Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2912 results about "Polyurethane adhesive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyurethane adhesive for windshield applications

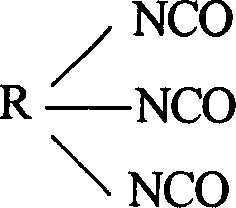

InactiveUS20030070741A1Sufficient developmentSufficient working timeWindowsWindscreensPrepolymerIsocyanate

A polyurethane adhesive which is useful in bonding porous and non-porous surfaces is provided. The adhesive is especially useful in bonding windshield glass into automotive frames under a variety of environmental conditions, particularly in after market windshield replacement applications. The polyurethane includes at least one urethane prepolymer which is based on at least one thermoplastic polyol. In one embodiment, the urethane prepolymer may be formed from one or more polyisocyanates, one or more polyetherpolyols and one or more thermoplastic polyesterpolyols, wherein the prepolymer has a free isocyanate content of from about 0.6 to about 3.5 % by weight, based on the weight of the polyurethane. In another embodiment, a one-part adhesive composition is provided which includes an isocyanate-functional and thermoplastic polyurethane prepolymer having a free isocyanate content of from about 0.6 to about 3.5 % by weight, based on the weight of the polyurethane, and a combination of several catalysts which are capable of catalyzing the reaction of isocyanate moieties with isocyanate-reactive moieties while providing less temperature dependent catalyzing of the reaction between isocyanate moieties and water. Also provided is a process for bonding two or more substrates together utilizing the polyurethane adhesive. In automotive windshield replacement applications, the polyurethane adhesive allows for a sufficient working time and development of green strength to provide a safe drive-away time within 1 hour at a temperature from about 0 to about 100° C.

Owner:SIKA TECH AG

Method for preparing hydroxyl acrylic acid water dispersoid

InactiveCN101457005AModerate molecular weightNarrow molecular weight distributionPolyurea/polyurethane coatingsPolyurethane adhesiveAcrylic resin

The invention relates to a preparation method for the hydroxyl acrylic aqueous dispersion of high performance and two-component waterborne polyurethane, which comprises four steps: synthesizing hydroxyl acrylic resin, removing a solvent, a neutralization salt forming reaction and deionization and aqueous dispersion. The hydroxyl acrylic aqueous dispersion prepared by the invention has proper molecular weight and the molecular weight is distributed much narrower, thus being beneficial for forming a uniform coating, reducing the plasticizing effect of small molecule substance to the coating, and increasing the comprehensive performance of the coating. The dispersion can be combined with an isocyanate curing agent to be used as wood coatings, corrosion protective coatings, industrial maintenance coatings, floor coatings and the like, and also can be used for preparing a two-component waterborne polyurethane adhesive, etc.

Owner:ZHEJIANG HUANDA PAINT IND GROUP +1

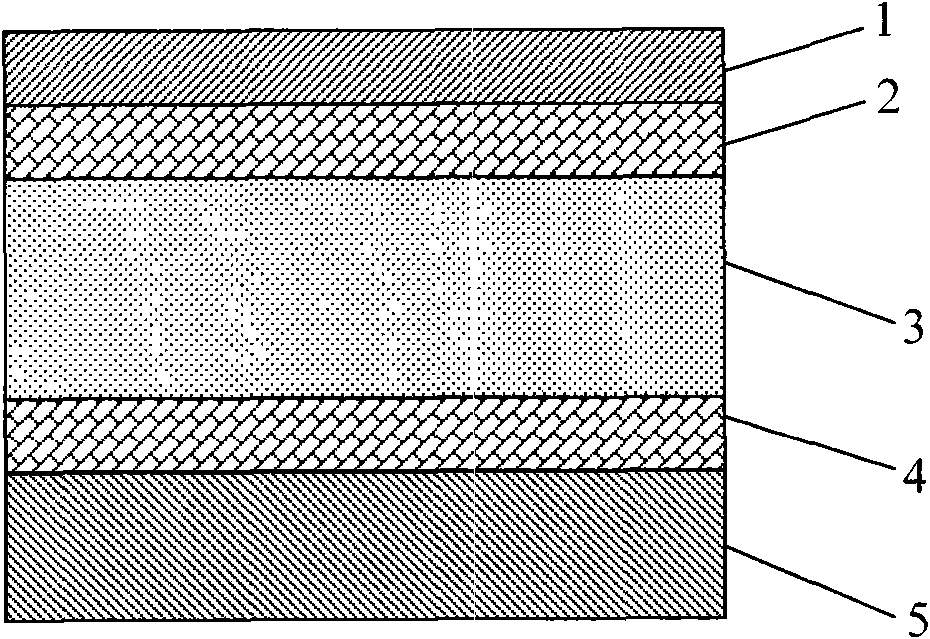

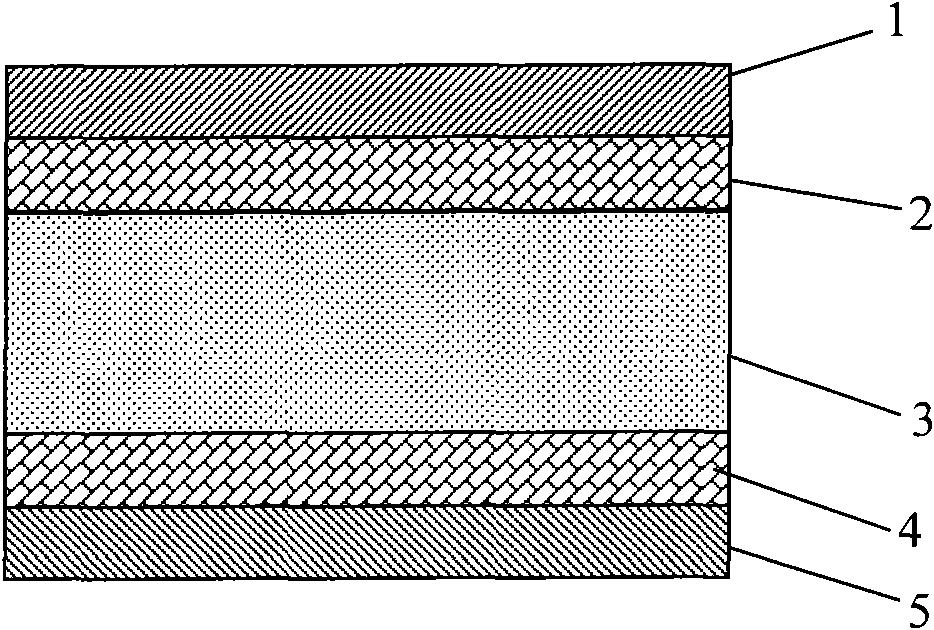

Novel solar battery backboard

ActiveCN101582458ANovel structureMaterials are readily availableSynthetic resin layered productsPhotovoltaic energy generationPolyurethane adhesiveAlloy

The invention relates to a novel solar battery backboard, which comprises the following components according to the adhesion in turn: a weathering layer, a first adhesive layer, a structure-enhancing layer, a second adhesive layer and an adhesive reflecting layer; wherein, the weathering layer is a polyvinylidene fluoride alloy layer modified by inorganic materials; the adhesive reflecting layer is a white polyethylene layer; preferably, the polyvinylidene fluoride alloy layer is a plastic alloy layer formed by the polyvinylidene fluoride and the inorganic materials with the thickness of 4-40 mum; the white polyethylene layer is a plastic alloy layer in which polyethylene is mixed with inorganic white pigment, anti-ultraviolet stabilizer and hot-oxygen ageing resistance stabilizer with the thickness of 10-300mum; the structure-enhancing layer is a polyethylene qlycol terephthalate layer; the first adhesive layer and the second adhesive layer can be one of the following three, namely, a polyurethane adhesive layer, an acrylic ester adhesive layer or an epoxy adhesive layer with the thickness of 1mum-30mum. The invention features novel structure, easily obtained materials, greatly reduced cost and good performance, conforms to the requirements of the backboard, and has important significance on solar energy industry.

Owner:SHANGHAI HIUV NEW MATERIALS

Method for preparing modified aqueous adhesion agent of polyurethane

InactiveCN101003715AIncrease the degree of cross-linkingImprove cohesive strengthPolyureas/polyurethane adhesivesEpoxyPolyester

This invention discloses a method for preparing modified aqueous polyurethane adhesive. The method comprises: (1) modifying epoxy resin with modifier to obtain modified epoxy resin; (2) reacting polyisocyanate with polyester or polyol polyether, and adding chain extender to obtain polyurethane with prepolymer; (3) modifying polyurethane prepolymer with modified epoxy resin to obtain modified polyurethane prepolymer; (4) adding water, dispersing by a high-speed disperser, and adding neutralizer and crosslinking agent to obtain modified aqueous polyurethane adhesive. This invention introduces epoxy resin into the modification of aqueous polyurethane adhesive, thus combines high modulus, high strength and good chemical resistance of epoxy resin with the advantages of polyurethane resin. The modified aqueous polyurethane adhesive can meet the needs of automobile inner decoration materials. The method has such advantages as simple process, and low cost.

Owner:SOUTH CHINA UNIV OF TECH

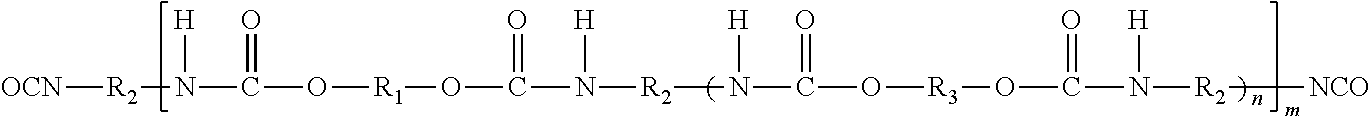

Hydrolysis-resistant double-component polyurethane adhesive for structure adhesion

ActiveCN102559126AImprove hydrolysis resistanceHigh bonding strengthPolyureas/polyurethane adhesivesPolyesterAdhesion force

The invention relates to a hydrolysis-resistant double-component polyurethane adhesive for structure adhesion. The hydrolysis-resistant double-component polyurethane adhesive for structure adhesion consists of a component A and a component B, wherein the component A comprises the following components in part by weight: 30 to 70 parts of polyisocyanate resin, 5 to 20 parts of plasticizing agent, 0.25 to 5 parts of thixotropic agent, 10 to 50 parts of incremental filler and 0.25 to 1 part of water-removing agent; and the component B comprises the following components in part by weight: 5 to 30 parts of polyester polyol, 5 to 30 parts of vegetable oil polyol, 5 to 30 parts of polyether polyol, 3 to 15 parts of water-absorbing filler, 1 to 10 parts of thixotropic agent, 3 to 15 parts of incremental filler, 0.1 to 10 parts of pigment, 0.1 to 5 parts of adhesion force accelerator, 0.1 to 2 parts of chain extender and 0.01 to 0.2 part of catalyst. An adhesion system improves adhesion property, solves the problem that a thermosetting composite material is subjected to surface roughening treatment before adhesion and improves the using efficiency. Aiming at the problem of poor hydrolysis resistance of a polyester type polyurethane adhesive system, the hydrolysis resistance is improved through molecule design of polyurethane soft and hard sections.

Owner:TONSAN ADHESIVES INC

Solvent free bi-component polyurethane adhesive and preparation method thereof

InactiveCN101597470ALow viscosityGood low temperature coatabilityPolyureas/polyurethane adhesivesPolyurethane adhesiveSolvent free

The invention discloses solvent free bi-component polyurethane adhesive and a preparation method thereof, wherein the solvent free bi-component polyurethane adhesive relates to a compound soft package adhesive in the fields of food, medicine, and the like. The adhesive comprises a component A and a component B, wherein the component A is an isocyanate compound, the component B is polyol, and the adhesive is obtained in such a way that the component A and the component B are mixed according to the weight percent of 2:1. The adhesive solves the problem that the use effect is influenced and the use range is limited because of poor properties of transparency, viscosity, low-temperature coating and stripping strength, and boiling resistance existing in the prior solvent free adhesive. The adhesive is environmental-friendly without solvent because the component A and the component B of the adhesive both are transparent liquid, has low viscosity as well as better low-temperature coating and stripping strength, and keeps better stripping strength after being boiled, thereby being environmental-friendly adhesive, wherein the viscosity of the component A is 2000-5000MPa.s and the viscosity of the component b is 400-2000MPa.s below 25 DEG C.

