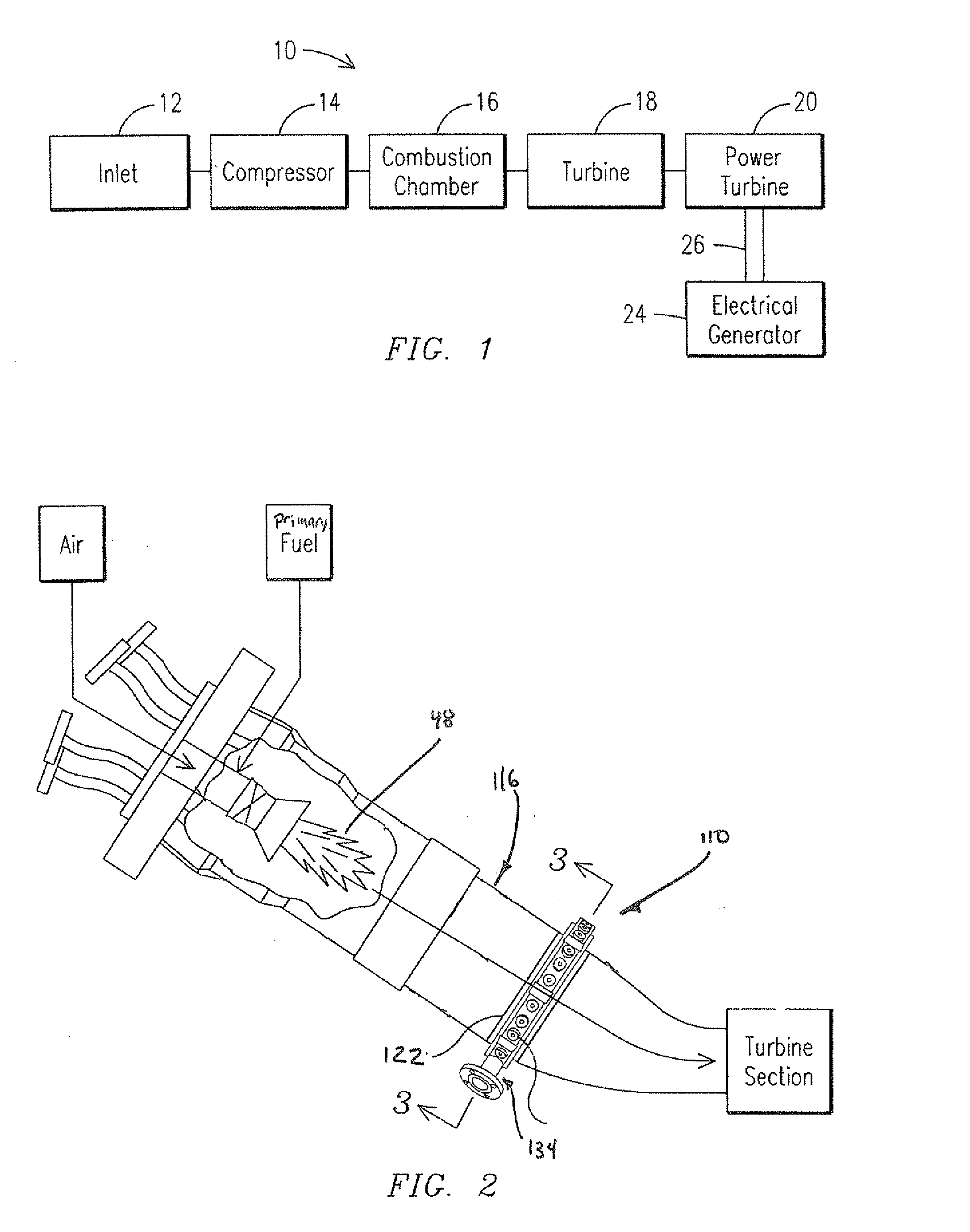

Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

621 results about "Effusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In physics and chemistry, effusion is the process in which a gas escapes from a container through a hole of diameter considerably smaller than the mean free path of the molecules. Such a hole is often described as a pinhole and the escape of the gas is due to the pressure difference between the container and the exterior. Under these conditions, essentially all molecules which arrive at the hole continue and pass through the hole, since collisions between molecules in the region of the hole are negligible. Conversely, when the diameter is larger than the mean free path of the gas, flow obeys the Sampson flow law.

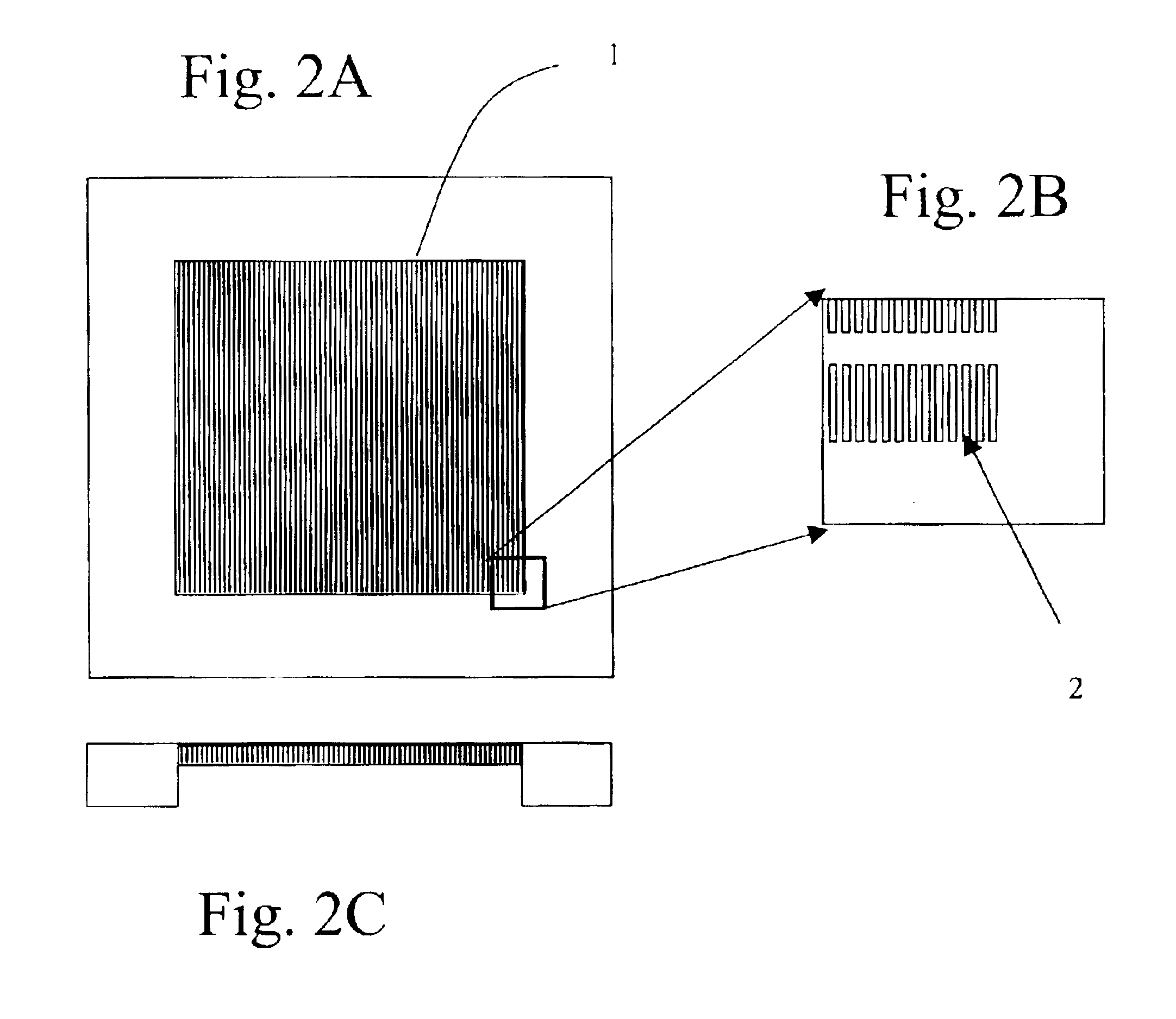

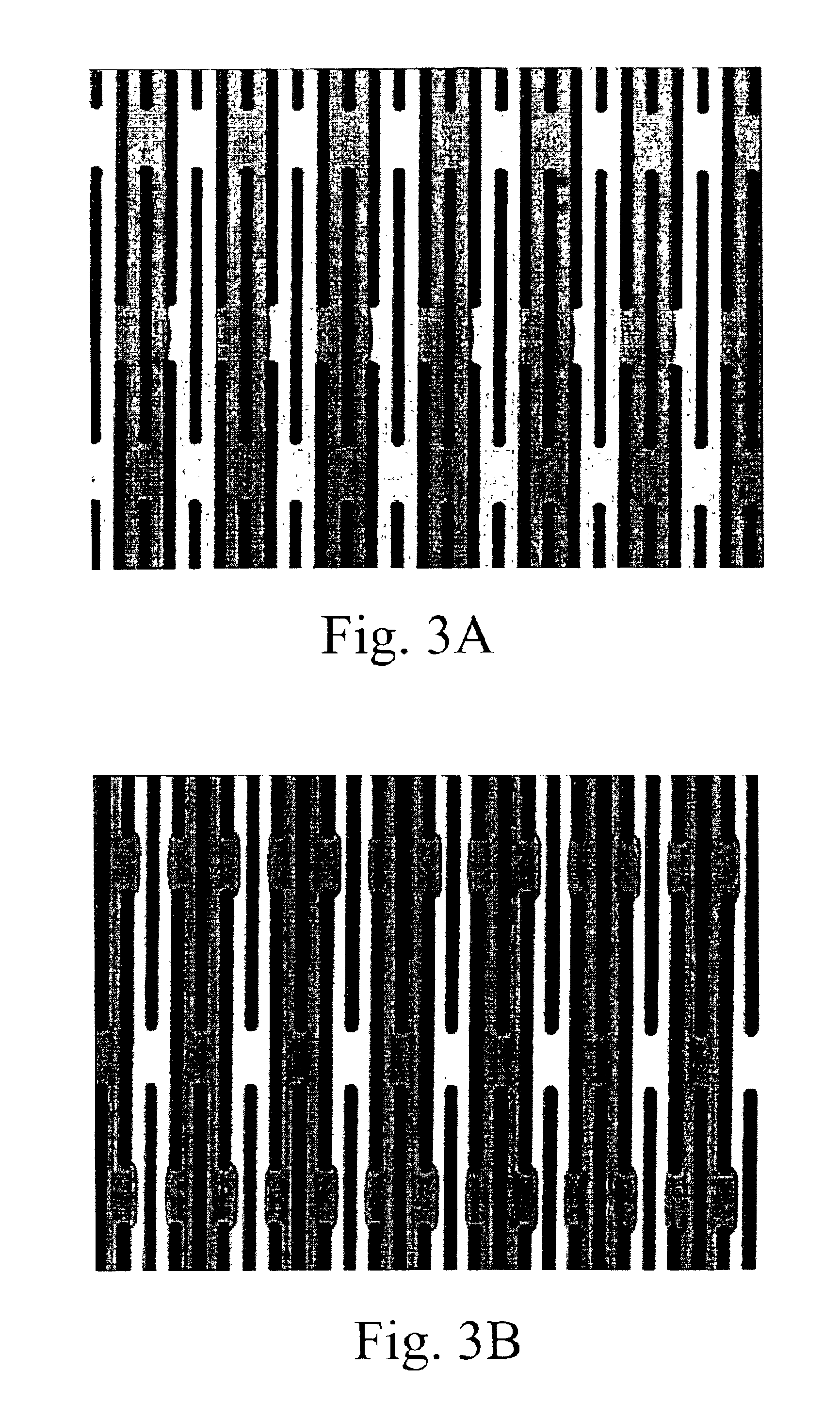

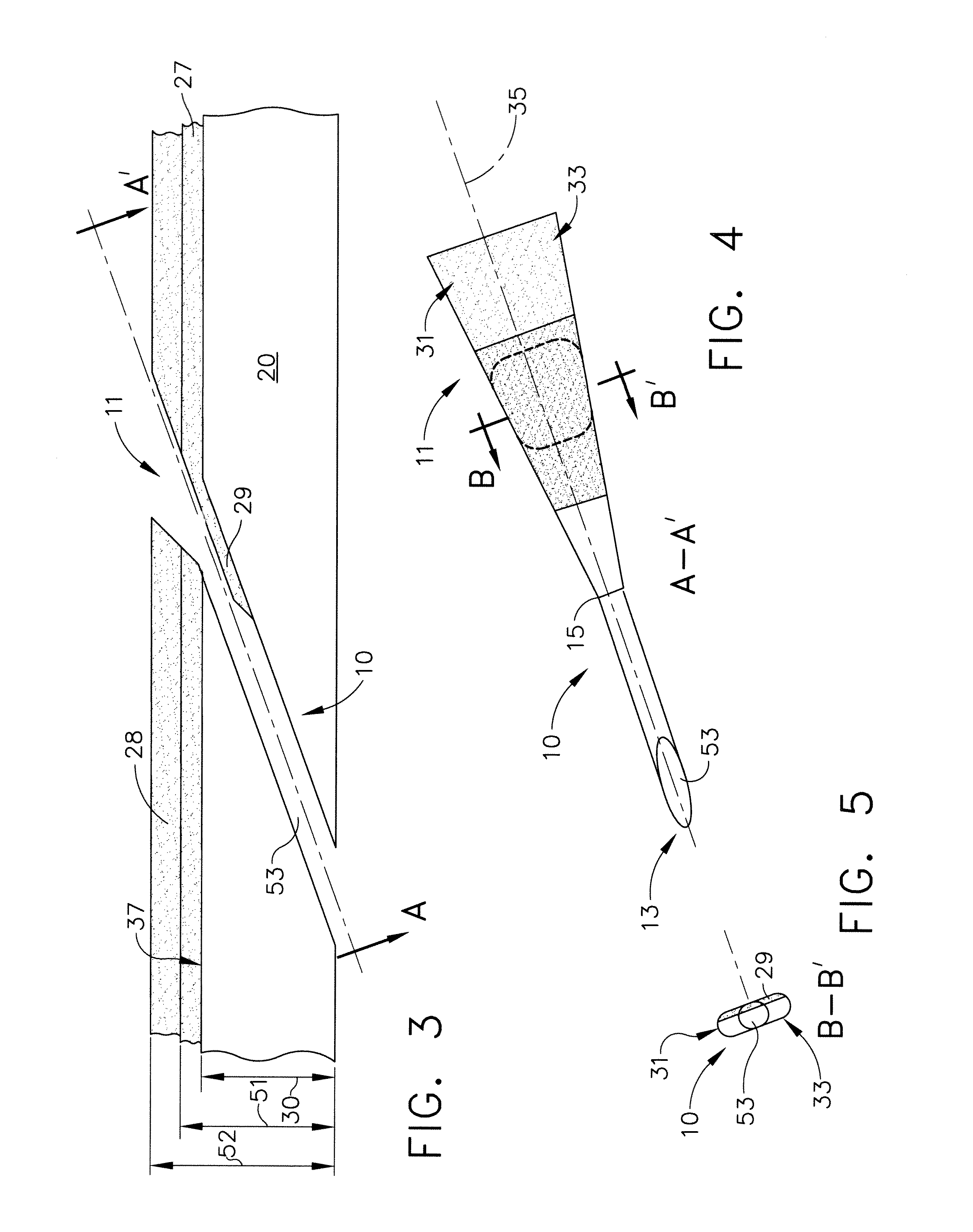

Methods, compositions, and automated systems for separating rare cells from fluid samples

InactiveUS7166443B2Aid in diagnosis and prognosisBioreactor/fermenter combinationsBiological substance pretreatmentsCancer cellRed blood cell

The present invention recognizes that diagnosis and prognosis of many conditions can depend on the enrichment of rare cells from a complex fluid sample. In particular, the enrichment of fetal cells from maternal samples, such as maternal blood samples, can greatly aid in the detection of fetal abnormalities or a variety of genetic conditions. In addition, the present invention recognizes that the enrichment of rare malignant cells from patient samples, can aid in diagnosis, prognosis, and development of therapeutic modalities for patients. The invention includes microfabricated filters for filtering fluid samples and methods of enriching rare cells of fluid samples using microfabricated filters of the present invention. The invention also includes solutions for the selective sedimentation of red blood cells (RBCs) from a blood sample and methods of using selective RBC sedimentation solutions for enriching rare cells of a fluid sample. Yet another aspect of the invention is an automated system for processing a fluid sample that includes: at least one filtration chamber that includes a microfabricated filter; automated means for directing fluid flow through at least one filtration chamber of the automated system, and means for collecting enriched rare cells. The present invention also includes methods of using automated systems for separating rare cells from fluid samples. Preferred fluid samples are blood, effusion, or urine samples, and rare cells that can be enriched from such sample include nucleated red blood cells and cancer cells.

Owner:AVIVA BIOSCI

Methods, compositions, and automated systems for separating rare cells from fluid samples

InactiveUS6949355B2Aid in diagnosis and prognosisBioreactor/fermenter combinationsBiological substance pretreatmentsCancer cellRed blood cell

The present invention recognizes that diagnosis and prognosis of many conditions can depend on the enrichment of rare cells from a complex fluid sample. In particular, the enrichment of fetal cells from maternal samples, such as maternal blood samples, can greatly aid in the detection of fetal abnormalities or a variety of genetic conditions. In addition, the present invention recognizes that the enrichment of rare malignant cells from patient samples, can aid in diagnosis, prognosis, and development of therapeutic modalities for patients.A first aspect of the present invention is a microfabricated filter for filtering a fluid sample. A microfabricated filter of the present invention comprises at least one tapered pore, and preferably comprises at least two tapered pores whose variation in size is 20% or less. The present invention also includes a method of enriching rare cells of a fluid sample using a microfabricated filter of the present invention.Another aspect of the invention is solutions for the selective sedimentation of red blood cells (RBCs) from a blood sample comprising a red blood cell aggregating agent and at least one specific binding member that selectively binds RBCs. Solutions of the present invention include a combined solution for rare cell enrichment that comprise RBC aggregating agents, at least one specific binding member that selectively binds RBCs, and at least one additional specific binding member for the removal of undesirable sample components other than RBCs. The invention also includes methods of using selective RBC sedimentation solutions and combined solutions for enriching rare cells of a fluid sample.Yet another aspect of the invention is an automated system for processing a fluid sample that includes: at least one filtration chamber that comprises or engages one or more microfabricated filters of the present invention; automated means for directing fluid flow through the one or more filtration chambers of the automated system, and means for collecting enriched rare cells. The present invention also includes methods of using an automated system for separating rare cells from a fluid sample. Preferred fluid samples are effusion, blood, or urine samples, and rare cells that can be enriched from such sample include nucleated red blood cells and cancer cells.

Owner:AVIVA BIOSCI

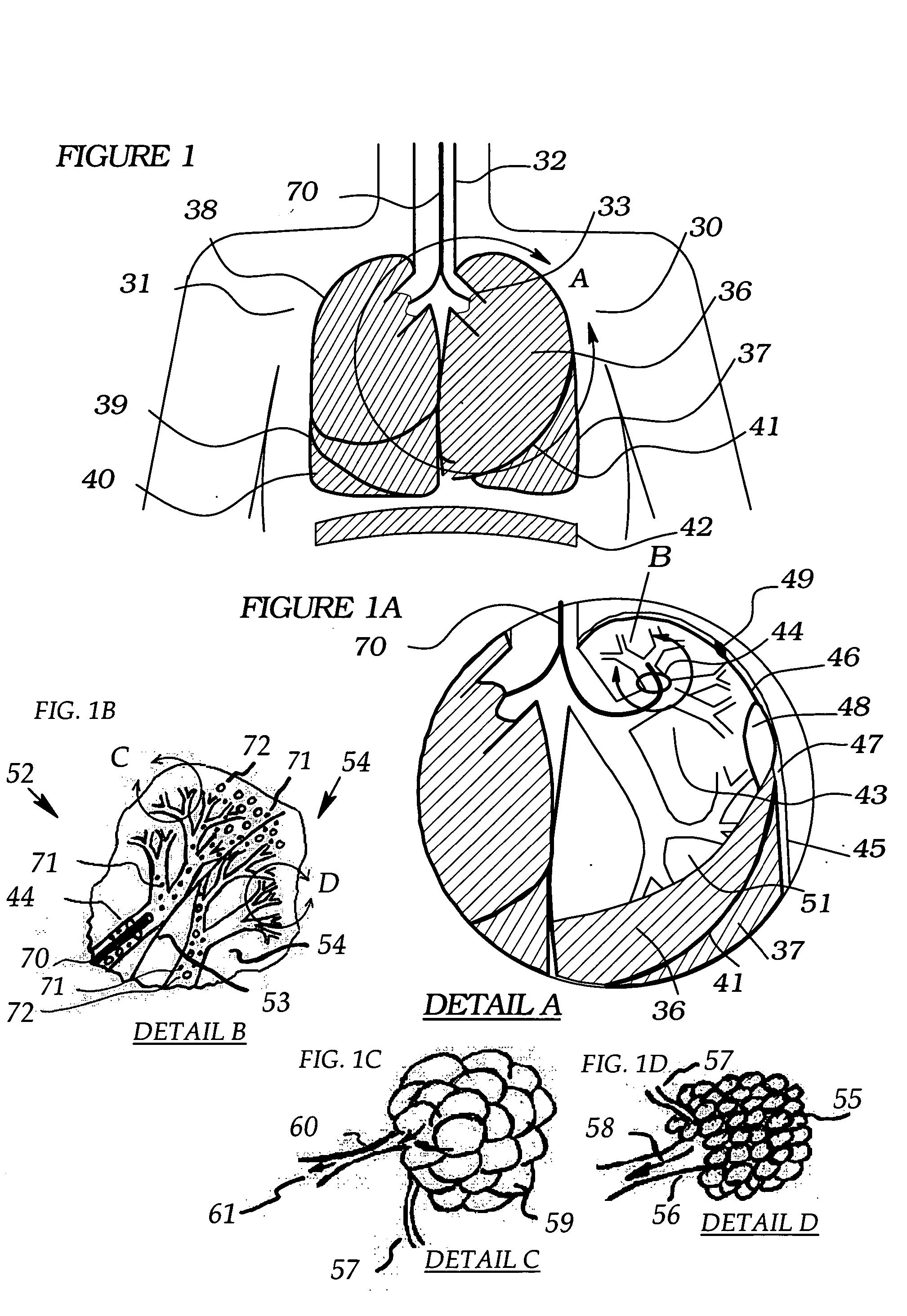

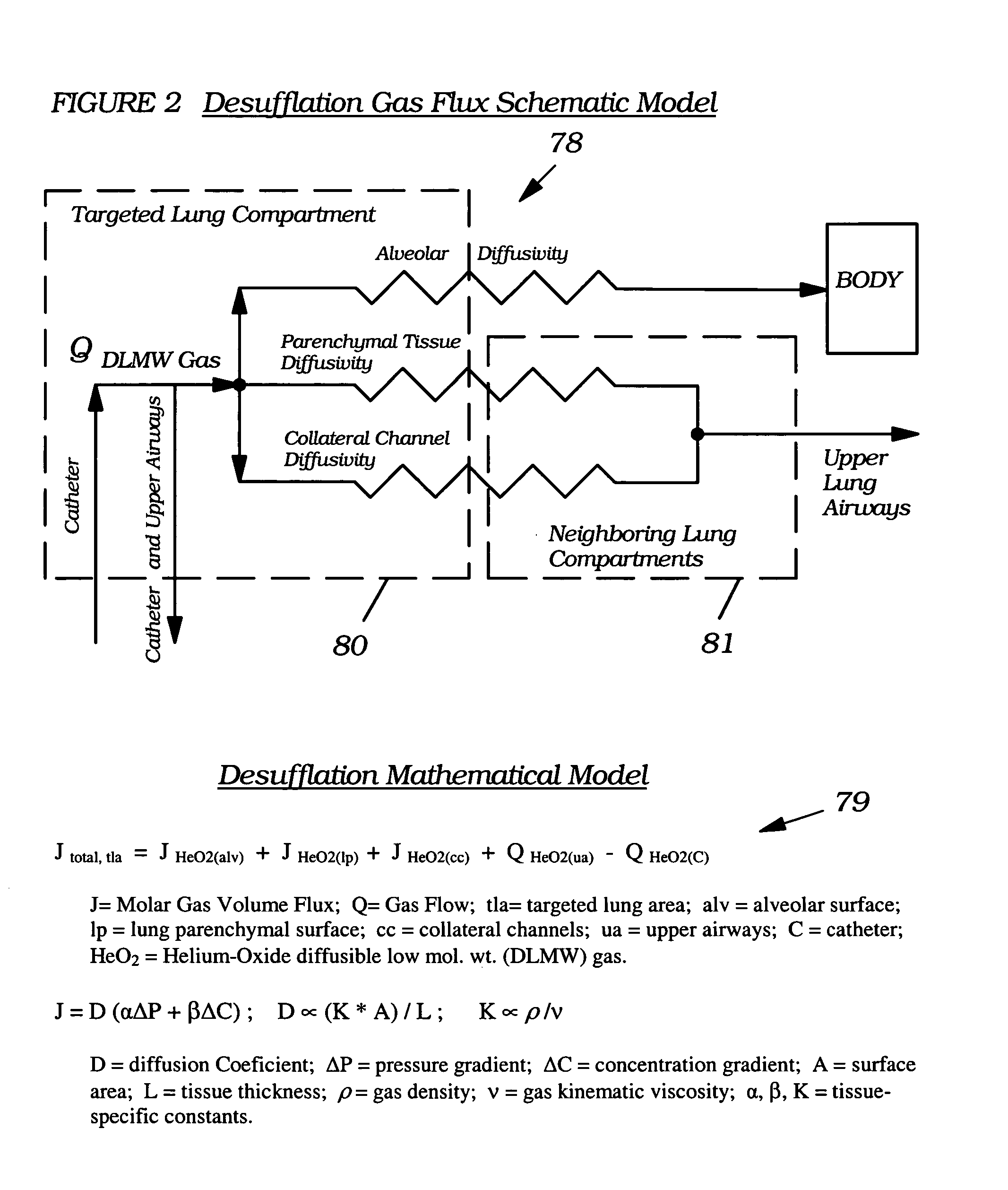

Methods, systems and devices for desufflating a lung area

InactiveUS20050022809A1Lower the volumeOut diffusionTracheal tubesBreathing masksCOPDPositive pressure

Methods, systems and devices are described for temporarily or permanently evacuating stagnating air from a diseased lung area, typically for the purpose of treating COPD. Evacuation is accomplished by displacing the stagnant CO2-rich air with a readily diffusible gas using a transluminal indwelling catheter specially configured to remain anchored in the targeted area for long term treatment without supervision. Appropriate elevated positive gas pressure in the targeted area is then regulated via the catheter and a pneumatic control unit to force under positive pressure effusion of the diffusible gas out of the area into neighboring areas while inhibiting infusion of other gases thus effecting a gradual gas volume decrease and deflation of the targeted area.

Owner:WONDKA ANTHONY DAVID

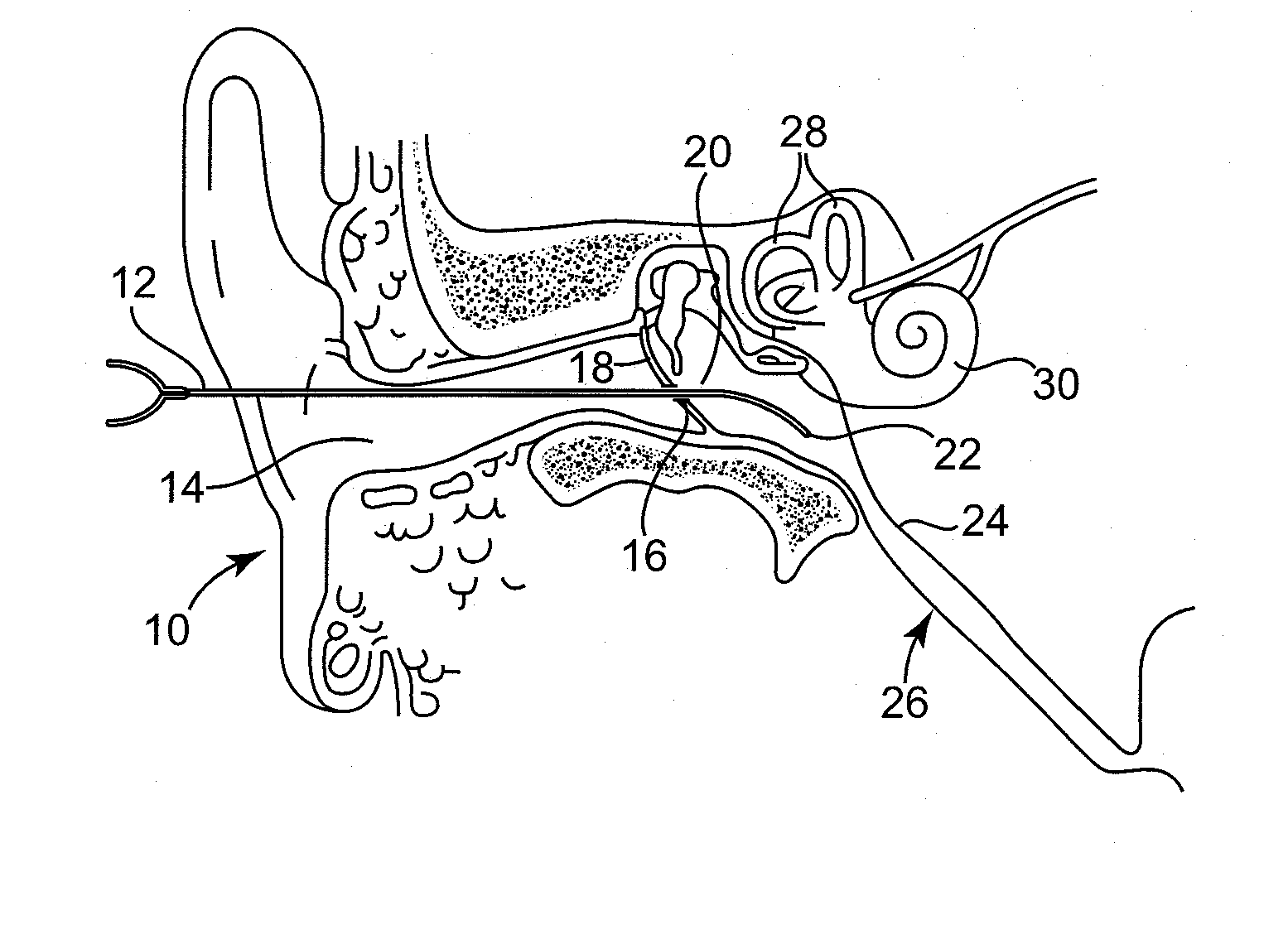

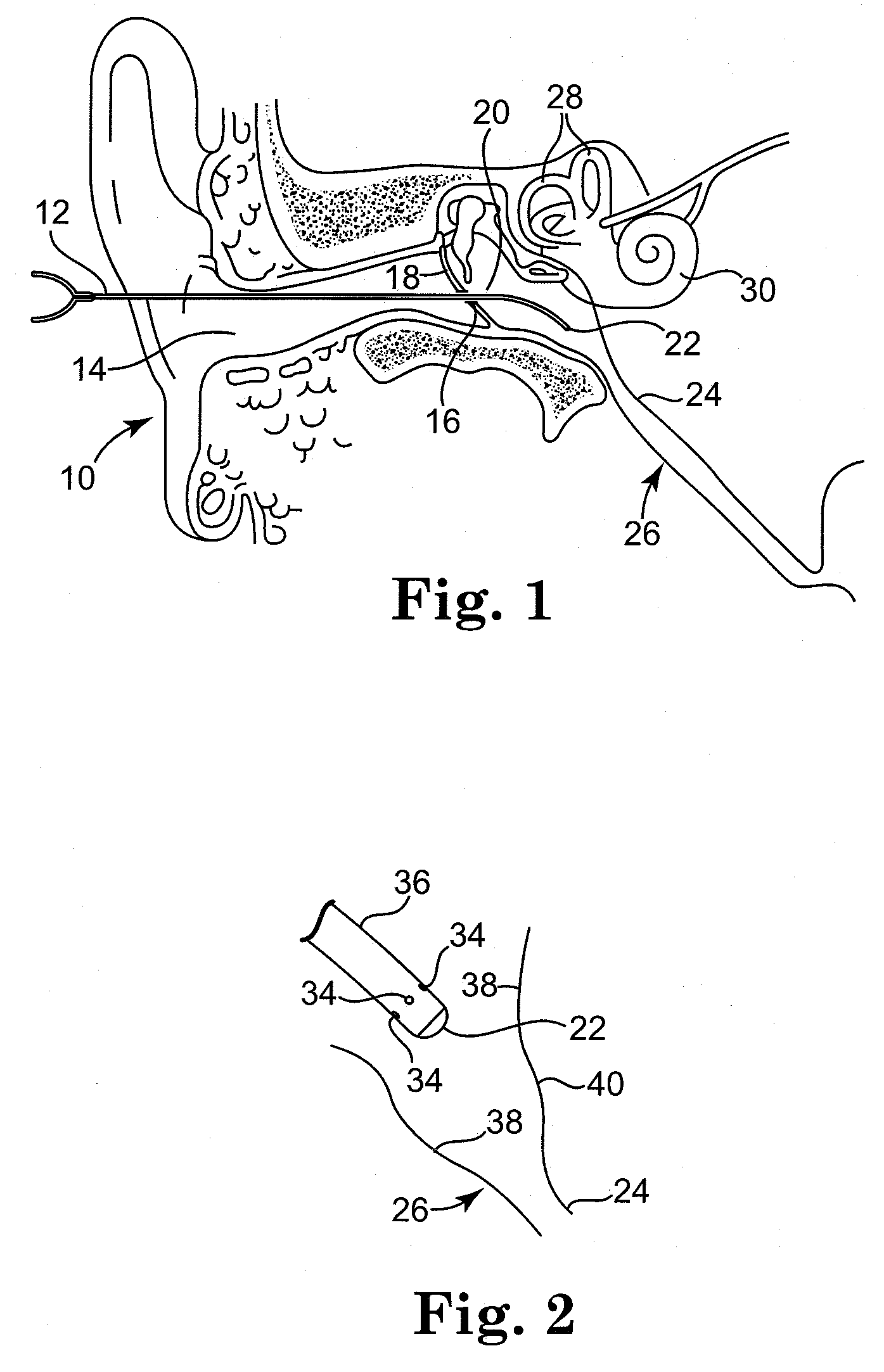

Solvating system and sealant for medical use in the middle or inner ear

ActiveUS20070264310A1Increased drug resistanceReduction and elimination in amountGogglesPharmaceutical delivery mechanismBiofilmEffusion

Chronic Otitis Media with Effusion (COME), Recurrent Acute Otitis Media (RAOM), cholesteatoma, and other bacterial ear conditions may be treated by applying a solvating system containing greater than 0.2 wt. % surfactant to a bacterial biofilm in the middle or inner ear, disrupting the biofilm, and applying a protective layer of a polymeric film-forming medical sealant.

