Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

225 results about "Nanocomposite coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

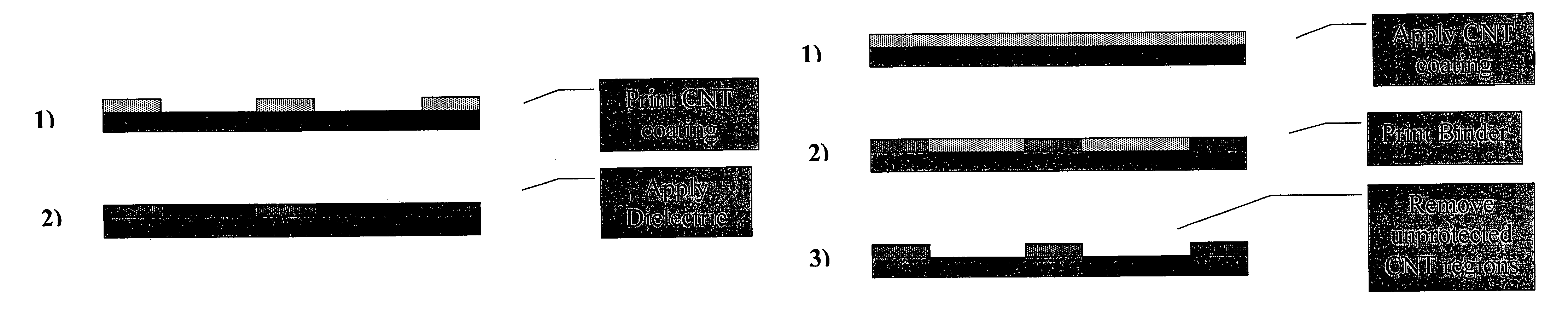

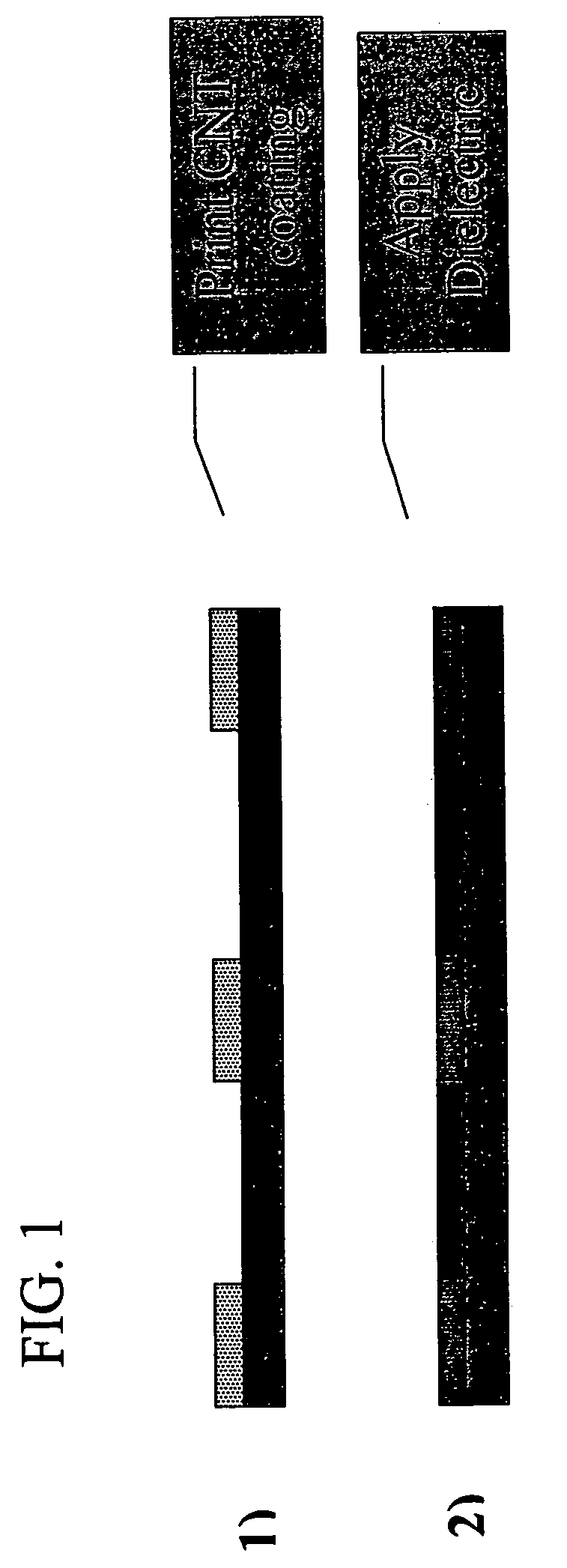

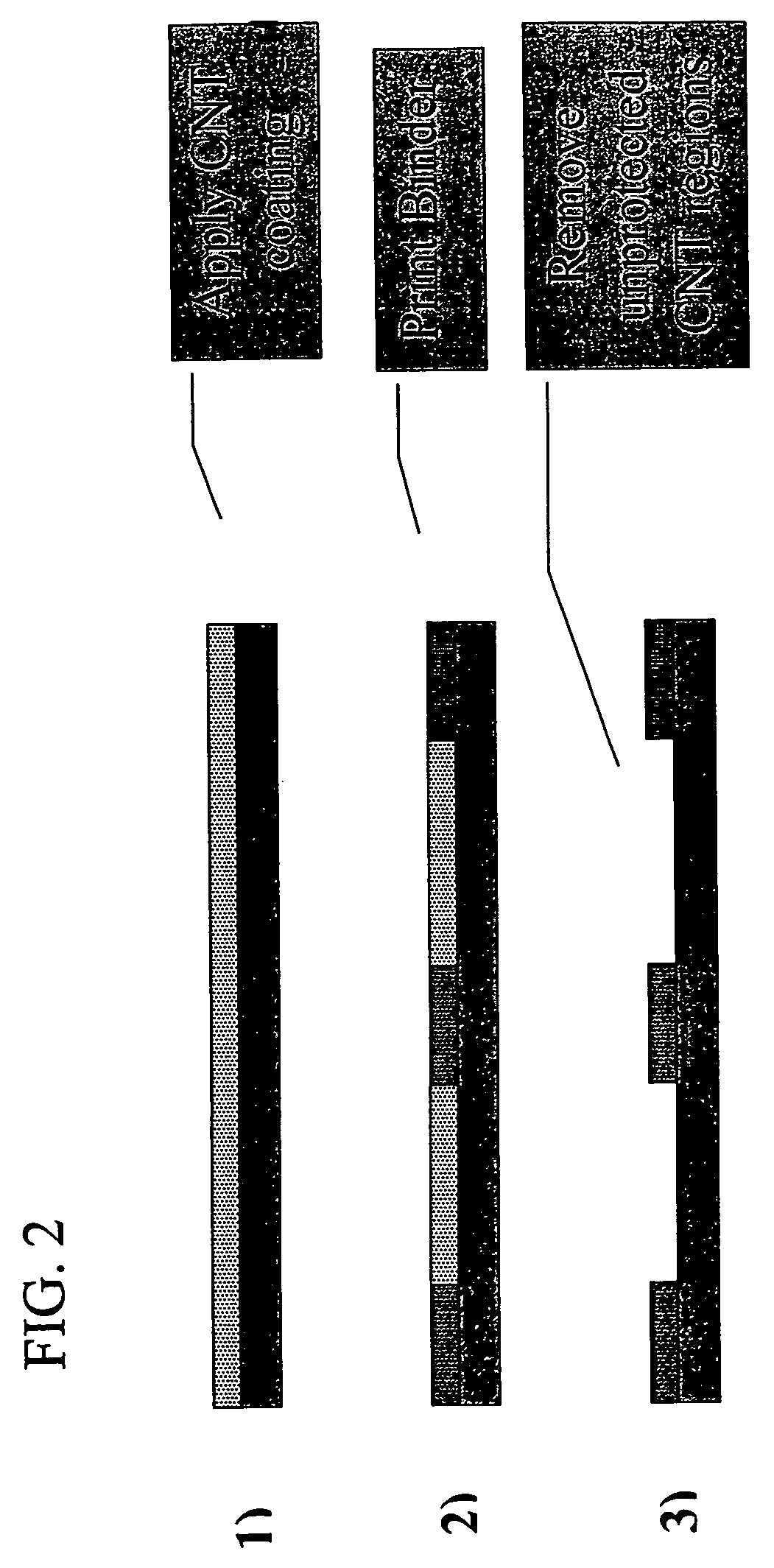

Method for patterning carbon nanotube coating and carbon nanotube wiring

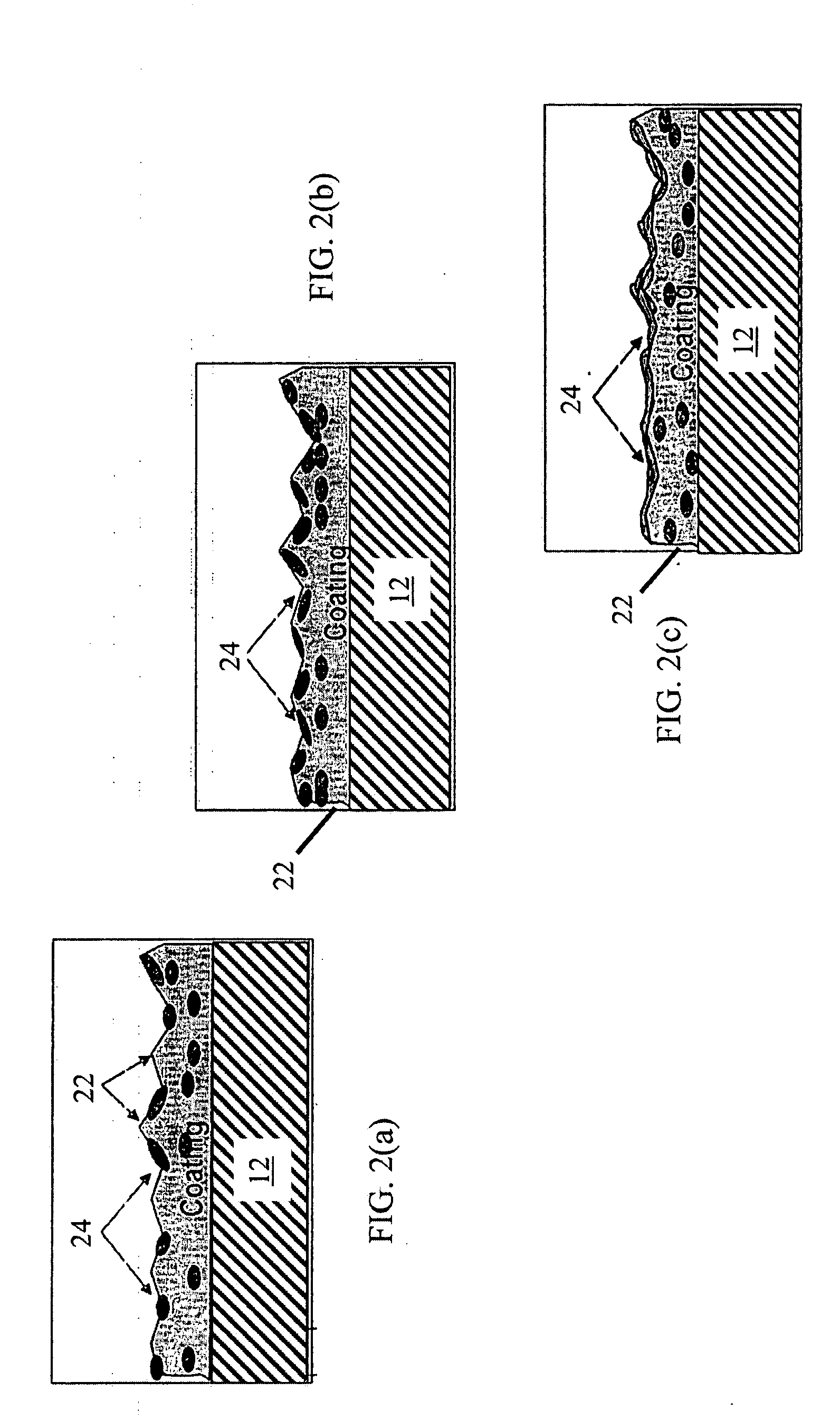

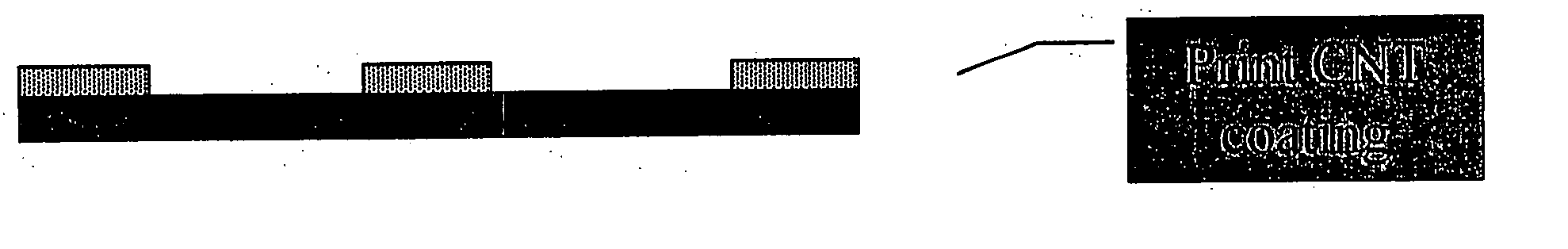

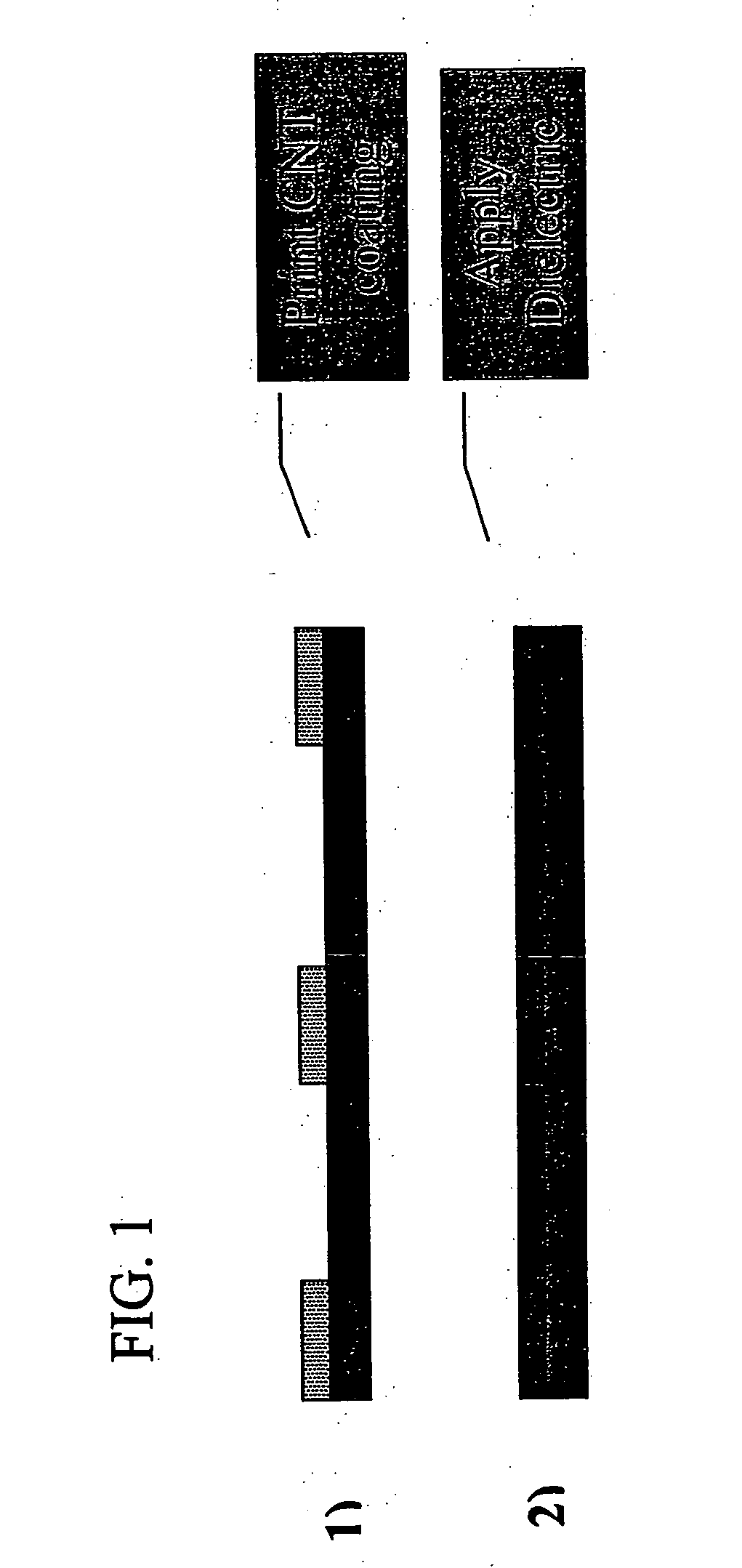

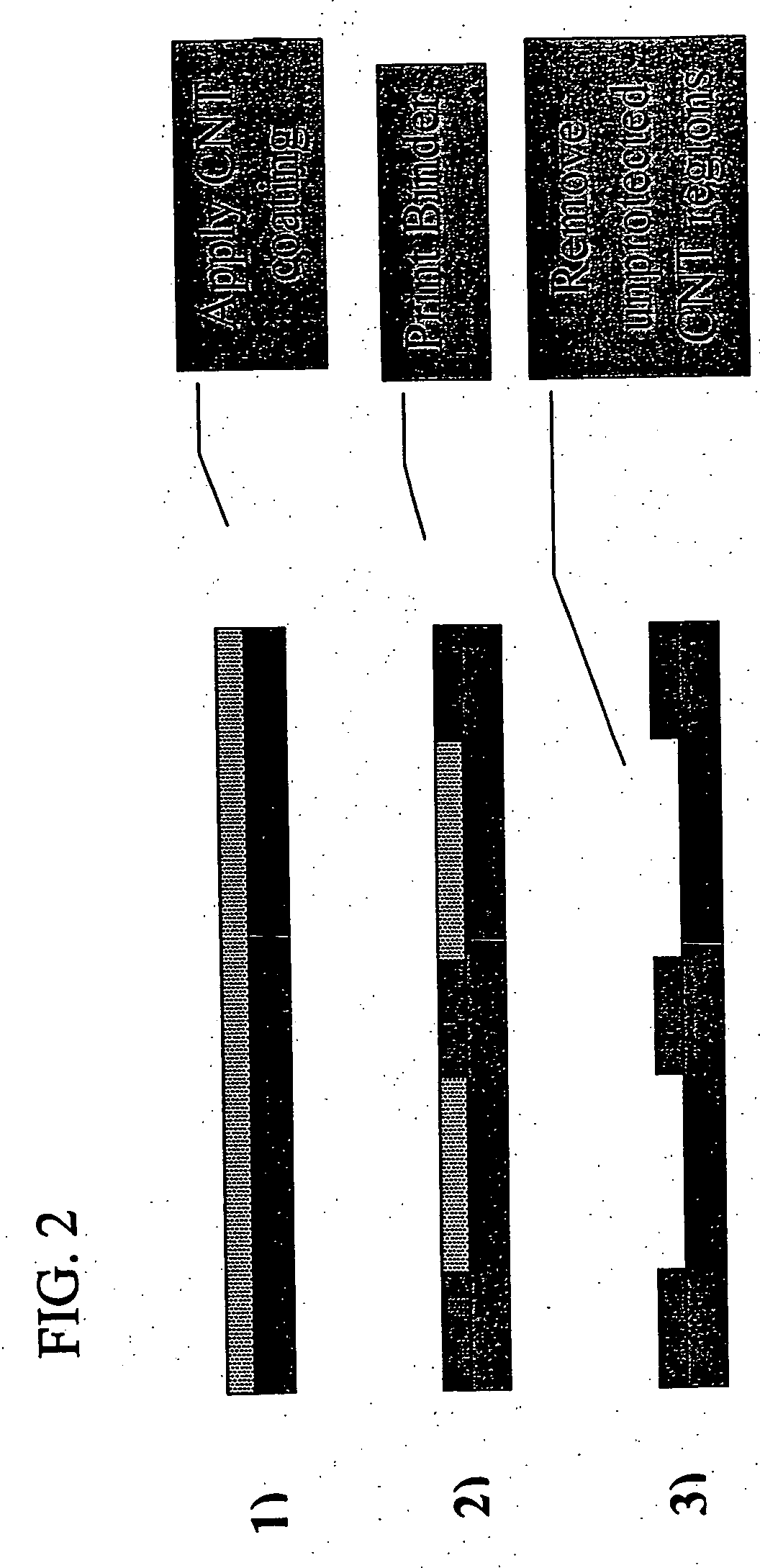

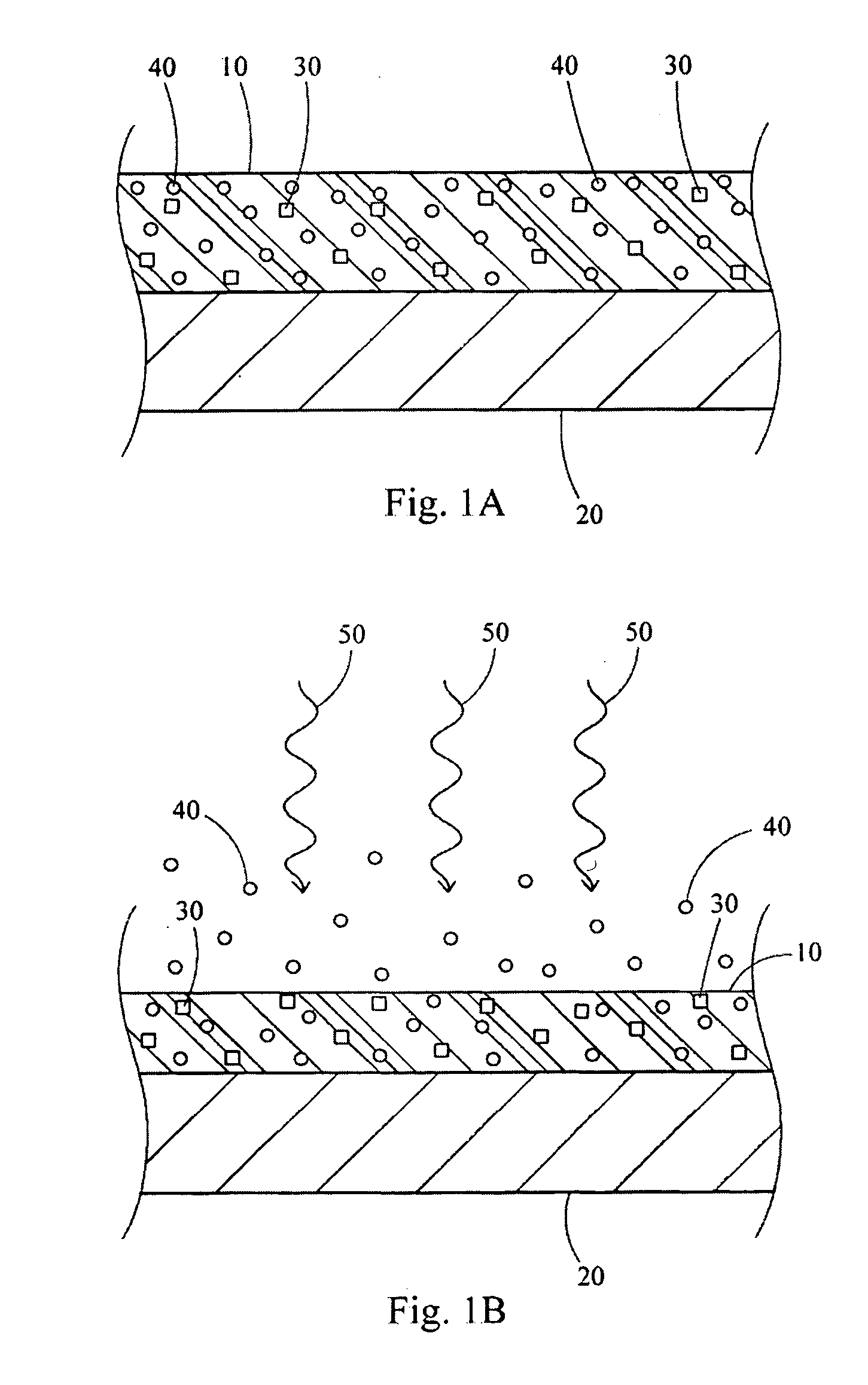

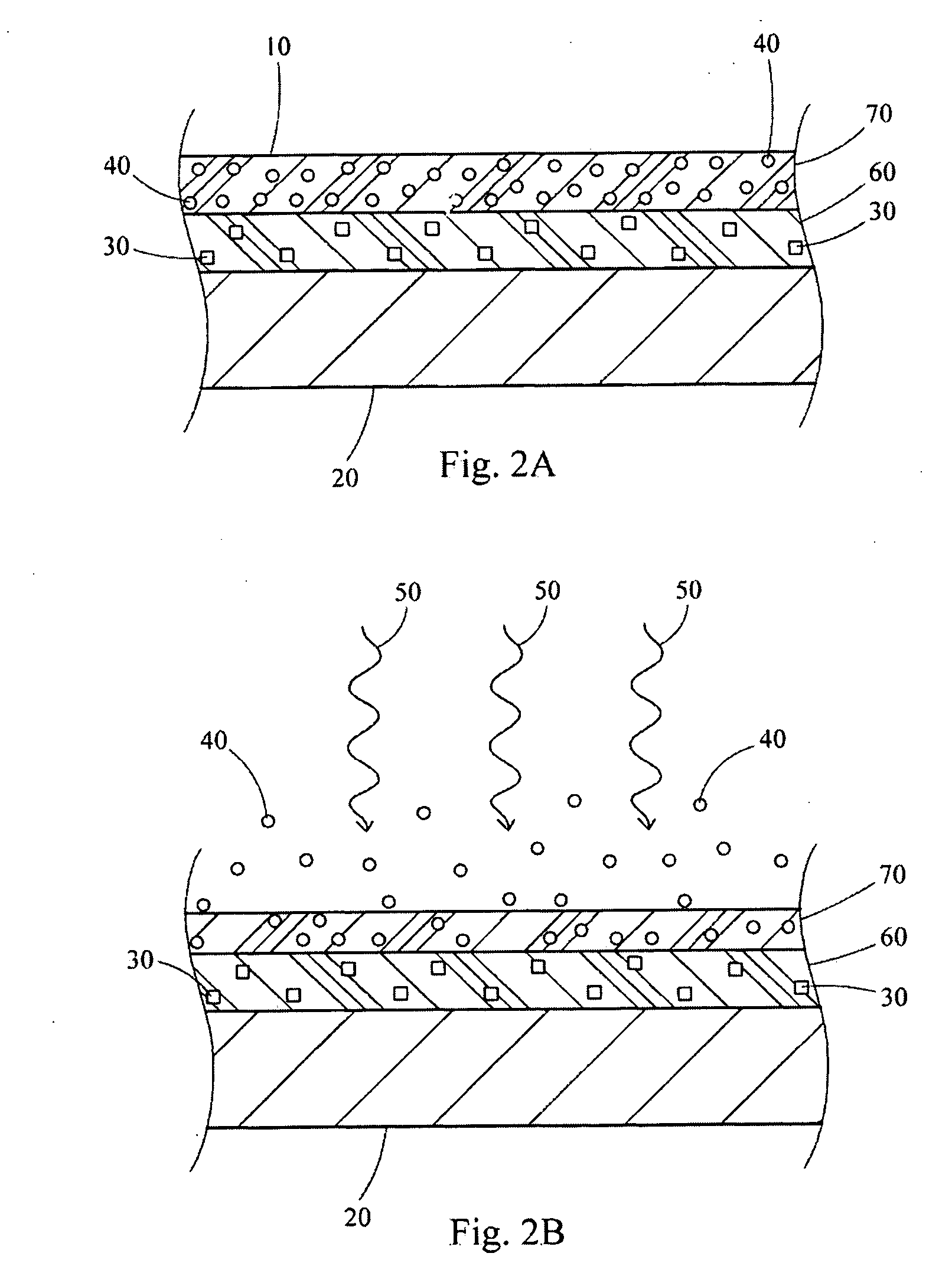

A method for making a nanocomposite electrode or circuit pattern includes forming a continuous carbon nanotube layer impregnated with a binder and patterning the binder resin using various printing or photo imaging techniques. An alternative method includes patterning the carbon nanotube layer using various printing or imaging techniques and subsequently applying a continuous coating of binder resin to the patterned carbon nanotube layer. Articles made from these patterned nanocomposite coatings include transparent electrodes and circuits for flat panel displays, photovoltaics, touch screens, electroluminescent lamps, and EMI shielding.

Owner:EIKOS

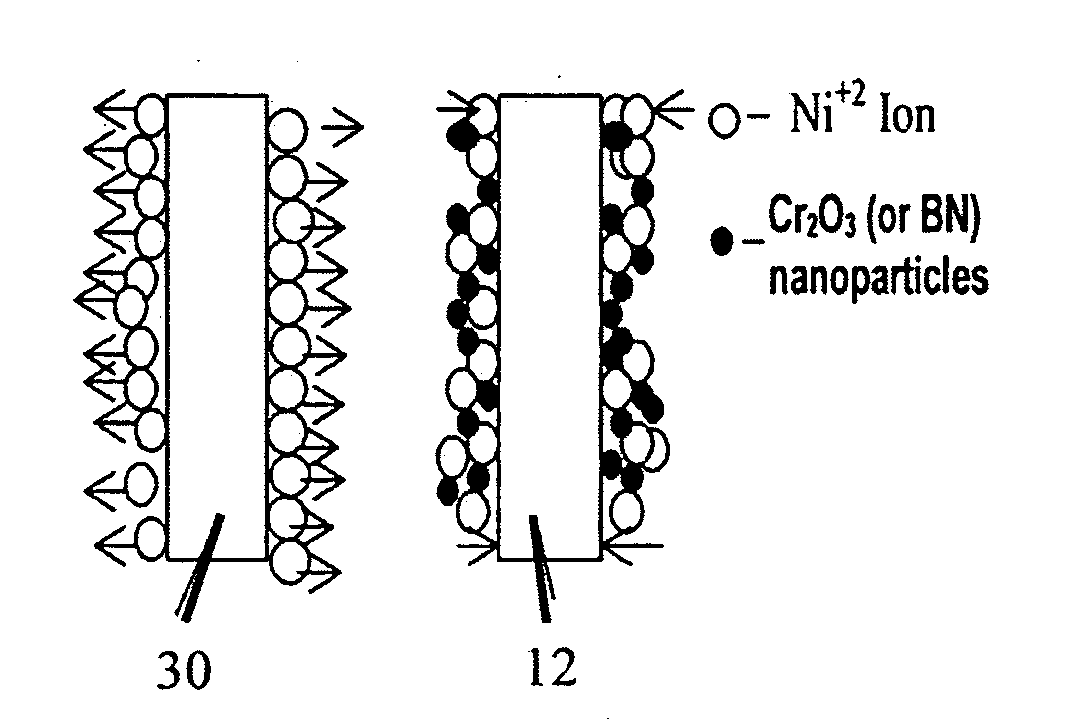

Lubricant-hard-ductile nanocomposite coatings and methods of making

InactiveUS20090155479A1Liquid surface applicatorsMolten spray coatingNanocomposite coatingWear resistance

Lubricant-hard-ductile composite coating compositions and methods of making the same are provided. In embodiment, a composite coating composition comprises: a lubricant phase for providing lubrication to a surface; a hard ceramic phase for providing structural integrity and wear resistance to the surface; and a ductile metal phase for providing ductility to the surface.

Owner:INFRAMAT CORPORATION

