Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2889 results about "Vacuum coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vacuum coating is a mechanized process for applying coatings to lengths of materials.

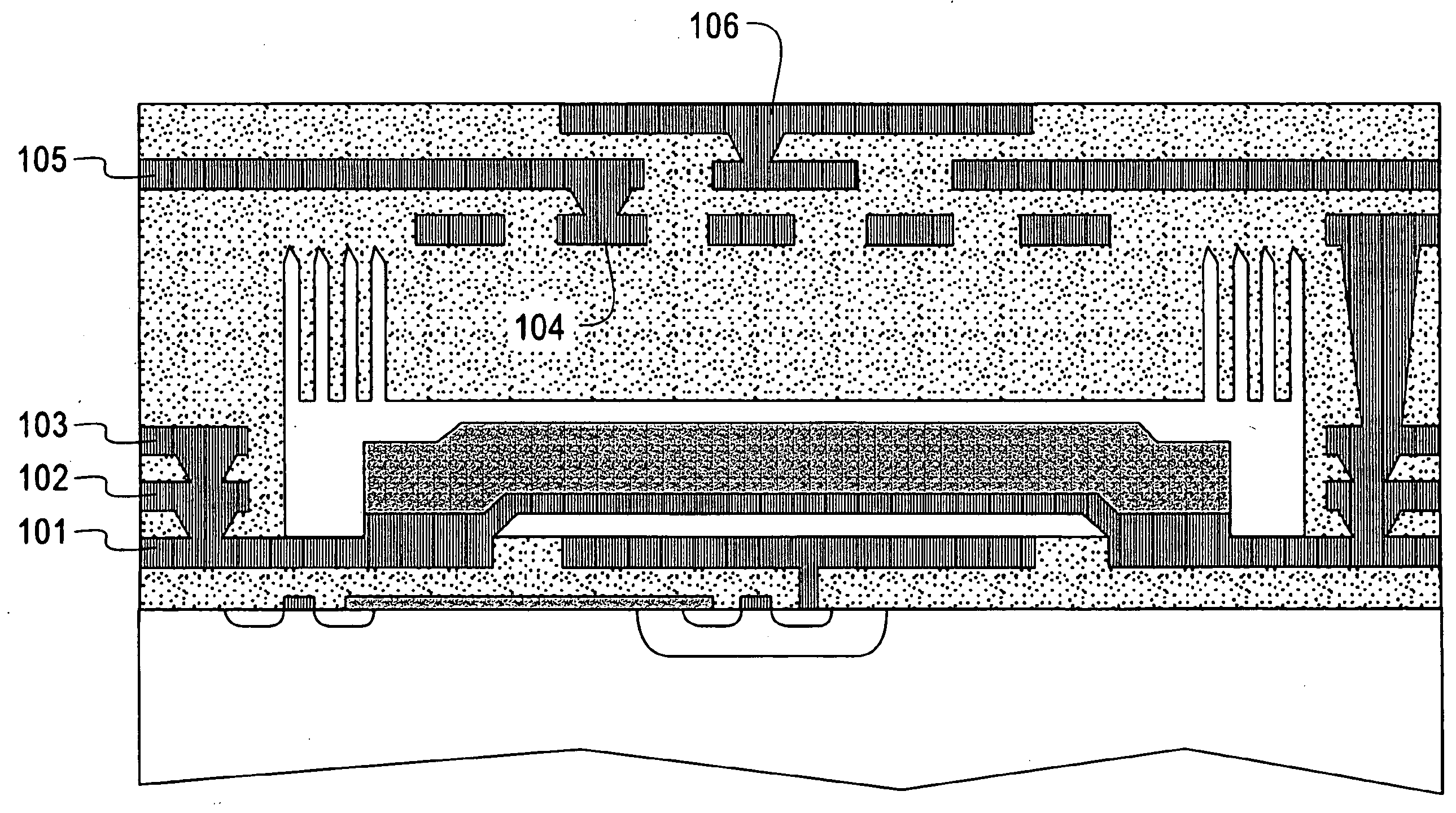

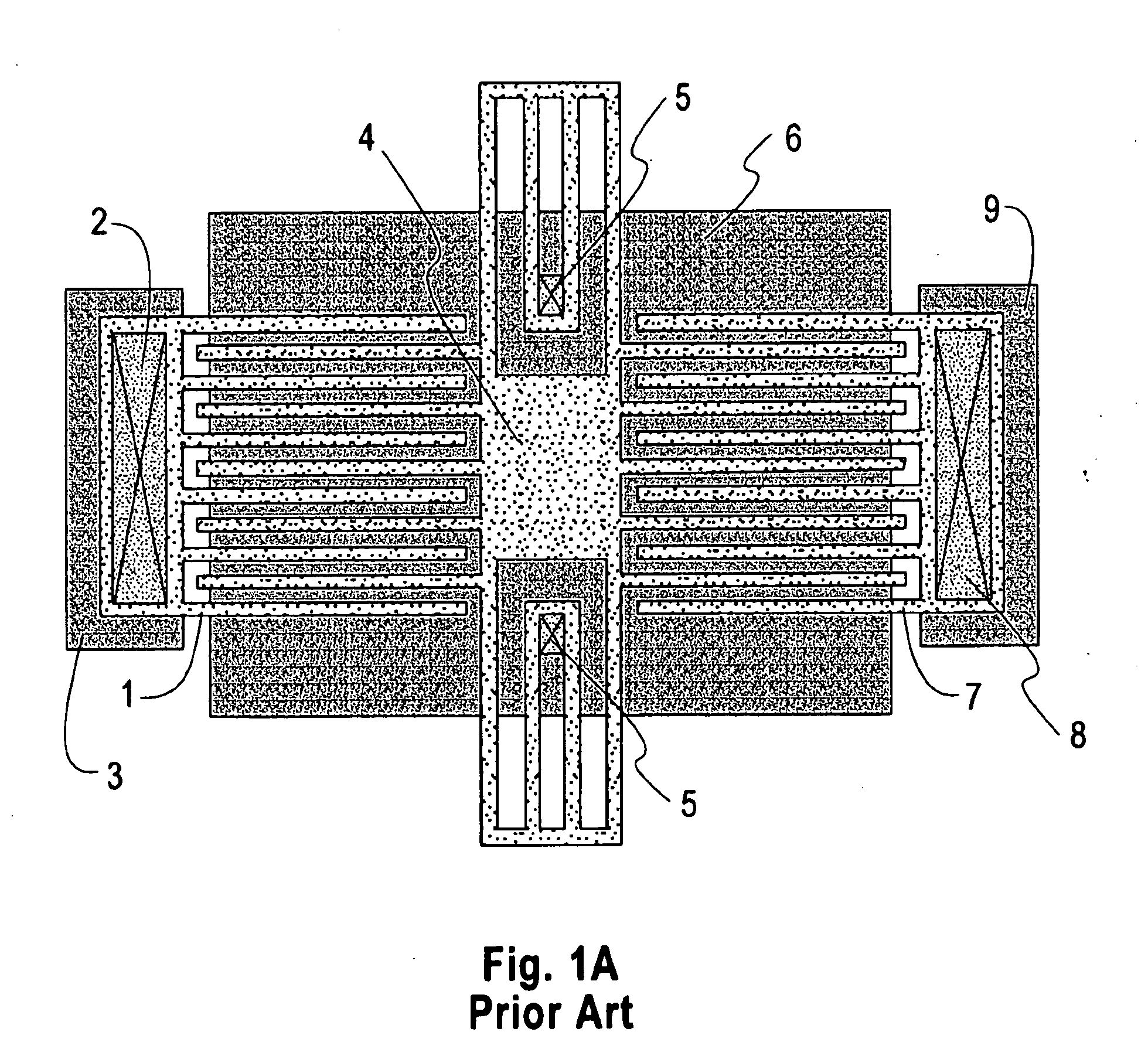

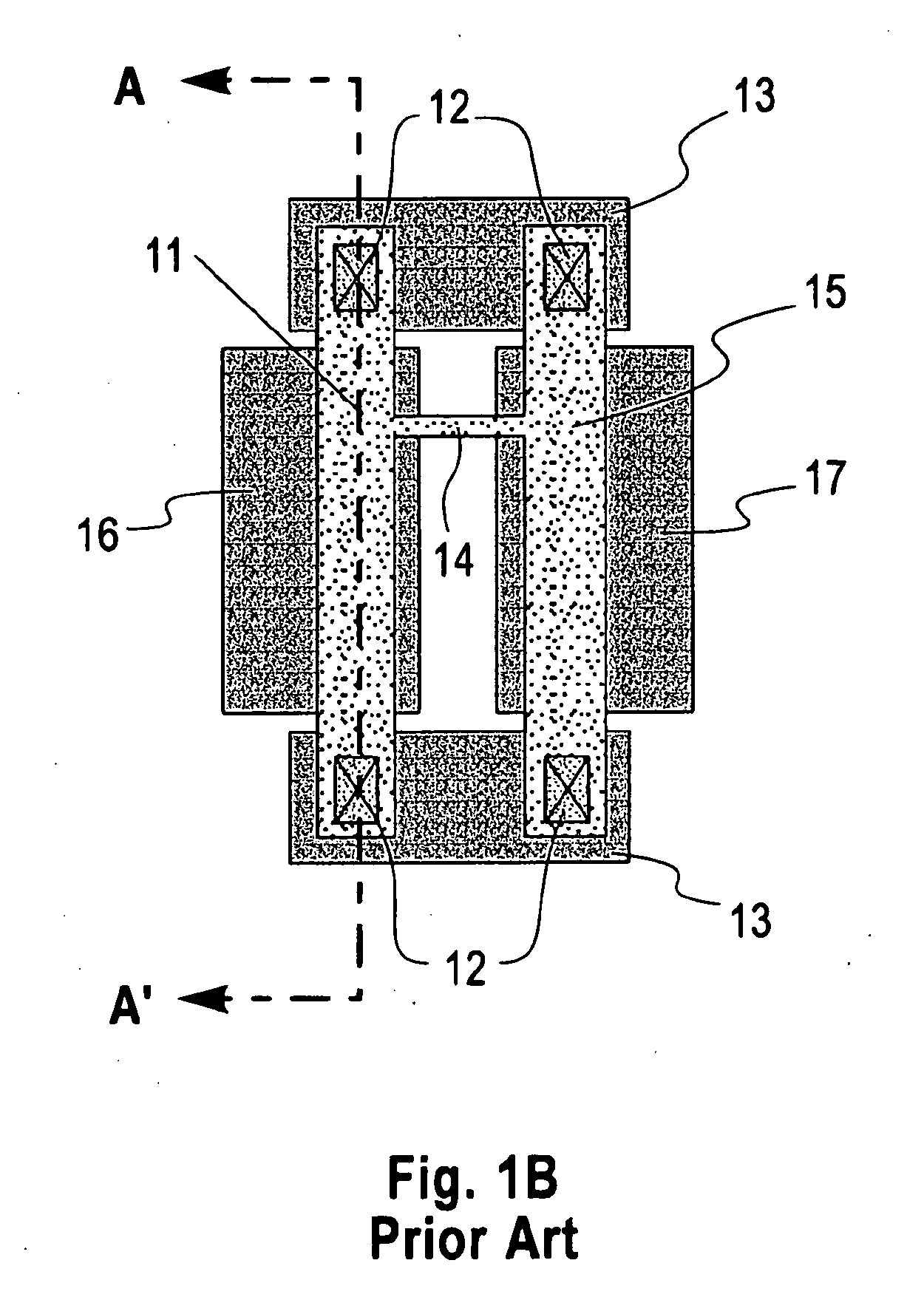

Low temperature bi-CMOS compatible process for MEMS RF resonators and filters

InactiveUS20090108381A1Impedence networksSemiconductor/solid-state device detailsMetal interconnectOxygen plasma

A method of formation of a microelectromechanical system (MEMS) resonator or filter which is compatible with integration with any analog, digital, or mixed-signal integrated circuit (IC) process, after or concurrently with the formation of the metal interconnect layers in those processes, by virtue of its materials of composition, processing steps, and temperature of fabrication is presented. The MEMS resonator or filter incorporates a lower metal level, which forms the electrodes of the MEMS resonator or filter, that may be shared with any or none of the existing metal interconnect levels on the IC. It further incorporates a resonating member that is comprised of at least one metal layer for electrical connection and electrostatic actuation, and at least one dielectric layer for structural purposes. The gap between the electrodes and the resonating member is created by the deposition and subsequent removal of a sacrificial layer comprised of a carbon-based material. The method of removal of the sacrificial material is by an oxygen plasma or an anneal in an oxygen containing ambient. A method of vacuum encapsulation of the MEMS resonator or filter is provided through means of a cavity containing the MEMS device, filled with additional sacrificial material, and sealed. Access vias are created through the membrane sealing the cavity; the sacrificial material is removed as stated previously, and the vias are re-sealed in a vacuum coating process.