Owner:MEDTRONIC XOMED INC

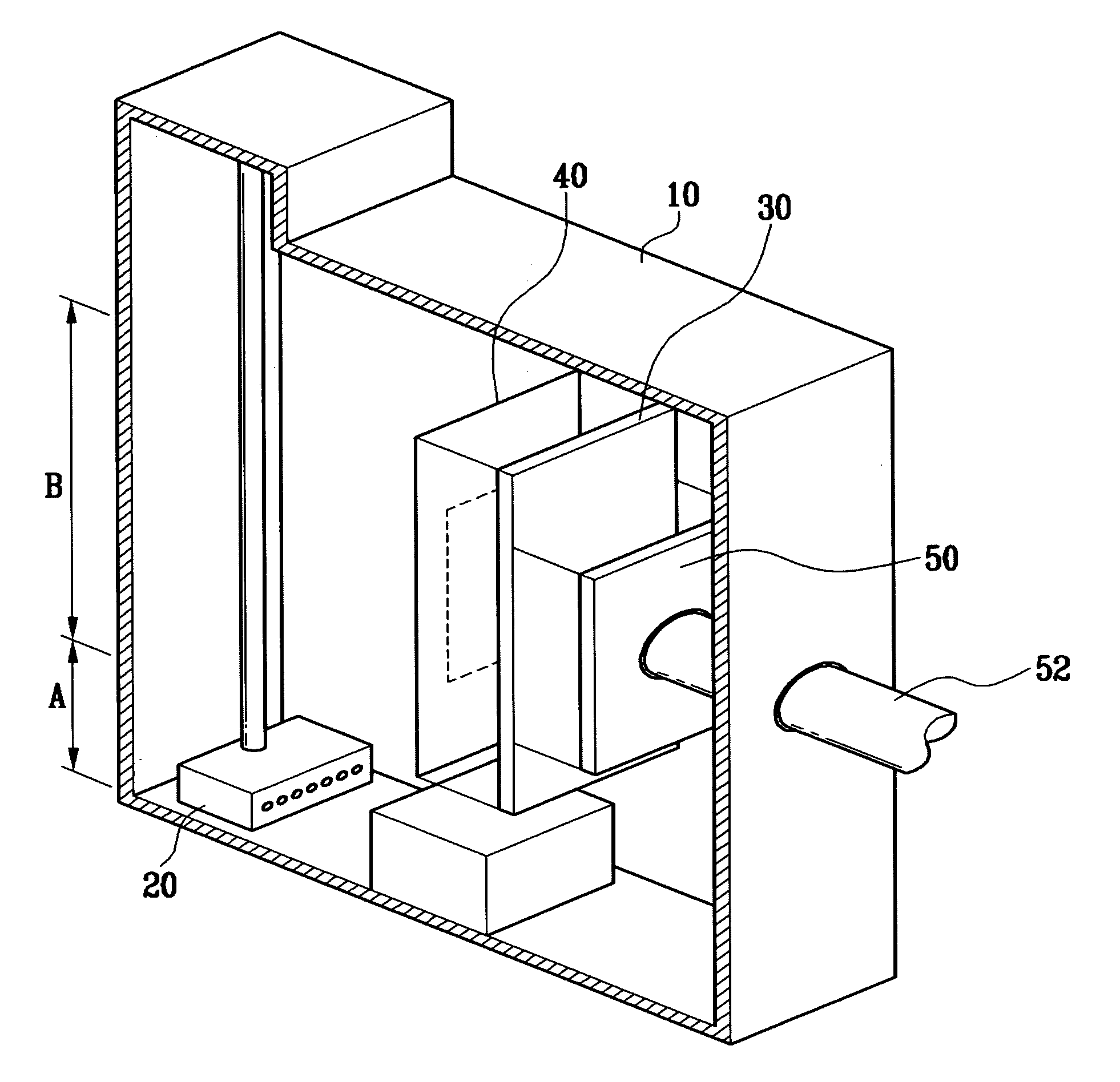

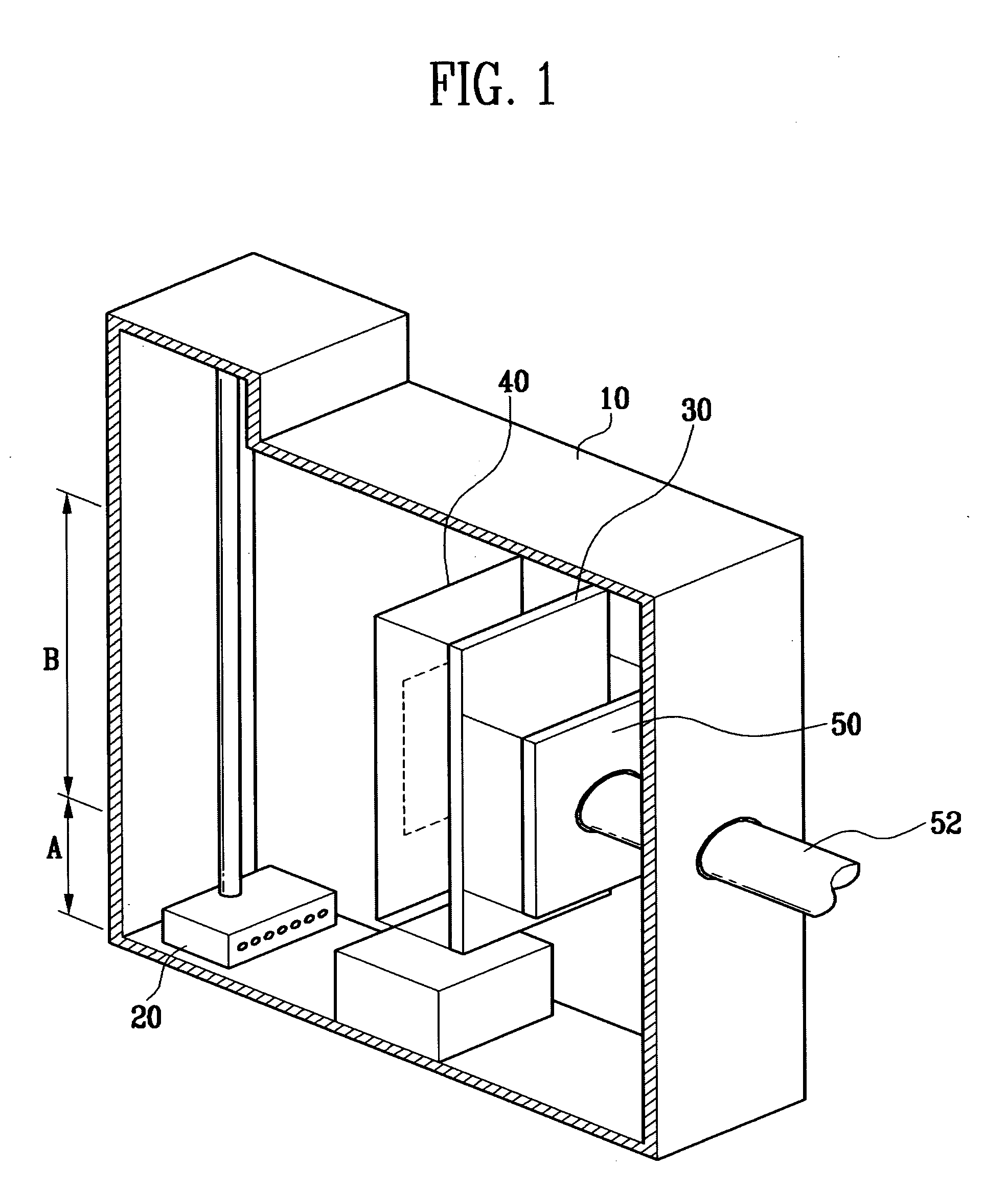

Driving shaft of effusion cell for deposition system and deposition system having the same

ActiveUS20060144325A1Avoid stickingPolycrystalline material growthVacuum evaporation coatingDrive shaftEffusion

