Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

97results about How to "Improve hole position accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

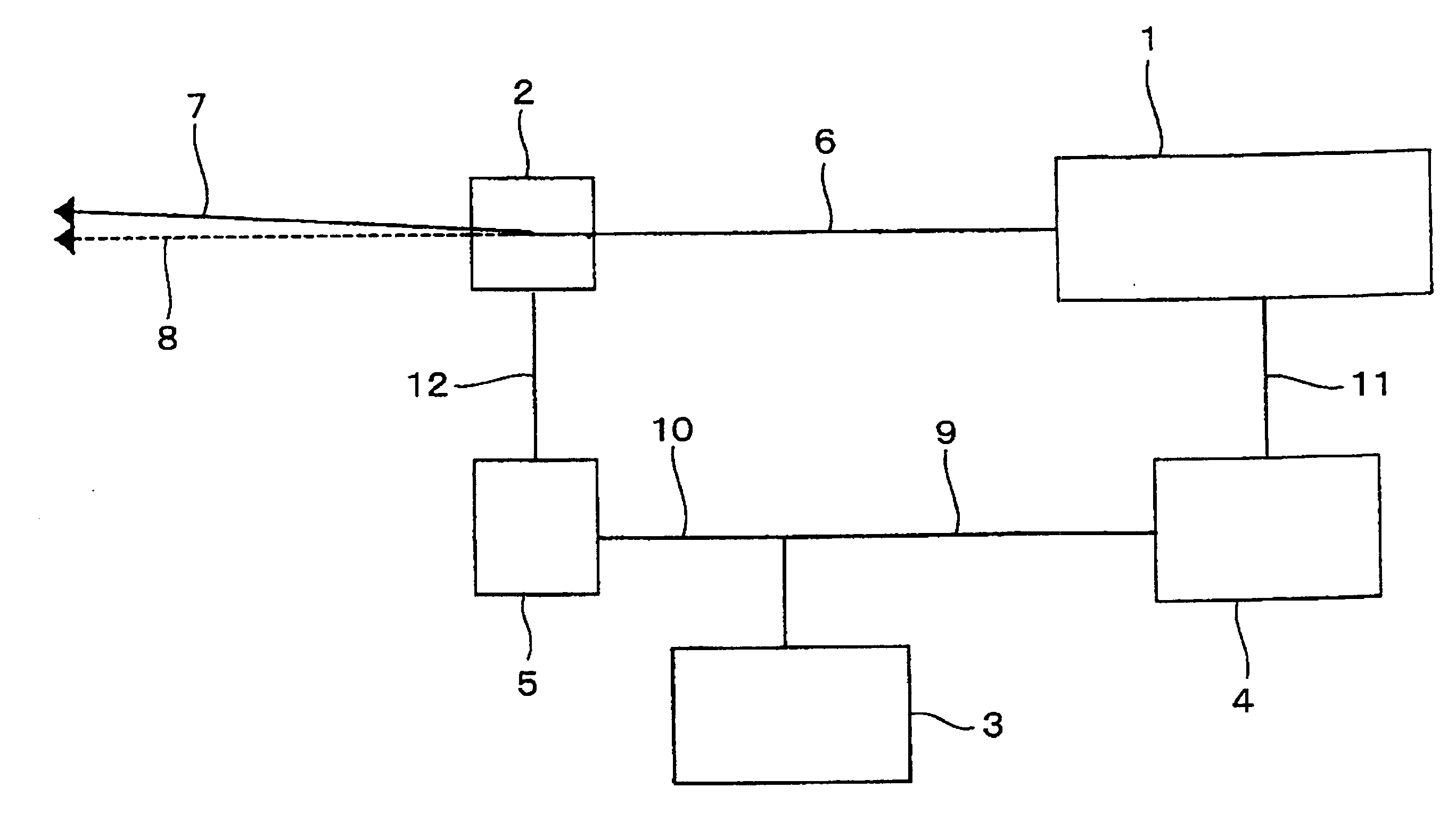

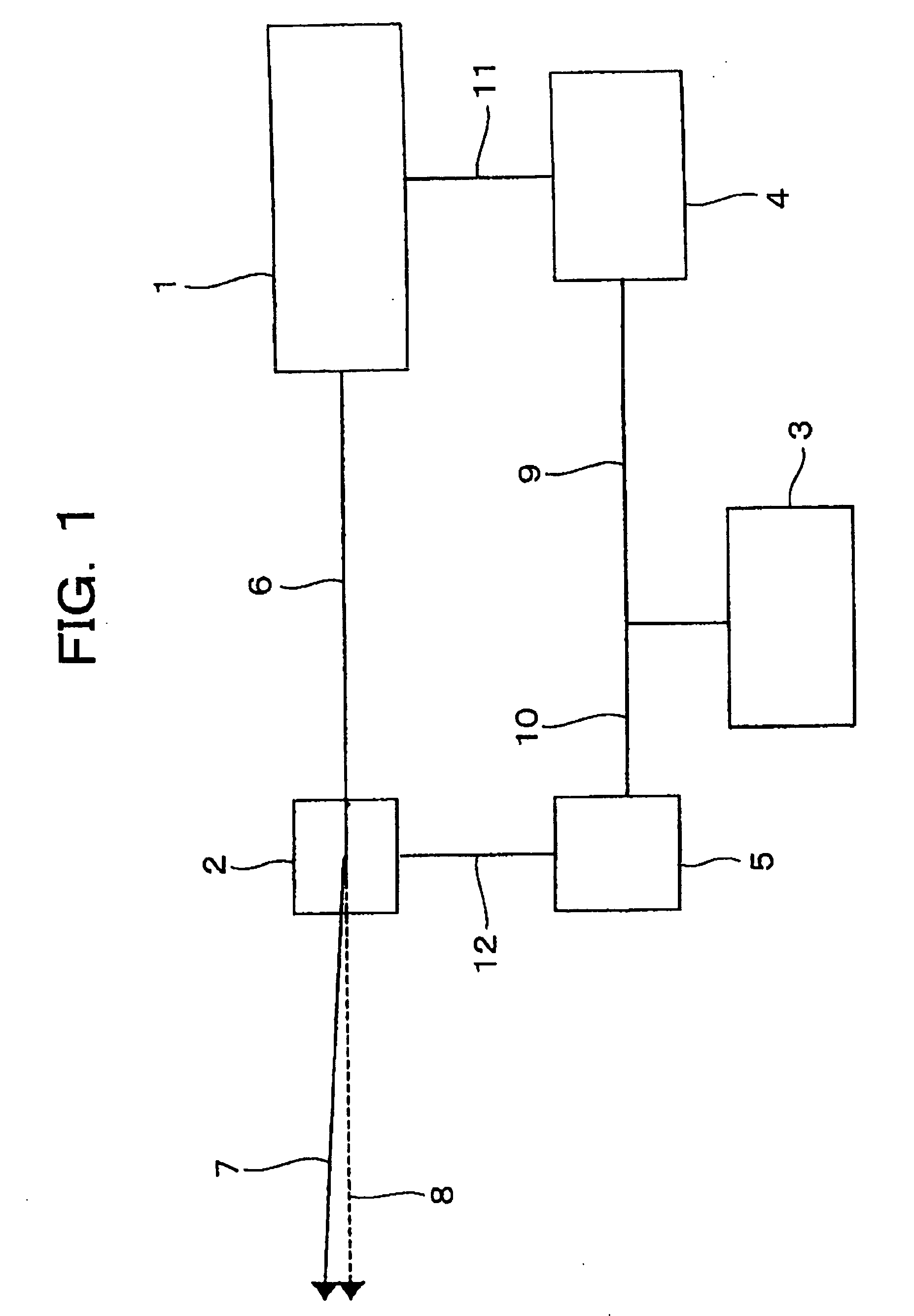

Laser machining method and laser machining apparatus

InactiveUS20050155958A1Improve hole position accuracyImprove hole qualityPrinted circuit manufactureWelding/soldering/cutting articlesLaser processingMetallic materials

A laser machining method and a laser machining apparatus superior in hole position accuracy and hole quality. An outgoing beam outputted as short pulses is shaped by a pulse shaping unit so as to form a #1 branch beam. The #1 branch beam is supplied to a portion to be machined, so as to machine the portion. In this case, the #1 branch beam may be controlled to synchronize with the outgoing beam. When a piece to be machined is made from a metal material and at least one of an organic material and an inorganic material, the metal material is machined with a laser beam shaped to have a pulse width not shorter than 100 ns, and at least one of the organic material and the inorganic material is machined with a laser beam shaped to have a pulse width shorter than 100 ns.

Owner:HITACHI SEIKO LTD

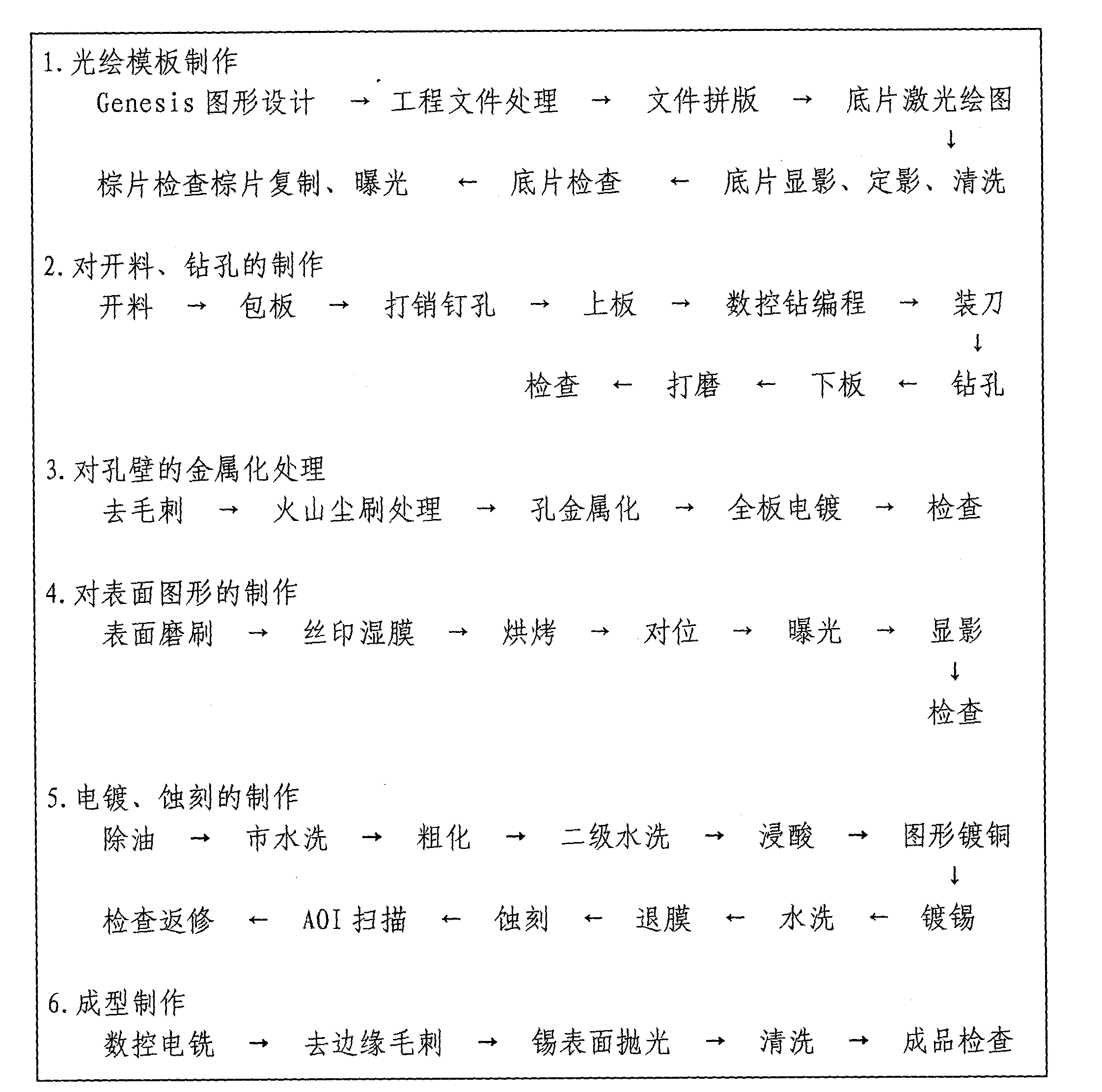

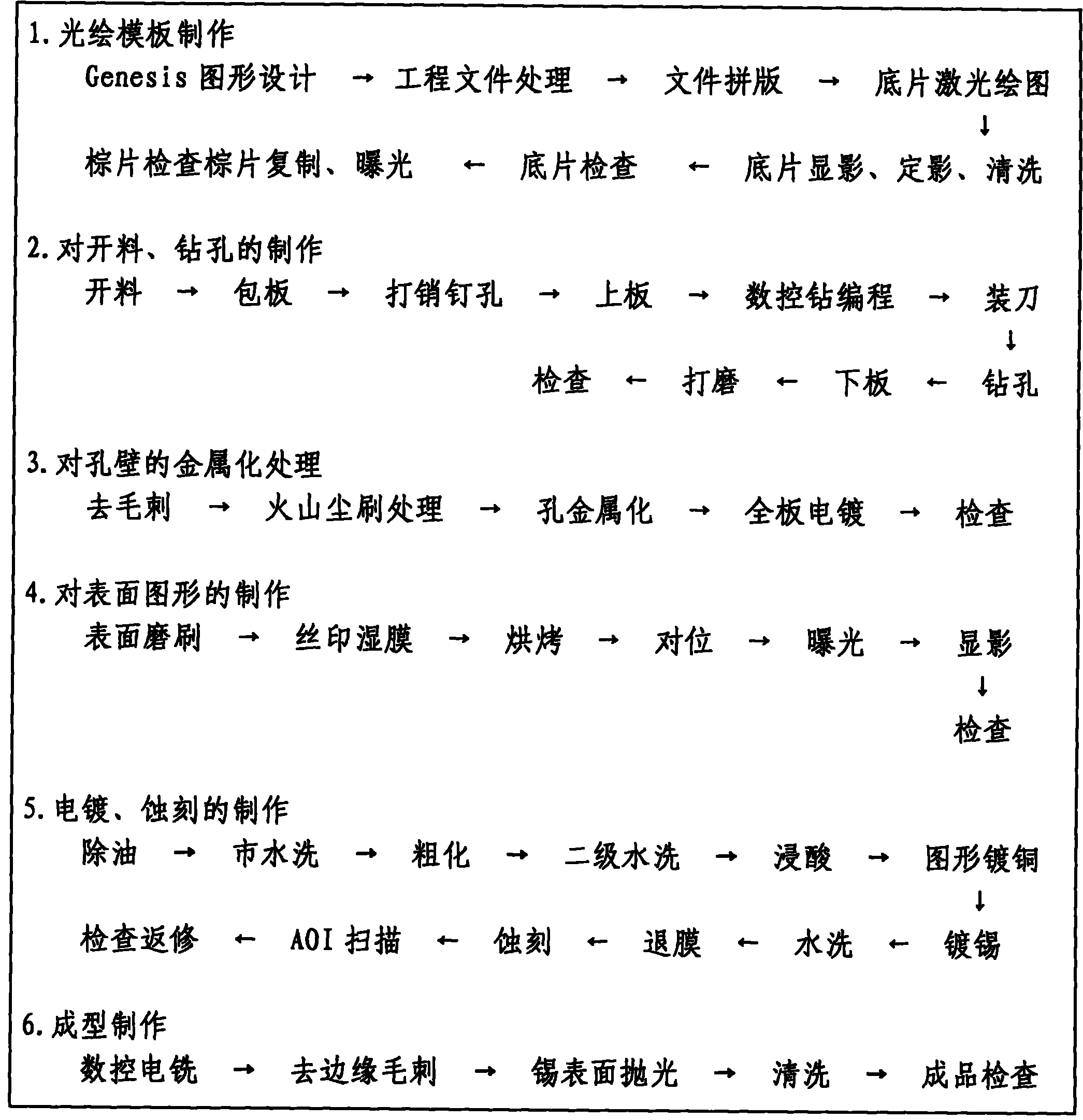

Method for manufacturing ultra-long microwave high-frequency circuit board

InactiveCN101808464AIncrease porosity densityImprove bindingConductive material chemical/electrolytical removalPrinted element electric connection formationMicrowaveEngineering

The invention discloses a method for manufacturing an ultra-long microwave high-frequency circuit board, comprising the following steps: (1) manufacturing a light potting template; (2) shearing to form an ultra-long combination board, and drilling holes on the ultra-long combination board; (3) metallizing the walls of the holes; (4) making patterns on the ultra-long combination board; (5) electroplating and etching the ultra-long combination board; and (6) forming the ultra-long combination board into the ultra-long microwave high-frequency circuit board. The method for manufacturing the ultra-long microwave high-frequency circuit board has high precision, and the ultra-long microwave high-frequency circuit board manufactured with the method has stable performance and can effectively improve the product quality and the work efficiency.

