Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Reaction can be limited" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

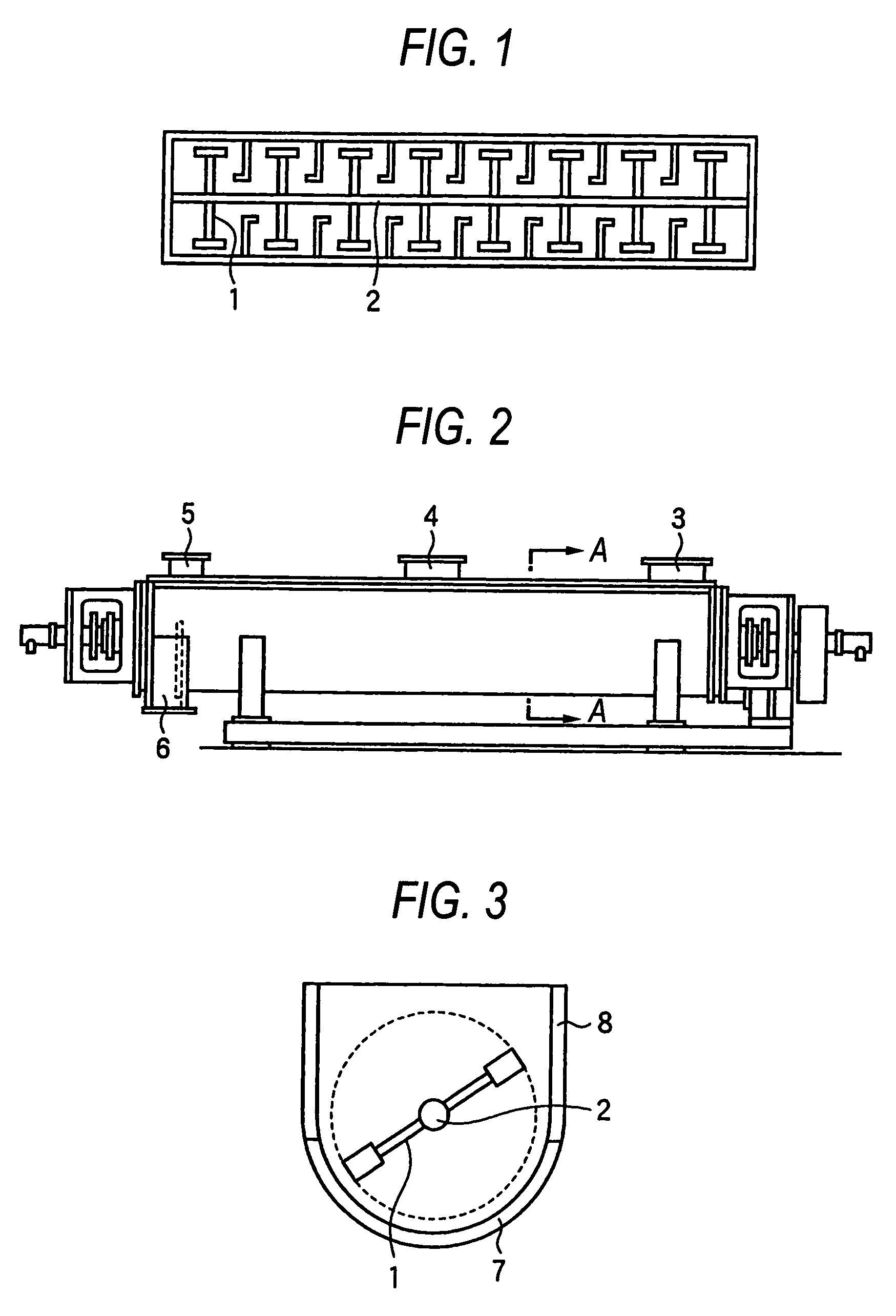

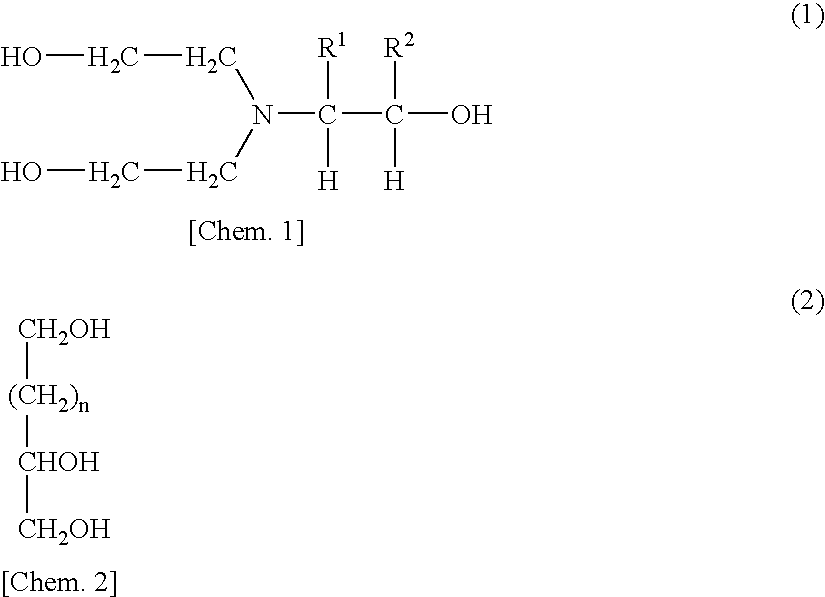

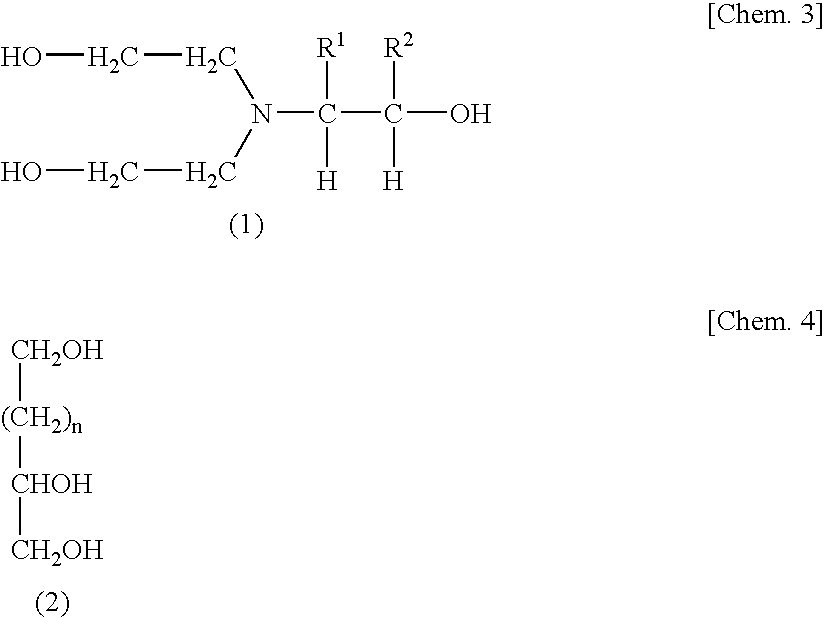

Surface crosslinking treatment method of water-absorbing resin powder

ActiveUS7378453B2Good physical propertiesMade stableAbsorbent padsDyeing processAqueous solutionIndustrial scale

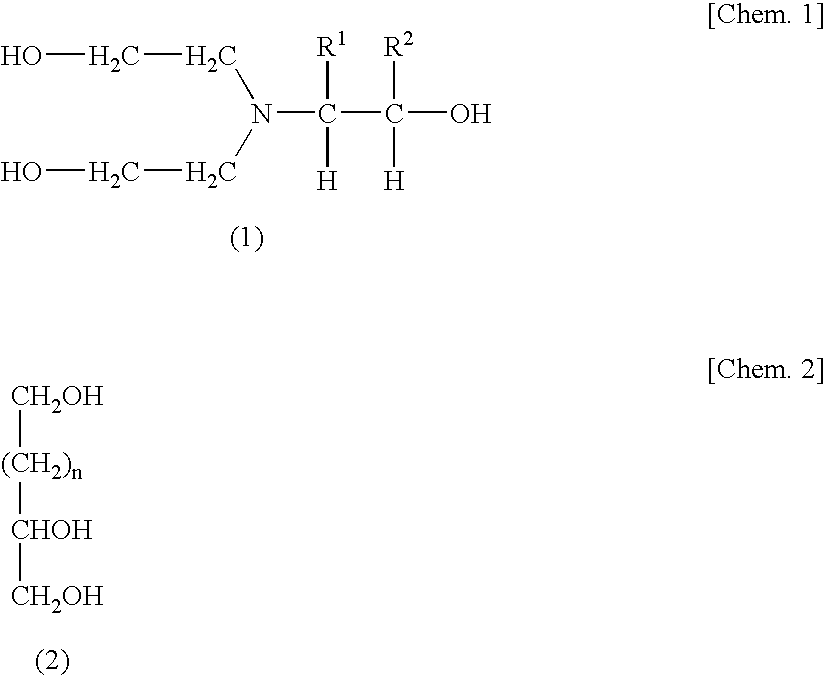

A surface crosslinking treatment method of a water-absorbing resin powder is disclosed that can overcome various problems in production encountered in the production of surface crosslinked water-absorbing resin powders on an industrial scale and can produce a water-absorbing resin powder having excellent physical properties without causing deterioration in physical properties of resin. The surface crosslinking treatment method of a water-absorbing resin powder includes adding a surface crosslinking agent to a water-absorbing resin powder and heat treating the mixture, wherein (1) the water-absorbing resin powder after the heat treatment is stirred and cooled under an air flow; (2) the water-absorbing resin powder after the heat treatment is cooled under an air flow, and at the same time, at least a part of fine particles of the water-absorbing resin powder and / or the residual crosslinking agent is removed by the air flow; or (3) the water-absorbing resin powder after the heat treatment is cooled and simultaneously granulated, and preferably an aqueous solution is added to the water-absorbing resin powder at a temperature of 40-100° C. during the cooling treatment.

Owner:NIPPON SHOKUBAI CO LTD

Surface crosslinking treatment method of water-absorbing resin powder

ActiveUS20040181031A1Good physical propertiesMade stableAbsorbent padsDyeing processAqueous solutionIndustrial scale

A surface crosslinking treatment method of a water-absorbing resin powder is disclosed that can overcome various problems in production encountered in the production of surface crosslinked water-absorbing resin powders on an industrial scale and can produce a water-absorbing resin powder having excellent physical properties without causing deterioration in physical properties of resin. The surface crosslinking treatment method of a water-absorbing resin powder includes adding a surface crosslinking agent to a water-absorbing resin powder and heat treating the mixture, wherein (1) the water-absorbing resin powder after the heat treatment is stirred and cooled under an air flow; (2) the water-absorbing resin powder after the heat treatment is cooled under an air flow, and at the same time, at least a part of fine particles of the water-absorbing resin powder and / or the residual crosslinking agent is removed by the air flow; or (3) the water-absorbing resin powder after the heat treatment is cooled and simultaneously granulated, and preferably an aqueous solution is added to the water-absorbing resin powder at a temperature of 40-100° C. during the cooling treatment.