Owner:SAMSUNG DISPLAY CO LTD

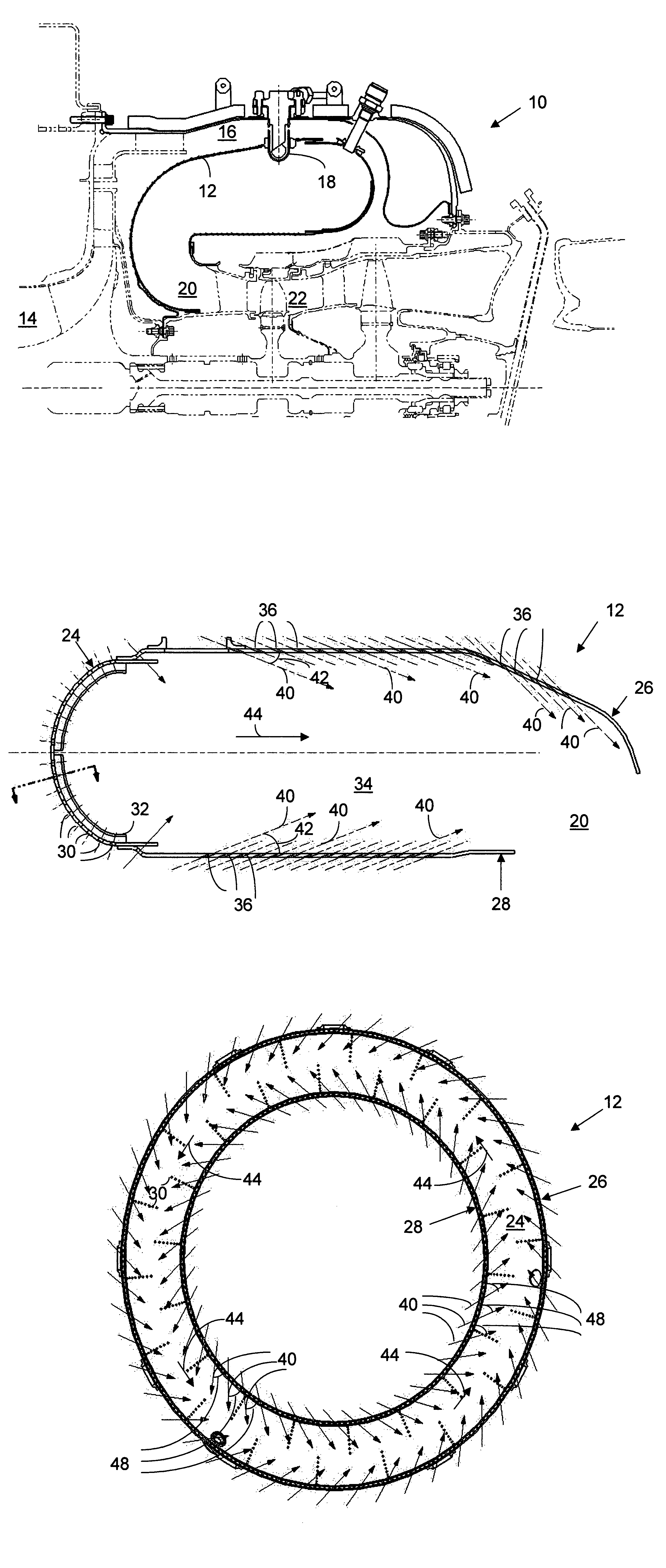

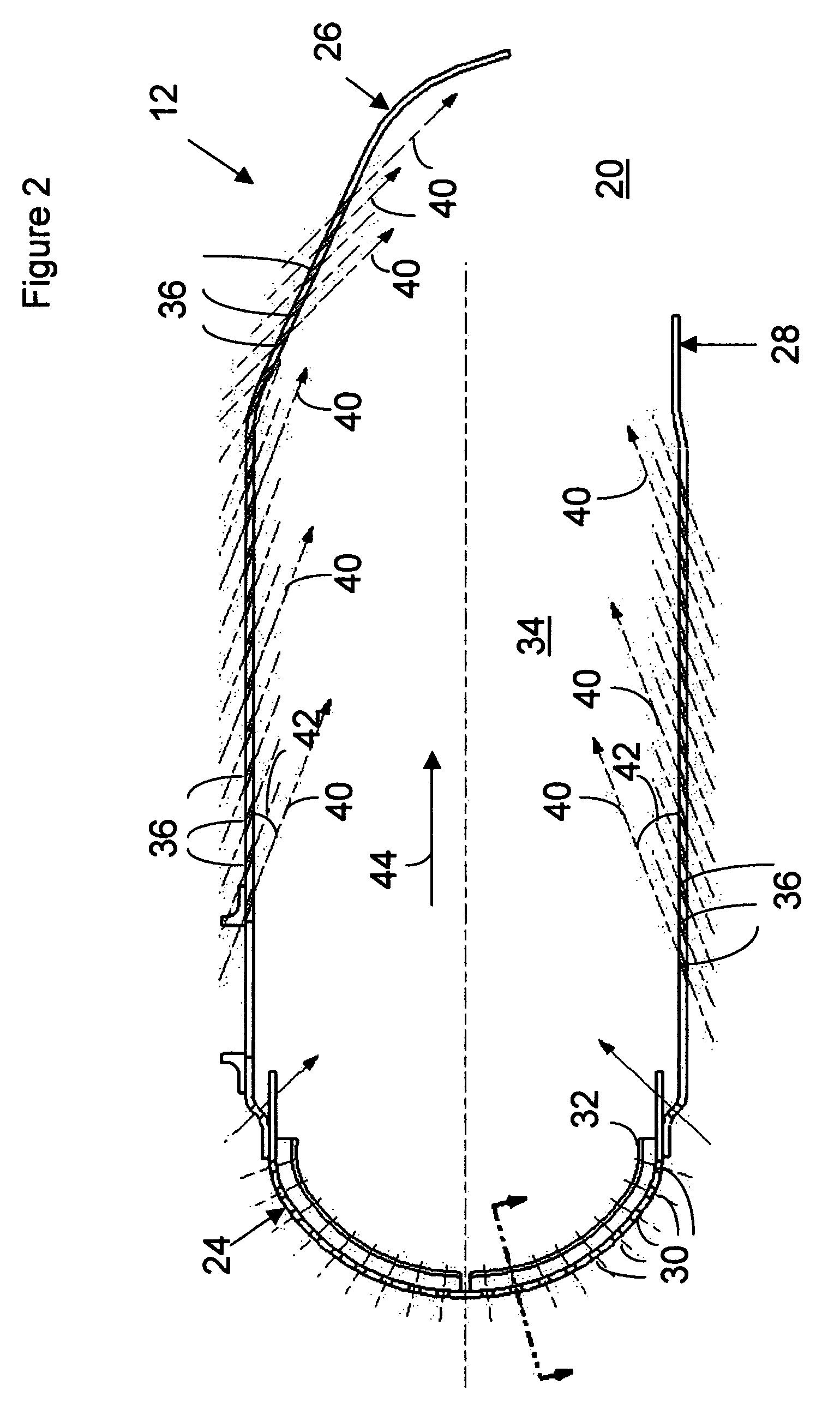

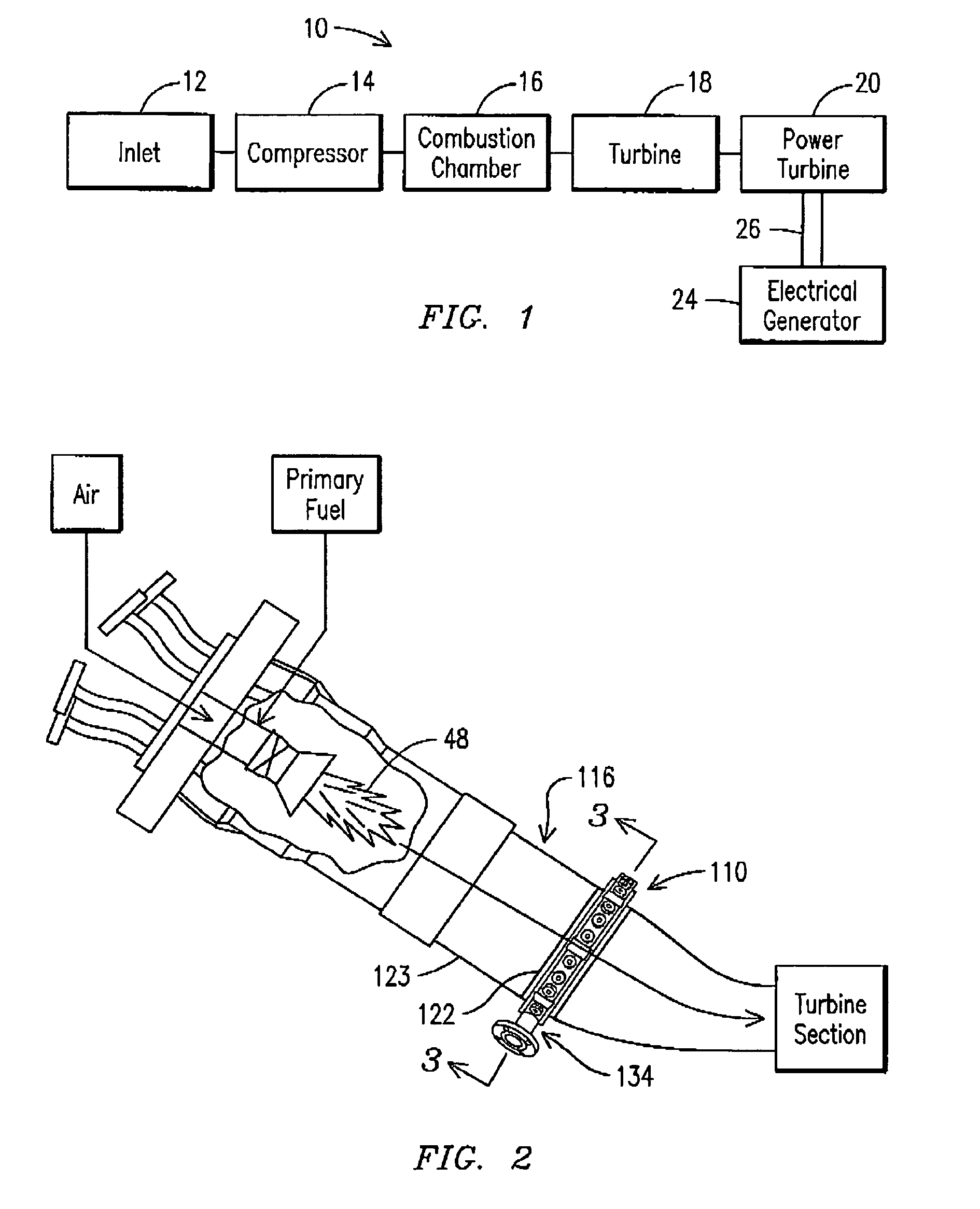

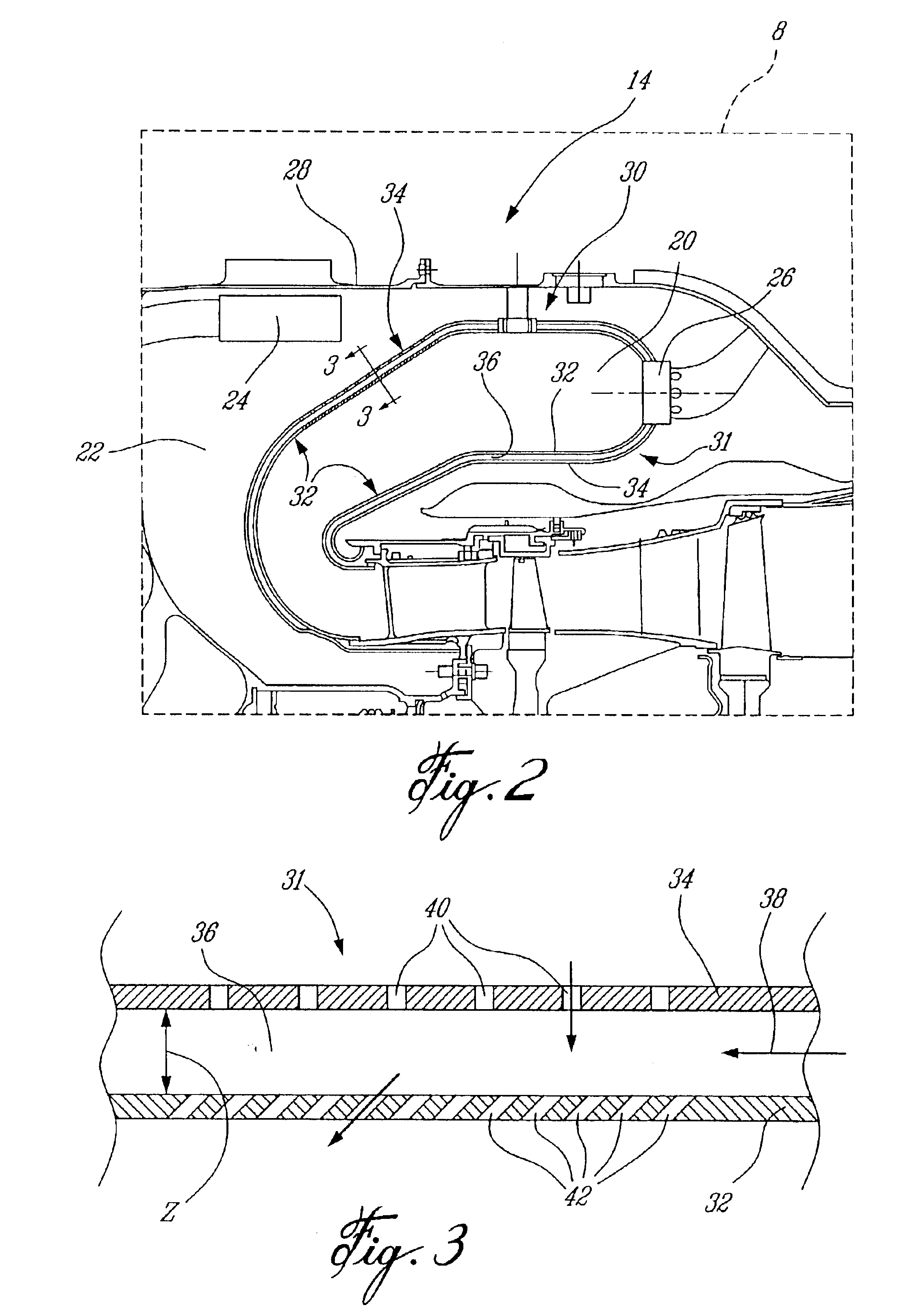

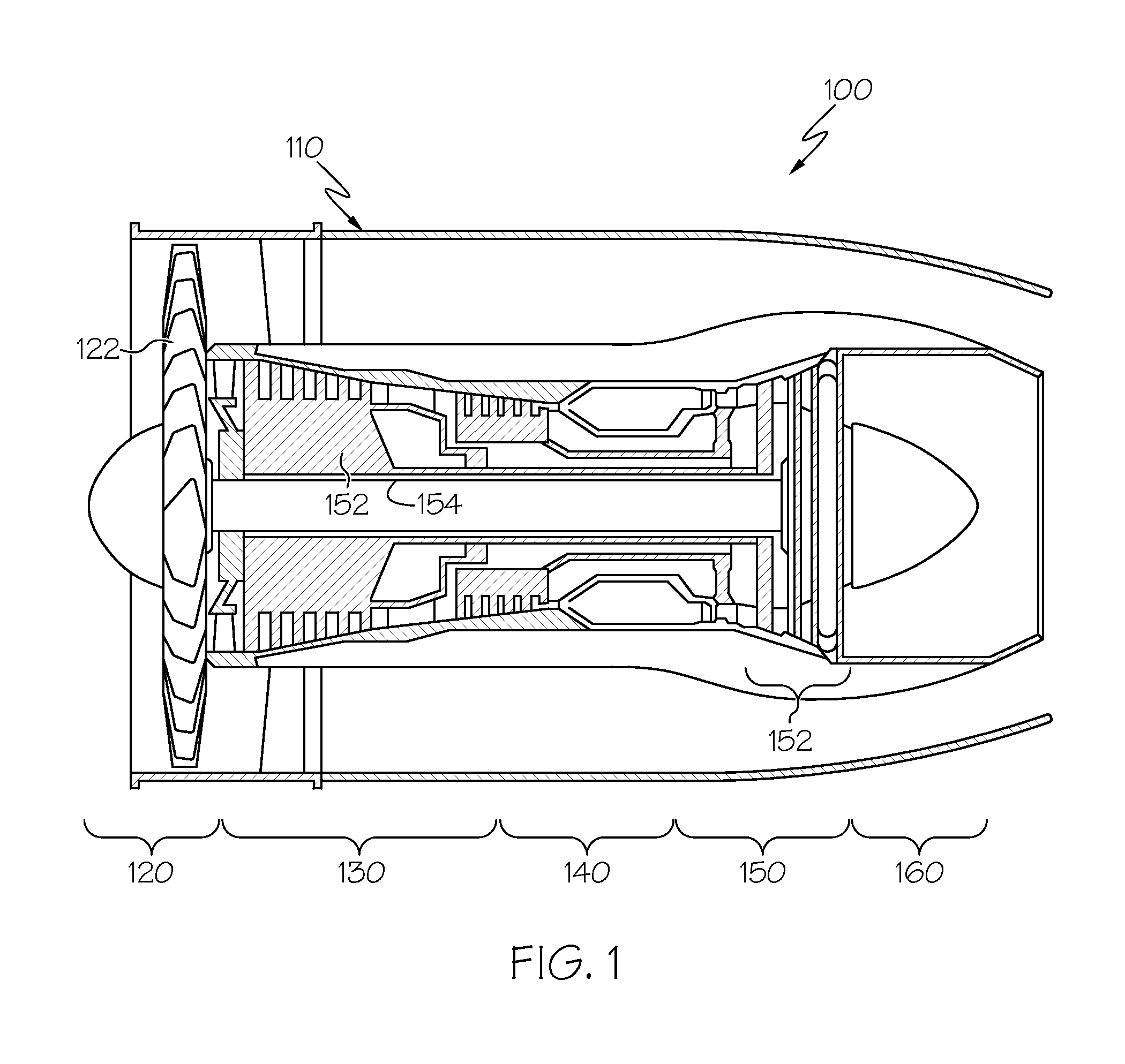

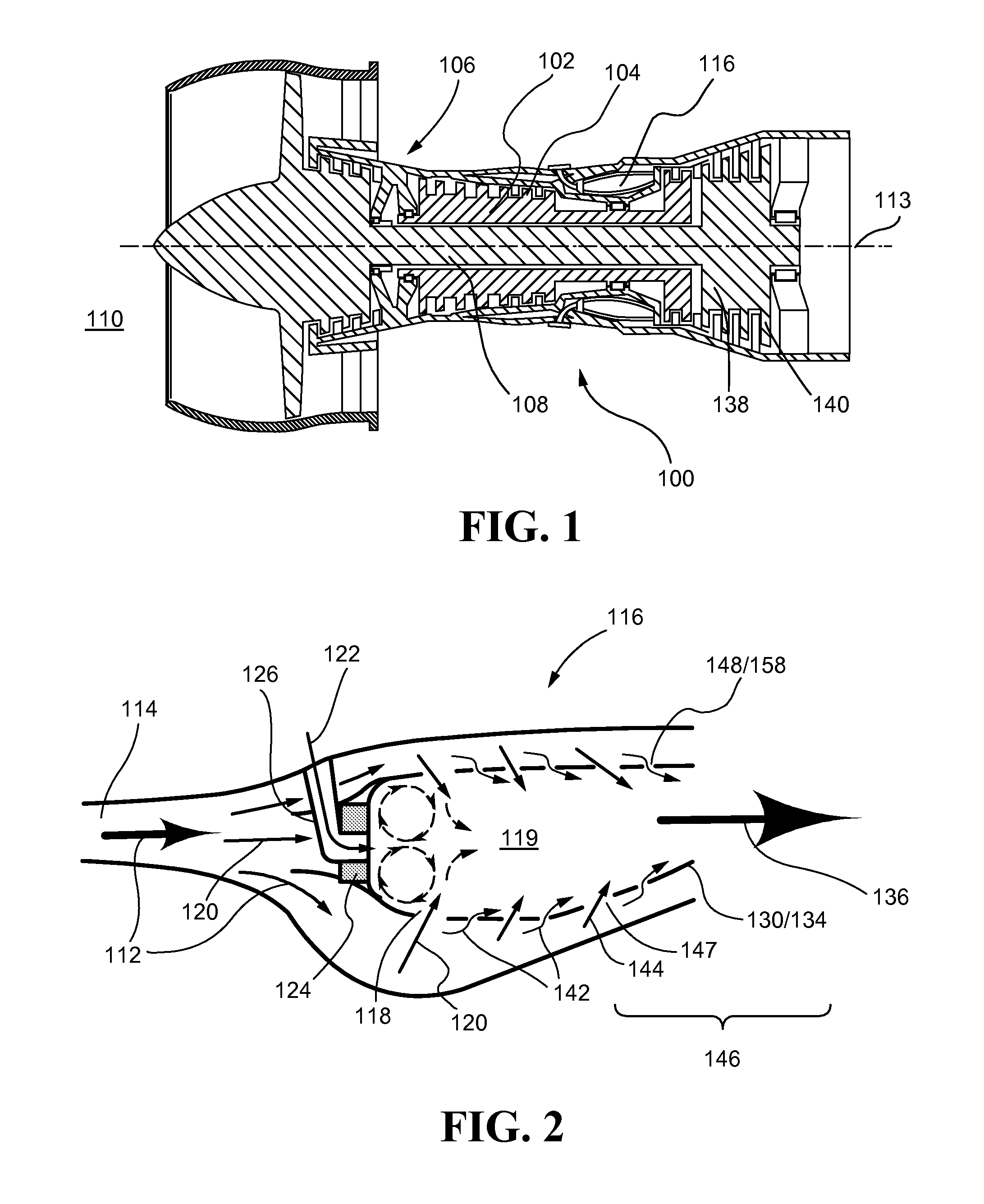

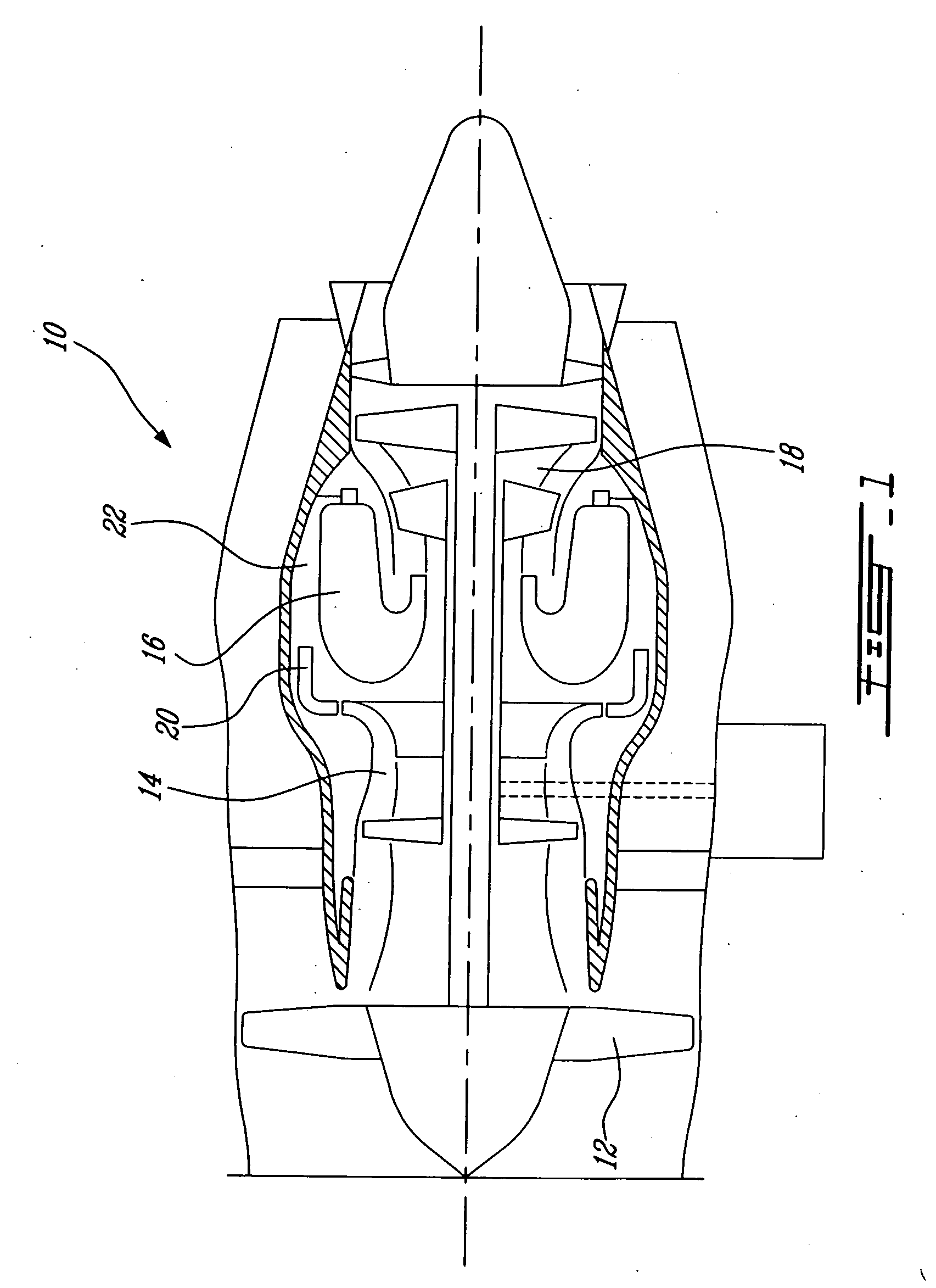

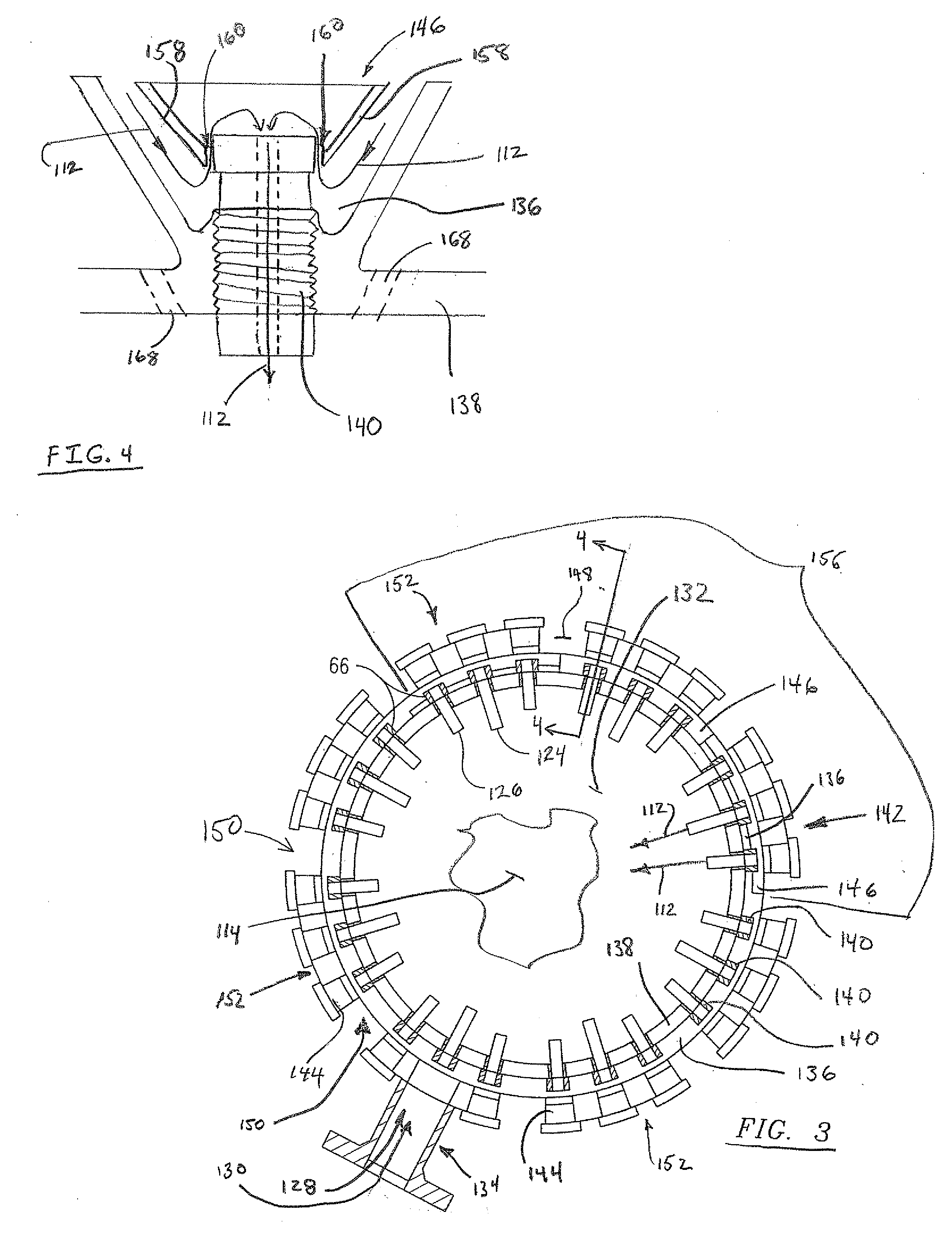

Pyrospin combuster

InactiveUS6955053B1Improve cooling effectEnhanced fire spinningContinuous combustion chamberGas turbine plantsCombustorEffusion

An annular combustor that has angled effusion holes through at least one surface of the combustor liner with the angle of the effusion holes oriented to cause the flow of air through the holes to facilitate swirling of the fuel and air within the combustor. The effusion holes thereby facilitate efficient cooling of the combustor liner combined with superior fuel / air mixing within the combustor.