Owner:NANTONG GAOMENG NEW MATERIAL

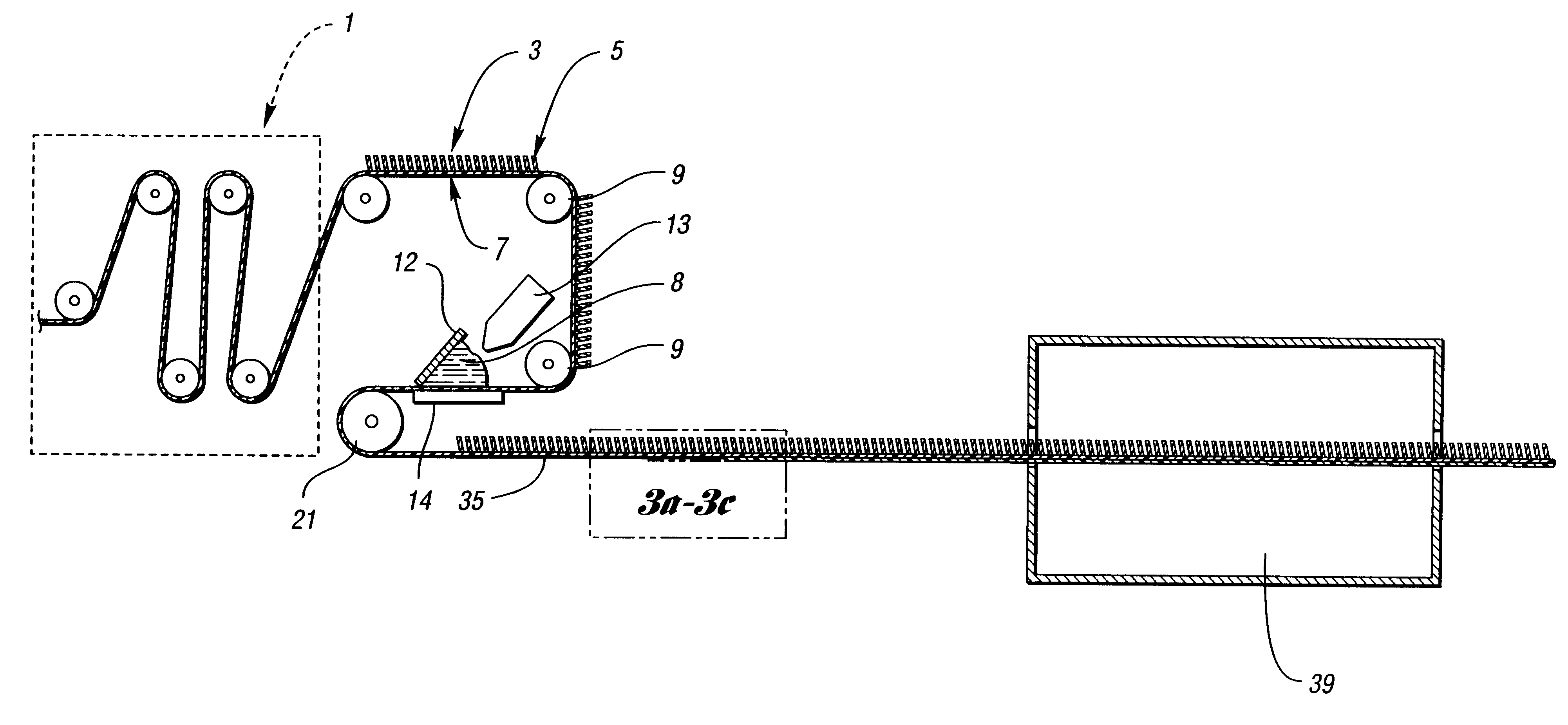

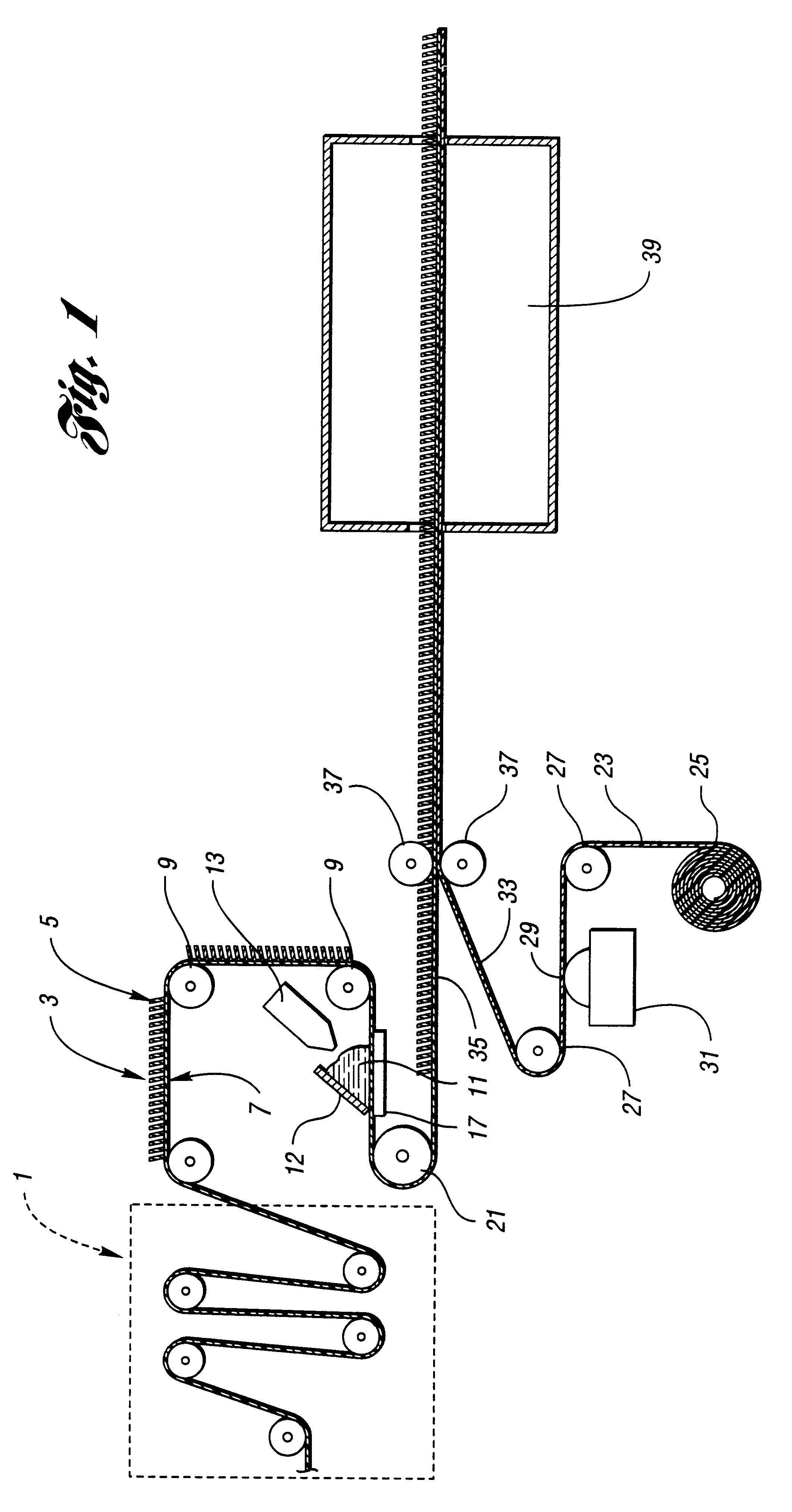

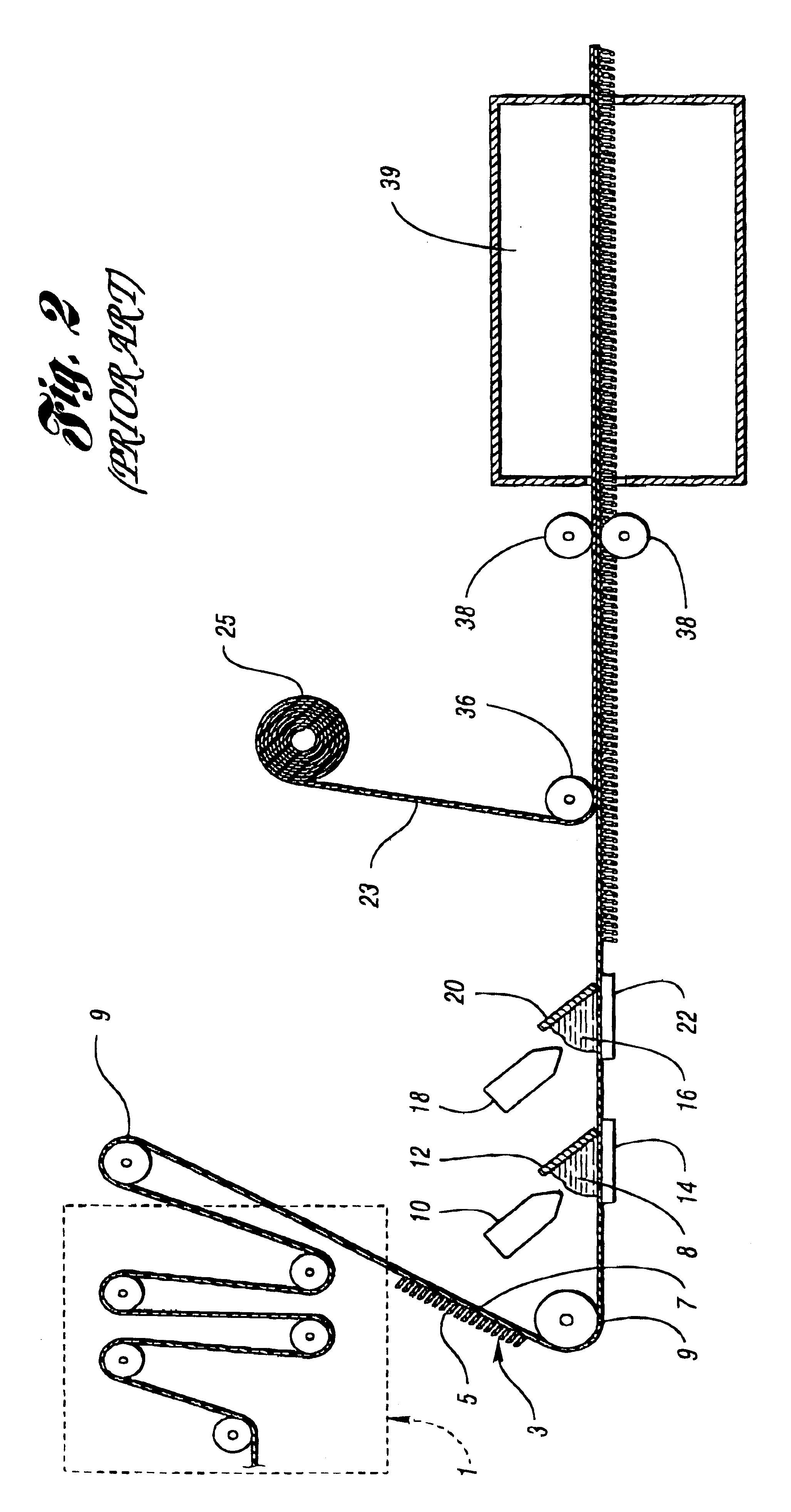

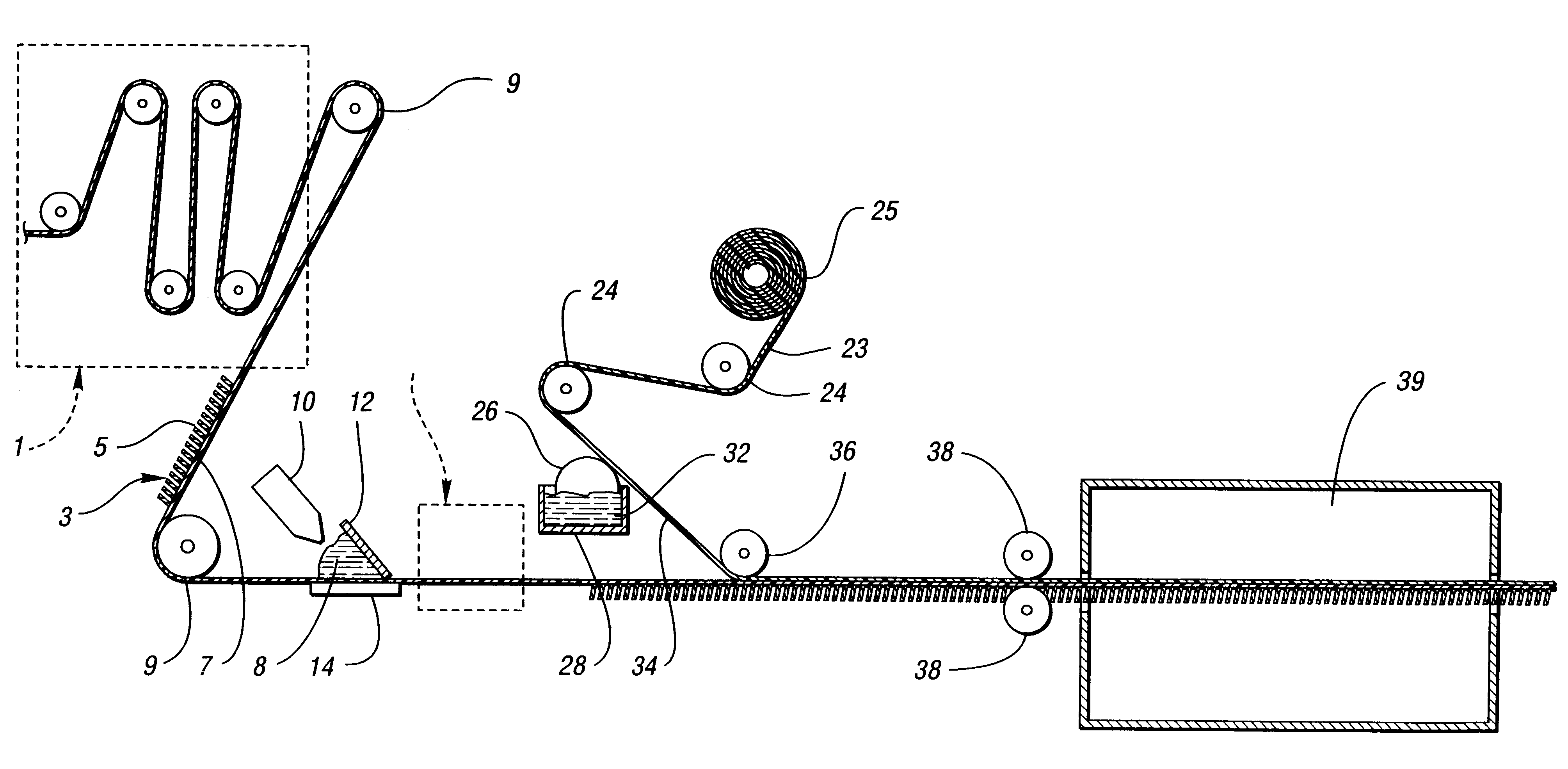

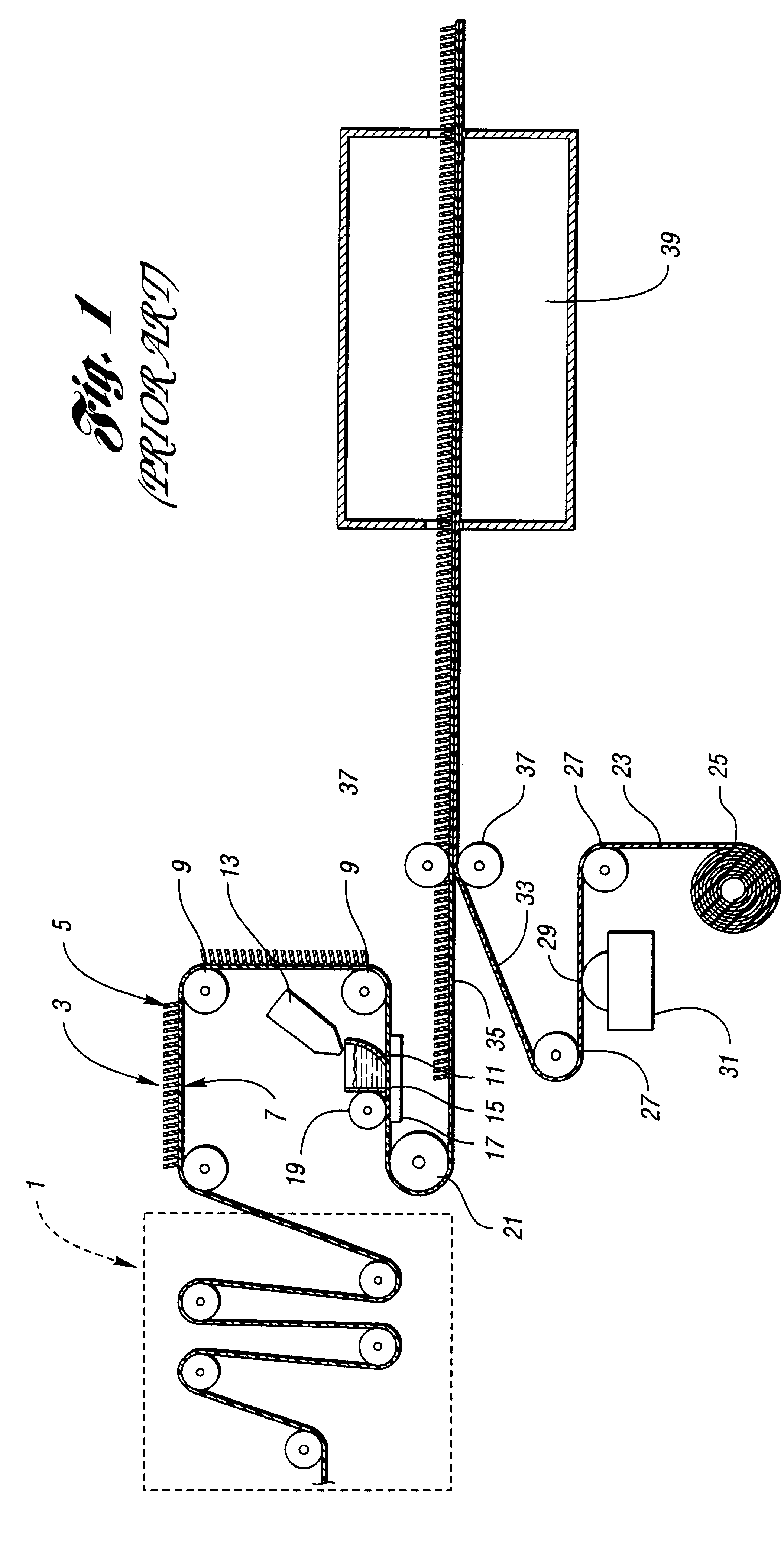

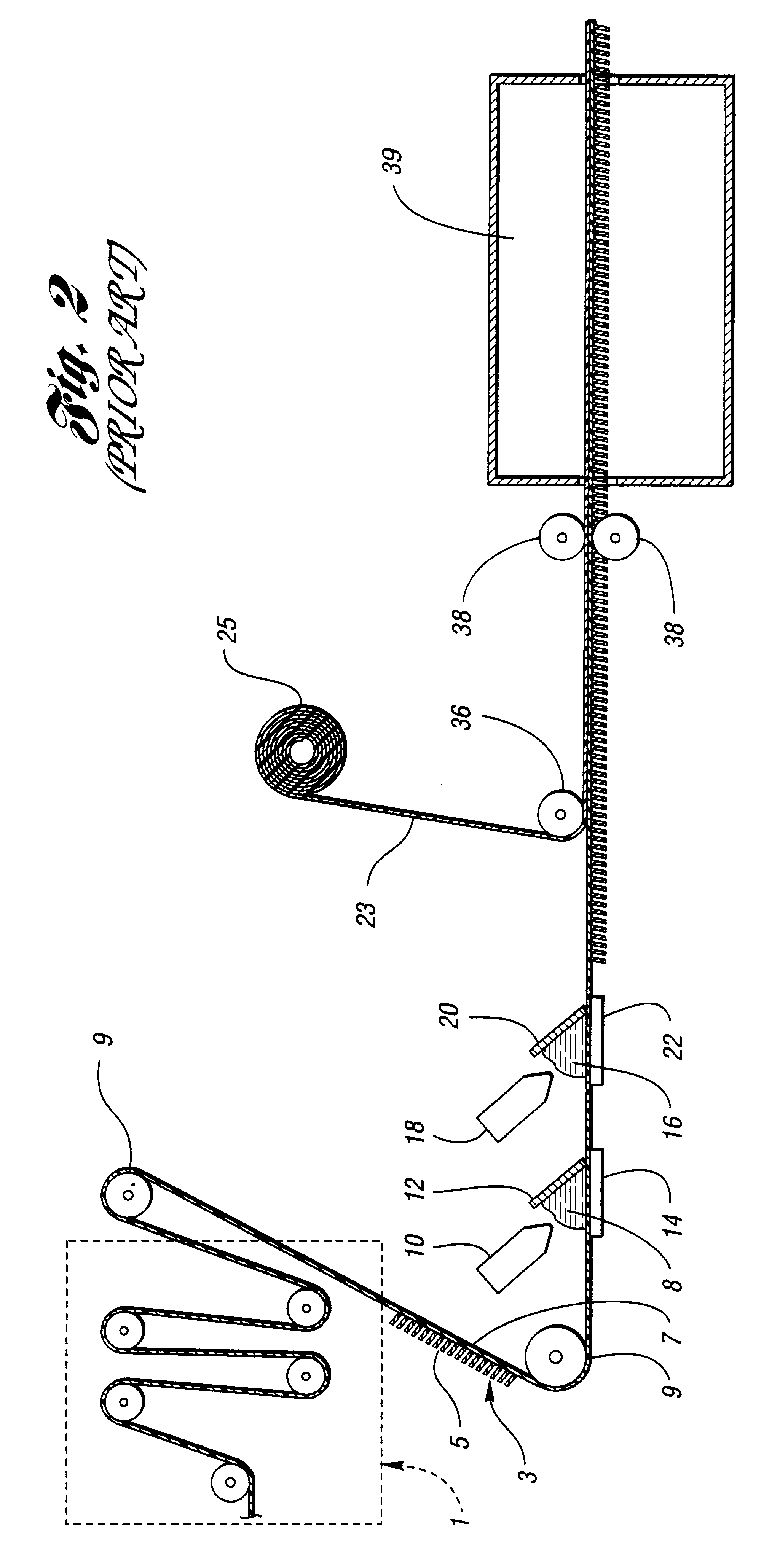

Face-up coating of carpet backs with polyurethane

InactiveUS6264775B1Weight controlEffectively wet outLayered productsBristlePolyurethane adhesiveChemistry

Owner:BAYER ANTWERPEN NV

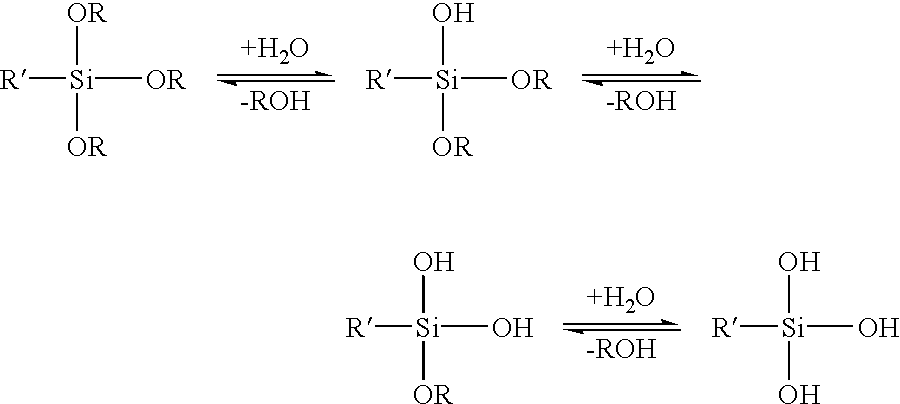

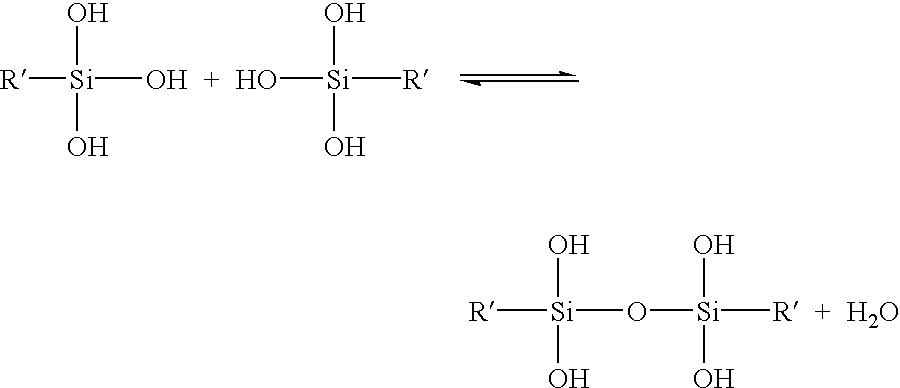

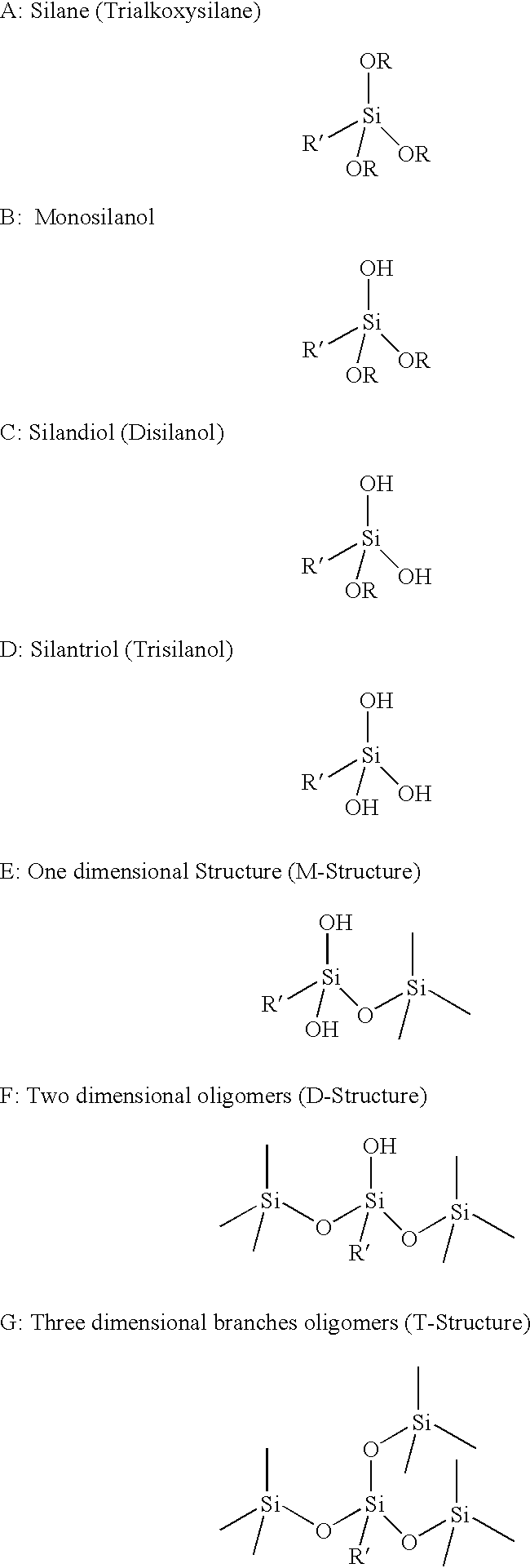

Water-based primer for promoting adhesion of polyurethane-based sealants and adhesives

InactiveUS6511752B1Improve adhesionLittle and no VOC emissionGroup 4/14 element organic compoundsOther chemical processesWater basedPolyurethane adhesive

A method is provided for adhering a polyurethane-based sealant or adhesive to a substrate. The method comprises: i) applying an aqueous primer solution onto a substrate, the primer solution comprising water, an aminotitanate compound, and preferably an epoxysilane compound having at least one epoxy group and at least two alkoxy groups; ii) applying a polyurethane adhesive or sealant to the primer-treated substrate; and iii) forming a reaction product of the primer and the polyurethane. Also provided are a substrate having a layer of a polyurethane adhesive or sealant, and a stabilized aqueous primer solution containing an epoxysilane compound and an aminotitanate compound.

Owner:SIKA AUTOMOTIVE

Method for preparing aqueous polyurethane adhesive and superfine fiber synthetic leather

