Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

455 results about "Superhydrophobic coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

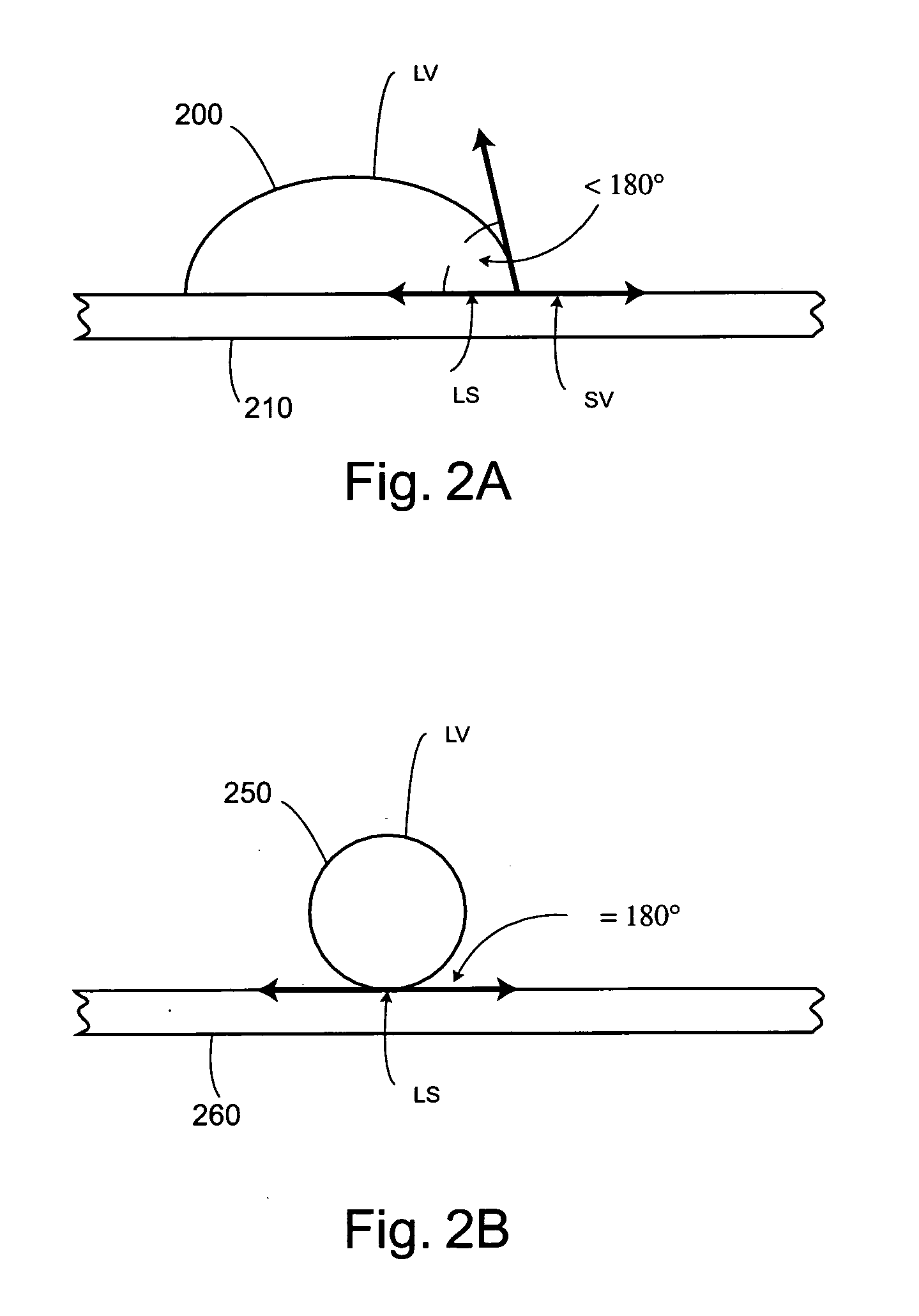

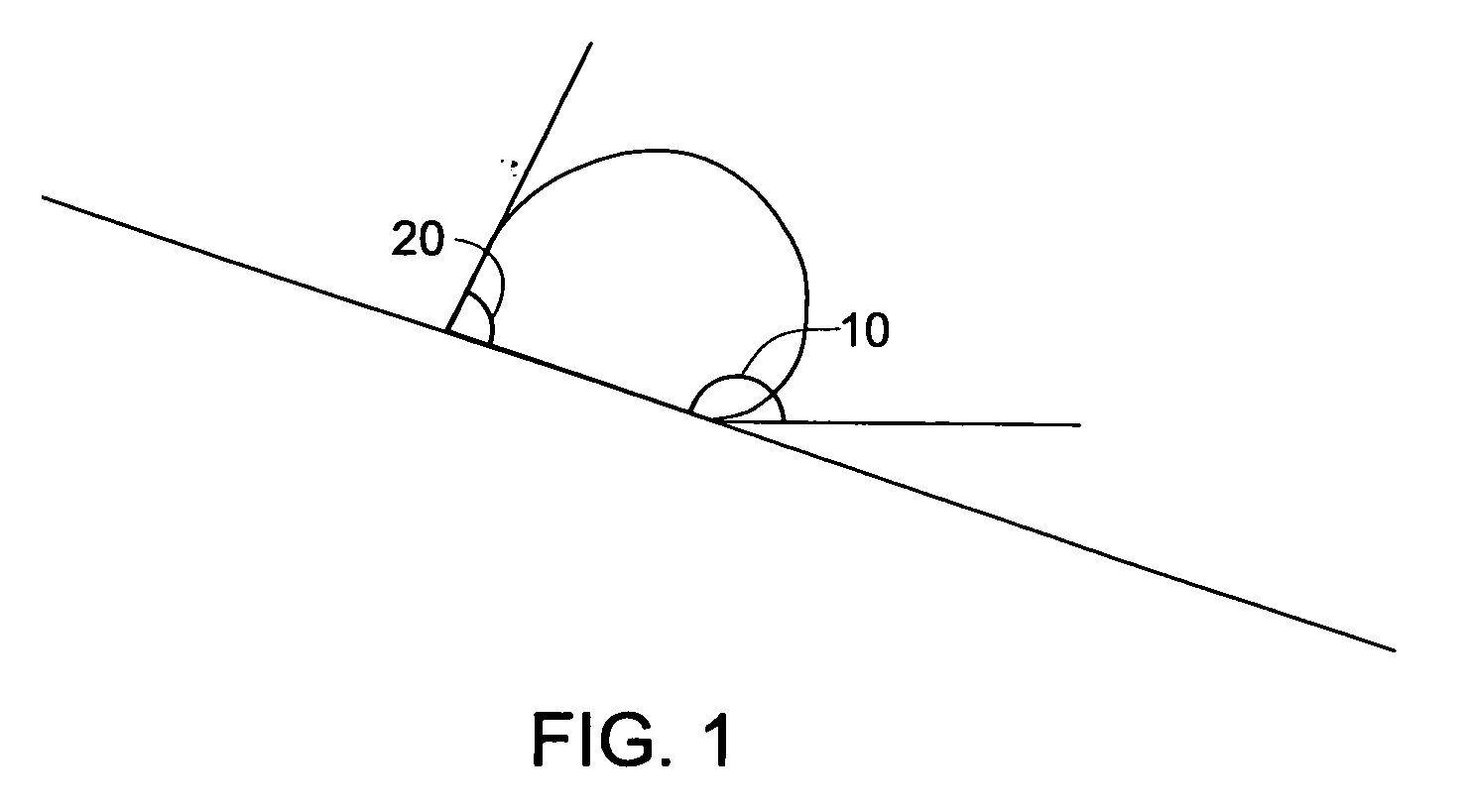

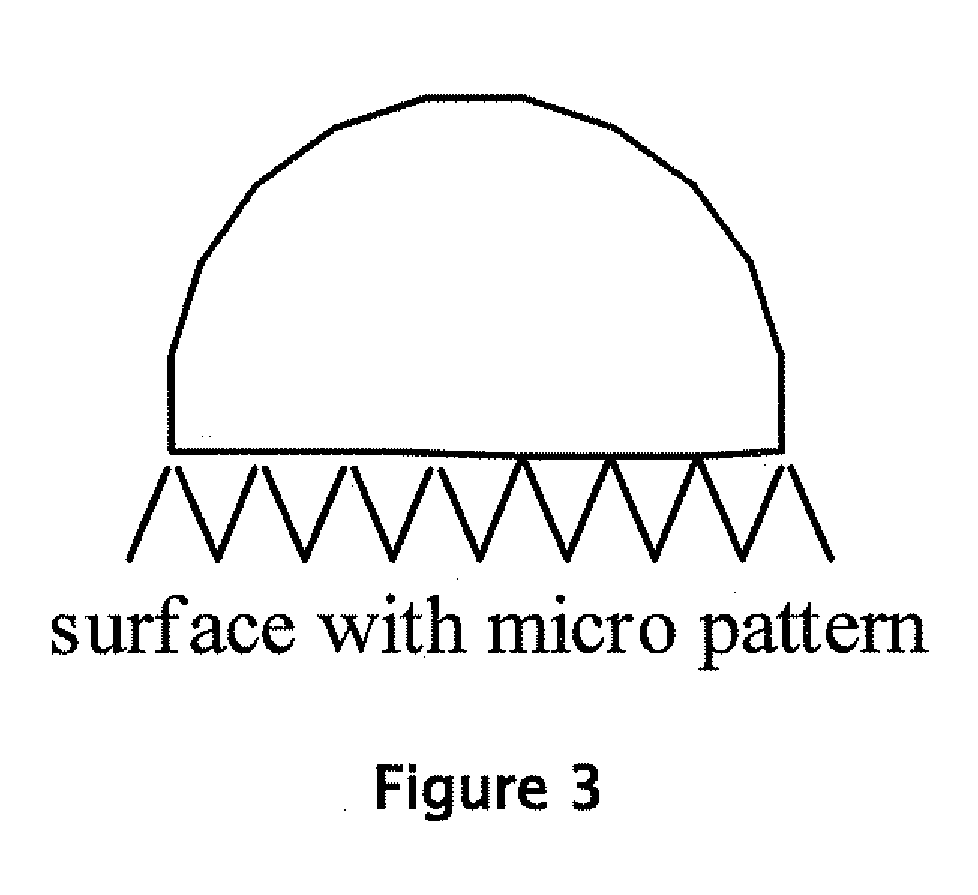

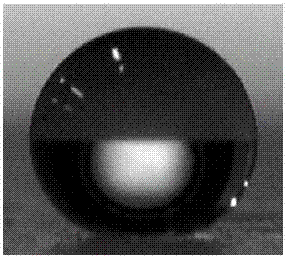

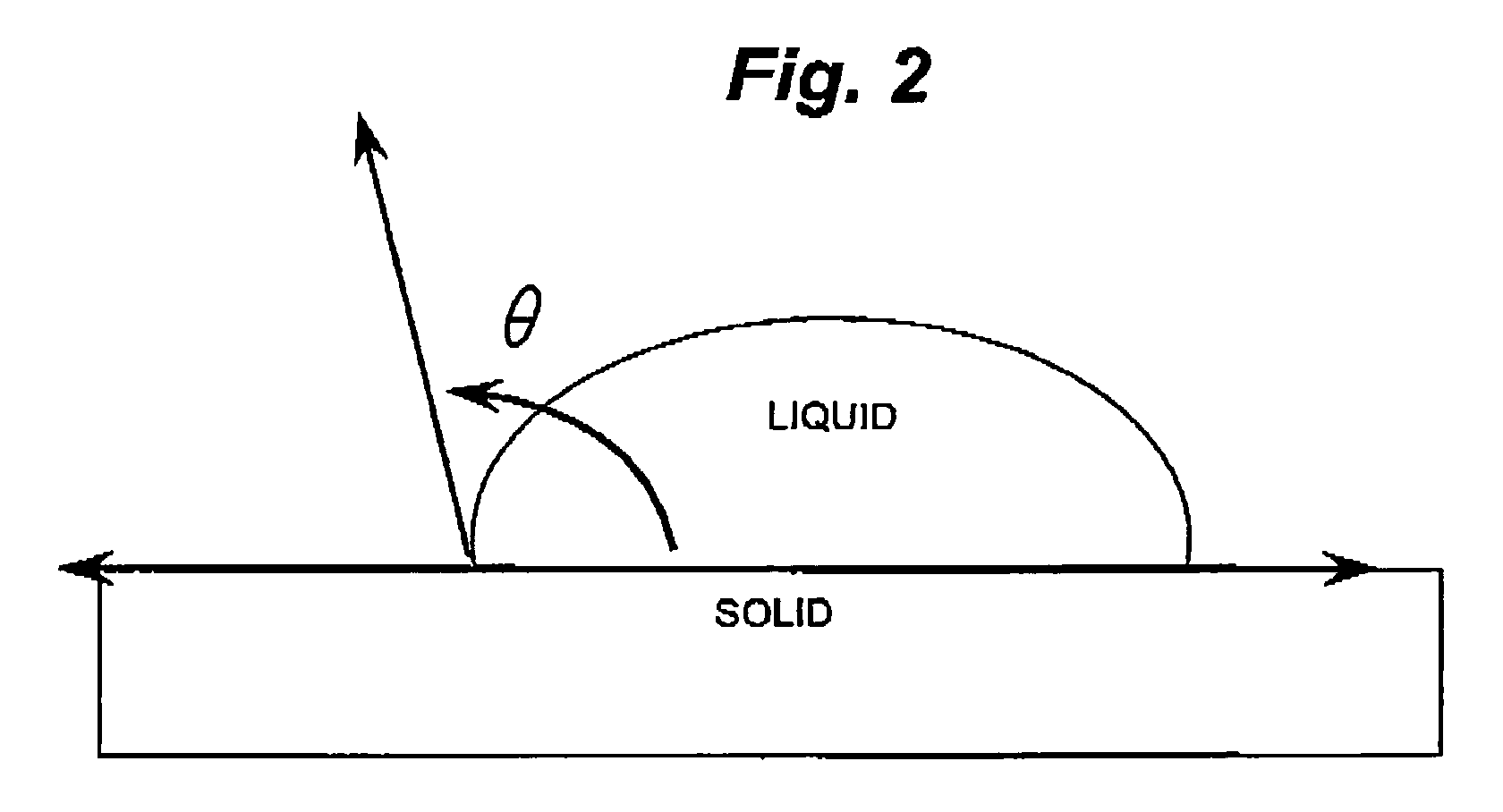

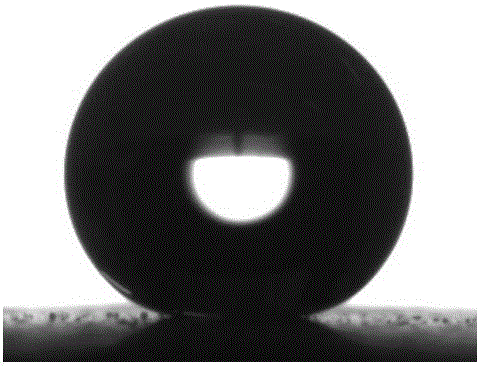

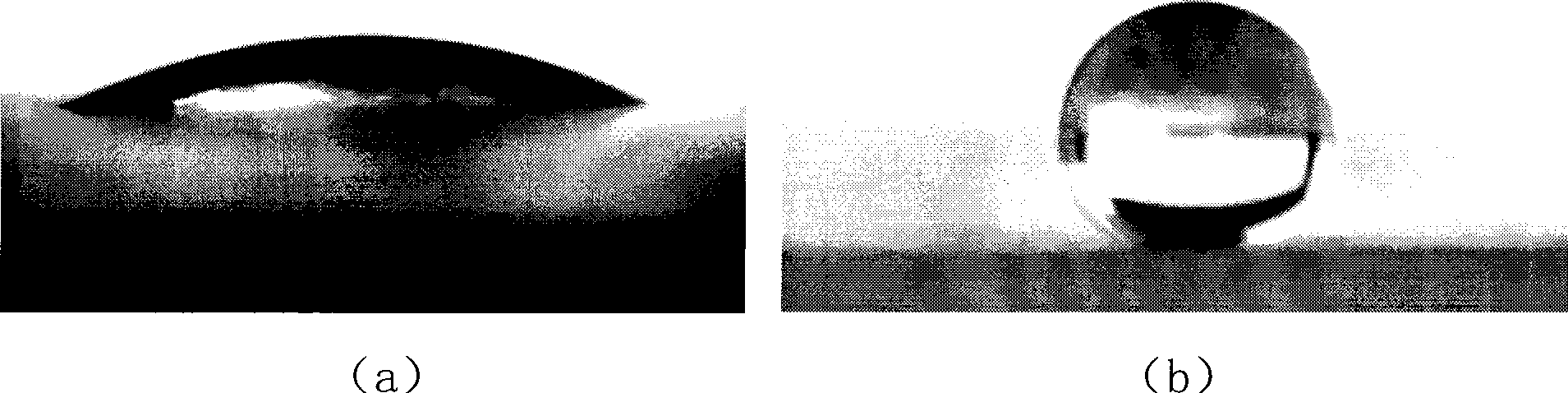

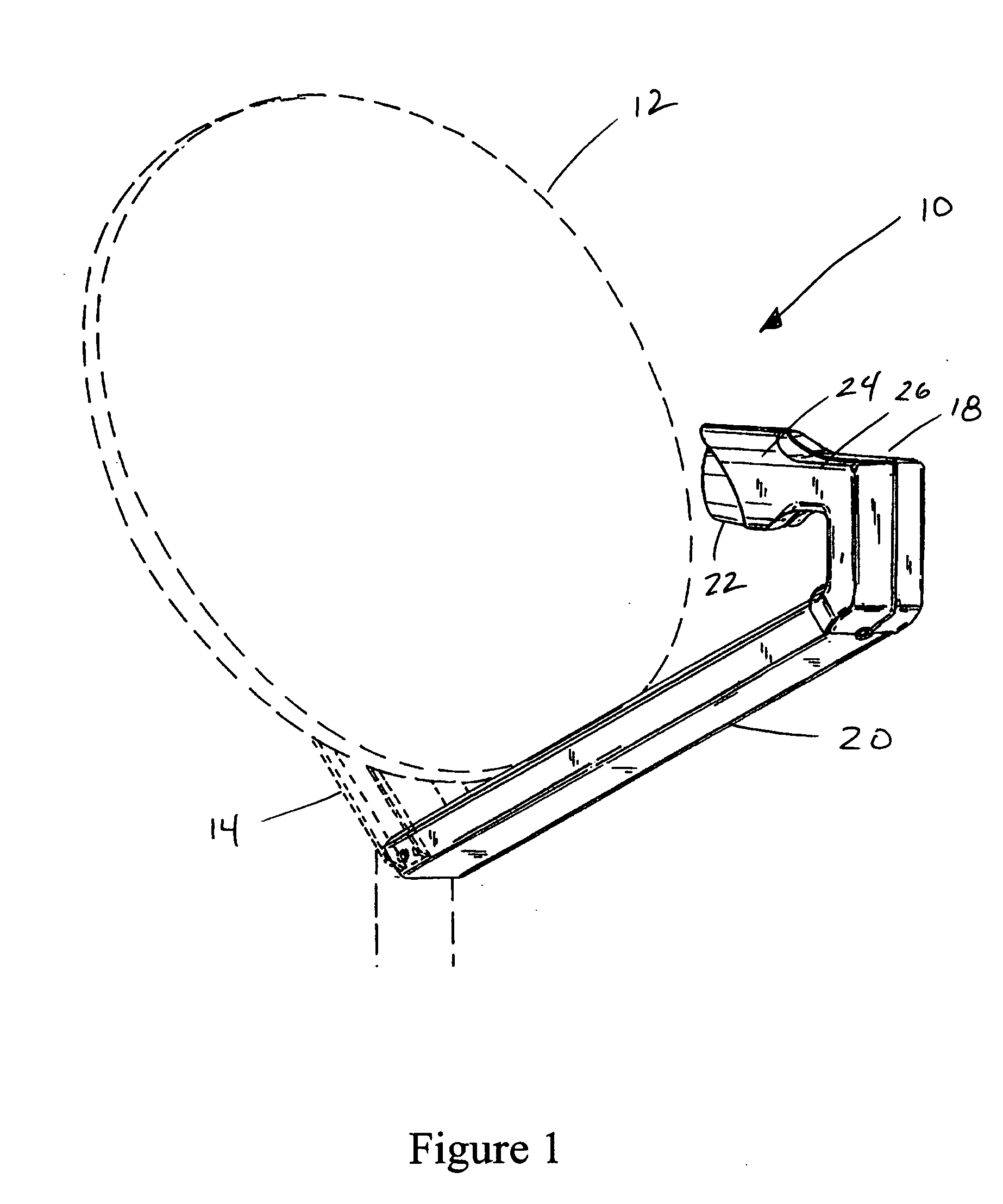

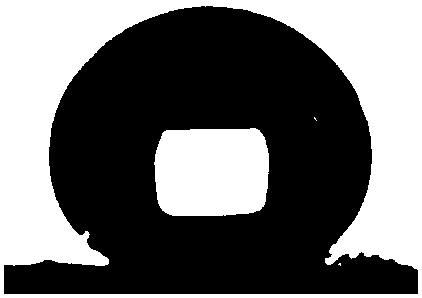

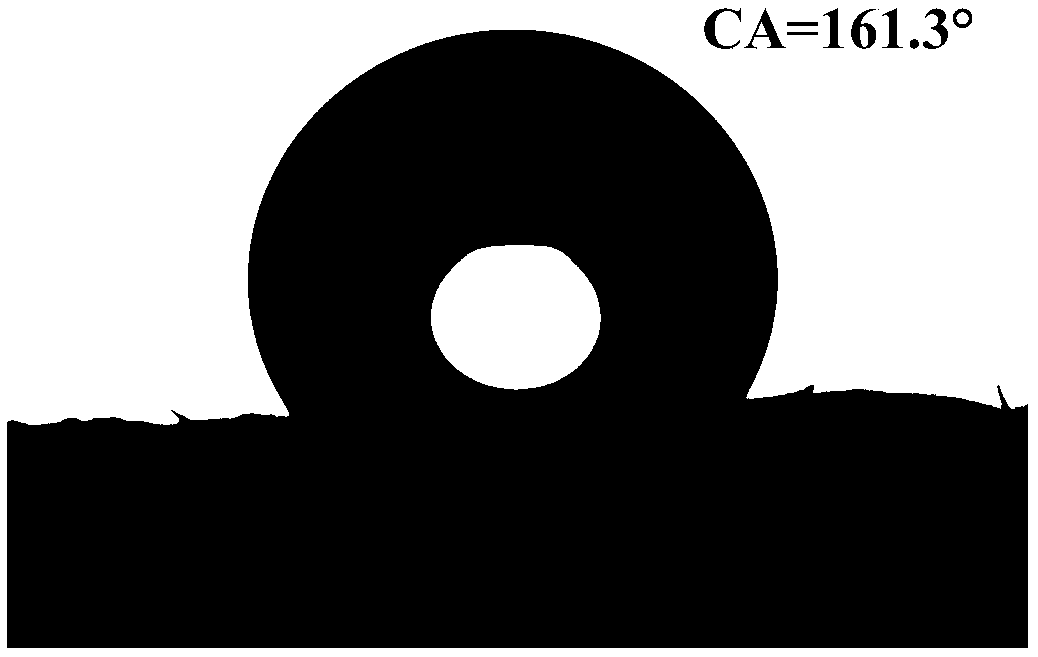

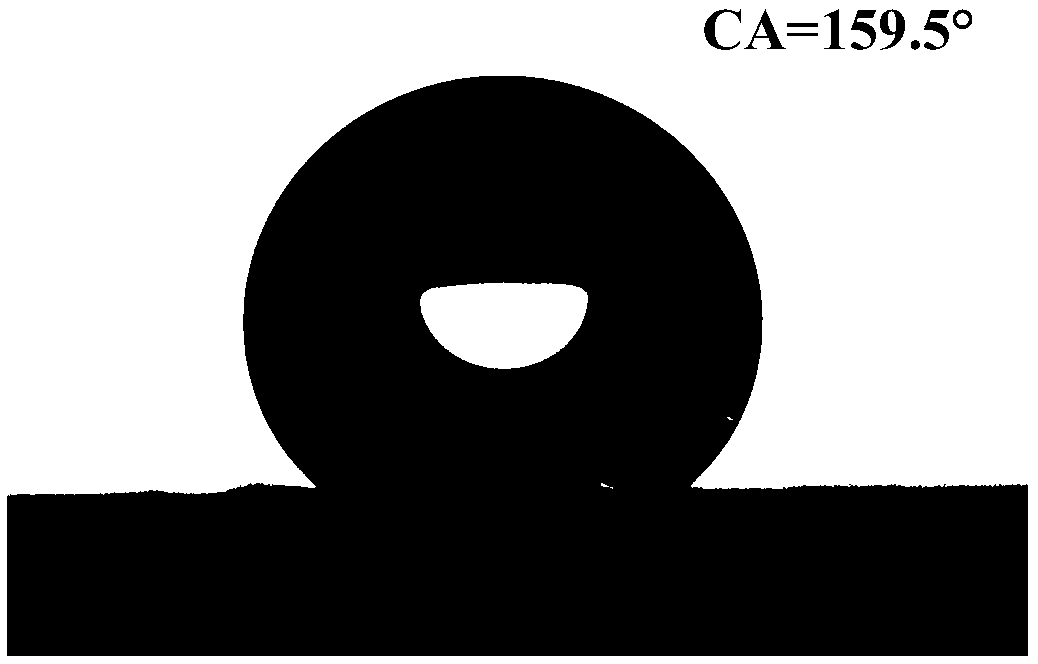

A superhydrophobic coating is a thin surface layer that repels water. It is made from superhydrophobic (ultrahydrophobicity) materials. Droplets hitting this kind of coating can fully rebound. Generally speaking, superhydrophobic coatings are made from composite materials where one component provides the roughness and the other provides low surface energy.