Owner:IBM CORP

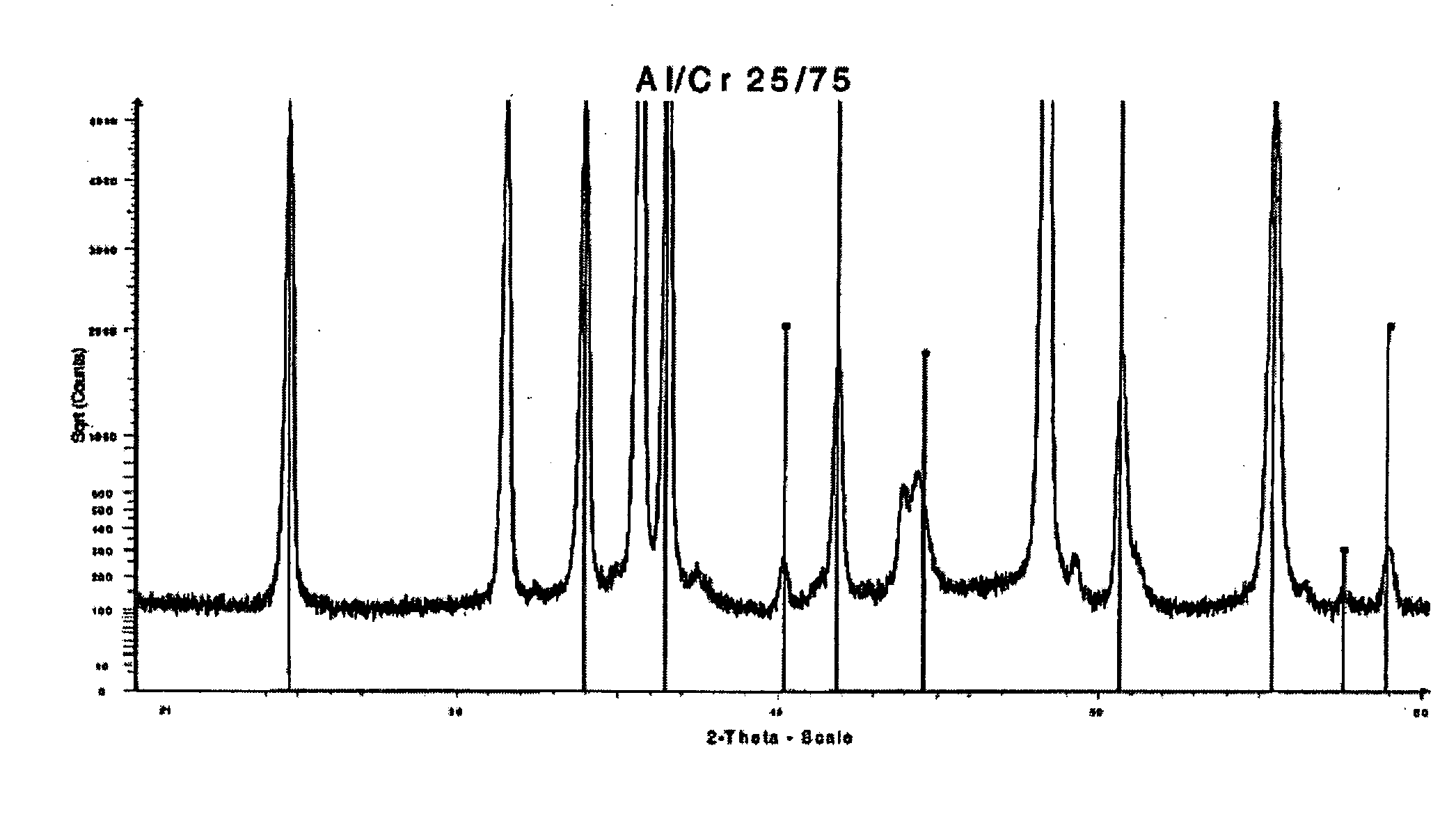

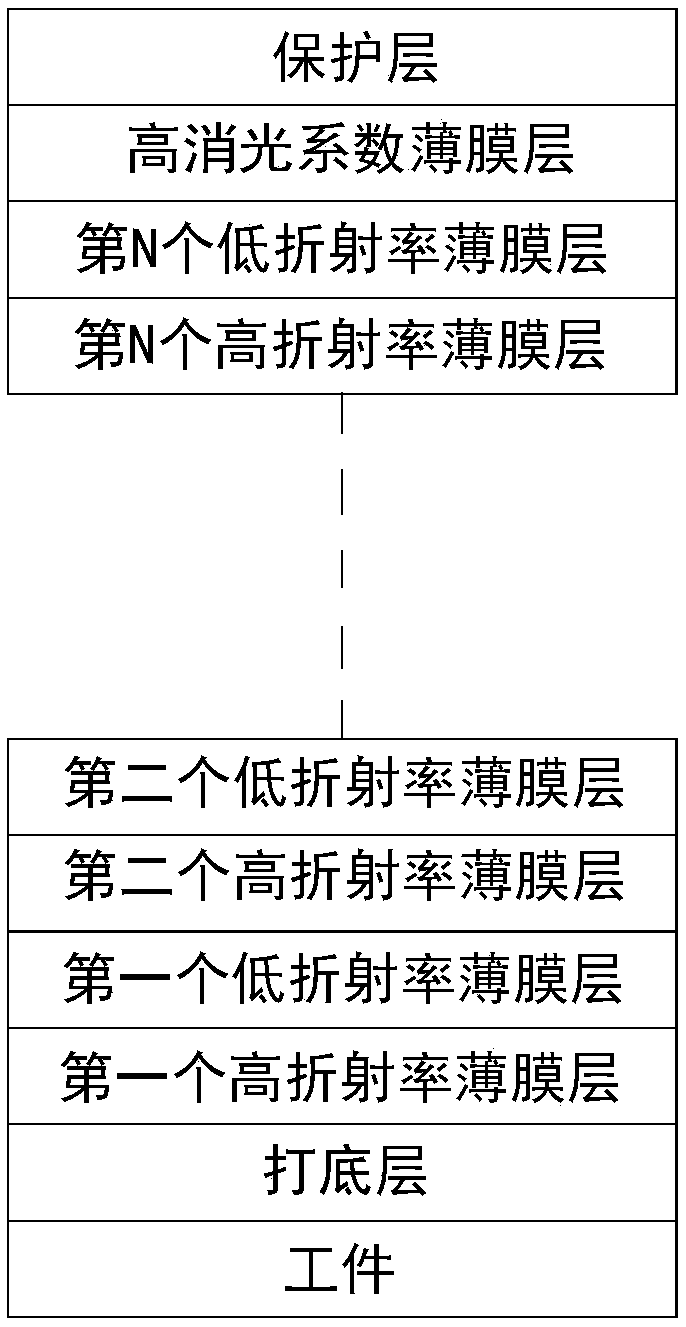

Layer system with at least one mixed crystal layer of a multi-oxide

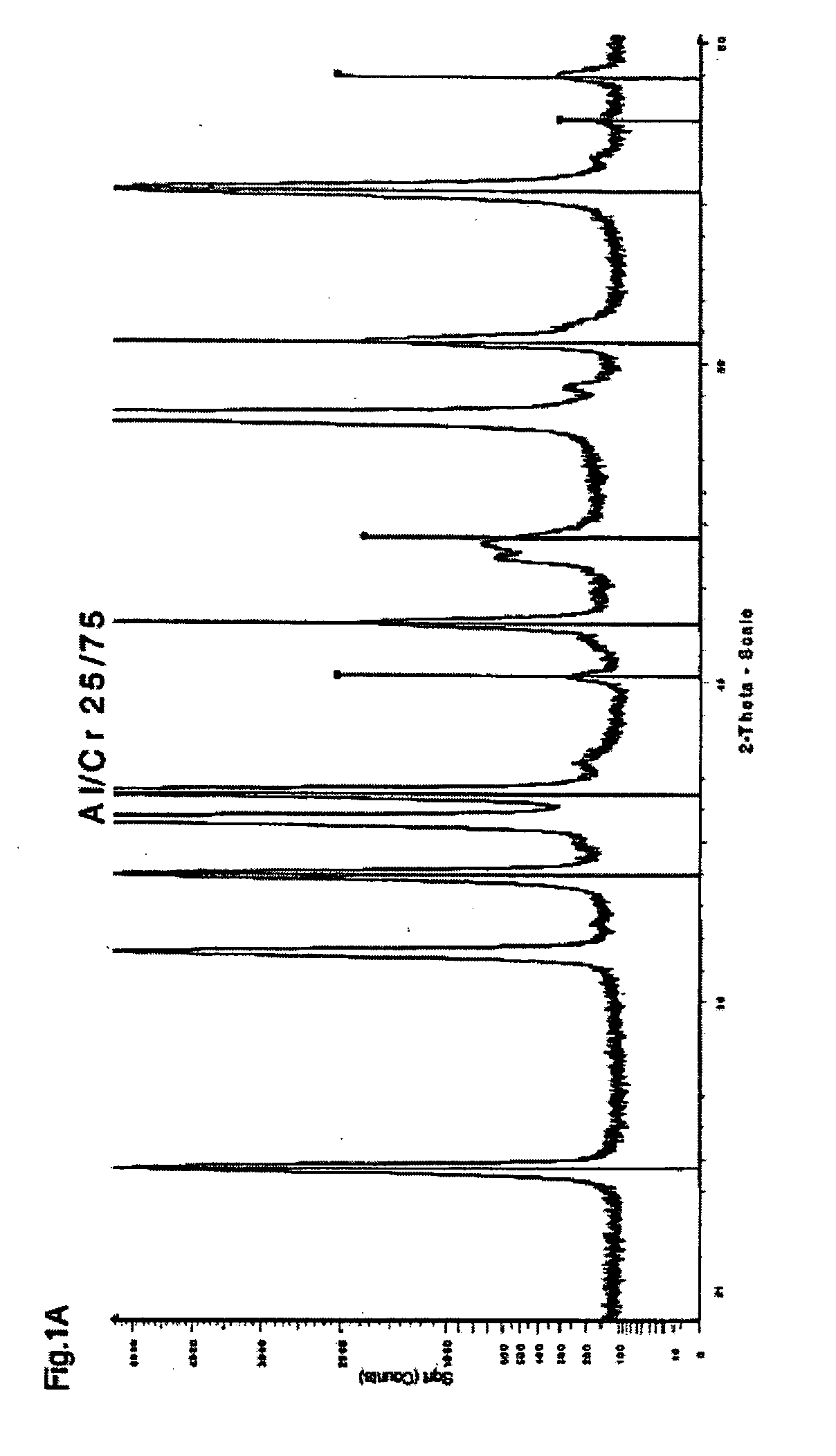

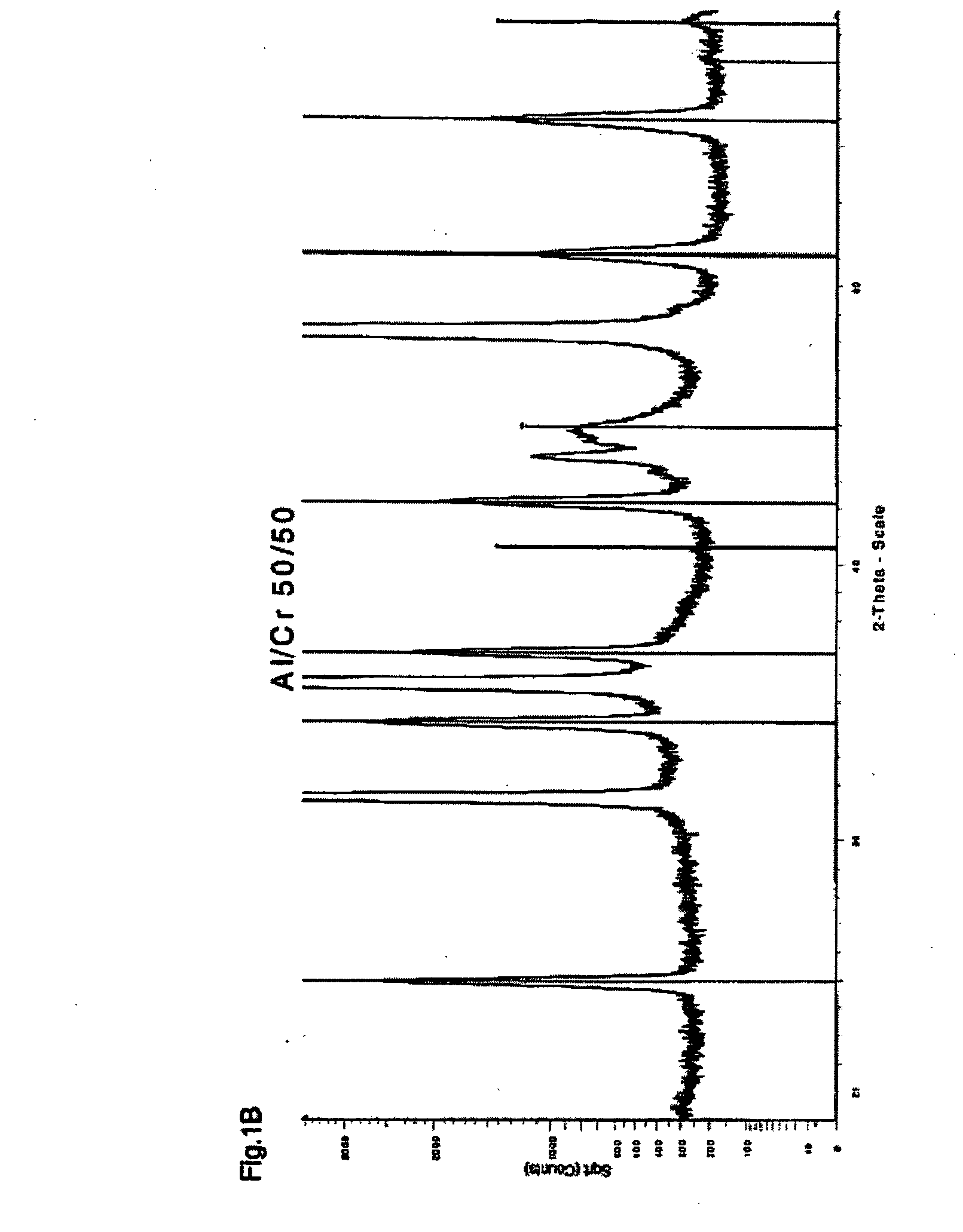

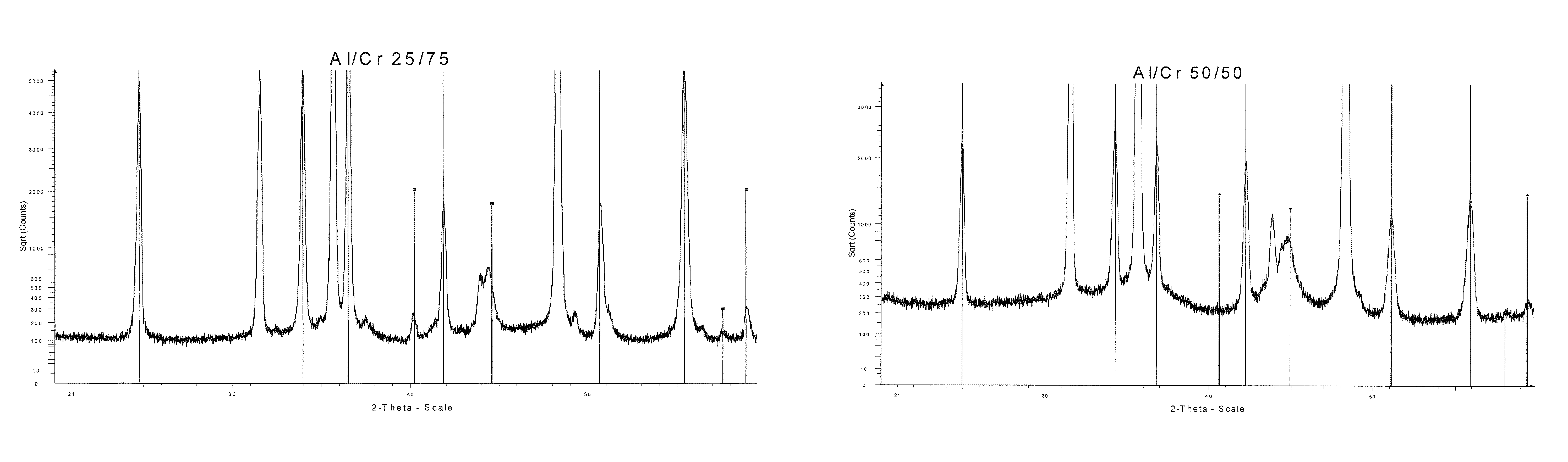

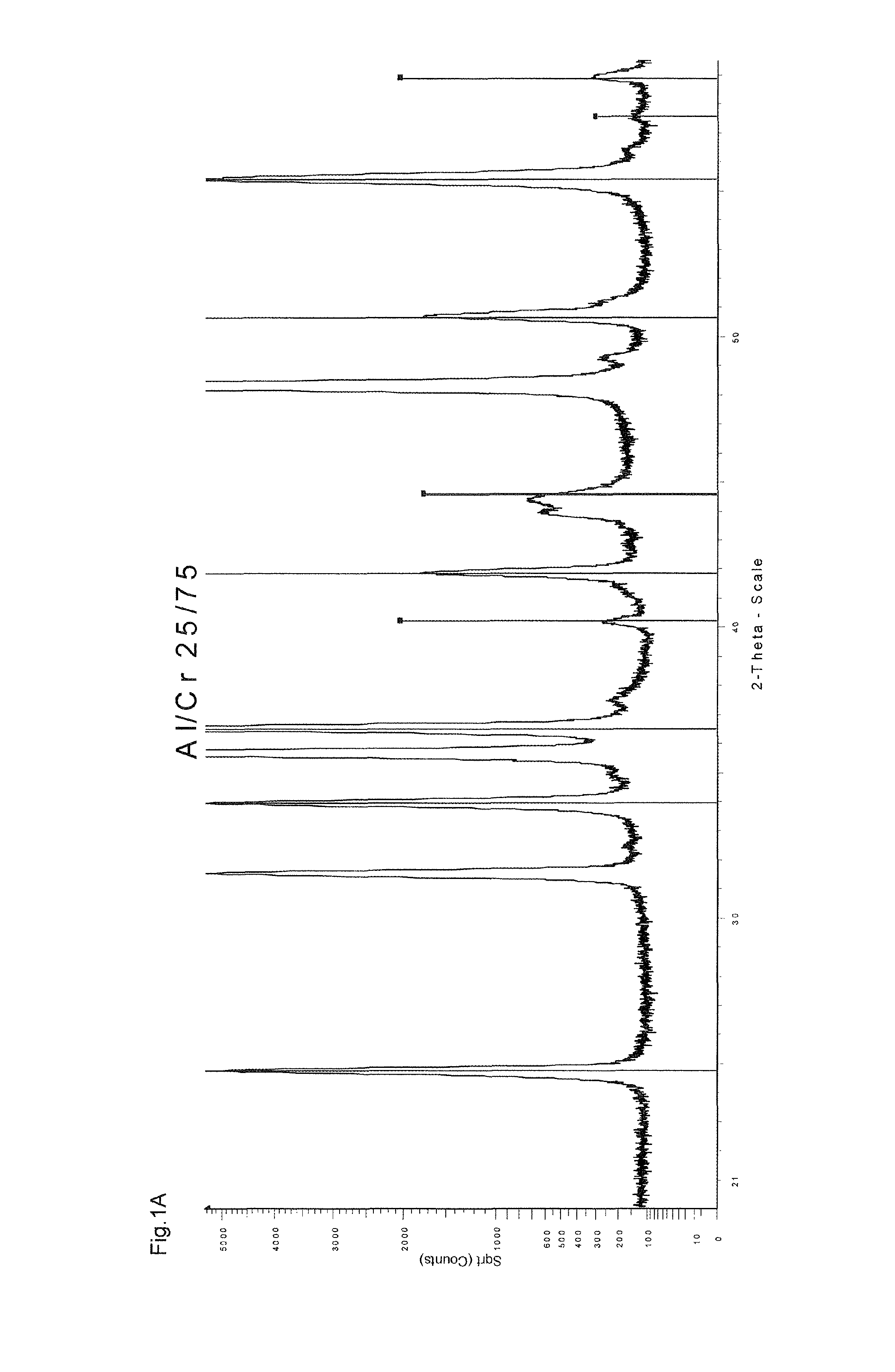

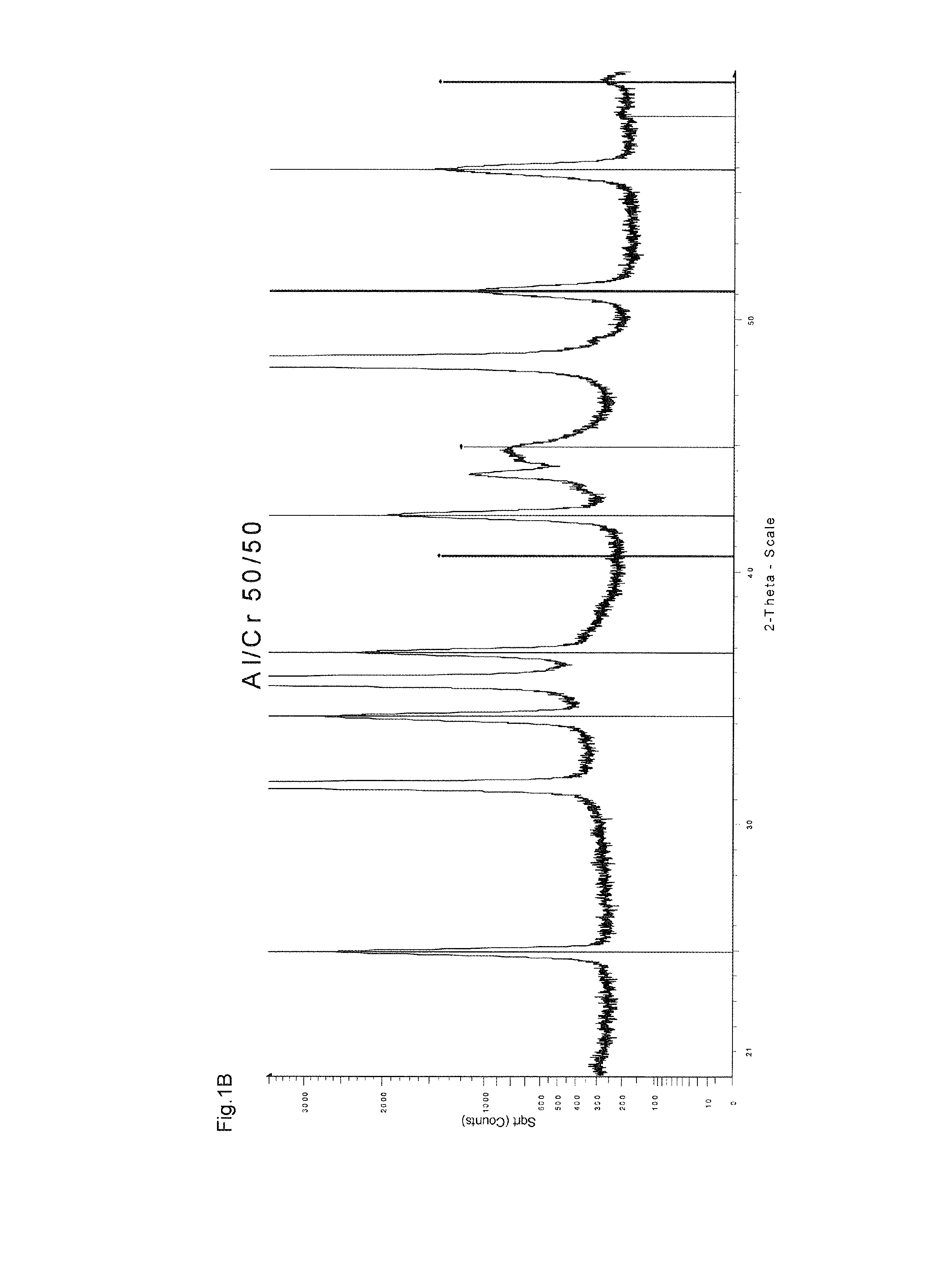

A PVD layer system for the coating of workpieces encompasses at least one mixed-crystal layer of a multi-oxide having the following composition: (Me11-xMe2x)2O3, where Me1 and Me2 each represent at least one of the elements Al, Cr, Fe, Li, Mg, Mn, Nb, Ti, Sb or V. The elements of Me1 and Me2 differ from one another. The crystal lattice of the mixed-crystal layer in the PVD layer system has a corundum structure which in an x-ray diffractometrically analyzed spectrum of the mixed-crystal layer is characterized by at least three of the lines associated with the corundum structure. Also disclosed is a vacuum coating method for producing a mixed-crystal layer of a multi-oxide, as well as correspondingly coated tools and components.

Owner:OERLIKON SURFACE SOLUTIONS AG PFAFFIKON

Highly wearable vacuum coating ultraviolet curing coatings

ActiveCN101157808AImprove adhesionImproved RCA wear performancePolyurea/polyurethane coatingsWear resistantLacquer

The invention relates to the electronic application-coating field, in particular to uv-curing coating with high wearing resistance and vacuum coating. The compositions and contents of the invention are: 10 wt percent to 30 wt percent of difunctional group polyurethane acrylate, 10 wt percent to 40 wt percent of high functional group polyurethane acrylate, 5 wt percent to 20 wt percent of high functional group acrylate monomer, 0 wt percent to 15 wt percent of monofunctional group acrylate monomer, 1 wt percent to 10 wt percent of acid adhesive promoter, 1 wt percent to 6 wt percent of photoinitiator, 0 wt percent to 5 wt percent of nano wearing resistance materials, 0.1 wt percent to 2 wt percent of additive and 10 wt percent to 50 wt percent of solvent. The invention is designed for providing surface protection for vacuum coating parts of electric products such as mobile phone, MP3, and digital camera, etc., and is characterized by good surface effect, good performances of ultrawear-resistance, high temperature and humidity resistance, anti-cold thermal cycling and anti-yellowing, etc., wherein, RCA wear can be up to more than 1500 times, which can effectively improve the service life of electric products. The invention effectively enhances the adhesion and wearing resistant performance of the uv-curing and vacuum coating dope, solves the matching problem of the bottom and surface lacquer of the uv-curing and vacuum coating dope, and has broad university.

Owner:HUNAN SOKAN NEW MATERIAL

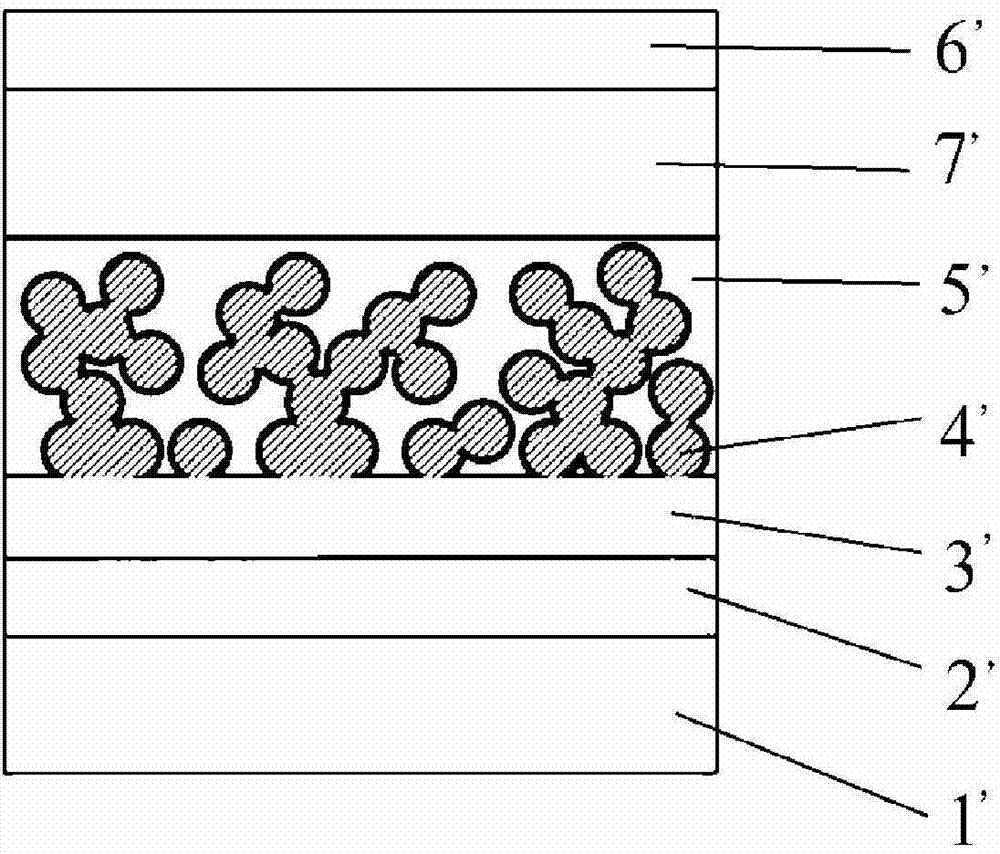

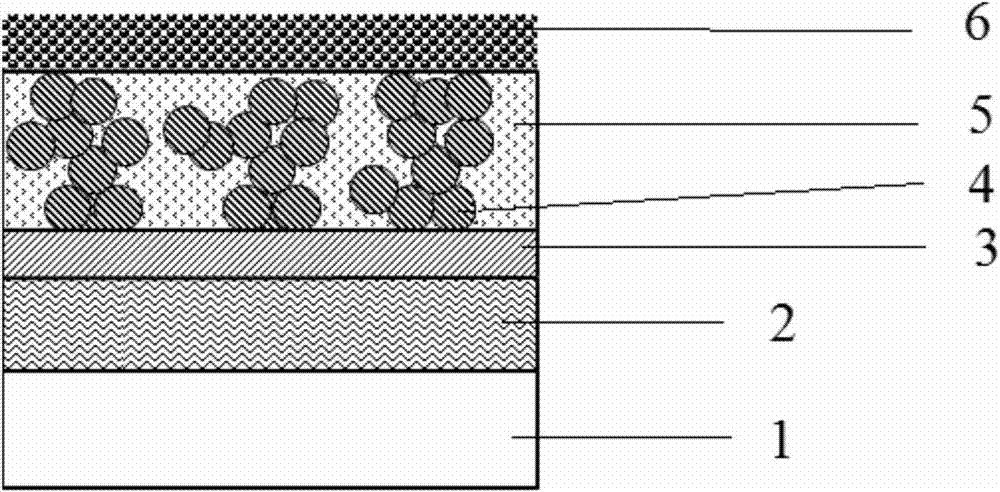

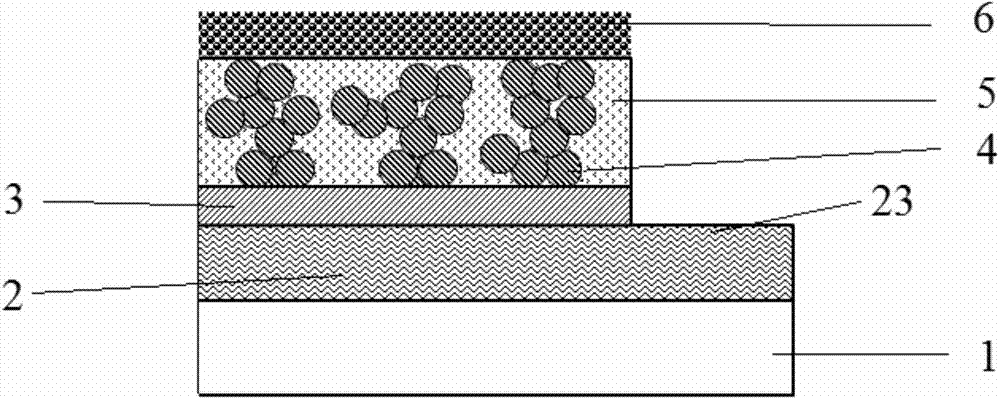

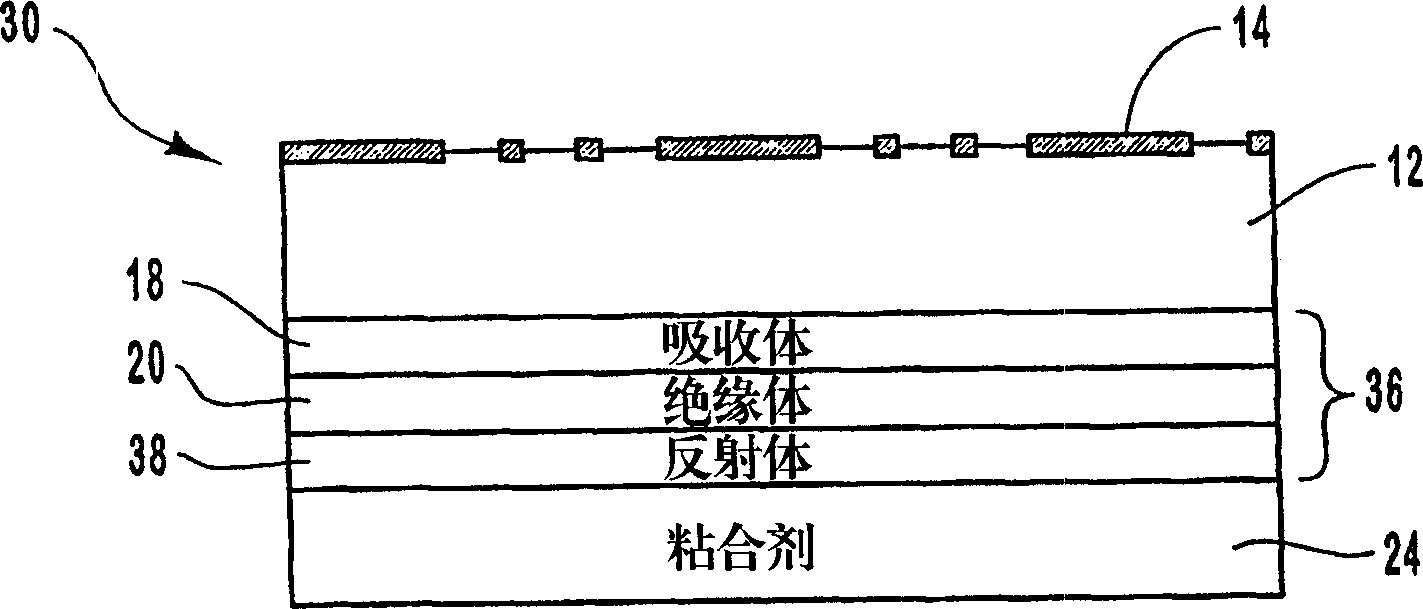

Perovskite-based thin film solar cell and method for preparing same

ActiveCN103490011ASolve problems that are difficult to achieve large-scale productionLow costFinal product manufactureSolid-state devicesSemiconductor materialsPorous carbon

The invention provides a perovskite-based thin film solar cell and a method for preparing the perovskite-based thin film solar cell. The perovskite-based thin film solar cell comprises a transparent substrate, a transparent conducting layer formed on the transparent substrate, a compact layer which is formed on the transparent conducting layer and made of semiconductor materials, a porous insulating layer formed on the compact layer, a porous carbon counter electrode layer formed on the porous insulating layer, and an organic metal semiconductor light absorption material which is filled into pores inside the porous insulating layer and has a perovskite structure. The invention provides application of carbon counter electrodes in the perovskite-based thin film solar cell. Compared with an existing method for preparing the perovskite-based thin film solar cell, the method has the advantages that the counter electrodes are made of carbon materials instead of expensive precious metal materials, and therefore the cost is greatly reduced. The vacuum coating method is replaced by a simple and rapid silk screen print method which allows large-scale production to be achieved, therefore, the cost is further saved, and the achievement of industrial production of the perovskite-based thin film solar cell is facilitated.