Owner:HAMILTON SUNDSTRAND CORP

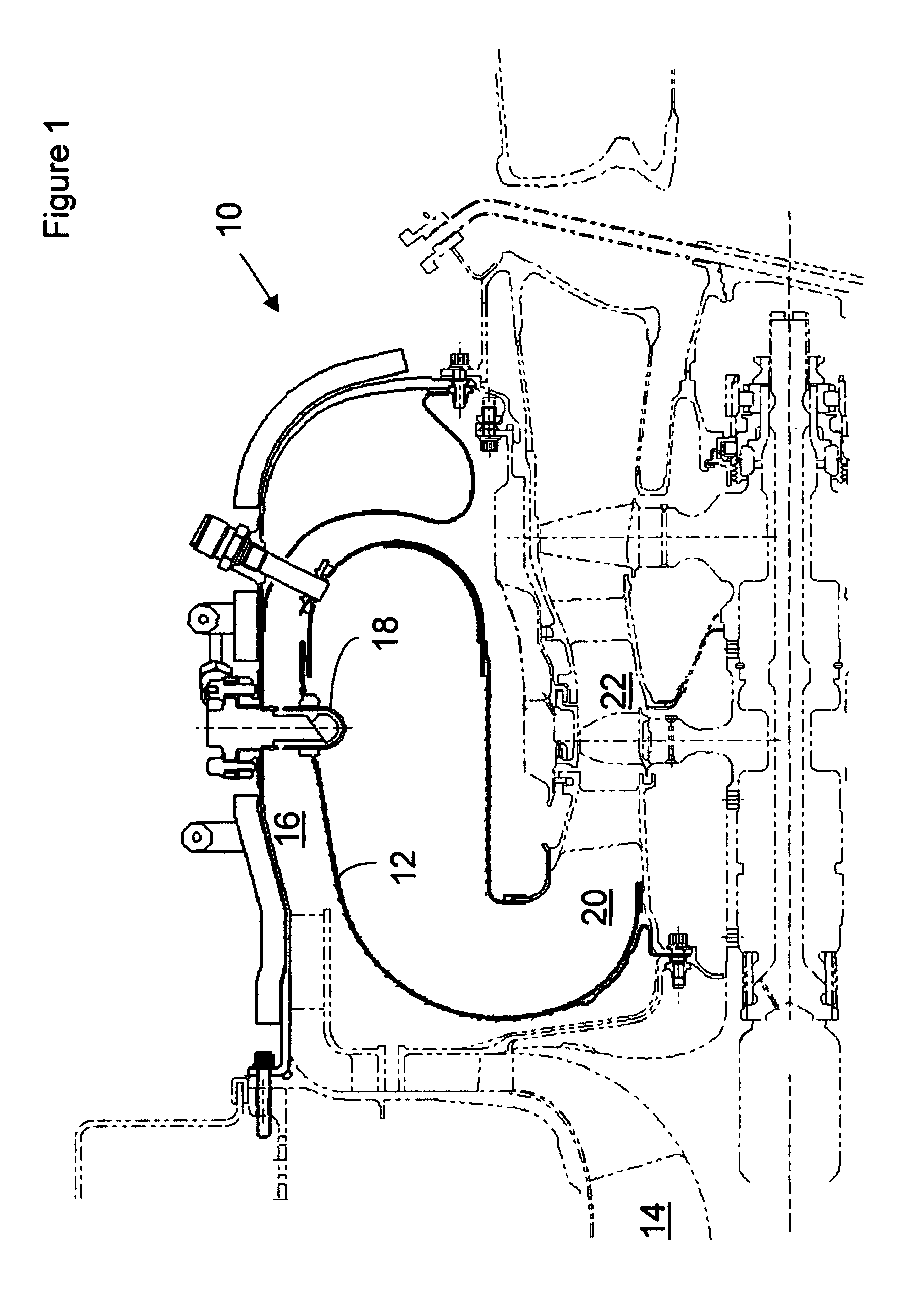

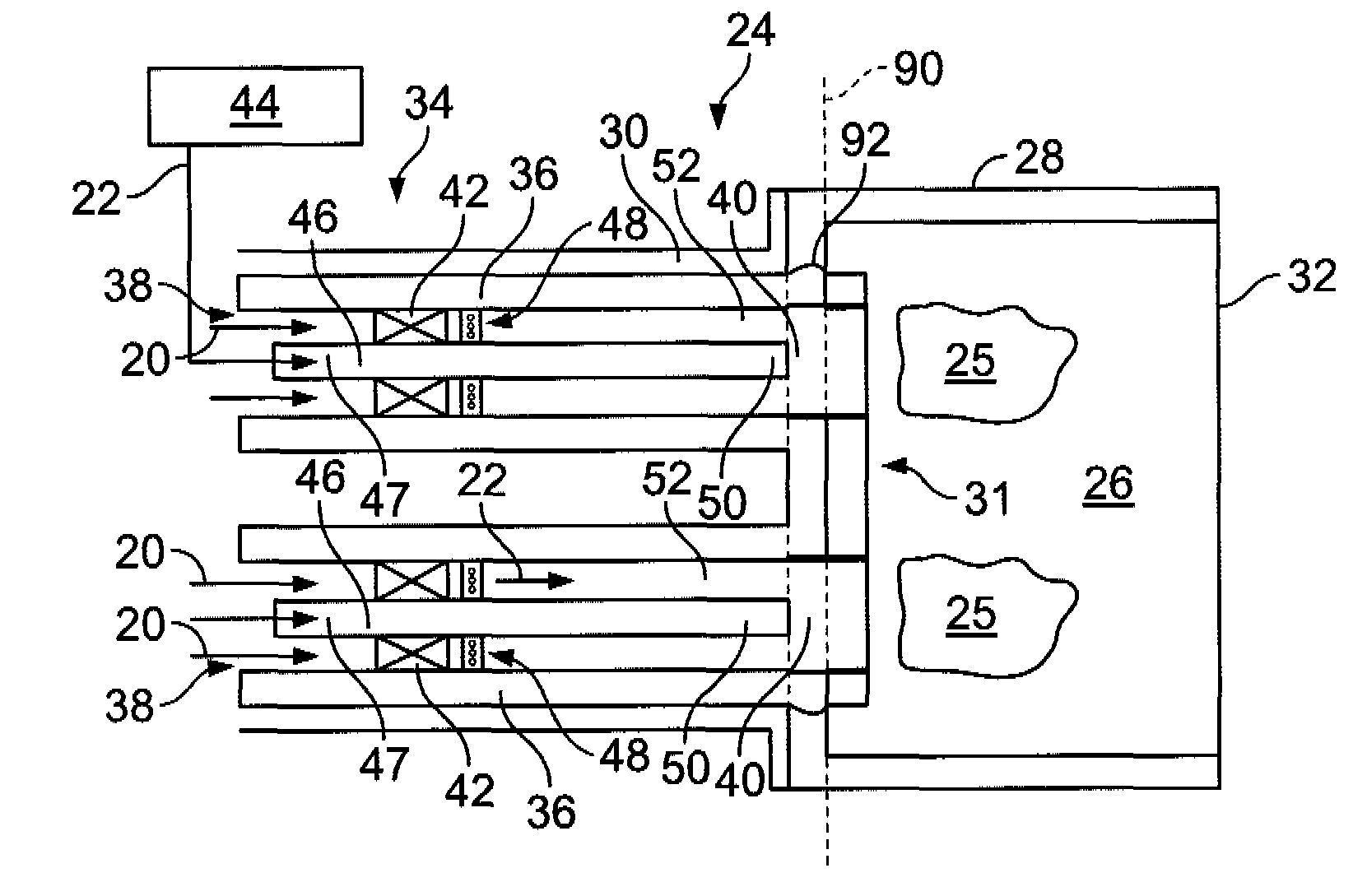

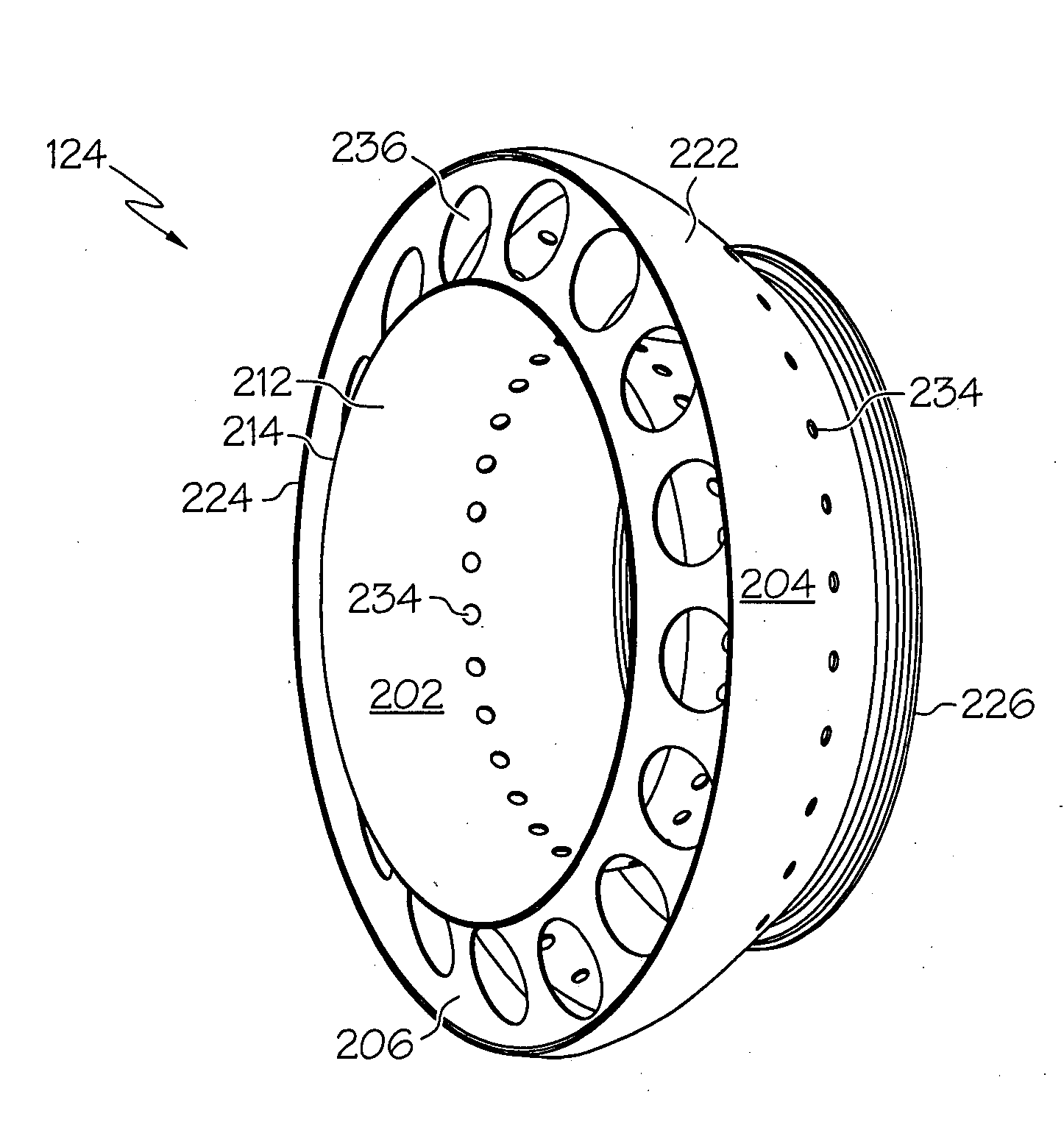

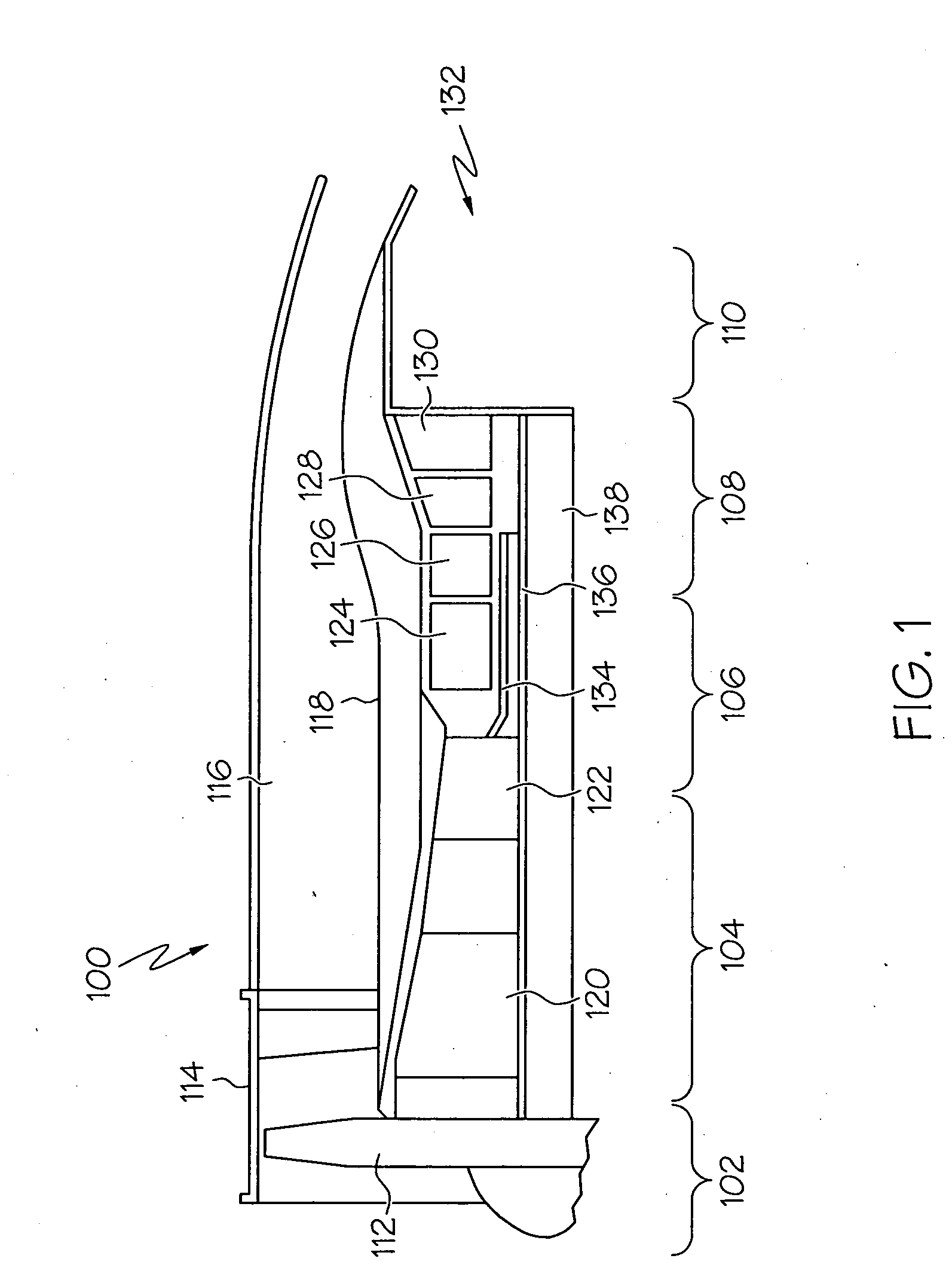

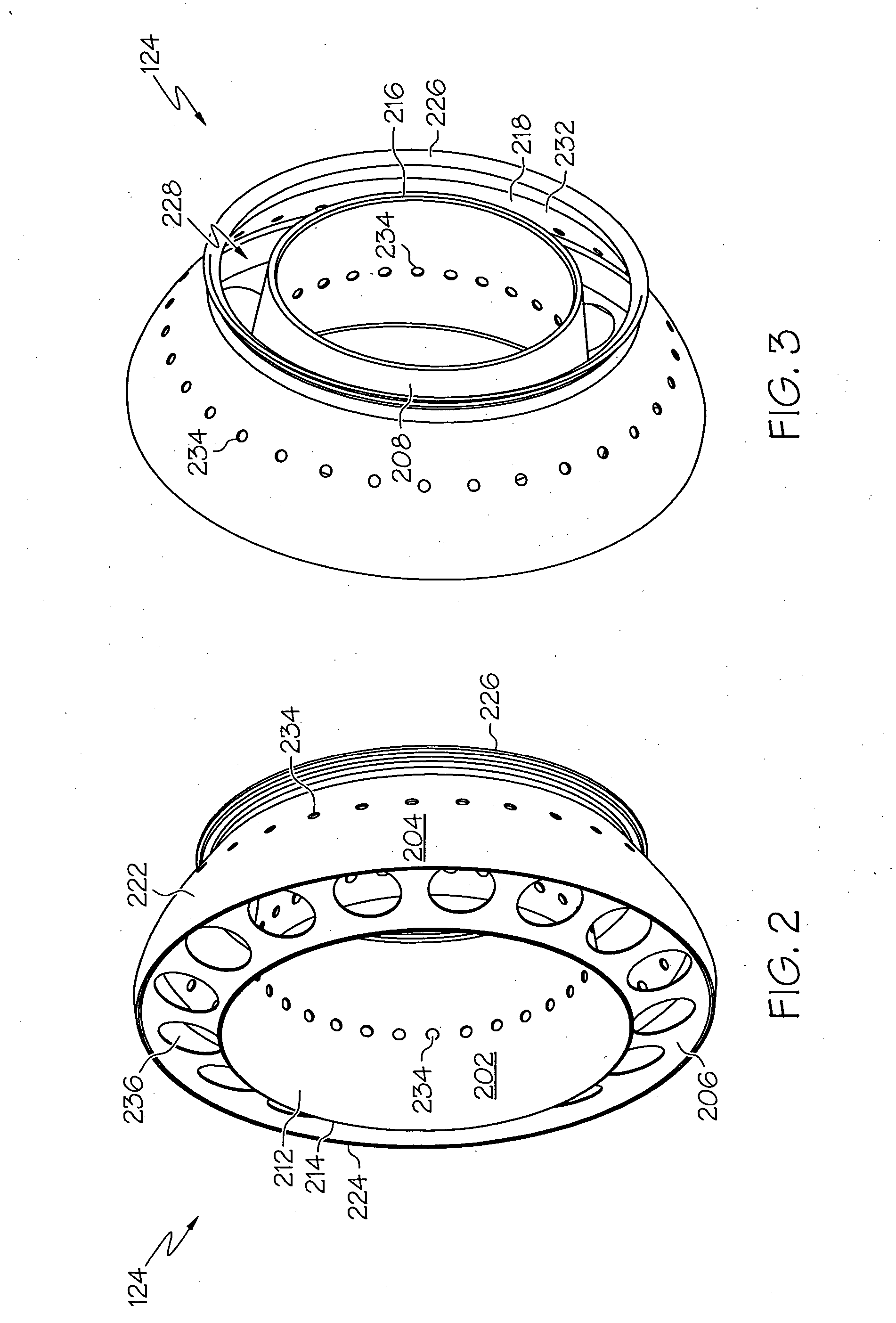

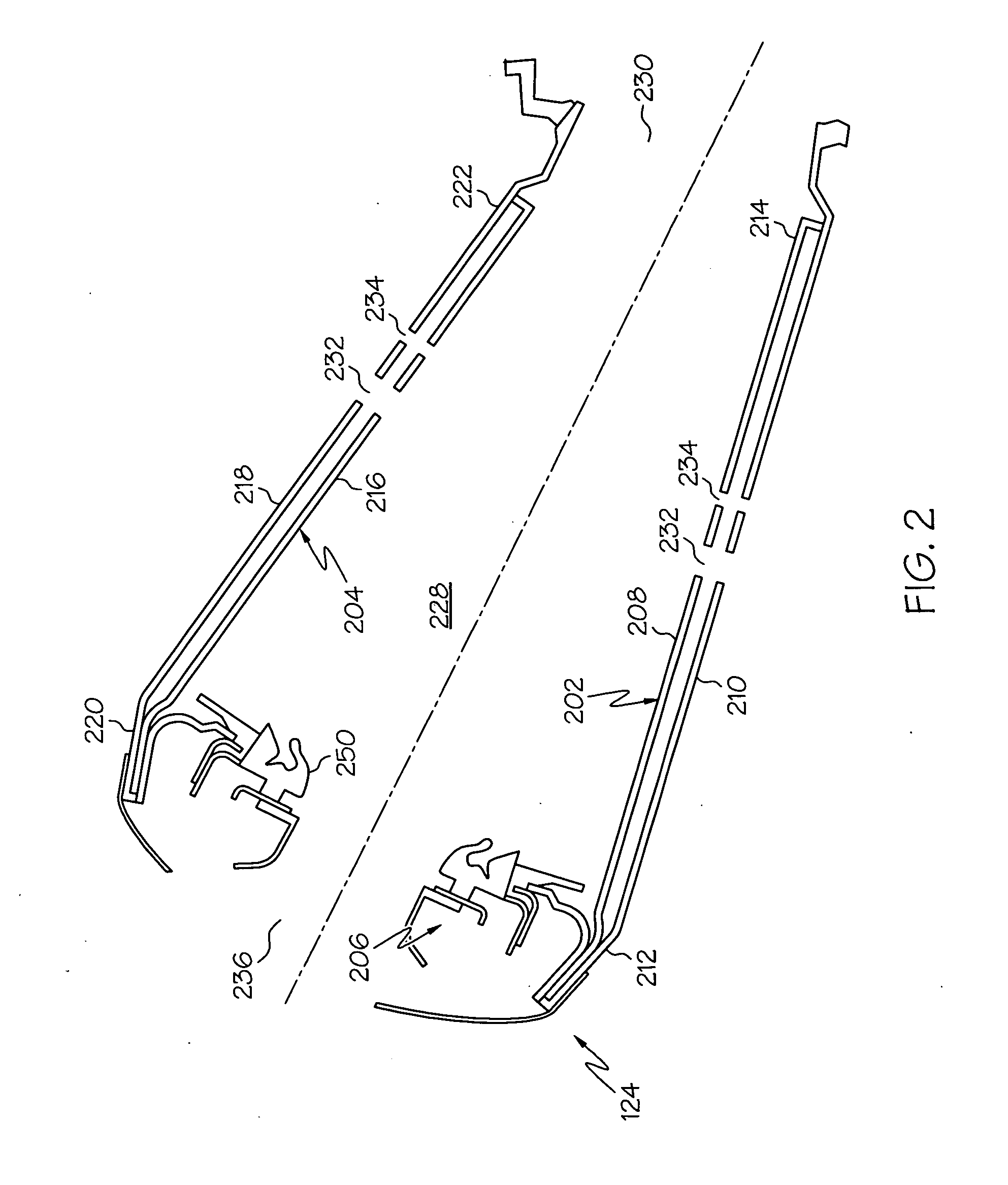

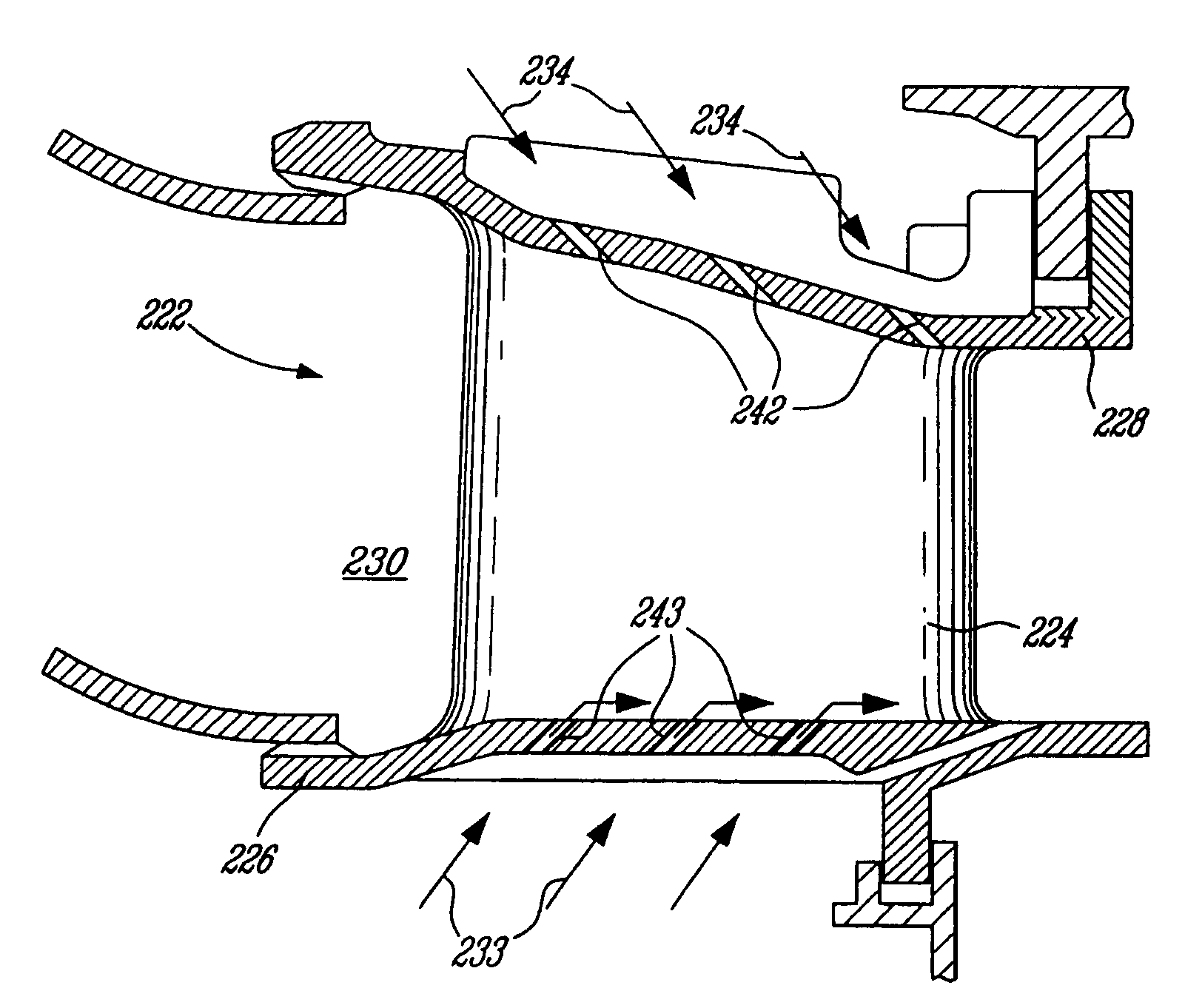

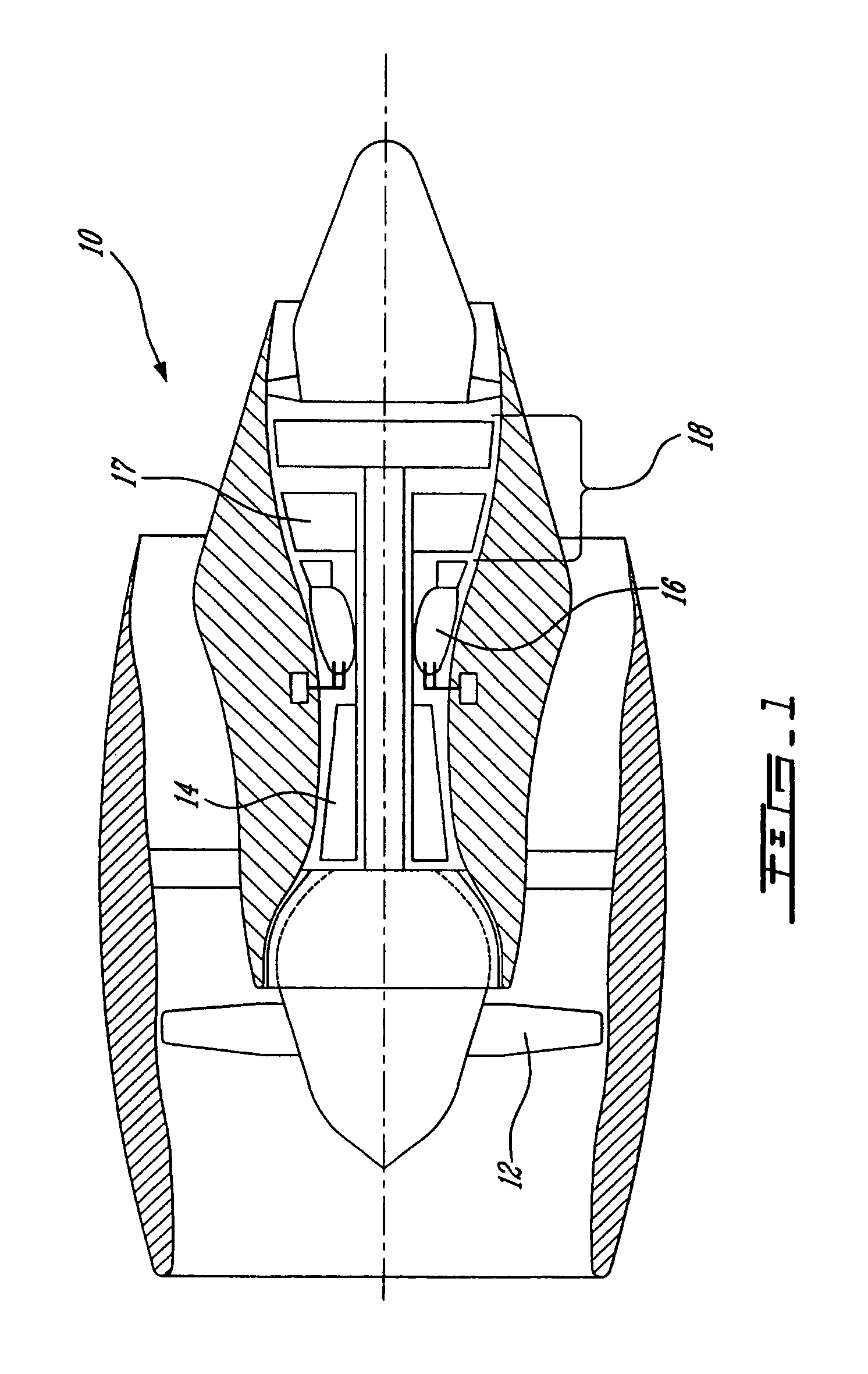

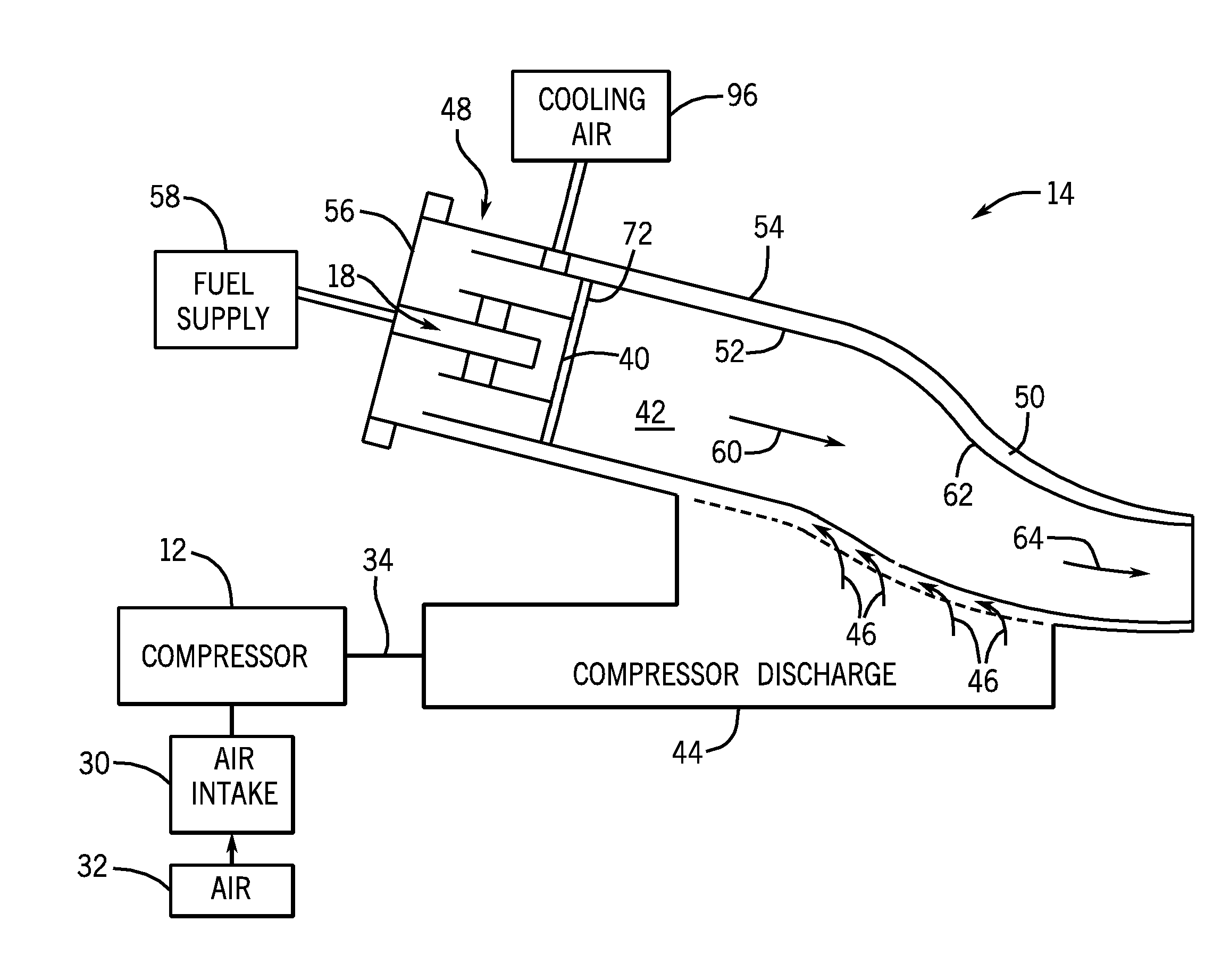

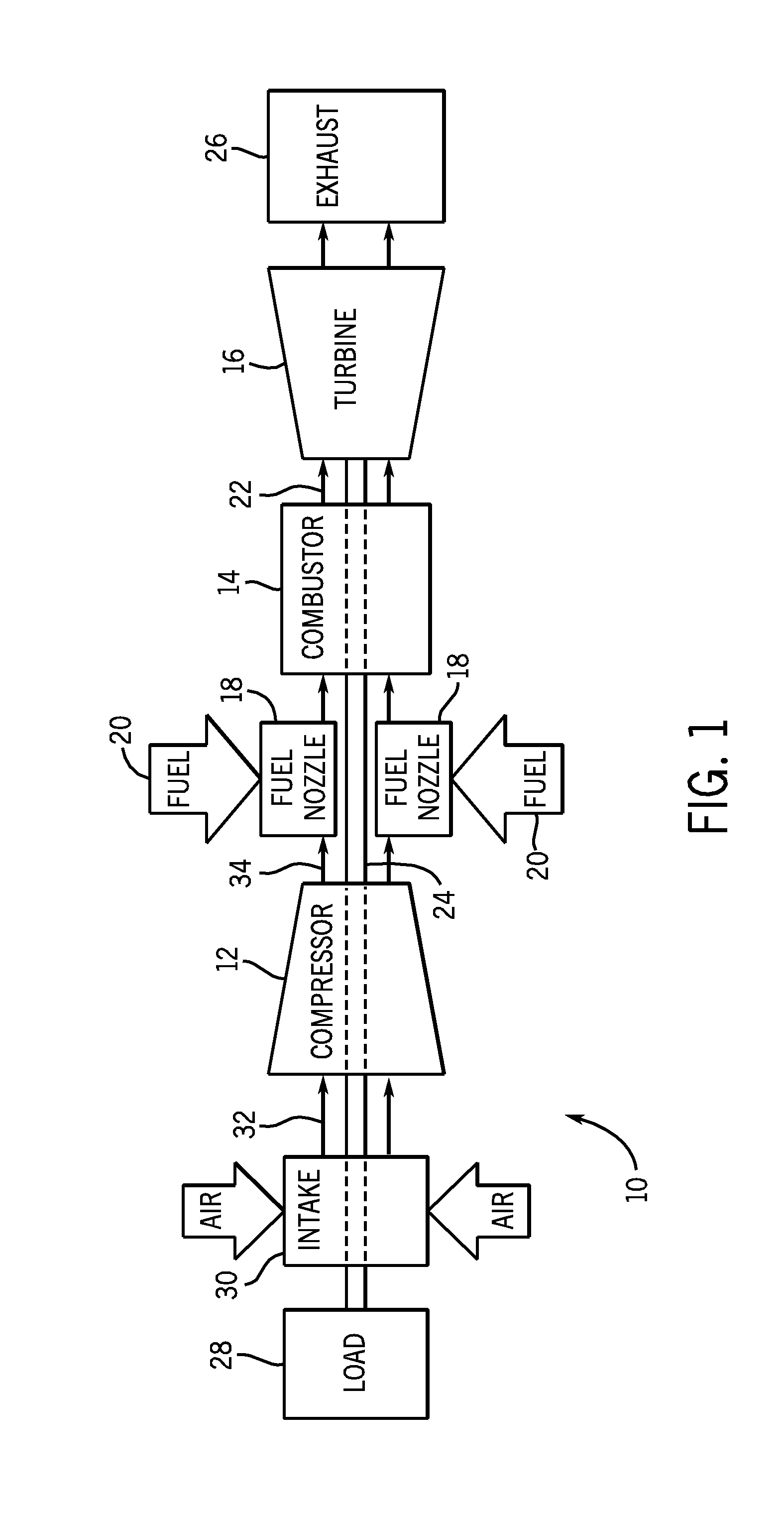

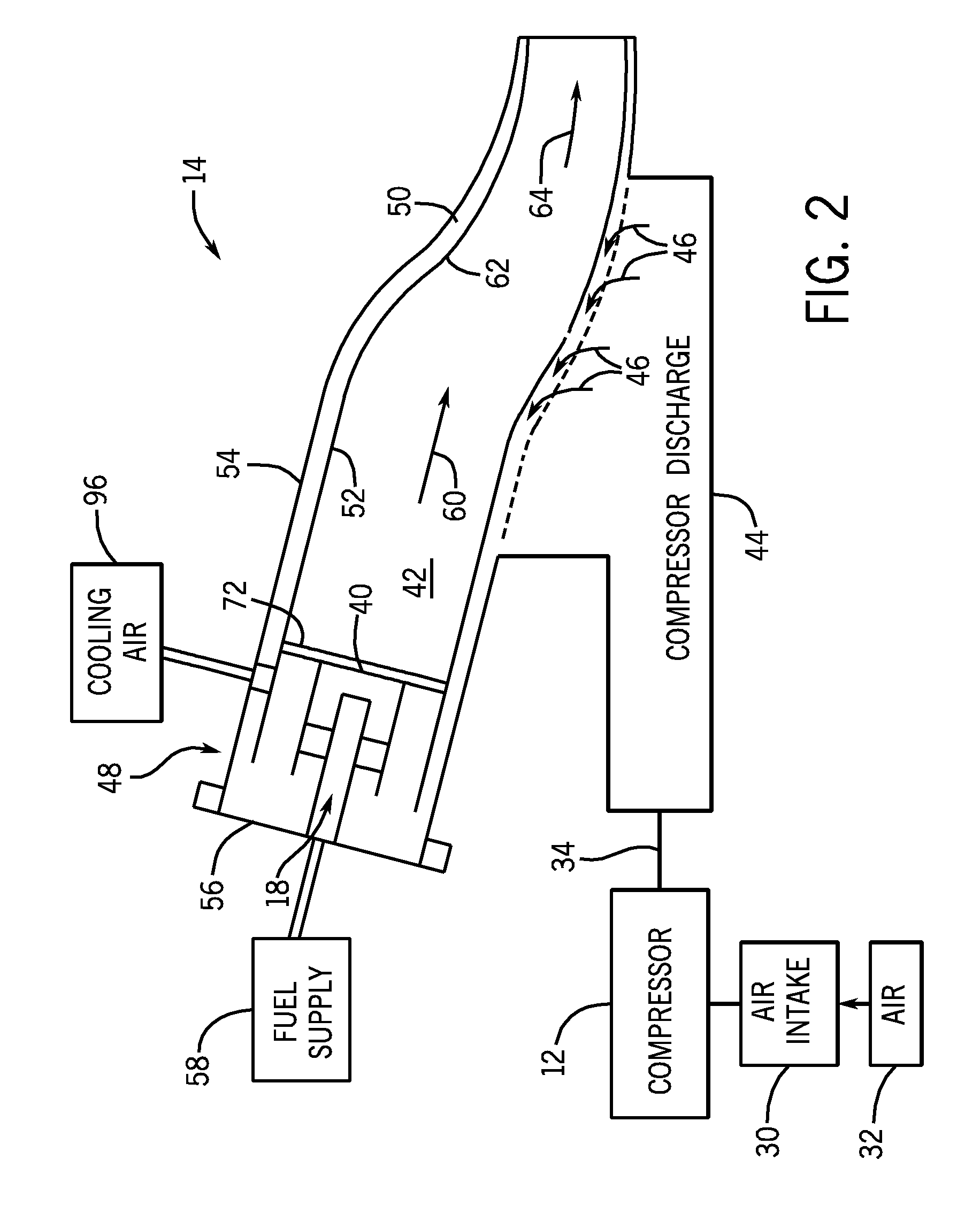

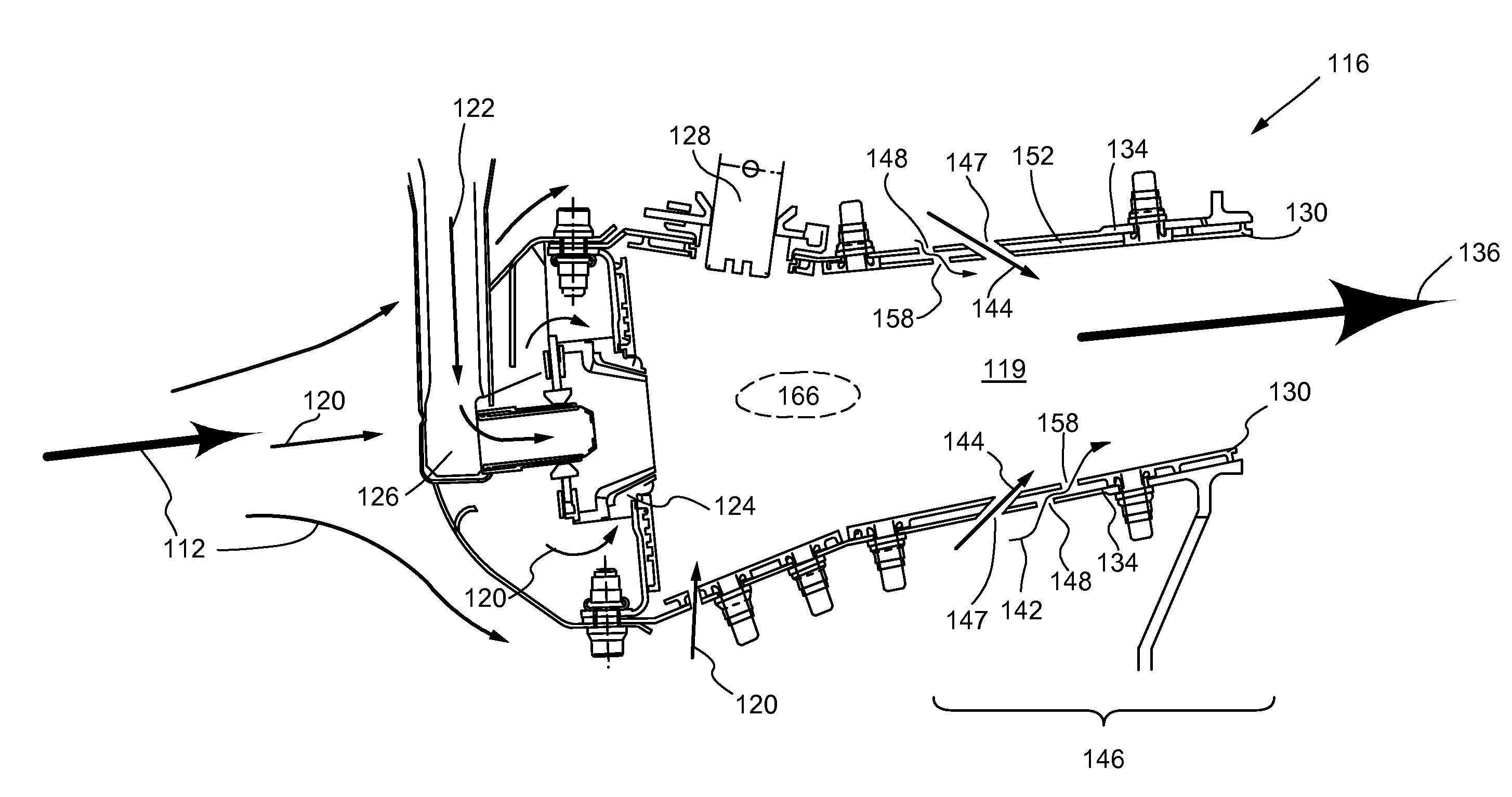

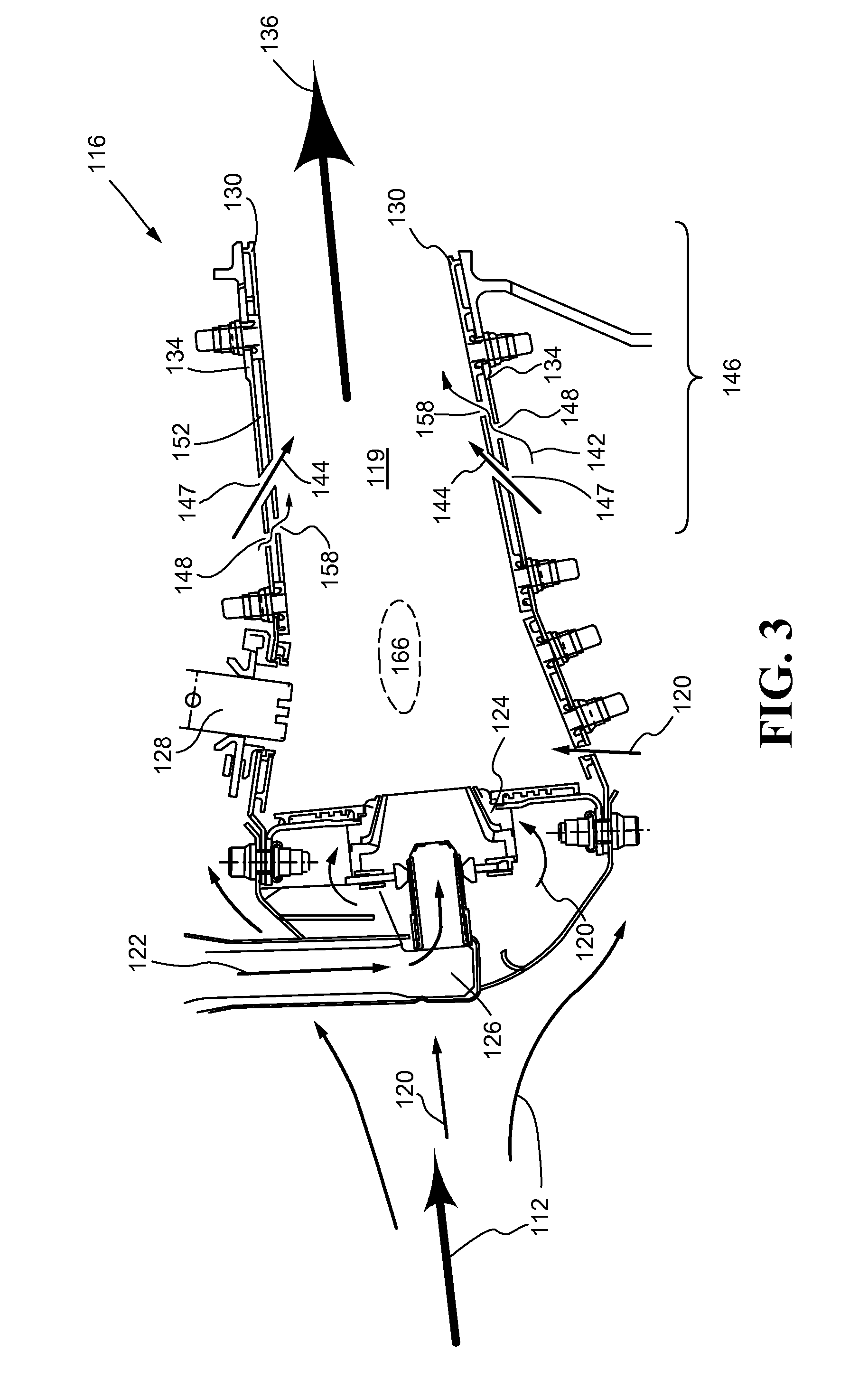

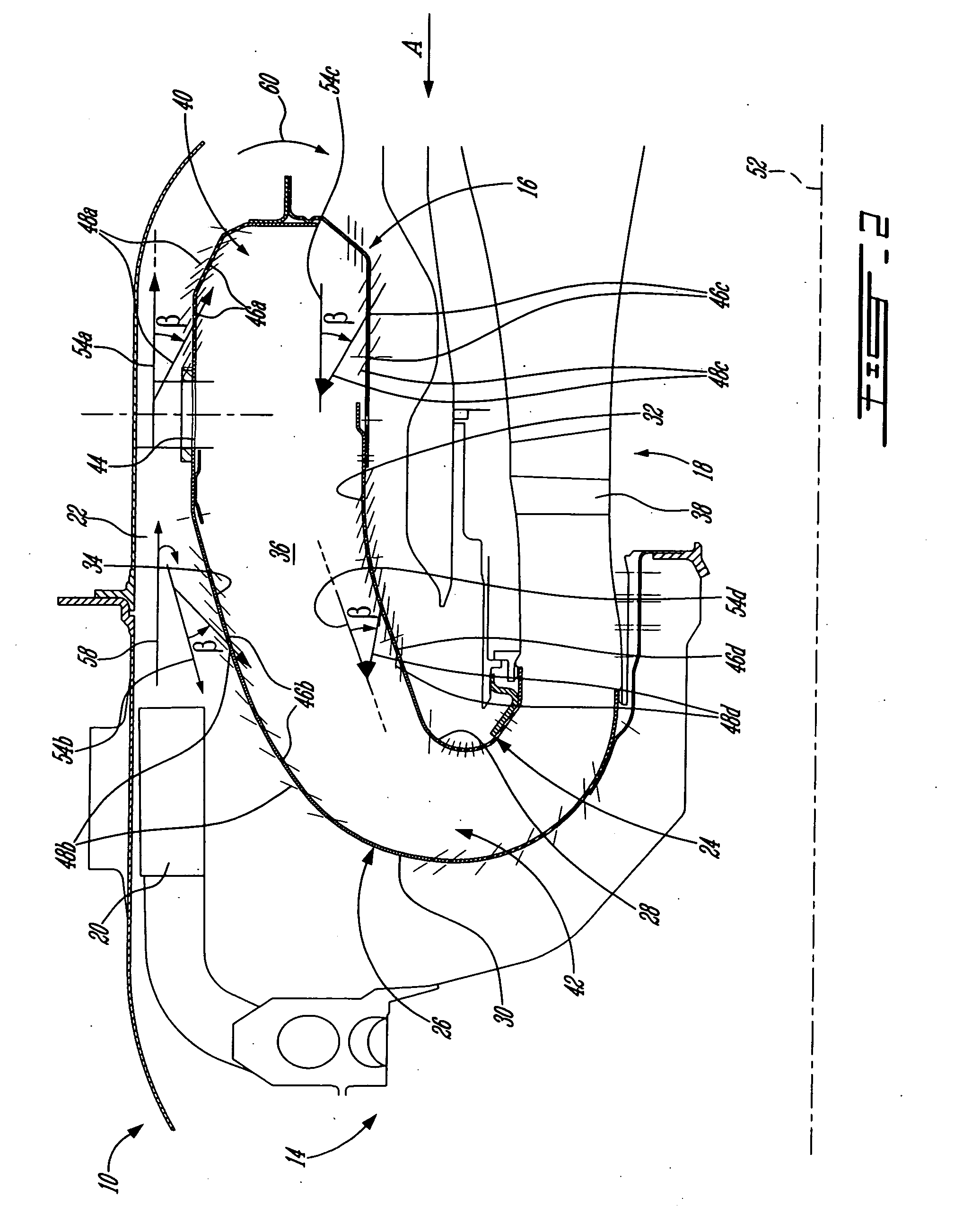

Injection assembly for a combustor

ActiveUS20080053097A1Facilitate reducing dynamicContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustorEffusion

An injection assembly for use with a combustor is provided. The injection assembly includes an effusion plate that has a plurality of plate openings and a plate sleeve having a sidewall portion that includes a forward edge. The forward edge is coupled to the effusion plate such that the effusion plate is oriented obliquely with respect to a centerline extending through the combustor. The injection assembly also includes a plurality of ring extensions where each of the ring extensions is coupled to one of the plurality of plate openings. Each ring extension extends rearwardly into the plate sleeve.

