Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

392 results about "Laser beam machining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser beam machining (LBM) is a non conventional Machining manufacturing process, a form of machining, in which a laser is directed towards the work piece for machining. This process uses thermal energy to remove material from metallic or nonmetallic surfaces. The high frequency of monochromatic light will fall on the surface then heating, melting and vaporizing of the material take place due to impinge of photons. Laser beam machining is best suited for brittle materials with low conductivity, but can be used on most materials.

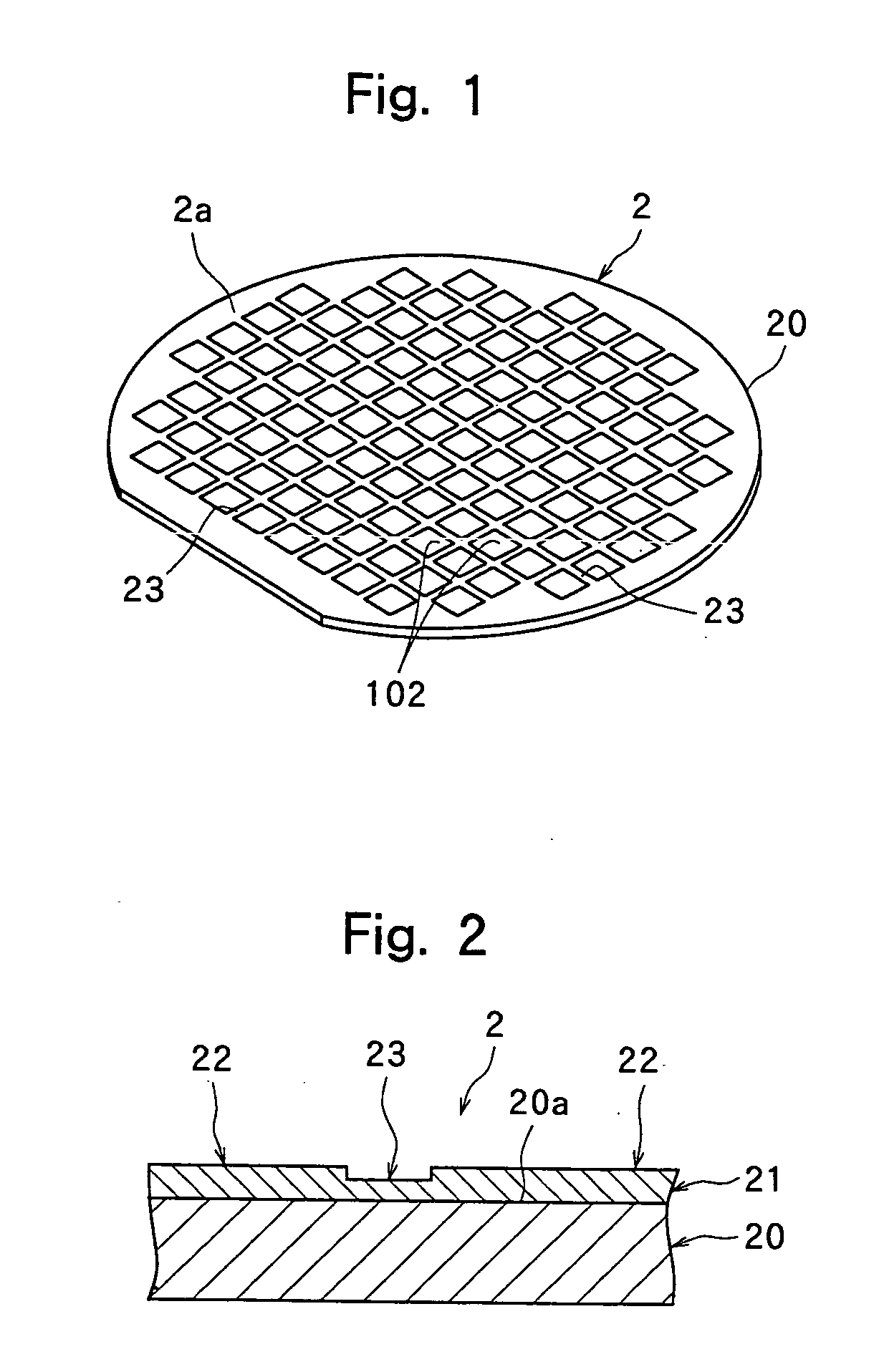

Laser processing method and laser processing apparatus

InactiveUS20050173387A1No unnecessary fracture in surfaceNo unnecessary fractureSolid-state devicesSemiconductor/solid-state device manufacturingLaser processingLaser beam machining

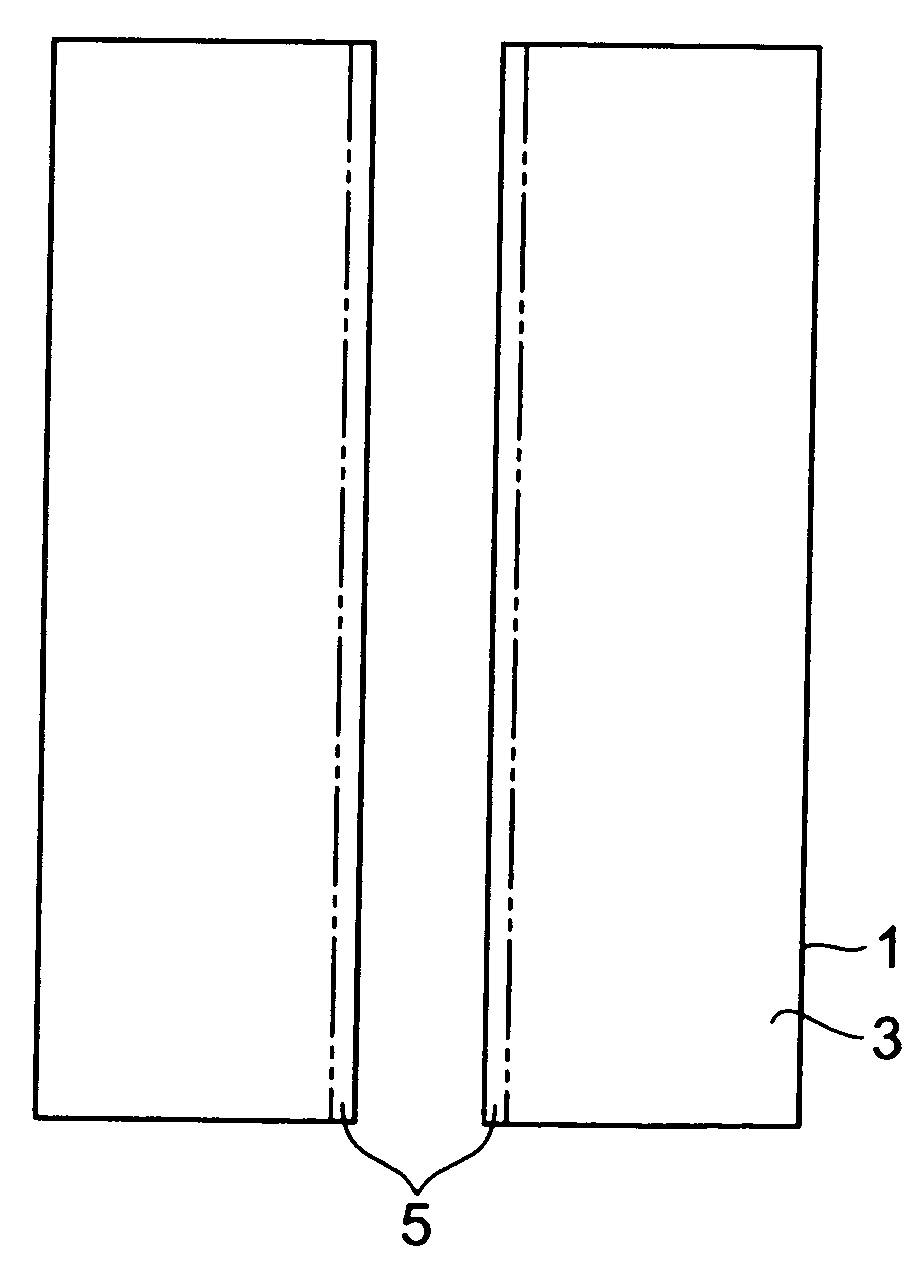

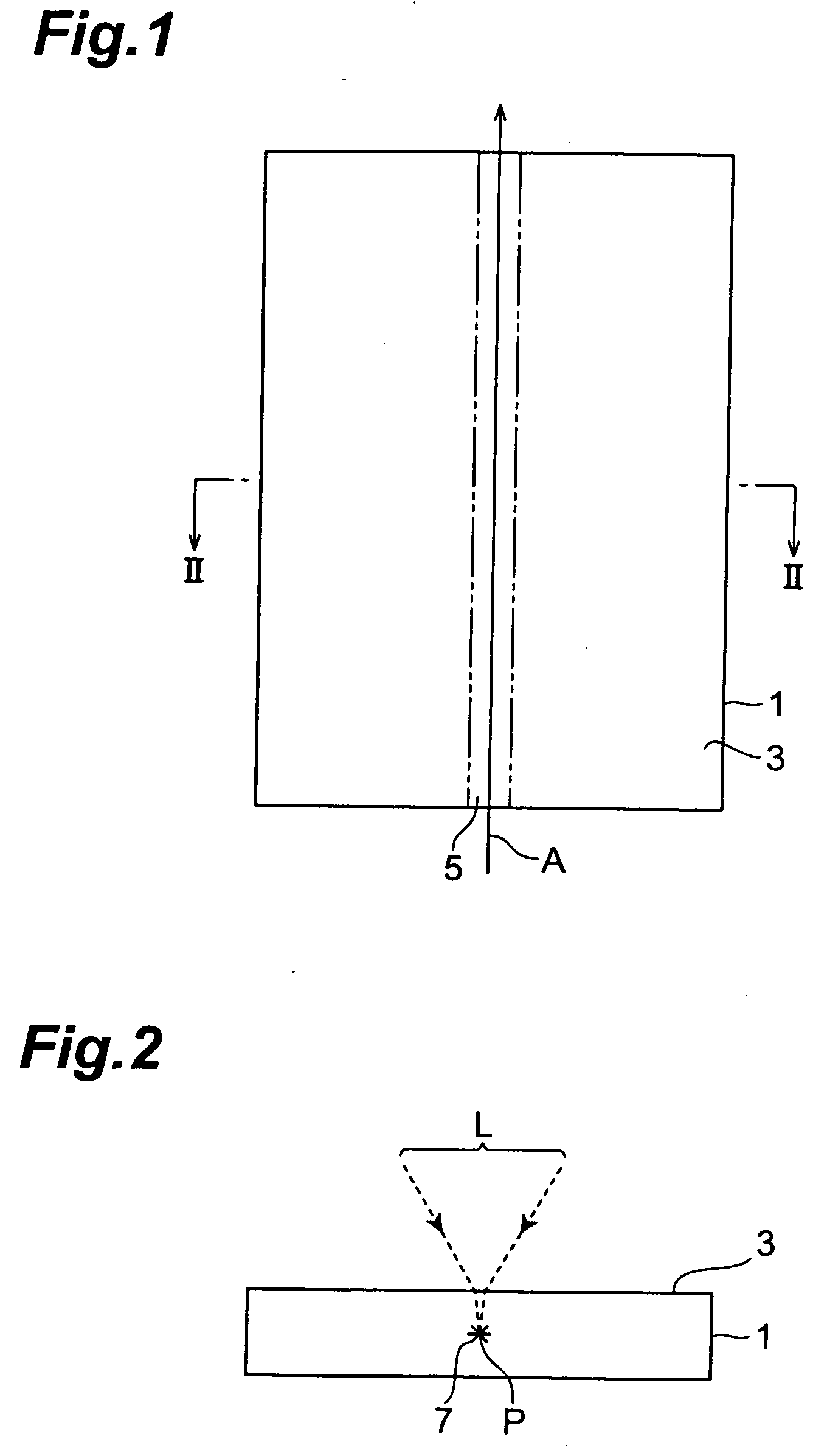

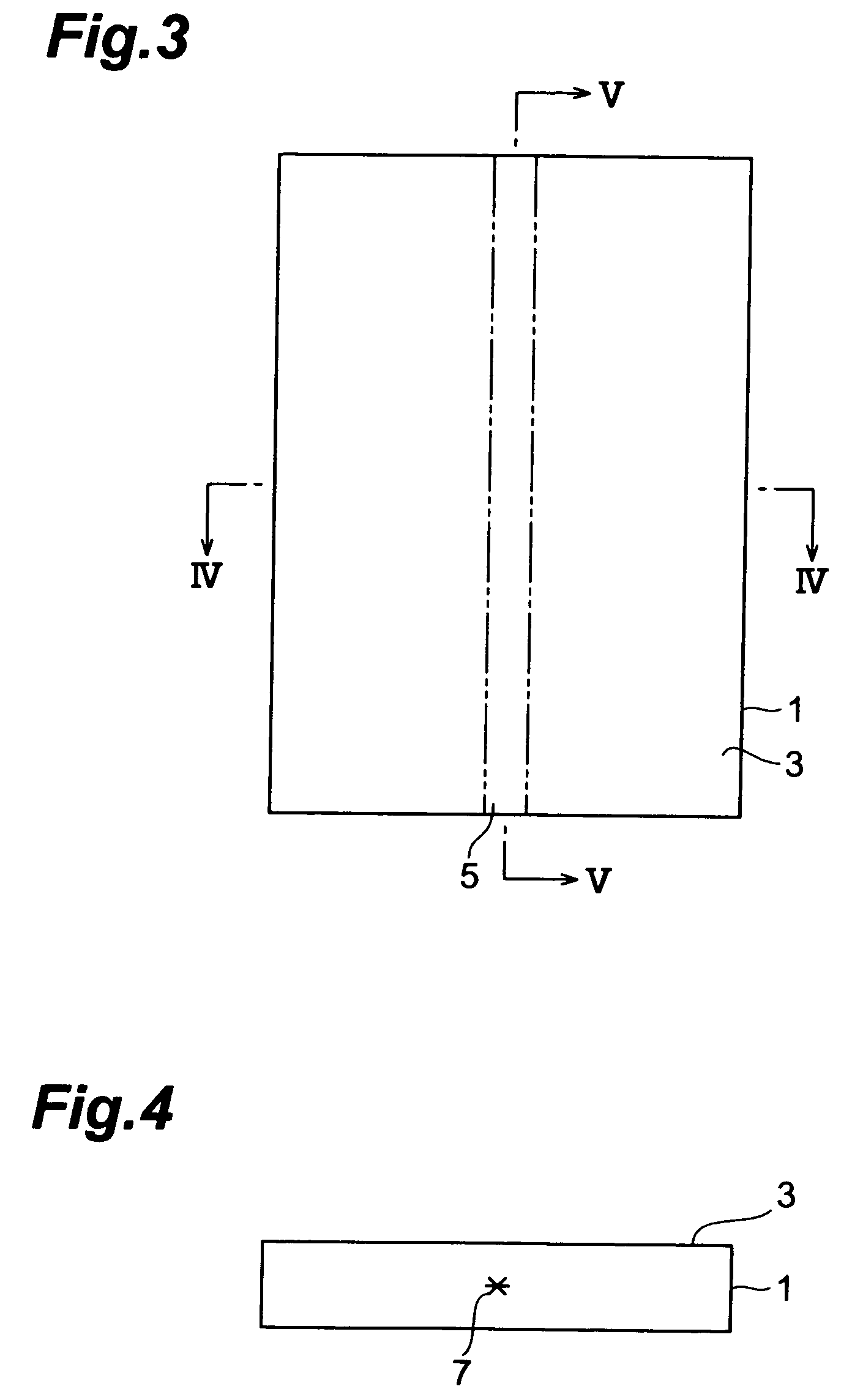

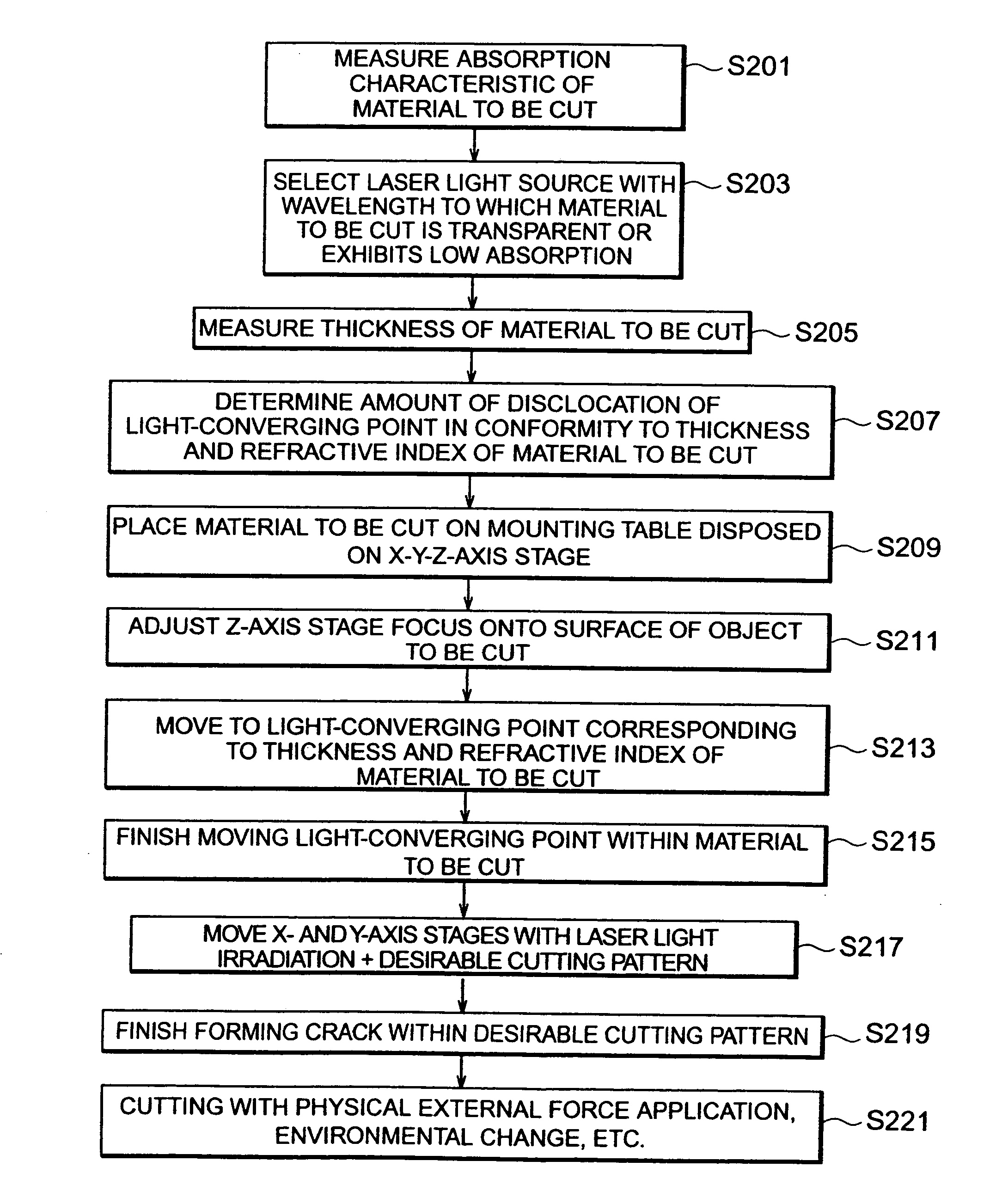

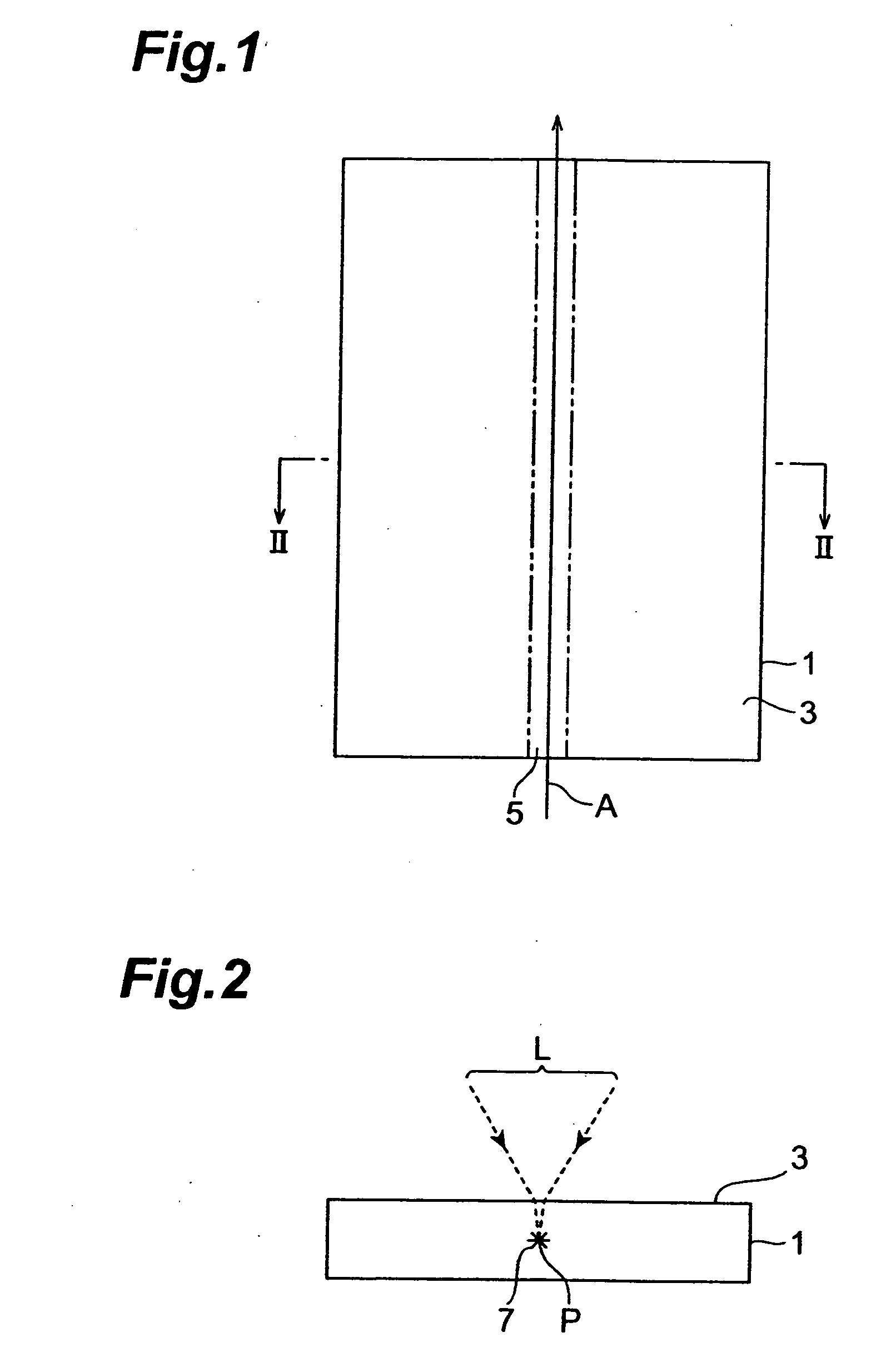

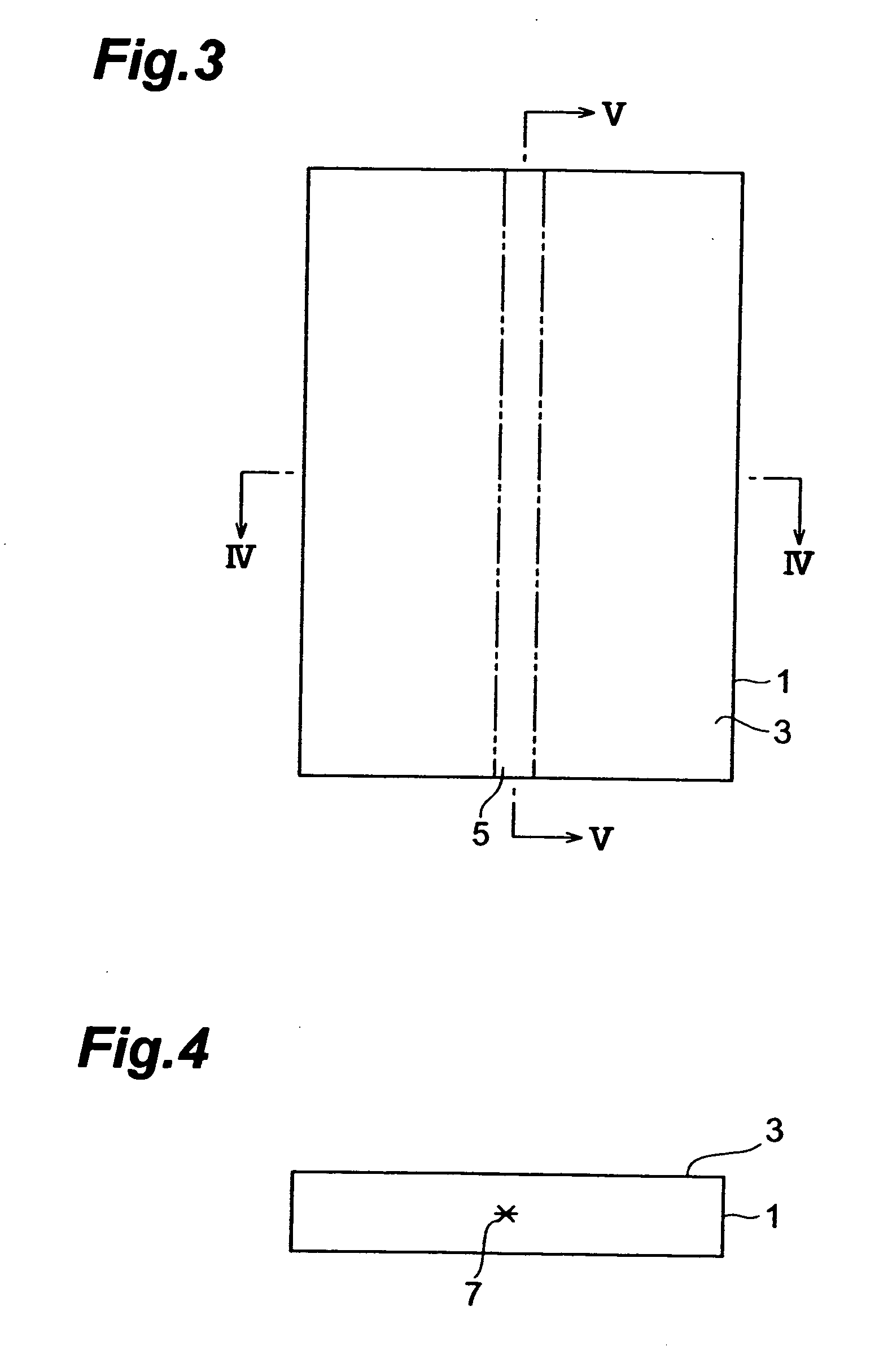

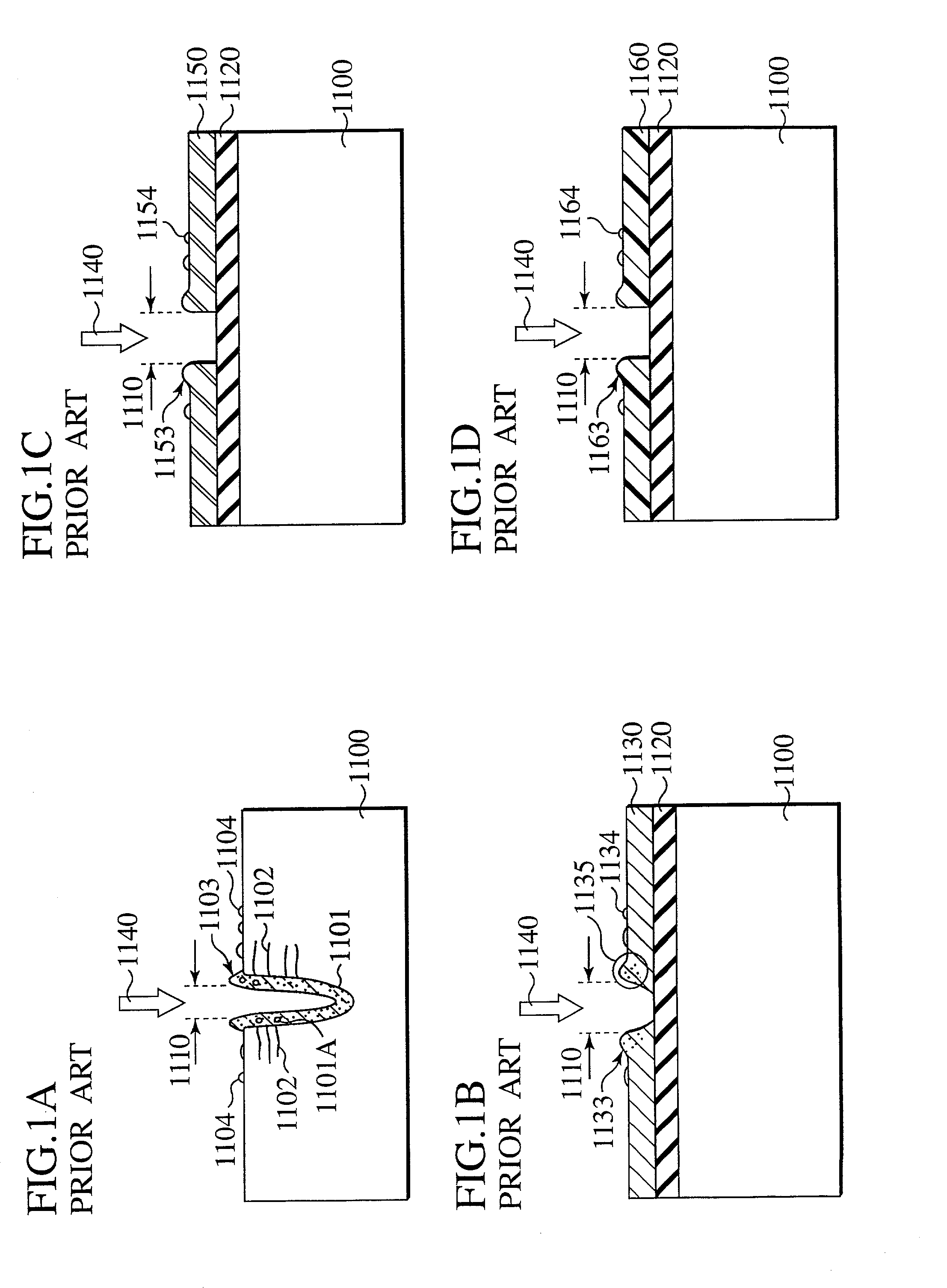

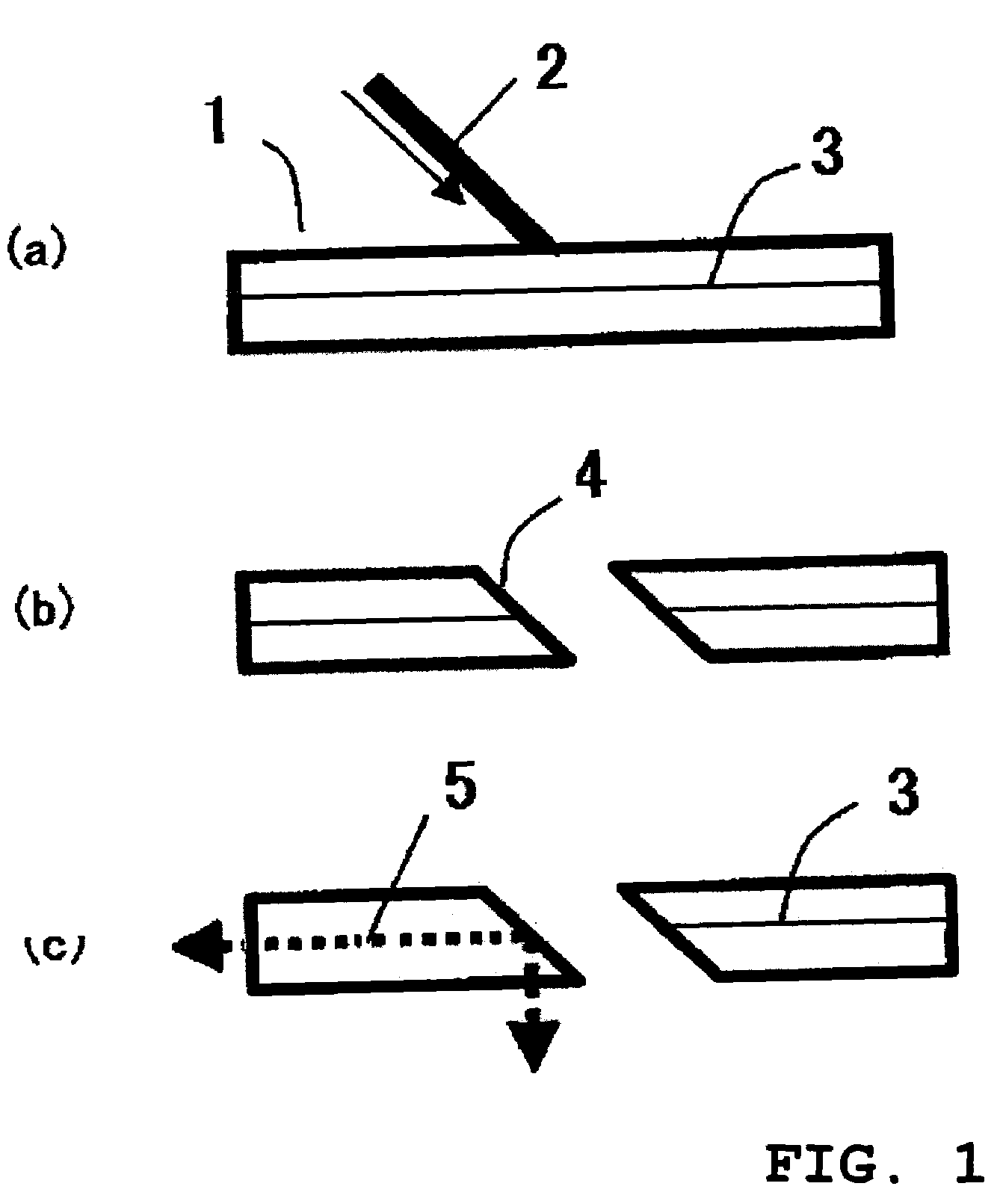

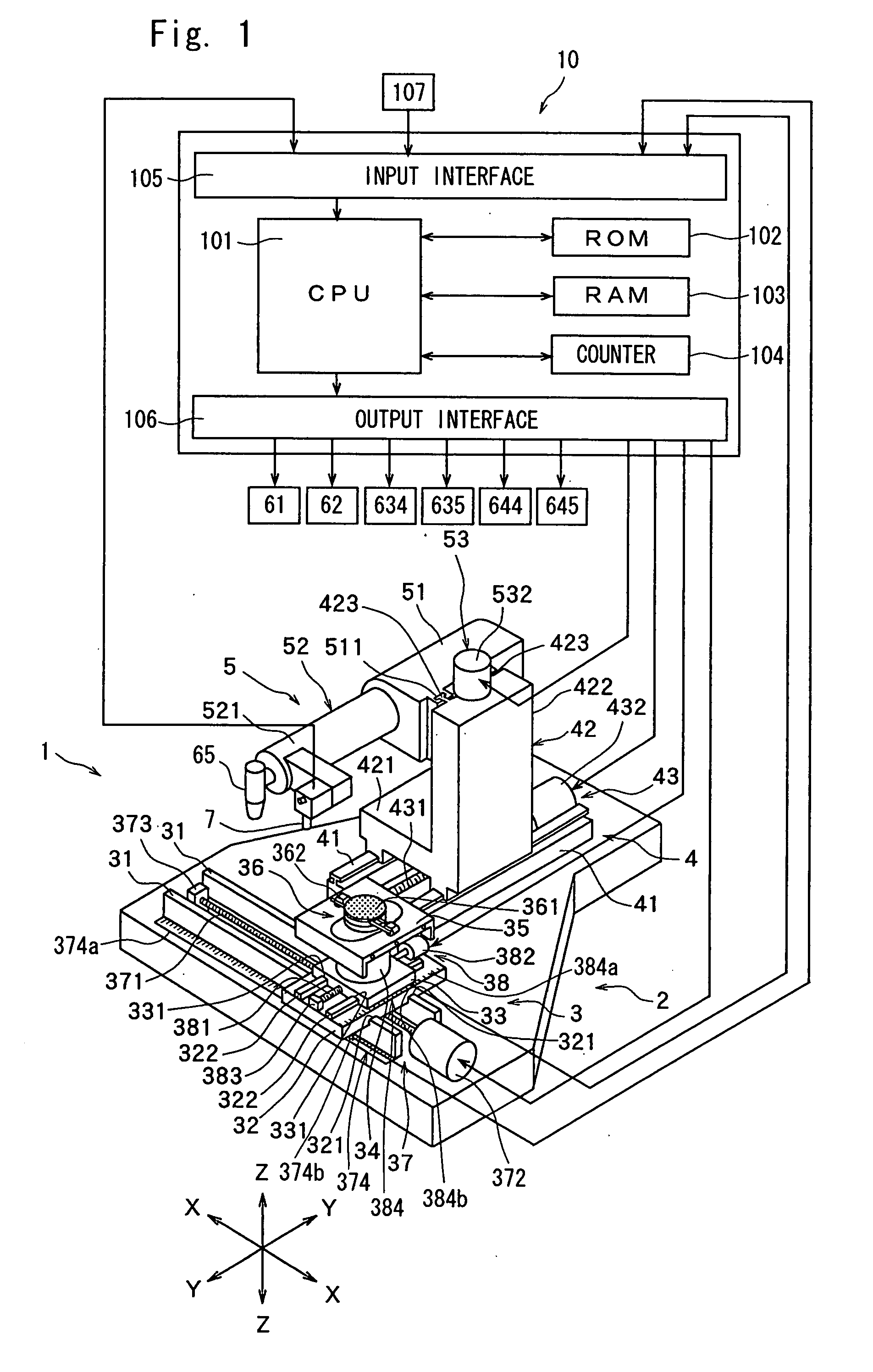

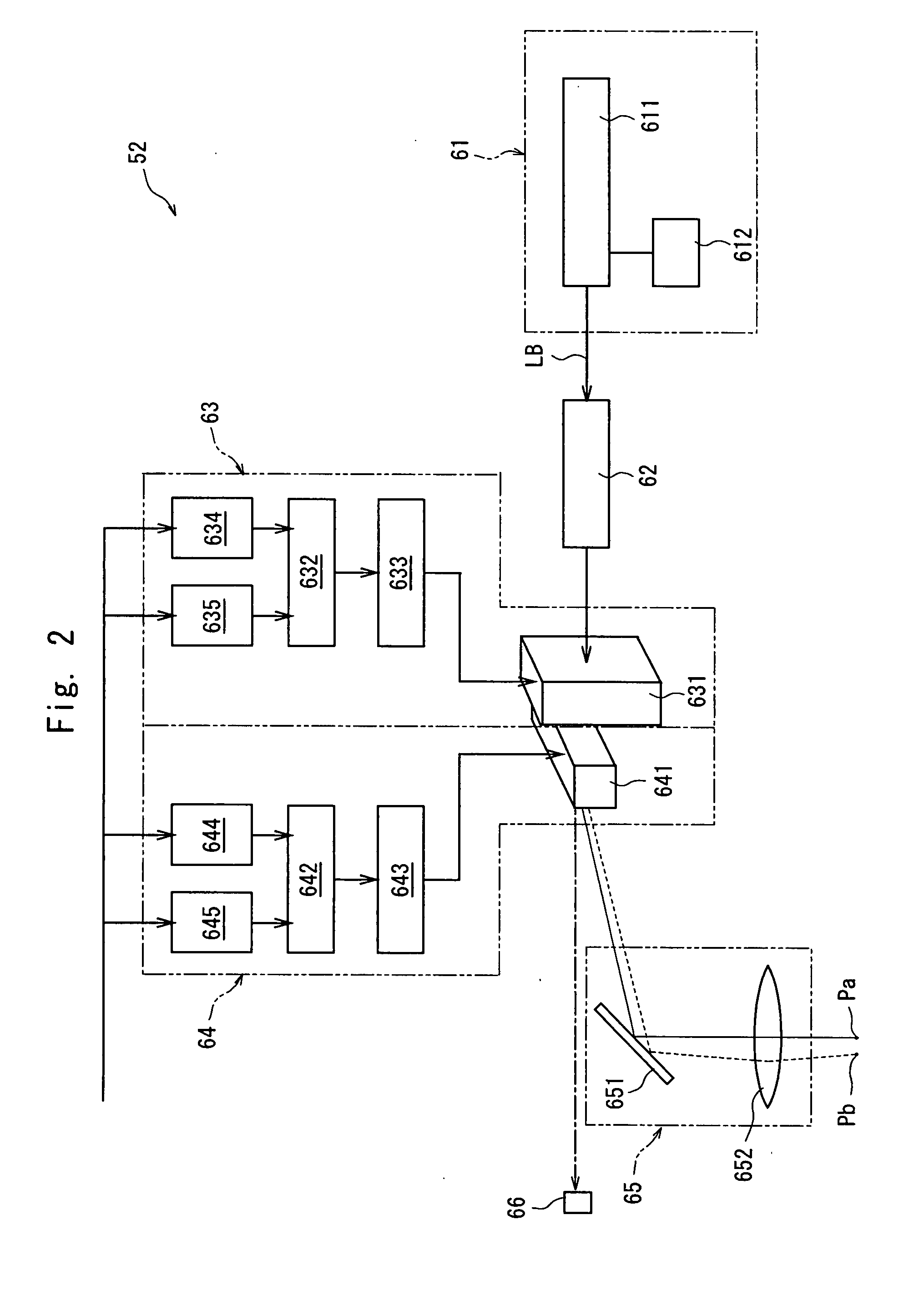

A laser beam machining method and a laser beam machining device capable of cutting a work without producing a fusing and a cracking out of a predetermined cutting line on the surface of the work, wherein a pulse laser beam is radiated on the predetermined cut line on the surface of the work under the conditions causing a multiple photon absorption and with a condensed point aligned to the inside of the work, and a modified area is formed inside the work along the predetermined determined cut line by moving the condensed point along the predetermined cut line, whereby the work can be cut with a rather small force by cracking the work along the predetermined cut line starting from the modified area and, because the pulse laser beam radiated is not almost absorbed onto the surface of the work, the surface is not fused even if the modified area is formed.