Owner:深圳市华物光能技术有限公司

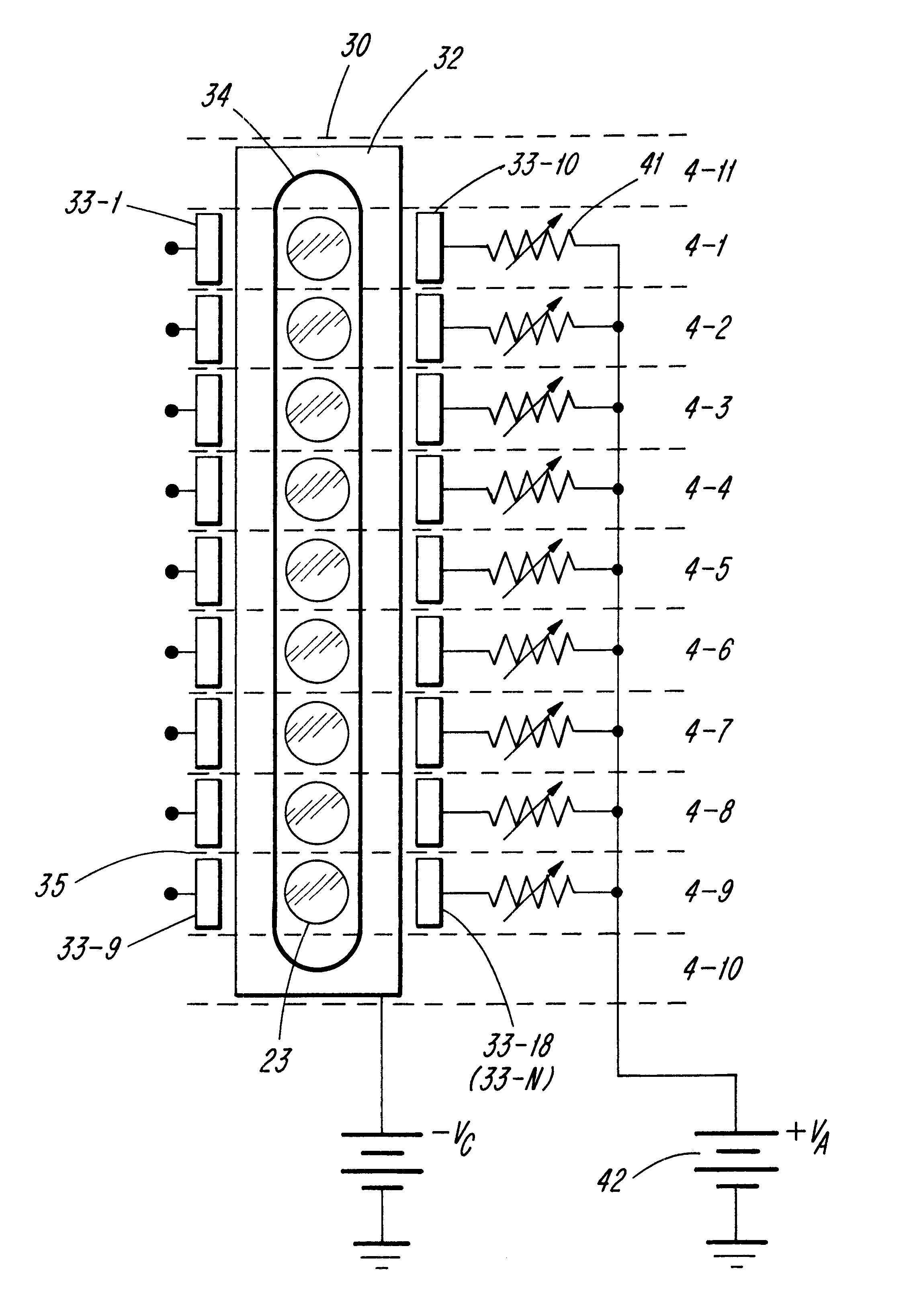

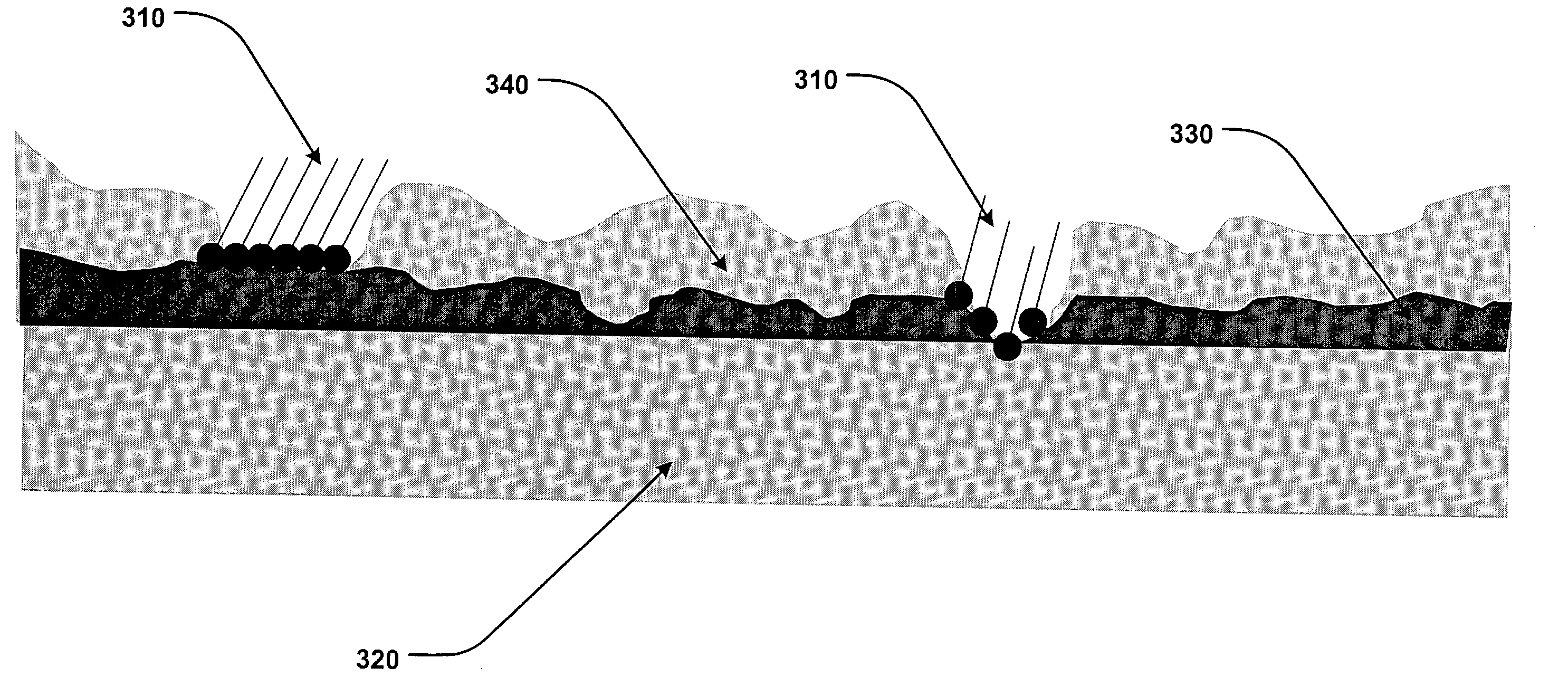

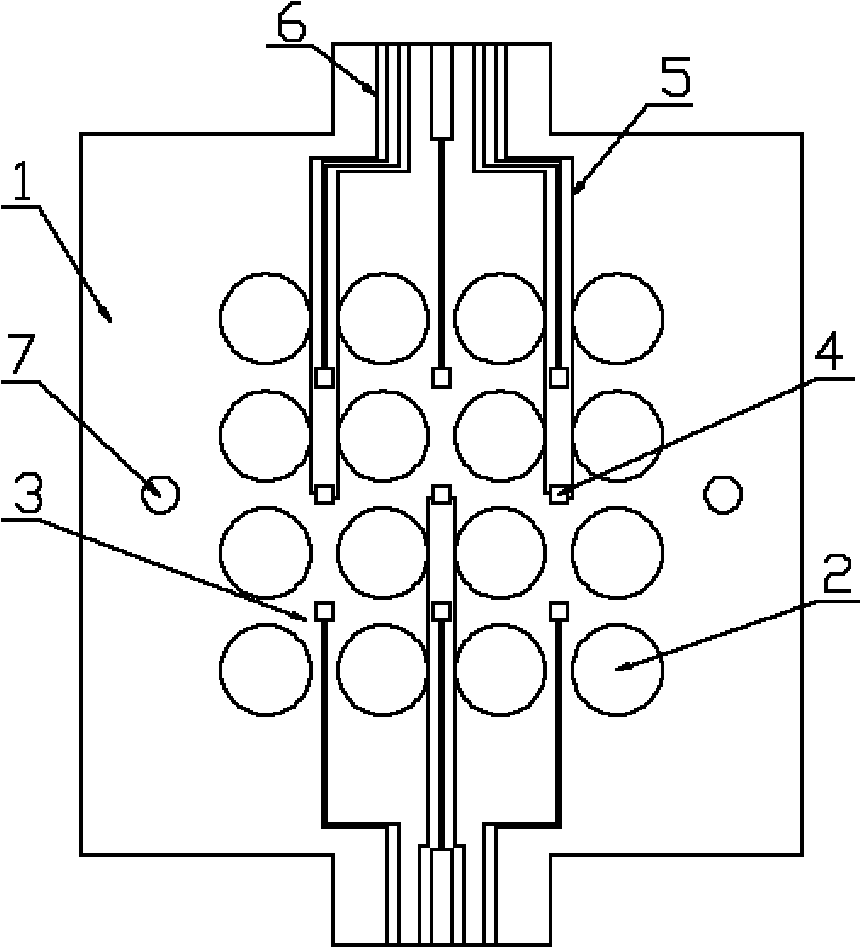

Low Pressure Arc Plasma Immersion Coating Vapor Deposition And Ion Treatment

A vacuum coating and plasma treatment system includes a magnetron cathode with a long edge and a short edge. The magnetic pole of the magnetron results in an electromagnetic barrier. At least one remote arc discharge is generated separate from the magnetron cathode and in close proximity to the cathode so that it is confined within a volume adjacent to the magnetron target. The remote arc discharge extends parallel to the long edge of the magnetron target and is defined by the surface of the target on one side and the electromagnetic barrier on all other sides. There is a remote arc discharge cathode hood and anode hood extending over the arc discharge and across the short edge of the magnetron cathode. Outside of the plasma assembly is a magnetic system creating magnetic field lines which extend into and confine the plasma in front of the substrate.

Owner:VAPOR TECH

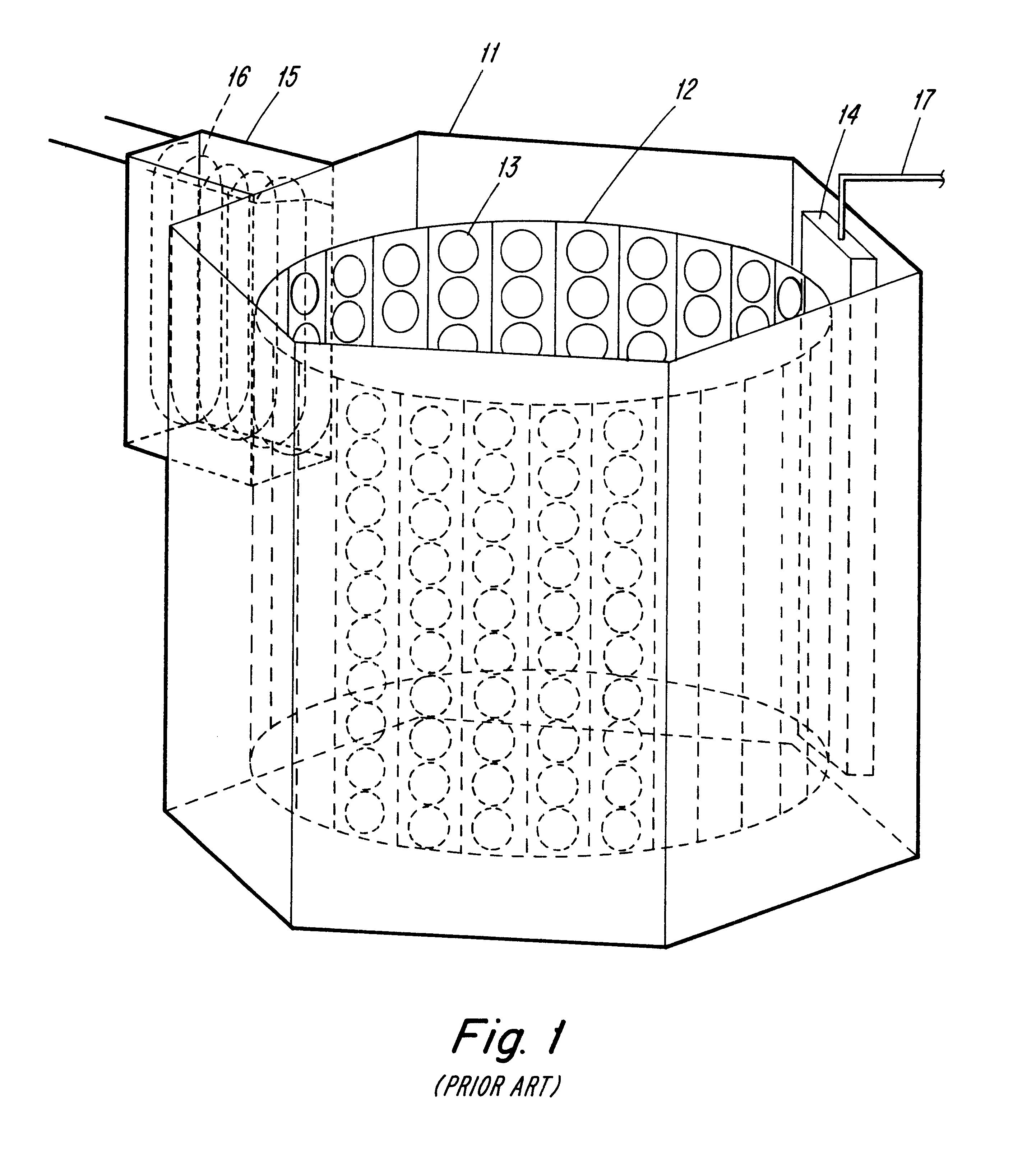

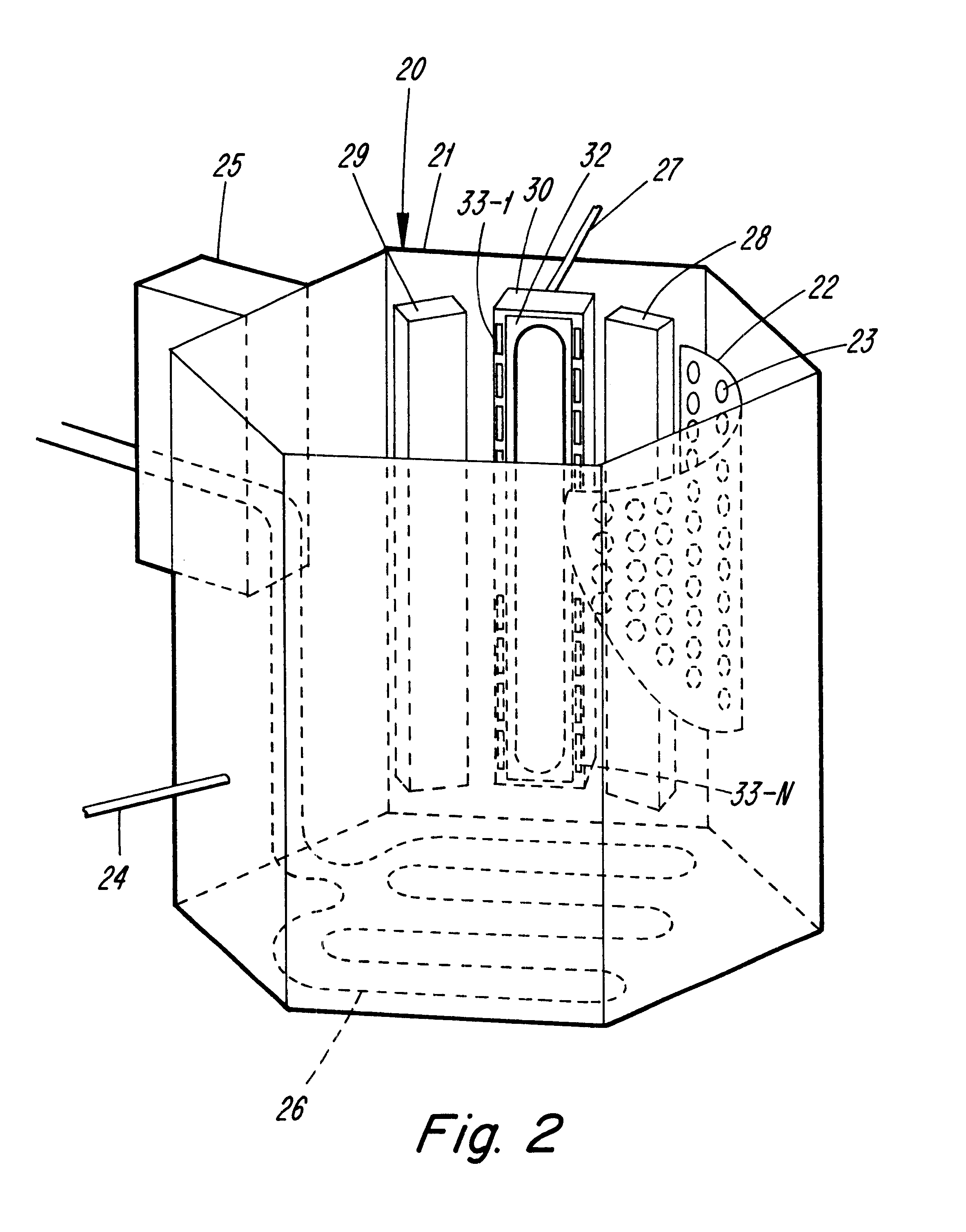

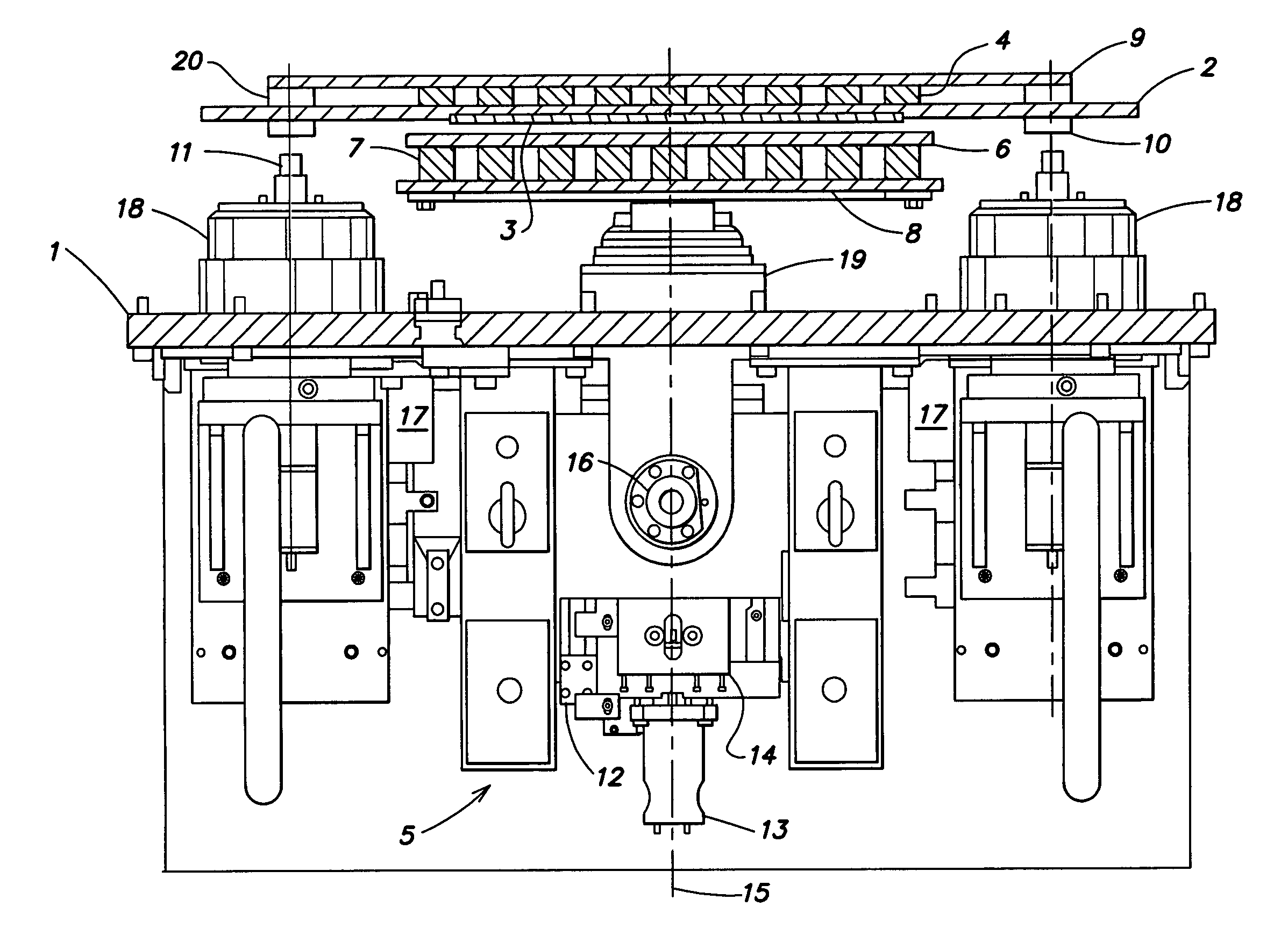

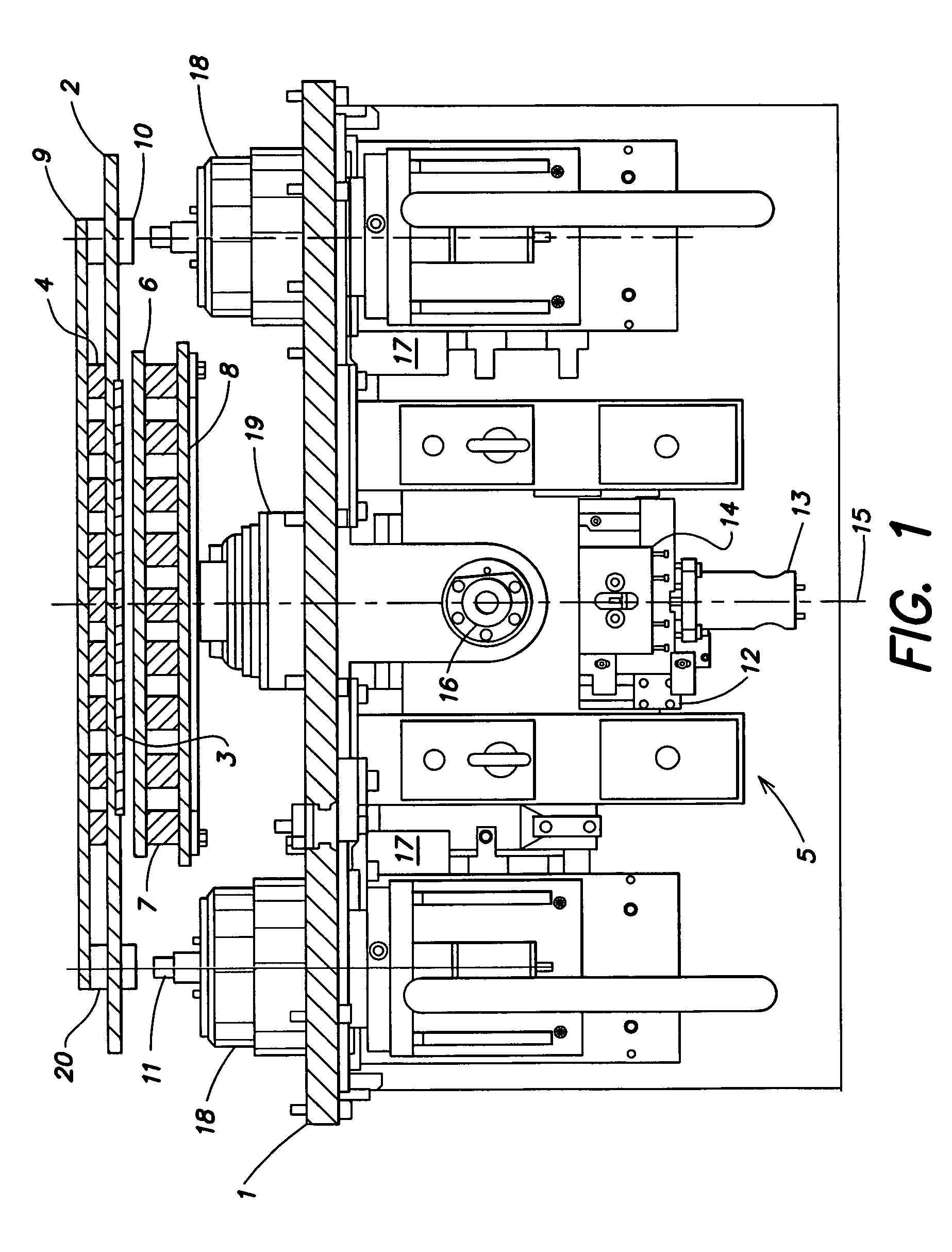

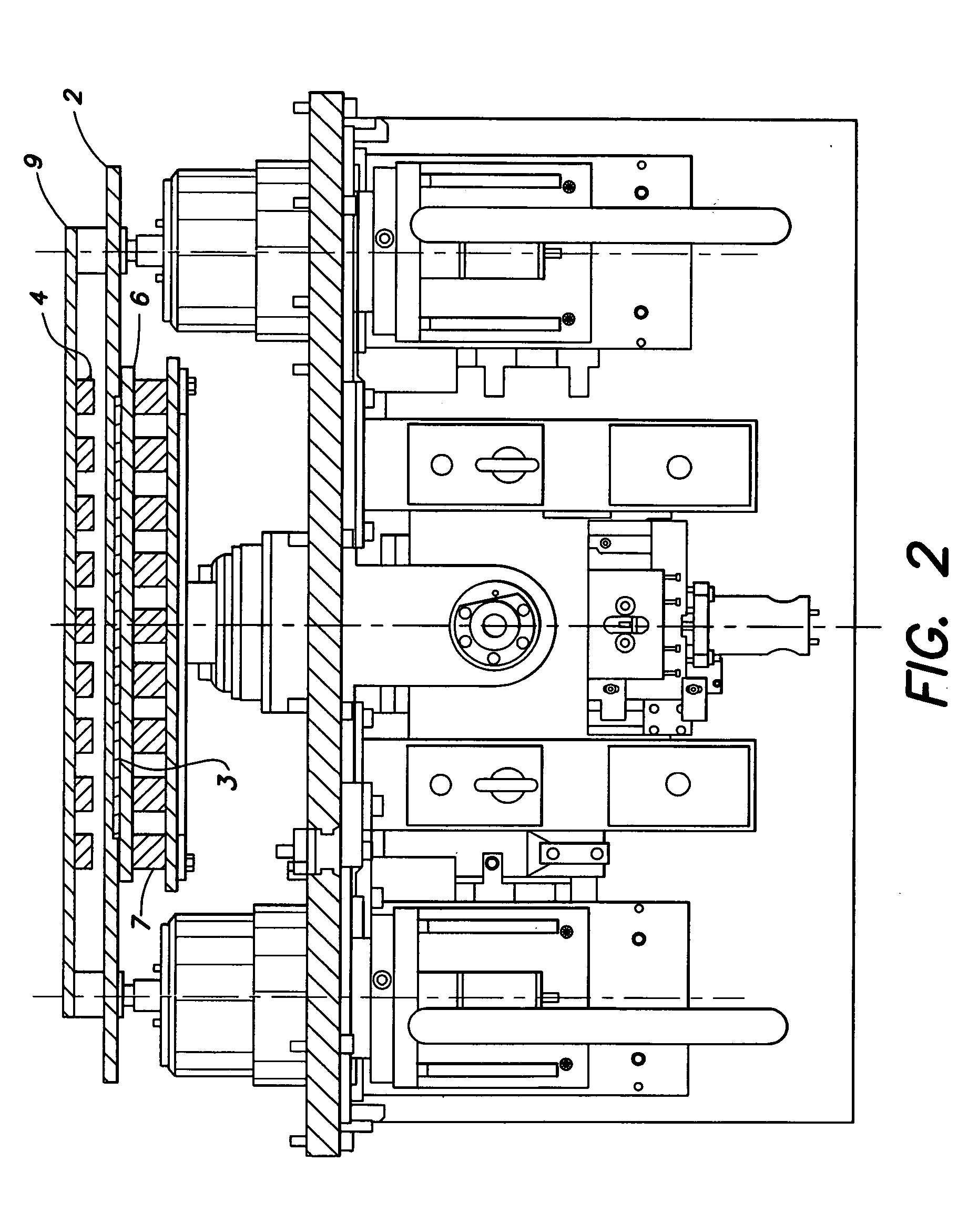

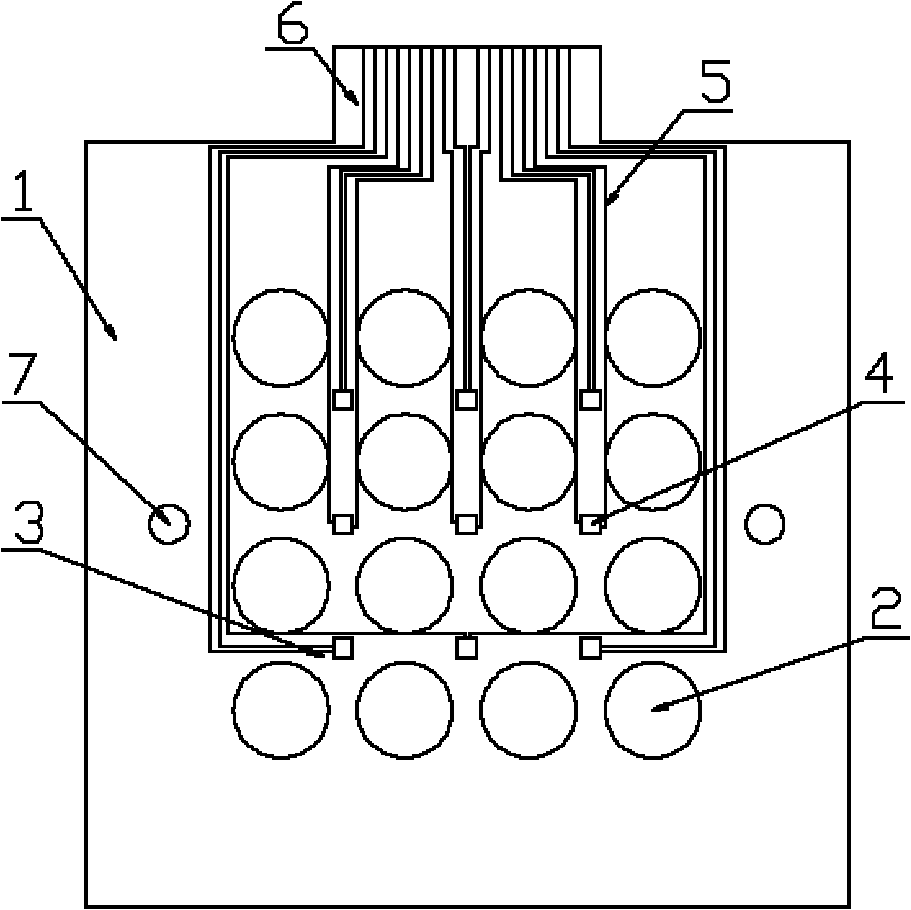

Multi-anode device and methods for sputter deposition

InactiveUS6440280B1Good lookingImprove transmittanceCellsElectric discharge tubesEngineeringSputter deposition

A method and apparatus for vacuum coating plural articles employs a drum work holder configuration and a sputter source with a plurality of individually controlled anodes for effectively providing uniform coatings on articles disposed at different locations on the drum work holder. A small number of measured process parameters are used to control a small number of process variable to improve coating uniformity from batch to batch.

