Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1925results about How to "Improve hydrolysis resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Radiation-curable liquid resin composition for coating optical fibers

InactiveUS6136880AConvenient coatingLow viscositySynthetic resin layered productsYarnPhotoinitiatorChemistry

Owner:DSM IP ASSETS BV

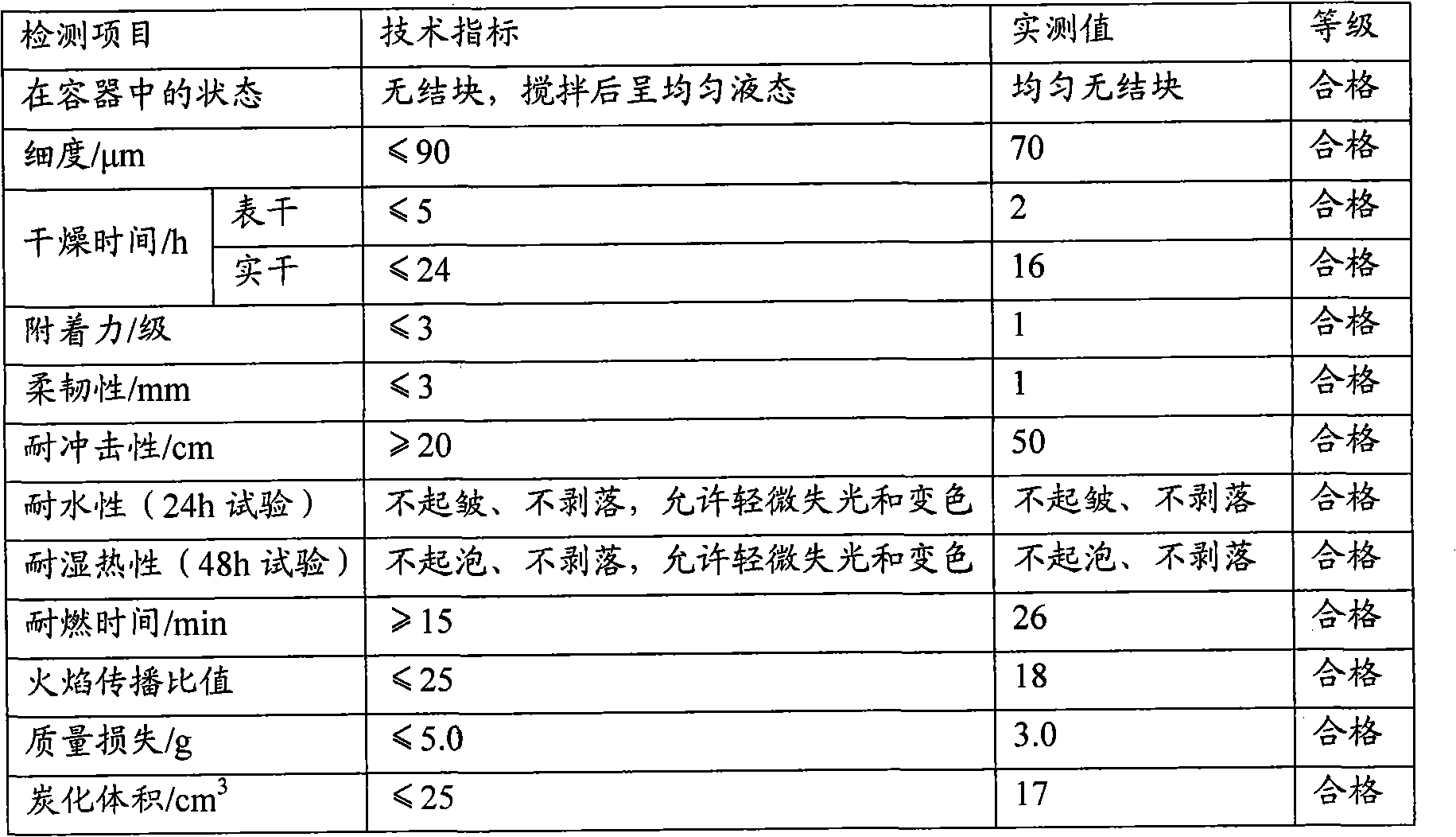

Expanded type fireproof coating and preparation method thereof

ActiveCN101659823AReduce usageLow costFireproof paintsPolyurea/polyurethane coatingsSolventAnti ageing

The invention discloses an expanded type fireproof coating and a preparation method thereof, which are characterized by comprising the steps of grinding and dispersing 15-35 percent of microcapsule flame retardants, 5-10 percent of fillers and 10-30 percent of solvent according to the percentage of the total mass of the coating after preparation until the fineness thereof is less than 90 microns;then adding and dispersing coating matrixes and additives which respectively take up 20-40 percent and 1-5 percent of the total mass of the coating after preparation until the system is uniform; and alternatively adding flame retardant synergist agents which account for 0-10 percent of the total mass of the coating after preparation before grinding. The obtained expanded type fireproof coating hasgood stability, overcomes the defects of poor high-temperature resistance, poor anti-aging performance, poor water resistance and the like in the traditional organic expanded type fireproof coating,lowers the use amount and cost of the flame-retardant additives which all realize non-halogenation, does not cause larger impact on the environment, and has very good application prospects.

Owner:UNIV OF SCI & TECH OF CHINA

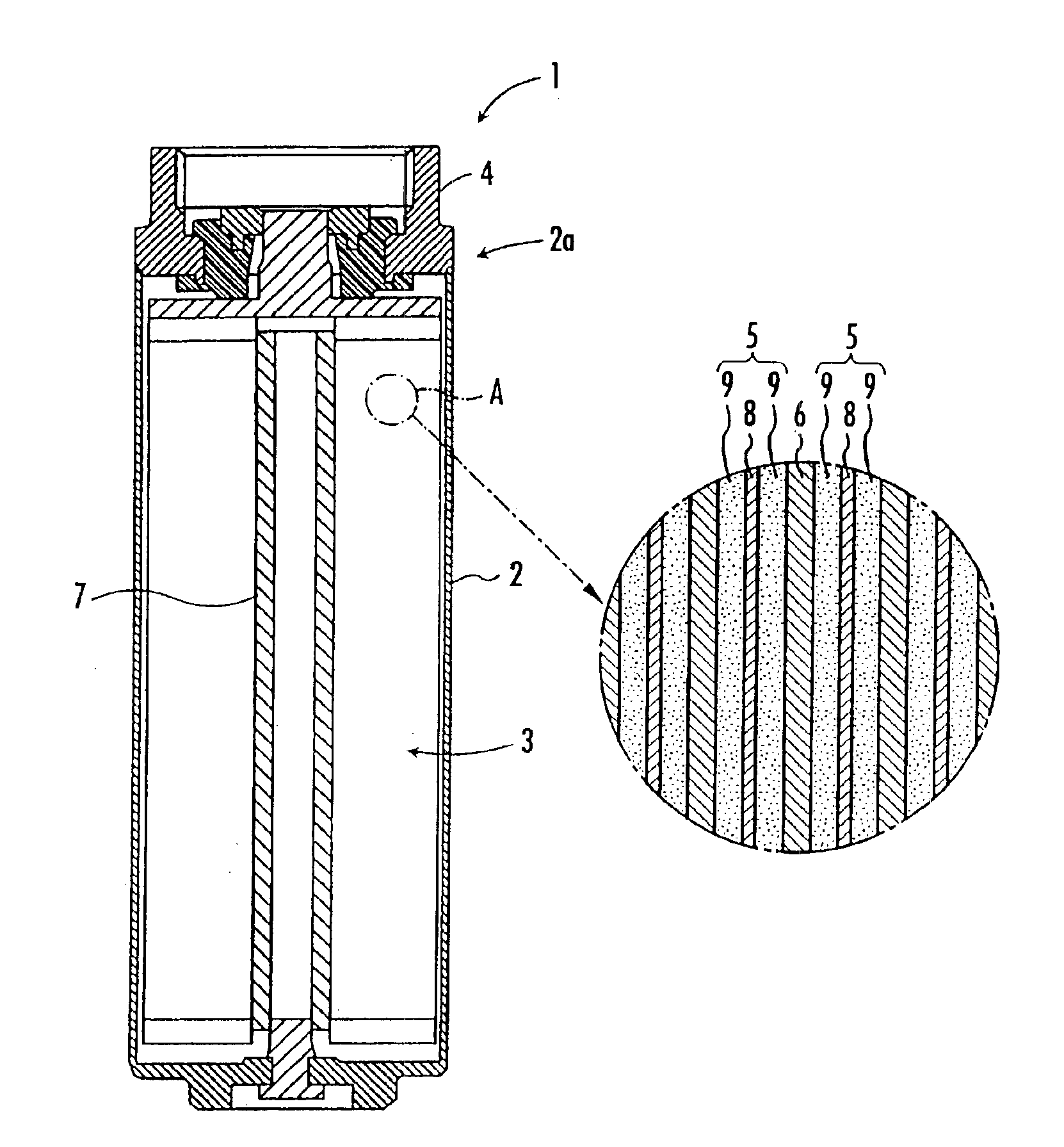

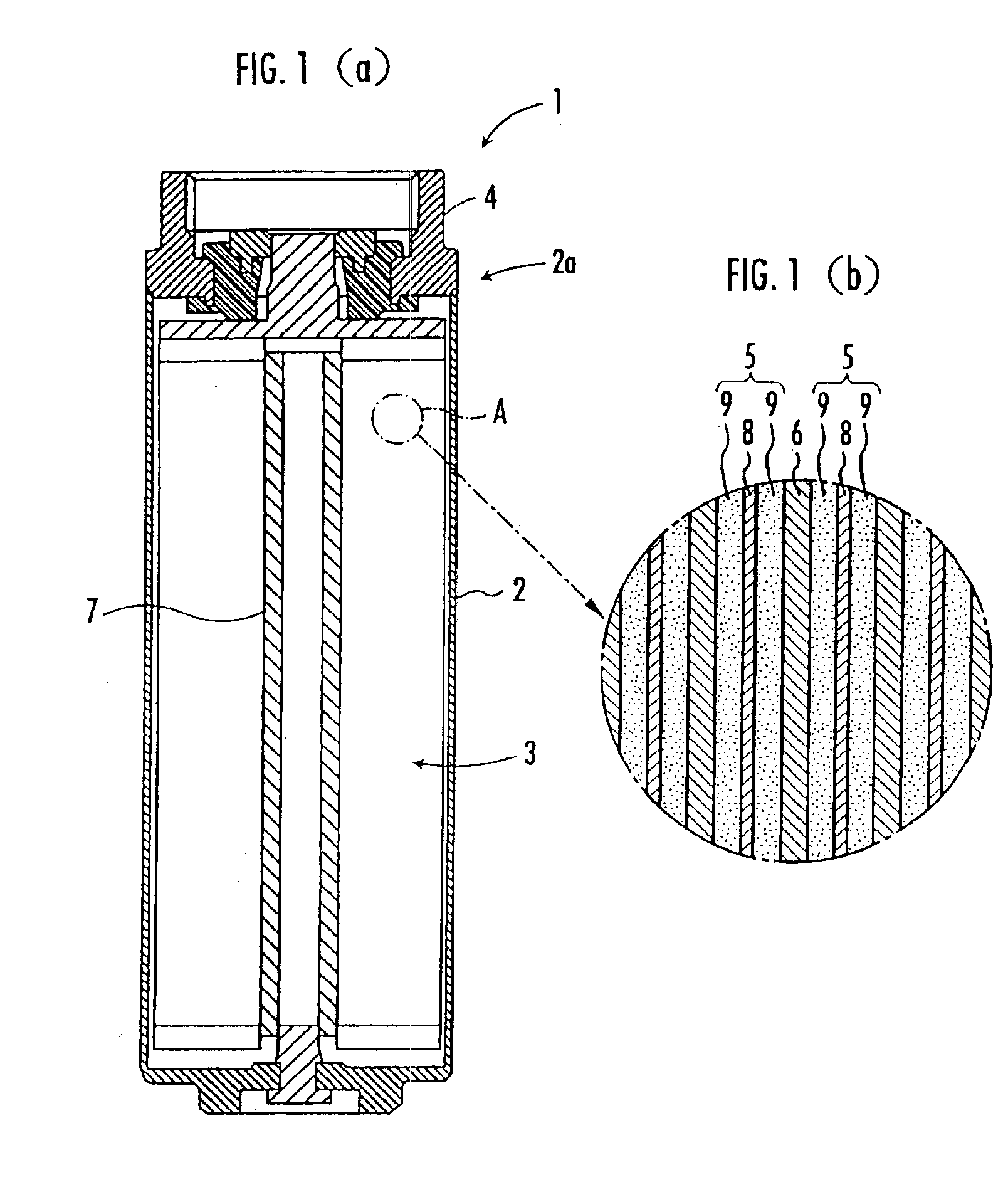

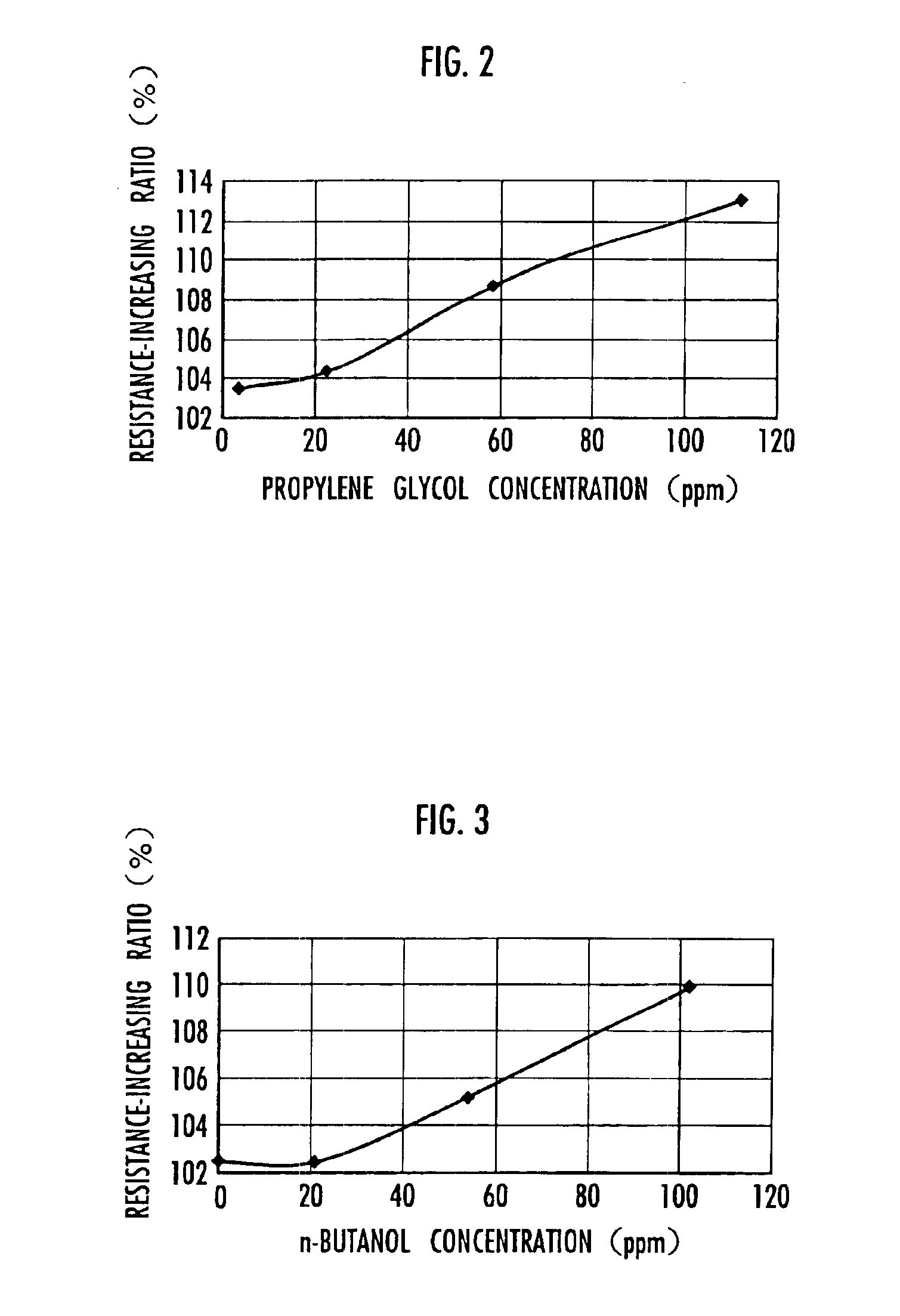

Electrical double-layer capacitor

ActiveUS6914768B2Small increase in resistanceIncrease the residual rateHybrid capacitor electrolytesProtecting/adjusting hybrid/EDL capacitorQuaternary ammonium cationTetrafluoroborate

An electrical double-layer capacitor showing a sleight increase of resistance when used under continuous application of high voltage and maintaining high energy residual ratio after standing for a long time includes an electrode element including a pair of electrodes disposed opposite to each other with a separator interposed therebetween, and is impregnated with a nonaqueous electrolyte solution prepared by dissolving quaternary ammonium salts into cyclic carbonates and containing impurities of 30 ppm or less of glycols, 30 ppm or less of primary alcohols and less than 20 ppm of tertiary amines. The water content may be 50 ppm or less. The quaternary ammonium salt may be triethylmethylammonium tetrafluoroborate. The cyclic carbonate may be propylene carbonate. The nonaqueous electrolyte solution may have a concentration of 0.1 to 2.5 mol / liter. The electrode may be a polarizable electrode composed of activated carbon.

Owner:MU IONIC SOLUTIONS CORP +1

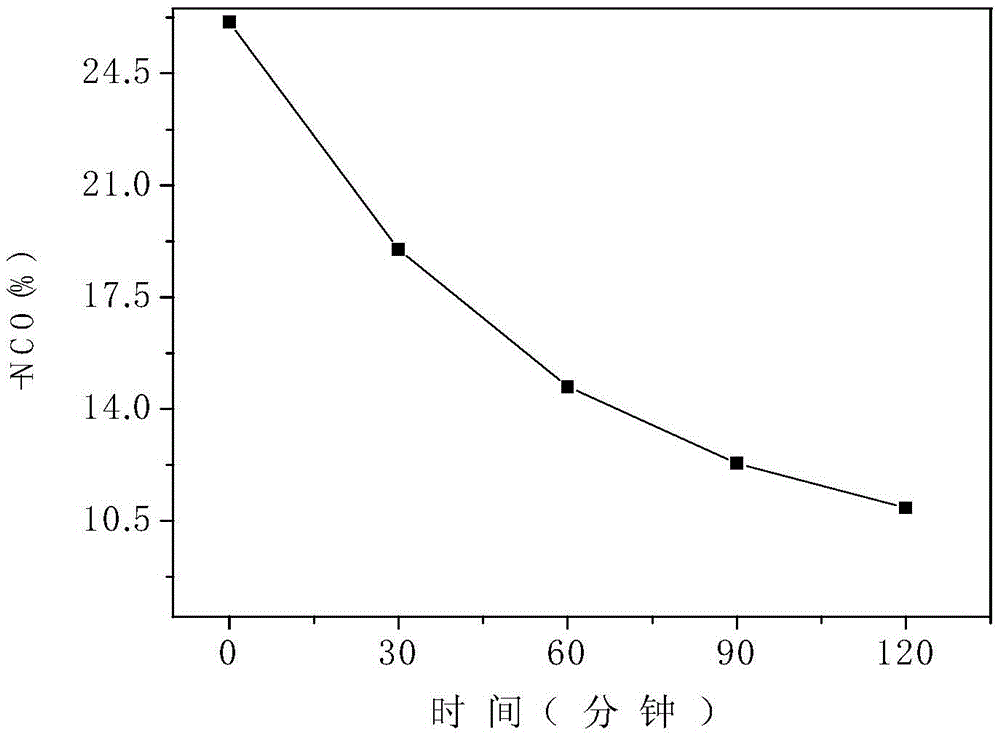

Polymerized thylene carbonate urethane elastomer and its preparation method

ActiveCN1865311AMolecular chain softRoom temperature and good flexibilityCross-linkMedical equipment

The invention discloses a polyethylene carbonate polyurethane elastomer and making method, which produces polycarbonate polyhydric alcohol through carbon dioxide and oxirane with 20-60 percent diisocyanate, 0.05-2 percent polymerization inhibitor, 2.4-17 percent chain-extending agent and or cross linking agent and 0-0.4 percent catalyst. The method possesses better mechanic property, plasticity, anti-oxidizing property and water weakened-durability, which can be applied in the liner, screen, sealing ring and medical equipments.