Method for patterning carbon nanotube coating and carbon nanotube wiring

A method for making a nanocomposite electrode or circuit pattern includes forming a continuous carbon nanotube layer impregnated with a binder and patterning the binder resin using various printing or photo imaging techniques. An alternative method includes patterning the carbon nanotube layer using various printing or imaging techniques and subsequently applying a continuous coating of binder resin to the patterned carbon nanotube layer. Articles made from these patterned nanocomposite coatings include transparent electrodes and circuits for flat panel displays, photovoltaics, touch screens, electroluminescent lamps, and EMI shielding.

Owner:ARTHUR DAVID J +1

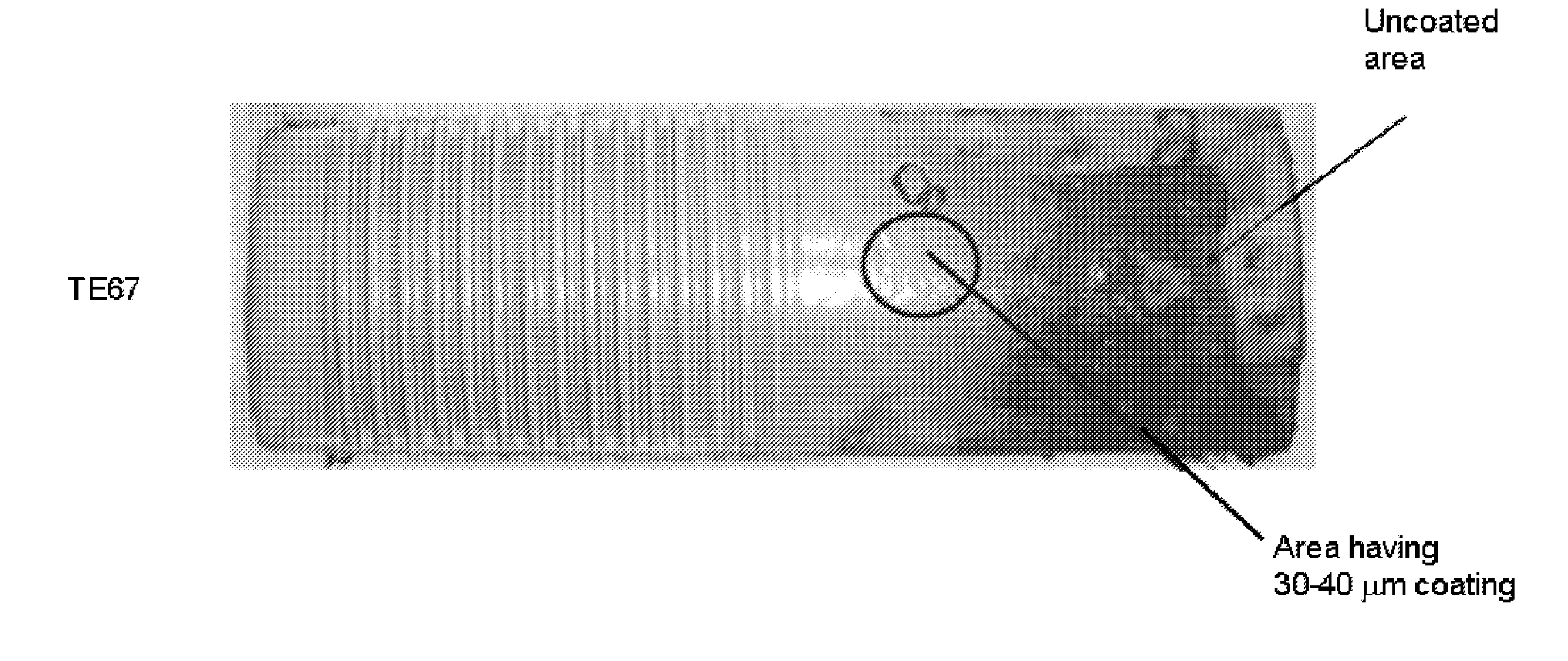

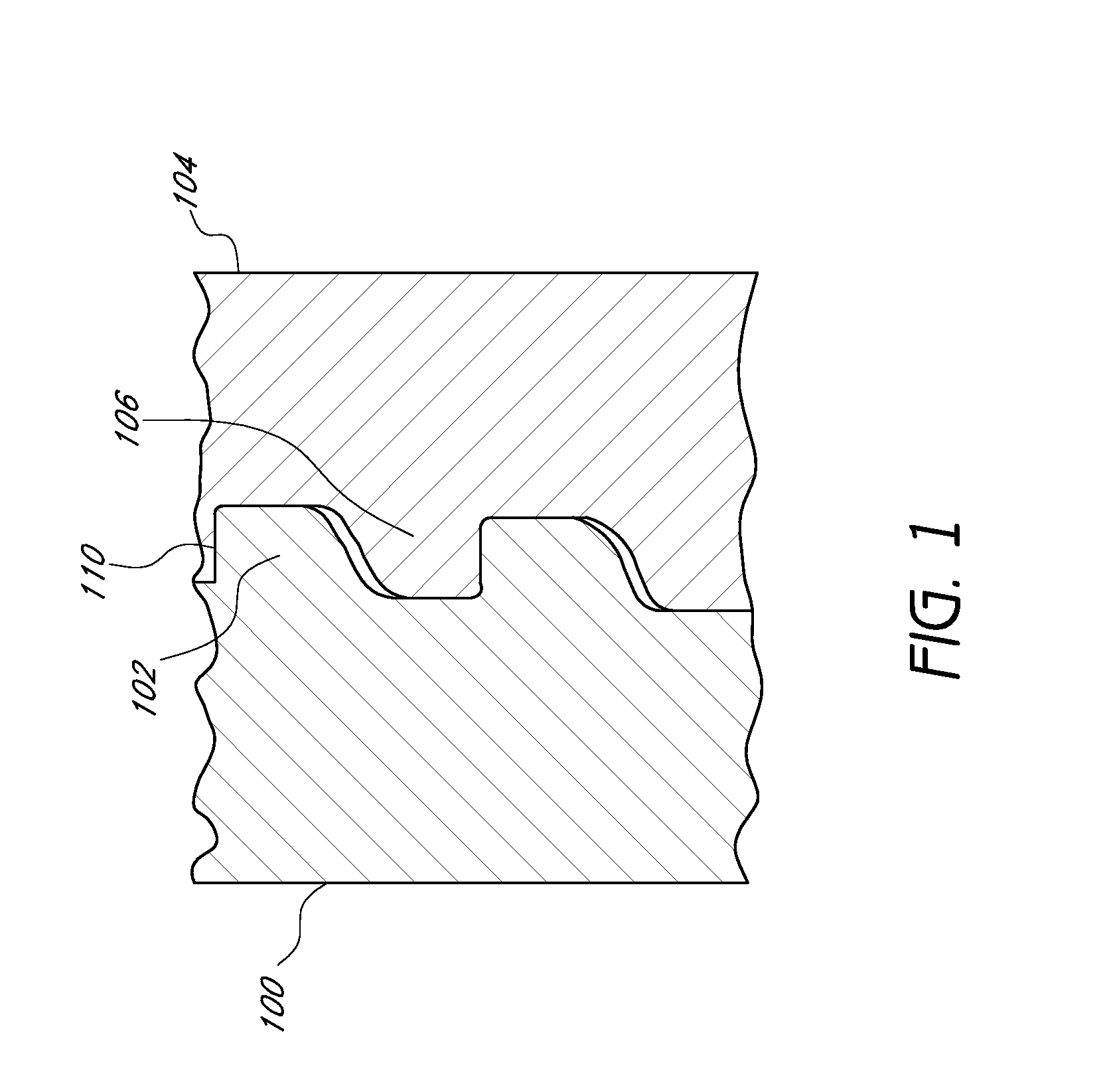

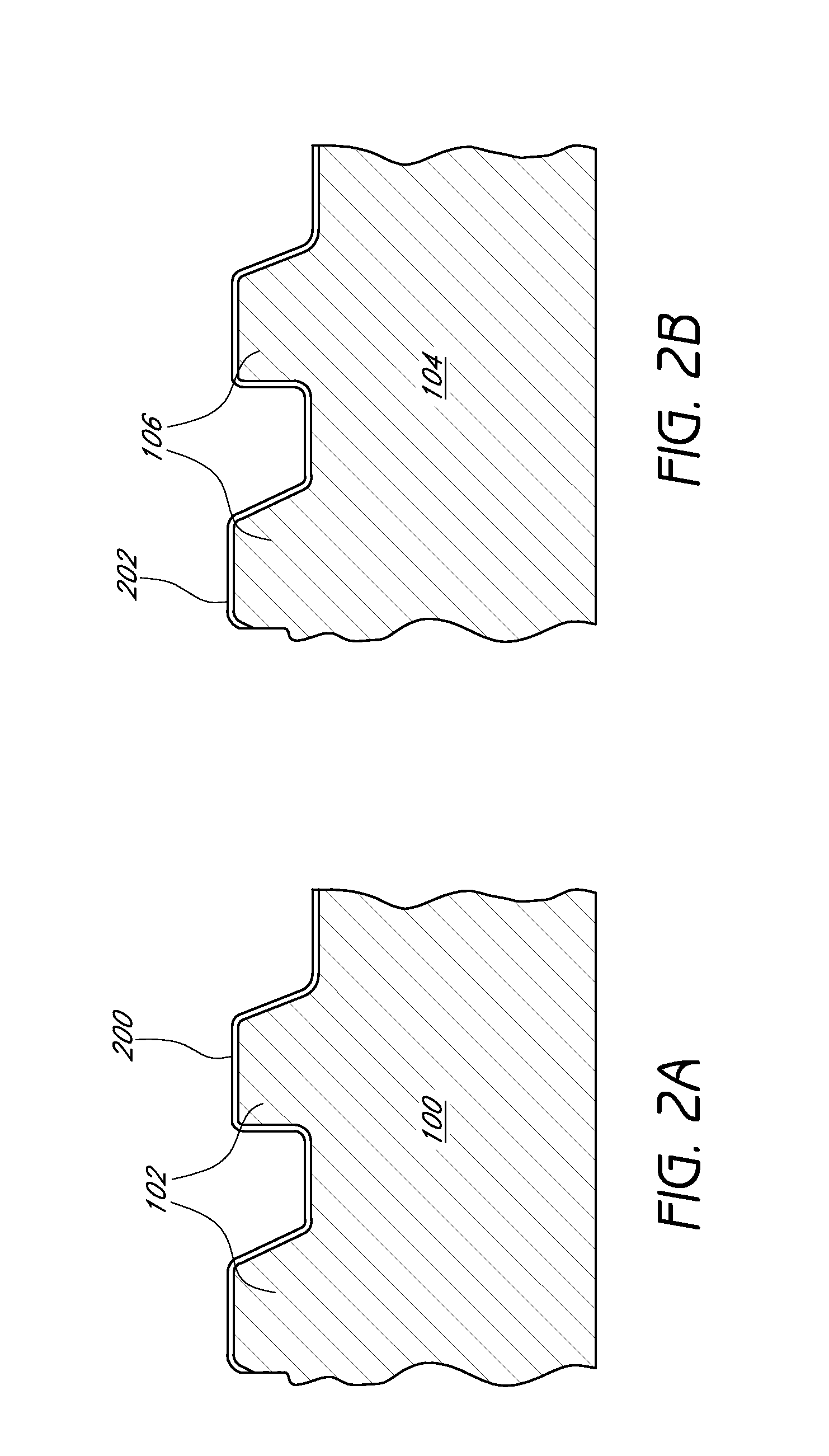

Nanocomposite coatings for threaded connections

Coating systems which provide corrosion resistance and, optionally, lubrication, for threaded connections are disclosed. The compositions comprise a first coating composition comprising polymer matrices of polyimides or epoxies which are modified with small amounts of a fluorine containing polymer. Also present in the coating compositions are corrosion inhibiting agents and inorganic particles having a mean diameter of between approximately 10 nm and 10 μm. Solid lubricants, which may include at least one of PTFE, HDPE, Graphite, and MoS2, are optionally added to provide the first coating with a low coefficient of friction. The coating systems may further comprise a second coating composition, comprising a solid lubricant dispersed within an epoxy resin and a solvent. The first and second coating compositions are deposited on at least a portion of at least one of the pin and box members of the threaded connections.

