Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1636 results about "Fuel delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

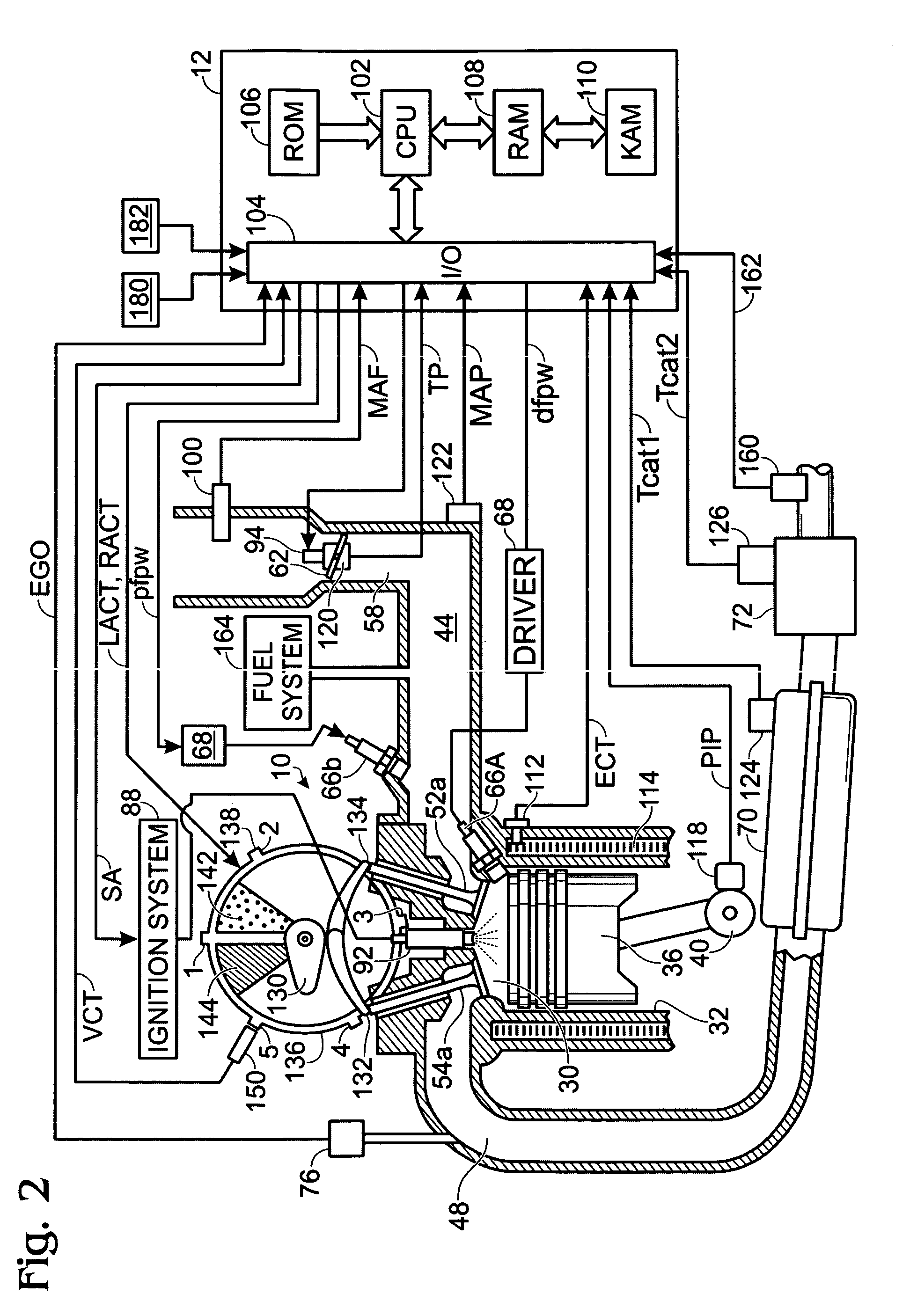

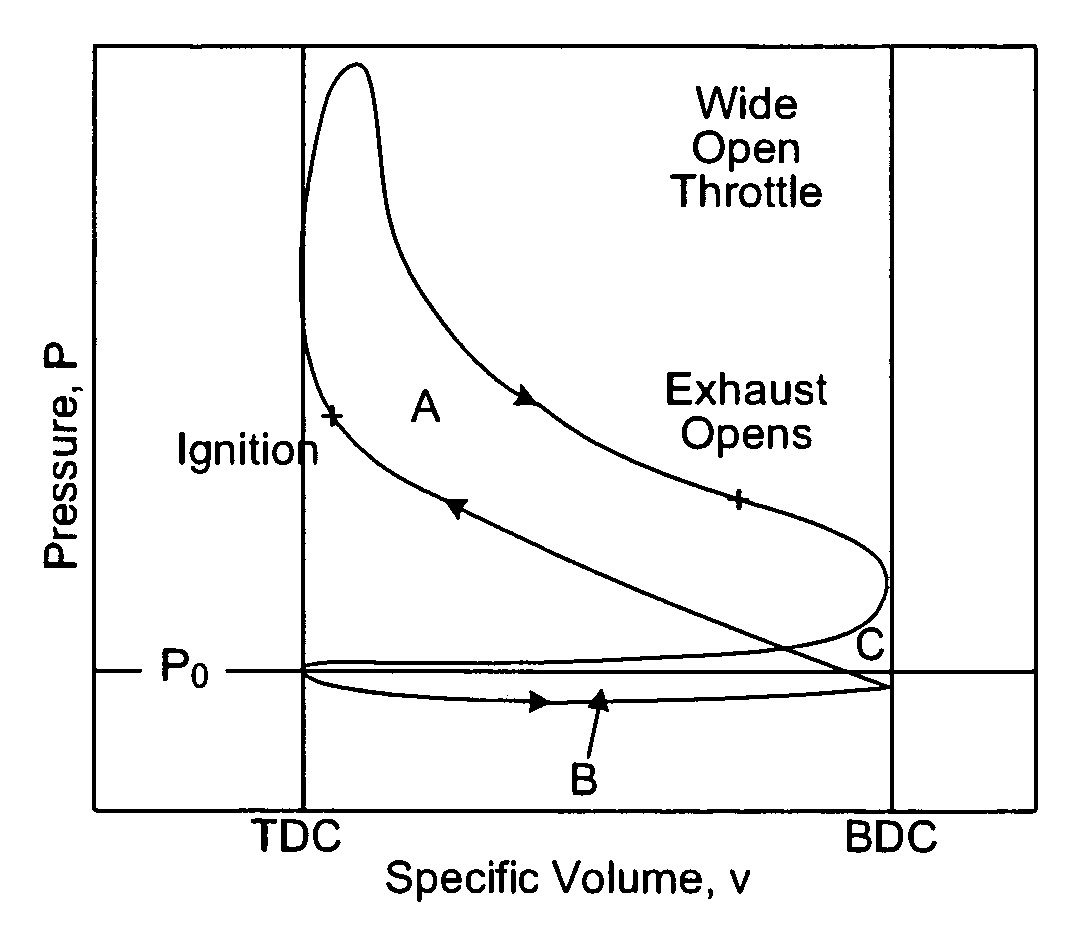

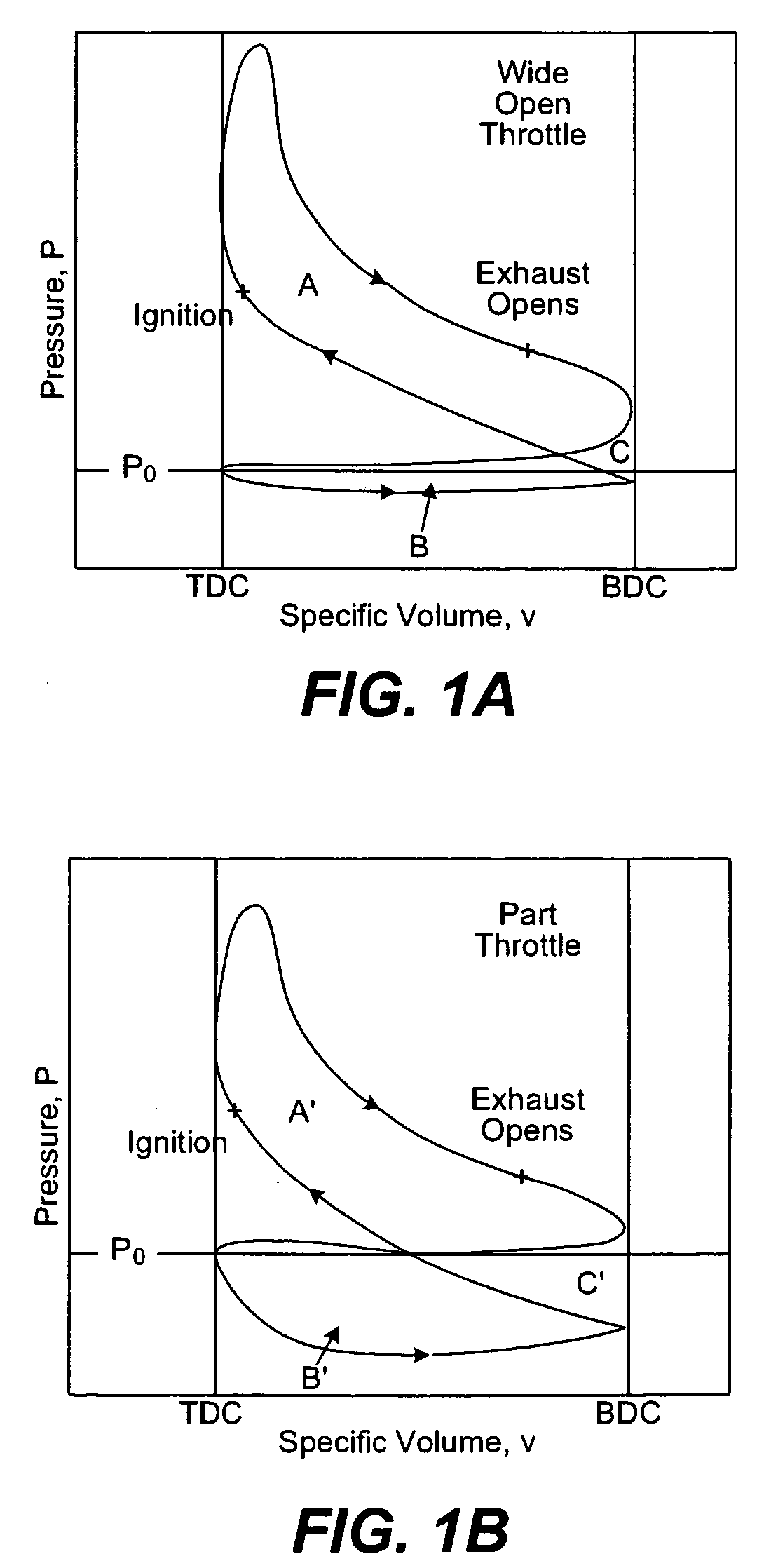

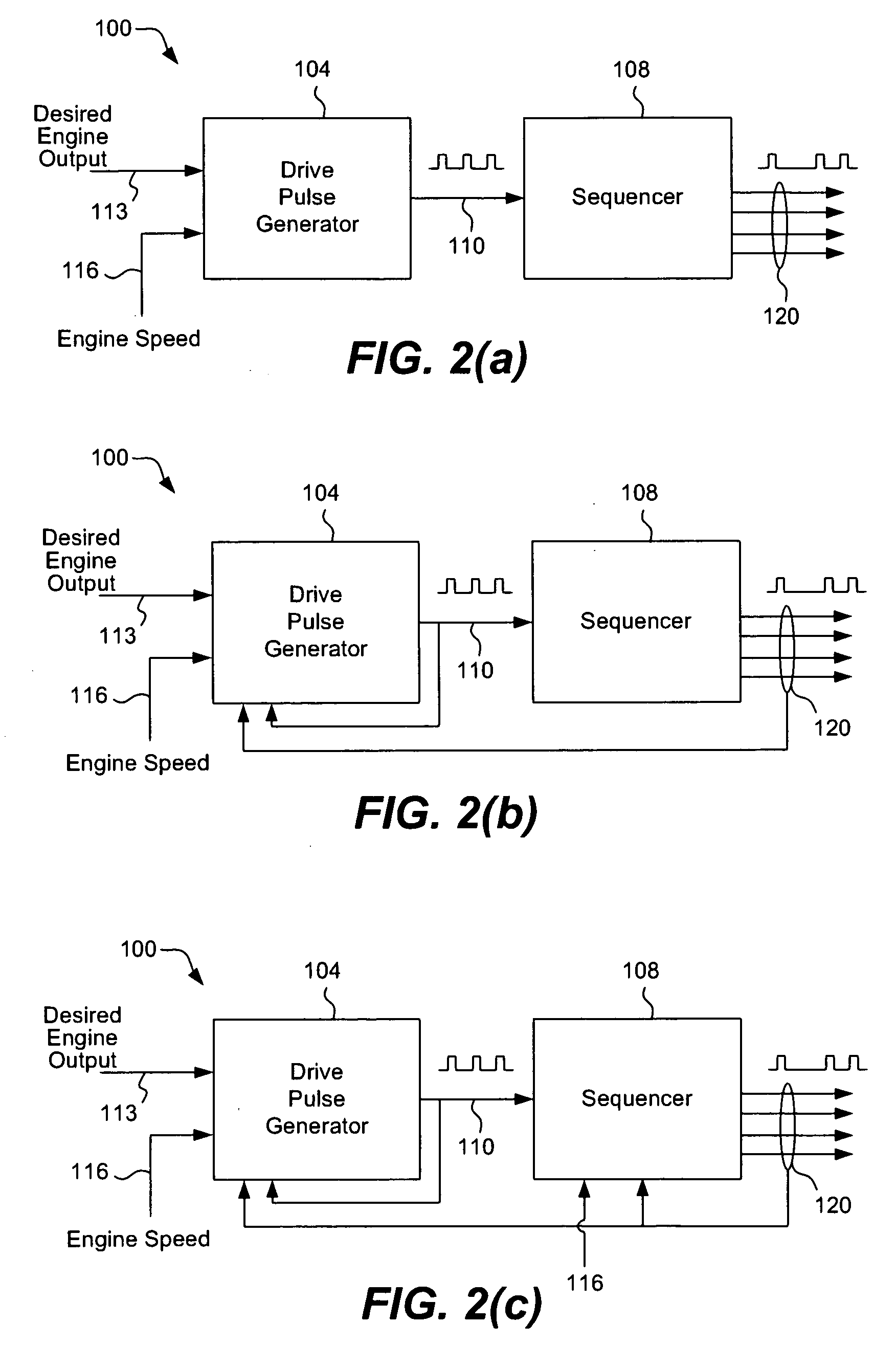

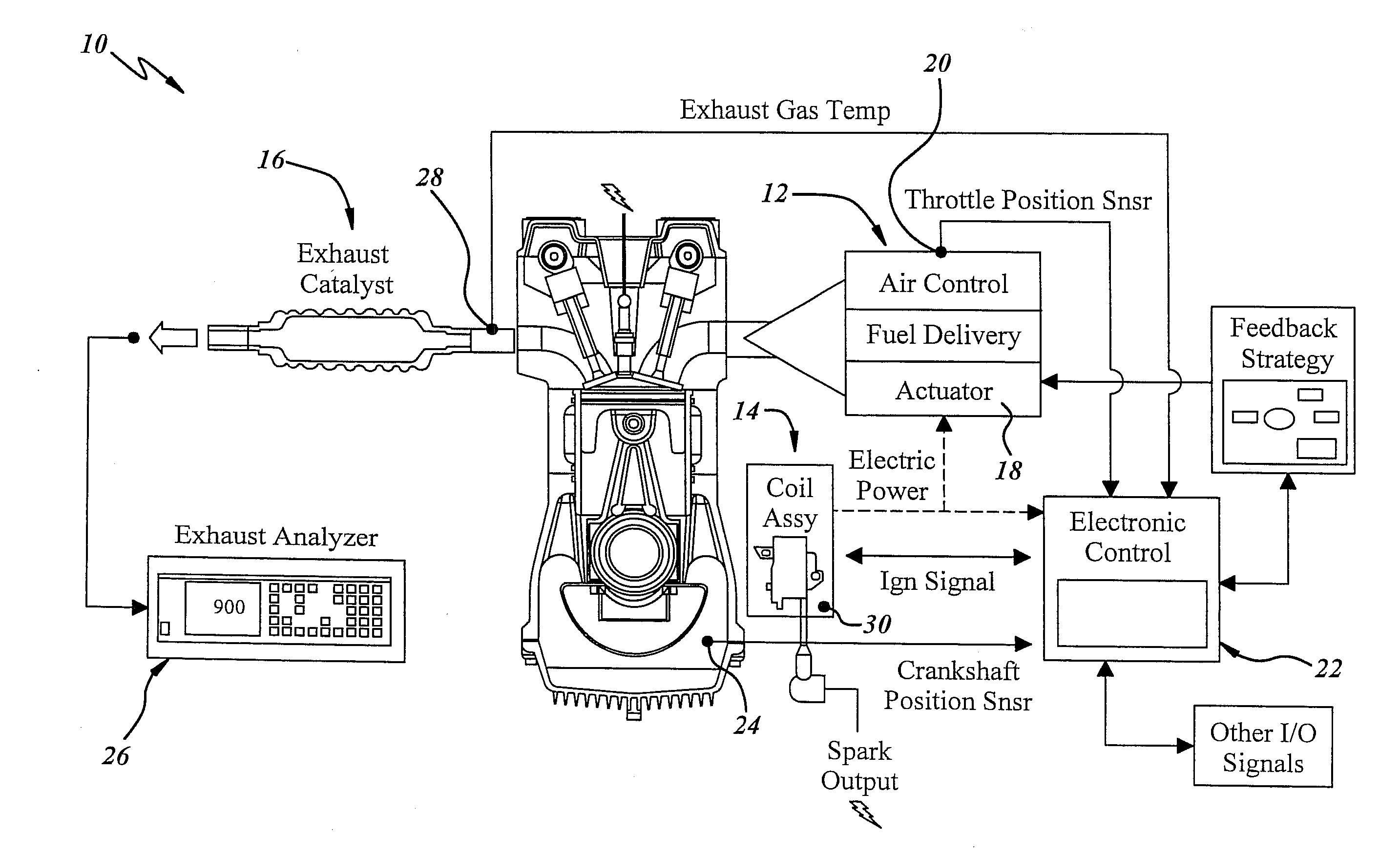

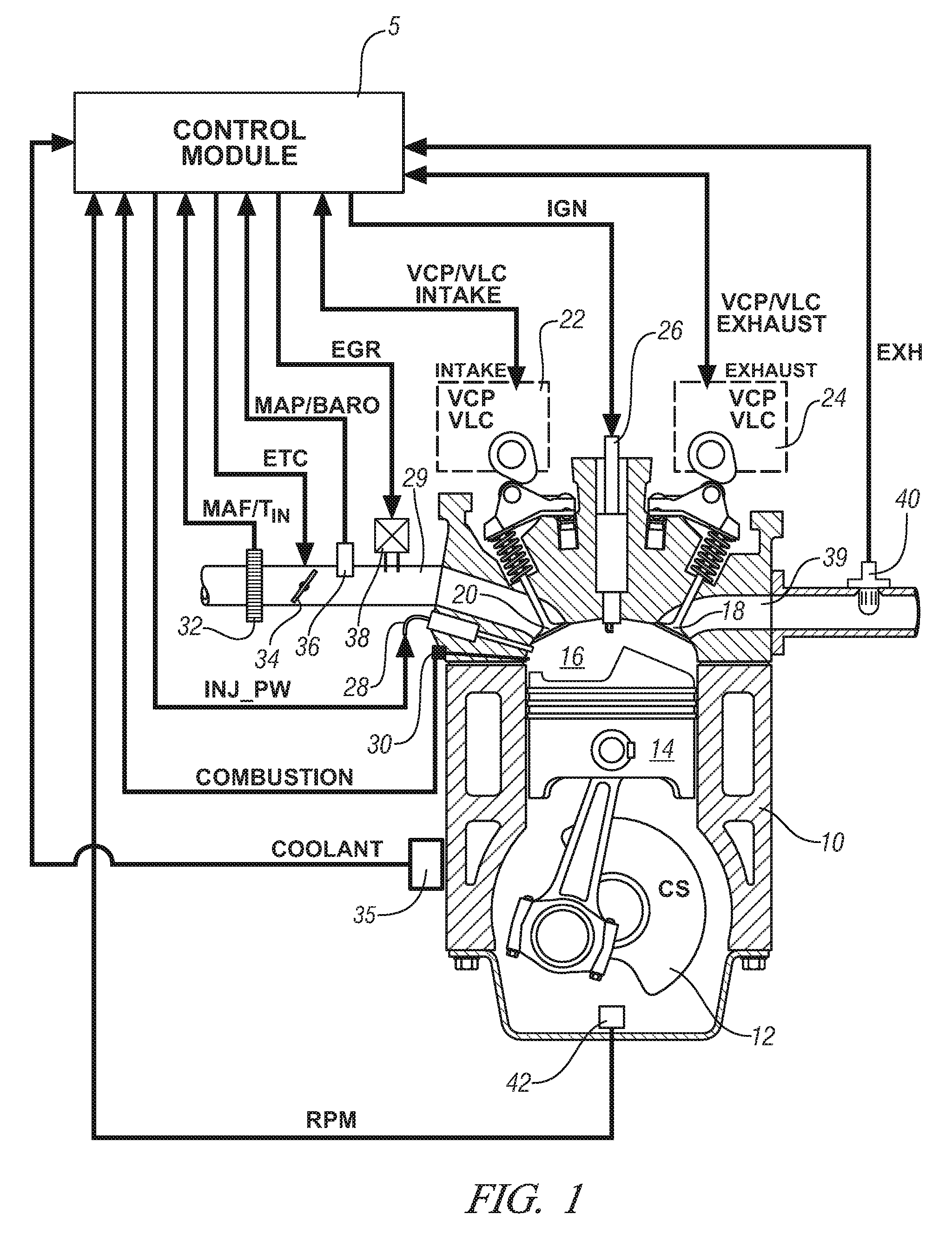

Internal combustion engine control for improved fuel efficiency

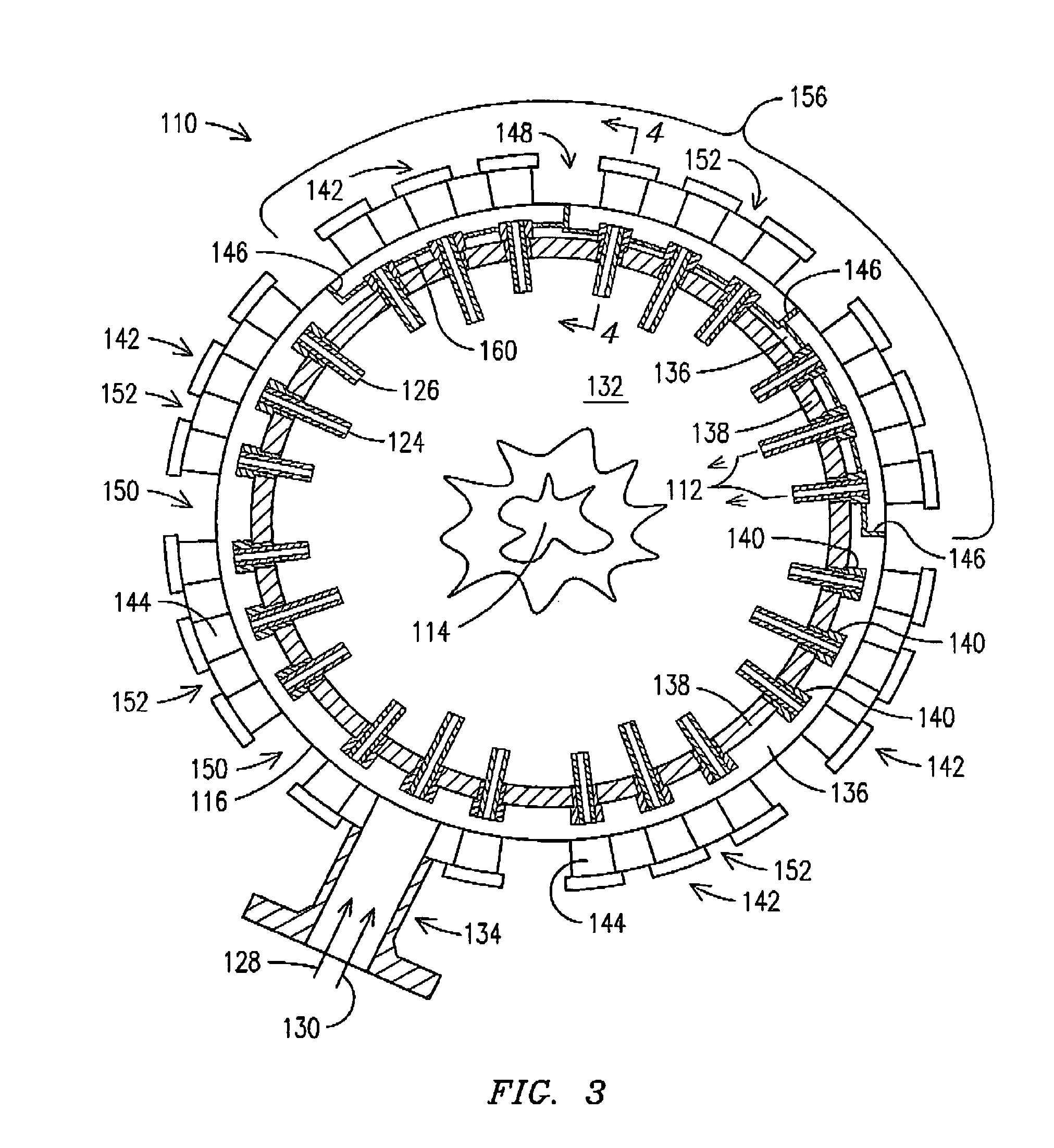

ActiveUS8131447B2Undesirable vibration reductionConvenient amountElectrical controlInternal combustion piston enginesCombustion chamberWork cycle

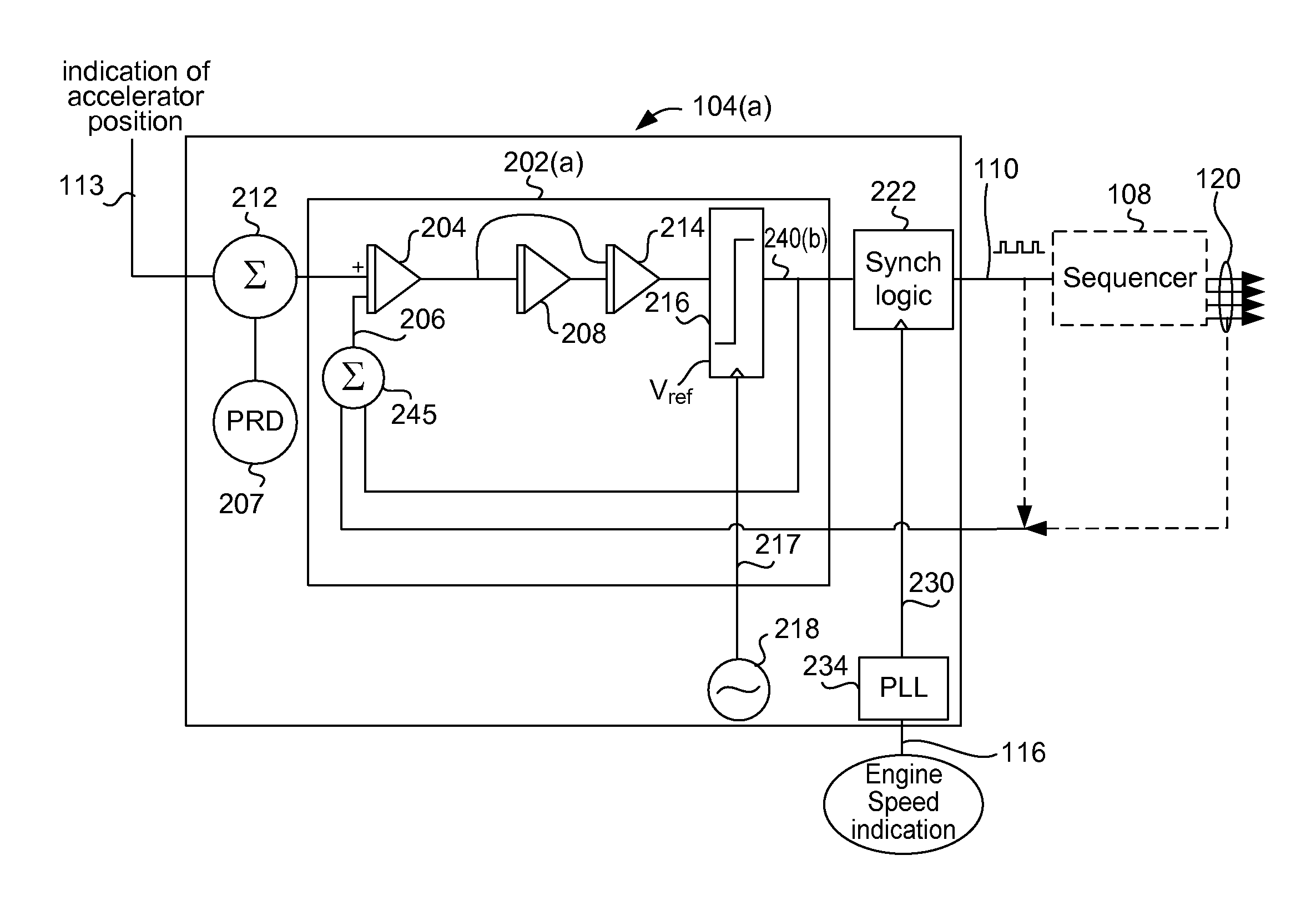

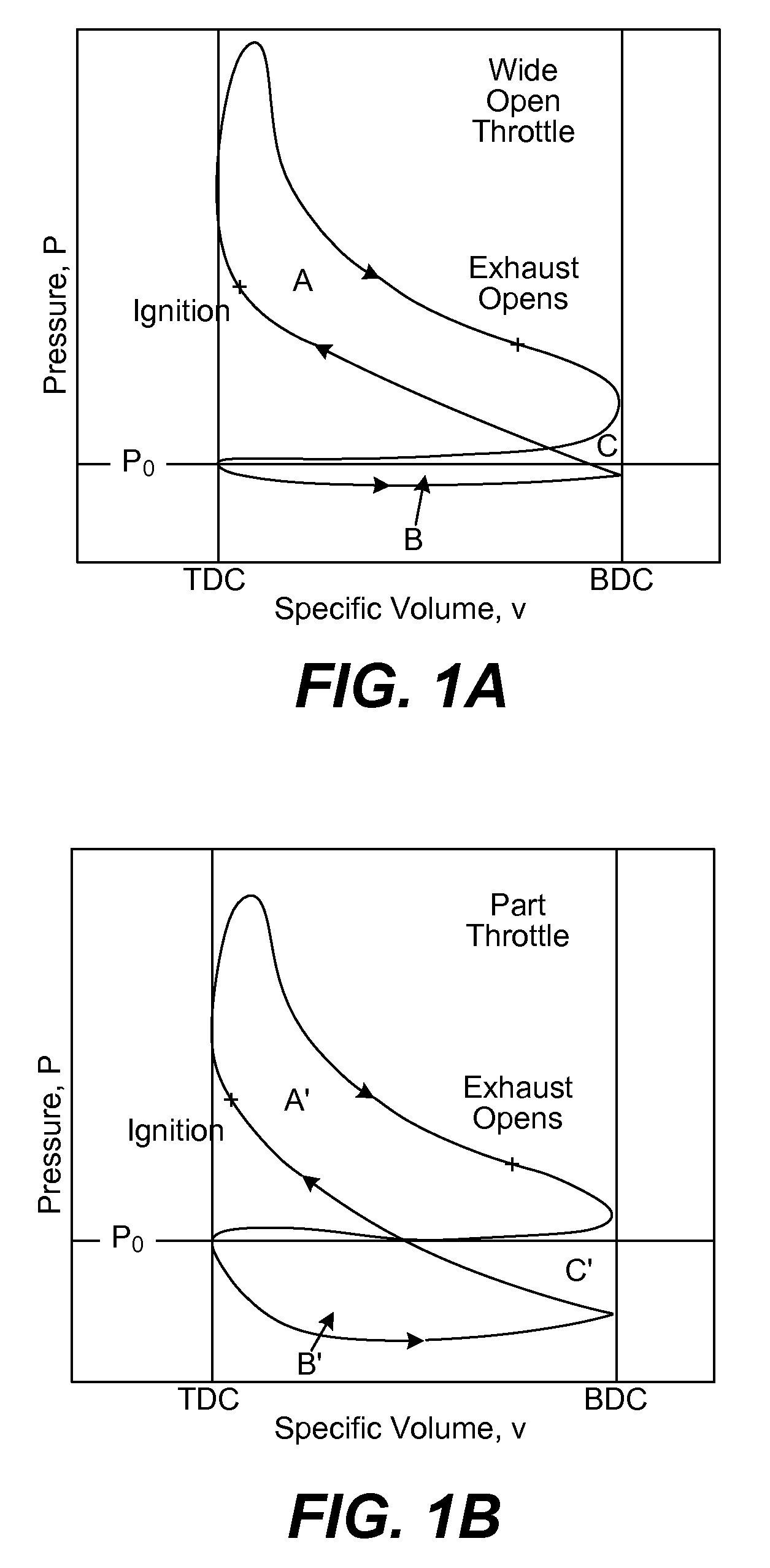

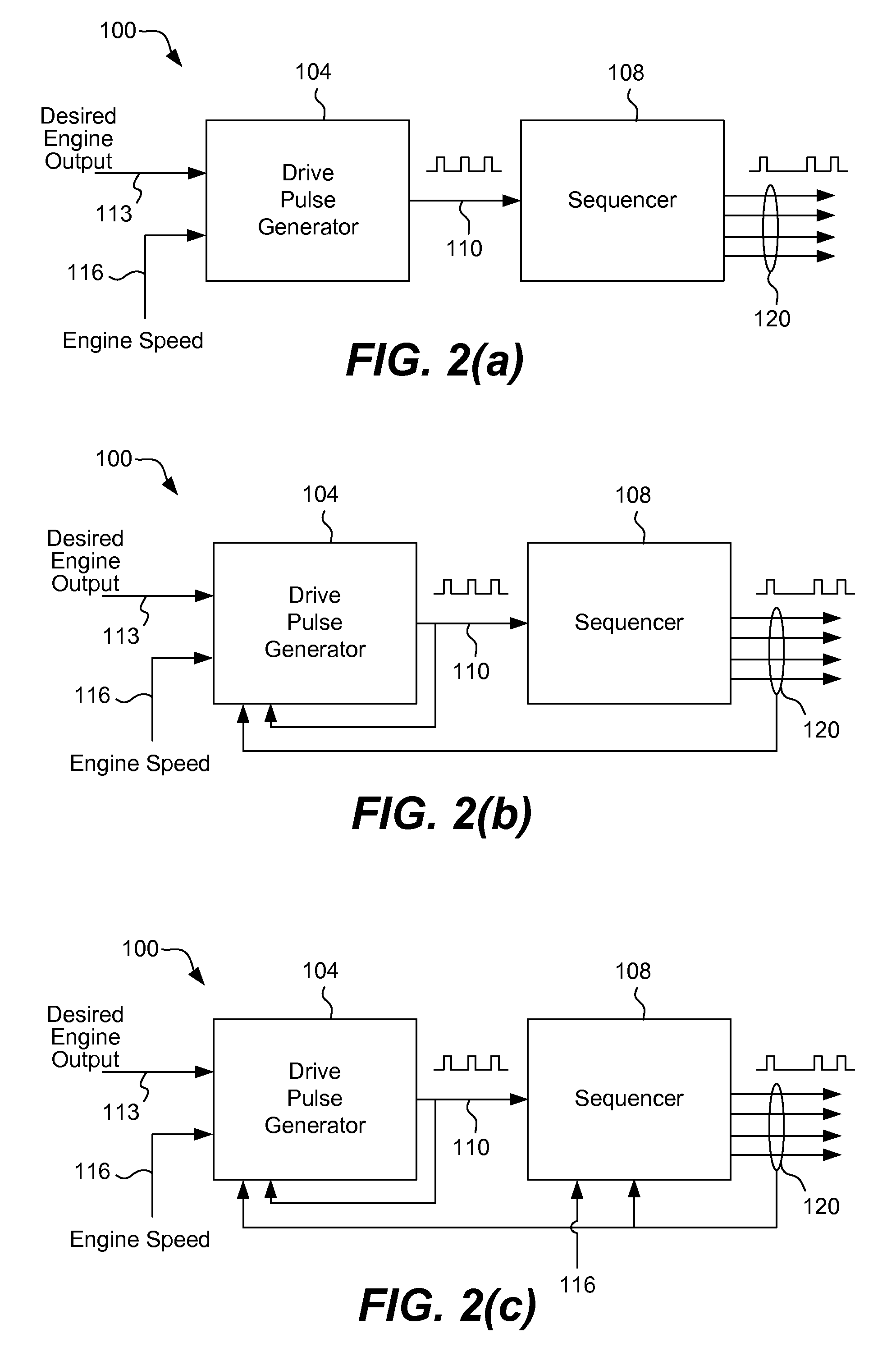

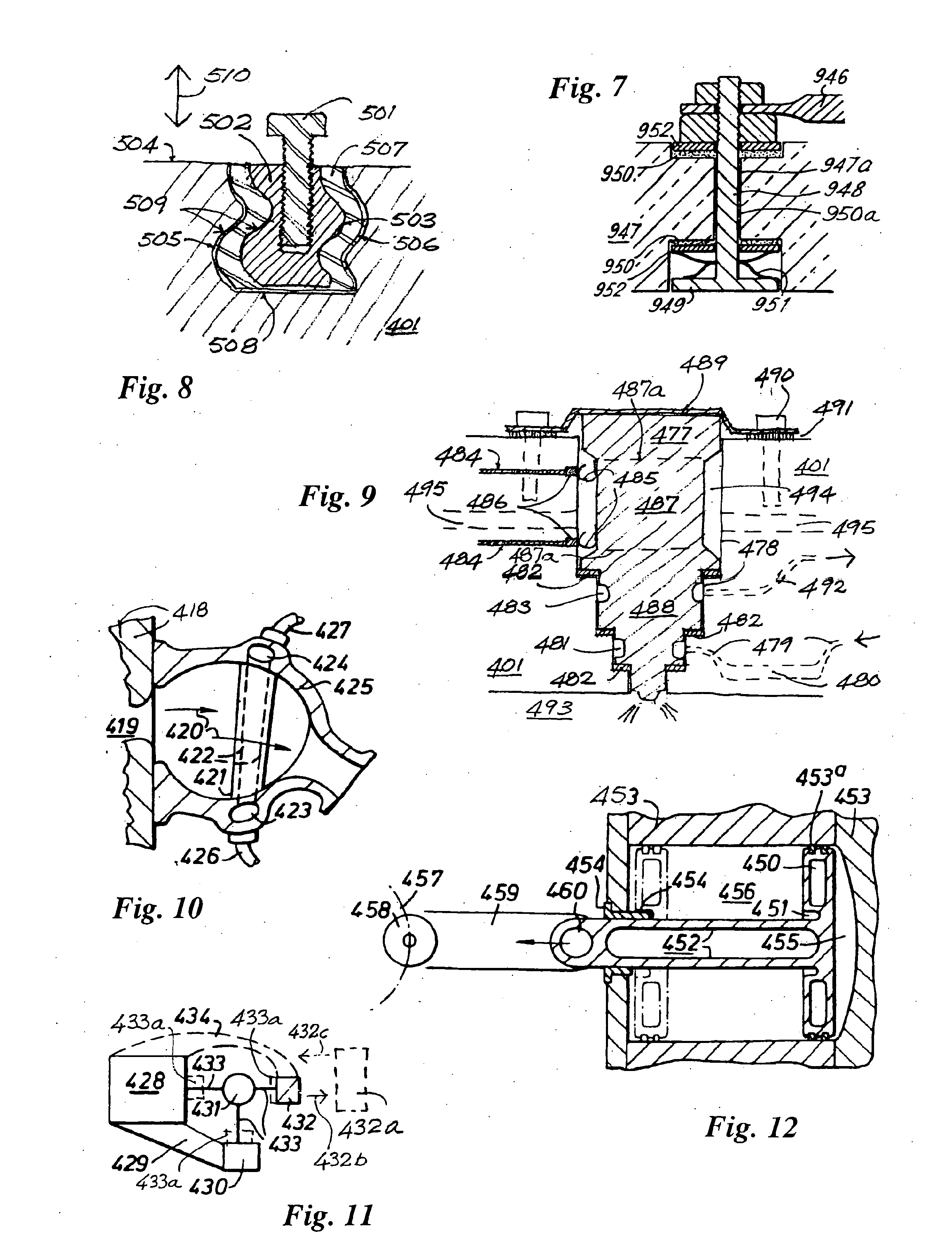

A variety of methods and arrangements for improving the fuel efficiency of internal combustion engines are described. Generally, selected combustion events are skipped during operation of the internal combustion engine so that other working cycles can operate at a better thermodynamic efficiency. In one aspect of the invention, an engine is controlled to operate in a variable displacement mode. In the variable displacement mode, fuel is not delivered to the working chambers (e.g. cylinders) during selected “skipped” working cycles. During active (“non-skipped”) working cycles, a maximum (e.g., unthrottled) amount of air and an optimized amount of fuel is delivered to the relevant working chambers so that the fired working chambers can operate at efficiencies closer to their optimal efficiency. A controller is used to dynamically determine the chamber firings required to provide the engine torque based on the engine's current operational state and conditions. The chamber firings may be sequenced in real time or in near real time in a manner that helps reduce undesirable vibrations of the engine.