Owner:JIANGSU ZHONGKE JINLONG CHEM

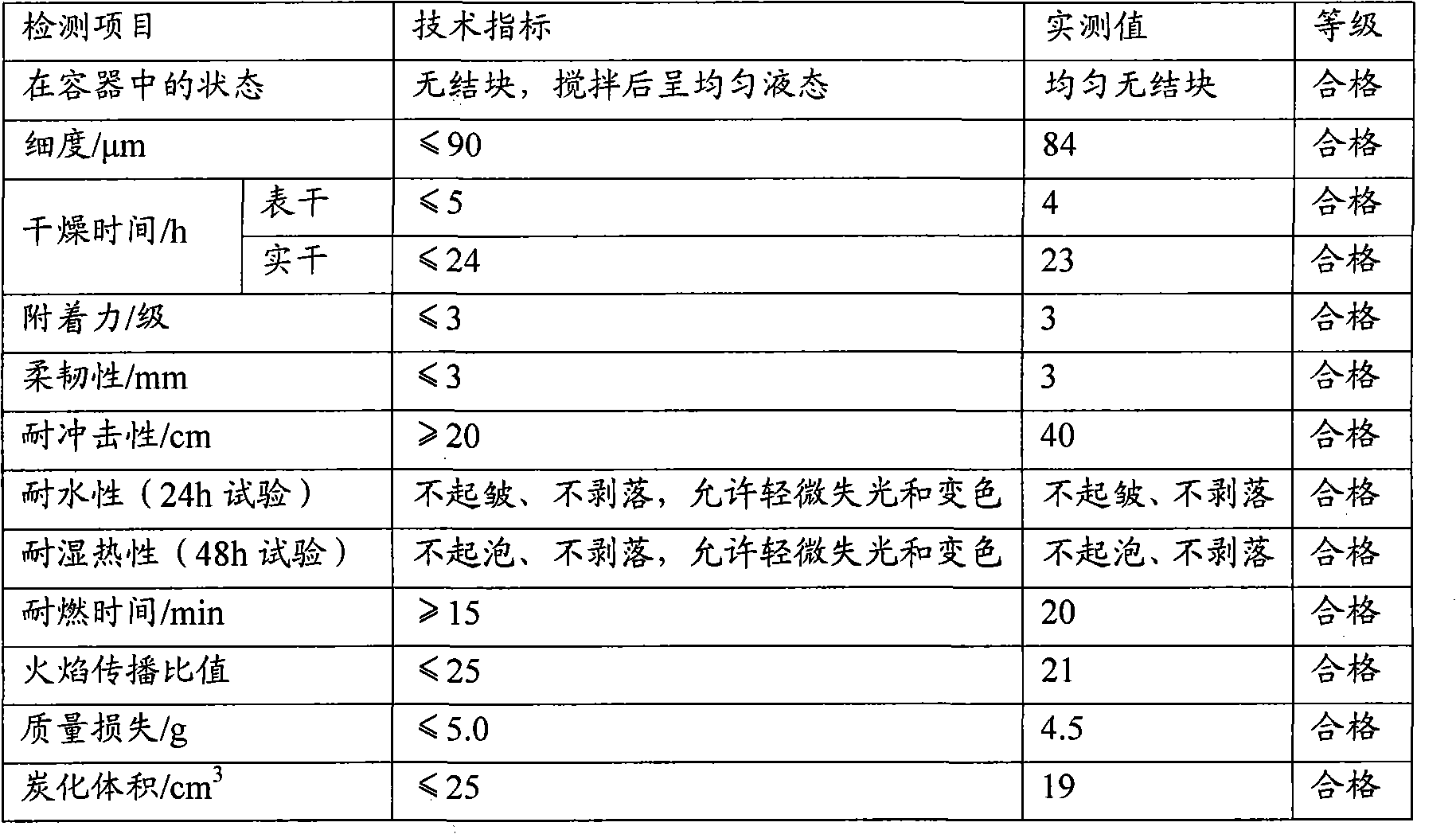

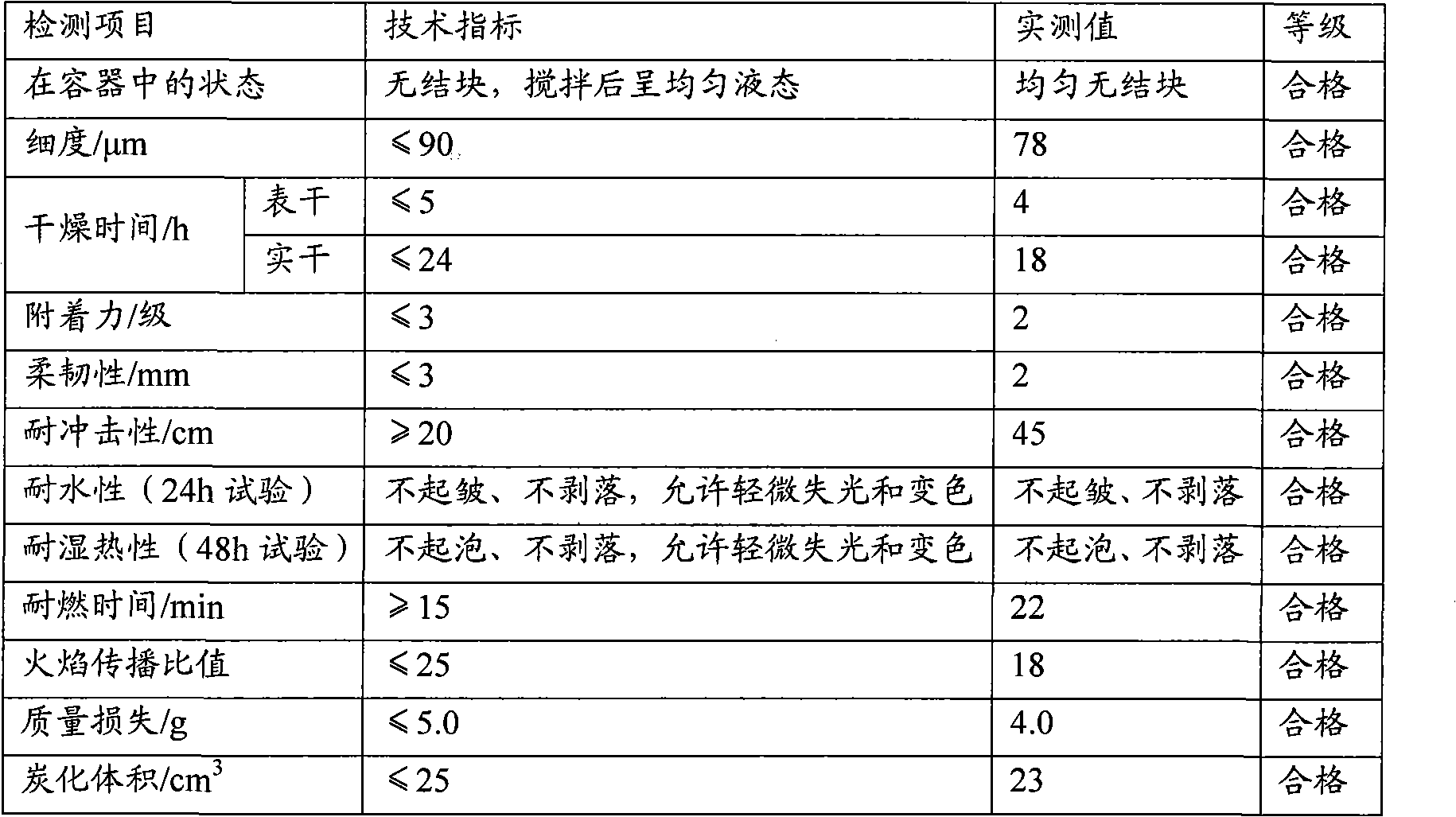

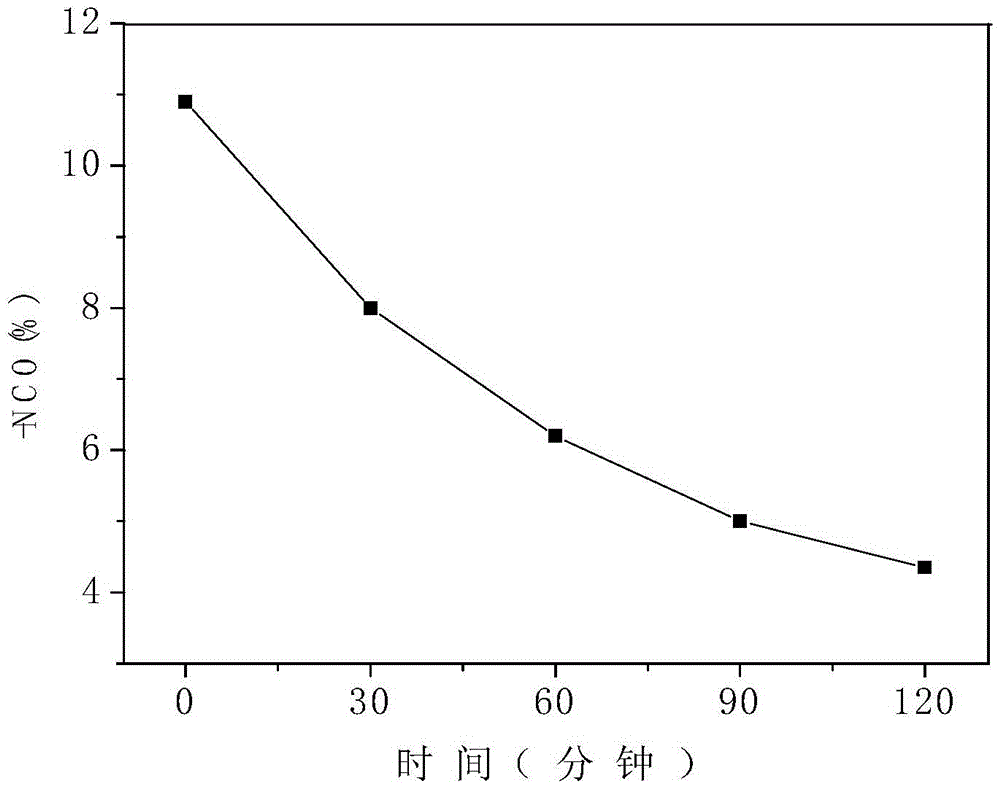

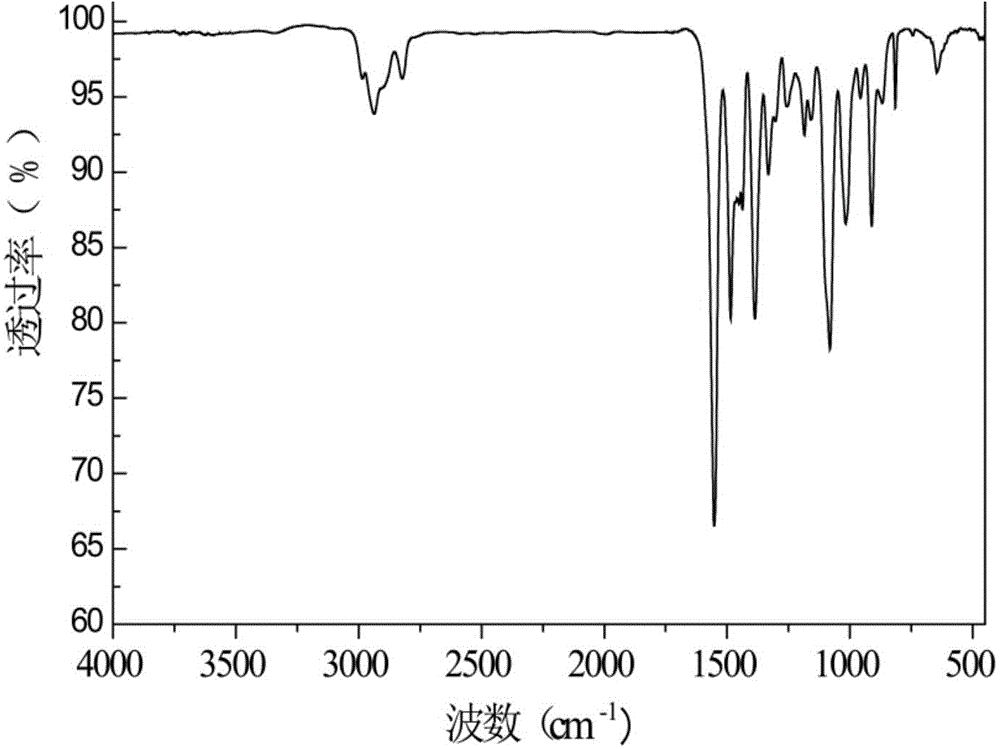

Poly(propylene carbonate)-based polyurethane fireproof coating and preparation method thereof

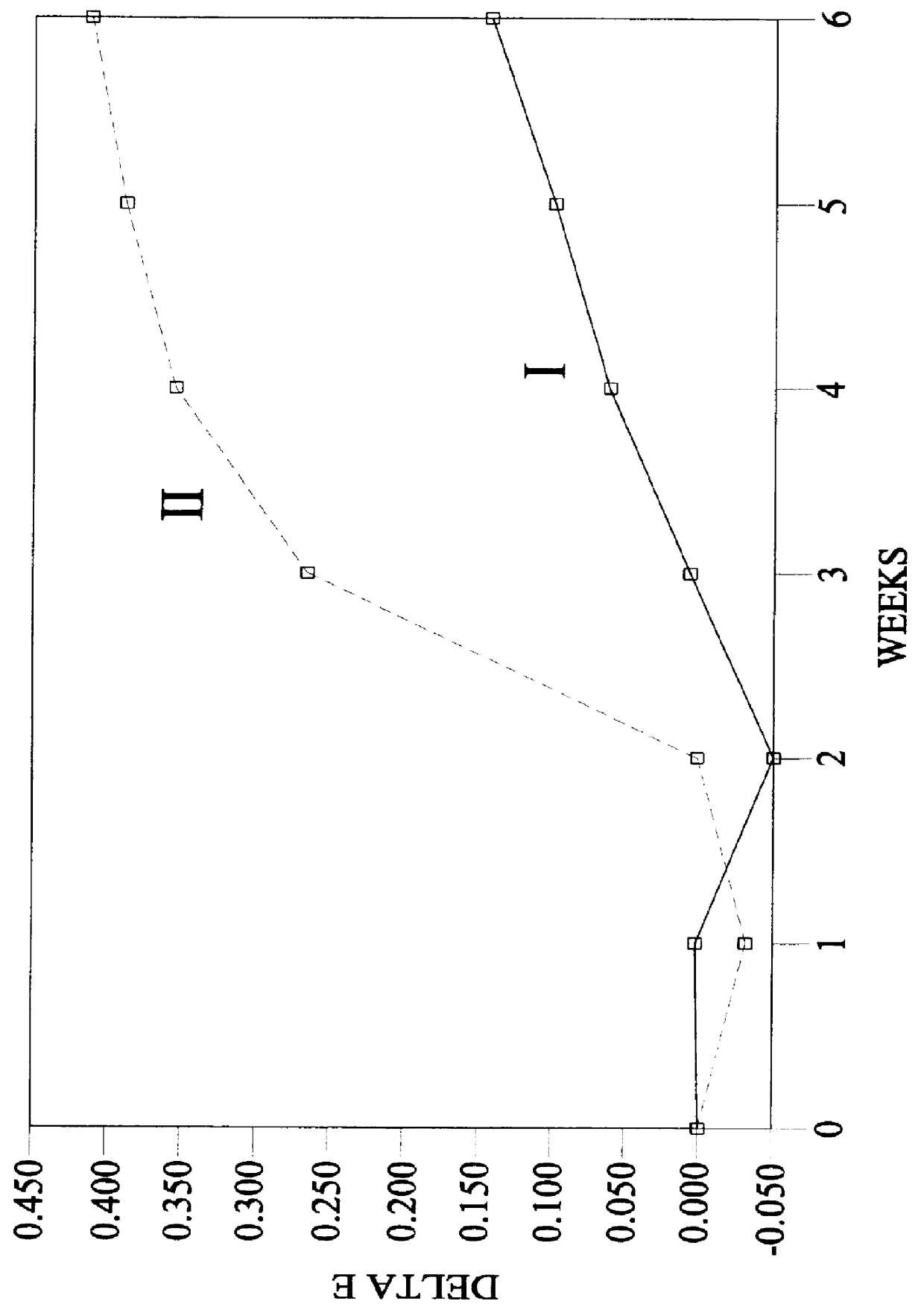

ActiveCN102241942AImprove hydrolysis resistanceImprove fire performanceFireproof paintsPolyurea/polyurethane coatingsSilane couplingFlame resistance

The invention relates to a poly(propylene carbonate)-based polyurethane fireproof coating and a preparation method thereof. The poly(propylene carbonate)-based polyurethane fireproof coating is prepared from 100 parts of poly(propylene carbonate) which is the polymer of carbon dioxide and propylene oxide, 15-30 parts of aromatic diisocyanate, 0.1-0.2 part of catalyst, 0-3 parts of non-ionic chainextender containing active hydrogen, 2-8 parts of active-hydrogen-containing ionic chain extender capable of forming a hydrophilic group, 1-6 parts of neutralizer, 1-10 parts of silane coupling agent, 200-350 parts of adjuvant, 40-140 parts of flame retardant, 10-50 parts of bentonite and 1-3 parts of dispersant. The fireproof coating has the advantages of good water resistance, strong adhesion force, flame retardance reaching one level, superior fireproof performance, strong integrated application capability and bright application prospect, and can be applied to the surface coating of wood, steel and other substrates.

