Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

267results about How to "Improved vaporization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

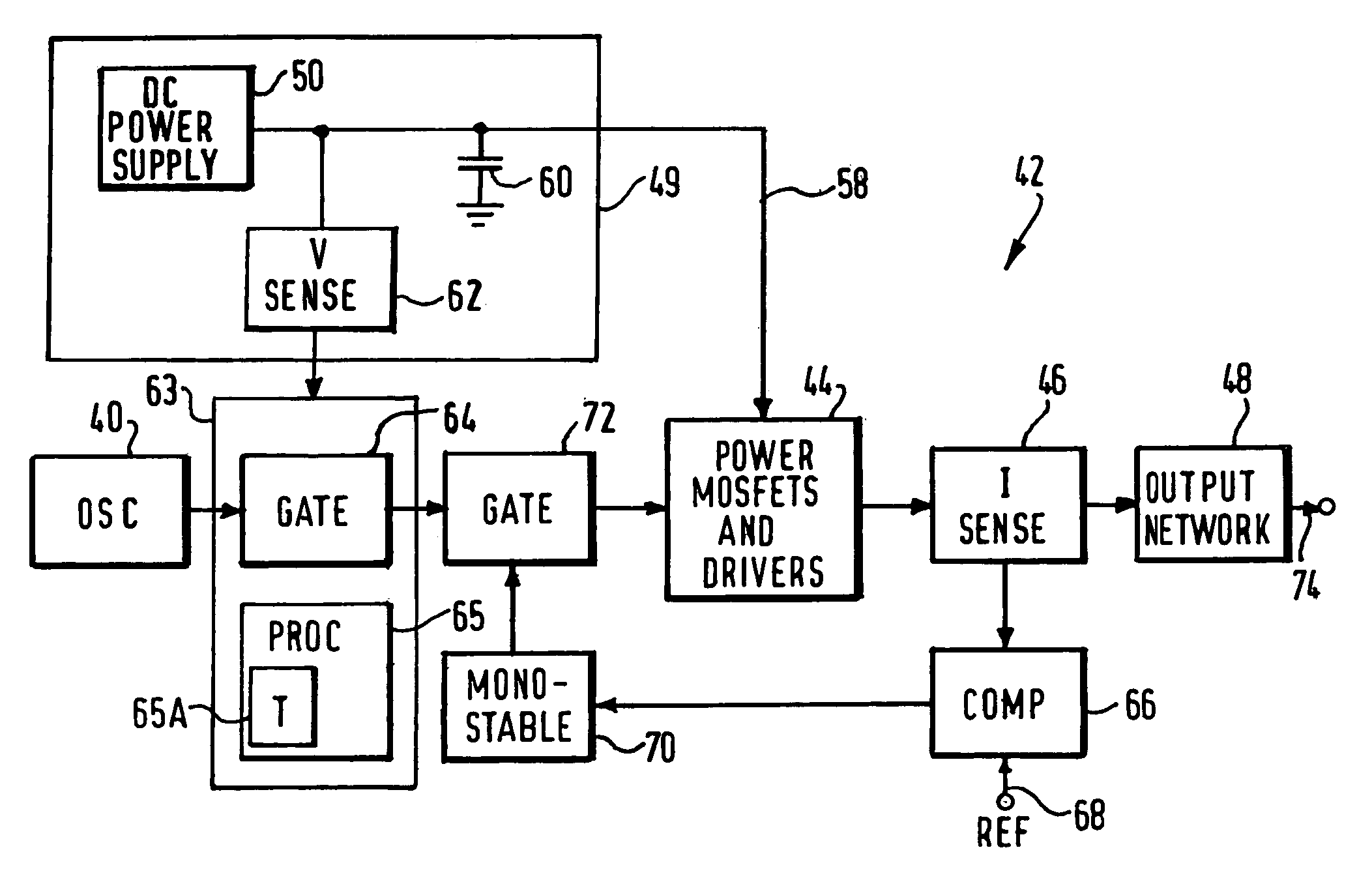

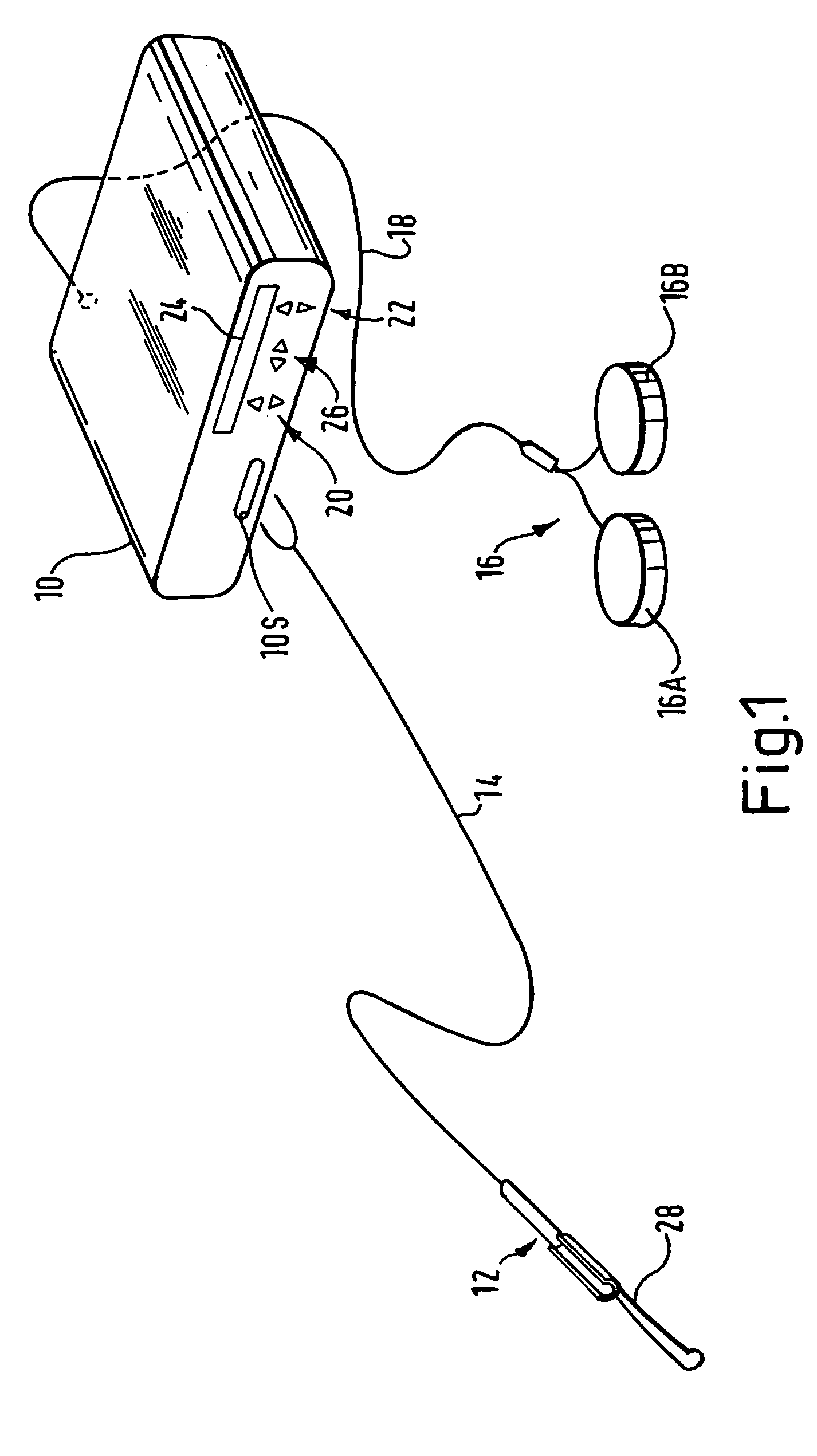

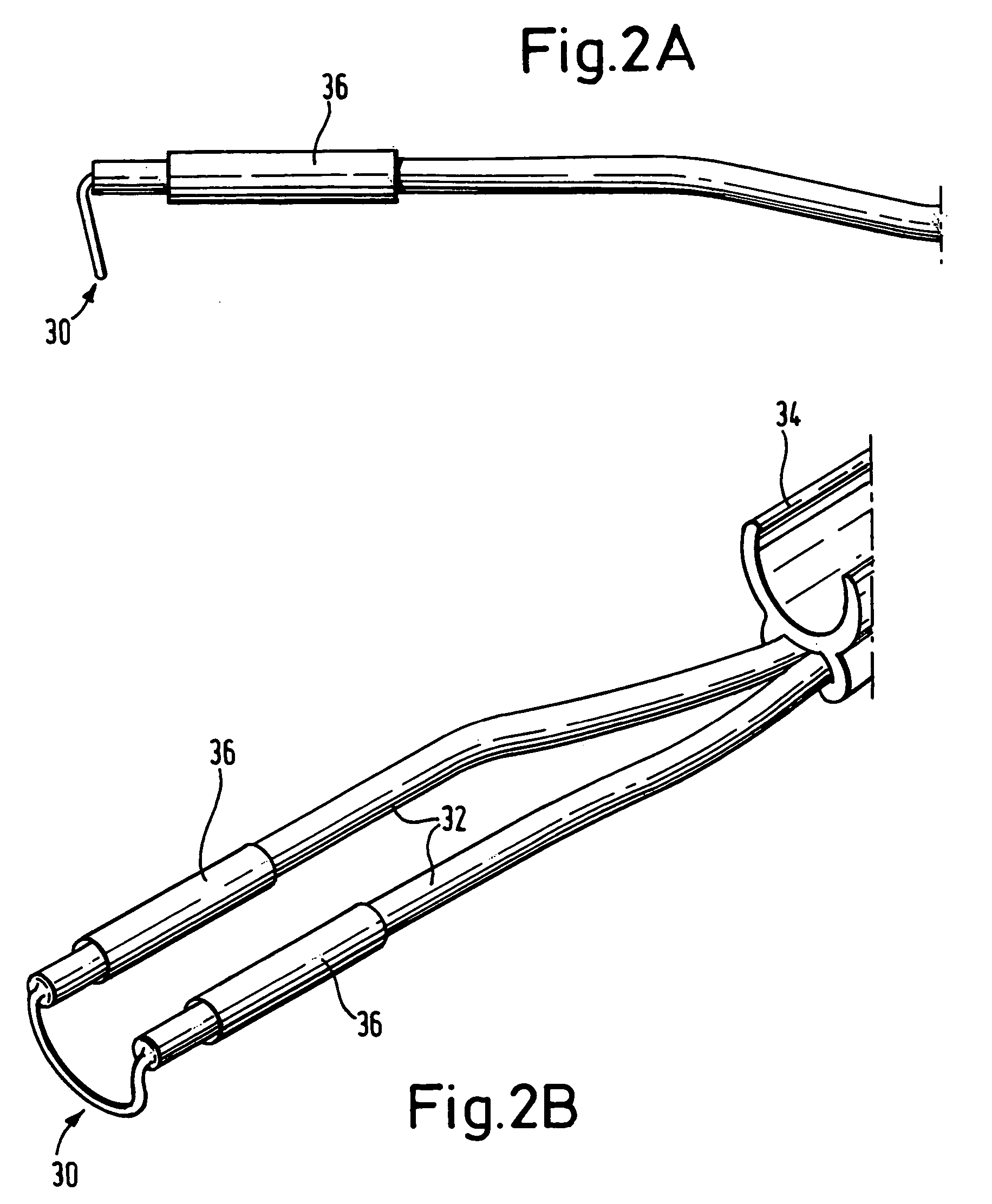

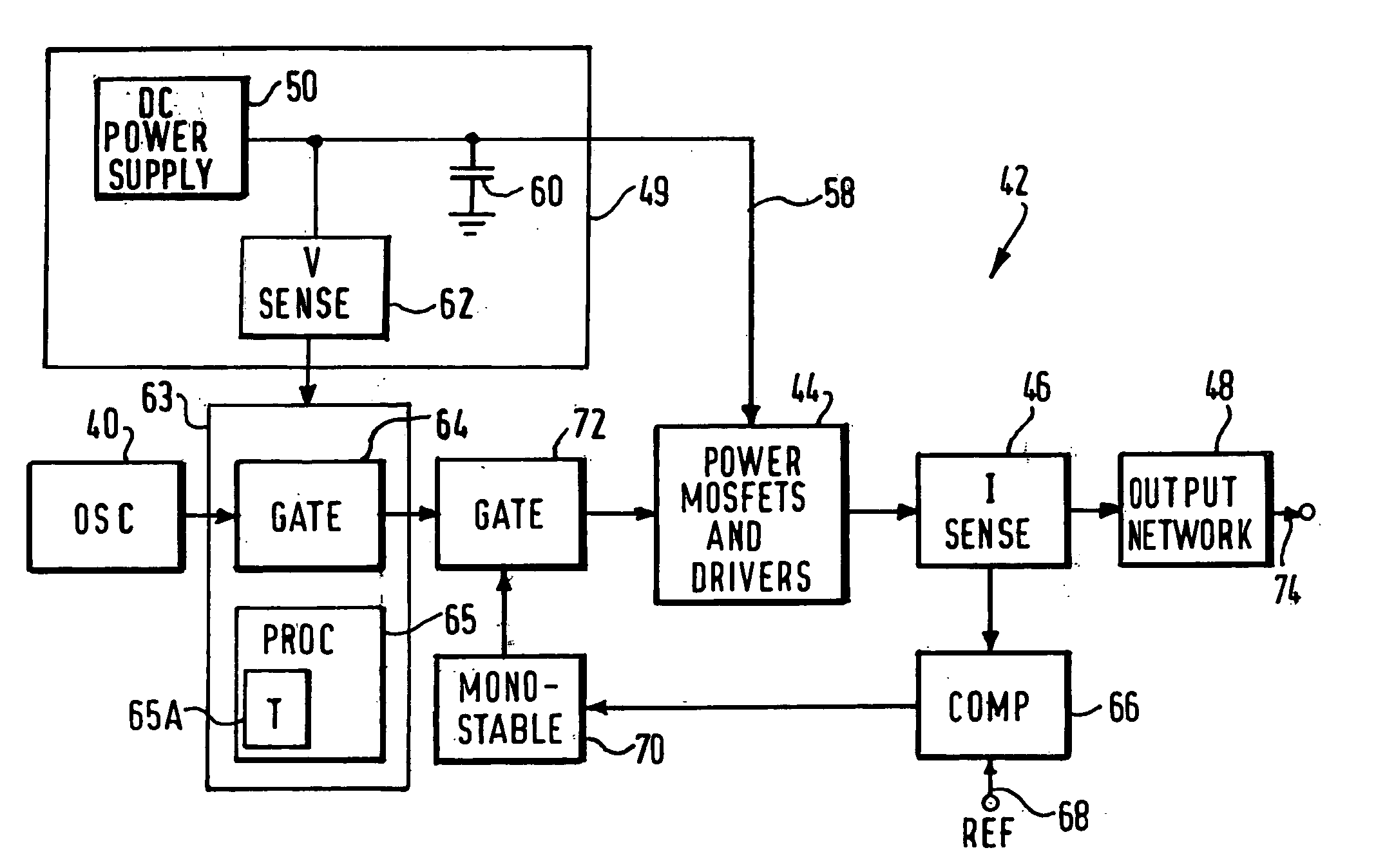

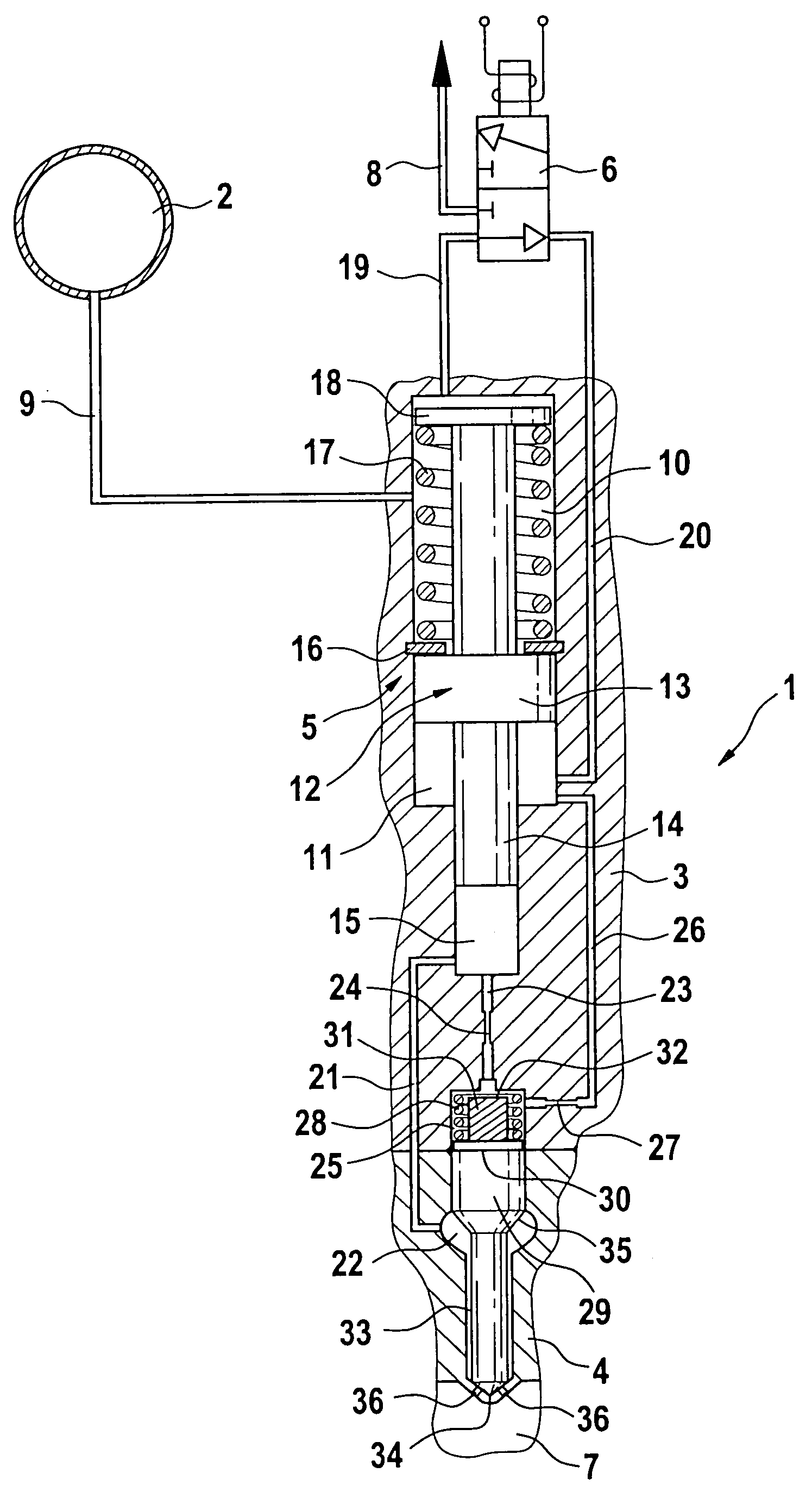

Electrosurgical generator

ActiveUS7195627B2High peak power capabilityReduces delay and unwanted coagulation effectSurgical instruments for heatingPeak valueContinuous wave

An electrosurgical generator for supplying RF power to an electrosurgical instrument for cutting or vaporising tissue has an RF output stage with RF output devices, a series-resonant output network and an RF output. The generator offers improved cutting and vaporising performance, especially in relation to the reliability with which an arc can be struck when presented with an initial load impedance load. This is achieved by virtue of the output stage being capable of maintaining output pulses of at least 1 kW peak by supplying the RF output devices from a large reservoir capacitor. An appropriate combination of cutting performance and haemostasis is provided by allowing for pulsed or continuous wave operation once an arc has been established, according to whether or not a surplus energy condition exists, as indicated by the voltage across the reservoir capacitor.

Owner:GYRUS MEDICAL LTD

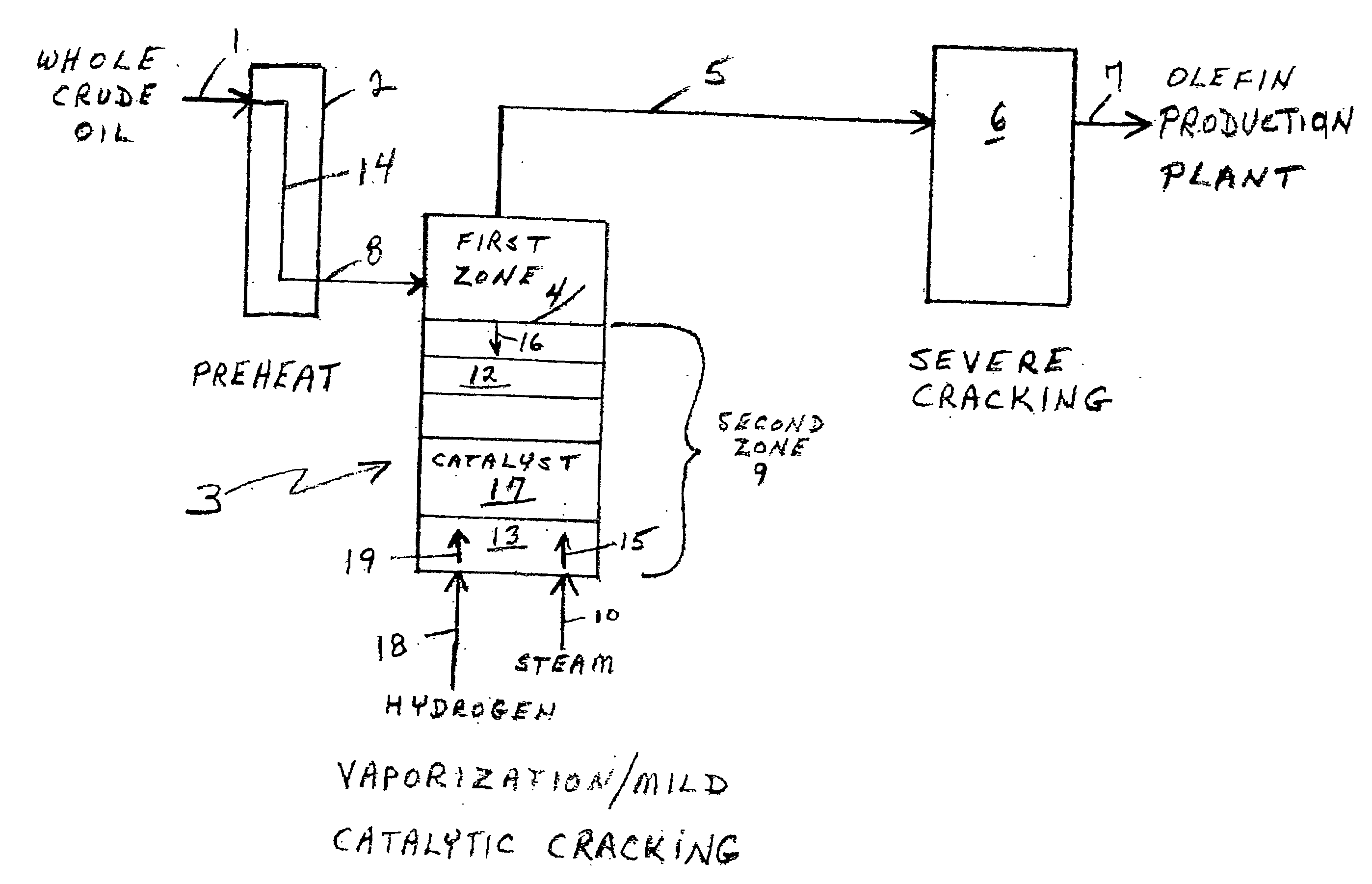

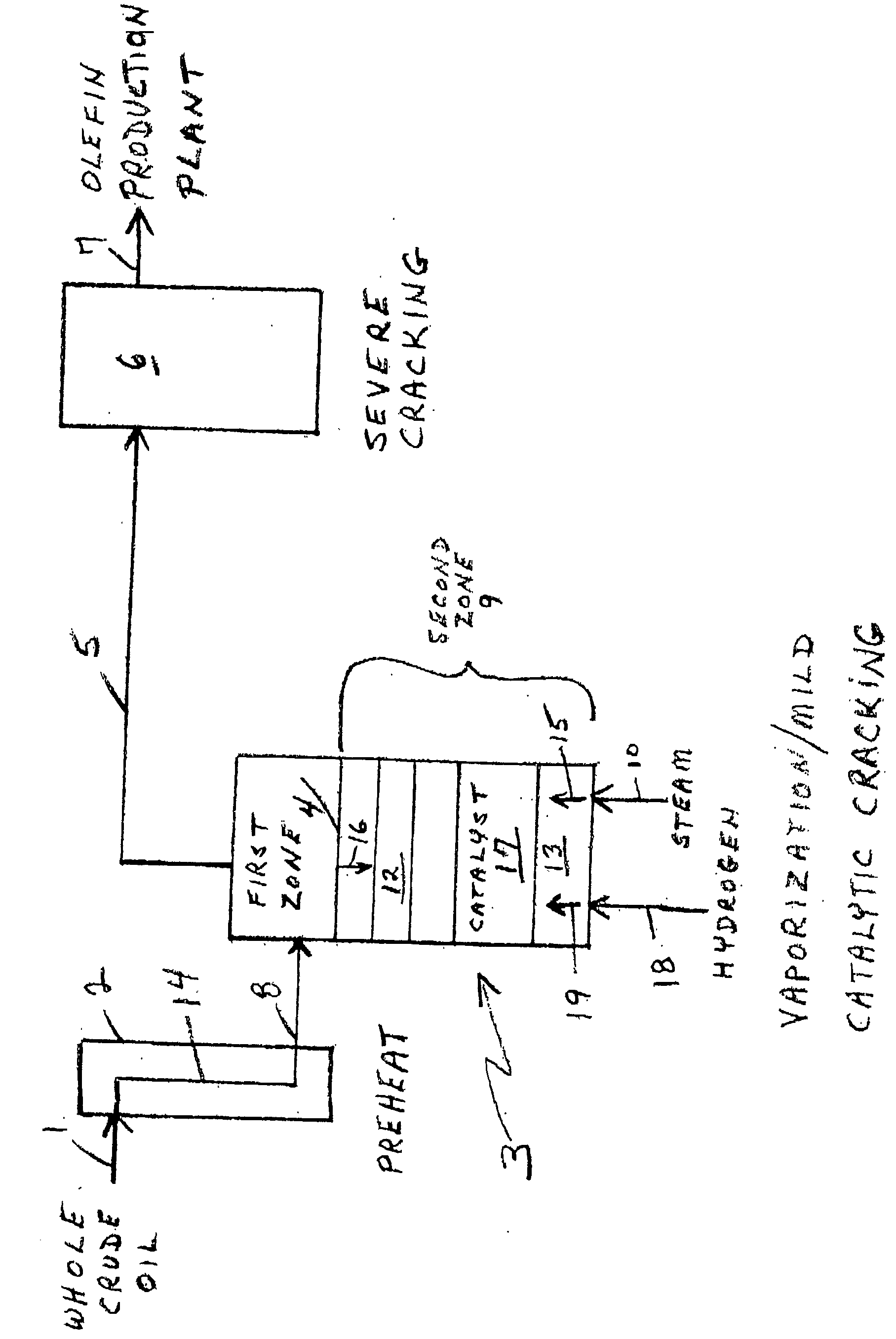

Olefin production utilizing whole crude oil and mild catalytic cracking

InactiveUS20040054247A1Lower temperature rangeImproved vaporizationThermal non-catalytic crackingCatalytic crackingChemistryPyrolysis

A method for utilizing whole crude oil as a feedstock for the pyrolysis furnace of an olefin production plant wherein the feedstock after preheating is subjected to mild catalytic cracking conditions until substantially vaporized, the vapors from the mild catalytic cracking being subjected to severe cracking in the radiant section of the furnace.

Owner:EQUSR CHEM LP

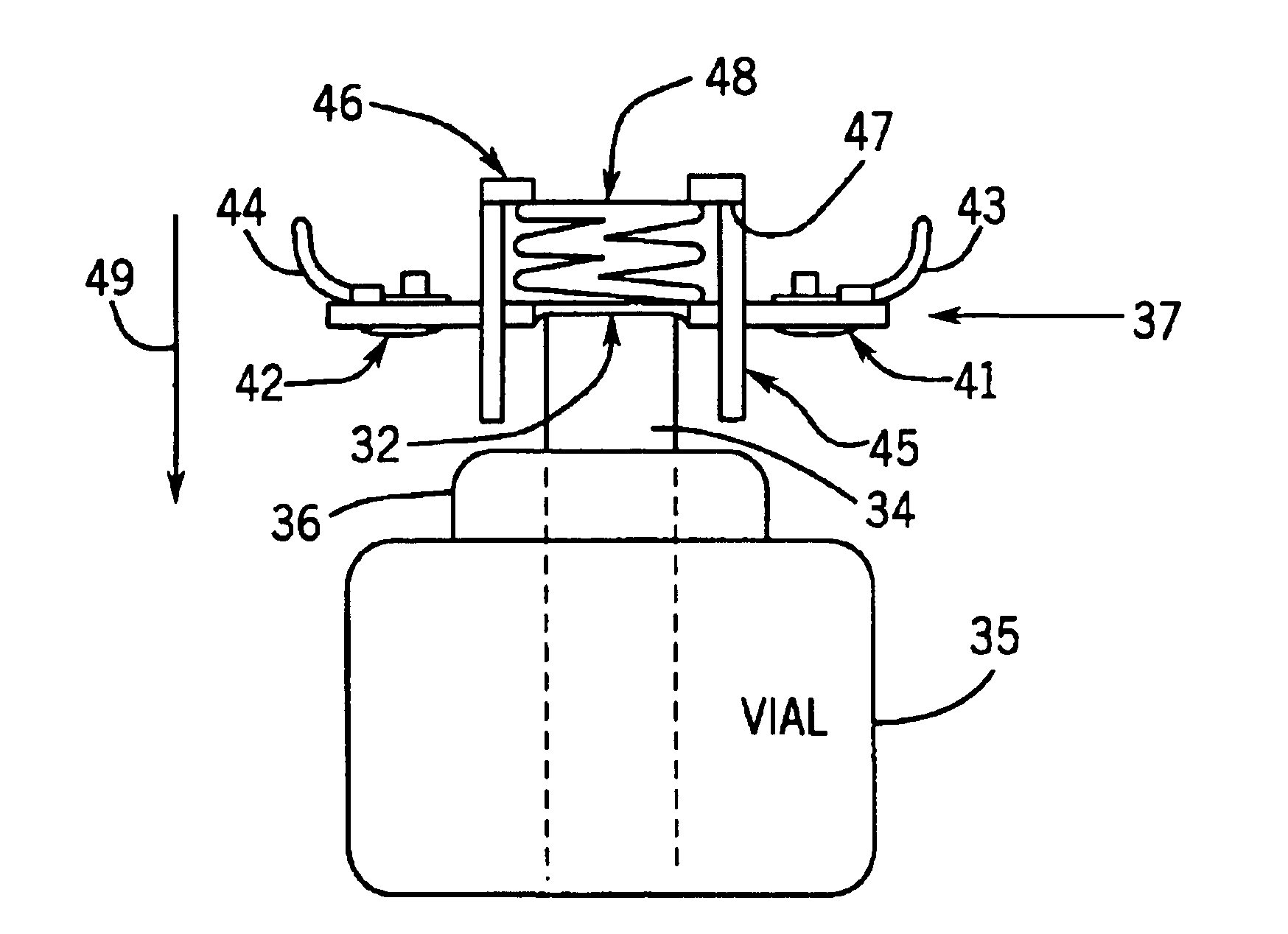

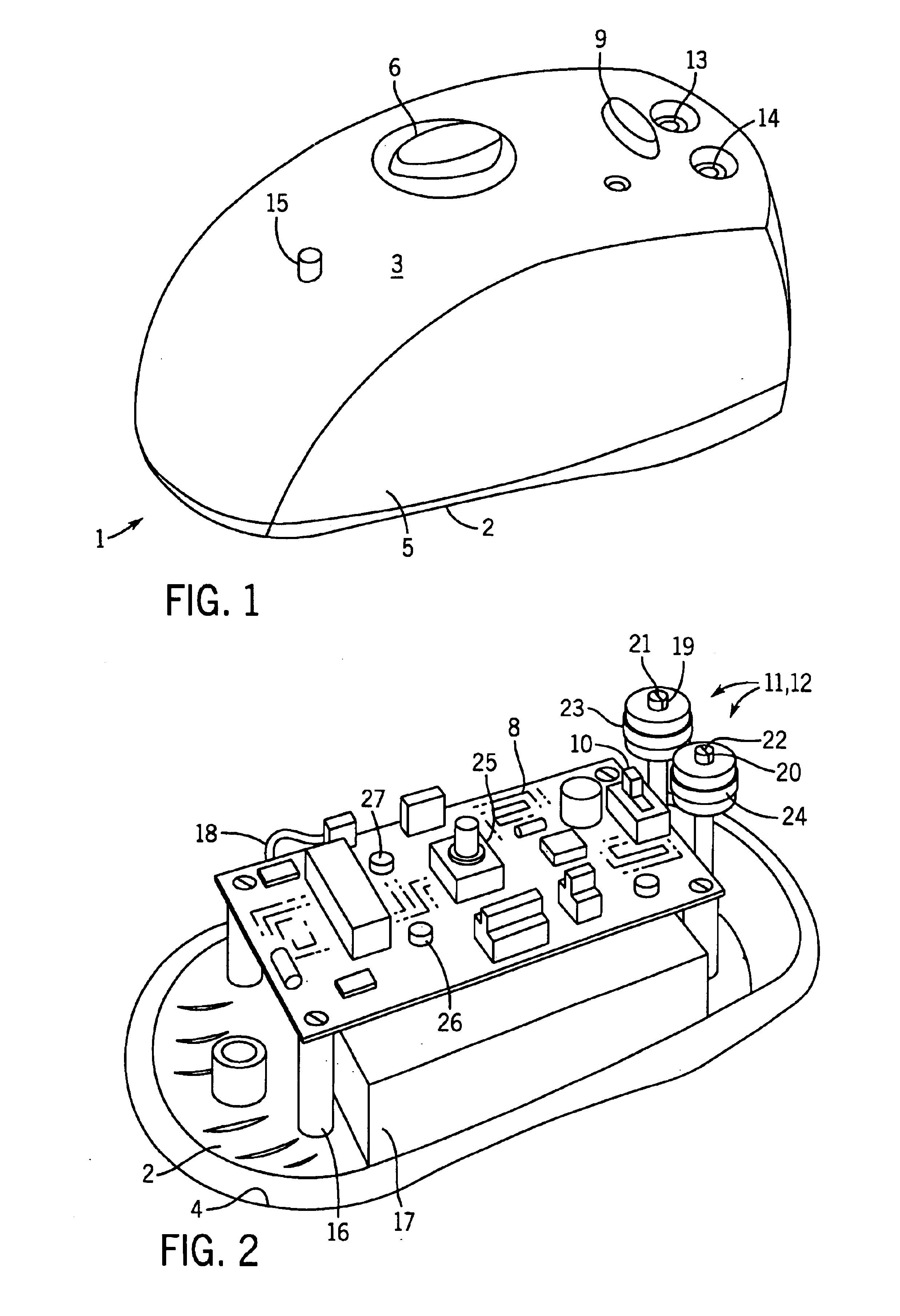

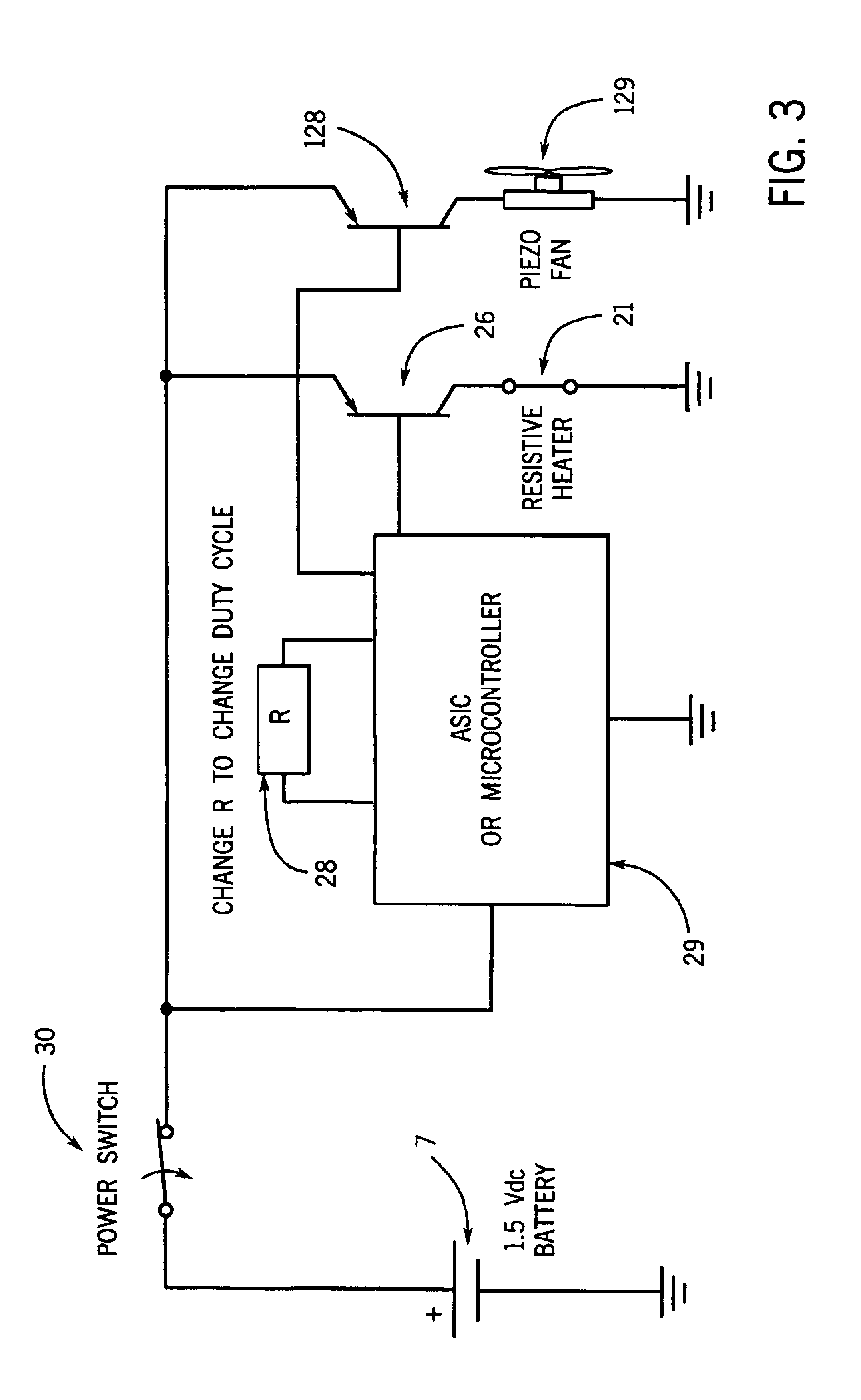

Localized surface volatilization

InactiveUS6909840B2Improved vaporizationIncrease vapor pressureDomestic stoves or rangesLiquid heating fuelElectrical resistance and conductanceProduct gas

The present invention relates to an apparatus and method for rapid flash-like volatilization of high and low vapor pressure components from liquid or solid emanators which is in contact with a point or localized heat source. Vaporization is promoted by a geometrically small electrically resistive heating element with variable activation for pulsed or cyclic heating of an emanating surface containing the volatile components. The apparatus is primarily directed towards the treatment of residential air for fragrancing, odor elimination, treatment of insects or pests, air sanitization, air and surface antibacterial or antimicrobial treatment, or other ambient air or surface modification by way of gas or vapor distribution.