Owner:GENERAL ELECTRIC CO

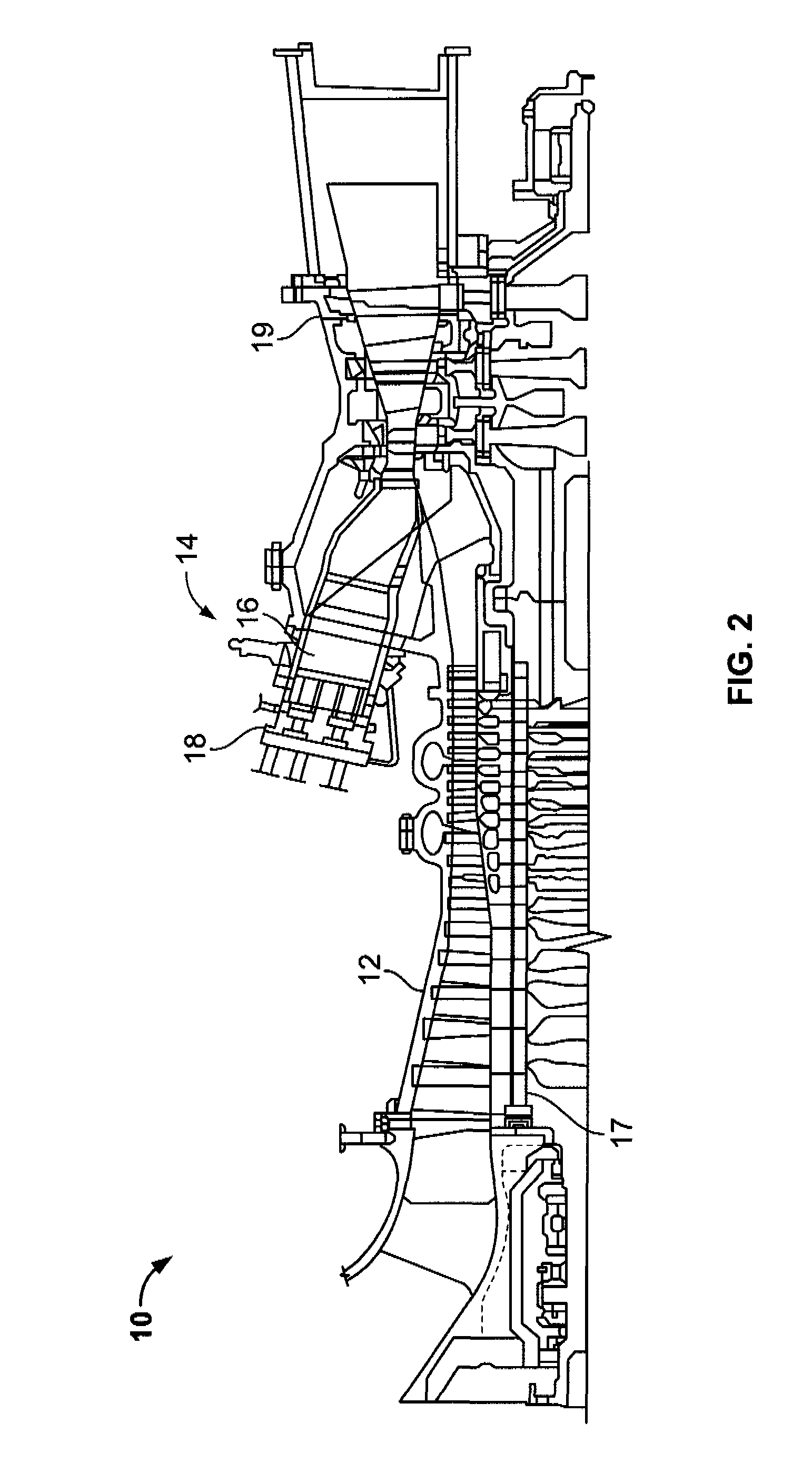

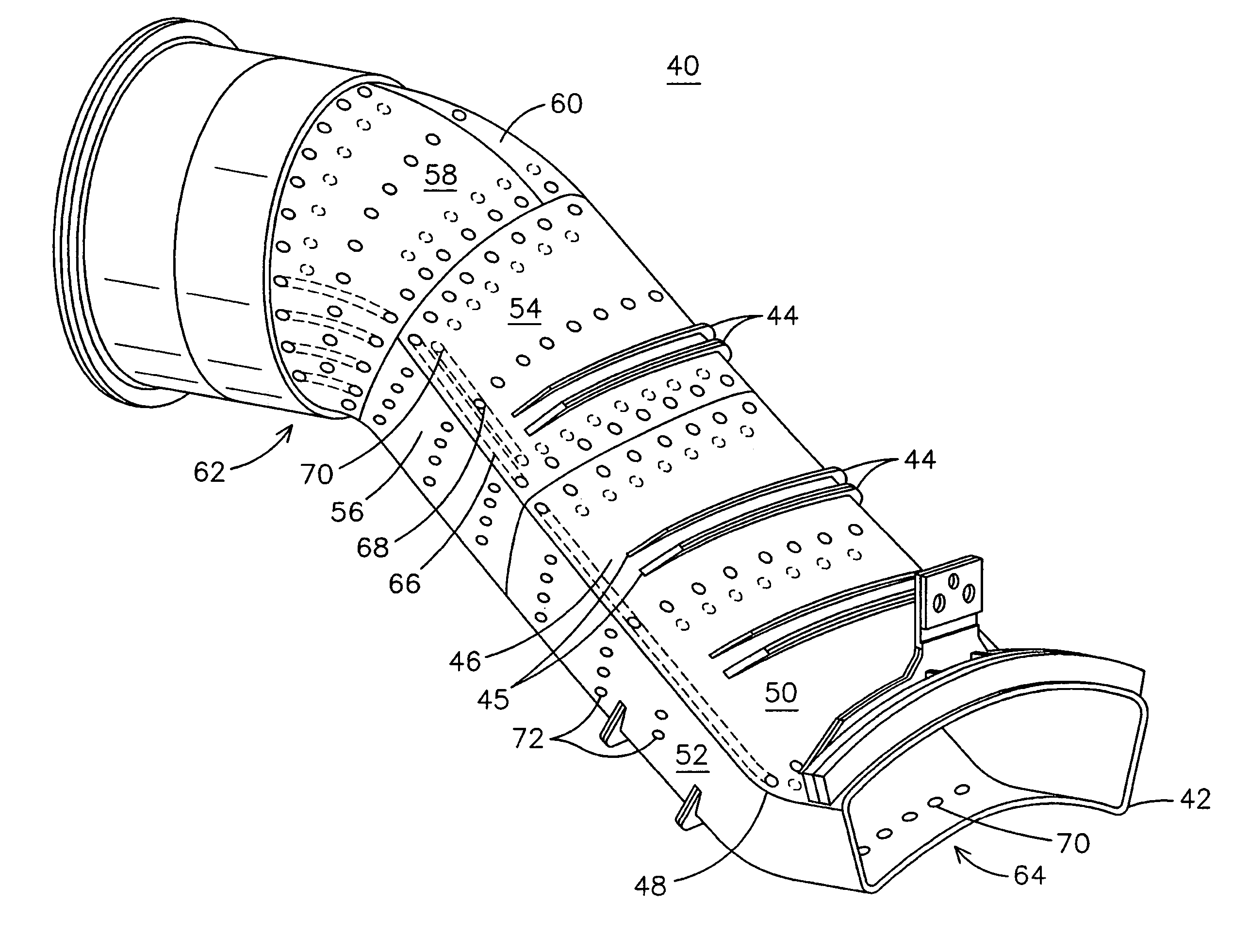

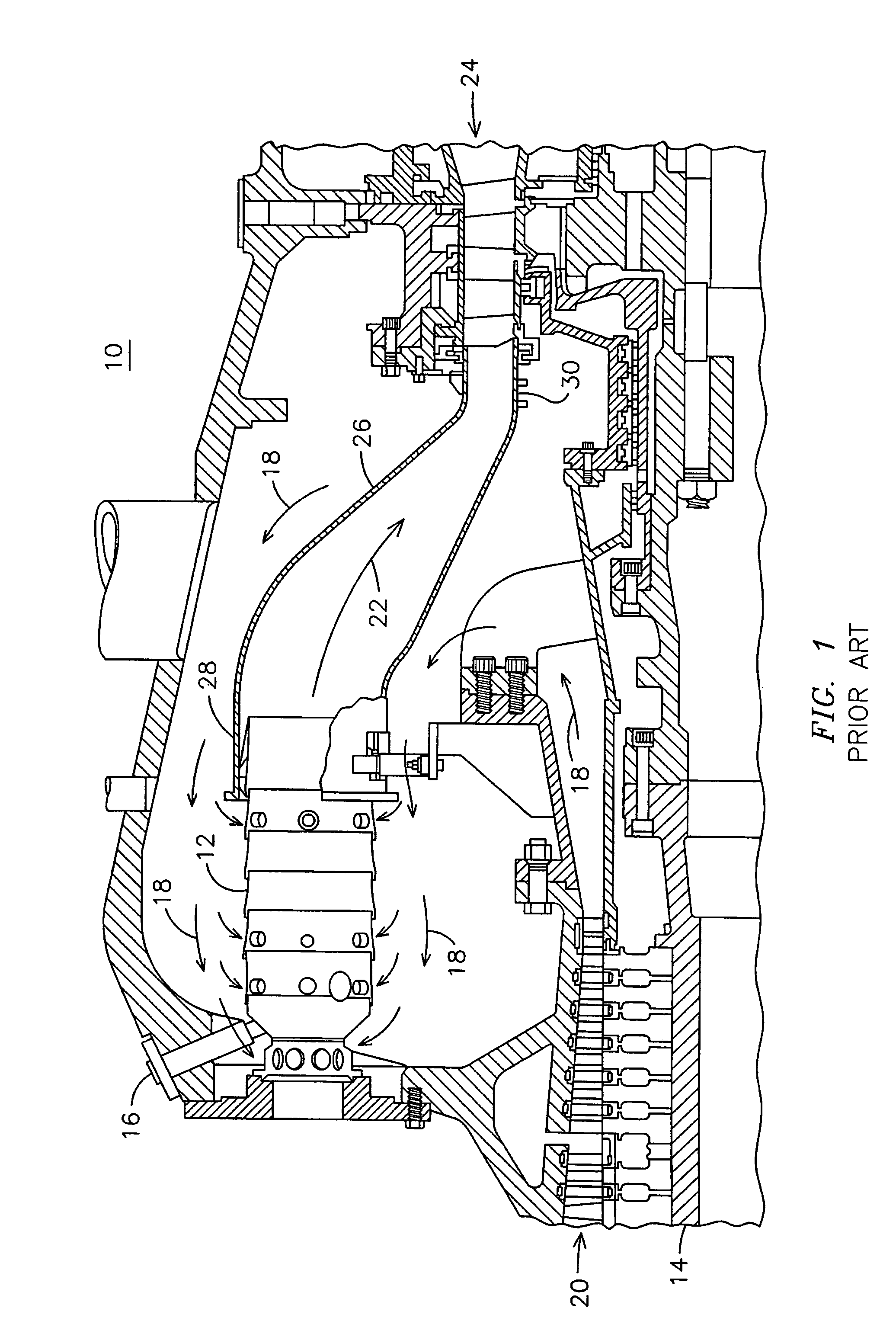

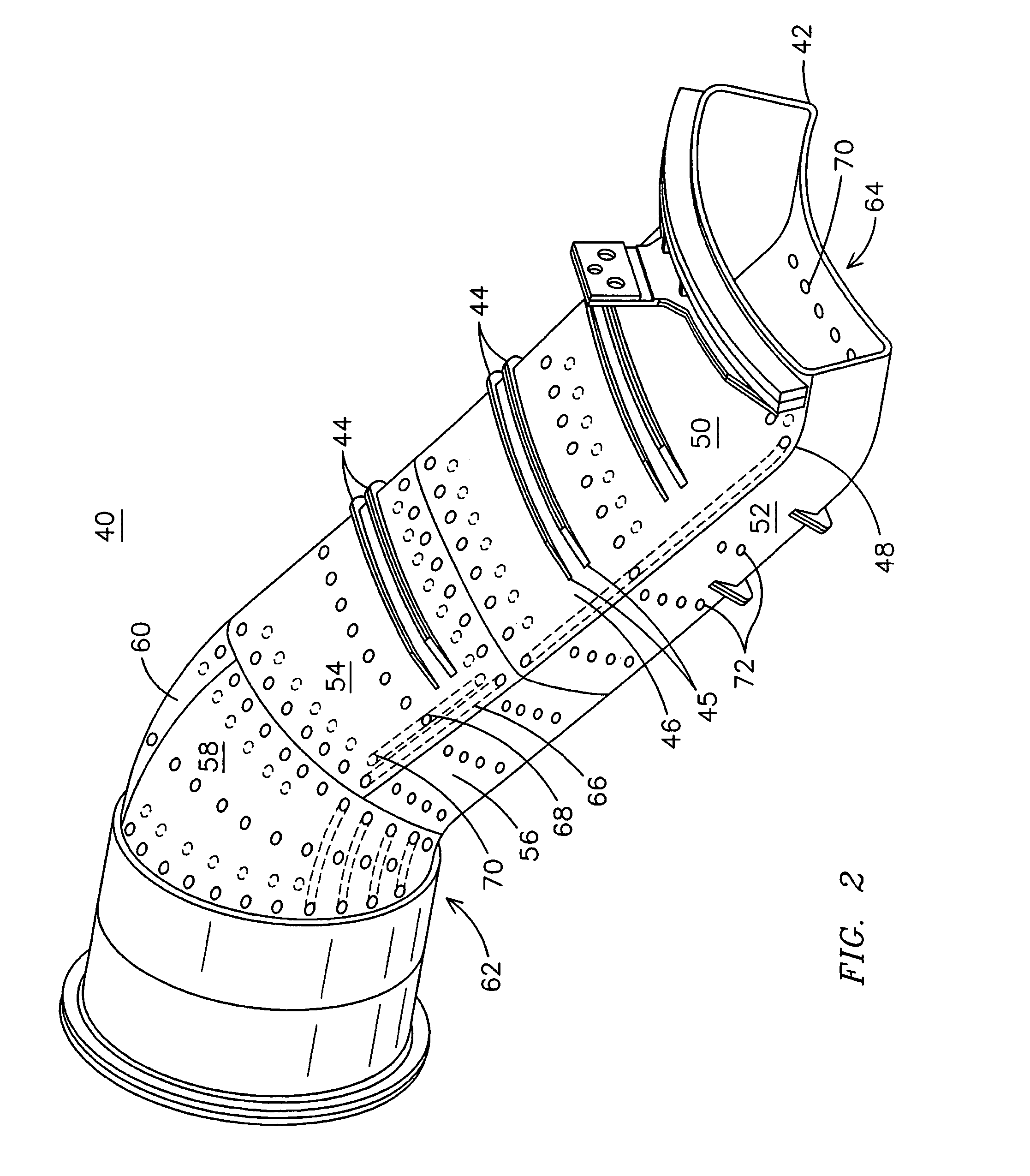

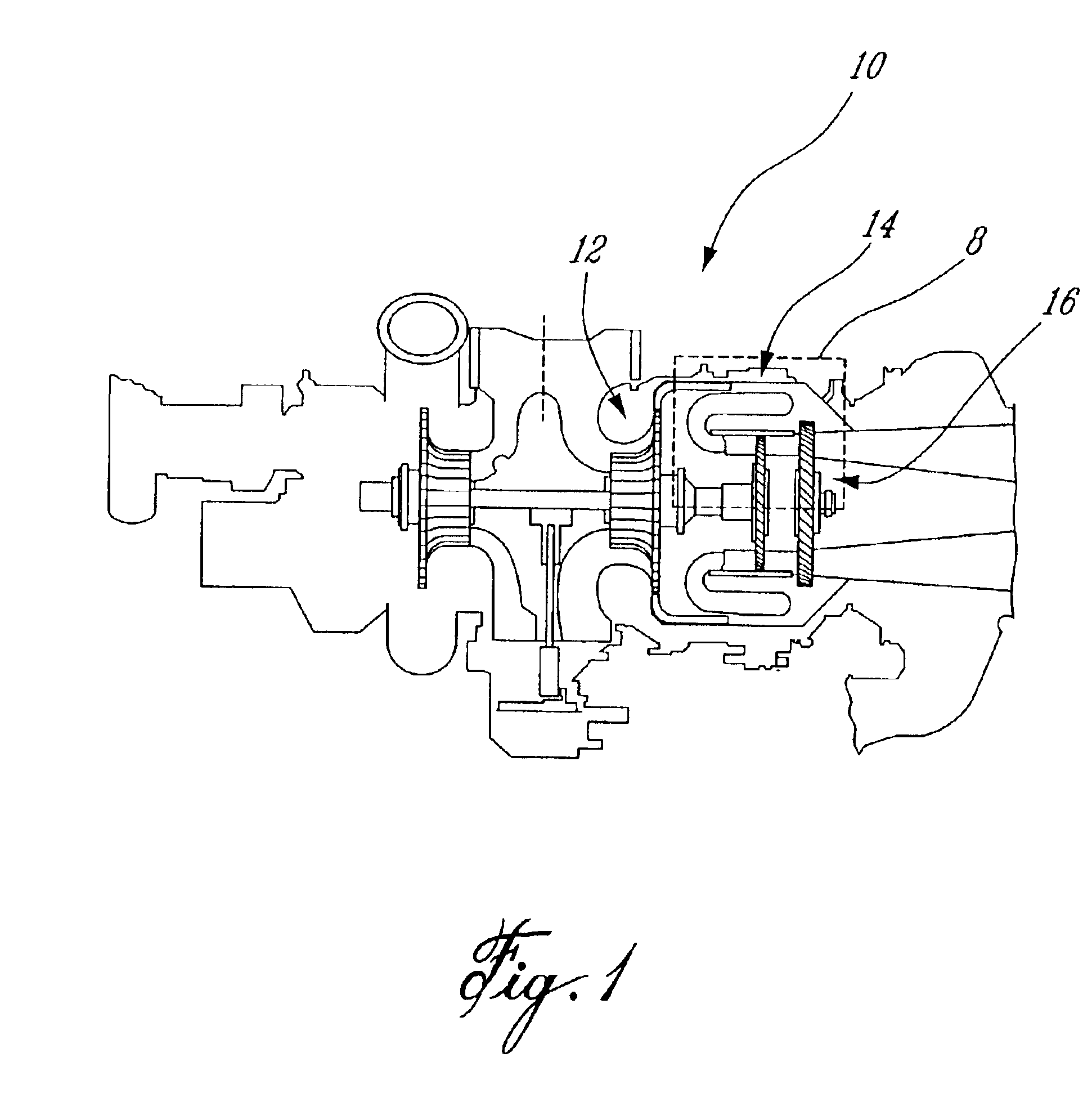

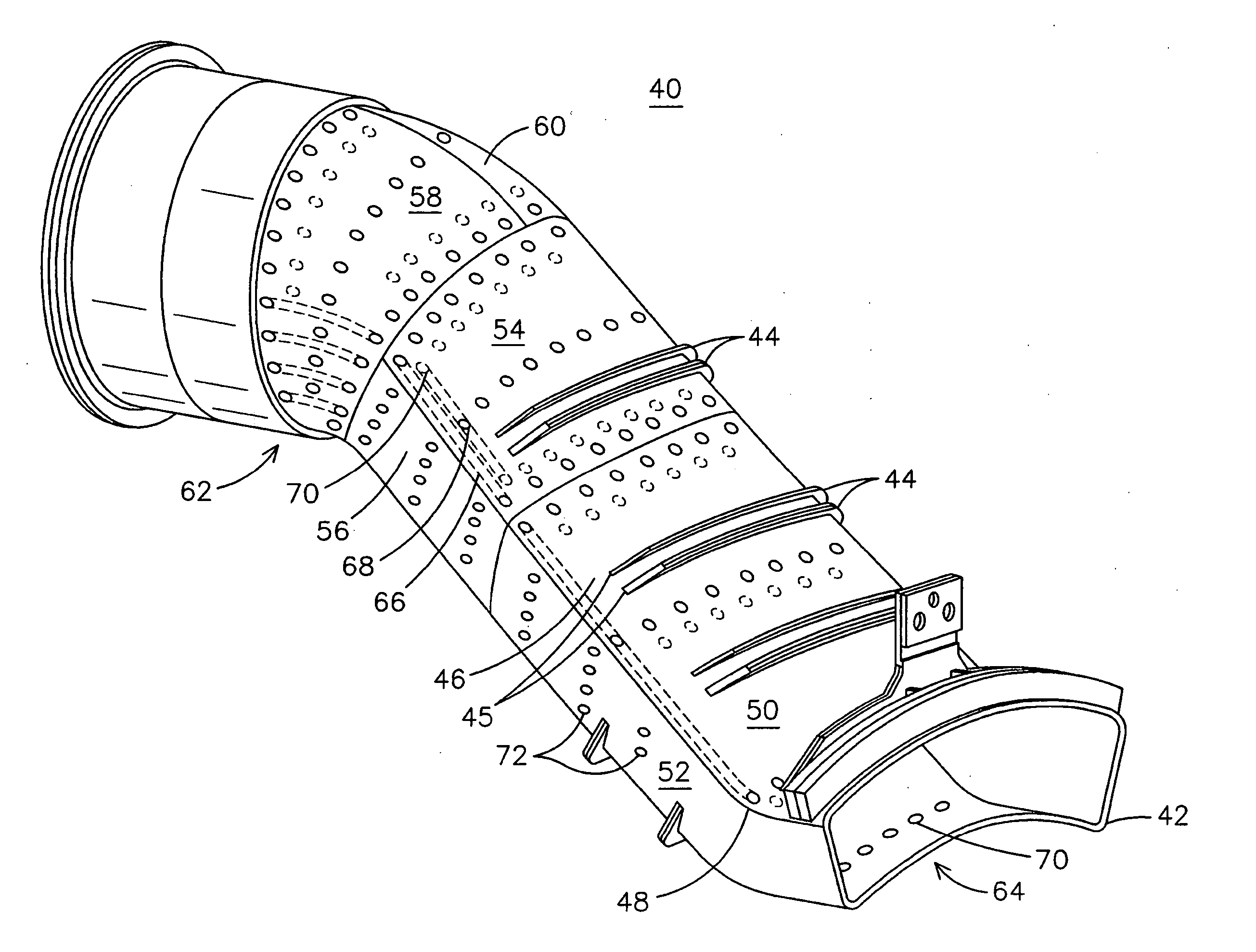

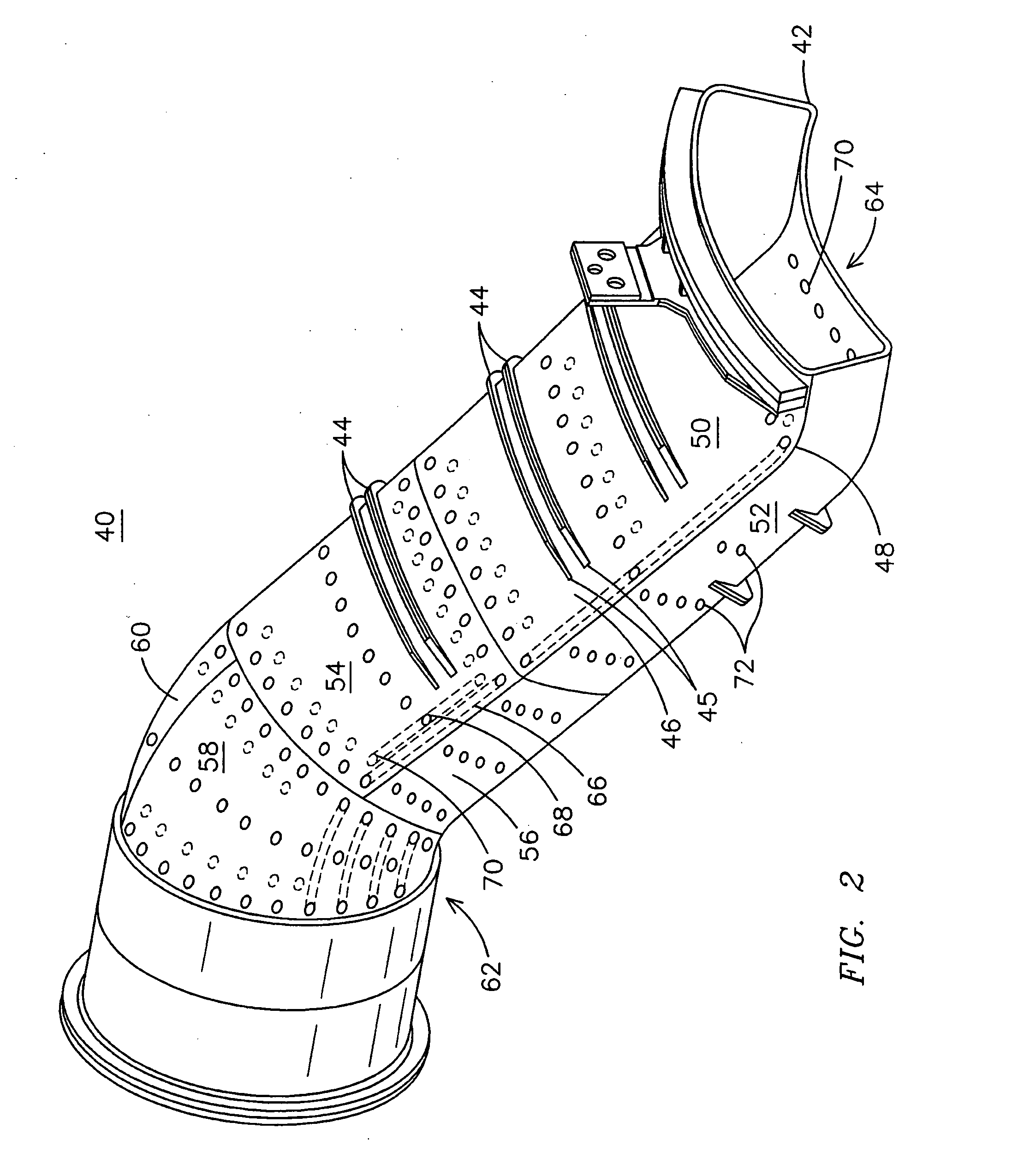

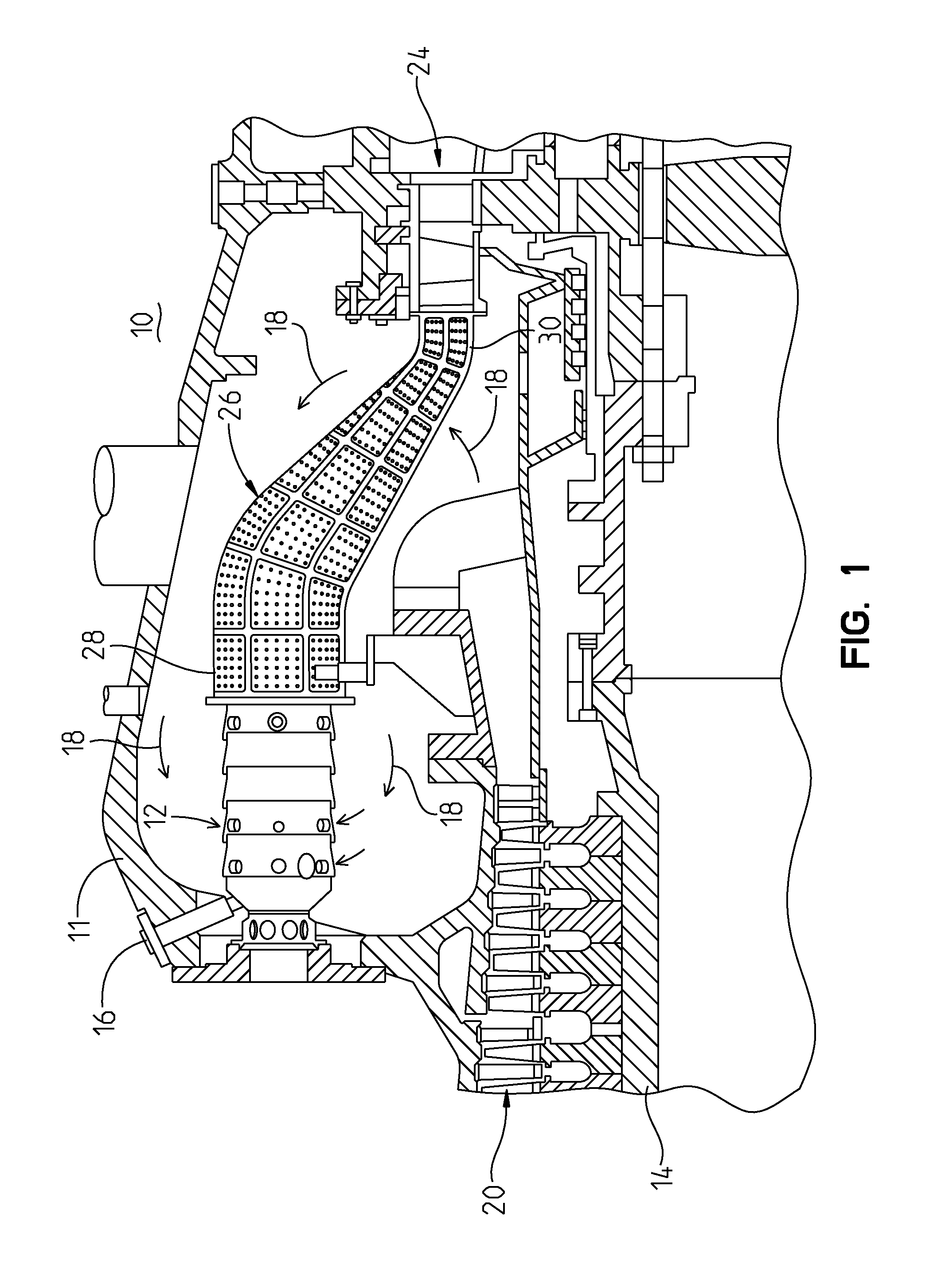

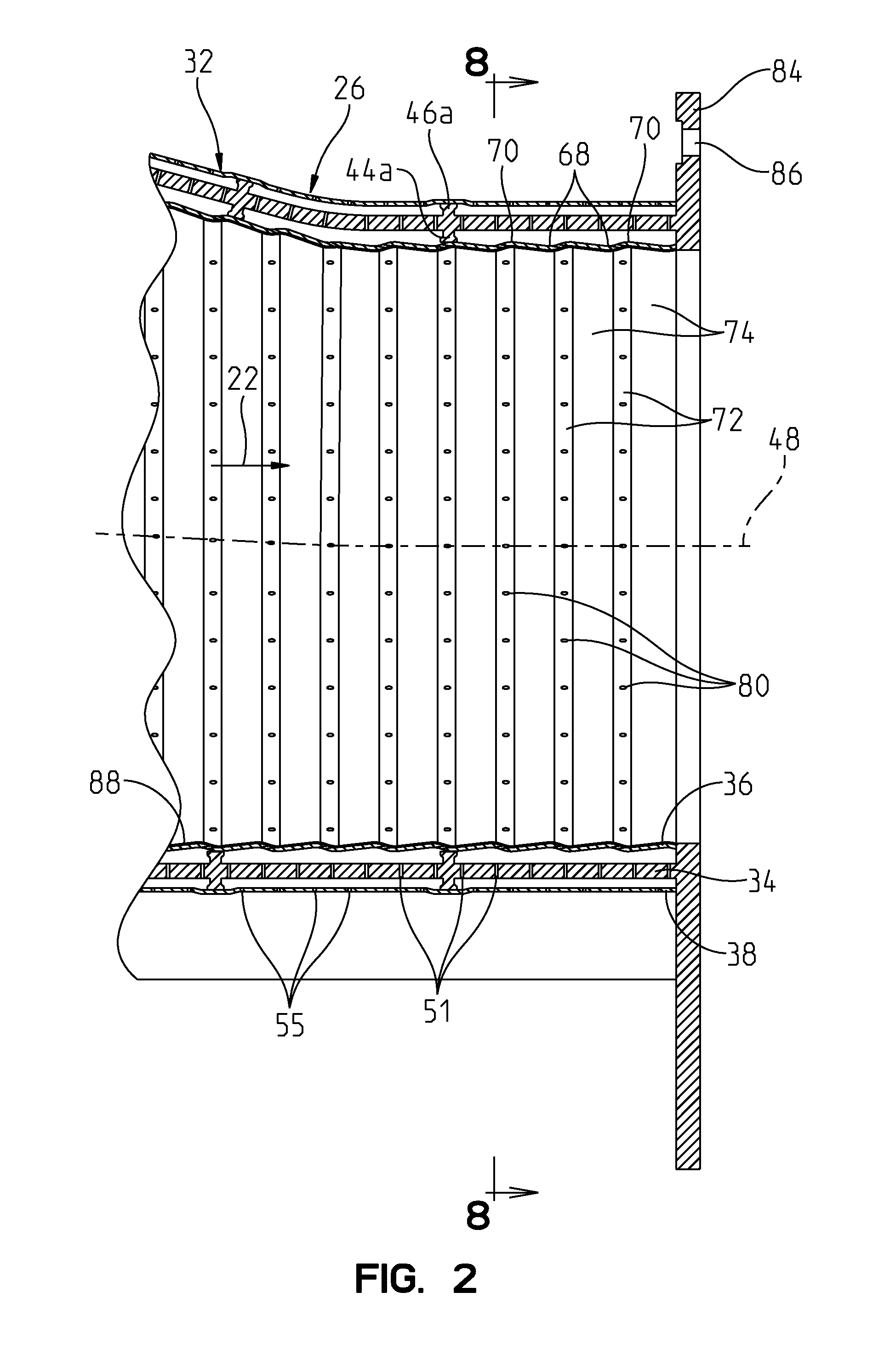

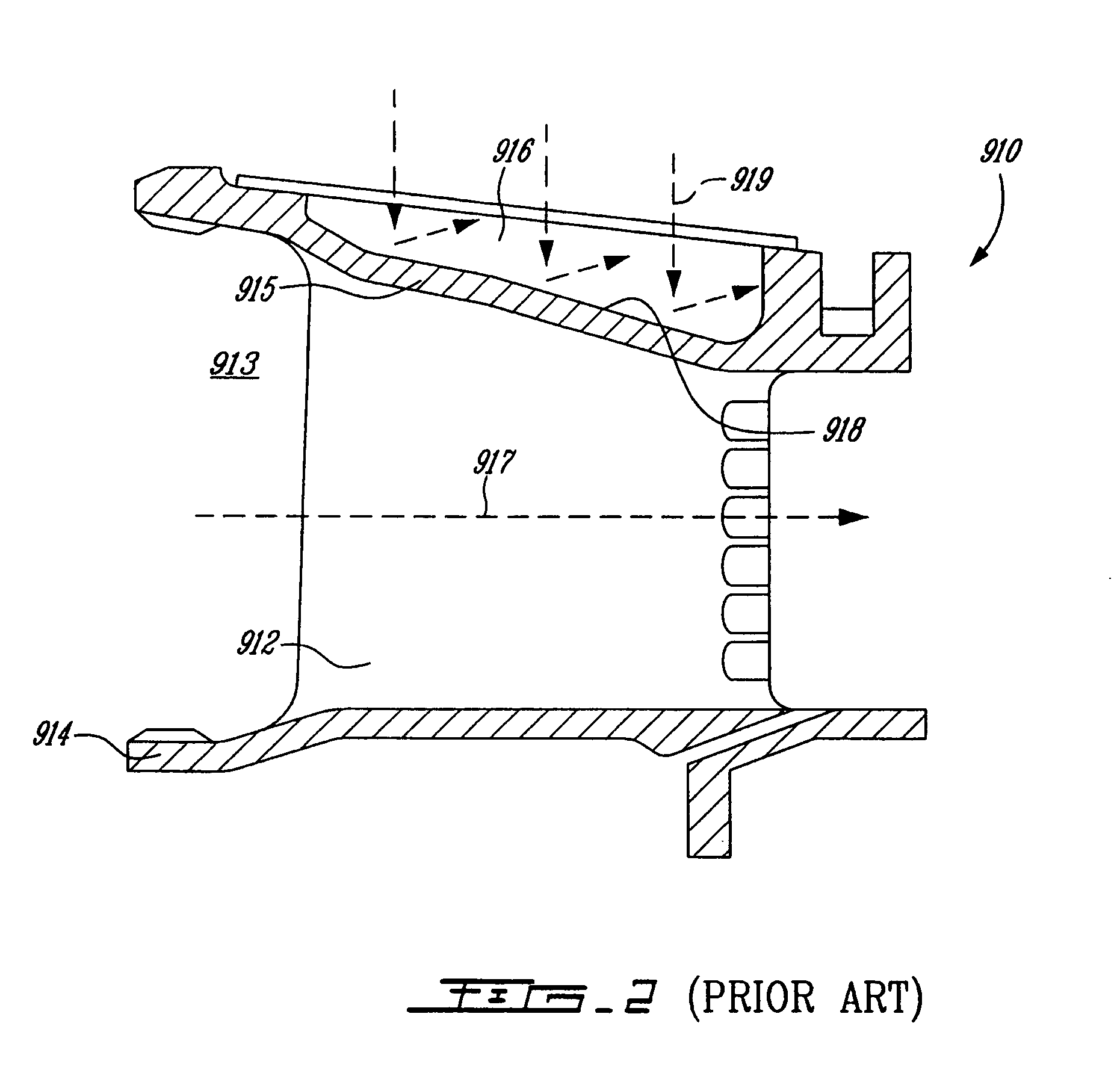

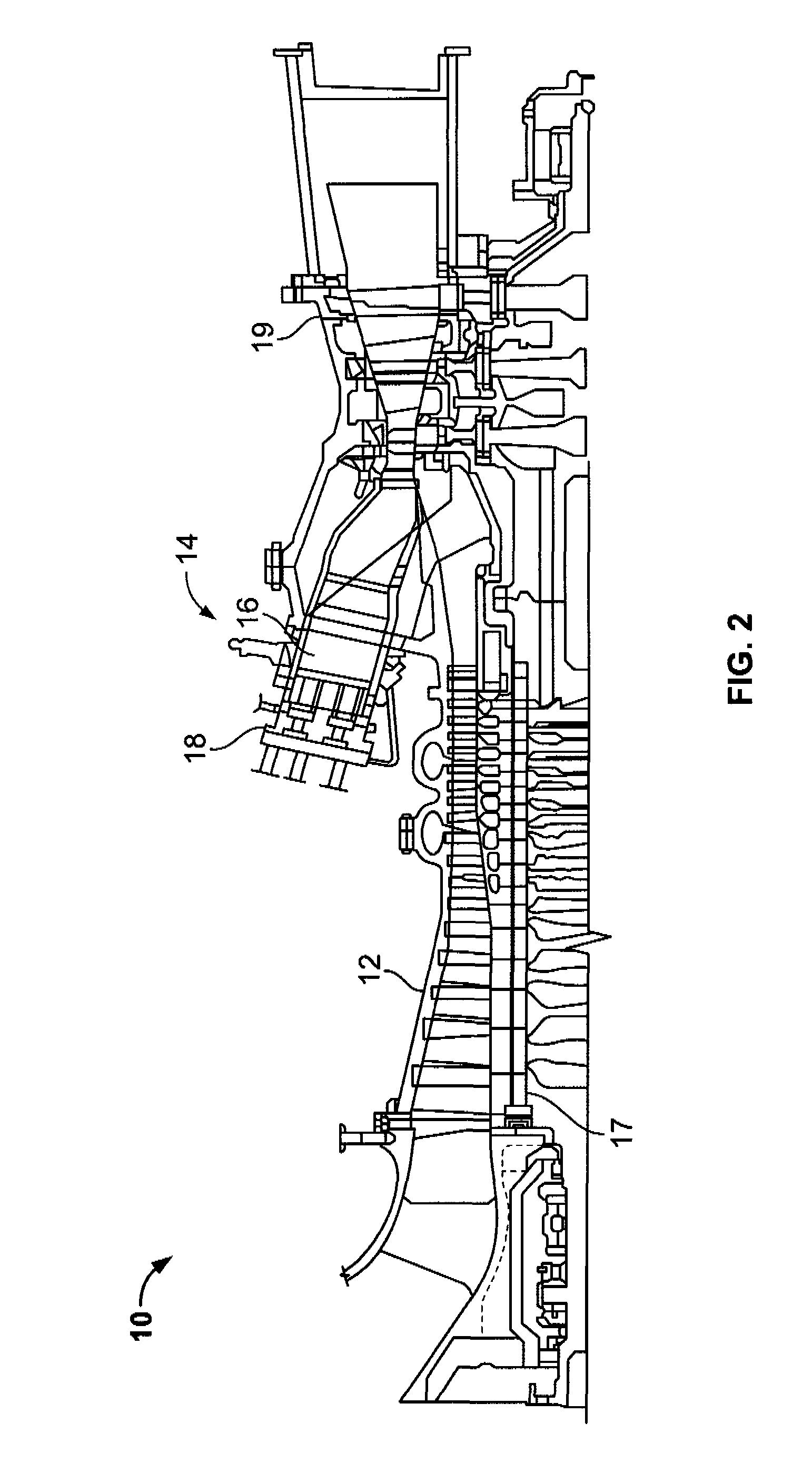

Cooled gas turbine transition duct

ActiveUS7310938B2Increase working temperatureSimple materialContinuous combustion chamberEngine fuctionsSurface coolingActive cooling

A transition duct (40) for a gas turbine engine (10) incorporating a combination of cooling structures that provide active cooling in selected regions of the duct while avoiding cooling of highly stressed regions of the duct. In one embodiment, a panel (74) formed as part of the transition duct includes some subsurface cooling holes (92) that extend under a central portion of a stiffening rib (90) attached to the panel and some subsurface cooling holes (94) that have a truncated length so as to avoid extending under a rib end (45). Effusion cooling holes (88) used to cool a side subpanel (48) of the panel may have a distribution that reduces to zero approaching a double bend region (48) of the panel. An upstream subpanel (76) of the panel may be actively cooled only when the panel is located on an extrados of the transition duct.