Owner:SOLA INTERNATIONAL INC

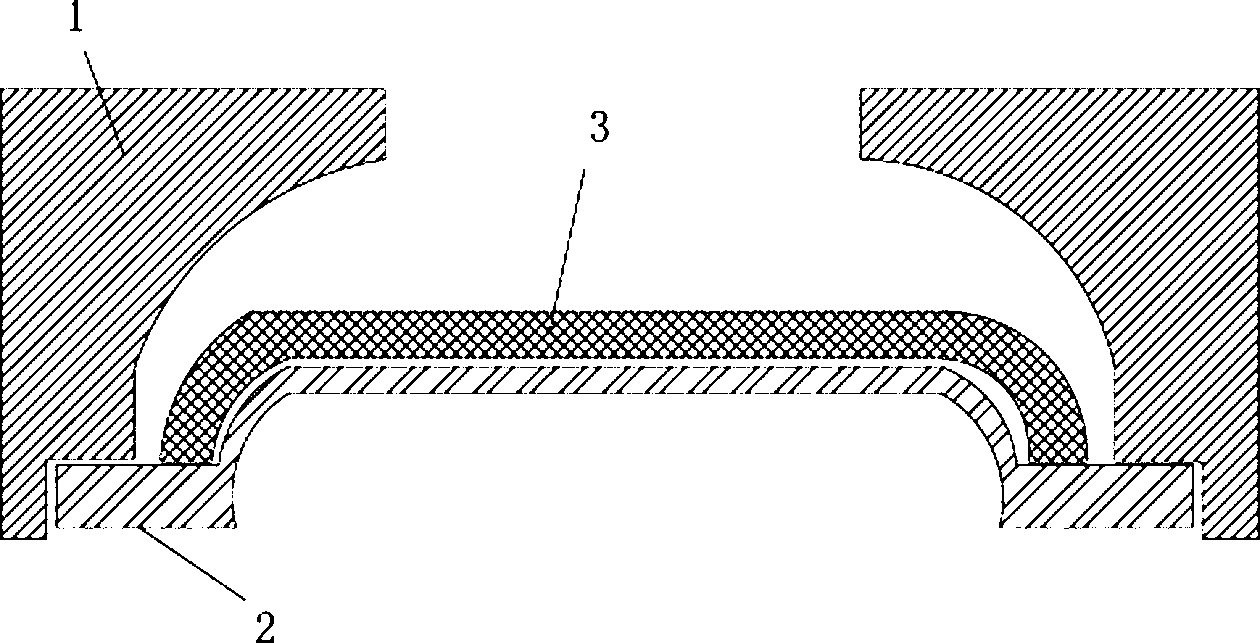

Magnetic mask holder

InactiveUS20070006807A1Precise and rapid and simple possibilityEasy to manufactureLiquid surface applicatorsElectroluminescent light sourcesEngineeringOrganic electroluminescence

Aspects of the present invention are directed to a mask holder for especially large-surface substrates, especially for the micro-structuring of organic electroluminescent materials (OLED) for the production of OLED screens, displays and the like by means of vacuum-coating processes, with a substrate carrier for receiving the substrate during coating processes, with the substrate carrier comprising one or more magnets and the mask features a frame of magnetic material, such that the frame of the mask is held by means of the magnets of the substrate carrier relative to the substrate to be coated.

Owner:APPLIED MATERIALS GMBH & CO KG

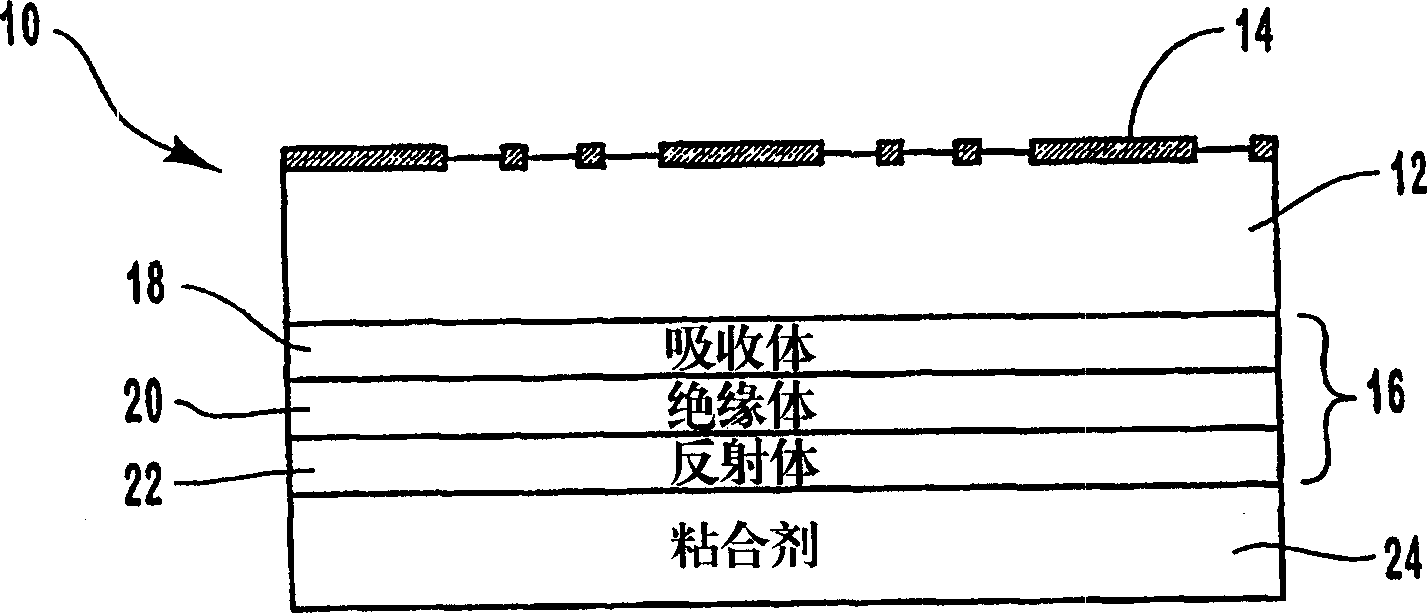

Uptically variable security devices

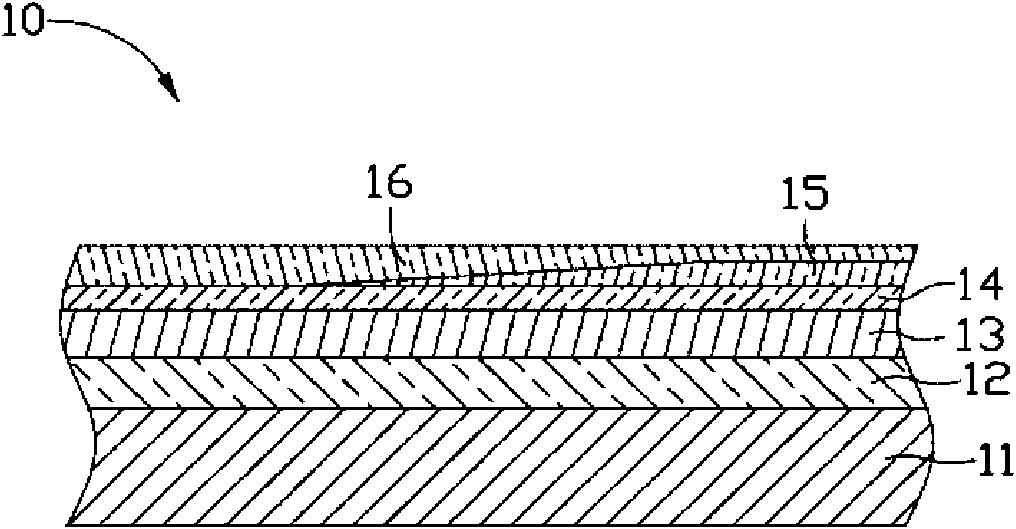

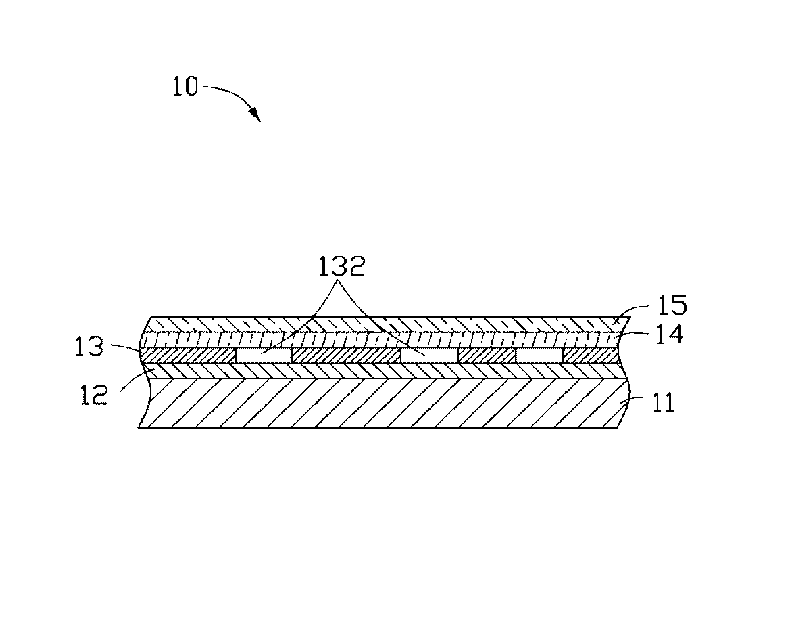

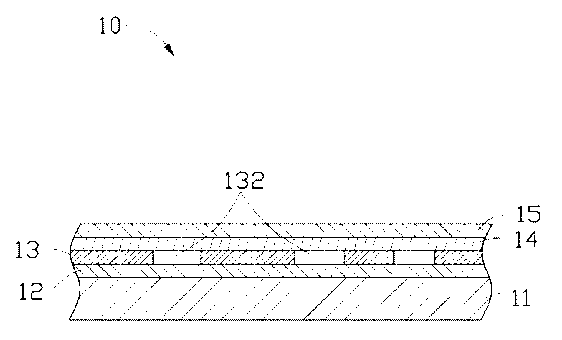

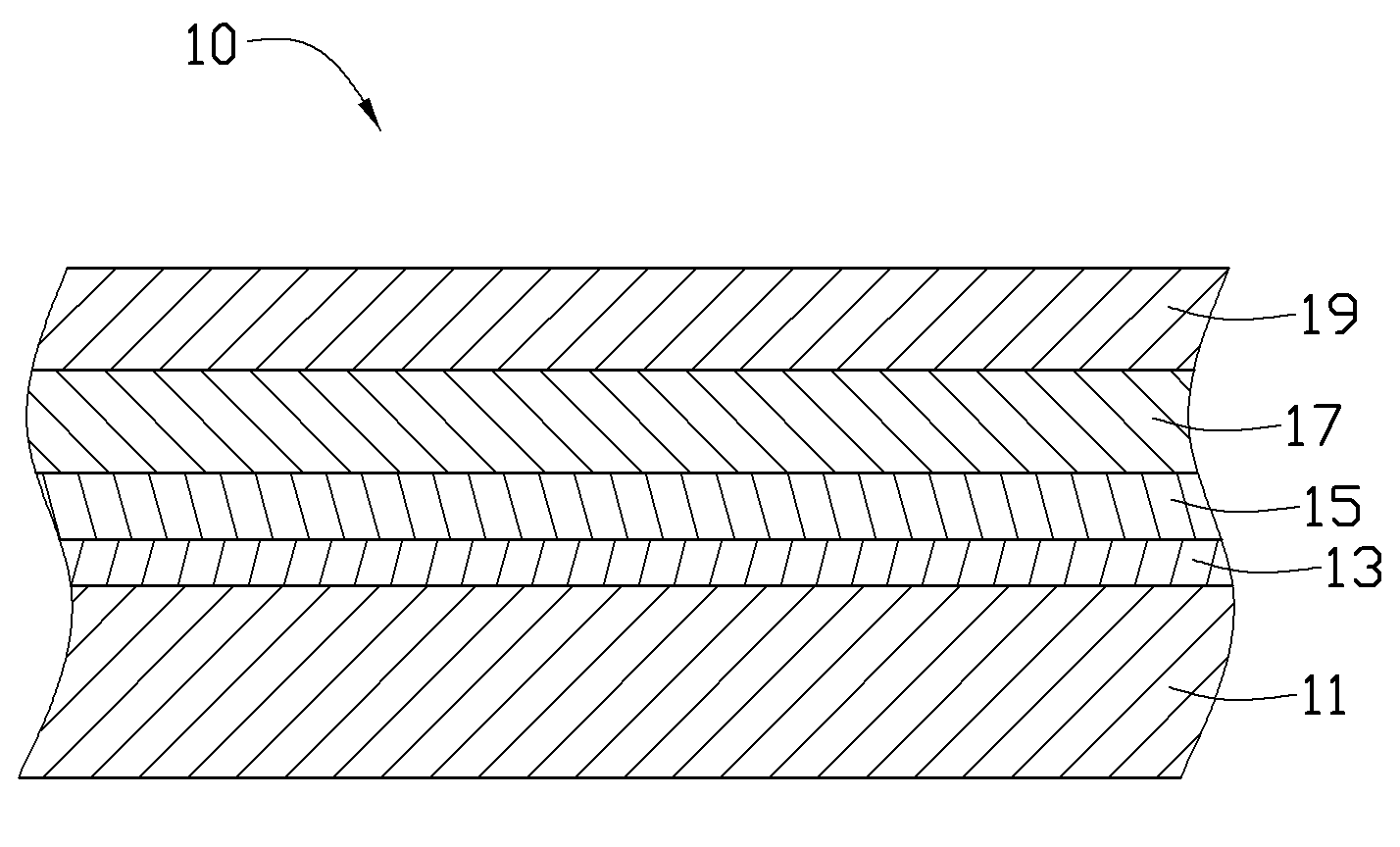

InactiveCN1423598AGood anti-counterfeiting measuresOther printing matterSynthetic resin layered productsHot stampingEngineering

A security article (10) includes a light transmissive substrate (12) having a first surface and an opposing second surface, with the first surface having an optical interference pattern (14) such as a holographic image pattern or an optical diffraction pattern thereon. A color shifting optical coating (16) is formed on the substrate such as on the interference pattern or on the opposing second surface of the substrate, with the optical coating providing an observable color shift as the angle of incident light or viewing angle changes. Various processes can be utilized to form the security article (10), such as vacuum coating processes, lamination, laser scribing, and laser imaging. The security article (10) can be affixed to a variety of objects through various attachment mechanisms, such as pressure sensitive adhesives or hot stamping processes, to provide for enhanced security measures such as anticounterfeiting.

Owner:光学涂层实验公司

Ultraviolet light curing vacuum coating foundation and finish

InactiveCN101250339AStrong adhesionExcellent environmental test performanceVacuum evaporation coatingSputtering coatingEpoxyUltraviolet lights

The invention discloses ultraviolet light curing vacuum plating primer and finish, wherein primer is formed by random proportion of double function aliphatic polyurethane acrylic ester, epoxy acrylic ester, trifunctional acrylic ester, double function acrylic ester, adhesion promoting resin, photo initiator, diluent, and auxiliary agent, finish is formed by random proportion of high function aliphatic polyurethane acrylic ester, large molecular resin, double functional aliphatic polyurethane acrylic ester, trifunctional aliphatic polyurethane acrylic ester, adhesion promoting resin, photo initiator, diluent, and auxiliary agent. The surface of substrate material is conducted with painting treatment of primer, which increases the plainness and adhesion fastness of the vacuum plating film, and vacuum plating film is conducted with the surface painting treatment of UV vacuum plating finish, which can prevent oxidization of metal film layer and endows vacuum plating film with excellent surface abrasion resistance and extreme wonderful hand feeling.

Owner:HUIZHOU CHANGRUNFA PAINT

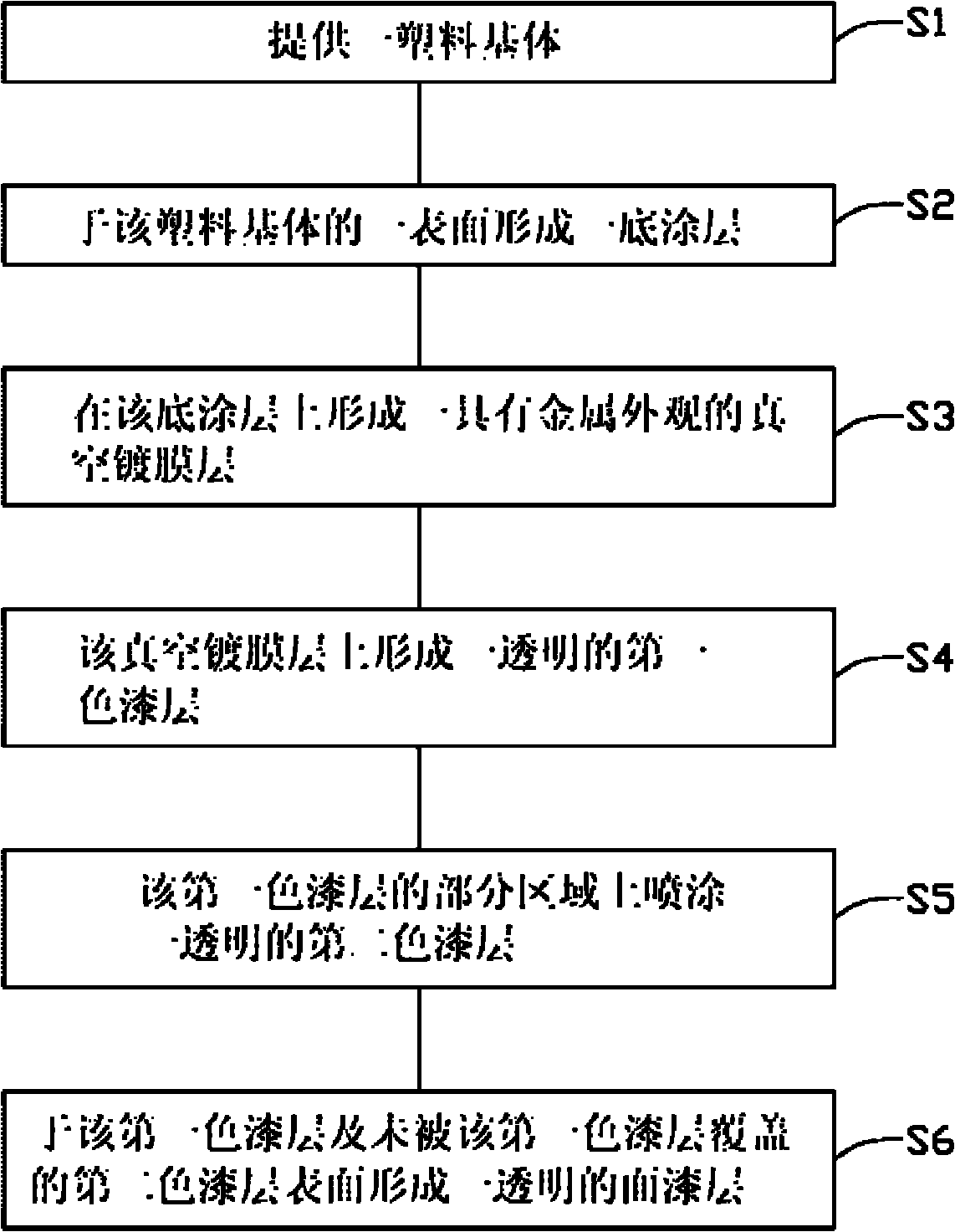

Making method of shell and shell fabricated through method

InactiveCN101955594ATo achieve the gradient effectDecorative surface effectsSpecial surfacesLacquerVolumetric Mass Density

The invention provides a making method of a shell, comprising the following steps of supplying a plastic substrate; forming a priming paint layer on the surface of the plastic substrate; forming a vacuum film plating layer with the metal appearance on the priming paint layer; forming a transparent or semi-transparent first colored paint layer on the vacuum film plating layer; forming a transparent or semi-transparent second colored paint layer on the surface of the first colored paint layer, wherein the second colored paint layer comprises a shielding region and a transition region which is connected with the shielding region, and the density of paints is gradually reduced from the position of the transition region neighboring the shielding region to a common boundary of the transition region and the first colored paint layer; and forming a transparent finish paint layer on the surface of the second colored paint layer and the surface of the first colored paint layer without coating with the second colored paint layer. The invention also provides the shell fabricated through the method. The shell has the effect of gradual change of colors.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

Method for manufacturing poorly conductive layers

ActiveUS20080020138A1High levelAvoid disadvantagesCellsElectric discharge tubesTarget surfaceElectricity

Method for producing poorly conductive and in particular nonconductive layers on at least one work piece by means of a vacuum-coating process in which an electric arc discharge is activated between at least one anode and the cathode of an arc source in a reactive-gas atmosphere, whereby on the surface of a target that is electrically connected to the cathode either none or only a small outer magnetic field is generated that extends essentially perpendicular to the target surface for assisting the evaporation process, the degree of recoating of the target surface by other coating sources is less than 10%, and the magnetic field is generated with a magnet system that encompasses at least one axially polarized coil with a geometry similar to the circumference of the target.

Owner:OERLIKON SURFACE SOLUTIONS AG PFAFFIKON

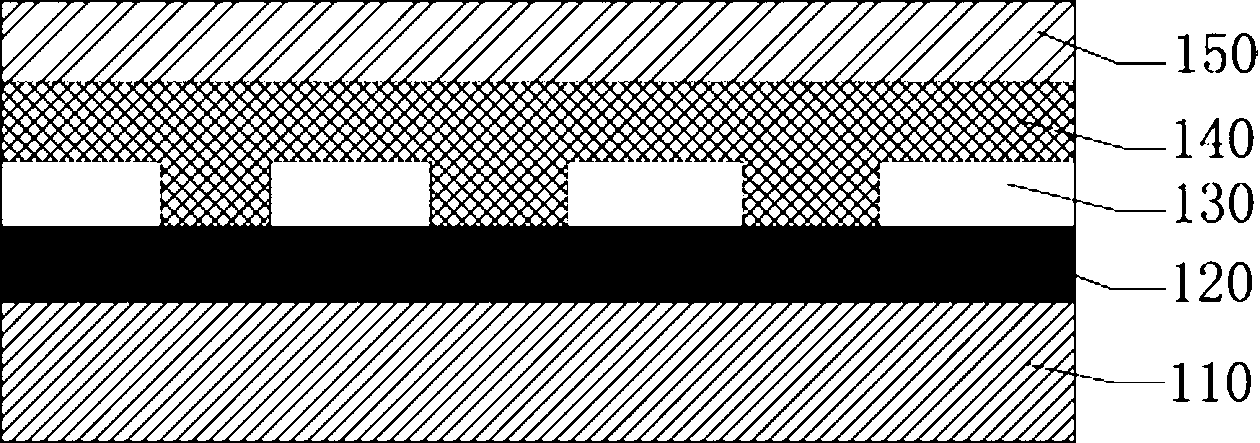

Housing and method for making same

InactiveCN101730409ABright Metal AppearanceElegant appearanceDecorative surface effectsLayered productsLacquerVacuum coating

The invention provides a housing. The housing comprises a plastic substrate, and further comprises a priming paint layer formed on the surface of the substrate, a vacuum film-coated layer with metal quality feeling, a transparent middle paint layer and a transparent finish paint layer, wherein the priming paint layer is directly formed on the surface of the substrate; the vacuum film-coated layer is formed on the priming paint layer; hollow patterns are formed on the vacuum film-coated layer; the middle paint layer is formed on the vacuum film-coated layer; and the finish paint layer is formed on the middle paint layer, and is formed of rubber paint with soft touch. The surface of the housing has a bright metal exterior and soft touch. The invention also provides a method for making the housing.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

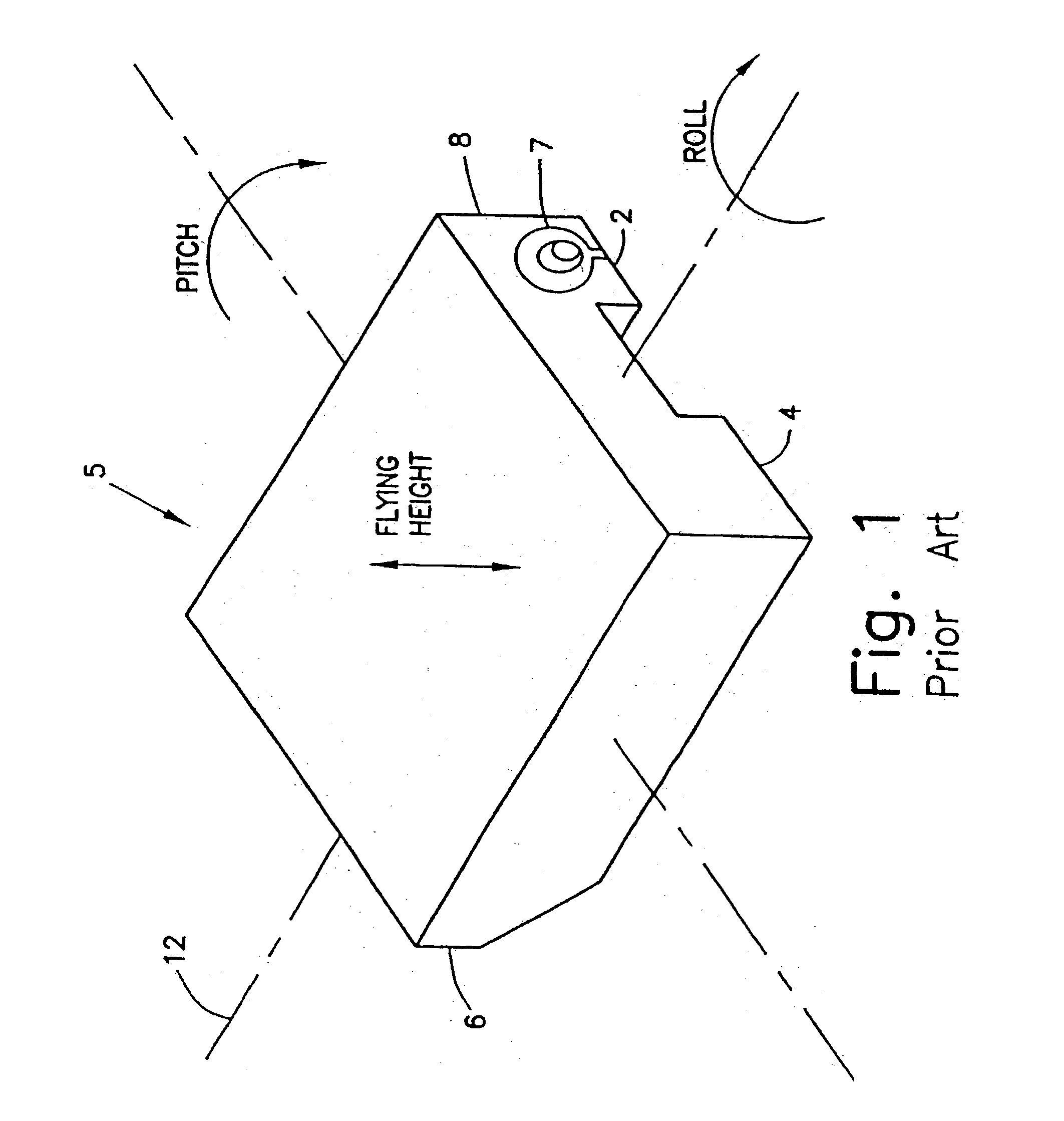

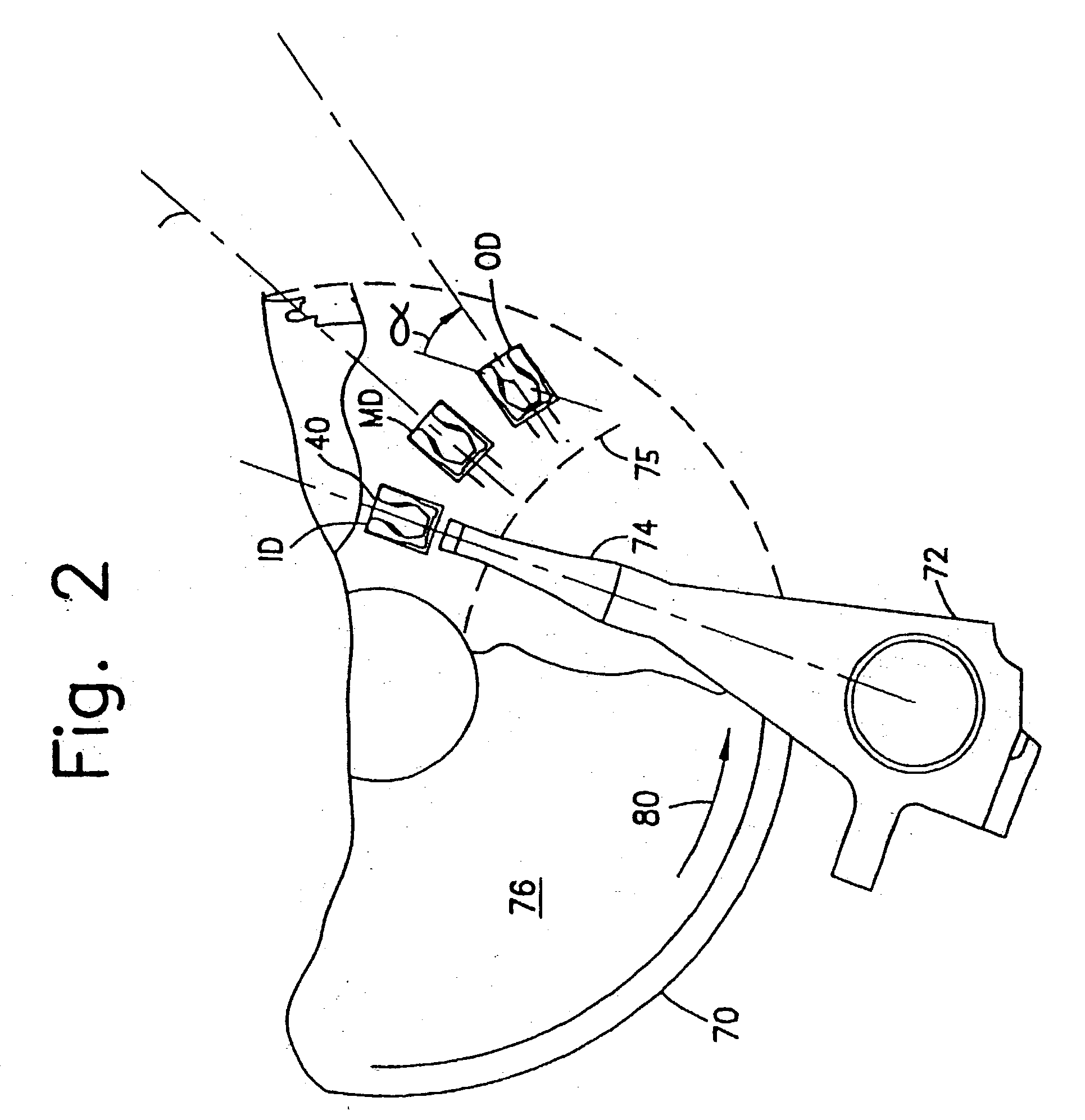

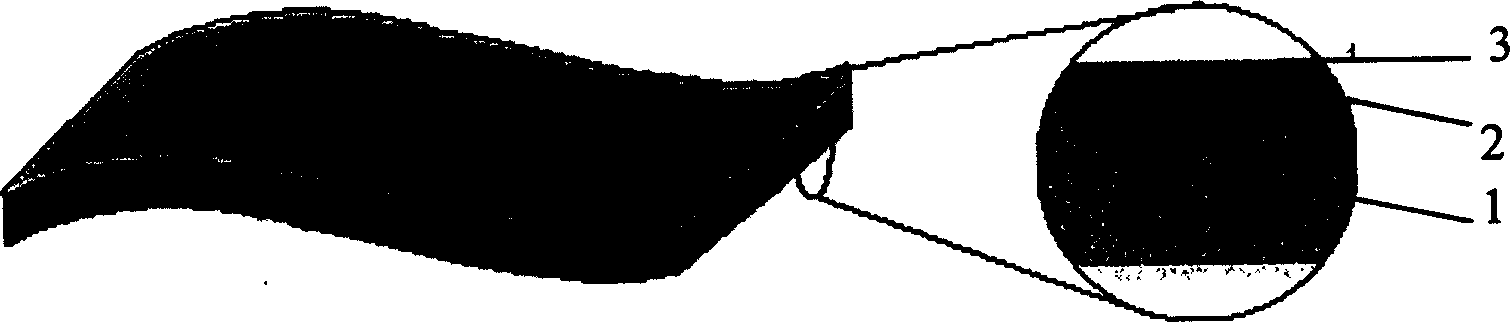

Hybrid coating for magnetic heads

ActiveUS20040223256A1Material nanotechnologyManufacture head surfaceSelf-assembled monolayerCarboxylic acid

