Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

440 results about "Work cell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Work cells are strategically arranged groups of resources that are assembled to accomplish a specific purpose within the operation of a business. The idea behind a work cell is usually to structure the use of these resources in a manner that reduces lag time between essential steps, enhances the efficiency of each individual step, and eliminates as much waste of raw materials as possible.

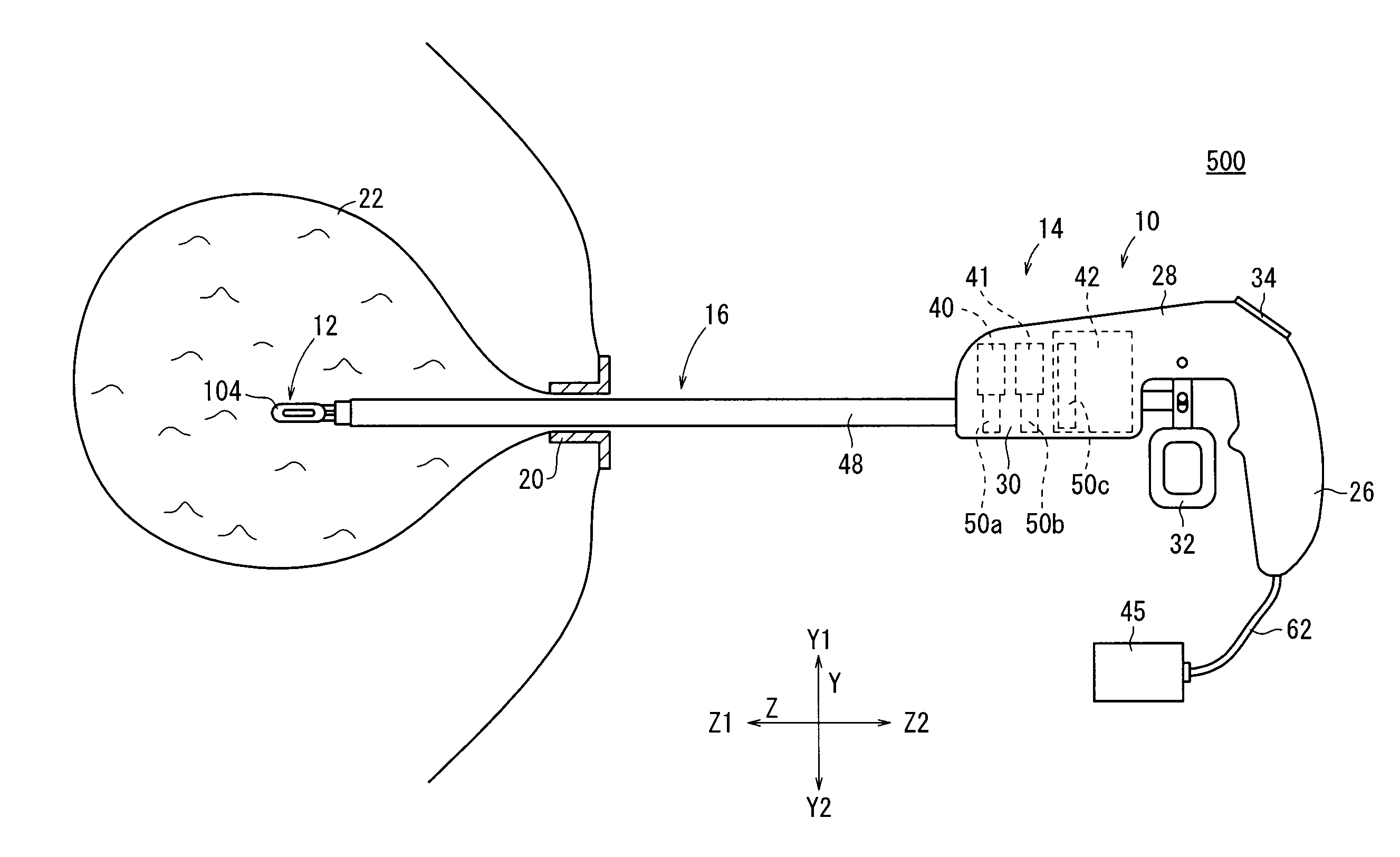

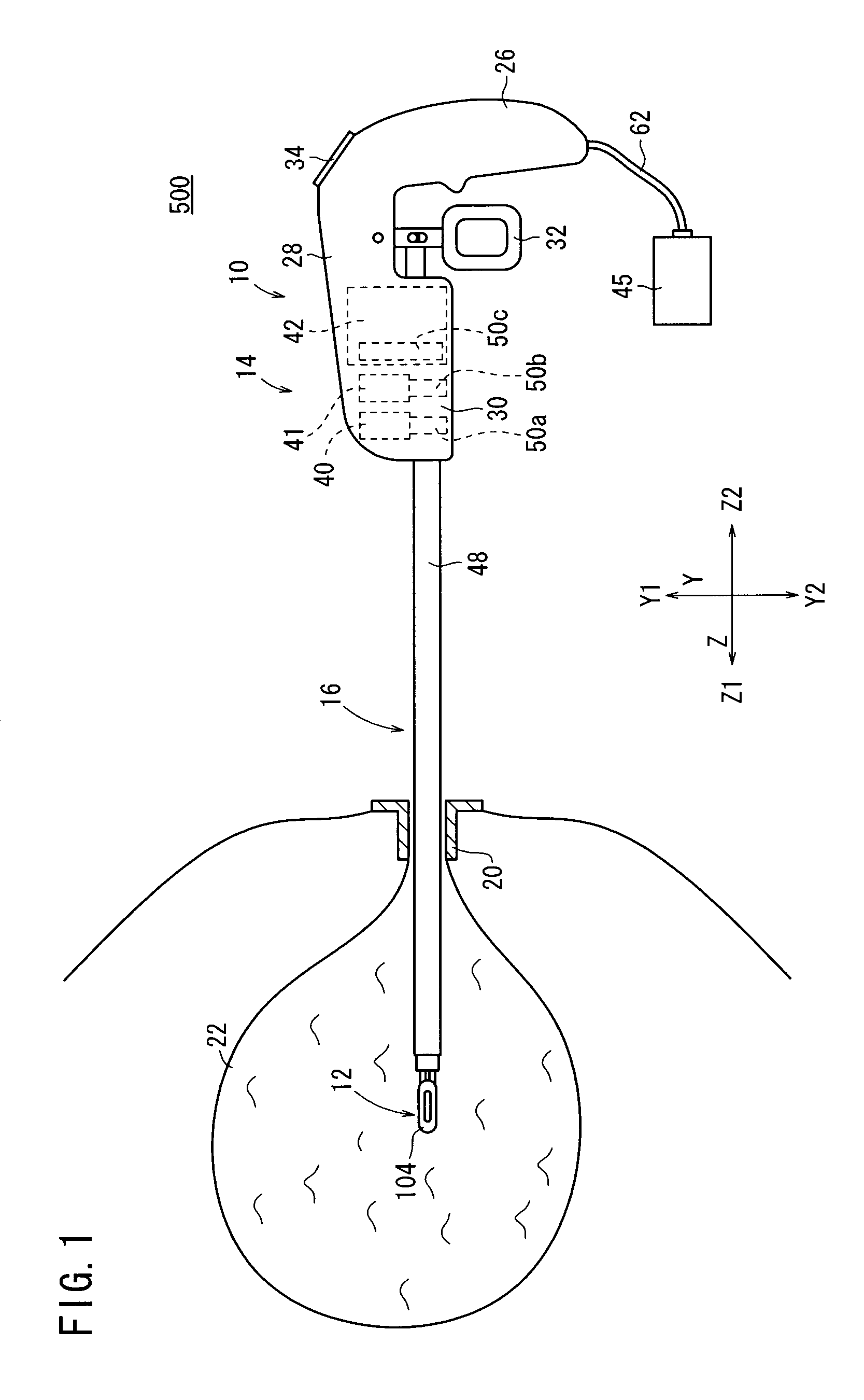

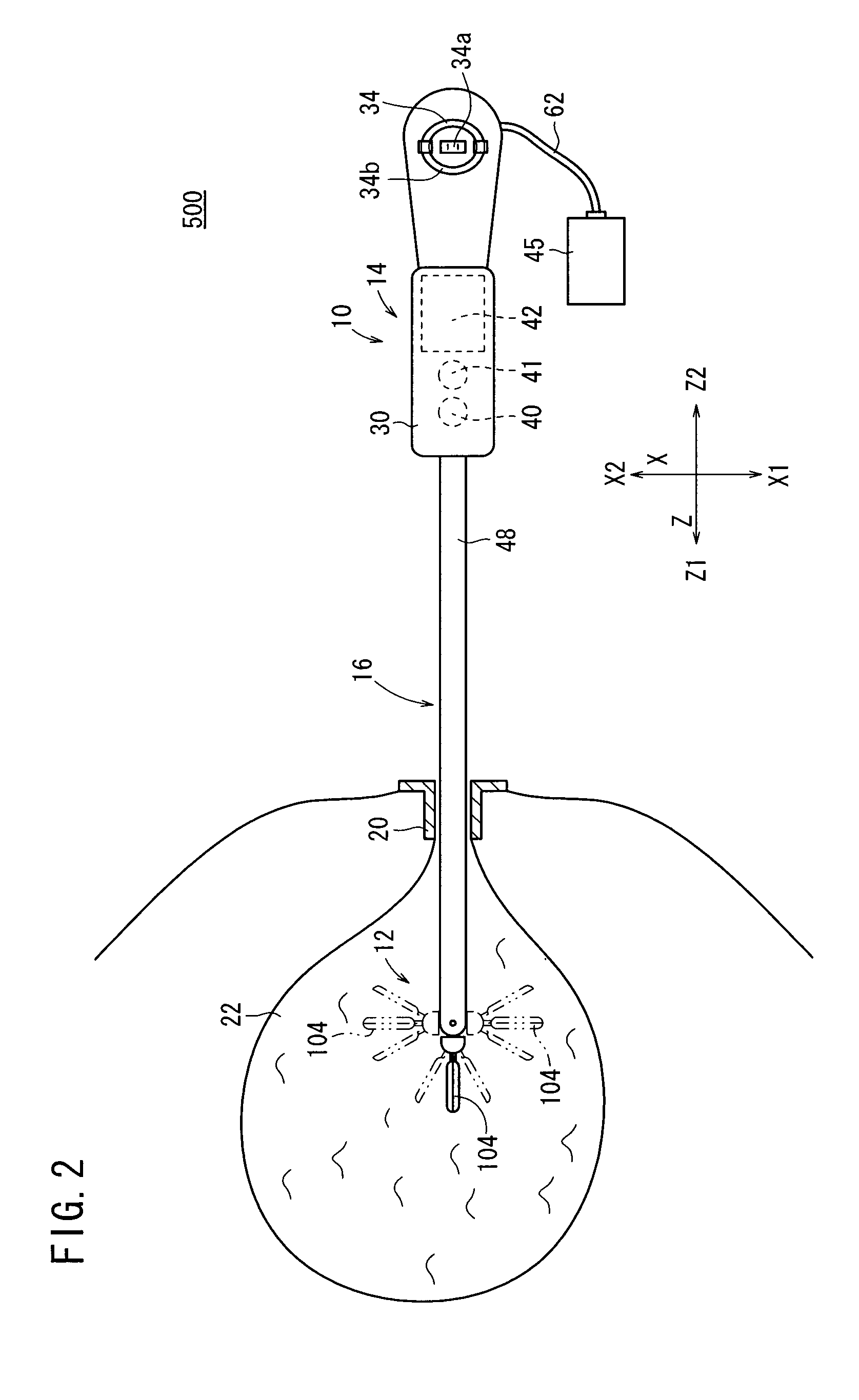

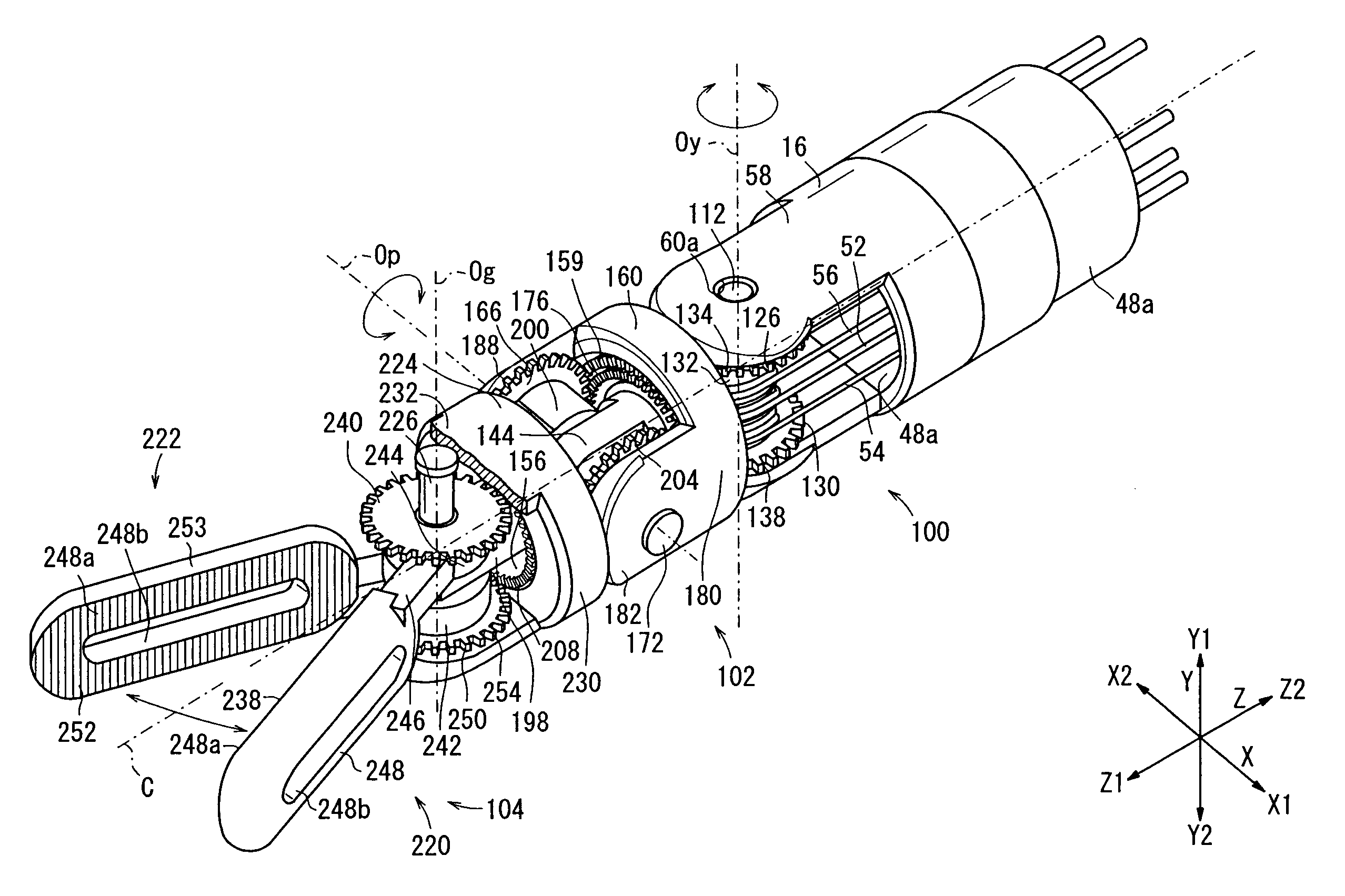

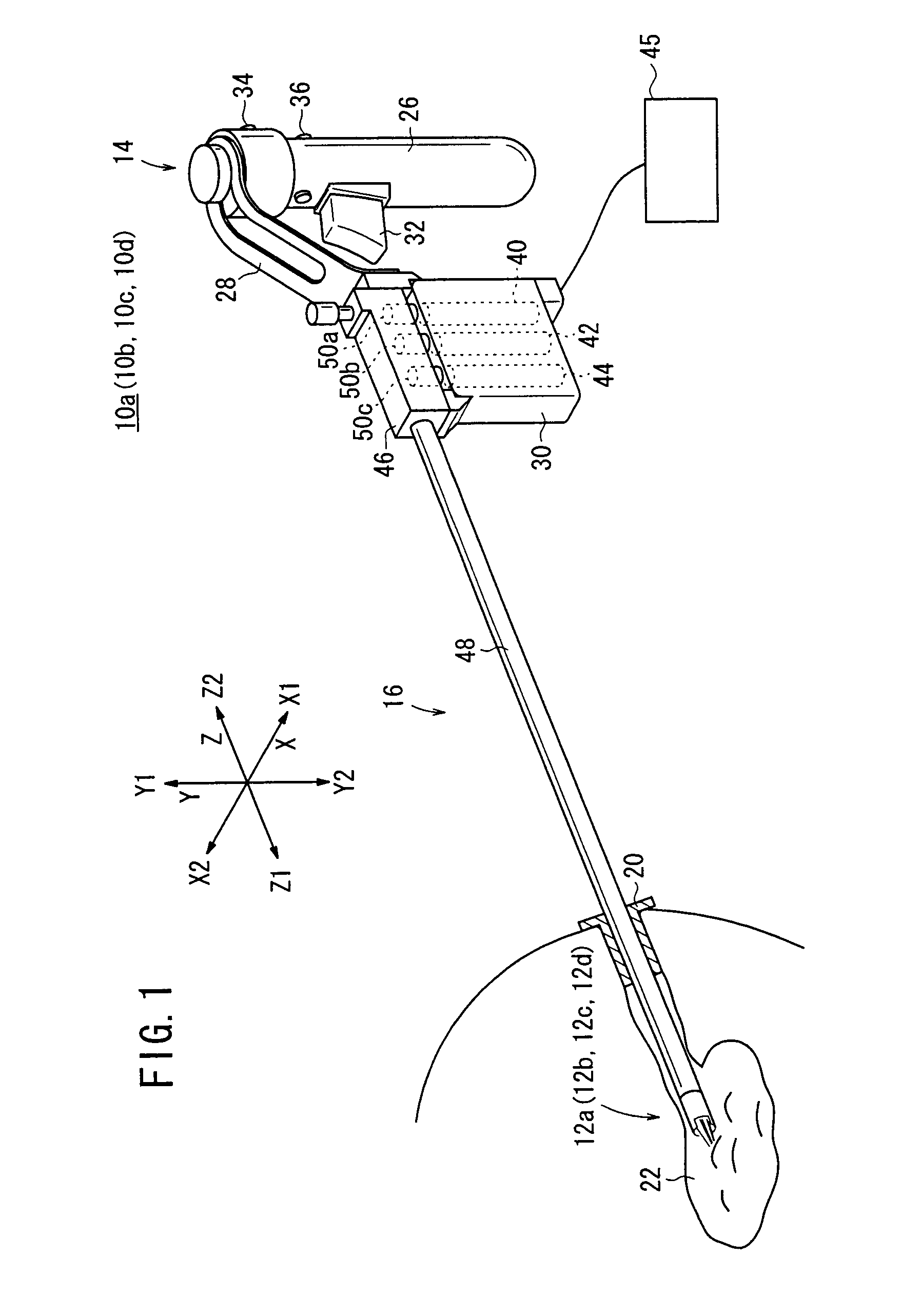

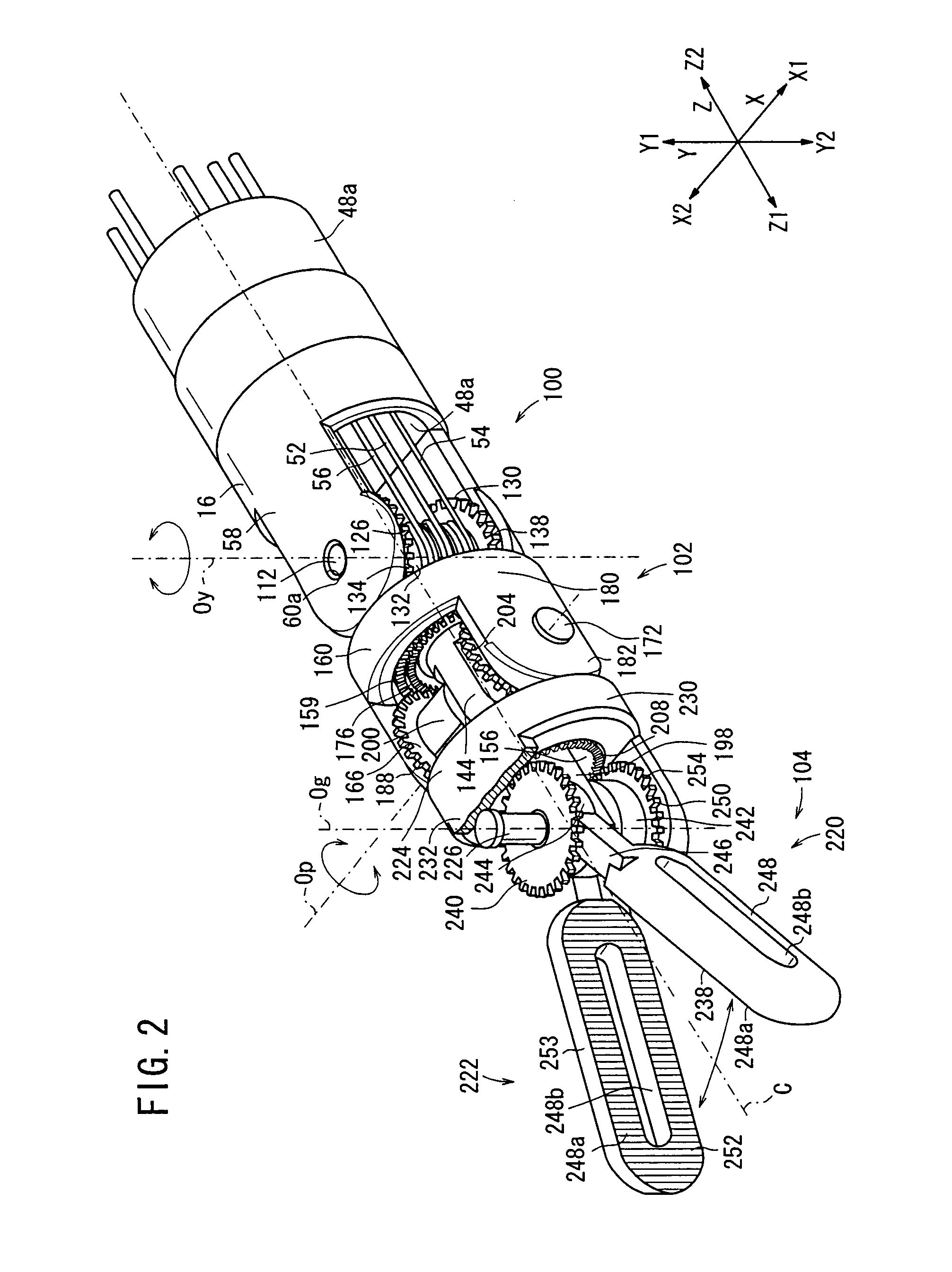

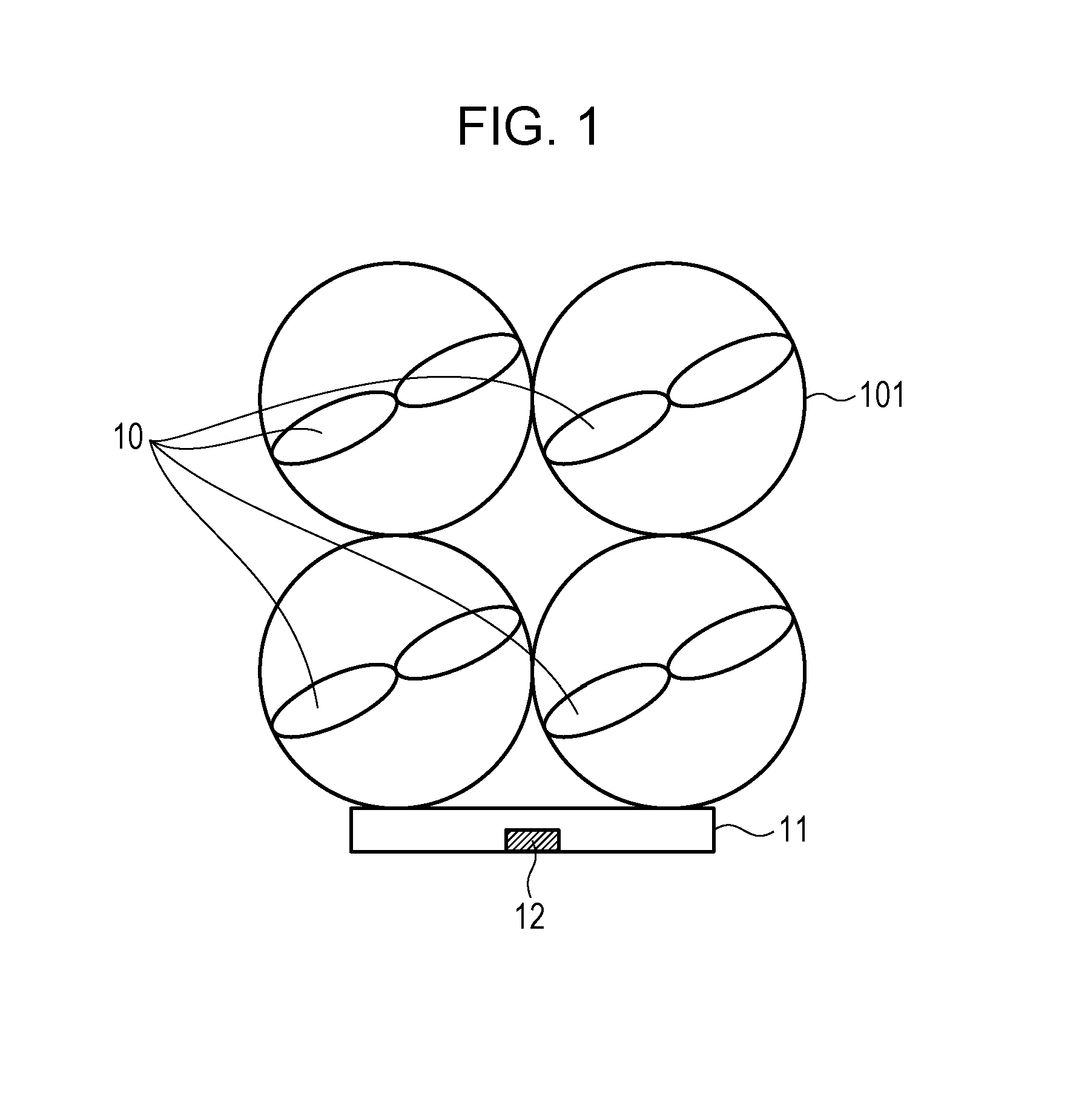

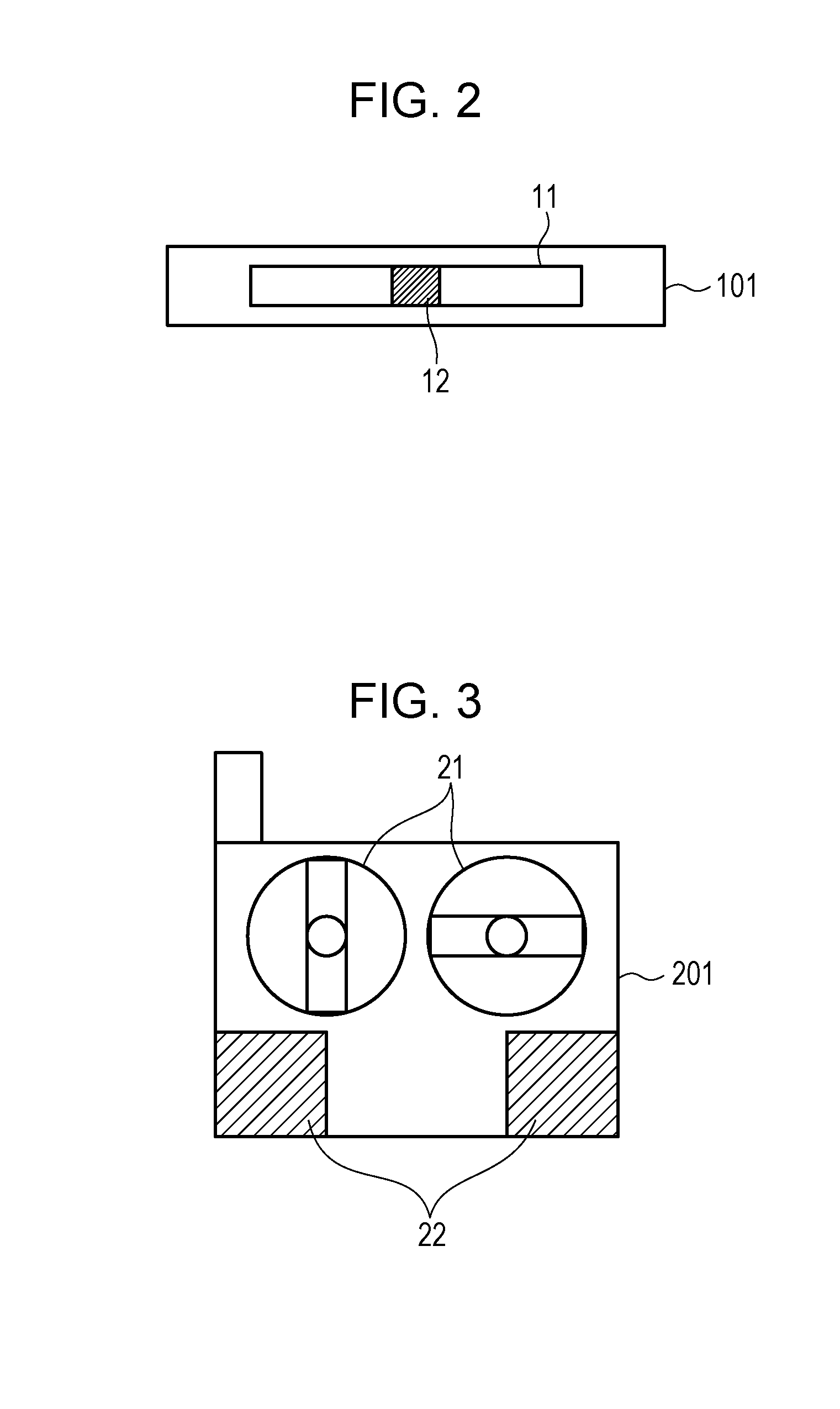

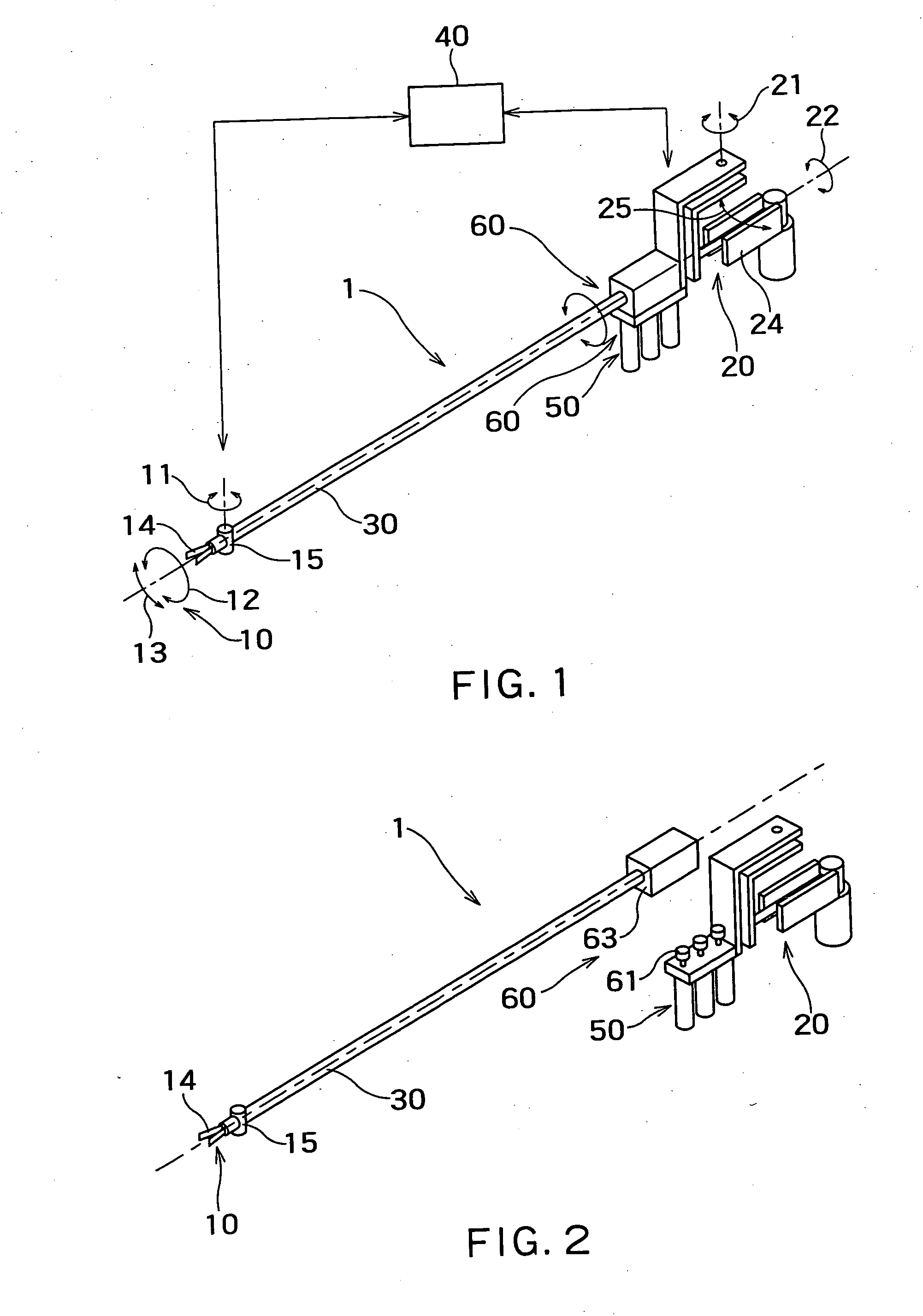

Manipulator system and manipulator control method

InactiveUS20090110533A1Increase freedomAdjustable effectDiagnosticsSemiconductor/solid-state device manufacturingWork unitActuator

A manipulator has an operating unit including a trigger lever, a distal end working unit including an end effector and a yaw axis and a roll axis for changing the direction of the end effector, and a connector shaft interconnecting the operating unit and the distal end working unit. The operating unit includes an actuator block housing therein motors for actuating the yaw axis and the roll axis and a gripper operational quantity corrector for mechanically transmitting an operational action of the trigger lever to actuate the end effector. A controller calculates an interference amount caused on the end effector by the attitude angles of the yaw axis and the roll axis. The gripper operational quantity corrector is controlled by the controller to extend or retract a push rod, for correcting the operational quantity of the operational action of the trigger lever to compensate for the interference amount.