Owner:HAMAMATSU PHOTONICS KK

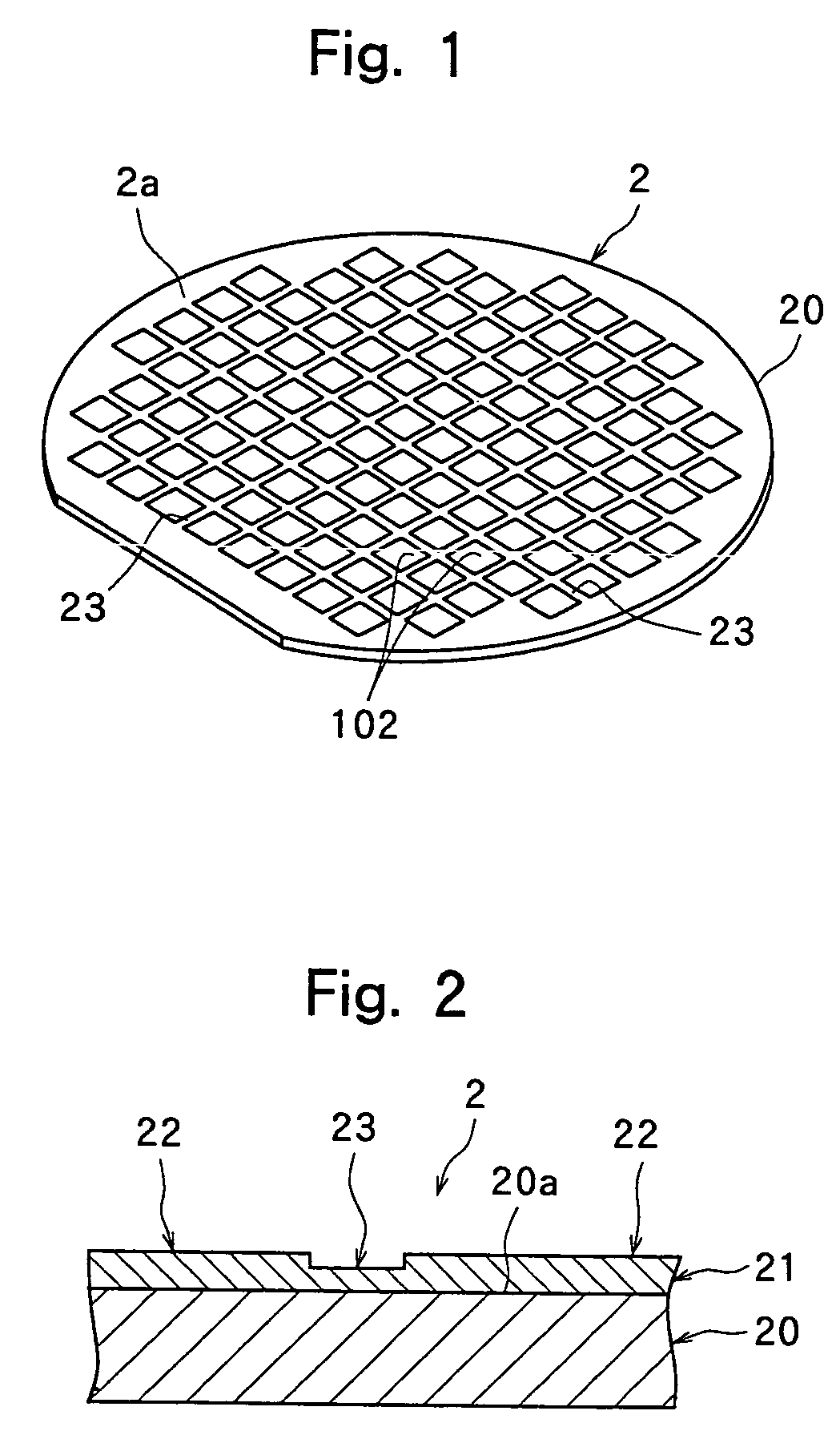

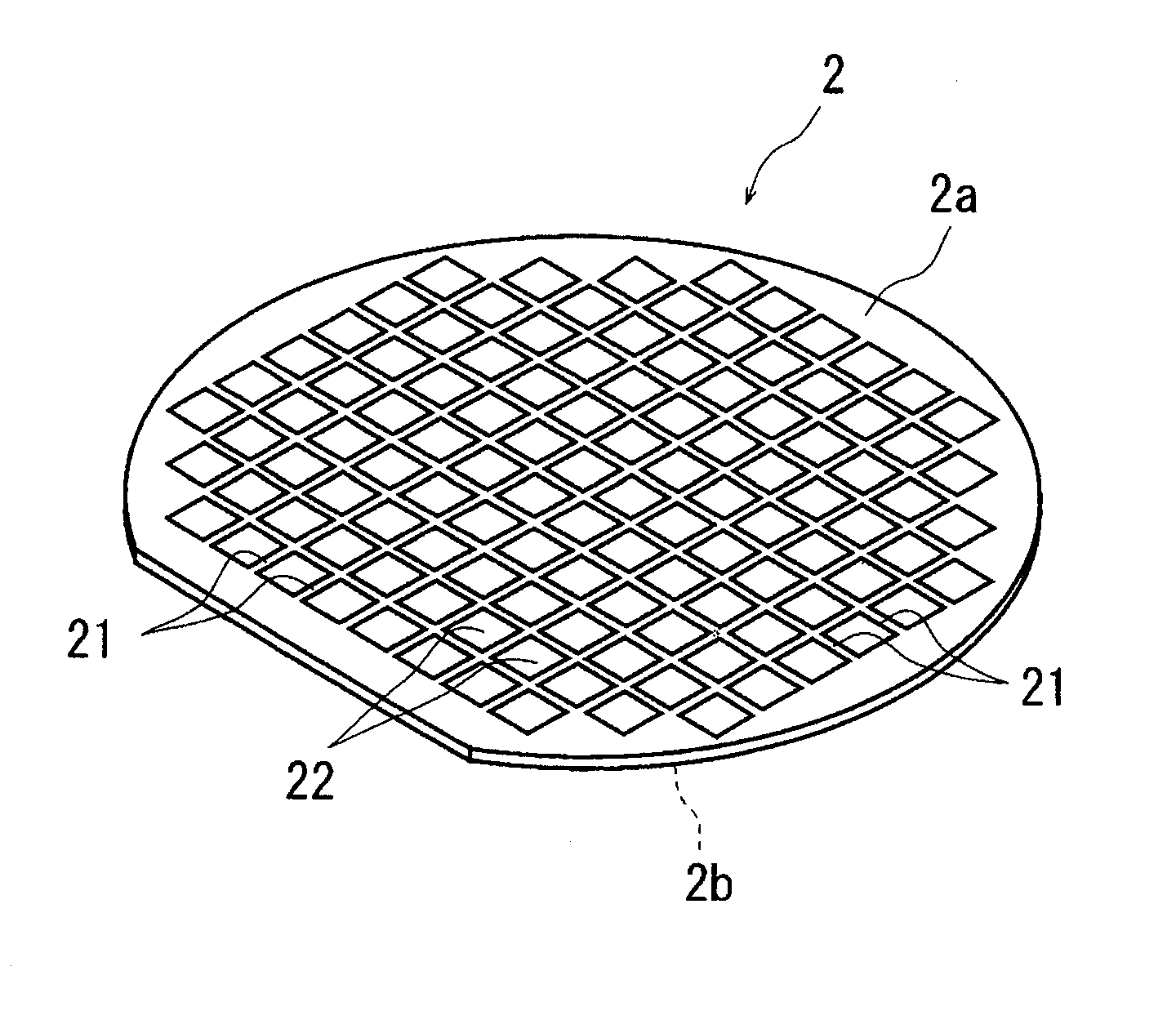

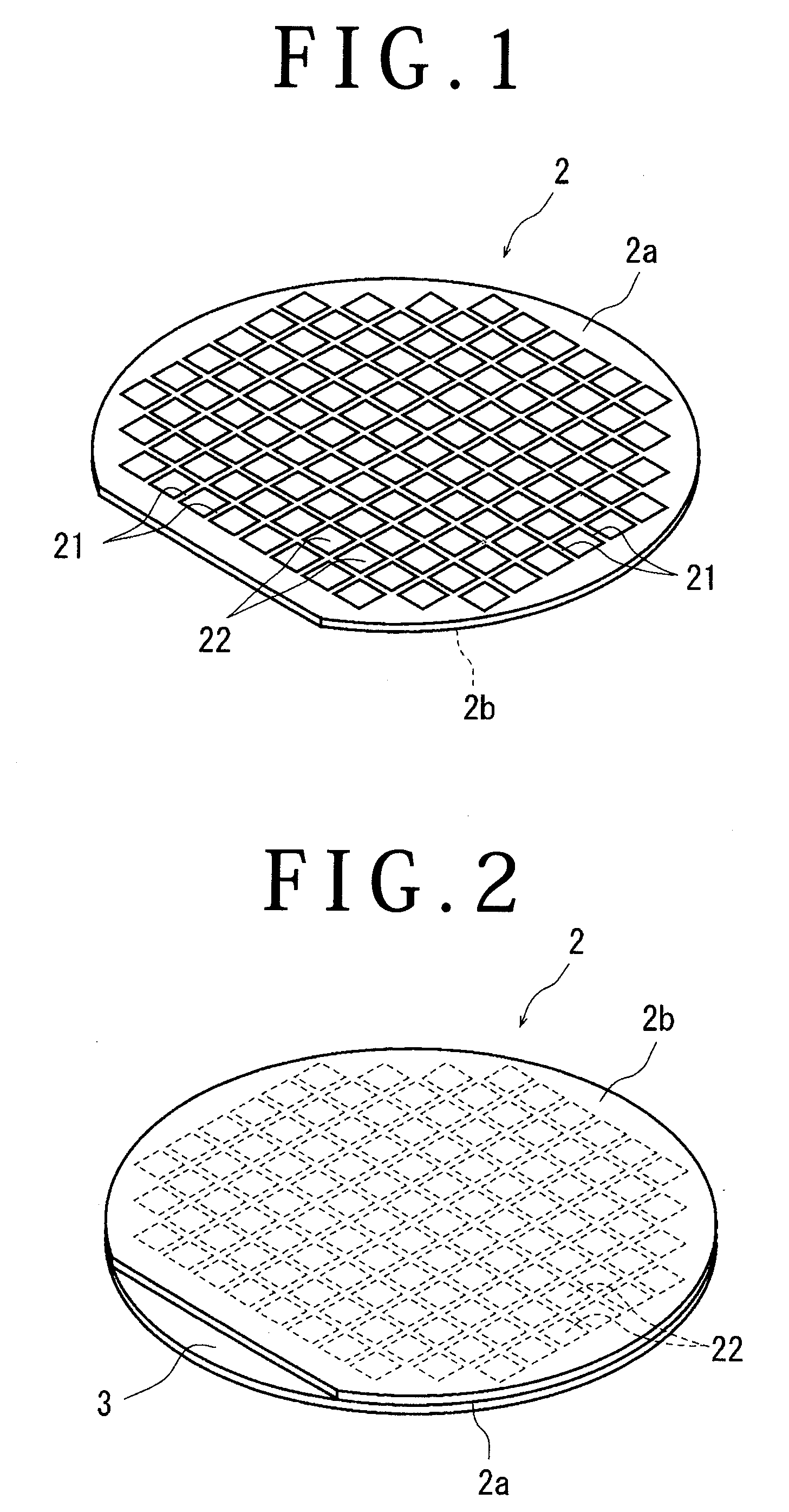

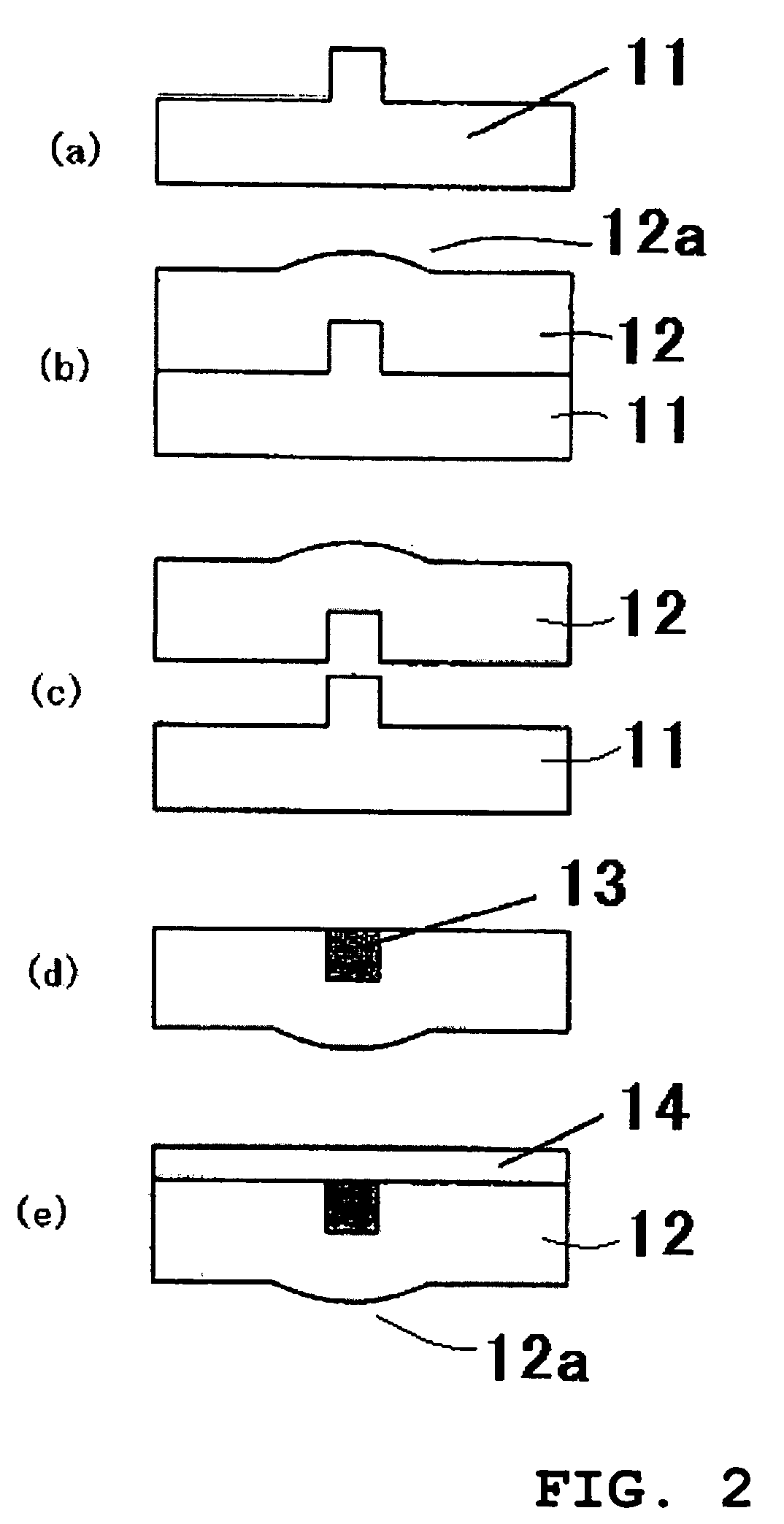

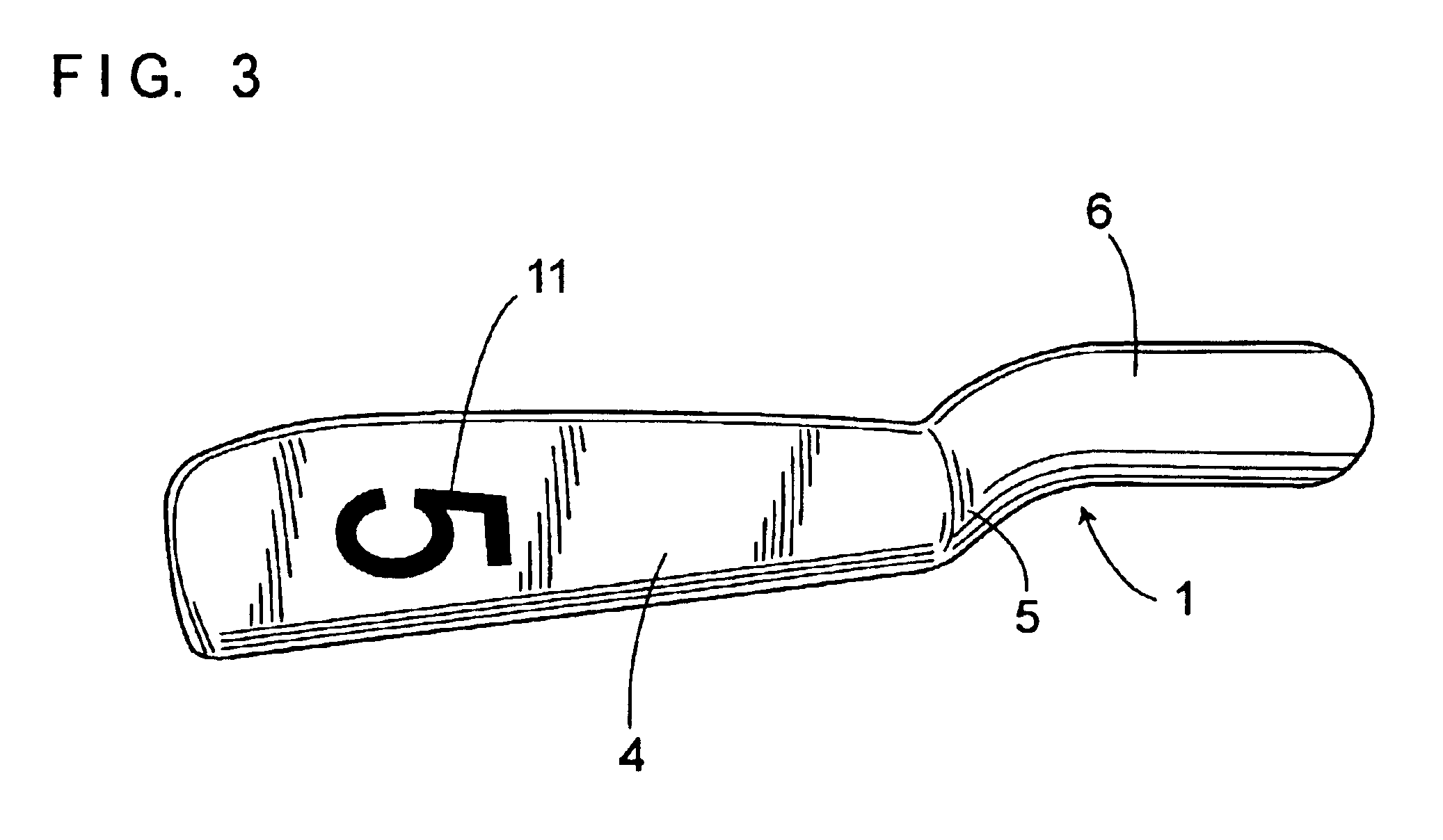

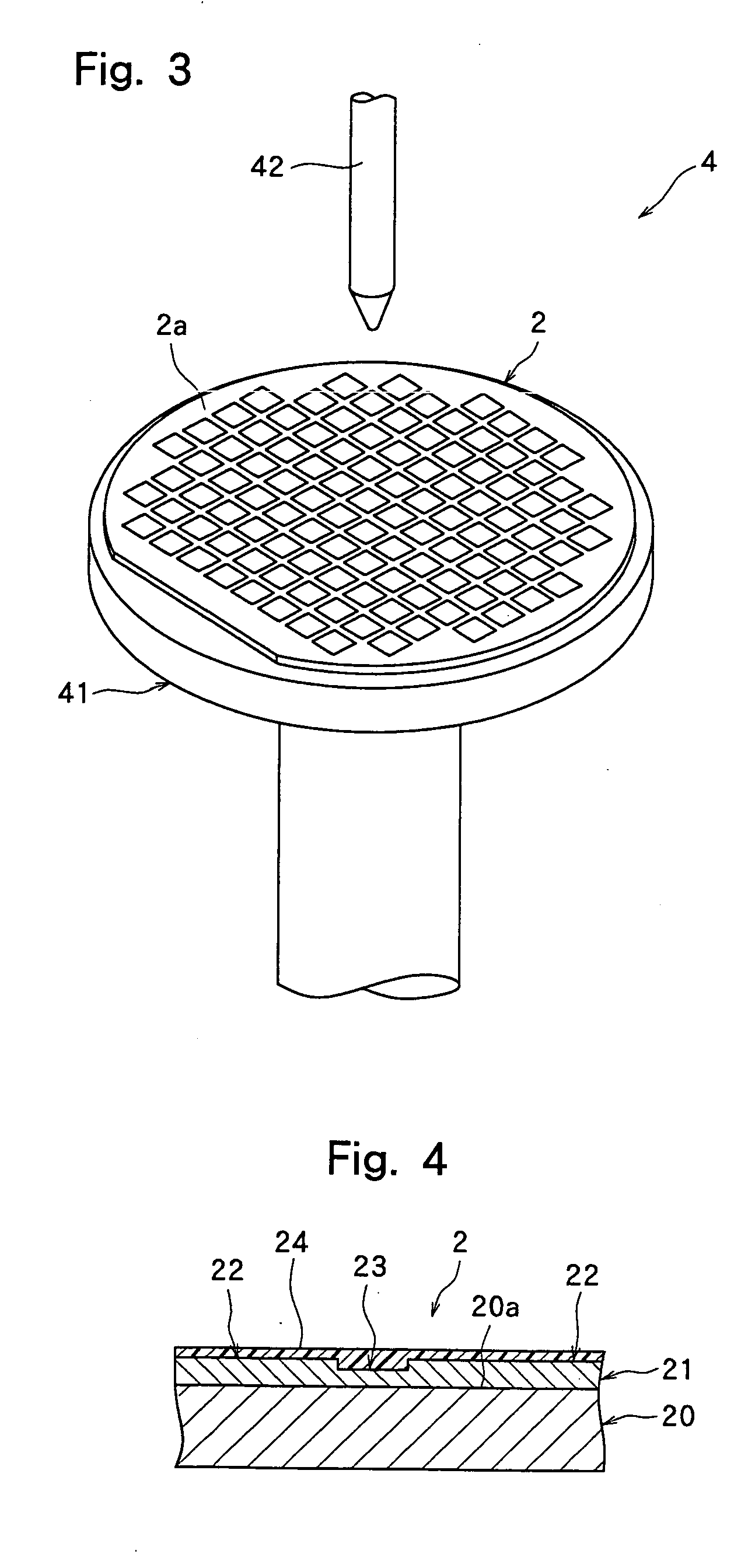

Wafer processing method

ActiveUS7179723B2Suppressing partial peelingAvoid it happening againSemiconductor/solid-state device manufacturingLaser beam welding apparatusLaser beam machiningOptoelectronics

A laser beam processing method for processing a wafer by applying a laser beam to a predetermined area, comprising the steps of forming a resin film which absorbs a laser beam, on the surface to be processed of the wafer; applying a laser beam to the surface to be processed of the wafer through the resin film; and removing the resin film after the laser beam application step.

