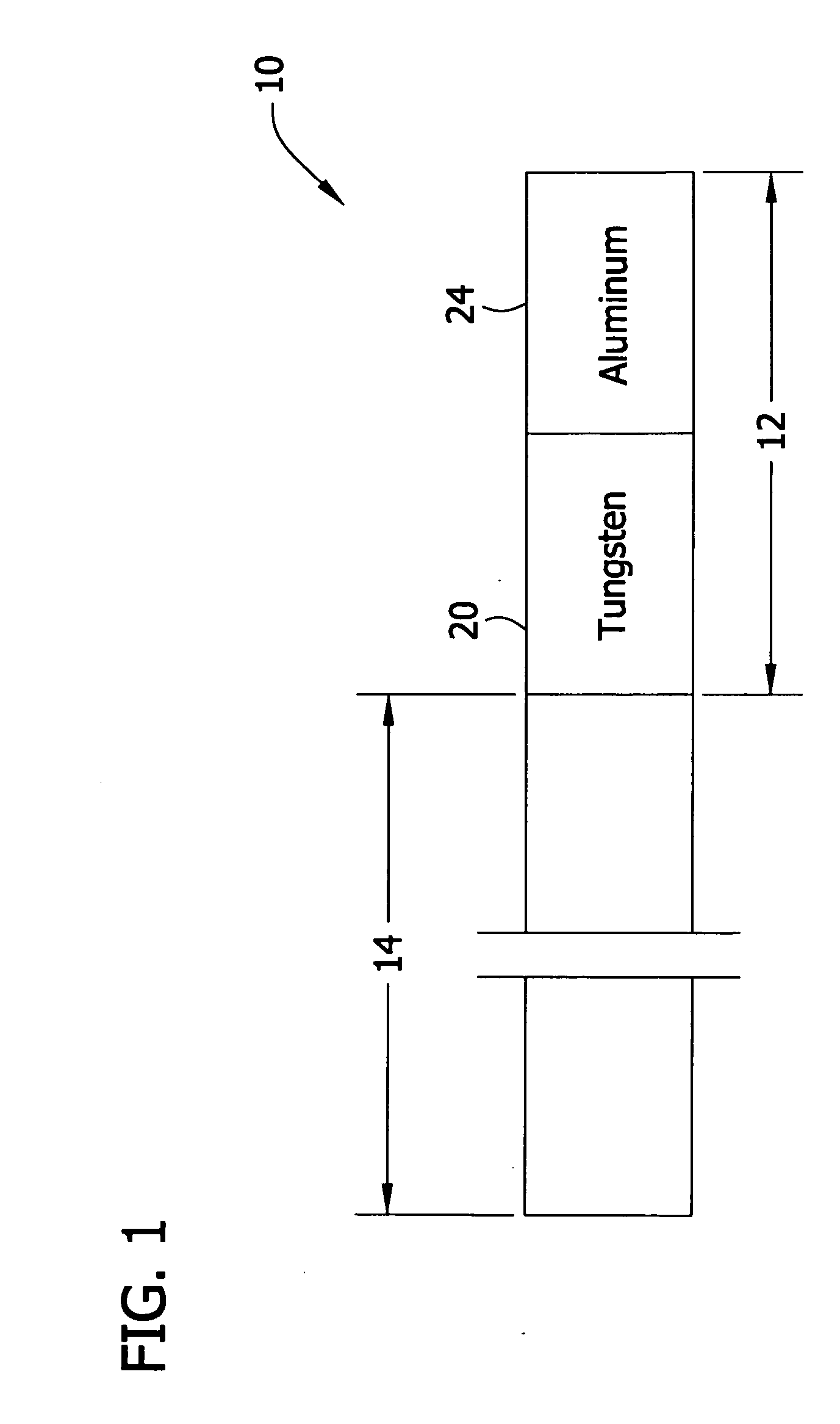

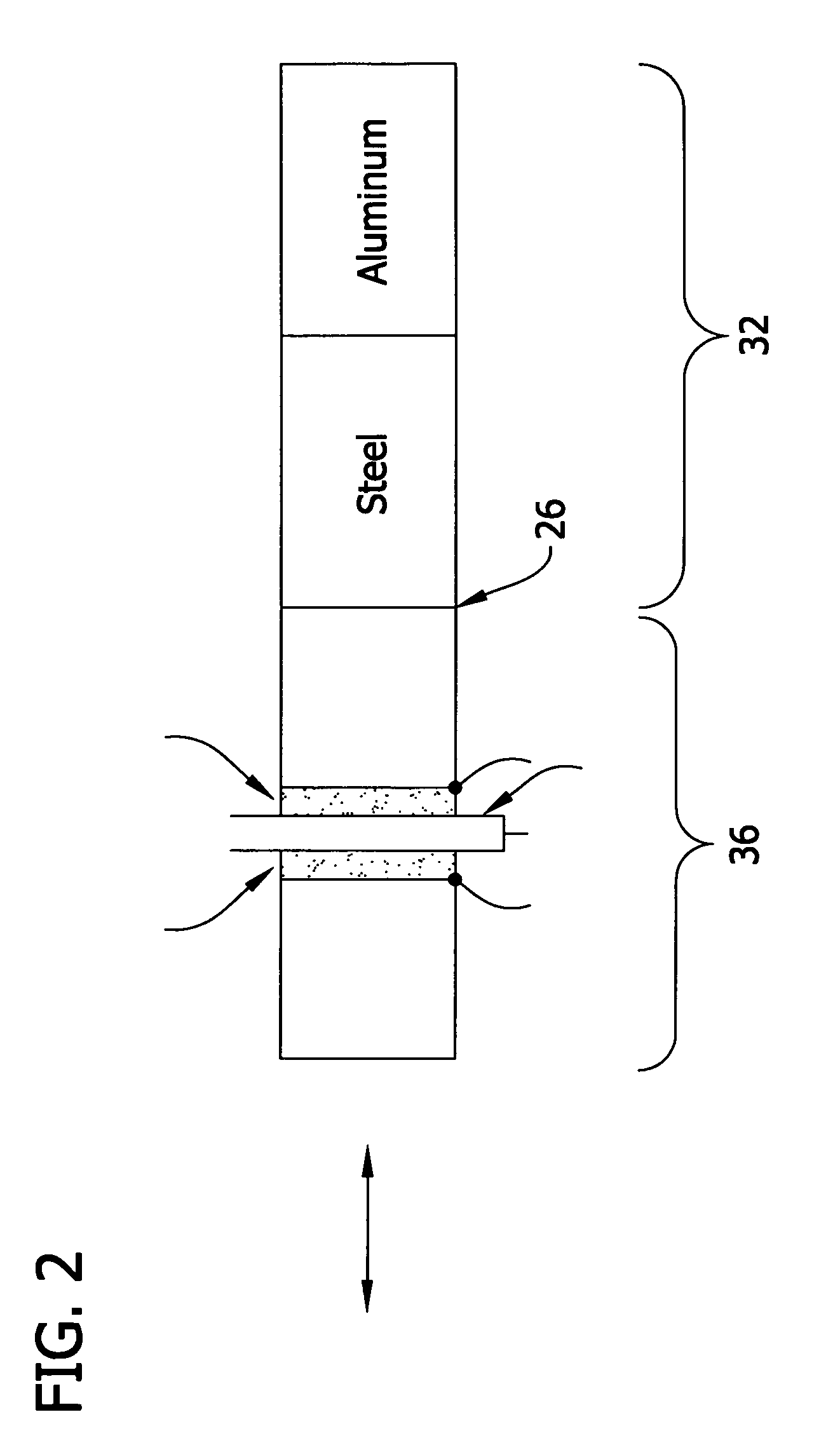

Methods for producing ultrasonic waveguides having improved amplification

InactiveUS20070130771A1High magnificationReduce stressElectrical transducersMaterial analysis using sonic/ultrasonic/infrasonic wavesAcousticsWaveguide

Methods for manufacturing ultrasonic waveguides having improved velocity gain are disclosed. Additionally, methods for manufacturing ultrasonic medical devices including the ultrasonic waveguides are disclosed. Specifically, the ultrasonic waveguides comprises a first material having a higher acoustic impedance and a second material having a lower acoustic impedance.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Method of modifying the thickness of a plating on a member by creating a temperature gradient on the member, applications for employing such a method, and structures resulting from such a method

InactiveUS6110823ASimple technologyTrend downSemiconductor/solid-state device testing/measurementFinal product manufactureEngineeringElectronic component

Contact structures exhibiting resilience or compliance for a variety of electronic components are formed by bonding a free end of a wire to a substrate, configuring thw wire into a wire stem having a springable shape, serving thw wire stem, and overcoating the wire stem with at least one layer of a material chosen primarily for its structural (resiliency, compliance) characteristics. A variety of techniques for configuring, serving, and overcoating the wire stem are disclosed. In an exemplary embodiment, a free end of a wire stem is bonded to a contact area on a substrate, the wire stem is configured to ahve a springable shape, the wire stem is served to be free-standing by an electrical discharge, and the free-standing wire stem is overcoating by plating.