Owner:JIANGSU ZHONGKE JINLONG CHEM

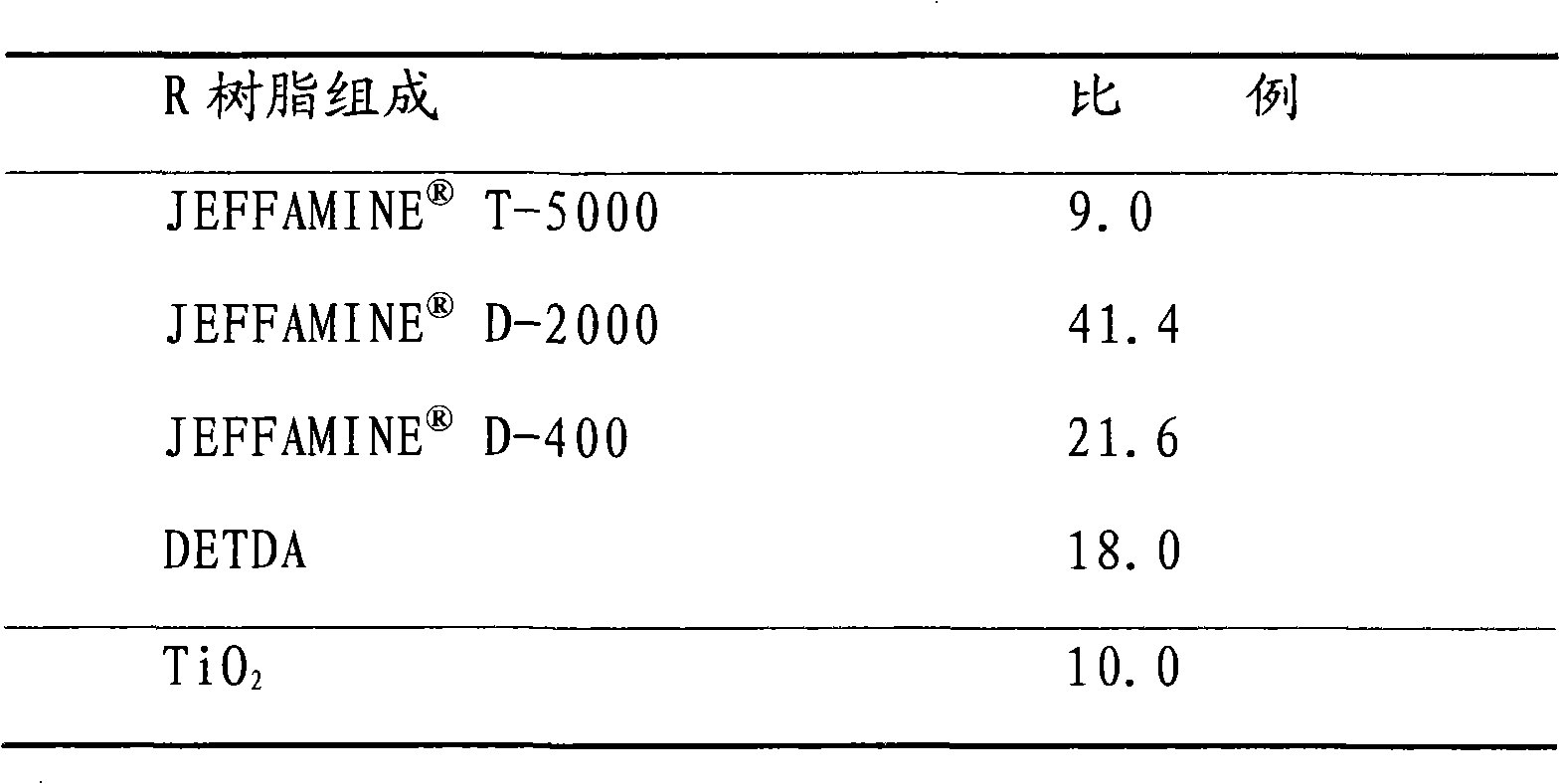

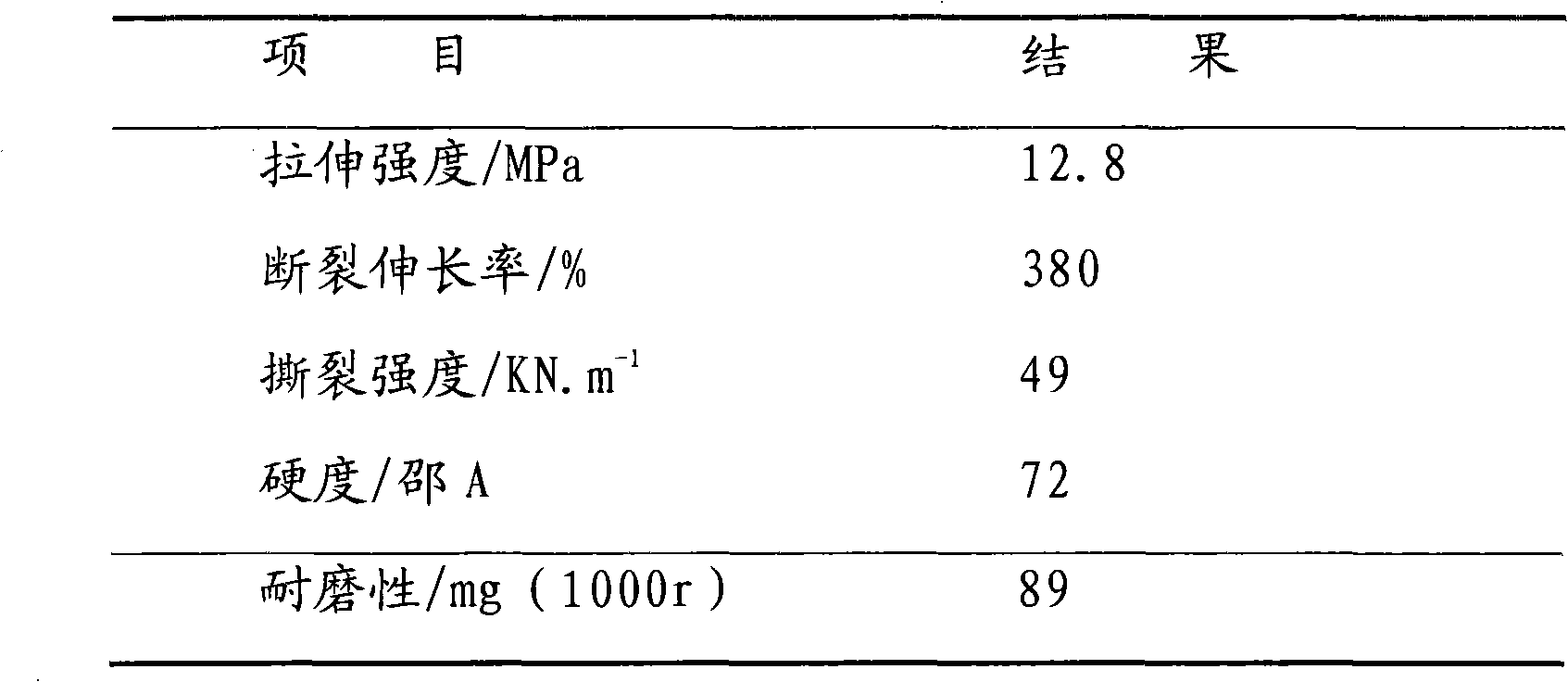

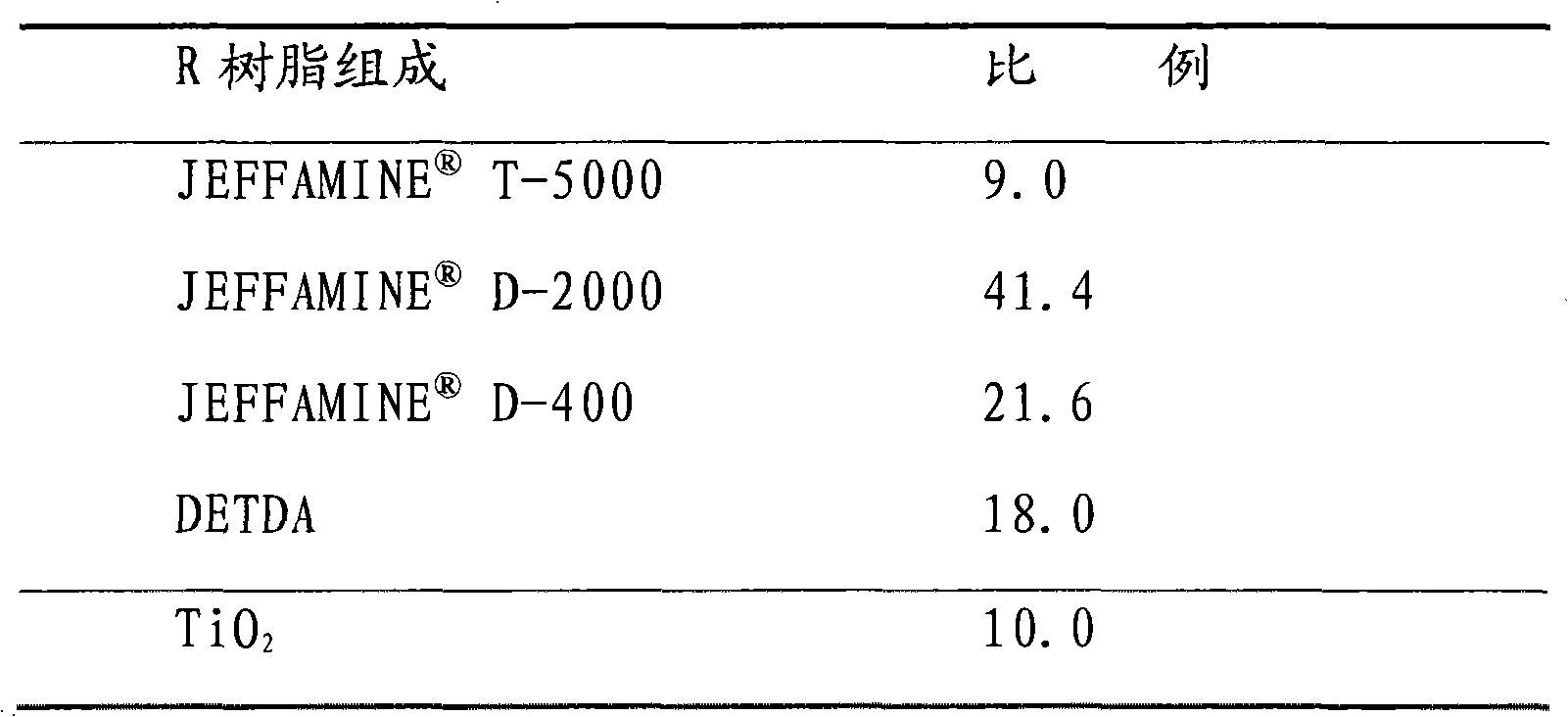

Spray polyurea elastomer for mine, preparation and construction method thereof

InactiveCN101302393ANot affected by ambient temperatureNot affected by ambient humidityLiquid surface applicatorsPolyurea/polyurethane coatingsElastomerPolyol

The invention provides a spraying polyurea elastomer applied to a mine, a method for making the same and a construction method. The spraying polyurea elastomer can solve the problem of poor wearing resistance in the prior art. The invention comprises the following technical proposals that: the spraying polyurea elastomer applied to the mine comprises two compositions A and R, wherein, the composition A is a semi-prepolymer synthesized by 45 to 65 portions of polyisocyanate and 35 to 55 portions of polyether polyol; the composition R comprises 55 to 80 portions of amine terminated polyether, 15 to 33 portions of chain extender and 5 to 25 portions of antiwear filler; and the compositions A and R are matched for use according to an isocyanate index of between 0.9 and 1.2. The spraying polyurea elastomer has good physical performance, high wearing resistance, good oil resistance, hydrolization resistance, bacteria resistance and aging resistance and good construction performance and can be used in a vibration sieve equipment lining, a flotation equipment lining, etc. of the mine and other application places which have high requirement on wearing resistance.

Owner:青岛佳联化工新材料有限公司

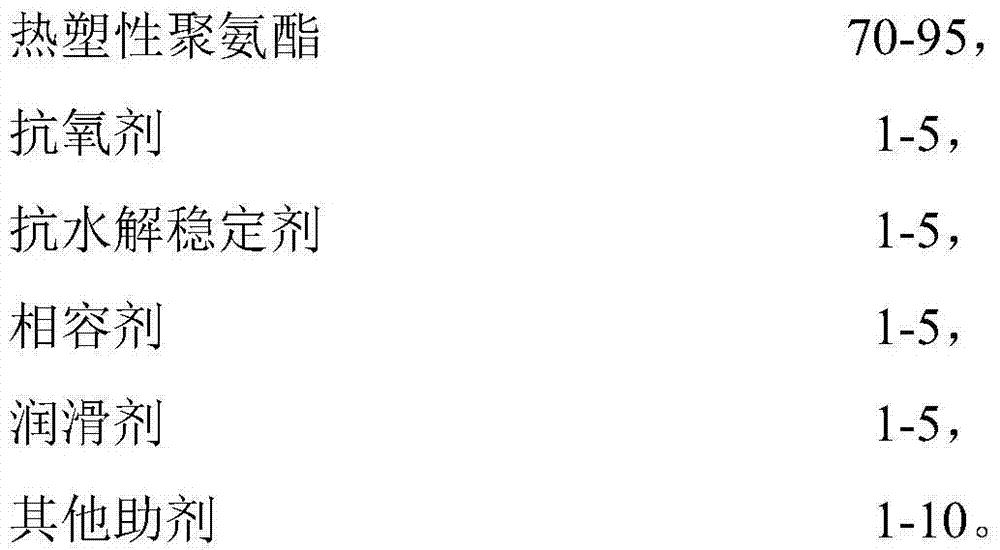

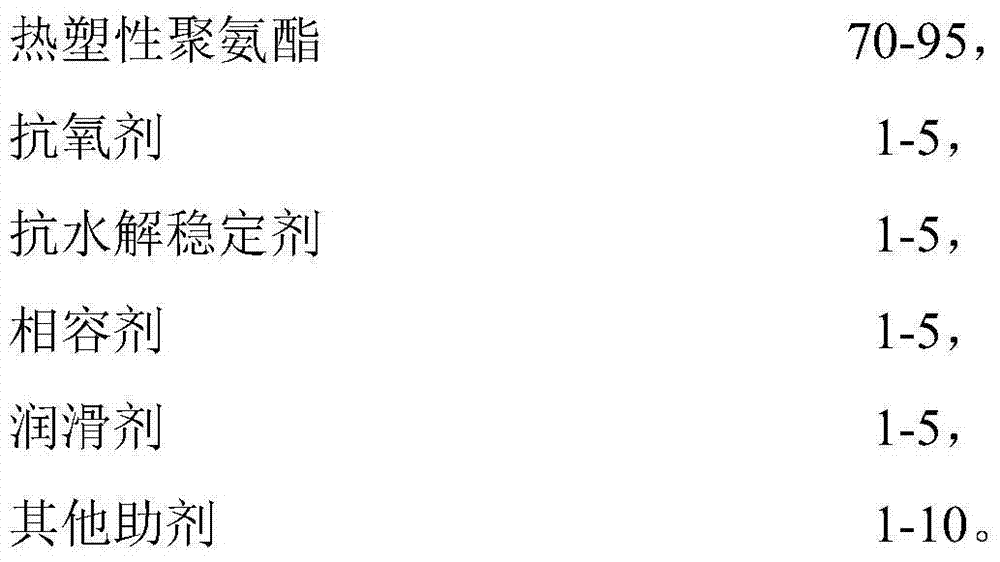

Thermoplastic polyurethane modified composite material for FDM (frequency division multiplexing) 3D printing and preparation method thereof

The invention relates to a thermoplastic polyurethane modified composite material for FDM (frequency division multiplexing) 3D printing and a preparation method thereof. The composite material is prepared from the following components in parts by weight: 70-95 parts of thermoplastic polyurethane, 1-5 parts of antioxidant, 1-5 parts of hydrolysis-resistant stabilizer, 1-5 parts of compatilizer, 1-5 parts of lubricant and 1-10 parts of other assistant. Compared with the prior art, the antioxidant, hydrolysis-resistant stabilizer, lubricant and other assistants are added, so that the modified composite material has the advantages of favorable mechanical properties, high elasticity, favorable wear resistance, higher heat stability, hydrolysis resistance, higher oxidation resistance and higher processability. When being used for FDM 3D printing, the thermoplastic polyurethane modified composite material has the characteristics of smooth printing process, no odor, smooth printing product surface, beautiful appearance, stable size, low tendency to shrinkage, favorable mechanical properties, high flexibility, high heat stability, high hydrolysis resistance, high oxidation resistance and high processability.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

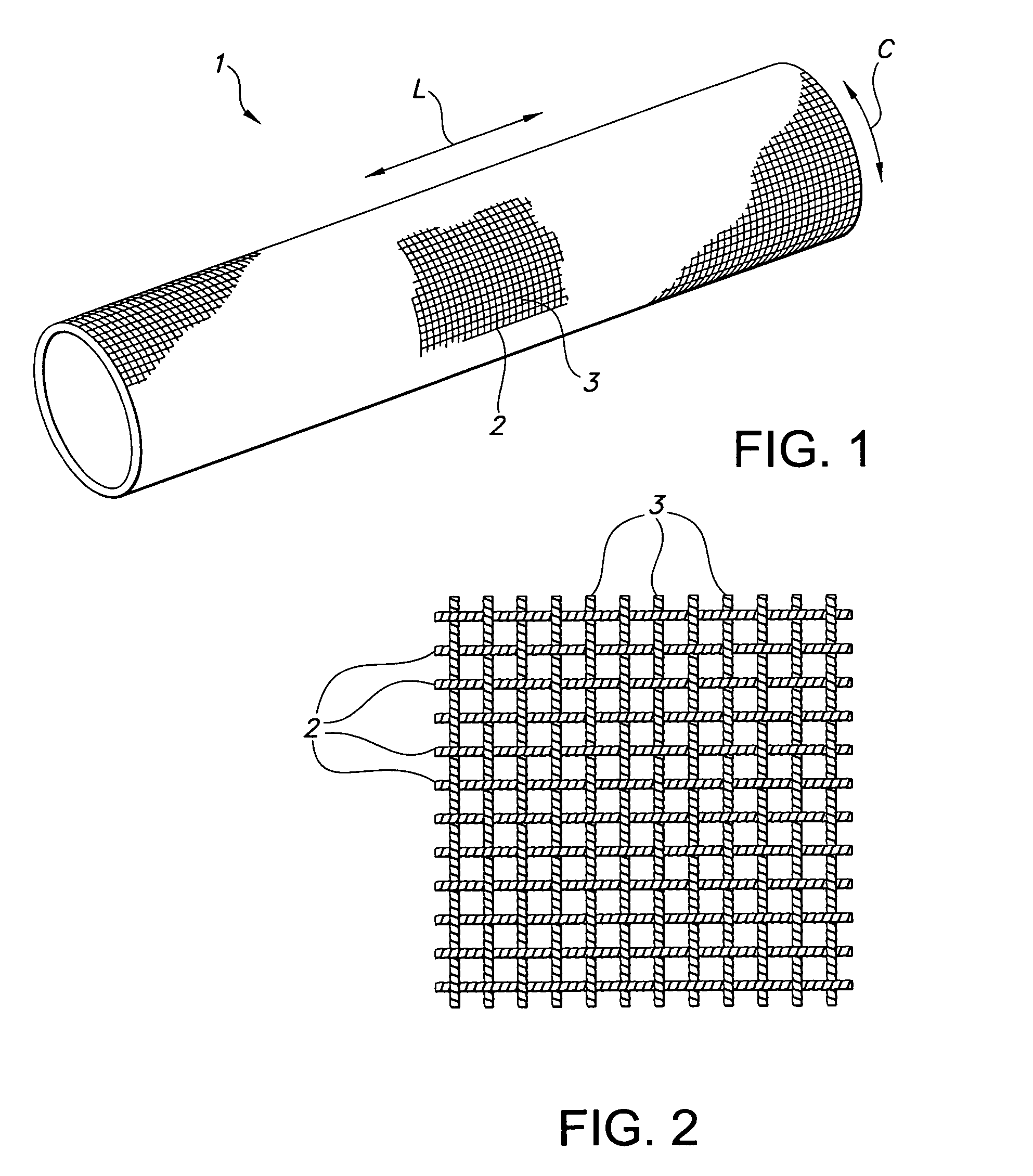

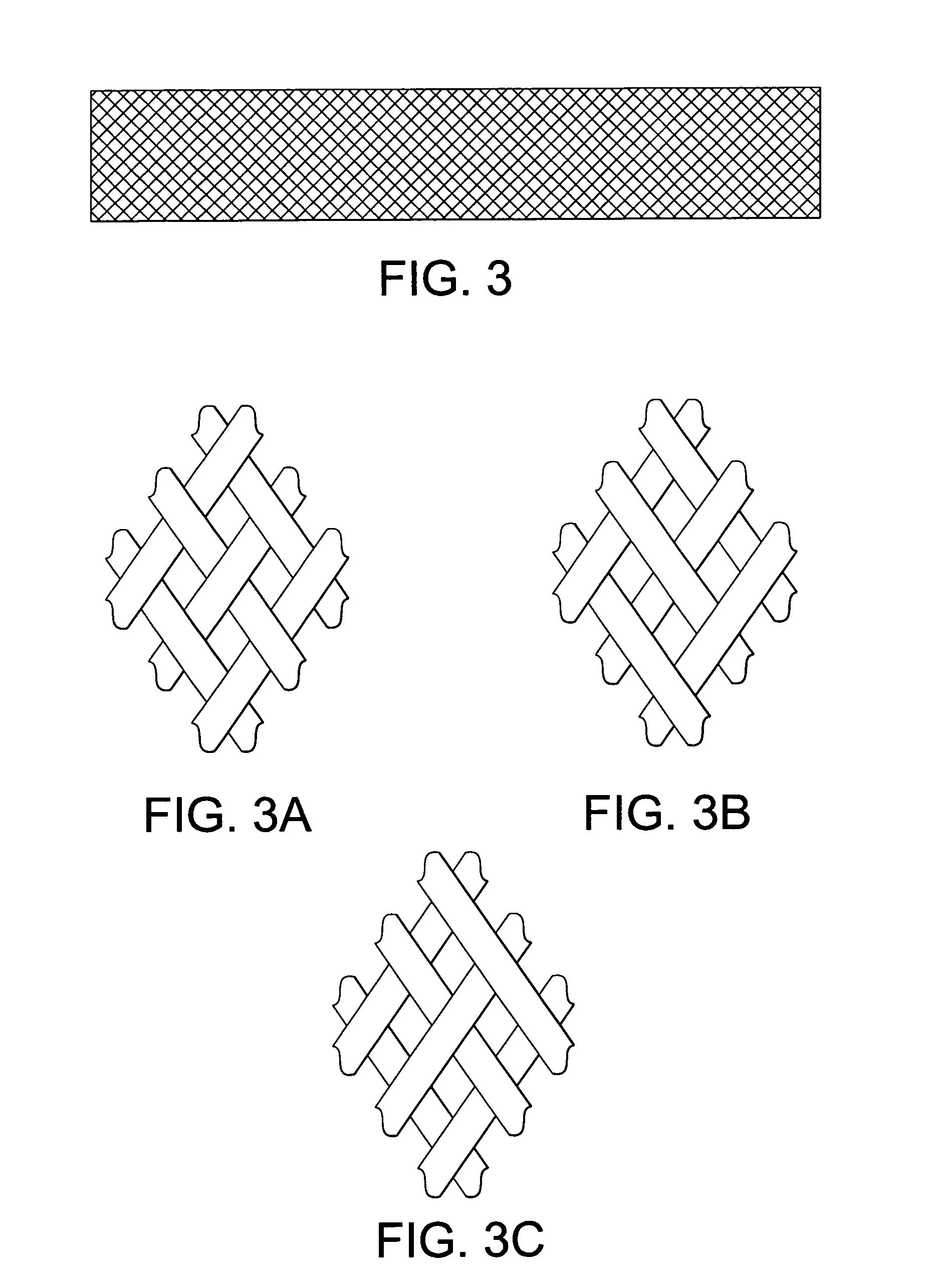

Implantable prostheses with improved mechanical and chemical properties

InactiveUS7083644B1Improved mechanical and chemical propertyImproved mechanical and thermal propertyBlood vesselsBiopolymerMechanical property

Prostheses with improved chemical and mechanical properties manufactured that includes a radiation resistant and hydrolytically stable biocompatible fabric having outer and first and second ends with a textile fabric that includes a naphthalene dicarboxylate derivative polymer having the general formula:wherein R1 and R3 are the same or different groups and are independently selected from the naphthalene dicarboxylate derivative repeating unit (I), a hydrogen radical and a methyl radical. R2 is an alkylene radical having 1 to 6 carbon atoms; n is from 10 to 200. Also contemplated are implantable prostheses that are flat constructions useful as patches and filters or tubular constructions useful as vascular grafts. A further aspect of this invention provides a method for making a radiation and thermal resistant and hydrolytically stable, steam sterilizable biocompatible prosthesis.