Owner:施吉连

Base plate for printed circuit board drilling and preparation method for base plate

ActiveCN104175658AGood lubrication and cooling functionImprove hole position accuracySynthetic resin layered productsLaminationFiberPolyvinyl alcohol

The invention discloses a base plate for printed circuit board drilling and a preparation method for the base plate. The preparation method comprises the steps of respectively coating the upper surface and the lower surface of a wood fiber board with lubricating heat dissipation resin to form lubricating heat dissipation resin layers, attaching wood pulp paper to the surfaces of the lubricating heat dissipation resin layers when the lubricating heat dissipation resin is not completely dried, and then preparing the base plate for printed circuit board drilling after the surfaces of the wood pulp paper are coated with non-saturated polyester resin to form non-saturated polyester resin layers, wherein the lubricating heat dissipation resin is prepared from the following components in parts by weight: 95 parts of a main component and 5 parts of a non-ion surfactant; the main component consists of two or more than two out of polyoxyethylene, polyethylene glycol, glycerinum, vinyl acetate and polyvinyl alcohol. Due to the lubricating heat dissipation resin, the base plate has a good lubricating heat dissipation function, so that the hole site precision during drilling of a drilling needle is improved, the quality of a hole wall is improved, and the temperature of the drilling needle is reduced.

Owner:YANTAI NEWCCESS NEW MATERIALS TECH CO LTD

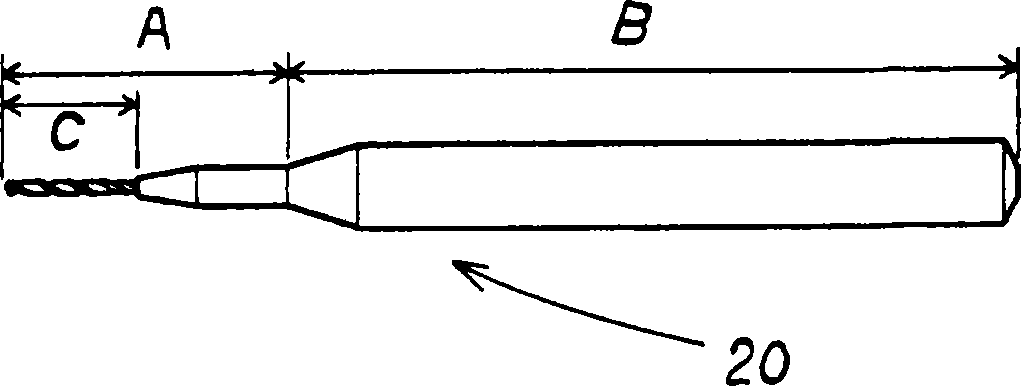

Drilling tool

ActiveCN101428354APracticalExcellent hole position accuracyTransportation and packagingWorkpiecesHelix angleBiomedical engineering

To provide a far more practical drilling tool that is capable of drilling holes having good hole position accuracy and hole wall roughness using a small-diameter drill of 0.4 mm or less. A drilling tool in which helical chip-evacuating flutes (2) are formed in the outer circumference of a tool main body (1), wherein the chip-evacuating flutes (2) have a first helical region (3) with a first helix angle +- 1 and a second helical region (4) with a second helix angle +- 2 greater than the first helix angle +- 1 , being provided on the tool base side of the first helical region (3); the tool main body 1 has a first taper region (6) with a first web taper and a second taper region (7) with a second web taper smaller than the first web taper, being provided on the tool base side of the first taper region (6); and a portion (8) where the first taper region (6) and the second taper region (7) are connected in a row is located more toward the tool base side than the portion (5) where the first helical region (3) and the second helical region (4) are connected in a row.

Owner:UNION TOOL

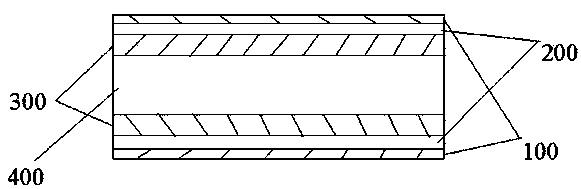

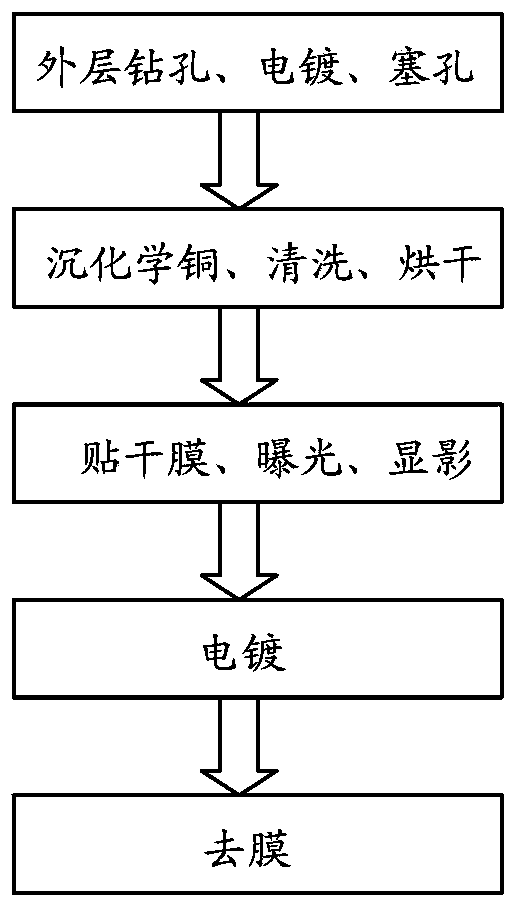

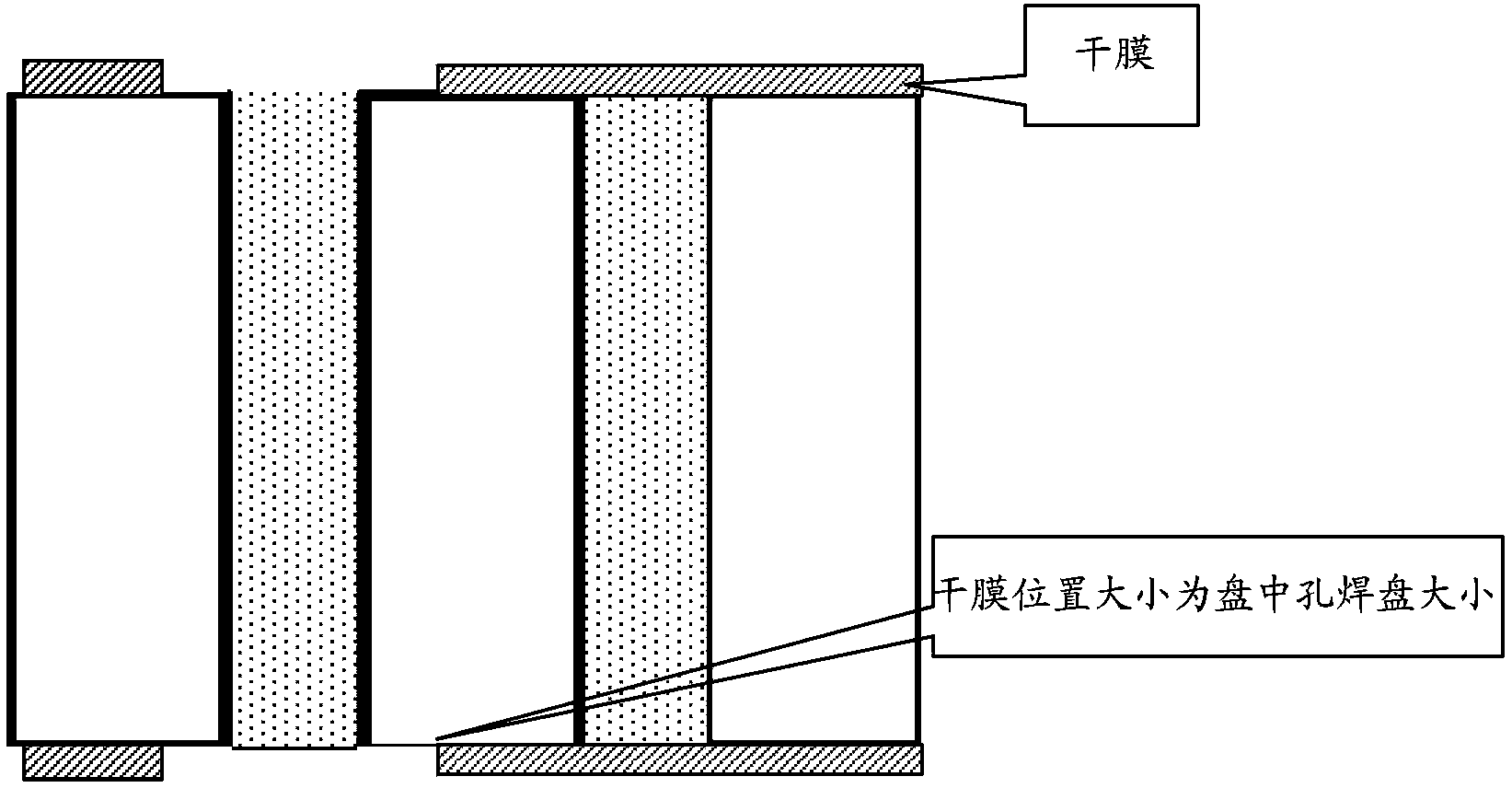

Printed circuit board and manufacturing methods of printed circuit board and plate hole of printed circuit board

ActiveCN104349589AEasy to makeImprove hole position accuracyPrinted circuit aspectsElectrical connection printed elementsHigh densityEngineering

The invention discloses a manufacturing method for a plate hole of a printed circuit board (PCB). The method includes the following steps: drilling an outer-layer hole, which includes a plate hole, of the printed circuit board; carrying out copper deposition on the drilled outer-layer hole and an outer-layer board; pasting a dry film on the outer-layer board and adopting exposure and development to remove the dry film at the position of the plate hole; and carrying out electroplating on the printed circuit board after development to remove the dry film after the development. Through use of the method, manufacturing of the PCB is convenient and rapid and the hole position precision is high and the thickness of surface copper is low and the printed circuit board is suitable for manufacturing high-density fine circuits.