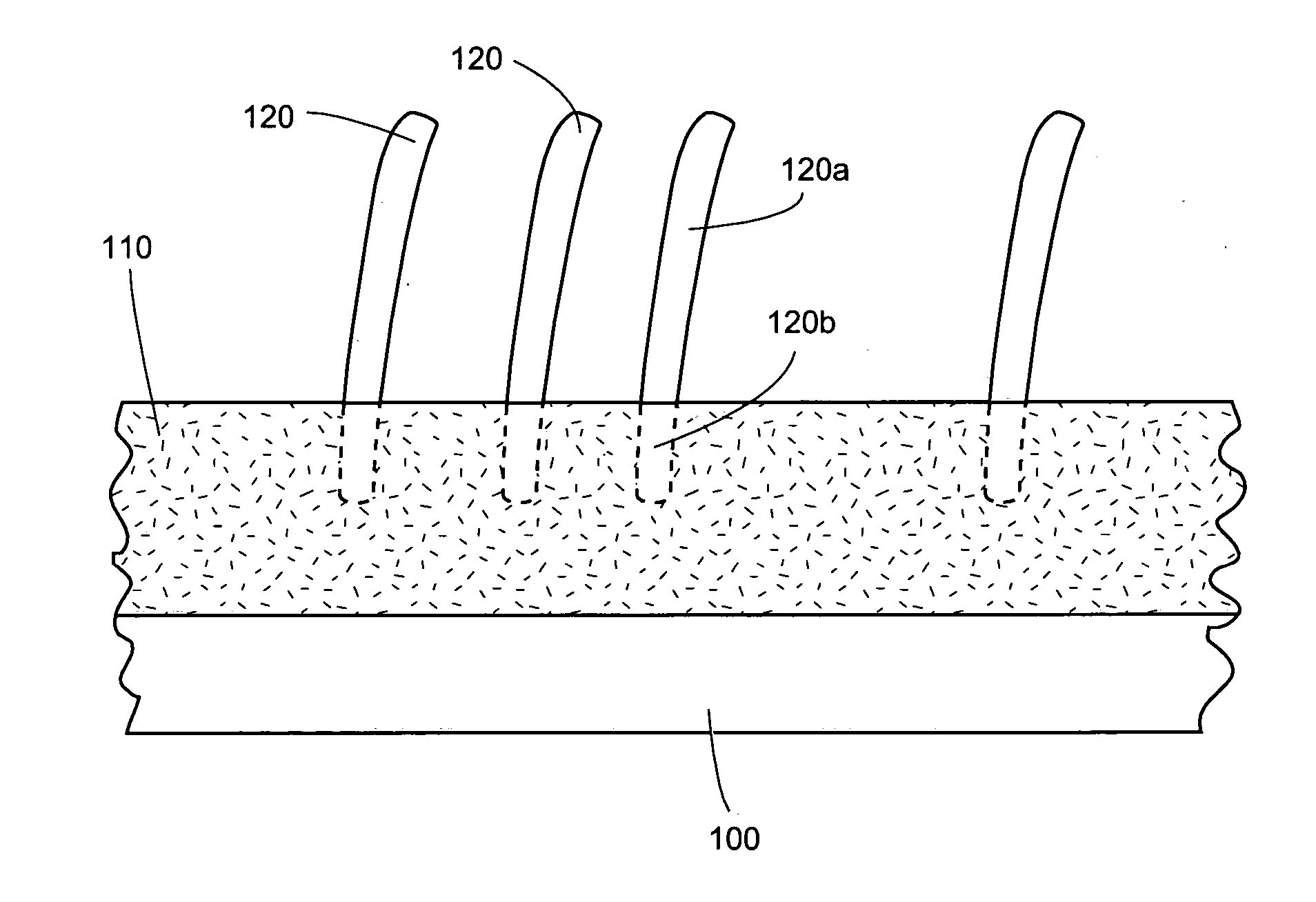

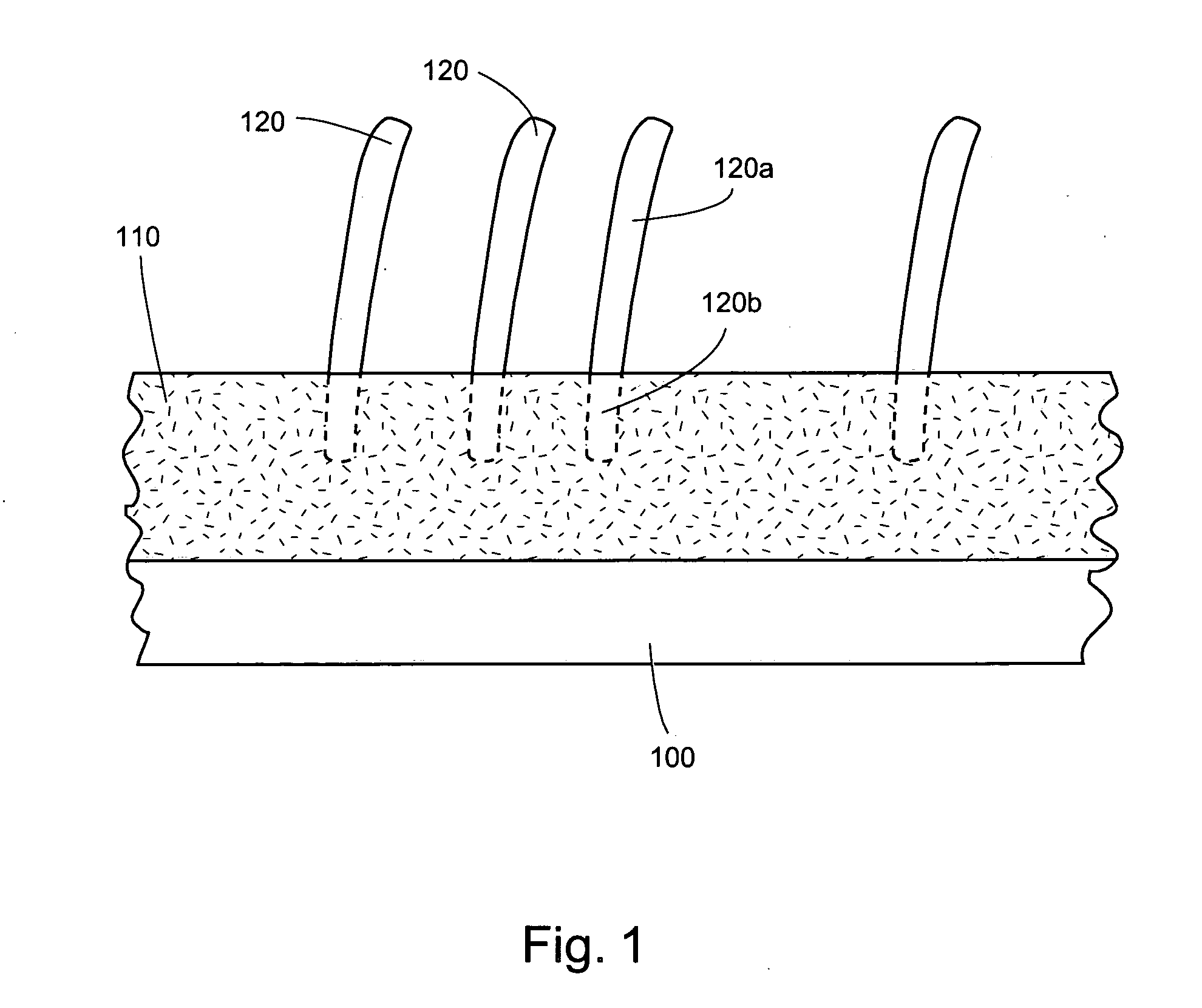

Paintable nonofiber coatings

InactiveUS20060240218A1Alter and enhance hydrophobicityAlter and enhance and hydrophilicityMaterial nanotechnologyLayered productsMetallurgyNanofiber

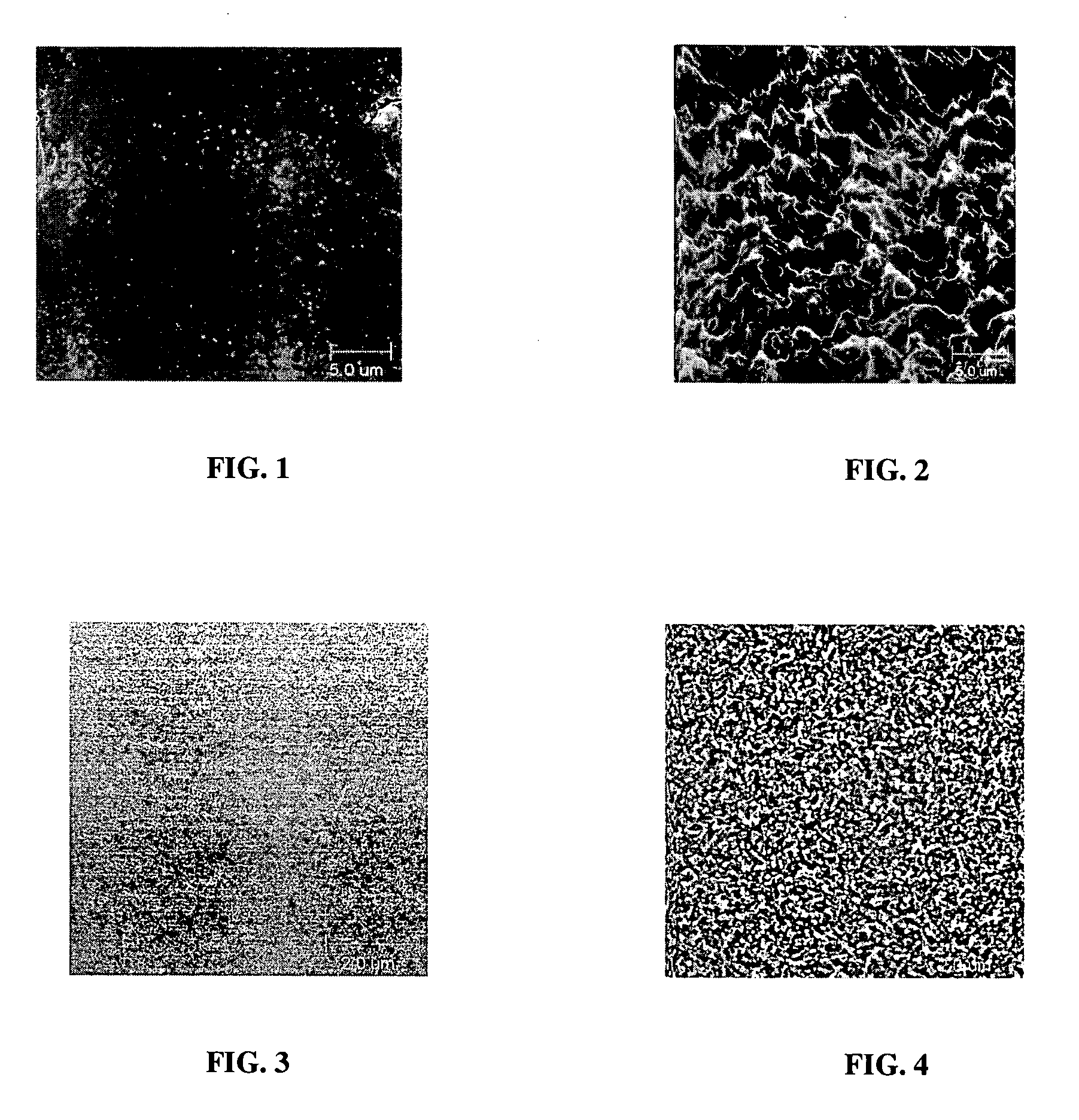

This invention provides novel superhydrophobic coatings comprising nanofiber heterostructures, as well as methods of creating and using such coatings.

Owner:NANOSYS INC

Superhydrophobic coating composition and coated articles obtained therefrom

A coating composition is provided comprising: (i) a fluorinated polymer comprising (a) structural units having the formula (I):—CR1R2—CFX— (I)wherein R1 and R2 are each independently an alkyl group, a fluorine atom, a chlorine atom, a hydrogen atom or a trifluoromethyl group, and X is a fluorine atom, a chlorine atom, a hydrogen atom or a trifluoromethyl group, and (b) structural units comprising at least one type of crosslinkable functional group; (ii) a crosslinking agent; and (iii) a plurality of particles functionalized with a functional group, wherein the functional group on the particles is essentially non-reactive with the fluorinated polymer and with the crosslinking agent. Articles comprising a coating composition described in embodiments of the invention are also provided.