Owner:SCI MED LIFE SYST +1

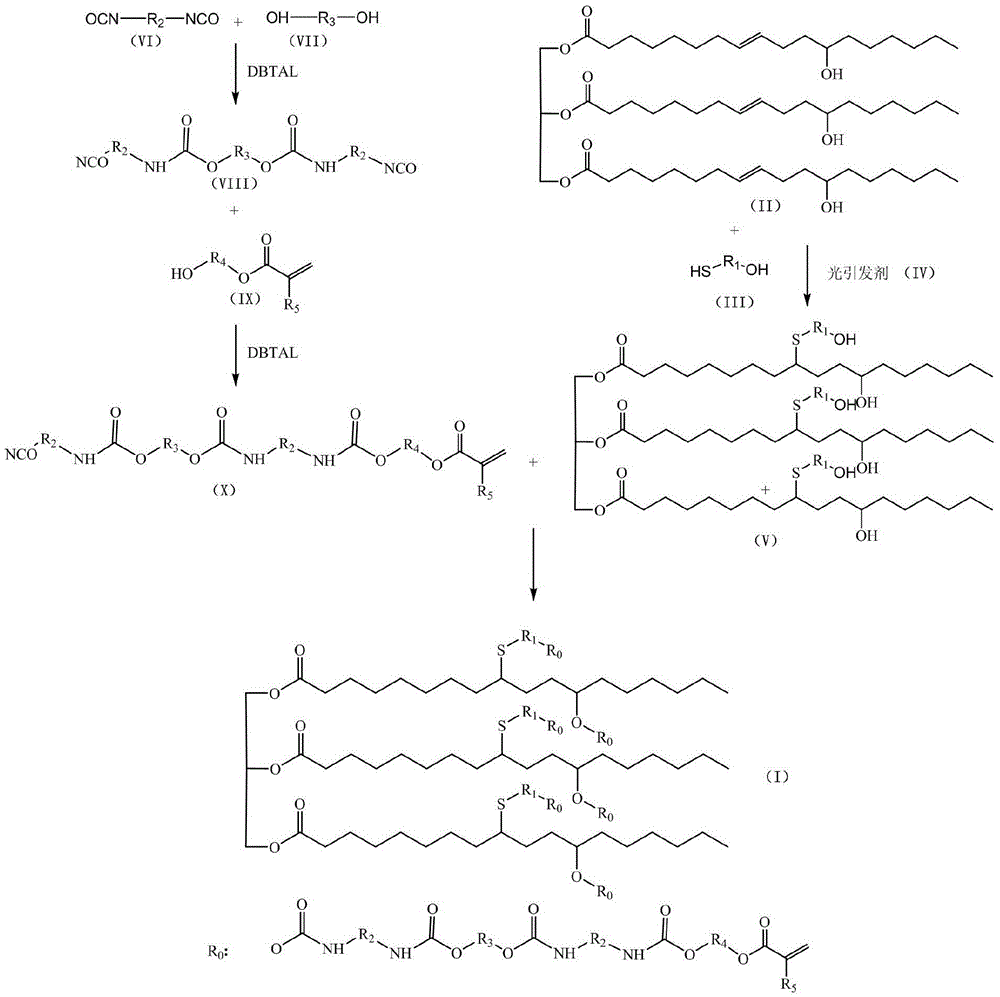

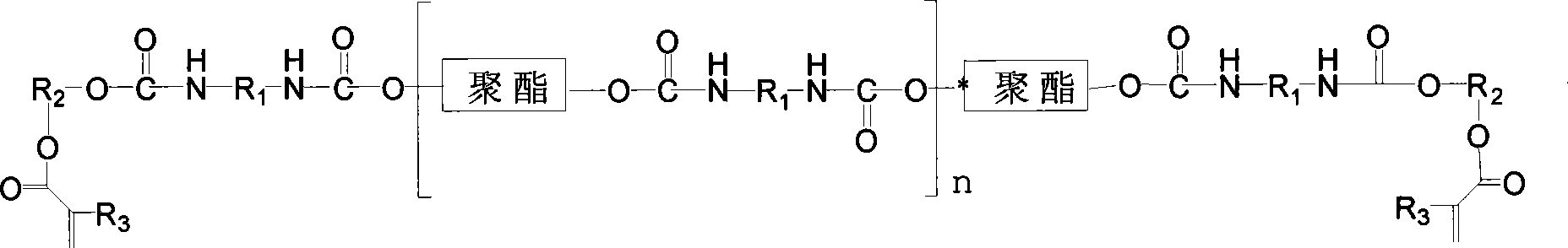

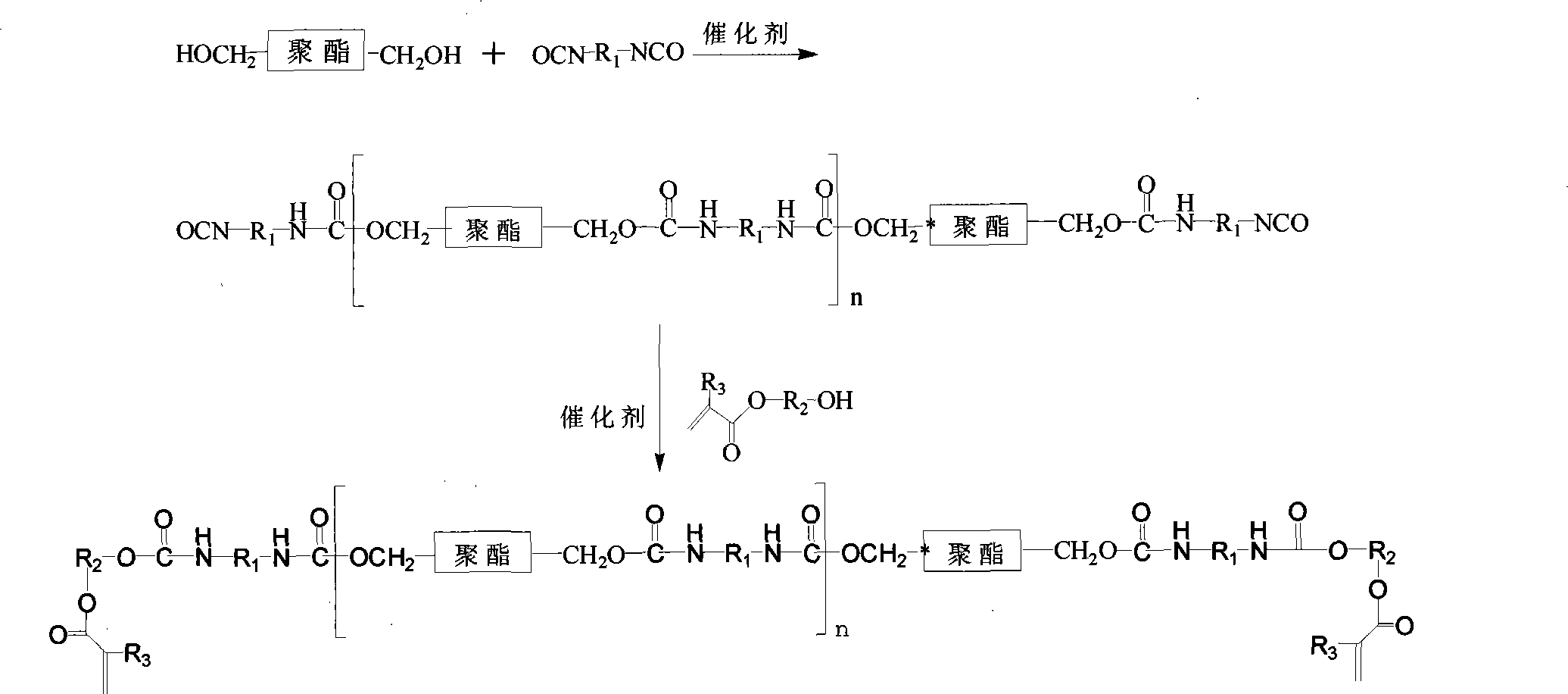

Castor oil-based polyurethane acrylate and preparation method as well as application thereof

ActiveCN105601880ALight curing speed is fastHigh tensile strengthPolyureas/polyurethane adhesivesInksCross-linkMethacrylate

The invention discloses castor oil-based polyurethane acrylate and a preparation method as well as application thereof. The castor oil-based polyurethane acrylate is hexa-functional or octa-functional castor oil-based polyurethane (methyl) acrylate resin. An acrylate radical comprises a methacrylate radical and an acrylate radical, and is suitable for carrying out free radical polymerization. Under the action of a photoinitiator, the resin is irradiated by ultraviolet light and can generate cross linking at a higher speed. A film formation product of the castor oil-based polyurethane acrylate has excellent flexibility and adhesive force; the hardness and the glossiness of a cured film are obviously improved; the castor oil-based polyurethane acrylate can be used as a formula ingredient of a photo-cured coating material, ink, and an adhesive.

Owner:广州纽楷美新材料科技有限公司

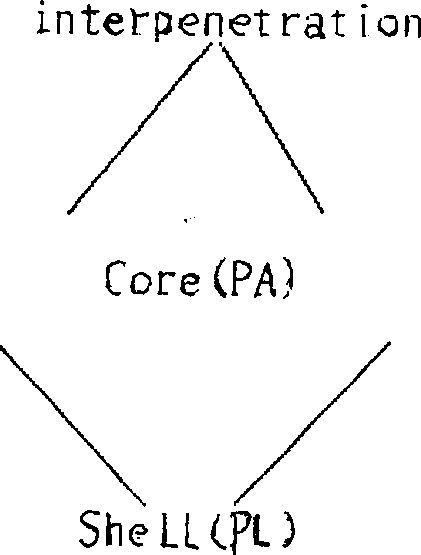

Water-soluble polyurethane latex adhesive with porous network formed by 'core-shell' structure

InactiveCN1355267AImprove adhesionHigh bonding strengthGraft polymer adhesivesPolyurethane adhesiveHigh energy

An acrylic acid modified polyurethane adhesive with networked "core-shell" structure is prepared through LIPN technique and seed emulsion polymerization. Its latex granularity is adjustable for distrilution in 20-200 mm. Its advantages include high adhesion, excellent resistance to fatigue, impact and abrasion, and wide application range including pressure-sensing adhesive, paint for fabric and leather, high-molecular medical material, passive-sensing package for high energy explosive, etc.

Owner:王申

EVA (Ethylene Vinyl-Acetate) packaging glue film with high gas-water barrier property and preparation method thereof

InactiveCN103756579AImprove barrier propertiesImprove hydrolysis resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesAntioxidantAging resistance

The invention discloses an EVA (Ethylene Vinyl-Acetate) packaging glue film with high gas-water barrier property and a preparation method thereof. The glue film is prepared from the following raw materials in parts by weight: 100 parts of an EVA copolymer, 0.5-5 parts of a crosslinking agent, 0.1-0.5 part of an antioxidant, 0.1-0.5 part of an ultraviolet absorber, 0.05-0.5 part of a light stabilizer, 0.1-3 parts of a silane coupling agent and 0.01-55 parts of a water resistant. The preparation method comprises the following steps: plastifying and extruding; stretching; drawing; rolling and the like. The glue film disclosed by the invention has the beneficial effects that the EVA glue film obtained by the invention has good gas-water barrier property and hydrolysis resistance as well as better damp-heat aging resistance.

Owner:CHANGZHOU SVECK PHOTOVOLTAIC NEW MATERIAL

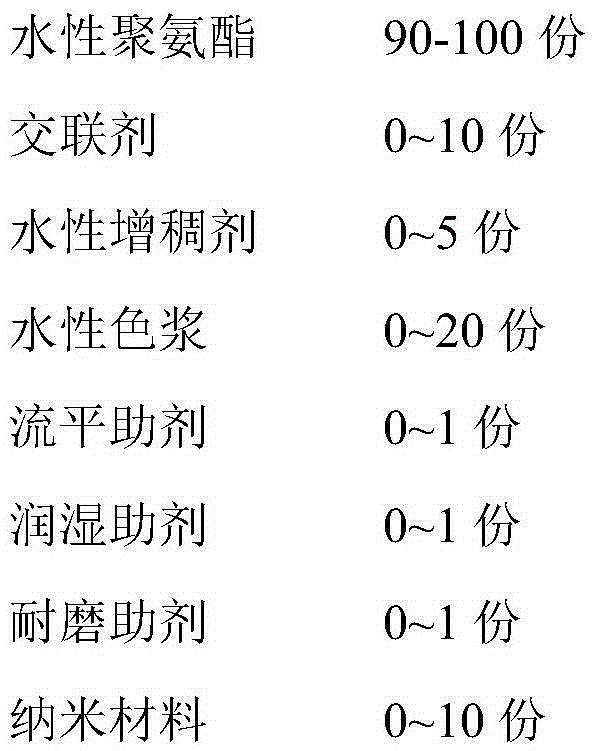

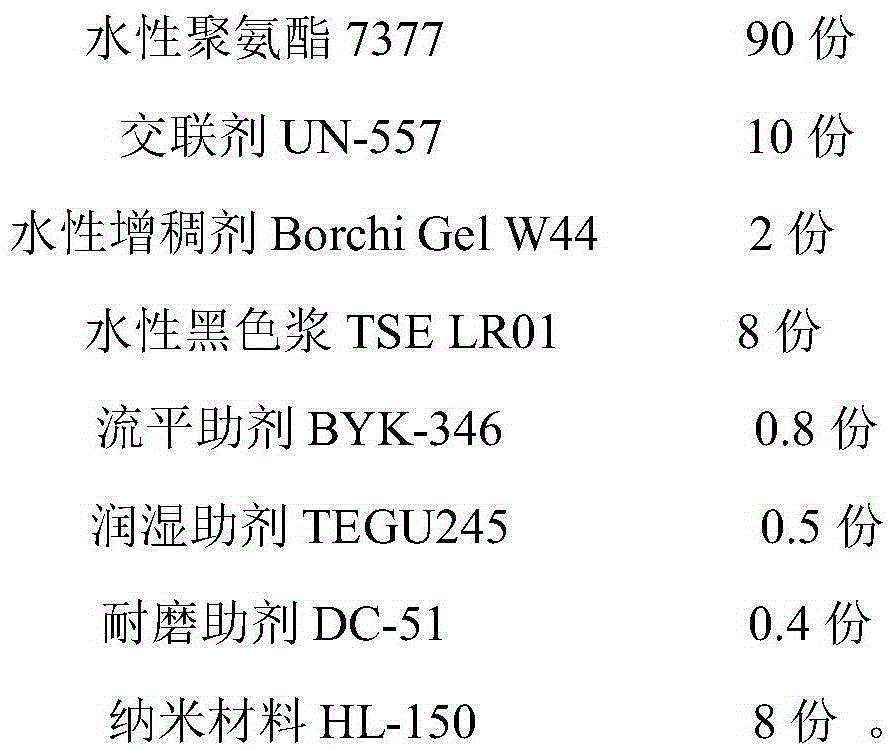

Preparation method of aqueous / solvent-free composite environmentally friendly polyurethane synthetic leather

ActiveCN105350342AStrong three-dimensional senseSoft touchFootwearTextiles and paperElastomerOrganic solvent

The present invention discloses a preparation method of aqueous / solvent-free composite environmentally friendly polyurethane synthetic leather, the synthetic leather comprises an aqueous elastomer surface layer and a solvent-free foaming intermediate layer, the aqueous elastomer surface layer resin is thermosetting polyether aqueous polyurethane resin, the solvent-free foaming intermediate layer is thermosetting two-component polyether solvent-free foaming polyurethane resin, and the two-component material is polyether combination A material and polyether B material prepolymer. The preparation process does not use any organic solvent, achieves the synthetic leather production and processing, finished product zero solvent use and health and environmental friendliness; at the same time, the advantages of the aqueous polyurethane resin and the solvent-free polyurethane resin are combined, and the obtained synthetic leather products has strong pattern stereoscopic impression, soft hand feeling, superior hydrolysis resistance and other physical properties, and skin and leather feeling equivalent to natural dermis.

Owner:ANHUI ANLI MATERIAL TECH

Polyether ester-based adhesive agent for solvent-free double-component polyurethane composite membrane and preparation method thereof

ActiveCN102174308AHigh bonding strengthImprove hydrolysis resistancePolyureas/polyurethane adhesivesVegetable oilPolyol

The invention relates to a polyether ester-based adhesive agent for a solvent-free double-component polyurethane composite membrane and a preparation method thereof. The preparation method of the adhesive agent comprises the following steps of: firstly, mixing 100 parts of polyisocyanates and 30 to 150 parts of polyol, and then raising temperature for reacting; secondly, adding a stabilizing agent to prepare a component A of the adhesive agent; and then, synthesizing a polyether ester polyol, and matching with 0.5 to 2 parts of polyether polyol, 0.1 to 1.0 part of vegetable oil polyol and 0.01 to 0.2 part of micromolecular polyol to prepare a component B of the adhesive agent. When the components A and B are in use, the functional group mole ratio of NCO to OH is (1.0 -2.0):1. The invention has the following advantages: the preparation method is safe and environmentally-friendly without solvent discharge; and the adhesive agent has low sizing quantity, high base material wetting property, wide serviceable range, high bonding strength and long usable life, and can be boiled at a high temperature (100 DEG C) for 40 minutes.