Owner:FORMFACTOR INC

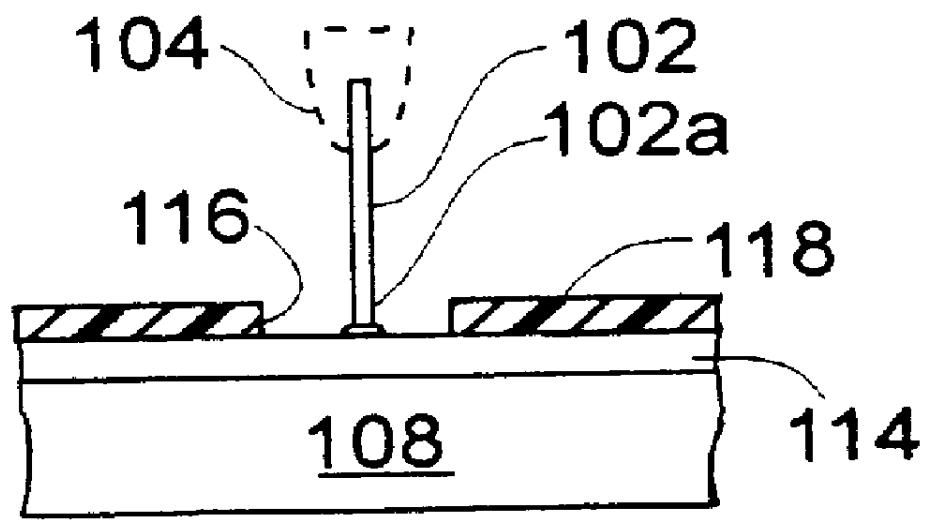

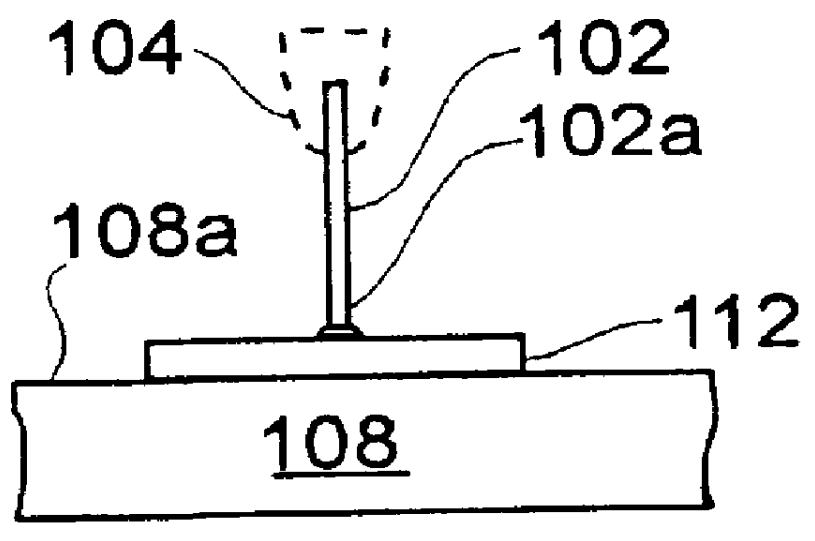

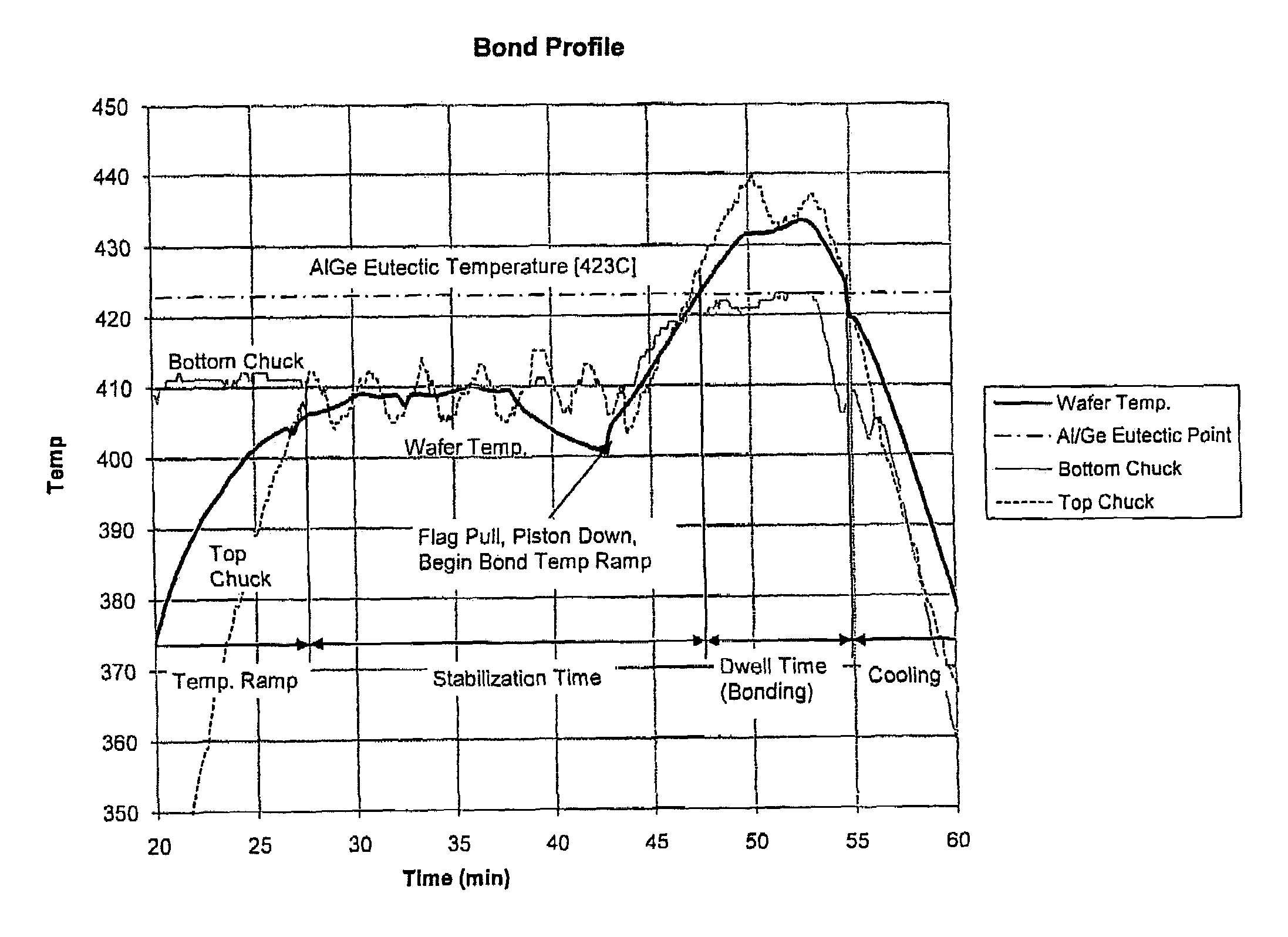

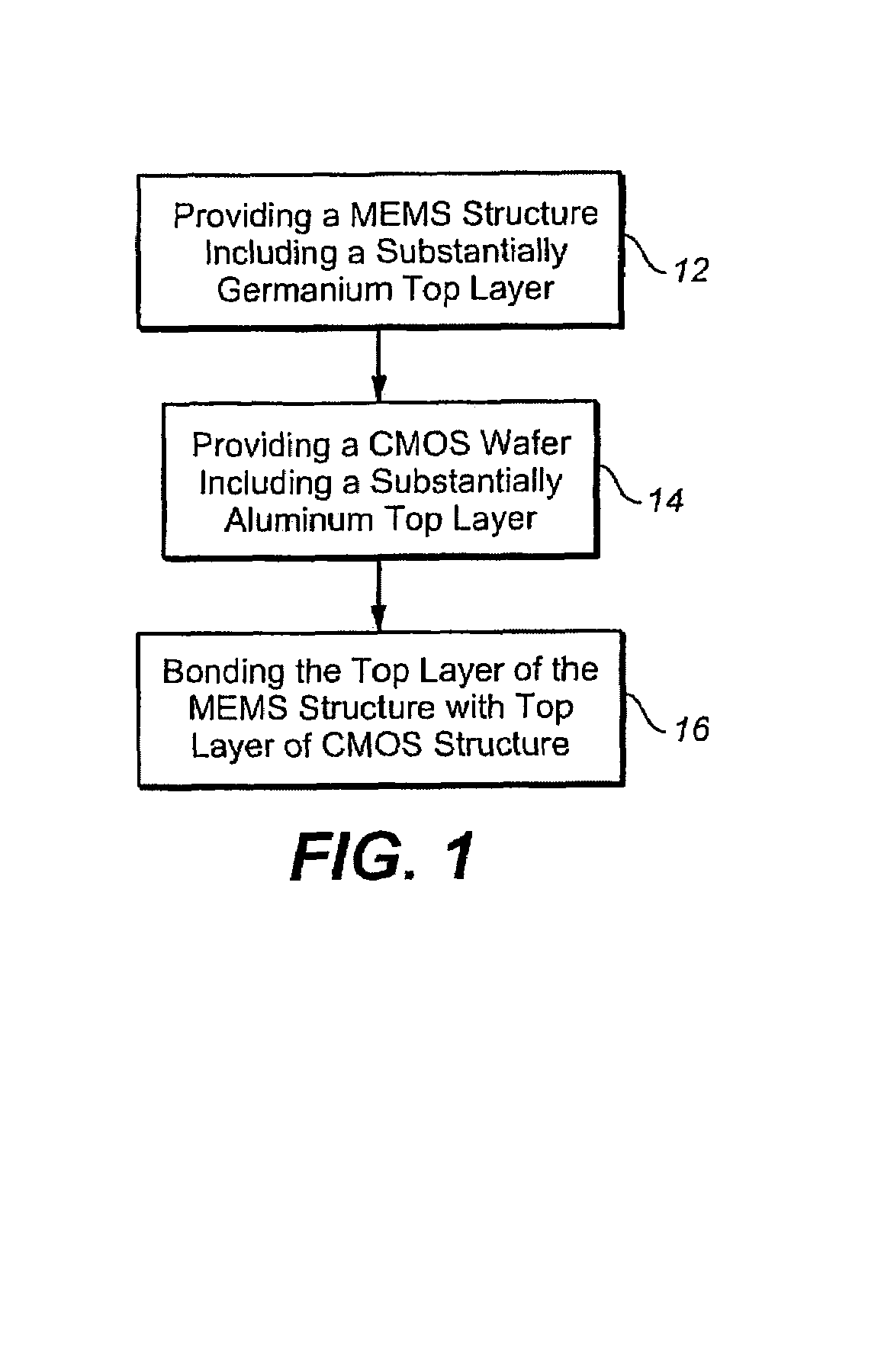

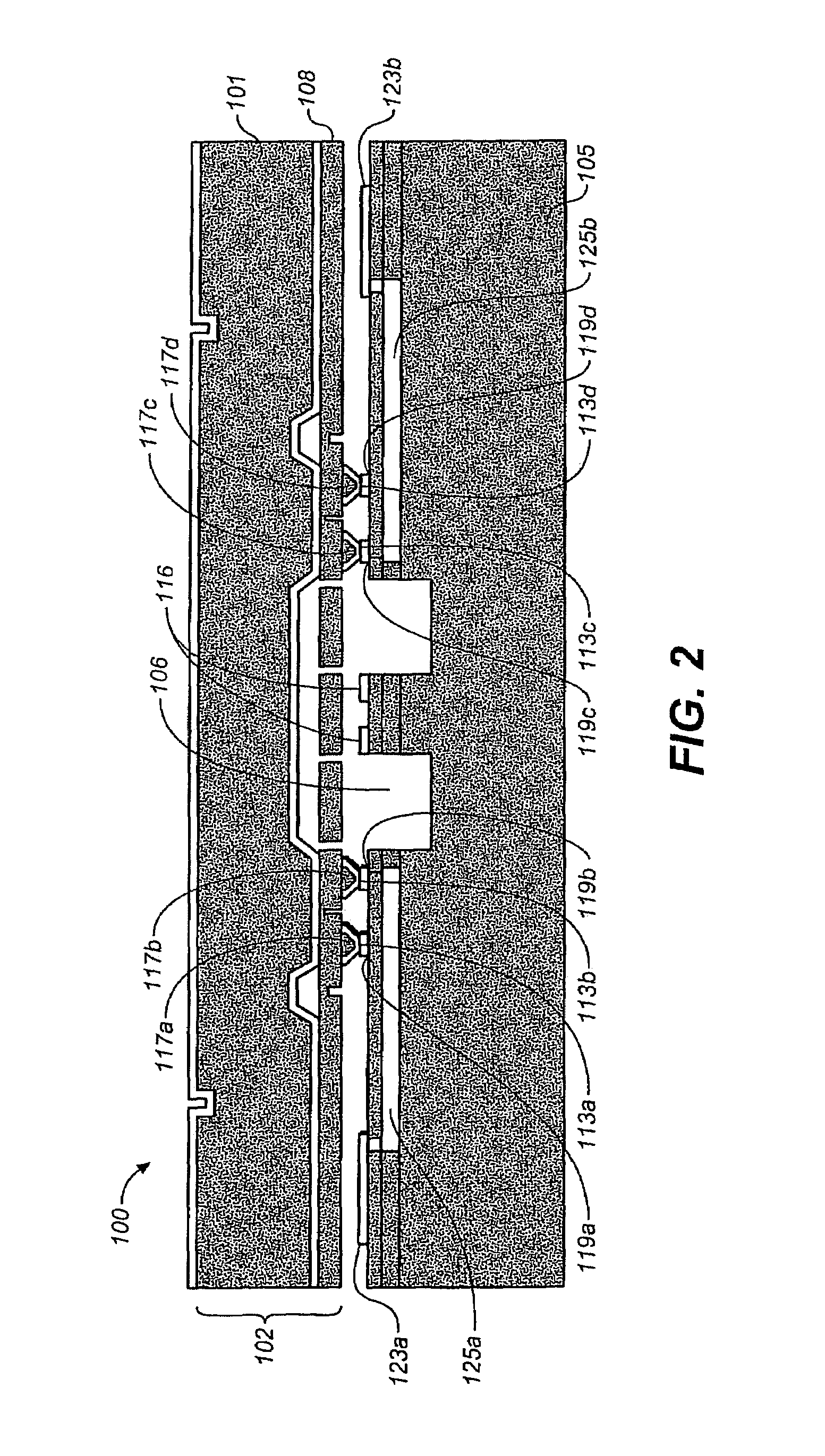

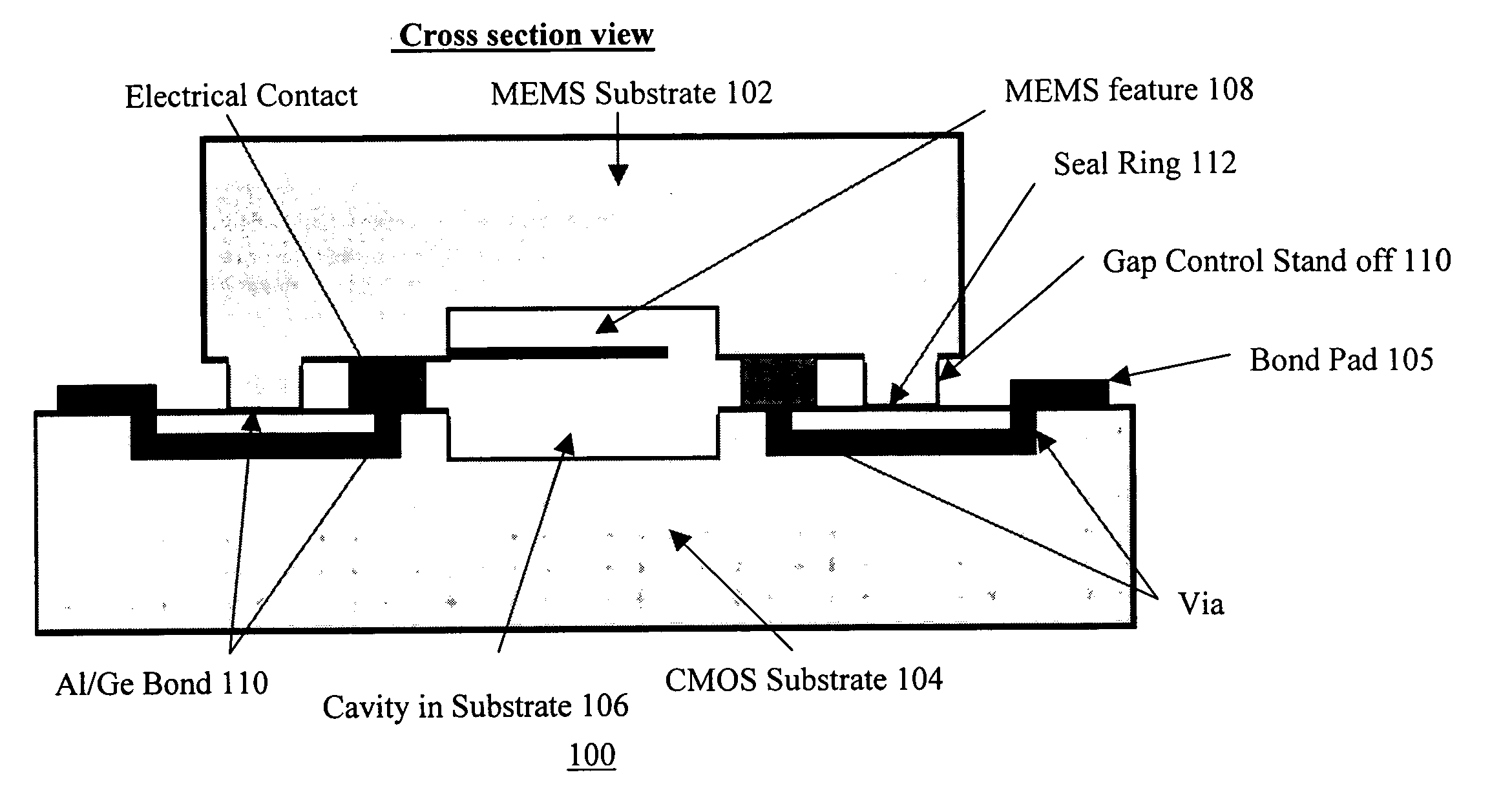

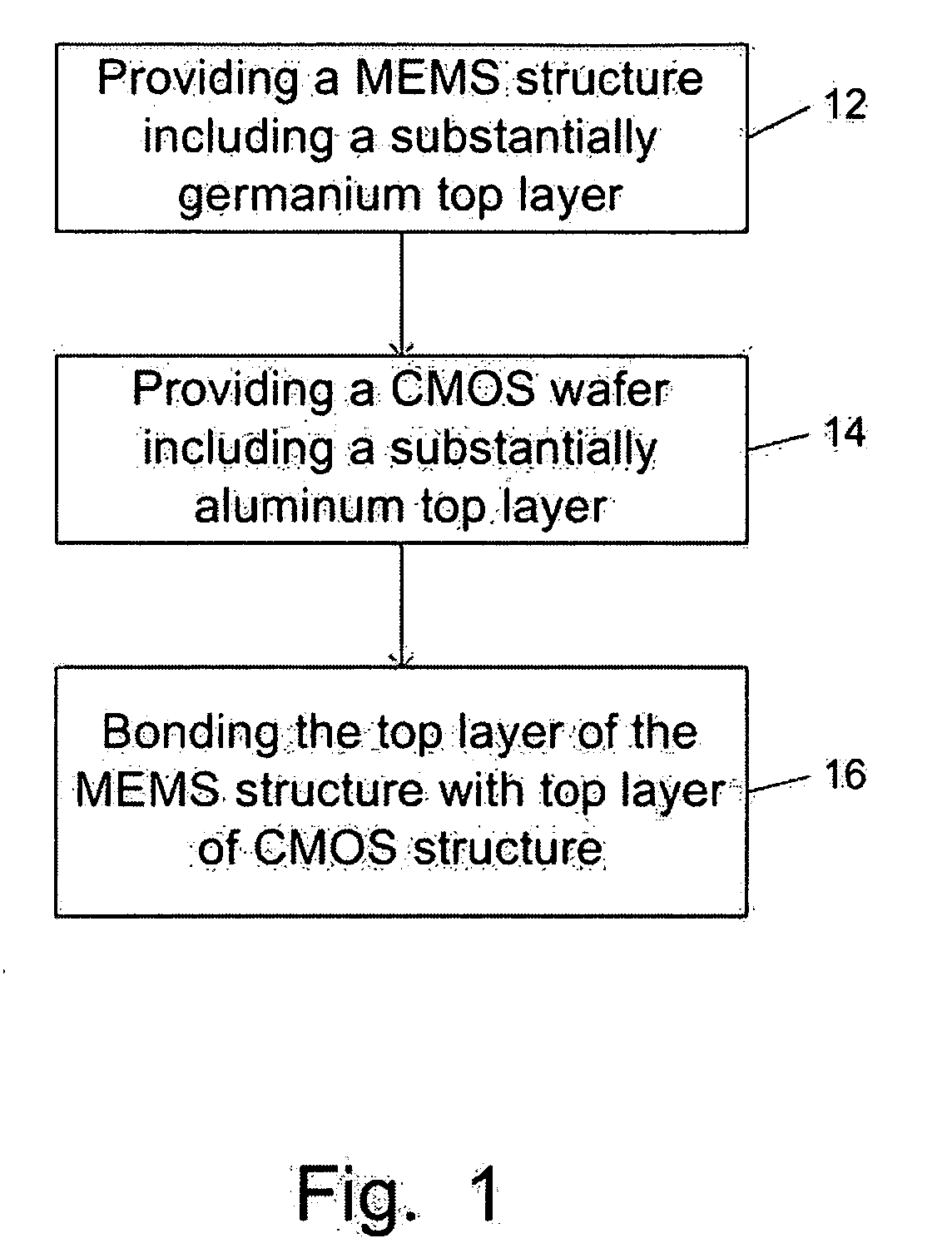

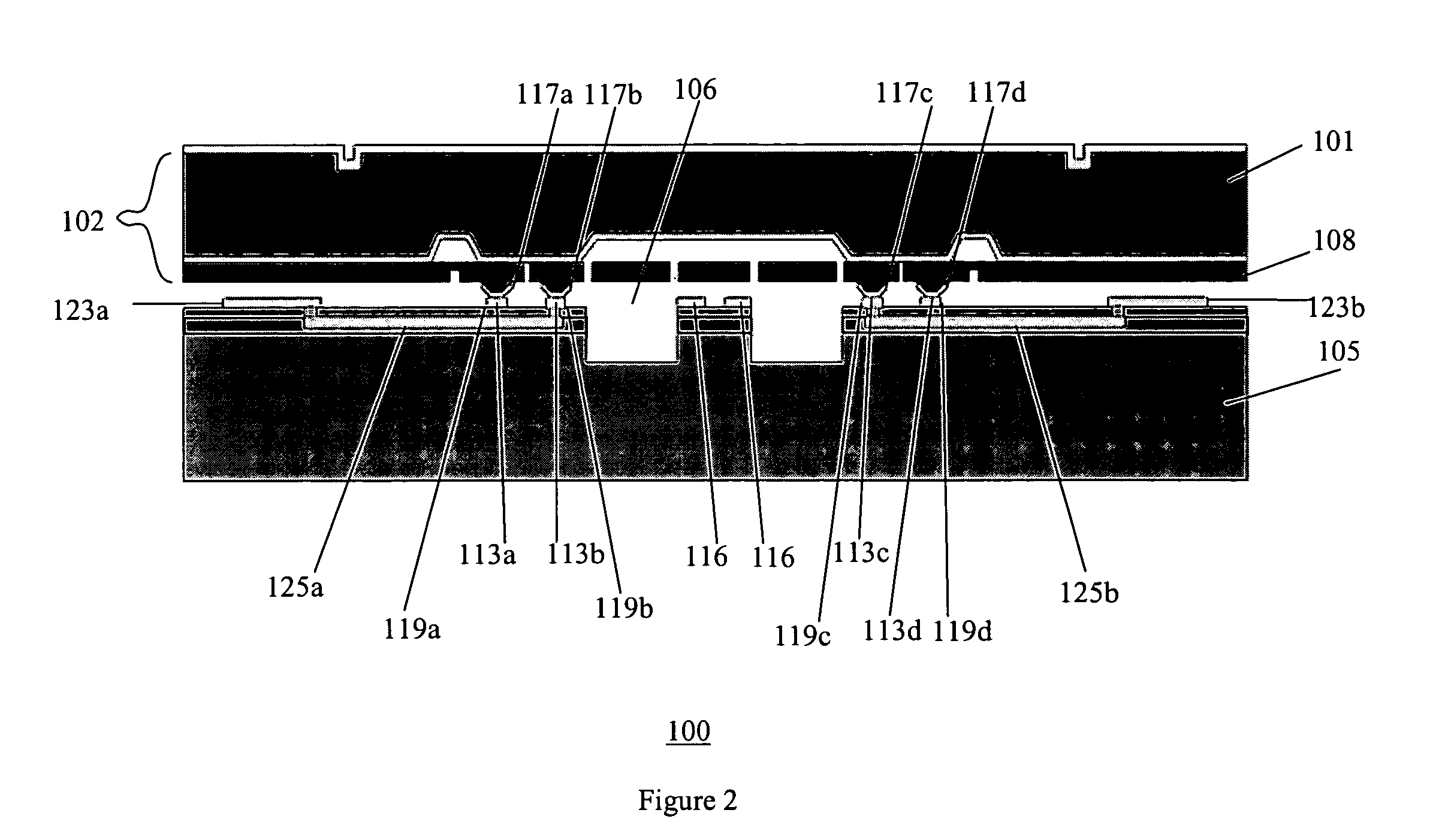

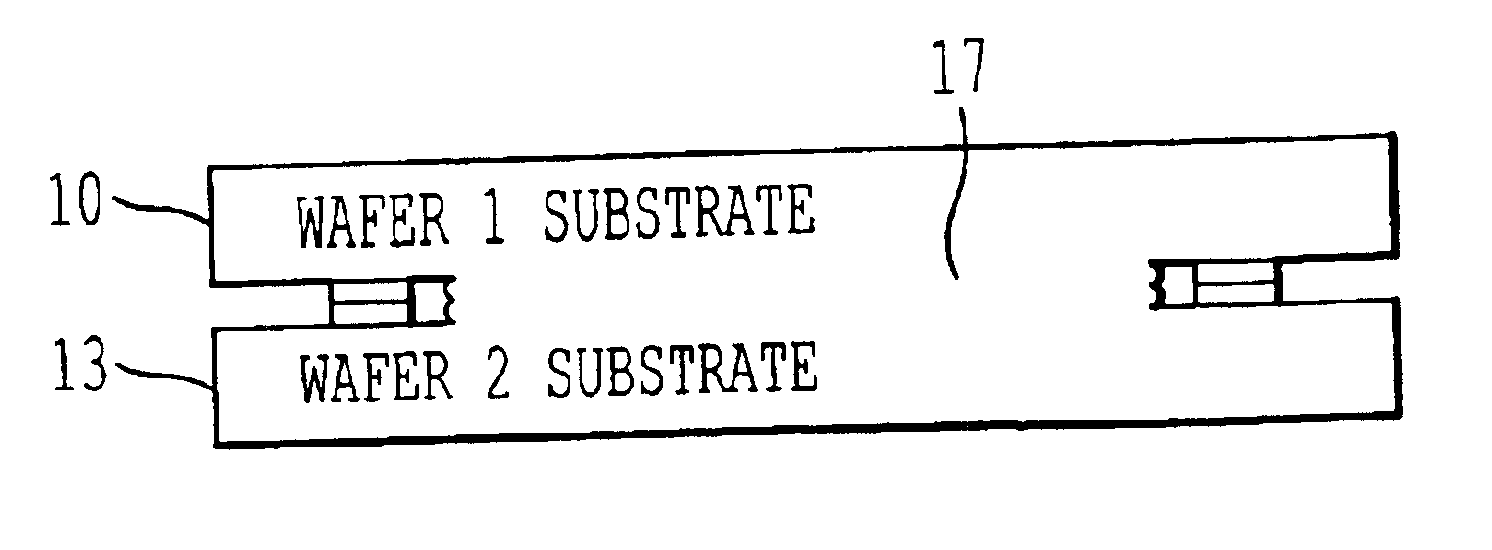

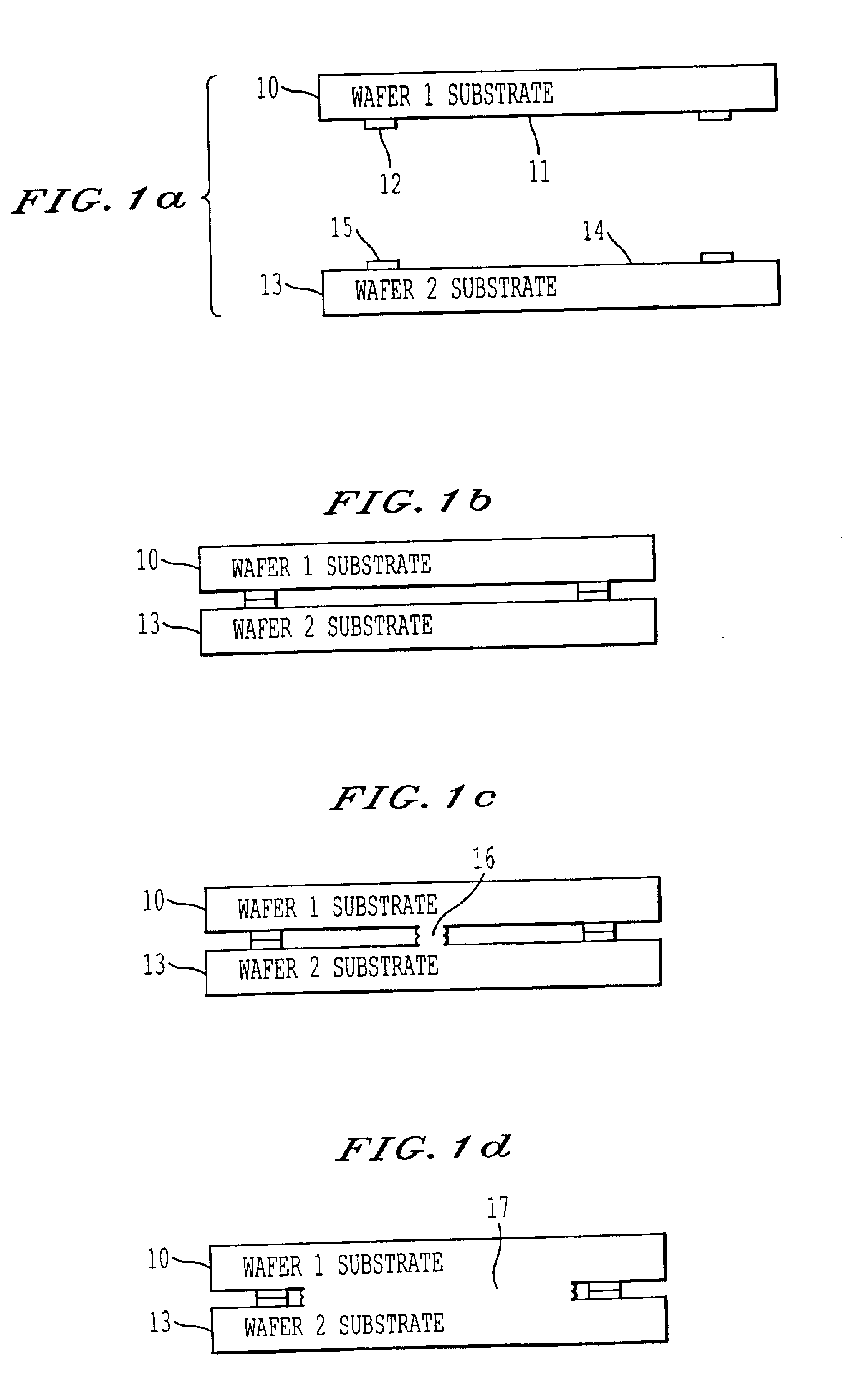

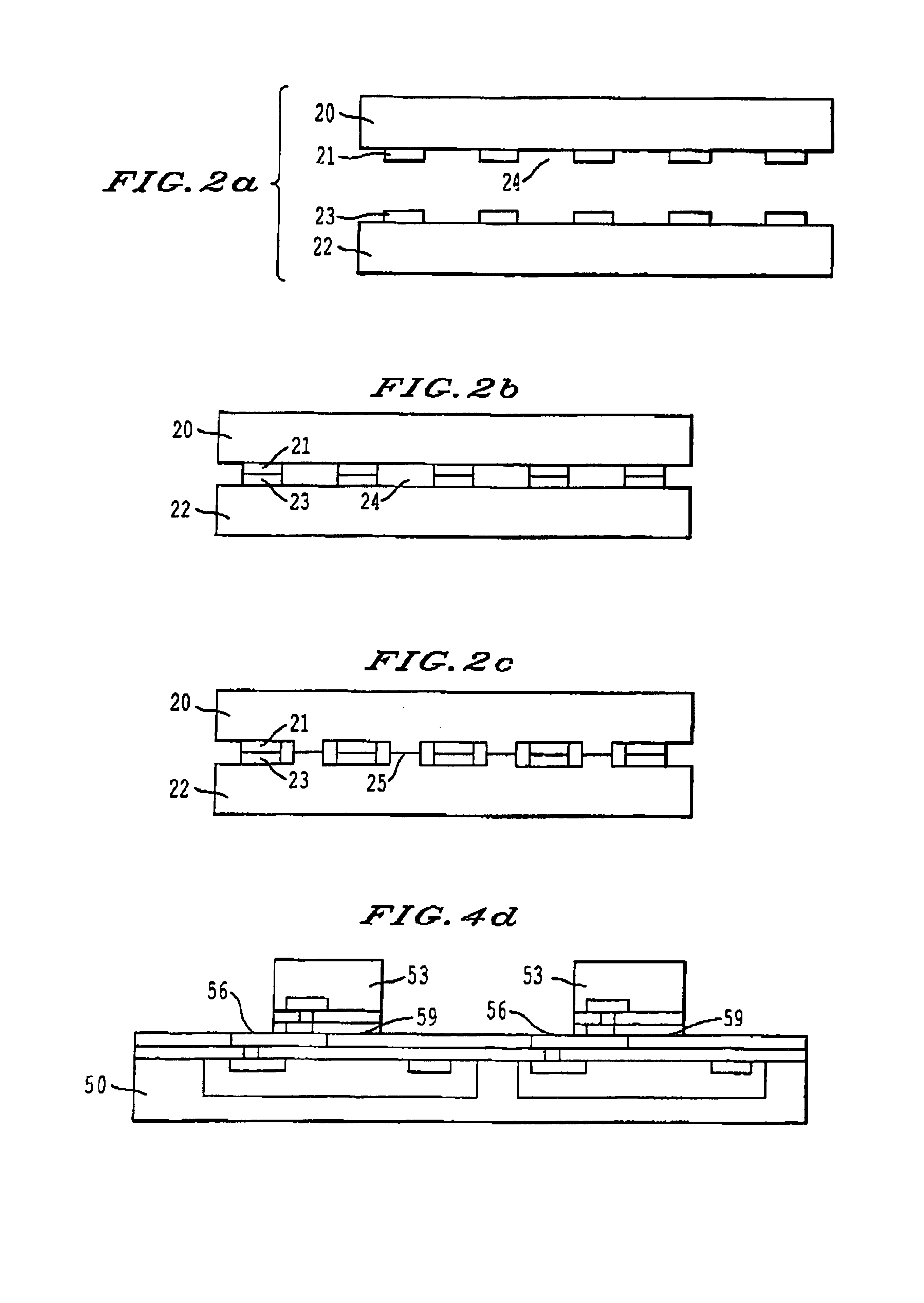

Method of fabrication of a AL/GE bonding in a wafer packaging environment and a product produced therefrom

ActiveUS7442570B2Robust and mechanical contactHighly controllableAcceleration measurement using interia forcesSemiconductor/solid-state device detailsFoundryHermetic seal

A method of bonding of germanium to aluminum between two substrates to create a robust electrical and mechanical contact is disclosed. An aluminum-germanium bond has the following unique combination of attributes: (1) it can form a hermetic seal; (2) it can be used to create an electrically conductive path between two substrates; (3) it can be patterned so that this conduction path is localized; (4) the bond can be made with the aluminum that is available as standard foundry CMOS process. This has the significant advantage of allowing for wafer-level bonding or packaging without the addition of any additional process layers to the CMOS wafer.

Owner:INVENSENSE

Method of fabrication of ai/ge bonding in a wafer packaging environment and a product produced therefrom

ActiveUS20060208326A1RobustHighly controllableAcceleration measurement using interia forcesSemiconductor/solid-state device detailsFoundryHermetic seal

A method of bonding of germanium to aluminum between two substrates to create a robust electrical and mechanical contact is disclosed. An aluminum-germanium bond has the following unique combination of attributes: (1) it can form a hermetic seal; (2) it can be used to create an electrically conductive path between two substrates; (3) it can be patterned so that this conduction path is localized; (4) the bond can be made with the aluminum that is available as standard foundry CMOS process. This has the significant advantage of allowing for wafer-level bonding or packaging without the addition of any additional process layers to the CMOS wafer.

Owner:INVENSENSE

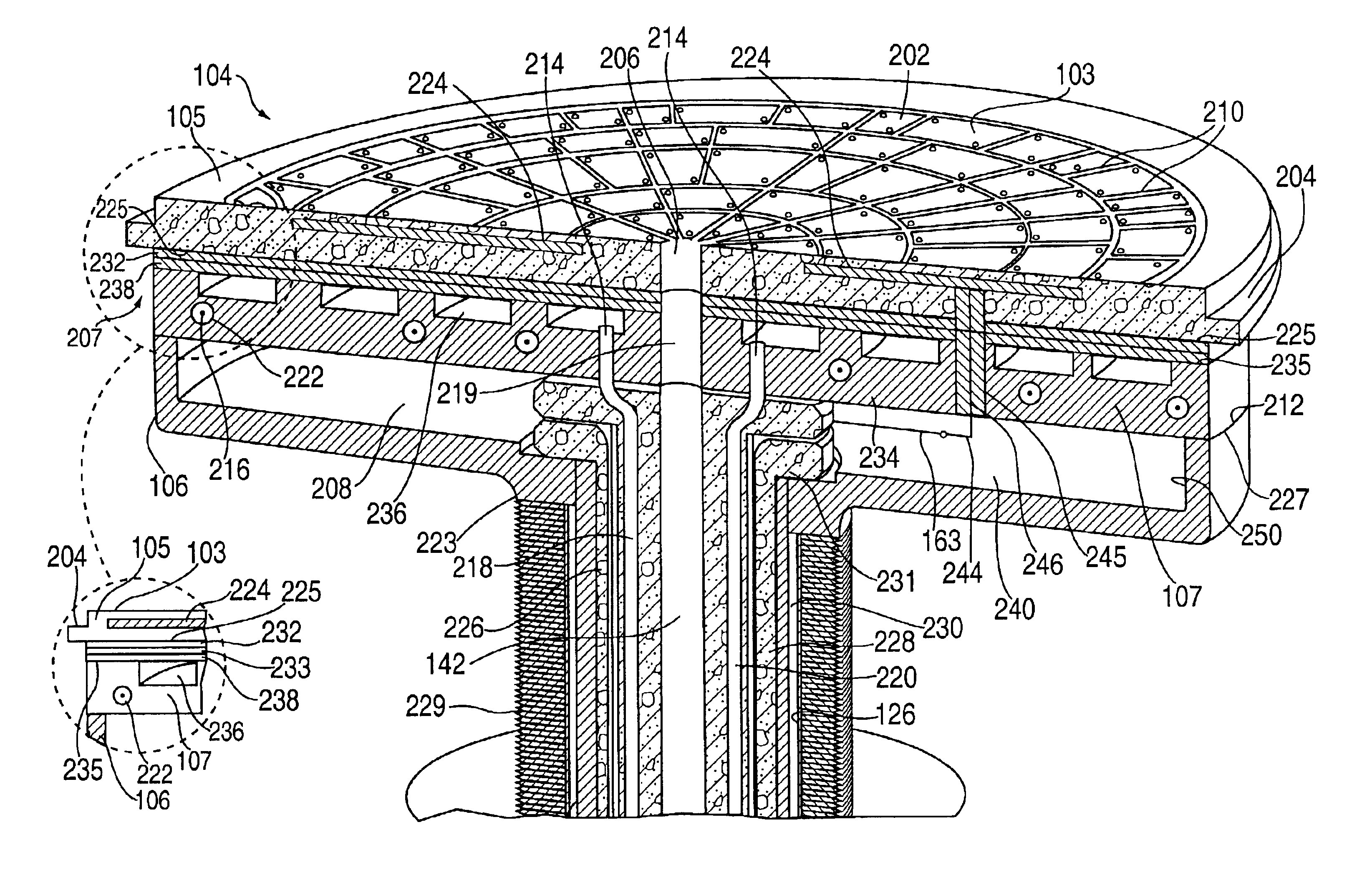

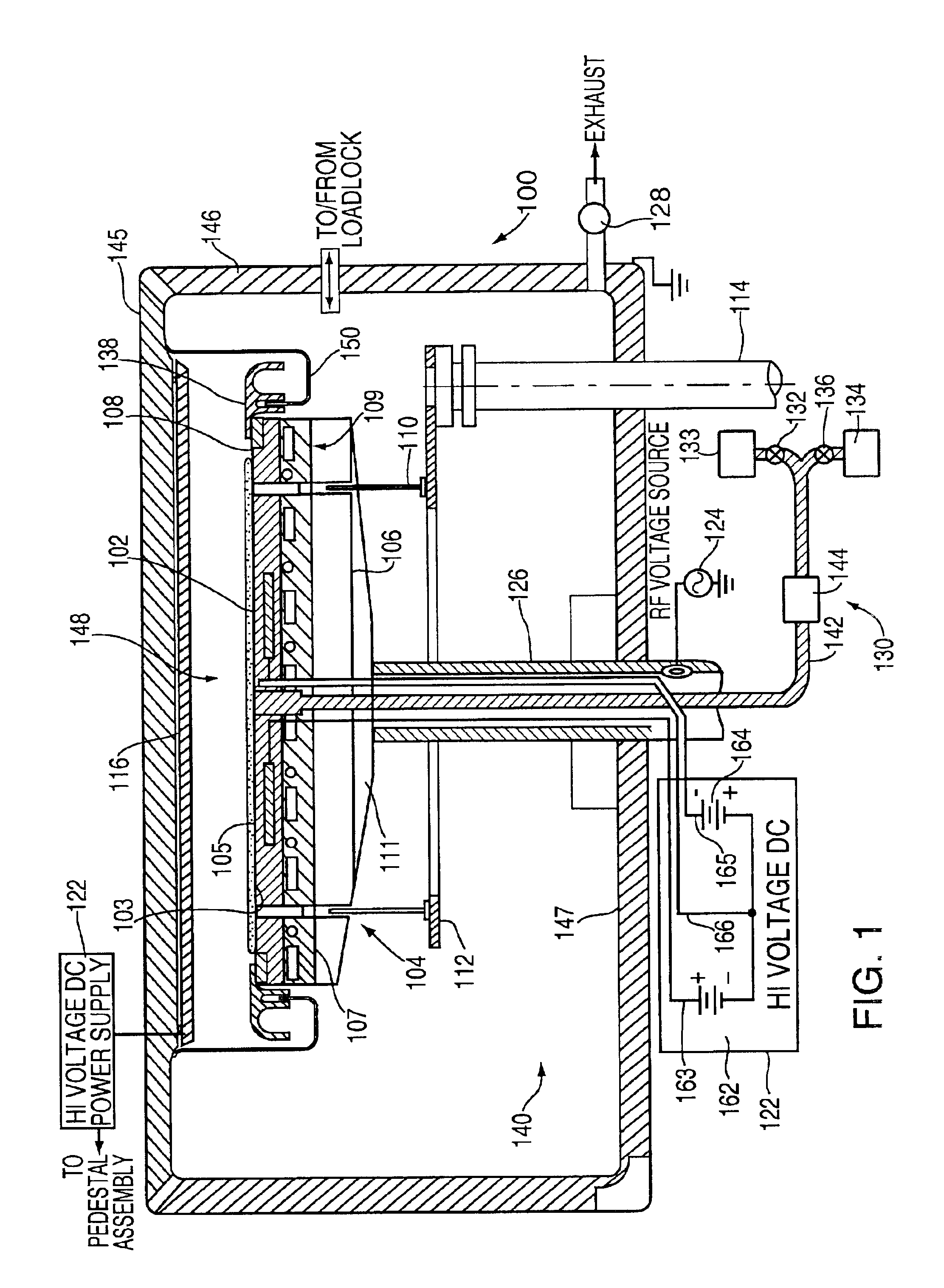

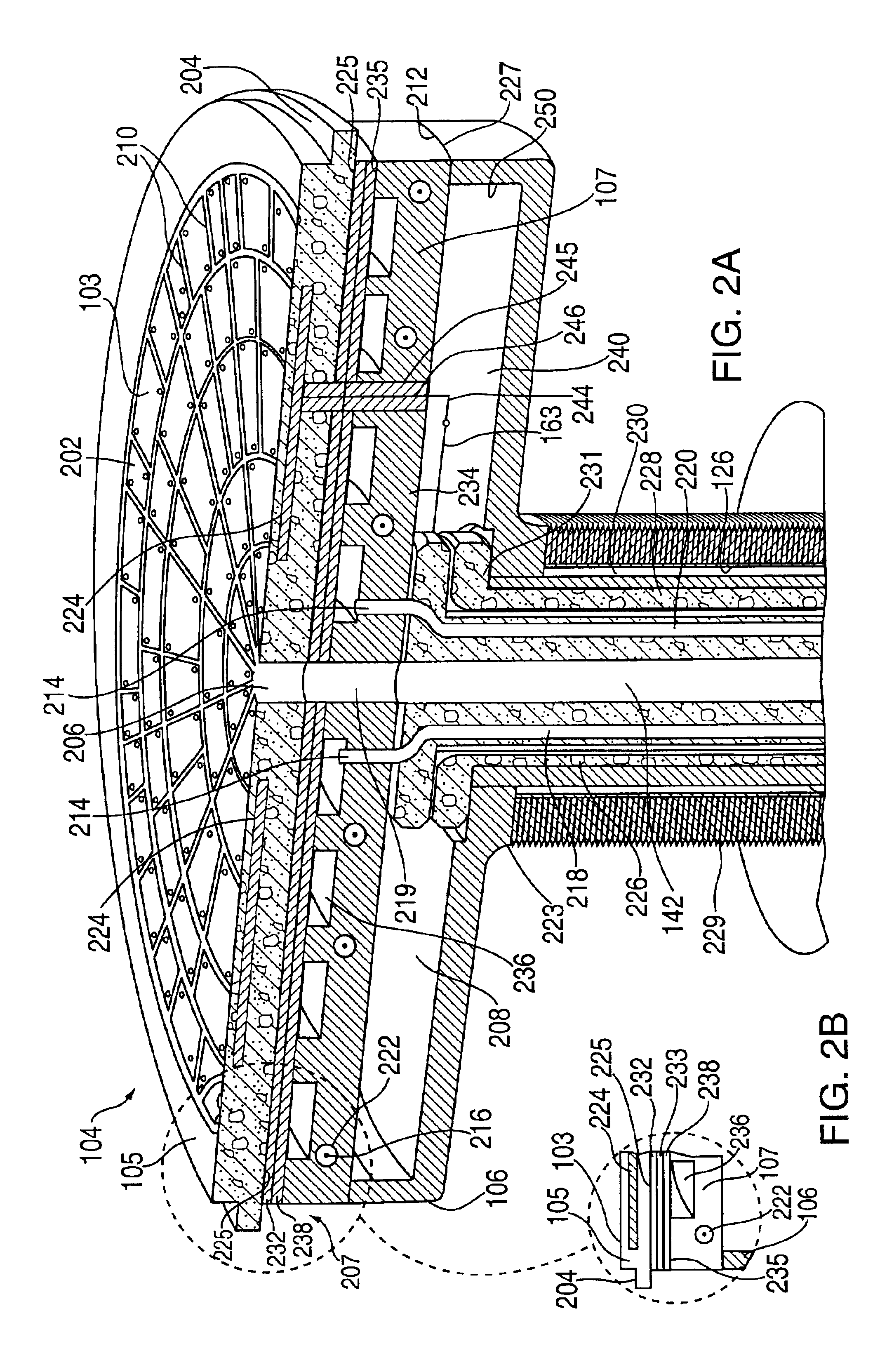

Full area temperature controlled electrostatic chuck and method of fabricating same

InactiveUS6853533B2Liquid surface applicatorsLighting and heating apparatusTemperature controlMetallurgy

A semiconductor wafer support assembly and method of fabricating the same are provided. In one embodiment, the method and resulting assembly include attaching a pedestal joining-ring to a bottom surface of a ceramic puck. Low temperature brazing a composite cooling plate structure to the bottom surface of the ceramic puck, where the pedestal joining-ring circumscribes the composite cooling plate structure. Thereafter, a pedestal is electron-beam welded to the pedestal joining-ring.

Owner:APPLIED MATERIALS INC

Method for room temperature metal direct bonding

InactiveUS6962835B2Solid-state devicesSemiconductor/solid-state device manufacturingBond interfaceRoom temperature

A bonded device structure including a first substrate having a first set of metallic bonding pads, preferably connected to a device or circuit, and having a first non-metallic region adjacent to the metallic bonding pads on the first substrate, a second substrate having a second set of metallic bonding pads aligned with the first set of metallic bonding pads, preferably connected to a device or circuit, and having a second non-metallic region adjacent to the metallic bonding pads on the second substrate, and a contact-bonded interface between the first and second set of metallic bonding pads formed by contact bonding of the first non-metallic region to the second non-metallic region. At least one of the first and second substrates may be elastically deformed.