Owner:TULA TECH INC

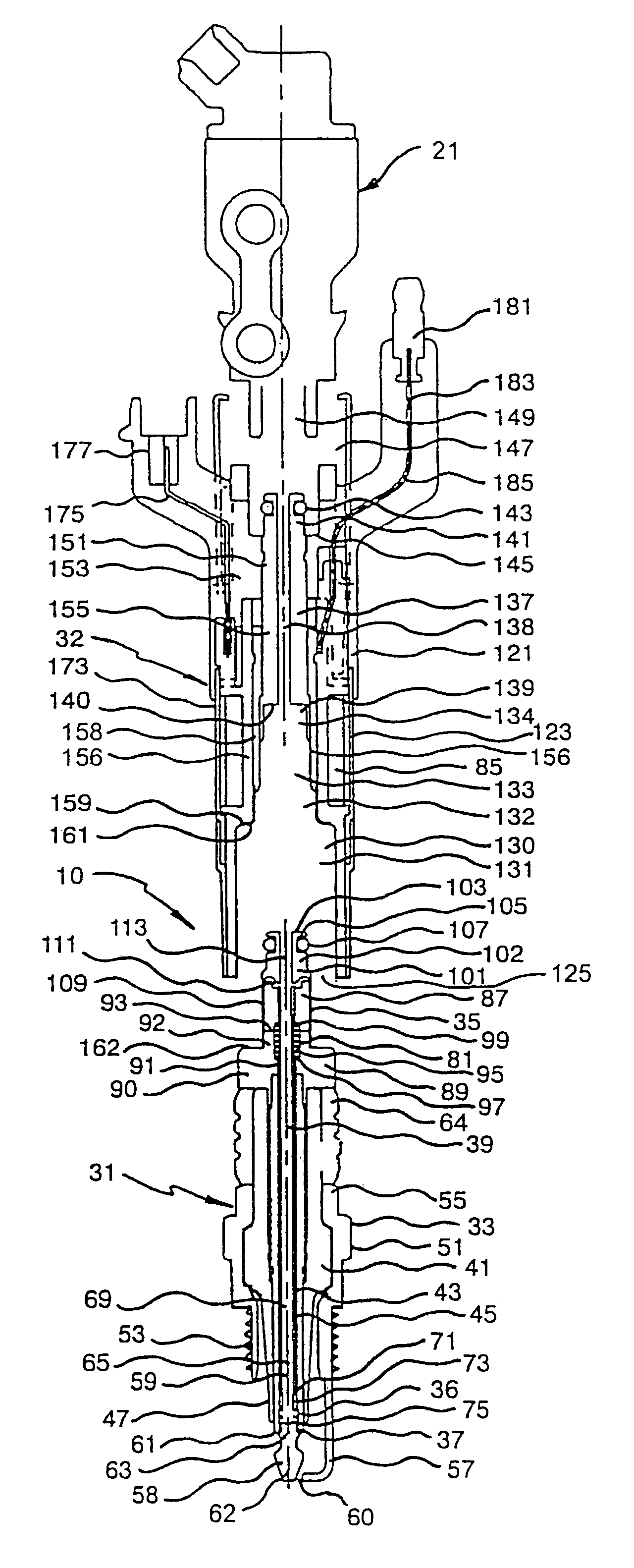

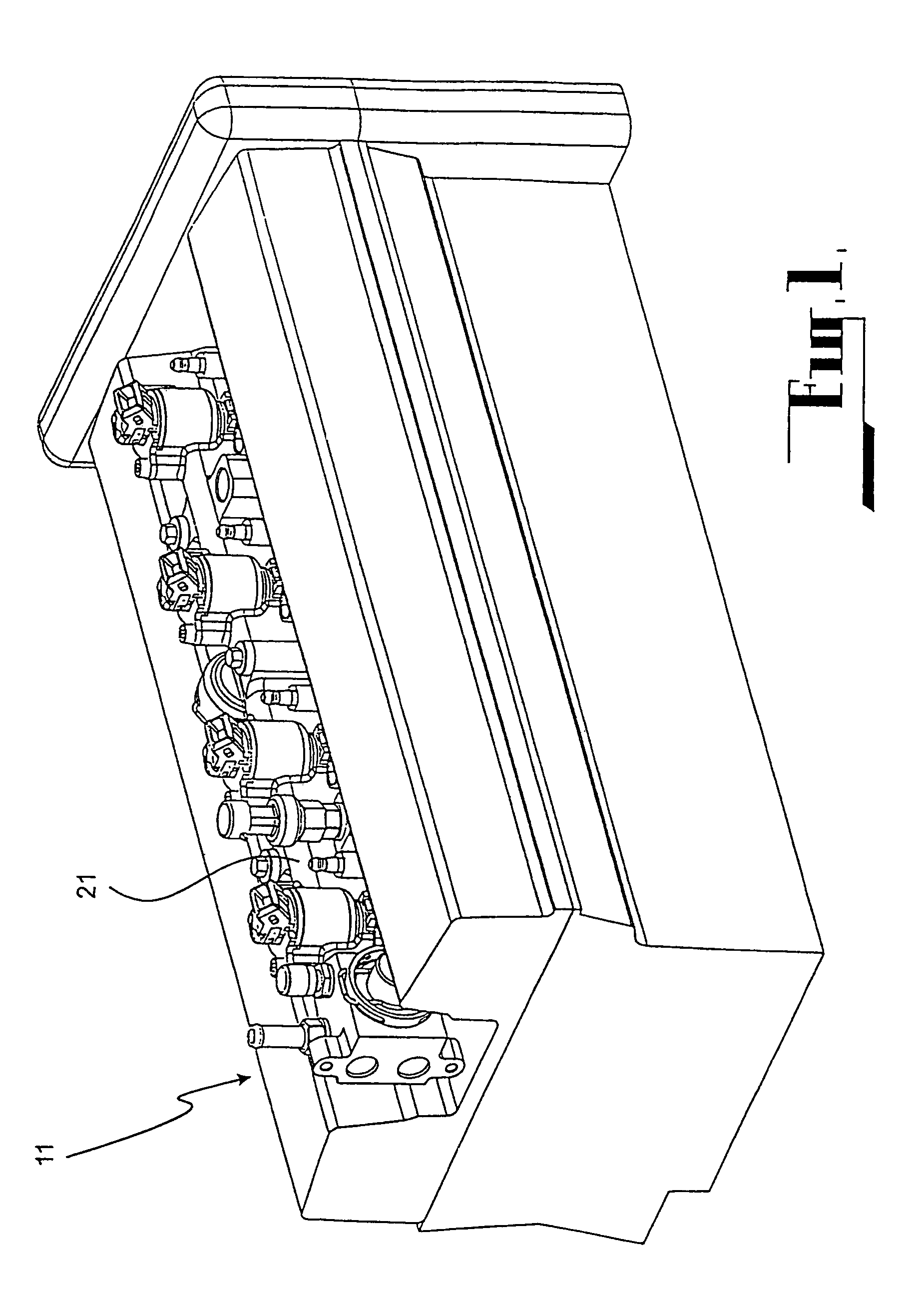

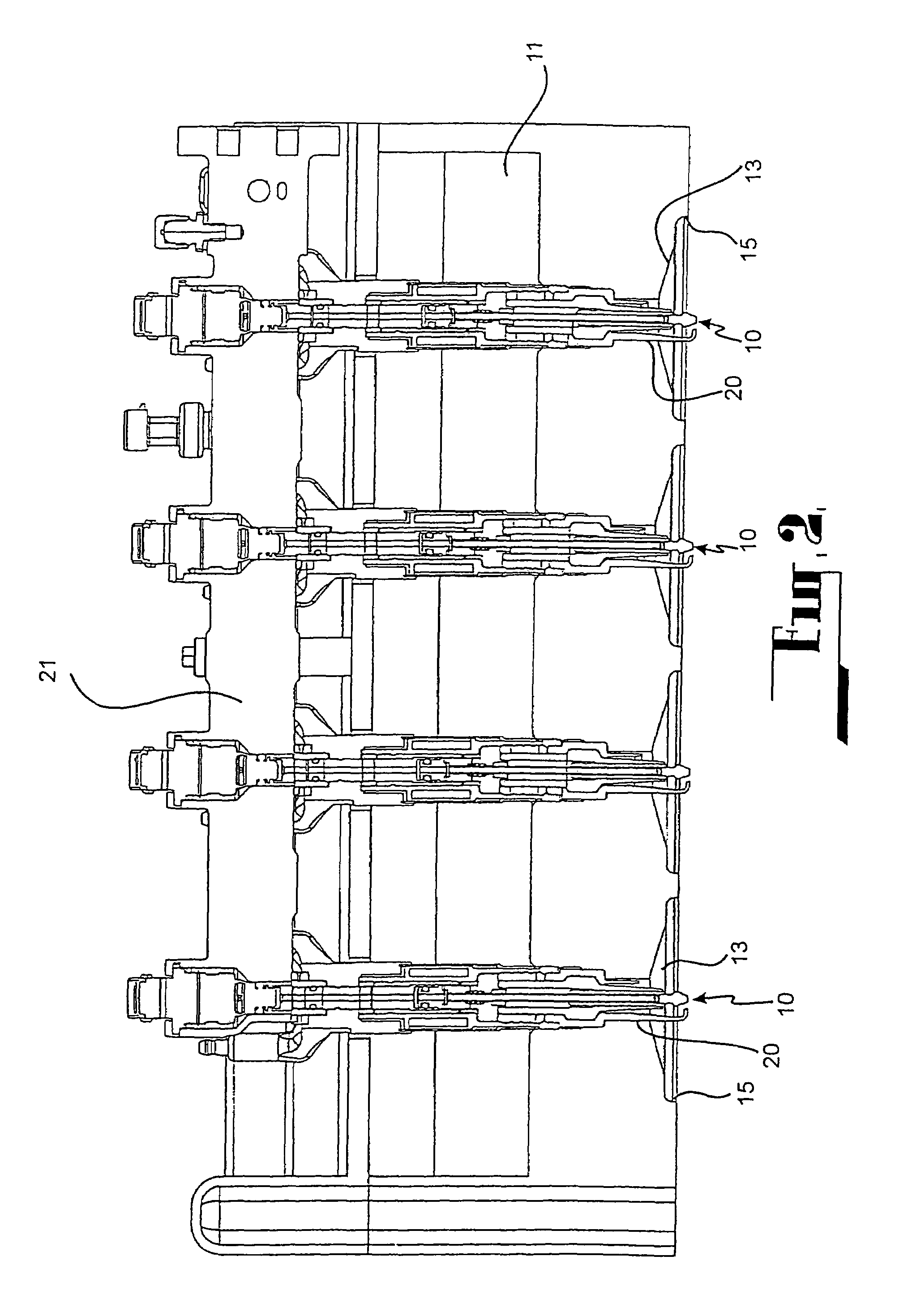

Reciprocating machine & other devices

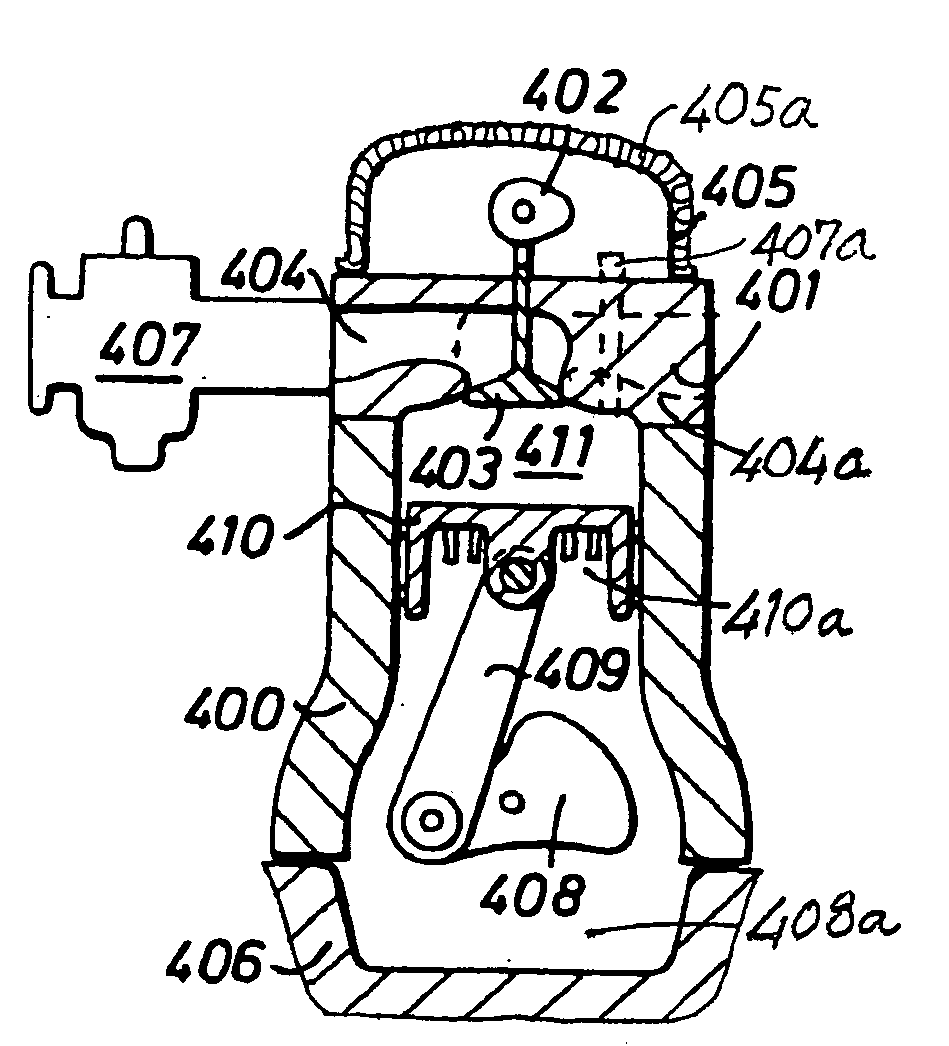

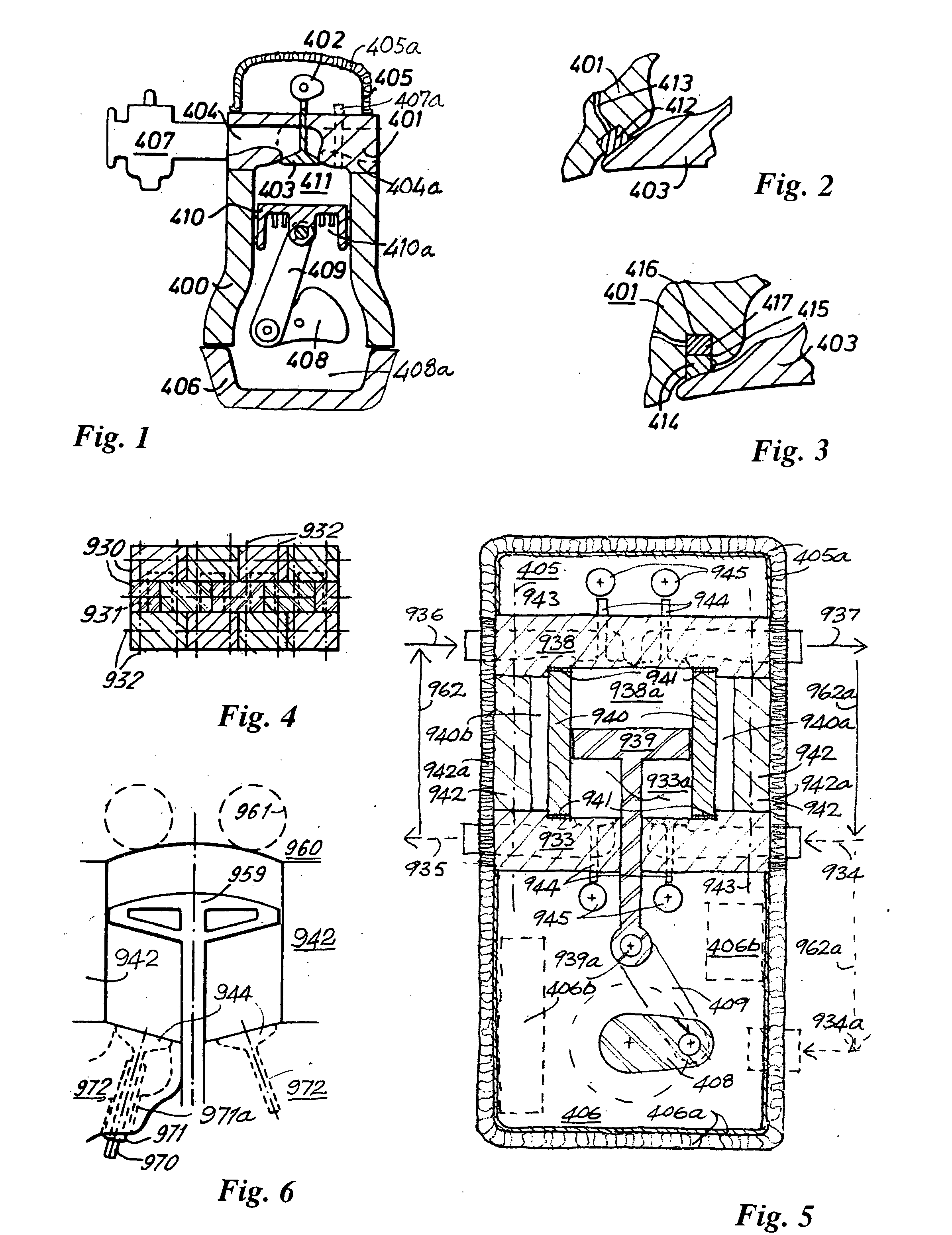

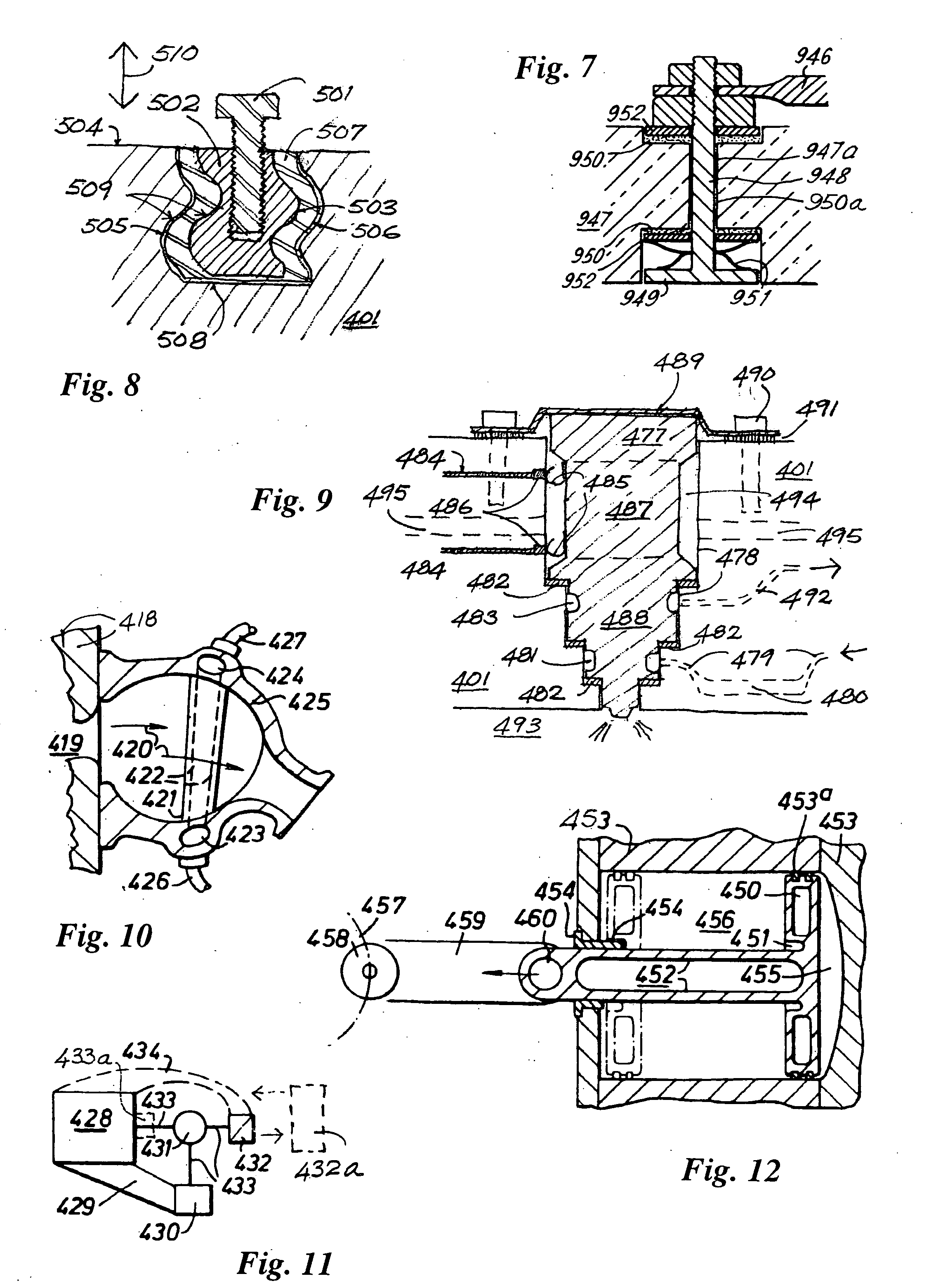

InactiveUS20120227389A1Improve power densityImprove efficiencyLiquid coolingCasingsCombustionReciprocating motion

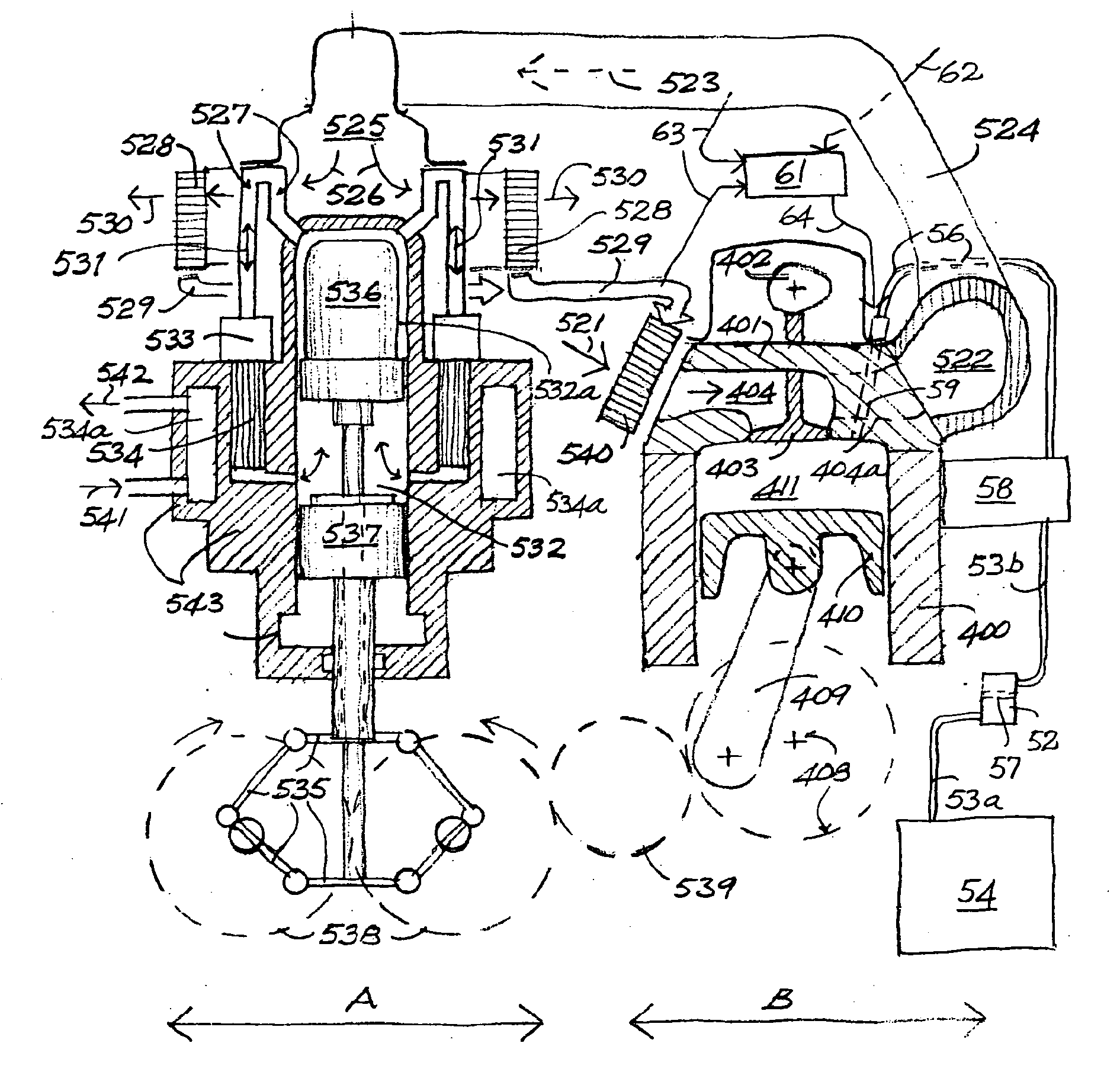

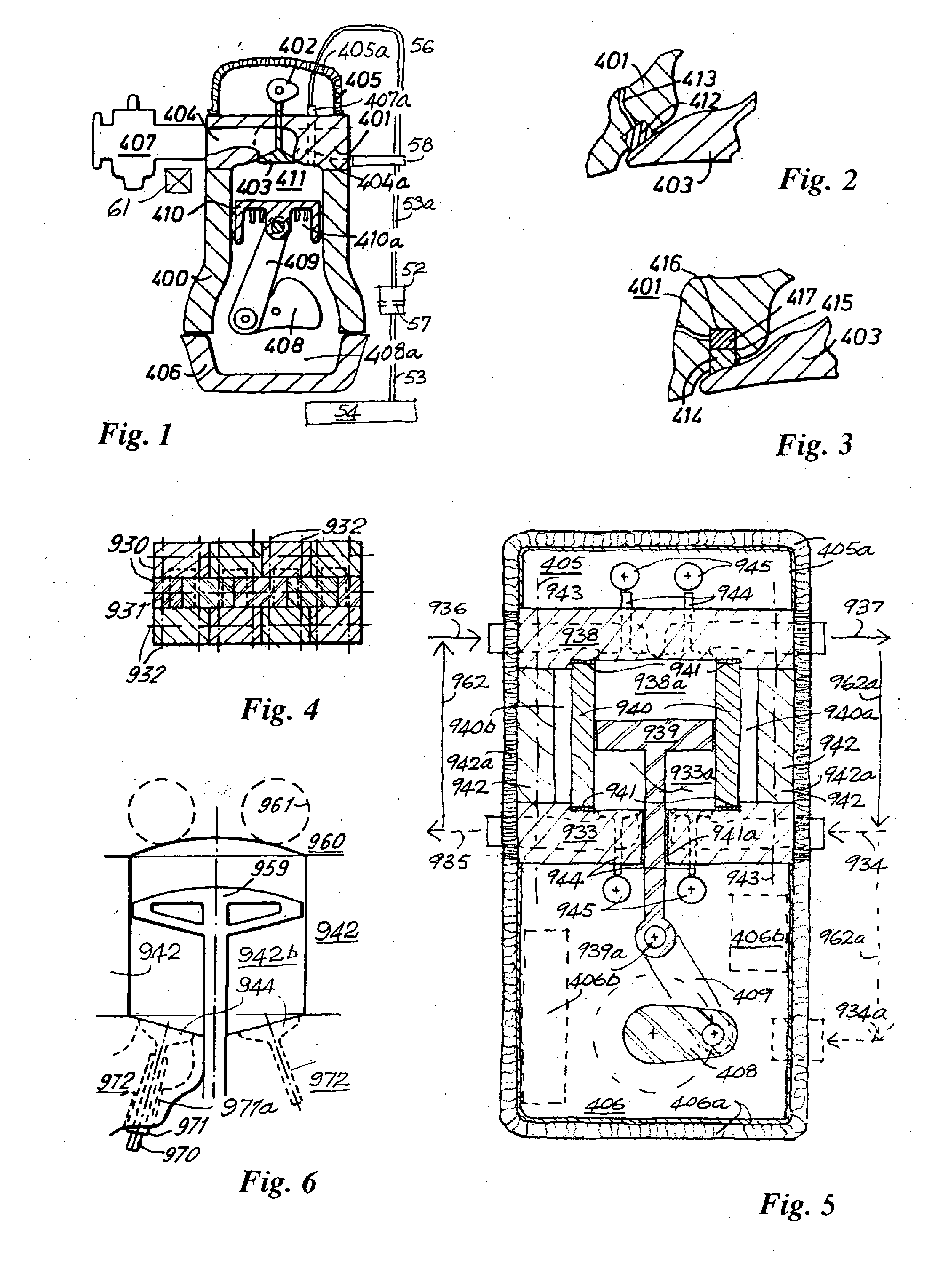

The disclosure relates to reciprocating fluid working devices including internal combustion engines, compressors and pumps. A number of arrangements for pistons and cylinders of unconventional configuration are described, mostly intended for use in IC engines operating without cooling. Included are toroidal combustion or working chambers, some with fluid flow through the core of the toroid, a single piston reciprocating between a pair of working chambers, tensile valve actuation, tensile links between piston and crankshaft, energy absorbing piston-crank links, crankshafts supported on gas bearings, cylinders rotating in housings, injectors having components which reciprocate or rotate during fuel delivery. In some embodiments pistons mare rotate while reciprocating. High temperature exhaust emissions systems are described, including those containing filamentary material, as are procedures for reducing emissions during cold start by means of valves at reaction volume exit. Also disclosed are improved vehicles, aircraft, marine craft, transmissions and exhaust emission systems suited to the engines of the invention.

Owner:HINDERKS MITJA VICTOR

System and method for engine fuel blend control

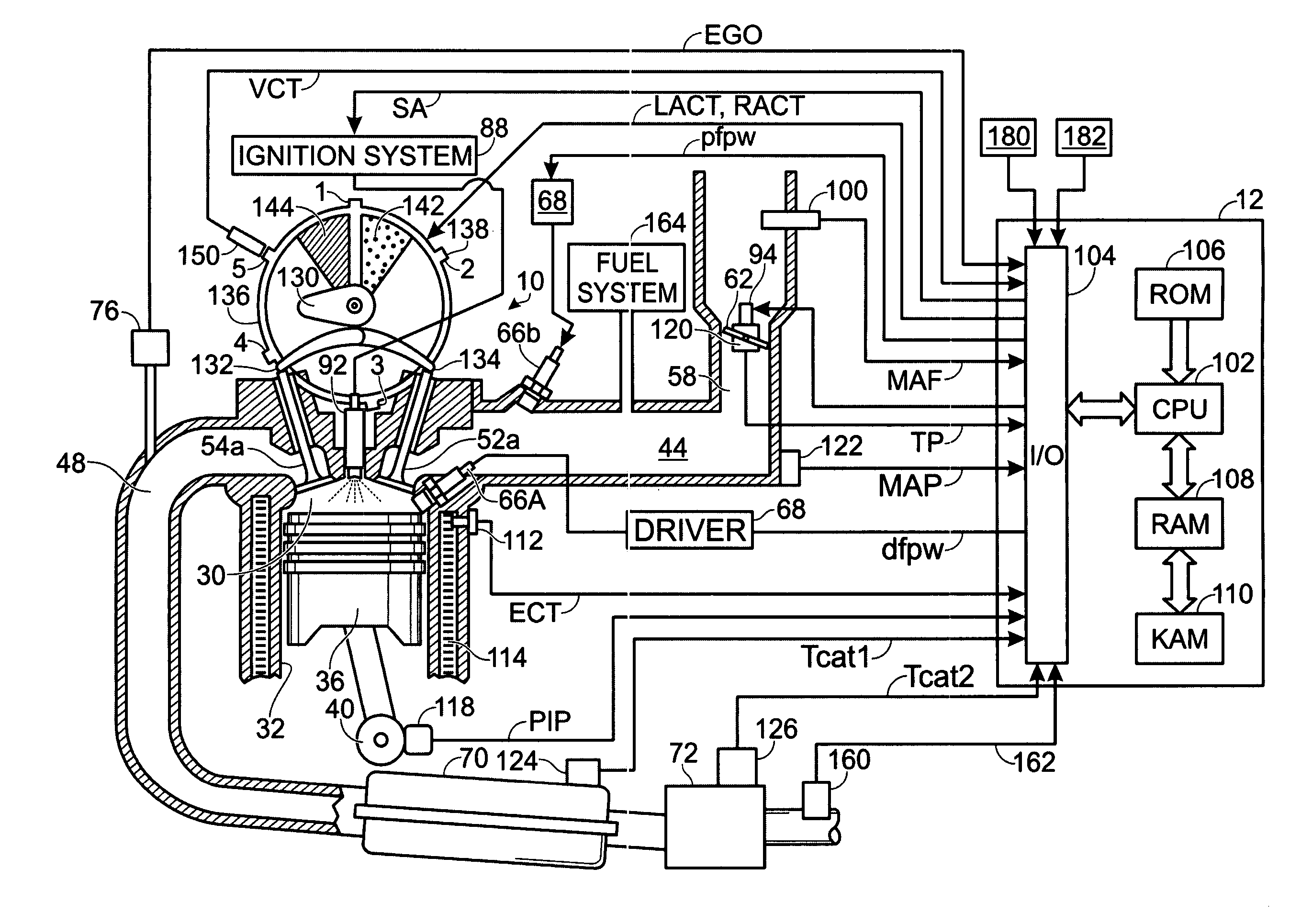

A system for an engine, comprising of a cylinder located in the engine, a fuel delivery system for varying relative delivery amounts of a first and second injection type into said cylinder, and a controller configured to adjust a parameter affecting flow through the engine in response to said relative delivery amounts of said first and second injection type.

Owner:FORD GLOBAL TECH LLC

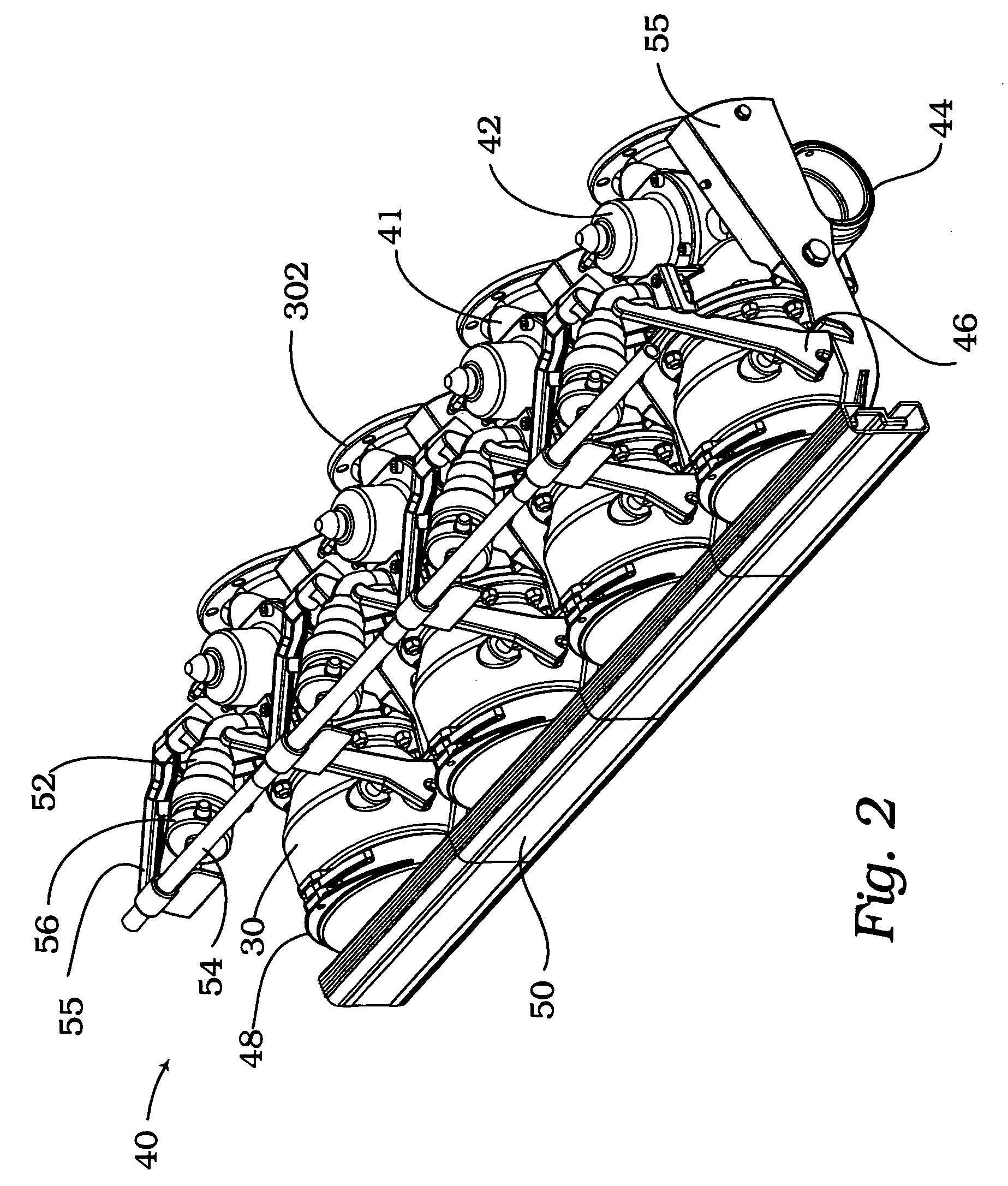

Reciprocating devices

ActiveUS20080141921A1Improve power densityImprove efficiencyHybrid vehiclesInternal combustion piston enginesExternal combustion engineEnergy absorption

The disclosure relates to fluid working devices including reciprocating internal combustion engines, compressors and pumps. A number of arrangements for pistons and cylinders of unconventional configuration are described, mostly intended for use in reciprocating internal combustion IC engines operating without cooling. Included are toroidal combustion or working chambers, some with fluid flow through the core of the toroid, pistons reciprocating between pairs of working chambers, tensile valve actuation, tensile links between piston and crankshaft, energy absorbing piston-crank links, crankshafts supported on gas bearings, cylinders rotating in housings, injectors having components reciprocate or rotate during fuel delivery. In some embodiments pistons mare rotate while reciprocating. High temperature exhaust emissions systems are described, including those containing filamentary material, as are procedures for reducing emissions during cold start by means of valves at reaction volume exit. Compound engines having the new engines as a reciprocating stage are described. Improved vehicles, aircraft, marine craft and transmissions adapted to receive or be linked to the improved IV engines are also disclosed.