Owner:WANHUA CHEM BEIJING +1

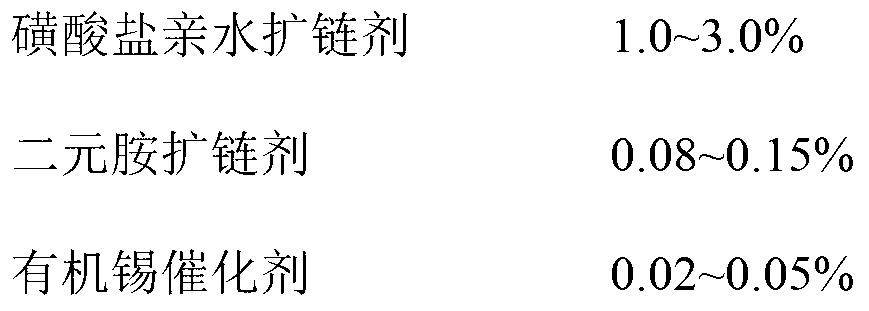

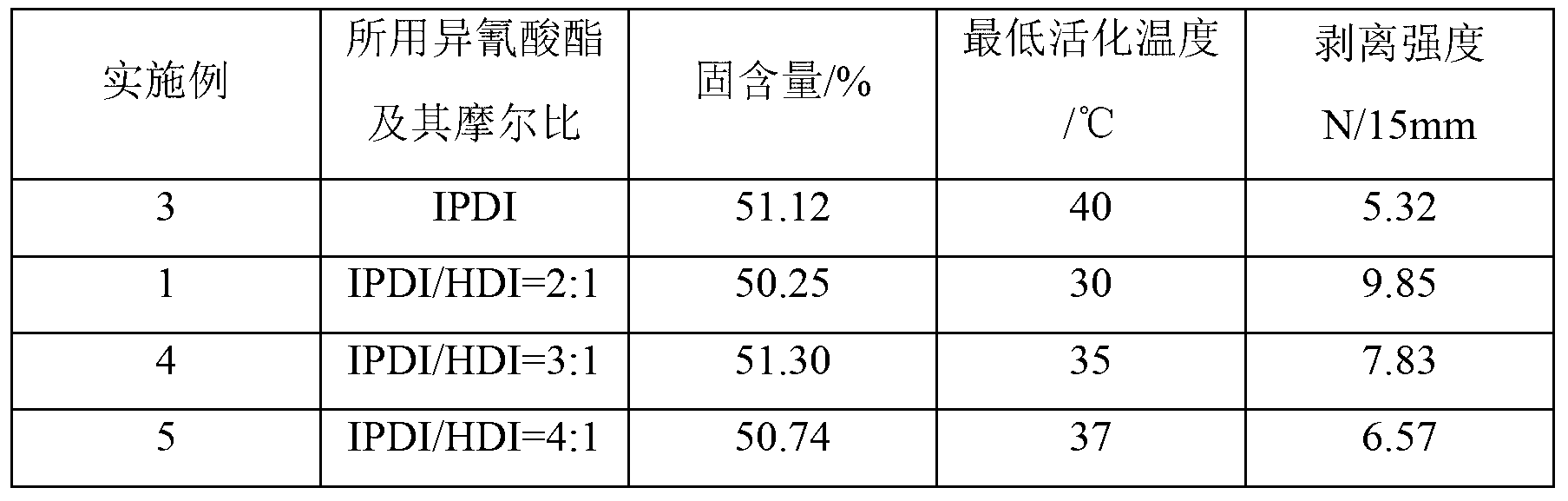

Preparation method of sulfonic acid type waterborne polyurethane adhesive

InactiveCN103254867AHigh solid contentLow activation temperaturePolyureas/polyurethane adhesivesPolyesterEthylenediamine

The invention discloses a preparation method of a sulfonic acid type waterborne polyurethane adhesive. The preparation materials of the sulfonic acid type waterborne polyurethane adhesive comprise the following components in percentage by weight: 75%-89% of polyalcohol, 8.5%-22% of diisocyanate, 0.06%-0.10% of cross-linking agent, 1.0%-3.0% of sulfonate hydrophilic chain extender, 0.08%-0.15% of diamine chain extender, and 0.02%-0.05% of organic tin catalyst, wherein the polyalcohol is polyester polyalcohol or polyether polyalcohol or a mixture of the polyester polyalcohol and the polyether polyalcohol; and the sulfonate hydrophilic chain extender is ethylenediamine-based sodium ethyl sulfonate or 1,2-dyhydroxyl-3-sodium propyl sulfonate. The sulfonic acid type waterborne polyurethane adhesive prepared by the preparation method disclosed by the invention has the characteristics of being high in solid content, low in lowest activation temperature and large in peel strength.

Owner:JUSHI GRP CO

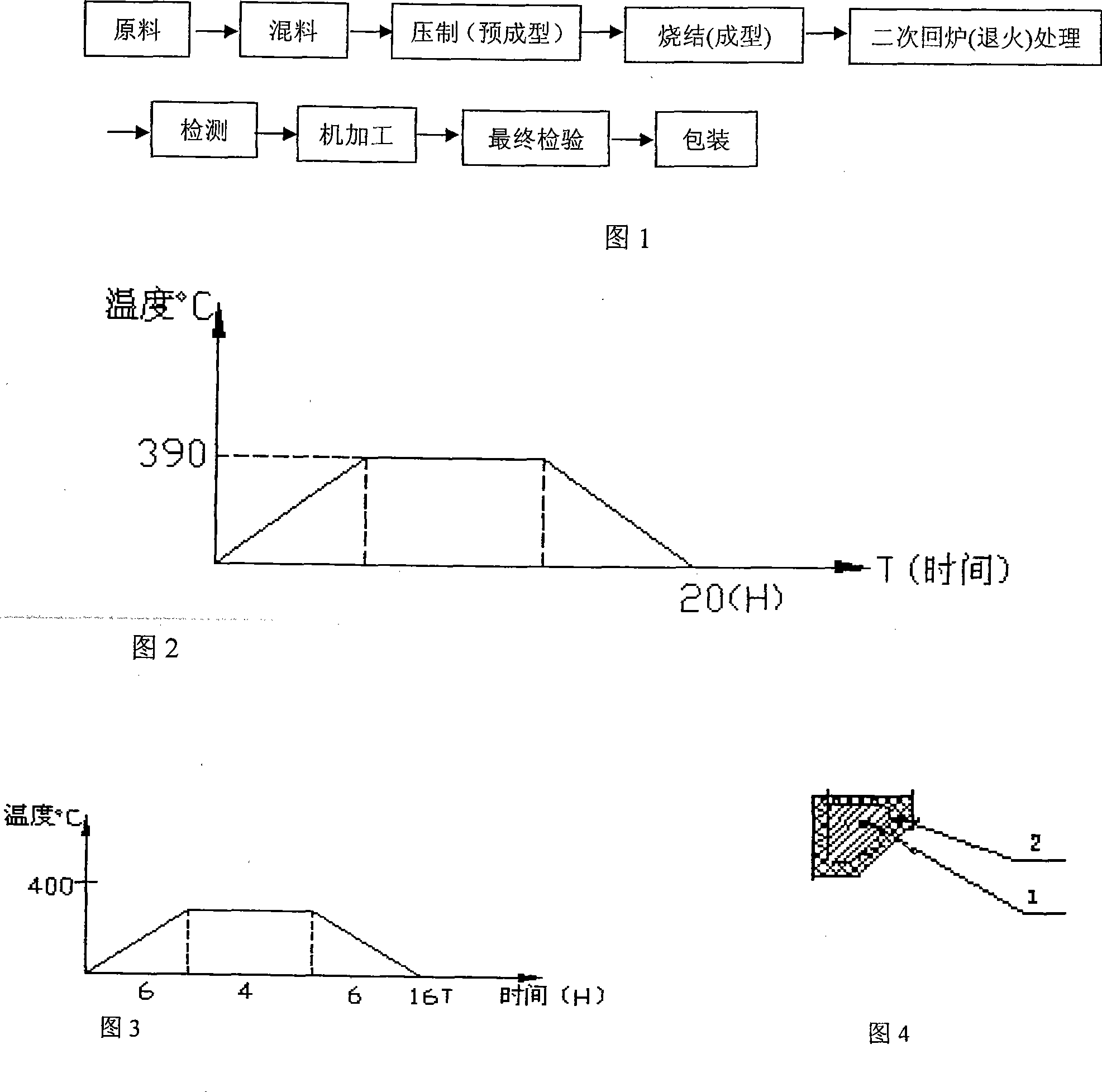

Poly(ether-ether-ketone) composite material, production method and application of sealing member

The invention relates to a polyether-ether-ketone composite material which consists of polyether-ether-ketone, nanoparticles, filling materials and addition agent materials. The composite material comprises 75 to 95 portions of polyether-ether-ketone powders, 5 to 10 portions of the nanoparticles, 10 to 20 portions of the filling materials and 2 to 5 portions of the additive agents by weight. The filling materials are glass fiber, carbon fiber, quartz powder and MoS2 or toner. A method of compression moulding forming adopted is that: materials is prepared according to the formula; materials are mixed: the materials prepared according to designed requirements poured into an automatic material mixing machine for evenly mixing, the mixing time is between 0.5 minute and 3 minutes, then compressing process is carried out, and the blended mixture is sent to a mould cavity for moulding. The material can be used for sealing materials products. Various valve sealing elements produced by the invention has properties of creep resisting, corrosion resistance, heat resistance and pressurization, etc.; the ability of pressurization and wear resistance of the material are improved, and at the same time the cost is lowered by 10 to 20 percent or even higher, thus being beneficial to using and promotion of the materials.

Owner:NANJING COMPTECH COMPOSITES CORP

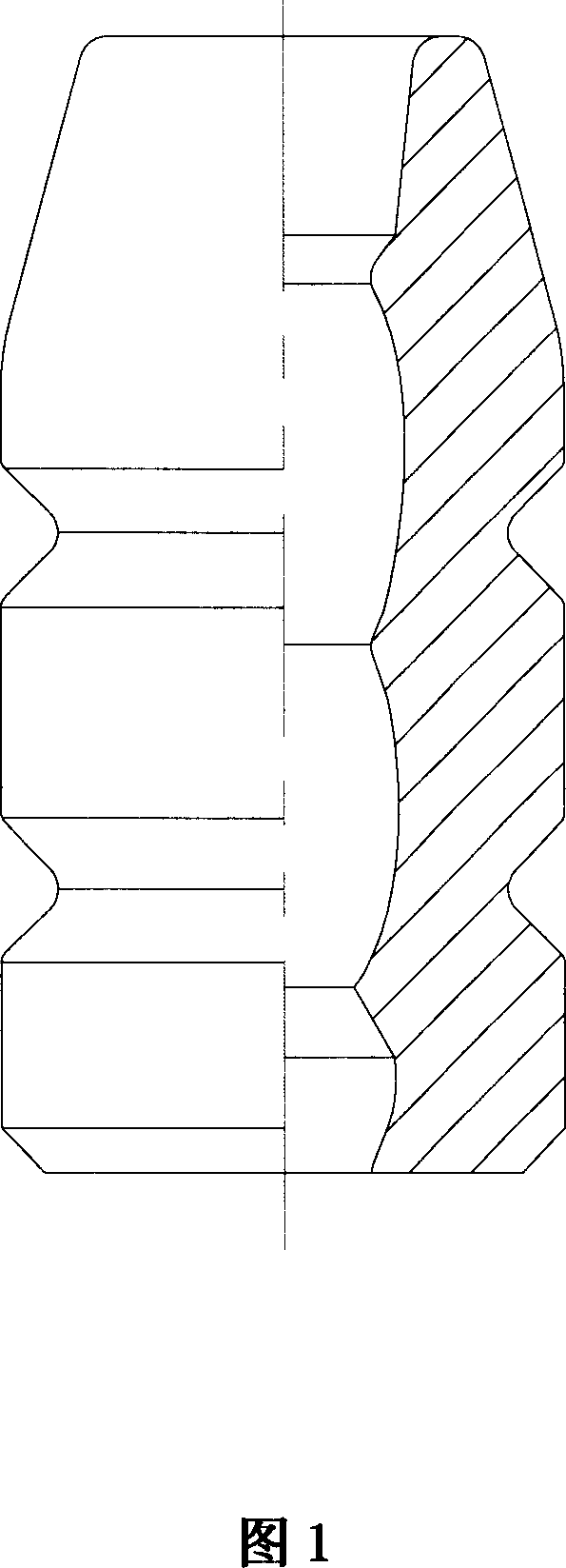

Production of NDI-polyurethane microporous elastomer

Production of NDI-base polyurethane micro-porous elastomer is carried out by preparing performed polymer, reacting excess polyisocyanate with polylol at 120-140degree to form NCO-base performed polymer, pouring, mixing performed polymer with chain extender proportionally, injecting reactive liquid into mould at 80-95degree, pre-curing, de-molding, and after-curing for de-molded product at 110degree for 13-16hrs. It has excellent weathering resistance and hydrolytic stability. It can be used for high-strength damping element, buffering component and shock-absorbing block.

Owner:上海凯众材料科技股份有限公司

Aromatic polycarbonate resin composition

InactiveUS6355767B1High impact strengthImprove hydrolysis resistanceTrans esterificationPolymer science

An aromatic polycarbonate resin composition comprising:(1) 10 to 90 wt % of an aromatic polycarbonate resin (component A) which is obtained from an ester exchange reaction between a diphenol and a dicarbonate ester and has a terminal hydroxyl group concentration of 10 to 70 mol % based on 100 molt of the total of all the terminal groups; and(2) 90 to 10 wt % of a thermoplastic graft copolymer resin (component B) which is obtained by grafting a vinyl cyanide monomer component and an aromatic vinyl monomer component to a diene-based rubber, the proportion of the vinyl cyanide monomer component to the copolymer resin being 10 to 27 wt % and the amount of a vinyl cyanide monomer contained in the copolymer resin being 200 ppm or less. According to the present invention, there is provided an aromatic polycarbonate resin composition which has excellent mechanical strength, particularly falling weight impact strength and improved hydrolysis resistance under a moist heat environment.

Owner:TEIJIN KASEK KK

Resin Composition and Molded Article Composed of the Same

ActiveUS20090030132A1Excellent in flowabilityImprove heat resistanceSpecial tyresOrganic dyesShell moldingGlass transition

A resin composition comprising a polylactic acid-based resin (A) and methacrylic resins (B), wherein the methacrylic resins having at least (a) a difference of 10° C. or more in glass transition temperature or (b) a difference of 3% or more in syndiotacticity; it is preferred that at least one of the methacrylic resins (B) is a methacrylic resin having a weight average molecular weight of 50,000 to 450,000, a glass transition temperature of 110° C. or higher and a syndiotacticity of 40% or more, and that the resin composition further contains a multilayer structure polymer formed as particles each consisting of a core layer and one or more shell layers covering it (C) A molded article made of said resin composition.

