Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

133 results about "Niobium nitride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Niobium nitride is a compound of niobium and nitrogen (nitride) with the chemical formula NbN. At low temperatures (about 16 K) NbN, niobium nitride becomes a superconductor, and is used in detectors for infrared light.

Methods for forming a transition metal niobium nitride film on a substrate by atomic layer deposition and related semiconductor device structures

ActiveUS20180158688A1TransistorSemiconductor/solid-state device detailsDevice materialAtomic layer deposition

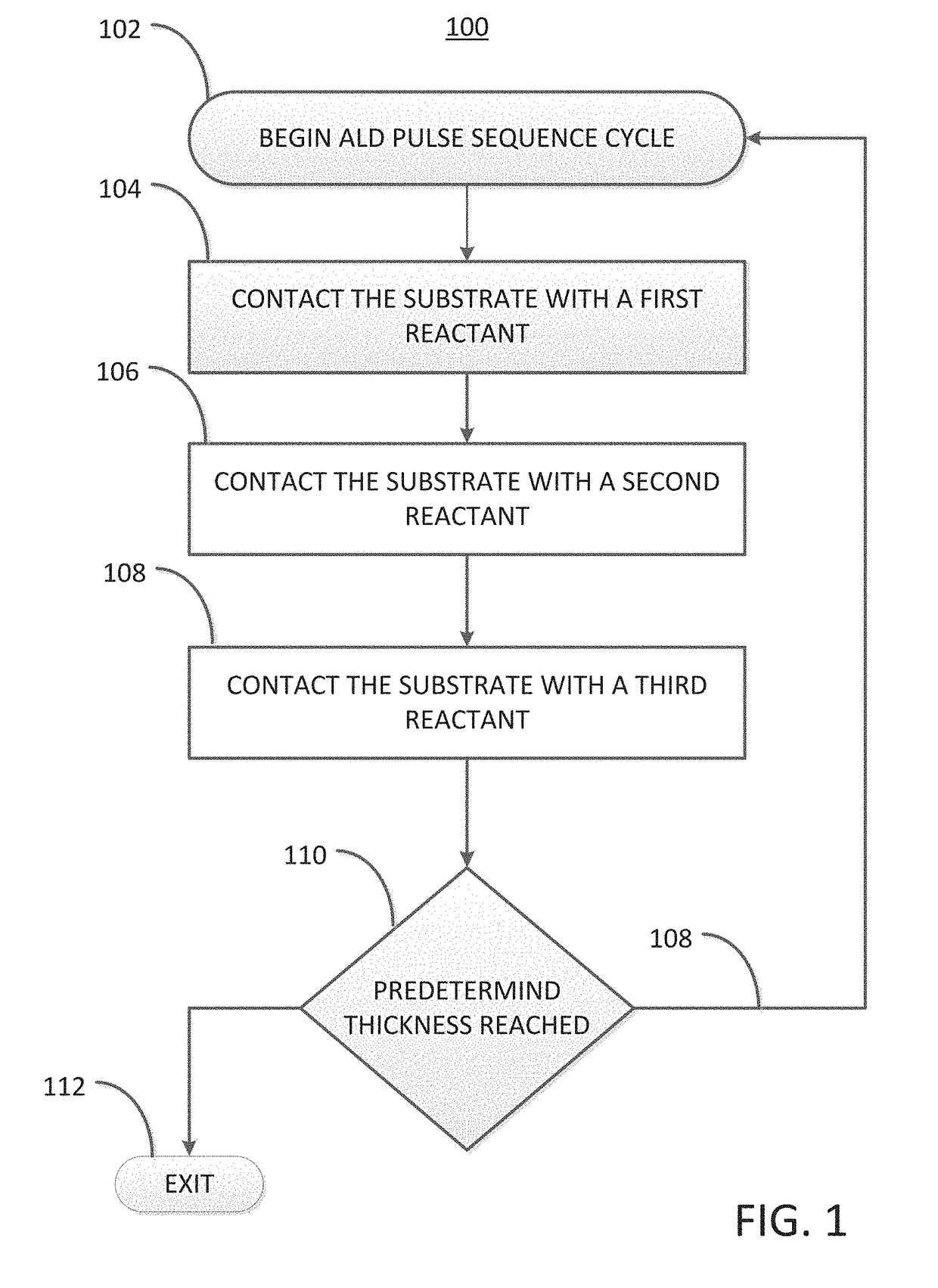

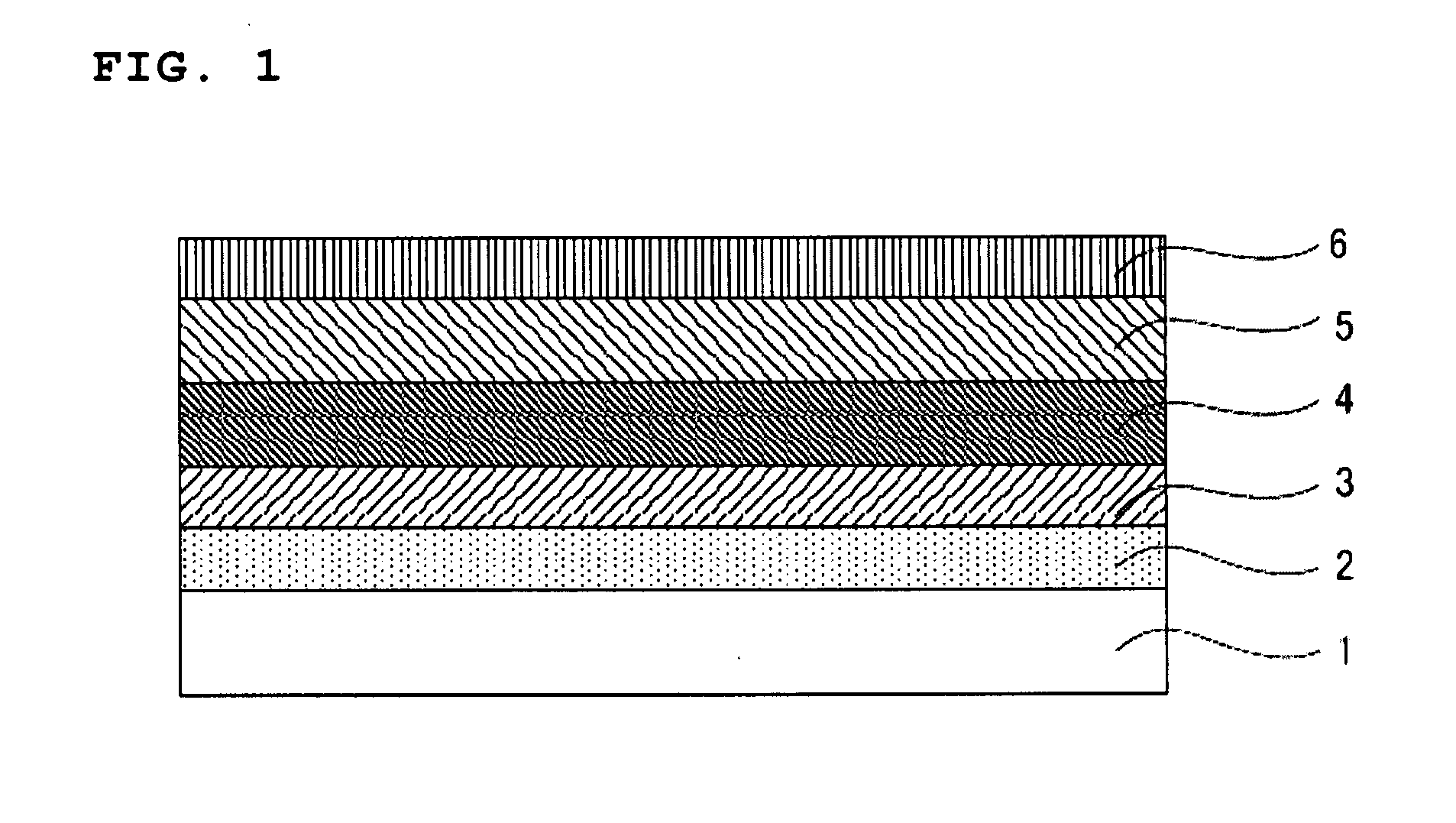

Methods for forming a transition metal niobium nitride film on a substrate by atomic layer deposition and related semiconductor device structures are provided. In some embodiments methods may include contacting a substrate with a first reactant comprising a transition metal precursor, contacting the substrate with a second reactant comprising a niobium precursor and contacting the substrate with a third reactant comprising a nitrogen precursor. In some embodiments related semiconductor device structures may include a semiconductor body and an electrode comprising a transition metal niobium nitride disposed over the semiconductor body.

Owner:ASM IP HLDG BV

Niobium nitride and method for producing same, niobium nitride-containing film and method for producing same, semiconductor, semiconductor device, photocatalyst, hydrogen generation device, and energy system

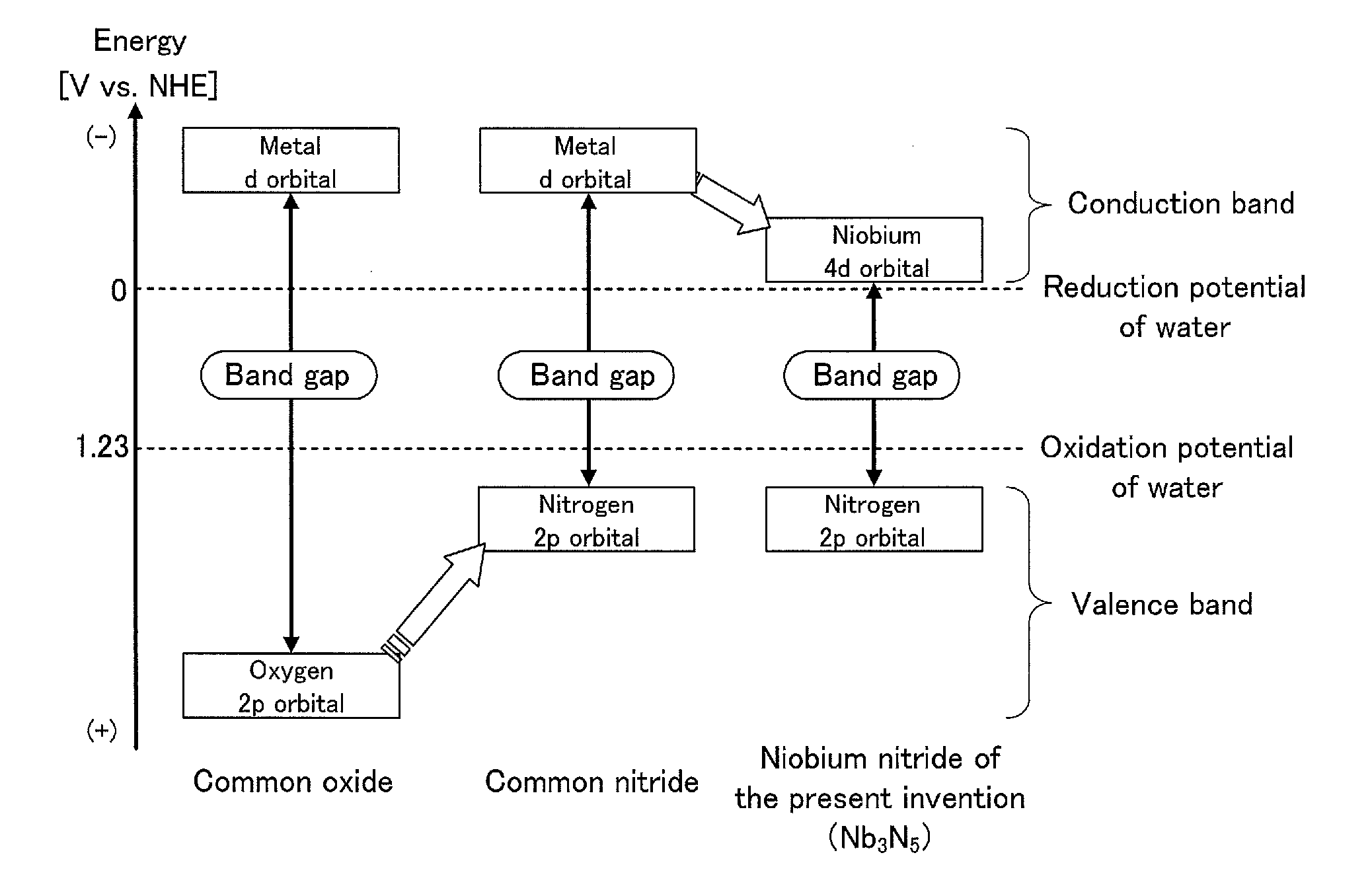

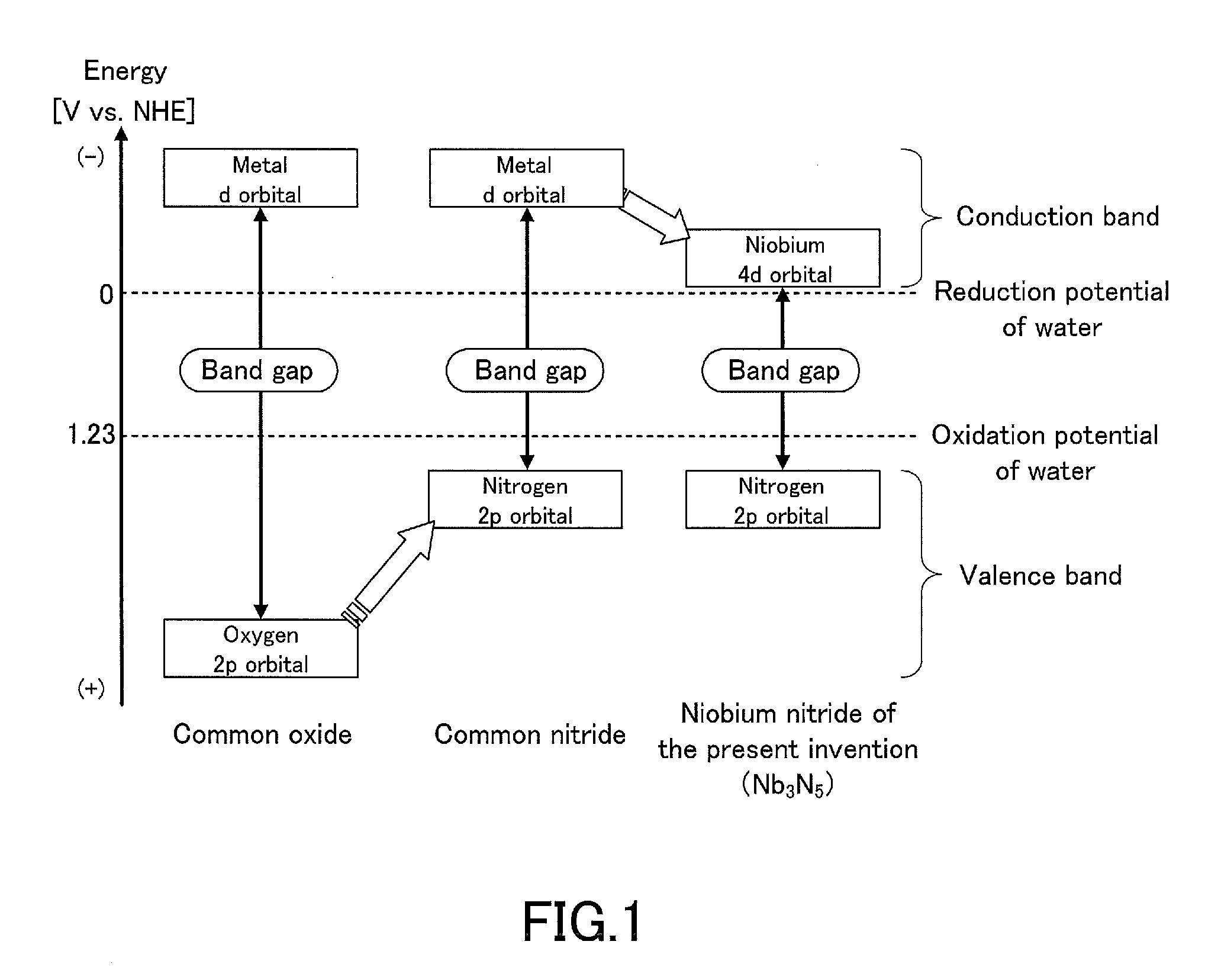

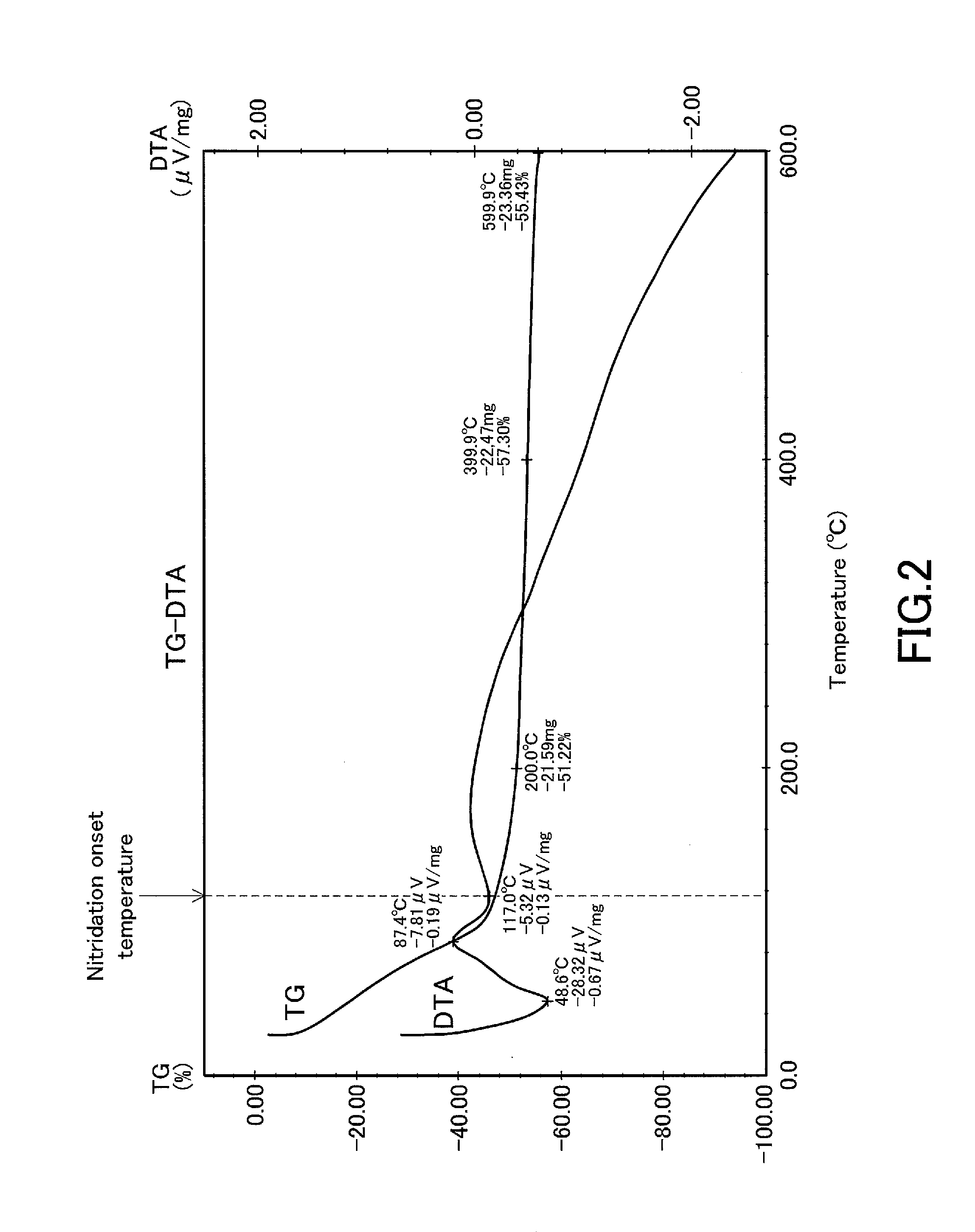

The present invention is a niobium nitride which has a composition represented by the composition formula Nb3N5 and in which a constituent element Nb has a valence of substantially +5. The method for producing the niobium nitride of the present invention includes the step of nitriding an organic niobium compound by reacting the organic niobium compound with a nitrogen compound gas.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

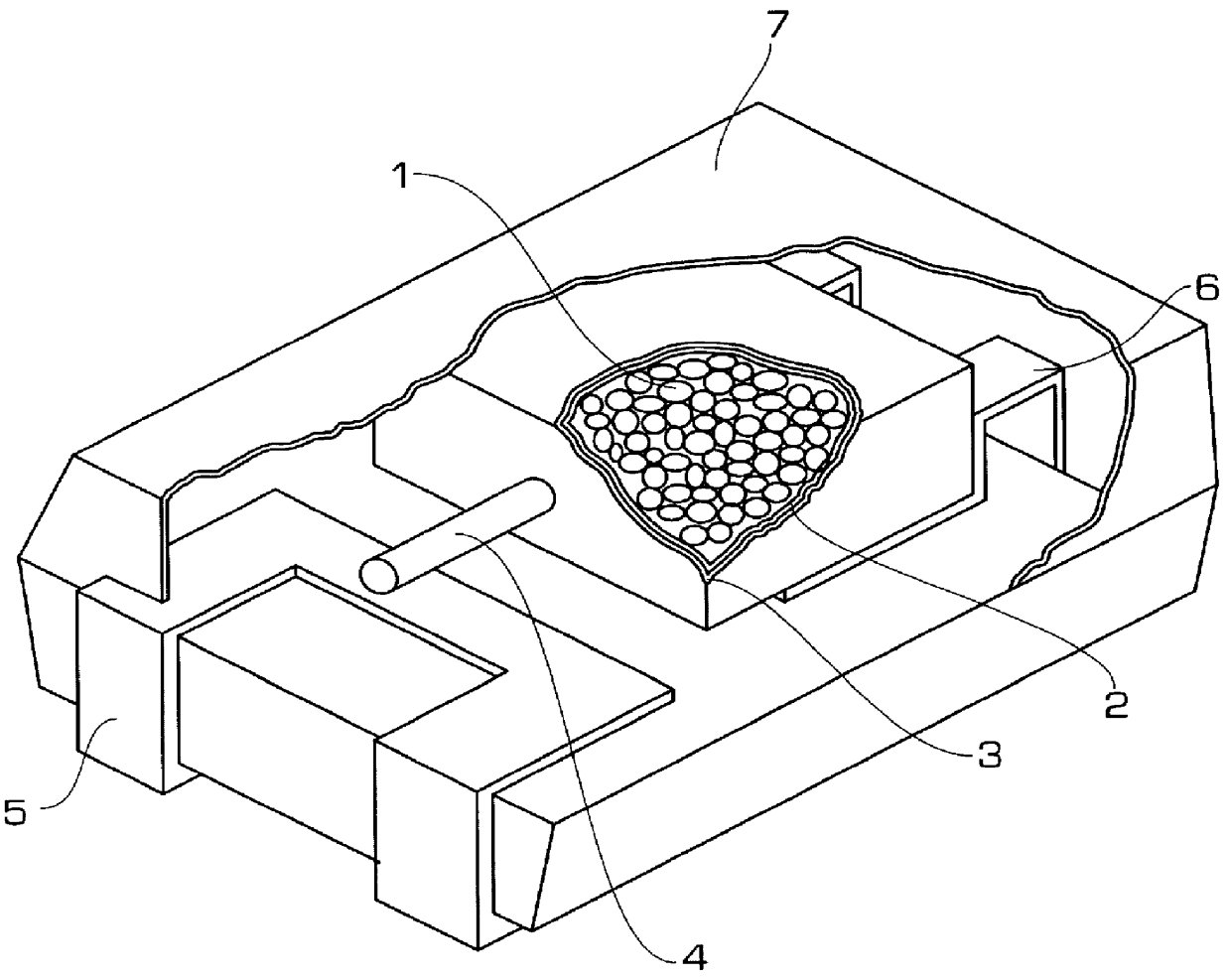

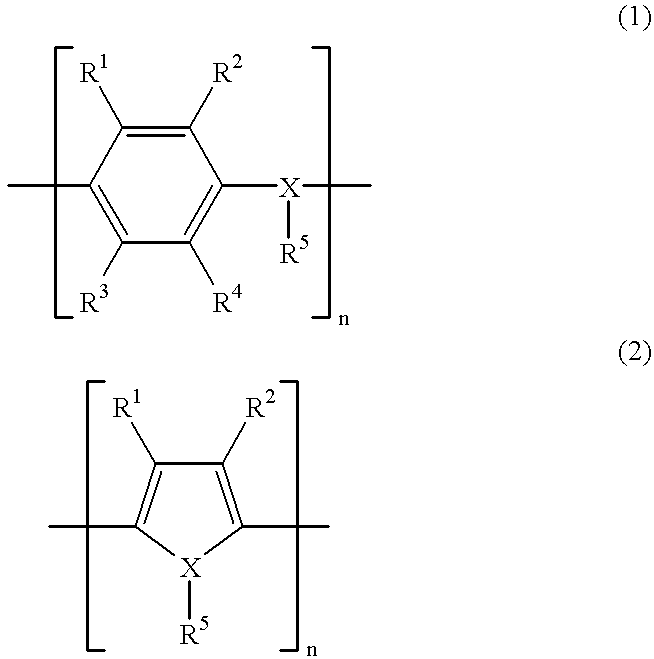

Capacitor

InactiveUS6115235AFixed capacitor electrodesLiquid electrolytic capacitorsOrganic semiconductorCapacitor

PCT No. PCT / JP98 / 00823 Sec. 371 Date Oct. 28, 1998 Sec. 102(e) Date Oct. 28, 1998 PCT Filed Feb. 27, 1998 PCT Pub. No. WO98 / 38660 PCT Pub. Date Sep. 3, 1998In a capacitor comprising a pair of electrodes and a dielectric substance intervening between the two electrodes, one of the electrodes is composed of sintered niobium nitride. Preferably, the dielectric substance is composed of niobium oxide and the electrode other than the electrode composed of sintered niobium nitride is composed of an ingredient selected from electrolytes, organic semiconductors and inorganic semiconductors. This capacitor has good environmental stability and good leak current characteristics.

Owner:SHOWA DENKO KK

Solid electrolytic capacitor and manufacturing method thereof

InactiveUS6215652B1Avoid volatilityIncrease capacitanceLiquid electrolytic capacitorsFixed capacitor dielectricElectrolysisMetal powder

A solid electrolytic capacitor is here disclosed in which a dielectric layer formed on the surface of an anode obtained by molding and then sintering a niobium metal powder which includes a niobium oxide layer and a niobium nitride region, and a method for manufacturing the solid electrolytic capacitor is also disclosed.

Owner:TOKIN CORP

Ferroelectric integrated circuit having hydrogen barrier layer

InactiveUS6365927B1Solid-state devicesSemiconductor/solid-state device manufacturingTitanium nitrideEngineering

A hydrogen diffusion barrier in an integrated circuit is located to inhibit diffusion of hydrogen to a thin film of metal oxide material in an integrated circuit. The hydrogen diffusion barrier comprises at least one of the following nitrides: aluminum titanium nitride (Al2Ti3N6), aluminum silicon nitride (Al2Si3N6), aluminum niobium nitride (AlNb3N6), aluminum tantalum nitride (AlTa3N6), aluminum copper nitride (Al2Cu3N4), tungsten nitride (WN), and copper nitride (Cu3N2). The thin film of metal oxide is ferroelectric or high-dielectric, nonferroelectric material. Preferably, the metal oxide comprises ferroelectric layered superlattice material. Preferably, the hydrogen barrier layer is located directly over the thin film of metal oxide.