Owner:SC JOHNSON & SON INC

Electrosurgical generator

ActiveUS20050177150A1Improved vaporizationLow levelSurgical instruments for heatingEngineeringContinuous wave

An electrosurgical generator for supplying RF power to an electrosurgical instrument for cutting or vaporising tissue has an RF output stage with RF output devices, a series-resonant output network and an RF output. The generator offers improved cutting and vaporising performance, especially in relation to the reliability with which an arc can be struck when presented with an initial load impedance load. This is achieved by virtue of the output stage being capable of maintaining output pulses of at least 1 kW peak by supplying the RF output devices from a large reservoir capacitor. An appropriate combination of cutting performance and haemostasis is provided by allowing for pulsed or continuous wave operation once an arc has been established, according to whether or not a surplus energy condition exists, as indicated by the voltage across the reservoir capacitor.

Owner:GYRUS MEDICAL LTD

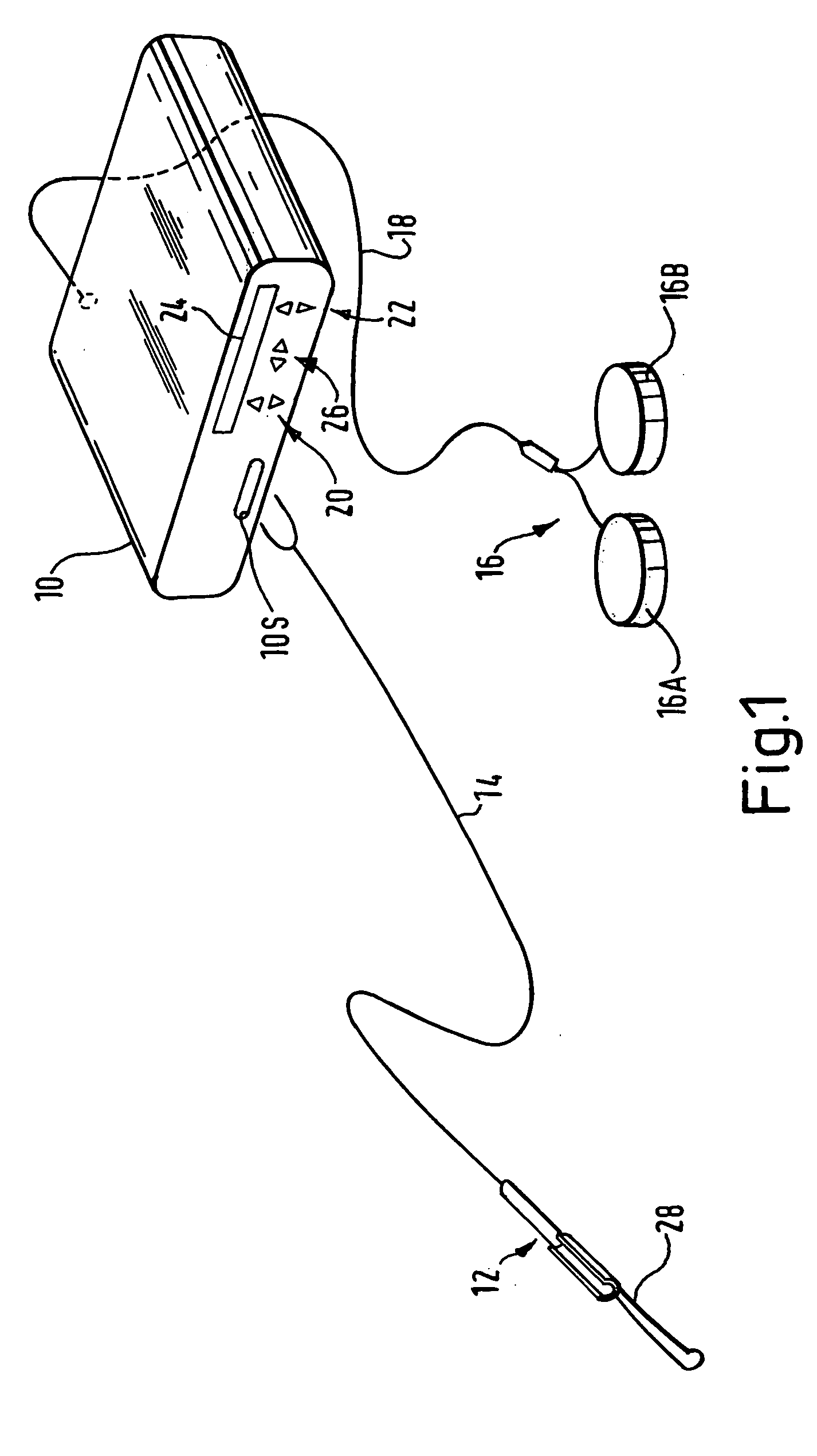

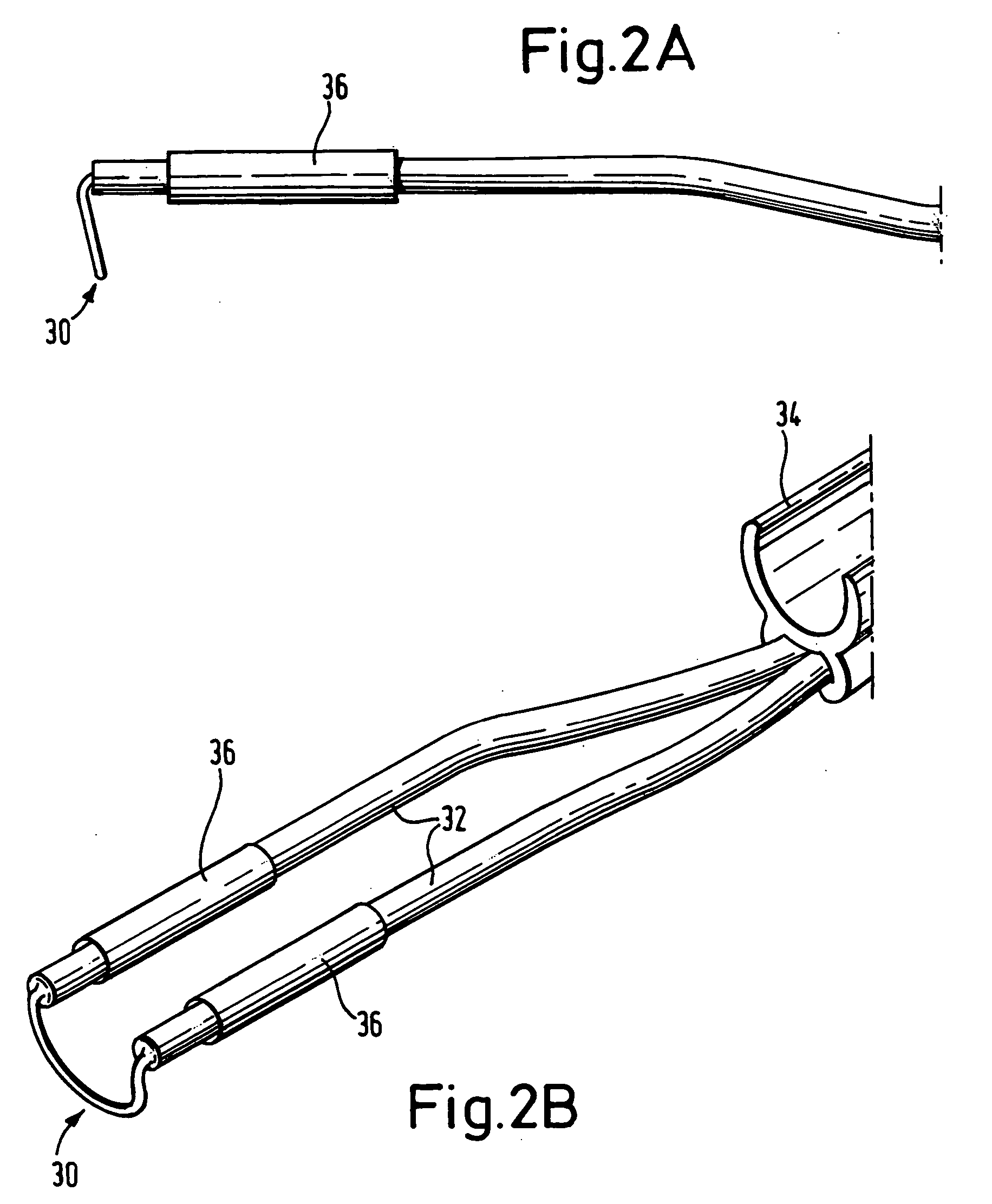

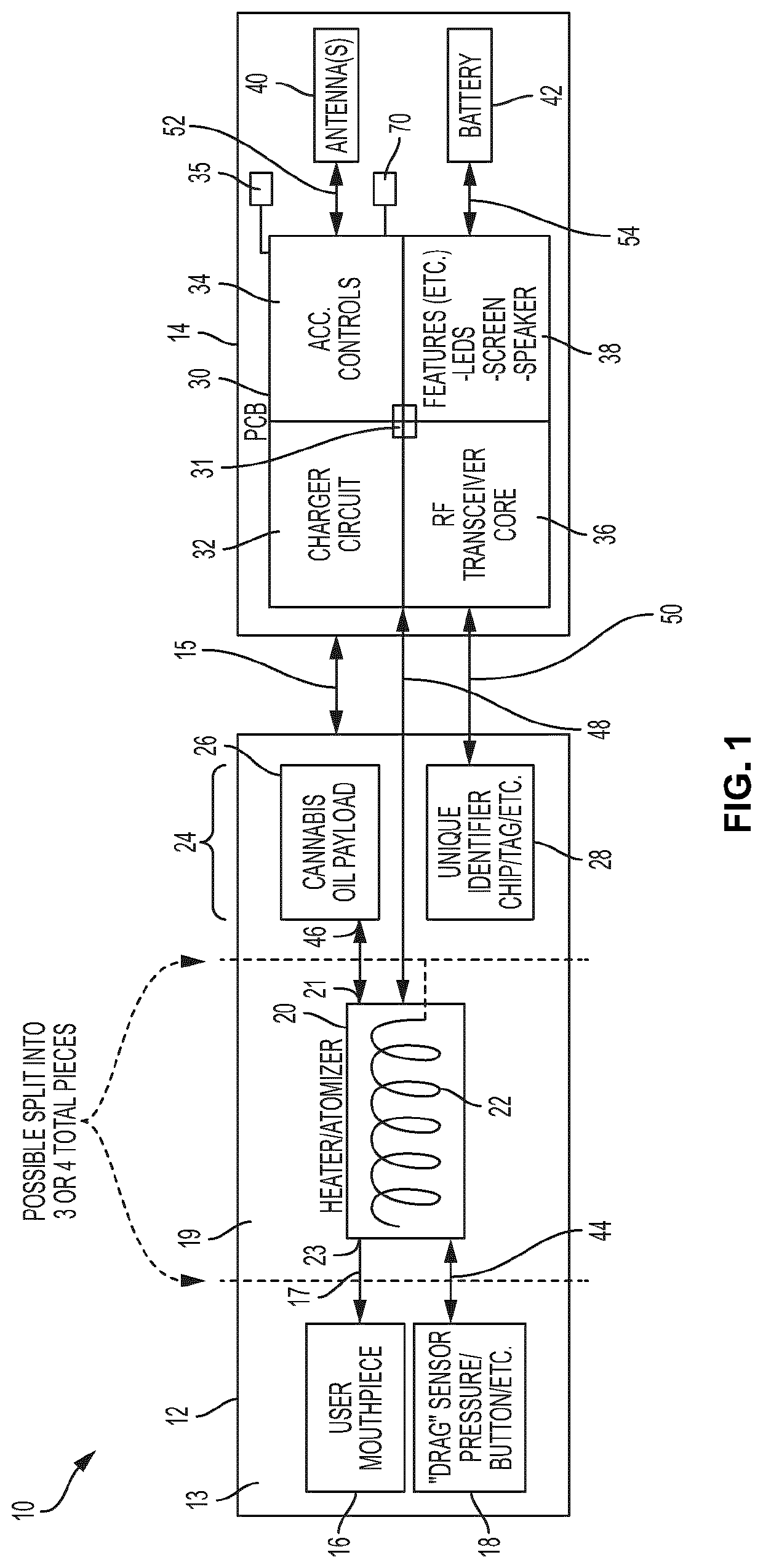

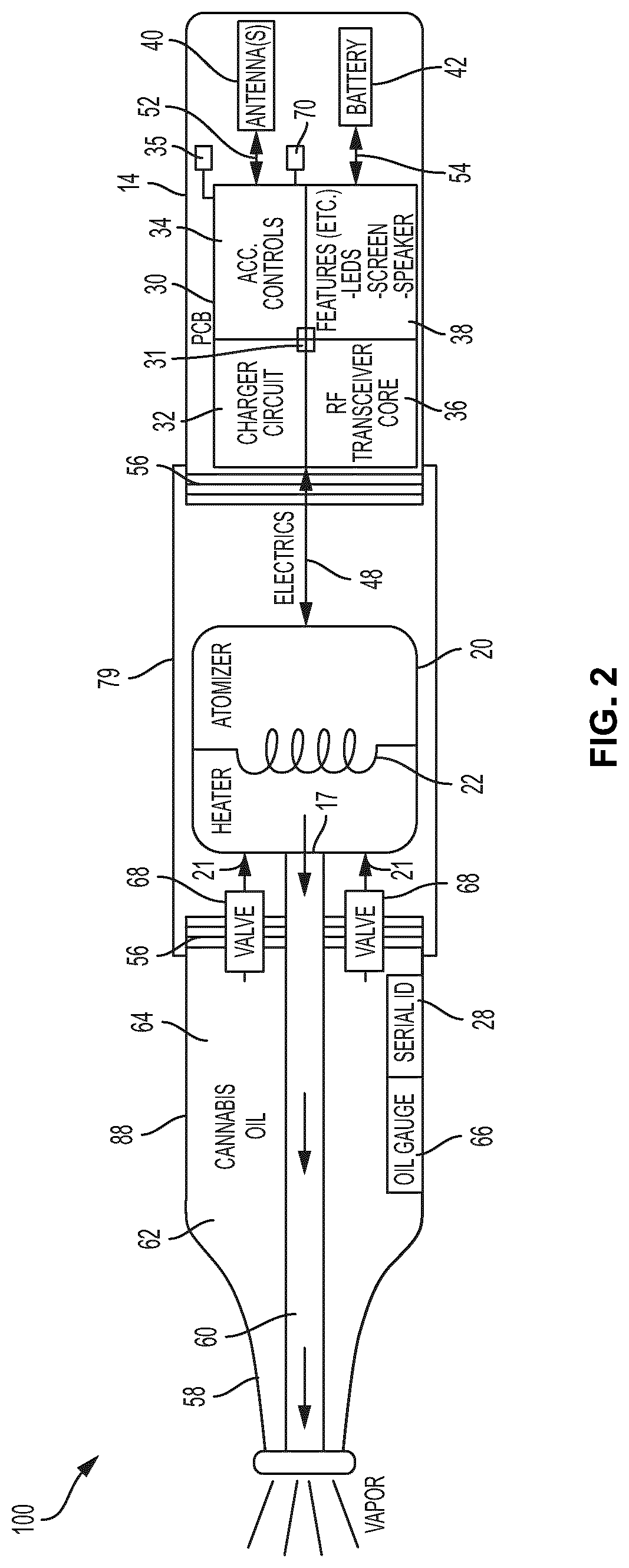

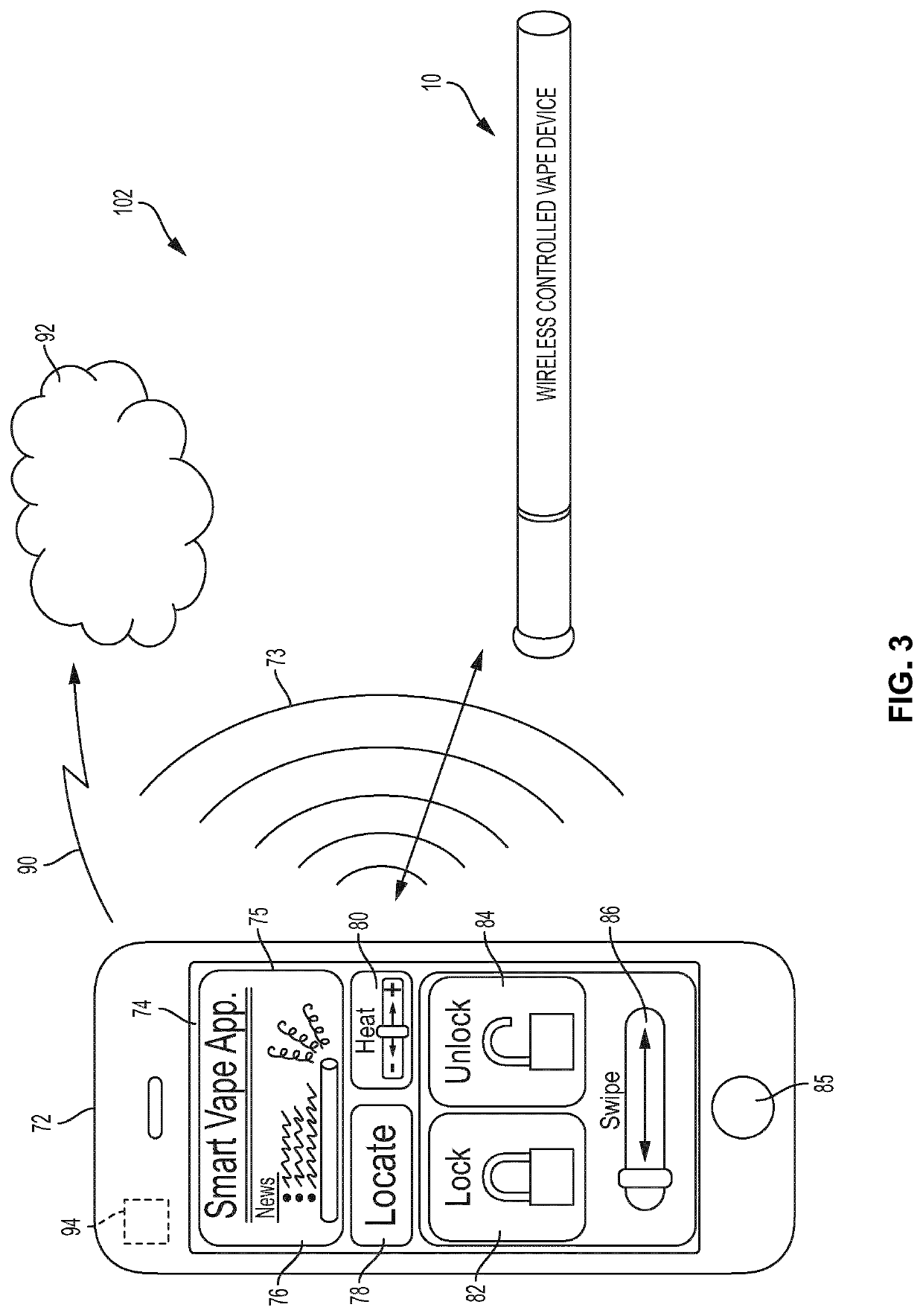

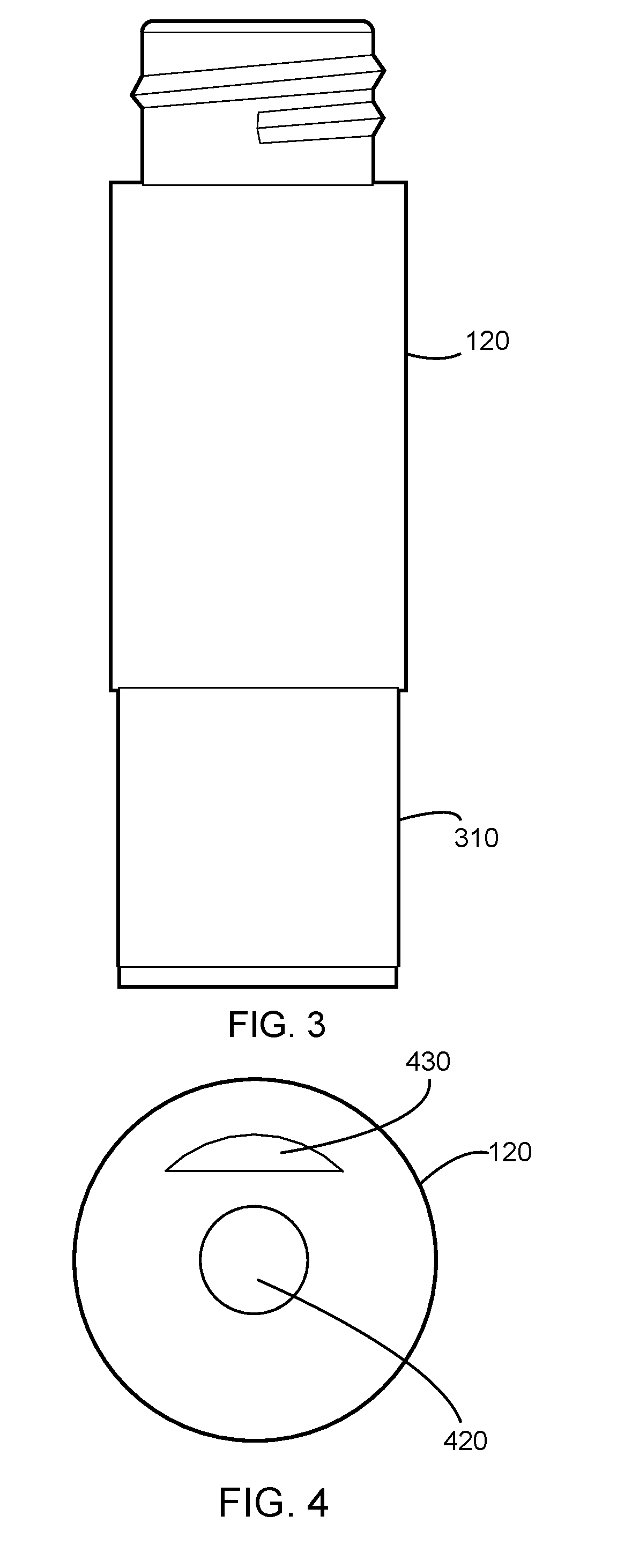

Vape devices, including cartridges, tablets, sensors, and controls for vape devices, and methods for making and using the same

Vape devices and methods of operating the same to prevent unauthorized use, allow for remote, centralized storage of operational settings associated with unique payload identifiers, and to optimize operation based on historical usage data, real-time operating conditions, and / or user information. Vape devices for vaporizing dry material and methods of operating the same. Tablets comprising dry material for vaporization and methods of making and using the same. Vape devices and cartridges to improve flow of a fluid payload to an atomizer and to prevent leaking and spurting of the fluid payload, including vape devices and cartridges that pressurize the fluid payload. Vapor measurement systems to determine dosage based on a measured capacitance of vaporized payload. A two-lead communication system that enables the communication of a plurality of electrical signals between a control assembly and cartridge. A cartridge temperature control system that provides localized temperature control for the cartridge.

Owner:CANOPY GROWTH CORP

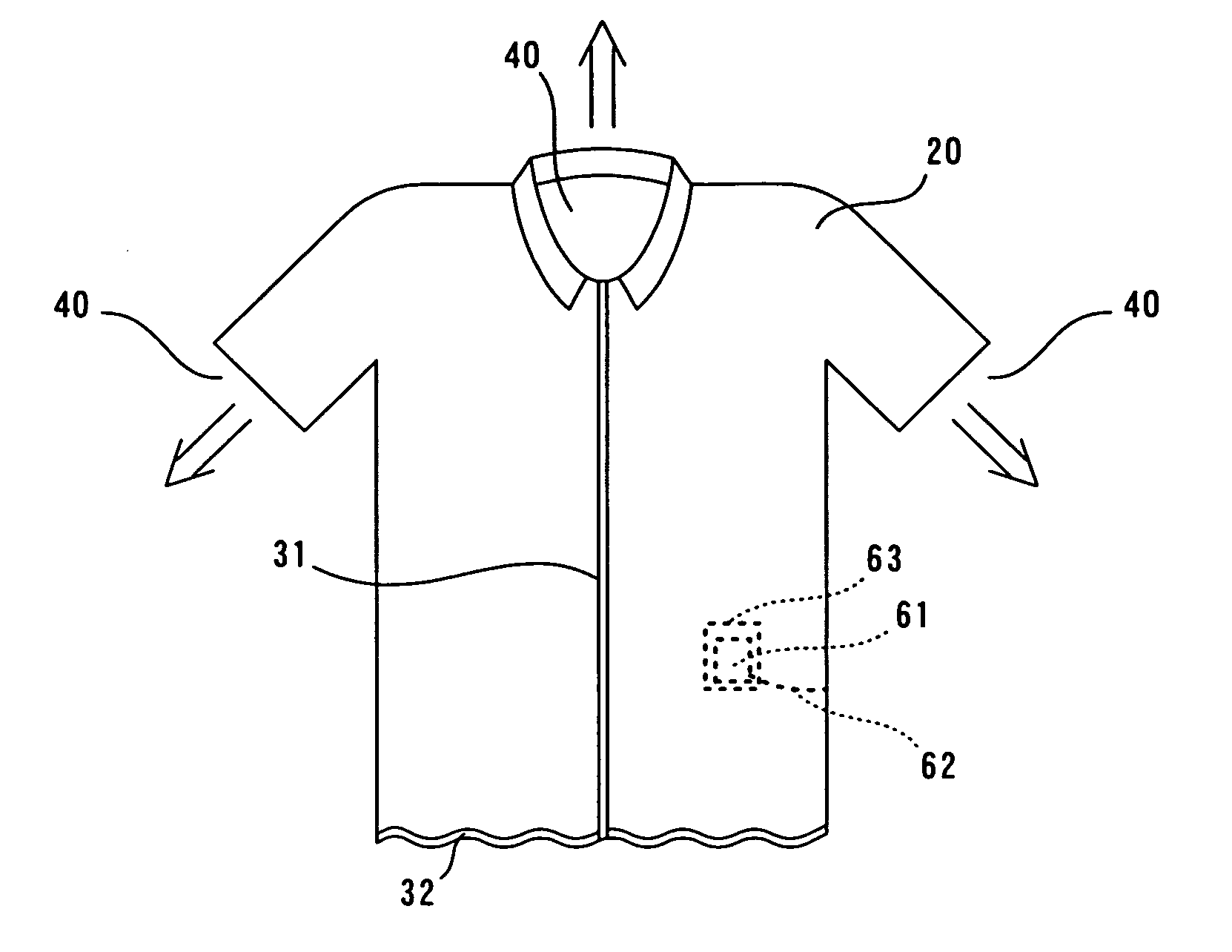

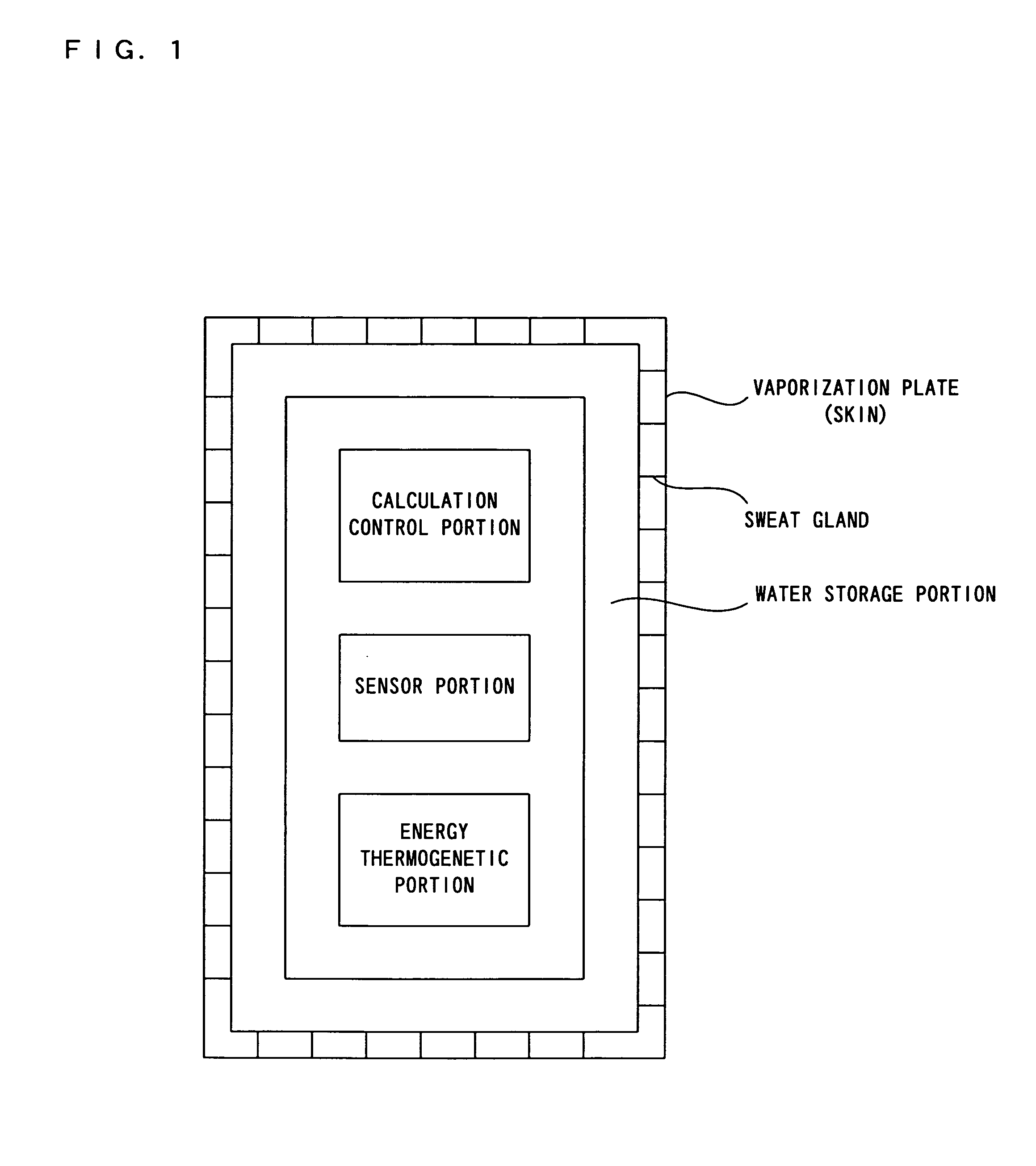

Air-Conditioning Garment

InactiveUS20070271939A1Solve the large power consumptionIncrease rangeGarment special featuresDomestic cooling apparatusCooling effectEngineering

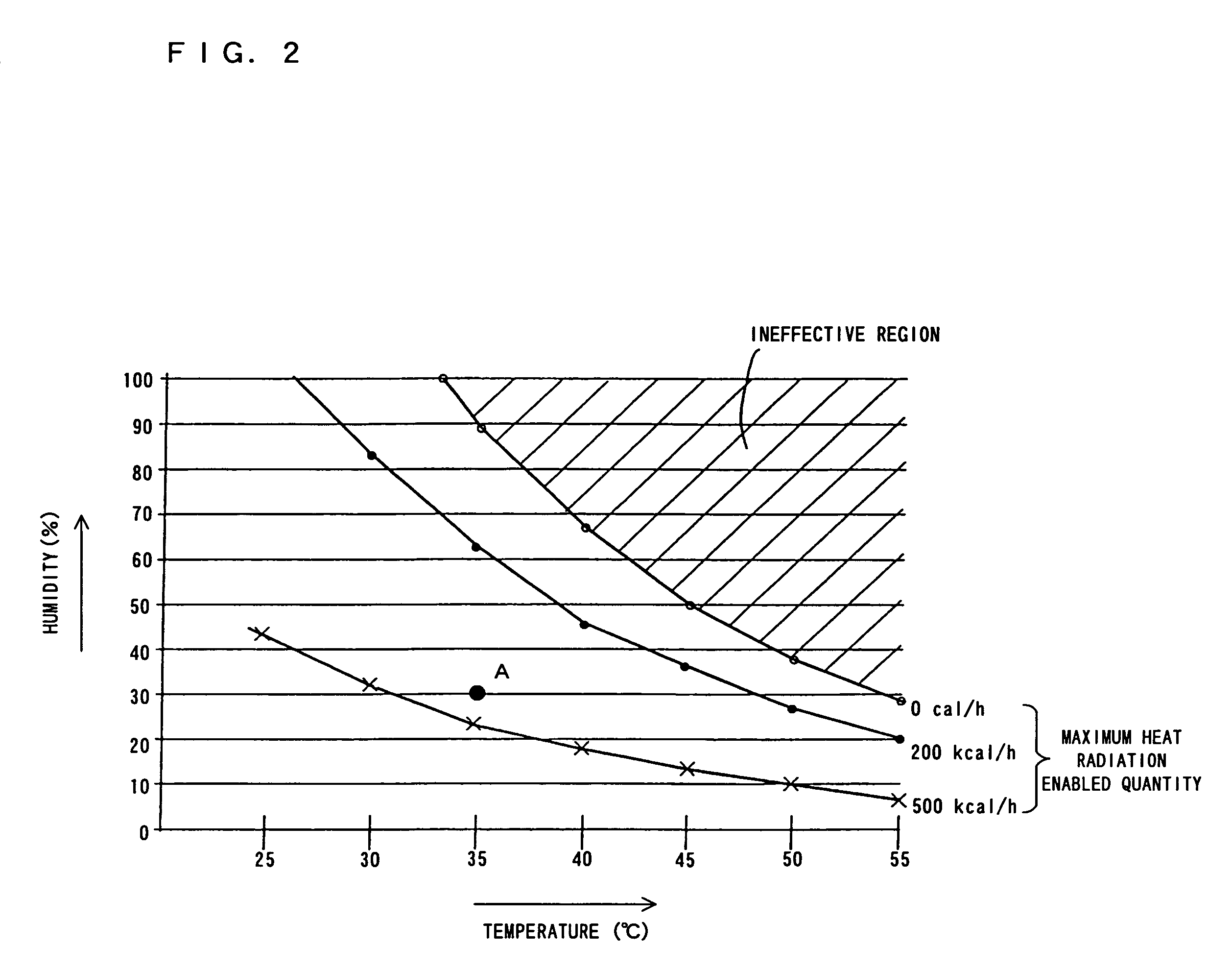

It is an object of the present invention to provide an air-conditioning garment capable of expanding a range in which a physiological cooler function originally included in a human body is effectively exercised, with a small power consumption in accordance with an individual difference or an intended use of a wearer. This air-conditioning garment is provided with a clothing material portion 20 which guides air along a surface of a body in a space between itself and the body, three air circulating portions 40, 40 and 40 which take air flowing in the space between the clothing material portion 20 and the body to the outside, two air sending means 50 and 50 for forcibly generating a flow of air in the space between the clothing material portion 20 and the body, and power supplying means 61 for supplying power to the air sending means 50 and 50. The air sending means 50 and 50 take outside air into the clothing material portion 20, and generate air flowing with a flow quantity of 6 liters / second. As a result, the air-conditioning garment can rapidly vaporize sweat, and hence the range in which the physiological cooler function originally included in a human body is effectively exercised can be expanded, thereby demonstrating a sufficient cooling effect.

Owner:SEFT DEVMENT LAB

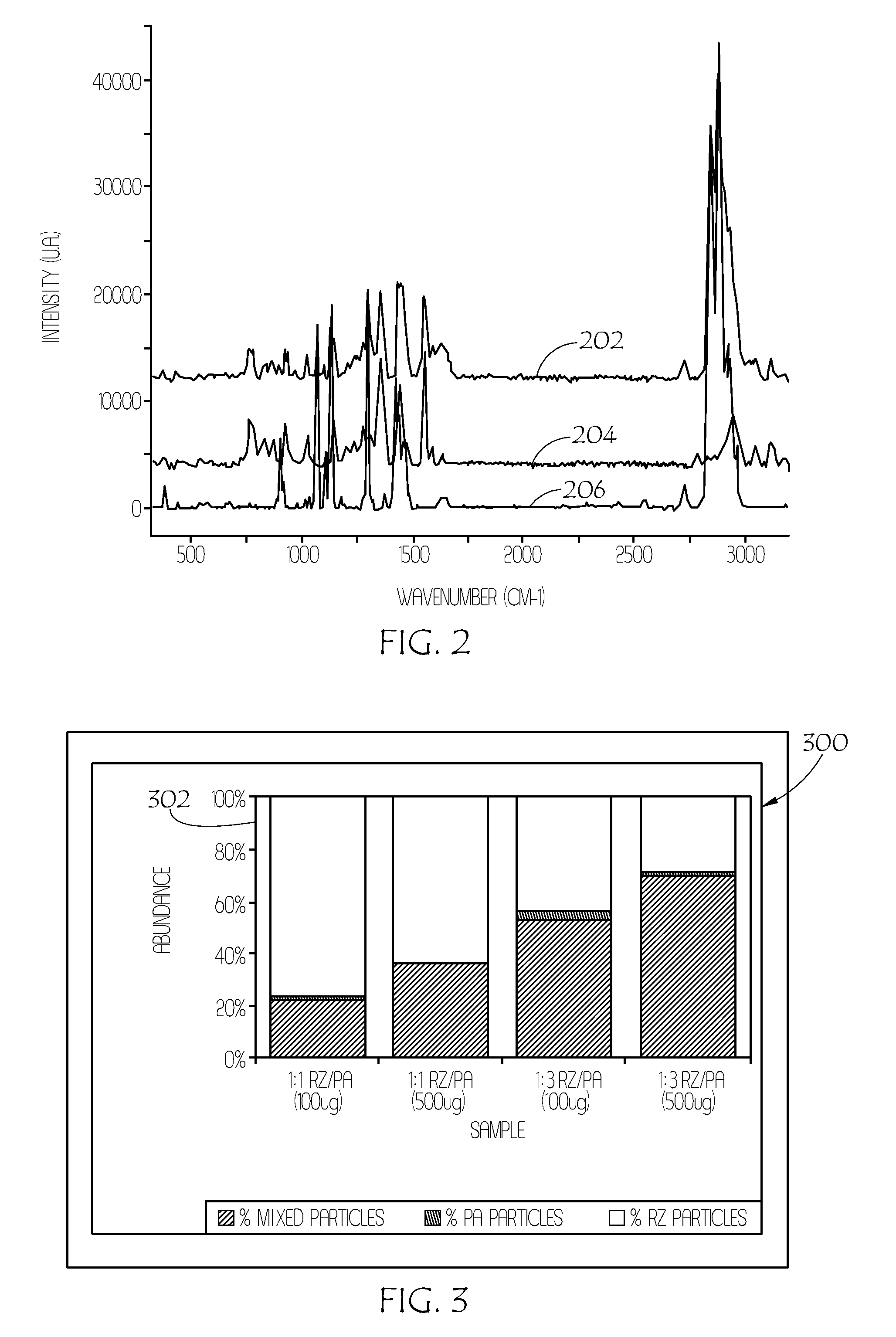

Mixed drug aerosol compositions

InactiveUS20080299048A1Overcome Manufacturing ComplexityOvercomes shelf-life stability issuePowder deliveryNervous disorderControlled drugsDrug aerosol

The present invention pertains to aerosols which comprise a first compound which is physiologically active and a second compound which is different from the first compound. Such aerosols may be produced “on demand” and can be used to control drug release, to improve vaporizability, or to reduce, modify or eliminate undesirable taste associated with a drug aerosol. The present invention also pertains to methods for producing such aerosols.