Owner:TENARIS CONNECTIONS

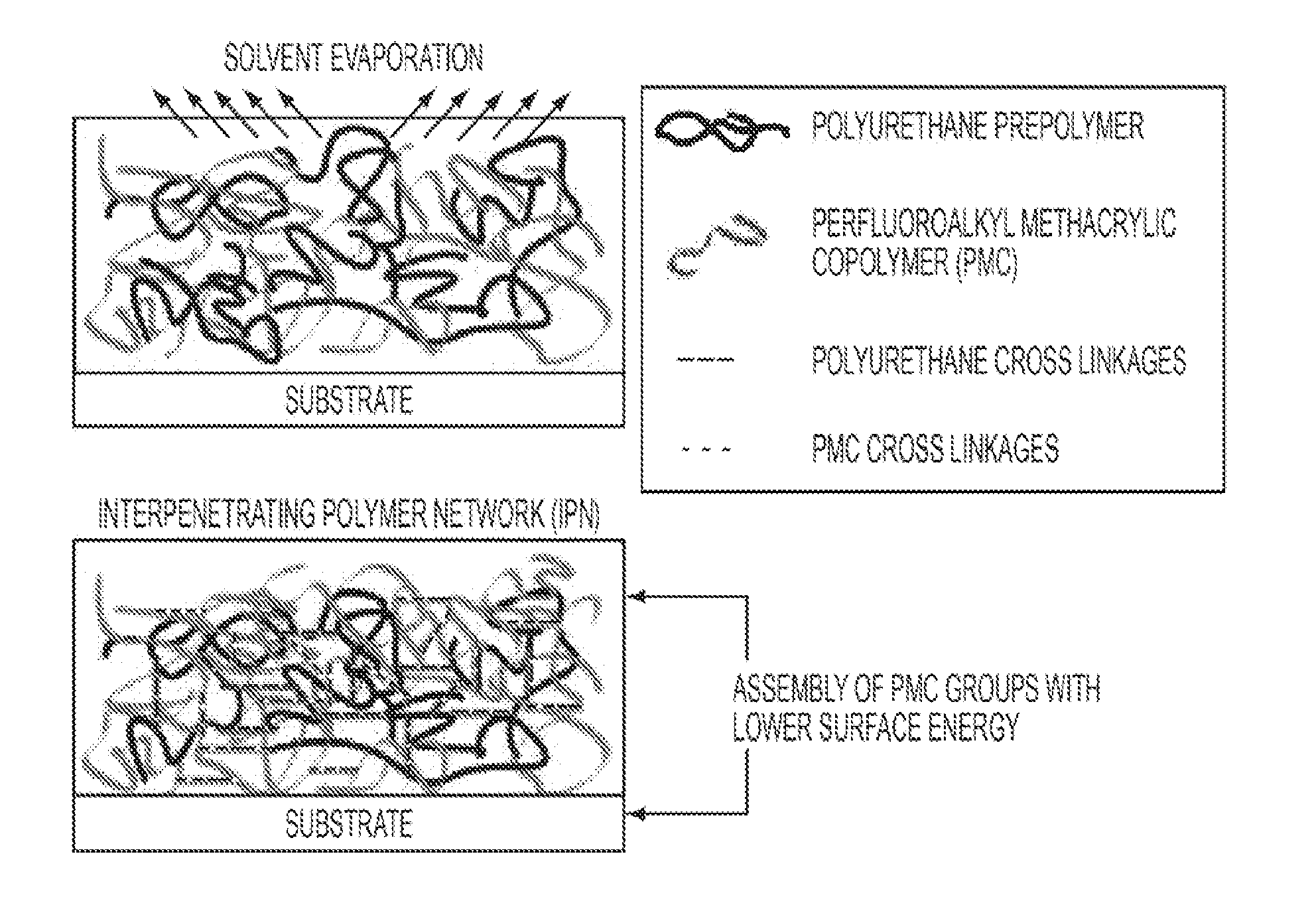

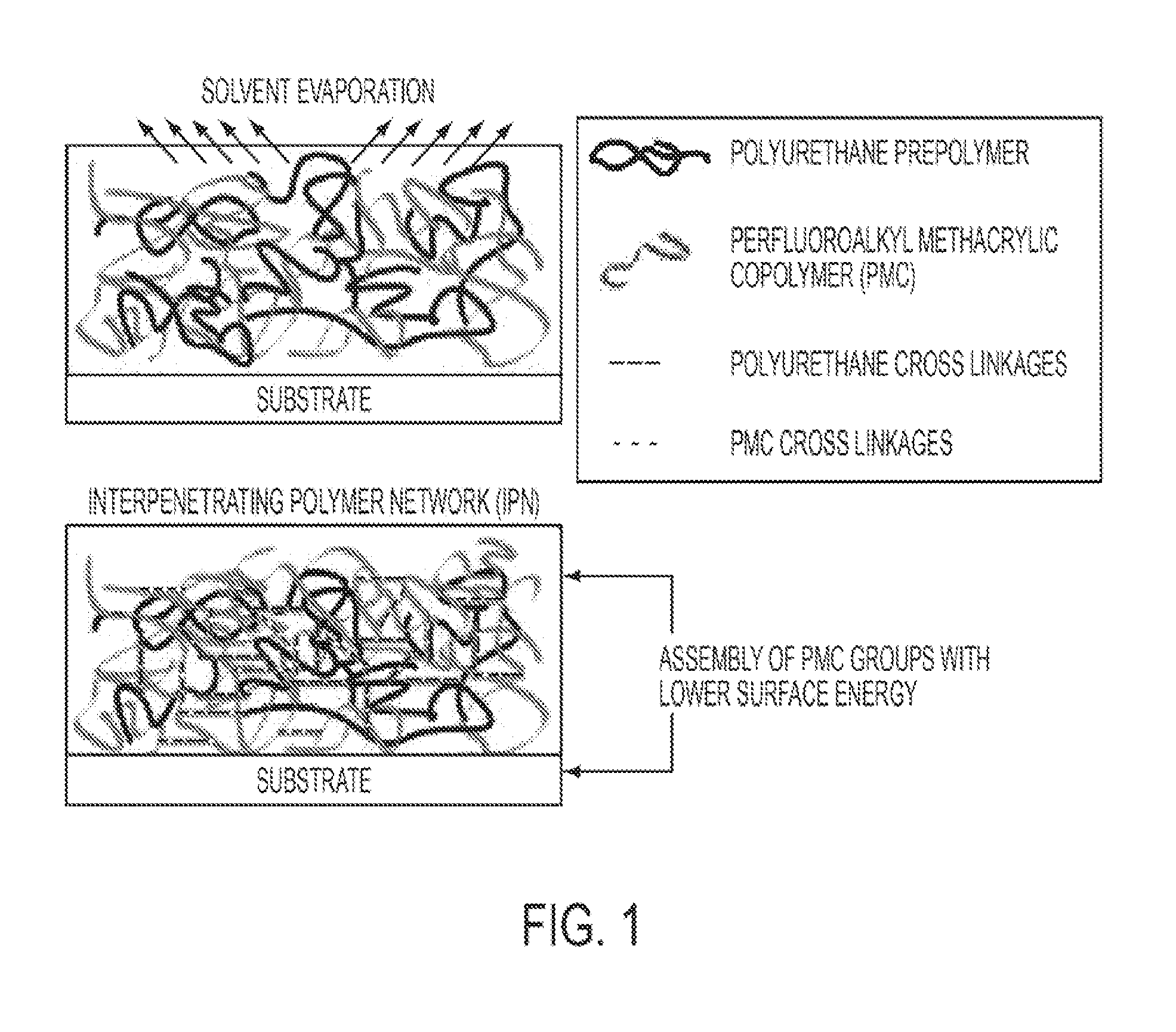

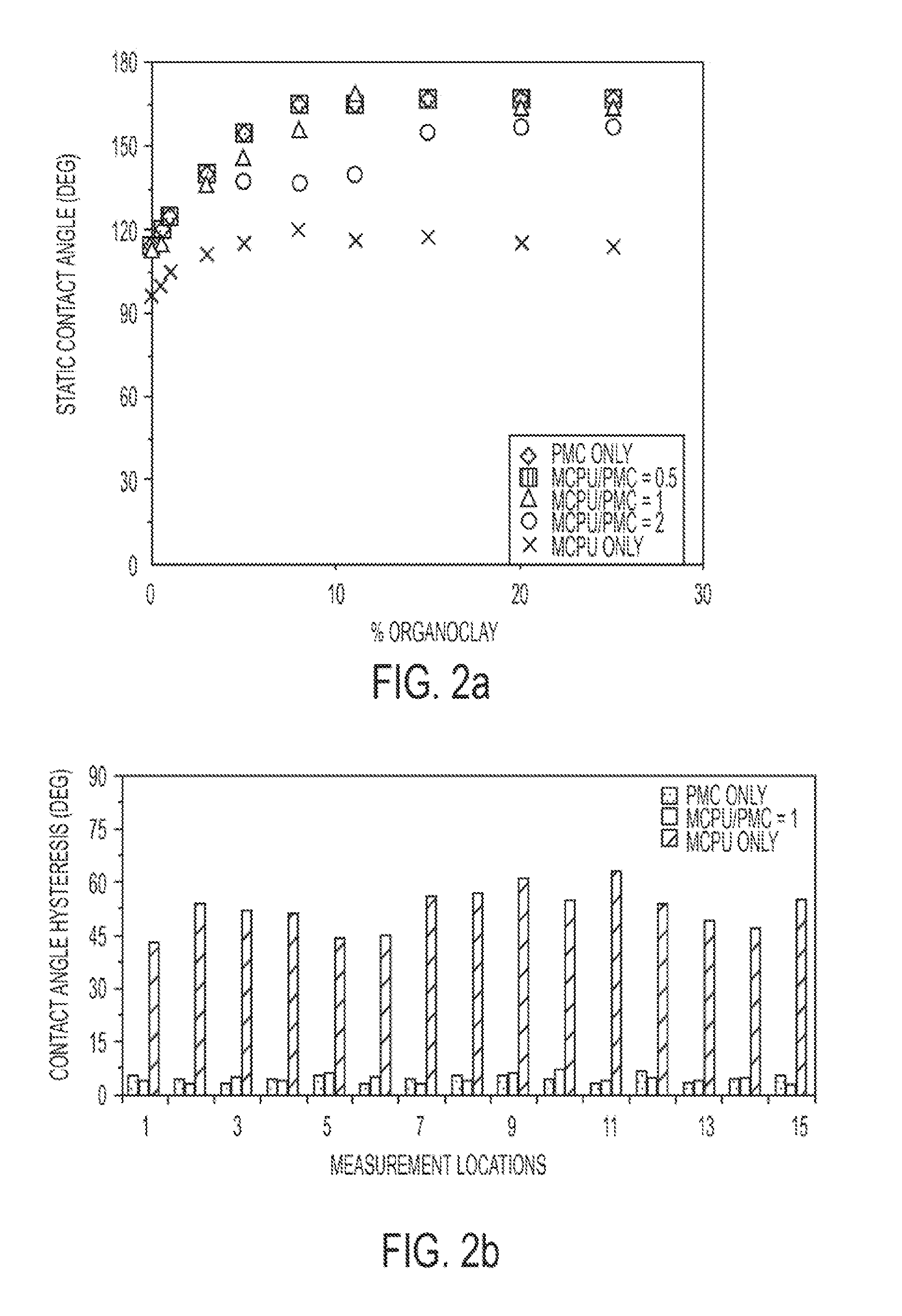

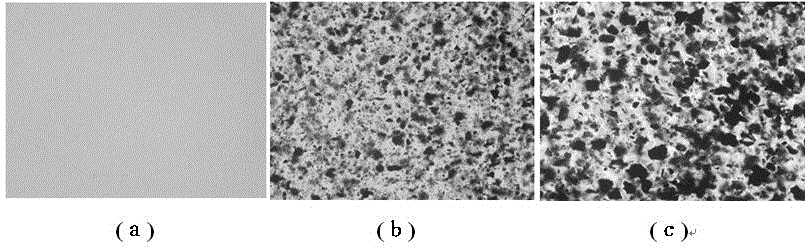

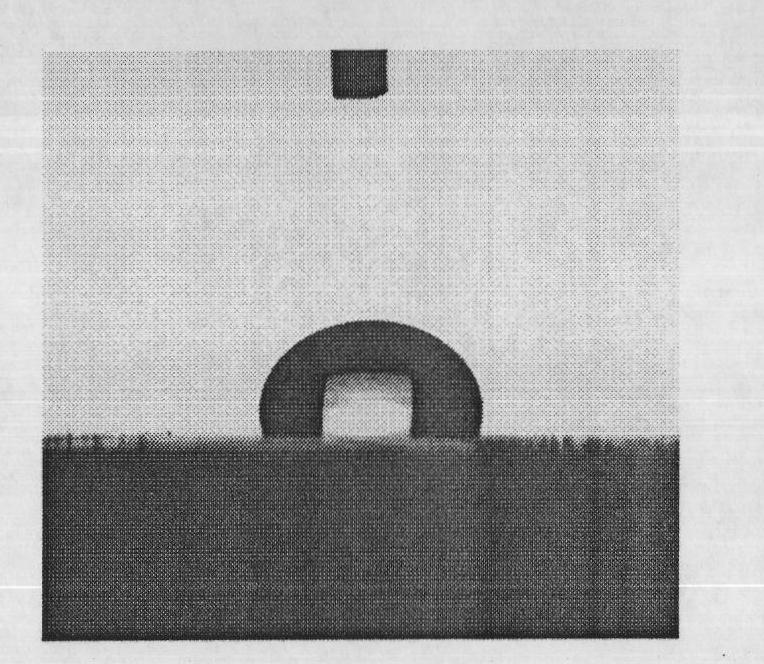

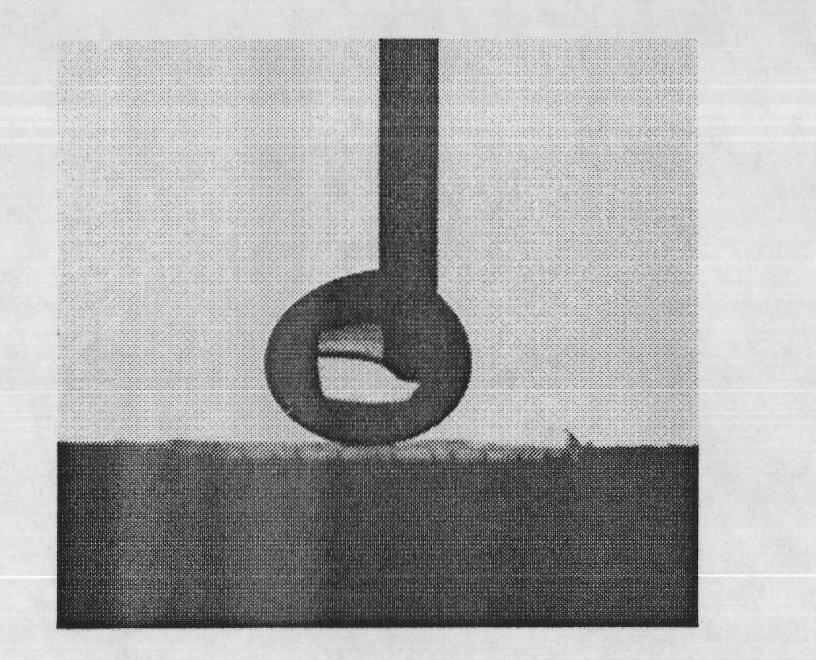

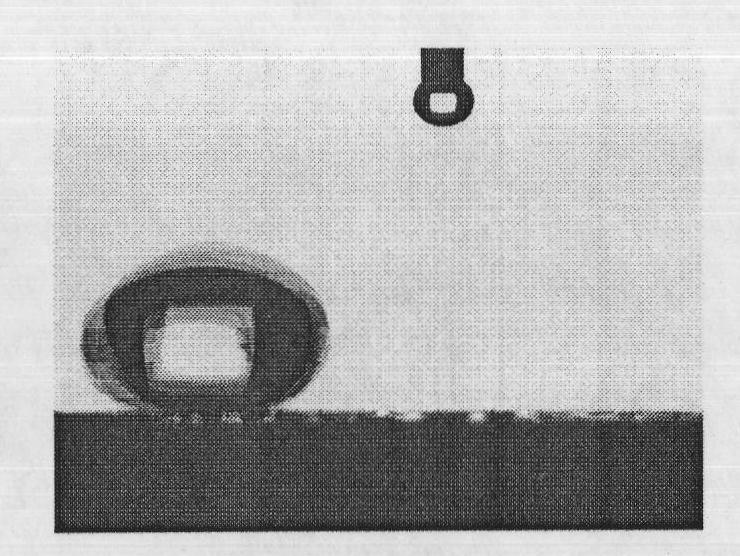

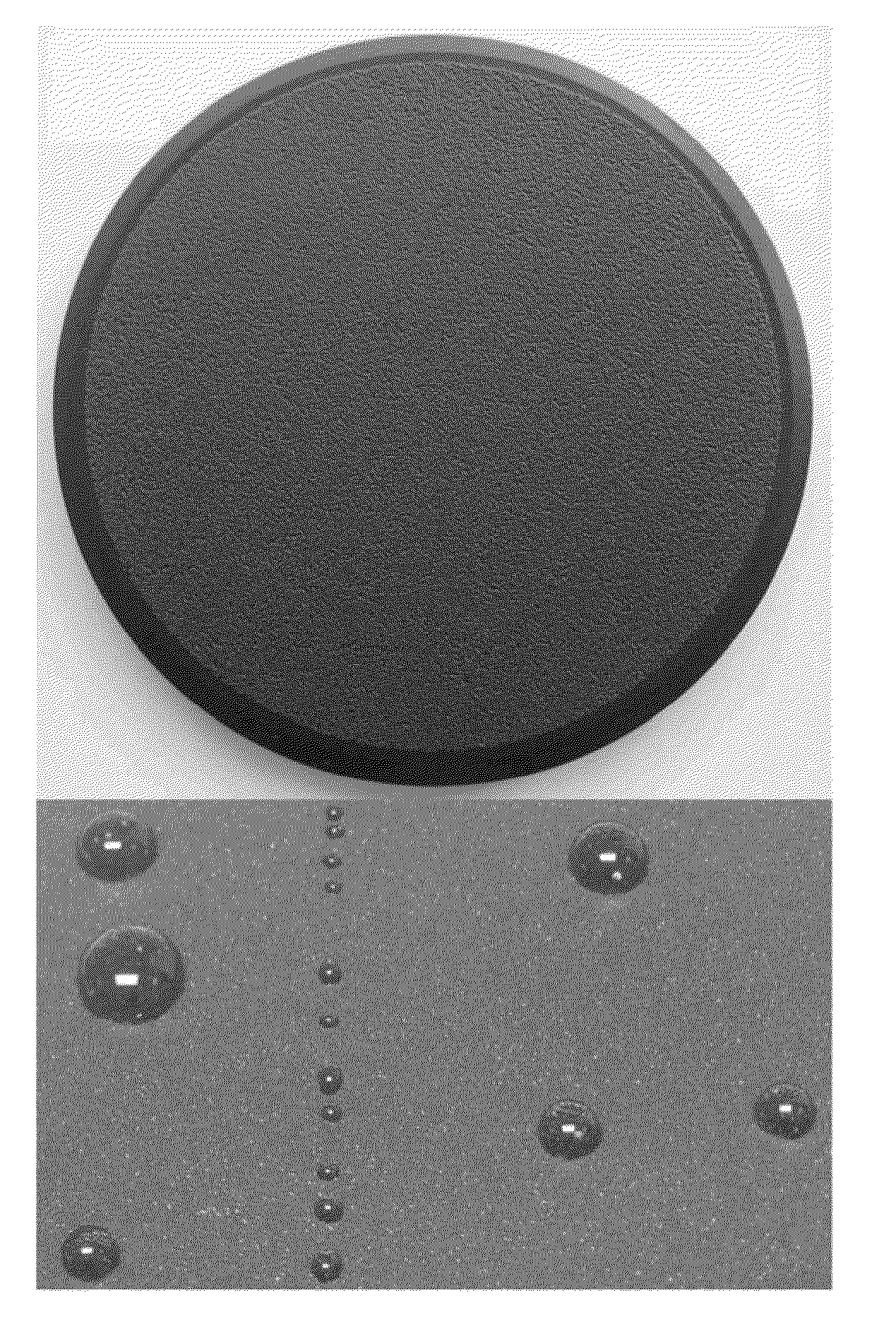

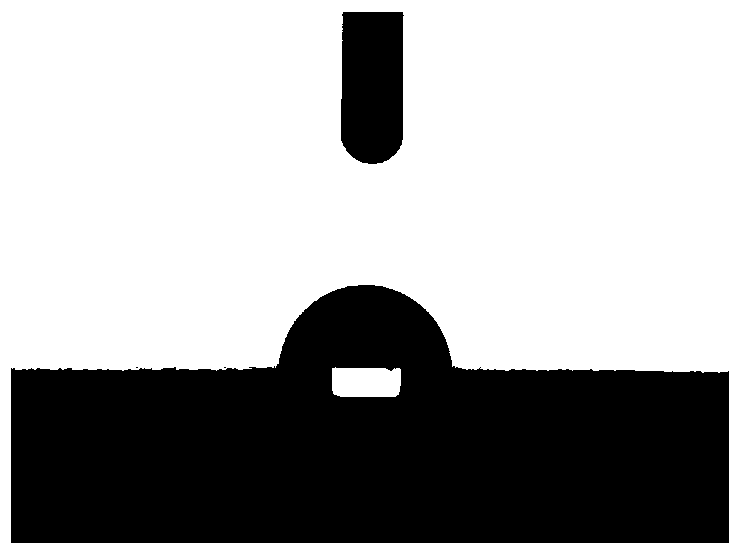

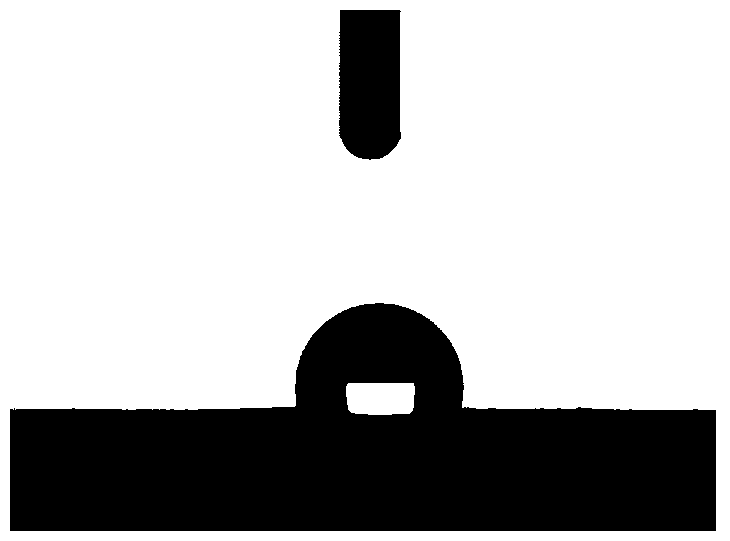

Superhydrophobic nanocomposite coatings

InactiveUS20140113144A1Fouling preventionSynthetic resin layered productsOrganic solventUltrasonic nozzle

The invention relates to a superhydrophobic coating composition containing a polyurethane; a fluoropolymer; a nanofiller; and an organic solvent. The polyurethane to fluoropolymer are present in a weight ratio from about 1:2 to about 15:1. Coated substrate having at least a portion of one surface coated with a hydrophobic coating using the superhydrophobic coating composition are disclosed as are methods for forming a superhydrophobic coating on a substrate. The invention also relates to a method of forming a superhydrophobic coating on a surface of a substrate by spray casting a superhydrophobic coating composition onto a surface of a substrate to form a coating using an ultrasonic nozzle or at an air pressure of about 20 to about 60 psi and from a height of about 3 to about 12 inches above the surface to form a coating, and curing the coating.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

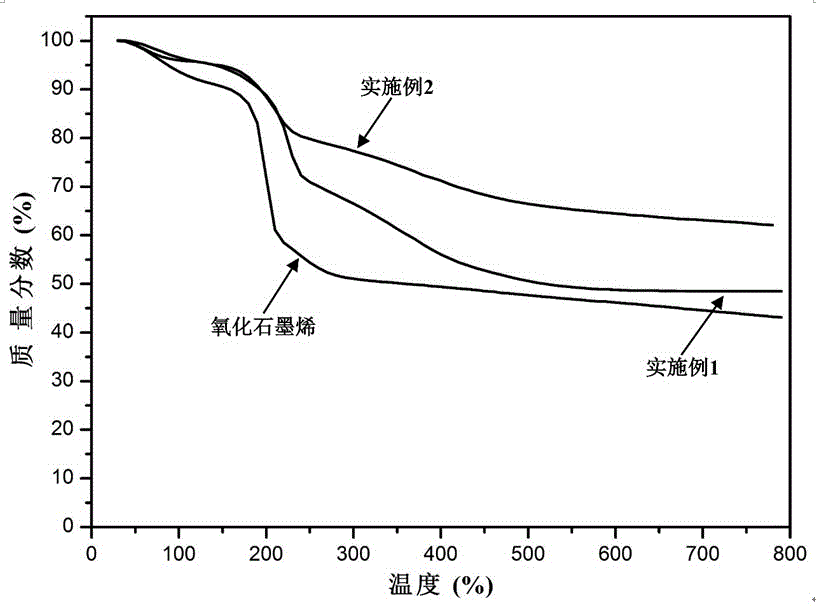

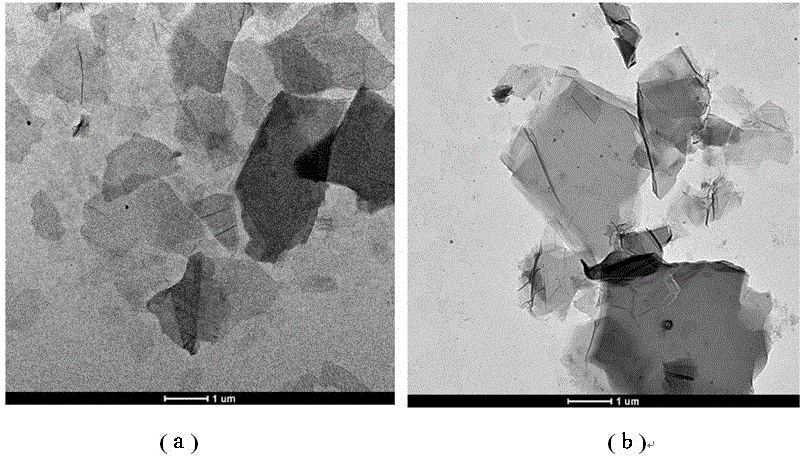

High-scratch-resistance abrasion-resistant coating material and preparation method thereof

InactiveCN106752923AIncrease elasticityAvoid scratch damageFireproof paintsAnti-corrosive paintsDispersityMechanical property

The invention provides a high-scratch-resistance abrasion-resistant coating material and a preparation method thereof. The preparation method comprises the following steps: modifying the graphene surface by using active groups by a chemical modification technique to obtain modified graphene, and blending the modified graphene with polysiloxane to obtain the high-scratch-resistance abrasion-resistant nano composite coating material. The surface modification is carried out to enhance the dispersity of the graphene and the interactions between the graphene and polysiloxane matrix, thereby enhancing the mechanical properties of the coating. No pigment or filler is added. The scratch resistance of the transparent graphene / polysiloxane composite coating is enhanced by 140% or above, and the abrasion loss is reduced by 60% or above. The transparent graphene / polysiloxane composite coating has excellent adhesion, heat resistance, weather resistance, flame retardancy and corrosion resistance. The graphene / polysiloxane composite coating can be used for surface protection and shielding of various metals, plastics, wood, concrete, glass and other substrates, and is applicable to the fields of automobile paints, photoelectric materials, precision instruments, marine heavy-corrosion protection, buildings and the like.