Owner:SYMETRIX

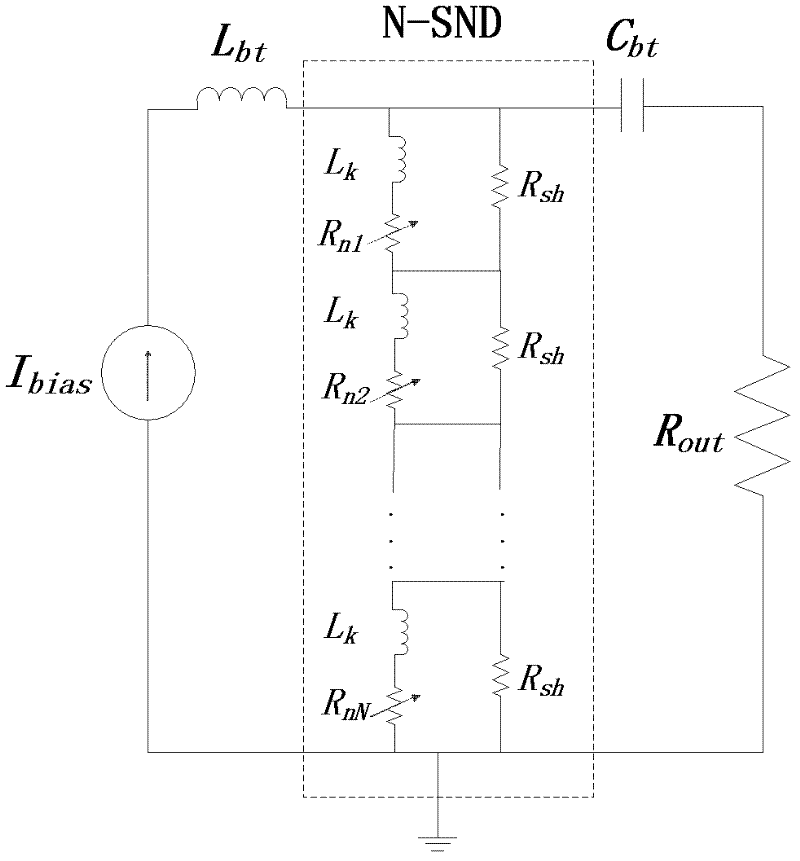

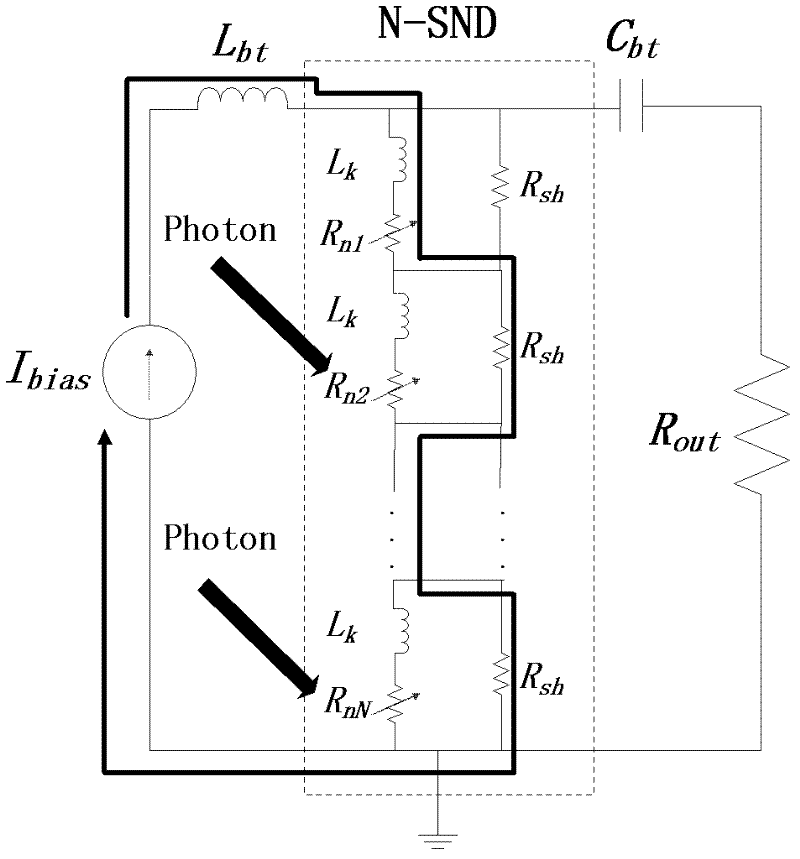

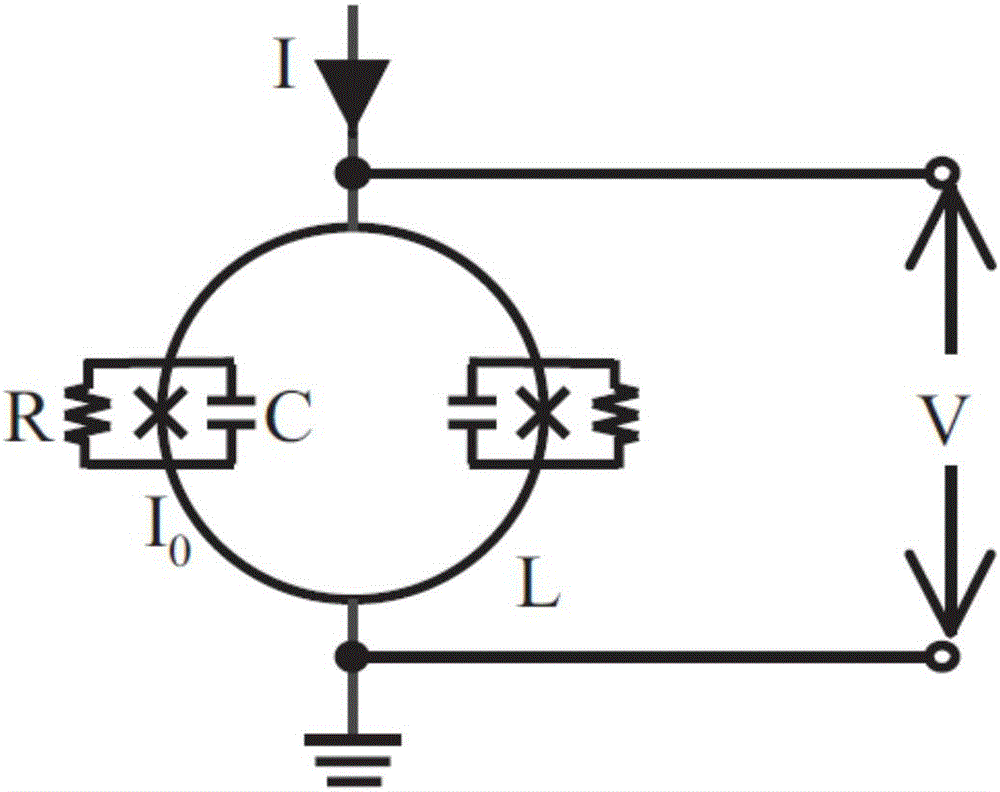

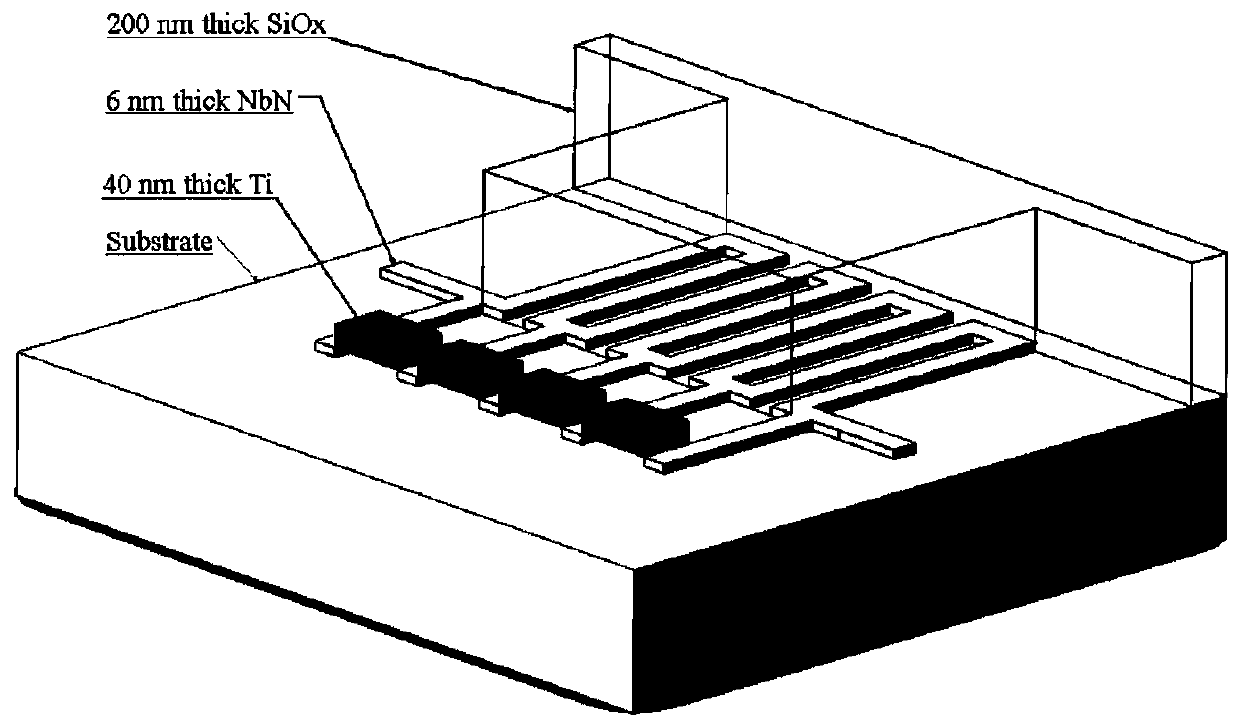

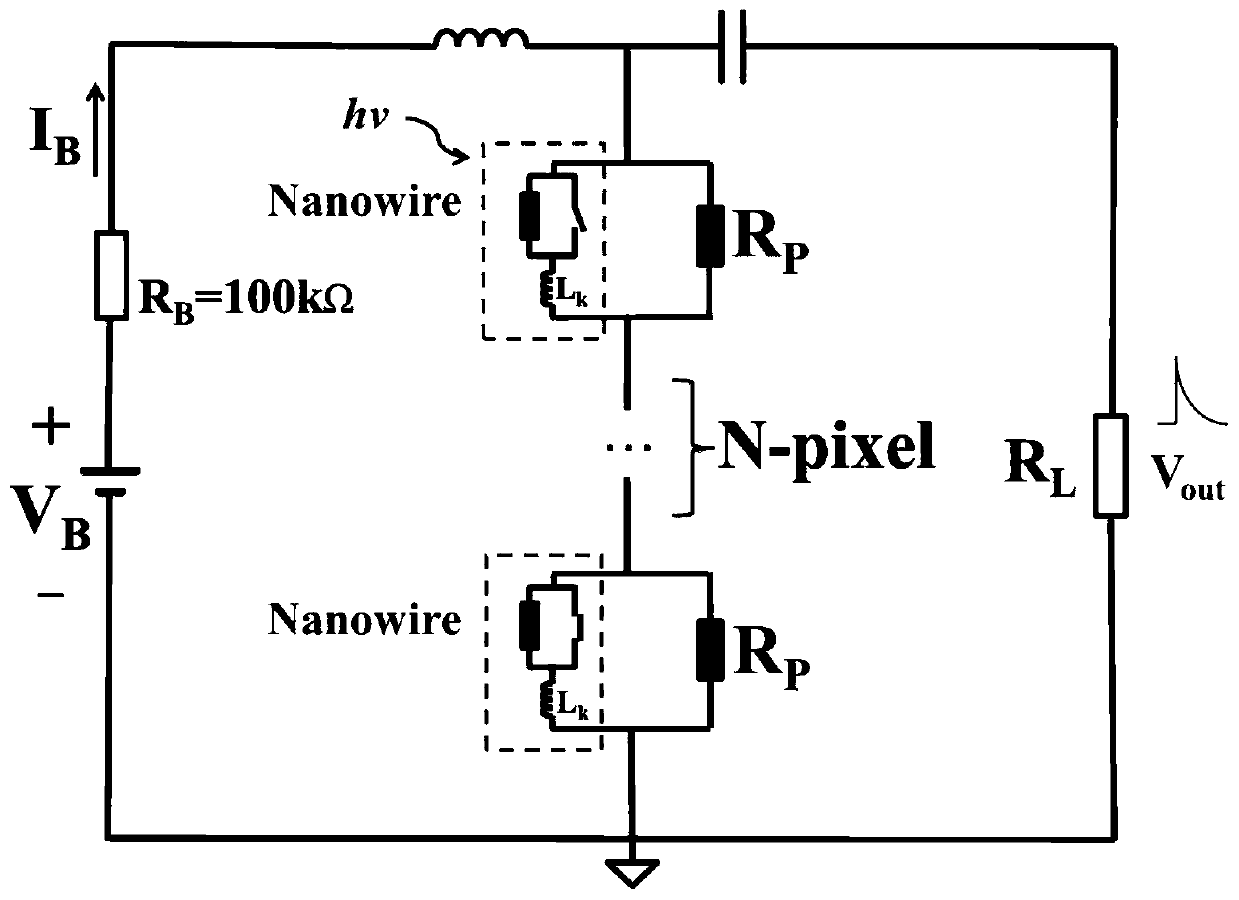

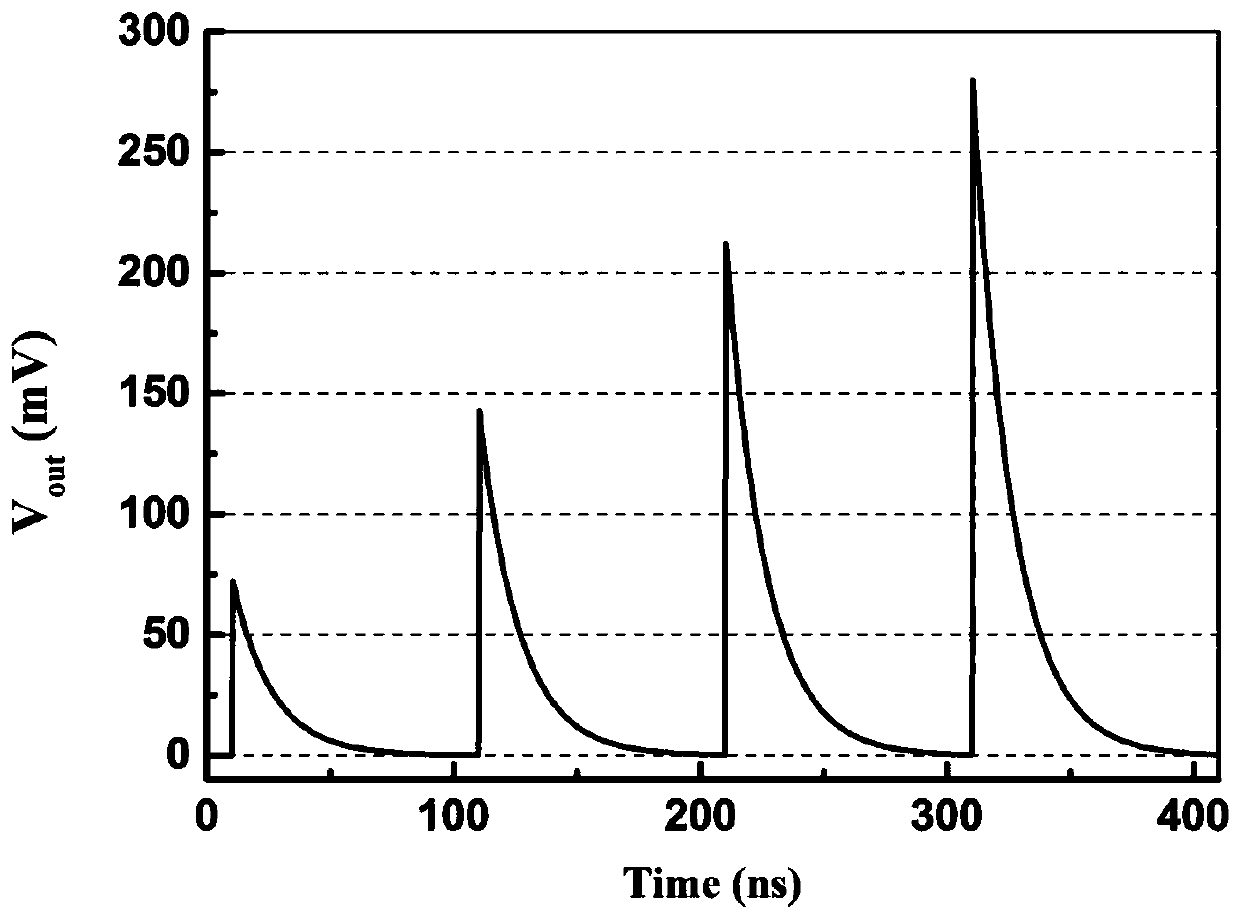

Superconductive nanowire single-photon detector capable of distinguishing photon number and preparation method thereof

ActiveCN102353464AImprove quantum efficiencyIncrease count rateDecorative surface effectsChemical vapor deposition coatingQuantum efficiencyElectrical resistance and conductance

The invention provides a superconductive nanowire single-photon detector capable of distinguishing photon number. The superconductive nanowire single-photon detector consists of N superconductive nanowires which are connected in series and corresponding N bypass resistors, wherein each bypass resistor is arranged between every two adjacent superconductive nanowires; the superconductive nanowires are made from superconductive materials such as niobium nitride or titanium niobium nitride and the like; and the bypass resistors are made from metal films such as gold or titanium and the like. The invention further provides a method for preparing the superconductive nanowire single-photon detector. The prepared superconductive nanowire single-proton detector has high quantum efficiency, high counting efficiency, low dark count and capability of distinguishing photon number, and is not influenced by leakage current.