Owner:TORAY IND INC

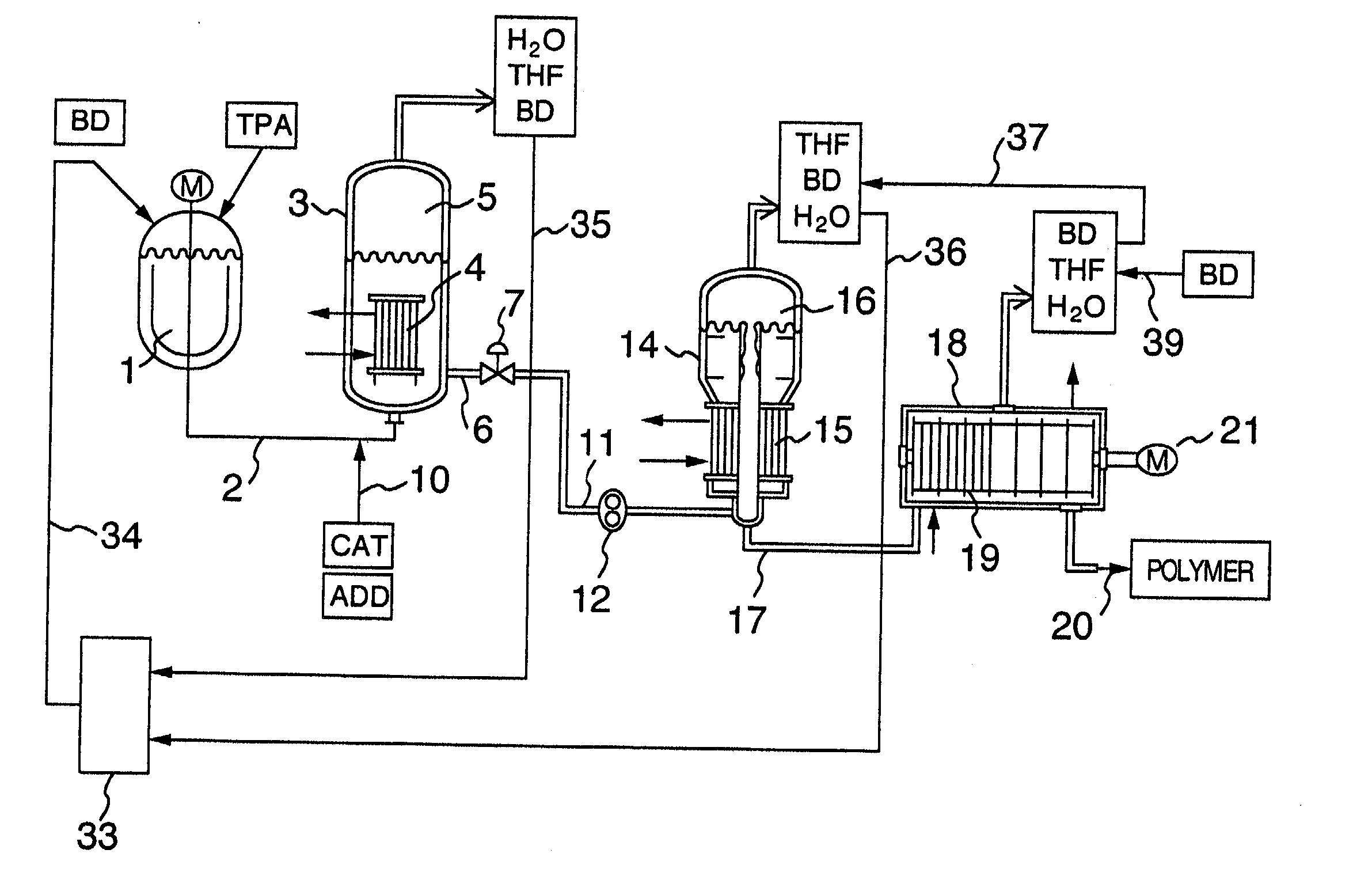

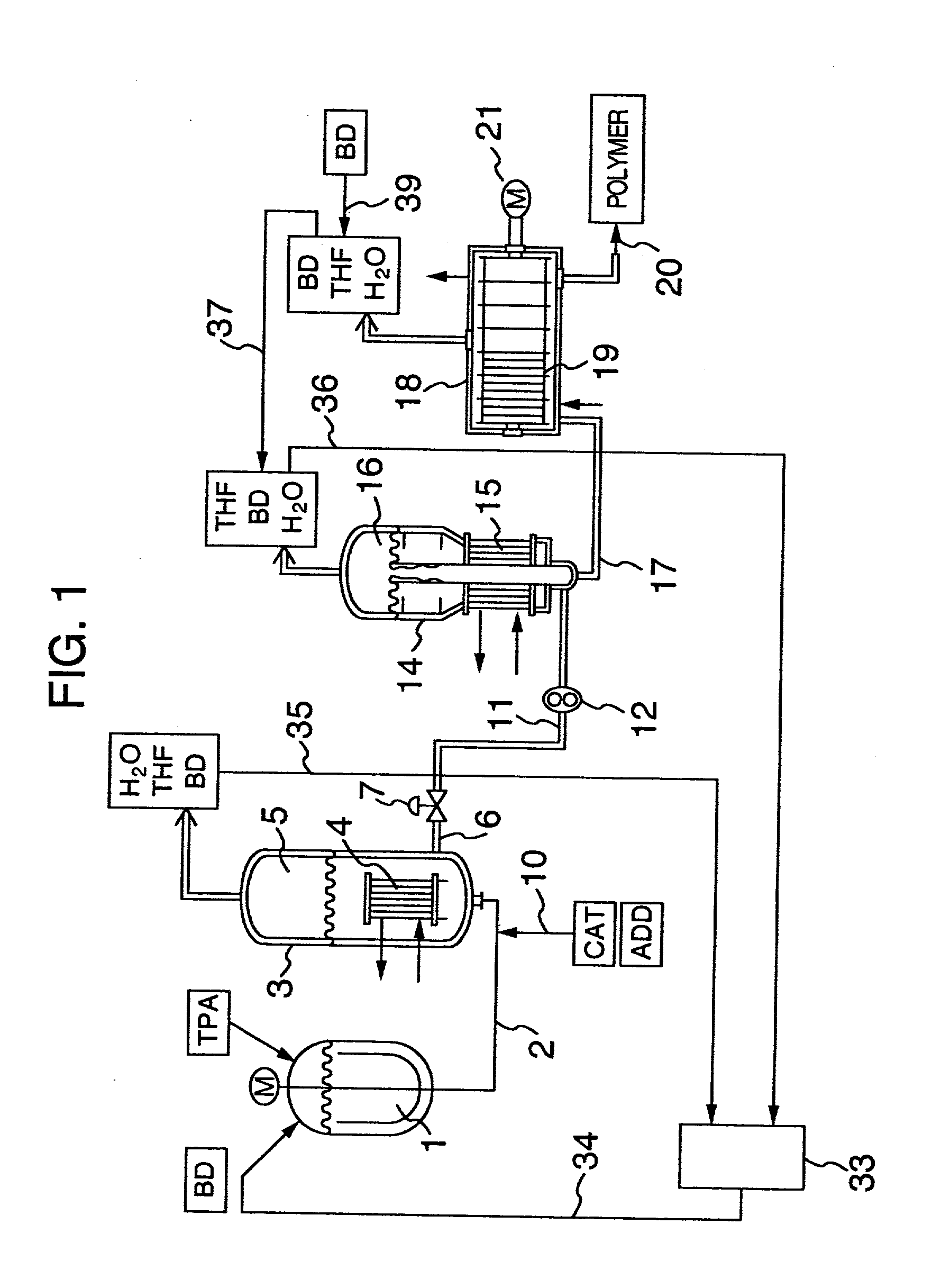

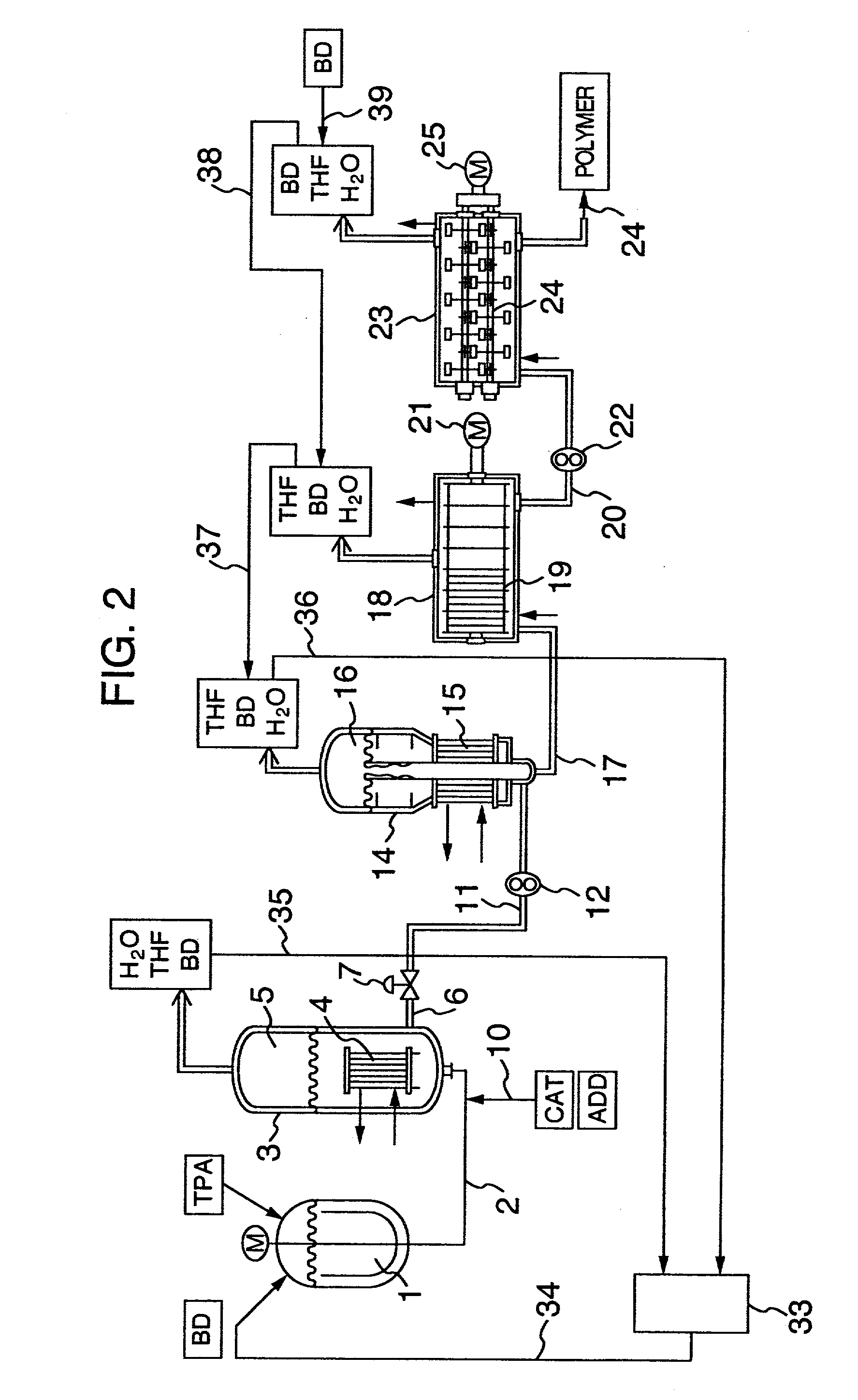

Process for continuously producing polybutylene terephthalate

InactiveUS20020128399A1Improve effectivelyGood molding effectChemical/physical/physico-chemical stationary reactorsLiquid-gas reaction processesPolytetramethylene terephthalatePolybutylene

Polybutylene terephthalate having good heat stability and excellent hydrolysis resistance is continuously produced in a series of a first reactor for reacting an aromatic dicarboxylic acid comprising terephthalic acid as a main ingredient or a derivative thereof with a glycol comprising 1,4-butanediol as a main ingredient, thereby producing an oligomer with an average degree of polymerization of 2.2 to 5, a second reactor for polycondensating the oligomer from the first reactor, thereby preparing a low polymerization product with an average degree of polymerization of 25 to 40, and a third reactor for further polycondensating the low polymerization product from the second reactor, thereby producing a high molecular weight polyester with an average degree of polymerization of 70 to 130, or followed by a fourth reactor for further polycondensing the polyester from the third reactor to an average degree of polymerization of 150 to 200, thereby producing a high molecular weight polyester. Another third reactor or a plurality of third reactors can be provided in parallel to the third reactor, thereby producing different kinds of polybutylene phthalate with different degrees of polymerization from that produced in the main line of the third and fourth reactors or adjusting operating conditions of each of a plurality of the third reactors to increase kinds, precise quality.

Owner:HITACHI LTD

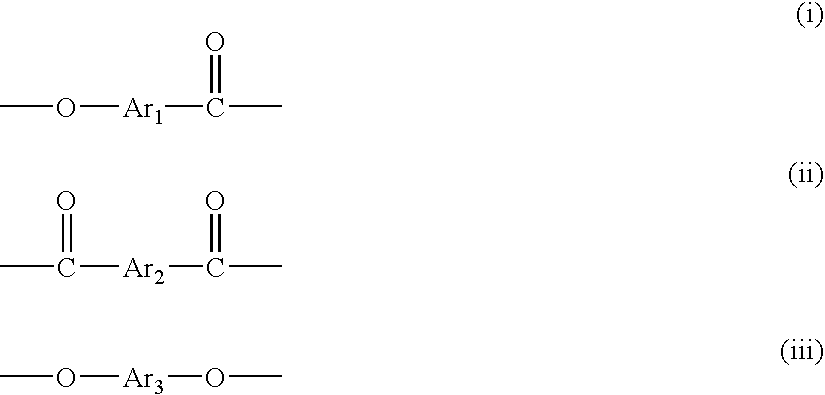

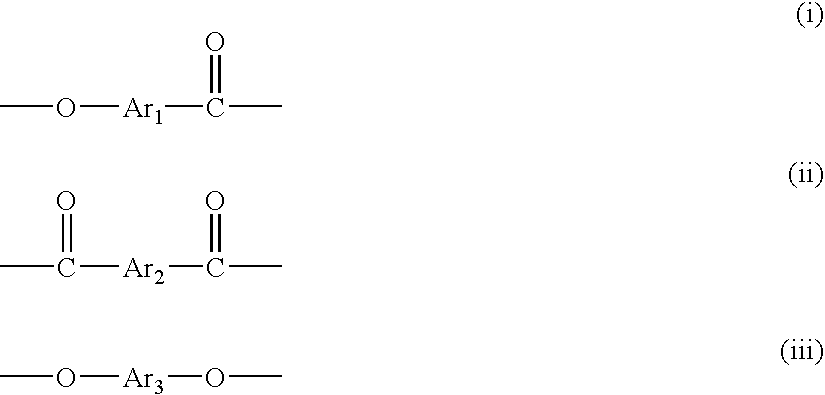

Conductive resin composition and the use thereof

InactiveUS20070057236A1Superior long-term stabilityHigh hydrolysis resistanceConductive materialNon-conductive material with dispersed conductive materialChemistryPolyester

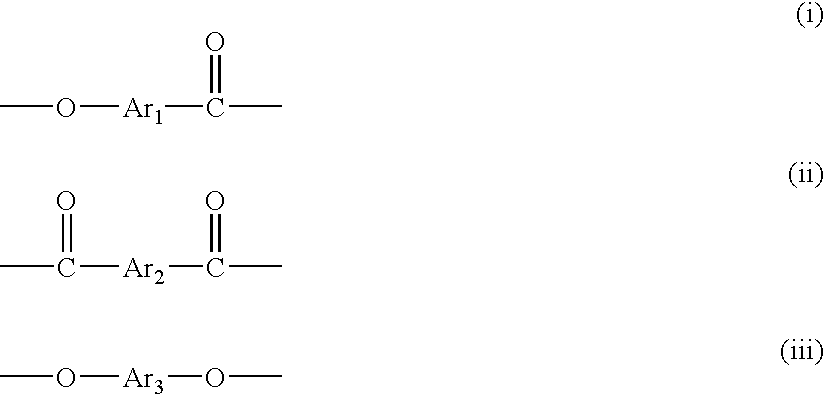

The present invention provides a conductive resin composition comprising a liquid crystalline polyester which comprises the following structure units having the formulas (i), (ii) and (iii), and has an aromatic group having 2,6-naphthalenediyl group in a ratio of not less than 5% by mole; and at least one filler selected from a metal oxide conductive filler and a carbon conductive filler. According to the present invention, the composition is easy to mold and can give molded products having high hydrolysis resistance. The resulting molded products are hardly to lower the strength even if they are exposed to high temperature and humid condition, and can be suitably used for a separator in a fuel cell.

Owner:SUMITOMO CHEM CO LTD

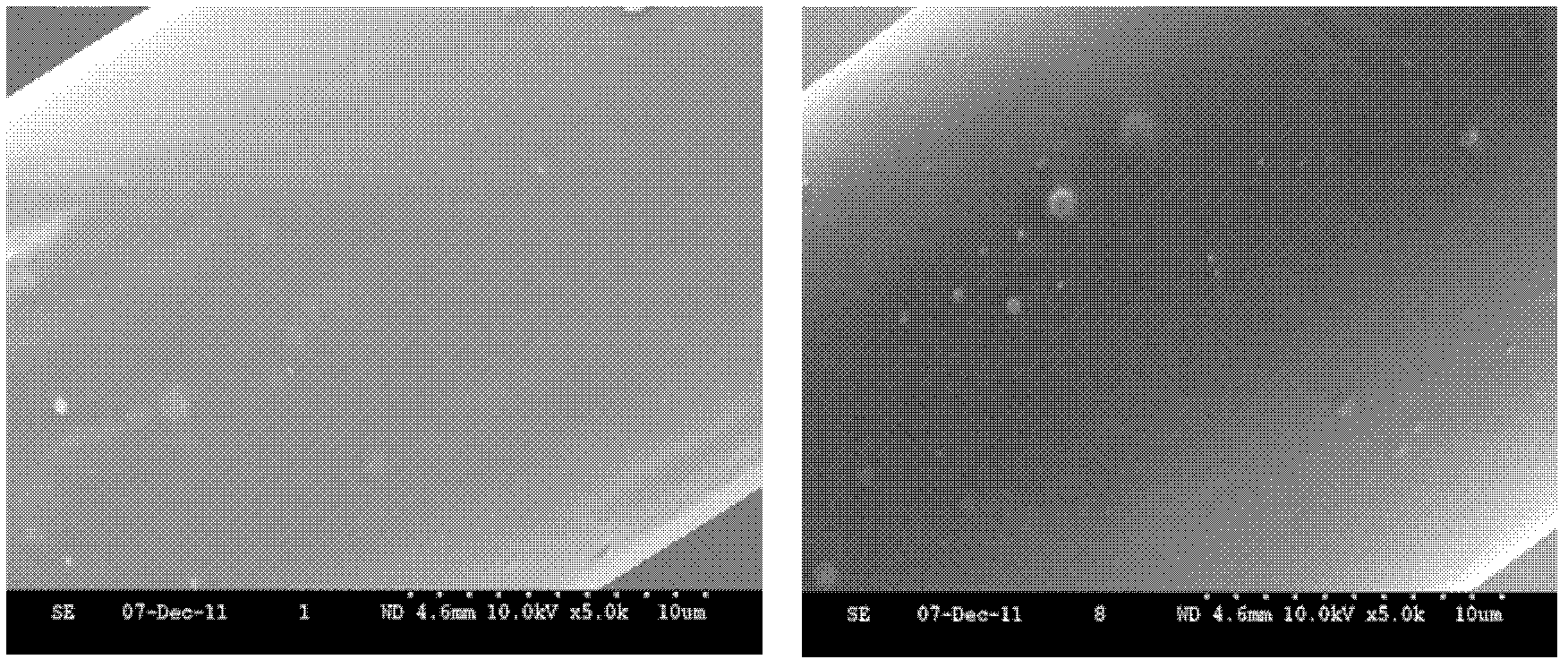

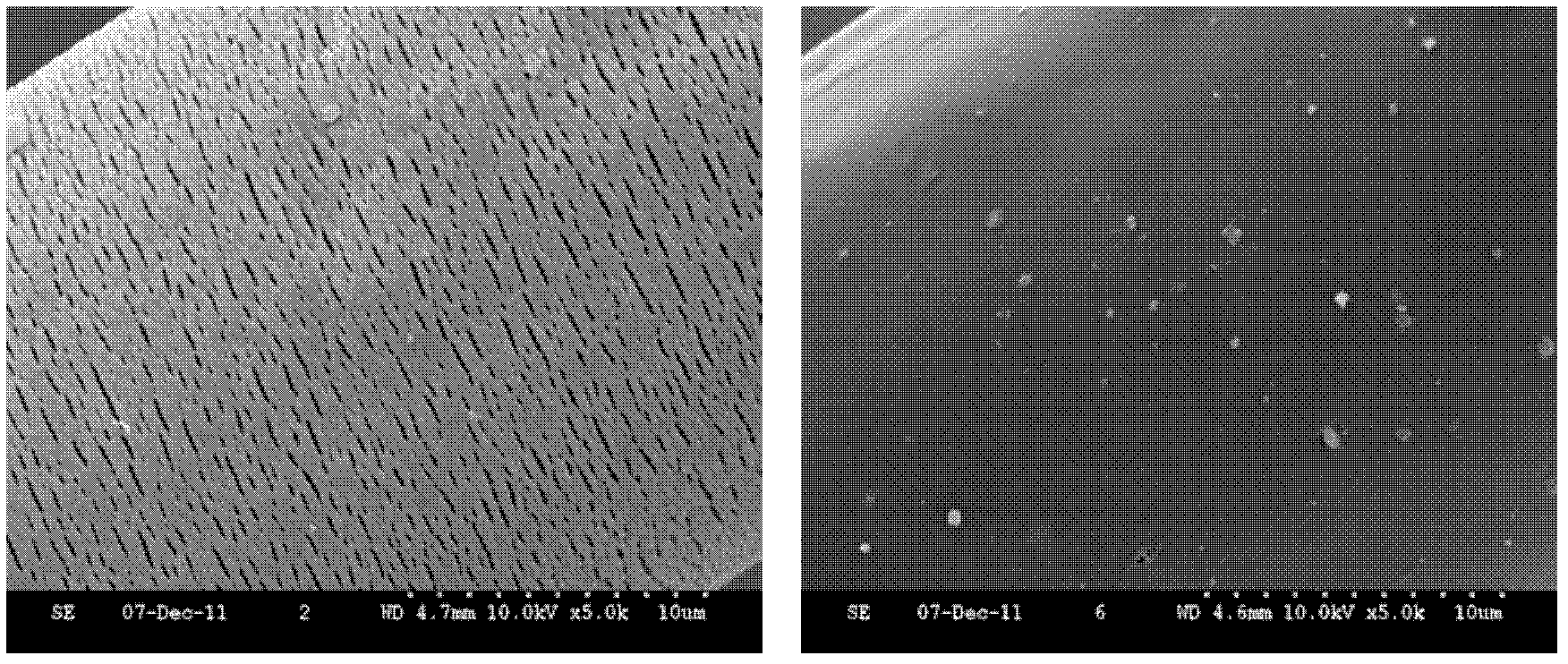

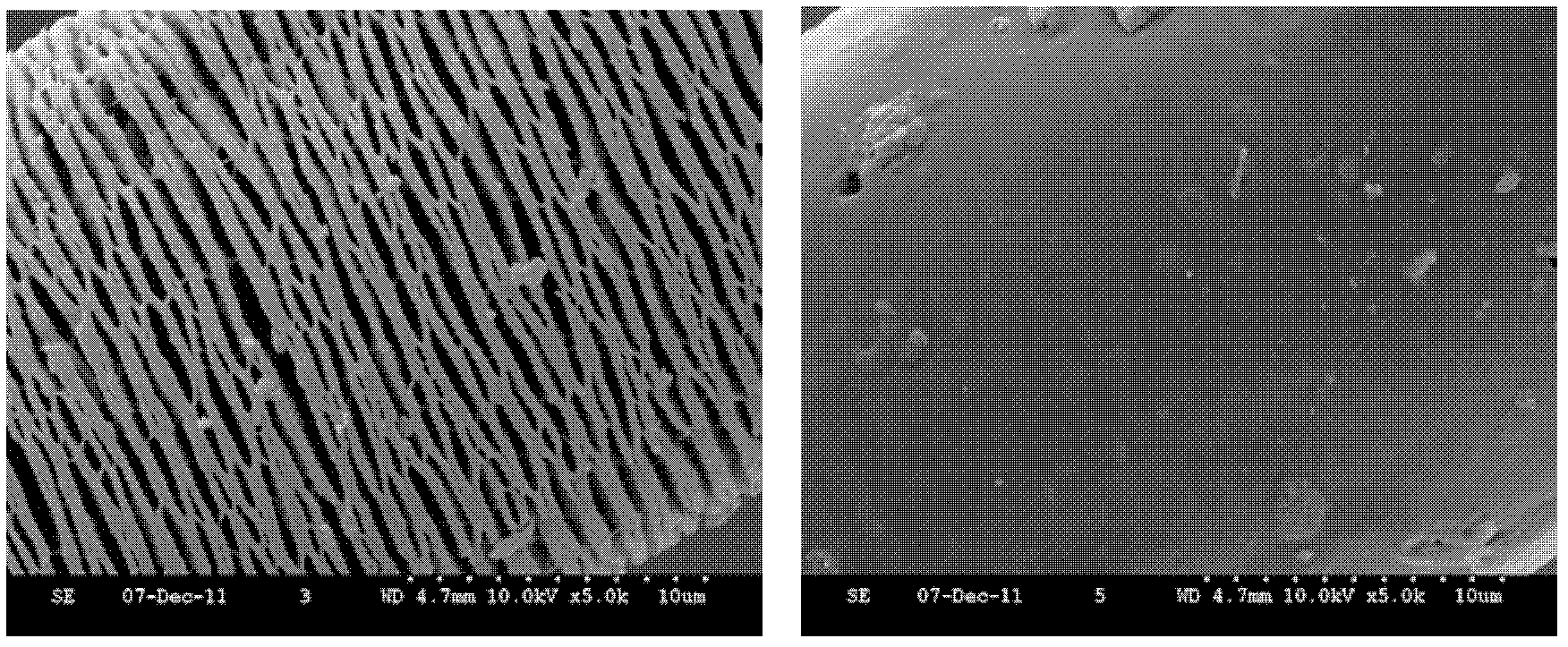

Method for preparing bio-carrier by porous foam polymer modification

InactiveCN102786710AAdapt to fixityAdaptive performanceChemical industryDispersed particle separationCross-linkPolymer modified