Owner:NIPPON SHOKUBAI CO LTD

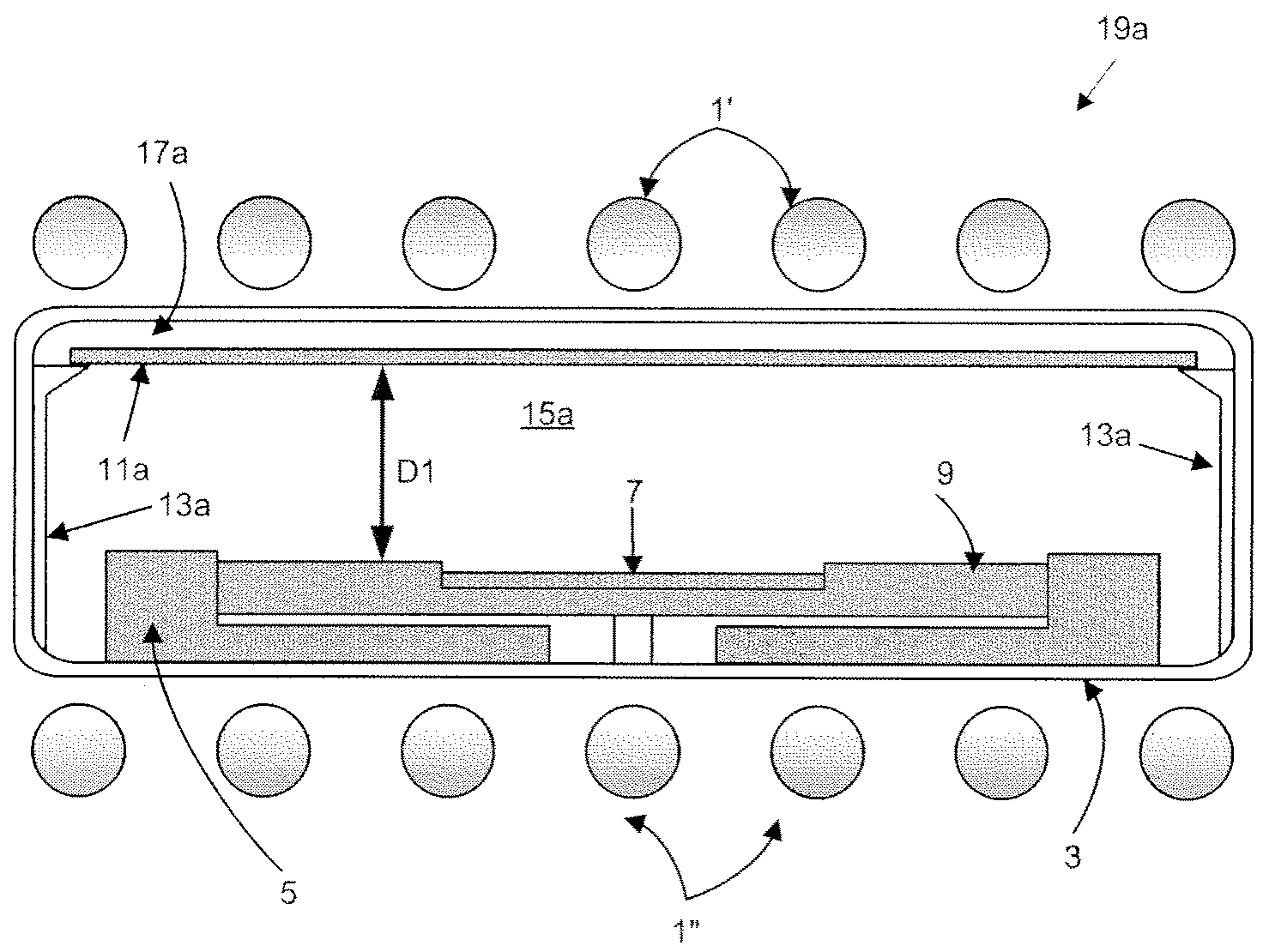

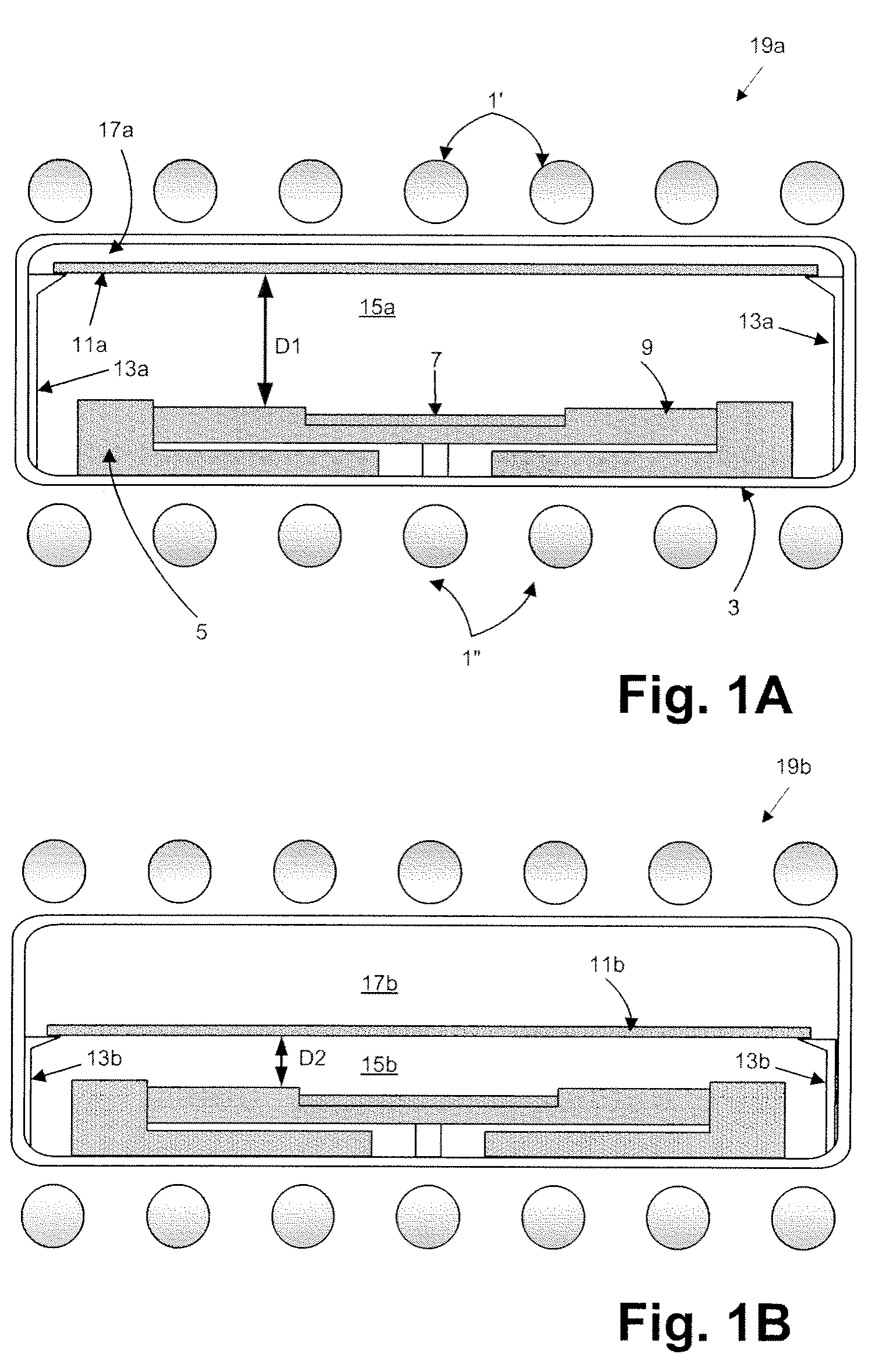

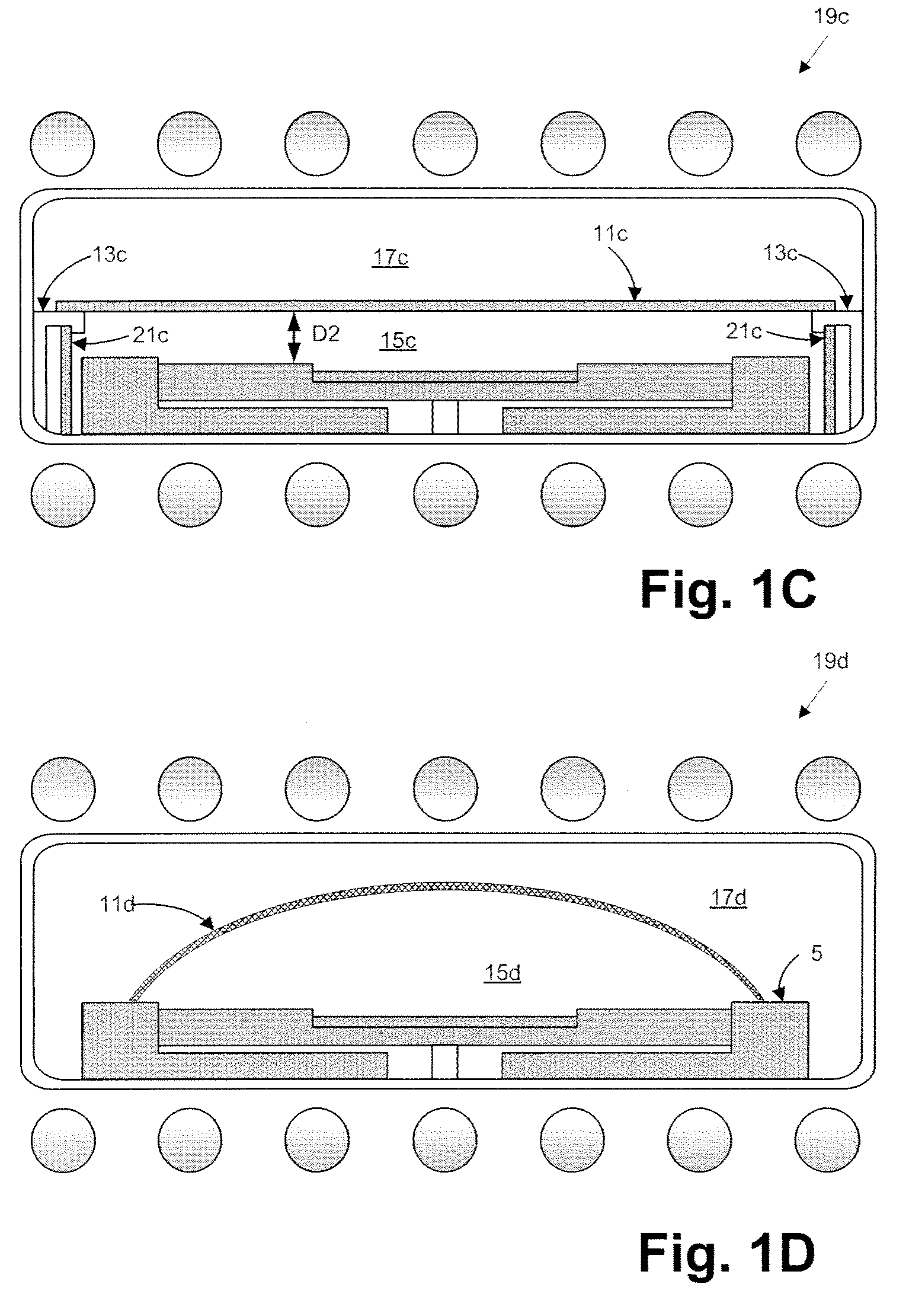

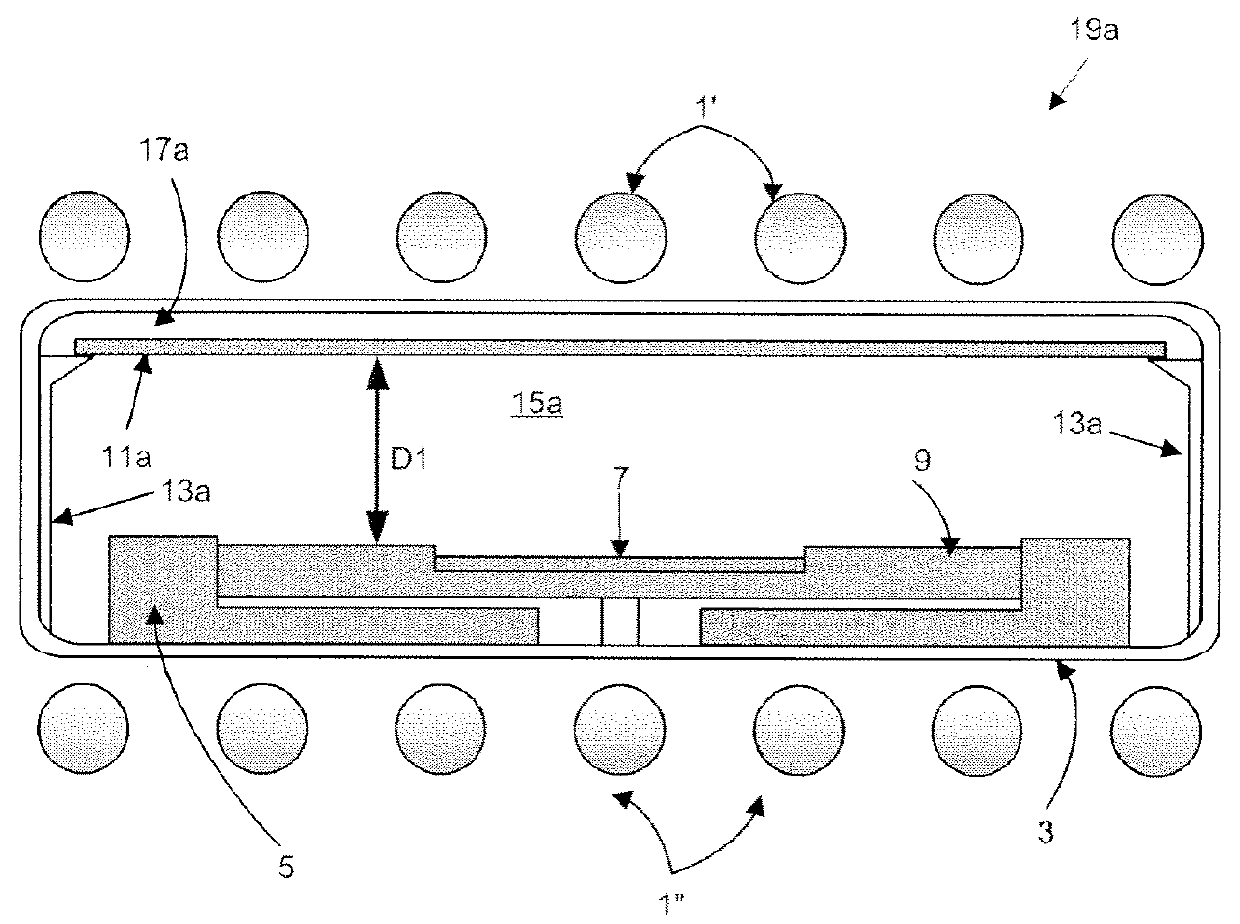

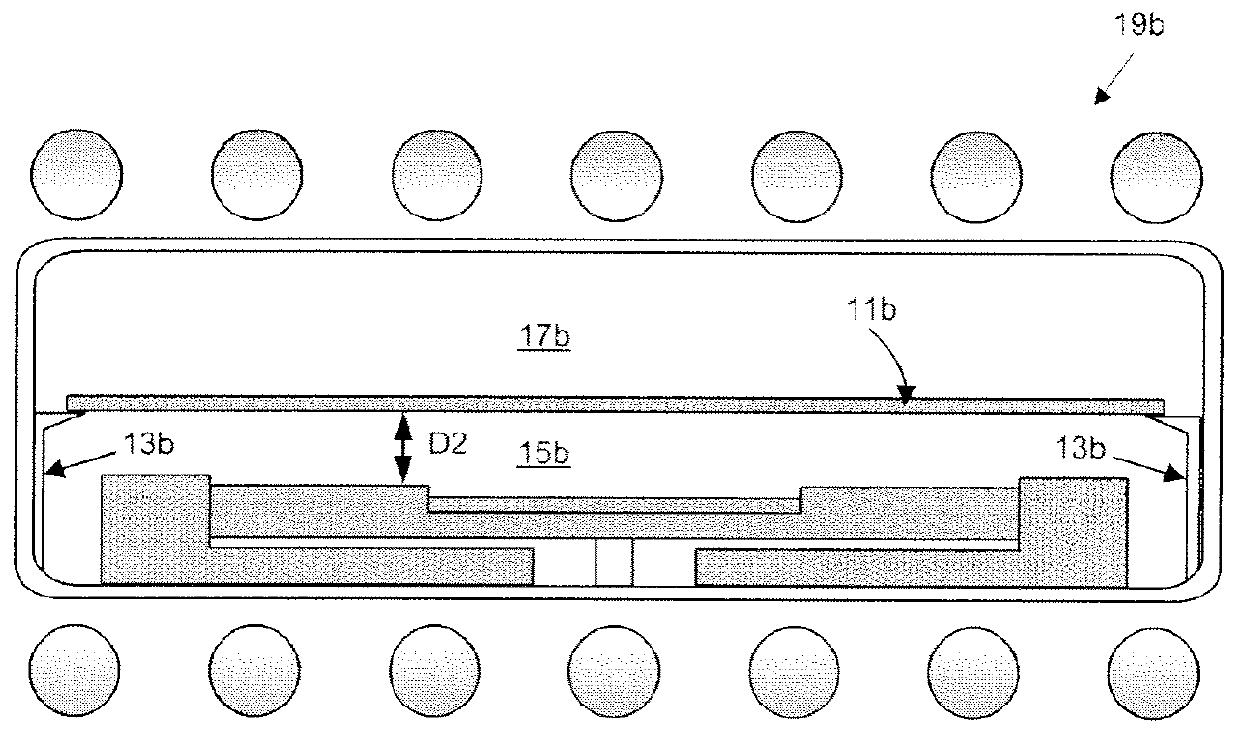

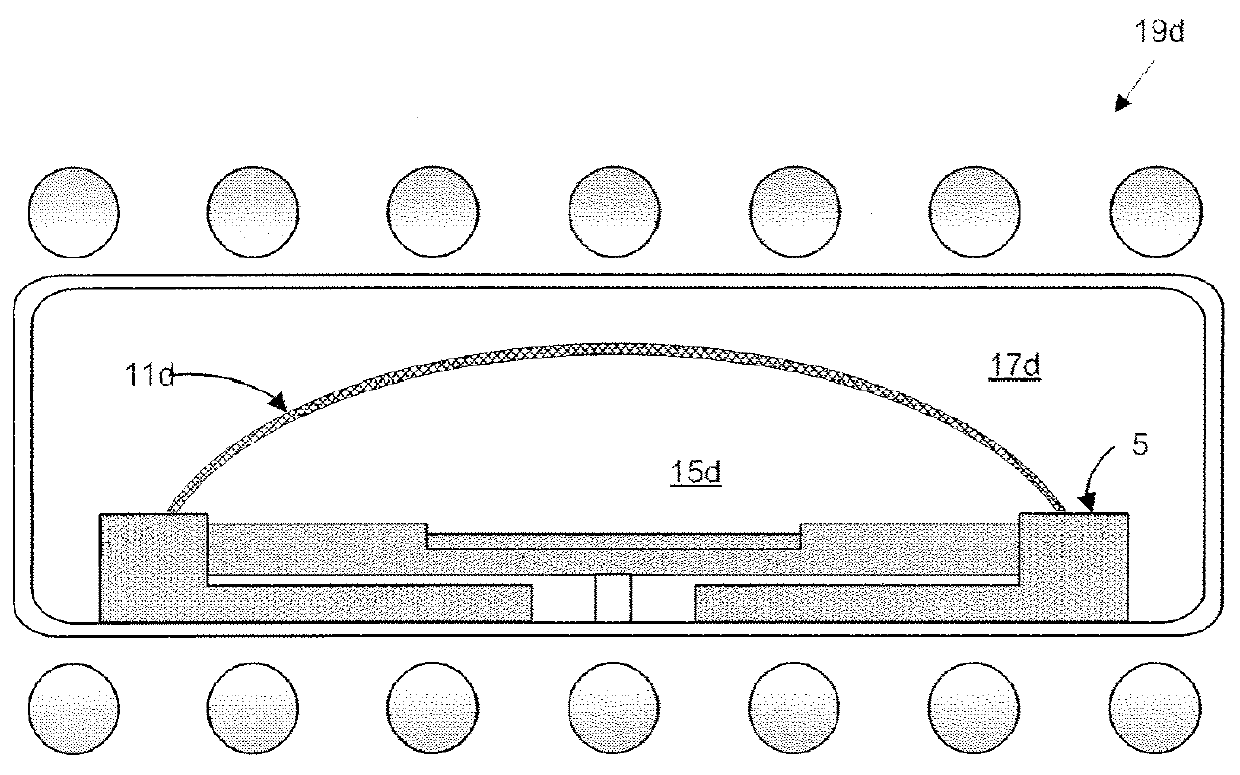

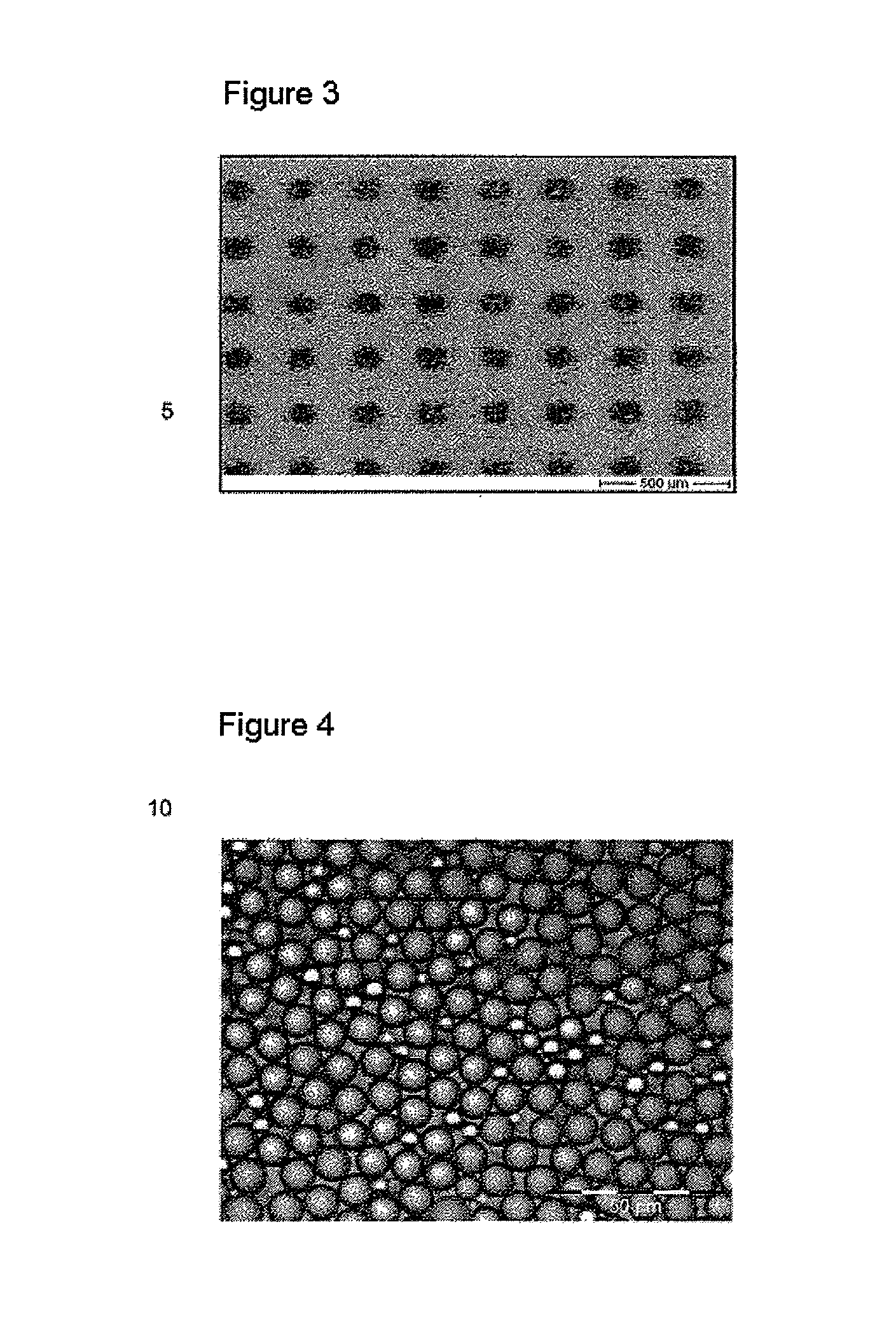

Device For Carrying Out A Biological Assay

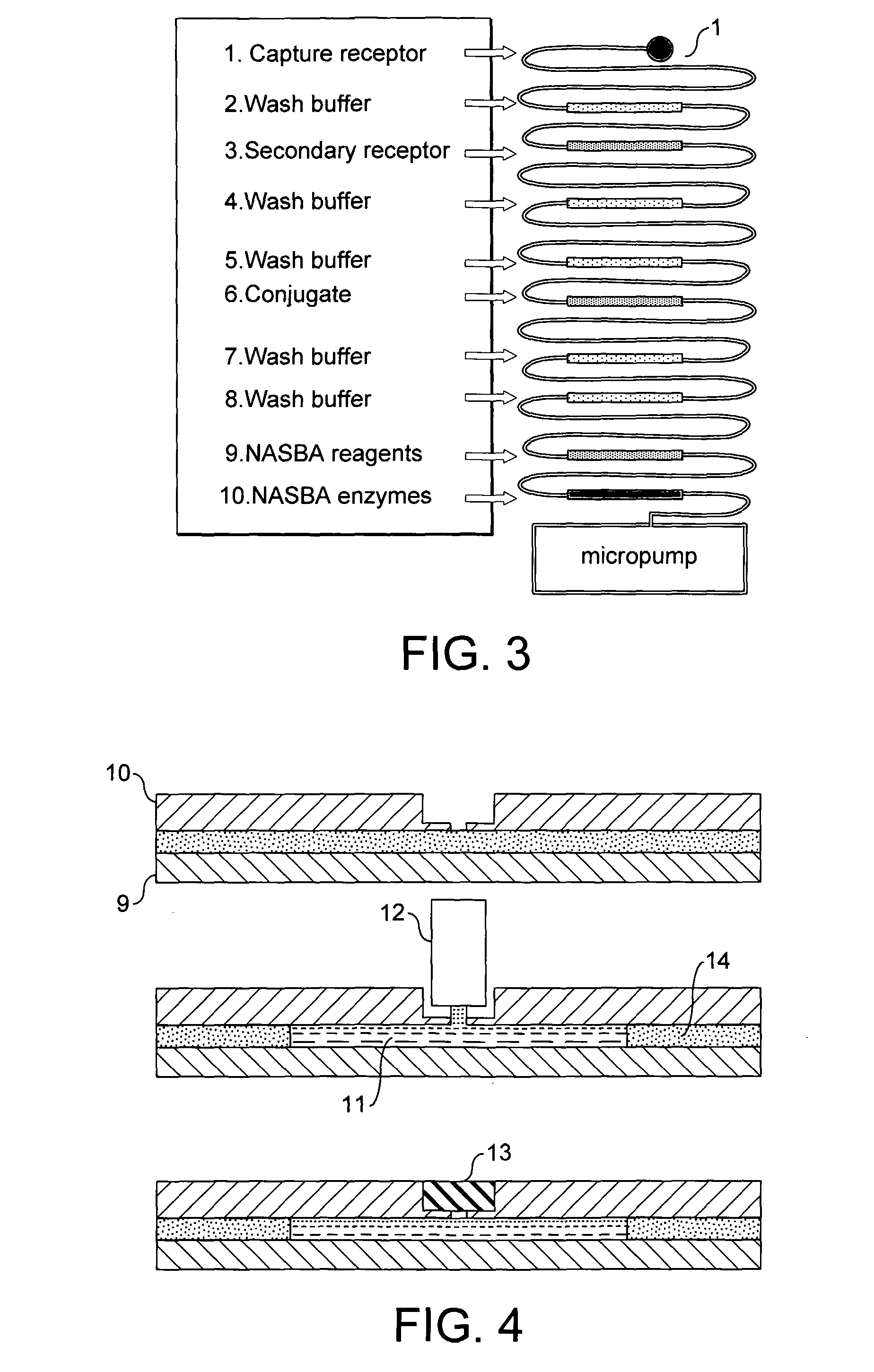

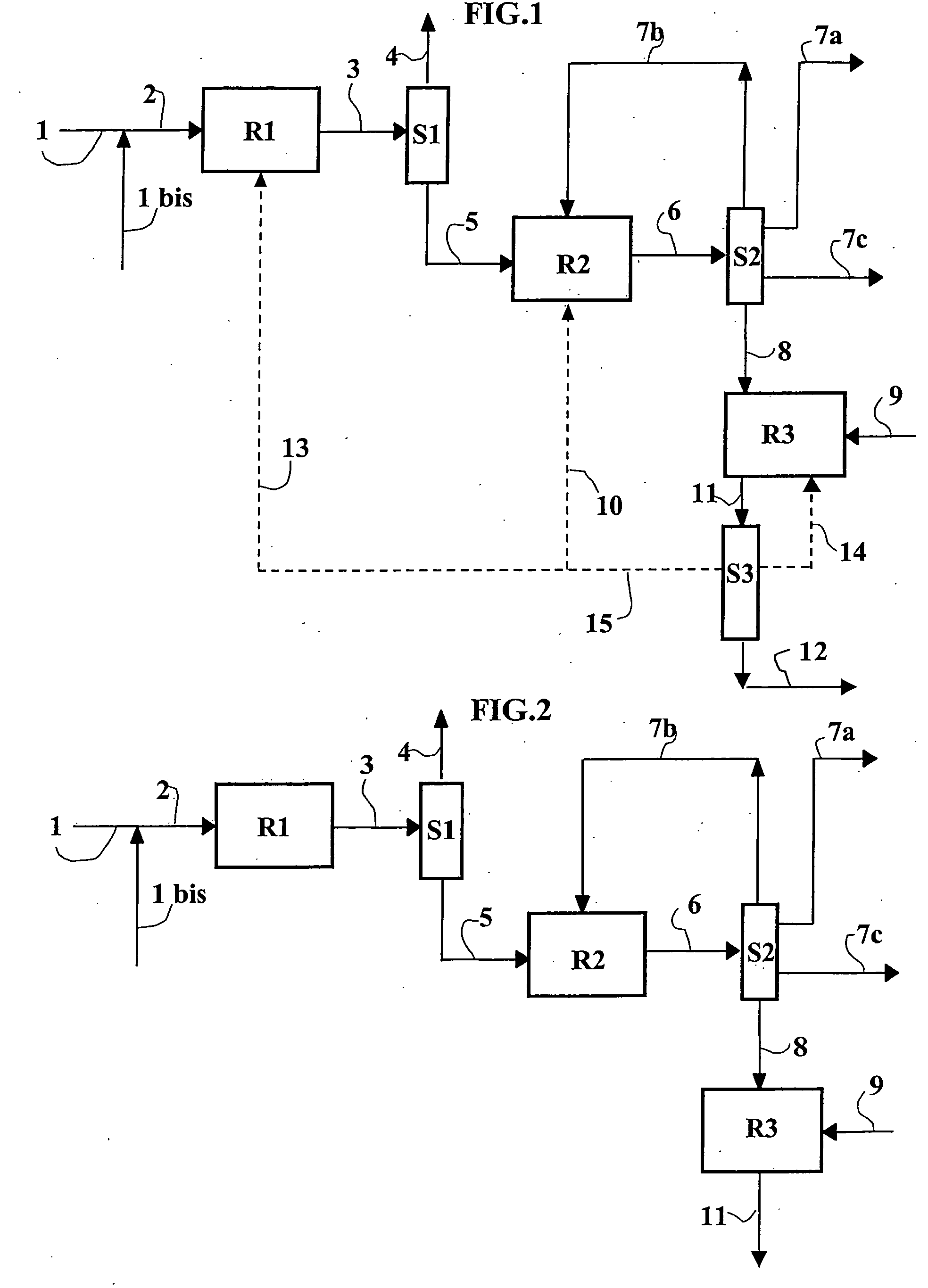

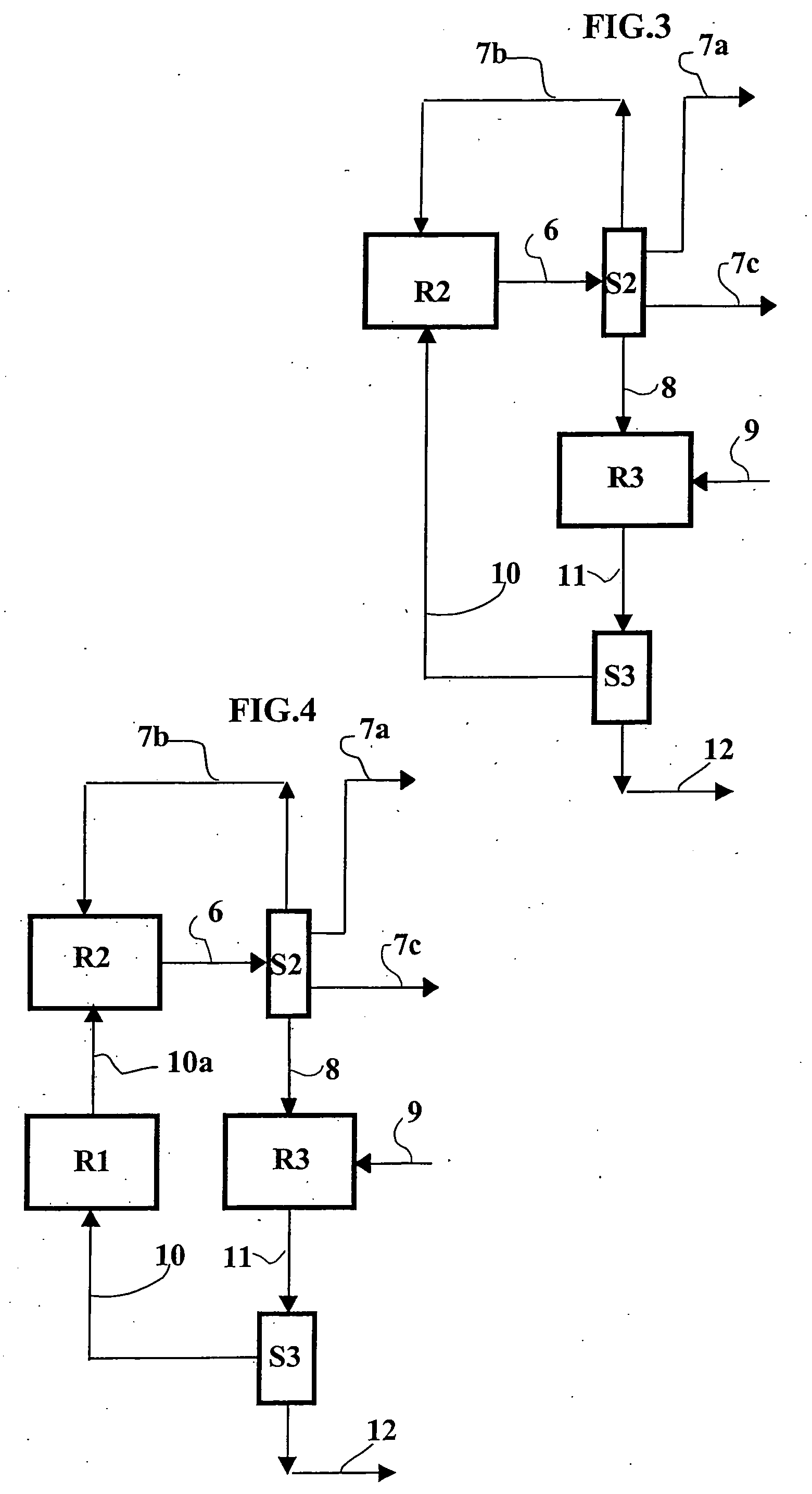

InactiveUS20080248590A1Minimize the possibilityReaction can be limitedBioreactor/fermenter combinationsBiological substance pretreatmentsBiologic AssaysBio molecules

An integrated lab-on-a-chip device for carrying out an assay to detect the presence of a biological molecule in a fluid sample, the device comprising: (a) an inlet for a fluid sample; (b) one or more reaction sites each in fluid communication with the inlet; (c) one or more reagent reservoir systems each containing reagents required for an assay to detect a biological molecule, the reagents being arranged sequentially in each reservoir system in the order in which they are required for the assay and separated from one another by a fluid.

Owner:NORCHIP AS

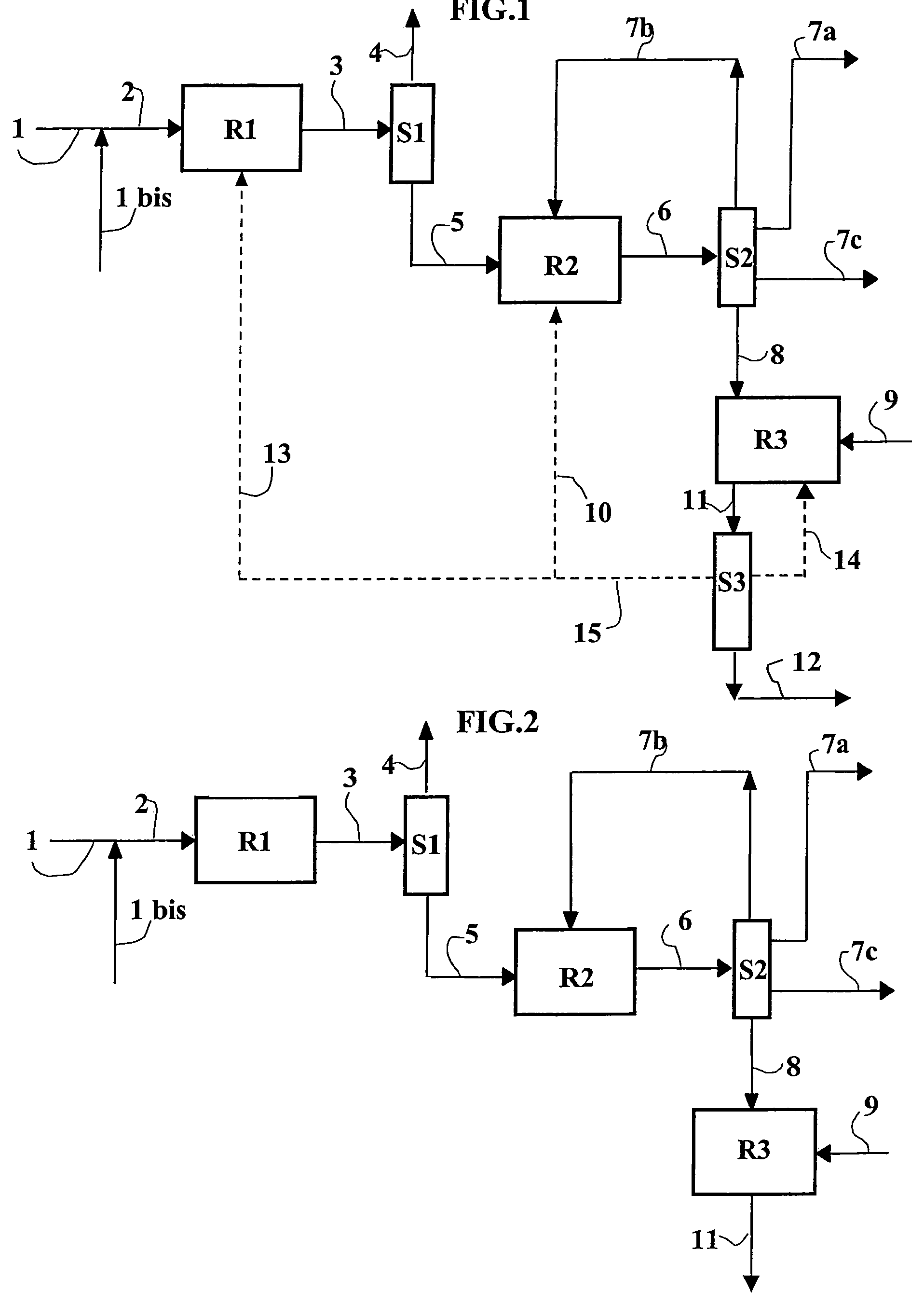

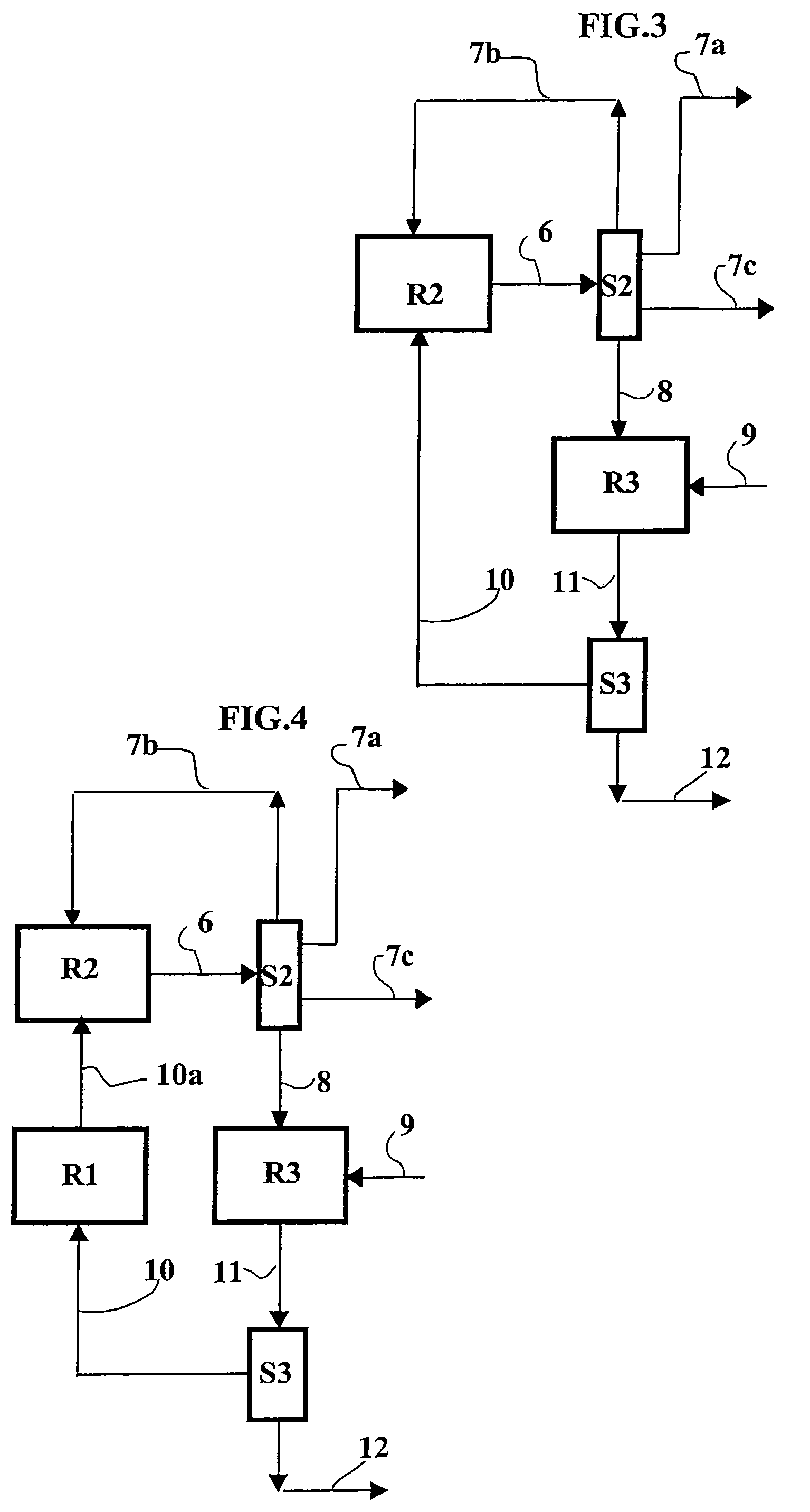

Method for jointly producing propylene and petrol from a relatively heavy charge

ActiveUS20050121361A1Increase in severityReaction can be limitedCatalytic crackingOrganic chemistry methodsOligomerBoiling point

A process for conversion of a hydrocarbon feedstock comprising a relatively heavy main feedstock with a boiling point above approximately 350° C., and a relatively light secondary feedstock with a boiling point below approximately 320° C., wherein, the main feedstock, representing at least 50 wt. % of the hydrocarbon feedstock, is cracked in a fluidized-bed reactor in the presence of a cracking catalyst, the secondary feedstock is cracked in a fluidized bed with the same cracking catalyst, separately or mixed with the main feedstock, said secondary feedstock comprising oligomers with at least 8 carbon atoms of light olefins with 4 and / or 5 carbon atoms.