Owner:GENERAL ELECTRIC CO

Superhydrophobic coating

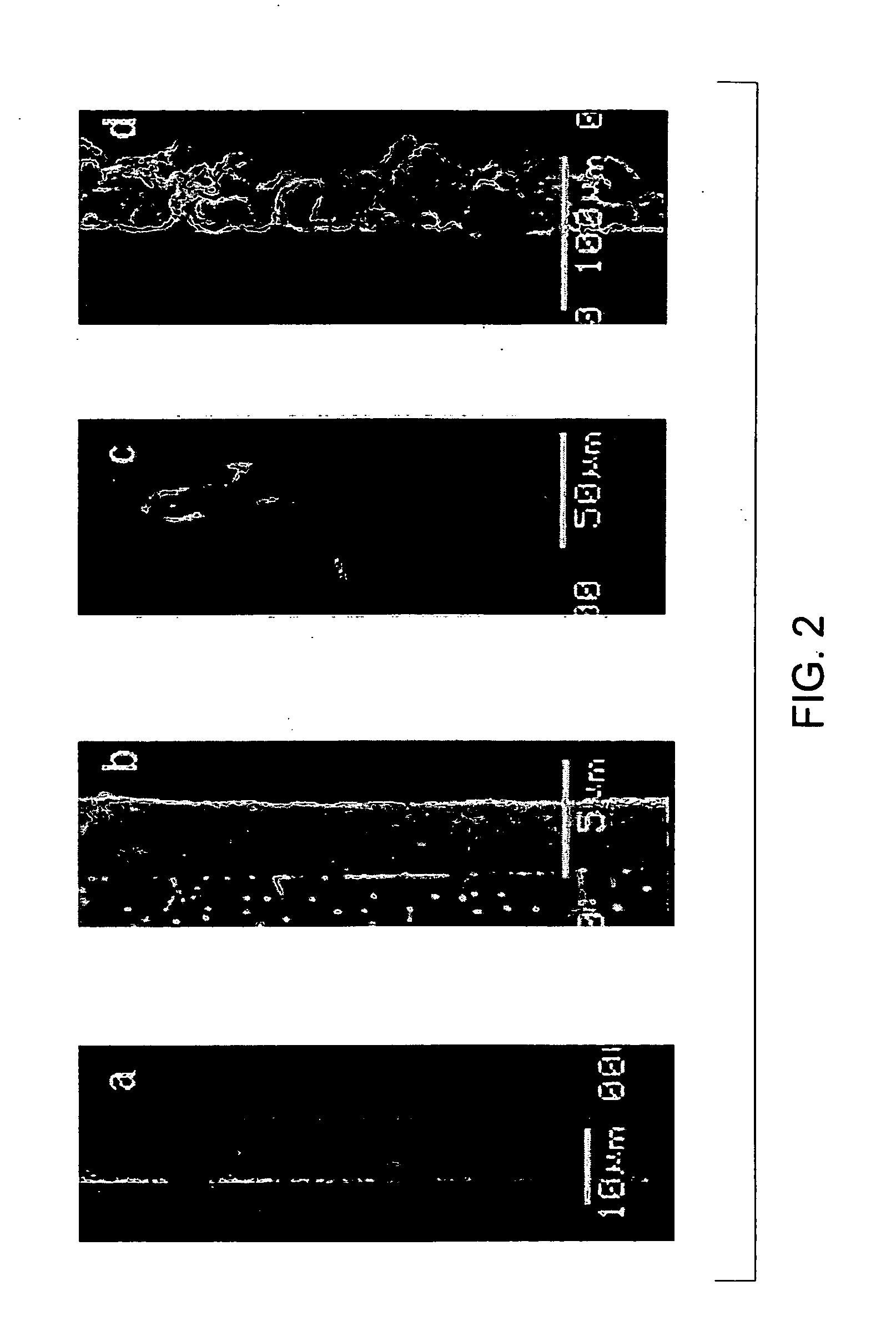

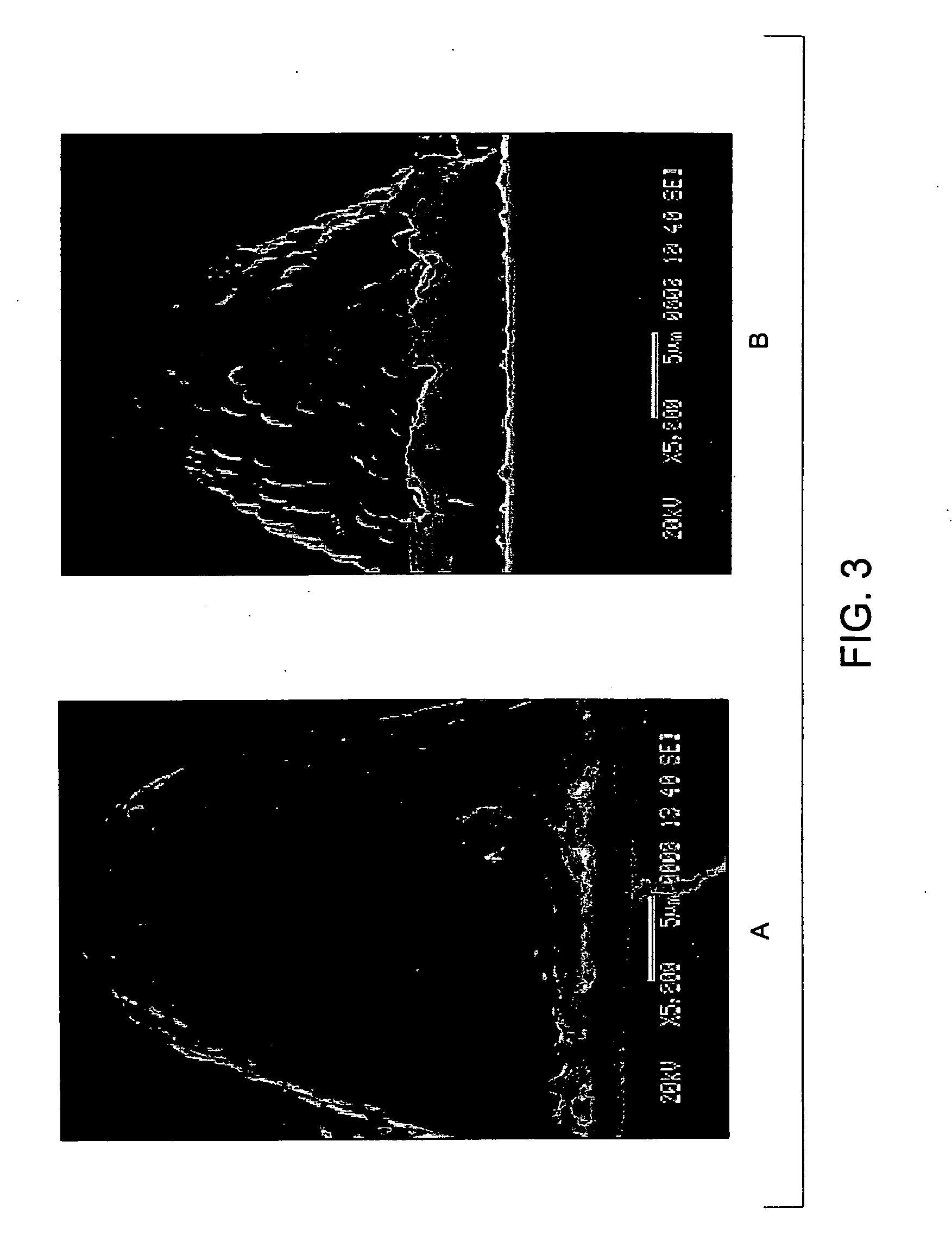

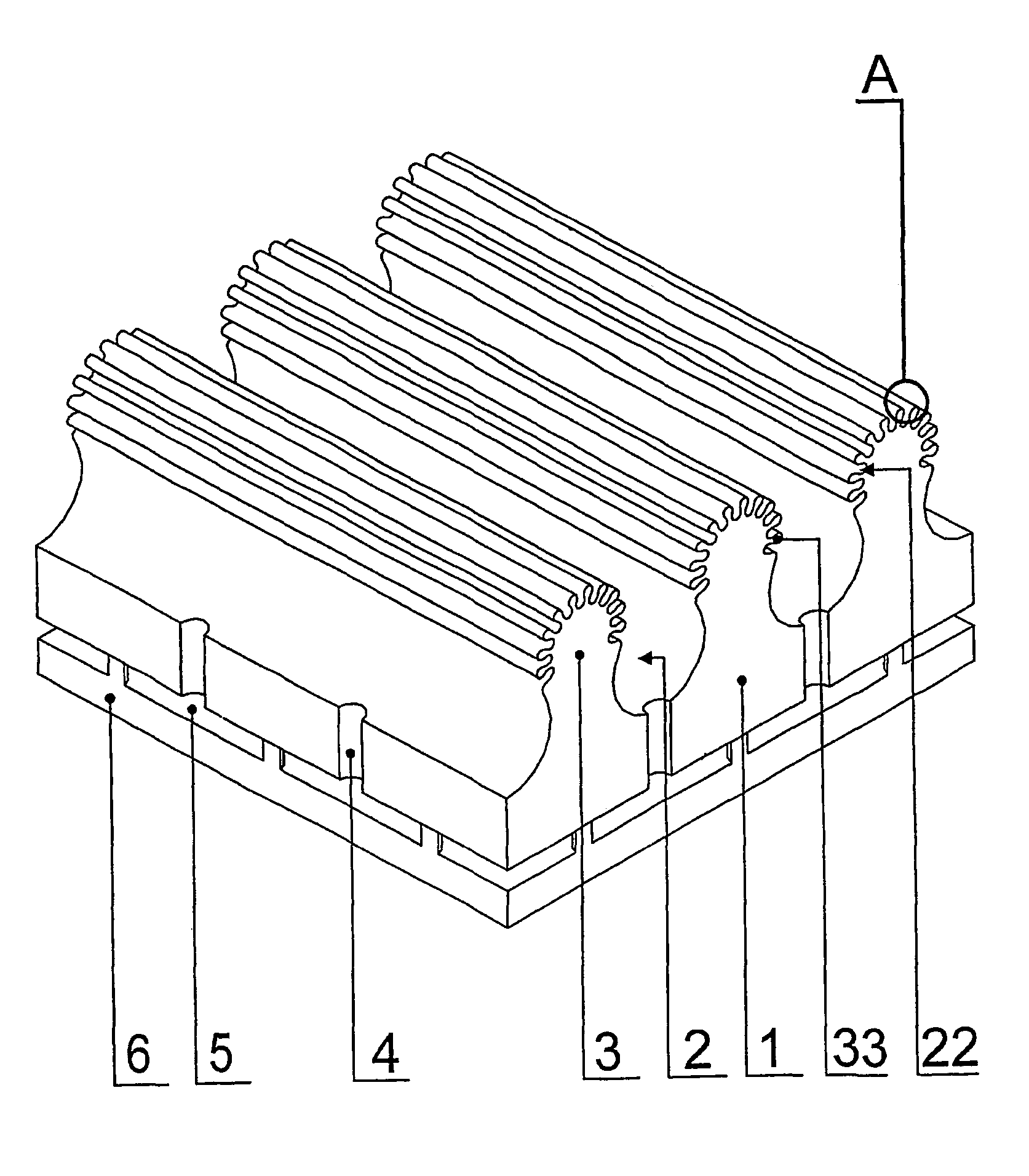

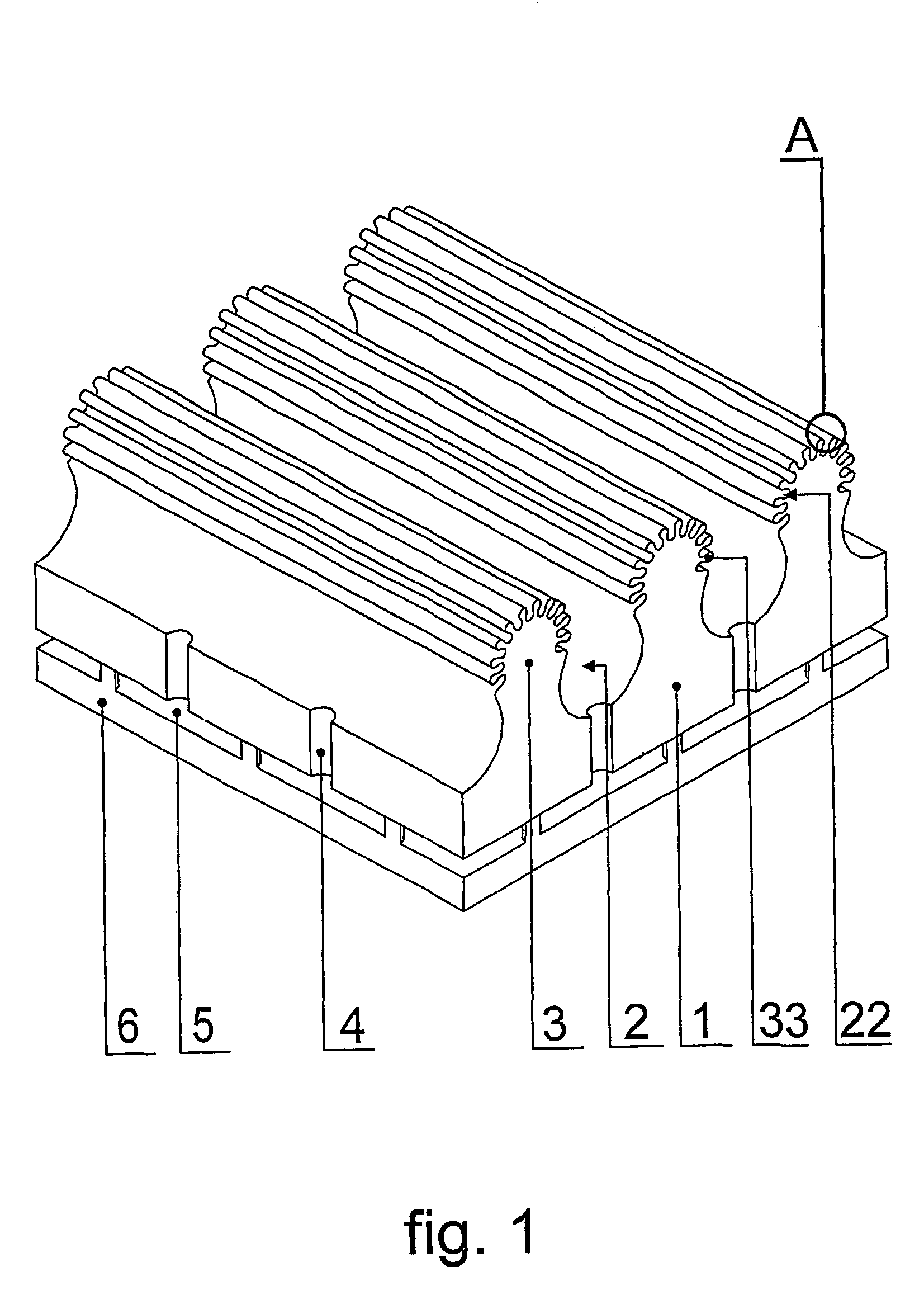

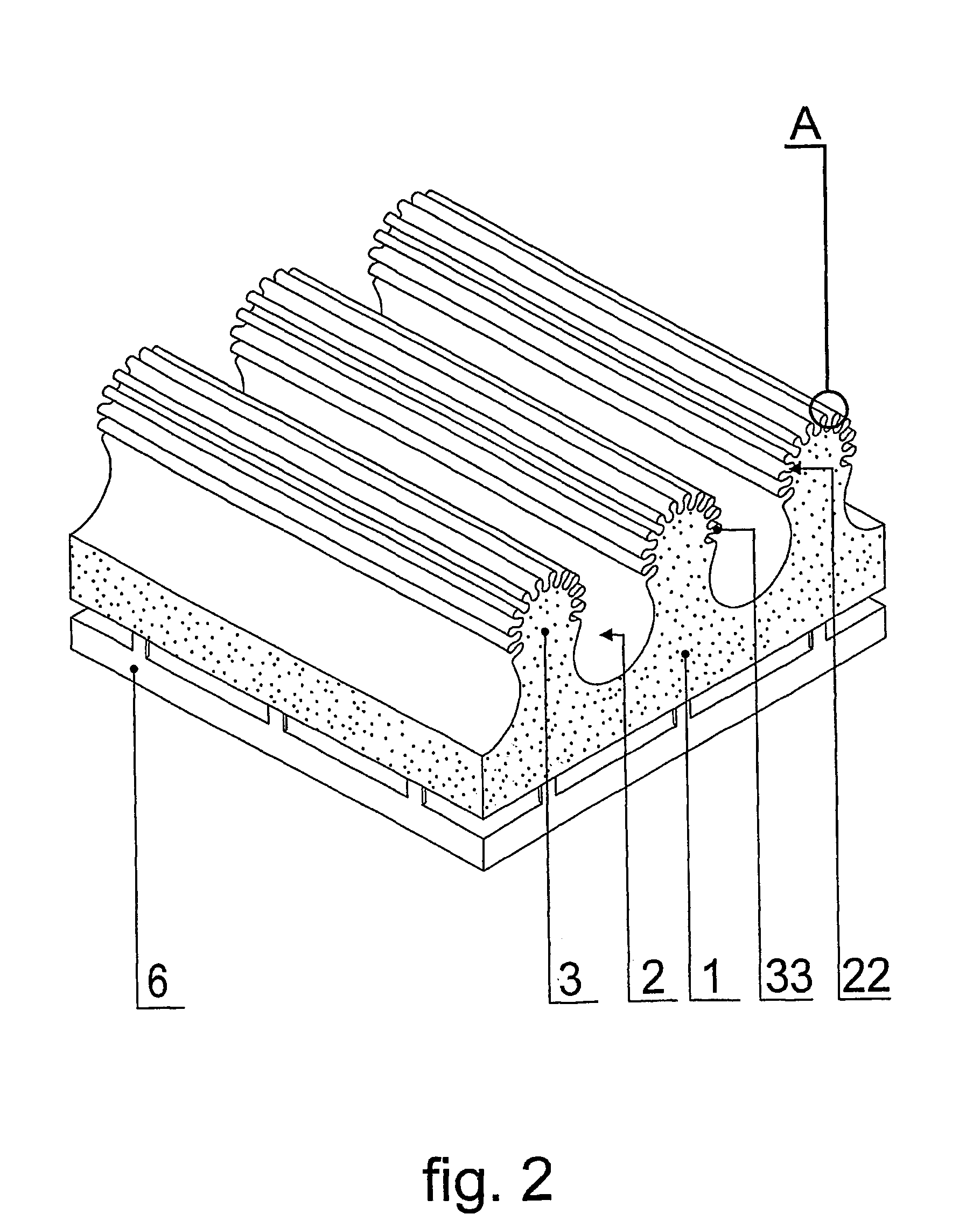

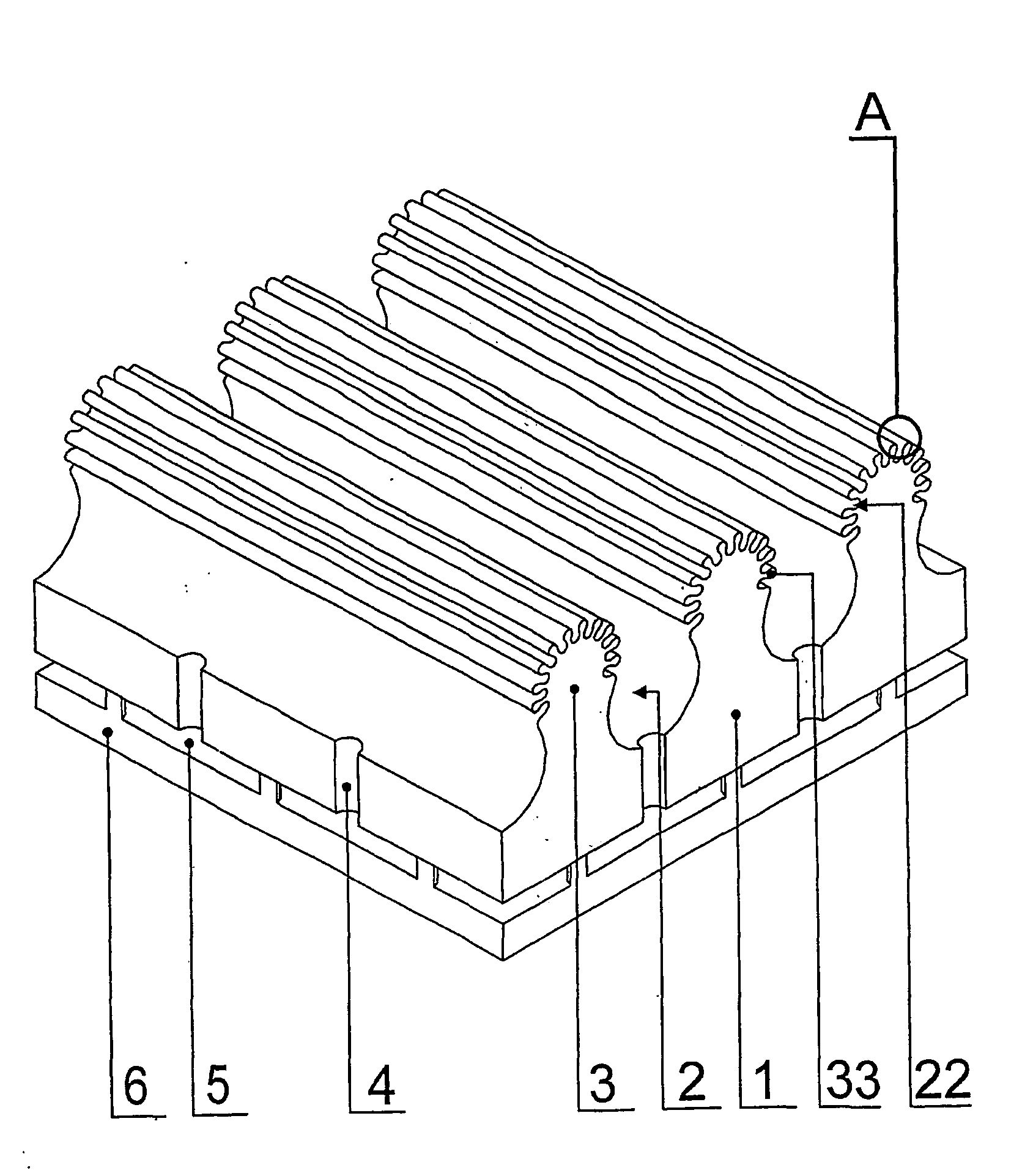

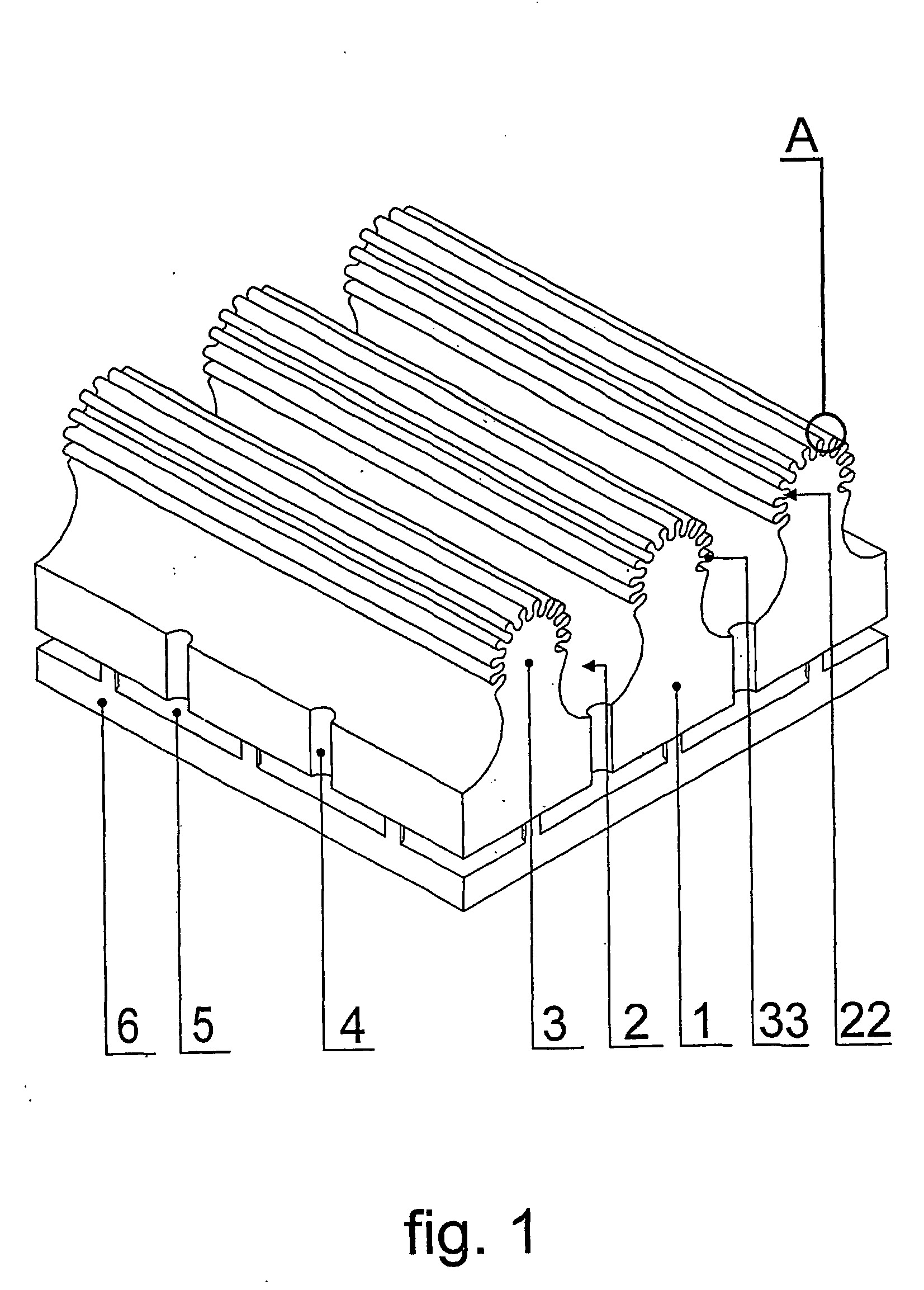

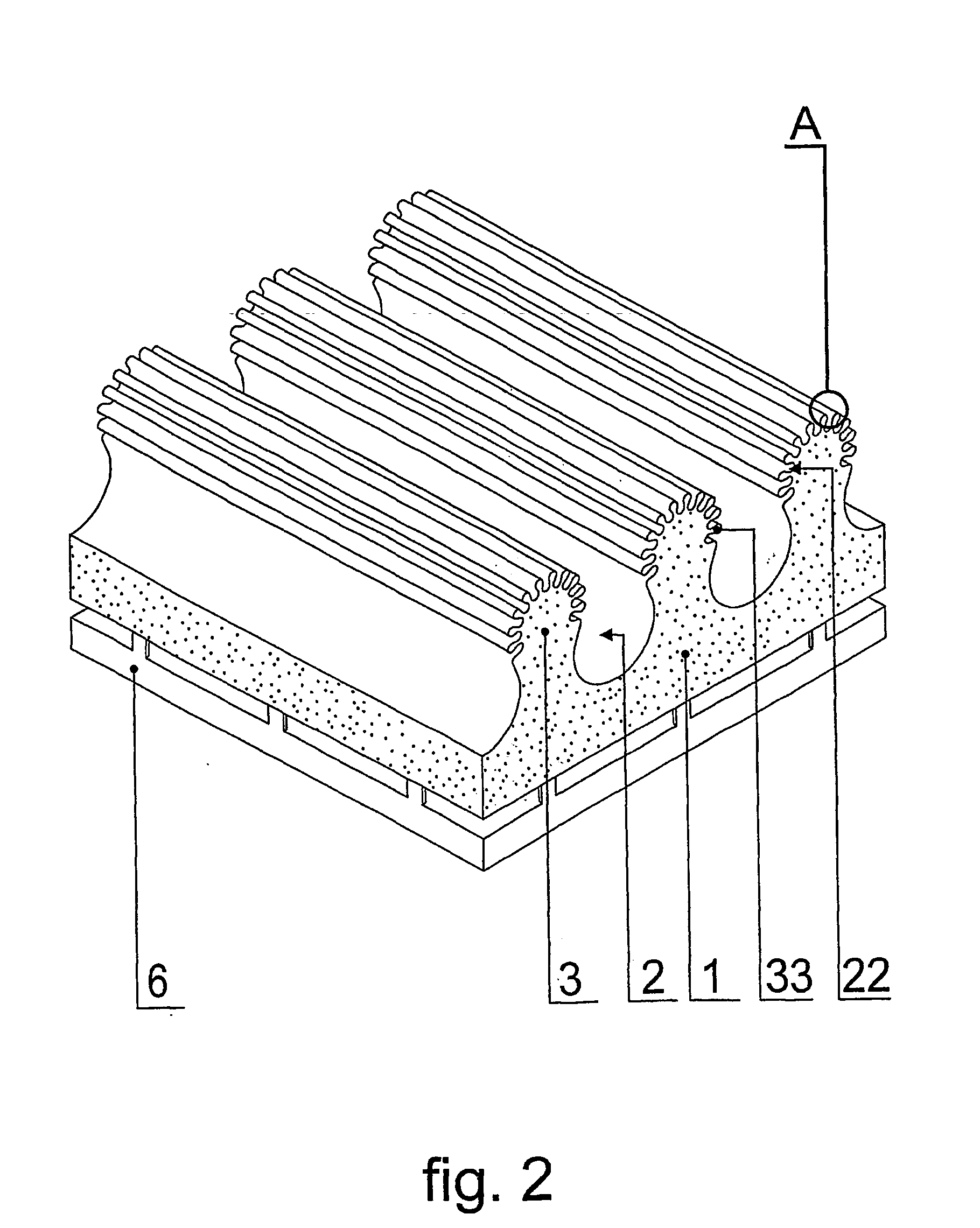

InactiveUS6994045B2Reduce frictionReduce resistanceWatercraft hull designWingsEngineeringProduct gas

This invention solves the problem of reducing the fluid friction resistance accompanying relative movement of surfaces of a solid and a liquid. A superhydrophobic coating acting as a substrate for a gaseous lubricant of very low viscosity, reducing the fluid skin friction, has a hierarchic fracal structural of the surface wherein the forms of the first hierarchic level (2, 3, 9) are located at the coating's substrate, and the forms of each successive hierarchic level (22, 33, 99) are located on the surface of the previous hierarchic level and the forms of individual higher hierarchic levels reiterate the forms of the lower hierarchic levels. Forms of at least two hierarchic levels of rows (2, 22) and ridges (3, 33, 99) occur in the coating and, also, the surface has anisotropic geometry, maximally developed fractally in the direction transverse to the direction of flow and maximally smooth in the direction of flow and, also, has channels located in the coating's substrate to ensure gas flow.

Owner:CNT SPOLKA Z O O

Durable superhydrophobic coating

InactiveUS20070009657A1Increased durabilityDurableCoatingsSpecial surfacesCross-linkSuperhydrophobic coating

A method for forming a hydrophobic coating on the surface of a substrate comprising linking particulate material by polymer strands and cross-linking at least some of the polymer strands. The invention further relates to hydrophobic coatings comprising particles of a particulate material linked together and to a surface by polymer strands, wherein some of the polymer strands are cross-linked. The method of the invention can be used to form superhydrophobic coatings.