Owner:FUDAN UNIV

Light curing nano composite coating

The invention relates to a photo-cured nanometer composite material which consists of 0 to 64 weight percent of film forming substance, 1 to 60 weight percent of inorganic nanometer particles, 1 to 56 weight percent of active thinner, 1 to 9.3 weight percent of evocating agent, 0 to 8 weight percent of coating additive and 0 to 31 weight percent of solvent. The manufacturing method comprises the following steps: (1) the prepared photo-cured nanometer composite material is counted by 100 weight percent; according to the proportion, each composition is weighed; (2) through a sol-gel method, a mechanical dispersion method or the combination of two methods, the inorganic nanometer particles are introduced to the active thinner to obtain a mixed master material; and (3) the mixed master material, an oligomer, the evocating agent, the coating additive and the solvent are mixed and evenly stirred to prepare the photocuring nanometer composite material. The photocuring nanometer composite material has the characteristics of high content of nanometer particles, good levelling performance, high transparency, good lustrousness, high adhesive force with a polymer substrate, high rigidity, scratching resistance, ultraviolet resistance and the like.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

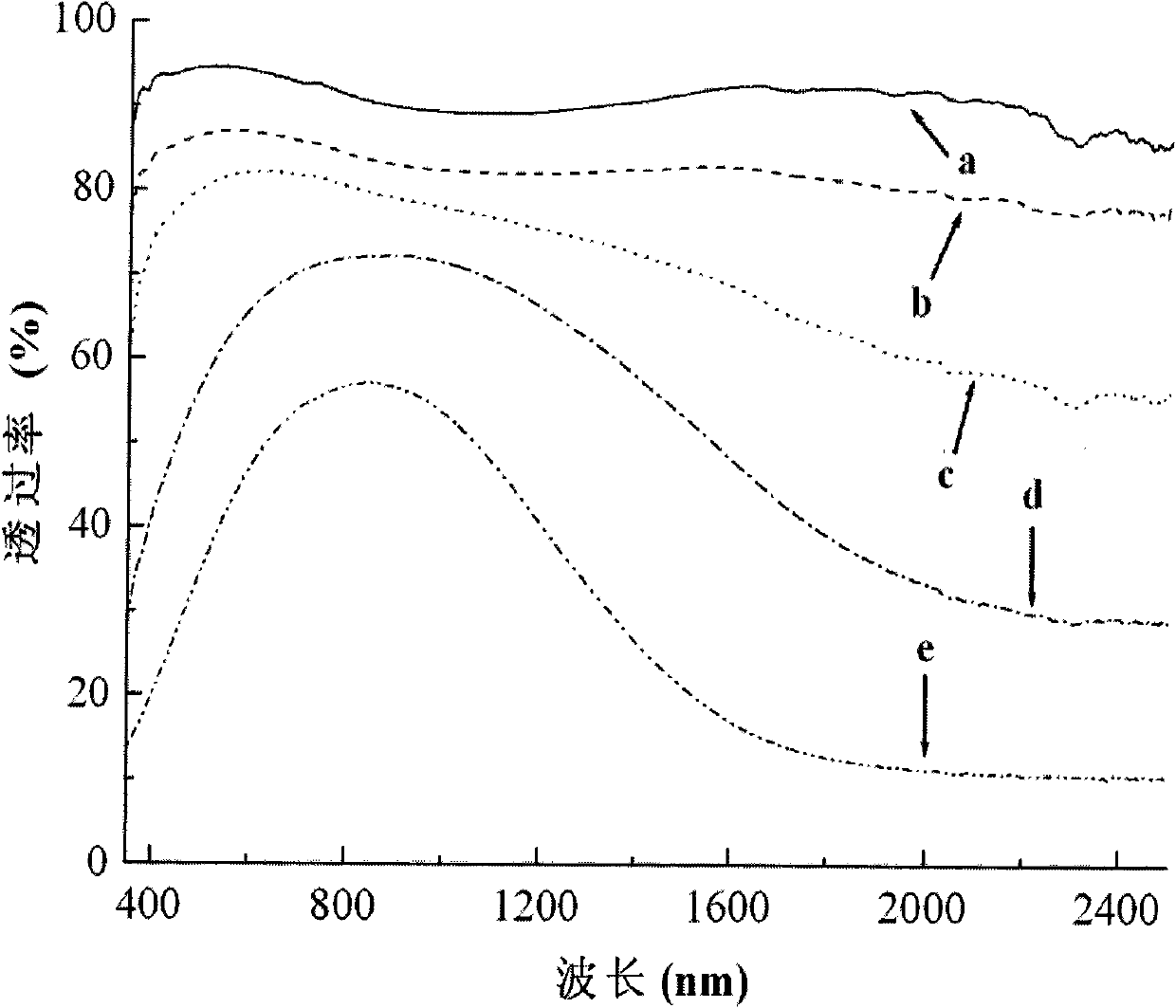

Super-hydrophobic nano-composite coating and preparation method thereof

InactiveCN101845242AExcellent superhydrophobic propertiesAchieve self-cleaning effectCoatingsProcess equipmentHydrophobic polymer

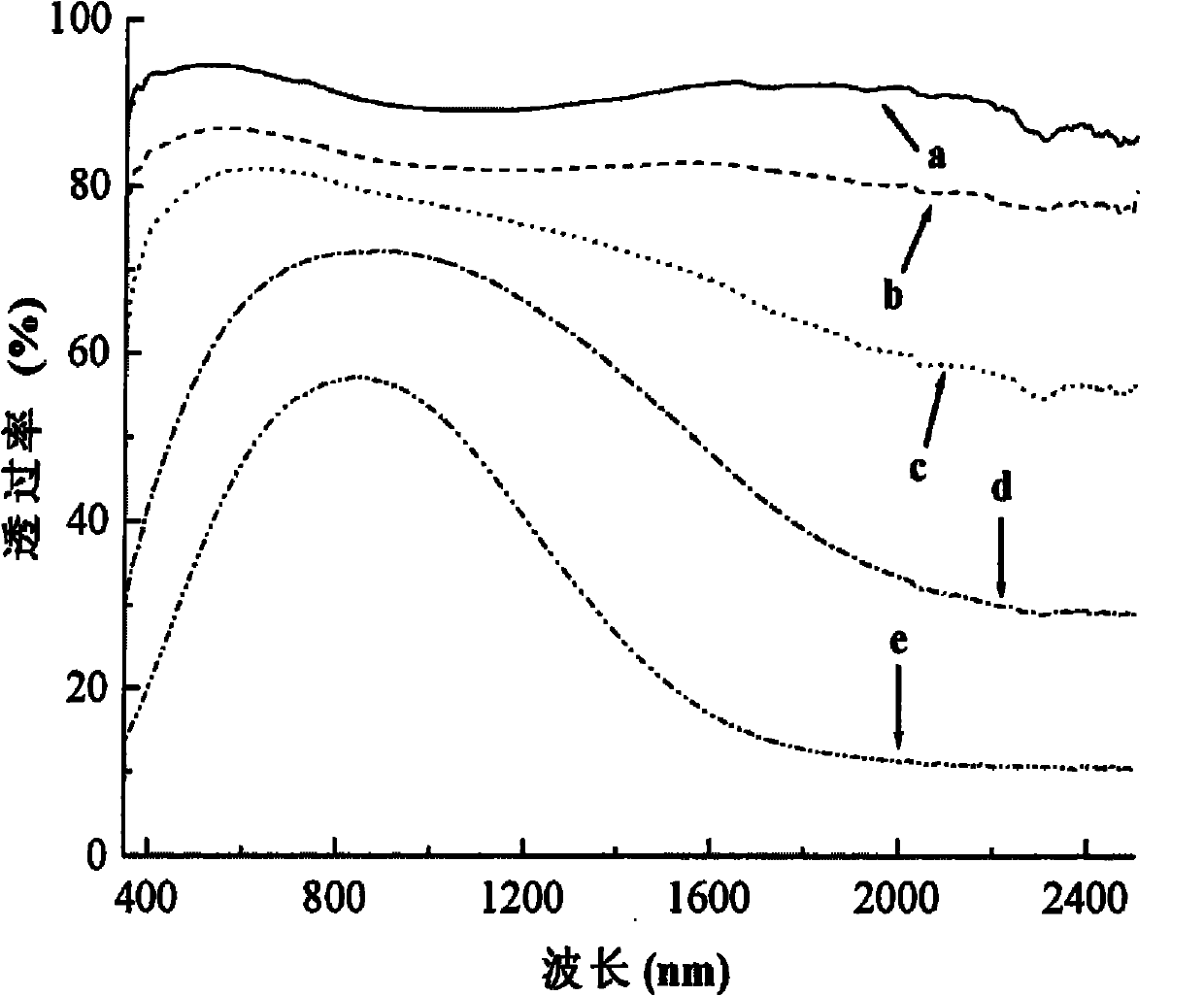

The invention discloses a super-hydrophobic nano-composite coating comprising the following components in percentage by weight: 0.5-10.5 percent of hydrophobic silicon dioxide, 0.2-5.4 percent of hydrophobic polymer material and 86.5-99.3 percent of solvent, wherein a contact angle of a water drop on a membrane surface prepared by the coating is 152-169 degrees, and a rolling angle is 1-9 degrees. When the coating is transparent, the visible light transmission of the membrane prepared from the coating is 80-94 percent. The invention also discloses a preparation method of the super-hydrophobic nano-composite coating. The nano-composite coating not only has excellent super-hydrophobicity and low cost of products, but also can obtain higher transparency by reducing the contents of the hydrophobic silicon dioxide and the hydrophobic polymer material and has simple preparation processing equipment and high production efficiency.

Owner:SICHUAN UNIV

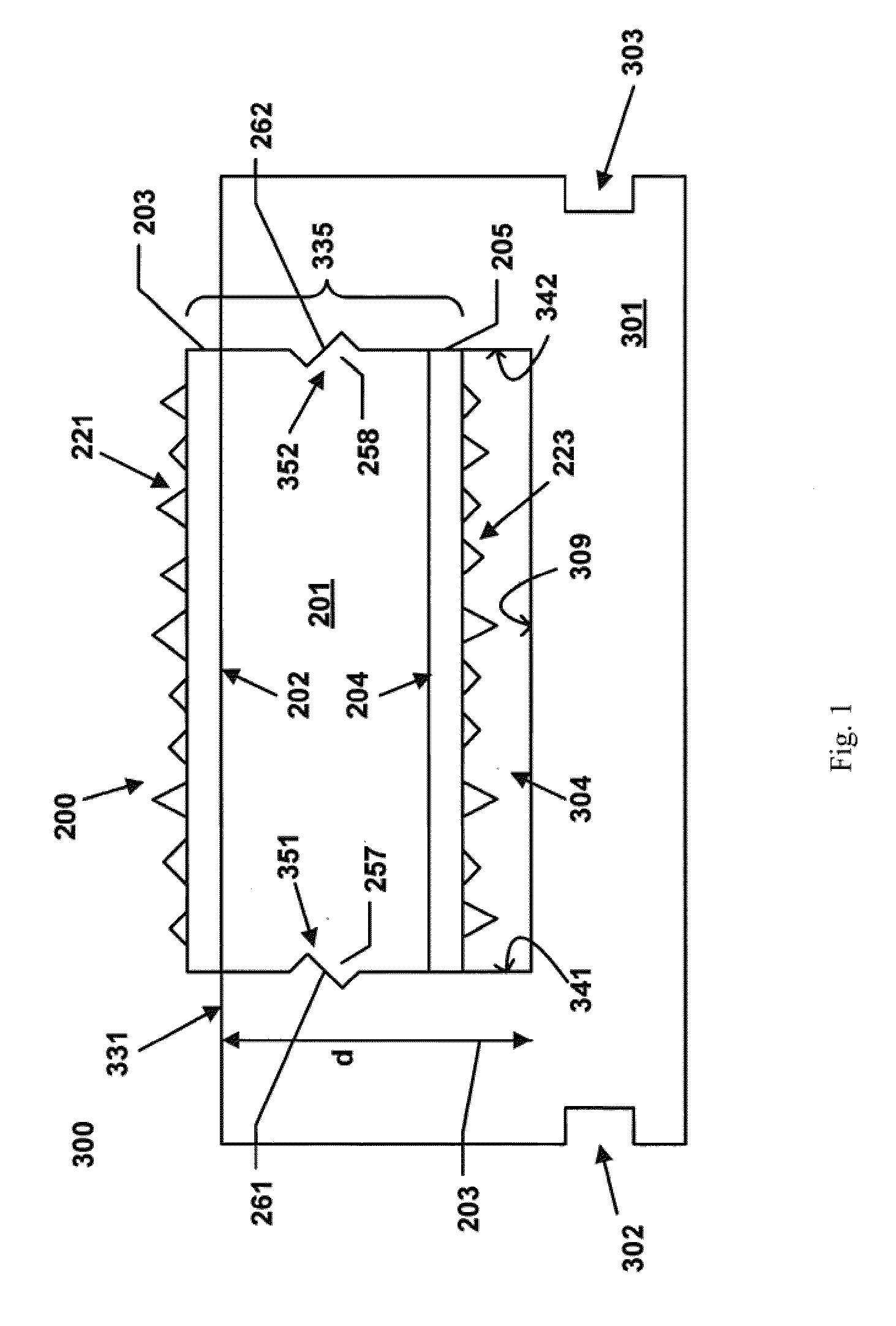

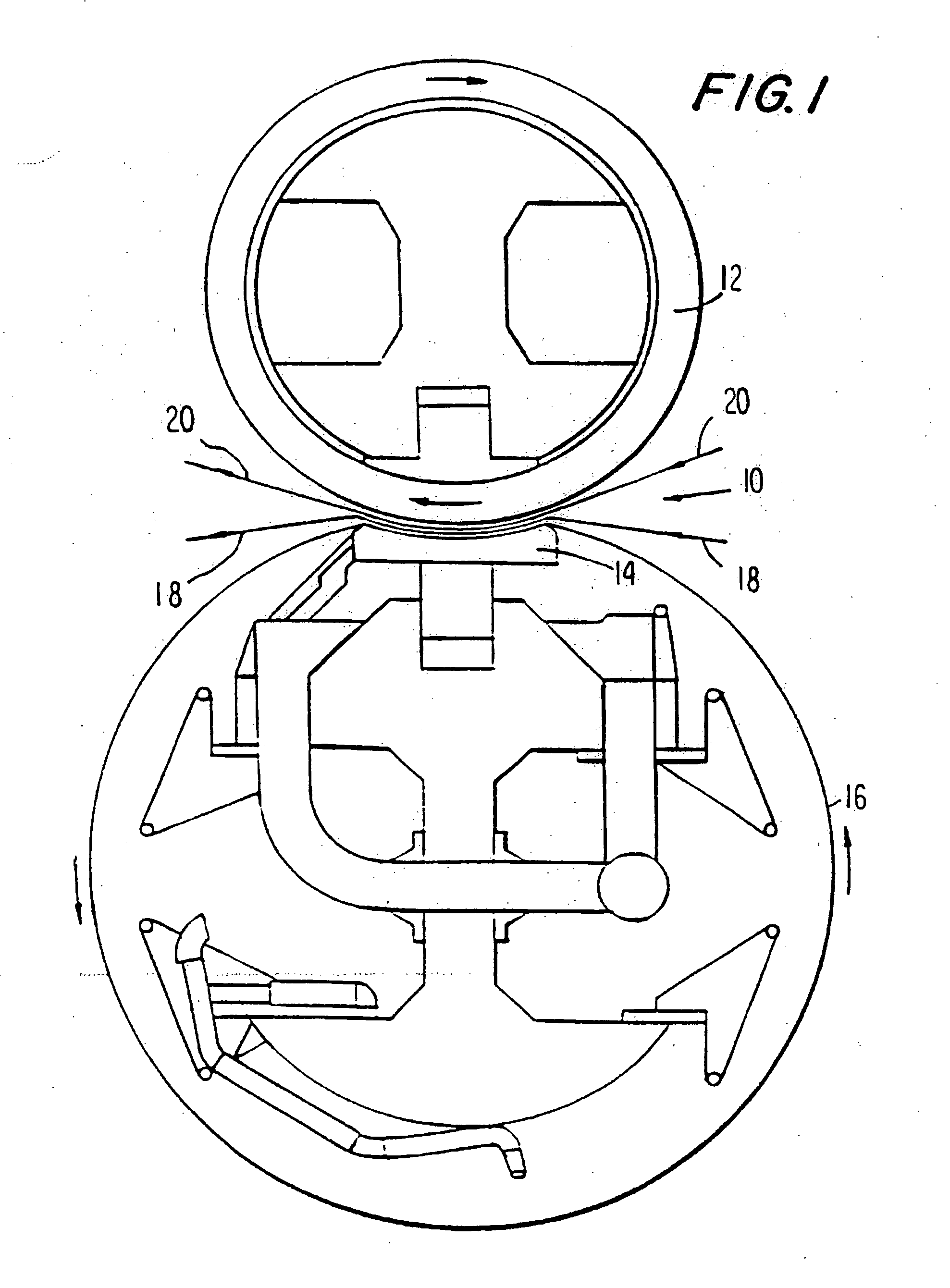

Corrosion-Resistant CMP Conditioning Tools and Methods for Making and Using Same

ActiveUS20100330886A1Reduce and minimize corrosive effectReducing minimizing and formationPigmenting treatmentOther chemical processesNanocomposite coatingMetal

An abrasive tool for conditioning CMP pads includes abrasive grains coupled to a substrate through a metal bond and a coating, e.g., a fluorine-doped nanocomposite coating. The abrasive grains can be arranged in a self-avoiding random distribution. In one implementation, an abrasive tool includes a coated plate and a coated abrasive article that has two abrading surfaces. Other implementations related to a process for producing an abrasive tool that includes a coating at one or more of its surfaces. Also described are methods for dressing a CMP pad.