Owner:INVENSAS BONDING TECH INC

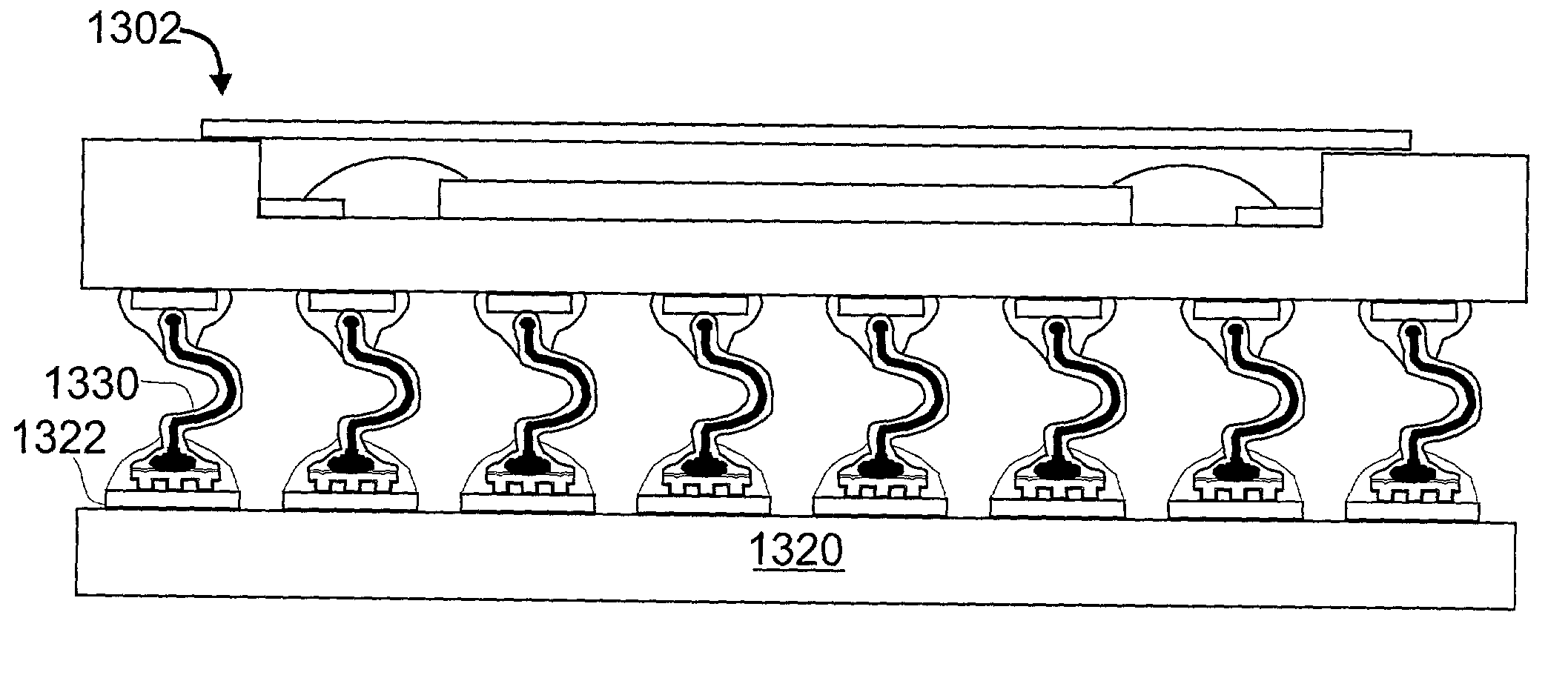

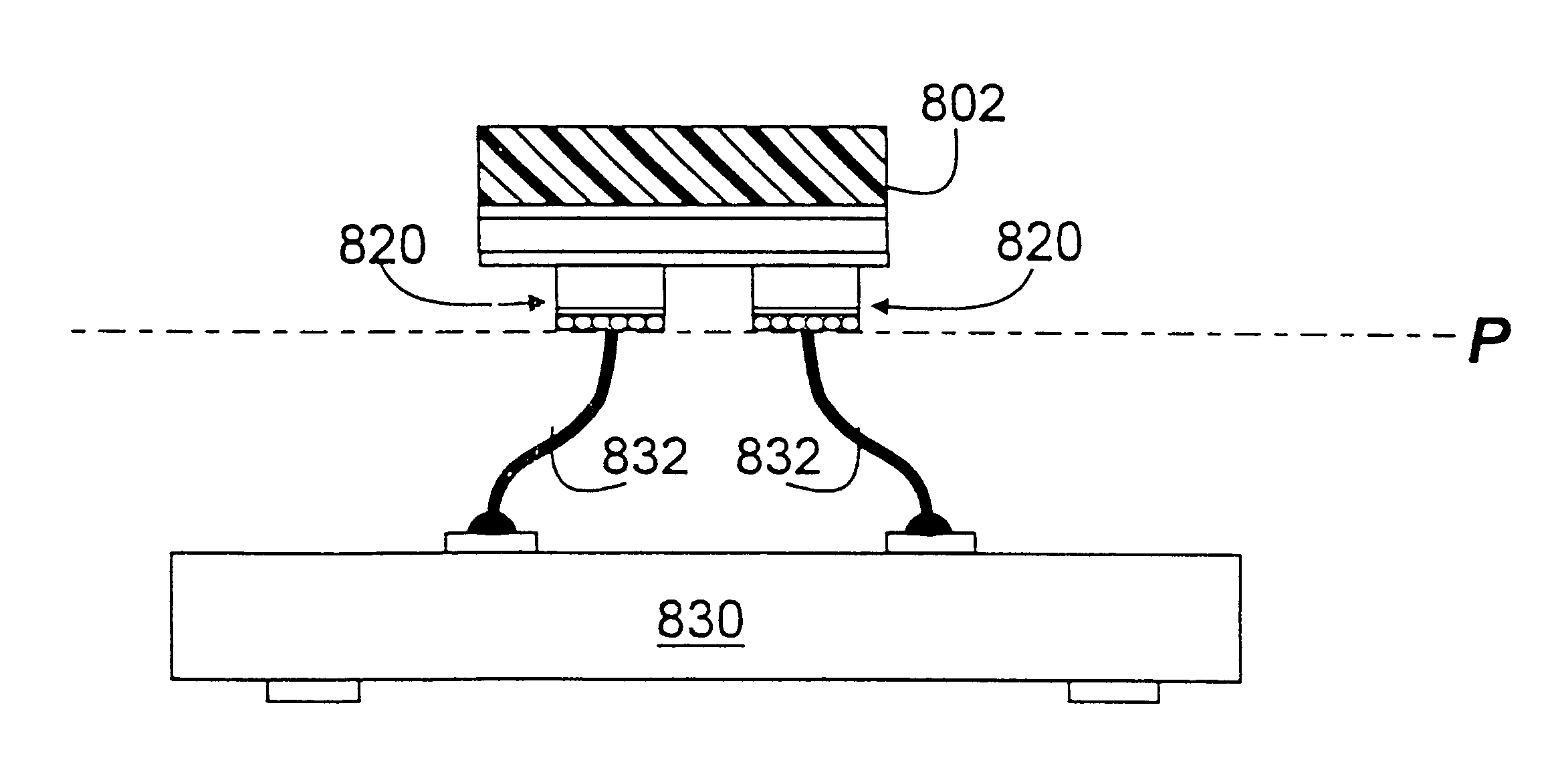

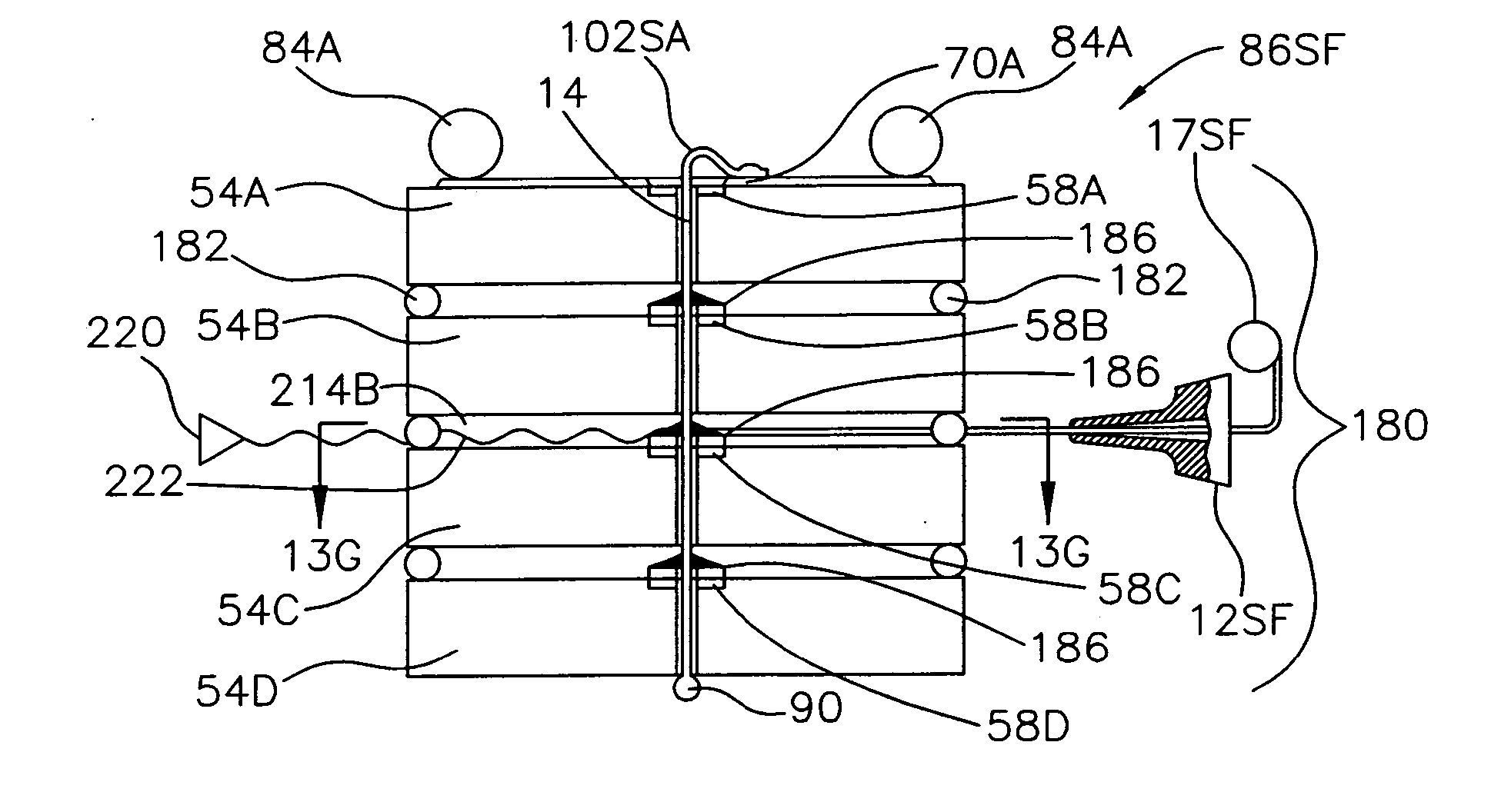

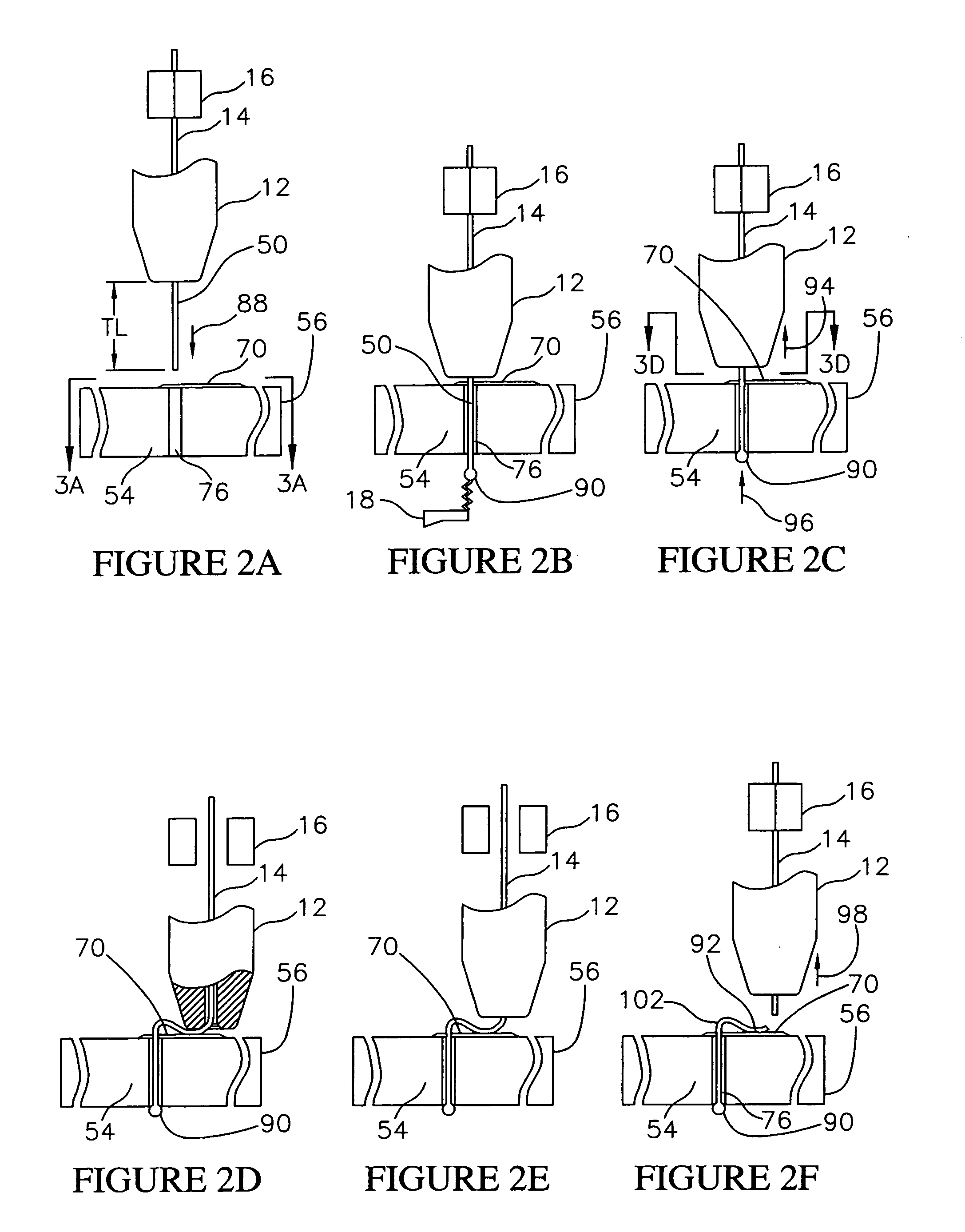

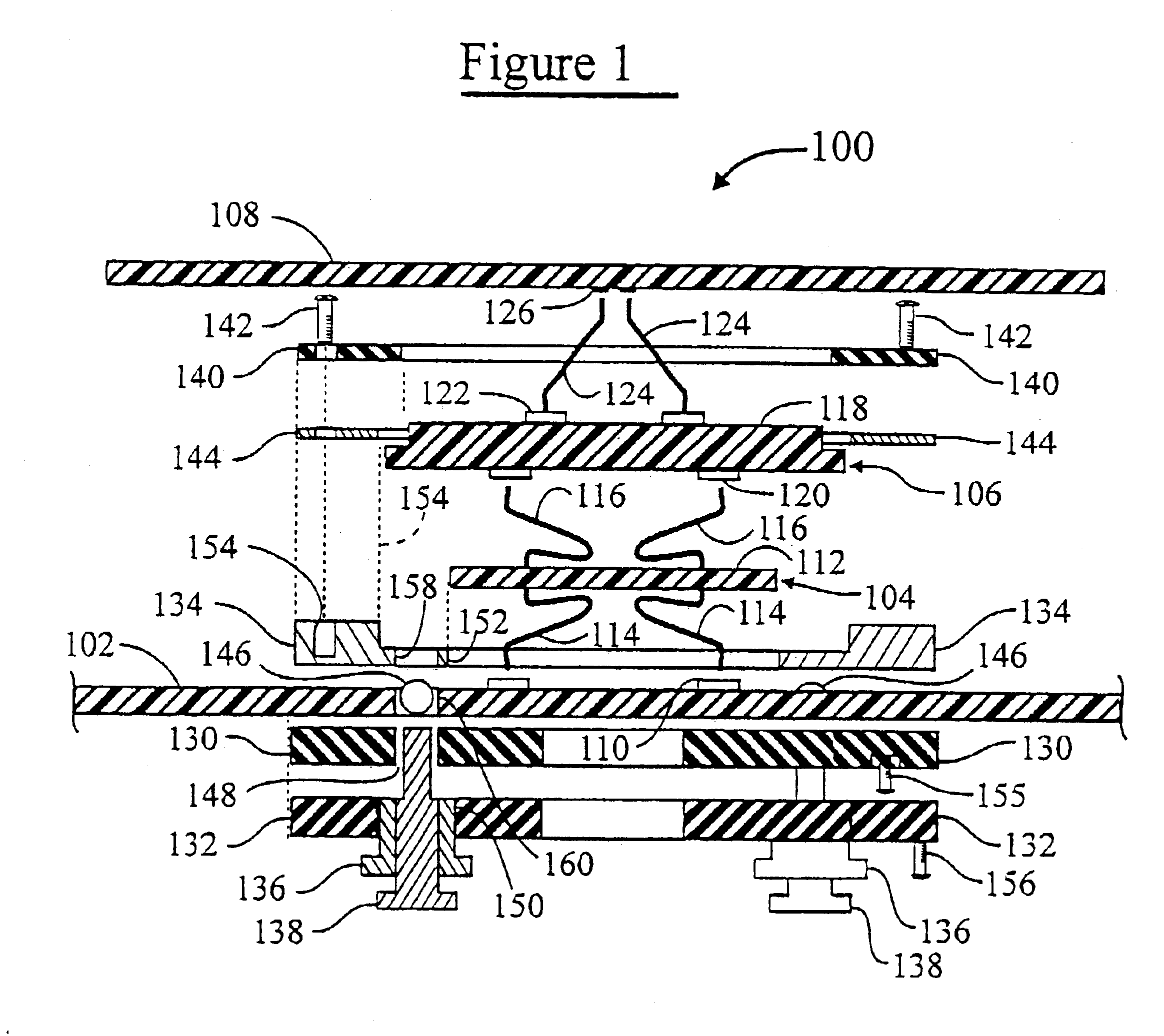

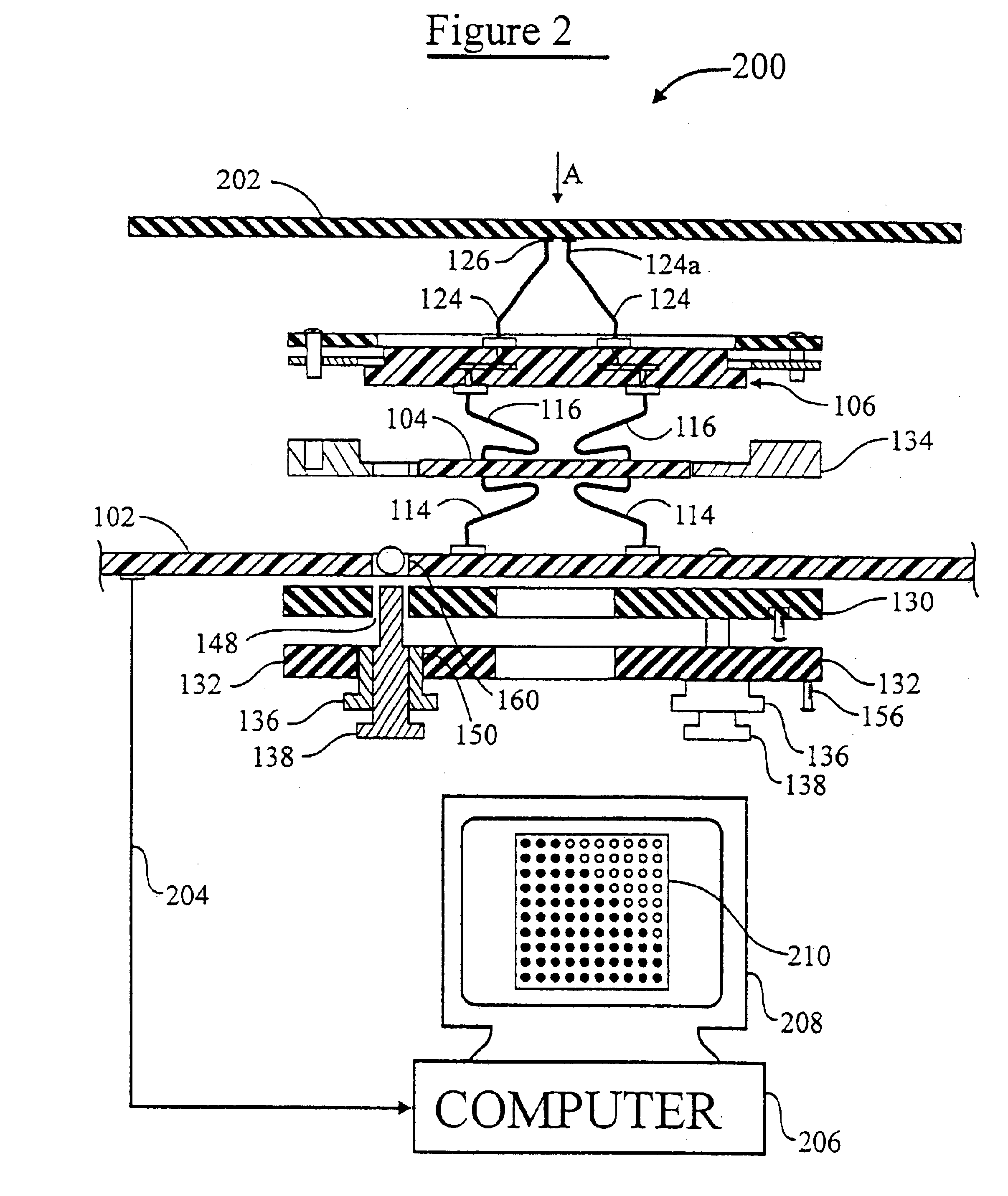

Probe card assembly and kit, and methods of using same

InactiveUS6246247B1Easy to disassembleEffective shieldingSemiconductor/solid-state device testing/measurementFinal product manufactureElectricityProbe card

A probe card assembly includes a probe card, a space transformer having resilient contact structures (probe elements) mounted directly thereto (i.e., without the need for additional connecting wires or the like) and extending from terminals on a surface thereof, and an interposer disposed between the space transformer and the probe card. The space transformer and interposer are "stacked up" so that the orientation of the space transformer, hence the orientation of the tips of the probe elements, can be adjusted without changing the orientation of the probe card. Suitable mechanisms for adjusting the orientation of the space transformer, and for determining what adjustments to make, are disclosed. The interposer has resilient contact structures extending from both the top and bottom surfaces thereof, and ensures that electrical connections are maintained between the space transformer and the probe card throughout the space transformer's range of adjustment, by virtue of the interposer's inherent compliance. Multiple die sites on a semiconductor wafer are readily probed using the disclosed techniques, and the probe elements can be arranged to optimize probing of an entire wafer. Composite interconnection elements having a relatively soft core overcoated by a relatively hard shell, as the resilient contact structures are described.

Owner:FORMFACTOR INC

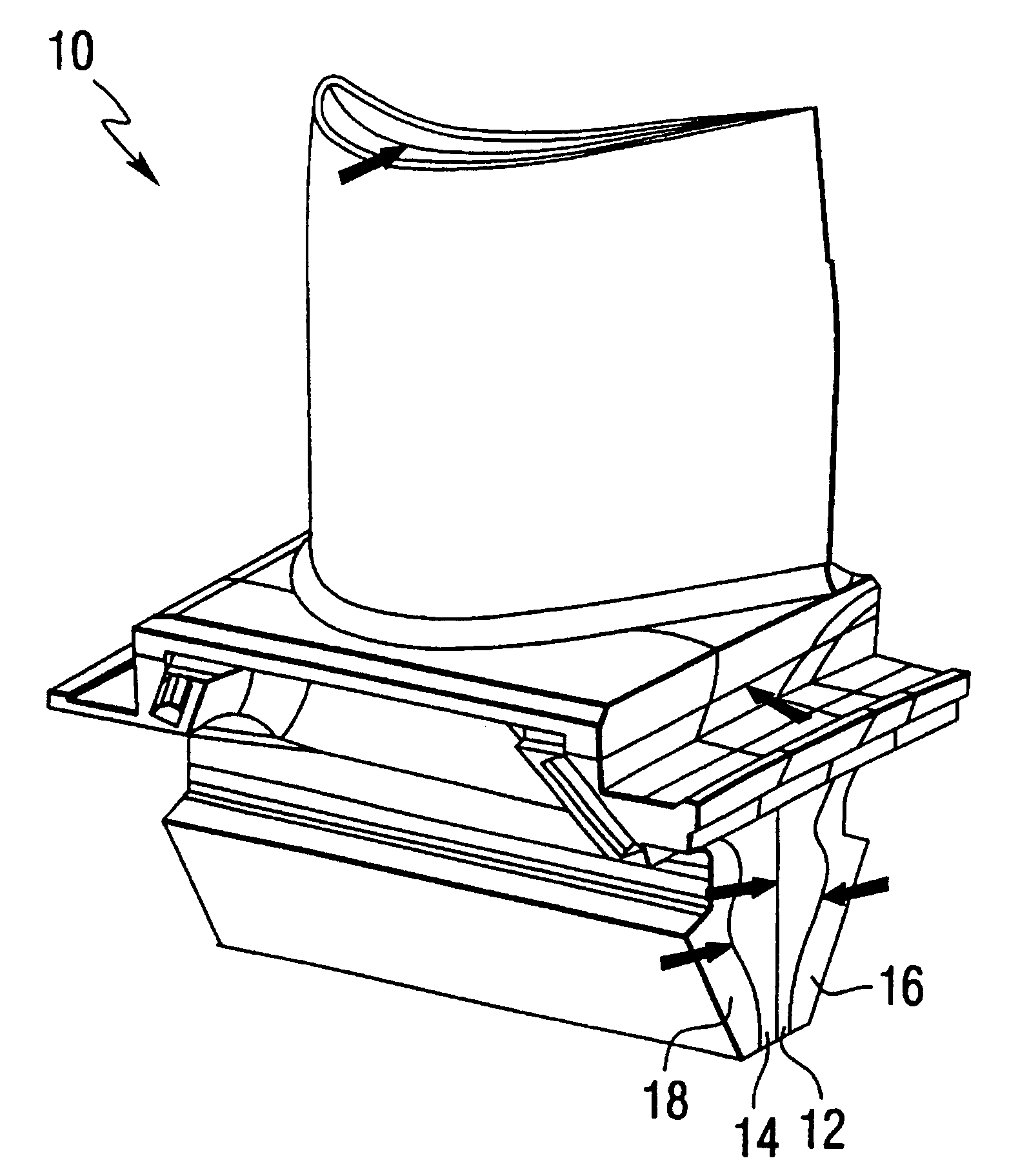

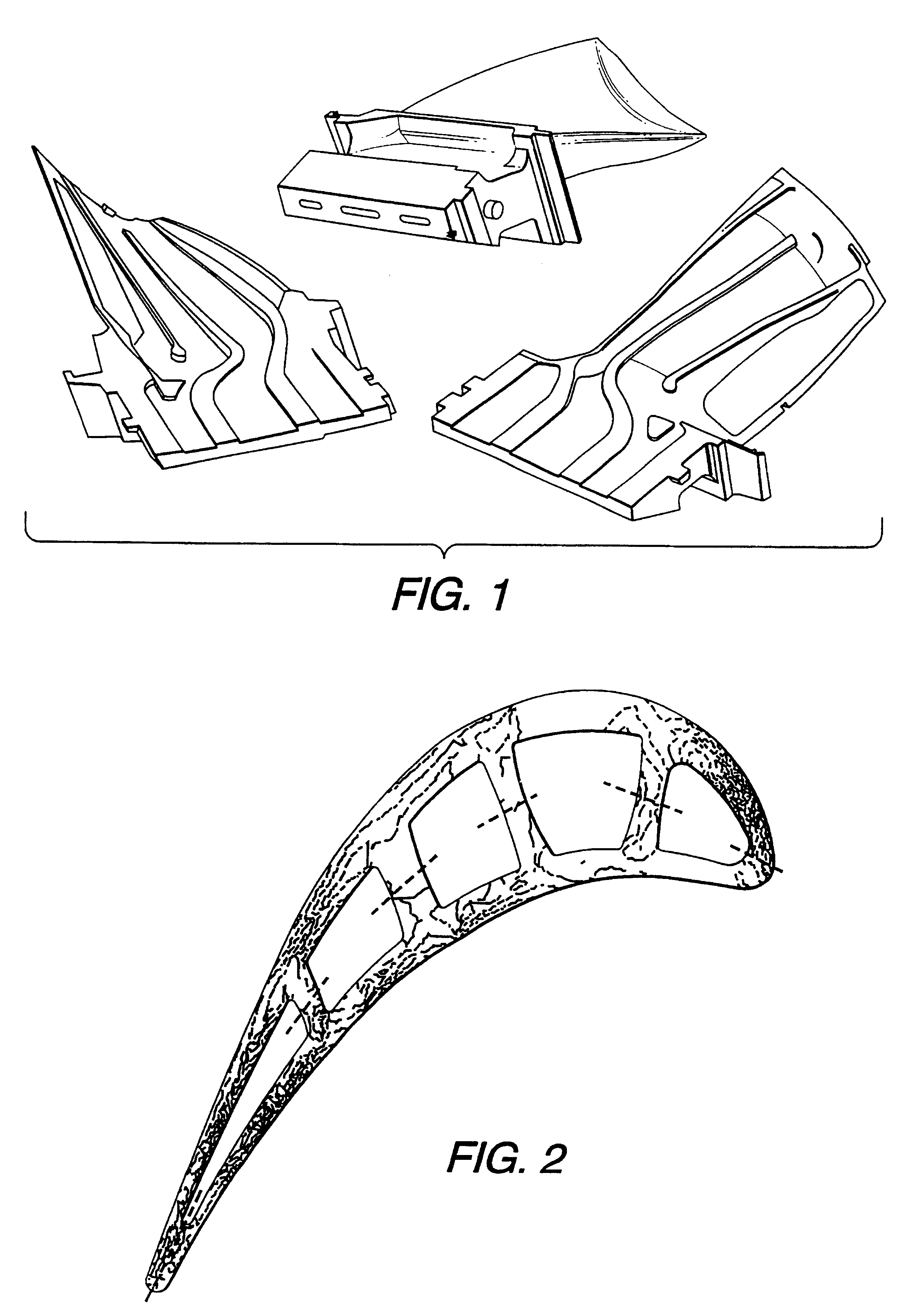

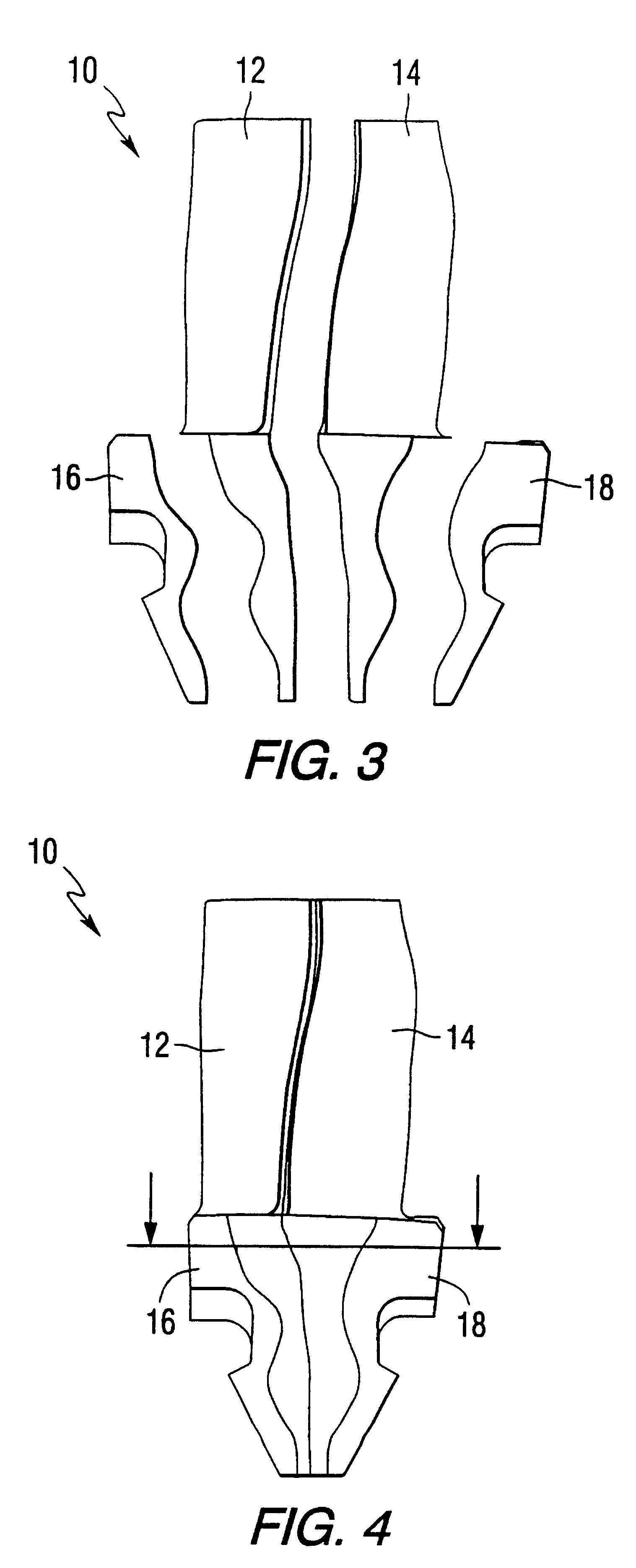

Turbine blades made from multiple single crystal cast superalloy segments

InactiveUS6331217B1Improve bindingQuality improvementPropellersFrom frozen solutionsTurbine bladeSingle crystal

Large gas turbine blades made from separate cast segments of superalloys are disclosed. The turbine blade is designed such that bond lines between adjacent segments are placed in low stress regions of the blade. The cast superalloy segments of the blades are aligned and fitted together with specified tolerances. The turbine blade segments are then joined by transient liquid phase bonding, followed by a controlled heat treatment which produces the desired microstructure in the bond region. The method allows for the production of large, high quality turbine blades by joining small, high quality cast superalloy sections, in comparison with prior attempts to cast large turbine blades as single pieces which have produced very low yields and high individual component costs.