ActiveCN101665675AHigh peel strengthIncrease elasticityPolyureas/polyurethane adhesivesSynthetic resin layered productsPolyesterFolding endurance

The invention relates to a method for preparing an aqueous polyurethane adhesive and superfine fiber synthetic leather, which belongs to the technical field of chemical products and preparation methods thereof. The method is characterized by comprising the following steps: mixing polyester polyol, isocyanate, a hydrophilic chain extending agent, a micromolecule chain extending agent and an amine environment friendly catalyst to obtain a hydrophilic aqueous polyurethane prepolymer; adding a neutralizing agent to the aqueous polyurethane prepolymer to obtain an aqueous polyurethane latex; then adding an amine chain expanding agent, a thickening agent, a defoaming agent and a flatting agent to the aqueous polyurethane latex to obtain the aqueous polyurethane adhesive; coating the aqueous polyurethane latex on release paper; drying the release paper; then coating the aqueous polyurethane adhesive on the dried release paper; and pressing the release paper and base cloth together to obtain the superfine fiber synthetic leather. The high solid content aqueous polyurethane adhesive prepared by the method has better initial tack and rebound resilience and higher final strength, and the prepared superfine fiber synthetic leather has higher peel strength and low-temperature folding endurance. The preparing process of the method greatly reduces the use and the discharge of organic solvents, reduces the energy consumption and furthest reduce the environmental pollution.