Owner:NEWSOUTH INNOVATIONS PTY LTD

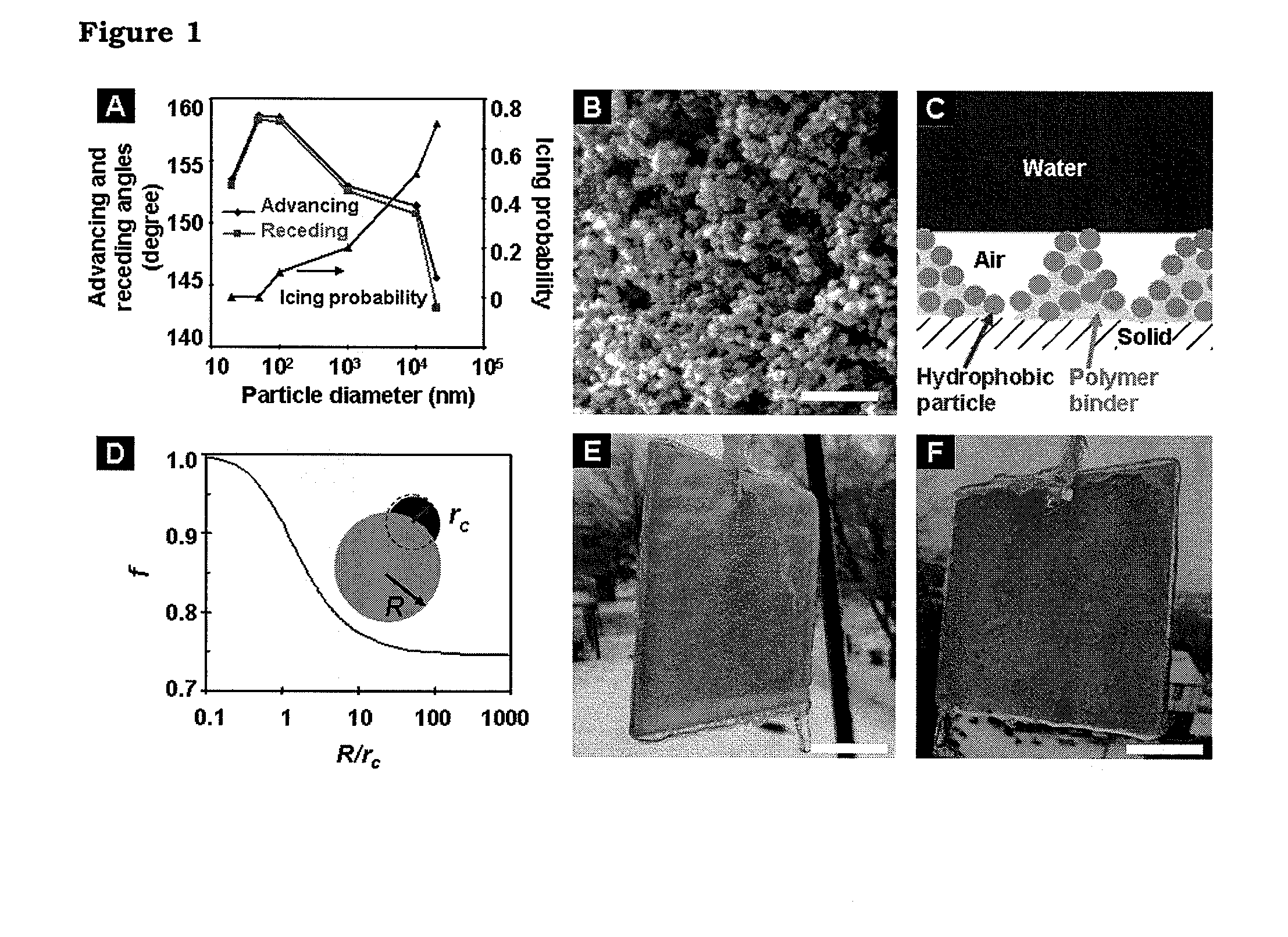

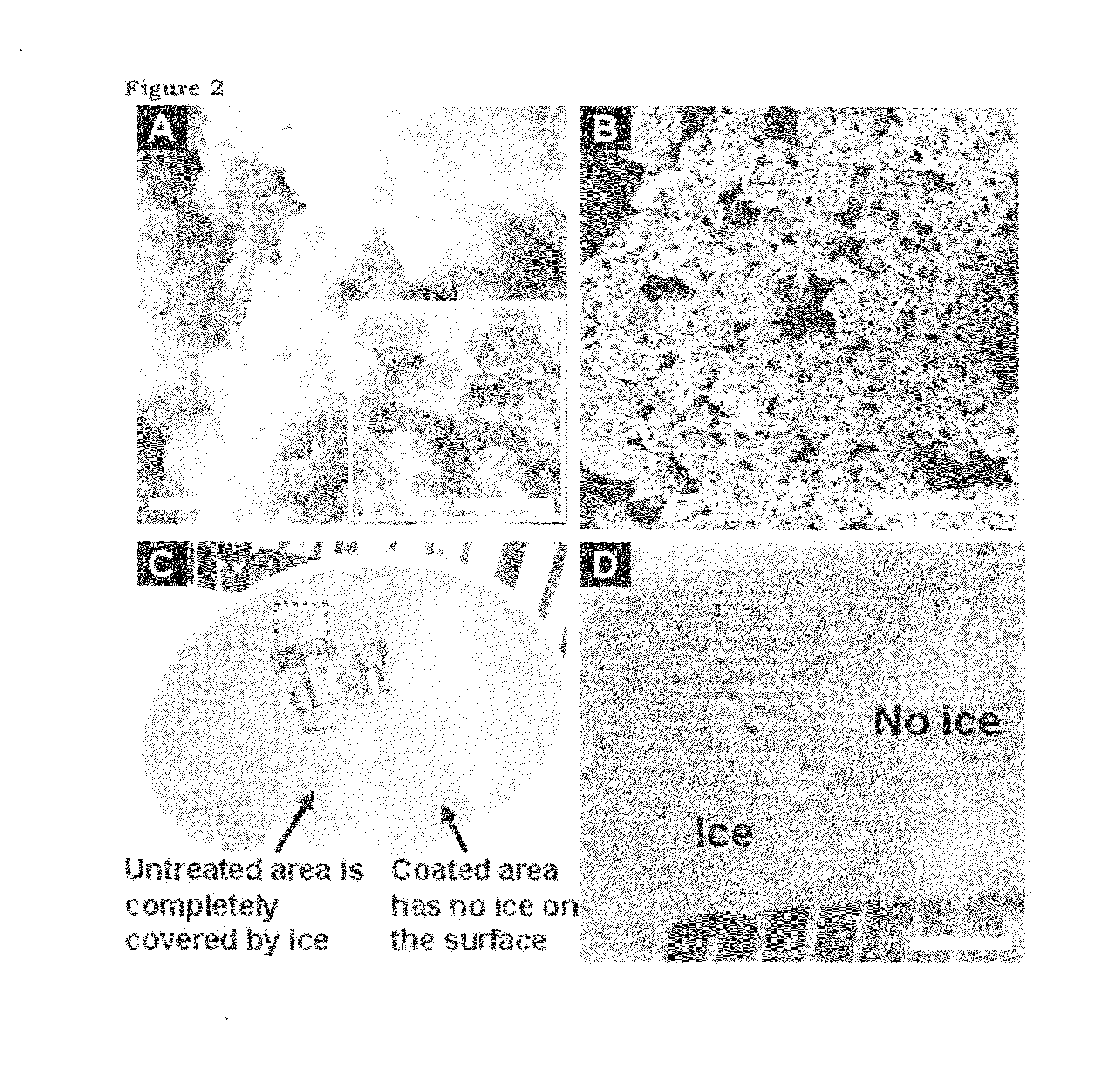

Anti-icing superhydrophobic coatings

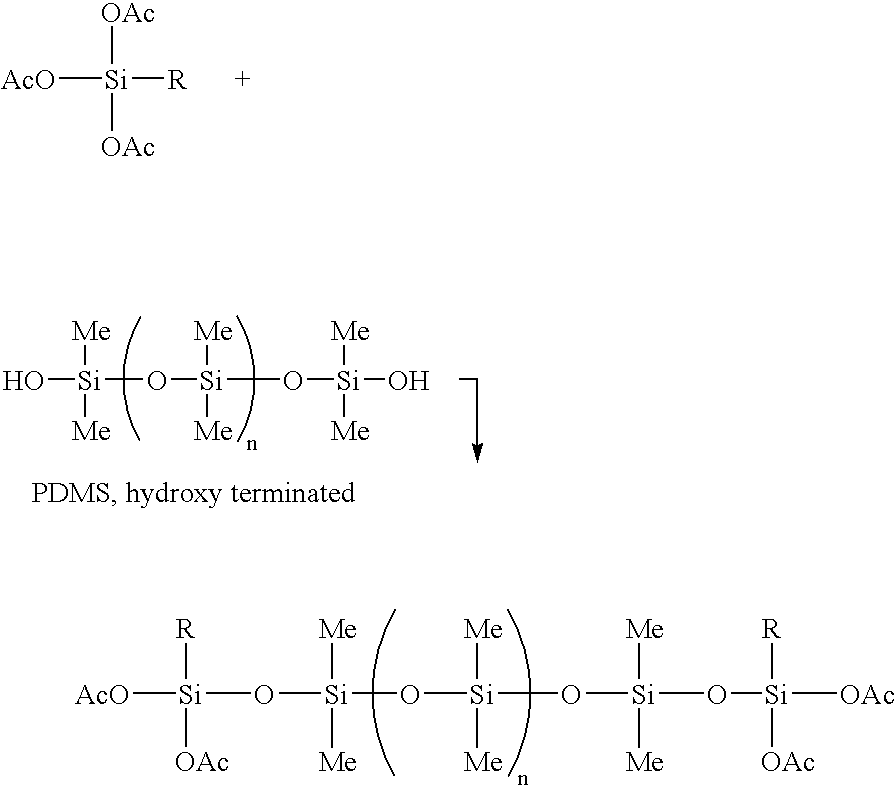

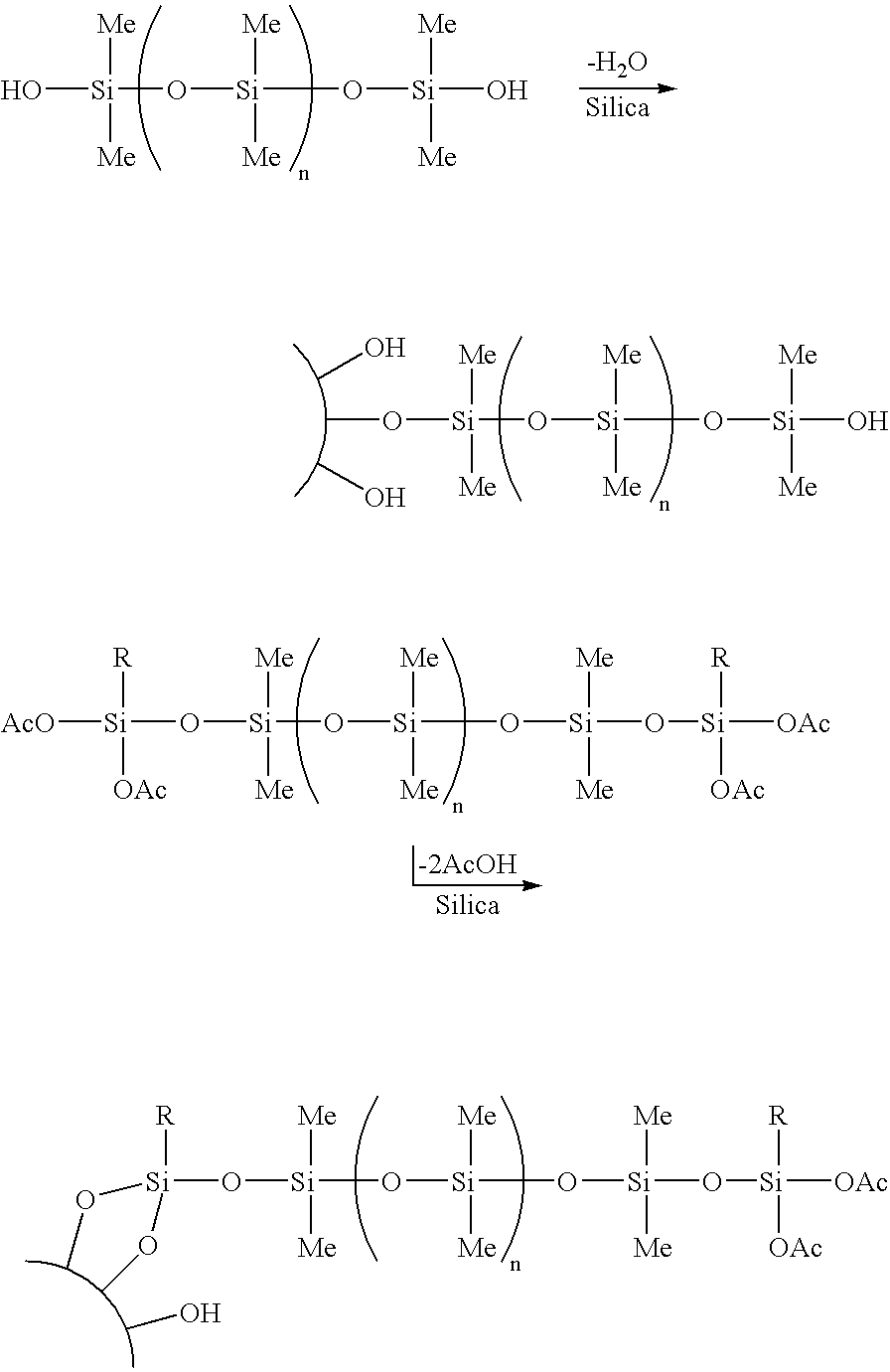

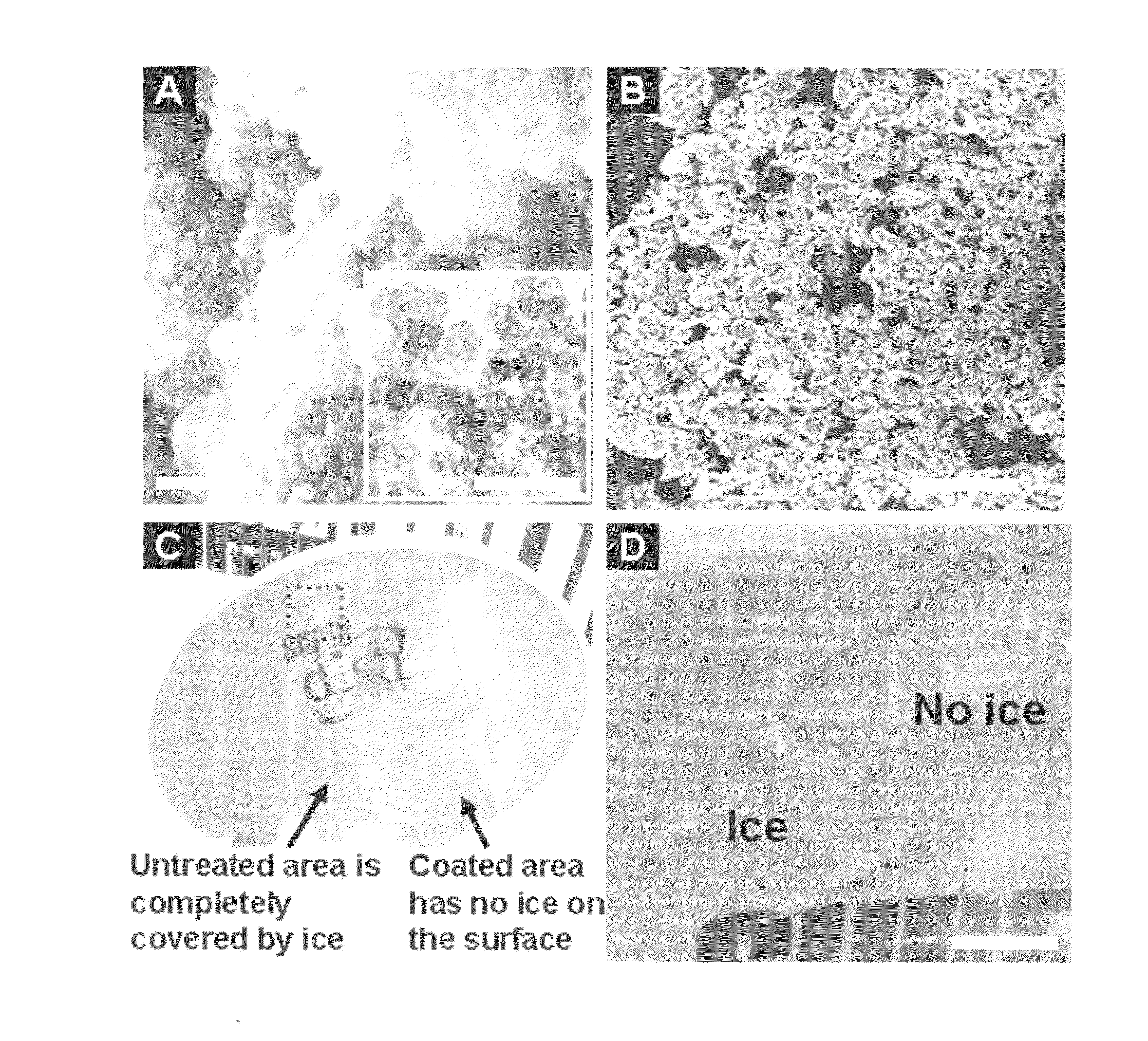

InactiveUS20100314575A1Increase probabilityOther chemical processesCoatingsNanoparticleSuperhydrophobic coating

Superhydrophobic coating compositions are provided. The compositions comprise nanoparticles between 5-100 nm in size and a polymeric binder. The compositions are effective in preventing ice formation on the surface of various substrates.

Owner:UNIVERSITY OF PITTSBURGH

Dispersions of carbon nanotubes in copolymer solutions and functional composite materials and coatings therefrom

A dispersion includes a plurality of non-chemically modified carbon nanotubes, a soluble block copolymer providing at least one block of a conjugated polymer and at least one block of a non-conjugated polymer, and at least one solvent. At 25° C. exclusive of any mechanical force and after one hour, at least 90% of the plurality of carbon nanotubes exist in the dispersion as isolated carbon nanotubes. The components of the dispersion can be combined with a polymer miscible with the block copolymer to form a carbon nanotube polymer composite upon removal of the solvent. The dispersion can be cast on a substrate and then dried to form a coating, including forming a superhydrophobic coating on the substrate. The non-conjugated polymer of the block copolymer or another miscible conjugated polymer including a copolymer can include functionalities that non-covalently attach to the carbon nanotube surface, such as for manipulating carbon nanotube properties including for enhanced solubility or enhanced biocompatibility.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

Water Repellant Golf Balls Containing a Hydrophobic or Superhydrophobic Outer Layer or Coating

InactiveUS20080280699A1Improve performanceSynthetic resin layered productsPaper coatingPolymer sciencePolyethylene glycol

Water-repellant, self-cleaning coatings and methods of making and using thereof are described herein. In one embodiment, a hydrophobic or super hydrophobic coating is applied to the surface of a golf ball to make the golf-ball water-repellant and self-cleaning. Suitable coating materials include silicone compounds, silicone compounds, nanoparticles, silanes, fluorocarbon polymers, perfluoroalkyl ethyl methacrylate (PPFEMA) coated polycaprolactone, hydrocarbons, polymer mats made of polystyrene and poly[tetrafluoroethylene-co-(vinylidene fluoride)-co-propylene] (PTVFP); polyethylene glycol with glucose and sucrose in conjunction with a hydrophobic substance; combinations of nanoparticles with polyethylene or polypropylene; high density polyethylene, technical waxes; films of rough particles of metal oxides, polymer binder layers containing a plurality of porous protrusions, and combinations thereof. Suitable coating techniques include, but are not limited to, spraying, dipping, painting, brushing, or wiping (such as applying the coating from a towel or sponge). The coating material or the outer layer of the golf ball may be modified to create nano- or micro roughness or patterns on the surface of the golf ball, which can induce the lotus effect. This roughness or pattern can be created using a variety of techniques known in the art including, but not limited to, etching, top / down methodologies, bottom / up methodologies, or combinations thereof.

Owner:JARVHOLM ERIK JONAS

Superhydrophobic coating

InactiveUS20050061221A1Reduction of fluid friction resistanceReduce resistanceWatercraft hull designWingsEngineeringSuperhydrophobic coating

This invention solves the problem of reducing the fluid friction resistance accompanying relative movement of surfaces of a solid and a liquid. A superhydrophobic coating acting as a substrate for a gaseous lubricant of very low viscosity, reducing the fluid skin friction, has a hierarchic fracal structural of the surface wherein the forms of the first hierarchic level (2, 3, 9) are located at the coating's substrate, and the forms of each successive hierarchic level (22, 33, 99) are located on the surface of the previous hierarchic level and the forms of individual higher hierarchic levels reiterate the forms of the lower hierarchic levels. Forms of at least two hierarchic levels of rows (2, 22) and ridges (3, 33, 99) occur in the coating and, also, the surface has anisotropic geometry, maximally developed fractally in the direction transverse to the direction of flow and maximally smooth in the direction of flow and, also, has channels located in the coating's substrate to ensure gas flow.

Owner:CNT SPOLKA Z O O

Insulator coating and method for forming same

ActiveUS20060081394A1Avoid pollutionImproves UV stabilityPlastic/resin/waxes insulatorsInsulated cablesCoating systemUltraviolet

The present invention is a method of applying Lotus Effect materials as a (superhydrophobicity) protective coating for external electrical insulation system applications, as well as the method of fabricating / preparing Lotus Effect coatings. Selected inorganic or polymeric materials are applied on the insulating material surface, and stable superhydrophobic coatings can be fabricated. Various UV stabilizers and UV absorbers can be incorporated into the coating system to enhance the coating's UV stability.