Owner:SAINT GOBAIN ABRASIVES INC +1

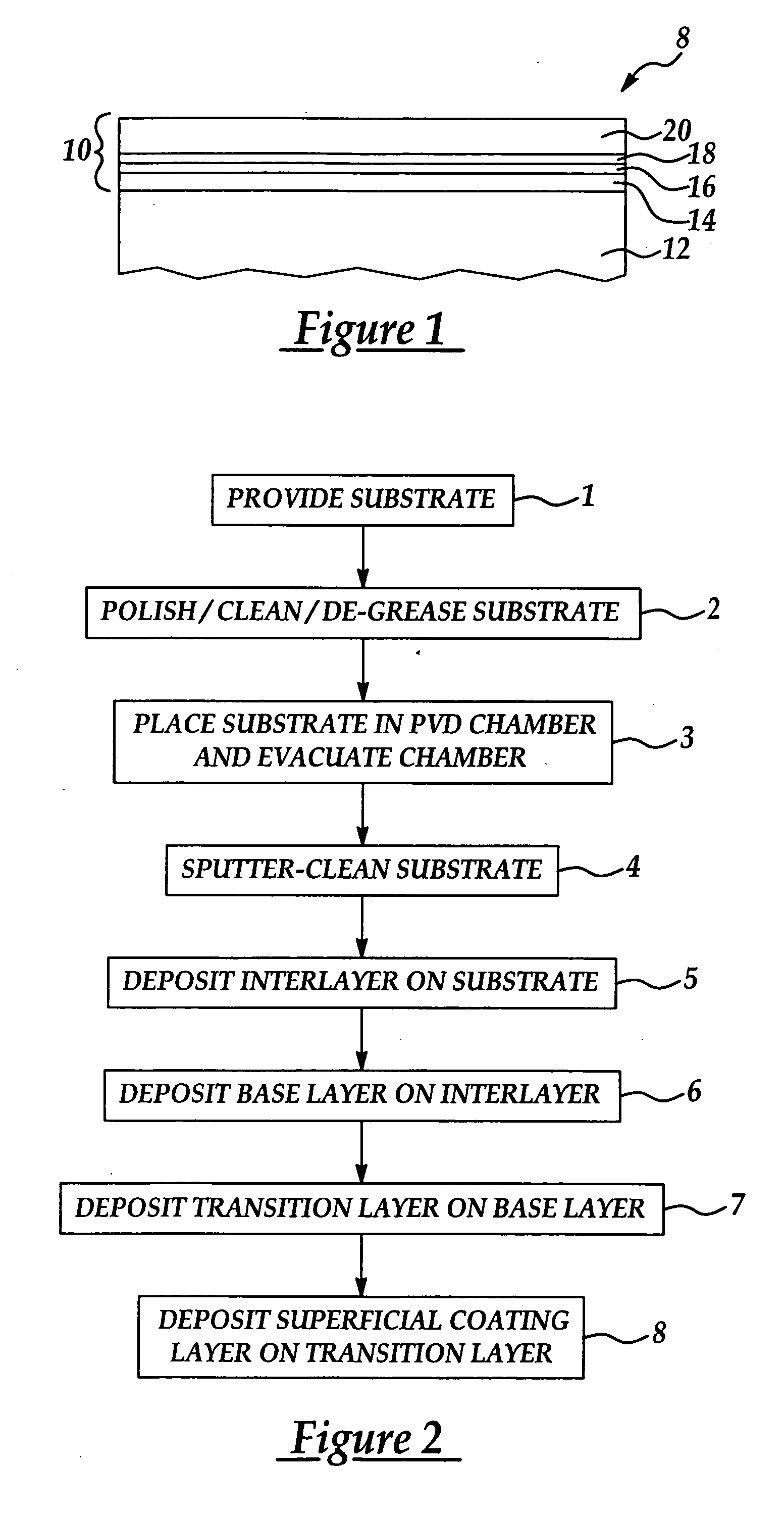

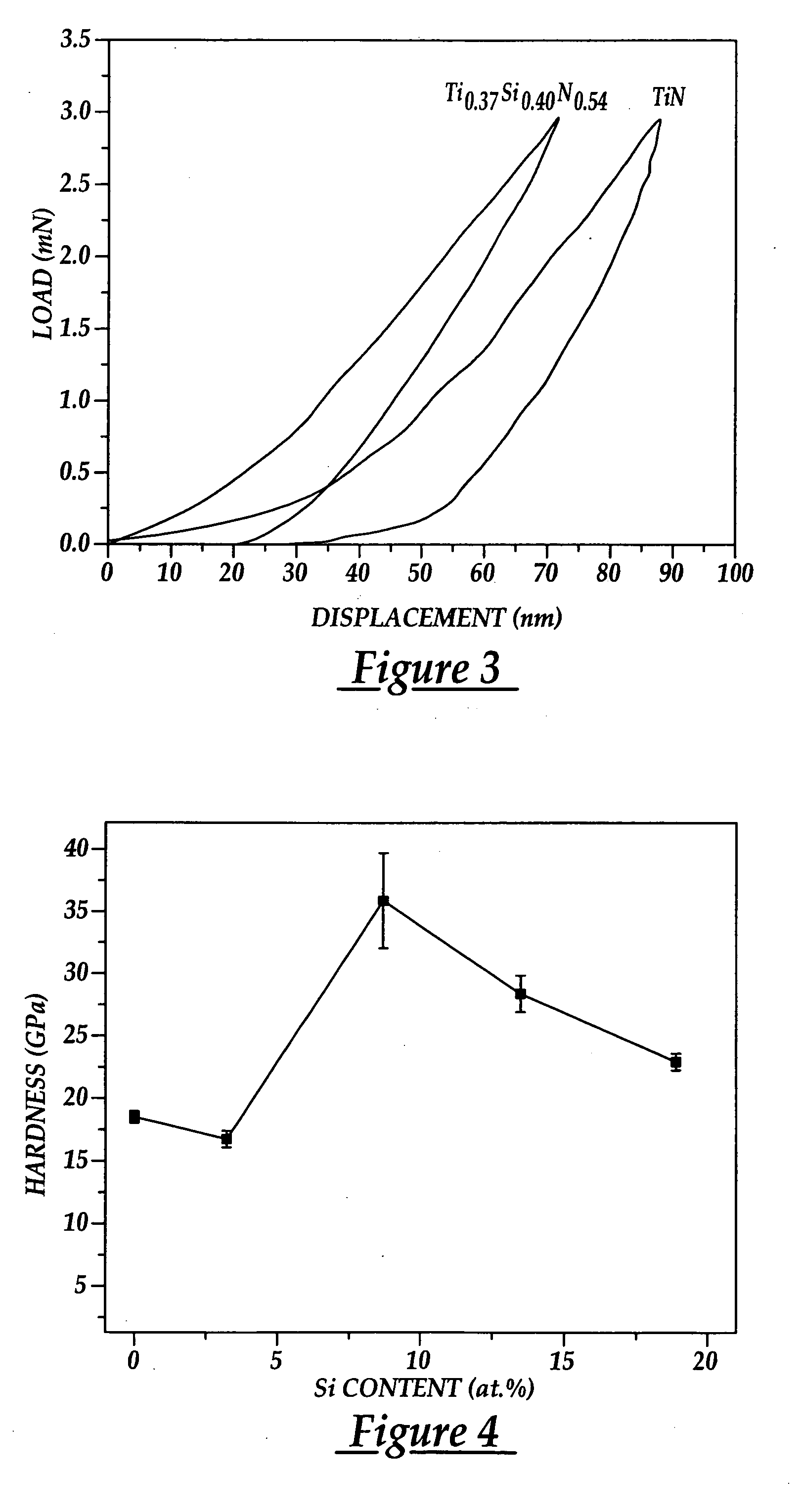

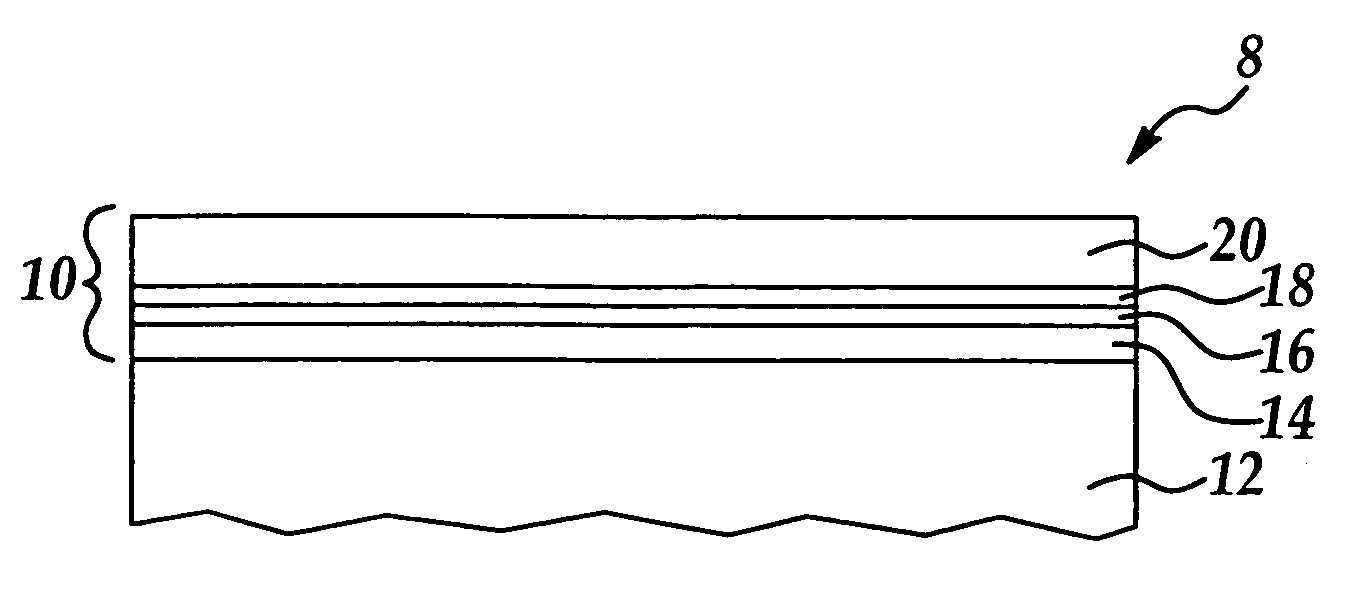

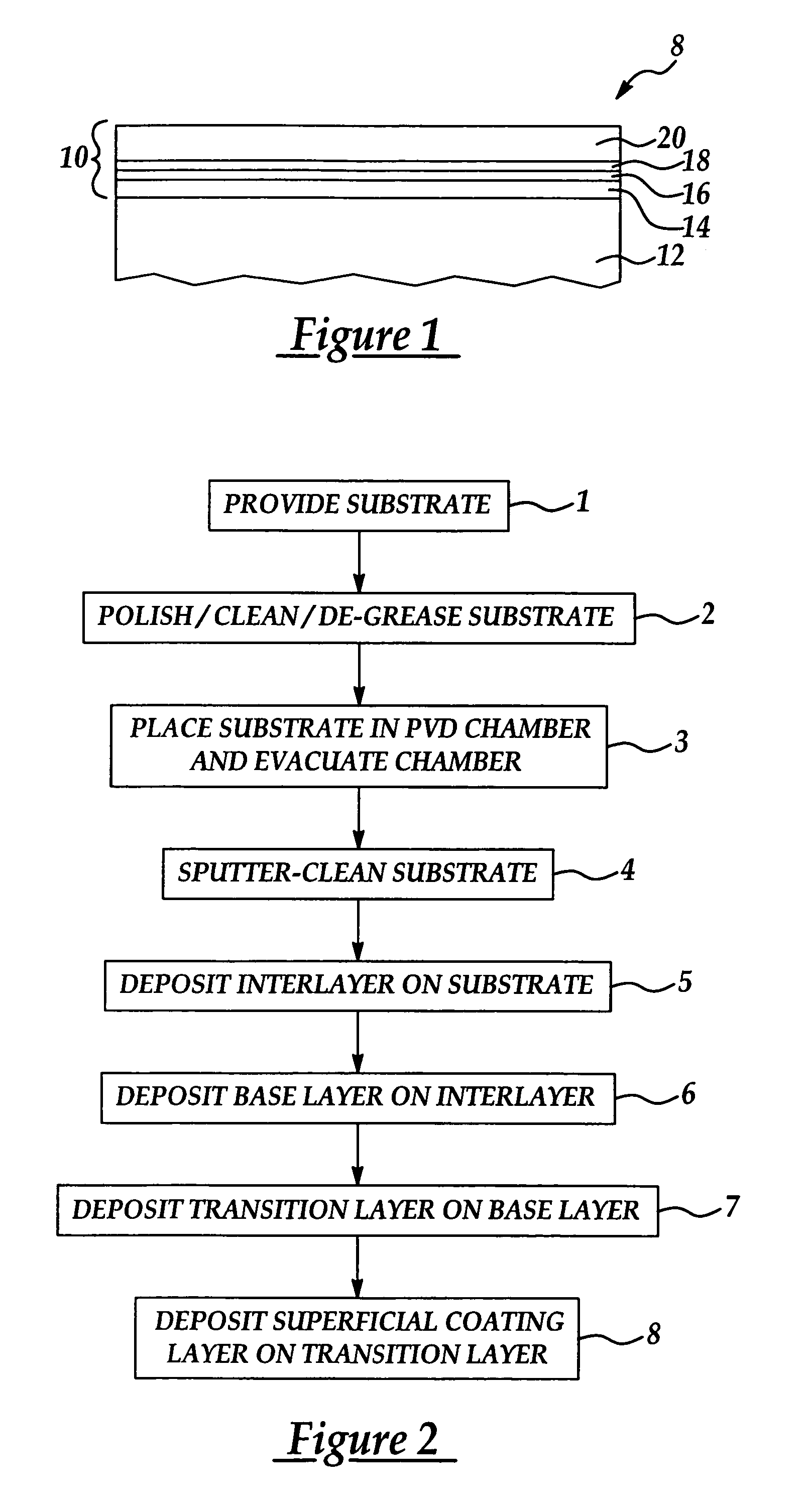

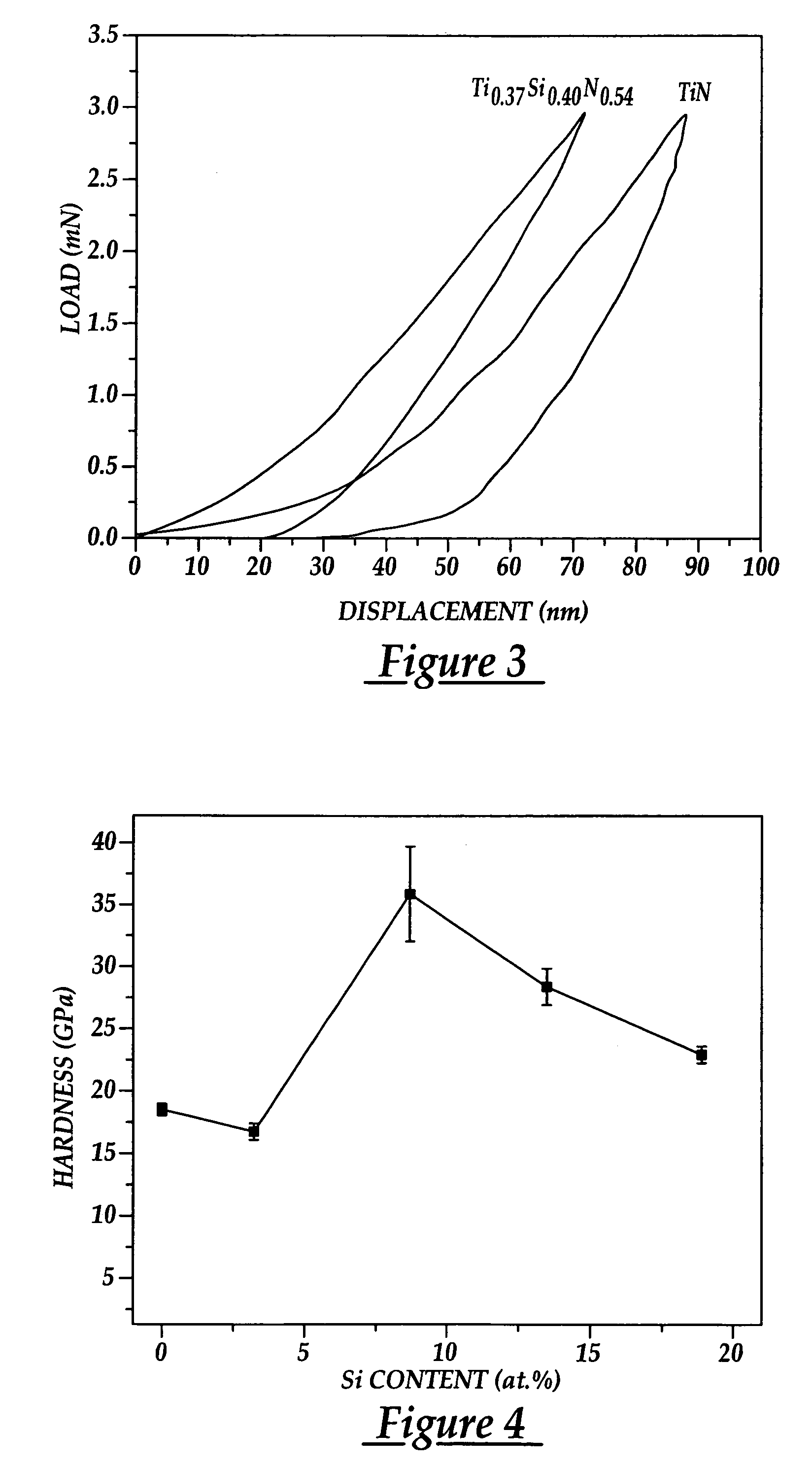

Multi-layered superhard nanocomposite coatings

InactiveUS20060147728A1Liquid surface applicatorsVacuum evaporation coatingNanocomposite coatingMaterials science

Superhard nanocomposite coatings which are applicable to coating contact surfaces on substrates in a variety of industrial processes are disclosed. In a typical embodiment, the superhard nanocomposite coating includes a refractory metal silicon nitride coating layer having silicon in a concentration of from about 6 atomic percent to about 12 atomic percent.

Owner:CITY UNIVERSITY OF HONG KONG +1

Organic-inorganic nanocomposite coatings for implant materials and methods of preparation thereof

The present invention provides inorganic-organic nanocomposite coatings for implant materials and methods for the production thereof. The coatings consist of a sequentially adsorbed polyelectrolyte film (SAPF) intergrown with calcium phosphate crystals. The substrate is selected from glass, polymer, metal or metal alloys. The SAPFs consist of successions of positively and negatively charged monolayers, comprising biocompatible polyelectrolytes, preferably polyaminoacids. The calcium phosphate crystals may comprise octacalcium phosphate, calcium deficient apatites, carbonate apatites, hydroxyapatite, or mixtures thereof, with particle sizes 50 nm to 2 μm. The inorganic phase is grown “in situ” within the polyelectrolyte organic matrix.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD +1

Ultraviolet-light curable aqueous heat-insulating nano composite coating and preparation method thereof

ActiveCN101792636AGood dispersionImprove stabilityPolyurea/polyurethane coatingsPolyether coatingsEmulsionUltraviolet lights

The invention discloses an ultraviolet-light curable aqueous heat-insulating nano composite coating and a preparation method thereof. The preparation method is characterized by comprising the following steps: adding 0.1 to 0.5 part of antifoaming agent, 0.2 to 0.5 part of dispersant, 0.2 to 2.0 parts of flatting agent and 0.5 to 3.0 parts of photo-initiator by mass into 60 to 85 parts of film forming emulsion, adding pH adjustor into the emulsion to reach the same pH value as tin oxide containing nano slurry to be added, then dripping 10 to 35 parts of the tin oxide containing nano slurry into the emulsion, and dispersing the mixture uniformly to obtain the ultraviolet-light curable aqueous energy-saving heat-insulating nano composite coating. The preparation method of the invention has the advantages of environment friendliness, energy conservation and the like; the prepared nano composite coating has high curing speed and good mechanical property; and the coating is coated on a basematerial during use, and an ultraviolet-light cured film has good transparency and heat insulation performance and can be used as a heat-insulating protective coat for automobile or building glass.

Owner:UNIV OF SCI & TECH OF CHINA

Ecological shell powder inorganic nanometer composite coating material and preparation method thereof

The present invention relates to an ecological shell powder inorganic nanometer composite coating material and a preparation method thereof. The ecological shell powder inorganic nanometer composite coating material comprises, by mass, 70-90% of shell powder and 10-30% of a composite glue adhesive, wherein the shell powder contains 1-3% by mass of titanium dioxide nanoparticles and 1-3% by mass of tourmaline powder, and the composite glue adhesive contains 80-90% by mass of water, 3-10% by mass of polyvinyl alcohol, and 0.5-3% by mass of cellulose. According to the present invention, natural shell powder is adopted as a main material, any toxic and hazardous substances are not added, and the ecological shell powder inorganic nanometer composite coating material has functions of indoor toxic gas absorption and decomposition, and has the following characteristics that: construction is simple, shedding due to scrubbing can not be generated, negative oxygen ions can be released for a long time so as to carry out a purification and sterilization treatment on indoor air.

Owner:山东贝壳屋新材料科技有限公司

Anti-corrosion nanocomposite coating

ActiveUS20180057696A1Good dispersionLiquid surface applicatorsAnti-corrosive paintsNanocomposite coatingPolymer coatings

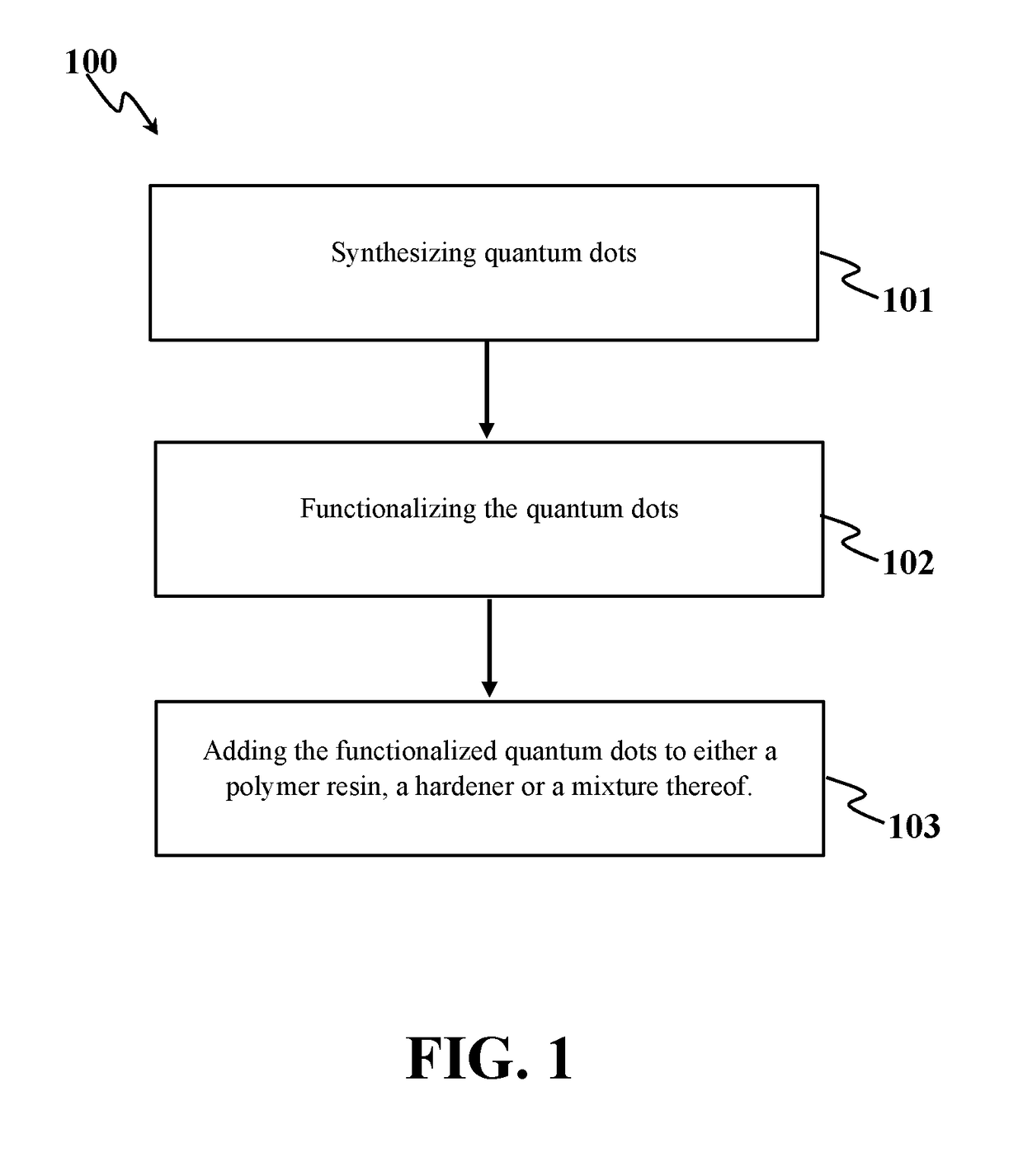

An anti-corrosion coating and a method for fabricating the anti-corrosion coating is disclosed. The coating includes a polymer, a curing agent, and quantum dots. The method includes adding carbon quantum dots to a polymer coating as a nanofiller to enhance the corrosion resistance properties of the polymer coating. The coating is configured to provide improved anti-corrosion properties at a lower cost.