Owner:NEW FOUNDER HLDG DEV LLC +1

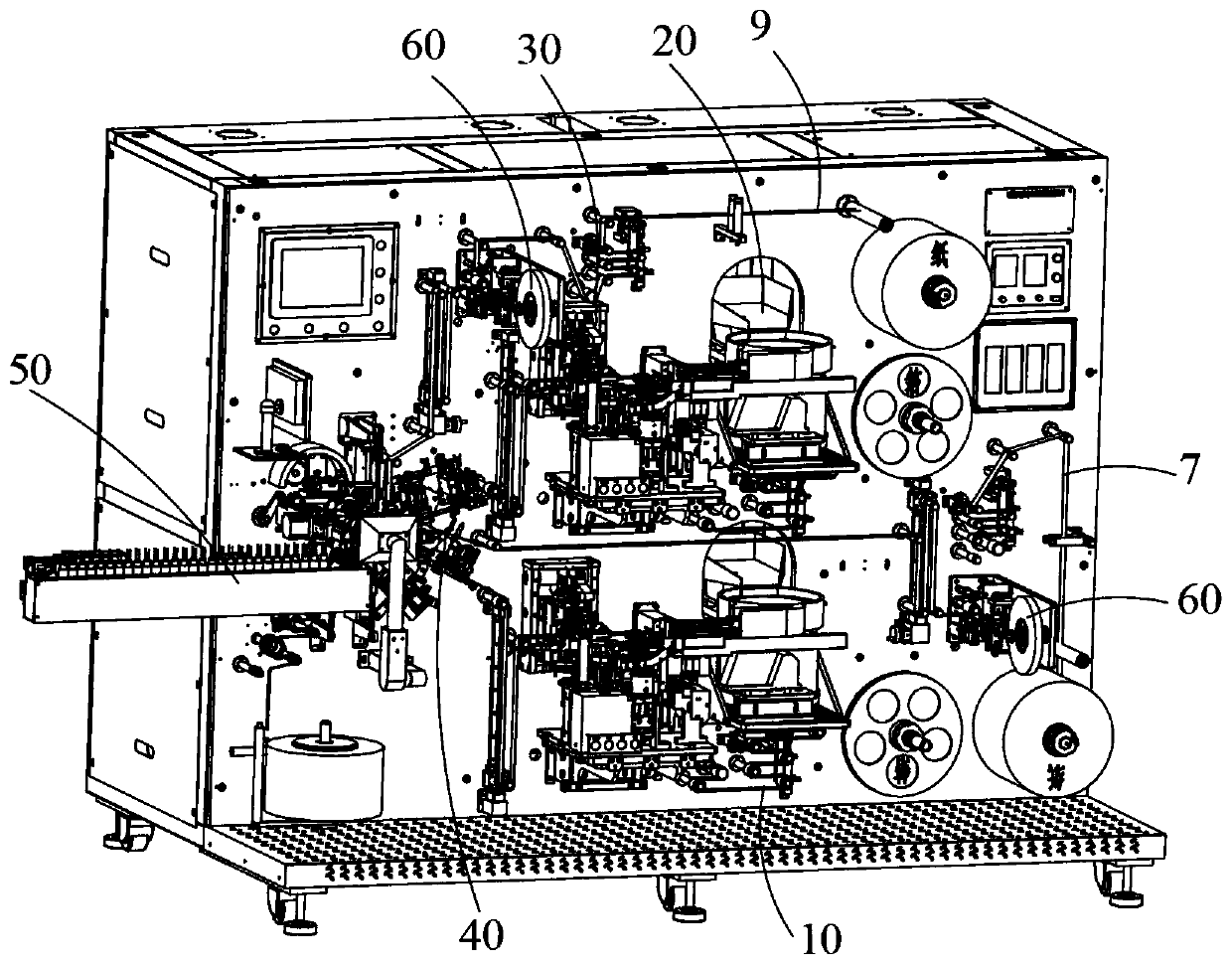

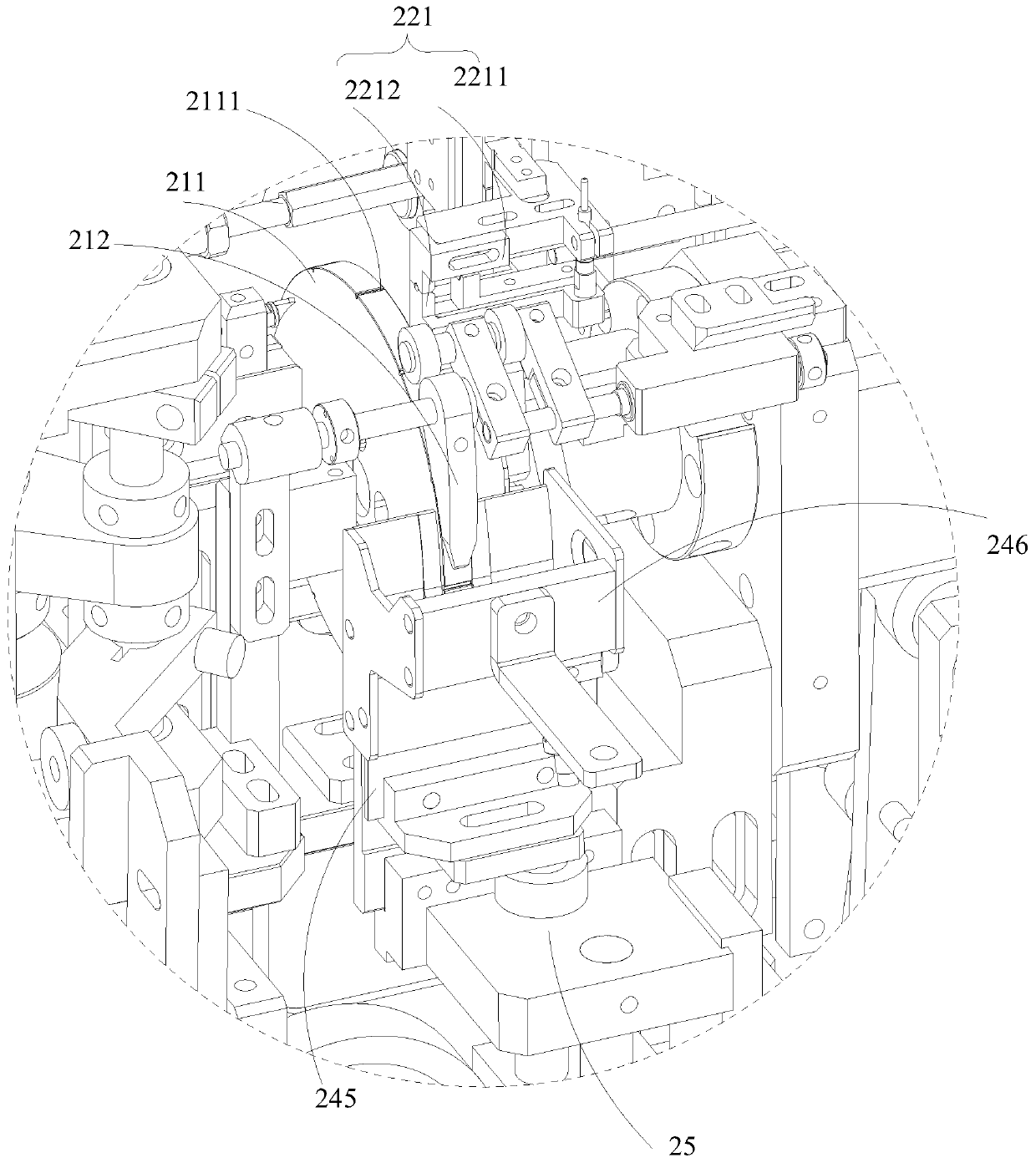

Fully automatic nailing and winding integrated machine

ActiveCN110140189AAvoid errorsImprove hole position accuracyWinding capacitor machinesTerminal applying apparatusWinding machineEngineering

The invention relates to the technical field of capacitor preparation, in particular to a fully automatic nailing and winding integrated machine. The automatic nailing and winding integrated machine comprises a foil conveying mechanism, a needle conveying mechanism, a nailing mechanism, a winding mechanism and a cutting mechanism, and the nailing mechanism only needs to move the mold assembly to be movable in the first direction And the movement of the molds on the mold assembly in the second direction can complete the nailing of the guide pins and the foil strips without changing the positionof the foil strips, omitting the foil-rolling wheel, and avoiding the foil-feeding wheel during the transmission process The error caused by the change of the tension improves the precision of the hole position of the first nailing hole and the second nailing hole, ensures the quality of the nailing, and improves the yield of the automatic nailing and winding machine.

Owner:SHENZHEN CHENGJIE INTELLIGENT EQUIP CO LTD

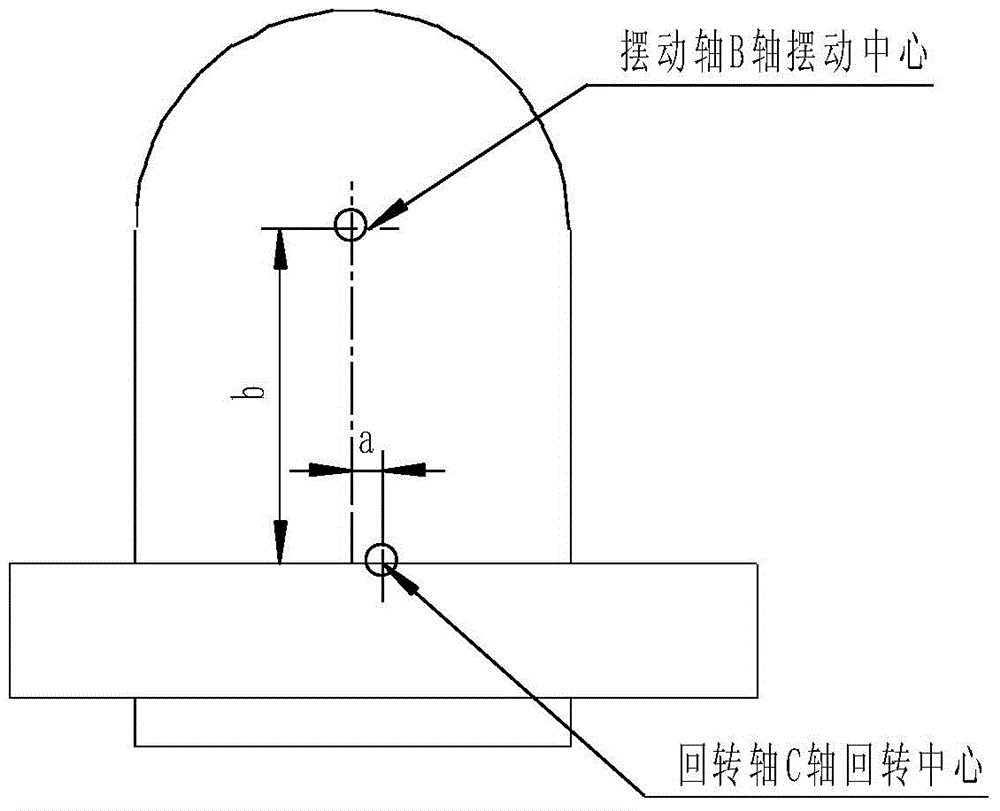

Electrical discharge machining method of three-dimensional space hole

InactiveCN104889516AImprove programming efficiencyImprove hole position accuracyElectric circuitsThree-dimensional spaceGyration

The invention provides an electrical discharge machining method of a three-dimensional space hole. The electrical discharge machining method of the three-dimensional space hole is characterized by comprising the steps that 1, a locating fixture is made; the locating fixture is capable of conducting clamping and locating on a workpiece and being connected with a machine tool rotating table stably and reliably, and the fixture can not interfere the machining position; 2, the coordinate zero points of each axis of a machine tool is defined; when the rotating table plane is parallel to the XY plane, the zero point state of a swing axis B axis is achieved, the position of the swing axis B axis is the zero point, the coordinate zero points of the X axis, the Y axis and the Z axis of the machine tool are the intersection points of a gyration center of a revolving axis C axis and the rotating table plane when the swing axis B axis is in a zero point state, and the zero point of the revolving axis C axis is a fixed position.

Owner:AECC AVIATION POWER CO LTD

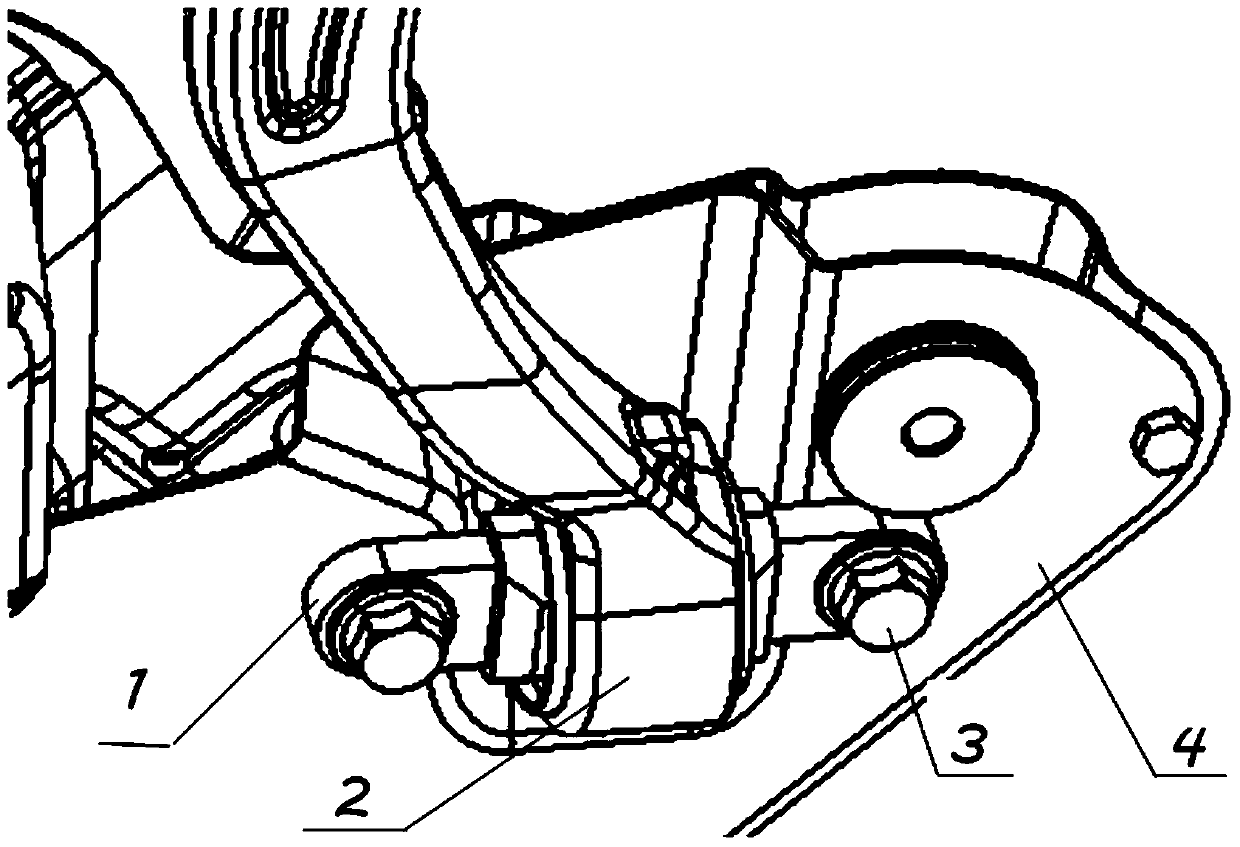

Structure for connecting swing arm lining with sub vehicle frame

ActiveCN104210322AImprove dynamic stiffnessEasy assemblyUnderstructuresPivoted suspension armsVehicle frameNoise, vibration, and harshness

The invention relates to a structure for connecting a swing arm lining with a sub vehicle frame. The inner framework of the swing arm lining is flat; the two ends of the swing arm lining are protruded out of a middle rubber body and a lining outer pipe; a bolt hole is formed in each of the two ends of the swing arm lining; a through hole is formed in a sub vehicle frame; a threaded casing pipe is arranged in the sub vehicle frame; the bolt holes, the through hole and the threaded casing pipe are communicated with one another; a sink which is toward the inner side is formed in the part, corresponding to each of the middle rubber body and the lining outer pipe, on the sub vehicle frame; the swing arm lining is fixedly connected with the sub vehicle frame in the way that a bolt is matched with the threaded casing pipe. In the technical scheme, due to the fact that the sub vehicle frame is flatly stuck to the inner framework, abnormal sound caused when the inner framework of the swing arm lining moves in the manner of being relative to a gear-starting structure is avoided, and the promotion of NVH (Noise Vibration and Harshness) is benefited; due to the fact that secondary welding of the frame is not required, the rigidity of a mounting part is high, and meanwhile, the mounting space is saved; due to the fact that the sub vehicle frame is molded by drilling and casting a complete plate, the drilling precision is high, and the production is easy to control; due to the fact that the threaded casing pipe is adopted, the assembling process is simple.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

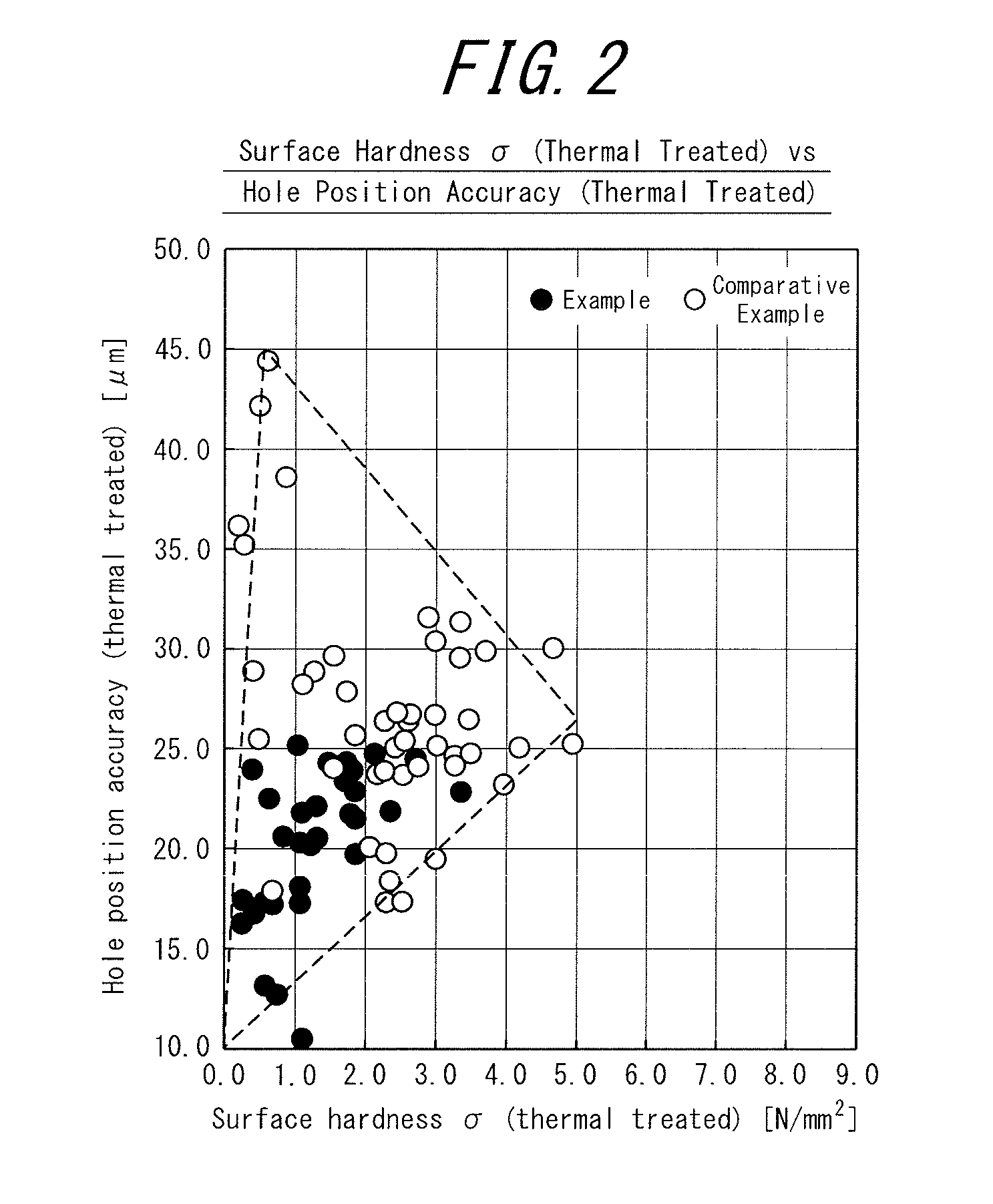

Entry sheet for drilling use

InactiveUS20150111049A1Improve hole position accuracyReduce thermal degradationFilm/foil adhesivesSynthetic resin layered productsUnsaturated fatty acidWater soluble

The present invention relates to an entry sheet for drilling use, which exhibits excellent hole position accuracy even when transported at ambient temperature for a long time and / or stored under a thermal environment having a higher temperature than in Japan, more specifically to an entry sheet for drilling use for a laminated board or a multi-layered board comprising a metallic support foil and a layer of water-soluble resin composition formed on at least one surface of the metallic support foil, wherein the water-soluble resin composition comprises a water-soluble resin, a water-soluble lubricant and a linear unsaturated fatty acid salt, the layer of water-soluble resin composition is formed by cooling from a cooling start temperature of 120° C. to 160° C. to a cooling end temperature of 25° C. to 40° C. within 60 seconds at a cooling rate of not less than 1.5° C. / sec, the water-soluble resin composition has a degree of crystallinity of not less than 1.2, the layer of water-soluble resin composition has a standard deviation σ of surface hardness of not more than 2, and a surface hardness of not less than 8.5 to not more than 25 N / mm2.