Owner:TSINGHUA UNIV

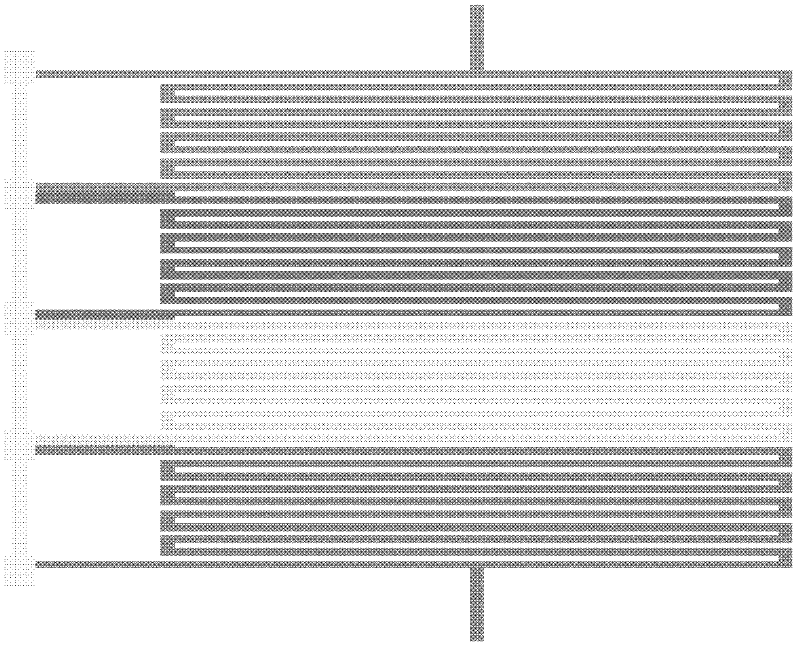

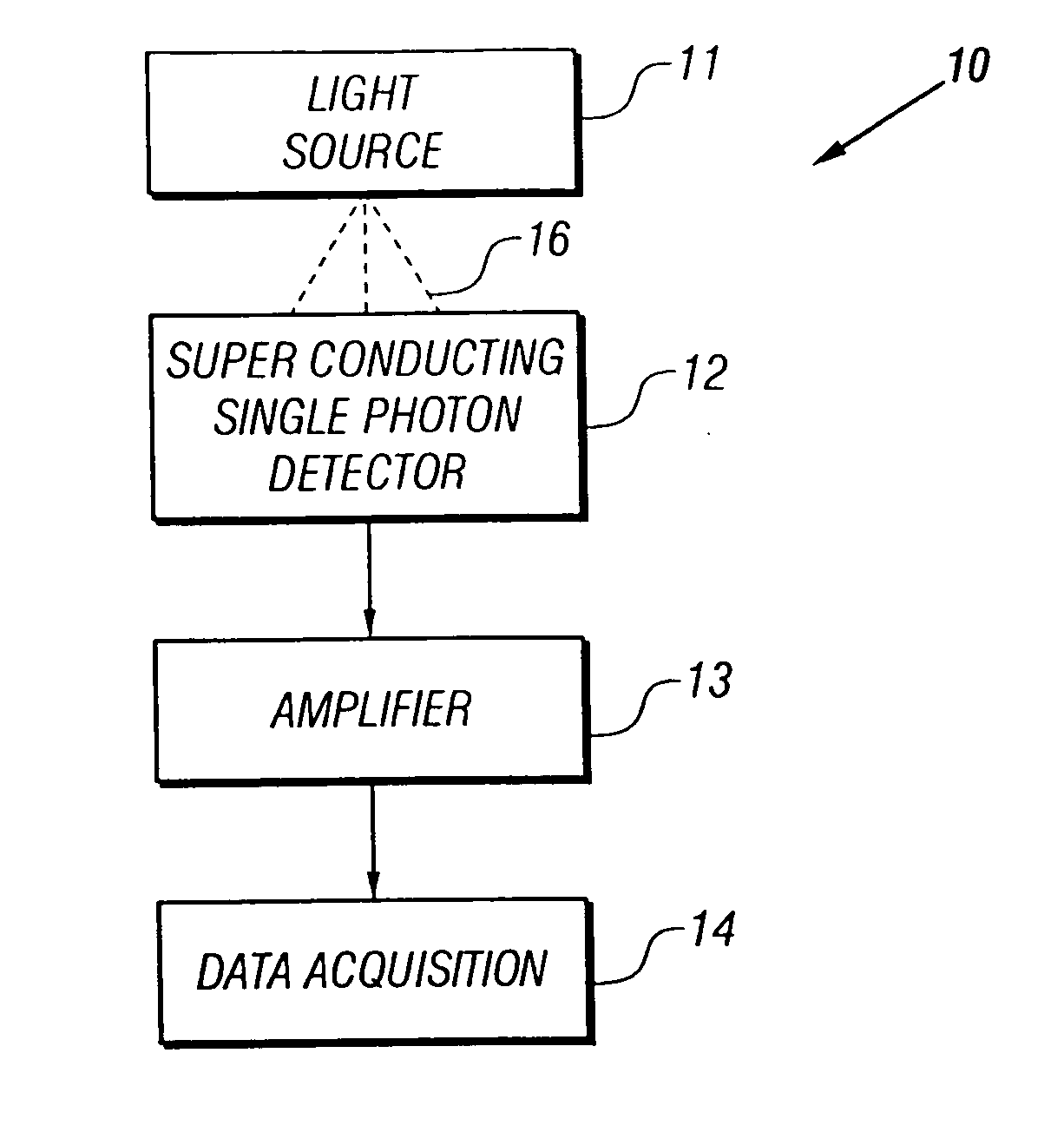

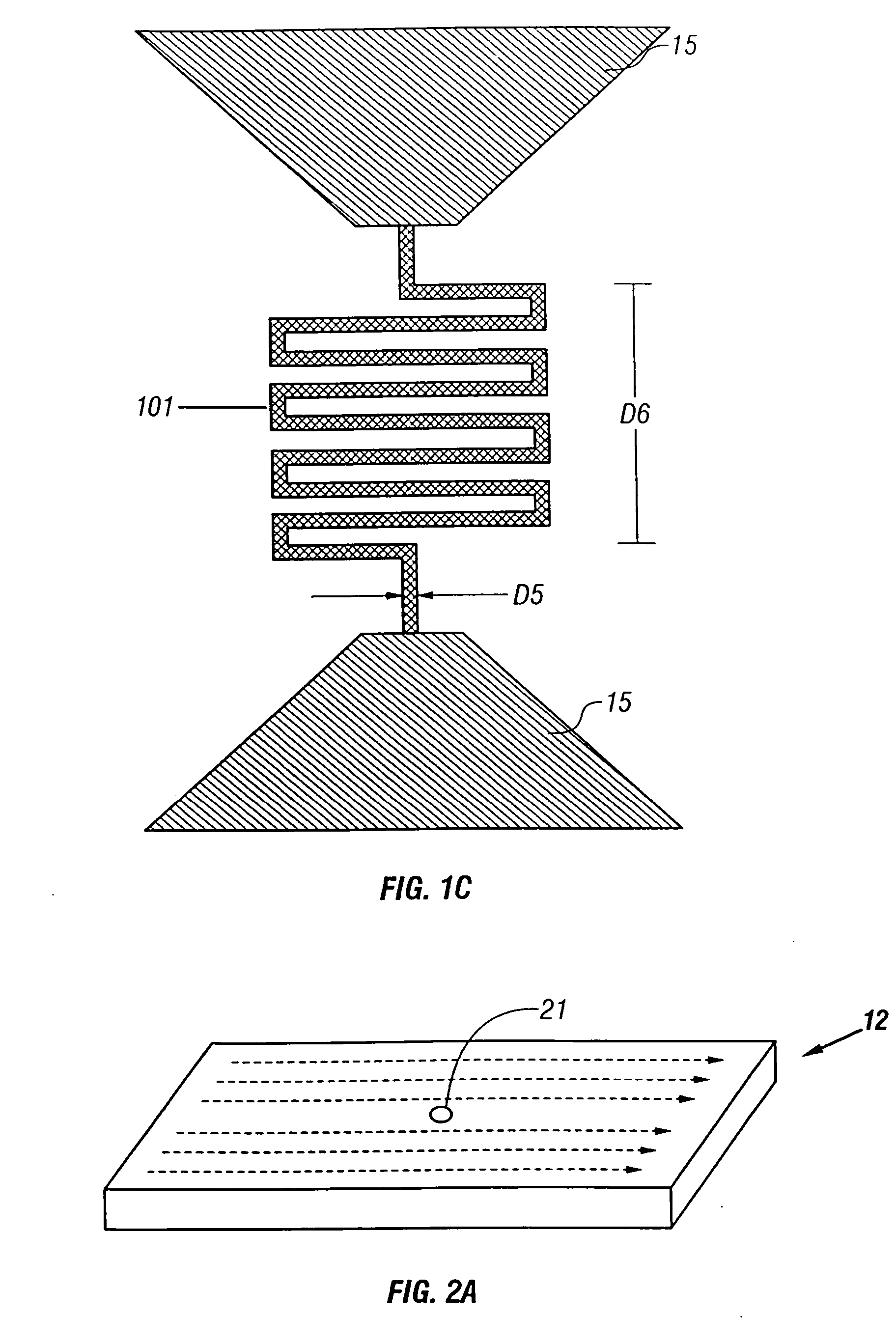

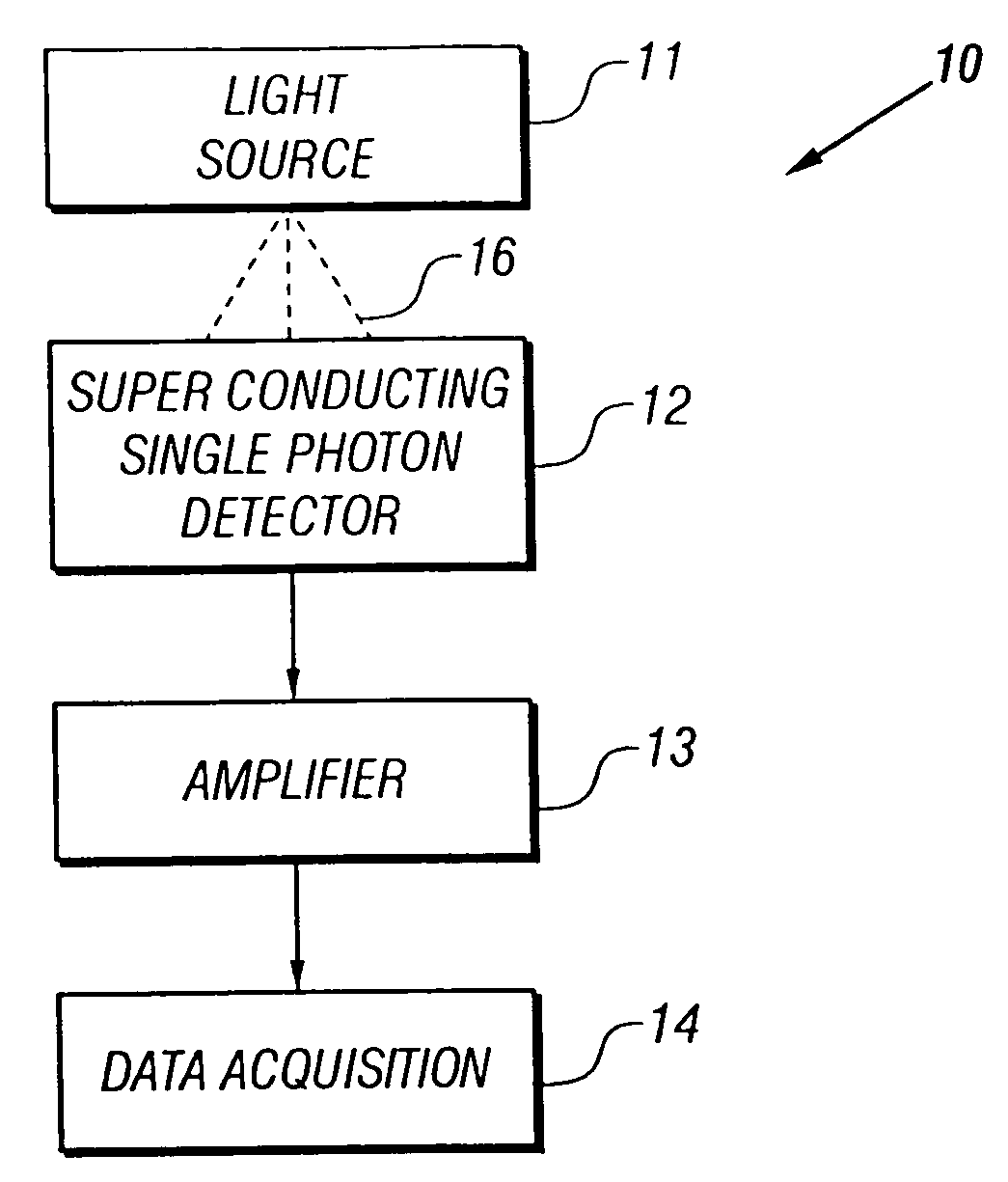

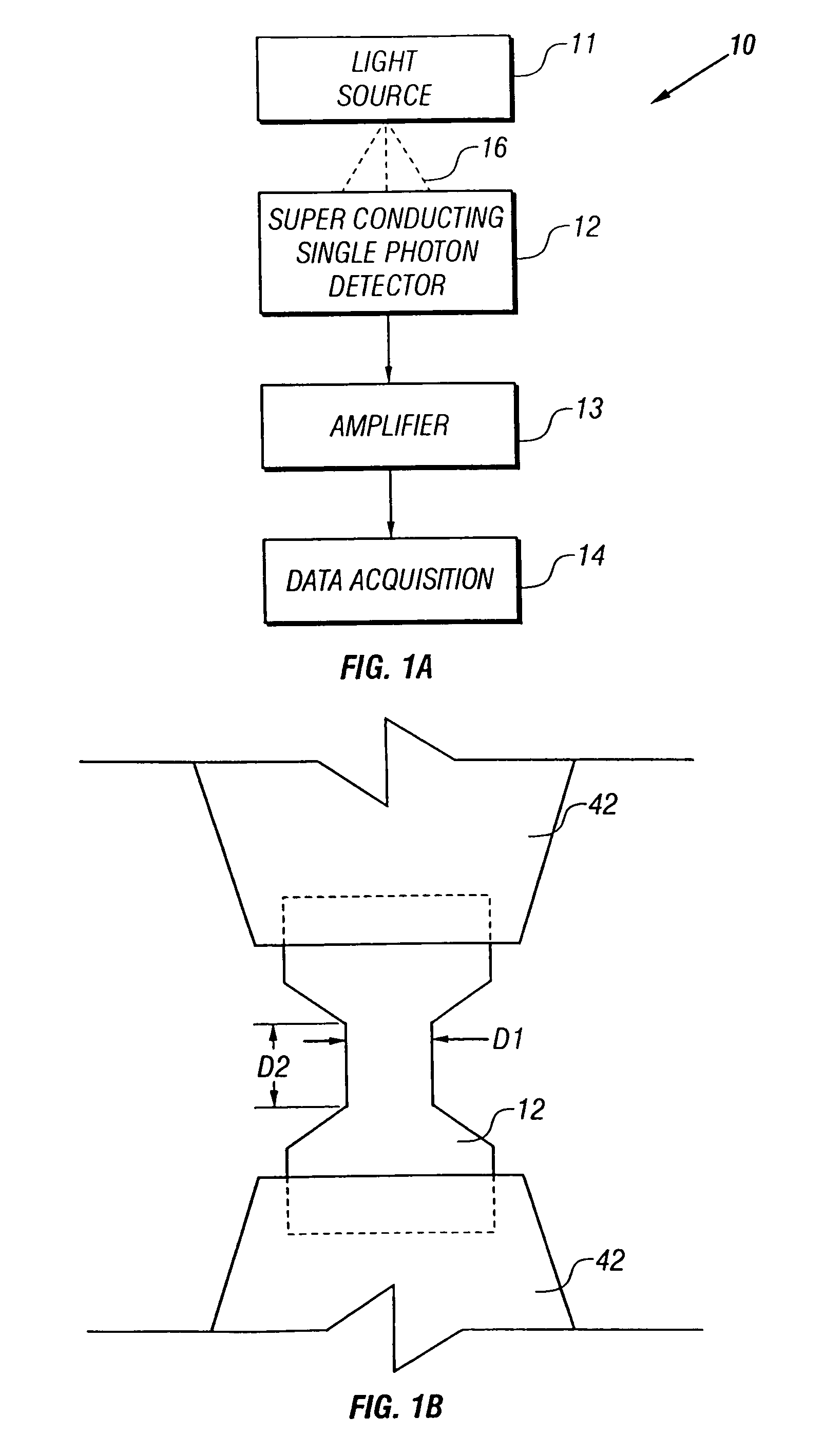

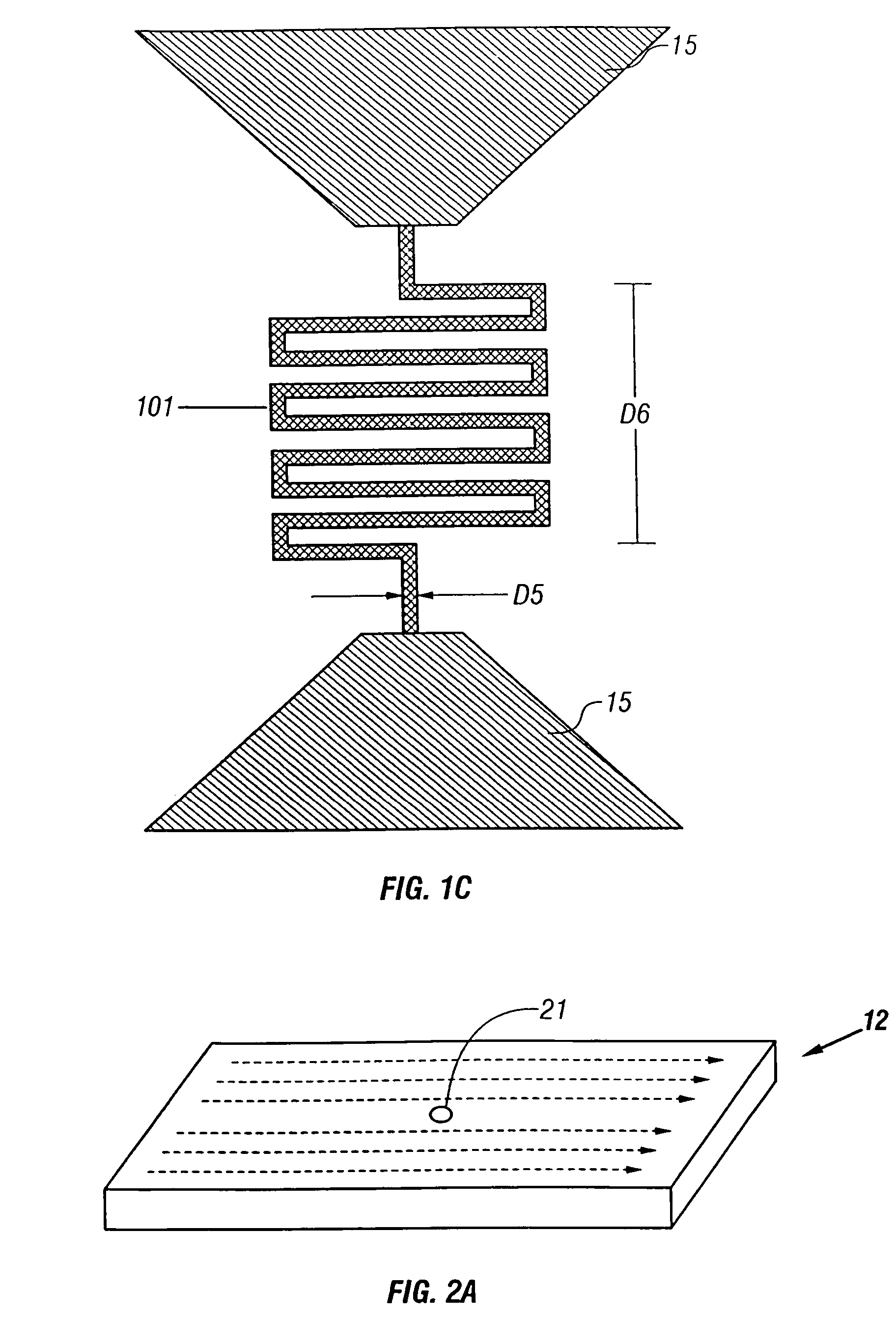

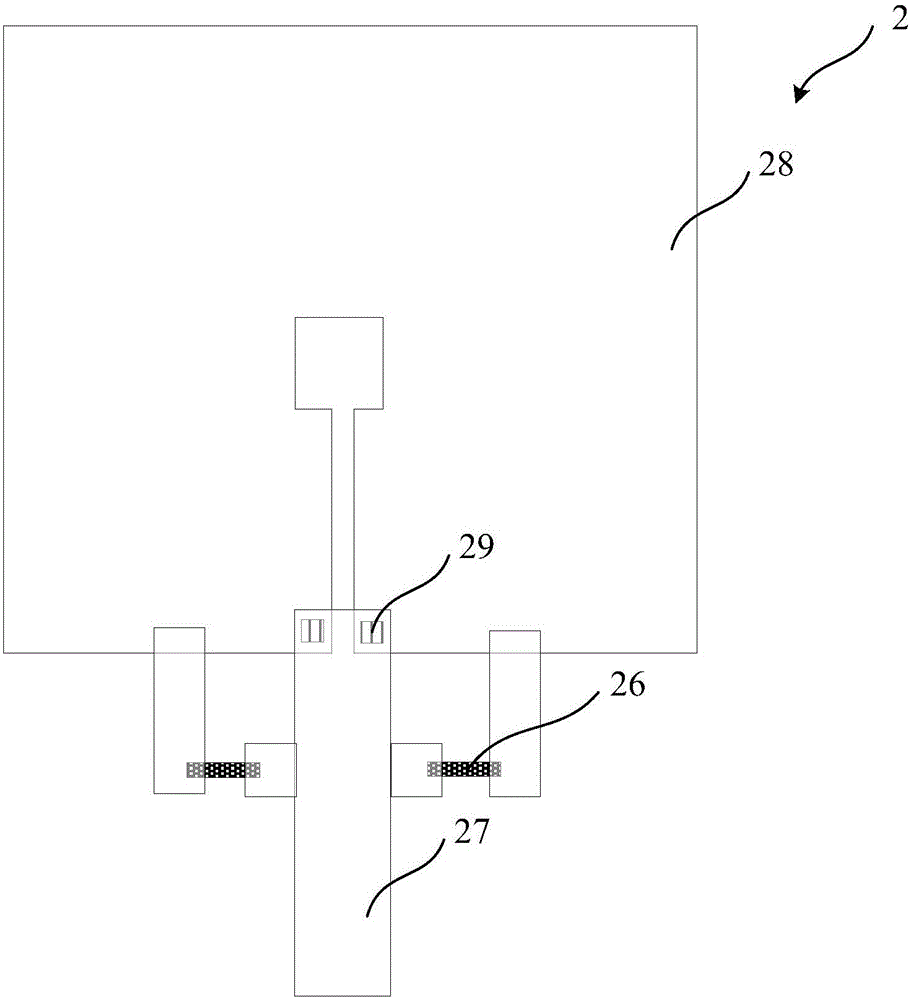

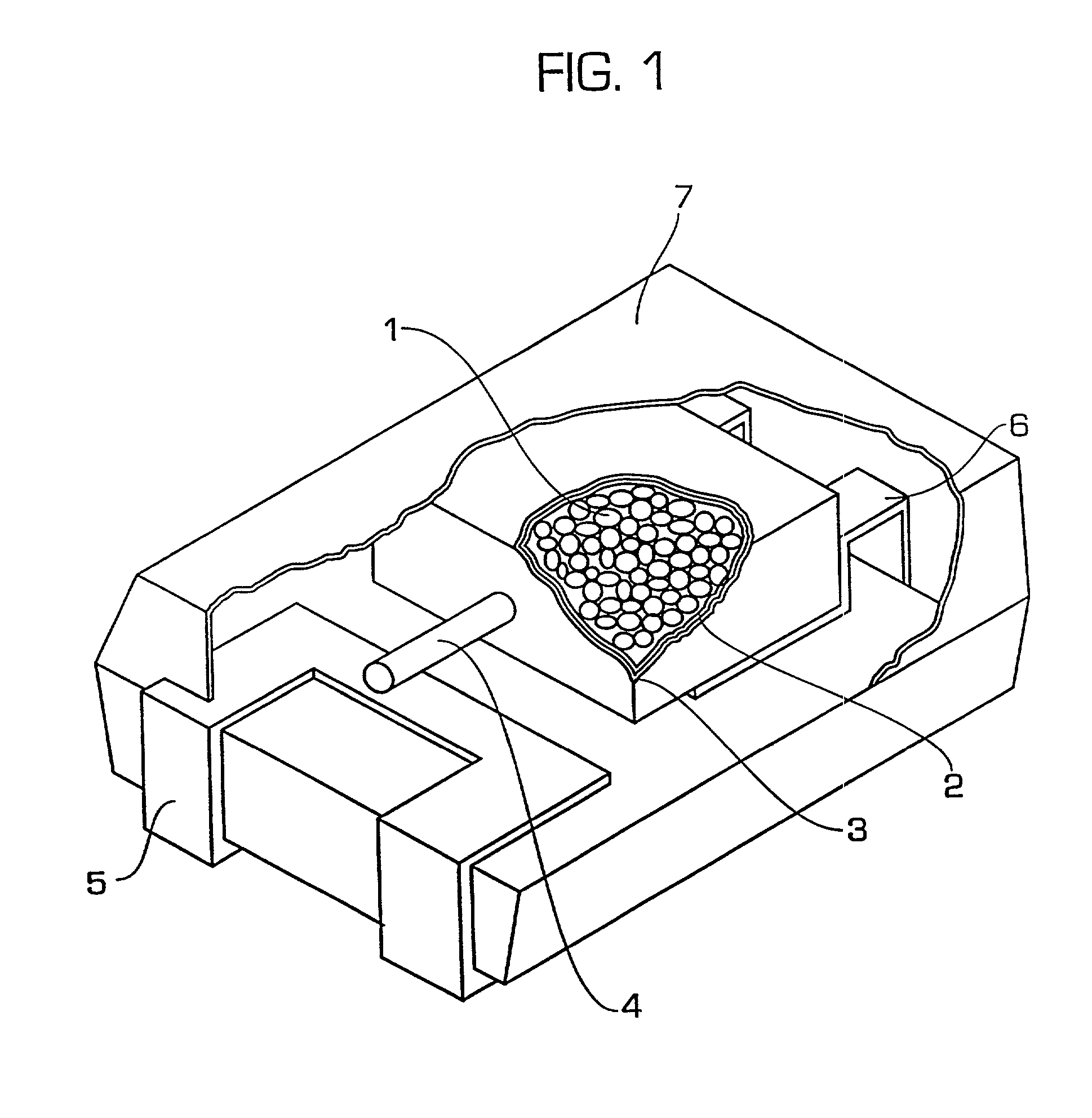

Superconducting single photon detector

InactiveUS20050051726A1Improve quantum efficiencyIncrease surface areaSolid-state devicesMaterial analysis by optical meansDevice materialSuperconductor classification

A single-photon detector includes a superconductor strip biased near its critical current. The superconductor strip provides a discernible output signal upon absorption of a single incident photon. In one example, the superconductor is a strip of NbN (niobium nitride). In another example, the superconductor strip meanders to increase its probability of receiving a photon from a light source. The single-photon detector is suitable for a variety of applications including free-space and satellite communications, quantum communications, quantum cryptography, weak luminescence, and semiconductor device testing.

Owner:DCG SYST +1

Superconducting single photon detector

InactiveUS7049593B2Improve quantum efficiencyIncrease surface areaRadiation pyrometrySolid-state devicesSuperconductor classificationLuminescence

A single-photon detector includes a superconductor strip biased near its critical current. The superconductor strip provides a discernible output signal upon absorption of a single incident photon. In one example, the superconductor is a strip of NbN (niobium nitride). In another example, the superconductor strip meanders to increase its probability of receiving a photon from a light source. The single-photon detector is suitable for a variety of applications including free-space and satellite communications, quantum communications, quantum cryptography, weak luminescence, and semiconductor device testing.

Owner:DCG SYST +1

Ceramic material suitable for repair of a space vehicle component in a microgravity and vacuum environment, method of making same, and method of repairing a space vehicle component

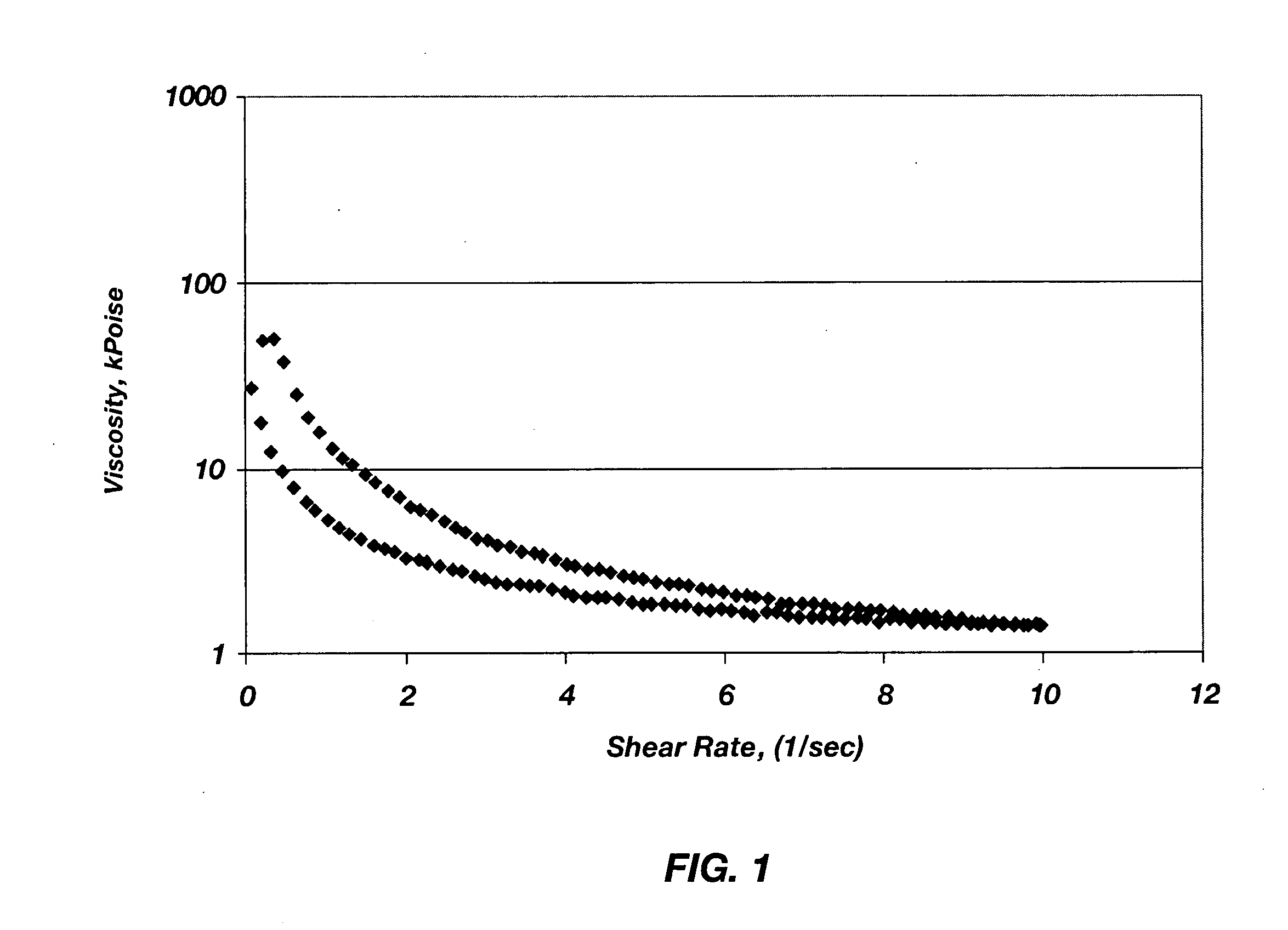

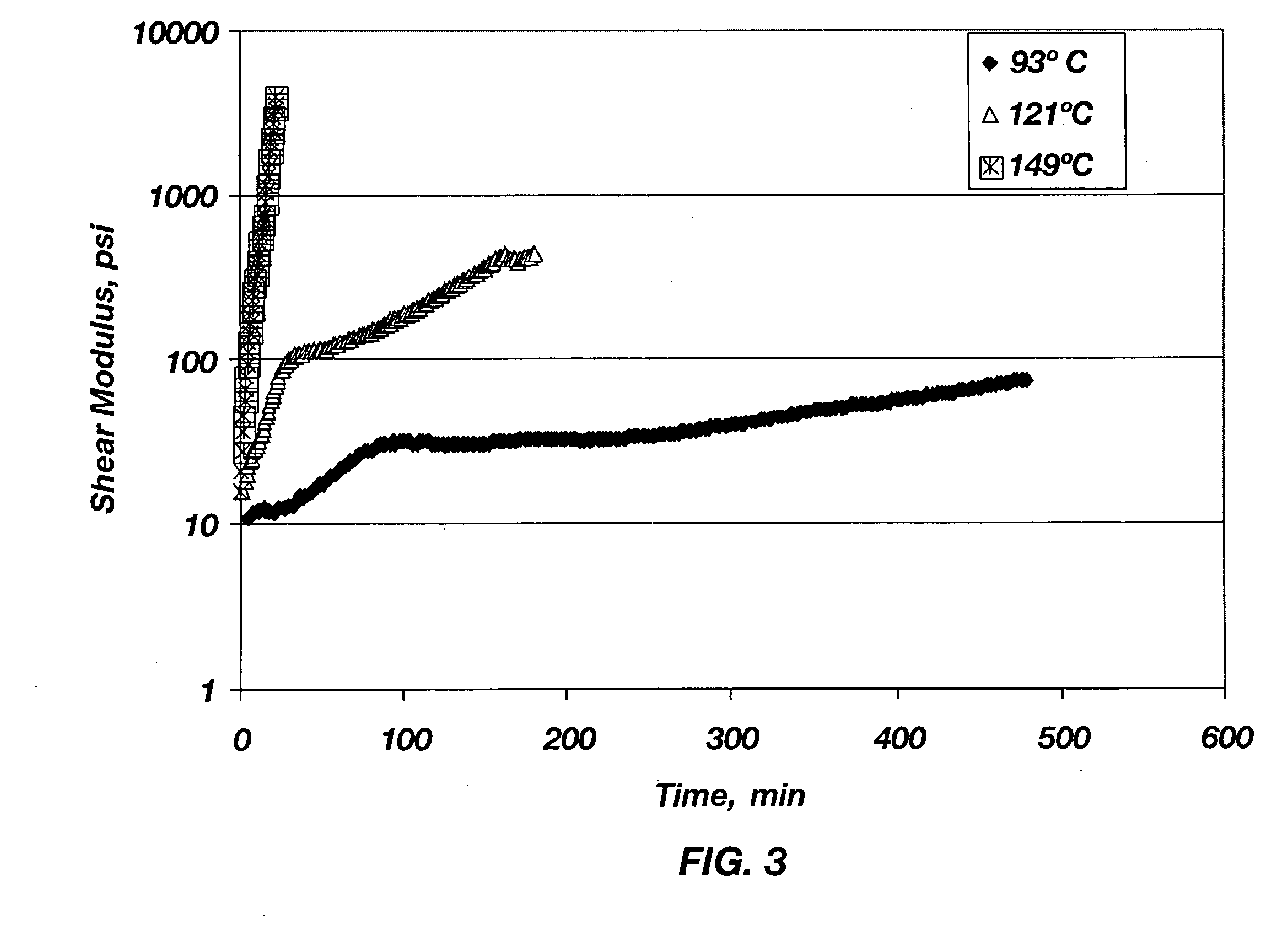

A precursor of a ceramic adhesive suitable for use in a vacuum, thermal, and microgravity environment. The precursor of the ceramic adhesive includes a silicon-based, preceramic polymer and at least one ceramic powder selected from the group consisting of aluminum oxide, aluminum nitride, boron carbide, boron oxide, boron nitride, hafnium boride, hafnium carbide, hafnium oxide, lithium aluminate, molybdenum silicide, niobium carbide, niobium nitride, silicon boride, silicon carbide, silicon oxide, silicon nitride, tin oxide, tantalum boride, tantalum carbide, tantalum oxide, tantalum nitride, titanium boride, titanium carbide, titanium oxide, titanium nitride, yttrium oxide, zirconium, diboride, zirconium carbide, zirconium oxide, and zirconium silicate. Methods of forming the ceramic adhesive and of repairing a substrate in a vacuum and microgravity environment are also disclosed, as is a substrate repaired with the ceramic adhesive.