Owner:HUADA CHEM GRP CO LTD

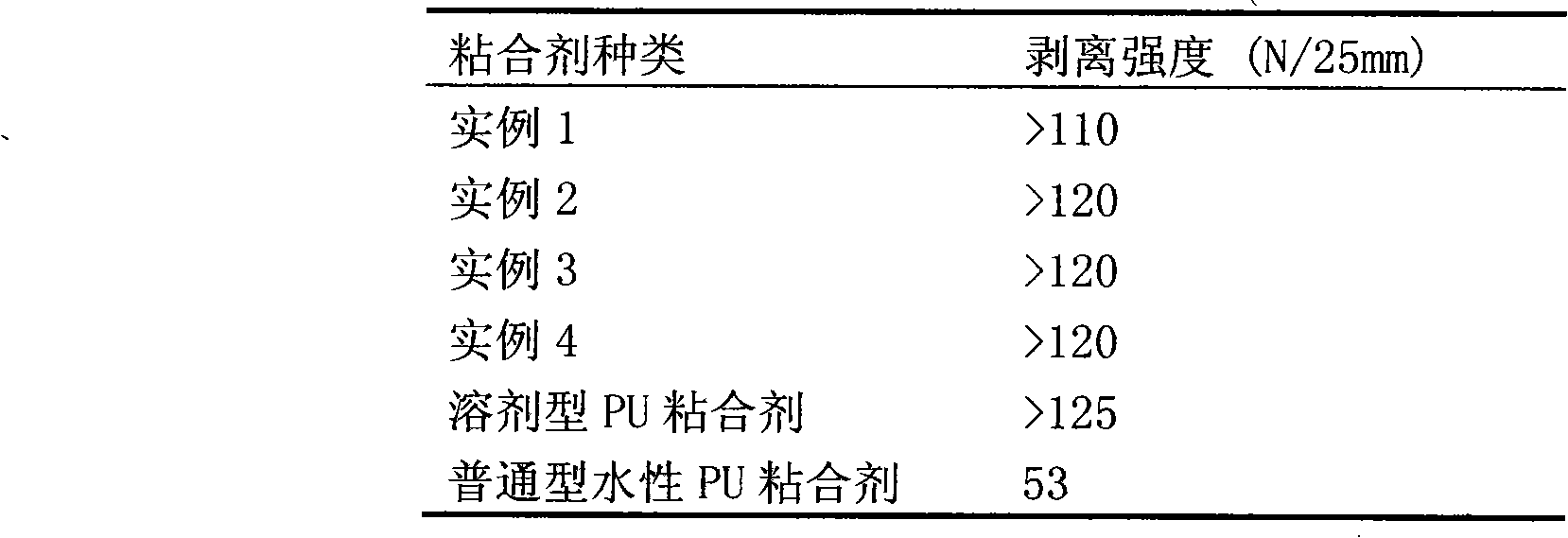

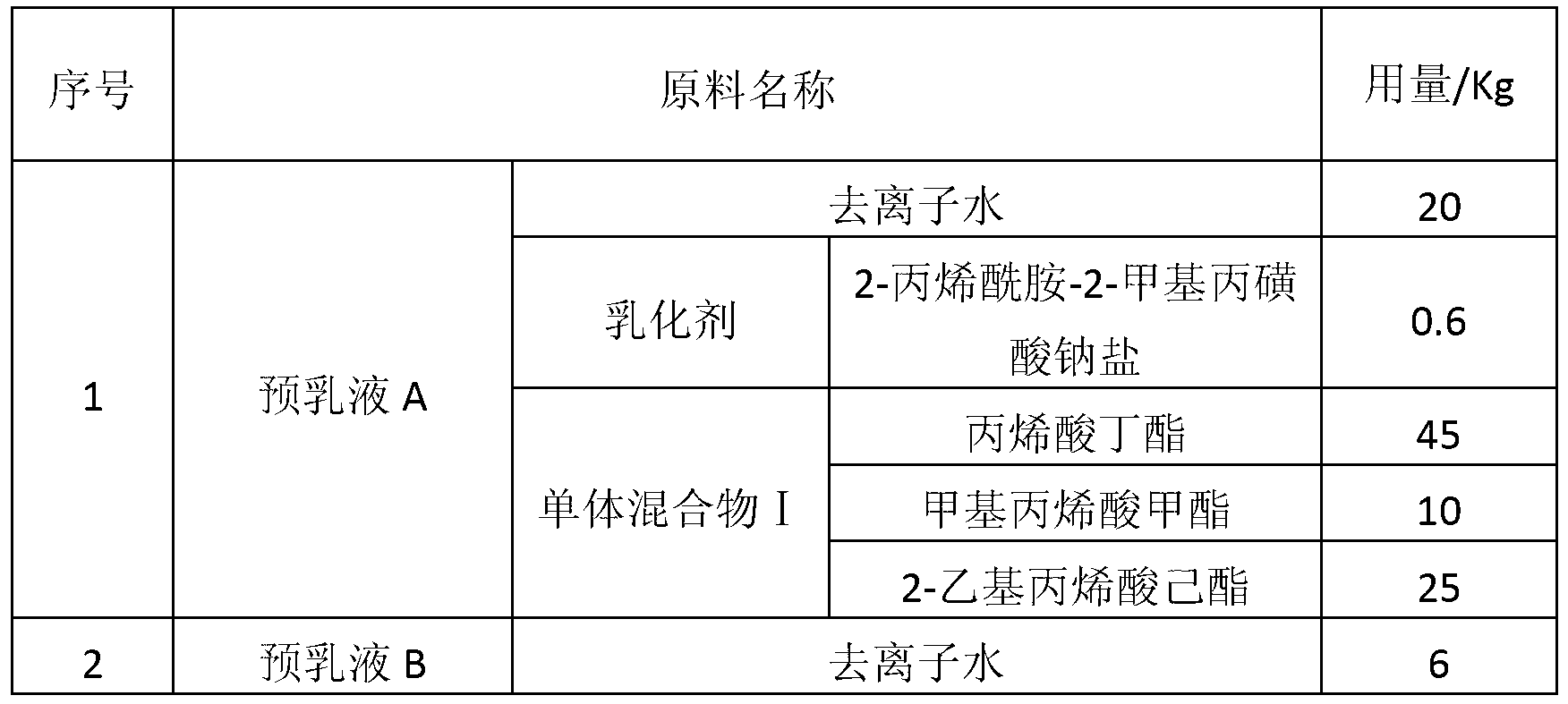

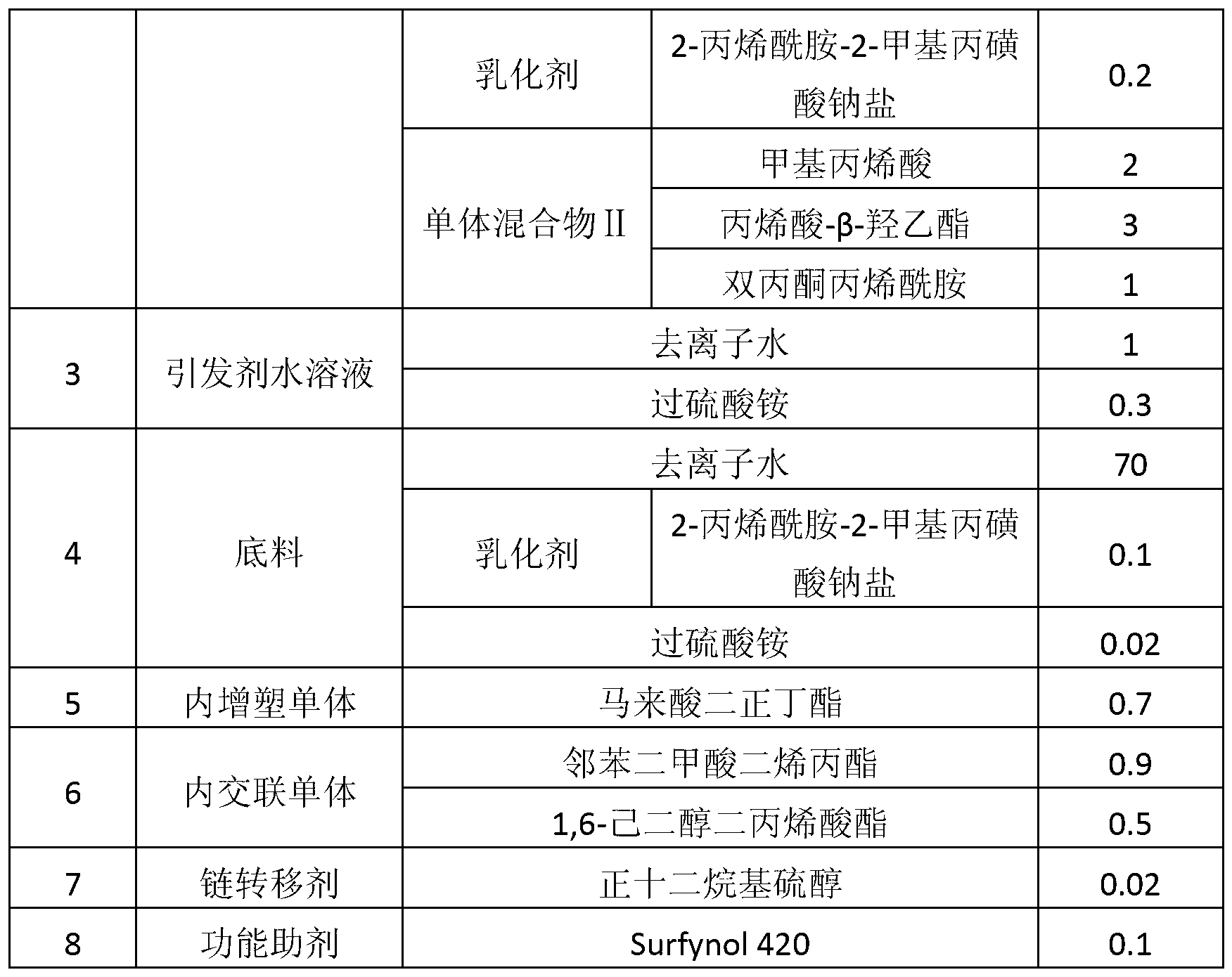

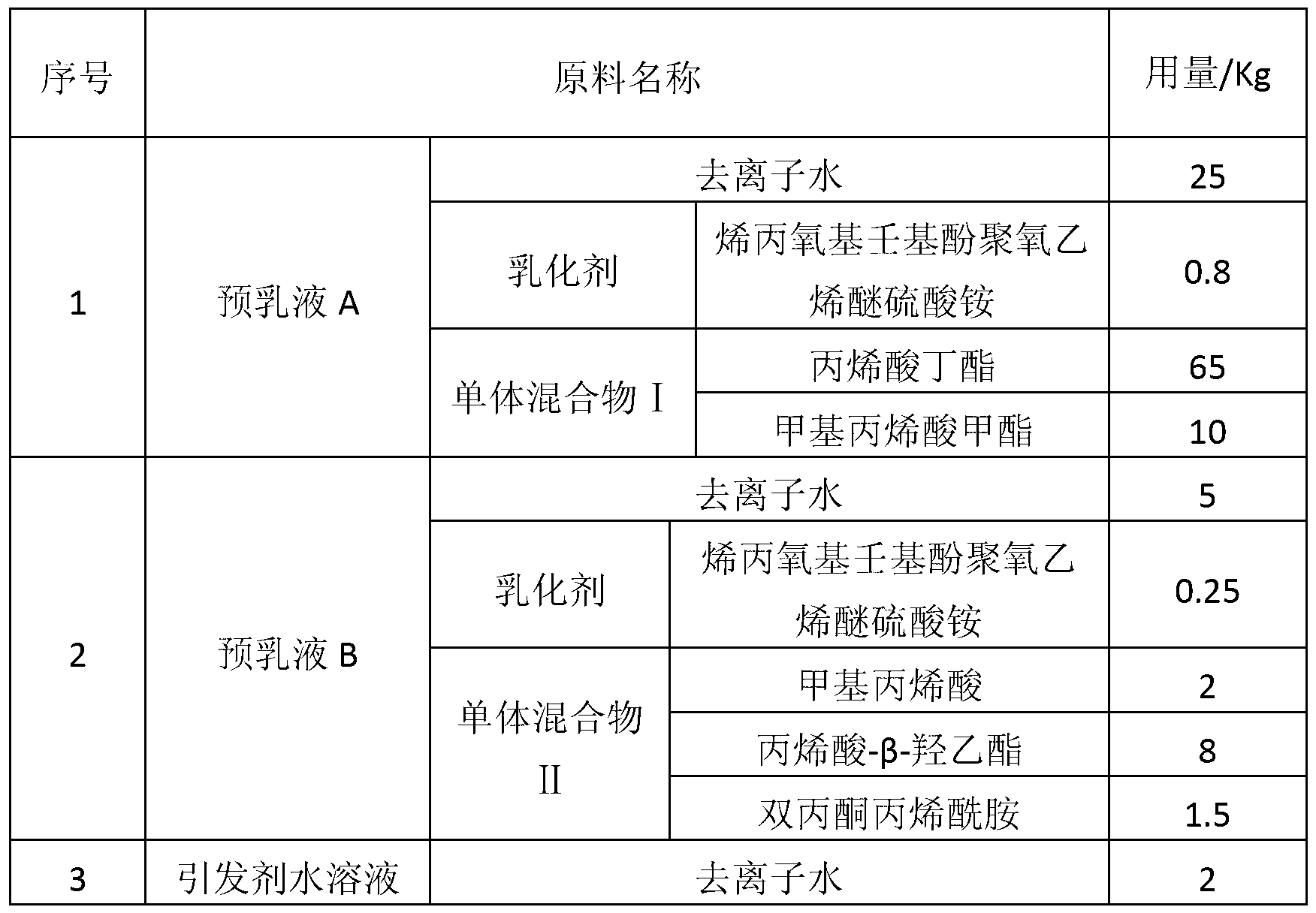

Water-based plastic-plastic compound adhesive for food and drug flexible package and preparation method thereof

ActiveCN103059784AHigh bonding strengthImprove stabilityEster polymer adhesivesWater basedPolyurethane adhesive

The invention discloses a water-based plastic-plastic compound adhesive for food and drug flexible packages and a preparation method thereof. The preparation method comprises the following steps of: carrying out pre-emulsification by using 20-30 parts by weight of deionized water, 0.4-1.0 part by weight of emulsifying agents and 75-90 parts by weight of monomer mixtures to obtain a pre-emulsion A; then carrying out the pre-emulsification by using 5-8 parts by weight of the deionized water, 0.2-0.3 part of the emulsifying agents and 3-20 parts by weight of the monomer mixtures to obtain a pre-emulsion B; preparing an initiator water solution C by using 1-3 parts by weight of the deionized water and 0.2-0.8 part by weight of initiators; and dropping the monomer mixture I with lower polarity and the monomer mixture II with higher polarity step by step by adopting a pre-emulsification seed emulsion polymerization process to obtain the water-based plastic-plastic compound adhesive for the food and drug flexible packages. The water-based plastic-plastic compound adhesive disclosed by the invention has the advantages of no organic solvent, no formaldehyde release, good adhesivity and high stripping strength and permanent adhesion and can be applied to a flexible package industry and substitute for a solvent type two-component polyurethane adhesive maturely applied to the present market.