Owner:KK TOSHIBA

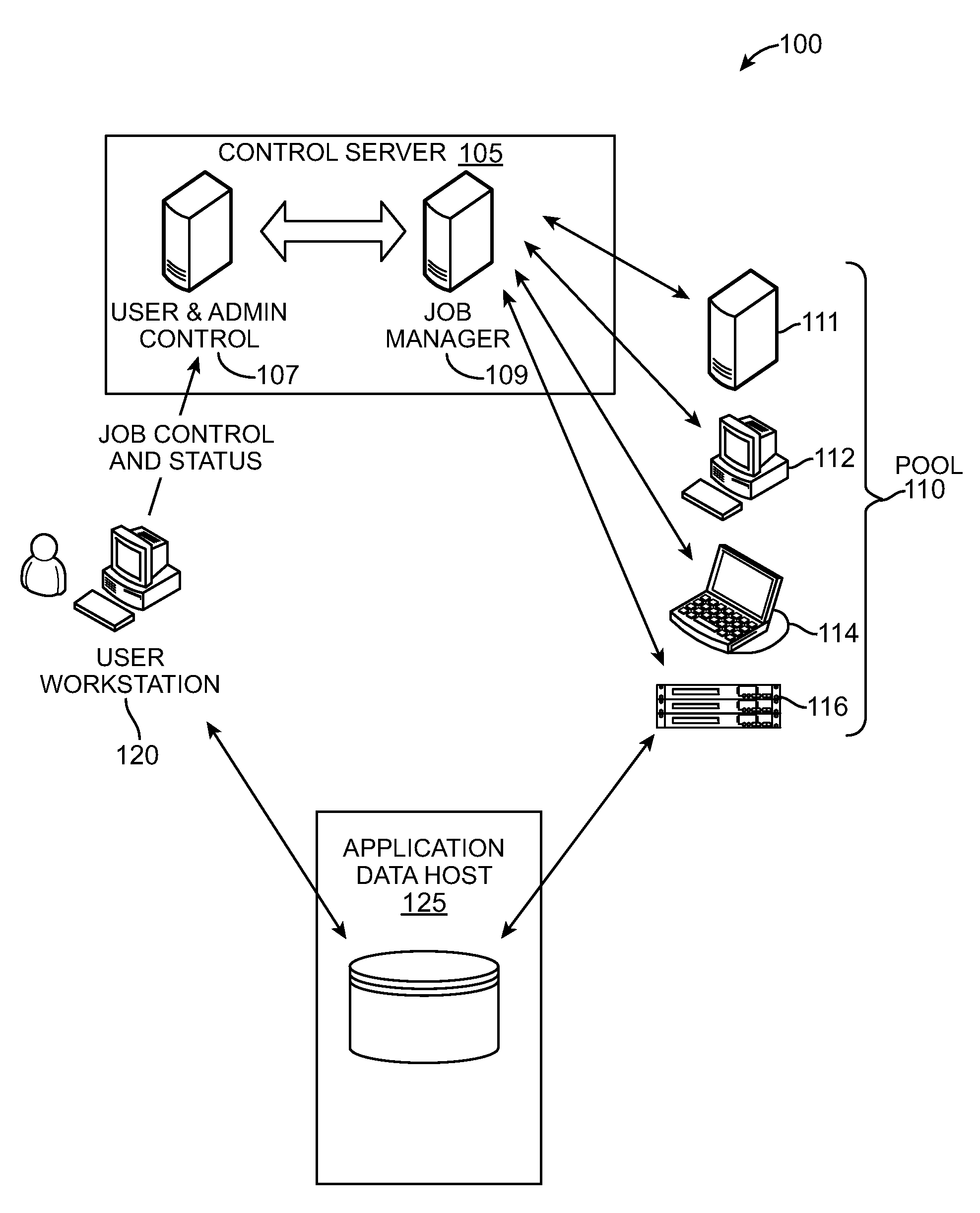

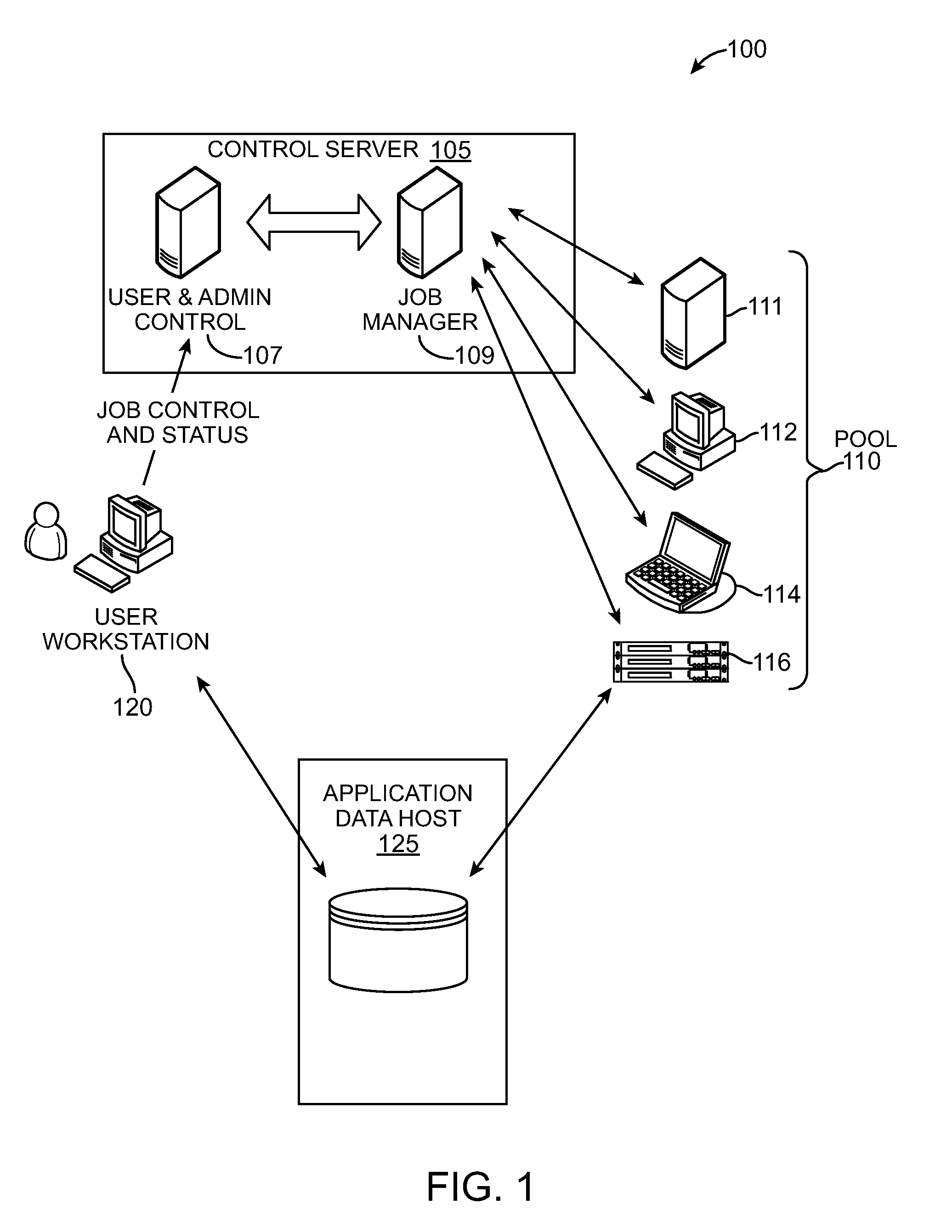

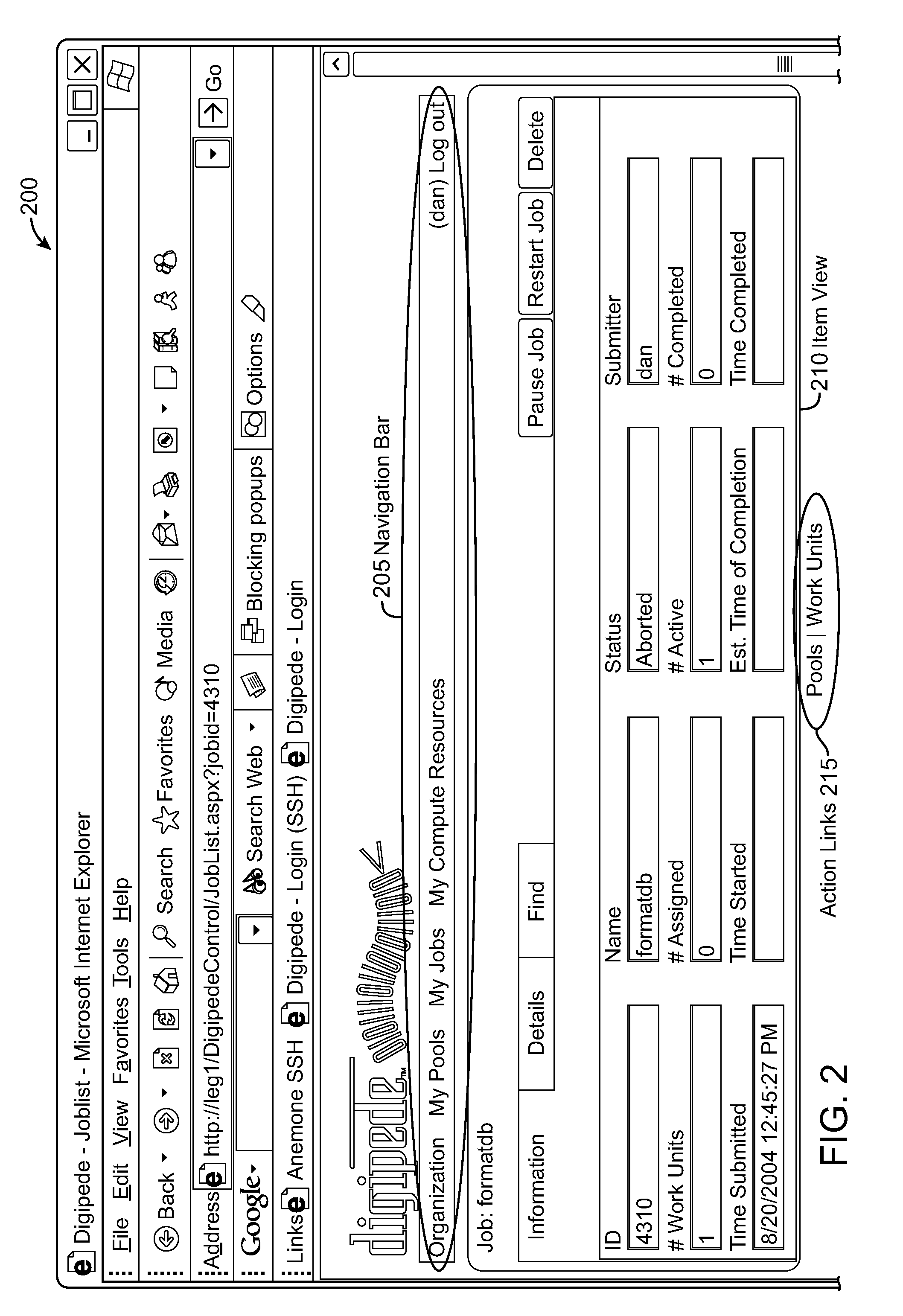

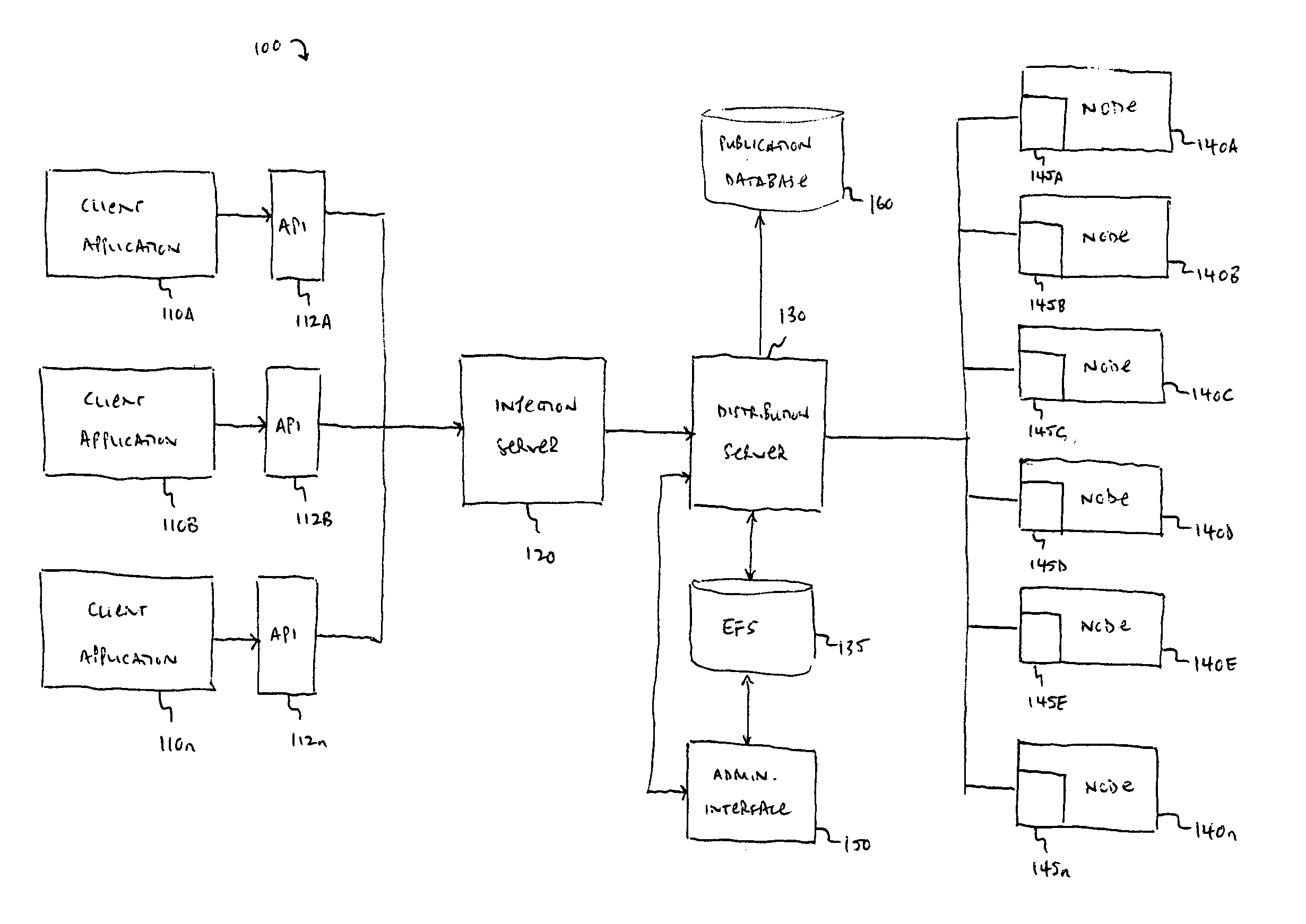

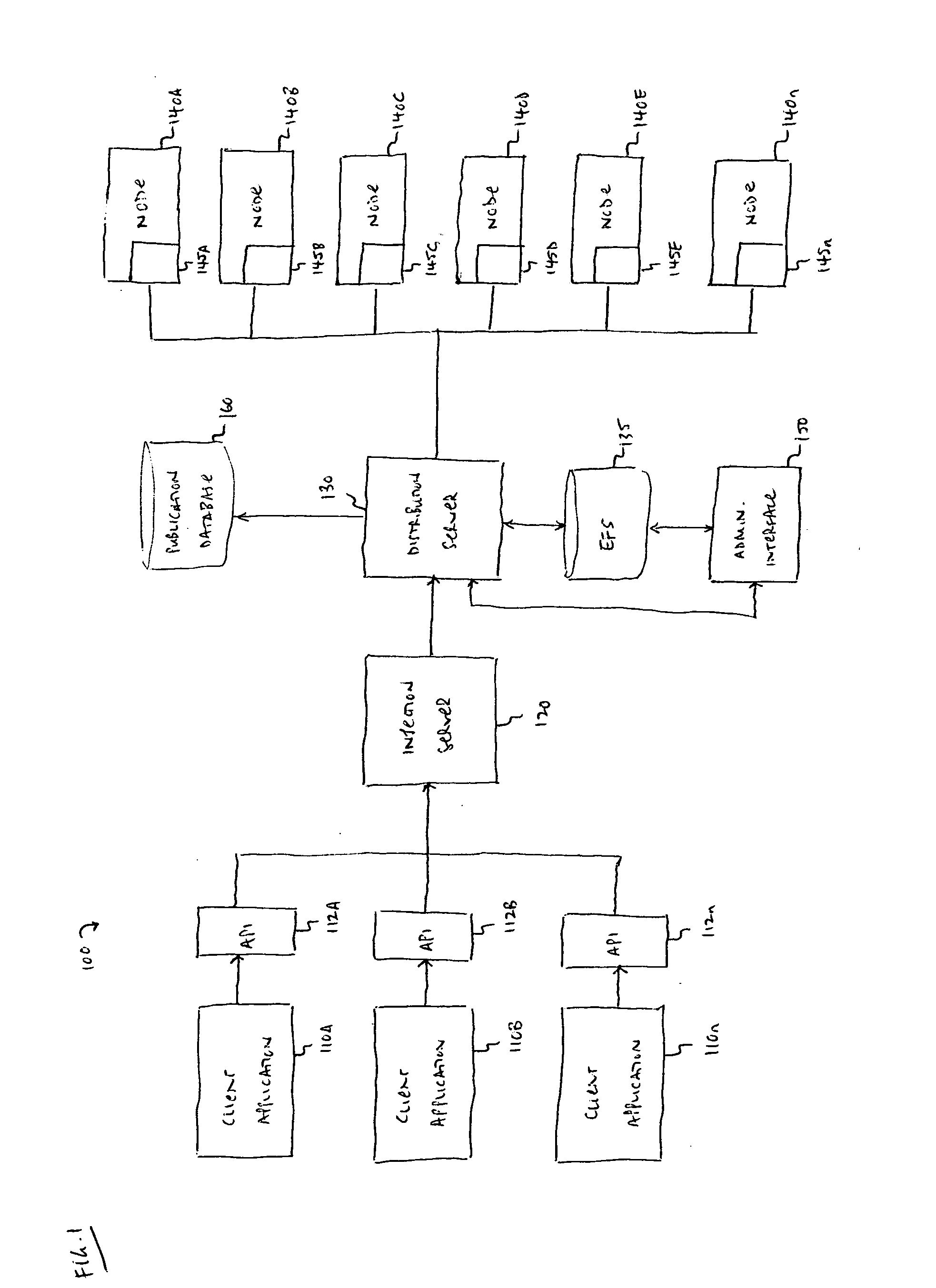

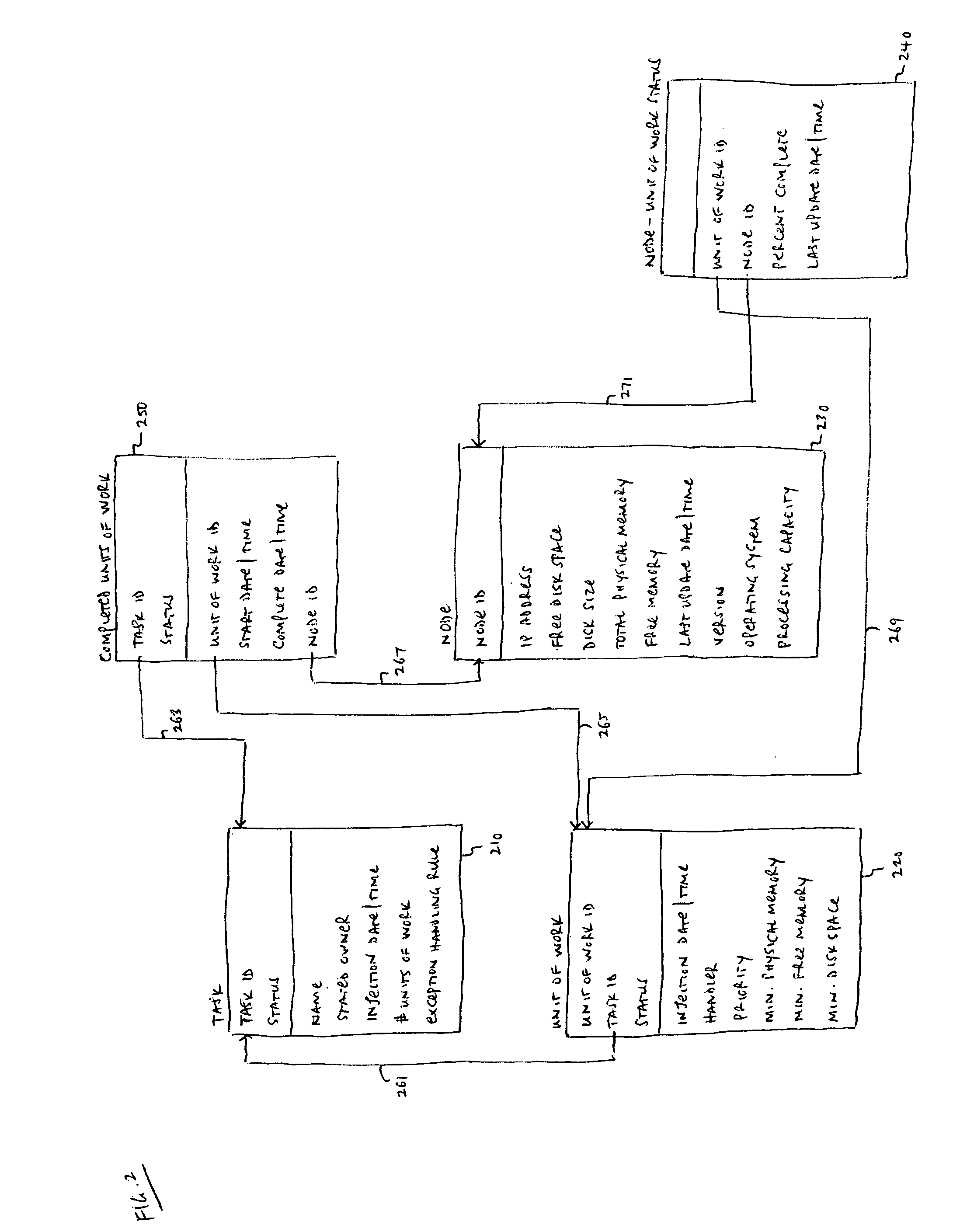

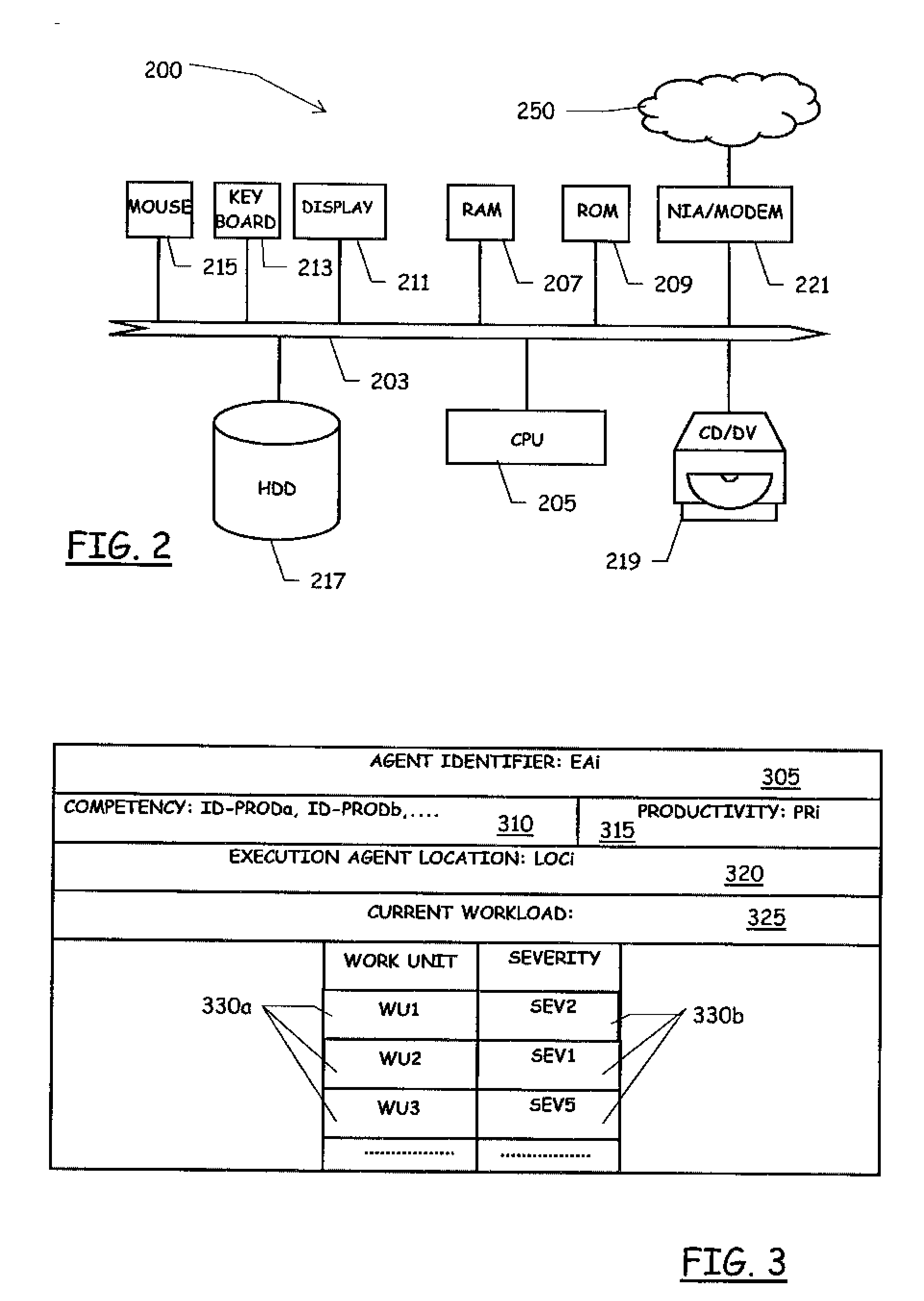

Multicore Distributed Processing System

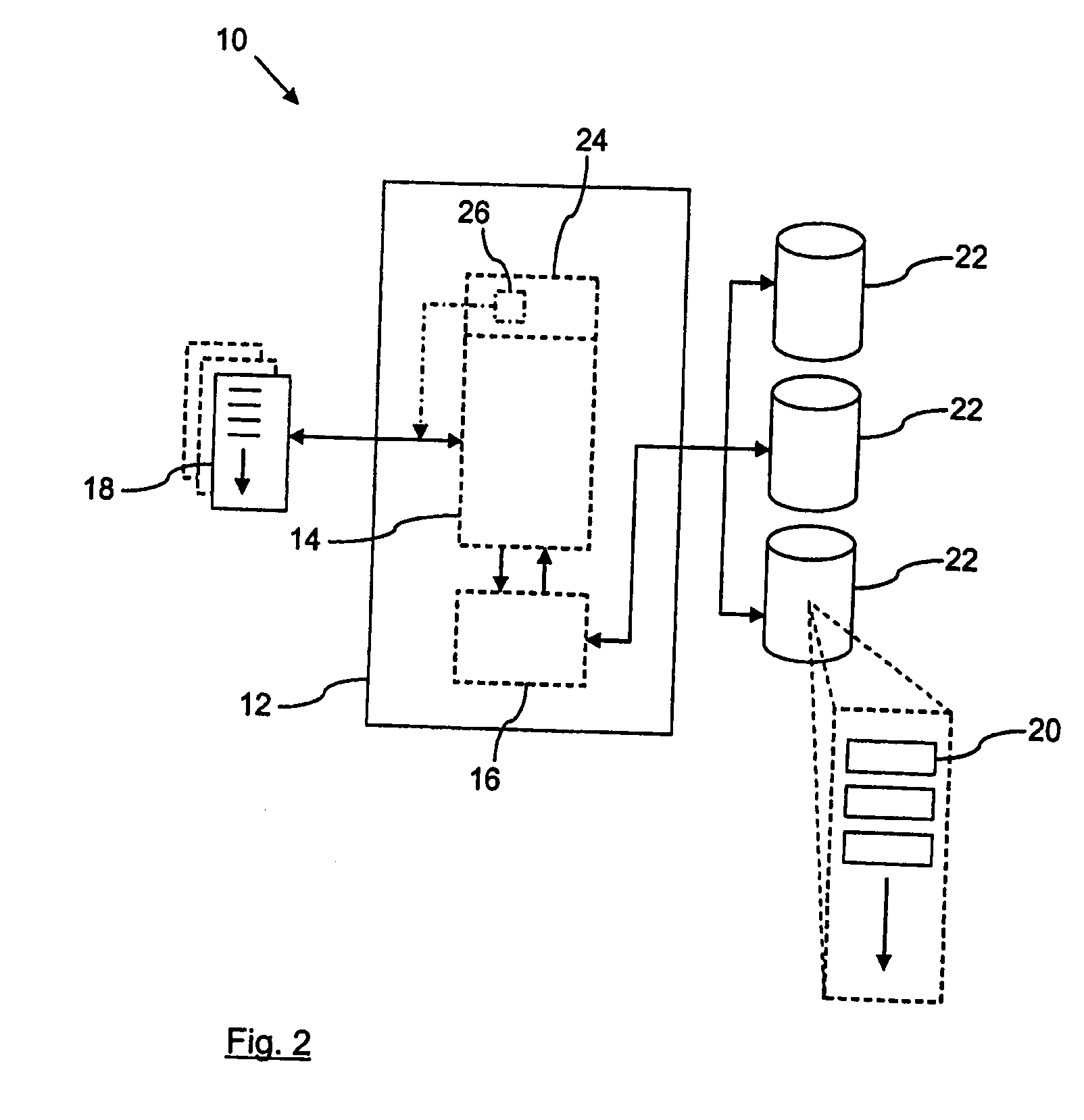

ActiveUS20090049443A1Improve application performanceFaster and relatively lightweightGeneral purpose stored program computerMultiprogramming arrangementsMulti processorWork unit

A distributed processing system delegates the allocation and control of computing work units to agent applications running on computing resources including multi-processor and multi-core systems. The distributed processing system includes at least one agent associated with at least one computing resource. The distributed processing system creates work units corresponding with execution phases of applications. Work units can be associated with concurrency data that specifies how applications are executed on multiple processors and / or processor cores. The agent collects information about its associated computing resources and requests work units from the server using this information and the concurrency data. An agent can monitor the performance of executing work units to better select subsequent work units. The distributed processing system may also be implemented within a single computing resource to improve processor core utilization of applications. Additional computing resources can augment the single computing resource and execute pending work units at any time.