Owner:GEORGIA TECH RES CORP

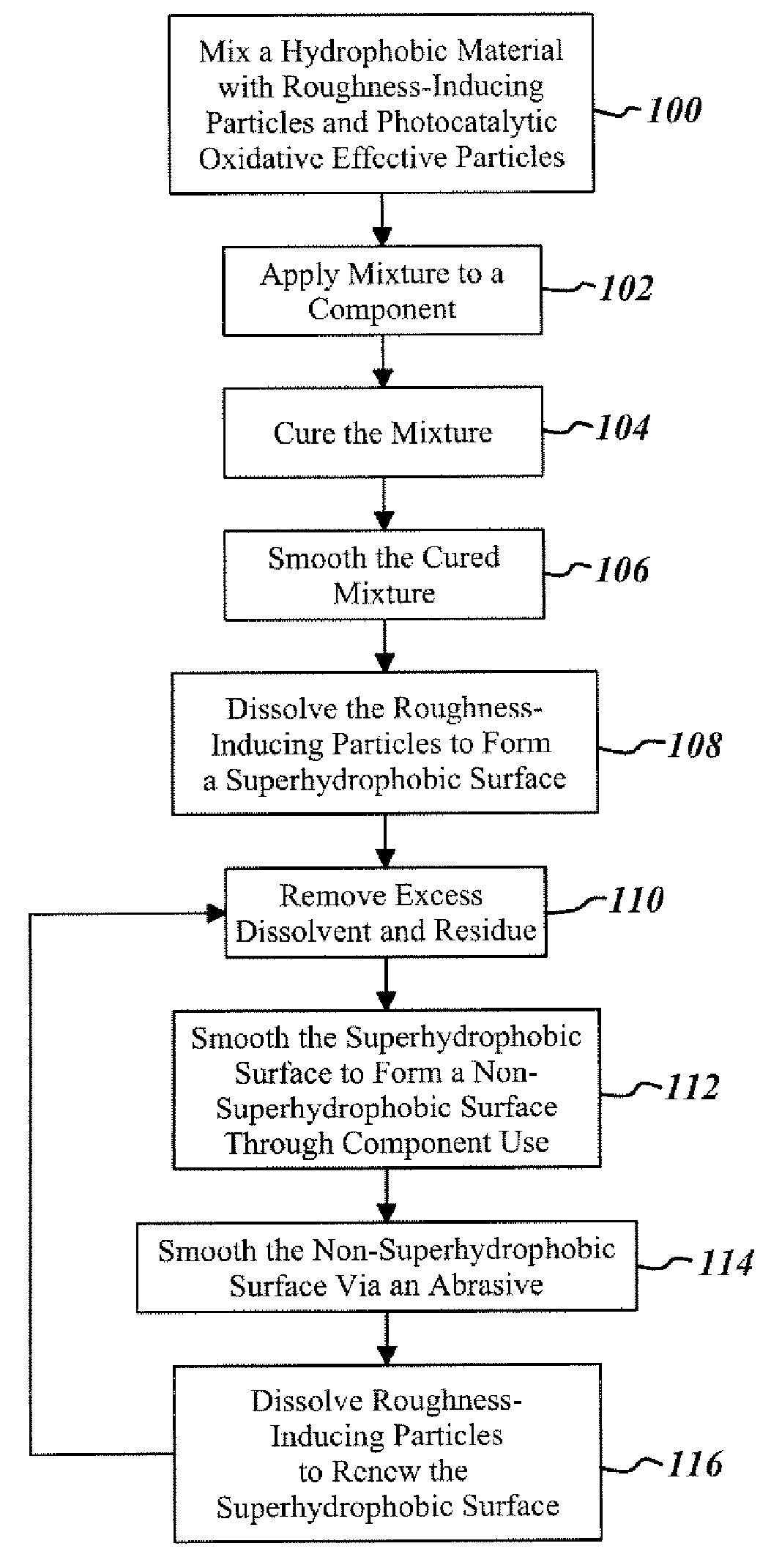

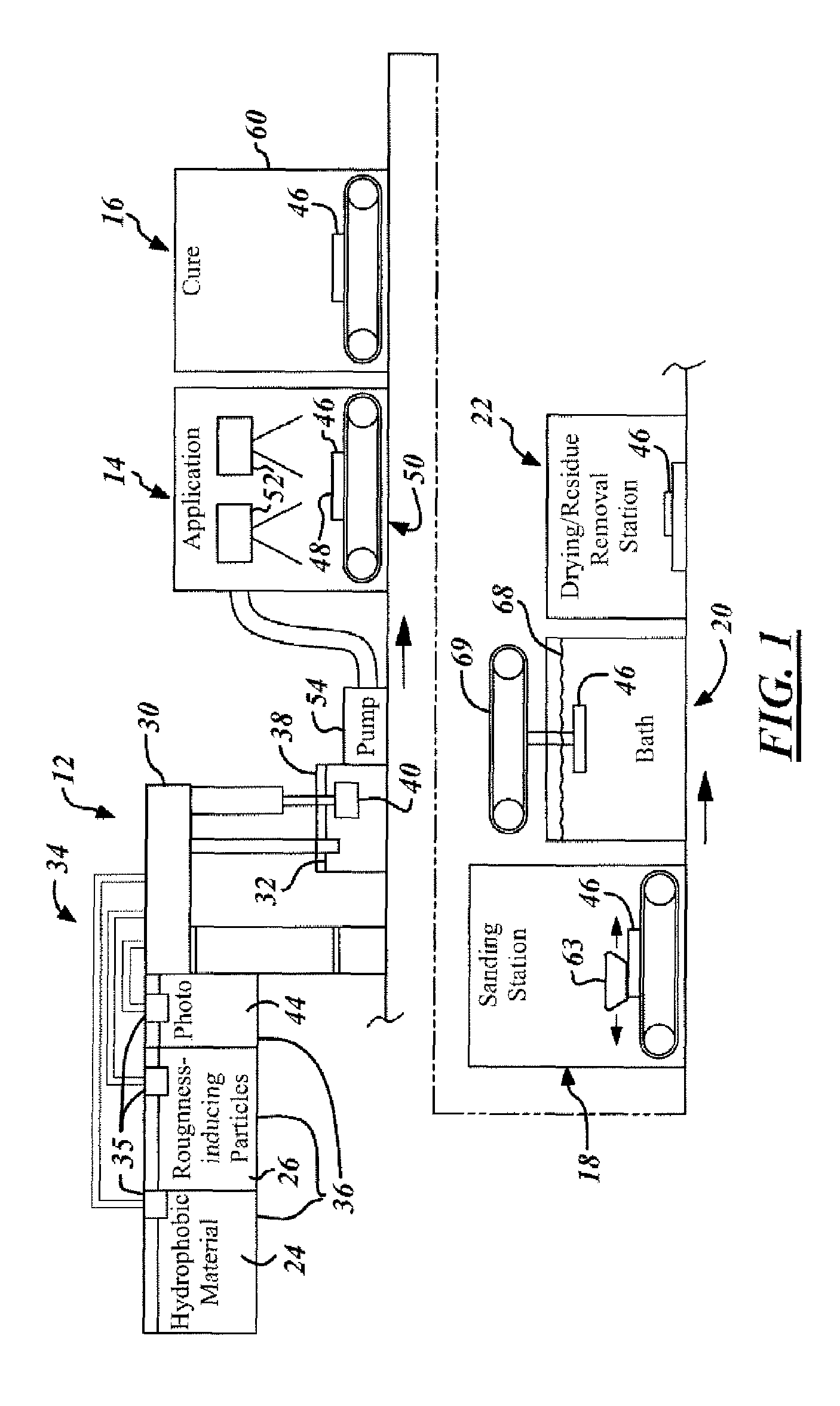

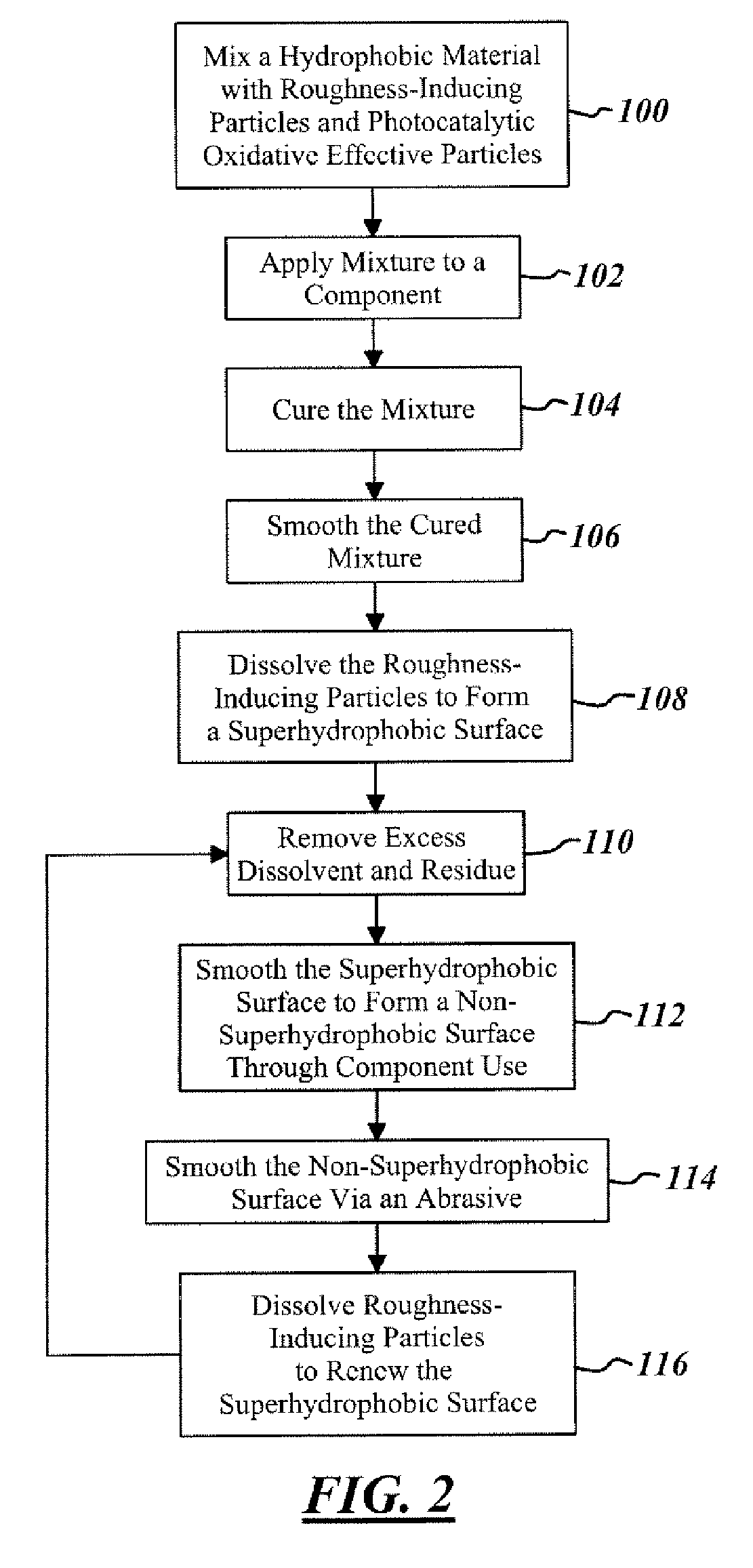

Renewable superhydrophobic coating

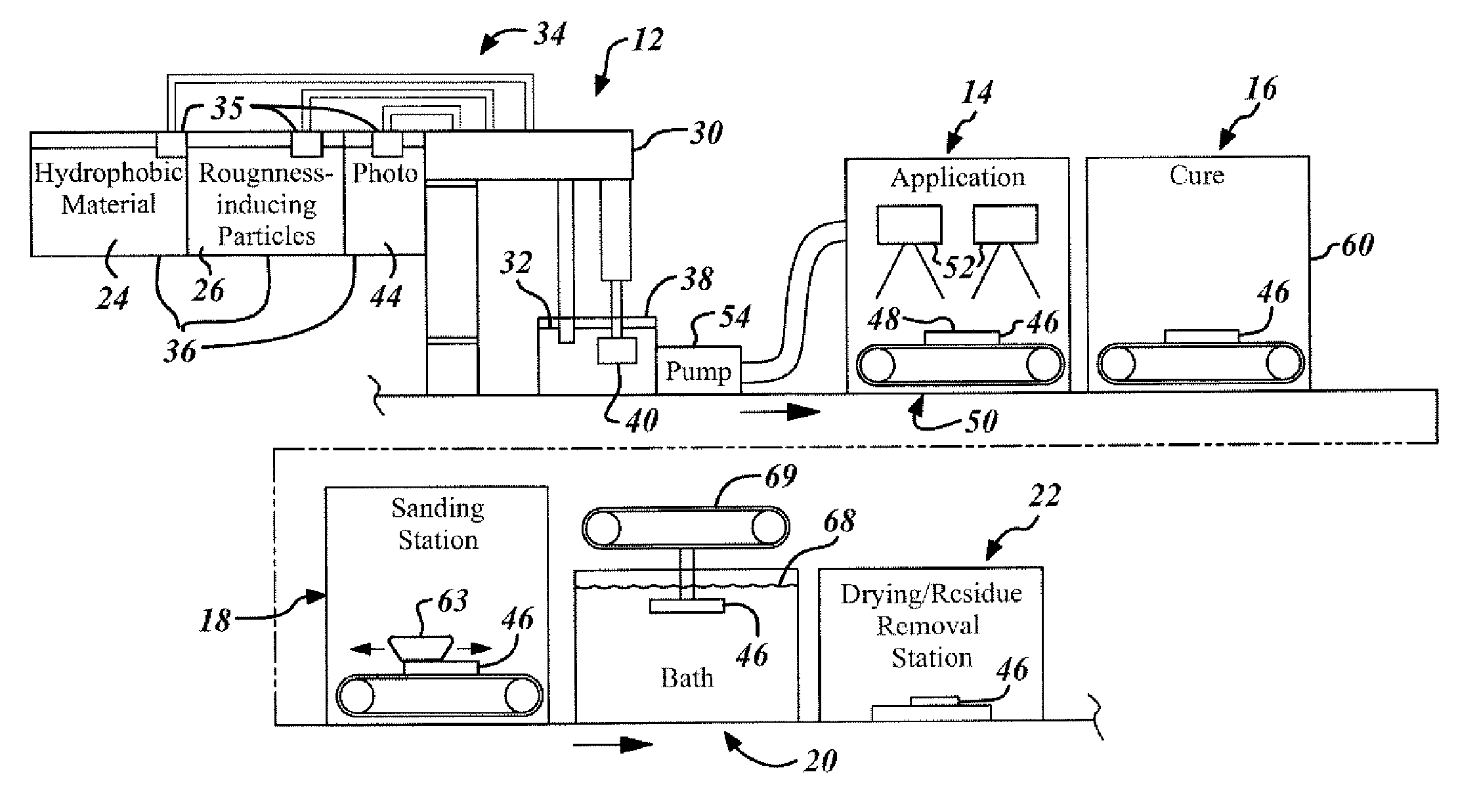

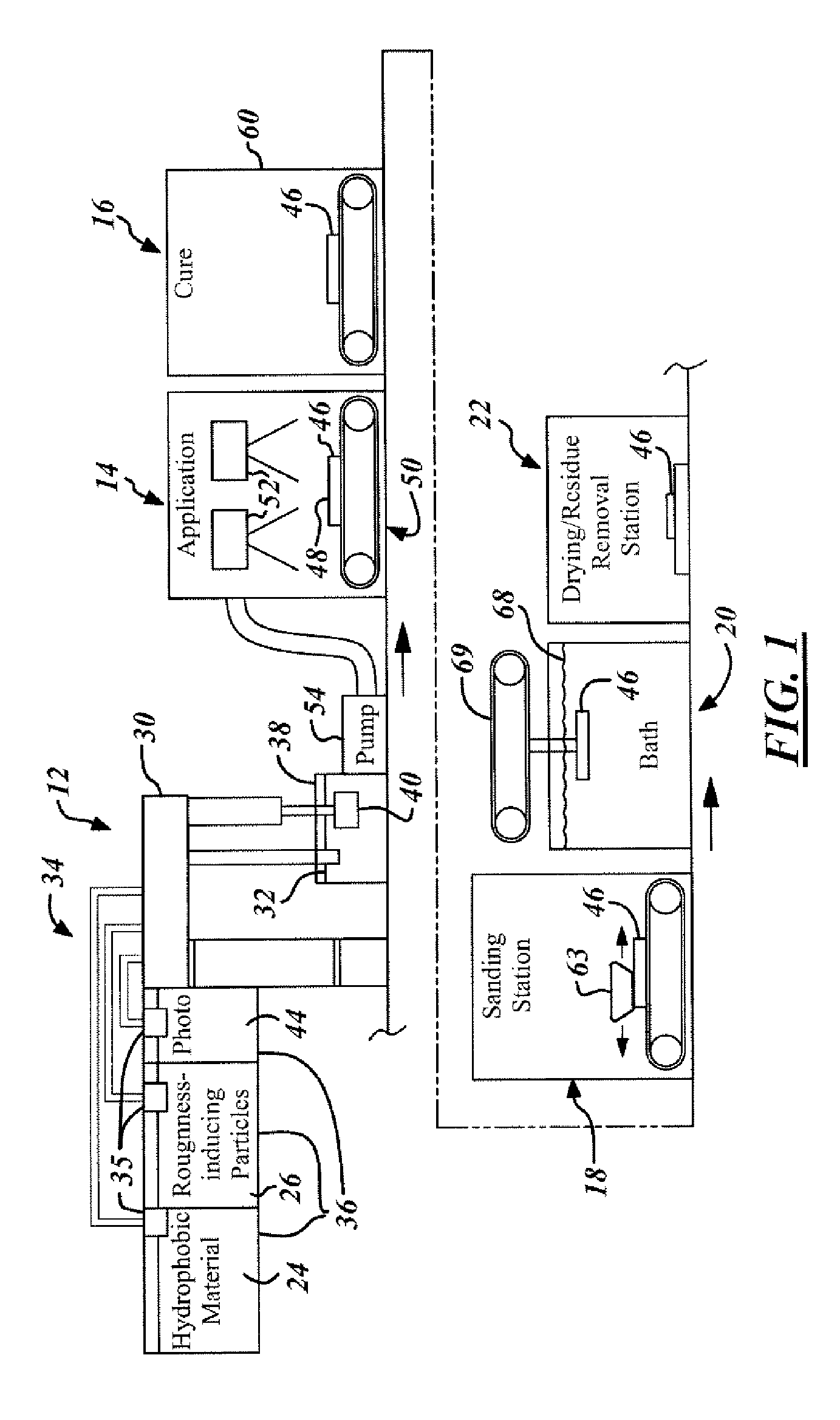

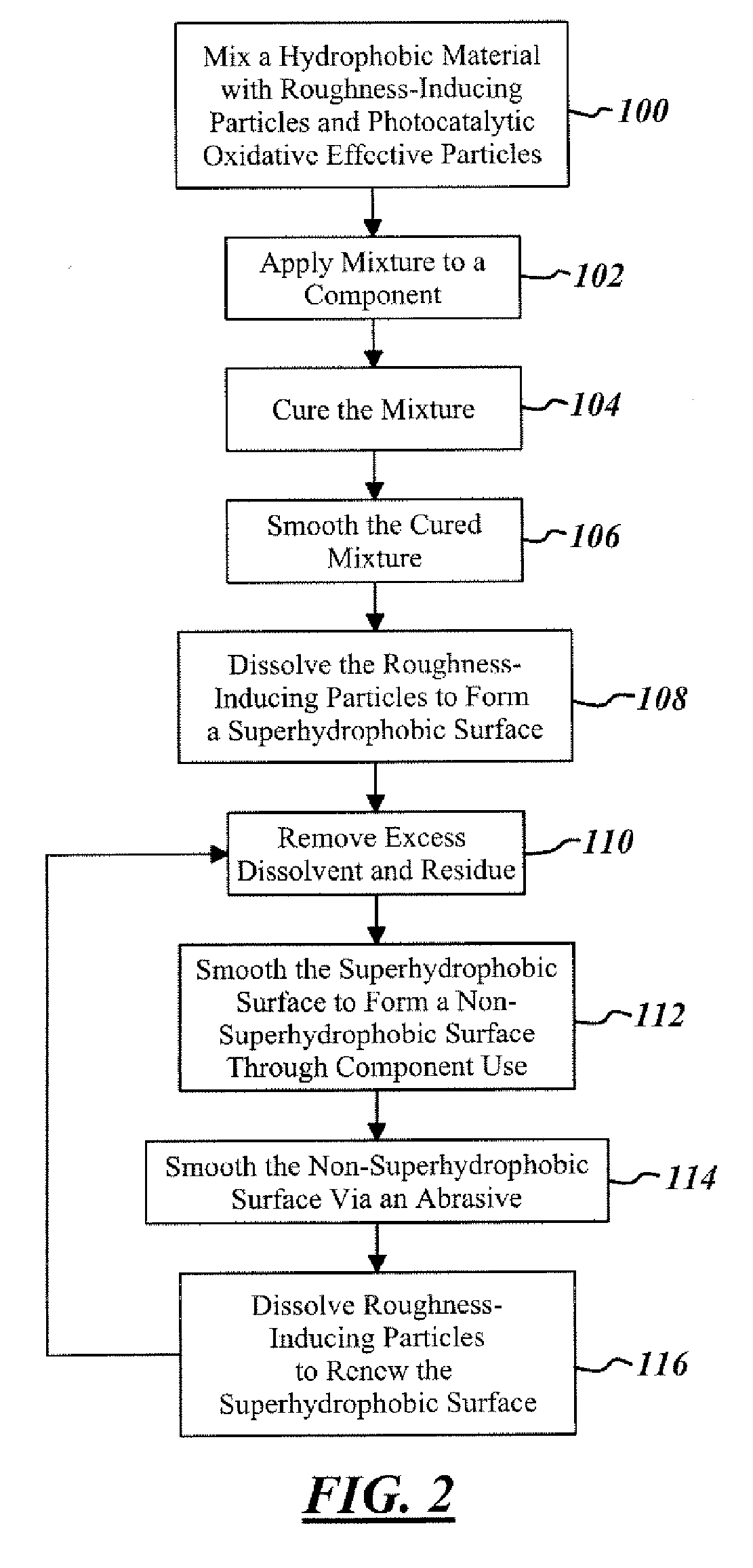

ActiveUS7419615B2Increases of componentFine surfaceFouling preventionDecorative surface effectsSuperhydrophobic coatingSolvent

A method of forming a superhydrophobic material (66) includes mixing a hydrophobic material (24) with soluble particles (26) to form a mixture (32). The mixture (32) is cured. A portion of the soluble particles (26) is etched away from the mixture (32) to form the superhydrophobic material (66). A superhydrophobic material forming system (10) includes a mixer (30) that mixes a hydrophobic binder (24) with soluble particles (26) to form the mixture (32). A curing station (16) cures the mixture (32). An applicator (69) applies a solvent (68) to the mixture (32) to etch away a portion of the soluble particles (26) from the mixture (32) to form the superhydrophobic material (66).

Owner:THE BOEING CO

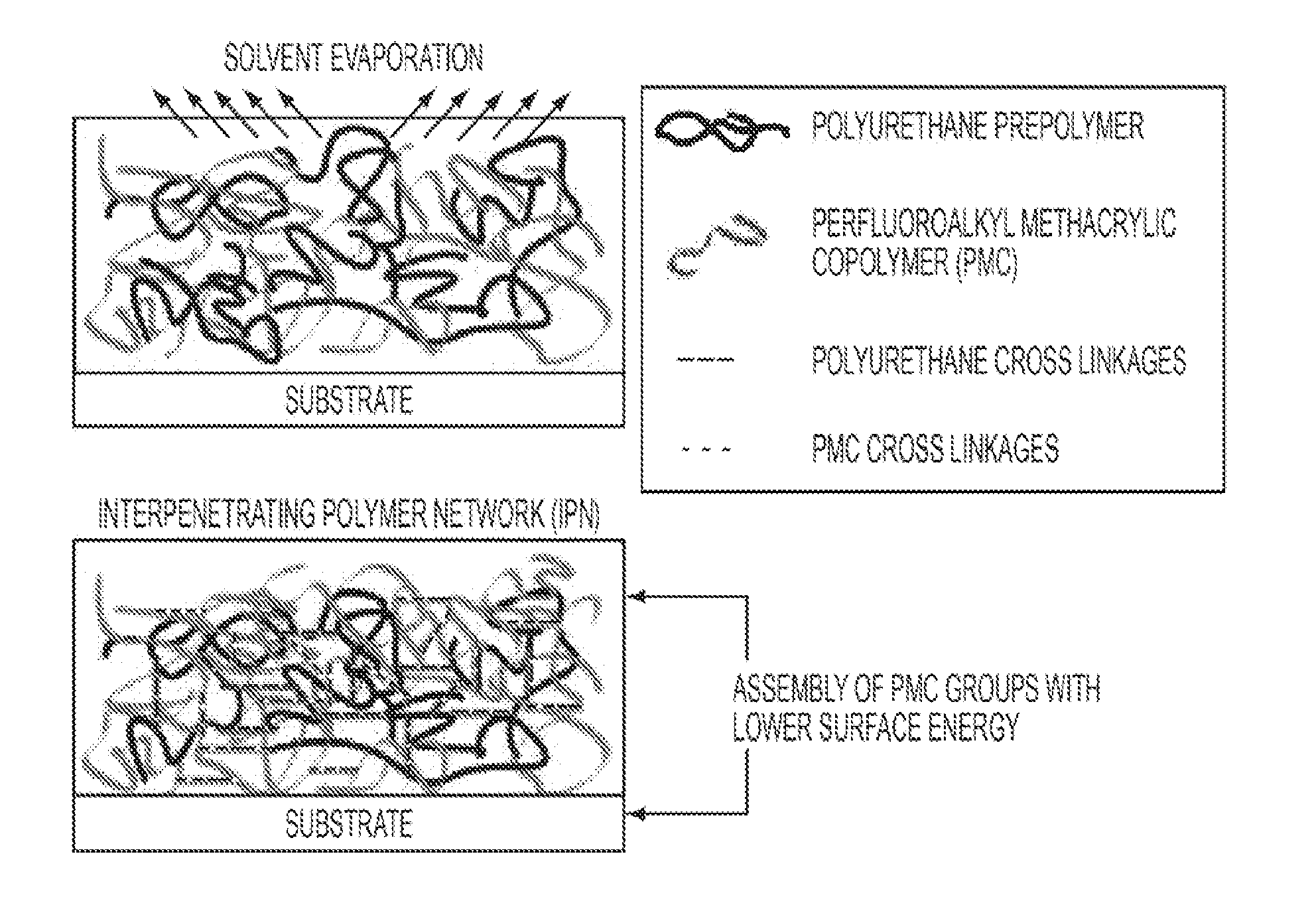

Superhydrophobic nanocomposite coatings

InactiveUS20140113144A1Fouling preventionSynthetic resin layered productsOrganic solventUltrasonic nozzle

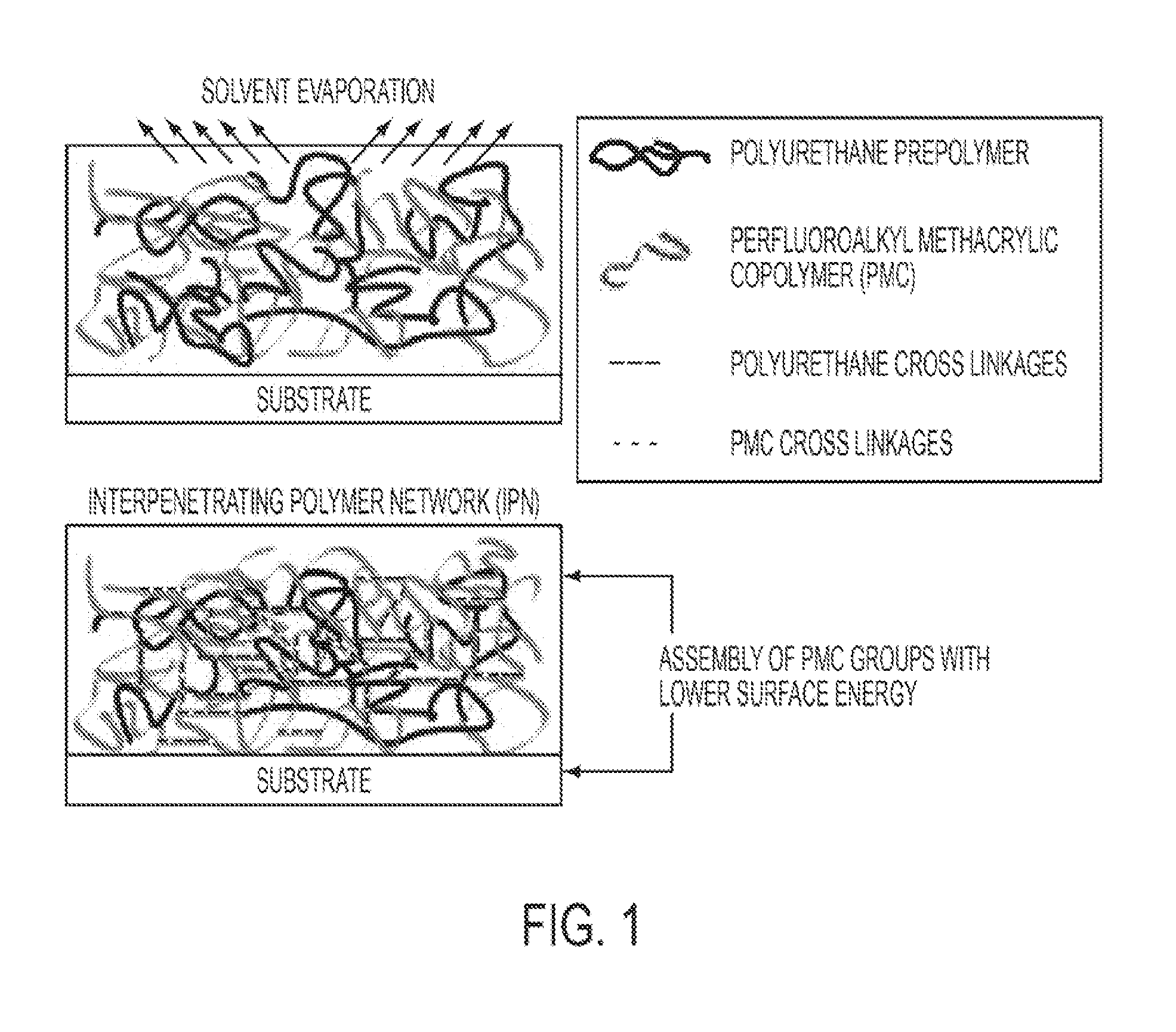

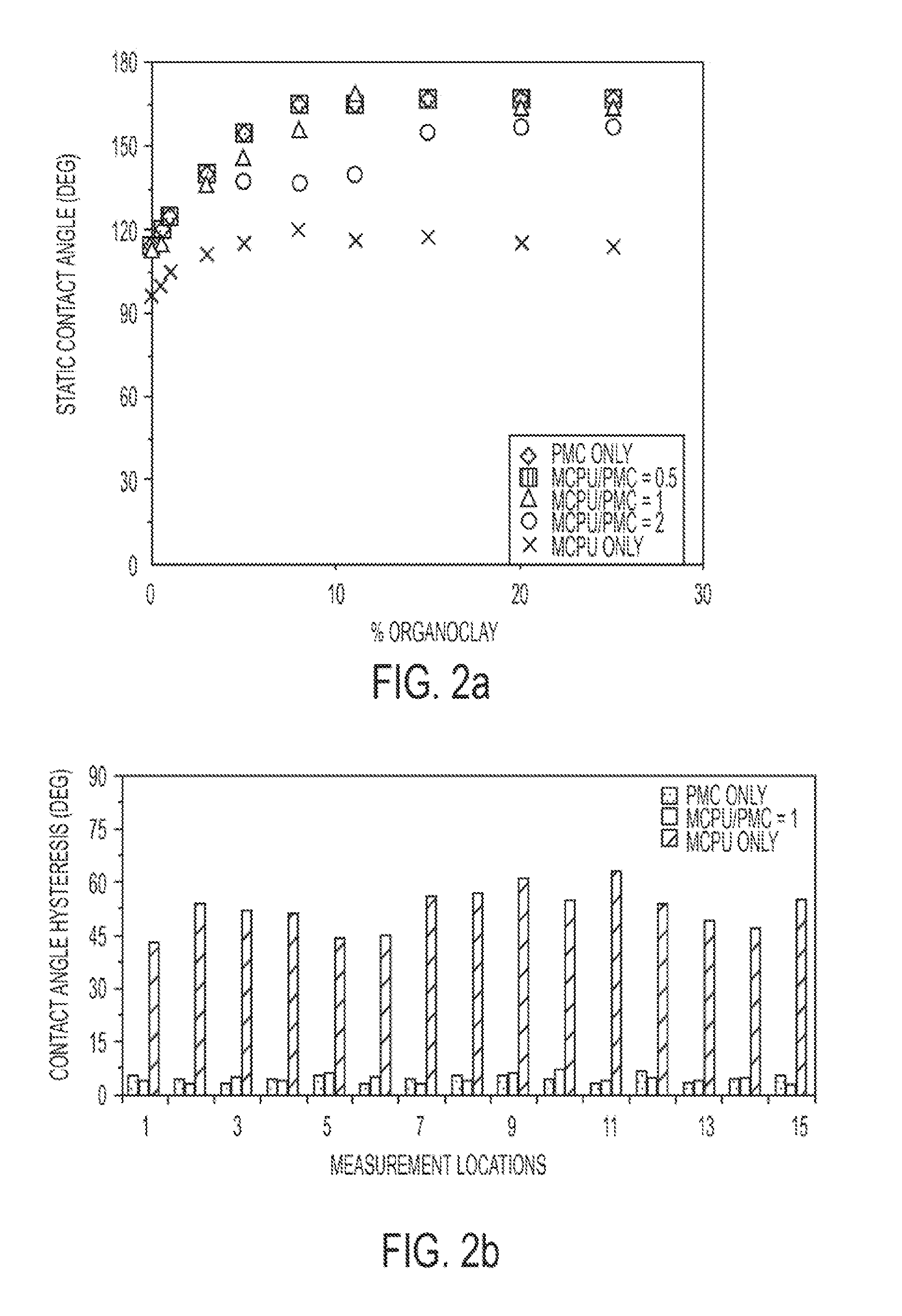

The invention relates to a superhydrophobic coating composition containing a polyurethane; a fluoropolymer; a nanofiller; and an organic solvent. The polyurethane to fluoropolymer are present in a weight ratio from about 1:2 to about 15:1. Coated substrate having at least a portion of one surface coated with a hydrophobic coating using the superhydrophobic coating composition are disclosed as are methods for forming a superhydrophobic coating on a substrate. The invention also relates to a method of forming a superhydrophobic coating on a surface of a substrate by spray casting a superhydrophobic coating composition onto a surface of a substrate to form a coating using an ultrasonic nozzle or at an air pressure of about 20 to about 60 psi and from a height of about 3 to about 12 inches above the surface to form a coating, and curing the coating.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

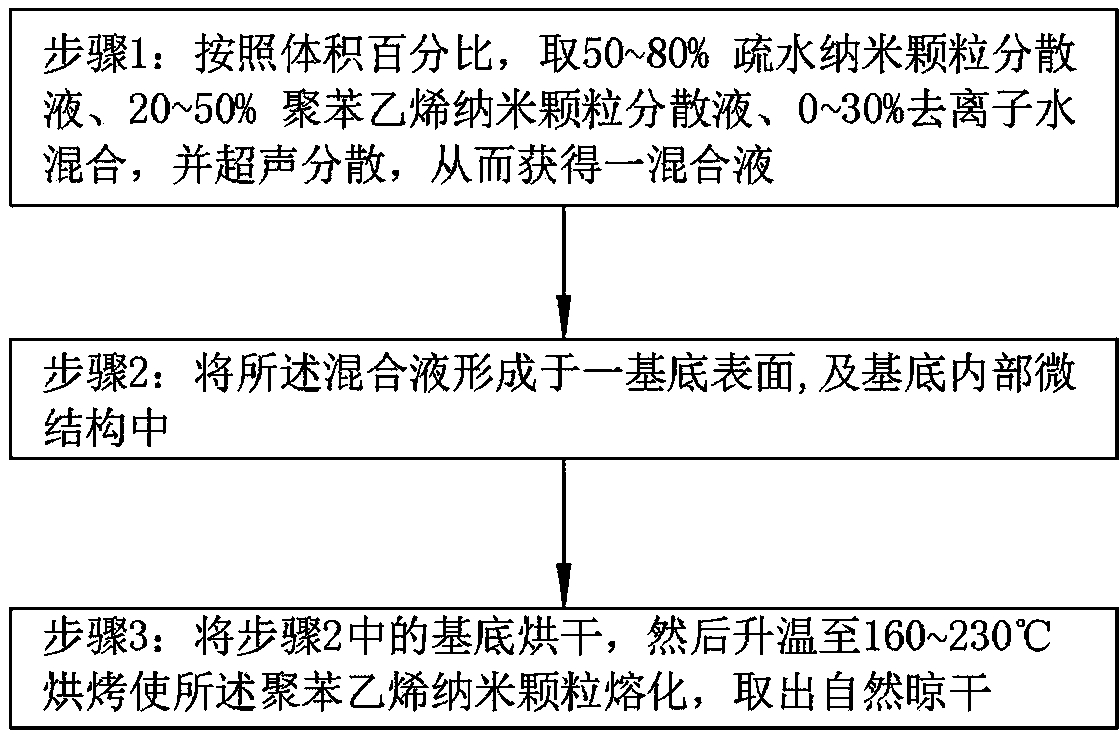

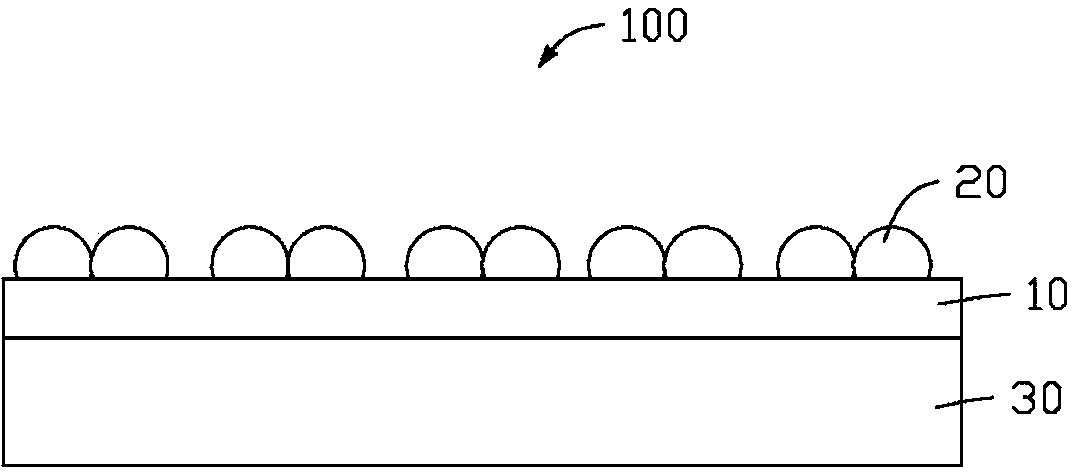

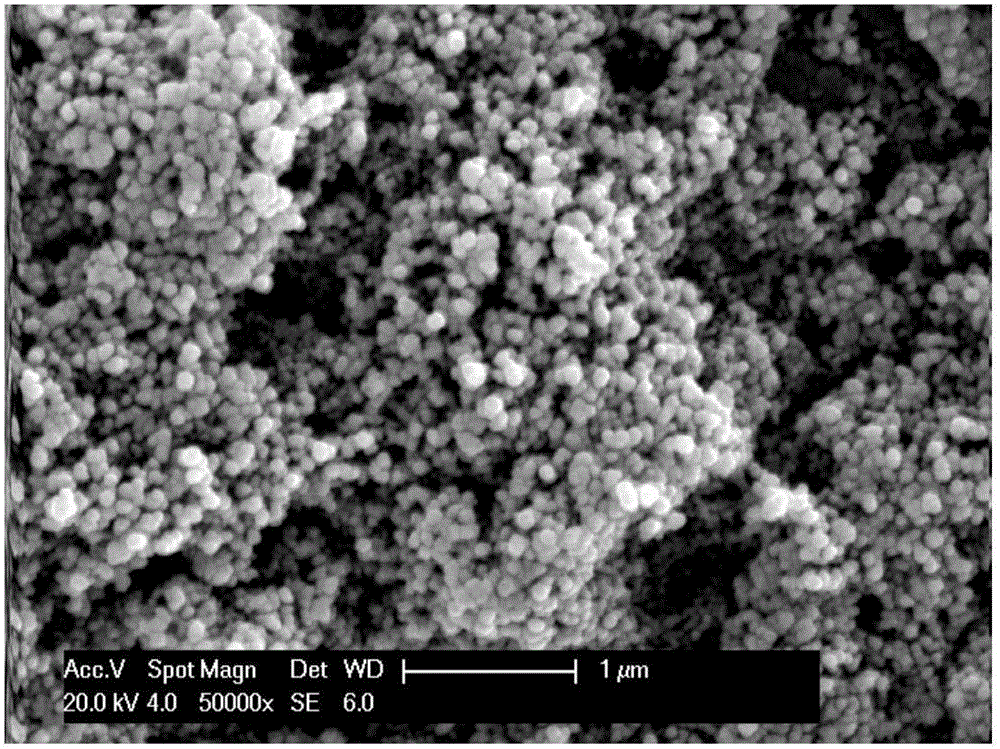

Superhydrophobic paint, superhydrophobic coating and preparation method thereof

The invention provides a preparation method of a superhydrophobic coating. The preparation method comprises the steps of 1, mixing 50-80 parts of hydrophobic nanoparticle dispersing liquid with the mass percentage of 2-15%, 20-50 parts of polystyrene nanoparticle dispersing liquid with the mass percentage of 1-10% and 0-30 parts of solvent according to the volume part ratio, and ultrasonically dispersing the mixture to obtain a mixed solution; 2, forming the mixed solution on the surface of a substrate and in a microstructure in the substrate; 3, drying the substrate obtained in the step 2, then, raising the temperature to 160-230 DEG C, baking to melt polystyrene nanoparticles, and taking out for naturally airing. The invention also relates to a superhydrophobic paint and the superhydrophobic coating.