Owner:ALEXZA PHARMA INC

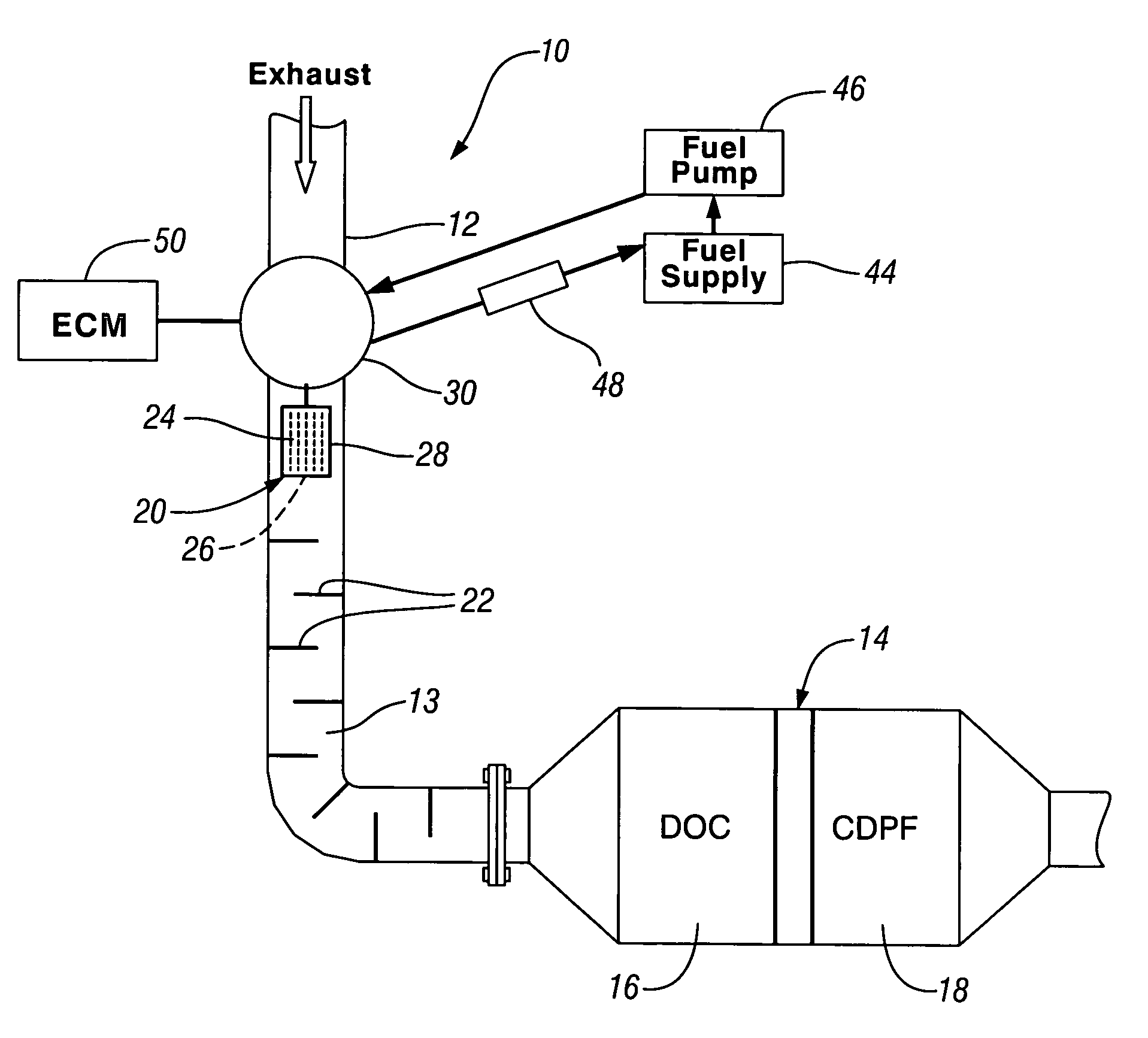

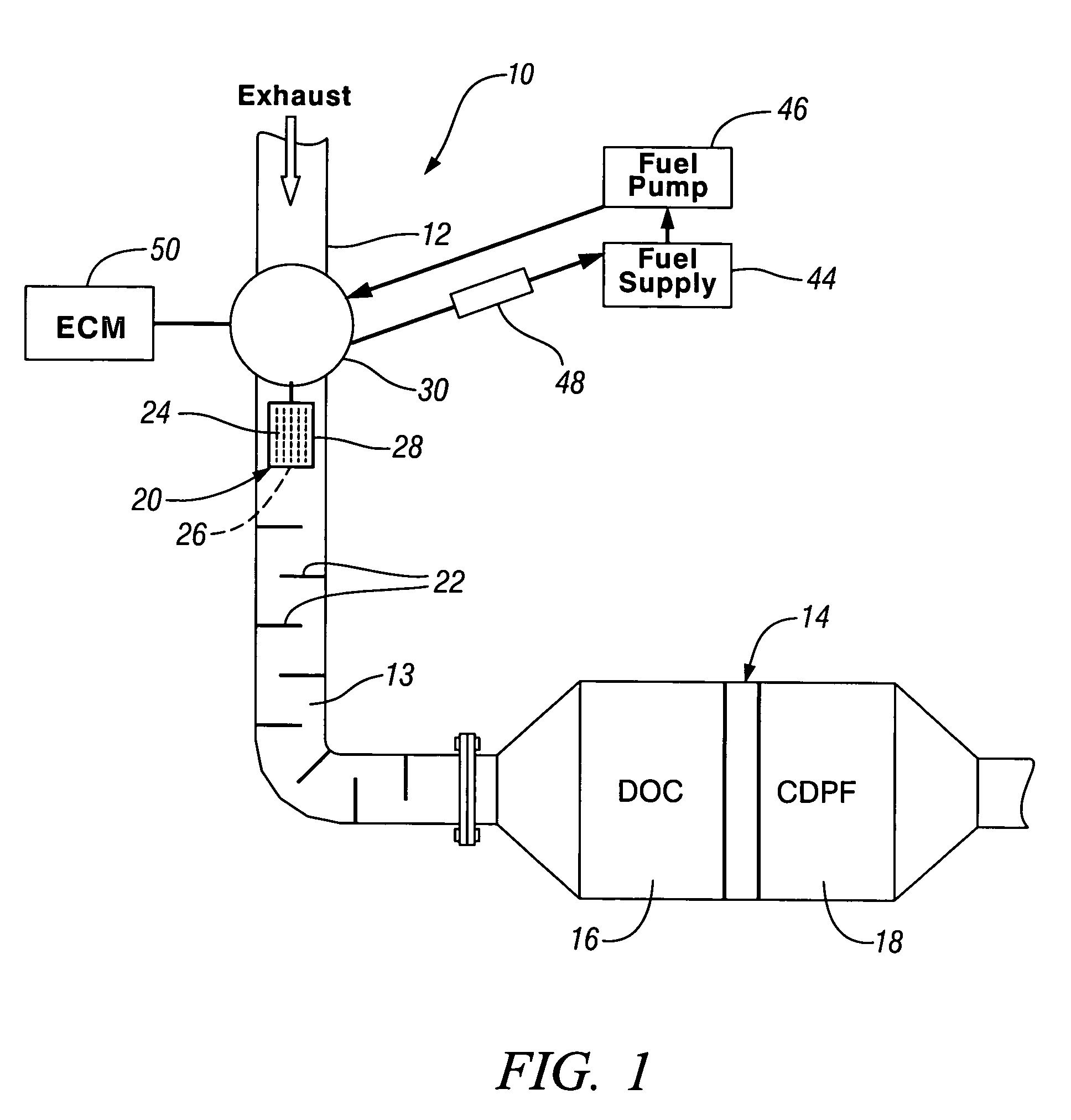

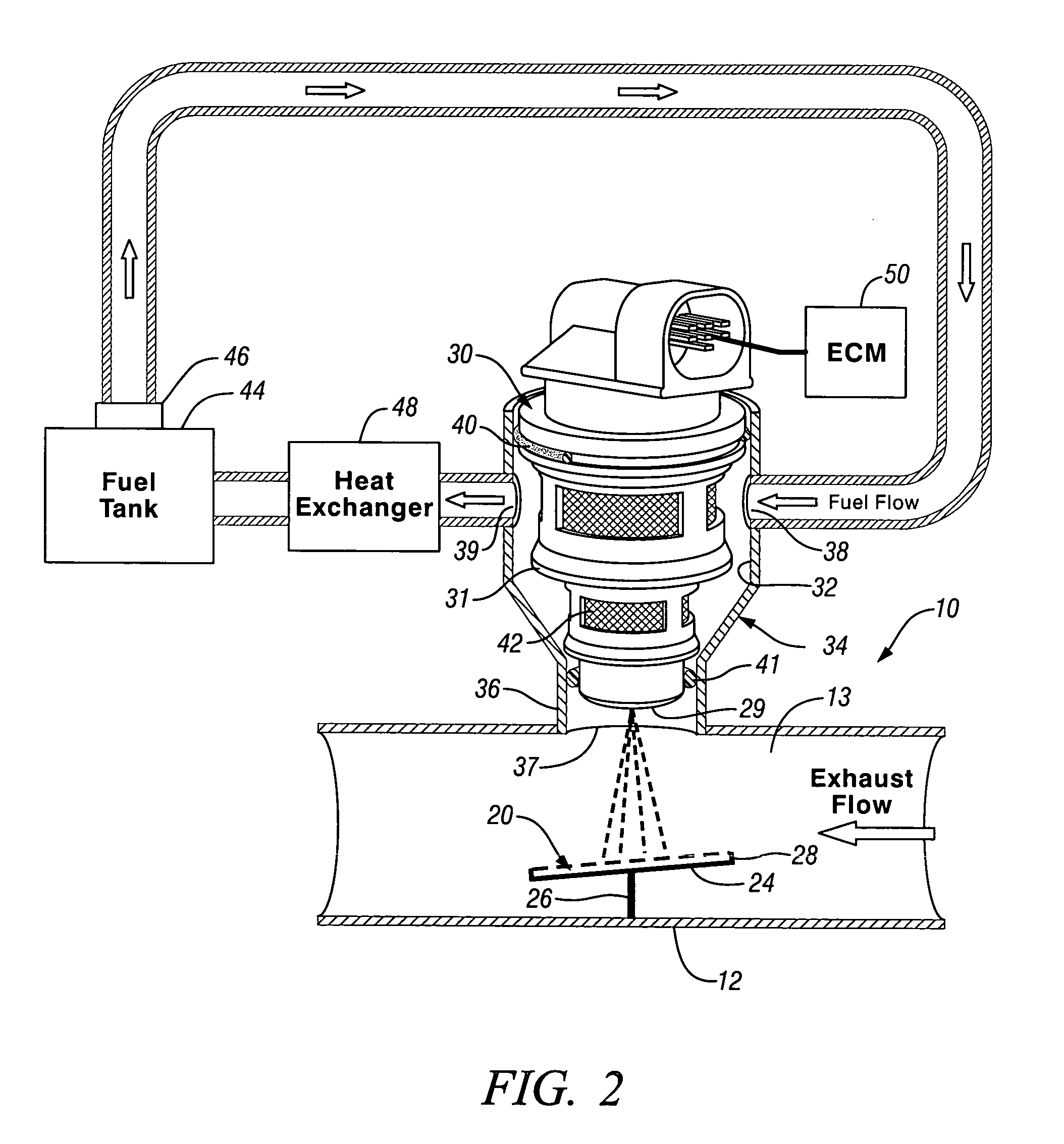

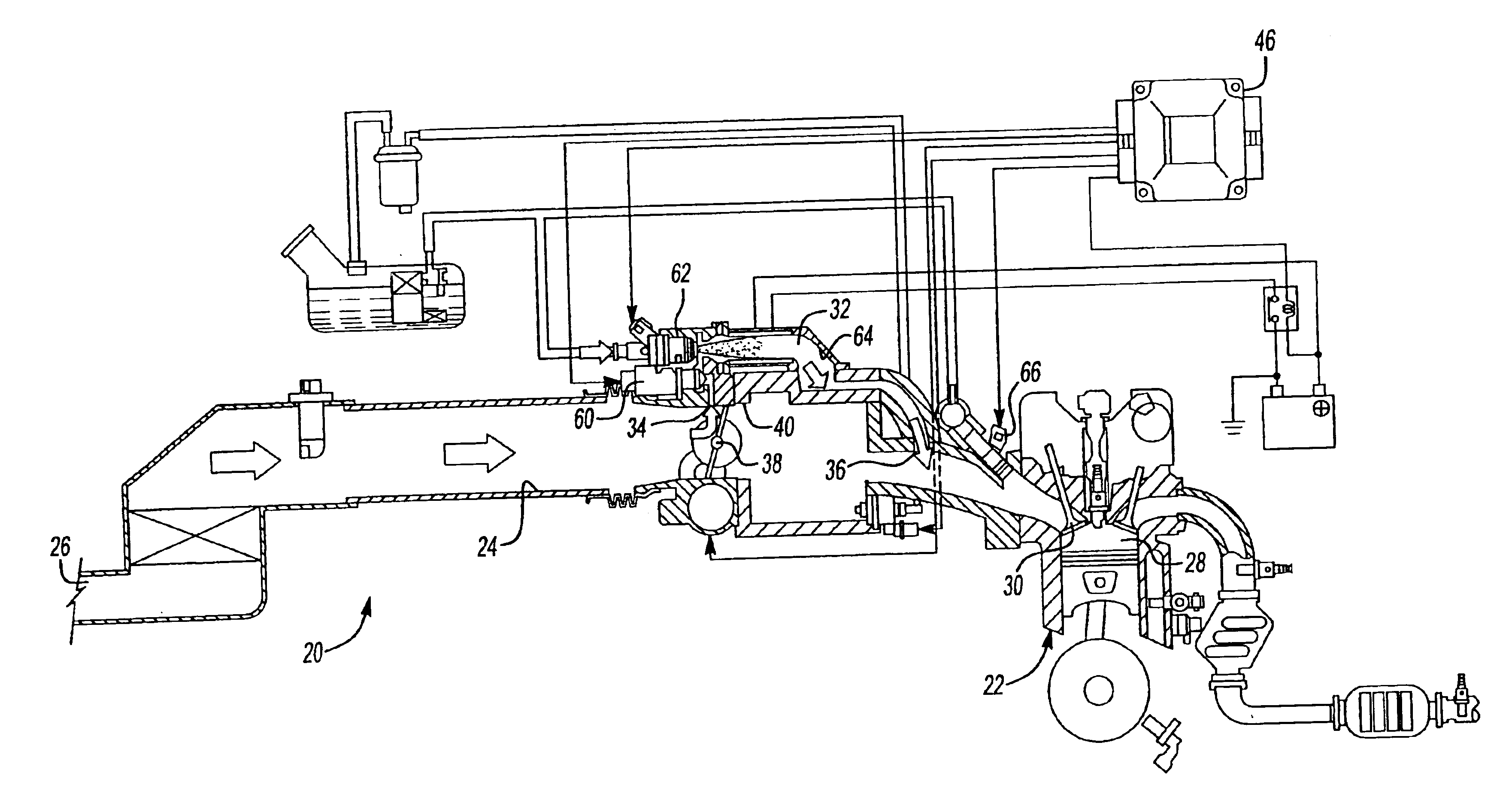

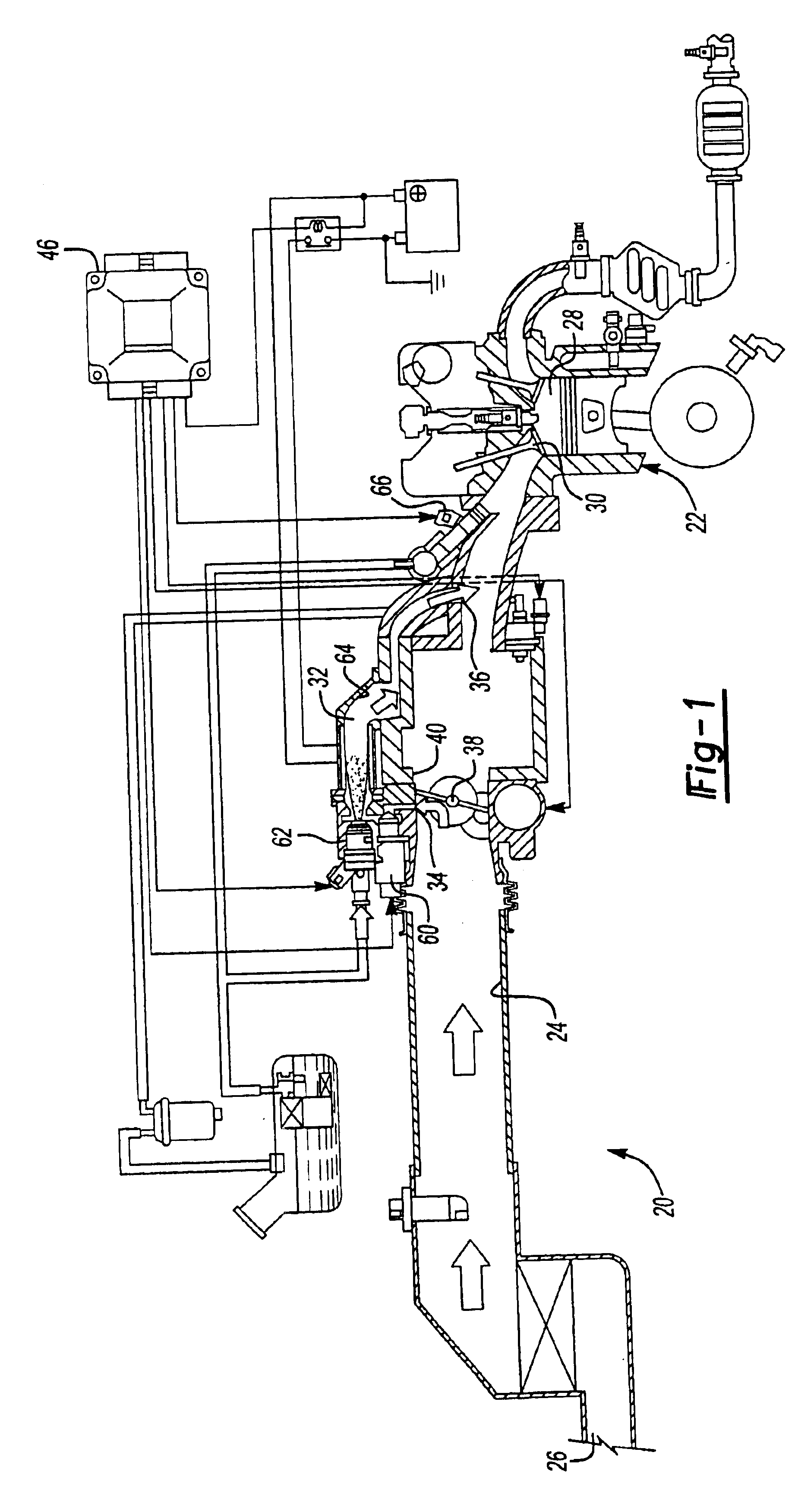

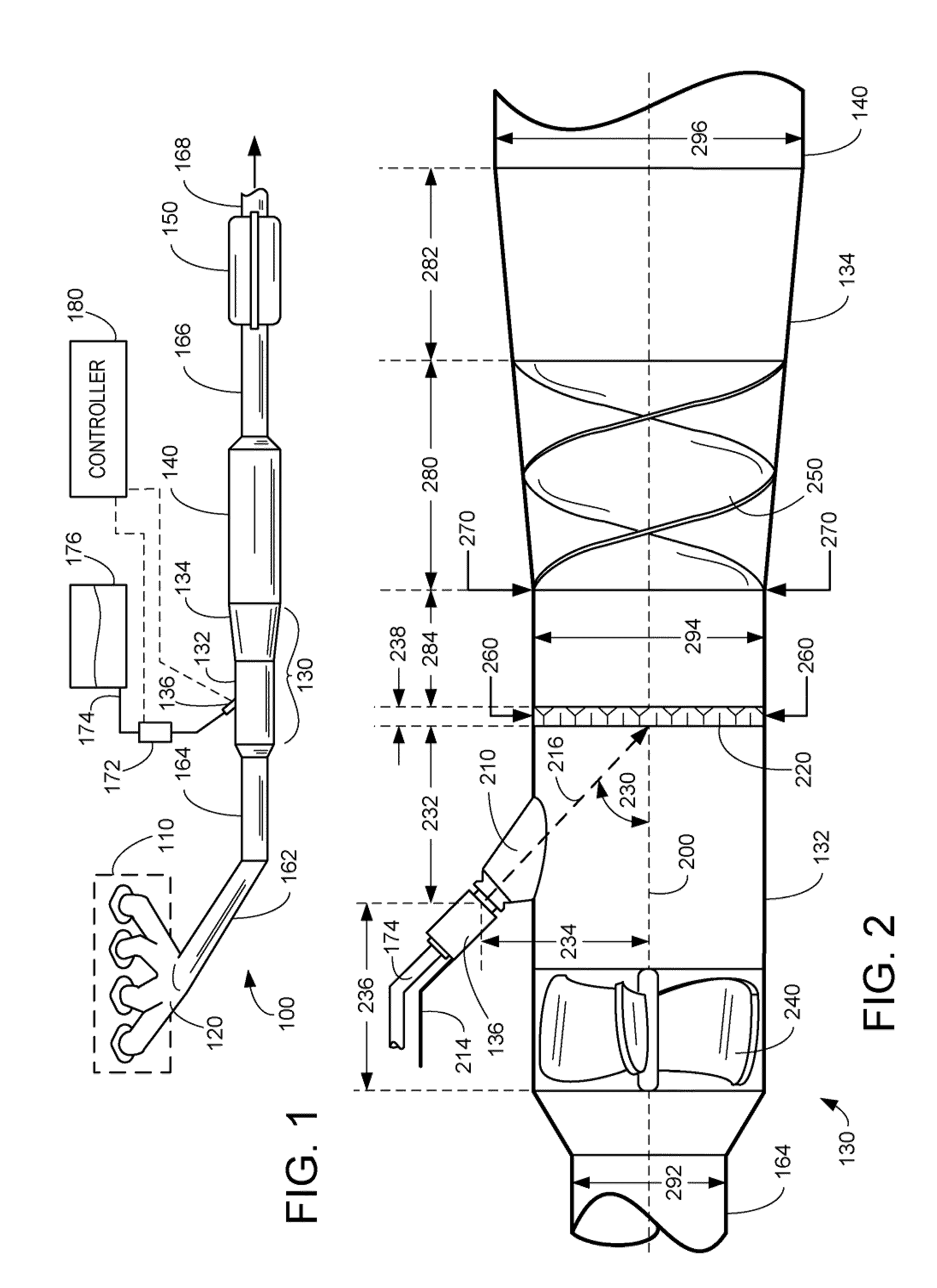

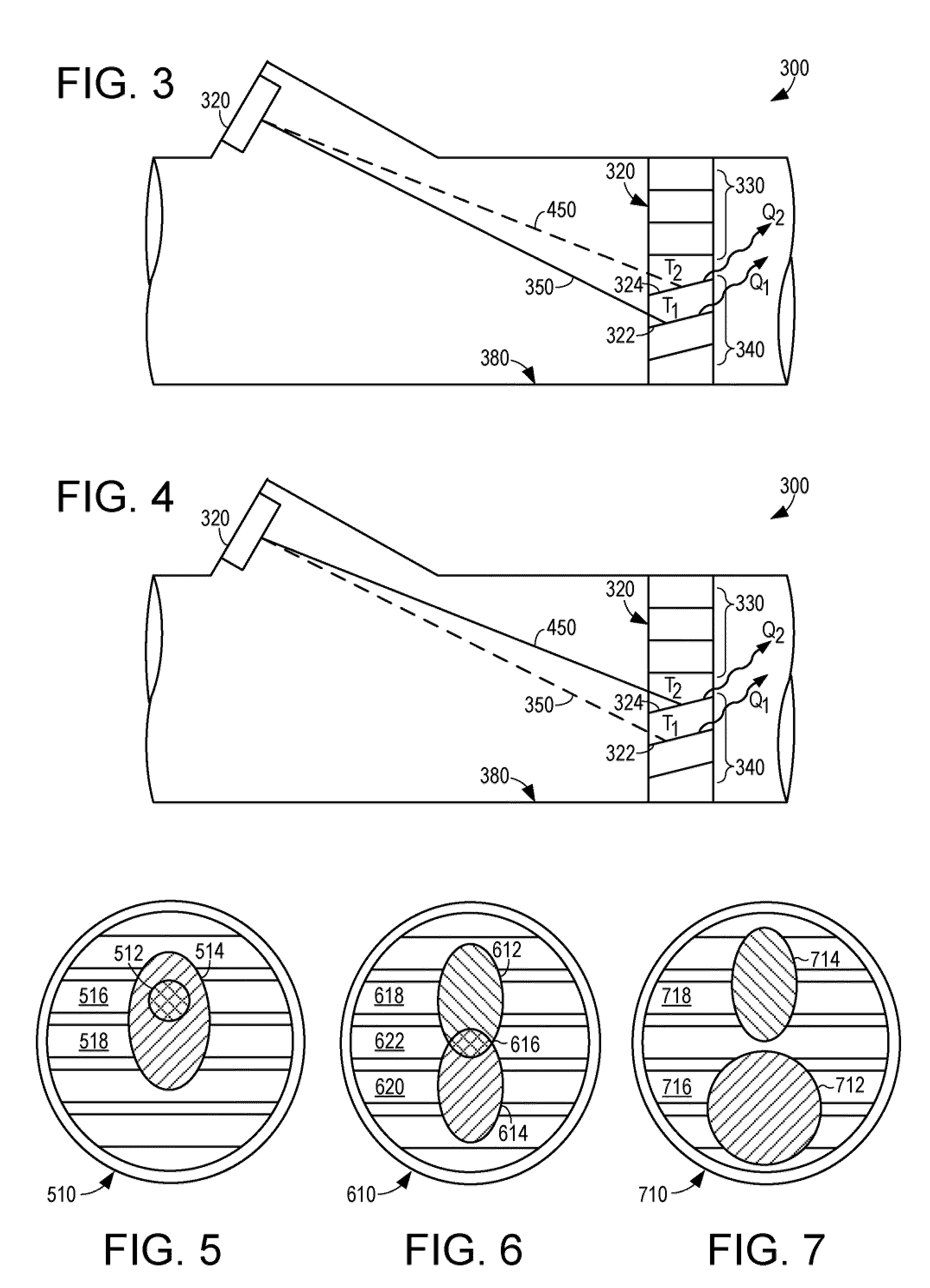

Diesel exhaust aftertreatment device regeneration system

ActiveUS7021047B2Improved vaporizationReduce the temperatureLiquid surface applicatorsInternal combustion piston enginesExhaust fumesEngineering

A diesel exhaust aftertreatment device regeneration system includes an exhaust conduit adapted to conduct exhaust gas to an exhaust gas aftertreatment device. The system further includes a low pressure bottom feed fuel injector having an inlet portion fully received within a chamber of an adaptor housing having a lower portion attached to the exhaust conduit. The housing is provided with fuel flow openings to allow low pressure fuel to circulate around and cool the fuel injector inlet portion within the chamber. Fuel injected into the exhaust conduit is preferably targeted toward a vaporization member, within the exhaust conduit, operative to absorb heat from the exhaust gas and vaporize fuel deposited thereon. A plurality of inwardly extending mixing baffles within the exhaust conduit intermediate the vaporization member and the aftertreatment device extend the mixing path to improve fuel vaporization for assisting regeneration of the device.

Owner:GM GLOBAL TECH OPERATIONS LLC

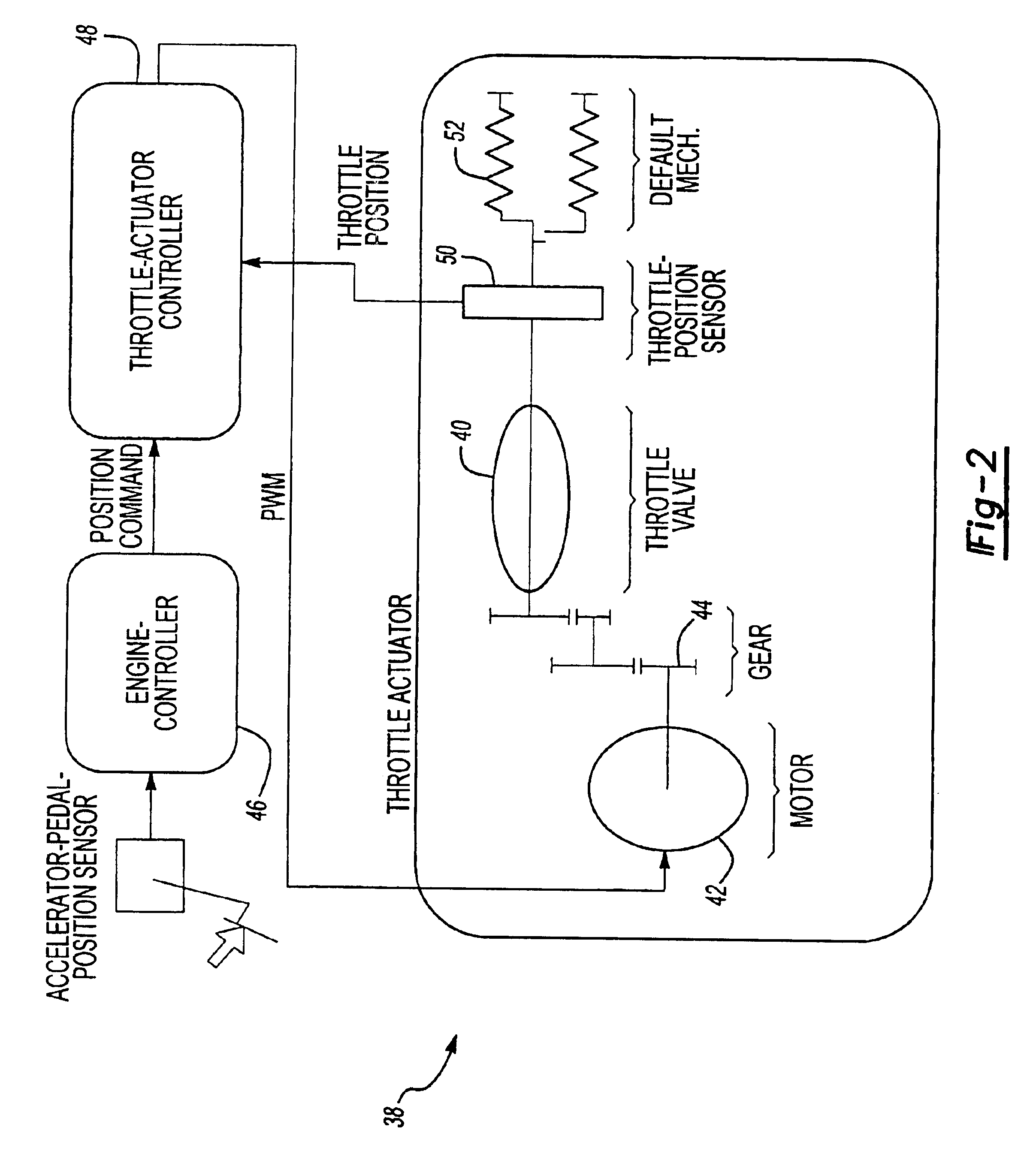

Fuel delivery system for an internal combustion engine

InactiveUS6874467B2Improved vaporizationElectrical controlNon-fuel substance addition to fuelEngine efficiencyIdle speed control

A fuel delivery system having an electronically controlled throttle valve operatively disposed in an intake manifold. An idle speed control valve is operatively disposed within a bypass gas flow passageway. A control system controls the actuation of both the throttle valve and idle speed control valve to control the delivery of a combustible charge to the internal combustion engine to maximize engine efficiency and minimize noxious emissions.

Owner:HITACHI LTD

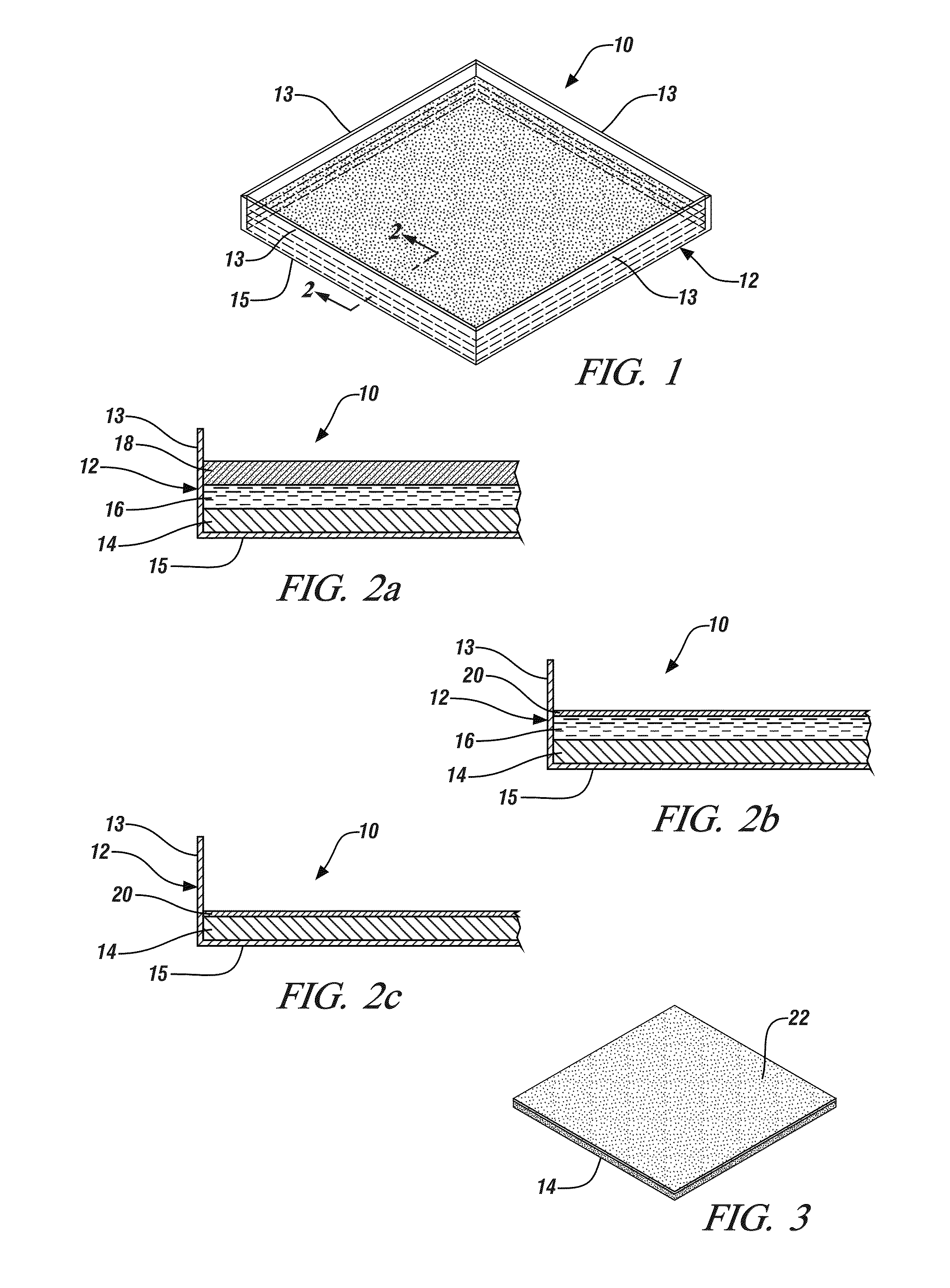

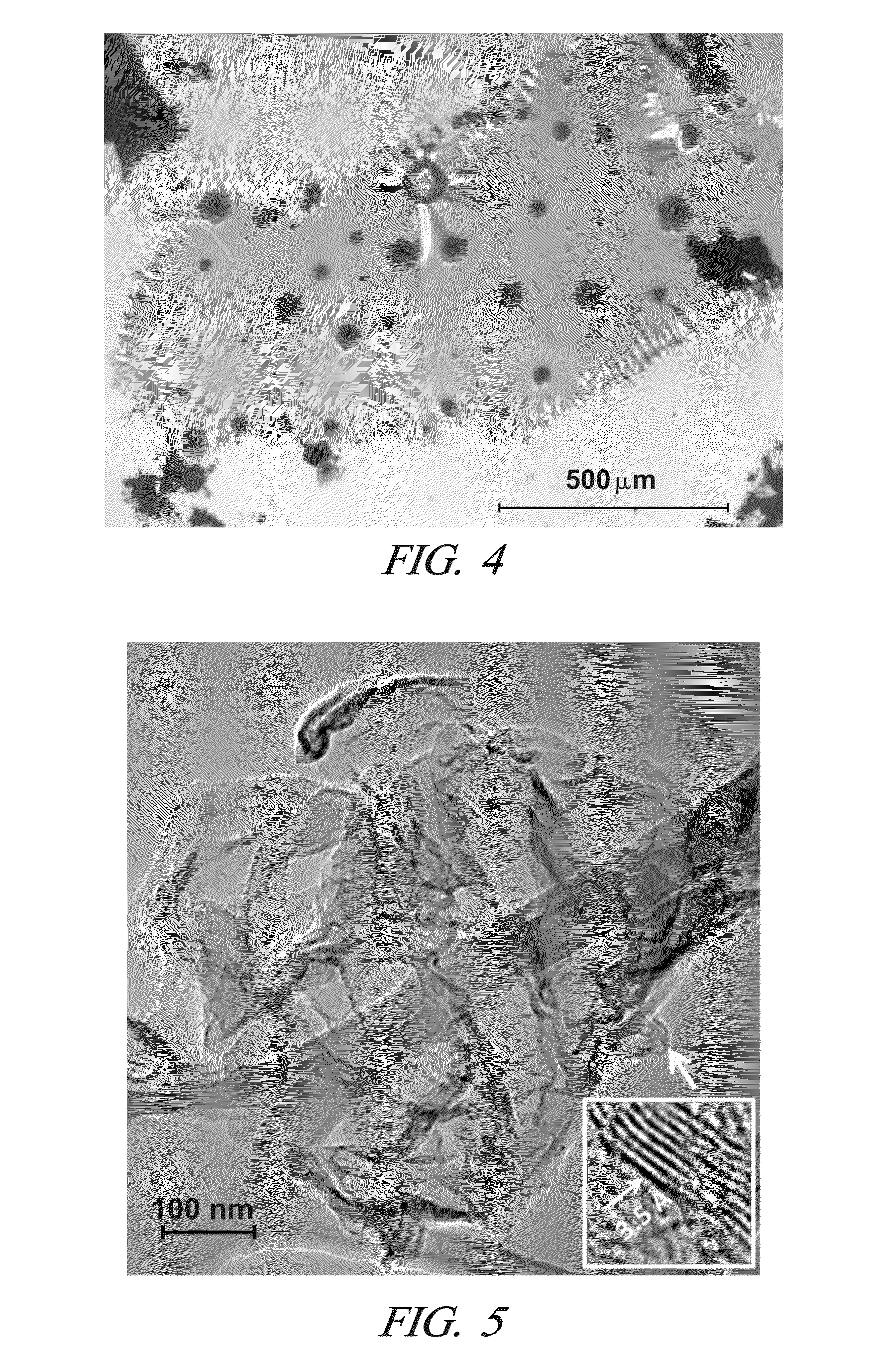

Self assembly of graphene materials

InactiveUS20130284338A1Avoid damageImproved vaporizationMaterial nanotechnologyLaminationPolycyclic aromatic hydrocarbonThin membrane

Graphene and graphene-like materials may be formed by preparing a solution of a suitable polycyclic aromatic hydrocarbon (PAH) in a solvent that is immiscible with water (or other suitable underlying liquid). A suitably thin layer of the PAH solution is formed on the surface of a thin layer of water. The solvent is evaporated from the solution layer to form a film of PAH material organized in contiguous molecular discs. The organized PAH material may be further processed by careful removal or evaporation of the water layer to deposit the PAH residue on a desired surface. The PAH residue may then be heated to remove hydrogen atoms and form a carbon-enriched or wholly carbon, graphene structure.