Owner:DIGIPEDE TECH LLC

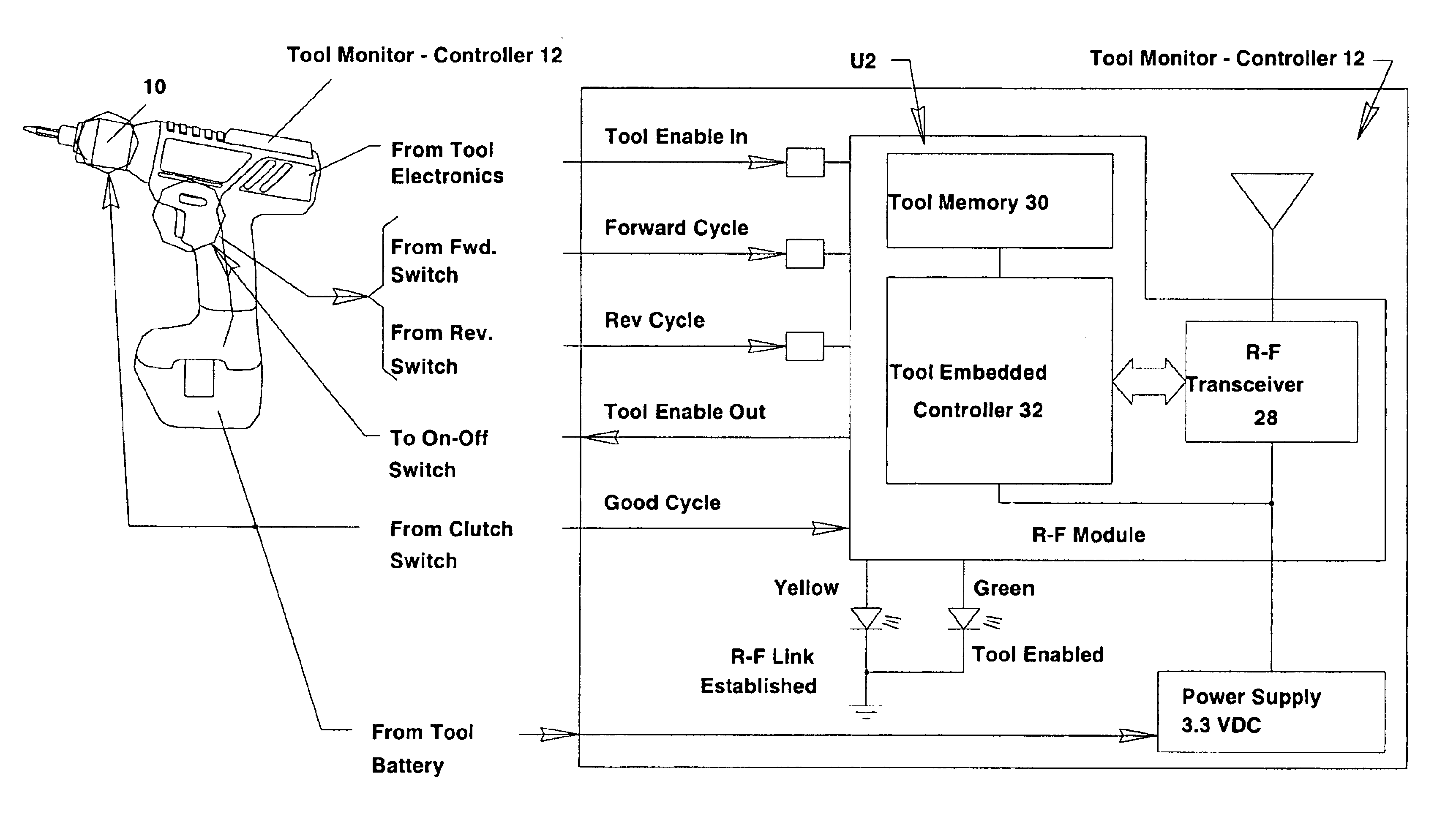

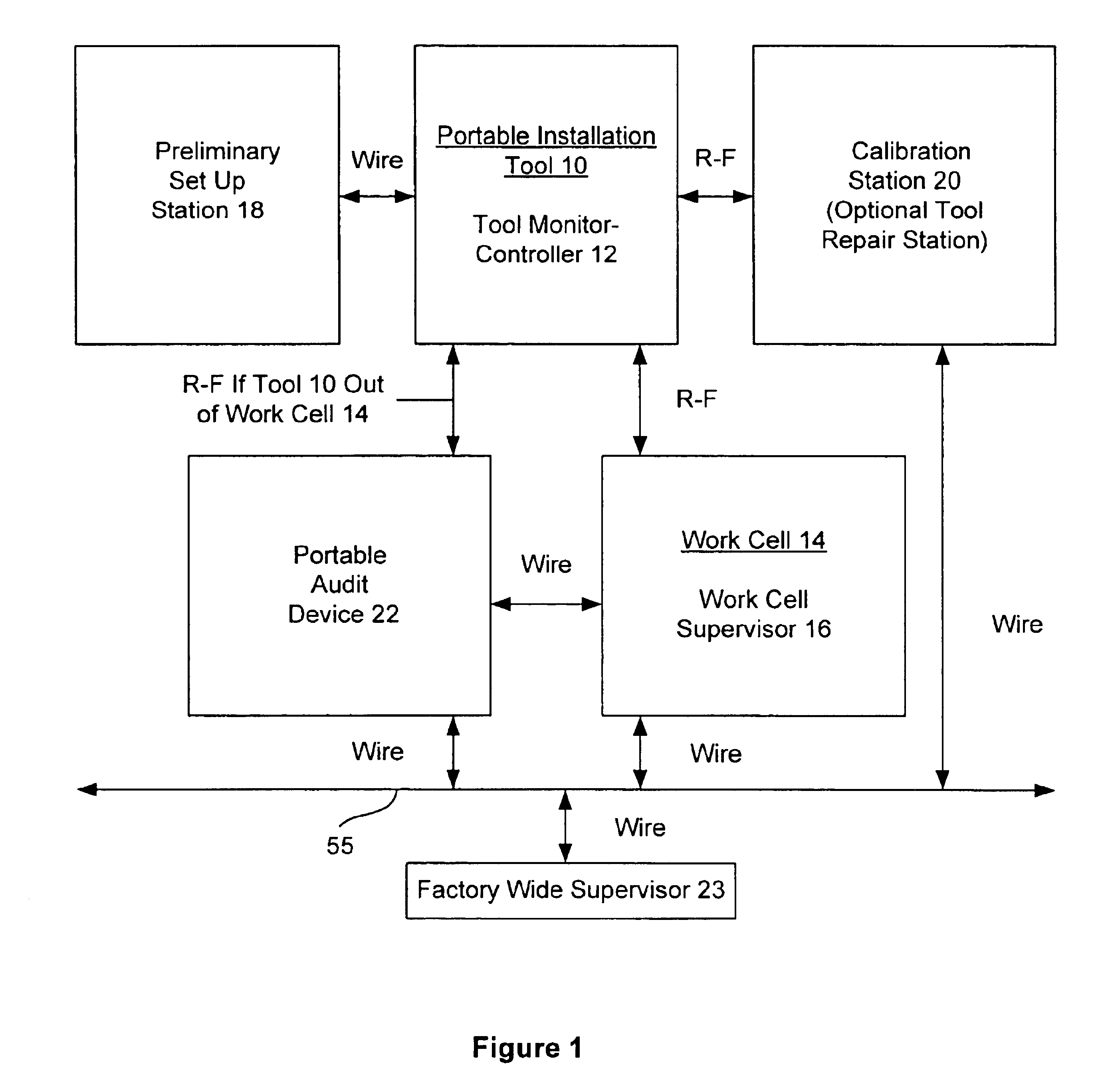

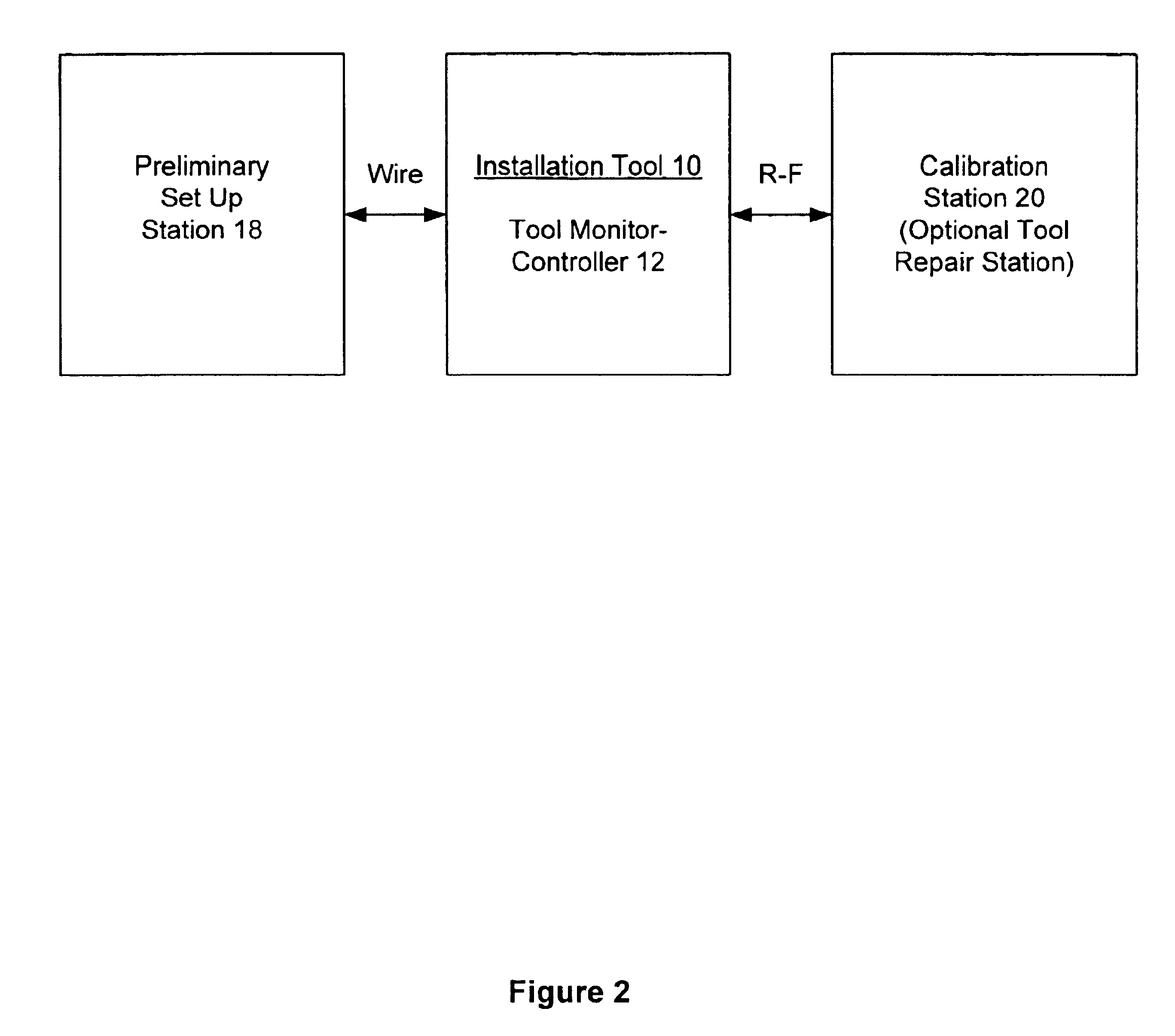

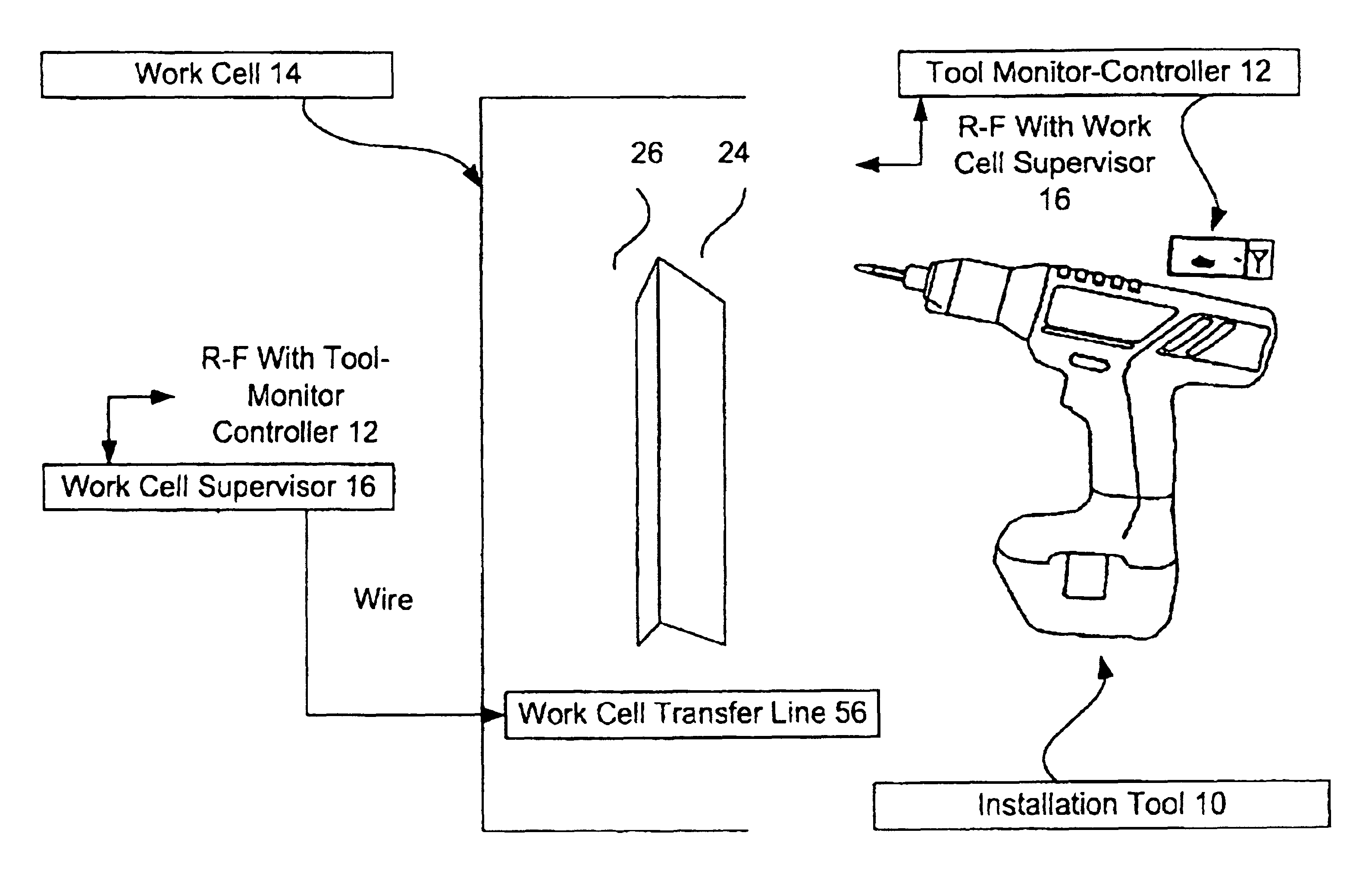

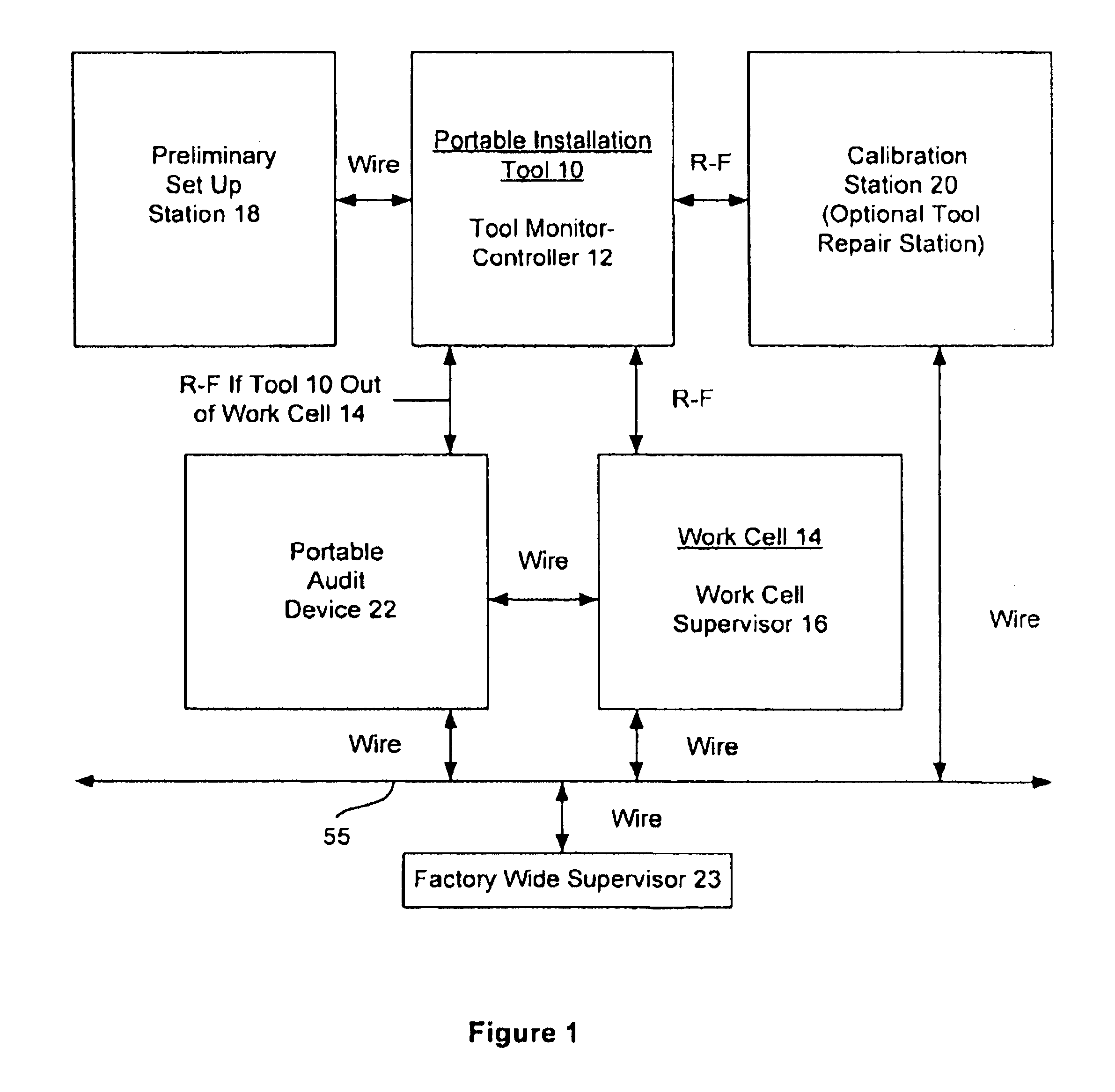

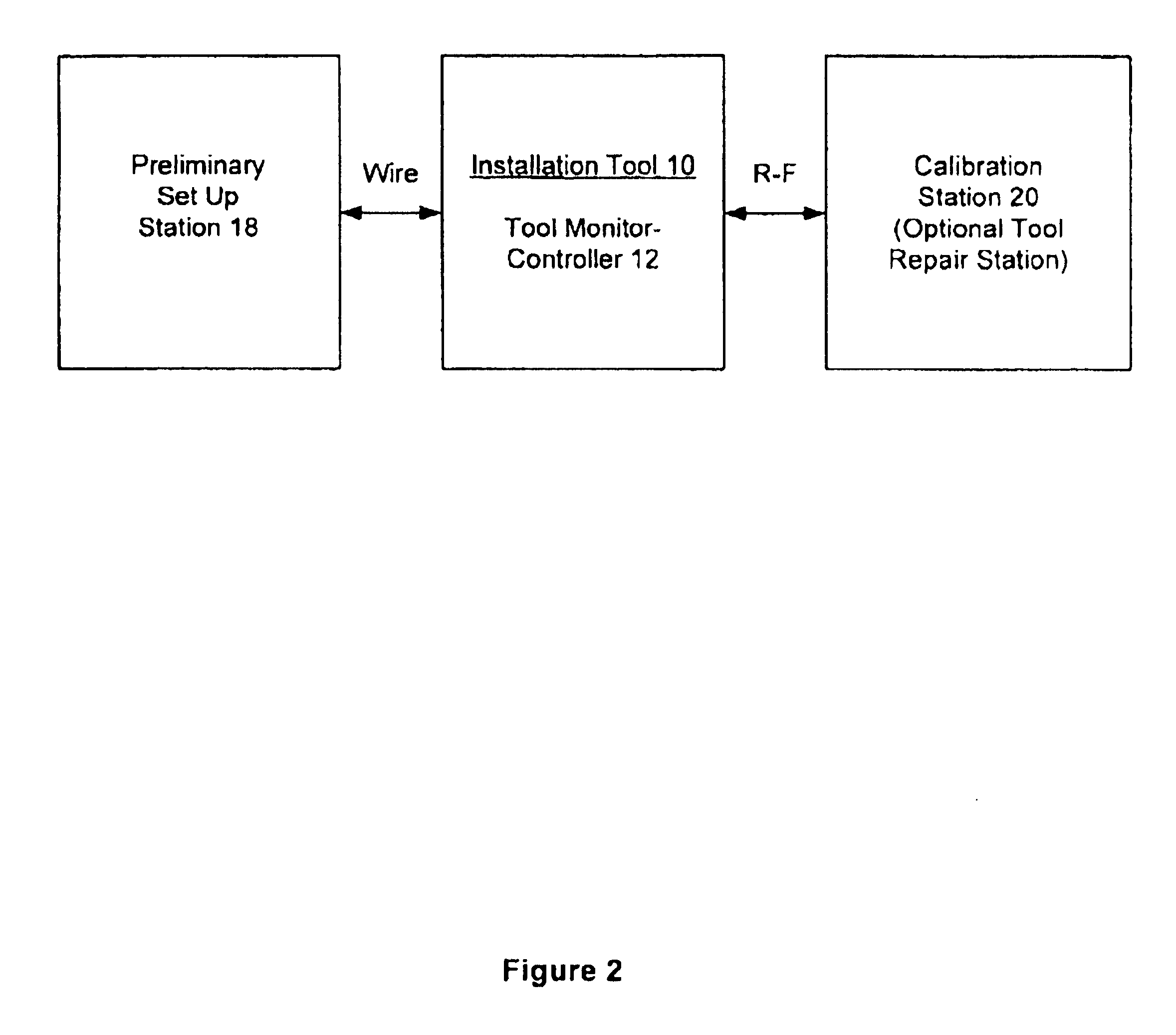

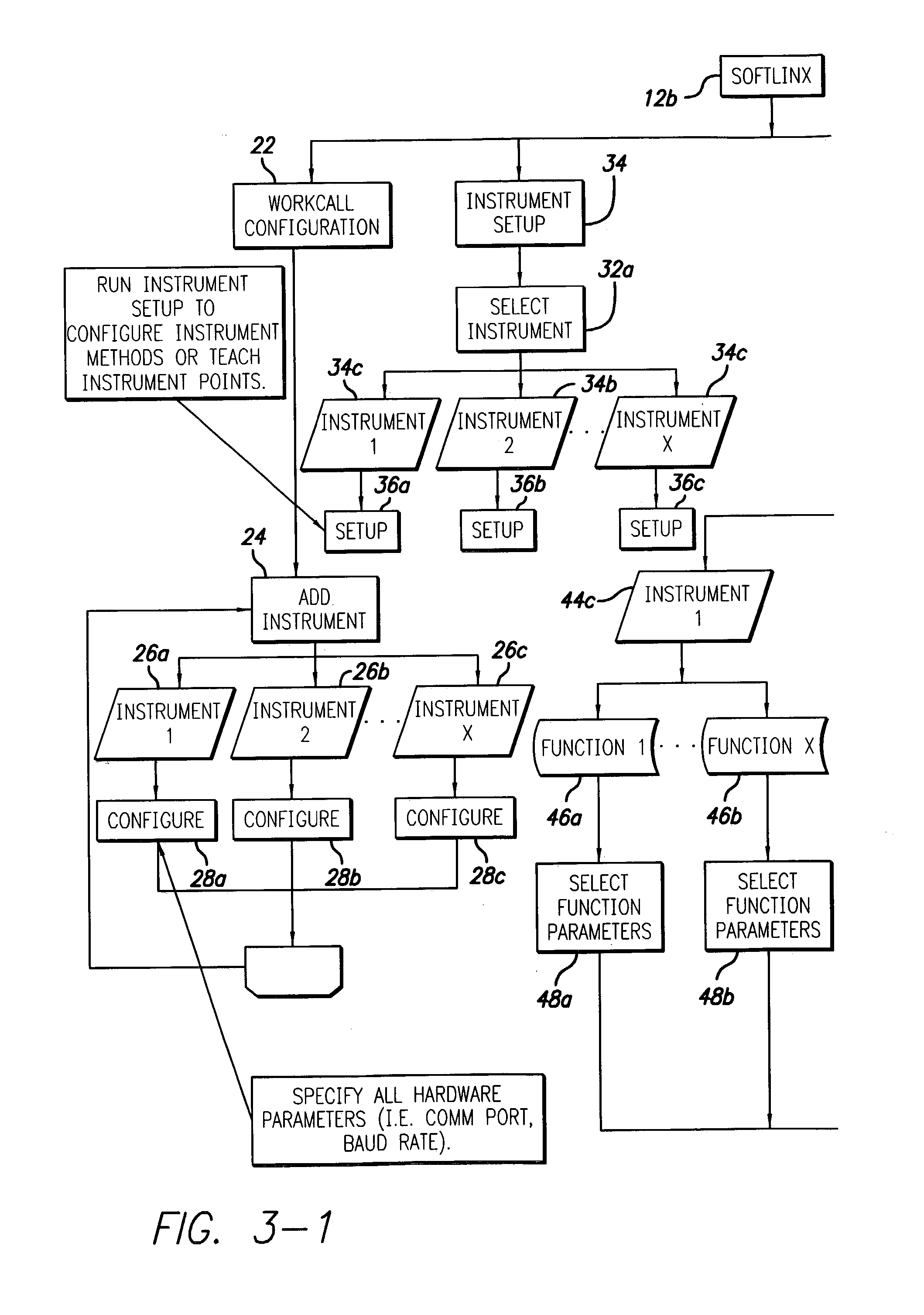

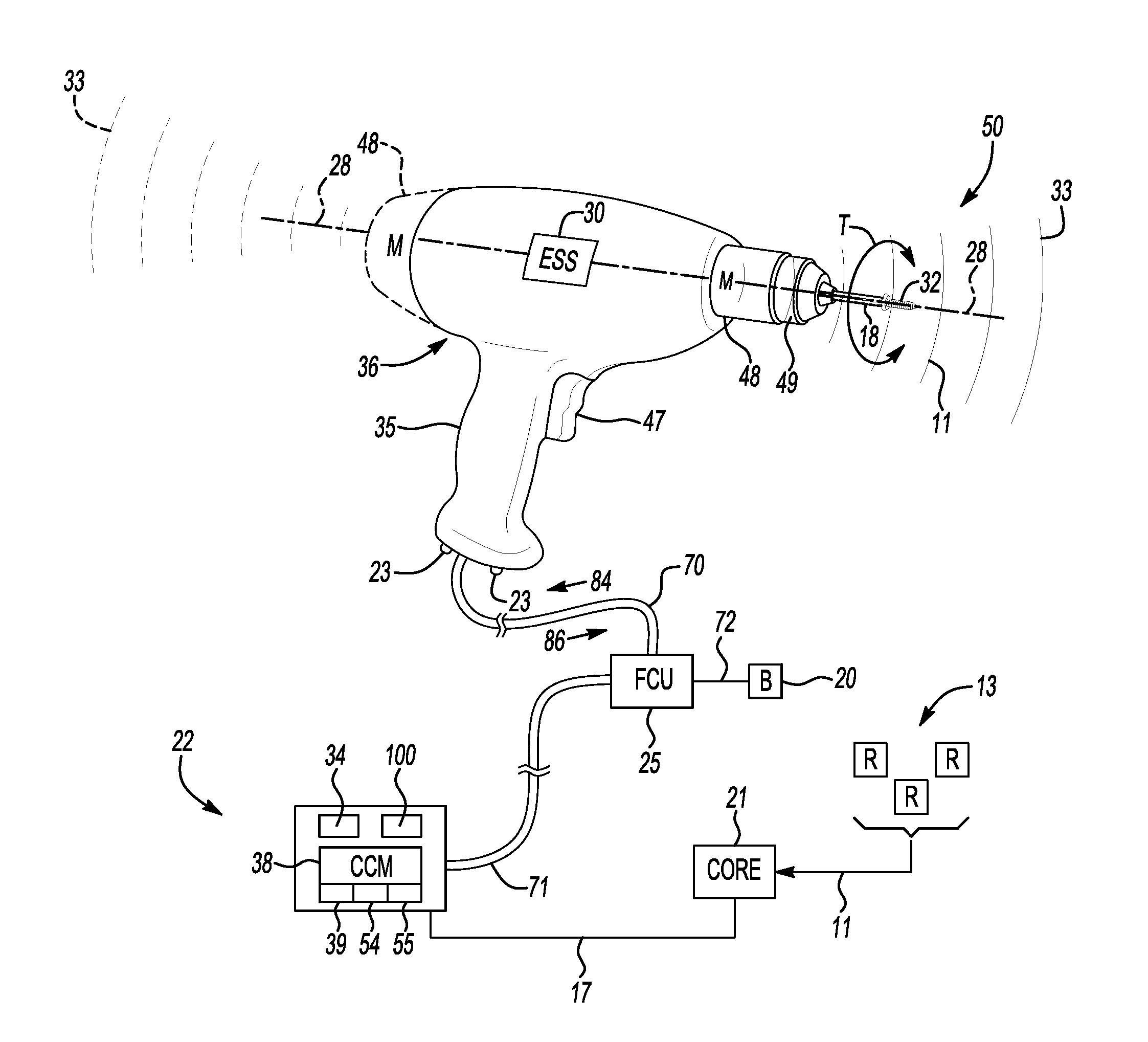

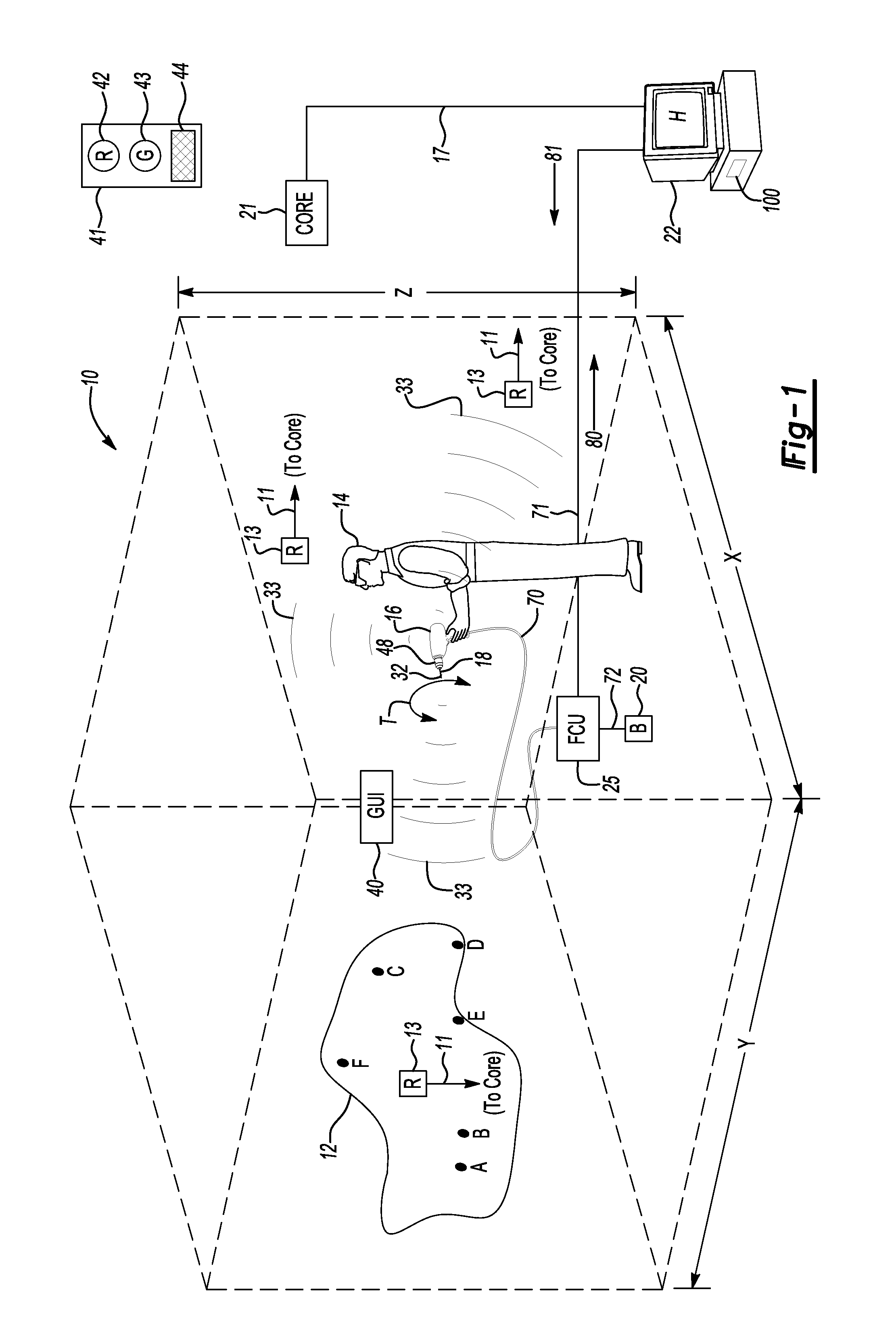

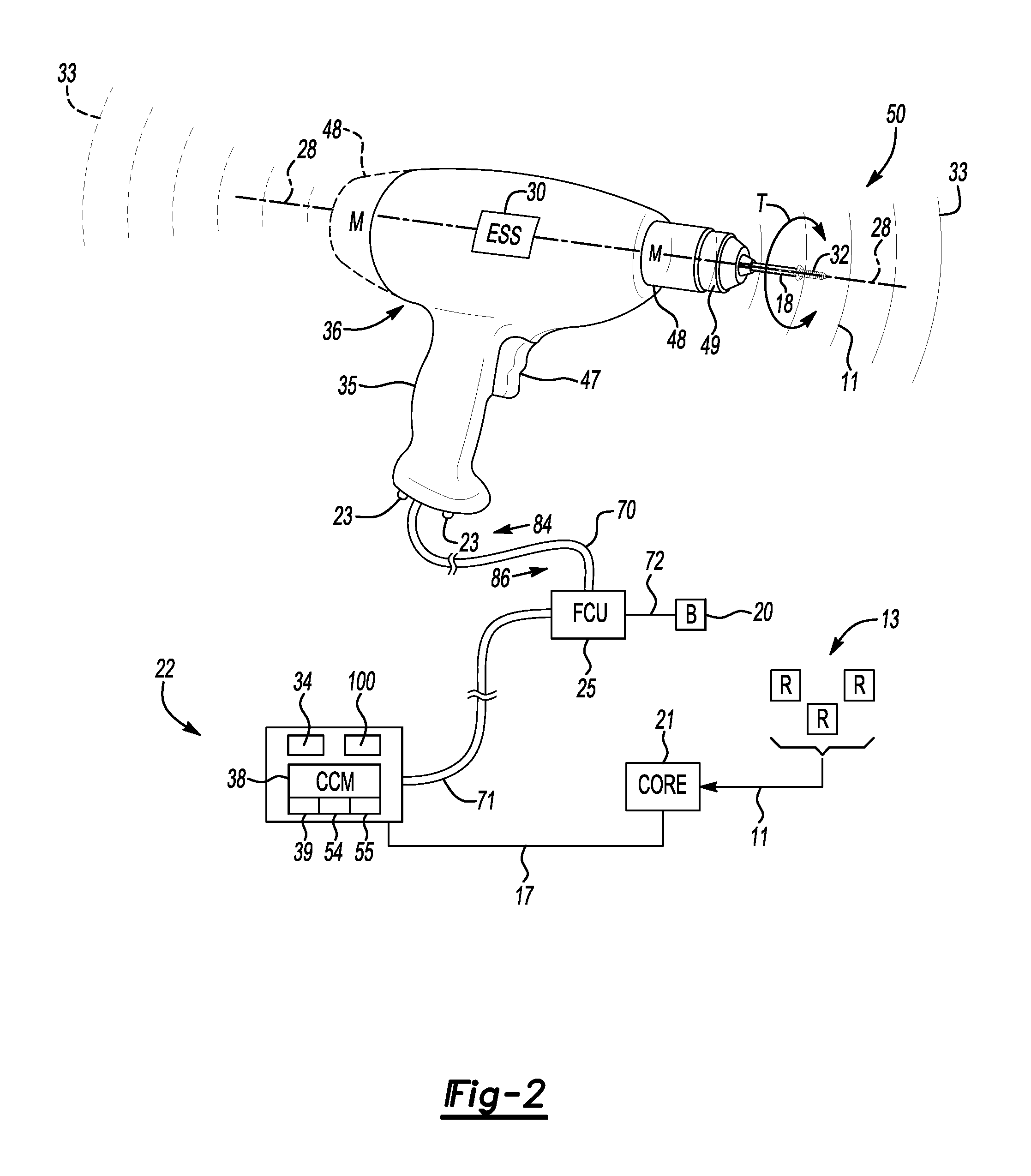

Error proofing system for portable tools

ActiveUS6845279B1Easy to useEasy to monitorProgramme controlComputer controlWork cellElectrical and Electronics engineering

A system for controlling and monitoring portable tools at a particular work cell remotely by R-F communication to provide error proofing of various parameters including that the correct tool is to be used at a work cell, the tool is properly calibrated for the operation to be performed, that it is being used a proper number of times per part being assembled or inspected, and that the tool has been calibrated within a selected service interval. The tools will be made actuable only by R-F communication with specific factory apparatus whereby theft of such portable tools will be inhibited.