Owner:DISCO CORP

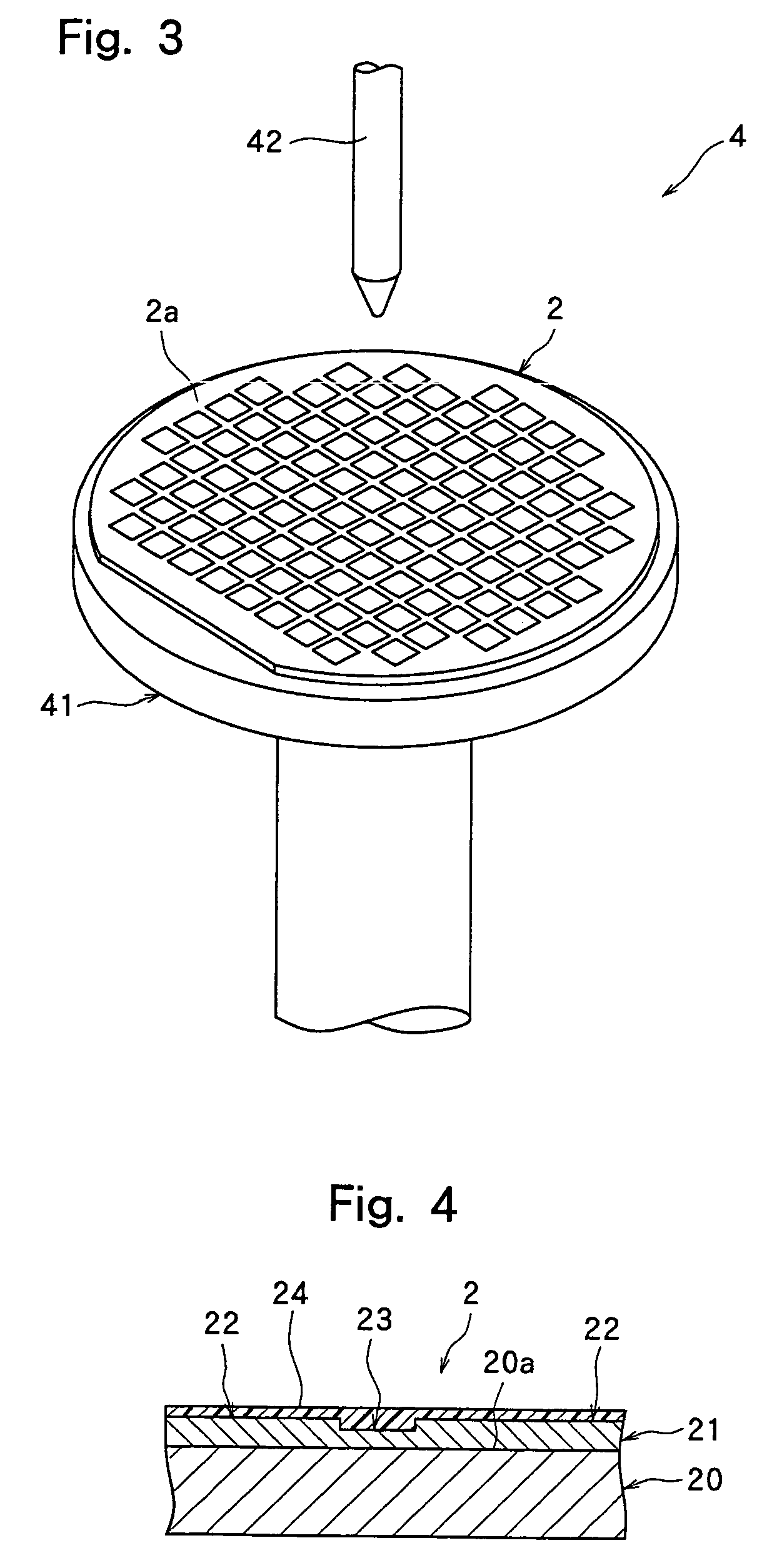

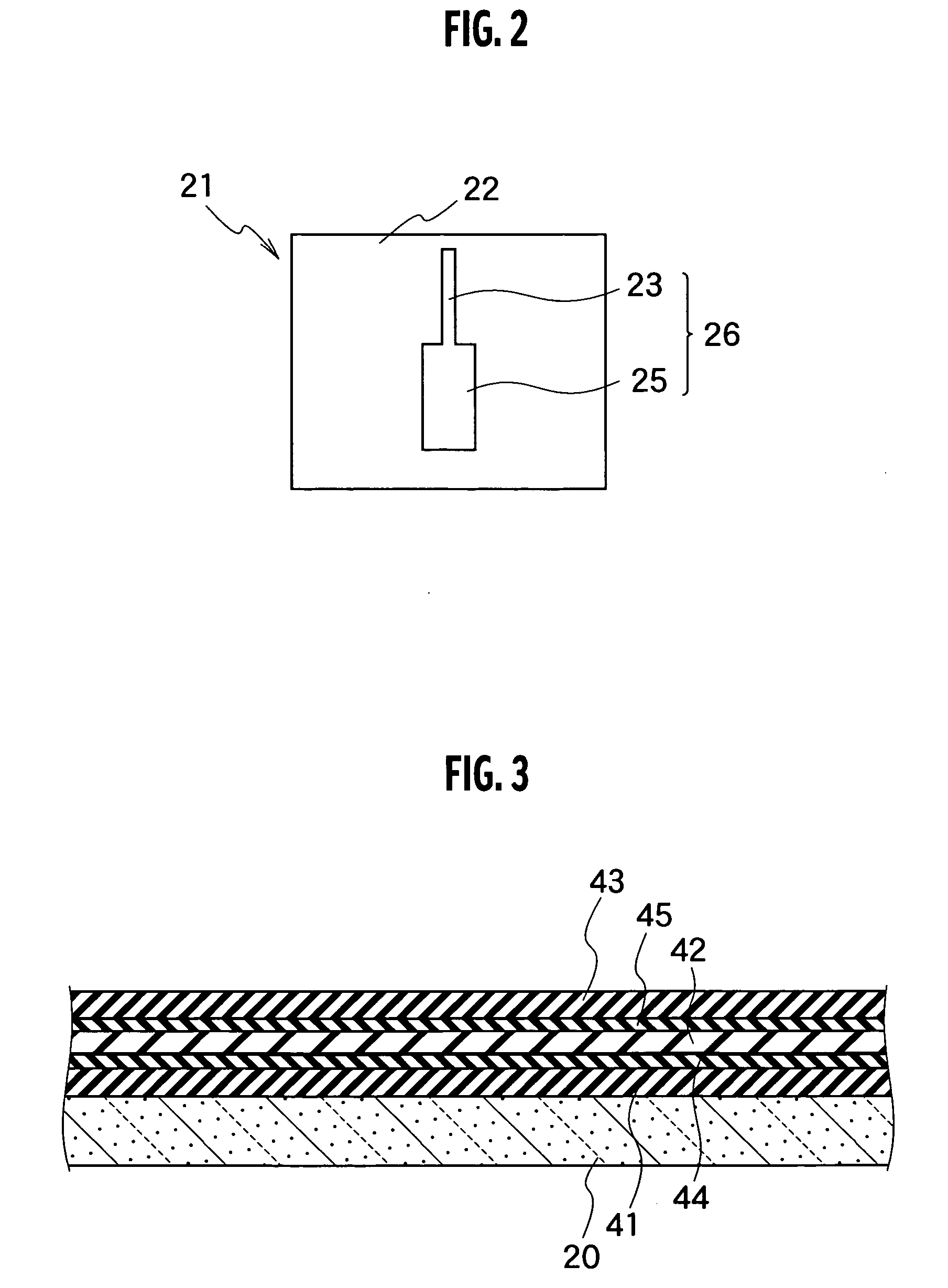

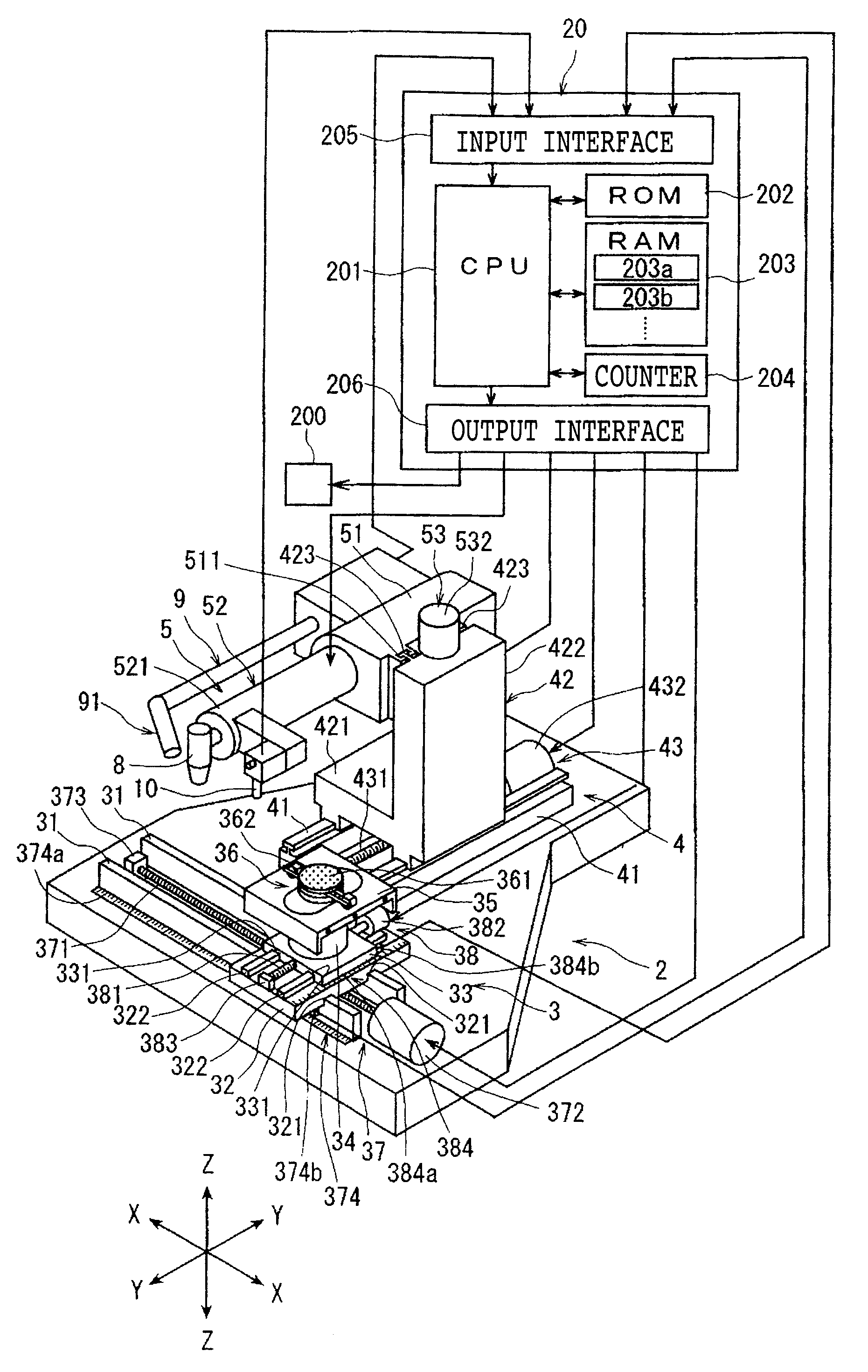

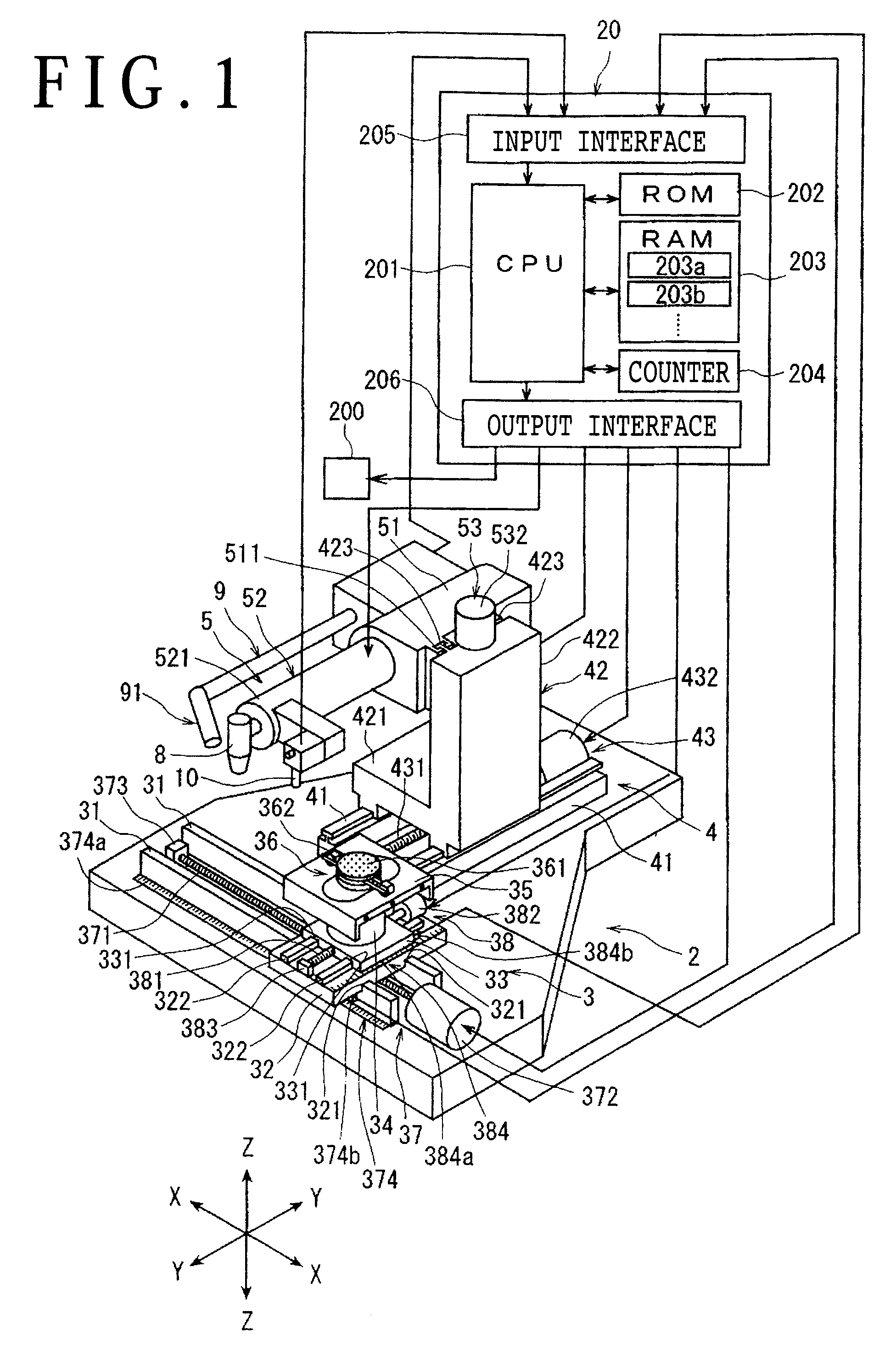

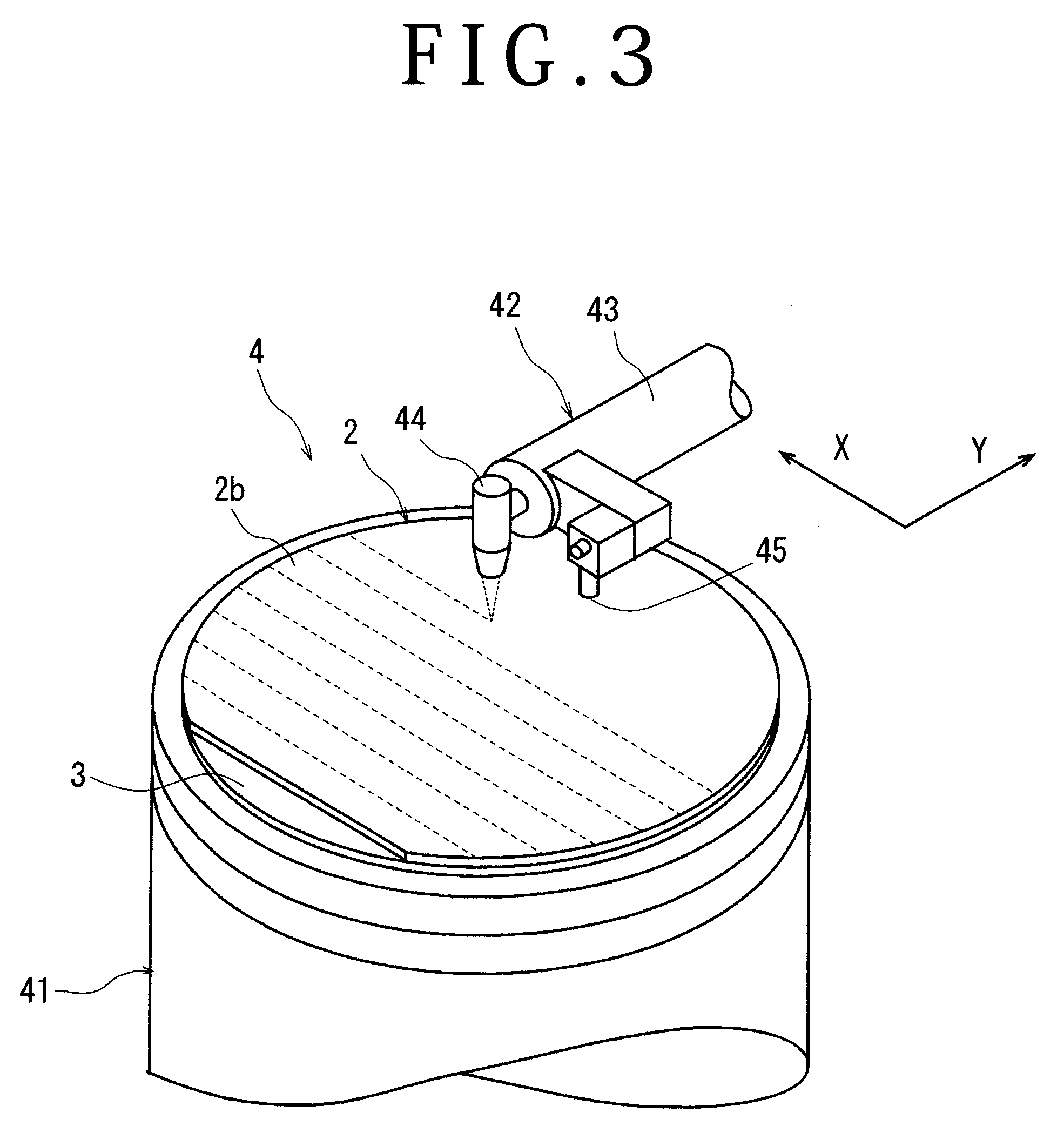

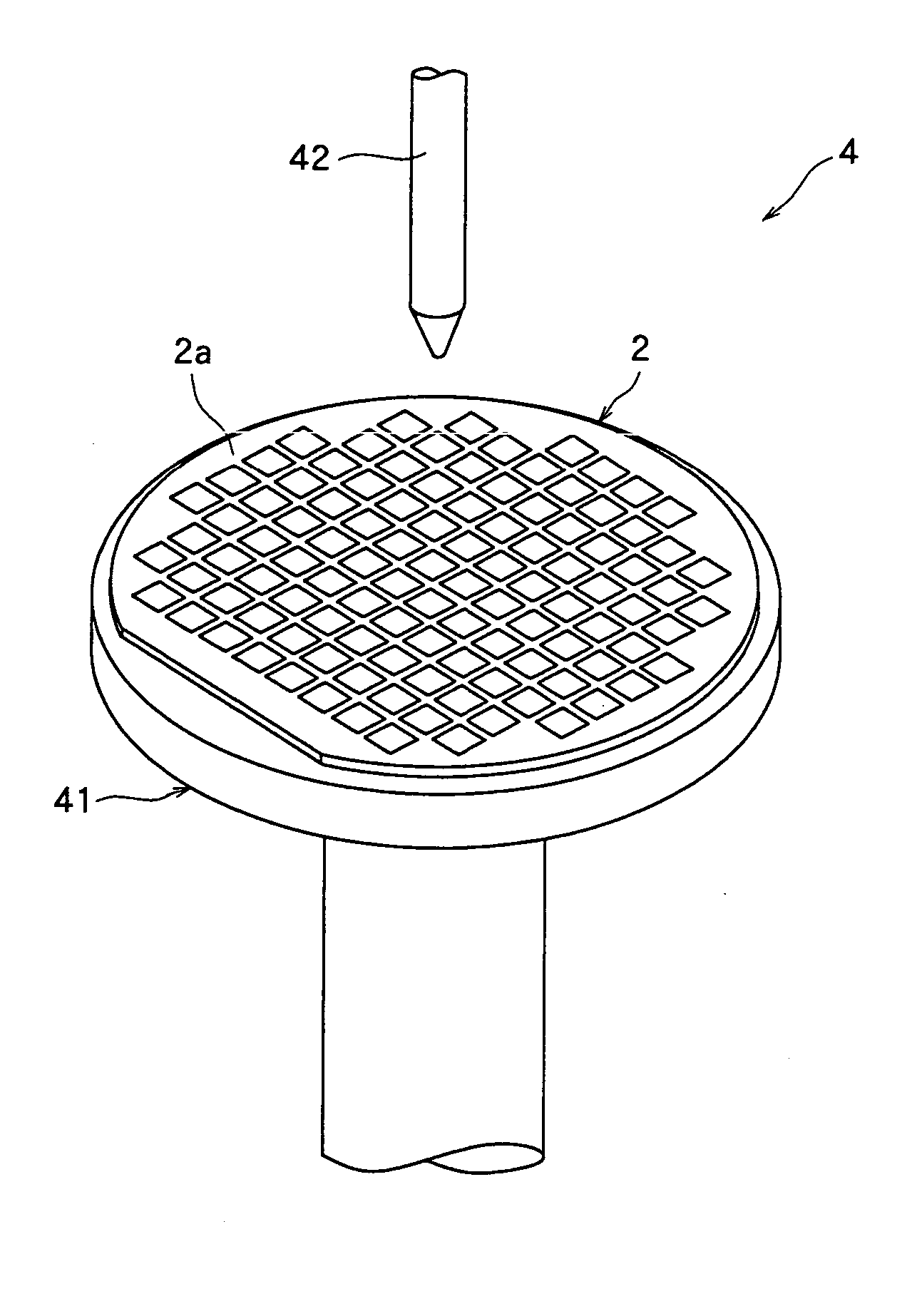

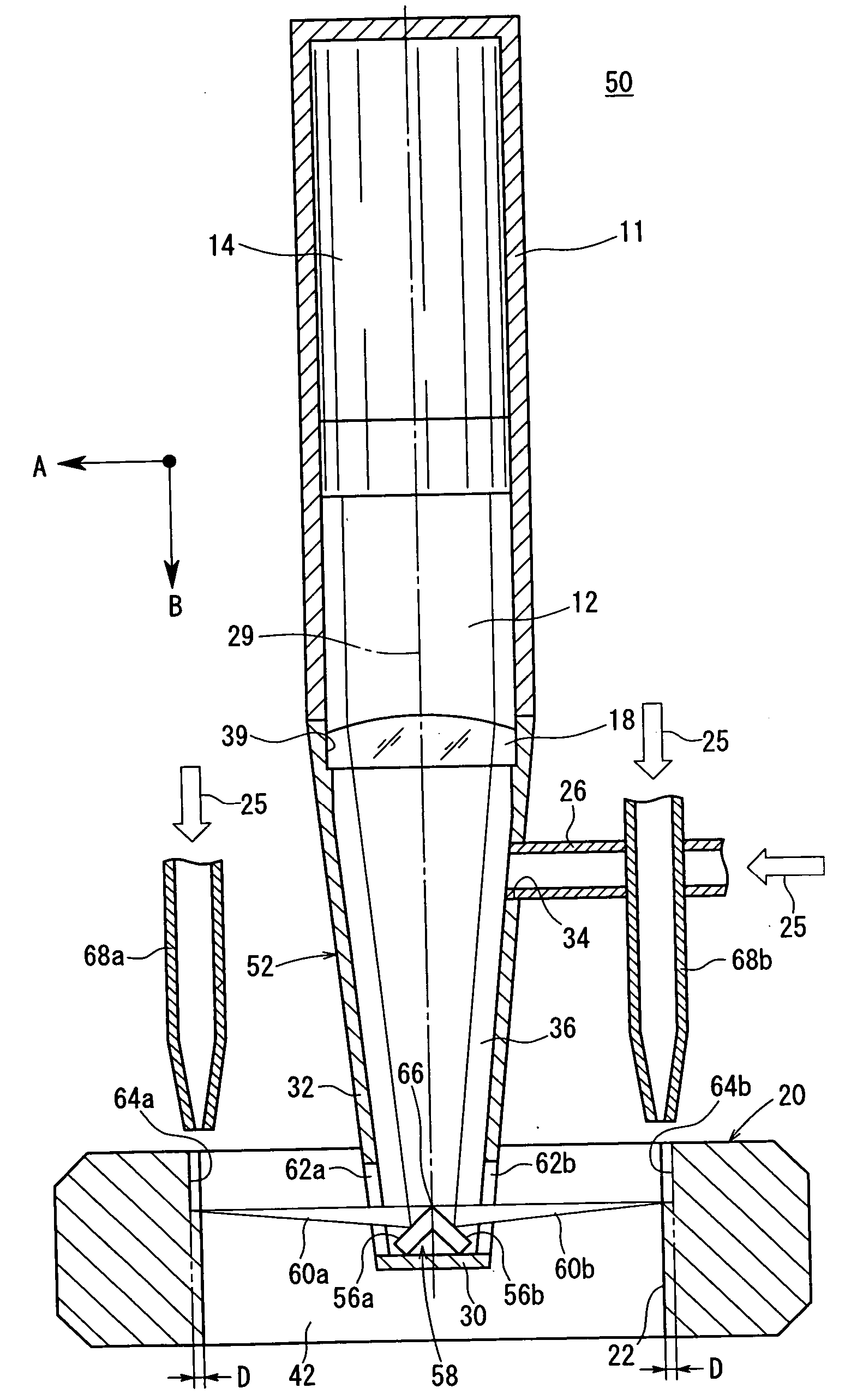

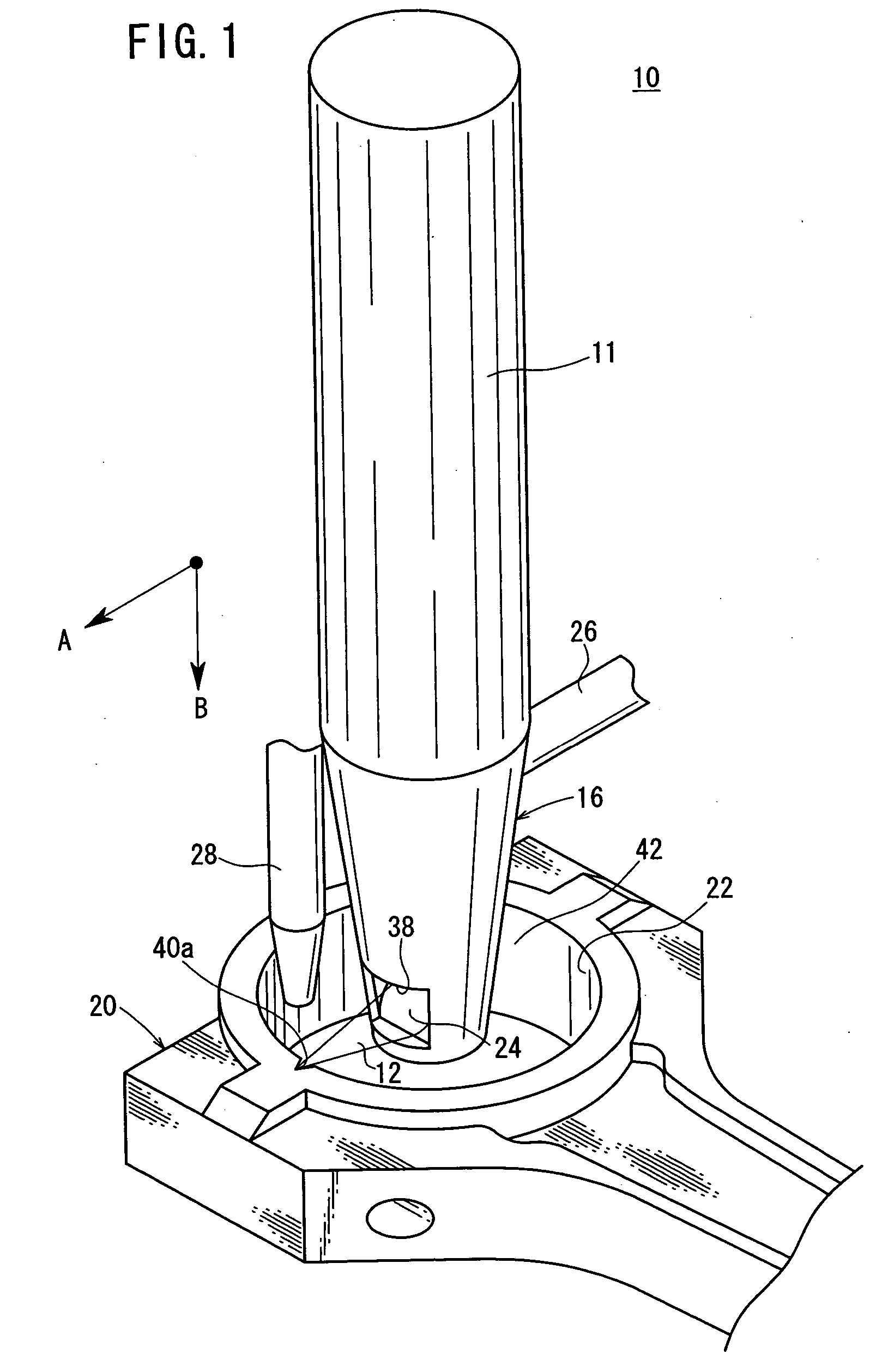

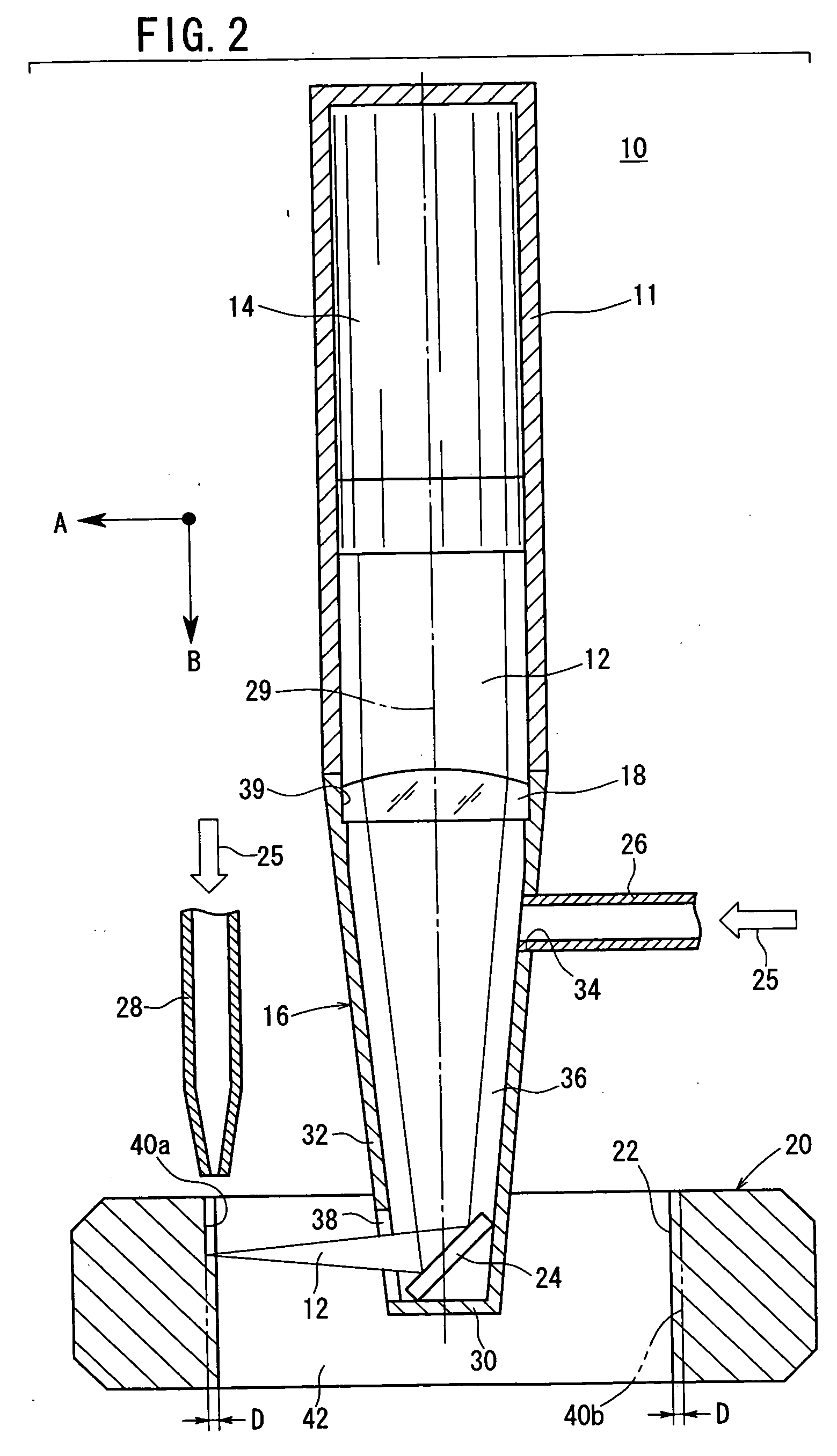

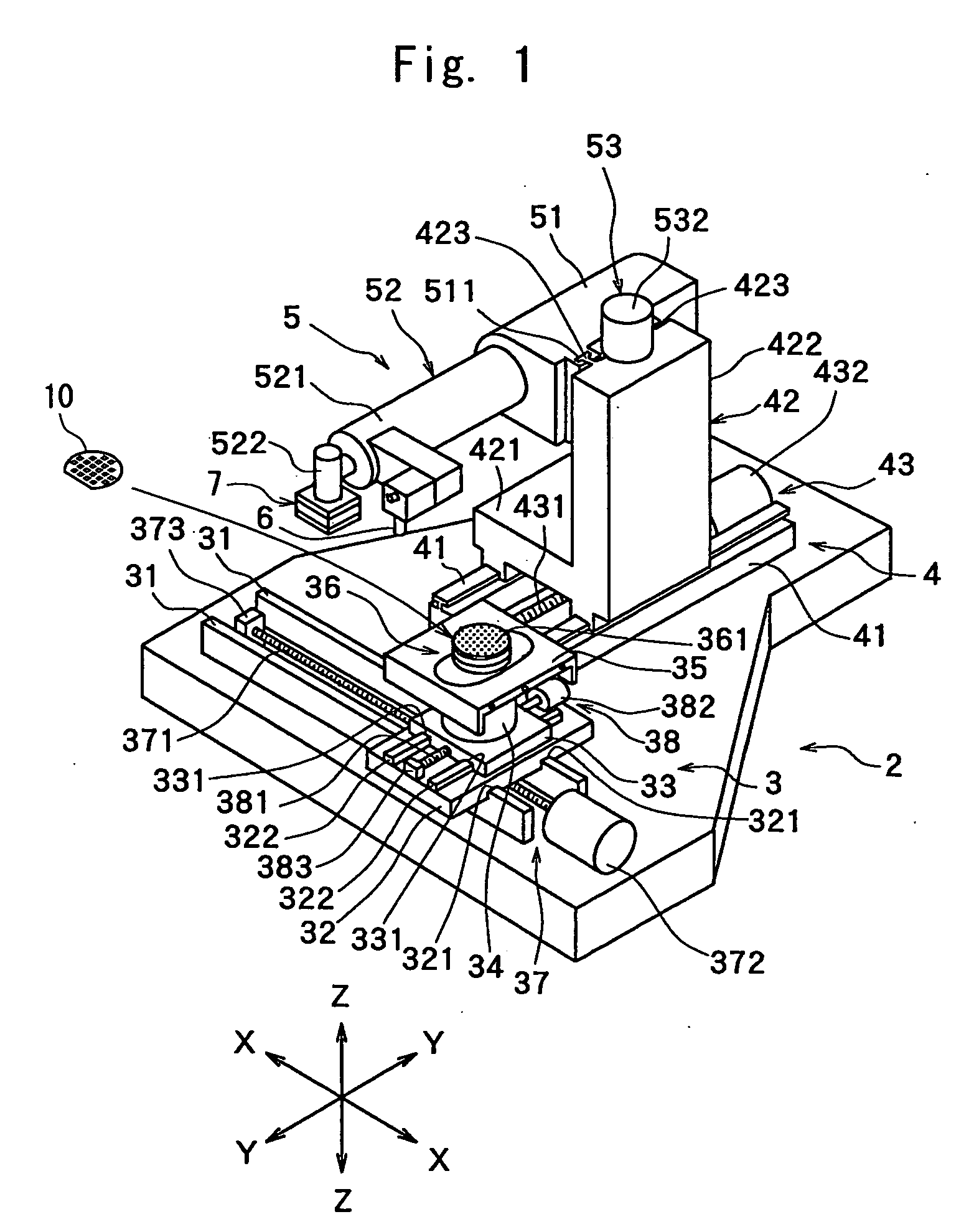

Laser beam processing machine

ActiveUS6998571B2Welding/cutting auxillary devicesSemiconductor/solid-state device manufacturingTectorial membraneLaser beam machining

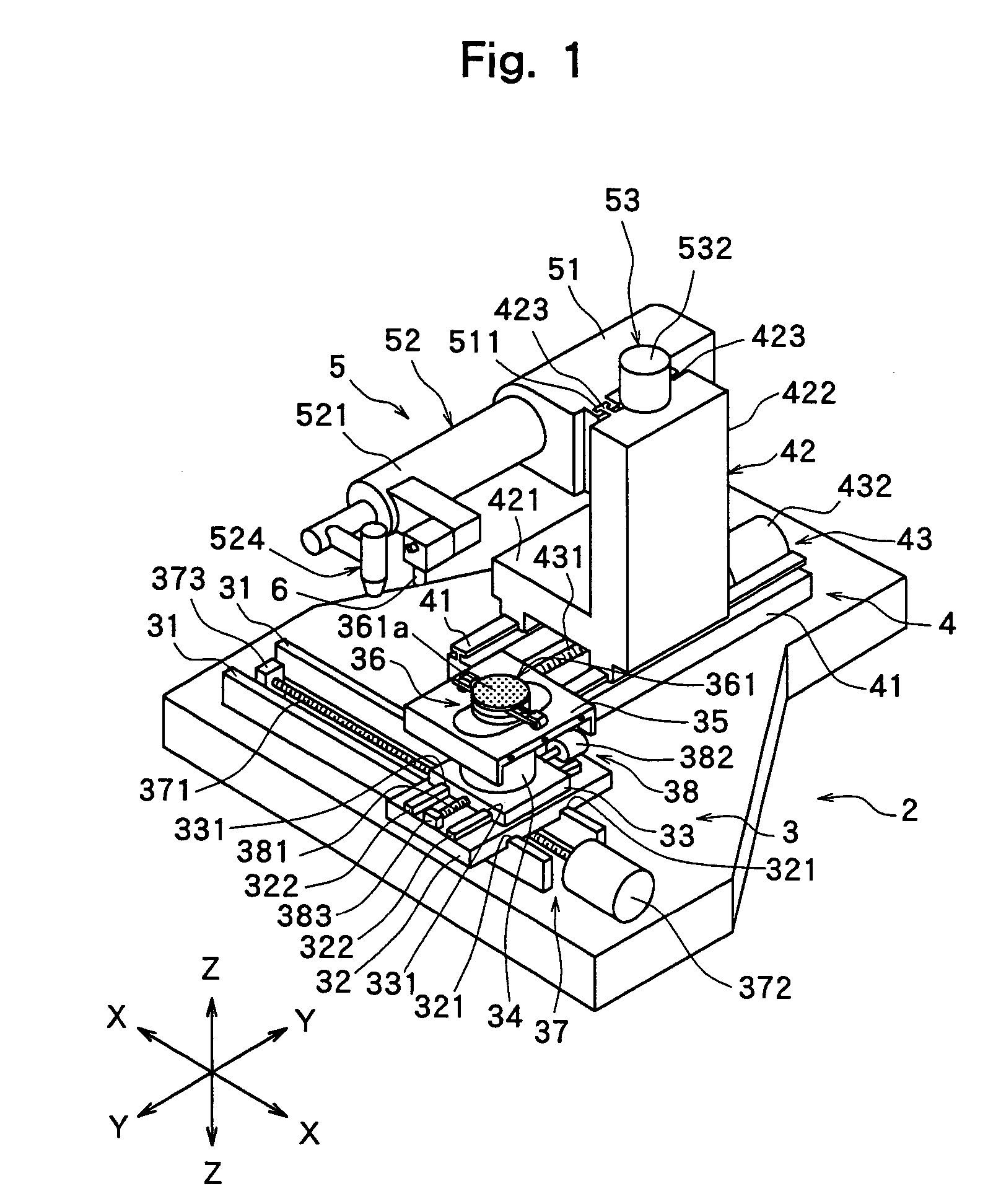

A laser beam processing machine comprising a chuck table for holding a workpiece and a laser beam application means for applying a laser beam to the workpiece held on the chuck table, wherein the machine further comprises a protective film forming means for forming a protective film on the to-be-processed surface of the workpiece before laser beam processing.

Owner:DISCO CORP

Laser processing method and laser processing apparatus

InactiveUS20050181581A1No unnecessary fractureSolid-state devicesSemiconductor/solid-state device manufacturingLaser processingLaser beam machining

A laser beam machining method and a laser beam machining device capable of cutting a work without producing a fusing and a cracking out of a predetermined cutting line on the surface of the work, wherein a pulse laser beam is radiated on the predetermined cut line on the surface of the work under the conditions causing a multiple photon absorption and with a condensed point aligned to the inside of the work, and a modified area is formed inside the work along the predetermined determined cut line by moving the condensed point along the predetermined cut line, whereby the work can be cut with a rather small force by cracking the work along the predetermined cut line starting from the modified area and, because the pulse laser beam radiated is not almost absorbed onto the surface of the work, the surface is not fused even if the modified area is formed.

Owner:HAMAMATSU PHOTONICS KK

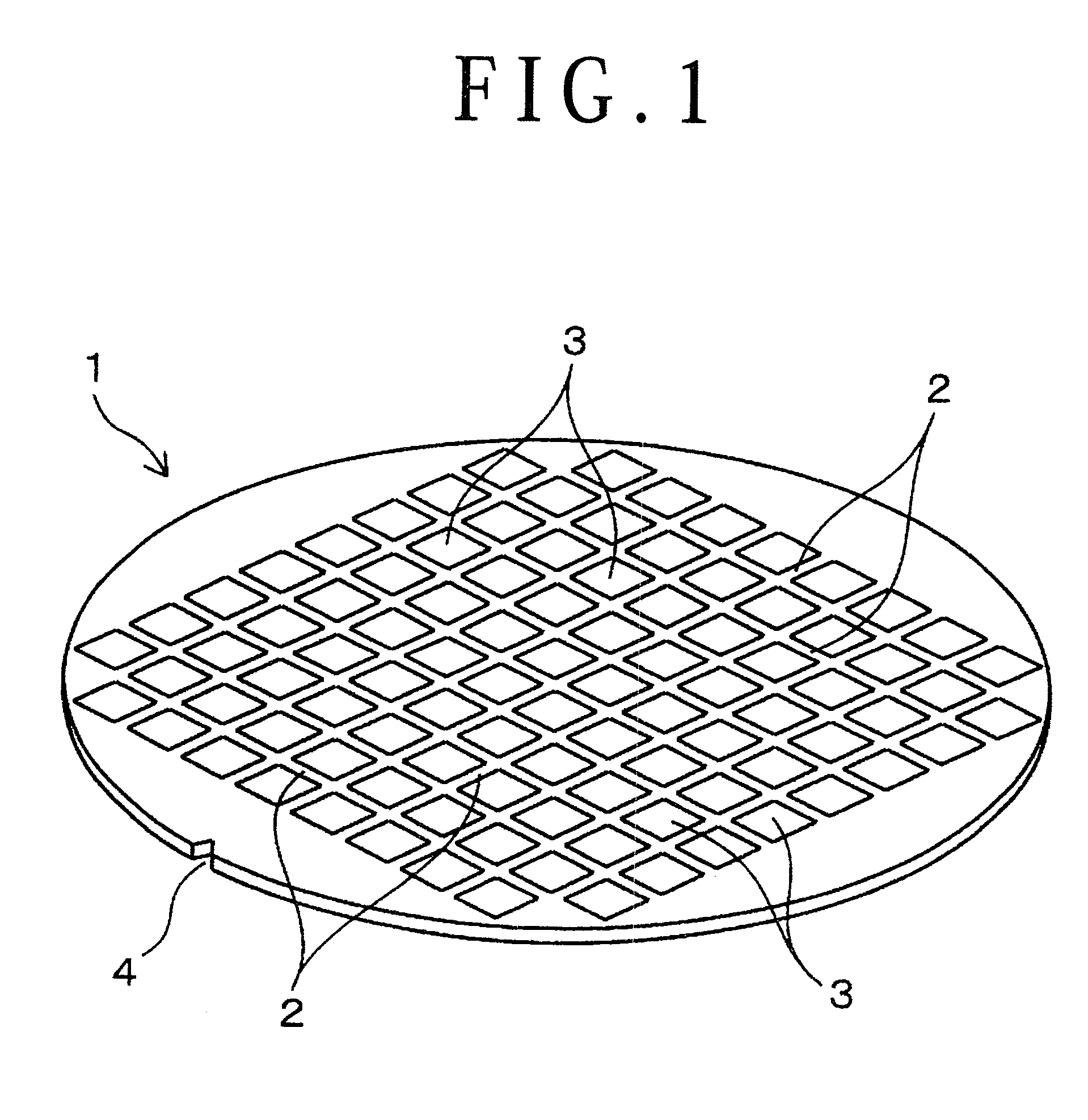

Laser beam processing method and laser beam machine

ActiveUS7364986B2Optimization mechanismSemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesLaser beam machiningOptoelectronics

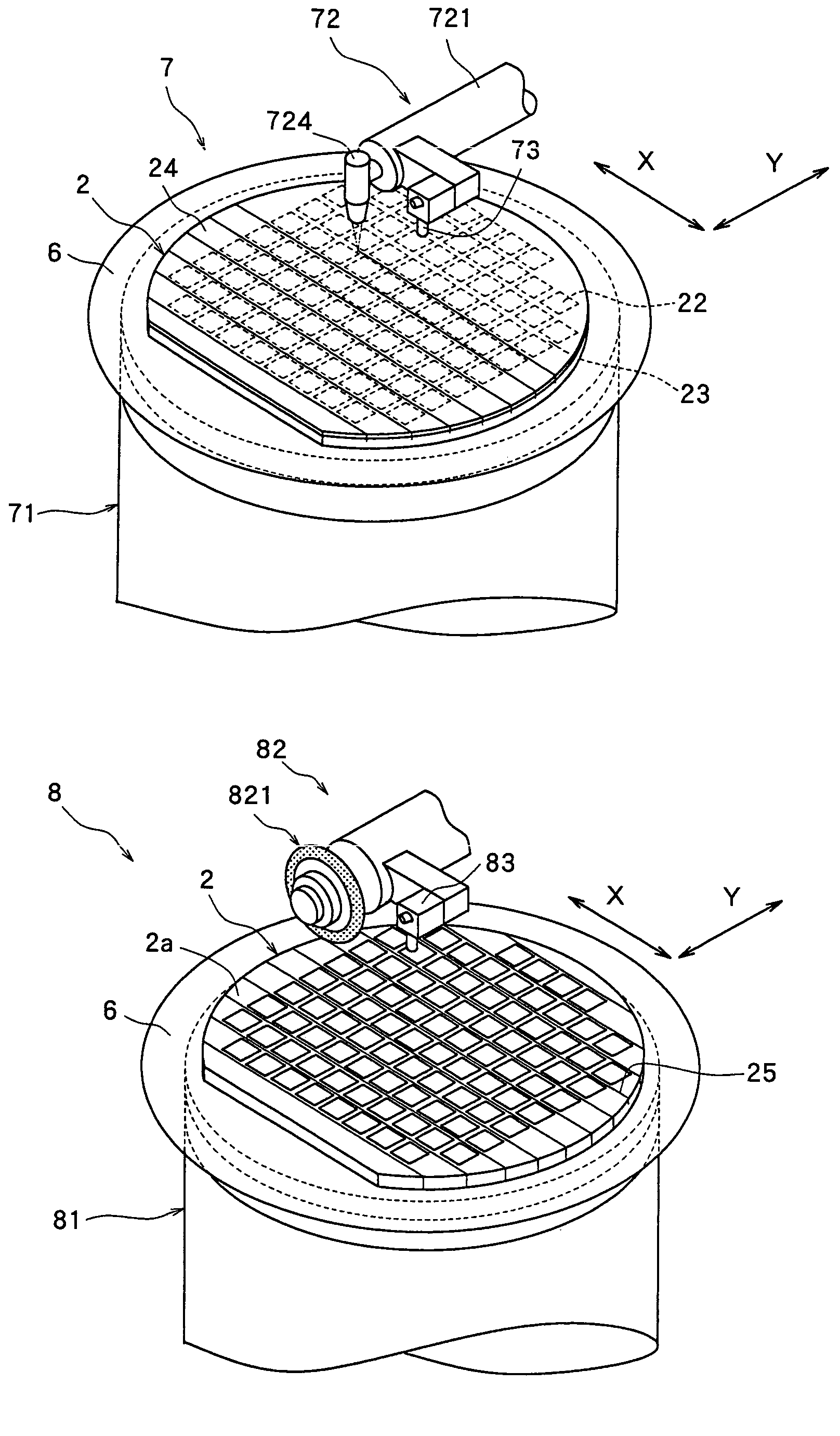

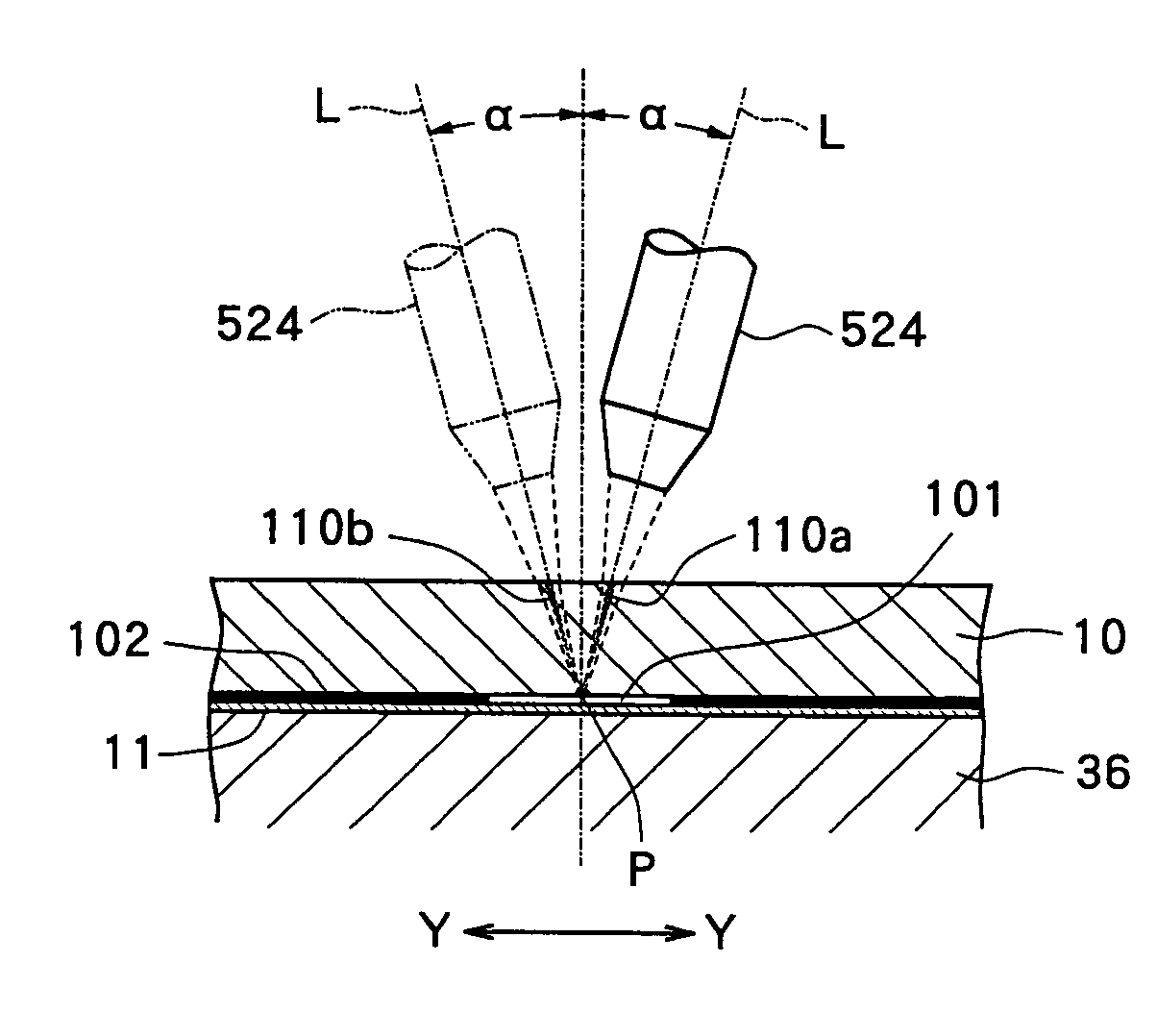

A laser beam processing method comprising the step of processing-feeding a wafer having devices which are formed in a large number of areas sectioned by streets arranged in a lattice pattern on the front surface while a laser beam capable of passing through the wafer is applied to the wafer to form deteriorated layers along the streets in the inside of the wafer, wherein the laser beam is applied at a predetermined angle toward a direction intersecting at right angles to the processing-feed direction relative to a direction perpendicular to the laser beam applied surface of the wafer.