Owner:POURHASHEM SEPIDEH +2

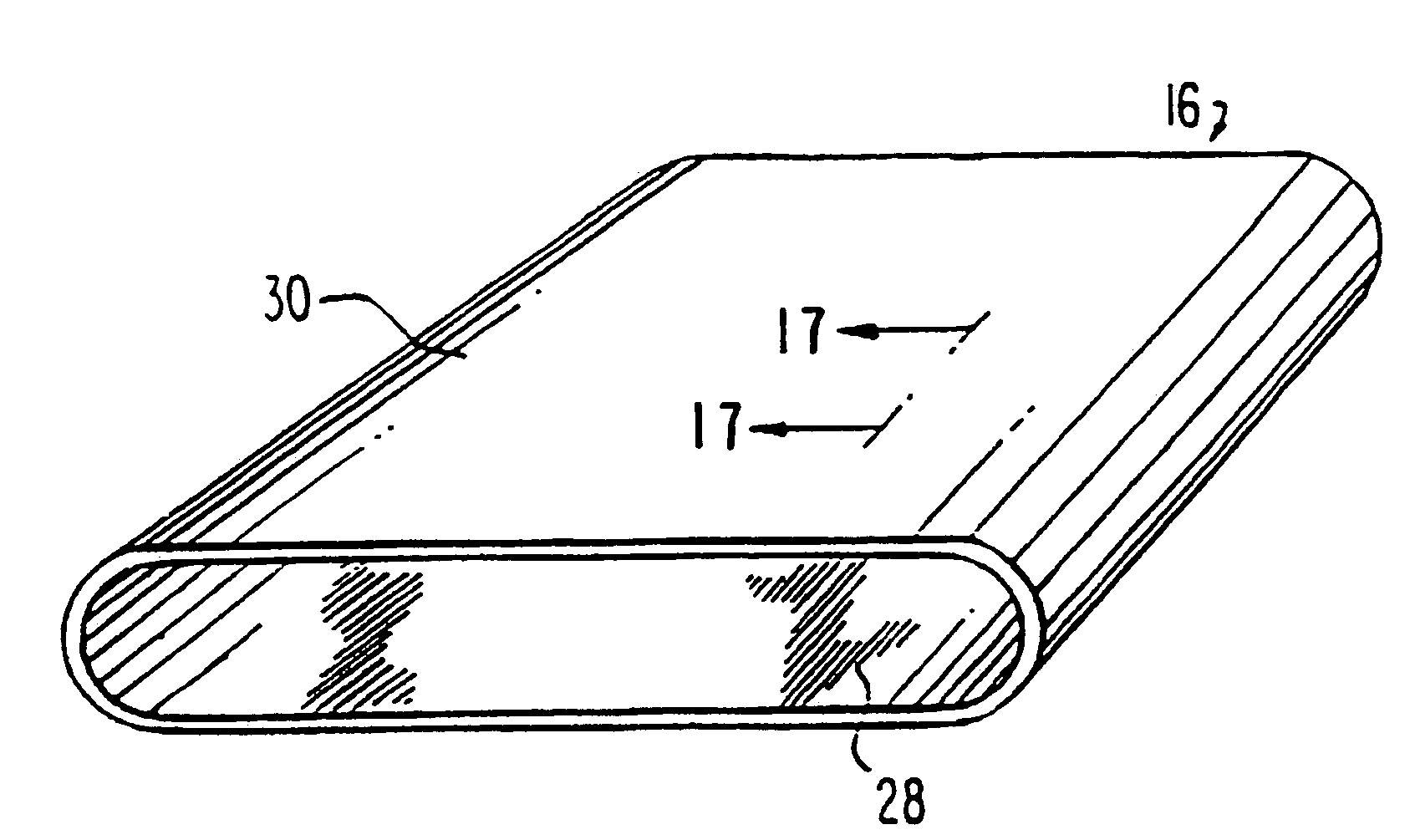

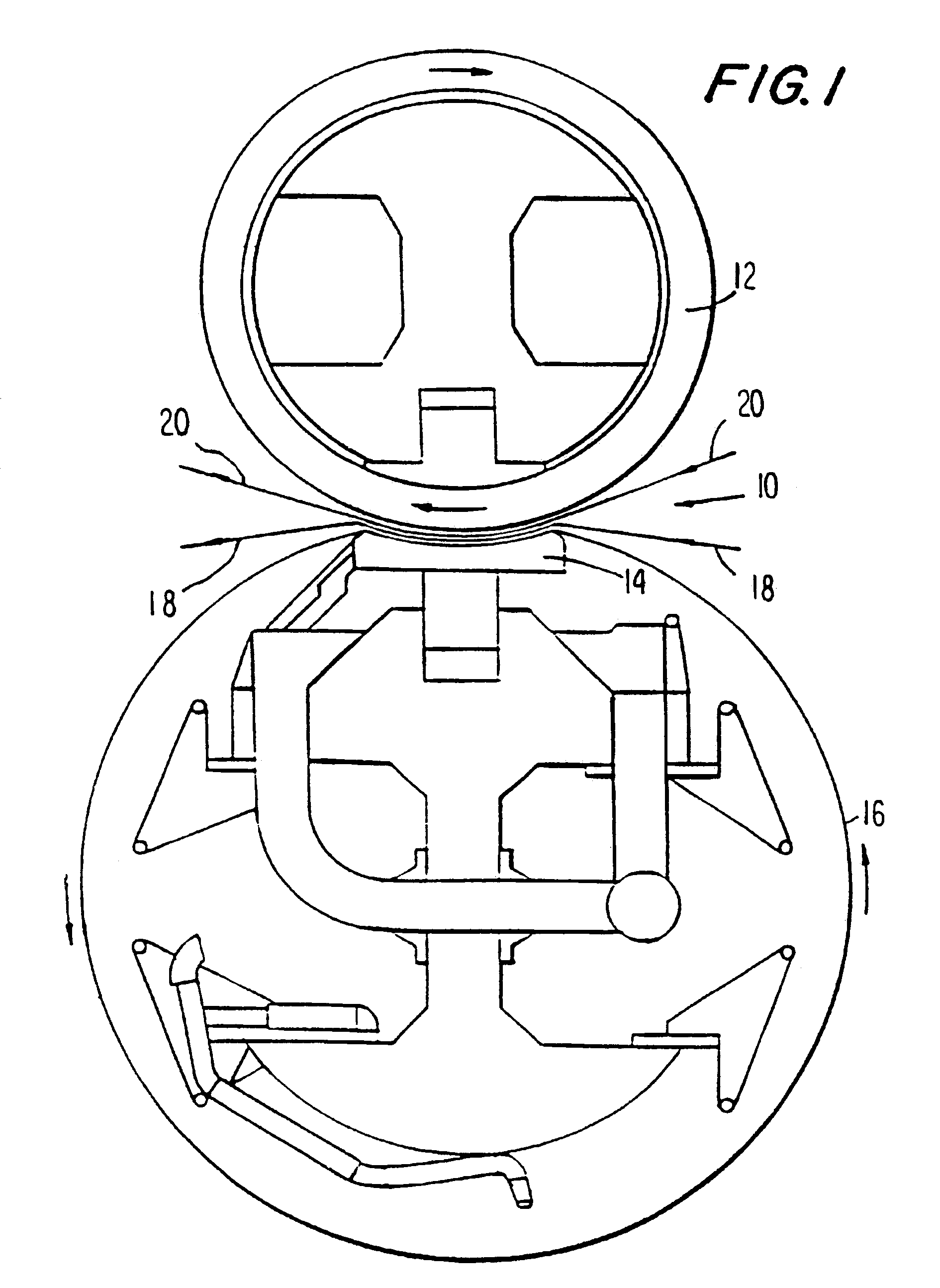

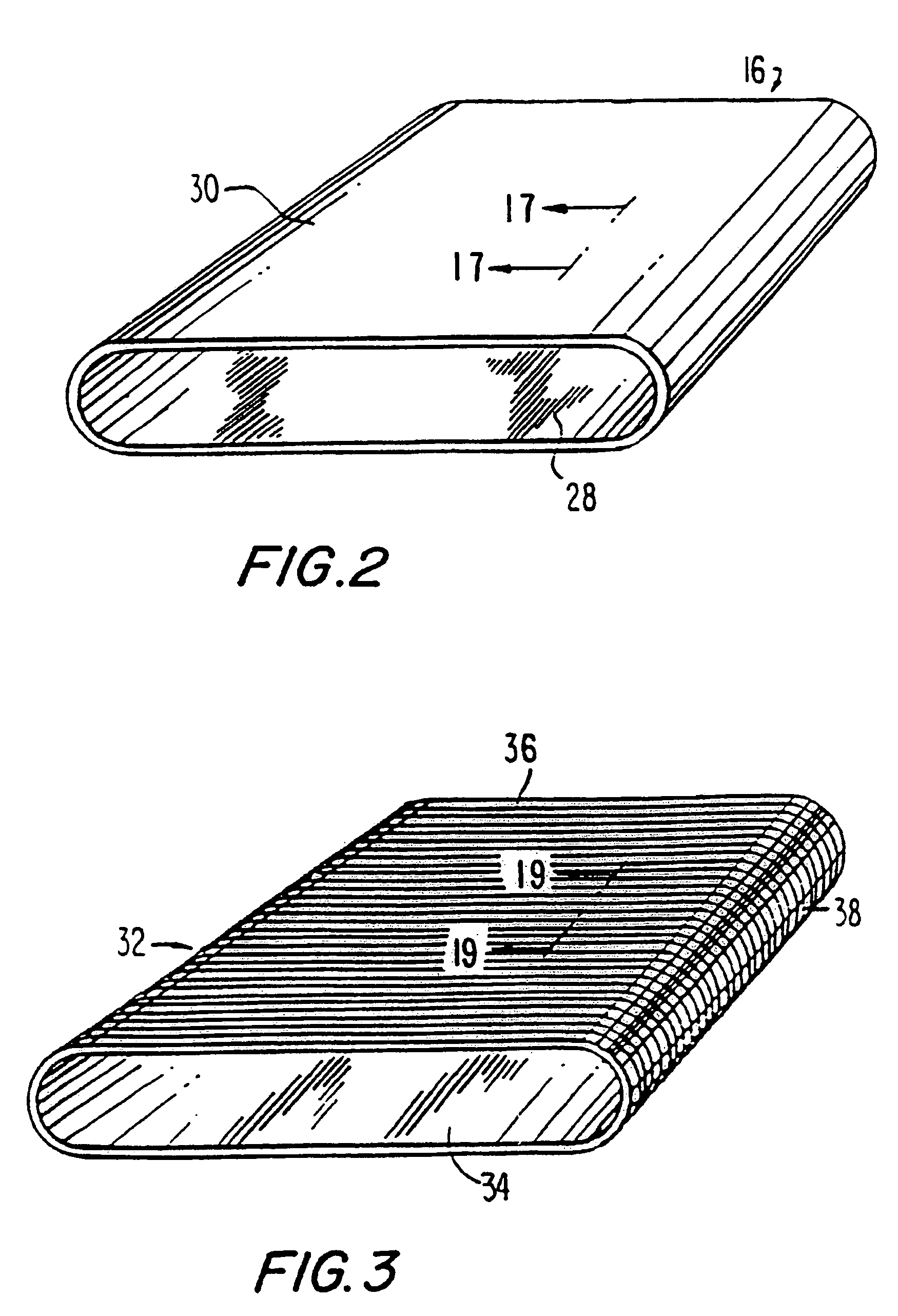

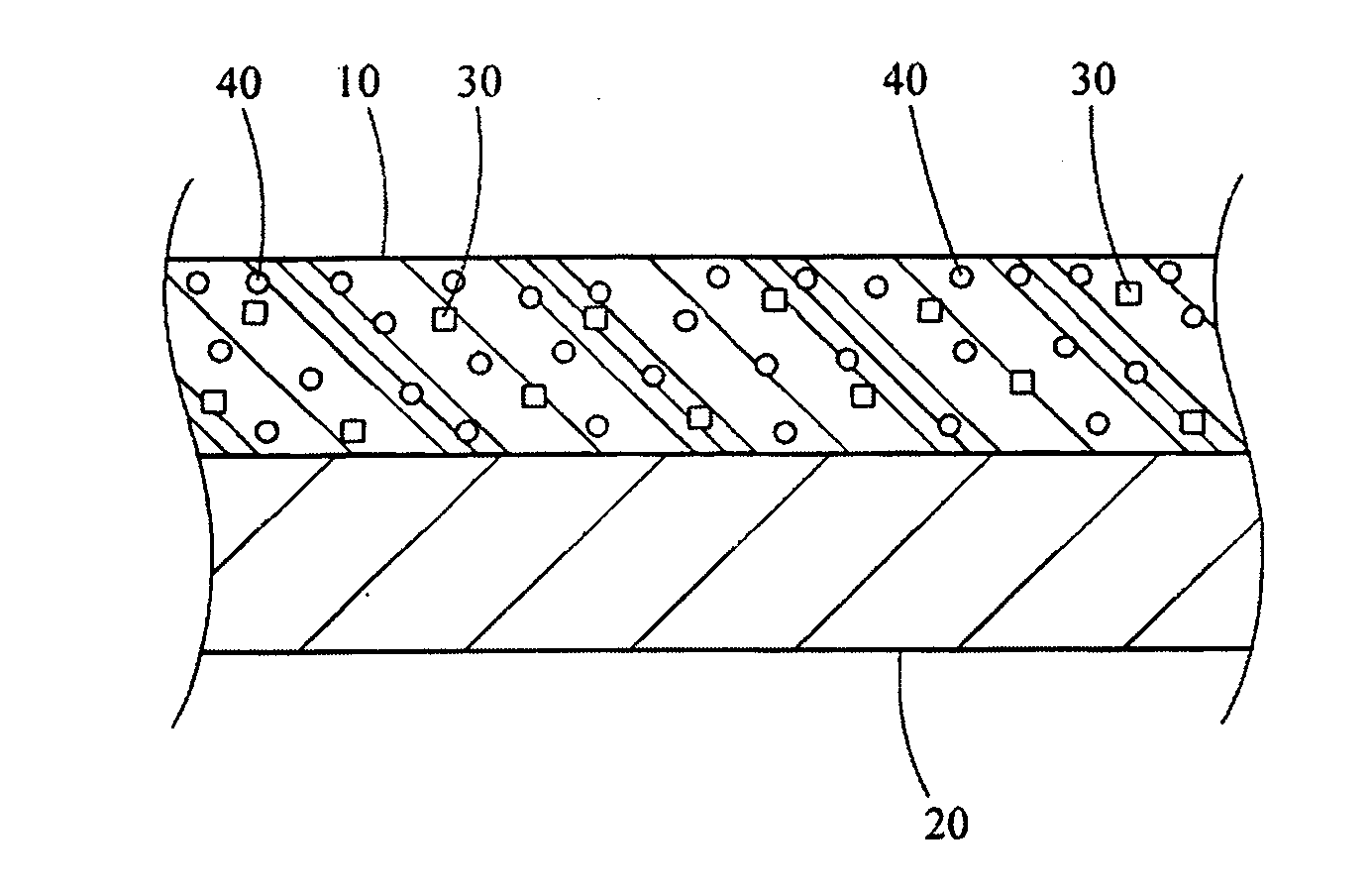

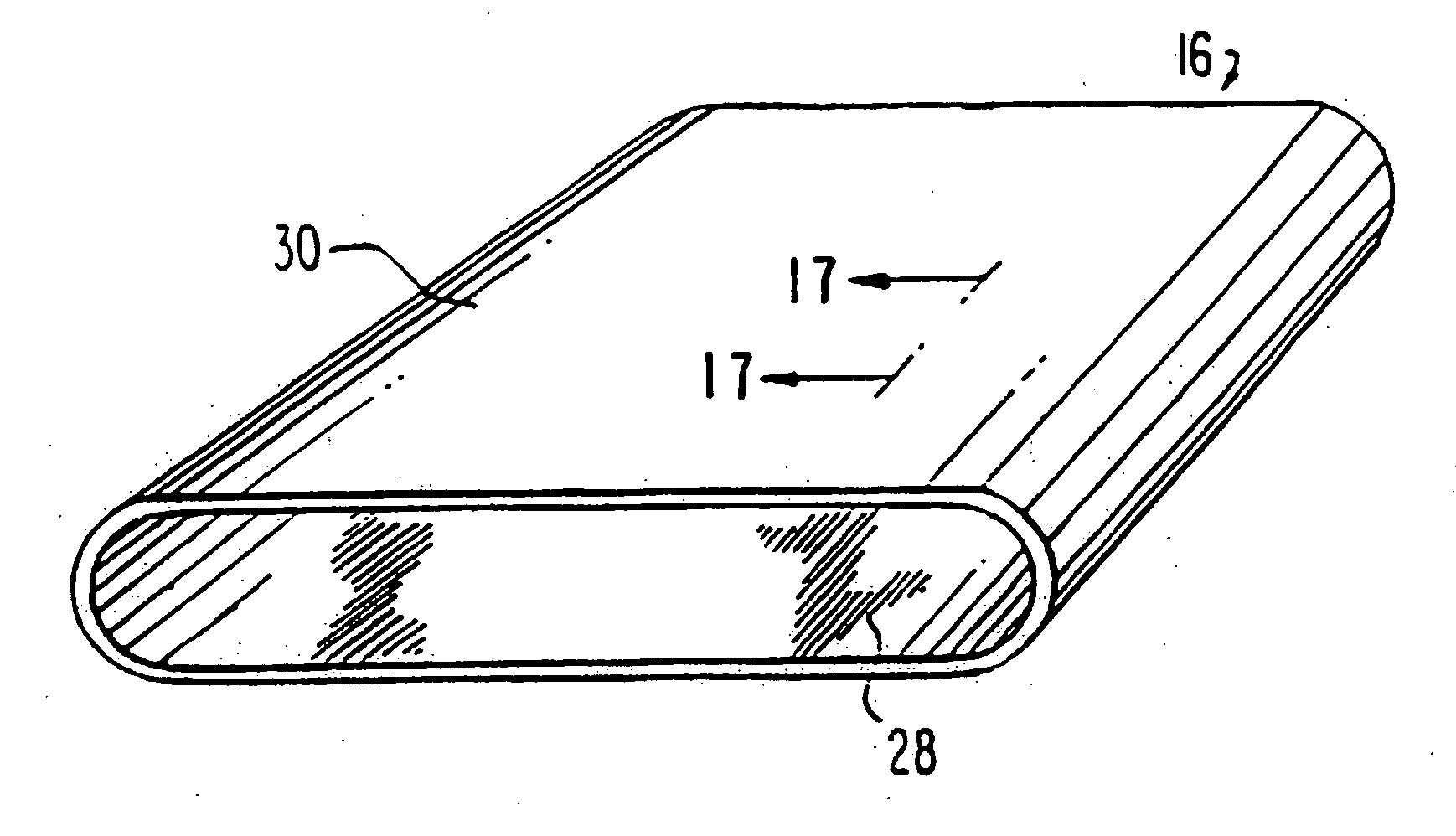

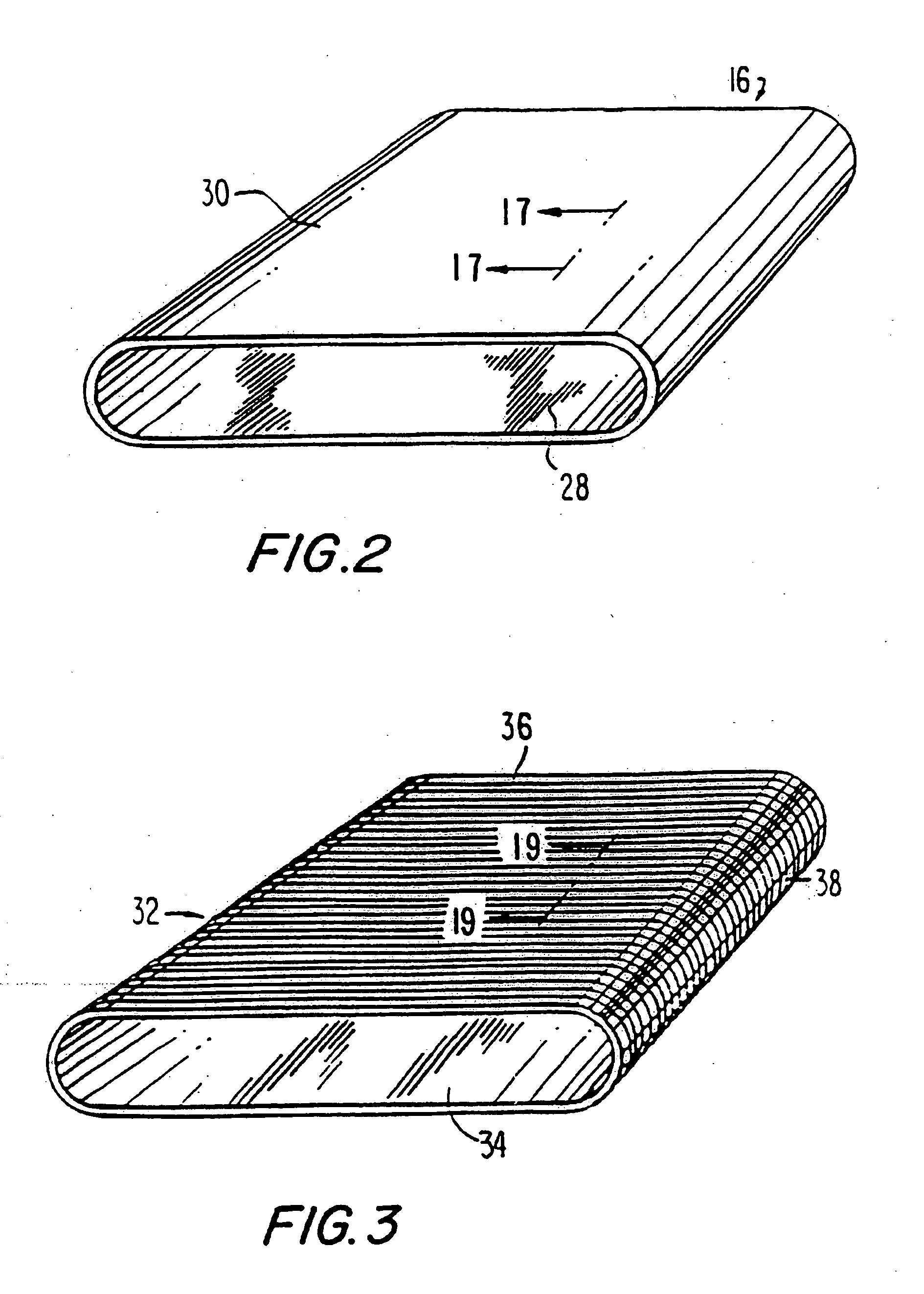

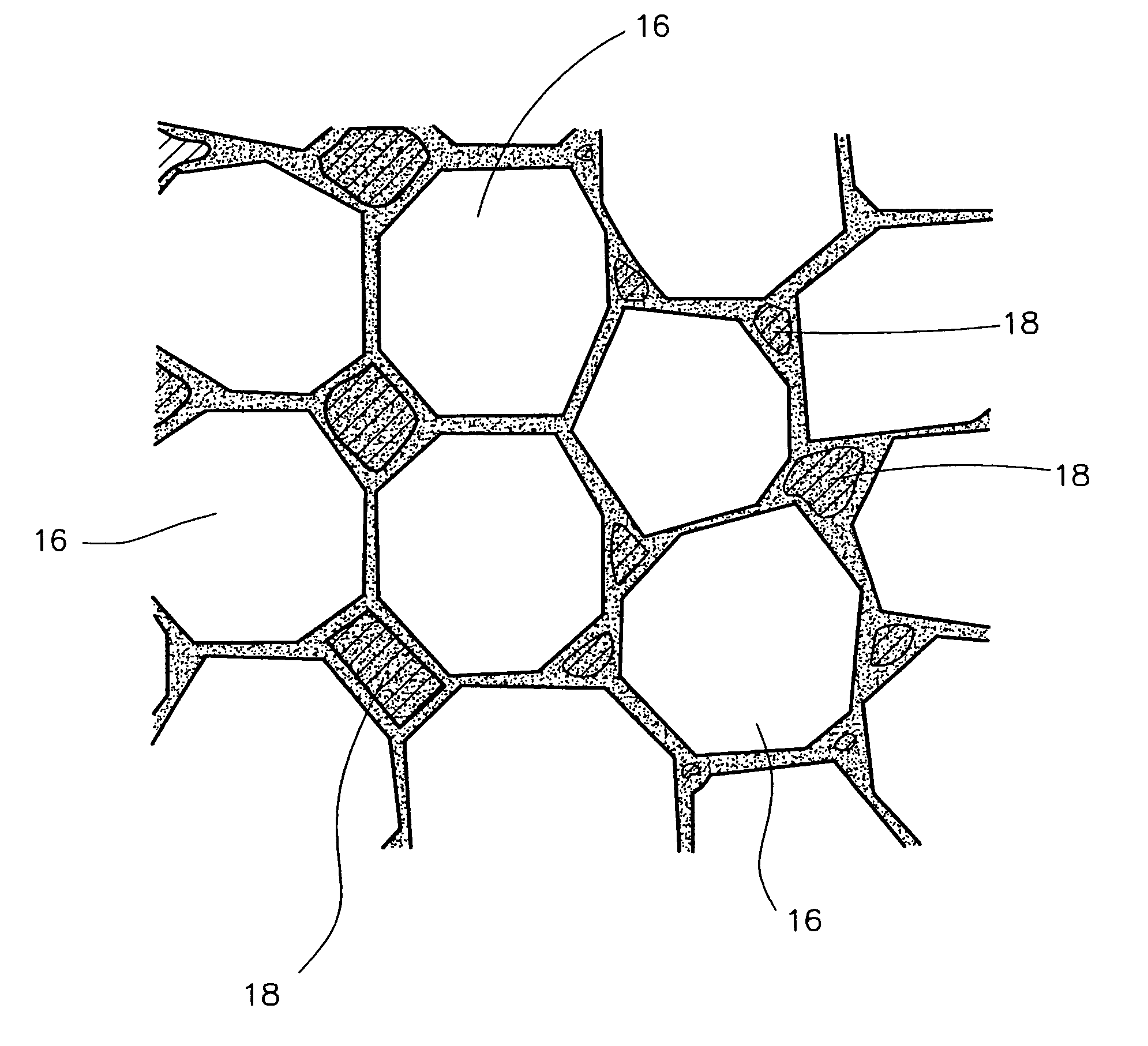

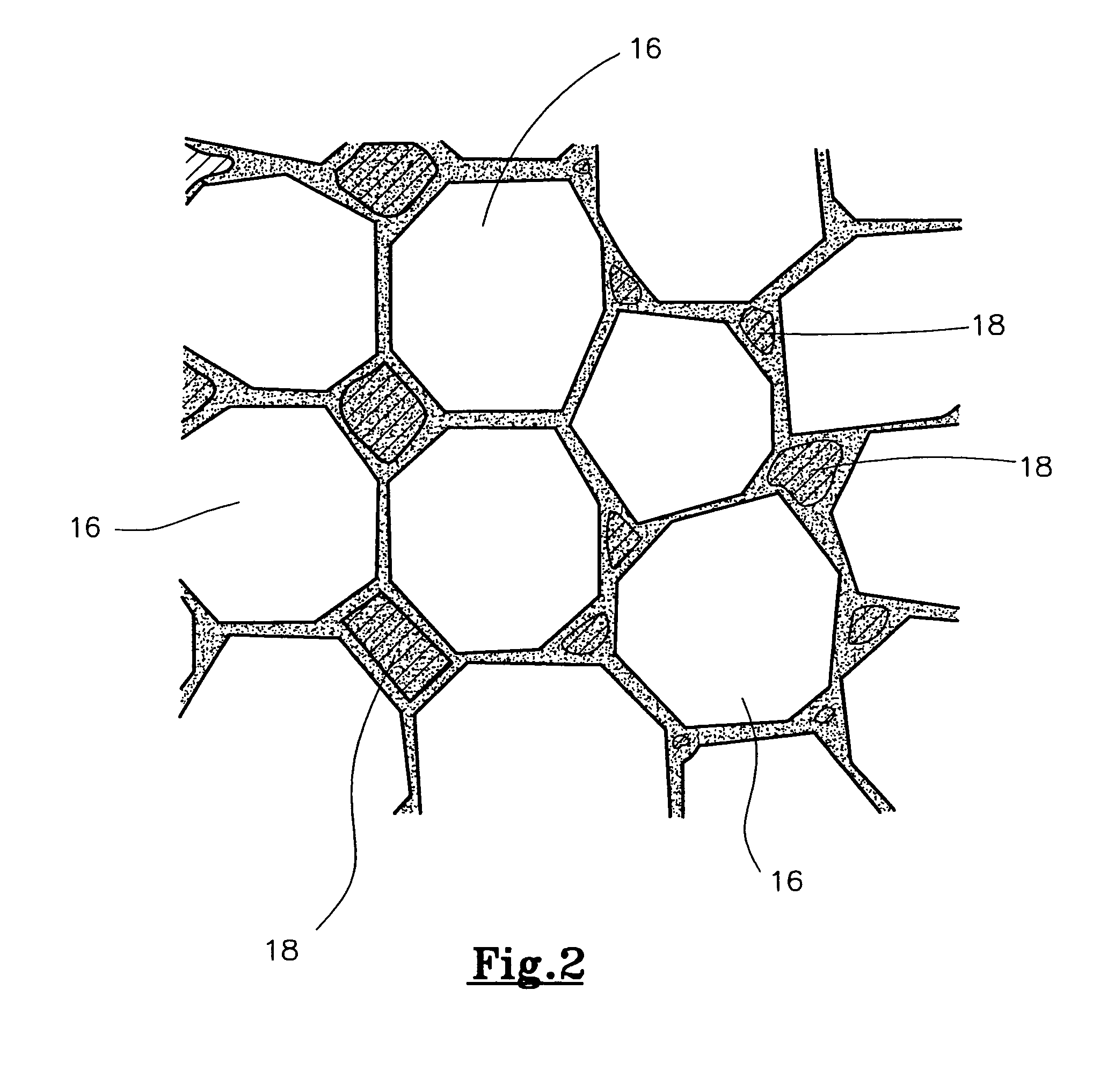

Belts and roll coverings having a nanocomposite coating

ActiveUS7413633B2Excellent characteristicsImprove fatigueSynthetic resin layered productsPretreated surfacesNanoparticleNanocomposite coating

The present invention relates to a urethane-based coating having nanoparticles for improving the characteristics of a papermaking process belt, roll cover and belts used in textile applications. For example, the present invention improves resistance to flex fatigue, crack propagation, groove closure and wear characteristics of urethane coatings on such belts and roll coverings. The present invention also improves the resistance to water and oil permeation characteristics of urethane coated belts and roll coverings.