Owner:HINDERKS MITJA VICTOR

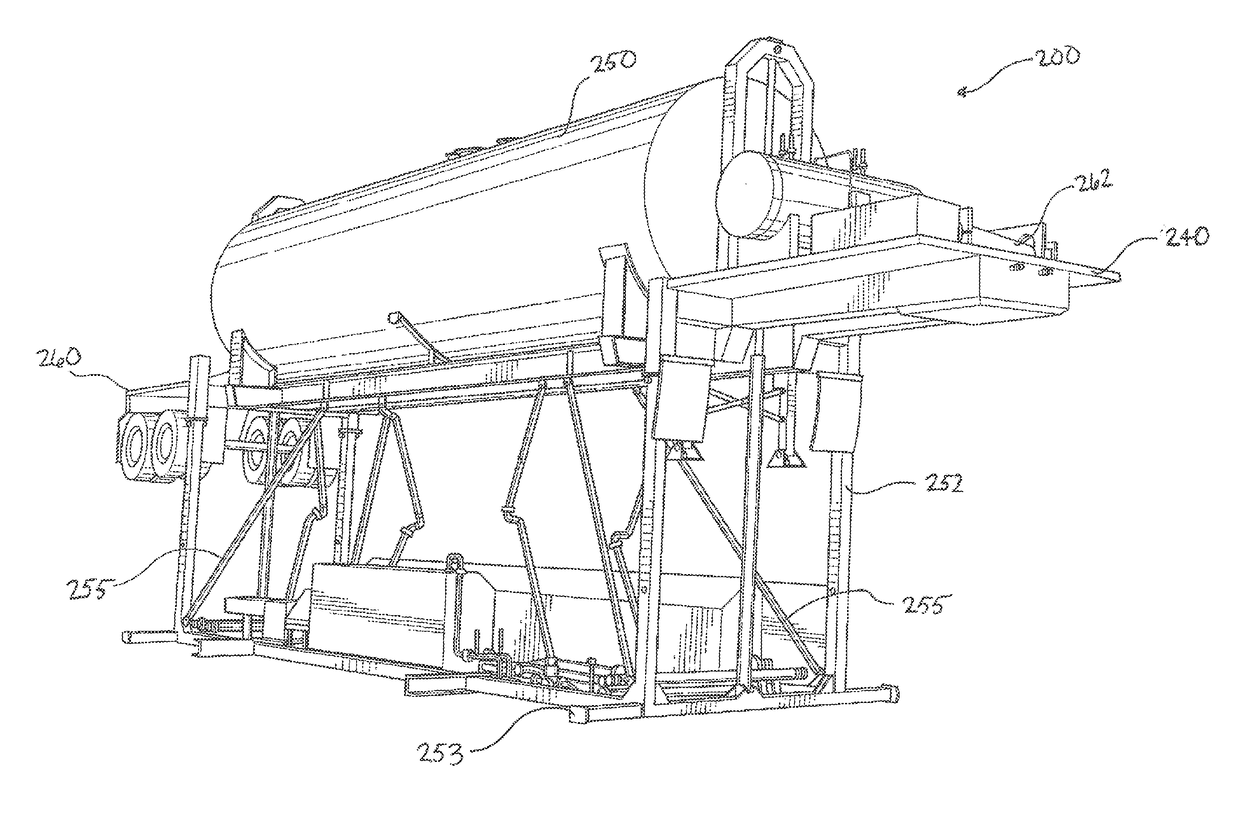

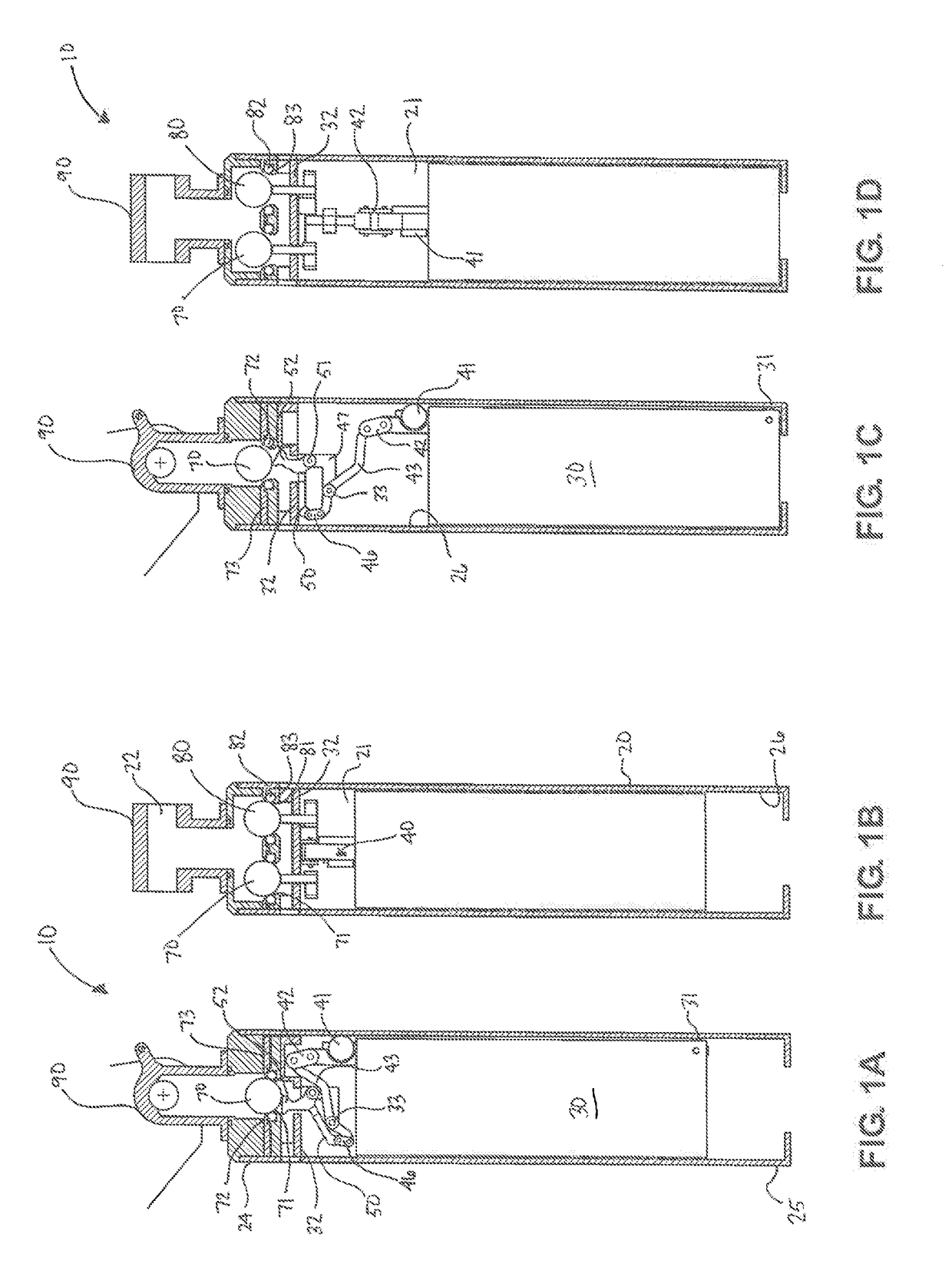

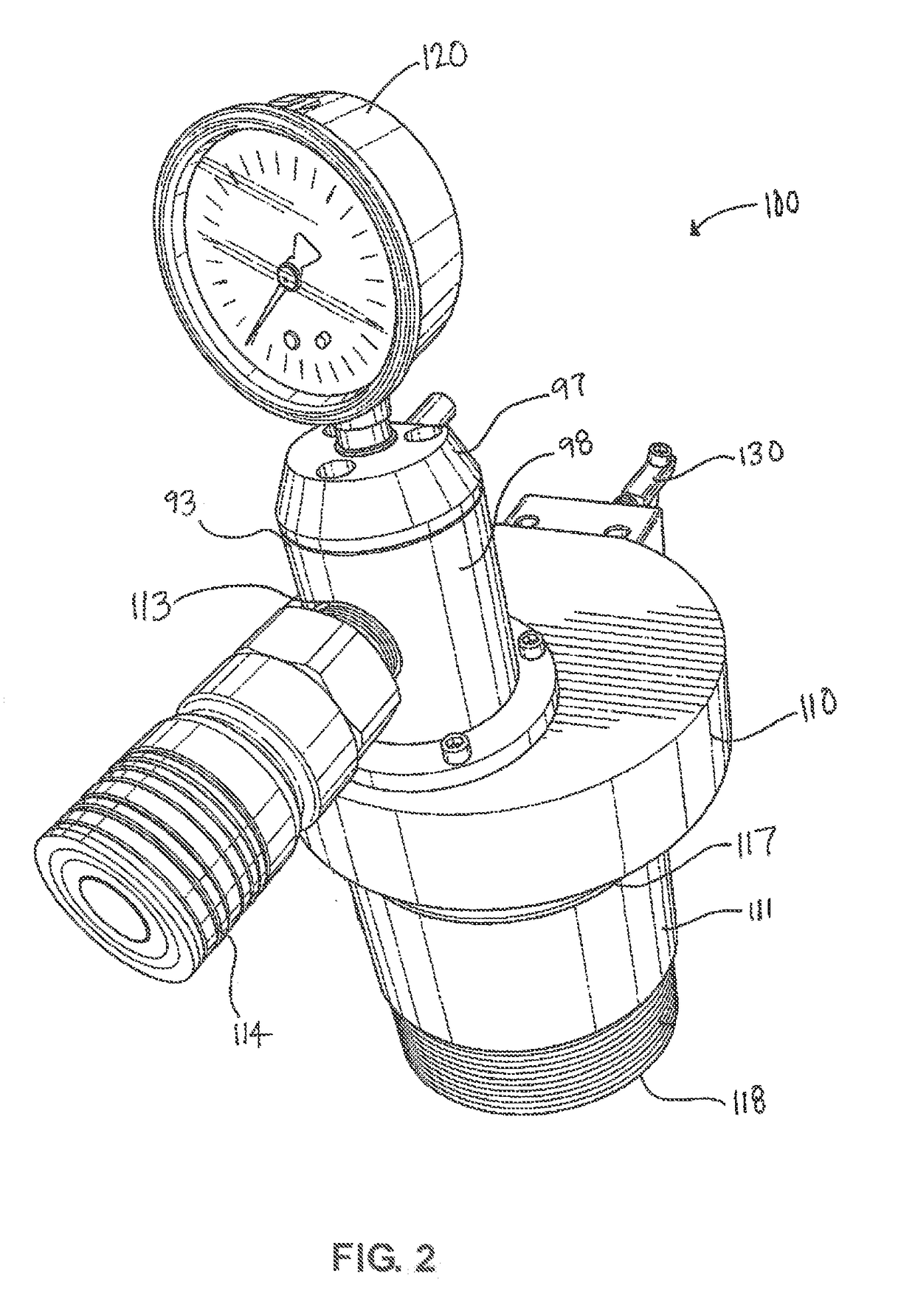

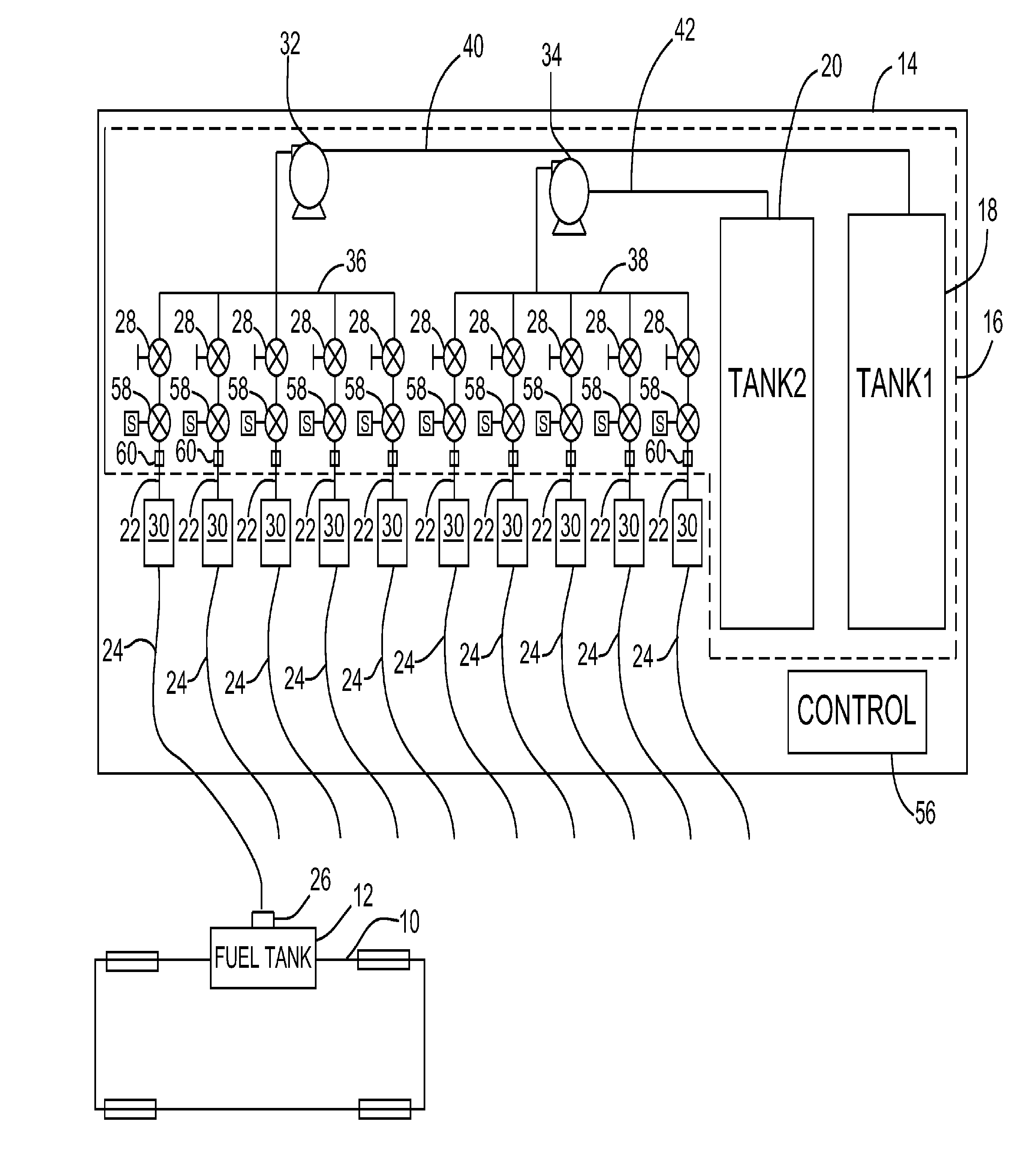

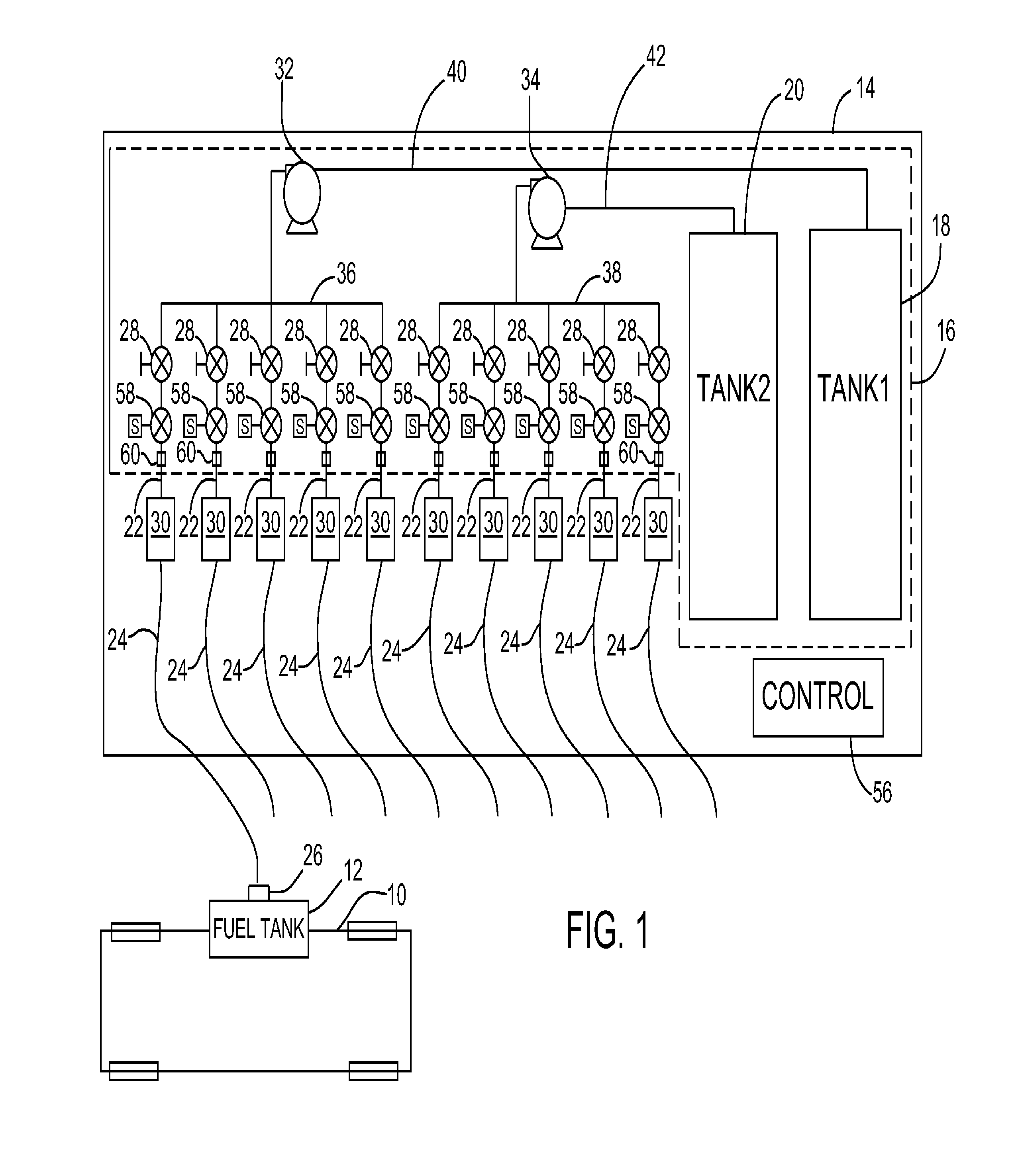

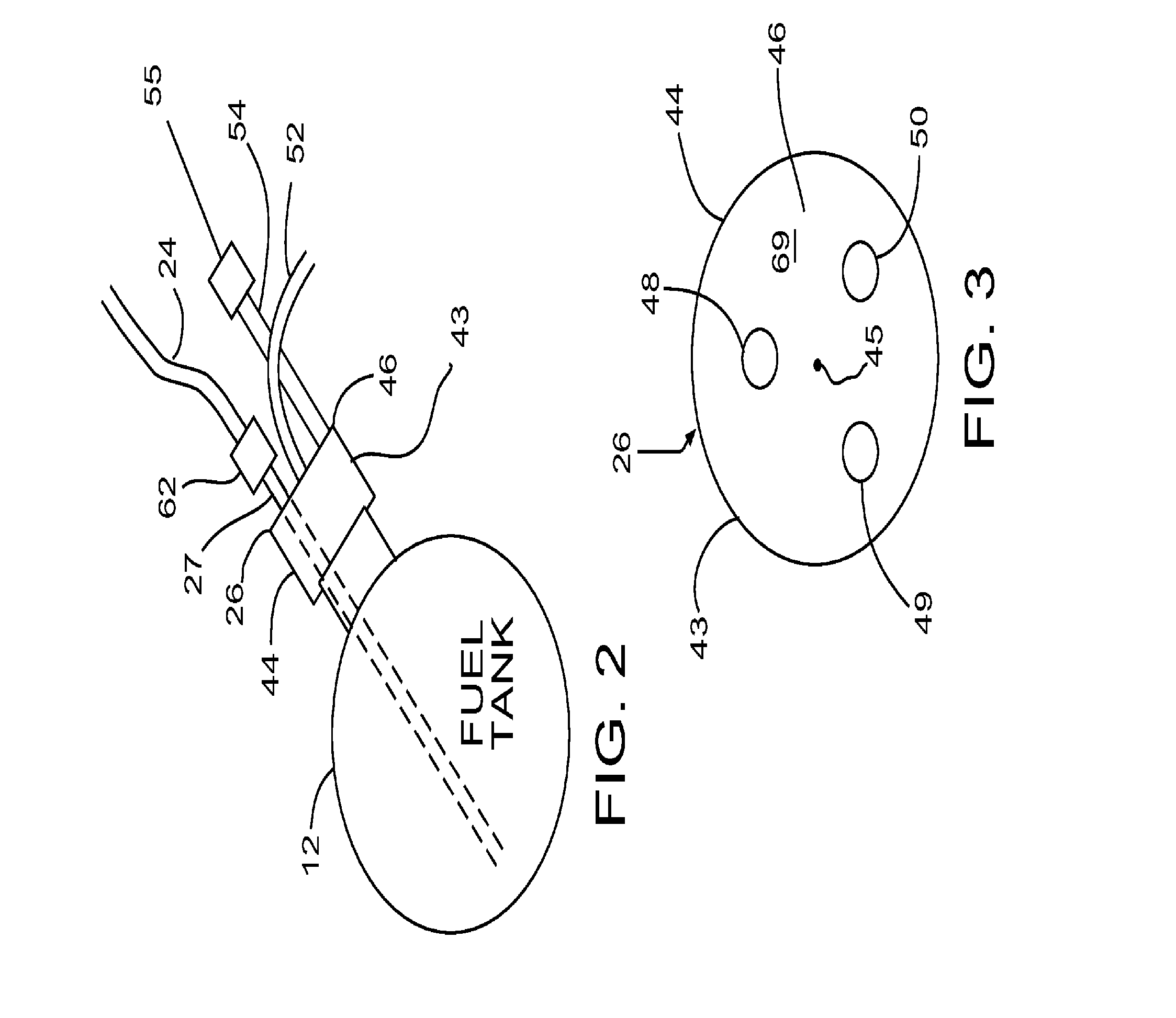

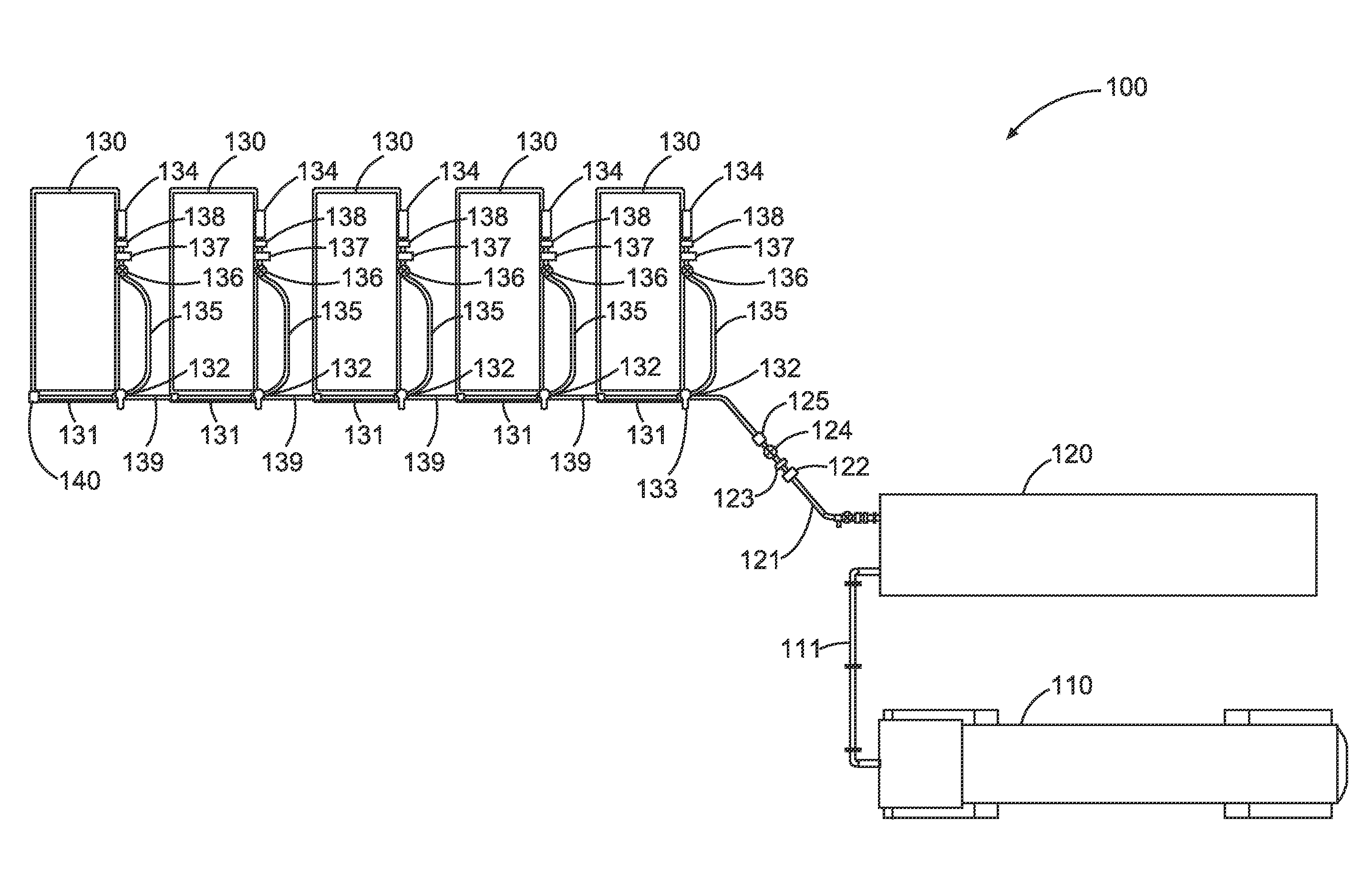

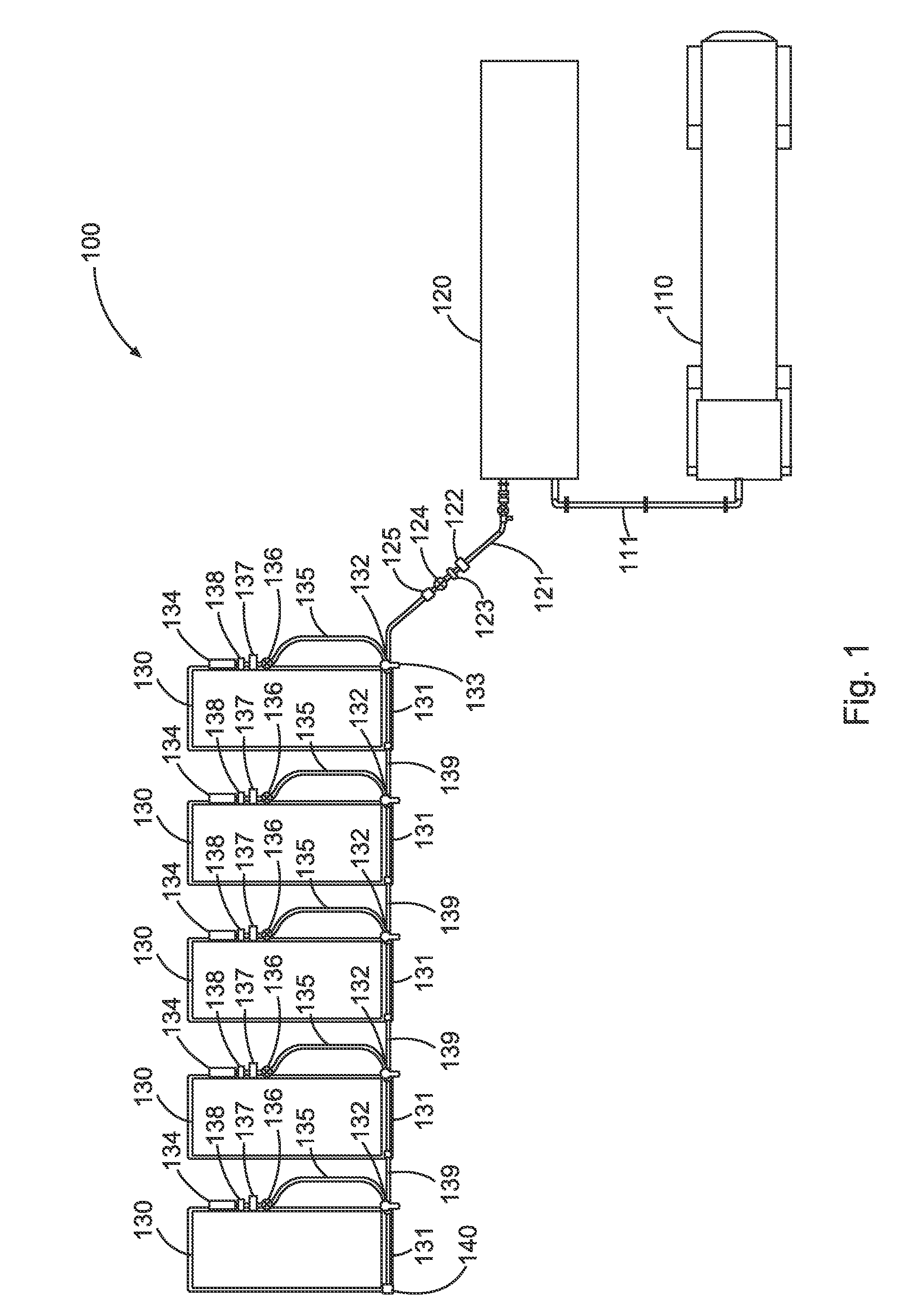

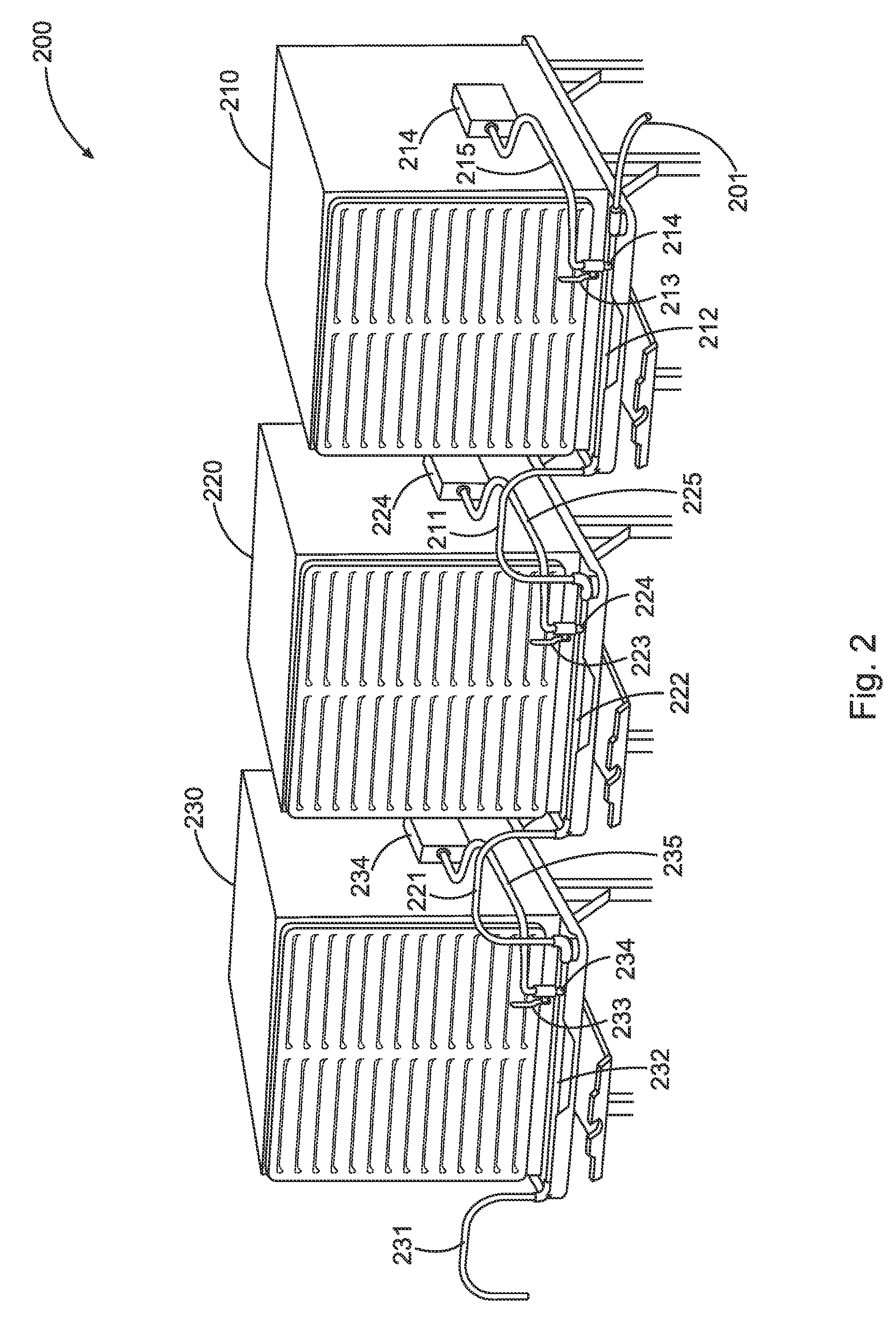

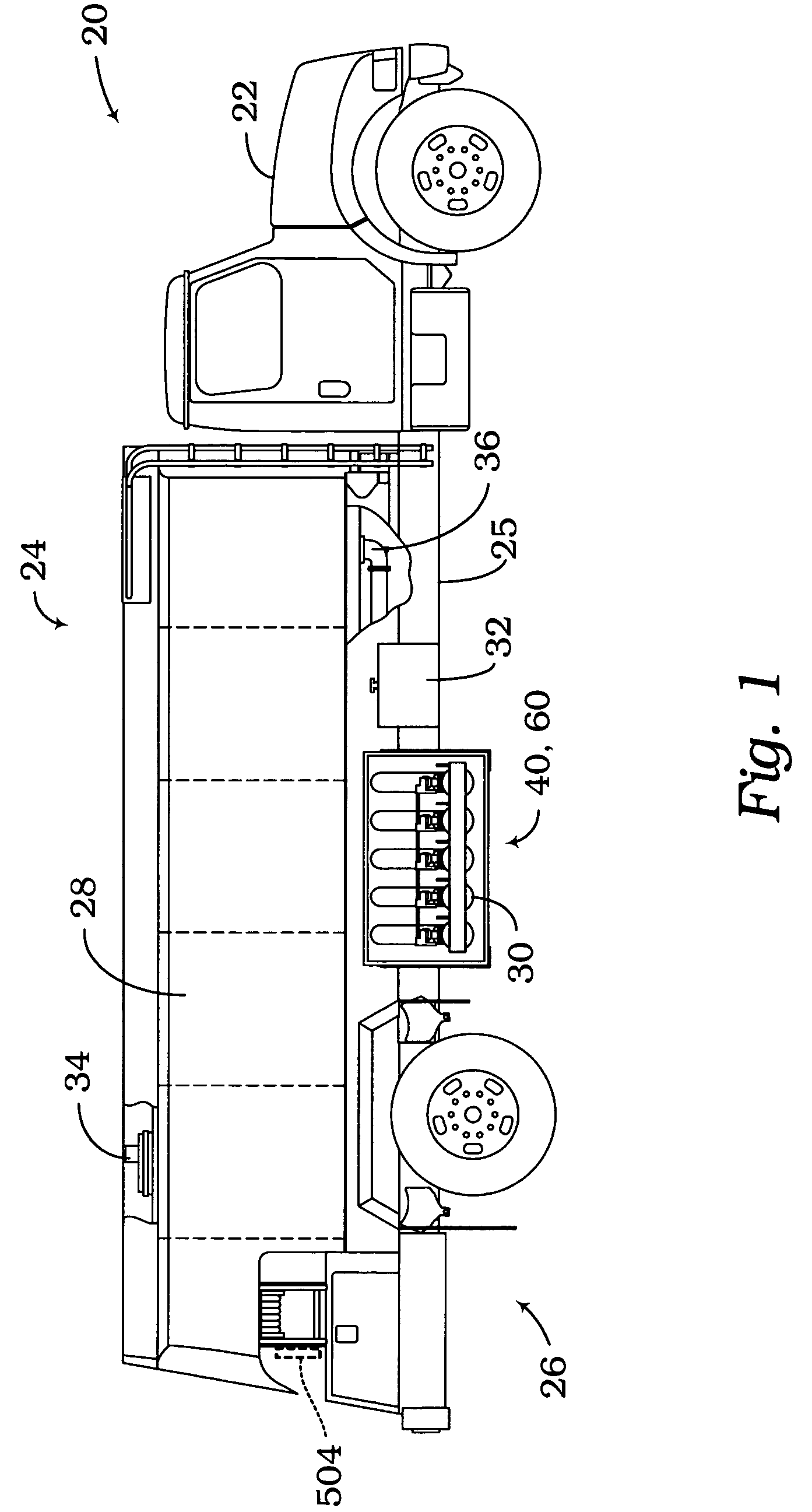

Method and Apparatus for Multi-Line Fuel Delivery

ActiveUS20170275149A1Prevent overflowMechanically operatedOperating means/releasing devices for valvesFluid removalFuel tankEngineering

A gravity-fed fuel delivery system is provided. A central storage tank holds fuel to re-supply a number of pump trucks or other mechanized equipment, such as on a hydraulic fracturing location, and can be selectively raised or lowered. Hoses or other conduits extend from the central storage tank to individual fuel tanks of the equipment to be refueled. Adapters allow connection of the distal end of each hose or conduit to an inlet opening of a fuel tank. A float valve assembly senses when fuel inside an individual fuel tank is below a predetermined level, thereby mechanically opening a valve assembly to permit fluid to flow from the central storage tank, through a conduit, through the float valve assembly and into the fuel tank.