Owner:INST FR DU PETROLE

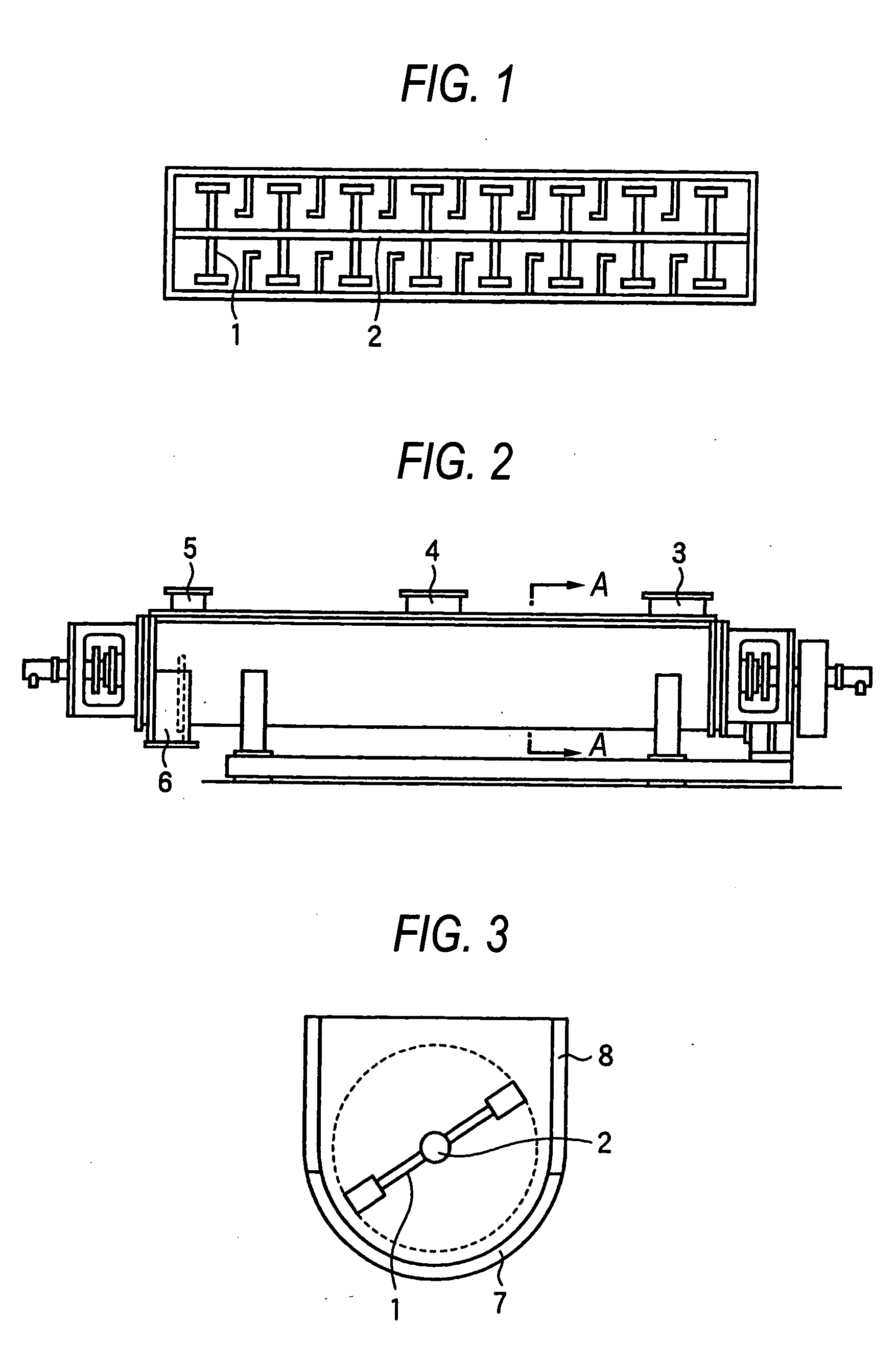

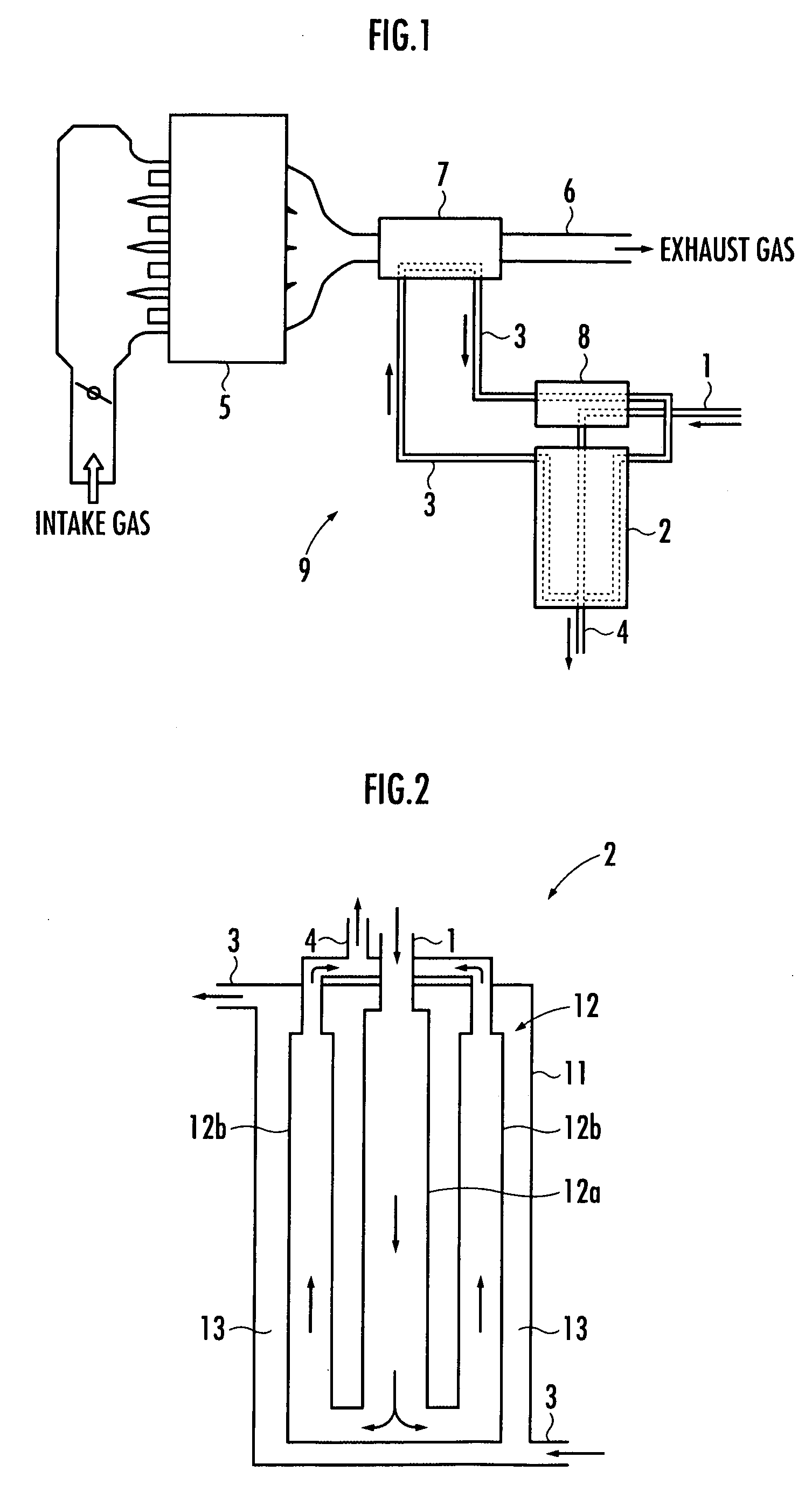

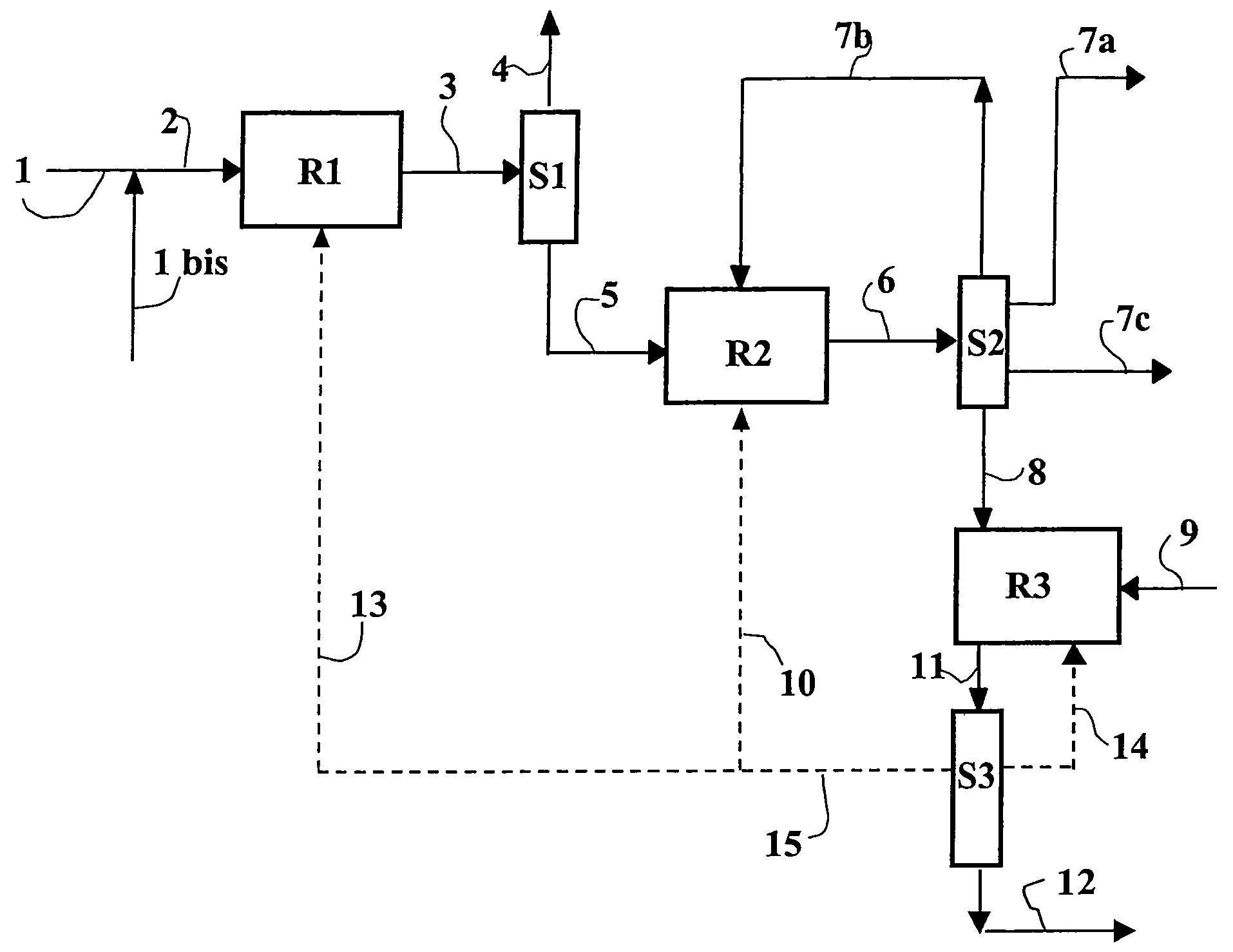

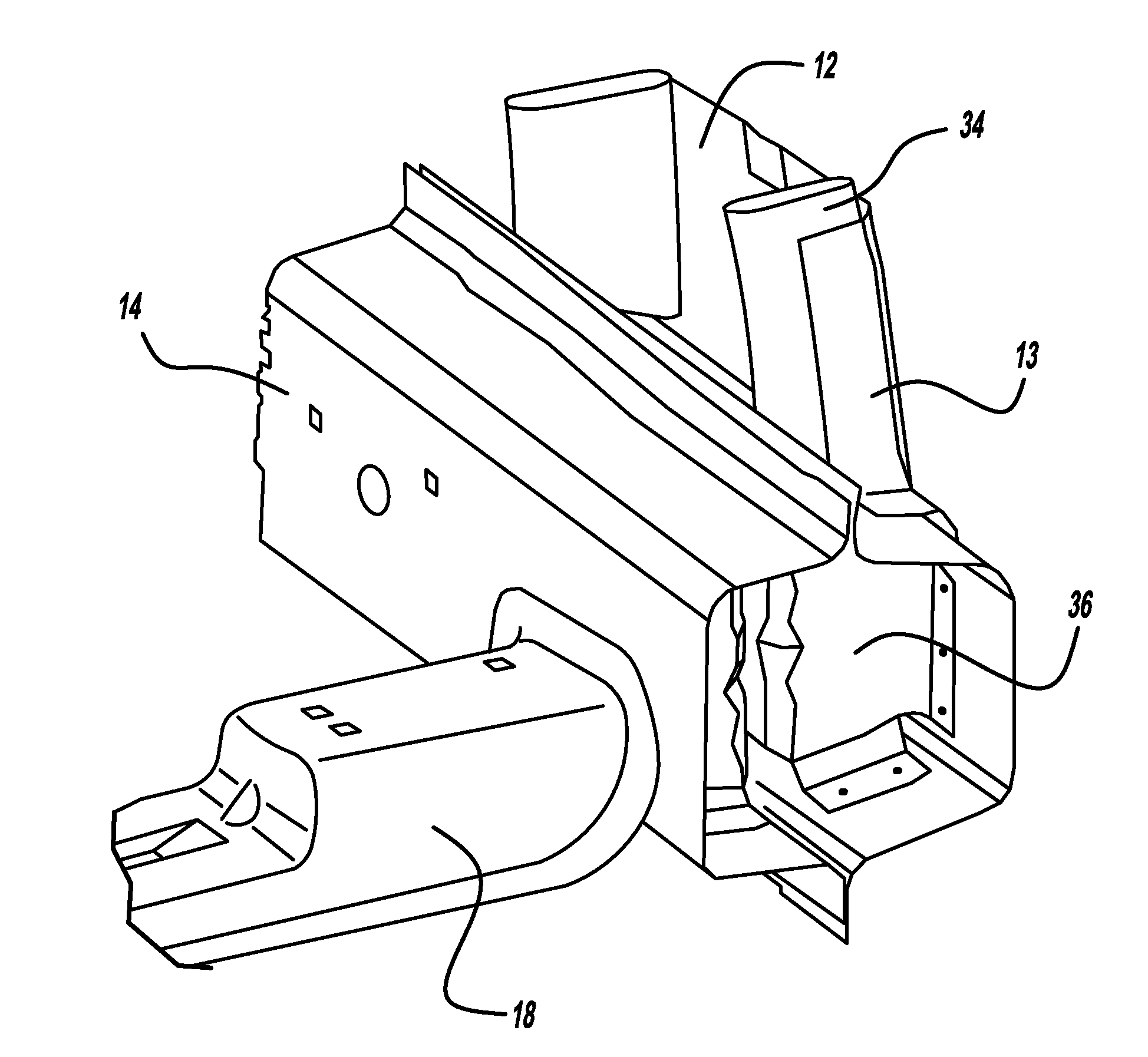

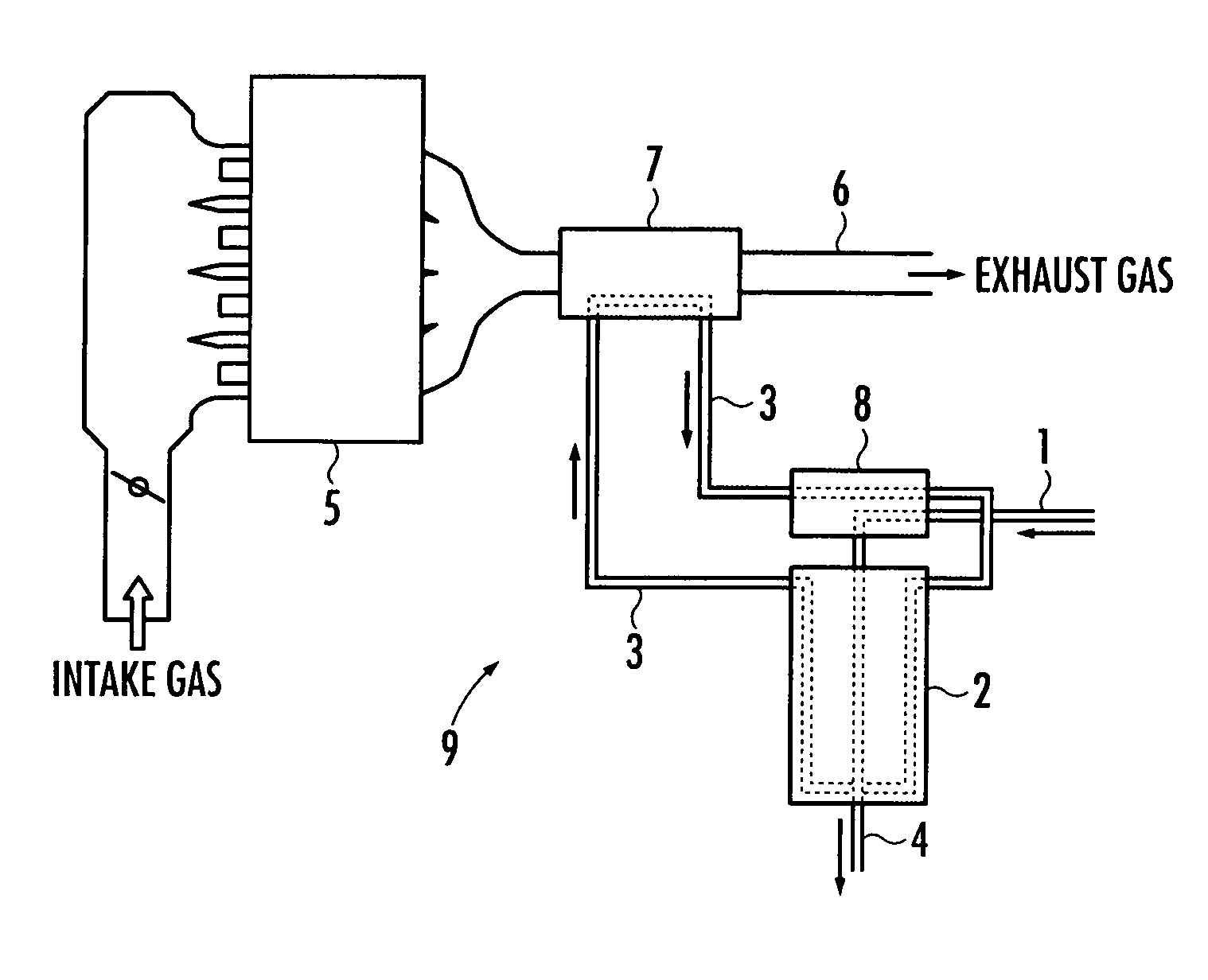

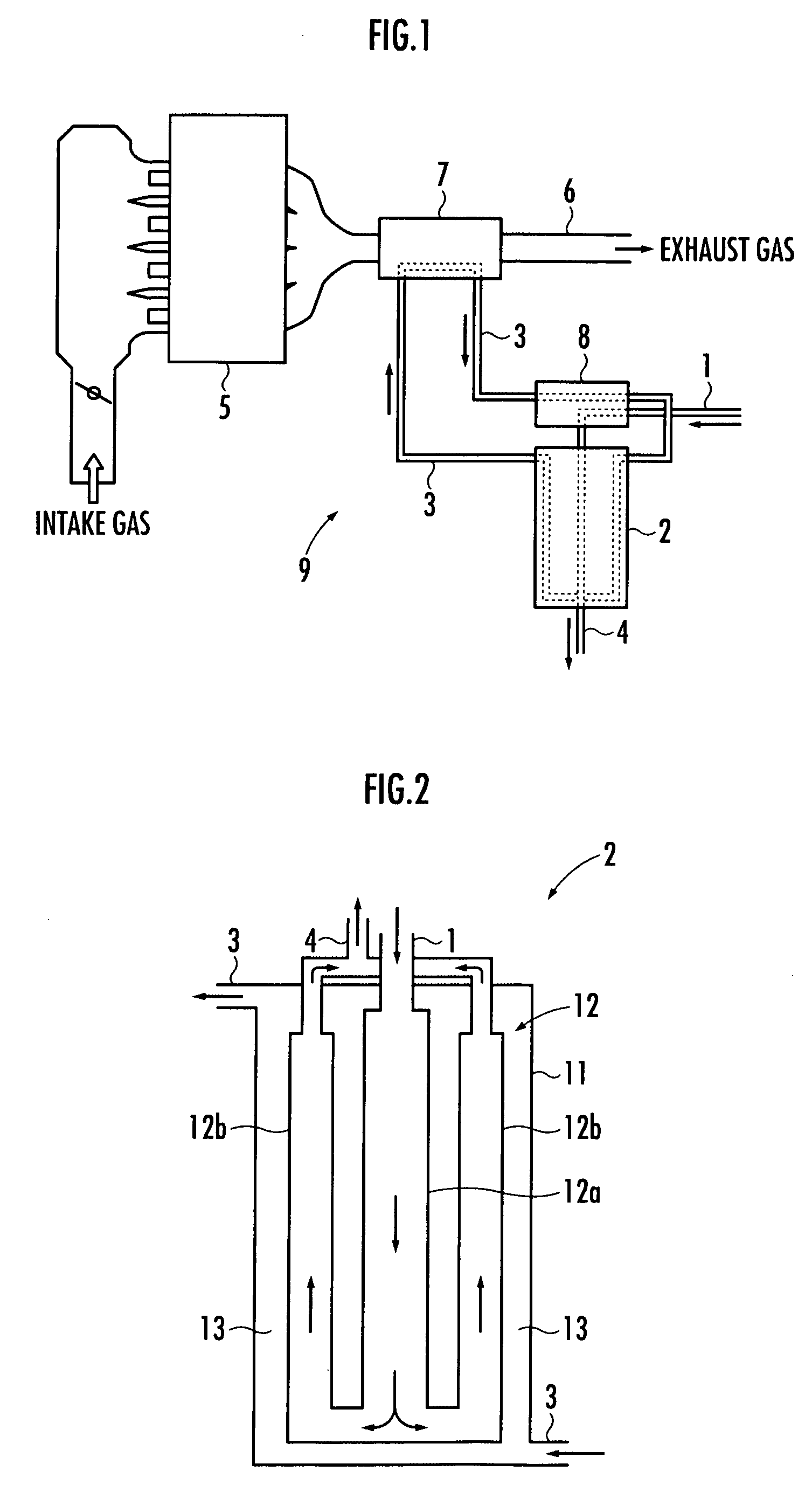

Ethanol fuel reforming system for internal combustion engines

InactiveUS20080282998A1Increase productionReaction can be limitedPhysical/chemical process catalystsNon-fuel substance addition to fuelExhaust gasProcess engineering

Provided is an ethanol fuel reforming system for internal combustion engines with which system a reaction of reforming ethanol into diethyl ether can be conducted at a constant temperature, and the reaction can be maintained with stability. The system comprises reforming means 2 for containing a reforming catalyst; a first heat exchanger 7 for heating a heating medium with the exhaust gas of an internal combustion engine 5; a second heat exchanger 8 for heating an ethanol fuel with the heating medium; and heating medium circulating means 9 for circulating the heating medium. The heating medium makes distribution of temperature in the reforming means 2 uniform. The heating medium heats the reforming means 2 and the ethanol fuel to an identical temperature. The reforming means comprises an ethanol fuel channel 12 filled with the catalyst, and the ethanol fuel channel 12 is bent in the reforming means 2.

Owner:HONDA MOTOR CO LTD

Thermalization of gaseous precursors in CVD reactors

InactiveUS20090214785A1Speed up the processLow efficiencySemiconductor/solid-state device manufacturingFrom chemically reactive gasesSemiconductor materialsEngineering

The present invention relates to the field of semiconductor processing and provides apparatus and methods that improve chemical vapor deposition (CVD) of semiconductor materials by promoting more efficient thermalization of precursor gases prior to their reaction. In preferred embodiments, the invention comprises heat transfer structures and their arrangement within a CVD reactor so as to promote heat transfer to flowing process gases. In certain preferred embodiments applicable to CVD reactors transparent to radiation from heat lamps, the invention comprises radiation-absorbent surfaces placed to intercept radiation from the heat lamps and to transfer it to flowing process gases.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

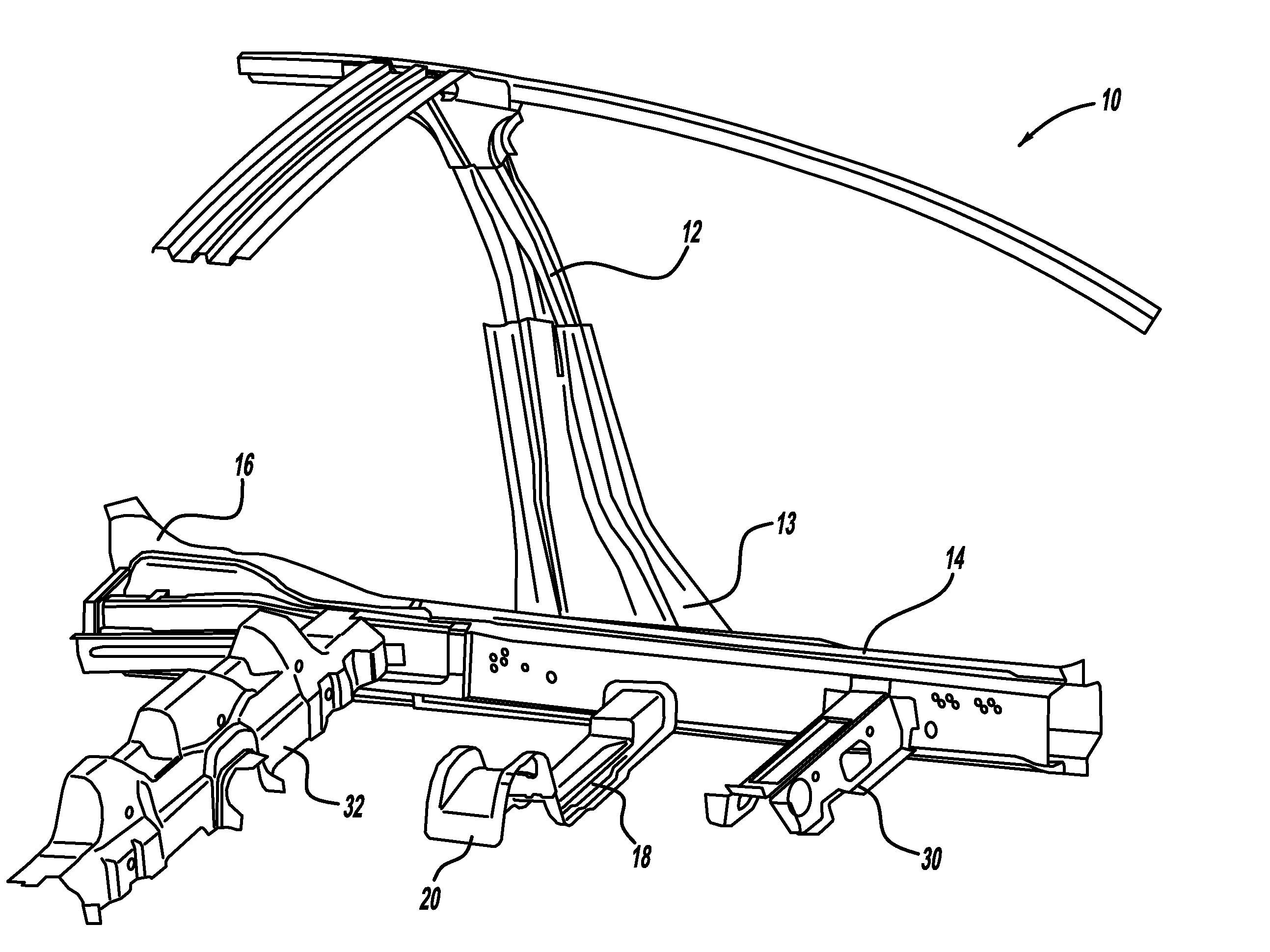

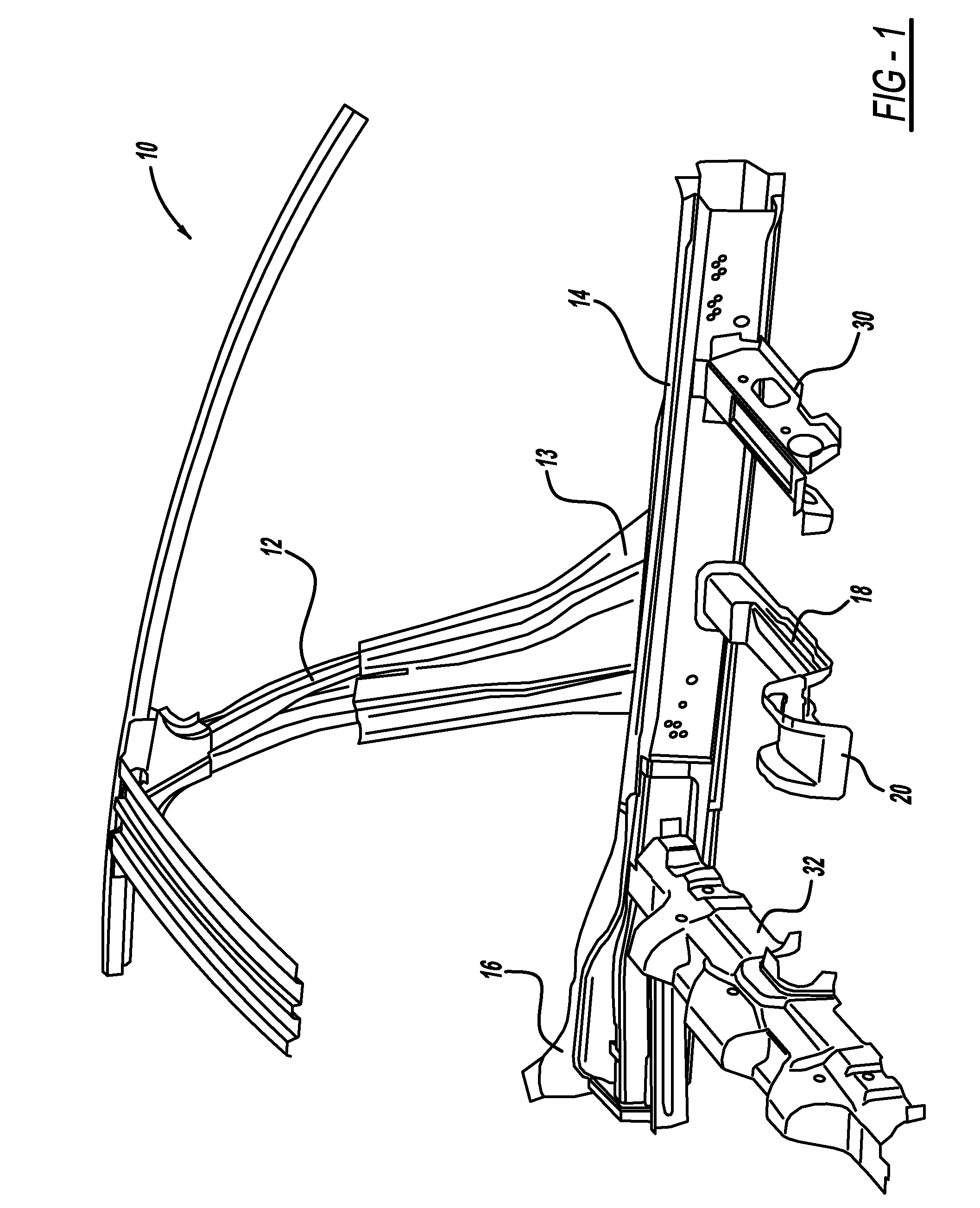

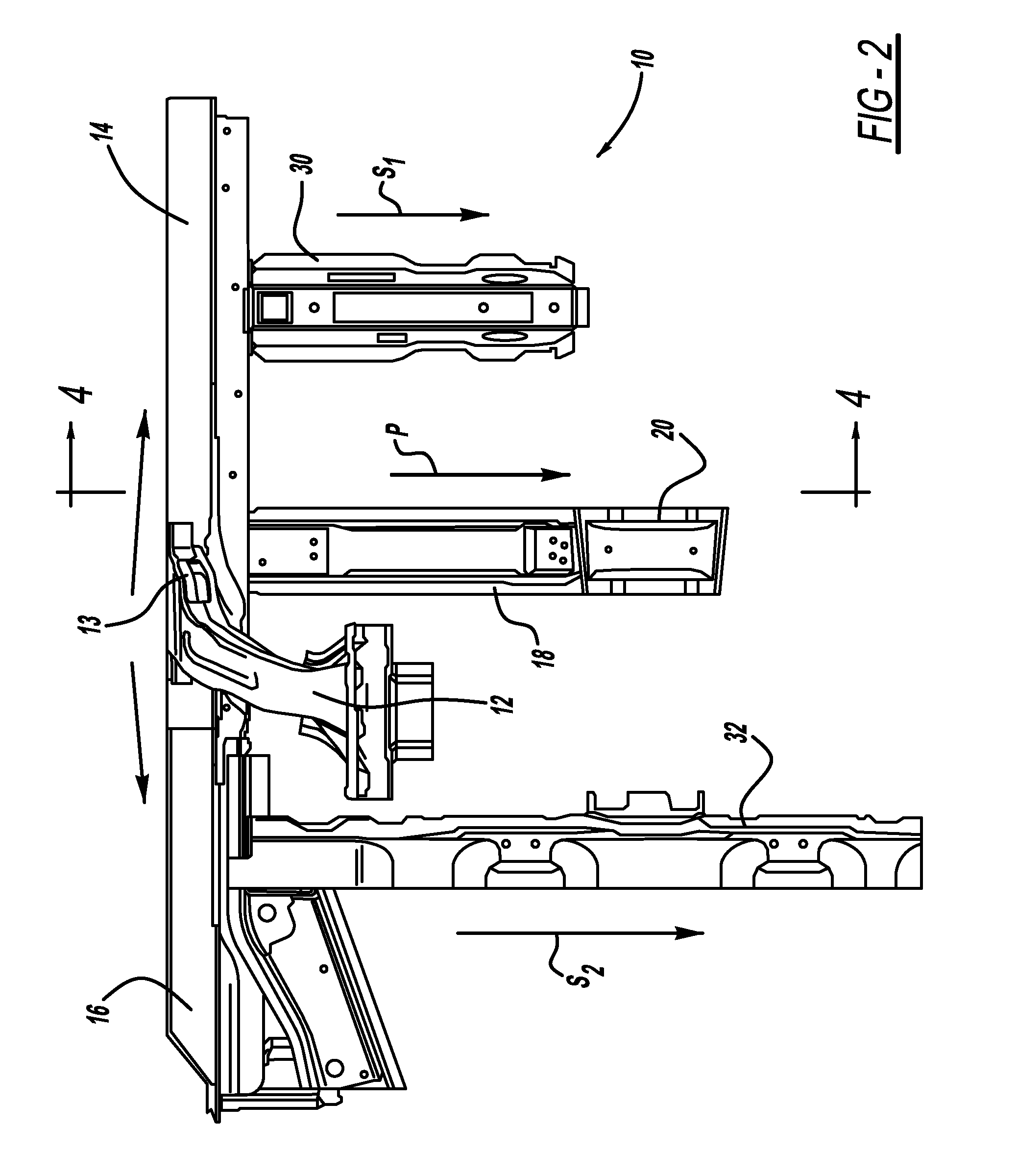

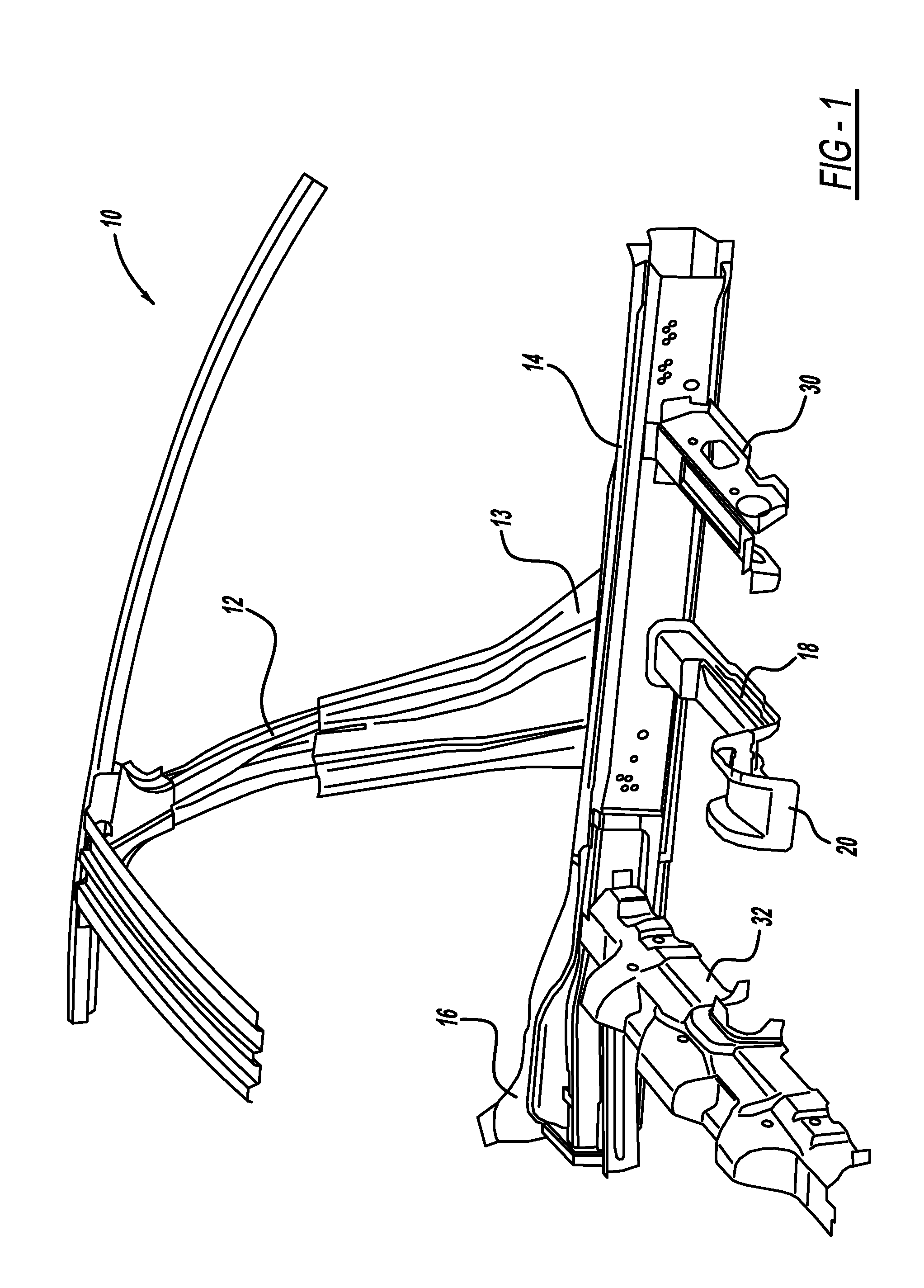

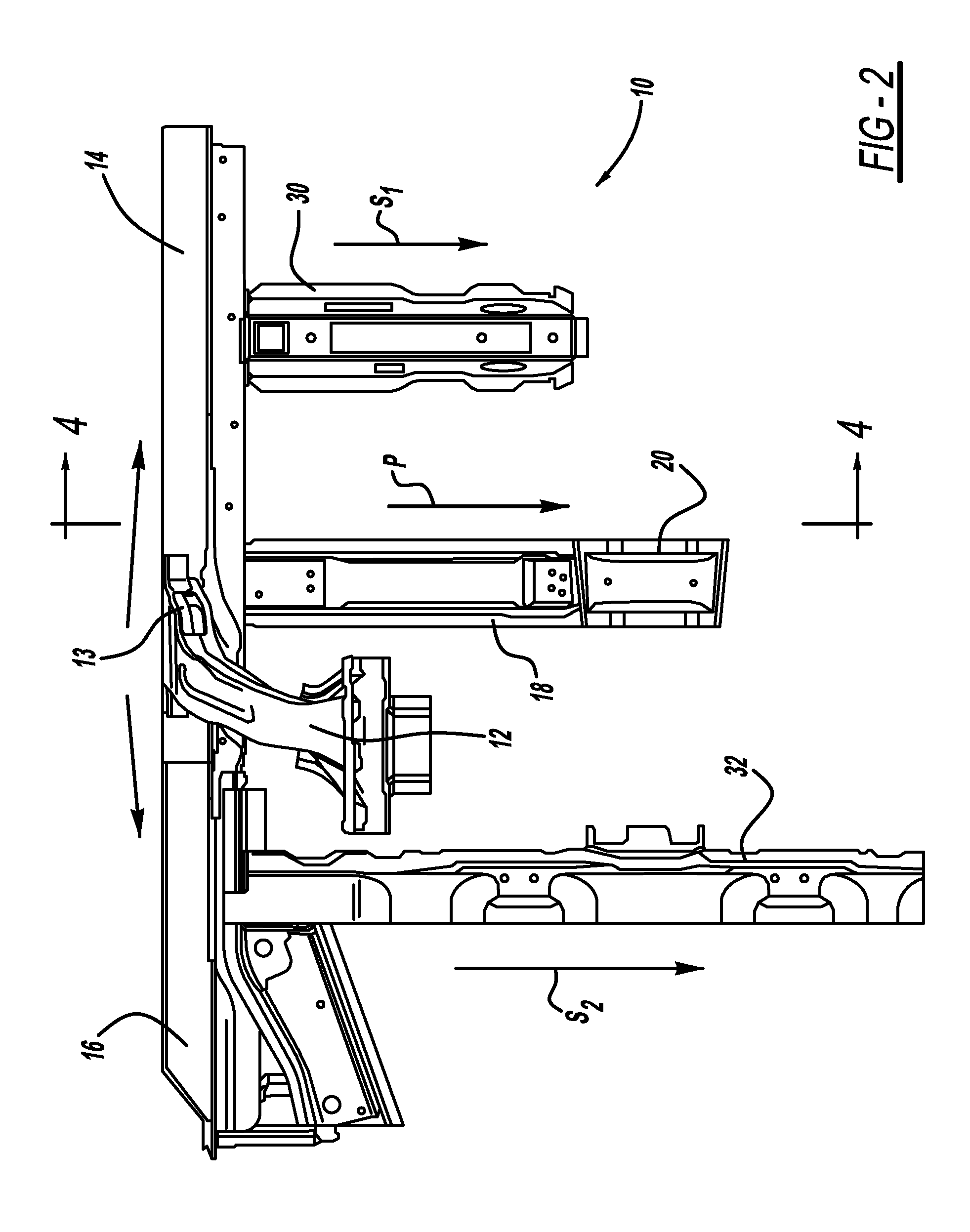

Energy distributing side structure for vehicle side impact occupant protection

ActiveUS8007032B1Less energyReduce the amount of distortionVehicle seatsUnderstructuresSide impactAutomotive engineering

An energy distributing side structure for a vehicle is disclosed. The side structure includes a B-pillar having a wide base and an internal reinforcing tube, a rocker having an internal bulkhead, a rear rocker, and at least one cross-member extending vehicle-inward from the rocker. The cross-member may extend to the vehicle tunnel and may be attached to a tunnel brace. One or more additional cross-members may be provided which also extend vehicle-inward from the rocker and define secondary load paths. By this arrangement loading is transferred to the floor and cross-members of the vehicle during a lateral impact event.

Owner:FORD GLOBAL TECH LLC

Method for jointly producing propylene and petrol from a relatively heavy charge

ActiveUS7374662B2Increase in severityReaction can be limitedCatalytic crackingOrganic chemistry methodsOligomerFluidized bed

A process for conversion of a hydrocarbon feedstock comprising a relatively heavy main feedstock with a boiling point above approximately 350° C., and a relatively light secondary feedstock with a boiling point below approximately 320° C., wherein,the main feedstock, representing at least 50 wt. % of the hydrocarbon feedstock, is cracked in a fluidized-bed reactor in the presence of a cracking catalyst,the secondary feedstock is cracked in a fluidized bed with the same cracking catalyst, separately or mixed with the main feedstock, said secondary feedstock comprising oligomers with at least 8 carbon atoms of light olefins with 4 and / or 5 carbon atoms.

Owner:INST FR DU PETROLE

Renewable, energetic, nanodimensional dispersion

InactiveUS20030190501A1Enhance safe transportation characteristicOdor suppressionOther chemical processesFuel cell auxillariesChemistryElectric energy

Fuel cells, and renewable-semi-liquid fuel mixtures, useful as anode materials, for said fuel cells are disclosed. The fuels are comprised in part of materials intercalated with hydrogen, alkali metals, or alkali metal hydrides, dispersed in liquid carriers. The chemical energy generated by the reaction of the fuel mixtures with oxygen, or an oxygen carrier such as air, water, or hydrogen peroxide, can be converted into electrical energy in fuel cells. Once converted, the by-products of the reaction may be collected and those components that where chemically modified in the reaction can be renewed by conversion or re-intercalation of hydrogen, alkali metals, or alkali metal hydrides.