Owner:SIEMENS ENERGY INC

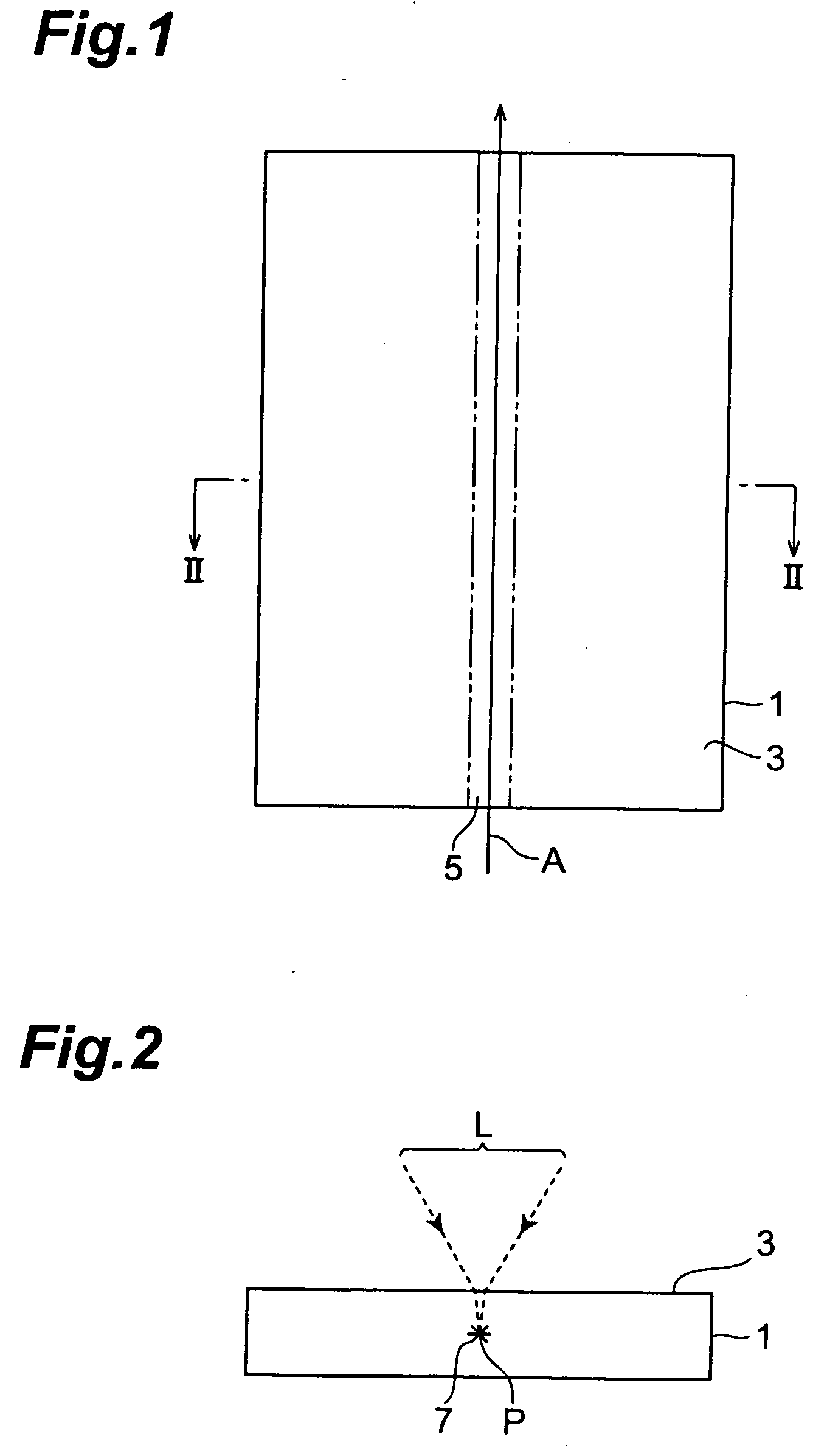

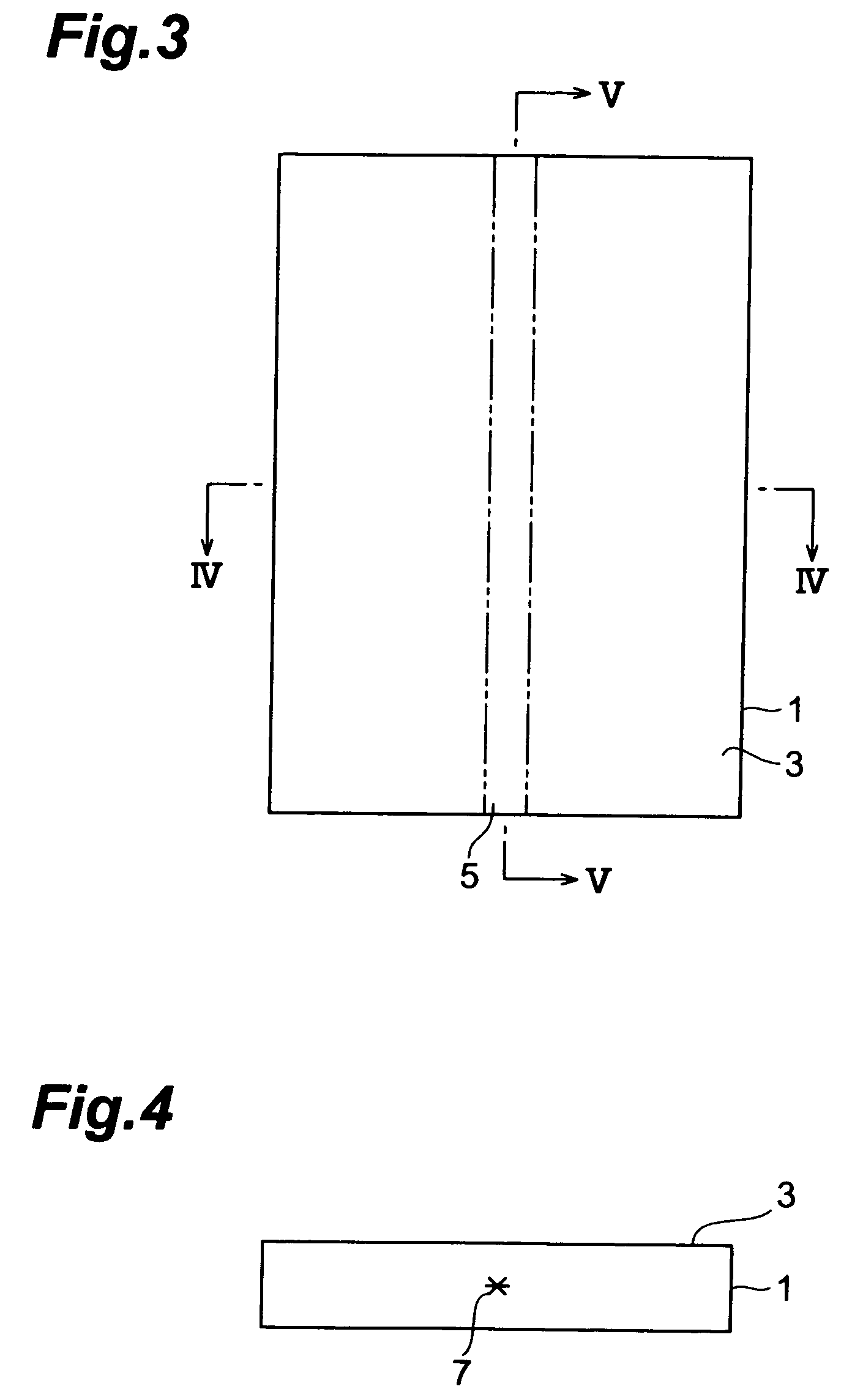

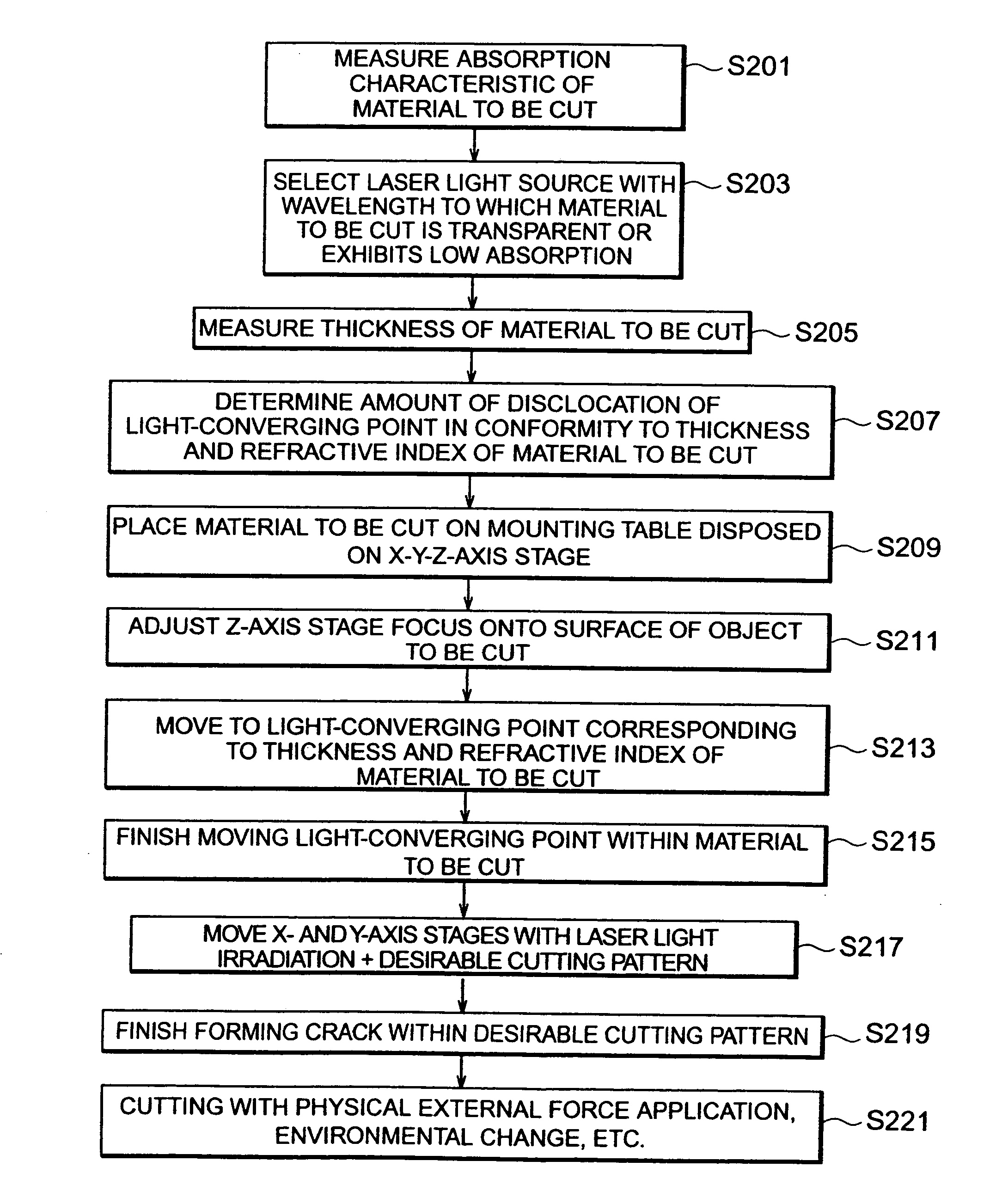

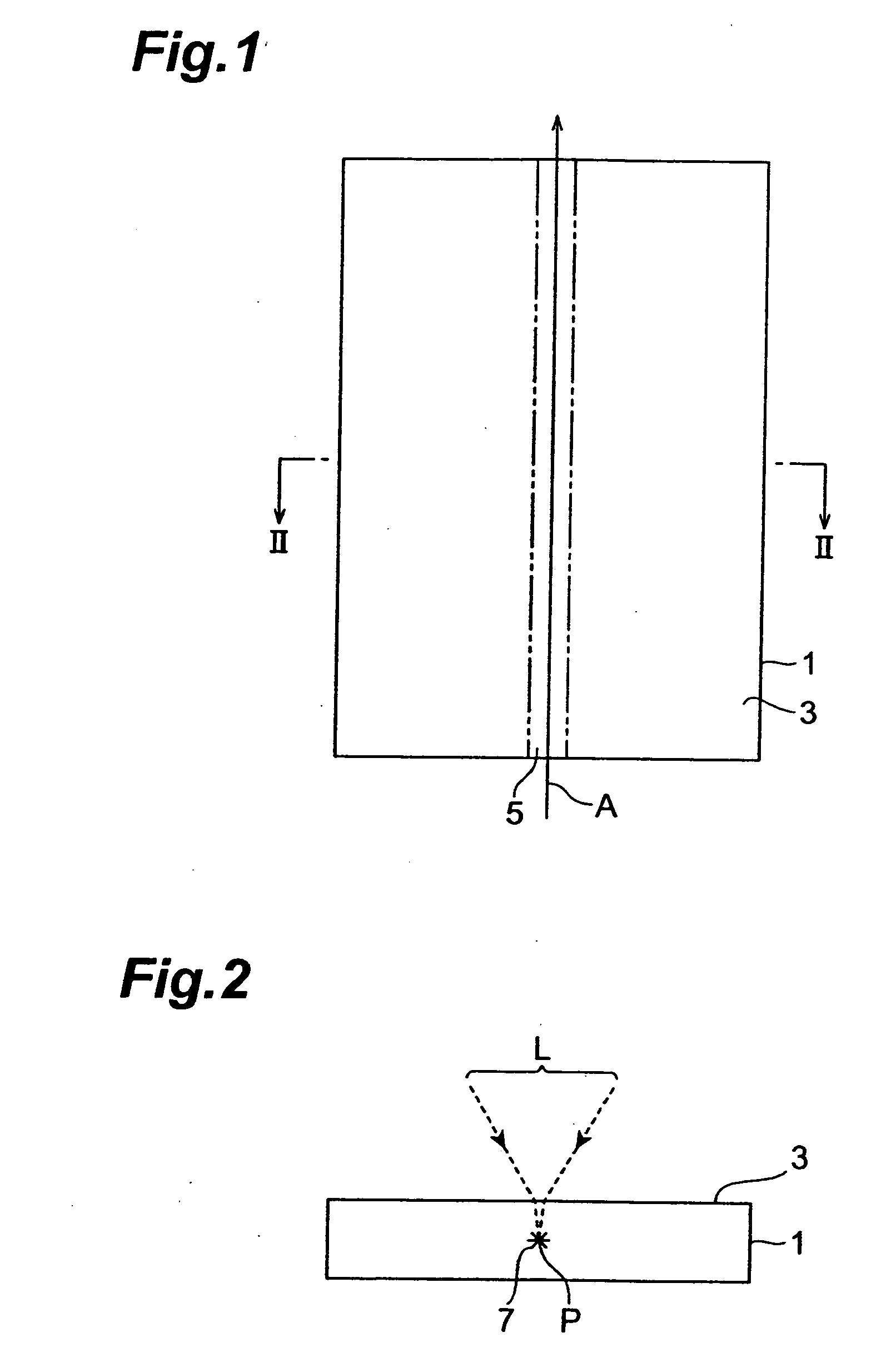

Laser processing method and laser processing apparatus

InactiveUS20050173387A1No unnecessary fracture in surfaceNo unnecessary fractureSolid-state devicesSemiconductor/solid-state device manufacturingLaser processingLaser beam machining

A laser beam machining method and a laser beam machining device capable of cutting a work without producing a fusing and a cracking out of a predetermined cutting line on the surface of the work, wherein a pulse laser beam is radiated on the predetermined cut line on the surface of the work under the conditions causing a multiple photon absorption and with a condensed point aligned to the inside of the work, and a modified area is formed inside the work along the predetermined determined cut line by moving the condensed point along the predetermined cut line, whereby the work can be cut with a rather small force by cracking the work along the predetermined cut line starting from the modified area and, because the pulse laser beam radiated is not almost absorbed onto the surface of the work, the surface is not fused even if the modified area is formed.

Owner:HAMAMATSU PHOTONICS KK

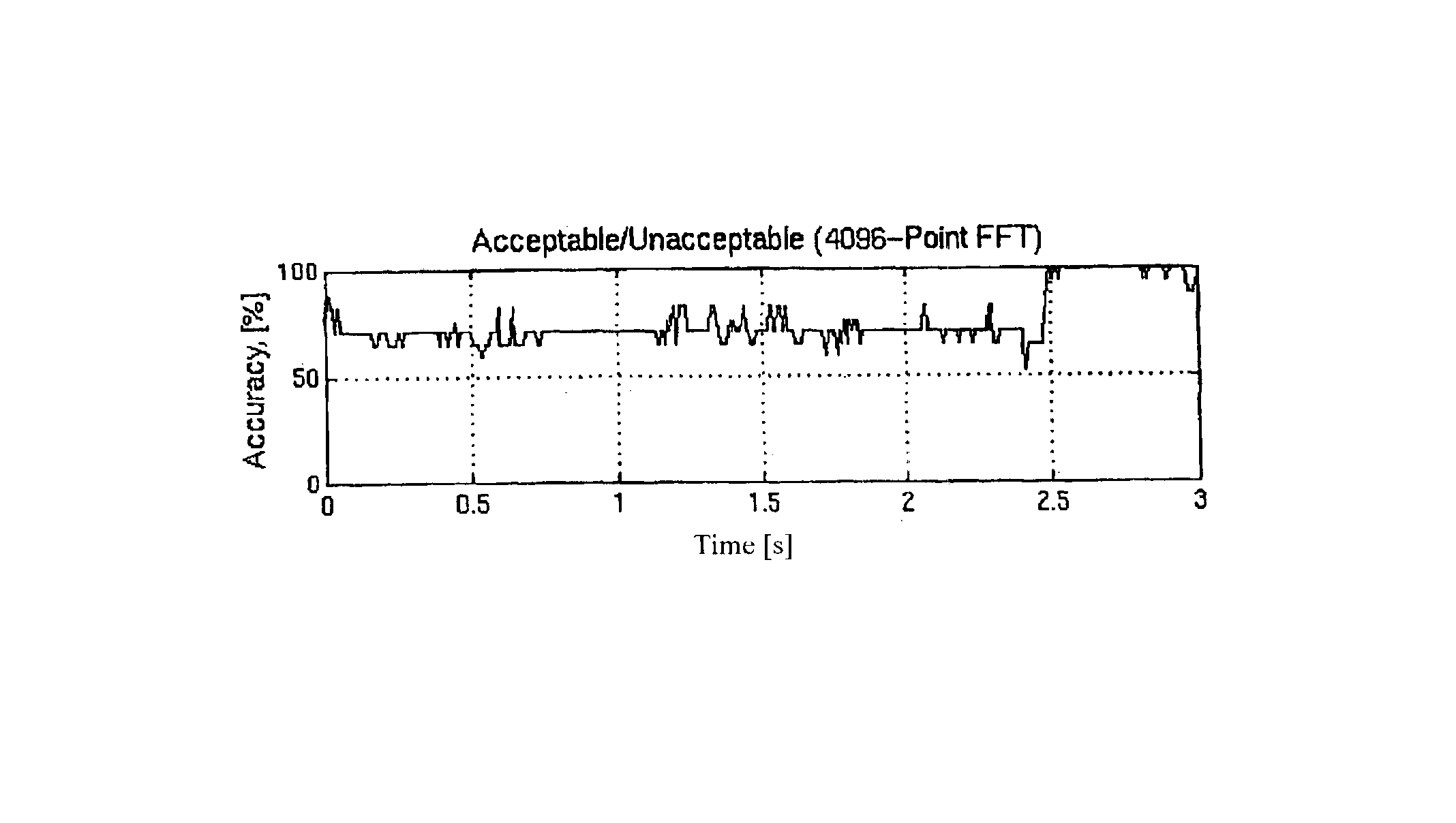

Method and apparatus for in-process sensing of manufacturing quality

InactiveUS6857553B1Low costShorten the timeAnalysing solids using sonic/ultrasonic/infrasonic wavesResonant frequencyFriction weldingAcoustics

A method for determining the quality of an examined weld joint comprising the steps of providing acoustical data from the examined weld joint, and performing a neural network operation on the acoustical data determine the quality of the examined weld joint produced by a friction weld process. The neural network may be trained by the steps of providing acoustical data and observable data from at least one test weld joint, and training the neural network based on the acoustical data and observable data to form a trained neural network so that the trained neural network is capable of determining the quality of a examined weld joint based on acoustical data from the examined weld joint. In addition, an apparatus having a housing, acoustical sensors mounted therein, and means for mounting the housing on a friction weld device so that the acoustical sensors do not contact the weld joint. The apparatus may sample the acoustical data necessary for the neural network to determine the quality of a weld joint.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

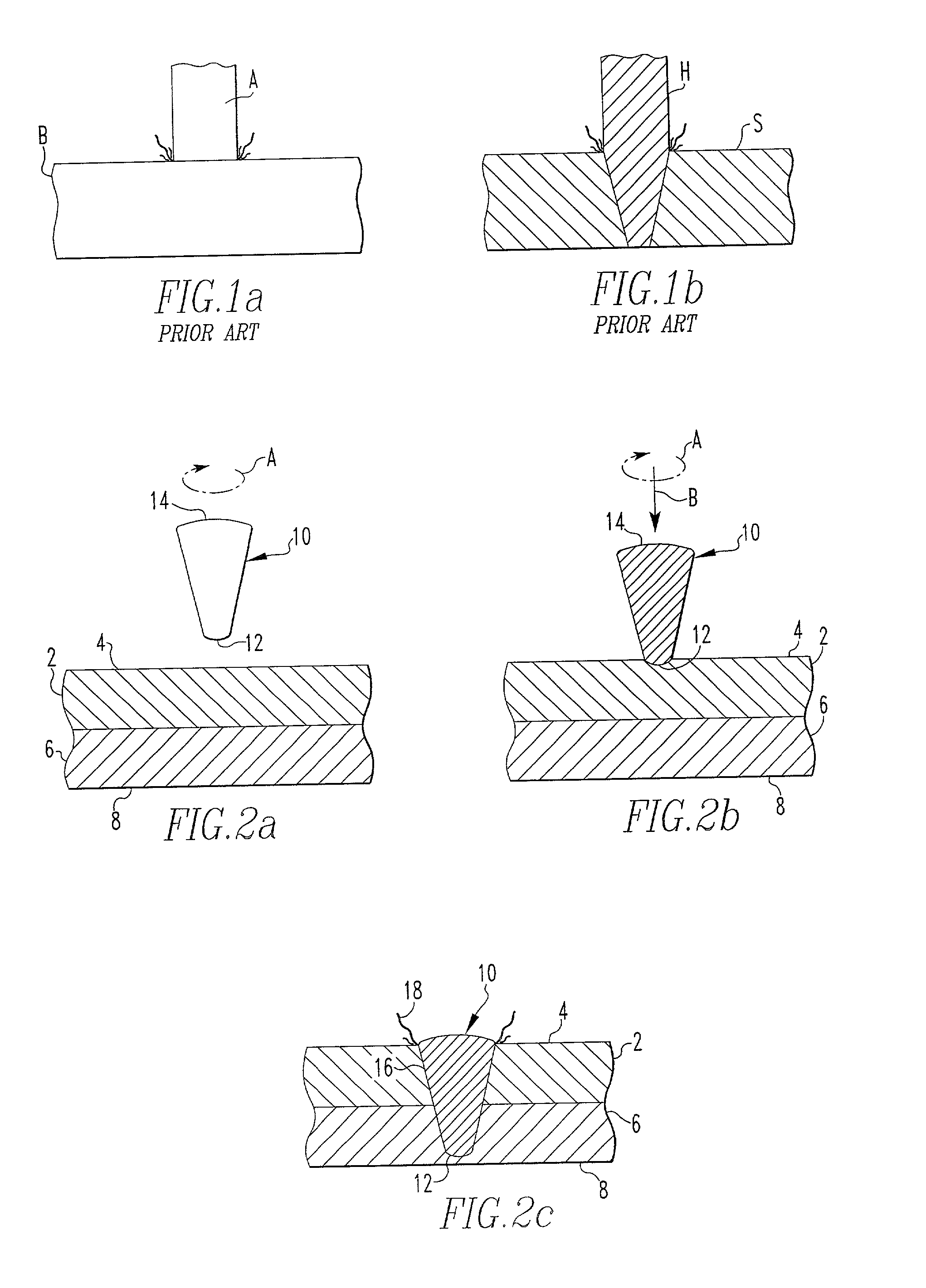

Friction plunge riveting

InactiveUS20020125297A1Welding/cutting auxillary devicesAuxillary welding devicesFriction weldingHardness

A method of joining a pair of metal components with a rivet having a hardness that is substantially similar to at least one of the metal components. The metal components are stack upon each other and the rivet is rotated and simultaneously plunged in the metal components under pressure to friction weld and metallurgically bond the rivet to the metal components.

Owner:ARCONIC INC

Method of making a product with improved material properties by moderate heat-treatment of a metal incorporating a dilute additive

InactiveUS6150186AStable mechanical propertiesImprove conductivitySemiconductor/solid-state device testing/measurementFinal product manufactureUltimate tensile strengthMechanical property

Deposition of metal in a preferred shape, including coatings on parts, or stand-alone materials, and subsequent heat treatment to provide improved mechanical properties. In particular, the method gives products with relatively high yield strength. The products often have relatively high elastic modulus, and are thermally stable, maintaining the high yield strength at temperatures considerably above 25 DEG C. This technique involves depositing a material in the presence of a selected additive, and then subjecting the deposited material to a moderate heat treatment. This moderate heat treatment differs from other commonly employed "stress relief" heat treatments in using lower temperatures and / or shorter times, preferably just enough to reorganize the material to the new, desired form. Coating a shape and heat treating provides a shaped deposit with improved material properties. Coating a shape with a portion connected to a base and a portion detached therefrom can provide a resilient, conductive contact useful for electronic applications.

Owner:FORMFACTOR INC

Method and system for fabricating semiconductor components with through wire interconnects

ActiveUS20060228825A1Semiconductor/solid-state device detailsPrinted circuit aspectsElectrical connectionEngineering

A method for fabricating a semiconductor component with a through wire interconnect includes the step of providing a substrate having a circuit side, a back side, and a through via. The method also includes the steps of: threading a wire through the via, forming a contact on the wire on the back side, forming a bonded contact on the wire on the circuit side, and then severing the wire from the bonded contact. The through wire interconnect includes the wire in the via, the contact on the back side and the bonded contact on the circuit side. The contact on the back side, and the bonded contact on the circuit side, permit multiple components to be stacked with electrical connections between adjacent components. A system for performing the method includes the substrate with the via, and a wire bonder having a bonding capillary configured to thread the wire through the via, and form the contact and the bonded contact. The semiconductor component can be used to form chip scale components, wafer scale components, stacked components, or interconnect components for electrically engaging or testing other semiconductor components.