Owner:GRAVITY FUEL SYST LLC

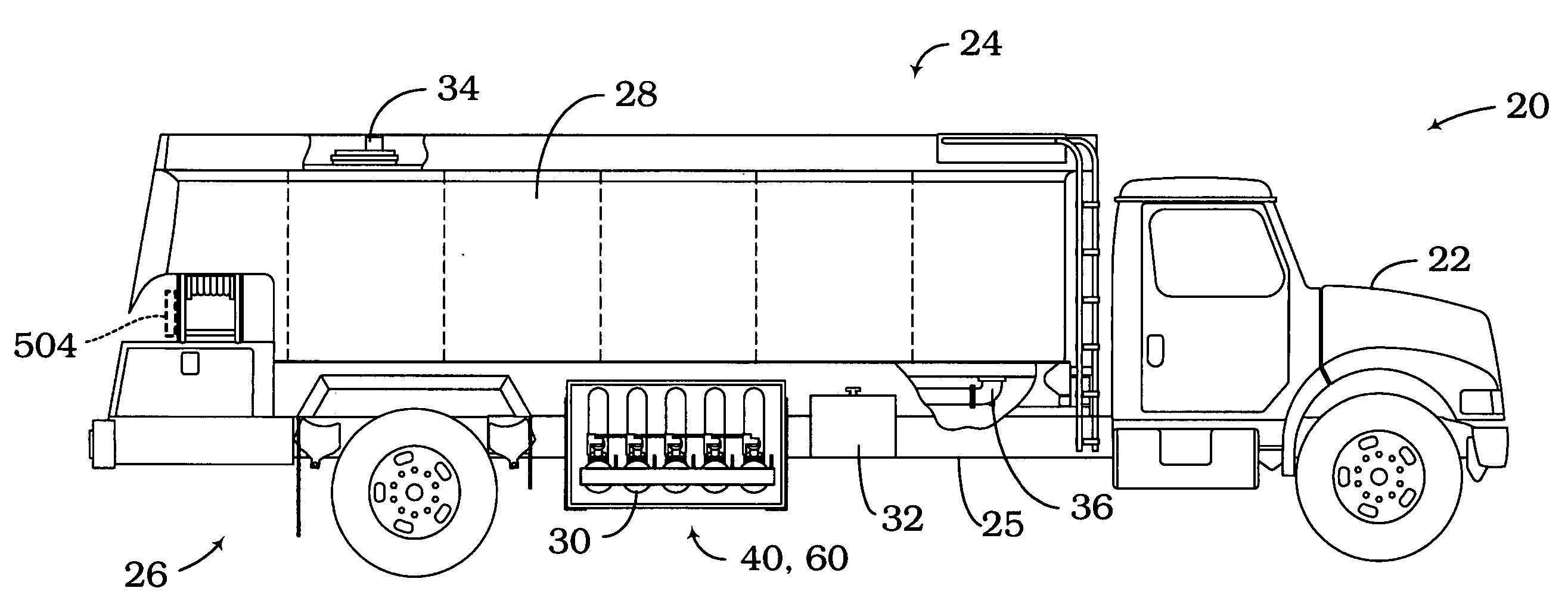

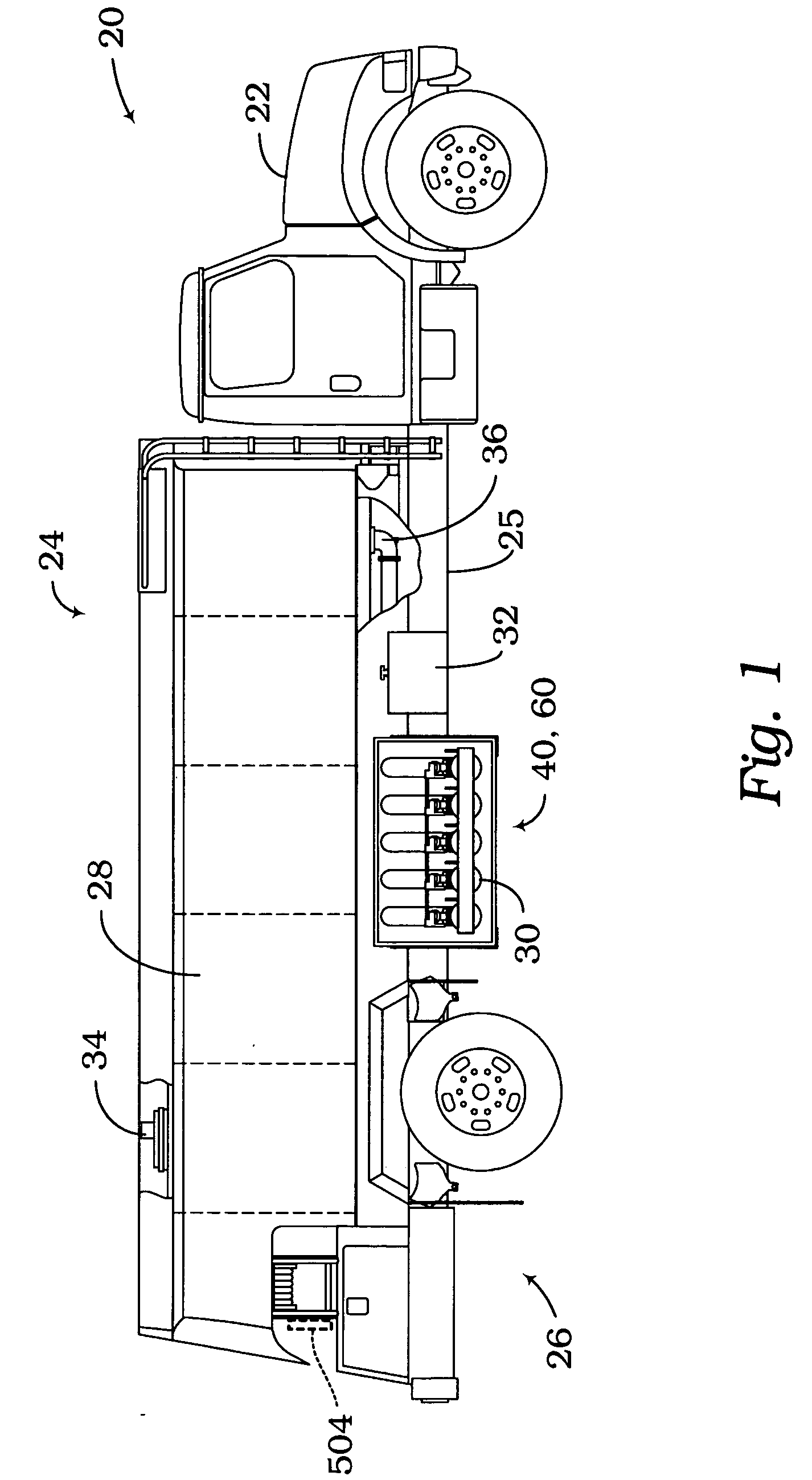

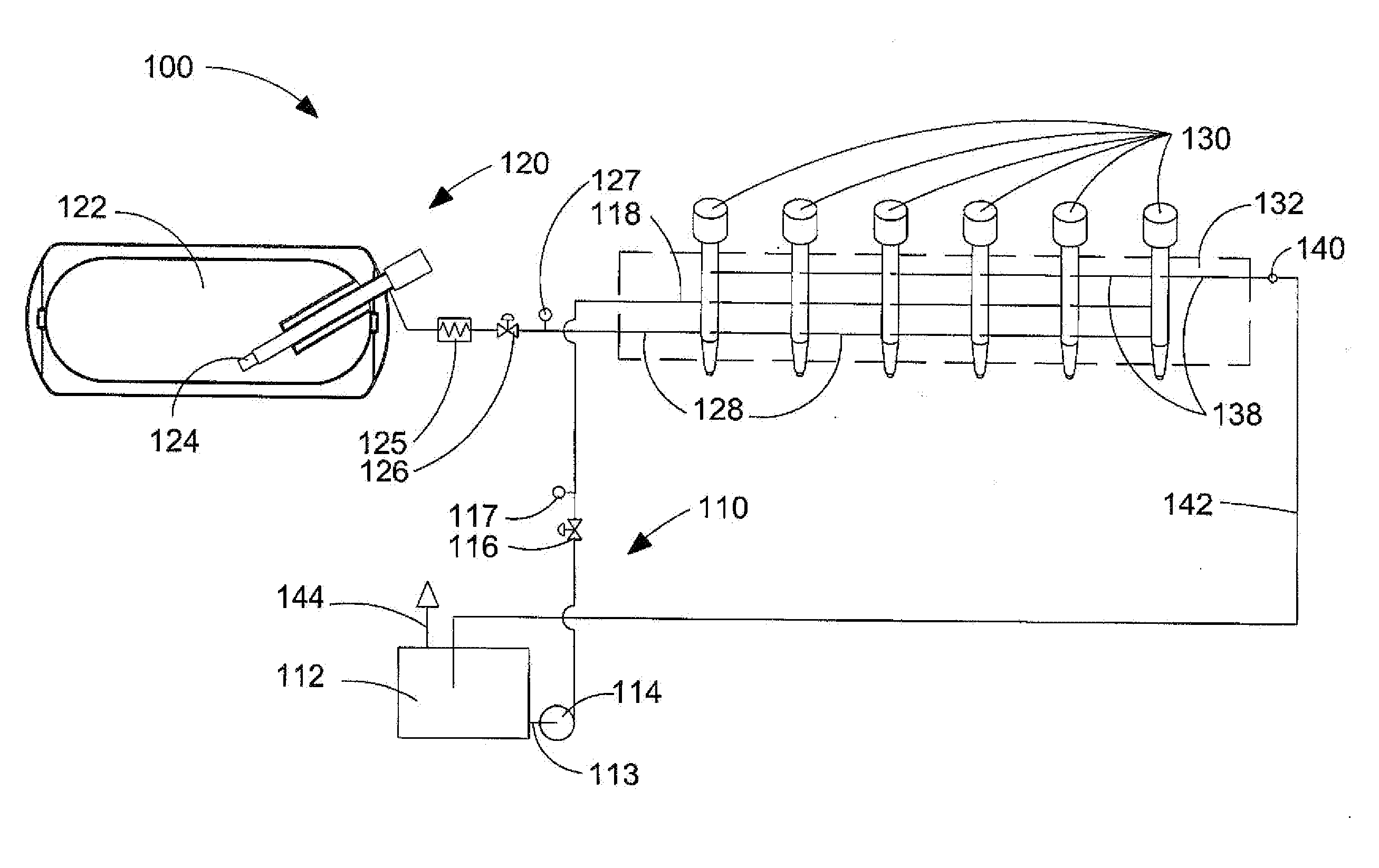

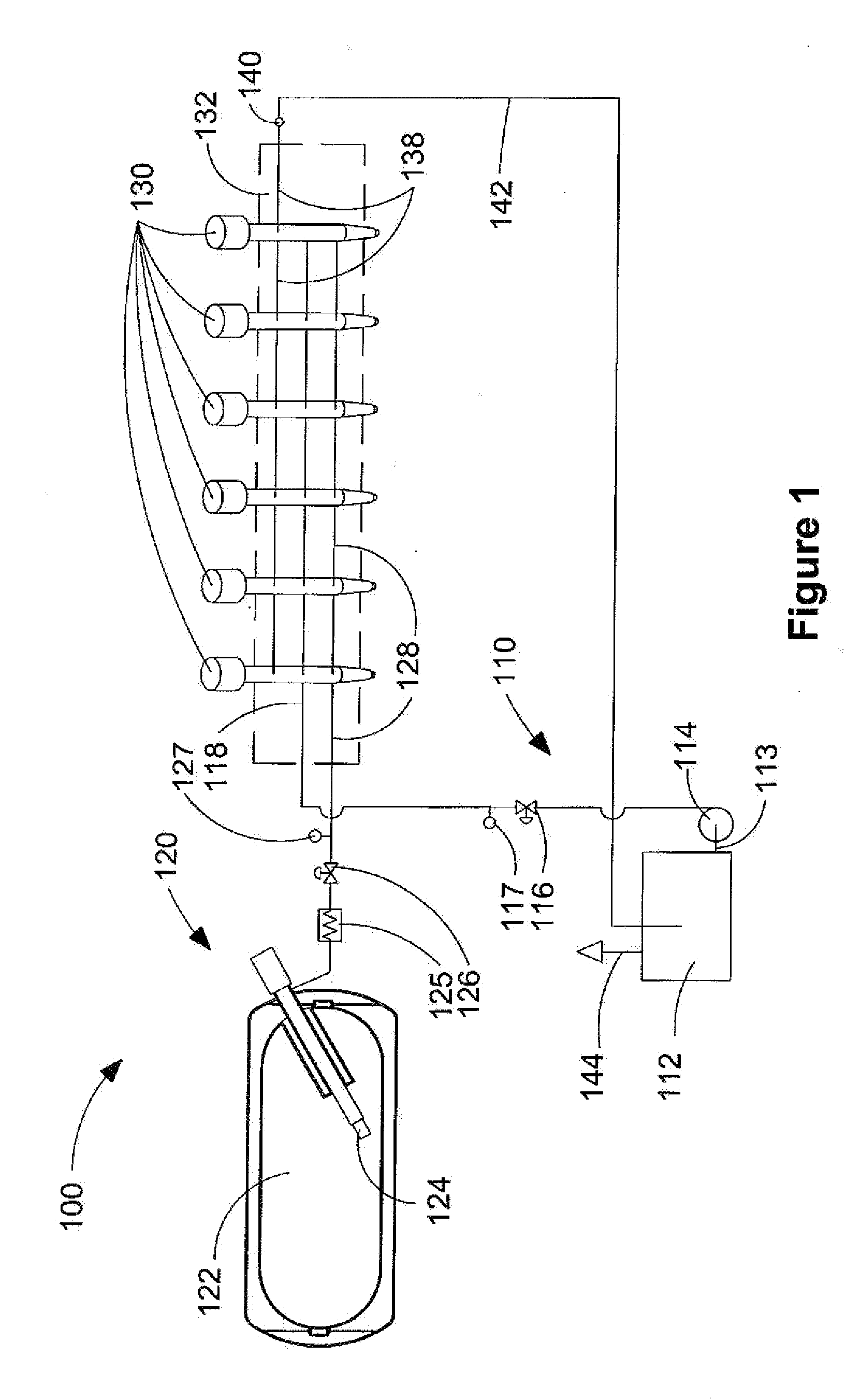

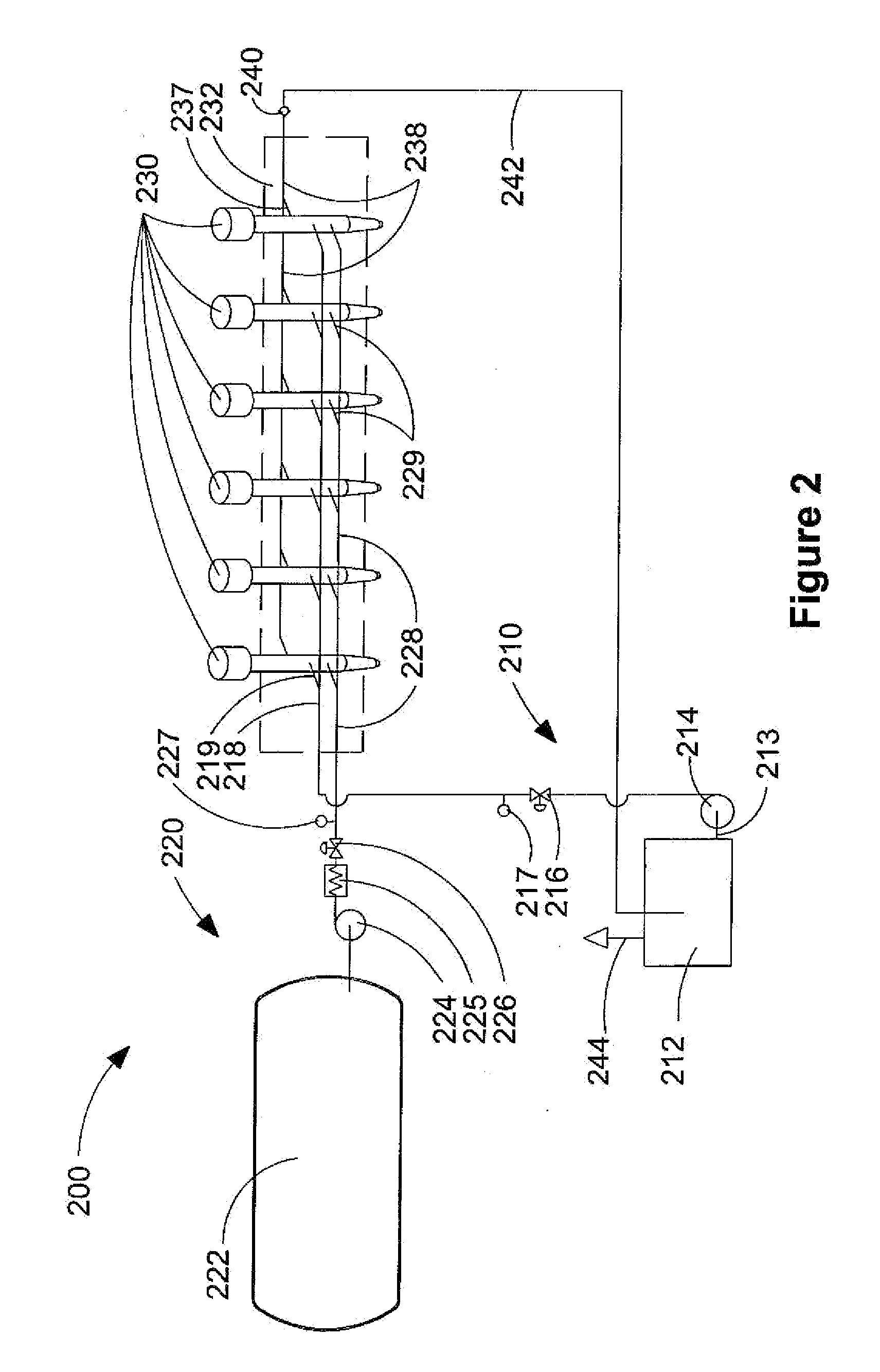

Fuel delivery system and method

A fuel delivery system and method for reducing the likelihood that a fuel tank of equipment at a well site during fracturing of a well will run out of fuel. A fuel source has plural fuel outlets, a hose on each fuel outlet of the plural fuel outlets, each hose being connected to a fuel cap on a respective one of the fuel tanks for delivery of fuel to the fuel tank. At least a manually controlled valve at each fuel outlet controls fluid flow through the hose at the respective fuel outlet.

Owner:ENERGERA INC +2

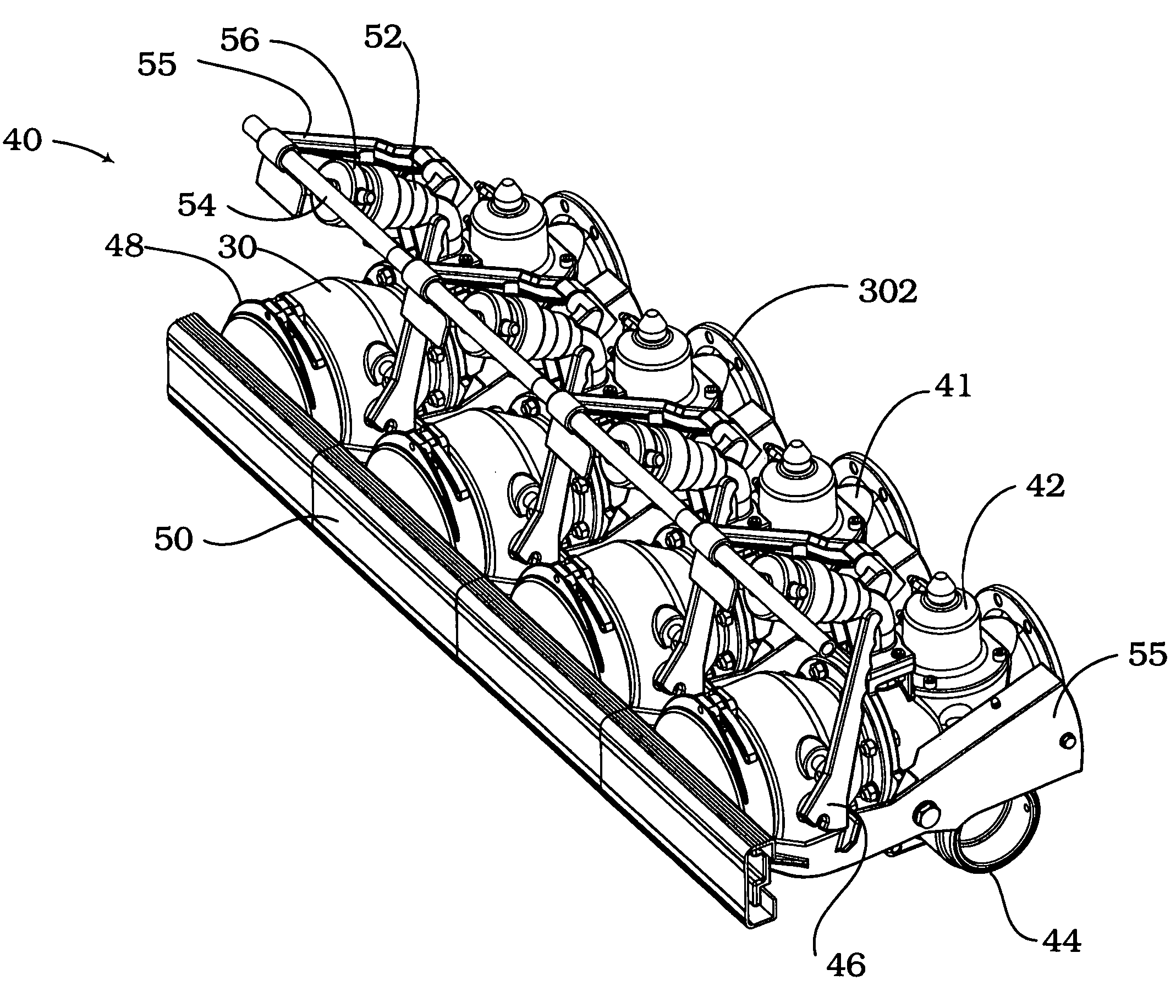

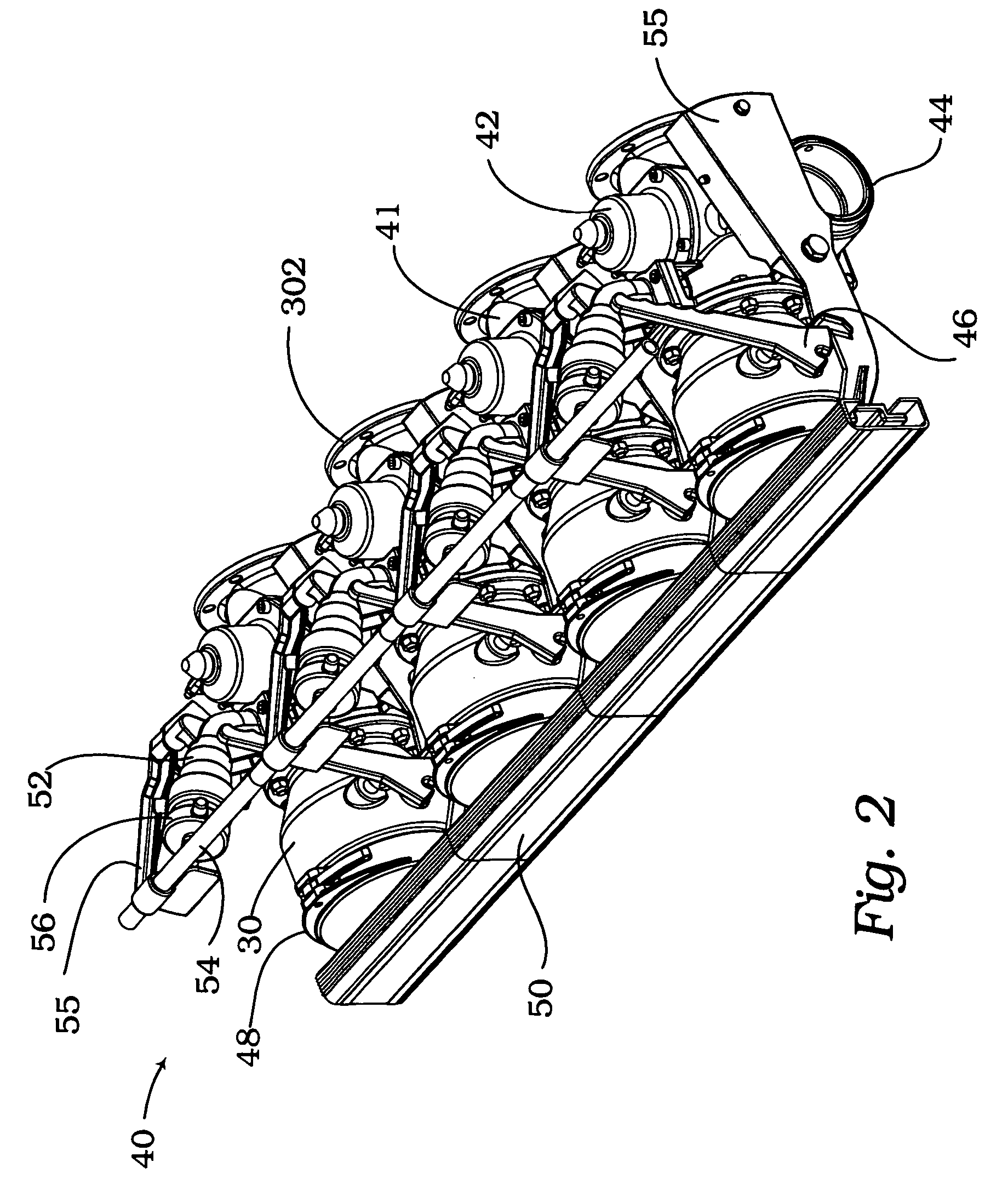

Modular multi-port manifold and fuel delivery system

InactiveUS20050139286A1Prevent openingLiquid transferring devicesPipeline systemsControl flowNuclear engineering

A modular multi-port manifold and fuel delivery system includes a plurality of ports in fluid communication with corresponding compartments of a fuel delivery vehicle, a collector conduit common to the ports, a control valve associated with each port to control flow of the fuel product from the associated compartment to the collector conduit to deliver the product, and a control system for operating each of the control valves.

Owner:DELAWARE CAPITAL FORMATION

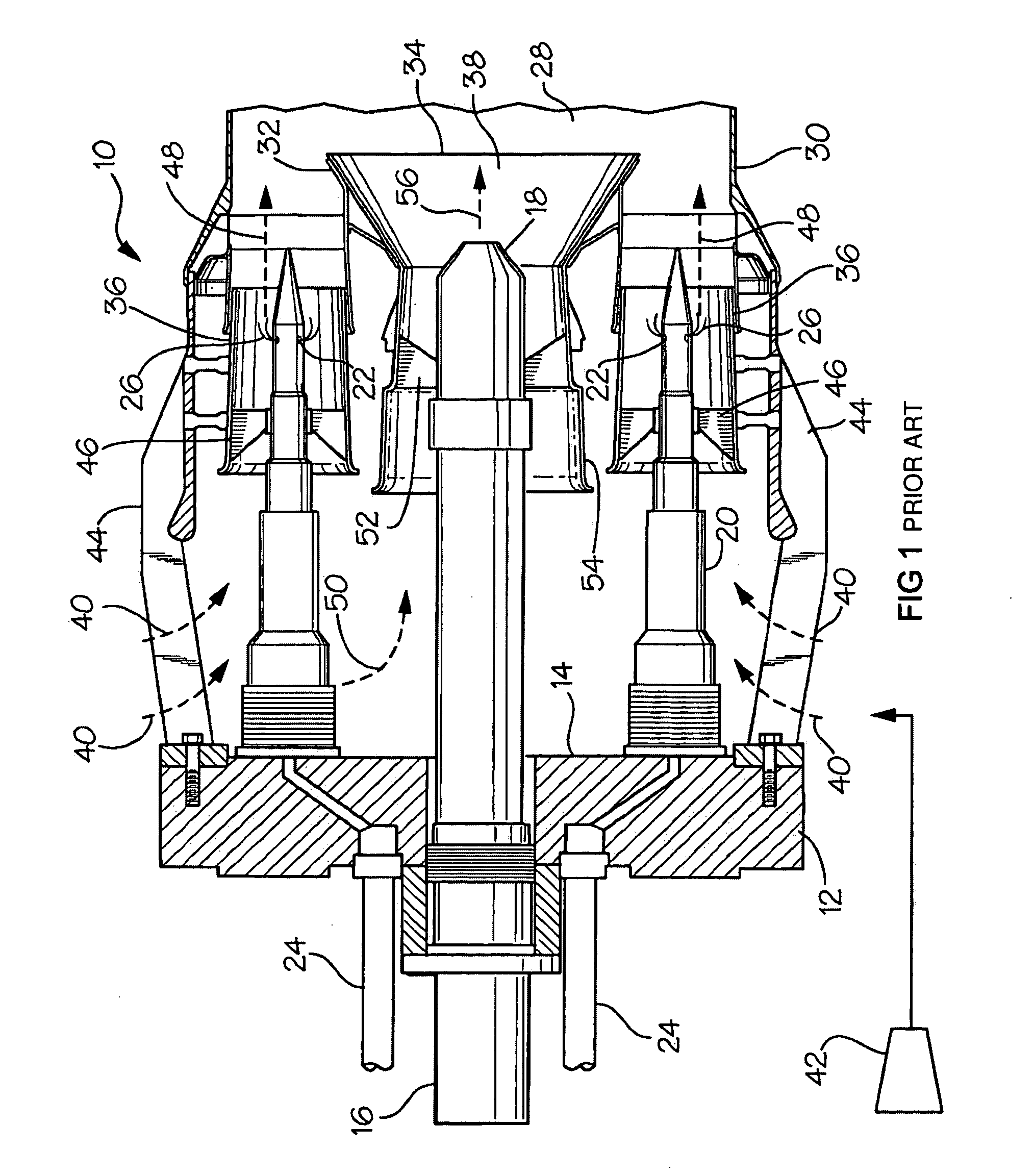

Method And Apparatus For Delivering Two Fuels To A Direct Injection Internal Combustion Engine

ActiveUS20070199539A1Saving operating costIncrease energy densityInternal combustion piston enginesFuel supply apparatusCombustion chamberLiquid fuel

An apparatus for delivering two fuels to a direct injection internal combustion engine comprises a liquid-fuel supply rail, a gaseous-fuel supply rail, a drain system with a shared drain rail for collecting both liquid fuel and gaseous fuel, and a venting device for venting gaseous fuel collected by the drain rail. The method comprises separately delivering a liquid fuel at injection pressure to an injection valve through a liquid-fuel rail, and actuating the liquid-fuel injection valve to introduce liquid fuel directly into the combustion chamber. The method further comprises delivering a gaseous fuel at injection pressure to an injection valve through a gaseous-fuel rail and actuating the gaseous-fuel injection valve to introduce gaseous fuel directly into the combustion chamber. The method further comprises collecting in a drain rail liquid fuel and gaseous fuel from the liquid-fuel injection valve and the gaseous-fuel injection valve, directing liquid fuel to a storage vessel, and directing gaseous fuel to a vent pipe.

Owner:WESTPORT FUEL SYST CANADA INC

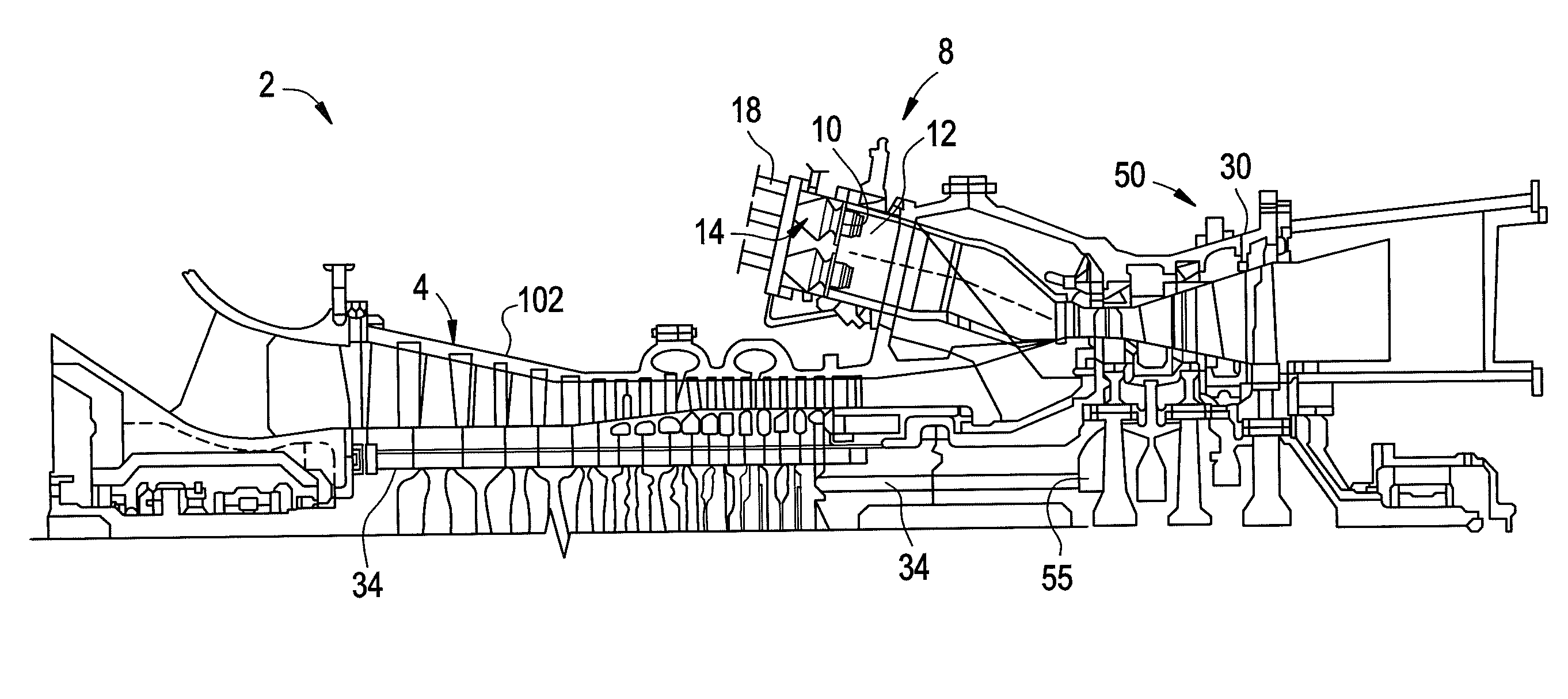

Lean direct injection atomizer for gas turbine engines

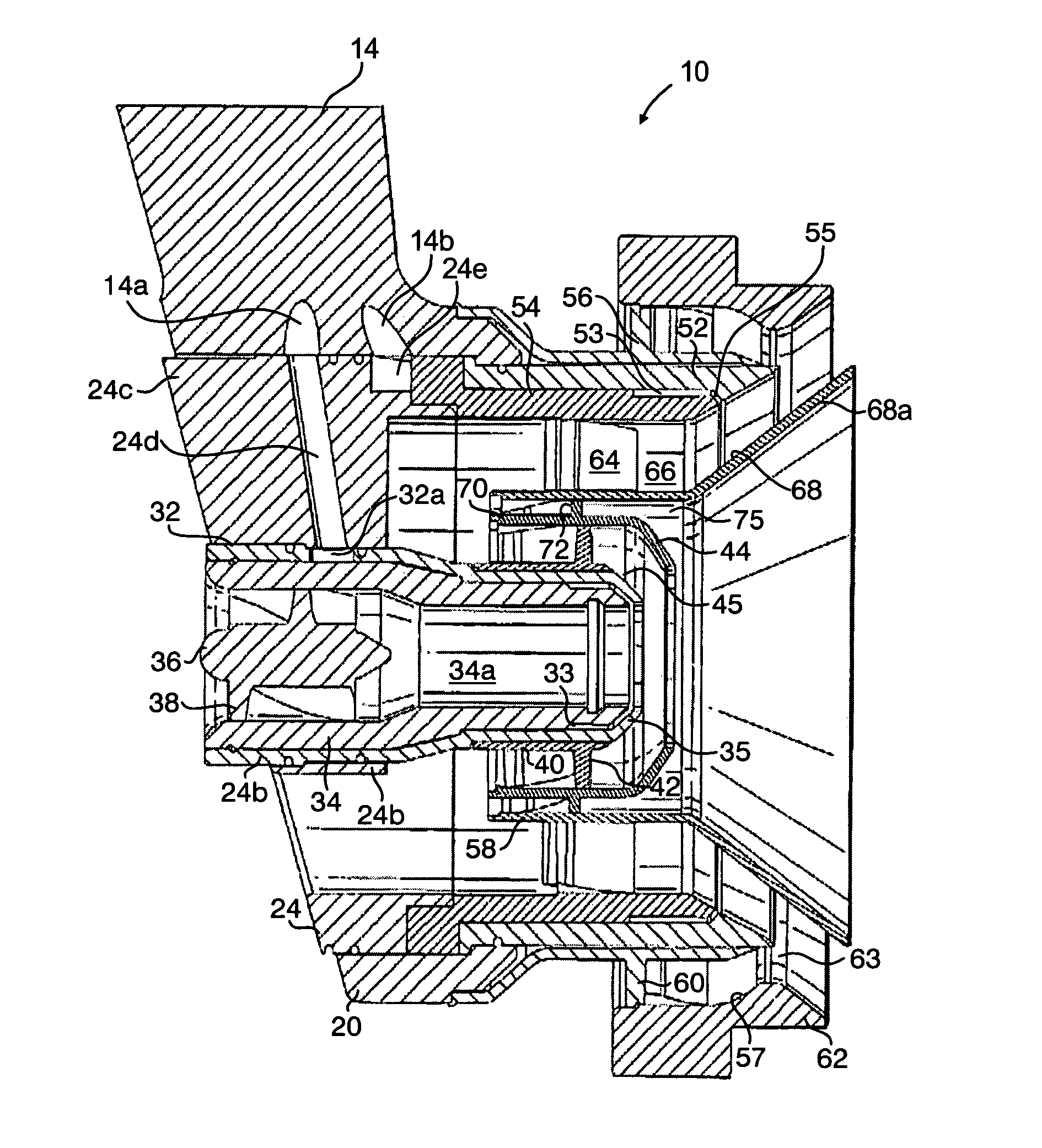

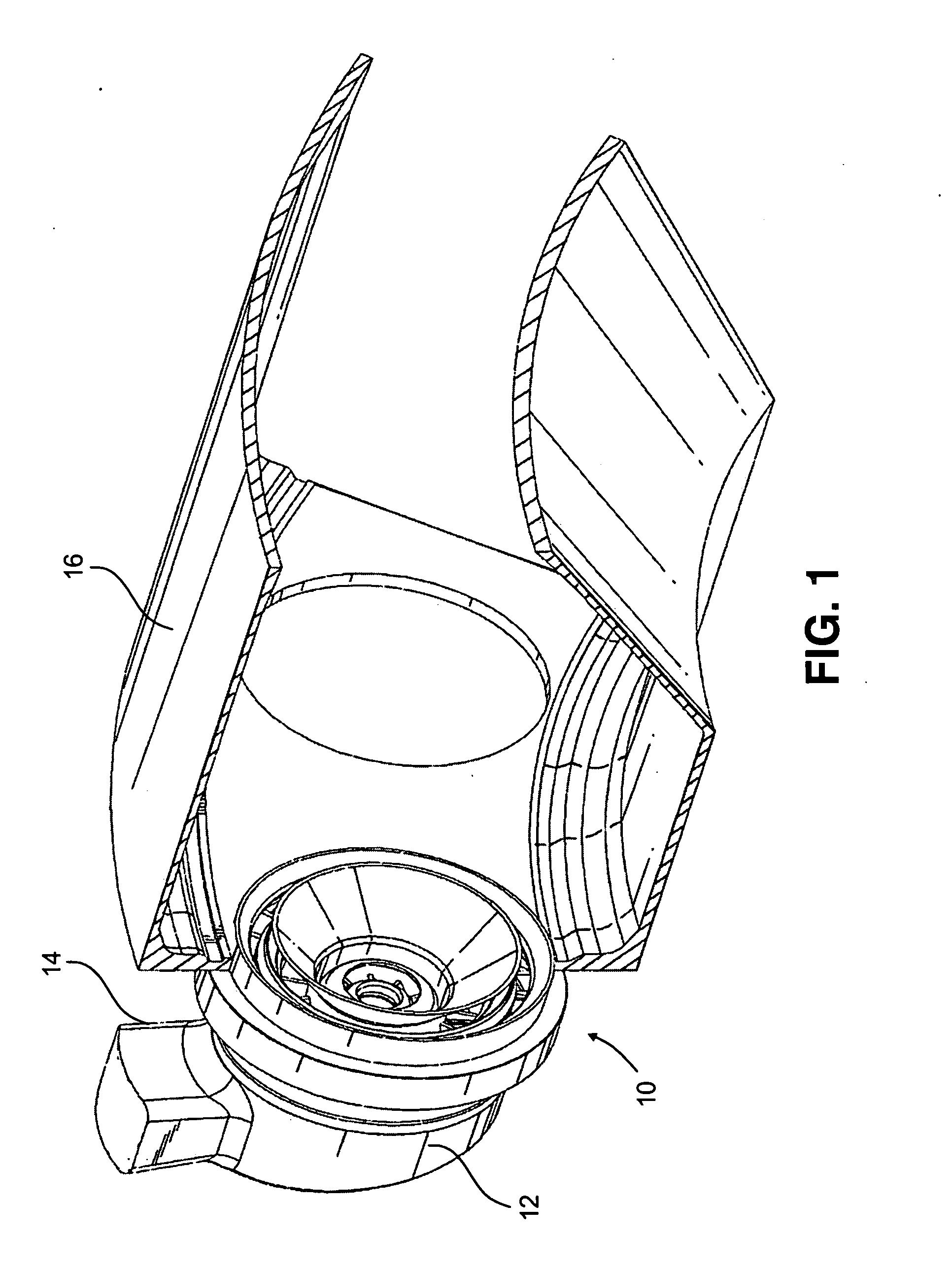

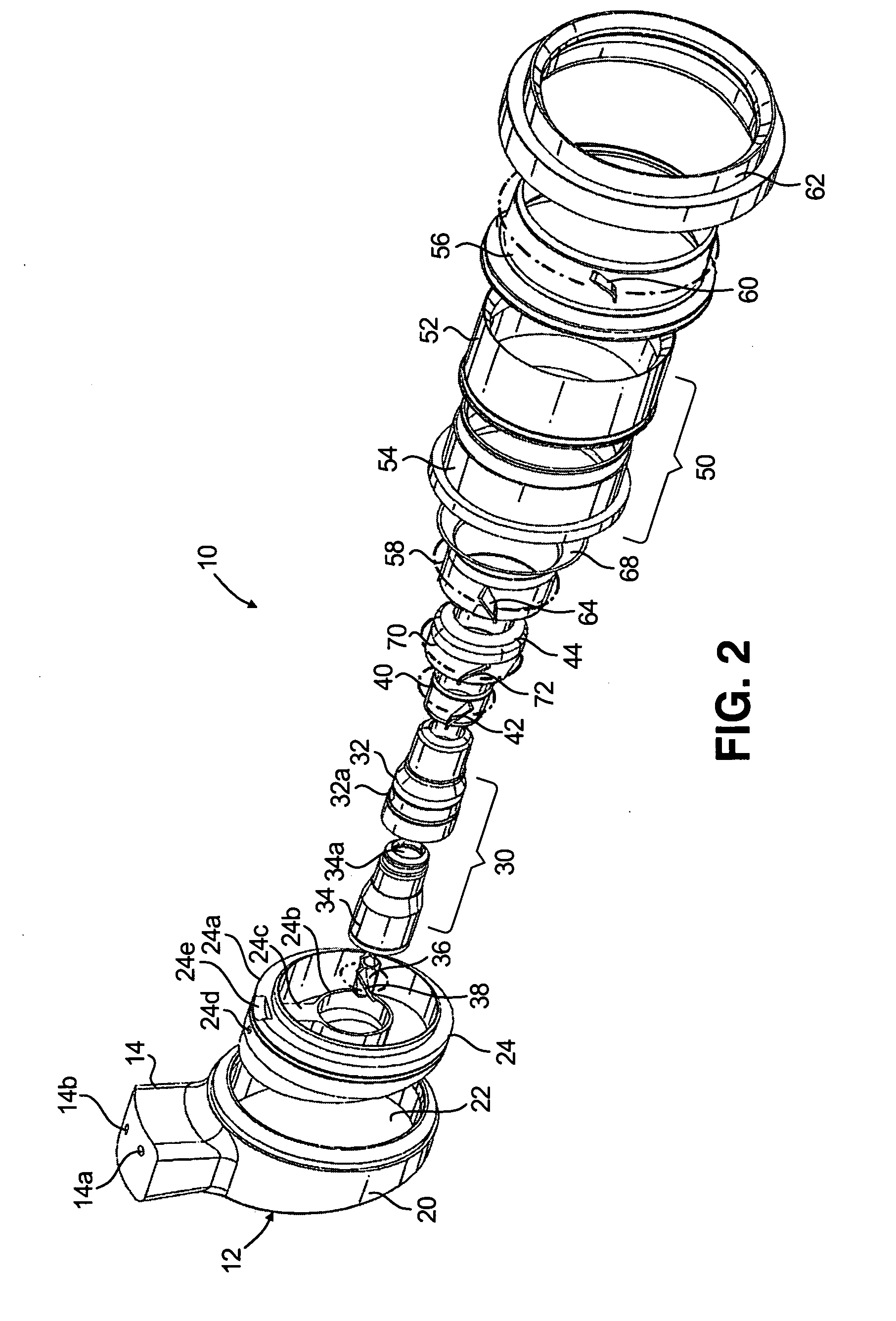

ActiveUS20060248898A1Increase pressureBurnersContinuous combustion chamberGas turbinesDelivery system

A lean direct injection fuel nozzle for a gas turbine is disclosed which includes a radially outer main fuel delivery system including a main inner air swirler defined in part by a main inner air passage having a radially inner wall with a diverging downstream surface, an intermediate air swirler radially inward of the main inner air swirler for providing a cooling air flow along the downstream surface of the radially inner wall of the main inner air passage, and a radially inner pilot fuel delivery system radially inward of the intermediate air swirler.

Owner:ROLLS ROYCE PLC

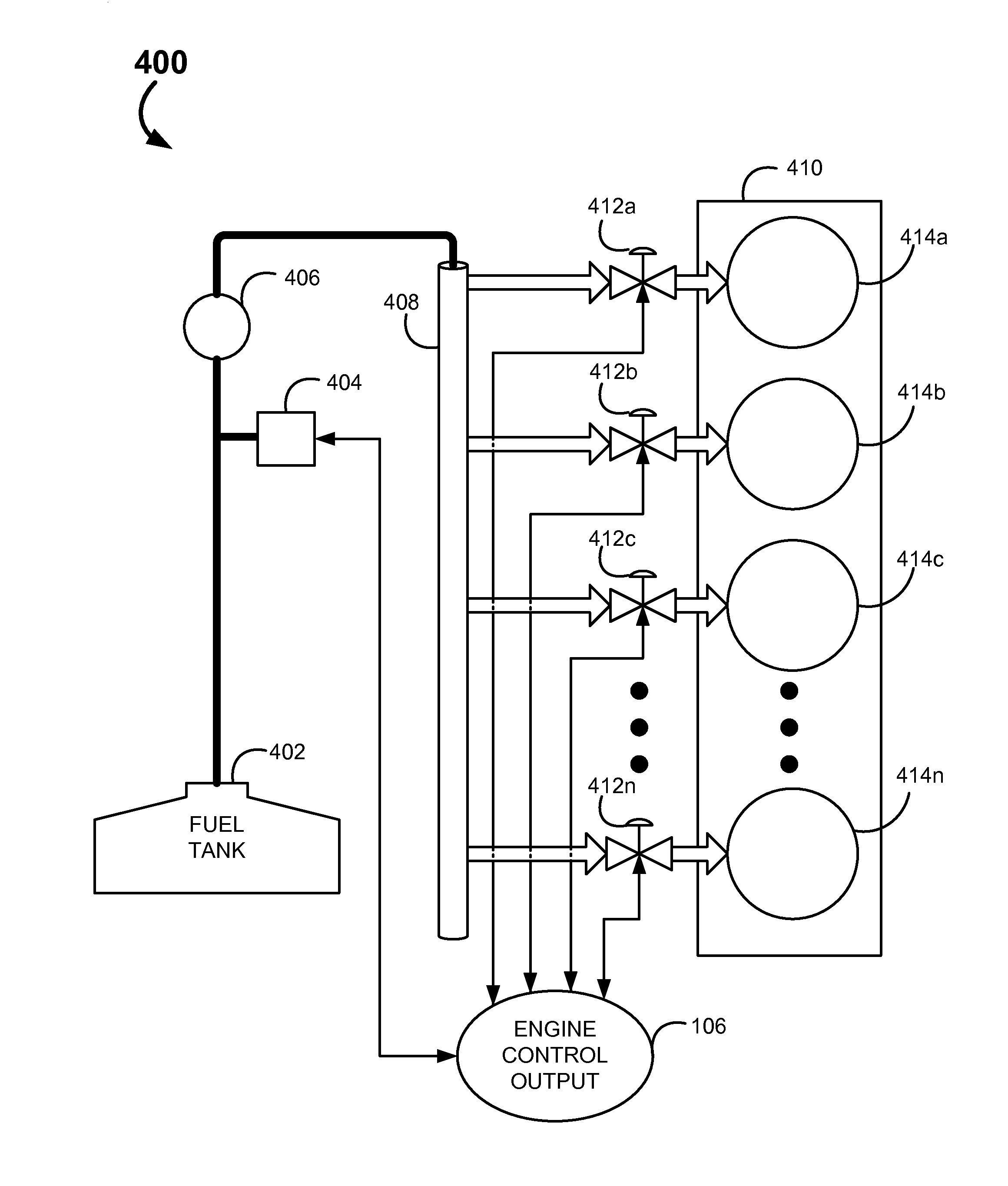

System and Methods for Stoichiometric Compression Ignition Engine Control

ActiveUS20110048372A1Enhanced skip fire operationEasy to controlElectrical controlInternal combustion piston enginesCombustionControl system

The present invention relates to a diesel engine control system and methods for substantially operating a diesel engine at stoichiometric fuel to air ratios. The system may include a fuel processor which receives instructions for a desired engine output and current operating conditions. The fuel processor may also generate fueling instructions for the cylinders, including: substantially regulating fuel delivery into to a first group of cylinders at or near stoichiometric fuel levels, and substantially disabling fuel injection into to a second grouping of cylinders. The number of cylinders being fueled, and therefore undergoing a combustion event corresponds to the desired engine output. This may be calculated by dividing the desired output by the power provided by one cylinder operating at substantially stoichiometric fuel levels. The number of cylinders receiving fuel may be varied over a succession of engine revolutions such that the actual average engine power output conforms to the desired output.