Owner:MITSUBISHI GAS CHEM CO INC

Composite base plate for drilling PCB (printed circuit board) and preparation method thereof

ActiveCN103935105AHigh surface hardnessImprove chip removal and cooling effectSynthetic resin layered productsLaminationFiberHigh density

The invention discloses a composite base plate for drilling a PCB (printed circuit board) and a preparation method thereof. A high-density fiber plate is taken as a base plate for the composite base plate; the upper surface and the lower surface of the base plate are respectively laminated with lamination inner paper and melamine surface paper sequentially and are compressed under a preset condition so as to form the composite base plate, wherein the lamination inner paper is formed by impregnating kraft paper with urea formaldehyde resin; the melamine surface paper is formed by impregnating balanced paper with urea formaldehyde resin modified from melamine. The composite base plate provided by the invention has obviously improved surface hardness, and can be used for solving the problems of curling of a traditional base plate and poor heat radiation effect, improving the chip removing and heat radiation effects, reducing the problems of excessive flashing and hole shift in the drilling process, improving the hole position precision, and meeting the small-pre-diameter hole drilling requirement.

Owner:SHENZHEN NEWCCESS IND

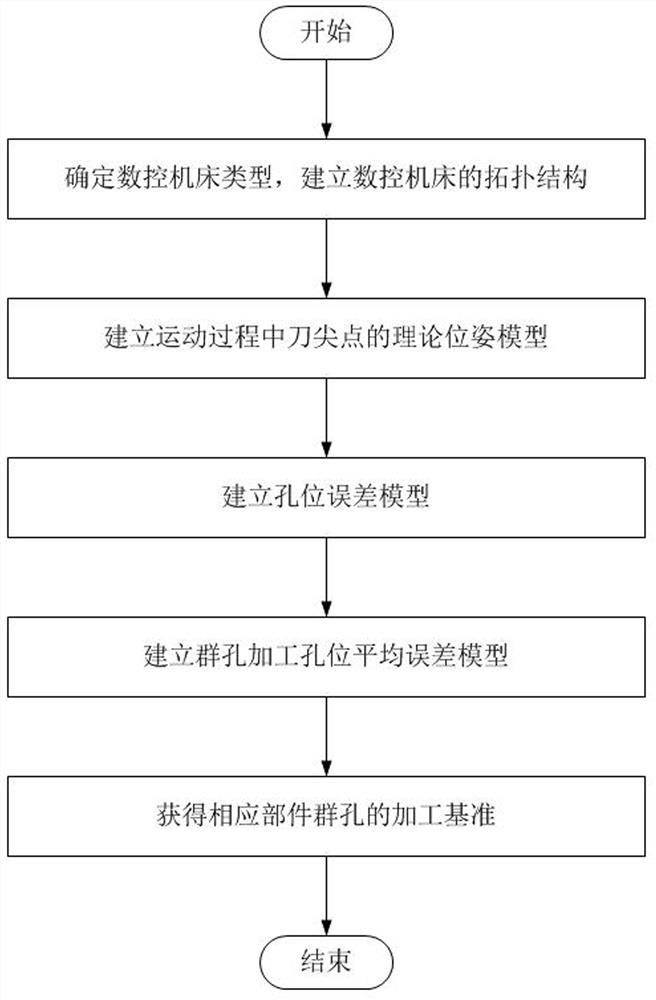

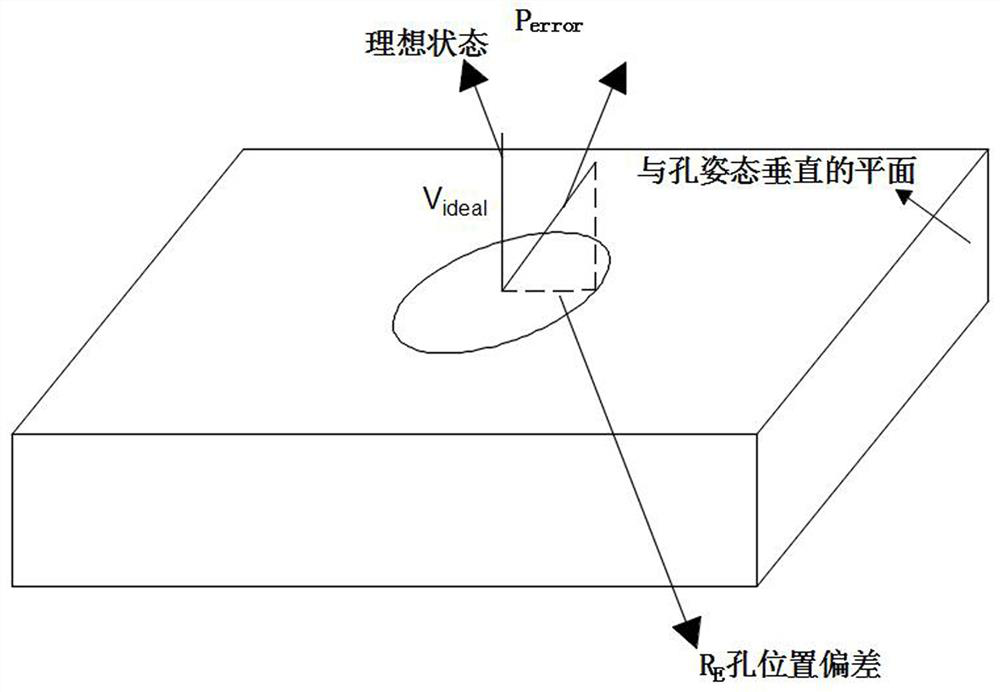

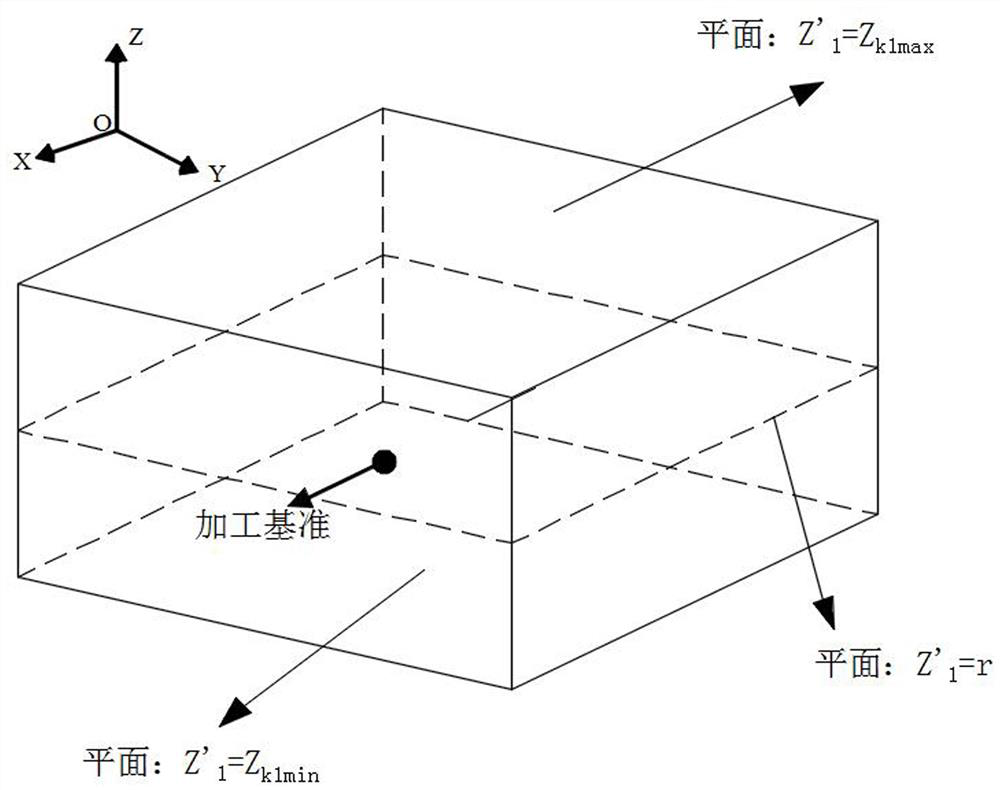

Benchmark selection method for minimizing hole site errors of large component group hole machining

ActiveCN112558549AHigh positioning accuracyHole position error is smallProgramme controlComputer controlNumerical controlEngineering

The invention discloses a benchmark selection method for minimizing hole position errors of large component group hole machining, which comprises the following steps of: 1) determining the type of a numerical control machine tool, and establishing a topological structure of the numerical control machine tool; 2) establishing a theoretical pose model of a tool nose point in the movement process; 3)establishing a hole site error model; 4) establishing a hole site average error model of group hole machining; and 5) obtaining the machining reference of the corresponding component group holes. According to the method, different benchmark selection principles are provided for aircraft component framework and skin group hole machining, the position precision of framework or skin group hole machining can be effectively improved, and meanwhile a more scientific and reasonable method is provided for selection of a large component group hole machining benchmark; by calculating the average valueof the hole site errors of a certain point in the space points and the hole sites of the group holes, the reference with the minimum hole site error is deduced, and the method is more scientific and reasonable; the method can also be applied to other numerical control machining fields and is suitable for wide popularization and application.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

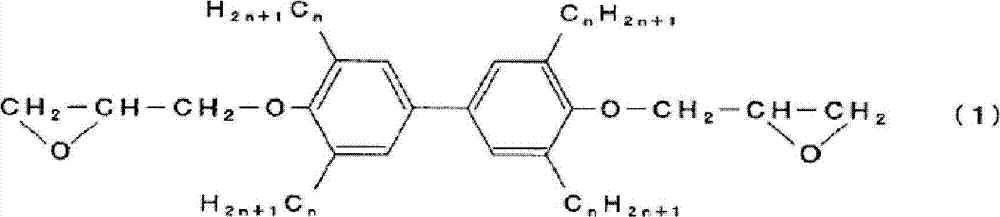

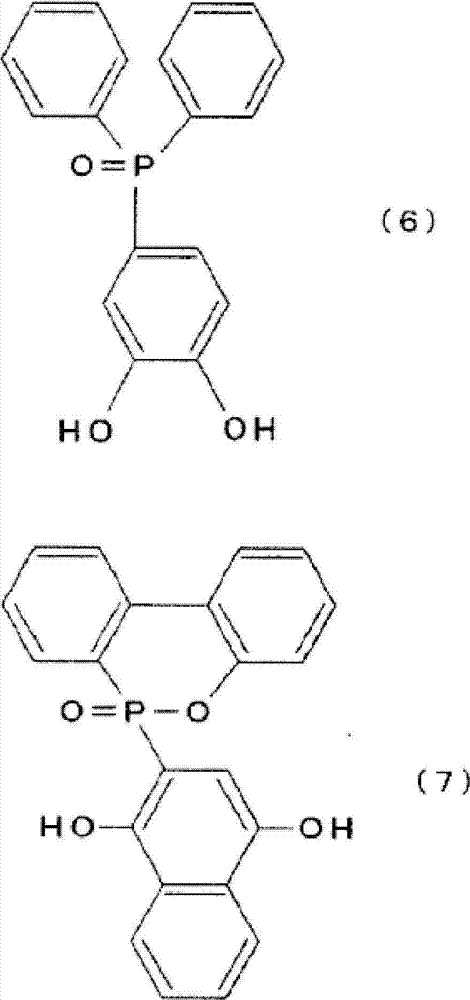

Epoxy resin composition for prepreg, prepreg, and multilayer printed circuit board

ActiveCN102822228AHigh glass transition temperatureImprove flame retardant performancePrinted circuit aspectsCircuit susbtrate materialsEpoxyCombustion

Owner:PANASONIC CORP

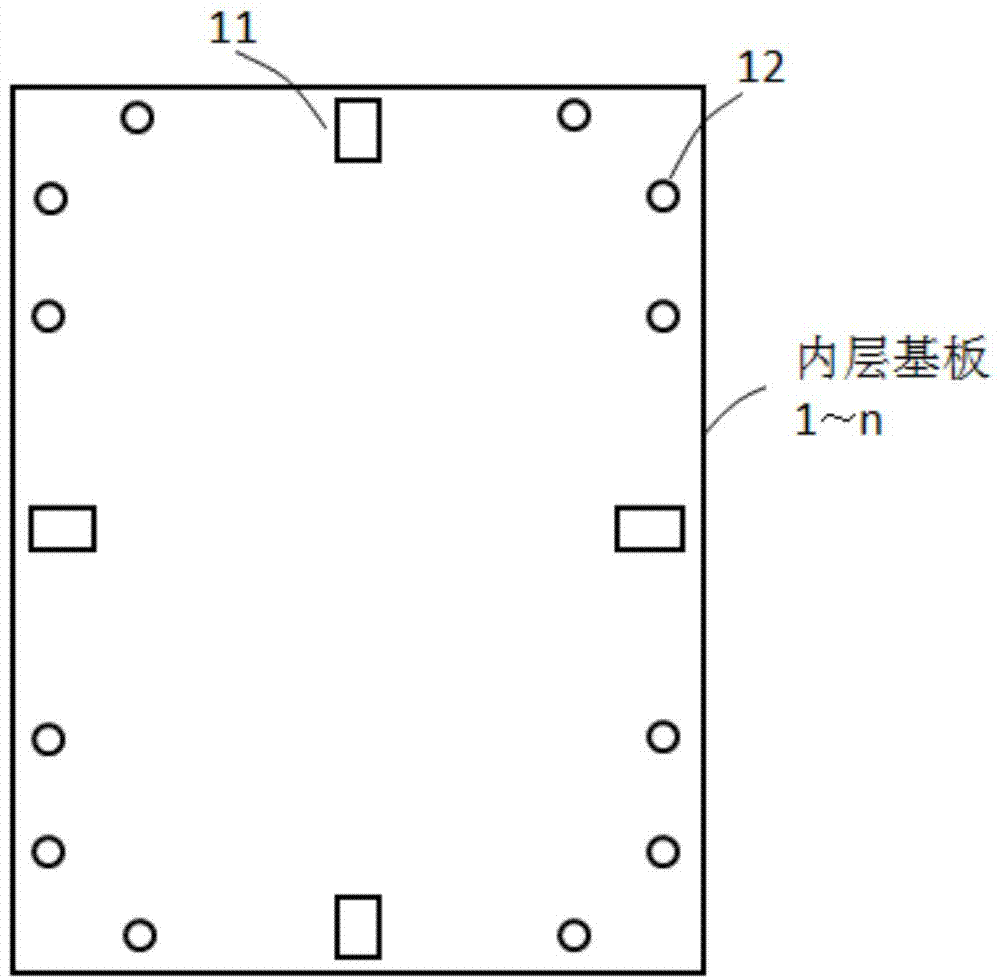

Manufacturing method of ultralarge line-card type printed circuit boards with large layer number and high alignment degree

ActiveCN104519681AEasy alignmentImprove hole position accuracyMultilayer circuit manufactureResistPunching

The invention belongs to the field of manufacturing process of printed circuit boards and particularly discloses a manufacturing method of ultralarge line-card type printed circuit boards with large layer number and high alignment degree. The manufacturing method includes steps of (1) providing an inner substrate; (2) punching pressed positioning holes; (3) pressing; (4) drilling holes; (5) electroplating; (6) paving outer liners; (7) printing in solder resist; (8) forming. The manufacturing method solves the problems of poor interlayer alignment and low accuracy of hole sites and patterns of finished products of the ultralarge line-card type printed circuit boards with high alignment degree and successfully develops ultralarge line card type products with large layer numbers and high alignment degree. The manufacturing method is simple and feasible, interlayer alignment and hole site accuracy of the ultralarge line-card type printed circuit boards with large layer number and high alignment degree can be greatly improved, and product demands are met.