Owner:GM GLOBAL TECH OPERATIONS LLC

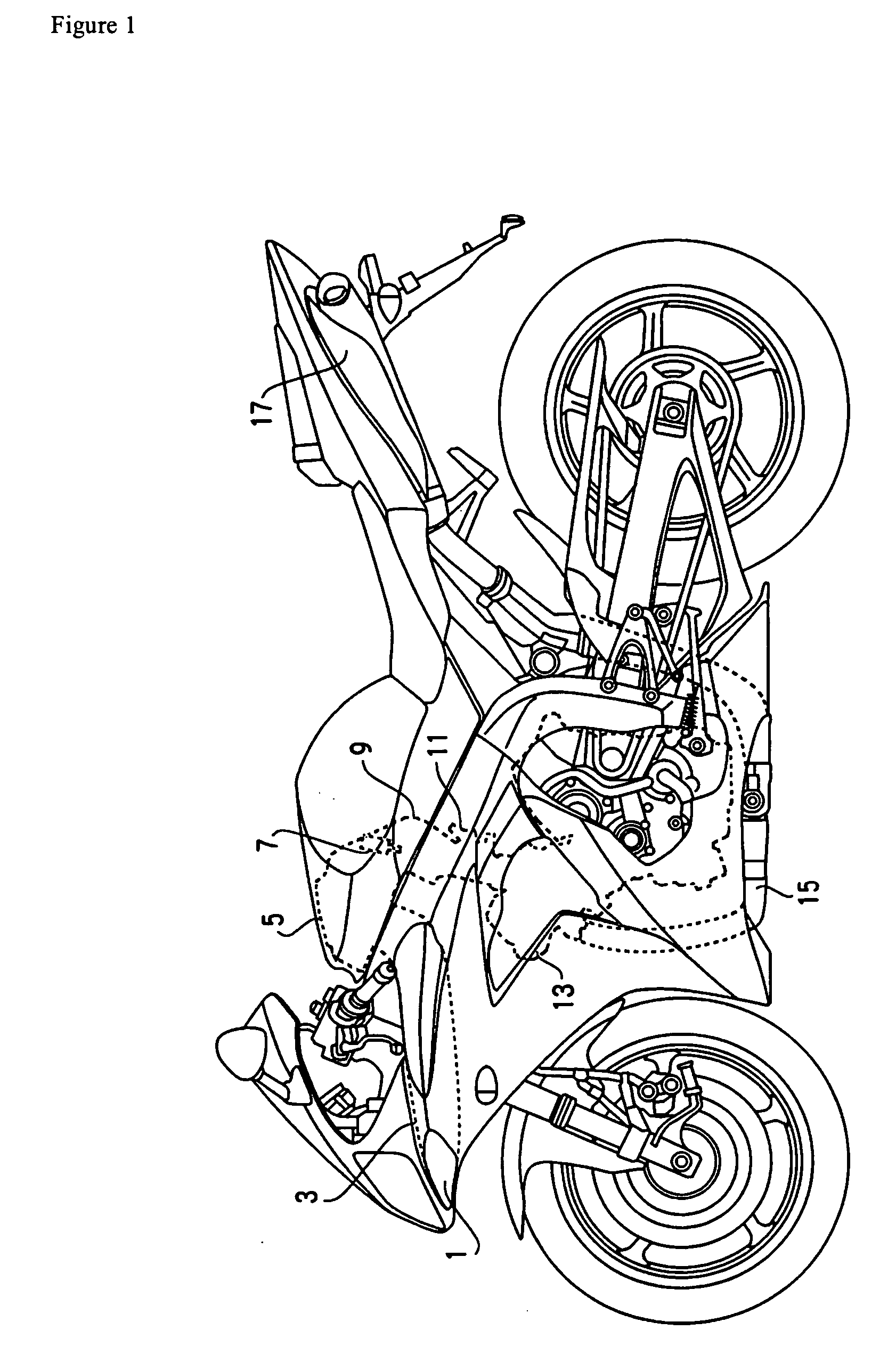

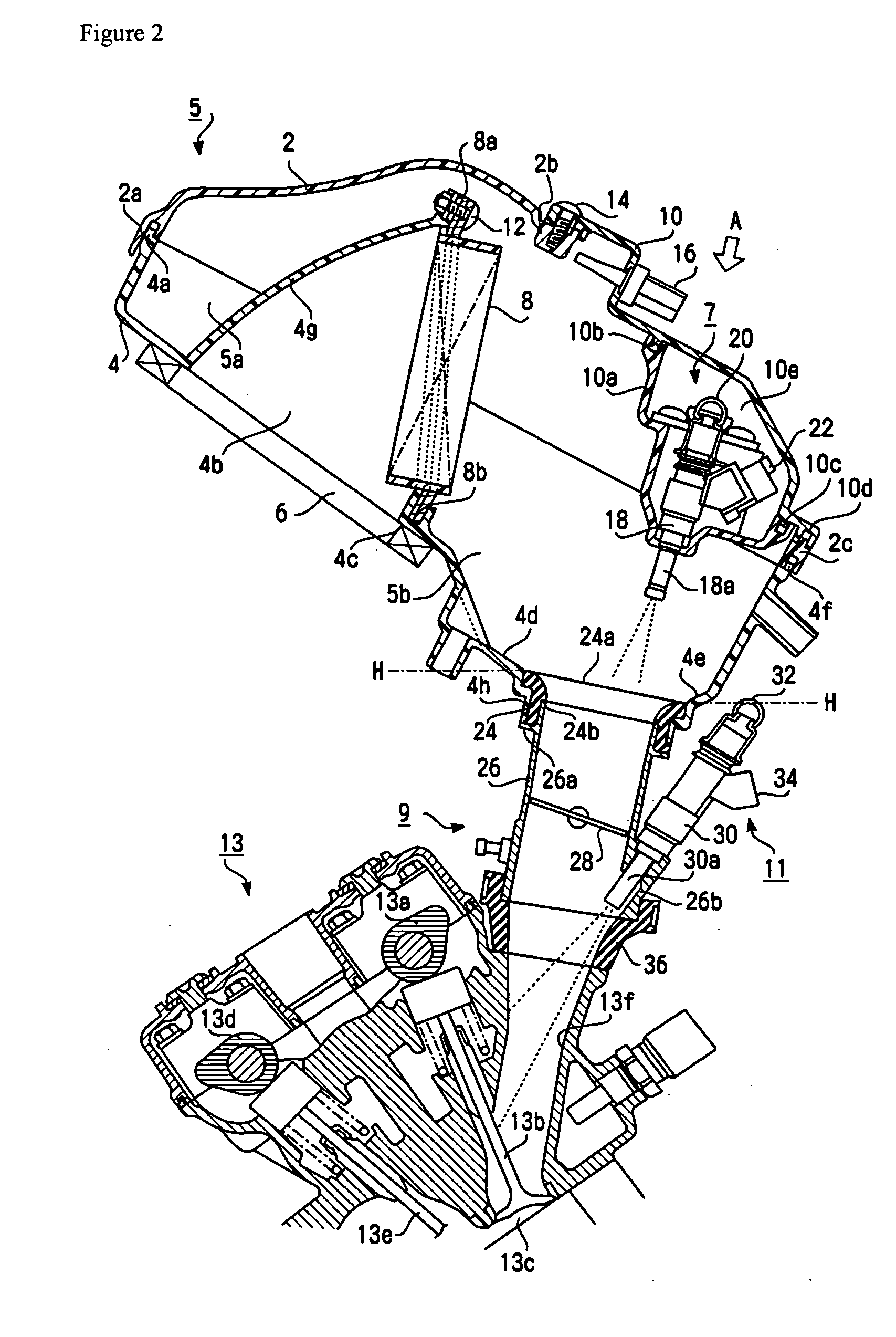

Fuel supply system and vehicle

ActiveUS20050205067A1Good fuel atomizationImprove engine performanceLow-pressure fuel injectionMachines/enginesFuel supplyInjector

A fuel supply system has an air chamber that contains a fuel injector. At least one aperture is formed in a substantially lowermost portion of a lower surface of the air chamber. The aperture and the lower surface have a generally uninterrupted or smooth transition or interface.

Owner:YAMAHA MOTOR CO LTD

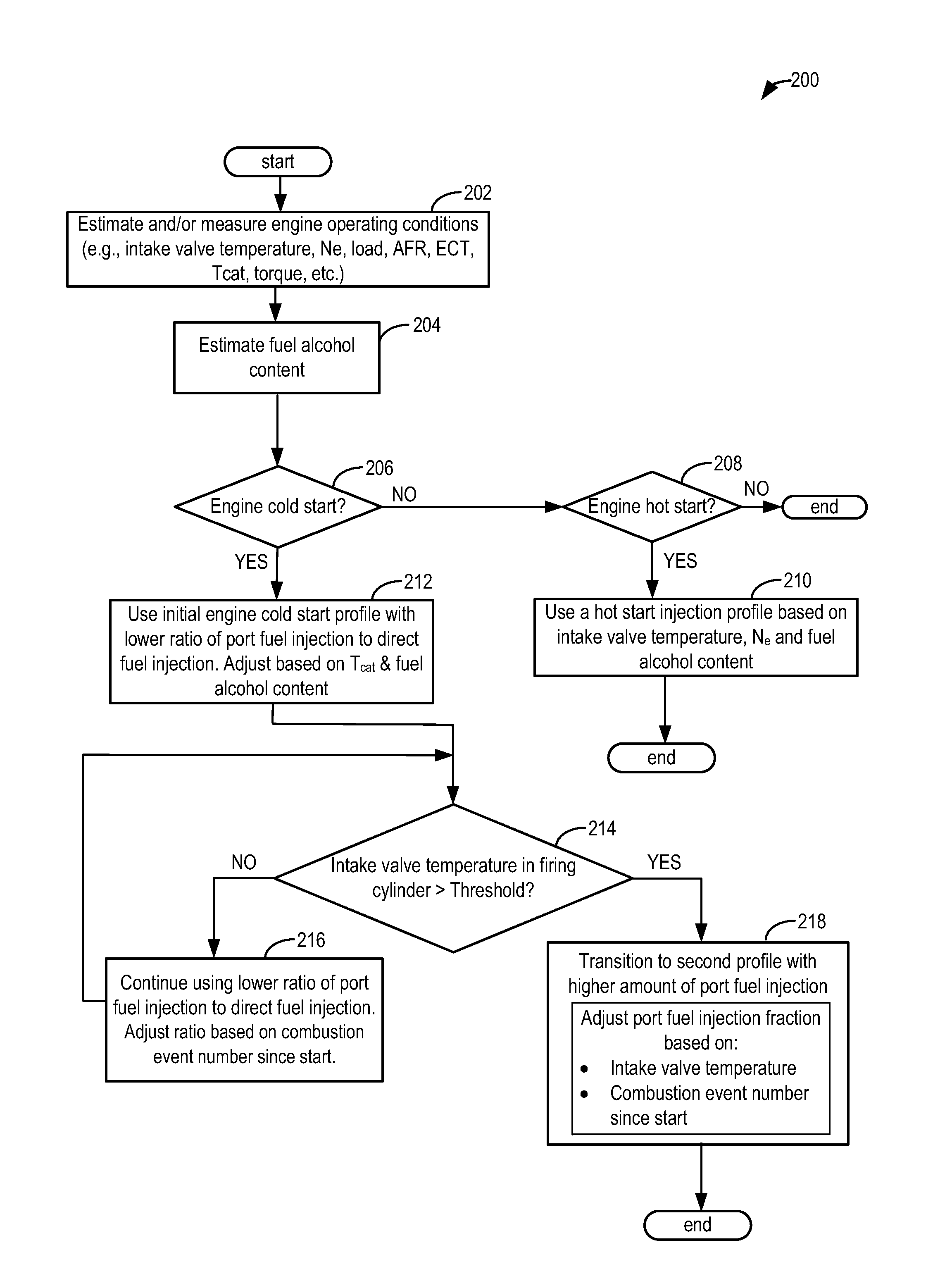

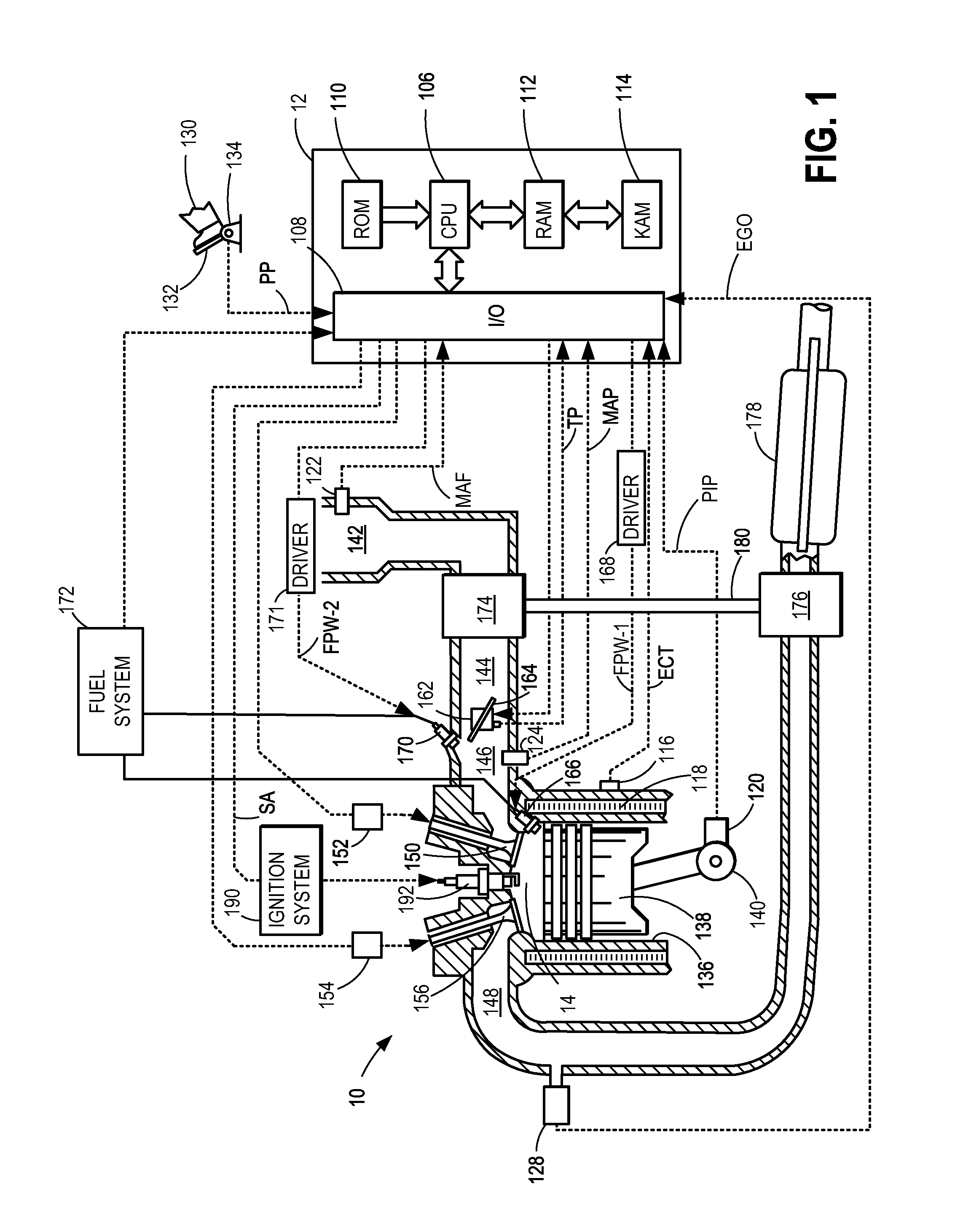

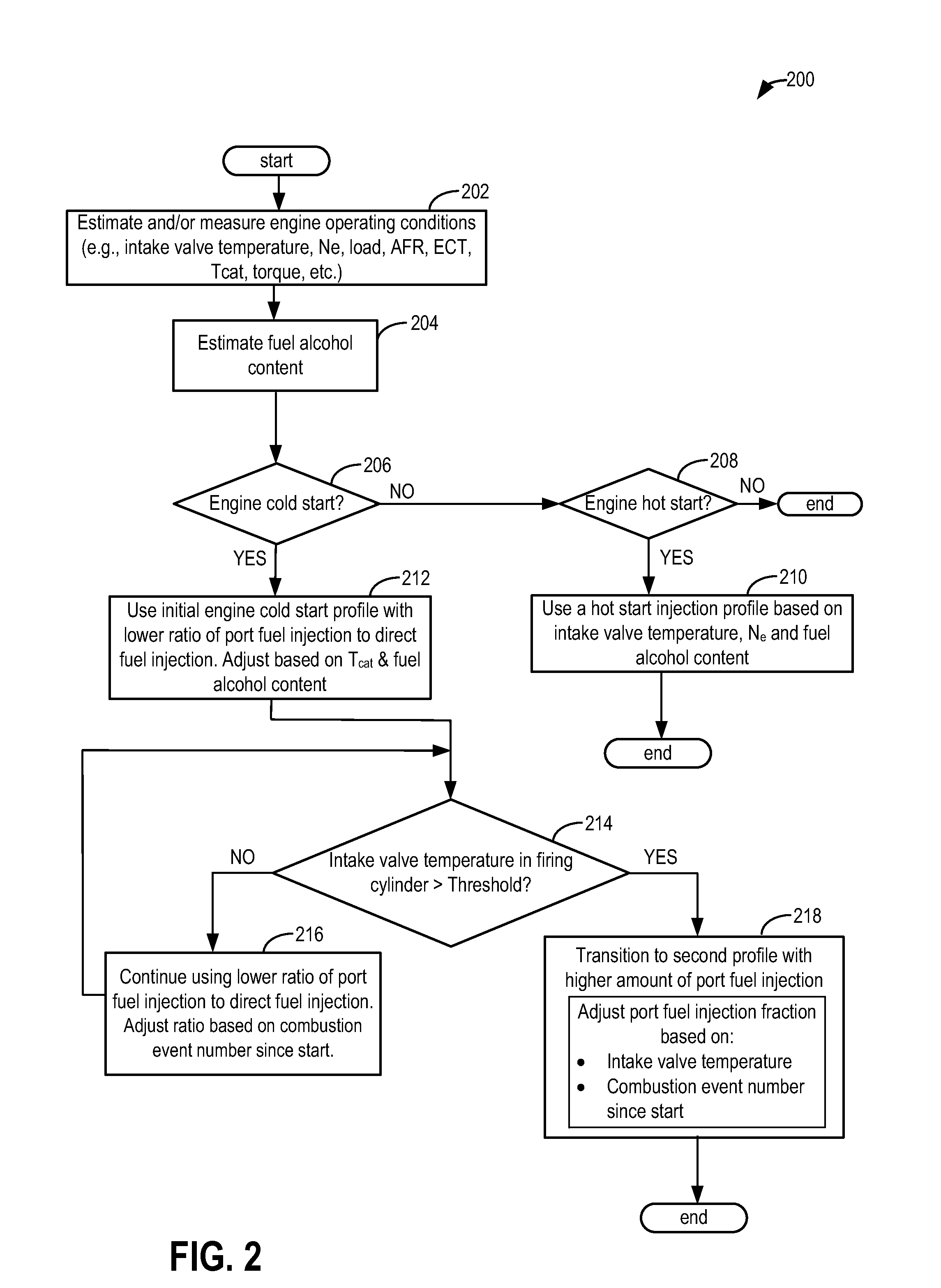

Method for fuel injection control

ActiveUS20150240737A1Improve fuel efficiencyDischarge cleaningElectrical controlInternal combustion piston enginesInlet valveVaporization

Methods and systems are described for controlling fuel injection in an engine equipped with a dual injector system including a port injector and a direct injector. A ratio of port injected fuel to direct injected fuel is adjusted based at least on intake valve temperature. The proportion of fuel port injected into a cylinder is increased as the intake valve temperature for the given cylinder increases to improve fuel vaporization in the intake port.

Owner:FORD GLOBAL TECH LLC

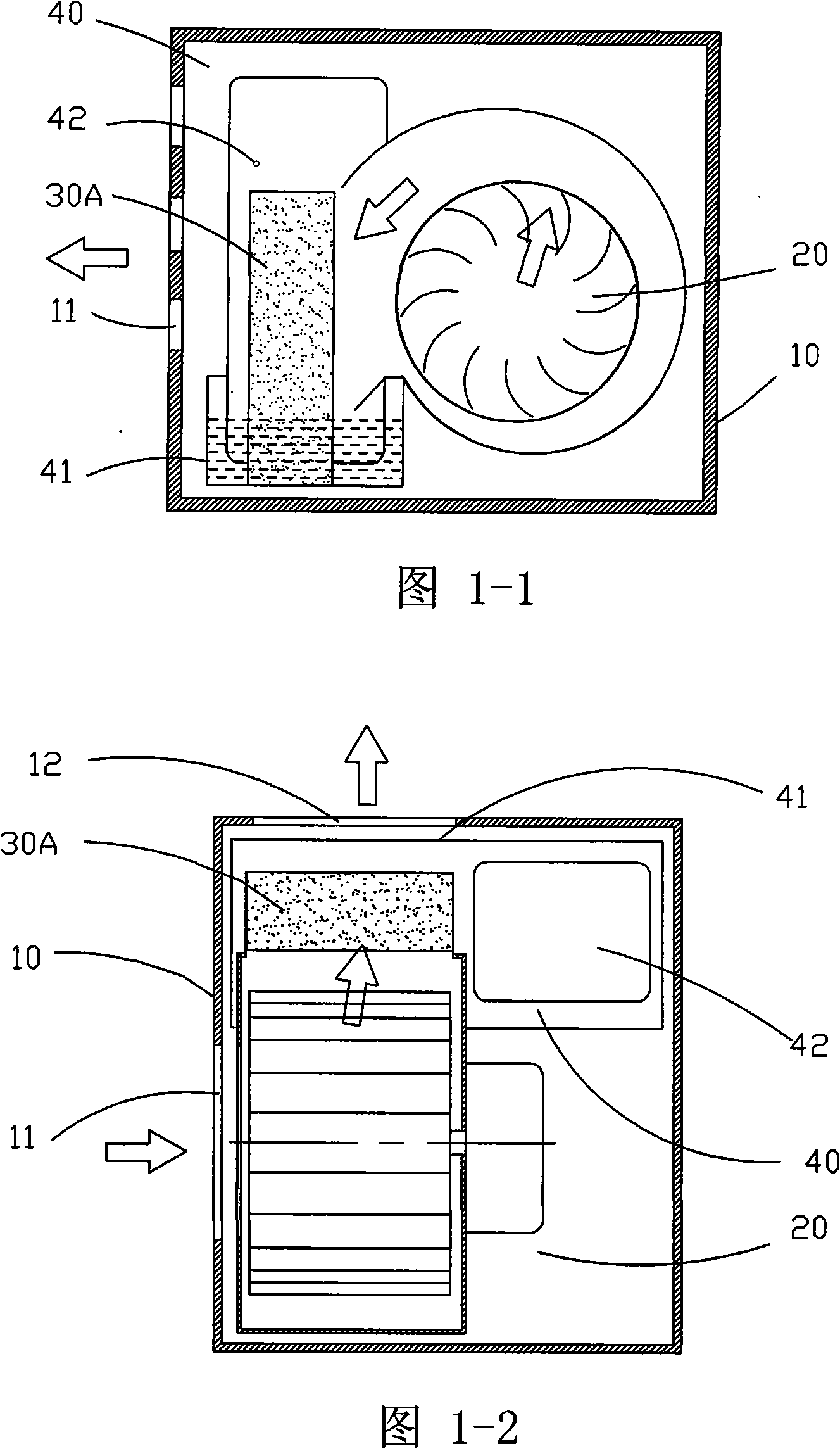

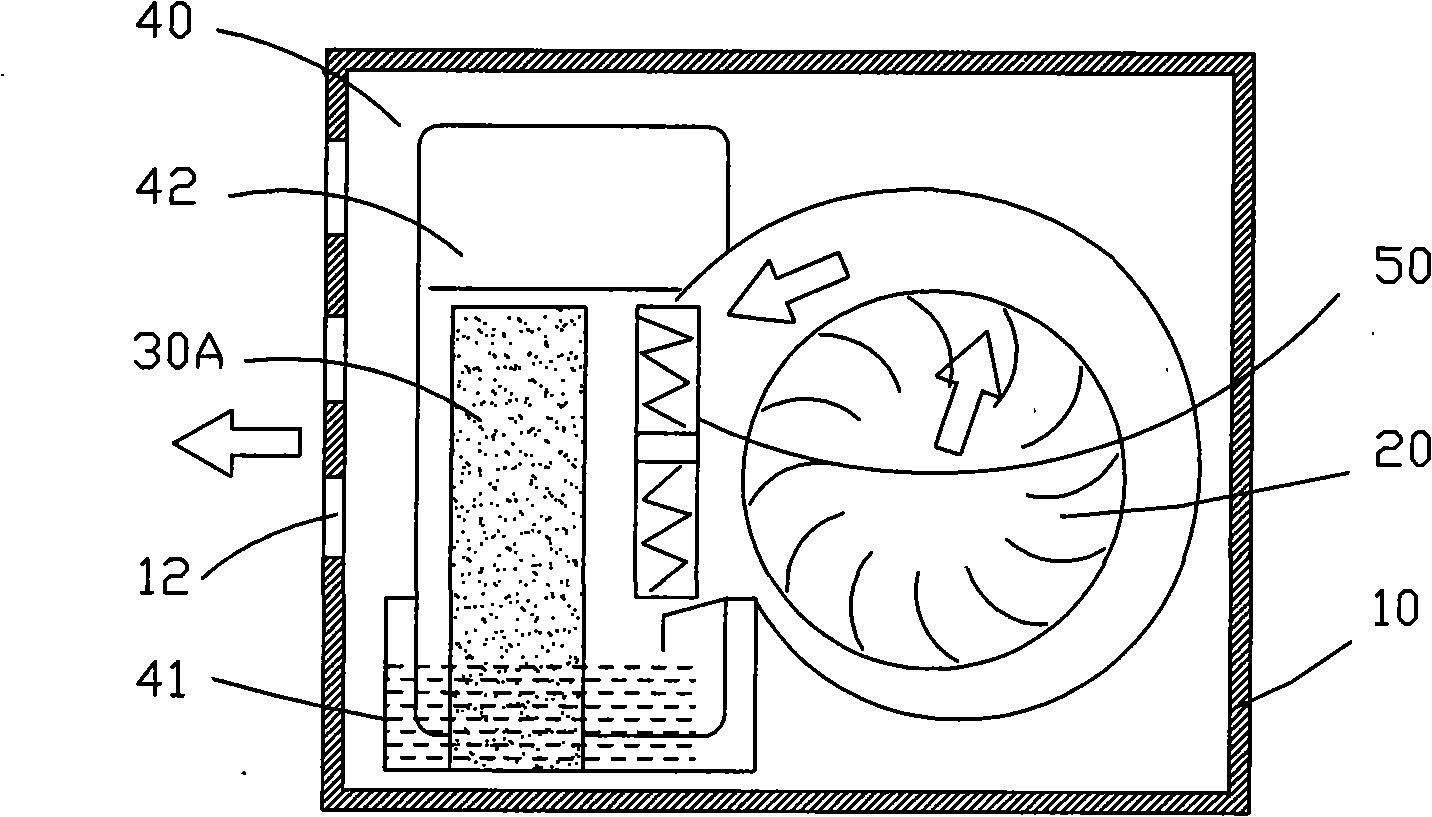

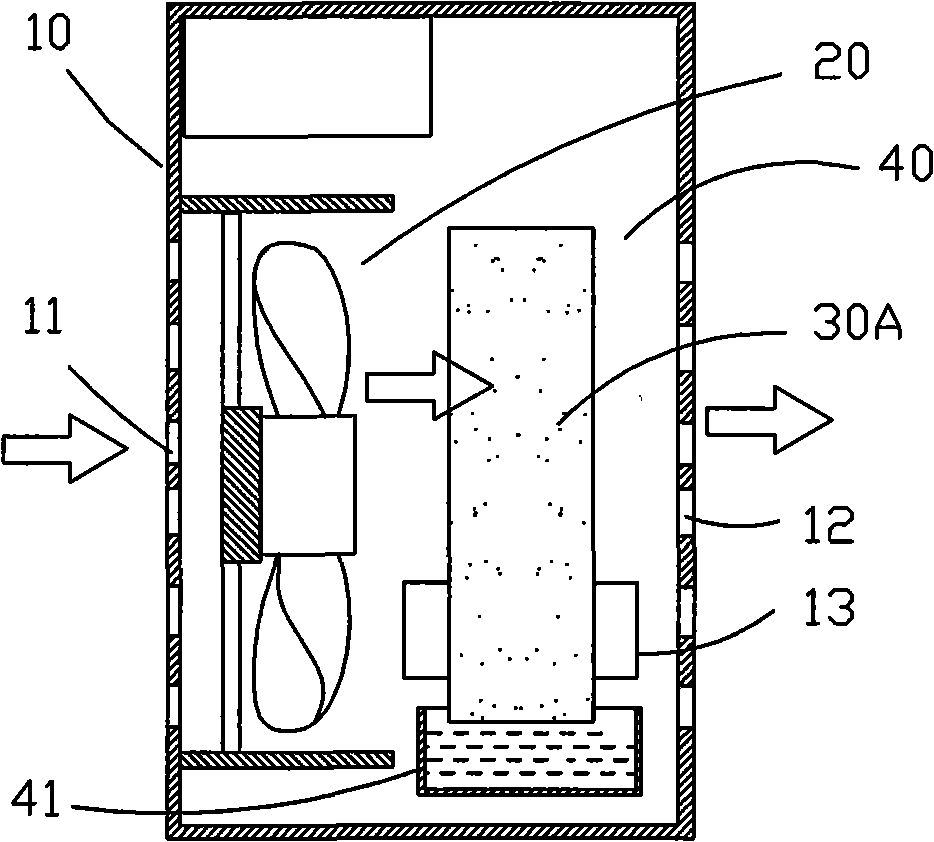

Method for using porous ceramic on air humidification and air conditioning unit

ActiveCN101493253AImproved vaporizationIncrease surface areaLighting and heating apparatusDeodrantsRoom temperatureLife time

The invention relates to a method for applying porous ceramics to air humidification and an air conditioning device; in a vaporizing air humidification device based on normal temperature, flowing air blows over humidifying carrier used for absorbing moisture to vaporize the moisture on the surface thereof to water vapour into air, so as to improve air humidity; in the invention, the open-cell porous ceramics body is taken as the humidifying carrier; the open-cell porous ceramics body is high temperature resistant and has long service life, thereby lowering cost of the air humidification device. The invention also relates to an air conditioning device adopting the method; namely the open-cell porous ceramics body is taken as the humidifying carrier; as the porous ceramics body is high temperature resistant, manufacturing the air conditioning device with sole humidification function, sole heating function and both the humidification function and the heating function is feasible, and the method of vaporizing high-temperature air into water greatly improves humidification amount, saves electric power and has considerable popularization and application value.

Owner:SHENZHEN LIANCHUANG TECHNOLOGY GROUP CO LTD

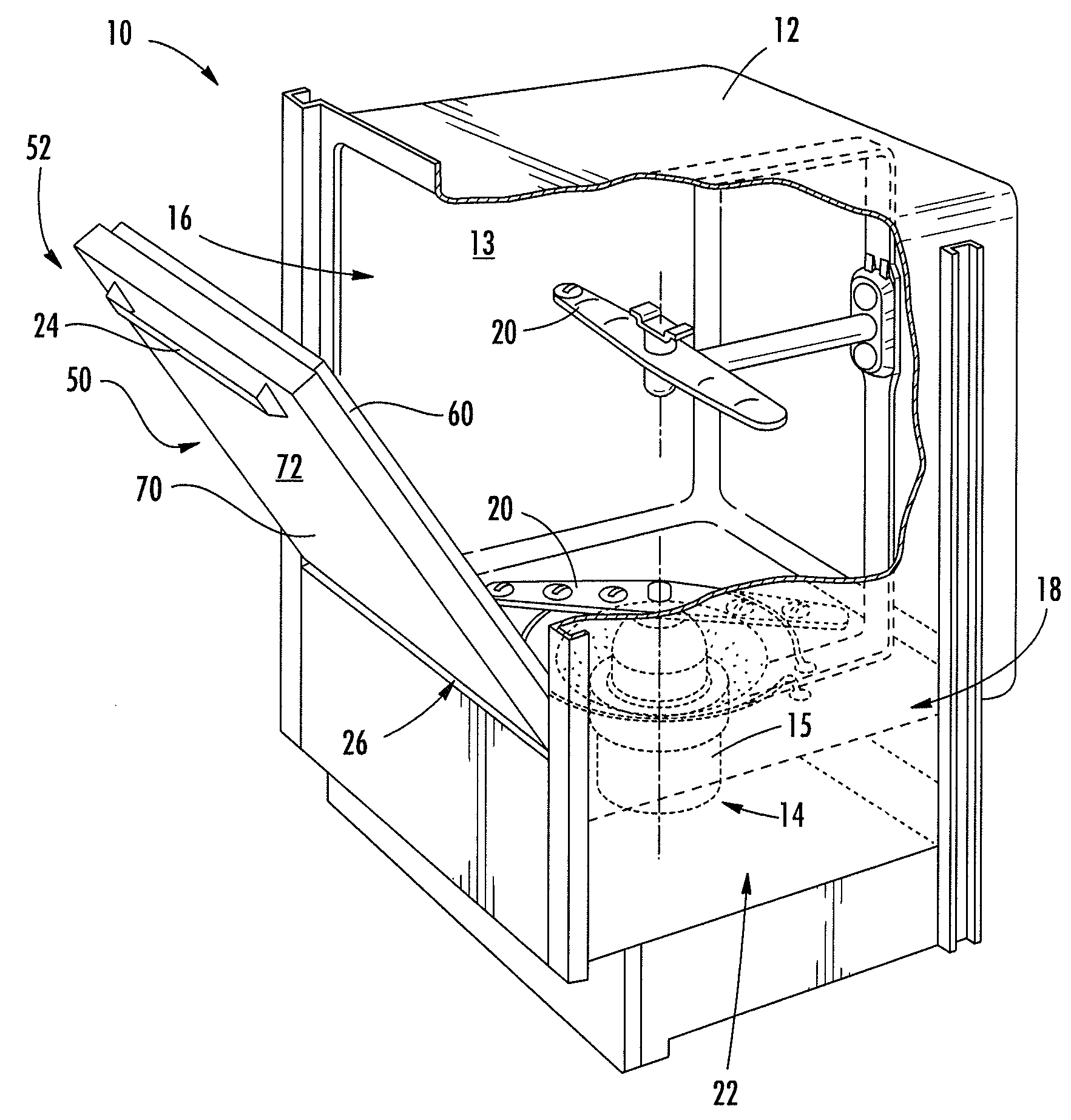

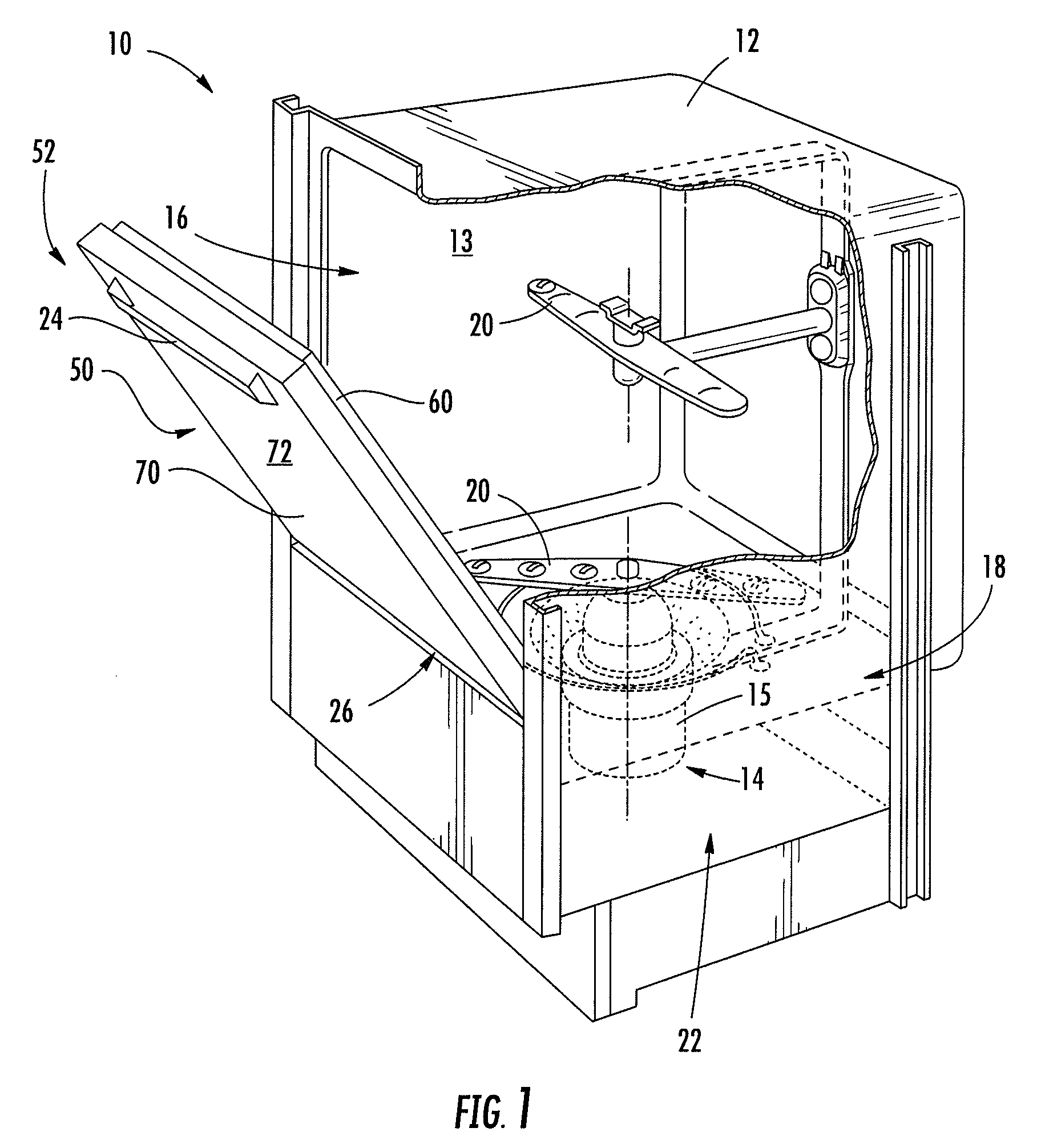

Dishwasher, a door assembly for the dishwasher, and an associated method for drying dishware

InactiveUS20100192977A1Improved vaporizationTableware washing/rinsing machine detailsAutomatic washing/rinsing machine detectionTurbidityEngineering

A dishwasher, a door assembly for the dishwasher and a method of drying the dishware in the dishwasher are provided. The dishwasher may include a sensor configured to measure the turbidity of the water in the dishwasher which is used to determine a wash load size. A control unit of the dishwasher may determine and control cycle times, temperatures, heating elements and a blower of the dishwasher based on the wash load size. The dishwasher may include a humidity level determination that may also be used by the control unit to control the operations of the dishwasher. The door assembly may include a duct configured to receive moisture-laden air creating during the drying cycle and encourage the condensation of the water from the air such that the water may be redirected back to the tub portion of the dishwasher and the dry air may be directed out of the dishwasher.