Owner:MICRON TECH INC

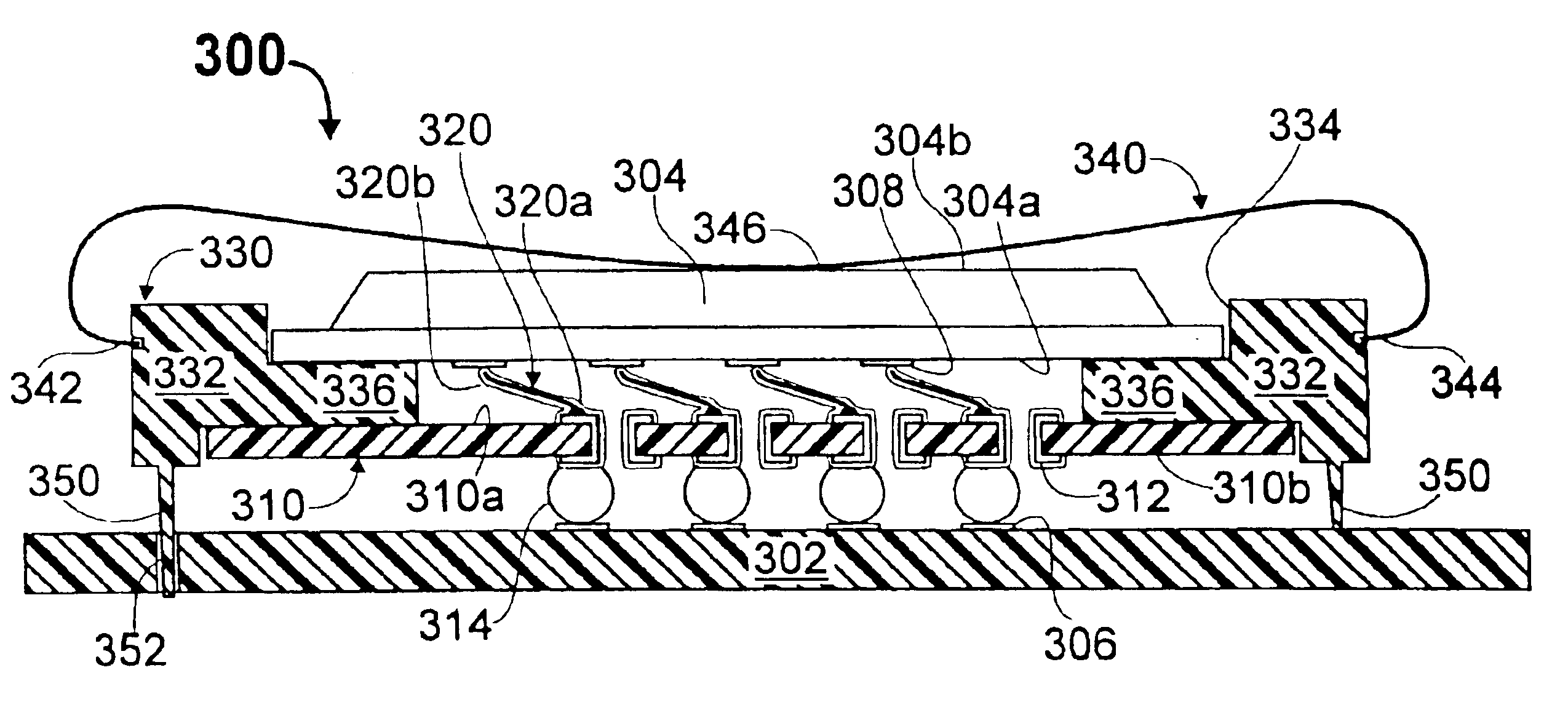

Probe card assembly

InactiveUS6838893B2Easy to disassembleEffective shieldingSemiconductor/solid-state device testing/measurementFinal product manufactureProbe cardTransformer

In a probe card assembly, a series of probe elements can be arrayed on a silicon space transformer. The silicon space transformer can be fabricated with an array of primary contacts in a very tight pitch, comparable to the pitch of a semiconductor device. One preferred primary contact is a resilient spring contact. Conductive elements in the space transformer are routed to second contacts at a more relaxed pitch. In one preferred embodiment, the second contacts are suitable for directly attaching a ribbon cable, which in turn can be connected to provide selective connection to each primary contact. The silicon space transformer is mounted in a fixture that provides for resilient connection to a wafer or device to be tested. This fixture can be adjusted to planarize the primary contacts with the plane of a support probe card board.

Owner:FORMFACTOR INC

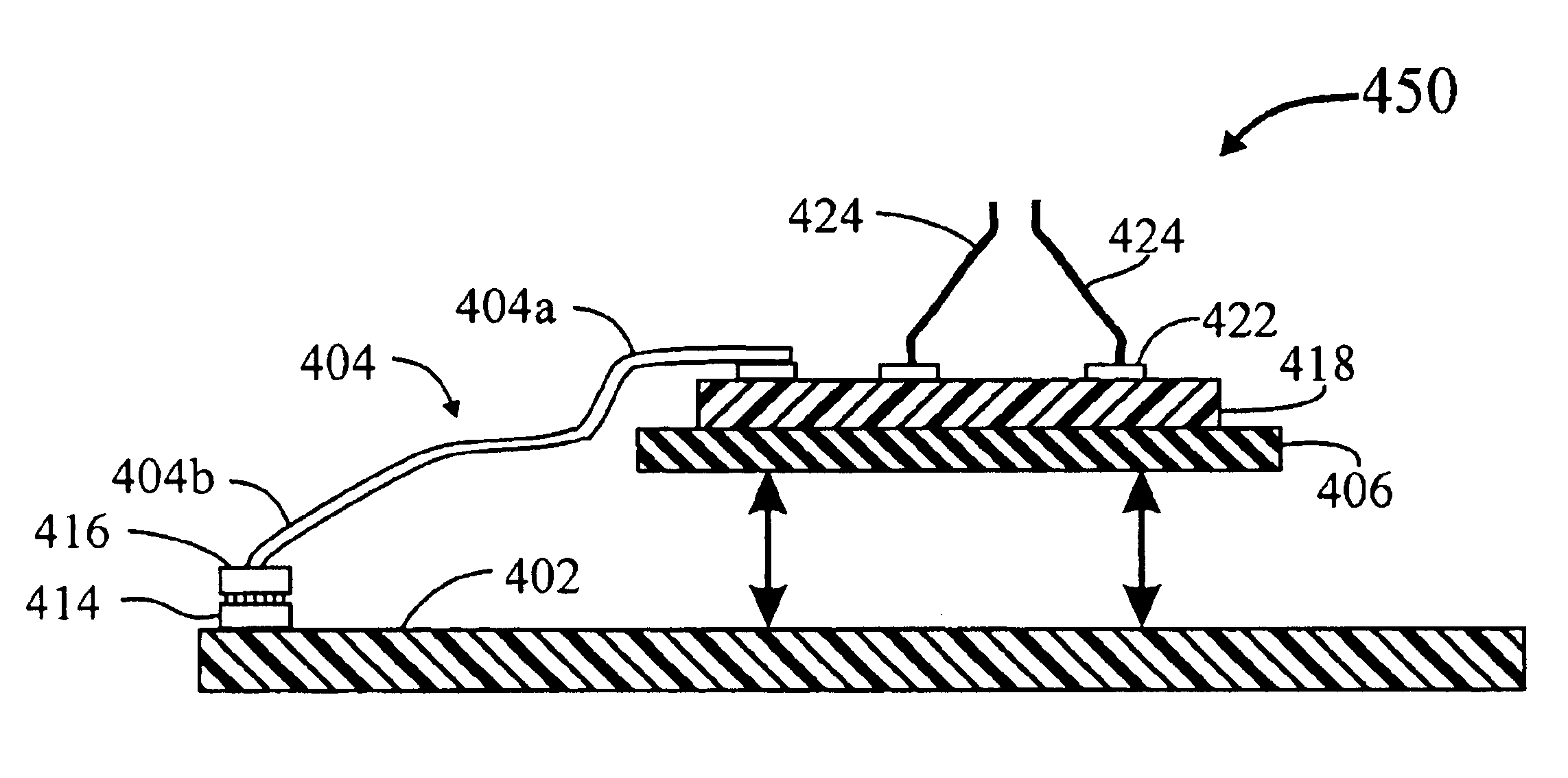

Methods of removably mounting electronic components to a circuit board, and sockets formed by the methods

InactiveUS6913468B2Easy to disassembleEffective shieldingSemiconductor/solid-state device testing/measurementFinal product manufactureSurface mountingSolder ball

Surface-mount, solder-down sockets are described which permit electronic components such as semiconductor packages to be releasably mounted to a circuit board. Generally, the socket includes resilient contact structures extending from a top surface of a support substrate, and solder-ball (or other suitable) contact structures disposed on a bottom surface of the support substrate. Composite interconnection elements are described for use as the resilient contact structures disposed atop the support substrate. In use, the support substrate is soldered down onto the circuit board, the contact structures on the bottom surface of the support substrate contacting corresponding contact areas on the circuit board. In any suitable manner, selected ones of the resilient contact structures atop the support substrate are connected, via the support substrate, to corresponding ones of the contact structures on the bottom surface of the support substrate.

Owner:FORMFACTOR INC

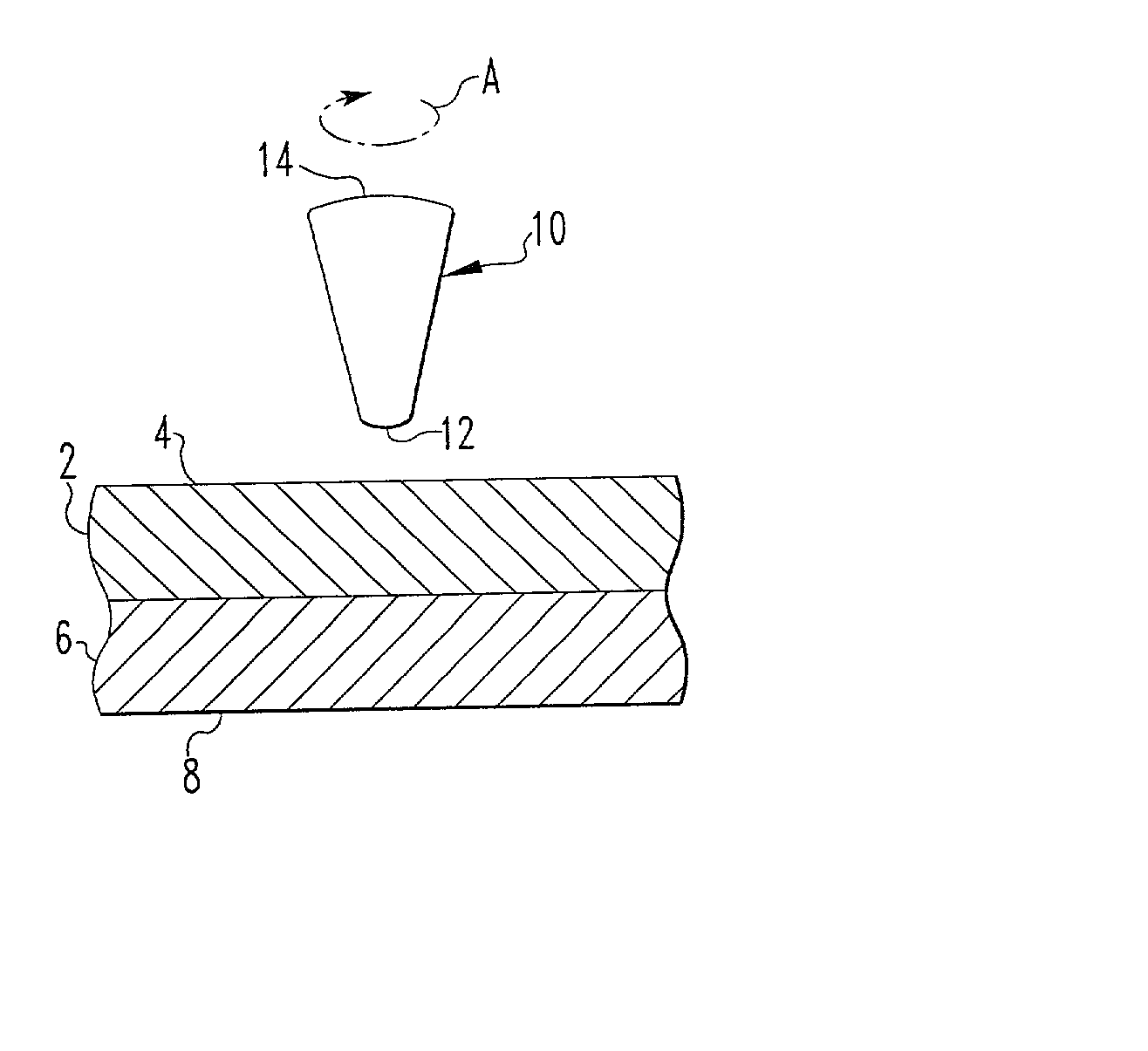

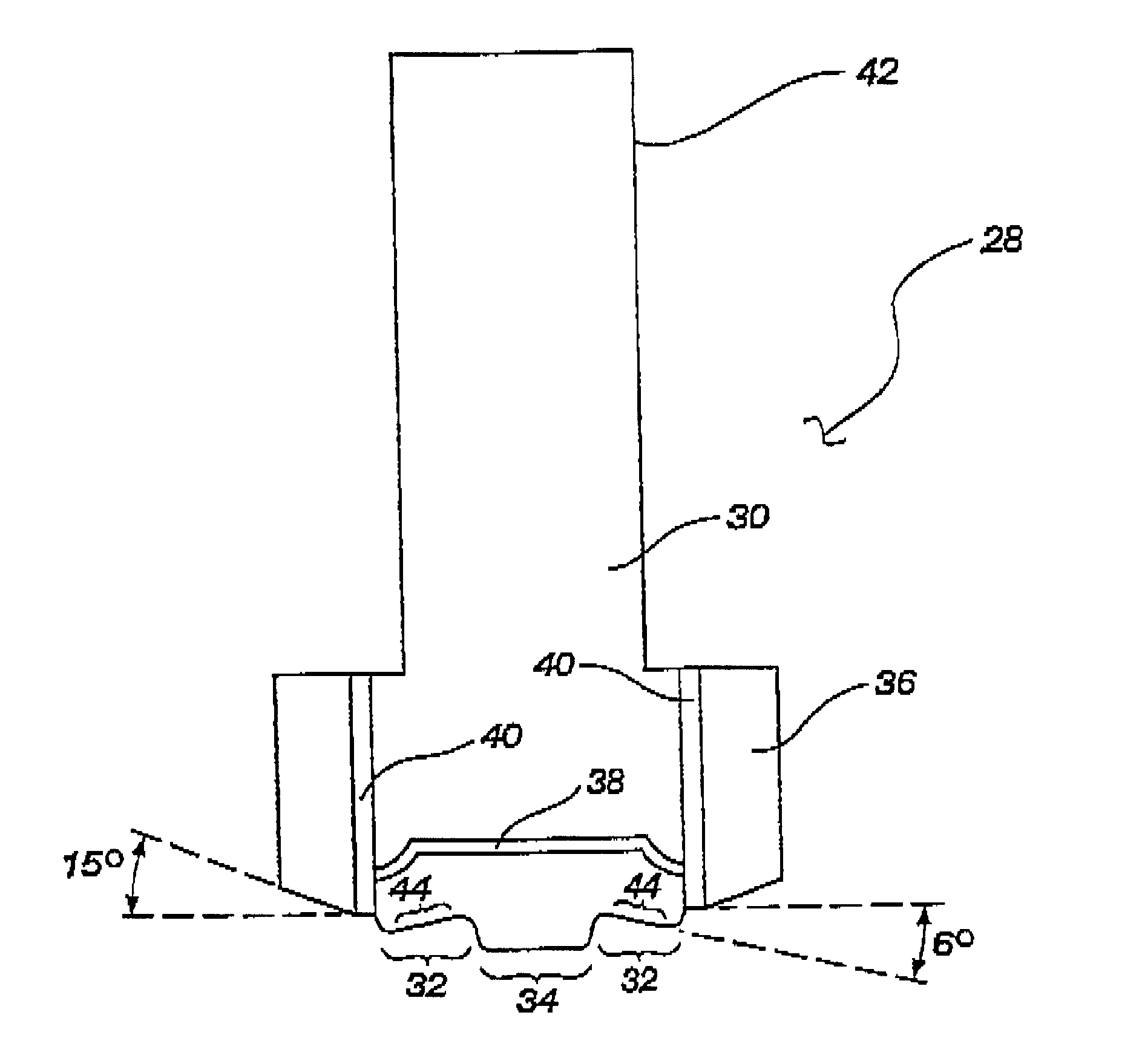

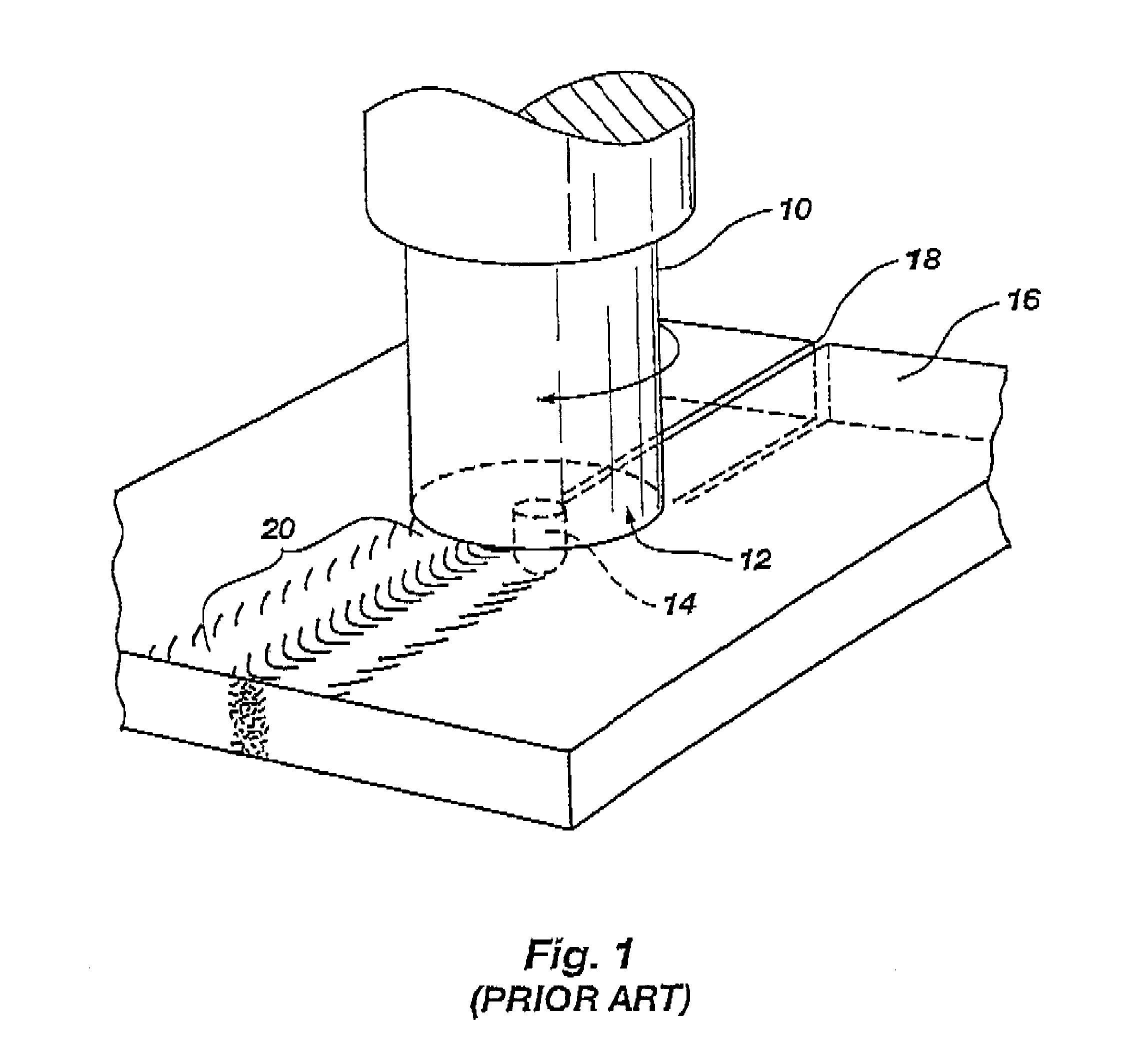

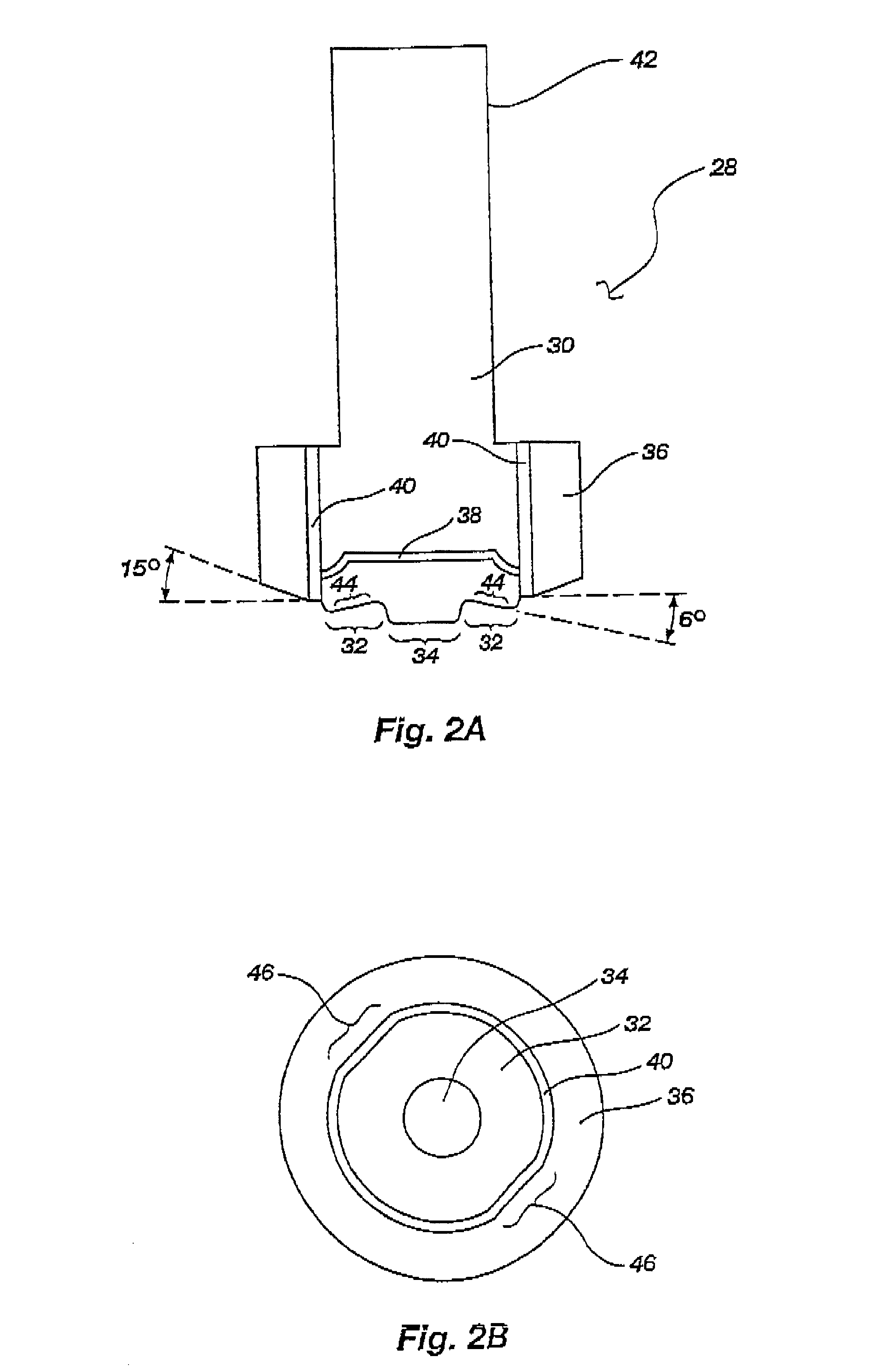

Friction stir welding using a superabrasive tool

InactiveUS6648206B2Improve wear characteristicsReduced tool wearWelding/cutting auxillary devicesVacuum evaporation coatingHeat flowEngineering

A probe for friction stir welding MMCs, ferrous alloys, non-ferrous alloys, and superalloys, as well as non-ferrous alloys, the probe including a shank, a shoulder, and a pin disposed through the shoulder and into the shank, wherein the pin and the shoulder at least include a coating comprised of a superabrasive material, the pin and shoulder being designed to reduce stress risers, disposing a collar around a portion of the shoulder and the shank to thereby prevent movement of the shoulder relative to the shank, and incorporating thermal management by providing a thermal flow barrier between the shoulder and the shank, and between the collar and the tool.

Owner:BRIGHAM YOUNG UNIV +1

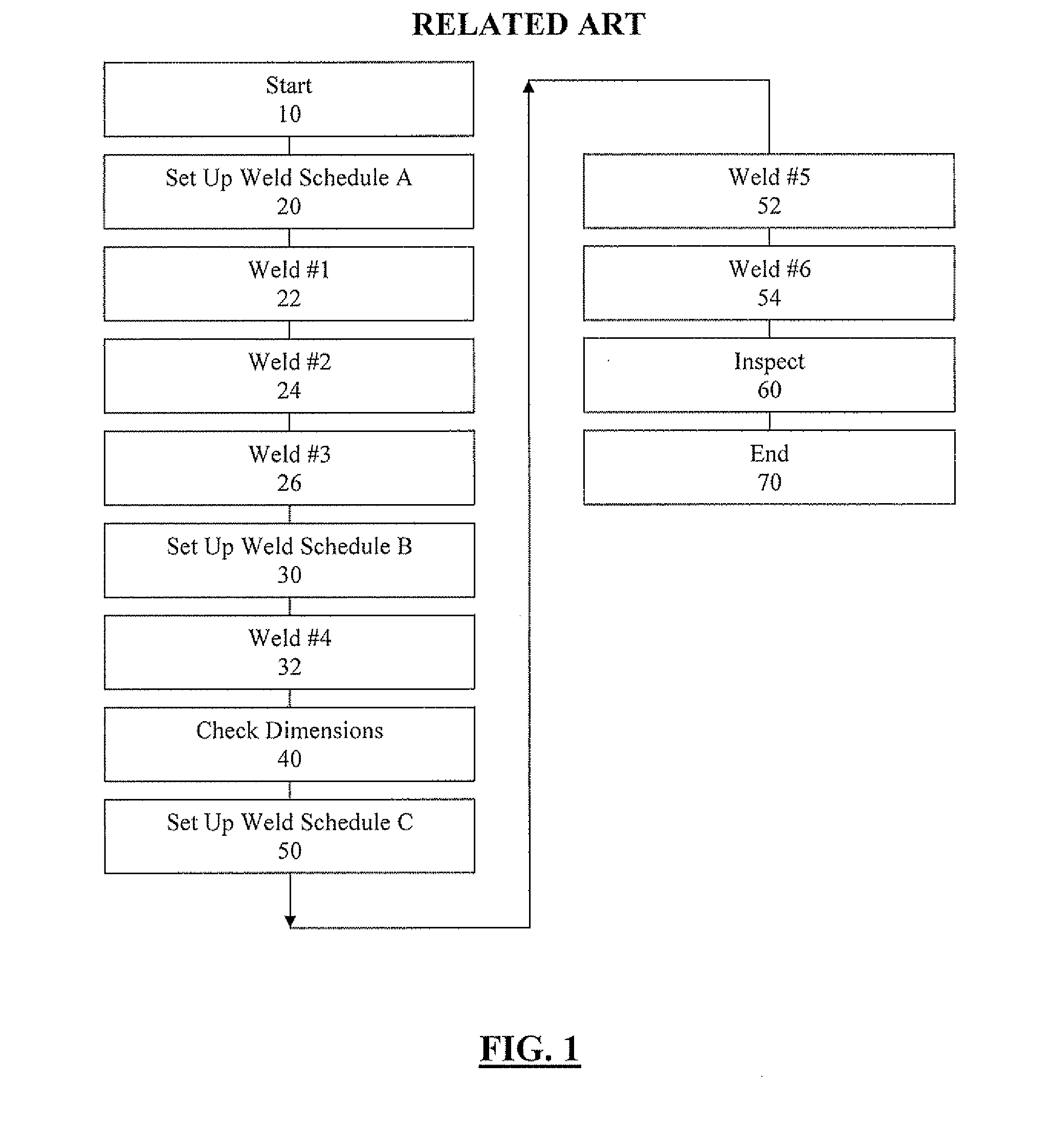

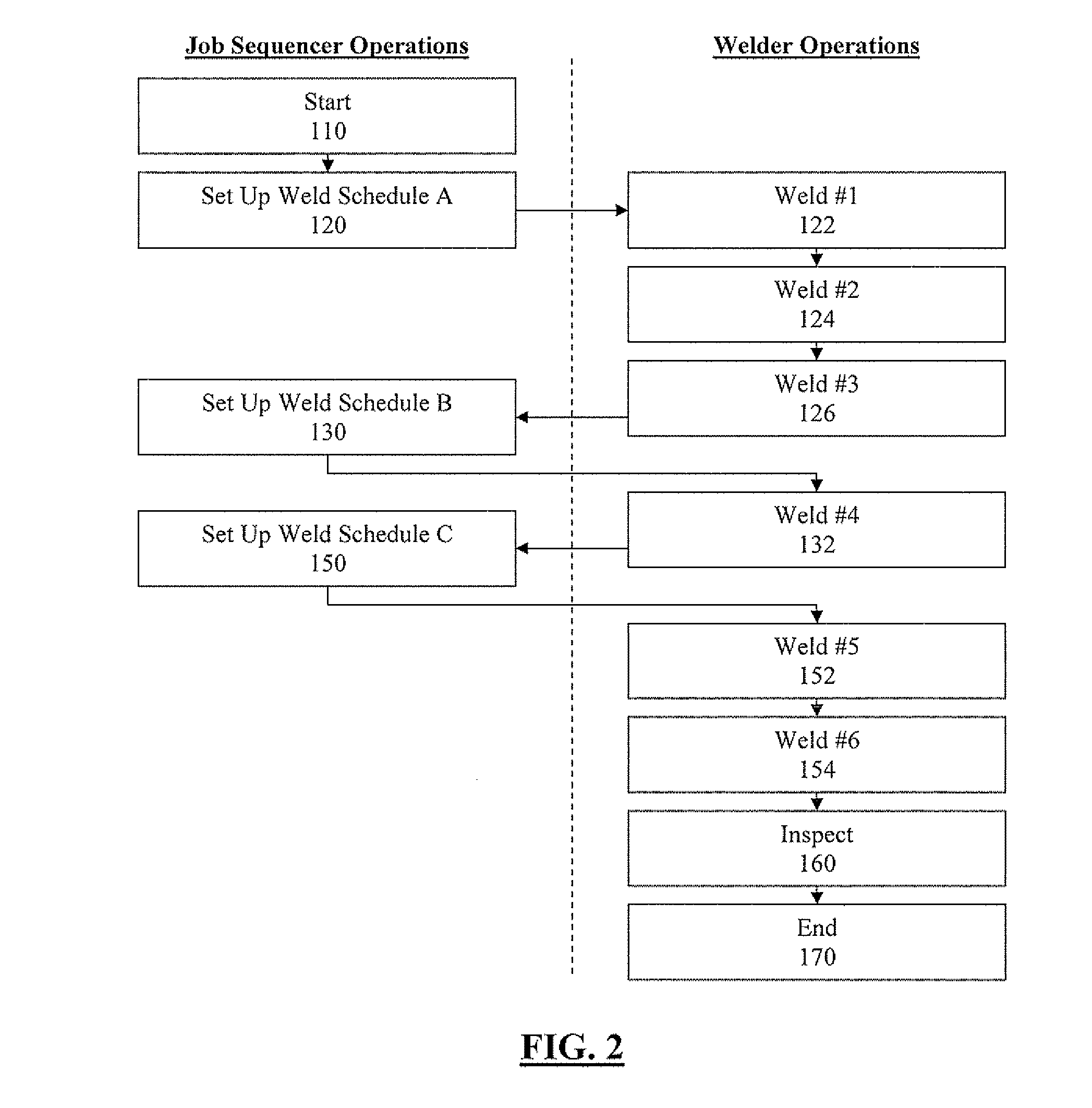

Welding Job Sequencer

A semi-automatic welding work cell, including a welding job sequencer that automatically selects a welding schedule for use by an operator in the semi-automatic welding work cell. The automatic selection may be by way of elapsed time, a detection of welding operations, a detection of the amount of welding wire supplied for the welding operation, or a detection of the amount of energy supplied for the welding operation.

