Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2124results about How to "Easy to crack" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

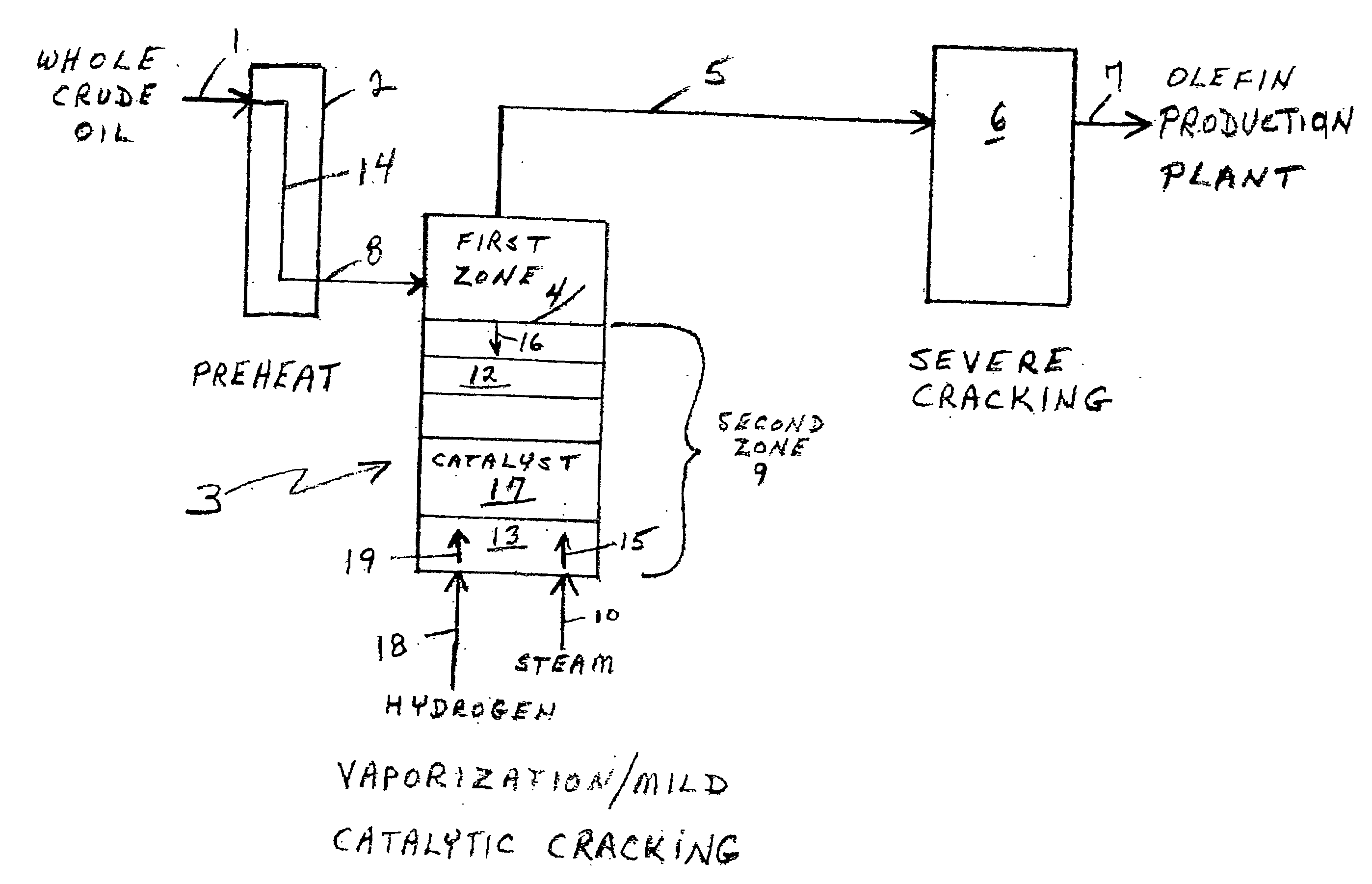

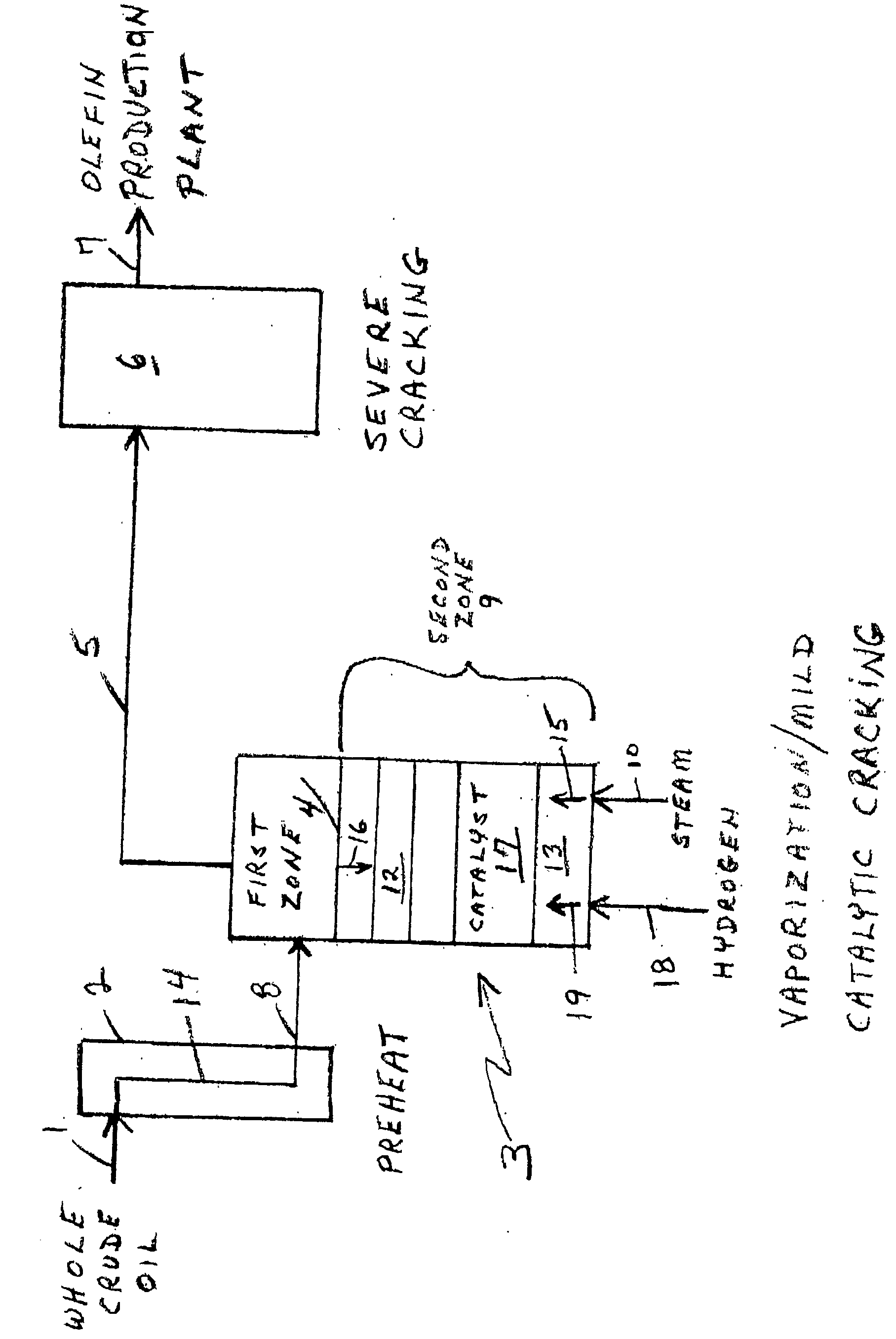

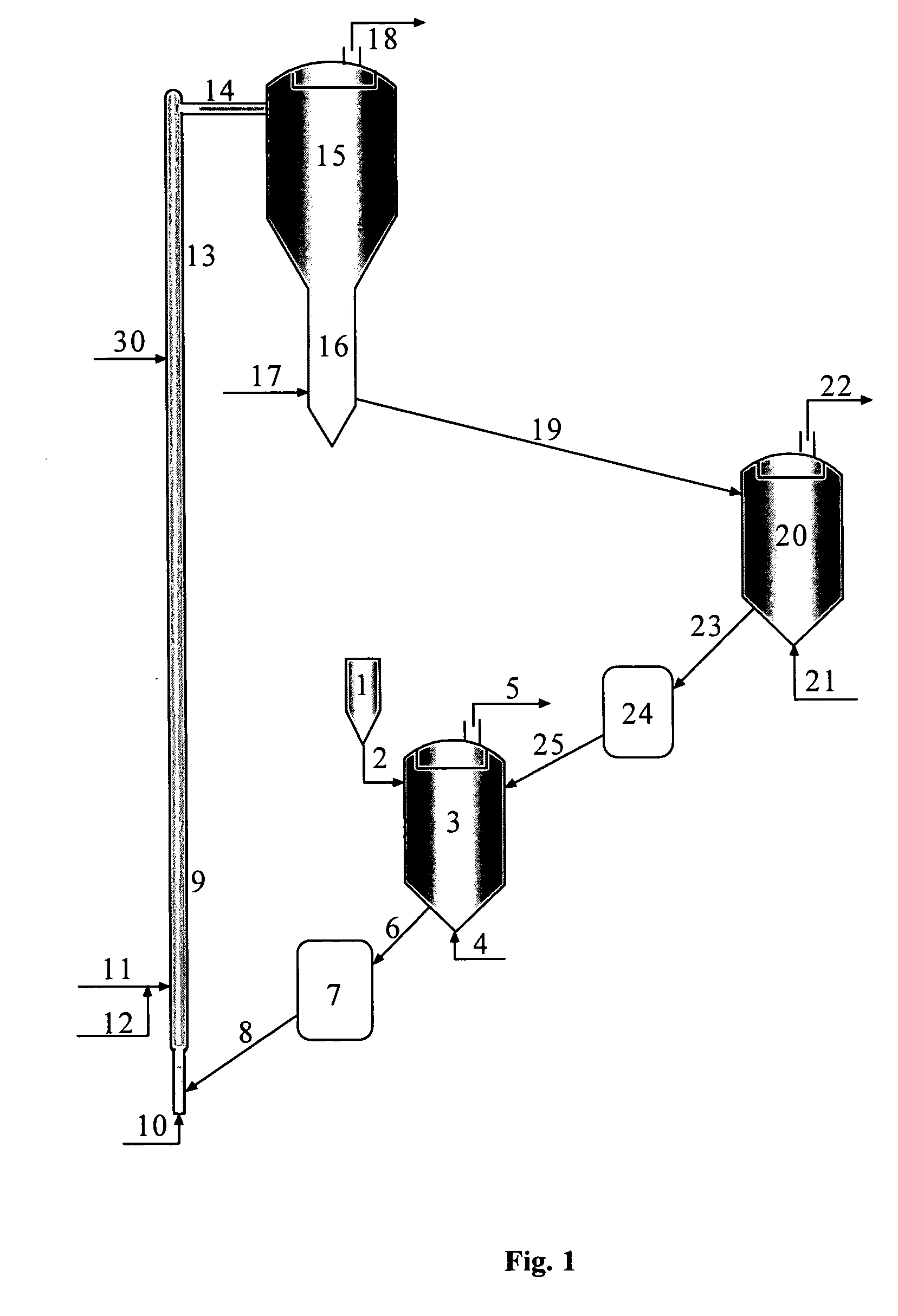

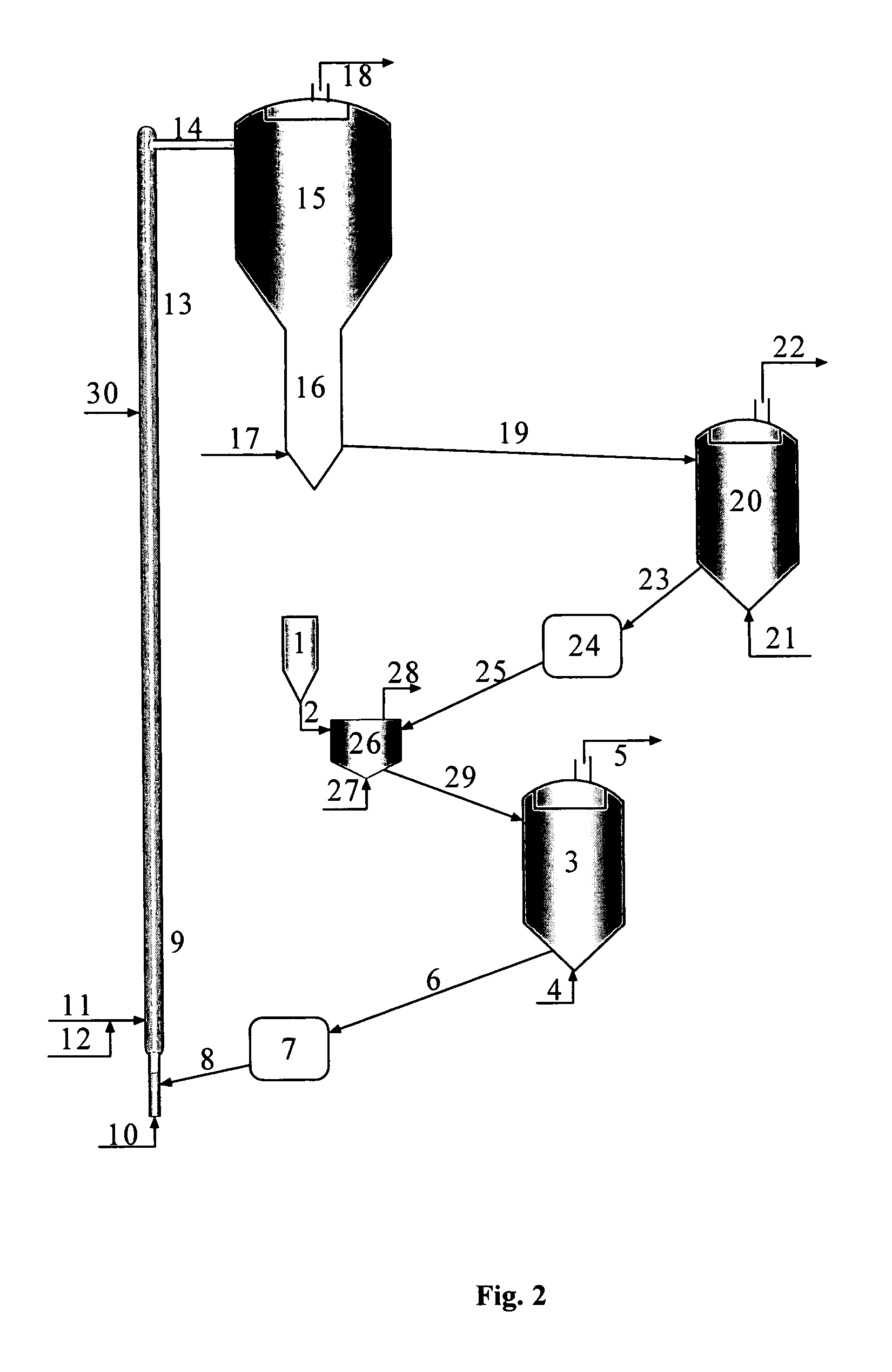

Olefin production utilizing whole crude oil and mild catalytic cracking

InactiveUS20040054247A1Lower temperature rangeImproved vaporizationThermal non-catalytic crackingCatalytic crackingChemistryPyrolysis

A method for utilizing whole crude oil as a feedstock for the pyrolysis furnace of an olefin production plant wherein the feedstock after preheating is subjected to mild catalytic cracking conditions until substantially vaporized, the vapors from the mild catalytic cracking being subjected to severe cracking in the radiant section of the furnace.

Owner:EQUSR CHEM LP

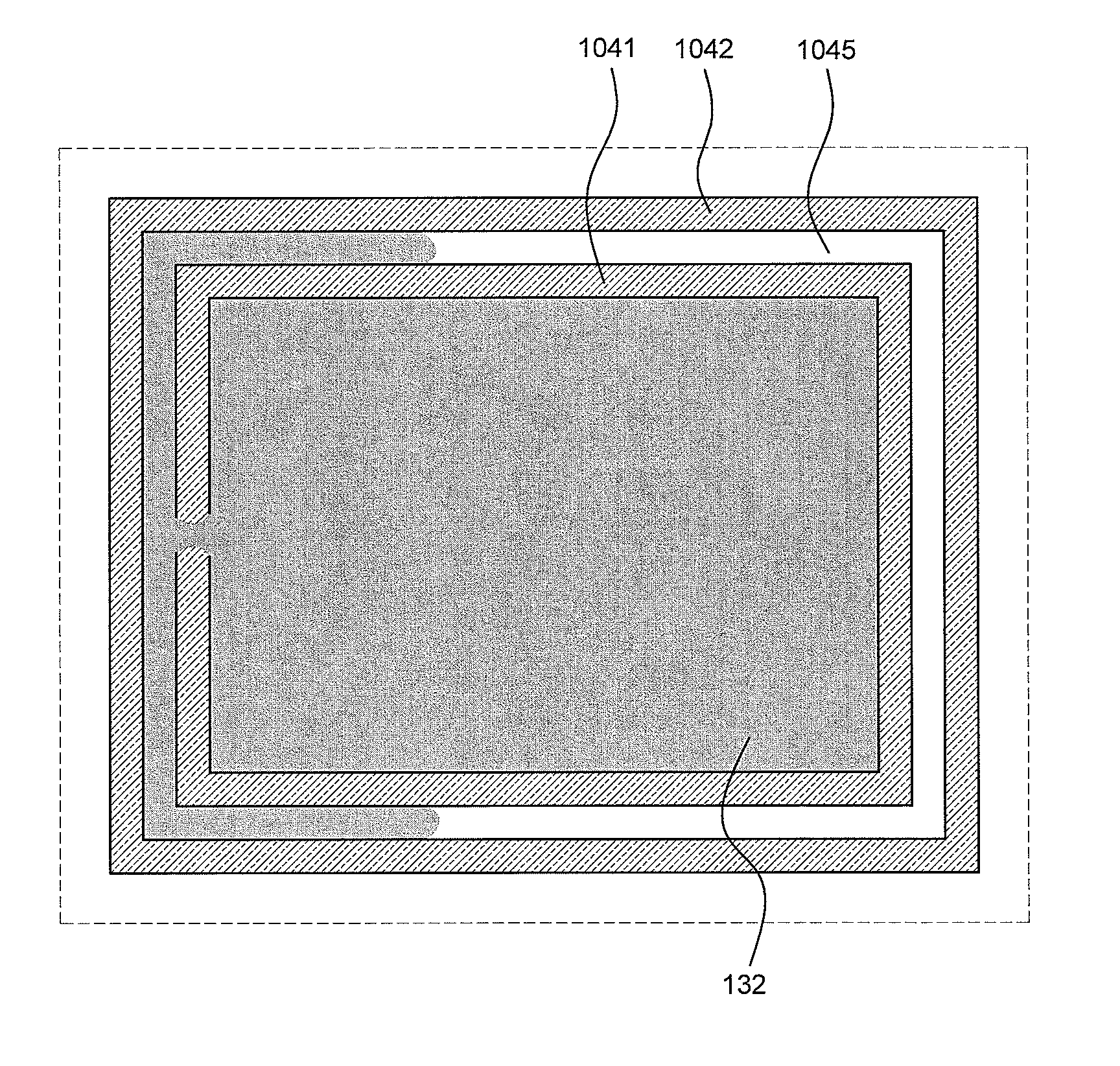

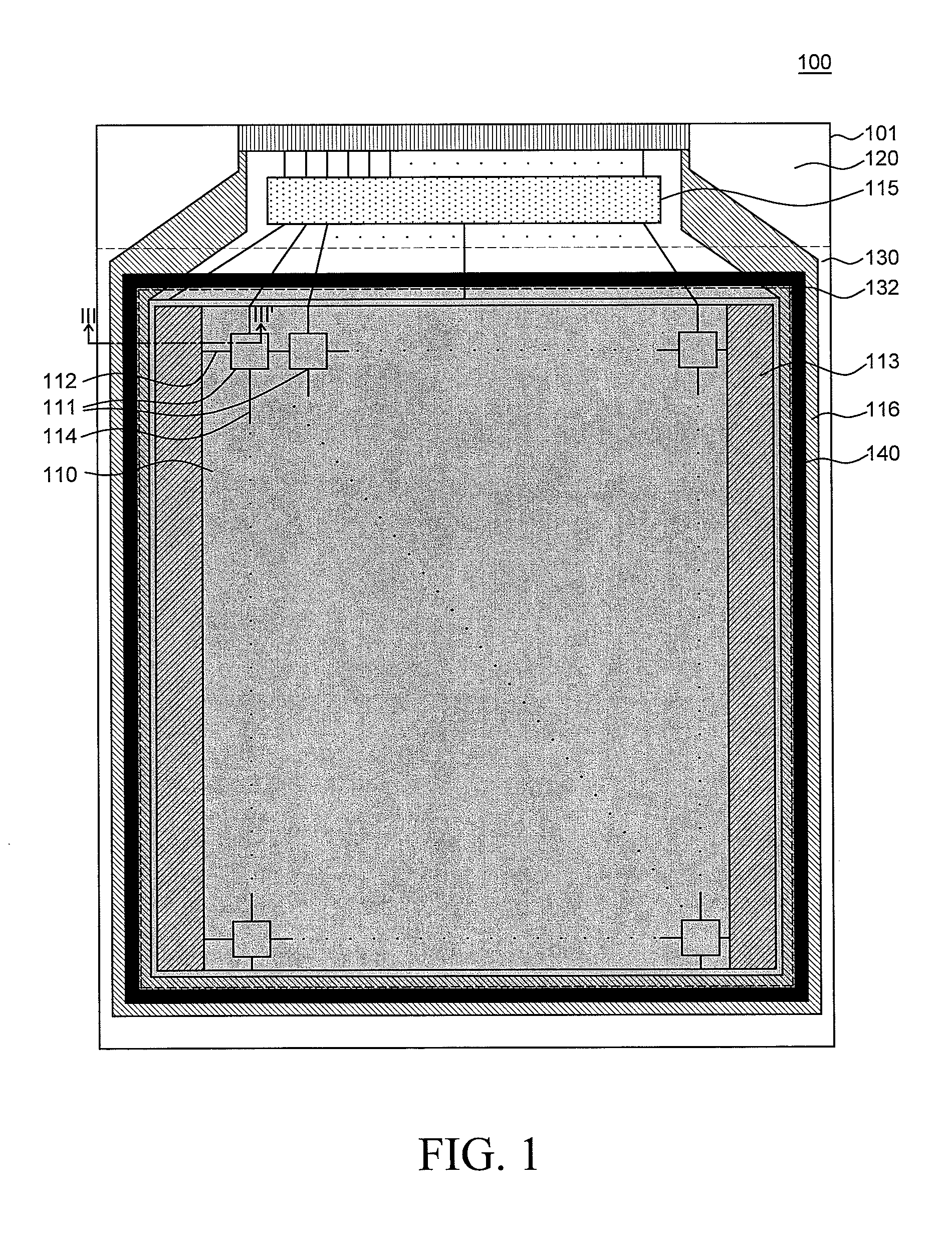

Organic light emitting display apparatus

ActiveUS20150380685A1Reduce liquidityEasy to crackSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsGate driver