Owner:SIEMENS ENERGY INC

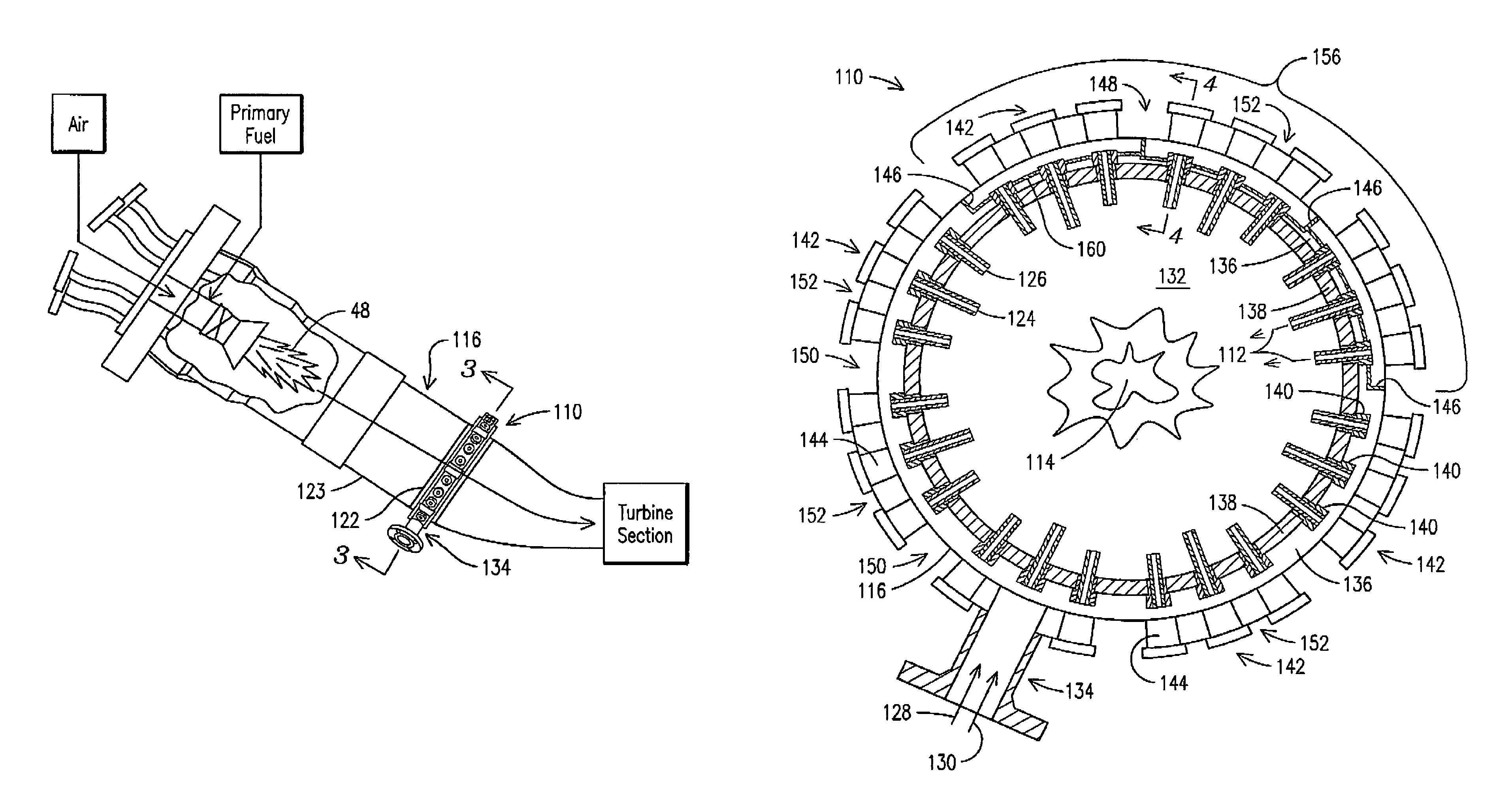

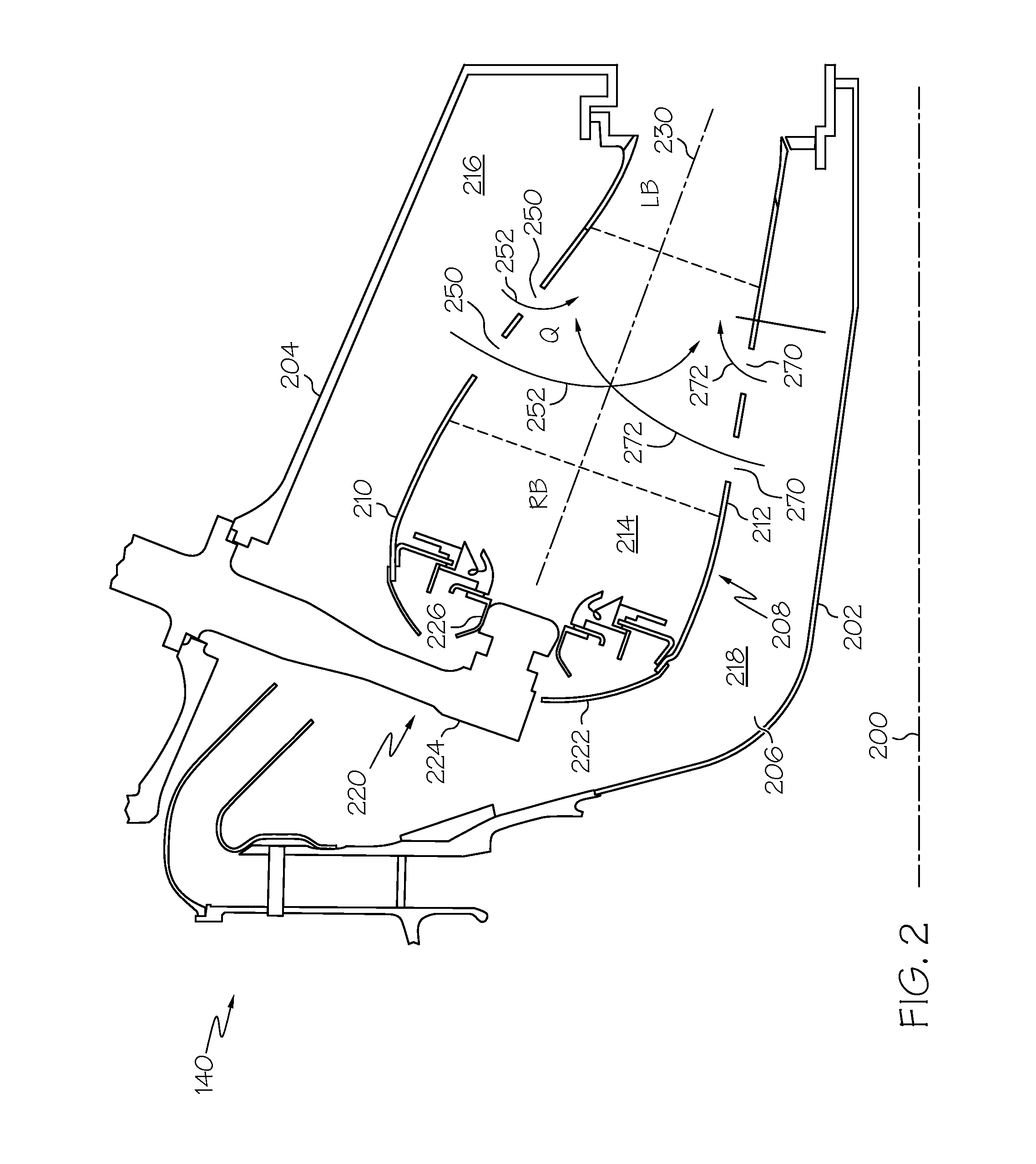

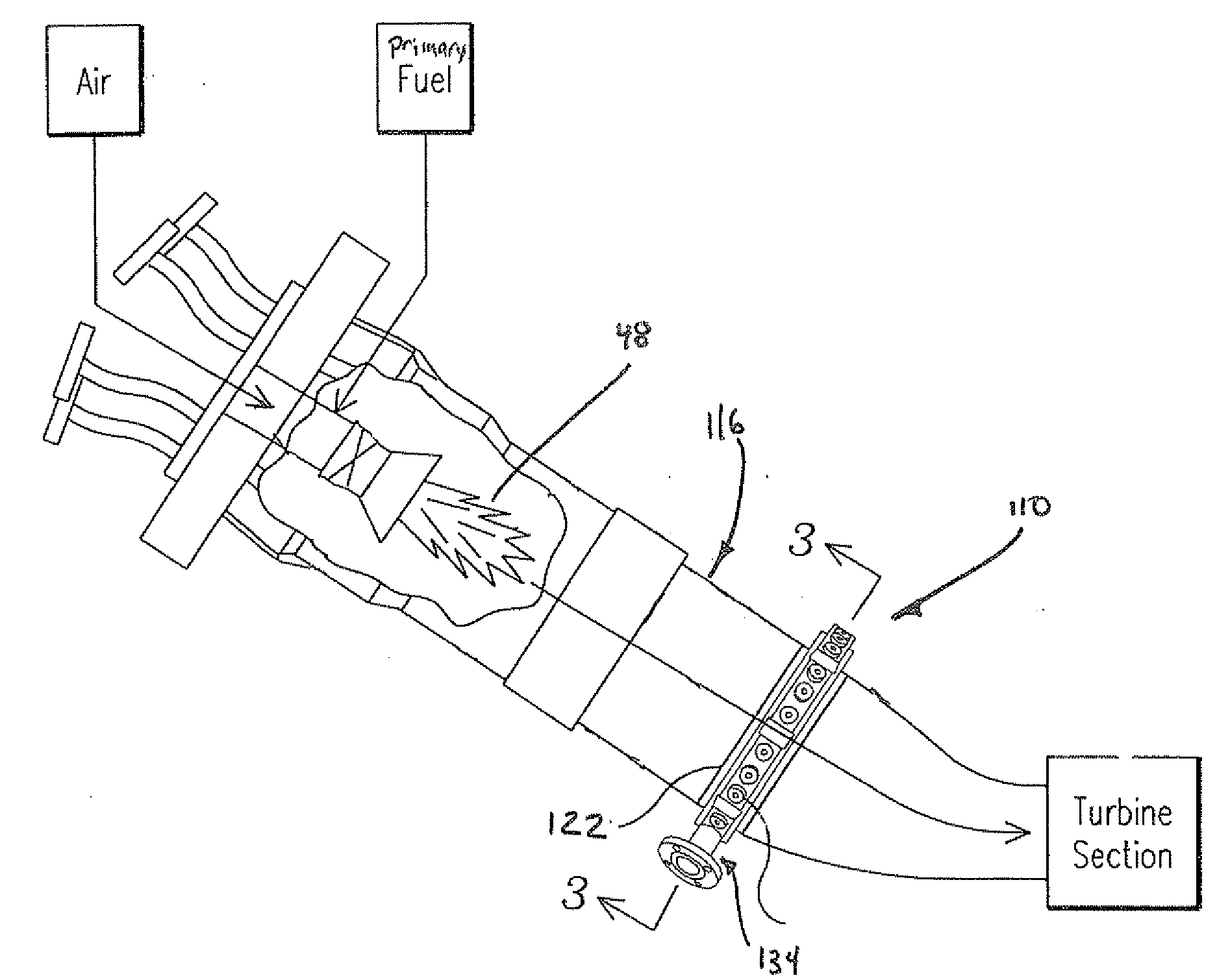

Secondary fuel delivery system

ActiveUS7665309B2Reduce impactAvoid heat dissipation difficultiesContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustionDiluent

A secondary fuel delivery system for delivering a secondary stream of fuel and / or diluent to a secondary combustion zone located in the transition piece of a combustion engine, downstream of the engine primary combustion region is disclosed. The system includes a manifold formed integral to, and surrounding a portion of, the transition piece, a manifold inlet port, and a collection of injection nozzles. A flowsleeve augments fuel / diluent flow velocity and improves the system cooling effectiveness. Passive cooling elements, including effusion cooling holes located within the transition boundary and thermal-stress-dissipating gaps that resist thermal stress accumulation, provide supplemental heat dissipation in key areas. The system delivers a secondary fuel / diluent mixture to a secondary combustion zone located along the length of the transition piece, while reducing the impact of elevated vibration levels found within the transition piece and avoiding the heat dissipation difficulties often associated with traditional vibration reduction methods.

Owner:SIEMENS ENERGY INC

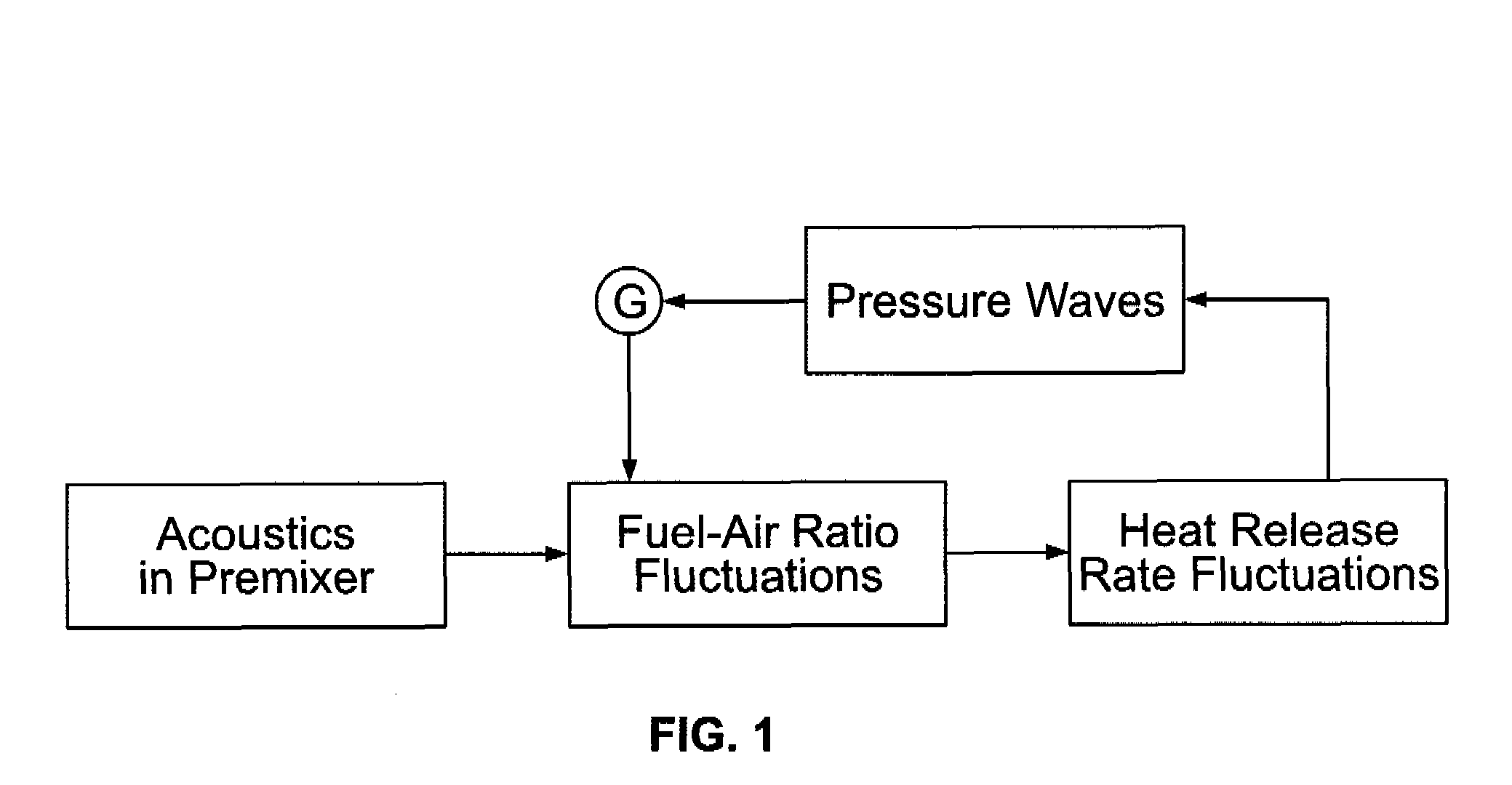

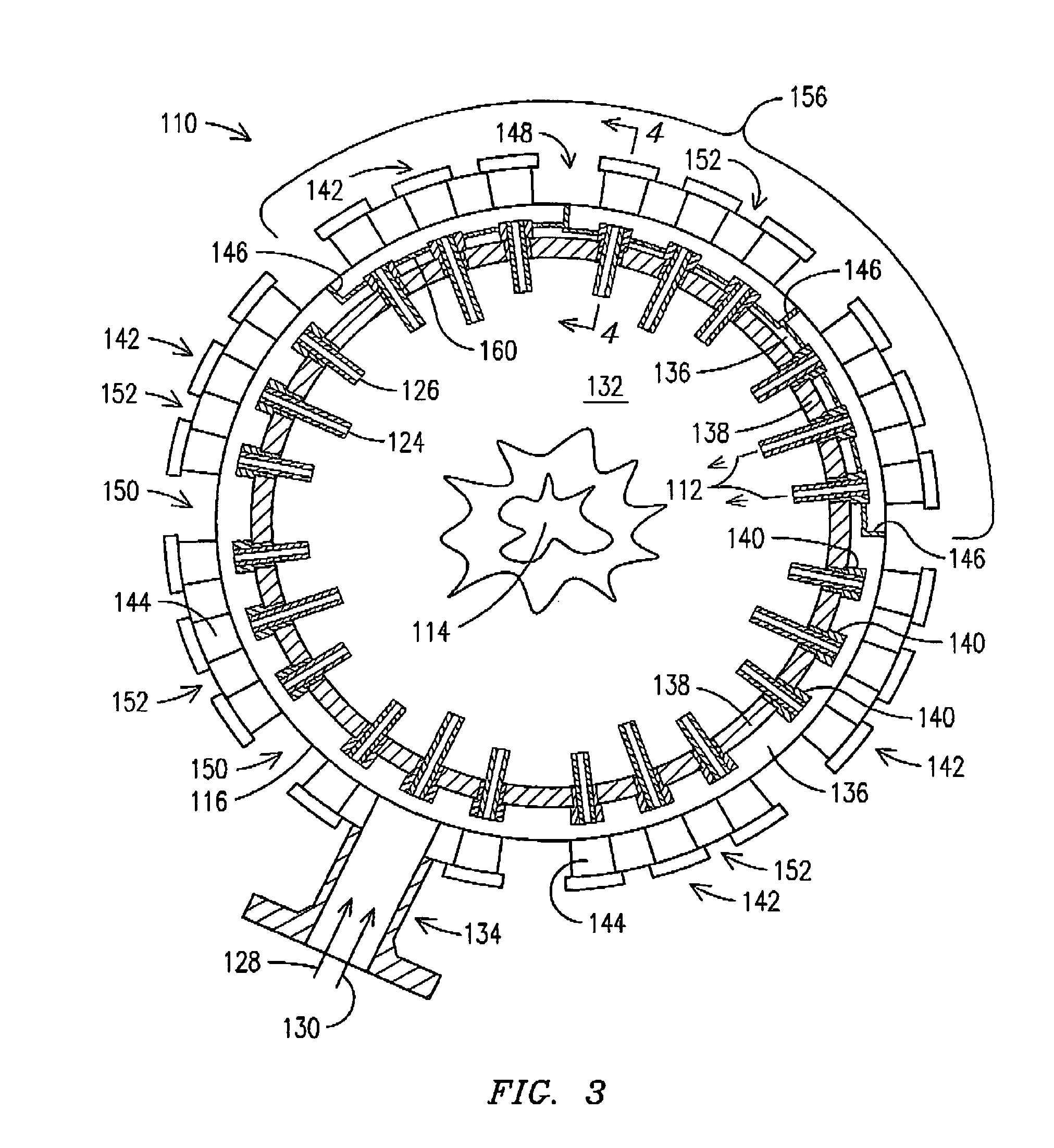

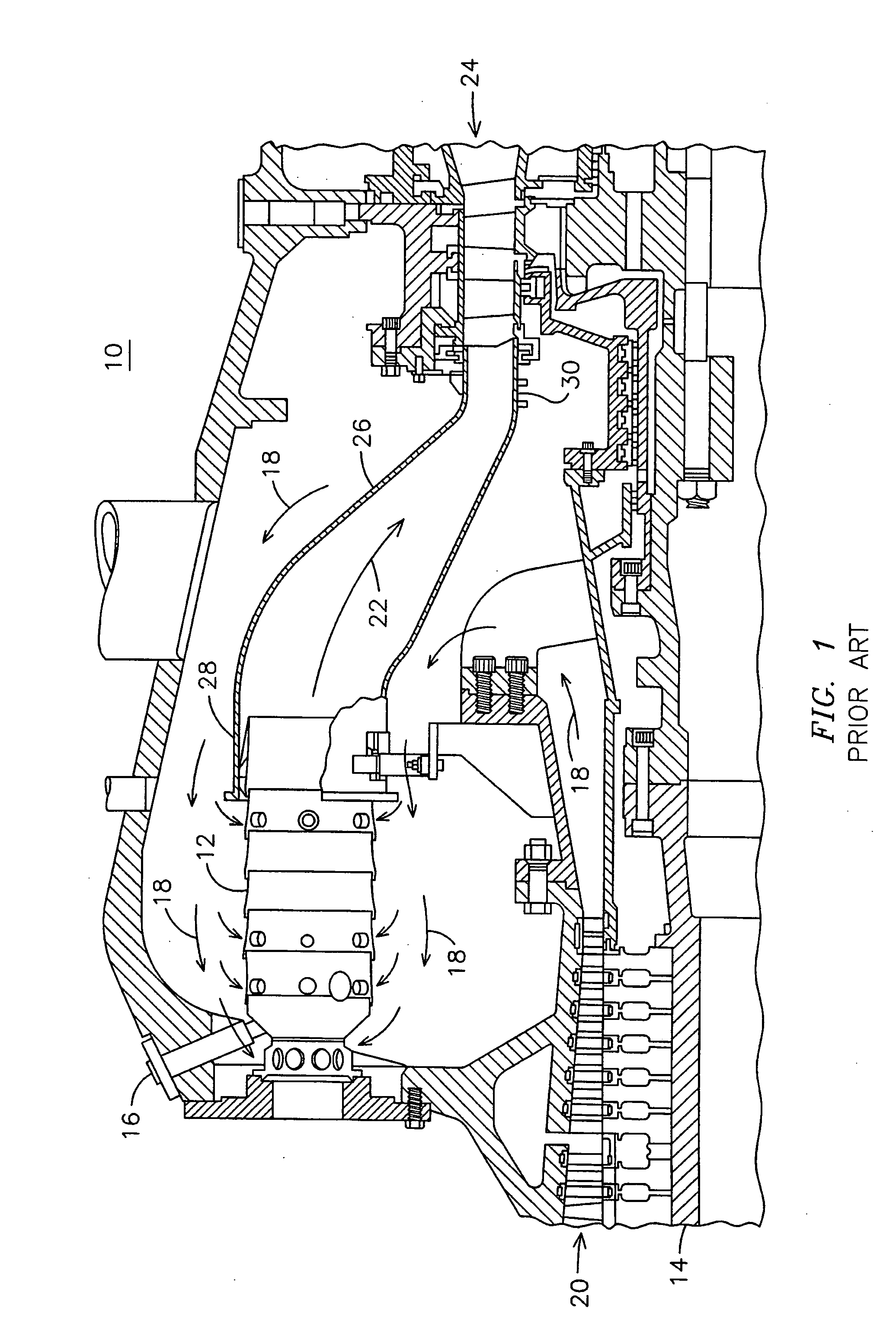

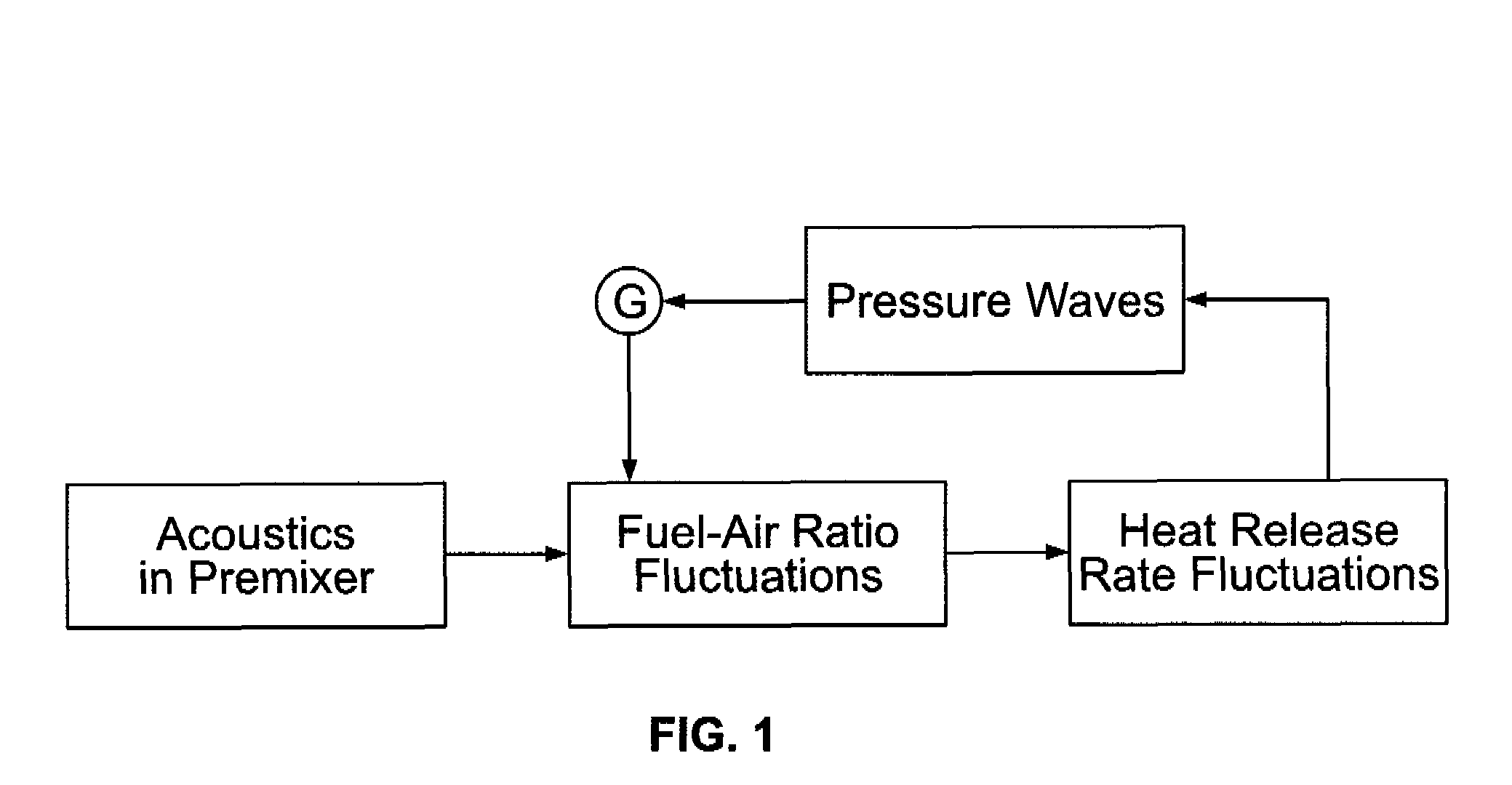

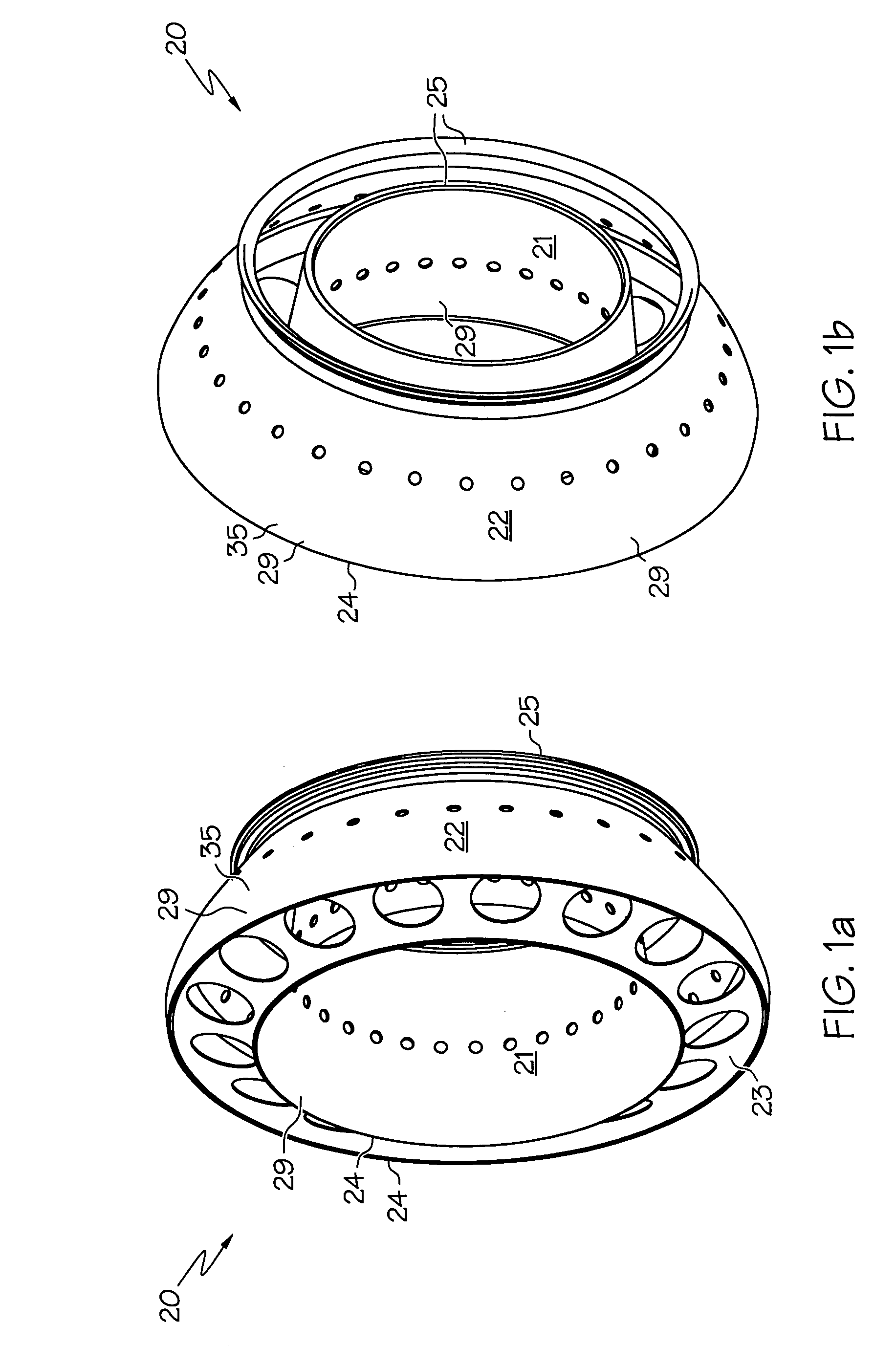

Noise reducing combustor

ActiveUS6964170B2Reduce frequencyReduce low frequency noiseContinuous combustion chamberGas turbine plantsCombustion chamberCombustor

A gas turbine engine combustor defining a combustion zone therein and being adapted for receiving compressed air from a compressor. The combustor comprises inner and outer walls spaced-apart by a predetermined spacing distance and defines a cavity therebetween. The outer wall has a first area defining at least an impingement aperture therein, the impingement aperture permits fluid flow communication between the compressor and the cavity. The inner wall has a second area corresponding to the first area and defines a plurality of effusion apertures therein, the effusion apertures permitting fluid flow communication between the cavity and the combustion zone, and each of the effusion aperture defines a cross-sectional area smaller than that of the impingement aperture. The effusion apertures are disposed in groups having a predetermined geometric arrangement relative to the impingement aperture and define a ratio of number of effusion apertures to the impingement aperture of between about 2:1 and about 4:1. The combustor thereby provides damping of audible frequencies less that about 1600 Hz passing therethrough.

Owner:PRATT & WHITNEY CANADA CORP

Segmented effusion cooled gas turbine engine combustor

ActiveUS20070169484A1Improve cooling efficiencyContinuous combustion chamberEfficient propulsion technologiesCombustorCombustion chamber

A combustor includes two or more sets of effusion cooling holes that extend through the inner and outer liners. Each set of effusion cooling holes includes one or more initial rows of effusion cooling holes, one or more final rows of effusion cooling holes disposed downstream of the one or more initial rows, and a plurality of interposed rows of effusion cooling holes disposed between the initial and final rows. Each effusion cooling hole is disposed at a tangential angle relative to an axial line. The tangential angle of the effusion cooling holes in each set of effusion cooling holes gradually transitions from a substantially transverse tangential angle in each initial row to a substantially axial tangential angle in each final row.