Owner:ELECTROLUX HOME PROD CORP NV

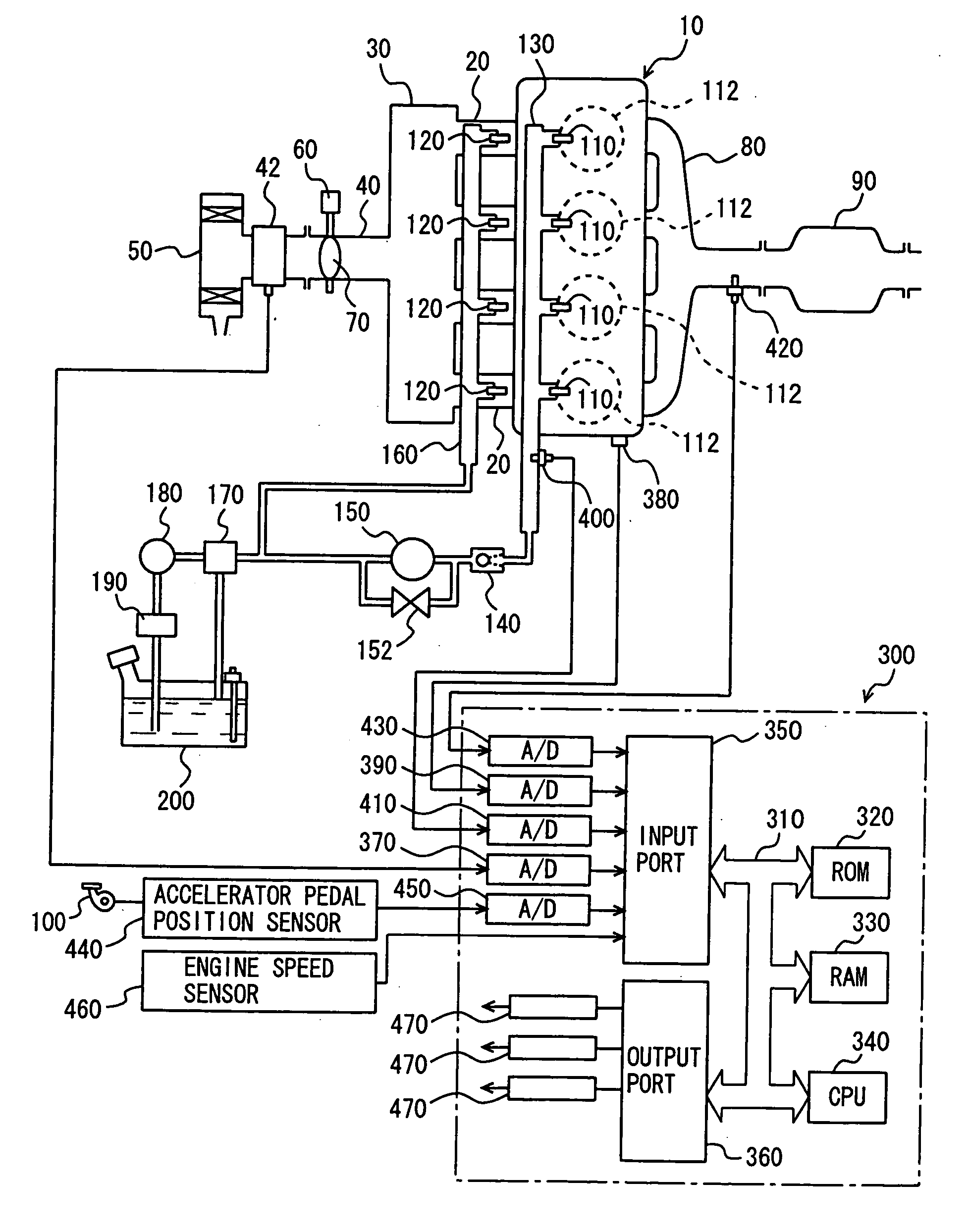

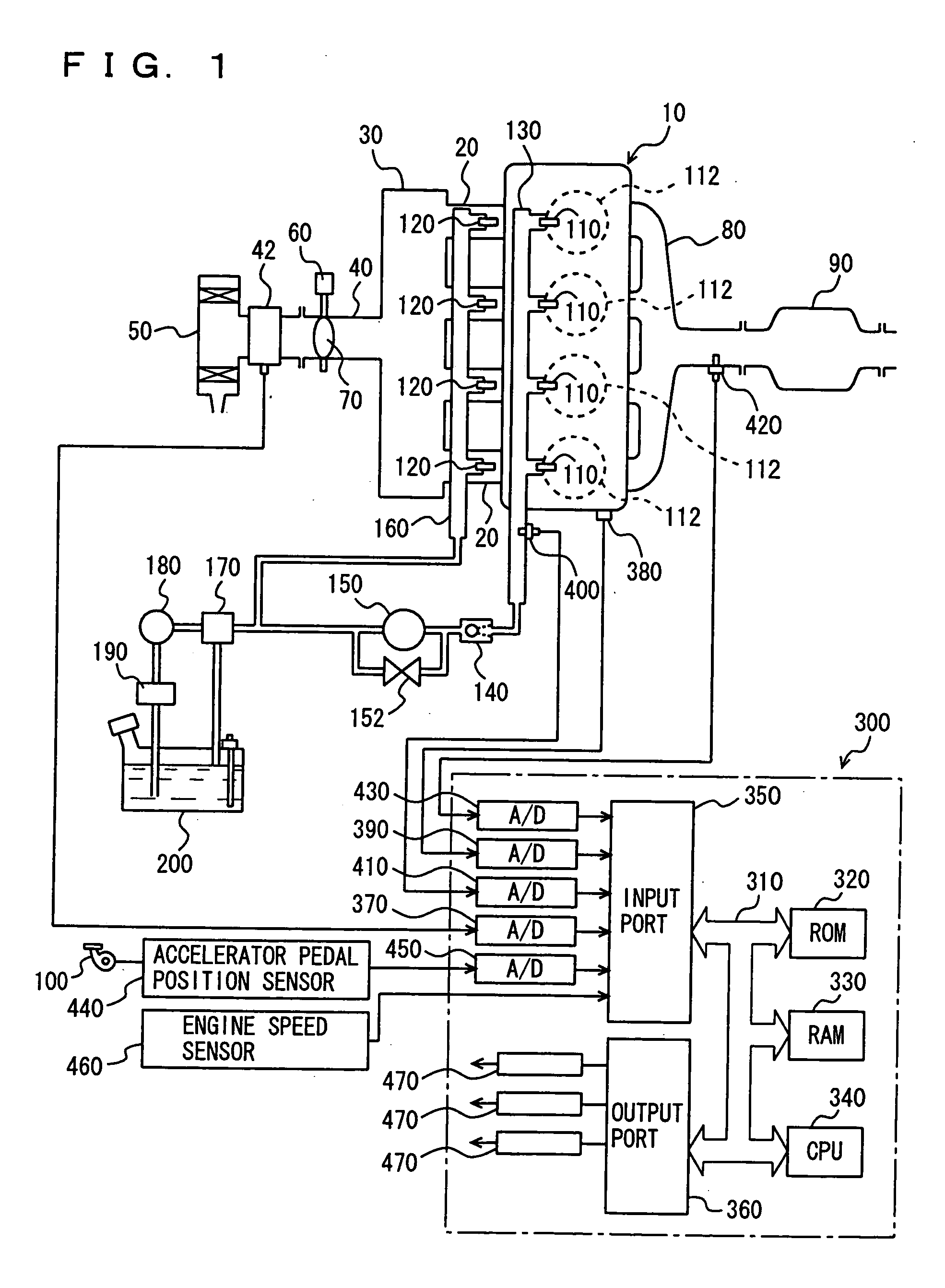

Control apparatus for internal combustion engine

InactiveUS20060207556A1Avoid it happening againImproved vaporizationElectrical controlCombustion enginesCoolant temperatureInlet manifold

An engine ECU executes a program including a step of sensing a coolant temperature TW of an engine, if a start request of the engine is sensed, a step of causing only an intake manifold injector to inject fuel to start engine 10, if coolant temperature TW is lower than a threshold value TW(0), and a step of causing only an in-cylinder injector to inject fuel to start engine 10, if coolant temperature TW is higher than threshold value TW(0).

Owner:TOYOTA JIDOSHA KK

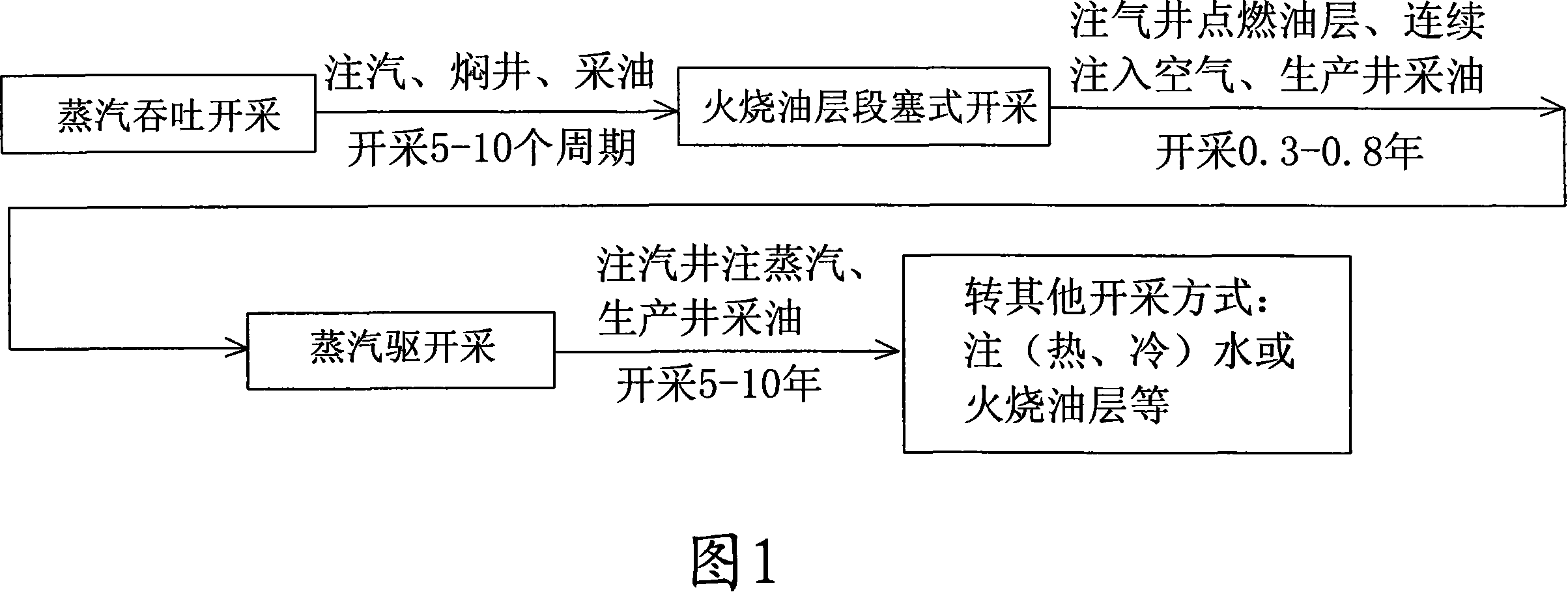

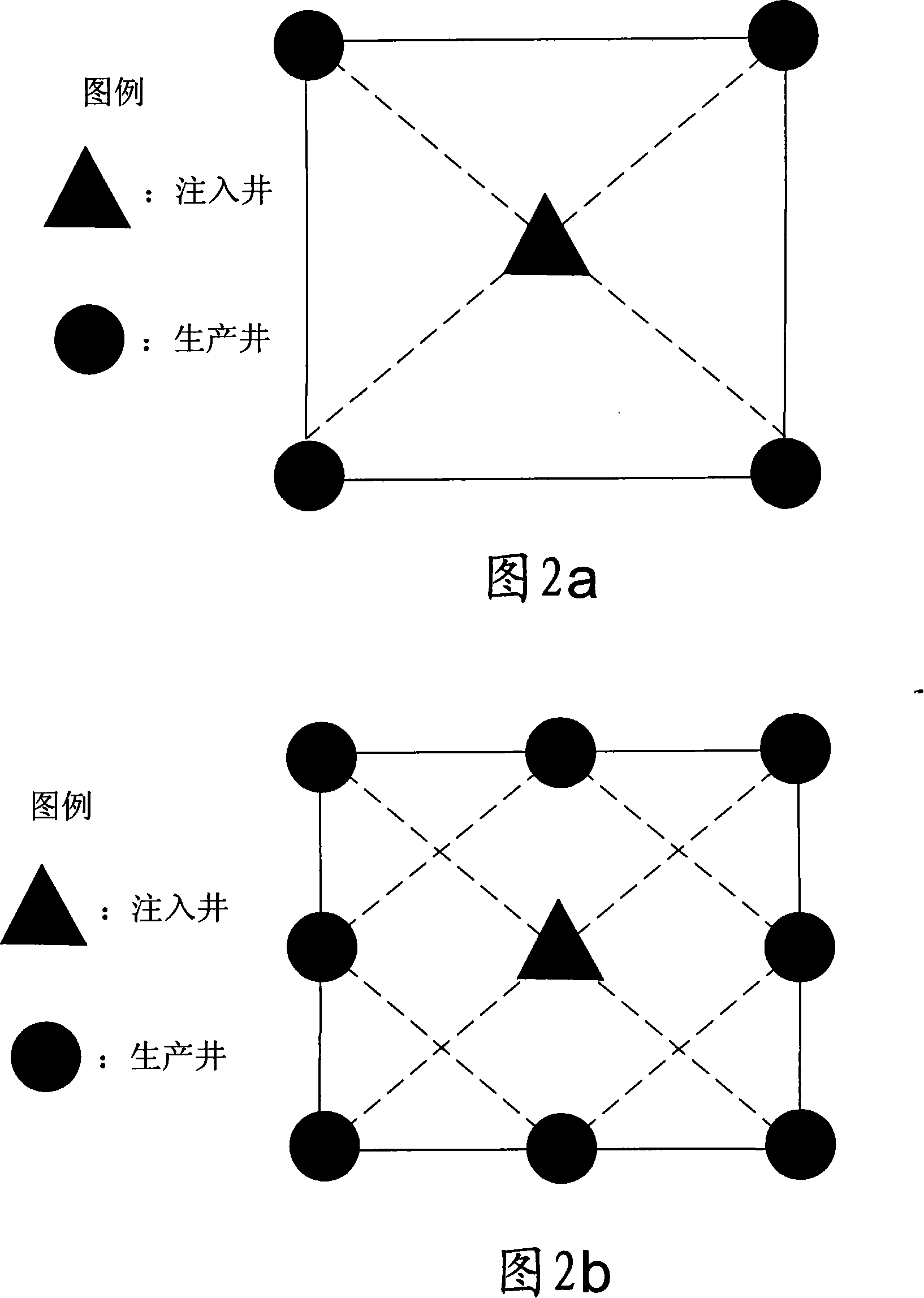

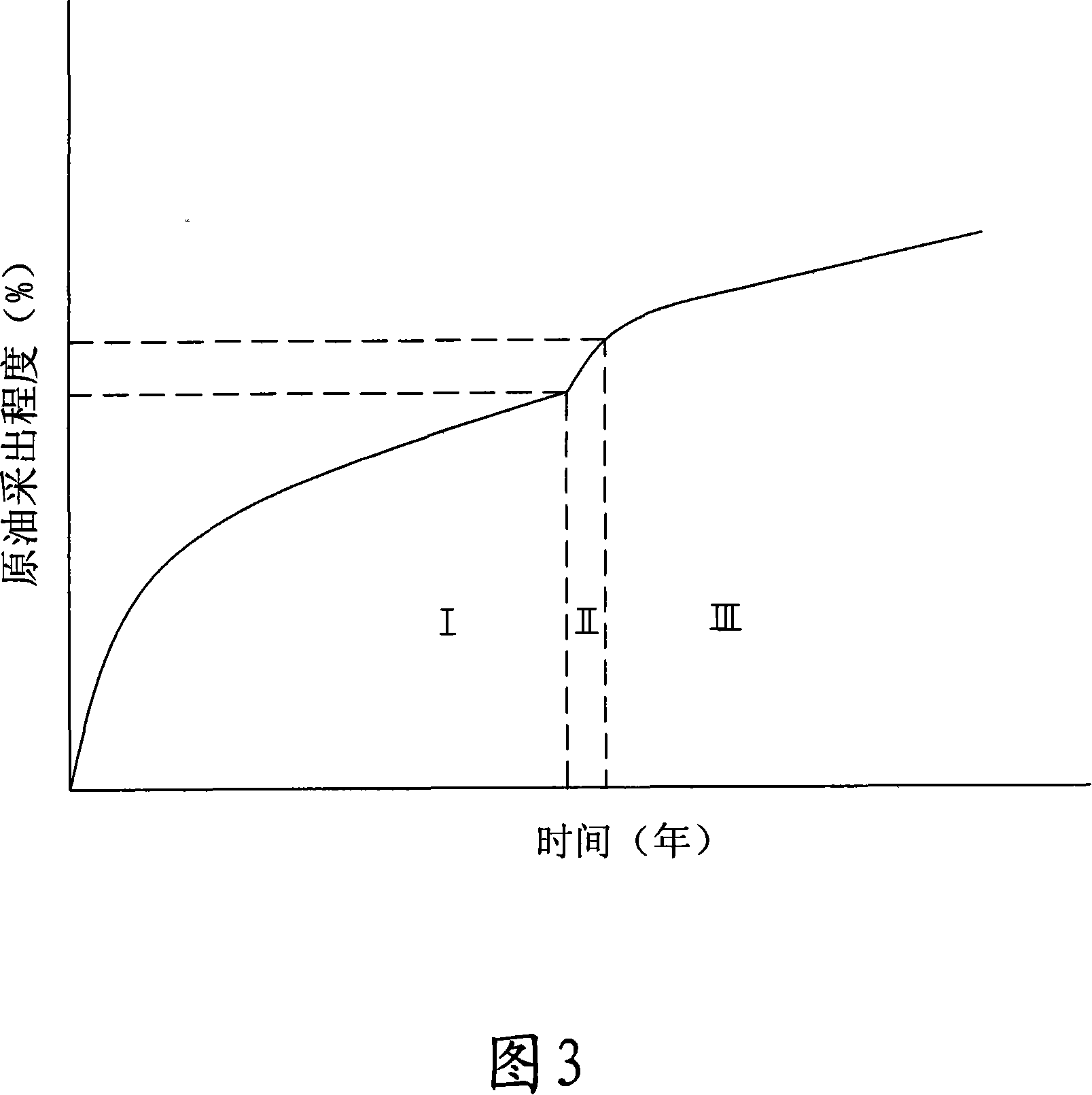

In situ combustion slug and steam driving combined type crude oil producing method

The invention discloses a method of oil pumping which adopts the combination of fire oil layer slug and steam drive and is applicable for the pumping of thick oil reservoir. After the steam soaking of the thick oil reservoir and before the pumping of the steam drive, the fire oil layer slug type pumping is performed; an ignition technology is adopted to ignite the oil layer to burn; an air compressor is used to inject air into the oil layer continuously from a center injection well; after 0.3 to 0.8 years of pumping, steam is injected into the oil layer through an injection well, and the steam drive type pumping is performed. The invention can generate the high temperature of 400 to 800 DEG C in the burning zone of the fire oil layer slug, which is in favor of the water stored in an individual well after the steam soaking to be vaporized as high-dryness steam; the temperature of the bottom of the injection well, and the dryness of the steam injected by the following steam drive are improved; the strata pressure is improved; larger producing pressure differential is achieved, which is in favor of improving the lifting rate of the oil well; moreover, the invention is in favor of shortening the low-production period at the beginning period of the steam drive and improving the developing effects of the steam drive and the recovery ratio of crude oil.

Owner:富象油气技术服务有限公司

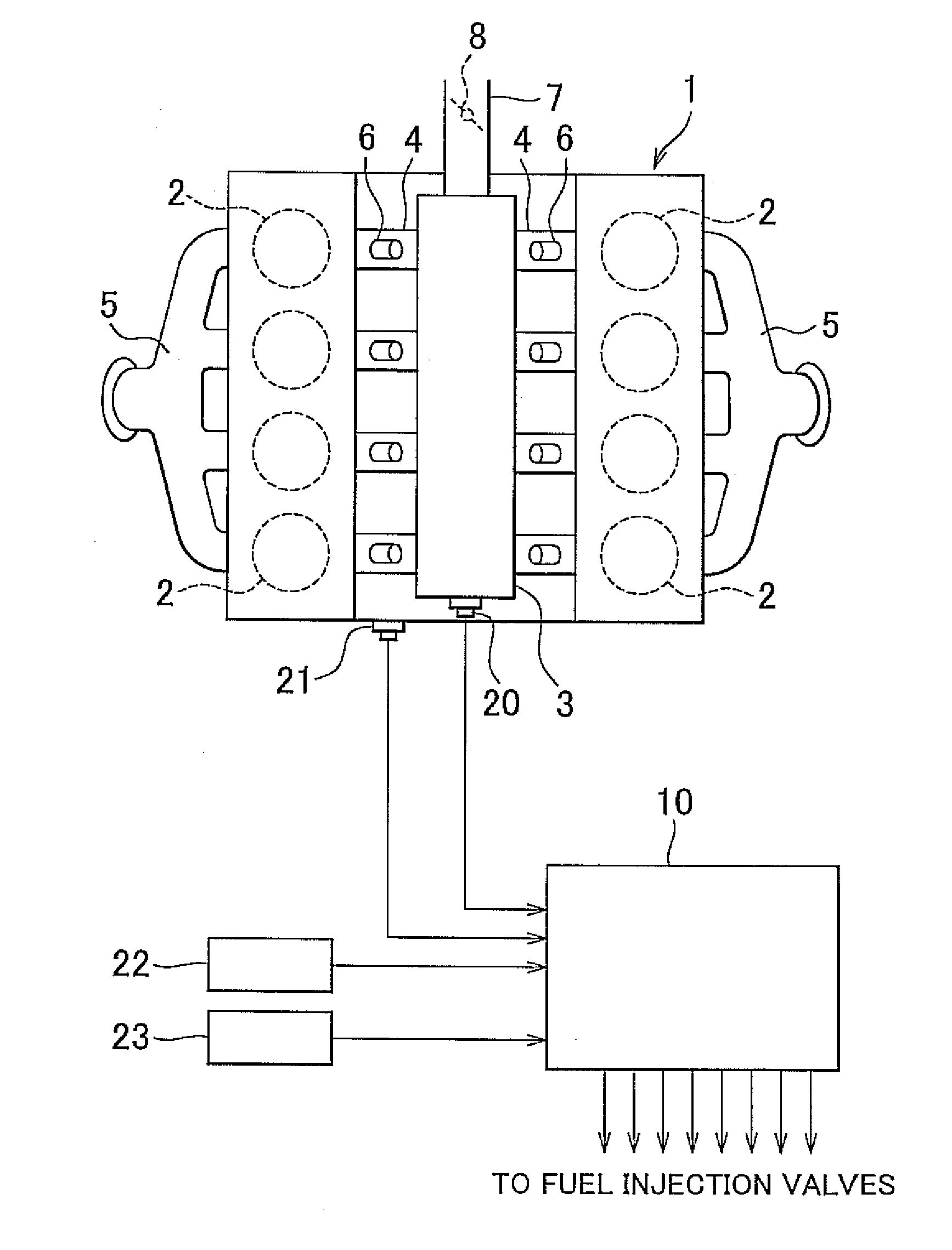

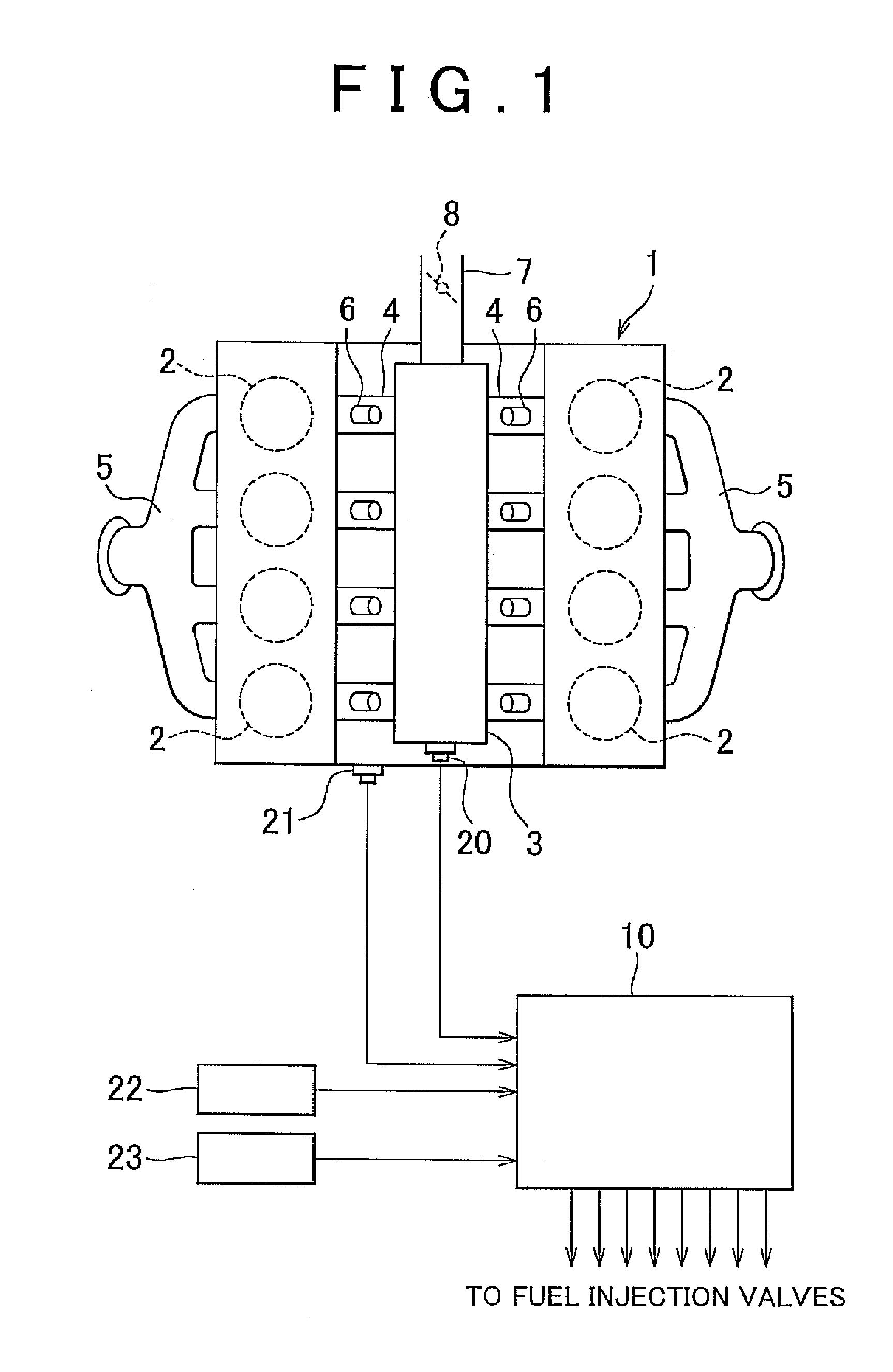

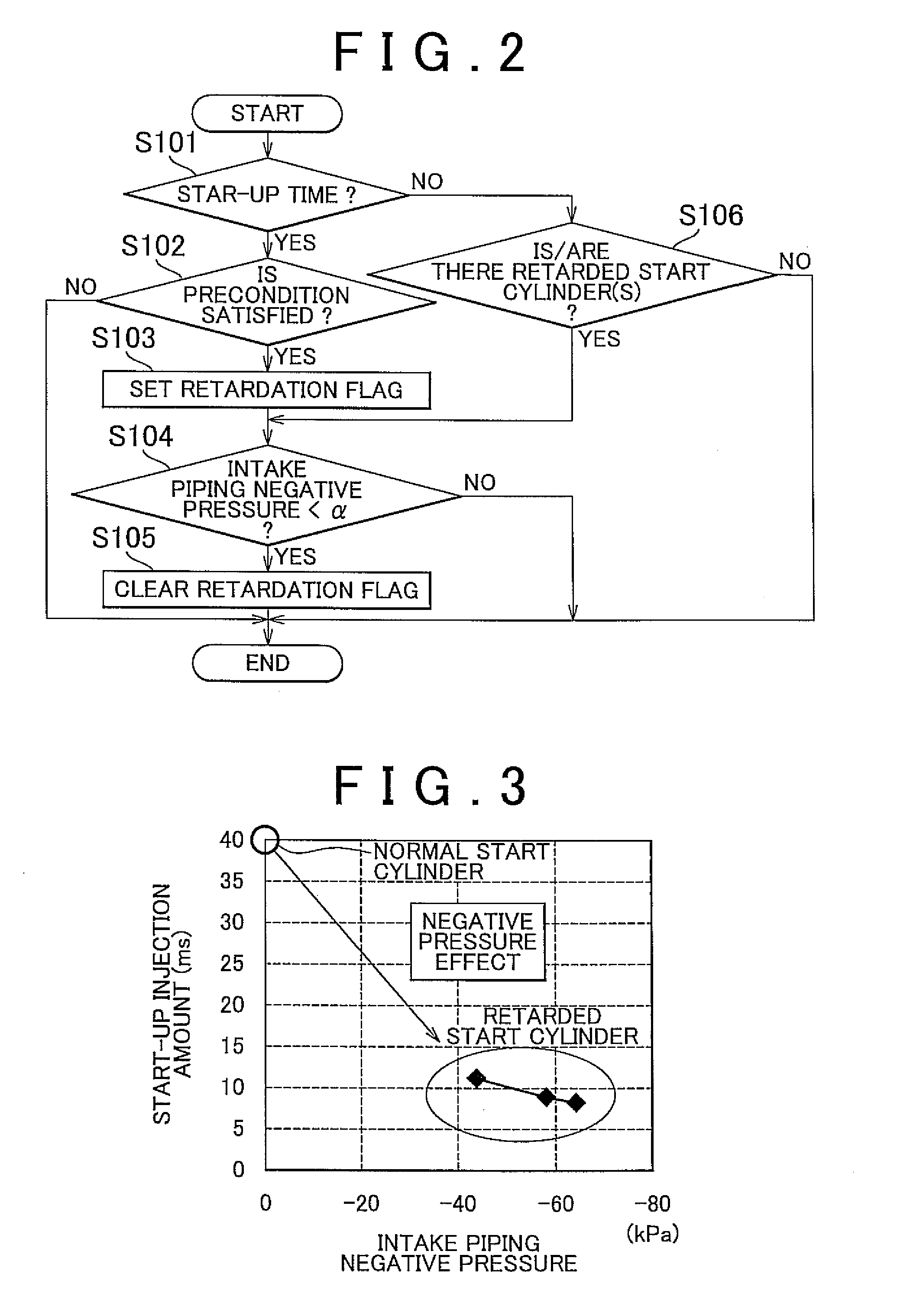

Internal combustion engine controller

InactiveUS20110197860A1Avoid dischargeReduce the amount requiredElectrical controlFuel injection apparatusExternal combustion engineControlled combustion engine

An internal combustion engine is started by performing fuel supply into part of a plurality of cylinders included in the internal combustion engine. After the magnitude of the negative pressure produced in intake piping of the internal combustion engine exceeds a predetermined reference value, fuel supply into the remaining cylinder(s) is started.

Owner:TOYOTA JIDOSHA KK

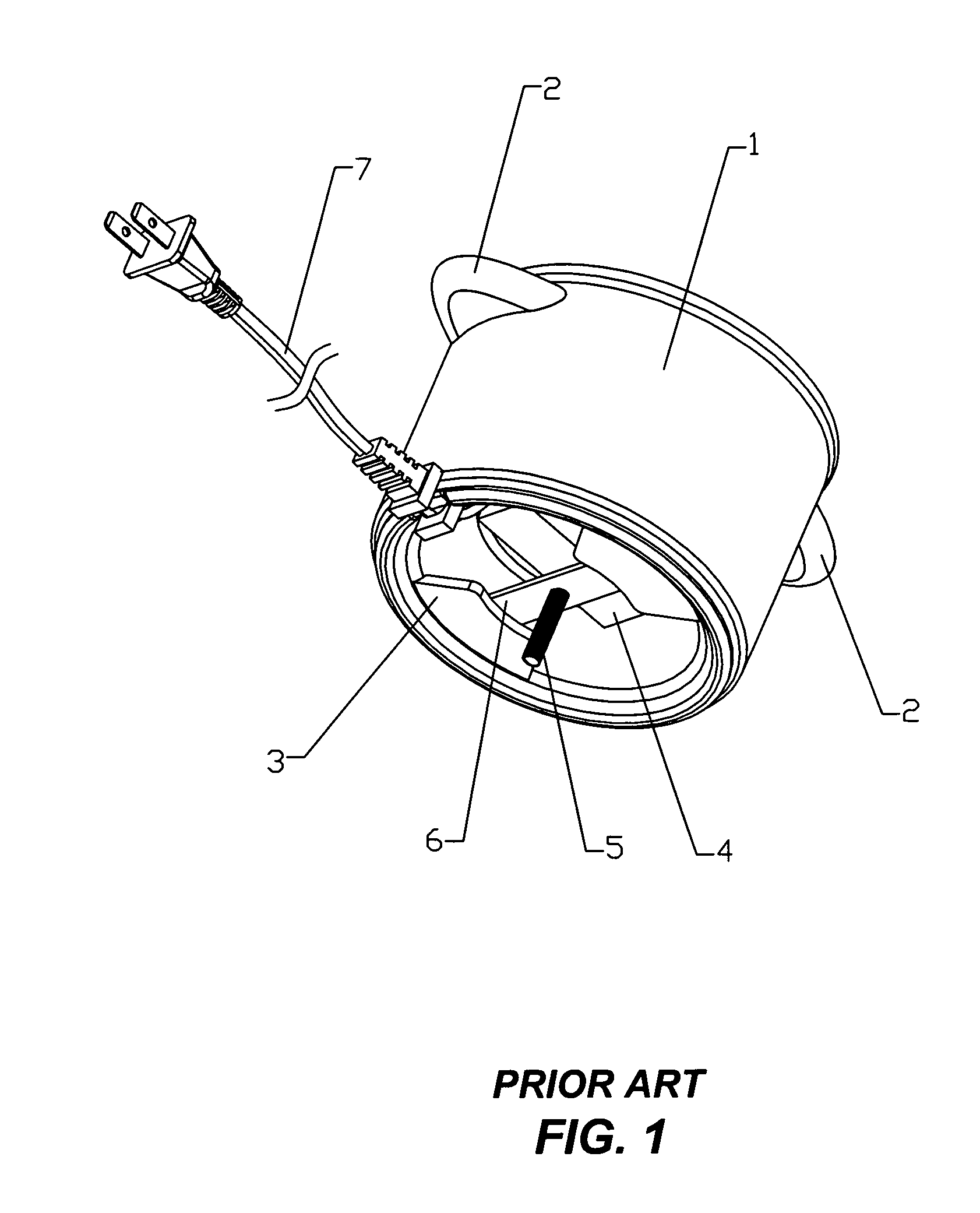

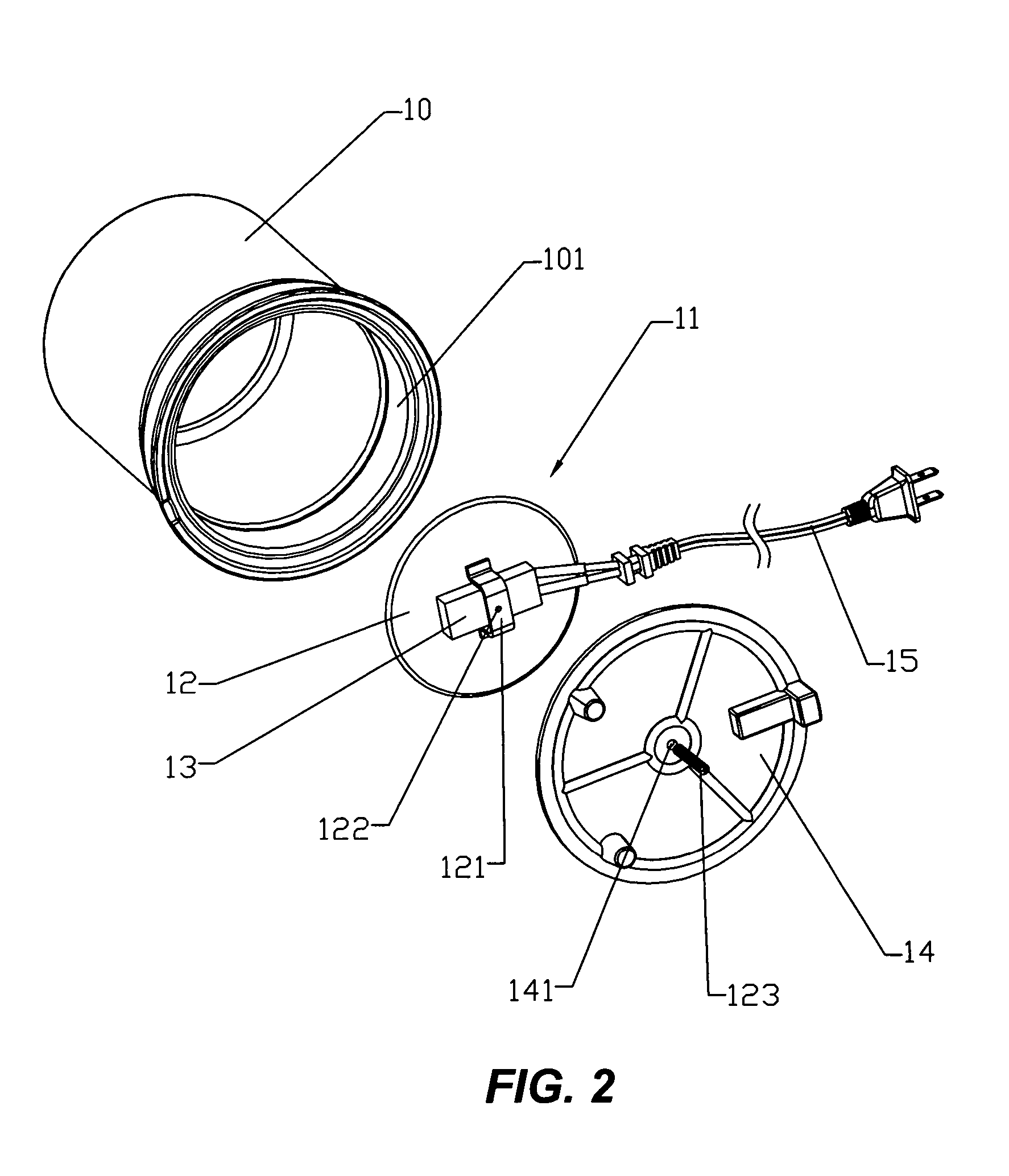

Mini scented wax heating device

InactiveUS20060163240A1Increase the heating areaEvenly heatedGaseous substancesElectric heating for furnacesWaxHeating time

A mini scented wax heating device includes a heating cylinder which is in a penetrating cylindrical form and installs a heating device therein. The heating device comprises a heat plate and a ceramic heating piece attached to the heat plate, and the heat plate is latched to a fixed end of the heating cylinder. The invention uses the heat plate to directly heat the bottom of the heating device. Since the heating device is a mini heating device that heats the heat plate directly by the ceramic heating piece, the heat plate can directly heat and vaporize a piece of scented wax. The invention increases the heating area of the scented wax by the heater, shortens the heating time, and evenly heats the scented wax in the heater, and thus can achieve a better vaporization effect. The invention features a simple structure, a low cost, and a powerful function.