Owner:DISCO CORP

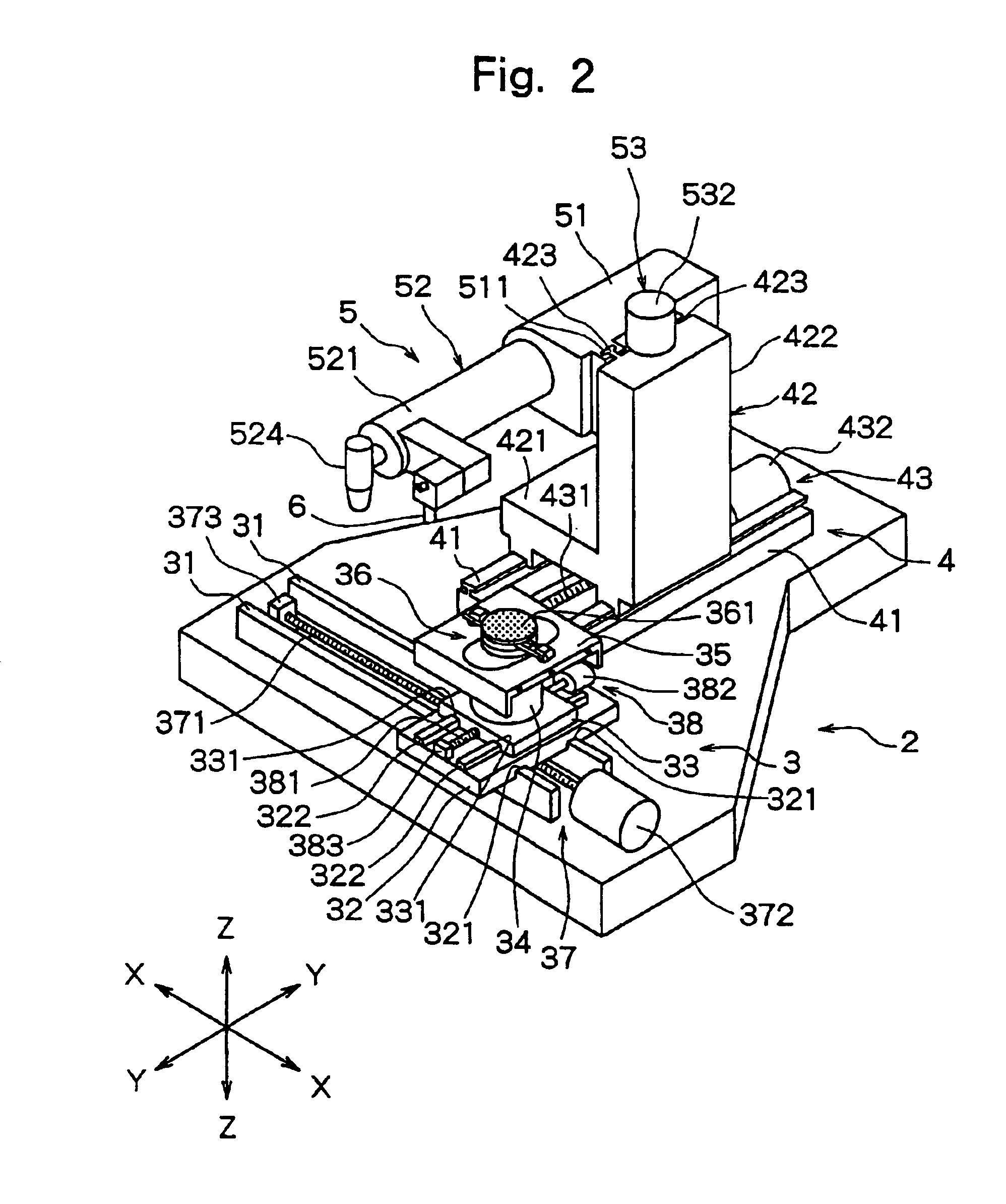

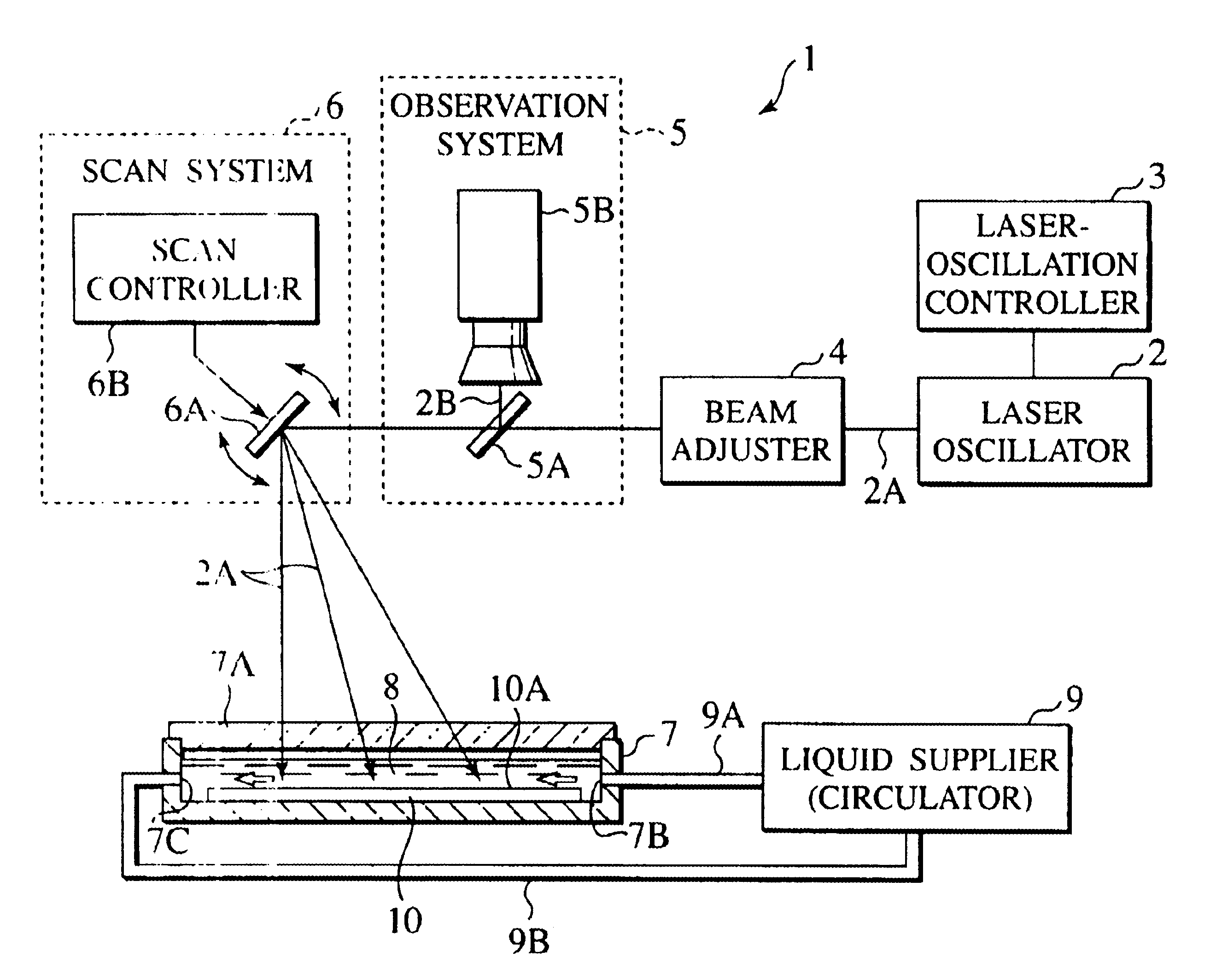

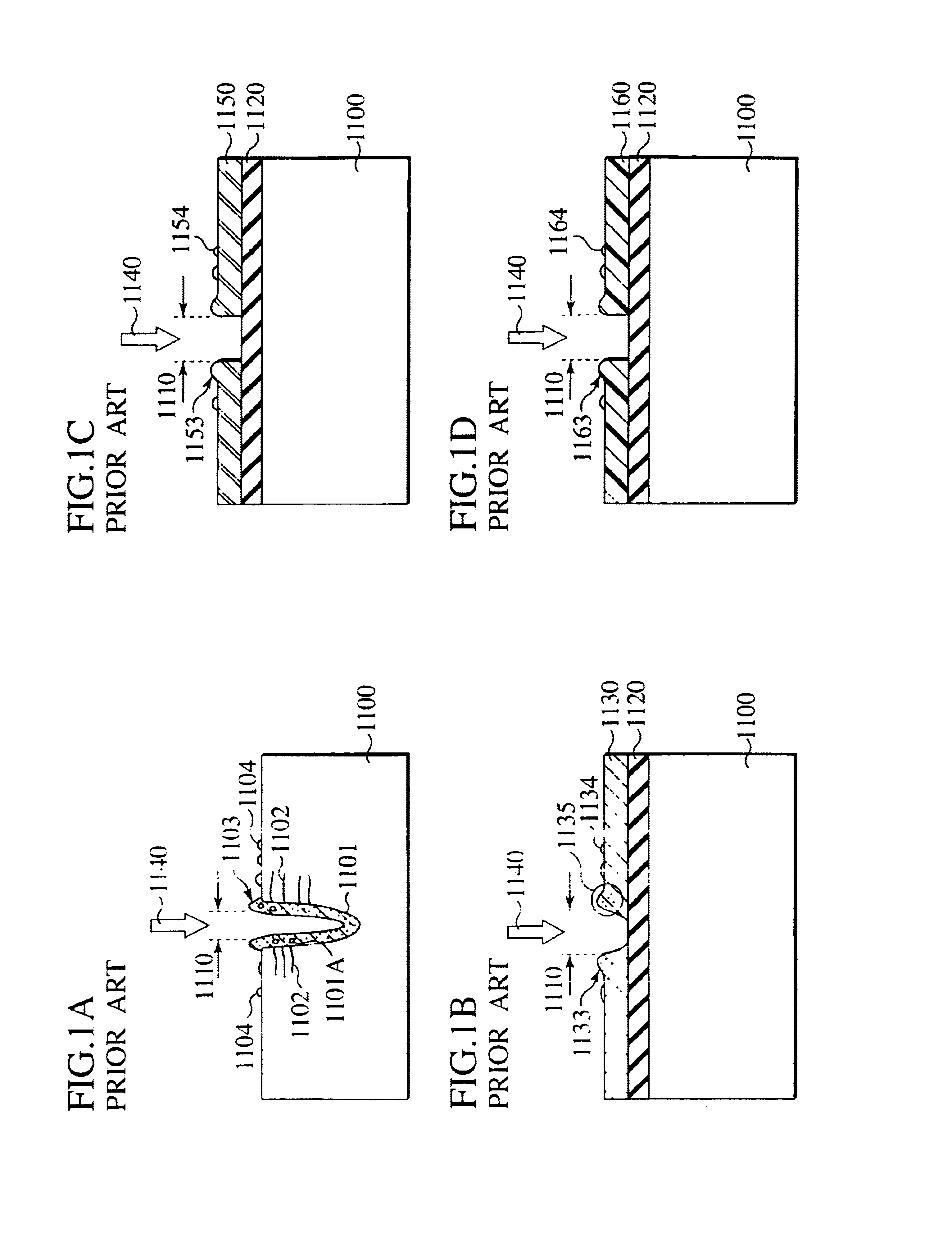

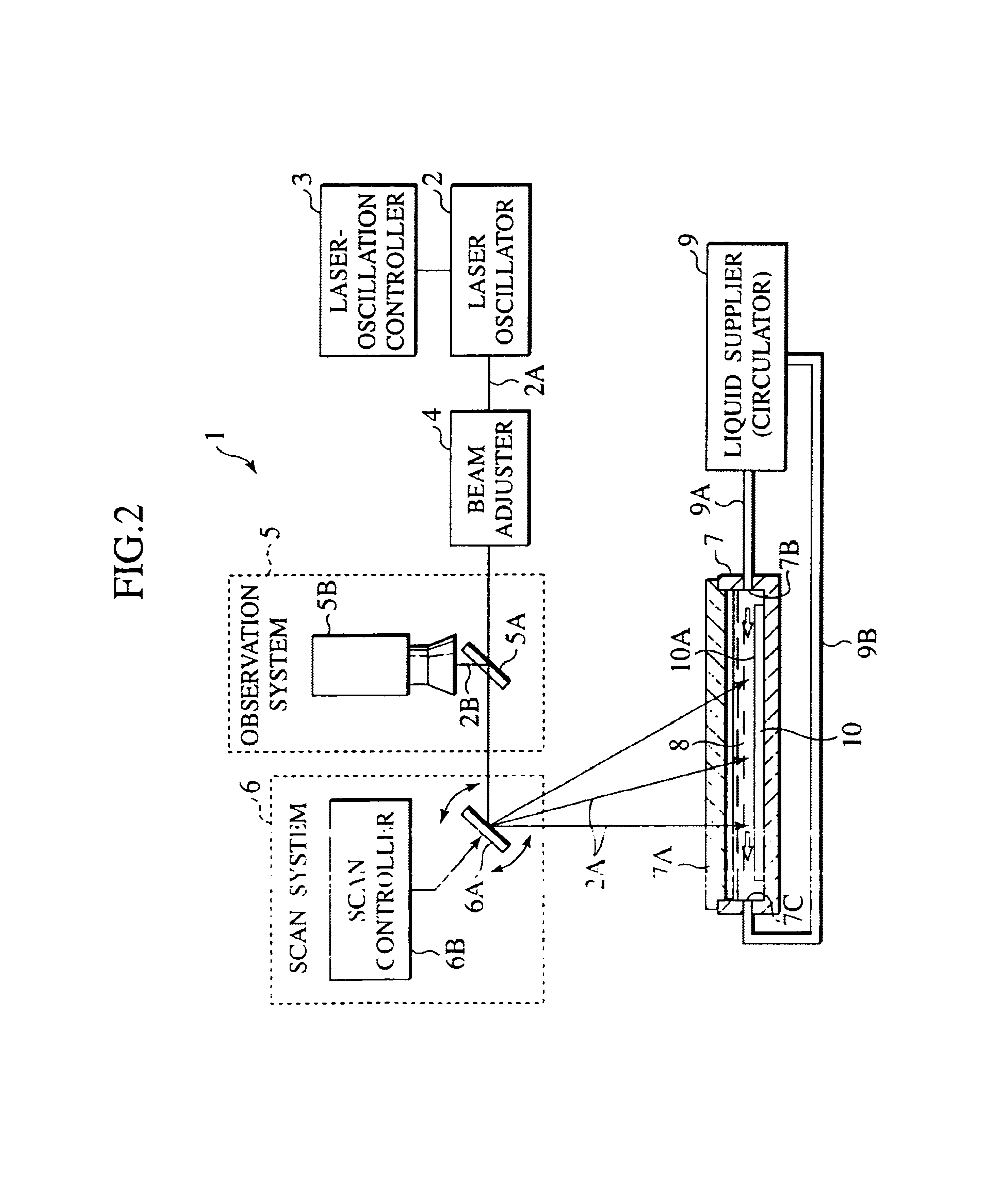

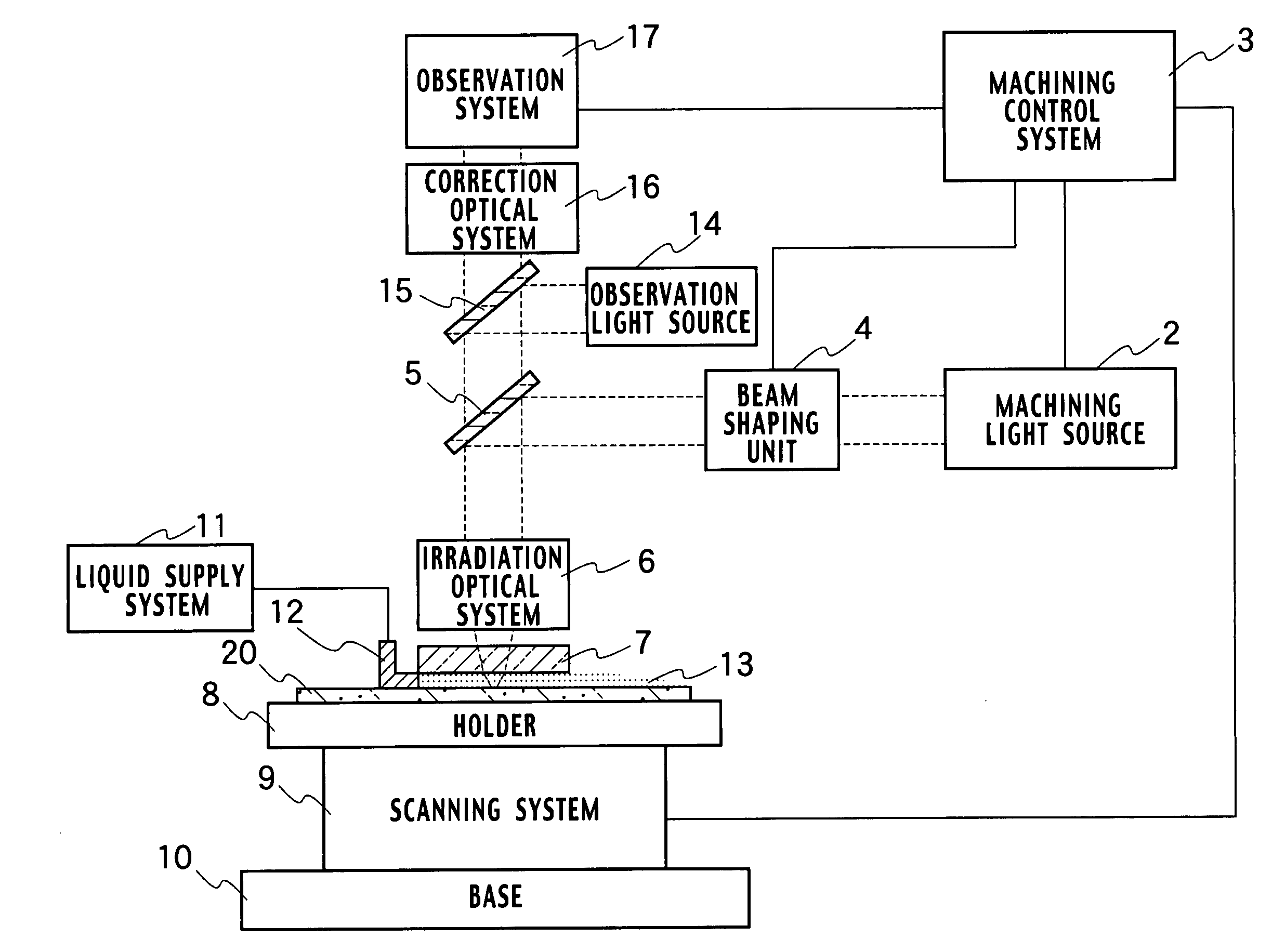

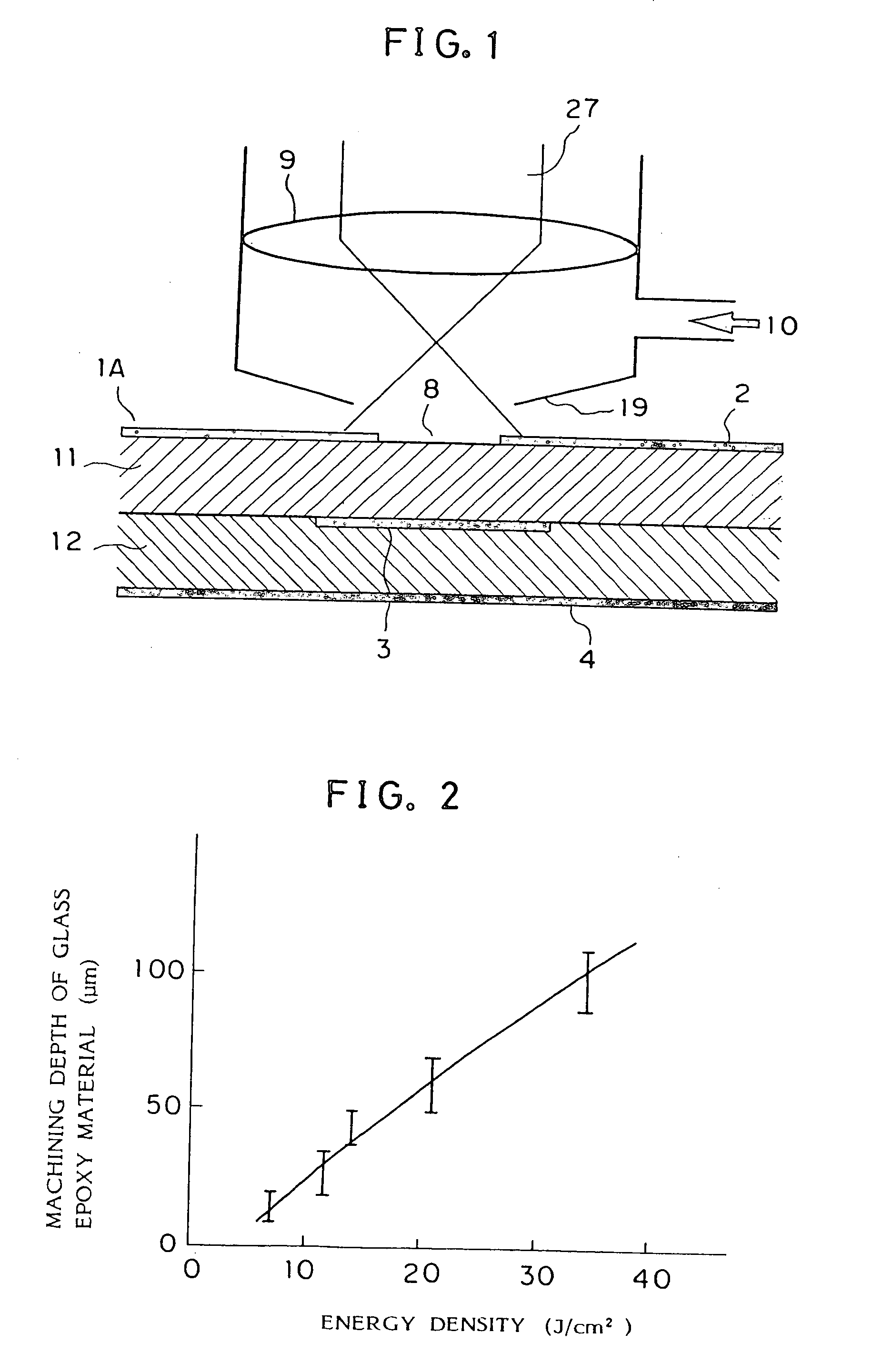

Apparatus and method for laser beam machining, and method for manufacturing semiconductor devices using laser beam machining

InactiveUS20020050489A1Semiconductor/solid-state device manufacturingWelding/soldering/cutting articlesTarget surfaceLight beam

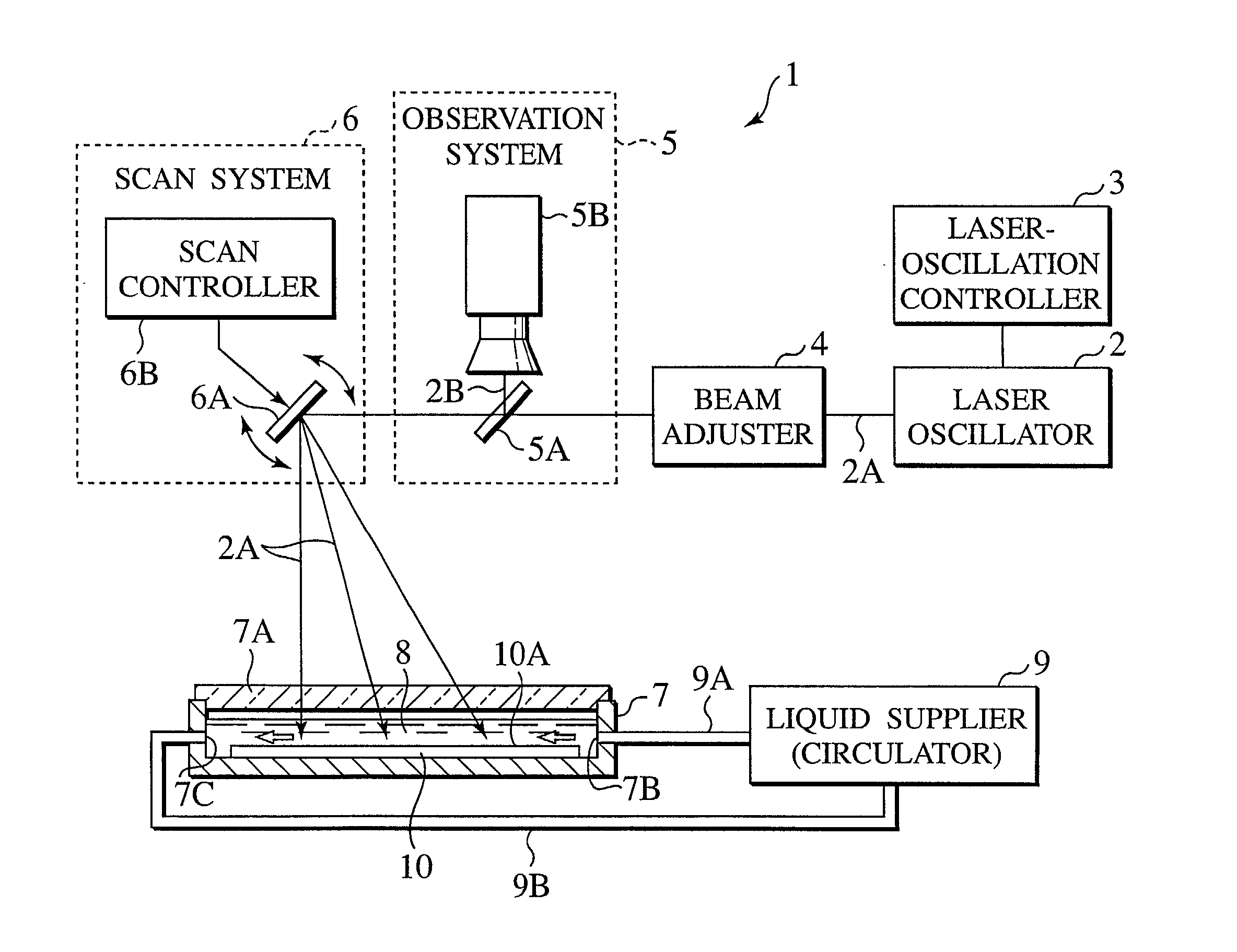

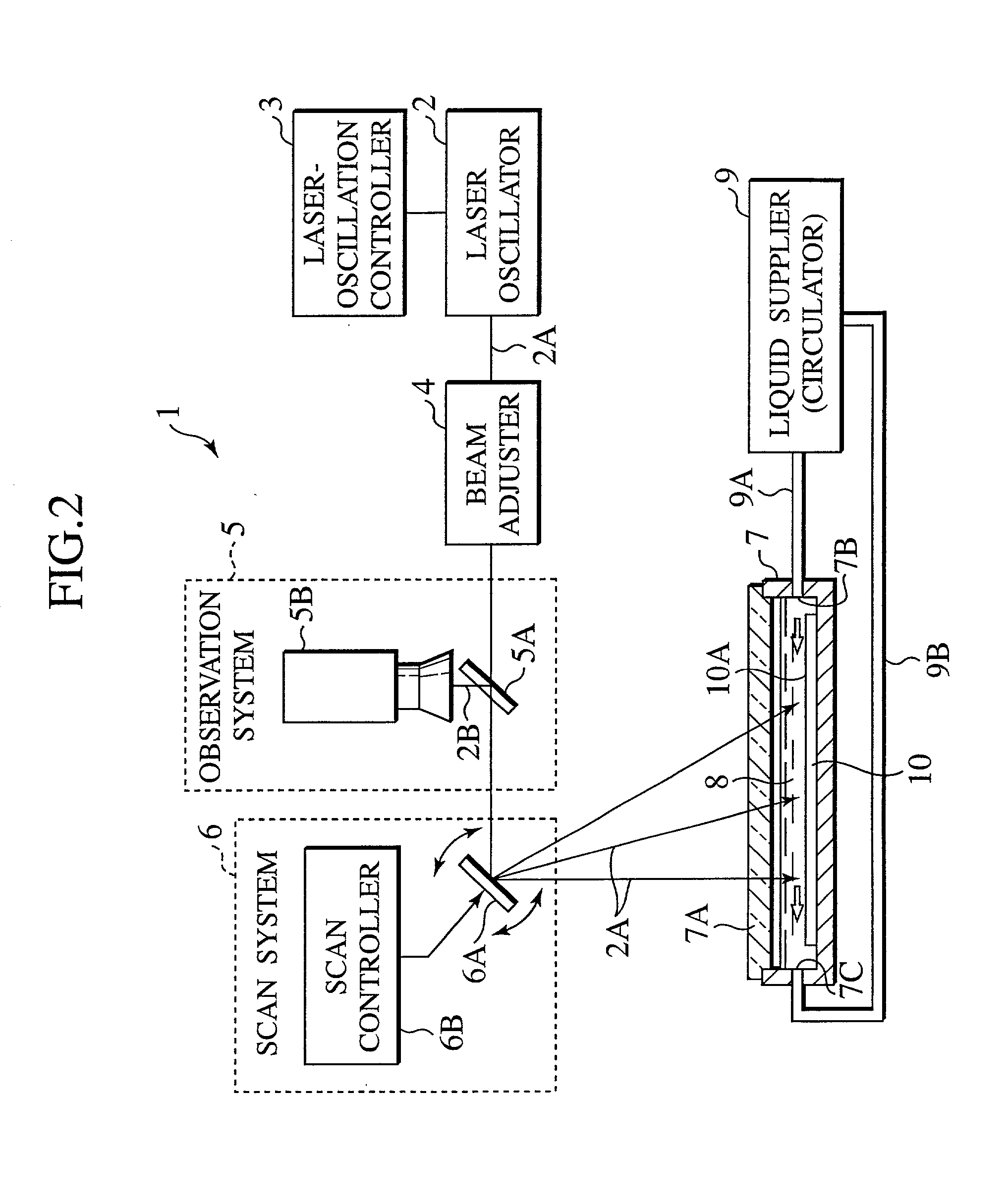

In a laser beam machining method, a liquid, through which a laser beam can be transmitted, is supplied to the target surface of an object to be processed. A laser beam is guided to the target surface through the liquid. The laser beam processes the target surface under the application of ultrasonic vibration.

Owner:KK TOSHIBA

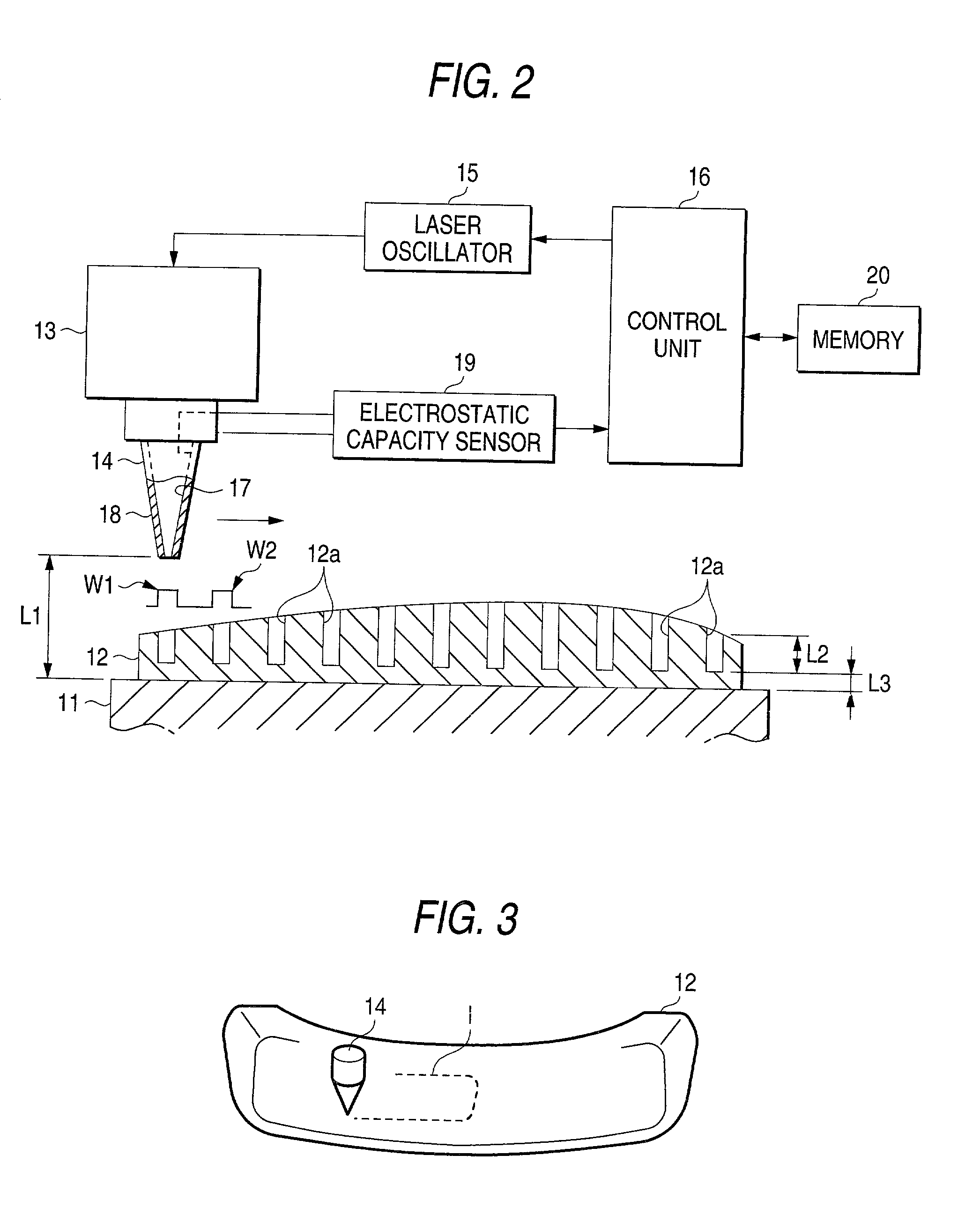

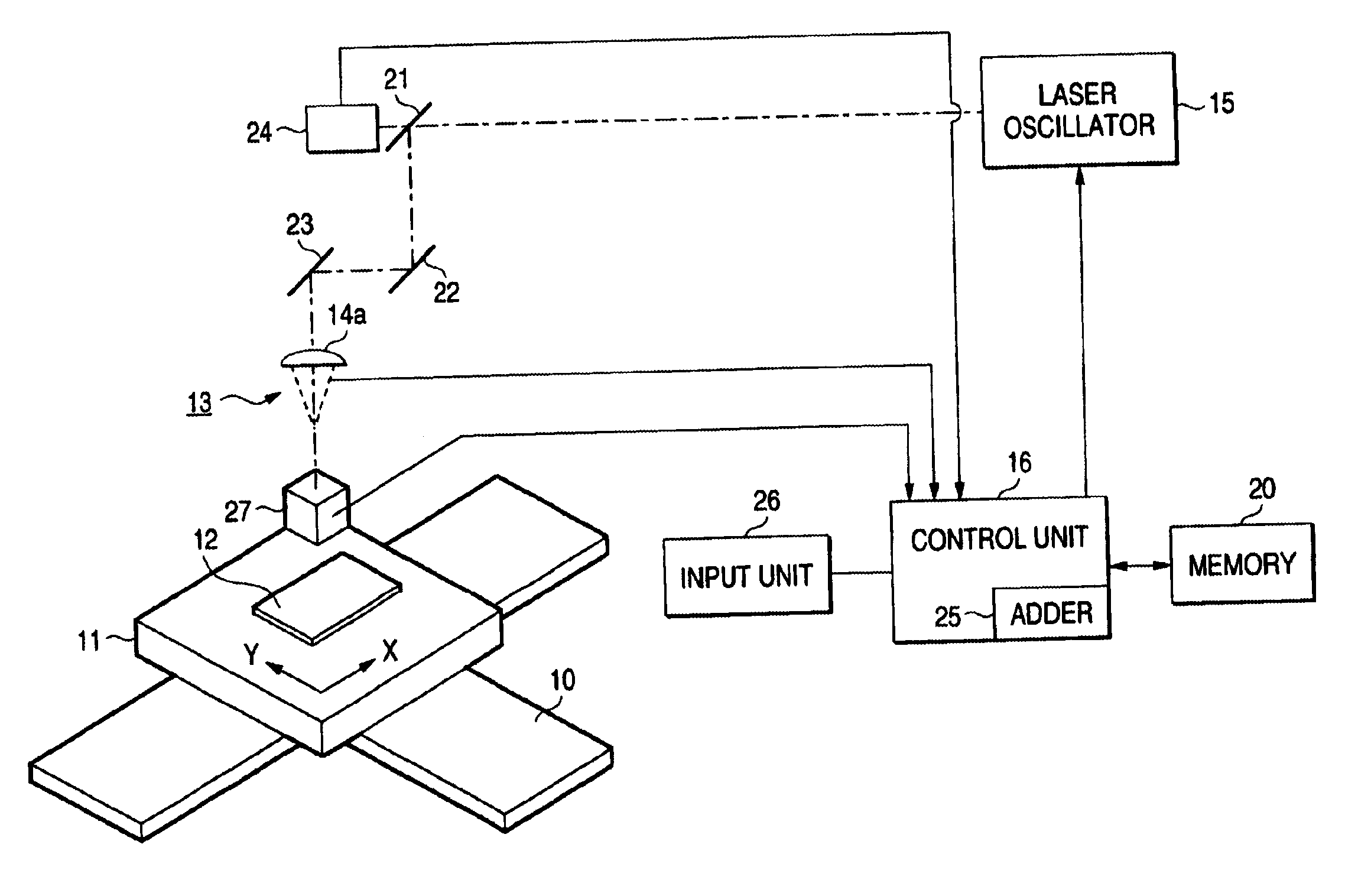

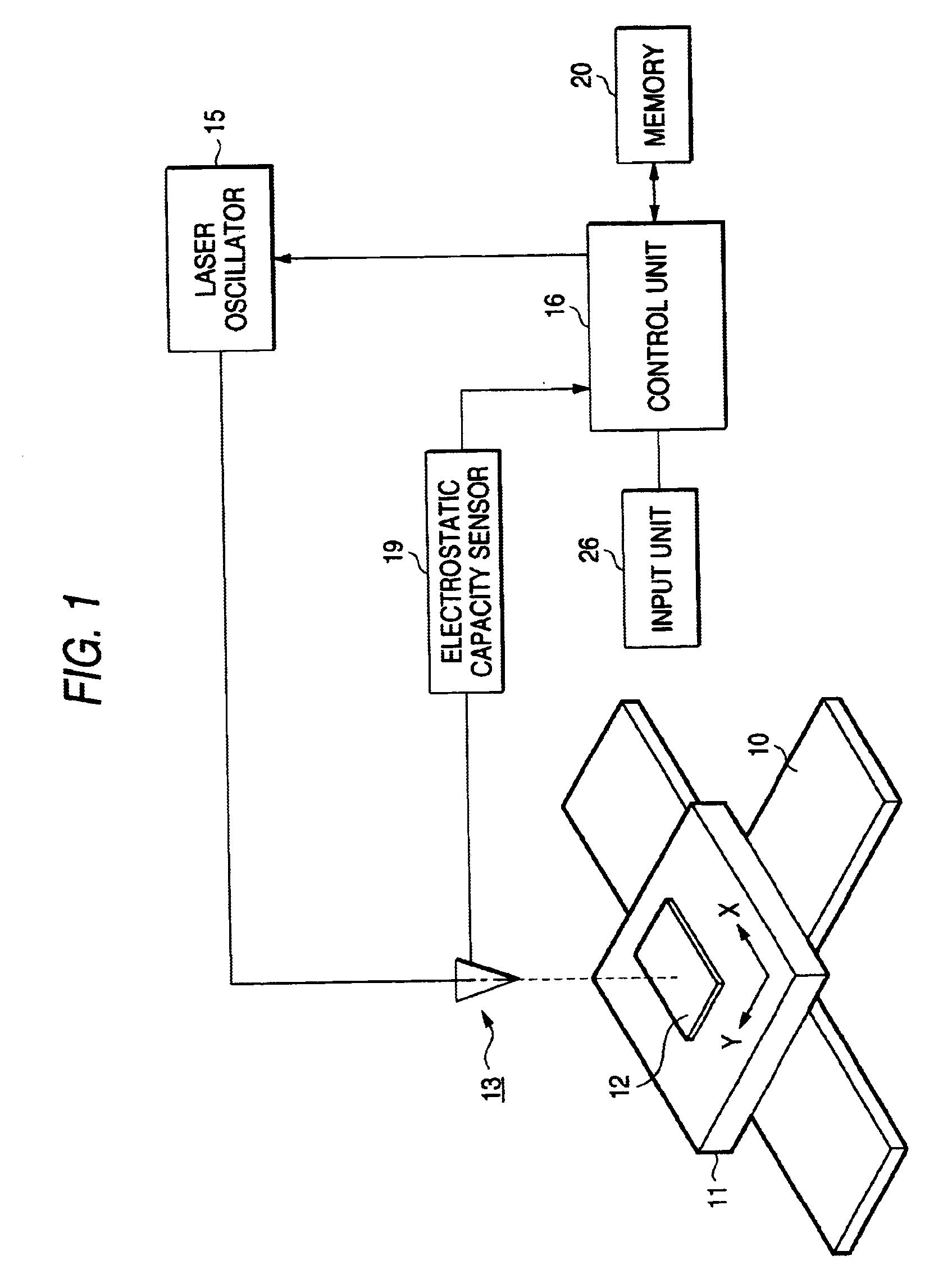

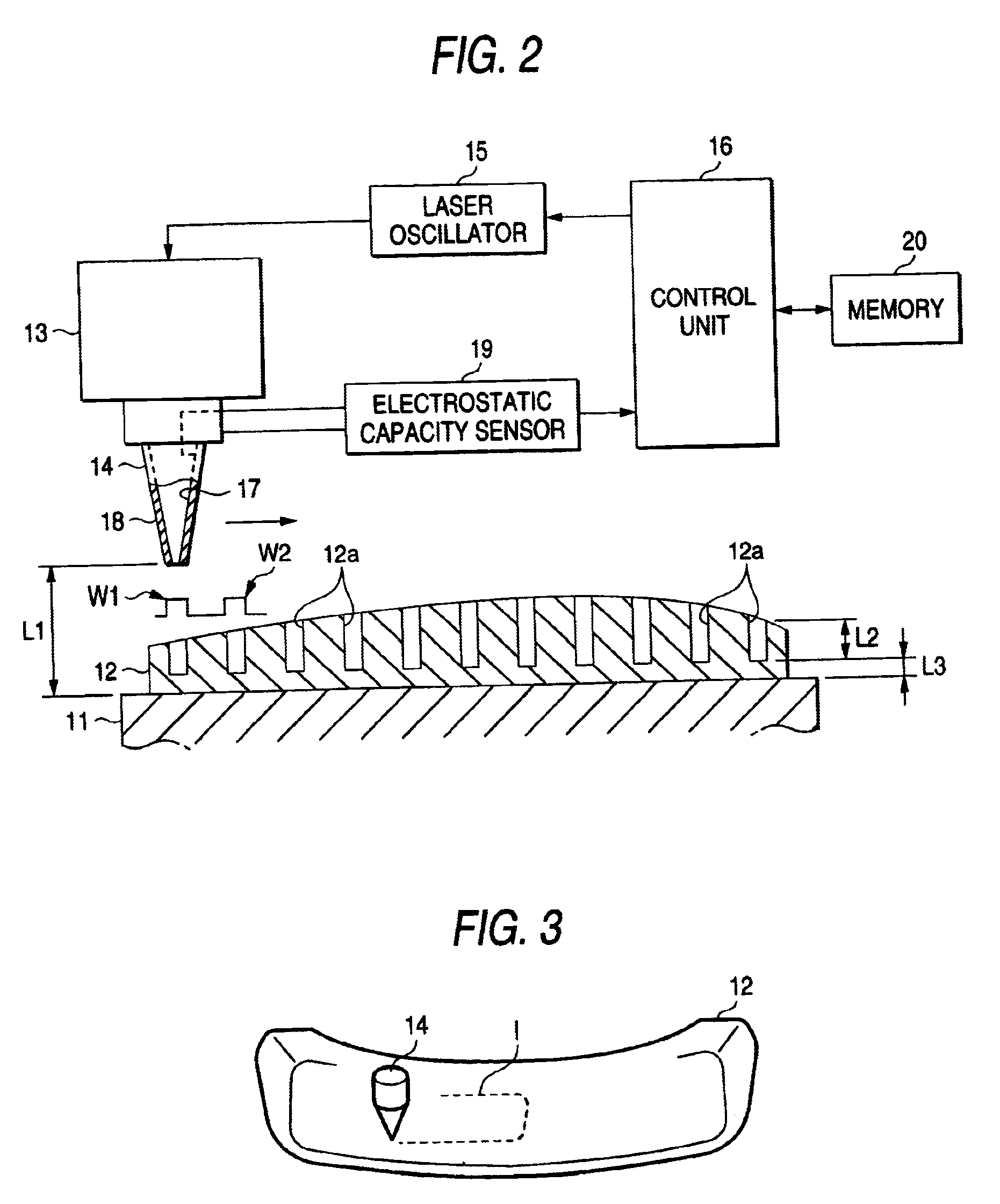

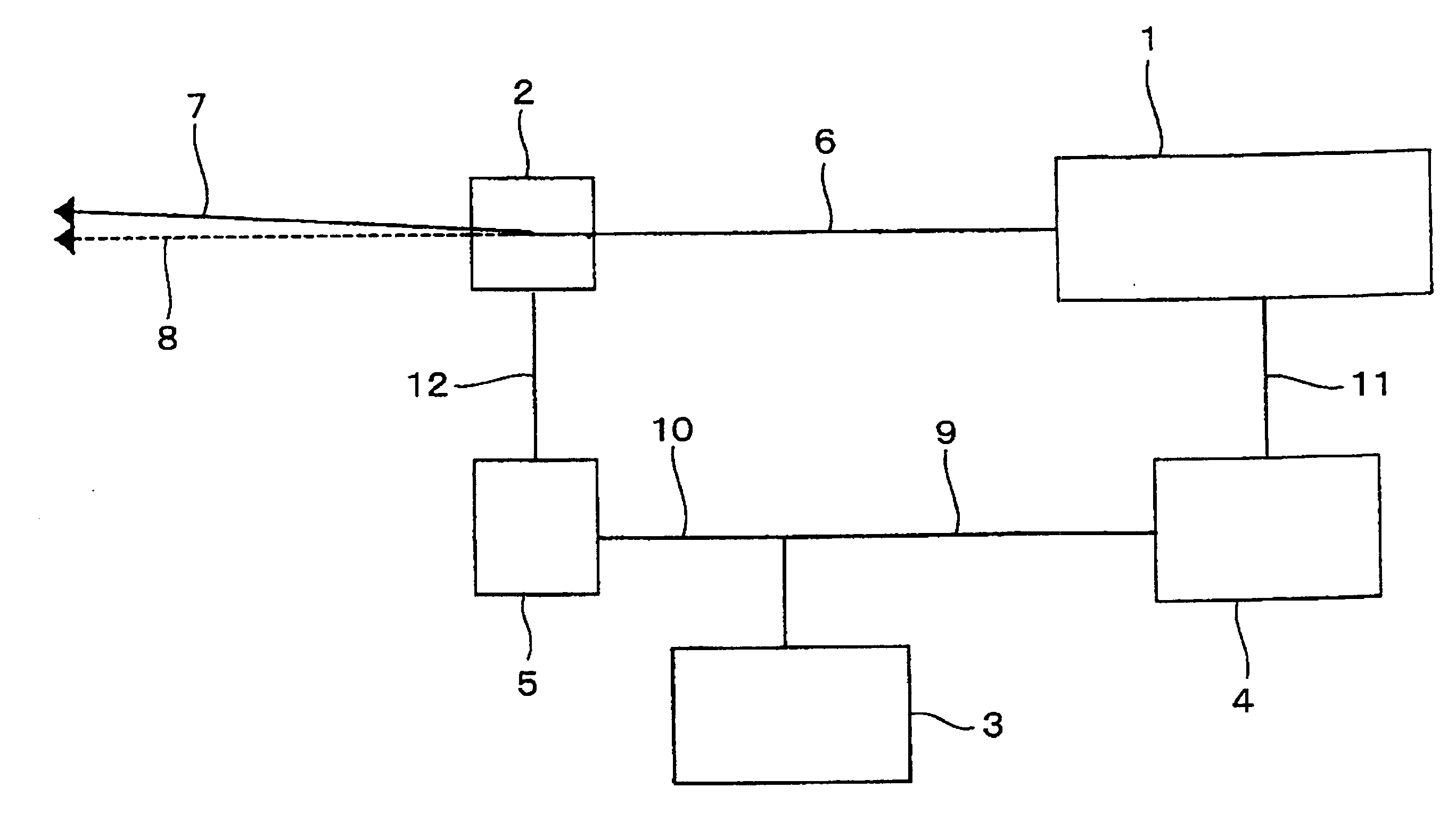

Laser beam machining apparatus and laser beam machining method

InactiveUS20030000927A1Pedestrian/occupant safety arrangementLaser beam welding apparatusLaser NozzleSpray nozzle