Owner:COI CERAMICS

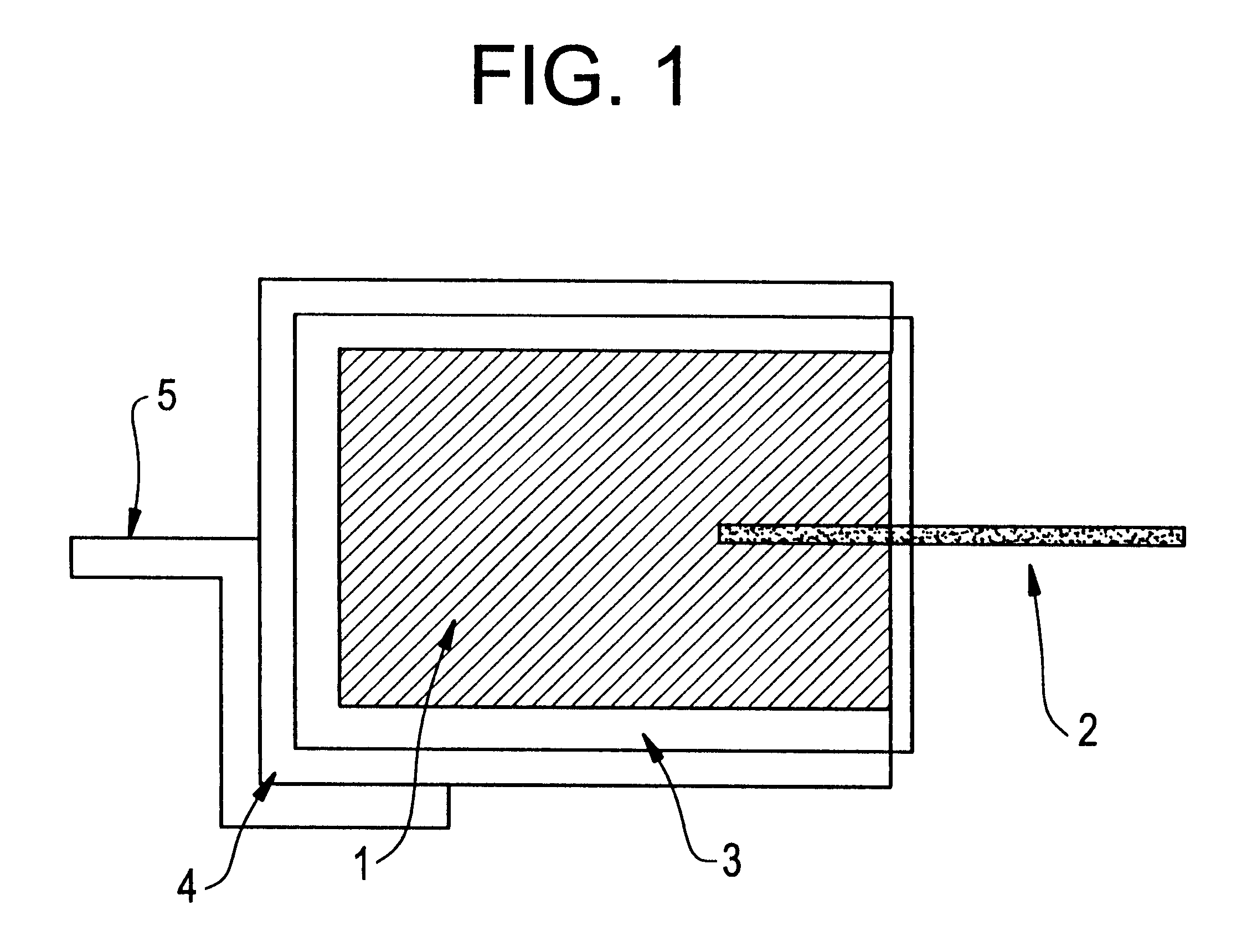

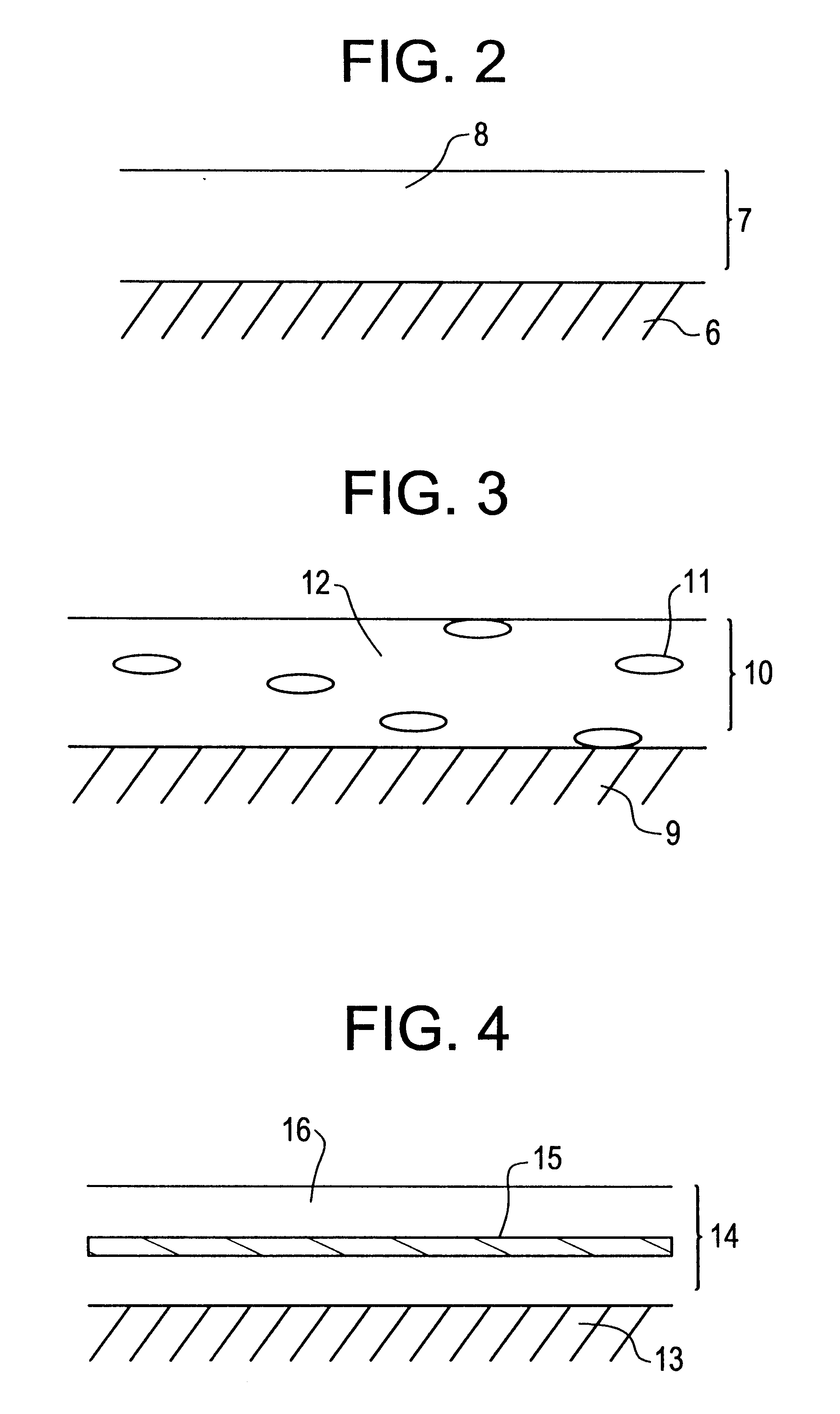

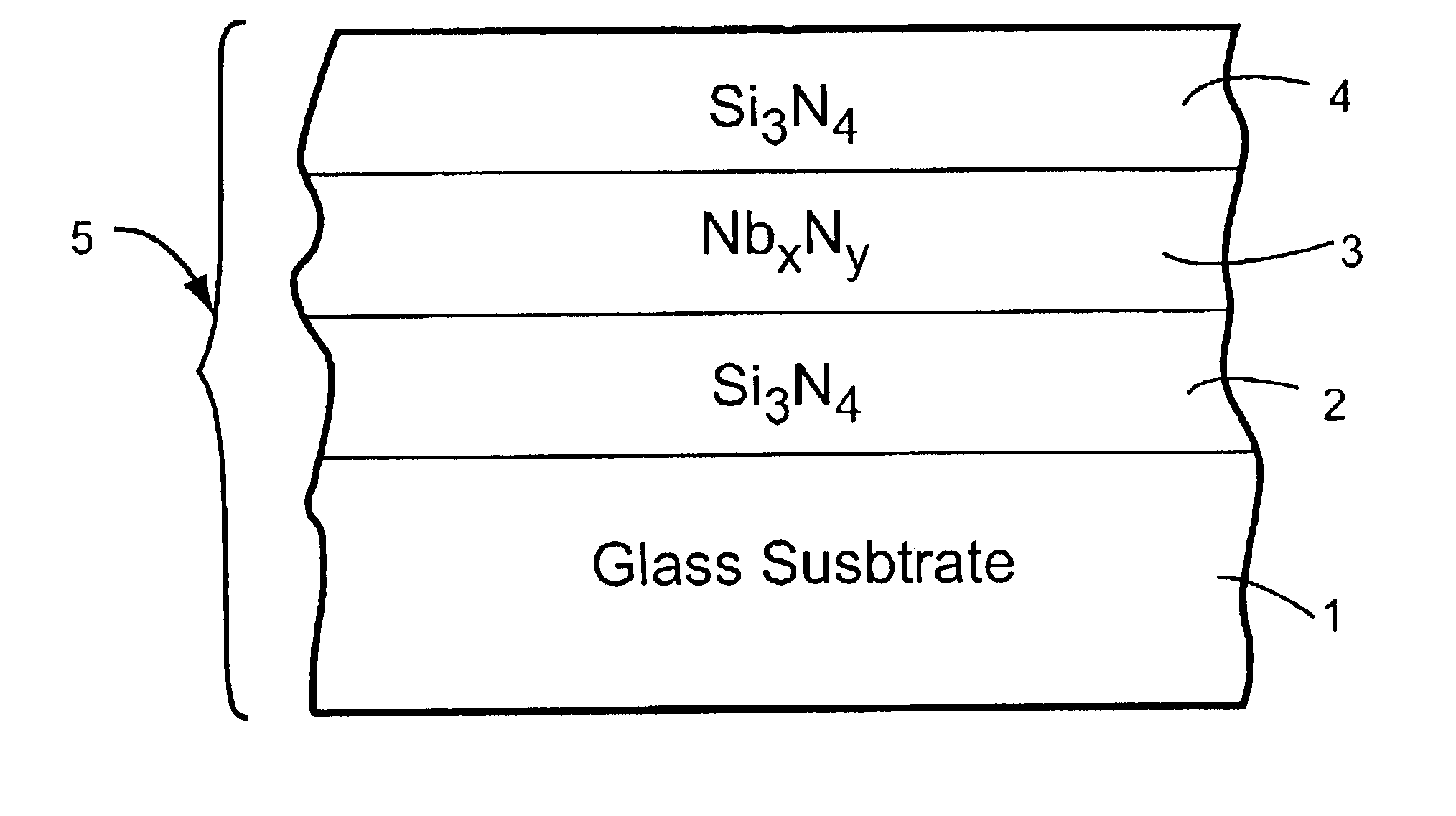

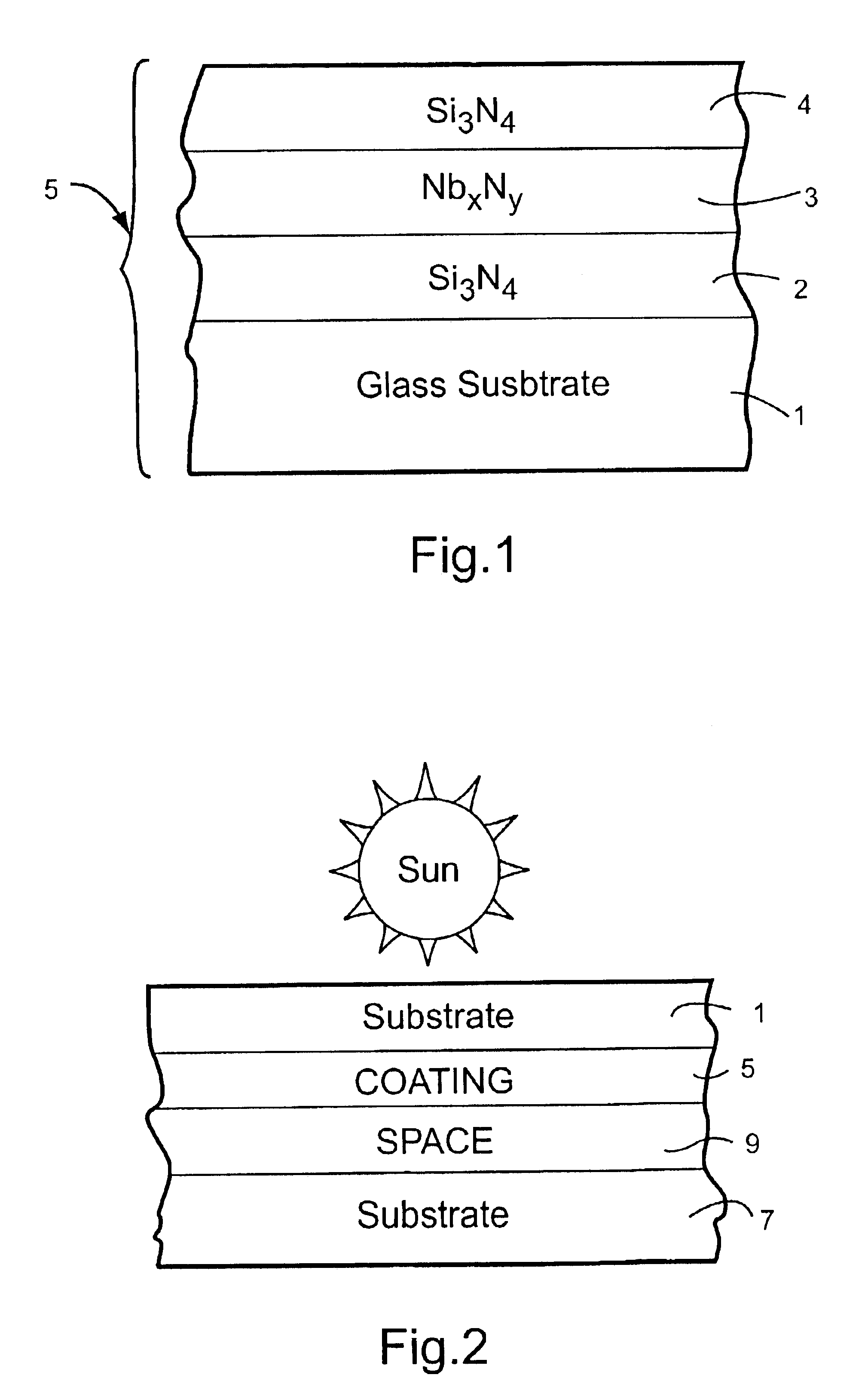

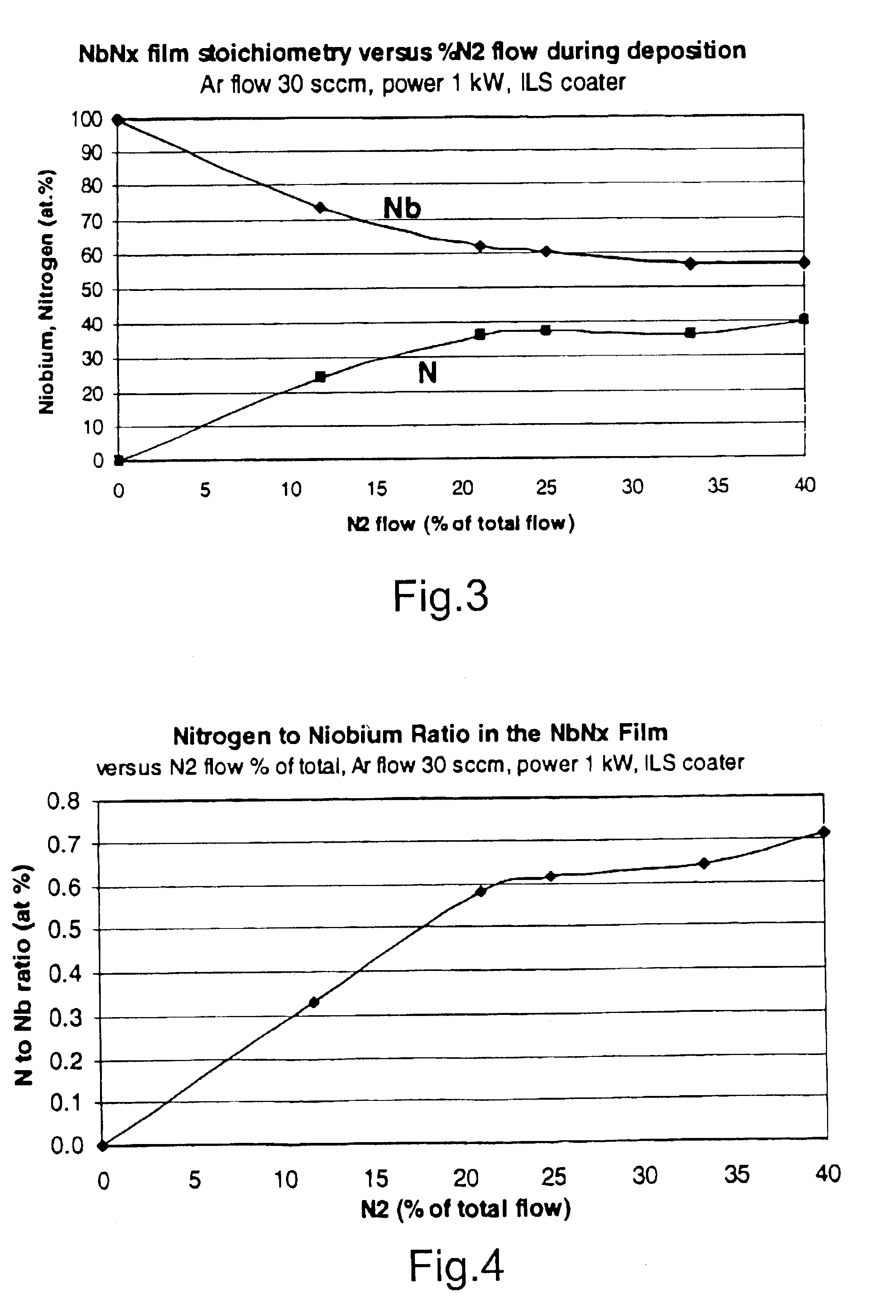

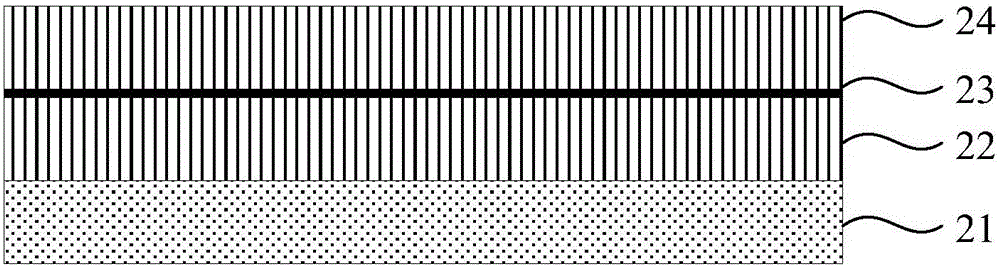

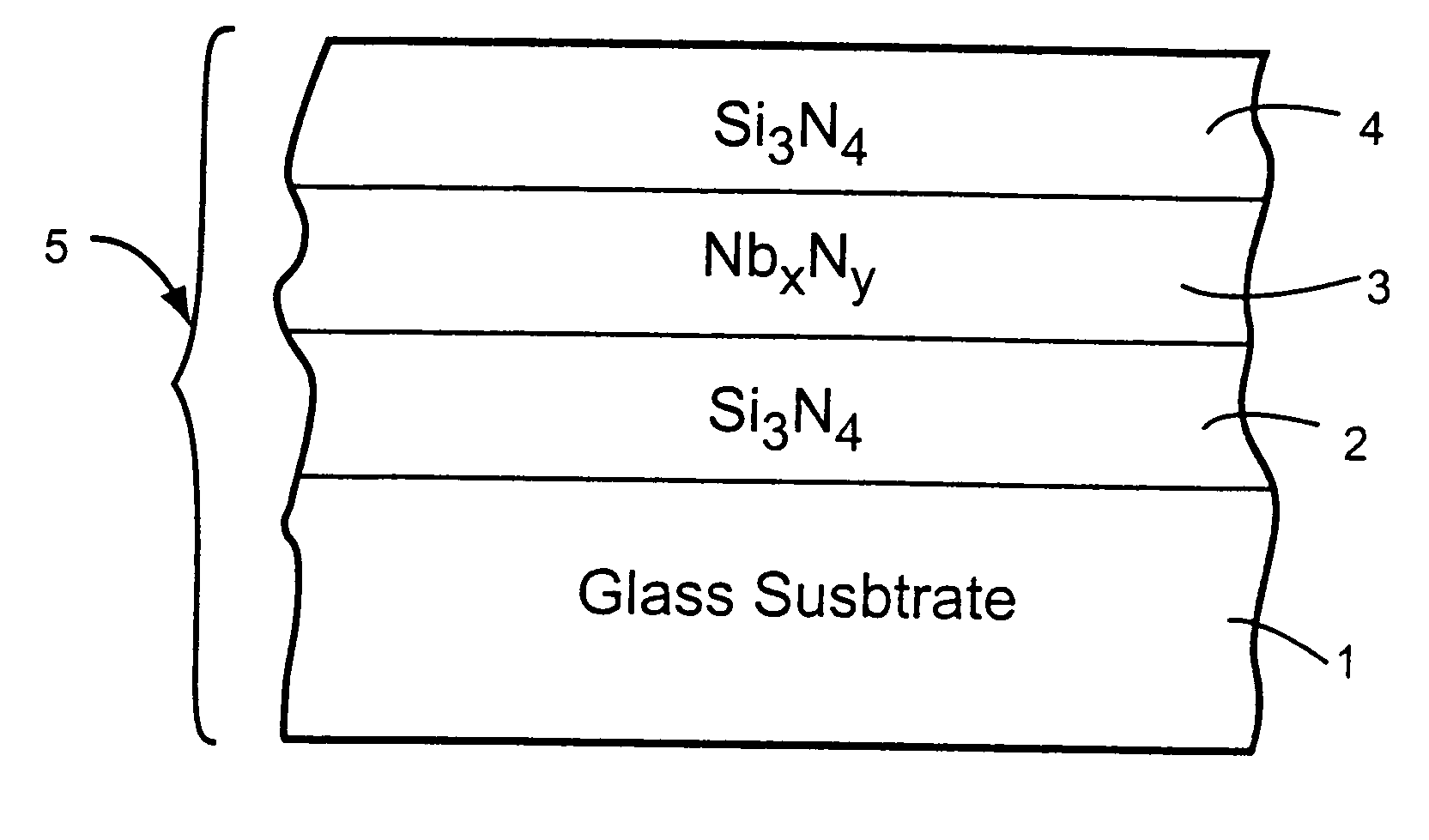

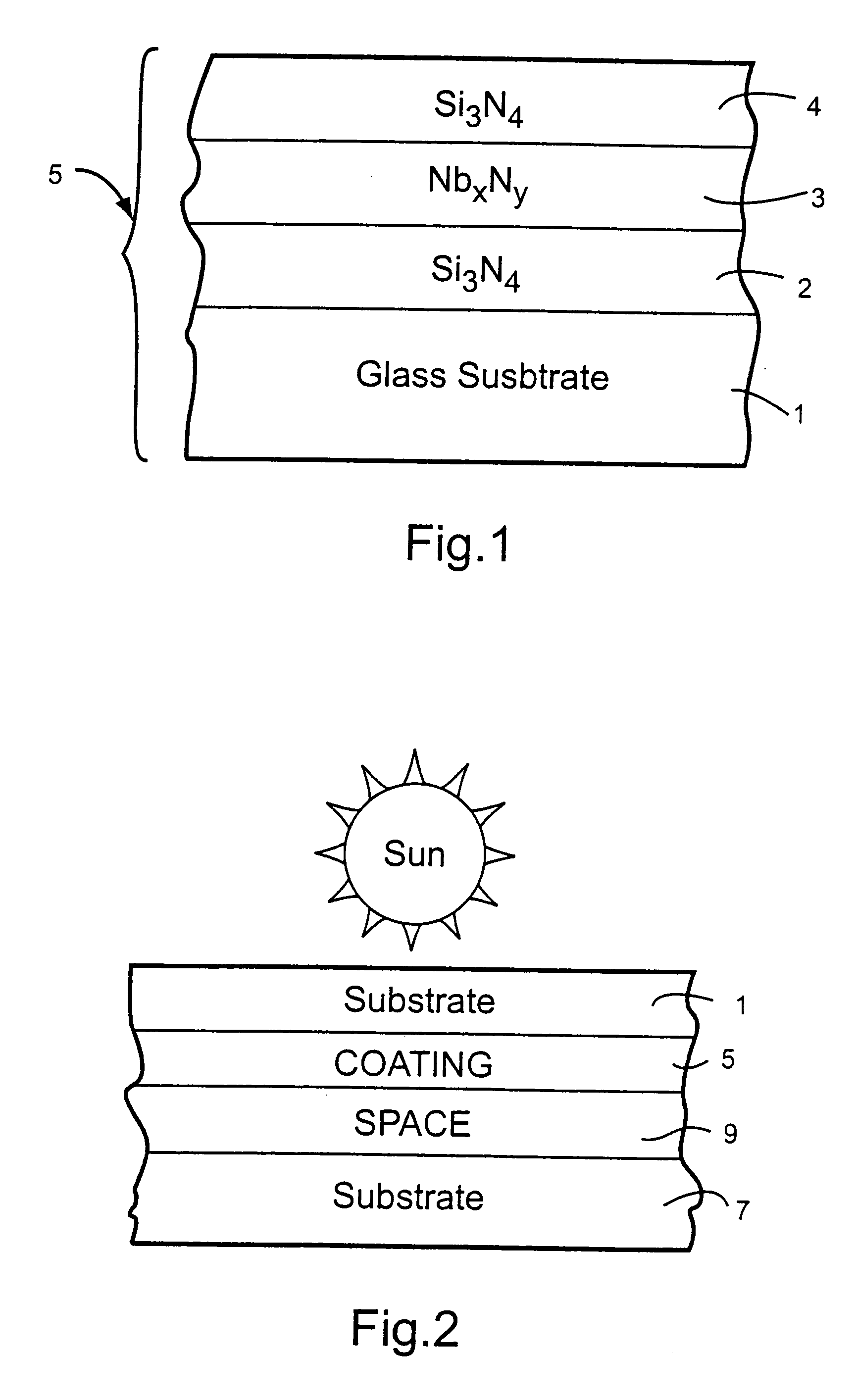

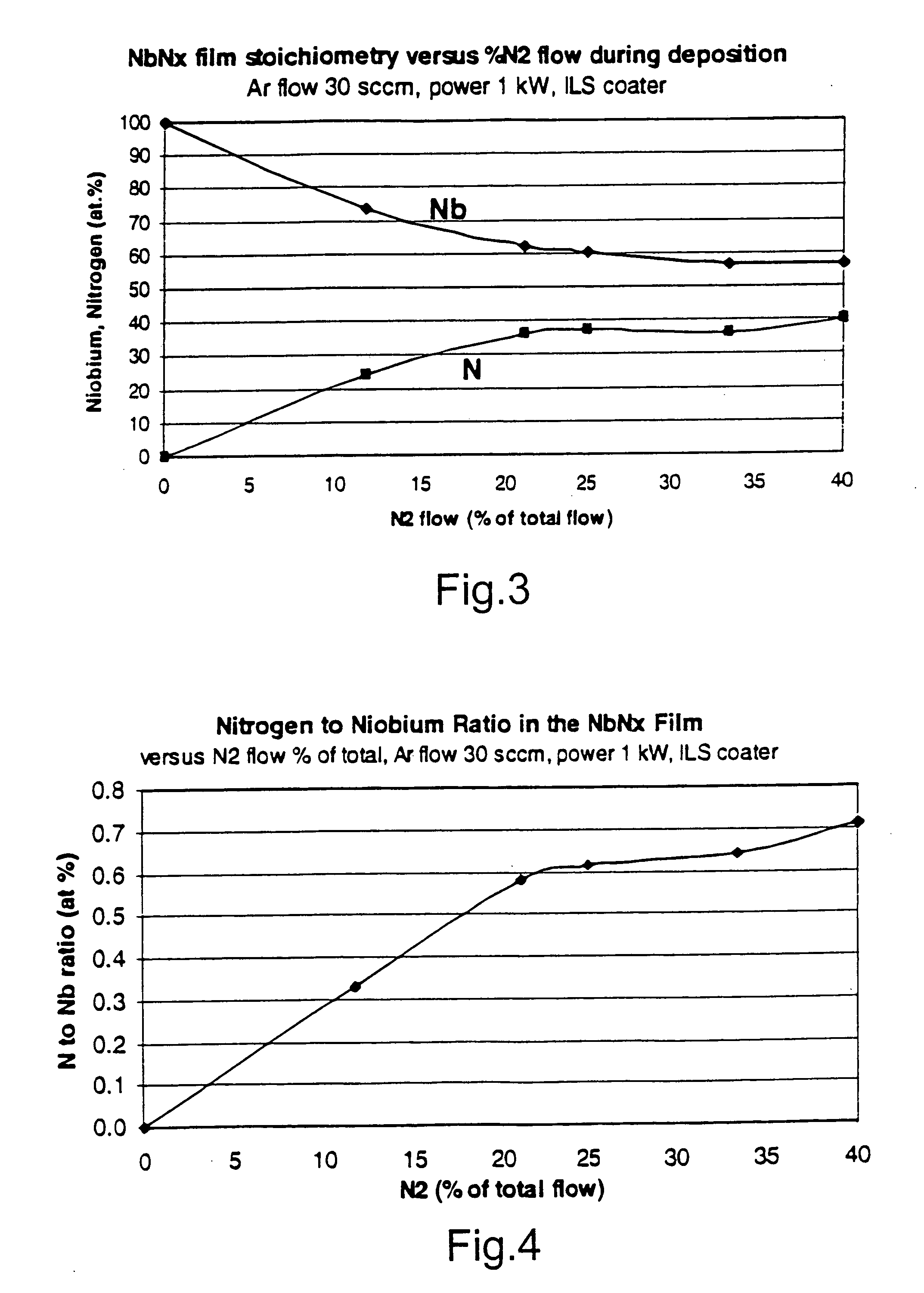

Heat treatable coated article with niobium nitride IR reflecting layer

InactiveUS6994910B2Improved color stabilityImprove mechanical propertiesGlass/slag layered productsNatural mineral layered productsOptoelectronicsMechanical property

A coated article is provided so as to include a solar control coating having an infrared (IR) reflecting layer sandwiched between at least a pair of dielectric layers. The IR reflecting layer includes niobium nitride (NbxNy). The use of niobium nitride enables the coated article to have good corrosion resistance to acid(s), good mechanical performance such as scratch resistance, and / or good color stability (i.e., a low ΔE* value(s)) upon heat treatment (HT). The coated article may be heat treated (e.g., thermally tempered) in certain example embodiments of the invention.