Owner:LINCOLN GLOBAL INC

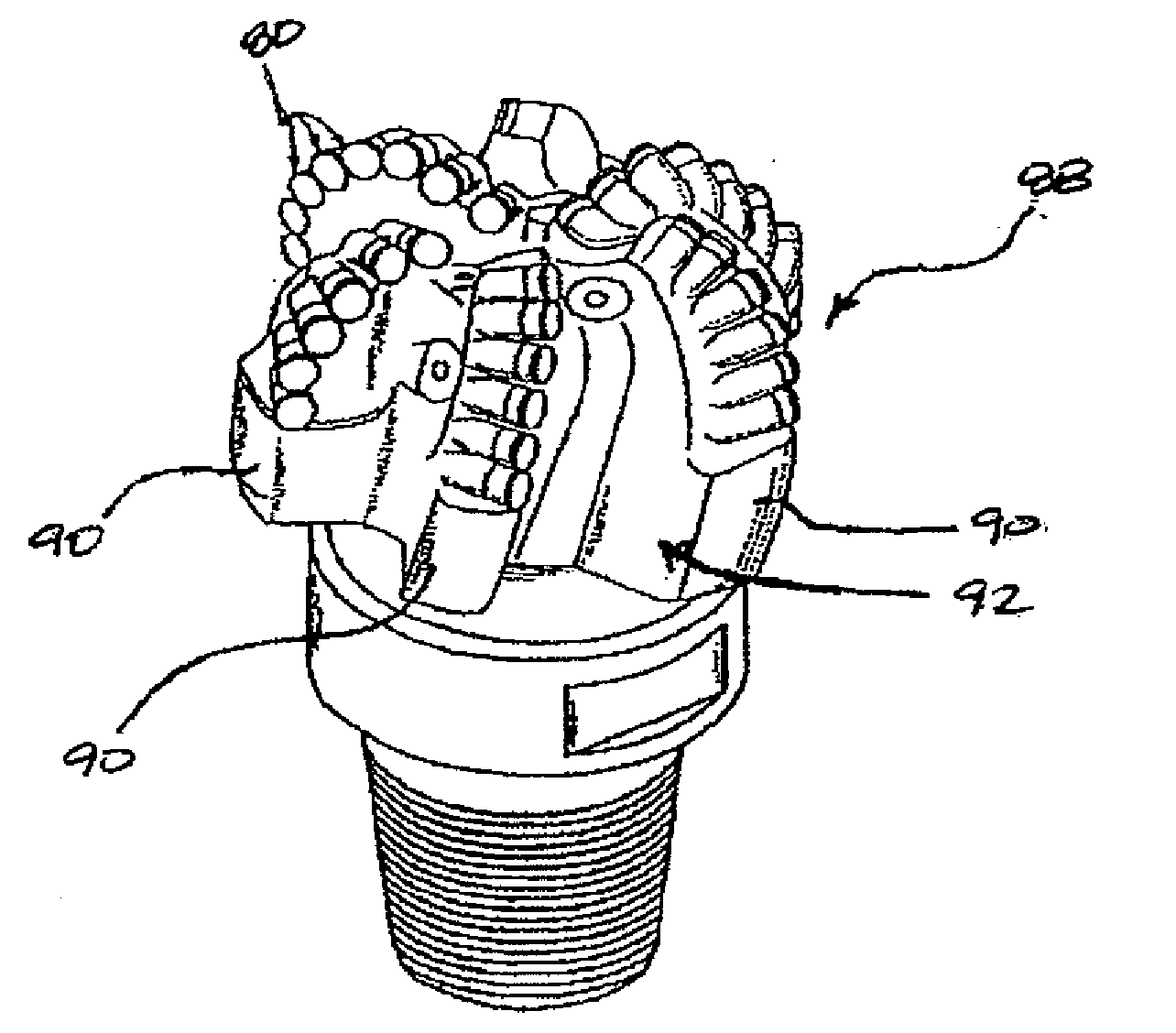

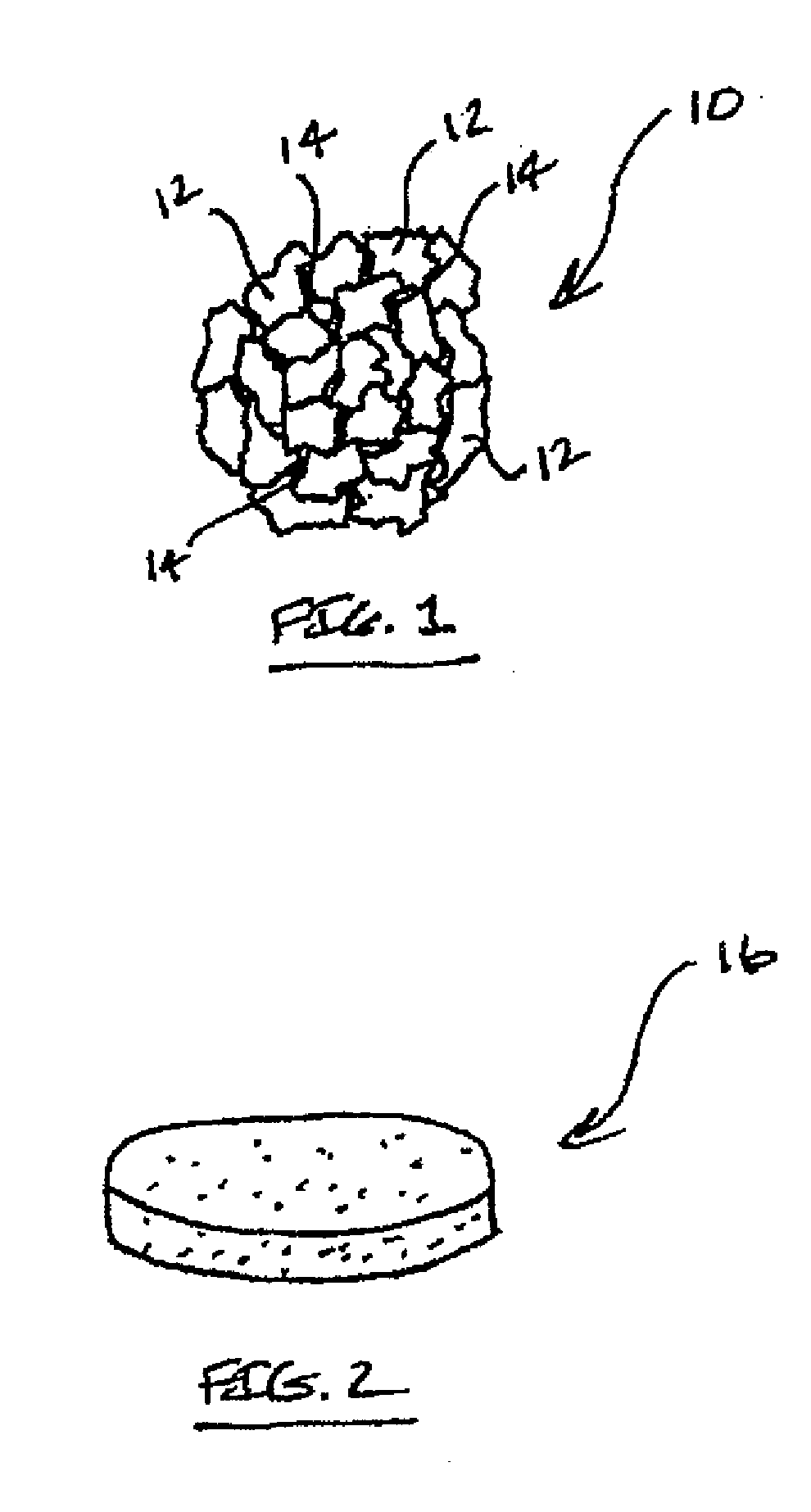

Thermally stable ultra-hard material compact constructions

InactiveUS20080142276A1Extend effective lifePigmenting treatmentDrill bitsSuperhard materialPolycrystalline diamond

Thermally stable ultra-hard compact constructions comprise a polycrystalline diamond body substantially free of a catalyst material, and a substrate that is joined thereto. The substrate can be ceramic, metallic, cermet and combinations thereof, and can be joined to the body by a braze material or other material that forms an attachment bond at high pressure / high temperature conditions. The body and substrate are specially formed having complementary interfacing surface features to facilitate providing an improved degree of attachment therebetween. The complementary surface features can in the form of openings and projections, e.g., one of the body or substrate can comprise one or more openings, and the other of the body or substrate can comprise one or more projections, disposed within or extending from respective interfacing surfaces. The complementary surface features operate to resist unwanted delamination between the body and substrate, thereby extending effective service life of the construction.

Owner:SMITH INT INC

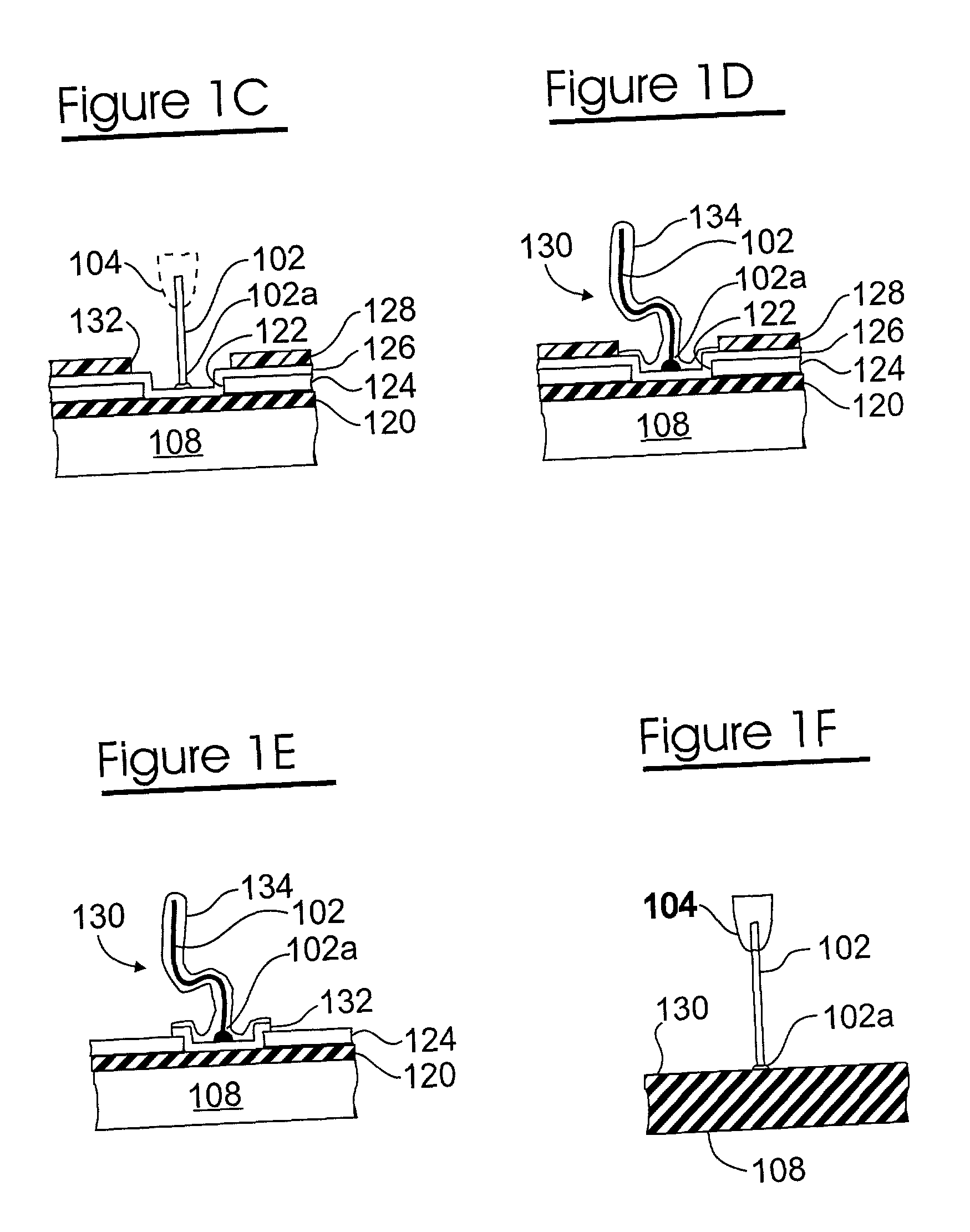

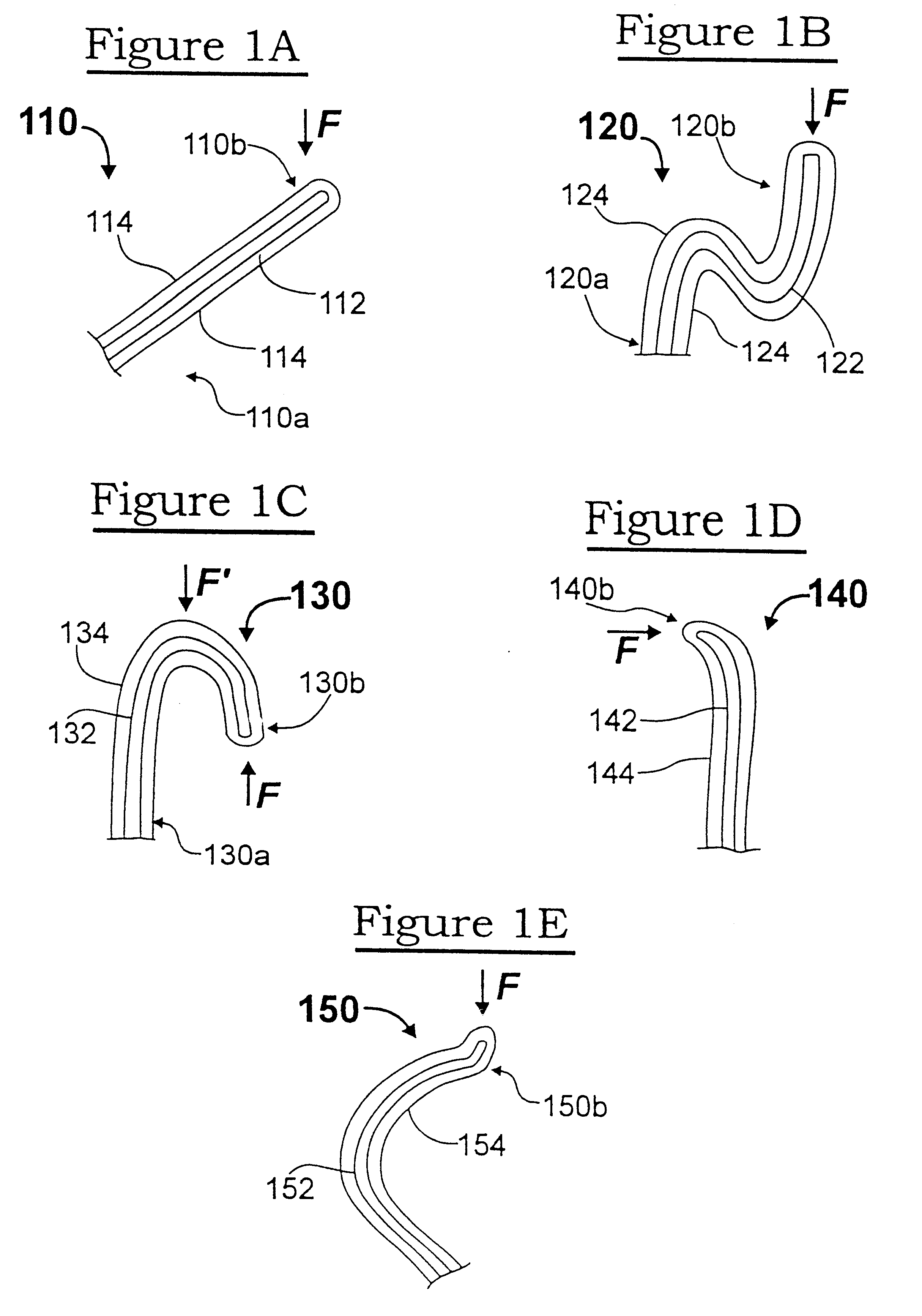

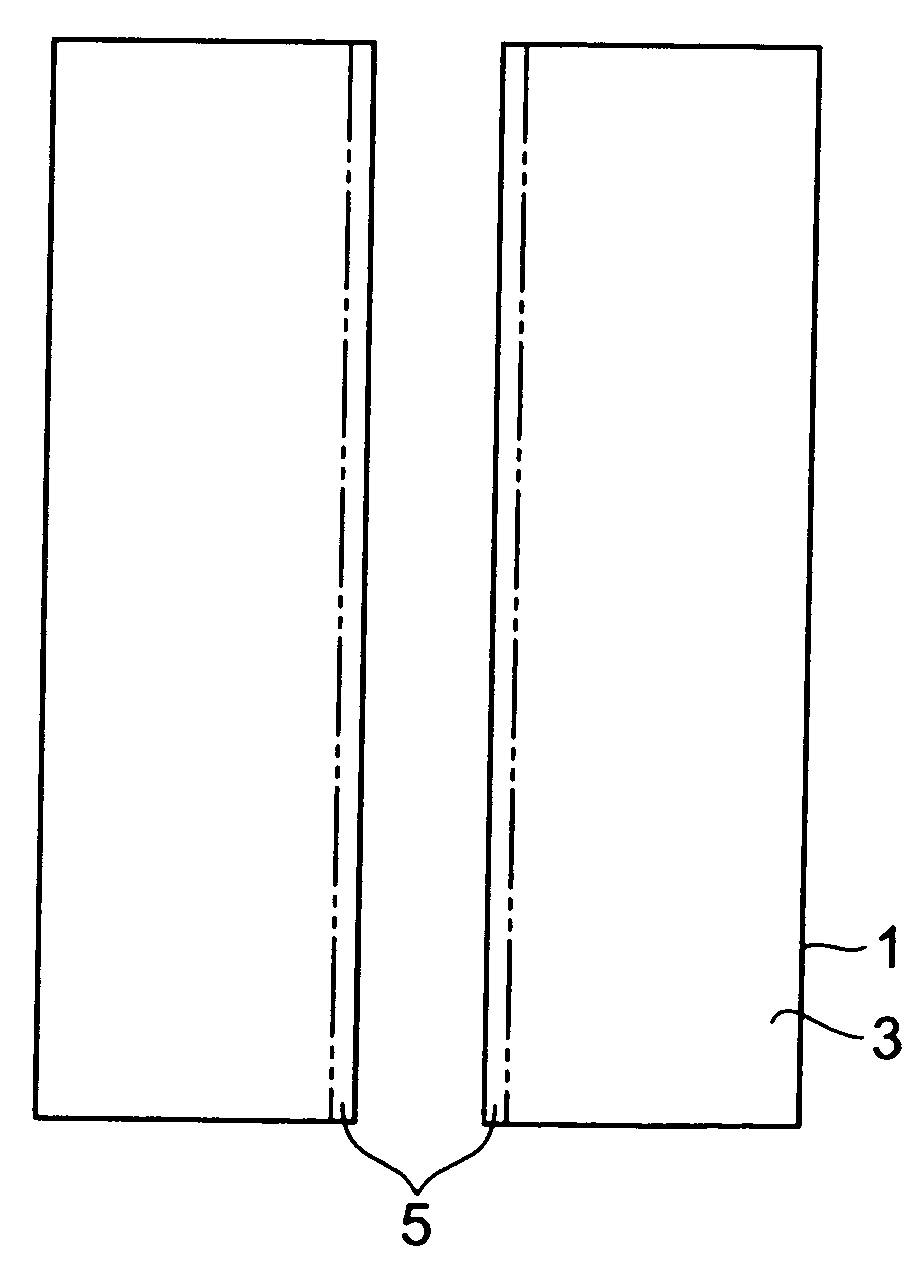

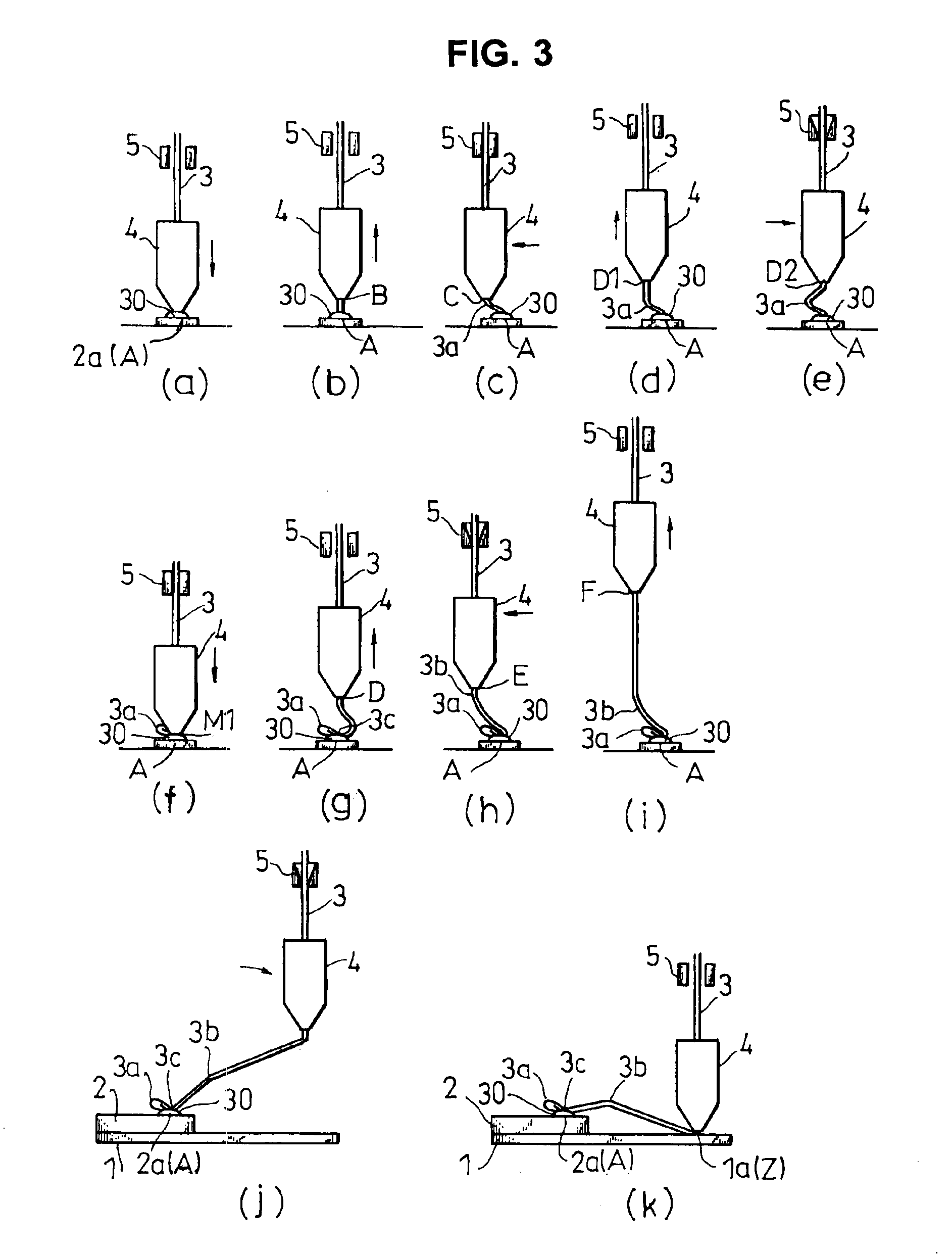

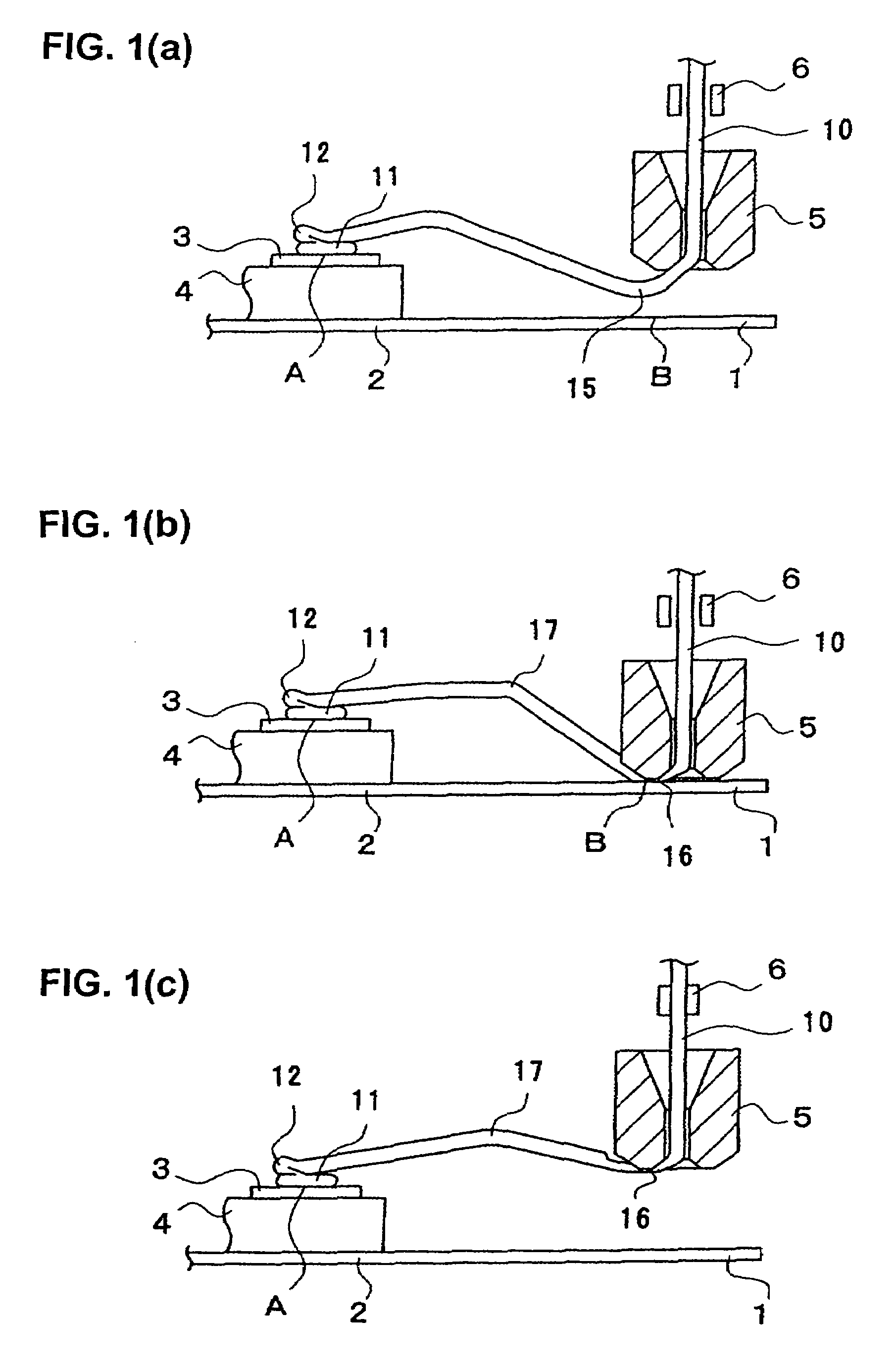

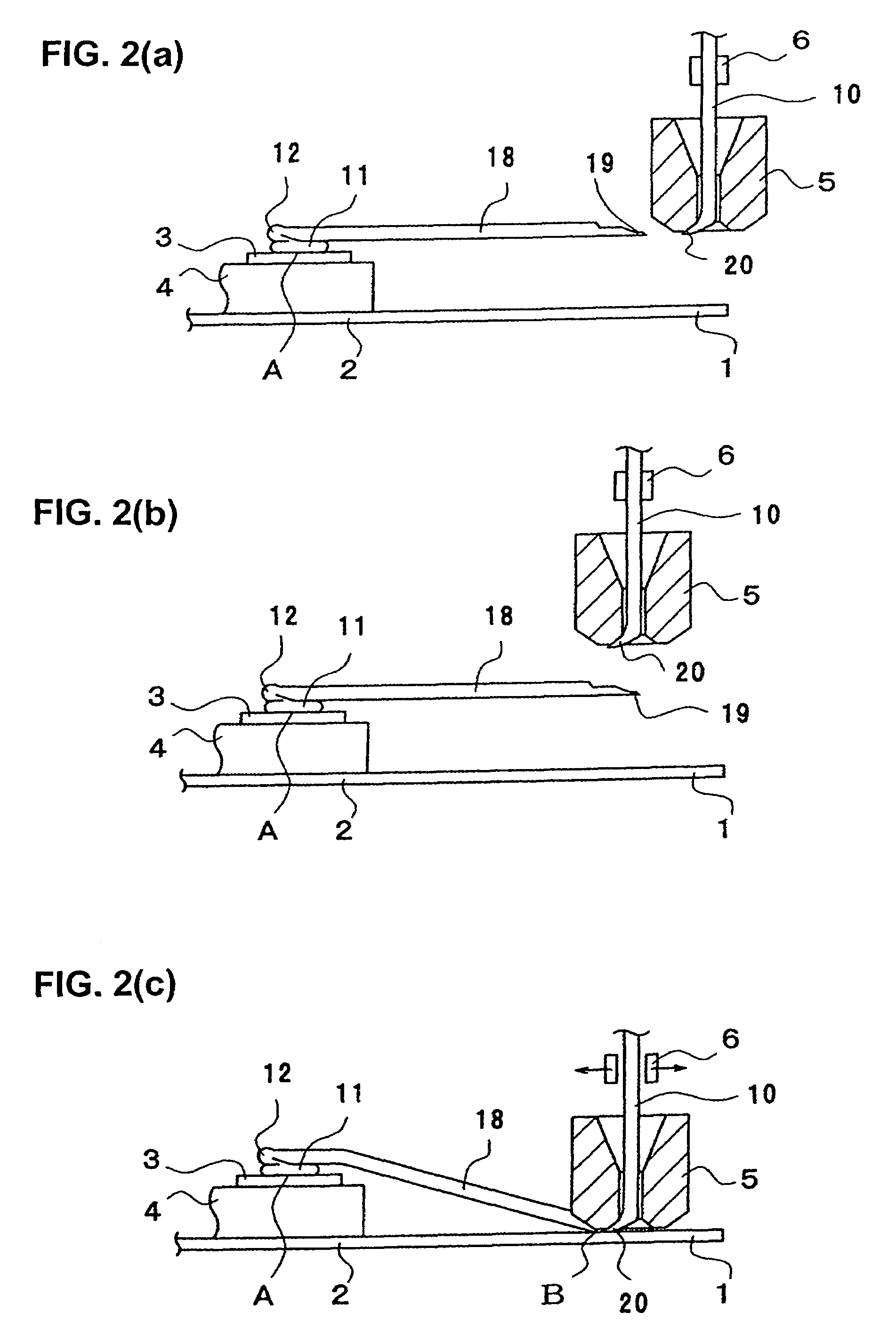

Wire loop, semiconductor device having same, wire bonding method and wire bonding apparatus

InactiveUS6933608B2Low profileNot easy to damageSemiconductor/solid-state device detailsSolid-state devicesWire rodLoop control

A wire loop comprises a wire connecting a first bonding point and a second bonding point therethrough, wherein the wire has a crushed part formed therein by crushing the part of the wire and a top of a ball bonded to the first bonding point with a capillary. The wire loop is formed by a wire bonding method which includes: bonding the wire to the first bonding point; moving the capillary horizontally and vertically while carrying out loop control; bonding the wire to the vicinity of the top of the ball bonded to the first bonding point; and thereafter, moving the capillary horizontally and vertically to the second bonding point while delivering the wire and carrying out loop control, and then bonding the wire to the second bonding point.