Owner:ALBANY INT CORP

Device with nanocomposite coating for controlled drug release

InactiveUS20070299518A1Overcome limitationsStentsPharmaceutical delivery mechanismActive agentDrug release

An implantable medical device including a nanocomposite coating deposited on at least a portion of a surface of at least one structural element of the device to provide a controlled release of a bioactive agent in one or more dosages is described. The nanocomposite coating includes a matrix, a bioactive agent and inorganic particles. The inorganic particles respond to a stimulus, preferably by generating heat. The response of the particles to the stimulus causes the matrix of the nanocomposite coating to undergo a volume change by, for example, contracting or swelling, thereby releasing at least a portion of the bioactive agent. A method of providing a controlled release of a bioactive agent from a nanocomposite coating on an implantable medical device is described. A method for providing a nanocomposite coating for the controlled release of a bioactive agent on the implantable medical device is also described.

Owner:MED INST INC

Belts and roll coverings having a nanocomposite coating

ActiveUS20050208288A1Excellent characteristicsImprove fatigueSynthetic resin layered productsPretreated surfacesNanoparticleNanocomposite coating

The present invention relates to a urethane-based coating having nanoparticles for improving the characteristics of a papermaking process belt, roll cover and belts used in textile applications. For example, the present invention improves resistance to flex fatigue, crack propagation, groove closure and wear characteristics of urethane coatings on such belts and roll coverings. The present invention also improves the resistance to water and oil permeation characteristics of urethane coated belts and roll coverings.

Owner:ALBANY INT CORP

Waterproof staining-resisting nano composite coating as well as preparation and application methods thereof

ActiveCN103436165ANo stimulationNo pollution in the processCovering/liningsAntifouling/underwater paintsRough surfaceSilanes

The invention discloses a waterproof staining-resisting nano composite coating belonging to the technical field of nano materials, as well as preparation and application methods of the coating. The coating consists of alkyl alkoxy silane, nano particles, an emulsifier and deionized water. The purposes of waterproofness and staining resistance are achieved by brushing the coating on the surface of stone or concrete and the like in a dry environment at the normal temperature. The coating is based on lotus effect, the alkyl alkoxy silane is taken as a substance with low surface energy, and the nano particles are taken as fillers of a rough surface structure of a waterproof agent coating.

Owner:SHANGHAI JIAO TONG UNIV +2

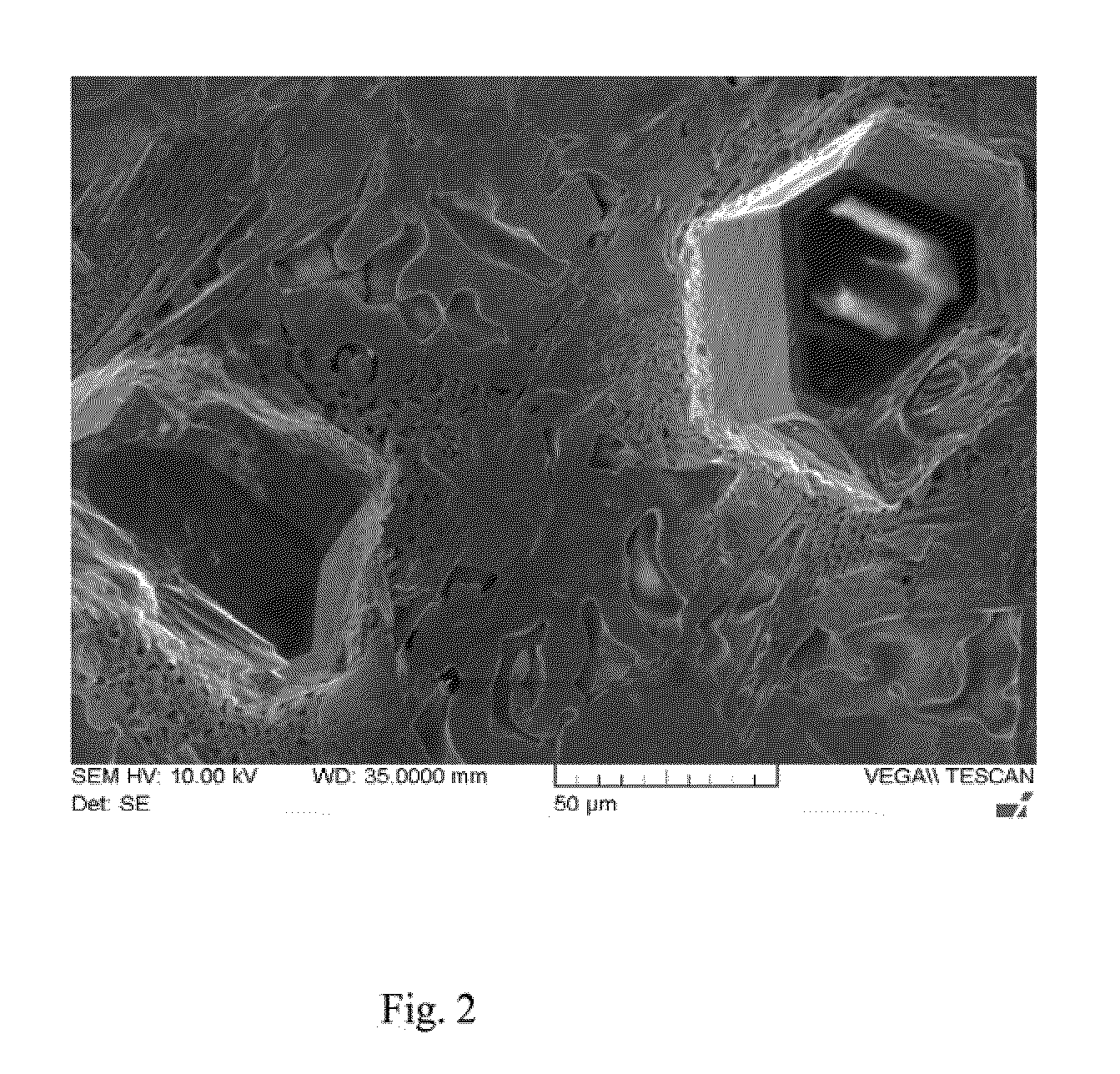

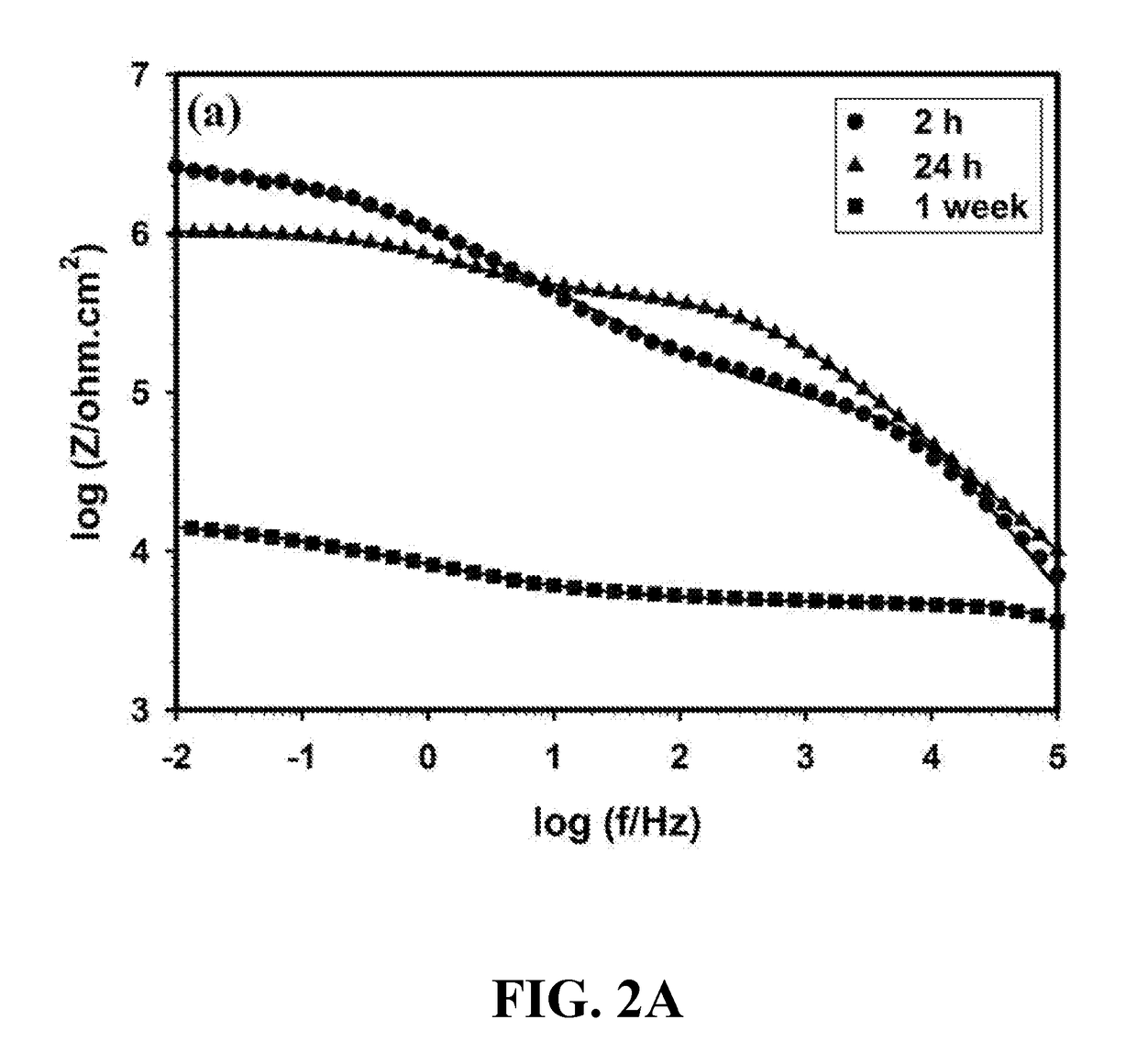

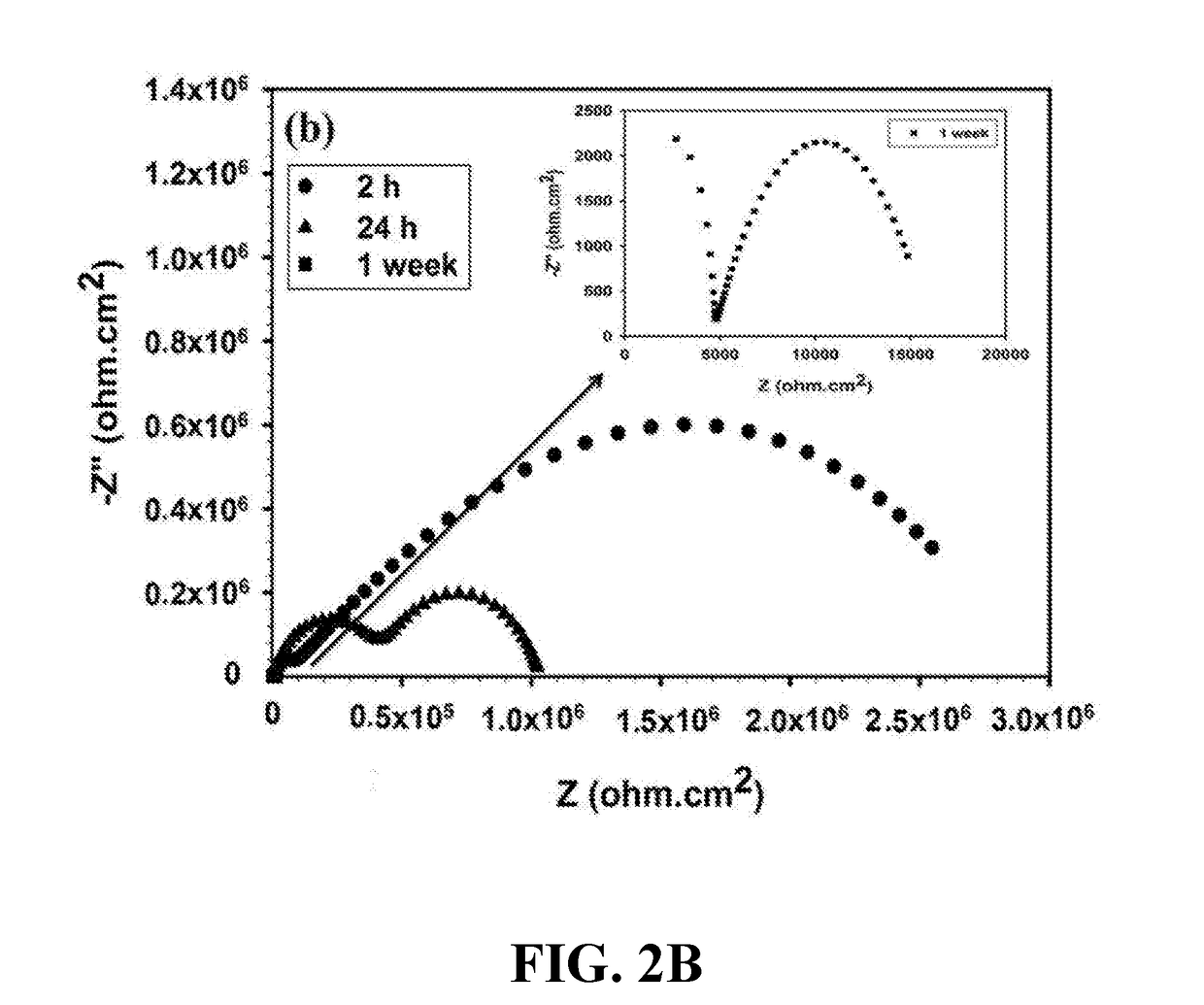

Corrosion-Resistant Epoxy Nanocomposite Coatings containing Submicron Emeraldine-Base Polyaniline and Organomodified Montmorrilonite

InactiveUS20100010119A1Good dispersionImprove barrier propertiesMaterial nanotechnologyLayered productsEpoxySalt spray test

Disclosed is a method of preparation of corrosion-resistant epoxy coatings. The coating composition contains two main corrosion resistant factors: The first one was Eemeraldine-Base polyaniline (EB-PANi), dissolved in the aminic hardener of epoxy. The other one was montmorrilonite clay, dispersed or exfoliated in the base component of epoxy resin. The hardener composition was prepared via dissolution of EB-PANi in functional amines like 3-(aminomethyl)-3,5,5-trimethylcyclohexan-1-amine adopting sonication and nanoscale filtering methods. The base component was prepared via gradual charging of MMT clay in epoxy resin via high-shear mixing plus sonication method. The morphology of the coatings during different stages of preparation was studied by optical microscopy and scanning electron microscopy and TEM. The corrosion-protective performance of the resultant coatings was evaluated by electrochemical impedance spectroscopy and salt spray tests. The results were compared with those of conventional epoxy zinc-chromate and neat resin coatings. Superior corrosion resistance was achieved via dissolution of 0.5-2.5 wt % of EB-PANi in the aminic hardener and 2-4 WT % of organomodified MMT in base component of coating.

Owner:ZAAREI DAVOOD +4

Nano-composite electric conduction anticorrosive paint and preparation method thereof

InactiveCN103627297AImprove conductivityImprove corrosion resistanceAnti-corrosive paintsPigment treatment with macromolecular organic compoundsEpoxySolubility

The invention discloses nano-composite electric conduction anticorrosive paint and a preparation method thereof. The preparation method is characterized in that firstly organic acid dodecylbenzene sulfonic acid is used as a doping agent so as to overcome the low solubility of doped polyaniline, a carbon nanotube is used for improving the electric conductivity of composite powder, and then the carbon nanotube is compounded with a precursor of organic acid dodecylbenzene sulfonic acid doped polyaniline and epoxy resin so as to prepare the nano-composite electric conduction anticorrosive paint. According to the technical scheme, the polyaniline / carbon nanotube and the epoxy resin are compounded, so that the excellent characteristics of the polyaniline / carbon nanotube and the epoxy resin are organically combined together. The nano-composite electric conduction anticorrosive paint has relatively high electric conduction performance and very high anticorrosive performance and is relatively low in cost; required processing equipment is simple; the industrialization of the nano-composite electric conduction anticorrosive paint is easy to realize.

Owner:TIANJIN UNIV

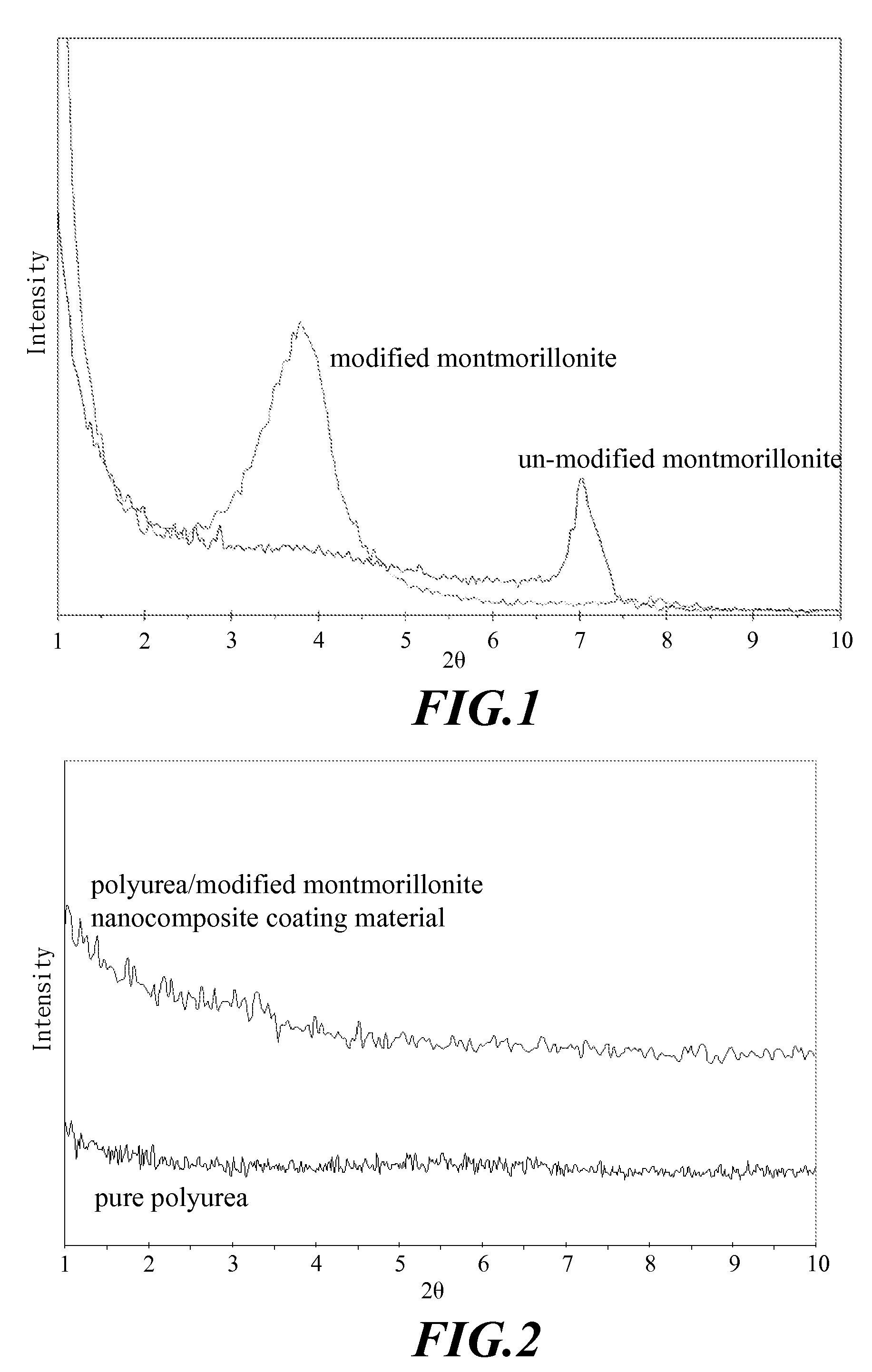

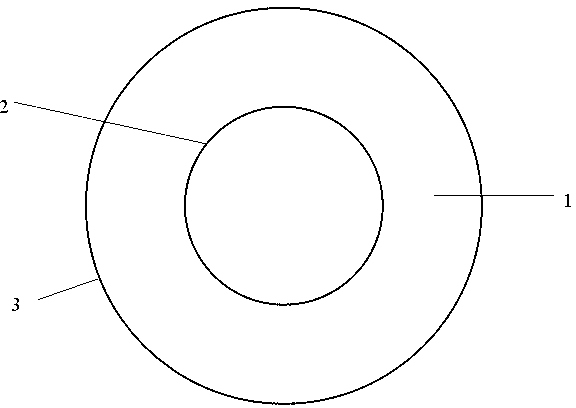

Anticorrosive Nanocomposite Coating Material, and a Preparation Process Thereof

InactiveUS20100119796A1Low corrosion rateSynthetic resin layered productsAnti-corrosive paintsOrganoclayNanocomposite coating

The invention relates to an anticorrosive nanocomposite coating material that comprises polyurea, organophilic clay and suitable additives, and is useful for preparing a polyurea / clay nanocomposites; whereby said nanocomposite coating material is coated on a substrate to greatly decrease the corrosion rate of the substrate; wherein said polyurea is combined from an amino terminated compounds and a isocyanate compound. The invention also provides a process for preparing said nanocomposite coating material, said process comprising: mixing homogeneously said amino terminated compound and an organophilic clay, followed by mixing homogeneously with isocyanate compound and suitable additives at a proper ratio, wherein, after a polymerization reaction, said organophilic clay can achieve a nano-scale dispersion extent, thereby obtaining said anticorrosive nanocomposite coating material.

Owner:BRIGHTEN ENG

High-hardness AlCrN nanocomposite coating and preparation process thereof

ActiveCN106893986AHigh hardnessImprove toughnessVacuum evaporation coatingSputtering coatingNanocomposite coatingHardness

The invention relates to a nanocomposite coating and a preparation technology of the nanocomposite coating, in particular to a preparation process for a high-Al-content AlCrN nanocomposite coating. The AlCrN nanocomposite coating is prepared on a metal or cemented carbide substrate by the adoption of an electric arc ion plating technology. Pure metal Al and Cr are used as targets, and the content of Al and Cr in the coating is adjusted and controlled by controlling the current of the Al targets and the Cr targets. The four pure Cr targets and the four pure Al targets are evenly distributed on the inner wall of a furnace body at intervals. Ar gas is introduced firstly before film plating, the bias pressure of 600-1,000 V is adopted, glow cleaning is conducted on the substrate for 10-20 min, then the Cr targets are opened, bombardment cleaning is conducted on the substrate, the bias pressure is gradually lowered to 30-100 V, and the metal Cr layer is deposited. The preparation process of the AlCrN nanocomposite coating is simple, and industrial production is facilitated; and the prepared AlCrN coating has the high hardness and strength and good high-temperature and oxidation resistance and corrosion resistance.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

Abrasion resistant cast tube with high temperature oxidation resistant anticorrosive coating

ActiveCN103277629AEvenly distributedHigh hardnessAnti-corrosive paintsRigid pipesTemperingNanocomposite coating

The invention relates to an abrasion resistant cast tube with a high temperature oxidation resistant anticorrosive coating. An abrasion resistant cast tube body is produced through centrifugal casting and is subjected to quenching, high-temperature tempering, solution strengthening thermal treatment and twice tempering dispersion hardening thermal treatment, then a rustproof coating is coated on the outer wall of the tube through electrostatic spraying, finally a water glass nanometer composite coating prepared through testing is sprayed on the inner wall of the tube, and a high temperature oxidation resistant anticorrosive coating film inner layer is obtained after high temperature curing and cooling. The obtained metal tube has high hardness and abrasion resistance, and the anticorrosive coating of the metal tube has excellent waterproof performance, antifouling effect and high temperature resistance.