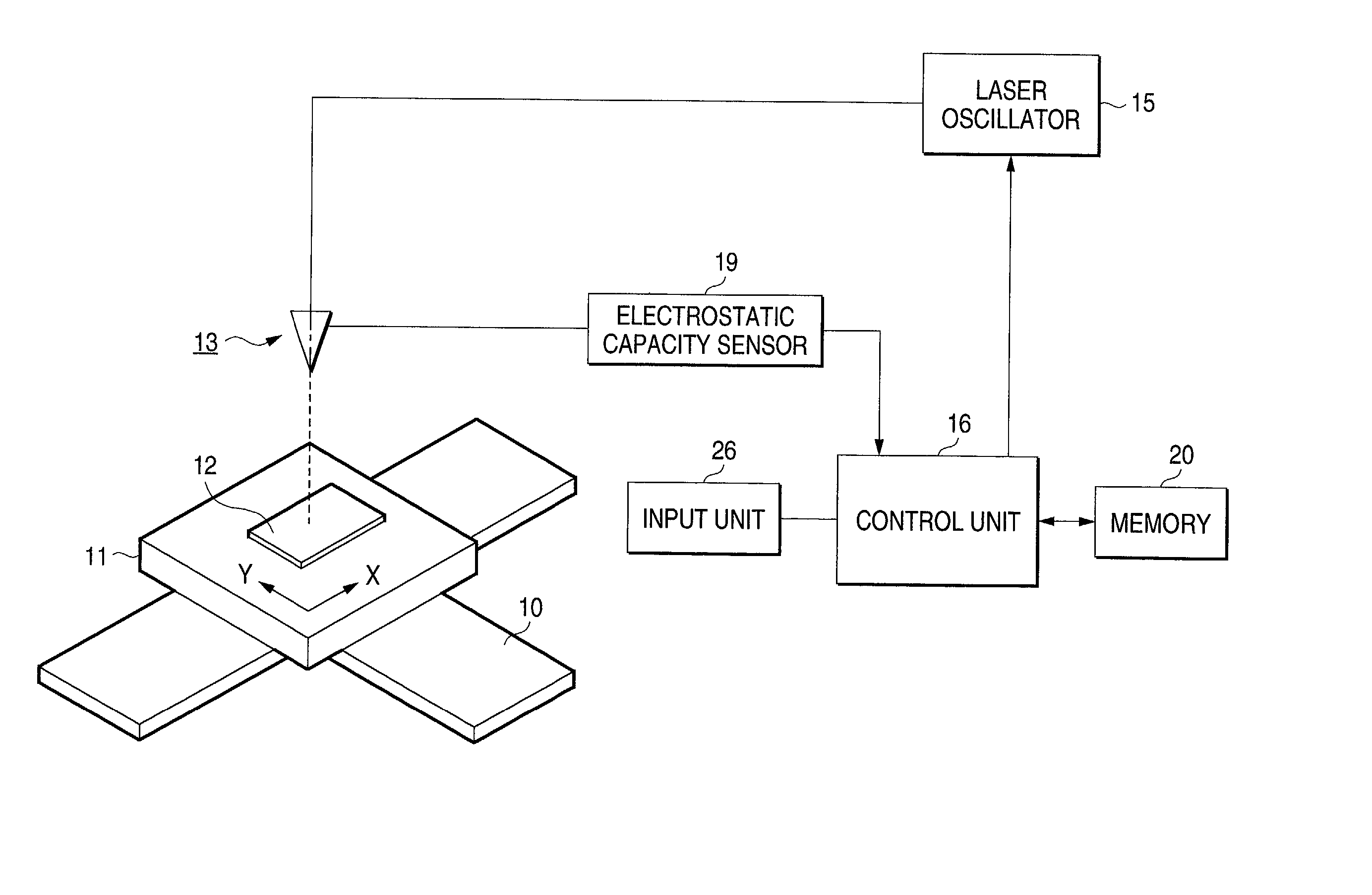

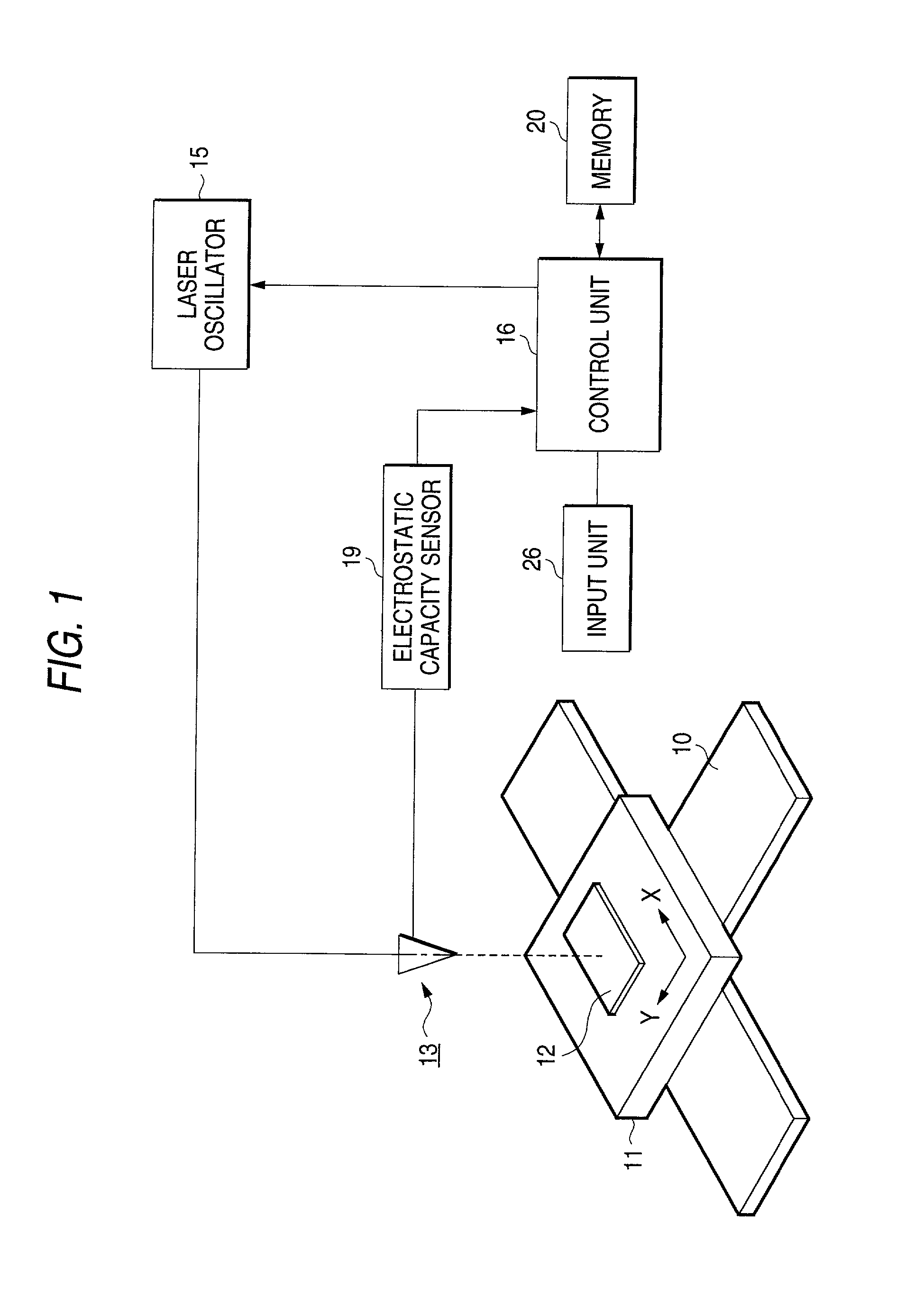

A laser beam machining apparatus forms blind holes at predetermined intervals in a workpiece by intermittently irradiating a laser beam from a laser nozzle to the workpiece while the laser nozzle and the workpiece being moved relatively. During the time the workpiece is subjected to machining, the electrostatic capacity between the support member and the laser nozzle is detected by an electrostatic capacity sensor while the workpiece made of conductive material is supported on the support member. The irradiation output power is controlled by a control unit which operates to vary the number of output pulses from the laser nozzle each time one hole is formed according to the result detected in response to variation in the thickness of the workpiece.

Owner:KOMATSU IND CORP

Laser beam machining apparatus and laser beam machining method

InactiveUS6680459B2Pedestrian/occupant safety arrangementLaser beam welding apparatusLaser NozzleSpray nozzle

A laser beam machining apparatus forms blind holes at predetermined intervals in a workpiece by intermittently irradiating a laser beam from a laser nozzle to the workpiece while the laser nozzle and the workpiece being moved relatively. During the time the workpiece is subjected to machining, the electrostatic capacity between the support member and the laser nozzle is detected by an electrostatic capacity sensor while the workpiece made of conductive material is supported on the support member. The irradiation output power is controlled by a control unit which operates to vary the number of output pulses from the laser nozzle each time one hole is formed according to the result detected in response to variation in the thickness of the workpiece.

Owner:KOMATSU IND CORP

Apparatus and method for laser beam machining, and method for manufacturing semiconductor devices using laser beam machining

InactiveUS6720522B2Semiconductor/solid-state device manufacturingWelding/soldering/cutting articlesTarget surfaceLight beam

In a laser beam machining method, a liquid, through which a laser beam can be transmitted, is supplied to the target surface of an object to be processed. A laser beam is guided to the target surface through the liquid. The laser beam processes the target surface under the application of ultrasonic vibration.

Owner:KK TOSHIBA

Laser machining of semiconductor materials

A semiconductor is cut by directing a green laser beam of high power, and subsequently directing a UV beam along the cut line. The first beam performs cutting with relatively rough edges and a high material removal rate, and the second beam completes the cut at the edges for the required finish, with a lower material quantity removal.

Owner:XSIL TECH

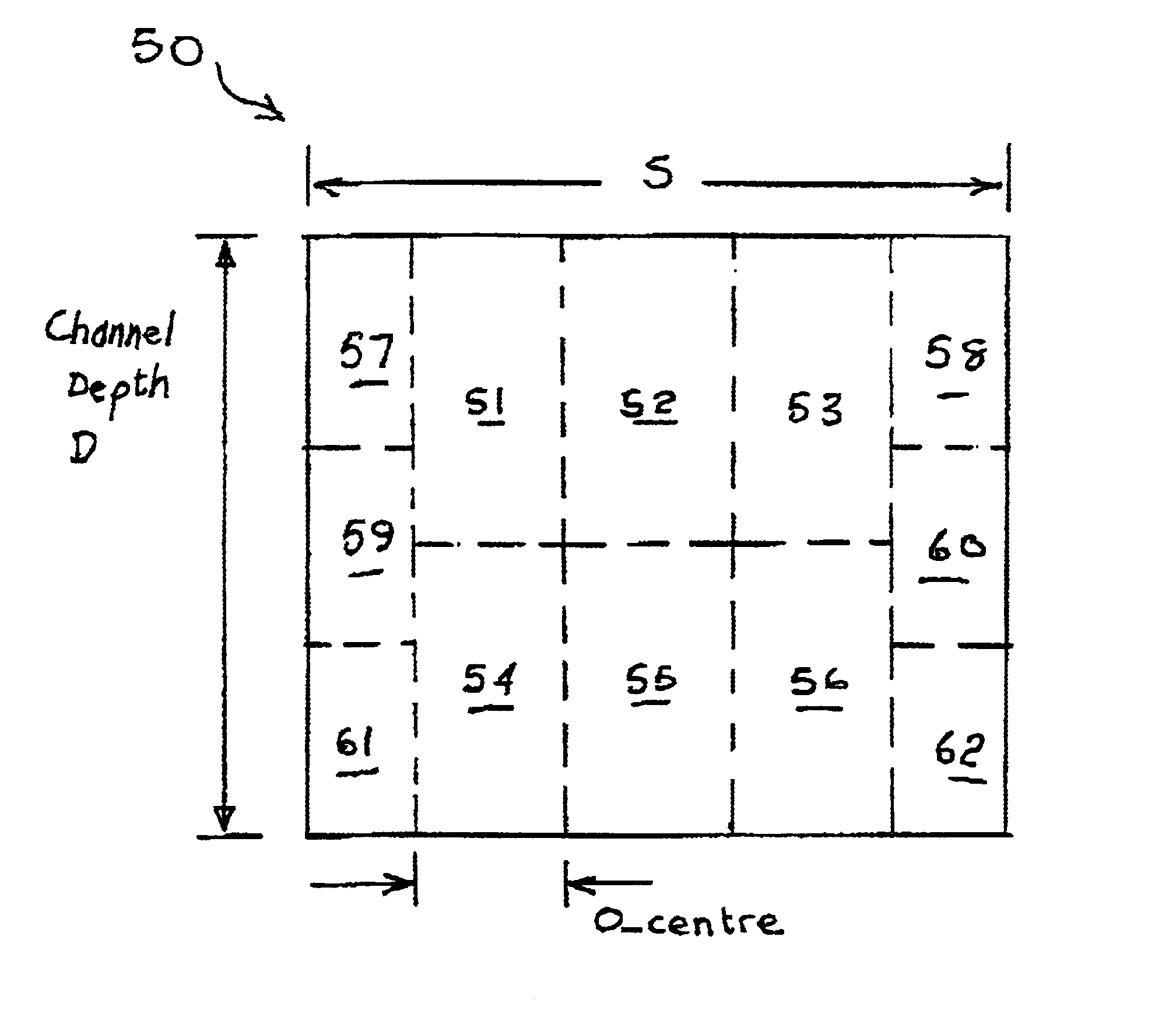

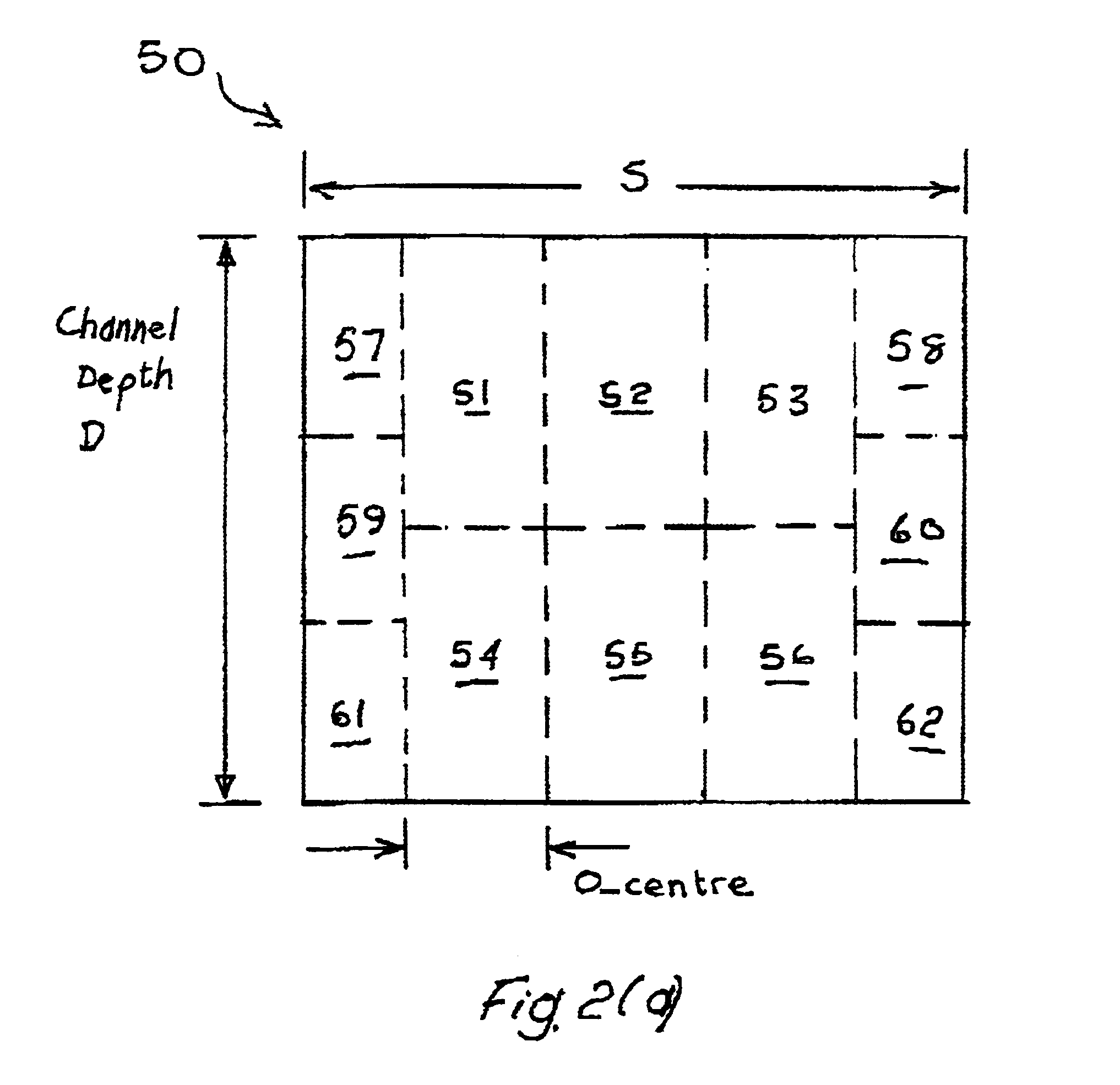

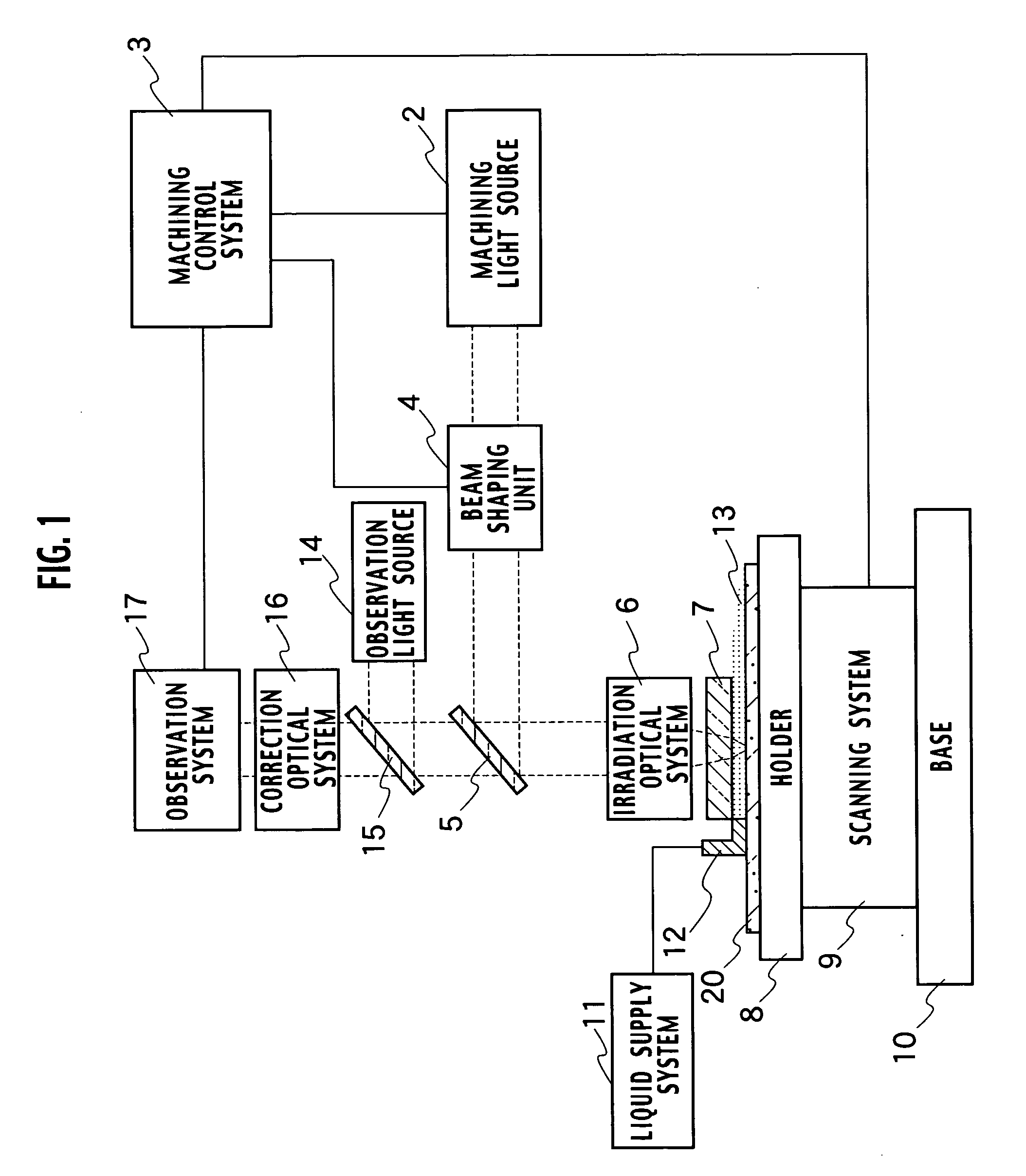

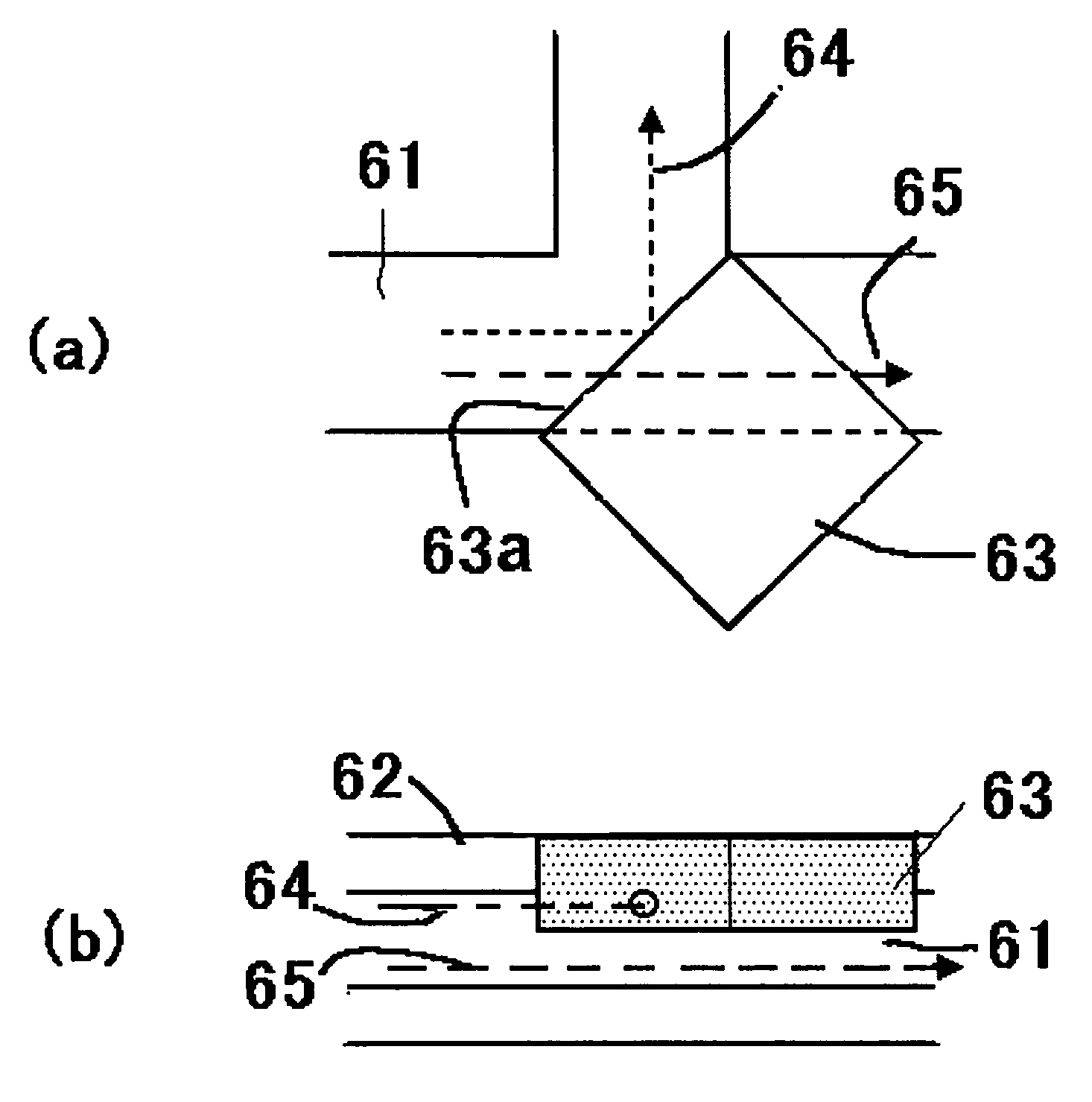

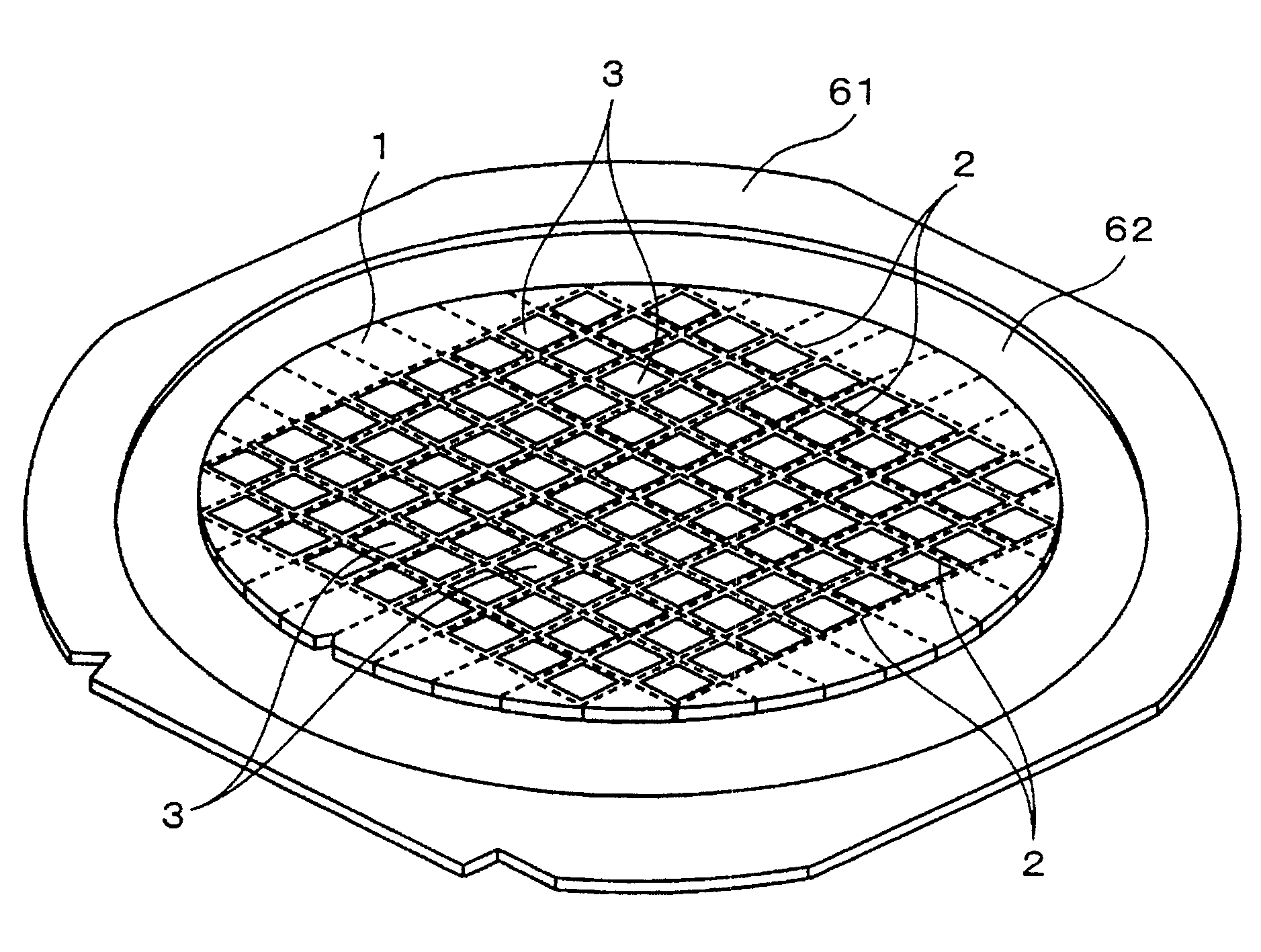

Apparatus for laser beam machining, machining mask, method for laser beam machining, method for manufacturing a semiconductor device and semiconductor device

InactiveUS20050045090A1High bonding strengthFrom gel statePolycrystalline material growthDevice materialOptical axis

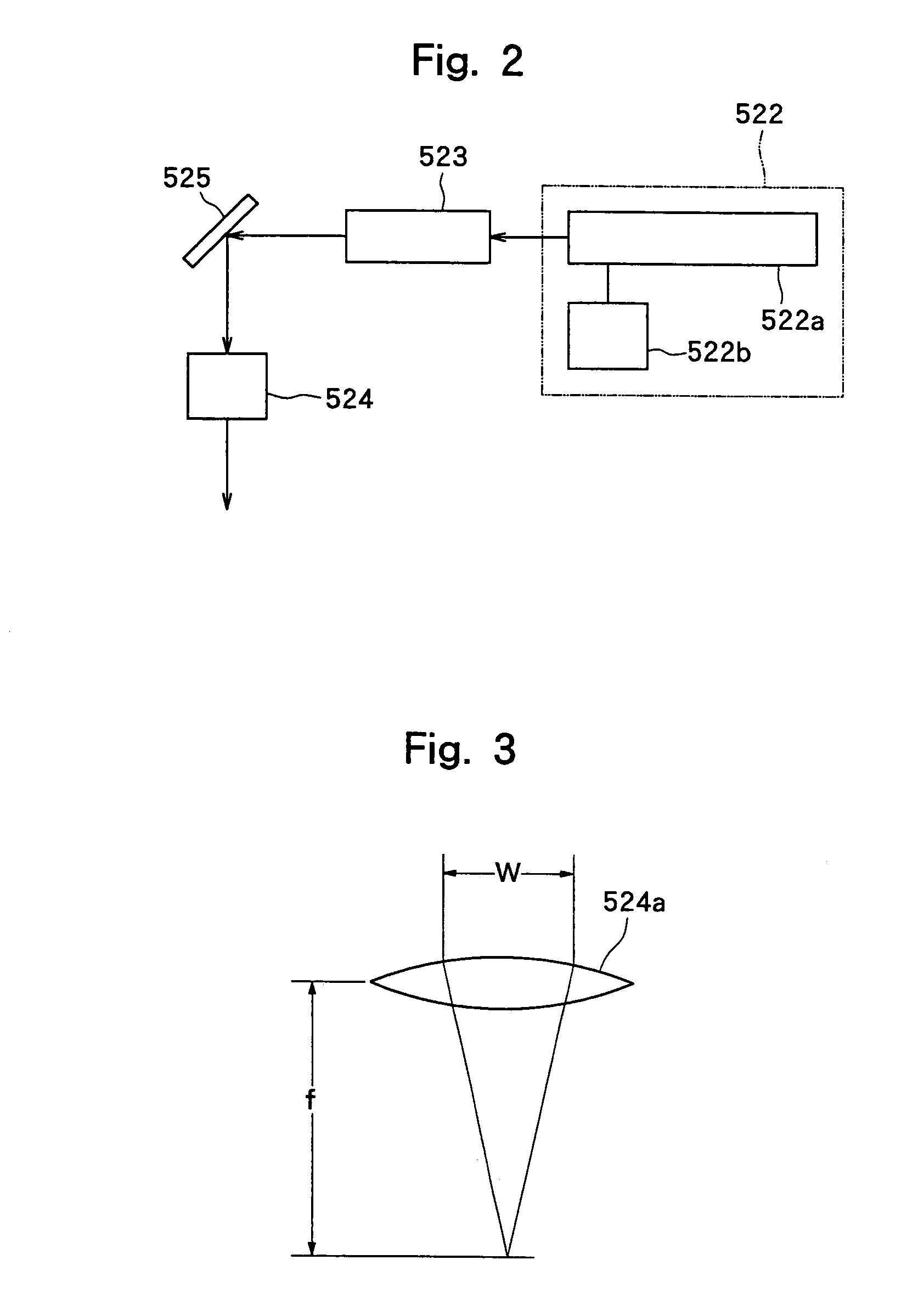

An apparatus for laser beam machining includes a scanning system configured to move an object in a scanning direction from a first edge of the object to another edge of the object; a beam shaping unit configured to convert a laser beam to an asymmetrical machining laser beam in the scanning direction on a plane orthogonal to an optical axis of the laser beam; and an irradiation optical system configured to irradiate the machining laser beam emitted from the beam shaping unit onto the object.

Owner:KK TOSHIBA

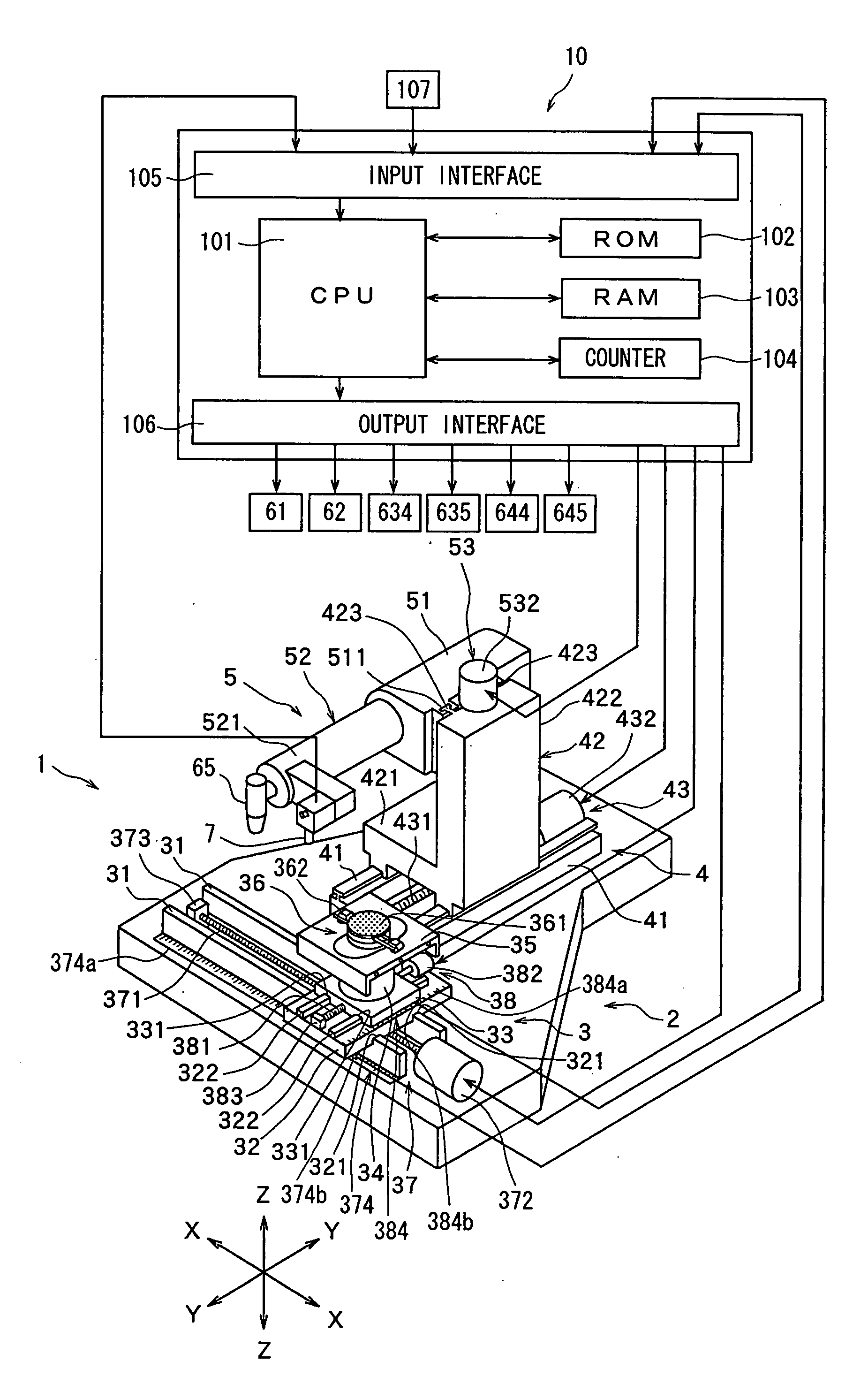

Laser beam machining apparatus

InactiveUS20090127233A1Avoid meltingEmission spectroscopySemiconductor/solid-state device manufacturingLaser processingLight beam

A laser beam machining apparatus including a chuck table for holding a wafer, and a laser beam irradiation unit for irradiating the wafer held on the chuck table with a pulsed laser beam. The laser beam machining apparatus further includes a plasma detecting part which includes a plasma receiving part for receiving a plasma generated by irradiation of the work with the laser beam radiated from the laser beam irradiation unit, and a spectrum analyzing part for analyzing the spectrum of the plasma received by the plasma receiving part; and a controller for determining the material of the work on the basis of a spectrum analysis signal from the spectrum analyzing part of the plasma detecting part and for controlling the laser beam irradiation unit.

Owner:DISCO CORP

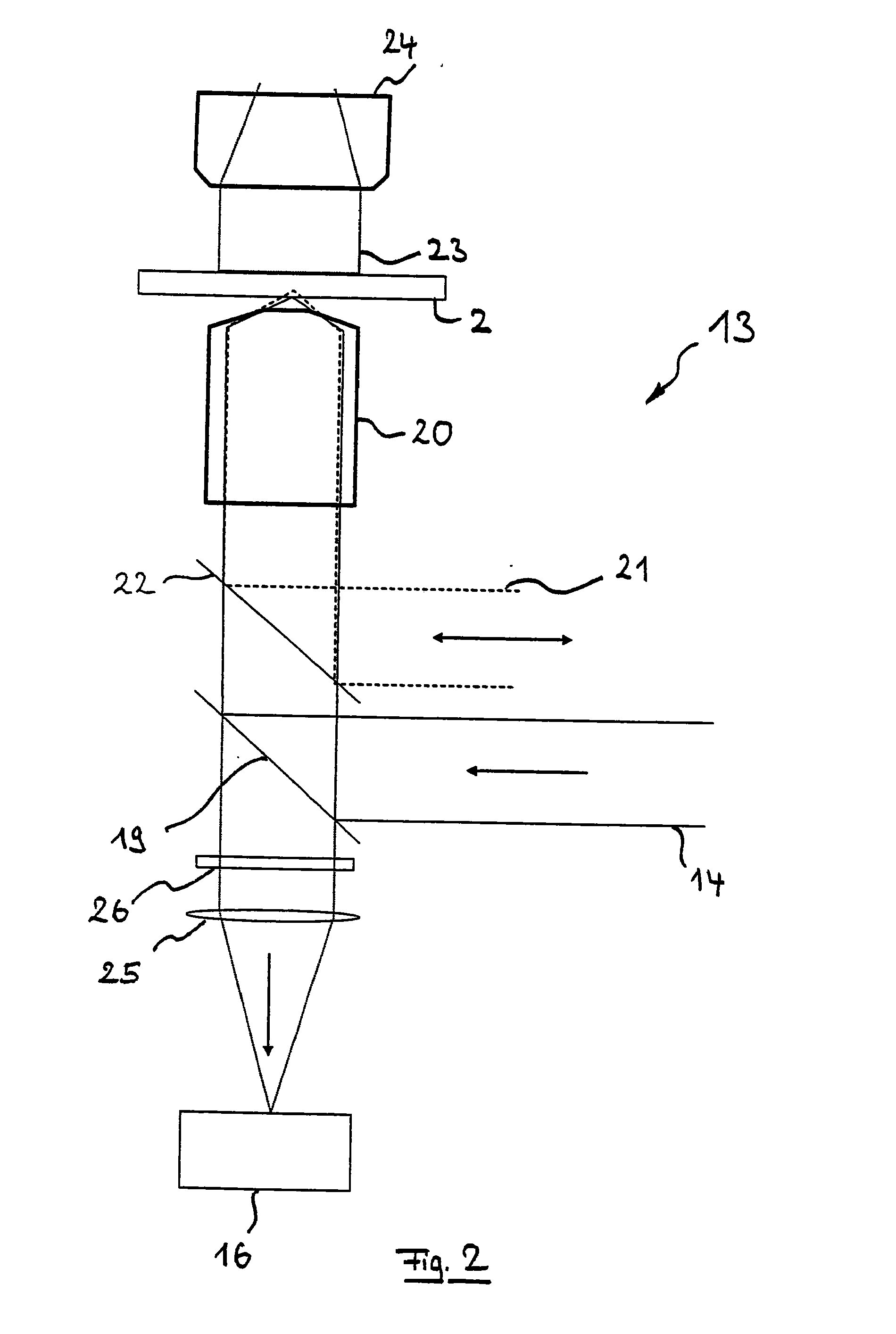

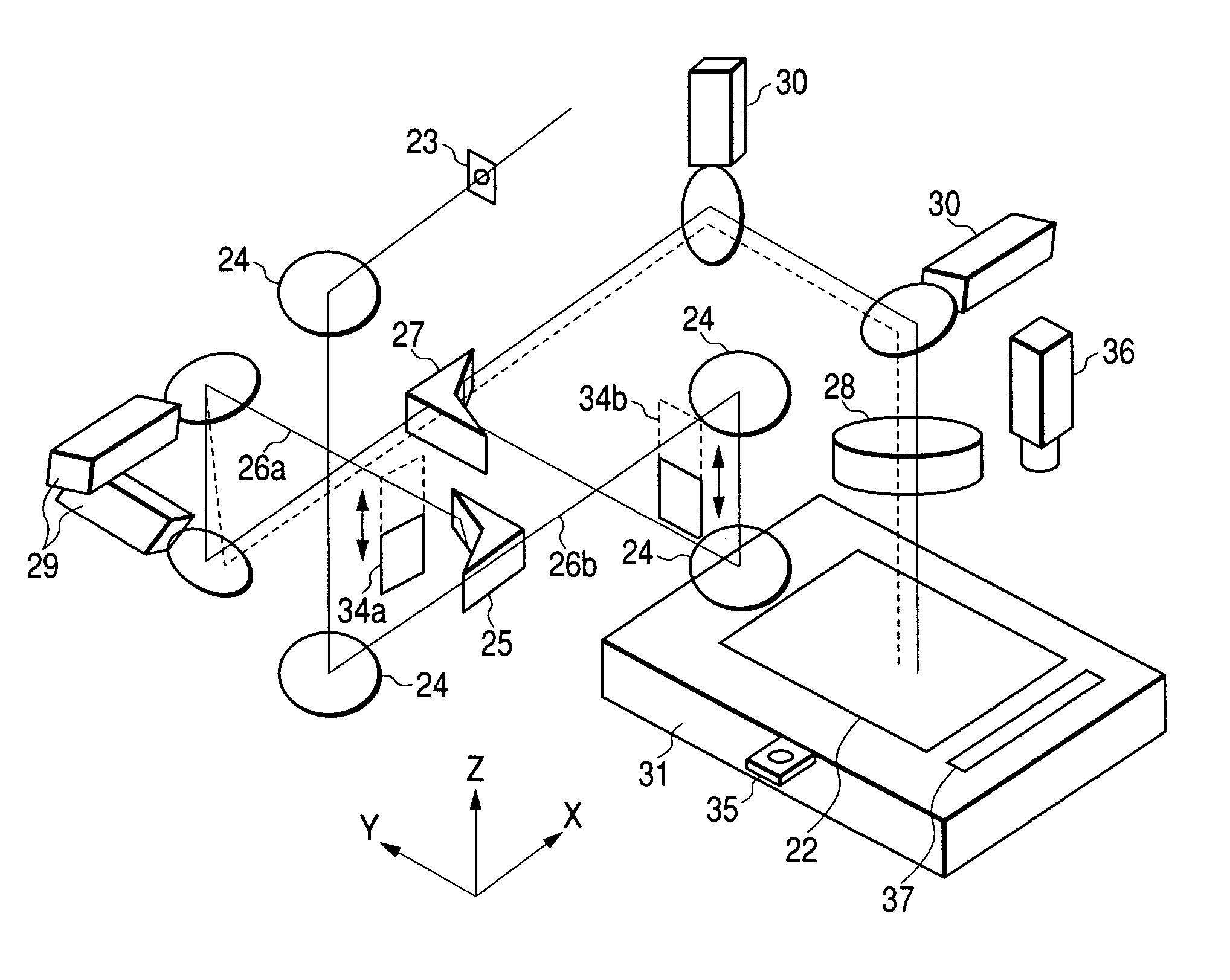

Laser beam machining

ActiveUS20100294749A1Way accurateImprove accuracyPhotomechanical apparatusMicroscopesCamera imageLaser beam machining

A method for laser beam machining of a workpiece in which a laser beam is focused by an objective, into or onto the workpiece having a boundary surface, to produce a machining effect by a two-photon process, and the position of the focal point with respect to the workpiece is shifted. To obtain a reference for the position of the focal point, an image of a luminating modulation object is projected through the objective onto the workpiece into the focal plane or so as to intersect it. Reflections of the image occurring at the boundary surface are imaged into an autofocus image plane, and are detected by a camera. The camera image plane either intersects the autofocus image plane when the image of the illuminating modulation object lies in the focal plane, or lies in the autofocus image plane when the image of the modulation object intersects the focal plane.