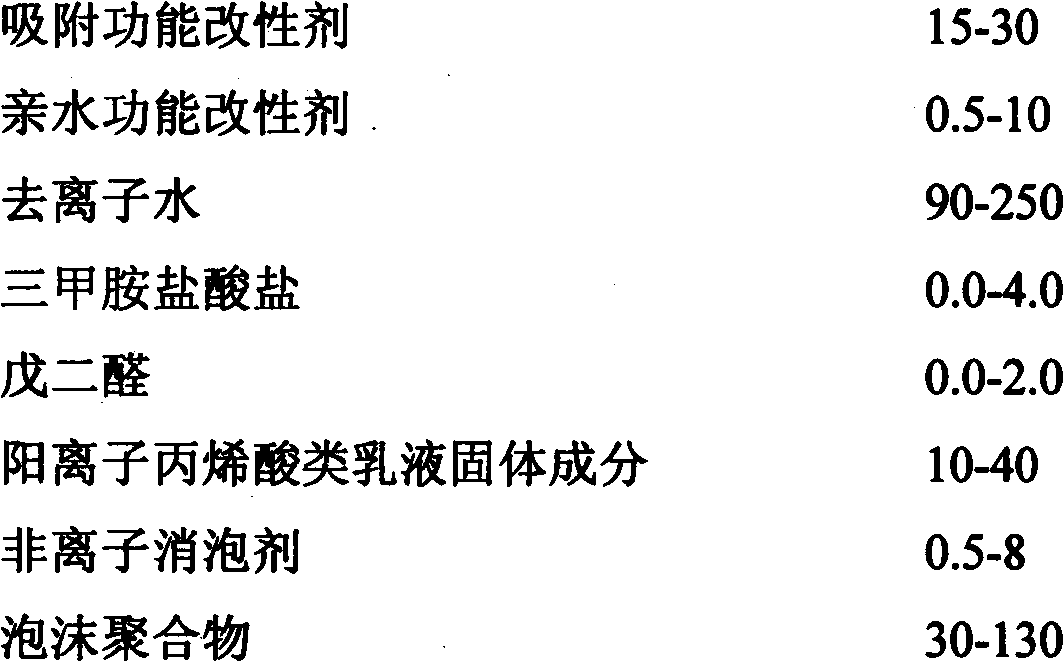

The invention discloses a method for preparing a bio-carrier by porous foam polymer modification. The method is used for coating bonding modification of porous foam polymers. The method comprises the following steps of adding one or more cationized porous high-adsorptivity functional materials and one or more cationized polyhydric hydrophilic functional materials into coating modification slurry, mixing the coating modification slurry and a cationic acrylic acid emulsion, carrying out coating bonding of the mixture on one or more porous foam polymers, and carrying out cross-linking curing to obtain the modified bio-carrier having strong adsorbability, hydrophily, surface active functional group diversity, positive surface charges and strong biocompatibility. The method provided by the invention is not limited by structures, shapes, aperture sizes and physical properties of foam polymers and can be widely used for external coating modification of multiple carrier materials. The method provided by the invention has the advantages of convenient and simple operation, low investment and making cost, excellent carrier performances and long service life. The bio-carrier obtained by the method can be widely used in fields of fixed attachment of various microorganisms, and enhanced biological treatment.

Owner:纪群

Preparation method of inner decoration material for automobile

ActiveCN1966265AOvercome the shortcoming that some functions are easily weakenedSoft touchLamination ancillary operationsFibre treatmentMetallurgySlurry

The invention relates to a method for producing decorates material of vehicle, wherein it comprises that: (1), pretreating base cloth, while the base cloth is immerged with disinfection and flameproof, dried, cooled and coiled; (2), wet solidifying coat that rolling the base cloth, scraping on coating machine, while the slurry amount is 100-300g / m2, drying, solidifying in solidifying groove, washing, drying and shaping, cooling and coiling; (3), dry transfer surface shaping that special paper transfer adhering; (4), rolling and drying the semi-product, coiling and packing. The inventive product has water resistance, etc.

Owner:HAININ JINDA COATING

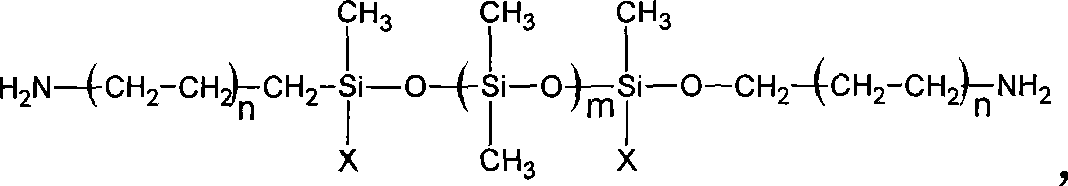

Method for synthesizing water-dispersion organosilicon-polyurethane block copolymer

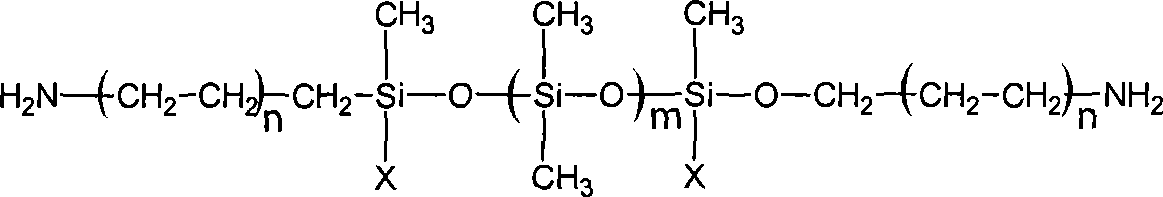

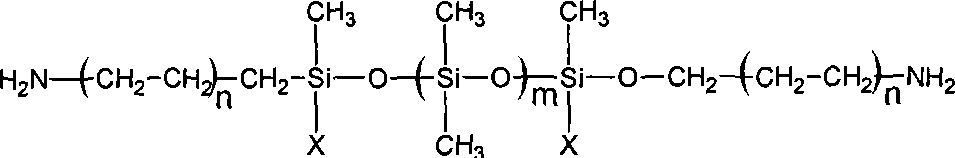

InactiveCN101225150AEvenly dispersedImprove stabilityNon-fibrous pulp additionLiquid surface applicatorsVegetable oilSynthesis methods

The invention discloses a synthesis method for waterborne organocilicon-polyurethane block copolymer, comprising steps as follows: reaction is carried out between polyisocyanate and polyol (the polyol comprises the one from the castor oil and carboxyl polyol) to generate isocyanate-terminated polyurethane prepolymer; then chain extension is carried out via amino alkyl polysiloxane; eventually alkaline aqueous solution is adopted for neutralization and dispersion, to prepare aqueous dispersion with excellent dispersion and stability. In addition, the aqueous dispersion is applied as coating for the wood and paper, as finishing agent for leathers and textiles, or as adhesives. Since natural vegetable oil from castor beans is selected and amino alkyl polysiloxane is adopted as the chain extender. The synthesis method for waterborne organocilicon-polyurethane block copolymer has the advantages of remarkably improved hydrophobic property, heat resistance and surface smoothness for the polymer films, simple preparation technique, and easy operation.

Owner:ZHEJIANG UNIV

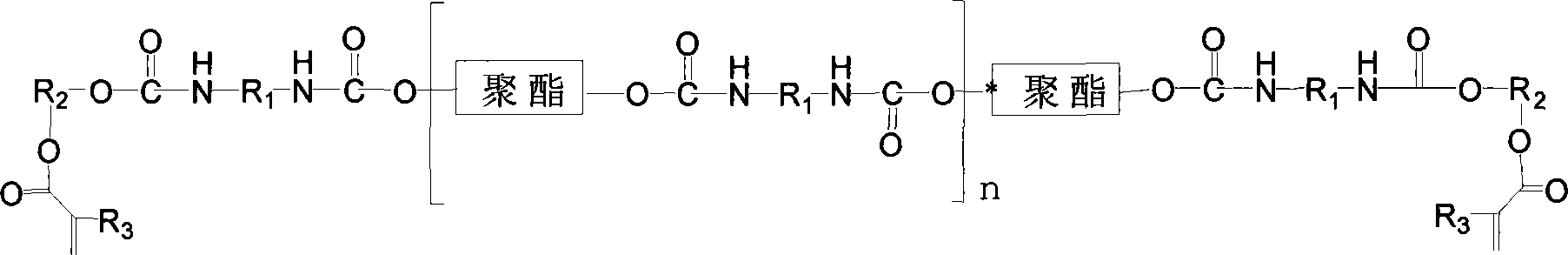

Large-molecular weight polyurethane acrylic ester and synthesizing method thereof

The invention discloses macromolecule weight urethane acrylate, which is formed by reaction on the basis of aliphatic polyester diatomic alcohol with the molecular weight of 500 to 8000, aliphatic diisocyanate and hydroxy acrylic acid monomer; wherein, polyesterglycol comprises ring-shaped resin, and the mechanical property and hydrolysis resistance property of light curing film are improved. The molecular weight of synthetic resin is 10000 to 50000 units, and acrylic ester double keys on the two ends of molecule chain enable the resin to produce high-efficiency free radical aggregation linkage under the effect of photoinitiators through the radiation of ultraviolet light. The aggregation linkage product of the finished film has good flexility and adhesive force, extremely low light curing contraction percentage, higher tensile strength and breaking elongation with hydrolysis resistance property improved. The invention can be used as the main ingredient or assistant matieral of light curing paint, light curing printing ink and light curing adhesive.

Owner:GUANGDONG BOSSIN NOVEL MATERIALS TECH CO LTD

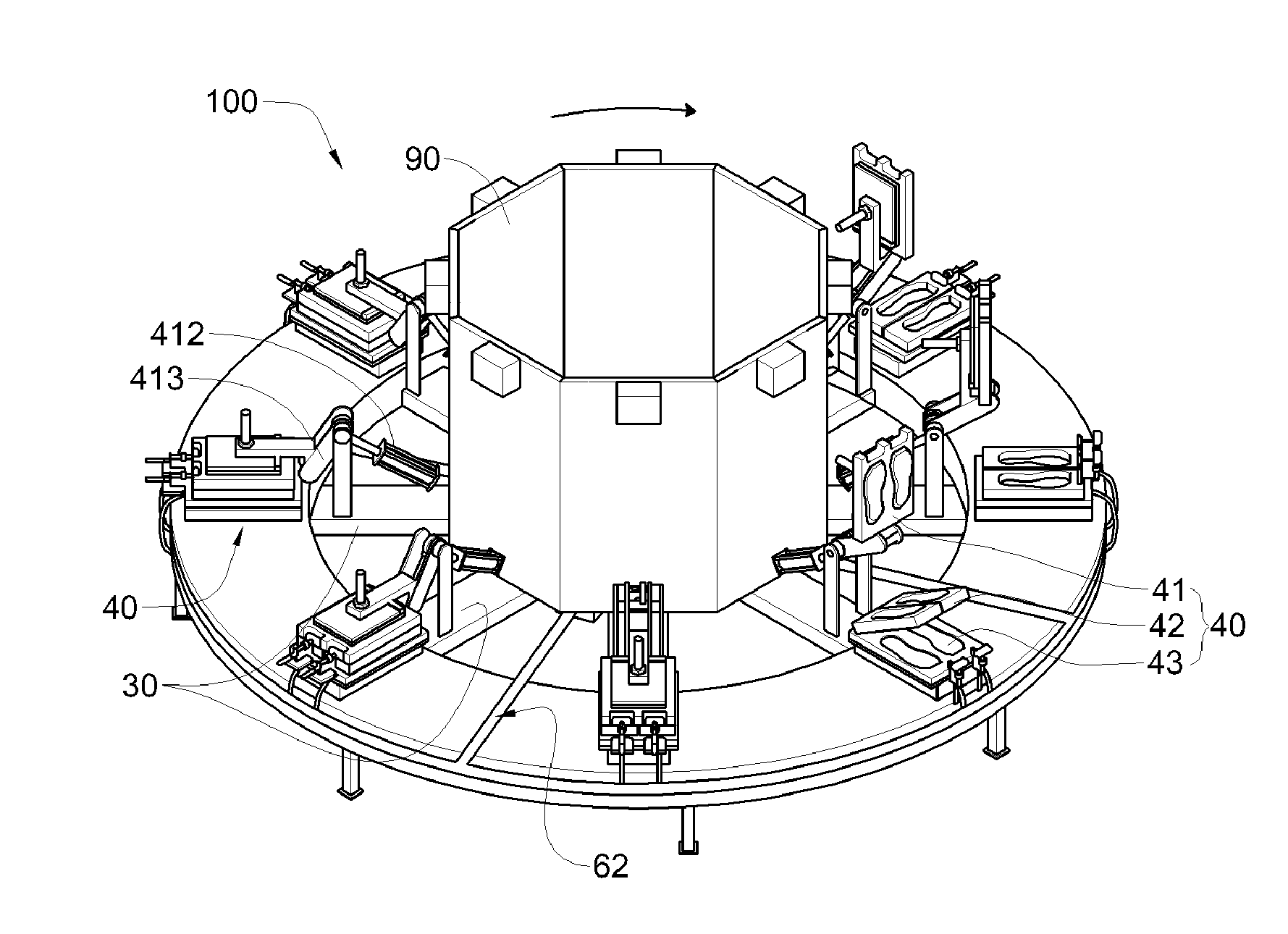

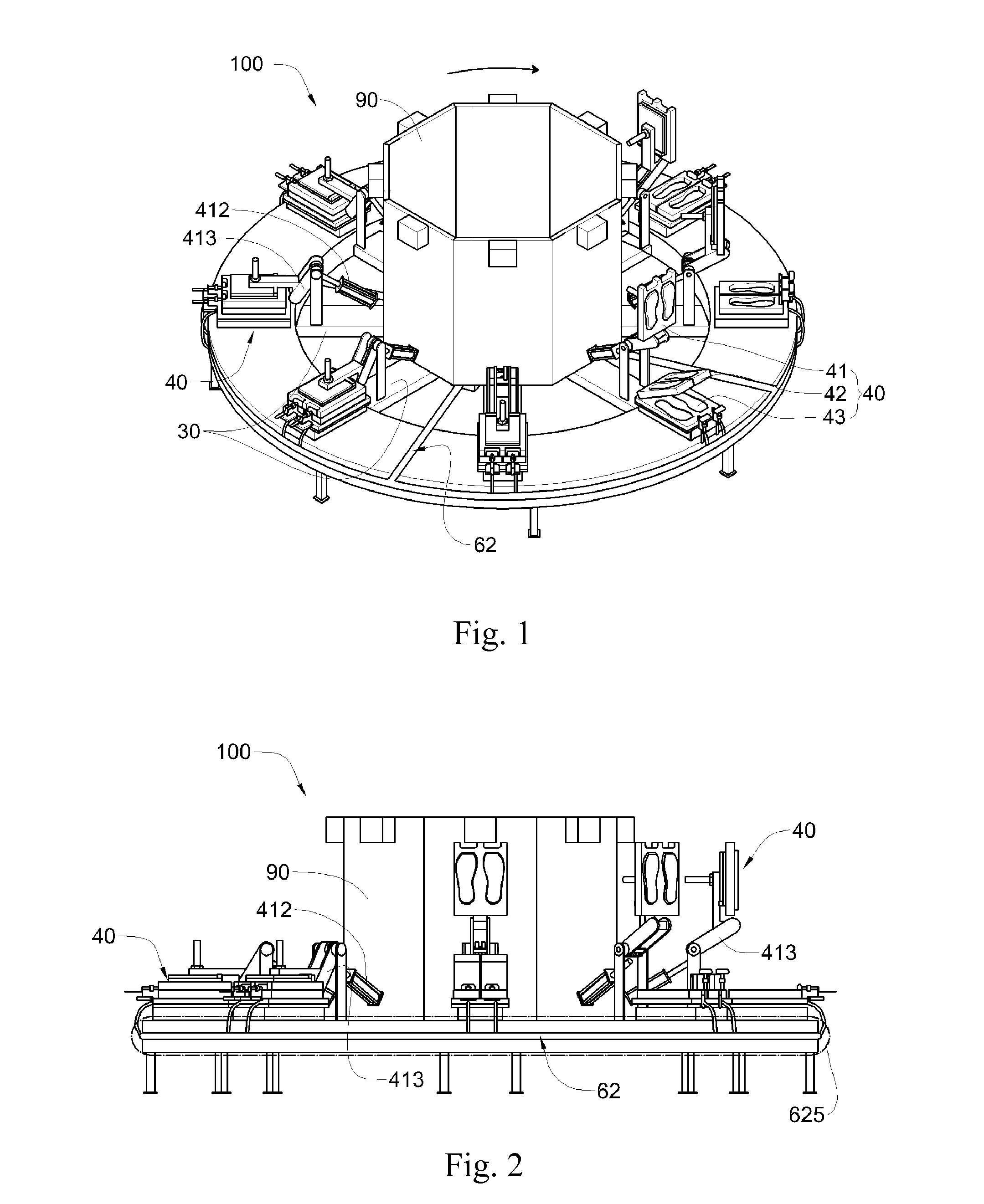

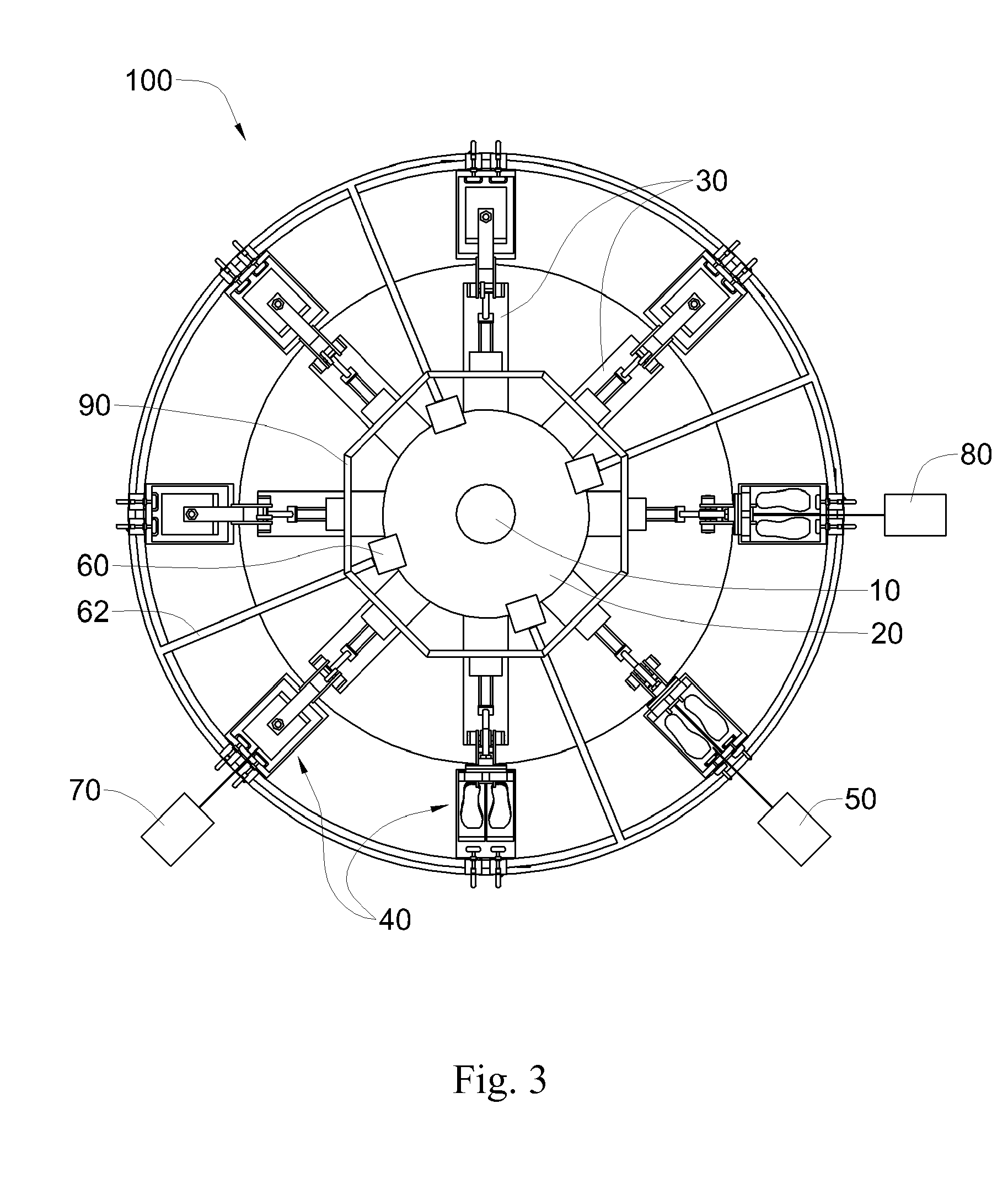

Polyurethane-coated spandex fabric-fused midsole and apparatus and method for manufacturing the same

ActiveUS20120056345A1Easily and conveniently manufacturedReduce laborTailstocks/centresConfectioneryEngineeringMechanical engineering

The present invention relates to a polyurethane-coated (PU-coated) spandex fabric-fused midsole, and an apparatus and method for manufacturing the same, which allow a shoe midsole to be easily and conveniently manufactured through a single automatic process, and allows a PU-coated spandex fabric to be easily fused to a surface of the midsole in the process of manufacturing the midsole. For this purpose, there is provided a polyurethane-coated (PU-coated) spandex fabric-fused midsole manufacturing apparatus including: a central axis rotated by a driving force of a motor; a rotary disc fitted on the central axis to be rotated together with the central axis; a plurality of midsole forming mold units, which are mounted on the outer ends of support members radially extending from the outer circumference of the rotary disc, respectively; a PU-coated spandex fabric supply apparatus installed above the trace of rotation of the midsole forming mold units to provide a PU-coated spandex fabric to each of the midsole forming mold units; vacuum means installed between the rotary disc and the midsole forming mold units to vacuum the inside of a midsole forming mold unit supplied with a PU-coated spandex fabric to such an extent that the PU-coated spandex fabric comes into close contact with the inner surface of the midsole forming mold unit; a resin introducing apparatus installed outside of the trace of rotation of the midsole forming mold units to introduce polyurethane (PU) resin into the midsole forming mold unit having the PU-coated spandex fabric film in contact with inner surface thereof; and a foam-molded product removal apparatus installed outside of the trace of rotation of the midsole forming mold units to remove a foam-molded product formed by foaming the polyurethane resin introduced into the midsole forming unit by leaving the polyurethane resin in the midsole forming mold unit at a predetermined temperature for a predetermined length of time.