Owner:WUS PRINTED CIRCUIT (KUNSHAN) CO LTD

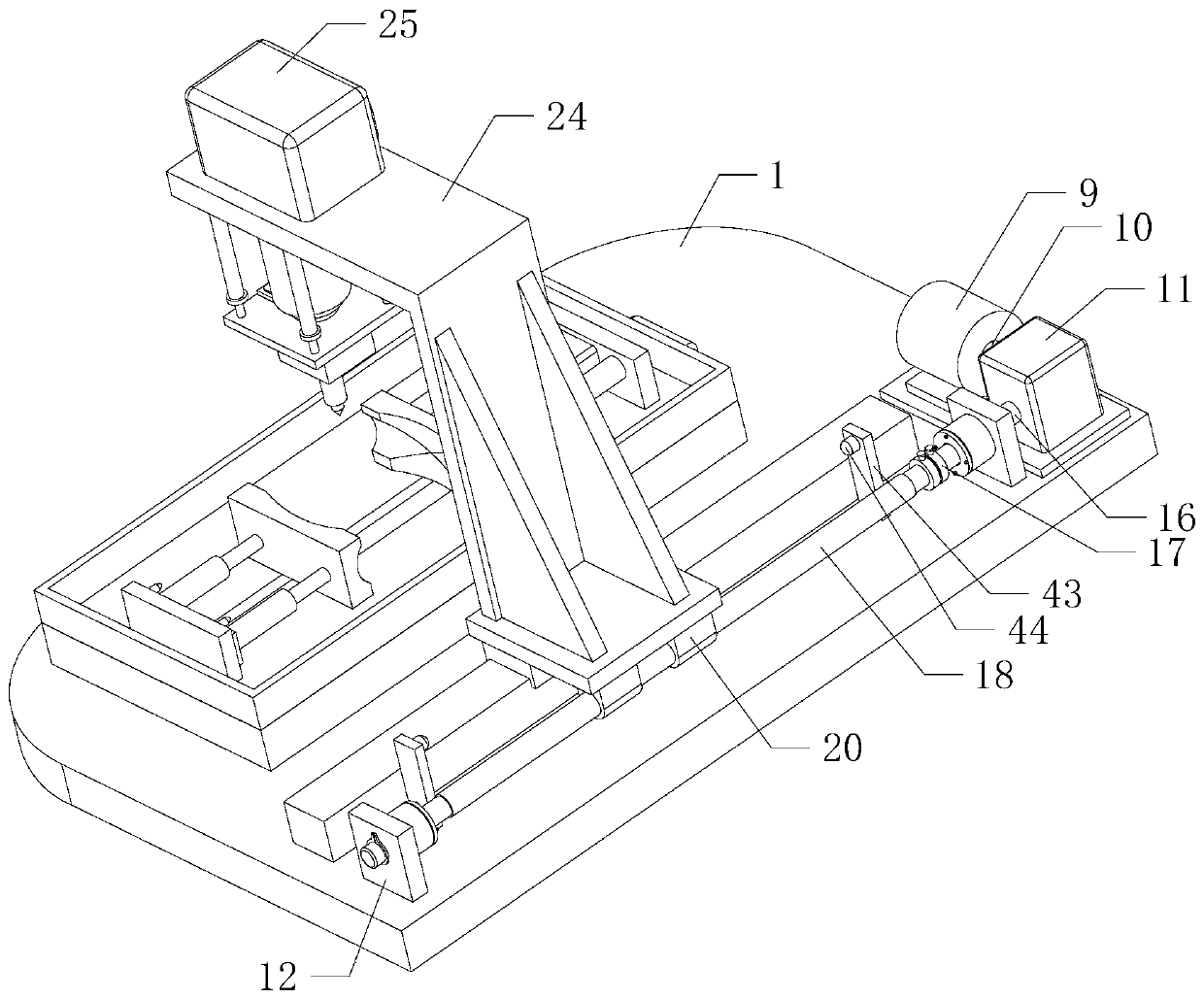

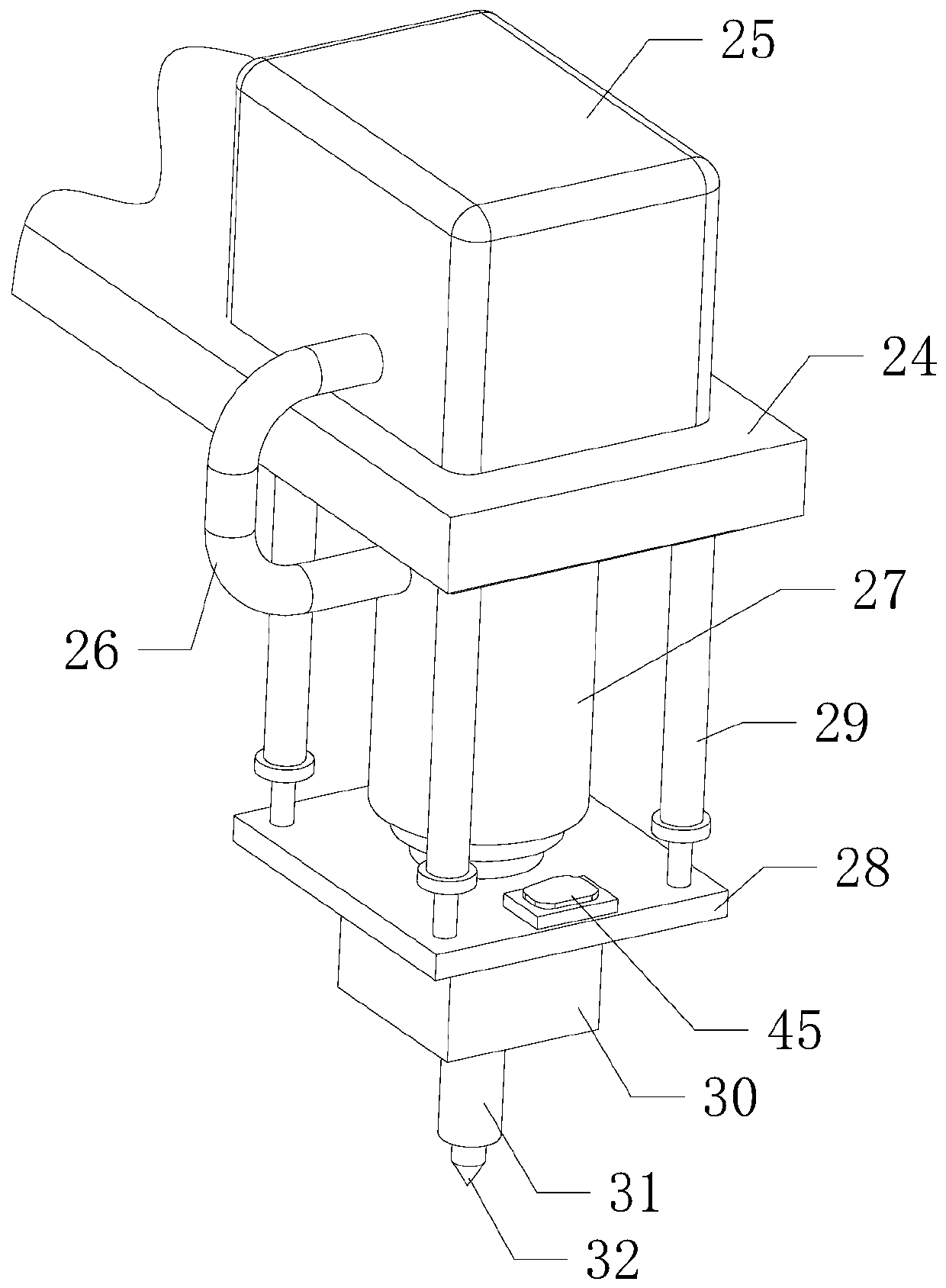

Production and machining equipment for relief butterfly valves

ActiveCN110788361AGuaranteed machining accuracyAvoid leaningPositioning apparatusBoring/drilling componentsReduction driveElectric machinery

The invention relates to the technical field of mechanical equipment, in particular to production and machining equipment for relief butterfly valves. The production and machining equipment comprisesa base, a workbench, a positioning plate, a first mounting plate, an air cylinder, a pushing rod, a clamping plate, a motor seat, a first motor, a first rotating shaft and a speed reducer, wherein thebottom end of the workbench is mounted on the front side of the top end of the base, an adjusting device is arranged on the right side of the top end of the workbench, the left end of the adjusting device is connected with the right end of the positioning plate, and the bottom end of the positioning plate is contacted with the top end of the workbench. According to the production and machining equipment for the relief butterfly valves, punching operation is carried out on the different positions on the valves, so that a punching process of the valves is effectively simplified, the punching time is shortened, the time and physical force for manually positioning the valves multiple times are saved, and the working efficiency is improved; and meanwhile, the position of a drill bit is precisely controlled, so that the position precision of a valve hole is effectively improved, the machining quality of the valves is improved, and the practicability and the reliability are improved.

Owner:SHANDONG ZHUCHENG JIANHUA VALVE MFG

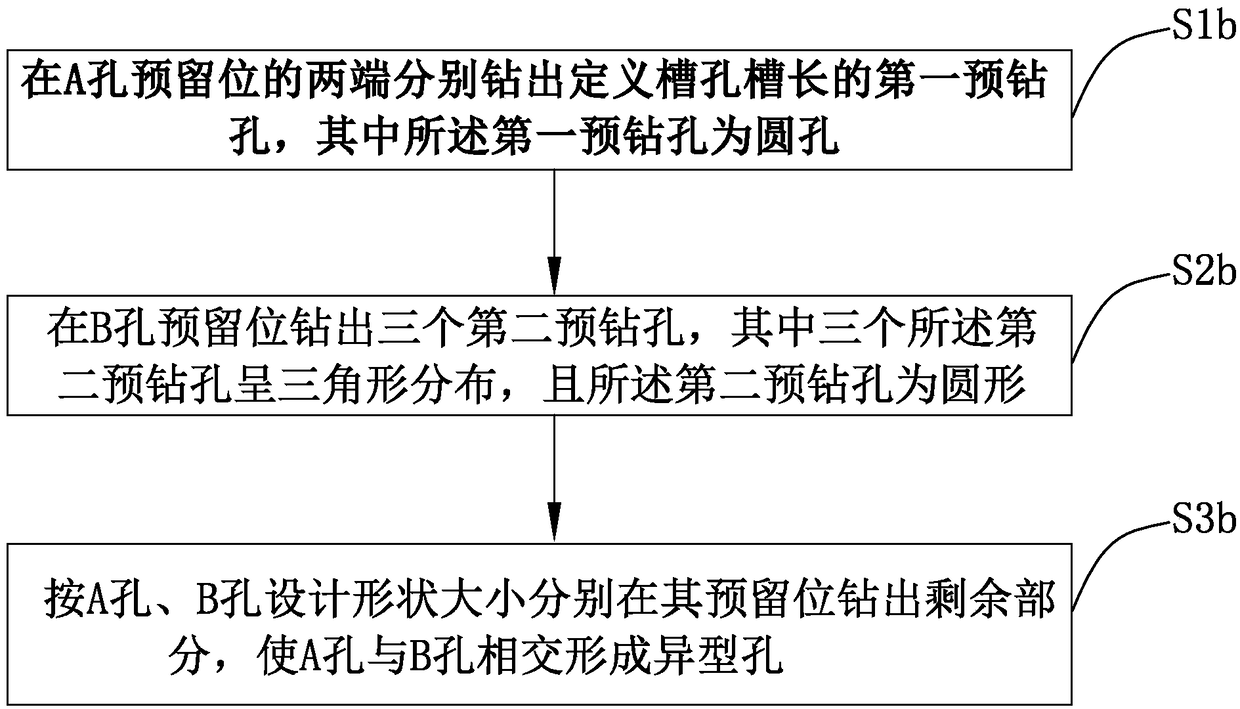

Formation method for irregularly-shaped hole of printed circuit board

InactiveCN108770209AReduce deformation rateImprove smoothnessPrinted circuit manufacturePrinted circuit boardEnvironmental geology

The invention discloses a formation method for an irregularly-shaped hole of a printed circuit board. The formation method comprises the steps of drilling at least two first pre-drilling holes in an Ahole reservation position; drilling at least two second pre-drilling holes in a B hole reservation position; respectively drilling remaining parts at the reservation positions according to the shapesand the sizes of the A hole and the B hole so that the A hole and the B hole intersect and the irregularly-shaped hole is formed. According to the formation method for the irregularly-shaped hole ofthe printed circuit board, provided by the invention, hole formation can be prevented, and the hole accuracy of the irregularly-shaped hole can be improved.