Owner:ATLAS COPCO INDAL TECHN AB

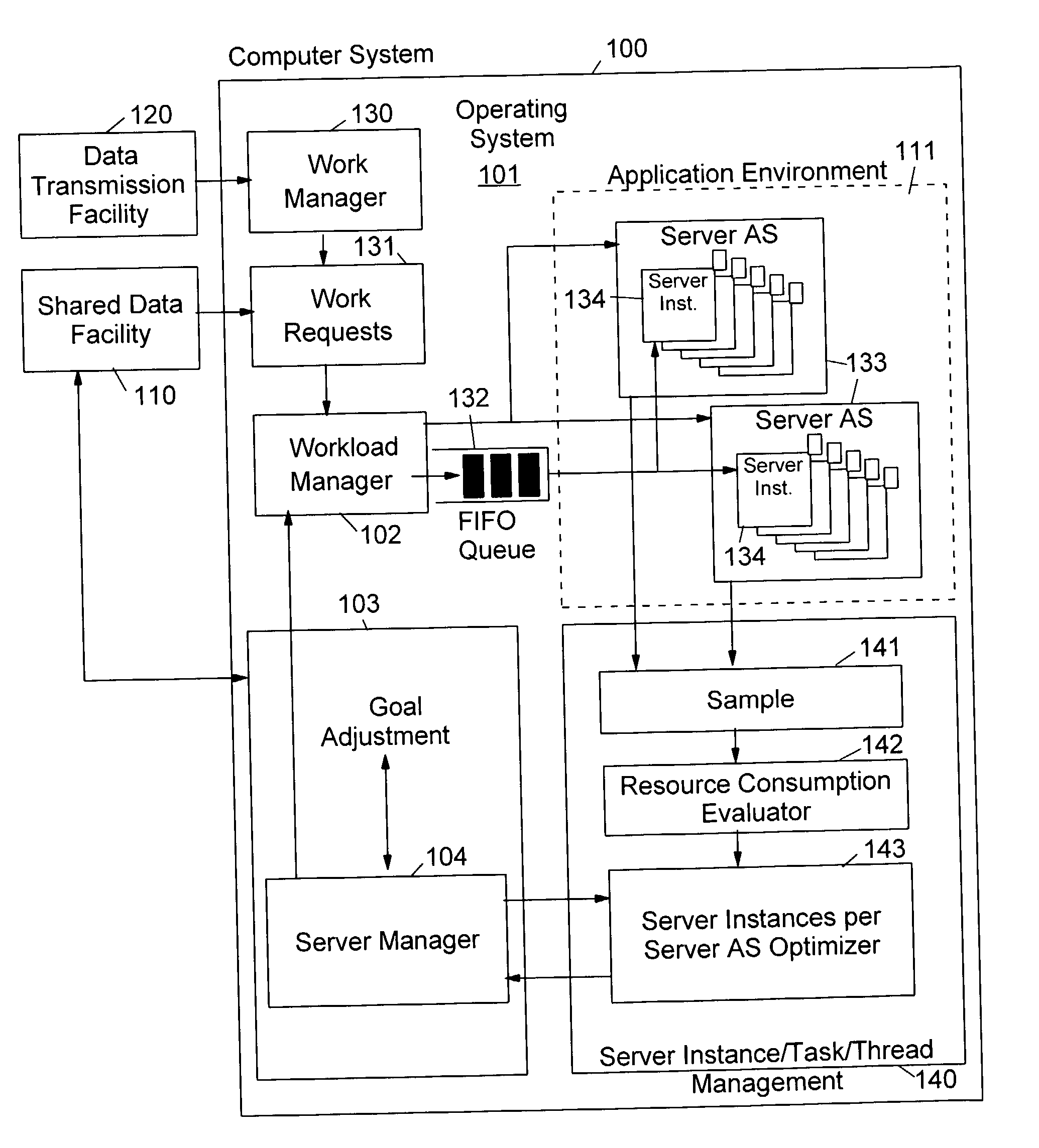

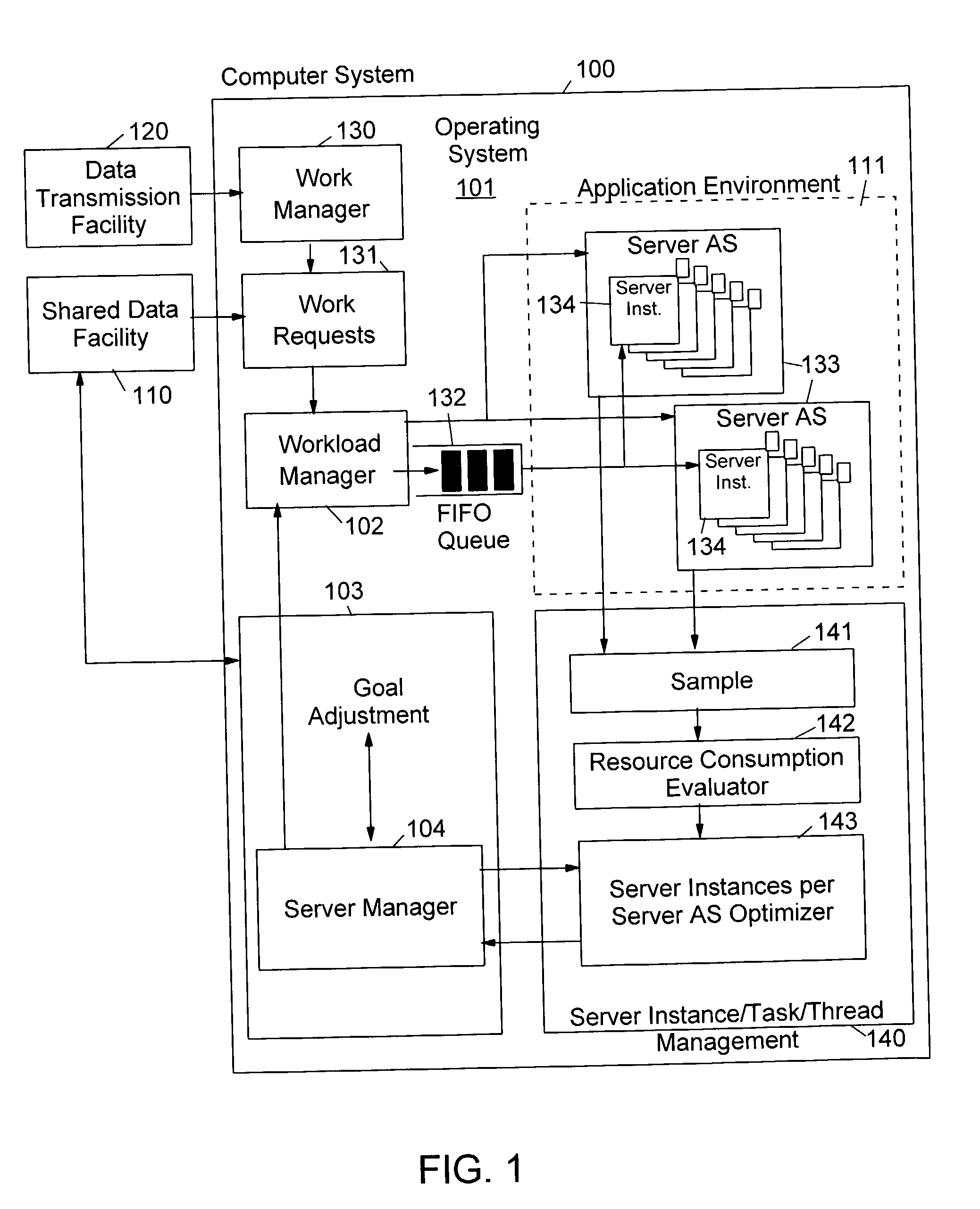

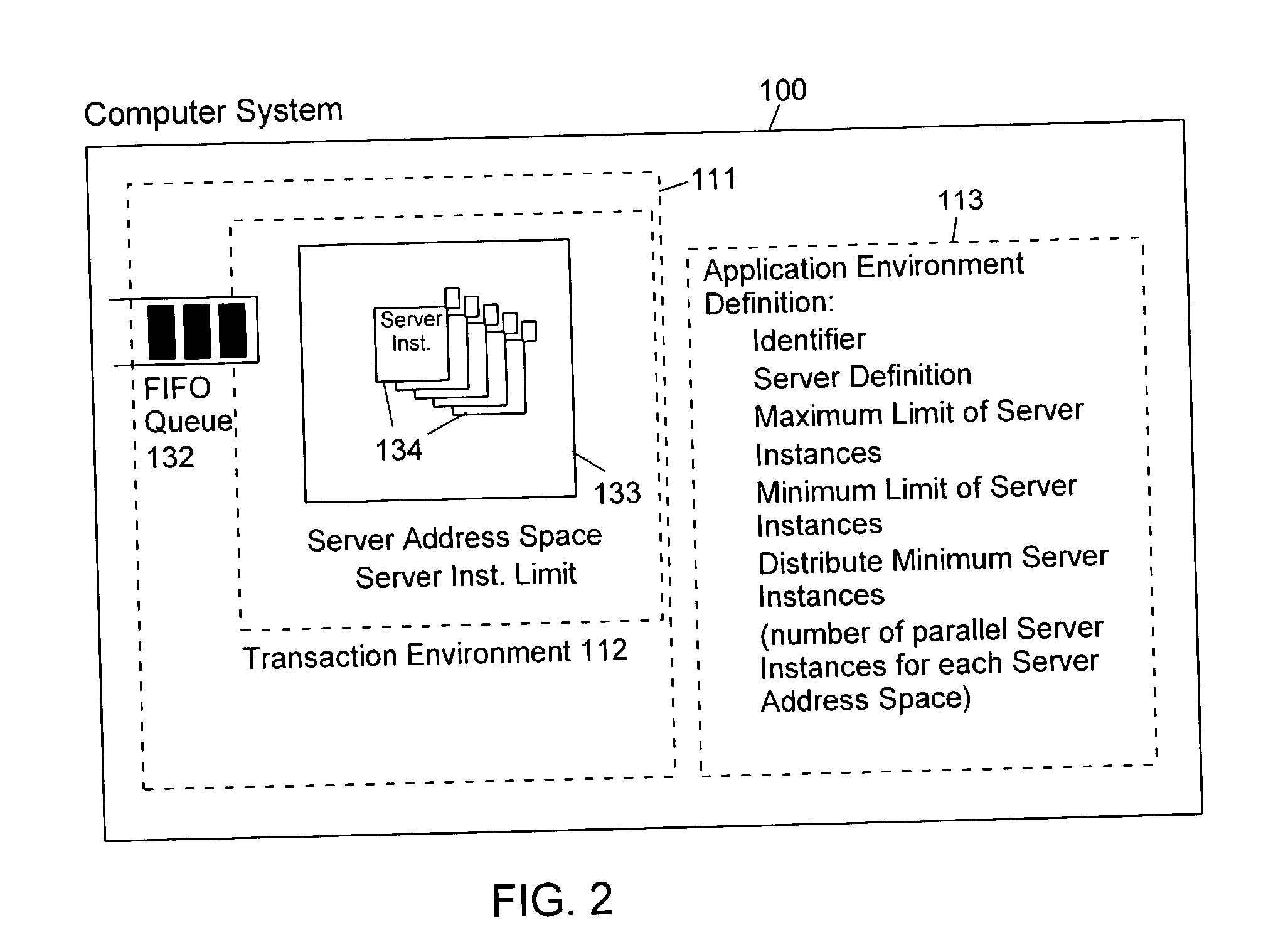

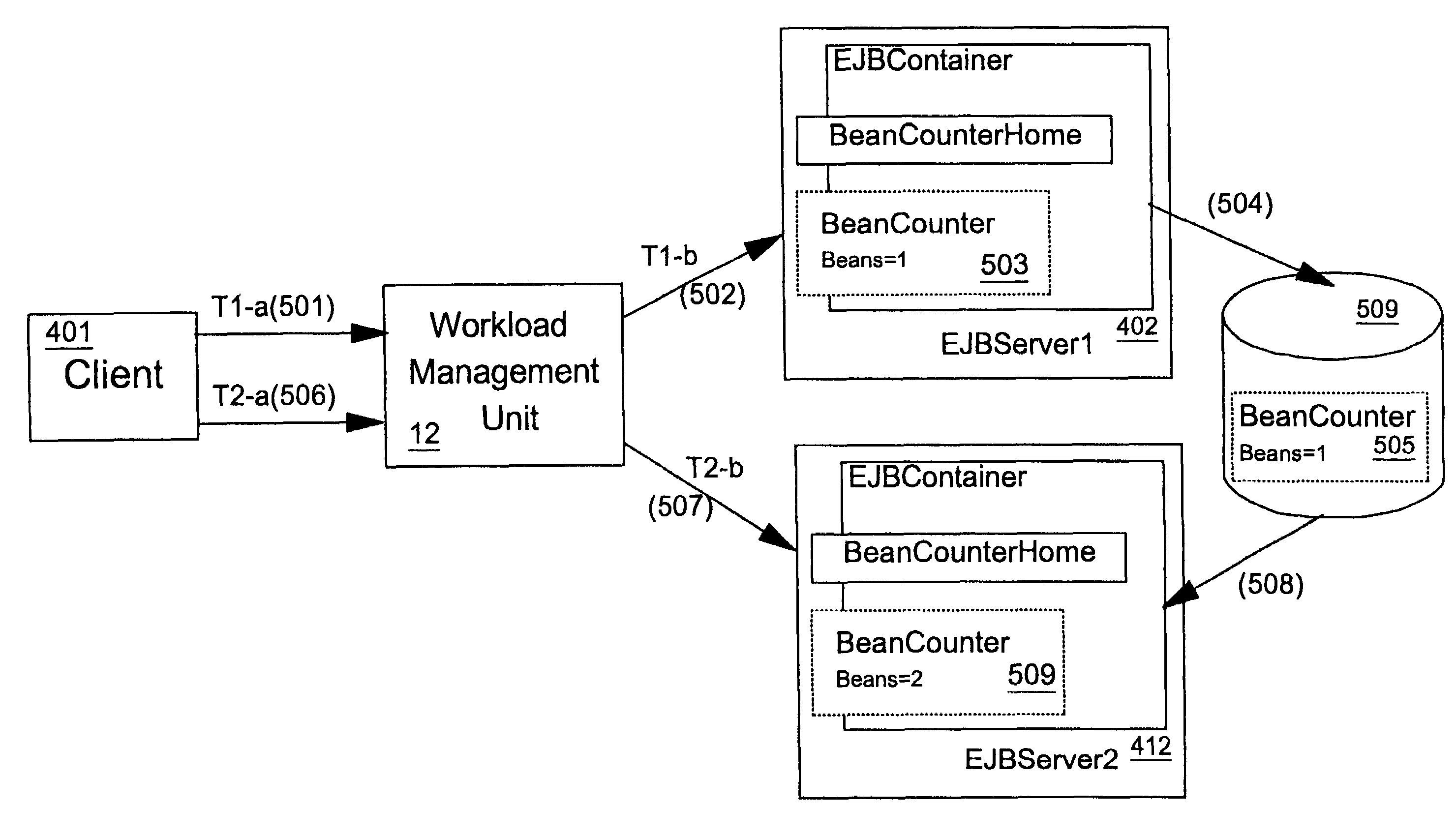

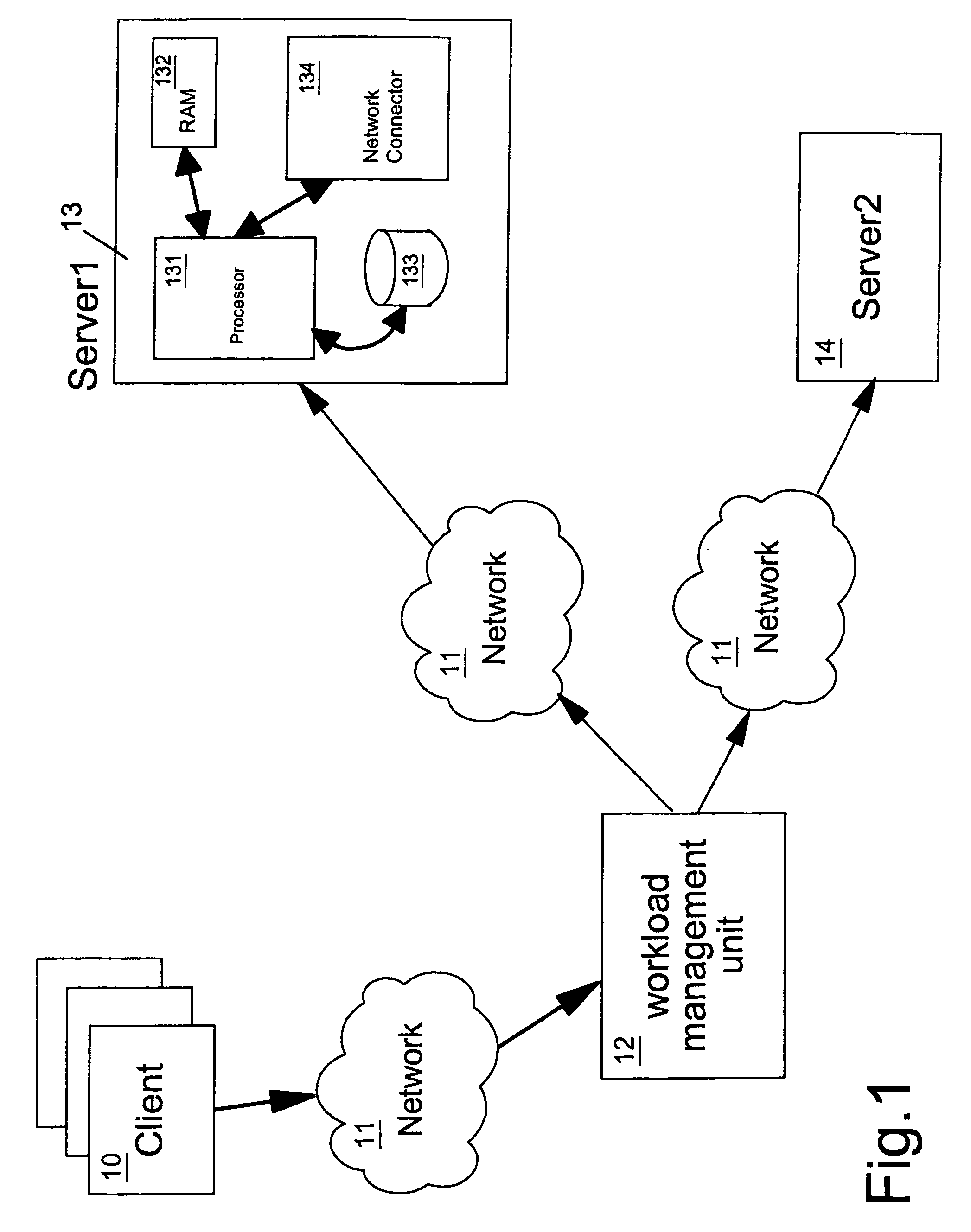

Method and apparatus for controlling the number of servers in a hierarchical resource environment

InactiveUS20030005028A1Improve overall utilizationImprove system performanceResource allocationMemory systemsResource consumptionComputerized system

The invention relates to the control of servers which process client work requests in a computer system on the basis of resource consumption. Each server contains multiple server instances (also called "execution units") which execute different client work requests in parallel. A workload manager determines the total number of server containers and server instances in order to achieve the goals of the work requests. The number of server instances started in each server container depends on the resource consumption of the server instances in each container and on the resource constraints, service goals and service goal achievements of the work units to be executed. At predetermined intervals during the execution of the work units the server instances are sampled to check whether they are active or inactive. Dependent on the number of active server instances the number of server address spaces and server instances is repeatedly adjusted to achieve an improved utilization of the available virtual storage and an optimization of the system performance in the execution of the application programs.

Owner:IBM CORP

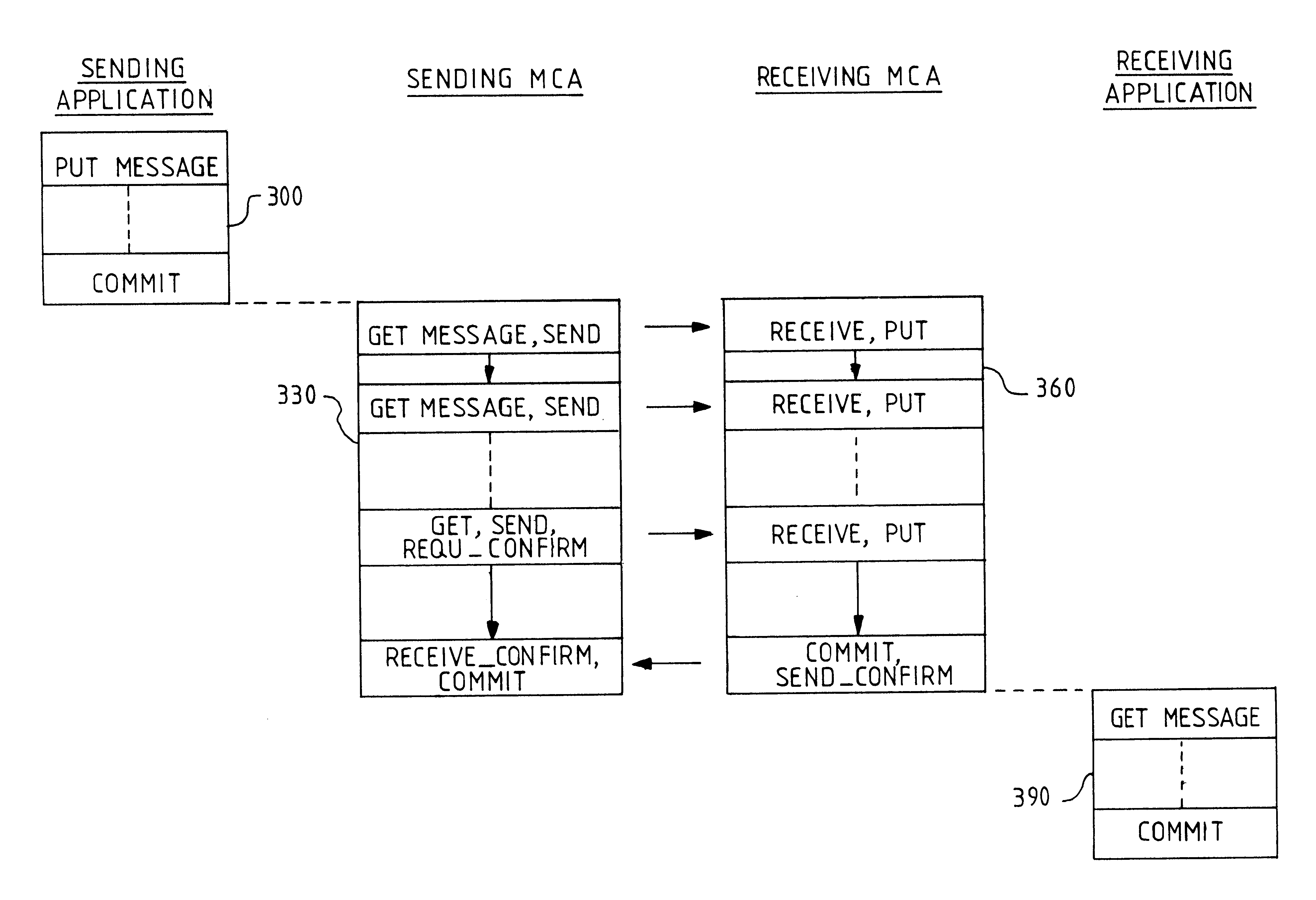

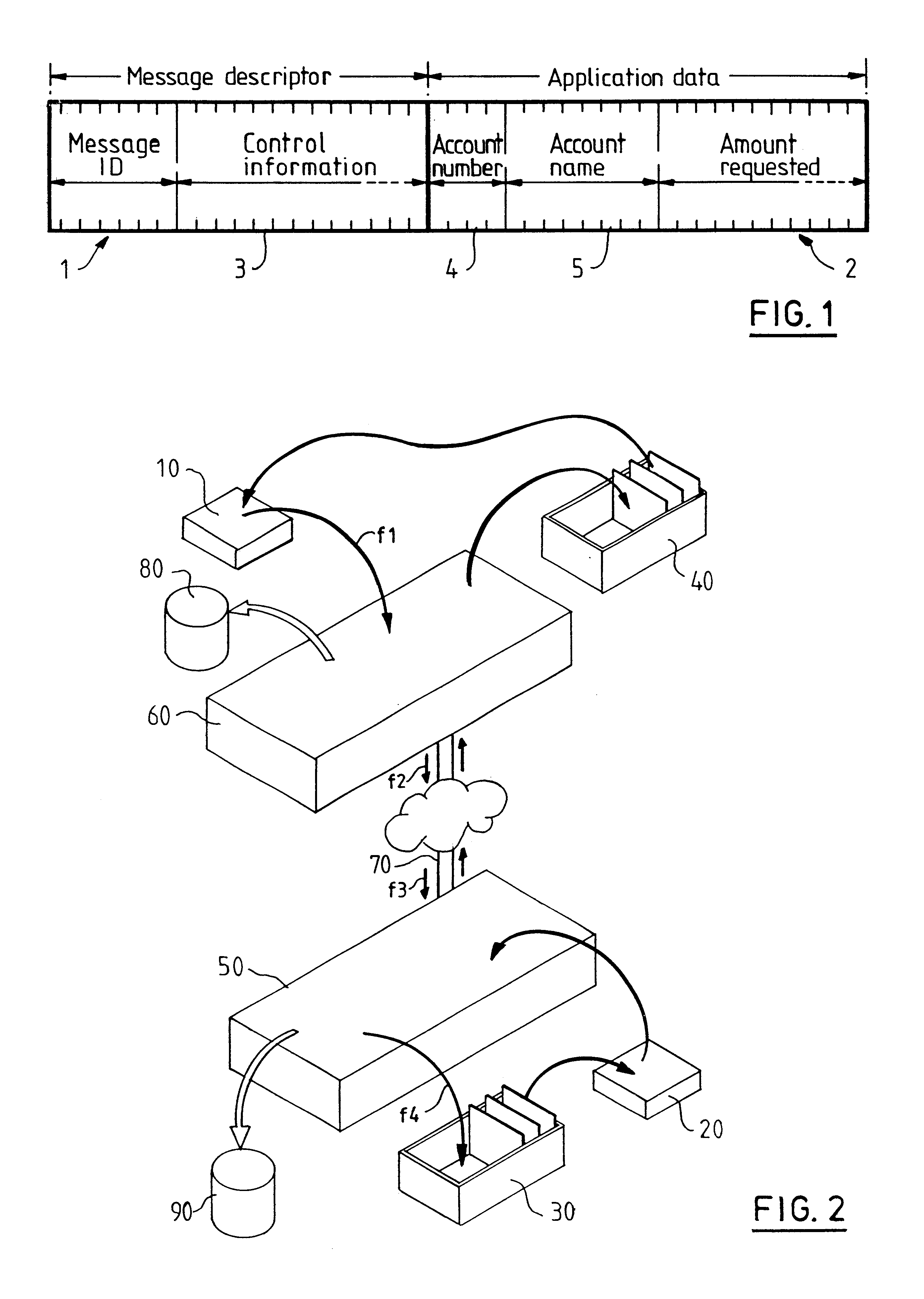

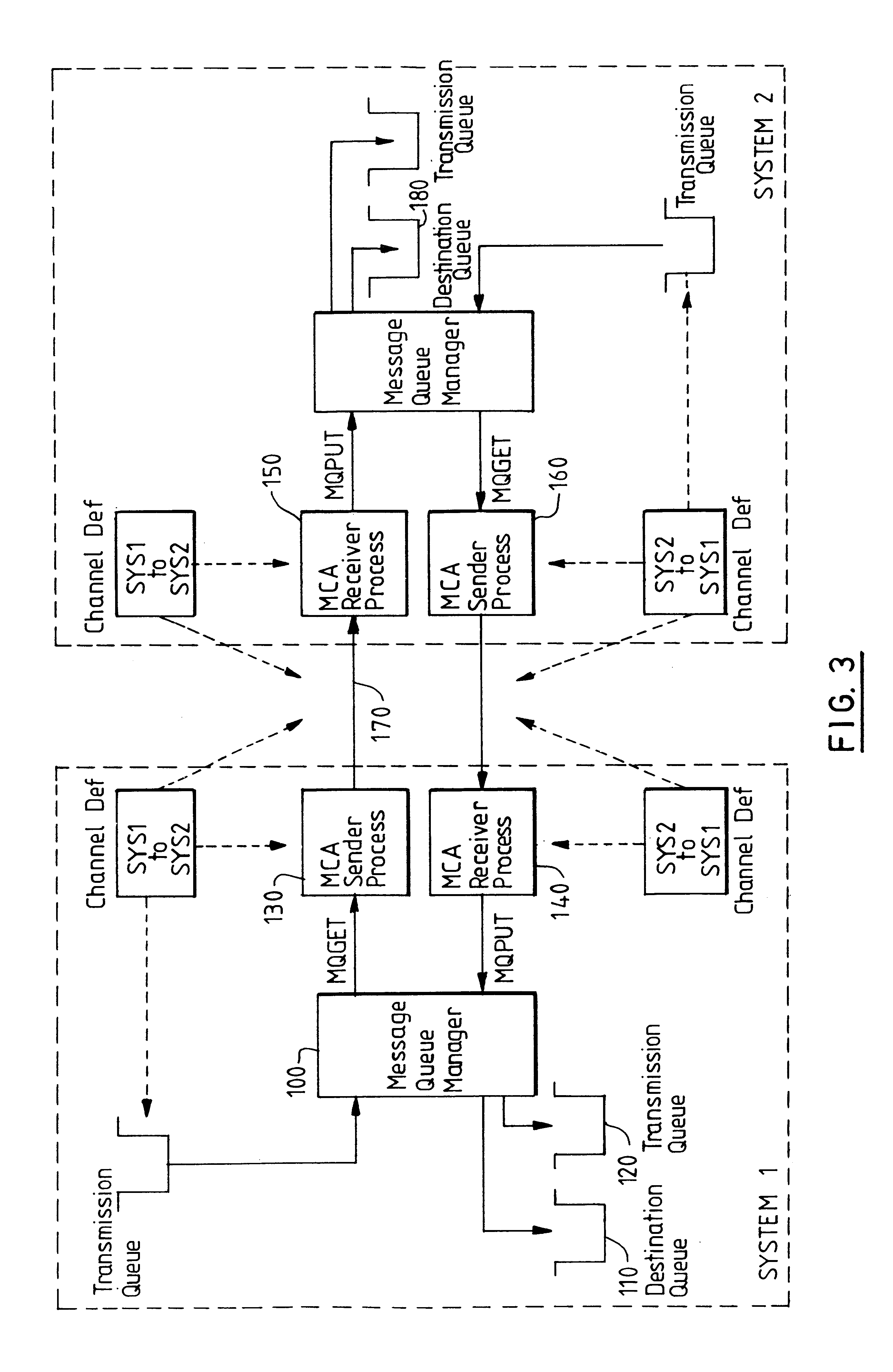

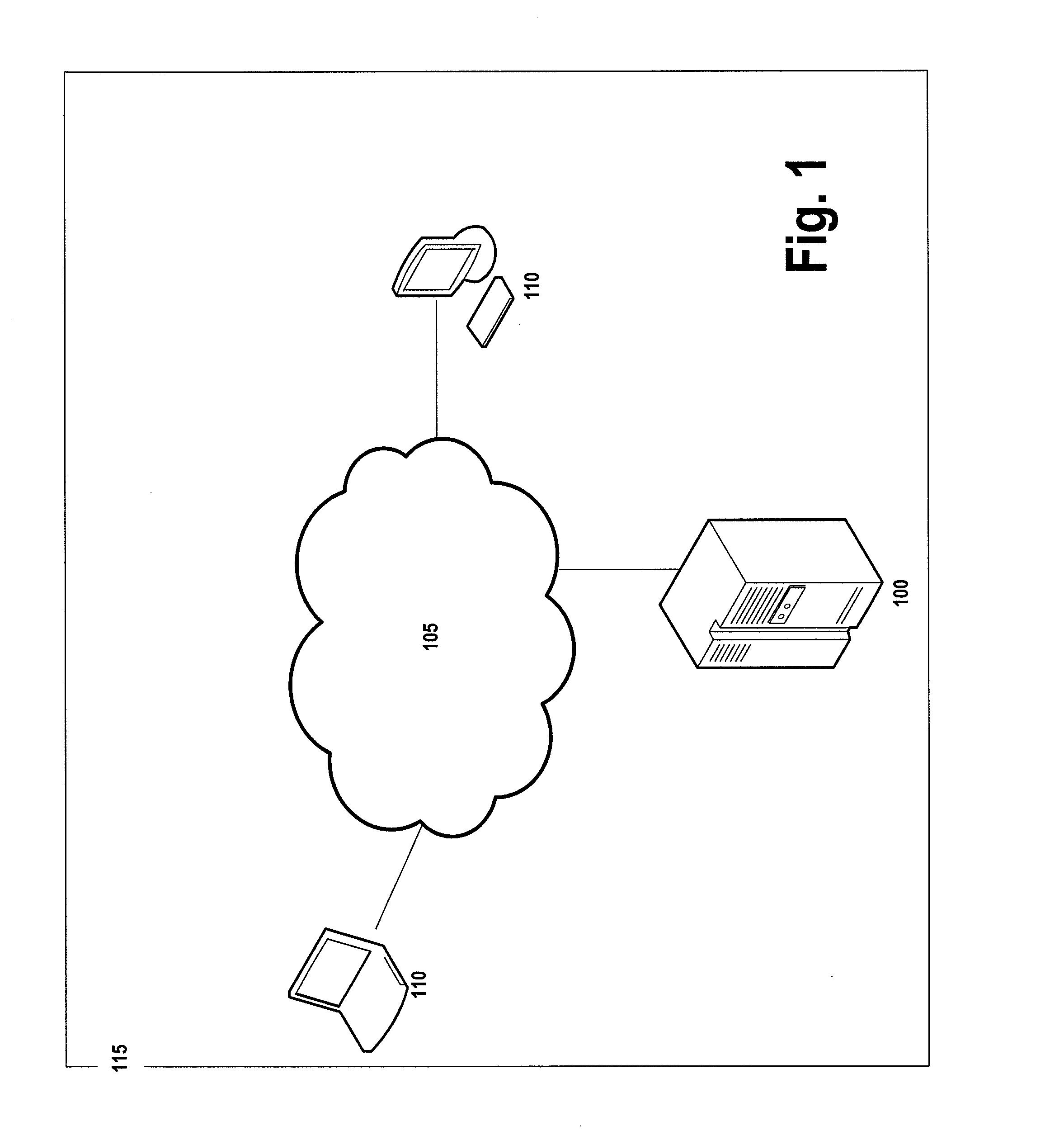

Method of transferring messages between computer programs across a network

A method of delivering messages between application programs is provided which ensures that no messages are lost and none are delivered more than once. The method uses asynchronous message queuing. One or more queue manager programs (100) is located at each computer of a network for controlling the transmission of messages to and from that computer. Messages to be transmitted to a different queue manager are put onto special transmission queues (120). Transmission to an adjacent queue manager comprises a sending process (130) on the local queue manager (100) getting messages from a transmission queue and sending them as a batch of messages within a syncpoint-manager-controlled unit of work. A receiving process (150) on the receiving queue manager receives the messages and puts them within a second syncpoint-manager-controlled unit of work to queues (180) that are under the control of the receiving queue manager. Commitment of the batch is coordinated by the sender transmitting a request for commitment and for confirmation of commitment with the last message of the batch, commit at the sender then being triggered by the confirmation that is sent by the receiver in response to the request.The invention avoids the additional message flow that is a feature of two-phase commit procedures, avoiding the need for resource managers to synchronise with each other. It further reduces the commit flows by permitting batching of a number of messages.

Owner:IBM CORP

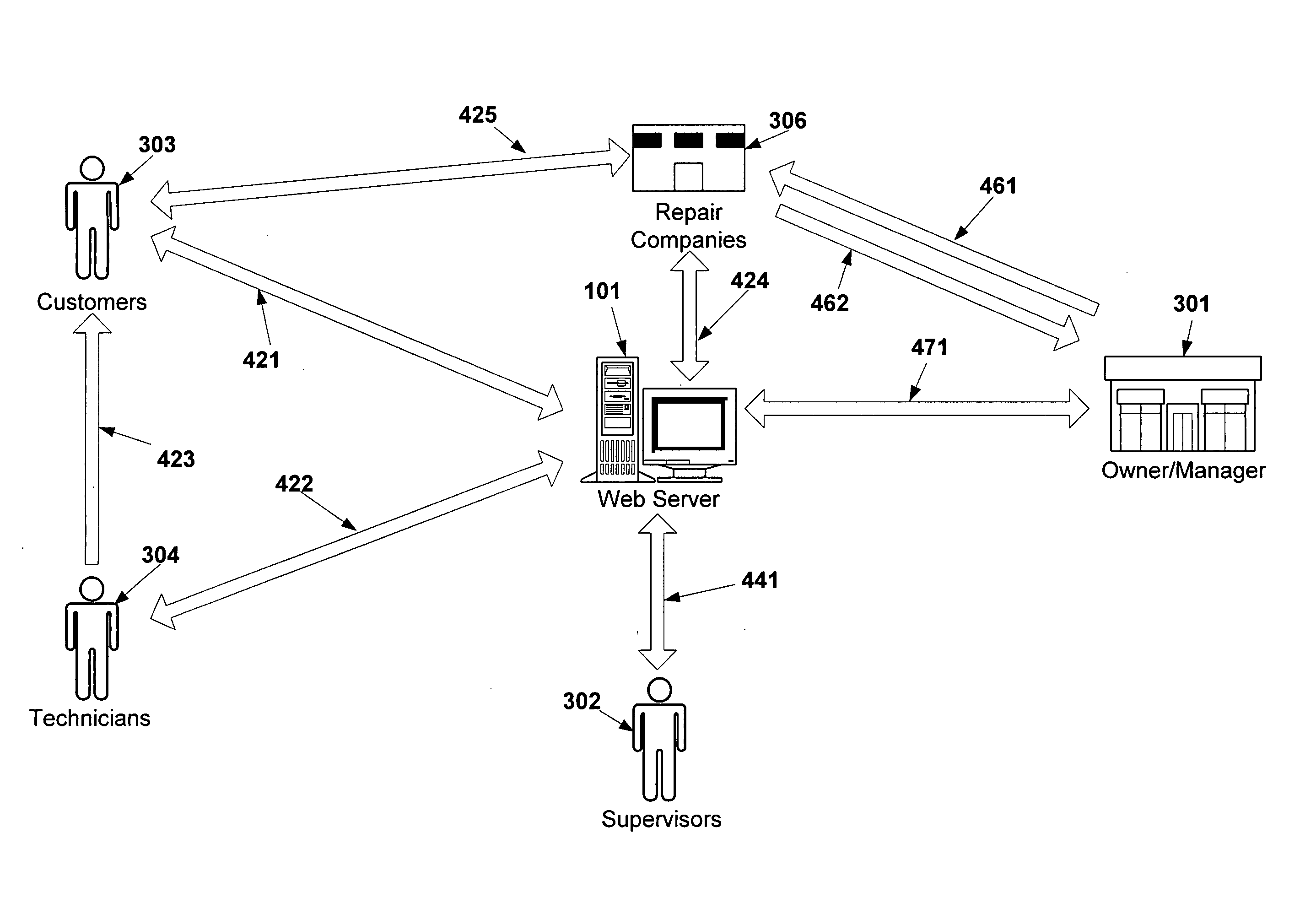

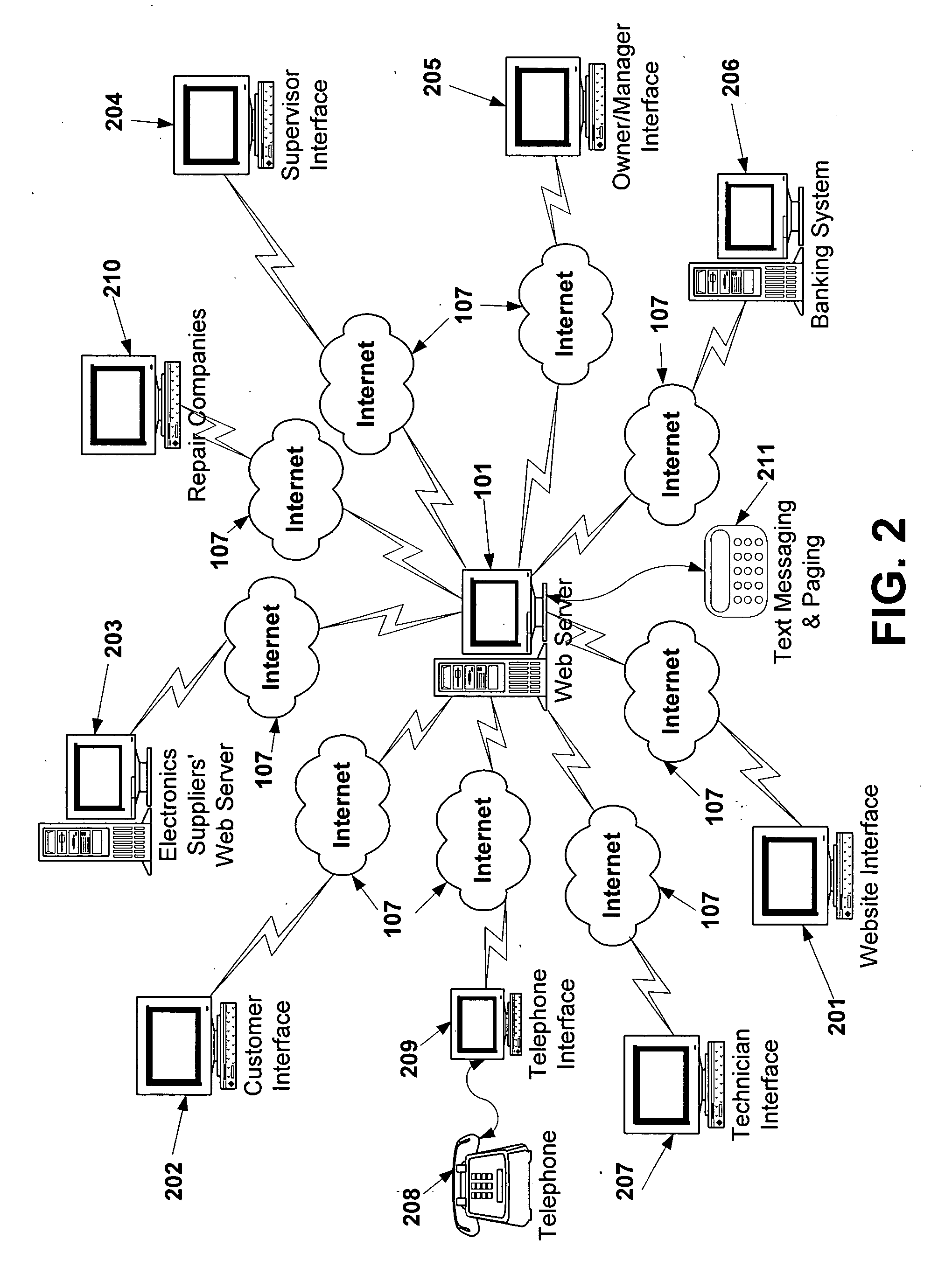

On-location electronics troubleshooting services system

InactiveUS20050015501A1Minimal supervisory involvementMultiple digital computer combinationsApparatus for meter-controlled dispensingResidenceLow voltage

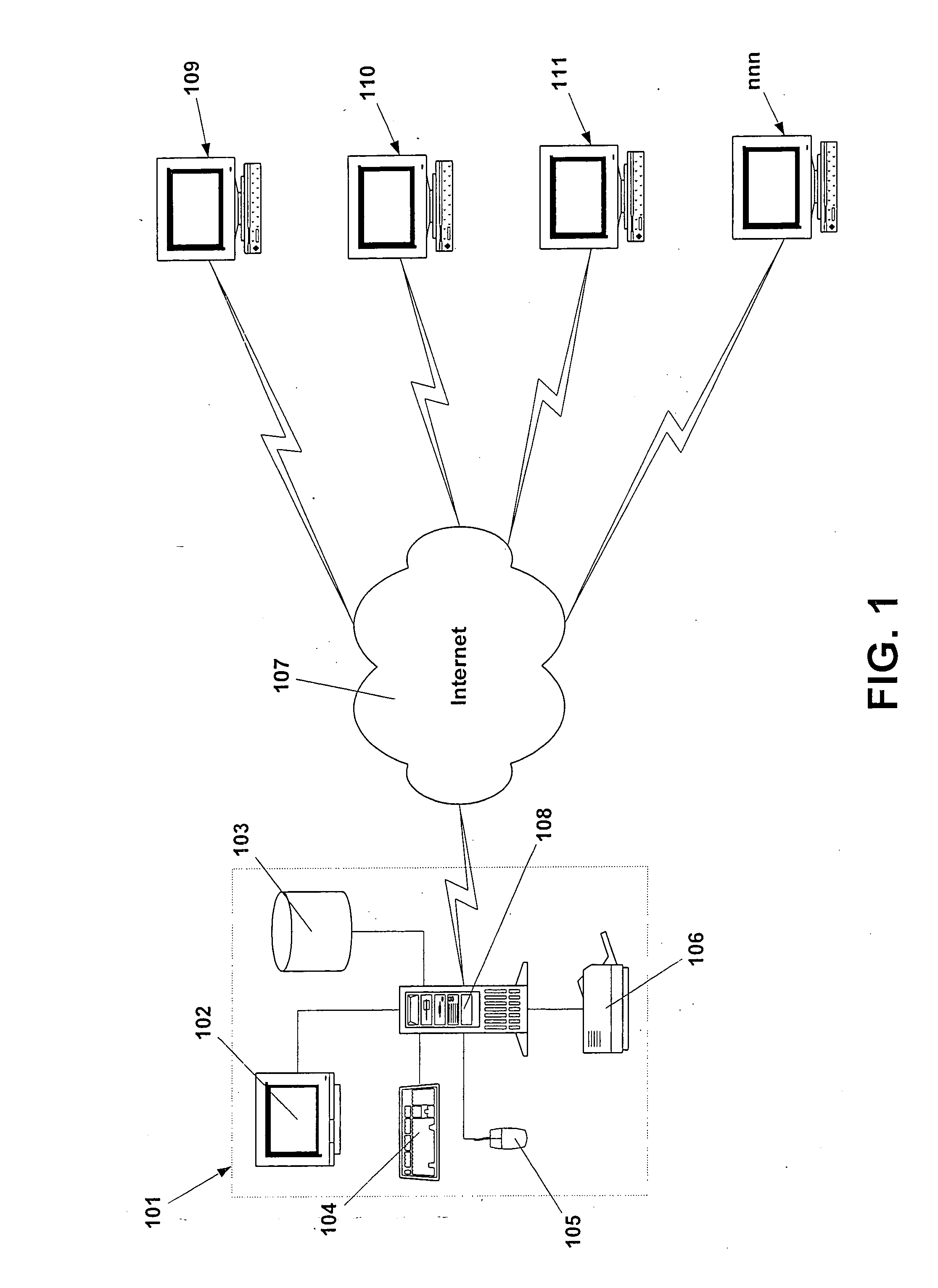

A method and system for providing on-location troubleshooting services to homeowners and businesses for low-voltage electronic equipment and other on-location services. It employs the use of an Internet-based system for recording customer requests for service and subsequently automatically dispatching technicians and managing provision of the requested services. It also provides functions to support customer and technician recruitment and sign up. Additionally, it provides functions for recording customer satisfaction, requesting repair services and links to low-voltage electronics equipment suppliers for purchasing desired low-voltage electronics equipment. Service areas, work cells are established for groups of customers which are closely located geographically. Technicians are recruited and assigned responsibility for work cells based on whether their residence is in or close to a particular work cell or group of work cells. Customers and technicians may also access certain functions of the Internet-based system through telephones and telephone interface to the Internet-based system.