A system and method for providing corrosion protection for a magnetic read / write head is disclosed. A monolayer surface coating is applied to cover those portions of the under layer of a magnetic read / write head not already covered by a previously applied diamond-like coating. This allows for a thinner diamond like coating than previously applied in the art. The monolayer surface coating can be a self-assembled monolayer, such as an organosilicon for hydroxylated surfaces or carboxylic acids for aluminum or other metal oxides. Alternatively, the monolayer surface coating can be directly applied to the under layer with no diamond-like coating being present. The monolayer surface coating can be applied by a surface immersion process or by a vacuum coating process.

Owner:SAE MAGNETICS (HK) LTD

Aerogel recombination flexible thermal insulation heat-proof thin film and process for preparing same

InactiveCN1546312AHigh porositySmall apertureWater-setting substance layered productThermal insulationVacuum coating

The invention is a kind of aerogel compound soft thermal retardation and insulation film and the manufacturing method. It uses orthosilicate ethyl ester and distilled water as material; the invention can produce transparent SiO2 multi-aperture aerogel with colloidal sols and jell. The aperture rate of the aerogel is bigger than 90%, the aperture radius size is about 20nm, the volume density is 0.03g / cm3, the specific surface is 1120m2 / g, the aerogel is blended with organic silicon resin after being crushed, and they are distributed onto polymide film. The other surface of the polymide uses vacuum plating deposited metal aluminum film forms the compound soft thermal retardation film which uses SiO2 multi-aperture aerogel / polymide film / metal aluminum as structure, the heat conductivity of aerogel compound soft thermal insulation film is 0.035w / mk under temperature of 500oC; it is a kind of excellent thermal insulation materials.

Owner:TONGJI UNIV

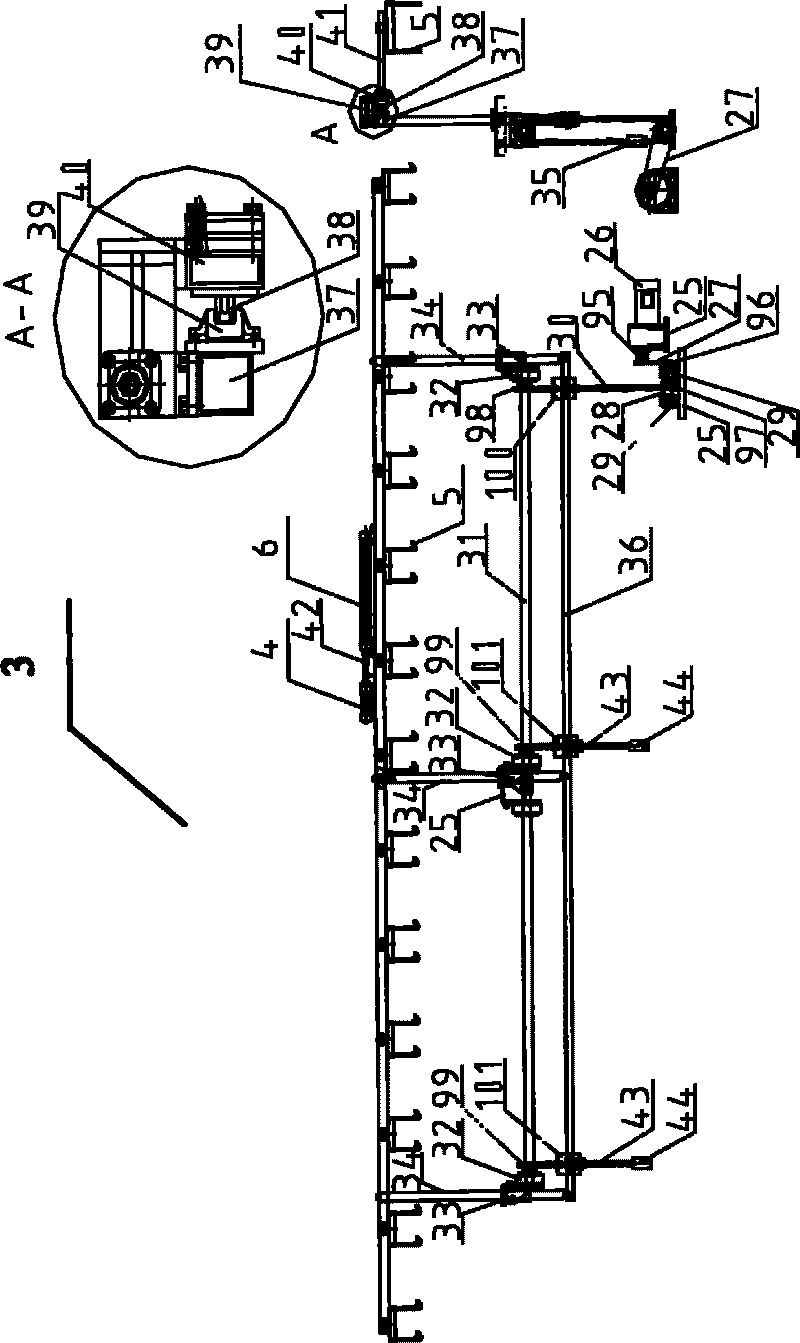

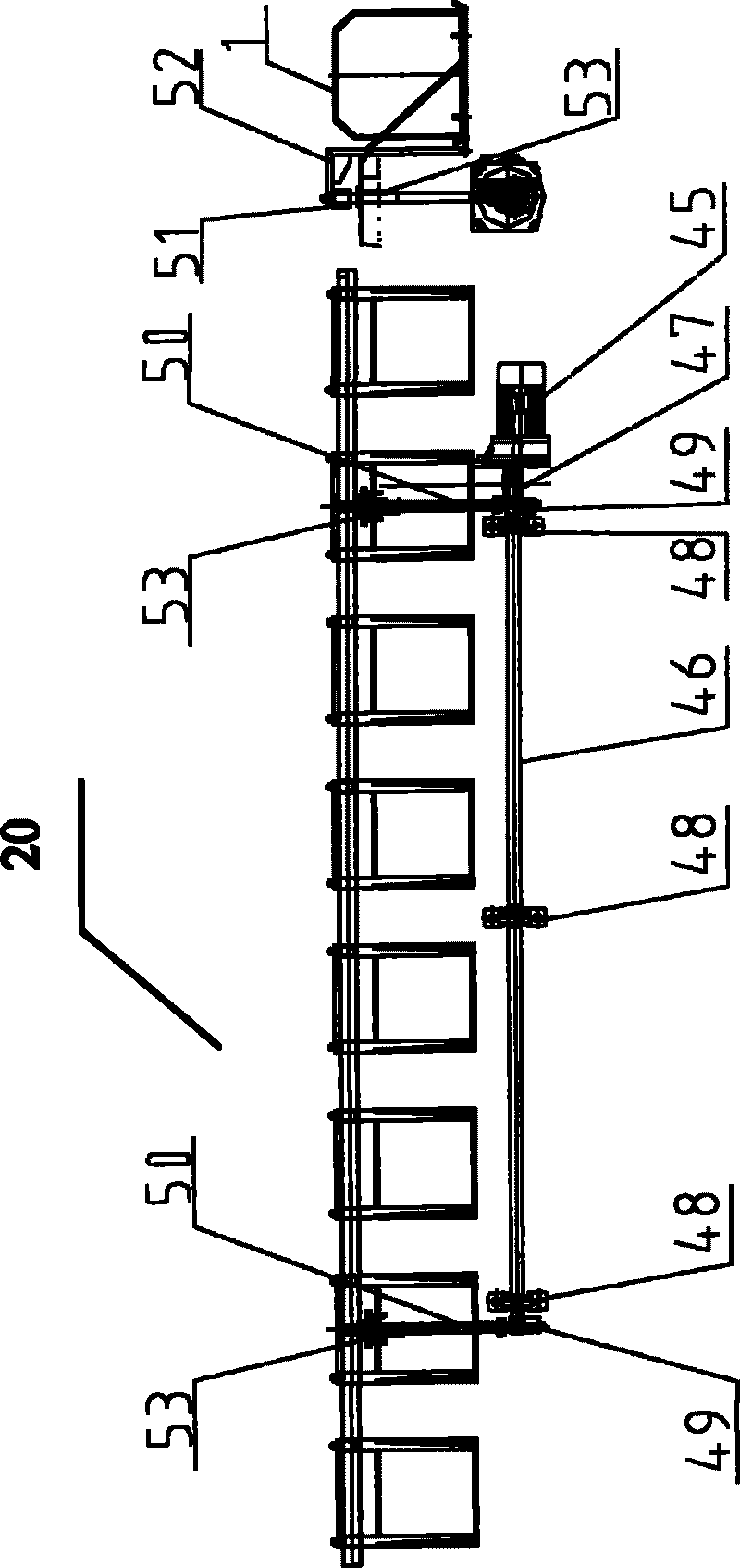

Ultrasonic wave cleaner for coating of optical lens and treatment method thereof

The invention discloses an ultrasonic wave cleaner for a coating of an optical lens and a treatment method thereof, which belong to the fields of metal surface treatment technology, vacuum coating technology and optical technology. The ultrasonic wave cleaner is characterized by performing ultrasonic alkali cleaning, pure water rinsing and ultrasonic pure water rinsing on the optical lens in cleaning medium under the condition of pendular motion respectively, slowly and perpendicularly lifting the optical lens or ensuring that a liquid slowly descends to break away from a workpiece when running water is circularly filtered, and using hot air to dry the optical lens under quiescent conditions. A structure of the ultrasonic wave cleaner is that: a conveyer is provided with traveling girders, the girders are provided with grab hooks, and the hooks are suspended with washing baskets; and different working procedures are finished by different devices, namely a liquid tank body is matched with a pendulous device, a dehydration device and a drying device to finish respective working procedures. The ultrasonic wave cleaner and the method have the advantages that the ultrasonic wave cleaner and the method do not use inflammable, explosive and toxic organic solvents to wash, reduce energy consumption, avoid the air pollution in workshops, can effectively improve the cleanliness of products, and ensure that the adhesive force of the coating of the optical lens is remarkably improved.

Owner:SHANGHAI MINGXING KAICHENG ULTRASONIC TECH

Method of manufacturing vacuum composite film coating on surface of neodymium iron boron magnet

InactiveCN101403093AAvoid the disadvantages of brittlenessImprove anti-corrosion performanceVacuum evaporation coatingSputtering coatingComposite filmChemical plating

The invention relates to the technical filed of vacuum plating, in particular to a preparation method for conducting vacuum compound plating on the surface of a neodymium iron boron magnet, which is characterized in that the preparation method comprises the following steps: A. pre-treatment, the mixed liquor of washing liquid and purified water is used for conducting oil removal and parting medium washing to the magnet surface in an ultrasonic wave cleaner; B. ion cleaning and activation, the pre-treated neodymium iron boron magnet which is dried at 80-100 DEG C for 5-10 minutes undergoes bombardment activation of a glow plasma in vacuum environment, so as to increase surface activation energy; and C. vacuum plating, vacuum plating treatment is conducted to the neodymium iron boron magnet washed by ions in a vacuum chamber, and a metal plating is prepared on the surface. The deposited metal film on the surface of the neodymium iron boron magnet has the advantages of good stability, high bonding force and tightness, stronger anti-corrosion performance in cold and hot alternation environment. Furthermore, in the physical vapor deposition plating process, the plating thickness is affected much less by the magnet workpiece corner than in electroplating and chemical plating, and the pollution problem is avoided in the preparation process.

Owner:兰州大成科技股份有限公司

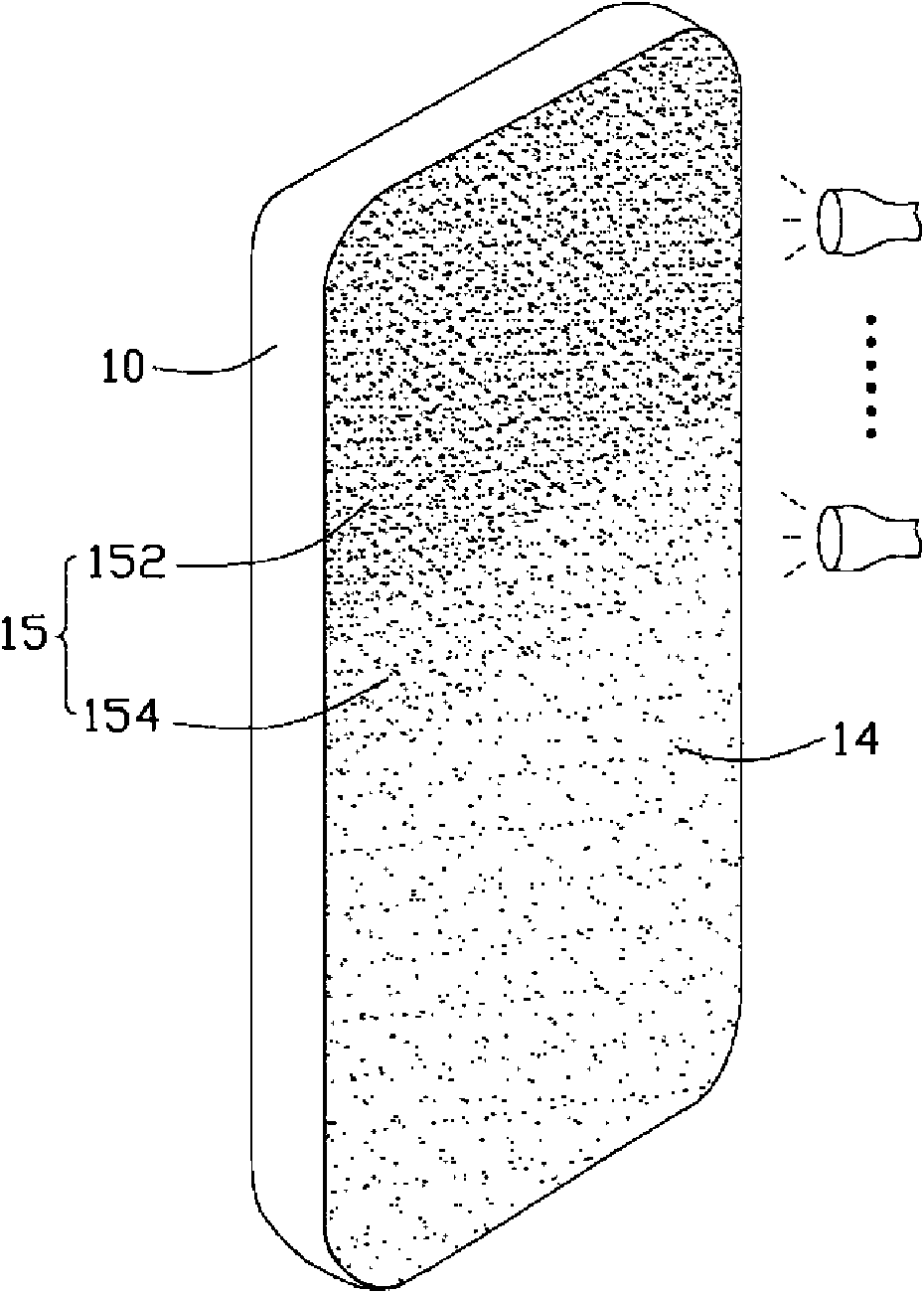

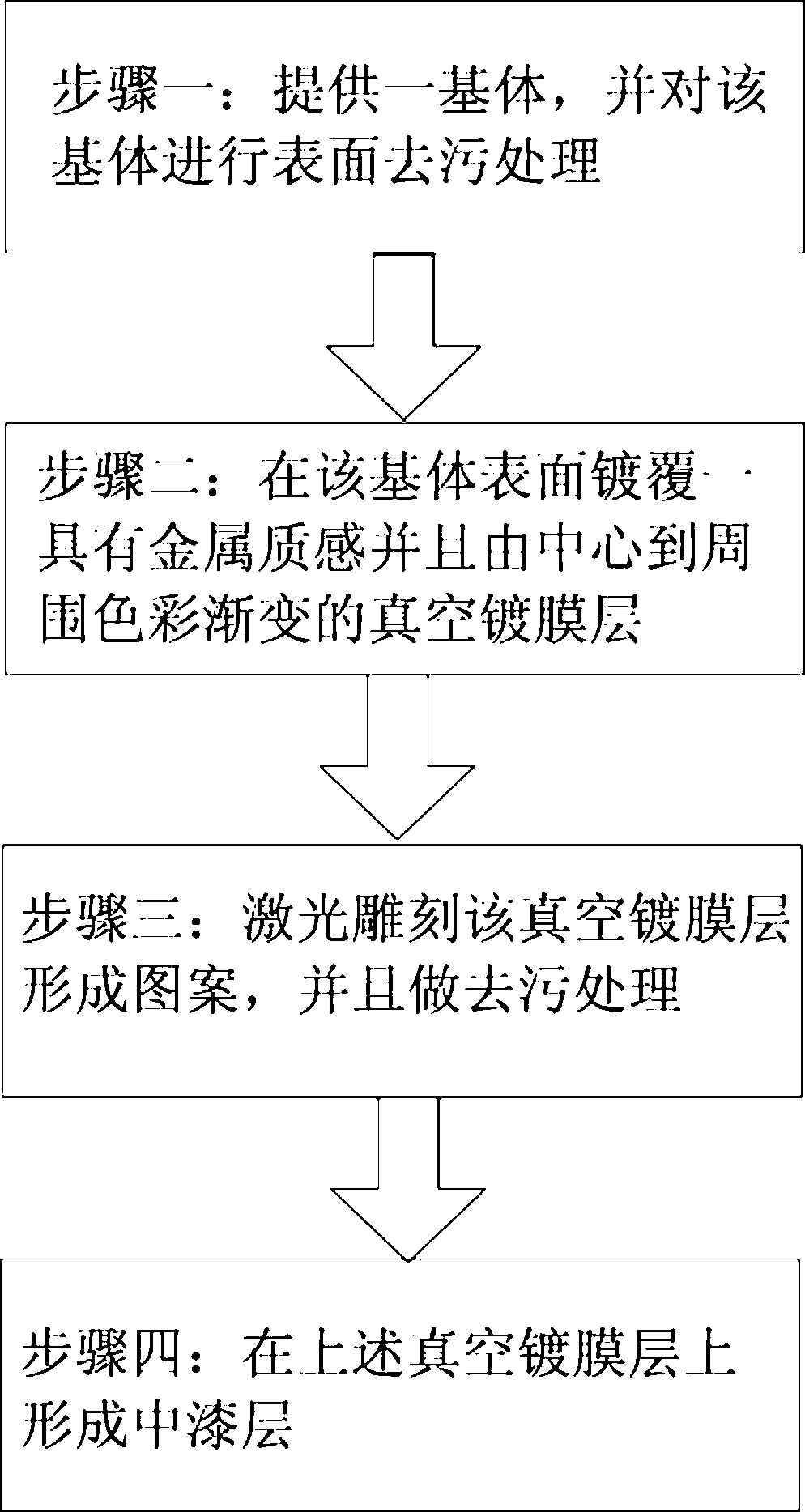

Electronic product shell and manufacturing method thereof

ActiveCN102858100AMeet the needs of colorVacuum evaporation coatingSpecial ornamental structuresLaser engravingVacuum coating

The invention discloses an electronic product shell which comprises a base body, a vacuum coating layer and a middle paint layer, wherein the vacuum coating layer is formed on the surface of the base body and has metal texture and color gradient from the center to the periphery; the middle paint layer is formed on the vacuum coating layer; and patterns are formed on the vacuum coating layer. The invention also provides a manufacturing method of the electronic product shell. According to the electronic product shell and the manufacturing method thereof provided by the invention, the middle paint layer is formed after the laser engraving of the vacuum coating layer, and the cleaning process can be performed after the laser engraving; and since the vacuum coating layer has color gradient from the center to the periphery, the needs for colors of people are met.

Owner:BYD CO LTD

Method for preparing silver metallized organic fiber and textile

This is a argent metallization producing method of organic fibre and fabric, which belongs to vacuum membrane plating and electroplating technologic field and mainly solves the problems of quality and producing batches of silver-gilt organic and fabric. Through physical vapour phase deposition technology, it firstly arranges smoothly and rolls up tidily the organic fibre bundle and fabric; lay them in the vacuum room, plate silver by magnetic controlling and sputtering, and monolayer or multilayer continuously plate membrane; then plate mulriple argent membrane according to different using demands. The binding force of the metallic argentic ion and organ fibre of the present invention is strong, it has no pollution, low costs and can be continuously produced. The products are applied in such industry as electronics, war industry communication, medical treatment, special type of spinning and so on. For instance, electric shielded products, military used shielded tent, special type of spinning antibacterial materials and civil health care spinning products.