Owner:江西旭昇电子有限公司

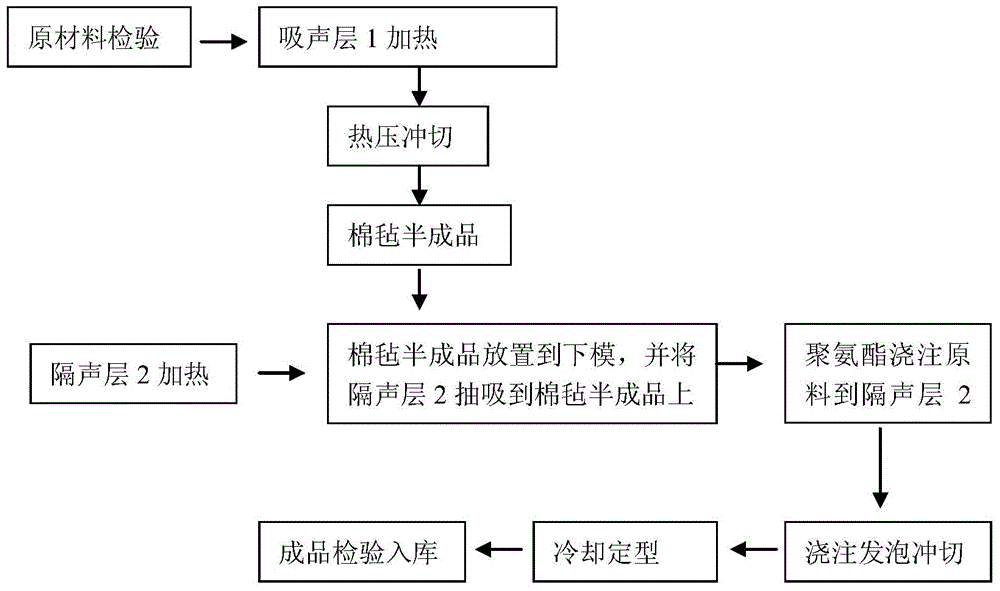

Environment-friendly light sound insulation pad and production method thereof

ActiveCN104590152AReduce weightGood balance of sound insulation and absorption performanceVehicle componentsWork in processEnvironmental resistance

The invention discloses an environment-friendly light sound insulation pad which is of a three-layer structure comprising a sound absorbing layer, a sound insulation layer and an elastic layer in sequence from top to bottom. The elastic layer makes contact with a car body metal plate. The invention further discloses a production method of the environment-friendly light sound insulation pad. The production method comprises the steps that the sound insulation layer is cut, and arc discharge processing is carried out on the sound insulation layer; the sound absorbing layer is heated; a semi-finished blanket is placed on a lower die of a sucking, foaming and punching integrated die to be positioned; the sound insulation layer is heated in a radiation mode; the sound insulation layer is sucked to the semi-finished blanket placed on the lower die of the sucking, foaming and punching integrated die; the surface skin of the sound insulation layer is heated and molten, an upper die and the lower die are closed, isocyanate and premixed polyether polyols are poured to the sound insulation layer, and the sound insulation layer forms the elastic layer; after die opening, the product is taken out. By the adoption of the structure, the weight of a single environment-friendly light sound insulation pad is reduced, the whole sound insulation level of the single environment-friendly light sound insulation pad is improved, the noise in the whole car is lowered, the product hole site precision is high, and the environment-friendly light sound insulation pad has the advantages of being low in odor intensity, low in VOC discharge and the like.

Owner:湖北三环汽车工程塑料有限公司

Nano niobium aluminum yttrium nitride/amorphous silicon nitride dual-phase ultra-hard coating and a deposition method thereof

ActiveCN110438442AImprove heat resistanceImprove bindingVacuum evaporation coatingSputtering coatingMilling cutterWear resistant

The invention relates to a nano niobium aluminum yttrium nitride / amorphous silicon nitride dual-phase ultra-hard coating and a deposition method thereof. The ultra-hard coating is of a four-layer structure, wherein the innermost layer is a pure niobium bonding layer, and thickness of the innermost layer is 0.05-0.5 micron; the secondary inner layer is a niobium nitride transition layer, and the thickness of the secondary inner layer is 0.05-1 micron; the secondary outer layer is a gradient layer, component of the niobium nitride is gradually reduced from inside to outside, and components of the niobium aluminum yttrium nitride / the silicon nitride are gradually increased, the thickness of the secondary outer layer is about 0.1-1.0 micron, and concentration on a stress interface can be prevented; and the outermost layer is composite wear-resistant layer of the niobium aluminum yttrium nitride / the silicon nitride, the thickness of the composite wear-resistant layer is 1-10 microns. The total thickness of the coating is 1.2-12.5 microns. Binding force of the coating and a hard alloy matrix reaches 70-105 N, hardness of the coating is 40-60 GPa, friction coefficient of the coating is 0.20-0.55, antioxidant temperature of the coating is 750 DEG C or higher, and service life of a coated micro drill or milling cutter is prolonged by 4-8 times compared with that of an uncoated micro drill or milling cutter.

Owner:JIANGXI SCI & TECH NORMAL UNIV

Processing process for connecting pipes

InactiveCN103028908AImprove hole position accuracyImprove pass rateMaterials preparationPulp and paper industry

The invention discloses a processing process for connecting pipes. The processing process comprises the following steps of 1, material preparation: an aluminum pipe is sawed and cut into small sections of aluminum pipes on a sawing machine according to the drawing dimension; 2, finish turning: the end surface, the excircle and the inner hole of the aluminum pipes are subjected to finish turning on a numerically controlled lathe according to the drawing dimension; 3, finish milling: the side edge, the positioning hole and the side hole of the aluminum pipes are subjected to finish milling according to the drawing dimension; 4, deburring: all burrs of workpieces are removed; and 5, surface treatment: the workpieces are treated by yellow chromate. Through the adoption of the mode, the processing process can reduce the processing difficulty of the connecting pipes, the production efficiency is improved, and a special tooling is used, so the processing precision is improved, and the qualified rate of products is improved.

Owner:SUZHOU ERIC MECHANICS & ELECTRONICS CO LTD

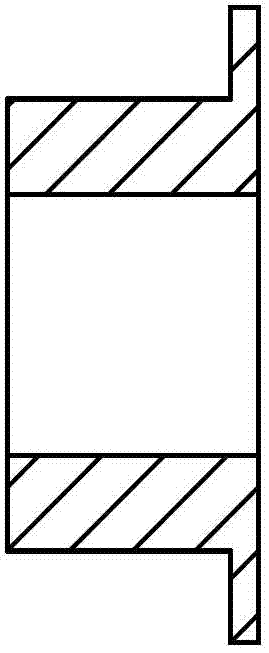

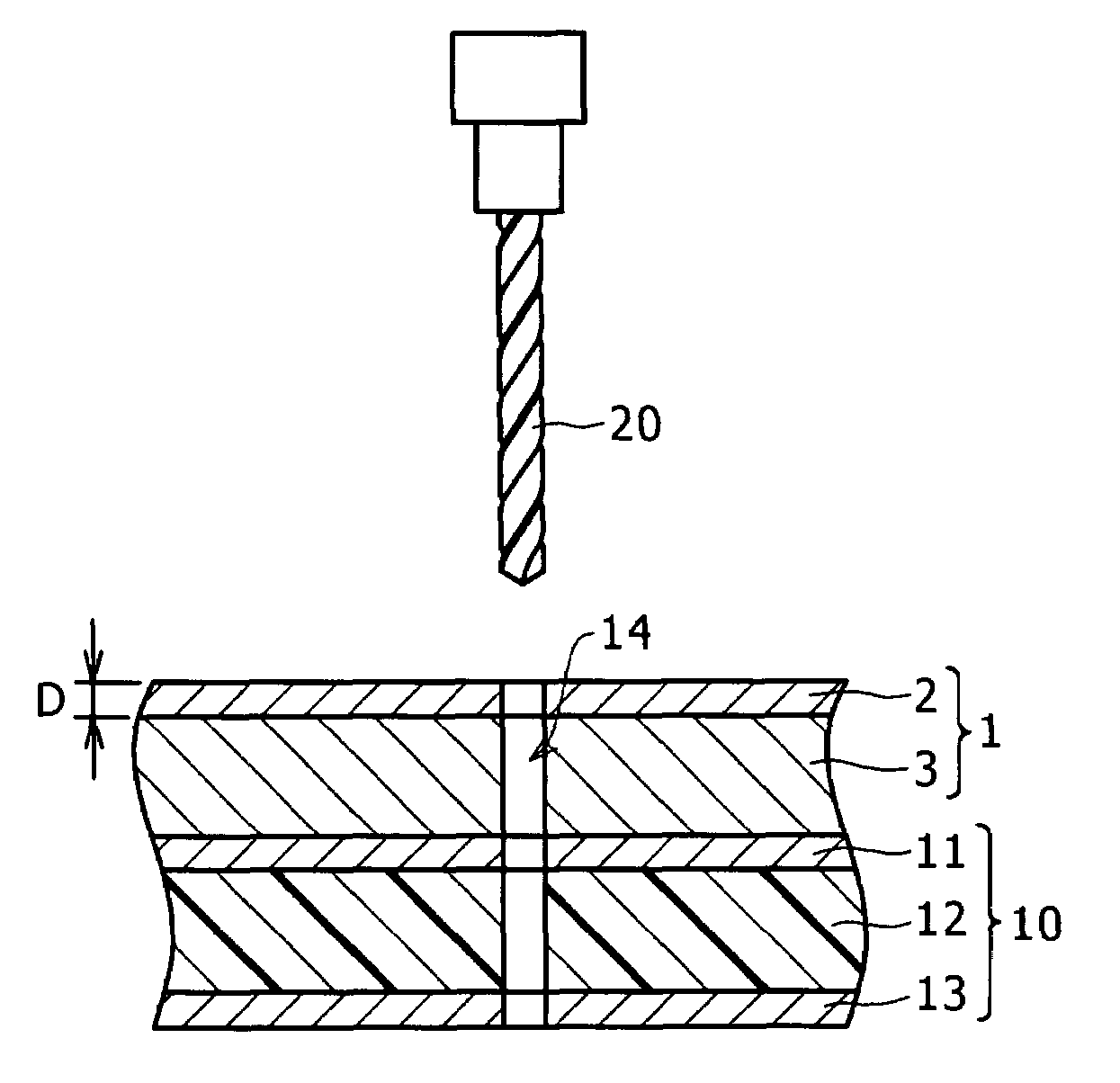

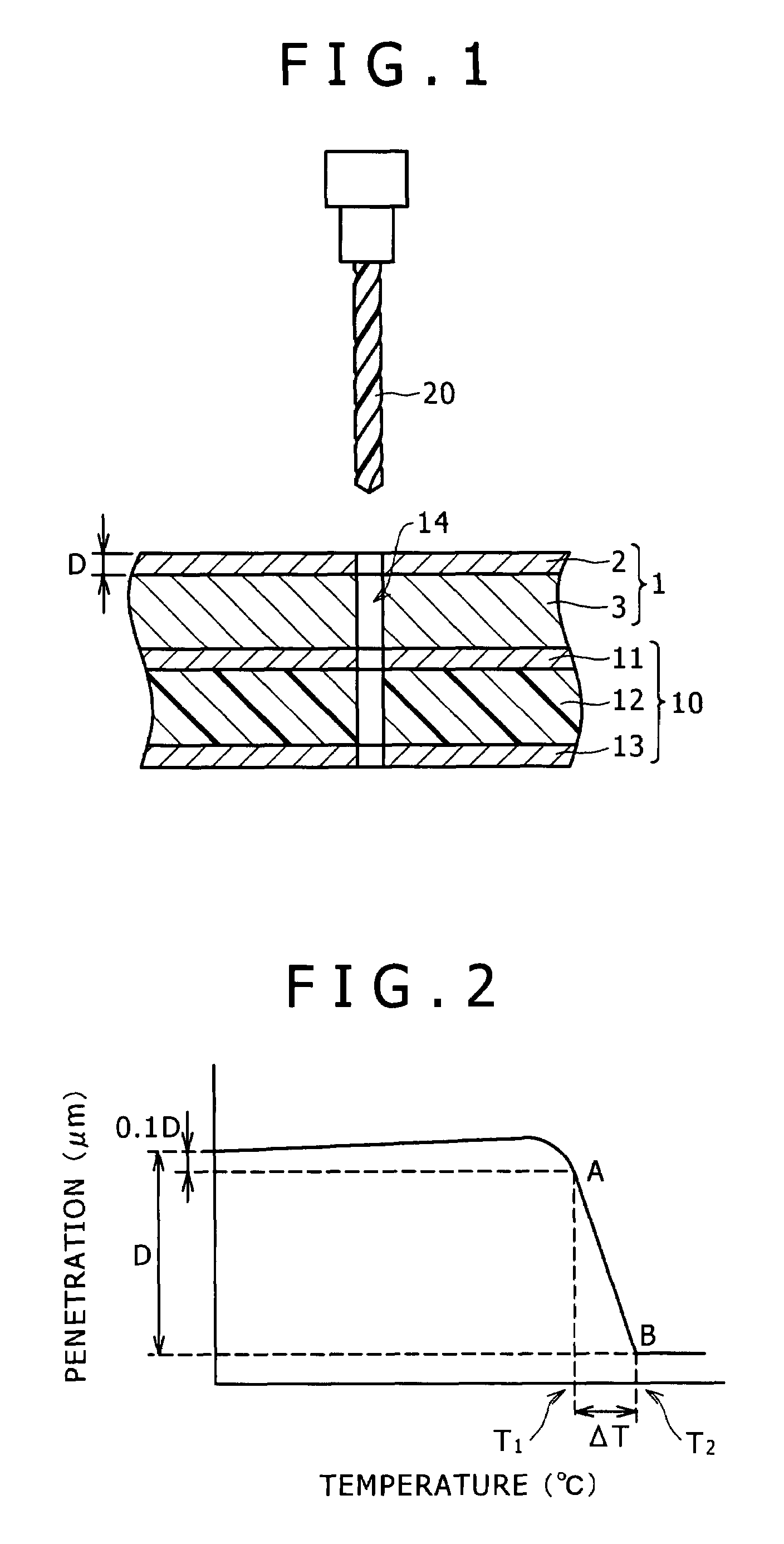

Resin-coated metal plate and method of drilling printed wiring board using the metal plate

ActiveUS7587815B2Improve smoothnessQuality improvementPrinted circuit assemblingTransportation and packagingTemperature differenceMetal

Owner:KOBE STEEL LTD

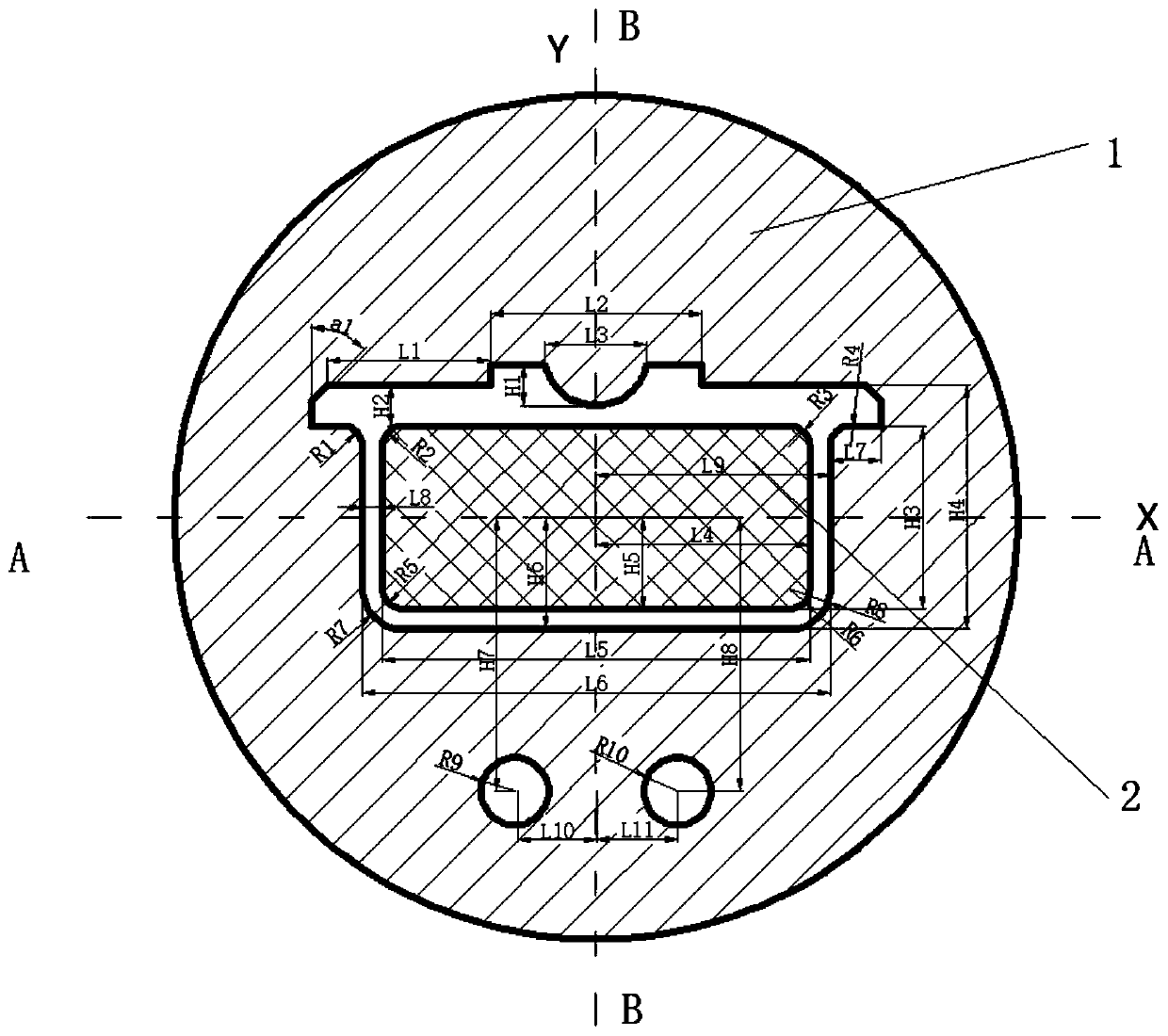

Hot extrusion die and hot extrusion overall forming method of special-shaped square pipe

ActiveCN111451309AImproves wall thickness uniformityImprove surface qualityShaping toolsExtrusion diesThermodynamicsManufacturing technology

The invention relates to a hot extrusion die and a hot extrusion overall forming method of a special-shaped square pipe, and belongs to the fields of an extrusion forming technology and a special-shaped material manufacturing technology. The problem that in the prior art, the special-shaped square pipe cannot be prepared with a hot extrusion overall forming method is solved. The hot extrusion overall forming method of the special-shaped square pipe includes the steps that 1, a blank is heated and broached; 2, the broached blank is heated at a second time; 3, the blank is subjected to hot extrusion through the hot extrusion die of the special-shaped square pipe; and 4, the special-shaped square pipe obtained after hot extrusion forming is air-cooled to room temperature, and the surface quality and the mechanical performance of the special-shaped square pipe are checked. The prepared special-shaped square pipe is good in surface quality and high in dimensional precision, all performanceindexes meet the design requirements through physical and chemical analysis and mechanical performance testing, and the overall quality meets the industrial use requirements.