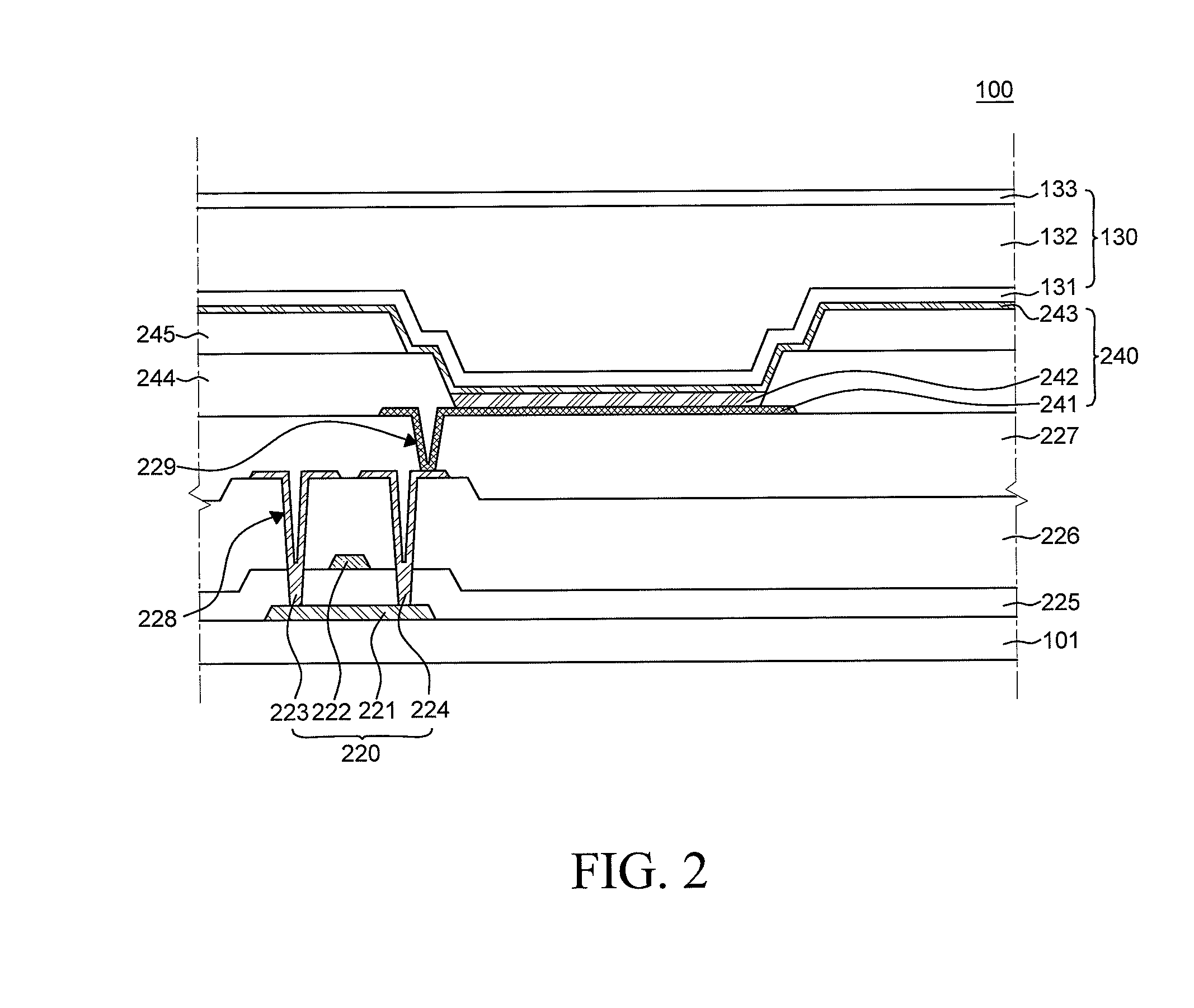

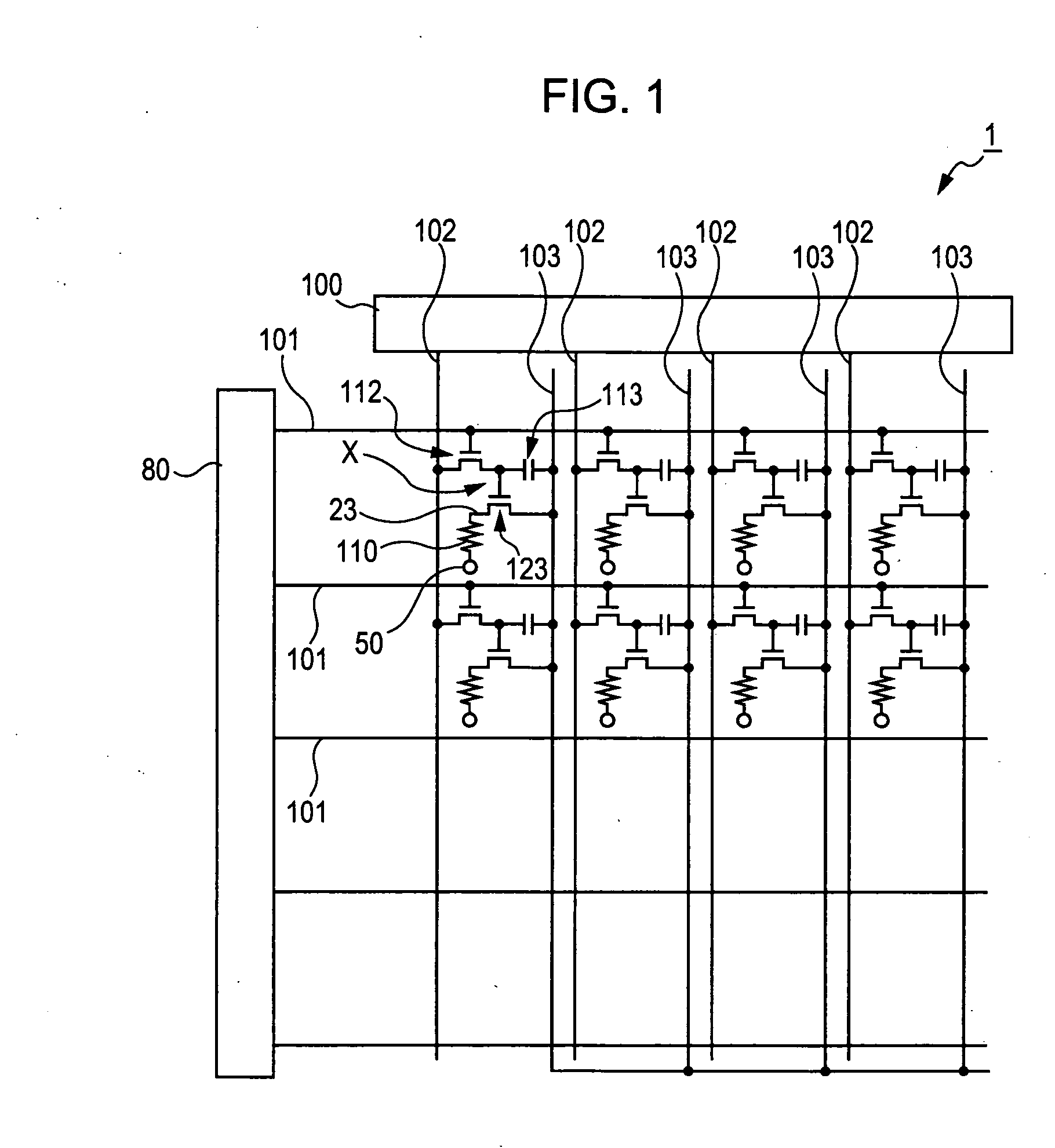

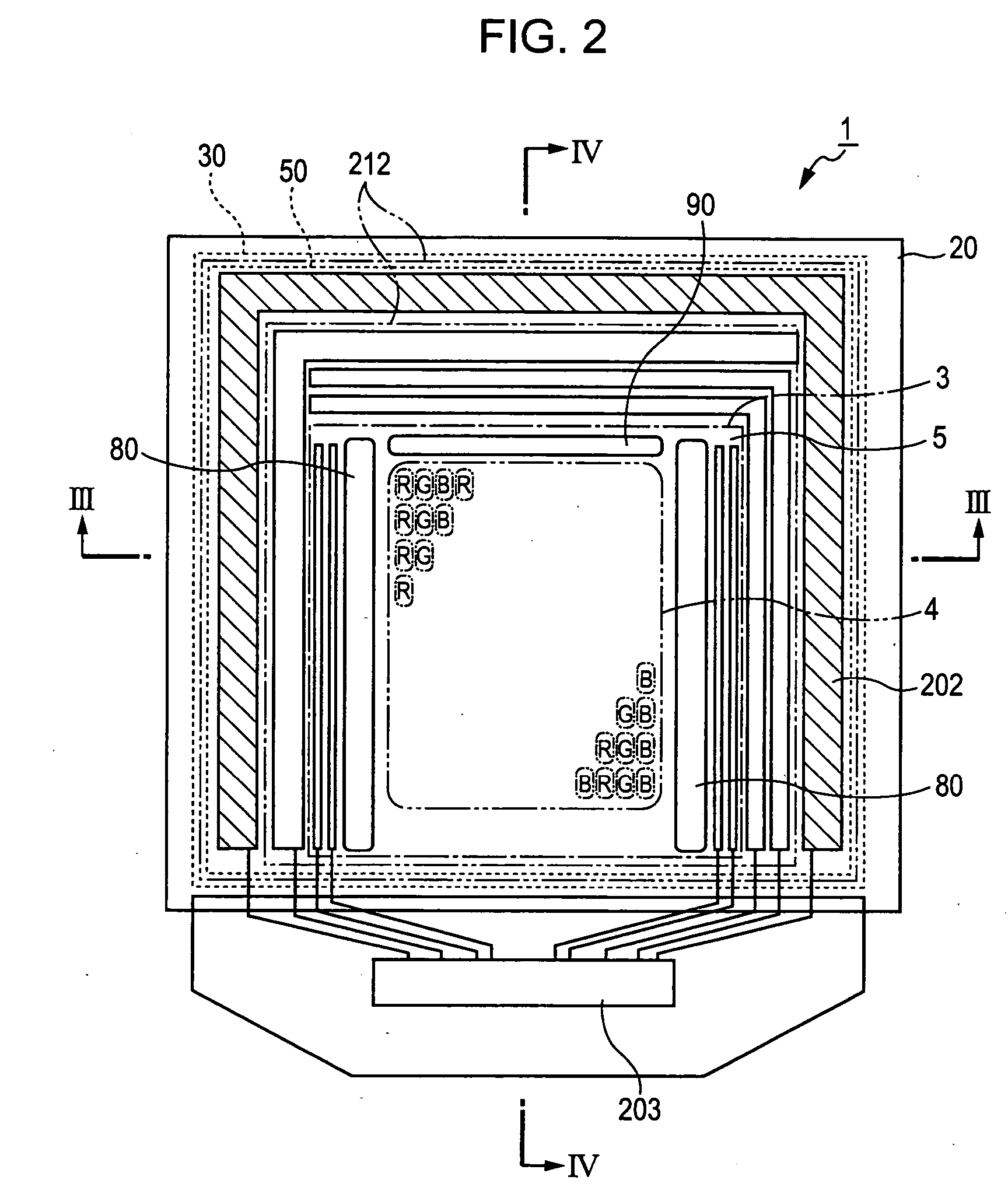

An organic light-emitting display (OLED) device includes: a pixel area defined by a plurality of pixels on a flexible substrate; a non-pixel area around the pixel area; a gate driver in the non-pixel area; a structure in the non-pixel area configured to surround the pixel area; a first encapsulation layer covering the plurality of pixels, the gate driver and the structure; and a particle cover layer covering the pixel area and suppressed from being excessively spread by the structure.

Owner:LG DISPLAY CO LTD

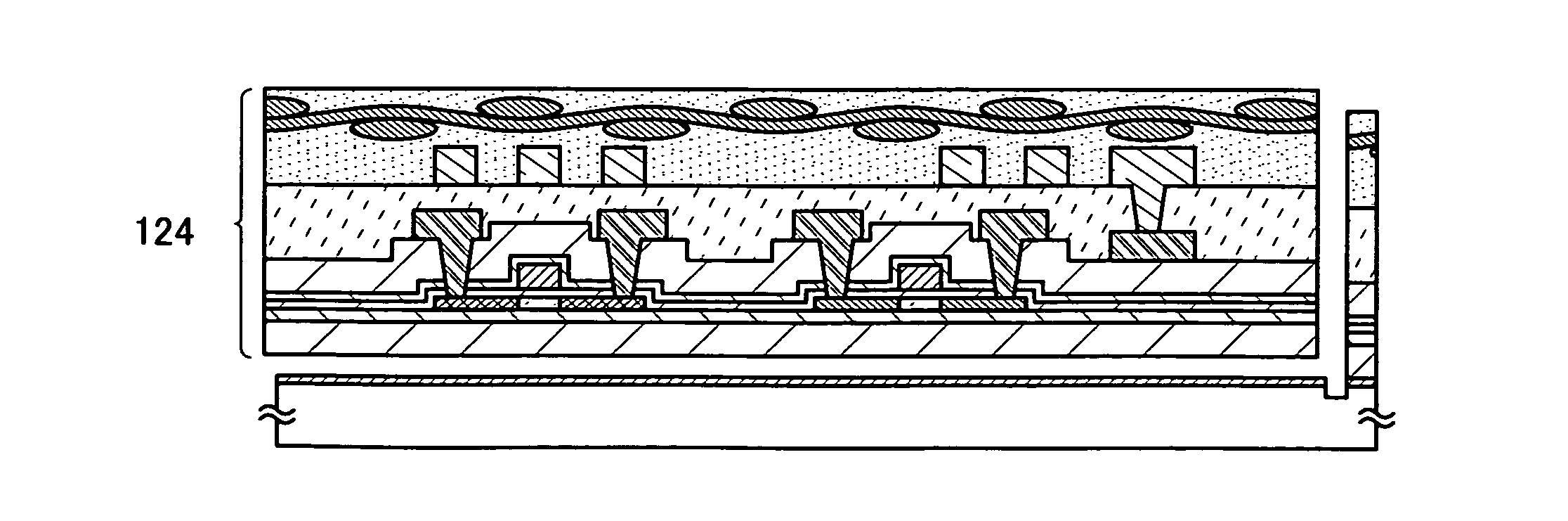

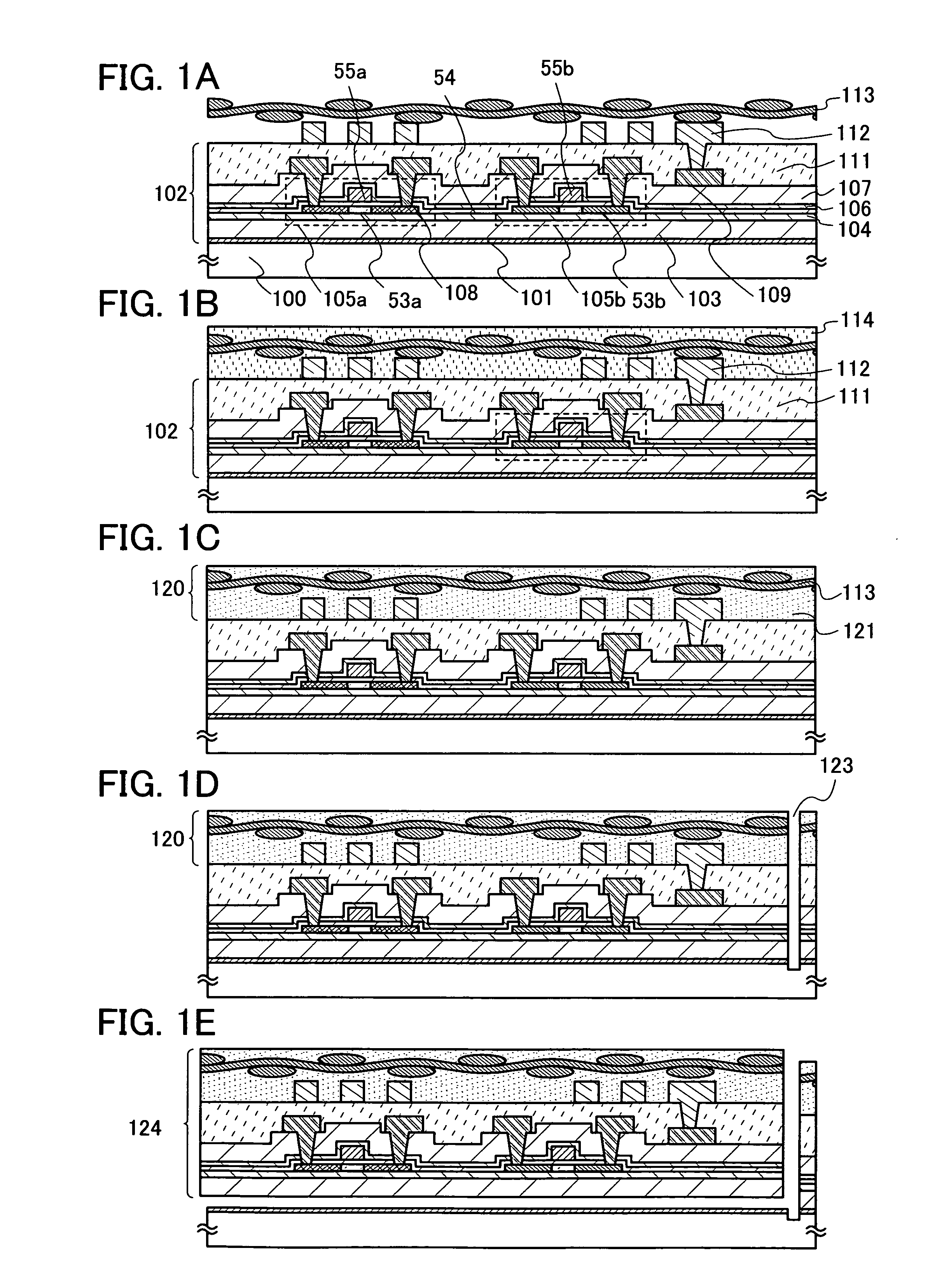

Light-emitting device, method for manufacturing light-emitting device, and electronic apparatus

ActiveUS20060158111A1Prevent moisture penetrationPrevent penetrationDischarge tube luminescnet screensLayered productsEngineeringProtection layer

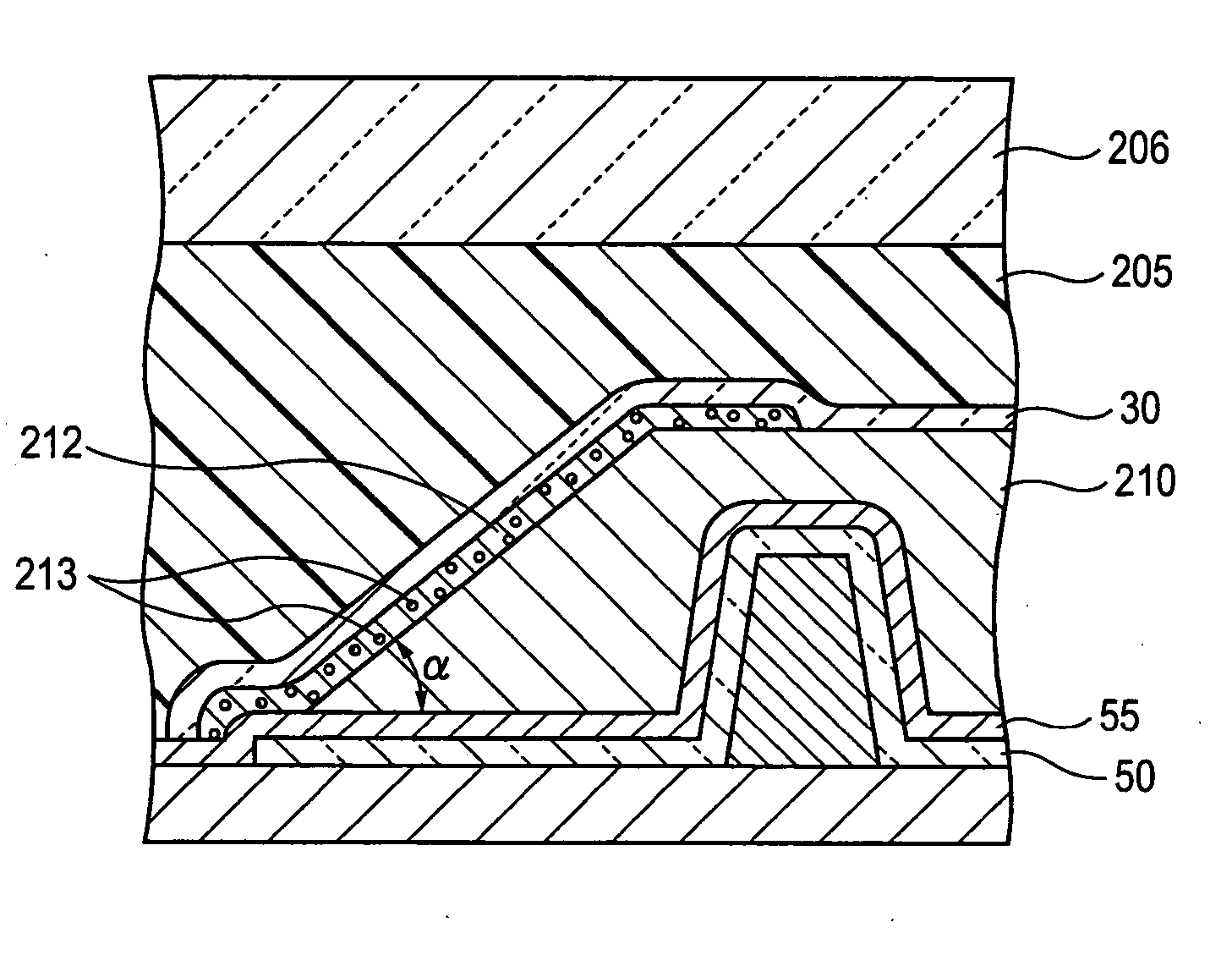

A light-emitting device includes a base; a plurality of first electrodes; a partition having a plurality of openings located at positions corresponding to the first electrodes; organic functional layers each arranged in the corresponding openings; a second electrode covering the partition and the organic functional layers; an organic buffer layer covering the second electrode; a gas barrier layer covering the organic buffer layer; and an intermediate protective layer, disposed between the organic buffer layer and the gas barrier layer, having an elasticity which is greater than that of the organic buffer layer and which is less than that of the gas barrier layer. These layers and electrodes are arranged on or above the base.

Owner:SEIKO EPSON CORP

Molecular sieve-containing catalyst for cracking hydrocarbons and a method for preparing the same

ActiveUS20040266608A1Reduced activityEasy to crackCatalytic crackingMolecular sieve catalystsReduction ActivityMolecular sieve

A molecular sieve-containing catalyst for cracking hydrocarbons, comprising molecular sieve, refractory inorganic oxide, clay and a metal component, wherein the amount of said molecular sieve is from 1 to 90% by weight, the refractory inorganic oxide is from 2 to 80% by weight, the clay is from 2 to 80% by weight, and the metal component is from 0.1 to 30% by weight, calculated as the oxide of said metal having its maximum valence state, based on the total amount of the catalyst, wherein said metal component exists essentially in a reduction state and is one or more metals selected from the group consisting of metals of Group III A(other than aluminum), and metals of Group IVA, VA, IB, IIB, VB, VIB and VIIB, and non-noble metals of Group VIII of the periodic table. The catalyst has higher cracking activity and higher sulfur reduction activity.

Owner:CHINA PETROCHEMICAL CORP +1

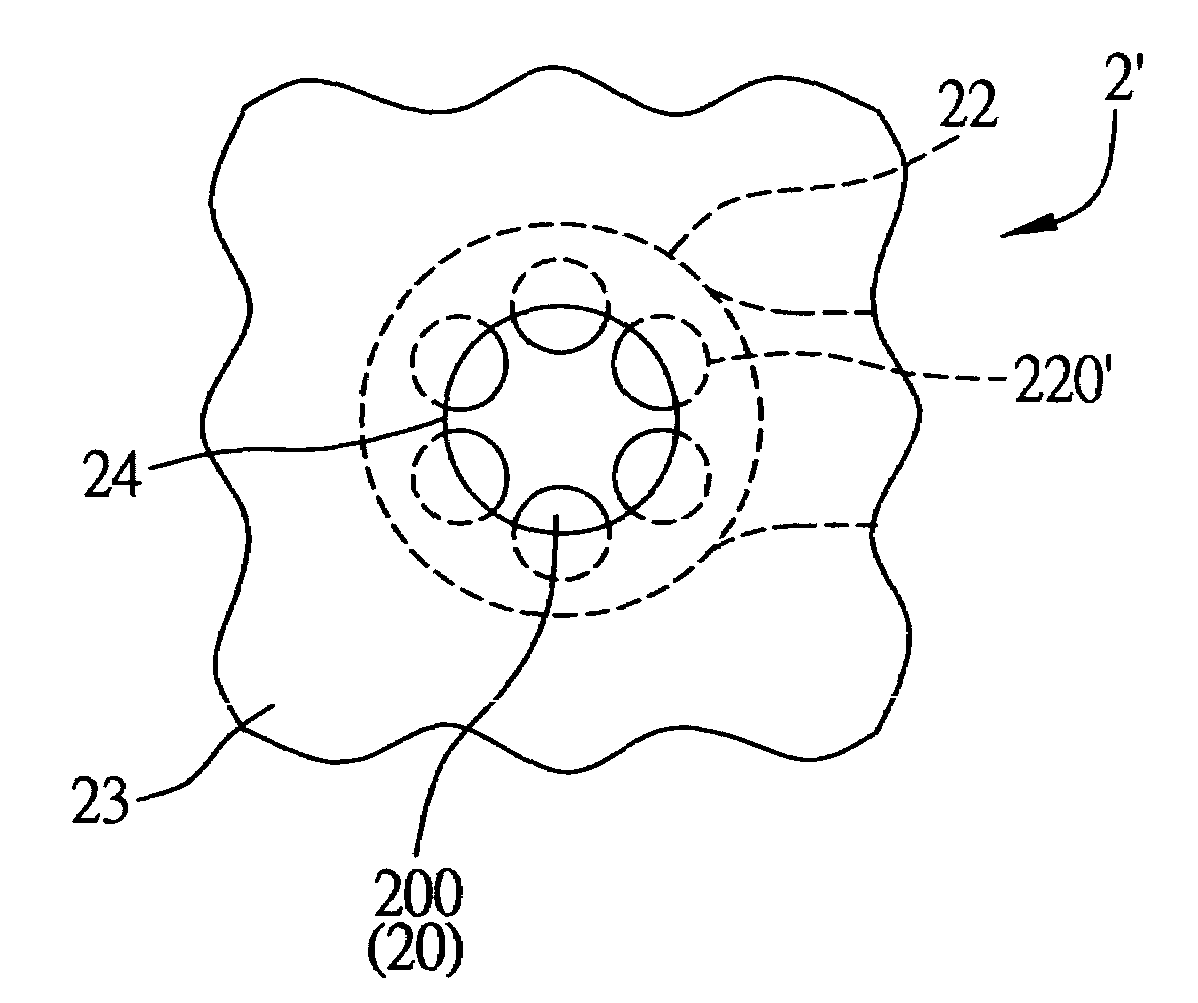

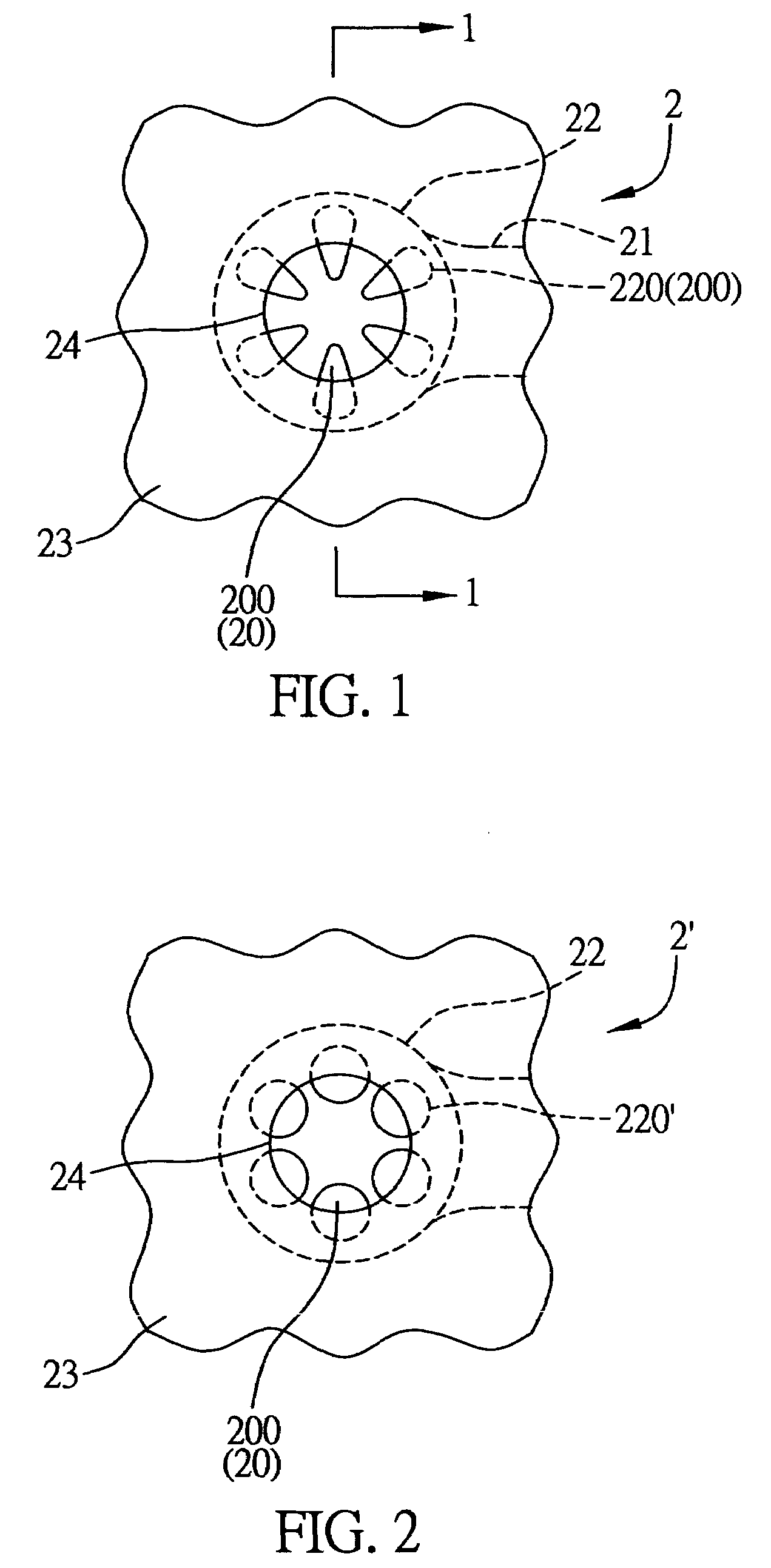

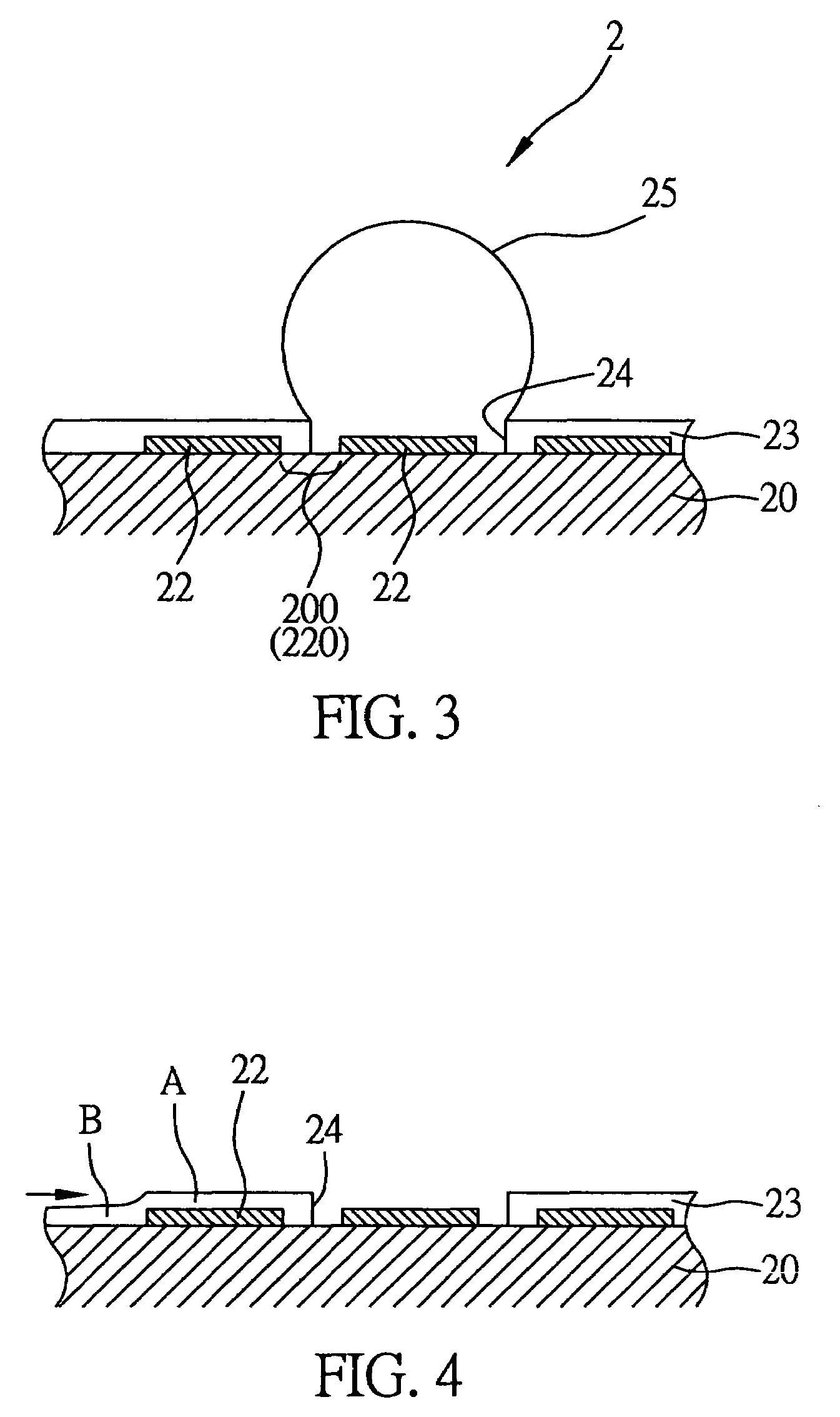

Substrate for solder joint

InactiveUS7224073B2Avoid pollutionPerformed easily and accuratelyPrinted circuit assemblingFinal product manufactureSolder maskEngineering

