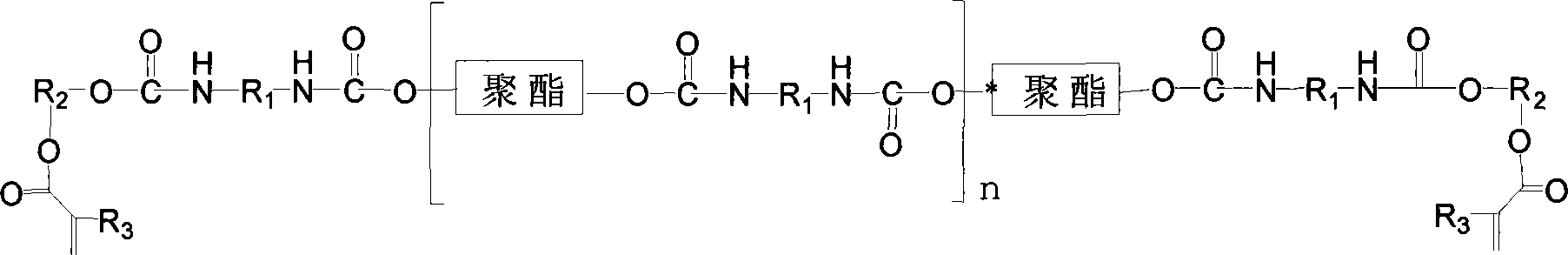

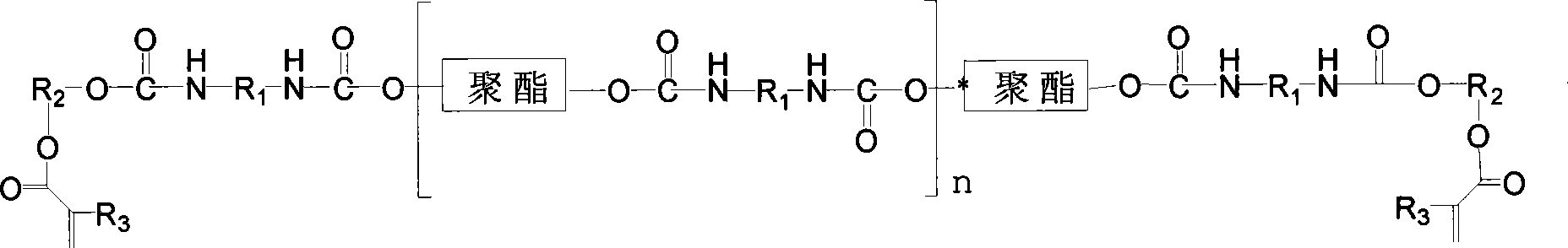

Large-molecular weight polyurethane acrylic ester and synthesizing method thereof

A urethane acrylate and high molecular weight technology, applied in the field of high molecular weight urethane acrylate and its synthesis, can solve the problems of easy occurrence of pinholes, pitting, poor heat resistance and the like on the surface of light-cured coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