Owner:HONEYWELL INT INC

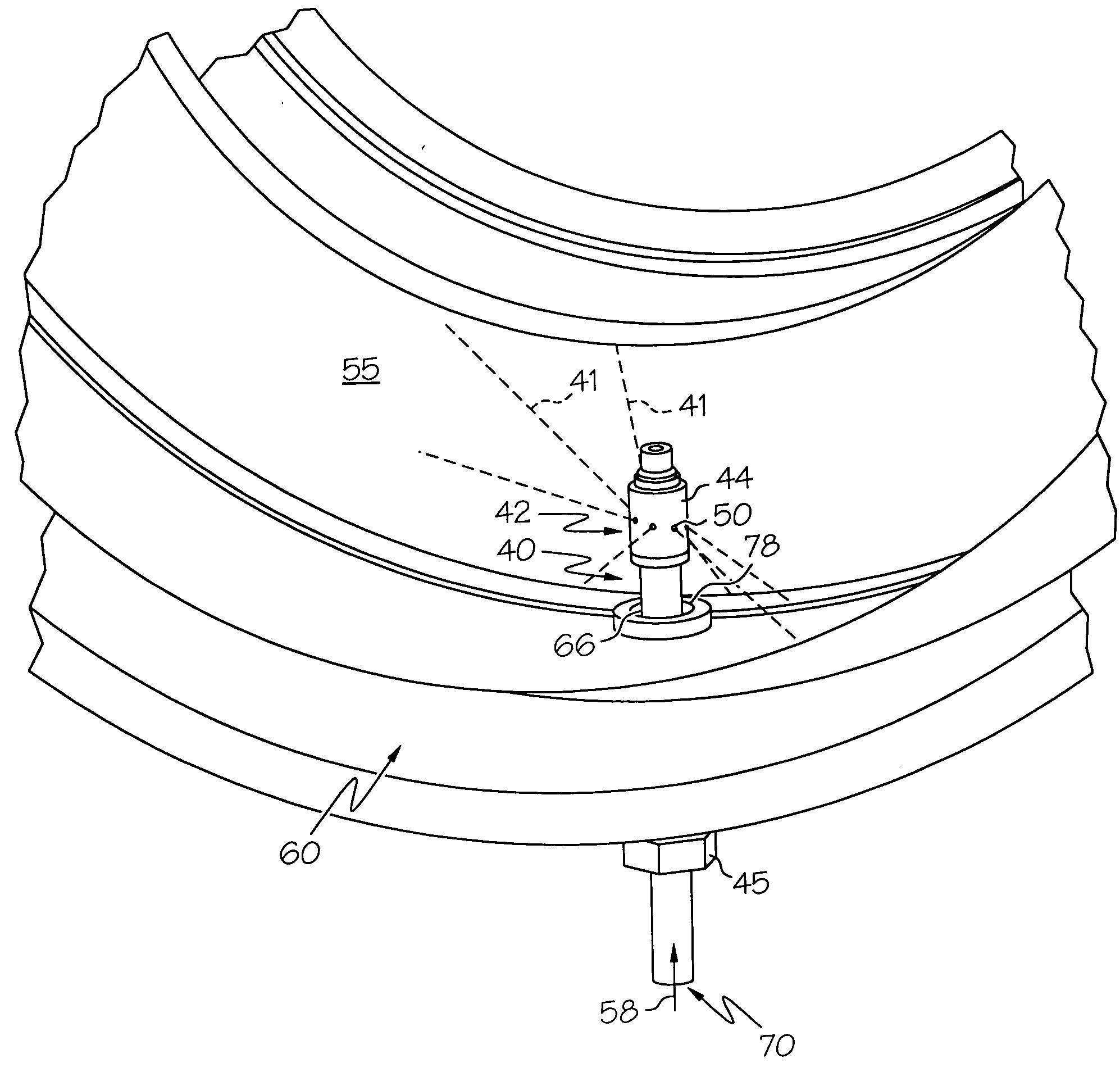

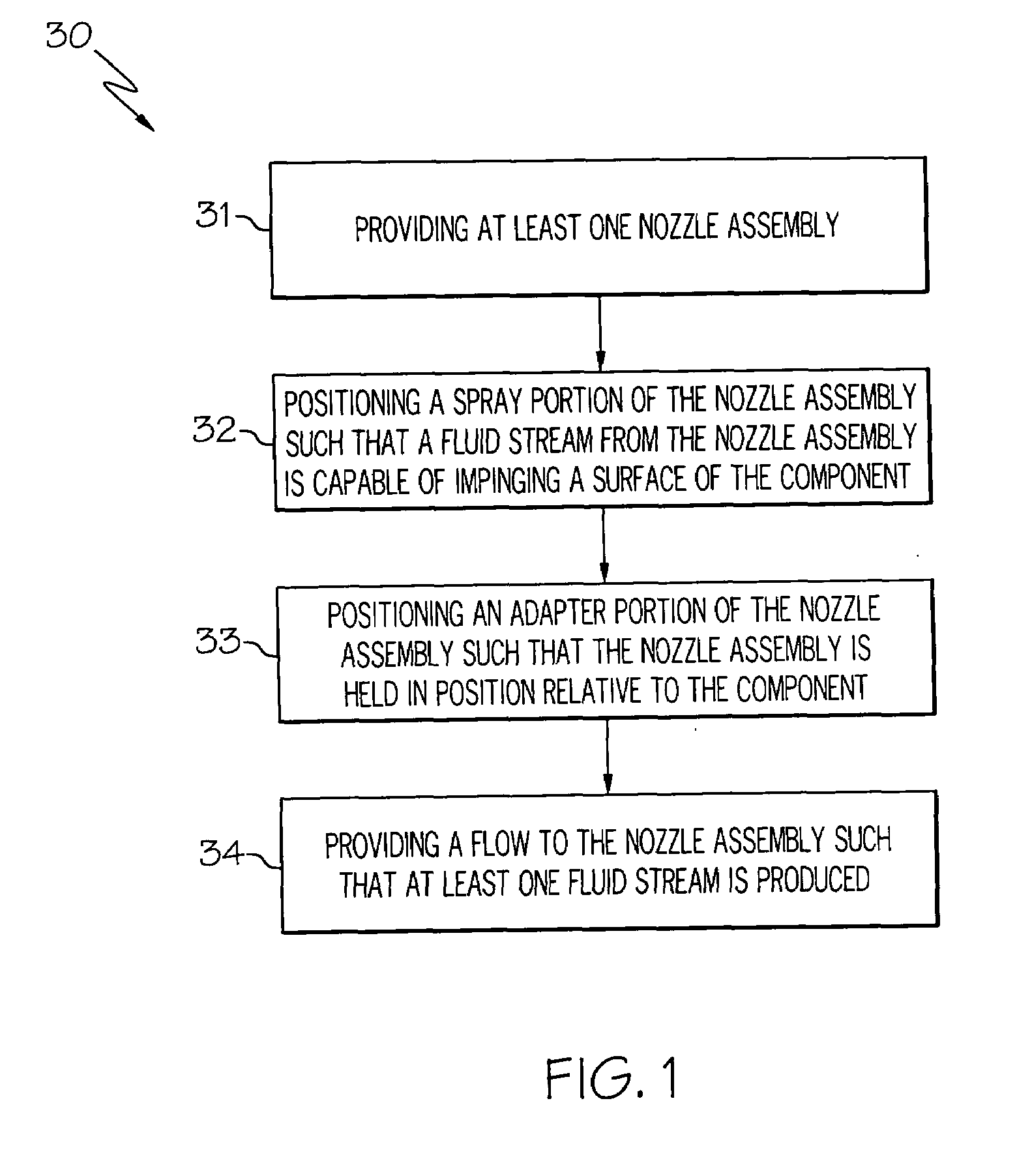

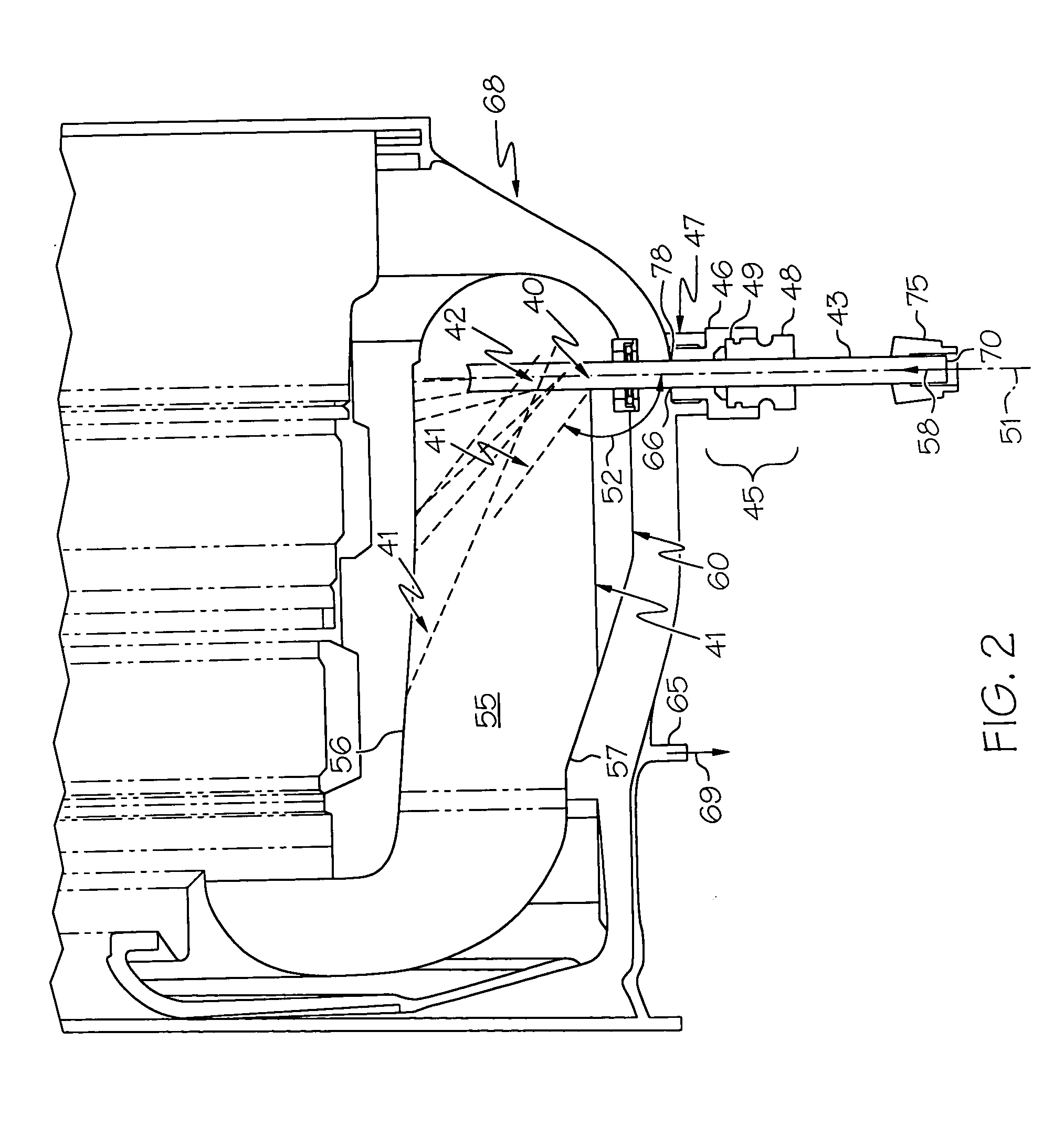

On-wing combustor cleaning using direct insertion nozzle, wash agent, and procedure

ActiveUS20090084411A1Lighting and heating apparatusHollow article cleaningCombustion chamberCombustor

A cleaning method for a combustor comprises positioning a spray portion of a nozzle through an igniter plug boss and spraying an acid solution inside the combustion chamber. The acid solution impinges the inner liner and the outer liner, dissolving contaminant deposits inside the effusion holes. The nozzle can have a second spray portion outside the combustion chamber to provide acid solution to the radially outward surface of the outer liner. After cleaning, distilled water is sprayed through the nozzle to remove the acid solution residue from the combustor. The used acid solution and distilled water can be collected, filtered and pumped through the nozzle to provide a recirculating cleaning / rinsing system.

Owner:HONEYWELL INT INC

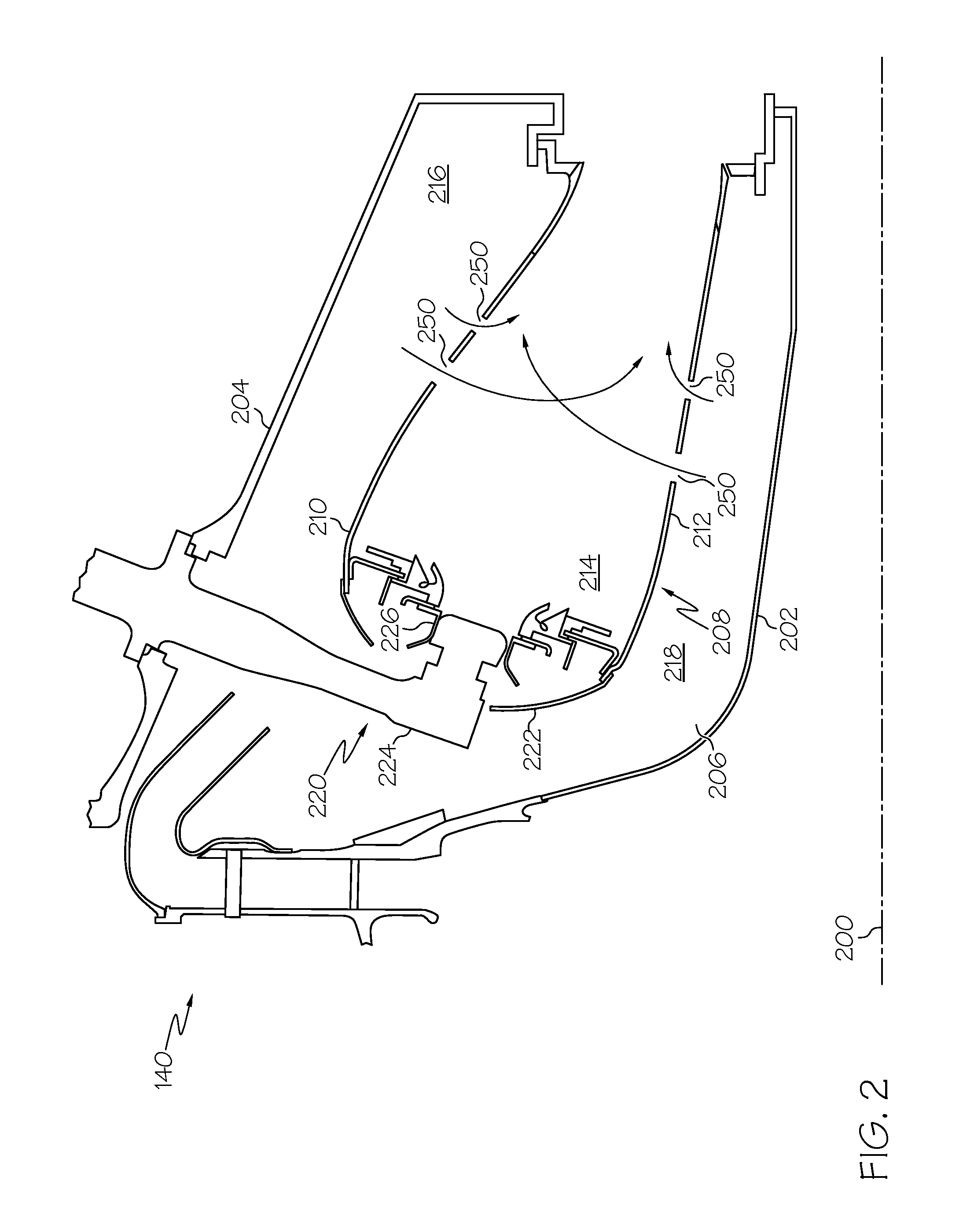

Effusion cooled dual wall gas turbine combustors

ActiveUS20110023495A1Continuous combustion chamberTurbine/propulsion engine coolingCombustorCombustion chamber

A gas turbine engine combustor is provided. An inner liner has an upstream end and a downstream end and extends in an axial direction between the upstream and downstream ends. A dual wall outer liner has a hot wall, a cold wall at least partially surrounding the hot wall, an upstream end, and a downstream end. The outer liner extends in the axial direction between the upstream and downstream ends. A dome assembly is coupled between the upstream ends of the inner and outer liners to define a combustion chamber between the inner liner and the hot wall of the outer liner. Effusion cooling holes are disposed in the hot wall, including a first row disposed at a tangential angle of between about 70° and about 90° and a second row disposed at a tangential angle of between about 0° and about 20°.

Owner:HONEYWELL INT INC

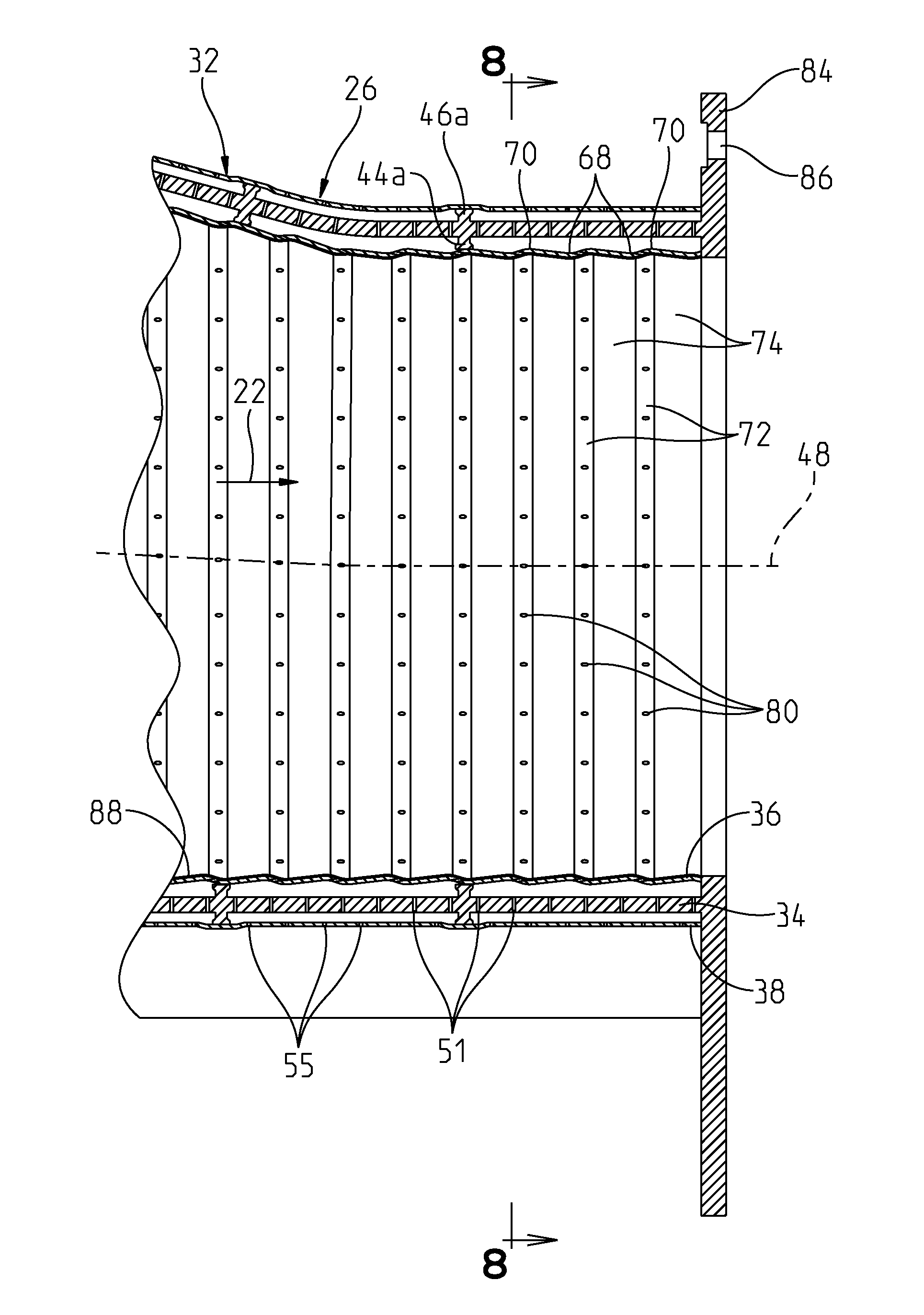

Cooled gas turbine transition duct

ActiveUS20060130484A1Increase working temperatureSimple materialContinuous combustion chamberEngine fuctionsActive coolingEffusion

A transition duct (40) for a gas turbine engine (10) incorporating a combination of cooling structures that provide active cooling in selected regions of the duct while avoiding cooling of highly stressed regions of the duct. In one embodiment, a panel (74) formed as part of the transition duct includes some subsurface cooling holes (92) that extend under a central portion of a stiffening rib (90) attached to the panel and some subsurface cooling holes (94) that have a truncated length so as to avoid extending under a rib end (45). Effusion cooling holes (88) used to cool a side subpanel (48) of the panel may have a distribution that reduces to zero approaching a double bend region (48) of the panel. An upstream subpanel (76) of the panel may be actively cooled only when the panel is located on an extrados of the transition duct.

Owner:SIEMENS ENERGY INC

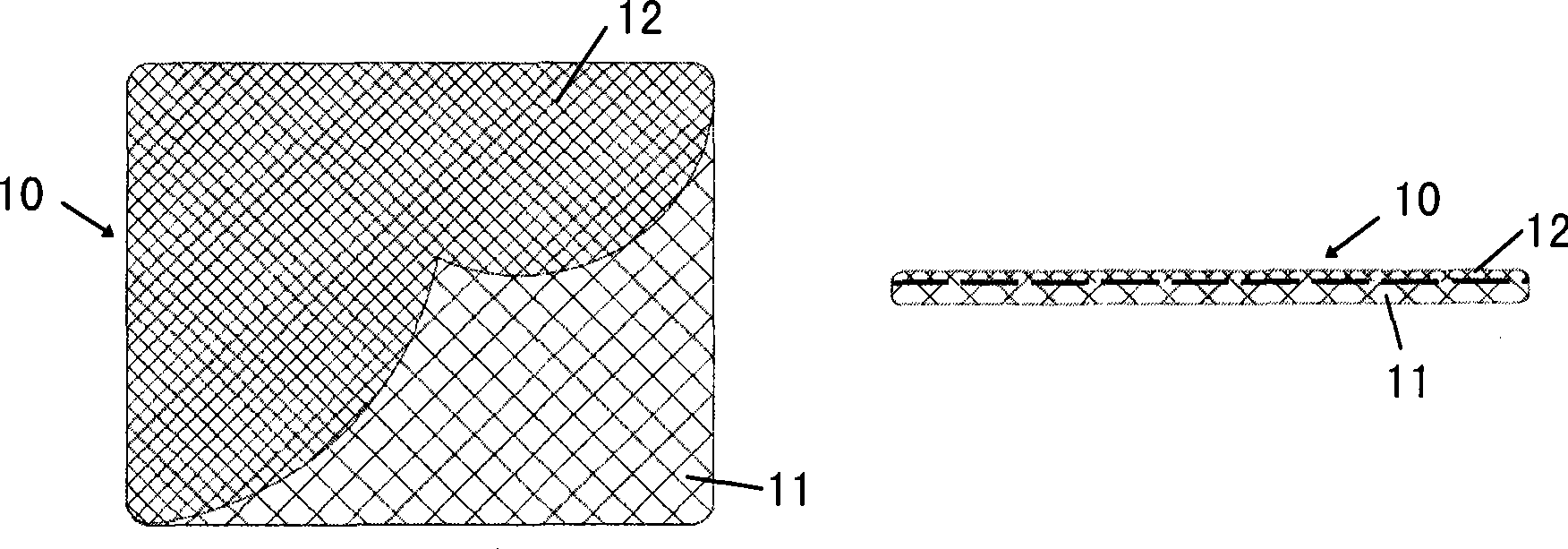

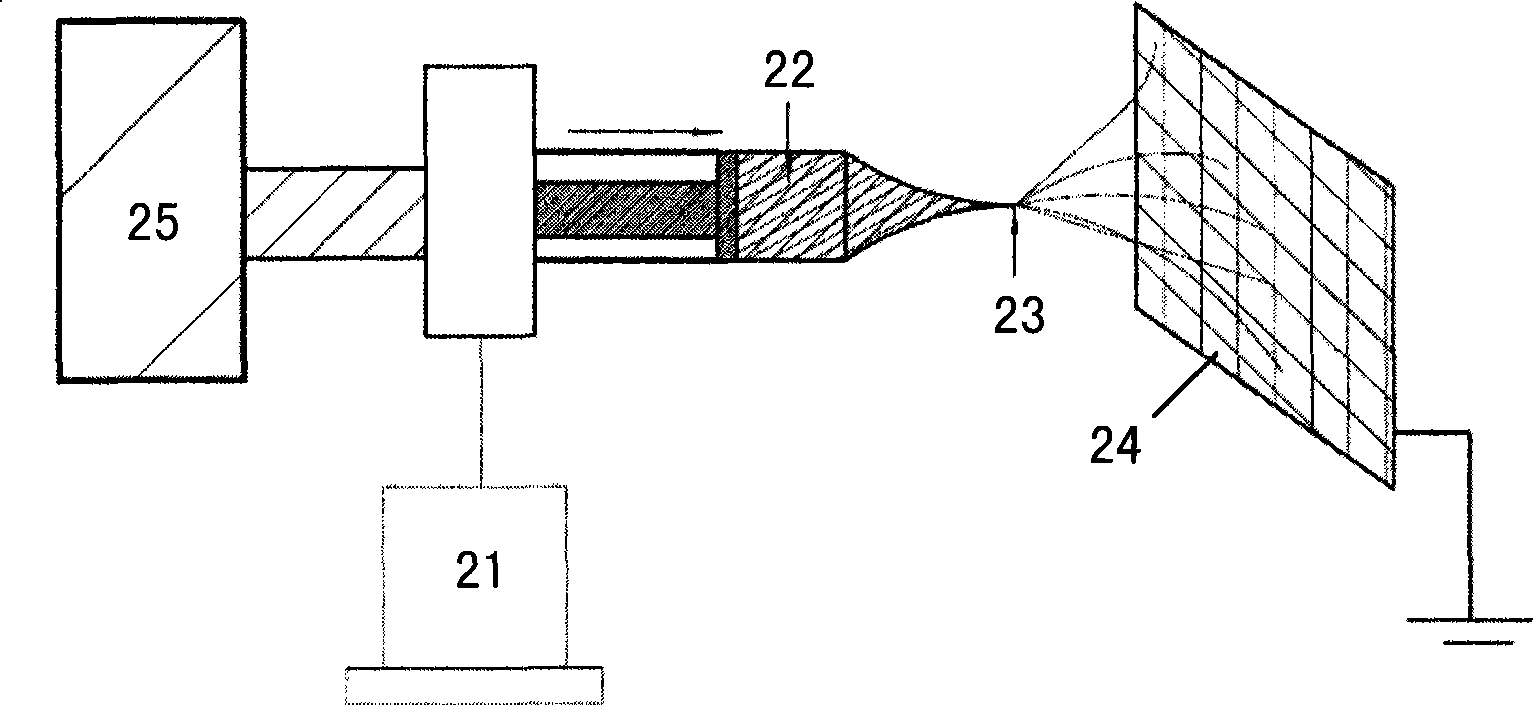

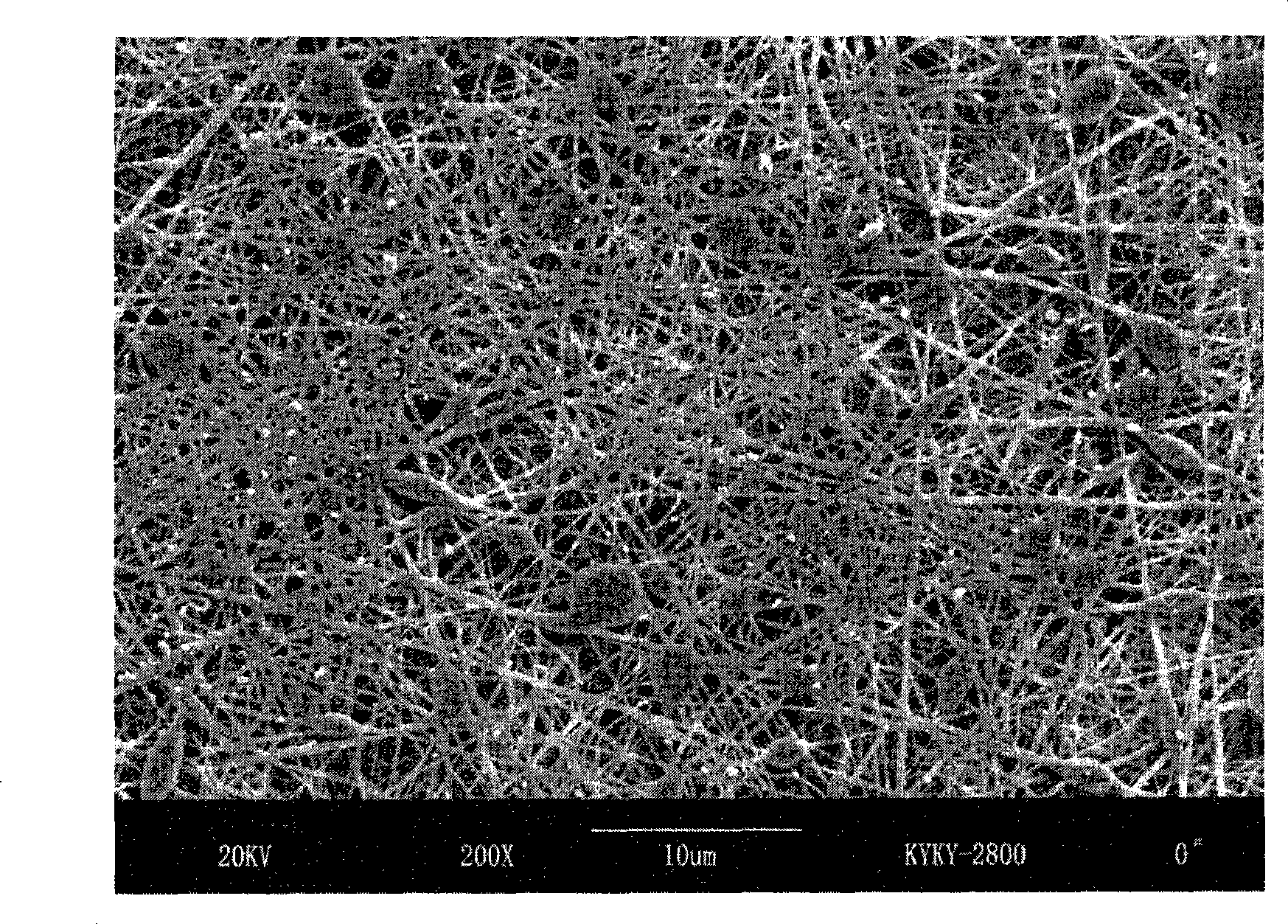

Anti-adhesion hernia repair patch

The invention relates to an anti-adhesion hernia repair patch which comprises a mesh fabric substrate and an electrostatic spinning anti-adhesion layer connected with the mesh fabric substrate. The pore diameter of the electrostatic spinning anti-adhesion layer is 10nm to 2,000nm, while the preferred pore diameter is 50nm to 1,500nm and the more preferred is 100nm to 800nm. After being transplanted into human body, the anti-adhesion hernia repair patch can not only repair hernia, but also prevent post-operation adhesion and can reduce effusion, thus reducing infection.