Owner:CENT IRON & STEEL RES INST +1

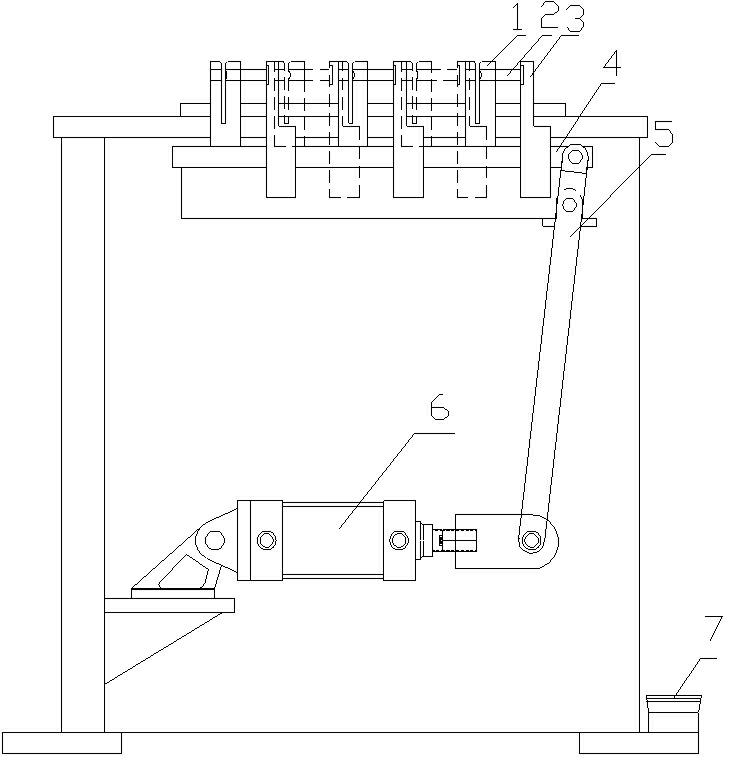

Perforating device of lead acid storage battery shell

The invention discloses a perforating device of a lead acid storage battery shell. A cylinder (6) is installed at the bottom of a machine frame (7). The piston rod of the cylinder (6) is connected to one end of a lever (5). The other end of the lever (5) is connected to a mould sliding block (4). The mould sliding block (4) is movably installed on the top of the machine frame (7). A set of mould movable blocks (3) is installed on the mould sliding block (4). A perforating cutter (2) is installed on each mould movable block (3). A set of mould fixed blocks (1) is installed on the top of the machine frame (7). Guide holes are arranged on the mould fixed blocks (1). The guide hole of each mould fixed block (1) corresponds with one perforating cutter (2). According to the perforating device of the lead acid storage battery shell disclosed by the invention, the device is used for integrally locating and perforating at one time in a lever manner; the process is reliable and rapid; and the direct push perforating manner by locating one by one of a membrane cylinder is avoided, therefore, the device has the advantages of less burrs after perforating a product, higher consistency, simplified process and low cost.

Owner:JIANGSU LEOCH BATTERY

High-density interconnection printed circuit board and method of increasing aligning degree of blind hole and graph

ActiveCN106341961AAvoid misalignmentImprove hole position accuracyPrinted circuit aspectsMultilayer circuit manufactureGraphicsHigh density

The invention discloses a high-density interconnection printed circuit board and a method of increasing an aligning degree of a blind hole and a graph. The method comprises the following steps of A, cutting; B, internal layer graph transfer; C, first stitching; D, laser blind hole operating; E, electroless plating copper electroplating; F, second graph transfer; G second stitching; H, X-RAY machine drilling; I, mechanical drilling; J, electroless plating copper electroplating; and K, external layer graph transfer. In the invention, a problem that the graph after the second graph transfer and a laser blind hole generate contraposition deviation can be effectively avoided and simultaneously hole site precision of the laser blind hole is higher than hole site precision of an X-RAY drilling hole. By using a technology in the invention, contraposition precision of the graph and the laser blind hole can be increased to a 2mil range from an original maximum 4mil range; and the technology only needs to be partially changed and cost is not increased.

Owner:KINWONG ELECTRONIC TECH (ZHUHAI) CO LTD

Cover plate for PCB drilling

InactiveCN105538387APrevent movementReduce gapSynthetic resin layered productsMetal working apparatusAgricultural engineering

The invention discloses a cover plate for PCB drilling. The cover plate comprises an original cover plate and an adhesive resin layer on the back of the original cover plate. According to the cover plate for PCB drilling, the back of the original cover plate is added with the adhesive resin layer, accordingly, the cover plate can be firmly attached to the surface of a to-be-drilled PCB plate in the using process, a clearance between the cover plate and the to-be-drilled PCB plate is prevented from being produced, and the cover plate and the to-be-drilled PCB plate are integrally formed. Burr to be appeared on the surface of the PCB plate is transferred to be on the surface of the cover plate, and the clearance between the cover plate and the PCB plate is prevented from being produced; accordingly, the hole position precision is improved, the chip discharging effect is improved, and meanwhile the cover plate is inhibited from moving relatively on the surface of the PCB plate.

Owner:烟台柳鑫新材料科技有限公司

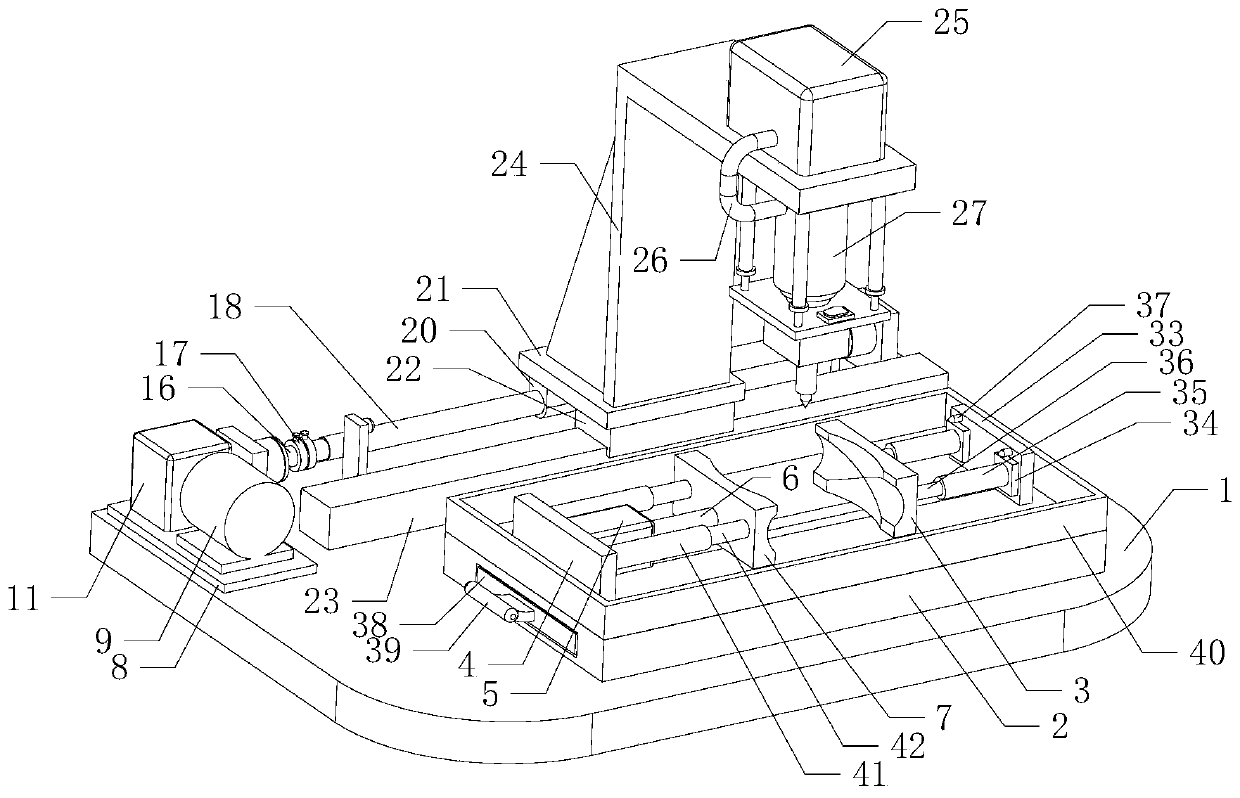

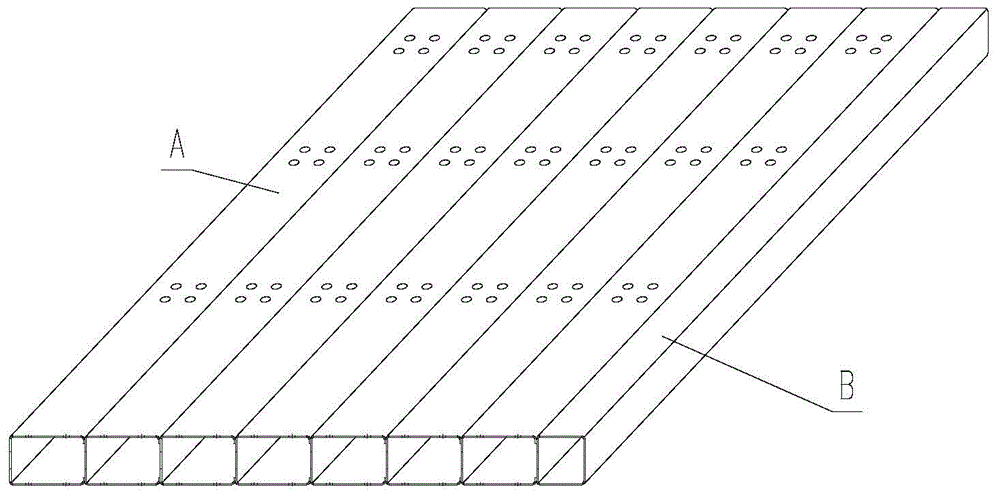

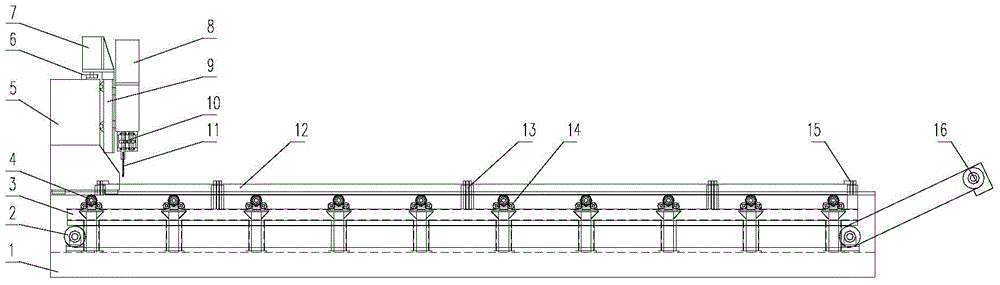

Numerical control machining device for steel pipe bundle flange hole

InactiveCN104874830AImprove processing efficiencyImprove hole position accuracyLarge fixed membersPositioning apparatusNumerical controlEngineering

The invention discloses a numerical control machining device for a steel pipe bundle flange hole. The numerical control machining device comprises a base playing a bearing role, and a plurality of conveying rollers arranged in the length direction of the base in parallel and used for forming a worktable for machining a steel pipe bundle component. The base is provided with a gantry rack which can move in the length direction of the base and is used for installing a plurality of drilling power heads, and the drilling power heads move in the transverse direction of the gantry rack through a gear and rack transmission pair. Drill bits used for a cutter for machining steel pipe bundle component holes are arranged at the bottoms of the drilling power heads. The steel pipe bundle flange drilling work is automatic, and the labor intensity of production workers is relieved while the product quality and the production efficiency are guaranteed.

Owner:HANGXIAO STEEL STRUCTURE

Minisize drill bit for PCB plate drilling hole

ActiveCN101176930AReasonable groove widthImprove borehole wall qualityTransportation and packagingTrepanning drillsBiochemical engineeringHelix angle

The invention discloses a PCB-drilling micro-bit, comprising an base line at the bottom of the groove and two side lines respectively arranged at both sides of the groove and smoothly connected with the base line, which is characterized in that: a spiral winding groove is arranged on the prismatic face; the cross-section profile vertical to the spiral line of the groove is U-shaped with wide bottom on the whole; wherein, the base line is a straight line segment or a circular arc line segment with large curvature radius; the two side lines are respectively straight line segment or circular arc line segment with small curvature radius. Optimally, Helix angle of the groove is 42 to 45 degrees. The invention has the advantages of having bigger space for removing chips and bigger core radius synchronously through optimizing the groove, not decreasing the width of the groove with the groove becoming shallower, having more reasonable groove amplitude ratio of the rear part in the drill bit, improving the quality of drill wall, the hole accuracy, lowering rod-breaking performance synchronously; by increasing the helix angle to 42 to 45 degrees, the invention improves the dust exhausting ability of the drill bit and the quality of hole wall.

Owner:SHENZHEN JINZHOU PRECISION TECH

Entry sheet for drilling and method for drilling processing using same

ActiveUS20180257148A1Strong adhesive strengthExcellent positioning accuracyPrinted circuit manufactureBase-materialsMetallic foilPolymer chemistry

An entry sheet for drilling comprising: a metallic foil; and a layer of a resin composition on at least one surface of the metallic foil, the resin composition comprising a polyolefin resin (A) and a water-soluble resin (B), wherein a content of the polyolefin resin (A) is 25 parts by mass or more and 50 parts by mass or less based on 100 parts by mass of the total of the polyolefin resin (A) and the water-soluble resin (B), a content of the water-soluble resin (B) is 50 parts by mass or more and 75 parts by mass or less based on 100 parts by mass of the total of the polyolefin resin (A) and the water-soluble resin (B), and the water-soluble resin (B) comprises a high-molecular-weight water-soluble resin (B-1) having a weight average molecular weight of 2×105 or higher and 1.5×106 or lower.