Owner:RENDINA DAVID DECK

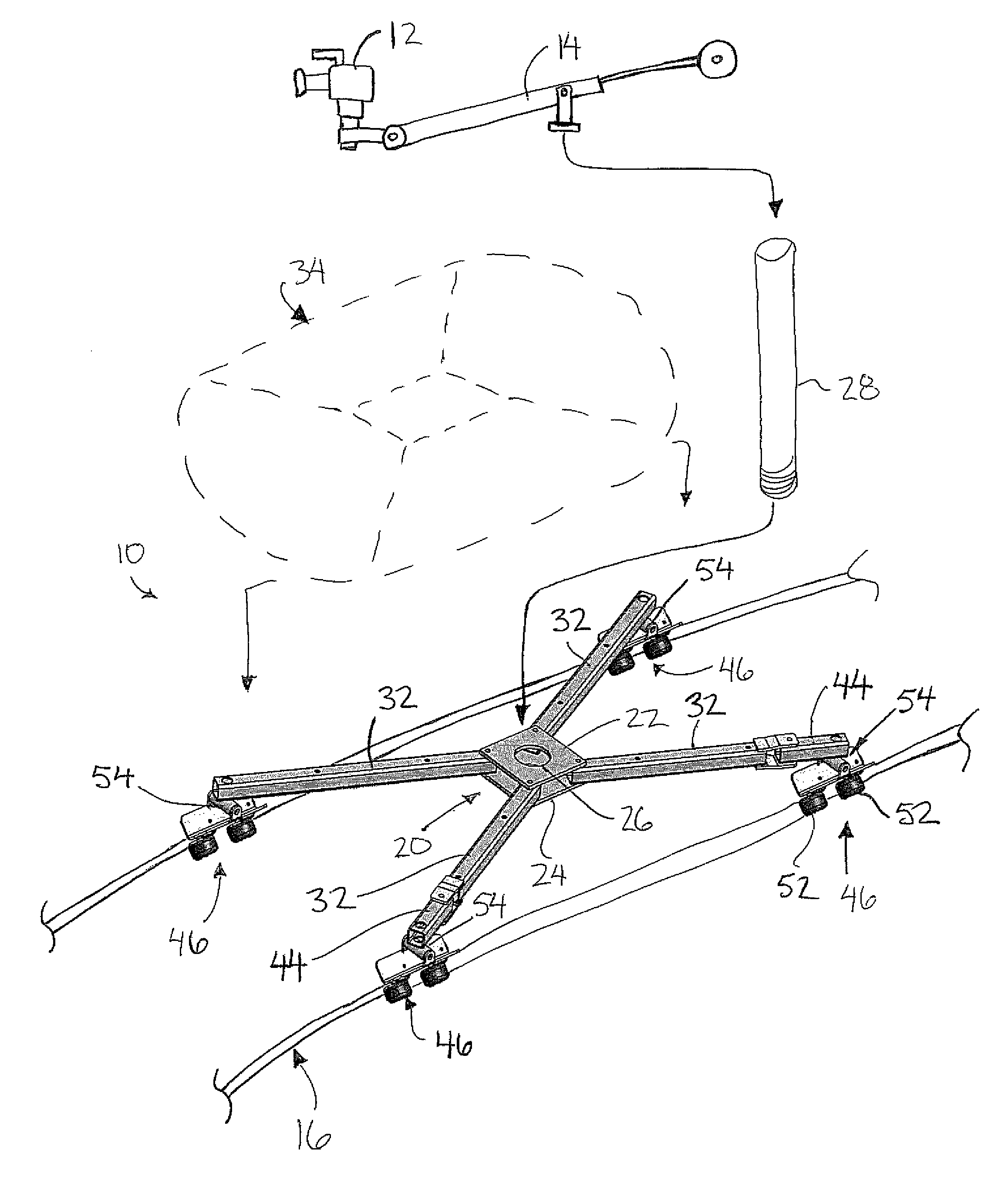

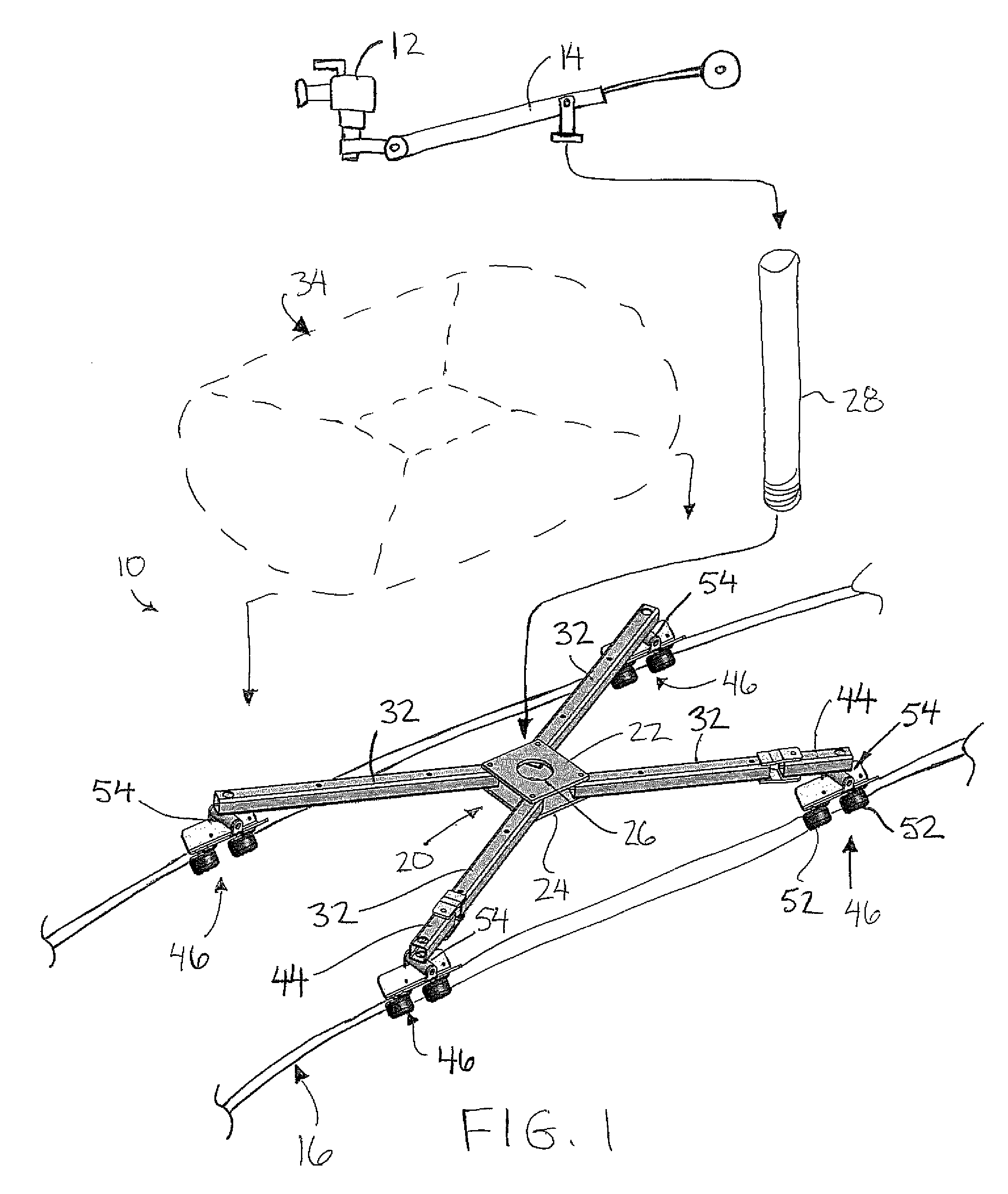

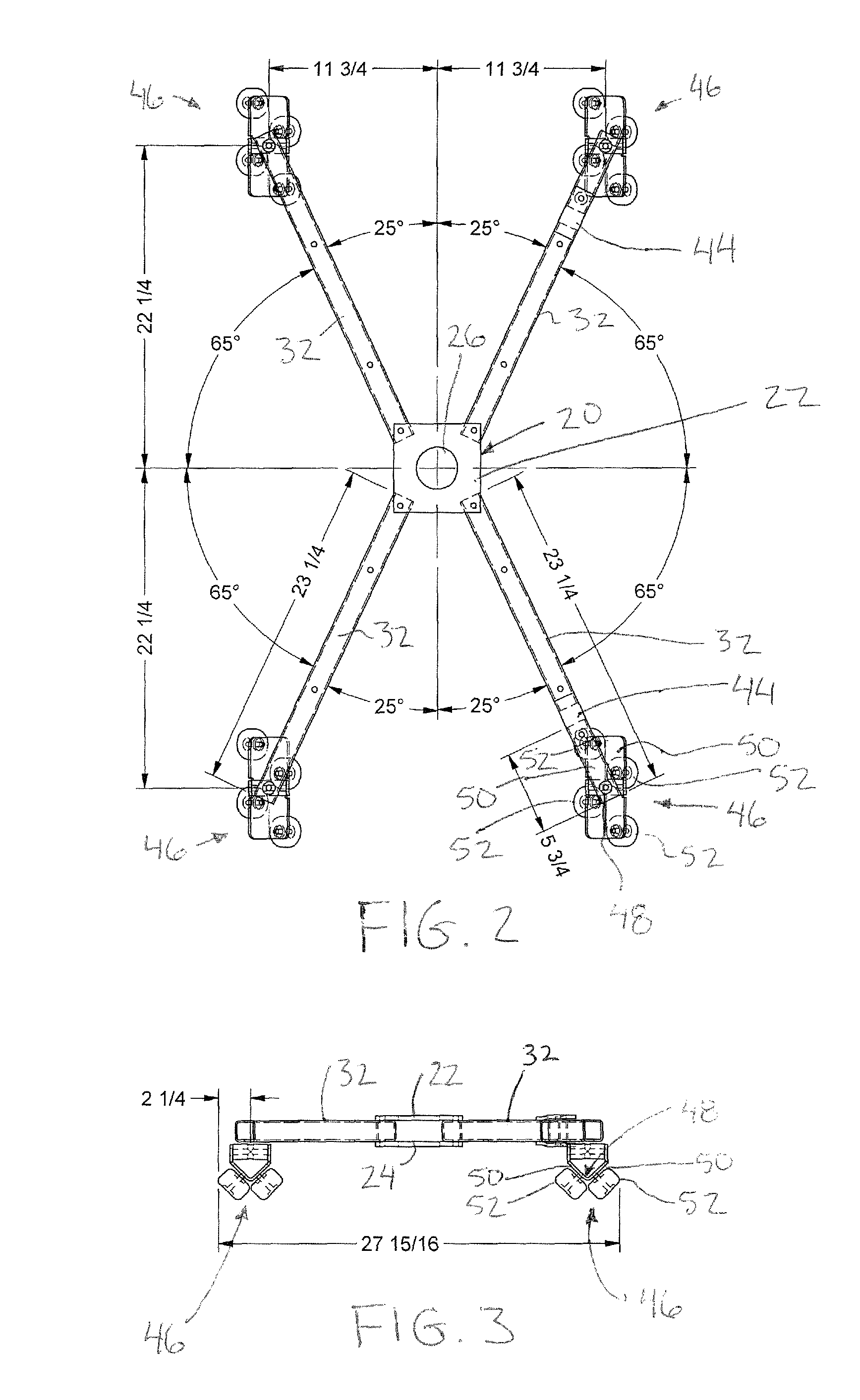

Camera dolly

InactiveUS8205841B2Reduce the possibilityReaction can be limitedWash-standsLifting devicesHorizontal axisEngineering

A camera dolly comprises a base and a plurality of legs extending radially outward from an inner end pivotally coupled on the base to an outer end supporting a wheel assembly thereon such that the wheel assemblies are arranged for rolling movement along a pair of rail members extending in a longitudinal direction. Each wheel assembly comprises a plurality of wheels spaced apart from one another in the longitudinal direction in two rows arranged to receive the respective rail member therebetween. Each wheel assembly is pivotal about an upright axis and a horizontal axis relative to the respective leg. A horizontal deck plate includes plural sets of mounting apertures therein corresponding to different relatively fixed relationships of the legs. A socket formed centrally in the base threadably receives an upright post therein which support the camera thereon spaced above the base.

Owner:WOOD DENNIS

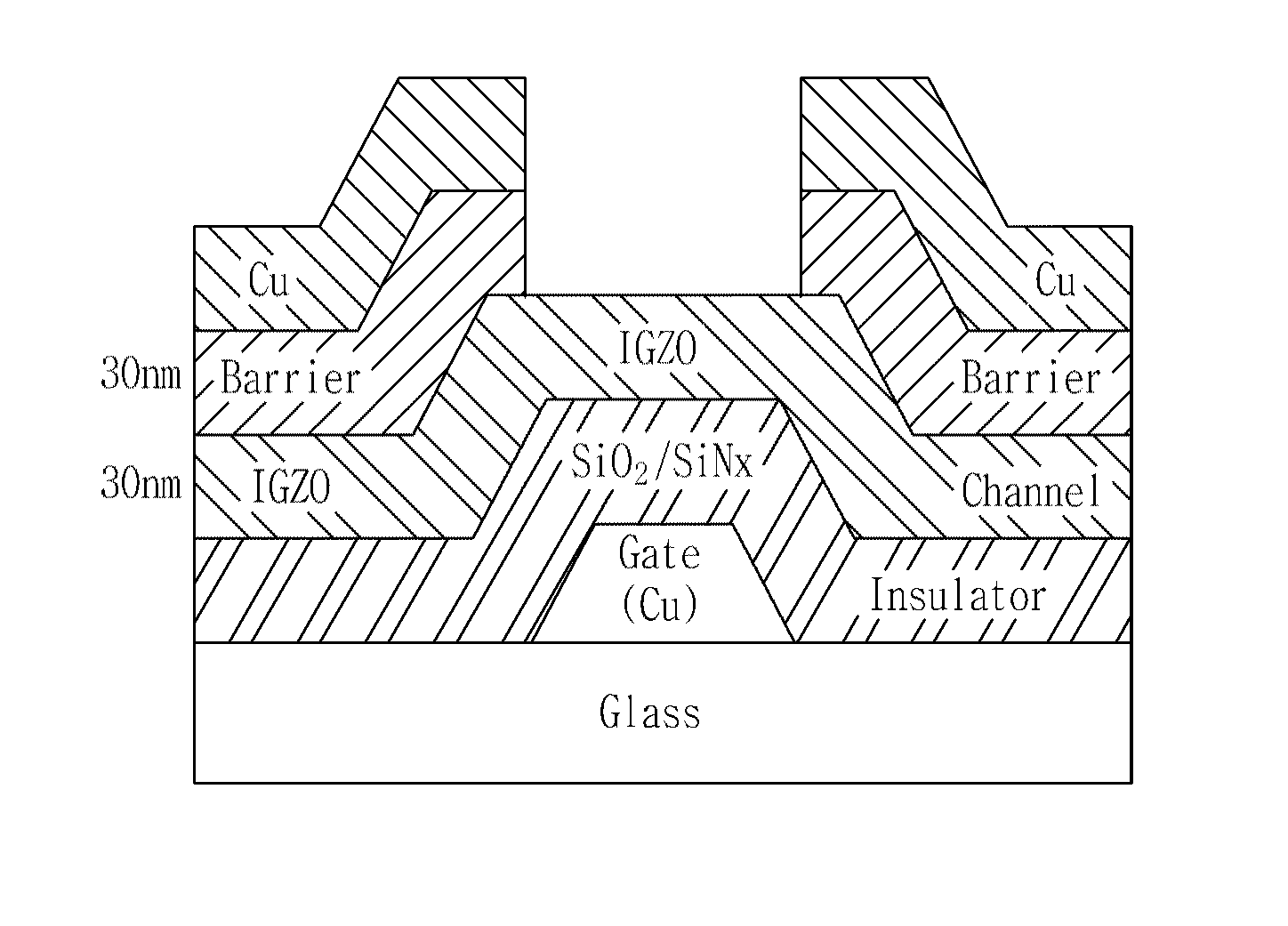

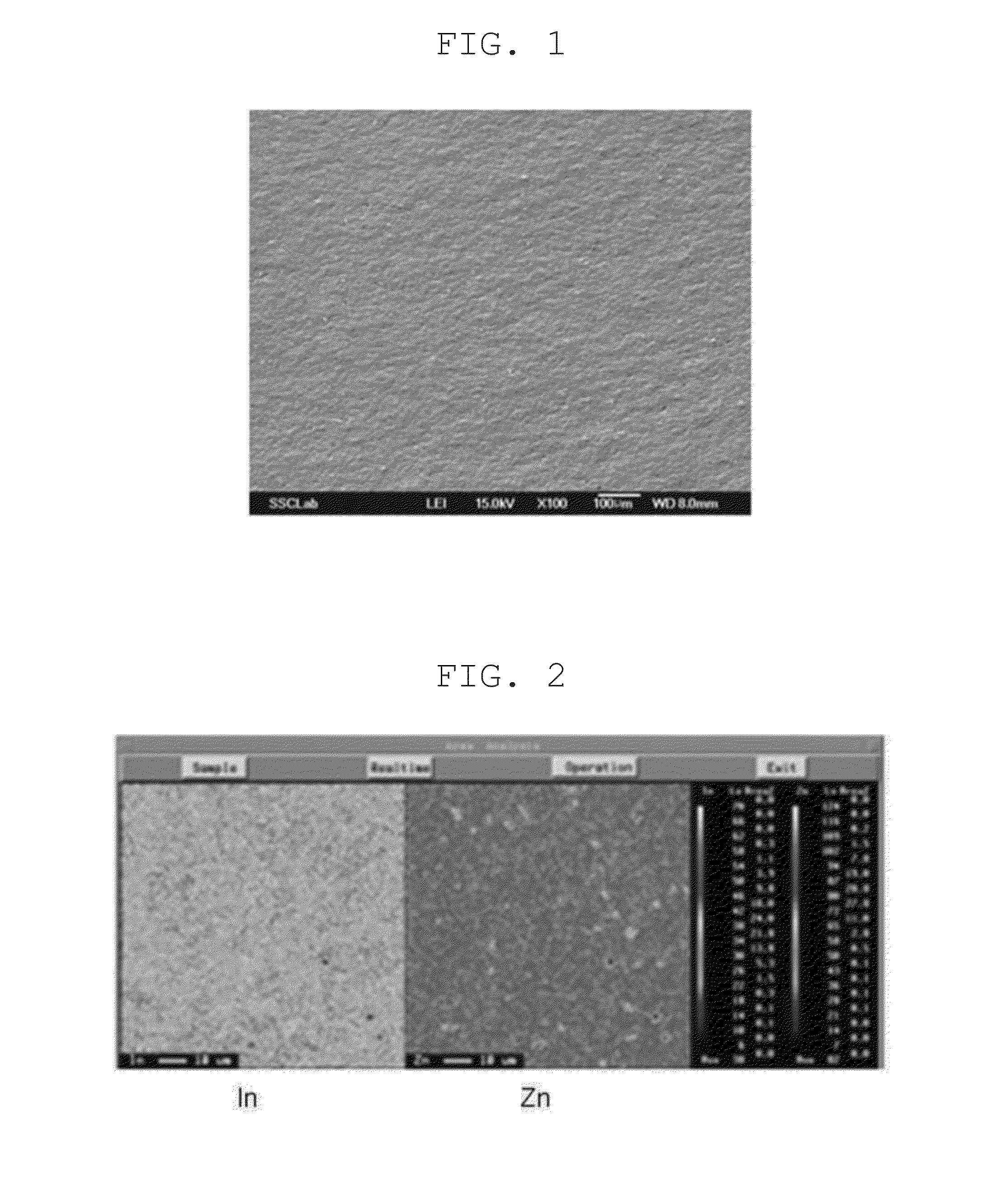

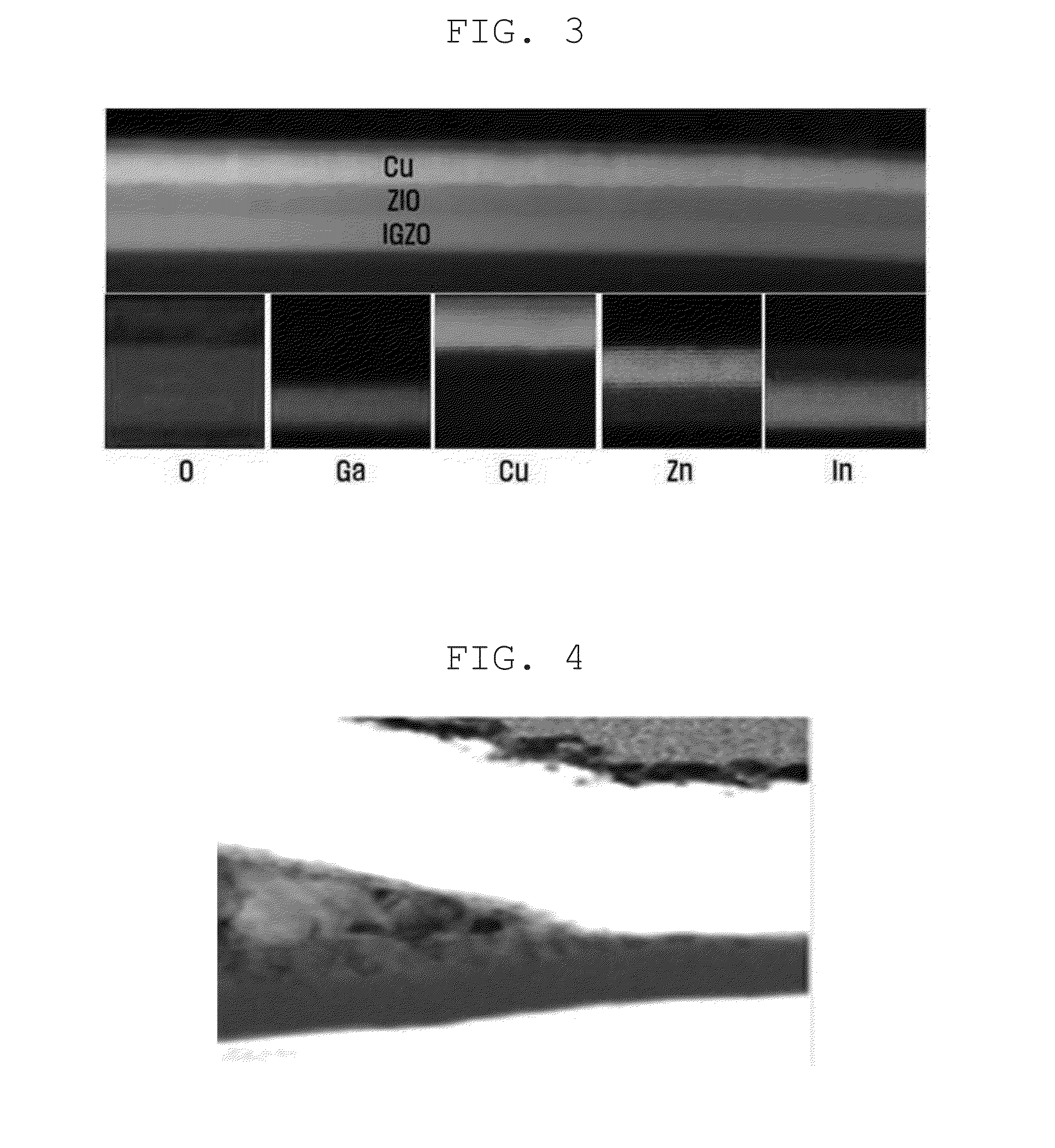

Thin-film transistor and zinc oxide-based sputtering target for the same

A thin-film transistor includes a metal electrode and a zinc oxide-based barrier film that blocks a material from diffusing out of the metal electrode. The zinc oxide-based barrier film is made of zinc oxide doped with indium oxide, the content of the indium oxide ranging, by weight, 1 to 50 percent of the zinc oxide-based barrier film. A zinc oxide-based sputtering target for deposition of a barrier film of a thin-film transistor is made of zinc oxide doped with indium oxide, the content of the indium oxide ranging, by weight, 1 to 50 percent of the zinc oxide-based sputtering target.

Owner:KV MATERIALS CO LTD +1

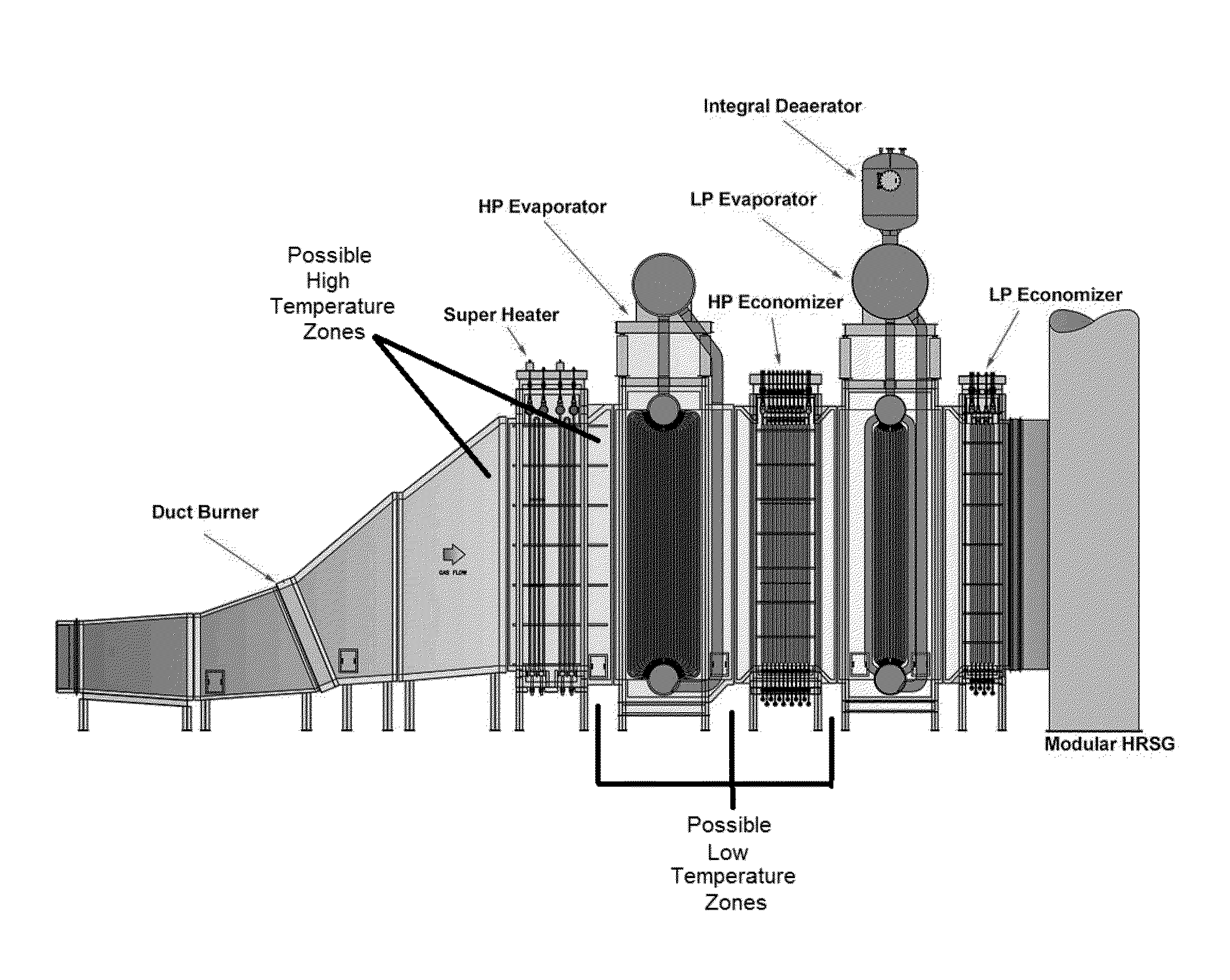

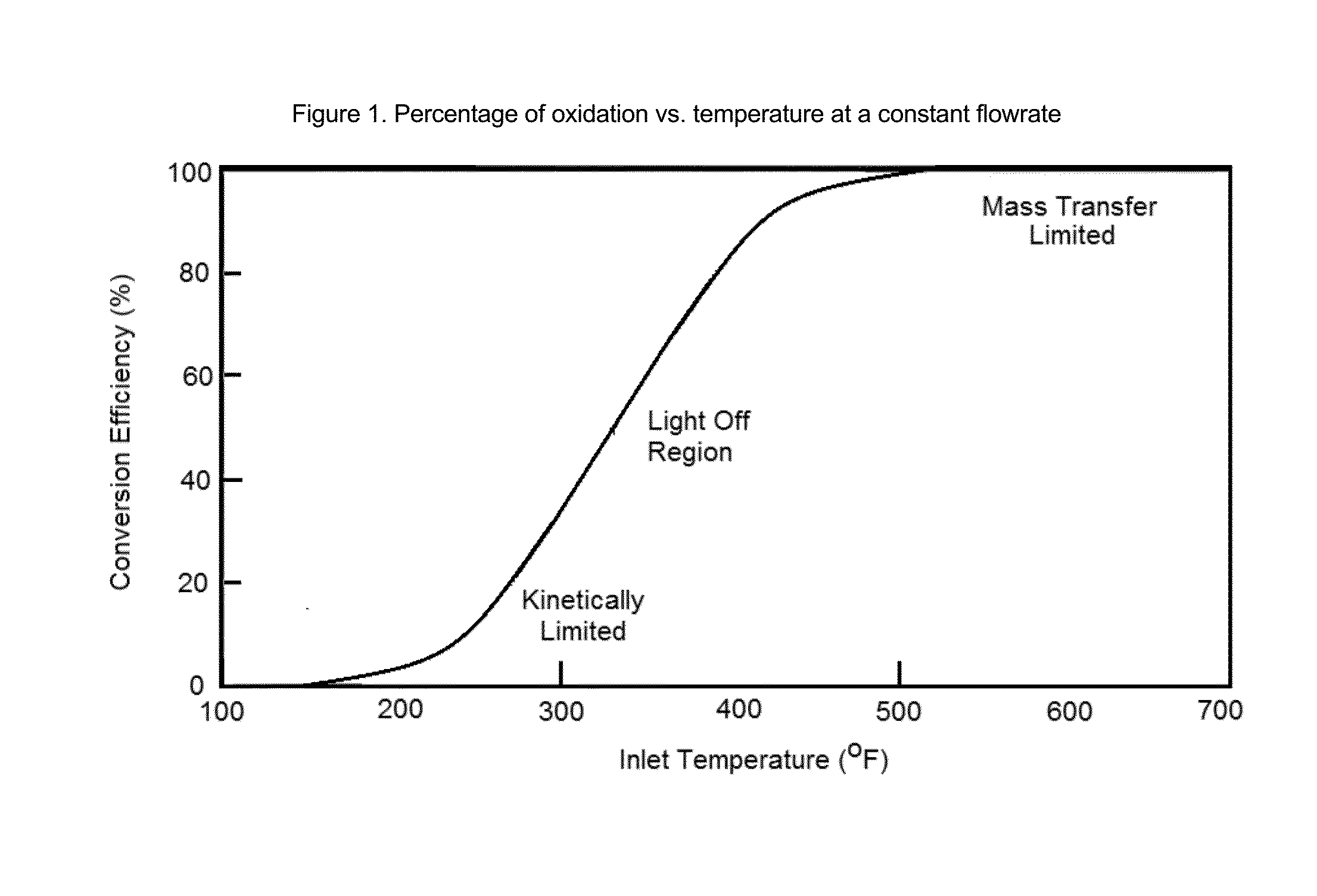

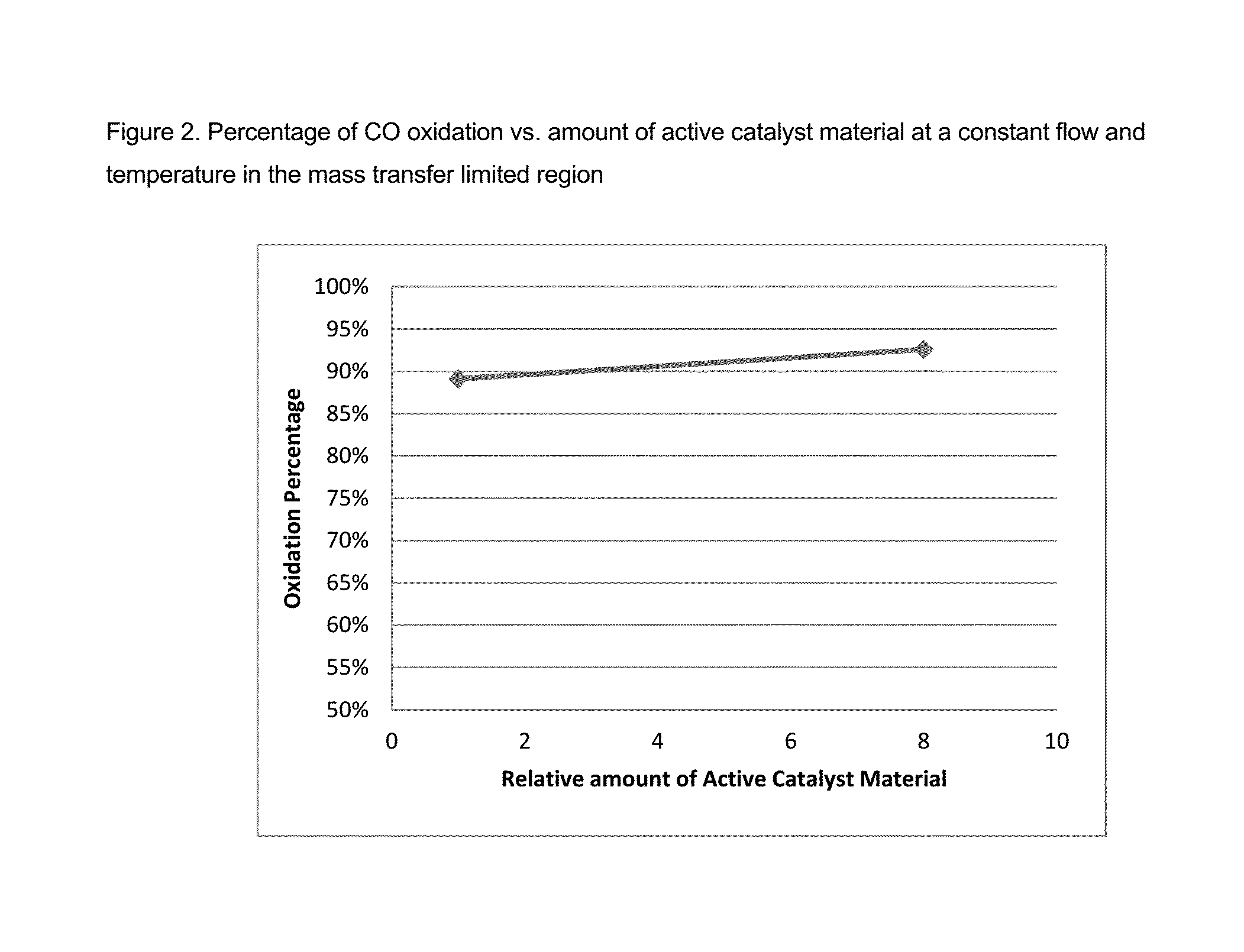

Exhaust system for power generating apparatus

InactiveUS20160245139A1Emission reductionReduce CO2Steam generation heating methodsExhaust apparatusExhaust gasExhaust fumes

An exhaust system for a power generating apparatus comprising a heat source for combusting a fuel in air to produce power, which exhaust system being adapted to receive a flowing exhaust gas and comprising a catalyst system for treating the exhaust gas, which catalyst system comprising a first oxidation catalyst and a second catalyst, wherein the first oxidation catalyst is positioned downstream from the heat source so that the flowing exhaust gas contacts the first oxidation catalyst before the second catalyst.