Owner:TSINGHUA UNIV

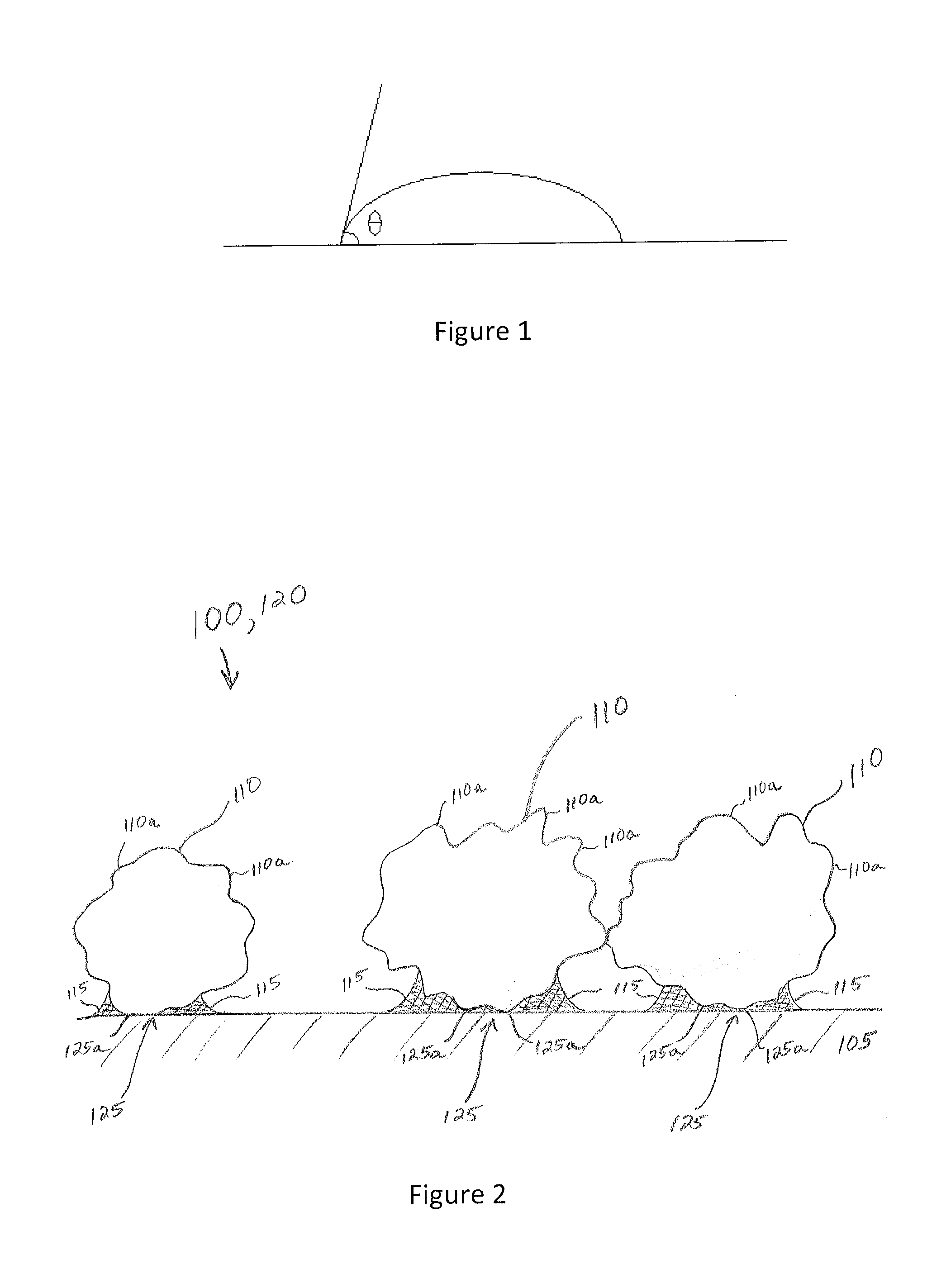

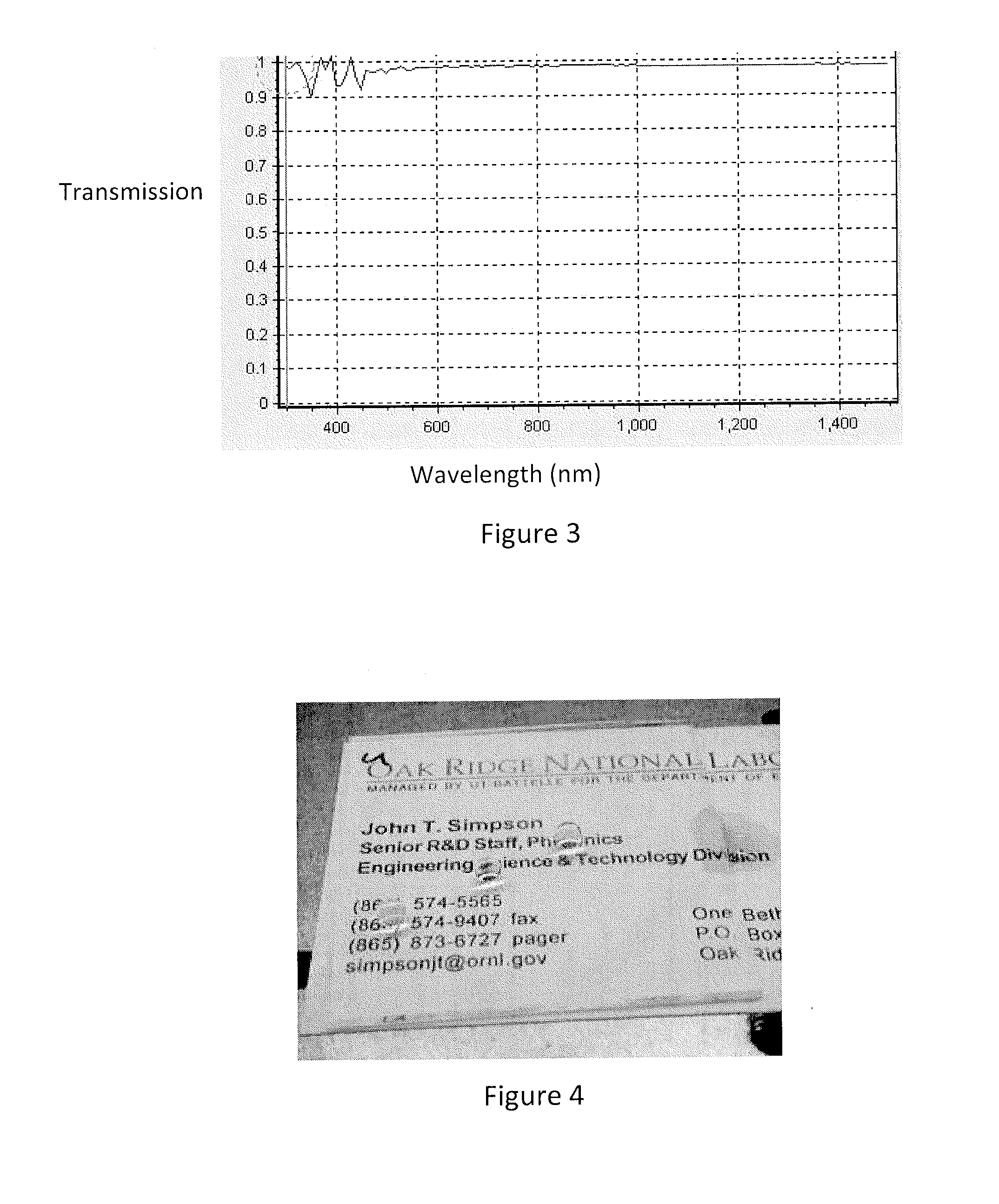

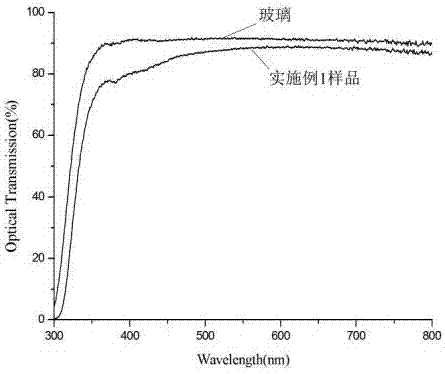

Composition for forming an optically transparent, superhydrophobic coating

ActiveUS20120107581A1Secure bondingLayered productsPolyurea/polyurethane coatingsSolventSuperhydrophobic coating

A composition for producing an optically clear, well bonded superhydrophobic coating includes a plurality of hydrophobic particles comprising an average particle size of about 200 nm or less, a binder at a binder concentration of from about 0.1 wt. % to about 0.5 wt. %, and a solvent. The hydrophobic particles may be present in the composition at a particle concentration of from about 0.1 wt. % to about 1 wt. %. An optically transparent, superhydrophobic surface includes a substrate, a plurality of hydrophobic particles having an average particle size of about 200 nm or less dispersed over the substrate, and a discontinuous binder layer bonding the hydrophobic particles to the substrate, where the hydrophobic particles and the binder layer form an optically transparent, superhydrophobic coating.

Owner:UT BATTELLE LLC

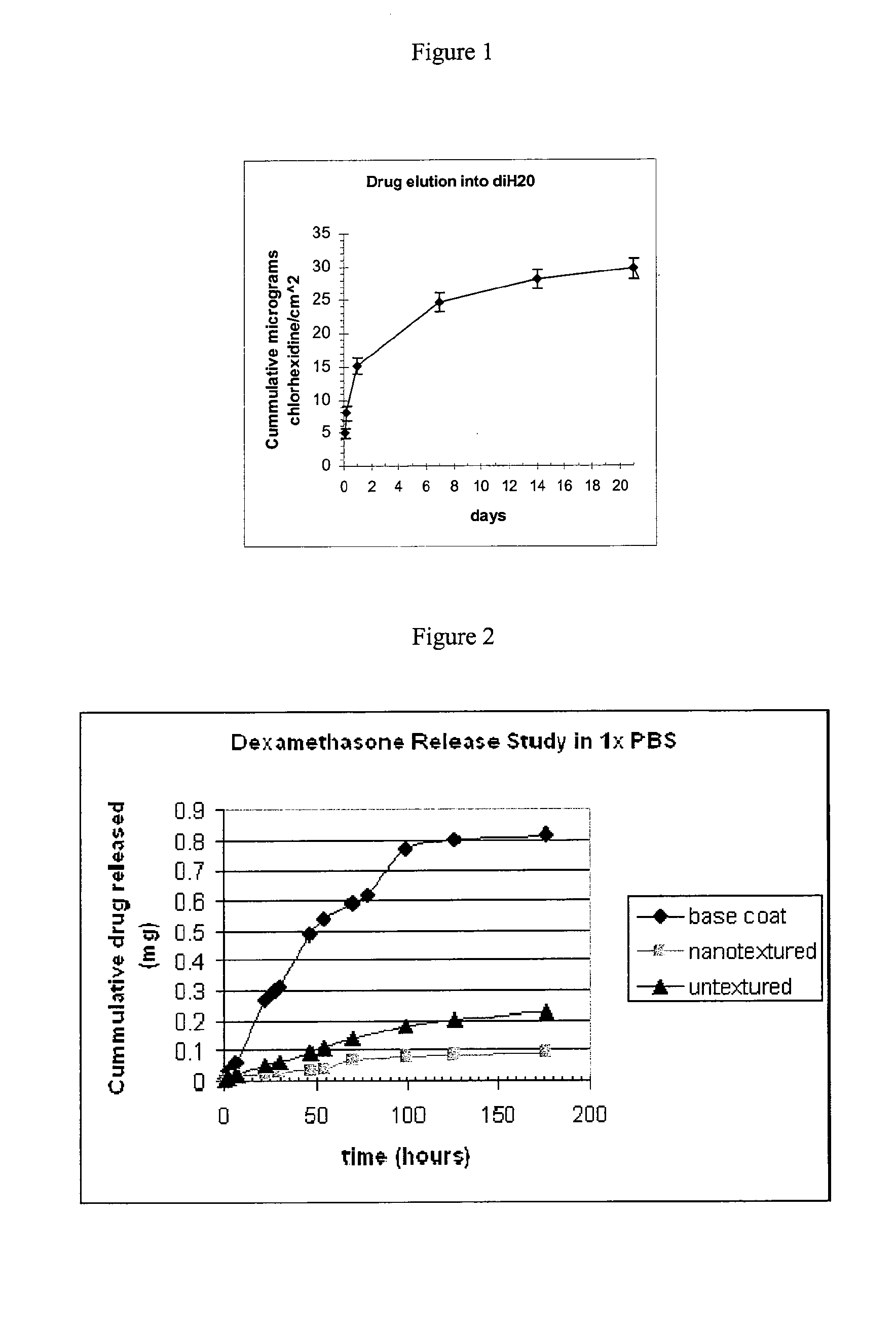

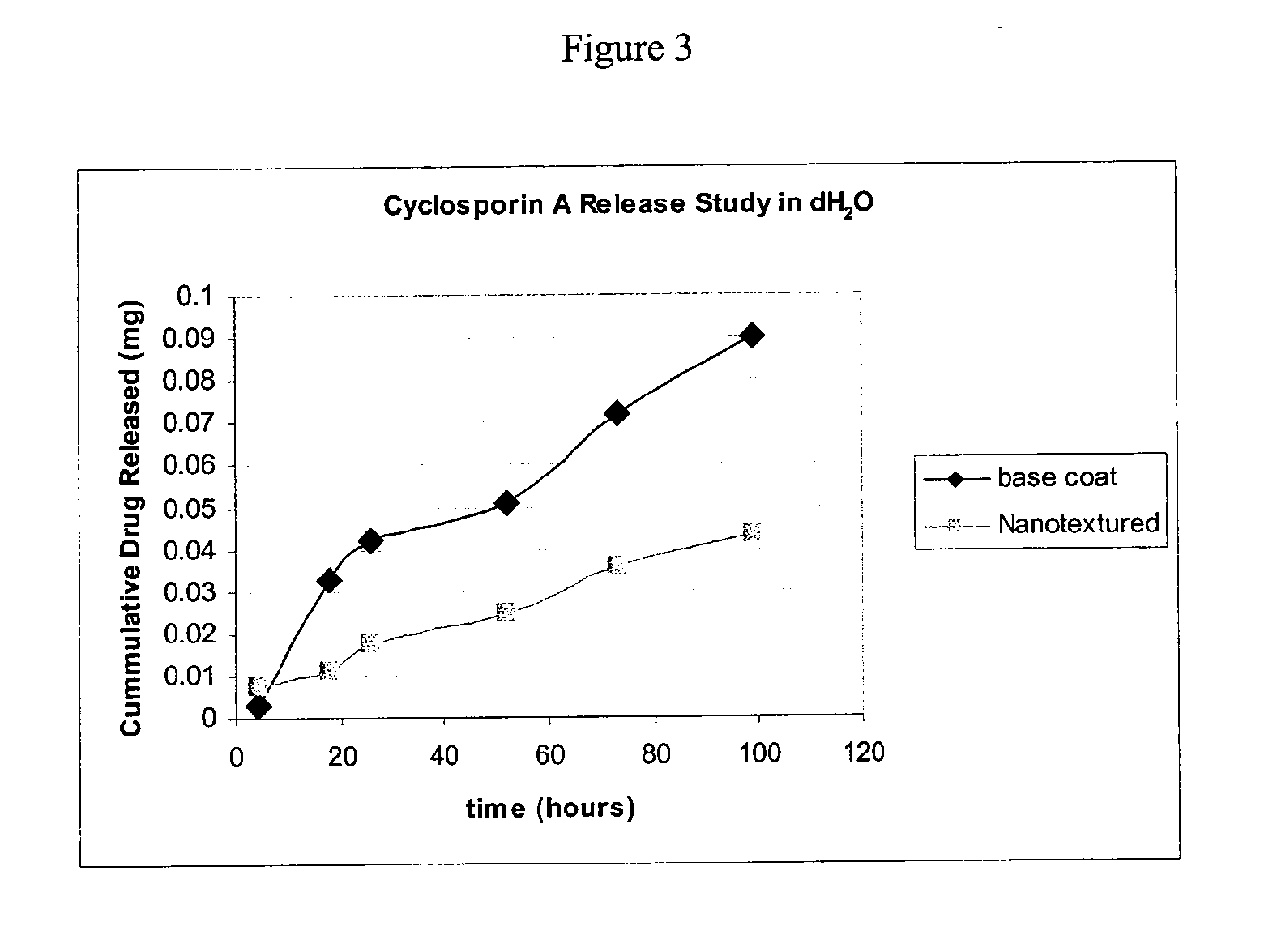

Drug eluting superhydrophobic coatings

InactiveUS20110223212A1Avoid stickingWet surfaceAntipyreticAnalgesicsActive agentCombinatorial chemistry

The invention describes nanotextured super hydrophobic coatings that contain active agents which can elute from the coating over a period of time.

Owner:INNOVATIVE SURFACE TECHNOLOGIES LLC

Superhydrophobic composite coating with self-repair function and preparation method thereof

ActiveCN105038439AIncrease storage capacityImprove adsorption capacityCoatingsSuperhydrophobic coatingMaterials science

The invention relates to a superhydrophobic composite coating with self-repair function, which solves the problem of low mechanical strength in the existing self-repair superhydrophobic coating. The superhydrophobic composite coating with self-repair function is prepared from the following raw materials in parts by weight: 1-20 parts of graphene, 1-20 parts of tetraethyl orthosilicate or tetrabutyl titanate, 1-20 parts of ammonia water, 1-5 parts of low-surface-energy modifier, 60-90 parts of low-surface-energy high-molecular polymer, 2-7 parts of pore forming agent, 5-25 parts of deionized water and 60-100 parts of organic solvent. The pore structure constructed inside the coating can keep a coarse structure for a long time in the friction process. The high-strength graphene can enhance the mechanical strength of the coating, thereby keeping high hydrophobicity and oleophobicity of the coating in the friction process. After the rubbed coating is subjected to simple heating treatment, the low-surface-energy substances stored and grafted in the nano storage tank structures among the multilayer graphene can be activated, and thus, can migrate to the coating surface, thereby implementing the hydrophobic and oleophobic repair of the coating.

Owner:NORTHEAST GASOLINEEUM UNIV

Renewable superhydrophobic coating

ActiveUS20070003705A1Increases of componentFine surfaceFouling preventionDecorative surface effectsSuperhydrophobic coatingSolvent

A method of forming a superhydrophobic material (66) includes mixing a hydrophobic material (24) with soluble particles (26) to form a mixture (32). The mixture (32) is cured. A portion of the soluble particles (26) is etched away from the mixture (32) to form the superhydrophobic material (66). A superhydrophobic material forming system (10) includes a mixer (30) that mixes a hydrophobic binder (24) with soluble particles (26) to form the mixture (32). A curing station (16) cures the mixture (32). An applicator (69) applies a solvent (68) to the mixture (32) to etch away a portion of the soluble particles (26) from the mixture (32) to form the superhydrophobic material (66).

Owner:THE BOEING CO

Preparation method of persistent icing-resistant superhydrophobic coating

ActiveCN106883650AImproved long-lasting anti-icing performanceLong-lasting anti-icing performanceAntifouling/underwater paintsPaper coatingSuperhydrophobePolymer science

The invention relates to the field of preparation of superhydrophobic coatings, in particular to a preparation method of a persistent icing-resistant superhydrophobic coating. The preparation method comprises the following steps: firstly, carrying out cleaning and sand-blasting roughen treatment on the surface of a substrate; secondly, blending epoxy resin, a curing agent and a first solvent to obtain an epoxy resin solution; thirdly, dispersing submicron particles and nanoparticles into a second solvent, and then adding a silane coupling agent to obtain particle composite suspension; fourthly, spraying the epoxy resin solution obtained in the second step on the surface of the substrate treated in the first step, and partially curing epoxy resin adhesive; fifthly, spraying the particle composite suspension obtained in the third step on the surface of the substrate obtained in the fourth step and completely curing; sixthly, obtaining the persistent icing-resistant superhydrophobic coating. The persistent icing-resistant superhydrophobic coating disclosed by the invention has the beneficial effects that the superhydrophobic coatings prepared on the surfaces of all the substrates have good durability and firmness and persistent icing-resistant property.

Owner:哈尔滨毓干科技有限公司

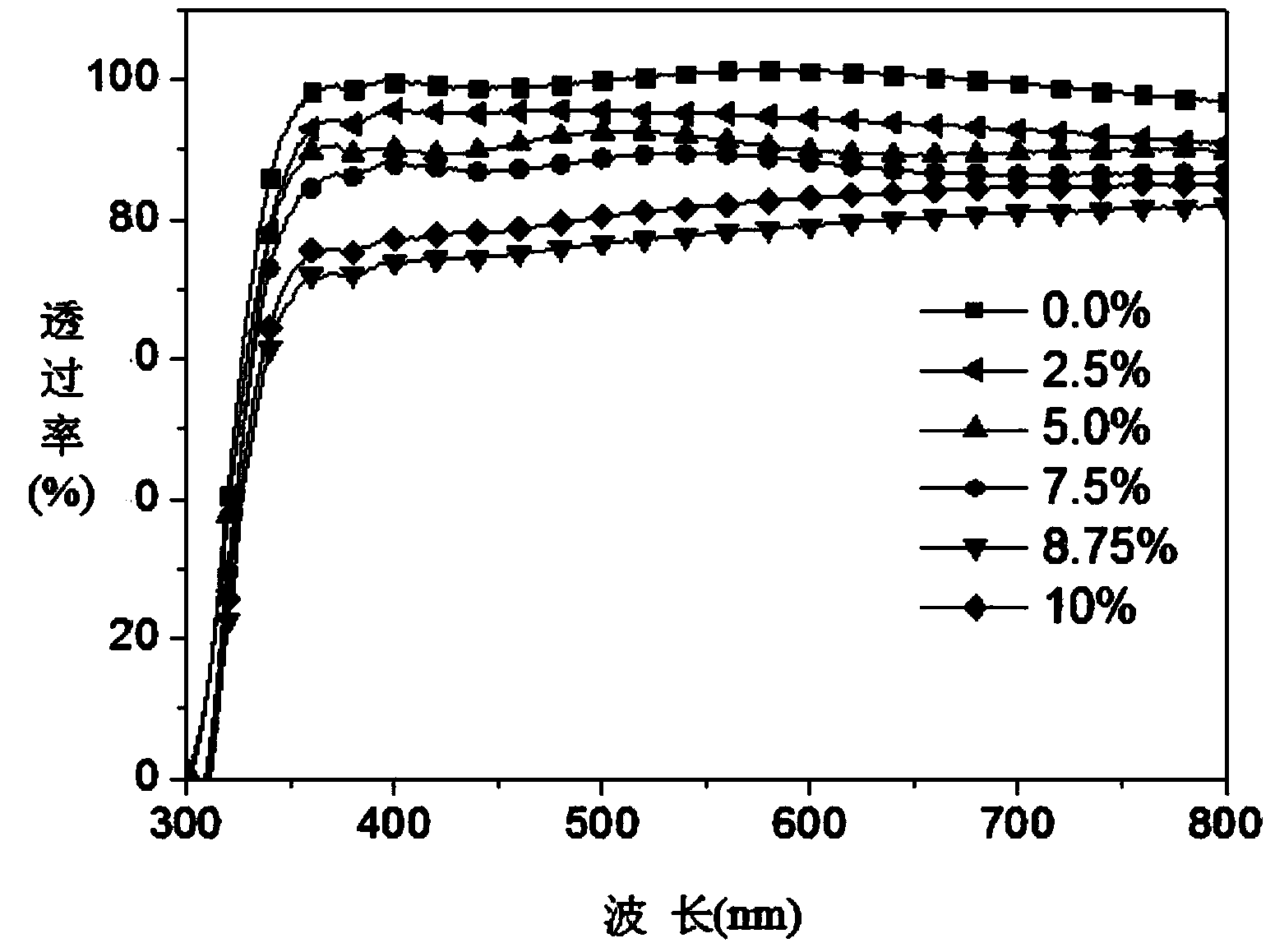

Preparation method of highly transparent wear-resistant superhydrophobic composite coating

ActiveCN107022279AEasy to prepareWide applicabilityEpoxy resin coatingsWear resistantSuperhydrophobic coating

The invention belongs to the technical field of superhydrophobic materials, and particularly relates to a preparation method of a highly transparent wear-resistant superhydrophobic composite coating. Surface-modified nano-silica powder prepared by a sol-gel method is dispersed in anhydrous ethanol to obtain a superhydrophobic coating solution. The surface of a substrate of stone, metal, glass and the like is coated with reactive-diluent-modified E-51 epoxy resin glue, standing is carried out for 1 to 2 hours at room temperature, the superhydrophobic coating solution is used for brushing to obtain the highly transparent wear-resistant superhydrophobic coating. The contact angle between the coating and water is 165 to 175 DEG, a rolling angle is 2 to 5 DEG, the light transmittance of coating glass in the 500 to 650nm is greater than 84%, and at pressure intensity of 2500 Pa, the contact angle between the coating and water is greater than 90 DEG after the coating is rubbed with 320-mesh sandpaper along a line. The preparation method of the coating is simple, environmentally friendly and low in cost, is suitable for the surface of glass, stone, ceramics, wood, metal and the like, and has a wide application prospect.