Owner:NANOSCRIBE HLDG GMBH

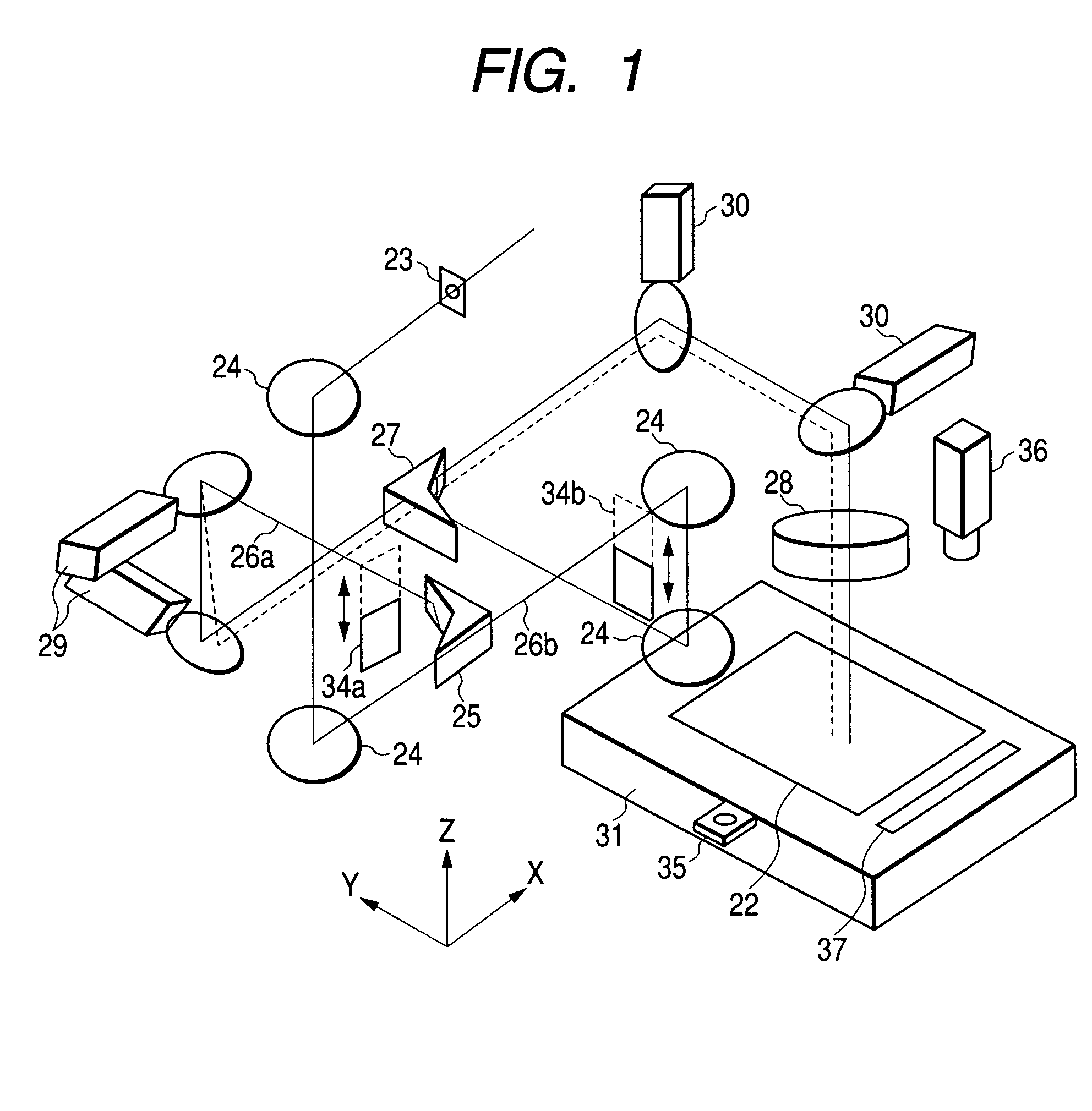

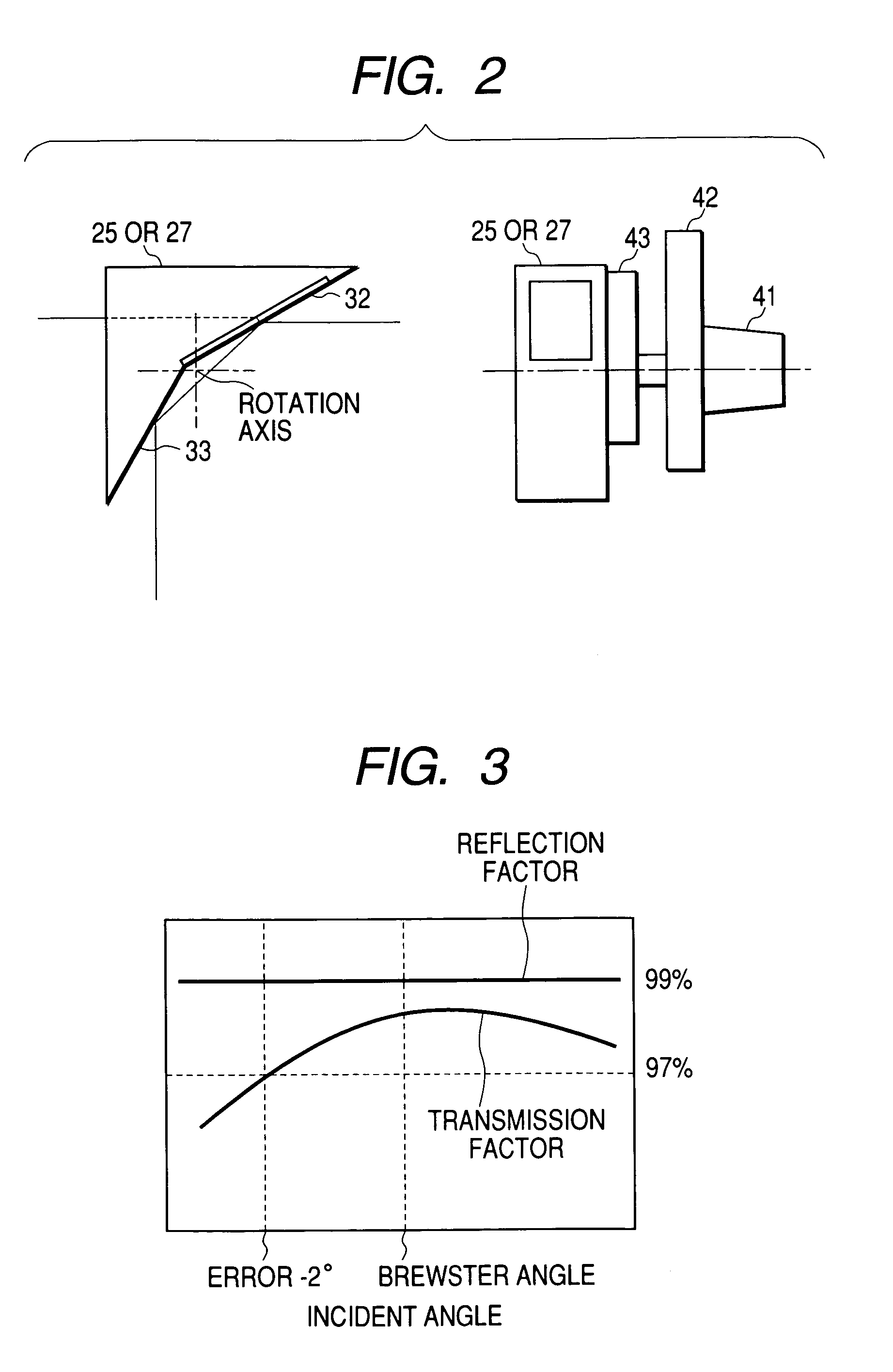

Laser beam machining device

InactiveUS6984802B2Improve productivityPrinted circuit manufactureWelding/soldering/cutting articlesLaser beam machiningOptoelectronics

A laser material processing apparatus for processing a workpiece (22) in such a way as to separate one laser light (26) into two laser beams (26a, 26b) via first polarizer (25), one laser beam being passed via the mirrors (24), the other laser beam being scanned biaxially by a first galvano scanner (29), and conduct two laser beams (26a, 26b) to a second polarizer (27) for scanning via a second galvano scanner (30), wherein an optical path is constituted such that the laser beam (26b) transmitted through the first polarizer (25) is reflected by the second polarizer (27), and the laser beam (26a) reflected by the first polarizer (25) is transmitted through the second polarizer (27).

Owner:MITSUBISHI ELECTRIC CORP

Method of manufacturing device

ActiveUS20090197395A1Improve device qualityLowering transverse rupture strengthSemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesDicing tapeLaser beam machining

A method of manufacturing a device includes: a laser beam-machined groove forming step of irradiating a wafer with a laser beam from the back side of the wafer along planned dividing lines so as to form laser beam-machined grooves along the planned dividing lines; an etching step of etching a back-side surface of the wafer having been subjected to the laser beam-machined groove forming step, so as to remove denatured layers formed at processed surfaces of the laser beam-machined grooves; an adhesive film attaching step of attaching an adhesive film to the back-side surface of the wafer having been subjected to the etching step, and adhering the adhesive film side of the wafer to a surface of a dicing tape; and an adhesive film rupturing step of expanding the dicing tape so as to rupture the adhesive film along individual devices.

Owner:DISCO CORP

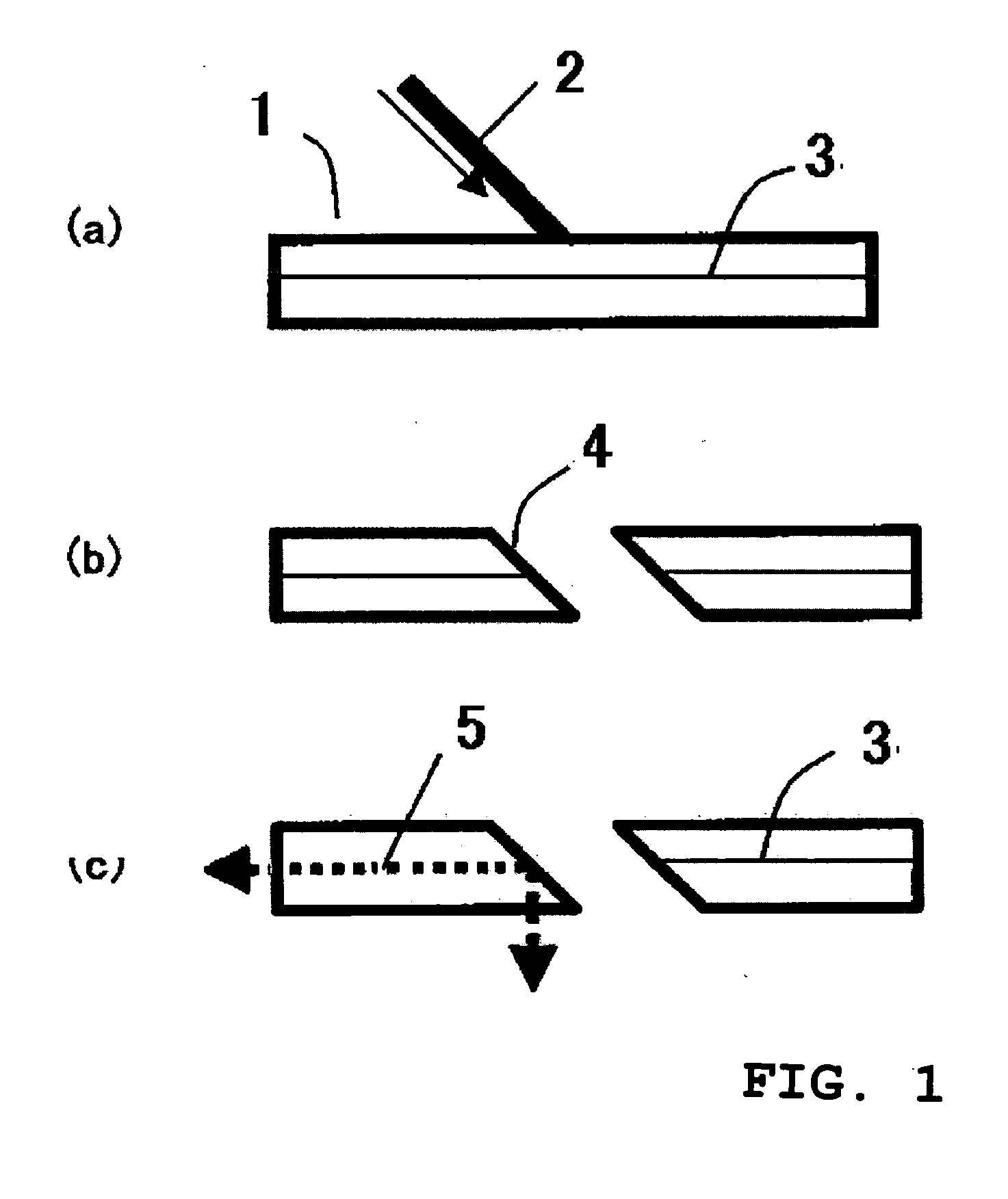

Optical waveguide having specular surface formed by laser beam machining

InactiveUS7324723B2Good effectObtain goodCladded optical fibreCoupling light guidesLaser beam machiningIrradiation

An optical waveguide having means for performing optical coupling with high efficiency at a predetermined position in an optical circuit substrate and which optionally includes an optical-electrical circuit board. Also provided are an optical waveguide, an optical path thereof being changed in an optical circuit at a steep angle and the optical waveguide for performing coupling and splitting of light being decreased in size in the optical circuit. The optical waveguide has a core and a cladding layer, and a wall surface, which is formed by cutting out at least a part of the core in a thickness direction of the core through irradiation of a laser beam and crosses at least a part of the core, which is a specular surface.

Owner:MITSUI CHEM INC

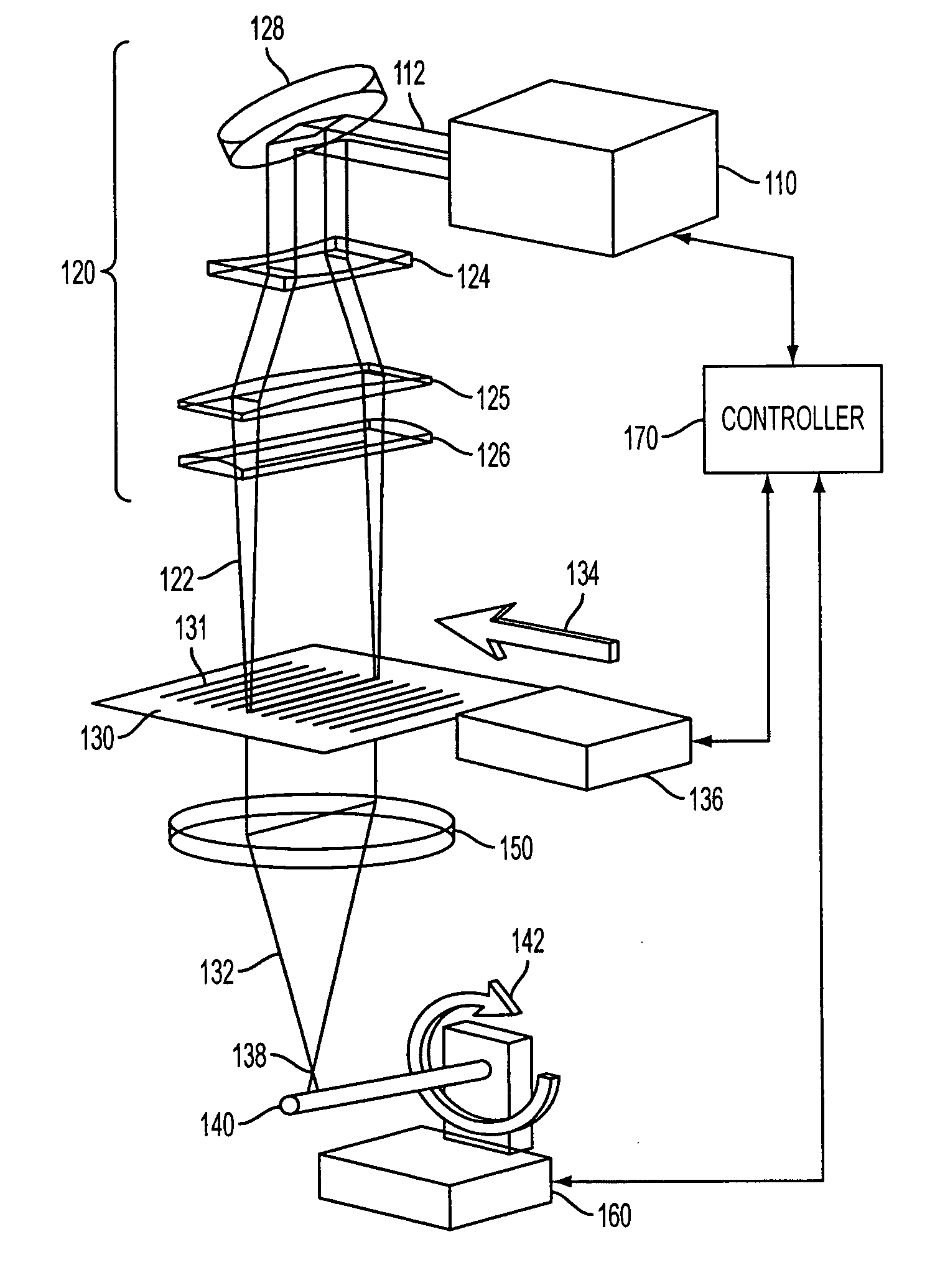

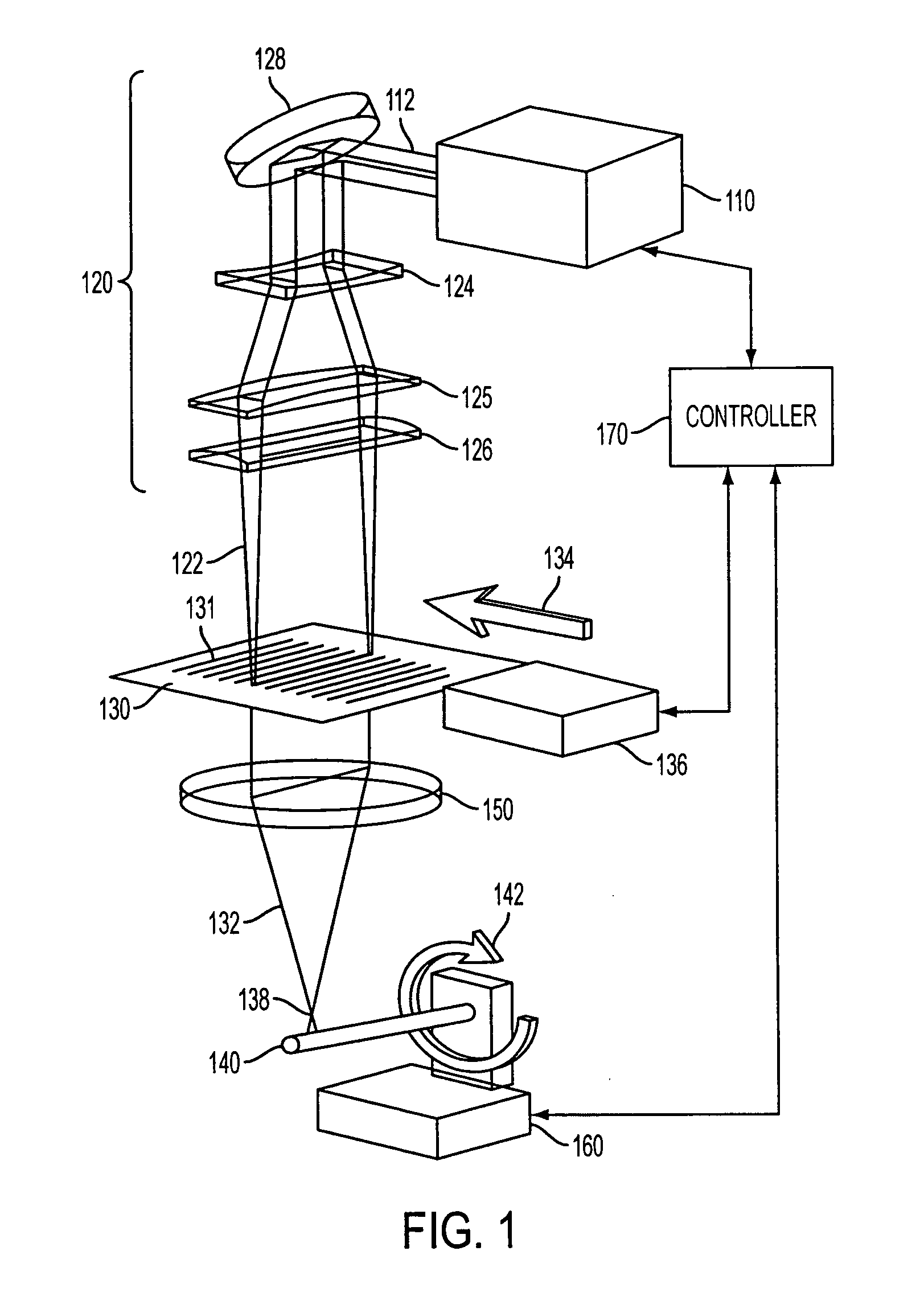

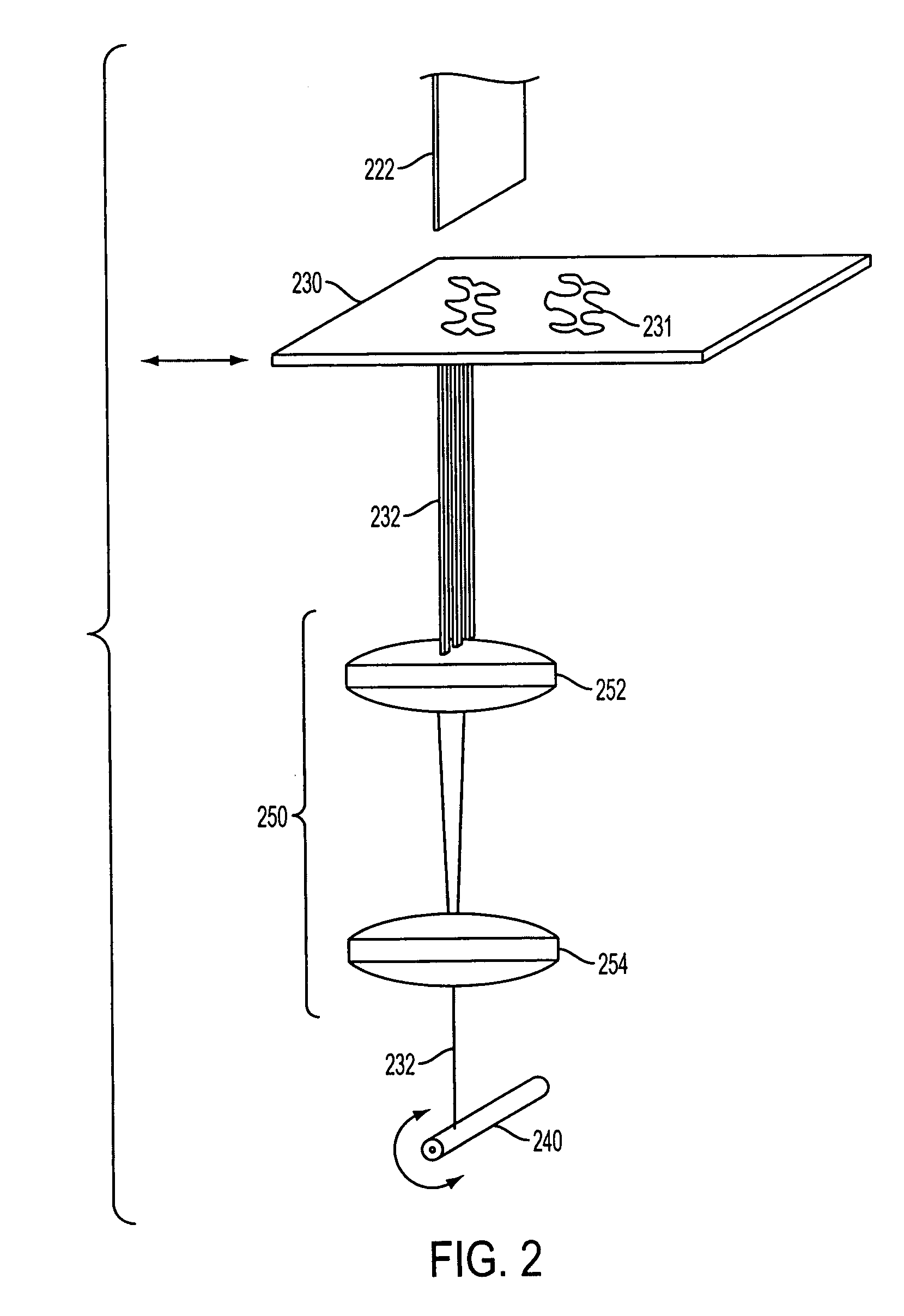

System and method for laser machining

ActiveUS20070017908A1Welding/soldering/cutting articlesMetal working apparatusThermal energyHigh rate

A laser machining system and method uses a shaped laser beam, such as a long, narrow beam, and effectively scans the beam in the narrow direction across a mask having an aperture pattern. The pattern on the mask is imaged onto a moving workpiece and the patterned laser beam selectively removes material from the workpiece. The workpiece may be moved using a coordinated synchronized rotational motion. The laser may use a longer wavelength (e.g., 248 nm) and the beam may be scanned at a high rate of speed to reduce the dissipation of the residual thermal energy in the material being machined. In one embodiment, this system and method may be used to machine a complex pattern into a curved surface with relatively high resolution and high speeds.

Owner:IPG PHOTONICS CORP

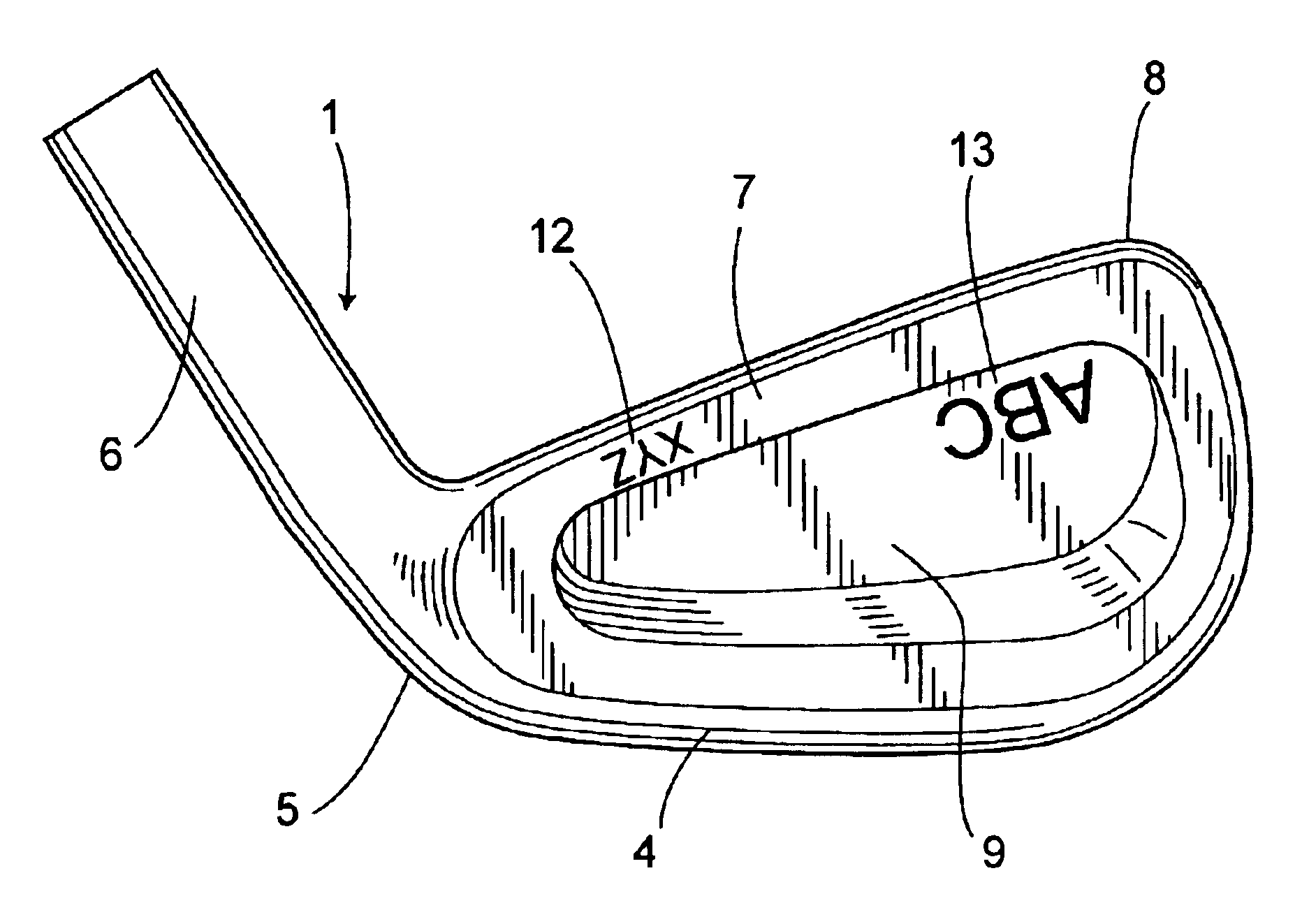

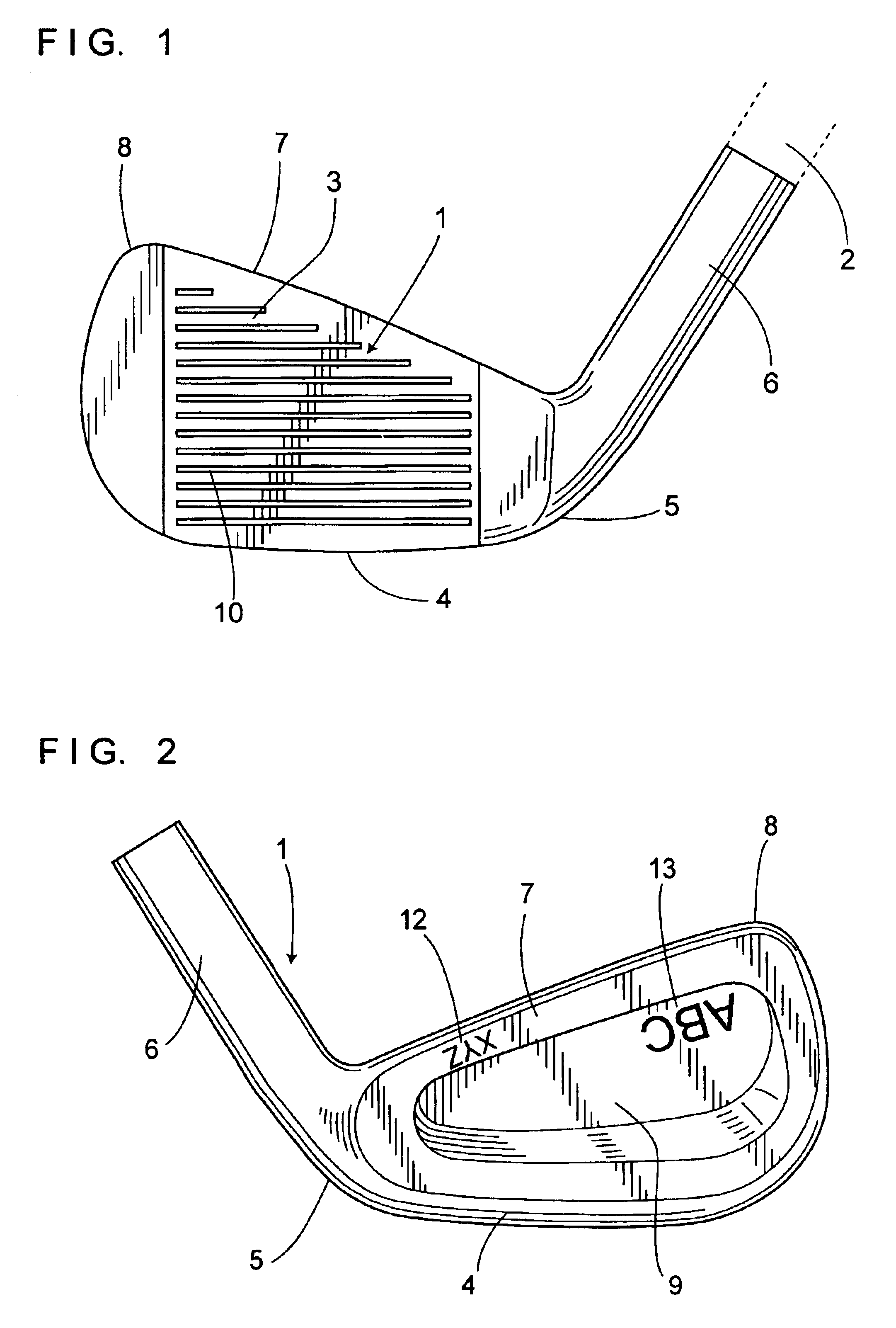

Method of manufacturing a golf club head

InactiveUS6713717B2Welding/soldering/cutting articlesMetal working apparatusDisplay deviceLaser beam machining

A method of manufacturing a golf club head by which face lines, a club number display and logo marks can be formed without being affected by the configuration and material of the club head. Face lines 10, a club number display 11 and logo marks 12 and 13 are formed on the surface of a golf club head 1, using a laser beam processing machine. Stamps and receiving dies are no longer required for a respective production lot number or a respective club number, so that costs and time required for fabricating impressing stamp dies and receiving dies can be saved. Further, face lines 10, club number display 11 and logo marks 12 and 13 are able to be formed without being affected by the configuration and material of the golf club head 1.

Owner:ENDO MFG COMPANY

Wafer processing method

ActiveUS20050106782A1Suppressing partial peelingAvoid it happening againSemiconductor/solid-state device manufacturingLaser beam welding apparatusLaser beam machiningOptoelectronics

A laser beam processing method for processing a wafer by applying a laser beam to a predetermined area, comprising the steps of forming a resin film which absorbs a laser beam, on the surface to be processed of the wafer; applying a laser beam to the surface to be processed of the wafer through the resin film; and removing the resin film after the laser beam application step.

Owner:DISCO CORP

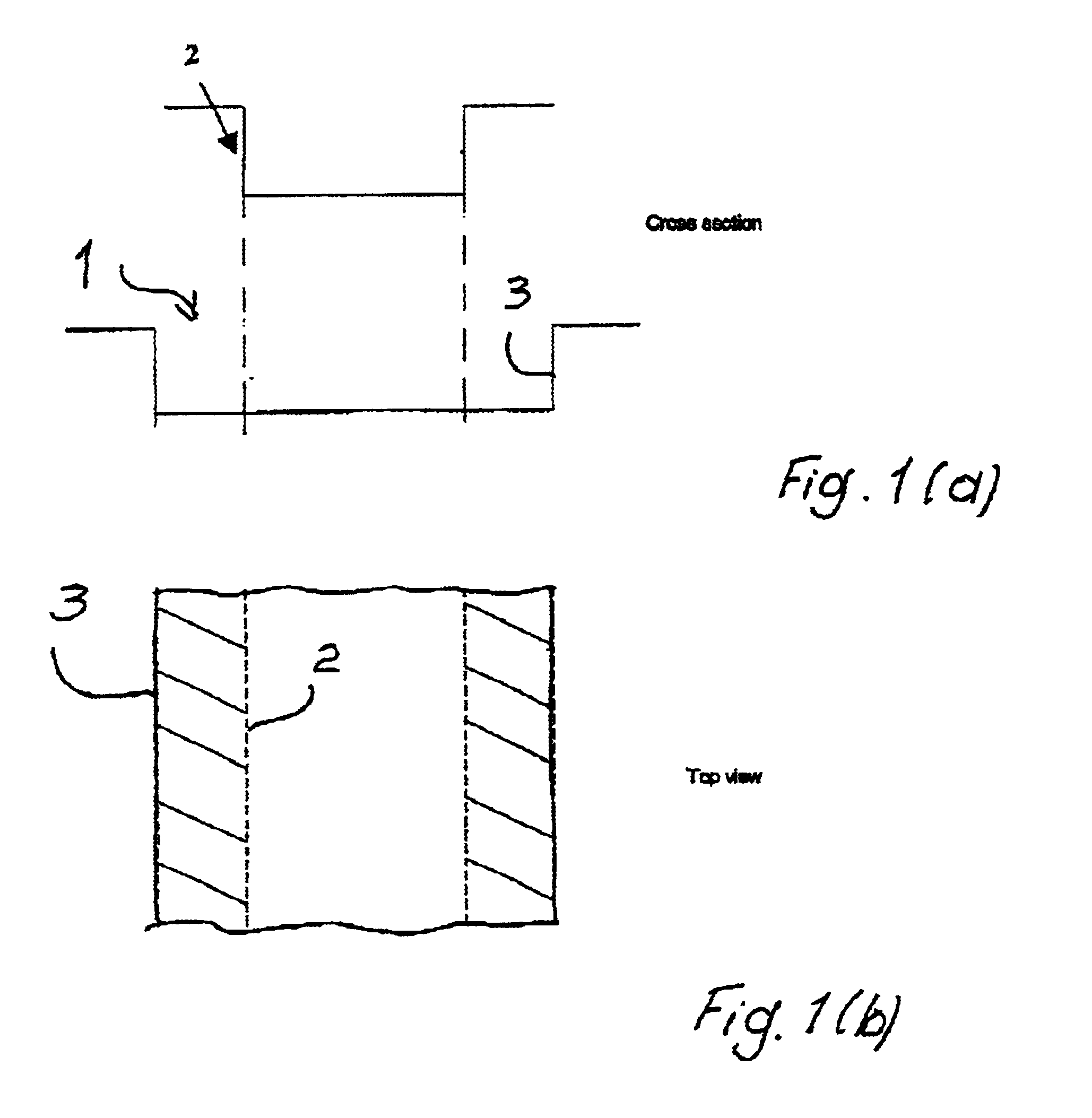

Method of and apparatus for machining groove with laser beam

A casing houses therein a laser oscillator for emitting a laser beam, and a tubular head is disposed coaxially with the laser oscillator and coupled to the casing. The laser beam emitted from the laser oscillator is converged by a condenser lens mounted on the head, and then reflected in a direction substantially perpendicular to the axis of the head by a reflecting mirror that is disposed in the head. The reflected laser beam is applied substantially perpendicular to the inner circumferential surface of a workpiece, forming grooves therein with the heat of the laser beam.