Owner:KAPLAN SCOTT P +2

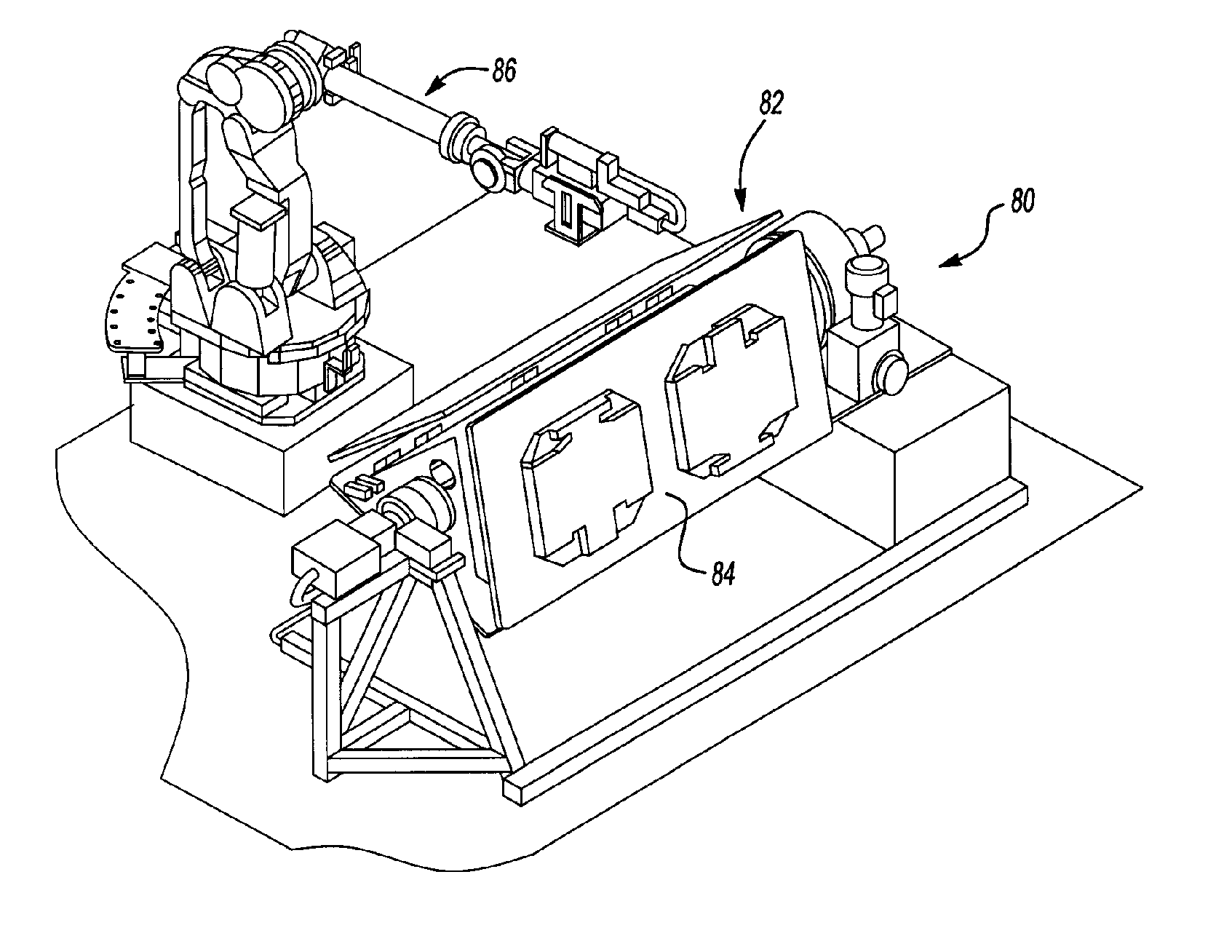

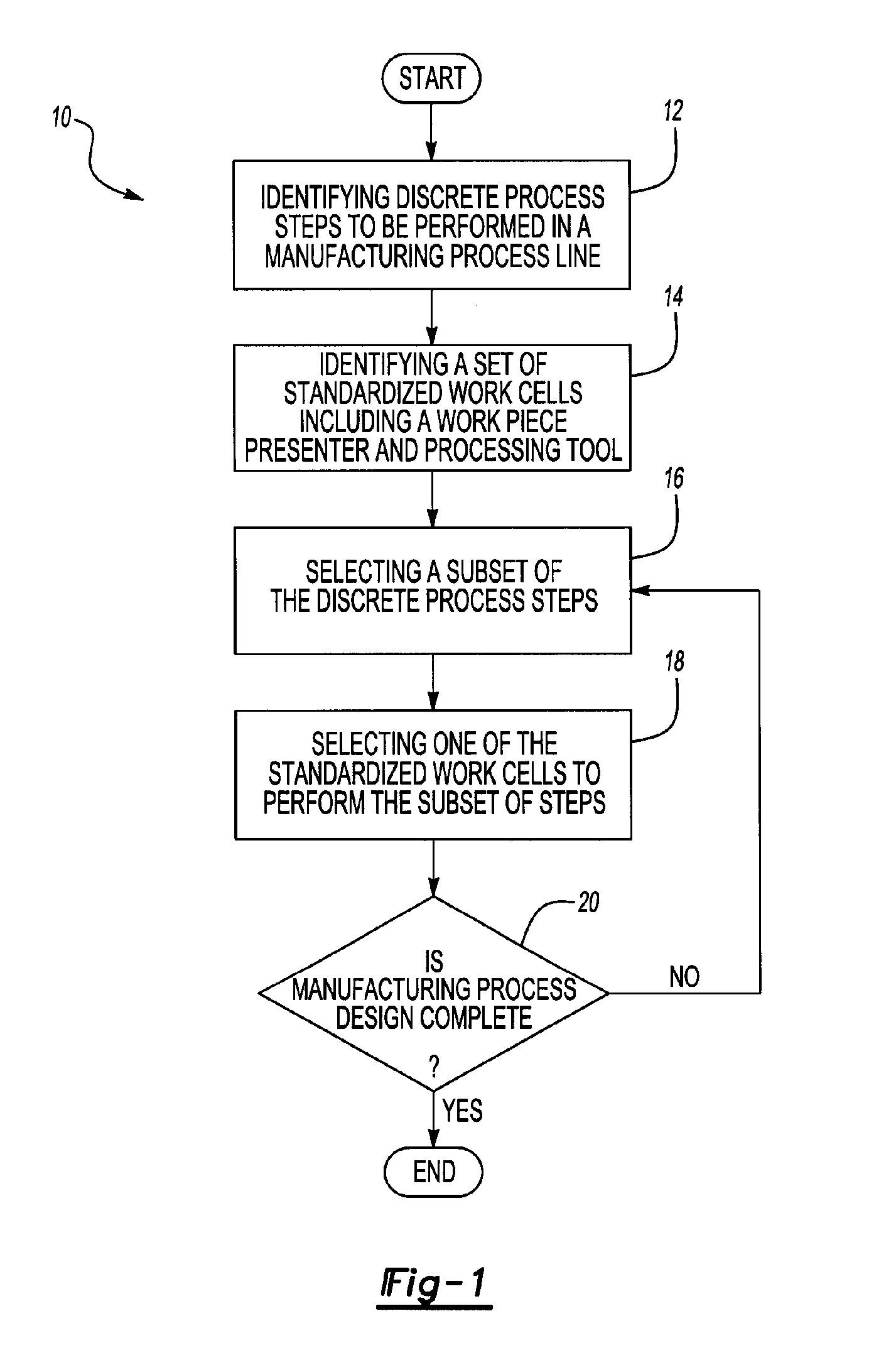

Manufacturing assembly line and a method of designing a manufacturing assembly line

InactiveUS20050044700A1Easy to adjustOptimal quality levelVehicle seatsPrecision positioning equipmentManufacturing technologyEngineering

A method of designing a manufacturing process line. A process is identified as a set of discrete steps. A subset of steps is assigned to one of a plurality of standardized work cells. The work cells include a standardized workpiece presenter and a standardized processing tool. Additional subsets of discrete steps are assigned to a standardized work cell until the design for the manufacturing process is completed.

Owner:FORD MOTOR CO

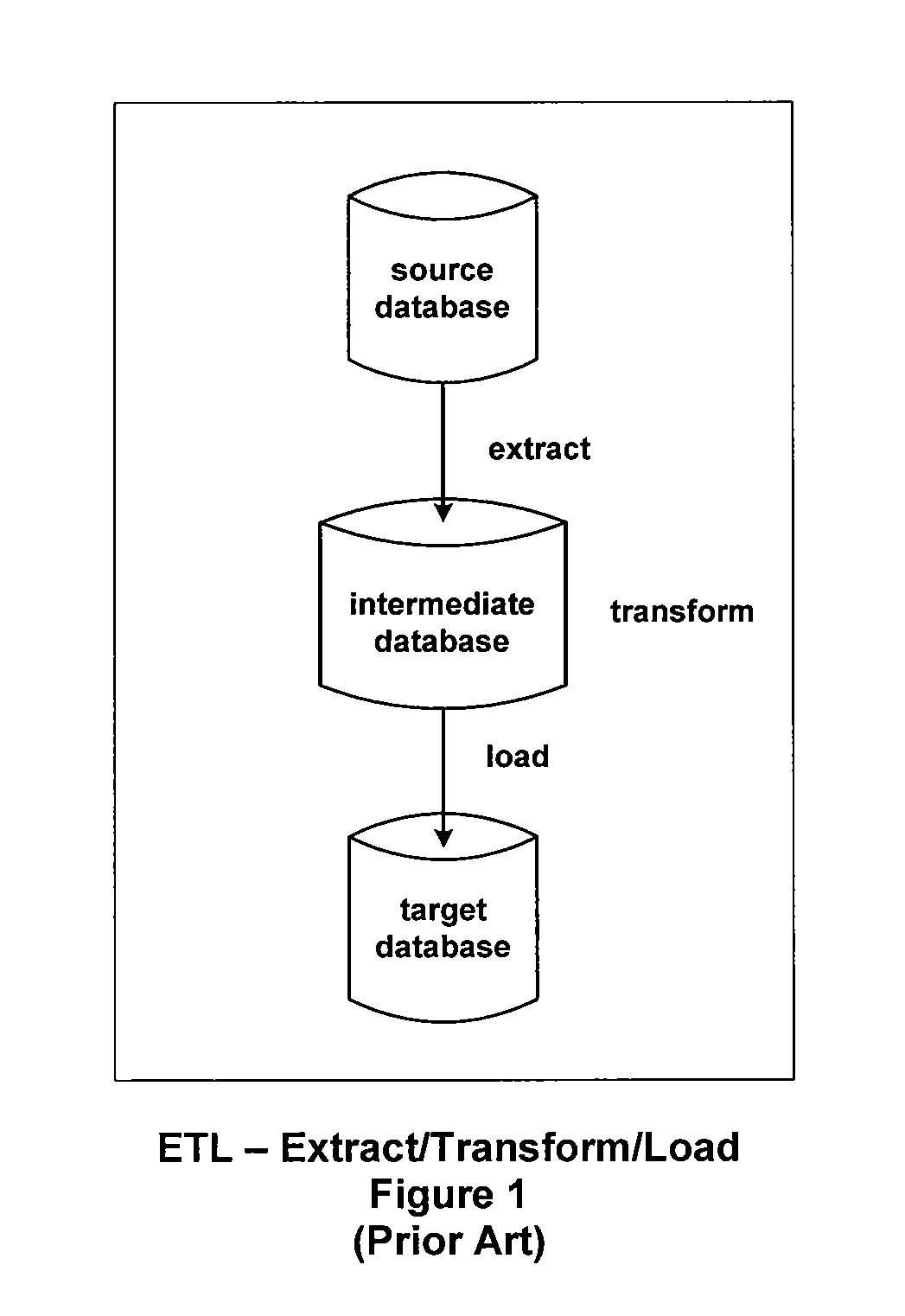

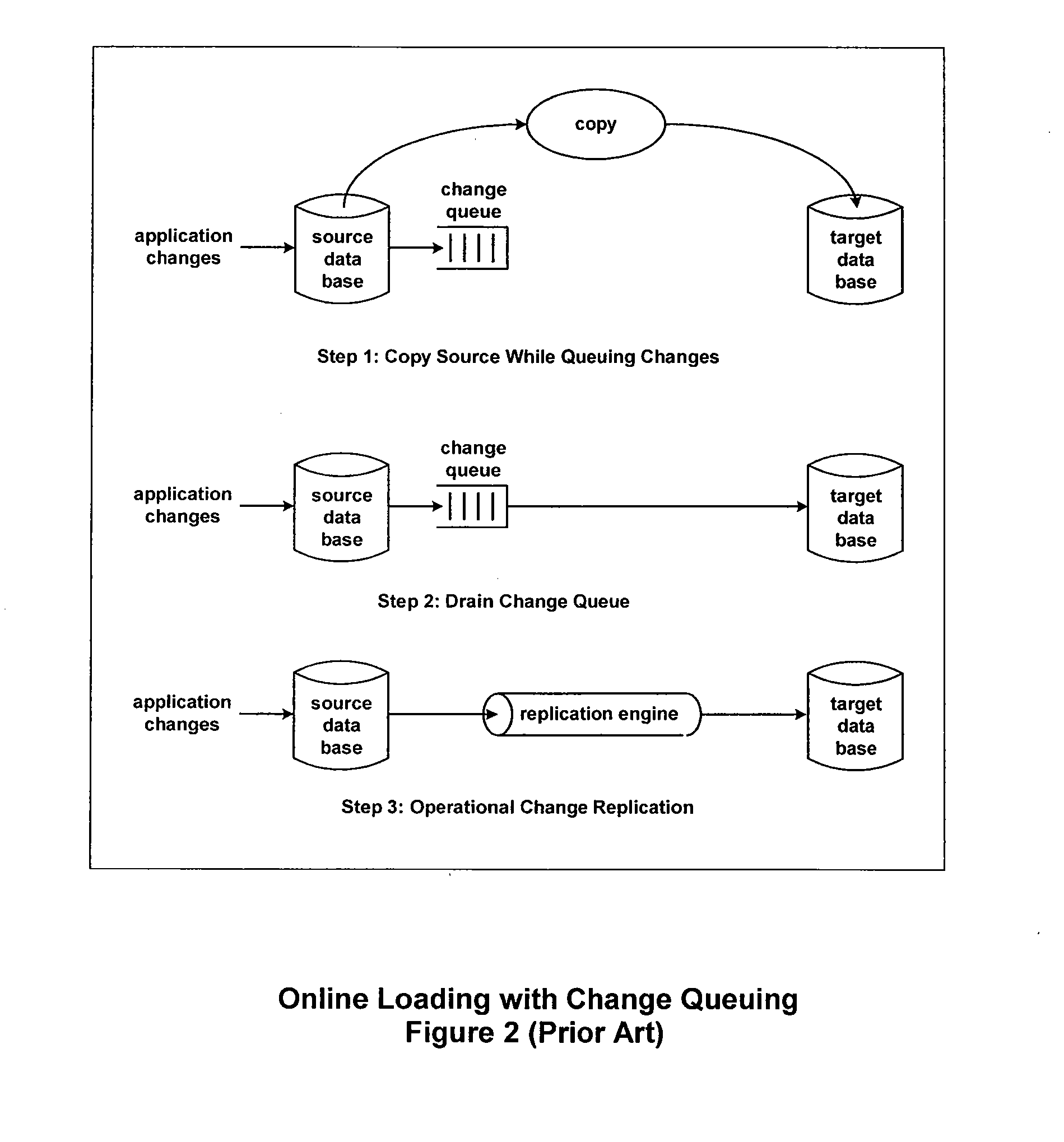

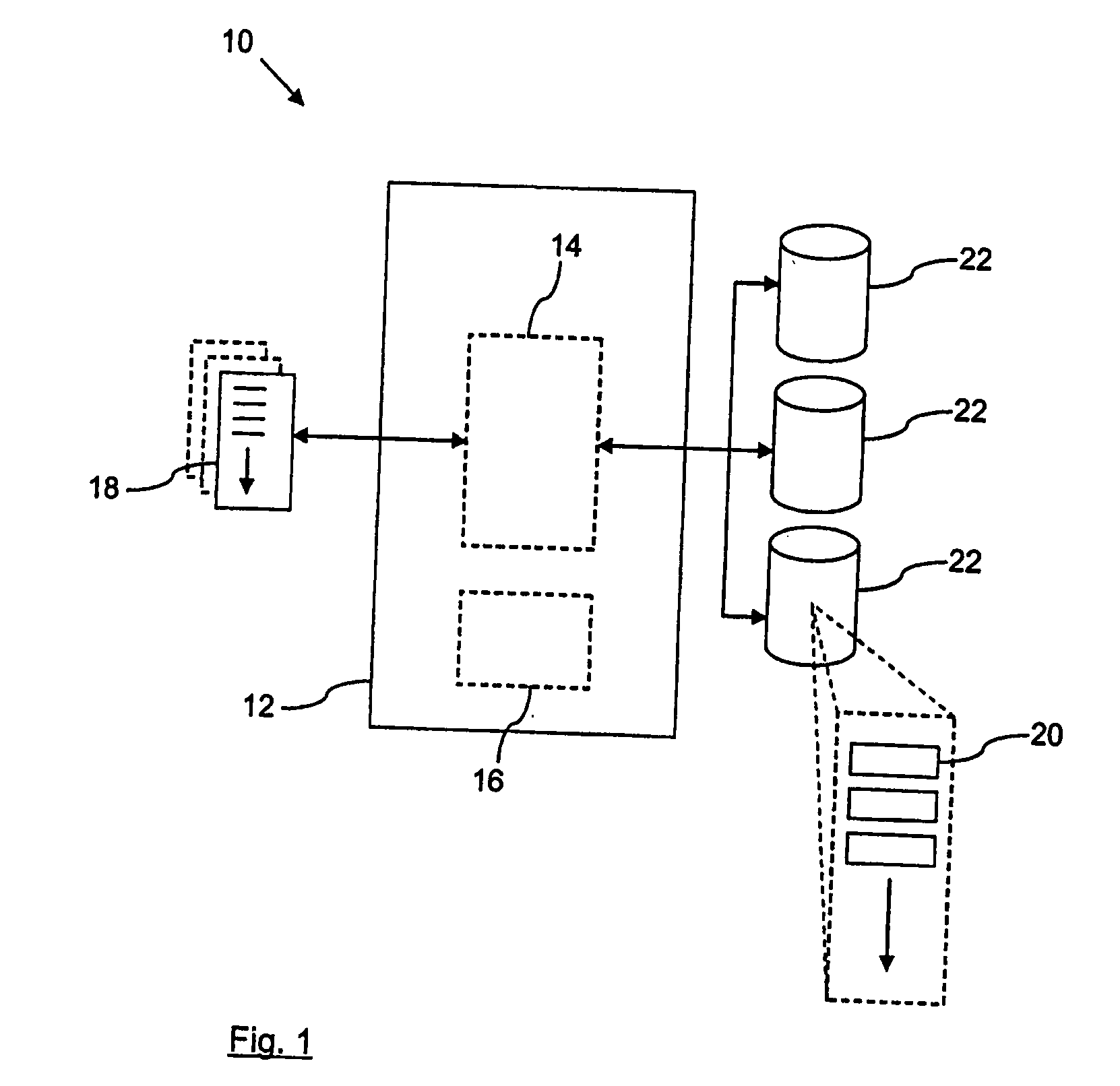

Referential Integrity, Consistency, and Completeness Loading of Databases

InactiveUS20100114841A1Digital data processing detailsSpecial data processing applicationsTarget databaseWork cell

A method is provided for loading data from a source database to a target database that includes at least one table. Prior to loading the data from the source database into the target database, at least one referential integrity constraint and / or at least one consistency requirement regarding the data is automatically identified. A subset of the data that satisfies the at least one referential integrity constraint and / or consistency requirement is then automatically identified. The identified subset of the data is then loaded into the target database as a unit of work.

Owner:INTEL CORP

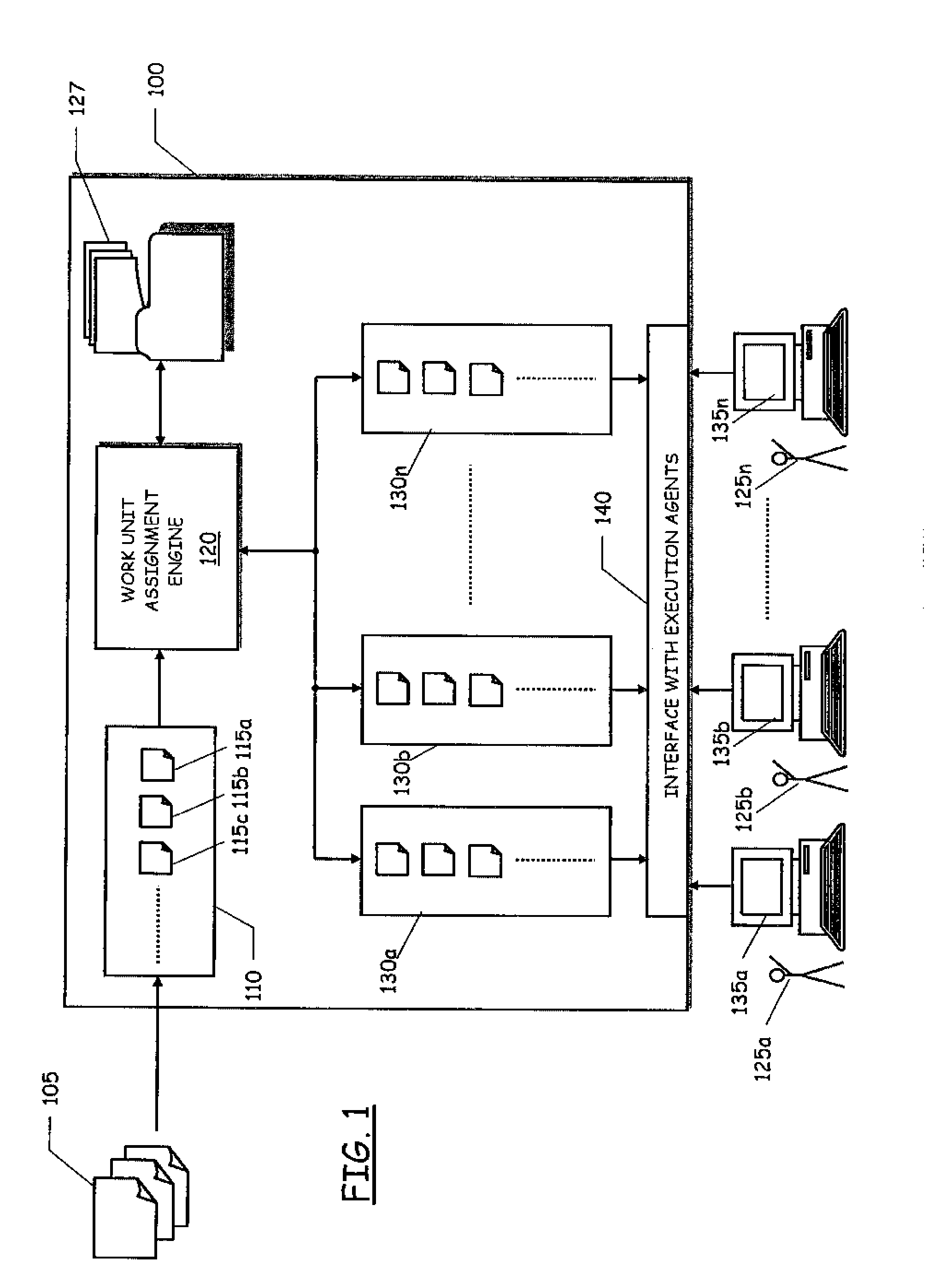

Scheduling and Assigning Units of Work

InactiveUS20110161128A1ResourcesInput/output processes for data processingGuidelineParallel computing

Systems, methods, and computer program products are provided for scheduling and assigning worker profiles to units of work. For example, in one embodiment, a scheduling system ensures that (a) workers are appropriately qualified to complete or perform units of work, (b) scheduling conflicts on a workers' schedule are avoided, and (c) customizable rules and guidelines are followed with respect to assigning the units of work.

Owner:MCKESSON FINANCIAL HLDG

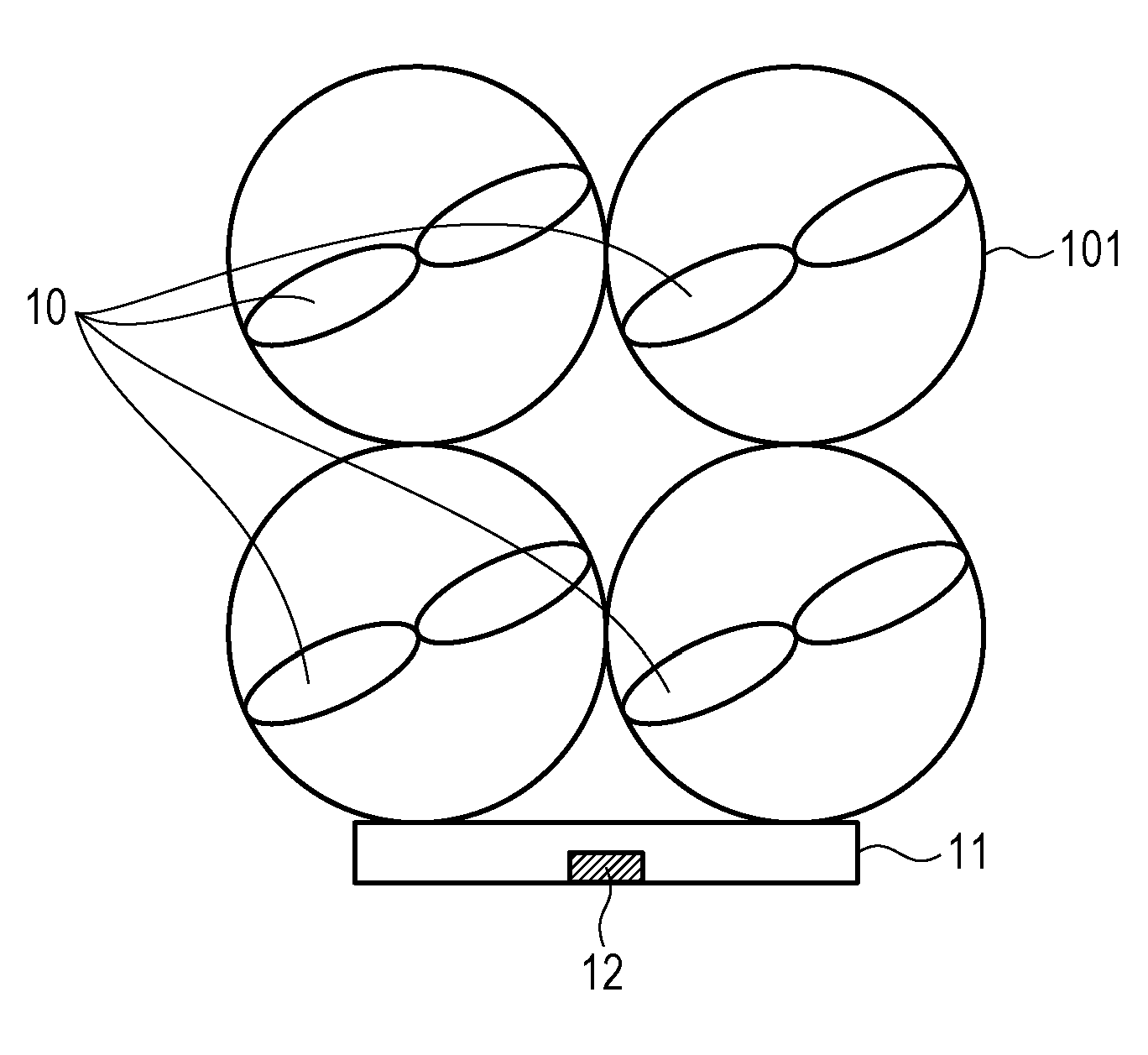

Working mechanical device and manipulator

A working unit comprises a gear body rotatable in a direction perpendicular to a reference axis, a gear ring including a proximal end surface held in contact with the gear body and rotatable about the reference axis to change the direction of rotation of the gear body, a first end effector body held in contact with an axially distal end surface of the gear ring at an upper portion thereof, and rotatable about a rotational axis perpendicular to the reference axis to change the direction of rotation of the gear ring, and a second end effector body held in contact with the axially distal end surface of the gear ring at a lower portion thereof, and rotatable in a direction opposite to the direction in which the first end effector body rotates, about the rotational axis. The first end effector body and the second end effector body are openable and closable symmetrically with respect to the reference axis.

Owner:KARL STORZ GMBH & CO KG

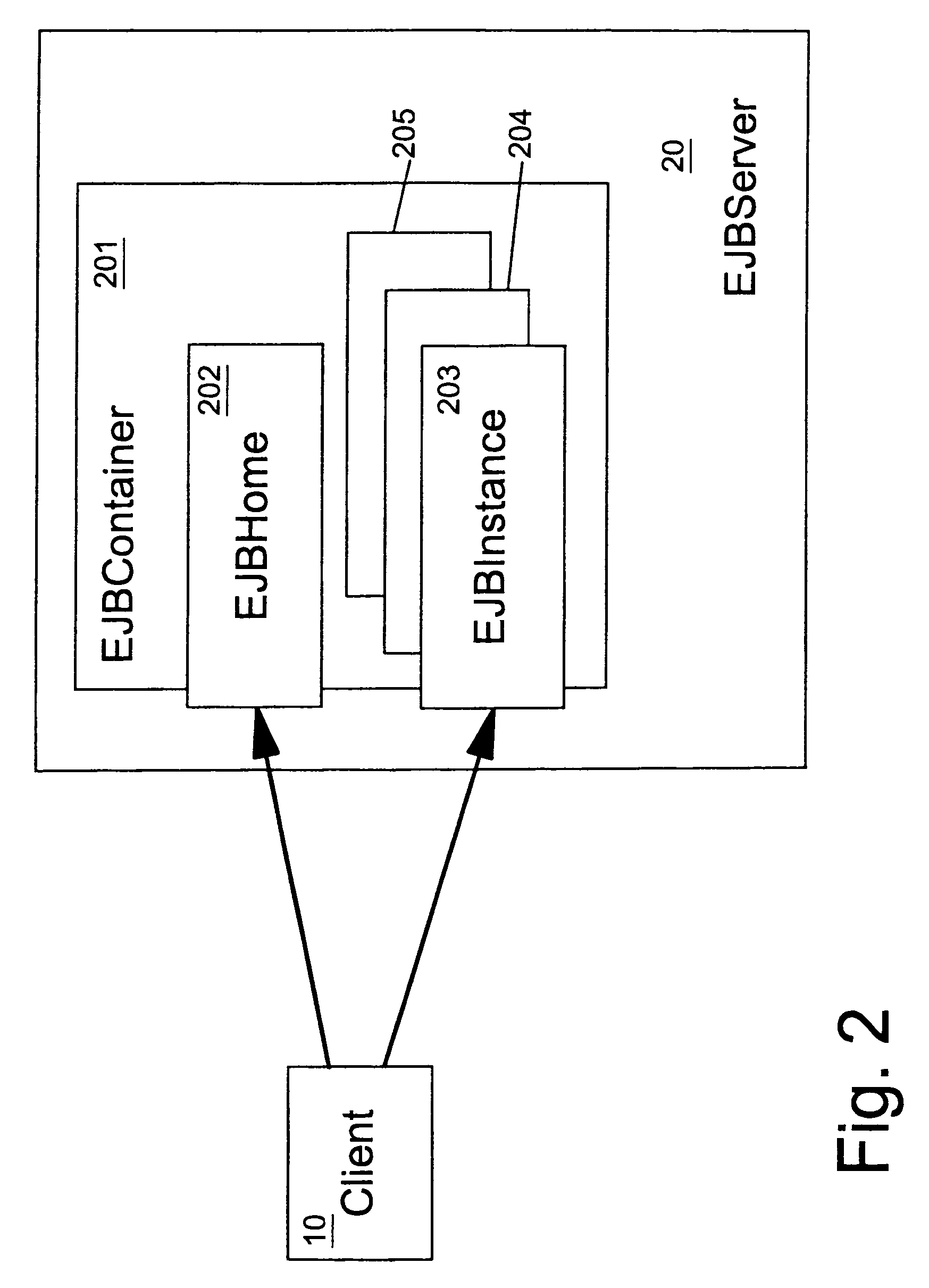

Workload management of stateful program entities

InactiveUS7349970B2Need be provideReduce accessResource allocationMultiple digital computer combinationsMass storageRouting table

In a workload managed system comprising a plurality of server processes each capable of supporting a given program entity, such as an Enterprise JavaBeans™ specified stateful session bean, a stateful session bean instance is passivated, by writing it to a bean store, on completion of a unit of work. On next use the session bean is reactivated, by reading it from the bean store, in any one of the plurality of servers thereby allowing workload management for stateful session beans. A routing table is maintained, in non-volatile mass storage, that contains location information for units of work and stateful session bean instances, used to maintain unit of work-server affinity for the lifetime of the unit of work Stateful session beans instances are associated with ID keys that include a flag that is used to indicate whether or not the routing table contains location information for the bean instance.

Owner:GOOGLE LLC

Error proofing system for portable tools

A system for controlling and monitoring portable tools at a particular work cell remotely by R-F communication to provide error proofing of various parameters including that the correct tool is to be used at a work cell, the tool is properly calibrated for the operation to be performed, that it is being used a proper number of times per part being assembled or inspected, and that the tool has been calibrated within a selected service interval. The tools will be made actuable only by R-F communication with specific factory apparatus whereby theft of such portable tools will be inhibited.