Owner:FUZHOU UNIV

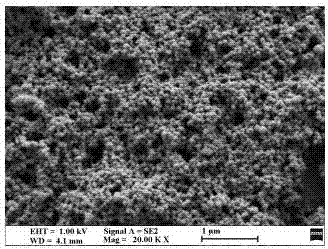

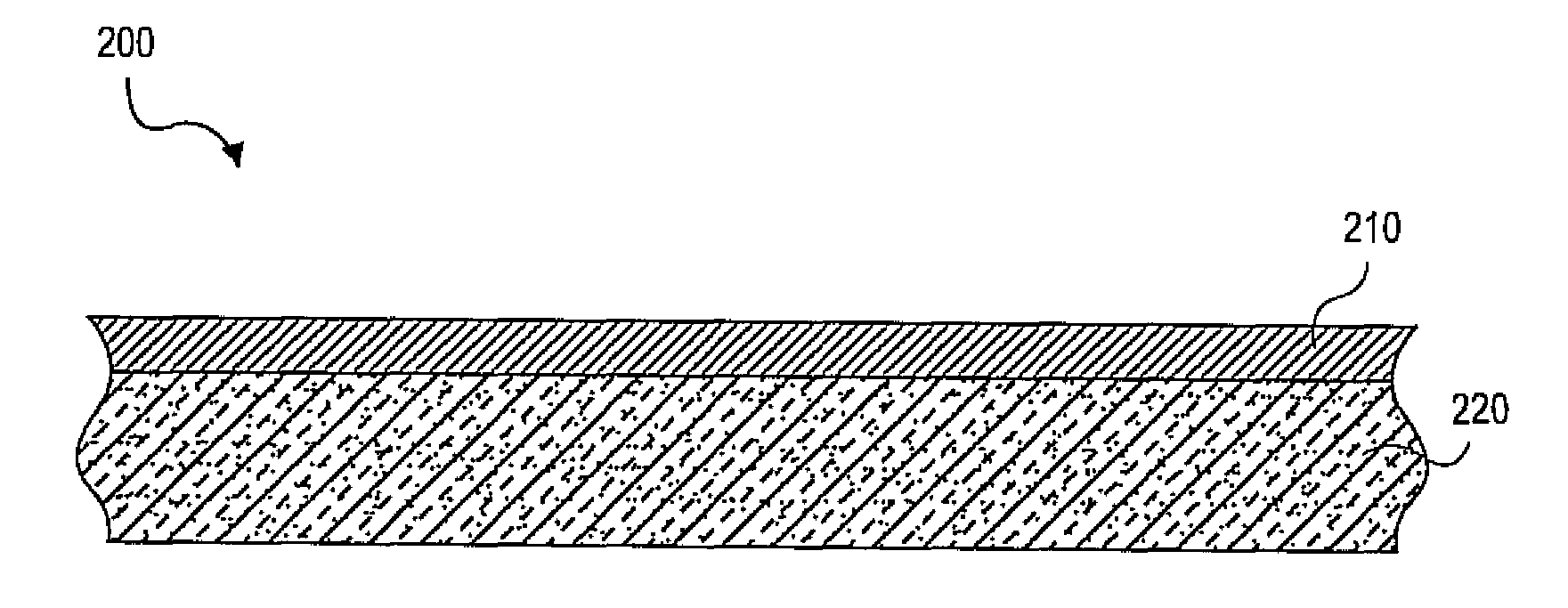

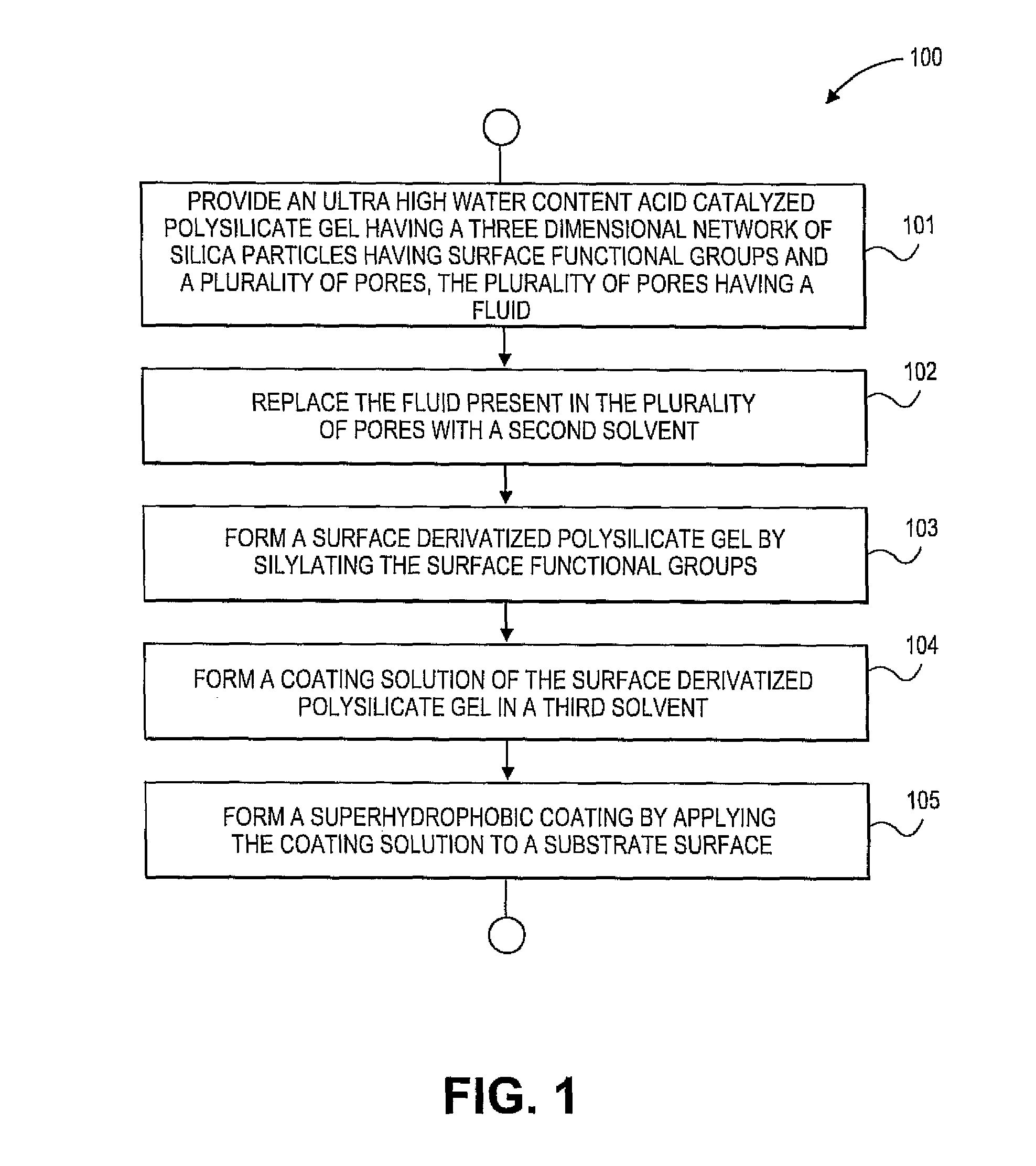

Superhydrophobic aerogel that does not require per-fluoro compounds or contain any fluorine

InactiveUS20120040577A1Increase moisture contentOther chemical processesSynthetic resin layered productsSilica particleHysteresis

Provided are superhydrophobic coatings, devices and articles including superhydrophobic coatings, and methods for preparing the superhydrophobic coatings. The exemplary superhydrophobic device can include a substrate component and one or more superhydrophobic coatings disposed over the substrate component, wherein at least one of the one or more superhydrophobic coatings has a water contact angle of at least about 150° and a contact angle hysteresis of less than about 1°. The one or more superhydrophobic coatings can include an ultra high water content acid catalyzed polysilicate gel, the polysilicate gel including a three dimensional network of silica particles having surface functional groups derivatized with a silylating agent and a plurality of pores.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC +1

Durable superhydrophobic coatings

Durable superhydrophobic coating composition having a composition ranging from about 10 to about 80 w.t. % of an acrylic polymer resin, from about 5 to about 40 w.t. % of a polysiloxane oil, from about 1 to about 50 w.t. % of hydrophobic particles, from about 0.1 to about 10 w.t. % metal oxides, and the remainder being one or more solvents and optionally other additives. Methods of making the coating, as well as coated substrates, are also provided.

Owner:UNIVERSITY OF PITTSBURGH

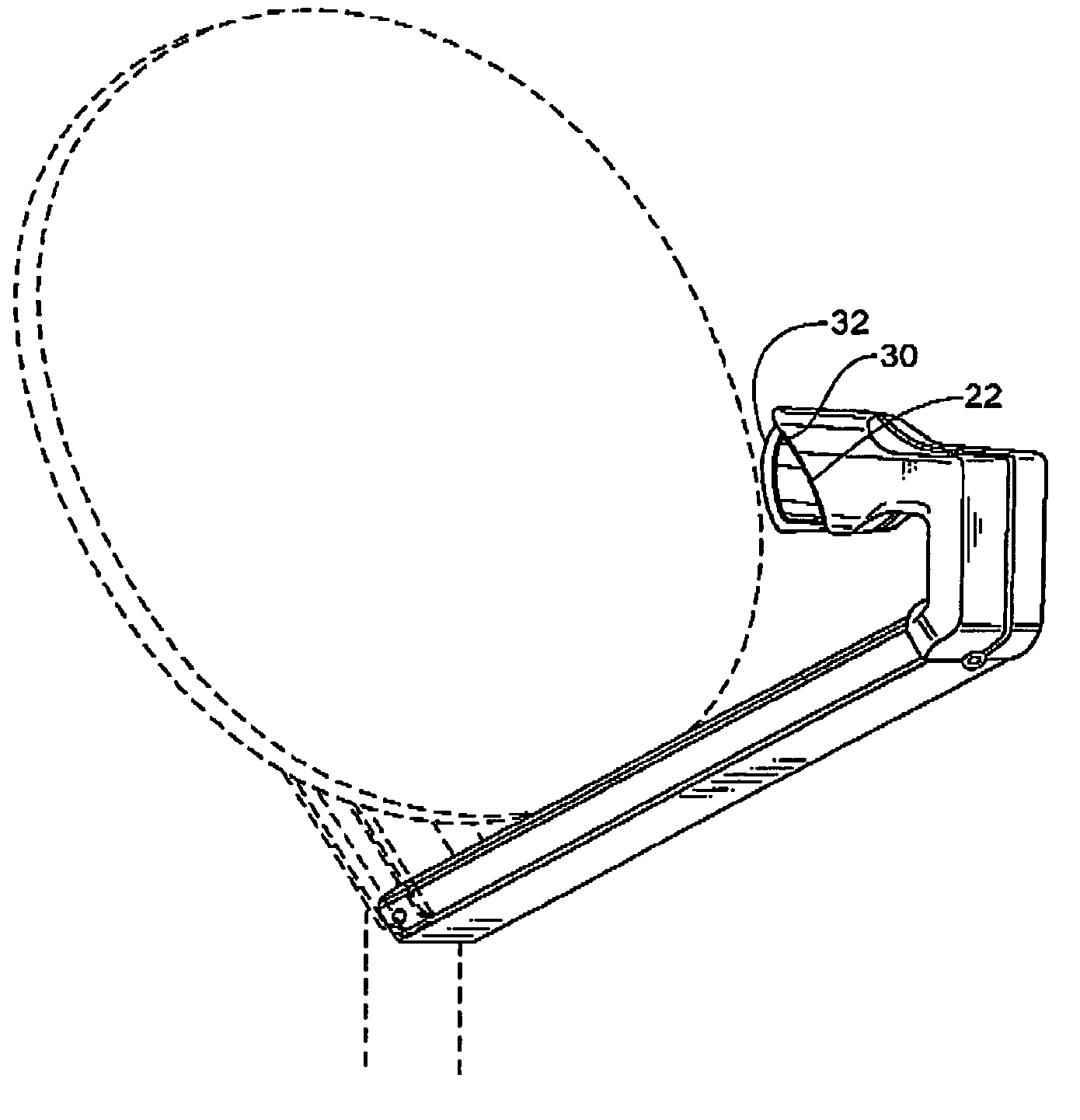

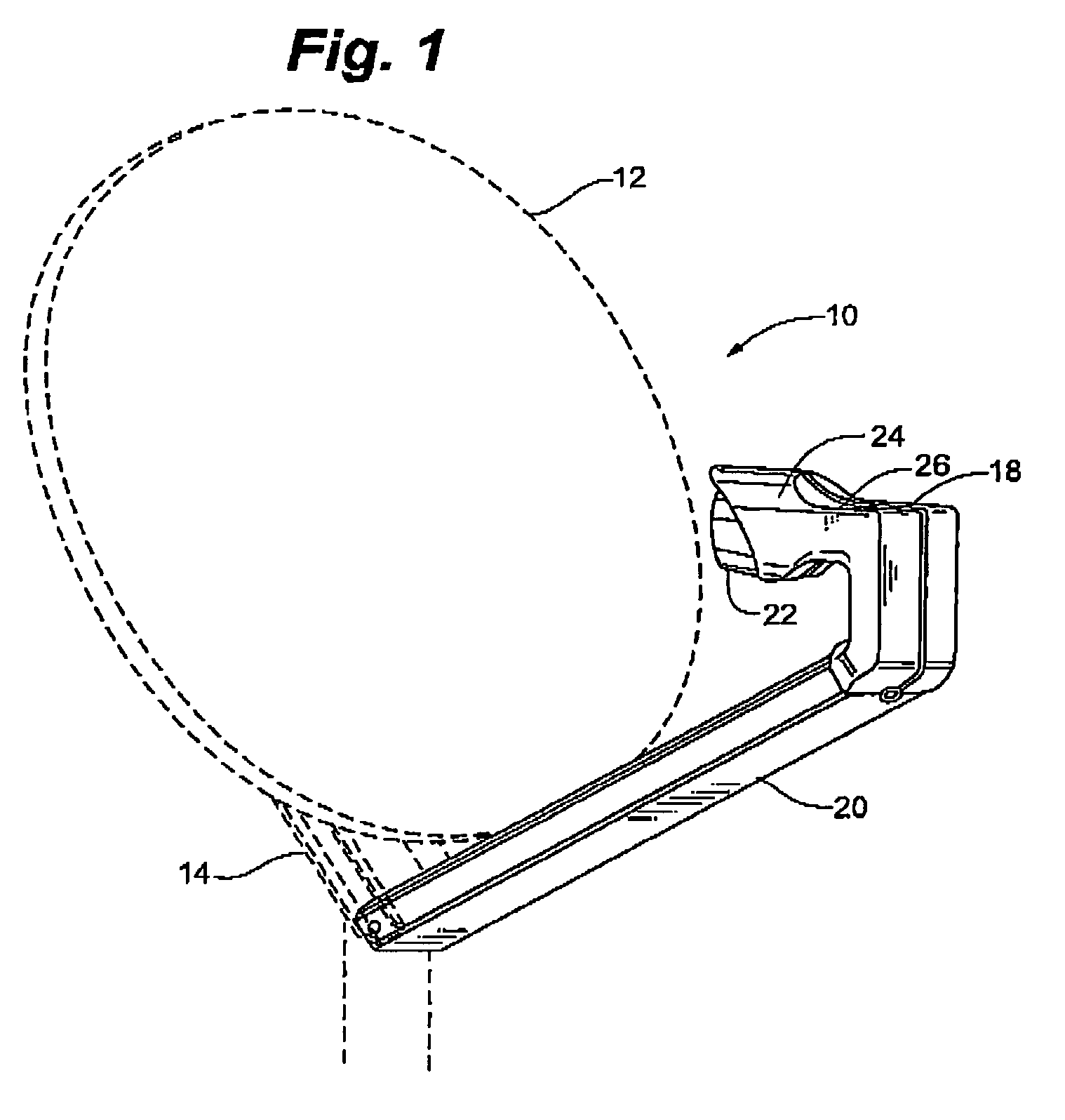

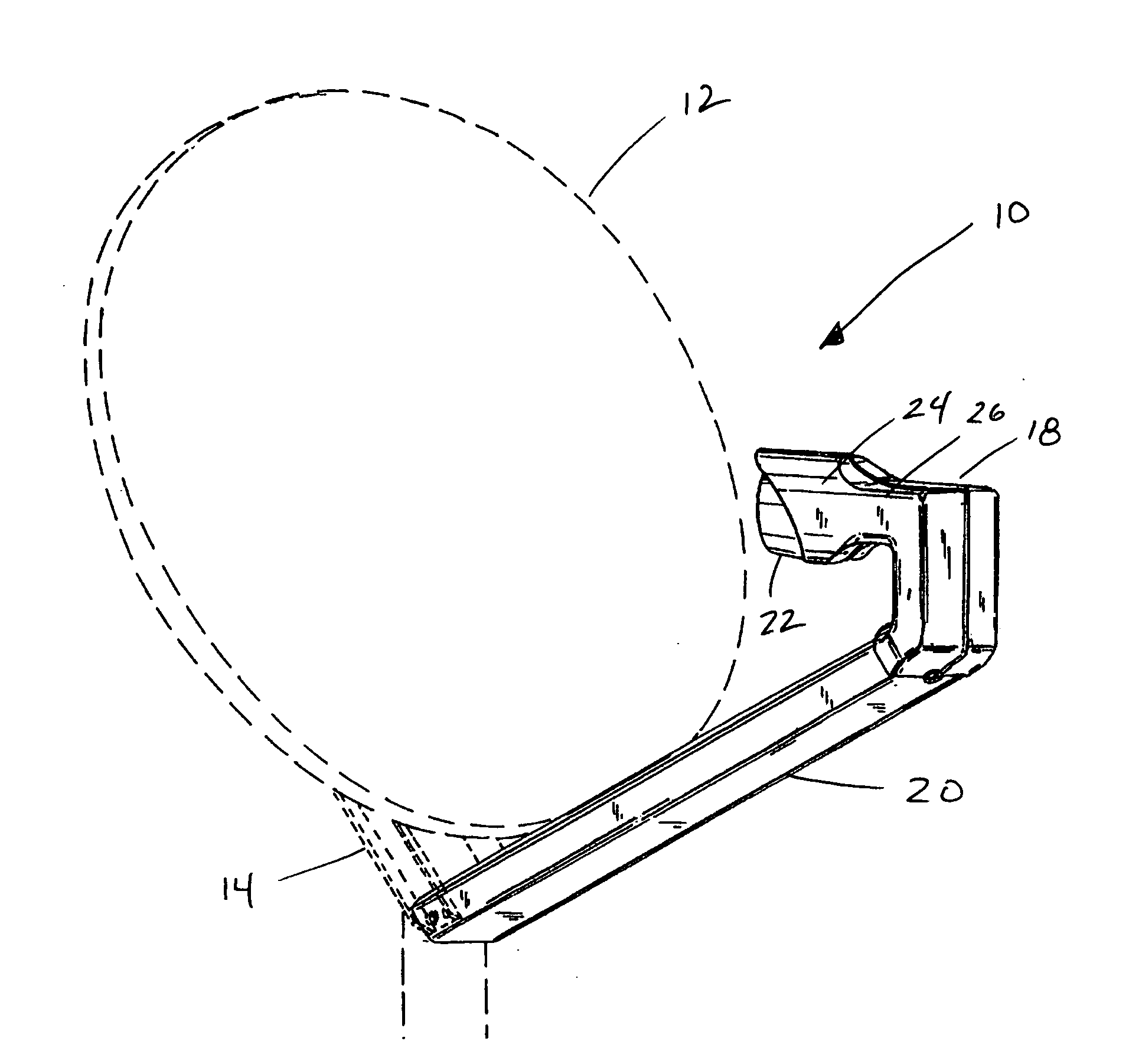

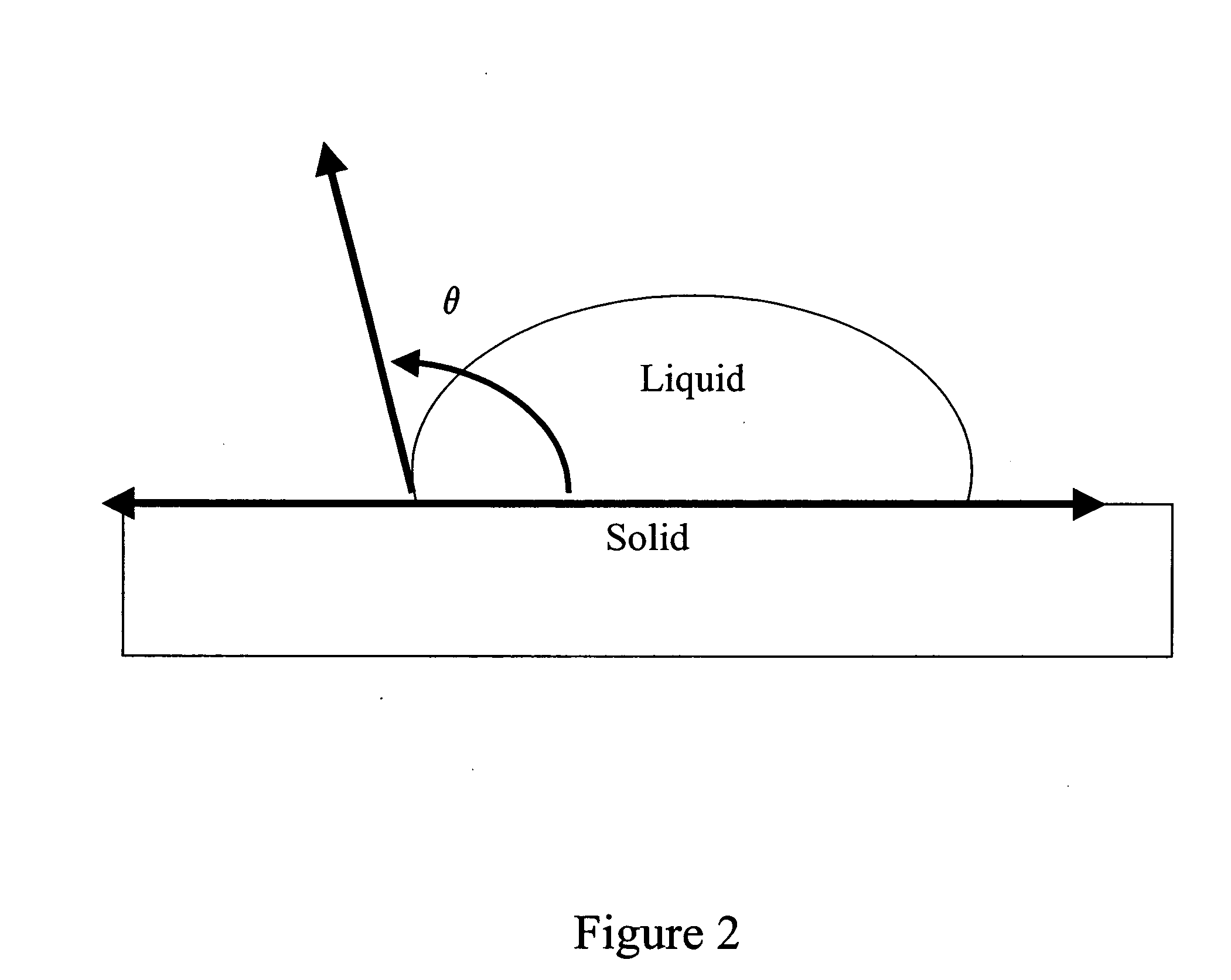

Antenna systems for reliable satellite television reception in moisture conditions

InactiveUS7342551B2Reliable receptionMinimize impactRadiating element housingsTransmittanceEngineering

More reliable satellite television reception in moisture conditions is provided by recognizing the critical relationship between satellite signal transmissivity and the effects of superhydrophobocity. Instead of trying to use a hydrophobic or superhydrophobic coating or material to shed water from a satellite antenna, superhydrophobic materials and coatings are strategically utilized to minimize the impact of water on the transmissivity of the satellite signal through transmissive surfaces in the antenna system. In a preferred embodiment, an exterior surface of a feed horn cover is coated with a superhydrophobic material to maintain a more consistent satellite signal reception. In an alternate embodiment, an exterior surface of a dome covering a small dish DBS satellite television antenna system is coated with a superhydrophobic material to minimize the overall satellite signal loss during moisture conditions so as to permit a dome to be effectively used over a small dish DBS satellite television antenna system.

Owner:ELECTRONICS CONTROLLED SYST

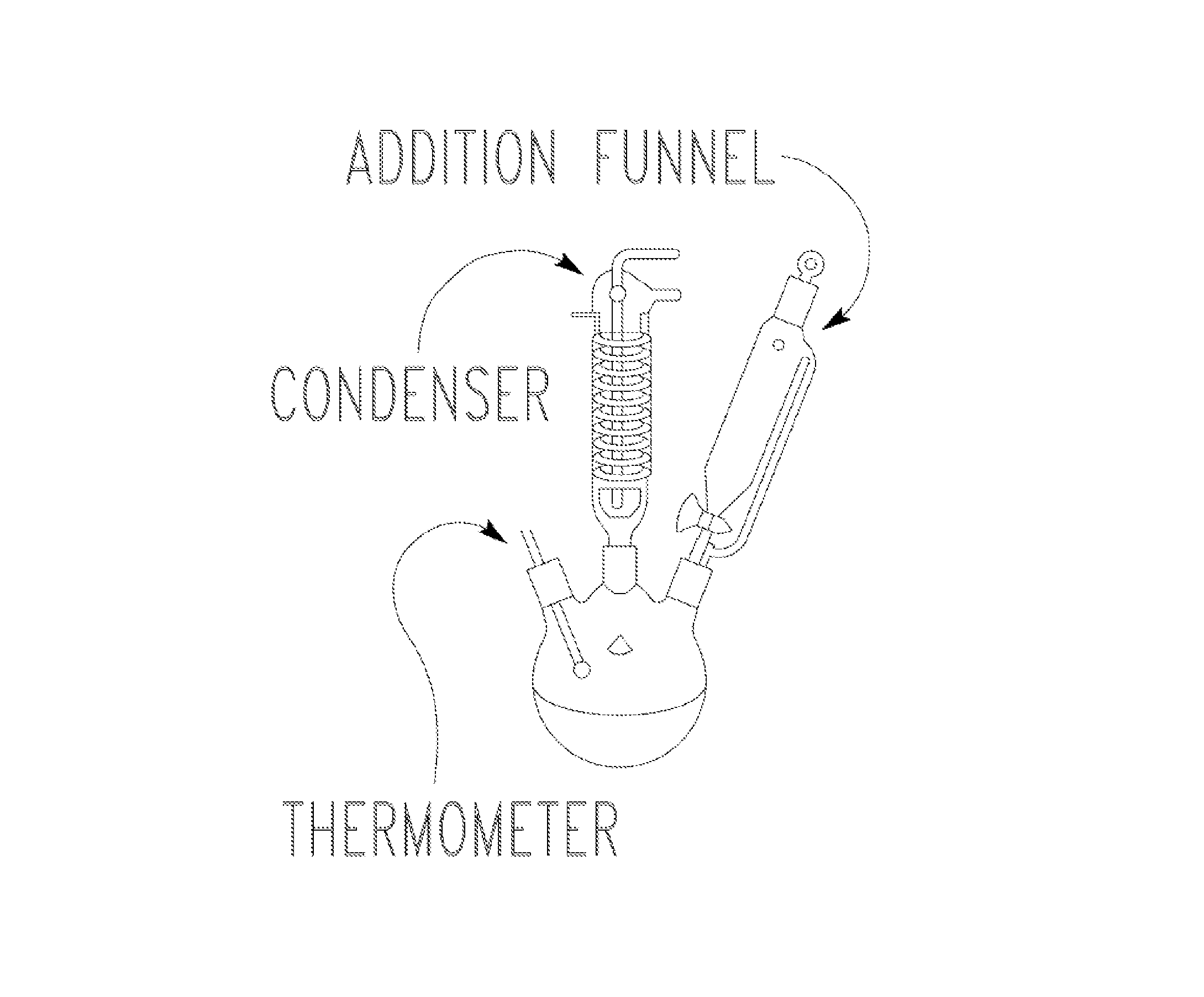

Hydrophobic anti-ice and snow coating of fluorosilicone acrylate copolymer and coating preparation method

InactiveCN102277060AReduce adhesionNot easy to accumulatePretreated surfacesCoatingsMicro nanoChemical treatment

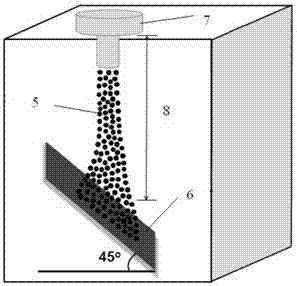

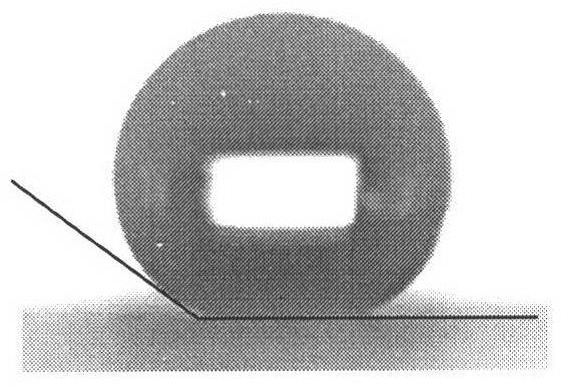

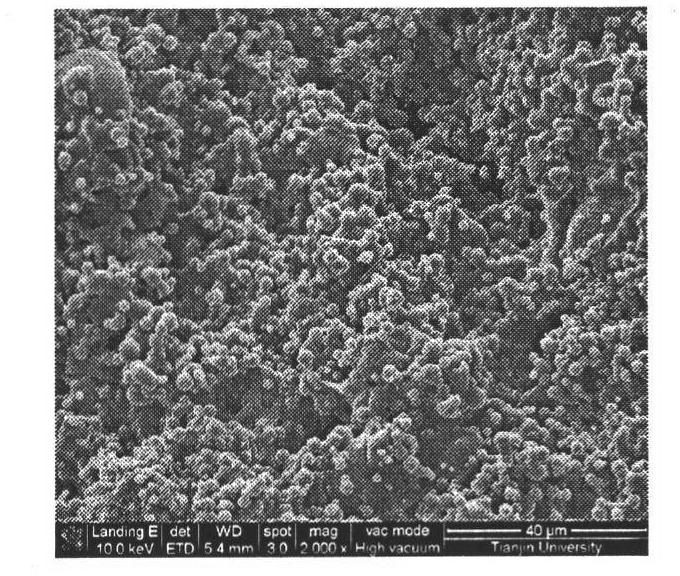

The invention discloses a hydrophobic anti-ice and snow coating of a fluorosilicone acrylate copolymer and a preparation method of the coating. The paint includes ethyl acetate as a solvent, and the solute contained in the solvent is a fluorosilicone acrylate copolymer and a curing agent. The process of preparing the coating with the coating includes using aluminum flakes as the substrate, cleaning the surface with acetone and water, and drying; the coating is sprayed with a spray gun, powered by air, and sprayed at different distances from the surface of the substrate to obtain micro-nano Superhydrophobic coating with raised rough structure. The invention has the advantages of simple coating preparation process, easy-to-obtain raw materials, good film formation, high strength and hardness of the formed coating, and is widely used for surface coating of outdoor facilities such as transportation and power transmission. The coating preparation method is simple, does not require chemical treatment, is easy to industrialize, is suitable for large-area applications, and has high practical value and good anti-ice and snow effect.