Owner:XIAO MING REN

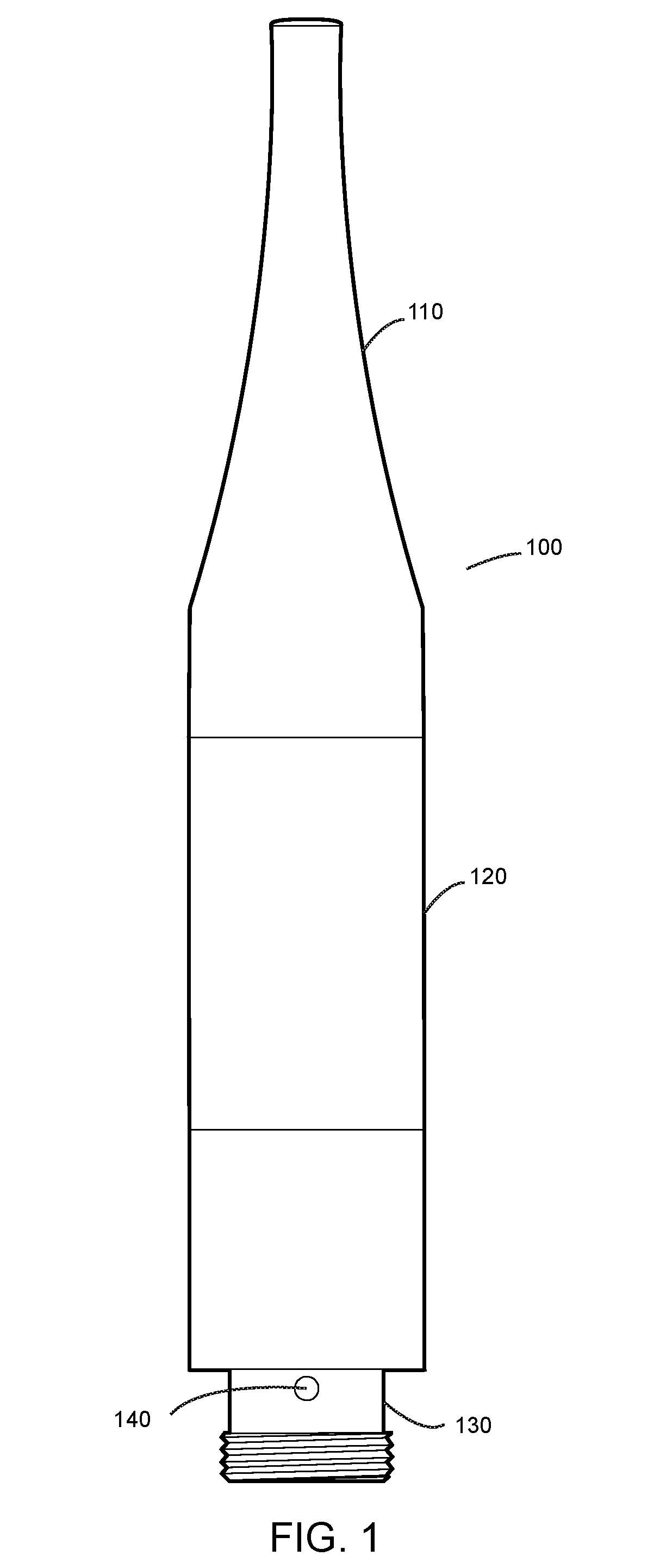

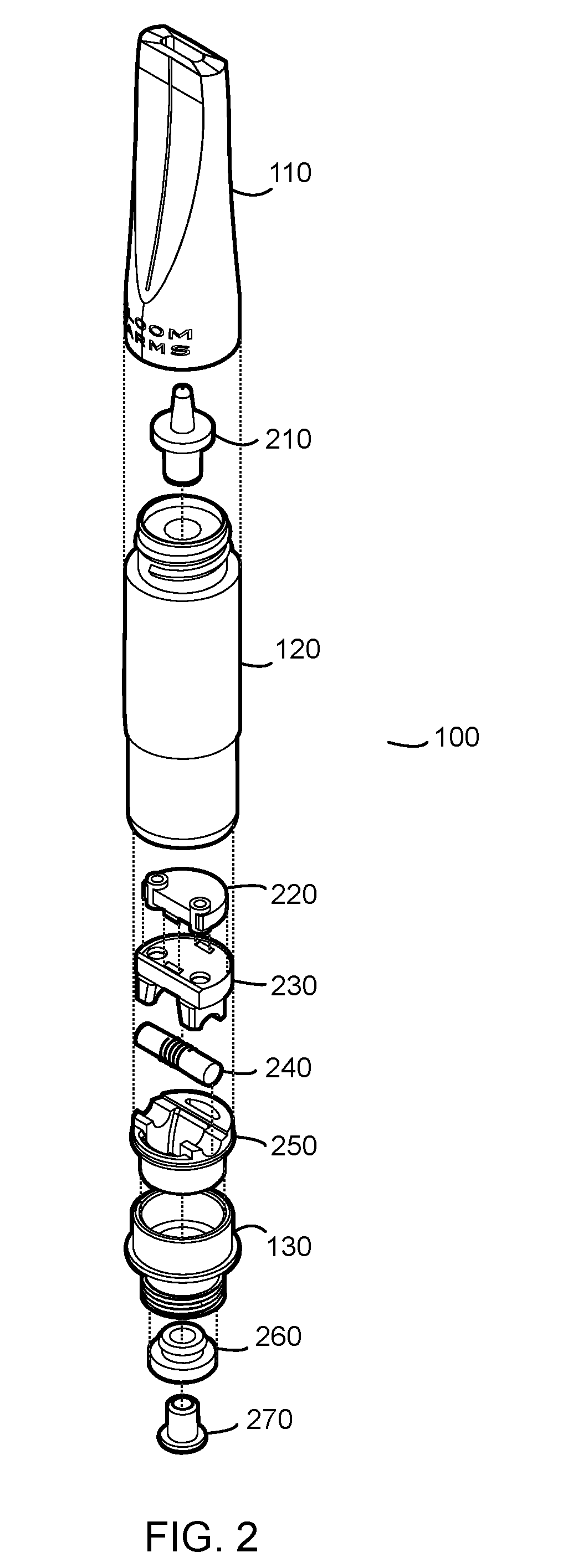

Variable Viscosity Vaporizer Cartridge

A vaporizer and vaporizer cartridge for inhaling vapors from vaporized oil. The vaporizer has a mouthpiece for use by a user to inhale the vapors. The mouthpiece is connected to a cartridge which contains the oil to be vaporized and the apparatus for vaporizing the oil. The vaporizer cartridge contains a reservoir of the oil which flows down to a wick, which is heated by a heating coil to a temperature necessary to vaporize the oil. Under the wick is a residue basin which collects any oil which fails to vaporize. The residue basin is placed at an optimal distance from the wick such that when the next user initiates another draw on the vaporizer, the un-vaporized oil in the residue basin is vaporized. Below the cartridge is a battery component that provides power to a heating coil which heats the wick to vaporize the oil. Air flows up from below the cartridge on one side, then cross-flows across the wick and residue basin, and up the other side of the cartridge to the mouthpiece.

Owner:ACROSS INFINITY LLC

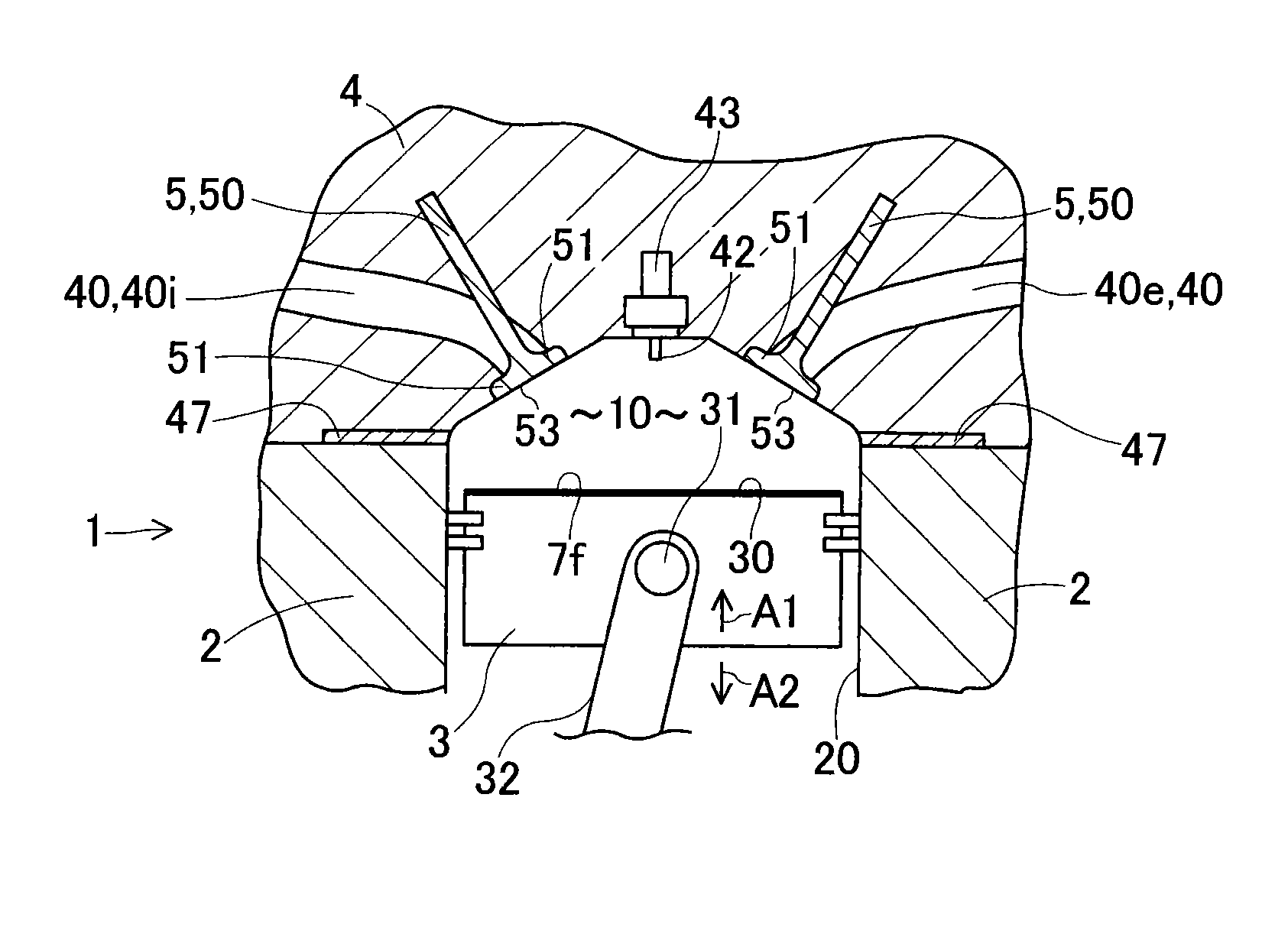

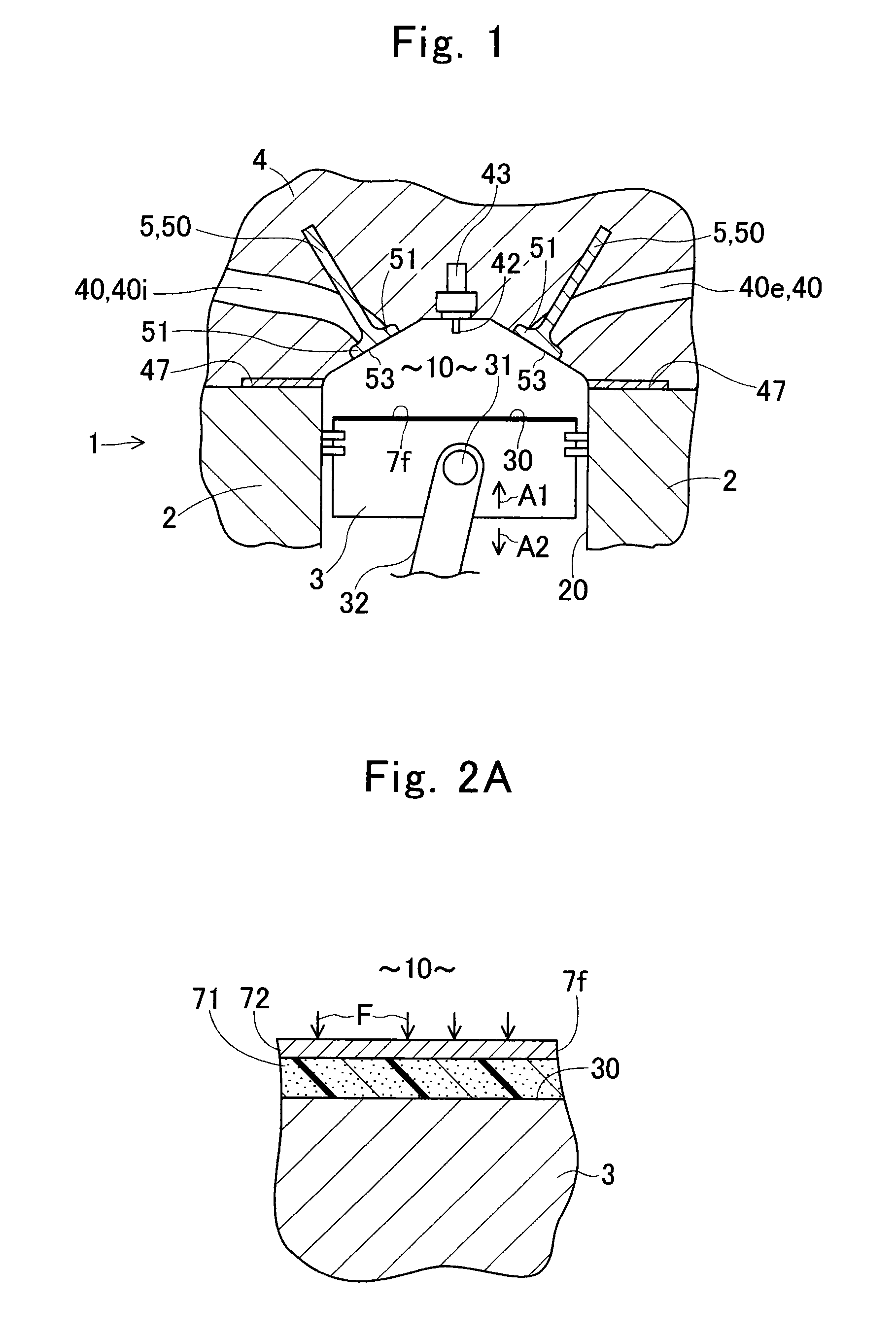

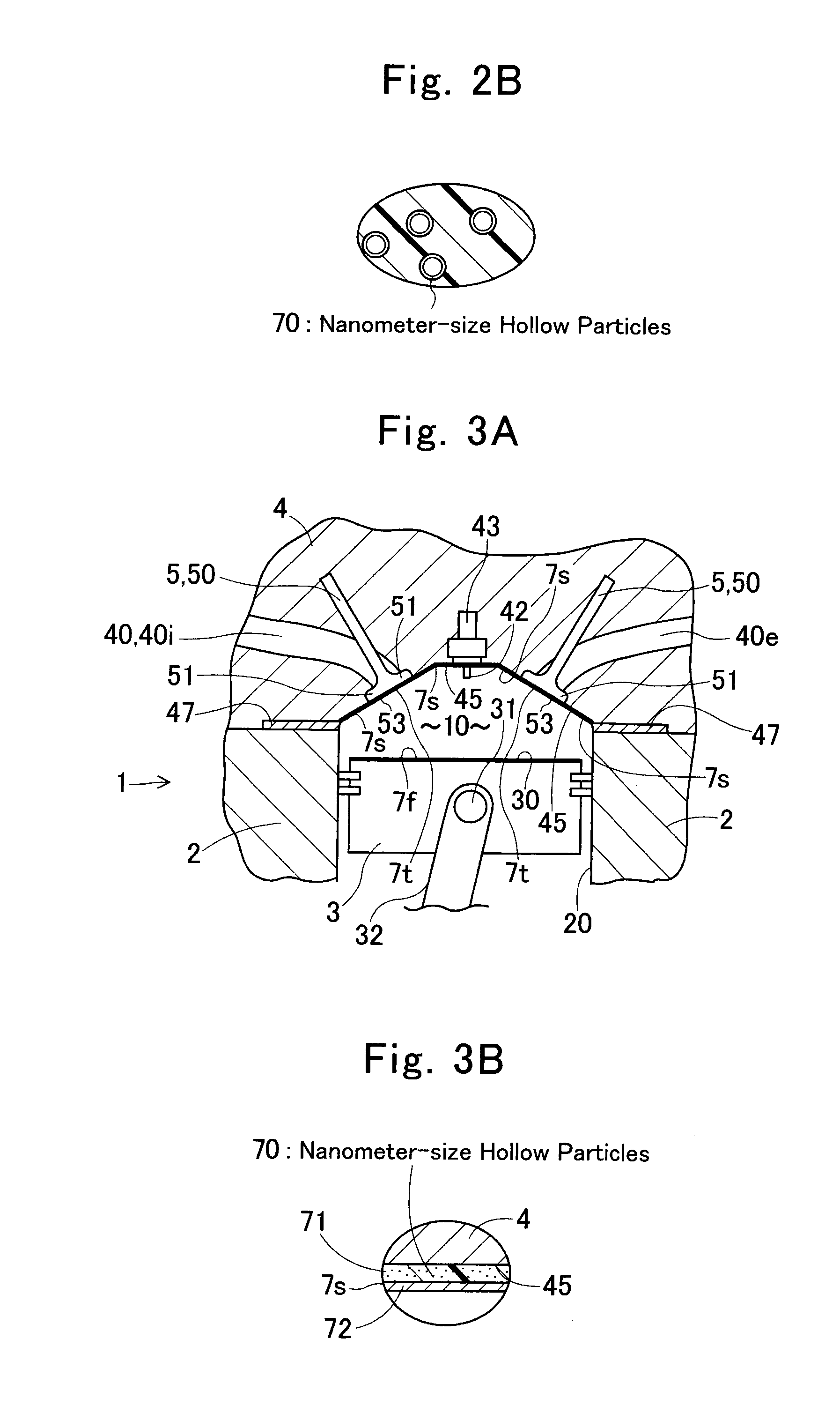

Engine and piston

ActiveUS20150204269A1Improve insulation performanceUpgrading mileagePlungersCylinder headsCombustion chamberCylinder head

Any one or more members of an engine, that is, a piston, a cylinder head and a valve, has a wall face disposed face-to-face to a combustion chamber, and the wall face is coated by a heat-insulation coating film. The heat-insulation coating film includes a heat-insulative layer formed on a surface of the wall face, and an inorganic-system coated-film layer formed on a surface of the heat-insulative layer. The heat-insulative layer includes a resin, and first hollow particles buried inside the resin and exhibiting an average particle diameter being smaller than a thickness of the heat-insulative layer. The inorganic-system coated-film layer includes an inorganic compound.

Owner:AISIN SEIKI KK +1

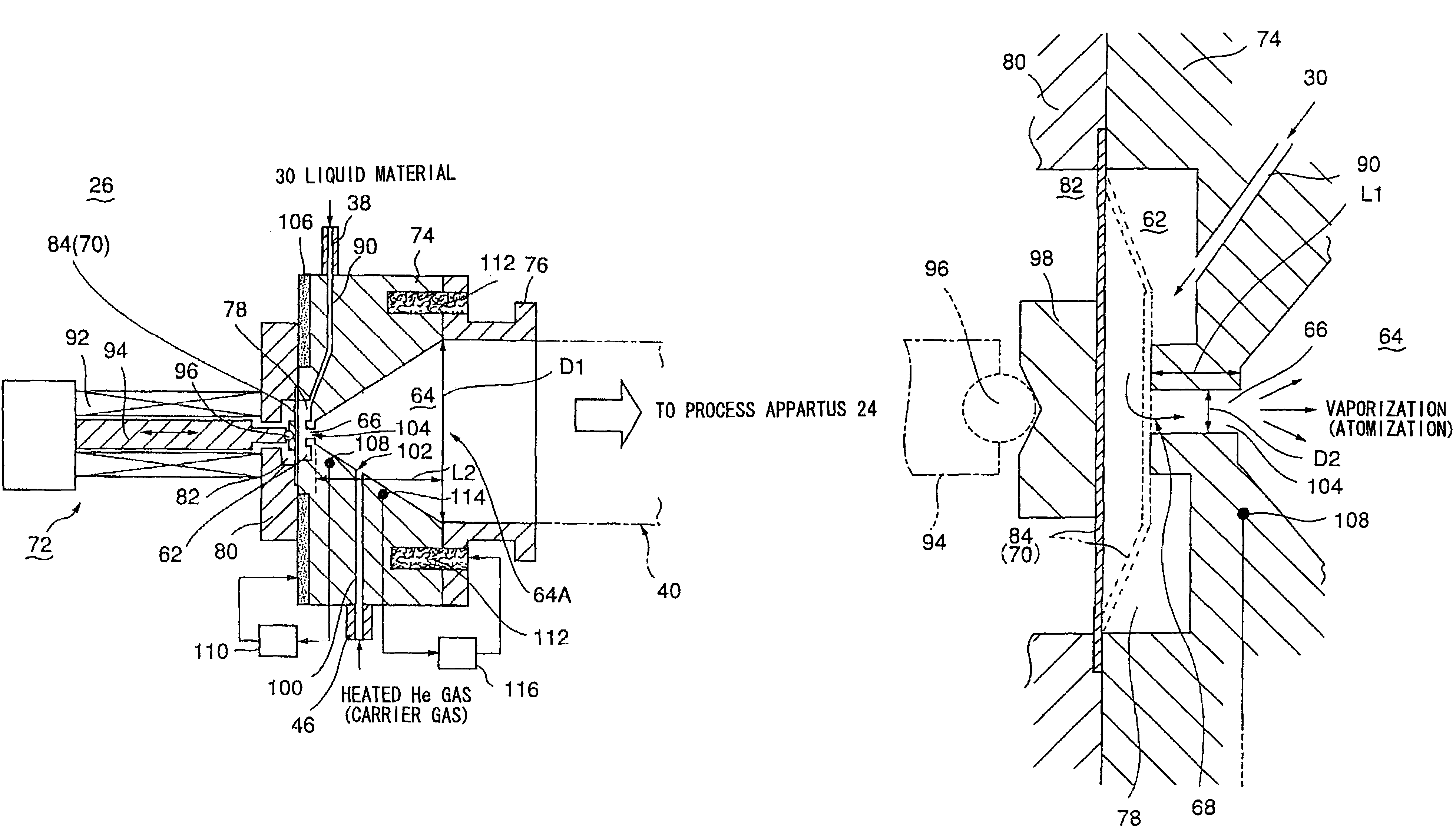

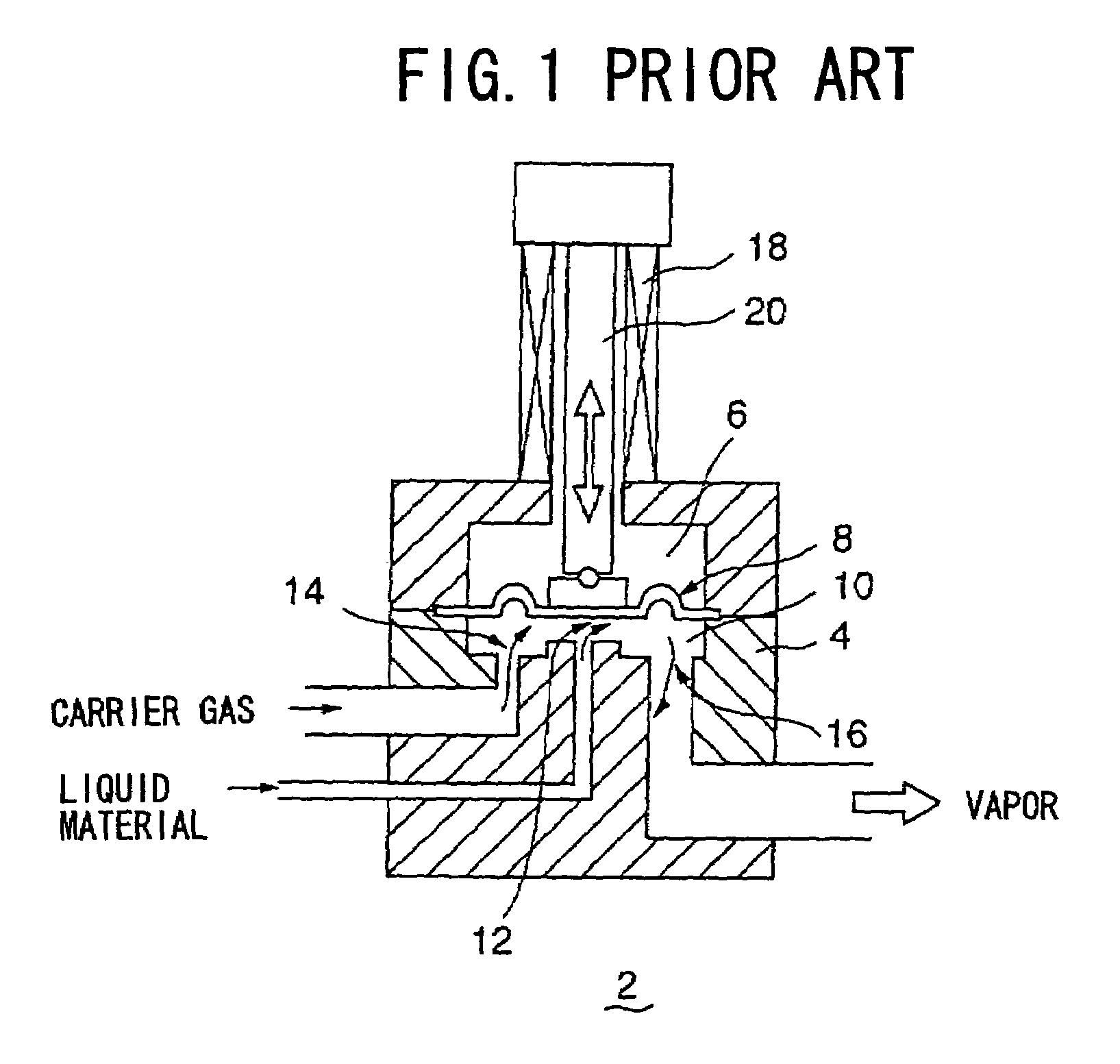

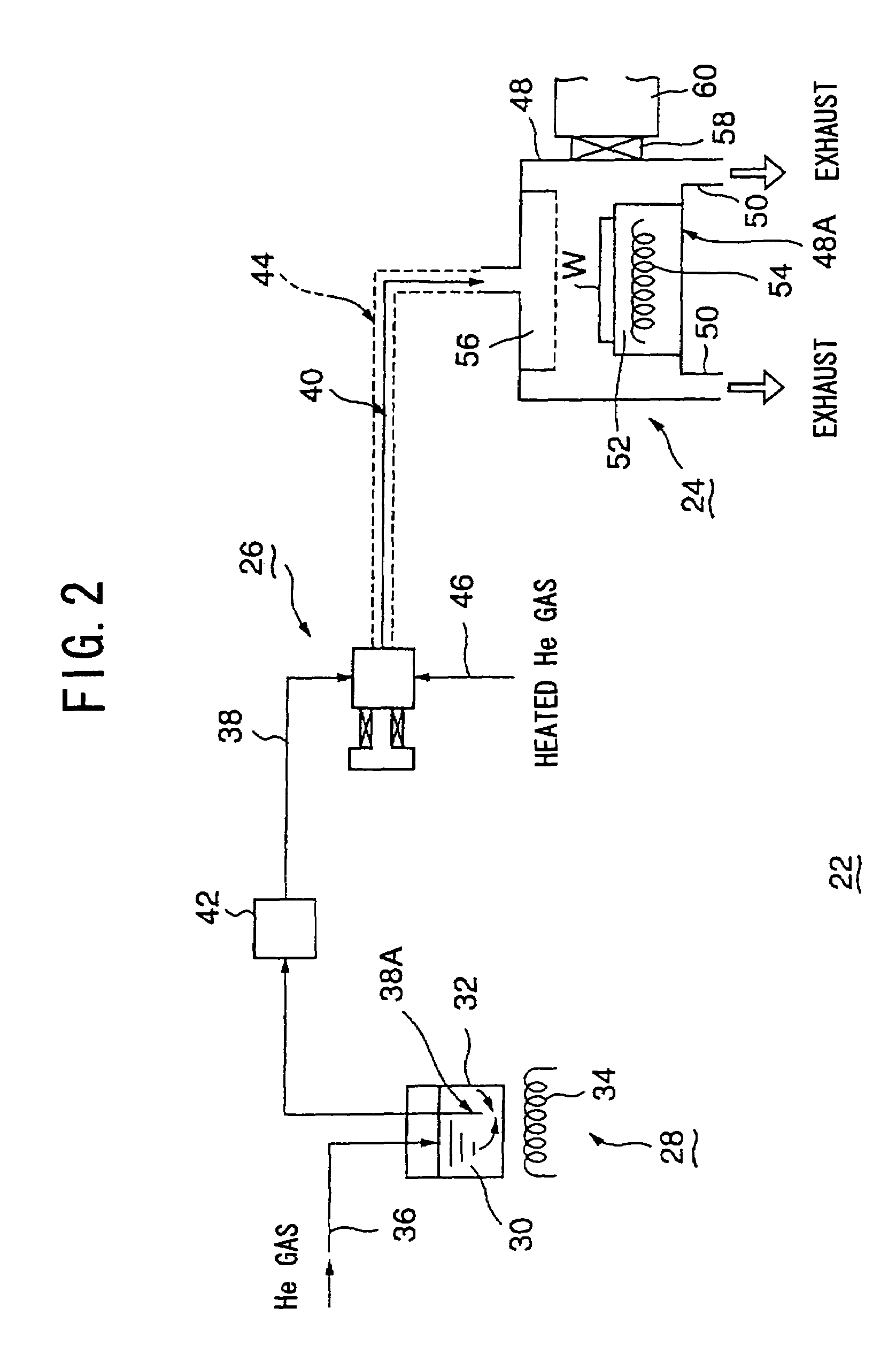

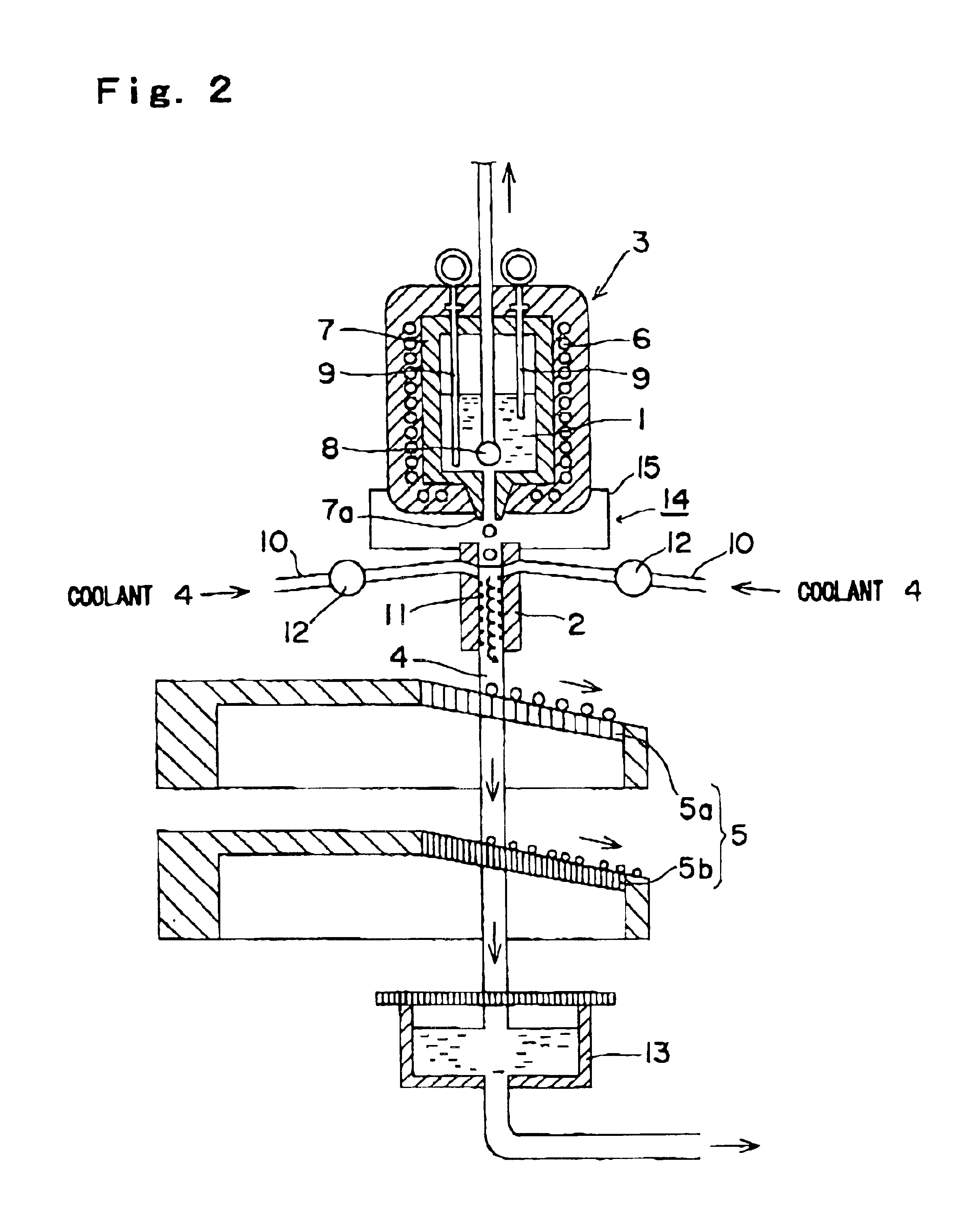

Semiconductor manufacturing system having a vaporizer which efficiently vaporizes a liquid material

InactiveUS7332040B1Obviates problemMaterial efficiencyFunctional valve typesEngine diaphragmsEvaporatorEngineering

A vaporizer can efficiently vaporize a liquid material under a depressurized atmosphere. The liquid material is temporarily stored in a liquid storing chamber, and is supplied to a vaporizing chamber set in the depressurized atmosphere via a small aperture. An inlet of the liquid storing chamber is opened or closed by a valve body, which is moved by an actuator controlling a degree of opening of the valve body.