Owner:夏芝林

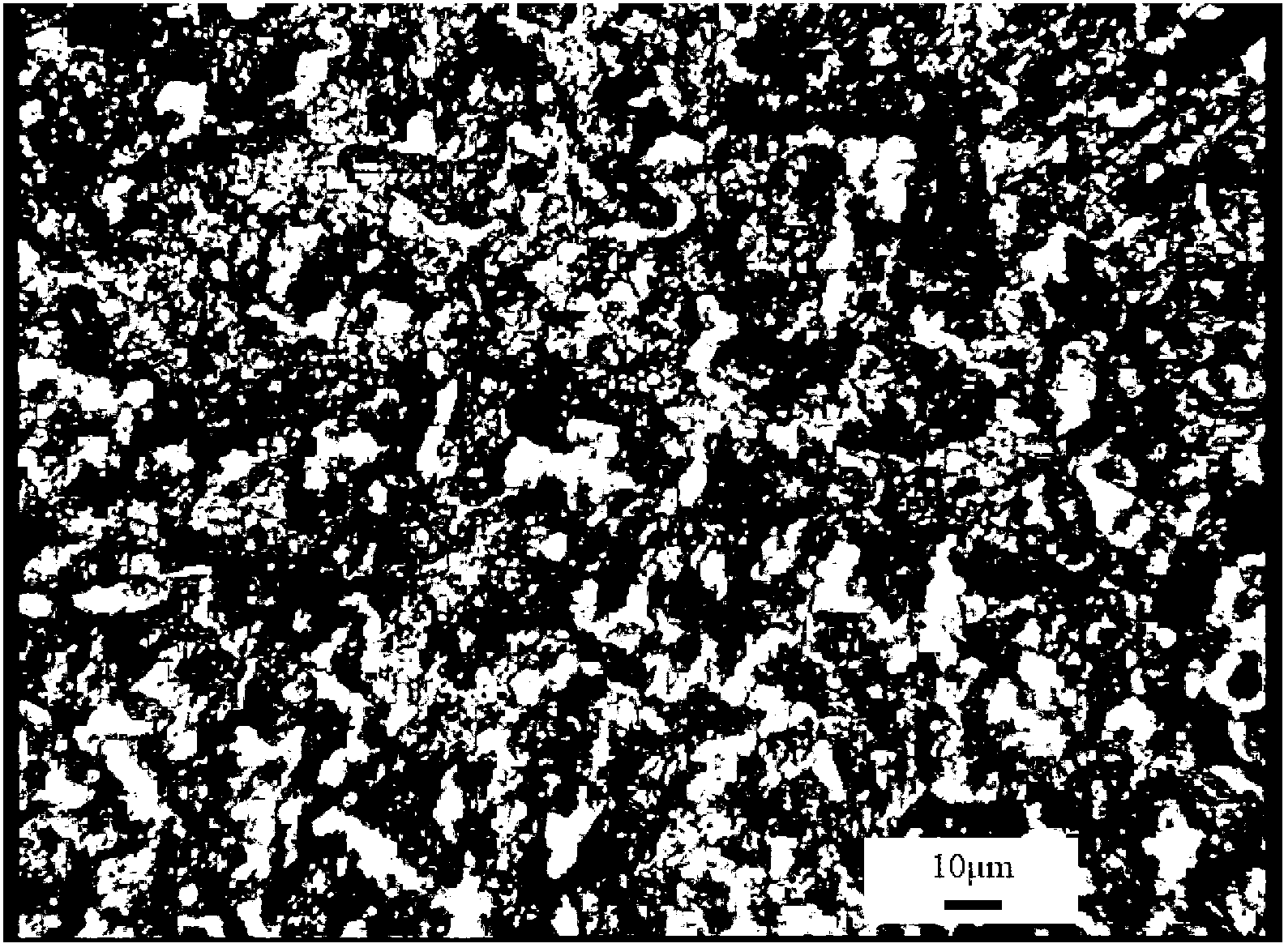

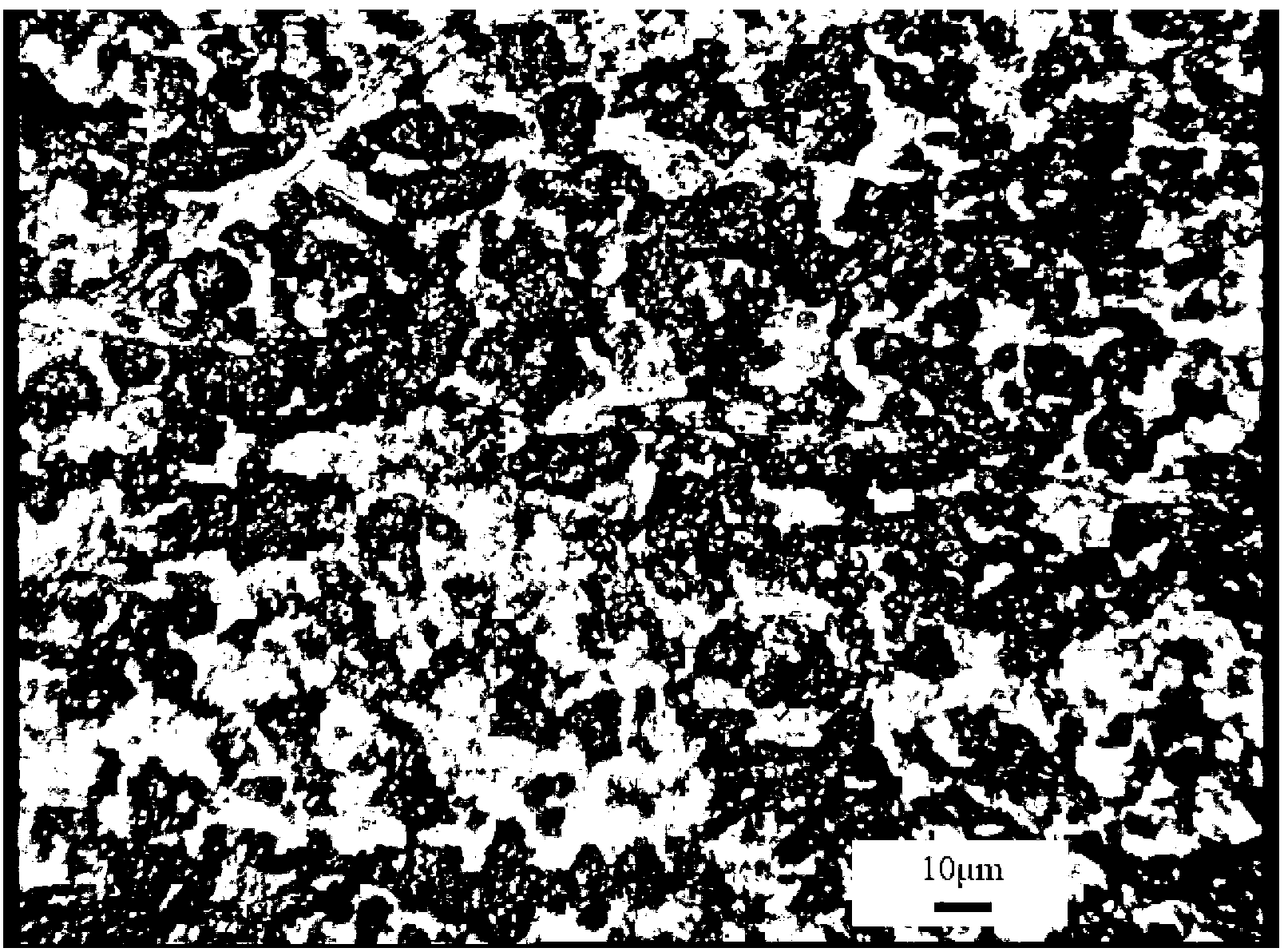

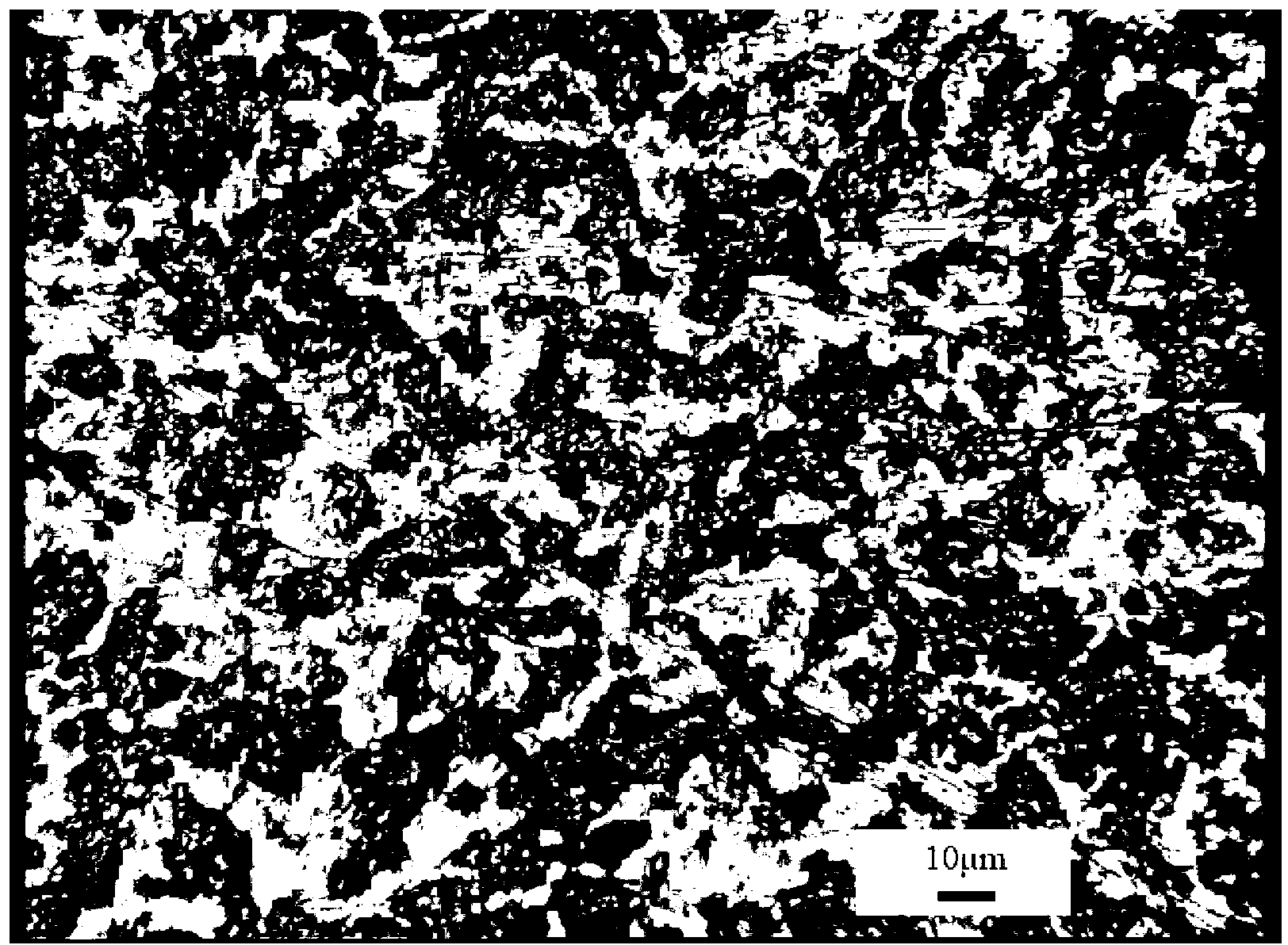

Layer system with at least one mixed crystal layer of a multi-oxide

A PVD layer system for the coating of workpieces encompasses at least one mixed-crystal layer of a multi-oxide having the following composition: (Me11-xMe2x)2O3, where Me1 and Me2 each represent at least one of the elements Al, Cr, Fe, Li, Mg, Mn, Nb, Ti, Sb or V. The elements of Me1 and Me2 differ from one another. The crystal lattice of the mixed-crystal layer in the PVD layer system has a corundum structure which in an x-ray diffractometrically analyzed spectrum of the mixed-crystal layer is characterized by at least three of the lines associated with the corundum structure. Also disclosed is a vacuum coating method for producing a mixed-crystal layer of a multi-oxide, as well as correspondingly coated tools and components.

Owner:OERLIKON SURFACE SOLUTIONS AG PFAFFIKON

Method for processing plastic surface

The invention provides a method for processing a plastic surface; comprising the following steps: providing a plastic base body, wherein the surface of the plastic base body is previously provided with a rough area; spraying a priming paint layer on the surface of the plastic base body; forming a vacuum plating film layer on the surface of the priming paint layer; spraying a transparent middle paint layer on the surface of the vacuum plating film layer; and spraying a transparent finish paint layer on the surface of the middle paint layer. By the method for processing the plastic surface, theplastic surface t can not only achieve bright metal appearance but also can show obvious bright and matte double-color effect.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

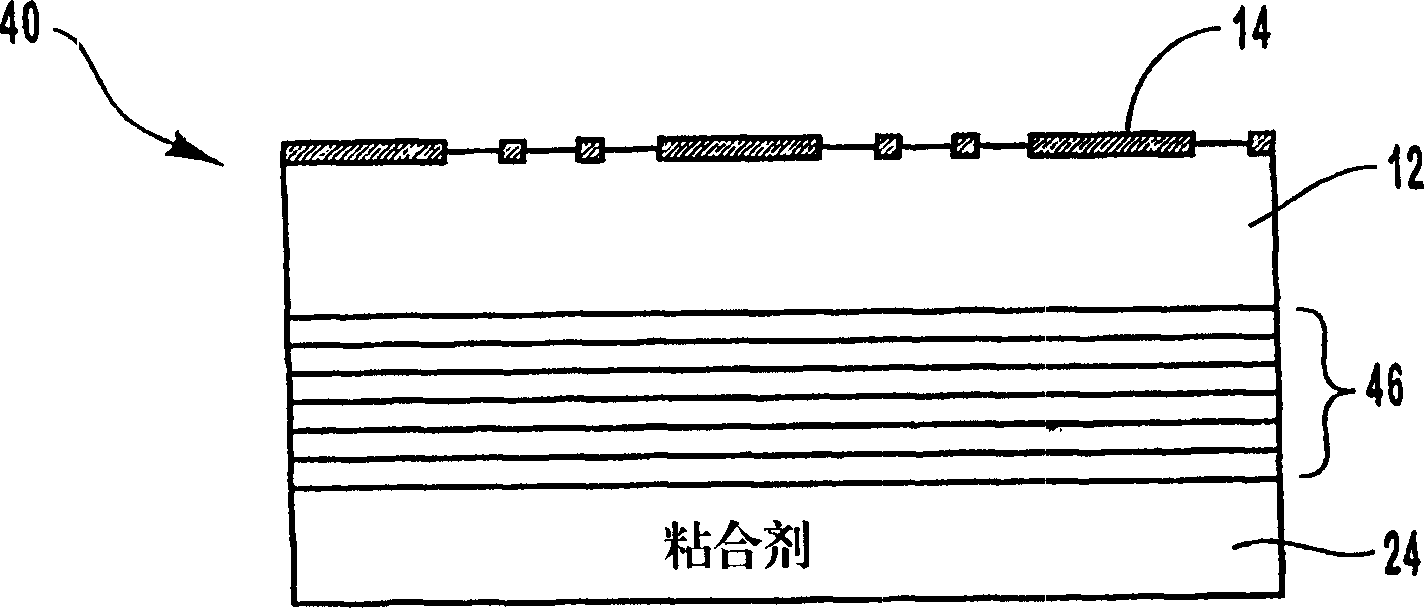

Housing of electronic device and preparation method thereof

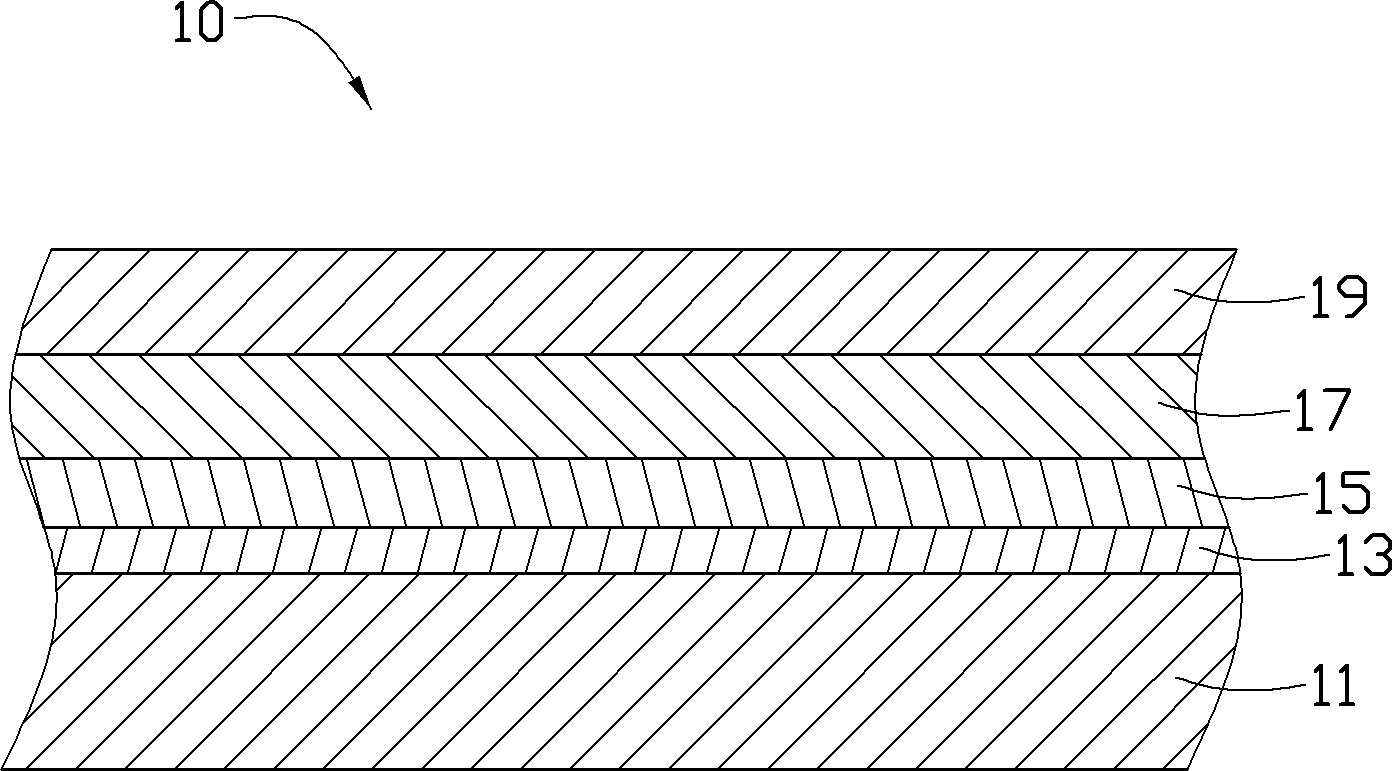

InactiveCN102605325AIncrease reflectionIllusion pearlescent effect is strongVacuum evaporation coatingSputtering coatingSilicon dioxideTitanium oxide

The invention provides a housing of an electronic device, which comprises a base body and a metal texture layer and a finish layer orderly formed on the surface of the base body. The metal texture layer is a non-conducting layer formed by means of vacuum coating and is a compound layer stacked alternately by multiple titanium oxide layers and silicon dioxide layers. The reflectivity of the metal texture layer is 50-80%. The finish layer contains magic pearlescent pigments. The housing of the electronic device has magic pearlescent and metal texture appearance. The invention further provides a preparation method of the housing of the electronic device.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

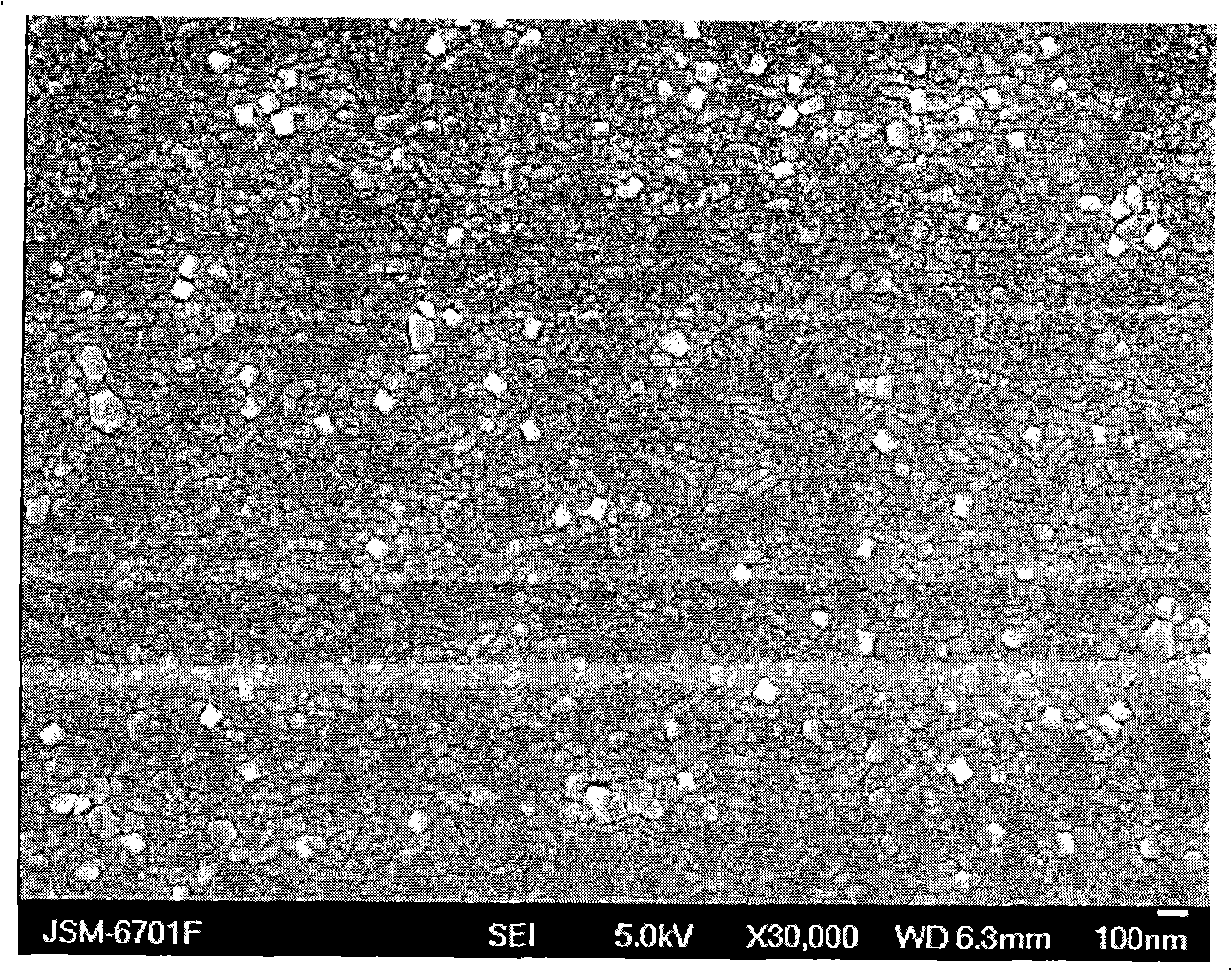

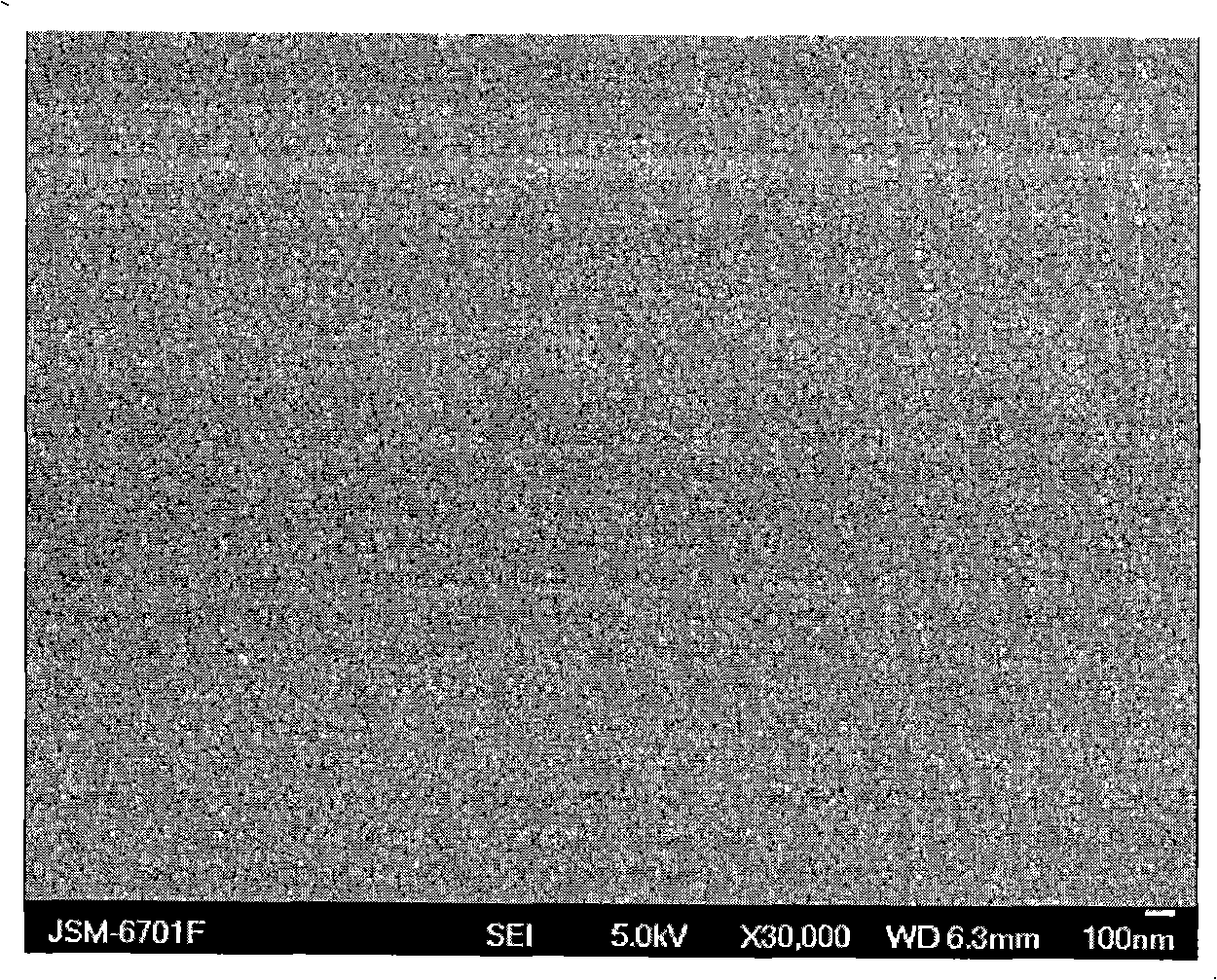

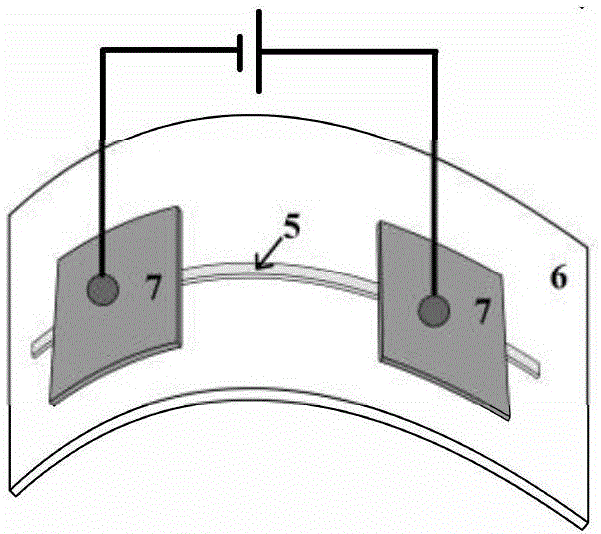

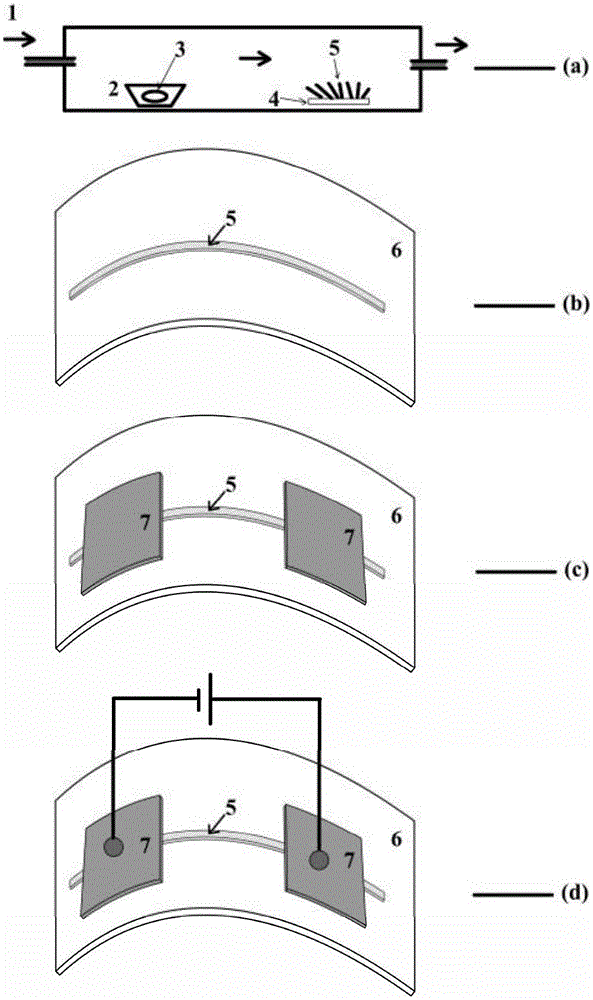

Flexible gallium oxide-based solar-blind ultraviolet photoelectric detector and preparation method thereof

InactiveCN106711270AWith repeated bending recoverabilityImprove portabilityFinal product manufactureSemiconductor devicesCharacteristic responsePhotovoltaic detectors

The invention discloses a flexible gallium oxide-based solar-blind ultraviolet photoelectric detector and a preparation method thereof. The preparation method specifically comprises the following steps: preparing a gallium oxide micron band material by utilizing a vapor deposition method, by taking the band material as a light-sensitive material of solar-blind ultraviolet light, transferring the gallium oxide micron band material onto a flexible substrate, and preparing metal electrodes at two ends of the gallium oxide micron band by combining masking and vacuum coating methods so as to finally obtain the flexible gallium oxide-based solar-blind ultraviolet photoelectric detector. According to the preparation method disclosed by the invention, the flexible gallium oxide-based solar-blind ultraviolet photoelectric detector is prepared first by combining the flexible gallium oxide micron band material with the flexible substrate, and the device has the bending characteristic aiming at characteristic response and flexibility of the solar-blind ultraviolet light. The flexible detector has repeated bending restorability and can be applied to the fields of wearable detection equipment, curved screen interaction equipment, bionic tissues and the like. Moreover, the convenience and freedom degree of arrangement and design of the solar-blind photoelectric detection system can be greatly improved.