A substrate for solder joint is provided, including: a core layer; at least one conductive trace formed on the core layer and having a circular terminal as a pad through which a plurality of hollow portions are formed and expose predetermined portions of the core layer underneath the pad, wherein the hollow portions are arranged at equal intervals and spaced from a periphery of the circular pad; and a solder mask for covering the conductive trace and having at least one opening bordered across each of the hollow portions of the pad, such that part of the pad and part of each of the predetermined portions of the core layer are exposed via the opening, to allow a conductive element to be bonded to the exposed part of the pad and the exposed part of the predetermined portions of the core layer in the opening of the solder mask.

Owner:UTAC HEADQUARTERS PTE LTD

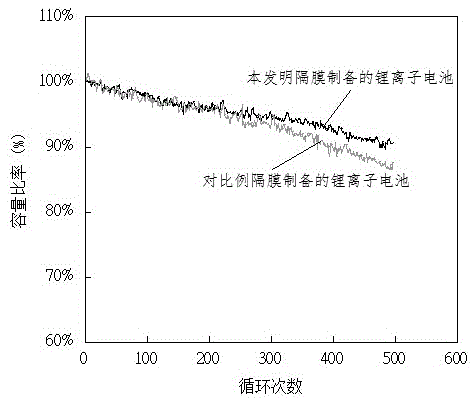

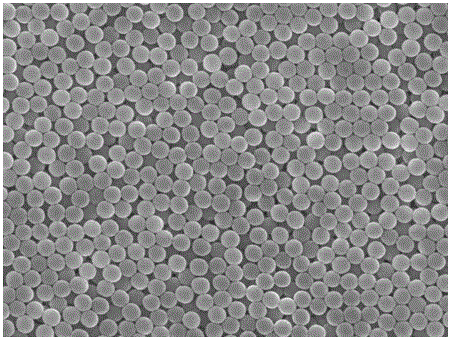

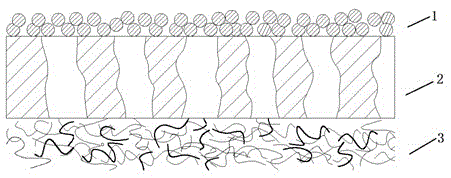

PVDF-coated lithium-ion battery separator and preparation method thereof

The invention provides a PVDF-coated lithium-ion battery separator and a preparation method thereof. The PVDF-coated lithium-ion battery separator comprises a base film and a coating, wherein the coating coats a single side or double sides of the base film; the coating is obtained by coating and drying slurry; and the coating is 0.1-0.5 micron in thickness and contains evenly arranged PVDF spherical particles. According to the PVDF-coated lithium-ion battery separator, a traditional technology that an existing PVDF-coated lithium-ion battery separator takes oil substances of acetone and the like as solvents is abandoned. Water is adopted as the solvent of a PVDF material; and no a thickening agent is added, so that the low-viscosity water-based PVDF coating slurry is obtained; an ultra-thin coating of which the PVDF particles are regularly arranged and which is relatively loose is obtained after the slurry is coated; the ultra-thin coating improves the hardness of a pole piece and the effective utilization space of the battery when effectively bonded to the lithium-ion battery separator and the pole piece; and the ventilation loss caused by the thickness of the coating is reduced.

Owner:CANGZHOU MINGZHU SEPARATOR TECH CO LTD

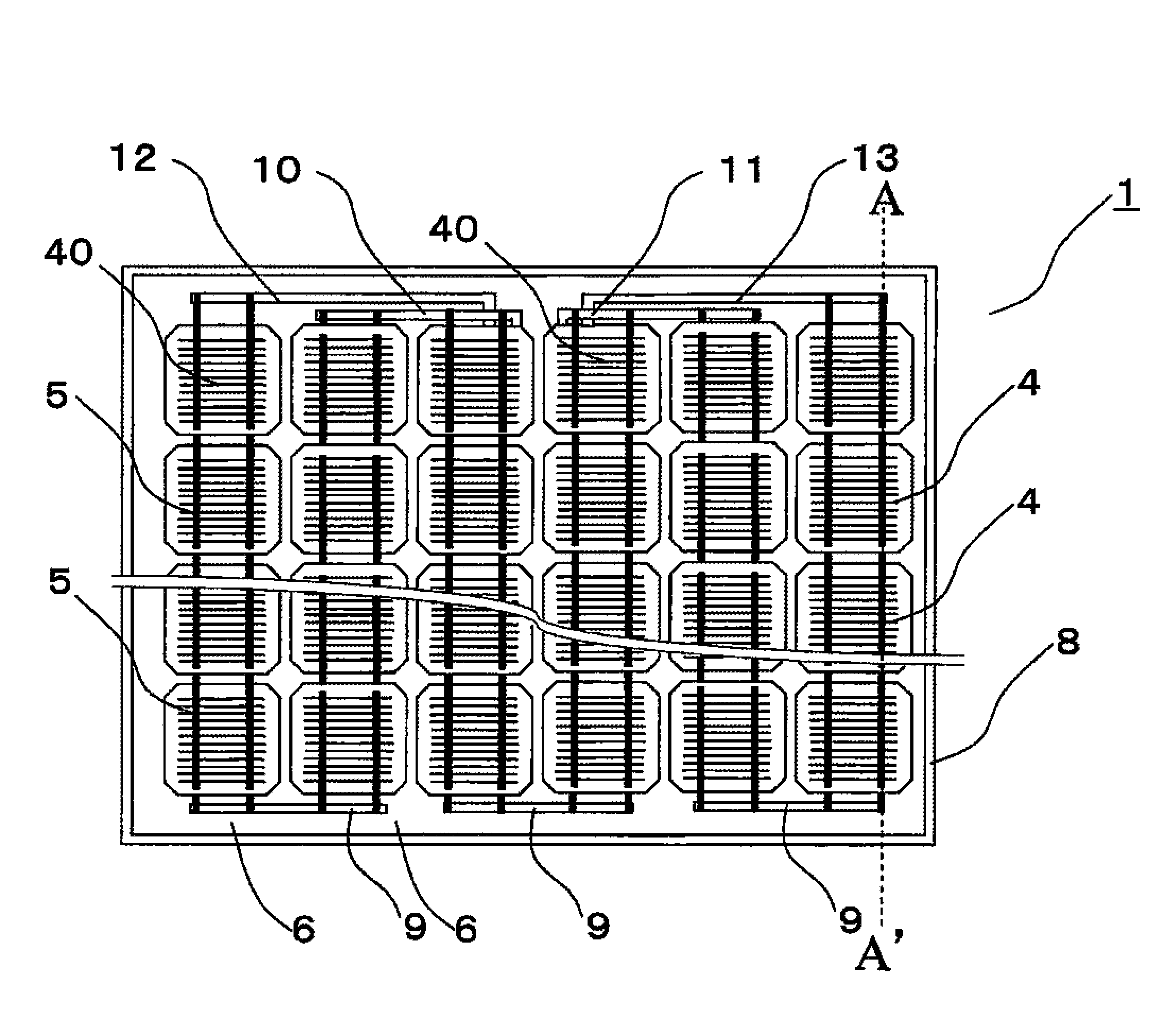

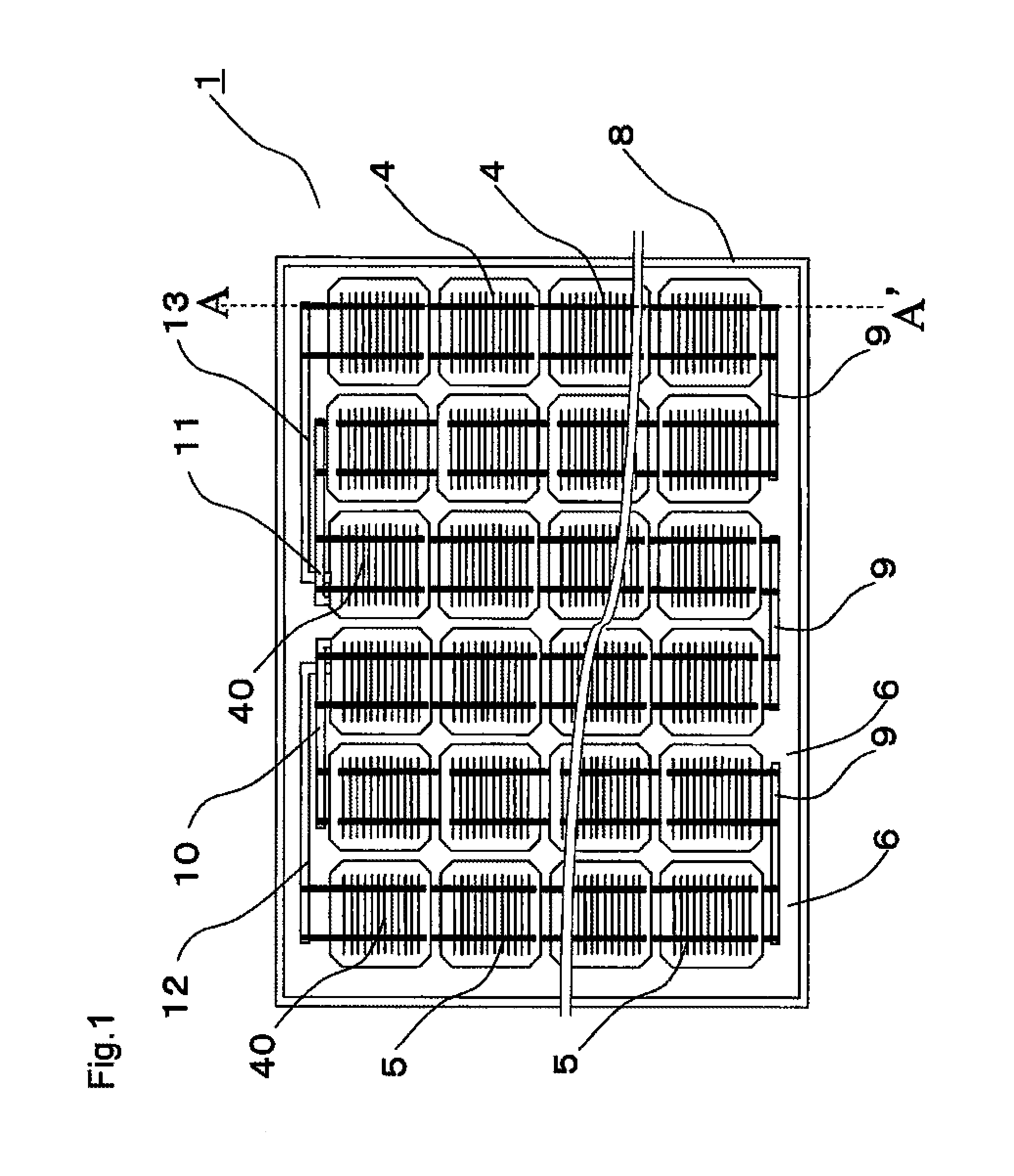

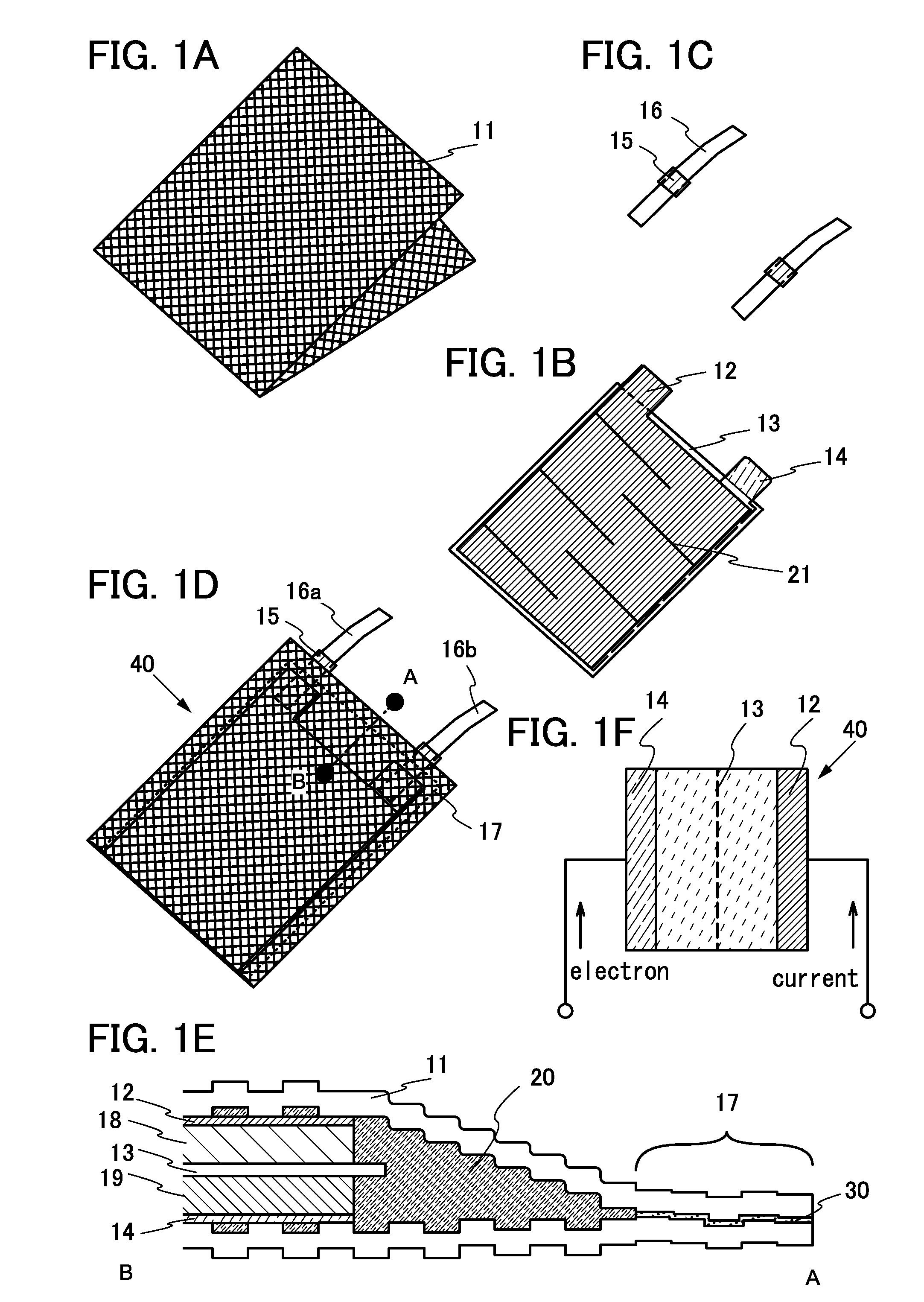

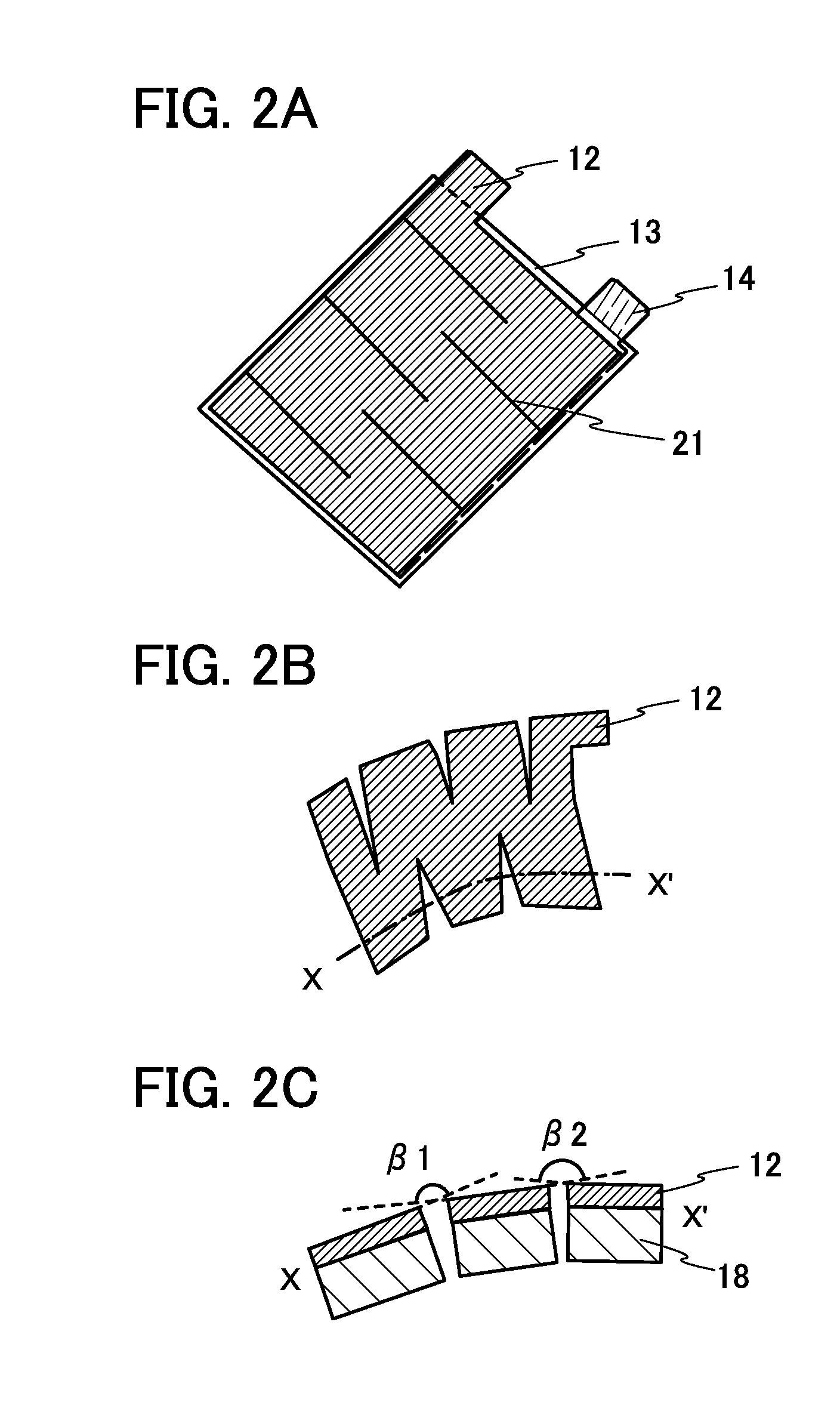

Solar cell, solar cell module and solar cell system

InactiveUS20100243024A1Reduce widthLow costPV power plantsPhotovoltaic energy generationEngineeringPhotoelectric conversion

A solar cell includes: a front surface electrode having a first current-collecting electrode and non-straight line electrodes connected to the first current-collecting electrode; a semiconductor substrate serving as a photoelectric conversion body; and a rear surface electrode having a second current-collecting electrode and line electrodes connected to the second current-collecting electrode. The front surface electrode, the semiconductor substrate and the rear surface electrode are arranged in that order. The non-straight line electrodes of the front surface electrode and the line electrodes of the rear surface electrodes are opposed to each other with the semiconductor substrate interposed there-between. The non-straight line electrodes of the front surface electrode and the line electrodes of the rear surface electrodes are different in shape while having a portion where the electrodes intersect each other, as seen in a direction perpendicular to the front surface of the semiconductor substrate.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

High strain tear resistant gels and gel composites for use as artificial muscle actuators

InactiveUS6909220B2Improve propertiesImprove tear resistanceCellsSludge treatmentPolymer sciencePlasticizer

Novel gels and articles are formed from one or more copolymers having at least one poly(ethylene) components and high levels of one or more plasticizers, said gels having an amount of crystallinity, glassy components, and selected plasticizers sufficient to achieve improvements in one or more physical properties including improved crack propagation resistance, improved tear resistance, improved resistance to fatigue, resistance to catastrophic failure, and exhibiting high strain under elongations not obtainable in amorphous gels which high strain making the gel suitable for use as film layers for artificial muscles.

Owner:APPLIED ELASTOMERICS

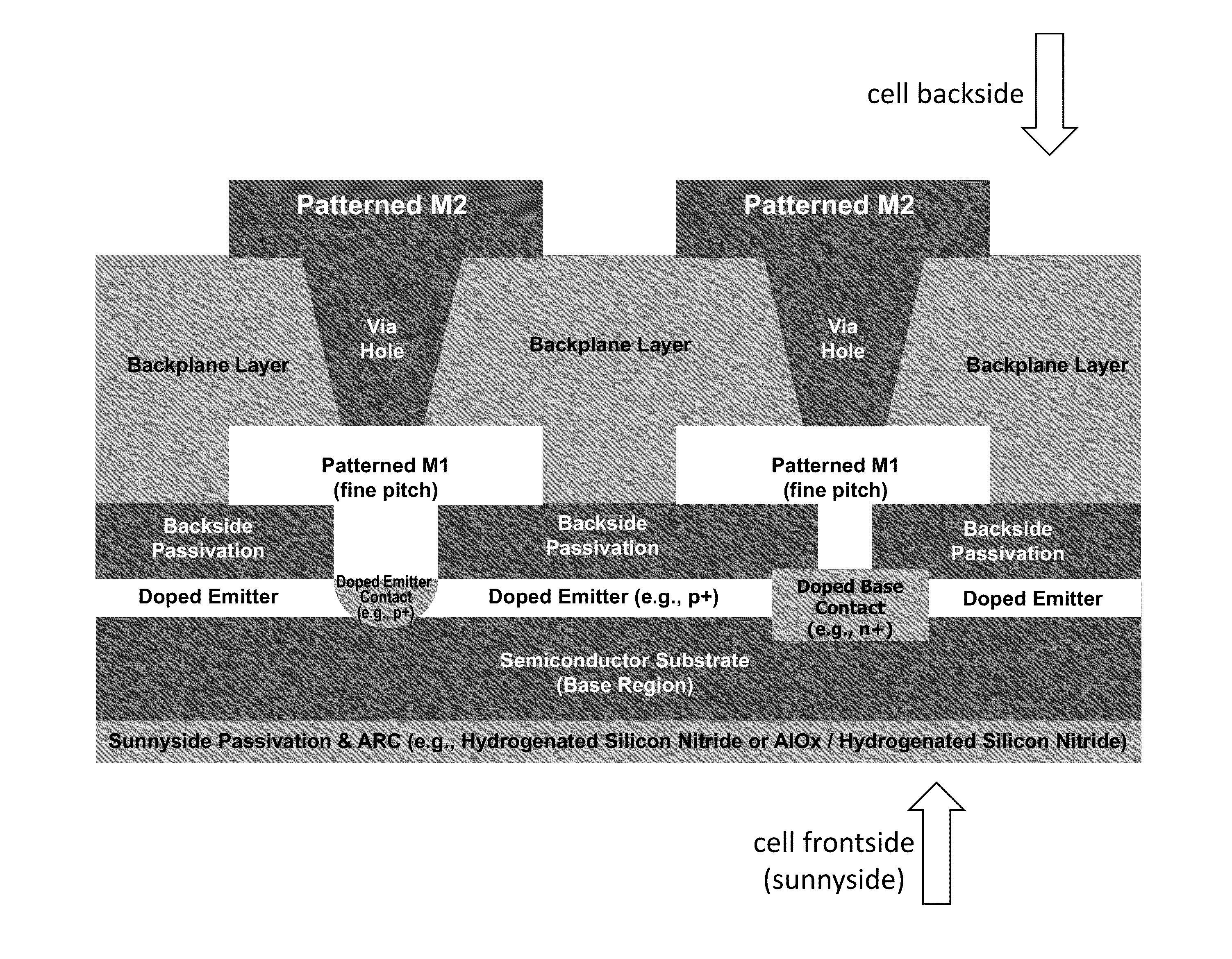

Method for manufacturing semiconductor device

InactiveUS20080242005A1Reduce communicationReduce connectionsSolid-state devicesSemiconductor/solid-state device manufacturingInorganic compoundSingle crystal

In the present application, is disclosed a method of manufacturing a flexible semiconductor device having an excellent reliability and tolerance to the loading of external pressure. The method includes the steps of: forming a separation layer over a substrate having an insulating surface; forming an element layer including a semiconductor element comprising a non-single crystal semiconductor layer, over the separation layer; forming an organic resin layer over the element layer; providing a fibrous body formed of an organic compound or an inorganic compound on the organic resin layer; heating the organic resin layer; and separating the element layer from the separation layer. This method allows the formation of a flexible semiconductor device having a sealing layer in which the fibrous body is impregnated with the organic resin.