Owner:GUARDIAN GLASS LLC

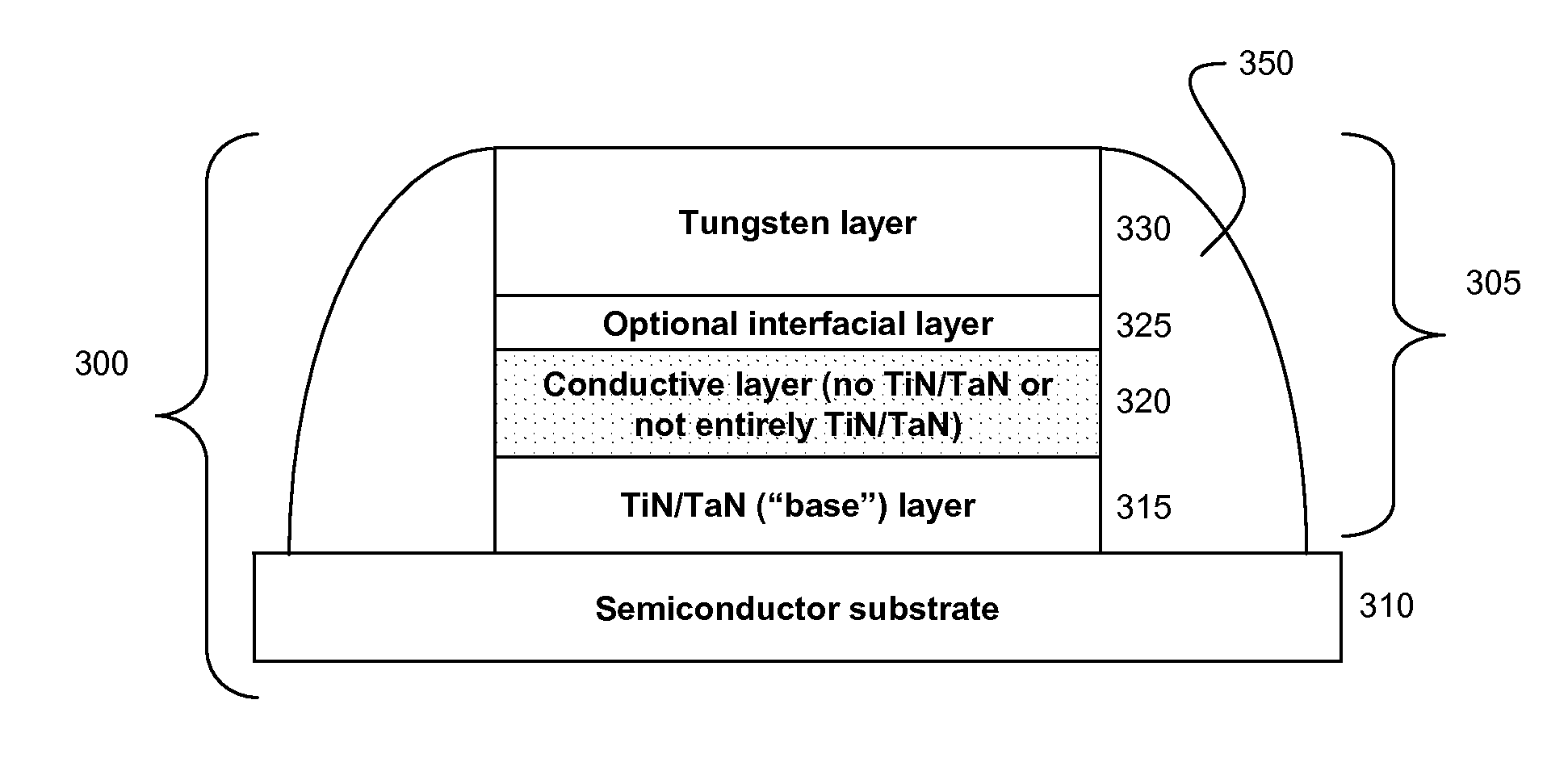

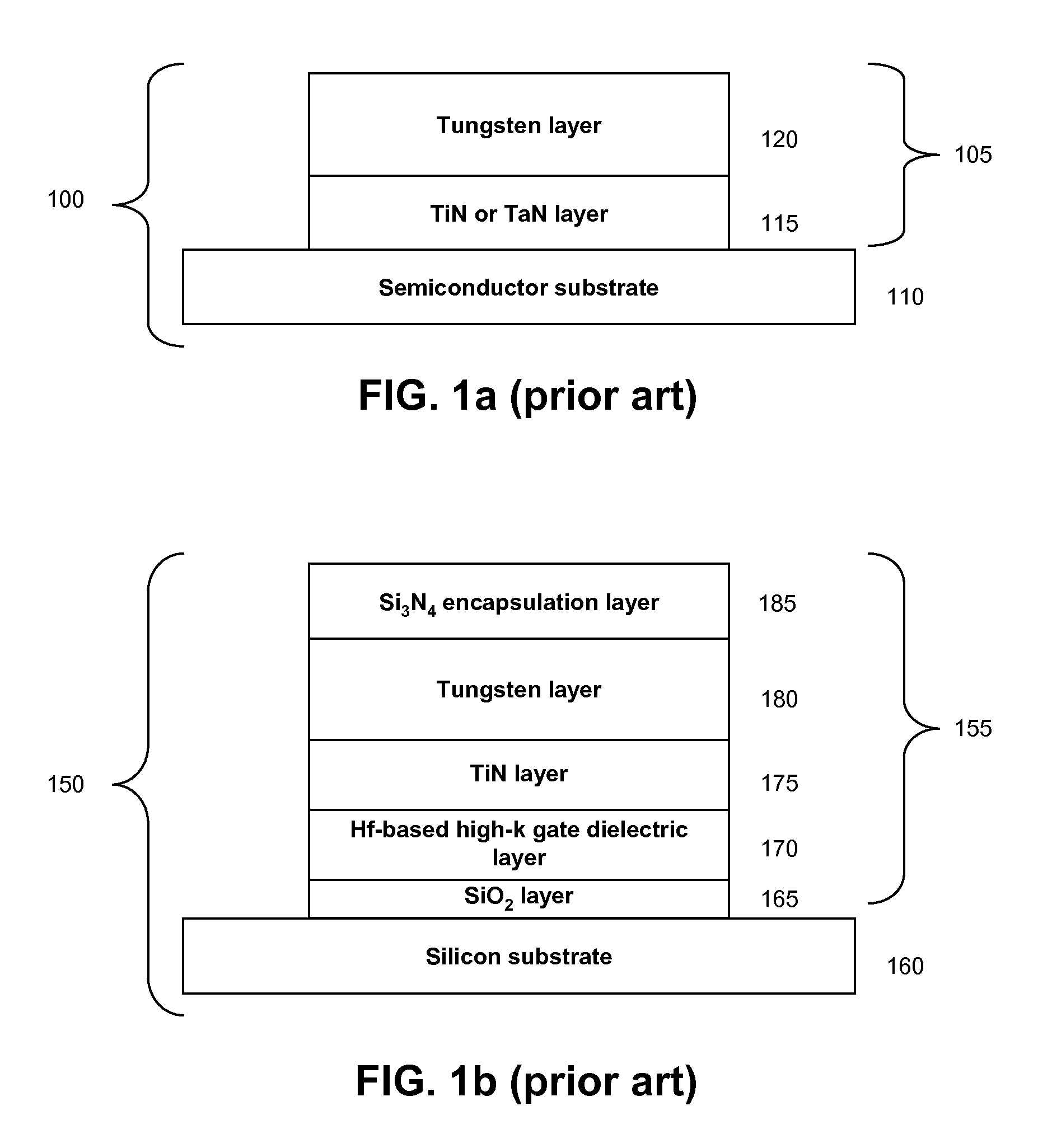

Large-grain, low-resistivity tungsten on a conductive compound

InactiveUS20120228773A1Semiconductor/solid-state device detailsSolid-state devicesTitanium nitrideHafnium

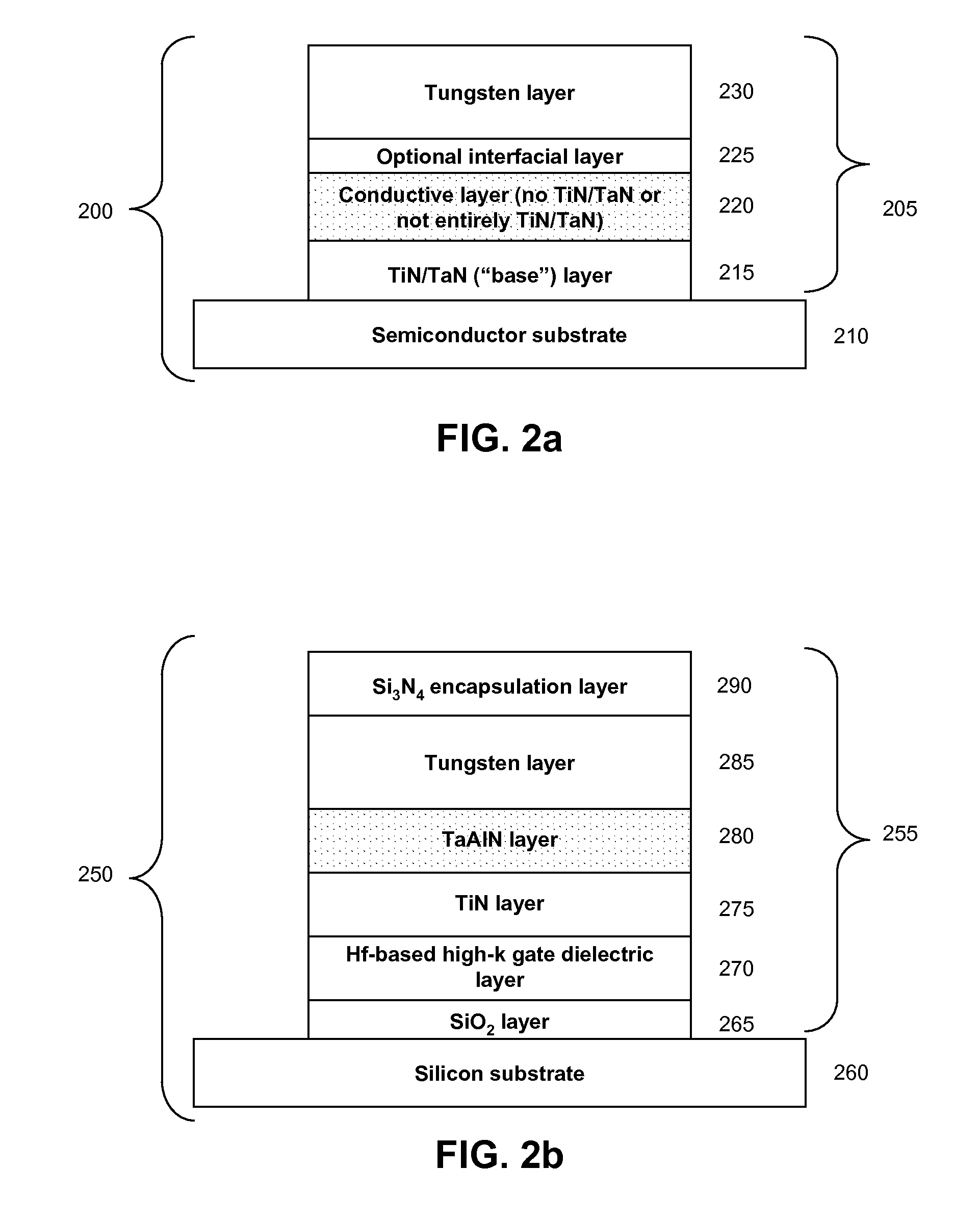

A layered structure and semiconductor device and methods for fabricating a layered structure and semiconductor device. The layered structure includes: a base layer including a material containing titanium nitride, tantalum nitride, or a combination thereof; a conductive layer including a material containing: tantalum aluminum nitride, titanium aluminum nitride, tantalum silicon nitride, titanium silicon nitride, tantalum hafnium nitride, titanium hafnium nitride, hafnium nitride, hafnium carbide, tantalum carbide, vanadium nitride, niobium nitride, or any combination thereof; and a tungsten layer. The semiconductor device includes: a semiconductor substrate; a base layer; a conductive layer; and a tungsten layer.

Owner:GLOBALFOUNDRIES INC

Ceramic material suitable for repair of a space vehicle component in a microgravity and vacuum environment, method of making same, and method of repairing a space vehicle component

A precursor of a ceramic adhesive suitable for use in a vacuum, thermal, and microgravity environment. The precursor of the ceramic adhesive includes a silicon-based, preceramic polymer and at least one ceramic powder selected from the group consisting of aluminum oxide, aluminum nitride, boron carbide, boron oxide, boron nitride, hafnium boride, hafnium carbide, hafnium oxide, lithium aluminate, molybdenum silicide, niobium carbide, niobium nitride, silicon boride, silicon carbide, silicon oxide, silicon nitride, tin oxide, tantalum boride, tantalum carbide, tantalum oxide, tantalum nitride, titanium boride, titanium carbide, titanium oxide, titanium nitride, yttrium oxide, zirconium diboride, zirconium carbide, zirconium oxide, and zirconium silicate. Methods of forming the ceramic adhesive and of repairing a substrate in a vacuum and microgravity environment are also disclosed, as is a substrate repaired with the ceramic adhesive.

Owner:COI CERAMICS

Method for preparing nitrogen0gradient hard reaction membrane of titanium aluminum niobium nitride (TiAlNbN)

InactiveCN103572220AStrong adhesionImprove adhesionVacuum evaporation coatingSputtering coatingTitanium nitridePhysical chemistry

The invention relates to a method for preparing a nitrogen-gradient hard reaction membrane of titanium aluminum niobium nitride (TiAlNbN). The method sequentially comprises steps of 1. confirmation of a deposition technique and ingredients of target materials; 2. selection and pretreatment of workpieces; 3. confirmation of a preliminary bombardment process; 4. confirmation of a deposition process; 5. vacuum heating treatment; 6. workpiece revolution. According to the method, the cost for coating is lowered, high adhesive force, high hardness and high thermal shock property of the membrane are guaranteed, furthermore, the inner stress of the membrane is reduced, and the reaction membrane has good stability and repeatability.

Owner:贵州中德西格姆精密制造有限公司

Niobium nitride superconducting quantum interference device (SQUID), preparation method and parameter post-processing approach

ActiveCN106816525AImprove production efficiencyImprove consistencySuperconductor detailsDissimilar materials junction devicesElectrical resistance and conductanceOptoelectronics

The present invention provides a niobium nitride SQUID, a preparation method and a parameter post-processing approach. The preparation method comprises the steps of firstly depositing a niobium nitride-insulating layer-niobium nitride three-layer thin film structure on a substrate, and then preparing a superconducting ring and a bottom electrode structure of the SQUID; then preparing a plurality of parallel Josephson junctions; and then depositing an insulating thin film on the surface of the device, and holing on the surface of each Josephson junction and the surface of the bottom electrode to lead out a top electrode in the subsequent step; and then depositing a metal thin film and preparing a metal bypass resistor; and finally depositing a niobium nitride thin film and preparing a comb-shaped top electrode. By the preparation method and the parameter post-processing method of the present invention, if the numerical values of a critical current and the bypass resistor of the NbN SQUID are discovered to have larger deviation with the design values by a test, the post processing can be carried out on the device, so that the numerical values of the critical current and the bypass resistor approach the design numerical values, and the consistency of the device is improved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