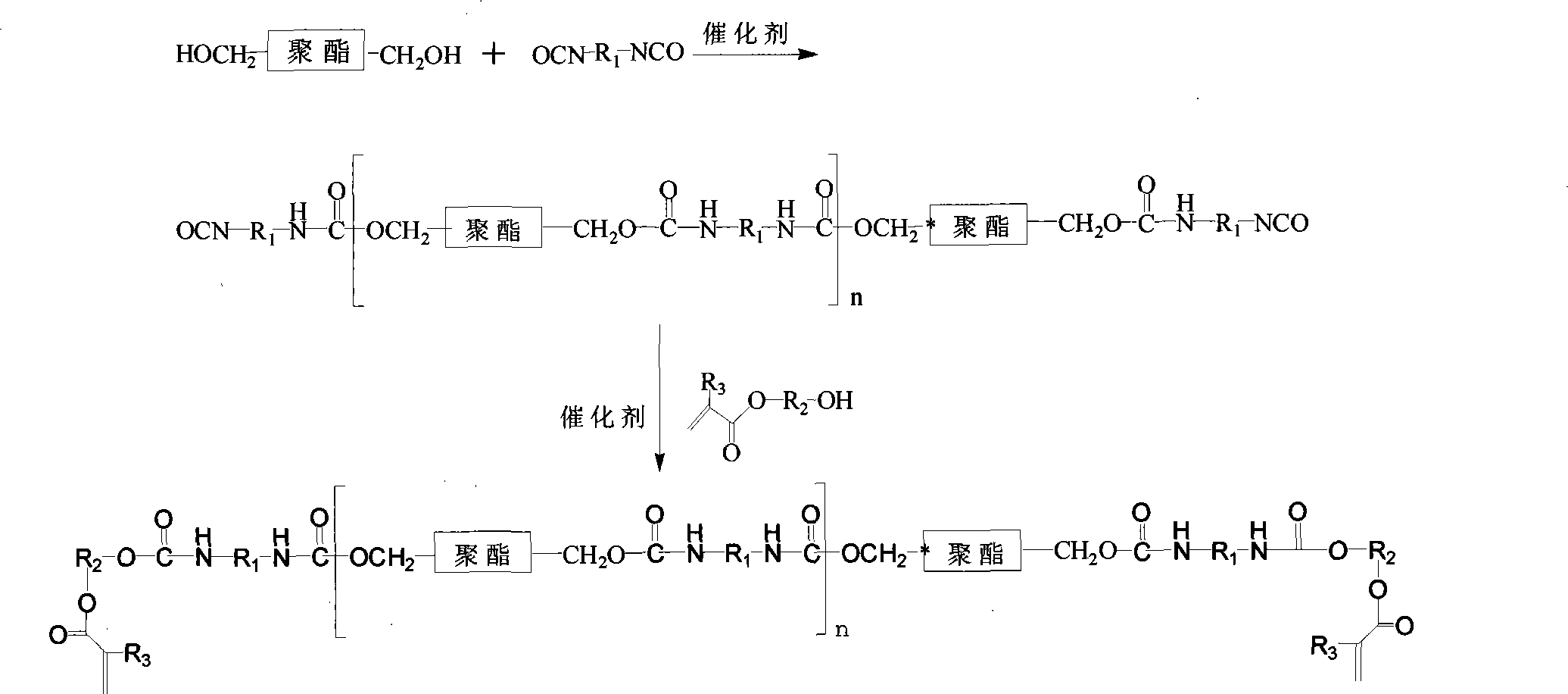

Method used

Image

Examples

Embodiment 1

[0031] Add 222.3 grams of IPDI in the 1000ml four-necked reaction flask, add 750.0 grams of PEGA (molecular weight is 1000 units, Unipol-210, United Carbon Company) that has been vacuum heated to remove water in the addition funnel, add 0.3 grams of dibutyl dilaurate Acid tin as catalyst, add 0.06 gram monochlorophosphate, mix with polyester diol, further remove residual water. Stir the isocyanate, feed polyester diol, heat slowly, control the temperature at 50-60°C, and wait for polyester diol to be added, stir and react at 80°C for 3 hours. 58.0 g of HEA monomer was added (0.2 g of p-methoxyphenol was added as a polymerization inhibitor), the temperature was raised to 80-90° C., and the reaction was stirred for 5 hours. Infrared spectrum detection reaction system NCO group reaction is complete. Viscosity 19700cps / 60℃, number average molecular weight 18400.

Embodiment 2

[0033] Follow the description of Example 1, but change PEGA to PBGA (molecular weight is 1000 units, Unipol-410, United Carbide Corporation), and the dosage is 750 grams. Resin viscosity is 21100cps / 60℃, molecular weight is 19100.

Embodiment 3

[0035] Follow the description of Example 1, but change PEGA to PHGA (molecular weight is 1000 units, Fomrez 66-112, Uniroyal Uniroyal Co., Ltd.), and the dosage is 750 grams. Resin viscosity is 23600cps / 60℃, molecular weight is 20300.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com