Owner:ATLAS COPCO INDAL TECHN AB

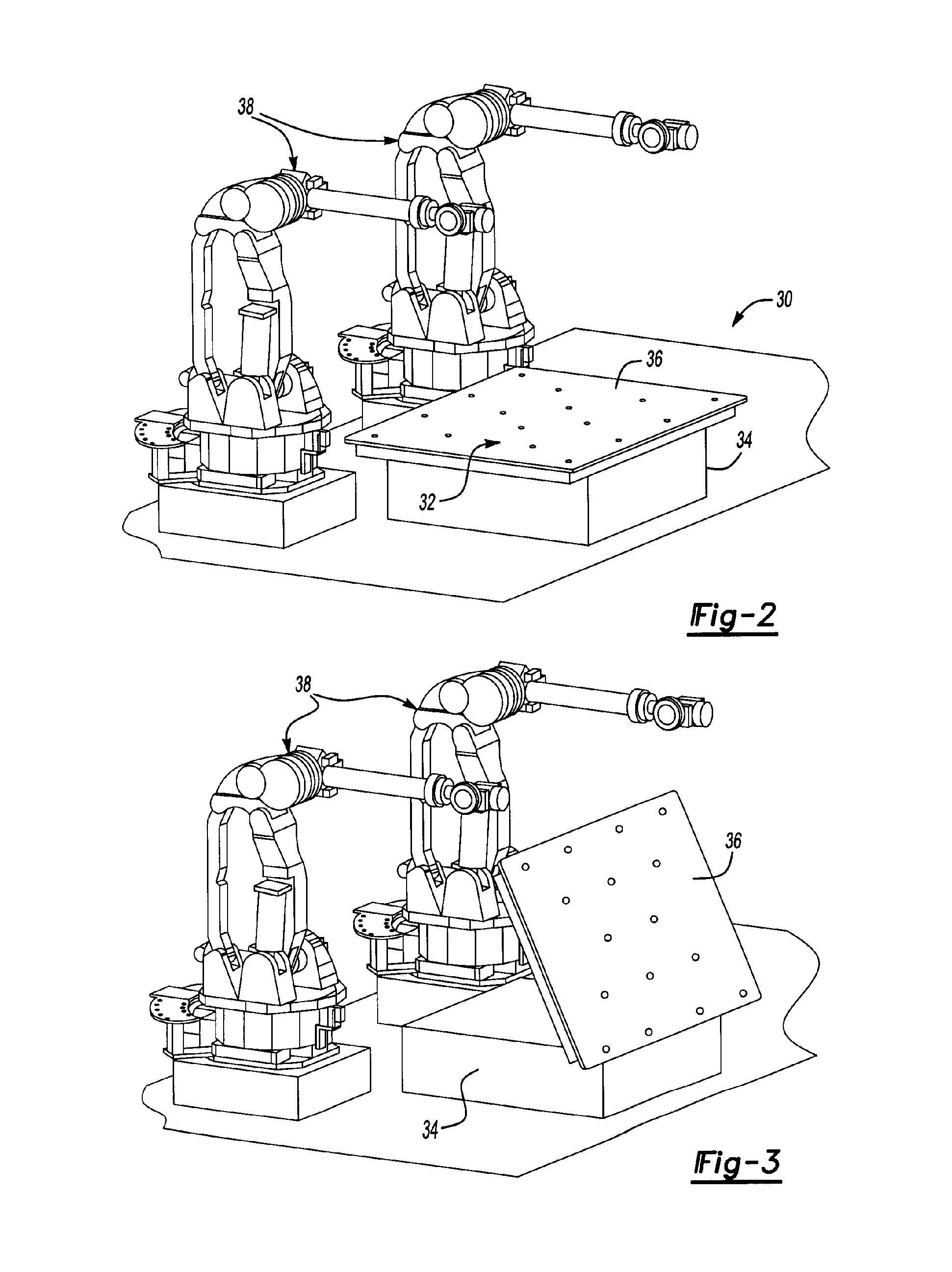

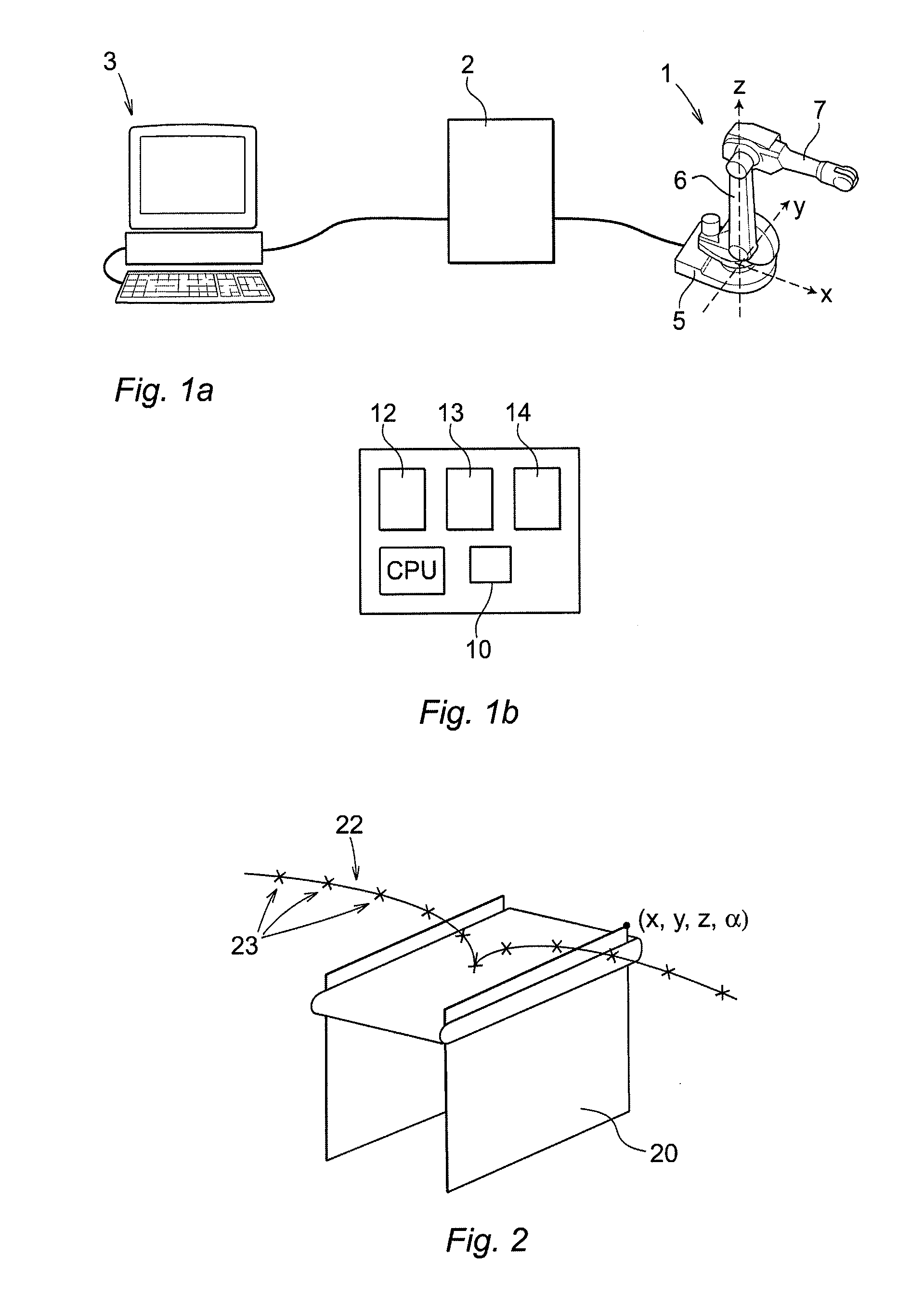

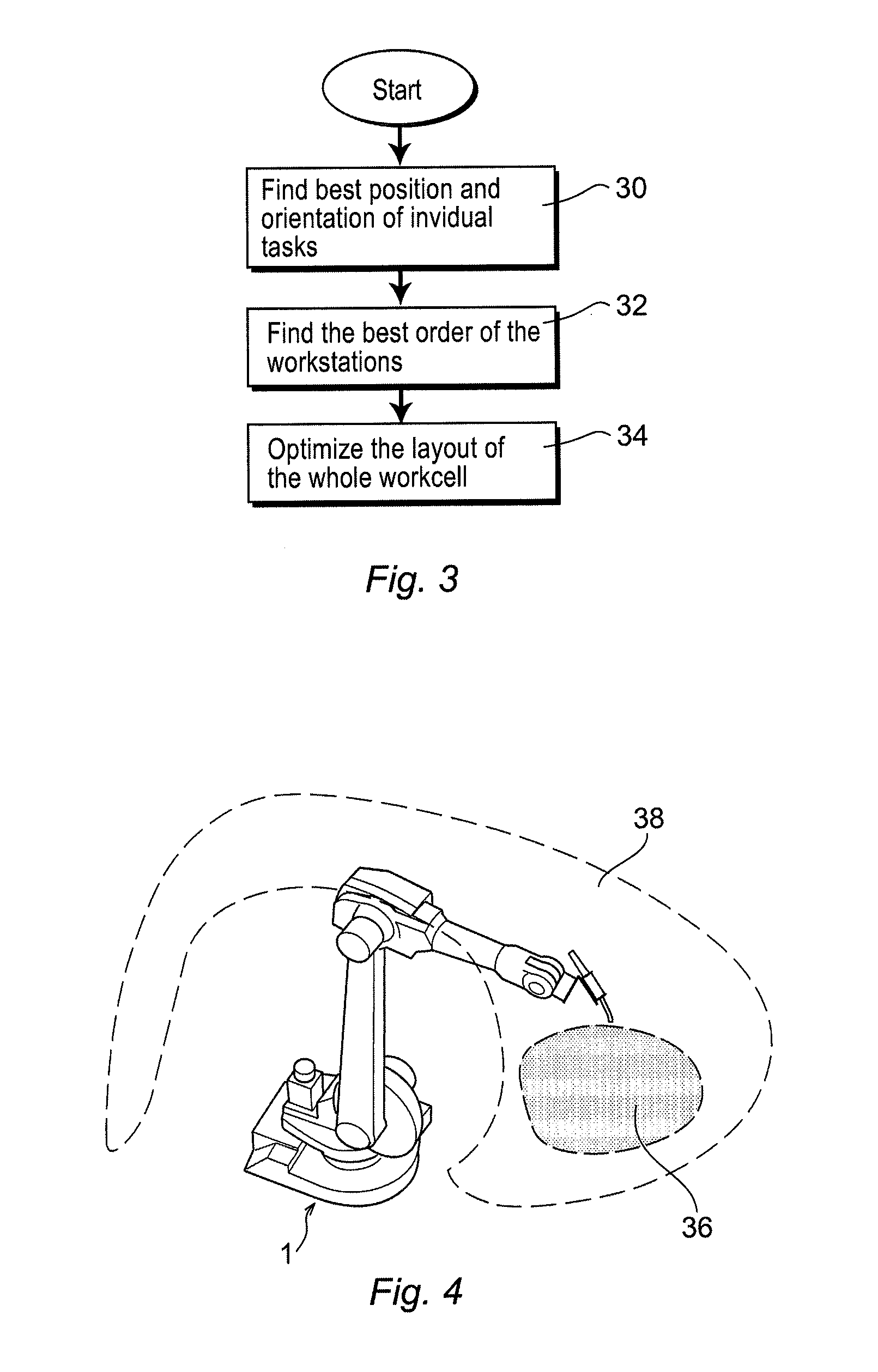

Method and system for optimizing the layout of a robot work cell

InactiveUS20100241248A1Improve productivityImprove performanceComputer controlSimulator controlSimulationWorkstation

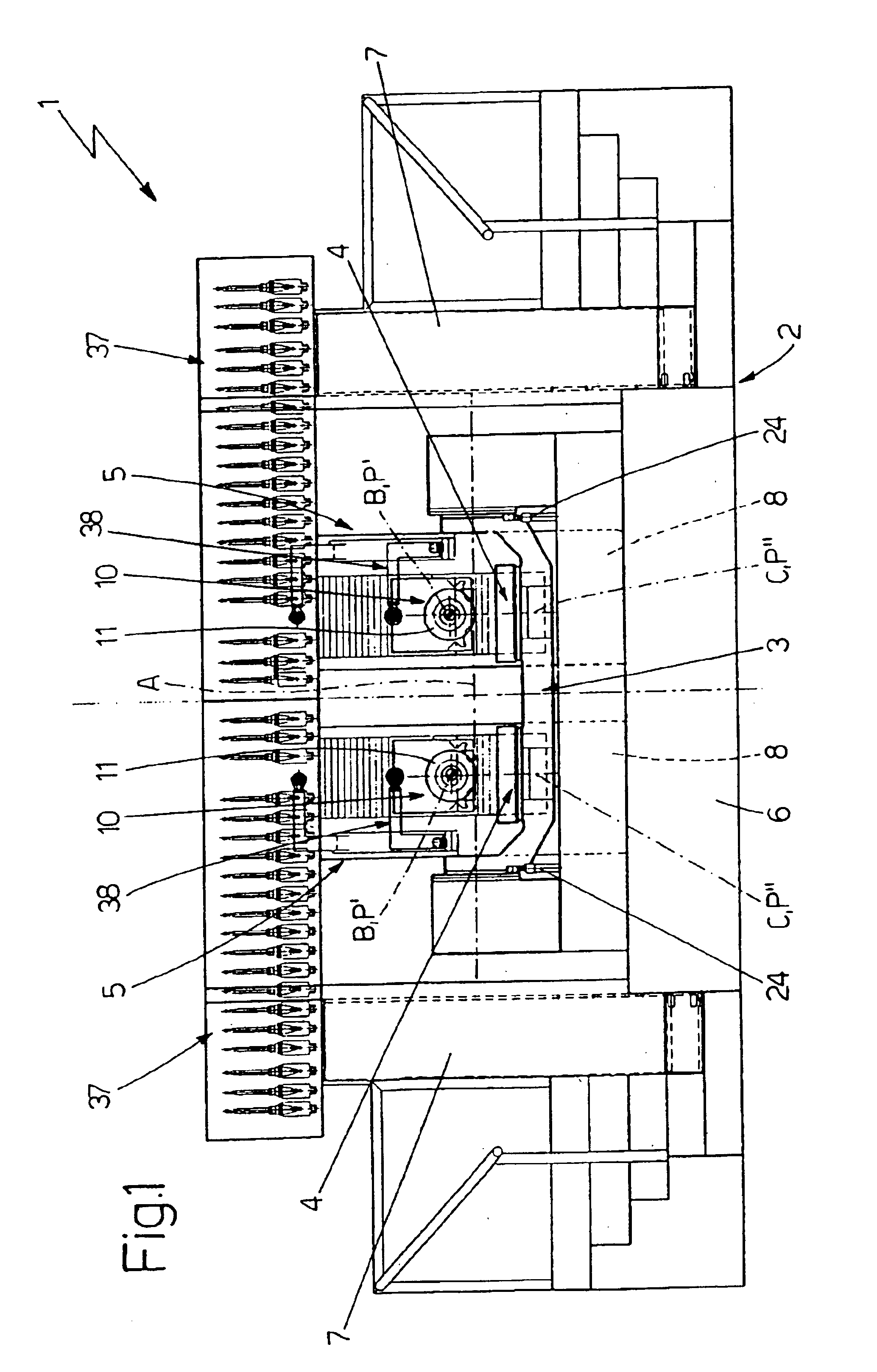

The present invention relates to a method for optimizing the placement of a plurality of workstations (20a-d) in a workcell including an industrial robot (1) programmed to execute a sequence of tasks on the workstations, wherein each task contains a series of robot targets linked as one or several paths to be visited by the robot when executing the task at the workstation. The method comprises the following steps: a) defining a preferred region (36) within the reachable range of the robot, placing the tasks inside or as close as possible to the preferred region using an evaluation criterion and an optimization algorithm, and based thereon assigning to each workstation a position inside or close to the preferred region, b) determining by means of an optimization algorithm a best order of the workstations to be placed relative to the robot with regard to the robot performance and a defined order in which the tasks has to be executed, and based thereon adjusting the positions of the workstations, and c) adjusting the positions (x, y, z, α) of the workstations by means of an optimization algorithm configured to run the robot program iteratively in order to optimize the placement of the workstations with regard to the robot performance.

Owner:ABB RES LTD

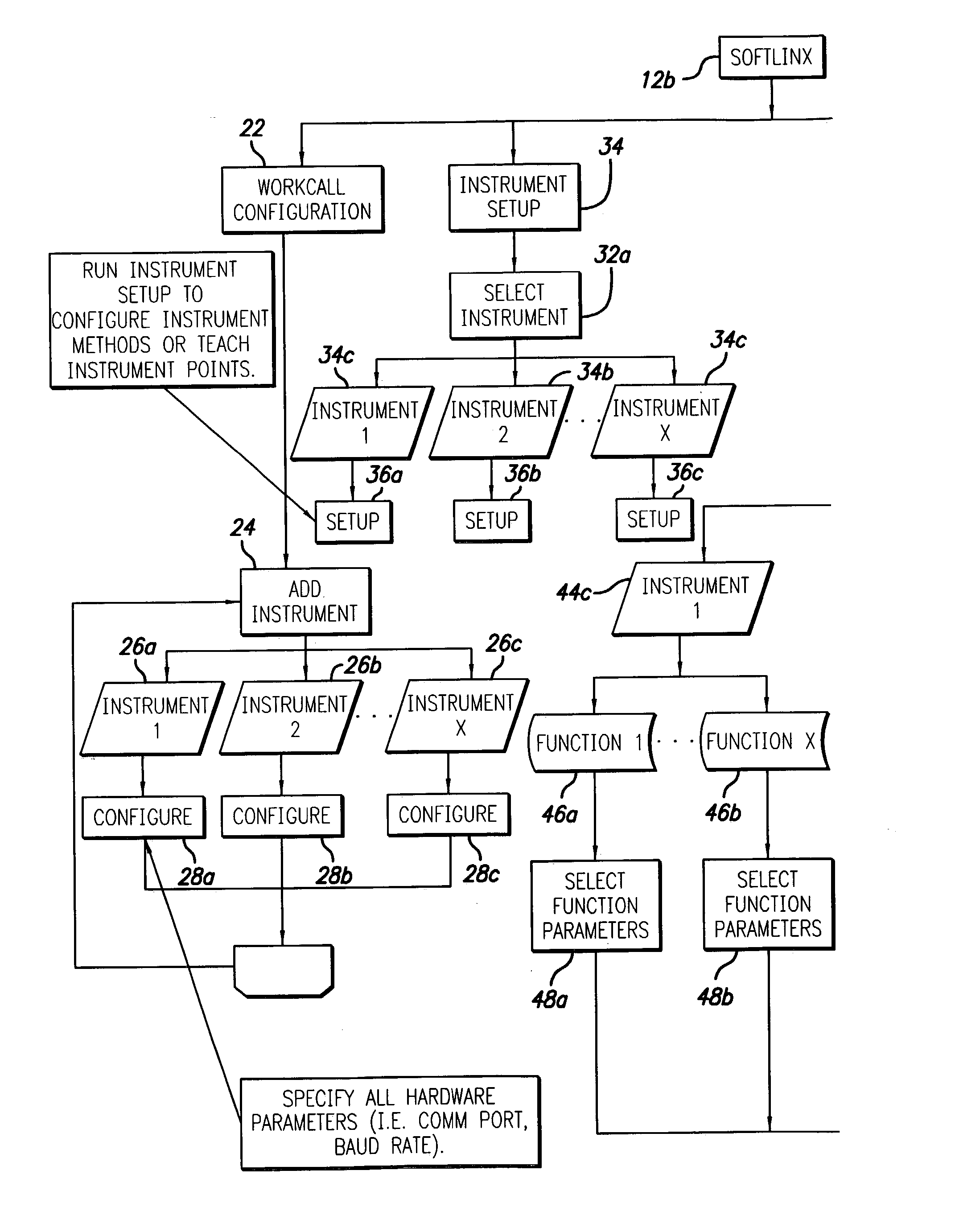

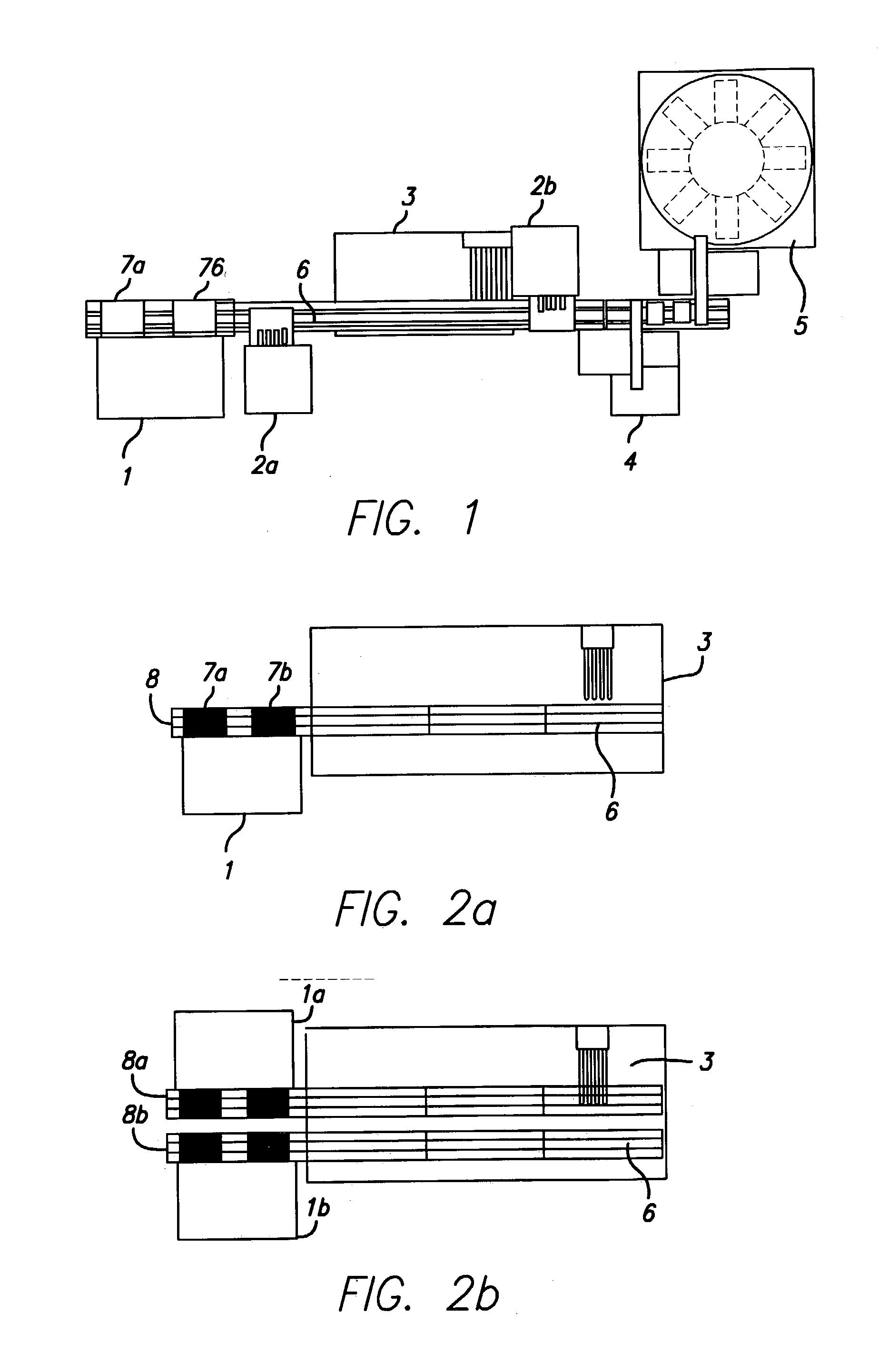

Modular equipment apparatus and method for handling labware

InactiveUS20030225477A1Move quicklyRapidly be moved into and out of position for washingDigital data processing detailsMaterial analysisLaboratory deviceElectrical connection

This invention discloses a system and method useful in moving labware between laboratory devices, such as liquid handlers, readers, washers, dispensers, sealers, incubators, microarrayers and labeling devices, such a bar code labelers, to aid in automation of laboratory tasks and assay procedures. Work cells addressing particular laboratory tasks comprise modular components such as stack links, track links, arm links and laboratory devices, such as washers or plate readers. Based upon the required flow of labware movement, the individual modular components are selected and interconnected to create a high-speed work cell. The work cells are easy to configure and setup and permit configuration on available bench top space or within other small spaces, such as laboratory fume hoods. All mechanical and electrical connections between the module components of the work cell are self-contained within the system. A mechanically robust and simple design of the work cell configuration permits reliable walk away automation.

Owner:HUDSON CONTROL GROUP

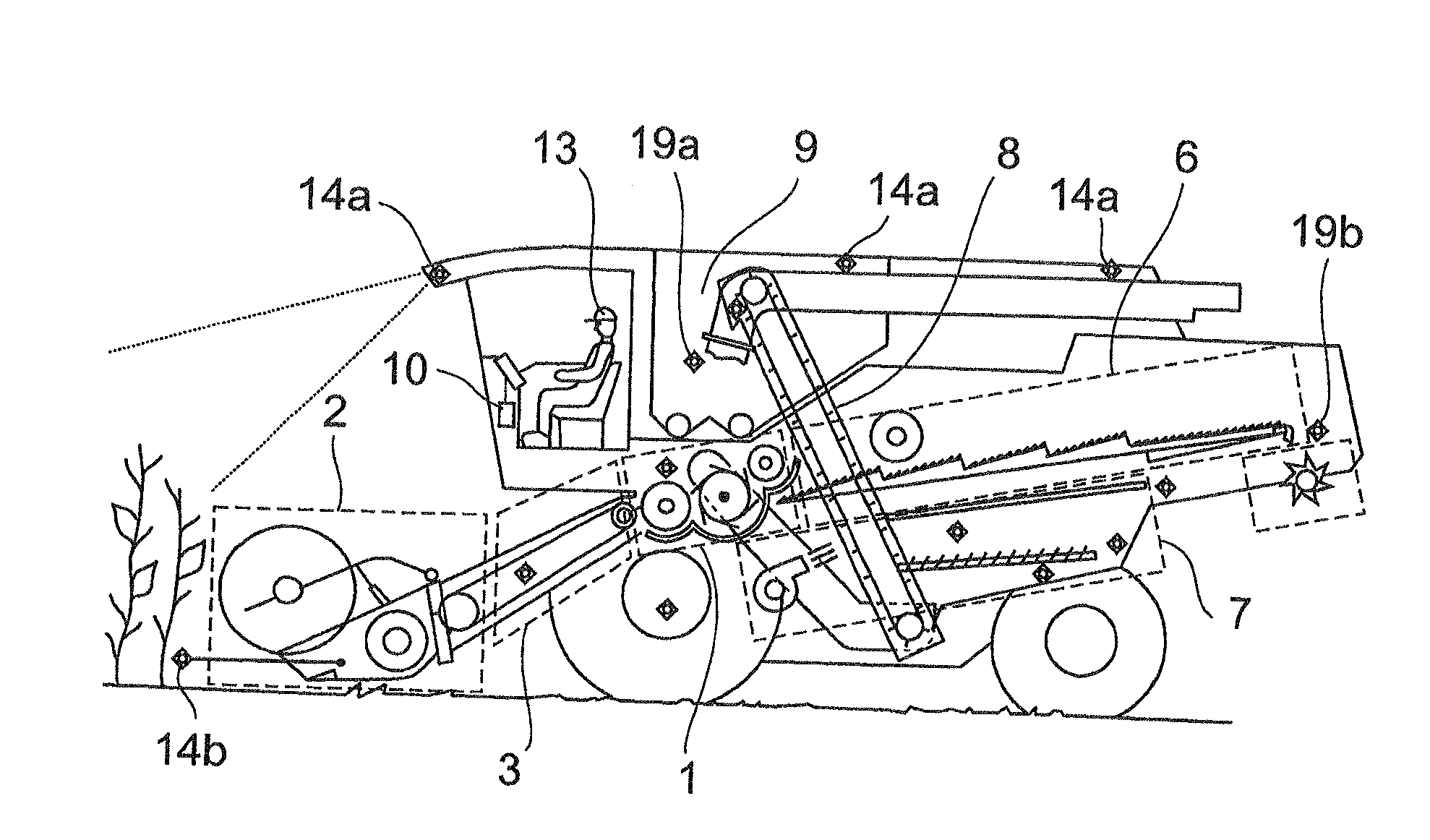

Harvesting system having a self-propelled harvesting machine

ActiveUS20160309656A1Easy to adjustGuaranteed throughputSimulator controlMowersDriver/operatorParallel computing

A self-propelled harvesting machine such as a combine harvester has multiple working units for processing crop picked up from a field, a driver assistance system for the sensor-supported control of the working units, an environmental sensor system for detecting environmental information and spatial areas of applicability located in the environment of the harvesting machine. The driver assistance system has a memory for storing data and a computing unit for processing data, including the data stored in the memory. A functional system model for at least one part of the harvesting machine is stored in the memory. The computing unit functions as a characteristic control on the basis of the system model and autonomously determines machine parameters of at least one working unit and specifies these to the particular working unit.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

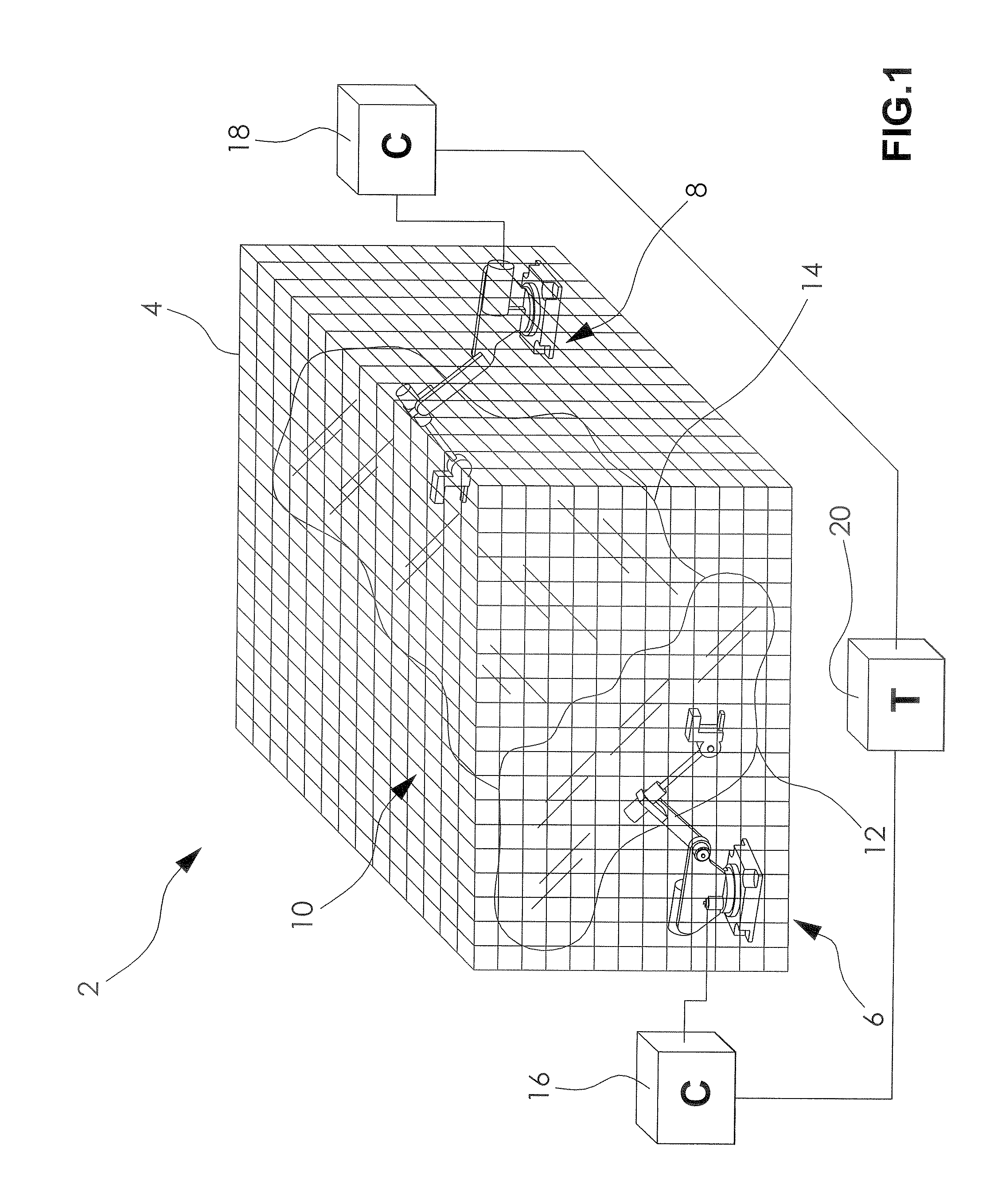

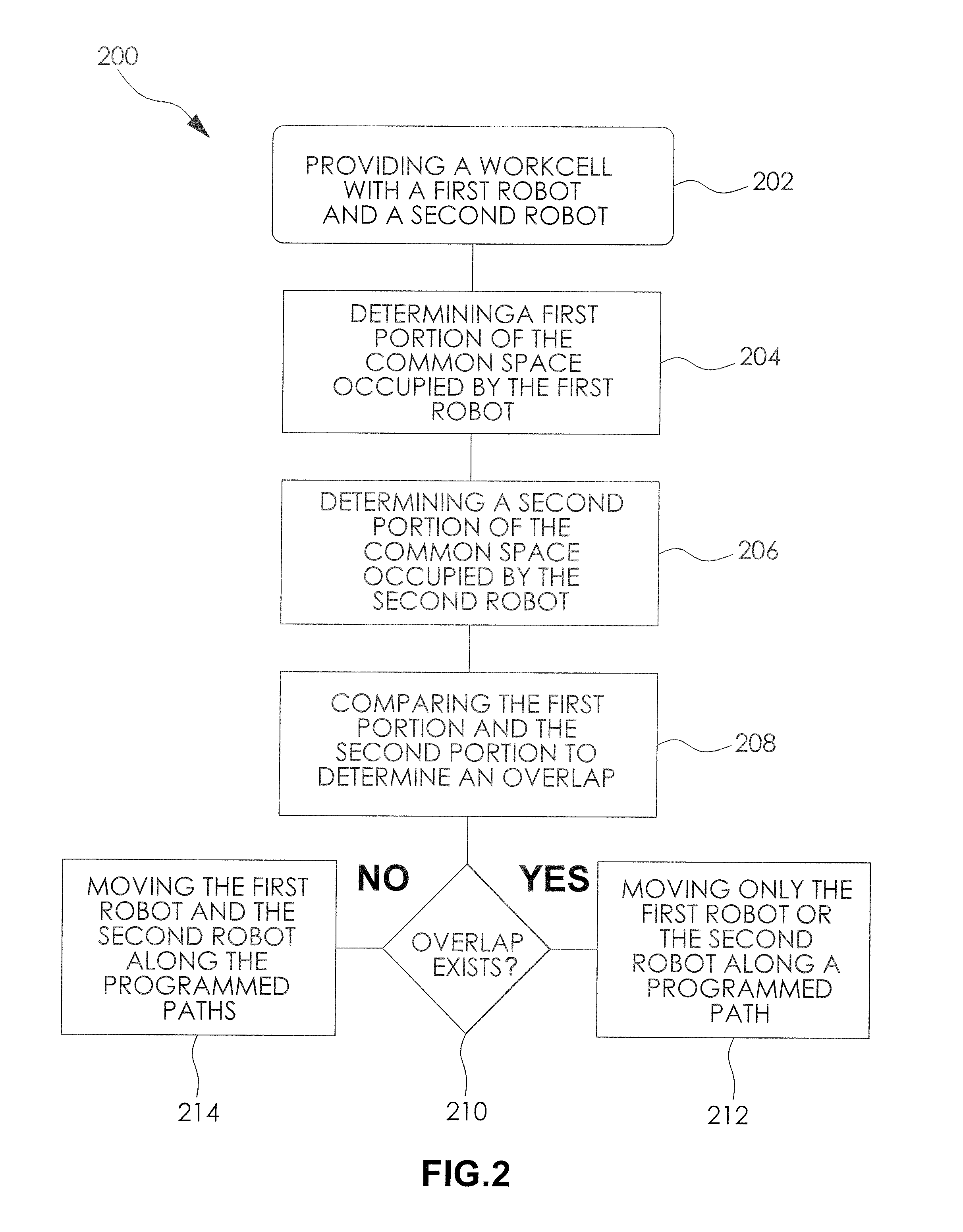

Multi-arm robot system interference check via three dimensional automatic zones

A system and method for controlling avoiding collisions in a workcell containing multiple robots is provided. The system includes a sequence of instructions residing on a controller for execution thereon to perform an interference check automatic zone method. The interference check automatic zone method includes the steps of: determining a first portion of a common space that is occupied during a movement of a first robot along a first programmed path; determining a second portion of the common space that is occupied during a movement of a second robot along a second programmed path; comparing the first portion and the second portion to determine if an overlap exists therebetween; and moving the first robot and the second robot in response to whether or not the overlap exists.

Owner:FANUC ROBOTICS NORTH AMERICA

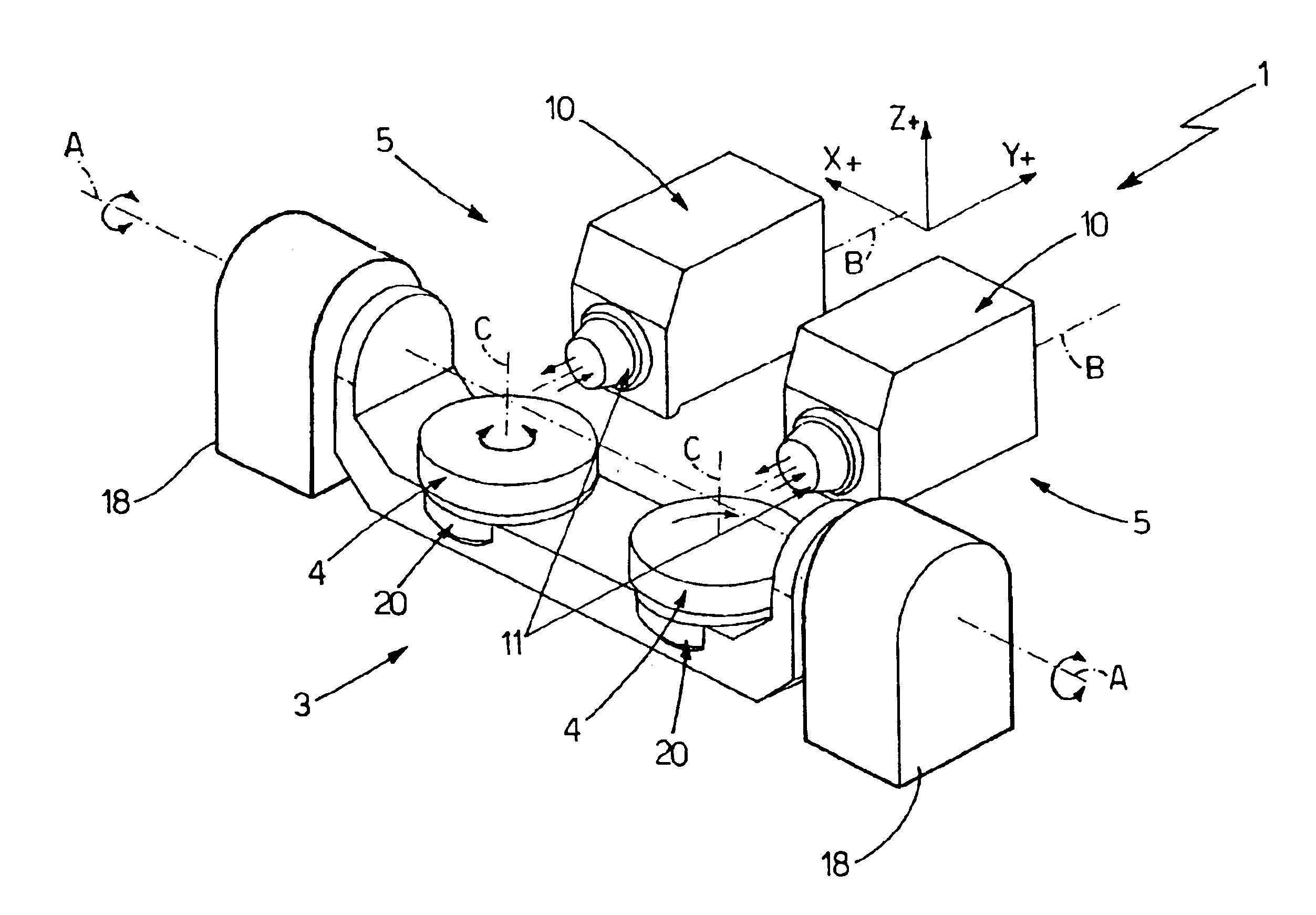

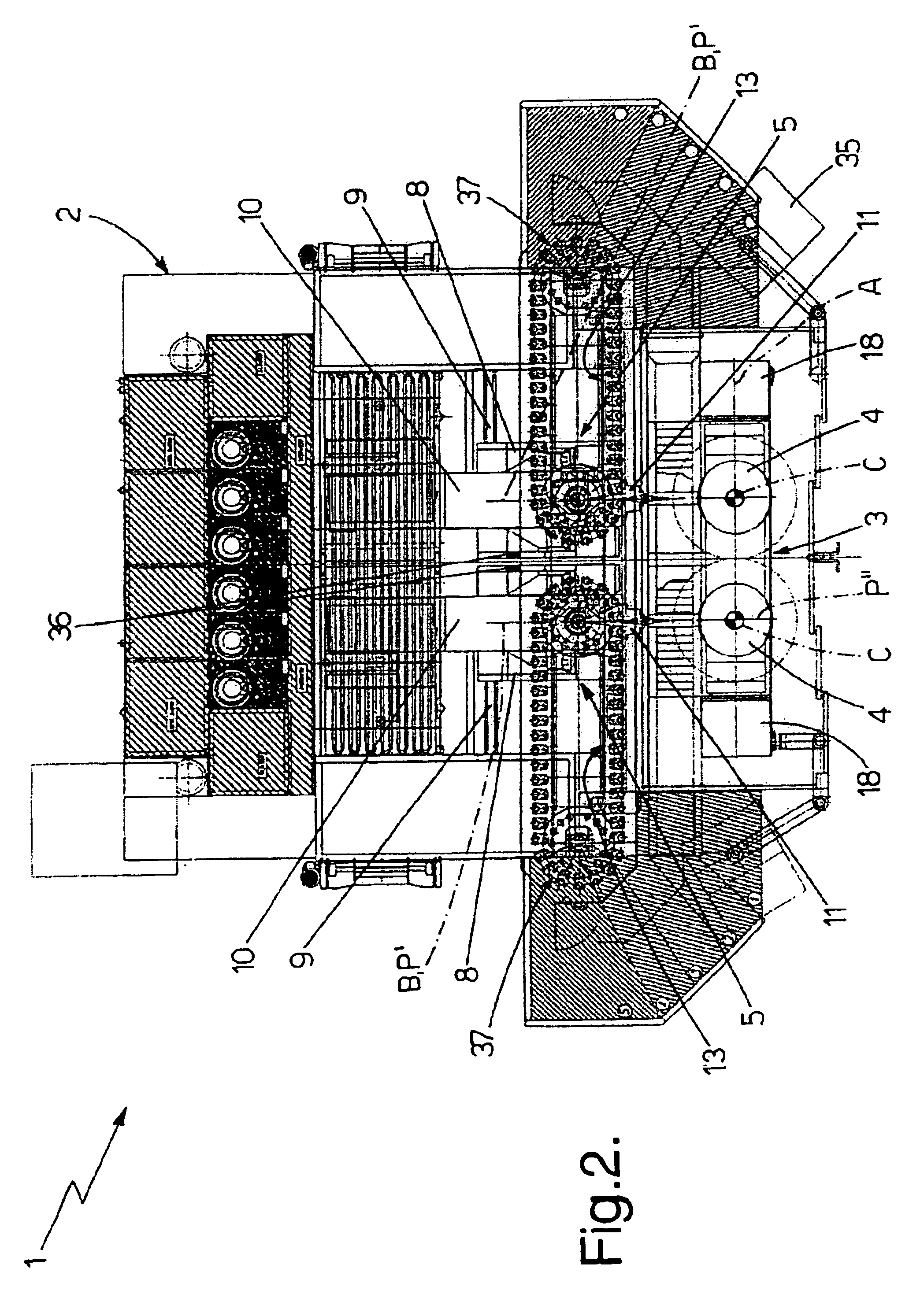

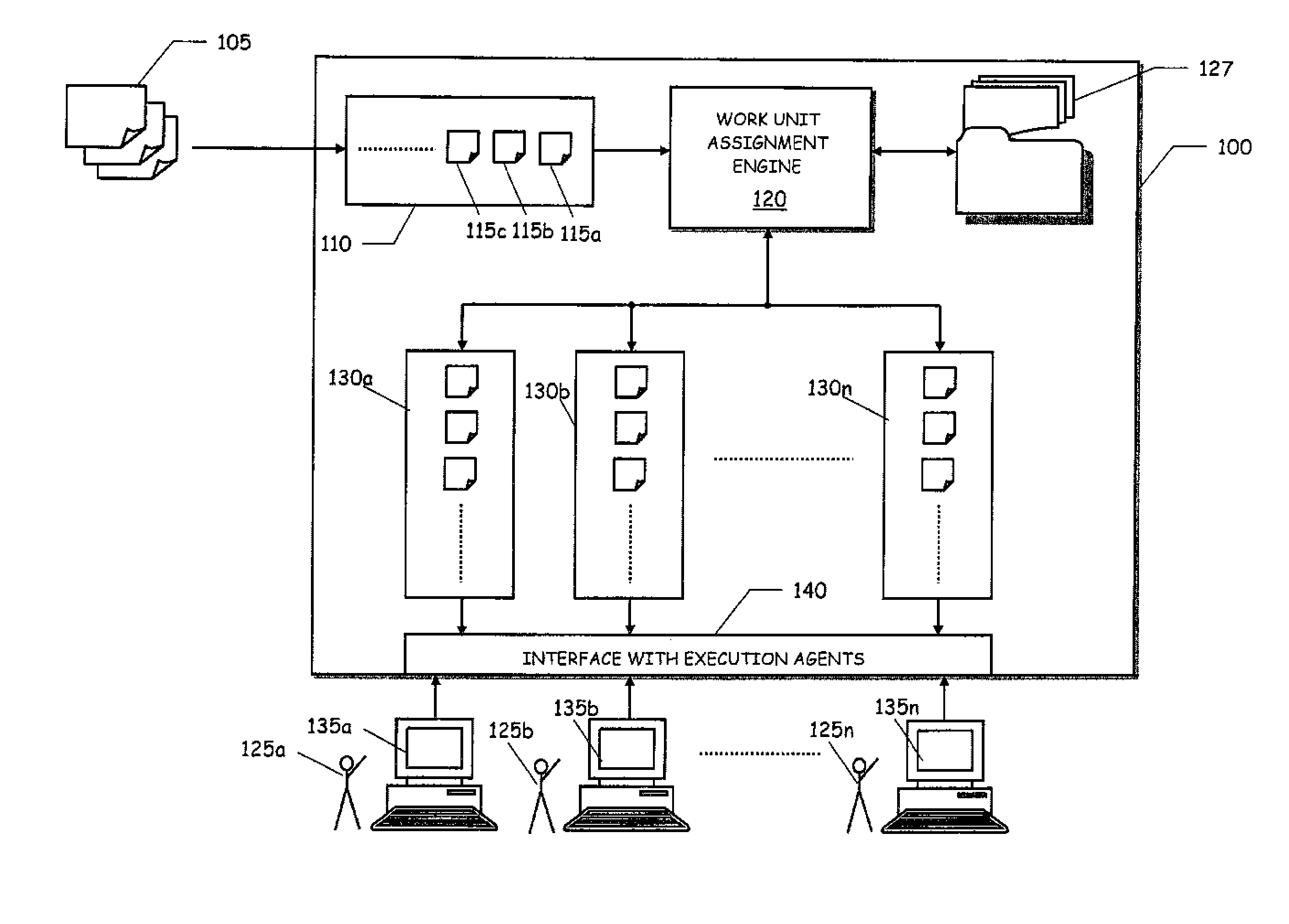

Numerical-control milling machine

InactiveUS6865788B2Drawback can be obviatedThread cutting feeding devicesThread cutting machinesRotational axisEngineering

A numerical-control milling machine having a supporting frame; a worktable fitted to the supporting frame so as to oscillate about a substantially horizontal first axis of rotation, and in turn having two rotary platforms, each for accommodating a workpiece; and two independent work units, each of which is fitted movably to the supporting frame, alongside the worktable, is positioned facing a corresponding platform, and provides for machining the workpiece on the platform; the two work units selectively operating either asynchronously, to machine the workpieces fixed to the two platforms independently of each other, or synchronously to perform the same machining operations simultaneously on the workpieces fixed to the two platforms.