Owner:SEMICON ENERGY LAB CO LTD

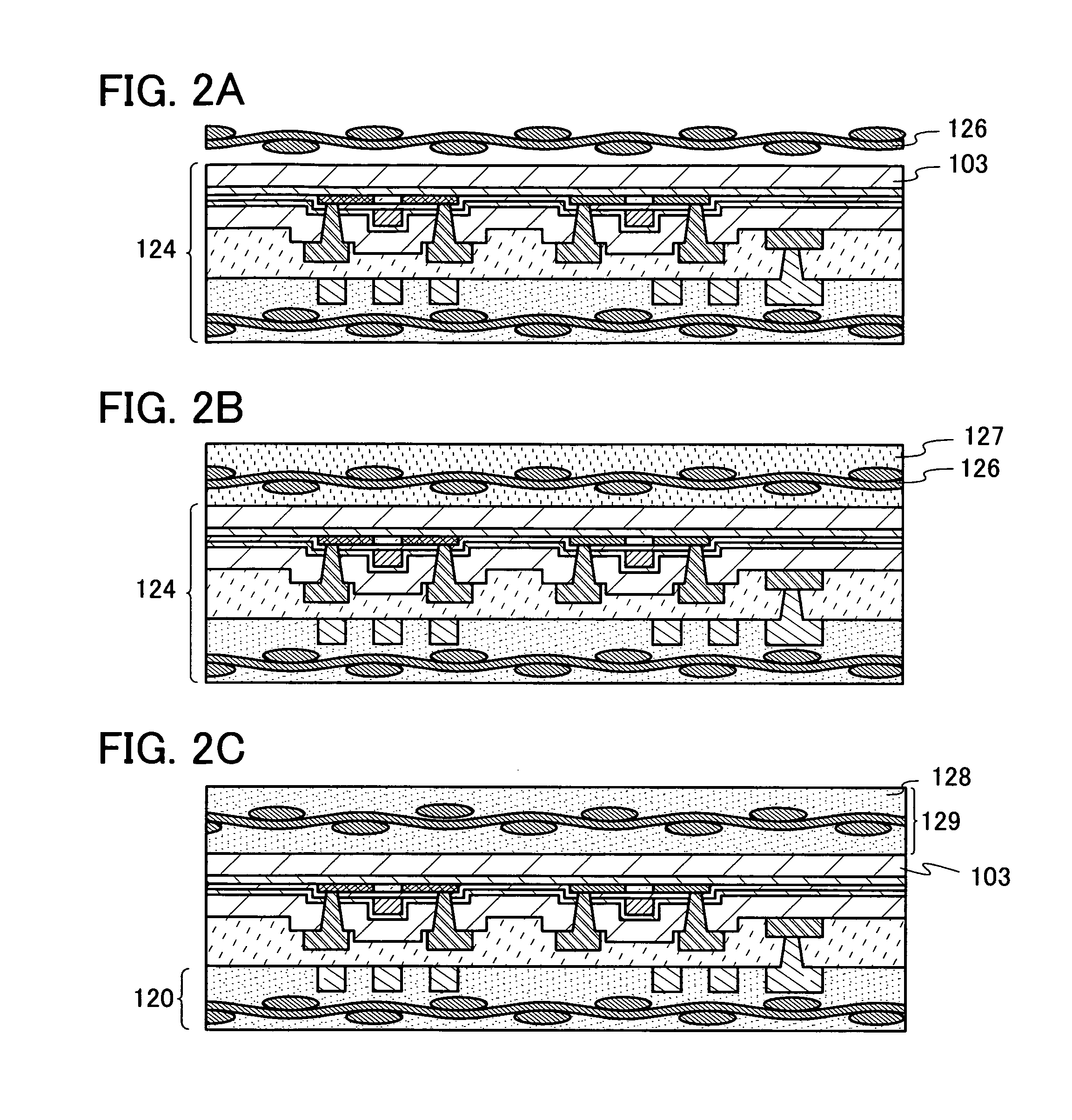

Systems and methods for monolithically isled solar photovoltaic cells and modules

InactiveUS20140326295A1Reduce and eliminate disadvantageReduce and eliminate and problemPhotovoltaic supportsPV power plantsEngineeringBattery cell

According to one aspect of the disclosed subject matter, a monolithically isled solar cell is provided. The solar cell comprises a semiconductor layer having a light receiving frontside and a backside opposite the frontside and attached to an electrically insulating backplane. A trench isolation pattern partitions the semiconductor layer into electrically isolated isles on the electrically insulating backplane. A first metal layer having base and emitter electrodes is positioned on the semiconductor layer backside. A patterned second metal layer providing cell interconnection and connected to the first metal layer by via plugs is positioned on the backplane.

Owner:BEAMREACH SOLAR INC

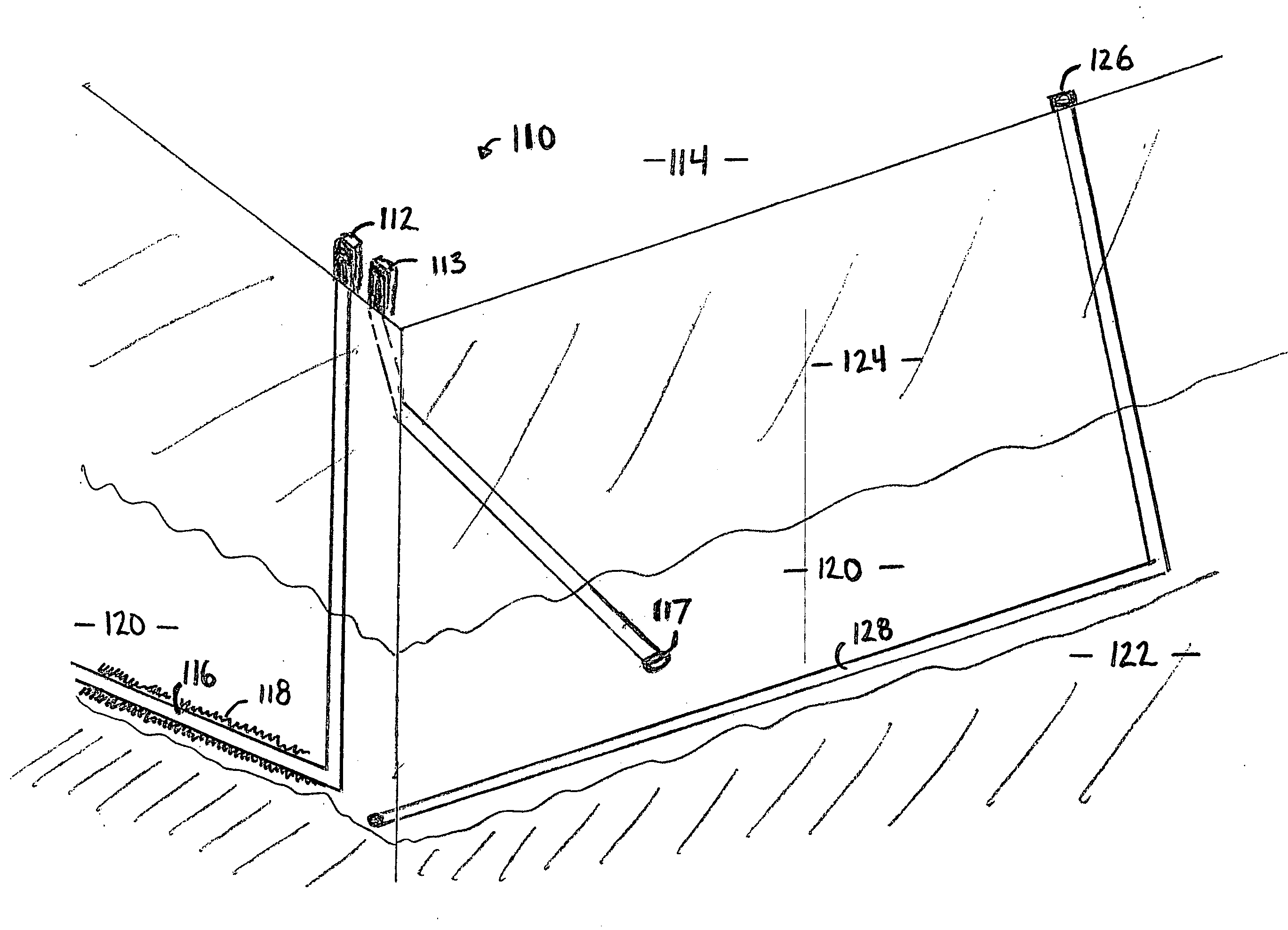

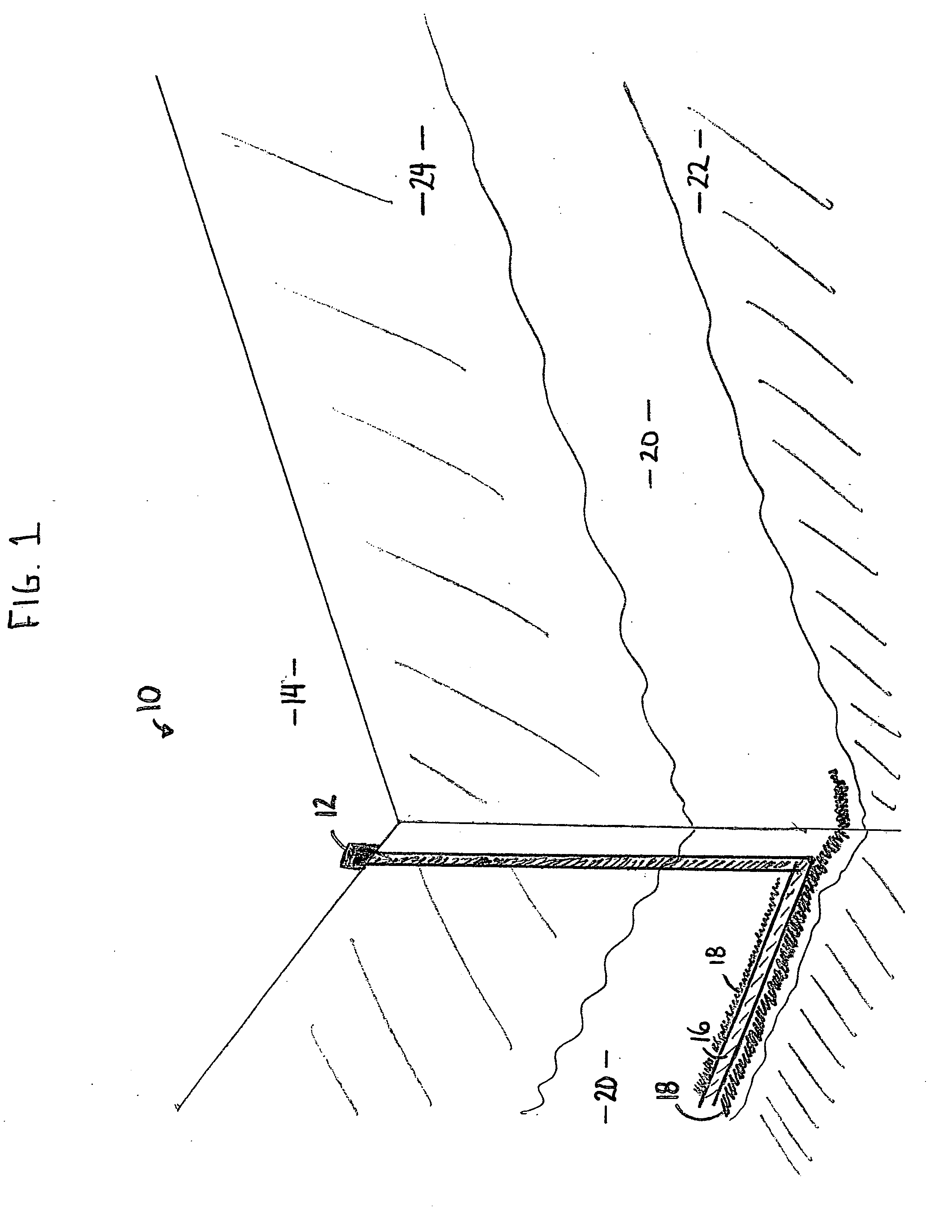

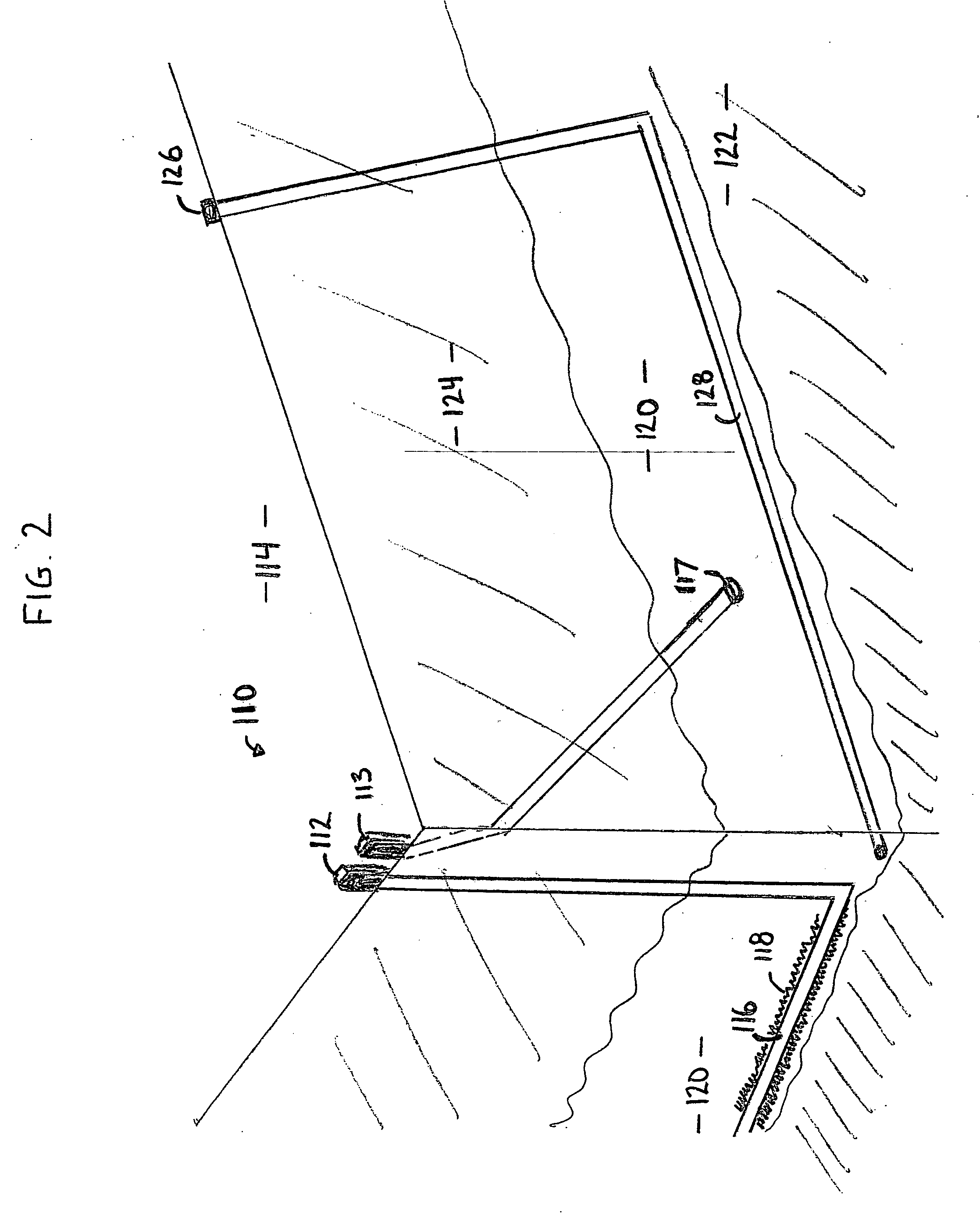

Method for extracting gas from high gas low permeability coal seam by punching, slotting, pressure releasing, and permeability increasing

InactiveCN101644166AImprove flow statusEasy to extractUnderground miningSurface miningHigh pressure waterHigh pressure

The invention discloses a method for extracting gas from high gas low permeability coal seam by punching, slotting, pressure releasing and permeability increasing, comprising the following steps: whena drill is drilled into a predetermined position of the coal seam, coal bodies at both sides of a drill hole are cut in the drill hole by high pressure water jet with a certain pressure and flow; a flat slot is formed at both sides of the drill hole; the cut coal bodies is led out the hole by the high pressure water jet. The exposed area of the coal body at the slotted part in the drill hole aregreatly increased, namely that an extremely thin protective layer is exploited with local scope of the flat slot, which enlarges effective influential range of pressure releasing, permeability increasing and gas discharging of the coal bodies in the drill hole, thus the air permeability of the coal bodies is increased about 200-300 times, the average amount of single-hole gas extraction reaches 0.3m<3> / min, the concentration of the gas extraction is 30-60%, gas drainage rate of working face of coal extraction is more than 50%, the number of drill holes for gas drainage is reduced by 10-20% after slotting, pressure releasing and permeability increasing. The method realizes the safety, high efficiency and uniform extraction of the gas from the high gas low permeability outburst coal seam, and changes high gas coal seam with outburst danger into low gas coal seam without outburst danger.

Owner:CHINA UNIV OF MINING & TECH

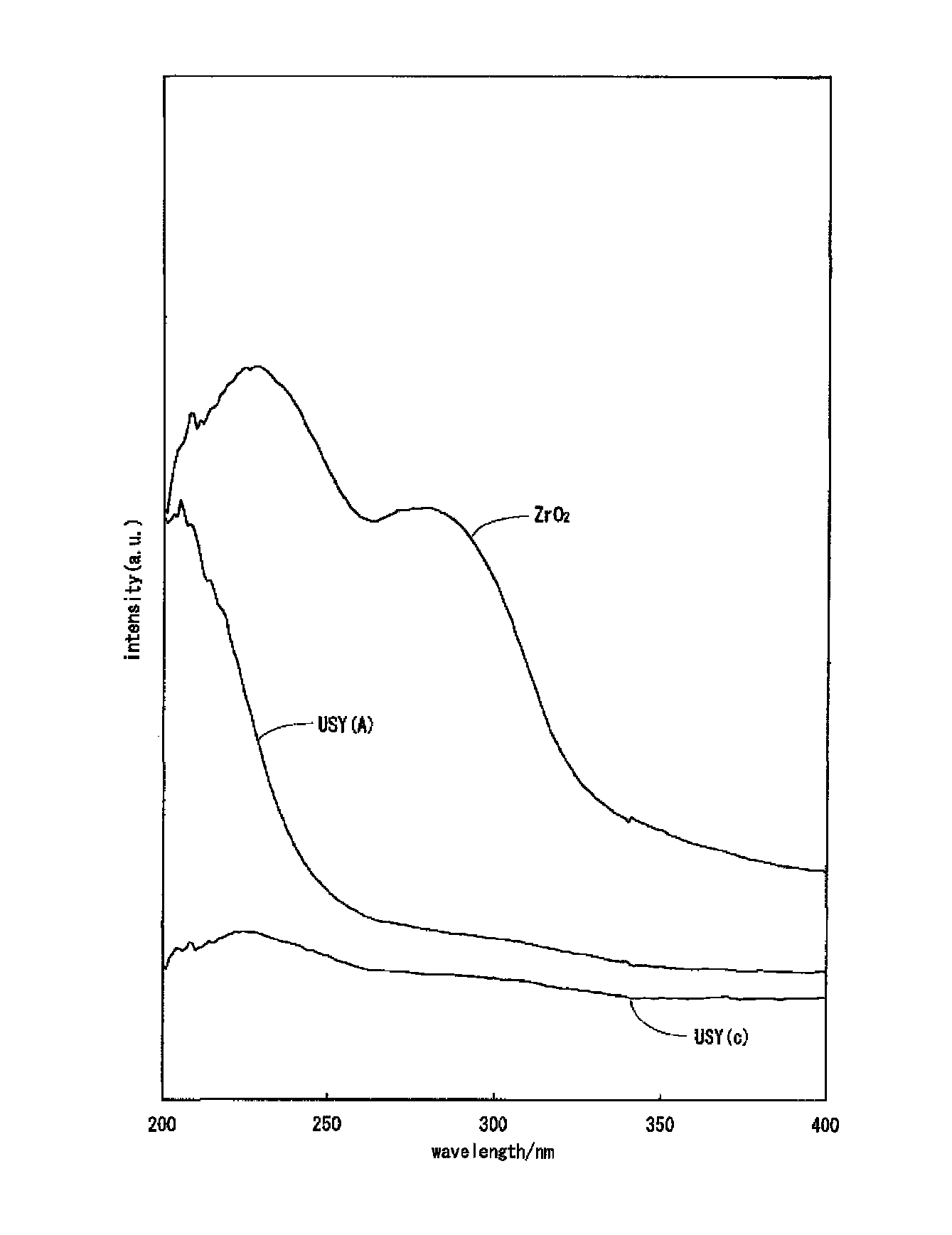

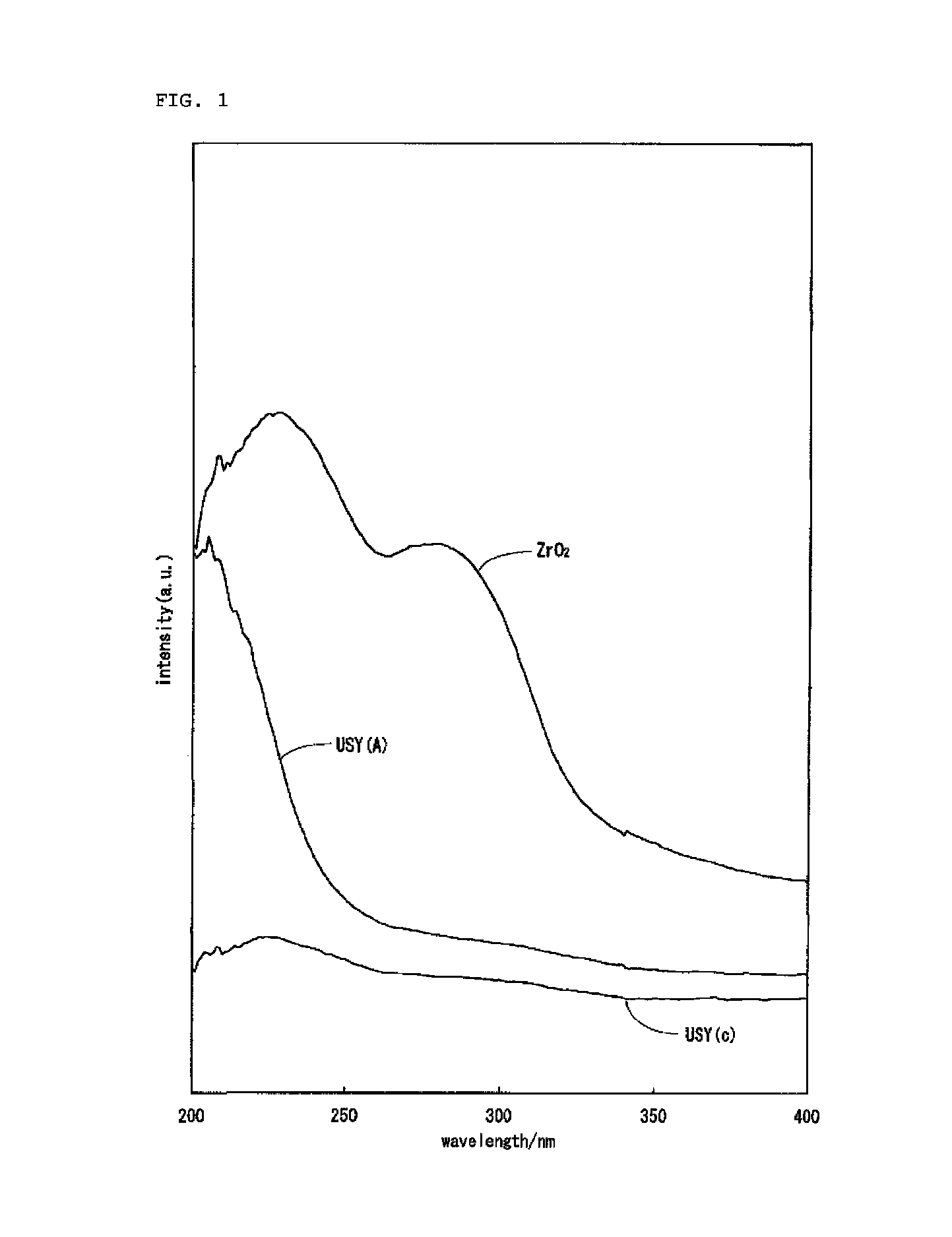

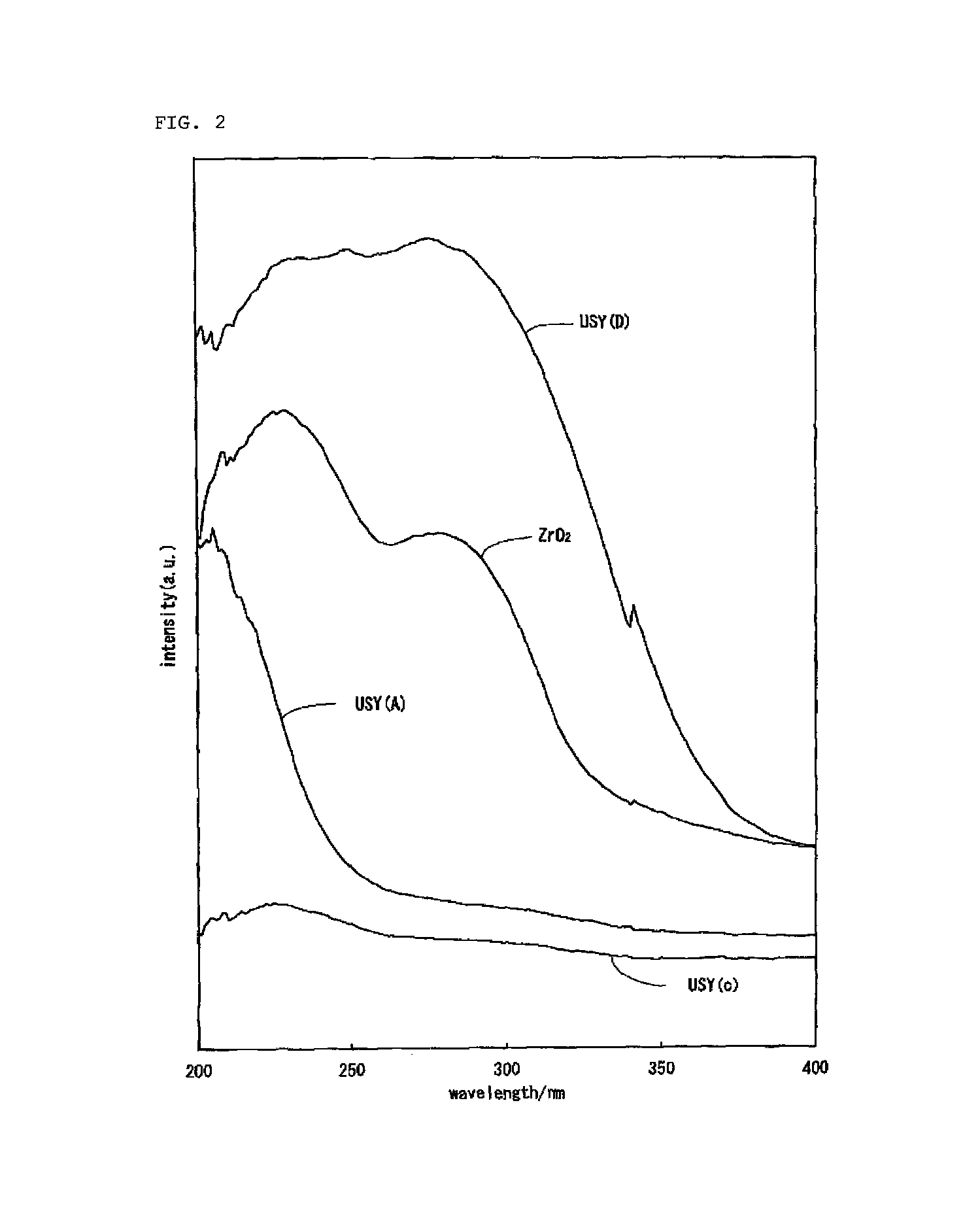

Hydrocracking catalyst for hydrocarbon oil, method for producing hydrocracking catalyst, and method for hydrocracking hydrocarbon oil with hydrocracking catalyst