Owner:江阴德耐特重工科技有限公司

Multi-layered superhard nanocomposite coatings

InactiveUS7097922B2Liquid surface applicatorsVacuum evaporation coatingNanocomposite coatingNanometre

Owner:CITY UNIVERSITY OF HONG KONG +1

Preparation of high solid polyester polyol/silica nanocomposite resin with low viscosity and related nanocomposite coatings

InactiveUS20060122314A1Excellent abrasion resistanceHigh hardnessSpecial tyresPolyurea/polyurethane coatingsPolyesterColloidal silica

A high solid polyester polyol / silica nanocomposite resin with low viscosity is synthesized by an in situ polymerization method, namely conducting condensation polymerization of polyol / diacid monomer with a molar ratio of 1.1˜1.5 in the presence of colloidal silica nanoparticles with a diameter of 10˜150 nm. The resulted nanocomposite resins has a solid content of >95%, molecular weight of 1000˜5000 g / mol and hydroxyl value of 80-200 mg KOH / g, and a viscosity in the range of 800-2000 mPa.s. The viscosities are especially lower than those obtained by a blending method. The nanosilica content in the nanocomposite resin is 1˜15% (based on the total solid content of nanocomposite resin). The high solid polyester polyol / silica nanocomposite resin was curable with isocyanate or melamine to prepare high solid transparent nanocomposite coatings with obviously improved abrasion and scratch resistance, hardness, weatherability etc.

Owner:FUDAN UNIV

Method for preparing nano composite coating of urushiol acetal epoxy resin/TiO2

InactiveCN1687270AStrong adhesionStrong UV Absorbing PropertiesNatural resin coatingsEpoxy resin coatingsEpoxyNanocomposite coating

The present invention discloses a method for preparing urushiol acetal epoxy resin / TiO2 nano composite paint. Said method is characterized by that after the raw material nano TiO2 particles are modified by using anionic surface active agent, the modified raw material nano TiO2 particles can be mixed with urushiol epoxy resin, and undergone the process of ultrasonic treatment so as to obtain the uniformly-dispersed nano composite paint with excellent mechanical property and acid-resisting, alkali-resisting and high-temperature-resisting properties. Said invention also provides its application range.

Owner:WUHAN UNIV

Method for preparing high-temperature oxidation-resistant coating on niobium tungsten alloy

ActiveCN102071419ACompact structureImprove densification performanceMetallic material coating processesLaser beam welding apparatusNiobiumNanocomposite coating

The invention relates to a method for preparing a high-temperature oxidation-resistant nanocomposite coating on the surface of niobium tungsten alloy (Nb521) by cold spraying and laser cladding technology, in particular to a method for preparing a high-temperature oxidation-resistant coating on niobium tungsten alloy. The method is characterized by comprising the following steps of: a, processing molybdenum (Mo) and silicon (Si) components in a high-temperature oxidation-resistant material respectively to be nanopowder for later use, mixing the rest components, and processing the mixture to be nanopowder for later use; b, cold-spraying the Si nanopowder on a niobium tungsten alloy base material; c, cold-spraying the nanopowder of the mixed rest components in the step a on the niobium tungsten alloy base material; d, cold-spraying the Mo nanopowder on the niobium tungsten alloy base material, wherein the total thickness of all the coatings is controlled to be 50 to 140 mu m; and e, irradiating, scanning and melting the coatings of the sprayed niobium tungsten alloy base material by using laser beams. By the method, the tissues among the coating powder are compact; and compactness of the coatings is greatly improved.

Owner:NINGXIA ORIENT TANTALUM IND

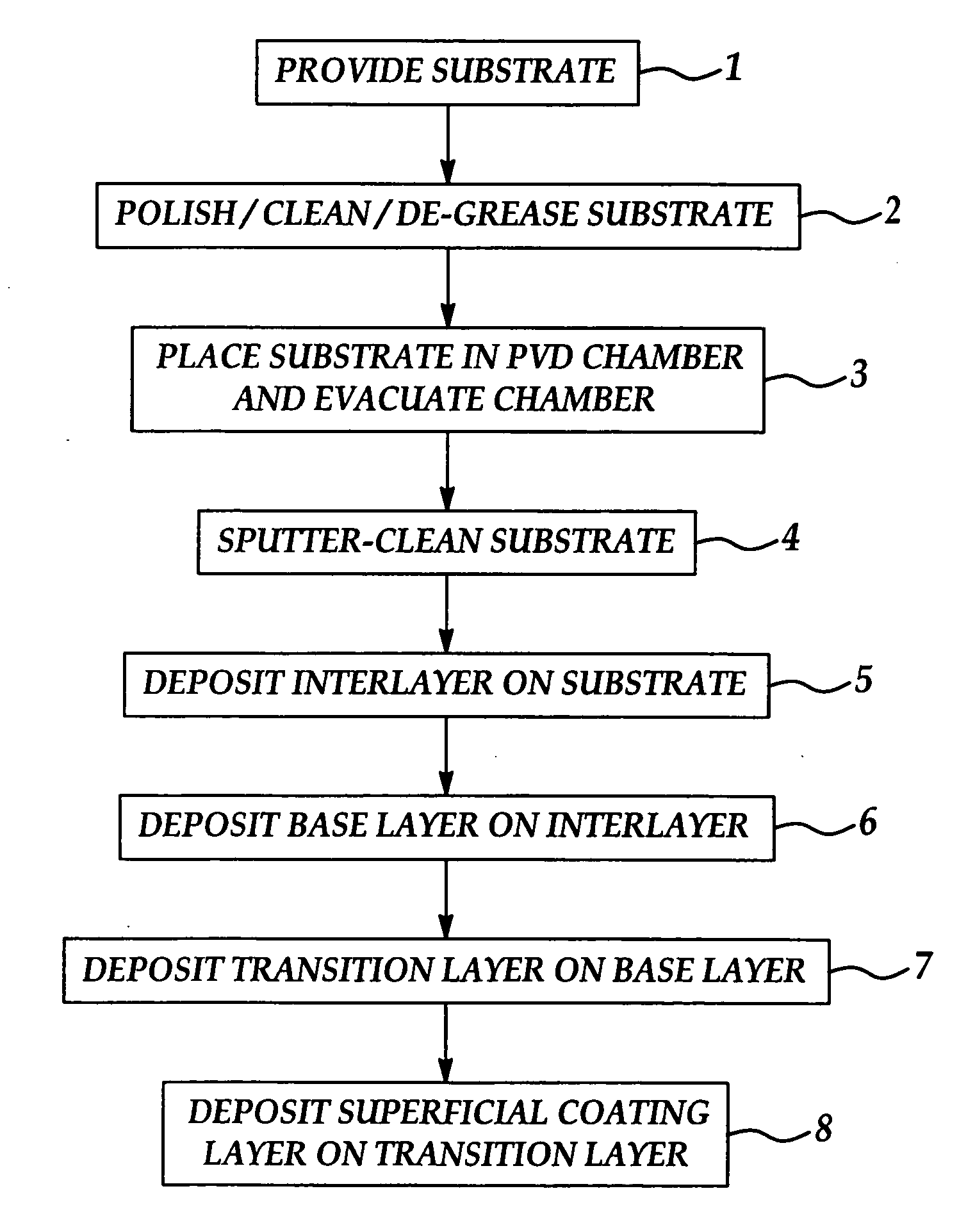

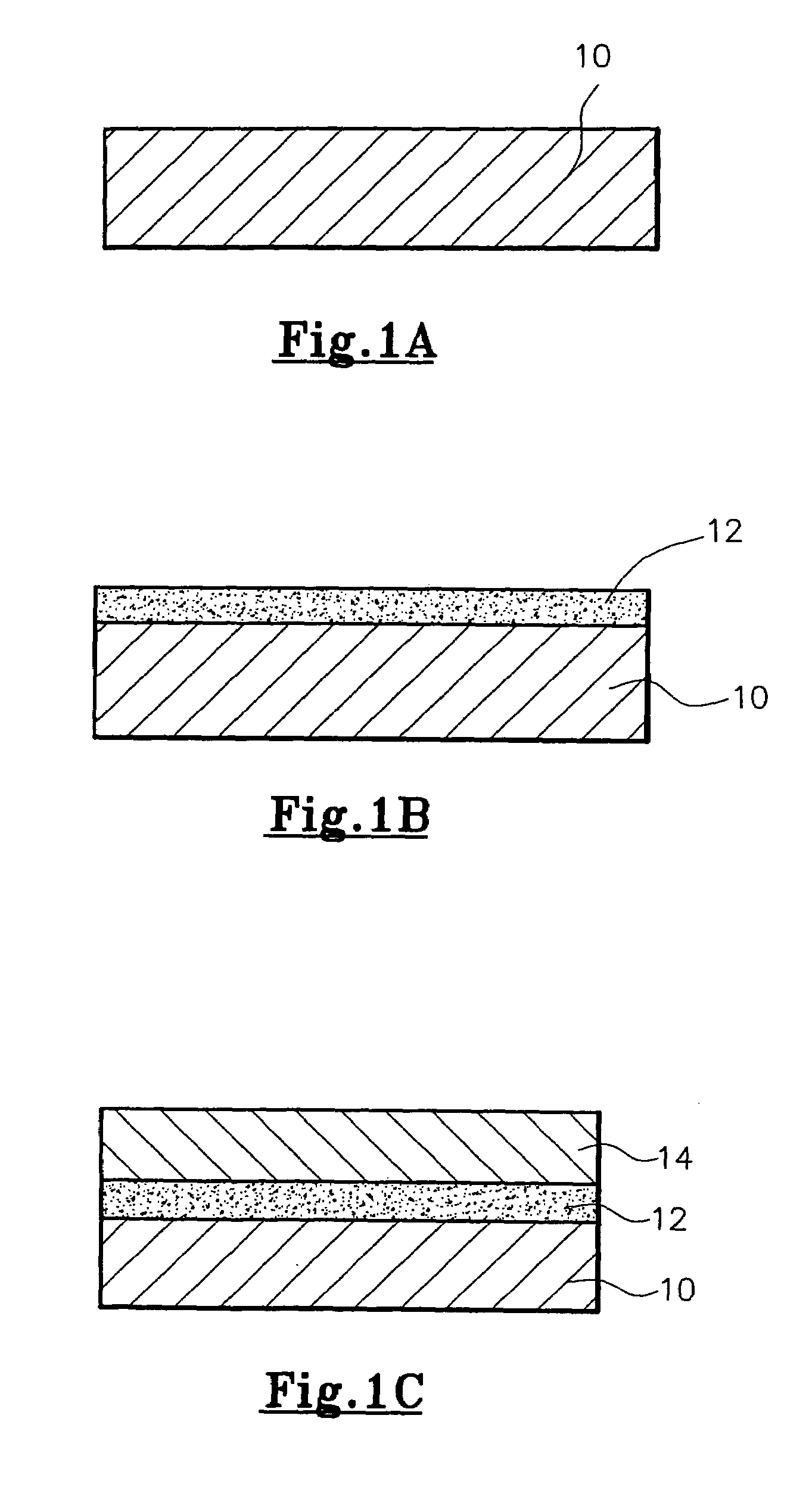

Method of forming a nanocomposite coating

InactiveUS7001675B2Liquid surface applicatorsNanostructure manufactureChromium carbideNanocomposite coating

There is disclosed a method of depositing a nanocomposite coating of stainless steel and a metallic carbide or metallic nitride, e.g. chromium carbide or chromium nitride, onto a stainless steel substrate 10, including the steps of (a) providing the stainless steel substrate 10; (b) depositing stainless steel on the substrate 10; (c) depositing chromium carbide or chromium nitride on the substrate 10; and allowing a nanocomposite coating 14 of the stainless steel and chromium carbide or chromium nitride to form on the substrate 10.

Owner:MAXFORD TECH LTD

Anticorrosion composite nano paint and its preparing process

InactiveCN1346860AHigh hardnessImprove mechanical propertiesCoatingsGranularityNanocomposite coating

An anticorrosion composite nano-paint contains film forming agent, dispersing liquid, antisticking agent and SiO2 colloid, where the granularity of SiO2 is 10-20 nm. Its coated layer is characterized by high hardness, adhesion and toughness, and excellent corrosion and abrasion resistance.

Owner:EAST CHINA UNIV OF SCI & TECH

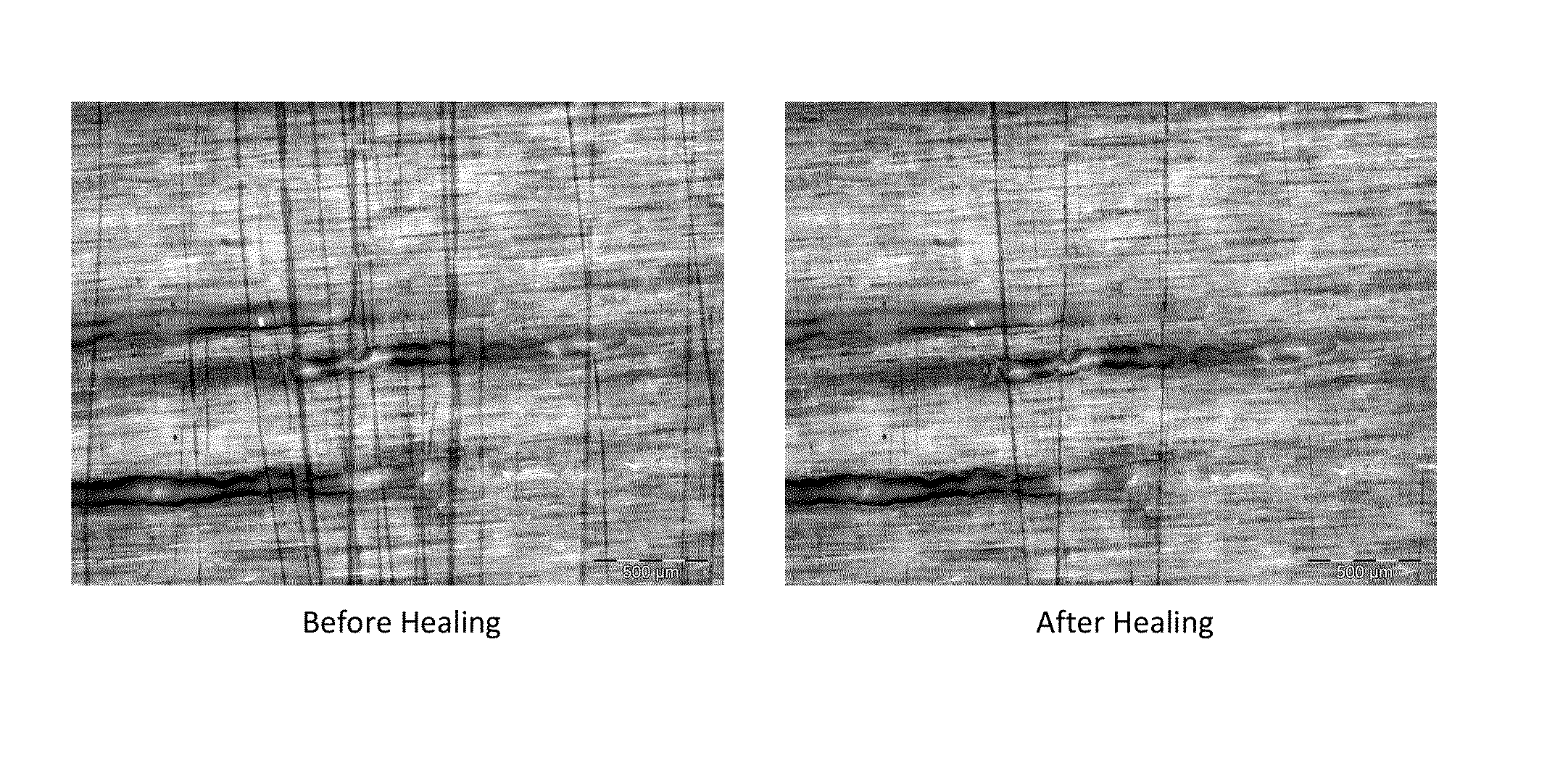

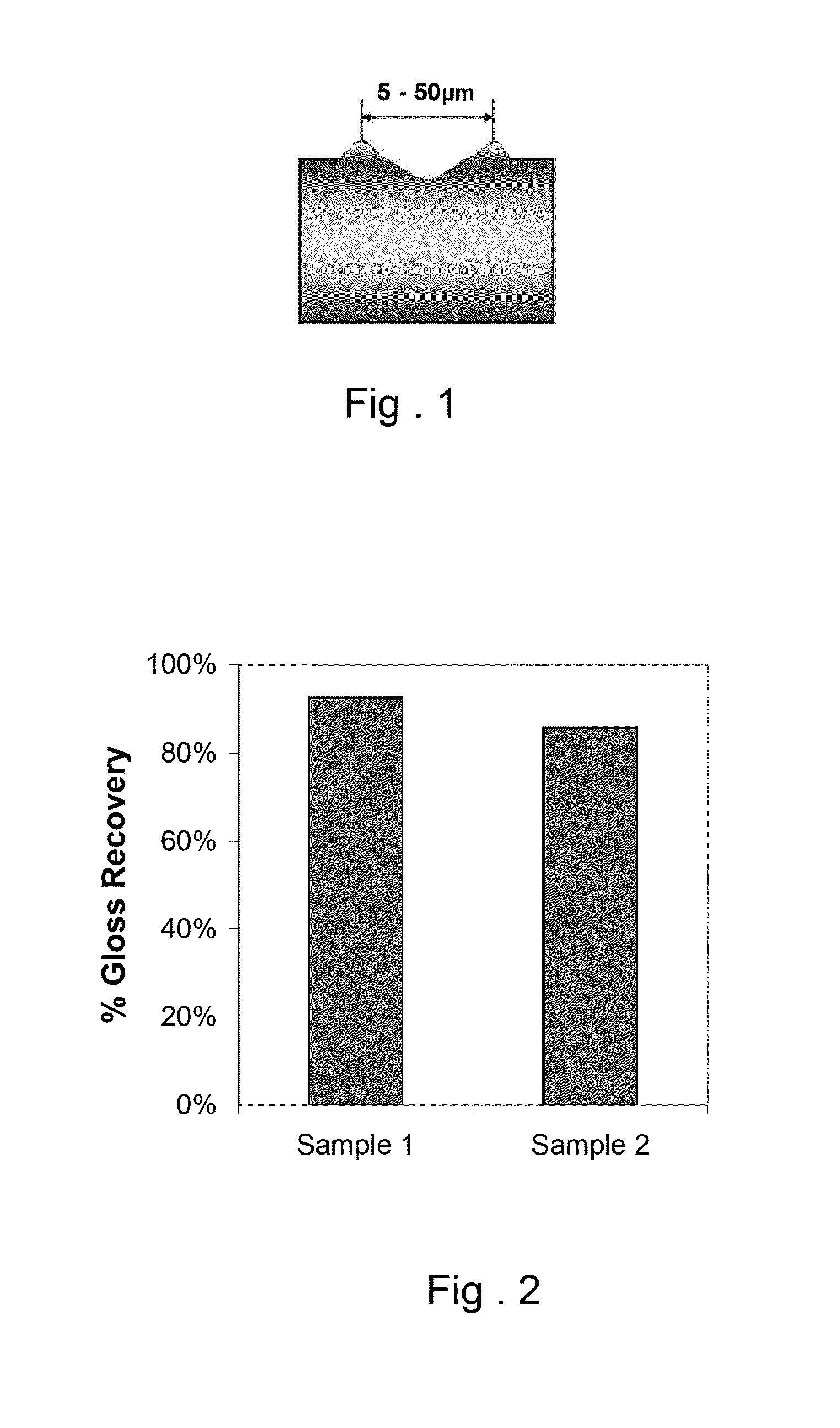

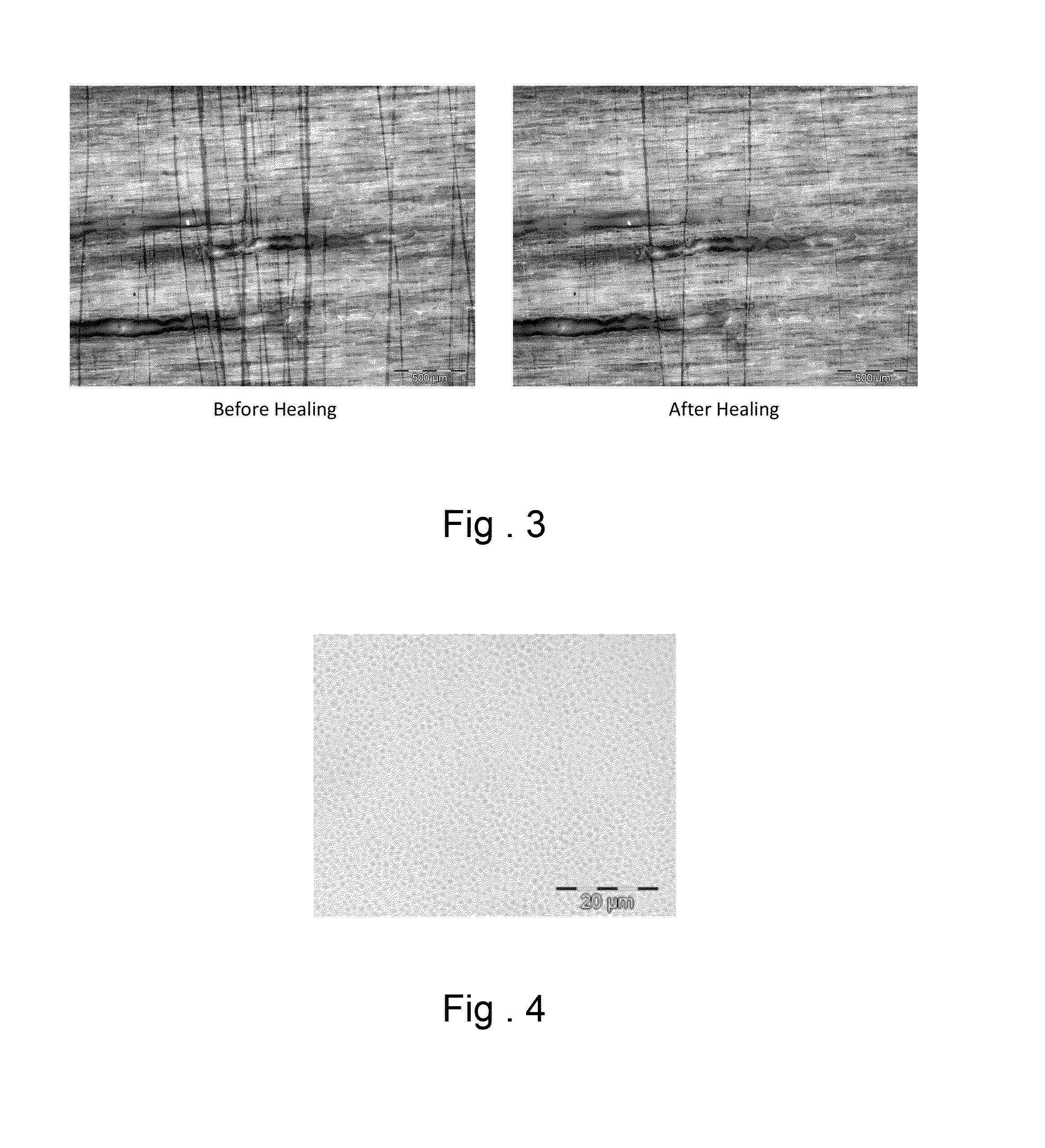

Self-healing polymer nanocomposite coatings for use on surfaces made of wood

Phase separated self-healing polymeric wood coatings having a “biphasic” thermoset / thermoplastic morphology to achieve self-healing. The biphasic structure has: (i) a major “load-bearing” thermoset phase that has superior strength and performs major mechanical and structural functions, and (ii) a “self-healing” phase of a thermoplastic healing agent to repair the material and restore its mechanical and structural integrity after being damaged. The phase-separated morphology is achieved through phase separation via a reaction process. Methodologies for achieving the above mentioned “biphasic” structure in solvent borne thermally cured resin, waterborne resin, and solvent borne UV-curable resin are described.

Owner:NORTHERN ENG IND PLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com