Owner:DONGGUAN STAR COSM POLYMER

Urethane adhesive-laminated carpeting

Laminated carpeting consisting of a secondary backing adhered to a greige good of yarn tufted into a primary backing are prepared from polyurethane adhesives by single puddle processes which allow for lowered use of polyurethane while producing carpets exhibiting excellent delamination strength. Preferably, a reactive polyurethane system is employed as a primary adhesive, and the secondary backing is skip-coated with a minor amount of a non-advancing skip coat.

Owner:BAYER ANTWERPEN NV

Solar battery backboard taking modified polyvinylidene fluoride alloy layer as weathering protective layer

ActiveCN101582459ANovel structureMaterials are readily availableSynthetic resin layered productsElectrical equipmentPolyurethane adhesiveAlloy

The invention relates to a solar battery backboard which takes a modified polyvinylidene fluoride alloy layer as a weathering protective layer. The backboard comprises the following components according to the adhesion in turn: a weathering layer, an adhesive layer, a structure-enhancing layer, a second adhesive layer and a second weathering layer; wherein, the first weathering layer and the second weathering layer are the polyvinylidene fluoride alloy layers modified by inorganic materials; preferably, the polyvinylidene fluoride alloy layer is a plastic alloy layer formed by the polyvinylidene fluoride and the inorganic materials with the thickness of 4-40 mum; the structure-enhancing layer is a polyethylene qlycol terephthalate layer; the first adhesive layer and the second adhesive layer can be one of the following three, namely, a polyurethane adhesive layer, an acrylic ester adhesive layer or an epoxy adhesive layer with the thickness of 1mum-30mum. The invention features novel structure, easily obtained materials, greatly reduced cost and fine performance, conforms to the requirement of backboard, and has important significance on solar energy industry.

Owner:SHANGHAI HIUV NEW MATERIALS

Method of preparing watersoluble polyurethane adhesive

InactiveCN101508879AGood flexibilitySmall smellPolyureas/polyurethane adhesivesPolyurethane adhesiveEmulsion

The invention discloses a preparation method of a waterborne polyurethane adhesive, comprising the following steps: evenly mixing vulcabond and polyglycols, adding in proper amount of catalyst, and reacting so as to obtain polyurethane prepolymer; reacting by adding in hydrophilic chain extender and crosslinking agent, adding 2-hydroxyethyl acrylate into the reaction system so as to obtain polyurethane, terminal group of which is double bond; reducing temperature, neutralizing and emusifying by adding in water under high-speed cutting so as to obtain polyurethane emulsion; and heating up, adding vinyl monomer into the emulsion, and polymerizing initiated by water-soluble initiator so as to obtain the modified waterborne polyurethane emulsion. The invention can completely eliminate the harmful effect to the application and the environment protection of the polyurethane emulsion product caused by small molecular emulsifier and organic solvent. The invention can make full use of combination property through the copolymerization modification between the polyurethane and polyacrylic ester.

Owner:SHAANXI UNIV OF SCI & TECH

Bicompenent high solid content aqueous polyurethane, its preparation method and application

InactiveCN1786055ASimple processReduce dosageFibre treatmentPolyureas/polyurethane adhesivesWater basedWater dispersible

The present invention relates to double-component high solid content water-based polyurethane, its preparation method and application. Said method includes the following procedures: preparing water-dispersible polyurethane adhesive; preparing water-dispersivity polyisocynate cross-linking agent; and before application mixing the water-dispersible polyurethane adhesive and water-dispersivity polyisocynate cross-linking agent, in which the preparation of polyurethane adhesive includes the preparation of prepolymer, the prepolymer is neutralized and dispersed into the deioniced water to obtain dispersion, then the dispersion is chain-extended so as to form water-based polyurethane.

Owner:SOUTH CHINA UNIV OF TECH

Aqueous polyurethane adhesive and preparation thereof

InactiveCN101348703ASmall molecular weightSolve process problemsFilm/foil adhesivesPolyureas/polyurethane adhesivesPolyurethane dispersionPolyurethane adhesive

The invention discloses a waterborne polyurethane adhesive which comprises the following compositions in mass portion: 100 portions of waterborne polyurethane dispersoid, 0.08 to 0.25 portion of thickener, 0.08 to 0.25 portion of flatting agent, 0.02 to 0.05 portion of antifoaming agent and 0.02 to 0.05 portion of antioxidant. The invention also discloses a method for preparing the adhesive. The preparation method is to drip multi-amine compound into the waterborne polyurethane dispersoid, to react for 15 to 30 minutes at a temperature of between 10 and 25 DEG C, to remove organic solvent in the waterborne polyurethane dispersoid, to add the thickener, the flatting agent, the antifoaming agent and the antioxidant again, to uniformly mix the materials, and then to obtain the waterborne polyurethane adhesive. The preparation method disclosed by the invention has a simple technology, and the waterborne polyurethane adhesive prepared has the characteristics of high solid content, quick drying speed, large bonding strength, large tensile strength, good elasticity, and superior water resistance, solvent resistance and high and low temperature resistance.

Owner:SUN YAT SEN UNIV

Gas-permeable moisture-absorption type environmentally-friendly polyvinyl chloride synthetic leather and manufacturing method thereof

InactiveCN102505513AEffective migrationHas vapor permeability and moisture absorption conductivitySynthetic resin layered productsTextiles and paperPolyurethane adhesivePlasticizer

The invention discloses a gas-permeable moisture-absorption type environmentally-friendly polyvinyl chloride synthetic leather and a manufacturing method thereof. The synthetic leather is prepared from an environmentally-friendly polyvinyl chloride formula by adopting release paper knife-coating. The gas-permeable moisture-absorption functional environmentally-friendly polyvinyl chloride synthetic leather is manufactured by adding gas-permeable moisture-absorption type protein powder to a non-phthalate environmentally-friendly plasticizer and an environmentally-friendly color paste, and simultaneously adopting aqueous polyurethane adhesive slurry to replace a traditional paste resin adhesion layer. The synthetic leather has high peeling strength and has gas permeability and moisture absorption property of true leather; the minus 20DEG C low-temperature flex resistance of the synthetic leather is up to 30000 times; and through third-party testing, the product can completely achieve European union REAC 46 environmentally-friendly tests.

Owner:HEFEI ANSHAN COATING FABRICS

Solvent-free polyurethane adhesive for compound film

ActiveCN101503611ANo pollution in the processImprove securityPolyureas/polyurethane adhesivesPolyesterComposite film

The invention discloses a solvent-free polyurethane adhesive for a composite film, which consists of an A component and a B component, wherein the A component is end-OH polyester polyol, and the B component is end NCO-polyurethane prepolymer; and the A component and the B component are mixed in the molar ratio of functional groups of NCO to OH being 1.2-1.9:1.0. The polyurethane adhesive for the composite film does not need to adopt solvent and has high safety. The adhesive shows low hydroscopic property as well as low hydrolysis and high shock strength due to introducing dimeric dibasic acid, and shows good adhesive property for some substrates which are particularly difficult to adhere and attach. The invention improves the adhesive strength of the composite film through the design of compositions and a molecular structure of the adhesive, the T peeling strength reaches more than 3.8N / 15mm after the plastic films are compounded for 3 to 5 days, and the T peeling strength between the plastic and an aluminum-plating film reaches more than 4.2N / 15mm.

Owner:黄山万丽美油墨科技有限公司

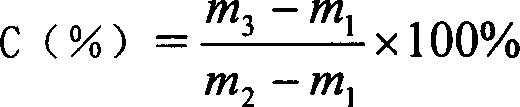

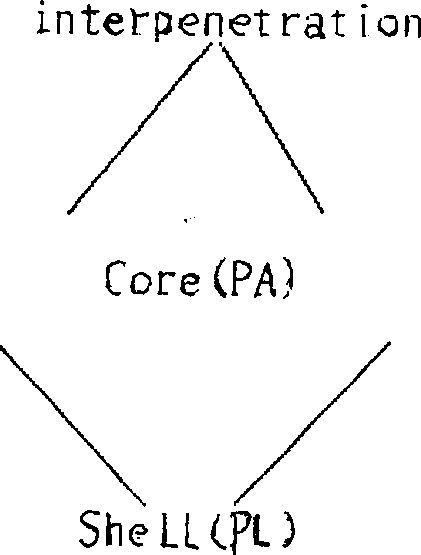

Water-soluble polyurethane latex adhesive with porous network formed by 'core-shell' structure

InactiveCN1355267AImprove adhesionHigh bonding strengthGraft polymer adhesivesPolyurethane adhesiveHigh energy

An acrylic acid modified polyurethane adhesive with networked "core-shell" structure is prepared through LIPN technique and seed emulsion polymerization. Its latex granularity is adjustable for distrilution in 20-200 mm. Its advantages include high adhesion, excellent resistance to fatigue, impact and abrasion, and wide application range including pressure-sensing adhesive, paint for fabric and leather, high-molecular medical material, passive-sensing package for high energy explosive, etc.