ActiveUS9221036B2Improve responseDisadvantageously reducing yieldMolecular sieve catalystsCatalyst activation/preparationHafniumTitanium

Owner:JAPAN COOP CENT FOR PETROLEUM & SUSTAINABLE ENERGY +2

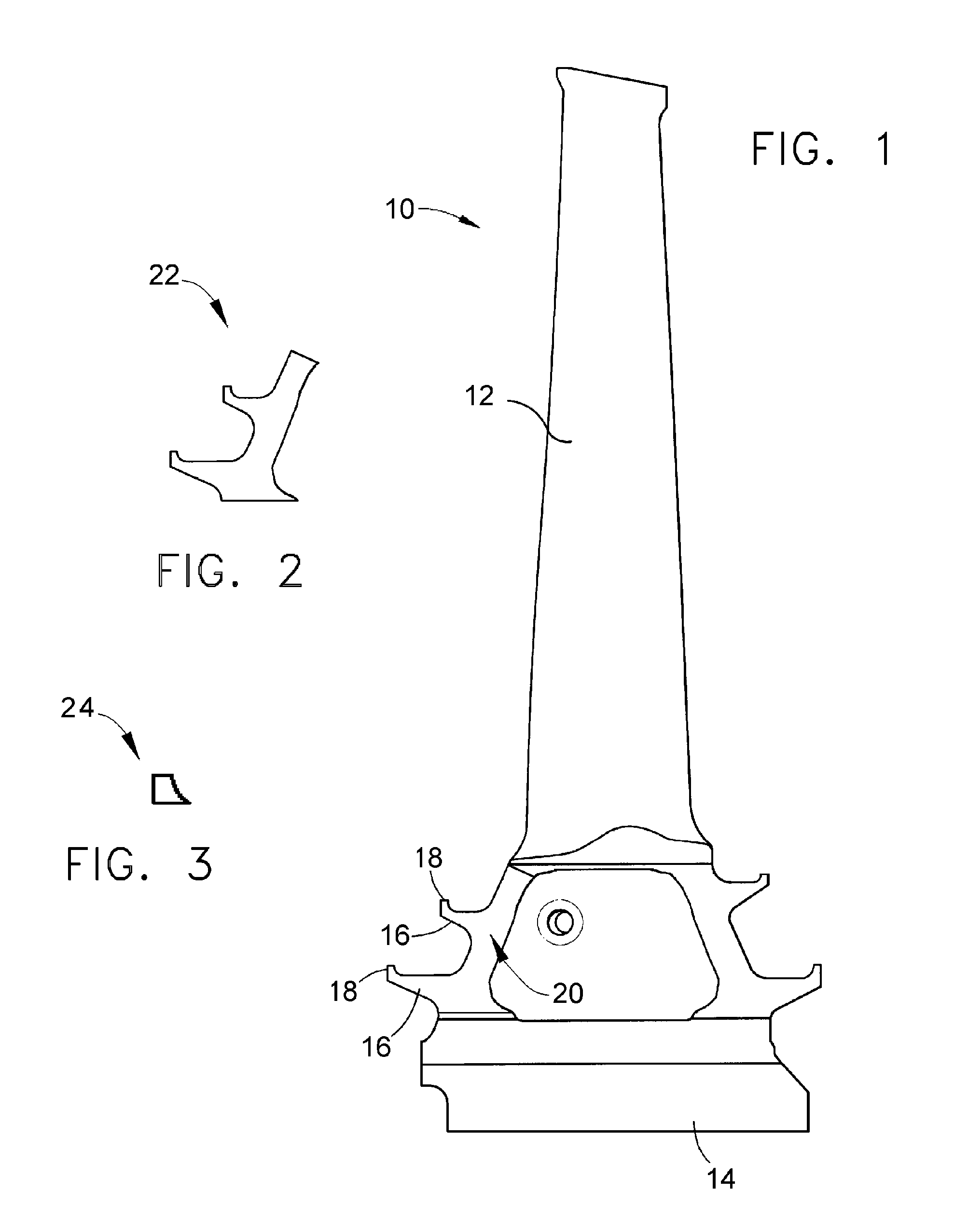

Aircraft fuselage shell component with crack propagation resistance

InactiveUS6595467B2Increasing weight and costEasy to crackFuselage bulkheadsWelding apparatusResidual strengthFiber-reinforced composite

Owner:AIRBUS OPERATIONS GMBH

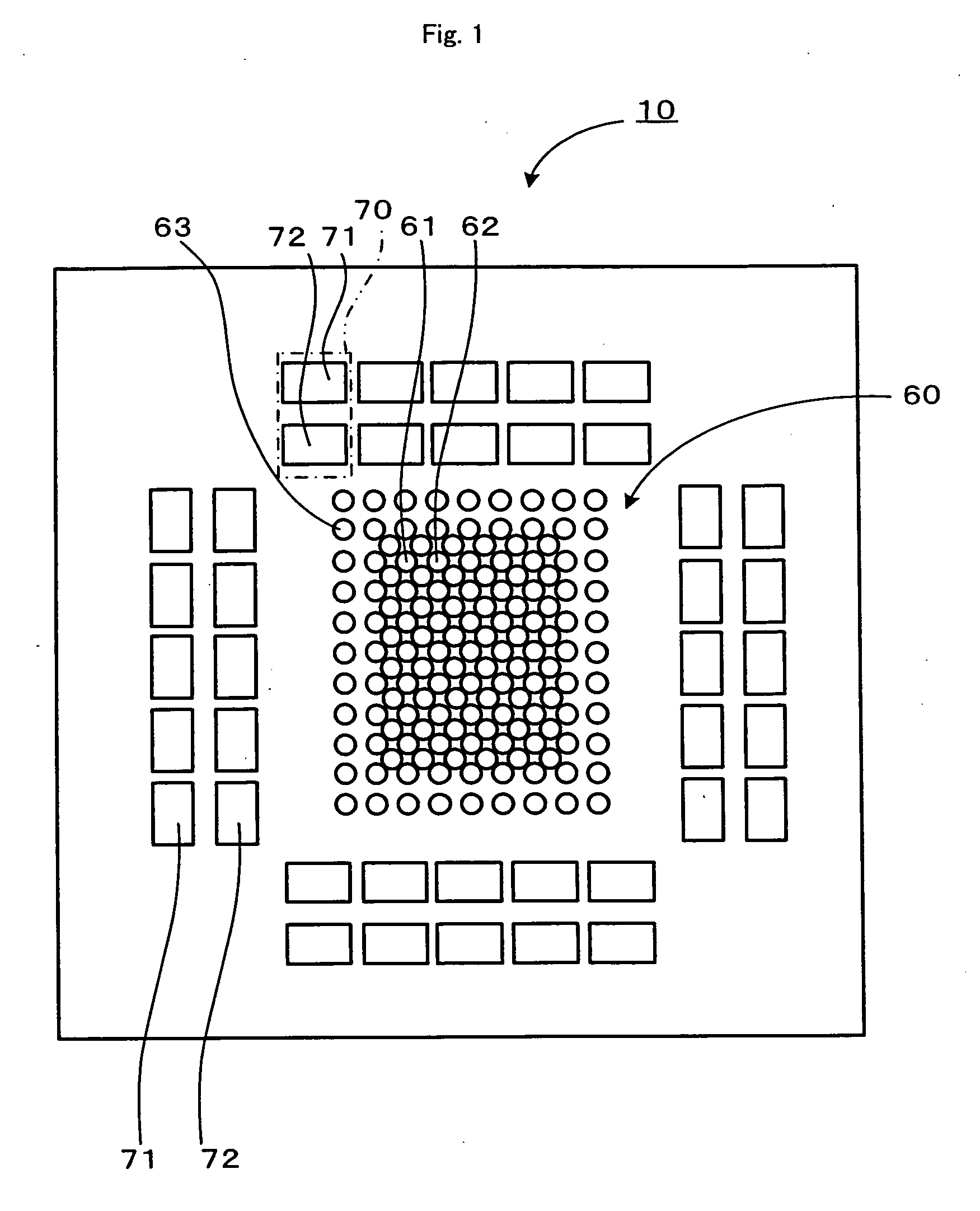

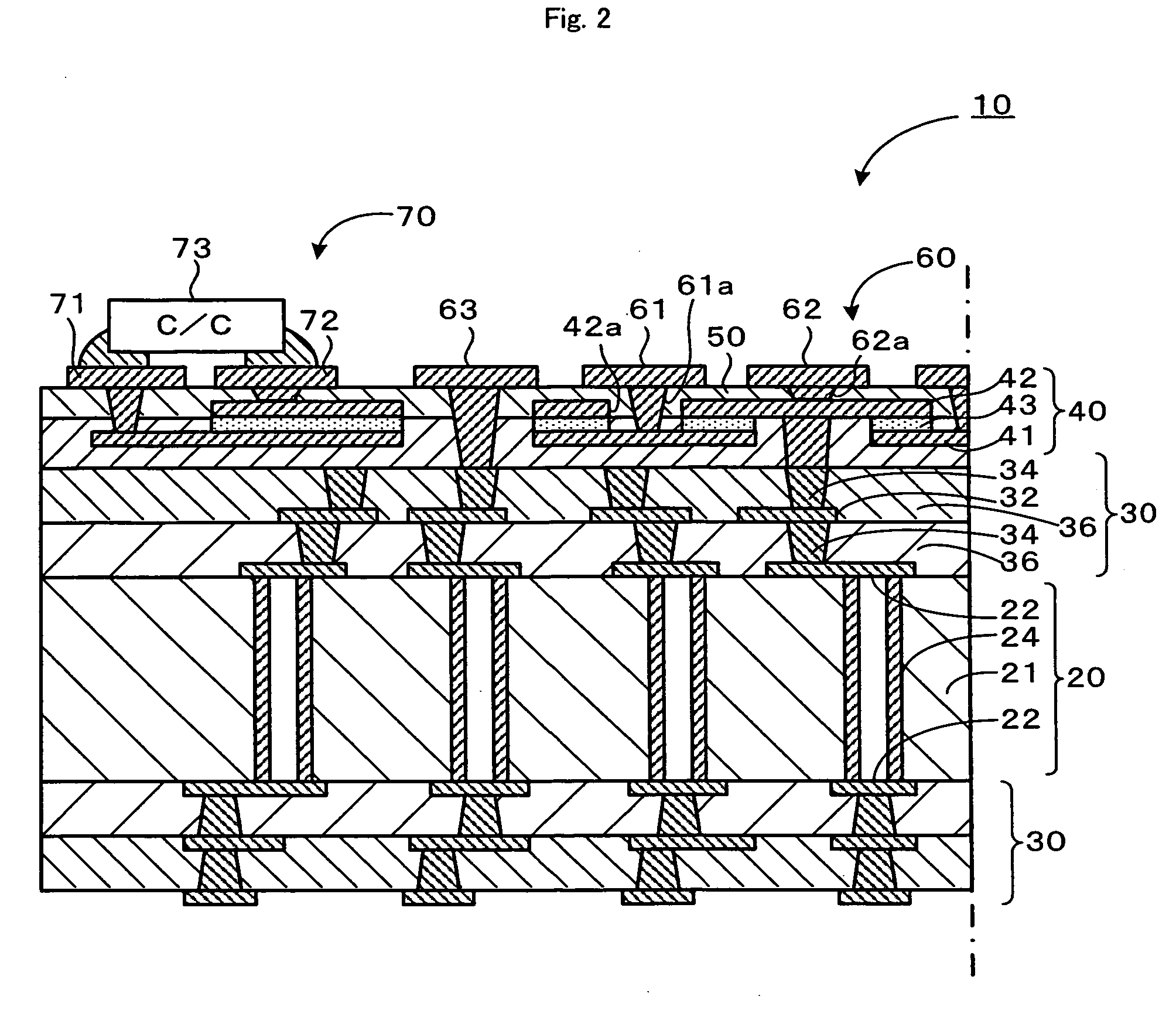

Multilayer printed wiring board

ActiveUS20060137905A1High capacitanceAdequate decoupling effectCross-talk/noise/interference reductionPrinted circuits stress/warp reductionCapacitanceEngineering

A multilayer printed wiring board 10 includes: a mounting portion 60 on the top surface of which is mounted a semiconductor element that is electrically connected to a wiring pattern 32, etc.; and a capacitor portion 40 having a high dielectric constant layer 43, formed of ceramic and first and second layer electrodes 41 and 42 that sandwich the high dielectric constant layer 43. One of either of the first and second layer electrodes 41 and 42 is connected to a power supply line of the semiconductor element and the other of either of the first and second layer electrodes 41 and 42 is connected to a ground line. In this multilayer printed wiring board 10, high dielectric constant layer 43 included in the layered capacitor portion 40, which is connected between the power supply line and the ground line, is formed of ceramic. With this structure, the static capacitance of the layered capacitor portion 40 can be high, and an adequate decoupling effect is exhibited even under circumstances in which instantaneous potential drops occur readily.

Owner:IBIDEN CO LTD

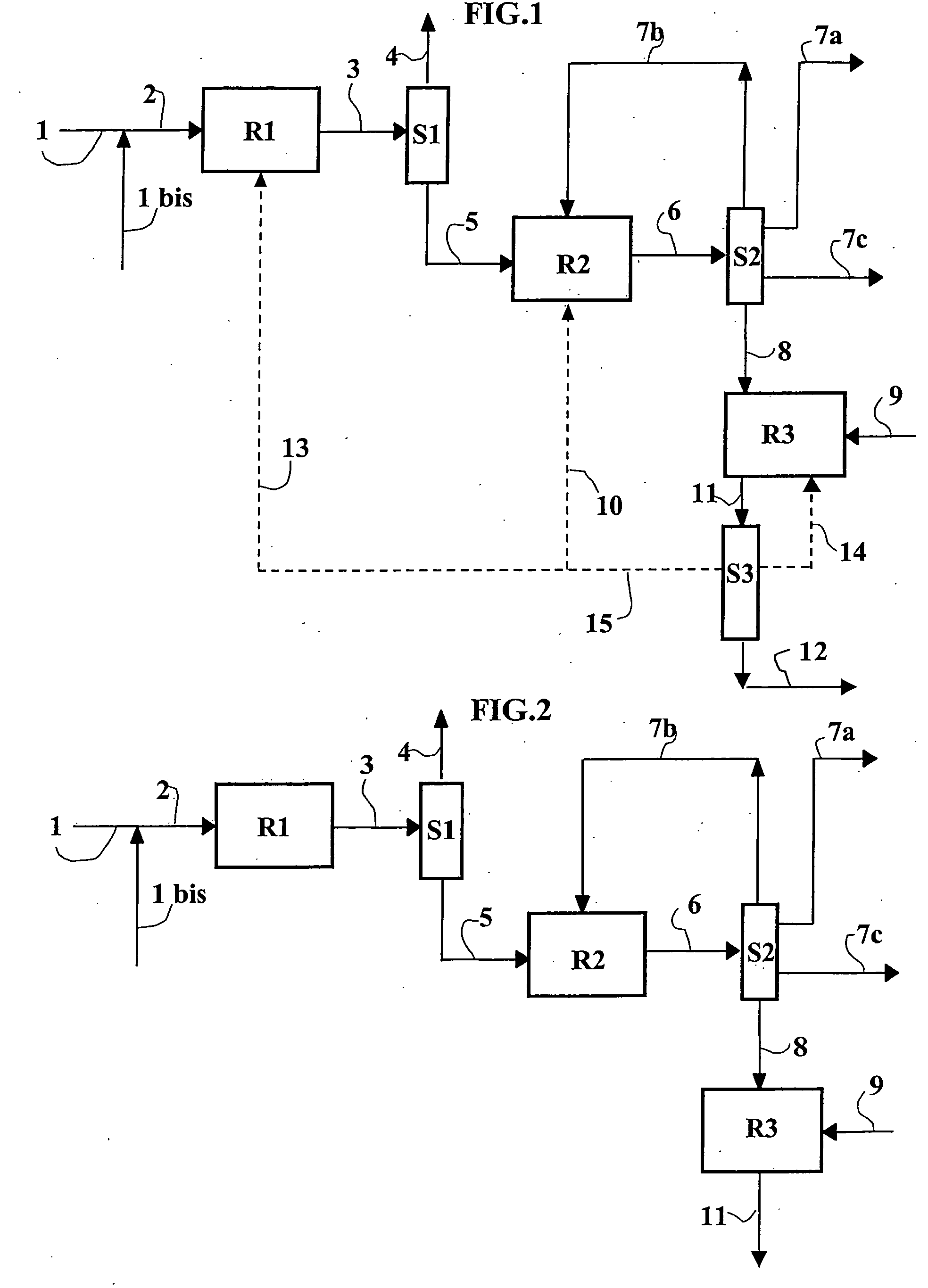

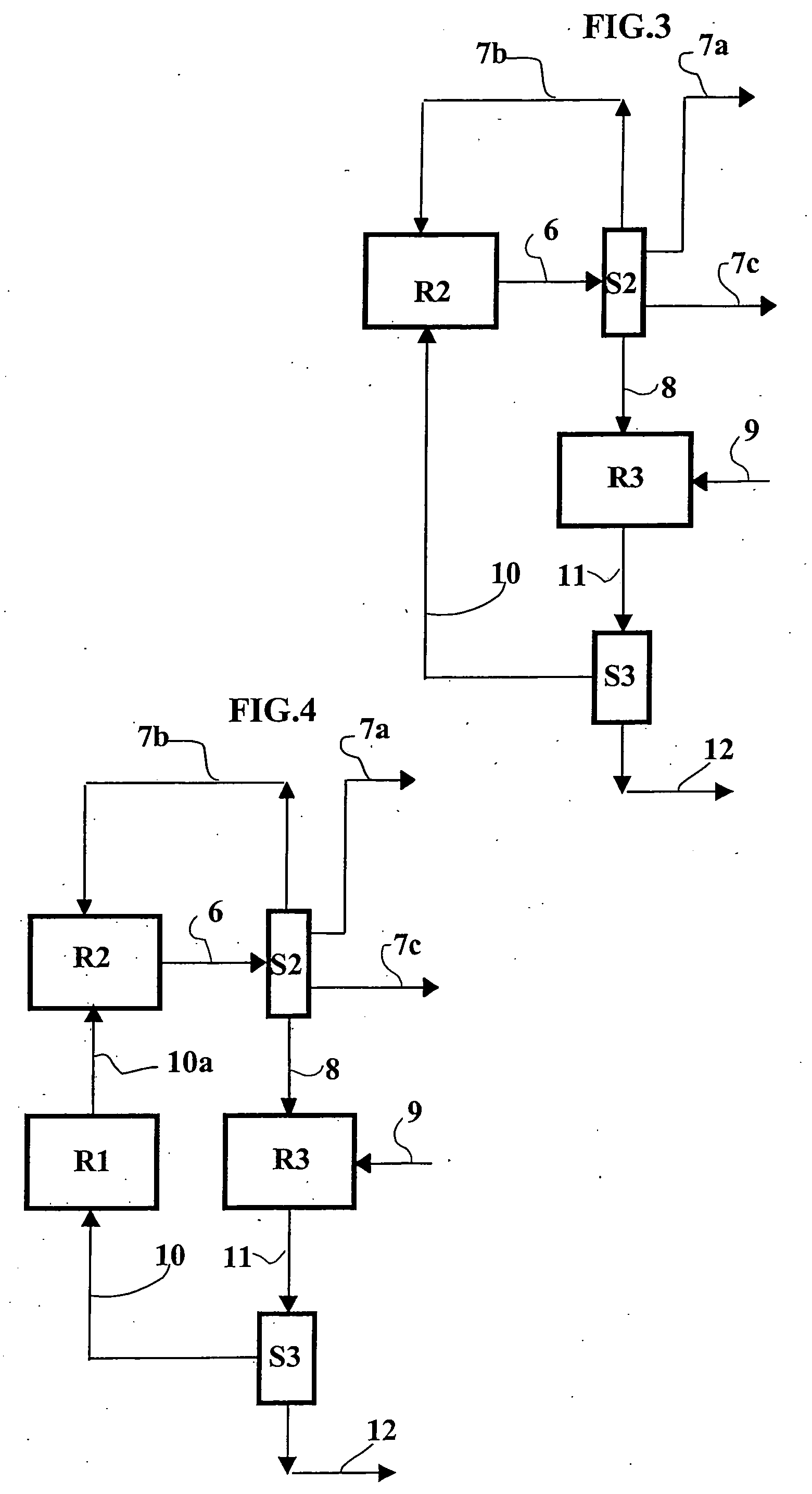

Method for jointly producing propylene and petrol from a relatively heavy charge

ActiveUS20050121361A1Increase in severityReaction can be limitedCatalytic crackingOrganic chemistry methodsOligomerBoiling point

A process for conversion of a hydrocarbon feedstock comprising a relatively heavy main feedstock with a boiling point above approximately 350° C., and a relatively light secondary feedstock with a boiling point below approximately 320° C., wherein, the main feedstock, representing at least 50 wt. % of the hydrocarbon feedstock, is cracked in a fluidized-bed reactor in the presence of a cracking catalyst, the secondary feedstock is cracked in a fluidized bed with the same cracking catalyst, separately or mixed with the main feedstock, said secondary feedstock comprising oligomers with at least 8 carbon atoms of light olefins with 4 and / or 5 carbon atoms.

Owner:INST FR DU PETROLE

Olefin based compositions and floor coverings containing the same

ActiveUS20080206583A1Improve performanceEliminating and decreasing needSynthetic resin layered productsThin material handlingPolyolefinFloor covering

A composition is described that includes at least one compatibilizer having at least one polyolefin and at least one polar group. The composition can include a blend of polymers. Surface coverings and floor coverings, such as laminated floor coverings, having the composition, are also described.

Owner:MANNINGTON MILLS

Preform and method of repairing nickel-base superalloys and components repaired thereby

InactiveUS20060134454A1Minimize distortionEasy to crackBlade accessoriesSolid state diffusion coatingPowder mixtureWear resistant

A process for repairing a turbine component of a turbomachine, as well as a sintered preform used in the process and a high gamma-prime nickel-base superalloy component repaired thereby. The sintered preform contains a sintered mixture of powders of a cobalt-base braze alloy and a cobalt-base wear-resistant alloy. The braze alloy constitutes at least about 10 up to about 35 weight percent of the sintered preform and contains a melting point depressant such as boron. The preform is formed by mixing powders of the braze and wear-resistant alloys to form a powder mixture, and then sintering the powder mixture. To use the preform, a surface portion of the turbine component is removed to expose a subsurface portion, followed by diffusion bonding of the preform to the subsurface portion to form a wear-resistant repair material containing the braze alloy dispersed in a matrix of the wear-resistant alloy.