Owner:FUJIAN AGRI & FORESTRY UNIV

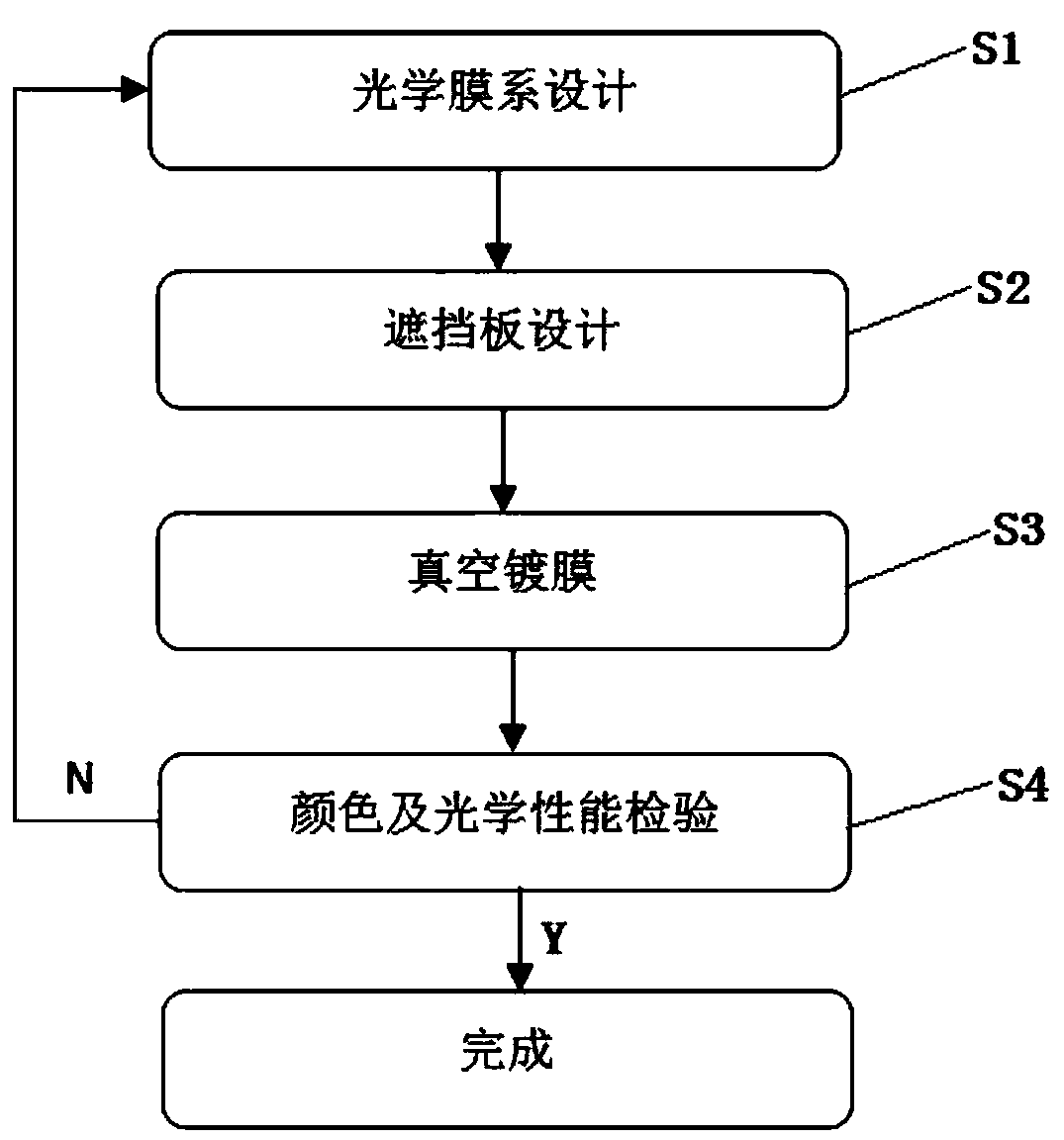

Method for preparing graduated color film through magnetron sputtering machine

ActiveCN109023280ACompact structureRefractive index stabilizationVacuum evaporation coatingSputtering coatingSputteringRefractive index

The invention discloses a method for preparing a graduated color film through a magnetron sputtering machine. The method comprises the following steps that S1, an optical film system is designed; S2,a baffle is designed, and the shape of the baffle is designed according to thickness change of an optical thin film structure simulated by software; S3, vacuum coating is conducted; and S4, color andoptical performance examination is conducted, the color LAB value, visible light reflectivity curve and visible light transmittance curve of a product obtained after vacuum coating are detected, if the test result is qualified, mass production preparation can be made, and if the test result is unqualified, operation returns to the step S1. A transition area of a graduated color film prepared withthe method is natural in gradual color change, the product color is easy to adjust, and graduated color films of different colors and visual effects can be prepared according to user preparations. Compared with electric beam evaporation deposition, a film layer prepared with the magnetron sputtering machine is compact in structure, the refractive index is stable, the film layer is more stable in optical performance, and thus color stability is better.

Owner:SHENZHEN THREE BEAM COATING TECH CO LTD

Process and apparatus for preparing porous metal by combined physical gas-phase deposition techinque

InactiveCN1397654AStrong noveltyCreativeElectrode carriers/collectorsVacuum evaporation coatingGas phaseWater jacket

A technology and apparatus for preparing porous metal by combined physical gas-phase deposition features that two of evaporating, sputtering and ion plating are combined in a coil-type vacuum coatingmachine. The said coil-type vacuum coating machine is composed of coiling-uncoiling reel and chamber, measuring roller, magnetically controlled plating chamber and its target, are evaporating chamberand its target, partition, cooling water jacket, etc.

Owner:HUNAN CORUN NEW ENERGY CO LTD

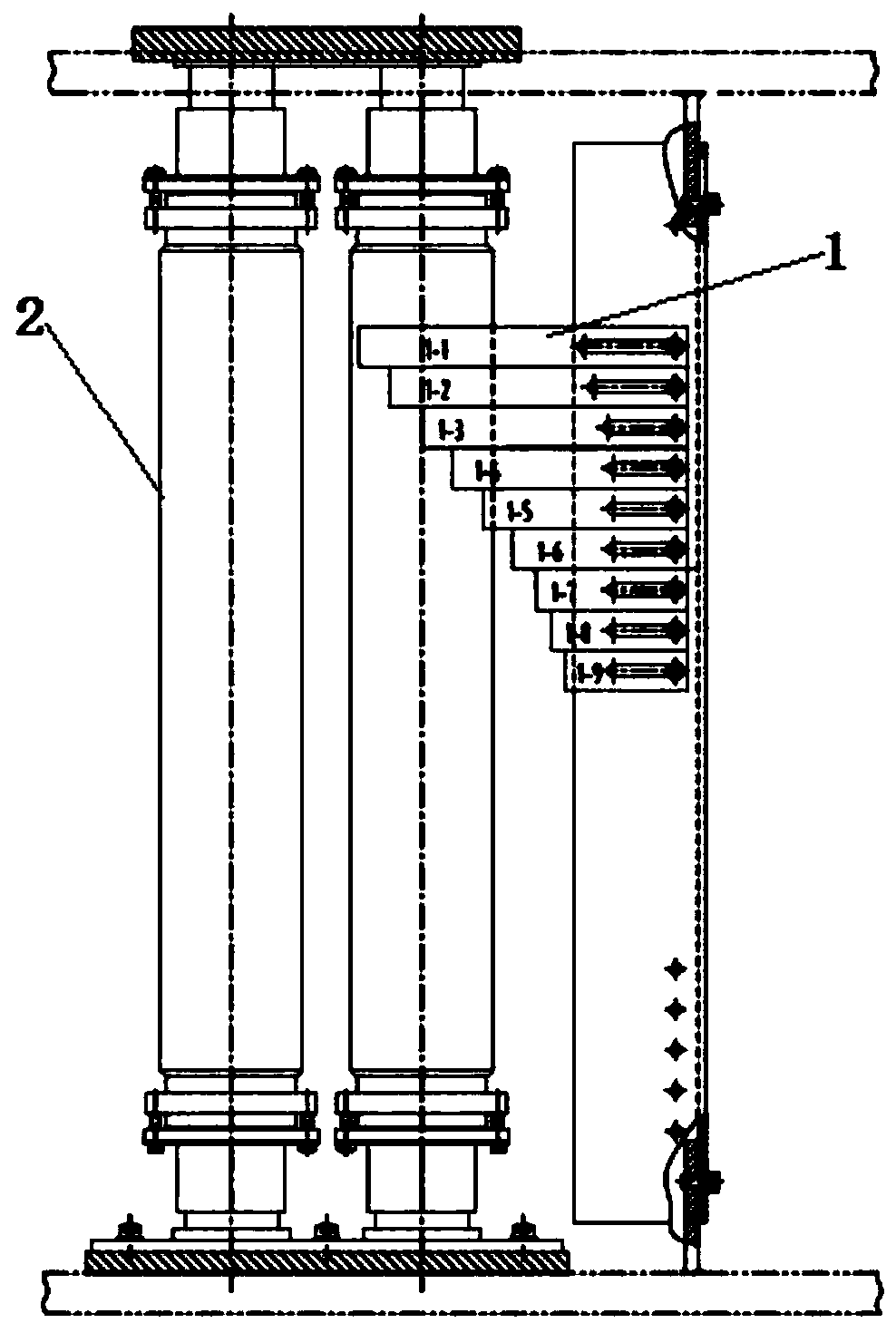

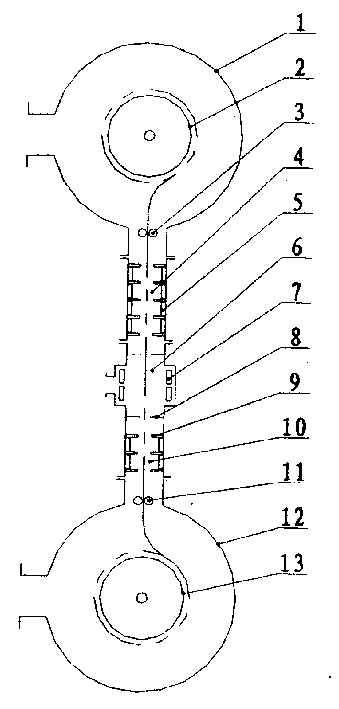

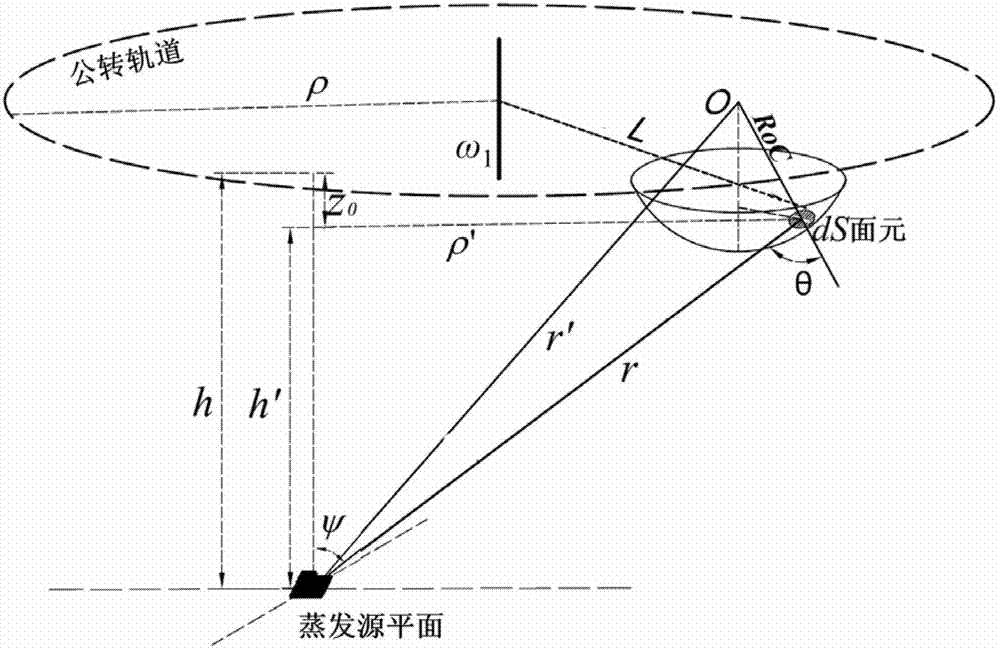

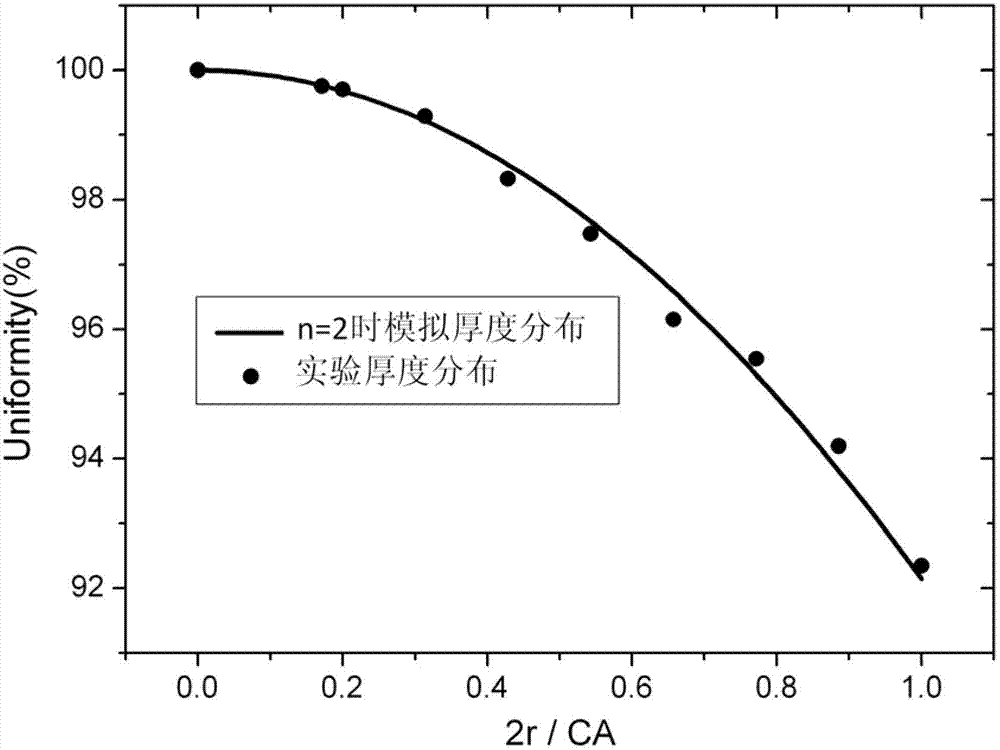

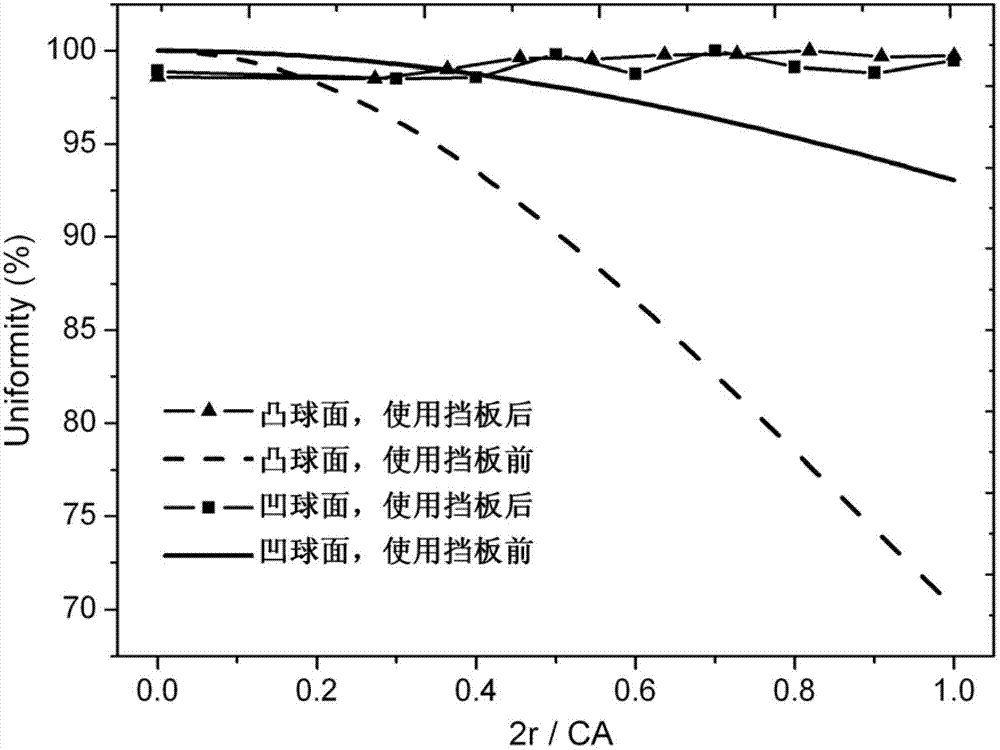

Method for designing coating uniformity correction mask for spherical optical elements on planetary rotating jigs of vacuum coating machines

ActiveCN102732844AImprove design efficiencyImprove thickness uniformityVacuum evaporation coatingSputtering coatingComputer optimizationMagnification

The invention discloses a method for designing a coating uniformity correction mask for spherical optical elements on planetary rotating jigs of vacuum coating machines, which is used for studying the film thickness distribution of a plane or spherical optical element (subjected to coating) on a planetary rotating jig through establishing a coating model in a vacuum environment. Through enabling an optical element coating process in a planetary rotating jig to be equivalent to a coating process in a simple rotating jig, the initial shape of the coating uniformity correction mask in the planetary rotating jig is designed. Through optimizing the arc length magnification factor of the correction mask by using a computer until the film thickness uniformity reaches the optimal result, the actual shape of the coating uniformity correction mask for the spherical optical elements is obtained. According to the invention, the control on the film thickness uniformity of the spherical optical element with a large caliber and a large caliber / curvature radius ratio can be realized, thereby obtaining the uniformity of multilayer-film spectral characteristics of the spherical optical element with a large caliber and a large caliber / curvature radius ratio.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Production method of chromium-aluminium alloy target material

ActiveCN103182507AHigh densityUniform grain size distributionVacuum evaporation coatingSputtering coatingAl powderHigh density

The invention relates to a production method of a chromium-aluminum alloy target material, which includes the following steps: (1) placing chromium powder and aluminum powder into a V-shaped mixer for mixing; (2) placing the powder into a cold isostatic pressing sheath, vacuumizing, sealing, suppressing for 10 to 20 minutes, then placing in a vacuum self-propagating high-temperature synthetic furnace, and performing self-propagating reaction to acquire foamed chromium-aluminium alloy; (3) smashing the chromium-aluminium alloy into alloy powder with size of -200 mesh, placing the alloy powder in the cold isostatic pressing sheath for suppressing, so as to obtain a chromium-aluminium alloy blank; (4) placing the alloy blank in a steel sheath for vacuum degassing, then, performing hot isostatic pressing sintering treatment to obtain a chromium-aluminium alloy ingot; and (5) machining the chromium-aluminium alloy ingot to obtain a finished chromium-aluminium alloy target material. According to the invention, after the two raw materials are fully mixed and before the hot isostatic pressing sintering treatment is carried out, the alloying treatment in the step (2) is particularly adopted, so the prepared chromium-aluminum alloy target material has high density, uniform crystallite size distribution and excellent vacuum coating property.

Owner:北京九州新科科技有限公司

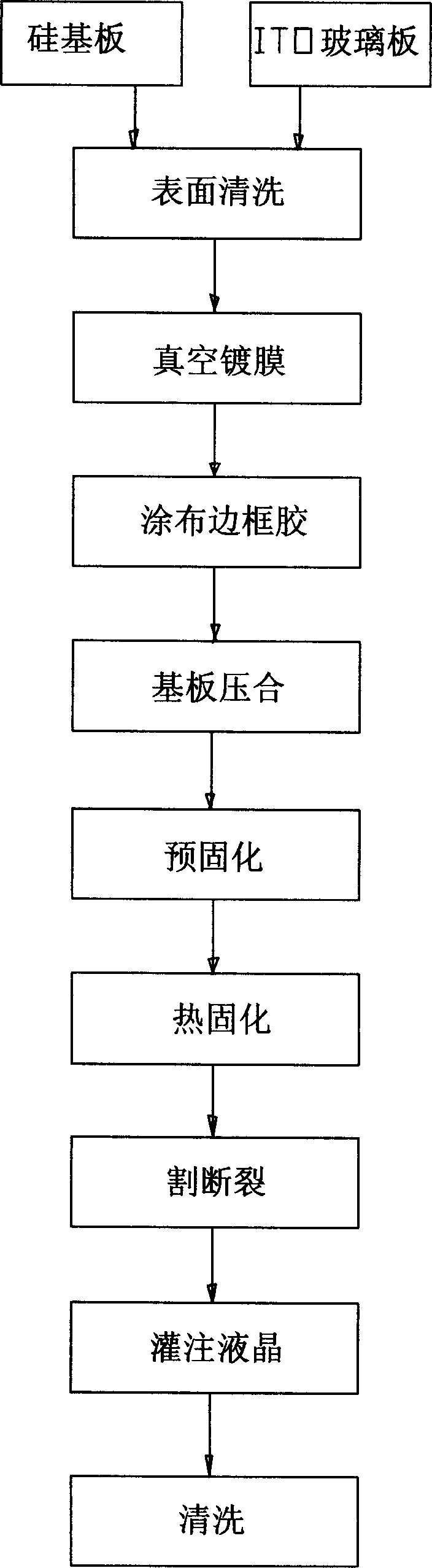

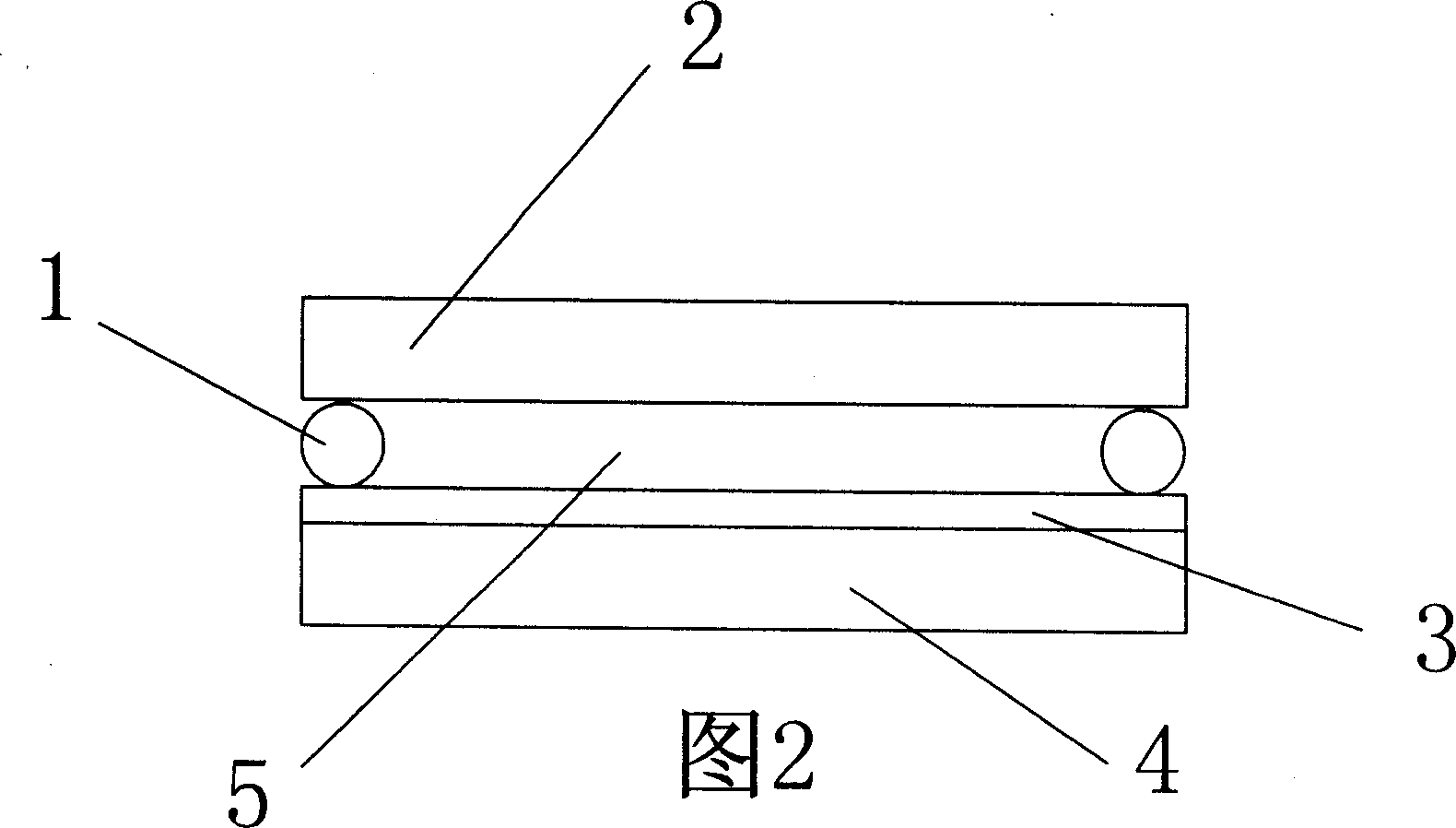

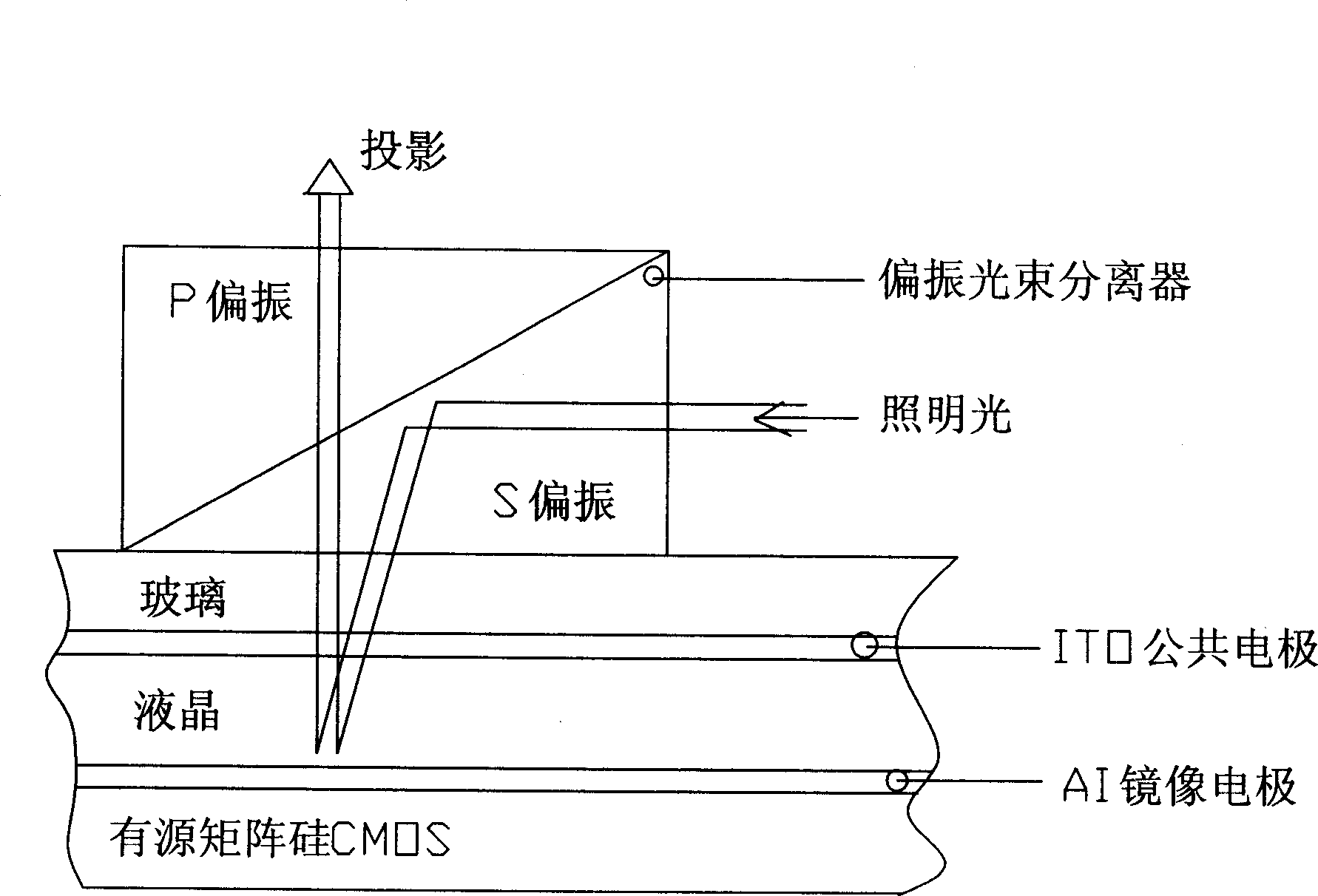

Making method for liquid crystal LCOS and laminating apparatus therefor

InactiveCN1804694AChange the manufacturing processIncrease profitSemiconductor/solid-state device manufacturingNon-linear opticsLiquid-crystal displayEngineering

The invention relates to a making method of liquid crystal display LCOS and its pressing device, which makes the LCOS liquid crystal display on an integer silicon base plate. It designs a plurality of LCOS Die integer silicon base plates and ITO glass plates as the common electrode of the silicon base plate liquid crystal display; the working surface coats the corresponding liquid crystal box frame glue on the silicon base plate after cleaning and vacuum coating SiO2 direction film; then it attaches the ITO glass plate on the silicon base plate as an integer after nailed procuring and heat curing; it then dose lower surface cutting and upper surface diamant marks; then it becomes a plurality of liquid crystal boxes which can become the product by charging the liquid crystal into the liquid crystal box.