Owner:TOKYO ELECTRON LTD

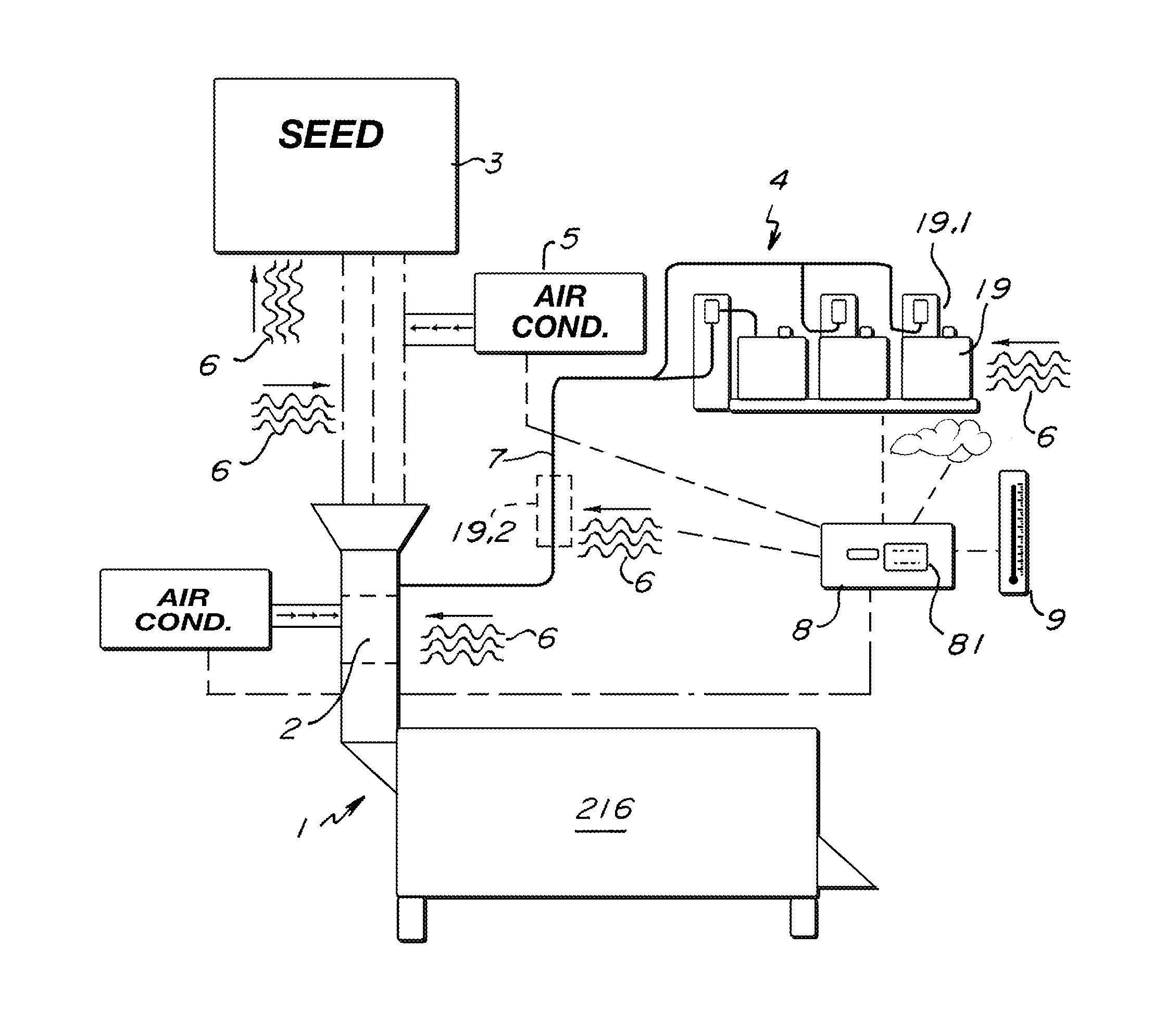

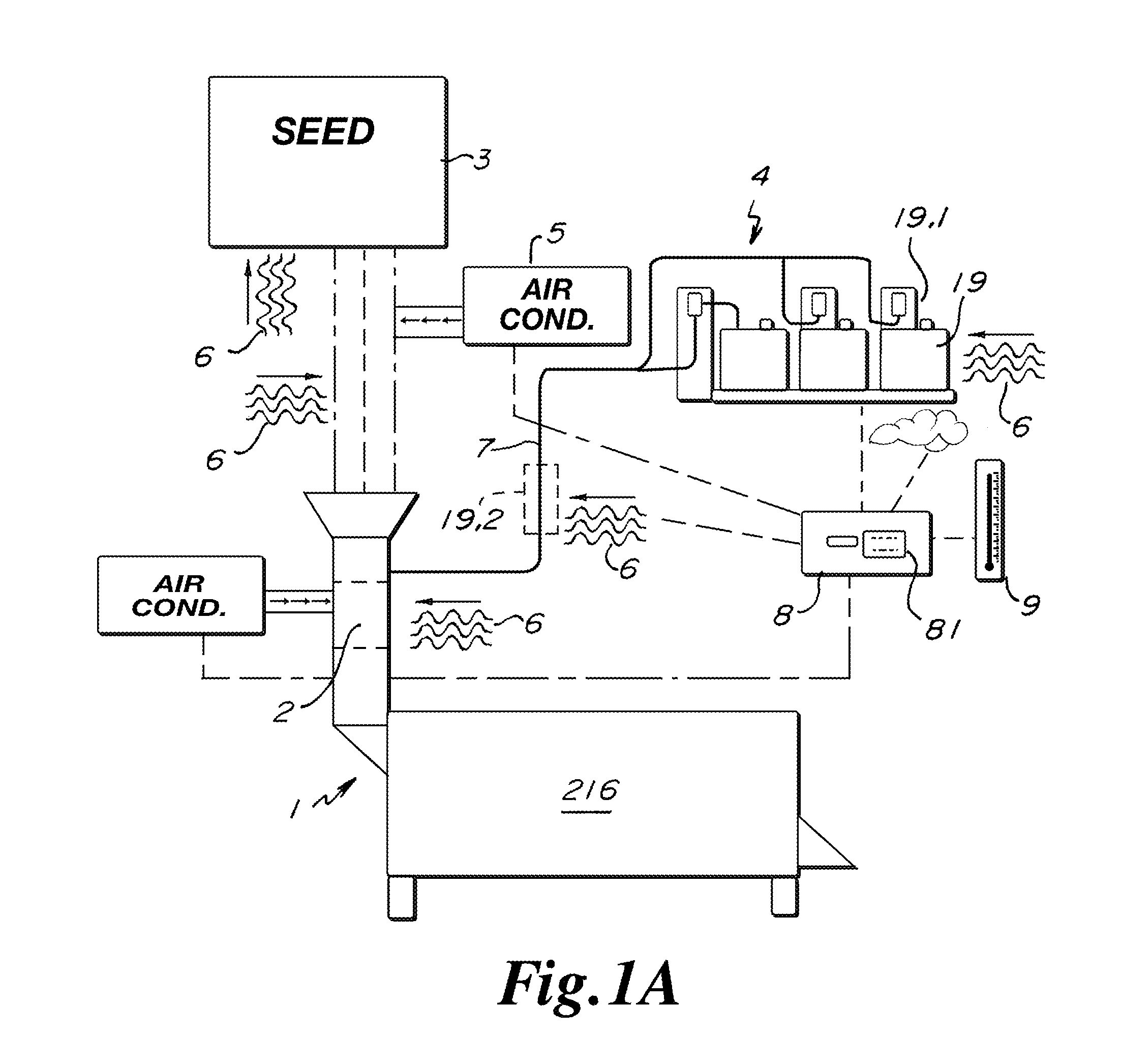

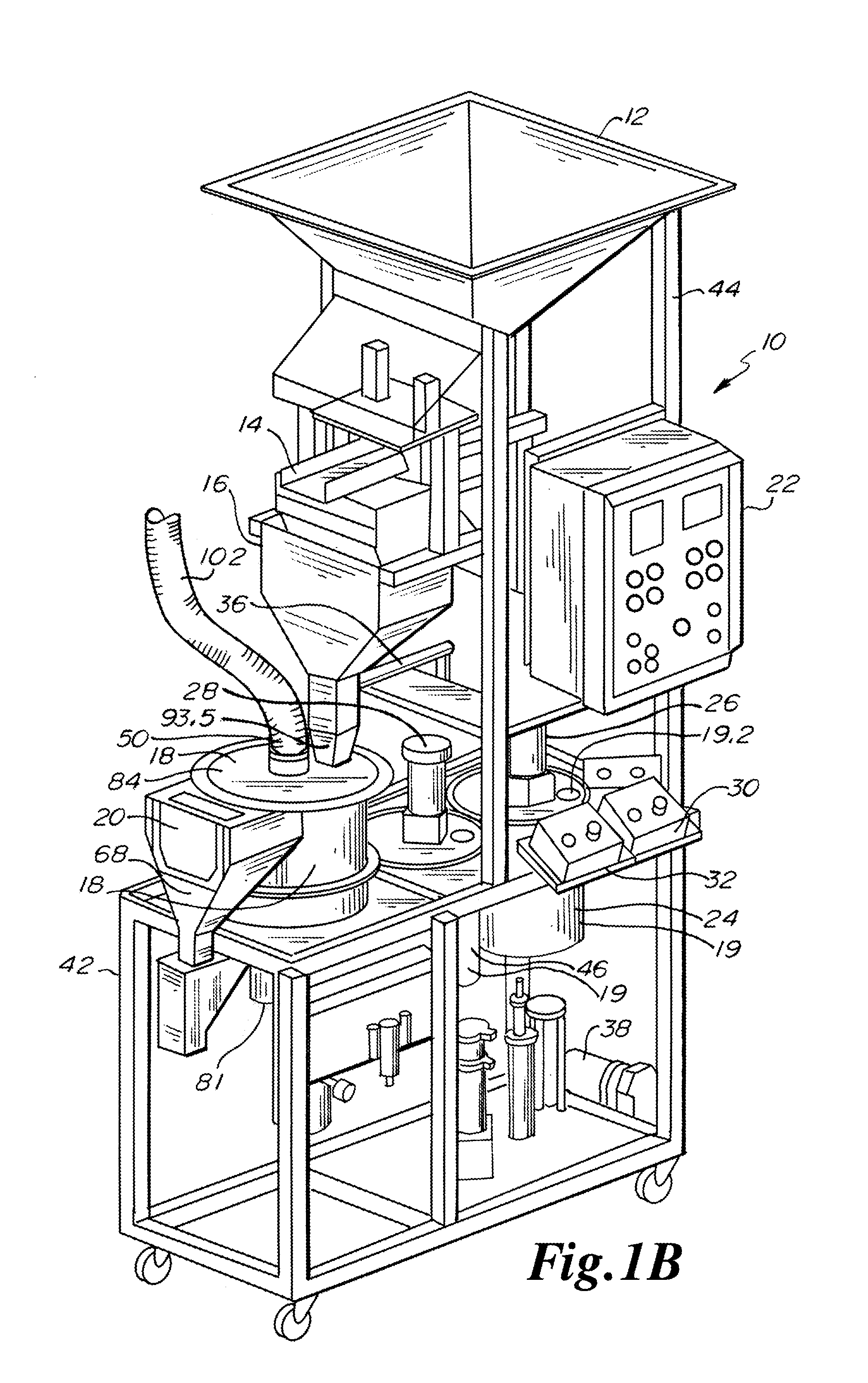

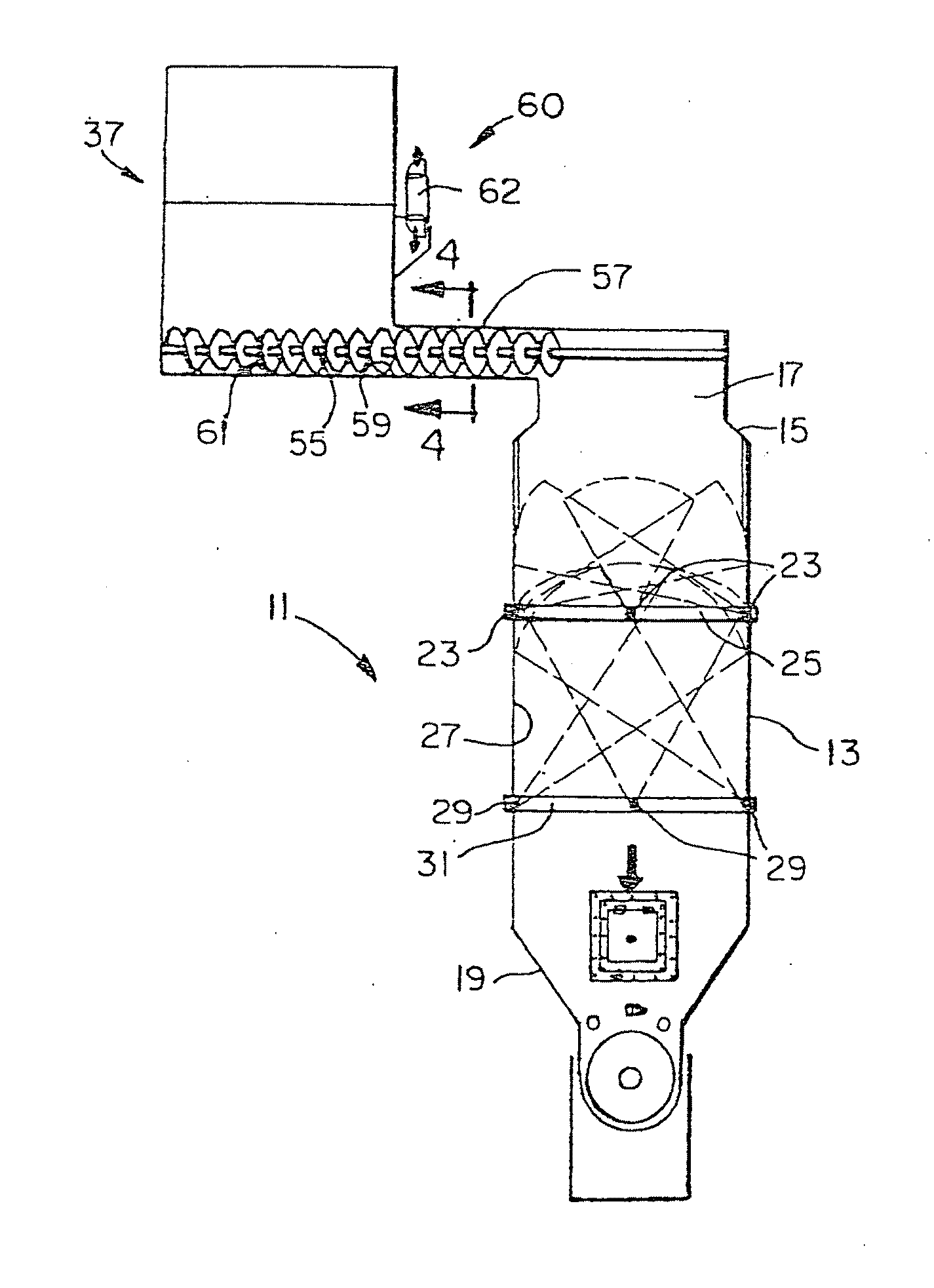

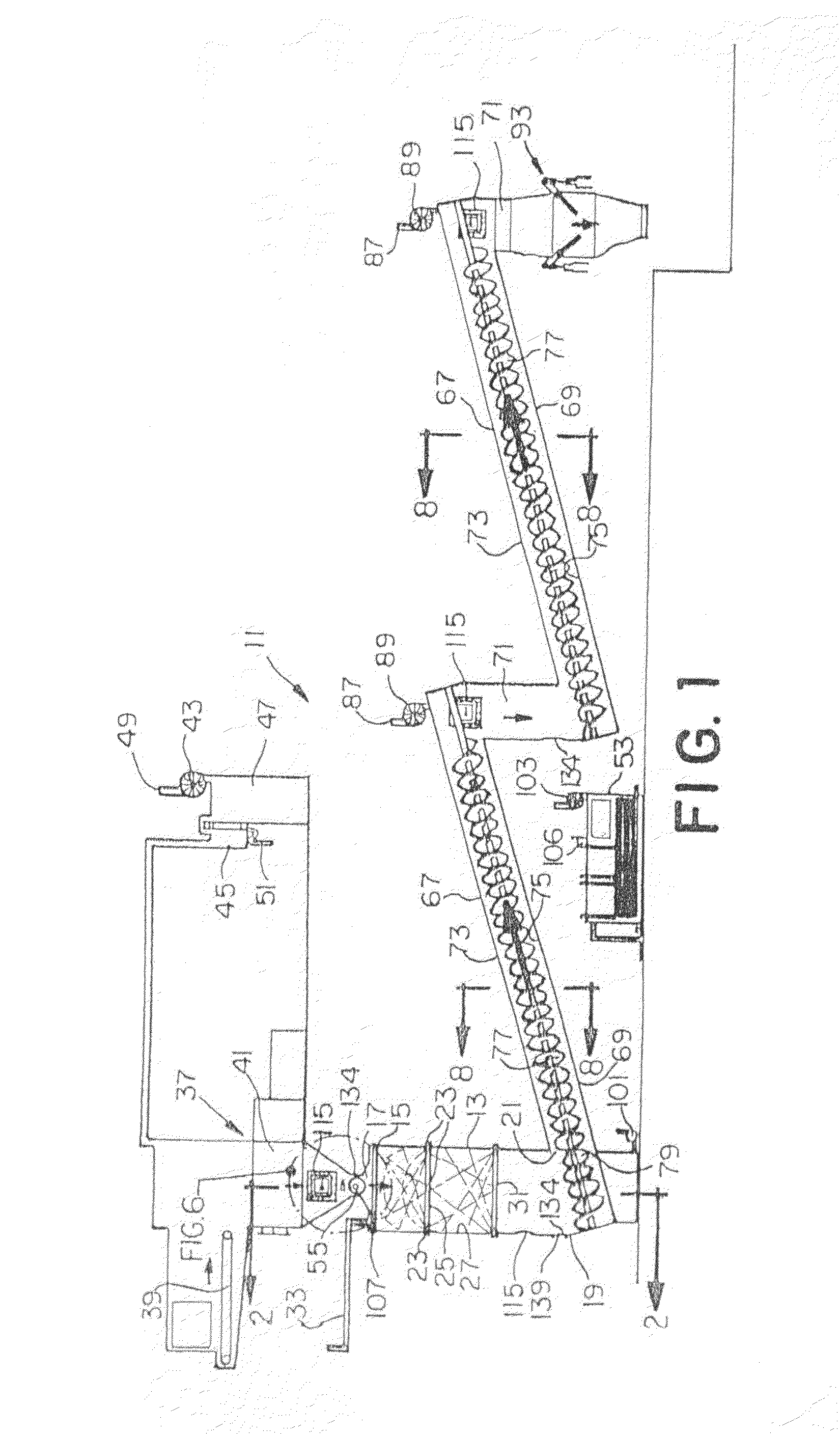

Seed treatment device with improved fluid application

InactiveUS20130273236A1Good dispersionPromote absorptionLiquid surface applicatorsDead plant preservationVaporizationEngineering

A seed treater provides enhanced seed coating capabilities and performance. The seed and / or treatment fluid may be heated for improving vaporization and absorption by the seed. Air may be injected in the seed treater to provide heat, dehumidified air, and to provide vaporization enhancement, and component cleaning functions. The functions may be controlled by a control processor based on recipes and may be changed dependent upon sensed or input environmental conditions such as temperature and humidity.

Owner:BAYER CROPSCI LP

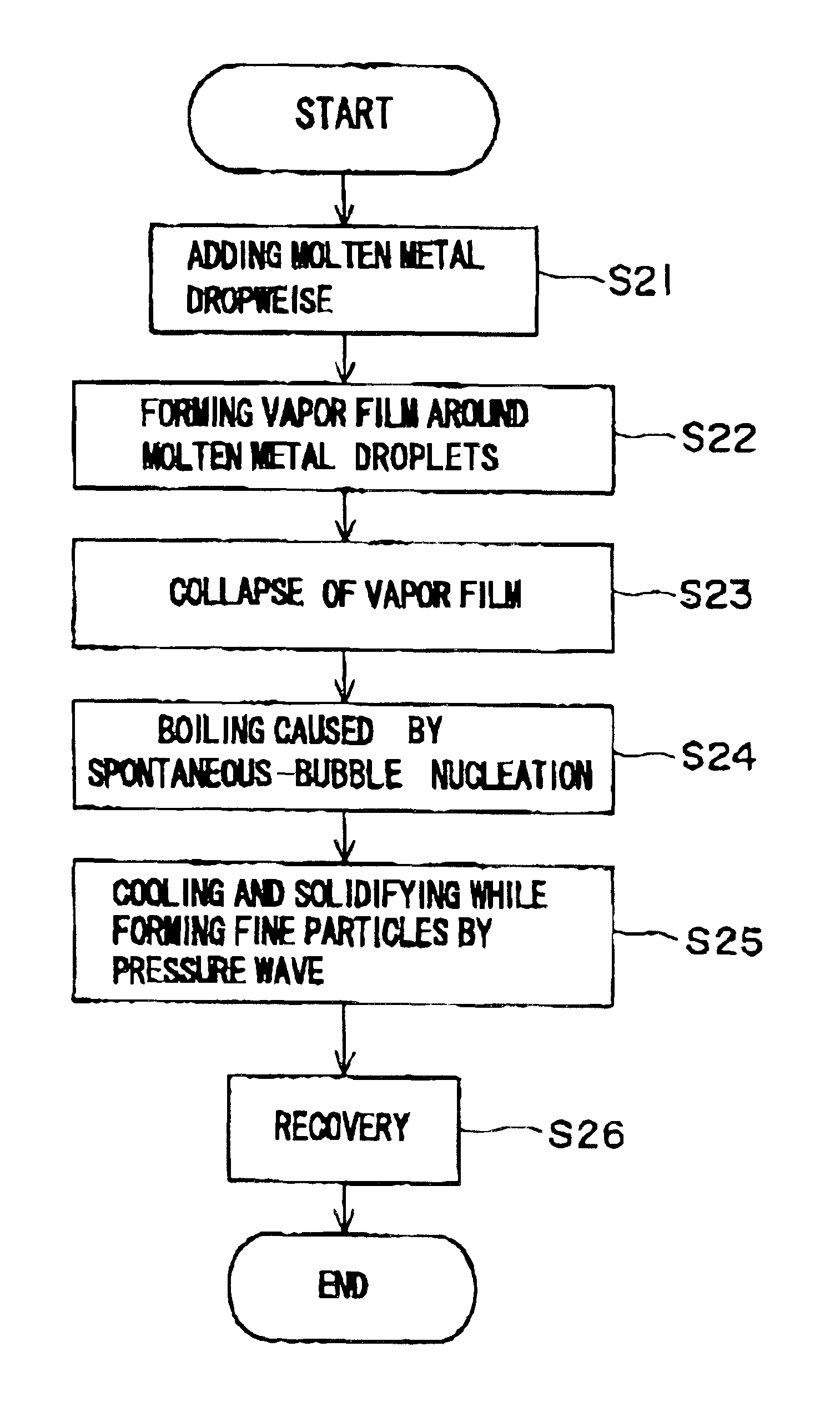

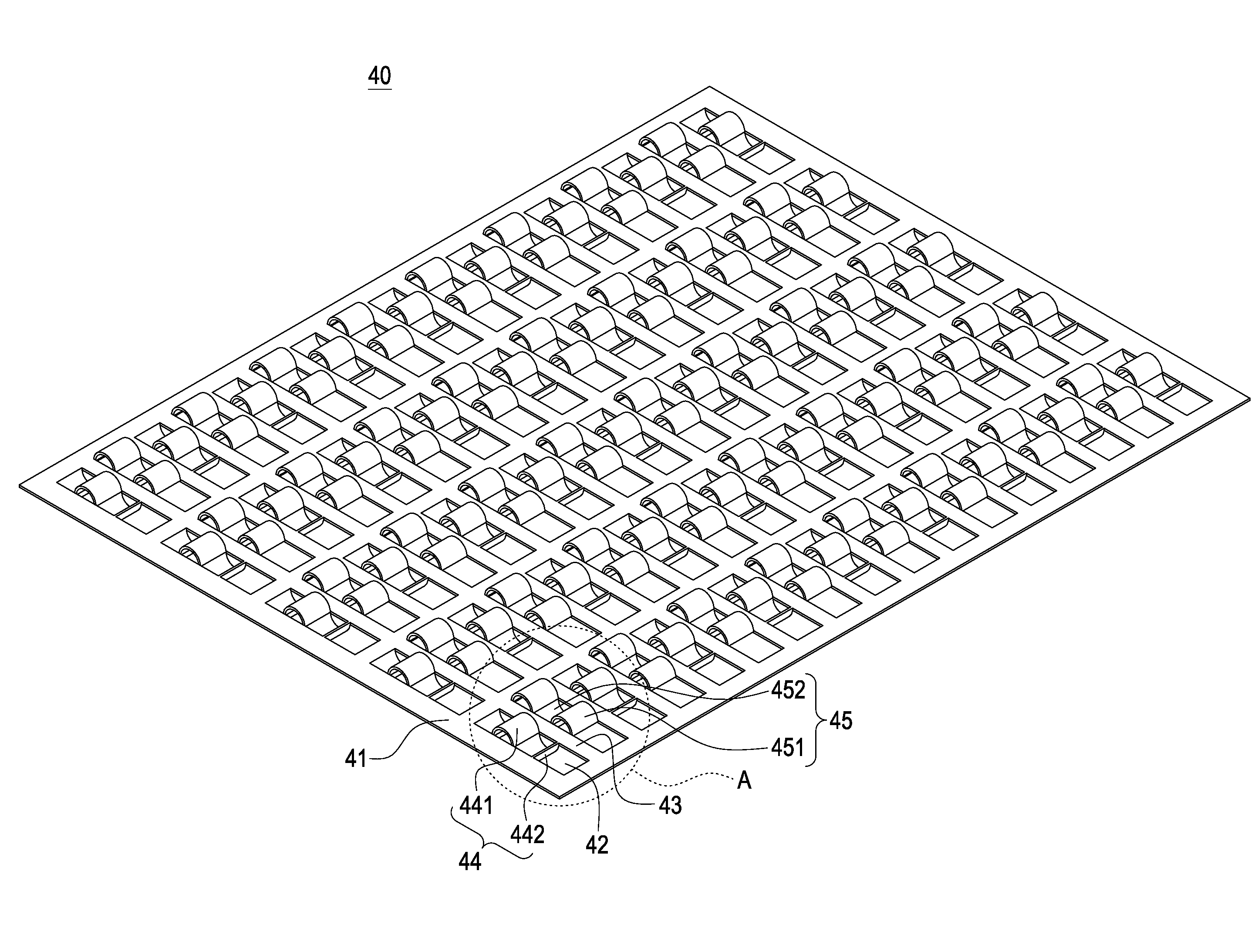

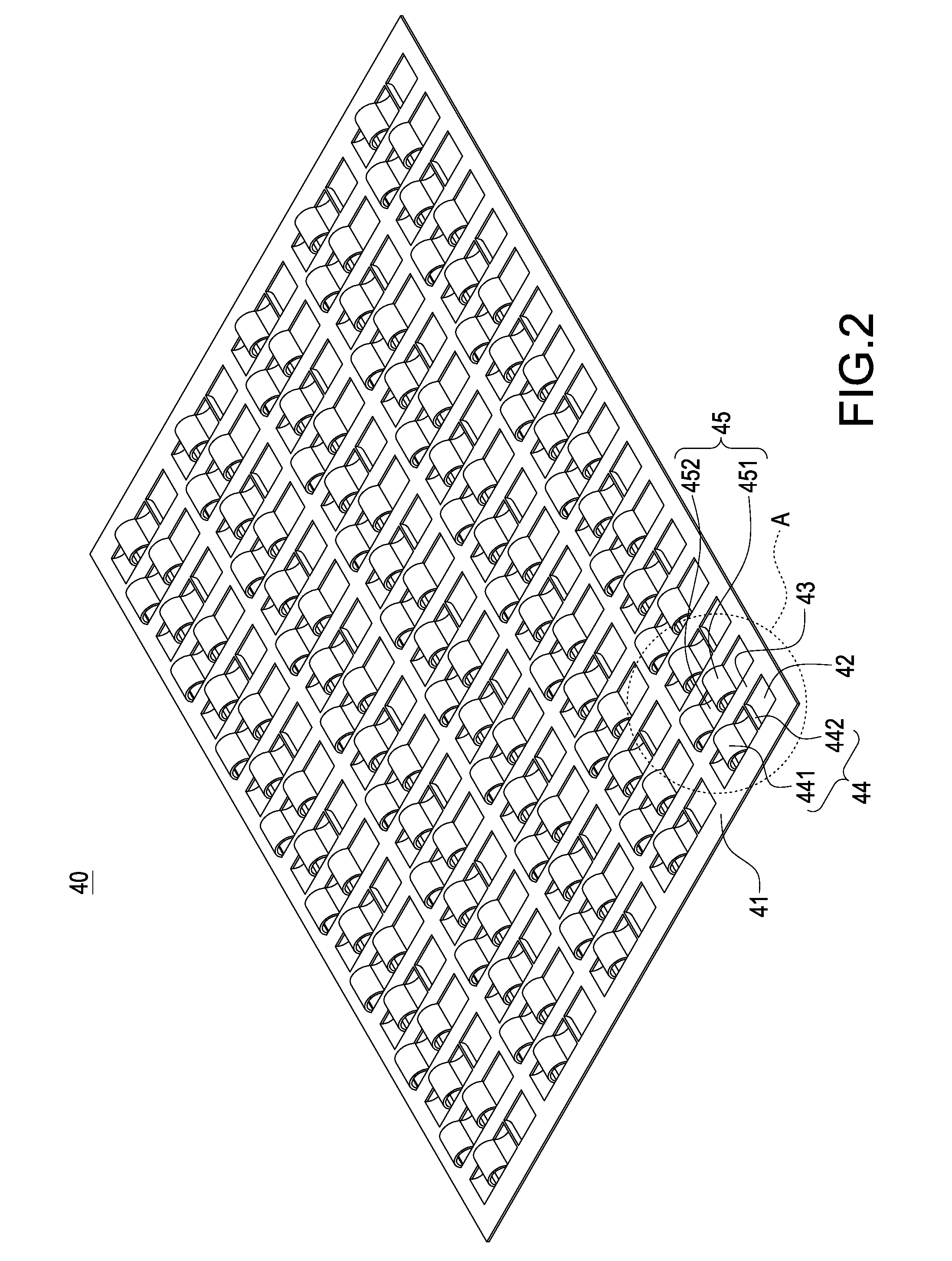

Method and apparatus for producing fine particles, and fine particles

InactiveUS6923842B2Effectively fragmentedIncrease surface areaAuxillary shaping apparatusMicrometerBubble nucleation

A method and apparatus are invented for producing fine particles, which can readily realize the formation of fine particles of sub-μm order to 100 micron order as well as fine particles of several micrometer which cannot be realized by a conventional method and apparatus available for producing fine particles, and a large quantity of fine particles having the desired particle diameter can be obtained with a high yield. A molten material (1), which is a molten raw material to be fragmented into fine particles, is supplied into a liquid coolant (4), boiling due to spontaneous-bubble nucleation is generated, and the molten material (1) is cooled and solidified while forming fine particles thereof by utilizing a pressure wave generated by this boiling. This production method is realized by apparatus comprising: material supplying means (3); a cooling section (2) which brings in the coolant (4) whose quantity is small and sufficient for cooling and solidifying the supplied molten material (1), and cools and solidifies the molten material (1) while forming fine particles thereof by utilizing a pressure wave generated by boiling due to spontaneous-bubble nucleation; and recovery means (5) for recovering fine particles from the coolant (4).

Owner:MITSUI MINING & SMELTING CO LTD

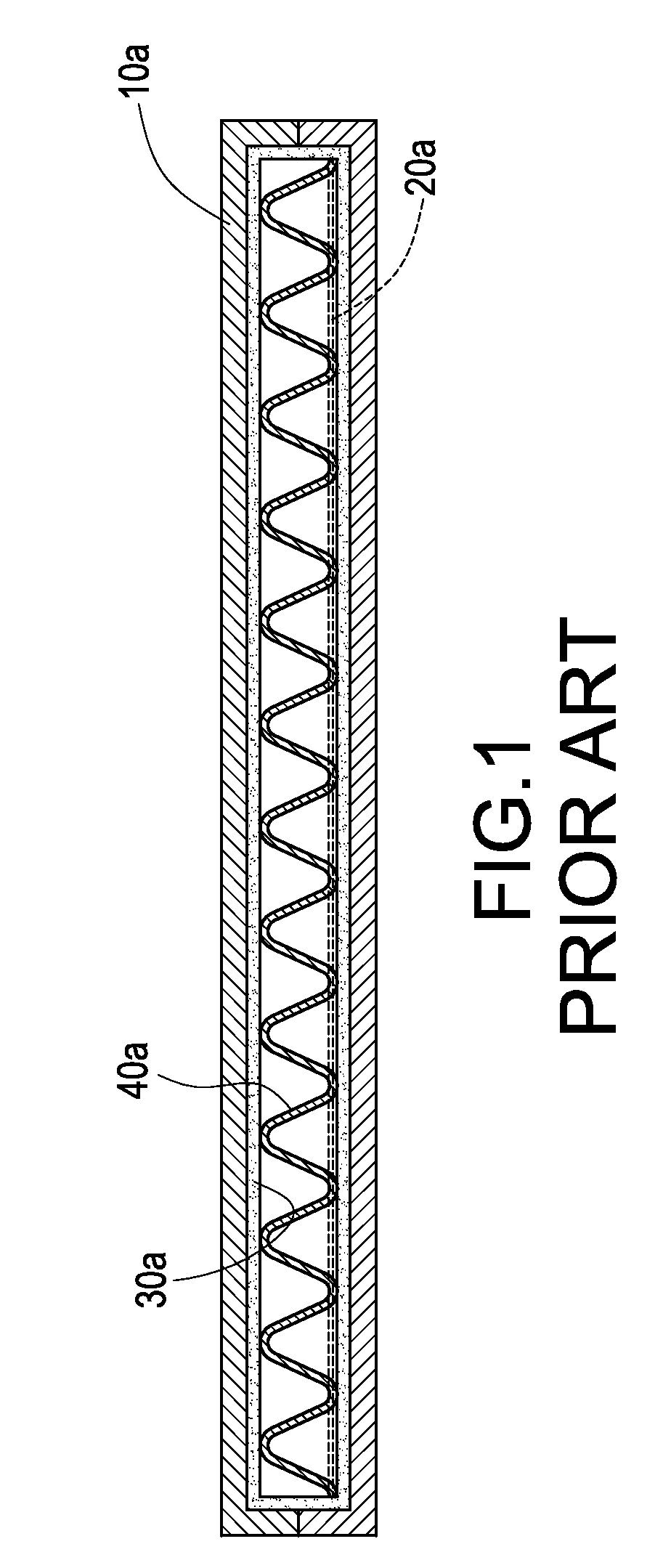

Vapor chamber and supporting structure thereof

InactiveUS20090194259A1Enhance tightly contact effectIncreased amount of workReinforcing meansIndirect heat exchangersEngineeringHeat conducting

Owner:CELSIA TECH TAIWAN INC

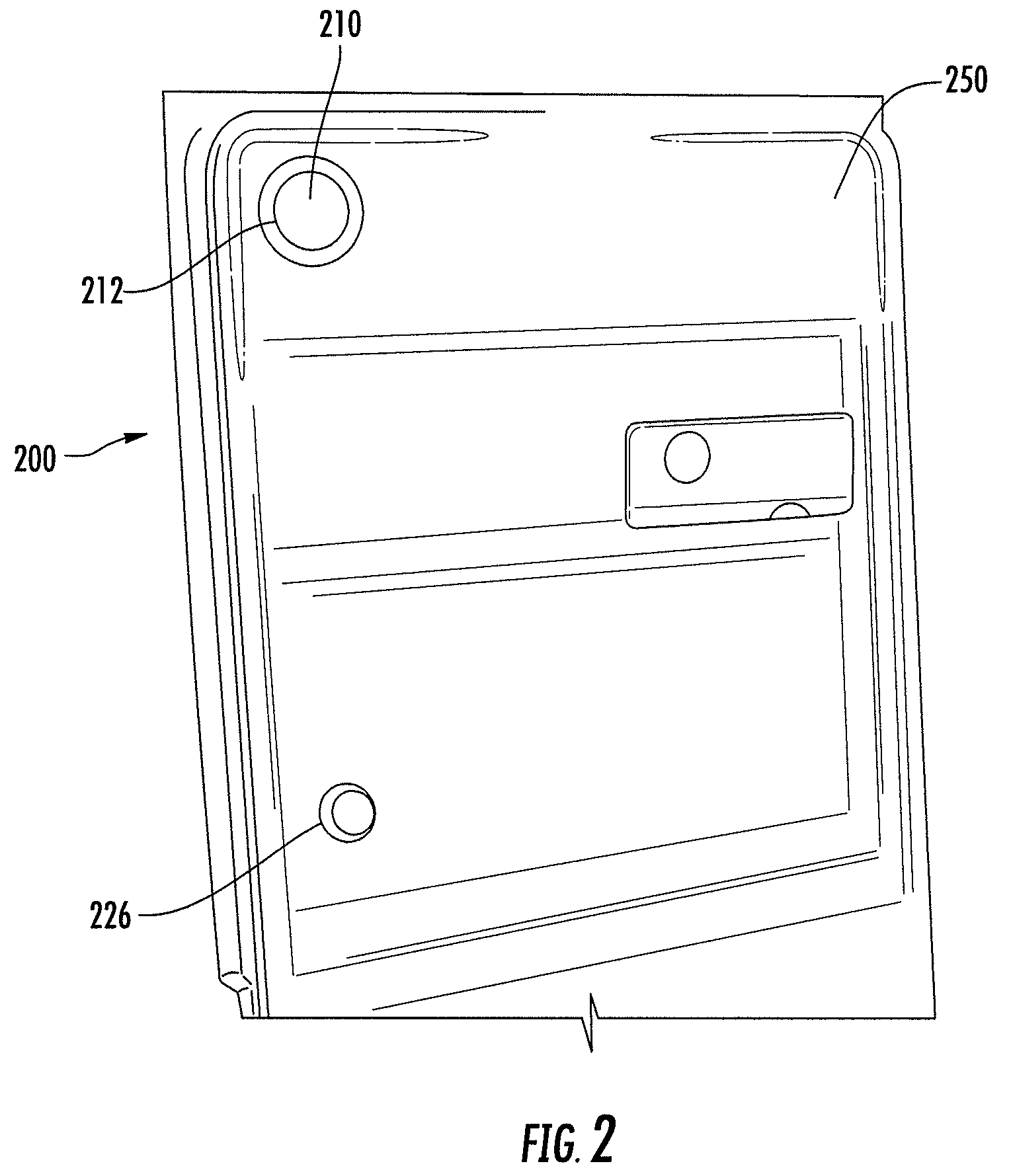

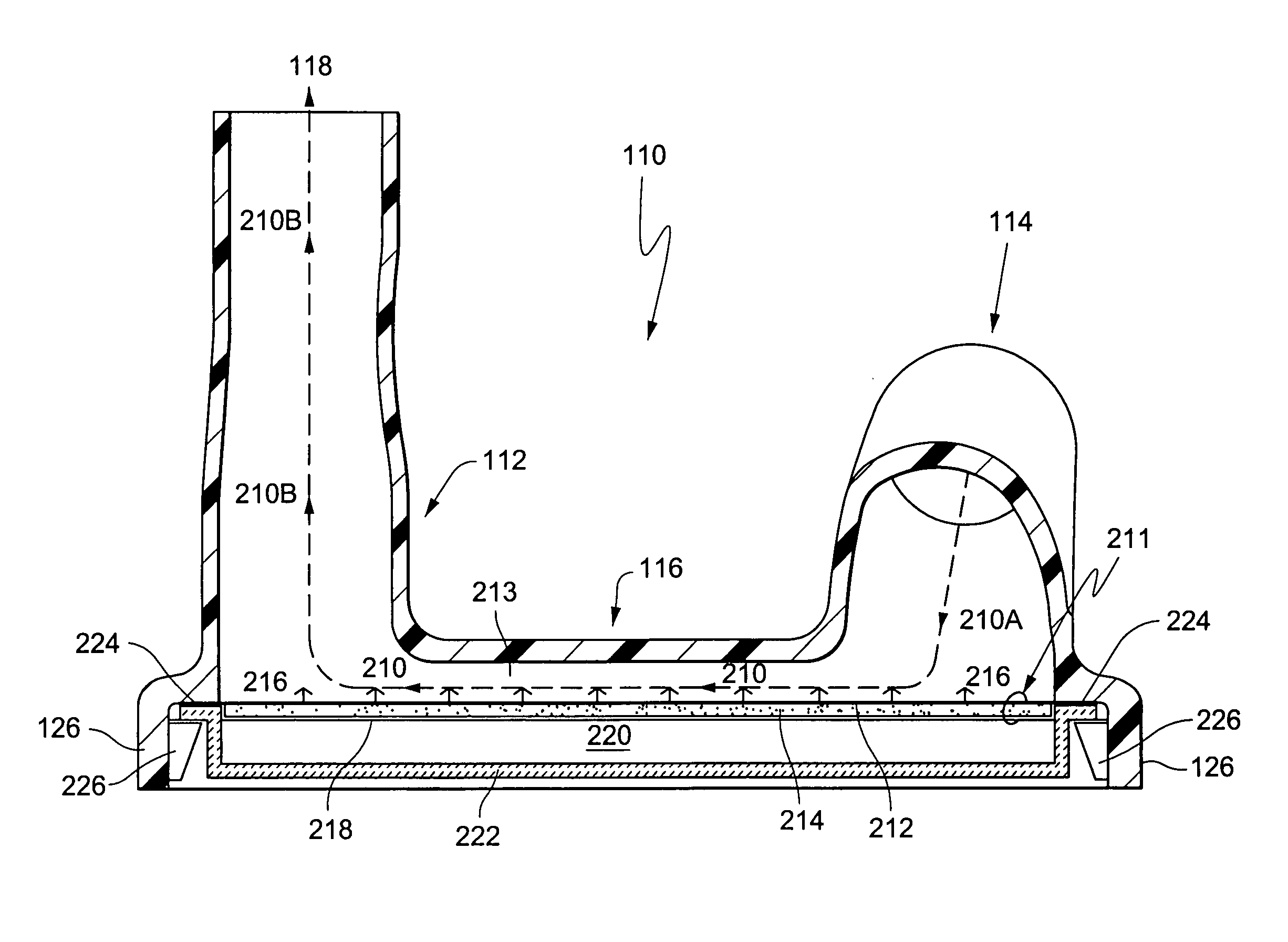

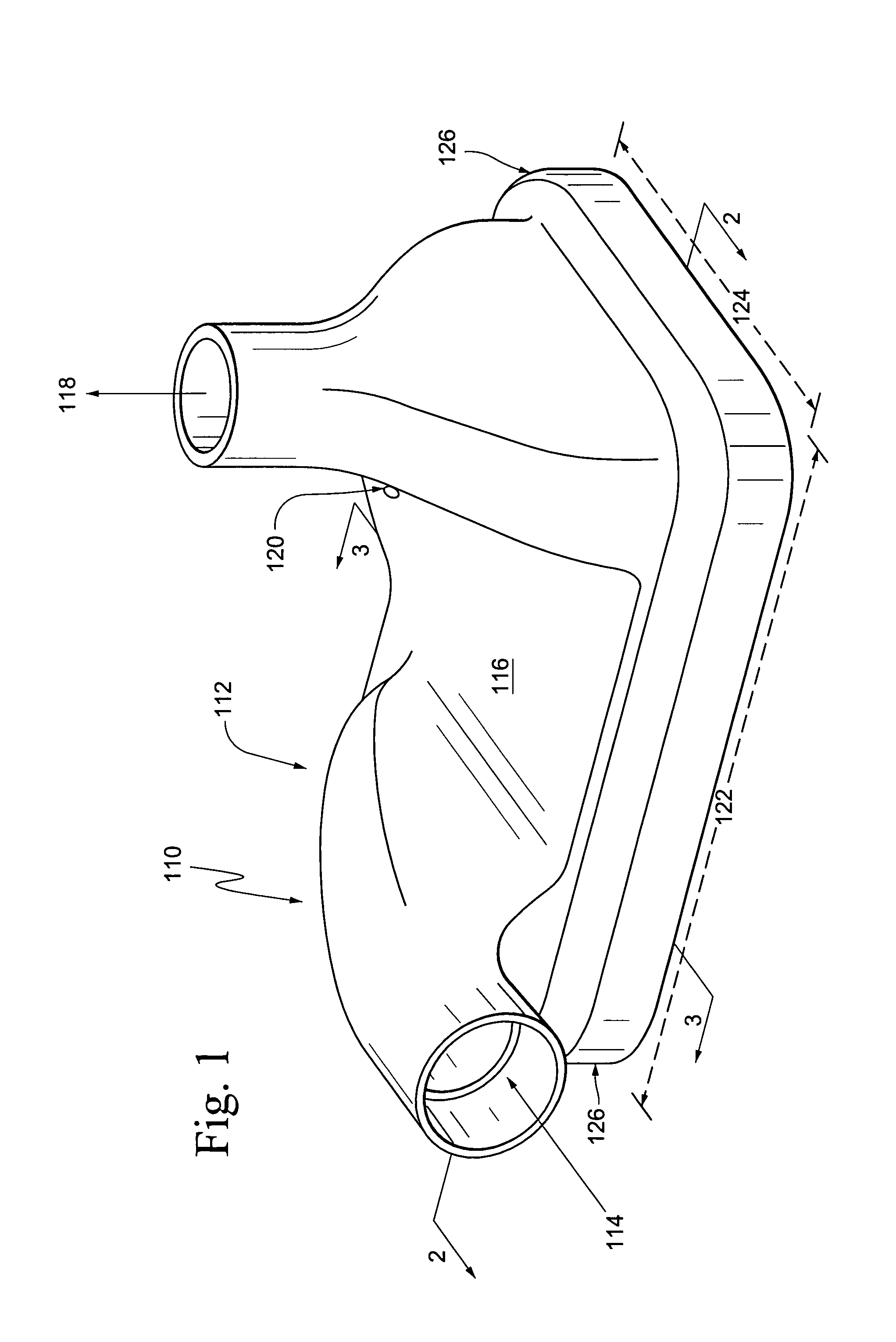

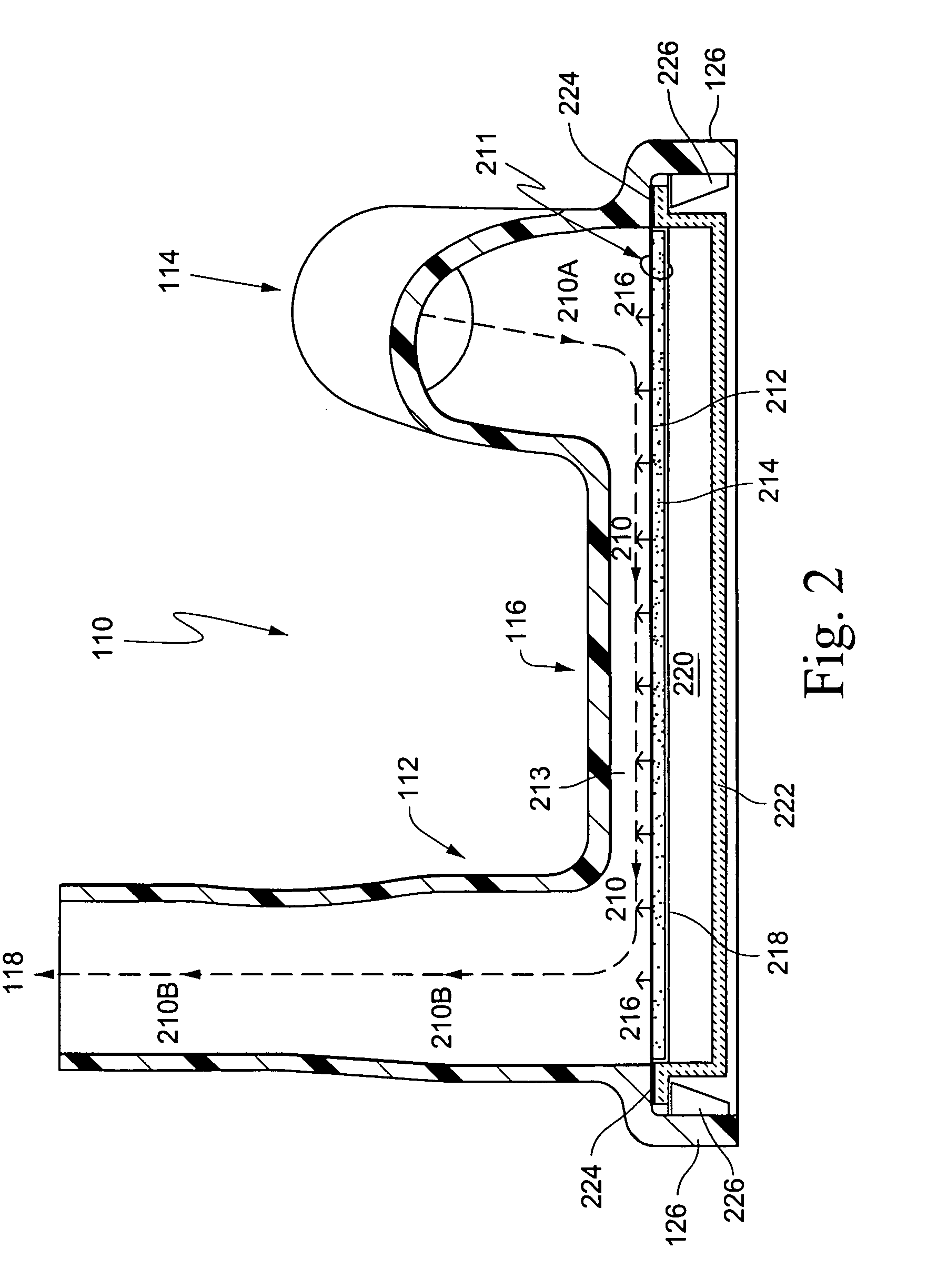

Removable and/or replaceable humidifier

ActiveUS8550075B2Improved vaporizationUsing liquid separation agentMedical devicesWater vaporElectrical and Electronics engineering