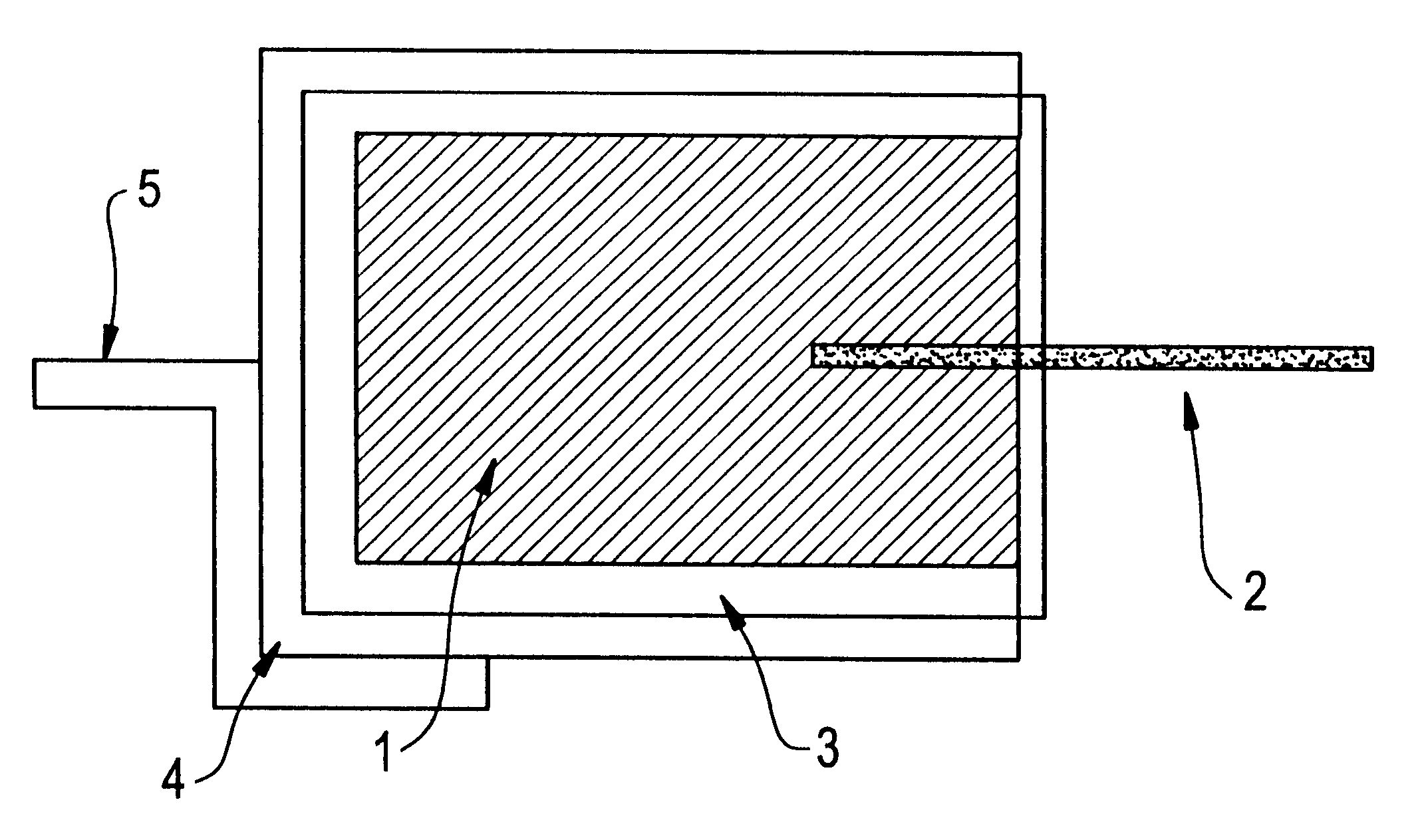

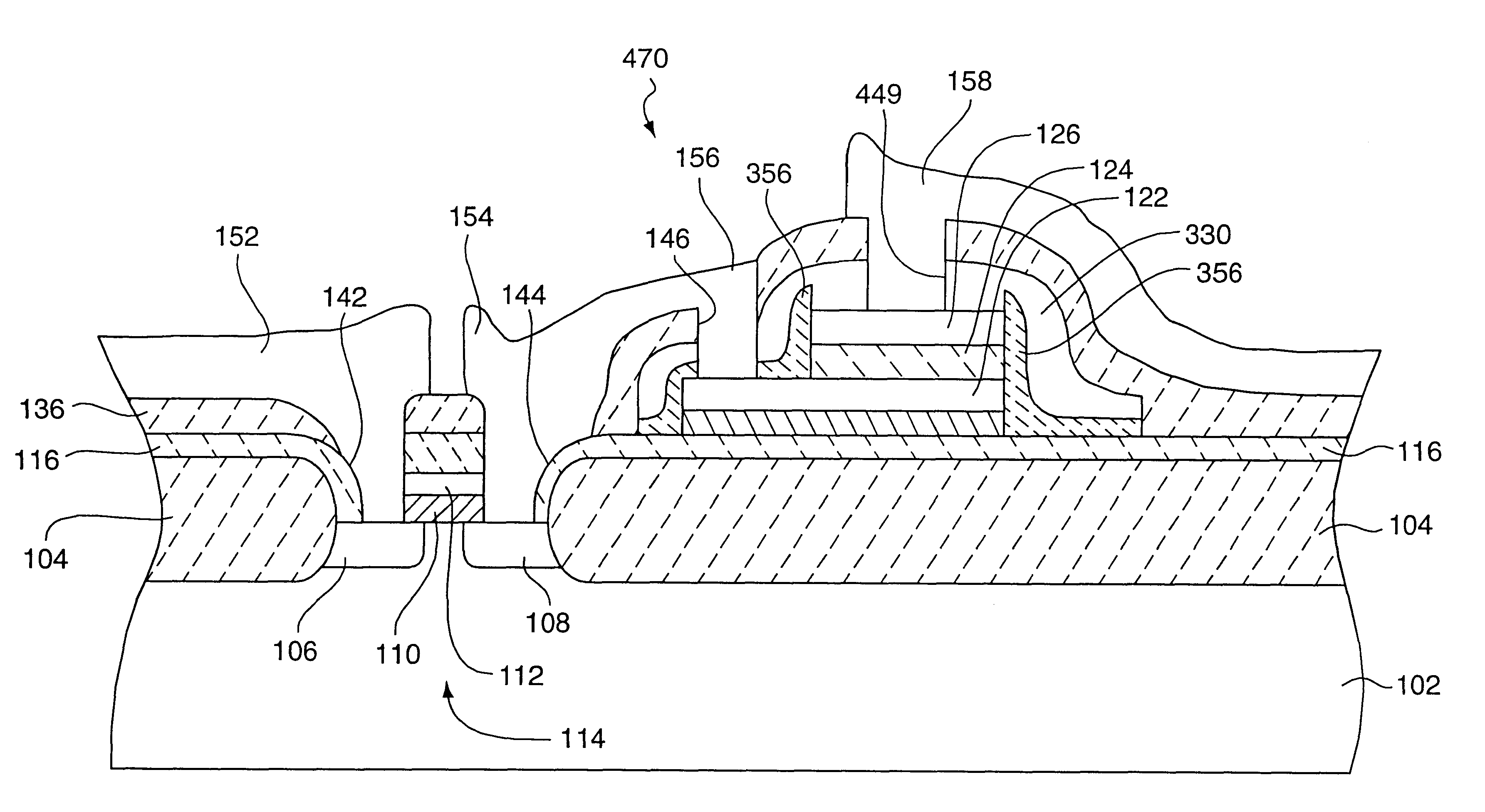

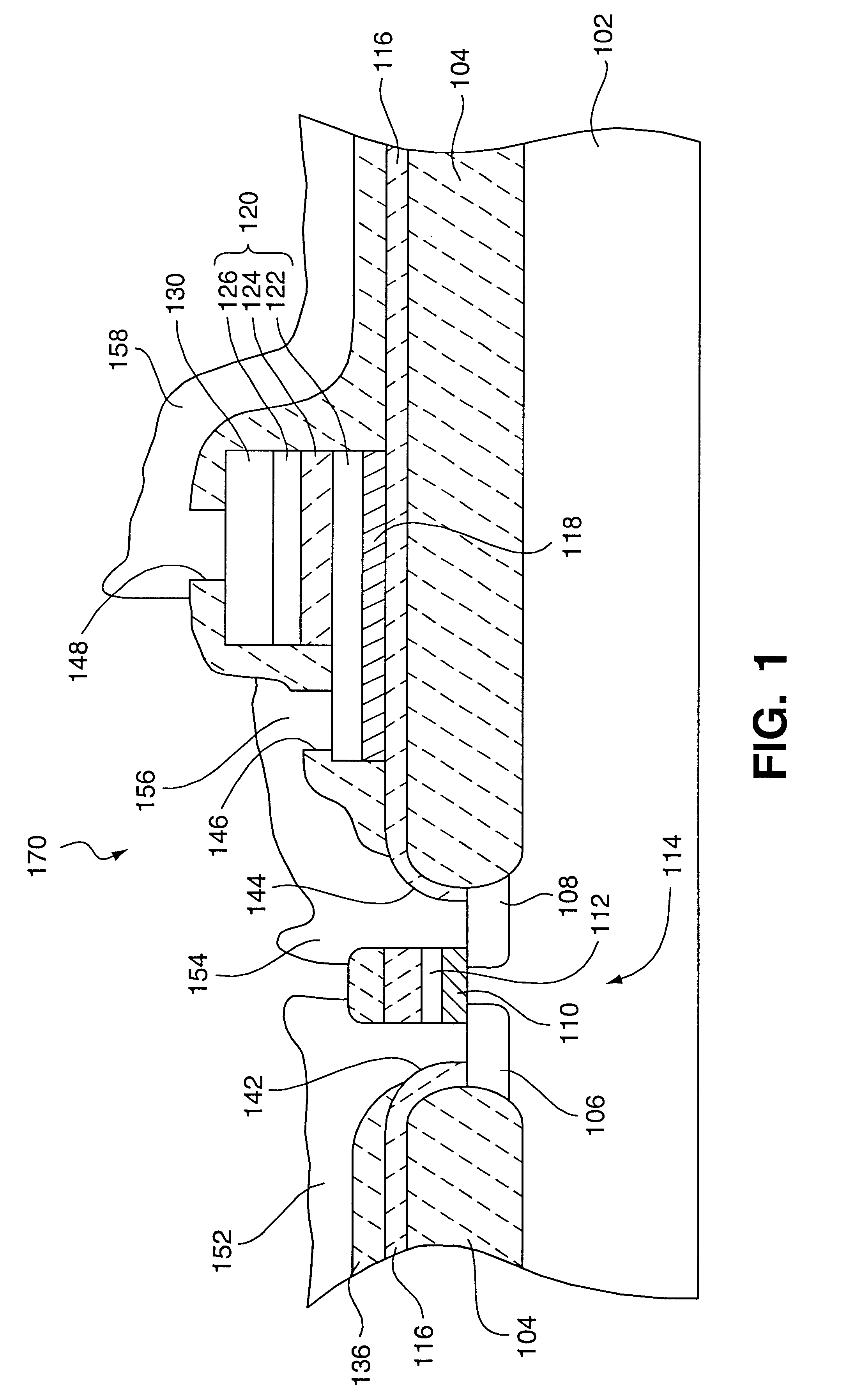

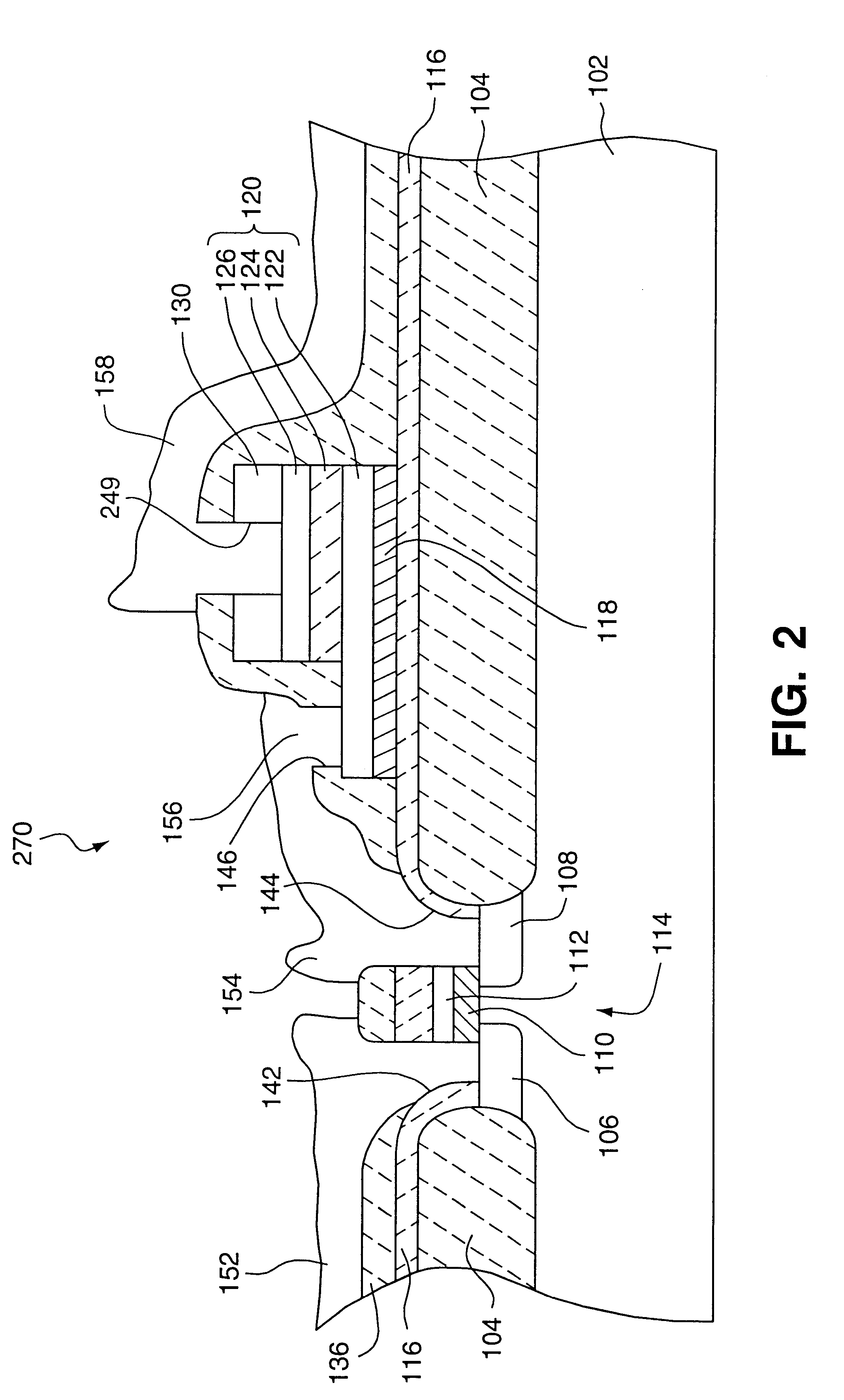

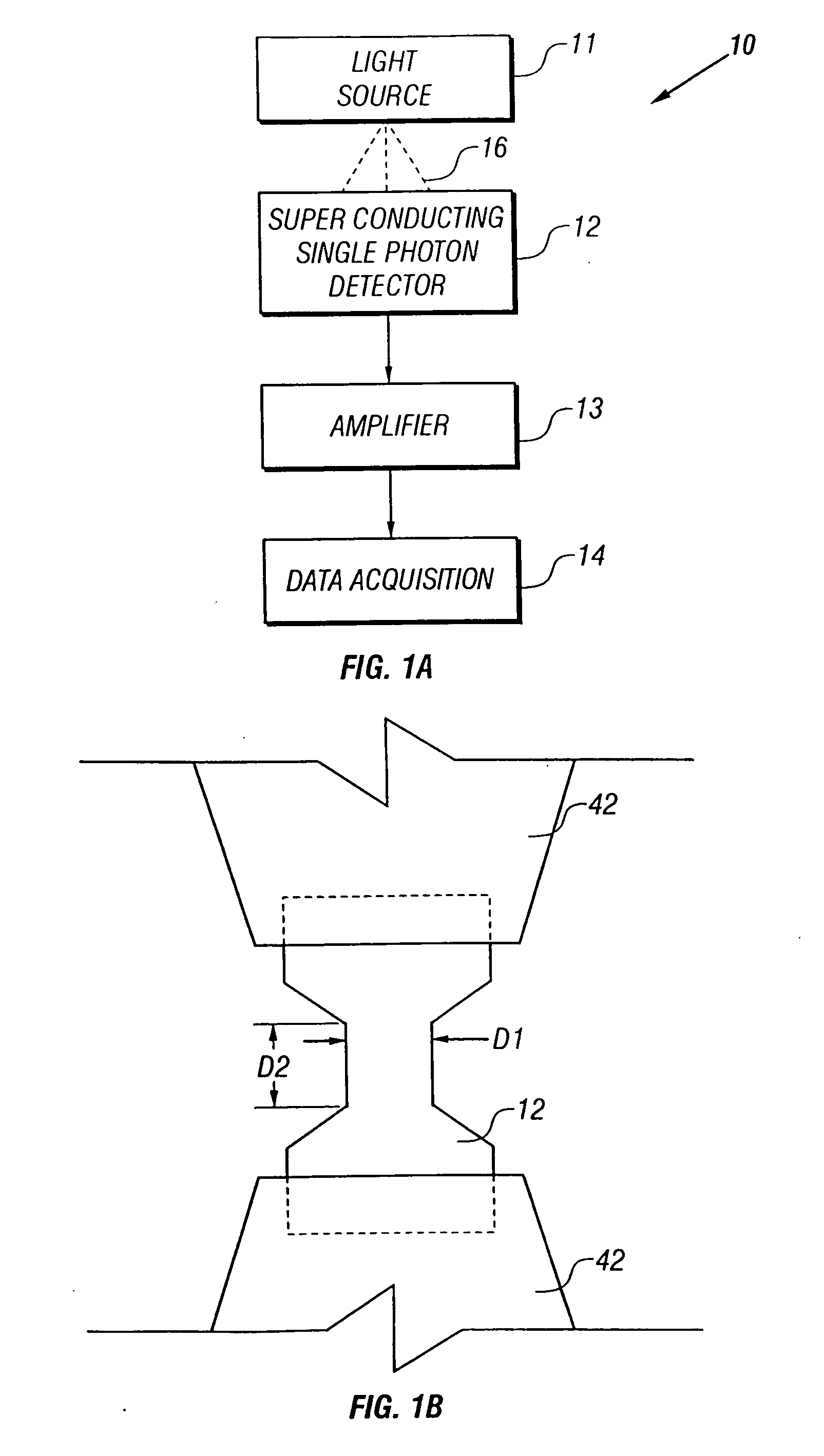

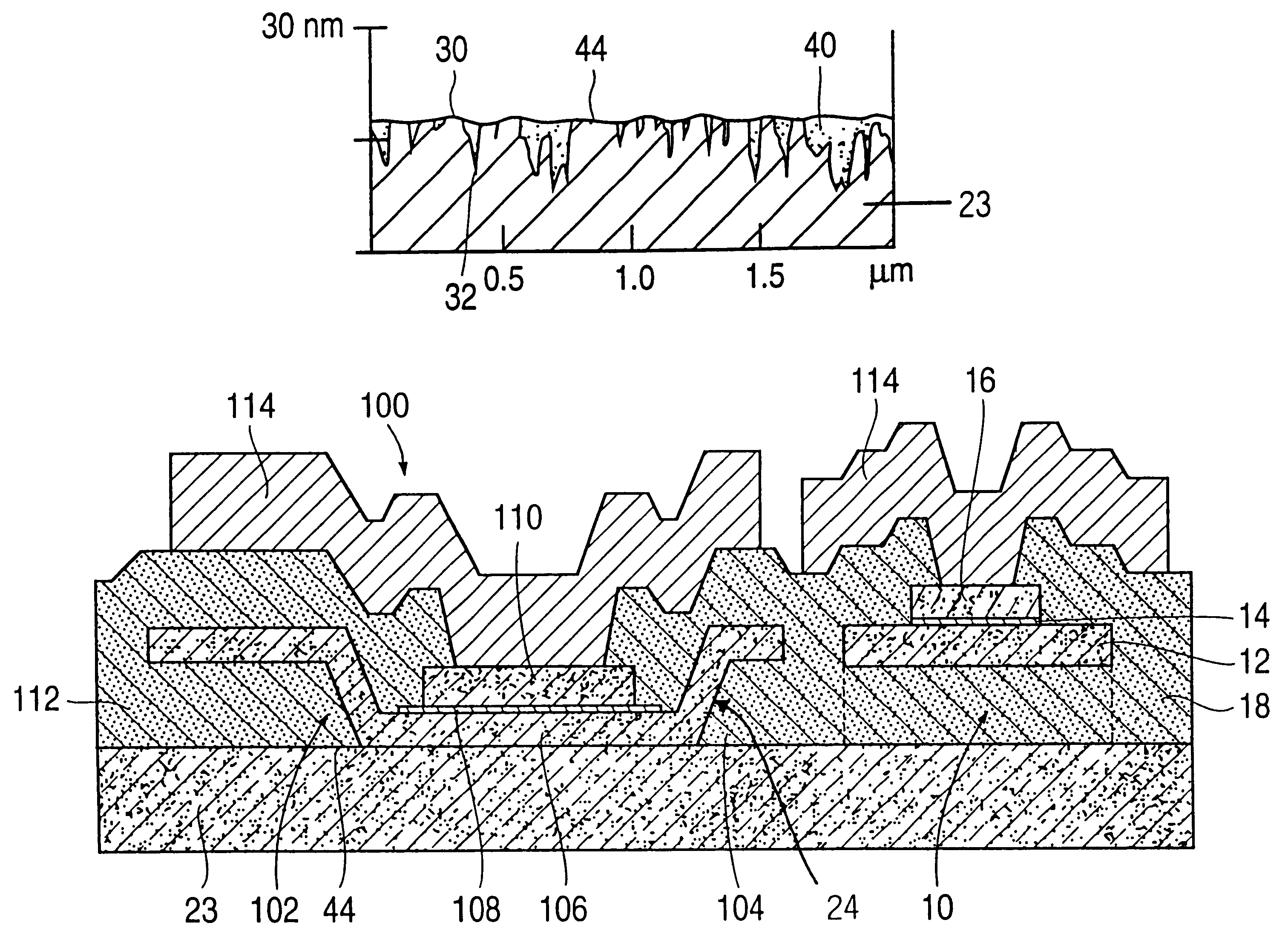

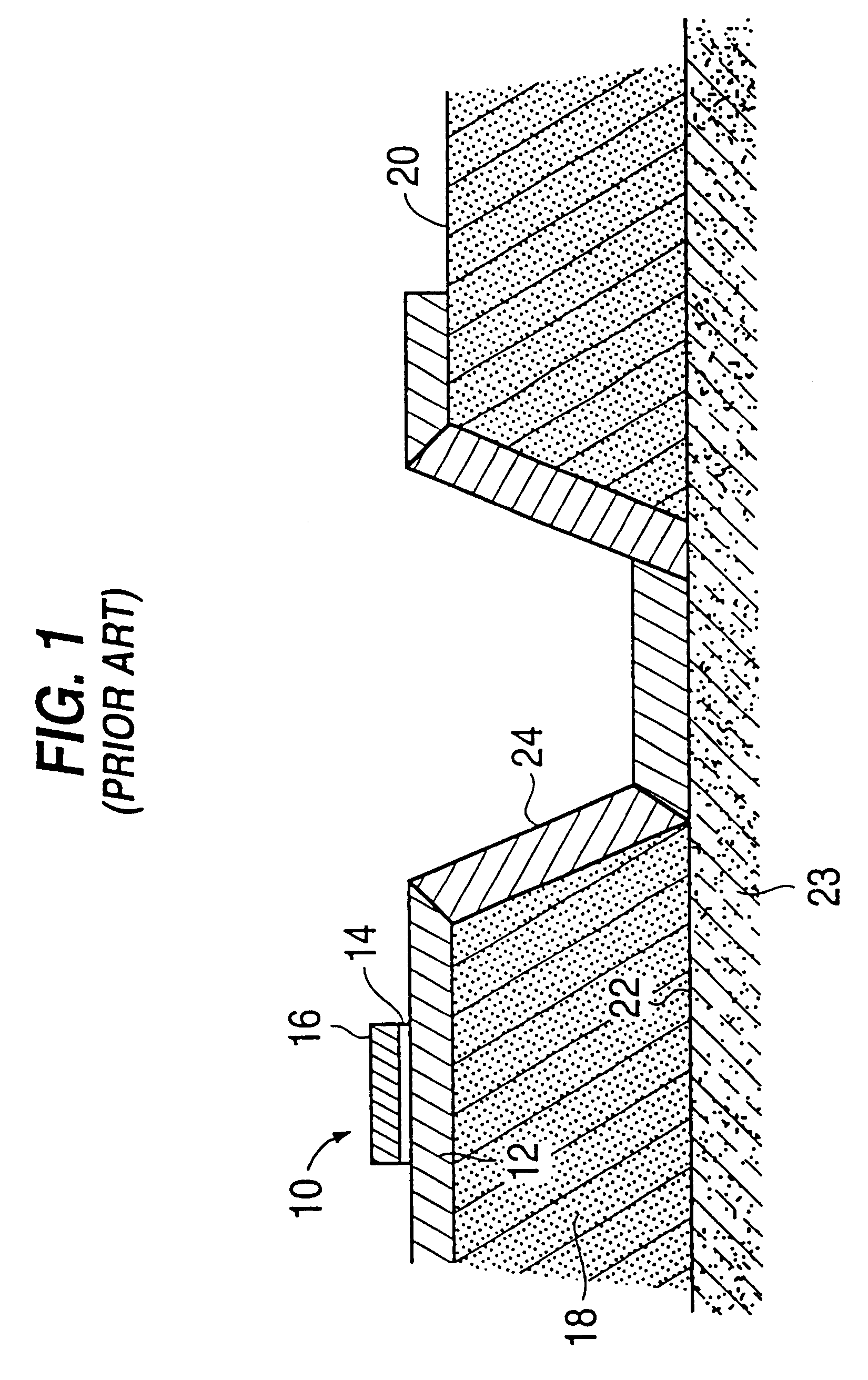

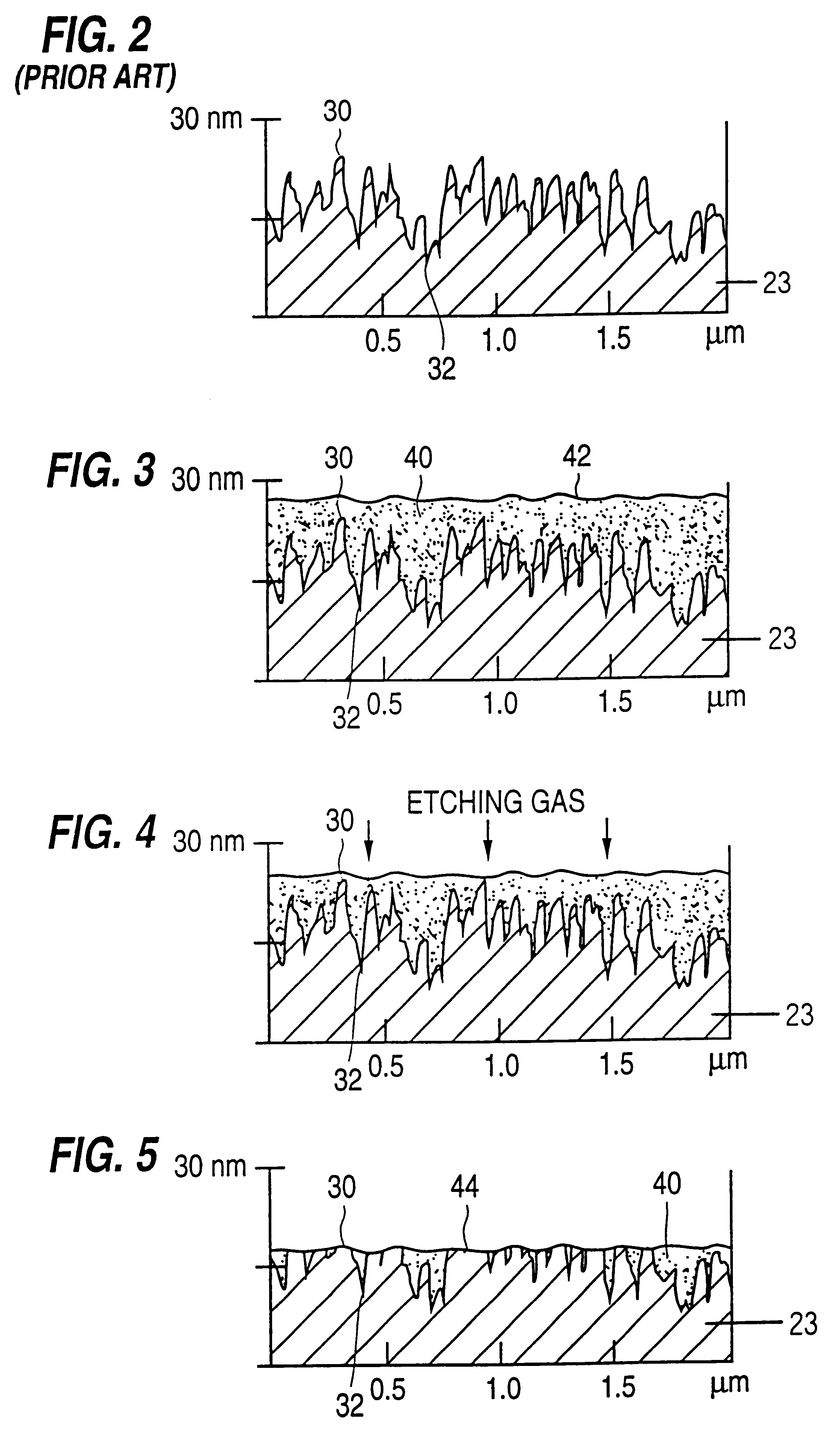

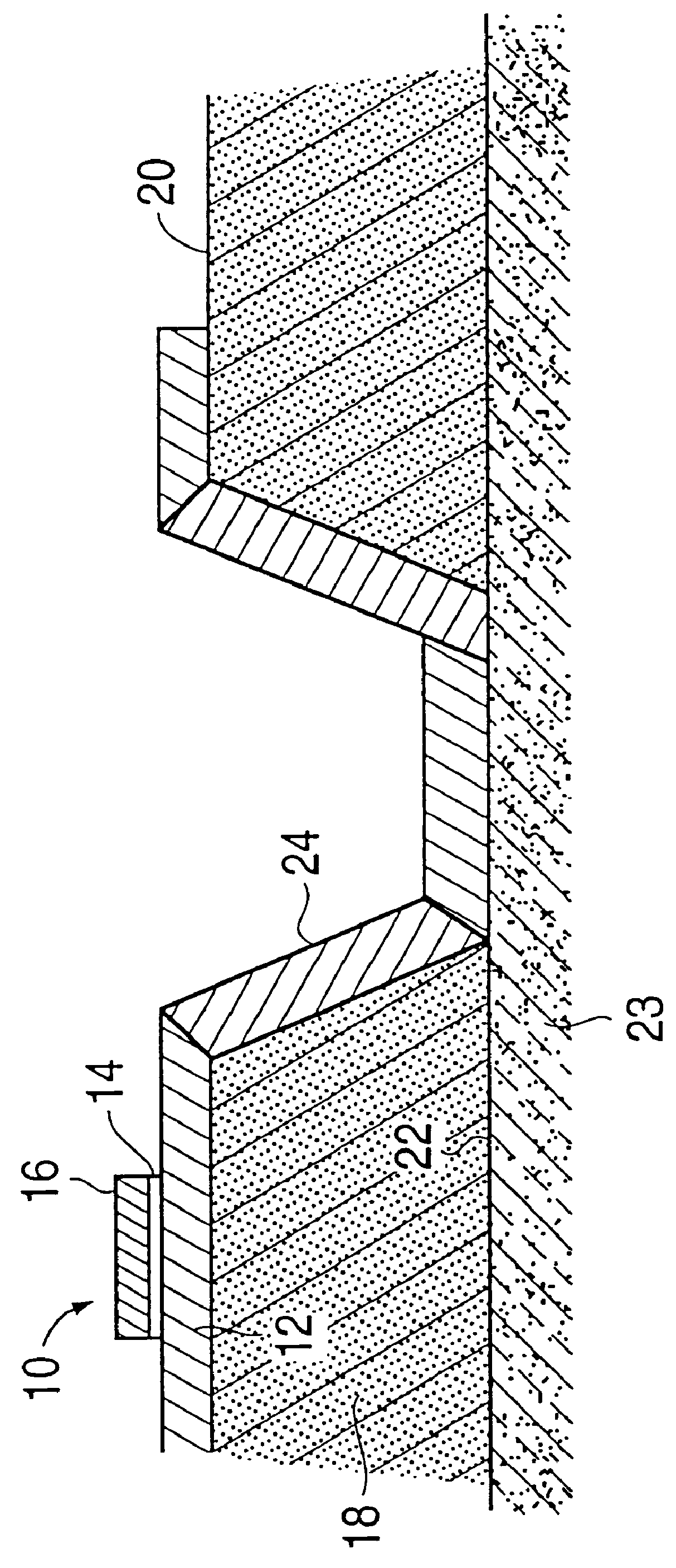

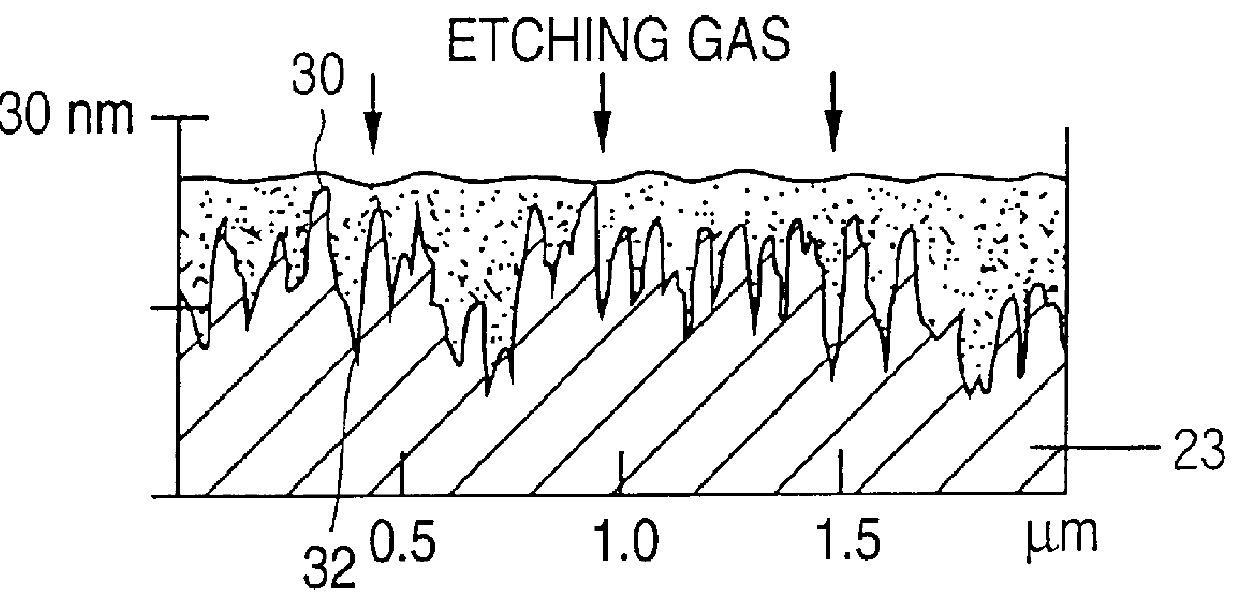

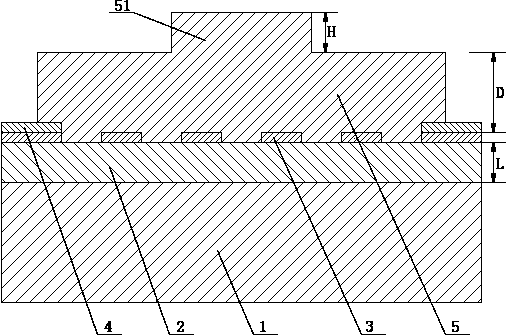

Process for reducing surface roughness of superconductor integrated circuit having a ground plane of niobium nitride of improved smoothness

InactiveUS6384423B1Superconductors/hyperconductorsSolid-state devicesElectrical conductorSurface roughness

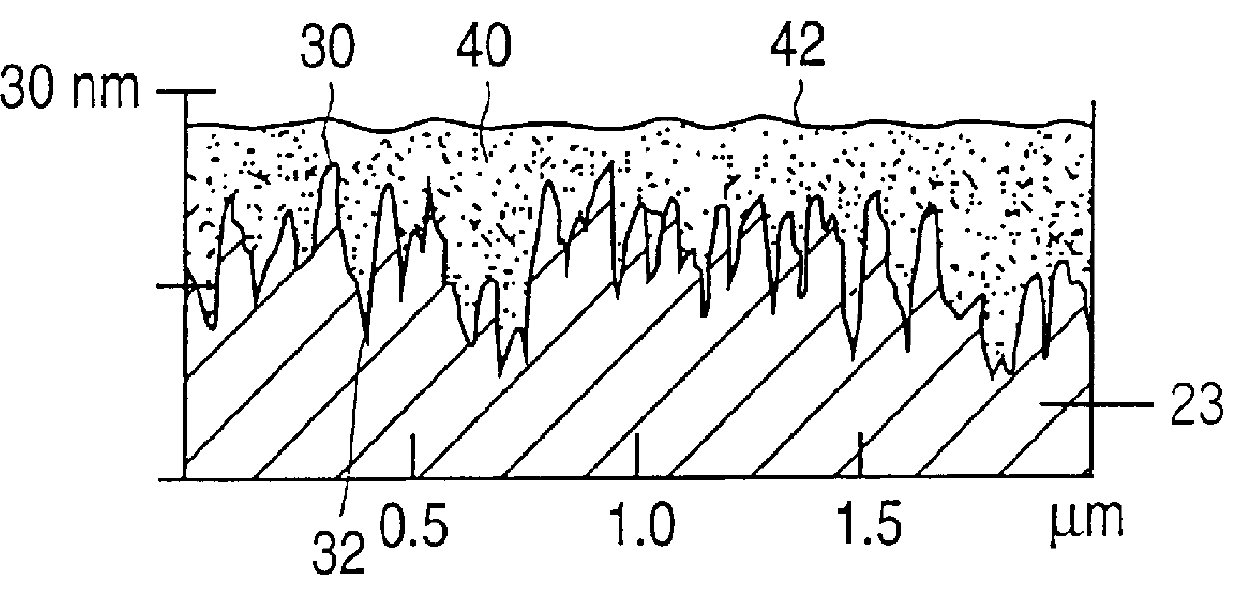

The invention is a process for reducing roughness of a surface of a superconductor material (23) having an undesirable surface roughness (30 and 32) and a trilayer superconductor integrated circuit (100). The process for reducing roughness of a surface of superconductor material having an undesirable surface roughness includes coating the surface with an oxide layer (40) to fill the undesirable surface roughness and to produce an exposed oxide surface (42) with a roughness less than the surface roughness; and etching the exposed oxide surface to remove a thickness of the oxide layer followed by removing at least a portion of the oxide layer filling the undesirable surface roughness and a portion of the surface of the superconductor material to produce an exposed etched surface (44) comprised of at least the superconductor material which has a surface roughness less than the undesirable surface roughness.

Owner:NORTHROP GRUMAN CORP

Process for reducing surface roughness of superconductor integrated circuit having a ground plane of niobium nitride of improved smoothness

InactiveUS6110392ASuperconductors/hyperconductorsDecorative surface effectsElectrical conductorSurface roughness

The invention is a process for reducing roughness of a surface of a superconductor material (23) having an undesirable surface roughness (30 and 32) and a trilayer superconductor integrated circuit (100). The process for reducing roughness of a surface of superconductor material having an undesirable surface roughness includes coating the surface with an oxide layer (40) to fill the undesirable surface roughness and to produce an exposed oxide surface (42) with a roughness less than the surface roughness; and etching the exposed oxide surface to remove a thickness of the oxide layer followed by removing at least a portion of the oxide layer filling the undesirable surface roughness and a portion of the surface of the superconductor material to produce an exposed etched surface (44) comprised of at least the superconductor material which has a surface roughness less than the undesirable surface roughness.

Owner:NORTHROP GRUMAN CORP

Heat treatable coated article with niobium nitride IR reflecting layer and method of making same

InactiveUS20050205416A1Improved color stabilityImprove mechanical propertiesVacuum evaporation coatingSputtering coatingReflective layerDielectric layer

A coated article is provided so as to include a solar control coating having an infrared (IR) reflecting layer sandwiched between at least a pair of dielectric layers. The IR reflecting layer includes niobium nitride (NbxNy). The use of niobium nitride enables the coated article to have good corrosion resistance to acid(s), good mechanical performance such as scratch resistance, and / or good color stability (i.e., a low ΔE* value(s)) upon heat treatment (HT). The coated article may be heat treated (e.g., thermally tempered) in certain example embodiments of the invention.