Owner:KAIJOO KK

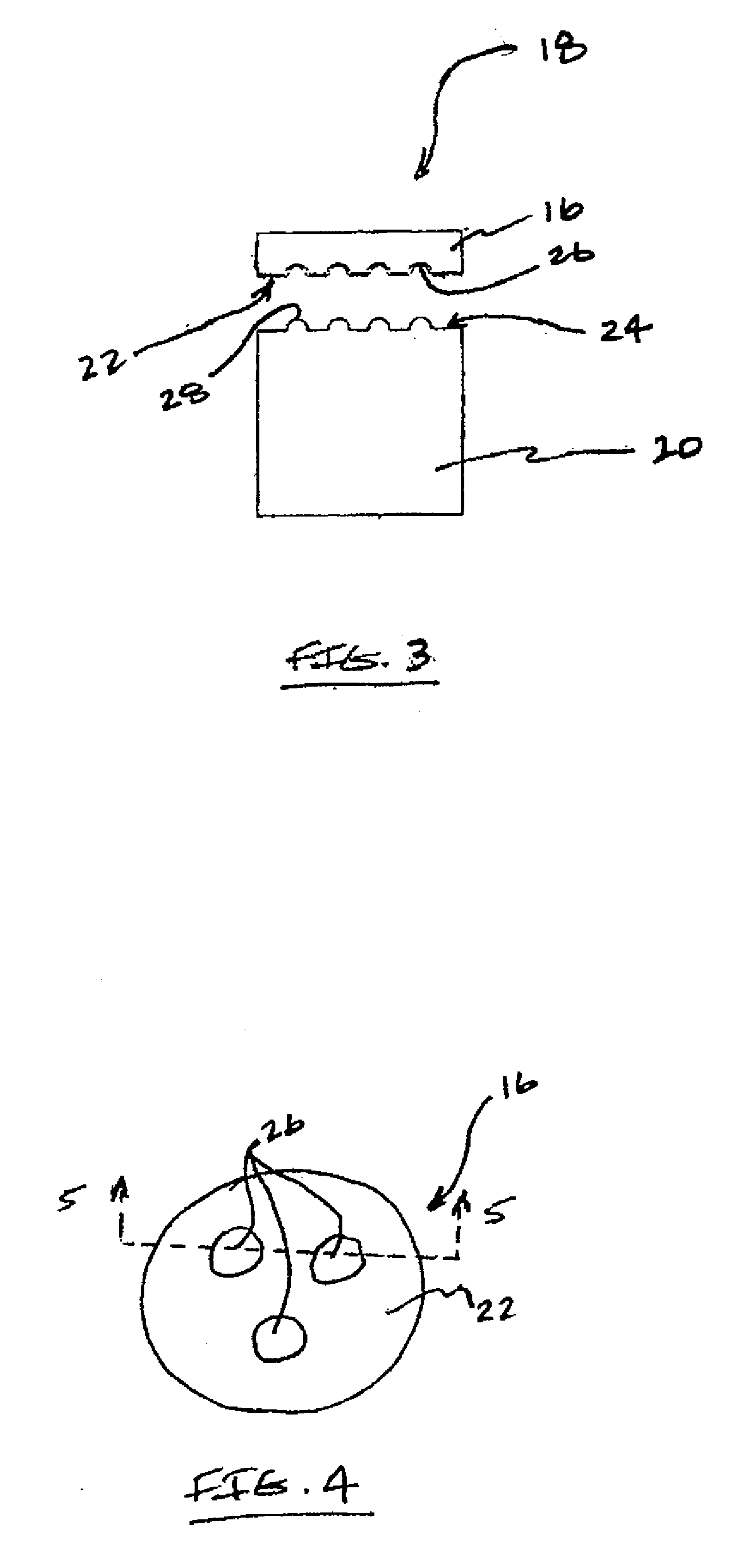

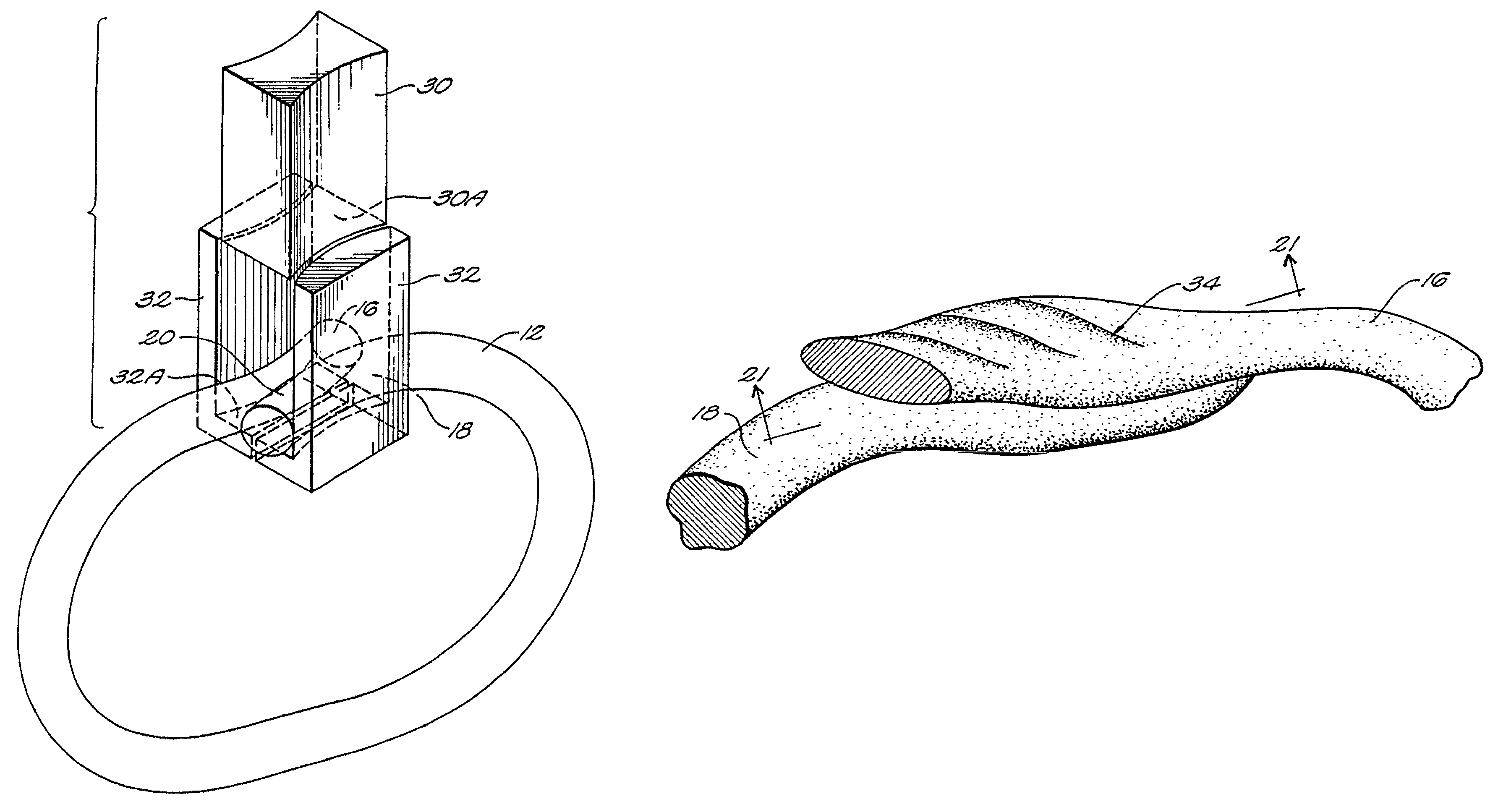

Fused loop of filamentous material and apparatus for making same

InactiveUS7090111B2Maximize joint strengthSuture equipmentsSurgical needlesSurface patternUltrasonic welding

A welding apparatus that includes a first member having a first suture-contacting surface, a second member having a second suture-contacting surface, and a device for moving the first member relative to the second member to define a gap between the respective suture-contacting surfaces. The first member is capable of vibrating and delivering mechanical energy at ultrasonic frequencies. The second member is stationary relative to the first member. A fixture element is adapted to receive and maintain two or more segments of a material to be welded in a predetermined alignment in the gap between the first and second surfaces of the first and second members during a welding operation. According to another aspect of the invention, an ultrasonic welding apparatus includes first and second members with patterned first and second suture-contacting surfaces. The patterned surfaces can be complementary or non-complementary and the surface patterns on each member may vary in either a periodic or a non-periodic manner.

Owner:TORNIER INC

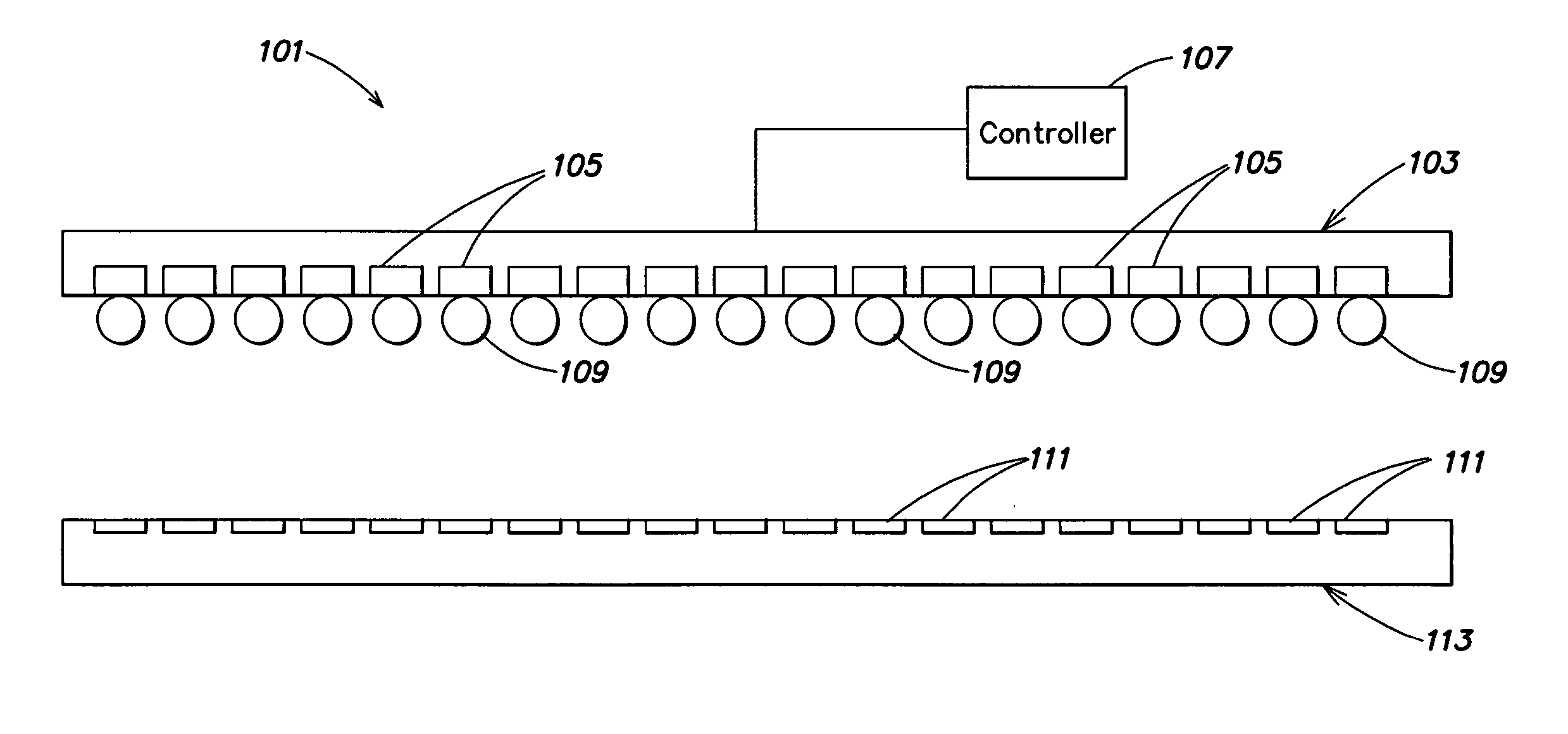

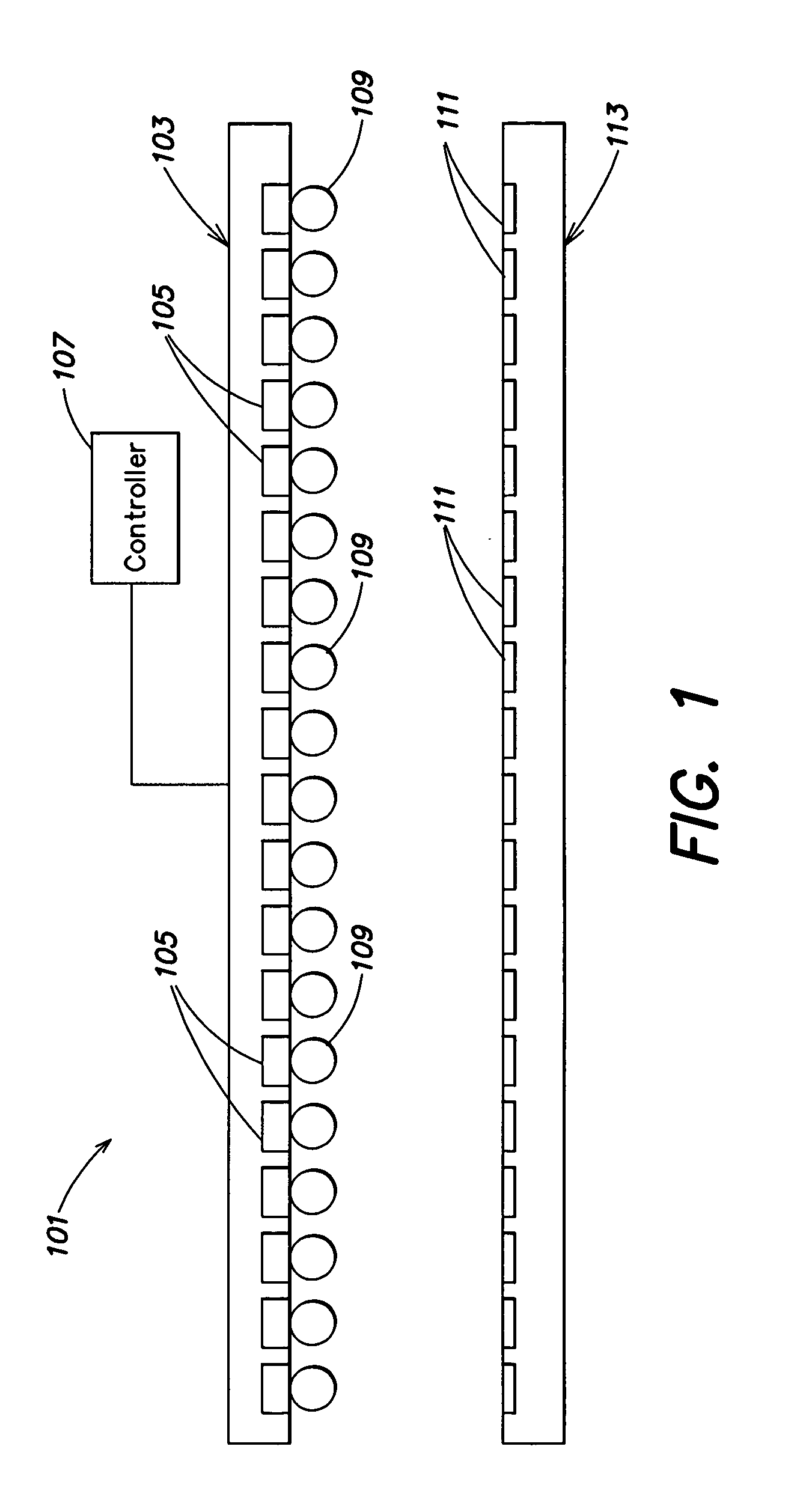

Methods and apparatus for transferring conductive pieces during semiconductor device fabrication

InactiveUS20050232728A1Semiconductor/solid-state device detailsSolid-state devicesSemiconductorSemiconductor device fabrication

In a first aspect, a programmable transfer device is provided for transferring conductive pieces to electrode pads of a target substrate. The programmable transfer device includes (1) a transfer substrate; and (2) a plurality of individually addressable electrodes formed on the transfer substrate. Each electrode is adapted to selectively attract and hold a conductive piece during transfer of the conductive piece to an electrode pad of a target substrate. Numerous other aspects are provided.

Owner:APPLIED MATERIALS INC

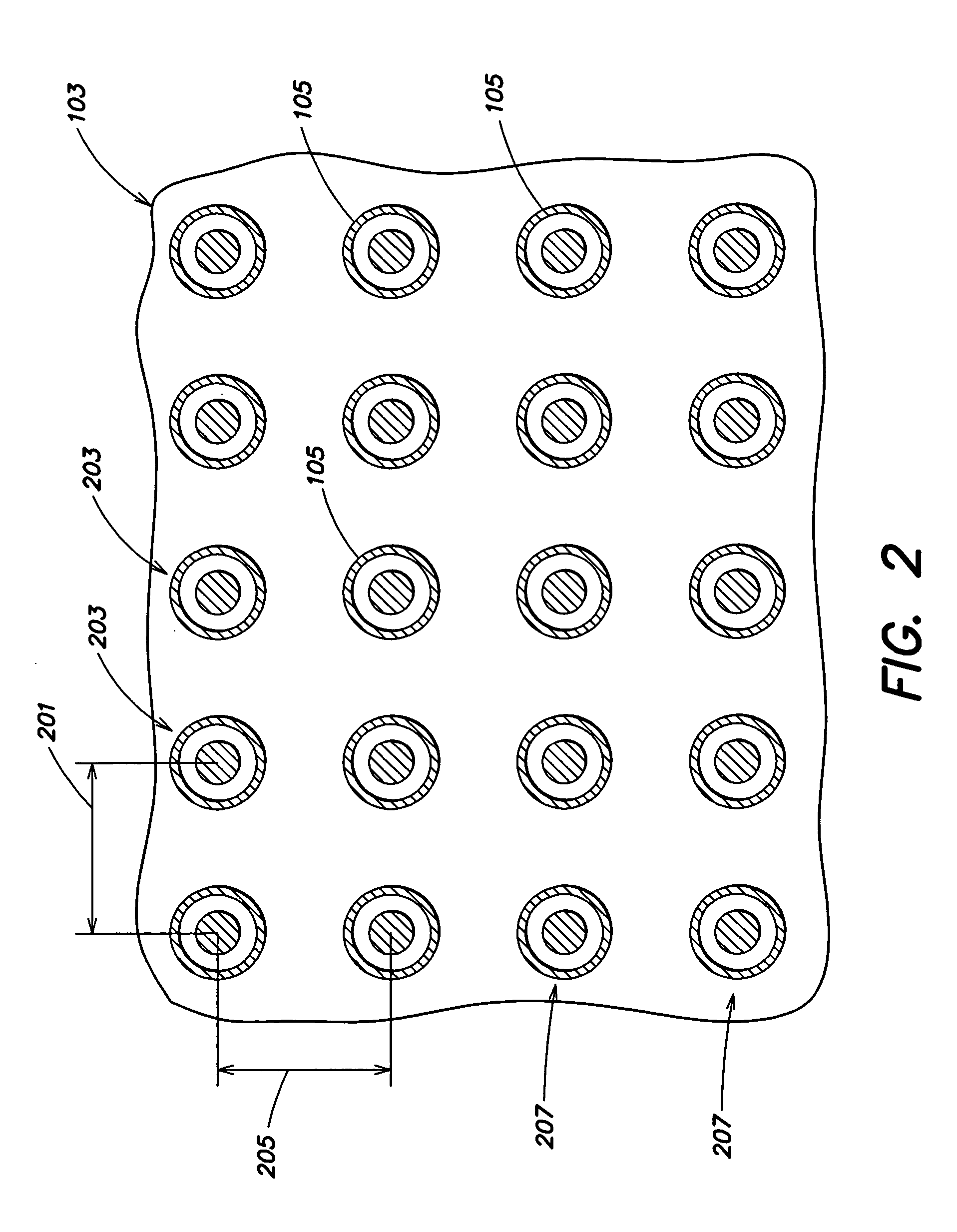

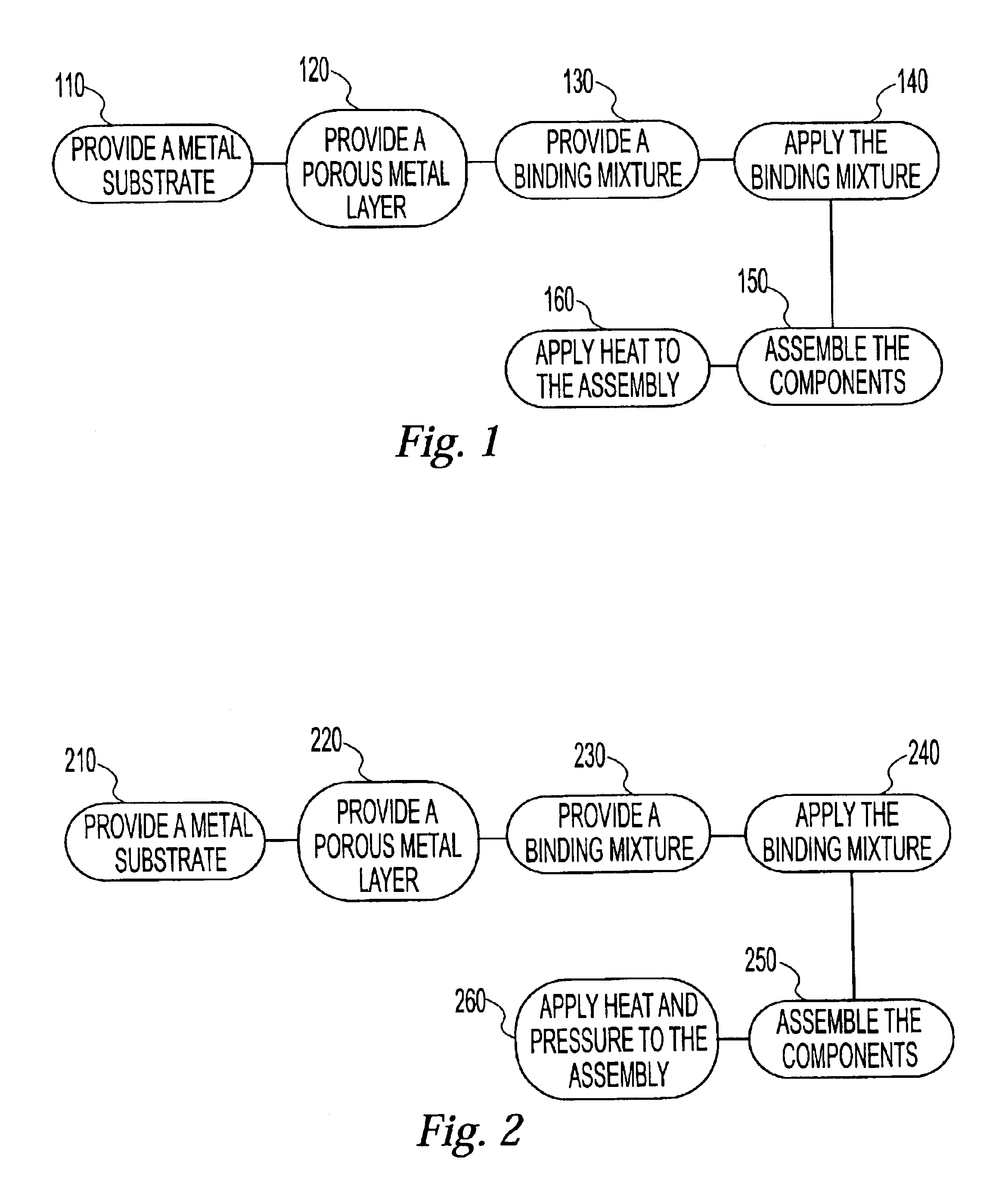

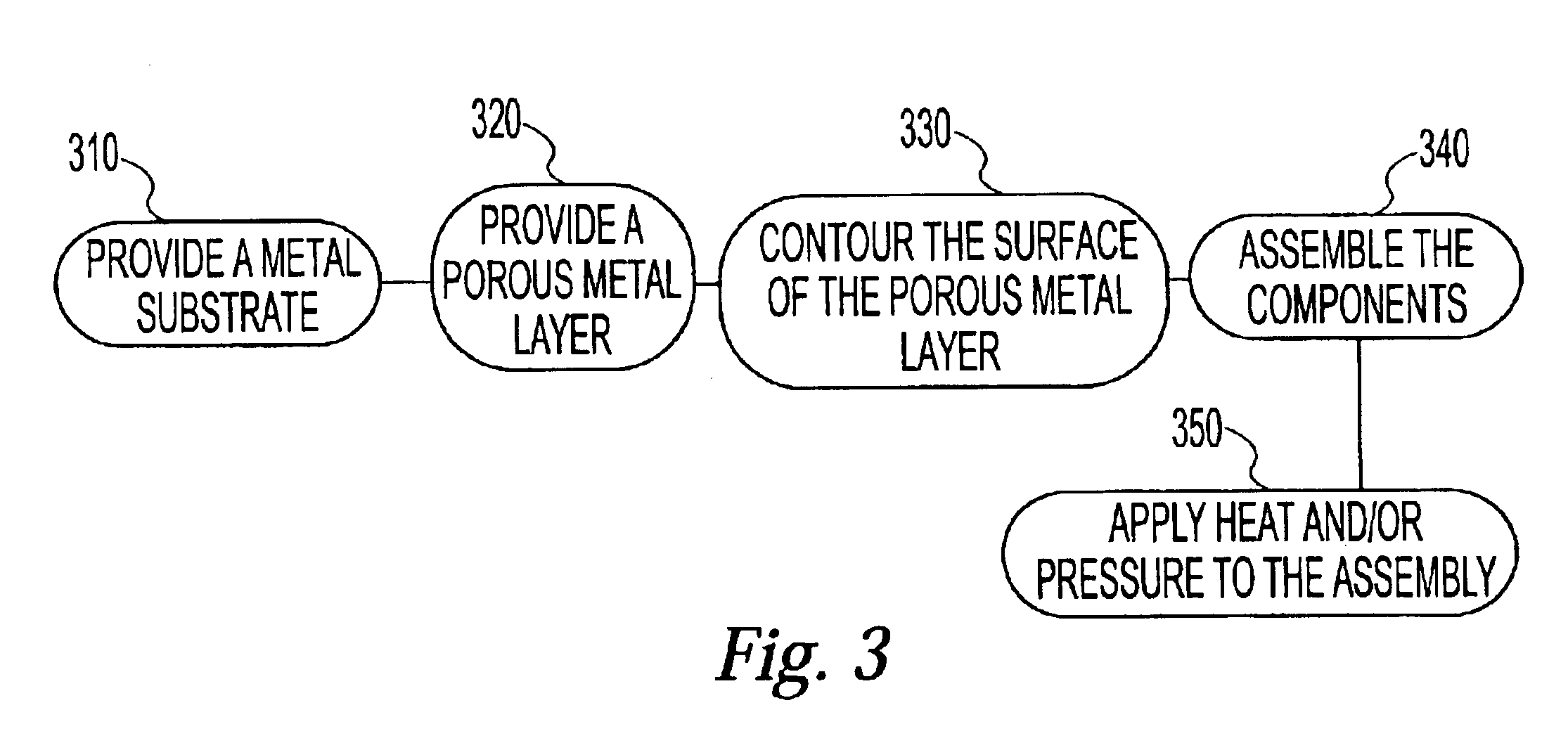

Method for attaching a porous metal layer to a metal substrate

InactiveUS6945448B2Increase resistanceHigh strengthImpression capsPretreated surfacesPorous layerSurgical implant

A method for attaching a porous metal layer to a dense metal substrate, wherein the method is particularly useful in forming orthopedic implants such as femoral knee components or acetabular cups. The method, in one embodiment thereof, comprises providing a structured porous layer; providing a dense metal substrate; providing a binding mixture; applying the binding mixture to the exterior of the substrate; placing the porous layer against the substrate such that the binding mixture is disposed there between forming an assembly; and heat treating the assembly to metallurgically bond the porous layer to the substrate.