Owner:O M V OFF MEC VENETE

Manipulator

InactiveUS7043338B2Easy constructionImprove reliabilityMicromanipulatorJointsWork unitRobot end effector

A manipulator comprises an operation command unit provided with an attitude adjusting unit and an end effector control unit, a connecting unit having one end connected to the operation command unit, a working unit connected to the other end of the connecting unit and provided with an end effector and a support unit supporting the end effector for motions, and a control unit that transmits an operation command provided by the attitude adjusting unit to the support unit to adjust the attitude of the end effector and transmits an operation command provided by the end effector control unit to the end effector to operate the end effector. The support unit includes a first joint capable of turning about a first axis perpendicular to the center axis of the connecting unit, and a second joint capable of turning about a second axis perpendicular to the first axis. The end effector can be turned for rolling about an axis substantially parallel to the second axis of the second joint. The attitude adjusting unit has a third joint having a third axis perpendicular to the center line of the connecting unit. The end effector control unit is formed such that the fingers of an operator gripping operating members included in the end effector control unit extend substantially in parallel to the fourth axis.

Owner:KARL STORZ GMBH & CO KG

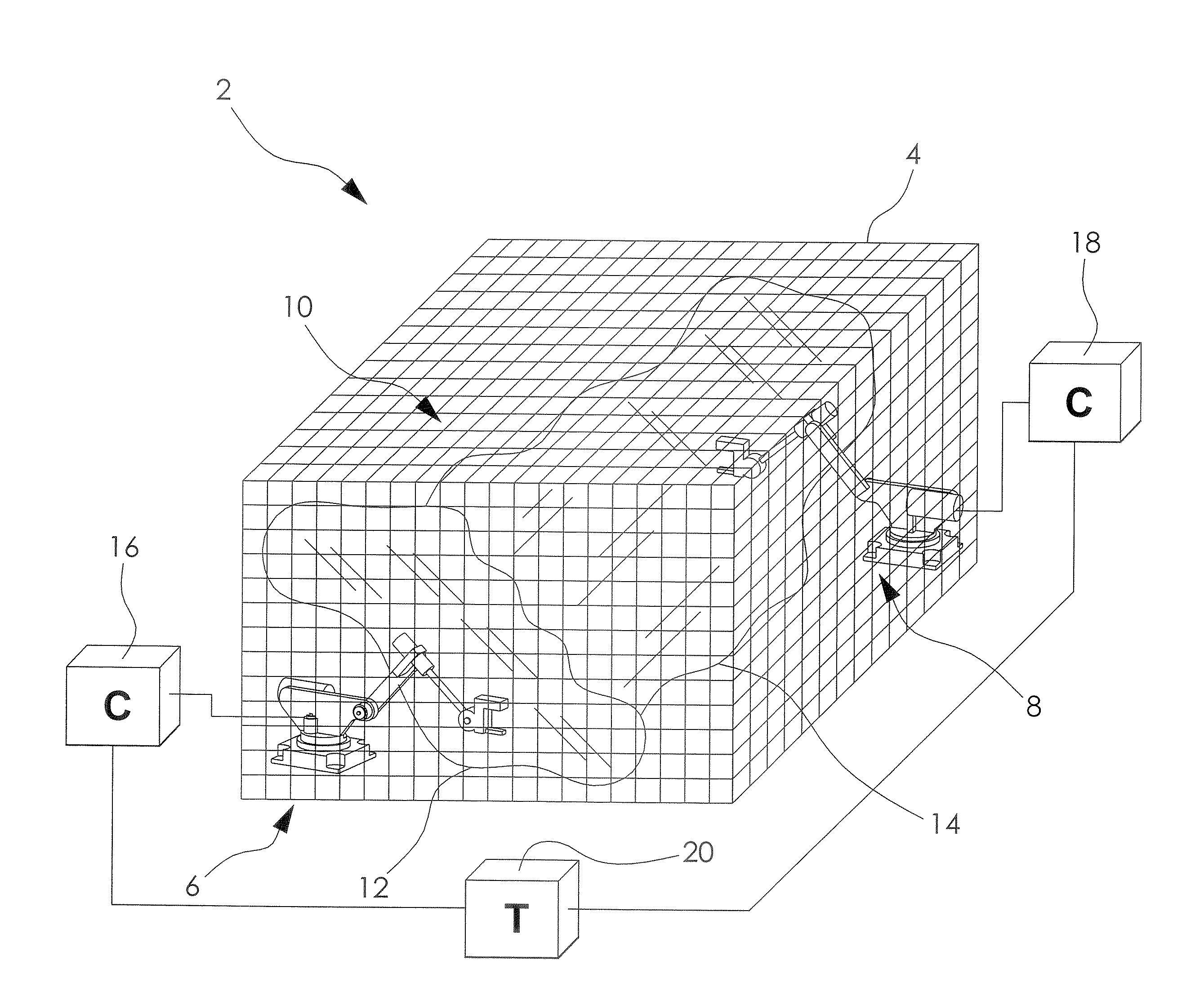

System and method for optimizing a production process using electromagnetic-based local positioning capabilities

A system includes a handheld tool for executing steps of a sequence within a work cell. An electromagnetic marker connected to the tool emits a magnetic field within the cell. A receptor detects the magnetic field and generates a raw position signal in response thereto. A control unit updates an assembly setting of the tool. The host executes a control action when a position determined using the raw data is not equal to an expected position in the sequence. A method calculates the present position of a torque wrench using magnetic fields generated by the marker and measured by a receptor array, and calculates a present position of the tool or a fastener. The present position of the fastener may be compared to an expected position in the calibrated sequence, and the torque wrench may be disabled when the fastener position is not equal to the expected position.

Owner:FIVES CINETIC

Method and apparatus for the processing of heterogeneous units of work

InactiveUS20070094270A1Improve abilitiesResource allocationSpeech recognitionParallel computingWork unit

Methods and apparatus are provided which may be employed to perform speech recognition processing on a grid computing system. In some embodiments, the grid computing system includes a server system which receives processing tasks from one or more client applications, divides the processing tasks into units of work, and assigns the units of work to one or more of the nodes. Dividing a processing task into units of work may involve dividing audio input data into segments defined by natural speech boundaries. A mathematical representation may be created for each segment prior to its distribution on the grid to minimize network traffic. A node in the system may perform heterogeneous units of work concurrently, such as by isolating the execution of each unit of work in an application domain.

Owner:CALLMINER INC

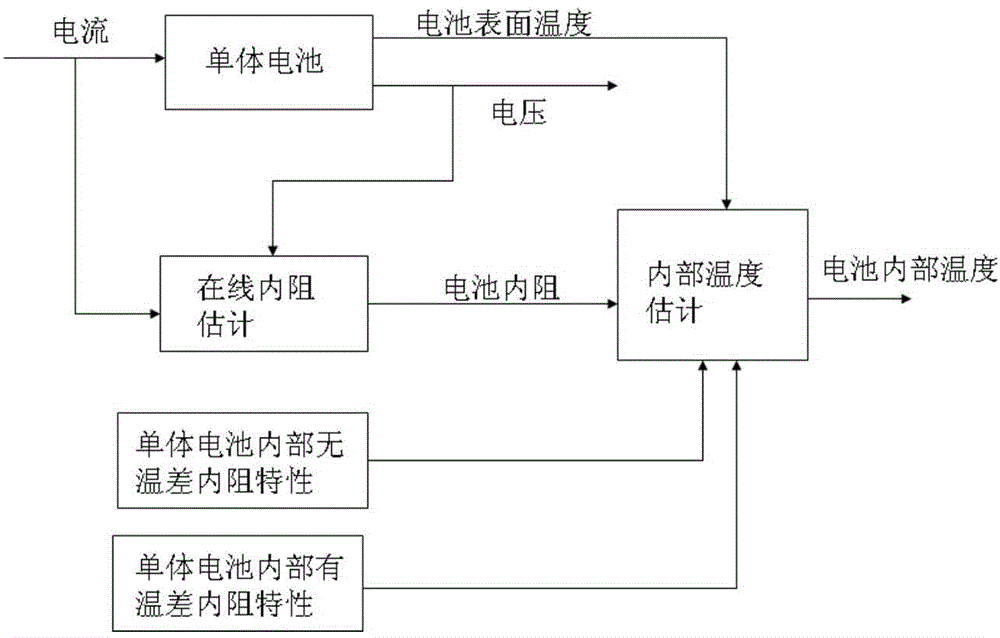

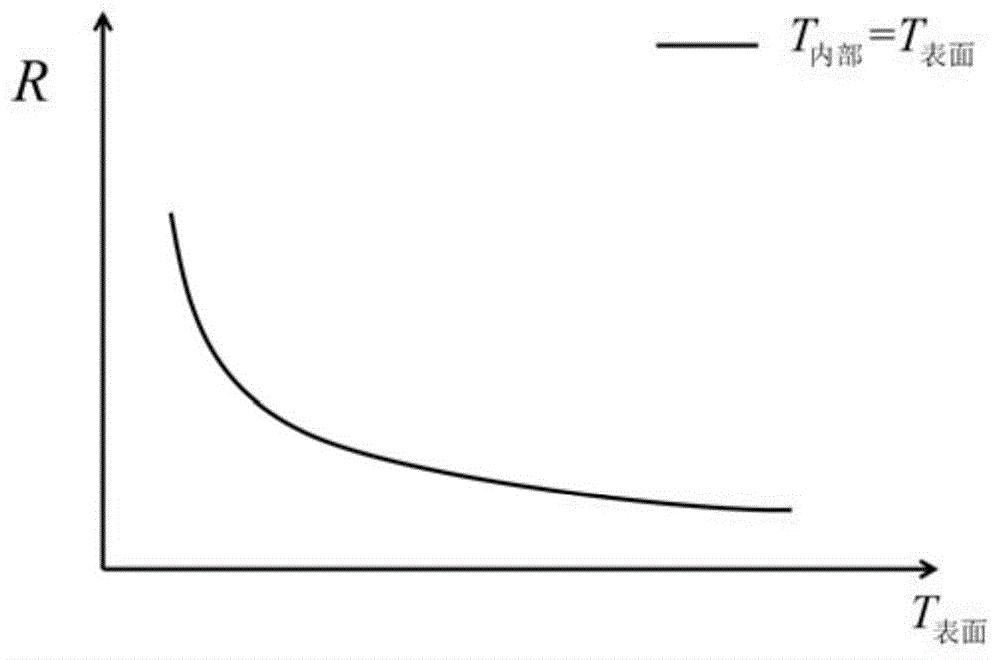

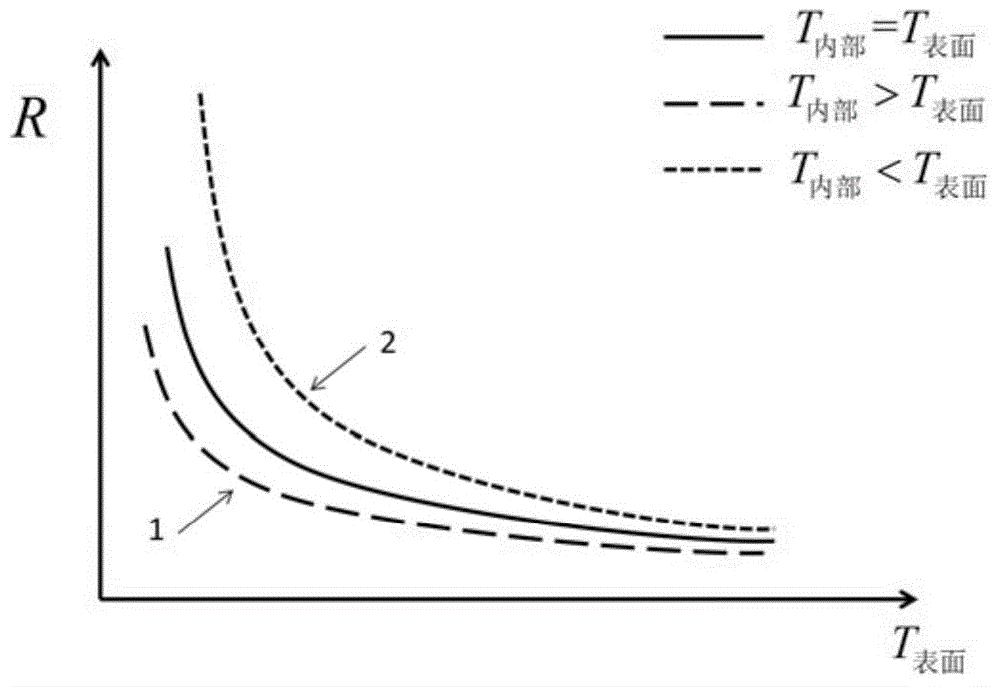

Inner temperature estimation method for single cell

ActiveCN104865534APerformance is not affectedWithout compromising securityElectrical testingInternal resistanceEstimation methods

The invention relates to an inner temperature estimation method for a single cell, which comprises an offline part and an online part. The offline part executes the steps of a1) acquiring the internal resistance characteristic of the single cell at different temperatures; and a2) acquiring a standard relationship between the inner temperature of the cell and the internal resistance of the cell according to the internal resistance characteristic. The online part executes the steps of b1) performing online detection on the current, end voltage and surface temperature of a current working cell; be) performing online estimation for the internal resistance of the current working cell according to the current and the end voltage; and b3) estimating the internal temperature of the current working cell according to the internal resistance acquired in the step b2), the surface temperature acquired in the step b1) and the standard relationship acquired in the step a2). Compared with the prior art, the inner temperature estimation method for the single cell has advantages of effective online estimation for the inner temperature of the single cell, simple operation, effective calculation amount reduction, etc.

Owner:TONGJI UNIV

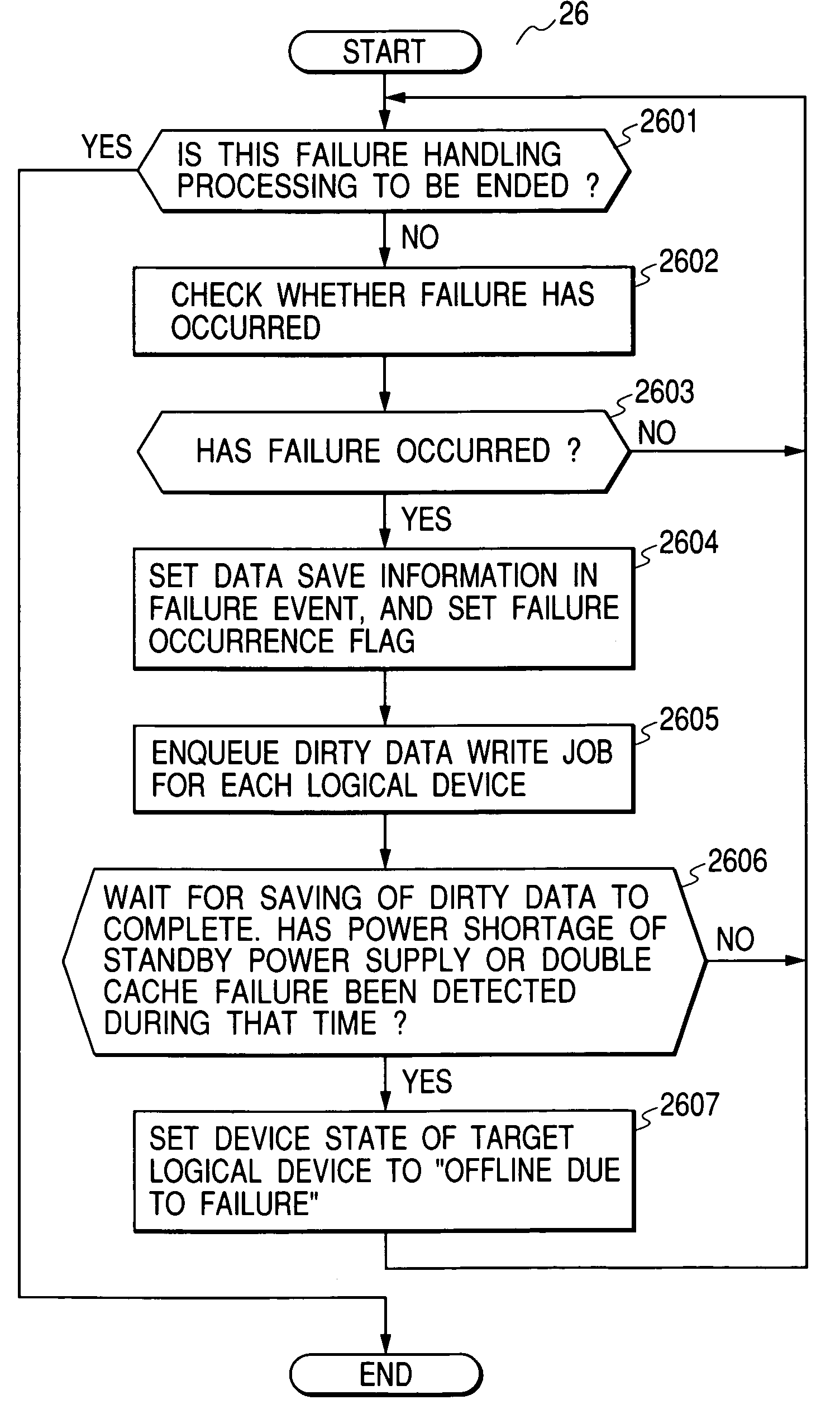

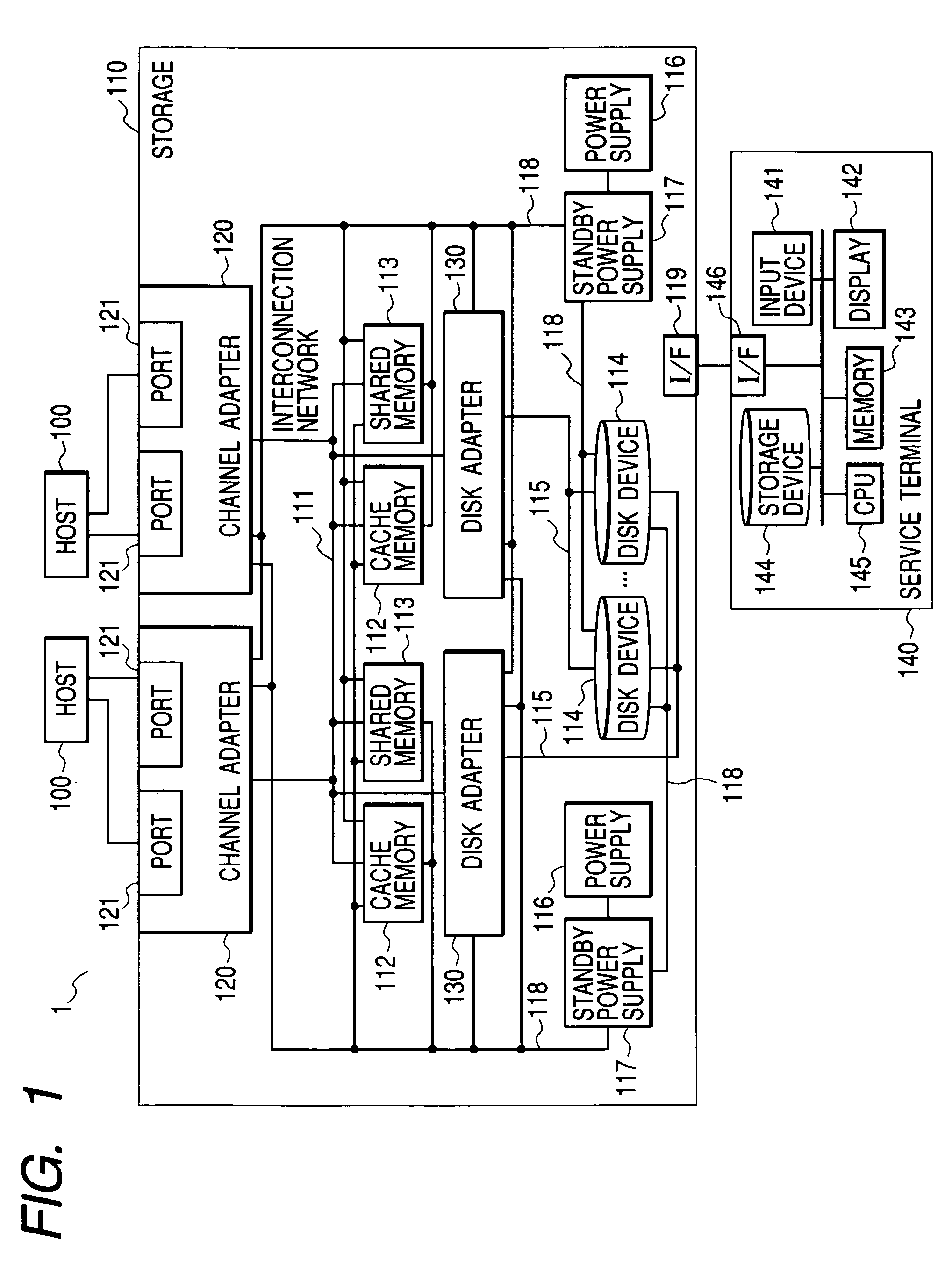

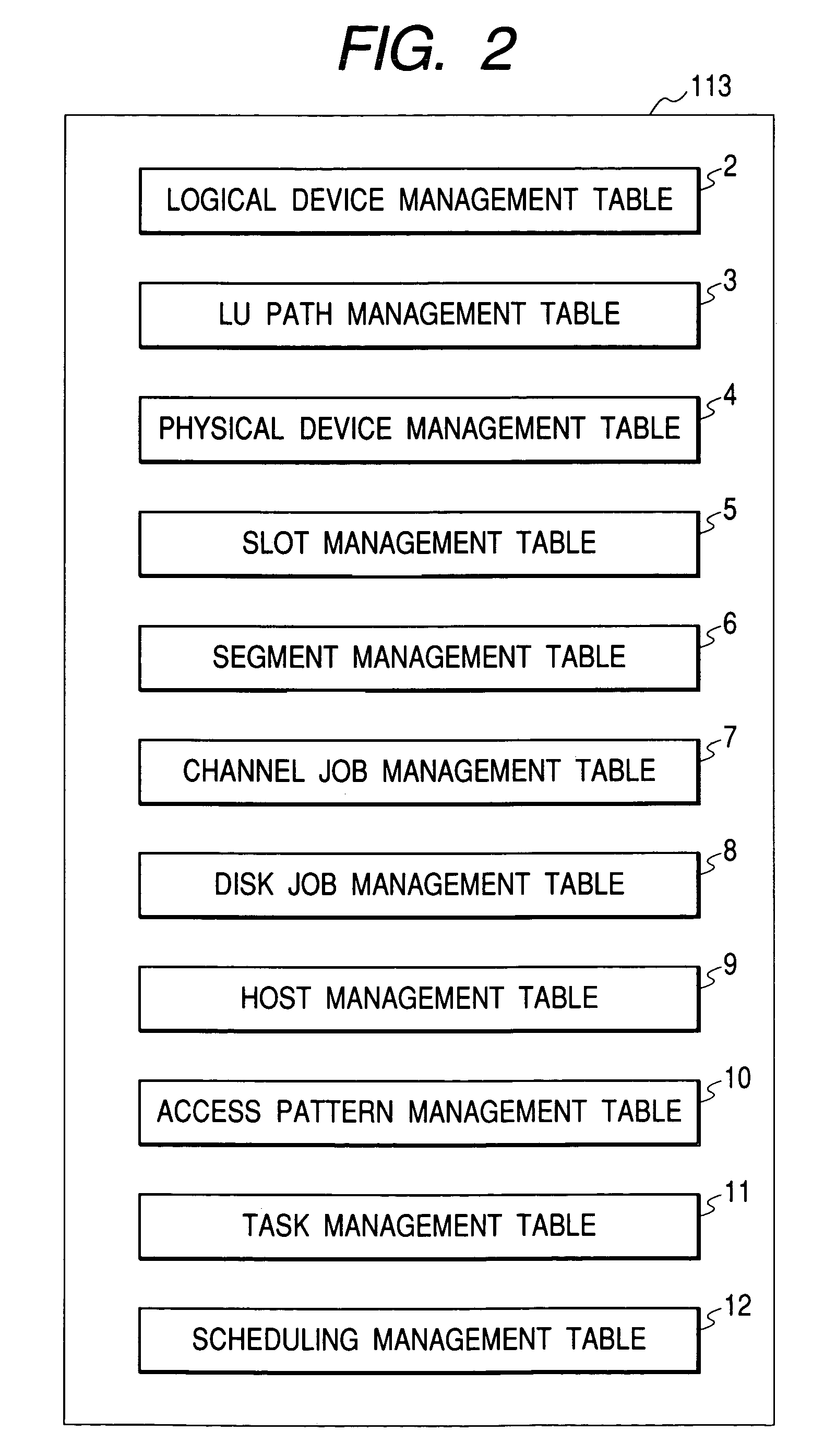

Storage system, and control method, job scheduling processing method, and failure handling method therefor, and program for each method

InactiveUS7100074B2Reduces total input/output processing performance of storageQuick saveMemory architecture accessing/allocationInput/output to record carriersComputer hardwareDirty data

An arbitrary number of a plurality of physical devices are mapped to each logical device provided for a host as a working unit, while considering a priority given to each logical device, and with each physical device being made up of a plurality of disk devices. This arrangement allows dirty data to be quickly saved to the disk devices in the order of logical device priority in the event of a failure. Furthermore, jobs are preferentially processed for important tasks in the event of a failure to reduce deterioration of the host processing performance.

Owner:HITACHI LTD

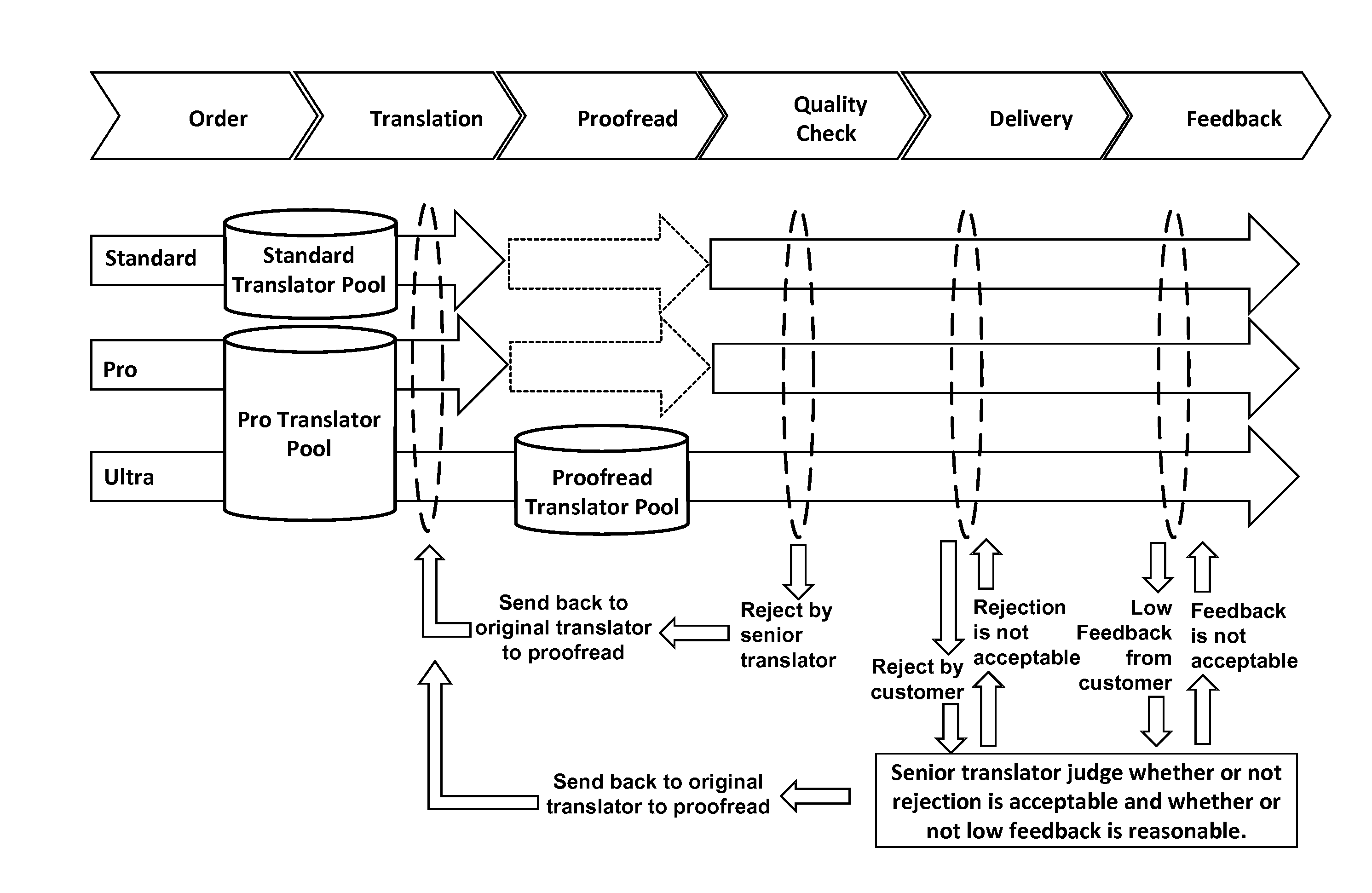

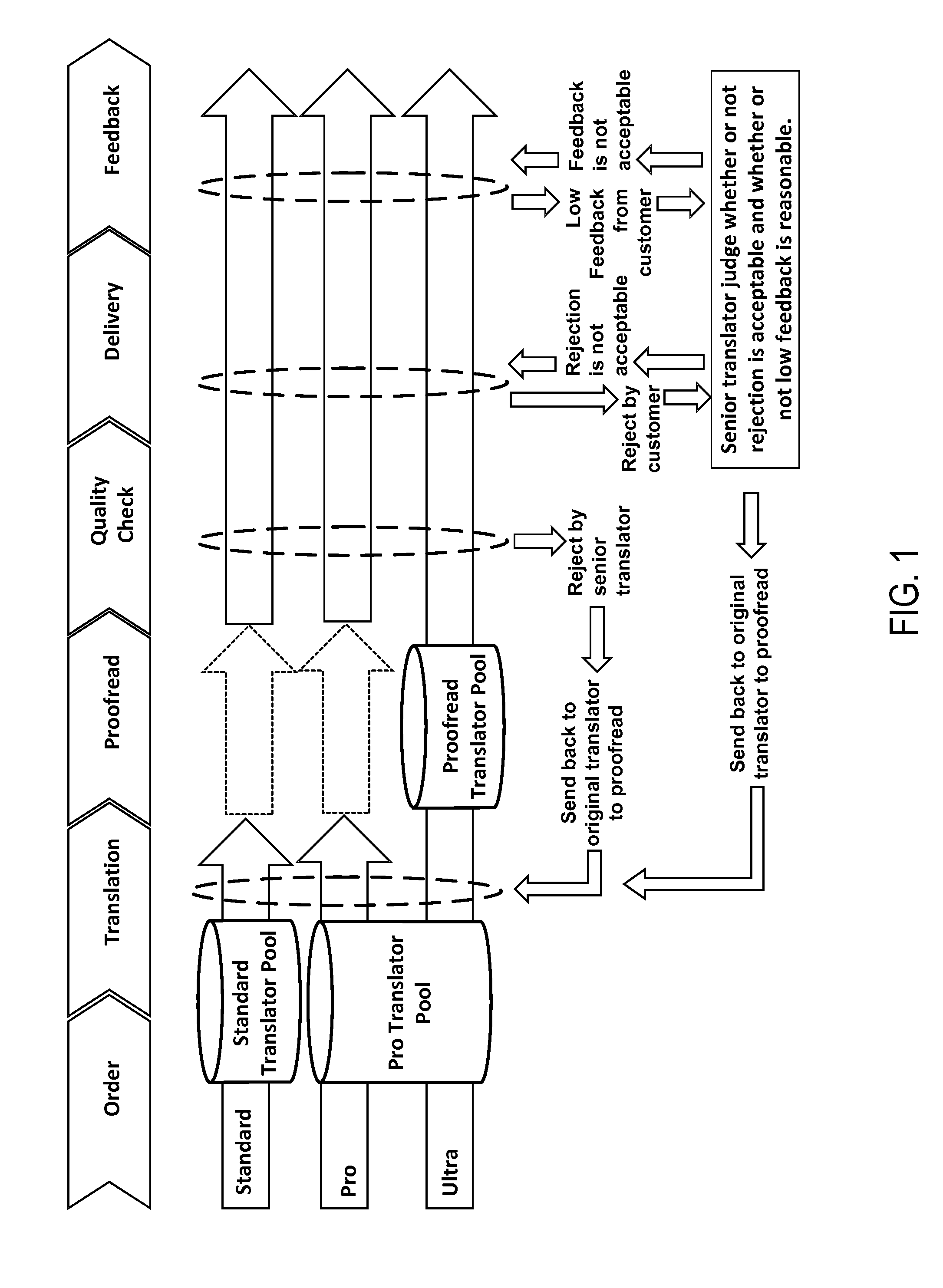

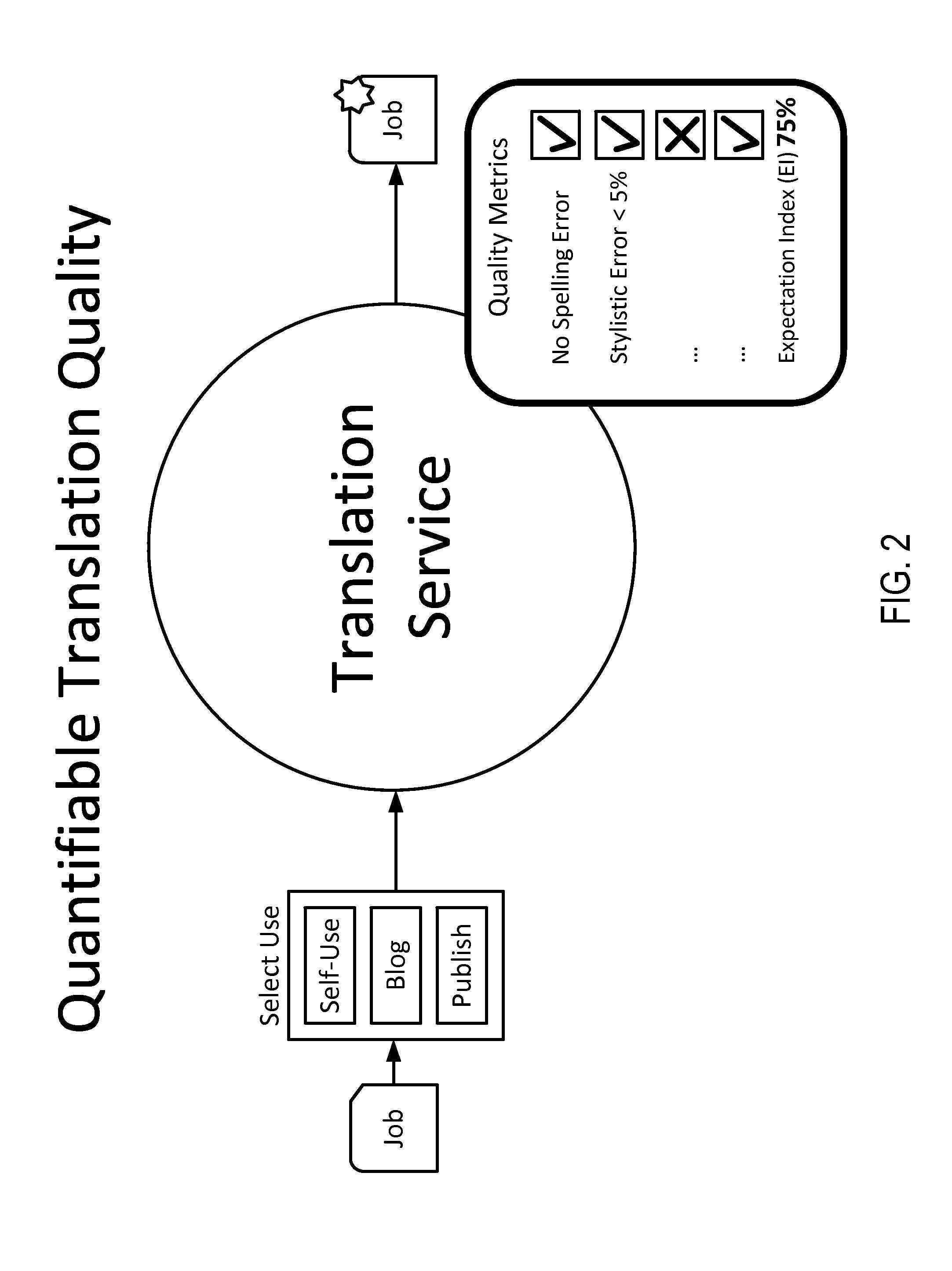

Systems and methods to control work progress for content transformation based on natural language processing and/or machine learning

Systems and methods are provided to compute indicators of completeness of the work output of a transformation of text-based content, worker capacity in performing the transformation, and / or the degree of matching between a unit of work and a worker, based on information collected about complexity of works, times and throughput of workers, rating of work outputs and using natural language processing techniques and machine learning techniques, such as language detection, longest common substring, length ratio, document similarity, etc. The indicators are utilized to optimize job pickup and output submission for online crowdsourcing tasks related to transformation of text-based content, such as transcription, translation, proofreading, etc.