Owner:TIANJIN UNIV

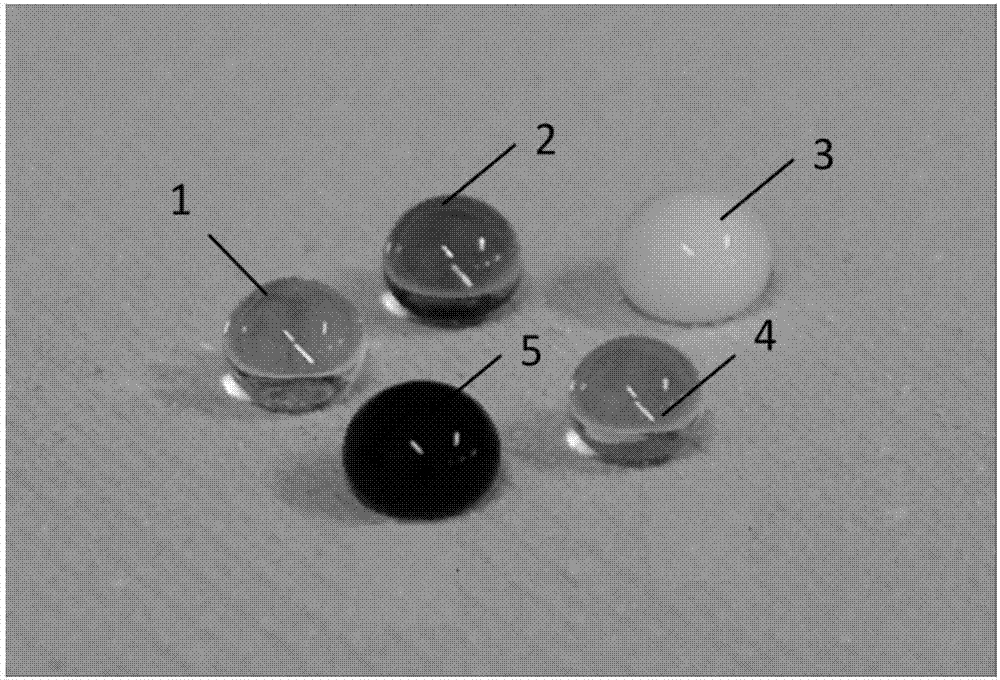

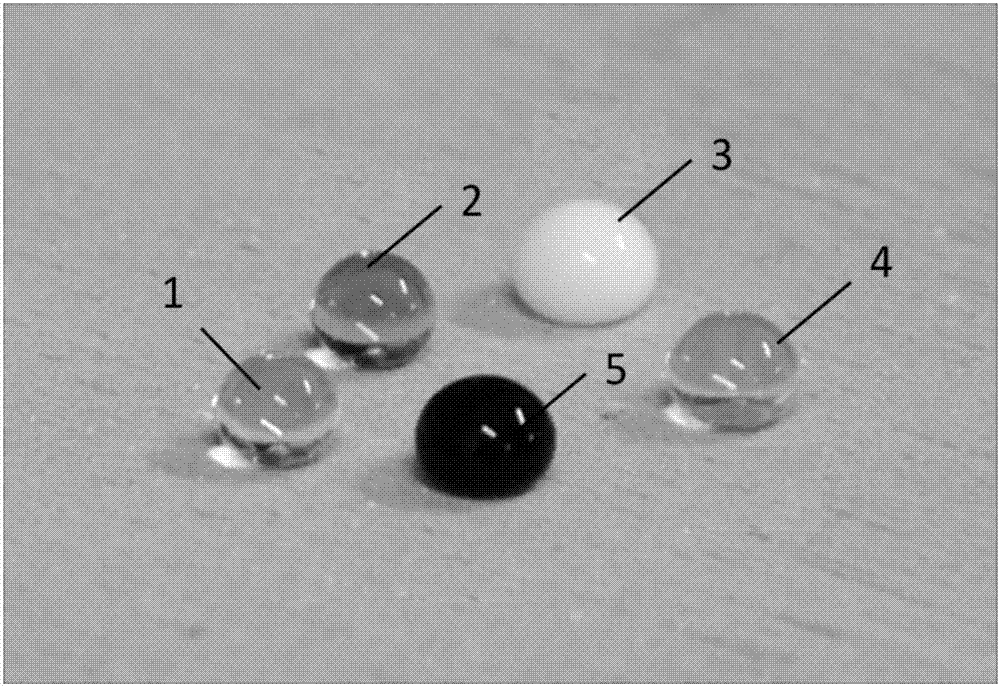

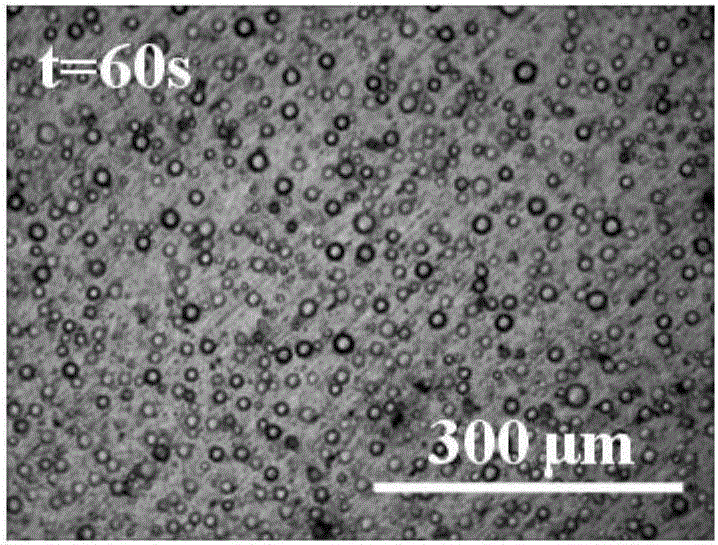

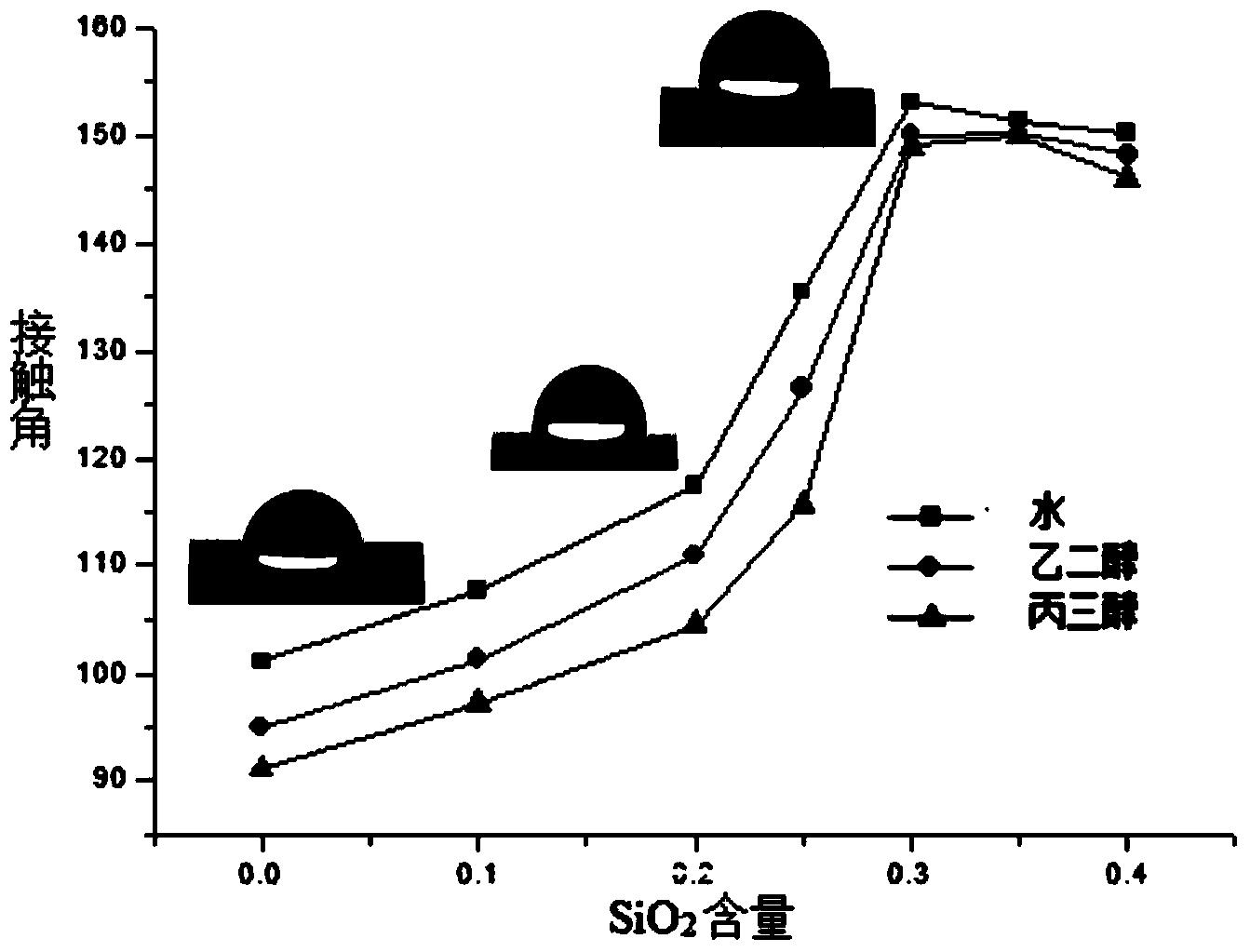

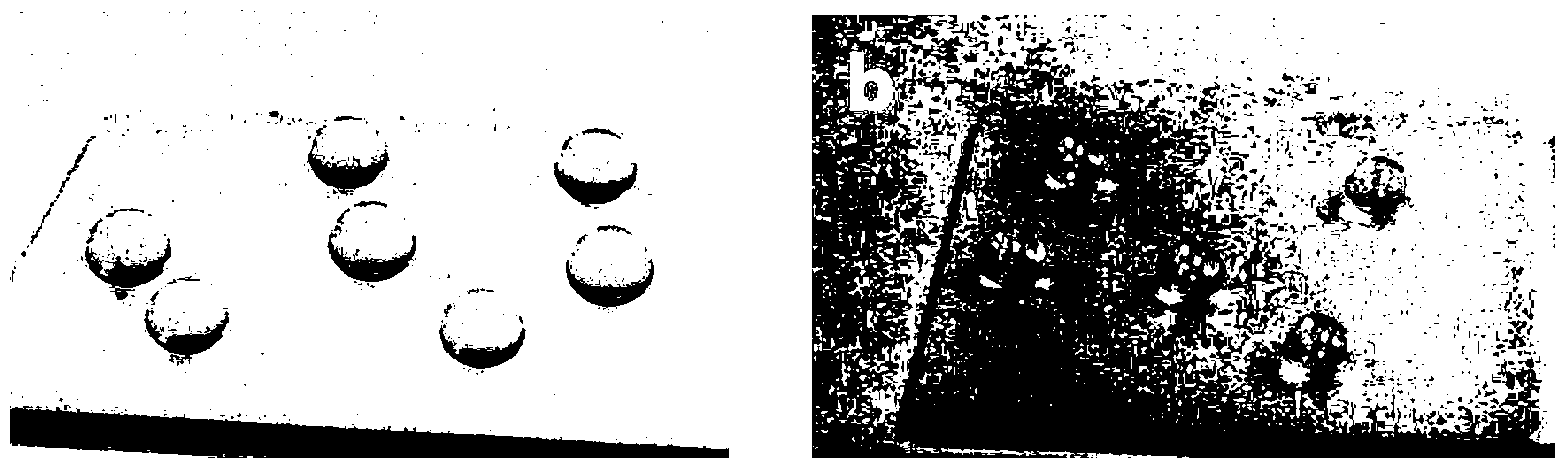

Super-hydrophilic particle hybridized super-hydrophobic coating and preparation method thereof

The invention relates to a super-hydrophilic particle hybridized super-hydrophobic coating and a preparation method thereof. A substrate is ultrasonically cleaned through acetone, absolute ethyl alcohol and deionized water in sequence for 15 min, and oil stain and dust on the surface are removed; then, absolute ethyl alcohol is used for elution, and cold-blast air is used for drying for use. Nanometer SiO2 sol is subjected to fluoroalkyl silane modification, a super-hydrophobic coating spraying solution is obtained, a super-hydrophilic monodisperse sphere type nanometer SiO2 solution, silica powder and glass beads are added into the super-hydrophobic coating spraying solution, stirred to be uniform and sprayed on the substrate, and after solidification, the super-hydrophilic particle hybridized super-hydrophobic coating is obtained. The coating has the low adhesion and super-hydrophobicity, and the condensation and dewfall efficiency and the dewdrop adsorption amount are remarkably high compared with a super-hydrophobic coating. The preparation technology is simple, no pollution is caused, operation is easy, the apparent mass is good, the cost is low, and wide application prospect and huge market benefits are achieved on the aspects of heat exchangers, water collection, seawater desalination and the like.

Owner:SOUTHEAST UNIV

Method for preparing porcelain insulator surface super-hydrophobic coating

The invention discloses a method for preparing a porcelain insulator surface super-hydrophobic coating, which takes ethyl orthosilicate as a presoma and absolute ethyl alcohol as flux, and comprises the following steps: preparing silicon dioxide sol through alkaline catalysis, and adding a silane coupling agent to perform the modification treatment; after the porcelain insulator surface is subjected to the cleaning treatment, dipping in the modified silicon dioxide sol for film coating through the czochralski method to form a primary coating and to obtain a micro-nanometer grade coarse structure which is similar to taro leaf; after drying, dipping in addition type liquid silicon rubber sol for secondary film coating through the czochralski method, and then placing into an oven for heat treatment at a temperature of 100-120 DEG C; and obtaining a transparent super-hydrophobic coating after subjecting the primary coating with the micro-nanometer coarse structure to the secondary film coating modification by the liquid silicon rubber with low surface energy.

Owner:XI AN JIAOTONG UNIV

Antenna systems for reliable satellite television reception in moisture conditions

InactiveUS20050225495A1Increase coverageReliable receptionRadiating element housingsTransmittanceEngineering

More reliable satellite television reception in moisture conditions is provided by recognizing the critical relationship between satellite signal transmissivity and the effects of superhydrophobocity. Instead of trying to use a hydrophobic or superhydrophobic coating or material to shed water from a satellite antenna, superhydrophobic materials and coatings are strategically utilized to minimize the impact of water on the transmissivity of the satellite signal through transmissive surfaces in the antenna system. In a preferred embodiment, an exterior surface of a feed horn cover is coated with a superhydrophobic material to maintain a more consistent satellite signal reception. In an alternate embodiment, an exterior surface of a dome covering a small dish DBS satellite television antenna system is coated with a superhydrophobic material to minimize the overall satellite signal loss during moisture conditions so as to permit a dome to be effectively used over a small dish DBS satellite television antenna system.

Owner:ELECTRONICS CONTROLLED SYST

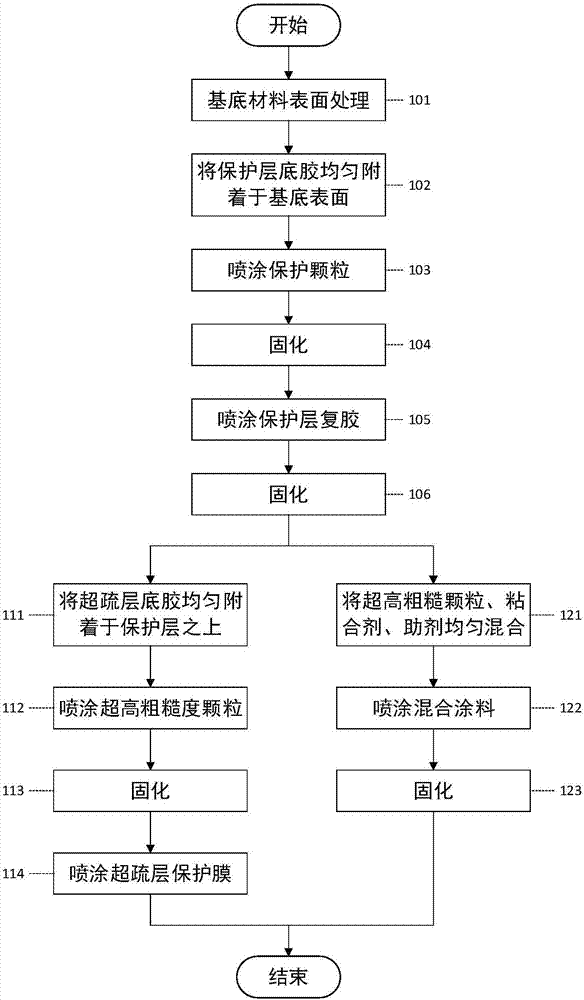

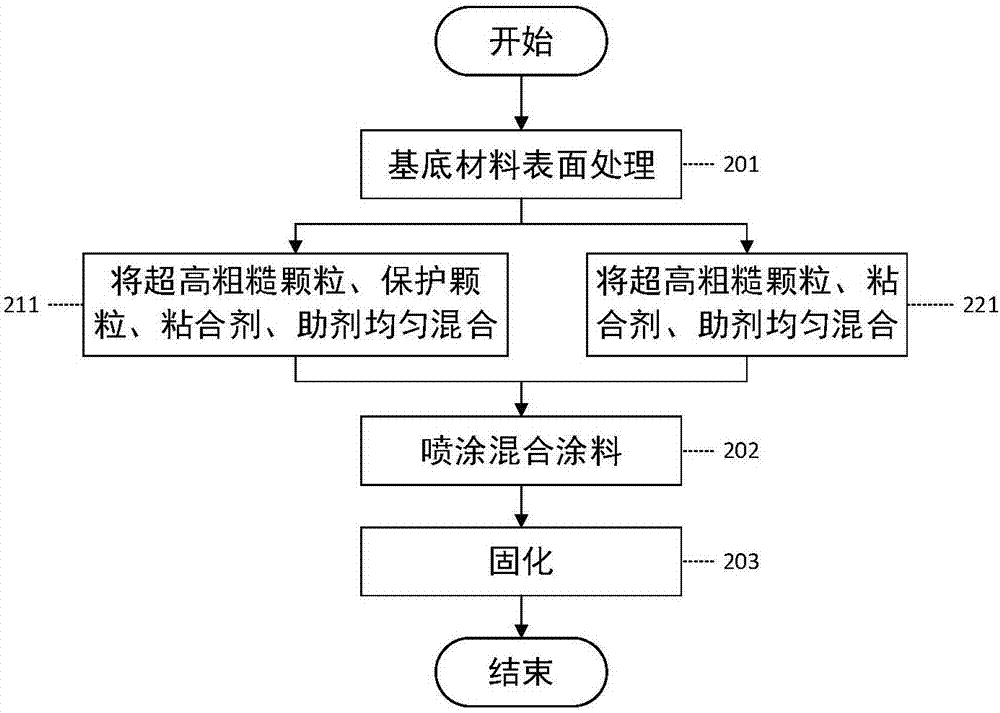

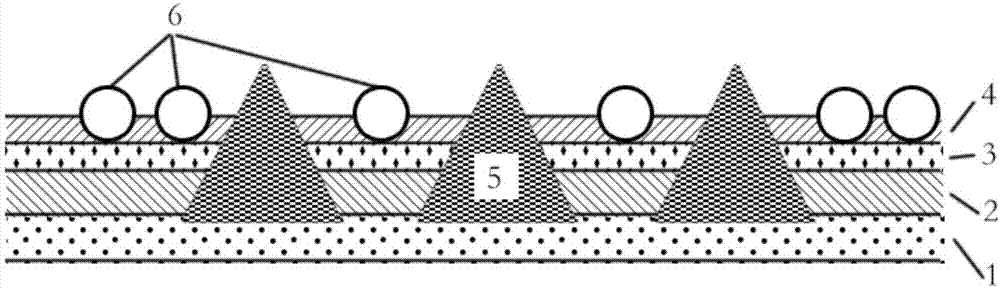

Coating prepared from particles with ultrahigh roughness

ActiveCN107254237AImprove performanceOvercome structurePretreated surfacesPolyurea/polyurethane coatingsSuperhydrophobic coatingLotus effect

The invention provides a superhydrophobic coating prepared from particles with ultrahigh roughness. The superhydrophobic coating is prepared from the following components: particles with protrusions or holes and unsmooth structures, protective particles, a bonding agent and an assistant, wherein the volume ratio of the particles with the protrusions or the holes and the unsmooth structures to the protective particles to the bonding agent is (0.1-7):(1-7):(1-10). A lotus effect technical theory is applied to obtain a super-hydrophobic, underwater superhydrophobic oil or super-amphiphobic surface coating, further the performance of the coating is improved, and the defects of the conventional superhydrophobic coating that the structure is easy to damage, the service life is short and the like are overcome. The prepared coating has super hydrophobic properties (super-hydrophobic, underwater superhydrophobic oil or super-amphiphobic properties), self-cleanness and excellent wear resistance; substrate materials suitable for the coating are glass, plastic, rubber, textiles, paper, metal, cement, ceramic materials or the materials covering other coatings.

Owner:HONGDA TECH BEIJING CO LTD

Preparation method of super-amphiphobic coating

InactiveCN104073116ALower surface energyImprove hydrophobicity and oleophobicityCoatingsSilanesHeat resistance

The invention discloses a preparation method of a super-amphiphobic coating, which comprises the following steps: preparing a fluorine-containing silane polymer solution; adding ethyl orthosilicate, water and hydrochloric acid into the fluorine-containing silane polymer solution to perform hydrolysis reaction to obtain a mixed solution; adding nano silicon dioxide into the mixed solution, and uniformly mixing to obtain a composite sol; and applying the composite sol on the substrate, curing and drying to obtain the super-amphiphobic coating. The cured superhydrophobic coating has the advantages of favorable hydrophobicity and oleophobicity, favorable mechanical properties, favorable heat resistance and favorable light transmittance.

Owner:SHENZHEN UNIV

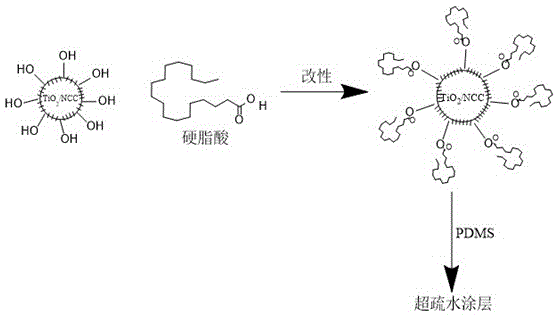

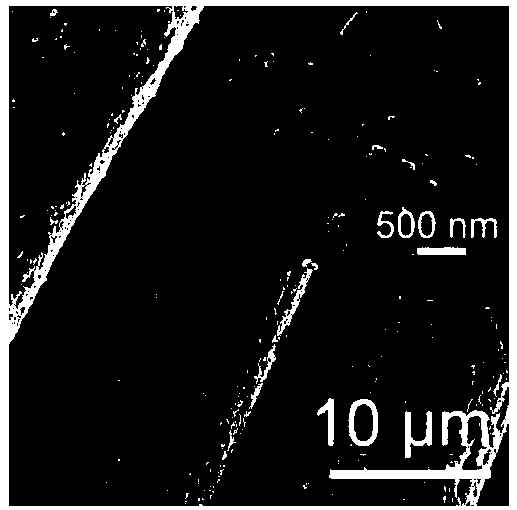

Method for preparing superhydrophobic coating by nano-crystalline cellulose template method

ActiveCN105153819ASimple preparation processImprove adhesionCellulose coatingsSuperhydrophobic coatingStearic acid

The invention provides a method for preparing a superhydrophobic coating by a nano-crystalline cellulose template method. Nano TiO2 with controllable particle diameter is generated on the surface of nano-crystalline cellulose in situ, the surface of nano TiO2 is subjected to hydrophobic modification through stearic acid, absolute ethyl alcohol is a solvent, and sodium dodecyl benzene sulfonate is a dispersant. TiO2 and PDMS (polydimethylsiloxane) which are modified by taking nano-crystalline cellulose (NCC) as the template are compounded and co-blended mechanically, and heat treatment is performed to obtain the superhydrophobic coating. The method has the advantages that as stearic acid serves as the modifier, and hydrophobic-CH3 group is introduced, the surface energy of TiO2 / NCC is reduced; polydimethylsiloxane and TiO2 / NCC are compounded, so that the adhesive force of the coating is improved, a micro / nano coarse structure is formed by interaction between TiO2 / NCC and inorganic nano particles, and accordingly, the shortcoming of poor adhesion of TiO2 / NCC is made up. The method is simple, the prepared coating can be widely added into various coatings to enhance the hydrophobicity, and the wearing resistance of a coating film can be guaranteed to a certain extent.

Owner:NANJING FORESTRY UNIV

Fluorosilicone resin based on click chemistry and preparation method of self-repairing superhydrophobic coating

ActiveCN107556477ARepairableRestore hydrophobicity and oleophobicityLiquid surface applicatorsPolyurea/polyurethane coatingsPolyurethane adhesiveSilanes

The invention relates to fluorosilicone resin based on click chemistry and a preparation method of a self-repairing superhydrophobic coating. Through click chemistry, low surface energy and a self-repairing function are led into a multi-level rough structure of nanoparticles fixed by a polyurethane adhesive, and the superhydrophobic / amphiphobic interfacial material with high mechanical strength and the self-repairing function is prepared. As a self-designed low-surface-energy segmental grid structure of polyfunctional fluoroalkyl silane is adopted, by use of the principle that a damaged surface is covered with self-repairing segmental orientation, the defects that low-surface-energy molecules in a conventional self-repairing material are long in migration time and high in probability of loss are overcome, and a new method is provided for realizing quick and long-acting self-repairing of the superhydrophobic coating.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

Water-based superhydrophobic coating and preparation method thereof

The invention provides a water-based superhydrophobic coating and a preparation method thereof. The coating is prepared from the following raw materials in percentage by mass: 1-20 percent of hydrophobic resin, 10-90 percent of good solvent of hydrophobic resin, 0.01-1 percent of an additive, 0.1-10 percent of nano-particles and the balance of water, wherein the additive is a curing agent or adhesive resin; the hydrophobic resin is one or more of organic silicon resin, fluorocarbon resin, fluorinated modified epoxy resin and fluorinated modified polyurethane; and the nano-particles are one ormore of fumed silica, nano-titanium dioxide, nano-alumina, fluorine-modified nano-silicon dioxide and alkyl modified nano-silicon dioxide. The water-based superhydrophobic coating is easily availablein raw materials and simple in preparation condition, and can be used for treating various substrates by a simple dip-coating or spraying process so as to obtain a superhydrophobic surface by curing.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com