Owner:GUARDIAN GLASS LLC

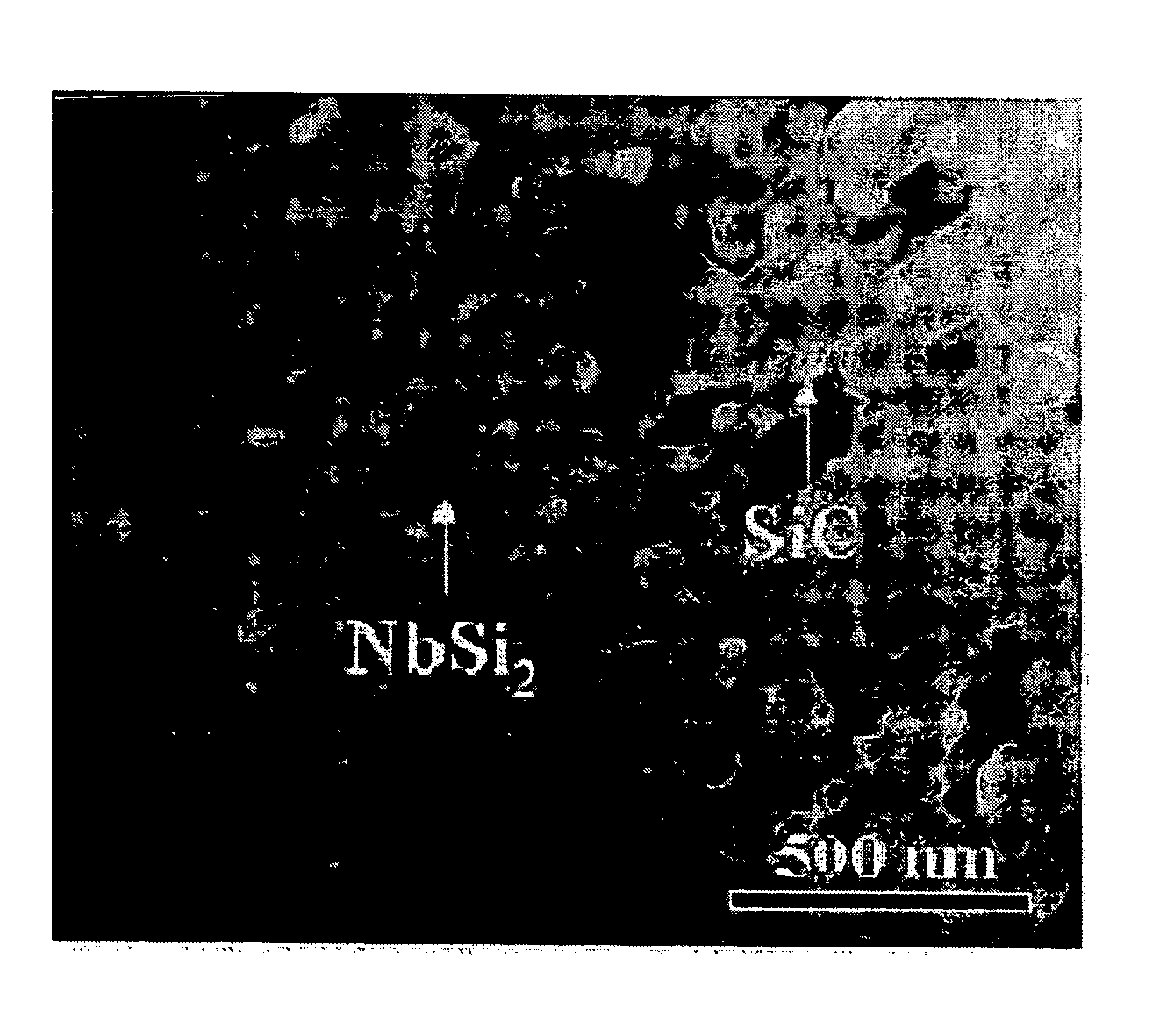

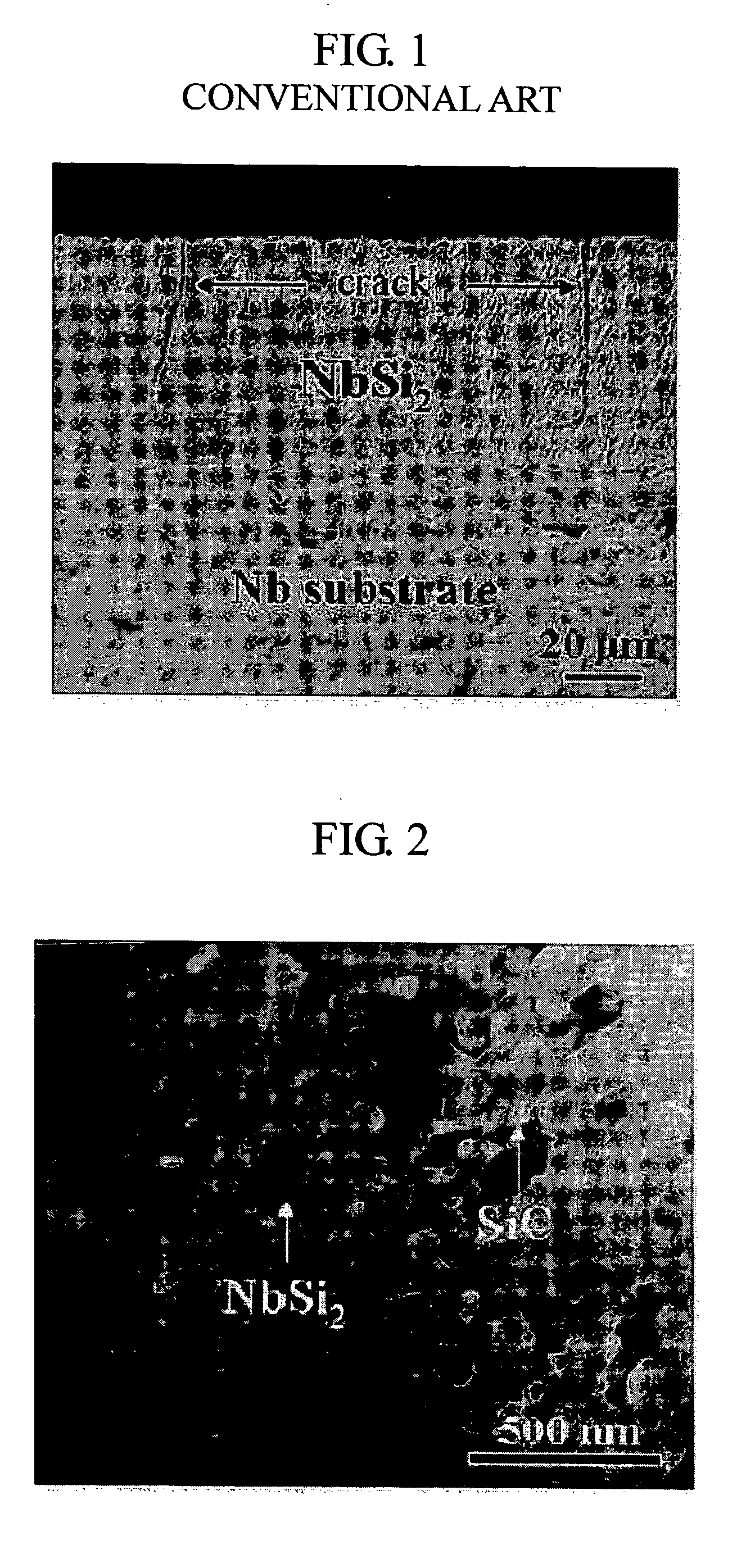

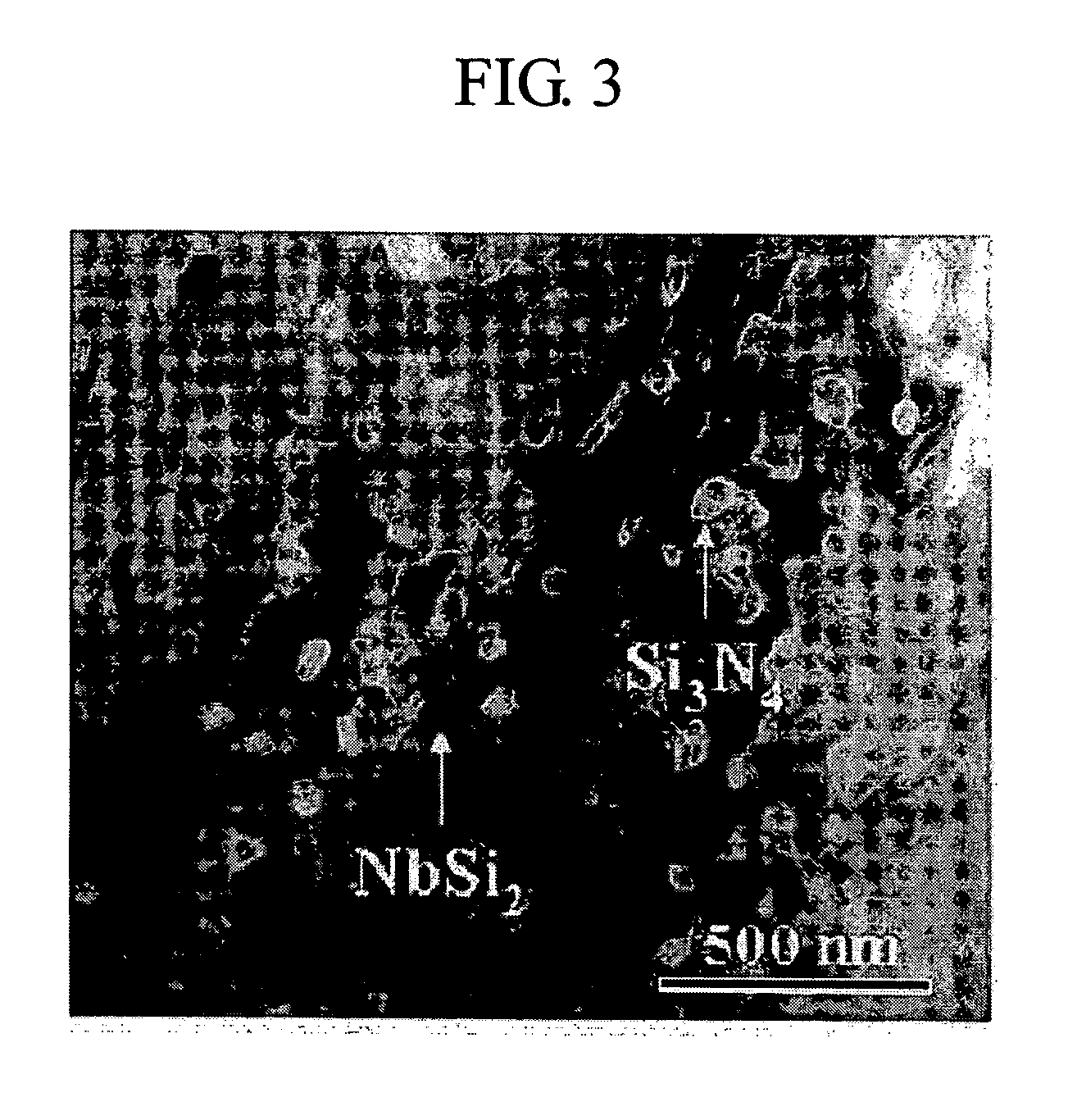

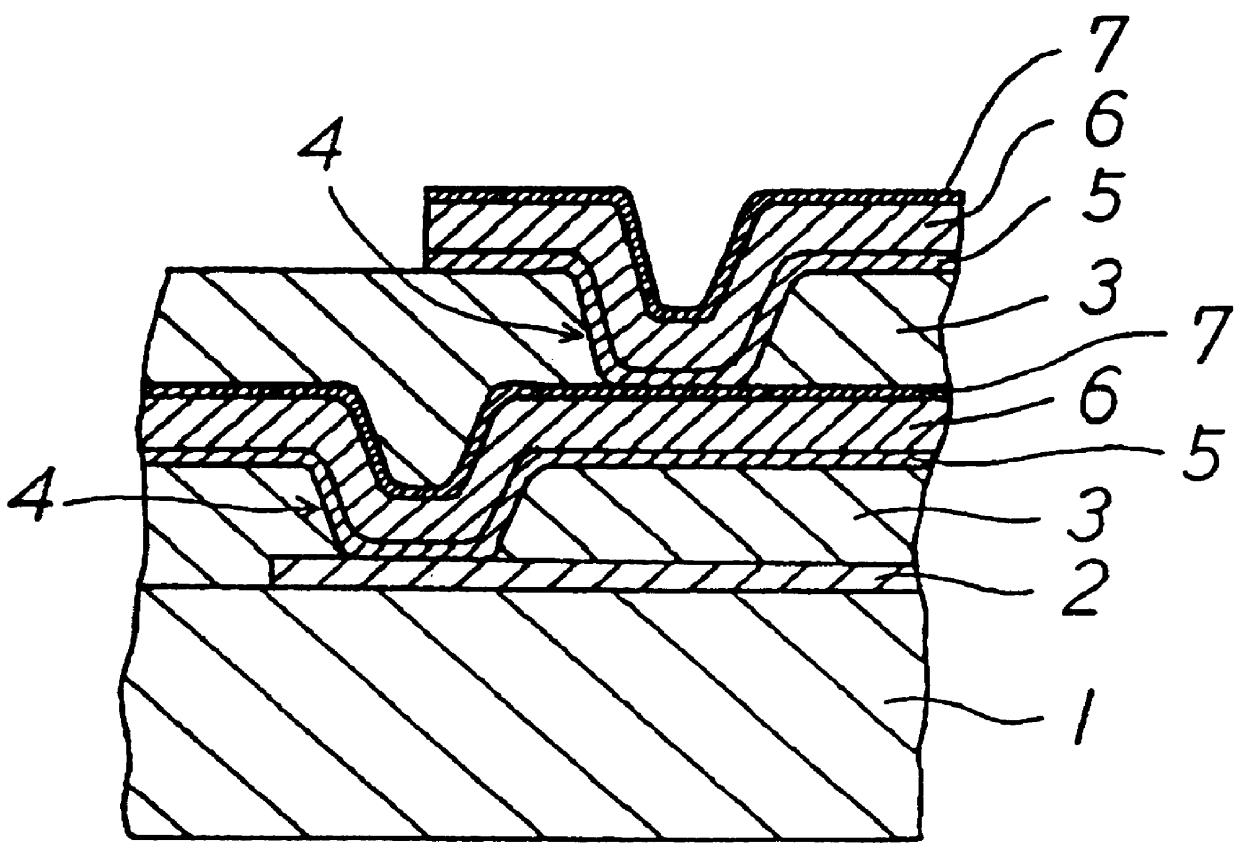

NbSi-2 base nanocomposite coating and manufacturing method thereof

InactiveUS20060029830A1Improve oxidation resistanceImprove corrosion resistanceMaterial nanotechnologyLiquid surface applicatorsCrazingAlloy

A NbSi2-base nanocomposite coating formed on the surface of niobium or niobium-base alloys is disclosed. The nanocomposite coating layer is manufactured by forming a niobium carbide layers or a niobium nitride layers by depositing of carbon or nitrogen on the surface, and then depositing silicon. The nanocomposite coating layer has a microstructure that SiC or Si3N4 particles are mostly precipitated on an equiaxed NbSi2 grain boundary. The thermal expansion coefficients of NbSi2-base nanocomposite coating layers become close to that of the substrates by adjusting the volume fraction of SiC or Si3N4 particles in the nanocomposite coating layers. Accordingly, the generation of cracks caused by thermal stress due to the mismatch in thermal expansion coefficient between the NbSi2-base nanocomposite coatings and the substrates can be suppressed, thereby improving the high-temperature oxidation resistance in the repeated thermal cycling use of the NbSi2-base nanocomposite coated substrates. Further, the increase in the volume fraction of dense SiO2 oxide phase formed on the surface of the NbSi2-base nanocomposite coating layers improves also high-temperature isothermal oxidation resistance.

Owner:KOREA INST OF SCI & TECH

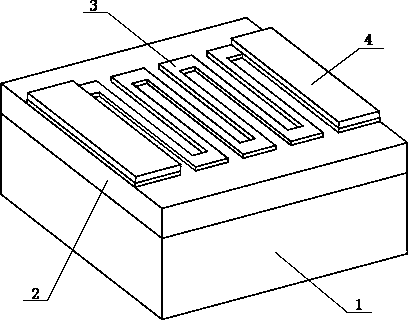

Electronic circuit component

InactiveUS6060664ASuperconductors/hyperconductorsSemiconductor/solid-state device detailsHigh densityCopper

A prior-art electronic circuit component comprising an insulating film and a circuit conductive layer made of a superconducting metal suffers low reliability resulting from insufficient adhesion between these layers. An electronic circuit component of the invention comprises an insulating film made of a high polymer material having a dielectric constant of 2.5 or less, a base metal layer formed of copper on the insulating film, having a thickness of 0.01 to 0.3 mu m, and a circuit conductive layer formed of at least one of niobium and niobium nitride on the base metal layer. The electronic circuit component of the invention can accomplish an increased adhesion between the insulating film and the circuit conductive layer. Furthermore, by sequentially forming, on the circuit conductive layer, a conductive-layer coating metal layer made of at least one of aluminum and copper, the insulating film, the base metal layer and the circuit conductive layer, there can be obtained a multi-layered circuit substrate with a superconducting circuit of high density and high-level function.

Owner:KYOCERA CORP

Capacitor

InactiveUS20010024351A1Fixed capacitor electrodesLiquid electrolytic capacitorsOrganic semiconductorSemiconductor

In a capacitor comprising a pair of electrodes and a dielectric substance intervening between the two electrodes, one of the electrodes is composed of sintered niobium nitride. Preferably, the dielectric substance is composed of niobium oxide and the electrode other than the electrode composed of sintered niobium nitride is composed of an ingredient selected from electrolytes, organic semiconductors and inorganic semiconductors. This capacitor has good environmental stability and good leak current characteristics.

Owner:SHOWA DENKO KK

Passivated niobium cavities

ActiveUS7151347B1High quality factorAssuring long-term chemical stabilityKlystronsAcceleratorsUltra-high vacuumSuperconducting transition temperature

A niobium cavity exhibiting high quality factors at high gradients is provided by treating a niobium cavity through a process comprising: 1) removing surface oxides by plasma etching or a similar process; 2) removing hydrogen or other gases absorbed in the bulk niobium by high temperature treatment of the cavity under ultra high vacuum to achieve hydrogen outgassing; and 3) assuring the long term chemical stability of the niobium cavity by applying a passivating layer of a superconducting material having a superconducting transition temperature higher than niobium thereby reducing losses from electron (cooper pair) scattering in the near surface region of the interior of the niobium cavity. According to a preferred embodiment, the passivating layer comprises niobium nitride (NbN) applied by reactive sputtering.

Owner:JEFFERSON SCI ASSOCS LLC

Superconducting single-photon detector with phase grating and manufacturing method for superconducting single-photon detector with phase grating

InactiveCN104167452AImprove absorption efficiencyFinal product manufactureInstrumentsNanowirePhase grating

The invention discloses a superconducting single-photon detector with a phase grating and a manufacturing method for the superconducting single-photon detector with the phase grating. The superconducting single-photon detector with the phase grating is characterized in that the phase grating is arranged on a nanowire area of a conventional superconducting single-photon detector based on niobium nitride. The grating height of the phase grating is odd-number times the thickness corresponding to the phase of the wavelength pi of incident light. The phase grating on the nanowire area generates the focusing interference effect on light beams, niobium nitride nanowires are located at the focal position, and therefore the absorption efficiency of the niobium nitride nanowires to photons is improved. Simulation results show that the superconducting single-photon detector with the phase grating has the quite high detection efficiency in multiple frequency bands of visible light and infrared light, and the photon absorption efficiency is as high as 72% when the wavelength is 850 nm.

Owner:NANJING UNIV

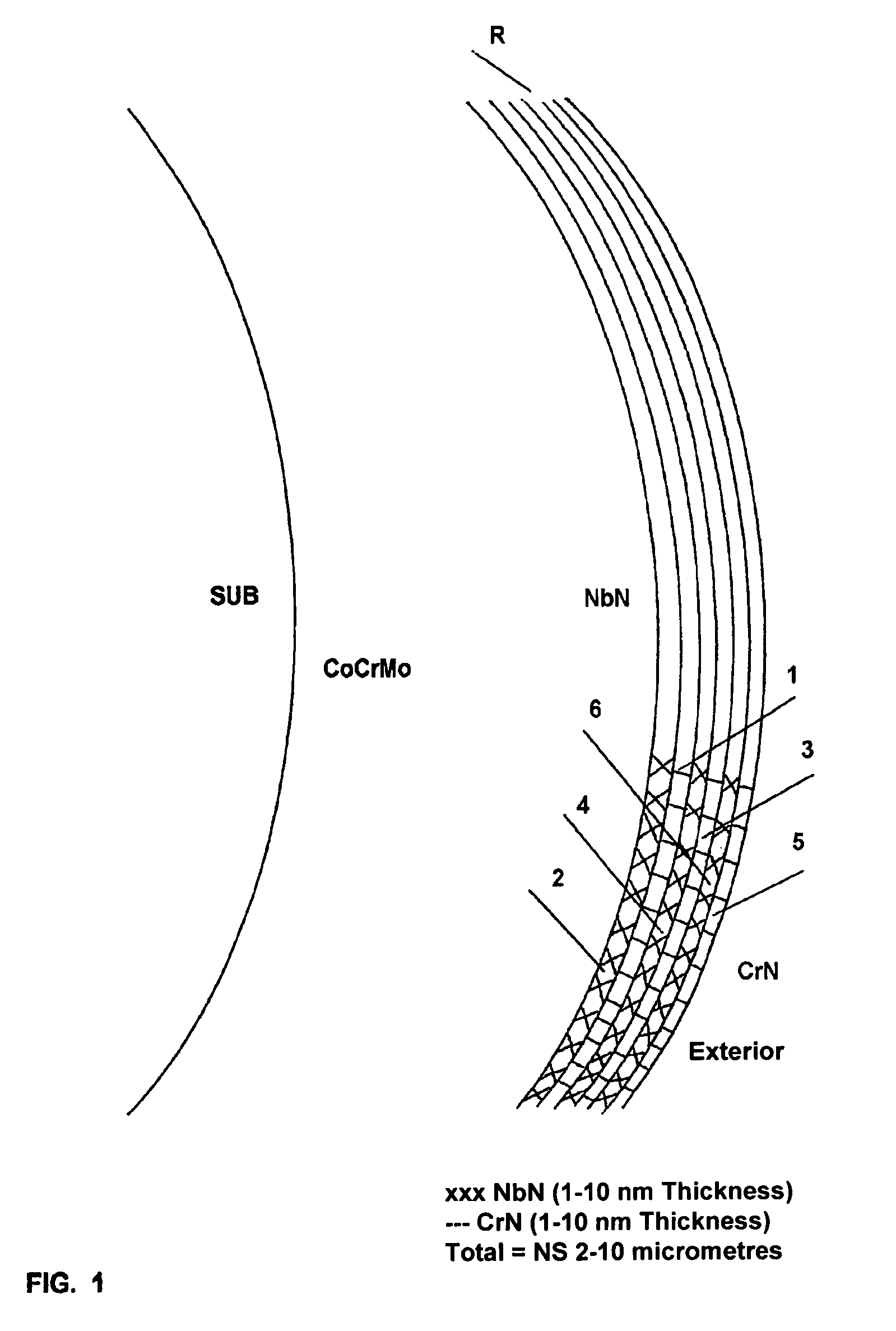

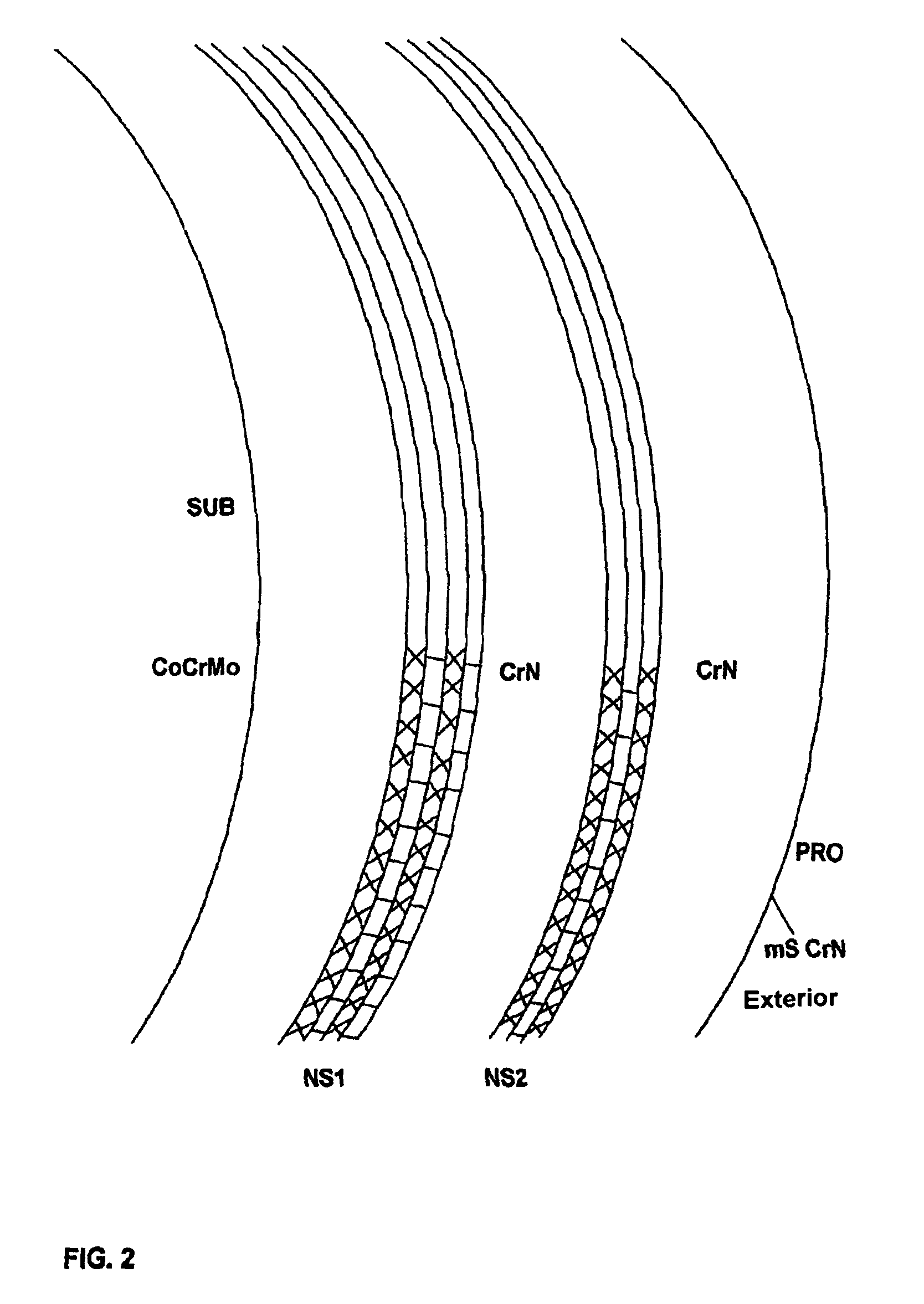

Substrate for wear-proof orthopaedic joints, of non ferrous metal with a nitride-based coating

Substrates for joints for orthopaedic implants are described, wherein at least one of the sliding surfaces of non-ferrous metal alloys, in particular of cobalt, chromium, molybdenum alloys, has a coating consisting of niobium nitride nanolayers alternating with chromium nitride nanolayers, the lot being protected by a chromium nitride microlayer.

Owner:MEDACTA INT SA

Methods of repairing a substrate

A precursor of a ceramic adhesive suitable for use in a vacuum, thermal, and microgravity environment. The precursor of the ceramic adhesive includes a silicon-based, preceramic polymer and at least one ceramic powder selected from the group consisting of aluminum oxide, aluminum nitride, boron carbide, boron oxide, boron nitride, hafnium boride, hafnium carbide, hafnium oxide, lithium aluminate, molybdenum silicide, niobium carbide, niobium nitride, silicon boride, silicon carbide, silicon oxide, silicon nitride, tin oxide, tantalum boride, tantalum carbide, tantalum oxide, tantalum nitride, titanium boride, titanium carbide, titanium oxide, titanium nitride, yttrium oxide, zirconium boride, zirconium carbide, zirconium oxide, and zirconium silicate. Methods of forming the ceramic adhesive and of repairing a substrate in a vacuum and microgravity environment are also disclosed, as is a substrate repaired with the ceramic adhesive.