Owner:GENERAL ELECTRIC CO

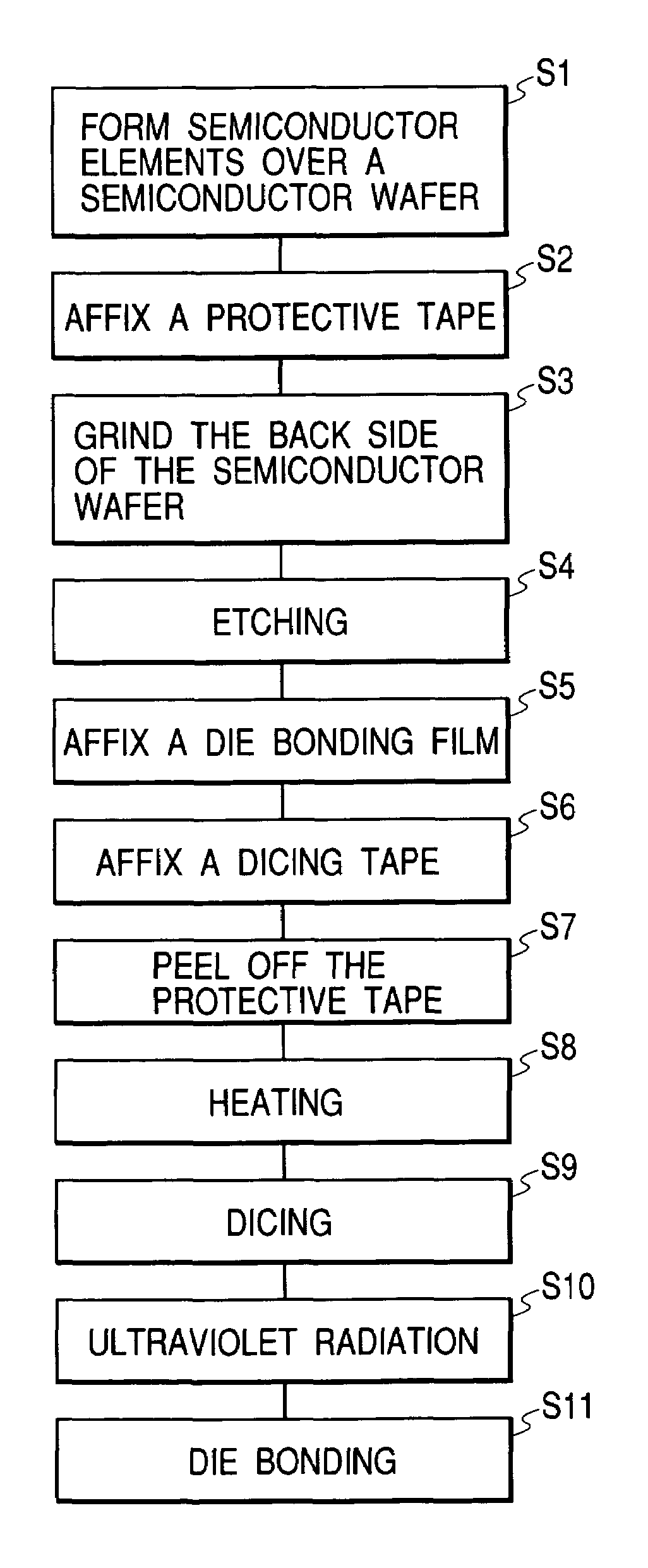

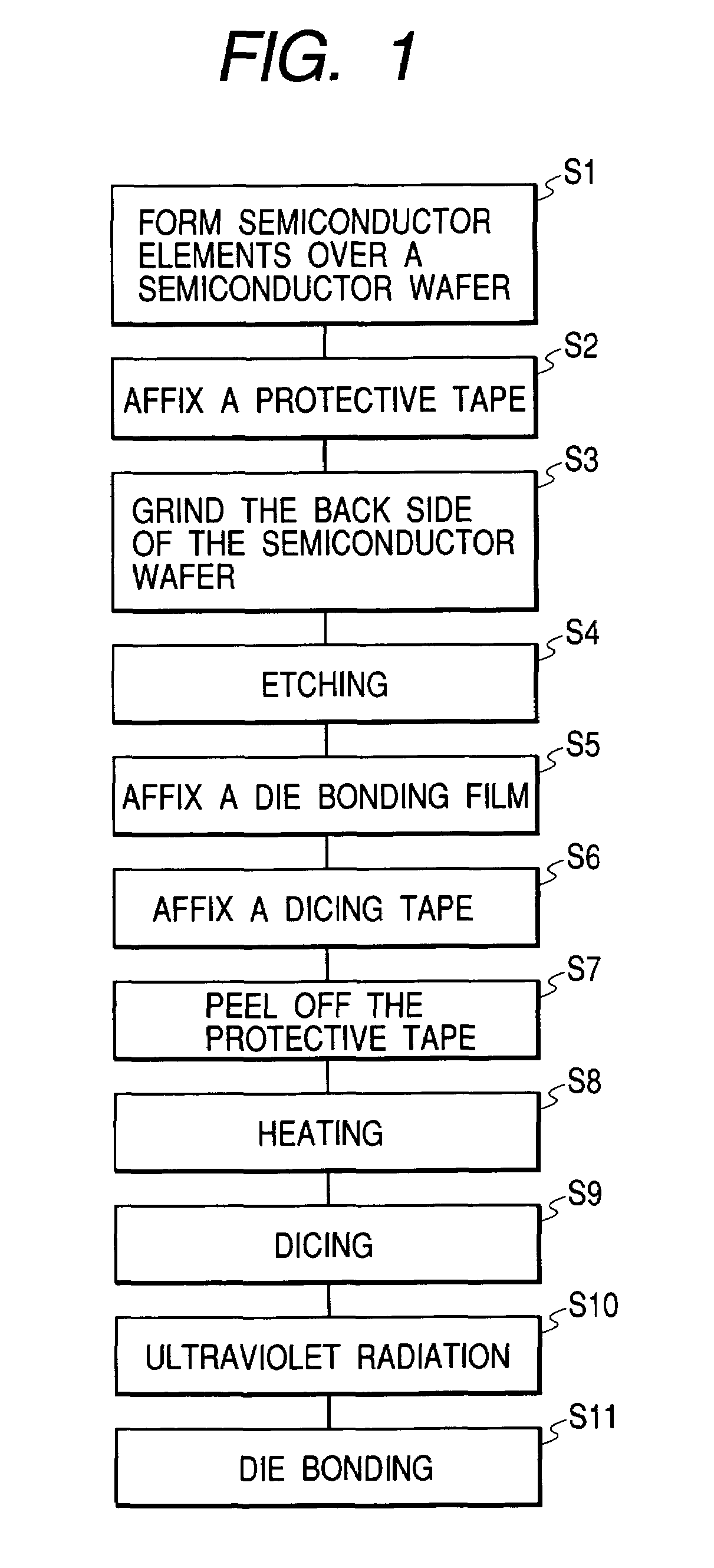

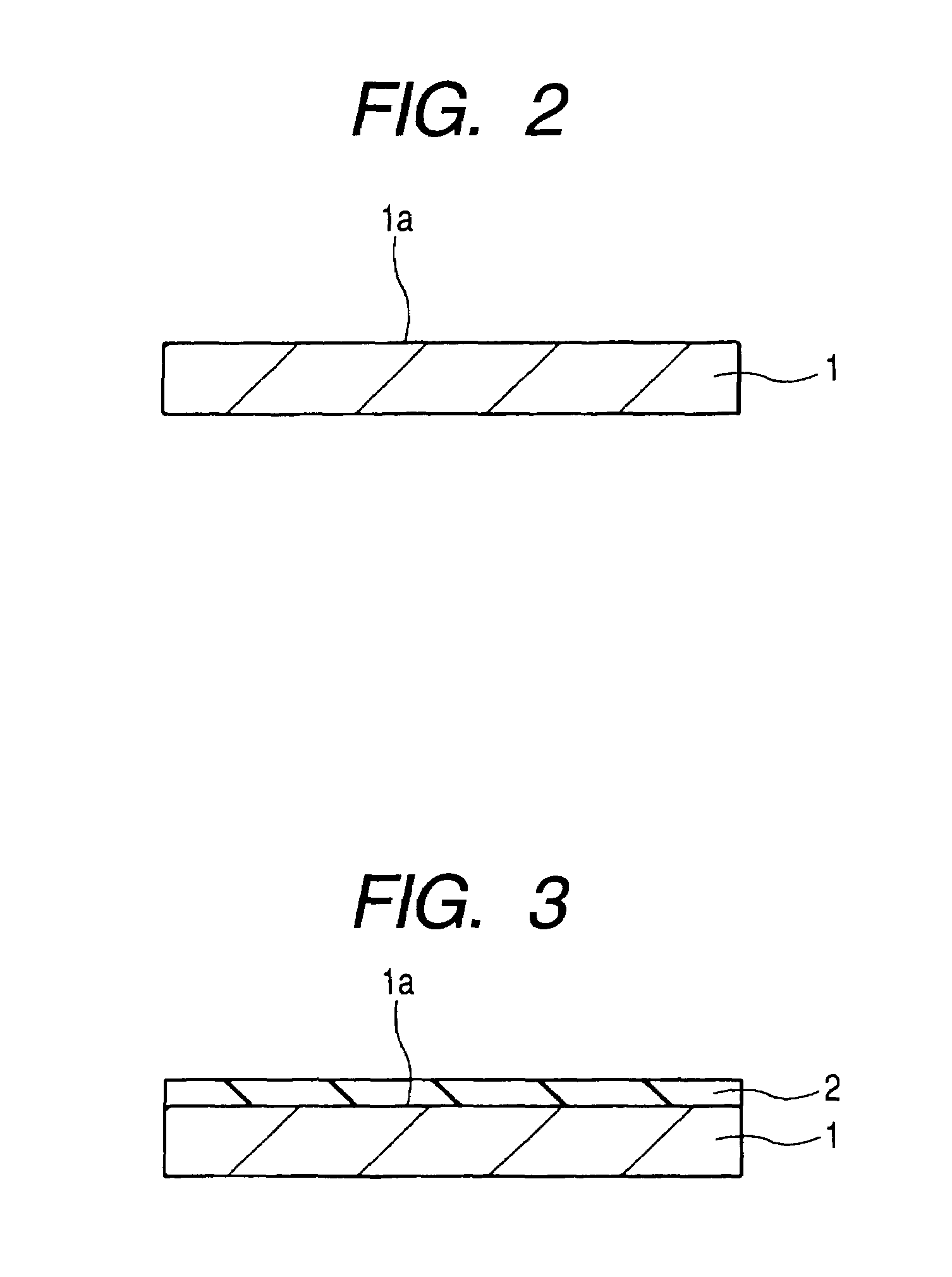

Fabrication method of semiconductor circuit device

InactiveUS7122447B2Prevent wrinklingEasier for the semiconductor wafer to warpSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorDicing tape

When a semiconductor wafer is formed to be thin, steps need to be taken to prevent warping of the wafer. For this purpose, a protective tape is affixed to a surface of the semiconductor wafer, and a back side of the semiconductor wafer is then ground to a predetermined thickness. A die bonding film is affixed to the back side of the semiconductor wafer, and a dicing tape is affixed on the die bonding film. The dicing tape that is affixed to the semiconductor wafer is held by a holding jig. The protective tape is peeled off from the wafer surface, and the die bonding film is heated to improve the adherence between the semiconductor wafer and the die bonding film. The semiconductor wafer is subjected to dicing for separation into individual semiconductor chips. The semiconductor chips are then die-bonded in a predetermined number onto a wiring substrate to fabricate a semiconductor device.

Owner:RENESAS ELECTRONICS CORP

Process for preparing self-sealing silicon carbide ceramic based composite material

The invention relates to a method for manufacturing a self-healing silicon carbide ceramic matrix composite. The method comprises the following steps: preparing fiber preform; filtrating a pyrolytic carbon interface layer by chemical gas phase; carrying out thermal treatment on the interface layer; infiltrating silicon carbide and boron carbide substrate by chemical gas phase alternately; and depositing three silicon carbide coatings by the chemical gas phase. The method has strong designability, simple process and good repeatability. The ceramic matrix composite manufactured by the method has good high temperature resistance and oxidation resistance, has excellent mechanical performance and thermal performance, and can meet the use requirement of a sealing strip / an adjustment sheet, an interior cone and other components of a high thrust-weight ratio aeroengine.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

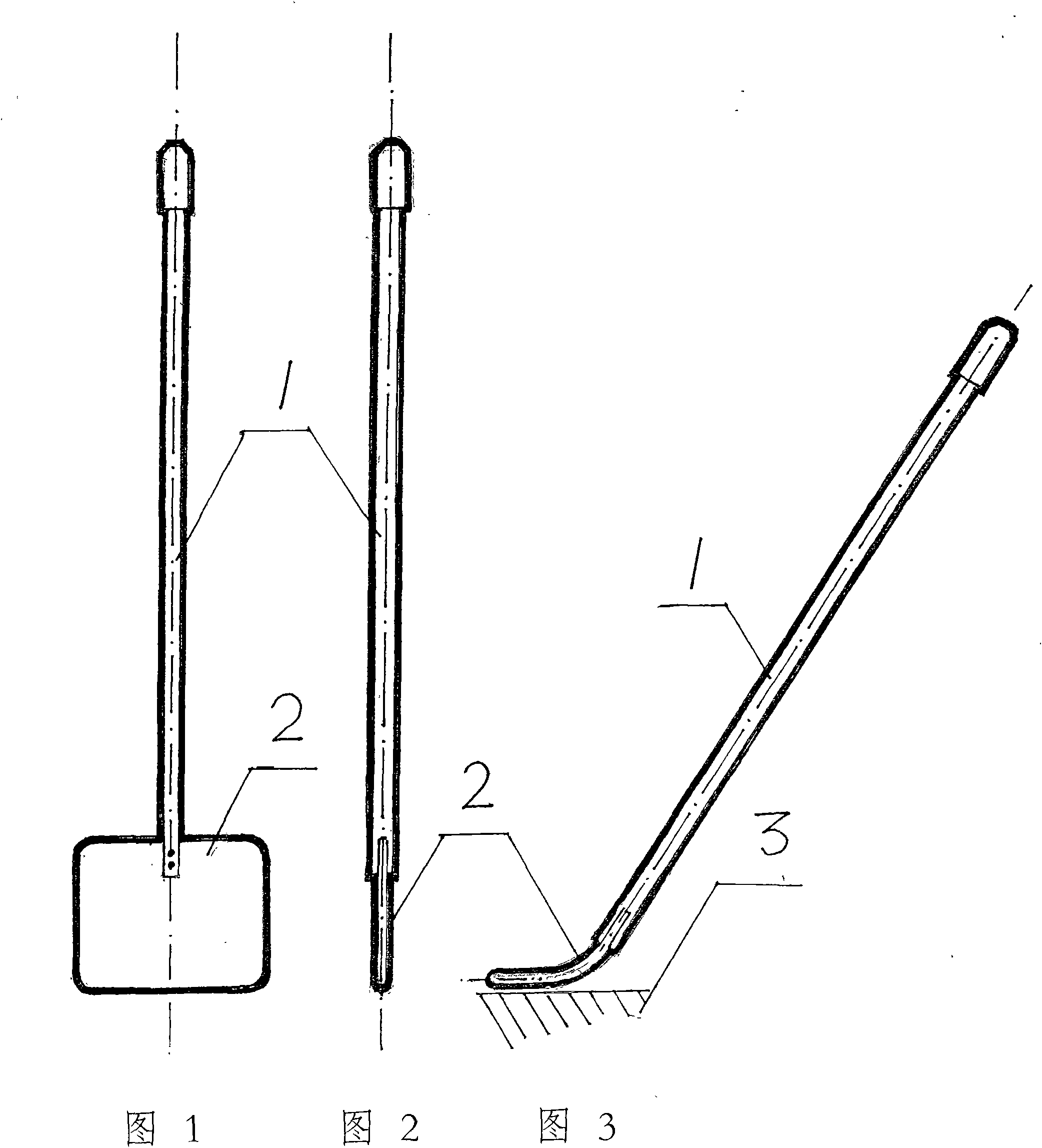

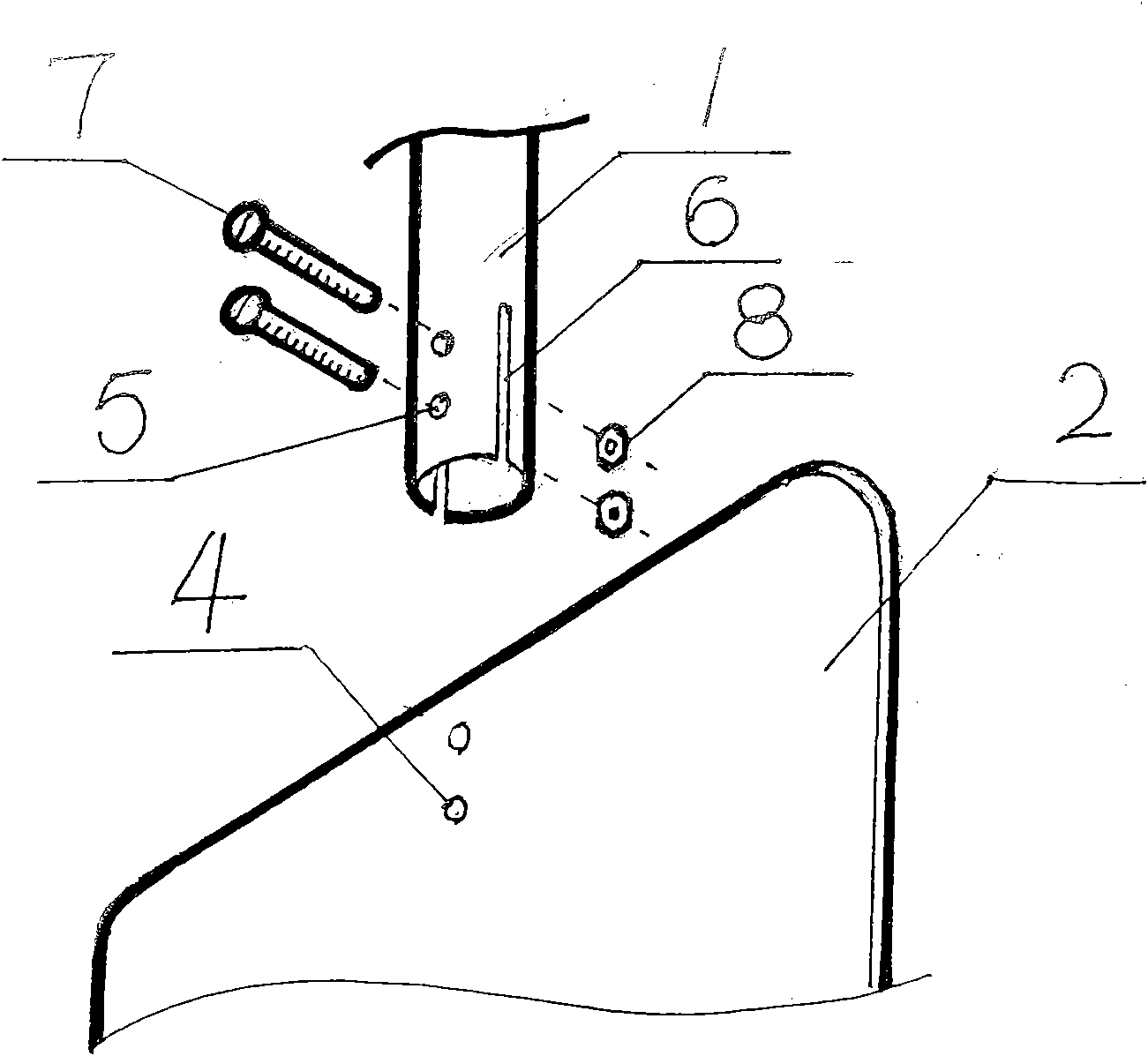

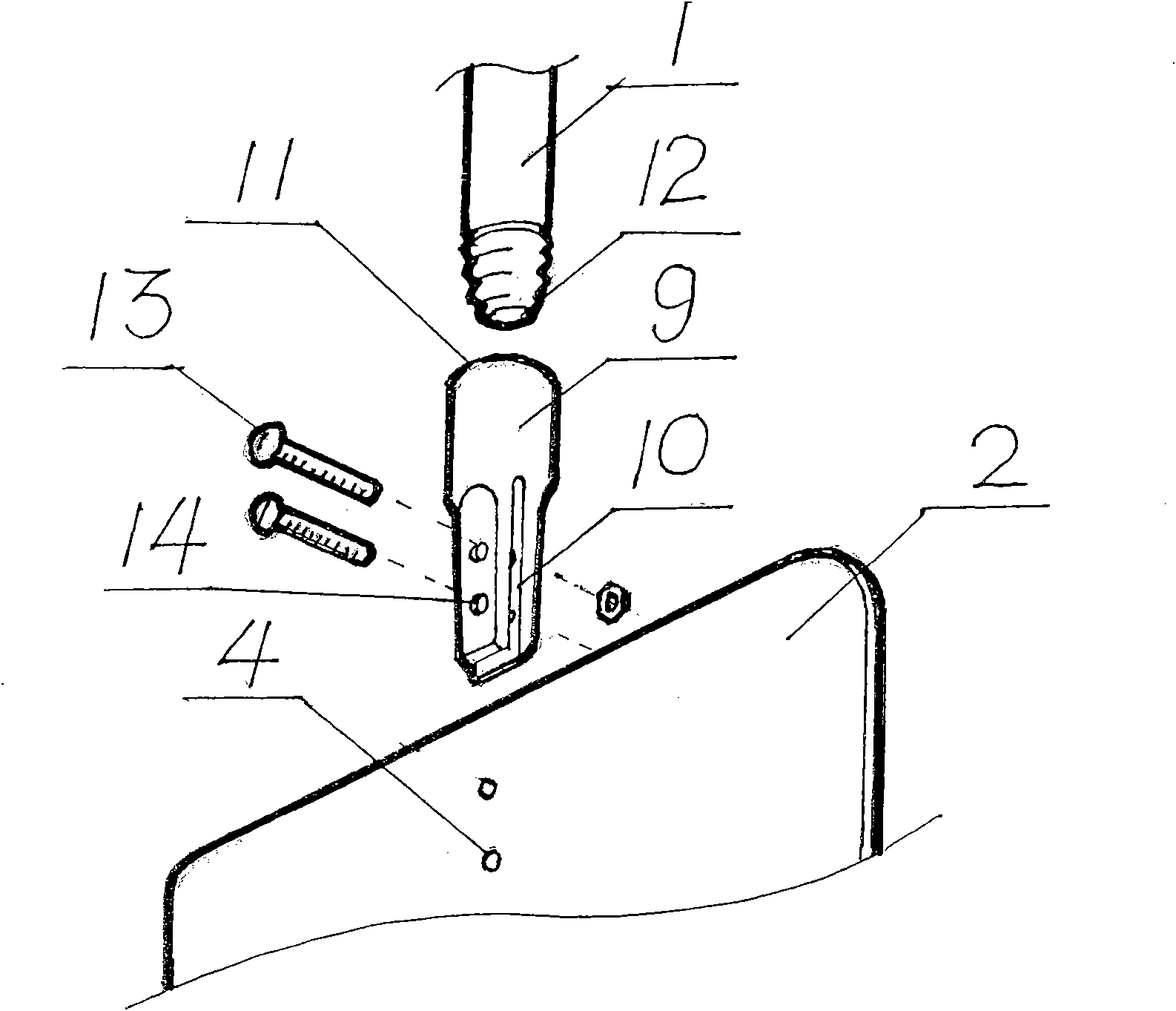

Portable mop and assorted mop barrel

The invention discloses a portable mop with simple structure, comprising a mop rod and a mop panel; the mop panel is a polygonal panel made of elastic material; an insertion connecting mechanism and a limiting device for rotating the mop panel forwardly and backwardly corresponding to the mop rod in a limiting angle are installed between the upper end of the mop panel and the lower end of the mop rod; the mop panel has straight and bent positions; in standby state, the central axis of the mop rod and the midline of the vertical section of the mop panel are located on the same straight line; in work state, the mop panel is deformed by means of external force; the upper end of the mop panel is parallel to a working surface; and the upper end of the mop panel has a crown face and can be formed into an angle with the mop rod. Meanwhile, the invention further discloses a mop barrel assorted to the portable mop. The mop barrel can remove the dirt on the mop and dehydrate the mop by means of upward and downward or forward and backward movements of the mop.

Owner:李军

Process for cracking hydrocarbon oils

ActiveUS20050279670A1Improve abilitiesImprove not only the desulfurizing ability but also the conversion of the hydrocarbon oilsThermal non-catalytic crackingCatalytic crackingChemistryCatalyst regeneration

This invention relates to a process for cracking hydrocarbon oils. Said process comprises contacting a hydrocarbon oil with a catalyst that has contacted with an atmosphere containing a reducing gas, separating cracked products and the catalyst, regenerating the catalyst, contacting the regenerated catalyst with said atmosphere containing a reducing gas, wherein said catalyst is a cracking catalyst containing a metal component, or a catalyst mixture of a cracking catalyst containing a metal component and a cracking catalyst free of metal component, contacting said catalyst with the atmosphere containing a reducing gas at a temperature of 100 to 900° C. for at least 1 second, wherein the amount of the atmosphere containing a reducing gas is not less than 0.03 cubic meters of reducing gas per ton of the cracking catalyst containing a metal component per minute, at a pressure of 0.1-0.5 MPa in the reduction reactor. The process has higher ability of desulfurizing and cracking heavy oils.

Owner:CHINA PETROCHEMICAL CORP +1

Method for high temperature steam

InactiveUS20060042794A1Reduces viscosity of oilImprove scanning efficiencyFluid removalGas phaseEngineering

A method for the recovery of upgraded oil from an oil-bearing formation is provided wherein a hot gas phase fluid comprising steam is brought into contact with a heavy oil reservoir, such as by injection, and the hot fluid heats at least a portion of the reservoir to a temperature high enough for steam cracking, and subsequently the steam is reacted with the heavy oil to produce steam cracked lighter oil.