Owner:TULA TECH INC

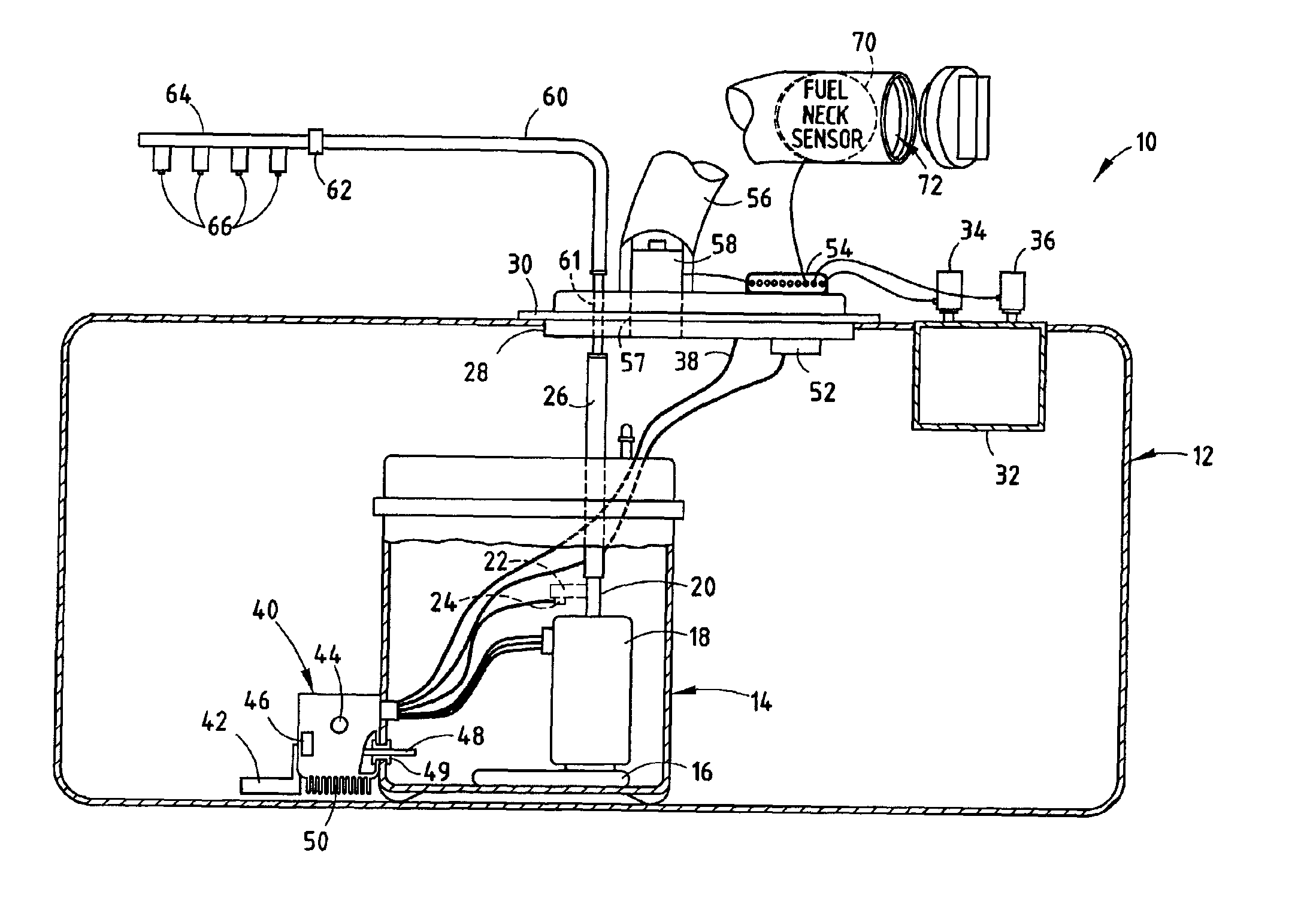

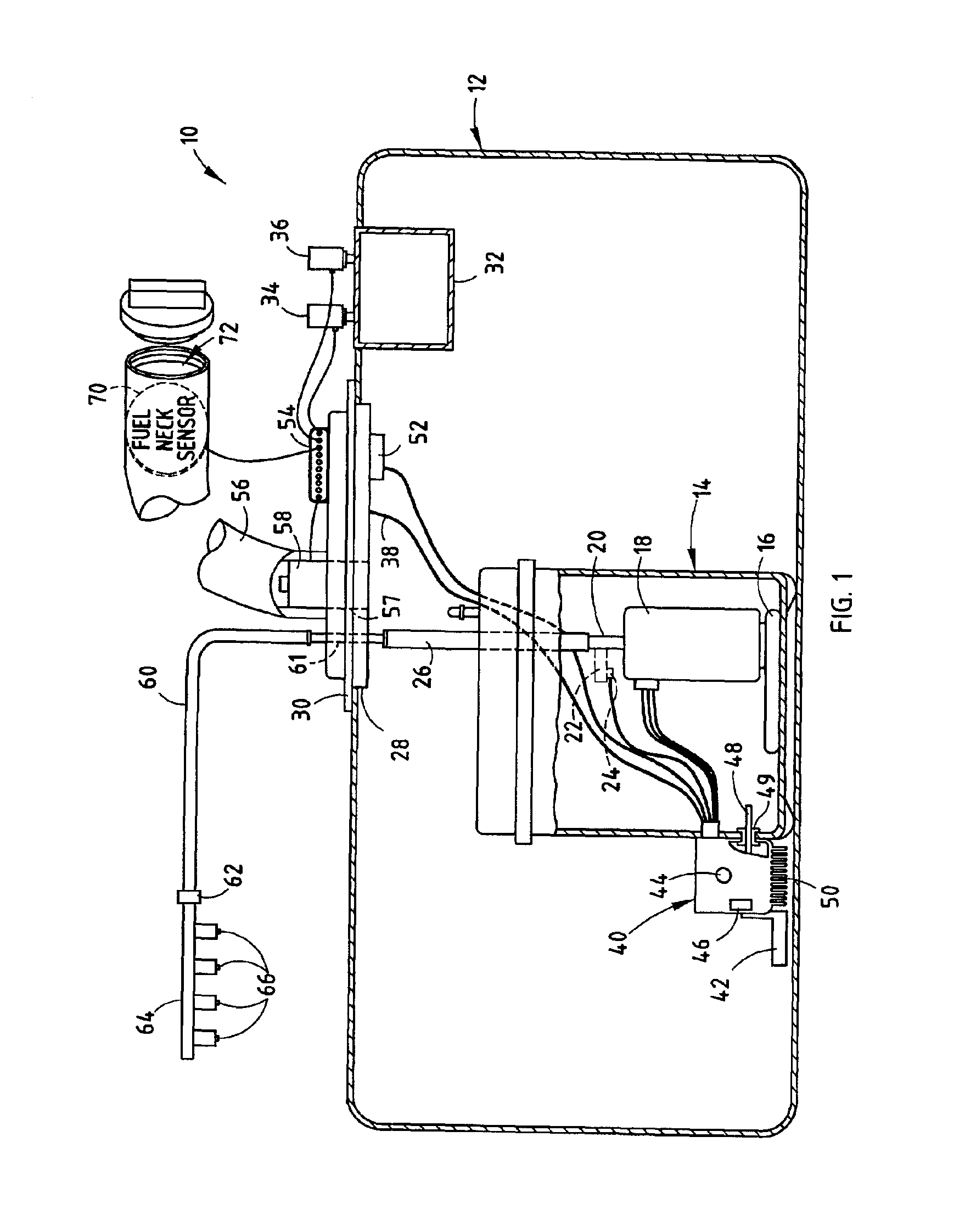

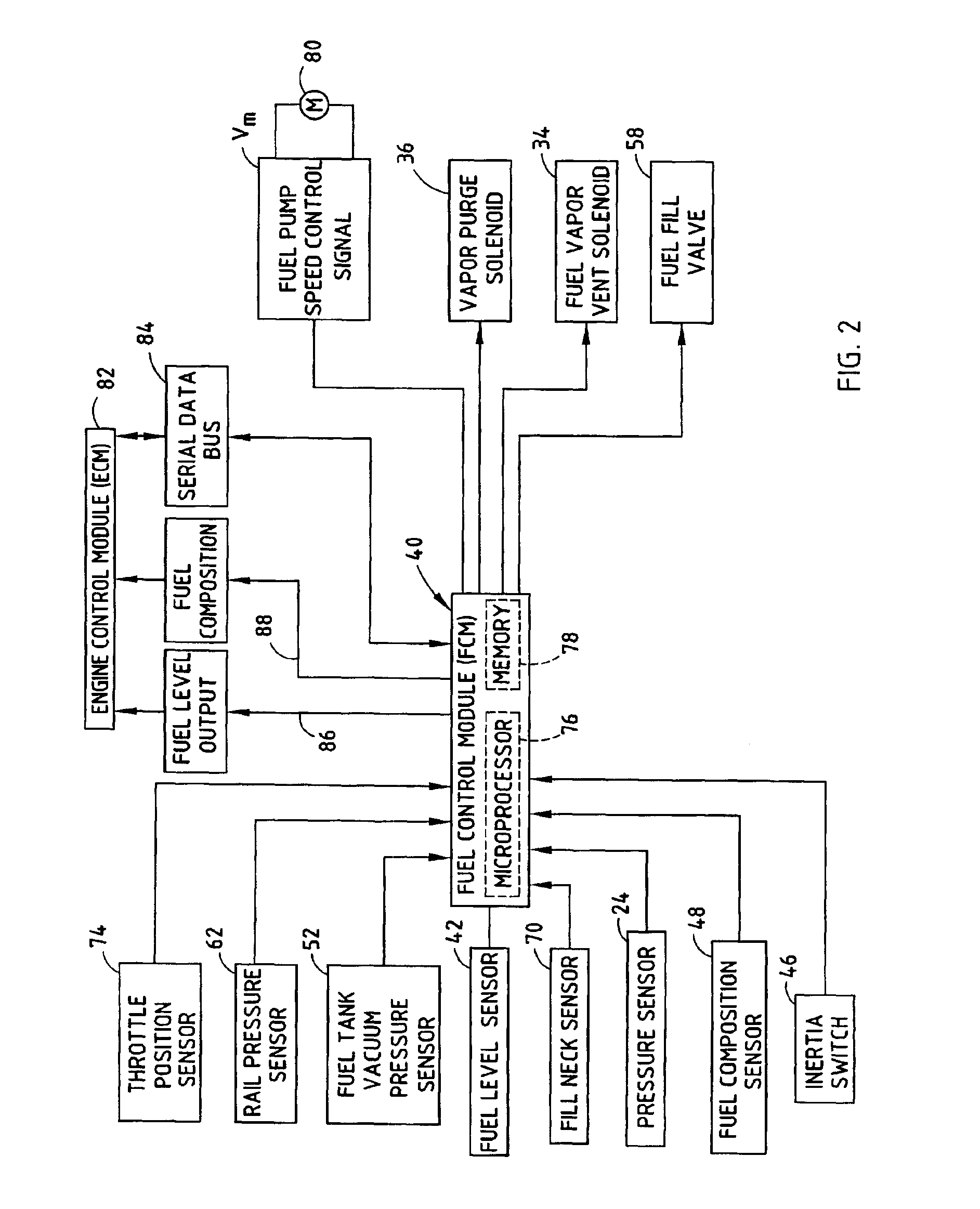

Vehicle fuel management system

InactiveUS6877488B2Affordable controlElectrical controlNon-fuel substance addition to fuelActuatorFuel vapor

An integrated fuel management system and method for controlling the fuel storage and delivery in a vehicle. The fuel management system includes a fuel storage tank for storing fuel in a vehicle, a vapor collection canister located within the fuel storage tank, a vent actuator coupled to the vapor collection canister for venting gas from the canister during a vent operation, and a purge actuator coupled to the canister for purging fuel vapor from the canister during a purge operation. A variable speed fuel pump is disposed within the fuel storage tank for delivering fuel to a fuel delivery line for an engine. The fuel management system has a controller provided in a module disposed in communication with the fuel for controlling the amount of fuel pumped with the variable speed fuel pump to deliver fuel to the fuel delivery line and further control the purge and vent actuators.

Owner:UUSI

Natural gas manifold for dual-fuel trailers

InactiveUS20140090729A1Internal combustion piston enginesFuel supply apparatusEngineeringNatural gas

A fuel delivery system comprising: a fuel source; a first trailer comprising a first manifold in fluid communication with a first fuel train; and a second trailer comprising a second manifold in fluid communication with a second fuel train, wherein the first and second manifolds are connected in series to the fuel source.

Owner:HALLIBURTON ENERGY SERVICES INC

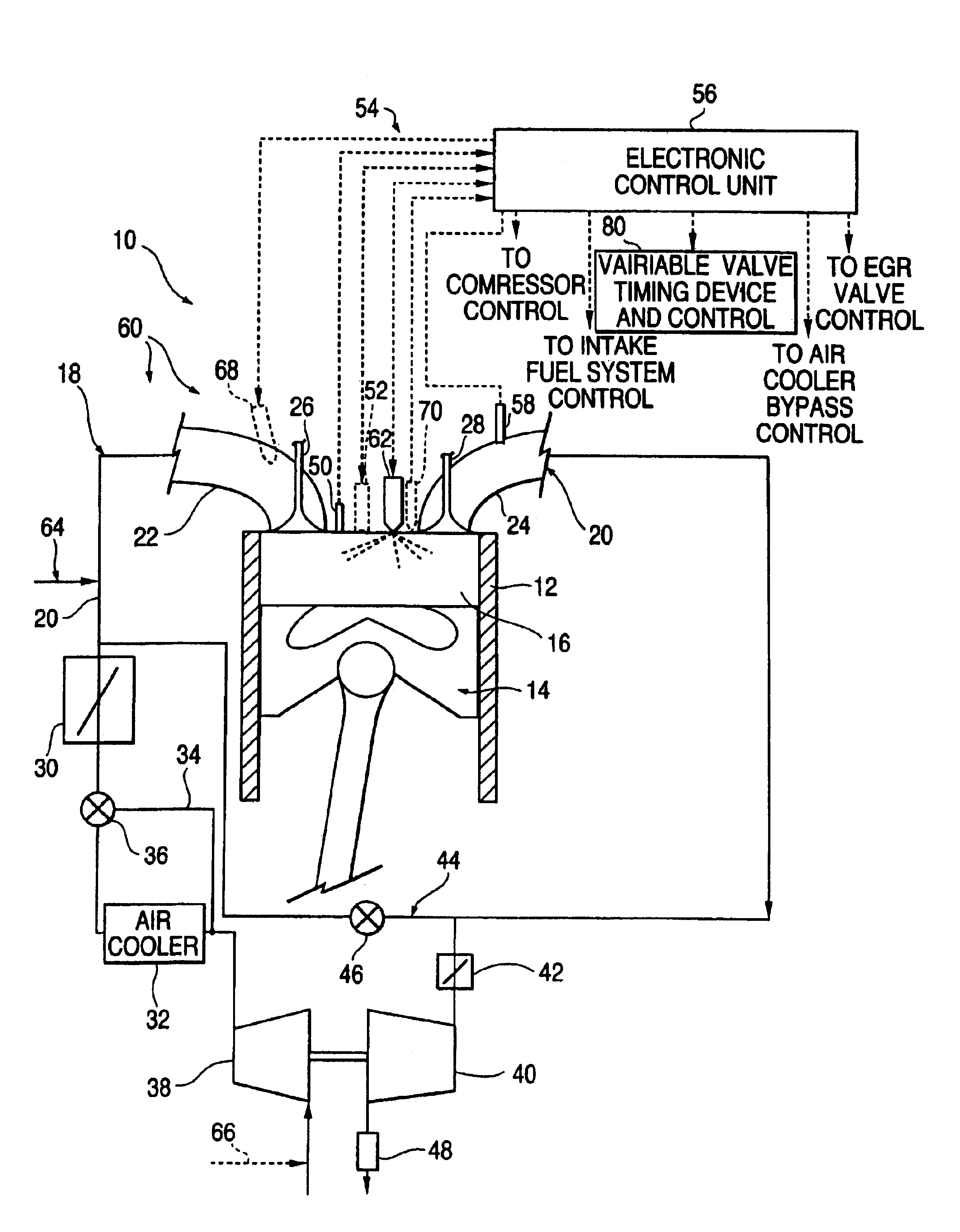

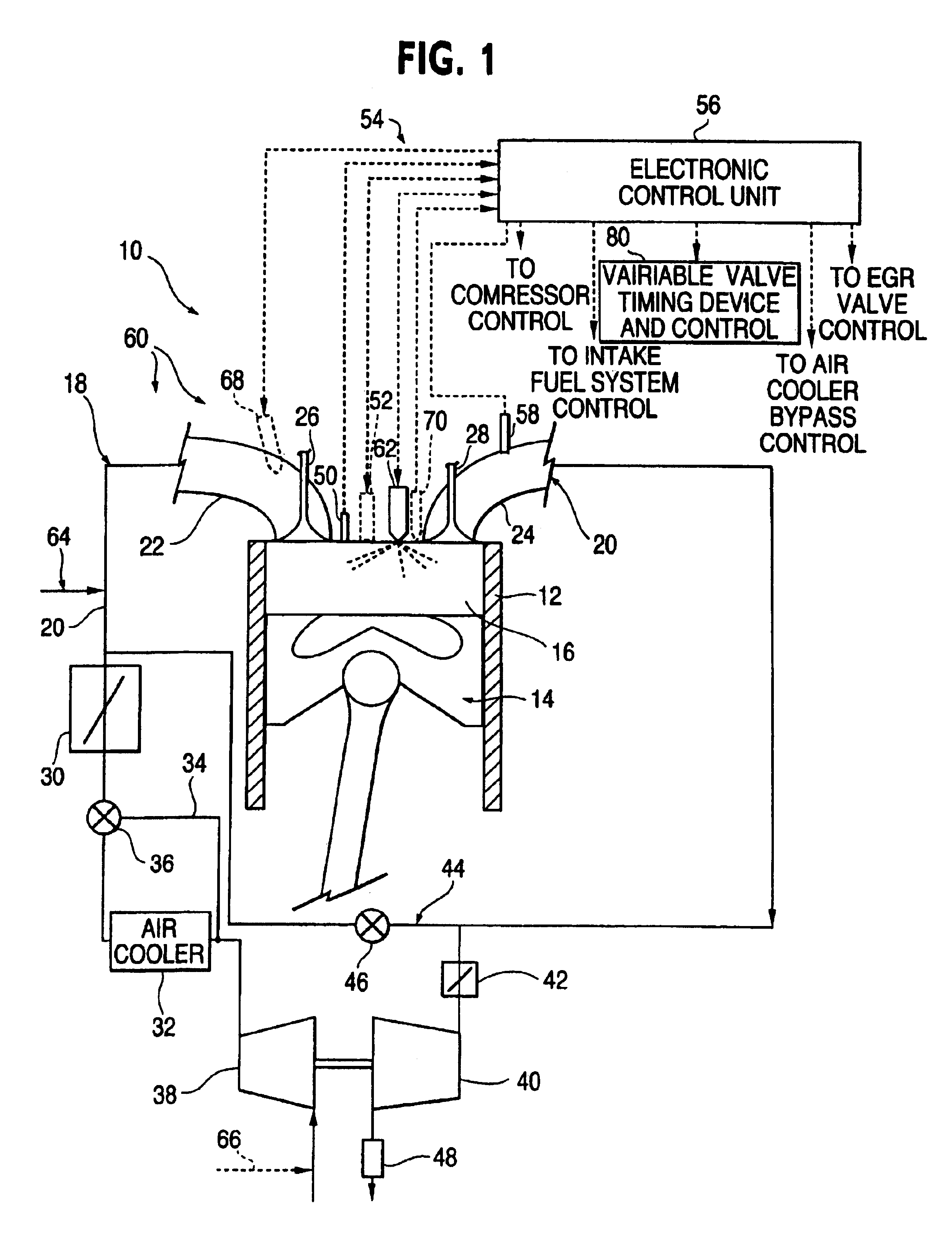

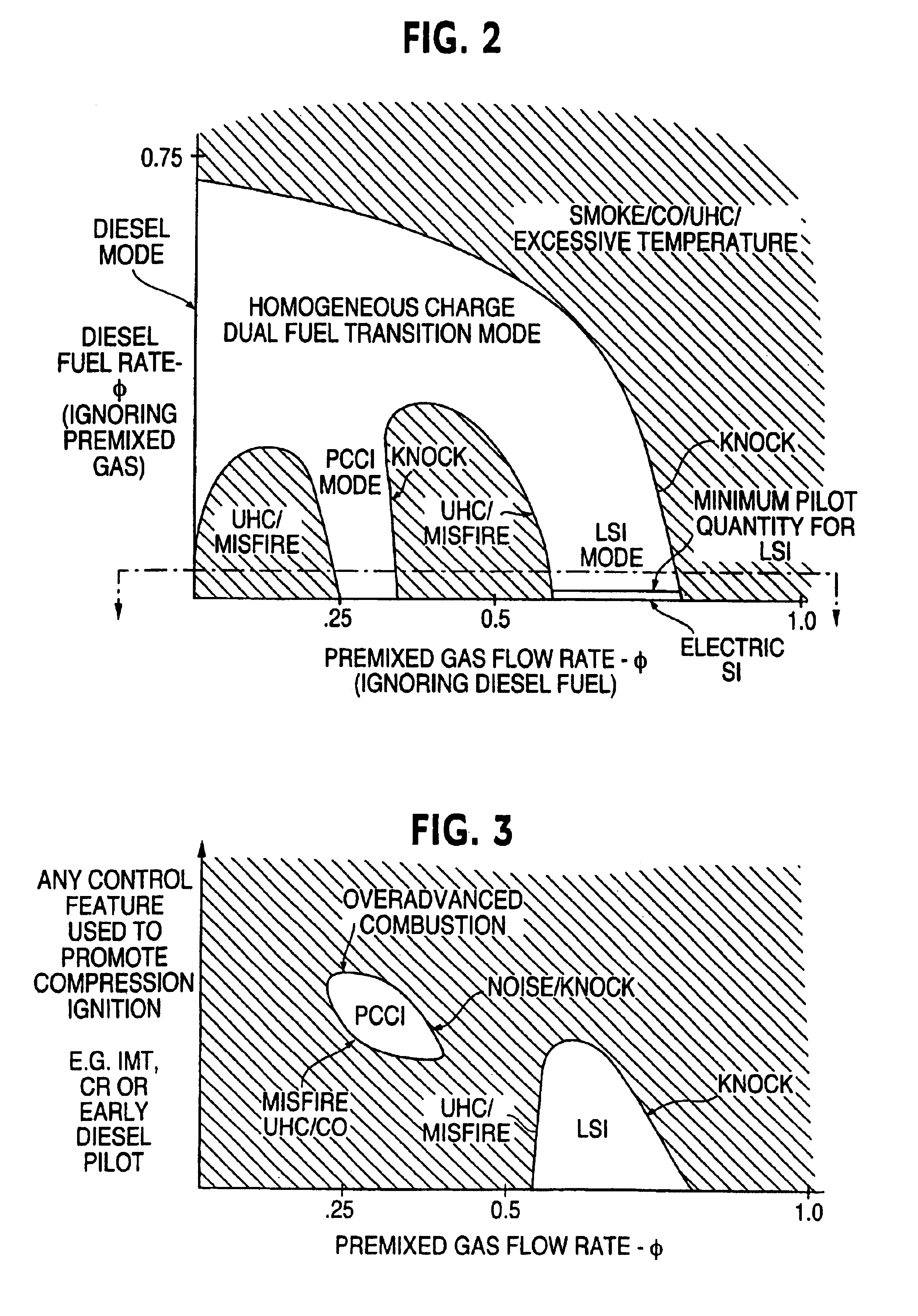

Multiple operating mode engine and method of operation

InactiveUS6907870B2Easy to operateOvercome deficienciesValve arrangementsElectrical controlControl systemFuel efficiency

A multi-mode internal combustion engine and method of operating the engine is provided which is capable of operating in a variety of modes based on engine operating conditions to enhance fuel efficiency and reduce emissions. The multi-mode engine include a fuel delivery system and control system for permitting the engine to operate in a diesel mode, a homogeneous charge dual fuel transition mode, a spark ignition or liquid spark ignition mode and / or a premixed charge compression ignition mode. The control system and method permits the engine operation to transfer between the various modes in an effective and efficient manner by controlling one or more fuel delivery devices or other engine components so as to move along a continuous transfer path while maintaining engine torque at a substantially constant level.

Owner:CUMMINS INC

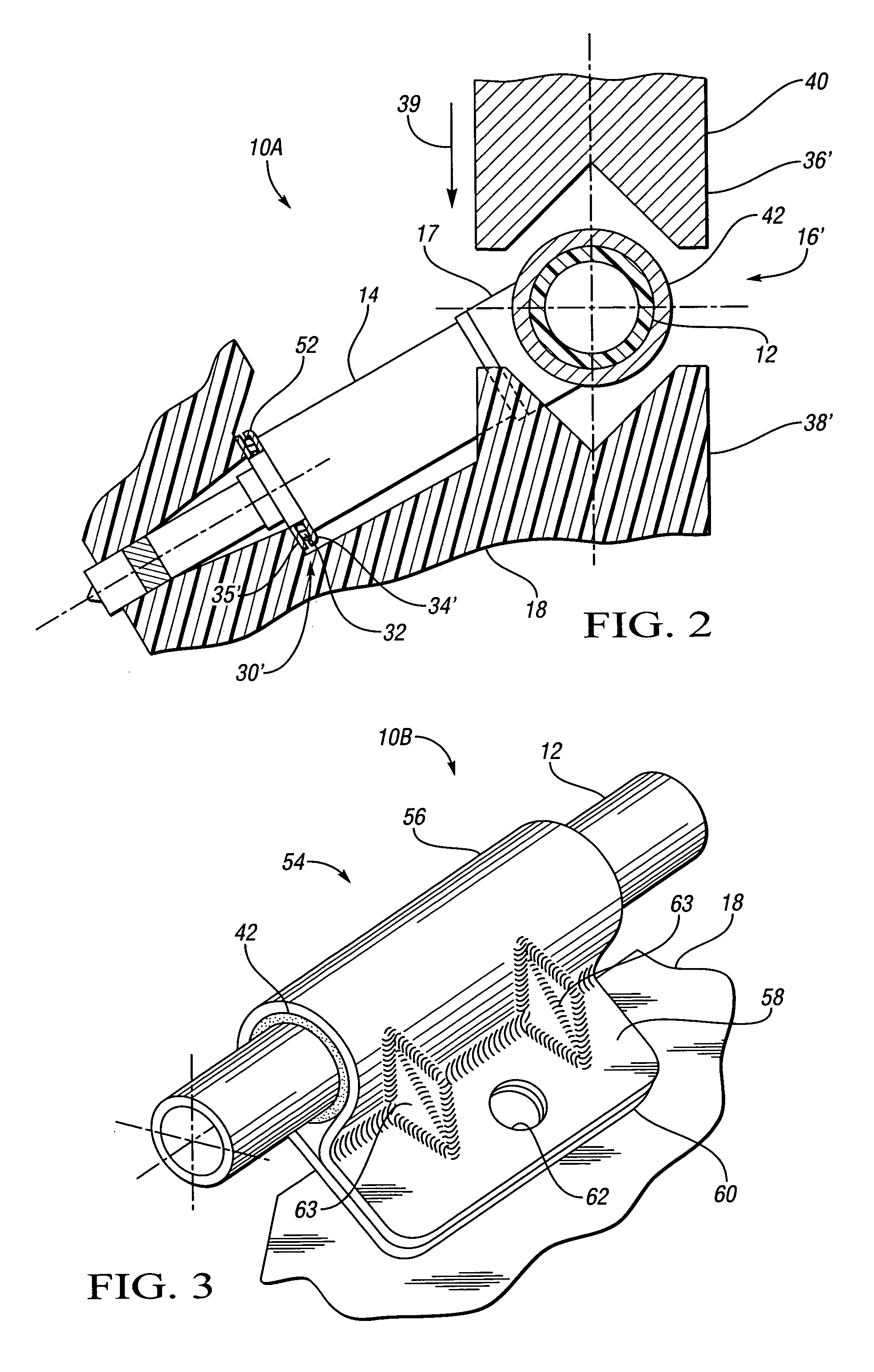

Flex-Fuel Injector for Gas Turbines

A fuel injector (36) for alternate fuels (26A, 26B) with energy densities that differ by at least about a factor of two. Vanes (47B) extend radially from a fuel delivery tube structure (20B) with first and second fuel supply channels (19A, 19B). Each vane has first and second radial passages (21A, 21B) communicating with the respective fuel supply channels, and first and second sets of apertures (23A, 23B) between the respective radial passages and the surface (49) of the vane. The first fuel supply channel, first radial passage, and first apertures form a first fuel delivery pathway providing a first fuel flow rate at a given backpressure. The second fuel supply channel, second radial passage, and second apertures form a second fuel delivery pathway providing a second fuel flow rate that may be at least about twice first fuel flow rate at the given backpressure.

Owner:SIEMENS ENERGY INC

Internal combustion engine control for improved fuel efficiency

ActiveUS20100006065A1Enhance emission characteristicOptimal thermodynamic efficiencyAnalogue computers for vehiclesElectrical controlSelf adaptiveAdaptive control

A variety of methods and arrangements for improving the fuel efficiency of internal combustion engines are described. Generally, an engine is controlled to operate in a skip fire variable displacement mode. Feedback control is used to dynamically determine the working cycles to be skipped to provide a desired engine output. In some embodiments a substantially optimized amount of air and fuel is delivered to the working chambers during active working cycles so that the fired working chambers can operate at efficiencies close to their optimal efficiency. In some embodiments, the appropriate firing pattern is determined at least in part using predictive adaptive control. By way of example, sigma delta controllers work well for this purpose. In some implementations, the feedback includes feedback indicative of at least one of actual and requested working cycle firings. In some embodiments, the appropriate firings are determined on a firing opportunity by firing opportunity basis. Additionally, in some embodiments, an indicia of the current rotational speed of the engine is used as a clock input for a controller used to selectively cause the skipped working cycles to be skipped.

Owner:TULA TECH INC

Direct injection of fuels in internal combustion engines

A fuel delivery injector for an internal combustion engine is provided. A fuel injector forms part of a device which provides a combined injection and ignition. The fuel delivery injector comprises first and second portions adapted to be detachably connected together. The first portion incorporates a valve structure having a valve member movable with respect to a valve seat for opening and closing a delivery port, and an actuating member operatively connected to the valve member. An actuator is provided in the second portion. When the first and second portions are connected together, the actuator is operably associated with the actuating member to provide an actuating assembly. Typically, the actuating assembly comprises an electromagnetic device in which the actuating member comprises a solenoid armature and the actuator comprises a solenoid coil, whereby connection of the first and second portions together completes assembly of the electromagnetic device.

Owner:ORBITAL ENGINE CO PTY LTD

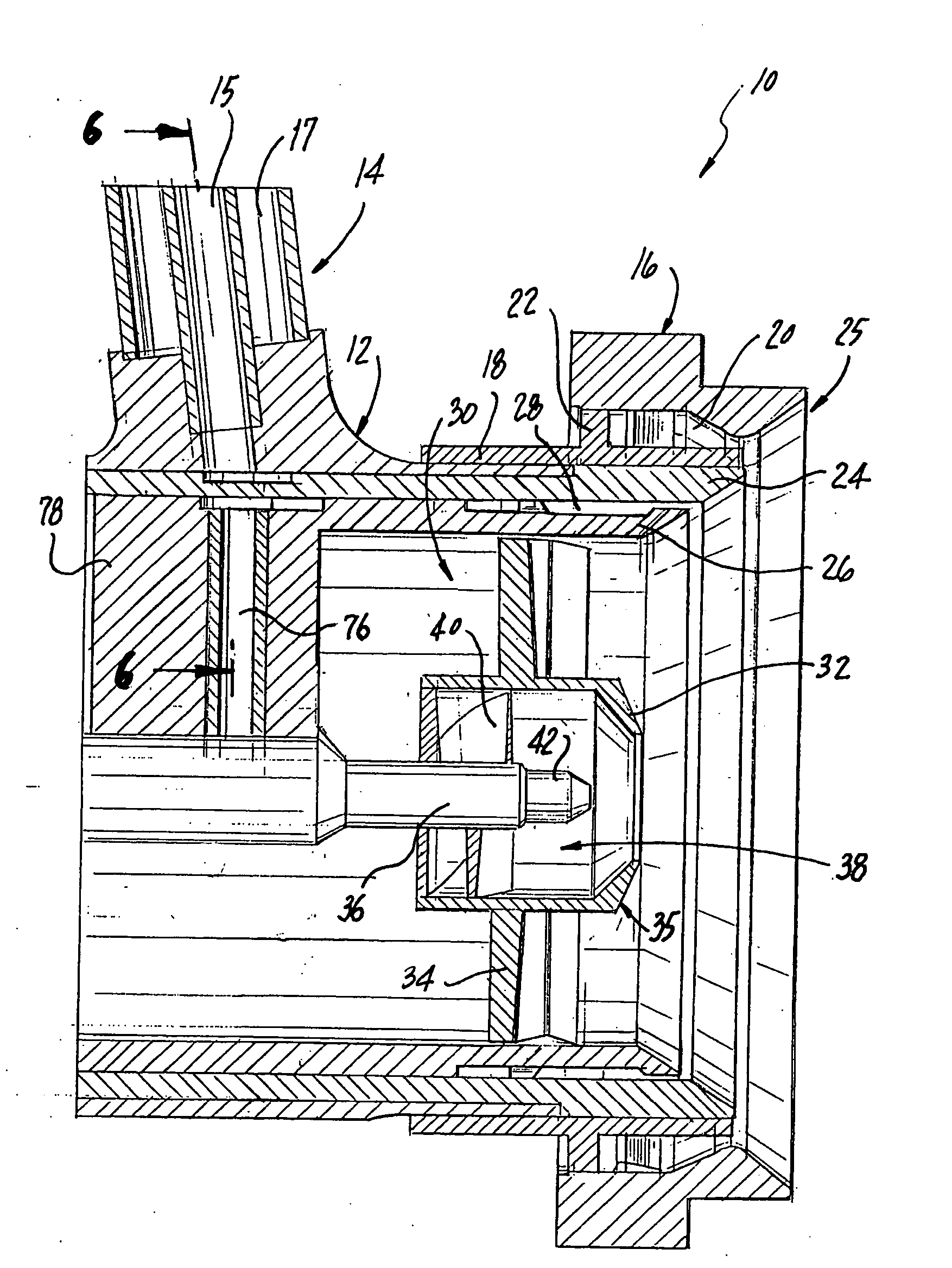

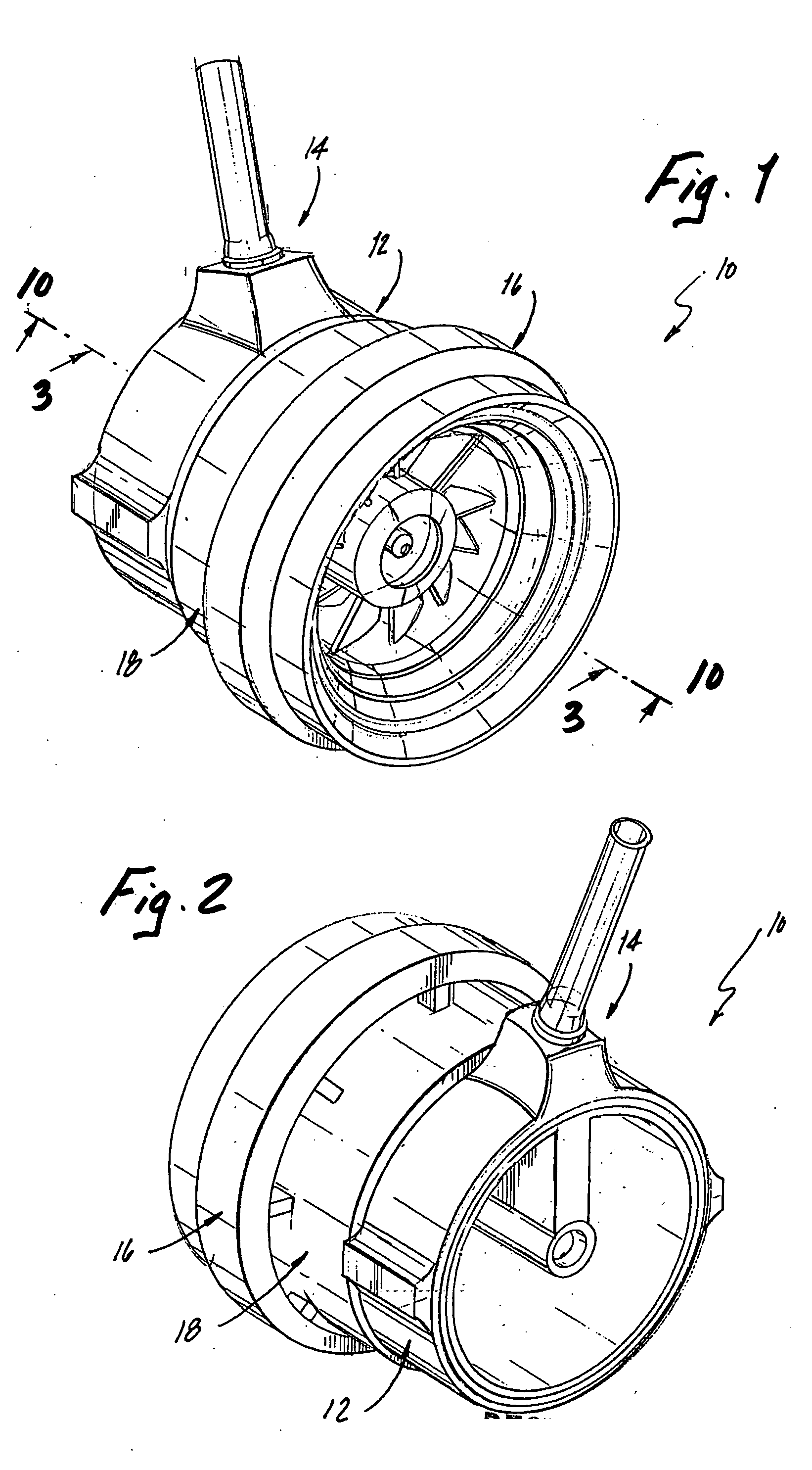

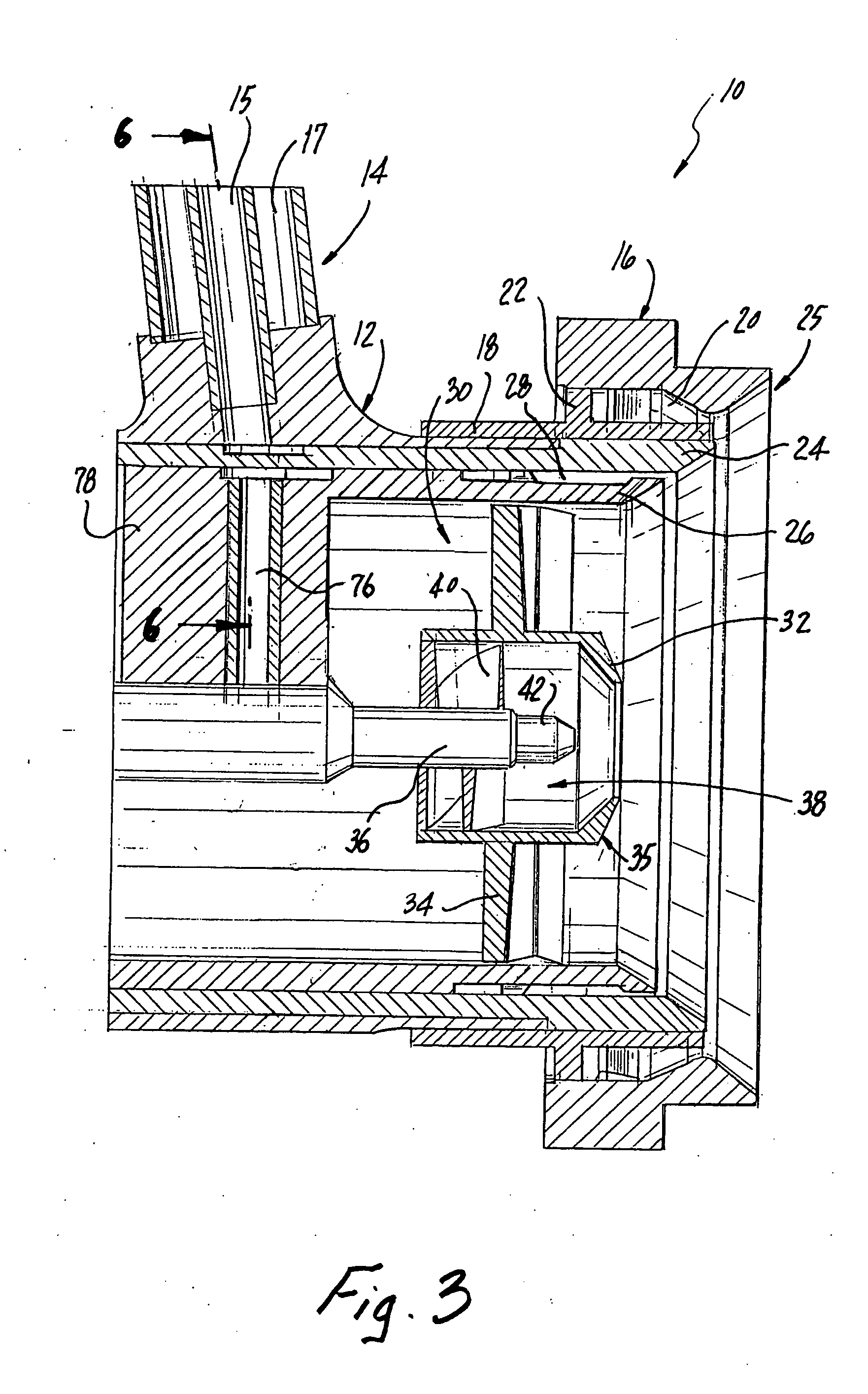

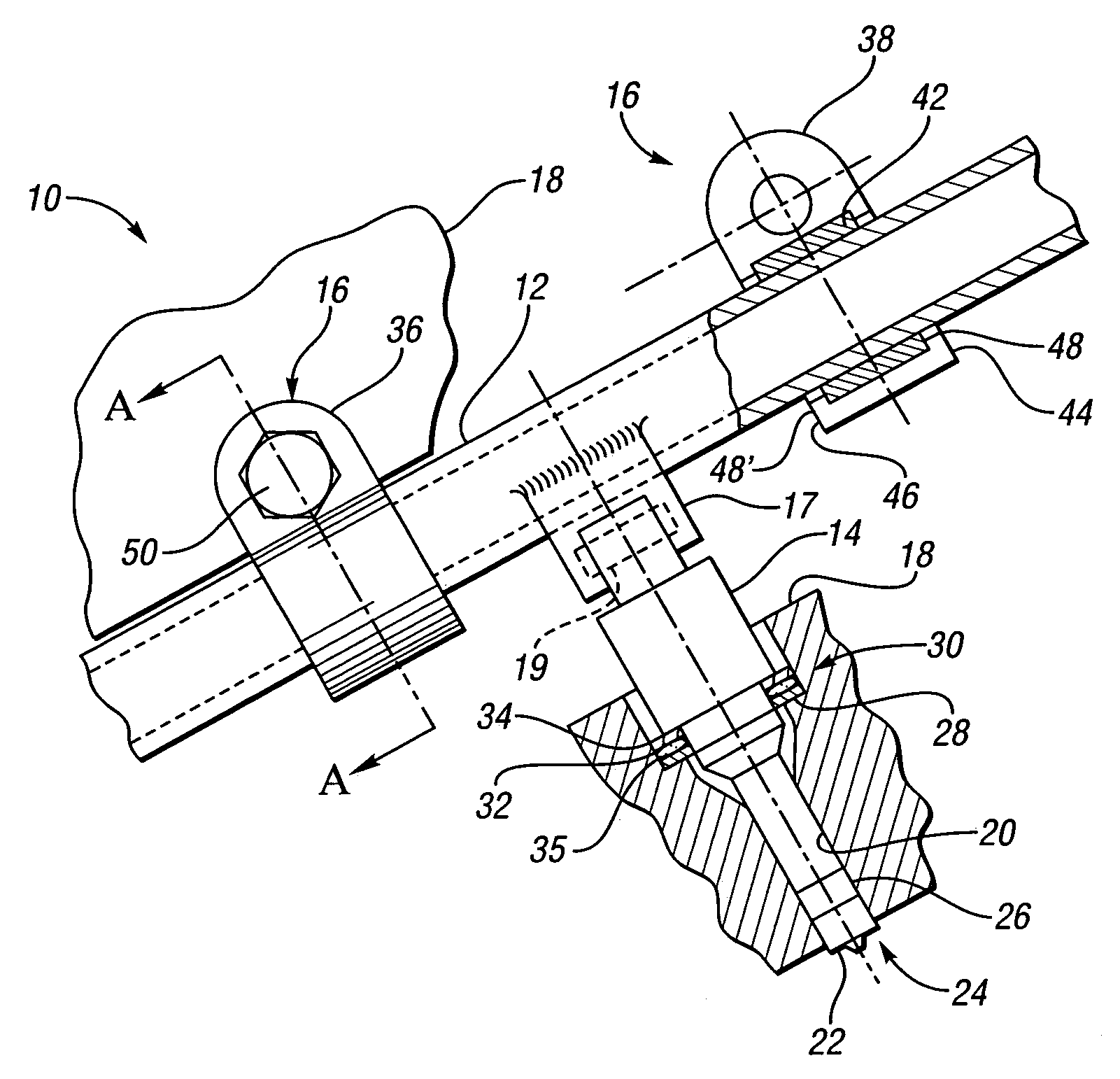

System and method for cooling a staged airblast fuel injector

A staged fuel injector is disclosed that includes a main fuel circuit for delivering fuel to a main fuel atomizer and a pilot fuel circuit for delivering fuel to a pilot fuel atomizer located radially inward of the main fuel atomizer. The pilot fuel circuit is in close proximity to the main fuel circuit enroute to the pilot fuel atomizer so that the pilot fuel flow cools stagnant fuel located within the main fuel circuit during low engine power operation to prevent coking.