Owner:王申

Flexible material for lighter-than-air vehicles

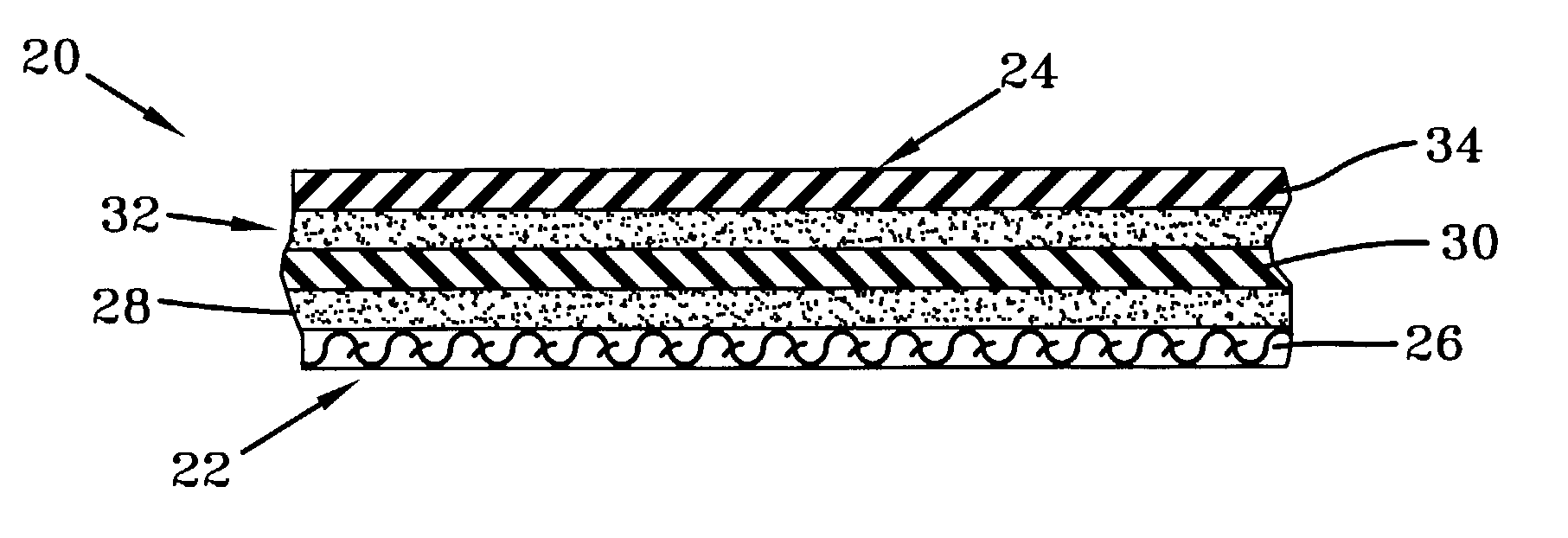

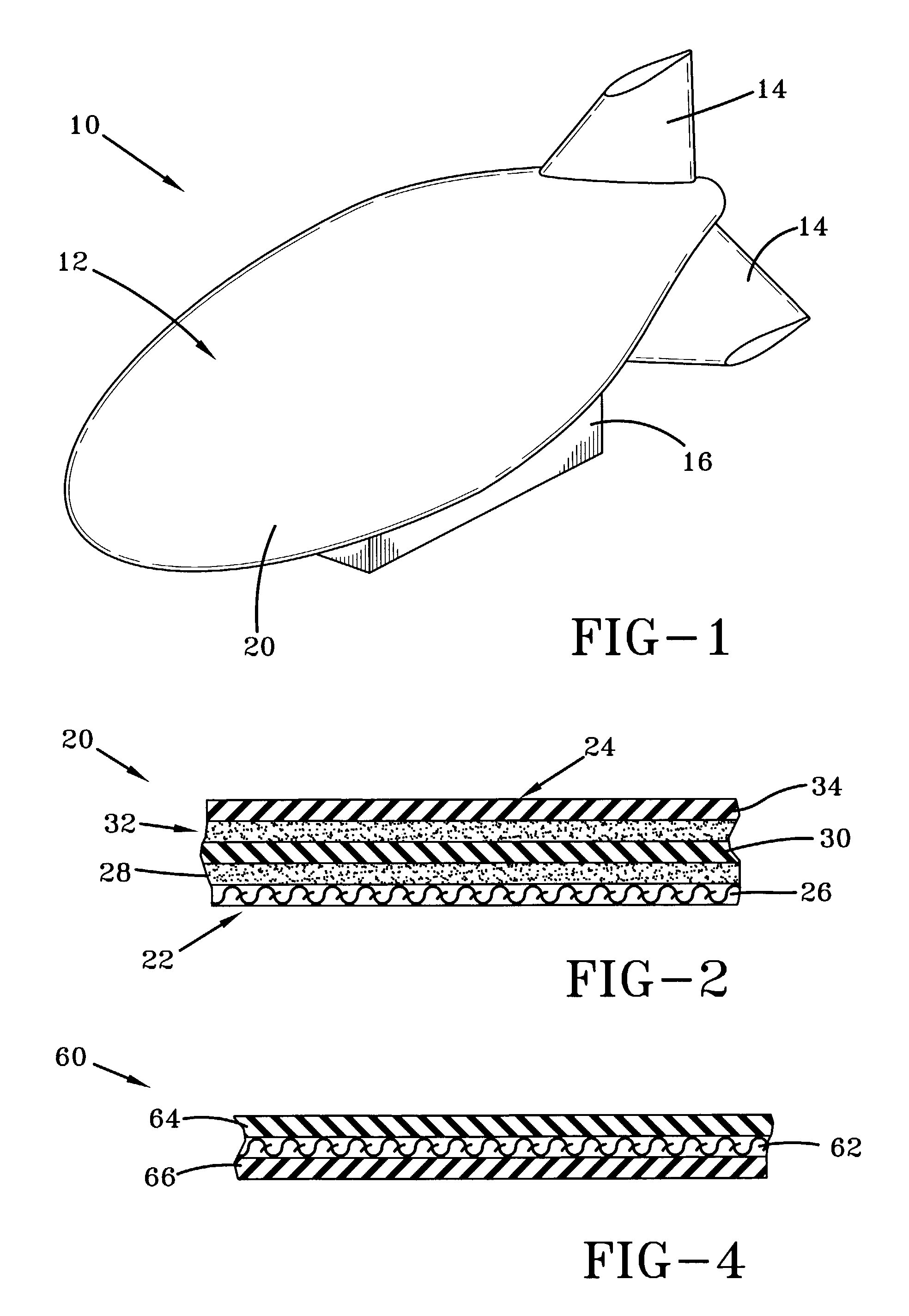

InactiveUS6979479B2Liquid crystal compositionsPedestrian/occupant safety arrangementPolyurethane adhesivePolyvinylidene fluoride

A laminate material for lighter-than-air vehicles includes a liquid crystal polymer fiber layer, a polyimide layer secured to the liquid crystal polymer fiber layer; and a polyvinylidene fluoride (PVDF) layer secured to the polyimide layer. The layers are secured to one another with a polyurethane adhesive. Adjacent laminates may be secured to one another by a PVDF cover tape on the exterior surfaces and a structural tape on the interior surfaces. The structural tape includes a liquid crystal polymer fiber layer and a polyimide layer to ensure the integrity of the vehicle. An alternative material may include a liquid crystal polymer fiber layer and a polyvinylidene fluoride (PVDF) layer disposed on both sides of the liquid crystal polymer fiber layer.

Owner:LOCKHEED MARTIN CORP

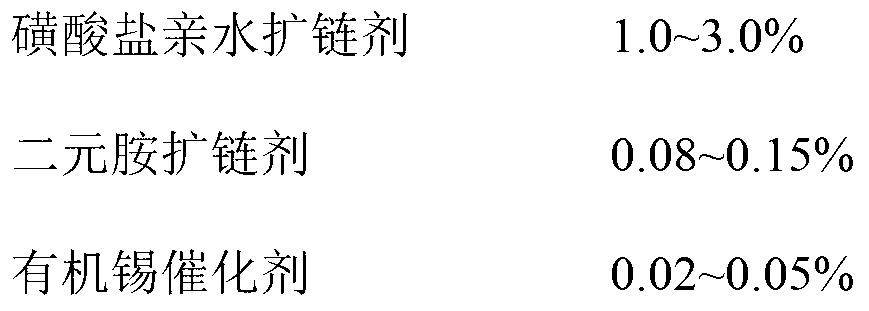

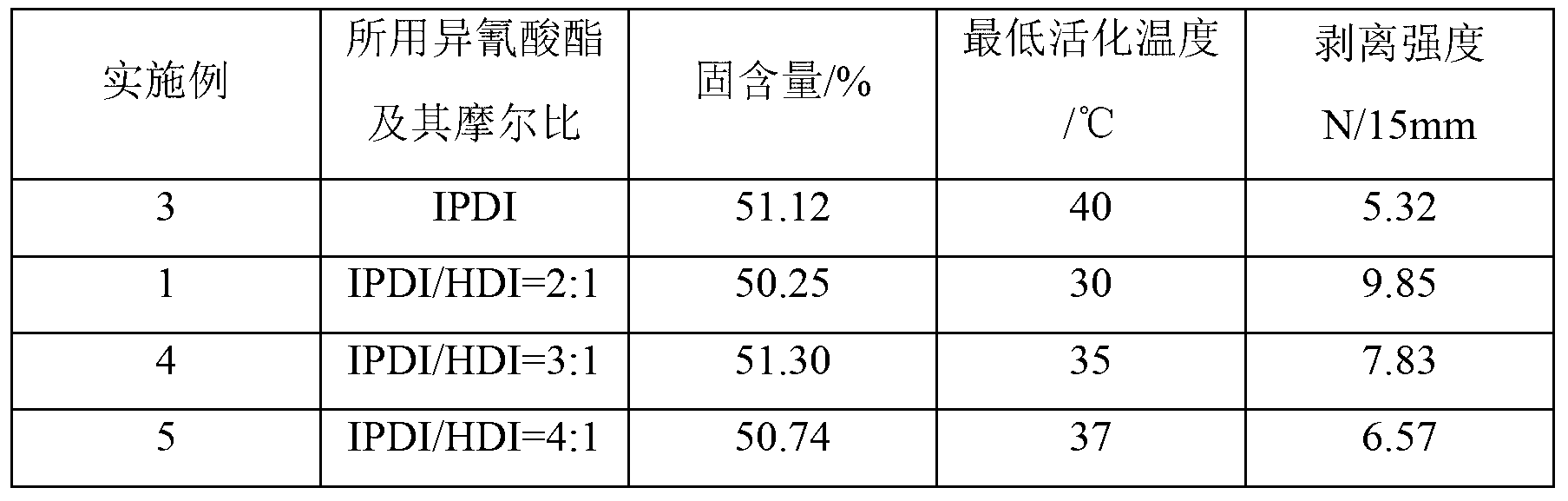

Preparation method of sulfonic acid type waterborne polyurethane adhesive

InactiveCN103254867AHigh solid contentLow activation temperaturePolyureas/polyurethane adhesivesPolyesterEthylenediamine

The invention discloses a preparation method of a sulfonic acid type waterborne polyurethane adhesive. The preparation materials of the sulfonic acid type waterborne polyurethane adhesive comprise the following components in percentage by weight: 75%-89% of polyalcohol, 8.5%-22% of diisocyanate, 0.06%-0.10% of cross-linking agent, 1.0%-3.0% of sulfonate hydrophilic chain extender, 0.08%-0.15% of diamine chain extender, and 0.02%-0.05% of organic tin catalyst, wherein the polyalcohol is polyester polyalcohol or polyether polyalcohol or a mixture of the polyester polyalcohol and the polyether polyalcohol; and the sulfonate hydrophilic chain extender is ethylenediamine-based sodium ethyl sulfonate or 1,2-dyhydroxyl-3-sodium propyl sulfonate. The sulfonic acid type waterborne polyurethane adhesive prepared by the preparation method disclosed by the invention has the characteristics of being high in solid content, low in lowest activation temperature and large in peel strength.

Owner:JUSHI GRP CO

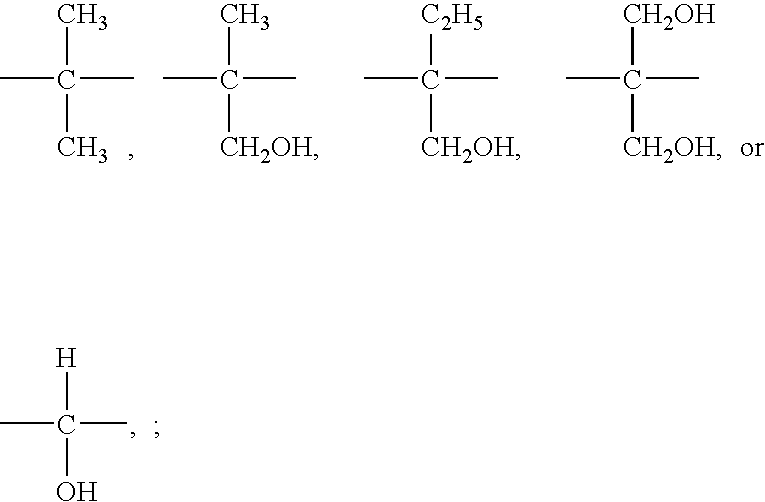

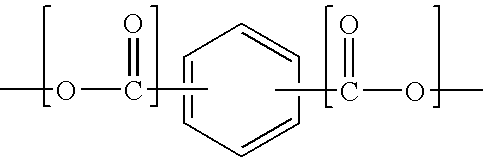

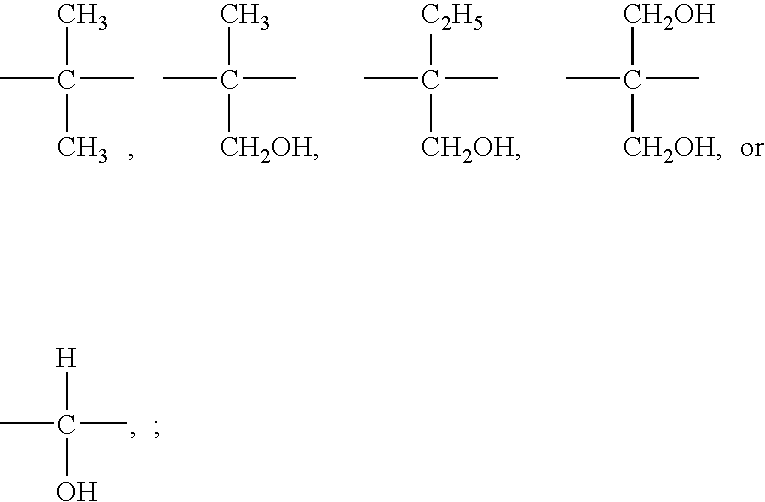

Polyester polyols for polyurethane adhesives

A polyester polyol prepared from a composition including a phthalic acid based material containing more than 10% by weight of ortho-phahalic or derivatives thereof, an aliphatic dicarboxylic acid (e.g., dodecanedioic acid), and a polyol (e.g., a glycol). A polyurethane adhesive, such as a polyurethane reactive hot-melt adhesive, is made using the polyester polyol, which exhibits improved initial bonding strength, shortened setting time, and ability to bond to low surface energy substrates such as ABS. The methods to prepare the polyester polyol and the polyurethane adhesive, and the method to use them are also disclosed.