Owner:PRECISION COMBUSTION

Catalyst for hydroprocessing of Fischer-Tropsch products

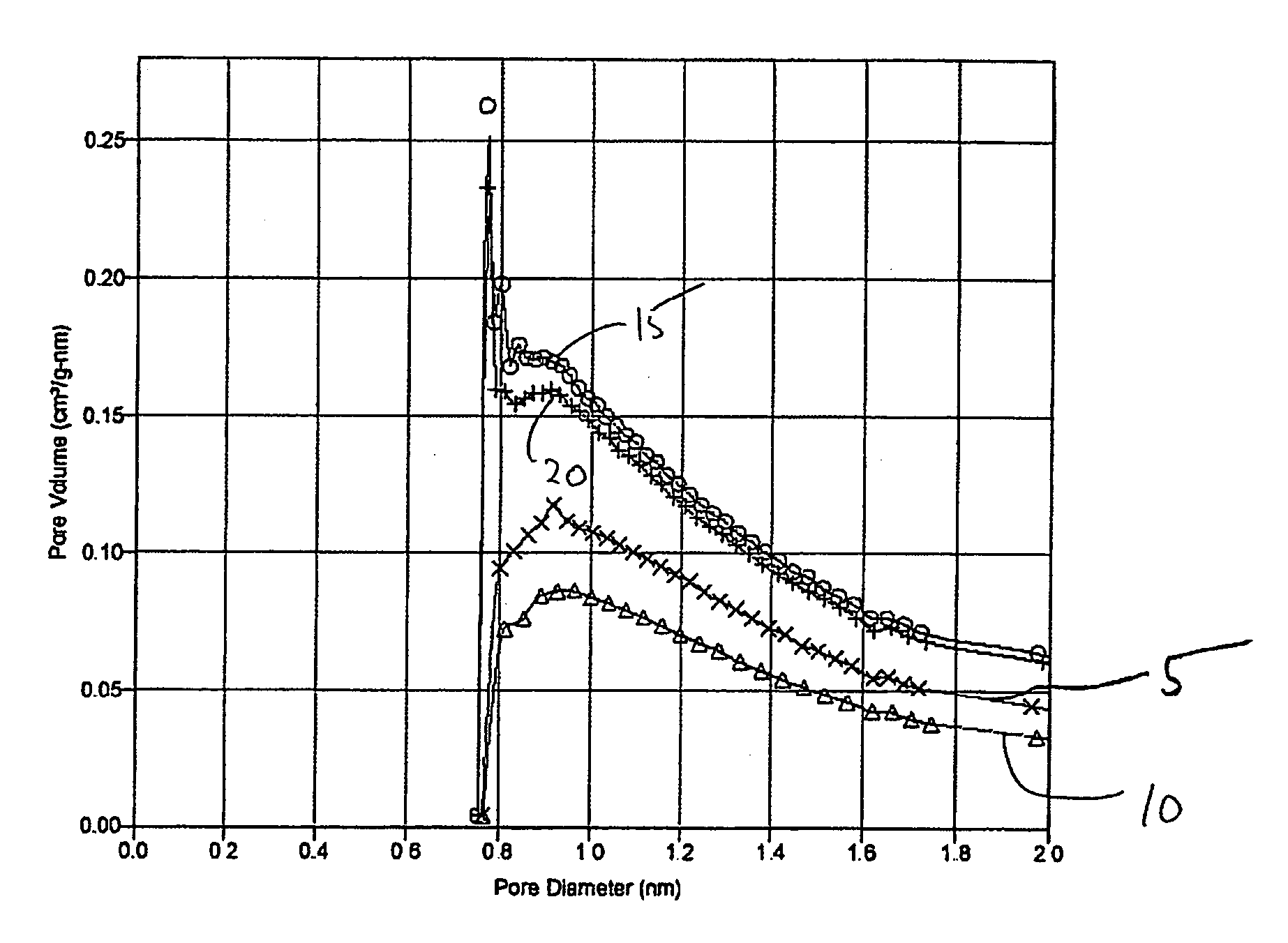

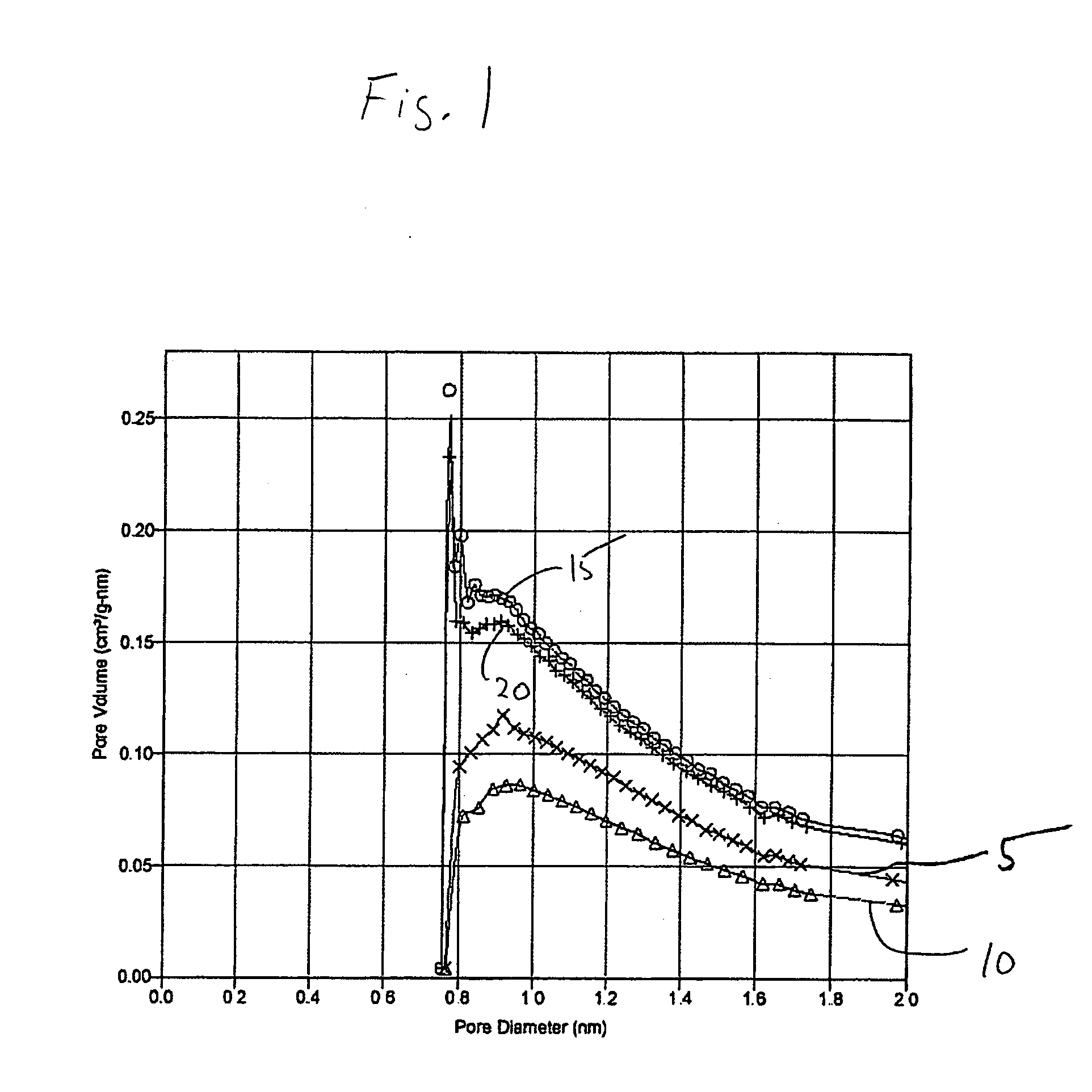

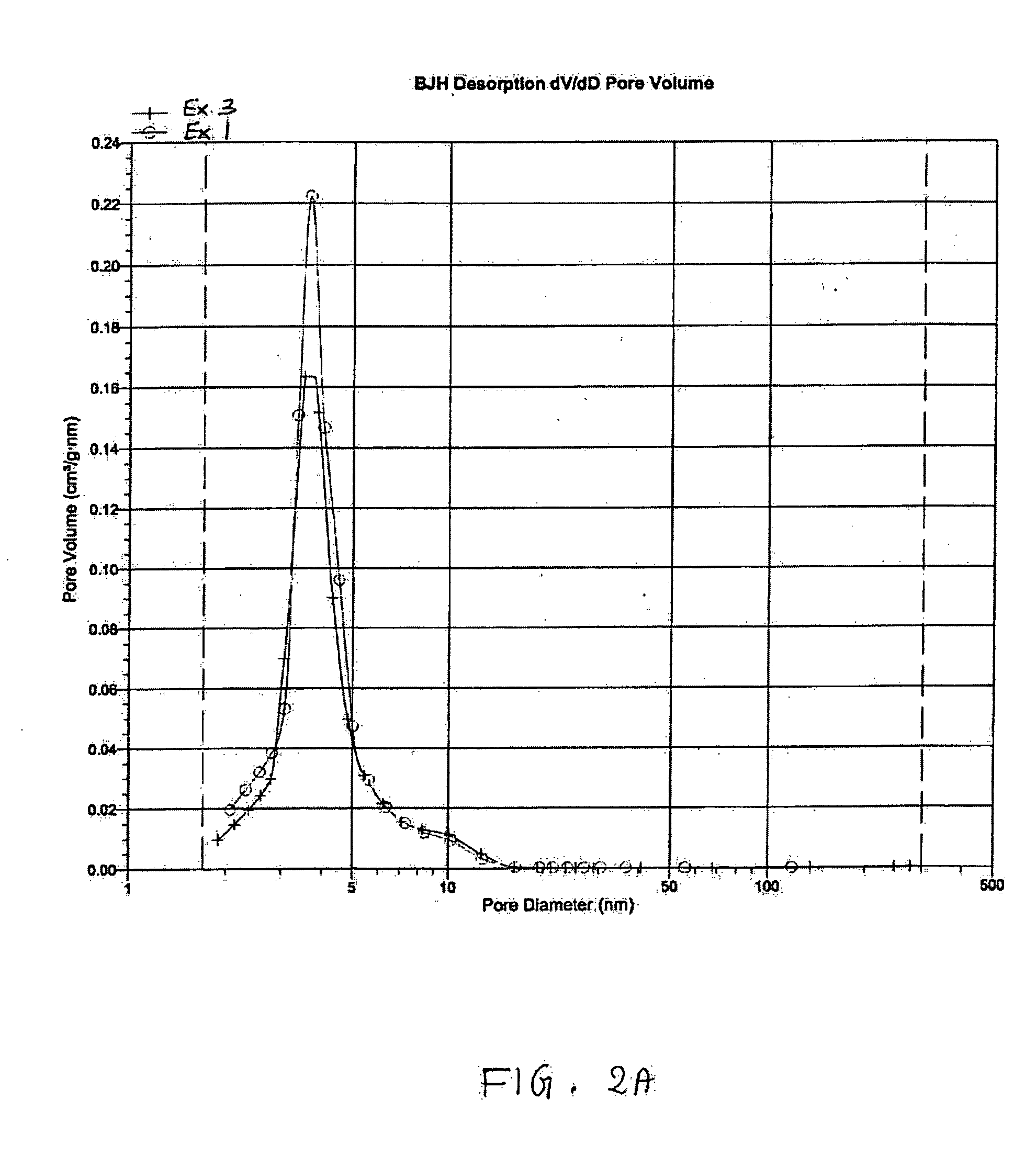

InactiveUS20050274646A1Lower the volumeLess economic valuePretreated surfacesCatalyst activation/preparationPore diameterSilicon dioxide

The invention generally relates to methods for modifying a porous amorphous material comprising micropores to reduce its micropore volume and to form a support for a hydroprocessing catalyst, to methods of making said catalyst, as well as to methods for hydrocracking employing said hydroprocessing catalyst characterized by a lower selectivity towards undesirable gaseous hydrocarbon products. In one embodiment, the method for modifying the amorphous material comprises depositing an inorganic oxide or inorganic oxide precursor to the amorphous material; and treating the deposited amorphous material so as to reduce its micropore volume by at least about 5 percent, while its mean pore diameter is substantially unchanged or changed by not more than about 10 percent. Further embodiments include the amorphous material comprising silica-alumina, and the deposited inorganic oxide or inorganic oxide precursor comprising silicon.

Owner:CONOCOPHILLIPS CO

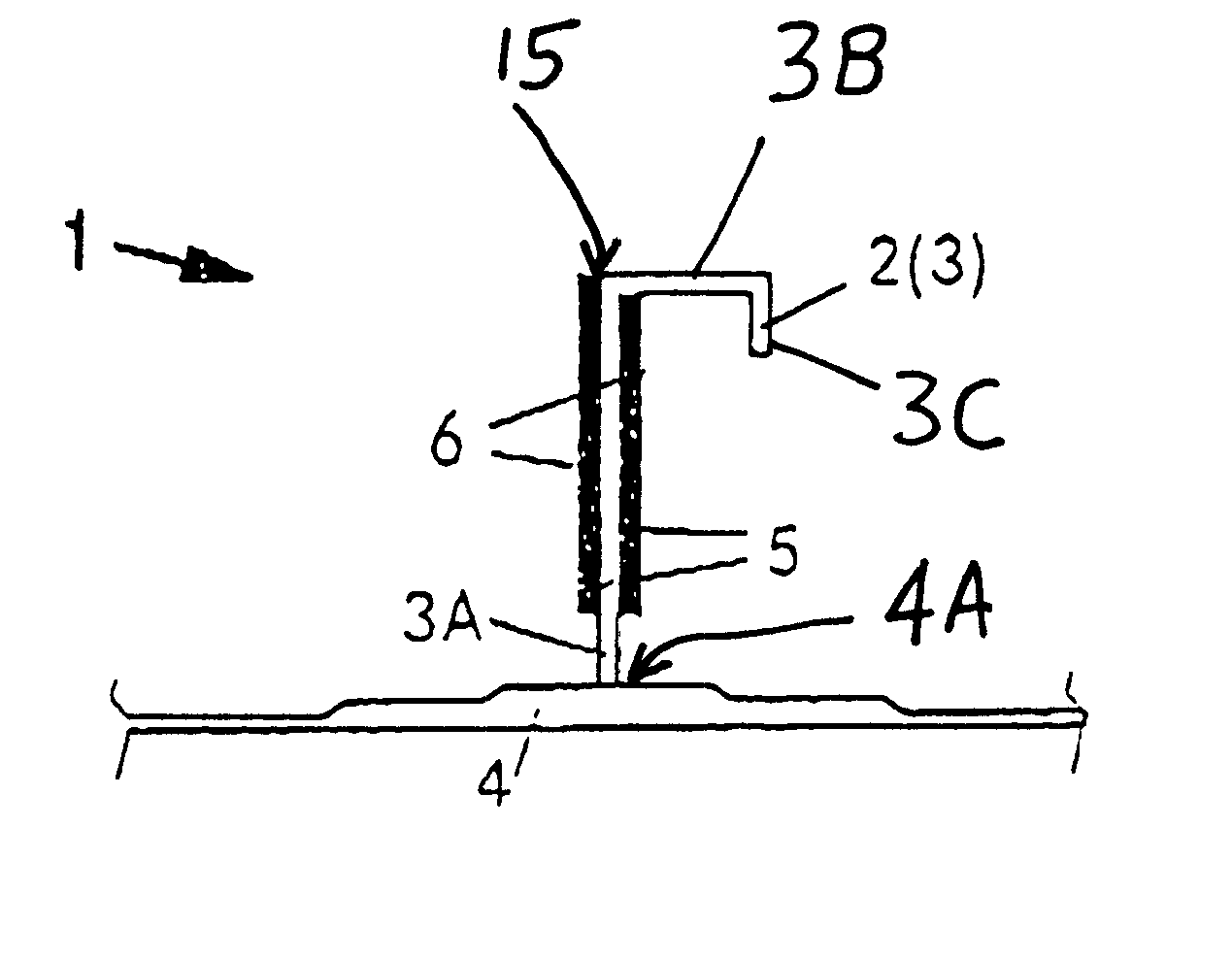

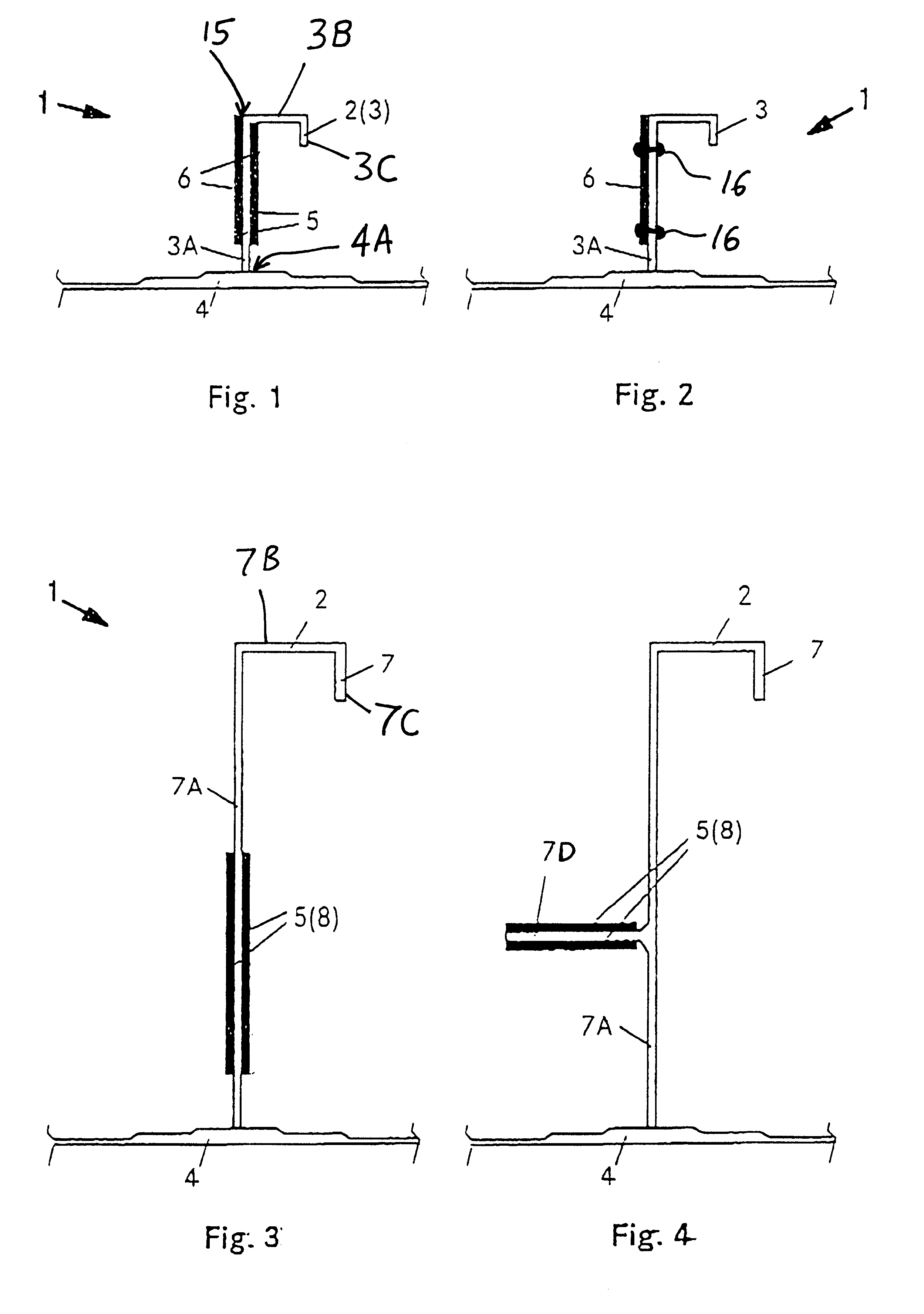

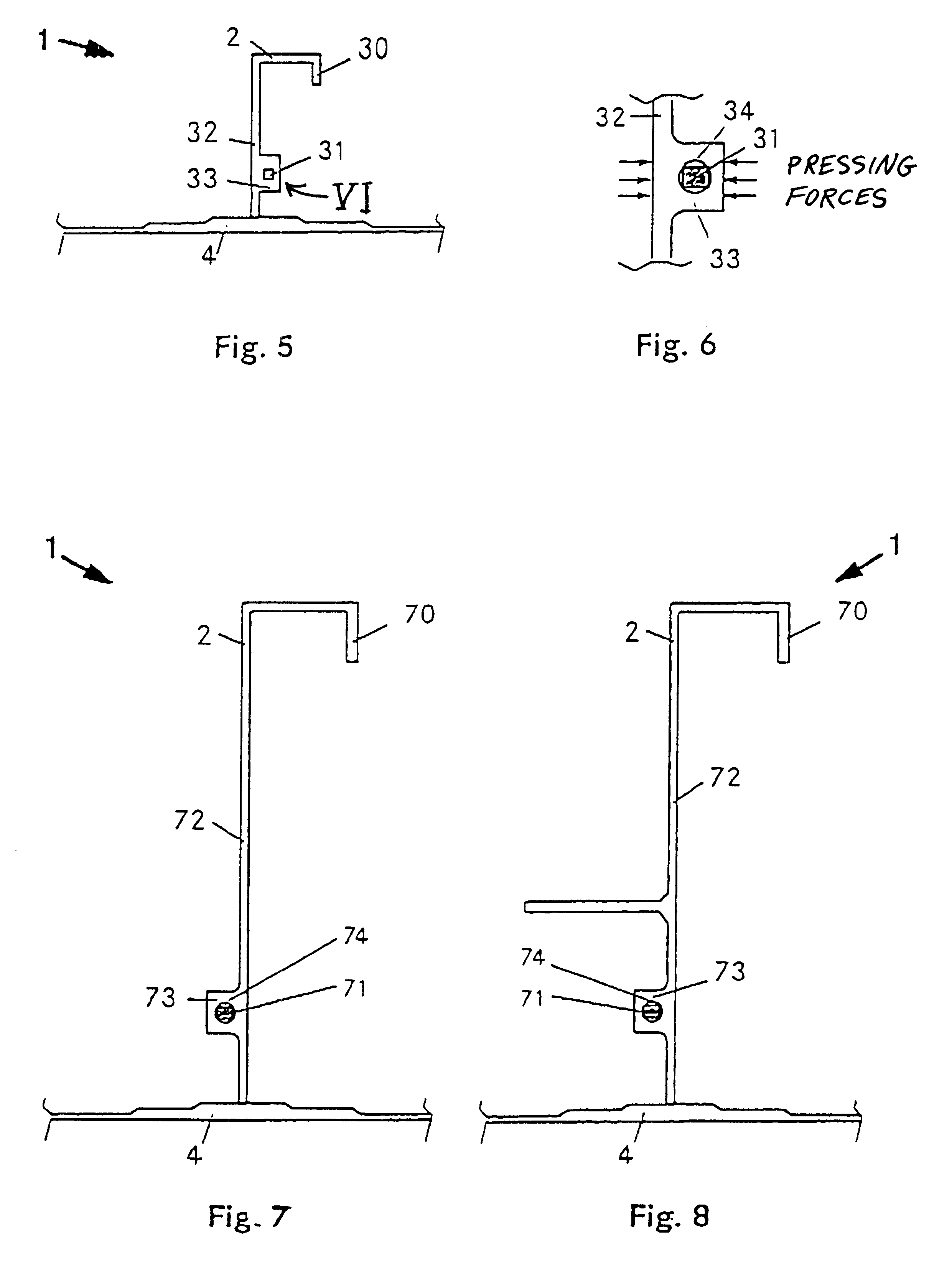

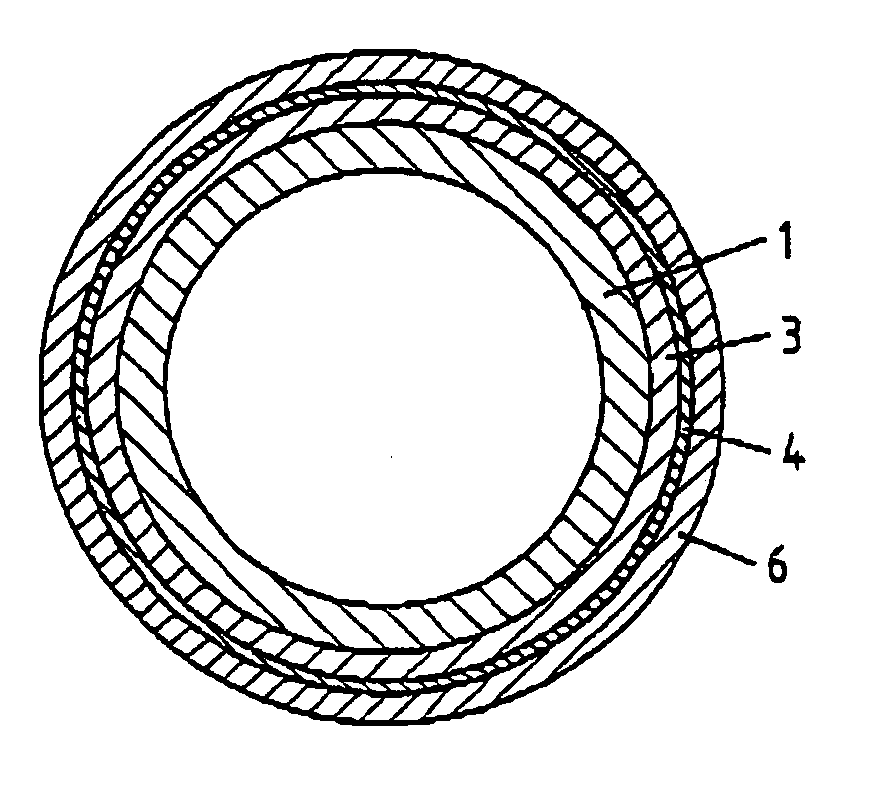

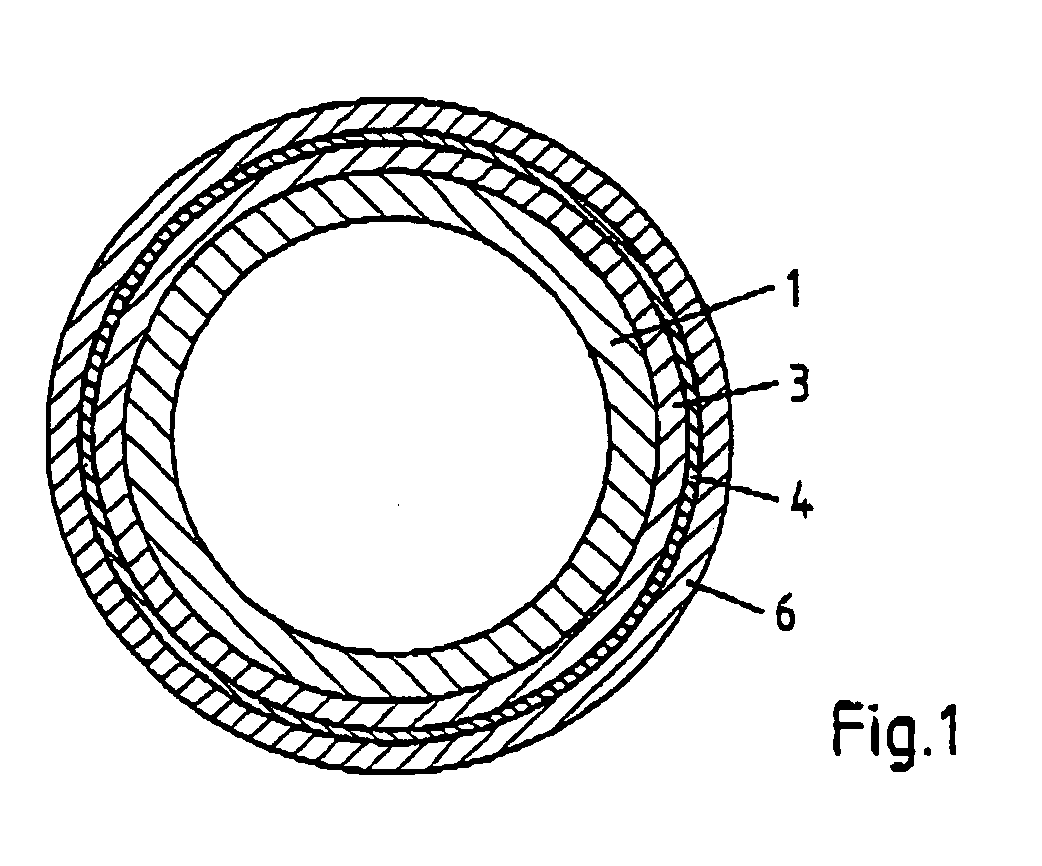

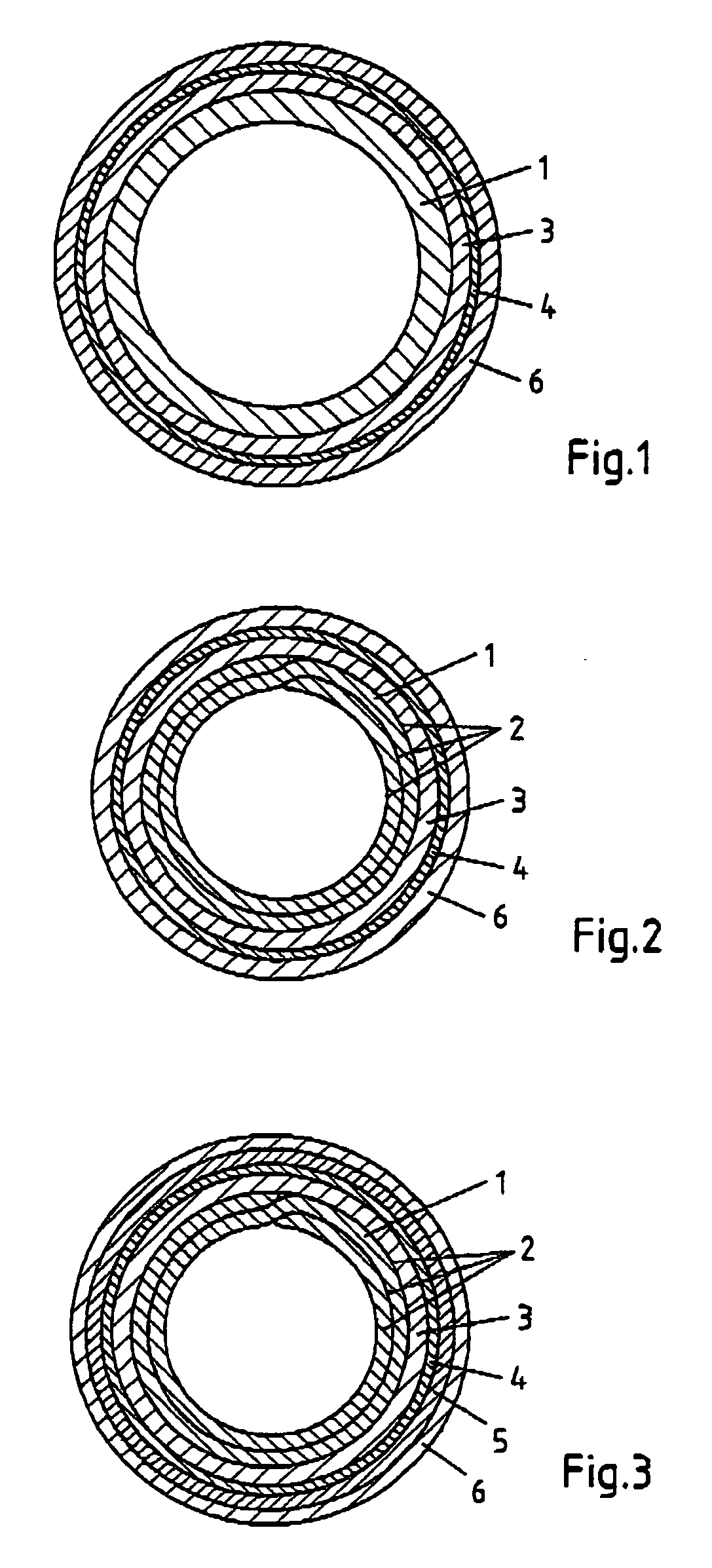

Multilayer coated corrosion resistant article and method of production thereof

InactiveUS20050031894A1Increase heightImprove heat resistanceSynthetic resin layered productsCoatingsPhosphateZinc

The disclosure relates to a corrosion resistant article comprising a metal body 1 and a protective coating applied on at least one surface of said metal body 1, said protective coating comprising: (a) a zinc layer 3 comprising metallic zinc; (b) a silicate layer 4 comprising at least one silicate; and (c) a synthetic resin layer 6 comprising at least one fluoroplastic material such as, for example, polyvinylfluoride. In particular, the disclosure relates to a corrosion resistant brake pipe or fuel pipe having a protective coating for use in motor vehicles. The protective coating is substantially free of chromates and phosphates and, hence, environmentally acceptable.