Owner:ROLLS ROYCE PLC

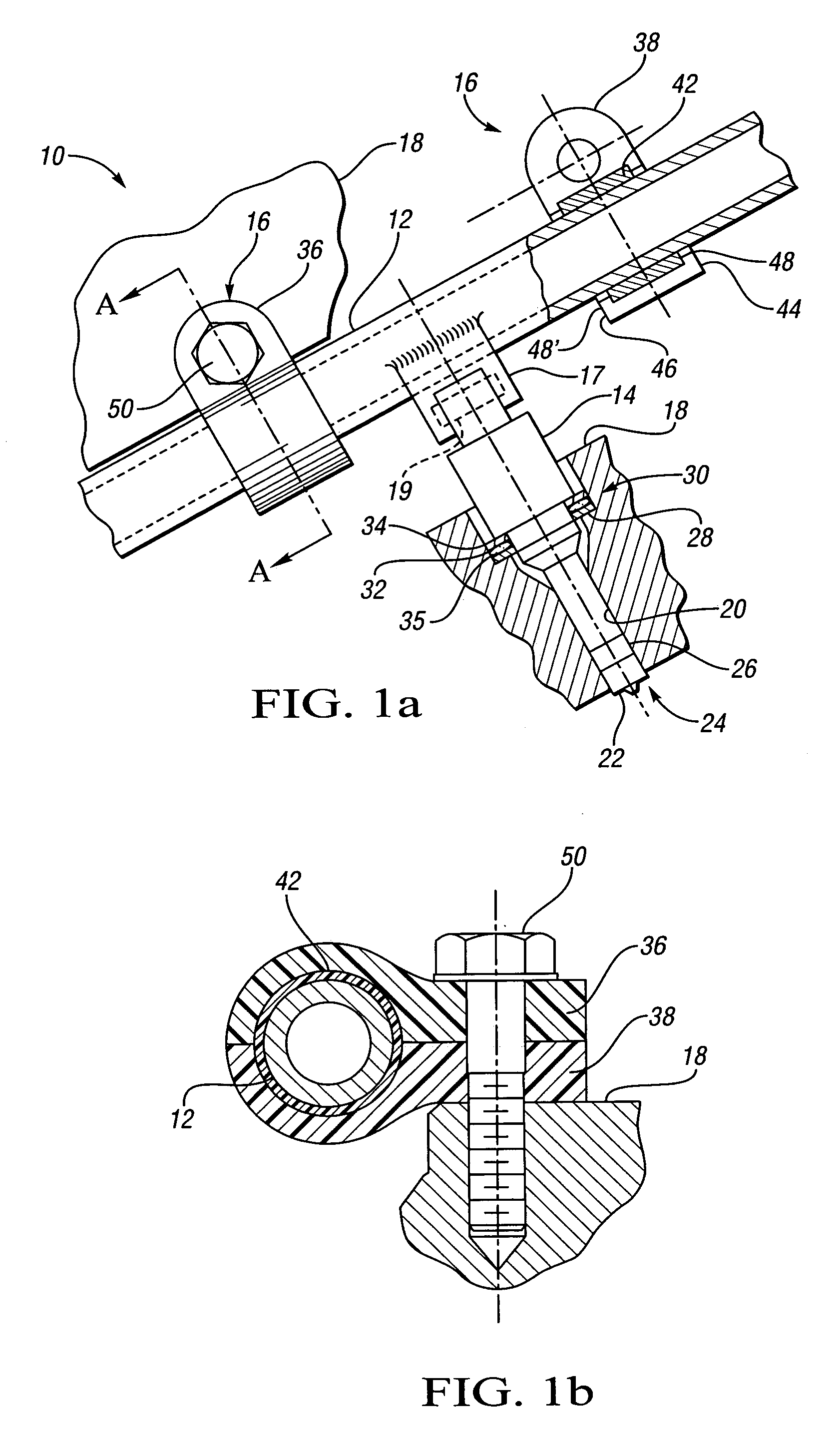

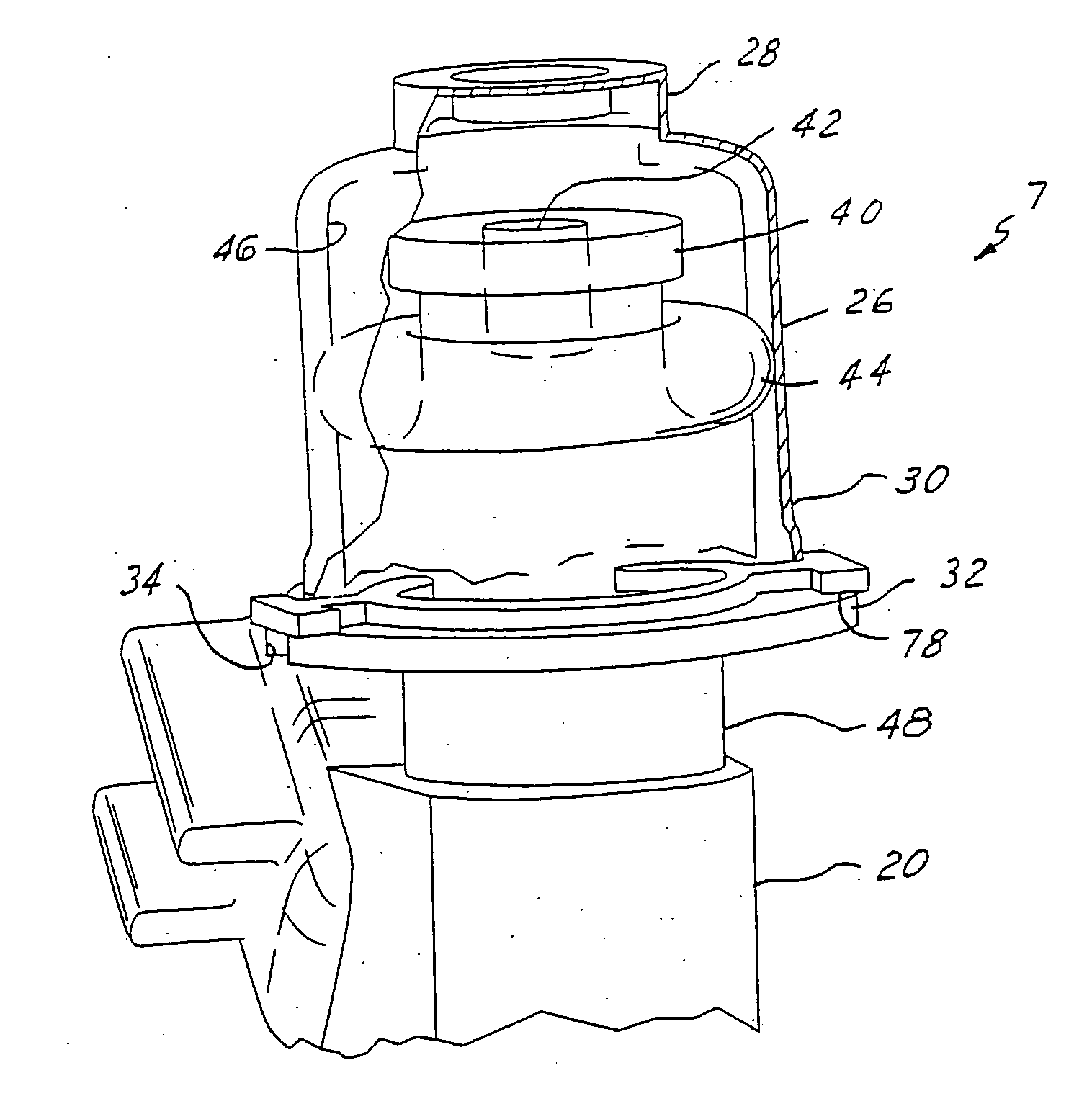

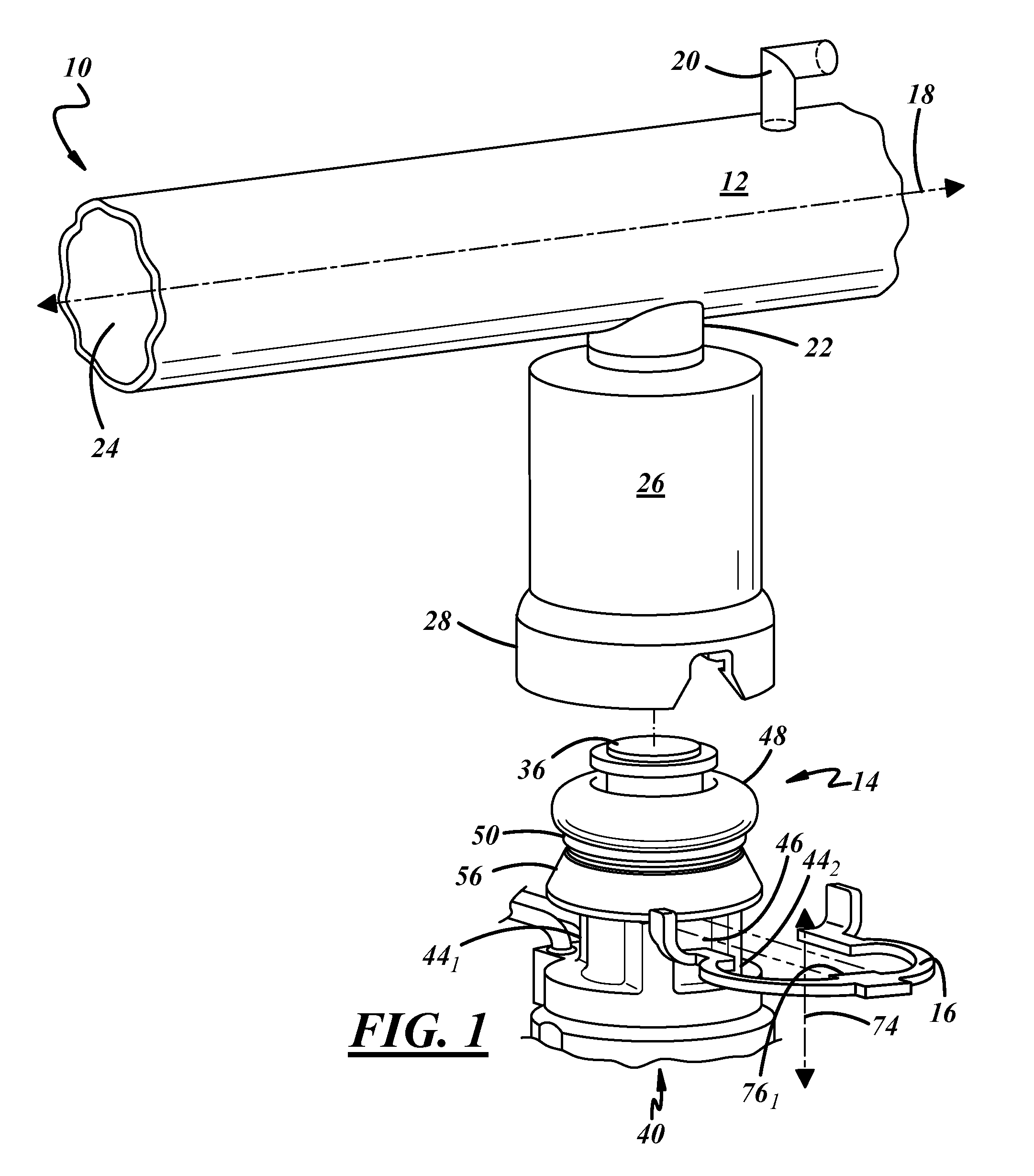

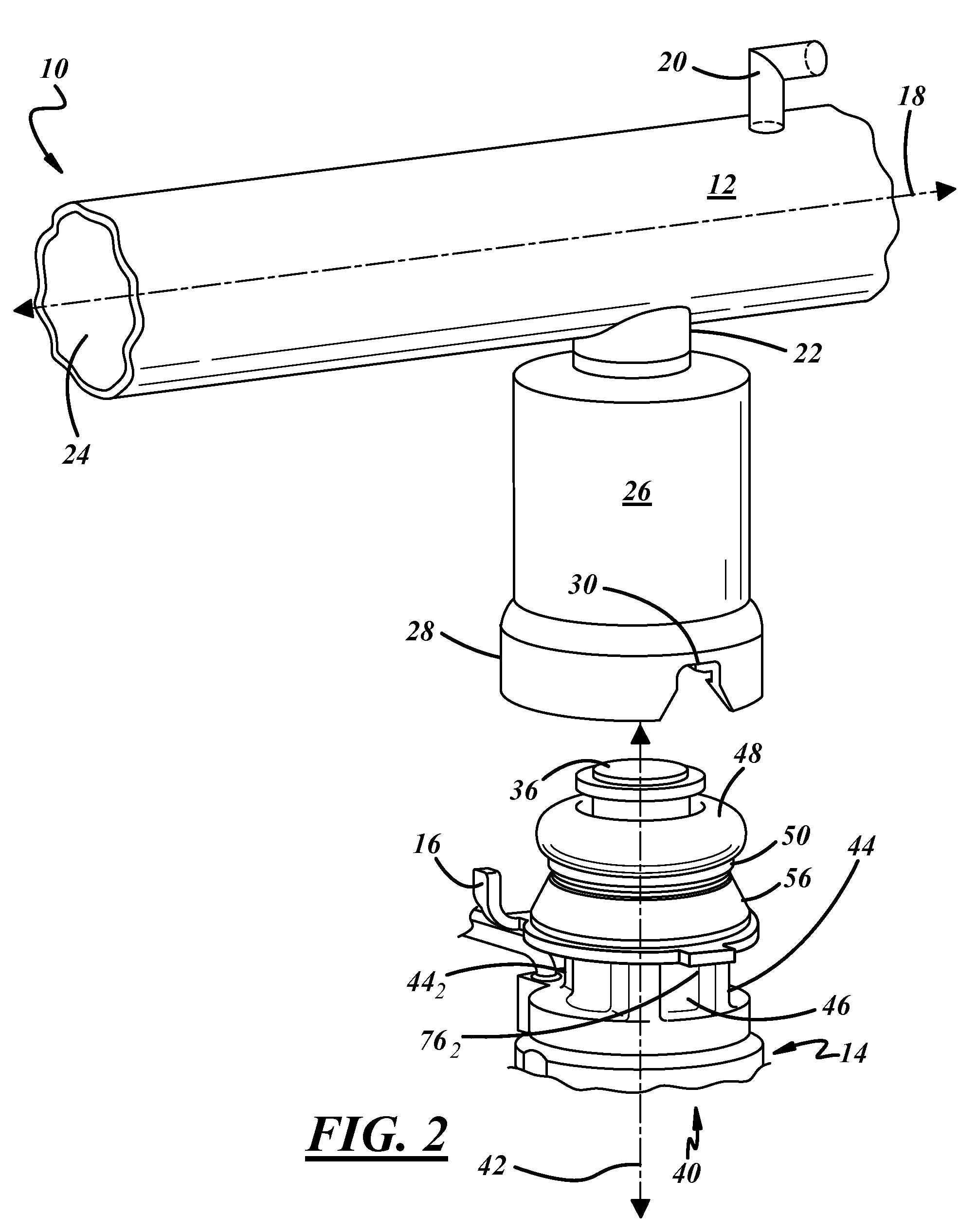

Isolated fuel delivery system

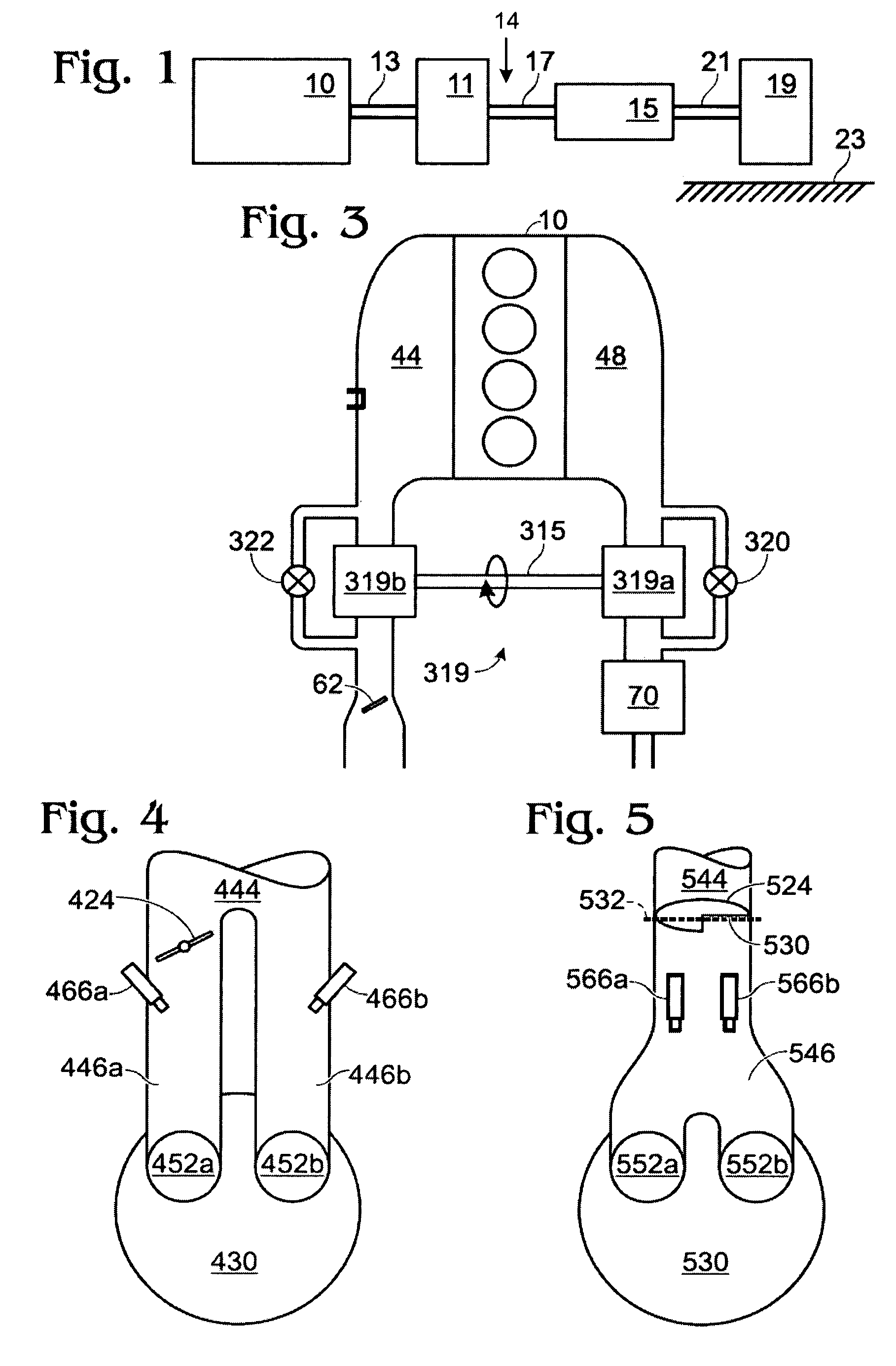

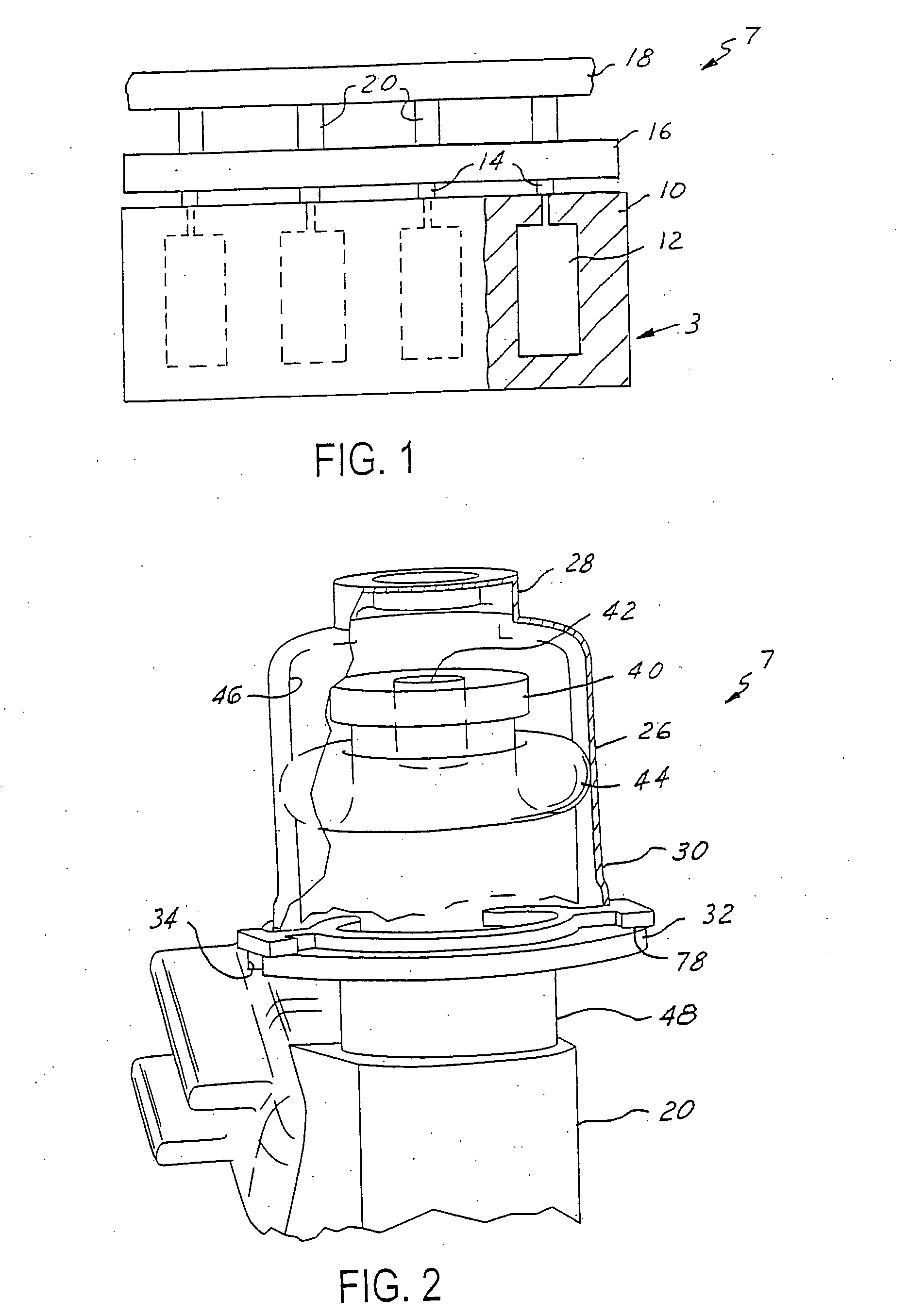

InactiveUS20070163545A1Reduce noise transmissionHigh-frequency vibrationNutsLow pressure fuel injectionCylinder headEngineering

An isolated fuel delivery system for an internal combustion engine includes a fuel rail with a clamping method operable to retain an isolating member with respect to the fuel rail. The isolating member operates to isolate the vibratory motion of the fuel delivery system form the attachment point or points. The attachment point is typically a cylinder head of the internal combustion engine. Additionally, an isolating ring assembly is provided having a first and second stiffening member with an isolating ring member disposed therebetween. The isolating ring assembly is disposed between a fuel injector of the isolated fuel delivery system and the cylinder head. The isolating ring member operates to isolate the vibratory motion of the fuel injector from the internal combustion engine.

Owner:GM GLOBAL TECH OPERATIONS LLC

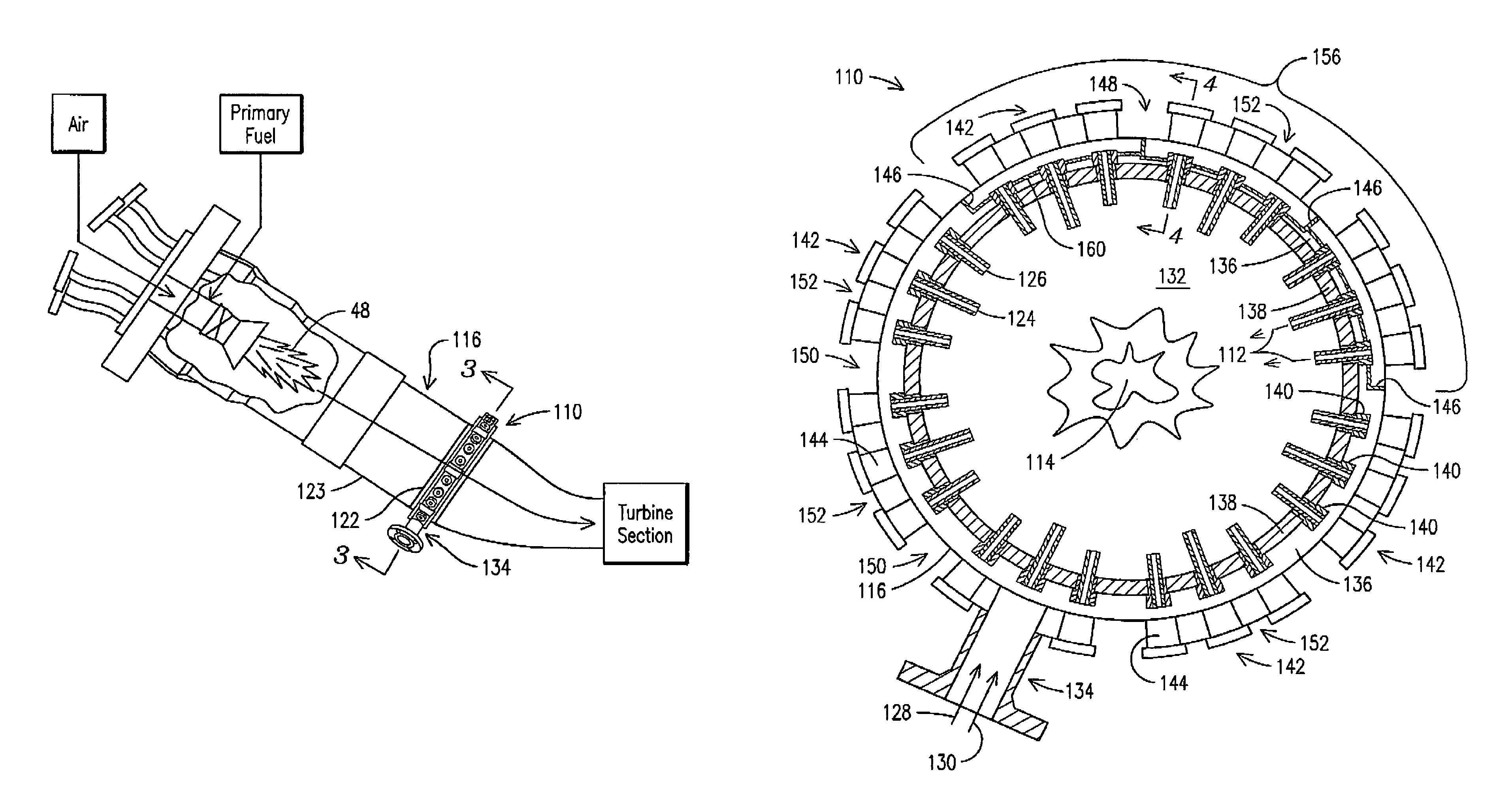

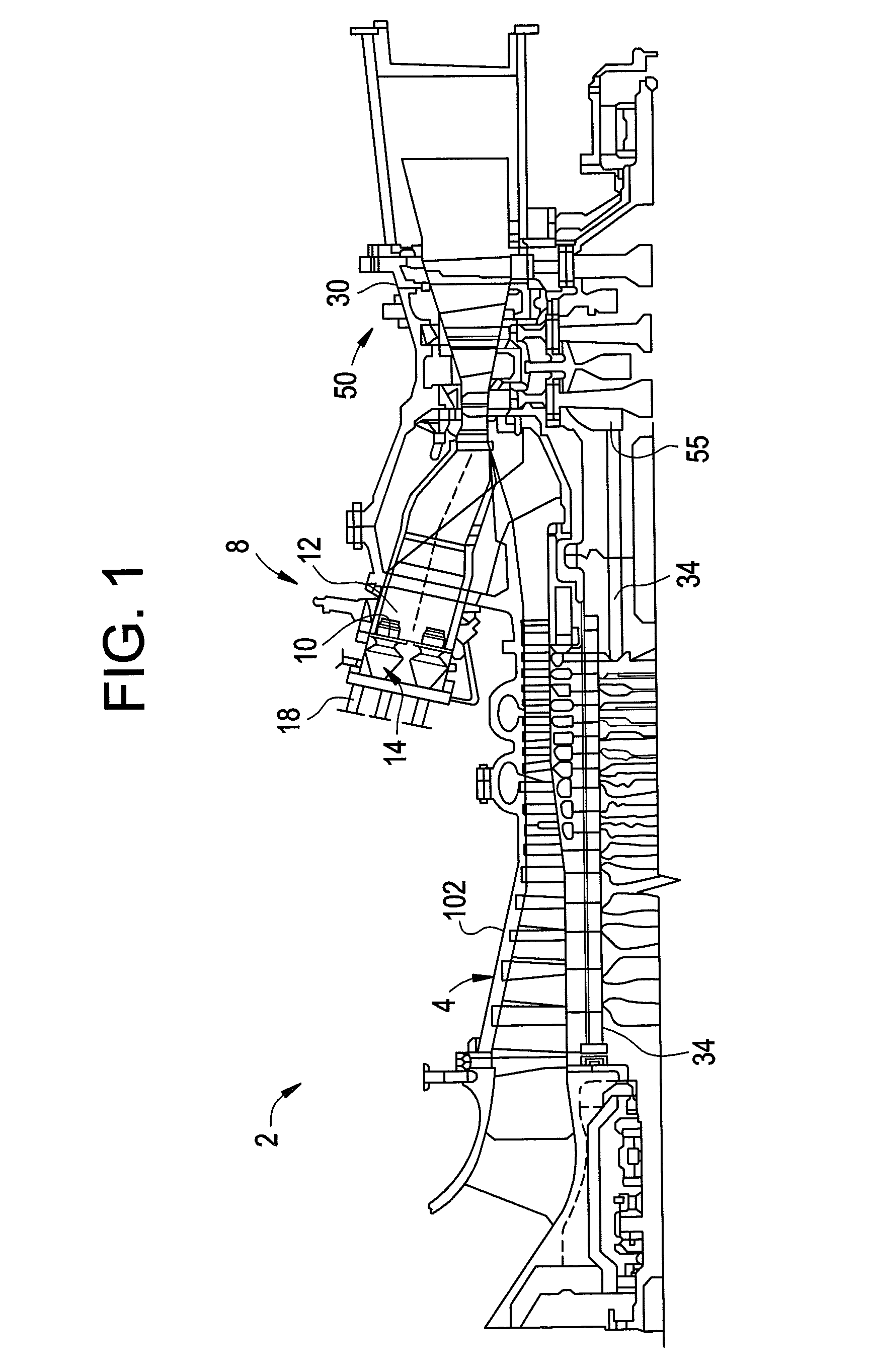

Secondary fuel delivery system

ActiveUS7665309B2Reduce impactAvoid heat dissipation difficultiesContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustionDiluent

A secondary fuel delivery system for delivering a secondary stream of fuel and / or diluent to a secondary combustion zone located in the transition piece of a combustion engine, downstream of the engine primary combustion region is disclosed. The system includes a manifold formed integral to, and surrounding a portion of, the transition piece, a manifold inlet port, and a collection of injection nozzles. A flowsleeve augments fuel / diluent flow velocity and improves the system cooling effectiveness. Passive cooling elements, including effusion cooling holes located within the transition boundary and thermal-stress-dissipating gaps that resist thermal stress accumulation, provide supplemental heat dissipation in key areas. The system delivers a secondary fuel / diluent mixture to a secondary combustion zone located along the length of the transition piece, while reducing the impact of elevated vibration levels found within the transition piece and avoiding the heat dissipation difficulties often associated with traditional vibration reduction methods.