Owner:NORTHROP GRUMMAN INNOVATION SYST INC

Preparation method of reaction titanium aluminum zirconium niobium nitride nitrogen-gradient hard reaction film

InactiveCN104328384AStrong adhesionImprove adhesionVacuum evaporation coatingSputtering coatingTitanium nitrideDeposition process

The invention relates to a preparation method of a reaction titanium aluminum zirconium niobium nitride nitrogen-gradient hard reaction film, which sequentially comprises the following steps: 1. determination of deposition technique and target components; 2. workpiece selection and pretreatment; 3. determination of pre-bombarding technique; 4. determination of deposition technique; 5. vacuum heating treatment; and 6. workpiece revolution. The method lowers the coating cost, reduces the internal stress of the film on the premise of ensuring the high adhesive force, high hardness and high thermal shock resistance of the film, and has favorable stability and repeatability.

Owner:SHENYANG UNIV

Nano niobium aluminum yttrium nitride/amorphous silicon nitride dual-phase ultra-hard coating and a deposition method thereof

ActiveCN110438442AImprove heat resistanceImprove bindingVacuum evaporation coatingSputtering coatingMilling cutterWear resistant

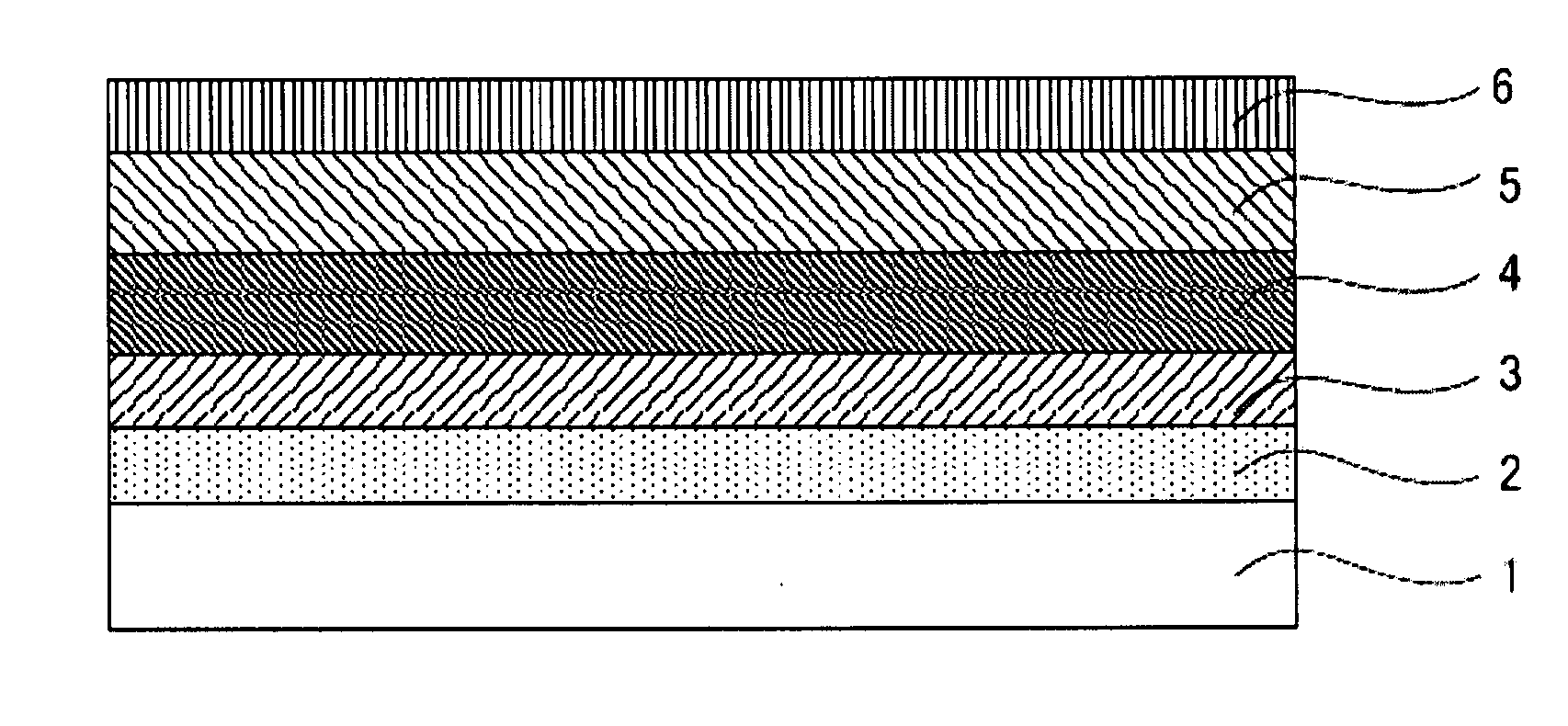

The invention relates to a nano niobium aluminum yttrium nitride / amorphous silicon nitride dual-phase ultra-hard coating and a deposition method thereof. The ultra-hard coating is of a four-layer structure, wherein the innermost layer is a pure niobium bonding layer, and thickness of the innermost layer is 0.05-0.5 micron; the secondary inner layer is a niobium nitride transition layer, and the thickness of the secondary inner layer is 0.05-1 micron; the secondary outer layer is a gradient layer, component of the niobium nitride is gradually reduced from inside to outside, and components of the niobium aluminum yttrium nitride / the silicon nitride are gradually increased, the thickness of the secondary outer layer is about 0.1-1.0 micron, and concentration on a stress interface can be prevented; and the outermost layer is composite wear-resistant layer of the niobium aluminum yttrium nitride / the silicon nitride, the thickness of the composite wear-resistant layer is 1-10 microns. The total thickness of the coating is 1.2-12.5 microns. Binding force of the coating and a hard alloy matrix reaches 70-105 N, hardness of the coating is 40-60 GPa, friction coefficient of the coating is 0.20-0.55, antioxidant temperature of the coating is 750 DEG C or higher, and service life of a coated micro drill or milling cutter is prolonged by 4-8 times compared with that of an uncoated micro drill or milling cutter.

Owner:JIANGXI SCI & TECH NORMAL UNIV

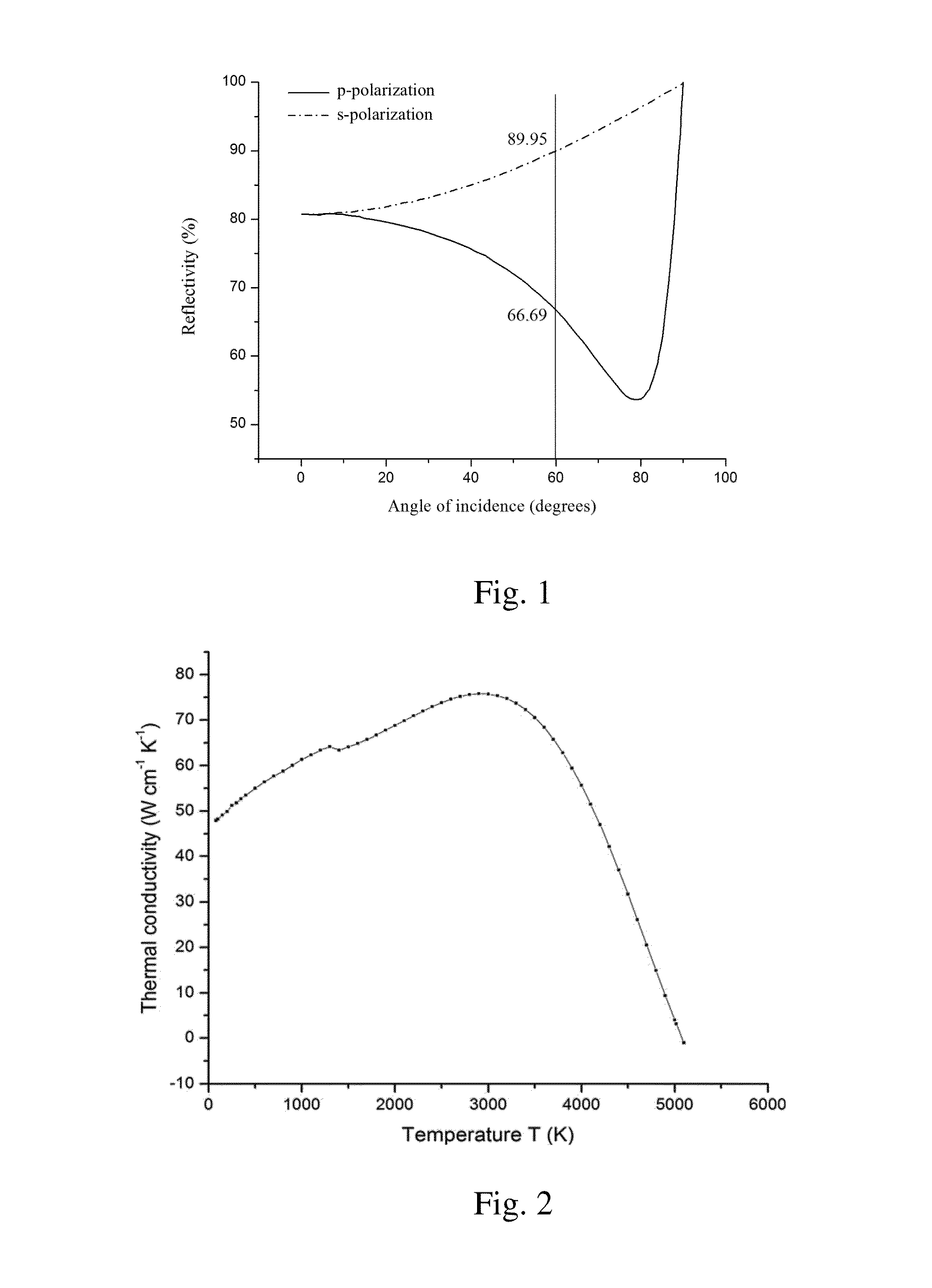

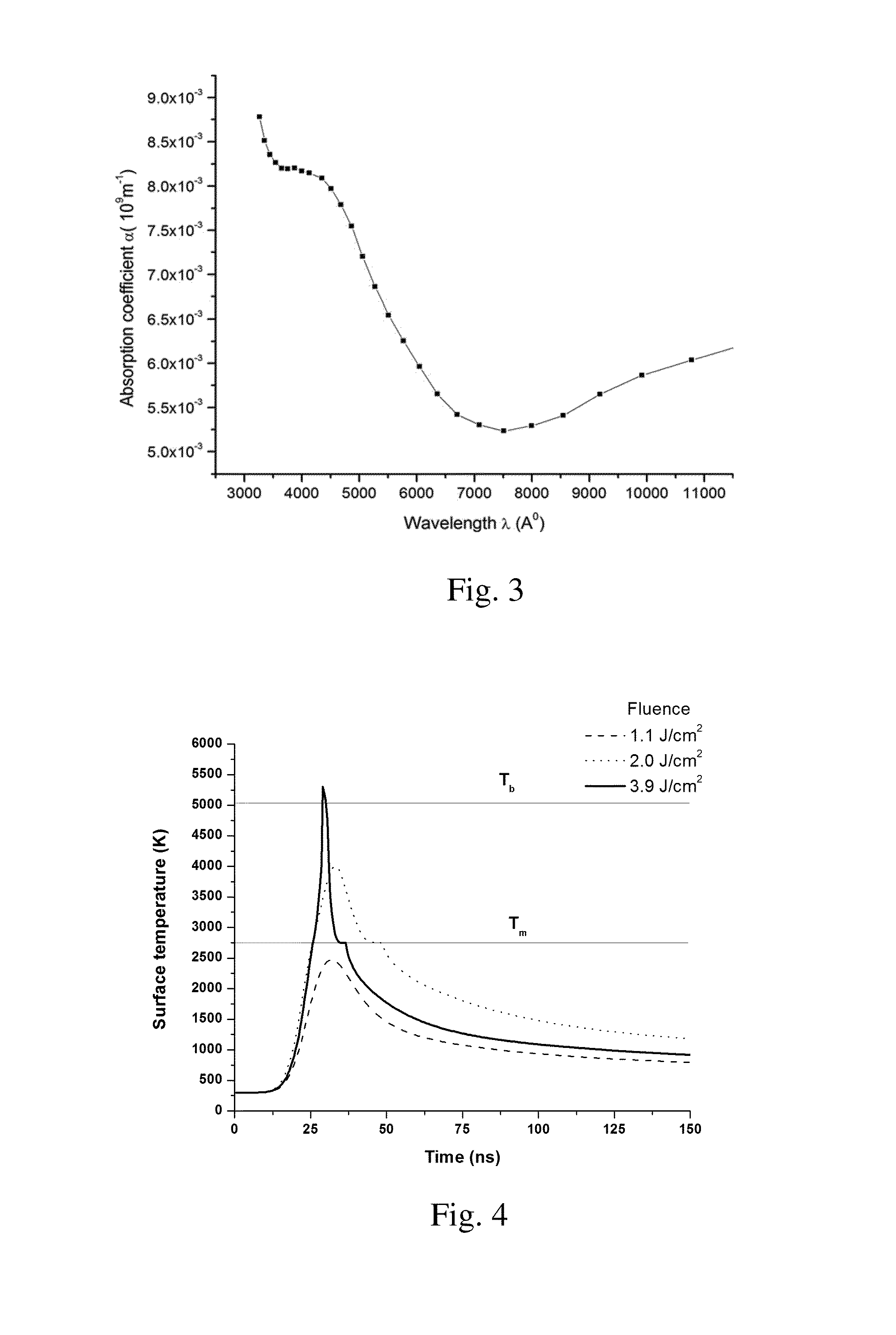

Method of nitriding niobium to form a superconducting surface

A method of forming a delta niobium nitride δ-NbN layer on the surface of a niobium object including cleaning the surface of the niobium object; providing a treatment chamber; placing the niobium object in the treatment chamber; evacuating the chamber; passing pure nitrogen into the treatment chamber; focusing a laser spot on the niobium object; delivering laser fluences at the laser spot until the surface of the niobium object reaches above its boiling temperature; and rastering the laser spot over the surface of the niobium object.

Owner:JEFFERSON SCI ASSOCS LLC

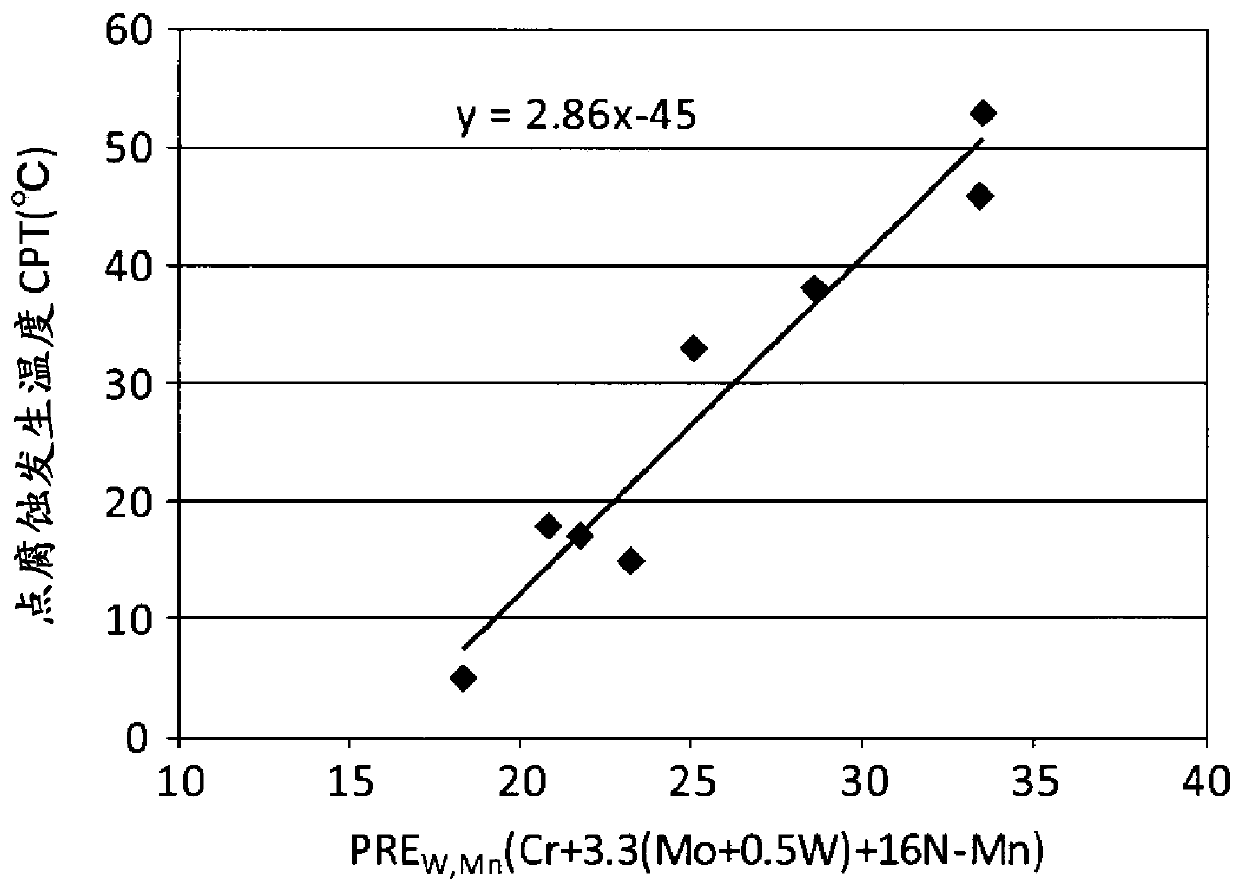

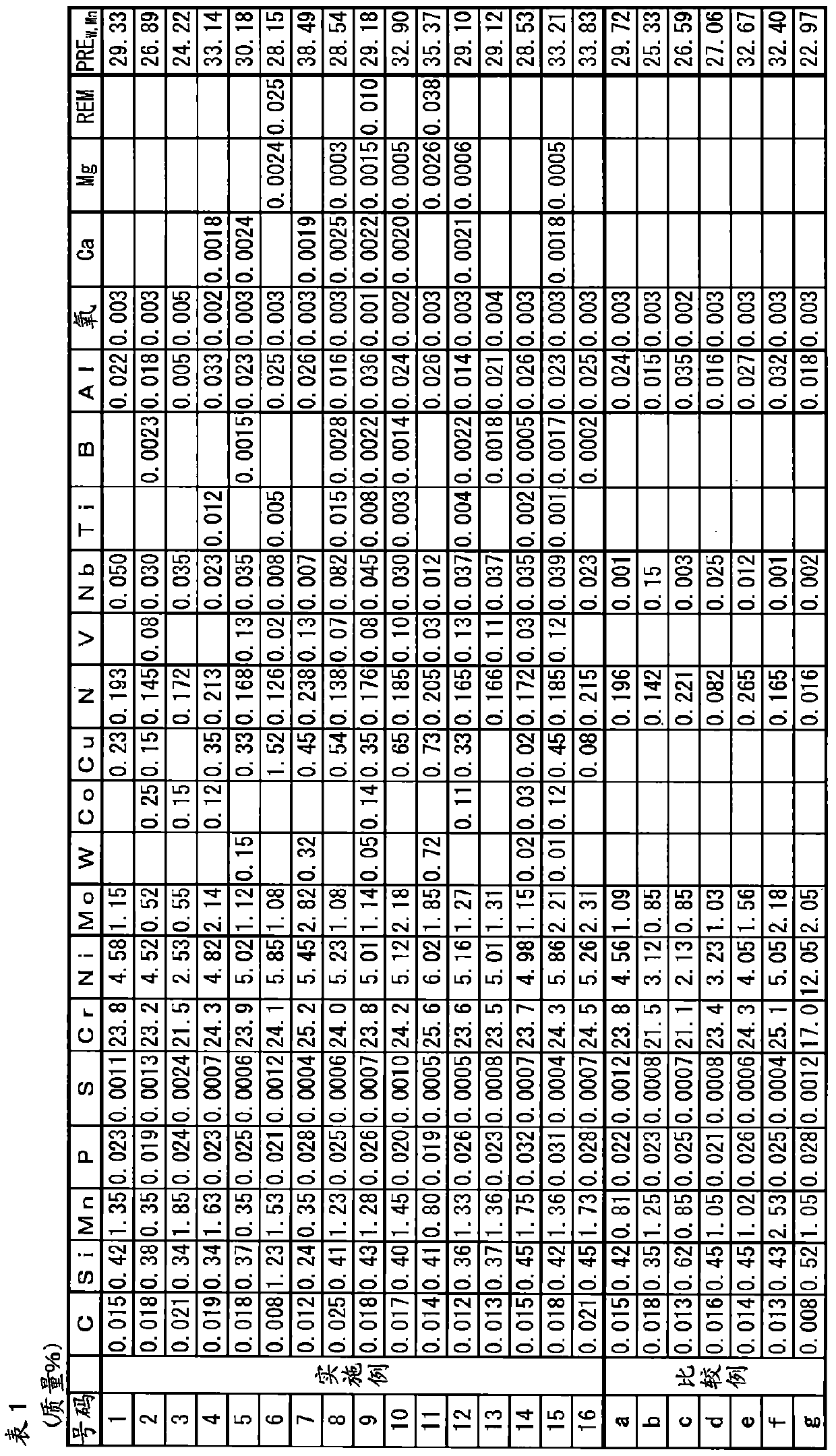

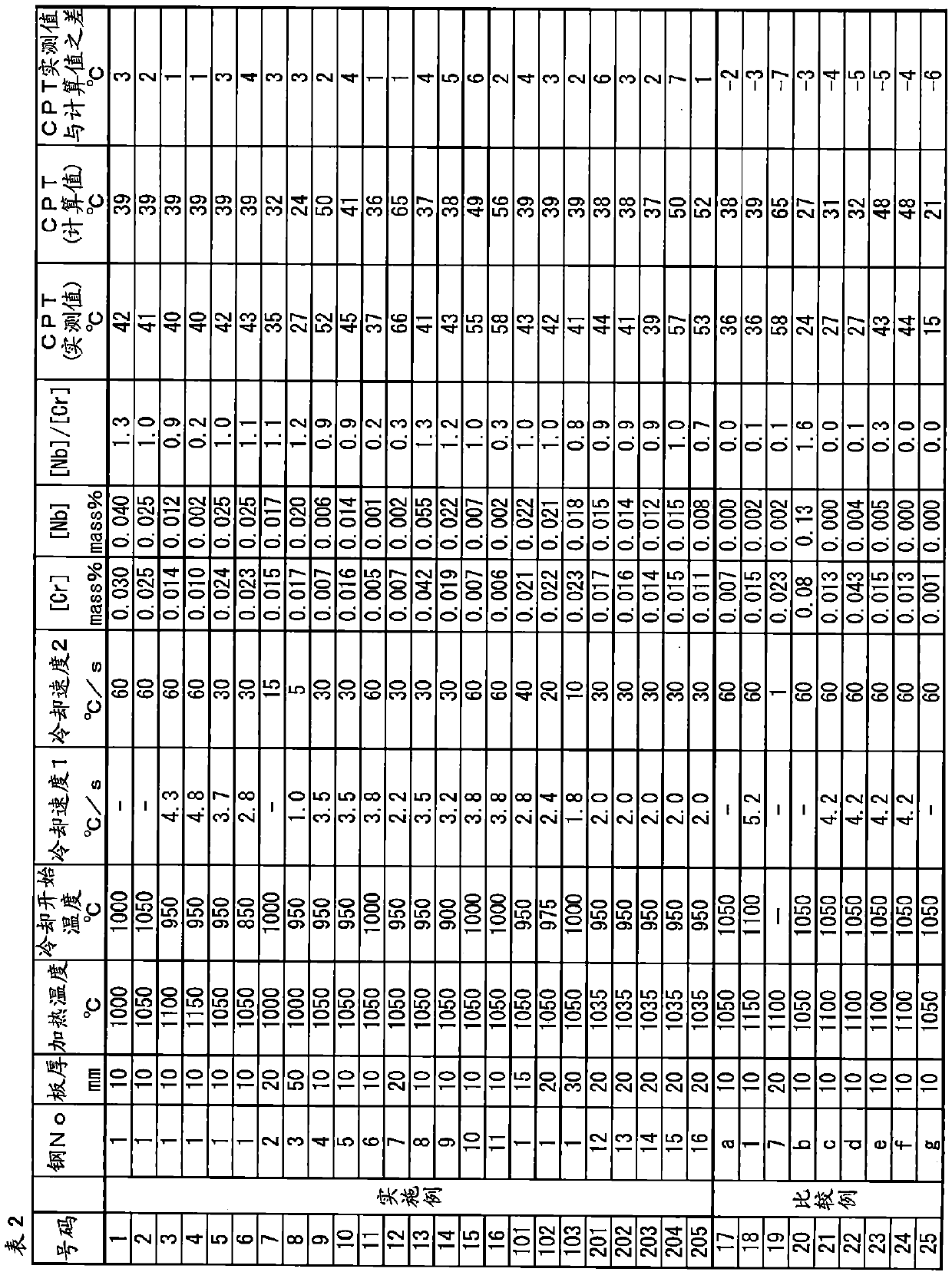

Two-phase stainless steel and manufacturing method therefor

ActiveCN110475895ACorrosion resistanceImprove corrosion resistanceFurnace typesProcess efficiency improvementChlorideSolid solution

The purpose of the present invention is to expand application to steel types having corrosion resistance of SUS329J1 or greater. The present invention addresses the problem of obtaining a two-phase stainless steel that both exhibits excellent corrosion resistance in environments with high chloride-ion concentration close to that of brackish water or seawater, and is economically advantageous. Theinventors found that the effect of improving critical pitting temperature (CPT) was likely to be achieved when a minute amount of Nb was added after reducing the amount of Mn to less than 2.0%, and Nto no more than 0.25%. The steel augmented with the minute amount of Nb was subjected to a solid-solution heat treatment, and on determining how depositions of Cr nitride and Nb nitride were affectedthereby, the inventors developed a two-phase stainless steel made of a base material having improved corrosion resistance. When the ratio between the Cr amount [Cr] and the Nb amount [Nb] in extraction residue is brought to 0.2 or greater by controlling the depositions of the chrome nitride and the niobium nitride through gradual cooling to 800 degrees centigrade followed by quick cooling to 600 degrees centigrade, the corrosion resistance can be improved.

Owner:NIPPON STEEL STAINLESS STEEL CORP

Optical Recording Medium

InactiveUS20080279079A1Mechanical record carriersRecord information storageReflective layerOptical recording

The main object of the present invention is to provide an optical recording medium with no need to use a control subject substance of the PRTR law, capable of using for an optical recording device with a blue laser, and giving consideration to the environmental aspect.To attain the object, the present invention provides an optical recording medium comprising: a reflective layer containing an aluminum composition as the main component including both aluminum or an aluminum alloy and a metal oxide of a metal other than aluminum; and a dielectric protective layer, formed in contact with the reflective layer, containing a niobium composition as the main component including both silicon dioxide or titanium dioxide and a niobium nitrided oxide.

Owner:PIONEER CORP

Waveguide structure integrated photon number resolution superconducting single-photon detector and preparation method thereof

PendingCN111129280AAbility to distinguish the number of photonsMeet photon number resolutionFinal product manufactureSuperconductor detailsPhoton detectionElectron-beam lithography

The invention discloses a waveguide structure integrated photon number resolution superconducting single-photon detector, and the detector comprises a substrate and a SiOx waveguide structure; a superconducting nanowire single photon detection array formed by connecting a plurality of units in series is arranged between the substrate and the SiOx waveguide, and each unit is formed by connecting aresistor and a nanowire in parallel. According to the invention, extremely weak photons transmitted by the waveguide can be detected at a high speed, the number of the detected photons can be distinguished, and the detector has important application in the field of quantum optical chips. A preparation method provided by the invention comprises the following steps: 1, carrying out magnetron sputtering on a niobium nitride superconducting film on a magnesium fluoride substrate; 2, performing photoetching and stripping to prepare an electrode; 3, preparing a nanowire pattern by electron beam lithography, and obtaining a niobium nitride nanowire array by reactive ion etching; 4, photoetching a resistor pattern, and preparing a parallel resistor; 5, preparing a waveguide pattern by electron beam lithography, and carrying out plasma enhanced chemical vapor deposition to deposit the SiOx waveguide. The preparation process disclosed by the invention is simple in steps and higher in yield.

Owner:NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com