Owner:JOHNSON MATTHEY PLC

Thermalization of gaseous precursors in CVD reactors

InactiveUS8388755B2Improve efficiencyQuick upgradeSemiconductor/solid-state device manufacturingFrom chemically reactive gasesSemiconductor materialsEngineering

The present invention relates to the field of semiconductor processing and provides apparatus and methods that improve chemical vapor deposition (CVD) of semiconductor materials by promoting more efficient thermalization of precursor gases prior to their reaction. In preferred embodiments, the invention comprises heat transfer structures and their arrangement within a CVD reactor so as to promote heat transfer to flowing process gases. In certain preferred embodiments applicable to CVD reactors transparent to radiation from heat lamps, the invention comprises radiation-absorbent surfaces placed to intercept radiation from the heat lamps and to transfer it to flowing process gases.

Owner:SOITEC SA

Process for production of urethane resin and adhesive agent

InactiveUS20080312386A1Easy to controlControlled molecular weightPolyureas/polyurethane adhesivesPolymer sciencePolyol

An object of the invention is to provide a process for urethane resin production in which the molecular weight of the urethane resin can be easily controlled regardless of the kind of polyisocyanate compound and which can yield a urethane resin for use as a removable pressure-sensitive adhesive usable in extensive applications ranging from a strong-tack region to a slight-tack region. The process for urethane resin production of the invention is a process for producing a urethane resin which comprises reacting a polyol with a first polyisocyanate compound in such a proportion that isocyanate groups are present in excess to thereby obtain an isocyanate-group-terminated prepolymer, subsequently reacting the isocyanate-group-terminated prepolymer with a chain extender, and further reacting the resultant polymer with a chain terminator, wherein the chain extender comprises a polyfunctional compound (X) having three or more functional groups reactive with an isocyanate group, wherein two of the functional groups of the polyfunctional compound (X) are primary hydroxyl groups and the remaining functional group(s) is secondary hydroxyl or tertiary hydroxyl group(s).

Owner:ASAHI GLASS CO LTD

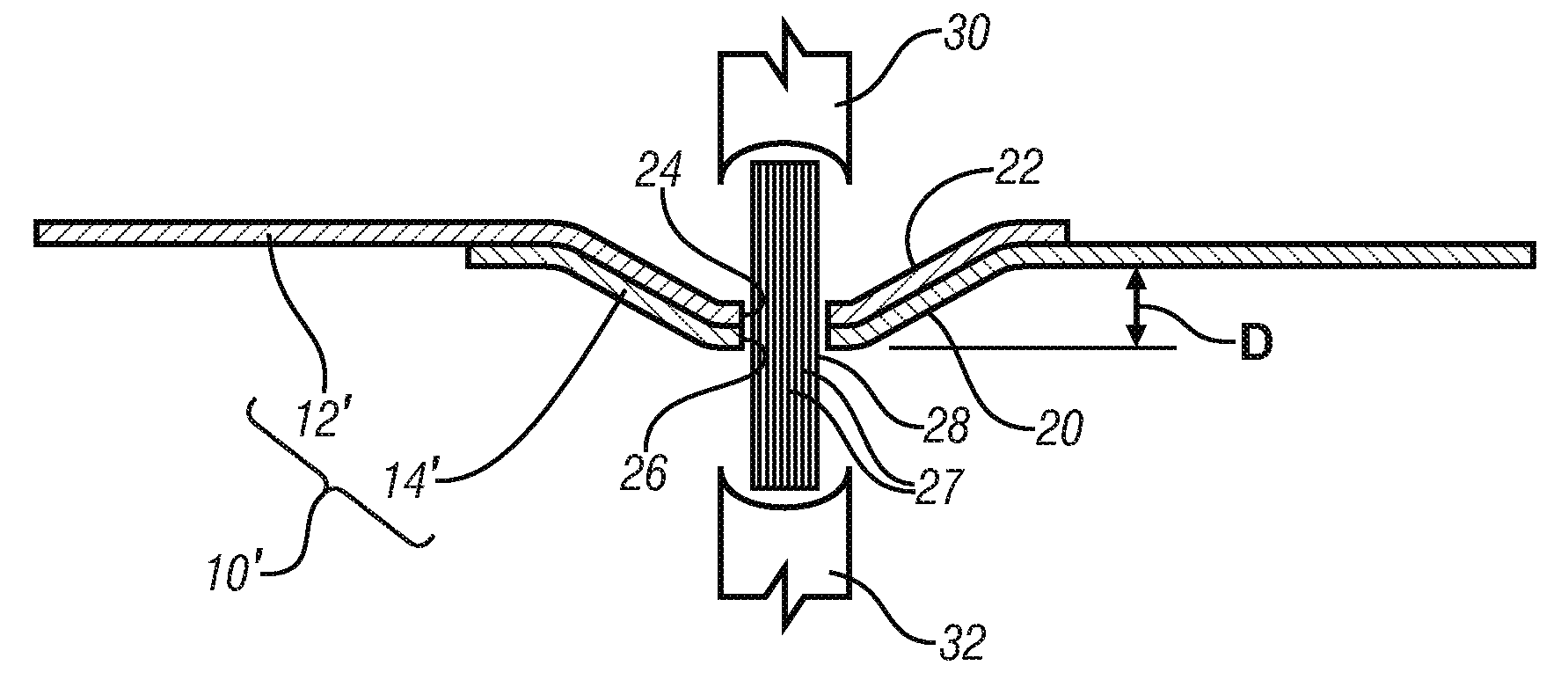

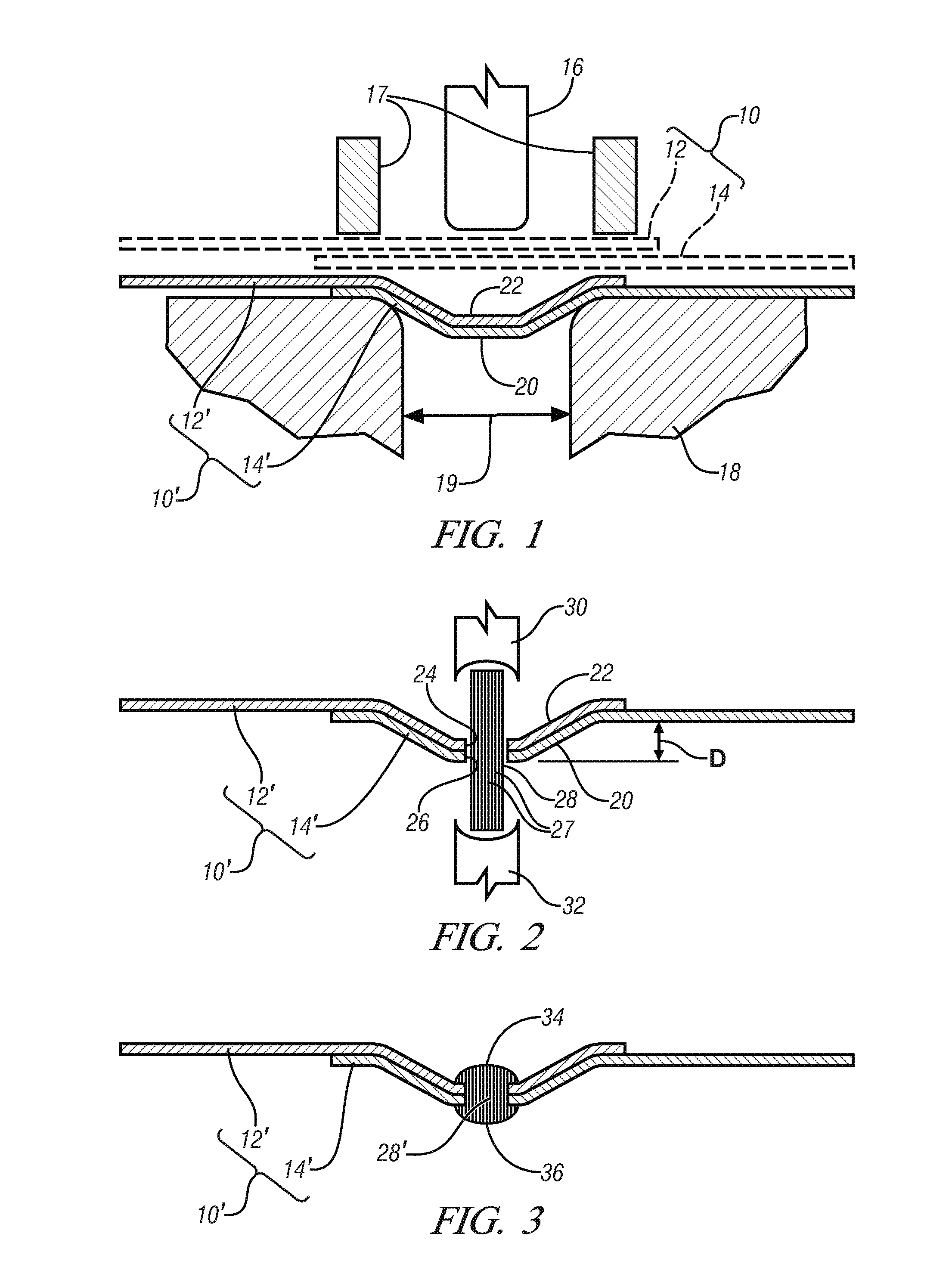

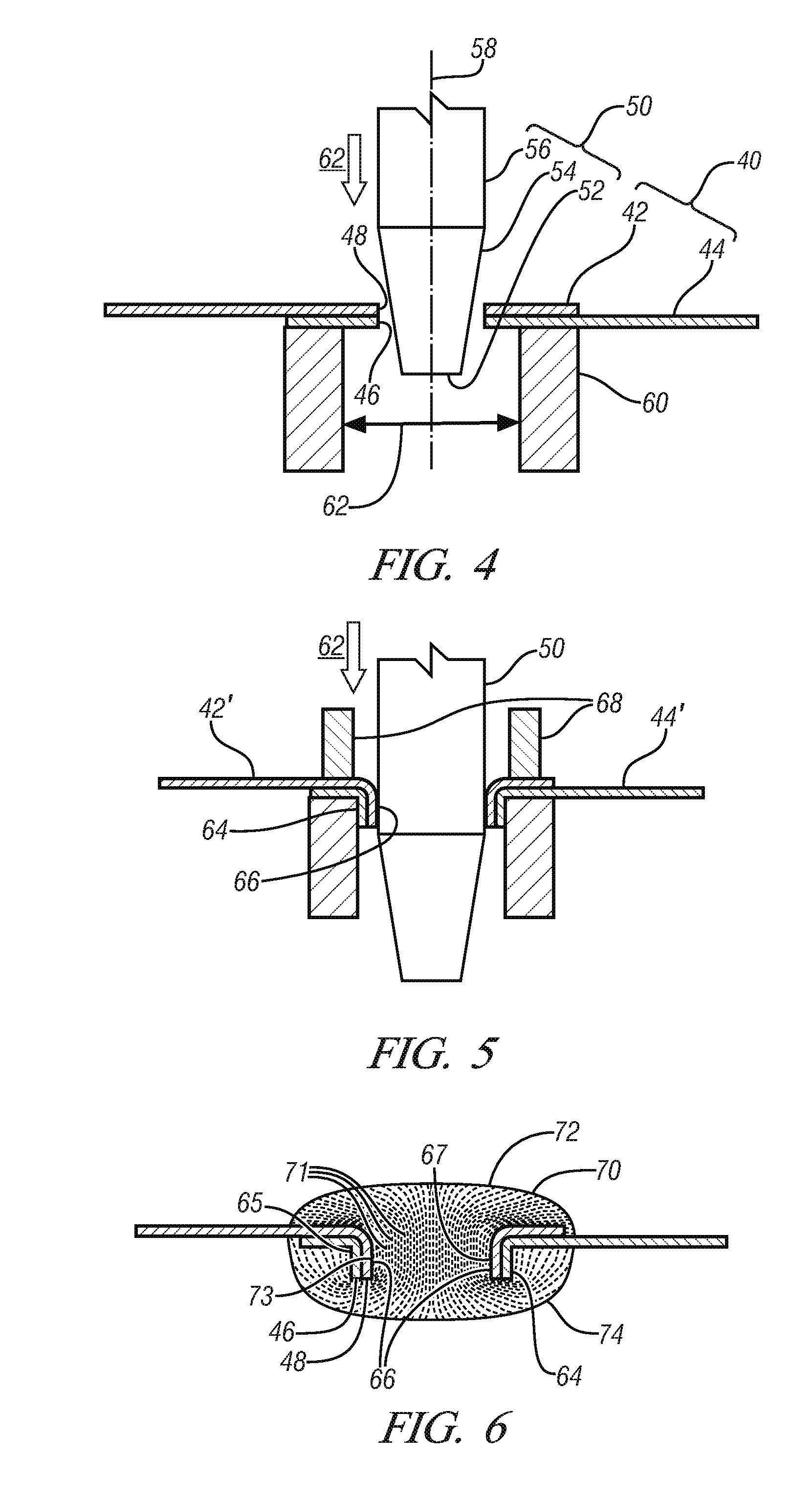

Joining magnesium with reinforced polymer composite fasteners

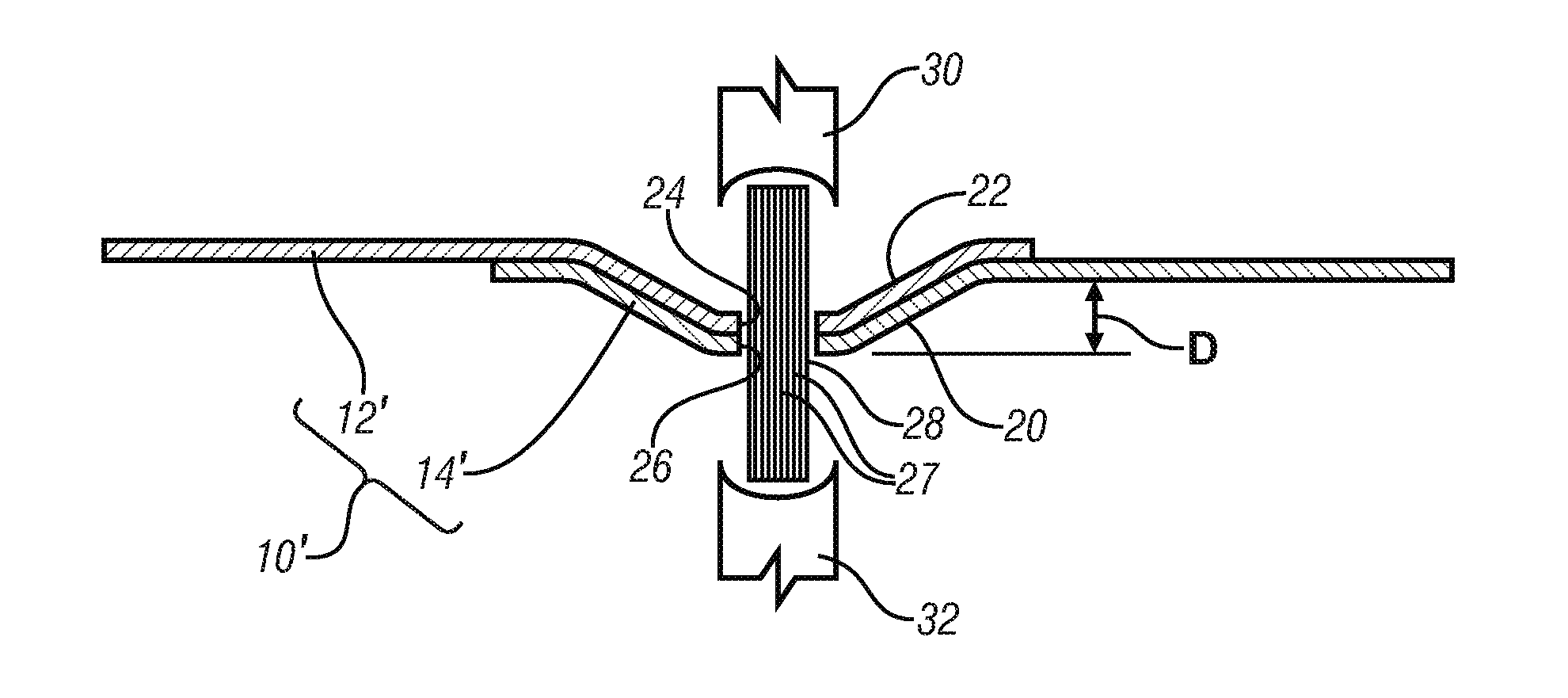

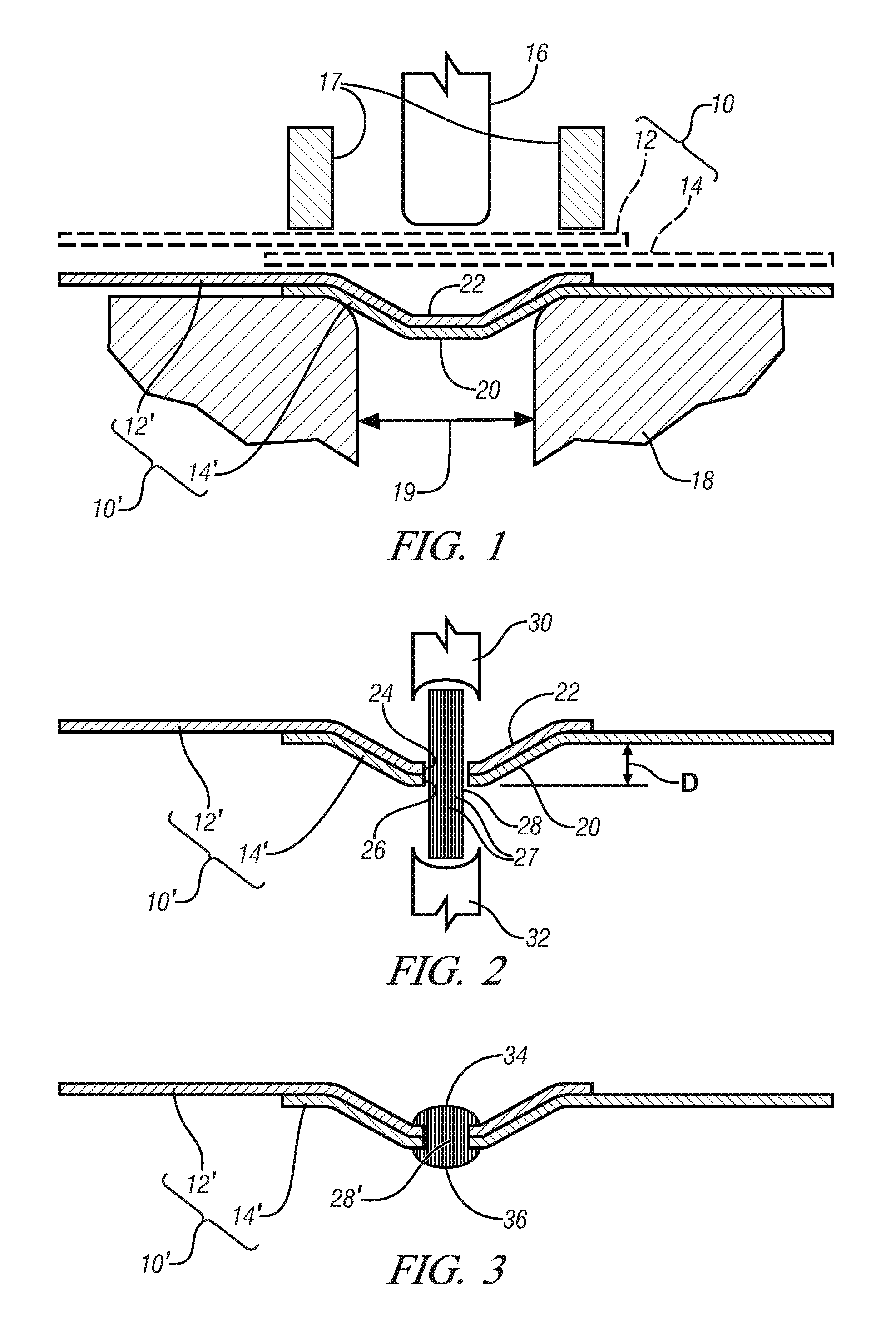

ActiveUS8448324B2Superior creep resistance and dimensional stabilityImprove deformationSheet joiningMetal working apparatusThin metalPolymer composites

A method is disclosed for forming corrosion-resistant joints in a plurality of overlapping thin metal sheet workpieces, at least one of which comprises at least 85% by weight of magnesium sheets. The fastener is a fiber-reinforced polymer rod shaped and sized for insertion into a coaxial opening formed in each sheet and subsequently upset on each end to form a head. The workpiece sheets are deformed to form mechanically-interfering features which cooperatively complement the strength of the fastener, under at least some joint loading patterns. The method may be used for other workpiece and fastener compositions.

Owner:GM GLOBAL TECH OPERATIONS LLC

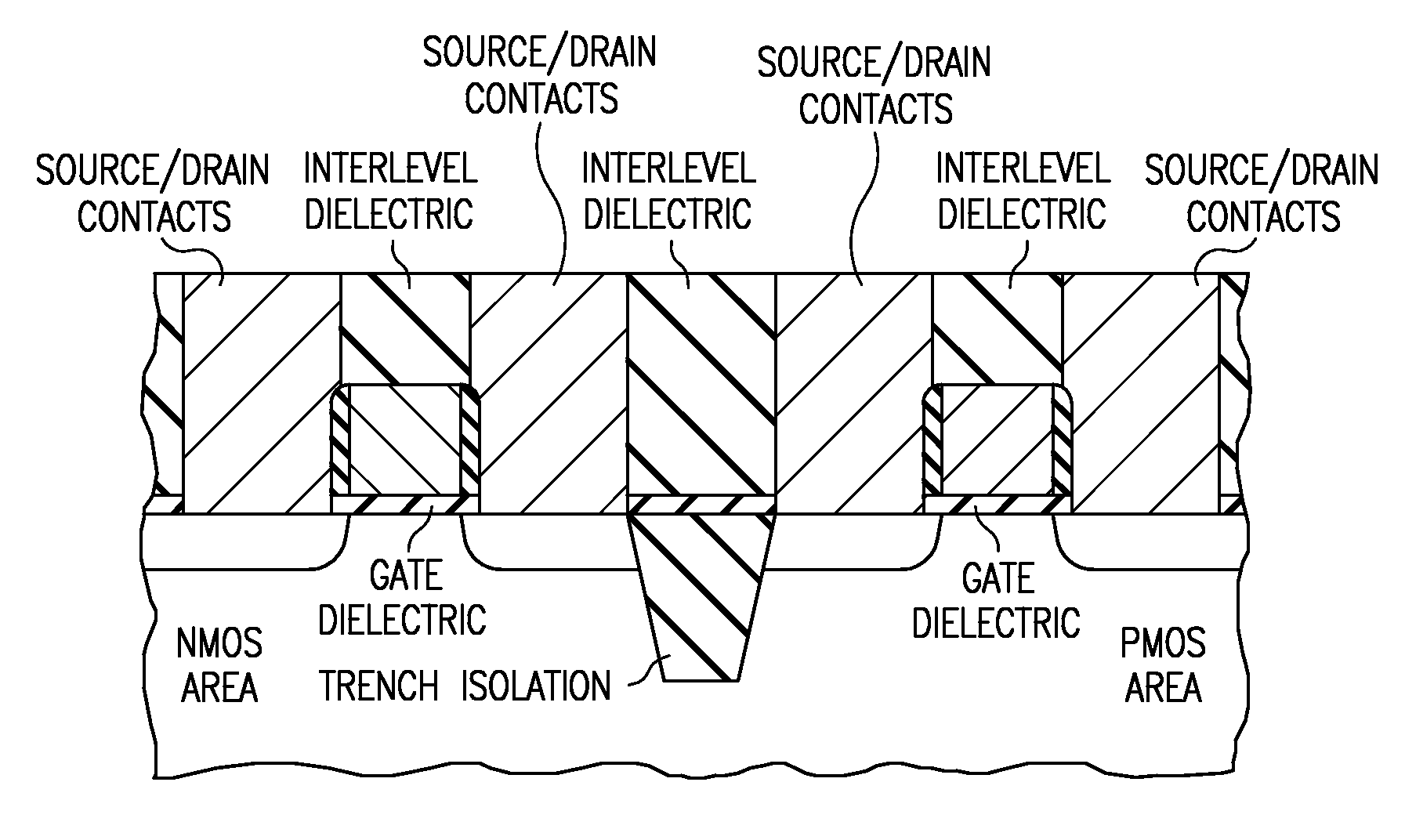

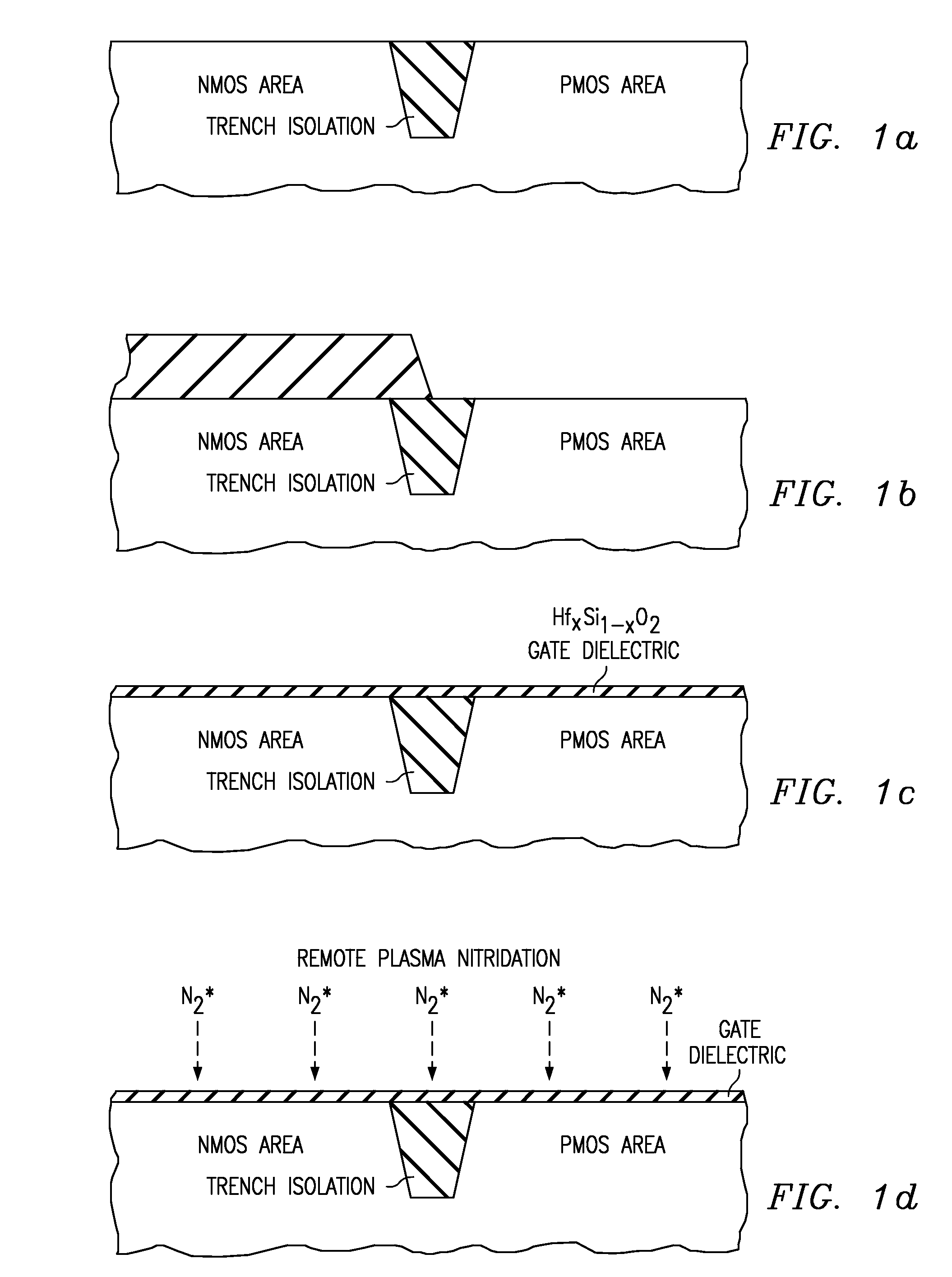

Gate structure and method

ActiveUS7535066B2Reaction can be limitedTransistorSemiconductor/solid-state device manufacturingMOSFETGate dielectric

A MOSFET structure including silicate gate dielectrics with nitridation treatments of the gate dielectric prior to gate material deposition.