Owner:HONDA MOTOR CO LTD

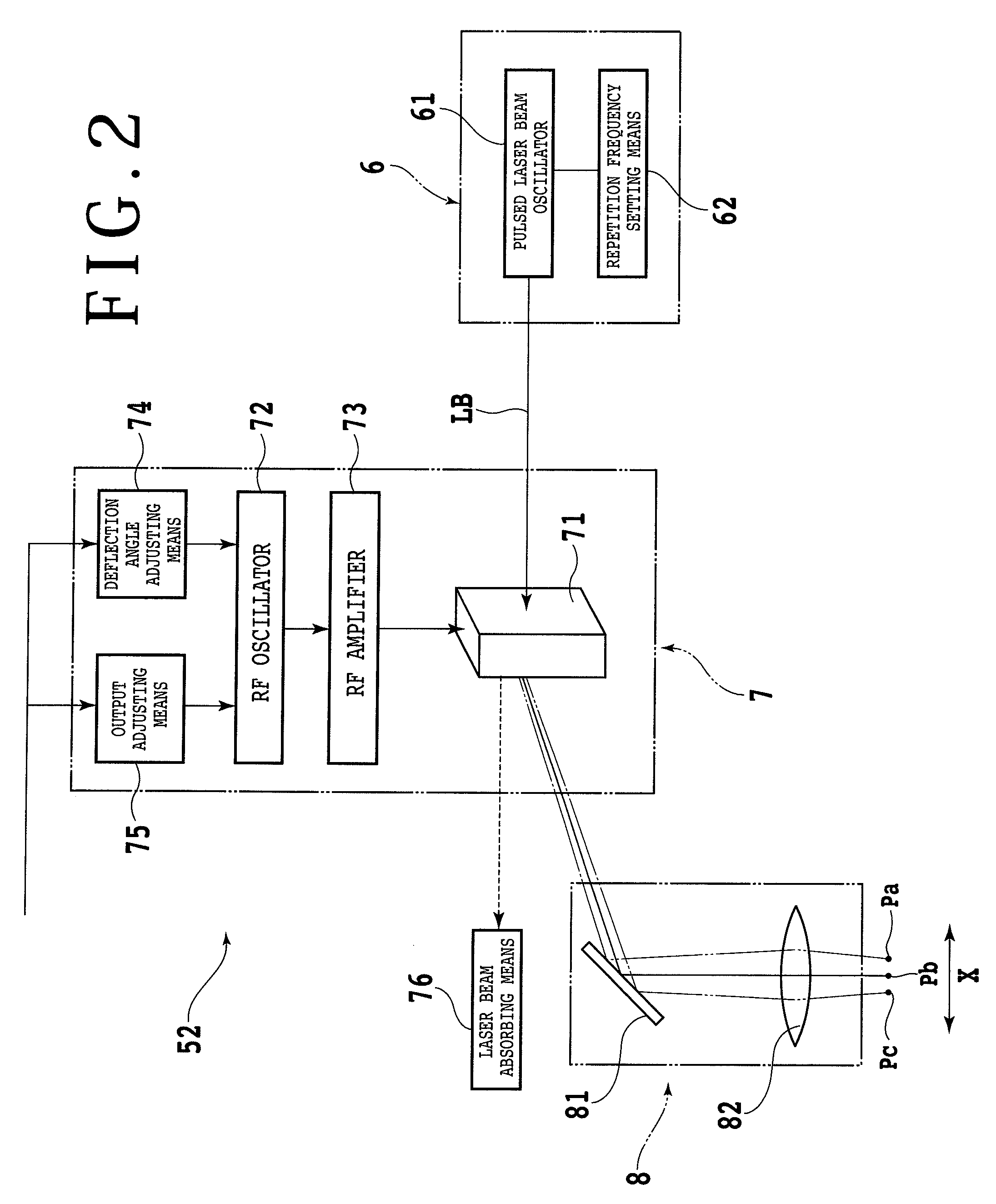

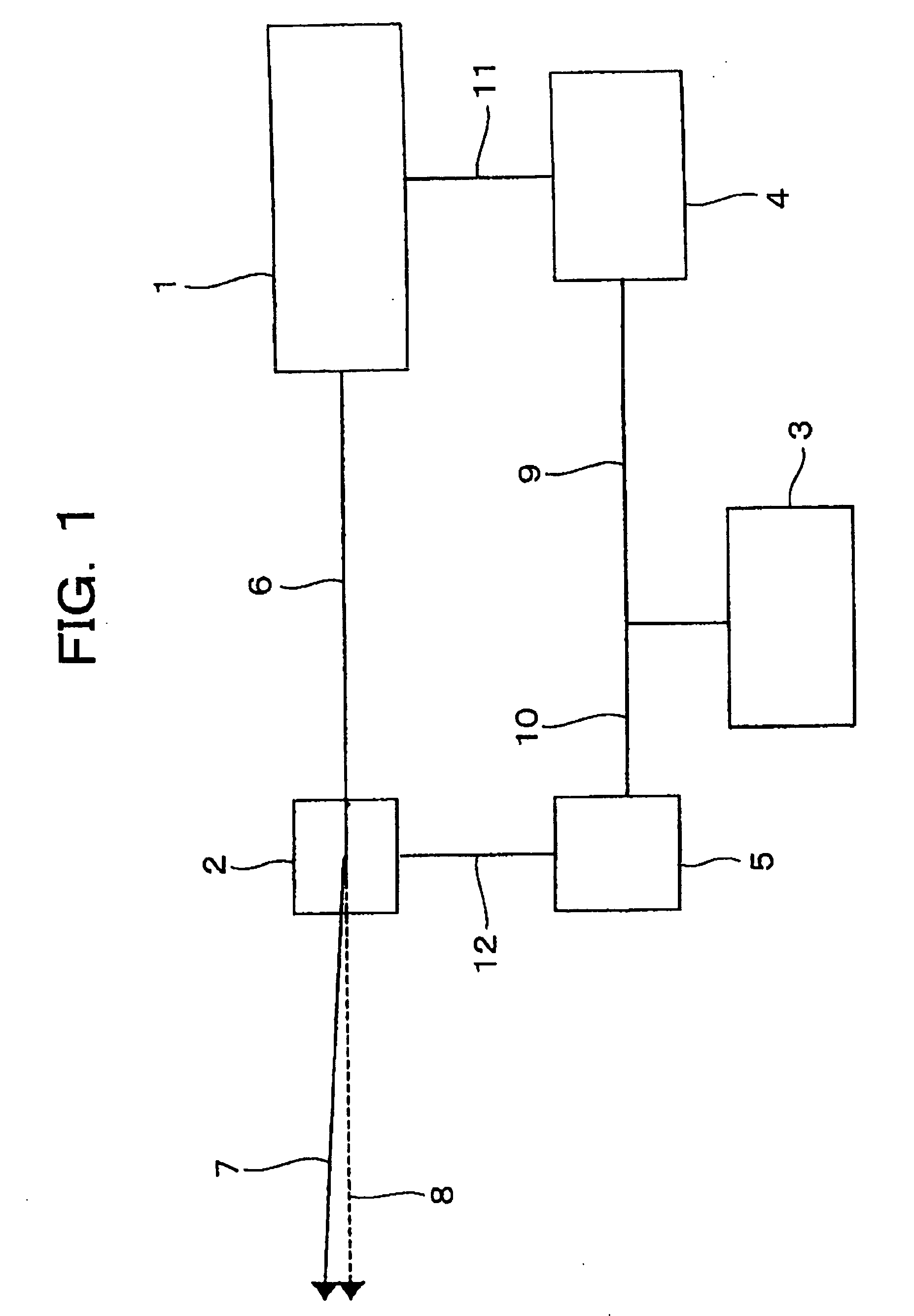

Laser machining method and laser machining apparatus

InactiveUS20050155958A1Improve hole position accuracyImprove hole qualityPrinted circuit manufactureWelding/soldering/cutting articlesLaser processingMetallic materials

A laser machining method and a laser machining apparatus superior in hole position accuracy and hole quality. An outgoing beam outputted as short pulses is shaped by a pulse shaping unit so as to form a #1 branch beam. The #1 branch beam is supplied to a portion to be machined, so as to machine the portion. In this case, the #1 branch beam may be controlled to synchronize with the outgoing beam. When a piece to be machined is made from a metal material and at least one of an organic material and an inorganic material, the metal material is machined with a laser beam shaped to have a pulse width not shorter than 100 ns, and at least one of the organic material and the inorganic material is machined with a laser beam shaped to have a pulse width shorter than 100 ns.

Owner:HITACHI SEIKO LTD

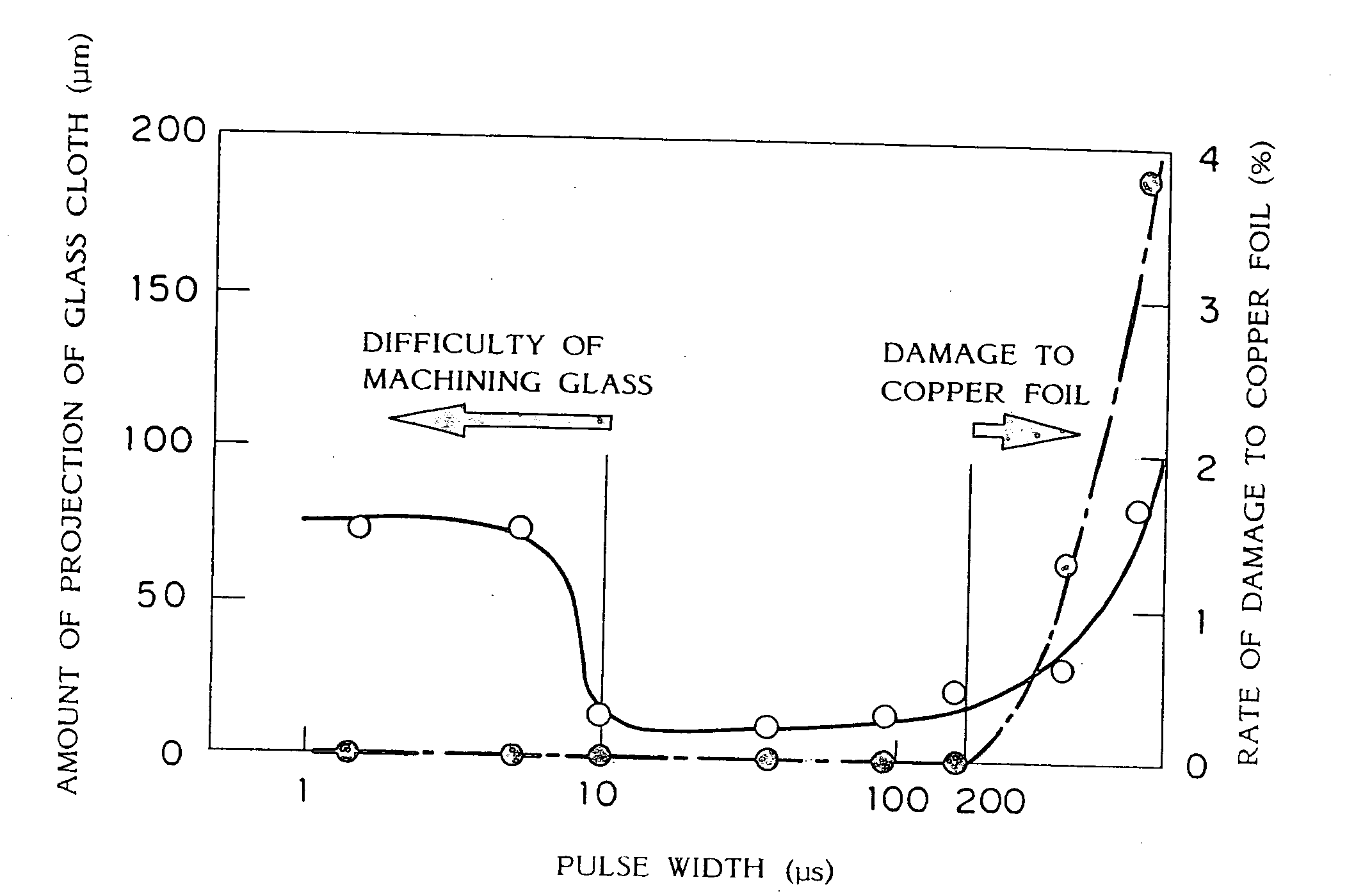

Pulsed laser beam machining method and apparatus for machining a wiring board at multiple locations

InactiveUS20050184035A1Rapidly and accurately be machinedLaser beam welding apparatusEtching metal masksLaser beam machiningLight beam

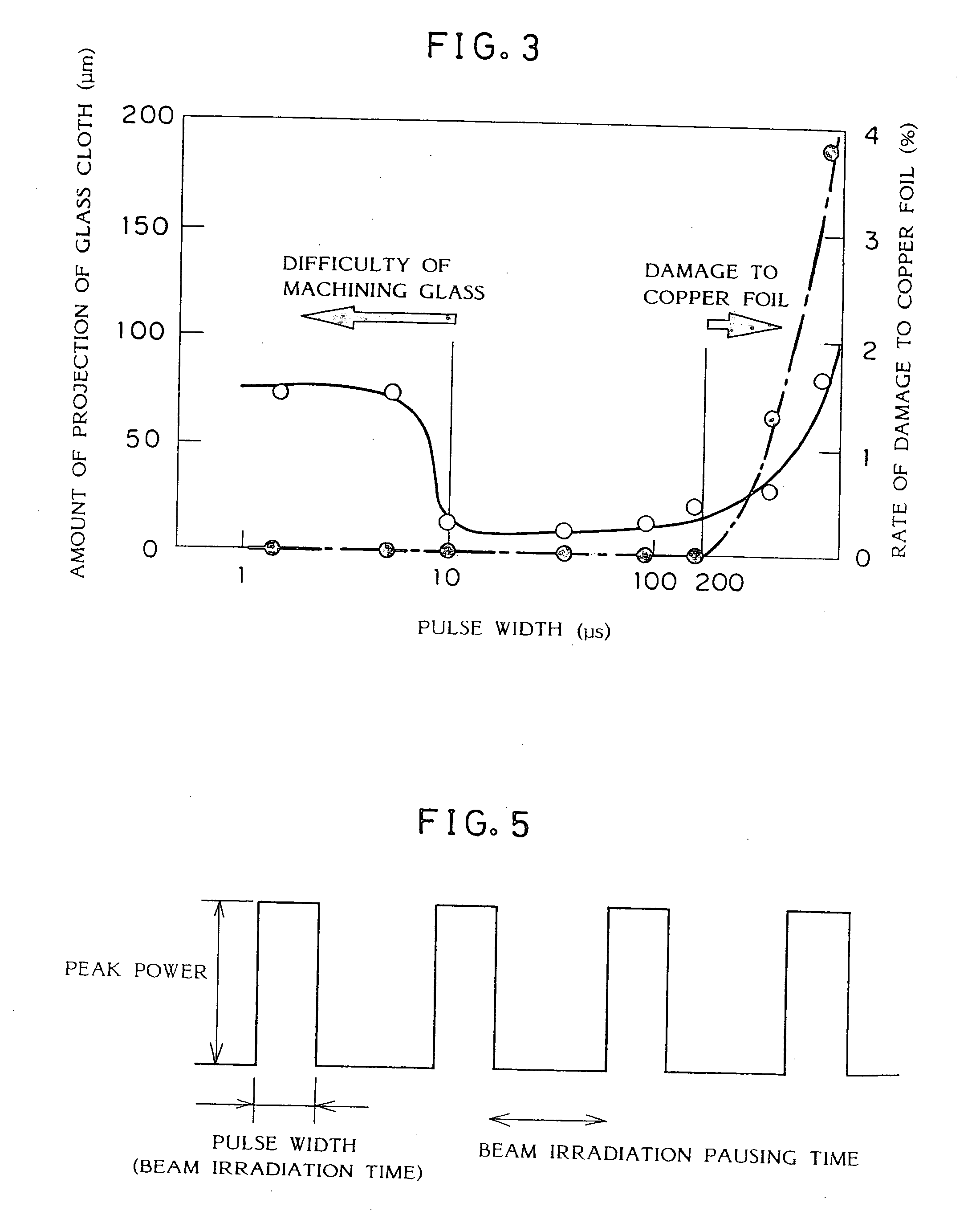

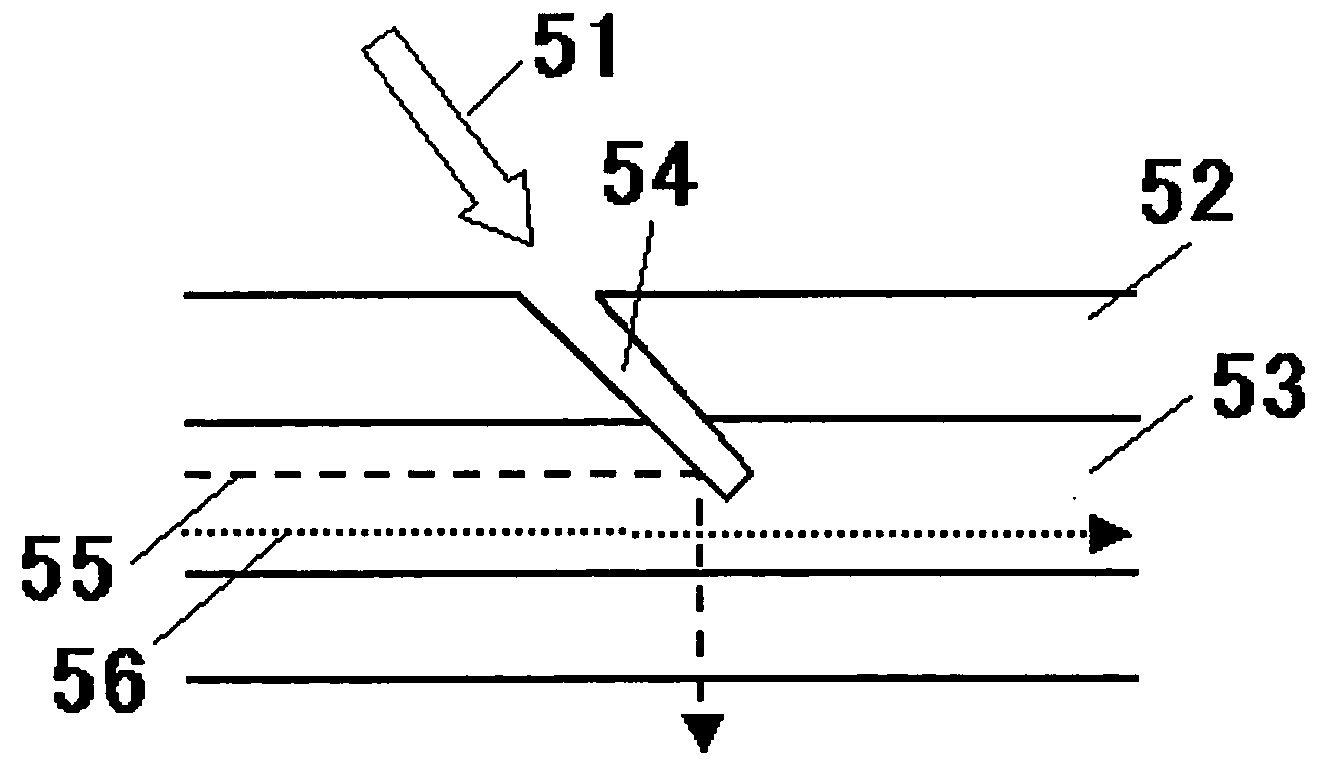

In a laser beam machining method for a wiring board, a machined portion of the wiring board is irradiated with a pulsed laser beam for a beam irradiation time ranging from about 10 to 200 μs and with energy density of about 20 J / cm2 or more, thereby machining the wiring board, for example, drilling for a through-hole and a blind via hole, grooving, and cutting for an outside shape. The laser beam operates at a frequency of more than 67 Hz, and the spot of the laser beam is sequentially moved to different drilling positions for each pulse. After all of many drilling positions in the range of a scan vision are irradiated with the laser beam pulse by pulse, or after the elapse of a time of 15 ms or more from irradiation of the first drilling position, the laser spot is returned to the first drilling position. The spot is sequentially moved once again, and the movement is repeated several times. A pause of 15 ms or more is required between pulses directed to the same drilling position to avoid formation of a thick char layer and projection of glass cloth into the hole.

Owner:MITSUBISHI ELECTRIC CORP

Optical waveguide having specular surface formed by laser beam machining

InactiveUS20050074207A1Small sizeCoupling efficiency is highCladded optical fibreCoupling light guidesLaser beam machiningOpto electronic

An optical waveguide having means for performing optical coupling with high efficiency at a predetermined position in an optical circuit substrate and which optionally includes an optical-electrical circuit board. Also provided are an optical waveguide, an optical path thereof being changed in an optical circuit at a steep angle and the optical waveguide for performing coupling and splitting of light being decreased in size in the optical circuit. The optical waveguide has a core and a cladding layer, and a wall surface, which is formed by cutting out at least a part of the core in a thickness direction of the core through irradiation of a laser beam and crosses at least a part of the core, which is a specular surface.

Owner:MITSUI CHEM INC

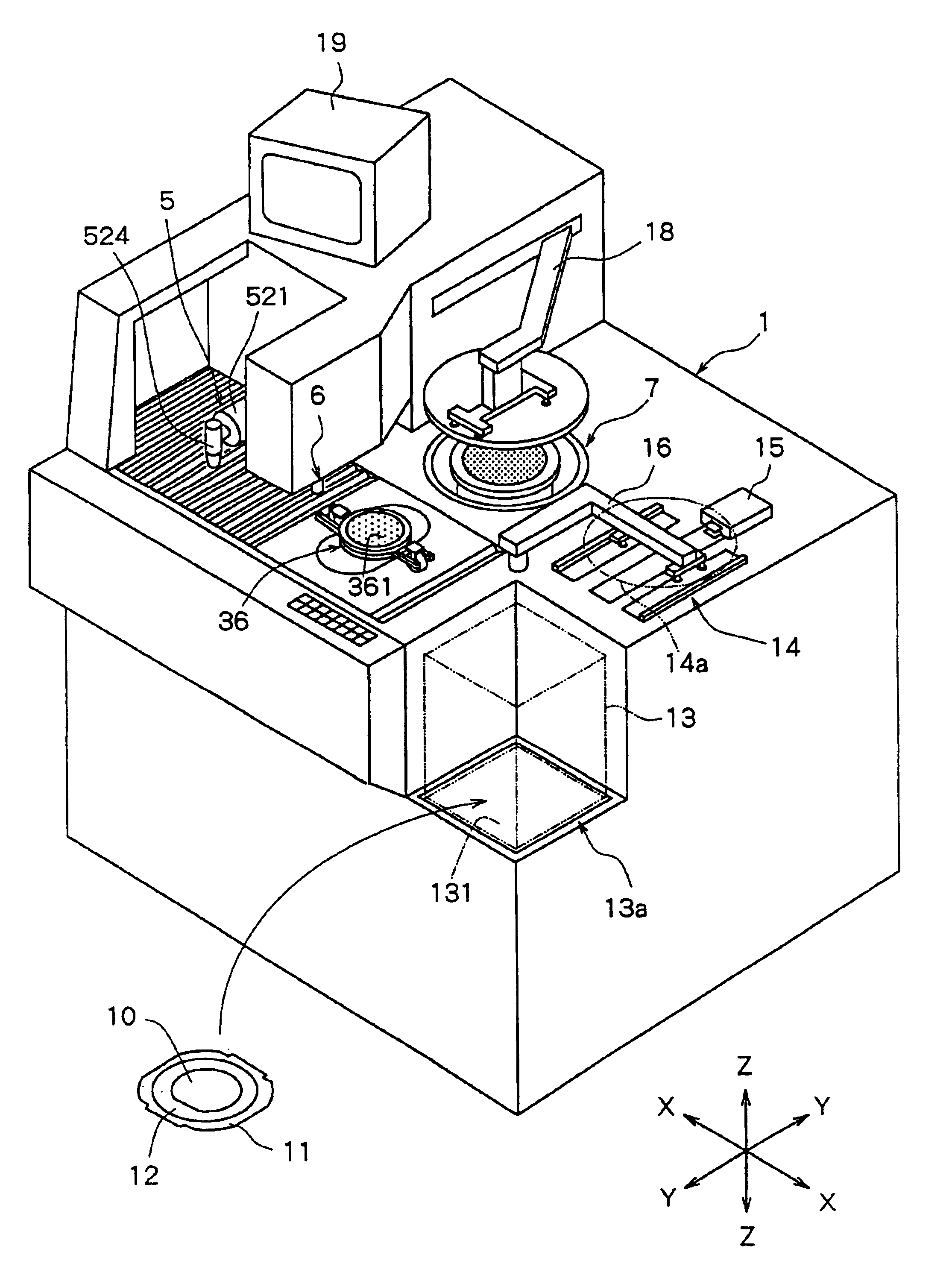

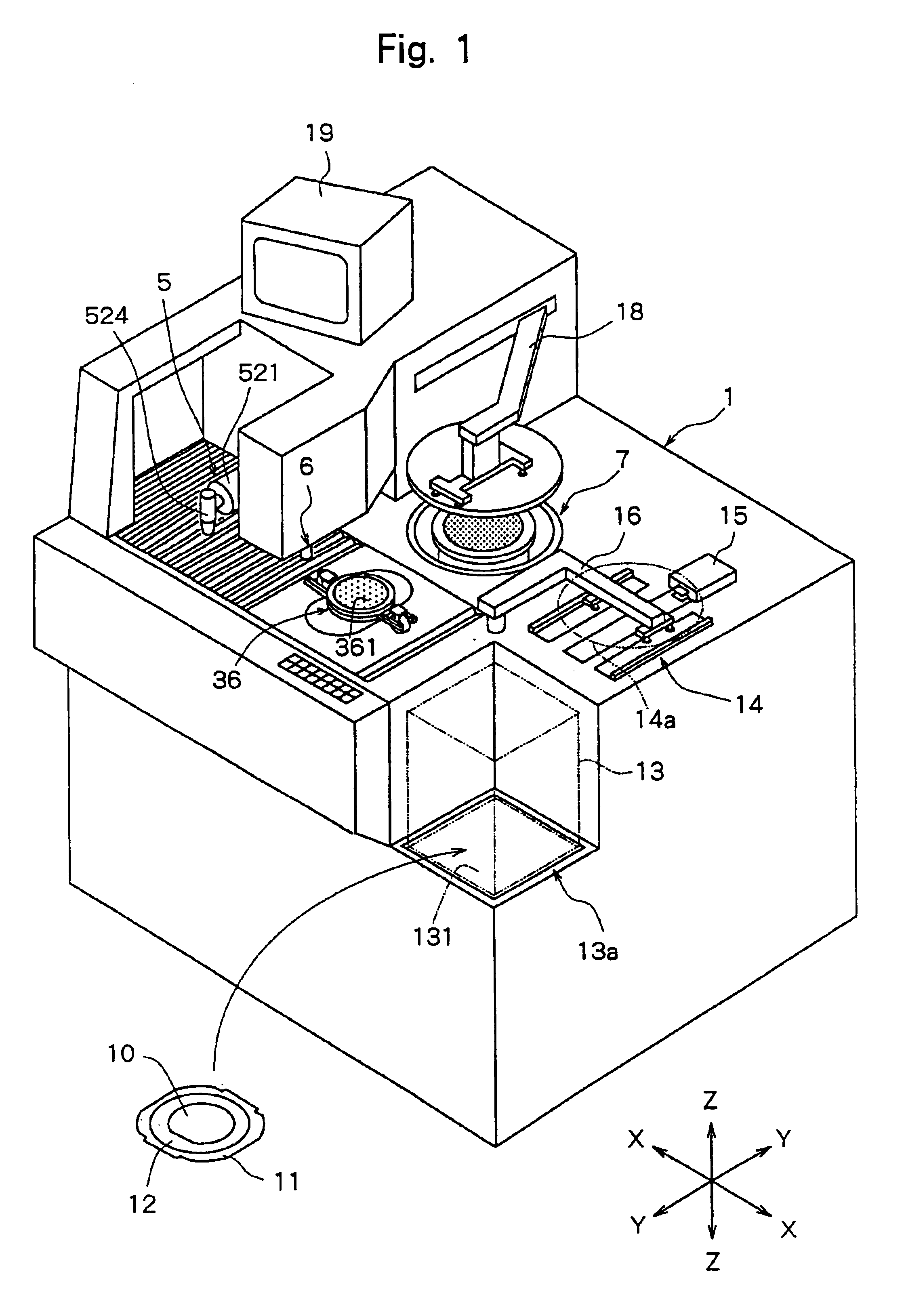

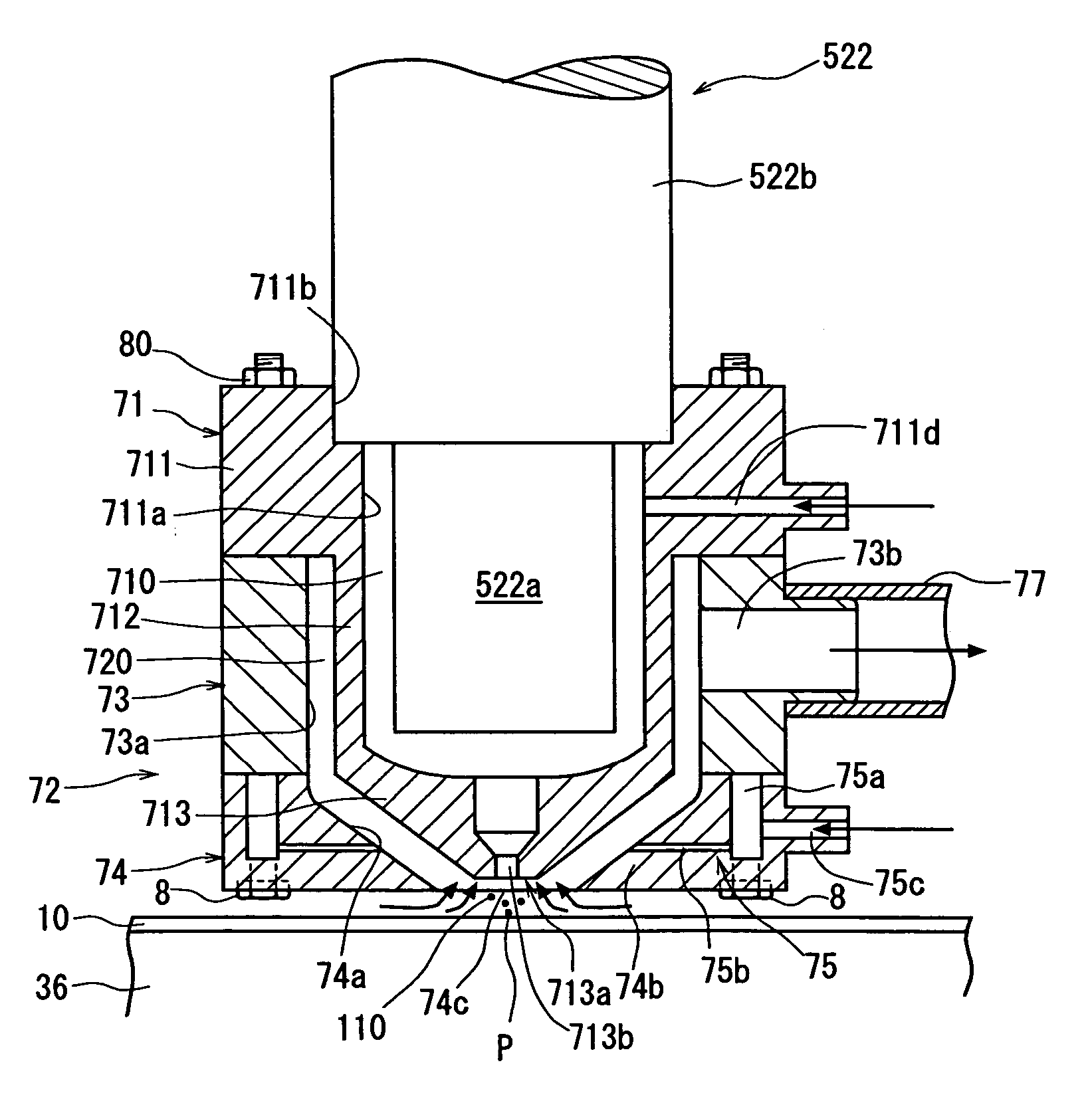

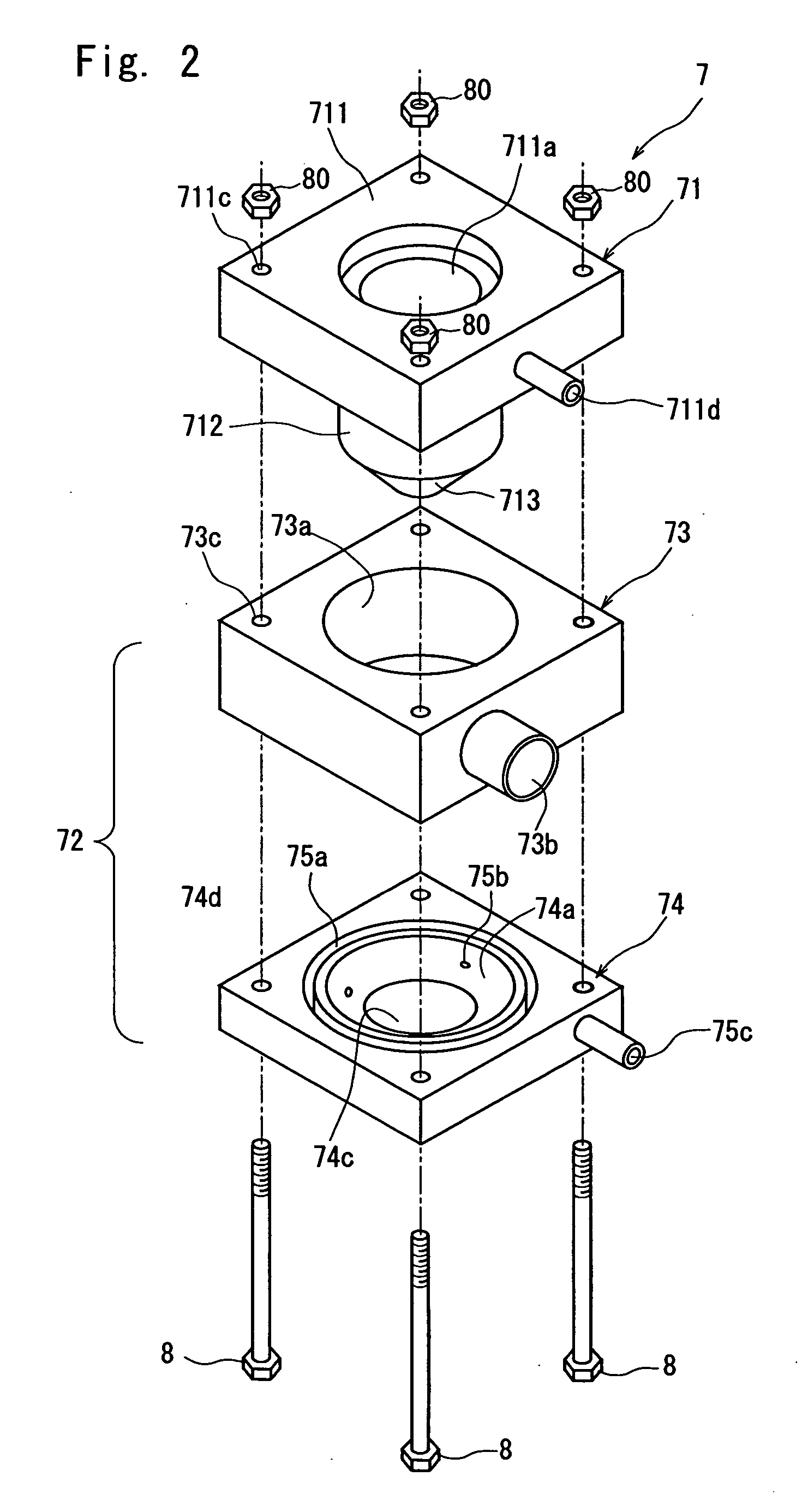

Laser beam processing machine

ActiveUS20070051710A1Smooth dischargeEfficient collection and dischargeDirt cleaningLaser beam welding apparatusLight beamLaser beam machining

A laser beam processing machine comprising a laser beam application means having a condenser for applying a laser beam to a workpiece held on a chuck table to process it, and a dust discharge means for collecting and discharging dust produced by the application of a laser beam to the workpiece, wherein the dust discharge means comprises a first cover member which is mounted to the lower end of the condenser and has a first opening for letting a laser beam applied from the condenser pass therethrough in the bottom wall, a second cover member which is arranged to surround the first cover member and has a second opening for allowing a laser beam applied from the condenser pass therethrough and sucking in dust in the bottom wall, an air introduction chamber which is formed between the first cover member and the condenser and communicates with the first opening, a dust collection chamber which is formed between the first cover member and the second cover member and communicates with the second opening, a first air supply means for supplying air to the air introduction chamber, and a swirling flow generating means for generating a swirling flow in the dust collection chamber.

Owner:DISCO CORP

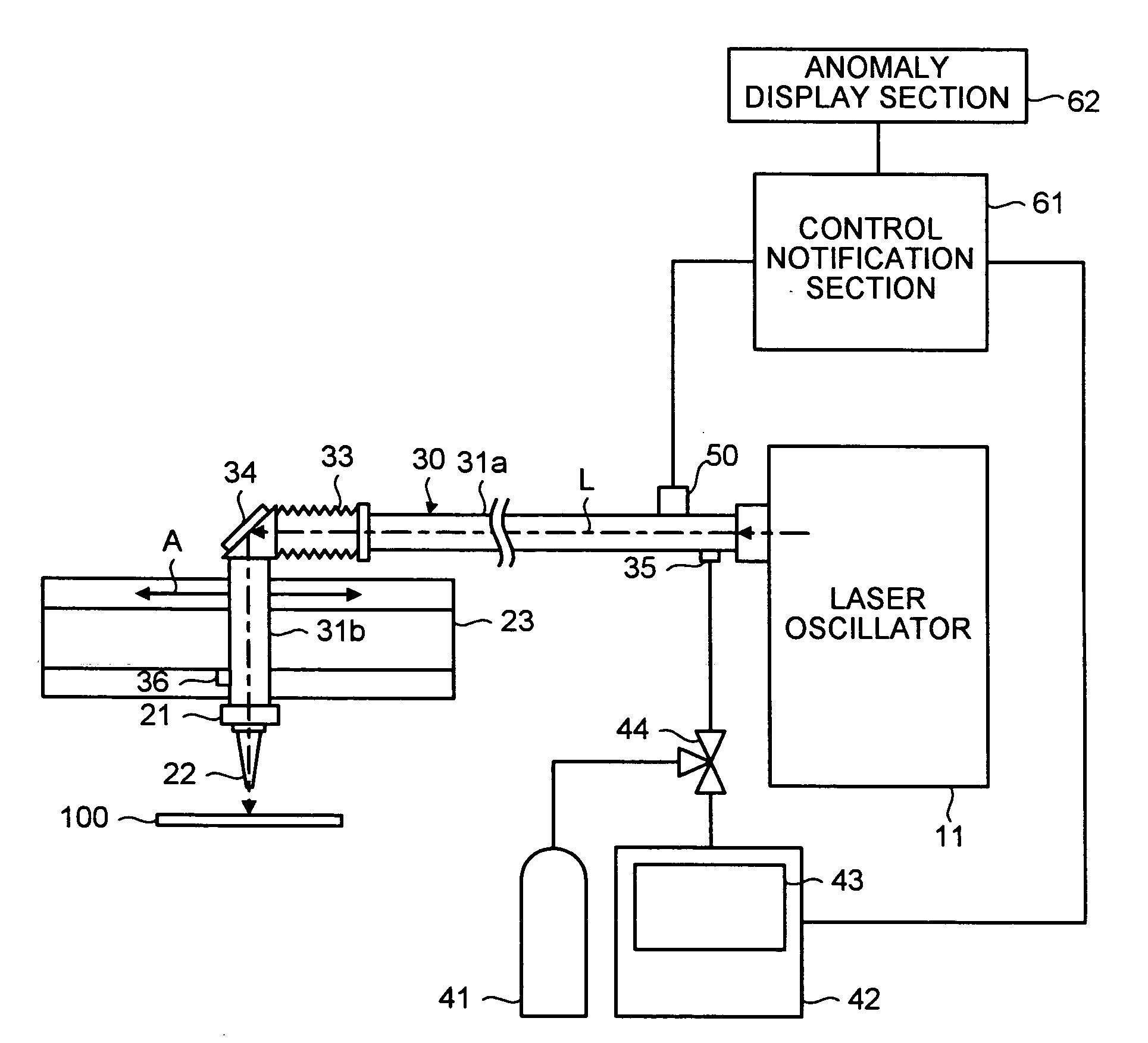

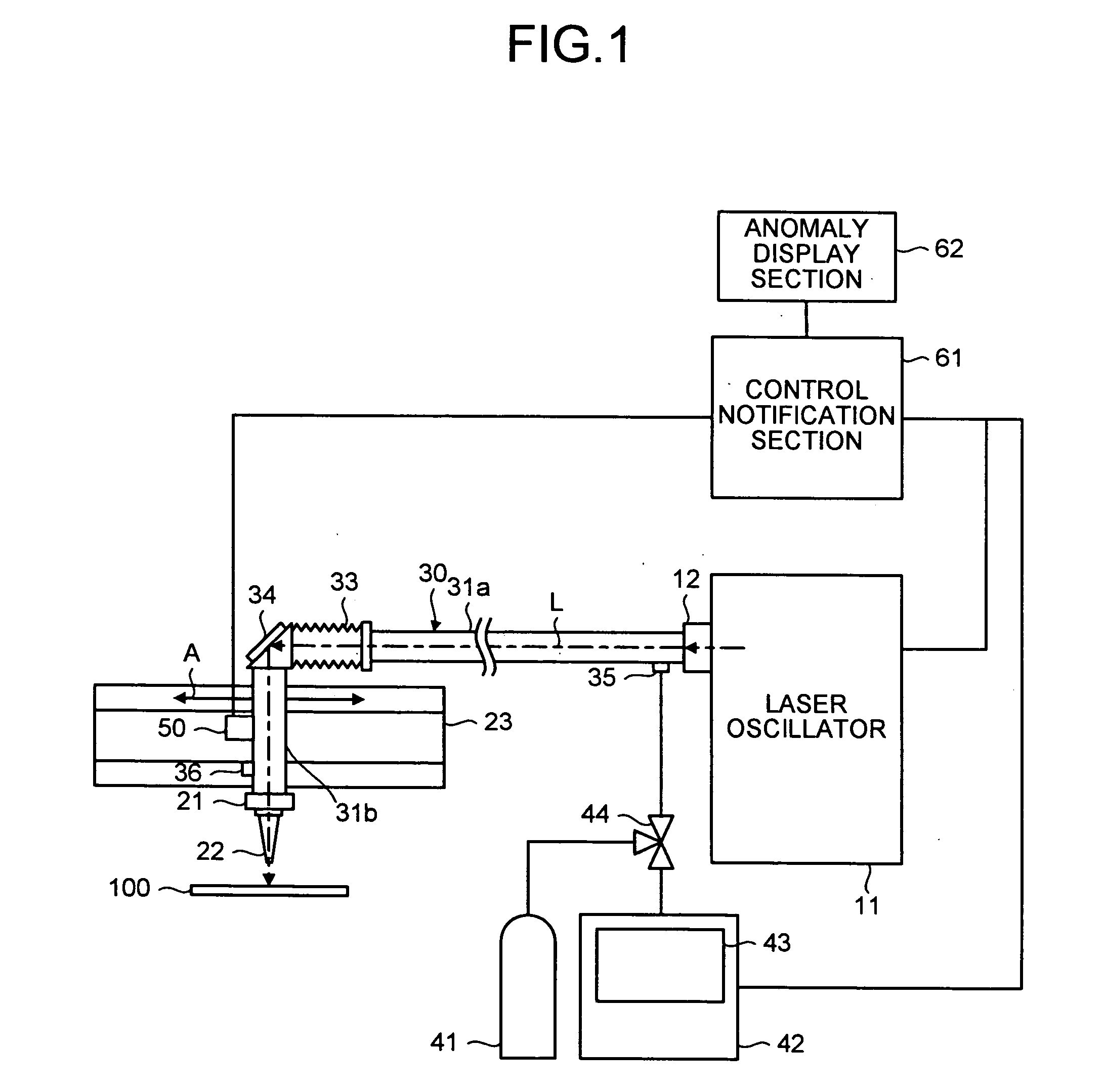

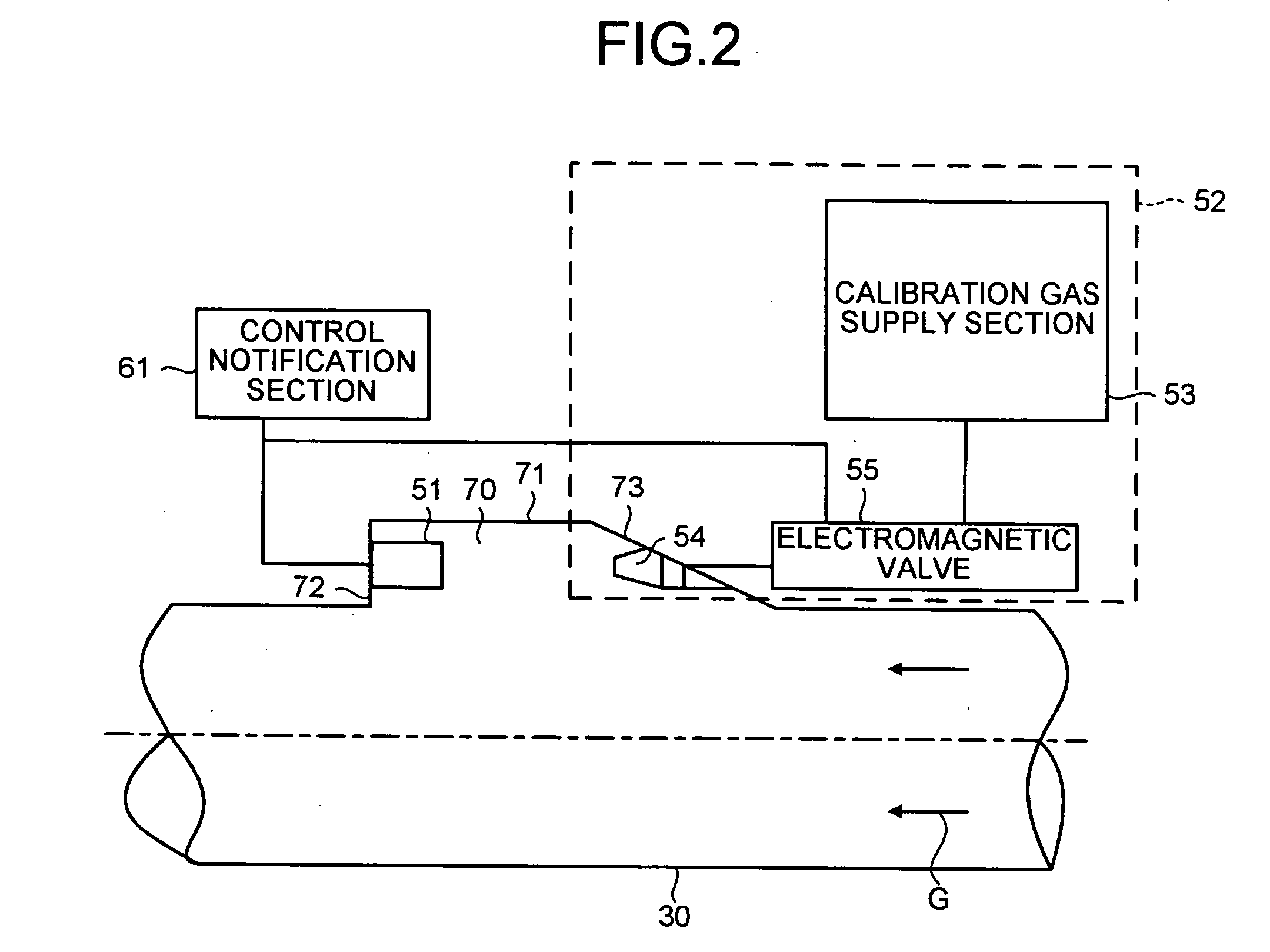

Laser beam machining apparatus

InactiveUS20050061778A1Laser constructional detailsLaser beam welding apparatusLaser processingLaser beam machining

A laser beam machining apparatus includes a laser oscillator, a machining head which that machines a workpiece using the laser beam. An optical duct has an optical system to guide the laser beam form the laser oscillator to the machining head. Purge gas is supplied into the optical duct from a purge gas supply port, and the purge gas is output from a purge gas exhaust port. A detector detects presence of undesired gas in the optical duct.