Owner:OBRIEN MICHAEL E

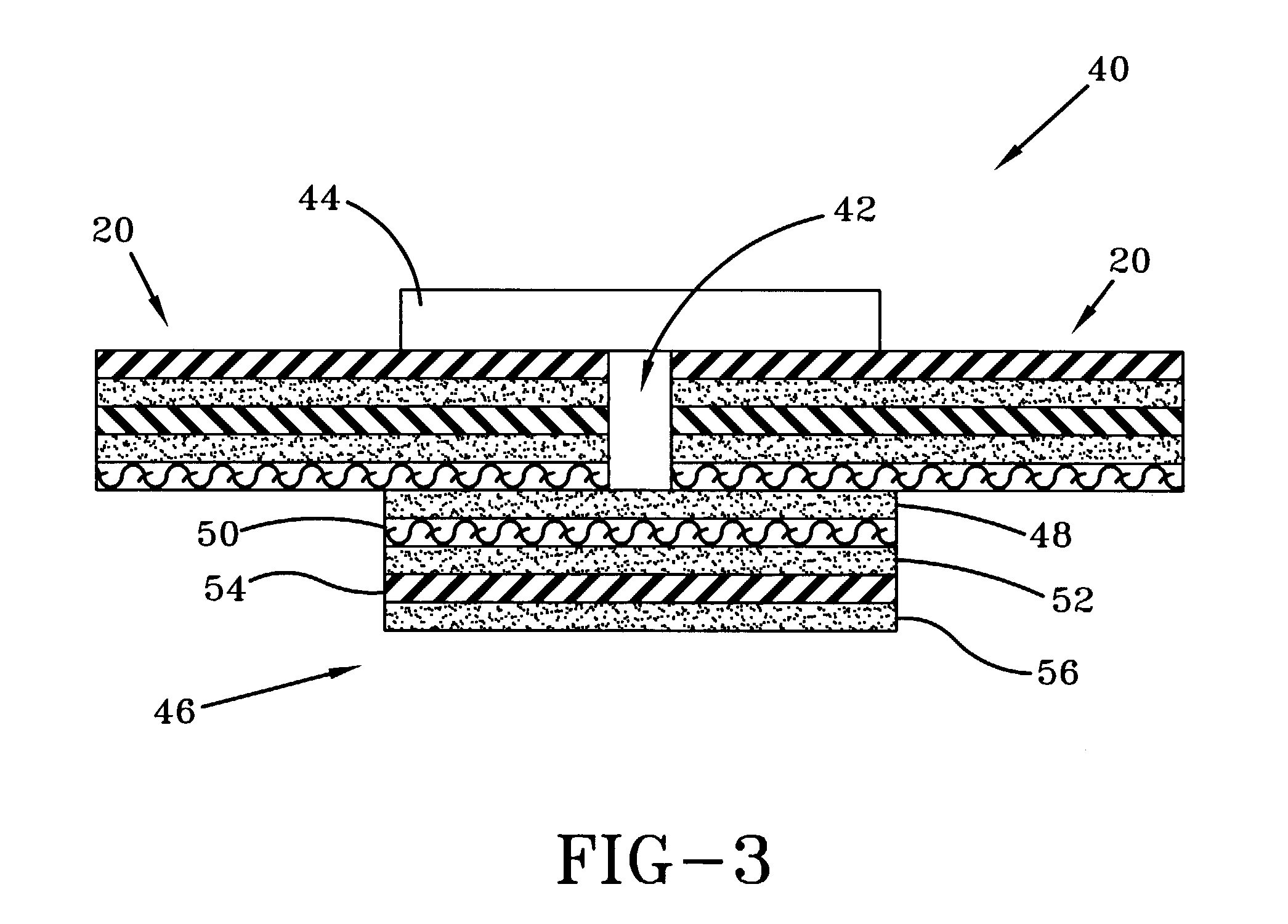

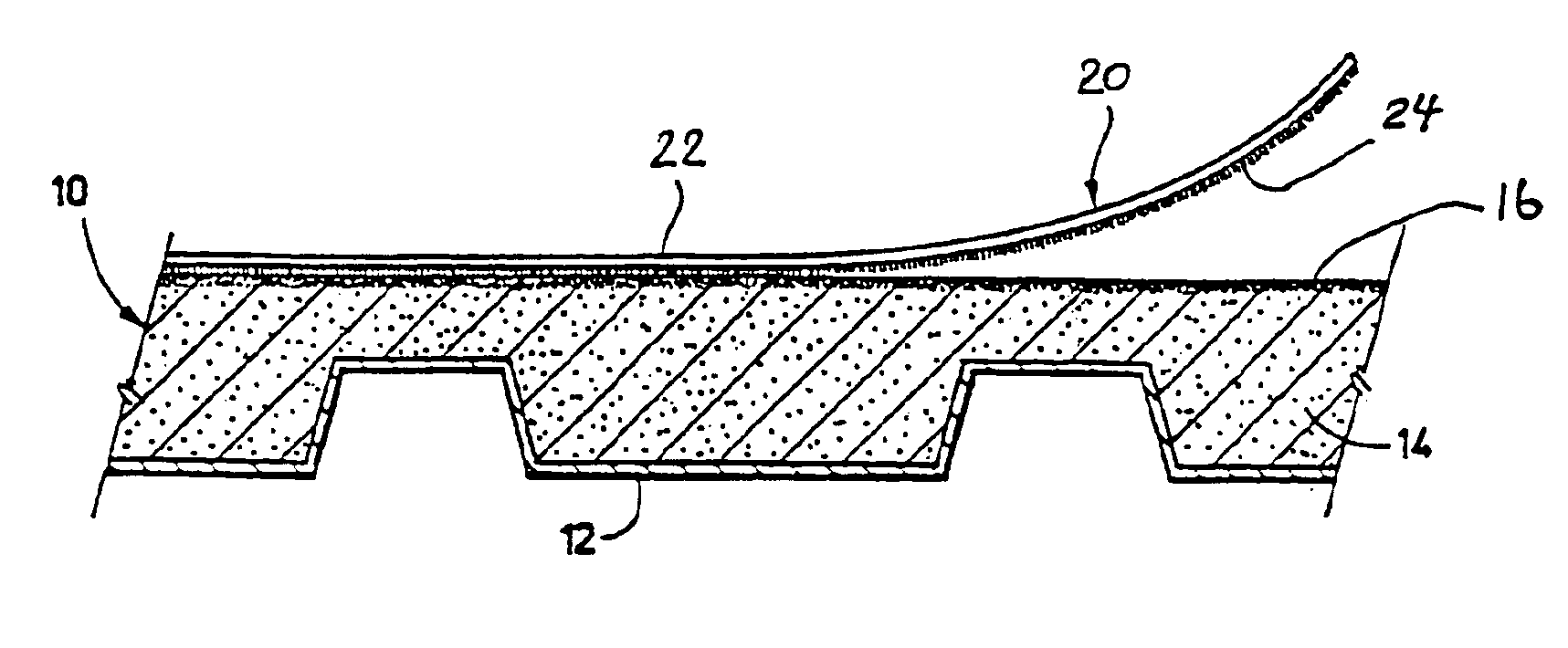

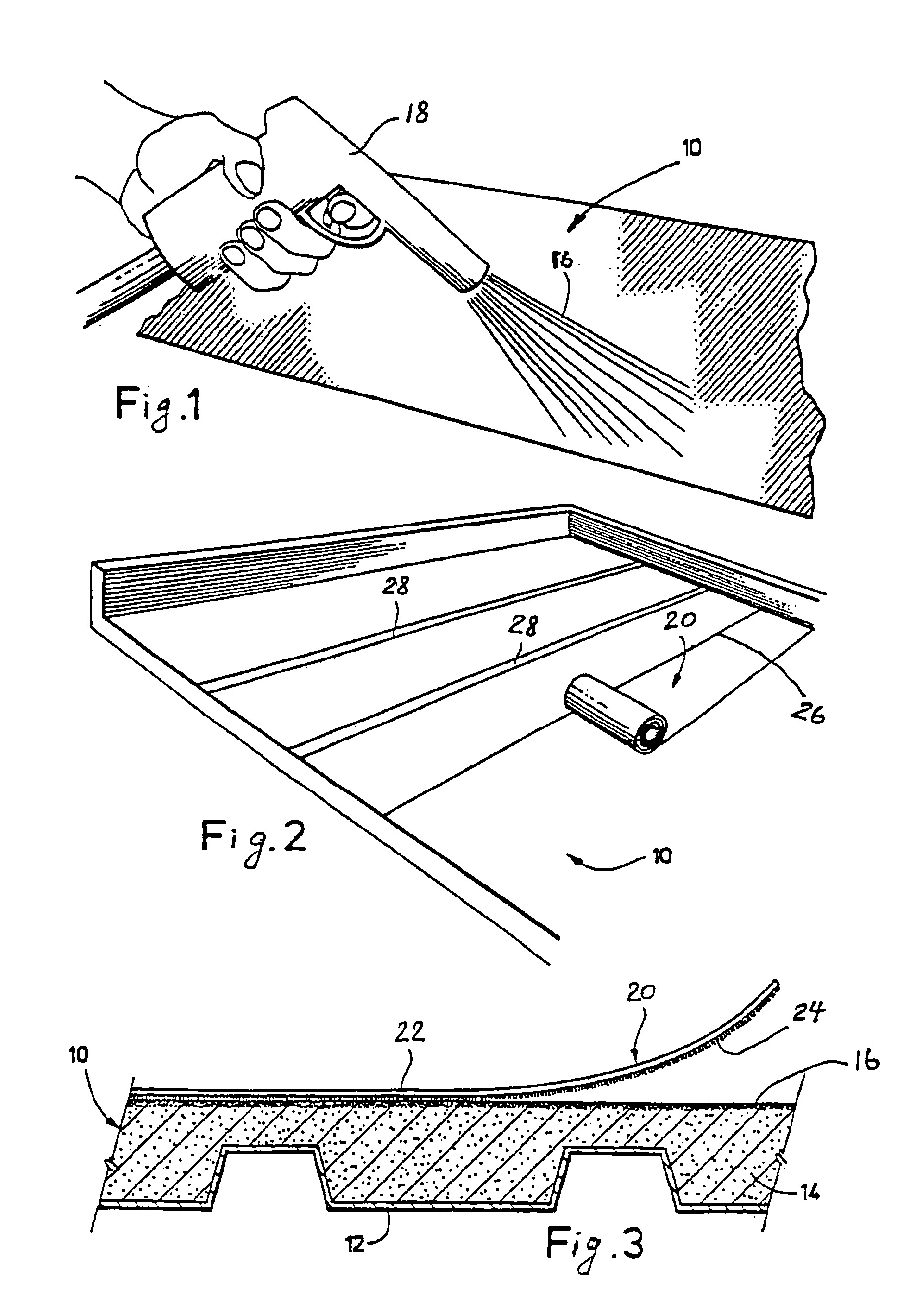

Non-cellular adhesive for composite roof structure

InactiveUS6938386B2Easy to controlRelieve stressBuilding roofsRoof covering using flexible materialsPolyurethane adhesiveEngineering

Owner:TECHN ROOFING SOLUTIONS

Preparation method of aqueous polyurethane adhesive for laminated composite fabrics

InactiveCN103173179AHigh bonding strengthSolve the contradiction that the bonding strength cannot meet the requirementsLayered productsFibre treatmentPolyurethane adhesiveChemistry

The invention relates to a preparation method of an aqueous polyurethane adhesive for laminated composite fabrics, and belongs to the technical field of adhesives. A blocking agent is utilized to block the excess -NCO groups in the synthesis, the -NCO groups are released in high temperature calendering and react with the hydroxy groups in the fabrics, and simultaneously the polar groups on the surfaces of materials comprising PVC and the like and urethane bonds, ester bonds, ether bonds and the like of polyurethane form hydrogen bonds, so the bonding strength is improved; and a thickening agent and / or a cross-linking agent are / is added after emulsification, so the viscosity of an emulsifier is improved, and an adhesive exudation problem during construction is solved. The adhesive can be stably stored in air at room temperature. The adhesive has the advantages of good adhesion, good water resistance, good yellowing resistance, and good mechanical performances.

Owner:CHANGZHOU UNIV +1

Boiling resistant polyurethane adhesive and method for preparing same

InactiveCN1629245AHigh bonding strengthHigh initial bond strengthPolyureas/polyurethane adhesivesPolyesterPolyurethane adhesive

The invention discloses a boiling resistant polyurethane adhesive and method for preparing same, wherein the adhesive comprises by weight ratio 50-90% of main component and 10-50% of curing agent, the main component comprises (A) polyether polyol with hydroxyl value being 10-30mgKOH / g and (B) polyester polyol with hydroxyl value being 30-100mgKOH / g, the curing agent is polyisocyanate prepolymer. The adhesive can be applied for an intaglio gluing dry-type compounding machine.

Owner:广东国望精细化学品有限公司

Solvent-free polyurethane adhesive for flexible package

ActiveCN101792650AImprove wettabilityHigh bonding strengthFlexible coversWrappersPolyesterPolyurethane adhesive

The invention discloses a solvent-free polyurethane adhesive for a flexible package, which is prepared by at least mixing a component A and a component B, wherein the component A is an endcapped polyurethane prepolymer containing terminal isocyanate groups, and the B component is a combination which is formed by compounding polyether polyol and polyester polyol of liquid styrene butadiene rubber containing terminal hydroxy groups and / or liquid acrylonitrile butadiene rubber containing terminal carboxyl groups. The solvent-free polyurethane adhesive of the invention is suitable for solvent-free compounding of the flexible package and has the advantages of low cost, wide compound substrate range (substrates such as plastic films, aluminum-coated films, aluminum foil and the like can be compounded), high bonding strength (the peeling strength of BOPP / PE reaches more than 4N / 15mm, the peeling strength of PET / VMPET reaches more than 4.5N / 15mm, and the peeling strength of the inner film of PET / AL / PE reaches more than 6N / 15mm), wide application temperature range (25-55 DEG C), long service life of a plastic plate (the service life is longer than 40 minutes when the plastic plate is used at 50 DEG C), good leveling property, no solvent discharge, environmental friendliness and the like.

Owner:广东国望精细化学品有限公司

Neutral-coloured 1K polyurethane adhesive

InactiveUS7199207B2Isocyanic acid derivatives preparationCarbamic acid derivatives preparationPolyurethane adhesivePolyol