Owner:ELISHA HLDG LLC

Cracking Catalyst and a Process for Preparing the Same

ActiveUS20080293561A1Increase lytic activityQuality improvementCatalytic crackingMolecular sieve catalystsMolecular sieveGasoline

A cracking catalyst, which contains alumina, phosphorus and molecular sieve, with or without clay, wherein said alumina is η-alumina or a mixture of η-alumina and χ-alumina and / or γ-alumina, and wherein the catalyst contains, on the basis of the total amount of the catalyst, 0.5-50 wt % of η-alumina, 0-50 wt % of χ-alumina and / or γ-alumina, 10-70 wt % of molecular sieve, 0-75 wt % of clay, and 0.1-8 wt % of phosphorus, measured as P2O5. The catalyst not only has higher cracking activity and higher cracking ability for cracking heavy oil, but also improves significantly quality and yield of gasoline, LCO and LPG in cracking products.

Owner:CHINA PETROCHEMICAL CORP +1

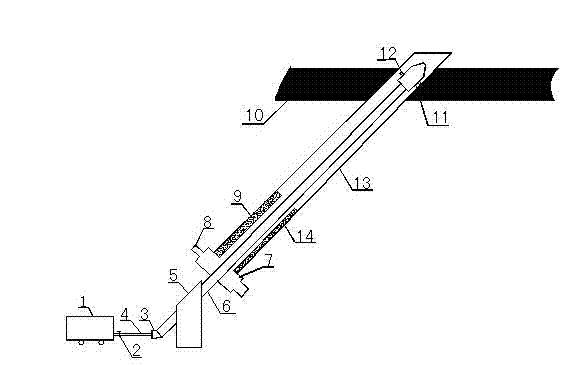

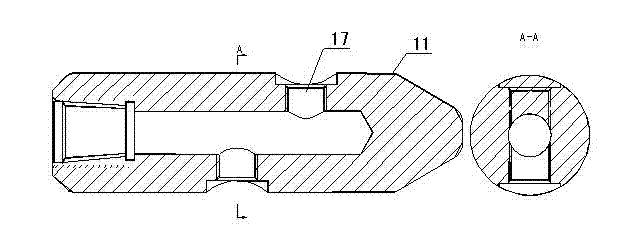

Coal seam reaming system using three-dimensional (3D) swirling water jet and reaming and fracturing method for permeability enhancement

InactiveCN102213077AEasy to crackLarge range of pressure reliefDrill bitsConstructionsHydraulic pumpHigh pressure water

The invention relates to coalmine gas extraction and permeability enhancement equipment and technology, and discloses a coal seam reaming system using three-dimensional (3D) swirling water jet. The system is connected to a high-pressure rotary joint through a high-pressure hose provided with a stop valve by virtue of a high-pressure hydraulic pump station and is characterized by being connected to a high-pressure water jet drill stem through a drilling machine, wherein the front end of the high-pressure water jet drill stem is connected with a high-pressure water jet head with nozzle bases; and high-pressure swirling water jet nozzles are arranged on the nozzle bases. The invention further discloses a coal seam reaming and fracturing method for permeability enhancement using the 3D swirling water jet. In the coal seam reaming method using the 3D swirling water jet, coal is sheared so as to lower the hydraulic pressure loss, improve the cutting efficiency and increase the cracks and bore diameter of the coal; high-pressure water is injected so as to fracture the coal between a hydraulic reamed hole and control bored holes; and a coal seam is fully depressurized within a large range so as to shorten the pre-extraction time of the coal seam.

Owner:CCTEG SHENYANG RES INST +1

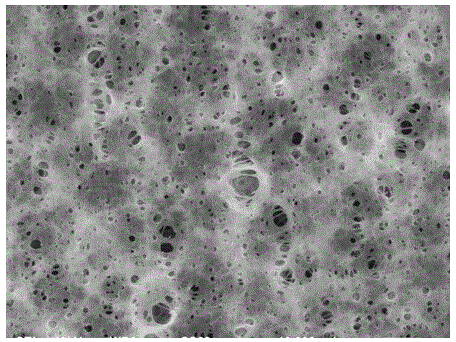

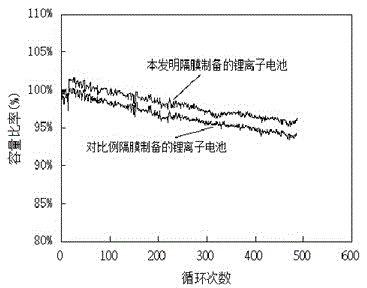

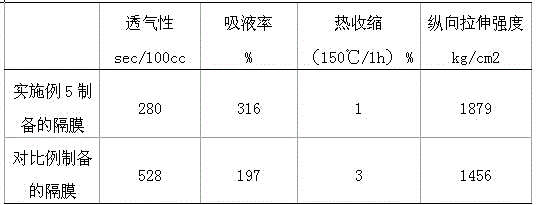

Composite coating lithium-ion battery separator and preparation method thereof

ActiveCN105552284AImprove thermal performanceImprove mechanical propertiesCell component detailsWater basedPole piece

The invention relates to a composite coating lithium-ion battery separator. The composite coating lithium-ion battery separator is composed of a base film, an aramid fiber coating coated on one side of the base film and a PVDF coating coated on the other side of the base film; the aramid fiber coating is obtained by an aramid fiber sizing agent after coating, soaking and drying, and the thickness of the coating is 0.5-4 microns; the PVDF coating is obtained by a water-based PVDF sizing agent after coating and drying, and the thickness of the coating is 0.1-2 microns. The invention also provides a preparation method of the separator. According to the composite coating lithium-ion battery separator and the preparation method thereof, the separator has the characteristics that the aramid fiber coating is good in thermal performance and mechanical performance and the PVDF coating has good wettability and liquid retention property for electrolytes, can effectively adhere batteries and pole pieces and is little in environmental pollution, and is beneficial for preparing lithium-ion batteries with longer cycle life and higher safety. Tests indicate that the separator has good air permeability, liquid absorption rate, thermal contraction and tensile strength, so that the cycle life of the batteries can be obviously prolonged by using the lithium-ion batteries prepared by the separator.

Owner:CANGZHOU MINGZHU SEPARATOR TECH CO LTD

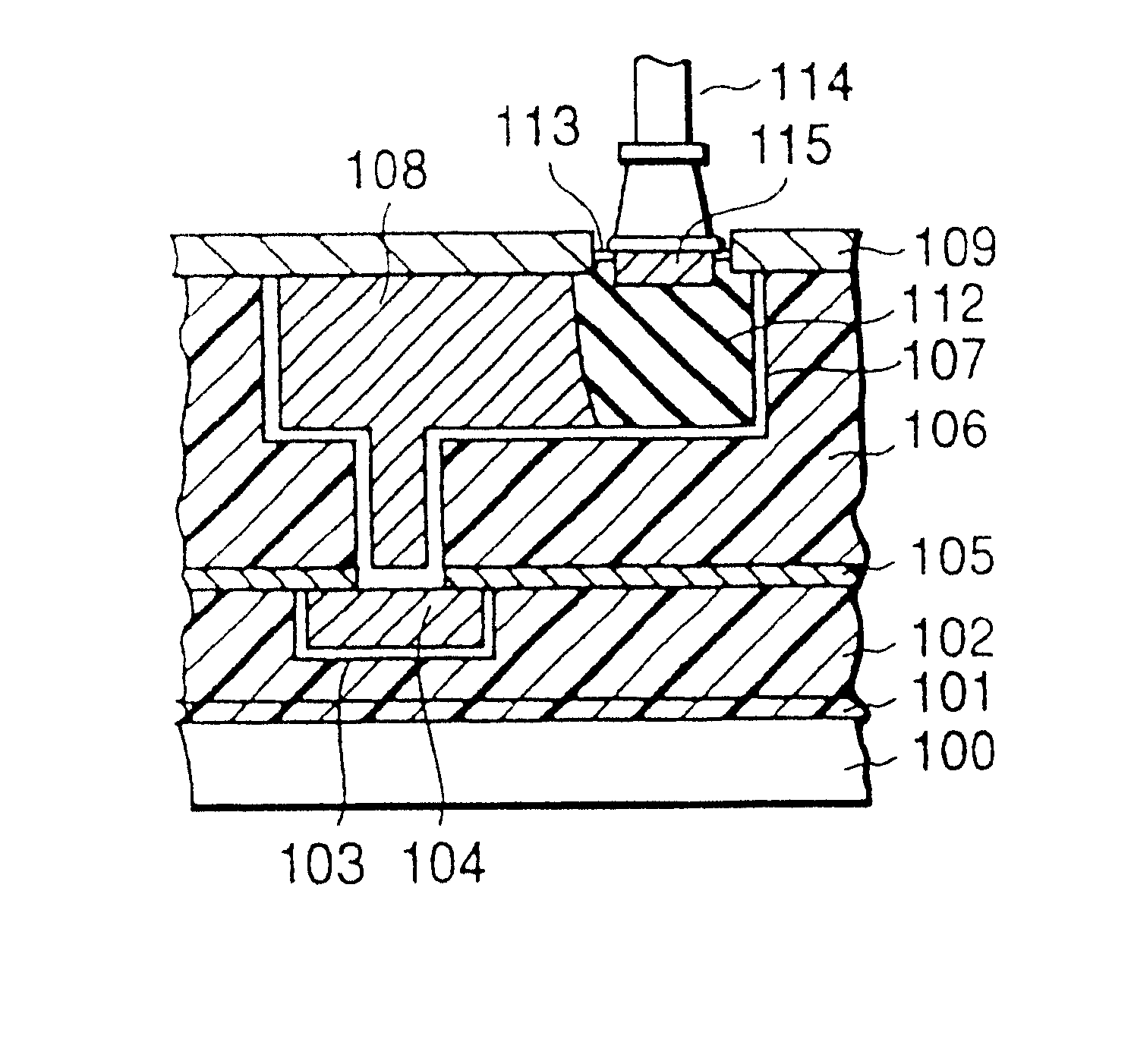

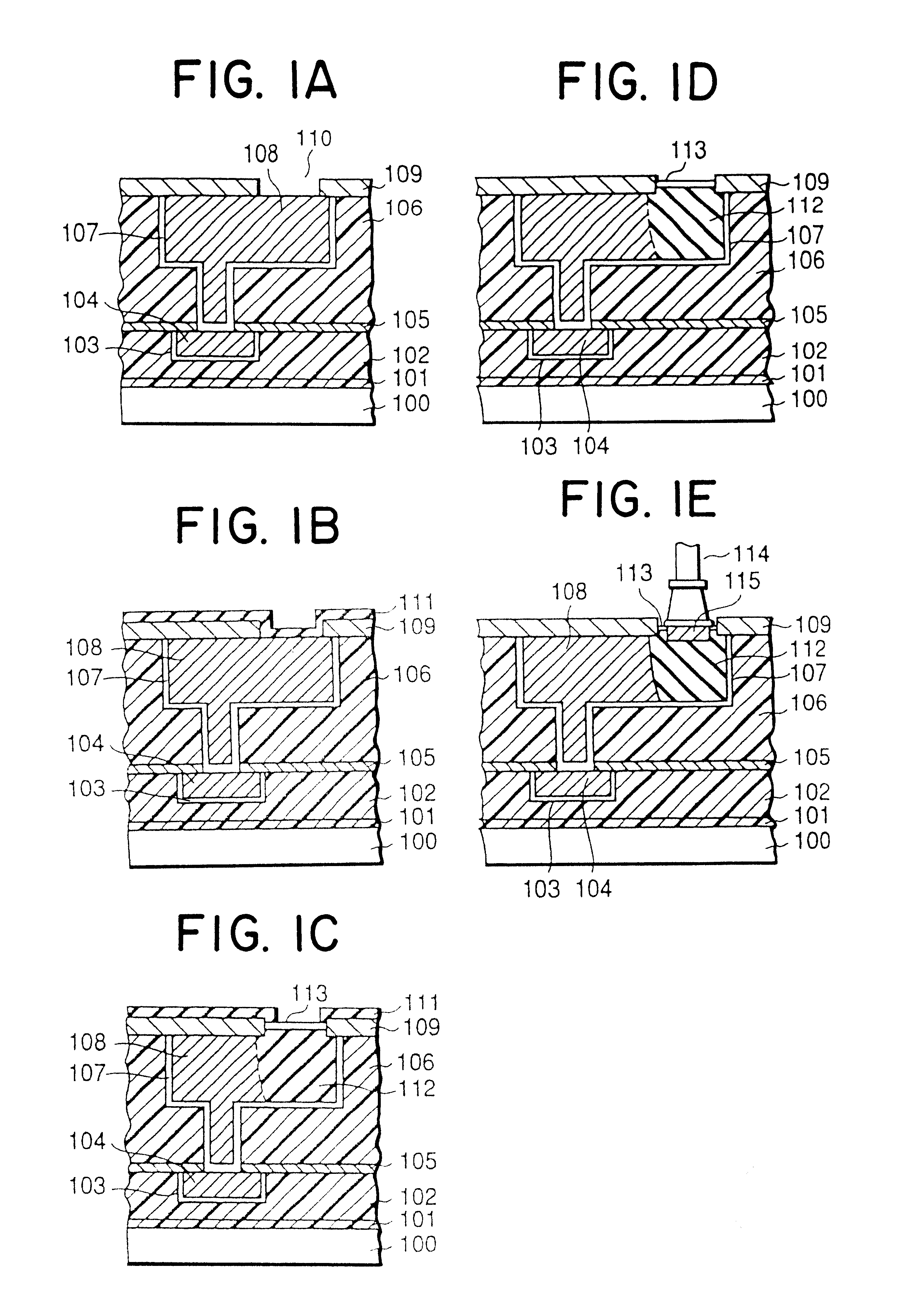

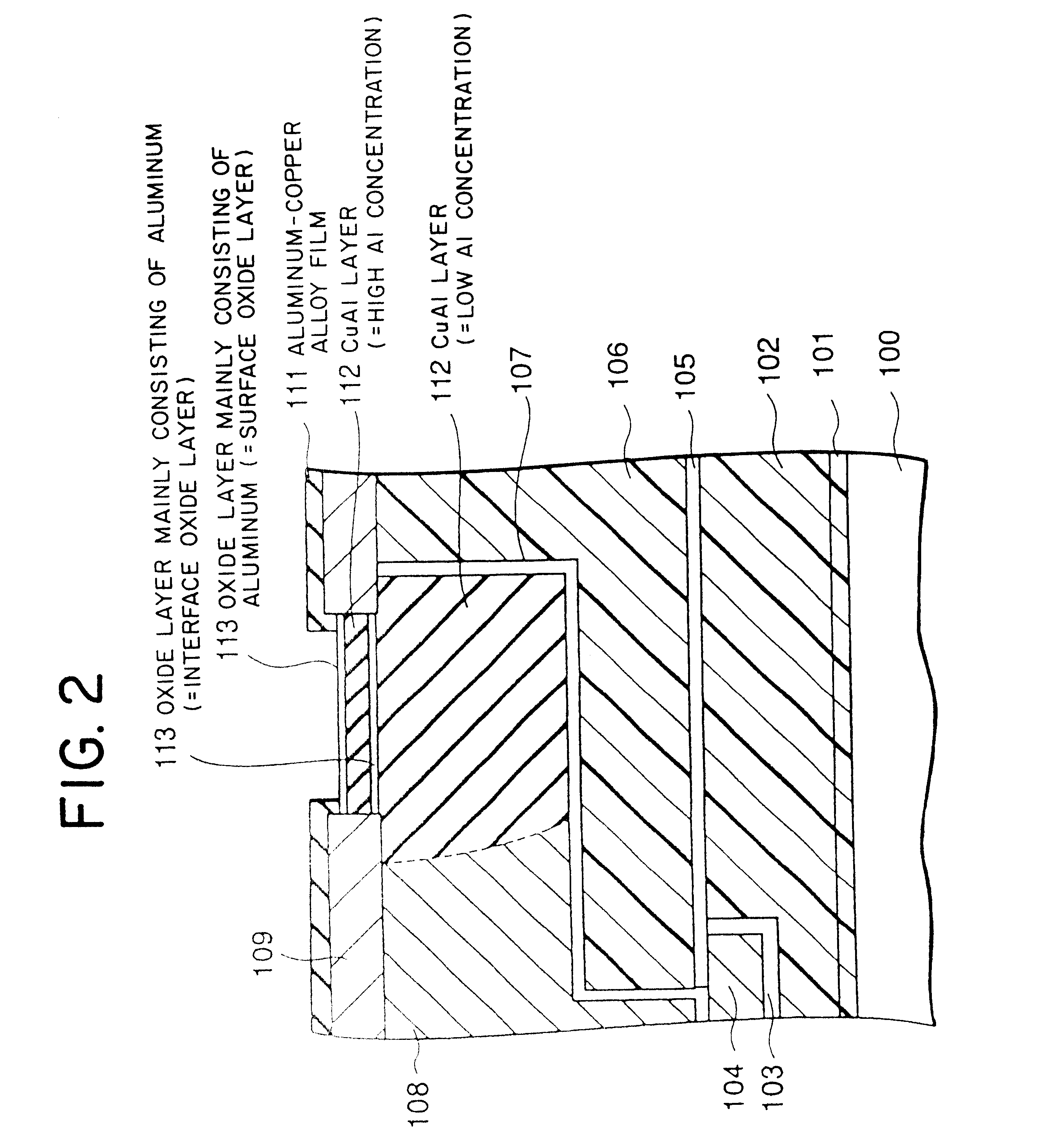

Semiconductor device with improved bonding

InactiveUS6727593B2Dust could be greatly decreasedSolution value is not highSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsDevice materialCopper-wiring

A semiconductor device, which is comprised of a copper wiring layer which is formed above a semiconductor substrate, a pad electrode layer which conducts electrically to the copper wiring layer and has an alloy, which contains copper and a metal whose oxidation tendency is higher than copper, formed to extend to the bottom surface, and an insulating protective film which has an opening extended to the pad electrode layer, is provided.

Owner:KIOXIA CORP

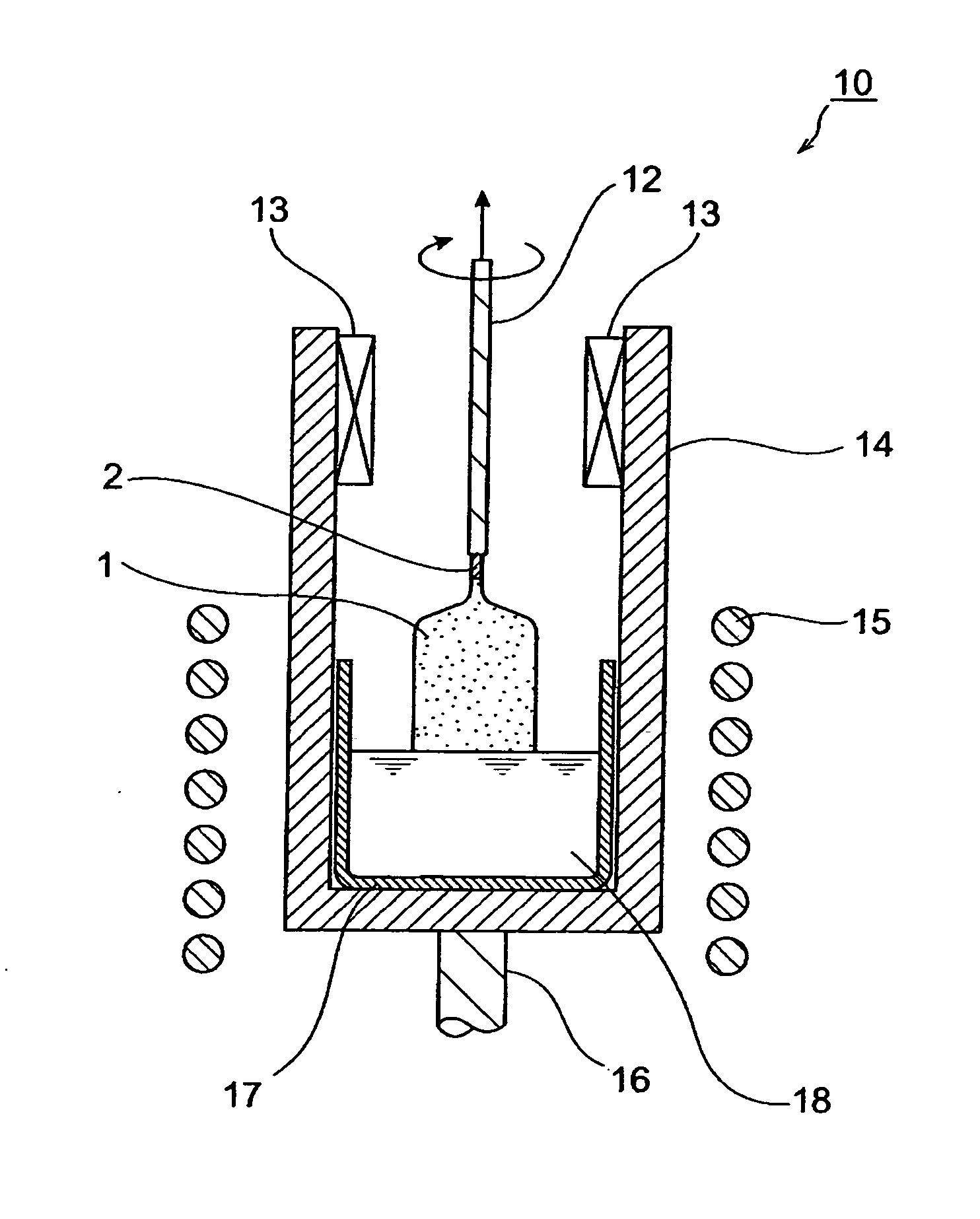

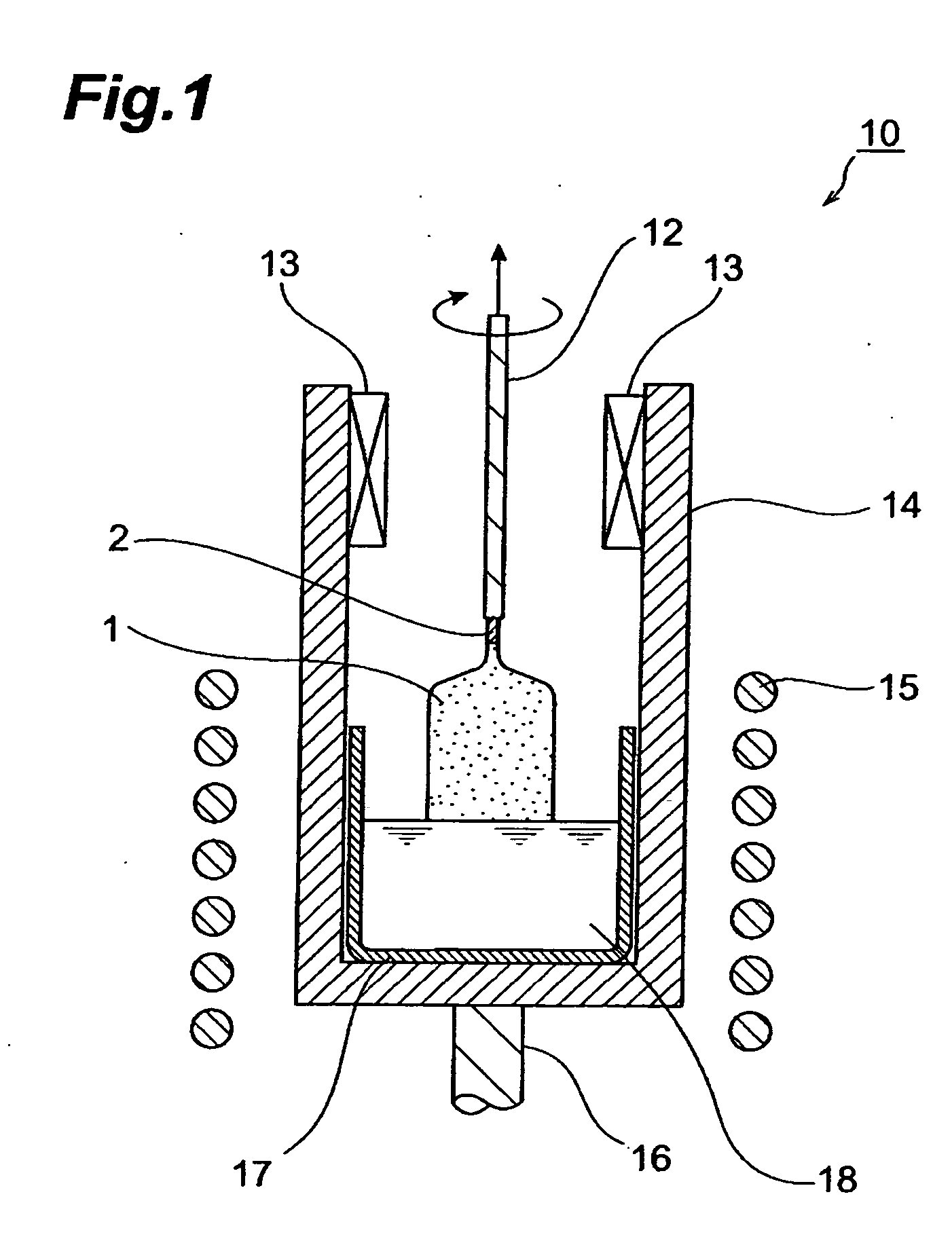

Scintillator single crystal and production method of same

ActiveUS20060288926A1Superior fluorescent propertyReduce impactPolycrystalline material growthBy pulling from meltSingle crystalCerium doping

A scintillator single crystal of a specific cerium-doped silicate compound that contains 0.00005 to 0.1 wt % of one or more types of element selected from the group consisting of elements belonging to group 2 of the periodic table based on the total weight of the single crystal.

Owner:OXIDE

Current collector, secondary battery, electronic device, and manufacturing method thereof

ActiveUS20150243962A1Suppress relative position shiftReduce tensionRadiation applicationsFinal product manufactureEngineeringElectron

An object is to provide a secondary battery suitable for a wearable device. Another object is to provide a novel power storage device. Part of an electrode, specifically a current collector and an active material layer, for a secondary battery is subjected to cutting processing to have a complex shape. This suppresses the positional shift of an end portion of an electrode far from a curvature center from an electrode close to the curvature center due to the larger degree of bending of the electrode far from the curvature center than that of the electrode close to the curvature center, or relieves tension to be applied to the electrode far from the curvature center.

Owner:SEMICON ENERGY LAB CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com