Owner:GENGO

Remote-operated working device and control method

A remote-operated working device includes a movement controller that controls movement of the remote-operated working device; a working unit that performs a predetermined work on the work target; a first detector that detects contact between the working unit and the target; and a communicator that transmits a signal for vibrating the remote control to the remote control in a case where contact between the working unit and the work target is detected by the first detector.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

Referential integrity, consistency, and completeness loading of databases

InactiveUS7949640B2Digital data information retrievalDigital data processing detailsTarget databaseWork cell

A method is provided for loading data from a source database to a target database that includes at least one table. Prior to loading the data from the source database into the target database, at least one referential integrity constraint and / or at least one consistency requirement regarding the data is automatically identified. A subset of the data that satisfies the at least one referential integrity constraint and / or consistency requirement is then automatically identified. The identified subset of the data is then loaded into the target database as a unit of work.

Owner:INTEL CORP

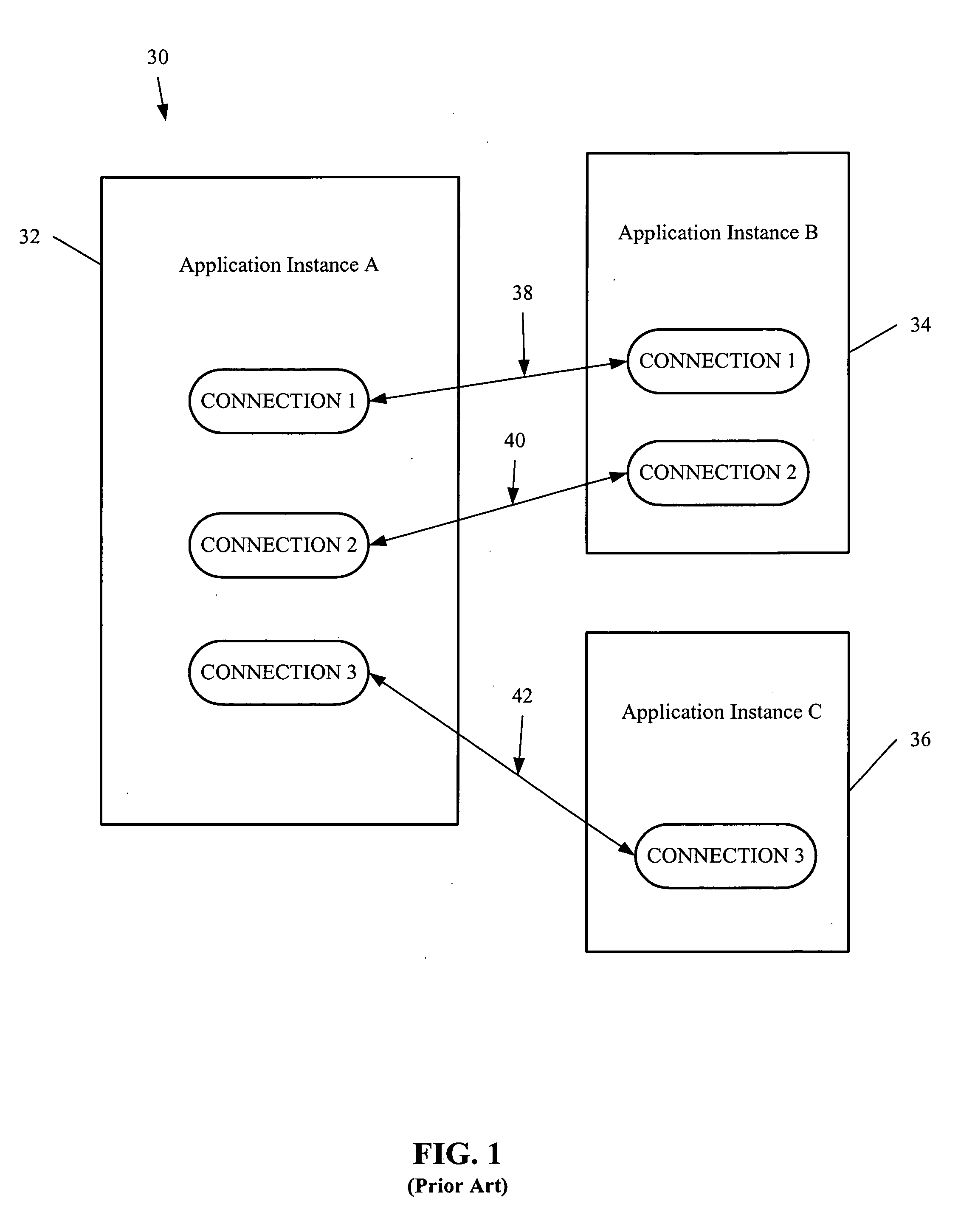

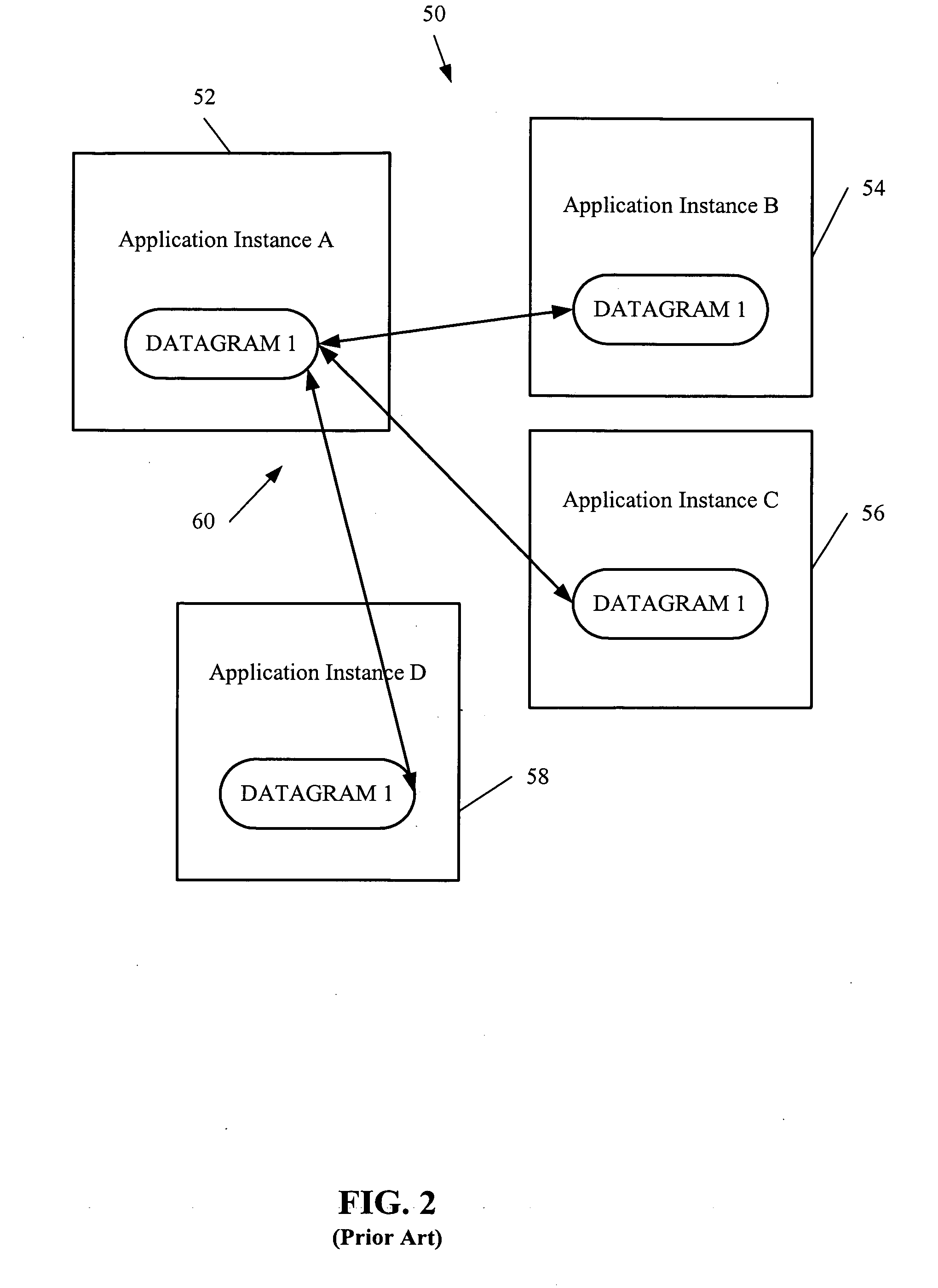

Reliable datagram

InactiveUS7318102B1Reduce in quantityImprove scalabilityError preventionMultiple digital computer combinationsSodium-potassium alloyComputer science

A reliable datagram service is implemented with a source and destination resource (SDR). Source SDR resources, at a source device, multiplex units of work produced by at least one source application instance (AI) into a serial unit of work stream having units of work in a defined order and transmit the serial unit of work stream over a communication services / fabric. Destination SDR resources, at a destination device, receive the serial unit of work stream, demultiplex the serial unit of work stream into units of work provided to at least one destination AI, and provide a negative acknowledgement (NAK) for a unit of work received ahead of its defined order.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

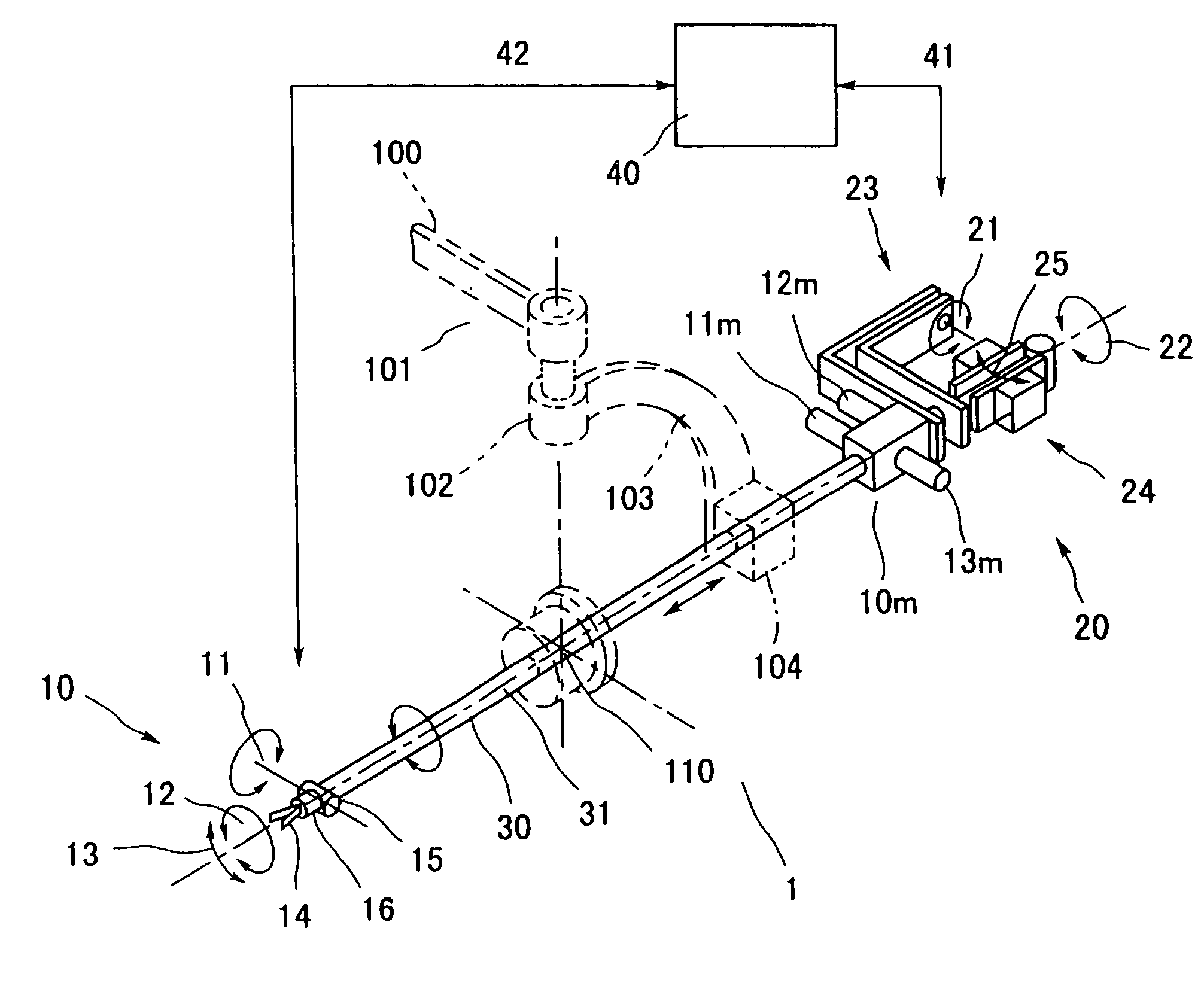

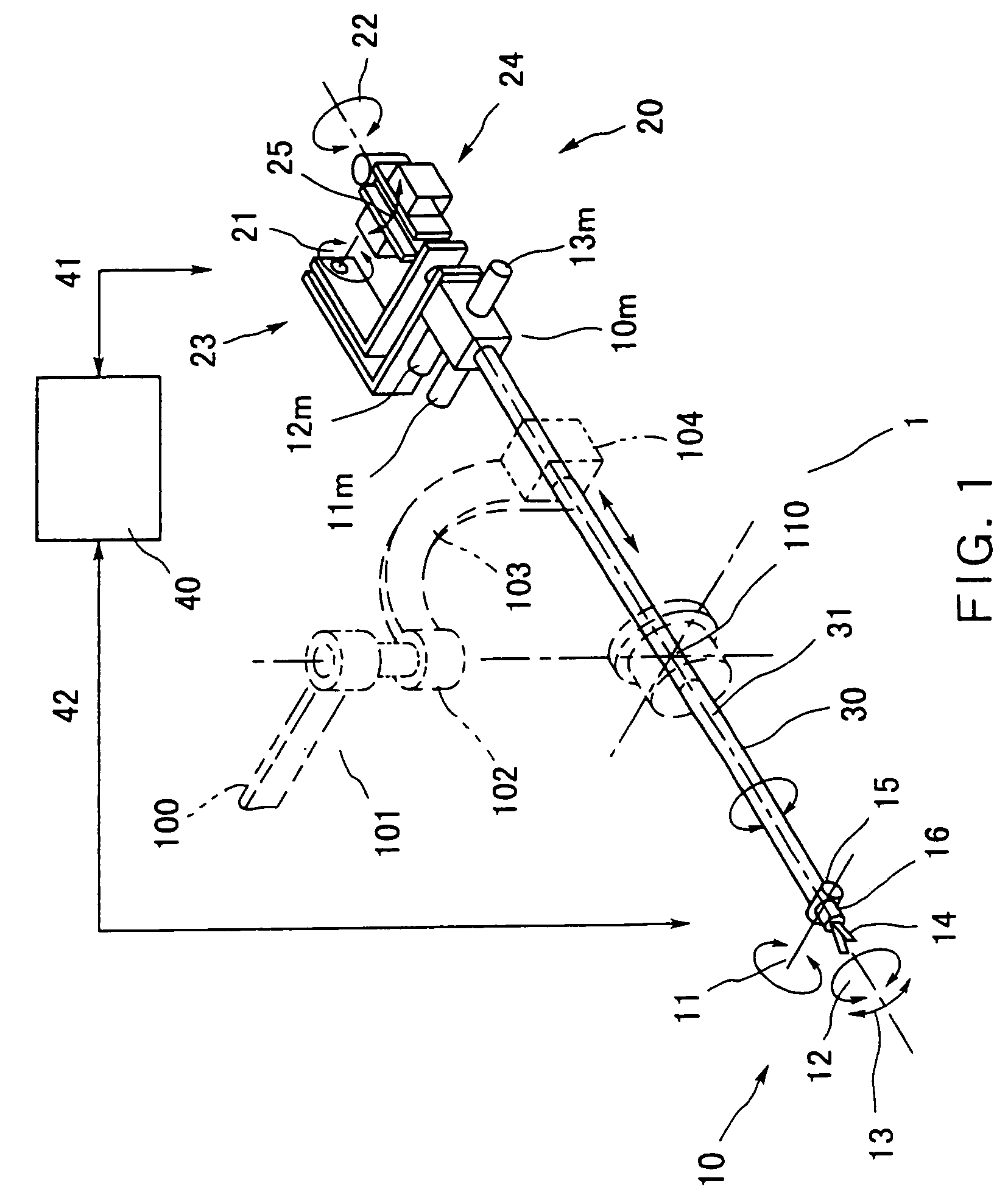

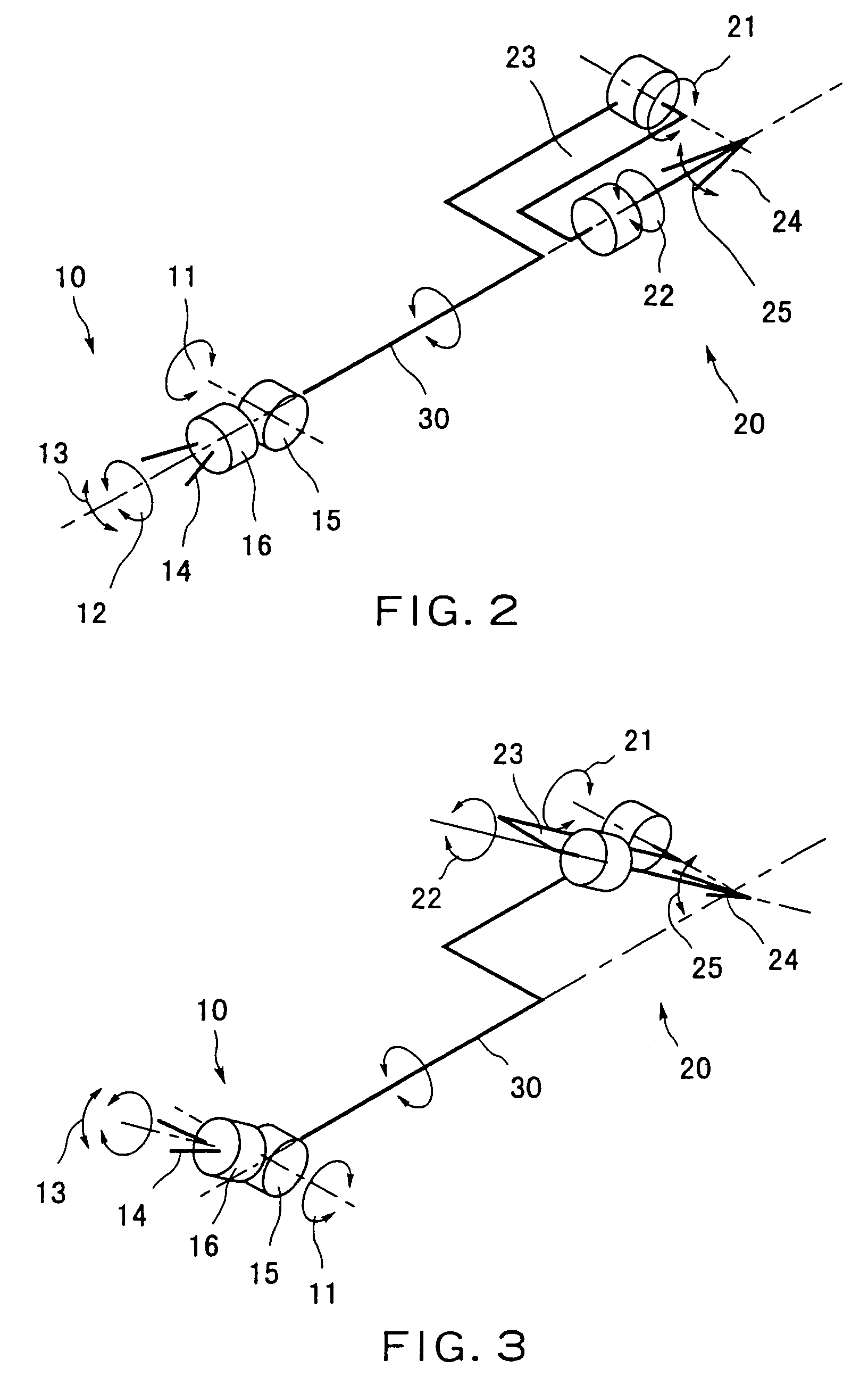

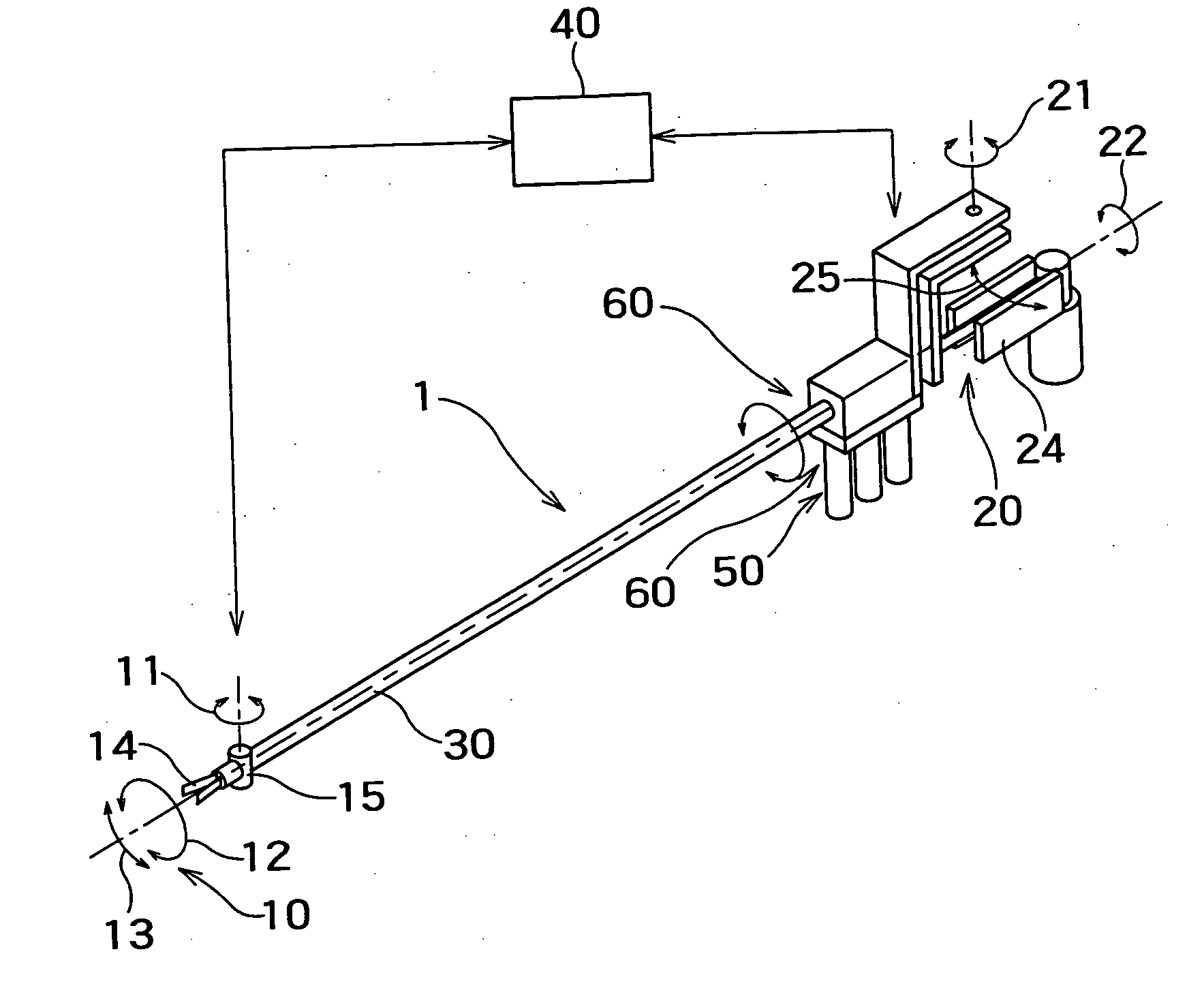

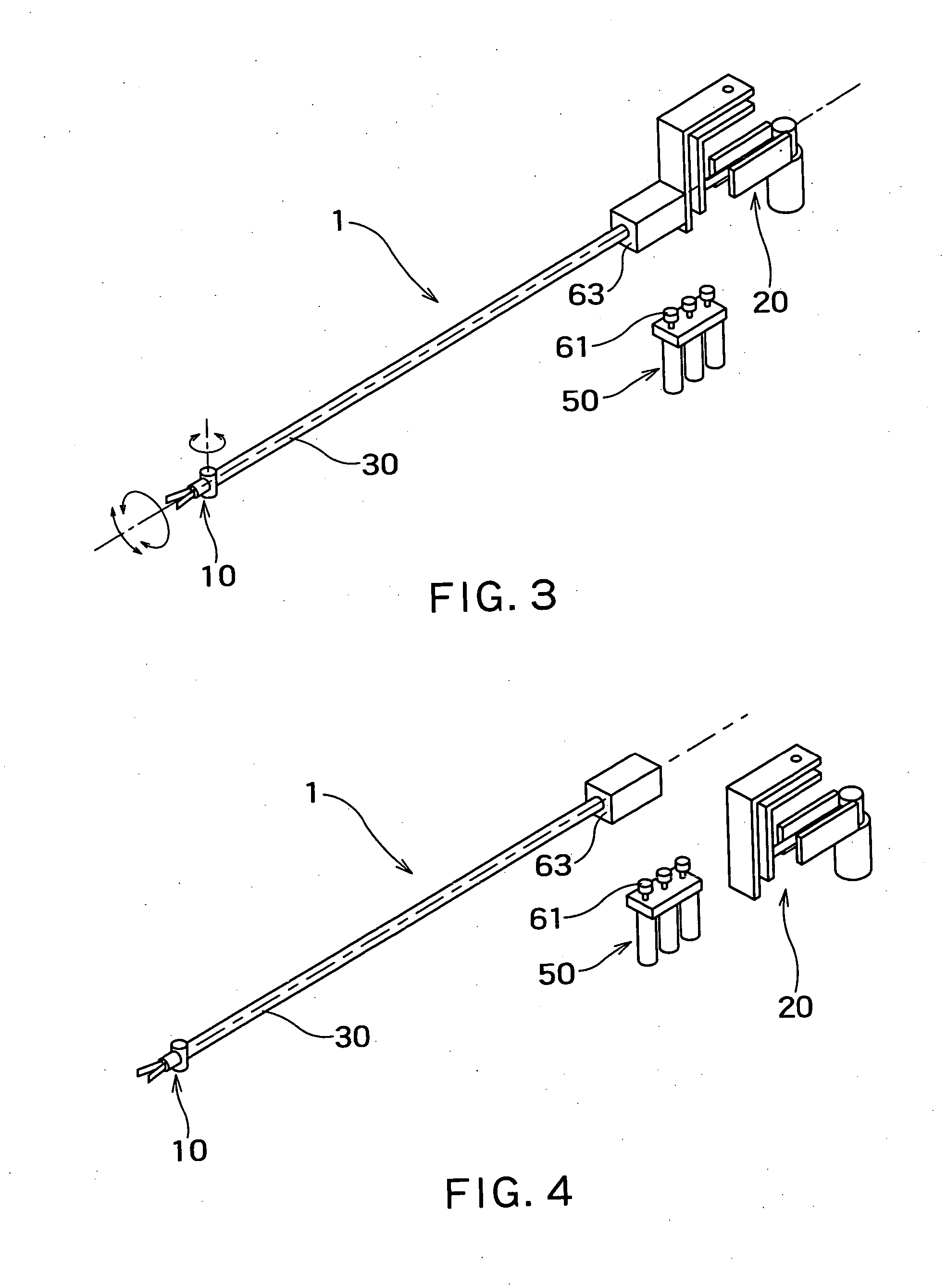

Medical manipulator

InactiveUS20060074408A1Easy to operateImprove surgical efficiencyGripping headsEndoscopesEngineeringWork unit

A medical manipulator comprises a working unit (10) that performs operations, an operating unit (20) that generates instructions, a drive unit (50) that drives the working unit on the basis of instructions given thereto by the operating unit, a power transmission mechanism (60) for transmitting driving force of the drive unit to the working unit, and a control unit (40) for controlling the power transmission mechanism on the basis of instructions given thereto by the operating unit. The power transmission mechanism includes a first power transmission unit (61) interlocked with the drive unit, and a second power transmission unit (63) interlocked with the working unit and capable of being detachably connected to the first power transmission unit. A back drive torque of the first power transmission unit is larger than aback drive torque of the second power transmission unit.

Owner:TERUMO KK

Method and system for determining work trajectories for a fleet of working units in a harvest operation

InactiveUS20180232674A1Minimize soil compactionPrevent travelResourcesSoil-working methodsWork unitPath plan

A method and system for determining path plans to be followed by a fleet of agricultural working units during a harvest operation includes receiving a first set of input parameters related to a crop field and receiving a second set of input parameters related to an available fleet of working units. The fleet of working units includes a harvesting machine and a crop carting unit. A computer simulation of a harvest operation is executed based upon the first and second sets of input parameters. From the simulation, path plans are generated for at least two mobile working units.

Owner:AGCO INT GMBH

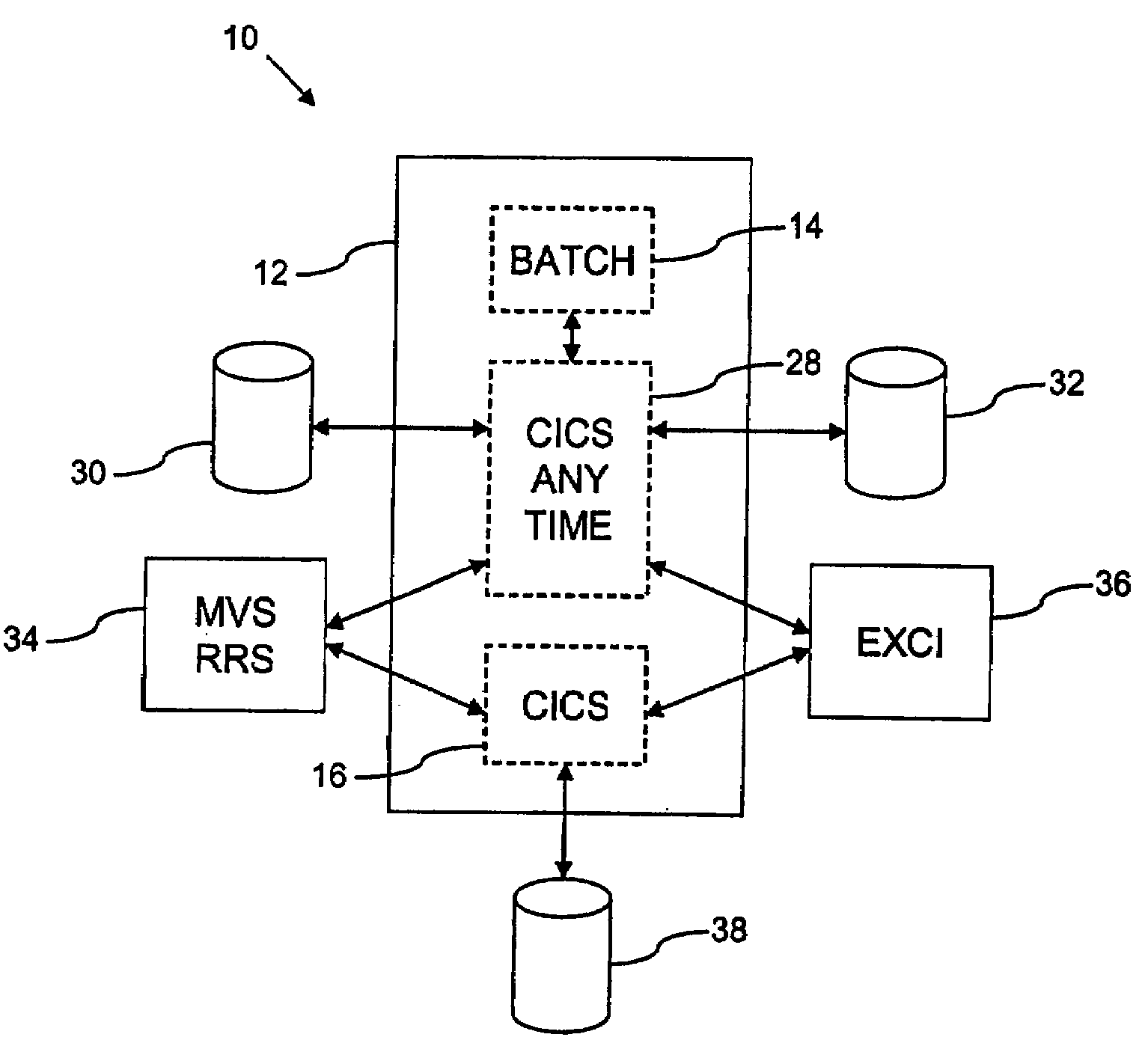

Issuing syncpoints during execution of a batch application to minimize or eliminate periods of record unavailability due to batch related record locking

ActiveUS20080120618A1Interference minimizationDigital data information retrievalError detection/correctionParallel computingData access

The present invention discloses a solution that automatically decomposes a batch process into multiple units of work without changing code of a preexisting batch application. In the solution, the batch application is first analyzed to identify a set of processing segments or units of work, where each unit of work is of a size that minimizes interference with other data accesses. Once each unit of work is defined, these units can execute one at a time. A syncpoint can be established for each unit before it is executed, which locks the records included in the unit. After the unit of work executes, the record lock can be released and a new syncpoint can be established for the next unit. If an execution problem occurs, execution for the unit of work can be terminated and chances can be restored to the syncpoint.

Owner:SAP AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com