Owner:MITSUBISHI GAS CHEM CO INC

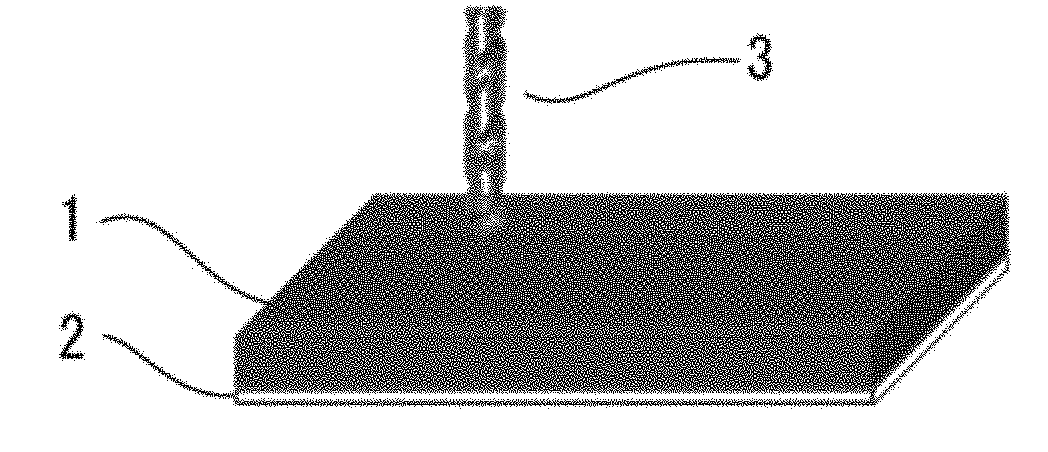

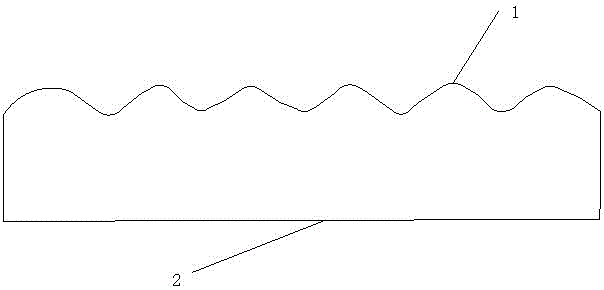

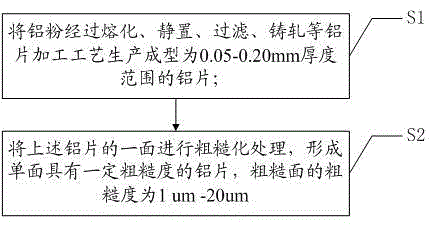

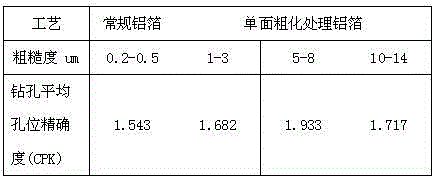

Aluminum sheet for improving accuracy of hole site of drill hole and manufacturing method

InactiveCN103056918AGood effectImprove hole position accuracyMetal working apparatusRough surfaceMaterials science

The invention discloses an aluminum sheet for improving accuracy of a hole site of a drill hole and a manufacturing method of the aluminum sheet. The method includes that an upper surface of the aluminum sheet is a rough surface, a lower surface of the aluminum sheet is a smooth surface, the roughness of the upper surface of the aluminum sheet is controlled within 1um to 20um, thereby when the aluminum sheet serves as a cover plate, a drill pin can be excellently prevented from momently slipping by the aid of fine concave pits on the rough upper surface of the aluminum sheet, simultaneously a certain locating effect when the drill pin drills down can be achieved, the deviation between an actual drill hole position and a set drill hole position is reduced, the accuracy of the hole site of the drill hole is improved, and a circuit board with good qualities can be produced.

Owner:SHENZHEN NEWCCESS IND

FPC hollowed-out circuit board preparation technology

InactiveCN108391382AImprove hole position accuracyOvercoming misalignmentLaminating printed circuit boardsConductive material chemical/electrolytical removalProduction linePunching

The invention discloses an FPC hollowed-out circuit board preparation technology, including the following steps: 1, performing RTR target drone punching on a copper foil; 2, performing CNC drilling ona covering film; 3, attaching the copper foil after punching to the covering film after drilling; 4, performing press-fitting on the attached copper foil and covering film to obtain a semi-finished product; 5, performing dry film pasting treatment, exposure treatment, developing treatment and etching treatment in sequence on the semi-finished product obtained in Step 4; and 6, performing coveringlayer pasting treatment on the semi-finished product after Step 5 is completed. The FPC hollowed-out circuit board preparation technology uses CNC equipment and RTR target punching equipment to perform perforation on the covering film and the copper foil, and then the covering film and the copper foil are attached to each other, the circumstance that dislocation of a printed circuit occurs in a subsequent exposure process is overcome, and improvement of the yield of products is facilitated; and in addition, precision of hole locations in the copper foil is high, so that a material pulling device can normally pull materials in an RTR manufacturing process, thereby ensuring long-time stable work of an FPC hollowed-out circuit board production line.

Owner:SHENZHEN JINGCHENGDA CIRCUIT TECH

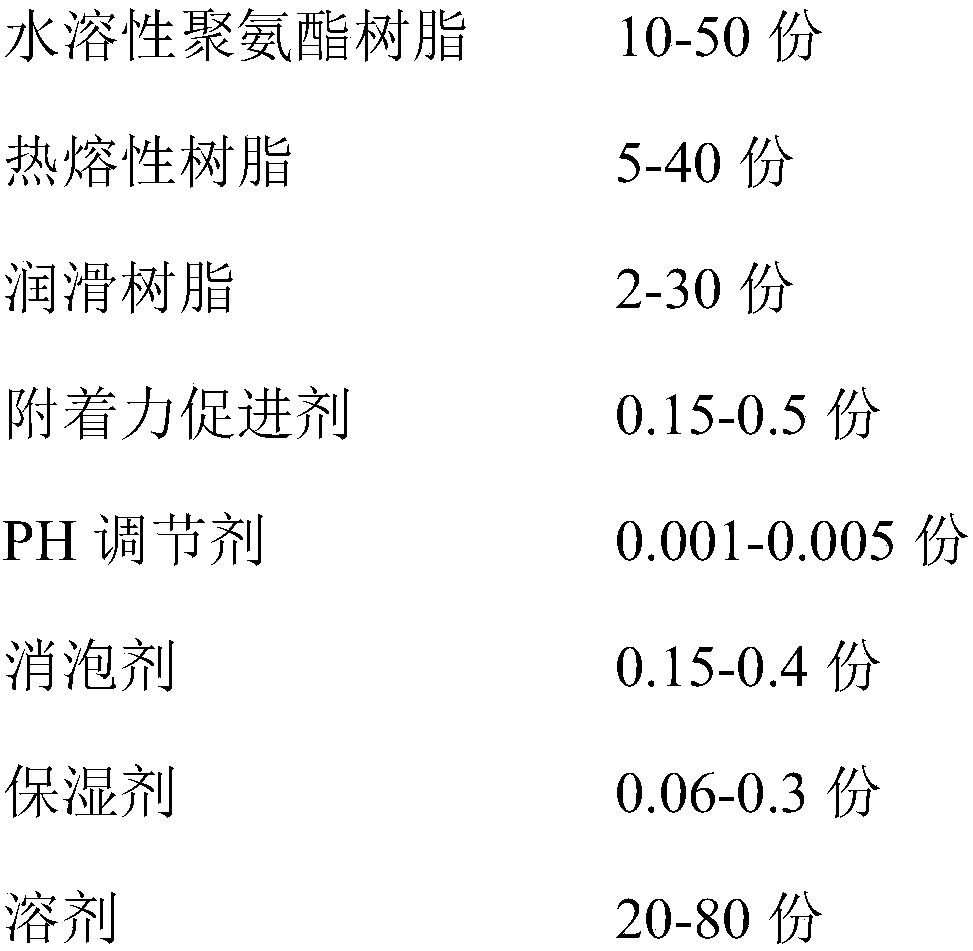

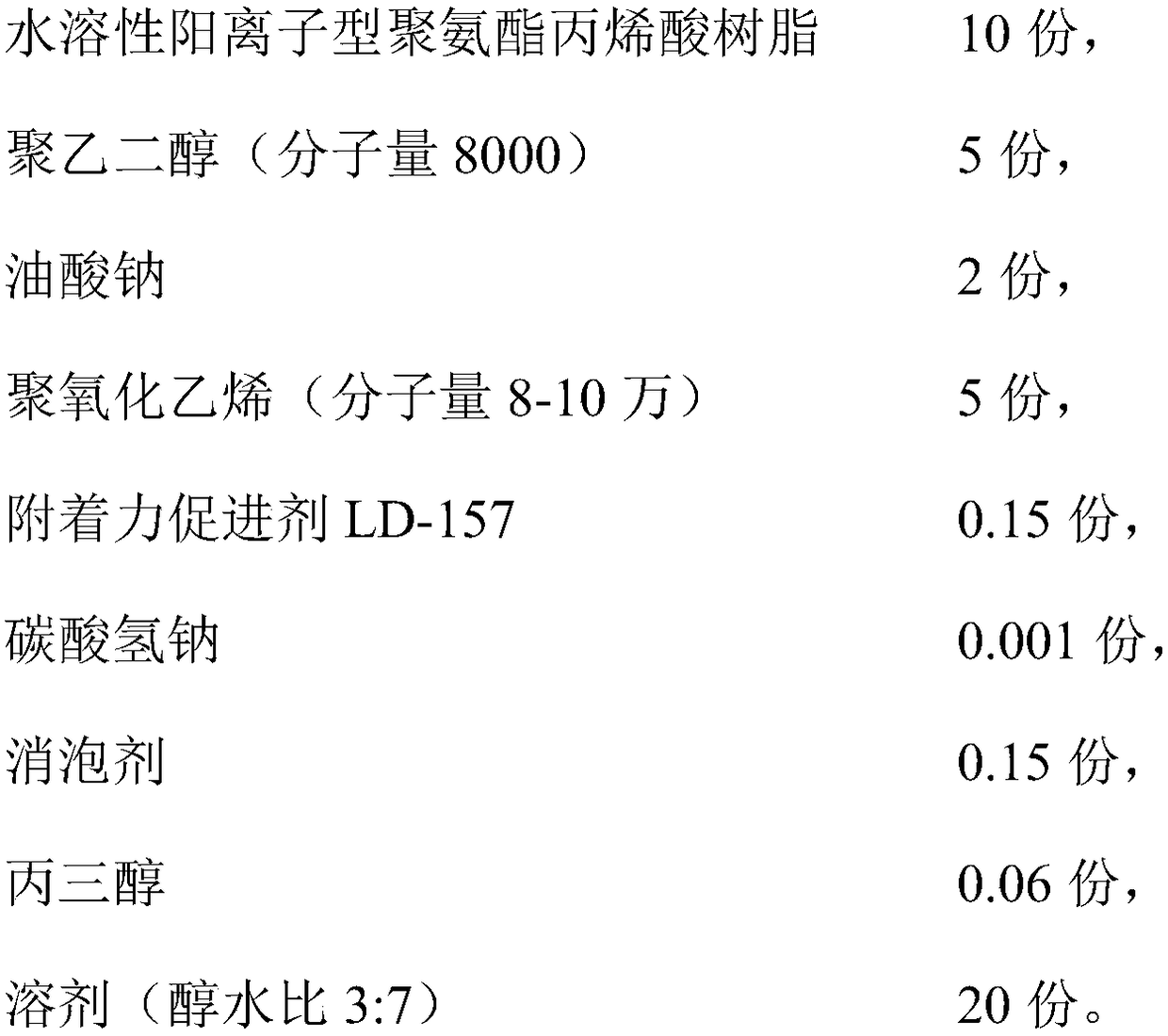

Waterborne polyurethane coating for coated aluminum sheets and preparation method of waterborne polyurethane coating

InactiveCN108395832AAvoid quality problems such as film dropWith bufferPolyurea/polyurethane coatingsPolyether coatingsEnvironmental resistanceWater soluble

The invention discloses a waterborne polyurethane coating for coated aluminum sheets and a preparation method of the waterborne polyurethane coating. The waterborne polyurethane coating comprises thefollowing components: 10-50 parts of water-soluble polyurethane resin, 5-40 parts of hot-melt resin, 2-30 parts of lubricating resin, 0.15-0.5 part of an adhesion promoter, 0.001-0.005 part of a PH regulator, 0.15-0.4 part of a defoaming agent, 0.06-0.3 part of a humectant and 20-80 parts of a solvent. The preparation method at least comprises the following steps: preparing a solvent according toan alcohol-water ratio of 8:2-3:7; sequentially stirring the water-soluble polyurethane resin with the hot-melt resin, the lubricating resin, the adhesion promoter, the PH regulator and the humectantin the solvent with a certain proportion until the materials are complete dissolved, slowly adding the defoaming agent, and continuing carrying out stirring for 30 minutes or more to prepare the waterborne polyurethane coating for the coated aluminum sheets. The waterborne polyurethane coating provided by the invention is applied to the coating of aluminum sheets, and the coating layers of aluminum sheets coated with the waterborne polyurethane coating provided by the invention have the effects of buffering, positioning, heat dissipation and lubrication, can solve the drilling processing problems of micro holes and dense holes, increase the hole-location accuracy, increase the drilling lamination number, improve the production capacity, avoid the quality problems such as hole plugging, film falling of the aluminum sheets, and the like, and has the advantages of good environmental resistance and convenient storage.

Owner:昆山久文电子材料有限公司

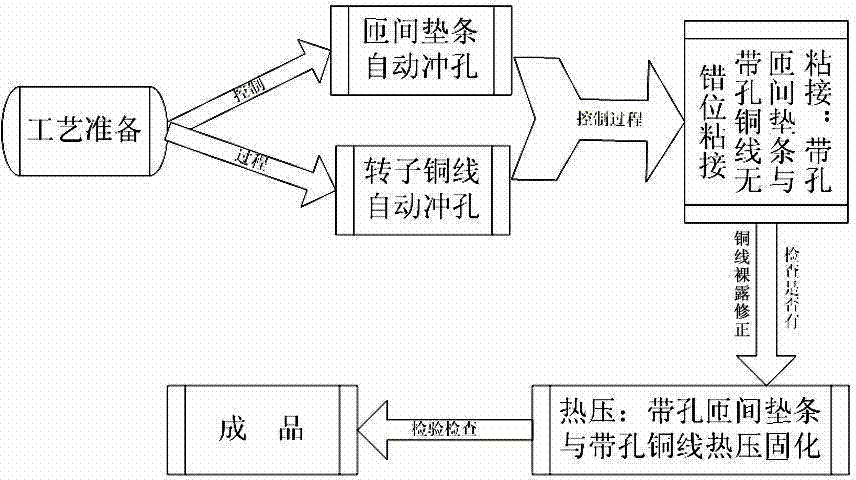

Turn-to-turn insulation manufacturing method for rotor of inner air-cooled steam-turbine generator

InactiveCN104124842AWill not cause short circuitImprove hole position accuracyApplying solid insulationCopper wireFirst pass yield

The invention discloses a turn-to-turn insulation manufacturing method for a rotor of an inner air-cooled steam-turbine generator. According to the technical method, turn-to-turn filler strip long holes and circular holes are formed automatically through special equipment, thereby realizing high accuracy and high production efficiency. After bonding, the first pass yield of a product is high, and the defects of low efficiency, damages to copper wires, production of metal burrs and the like in an original machining process are overcome.

Owner:CITIC HEAVY INDUSTRIES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com