Owner:SIEMENS ENERGY INC

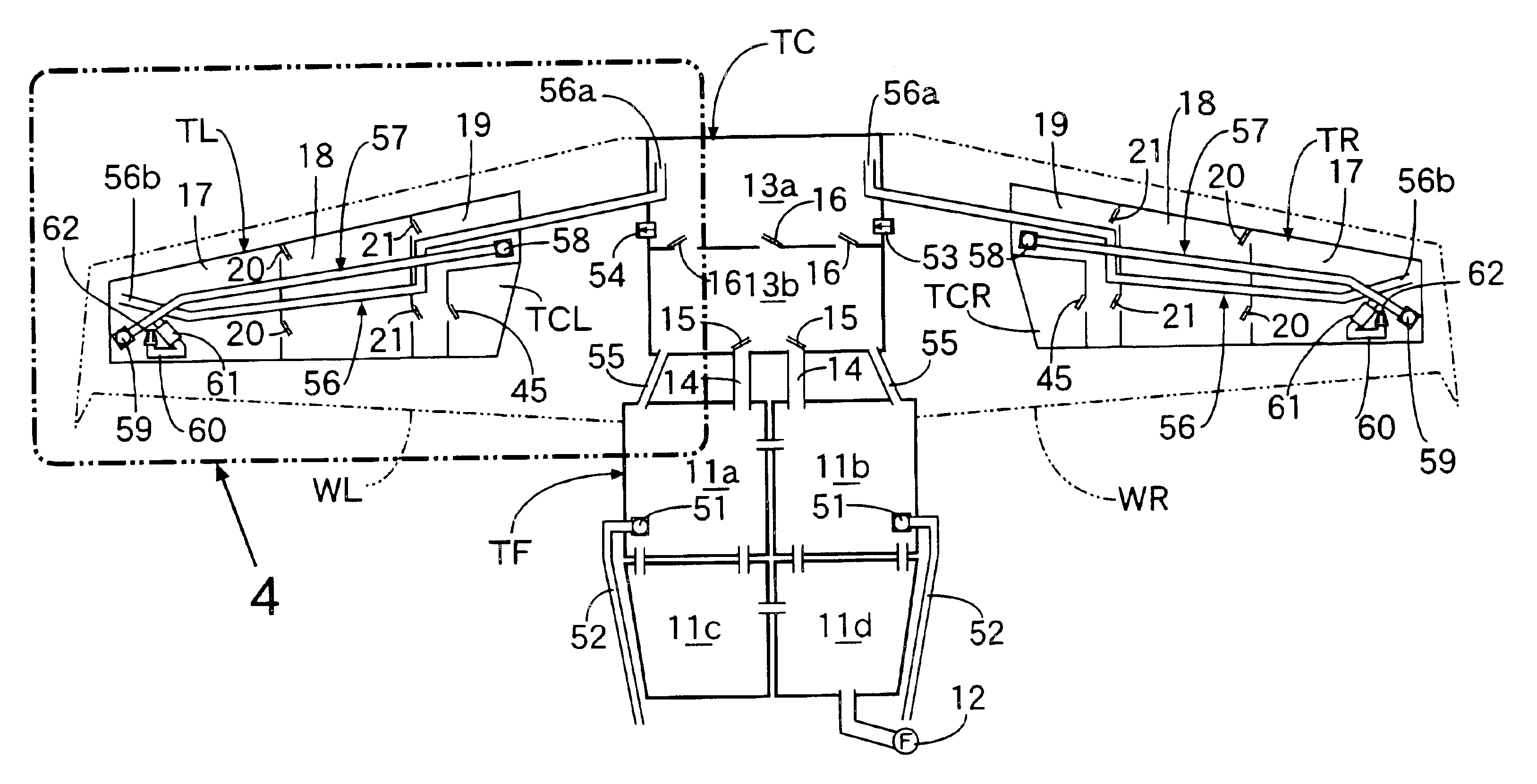

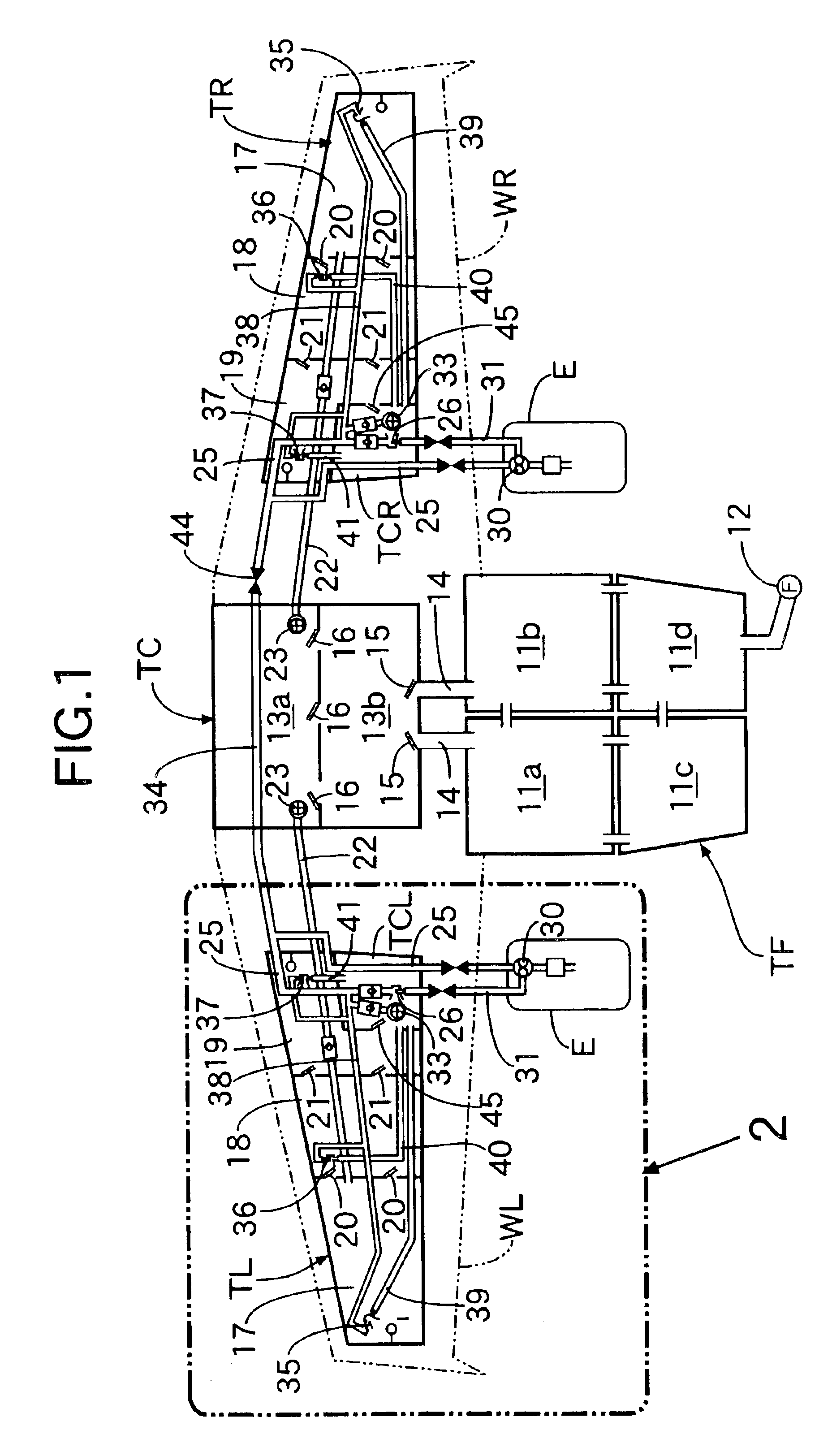

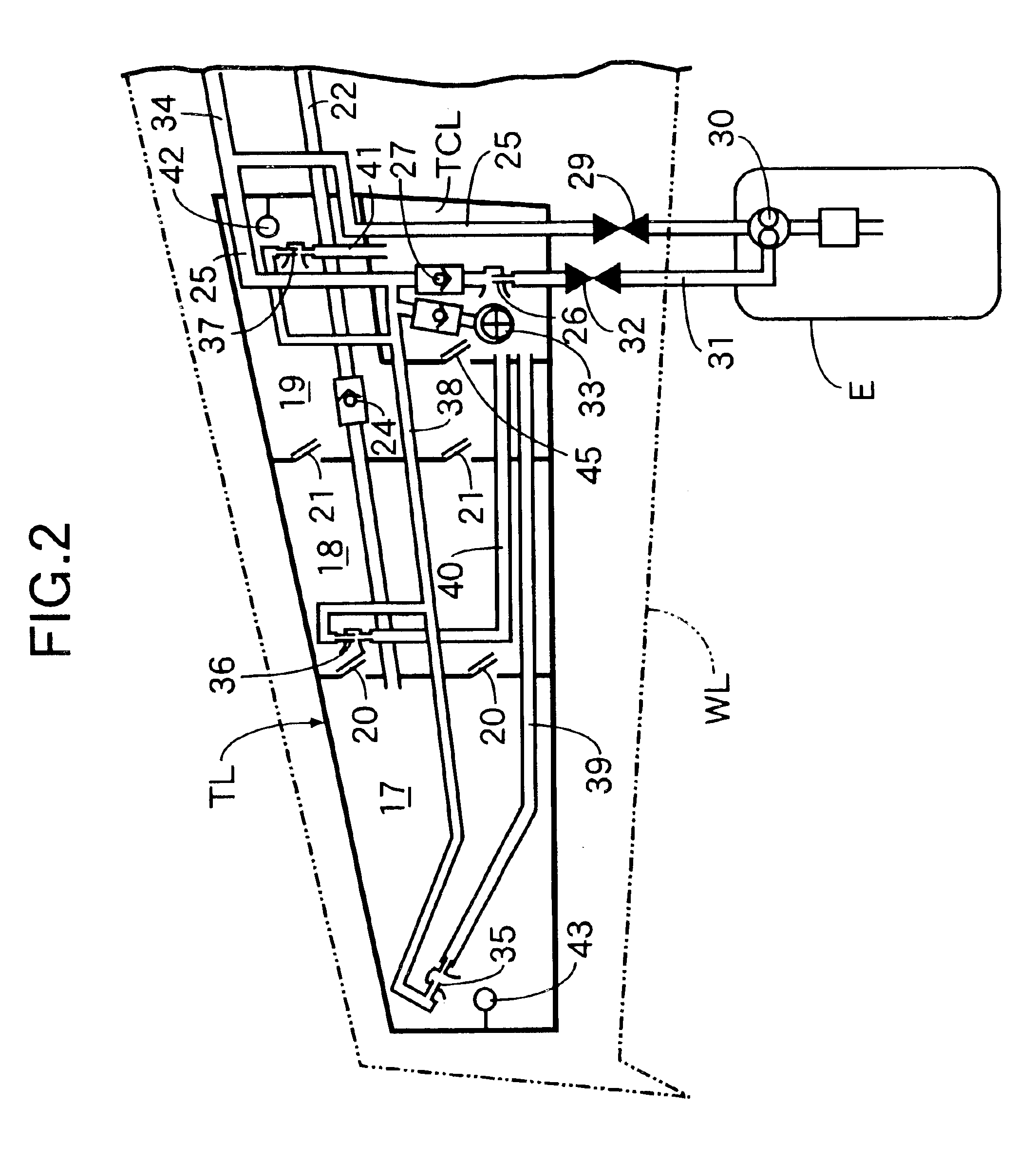

Airplane fuel supply system and airplane wing pipeline assembly method

An airplane fuel supply system includes a wing fuel tank that is formed from a wing tip fuel tank having a wing tip fuel pump; a central fuel tank having a central fuel pump; and a wing root fuel tank having a wing root fuel pump. Fuel movement from the wing tip fuel tank to the central fuel tank is allowed by a flapper valve, and fuel movement from the central fuel tank to the wing root fuel tank is allowed by another flapper valve. When the fuel delivery volume of the wing tip fuel pump is represented by Vt, the fuel delivery volume of the central fuel pump is represented by Vc, the fuel delivery volume of the wing root fuel pump is represented by Vr, and the fuel delivery volume from a collector tank to the engine is represented by Ve, the fuel delivery volumes Vt, Vc, Vr, and Ve are set so as to satisfy the relationships Vr>Ve, Vt+Vc>Ve, and Vc<Ve. This can minimize the size of the fuel pumps for supplying fuel from the airplane wing fuel tank to the engine.

Owner:AMERICAN HONDA MOTOR COMPANY

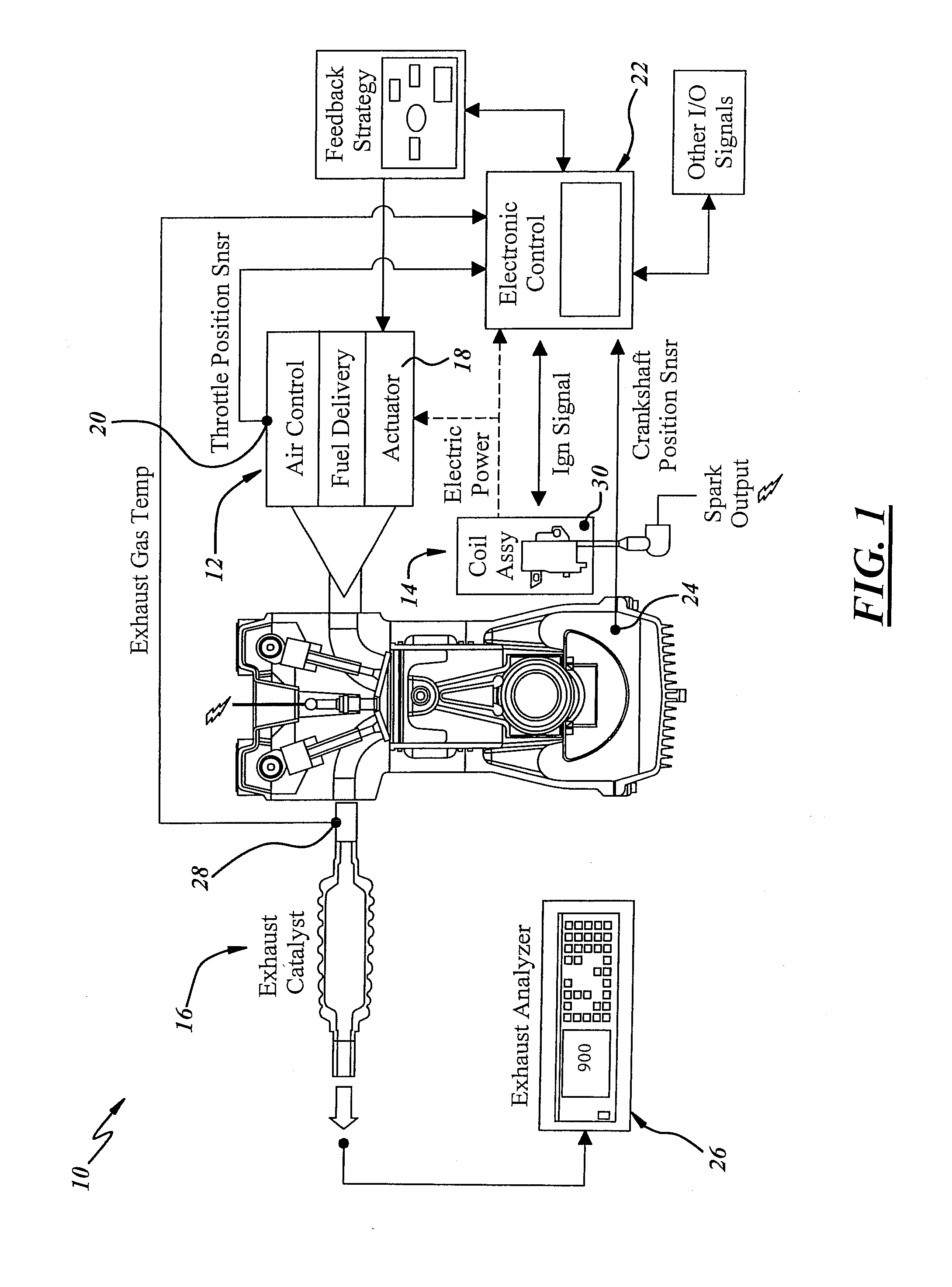

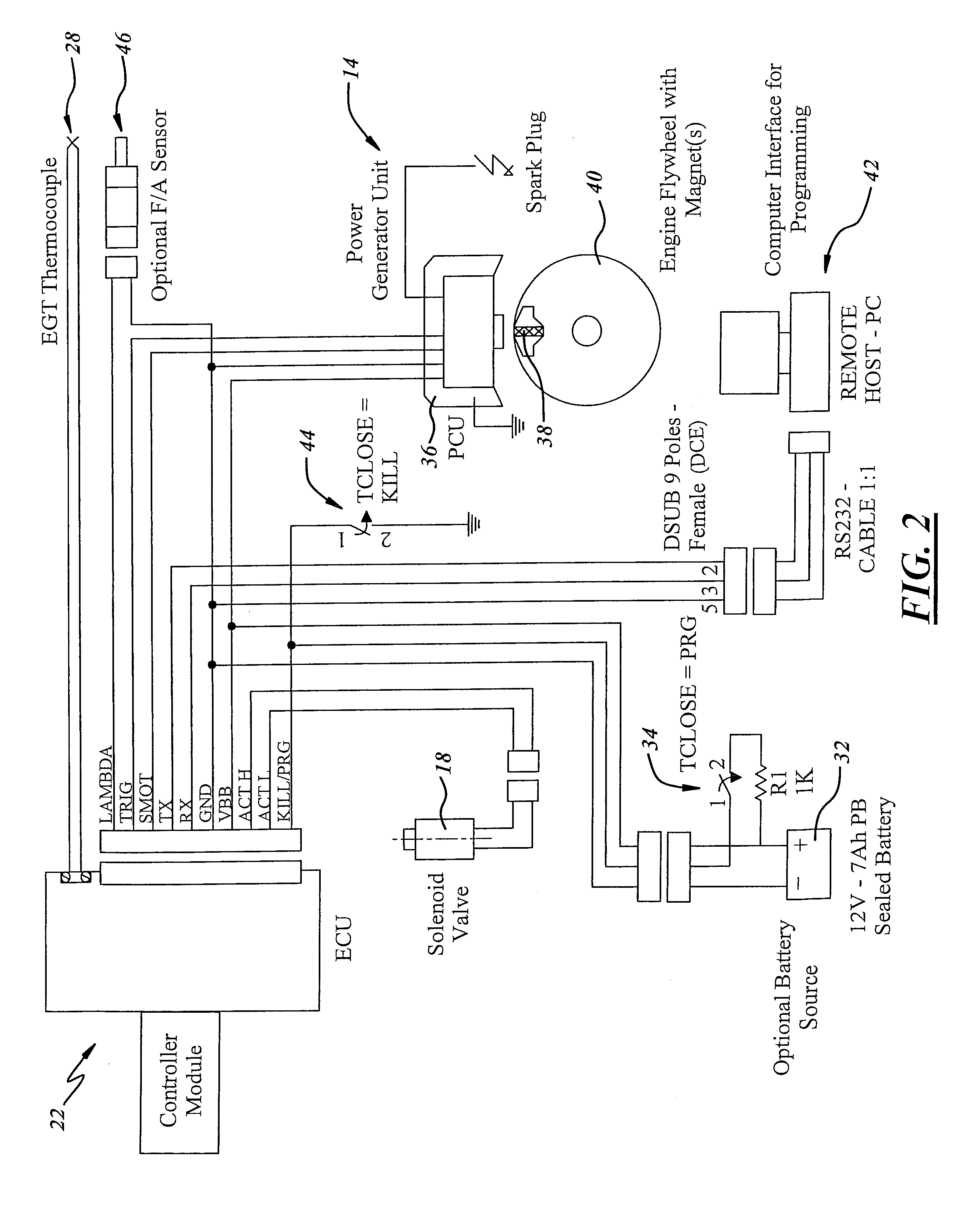

Engine fuel delivery systems, apparatus and methods

ActiveUS20100258099A1Avoid communicationAnalogue computers for vehiclesElectrical controlControl systemEngineering

A method of operating an engine is disclosed, which includes determining a peak power condition for the engine, measuring a temperature associated with the engine at said peak power condition, comparing the temperature measured with a previously determined temperature associated with a known peak power condition of the engine, determining an offset value based on the comparison made in step, controlling at least one of an air-fuel mixture delivered to the engine or ignition spark timing based on said offset value. Various engine fuel delivery systems, carburetors, fuel injection and control systems also are disclosed.

Owner:WALBRO LLC

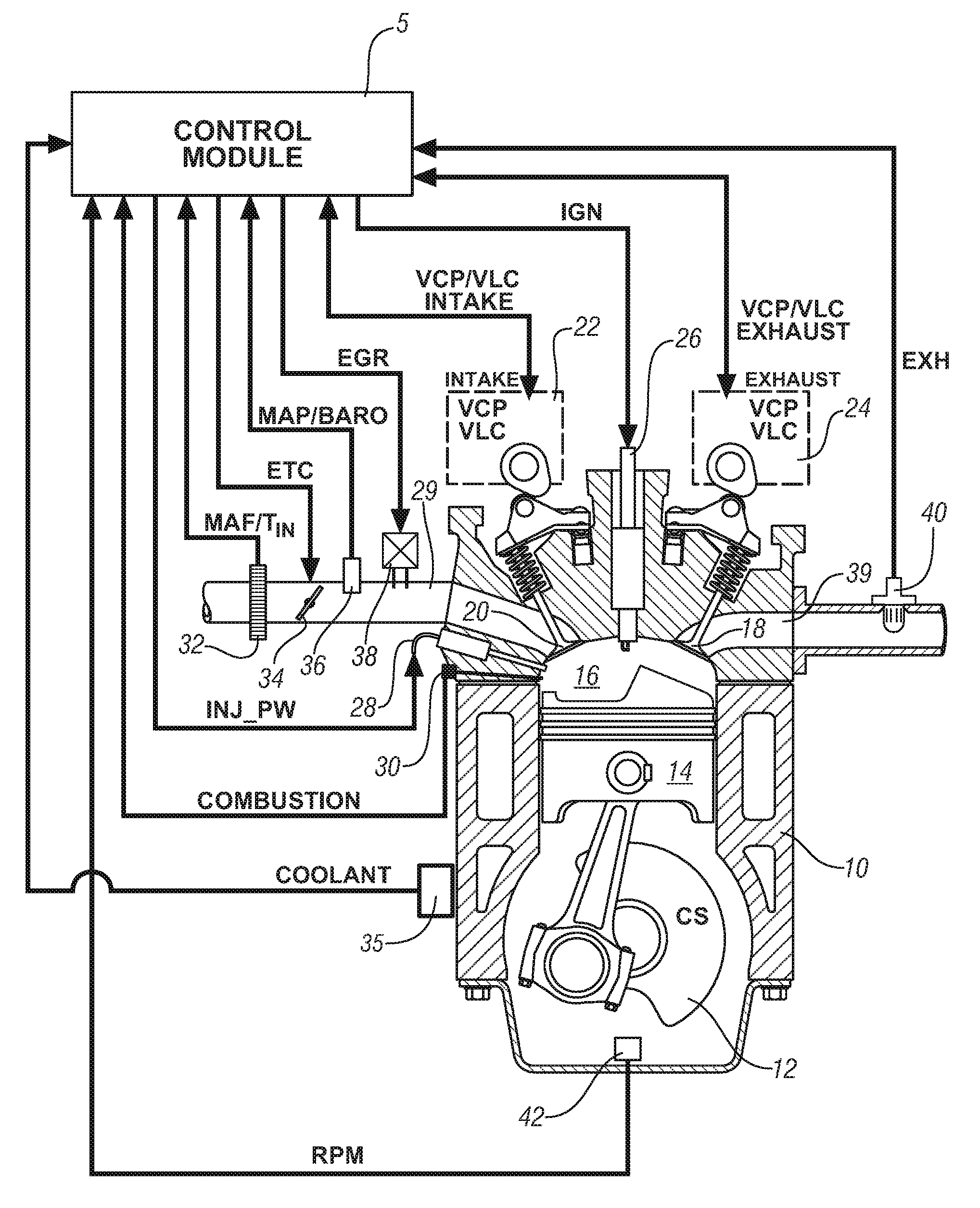

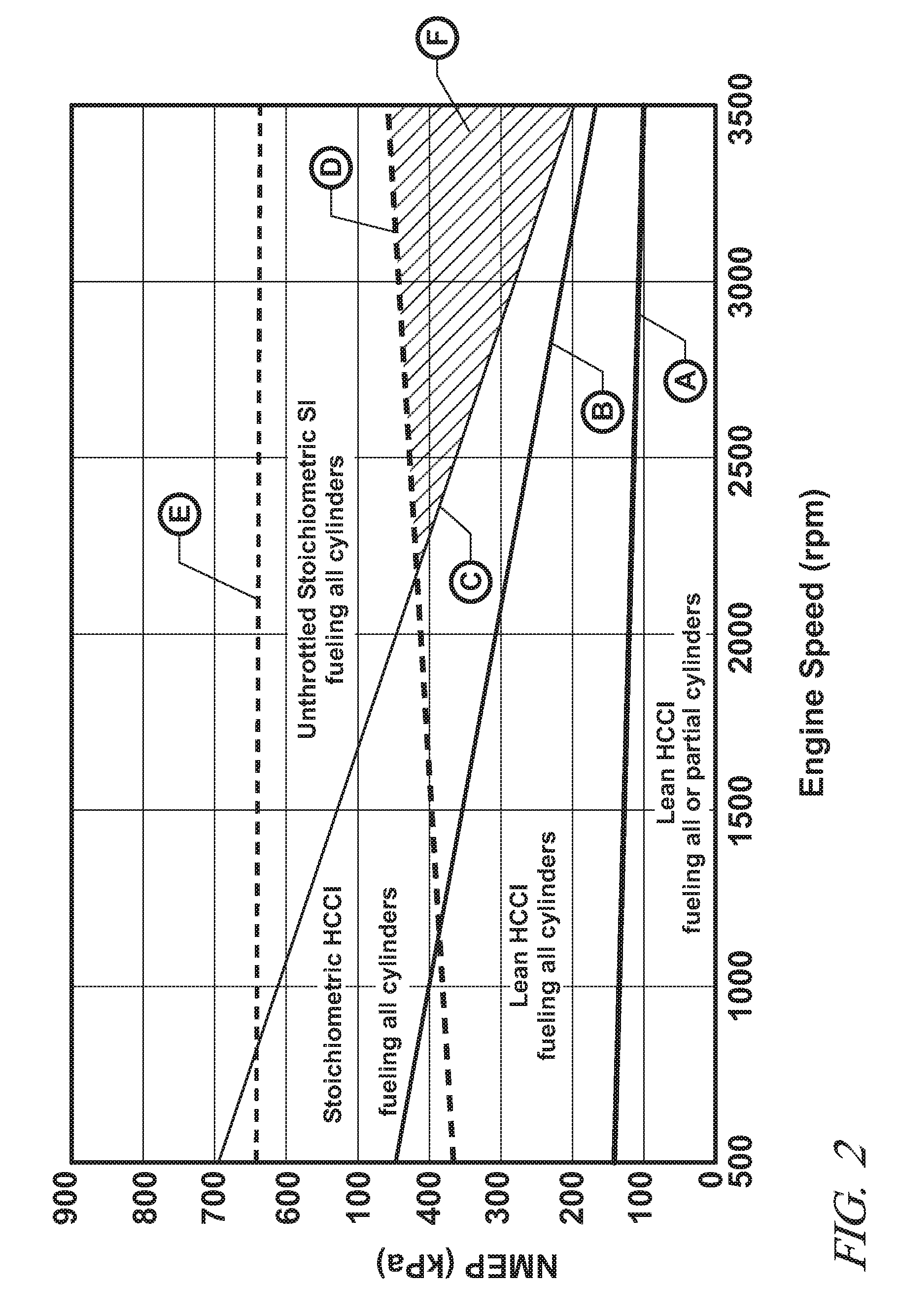

Method and apparatus to control a transition between HCCI and SI combustion in a direct-injection gasoline engine

InactiveUS20070272202A1Increased torque outputValve arrangementsElectrical controlOperating pointGasoline

A method to operate a multi-cylinder direct-injection engine in one of a controlled auto-ignition and a spark-ignition combustion mode is described. Engine operation and an operator torque request are monitored. Fuel delivery to a portion of the cylinders is selectively deactivated and torque output from non-deactivated cylinders is selectively increased to achieve the operator torque request when the monitored engine operation is above a predetermined threshold. An engine operating point at which an engine load demand exceeds an operating capability of the engine in a stoichiometric HCCI mode is identified. The engine is selectively operated in an unthrottled spark-ignition mode with at least one cylinder unfueled and torque output from the remaining cylinders is selectively increased.

Owner:GM GLOBAL TECH OPERATIONS LLC

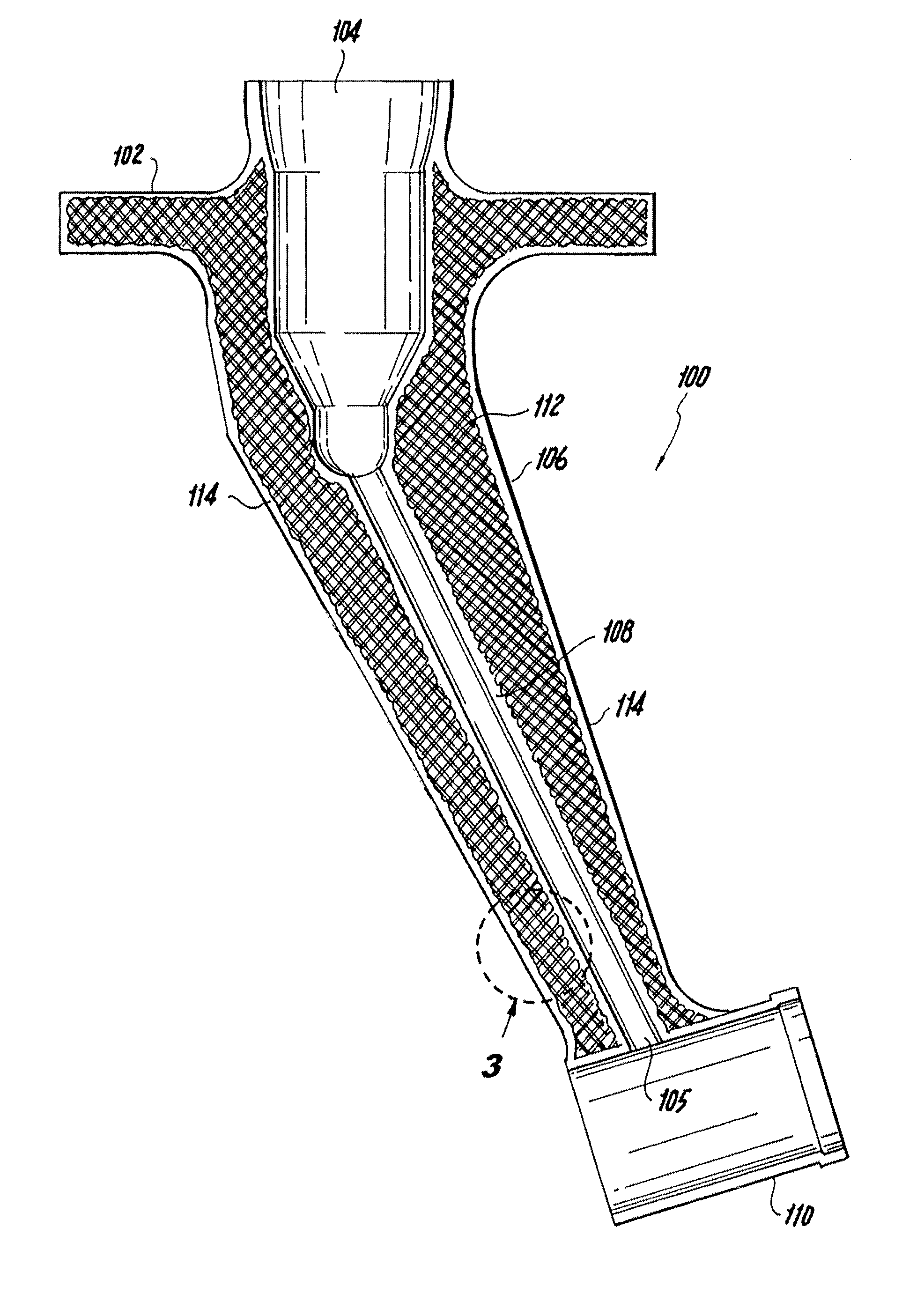

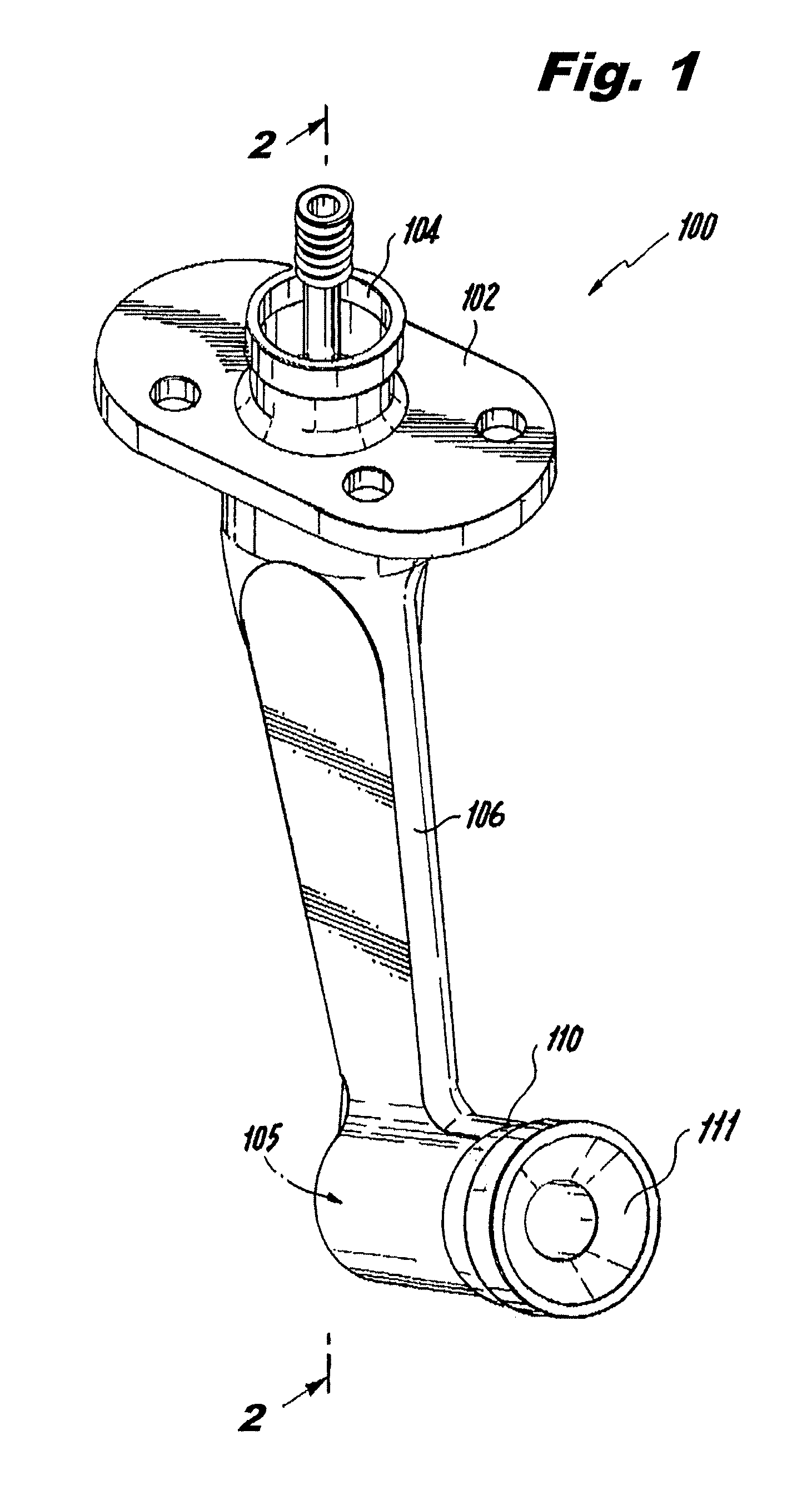

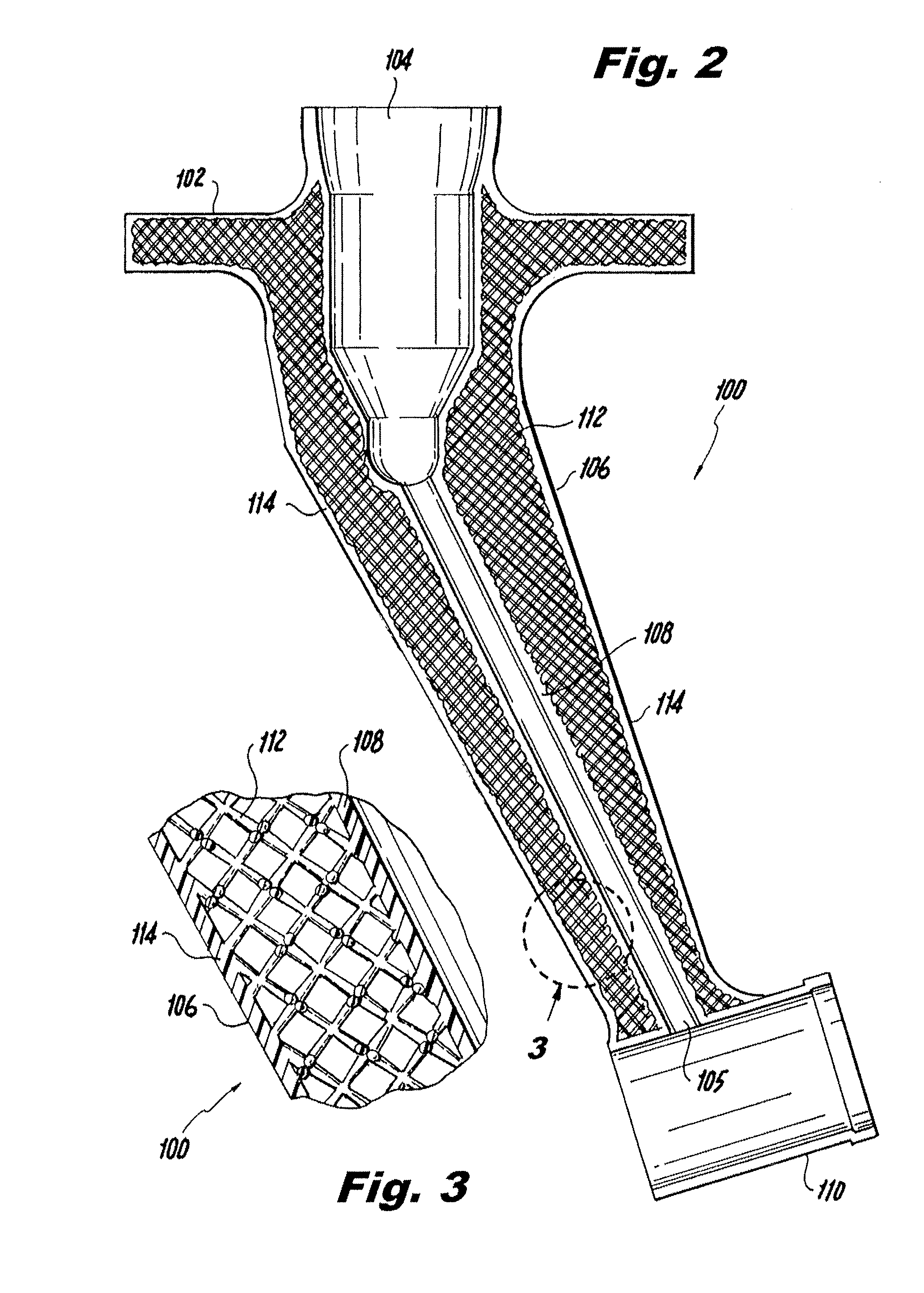

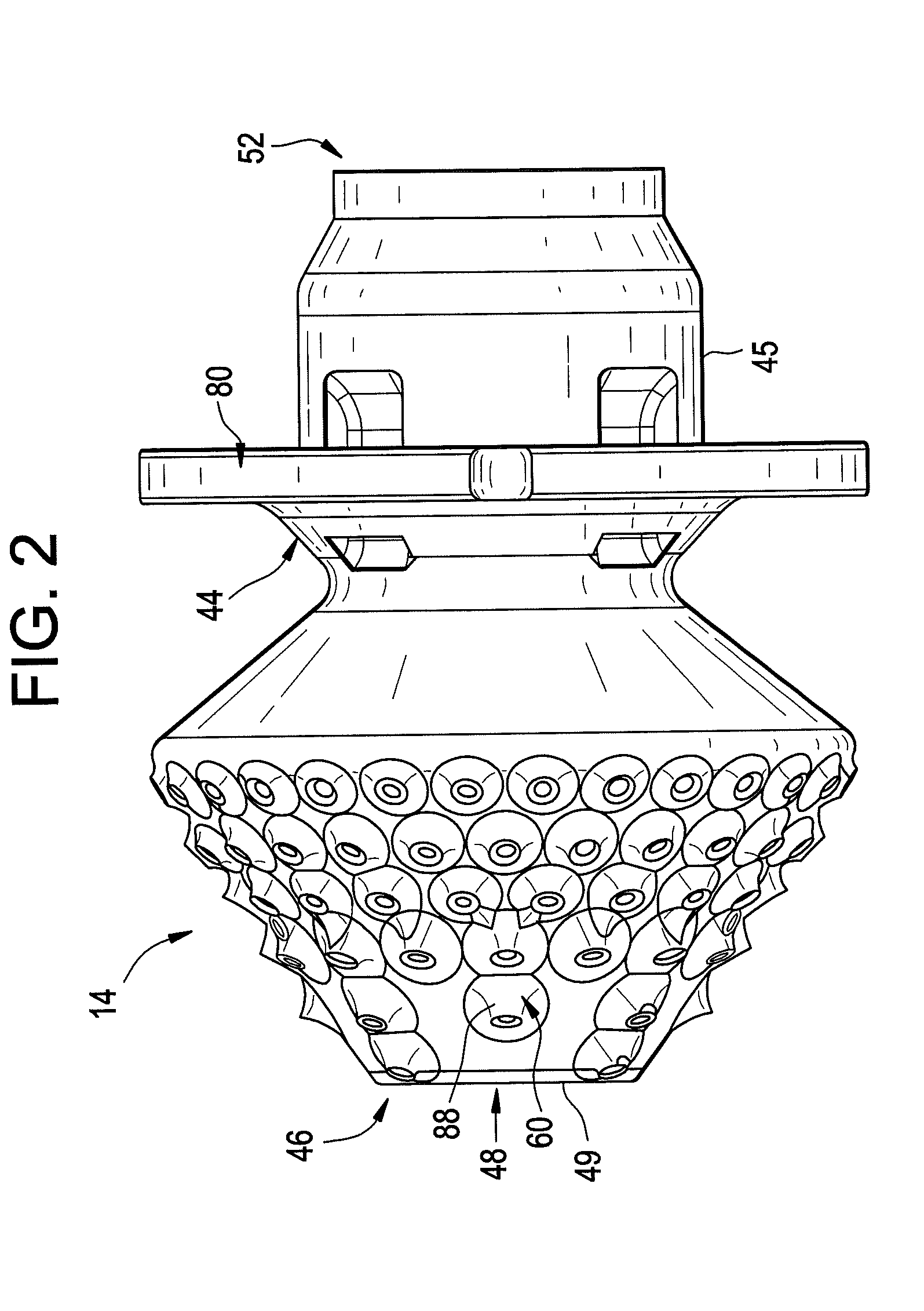

Injectors utilizing lattice support structure

A fuel injector for a gas turbine engine includes an inlet having a fuel inlet fitting for receiving fuel. A feed arm is mounted to the inlet and has an internal conduit in fluid communication with the inlet for conveying fuel from the inlet fitting through the feed arm. A nozzle body is operatively connected to the feed arm for injecting fuel from the internal conduit into a combustor of a gas turbine engine. At least one of the inlet, feed arm, and nozzle body includes a lattice support structure.

