Turn-to-turn insulation manufacturing method for rotor of inner air-cooled steam-turbine generator

A technology of steam turbine generator and turn-to-turn insulation, which is applied in laying solid insulation and other directions, can solve the problems of labor-intensive removal, secondary damage to copper wires, and burr generation, and achieves an increase in the first pass rate and high hole position accuracy. , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

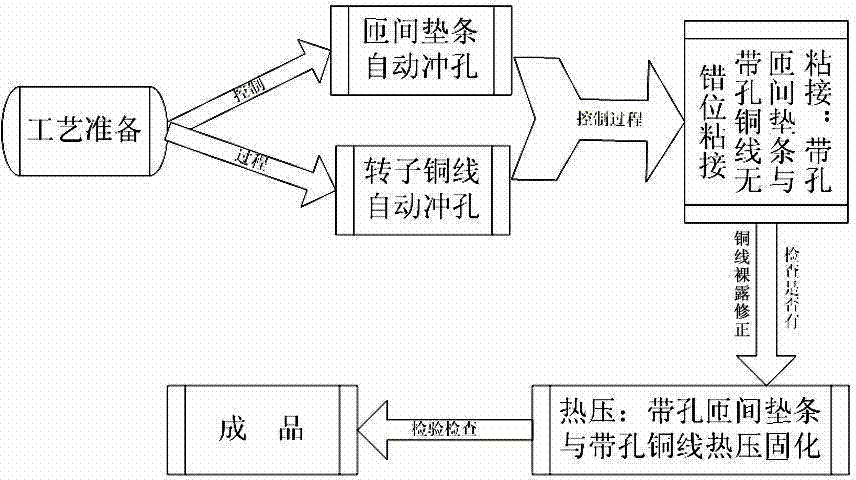

Image

Examples

Embodiment Construction

[0018] The special equipment, that is, copper wire automatic punching equipment, is specially manufactured for punching copper wire ventilation holes. It consists of 100T punch press, air compressor, punch tool (self-made), feeding device (roller device) and material receiving positioning device. . When performing the punching of the inter-turn insulating pads of the rotor, counter-rollers are installed on the feeding device to ensure uniform and smooth feeding, prevent the pads from bulging, and improve the punching accuracy.

[0019] like image 3 , Figure 4 The pressure plate of the roller device shown is equipped with adjusting bolts to adjust the gap between the two rollers (tighten the bolts and press the rollers to reduce the gap and increase the tightness, loosen the bolts to reduce the pressure of the rollers to reduce the gap and increase the tightness) to ensure that the rotor The conveying tightness of the inter-turn insulation pads. Because the thickness of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com