Owner:TEXAS INSTR INC

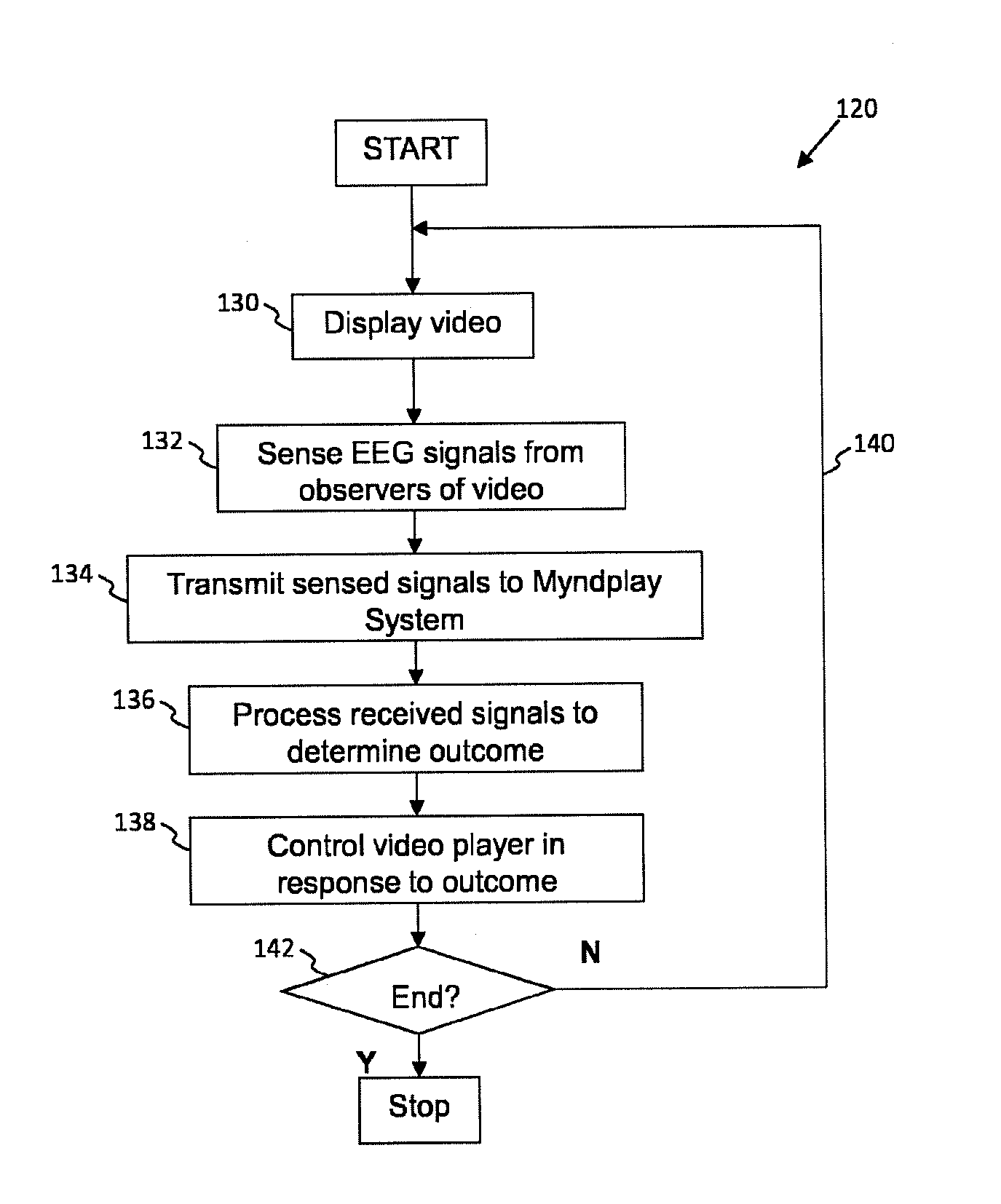

Control mechanisms

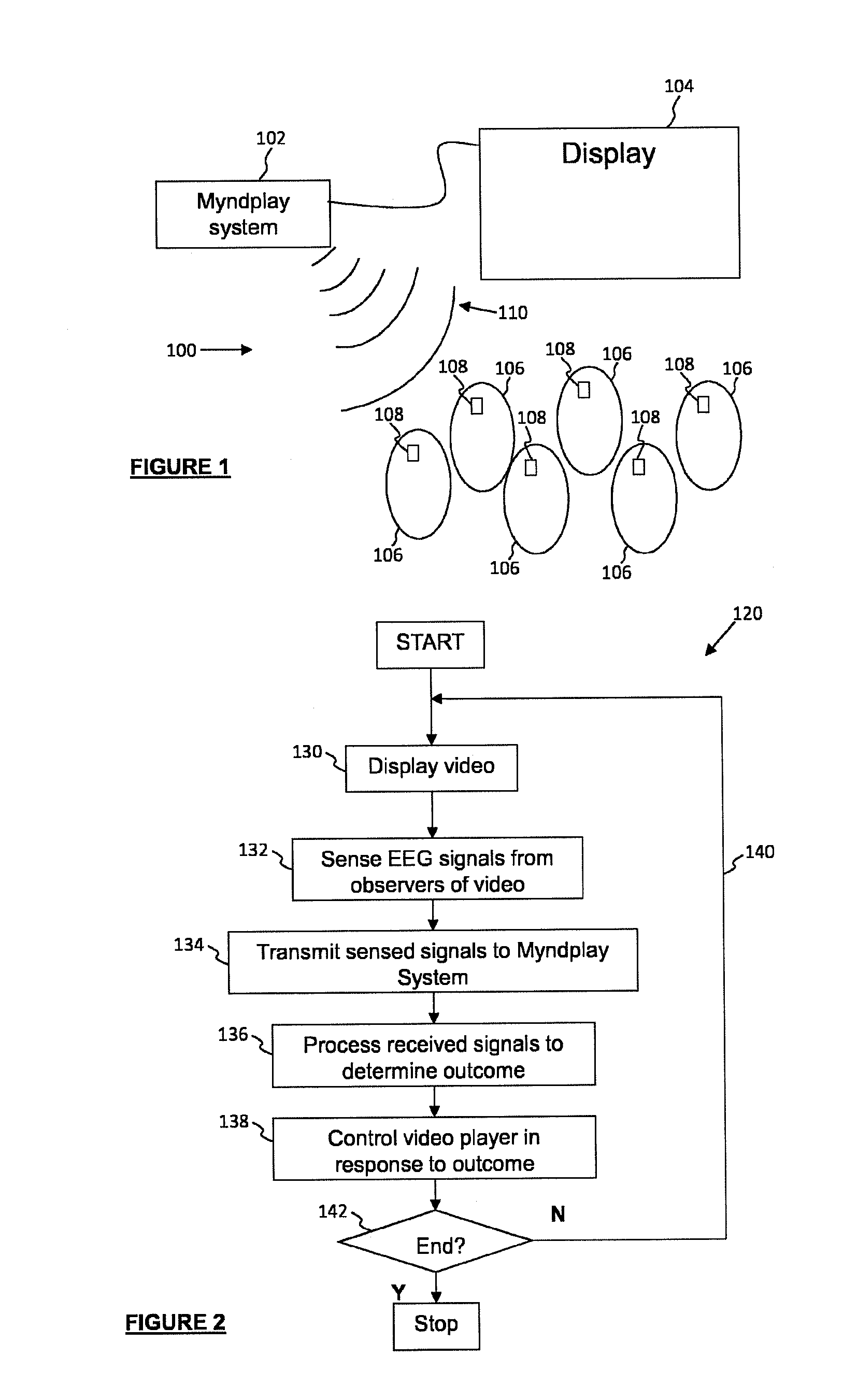

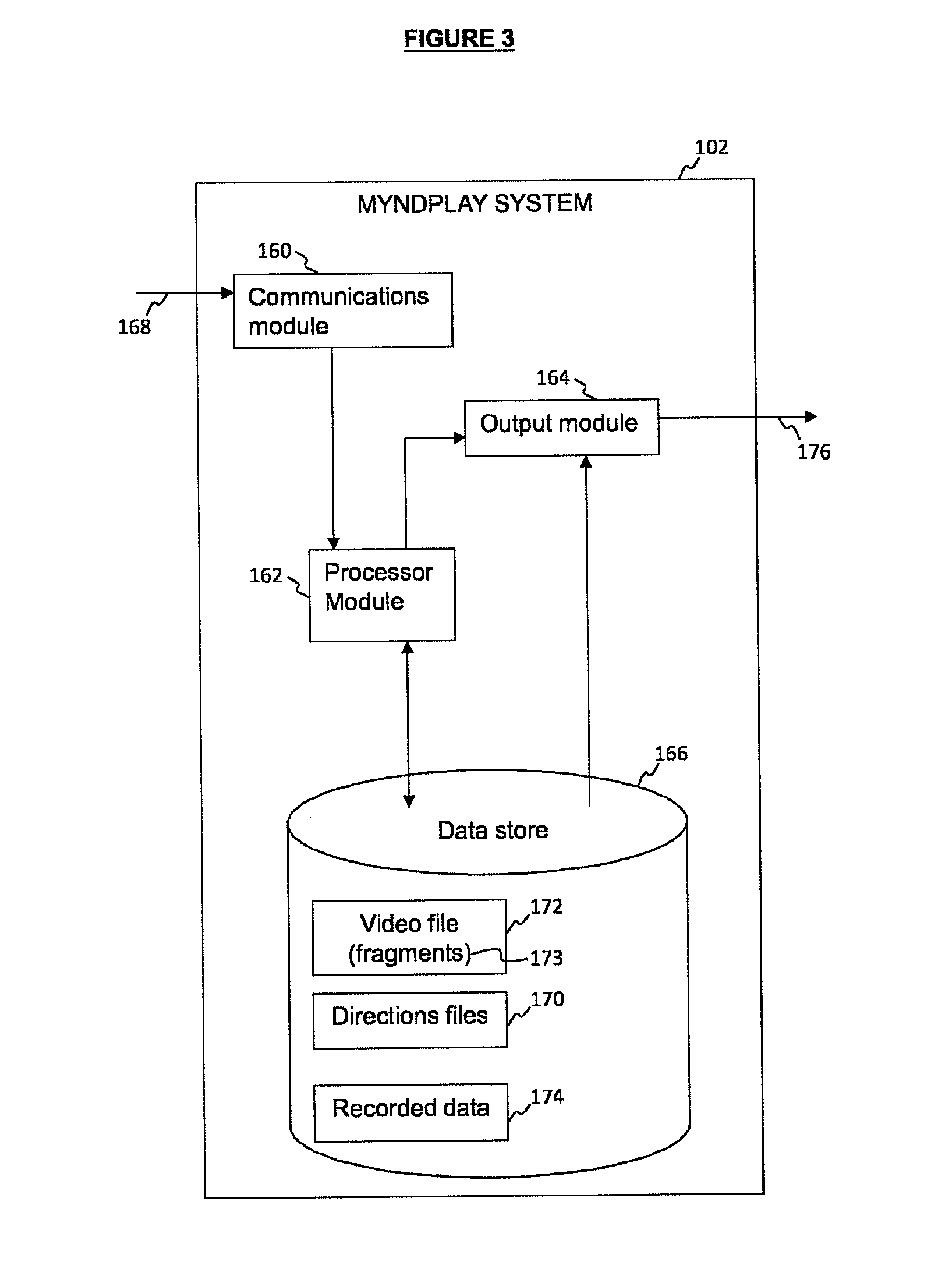

ActiveUS20150071600A1Conveniently configuredEasy accessTelevision system detailsColor television detailsControl signalComputer graphics (images)

A method of controlling a video clip player is described. The method comprises sending a control signal from a controller to the video clip player to output a pre-recorded video clip to a display; using a sensor to sense EEG signals from the brain of an observer of the displayed video clip; transmitting the sensed EEG signals from the sensor to the controller; processing the received EEG signals to determine an outcome, the outcome being achieved by the received signal comprising a predetermined frequency or a predetermined combinations of frequencies of EEG signals above a threshold level for a predetermined period of time; and controlling the video clip player in response to the determined outcome. The controlling step comprises selecting a next pre-recorded video clip to be output by the video clip player from a plurality of stored pre-recorded video clips; and instructing the video clip player to output the selected pre-recorded video clip to the display for presentation to the observer.

Owner:MYNDPLAY

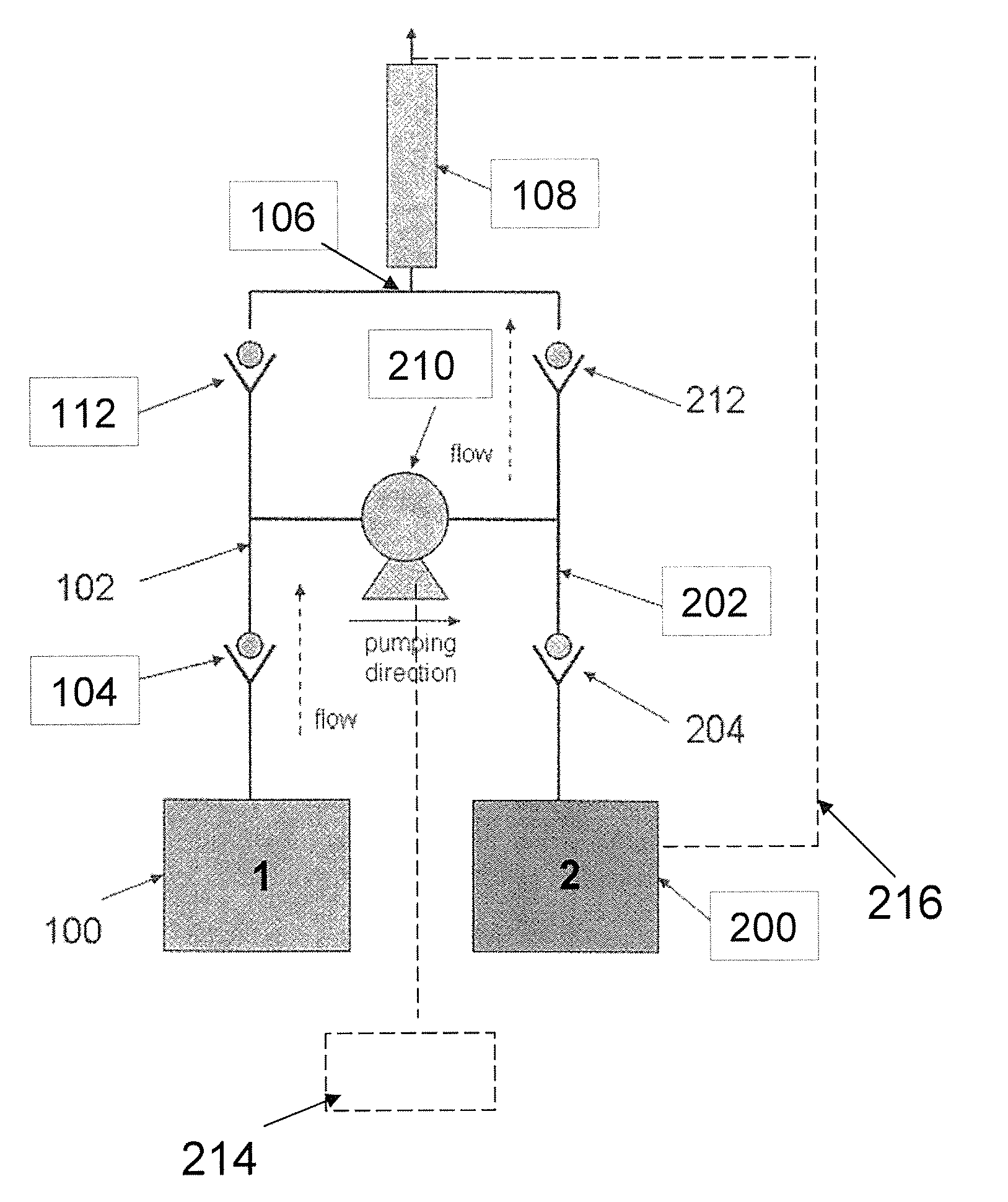

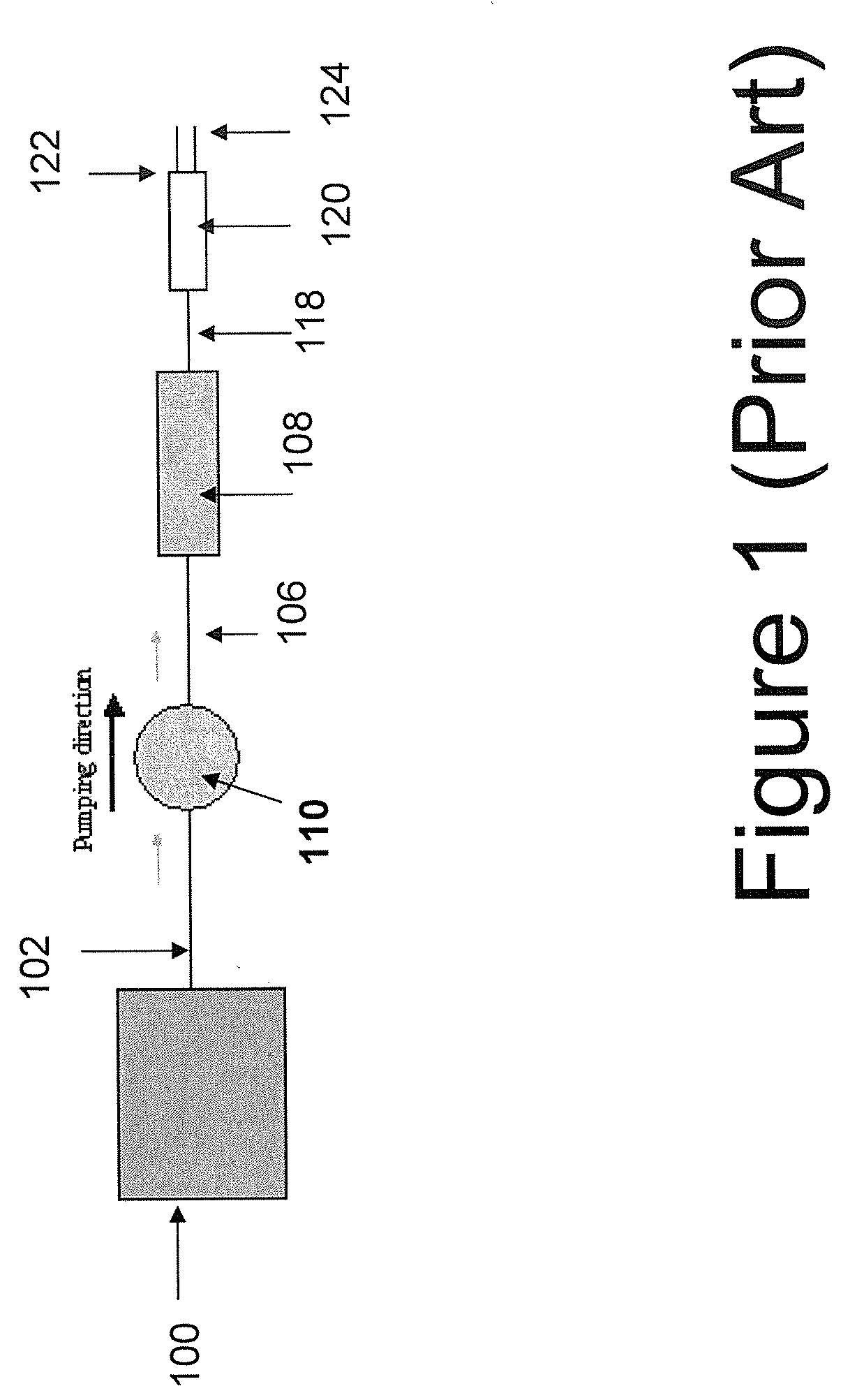

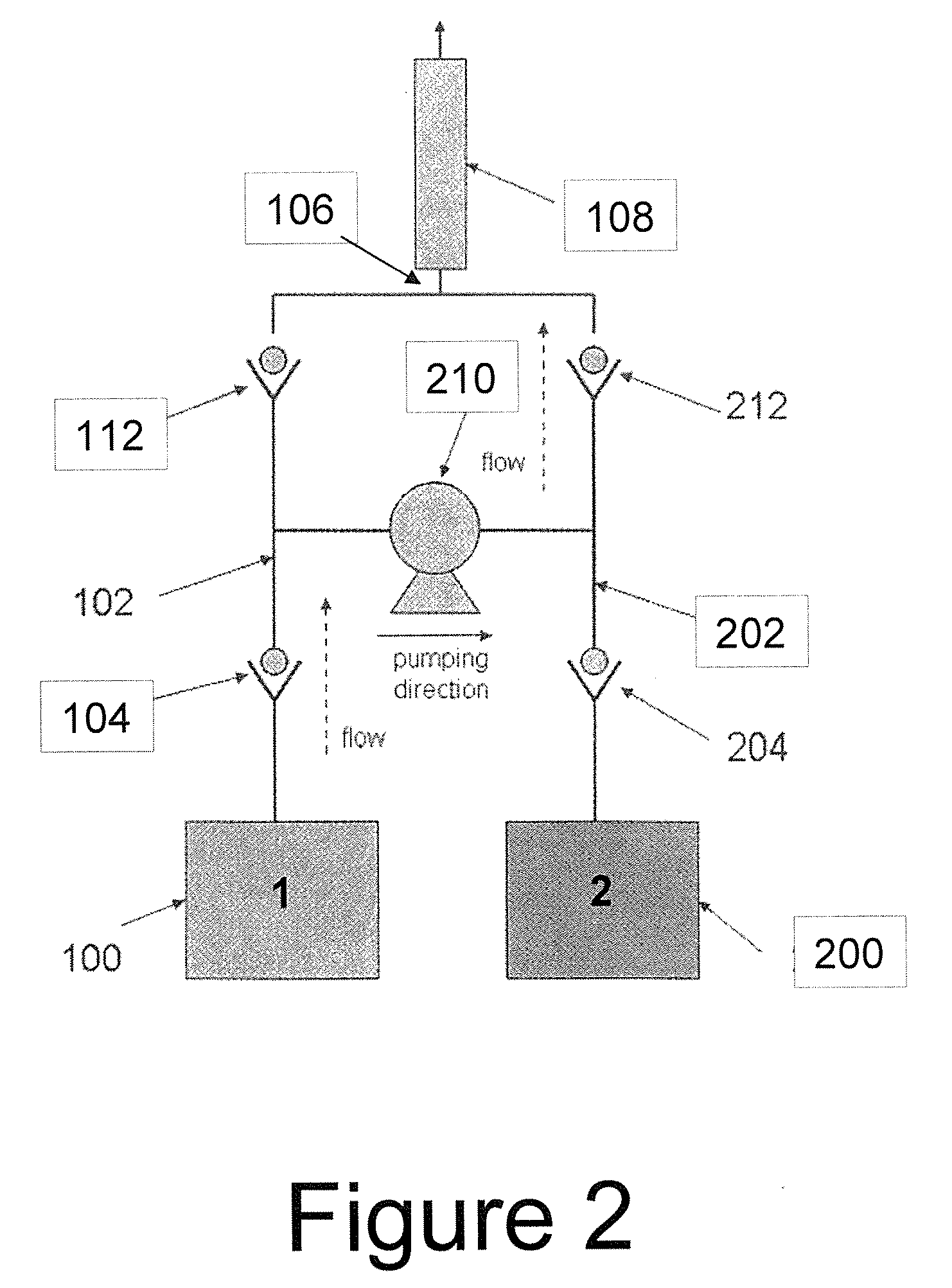

Systems and methods for generating hydrogen gas

InactiveUS20090020174A1Reduce cloggingReaction can be limitedSedimentation separationHydrogen productionHydrogenPulsed mode

Systems and methods are provided for hydrogen generation utilizing two or more liquid fuel components, using a fuel delivery system comprising a single reversible or bi-directional pump co-operable with flow control means comprising passive or active valves to deliver two or more fuel components to a mixing zone, reaction zone, or reaction chamber of a hydrogen generation system. The pump is operable in a forward direction to deliver one fuel component, and in a reverse direction to deliver a second fuel component. Control of the pump speed, direction and duty cycle of the pump in continuous or pulsed modes provides for delivery of first and second fuel components in desired proportions, to control hydrogen generation. The system also allows for dilution, mixing and flush cycles to be provided using a single pump, reducing the number of active elements required for fuel delivery and flow control in systems using two or more liquid fuel components.

Owner:SILICON VALLEY BANK

Joining magnesium with reinforced polymer composite fasteners

ActiveUS20120124816A1Superior creep resistance and dimensional stabilityImprove deformationSheet joiningMetal working apparatusPolymer compositesUltimate tensile strength

A method is disclosed for forming corrosion-resistant joints in a plurality of overlapping thin metal sheet workpieces, at least one of which comprises at least 85% by weight of magnesium sheets. The fastener is a fiber-reinforced polymer rod shaped and sized for insertion into a coaxial opening formed in each sheet and subsequently upset on each end to form a head. The workpiece sheets are deformed to form mechanically-interfering features which cooperatively complement the strength of the fastener, under at least some joint loading patterns. The method may be used for other workpiece and fastener compositions.

Owner:GM GLOBAL TECH OPERATIONS LLC

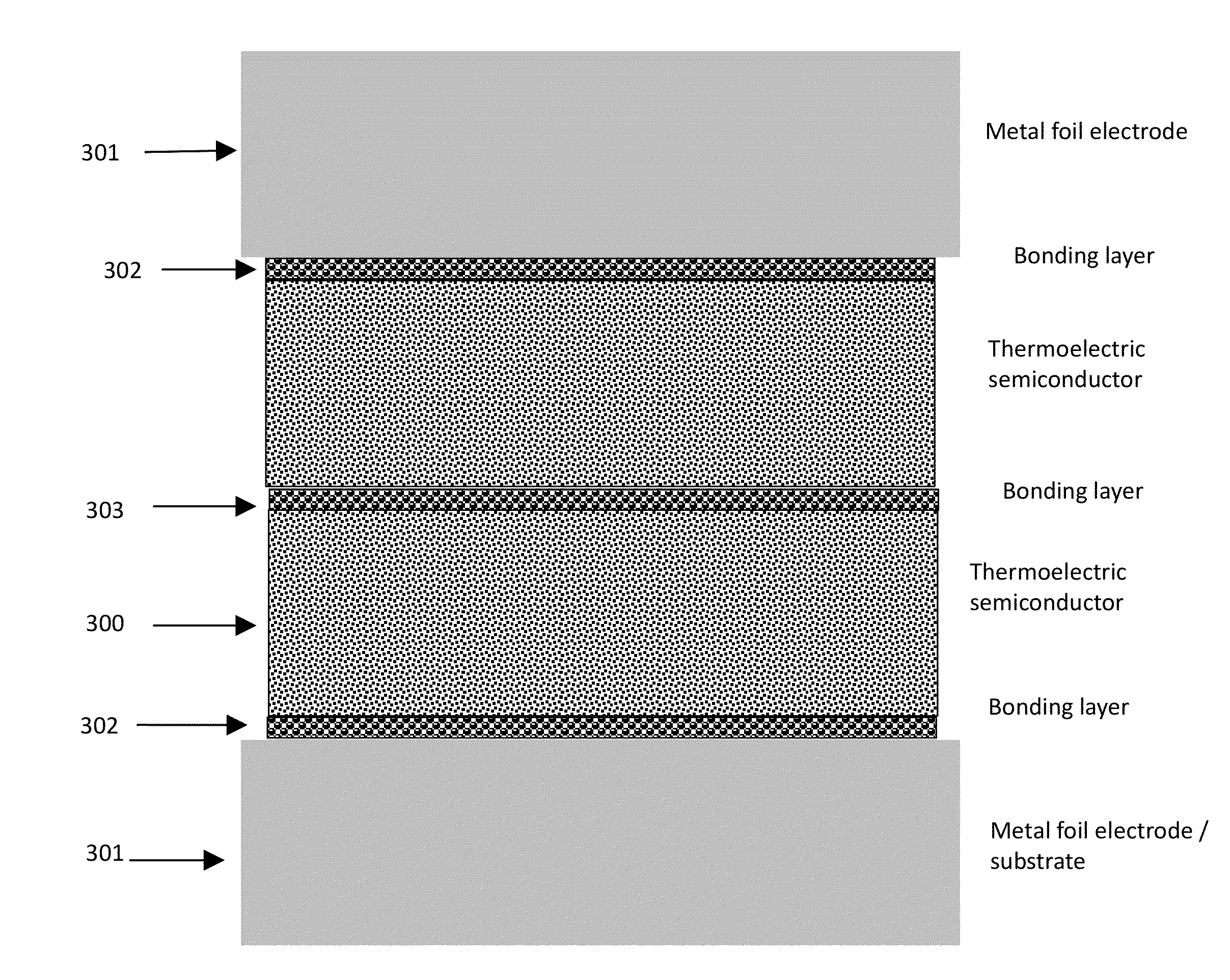

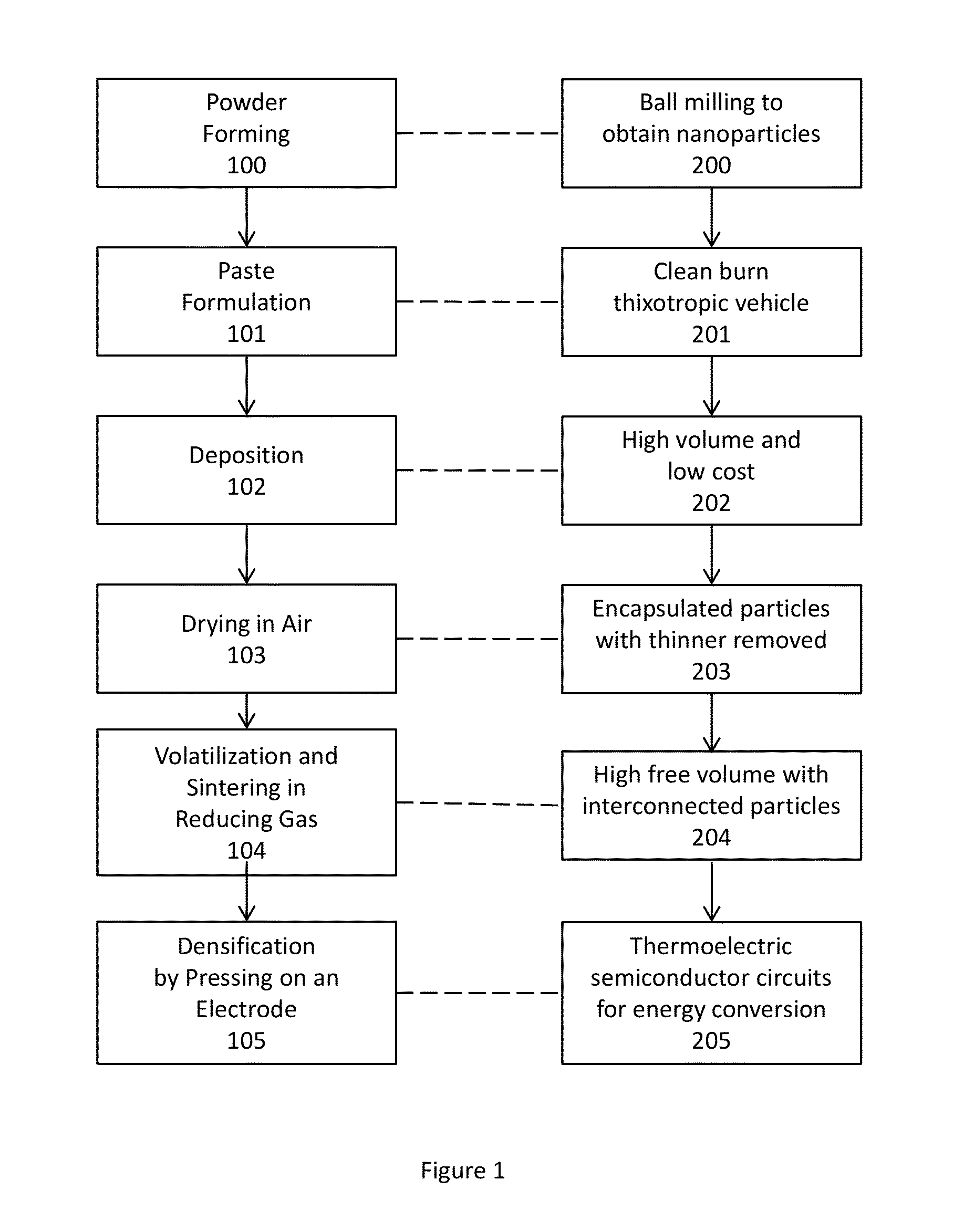

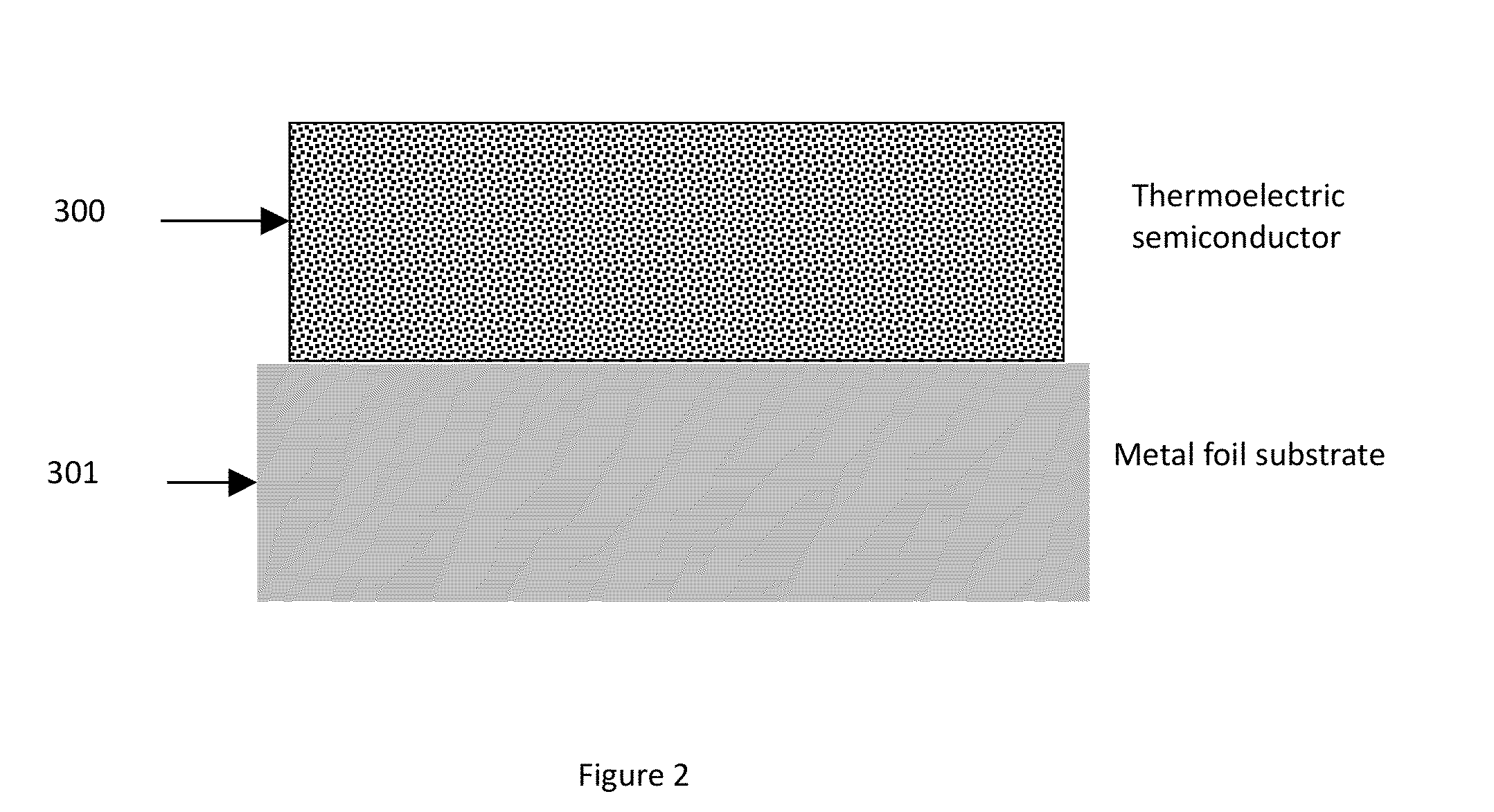

Methods For Thick Films Thermoelectric Device Fabrication

ActiveUS20140315345A1Reduced responseSufficient structural integrityThermoelectric device manufacture/treatmentSemiconductor/solid-state device manufacturingBonding processHeat treated

Solid state thermoelectric energy conversion devices can provide electrical energy from heat flow, creating energy, or inversely, provide cooling through applying energy. Thick film methods are applied to fabricate thermoelectric device structures using microstructures formed through deposition and subsequent thermal processing conditions. An advantageous coincidence of material properties makes possible a wide variety of unique microstructures that are easily applied for the fabrication of device structures in general. As an example, a direct bond process is applied to fabricate thermoelectric semiconductor thick films on substrates by printing and subsequent thermal processing to form unique microstructures which can be densified. Bismuth and antimony are directly bonded to flexible nickel substrates.