Owner:LEE DONG GUN

Resin Composition And Molded Articles Thereof

ActiveUS20080085955A1Good molding effectImprove the immunityOrganic dyesPolymer scienceCarbonate ester

This invention seeks to provide a resin composition that can simultaneously satisfy resistances such as heat resistance and environmental resistance and moldability at high levels and that has excellent optical properties such as high refractivity and low birefringence and molded article thereof.The present invention is a resin composition containing a polyester resin formed from a dicarboxylic acid component and a diol component (a) and a polycarbonate resin formed from a carbonate-forming component and a diol component (b), the diol component (a) containing a specific fluorene-containing compound and the diol component (b) containing a specific fluorene-containing compound.

Owner:OSAKA GAS CO LTD

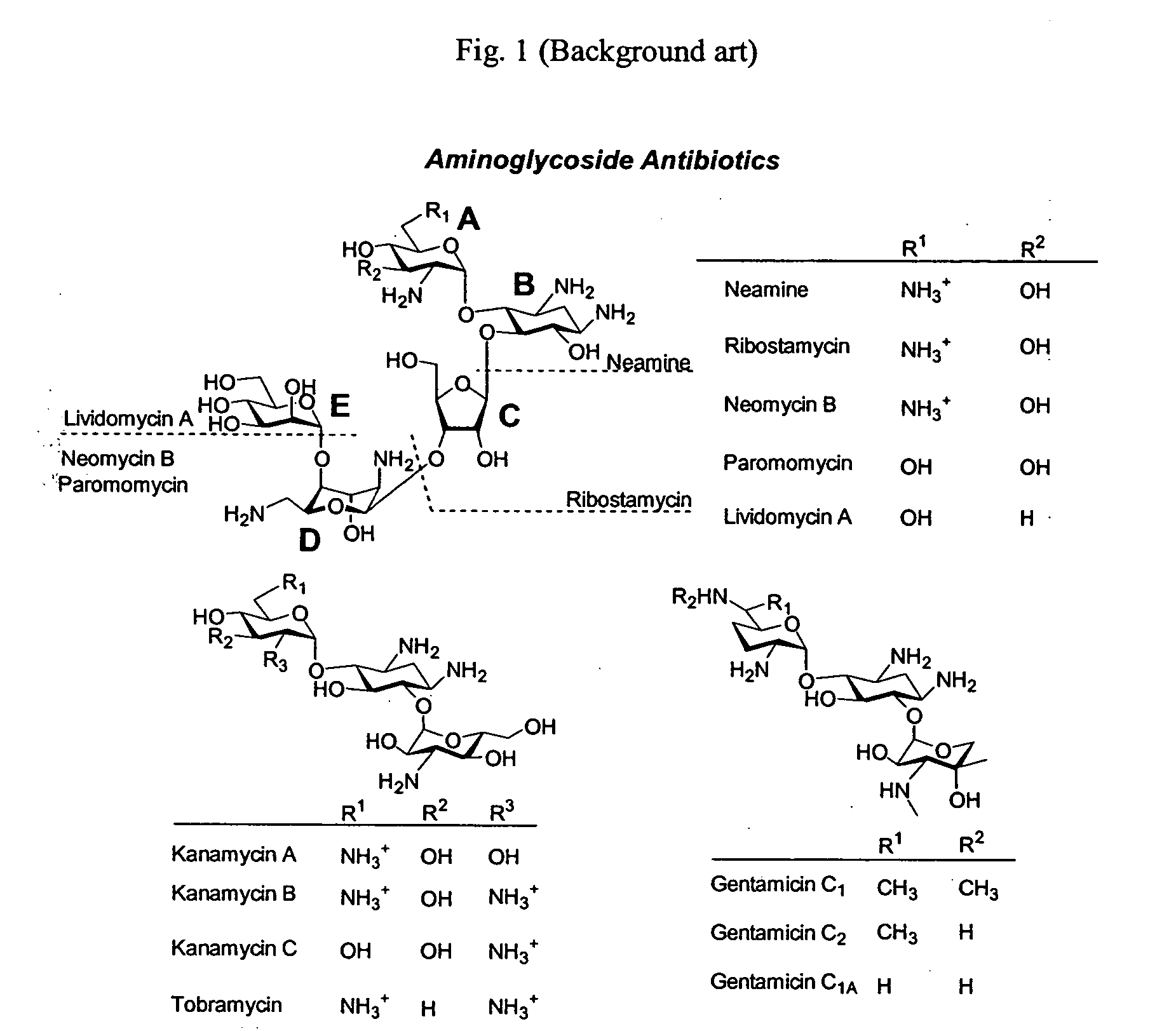

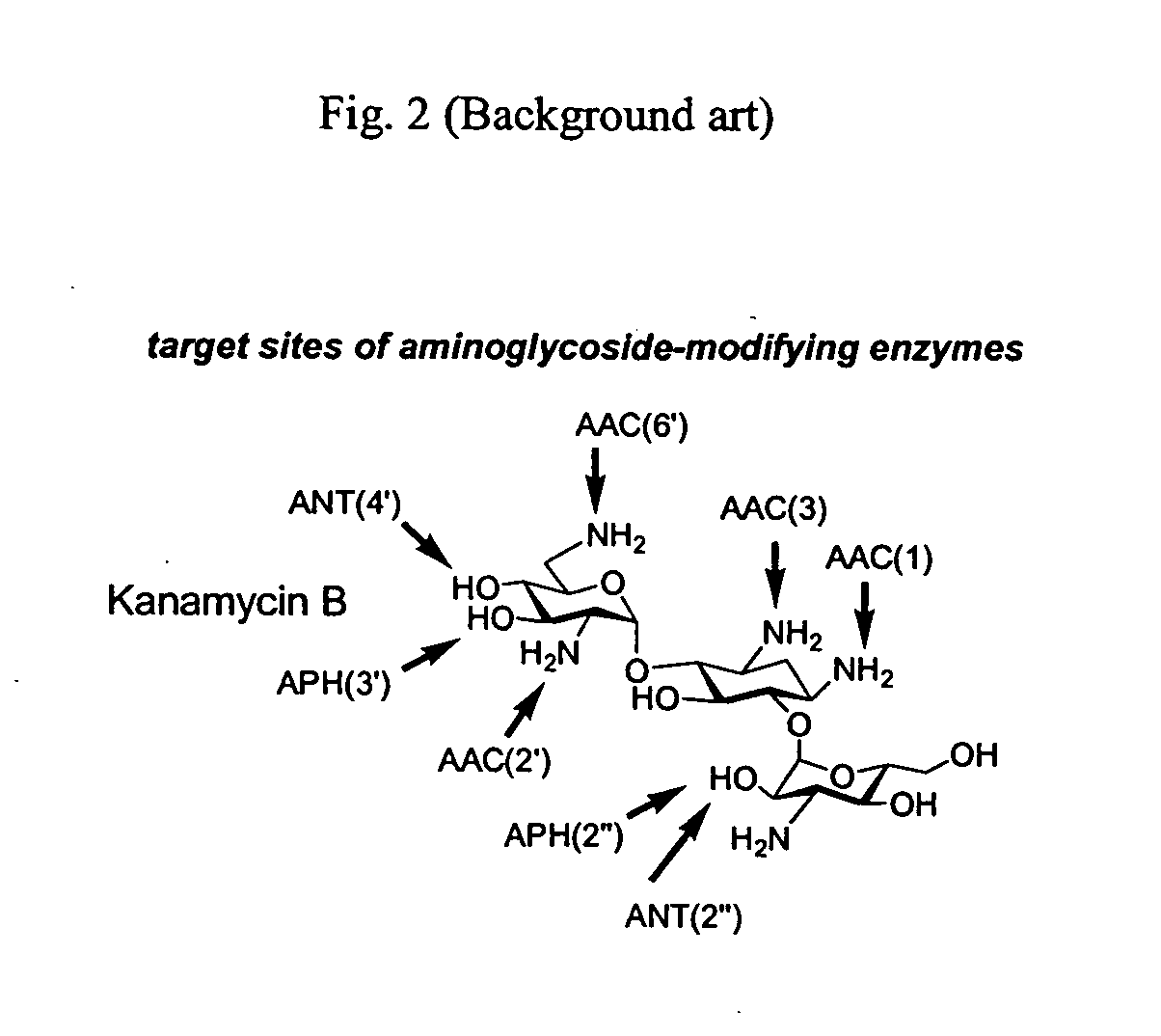

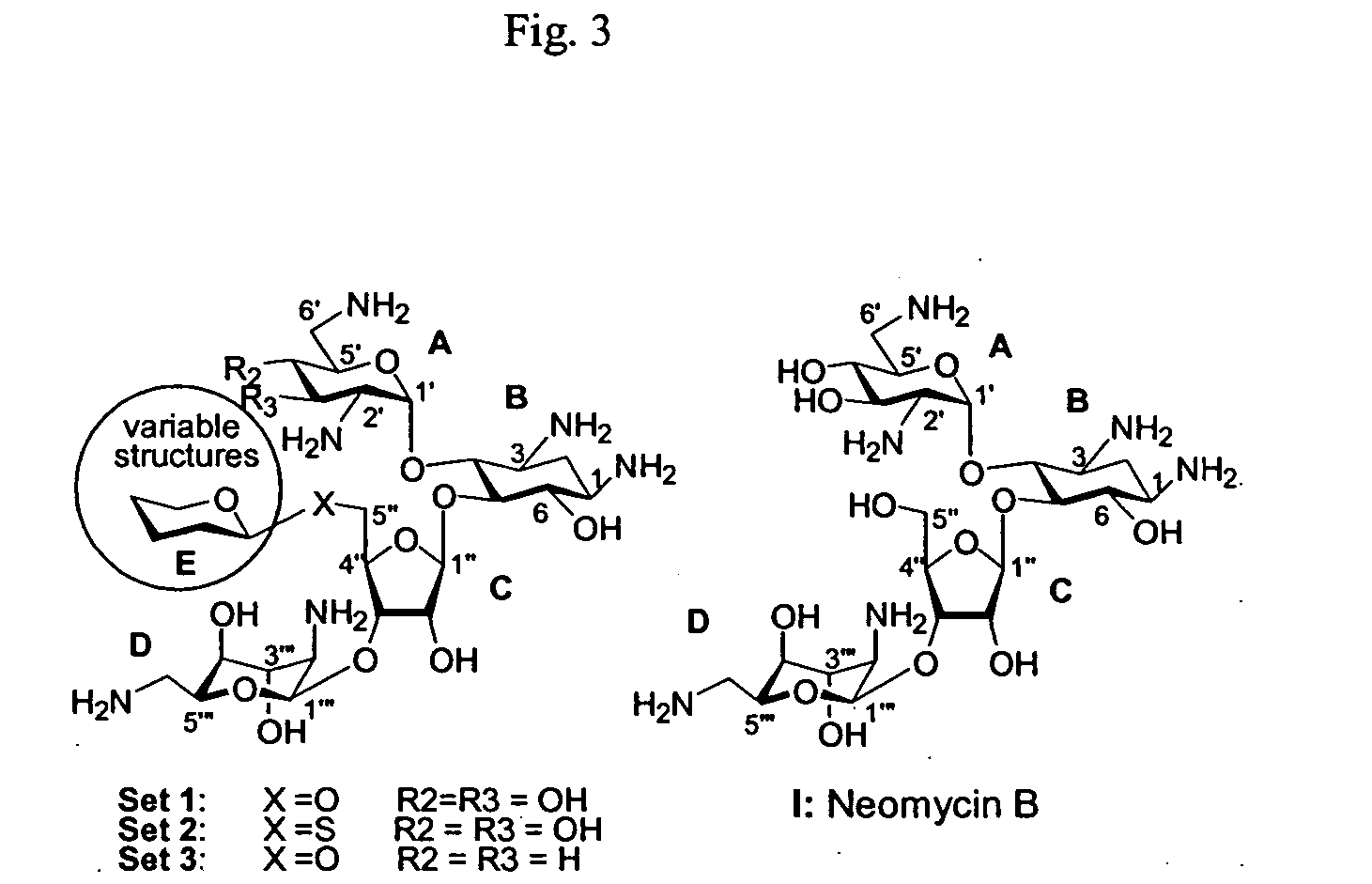

Bifunctional antibiotics for targeting rRNA and resistance-causing enzymes

InactiveUS20050004052A1High activityOvercome resistanceBiocideSugar derivativesAntibiotic resistanceAntibiotic Y

A novel group of aminoglycosides which share some structural features of currently available aminoglycosides with regard to the backbone, while also having significant structural differences. The similarity enables these aminoglycosides to be highly potent and effective antibiotics, while the significant differences enable these aminoglycosides to reduce or even block antibiotic resistance.

Owner:TECHNION RES & DEV FOUND LTD

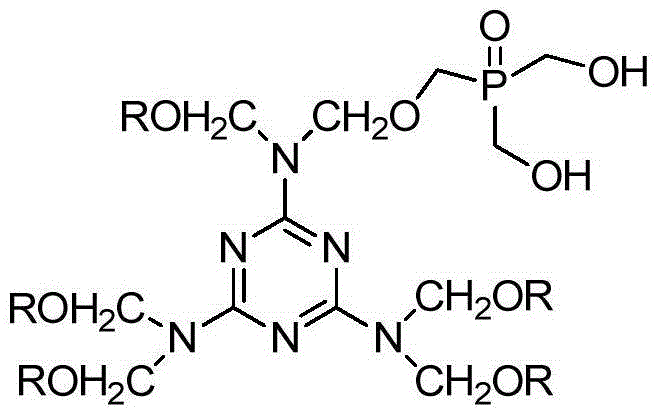

Phosphorus-nitrogen synergistic flame-retardant polyalcohol and preparation method thereof

InactiveCN103980313AEfficient Flame RetardancyAvoid the weakness of easy hydrolysisGroup 5/15 element organic compoundsDistillationPhosphine oxide

The invention discloses phosphorus-nitrogen synergistic flame-retardant polyalcohol and a preparation method thereof, relating to the synthesis of flame-retardant polyalcohol. The preparation method of the phosphorus-nitrogen synergistic flame-retardant polyalcohol comprises the following steps: 1) with quaternary phosphorus salt as a raw material, adding alkali and stirring for reacting, filtering and separating the salt generated by reacting, then oxidizing with a hydrogen peroxide solution, and performing reduced-pressure distillation for removing moisture to obtain tris(hydroxymethyl)phosphine oxide; 2) performing an ether exchange reaction between hexakis(methoxymethyl)melamine and the tris(hydroxymethyl)phosphine oxide obtained in the step 1) at 50-100 DEG C in the presence of an acid catalyst, and reducing pressure for removing small-molecular methanol to obtain the phosphorus-nitrogen synergistic flame-retardant polyalcohol. The prepared phosphorus-nitrogen synergistic flame-retardant polyalcohol is formed by connecting phosphorus elements through phosphorus-carbon bonds, and the weakness that the phosphorus-carbon bonds (phosphorus-ester bonds) are hydrolyzed easily is avoided, thus the phosphorus-nitrogen synergistic flame-retardant polyalcohol has the characteristic of relatively high hydrolysis resistance.

Owner:XIAMEN UNIV

Preparation method of hydrolysis-resistant modified polylactic acid fibers

InactiveCN102660797AFeel goodGood flexibilityMelt spinning methodsMonocomponent polyesters artificial filamentPolyesterHydrolysis

The invention relates to a preparation method of hydrolysis-resistant modified polylactic acid fibers. The preparation method comprises the following steps of uniformly mixing 70 to 98.9 parts by weight of polylactic acid, 1 to 30 parts by weight of one or more low-molecular weight polyesters and 0.1 to 5.0 parts by weight of multifunctional polycarbodiimides, carrying out melt blending granulation of the mixture to obtain master batches, carrying out vacuum drying of the master batches, carrying out melt spinning and winding to obtain winded wires, and carrying out drafting to obtain the hydrolysis-resistant modified polylactic acid fibers. The preparation method is simple, has a low cost and is suitable for large-scale production. The hydrolysis-resistant modified polylactic acid fibers have excellent handle and softness, realize low temperature dying, have high dye-uptake in high temperature dying and have good hydrolysis resistance so that the problem of mechanical property degradation produced in high temperature treatment is avoided.

Owner:DONGHUA UNIV

Polyester high-hydrolysis resistance and high-peeling strength polyurethane resin for wet-method synthetic leather and preparation method thereof

ActiveCN101851325ASolve the problem of poor film formationSolve the speed problemFibre treatmentPolyesterOrganic solvent

The invention relates to an esterified polyurethane resin for wet-method synthetic leather, in particular to the polyester high-hydrolysis resistance and high-peeling strength polyurethane resin for the single-component wet-method synthetic leather and a preparation method thereof. The polyurethane resin is prepared from the following components in weight percentage: 2%-15% of isocyanate, 20%-30% of polyester polyol compound, 0%-5% of dihydric alcohol chain extender, 0.01%-0.5% of catalyst, 0.01%-0.5% of additive and 50%-80% of water-soluble organic solvent. The high-hydrolysis resistance and high-peeling strength polyurethane resin by a wet method completely solves the defects of the impregnated resin for the wed-method hydrolysis resistance synthetic leather such as poor film-forming properties, slow impregnation speed, low peeling strength and the like, and meanwhile the hydrolysis resistance thereof can also meet the requirements of the hydrolysis resistance synthetic leather.

Owner:ZHEJIANG SUNLIGHT MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com