Owner:HENKEL KGAA

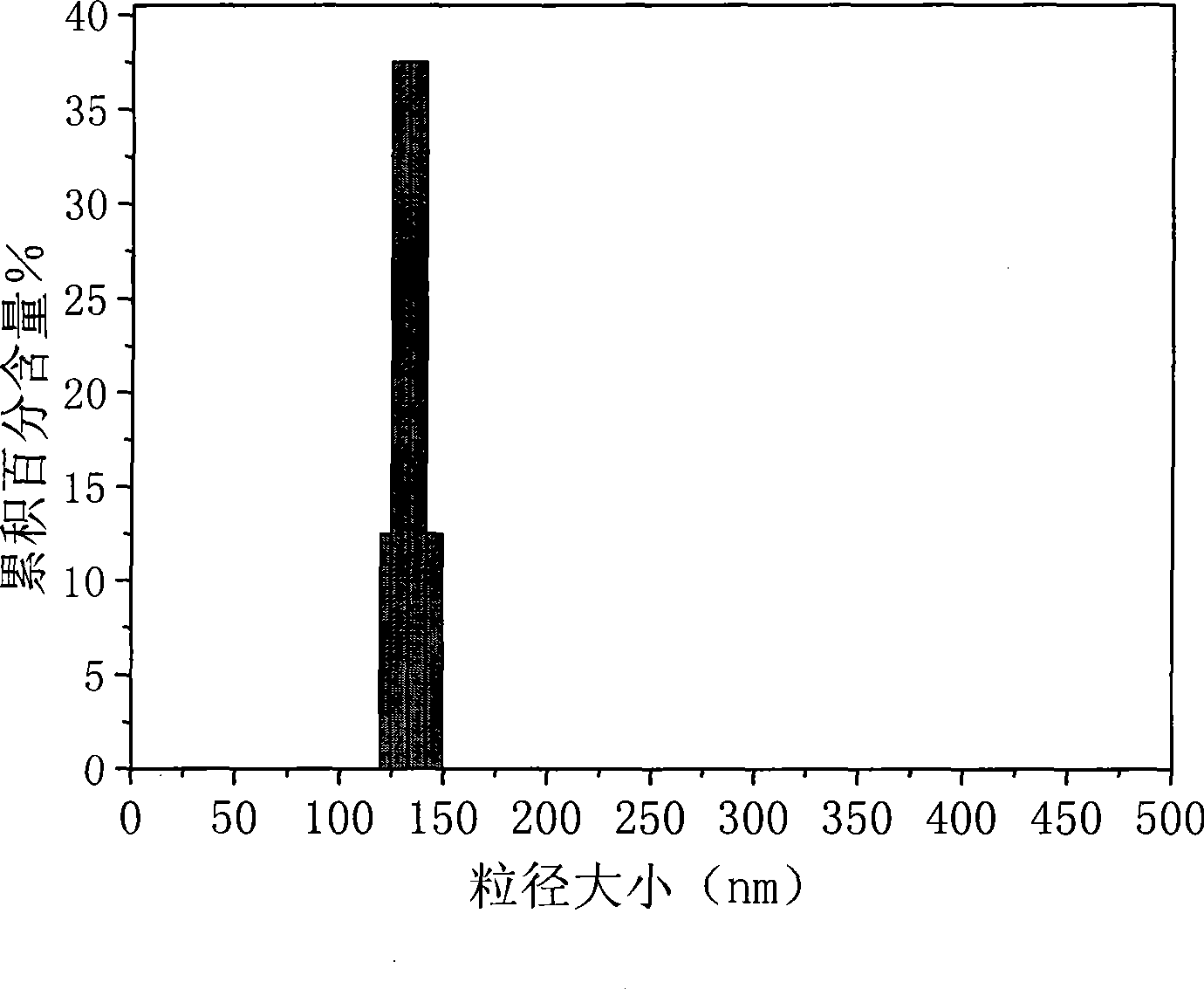

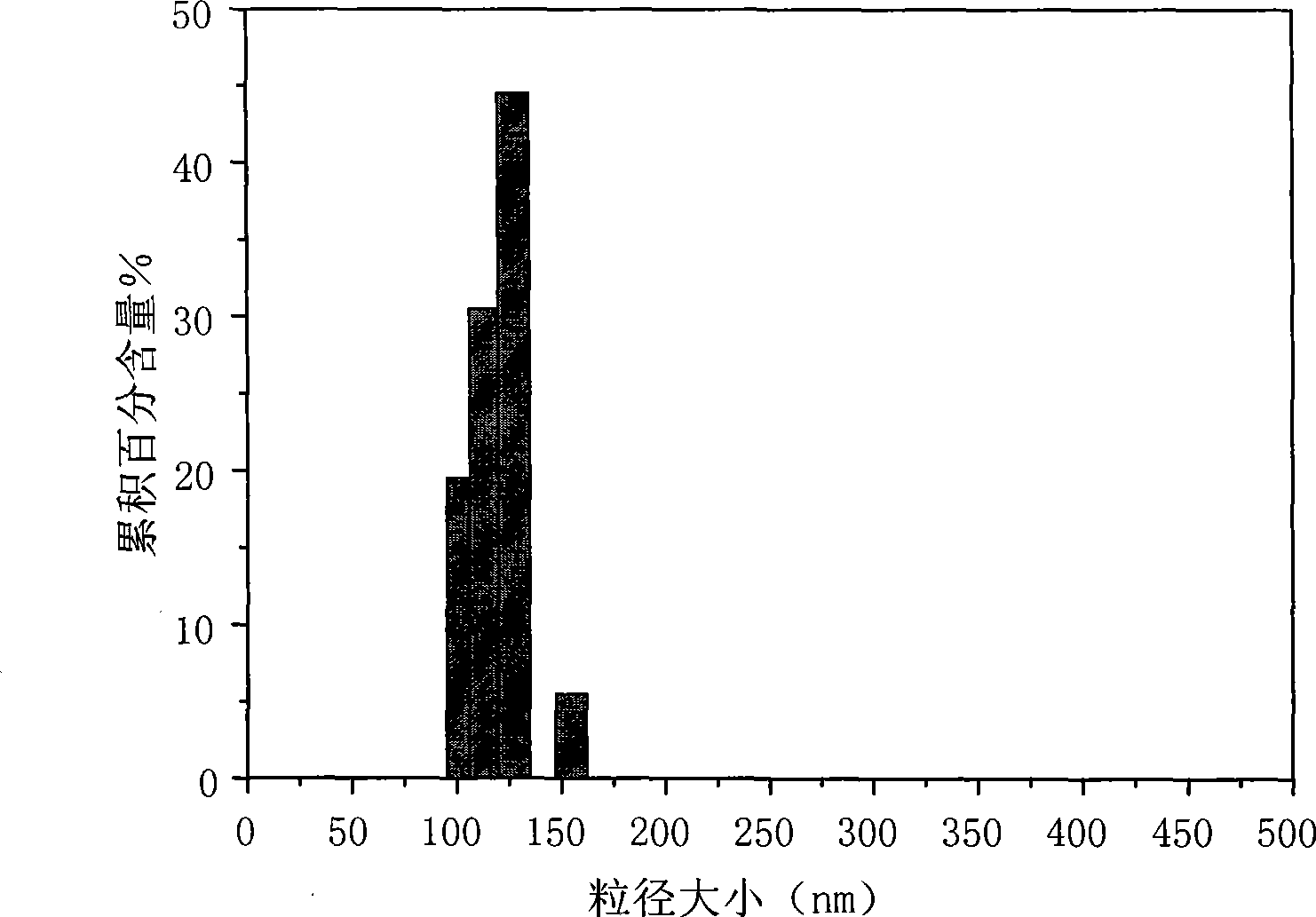

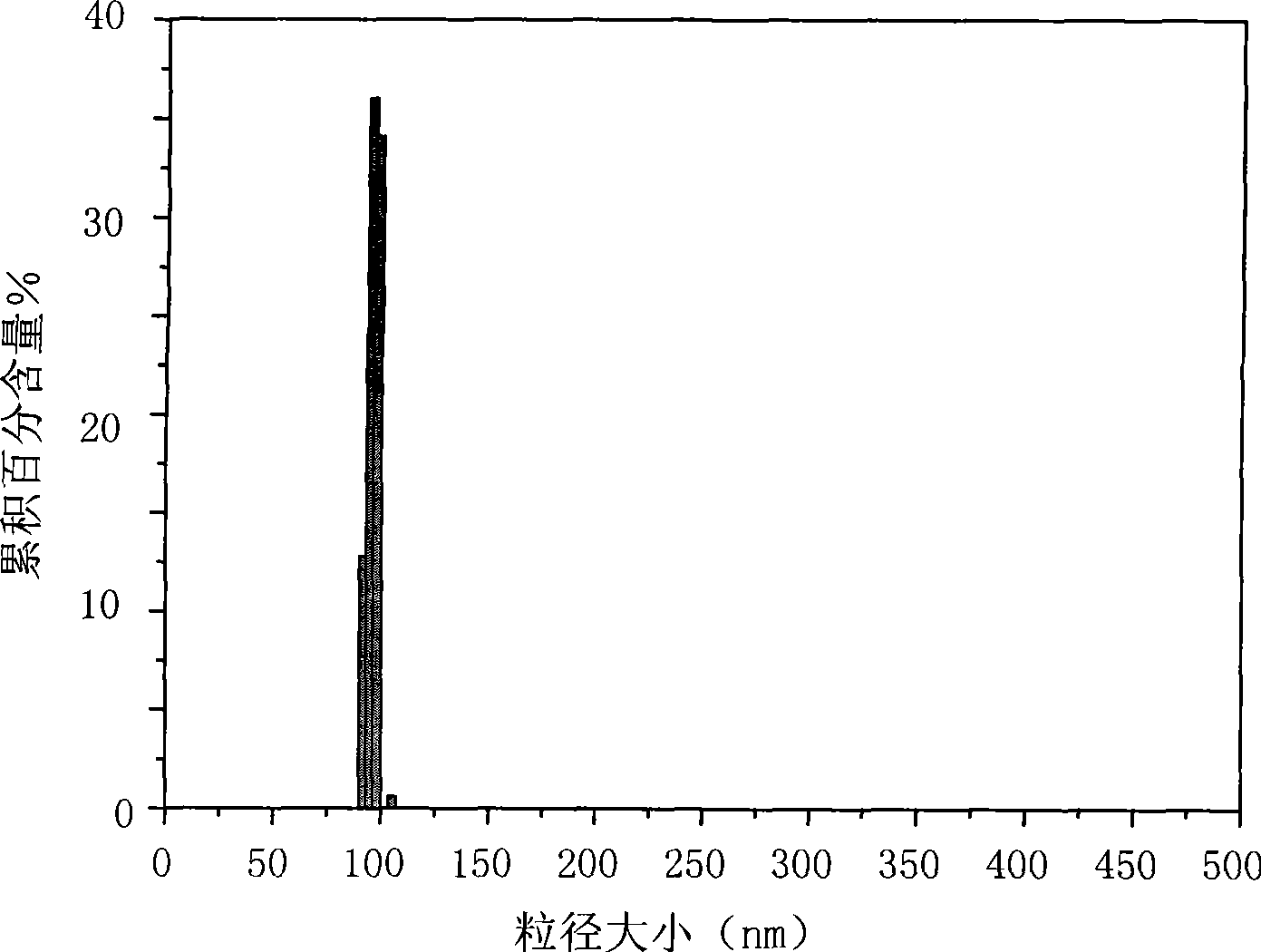

Practical method for preparing high thixotropy surface treating nano calcium carbonate

InactiveCN101475759AImprove thixotropyParticle size controllablePigment treatment with non-polymer organic compoundsPolyurethane adhesiveCarbonization

The invention discloses a practical method for preparing high-thixotropy surface treatment nano calcium carbonate, which comprises the following steps: firstly, calcining and digesting preferable limestone, and then controlling carbonization of the limestone in a special reactor to obtain nano calcium carbonate primary slurry; secondly, carrying out surface treatment on the nano calcium carbonate according to practical and special control technology; and finally dehydrating, drying, crushing and grading the coated slurry. The shape of the obtained calcium carbonate is cubic, the particle diameter is 50 to 100 nanometers, and the specific surface area is 20 to 40 m / g. The obtained powder has good dispersion effect and thixotropy, is suitable for occasions needing high thixotropy, such as high-performance silicone adhesive, epoxy adhesive, polysulfide adhesive, polyurethane adhesive, automotive primary coat, floor coating and the like, and has wide market prospect. The method has simple raw materials and process requirement, stabalizes the production and reduces the cost.

Owner:山东海泽纳米材料有限公司

High-adhesive property watersoluble polyurethane adhesion agent and method of producing the same

InactiveCN101429417AHigh solid contentFast dryingPolyureas/polyurethane adhesivesWater basedPolyurethane adhesive

The invention relates to water-based polyurethane adhesive with high adhesive property and a preparation method thereof, and belongs to the field of polyurethane adhesive. The preparation method comprises the following steps: (1) drying a polylol polymer for 1 to 3 hours in vacuum at a temperature of between 100 and 120 DEG C, reducing the temperature to between 80 and 90 DEG C, dripping diisocyanate into the polylol polymer, polymerizing the mixture for 1 to 1.5 hours, adding small molecular polylol and hydrophilic polylol into the mixture to carry out chain extension and polymerization reaction for 1 to 1.5 hours, then adding the diisocyanate into the mixture, and making the mixture subjected to end capping reaction for 0.5 to 1 hour; (2) dripping neutralizing agent into cross linking polyurethane pre-polymer, and adding acetone into the pre-polymer at the same time to reduce viscosity, wherein the neutralization degree is 95 to 100 percent after the mixture is reacted for 0.5 to 1 hour at a temperature of between 35 and 45 DEG C; (3) dripping the obtained hydrophilic cross linking polyurethane pre-polymer into a mixture of a polyamine compound and water, and dispersing the mixture evenly under high-speed shearing function of an emulsifying machine to obtain water-based polyurethane dispersant; and (4) removing organic solvent in the water-based polyurethane dispersant obtained in step (3) by a vacuum decompressing method. The preparation method effectively solves the problem of difficult emulsifying dispersion caused by cross linking, has simple emulsifying process, and reduces equipment requirement remarkably, has high solid content, reduces cost for production, storage and transportation, improves drying time, and is convenient for gluing operating process.

Owner:GUANGZHOU KELIN WAER BORNE MATERIAL

Hair cosmetic composition containing a polyurethane latex polymer and a silicone-organic polymer compound

Disclosed are hair cosmetic compositions comprising, in a cosmetically acceptable carrier, at least one polyurethane latex polymer and at least one silicone-organic polymer compound. Methods of imparting durable styling or shaping benefits to hair and / or of controlling frizziness of hair by applying the hair cosmetic compositions onto hair are also disclosed.

Owner:LOREAL SA

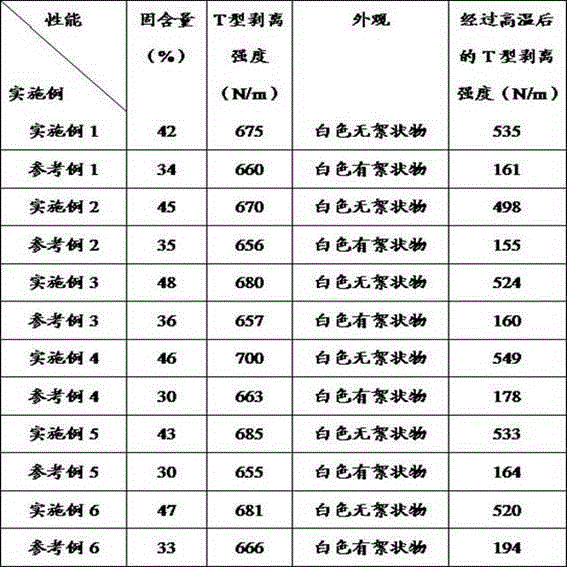

High-bonding-strength and high-temperature-resisting phenolic resin modified polyurethane adhesive and preparation method thereof

The invention discloses a high-bonding-strength and high-temperature-resisting phenolic resin modified polyurethane adhesive and a preparation method thereof. The preparation method comprises the following steps of: synthesizing modified phenolic resin, preparing polyurethane prepolymer, synthesizing modified polyurethane prepolymer, and synthesizing the modified polyurethane adhesive, wherein the step of synthesizing the modified phenolic resin is carried out by adding methoxyl dimethylbenzene monomer and phenols in phenolic resin to react under the effect of an acid catalyst, cooling the mixture, and then adding a basic catalyst, solvent and formaldehyde in the mixture for dehydration reaction under vacuum until the mixture is transparent, thus obtaining the modified phenolic resin; the step of preparing the polyurethane prepolymer is carried out by adding polyisocyanates and polyester polyol in the modified phenolic resin for reacting; the step of synthesizing the modified polyurethane prepolymer is carried out by modifying the polyurethane prepolymer through the modified phenolic resin to obtain the modified polyurethane prepolymer; and the step of synthesizing the modified polyurethane adhesive is carried out by adding water to the modified polyurethane prepolymer, and dispersing the modified polyurethane prepolymer through dispersing agent, and finally adding neutralizing agent, cross-linking agent and chain extender into the dispersed modified polyurethane prepolymer to obtain the modified aqueous polyurethane adhesive. The preparation method disclosed by the invention is simple, and improves the bonding strength and high temperature resistance of the polyurethane adhesive.

Owner:高金技术产业集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com