Owner:RESMED LTD

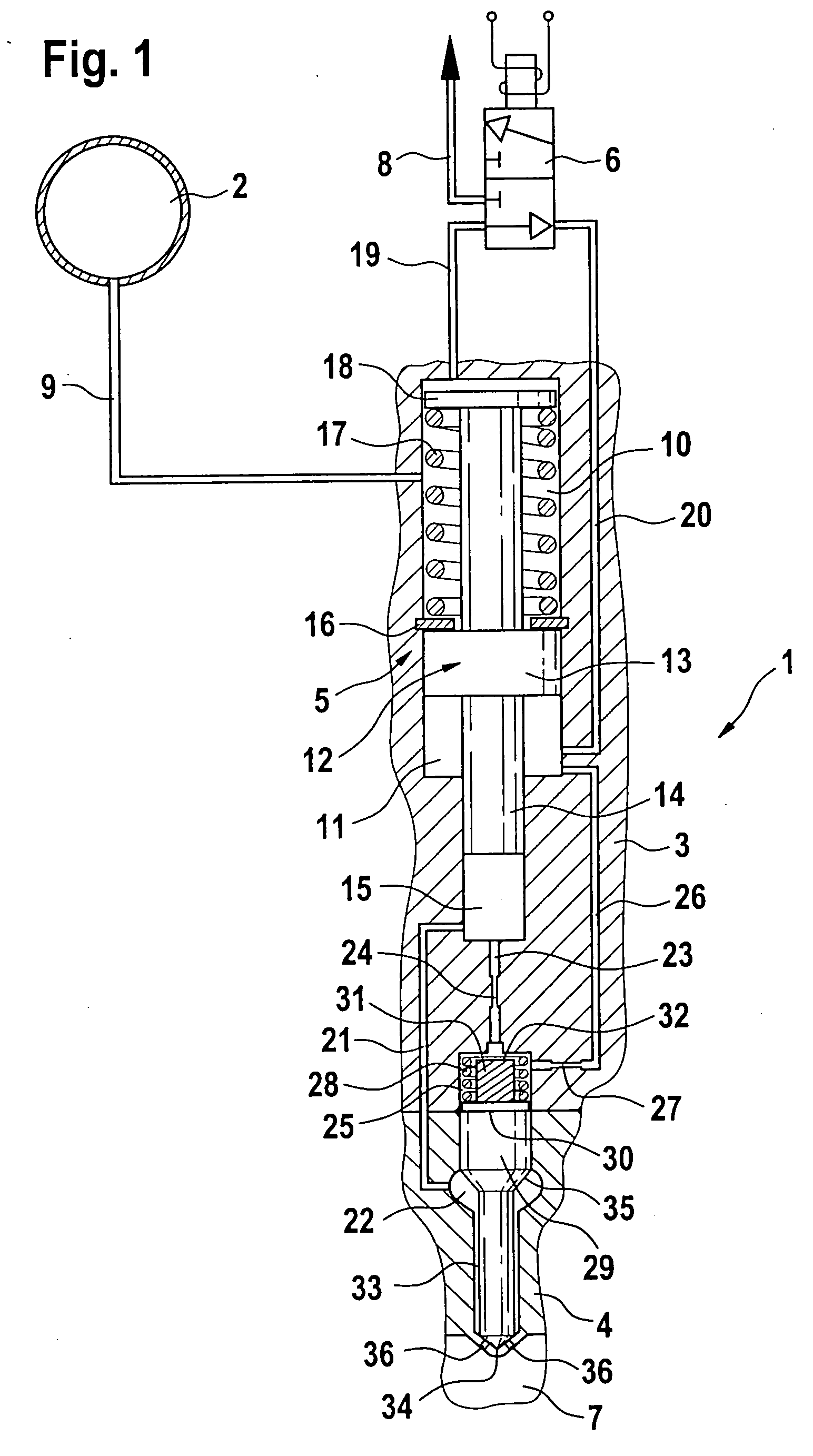

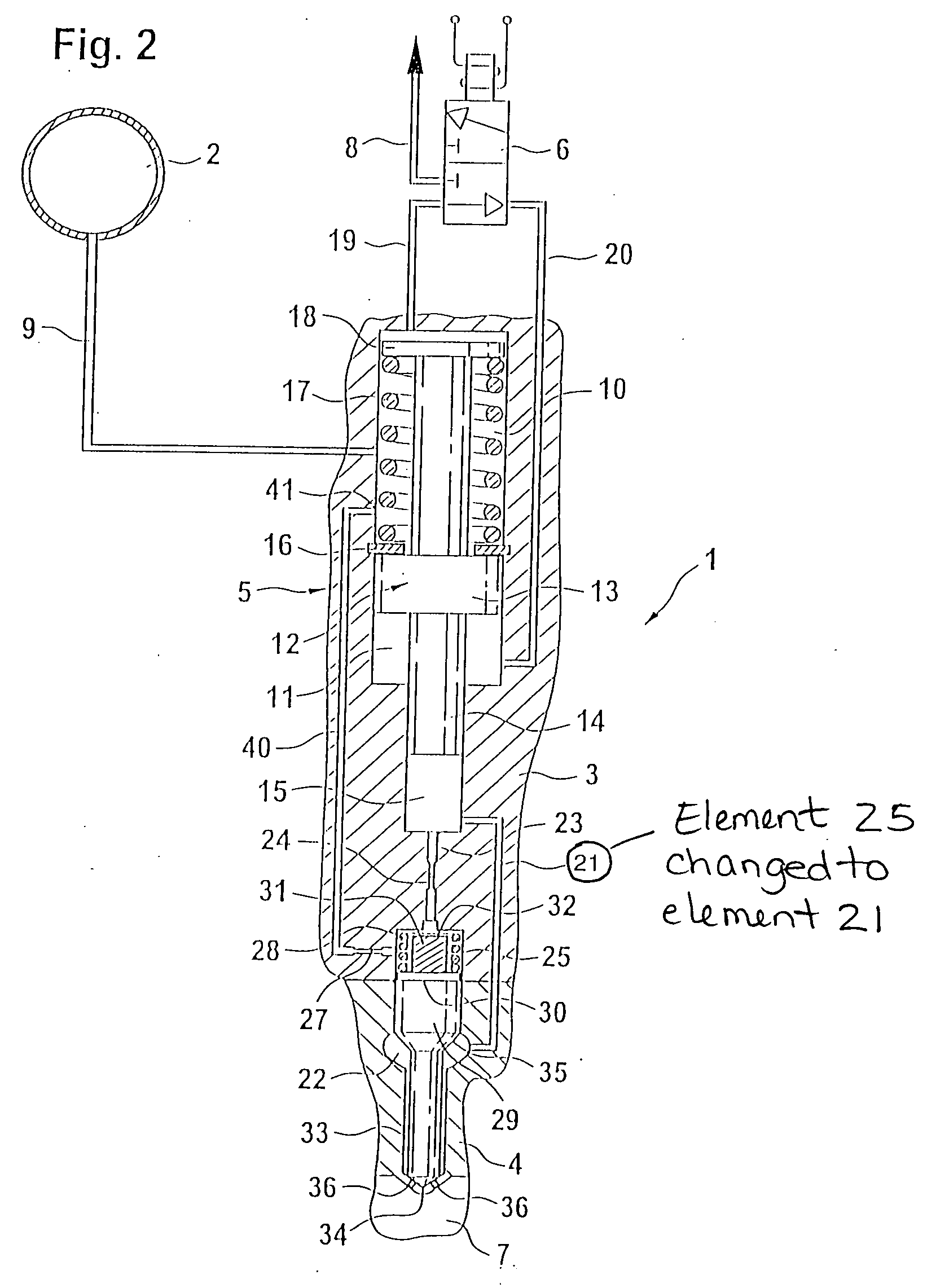

Device for damping the needle lift in fuel injectors

InactiveUS20050077378A1Quick closeRaise emission levelsMachines/enginesFuel injecting pumpsCombustion chamberPiston

A fuel injection apparatus for injecting fuel into the combustion chambers of an internal combustion engine includes a high pressure accumulator, a pressure booster, and a metering valve. The pressure booster includes a working chamber and a control chamber that are separated from each other by an axially movable piston. A pressure change in the control chamber produces a pressure change in a compression chamber that acts on a nozzle chamber via a fuel inlet. The nozzle chamber encampasses a nozzle needle. A nozzle spring chamber that acts on the injection valve element can be filled on the high-pressure side via a line that leads from the compression chamber and contains an inlet throttle restriction. On the outlet side, the nozzle spring chamber is connected to a chamber of the pressure booster via a line that contains an outlet throttle restriction.

Owner:ROBERT BOSCH GMBH

Method for NOx Reduction

ActiveUS20110067381A1Degrade engine performanceReduce depositionInternal combustion piston enginesExhaust apparatusGasolineDiesel fuel

The present application relates to mitigating NOx emissions, and more particularly, to vehicles including a selective catalytic reduction (SCR) system in the exhaust of a diesel or gasoline engine. In one example a method includes temporarily increasing a liquid reductant dosing value injected by an injector from a first dosing value to a second dosing value, the temporary increase in response to a change from injecting liquid reductant onto a first impact location on a disperser device to injecting onto a second impact location on the disperser device.

Owner:FORD GLOBAL TECH LLC

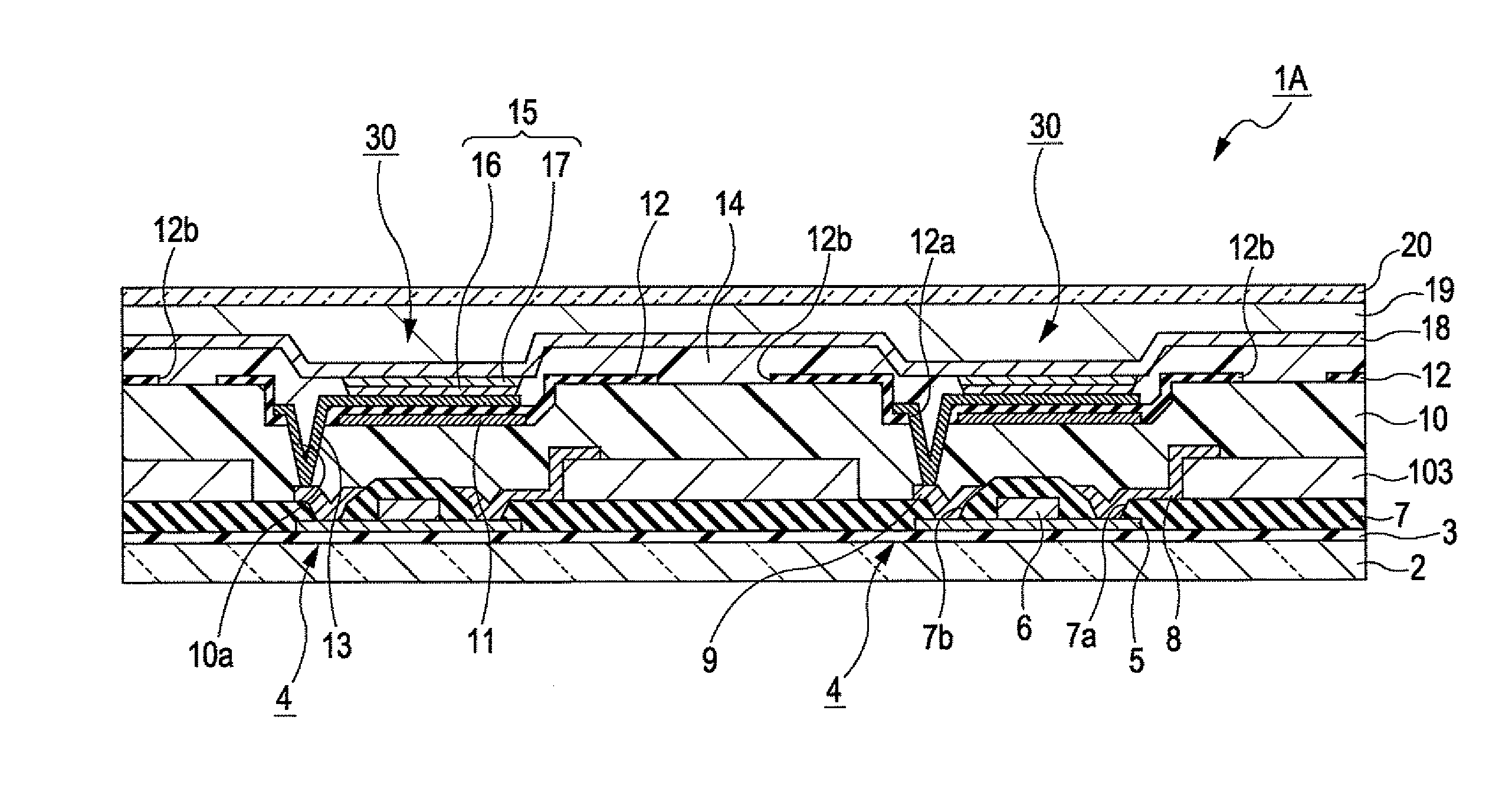

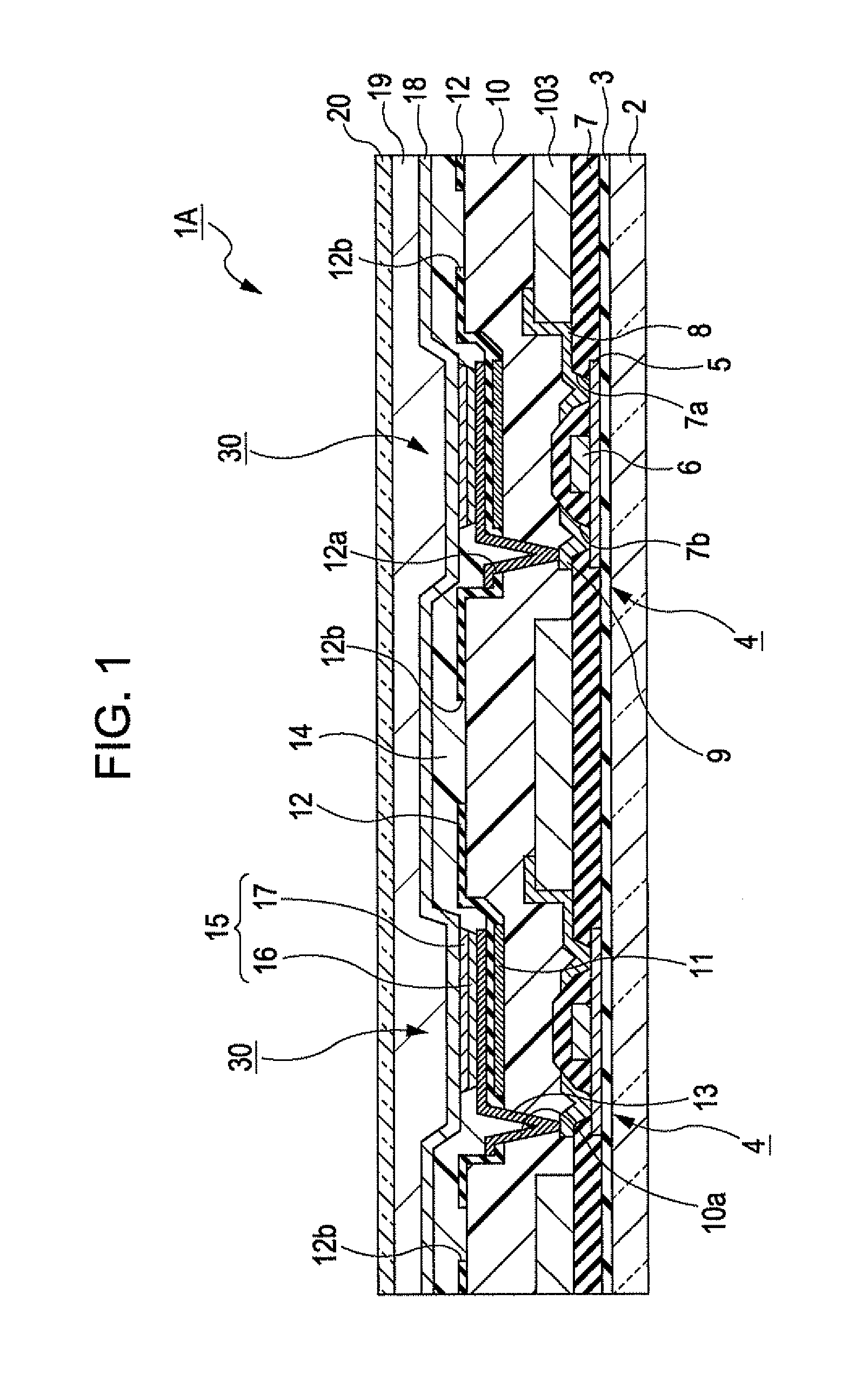

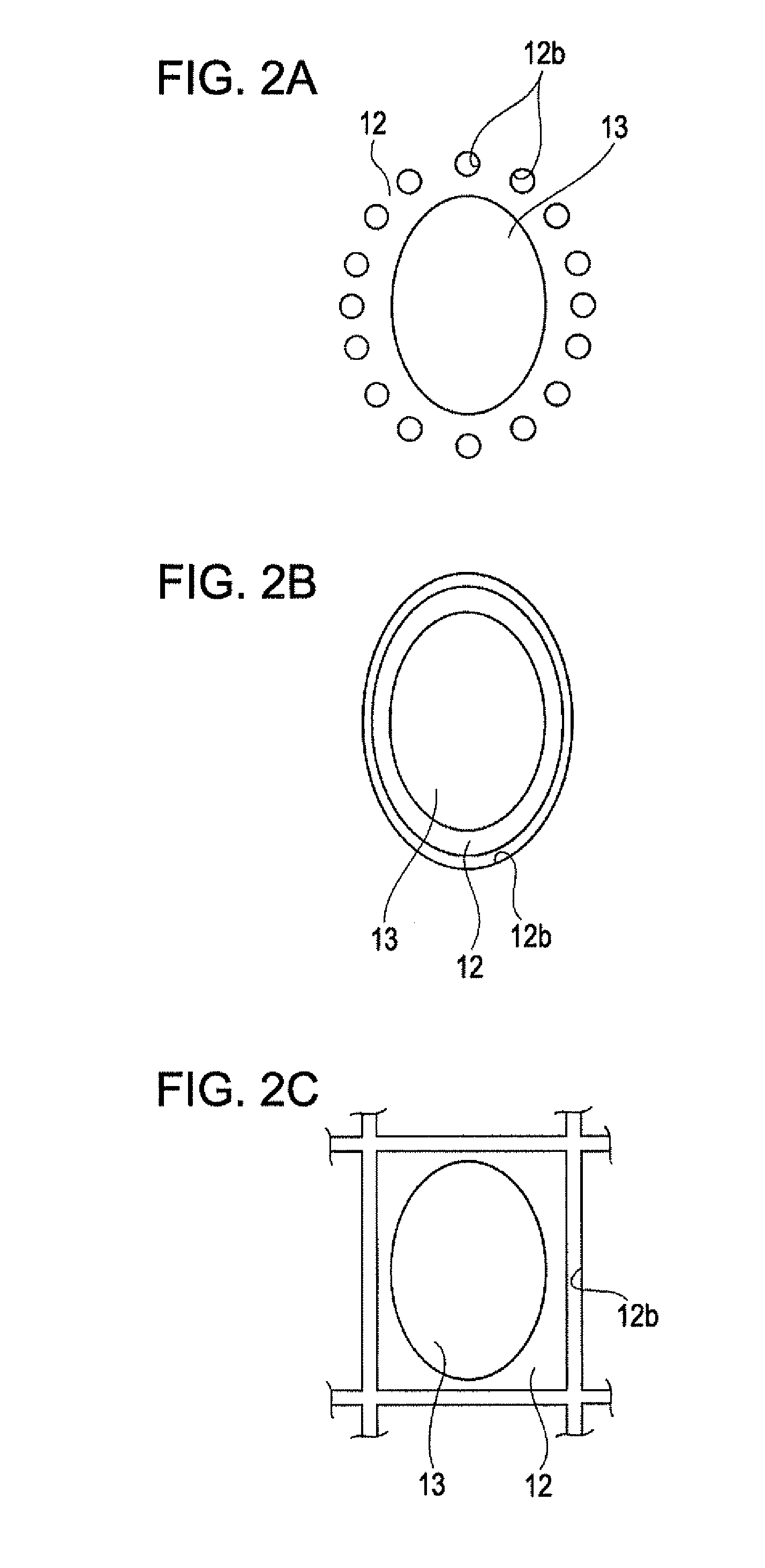

Organic electroluminescent device and electronic apparatus

ActiveUS20100200875A1Improve reliabilityDeterioration in display qualitySolid-state devicesSemiconductor devicesEngineeringReflective layer

An organic electroluminescent device includes a substrate; a plurality of light-emitting elements disposed on the substrate and including first transparent electrodes, a second transparent electrode, and light-emitting layers held therebetween; reflective layers disposed opposite the light-emitting layers with the first electrodes therebetween; a first insulating film disposed between the substrate and the reflective layers and formed of an organic material; and a second insulating film disposed between the first electrodes and the reflective layers so as to cover the reflective layers and the first insulating film. The second insulating film has a first through-hole at a position not overlapping the first electrodes in plan view. The first through-hole extends through the second insulating film to reach the first insulating film.

Owner:SEIKO EPSON CORP

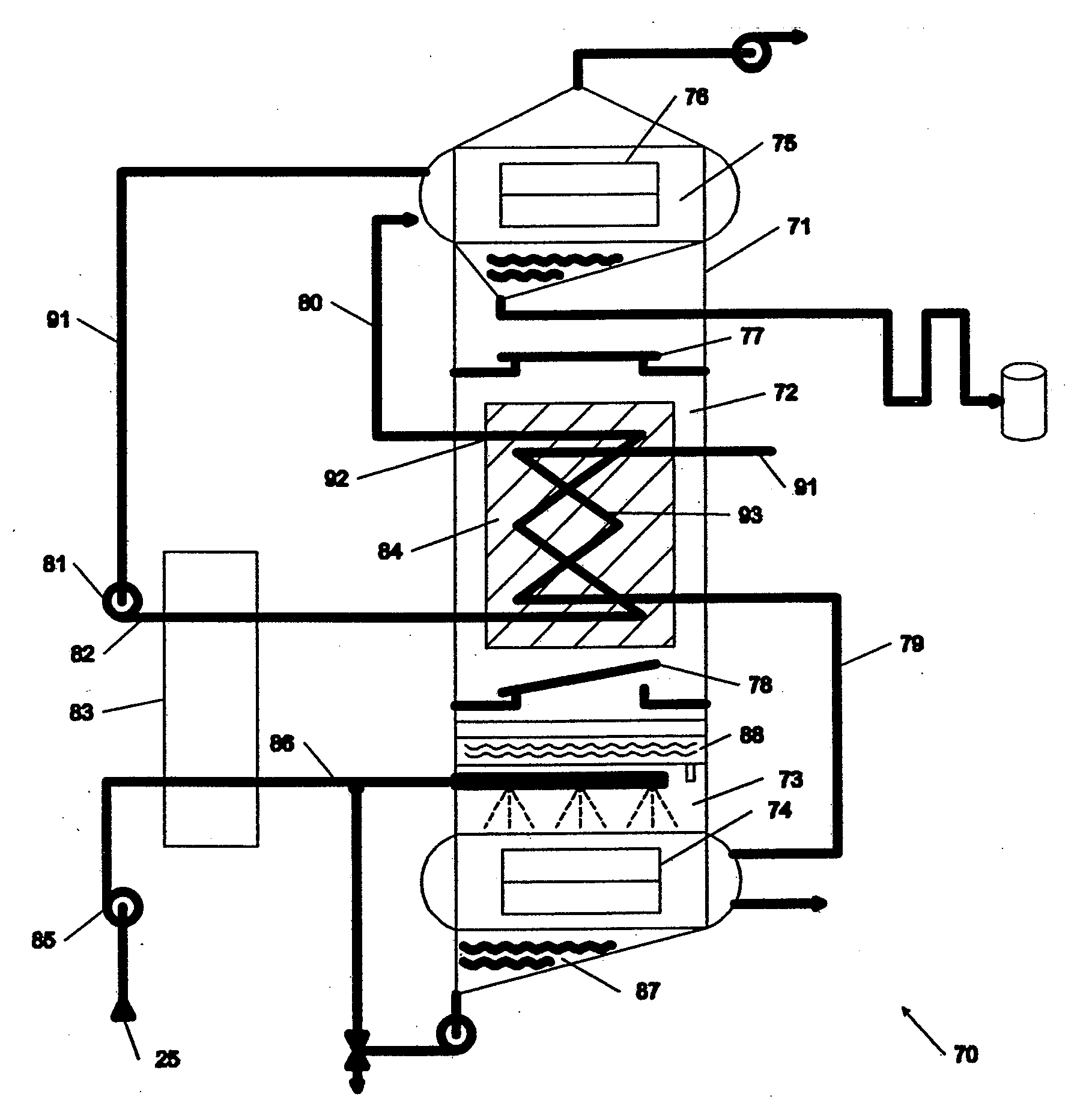

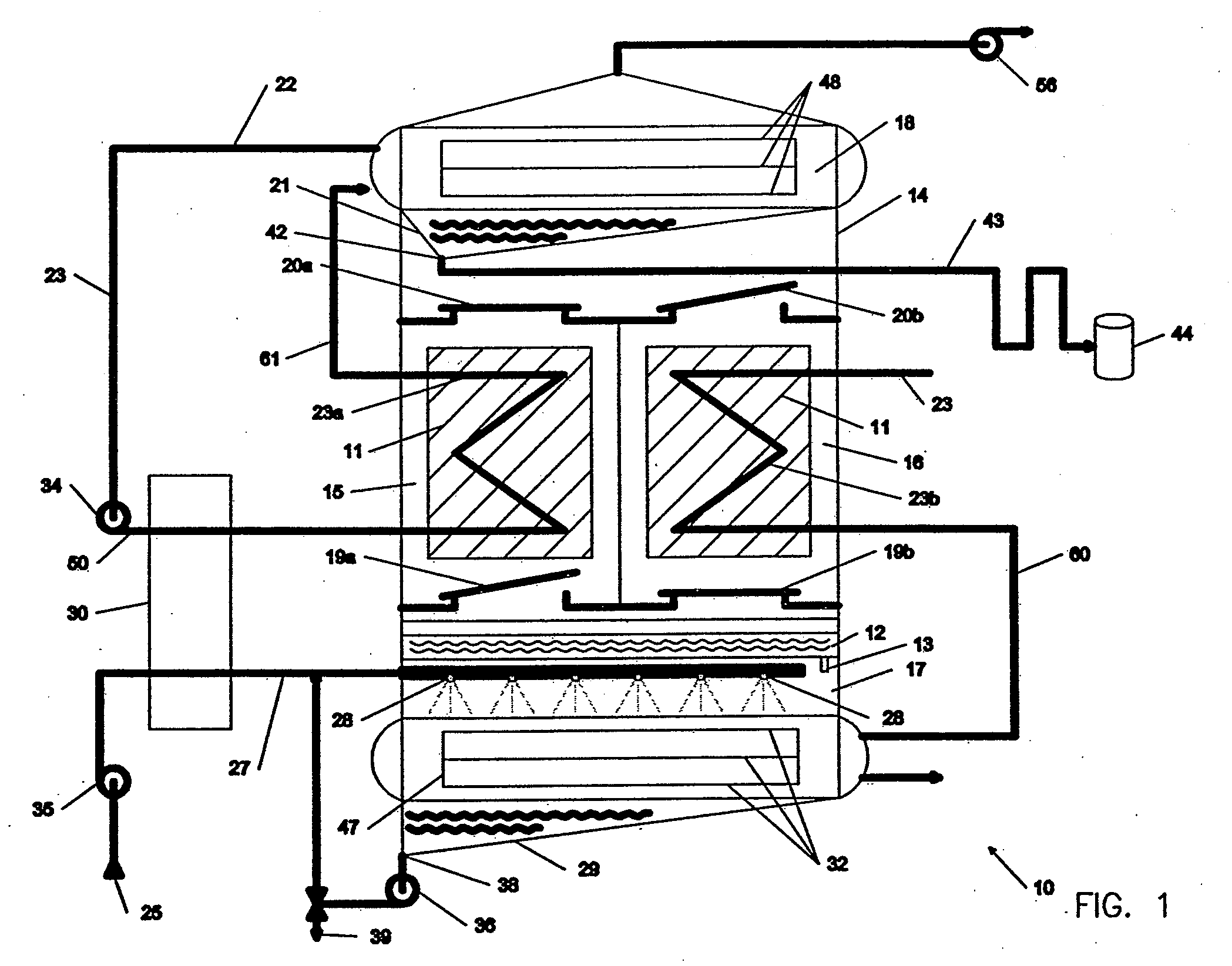

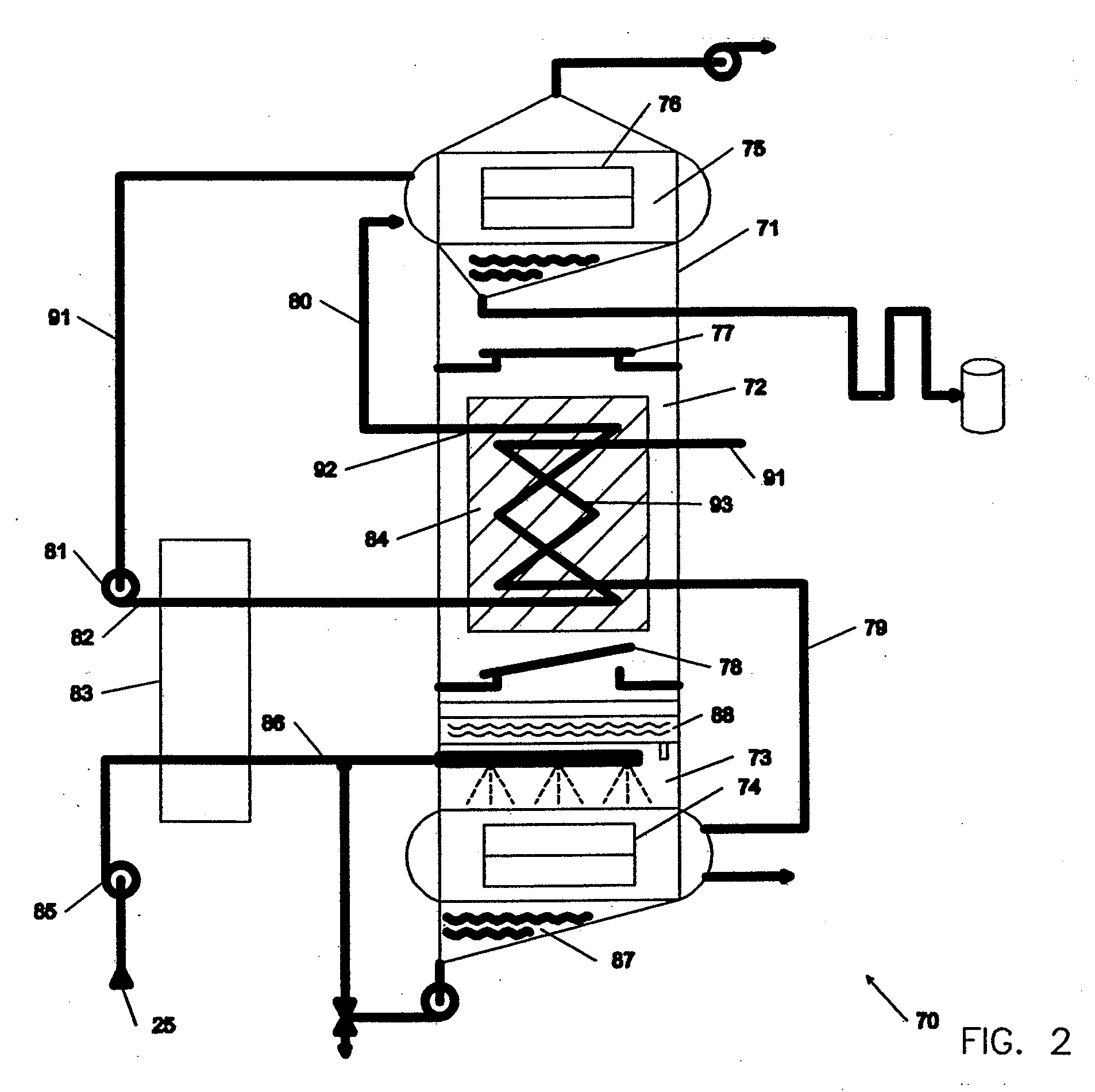

Adsorbent - Adsorbate Desalination Unit and Method

InactiveUS20110048920A1Reduce demandImprove efficiencyGeneral water supply conservationAuxillariesSeawaterEvaporator

An adsorption-desalination unit utilizing a silica gel—water working pair adsorbent—adsorbate having an economizing heat exchanger to pre-heat the incoming source seawater to be desalinated in an evaporator from about 8° C. to about 1° C. above the ambient seawater temperature. The economizing heat exchanger employs heat captured during the adsorption cycle to pre-heat incoming source seawater, thereby increasing the efficient use of energy in the unit. The heating fluid utilized to drive the desorption cycle is further utilized to heat the evaporator. A mist eliminator positioned intermediate the evaporator and the adsorbent heat exchanger chambers prevents non-vaporized water from entering the adsorbent heat exchanger chambers.

Owner:INDAL IDEA PARTNERS

Waste treatment apparatus and method

InactiveUS20110165035A1Improved vaporizationEasily damagedLavatory sanitoryCleaning using toolsVaporizationWaste treatment

An apparatus for treating waste comprises a gravity drop steam heating tower for heating the waste to the biological kill temperature using pressurized steam, a first feed member for feeding the waste to be sterilized to the gravity drop steam heating tower, and a vaporization system. The vaporization system includes a heating chamber for facilitating vaporization of liquids in the waste, a conveying member for conveying the waste from the lower end portion of the gravity drop steam heating tower into and through the heating chamber, and a vaporization chamber for receiving the waste from the heating chamber and for releasing vapor entrained in the waste into the vaporization chamber.

Owner:ONSITE STERILIZATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com