Owner:MITSUBISHI ELECTRIC CORP

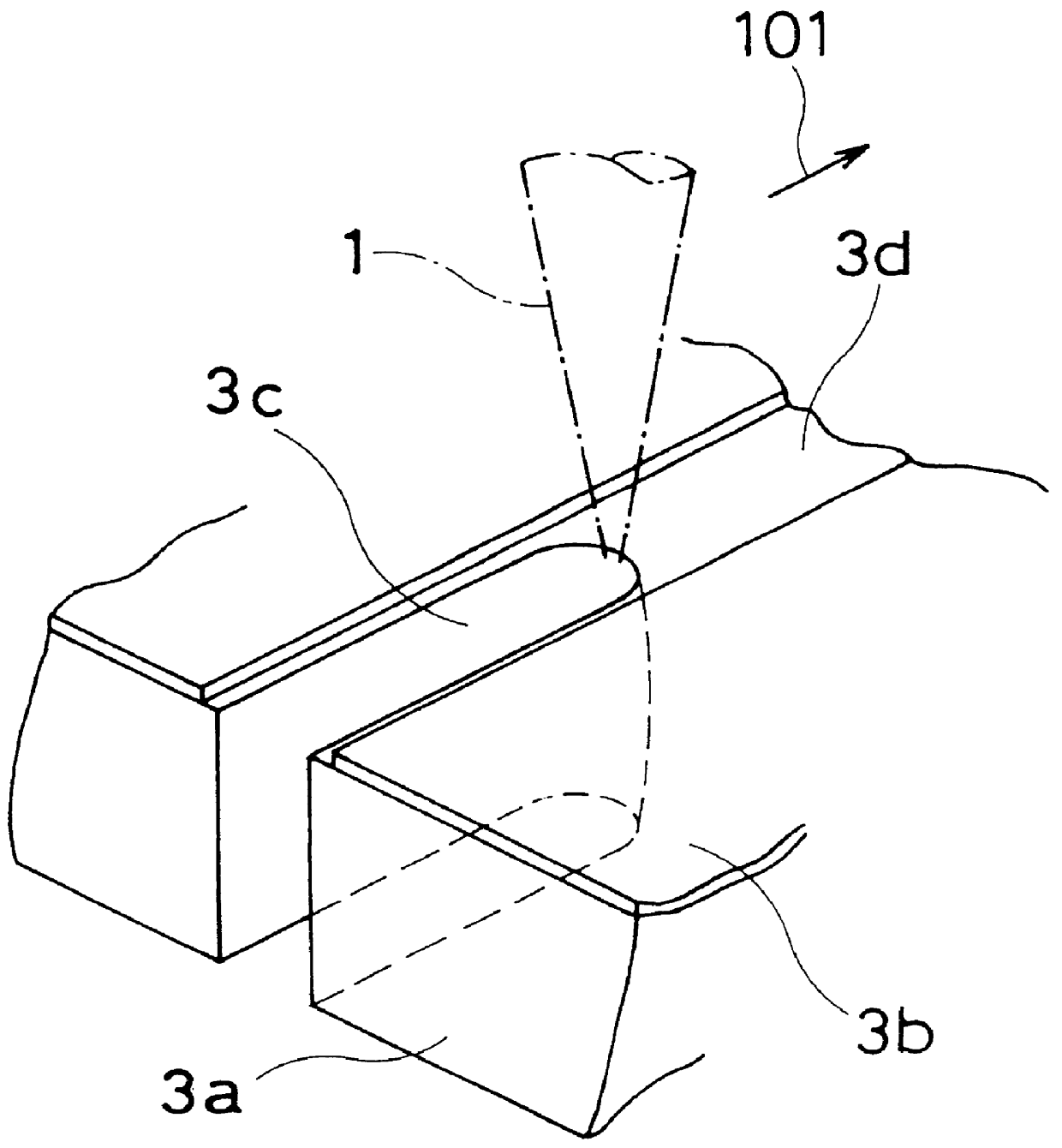

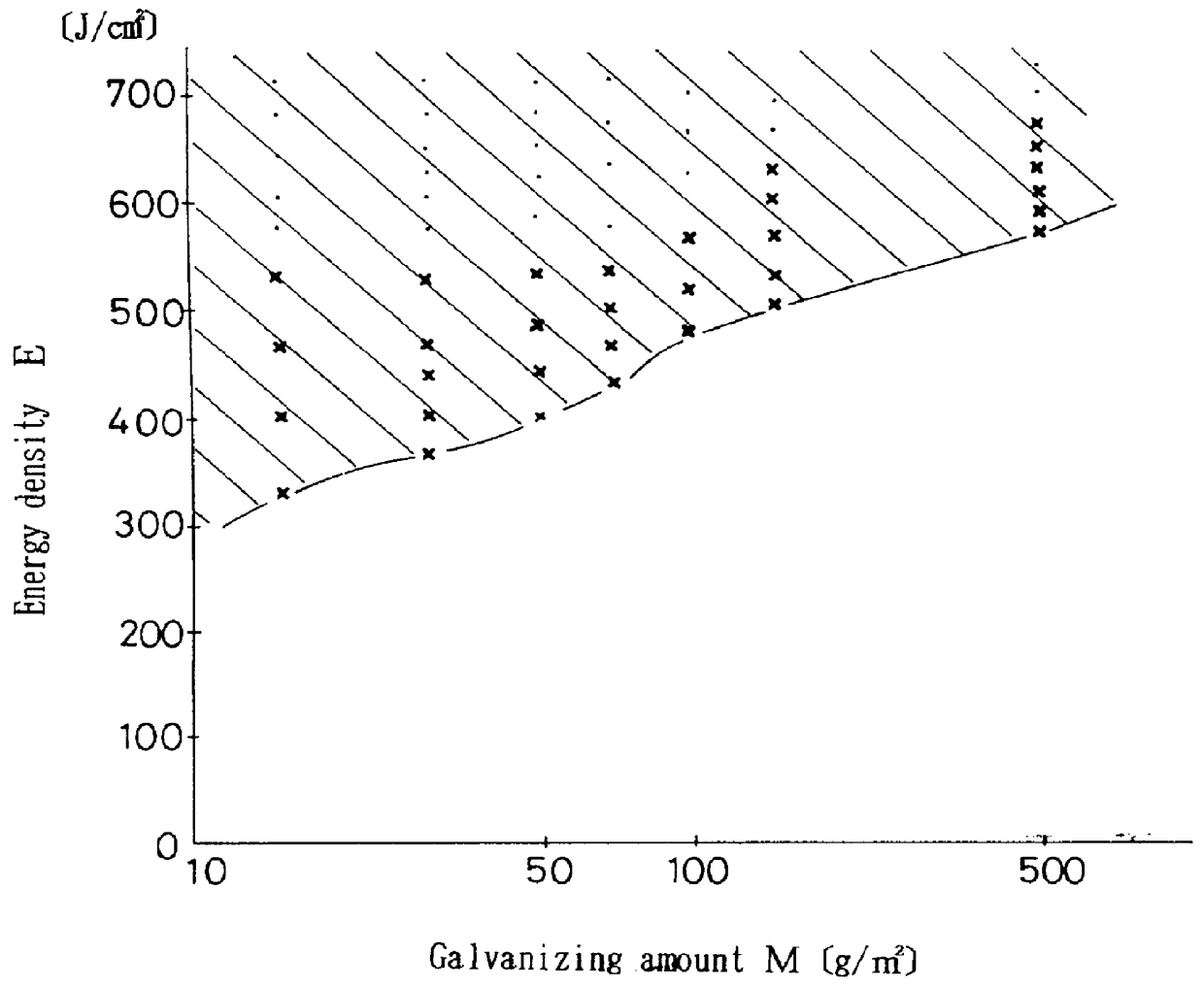

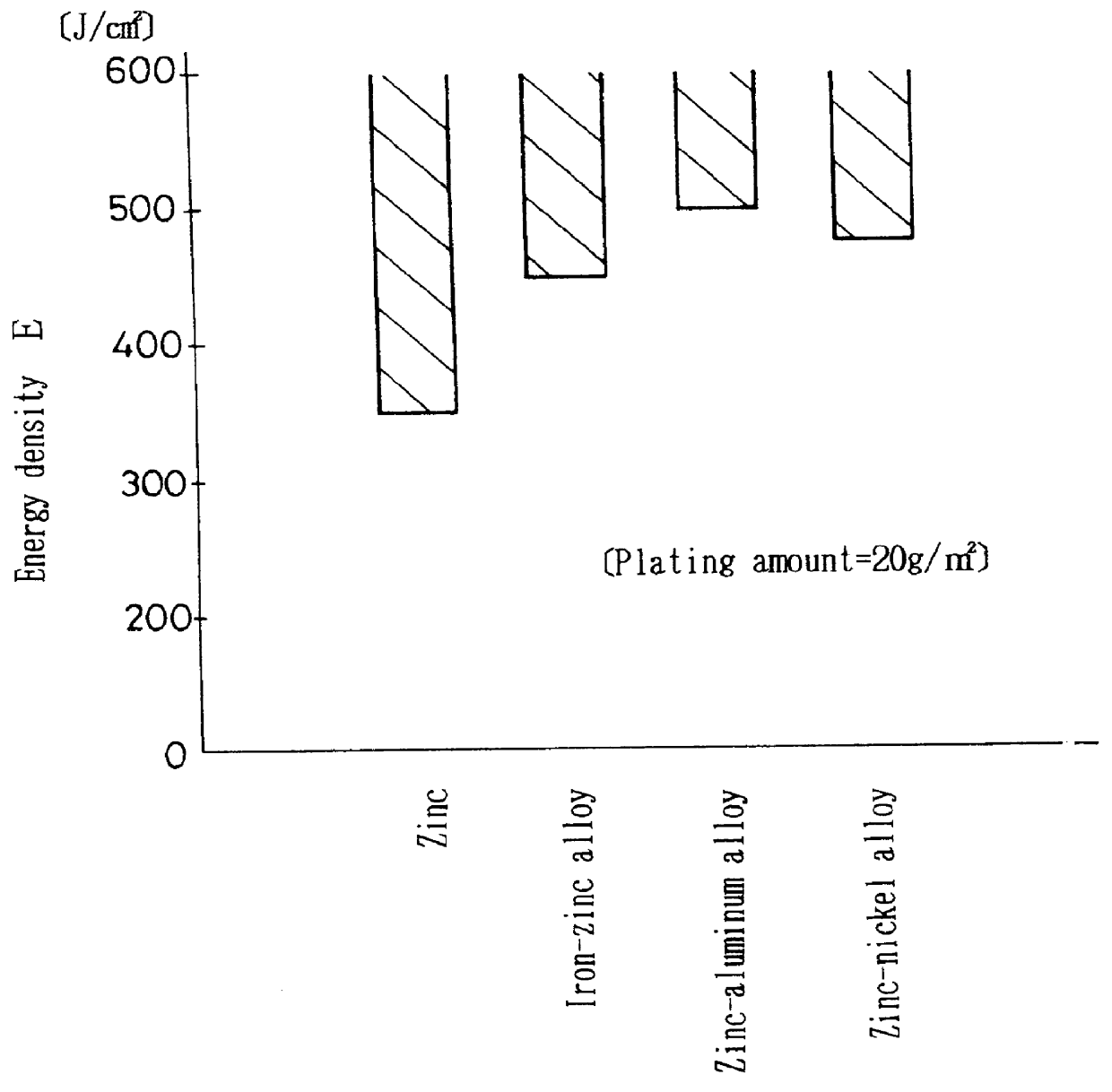

Laser beam machining apparatus and corresponding method which employs a laser beam to pretreat and machine a workpiece

InactiveUS6040549AWelding/soldering/cutting articlesMetal working apparatusLight beamLaser beam machining

A laser beam machining is carried out by irradiating beforehand the laser beam along a final locus for a main machining, under such a condition as to obtain an energy density for removing a galvanized layer as a surface substance of a work. Thereafter, the laser beam is irradiated to a bare area on which the zinc has been removed, while changing only the energy density according to a cutting condition to cut the work.

Owner:MITSUBISHI ELECTRIC CORP

Laser beam machining method for wafer

ActiveUS20090004828A1Carry-out smoothly and easilyMachining efficiency can be moreSemiconductor/solid-state device manufacturingFine working devicesSplit linesLaser beam machining

A laser beam machining method for a wafer, wherein an operation of irradiating the inside of a wafer with a laser beam L along each of planned dividing lines is repeated a plural number of times from a position proximate to a back-side surface of the wafer toward a face-side surface of the wafer so that a plurality of composite layers each including a denatured layer and a cracked layer extending from the denatured layer toward the face-side surface are formed stepwise at intervals (first laser beam irradiation step). Subsequently, each of some of non-cracked layers between the composite layers is irradiated with the laser beam L so as to extend the cracked layer of a given one of the composite layers and to cause the cracked layer to reach the denatured layer of the composite layer which is adjacent to the given one composite layer. The denatured layers and the cracked layers which are sufficient for enabling the wafer to be split are formed by a reduced number of laser beam irradiation operations.

Owner:DISCO CORP

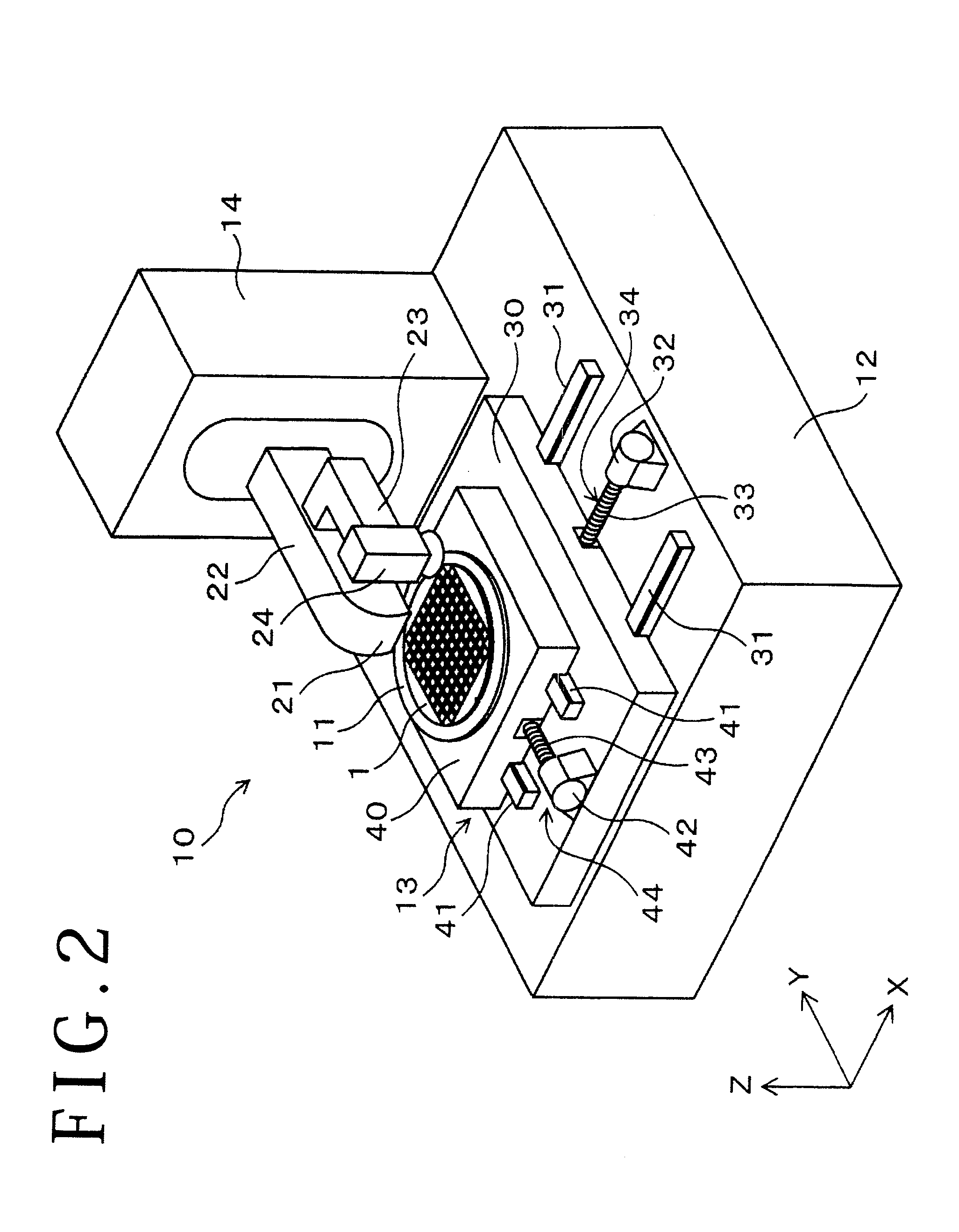

Alignment method of a laser beam processing machine

ActiveUS20080029715A1Accurate locationMaterial analysis using wave/particle radiationPhotometryCrystal orientationLaser beam machining

An alignment method of a laser beam processing machine comprising a chuck table, a laser beam application means having a condenser for applying a laser beam to the workpiece held on the chuck table, an image pick-up means for picking up an image of the workpiece held on the chuck table and a control means having a memory for storing the specifications of the workpiece, the method comprising the steps of storing the design coordinates of a processing position set based on the mark indicating the crystal orientation of a wafer and alignment marks; picking up an image of the periphery of the wafer with the image pick-up means and locating the mark indicating the crystal orientation of the wafer at a predetermined position; positioning the design coordinate position of each of the alignment marks set based on the mark indicating the crystal orientation of the wafer right below the condenser and applying a laser beam from the condenser so as to remove the insulating film in the alignment mark areas; and picking up an image of the alignment marks with the image pick-up means and adjusting the coordinates of the processing position of the wafer on the chuck table based on the image of the alignment marks.

Owner:DISCO CORP

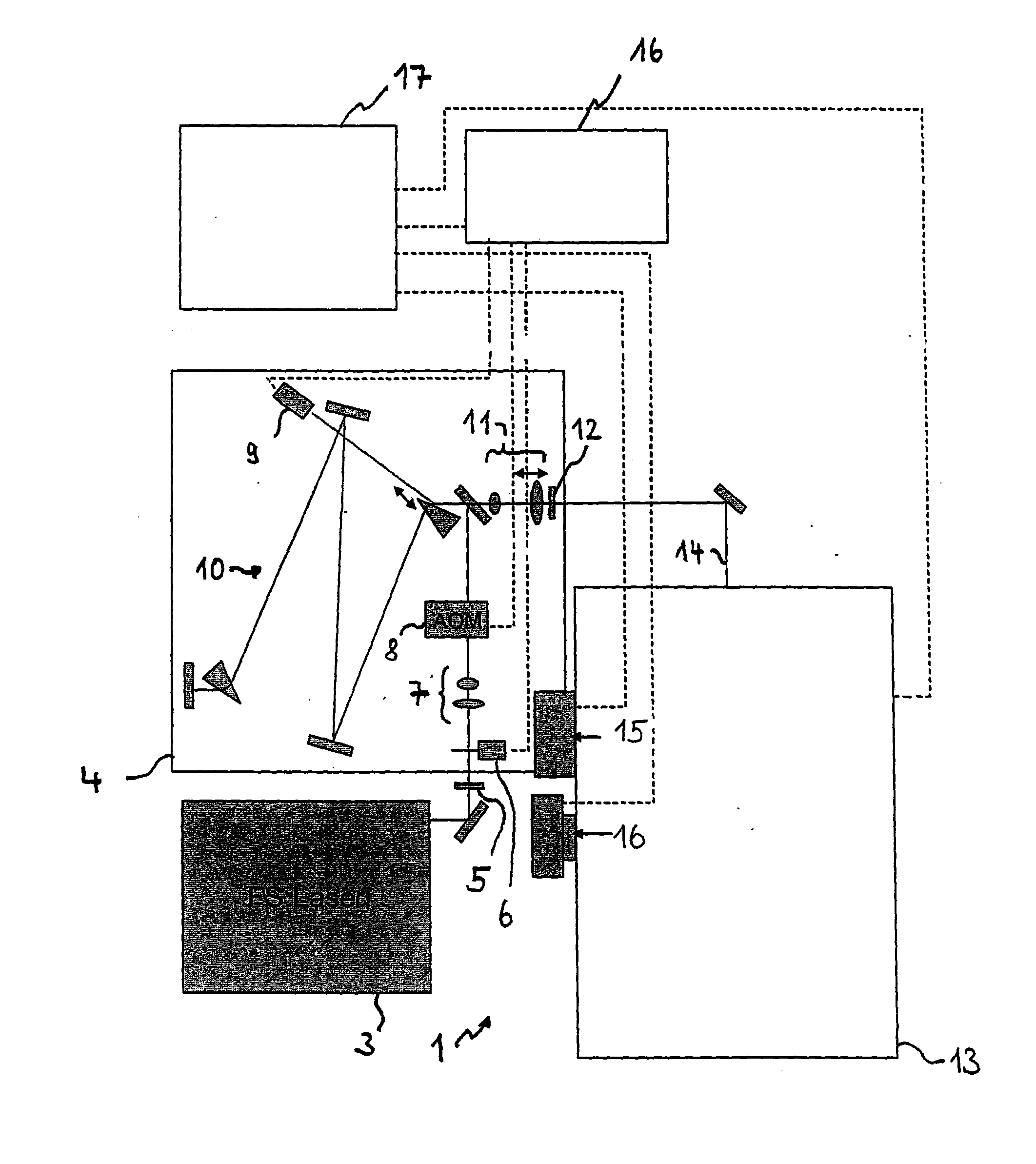

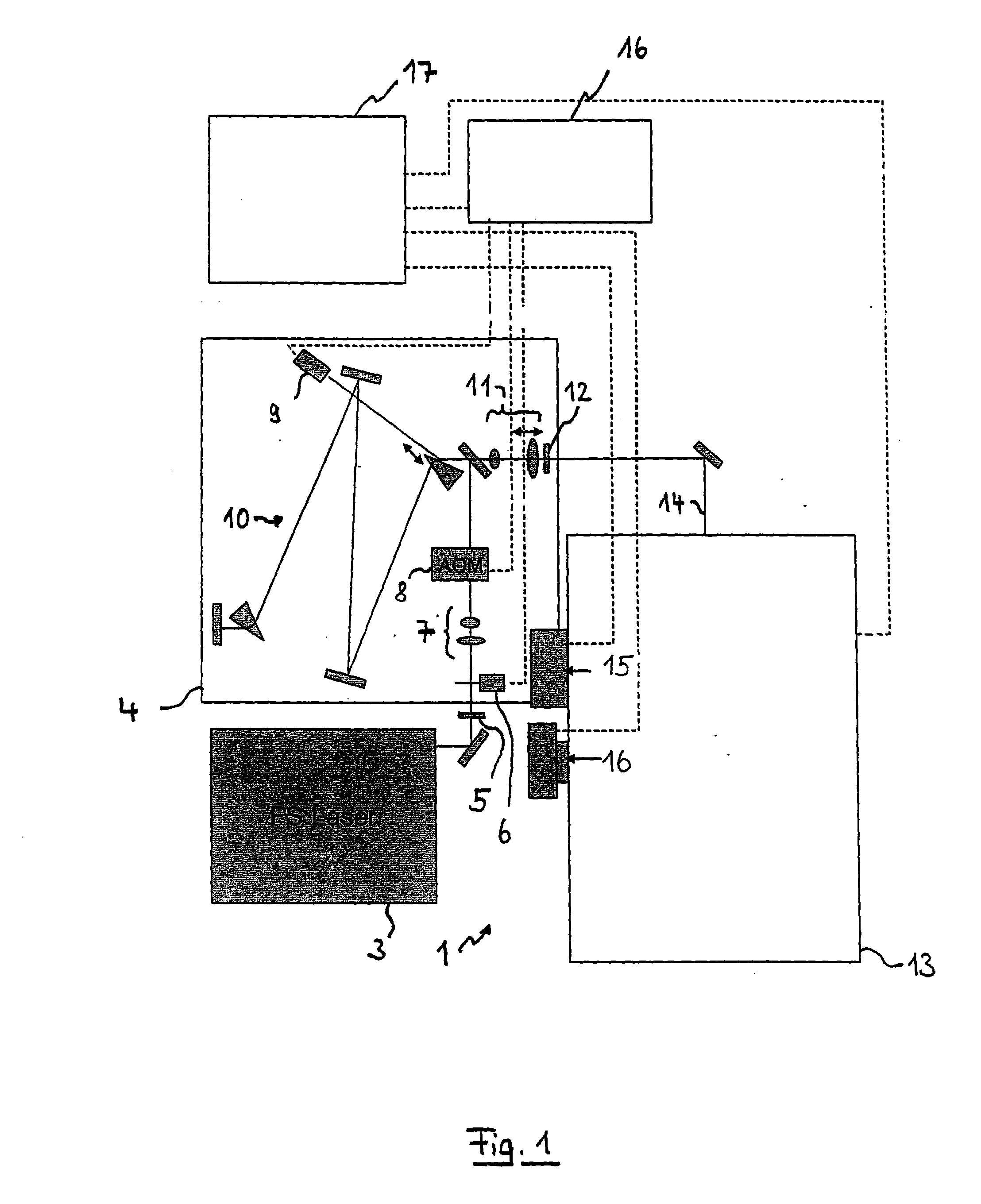

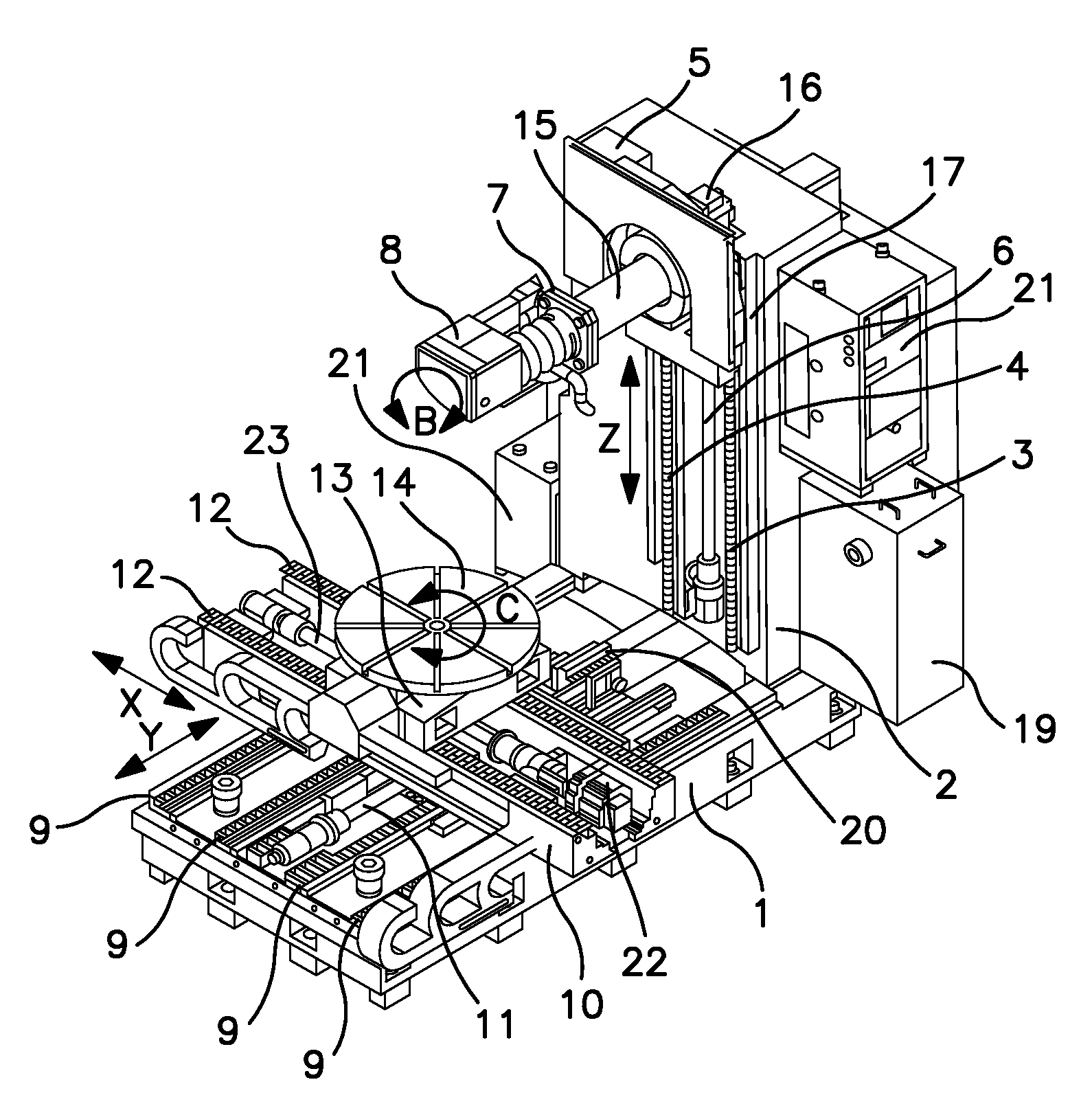

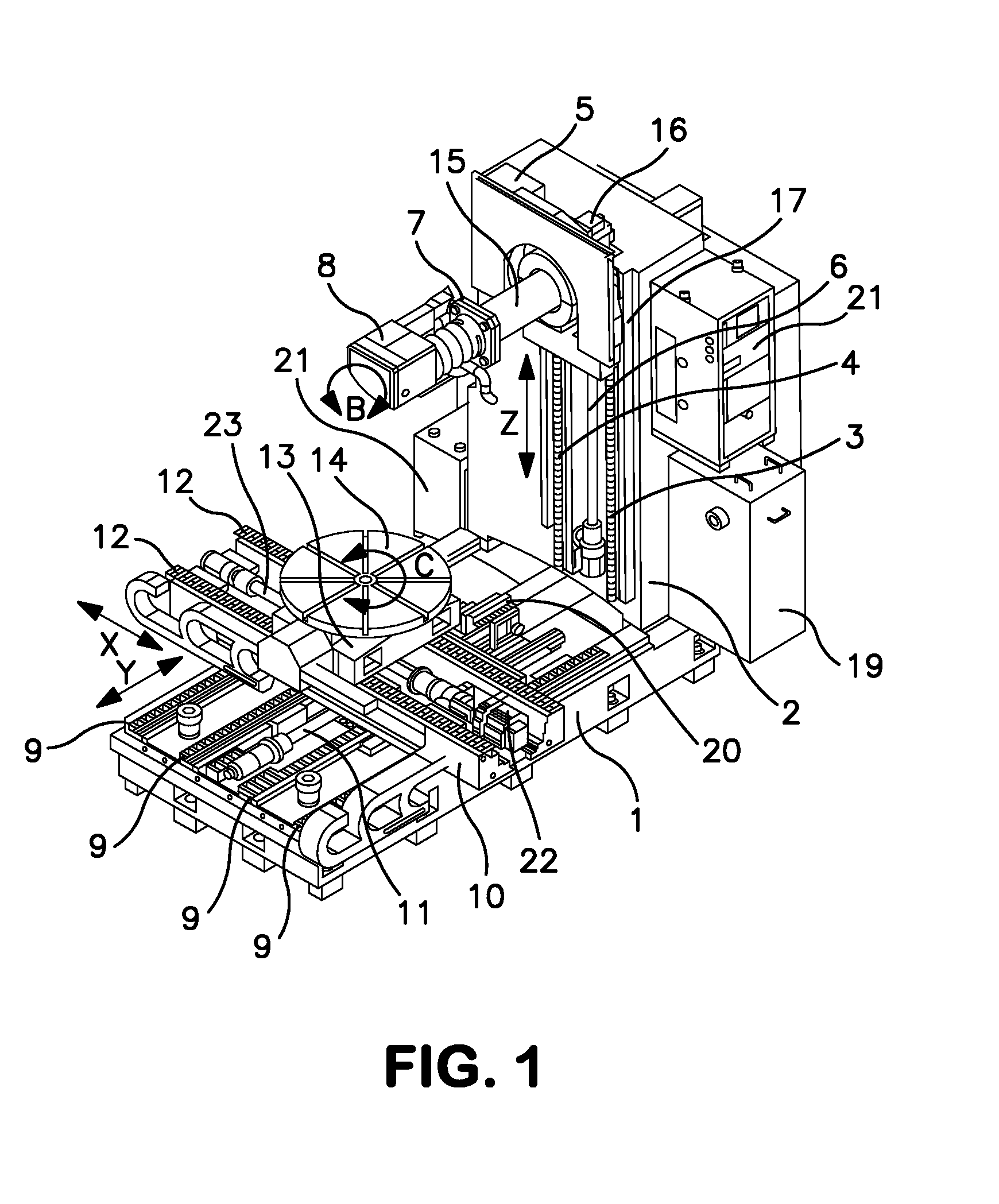

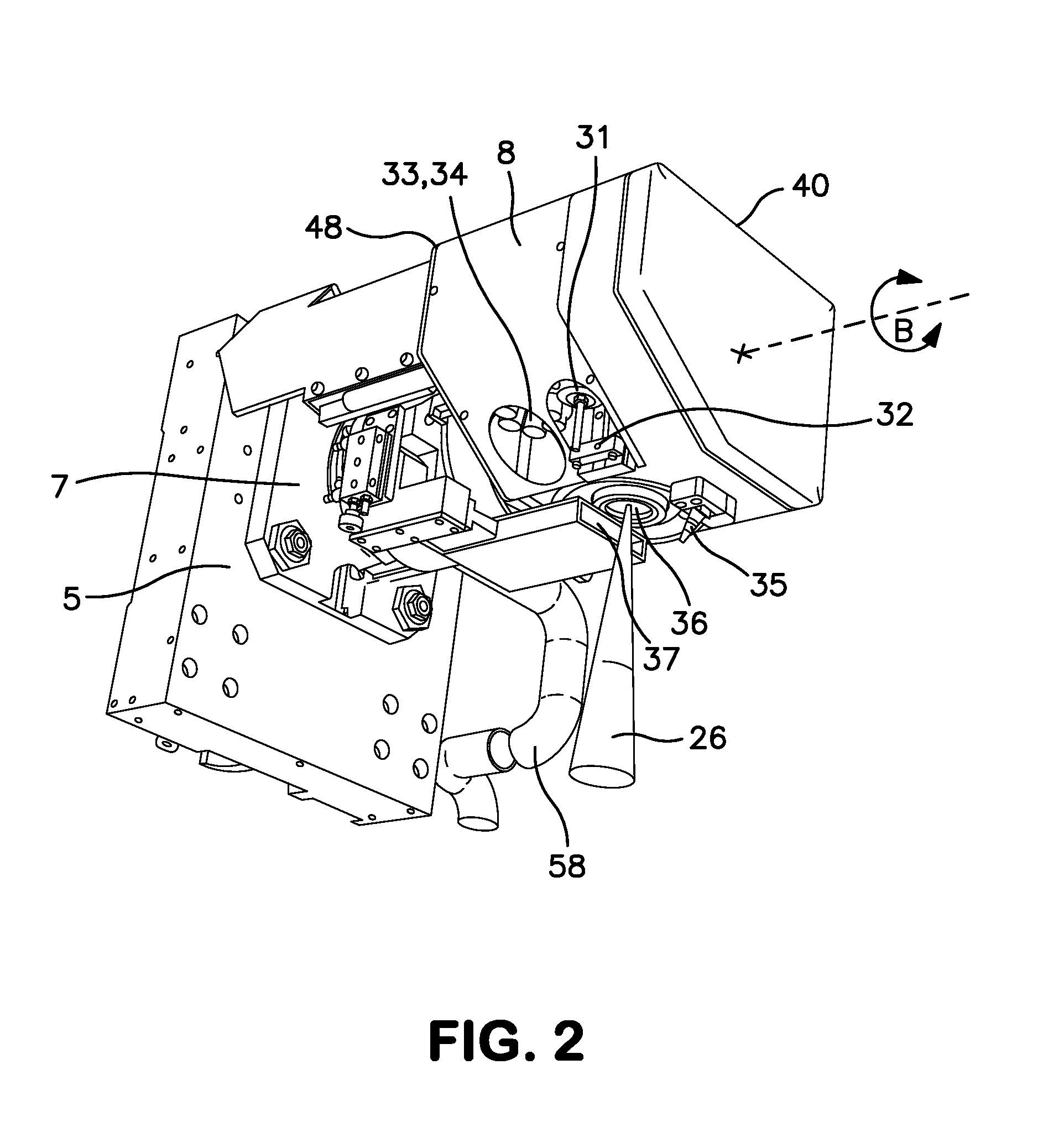

Laser machining machine

ActiveUS20110120981A1High precisionWelding/cutting auxillary devicesAuxillary welding devicesLaser processingOptical axis

A machine for machining workpieces by a laser beam. The optical fibre terminates at an optical output head (27) that defines the optical axis of the laser light beam, which vaporizes the material. The optical output head (27) is rigidly attached to the frame (49) or to the casing of the laser head so that said optical output head remains integrally fastened to said frame or casing during the rotation of the laser head about the horizontal pivot axis (B). The polluted gases generated in the machining area by the evaporation of material are collected by a suction nozzle (37) which is driven with the laser machining head during its rotation about the horizontal axis (B). A stream of clean dry gas is injected into the machining area by an injection nozzle (35) which is also driven with the laser machining head (8) during its rotation about the horizontal axis (B).

Owner:CHARMILLES TECH SA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com