Owner:DELAVAN

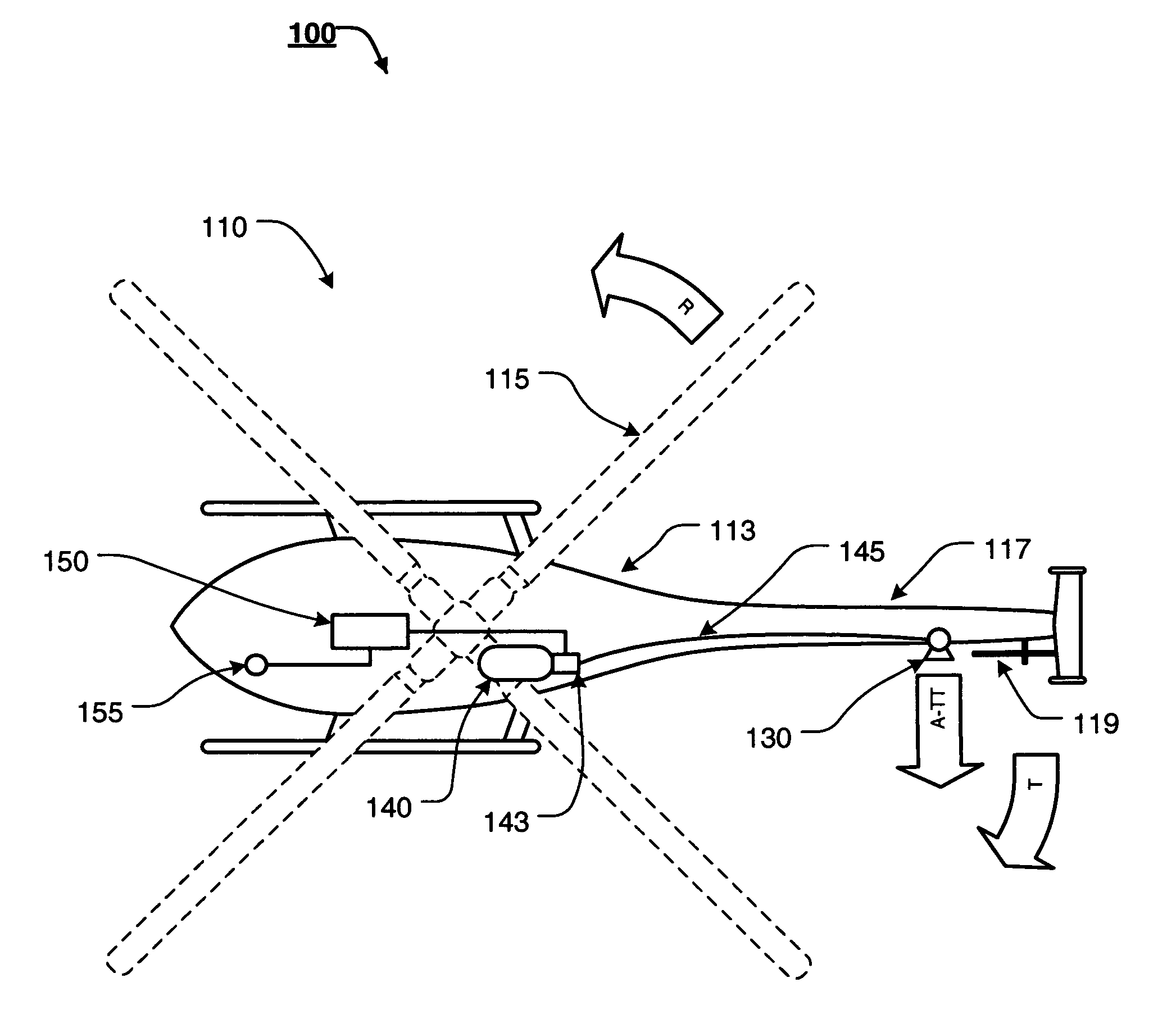

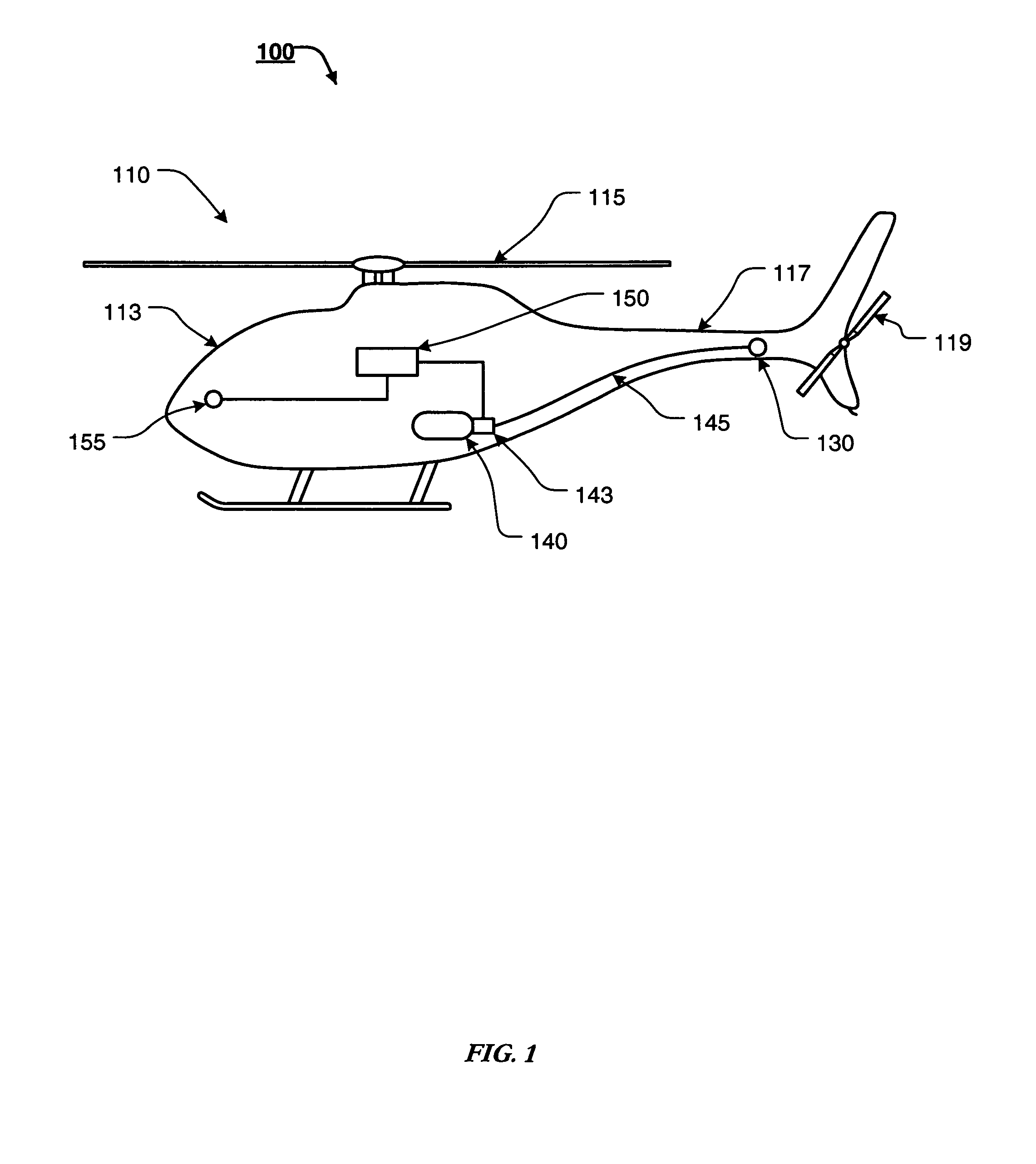

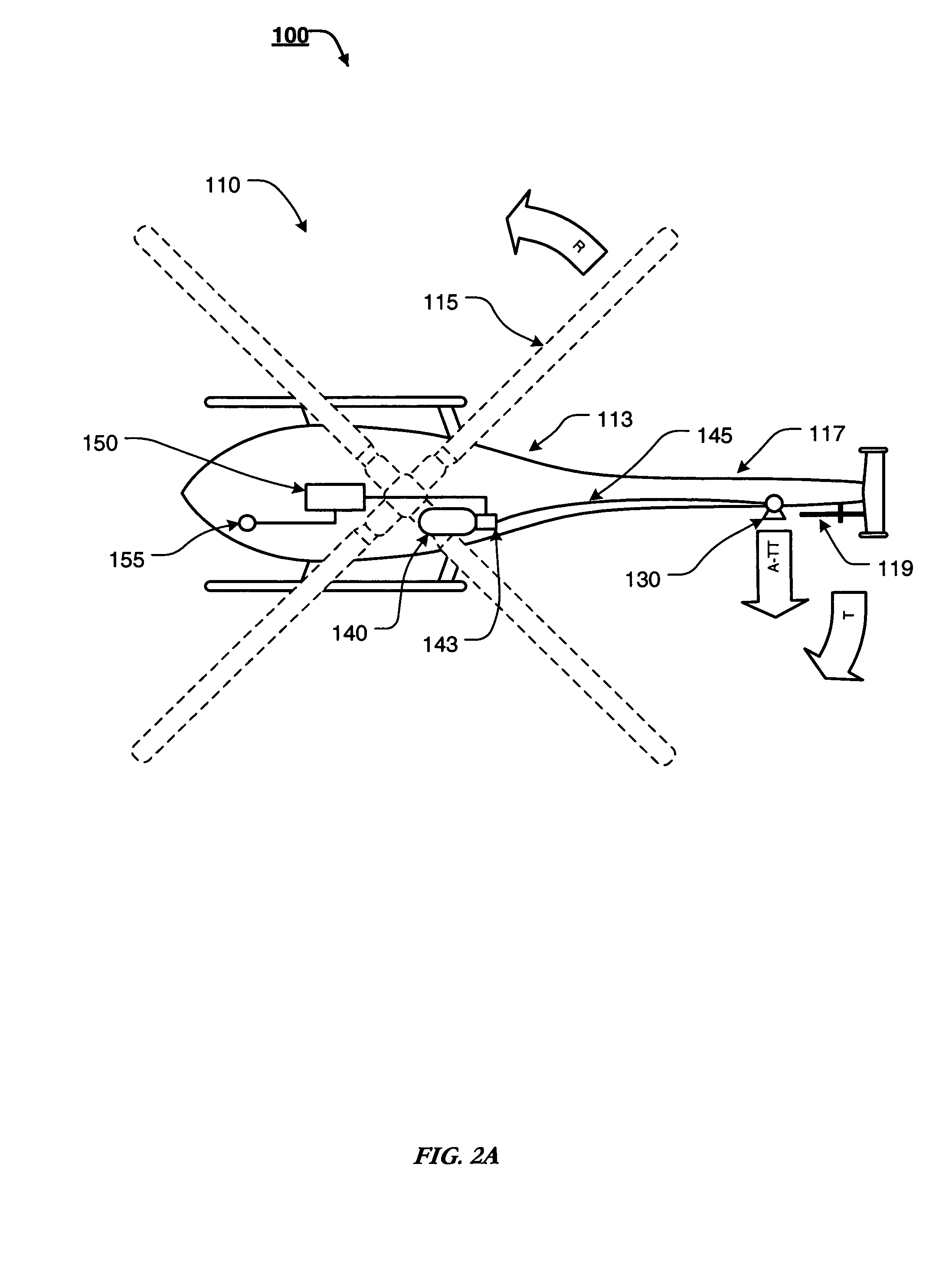

Emergency anti-torque thruster system

An anti-torque thruster system implemented onboard an aircraft comprising a propulsion means coupled to the aircraft, wherein the propulsion means is capable of providing a measure of anti-torque thrust to the aircraft, a fuel storage container coupled to the propulsion means via a fuel delivery conduit, wherein the fuel storage container is capable of storing an appropriate fuel for the propulsion means, a valve means disposed between the fuel storage container and the propulsion means, wherein the valve means may be useable to regulate the flow of fuel from the fuel storage container to the propulsion means, and a controller for controlling the valve means to regulate the flow of fuel from the fuel storage container to the propulsion means, wherein the controller is capable of receiving input from at least one input device.

Owner:EATTS

Modular multi-port manifold and fuel delivery system

InactiveUS7628182B2Prevent openingLiquid transferring devicesPipeline systemsControl flowNuclear engineering

Owner:DELAWARE CAPITAL FORMATION INC

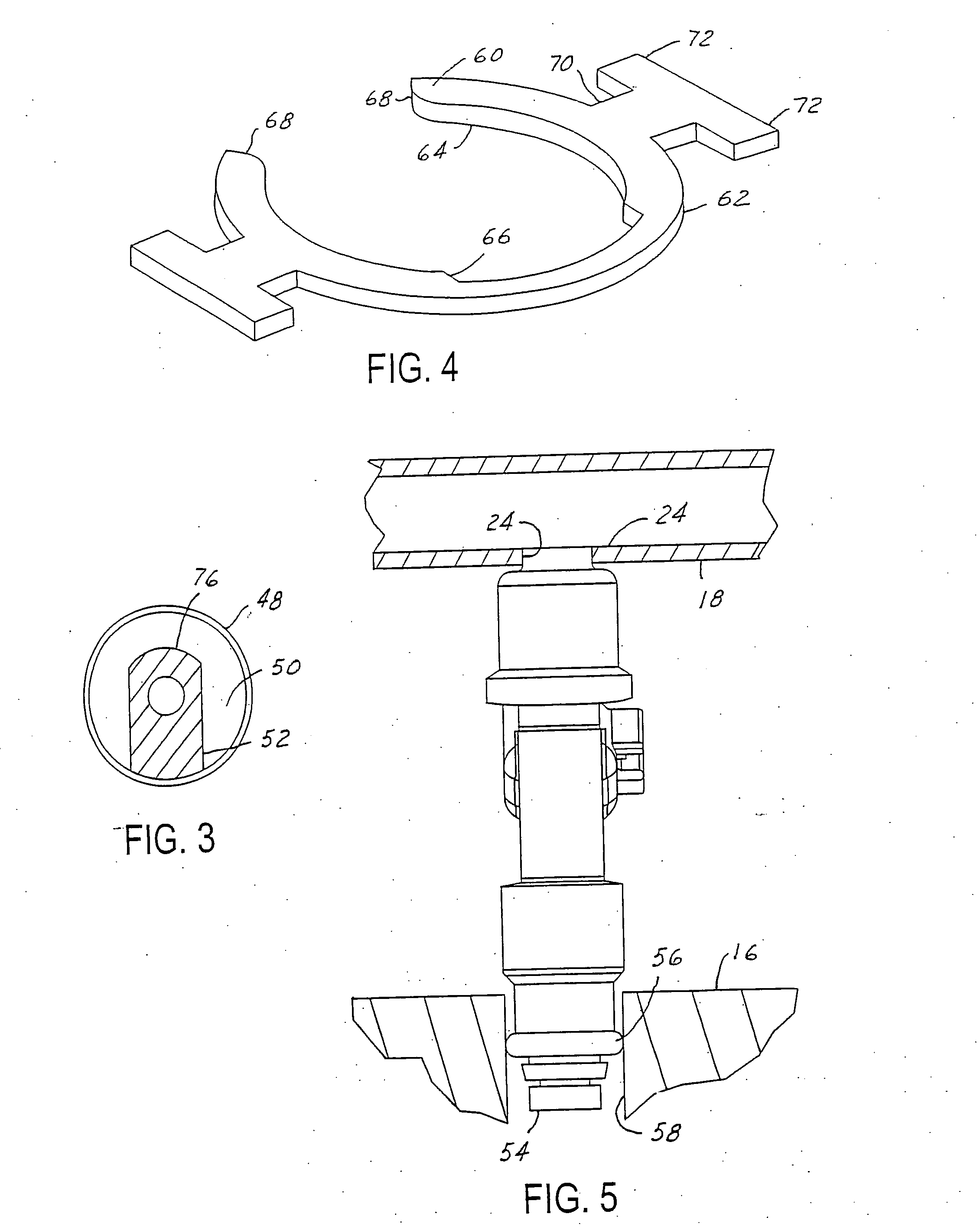

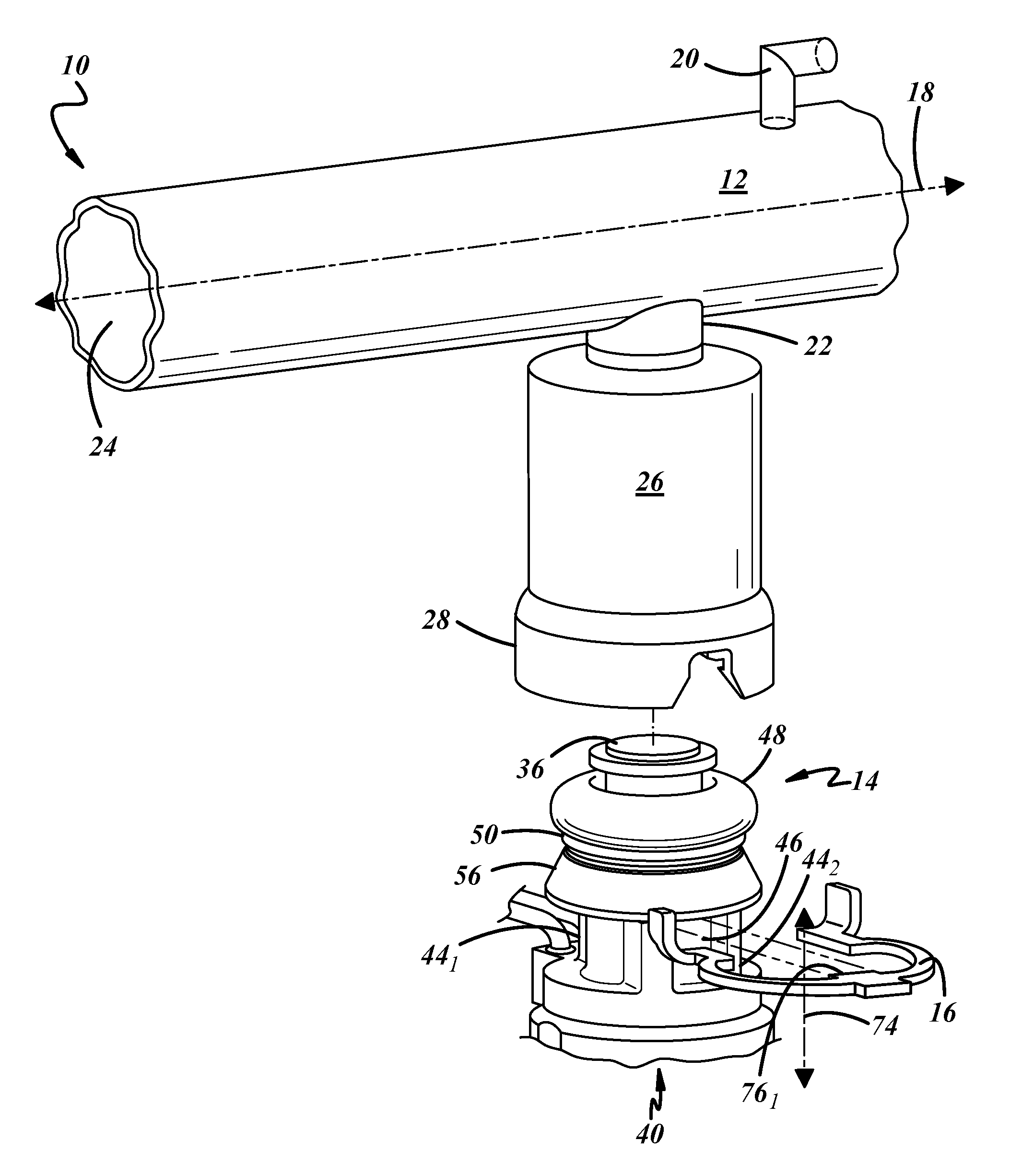

Fuel injector retention clip

A fuel delivery system in accordance with the present invention comprises a fuel rail having an outlet opening and an outlet cup that is insertable into the outlet opening. The cup includes a flange. The flange includes at least one tab extending therefrom. The cup further defines a vertical axis extending therethrough. The system further includes a fuel injector with an inlet insertable within the cup. The system still further includes a retention clip. The clip includes an inner peripheral surface, at least a portion of which is configured for engagement with the injector when the clip and injector are assembled together. The clip further includes at least one arm, the arm further including a finger configured for spring engagement with the tab of the cup. The clip is operative to limit the movement of the fuel injector when it is assembled with the clip and inserted in the cup.

Owner:MILLENNIUM INDS

Multi-tube thermal fuse for nozzle protection from a flame holding or flashback event

A protection system for a pre-mixing apparatus for a turbine engine, includes: a main body having an inlet portion, an outlet portion and an exterior wall that collectively establish a fuel delivery plenum; and a plurality of fuel mixing tubes that extend through at least a portion of the fuel delivery plenum, each of the plurality of fuel mixing tubes including at least one fuel feed opening fluidly connected to the fuel delivery plenum; at least one thermal fuse disposed on an exterior surface of at least one tube, the at least one thermal fuse including a material that will melt upon ignition of fuel within the at least one tube and cause a diversion of fuel from the fuel feed opening to at least one bypass opening. A method and a turbine engine in accordance with the protection system are also provided.

Owner:GENERAL ELECTRIC CO

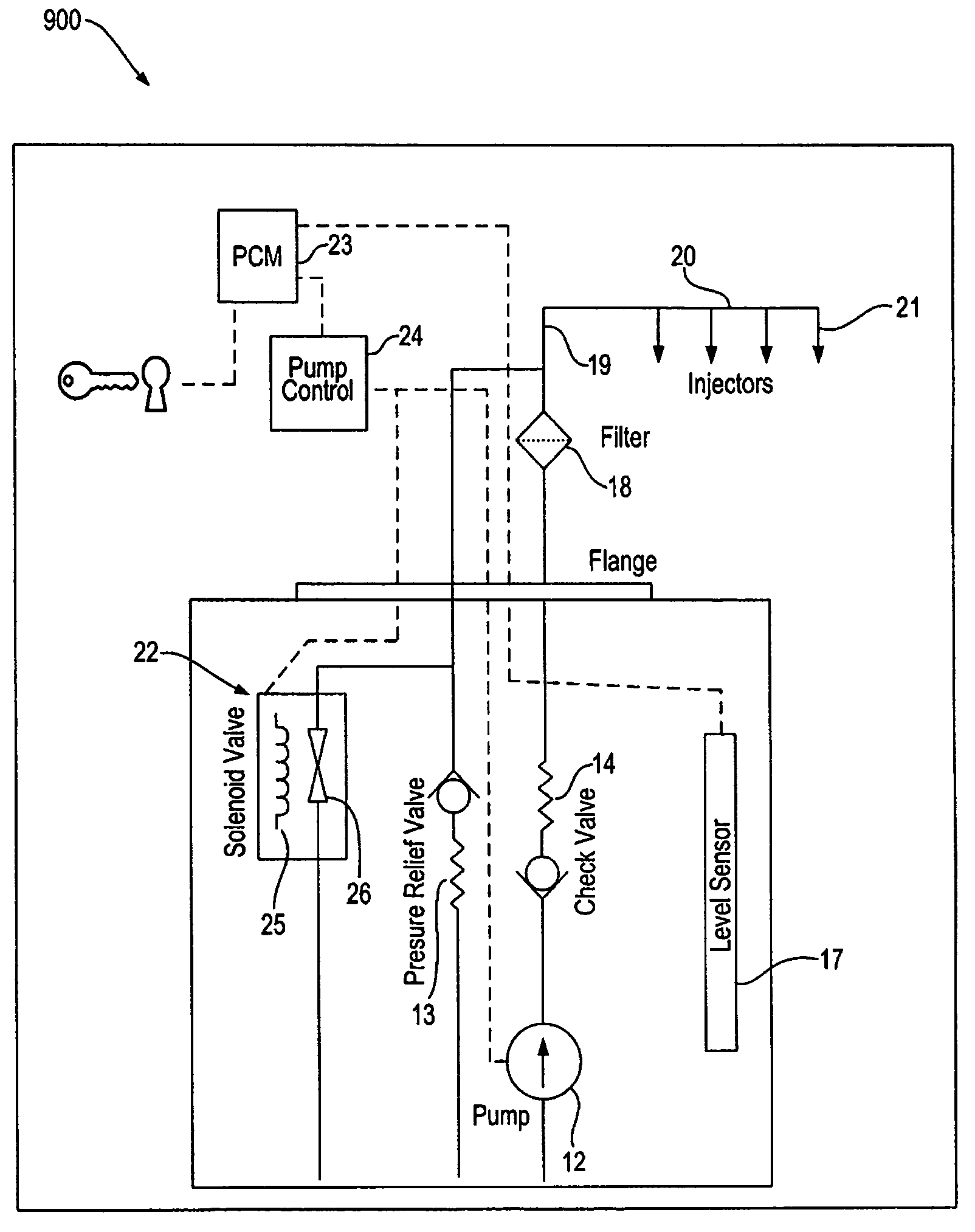

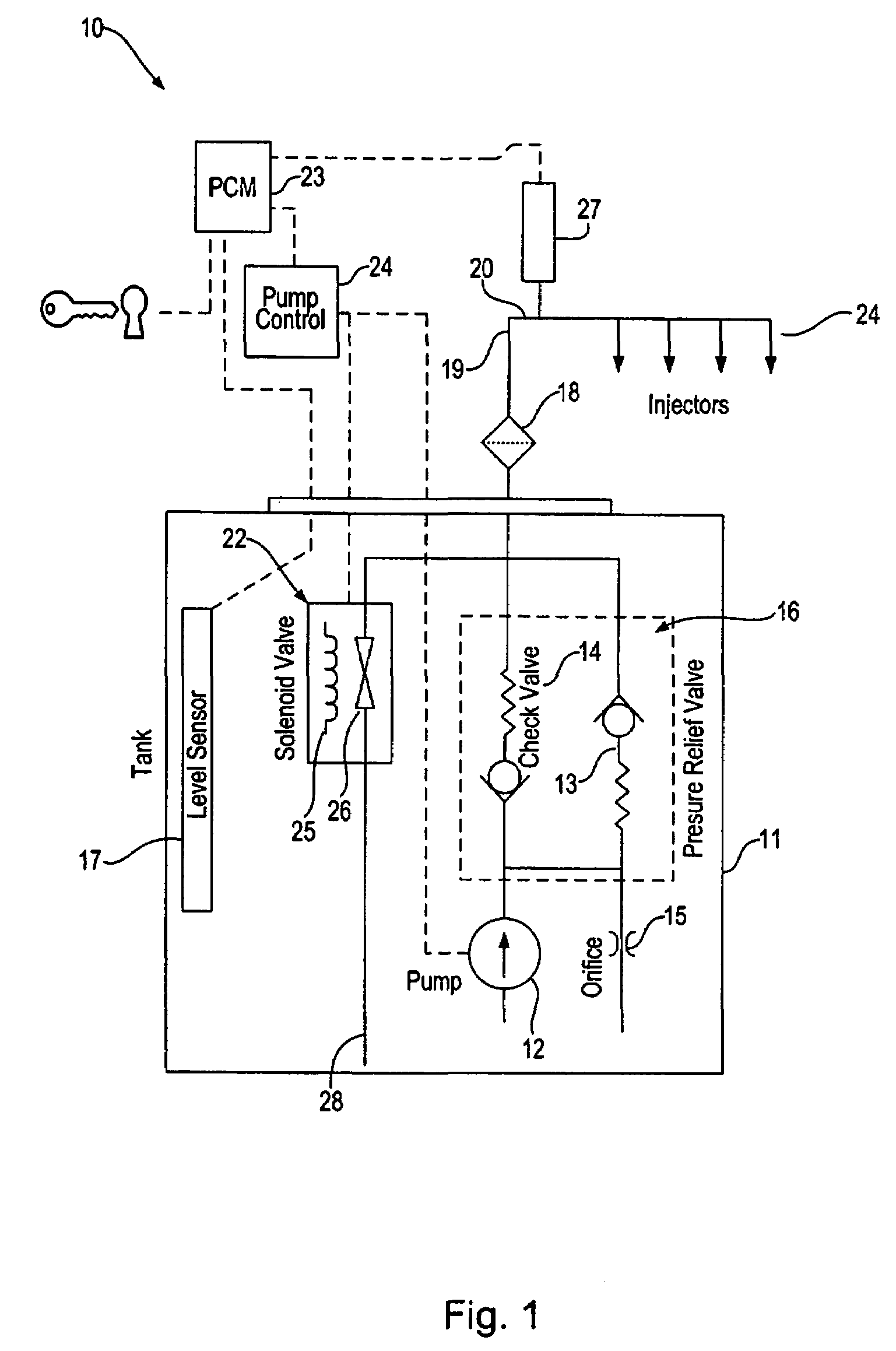

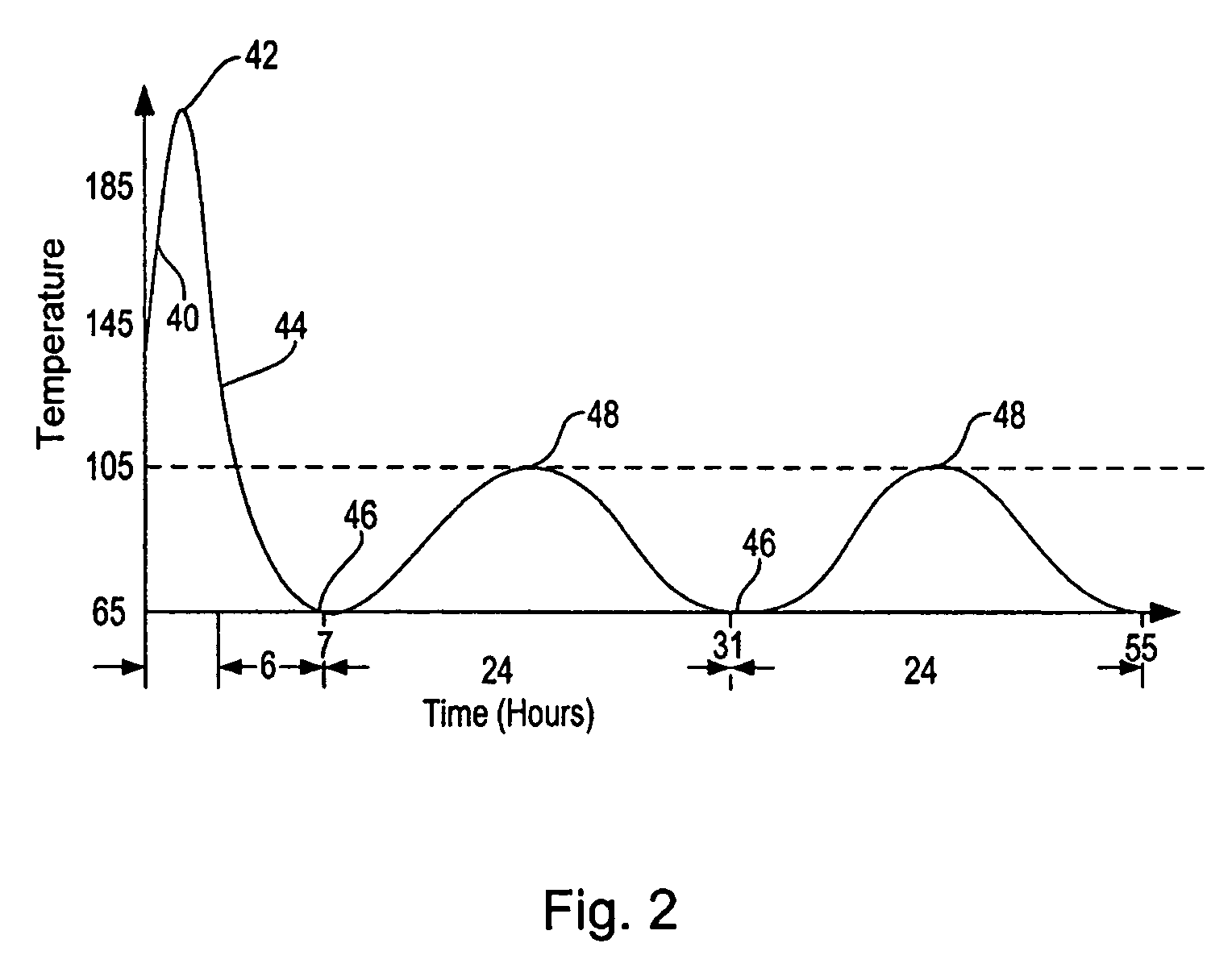

Low evaporative emission fuel system depressurization via solenoid valve

InactiveUS7066152B2Minimizes risingEmission minimizationNon-fuel substance addition to fuelEngine controllersPressure riseSolenoid valve

A fuel delivery system is provided with a fuel solenoid valve to minimize fuel leakage and evaporative emissions during diurnal cycles by preventing pressure buildup as the temperature of the fuel system rises. The fuel solenoid valve is located between a pressurized side of the delivery system and a fuel tank. In one embodiment, the fuel solenoid valve is closed when the engine is running or when the engine is off and the rail is hot. When the fuel rail cools down, the solenoid valve opens to bleed a desired amount of fuel thereby creating a fuel vapor space. Thereafter, during hot soak conditions of the diurnal cycles when the fuel rail is hot again while the engine is off, the pressure will rise due to the thermal expansion of the fuel and the created fuel vapor space minimizes further rising of the fuel pressure. Further, by adjusting the solenoid valve opening time, the pressure rising limit may be set at a desired pressure to minimize injector leakage.

Owner:FORD GLOBAL TECH LLC

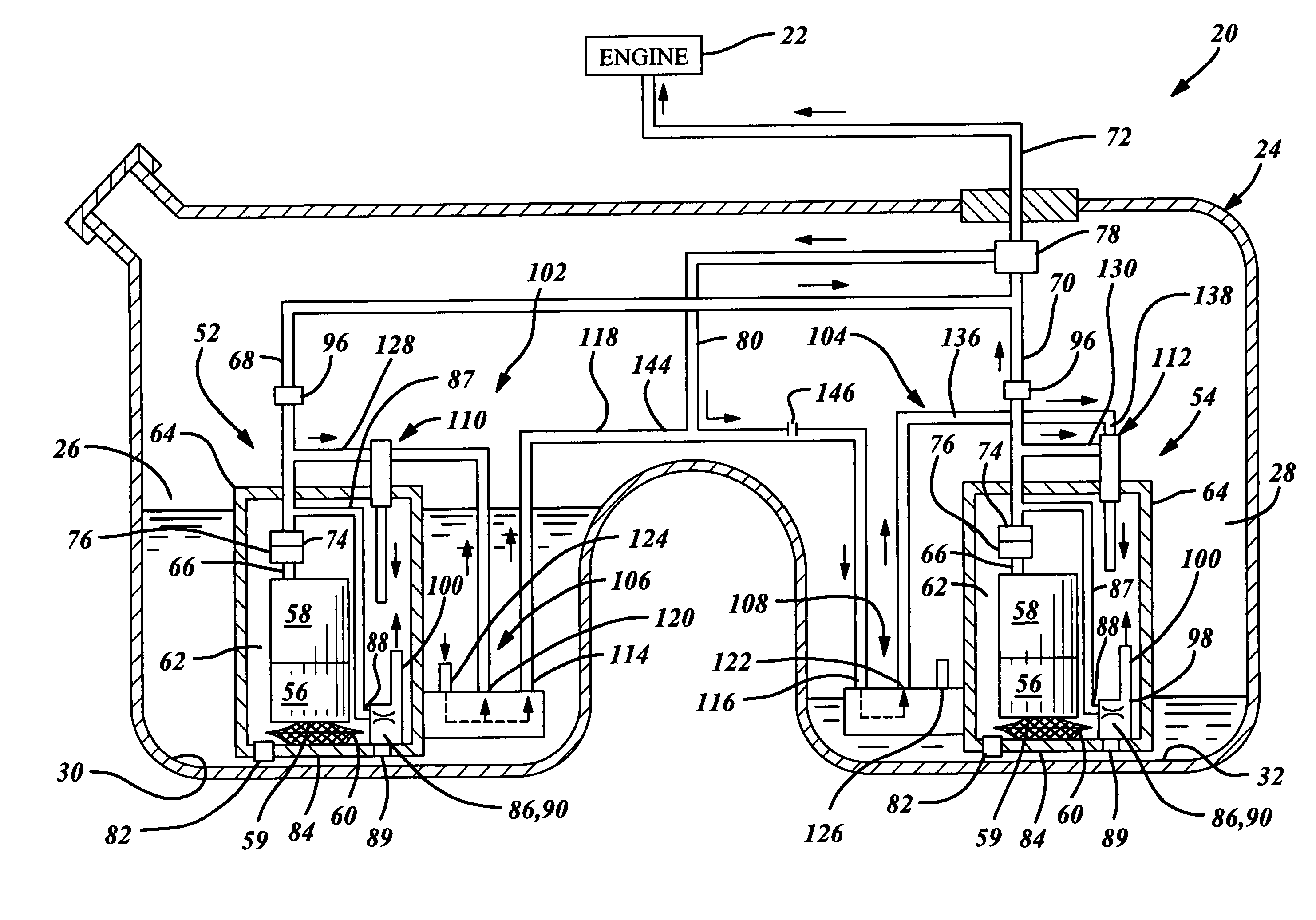

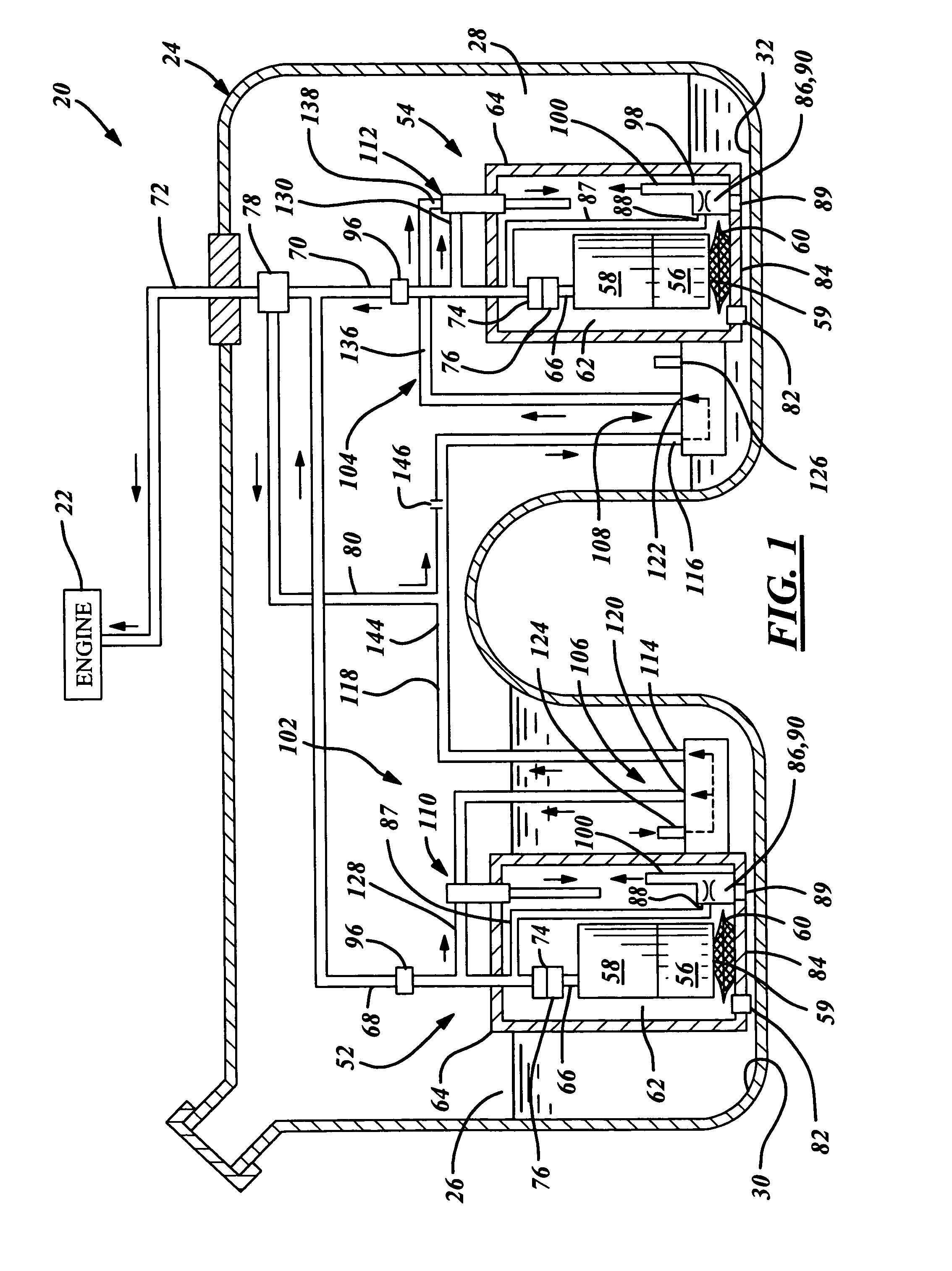

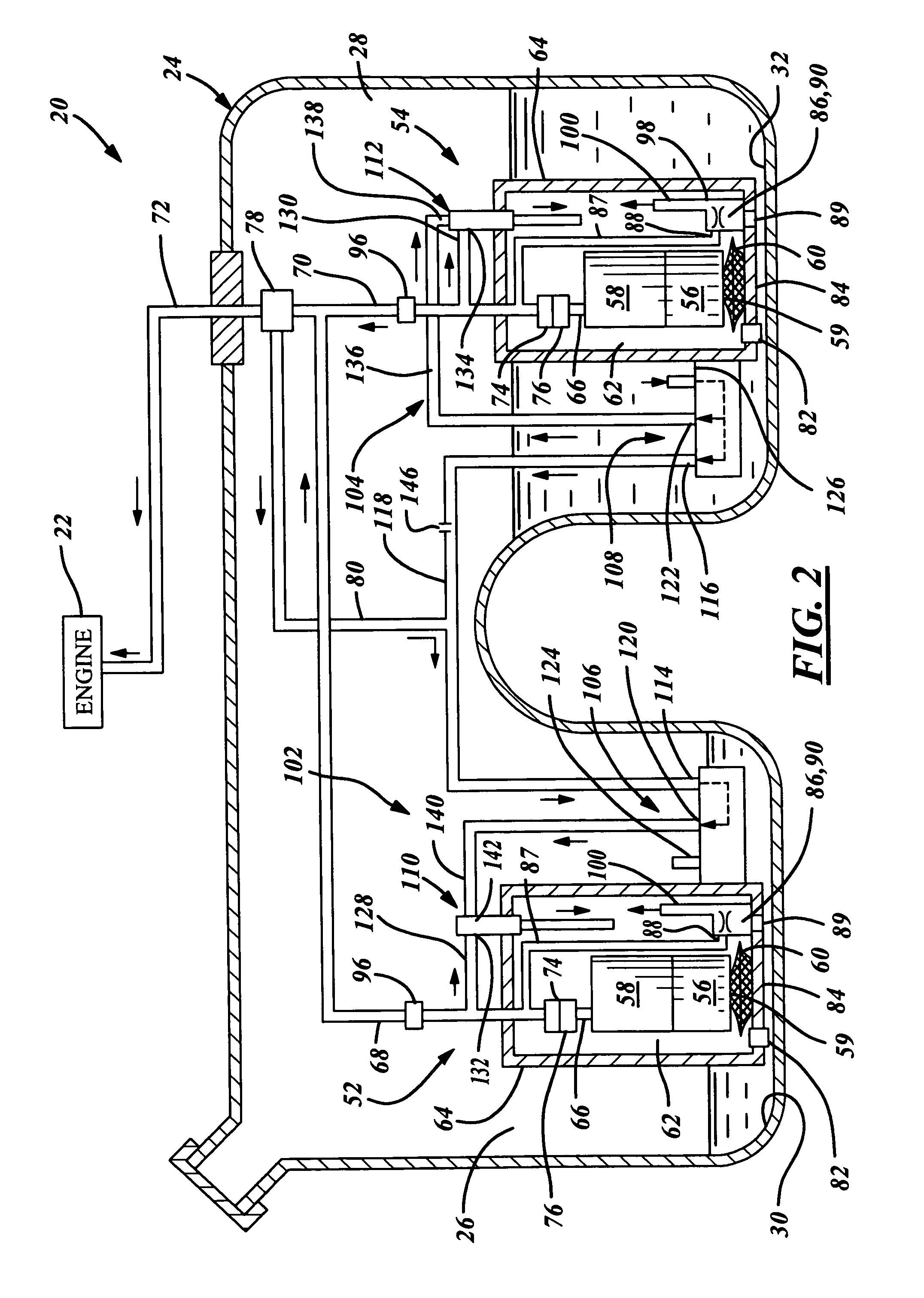

Fuel delivery system for a combustion engine

InactiveUS7069913B1Increase fuel consumptionEconomical and robust fuel deliveryMachines/enginesLiquid fuel feedersCombustionFuel tank

A fuel delivery system with at least one fuel tank and at least two fuel chambers has a fuel transfer assembly preferably integrated into an in-tank fuel pump module for controlling fuel levels between the at least two fuel chambers. The fuel transfer assembly has a transfer jet which receives pressurized fuel from a fuel pump of the module and at least two control valves for dictating the source of low pressure fuel flowing into the transfer jet and discharged therefrom preferably into a fuel reservoir of the module. Preferably, one control valve is located in each fuel chamber. The control valve opens upon a pre-established high fuel level and closes upon low fuel level. The fuel chamber containing the open control valve is generally the source of fuel for the fuel pump module.

Owner:TI GRP AUTOMOTIVE SYST LLC

Attachment for fuel injectors in direct injection fuel systems

A fuel delivery system comprising a fuel rail having an outlet and a receptor cup associated therewith. The system further including a fuel injector having an inlet, an outlet and a body therebetween. The inlet is configured for insertion into the cup of the fuel rail and for fluid communication with the outlet thereof. The system still further including a retention clip configured for engagement with the fuel injector and the cup in order to couple the fuel injector with the fuel rail. In the inventive system, the fuel injector further includes a load distribution feature. This feature is configured to engage a portion of the retention clip and to assist with the distribution about the clip of a load applied to the injector.

Owner:MILLENNIUM INDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com