Owner:ZIMMER TECH INC

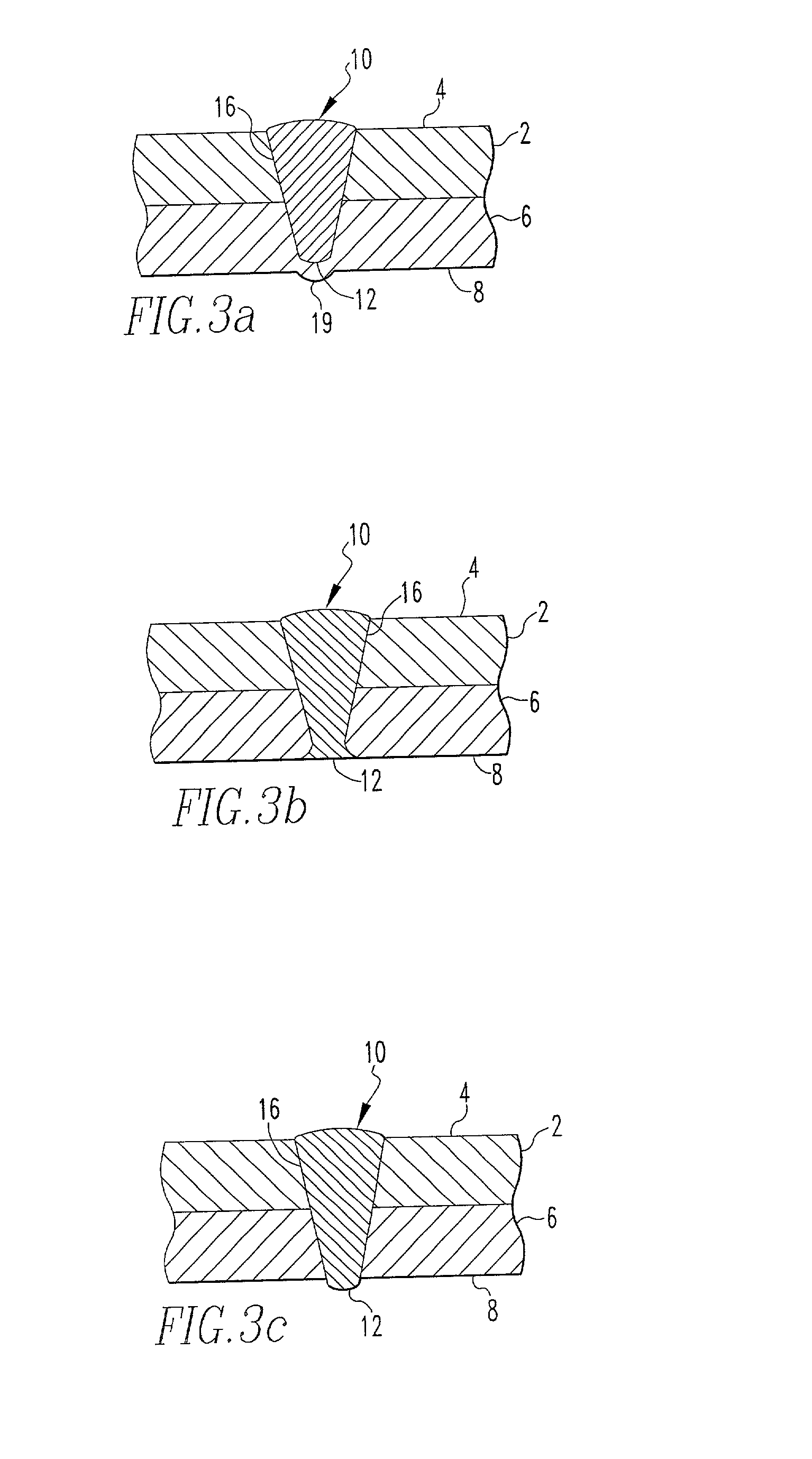

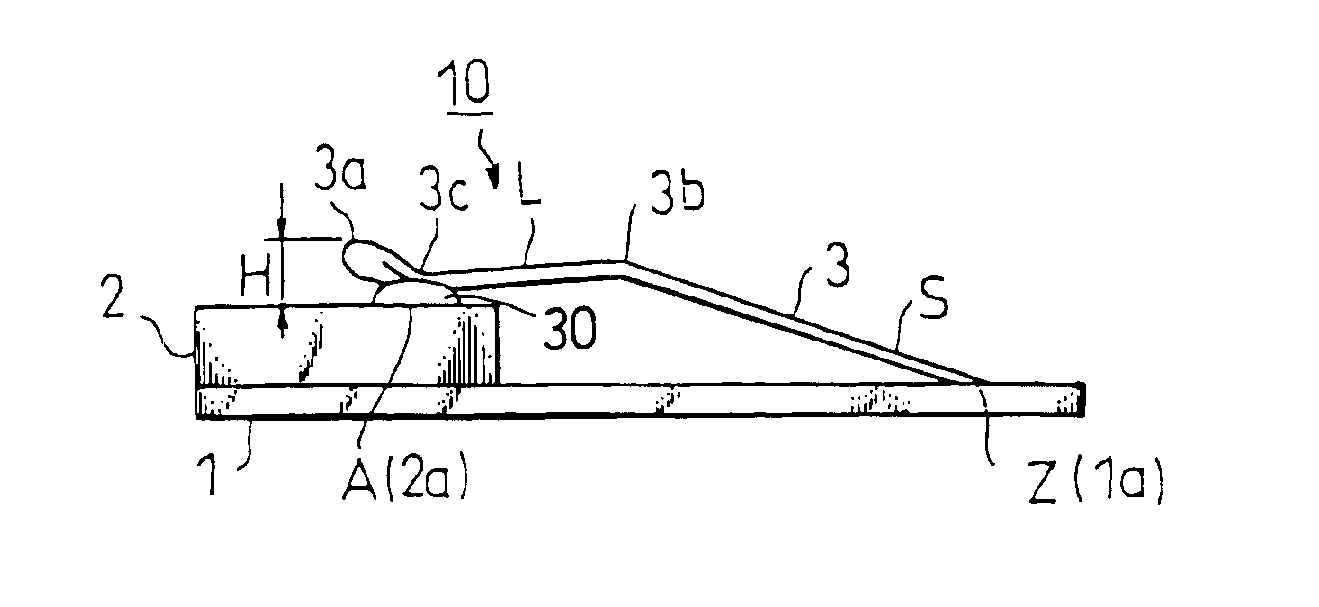

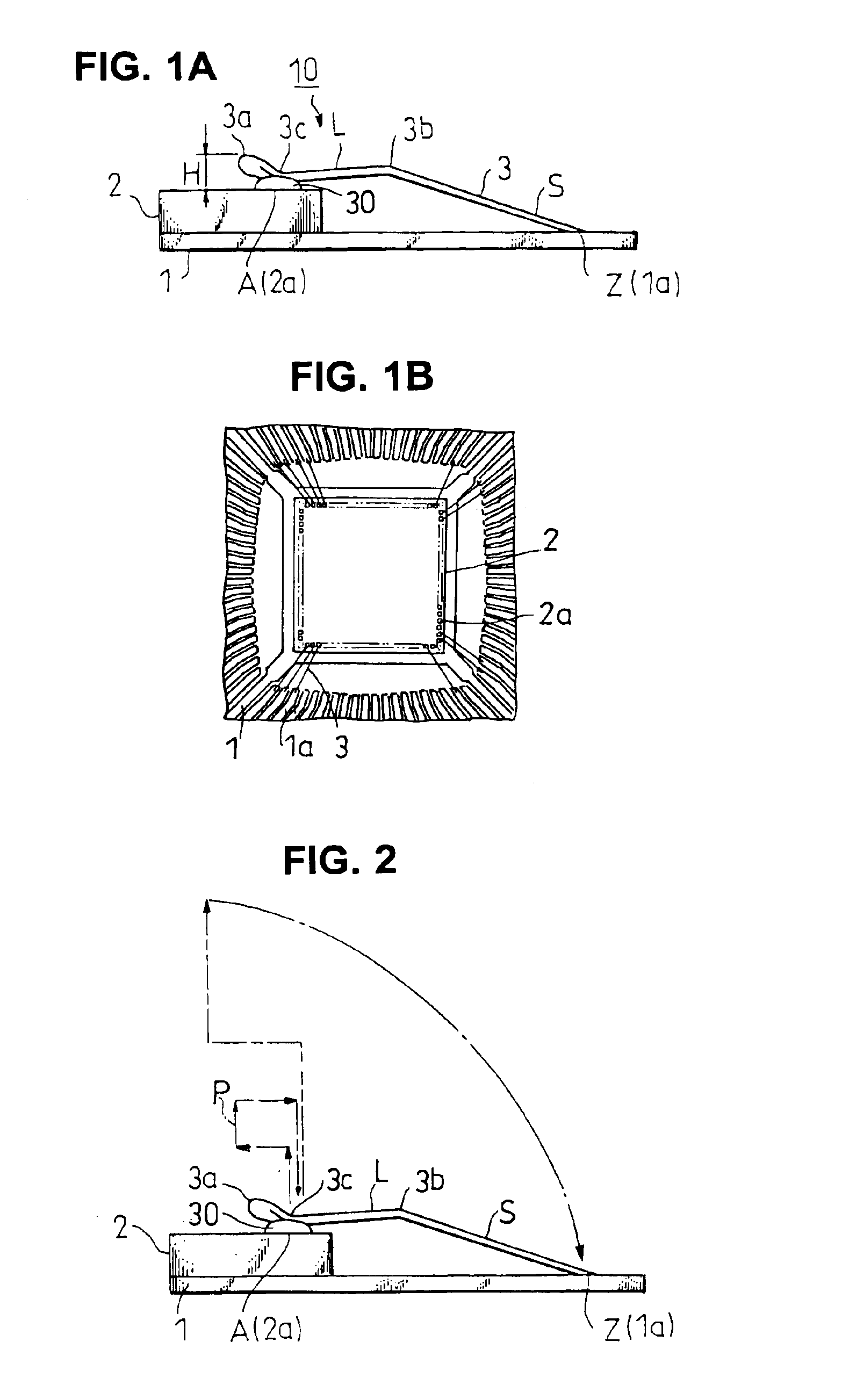

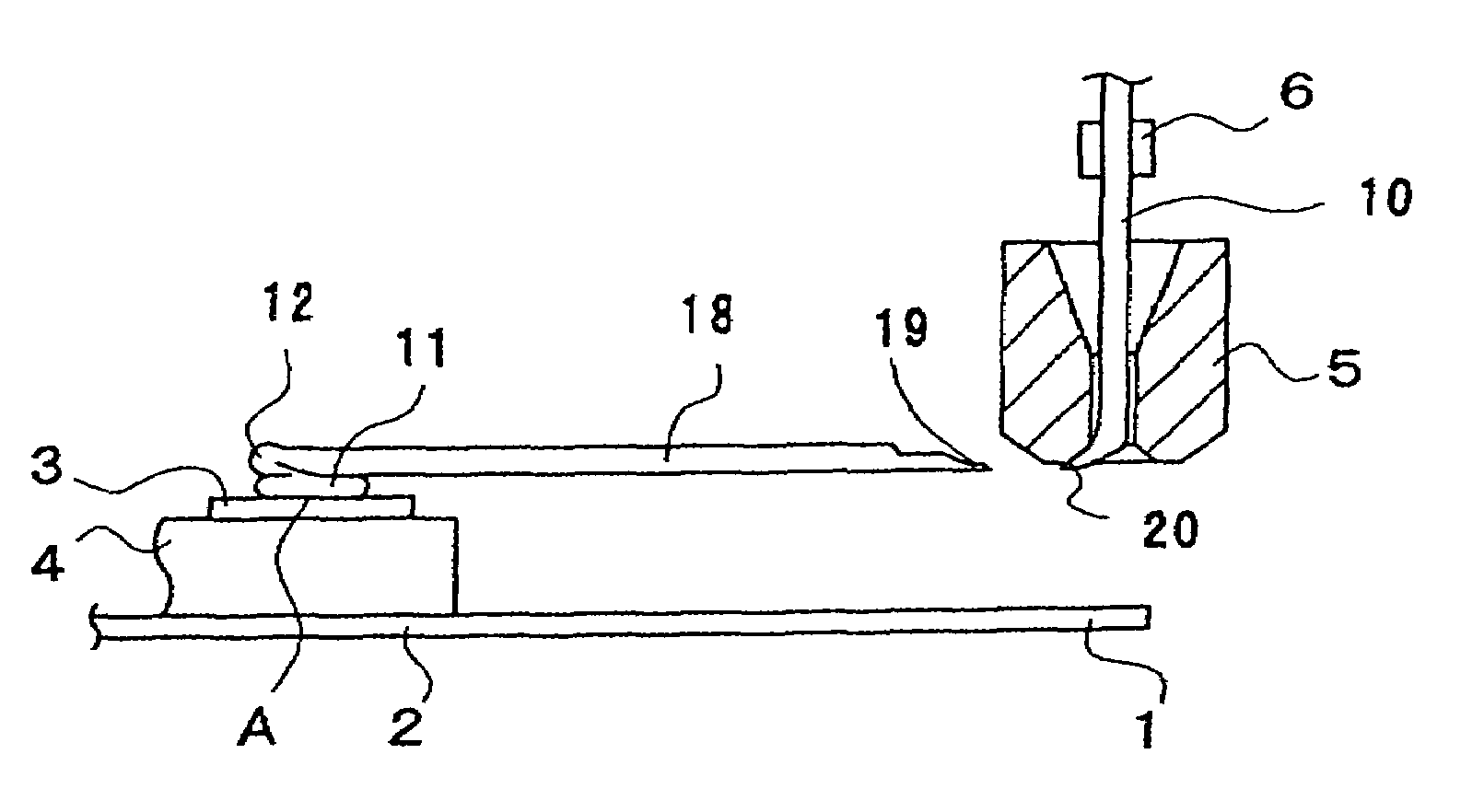

Wire bonding method

InactiveUS7621436B2Inhibit swellingImprove straightnessSolid-state devicesWelding/cutting auxillary devicesEngineeringWire bonding

A wire bonding method including the steps of: descending a capillary 5 from above an external lead 1 to press a wire 10 to such an extent that the wire is not completely connected to the external lead 1, thus forming a thin part 16 in the wire; next ascending the capillary 5 and the thin part 16 to substantially the same height as a first bonding point A, then moving the capillary 5 in a direction away from the first bonding point A, thus making a linear wire portion 18 and then cutting the wire at the thin part 16; then connecting the end 19 (thin part) of the linear wire portion 18 and the wire tip end 20 at the lower end of the capillary 5 are connected to the external lead 1; and then separating the wire tip end 20 from the external lead 1.

Owner:SHINKAWA CO LTD

Laser processing method and laser processing apparatus

InactiveUS20050181581A1No unnecessary fractureSolid-state devicesSemiconductor/solid-state device manufacturingLaser processingLaser beam machining

A laser beam machining method and a laser beam machining device capable of cutting a work without producing a fusing and a cracking out of a predetermined cutting line on the surface of the work, wherein a pulse laser beam is radiated on the predetermined cut line on the surface of the work under the conditions causing a multiple photon absorption and with a condensed point aligned to the inside of the work, and a modified area is formed inside the work along the predetermined determined cut line by moving the condensed point along the predetermined cut line, whereby the work can be cut with a rather small force by cracking the work along the predetermined cut line starting from the modified area and, because the pulse laser beam radiated is not almost absorbed onto the surface of the work, the surface is not fused even if the modified area is formed.

Owner:HAMAMATSU PHOTONICS KK

Fabrication of low defectivity electrochromic devices

Prior electrochromic devices frequently suffer from high levels of defectivity. The defects may be manifest as pin holes or spots where the electrochromic transition is impaired. This is unacceptable for many applications such as electrochromic architectural glass. Improved electrochromic devices with low defectivity can be fabricated by depositing certain layered components of the electrochromic device in a single integrated deposition system. While these layers are being deposited and / or treated on a substrate, for example a glass window, the substrate never leaves a controlled ambient environment, for example a low pressure controlled atmosphere having very low levels of particles. These layers may be deposited using physical vapor deposition.

Owner:VIEW INC

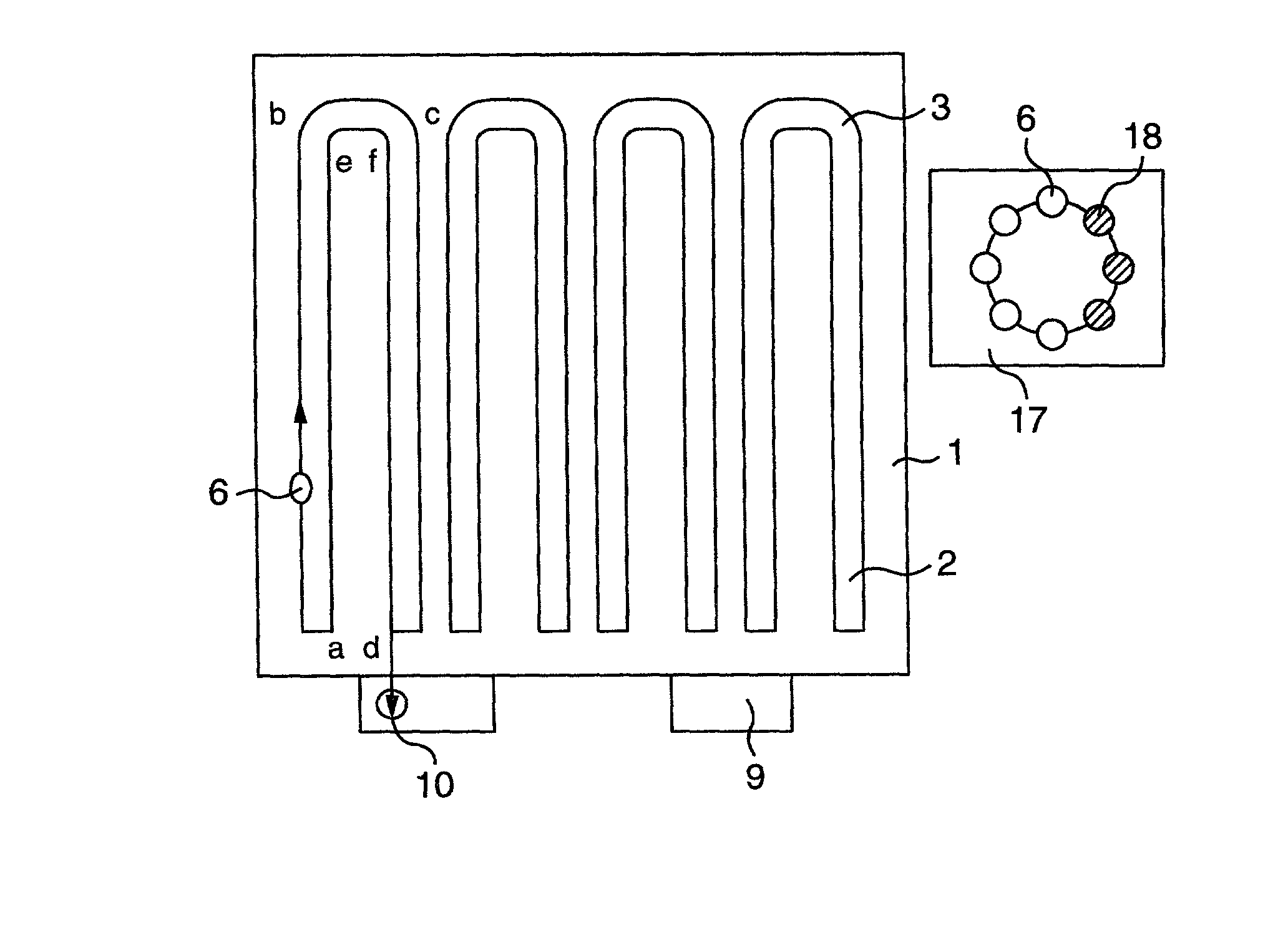

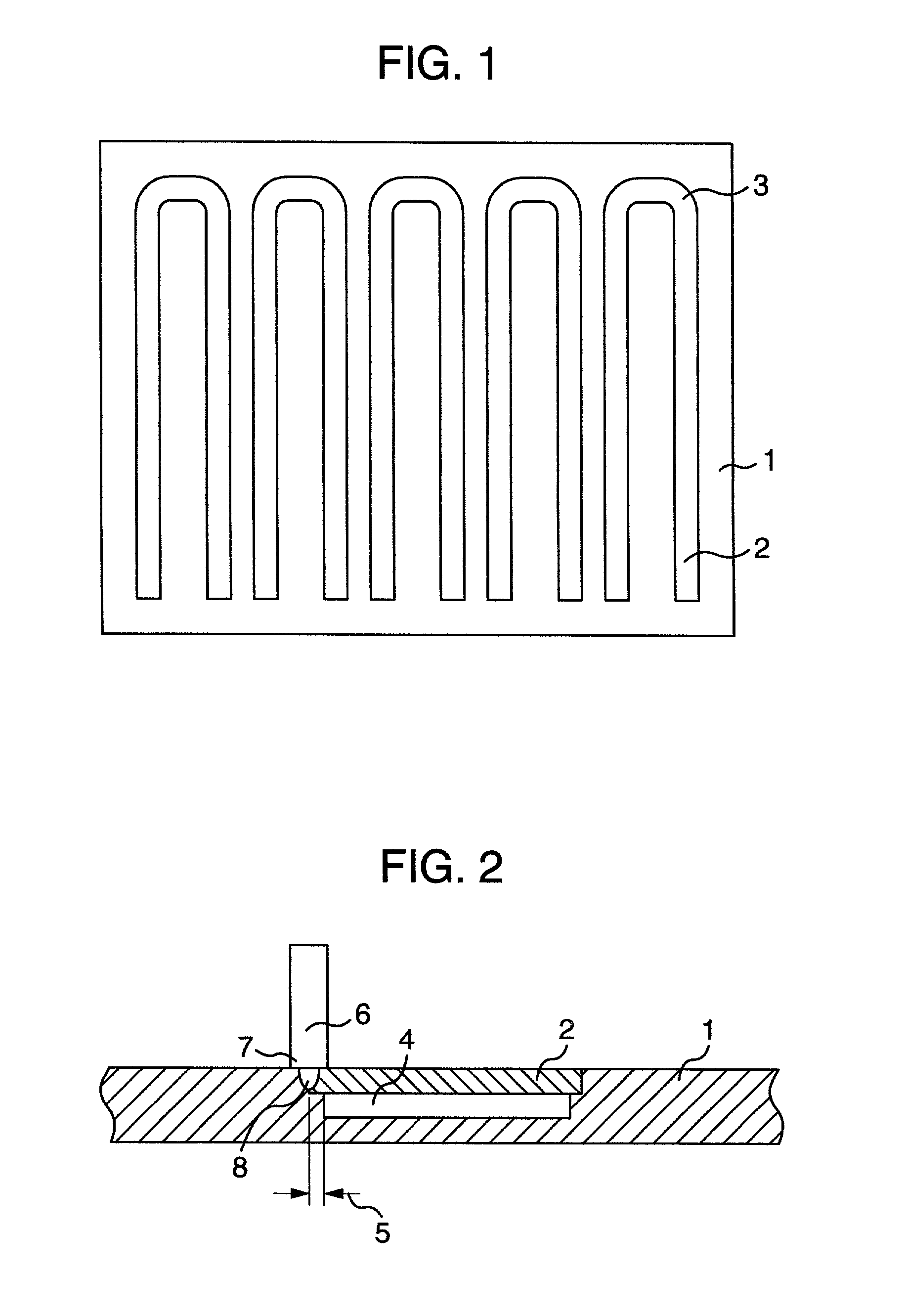

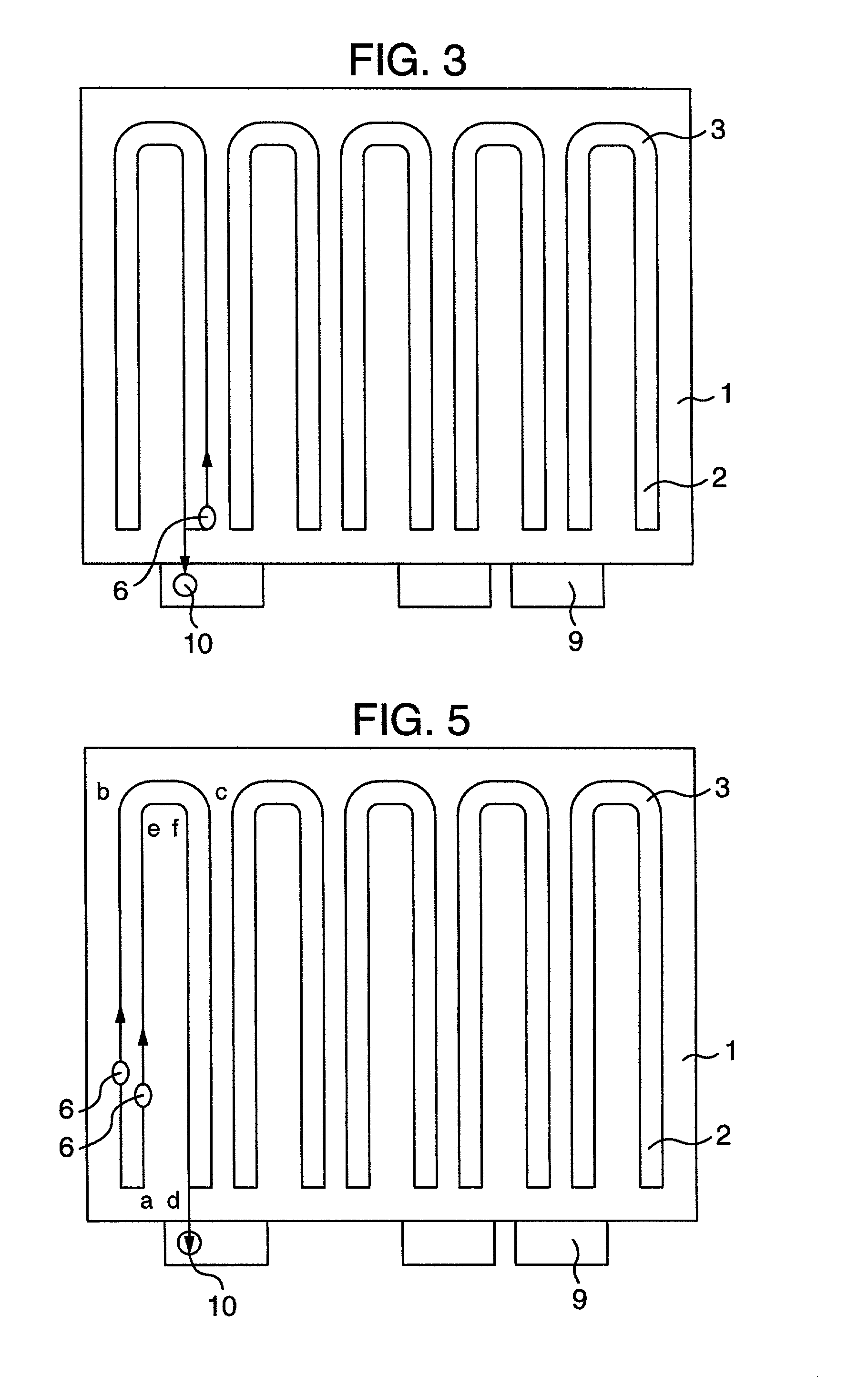

Cooling plate and manufacturing method thereof, and sputtering target and manufacturing method thereof

InactiveUS20020153130A1Improve accuracyAccurate stepElectric discharge tubesVacuum evaporation coatingSputteringEngineering

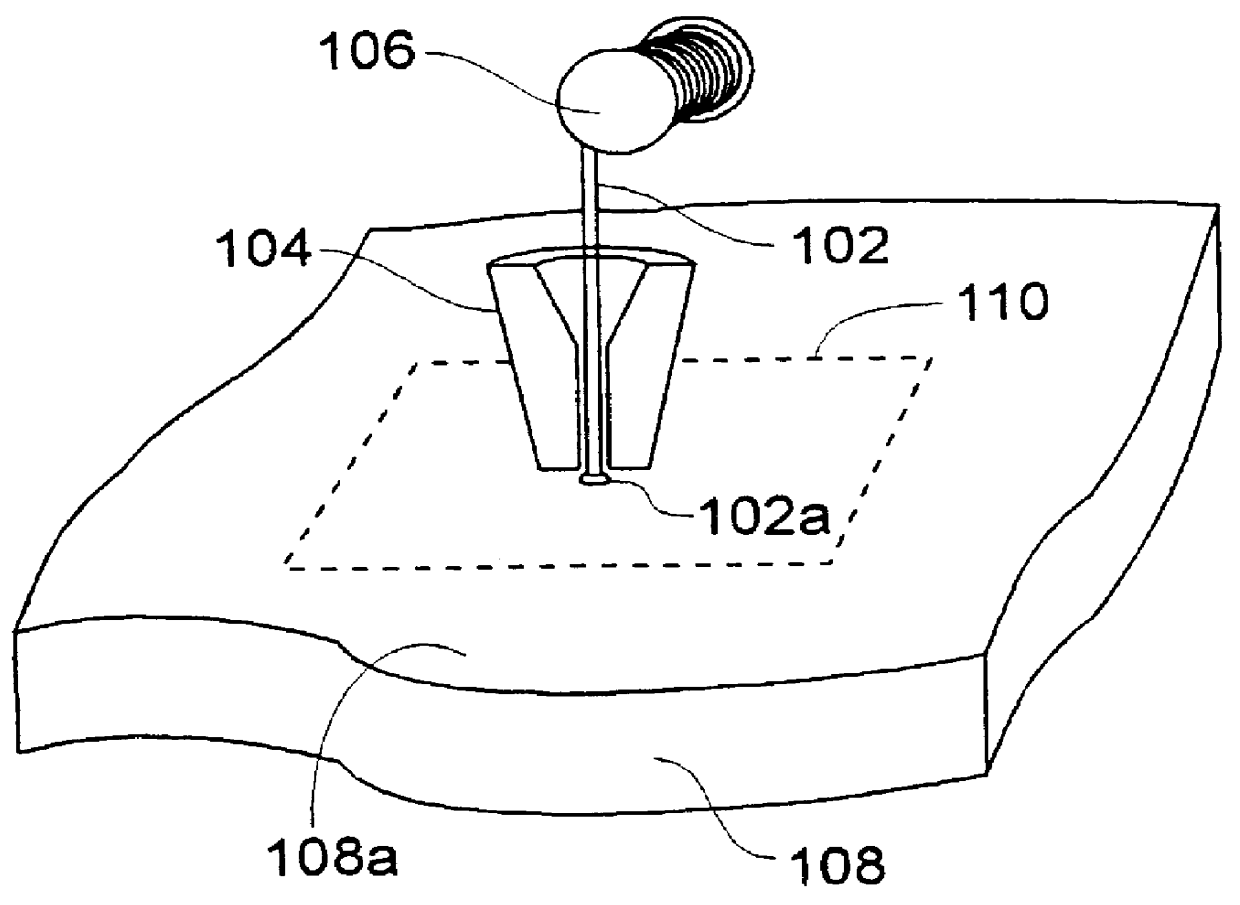

The present invention is a cooling plate including a groove, which becomes a passage of a coolant, inside a body, wherein one or more fins are provided inside the groove, wherein the groove is covered with a lid having width larger than the groove, wherein the lid is joined to the body by friction stir welding, and wherein a weld bead formed by the joining is outside the passage, and the weld bead formed by the joining is formed within the body and further, is characterized by a manufacturing method of a cooling plate that has a first groove, which becomes a passage of a coolant, and a second groove, which has width larger than the first groove and receives a lid on the first groove, inside a body, receives the lid on the second groove, and is joined to the body, the manufacturing method of a cooling plate wherein, while the lid and the body are joined together by the friction stir welding owing to insertion of a rotation tool having a shoulder and a pin, the joining is performed so that a weld bead formed by the joining may become out of the passage, and furthermore, is characterized in that a target for sputtering is joined to the cooling plate.

Owner:HITACHI CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com