Owner:SHENZHEN KECHUANG DIGITAL DISPLAY TECH

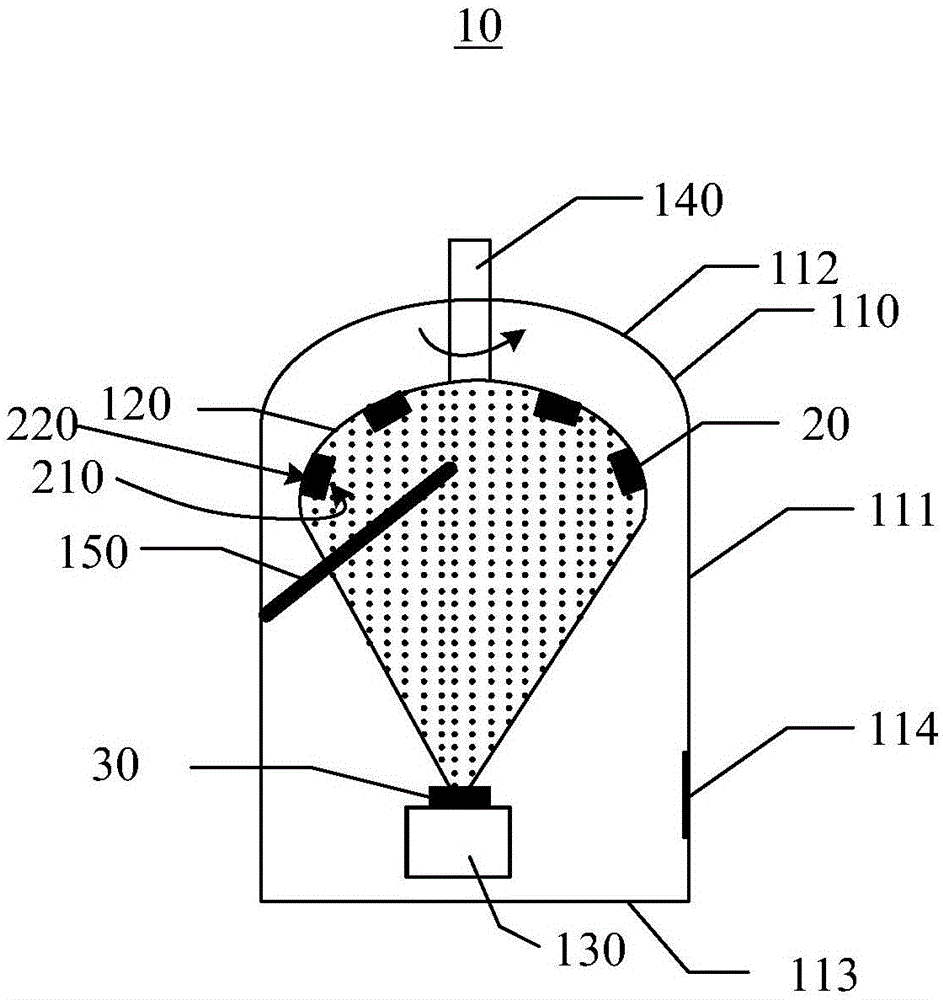

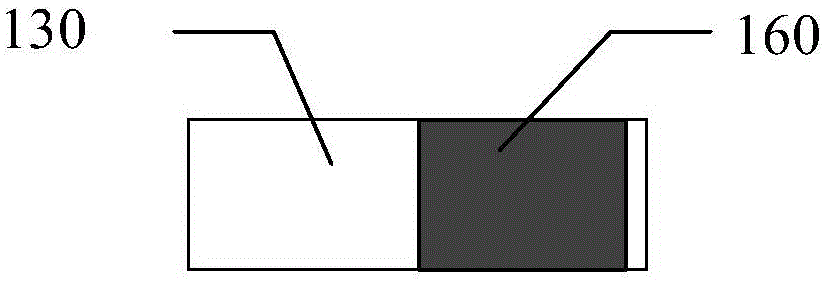

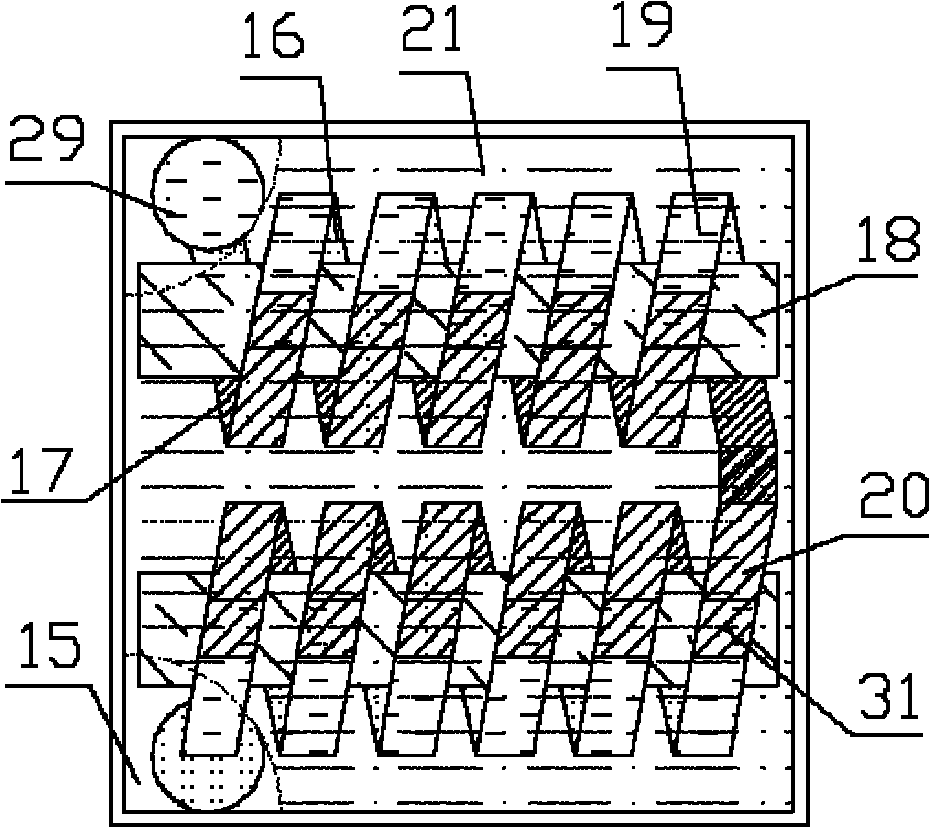

Gradual color changing base plate preparing device and gradual color changing base plate preparing method

InactiveCN106399926AGradient color effect is goodVacuum evaporation coatingSputtering coatingBiochemical engineeringColor changes

The invention provides a gradual color changing base plate preparing device and a gradual color changing base plate preparing method. The gradual color changing base plate preparing device comprises a vacuum coating chamber, a first installing part, a second installing part, a drive part and a baffle. The vacuum coating chamber is used for containing the first installing part, the second installing part and the baffle. The first installing part is used for installing a base plate to be coated. The base plate comprises a first surface and a second surface which are oppositely arranged. The second installing part is used for installing a coating source. The coating source is adjacent to the first surface of the base plate and is used for providing a coating material. The drive part is used for driving the vacuum coating chamber to rotate. The baffle is arranged between the base plate and the coating source. The baffle comprises at least one shielding unit, the different parts of the shielding unit are different in width, and the shielding unit is used for conducting uneven shielding on the coating material sent by the coating source so that an optical film with the thickness linearly changing can be formed on the first surface.

Owner:NANCHANG O FILM TECH CO LTD +2

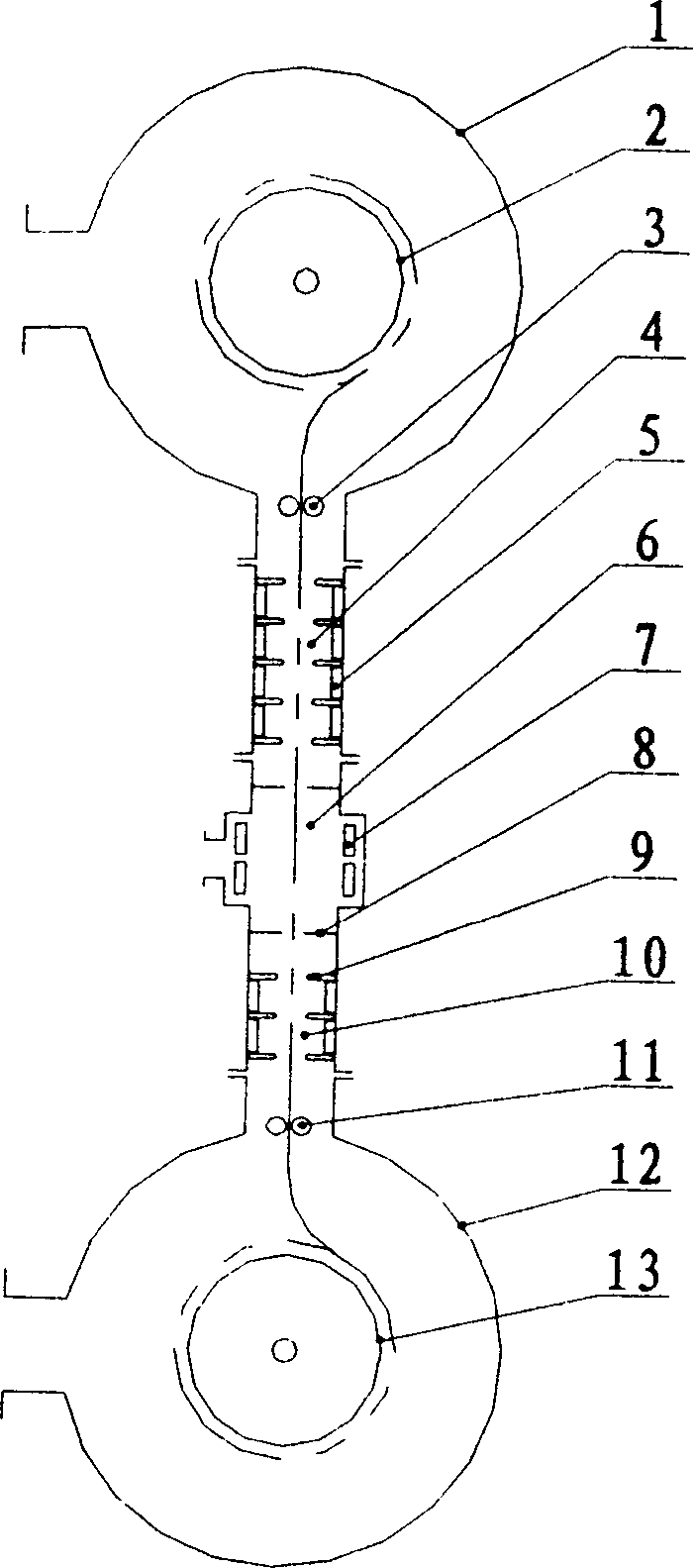

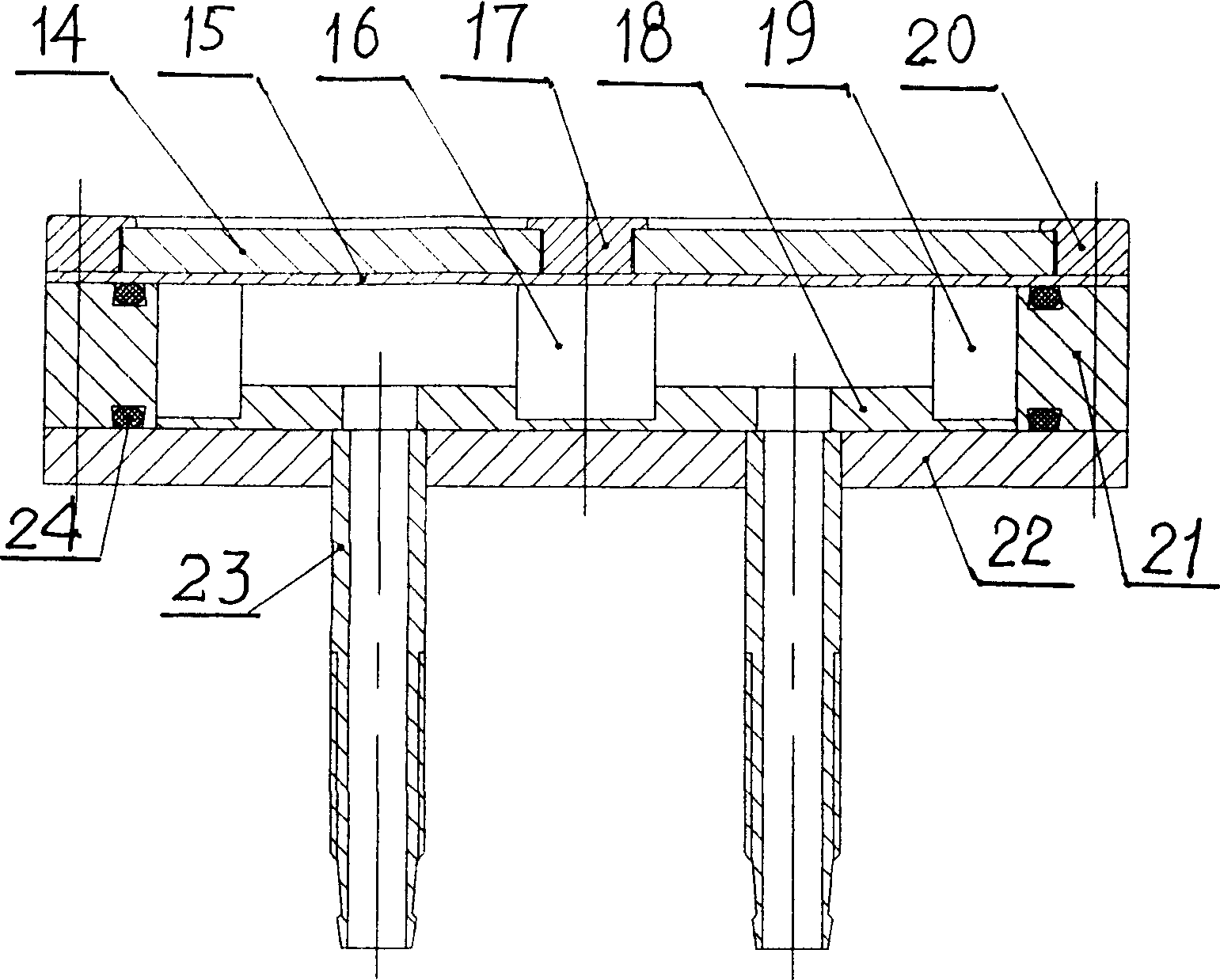

Insertion piece for measuring transient heat flow density distribution in fuel cell

ActiveCN102116679ADoes not affect deliveryEasy to disassembleMaterial heat developmentThermometers using electric/magnetic elementsHeat flowMeasurement device

The invention discloses an insertion piece for measuring heat flow density distribution in a fuel cell, which is a device for measuring the heat flow density distribution in the fuel cell. The insertion piece comprises a gold-plated stainless steel substrate, and leaks and ribs, which are in the same sizes, the same shapes and the corresponding positions with grooves and ridges on a flow field plate of the fuel cell to be measured, are arranged on the substrate. A thin film heat flow meter is arranged on the rib between the adjacent leaks or holes on the measuring insertion piece respectively, the vacuum film coating technology is adopted for vapor deposition of seven layers of thin films, leading-out wires of the thin film heat flow meters extend to the edge of the substrate by adopting the method of printing a circuit, and a standard wiring port connected with an external circuit is further formed. The measuring insertion piece is placed between the flow field plate of the fuel cell and a membrane electrode. The insertion piece for measuring the heat flow density distribution in the fuel cell is completely independent of a measured object, and the fuel cell does not need to be transformed; furthermore, as the placement position of the insertion piece is very near to the membrane electrode, the insertion piece can measure the real-time heat flow density distribution situation in the fuel cell.

Owner:BEIJING UNIV OF TECH

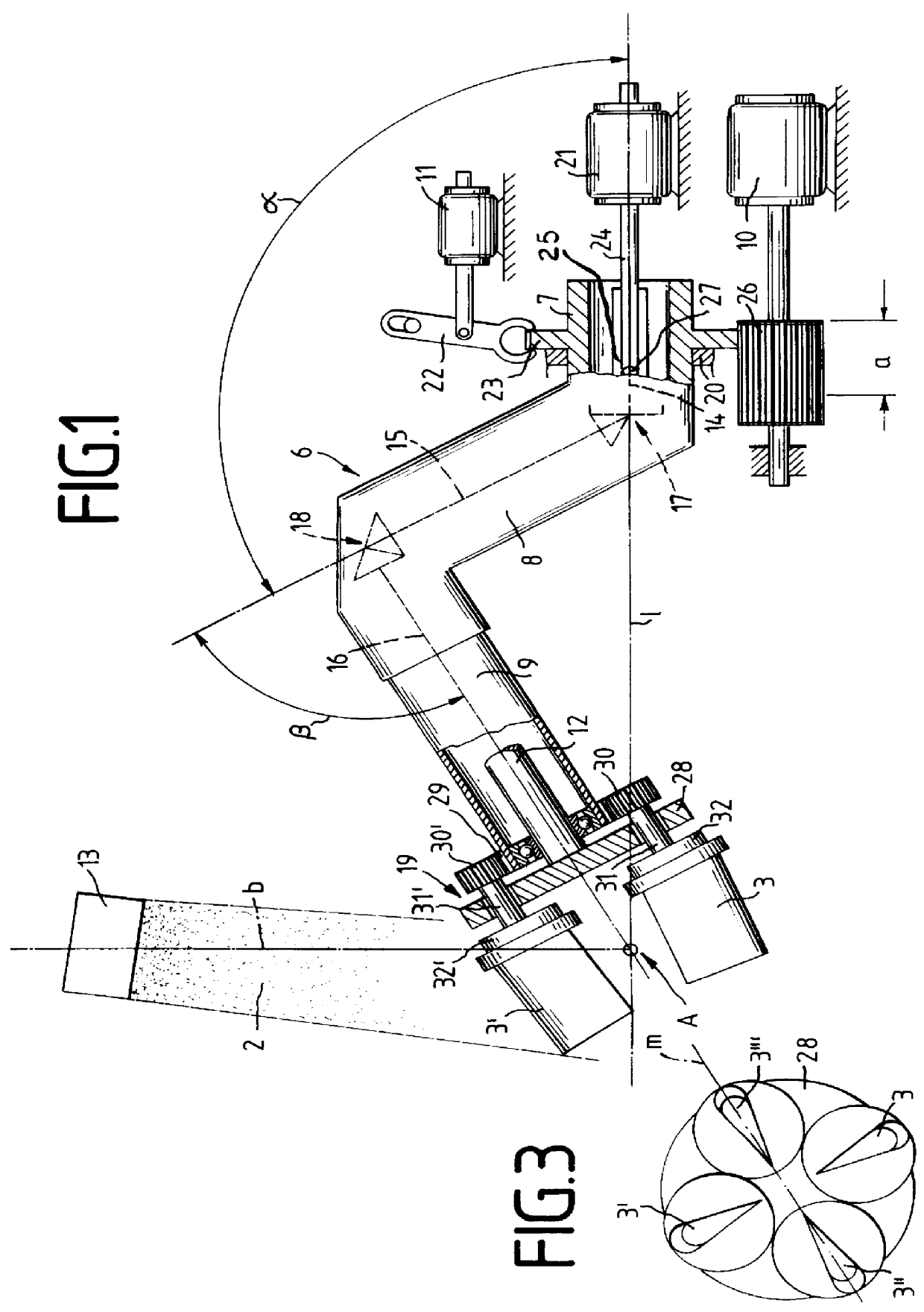

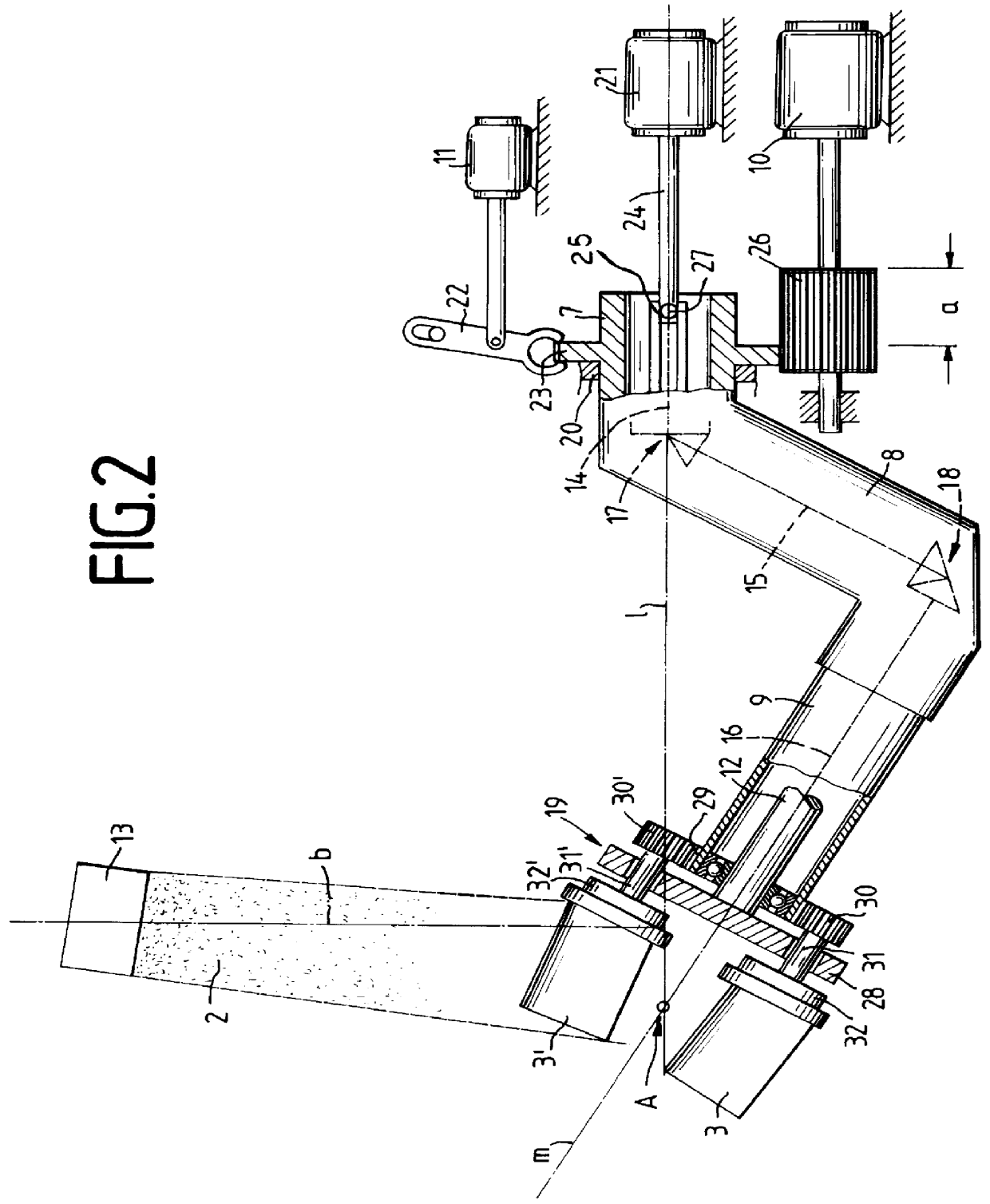

Vacuum coating device for coating substrates on all sides

A vacuum coating device coats substrates on all sides by rotating the substrates in a material flow. The device is for use in a vacuum chamber with a material source, and includes a holder for holding the substrates opposite the material source and drives correlated with the holder to bring about a rotation and shifting movement of the substrates. The device includes a hollow manipulator arm formed from three legs which extend at an angle with respect to one another. More specifically, the first leg extends at an obtuse angle with respect to the second leg, and the second leg extends at an approximately right-angle with respect to the third leg. The substrates are then held at the end of the third leg by the holder. The manipulator arm, when driven by a motor, can rotate around the longitudinal axis of the first leg, and, moreover, can move back and forth in the direction of this longitudinal axis. The holder includes a planetary gear system and substrate holders, which are made to rotate by the planetary gear system.

Owner:ALD VACUUM TECH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com