Owner:ATS IP LLC

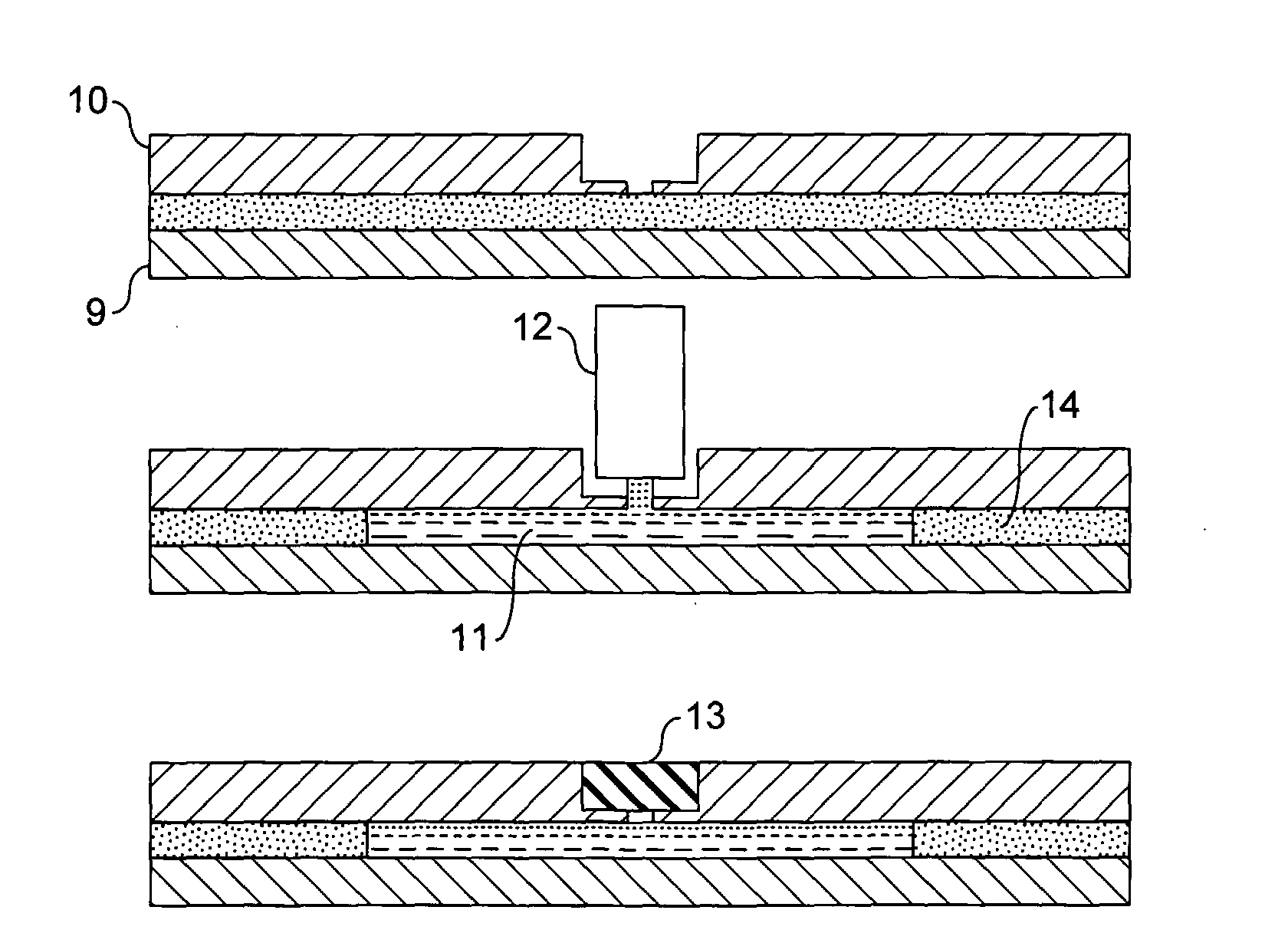

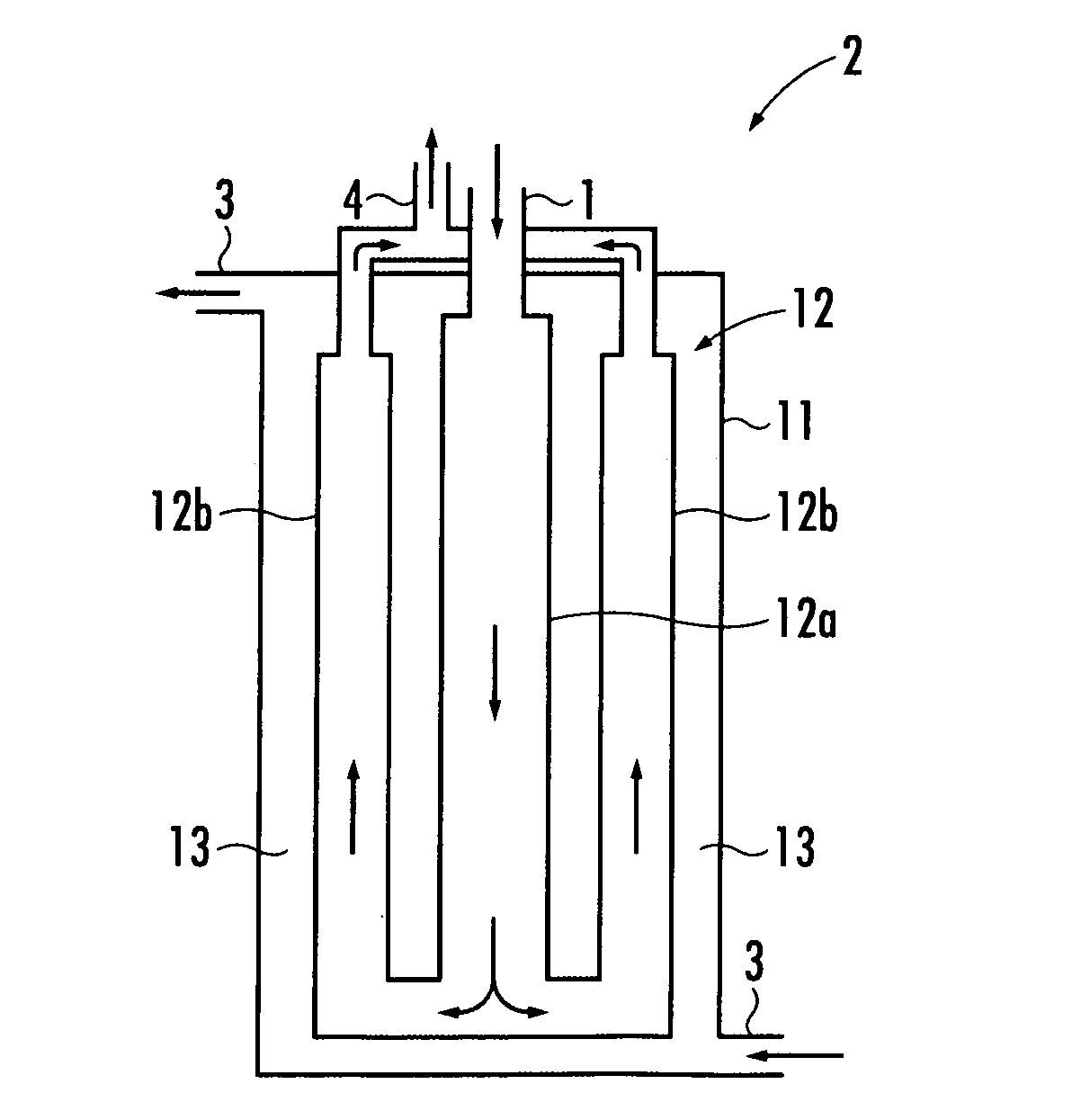

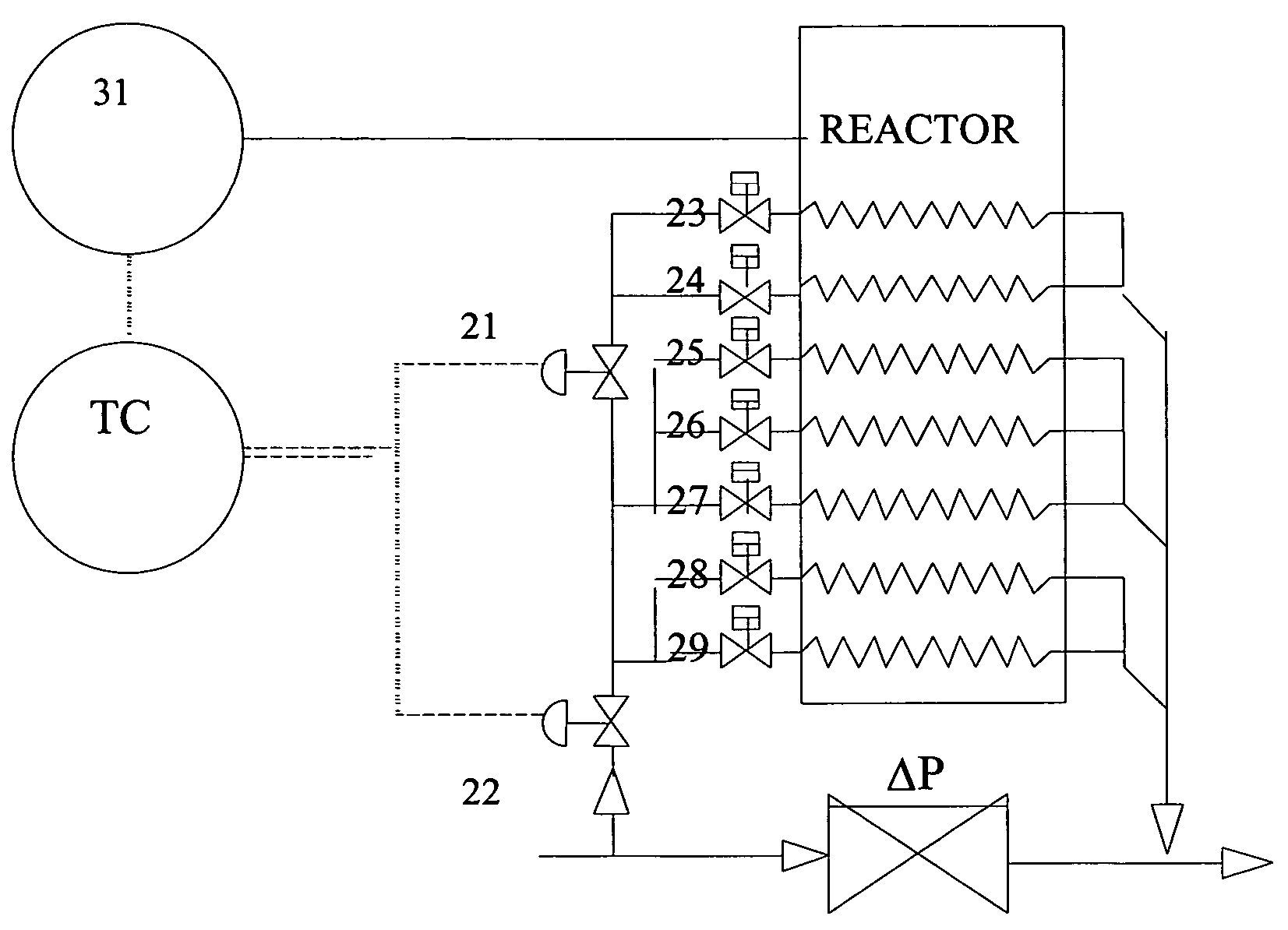

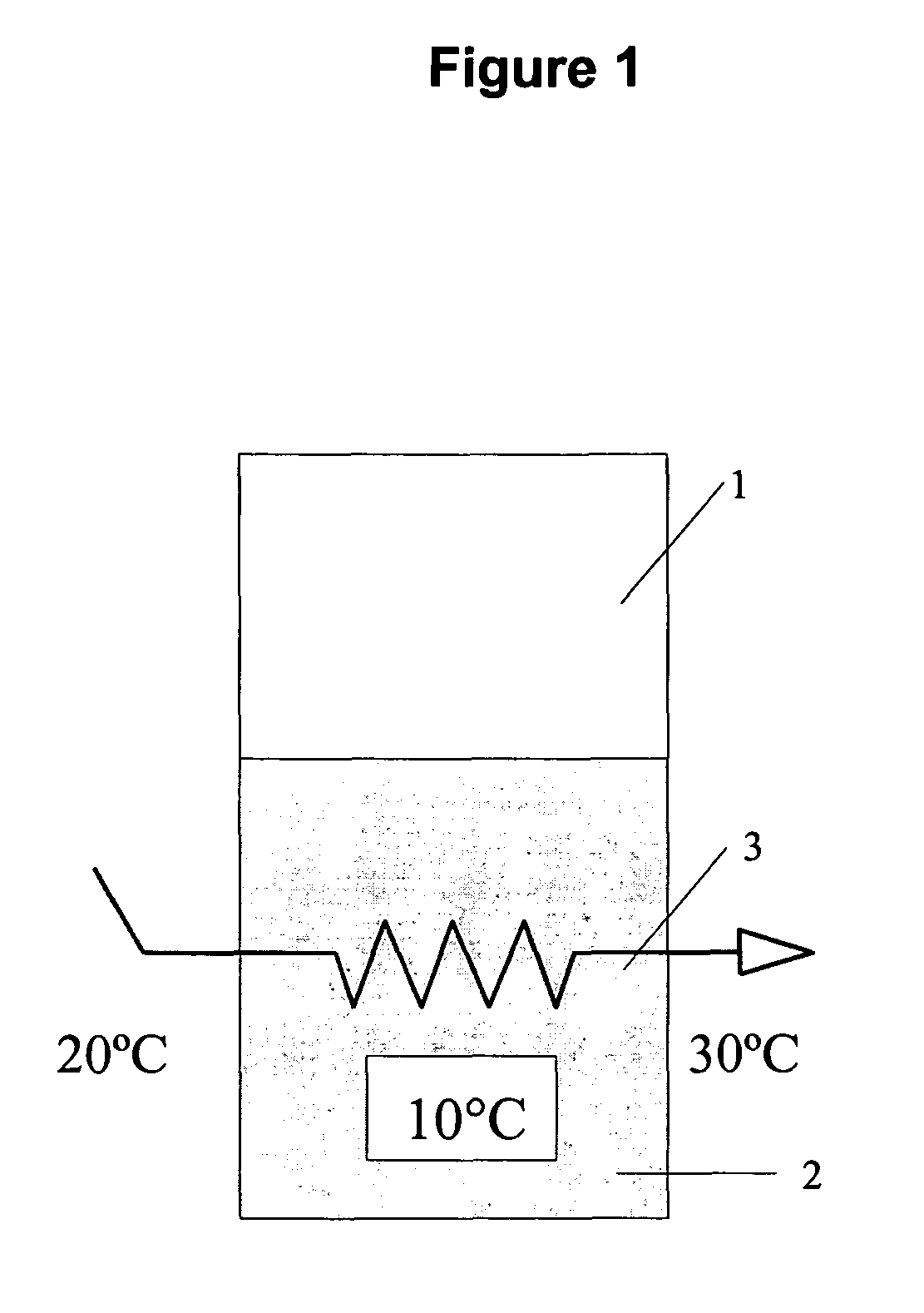

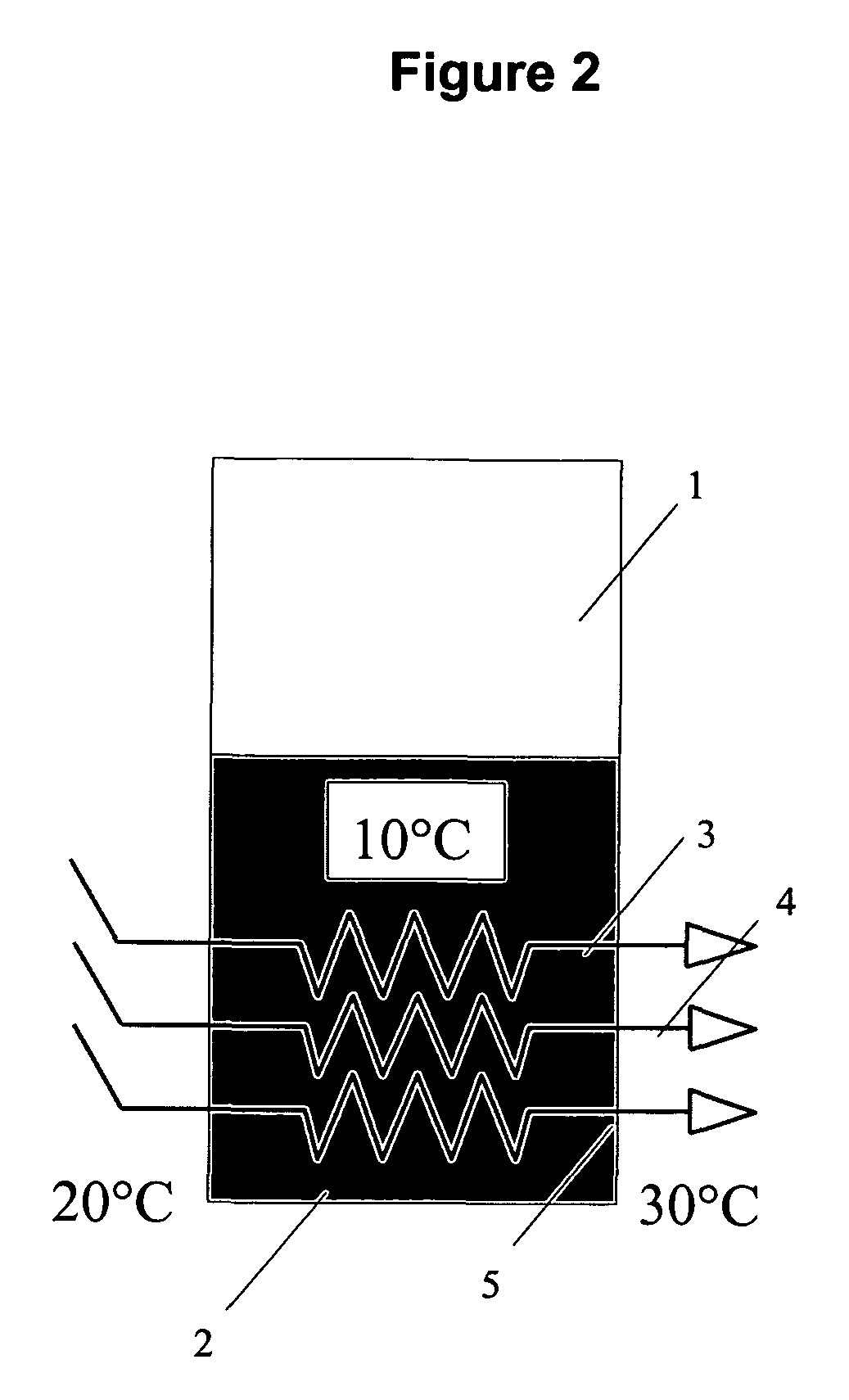

Reactor heat transfer systems

InactiveUS7771664B2The implementation process is simpleEasy to measureExhaust apparatusMaterial heat developmentEngineeringHeat transfer fluid

A reaction system in which a heat transfer fluid is carried through a process fluid in a conduit and the heat transfer surface area between the conduit and the process fluid can be varied according to the heat generated or absorbed by the reaction as determined by the temperature change in the heat transfer fluid across the reaction and the mass flow of the heat transfer fluid through the conduit.

Owner:ASHE ROBERT +1

Energy distributing side structure for vehicle side impact occupant protection

InactiveUS20110227368A1Reduce the amount of distortionLess energyVehicle seatsUnderstructuresEngineeringSide impact

An energy distributing side structure for a vehicle is disclosed. The side structure includes a B-pillar having a wide base and an internal reinforcing tube, a rocker having an internal bulkhead, a rear rocker, and at least one cross-member extending vehicle-inward from the rocker. The cross-member may extend to the vehicle tunnel and may be attached to a tunnel brace. One or more additional cross-members may be provided which also extend vehicle-inward from the rocker and define secondary load paths. By this arrangement loading is transferred to the floor and cross-members of the vehicle during a lateral impact event.

Owner:FORD GLOBAL TECH LLC

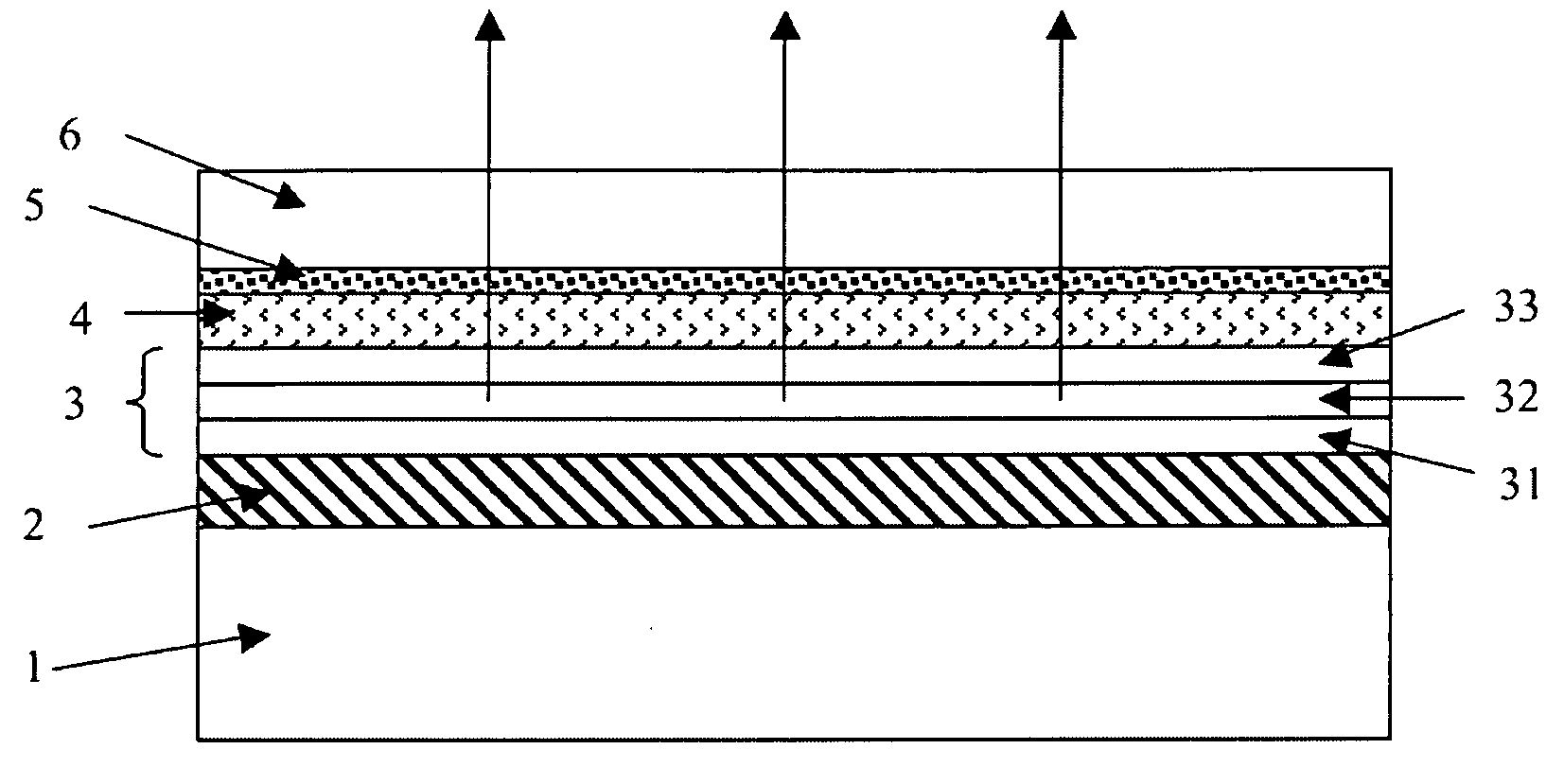

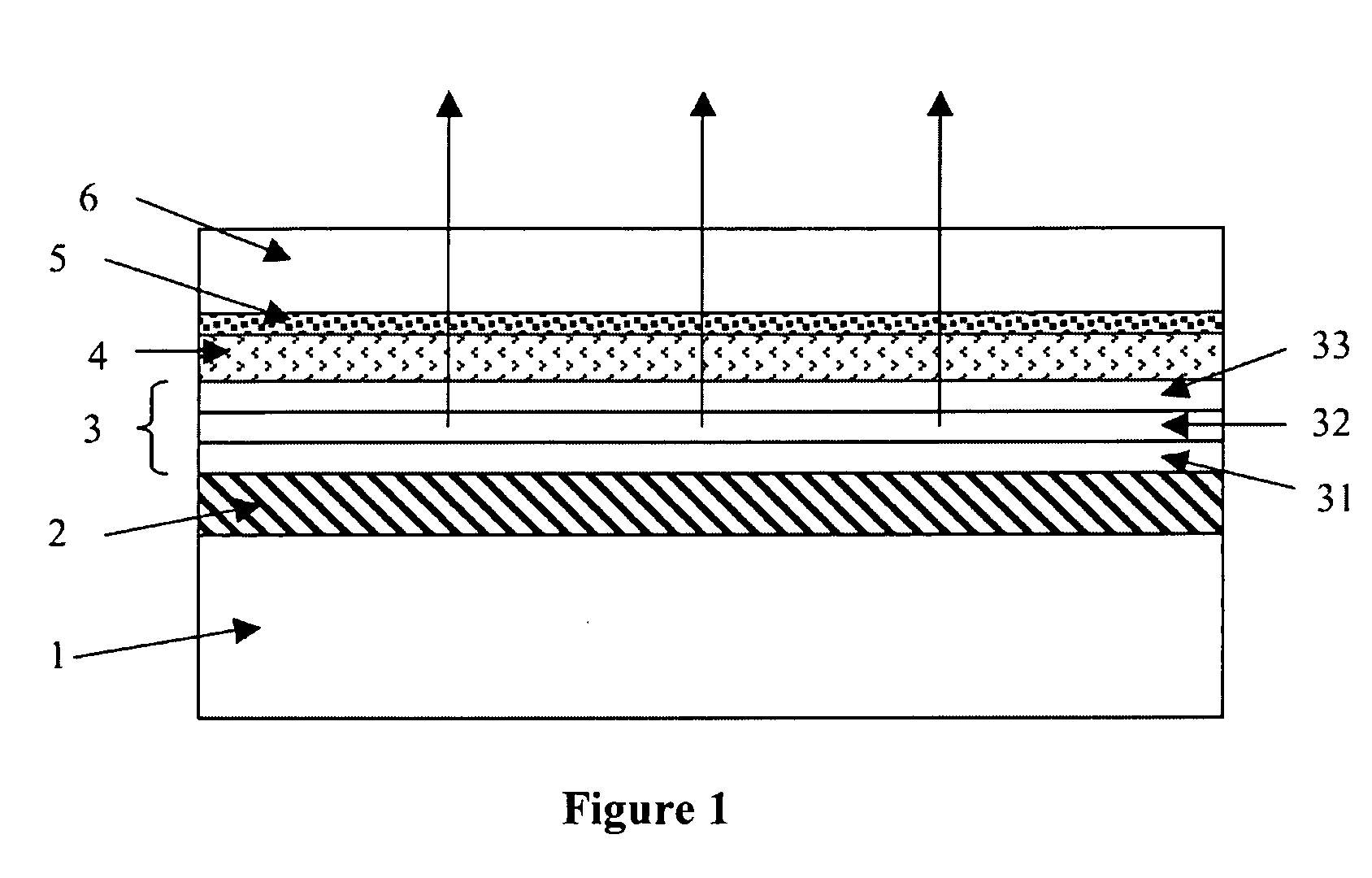

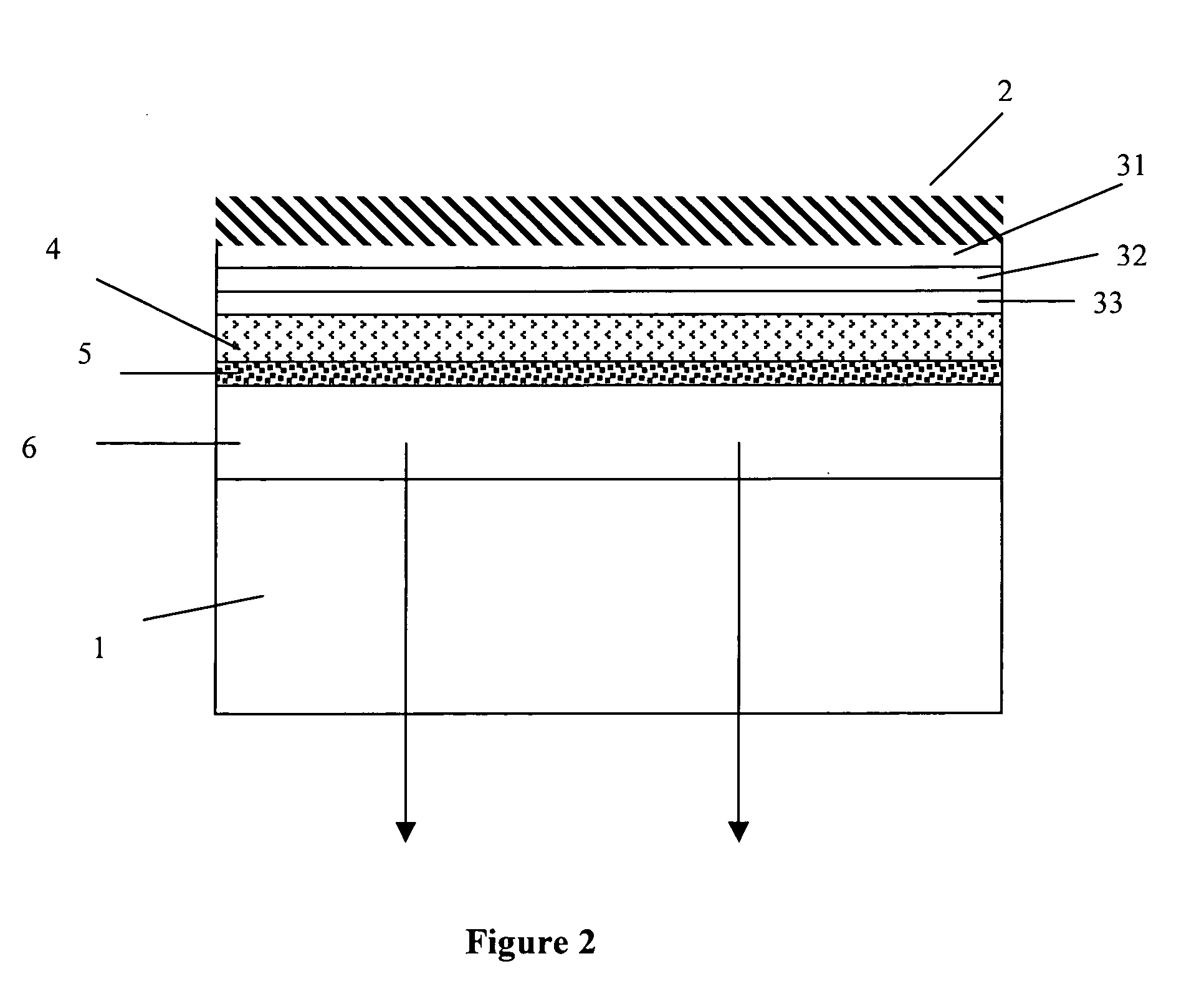

Organic Light-Emitting Diode With Transparent Multilayer Electrode

ActiveUS20090251045A1Prevent degradationReaction can be limitedDischarge tube luminescnet screensLamp detailsLight-emitting diodeDielectric layer

An organic light-emitting diode comprising a substrate (1), an organic light-emitting layer (3) arranged between a first electrode (2) and a transparent and semi-reflecting second electrode with a multilayer structure subdivided into:a first silver-based metallic layer (4) in contact with the organic light-emitting layer (3),a second aluminum-based metallic layer (5),and a third dielectric layer (6),characterized in that the second metallic layer (5) is inserted between the first metallic layer (4) and the third dielectric layer (6) of the transparent second electrode, that the organic light-emitting layer (3) comprises a doped sub-layer in contact with the first metallic layer (4) of the transparent second electrode, and that the thickness of said third dielectric layer (6) is adjusted to limit the absorption by said first (4) and second (5) metallic layers of the light emitted by the diode.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Ethanol fuel reforming system for internal combustion engines

InactiveUS7856950B2Heating fastMaintain stabilityPhysical/chemical process catalystsNon-fuel substance addition to fuelPlate heat exchangerCombustion

An ethanol fuel reforming system for internal combustion engines performs a reaction of reforming ethanol into diethyl ether at a constant temperature with stability. The system has a reformer for containing a reforming catalyst, a first heat exchanger for heating a heating medium with the exhaust gas of an internal combustion engine, a second heat exchanger for heating an ethanol fuel with the heating medium, and heating medium circulating means for circulating the heating medium. The heating medium makes distribution of temperature in the reformer uniform. The heating medium heats the reformer and the ethanol fuel to an identical temperature. The reformer is an ethanol fuel channel filled with the catalyst, and the ethanol fuel channel is bent in the reformer.

