Flexible gallium oxide-based solar-blind ultraviolet photoelectric detector and preparation method thereof

An electrical detector, gallium oxide technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problem of inflexibility of gallium oxide-based solar-blind ultraviolet photodetectors, improve portability, reduce overall production costs, Prepare simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

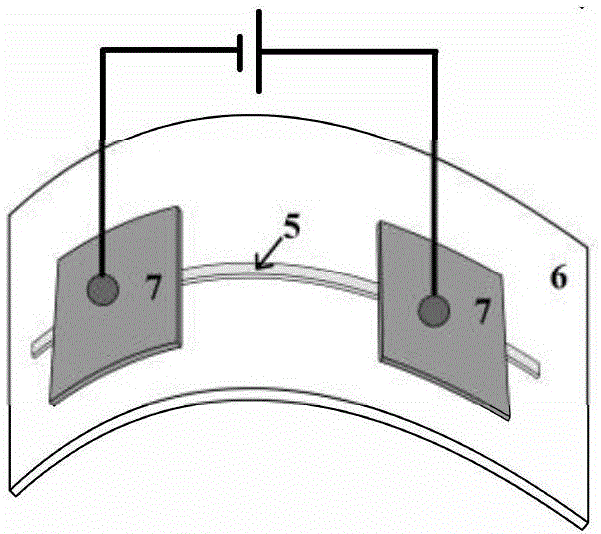

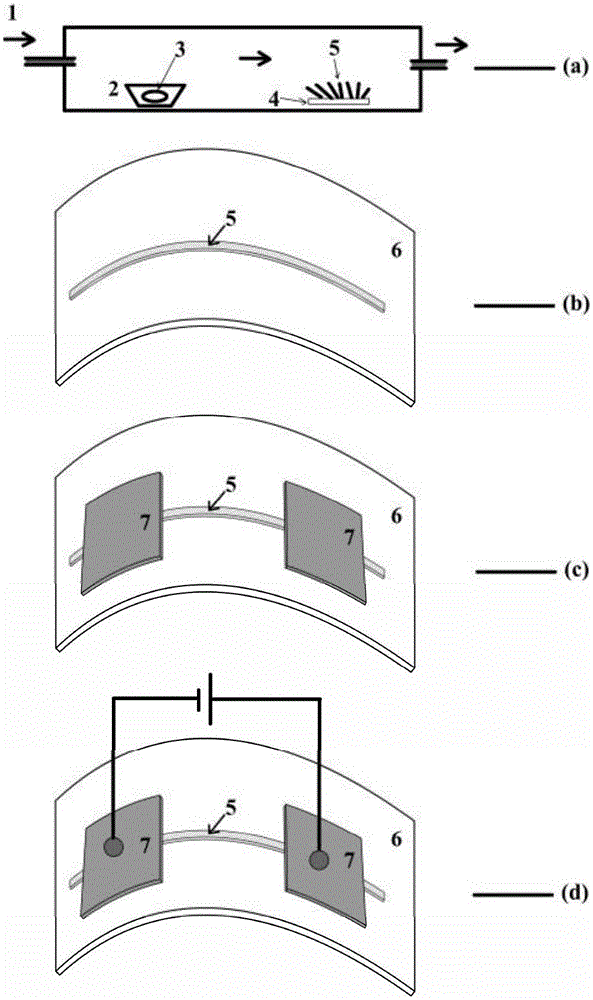

[0037] See attached figure 2 The chemical vapor deposition method uses a high temperature tube furnace as the growth equipment, mixes the reaction gas oxygen and the carrier gas argon to form the growth gas 1, and puts 1g of metal gallium in the quartz boat 2 as the gallium source 3, and puts it on the quartz substrate 4 on gallium oxide microribbons 5 (see figure 2 Process a) in the process; the gallium oxide microribbons 5 grown on the quartz substrate are transferred to the flexible substrate 6 of polyethylene terephthalate (PET) (see figure 2 Process b) in the process; using a magnetron sputtering coating device combined with a metal mask, a metal electrode 7 using Au material is prepared at both ends of the gallium oxide microribbon 5, and the thickness of the metal electrode 7 using Au material is 200nm (see figure 2 in procedure c); connect the power supply for performance testing (see figure 2 in process d). Finally, a flexible gallium oxide-based sun-blind ult...

Embodiment 2

[0042] See attached figure 2, the physical vapor deposition method uses a high-temperature tube furnace as a growth device, a single carrier gas argon as a growth gas 1, and a mixture of 1 g of gallium oxide and carbon powder in a quartz boat 2 as a gallium source 3. Gallium oxide microribbons 5 are grown on the substrate 4 (see figure 2 Process a) in the process; the gallium oxide microribbon 5 grown on the quartz substrate is transferred to the flexible substrate 6 of polyvinyl chloride (PVC) material (see figure 2 Process b) in the process; using electron beam evaporation coating equipment combined with a metal mask to prepare a metal electrode 7 using a Ti / Au composite layer at both ends of the gallium oxide microribbon 5, the thickness of the metal electrode 7 using a Ti / Au composite layer is 300nm (see figure 2 in procedure c); connect the power supply for performance testing (see figure 2 in process d). Finally, a flexible gallium oxide-based sun-blind ultravio...

Embodiment 3

[0044] See attached figure 2 , the physical vapor deposition method uses a high-temperature tube furnace as a growth device, a single carrier gas argon as a growth gas 1, and 1 g of gallium oxide and carbon powder in a quartz boat 2 as a gallium source 3, on a quartz substrate 4 GaO microribbons were grown on 5 (see figure 2 Process a) in the process; the gallium oxide microribbon 5 grown on the quartz substrate is transferred to the flexible substrate 6 of polyethylene (PE) material (see figure 2 Process b) in the process; using thermal evaporation coating equipment combined with photolithography mask technology, metal electrodes 7 using Ni / Au composite layers are prepared at both ends of gallium oxide micro-ribbon 5, and the thickness of metal electrodes 7 using Ni / Au composite layers is 500nm (see figure 2 in procedure c); connect the power supply for performance testing (see figure 2 in process d). Finally, a flexible gallium oxide-based sun-blind ultraviolet phot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com