Owner:HONDA MOTOR CO LTD

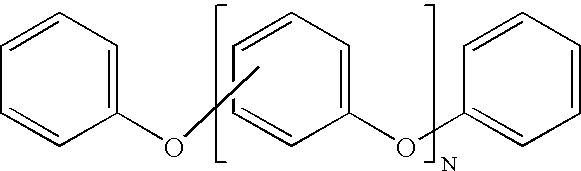

Oxidation resistant organic hydrogen getters

ActiveUS20050051757A1Efficient removalReaction can be limitedHydrogen separation by selective and reversible uptakeGas treatmentWater vaporOxidation resistant

A composition for removing hydrogen from an atmosphere, comprising a mixture of a polyphenyl ether and a hydrogenation catalyst, preferably a precious metal catalyst, and most preferably Pt. This composition is stable in the presence of oxygen, will not polymerize or degrade upon exposure to temperatures in excess of 200° C., or prolonged exposure to temperatures in the range of 100-300° C. Moreover, these novel hydrogen getter materials can be used to efficiently removing hydrogen from mixtures of hydrogen / inert gas (e.g., He, Ar, N2), hydrogen / ammonia atmospheres, such as may be encountered in heat exchangers, and hydrogen / carbon dioxide atmospheres. Water vapor and common atmospheric gases have no adverse effect on the ability of these getter materials to absorb hydrogen.

Owner:SANDIA NAT LAB

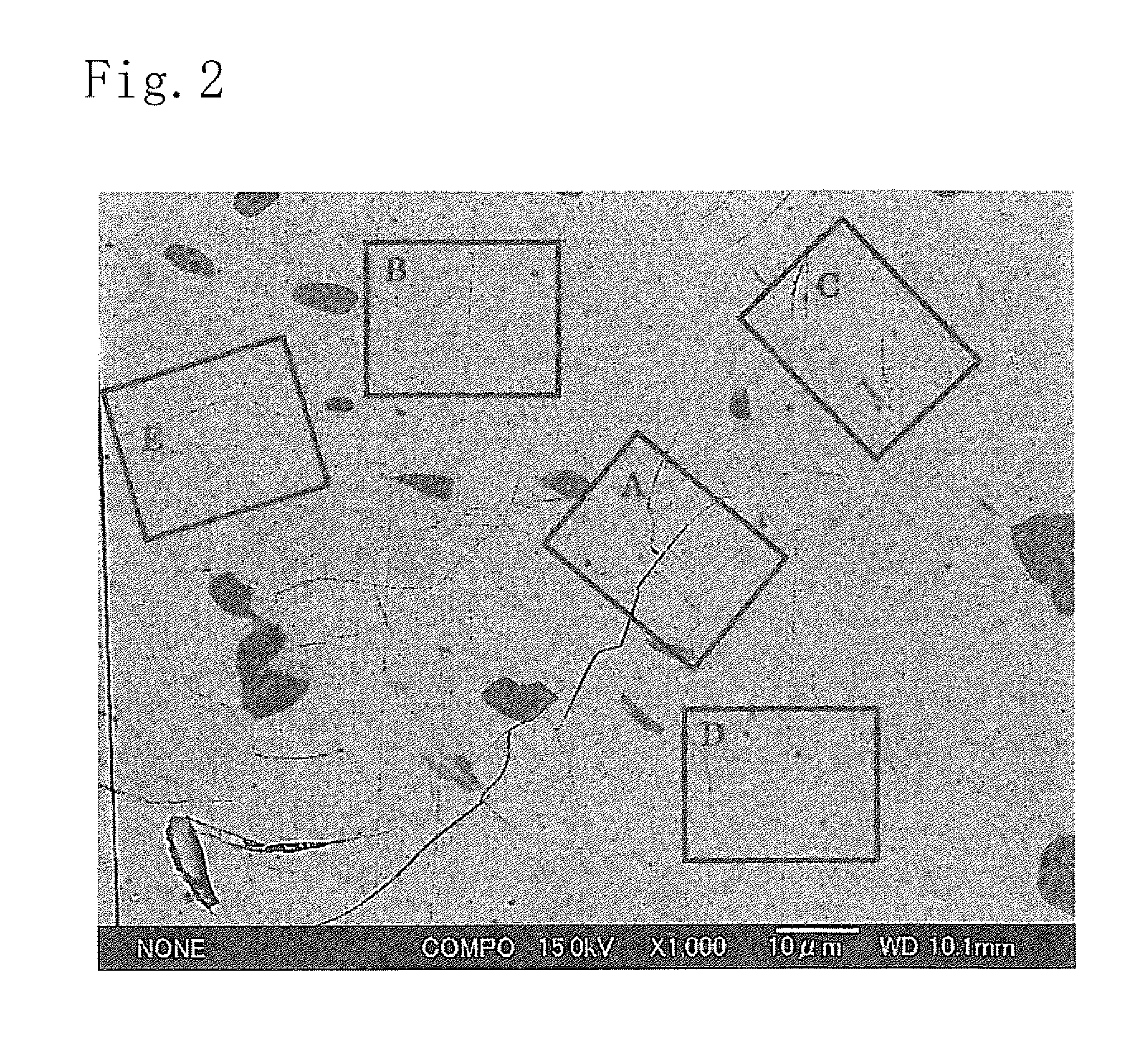

Hydrogen-absorbing alloy, fabrication method thereof and alkaline storage battery

ActiveUS20110151320A1Increased durabilityImprove cycle lifeOther chemical processesActive material electrodesRare-earth elementCrystal structure

An alkaline storage battery has a negative electrode using a hydrogen-absorbing alloy represented by a general formula Ln1-xMgxNiyAz wherein Ln is at least one element selected from rare-earth elements including Y, Ca, Zr, and Ti, A is at least one element selected from Co, Fe, Mn, V, Cr, Nb, Al, Ga, Zn, Sn, Cu, Si, P and B, and 0.15≦x≦0.30, 0<z≦1.5, and 2.8≦y+z≦4.0 are satisfied. The hydrogen-absorbing alloy has a hexagonal system crystal structure or a rhombohedral system crystal structure as its main phase and has a subphase of line which average number of not less than 50 nm in thickness existing in the range of 10 μm×10 μm in the cross section of the main phase is 3 or less.

Owner:FDK CORP

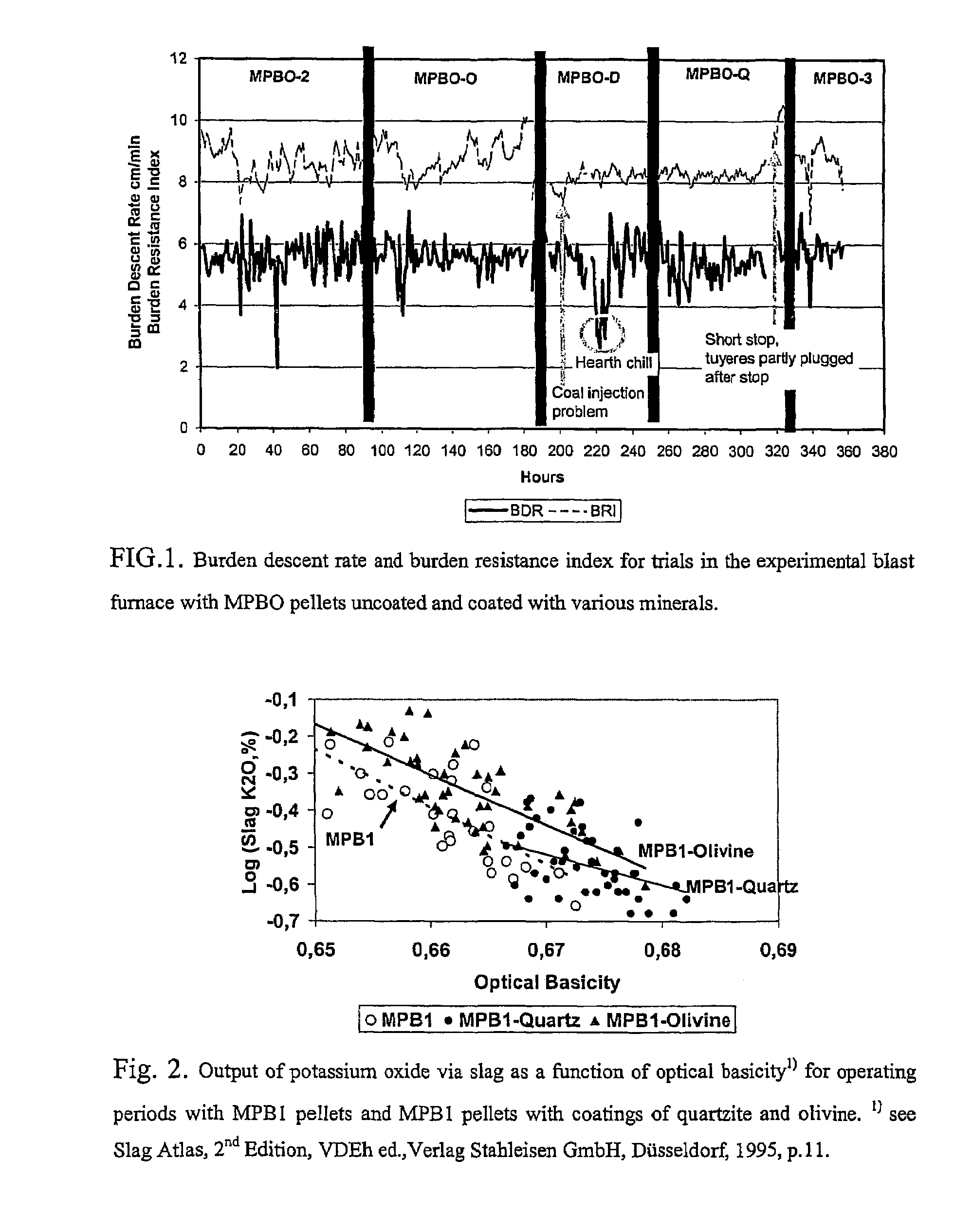

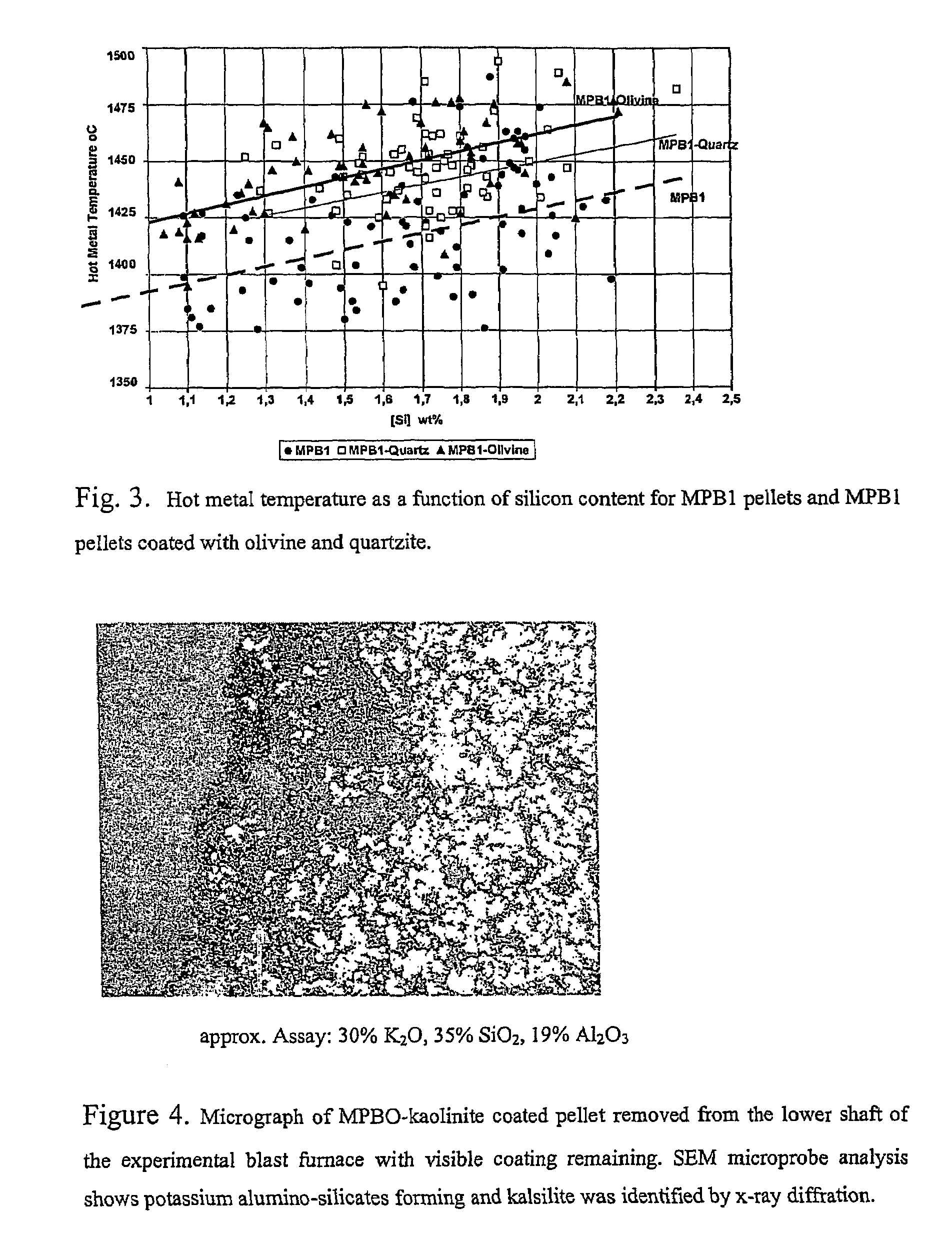

Method to improve iron production rate in a blast furnace

InactiveUS7442229B2Increase ratingsLarge specific surface areaBlast furnace detailsProduction rateSlag

The present invention relates to a method to improve the iron production rate in a blast furnace being charged by iron containing agglomerates. The method includes contacting the chargeable iron containing material with a slag modifying effective amount of a dispersion of a particulate material, wherein the contacting occurs prior to the charging of the agglomerate to blast furnace process.

Owner:LOUSSAVAARA KIIRUNAVAORA AB

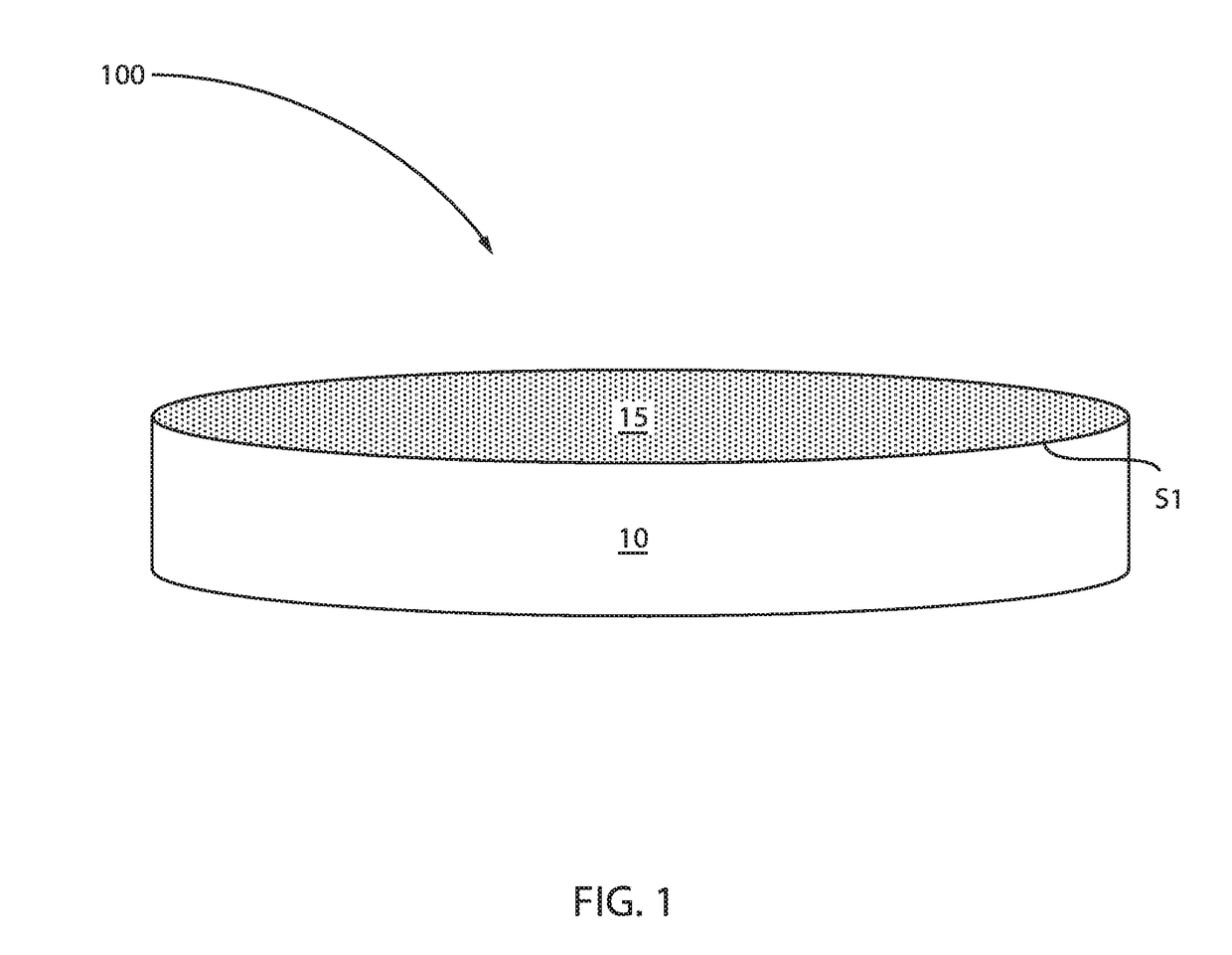

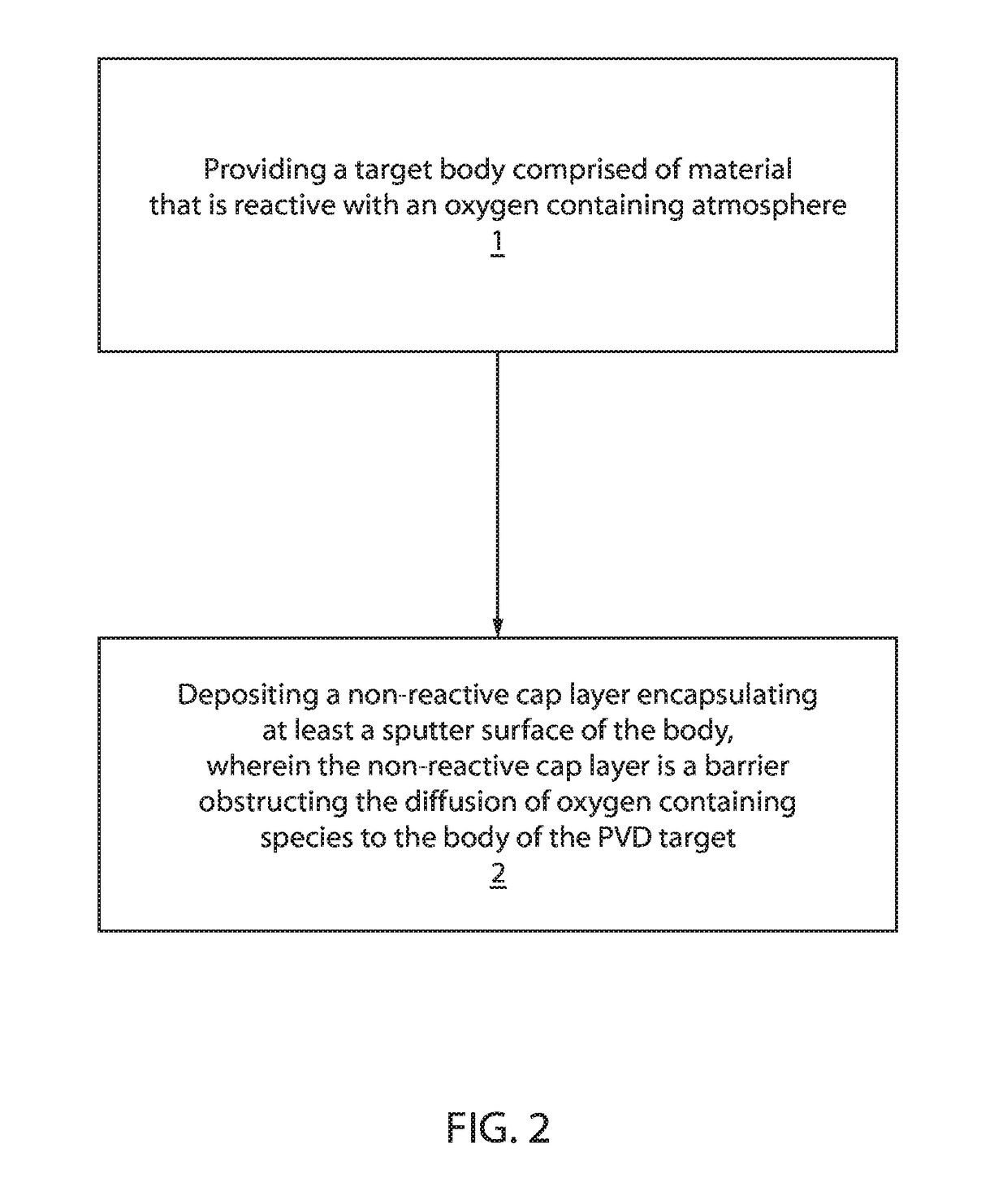

Structure and method to fabricate highly reactive physical vapor deposition target

ActiveUS20180312959A1Controlled absorptionLimit absorptionElectric discharge tubesVacuum evaporation coatingDiffusionPhysical chemistry

A physical vapor deposition (PVD) target that includes a body composed of material that is reactive with an oxygen containing atmosphere; and a non-reactive cap layer encapsulating at least a sputter surface of the body. The non-reactive cap layer is a barrier obstructing the diffusion of oxygen containing species to the body of the PVD target.

Owner:IBM CORP

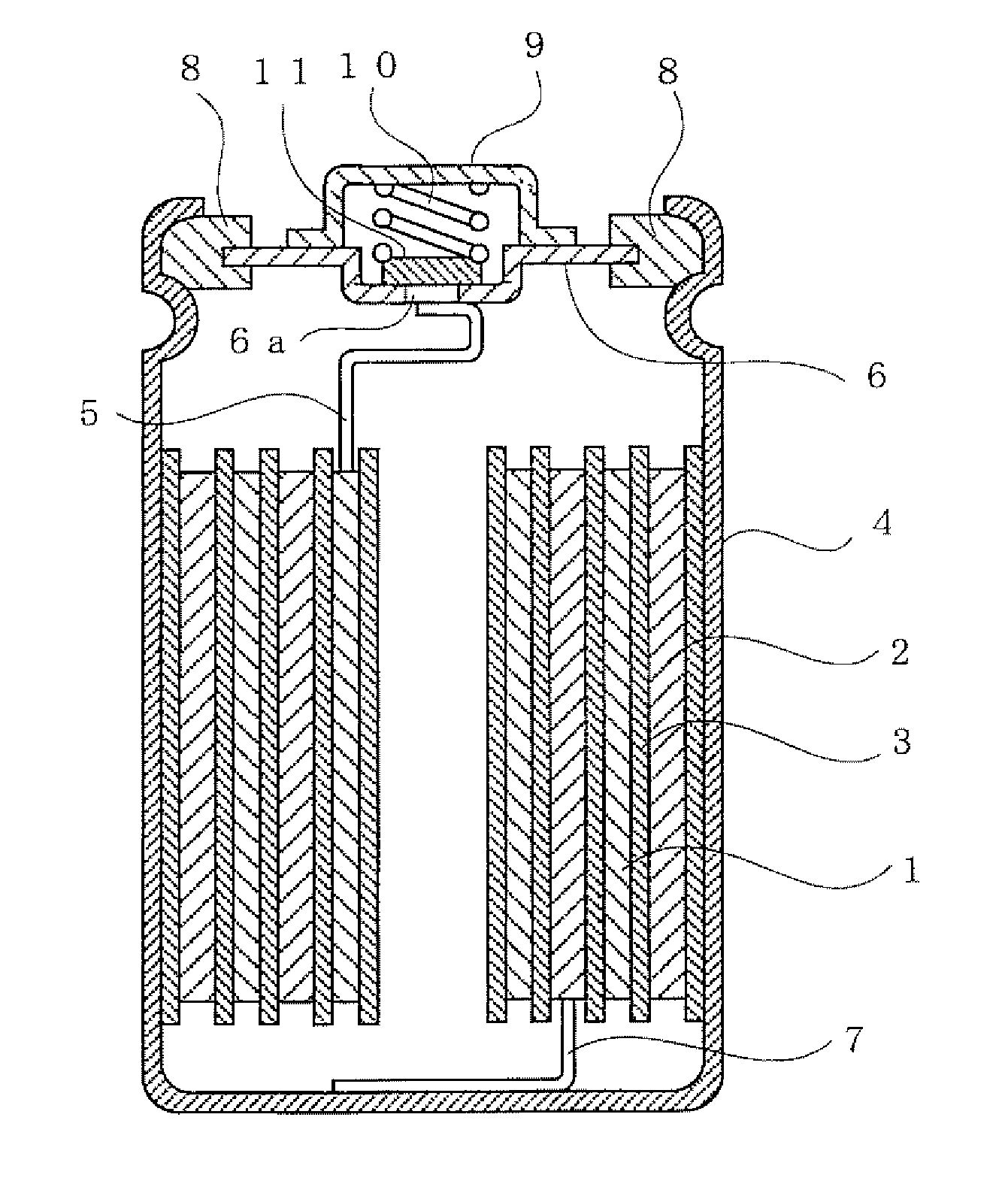

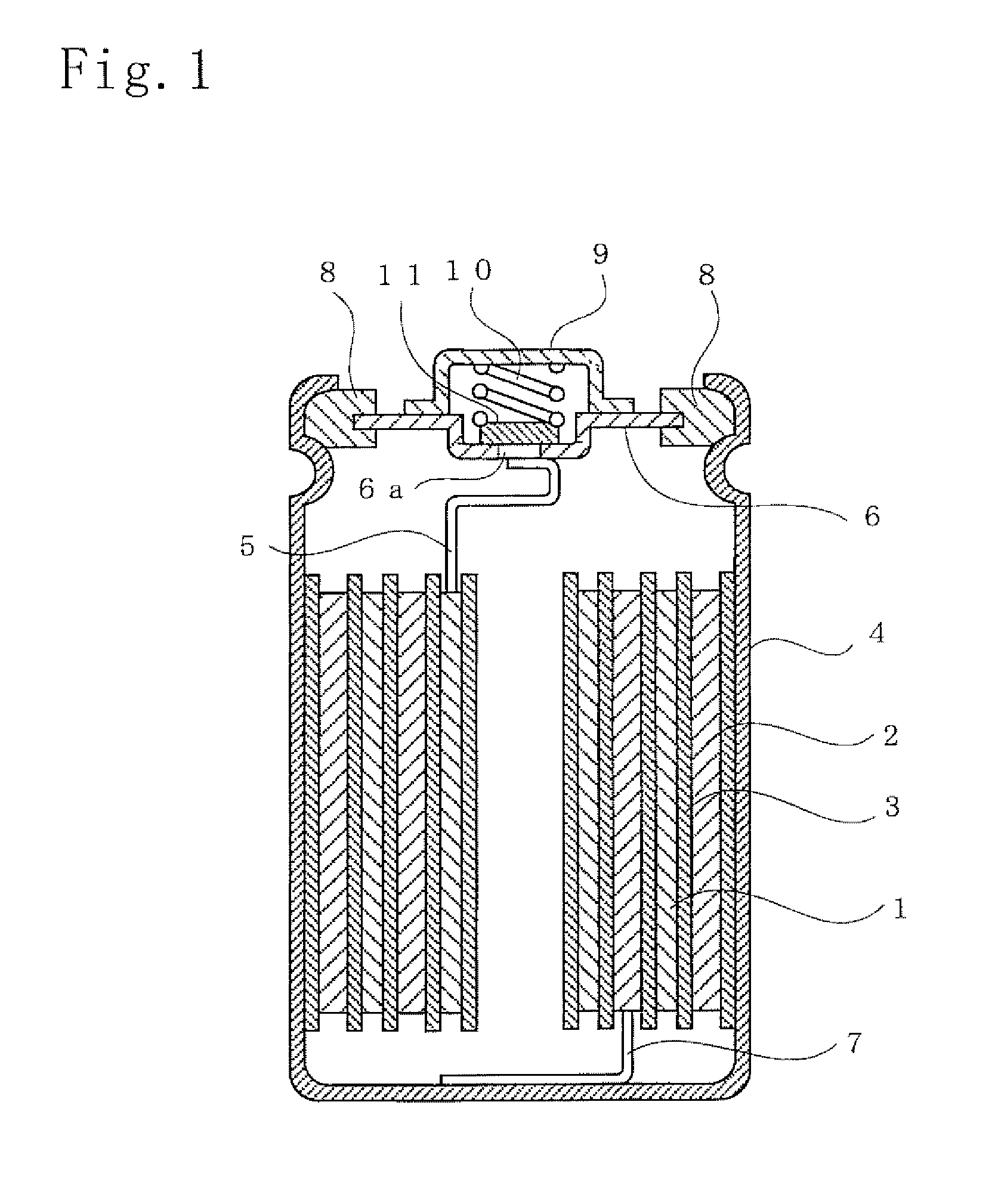

Electric double layer capacitor and electrolytic solution therefor

InactiveUS7391603B2Maintained ratio of capacitanceImprove performanceHybrid capacitor electrolytesHybrid capacitor electrodesCapacitanceDecomposition

Owner:HONDA MOTOR CO LTD +1

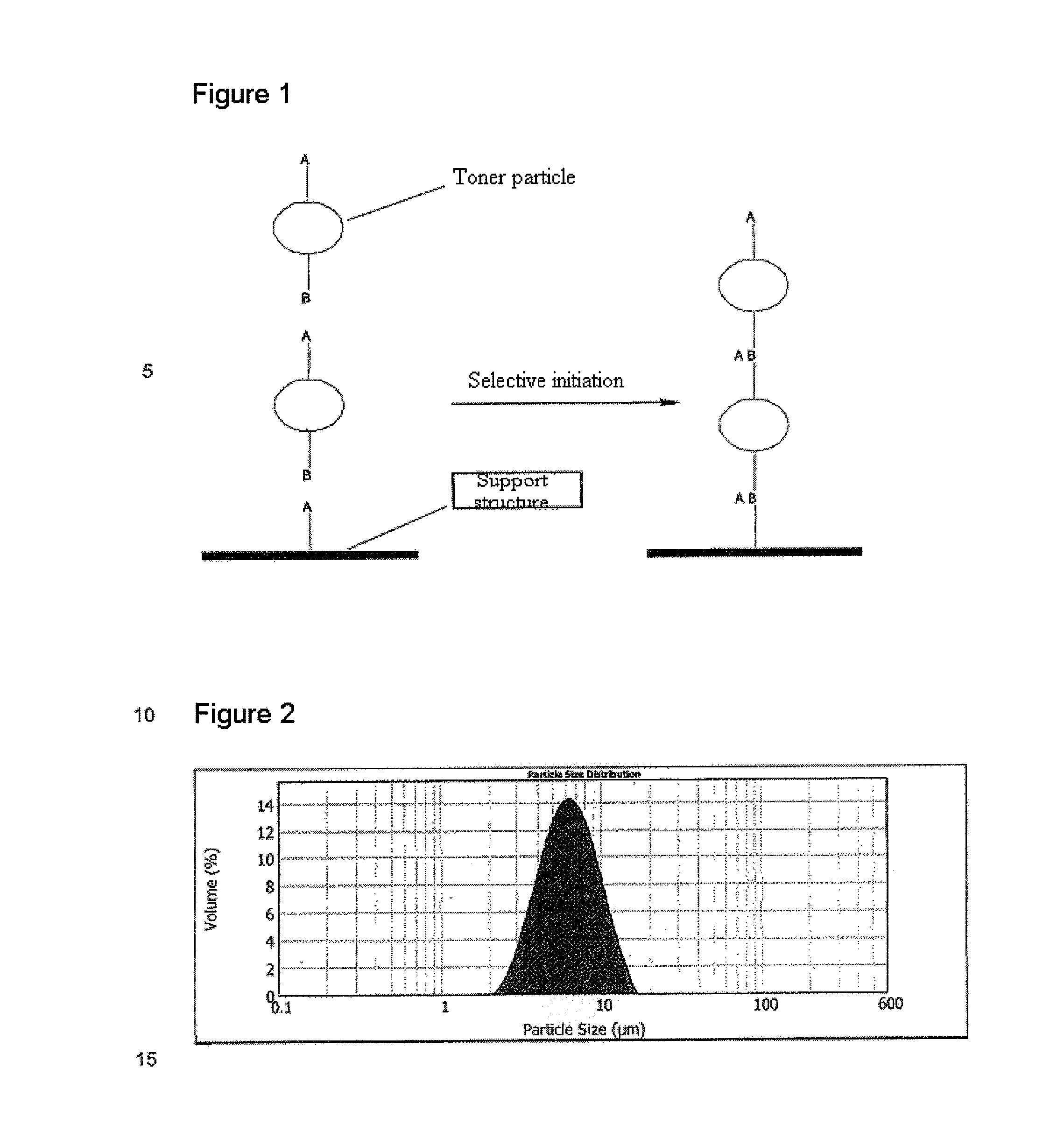

Process of making a three-dimensional structure on a support structure

InactiveUS9098000B2Inhibit thermal stressImprove adhesionLayered productsElectrographic process apparatusPolymer scienceThioketone

The present disclosure relates to polymer particles comprising a polymer matrix having a coating of an inorganic semimetal oxide or metal oxide, wherein the polymer matrix has at least one first functional group A and at least one second functional group B, both functional groups A and B being able to enter into at least one covalent bond with one another, functional group A being selected from the group consisting of an azide group, C —C double bond, C —C triple bond, aldehyde group, ketone group, imine group, thioketone group and thiol group, and functional group B being selected from the group consisting of a C —C double bond, C —C triple bond, C —N triple bond, diene group, thiol group and amine group.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com