Owner:TRANSEASY MEDICAL TECH

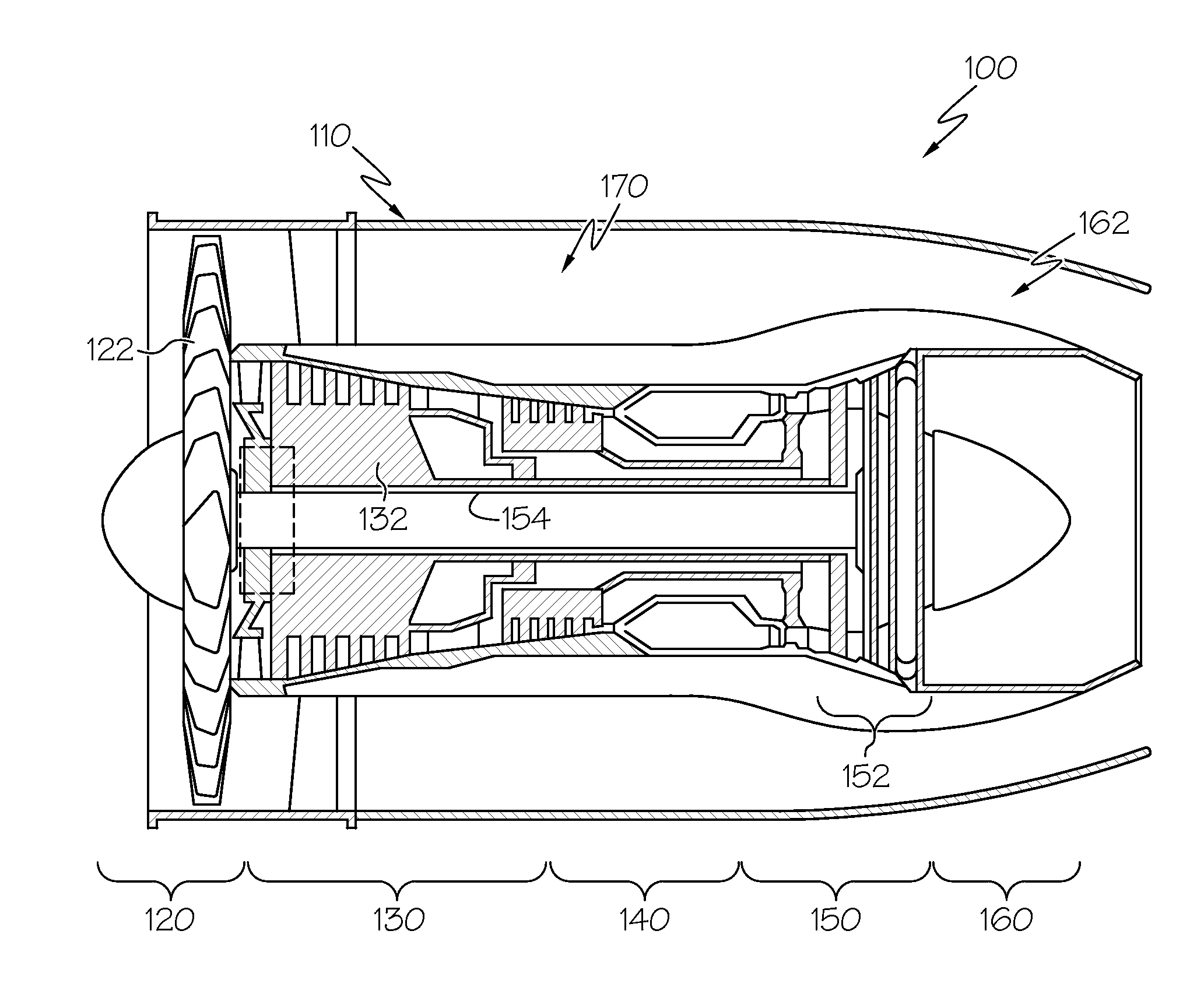

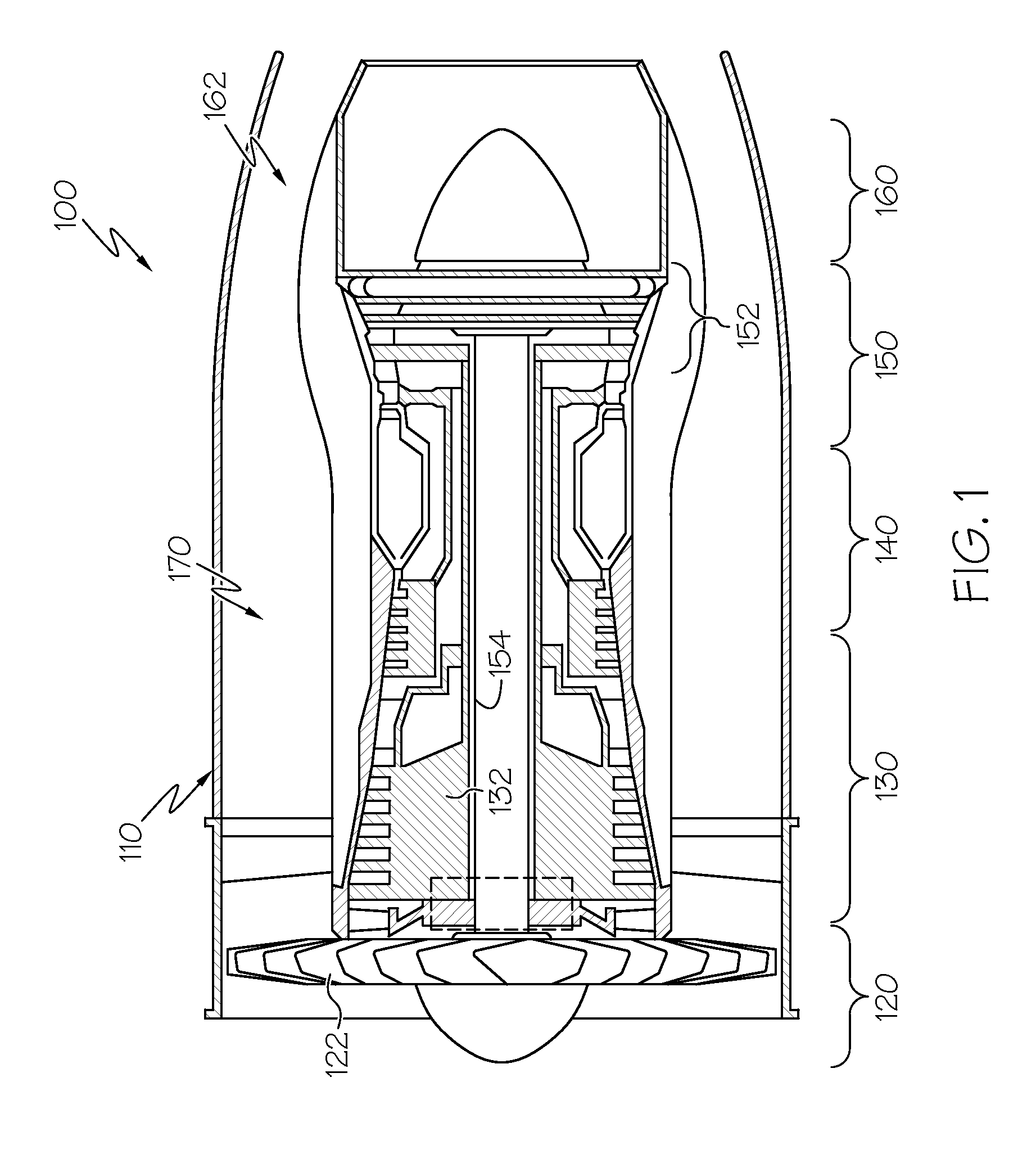

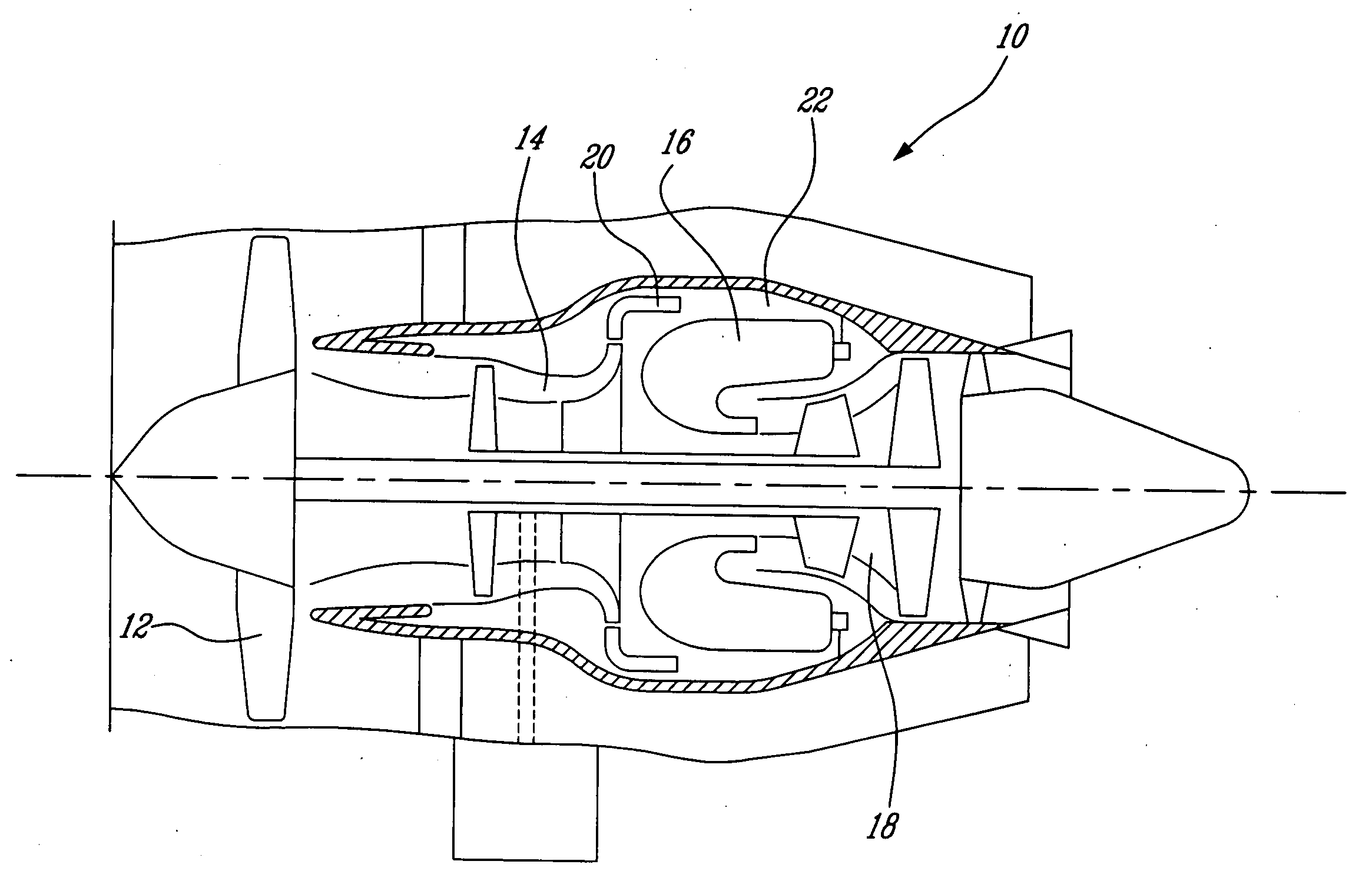

Cooling Structure For Gas Turbine Transition Duct

A transition duct for conveying hot combustion gas from a combustor to a turbine in a gas turbine engine. The transition duct includes a panel including a middle subpanel, an inner subpanel spaced from an inner side of the middle subpanel to form an inner plenum, and an outer subpanel spaced from an outer side of the middle subpanel to form an outer plenum. The outer subpanel includes a plurality of outer diffusion holes to meter cooling air into the outer plenum. The middle subpanel includes a plurality of effusion holes to allow cooling air to flow from the outer plenum to the inner plenum. The inner subpanel includes a plurality of film holes for passing a flow of cooling air from the inner plenum through the film holes into an axial gas flow path adjacent to the inner side of the inner subpanel.

Owner:SIEMENS ENERGY INC

Cooled turbine vane platform

A vane assembly for a gas turbine engine comprises a plurality of airfoils extending between platforms and a plurality of effusion holes which are defined in at least one of the inner and outer platforms in a region intermediate adjacent airfoils. The effusion holes provide fluid flow communication between a cooling air source and the gas path.

Owner:PRATT & WHITNEY CANADA CORP

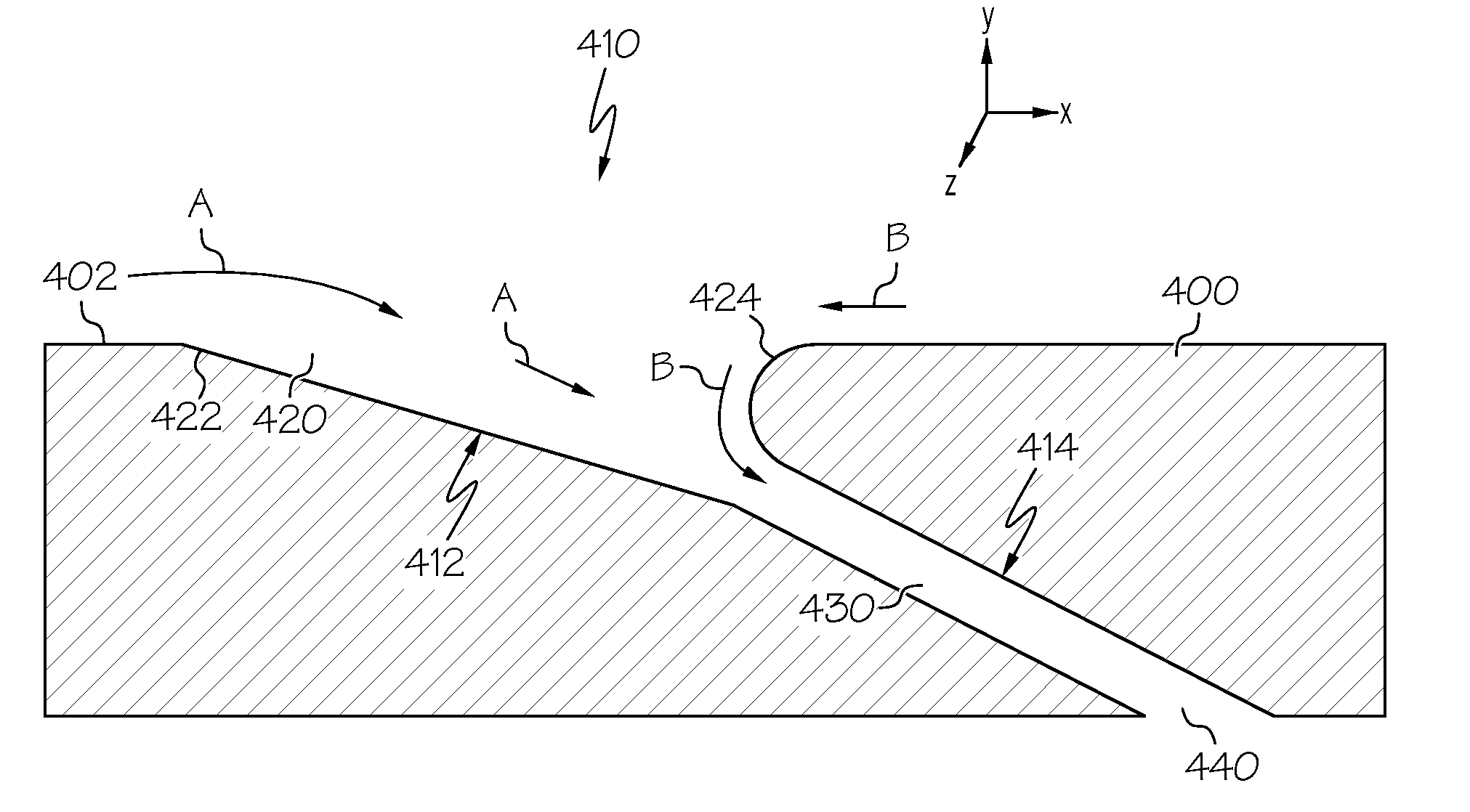

Substrate with shaped cooling holes and methods of manufacture

InactiveUS20120102959A1Improve film propertiesContinuous combustion chamberLayered productsCombustorEffusion

A substrate having one or more shaped effusion cooling holes formed therein. Each shaped cooling hole has a bore angled relative to an exit surface of the combustor liner. One end of the bore is an inlet formed in an inlet surface of the combustor liner. The other end of the bore is an outlet formed in the exit surface of the combustor liner. The outlet has a shaped portion that expands in only one dimension. Also methods for making the shaped cooling holes.

Owner:GENERAL ELECTRIC CO

Combustors with complex shaped effusion holes

ActiveUS20140338347A1Continuous combustion chamberEfficient propulsion technologiesCombustorCombustion chamber

A combustor is provided for a turbine engine. The combustor includes a first liner having a first side and a second side and a second liner having a first side and a second side. The second side of the second liner forms a combustion chamber with the second side of the first liner, and the combustion chamber is configured to receive an air-fuel mixture for combustion therein. The first liner defines a plurality of effusion cooling holes configured to form a film of cooling air on the second side of the first liner. The plurality of effusion cooling holes including a first effusion cooling hole extending from the first side to the second side with a non-linear line of sight.

Owner:HONEYWELL INT INC

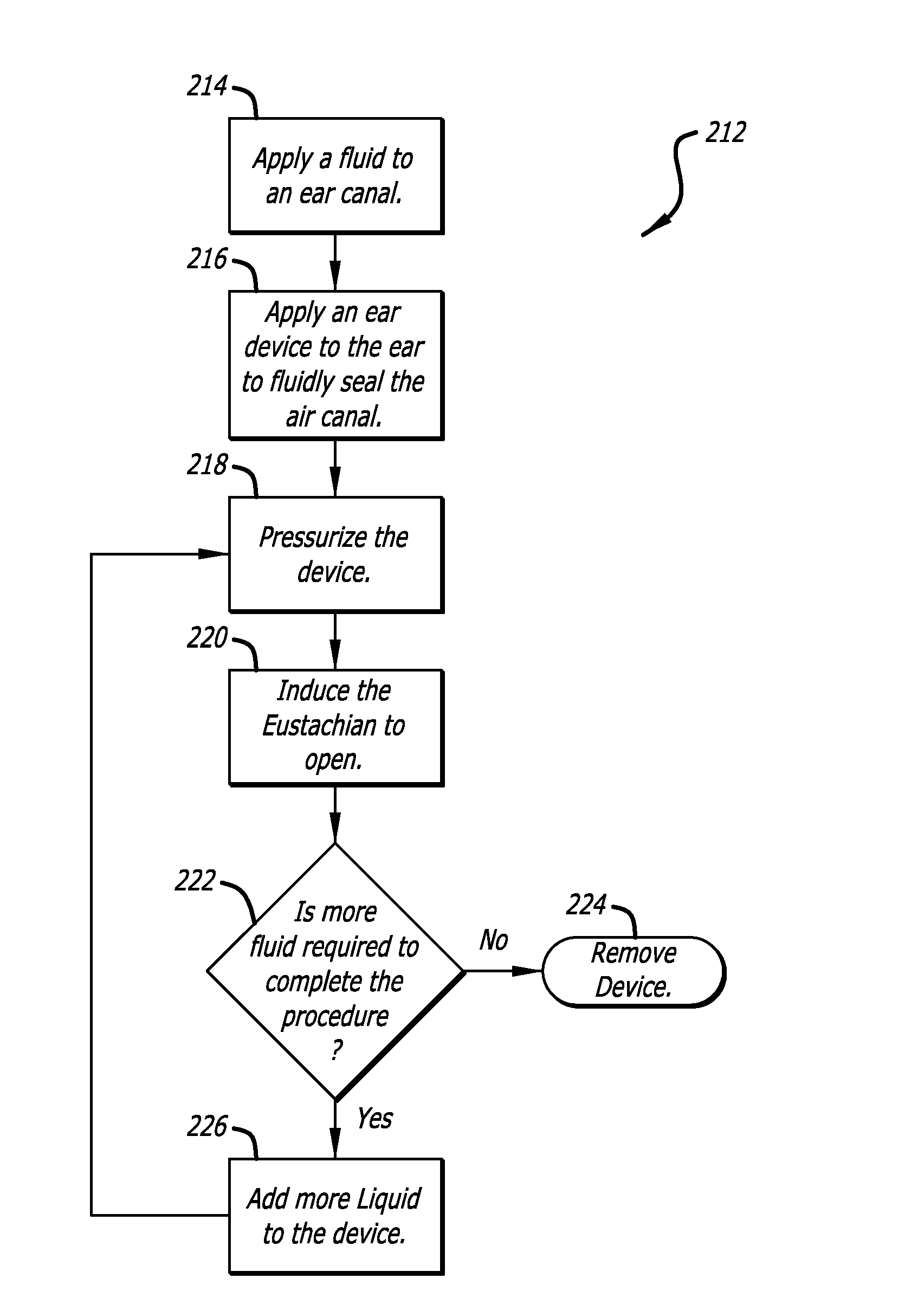

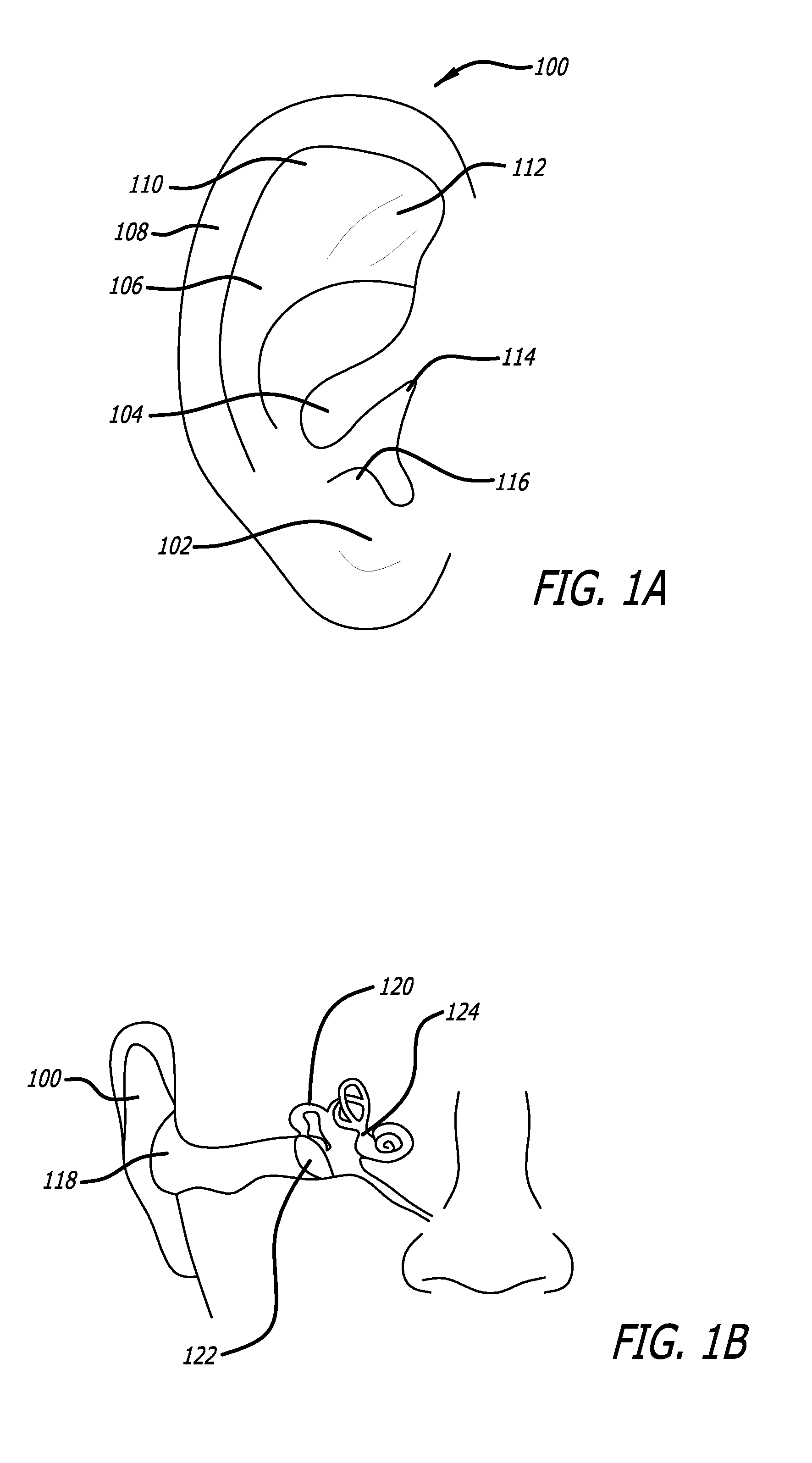

Silent Effusion Removal

ActiveUS20100217296A1Reduce noiseReduce suctionEar treatmentCannulasEffusionPERFORATED TYMPANIC MEMBRANE

A method is disclosed for clearing effusion from an ear. The method may include applying liquid to an ear canal, which is proximal to a perforated tympanic membrane, which is proximal to a middle ear containing effusion, applying an ear device to seal and pressurize the liquid inside the ear canal, the ear device regulating the amount of pressure inside the ear canal, and inducing a Eustachian tube, which is distal to the middle ear, to open, which causes the fluid to displace the effusion into the Eustachian tube.

Owner:ACCLARENT INC

Effusion plate using additive manufacturing methods

Additive manufacturing techniques may be utilized to construct effusion plates. Such additive manufacturing techniques may include defining a configuration for an effusion plate having one or more internal cooling channels. The manufacturing techniques may further include depositing a powder into a chamber, applying an energy source to the deposited powder, and consolidating the powder into a cross-sectional shape corresponding to the defined configuration. Such methods may be implemented to construct an effusion plate having one or more channels with a curved cross-sectional geometry.

Owner:GENERAL ELECTRIC CO

Injection assembly for a combustor

ActiveUS7827797B2Facilitate reducing dynamicContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustorEffusion

An injection assembly for use with a combustor is provided. The injection assembly includes an effusion plate that has a plurality of plate openings and a plate sleeve having a sidewall portion that includes a forward edge. The forward edge is coupled to the effusion plate such that the effusion plate is oriented obliquely with respect to a centerline extending through the combustor. The injection assembly also includes a plurality of ring extensions where each of the ring extensions is coupled to one of the plurality of plate openings. Each ring extension extends rearwardly into the plate sleeve.

Owner:GE INFRASTRUCTURE TECH INT LLC

Gas turbine engines with plug resistant effusion cooling holes

InactiveUS20160061451A1Continuous combustion chamberTurbine/propulsion engine coolingCombustorCombustion chamber

A combustor for a turbine engine is provided. A first liner has a first surface and a second surface. A second liner forms a combustion chamber with the second side of the first liner, and the combustion chamber configured to receive an air-fuel mixture for combustion therein. The first liner defines a plurality of effusion cooling holes configured to form a film of cooling air on the second surface of the first liner. The plurality of effusion cooling holes includes a first effusion cooling hole extending from the first surface to the second surface and including an inlet portion extending from the first surface, a metering portion fluidly coupled to the inlet portion, and an outlet portion fluidly coupled to the metering portion and extending to the second surface. The inlet portion is larger than the metering portion.

Owner:HONEYWELL INT INC

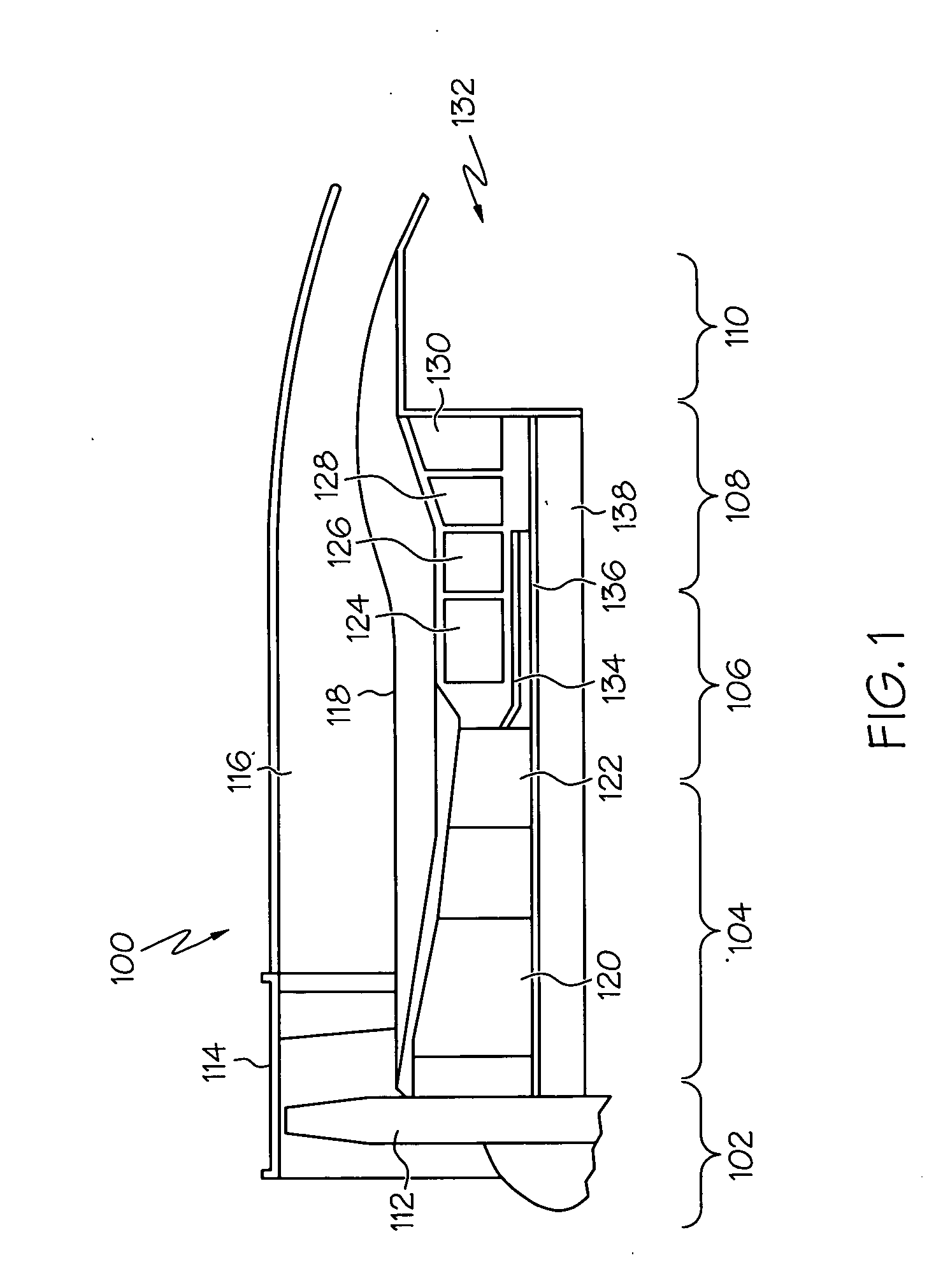

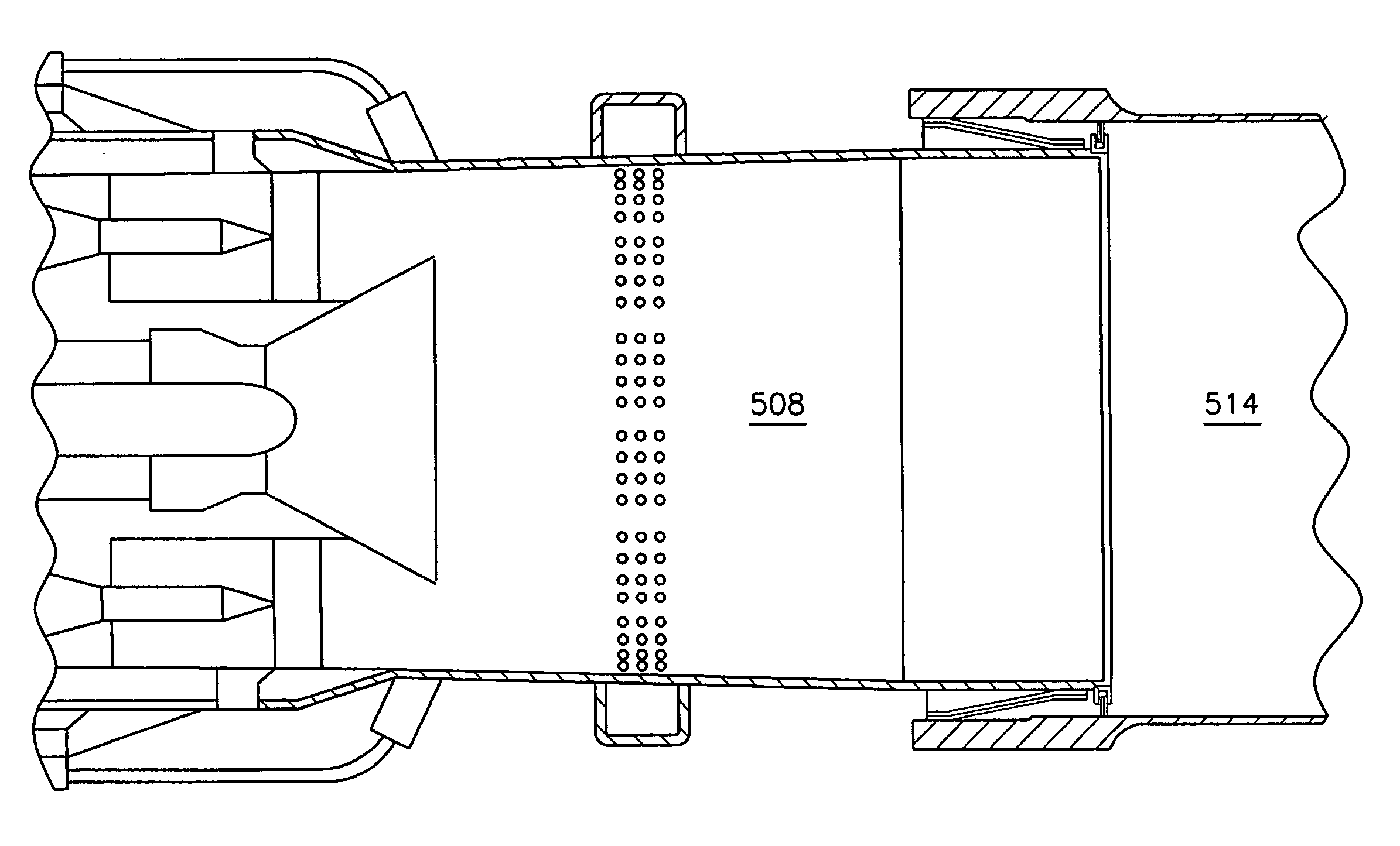

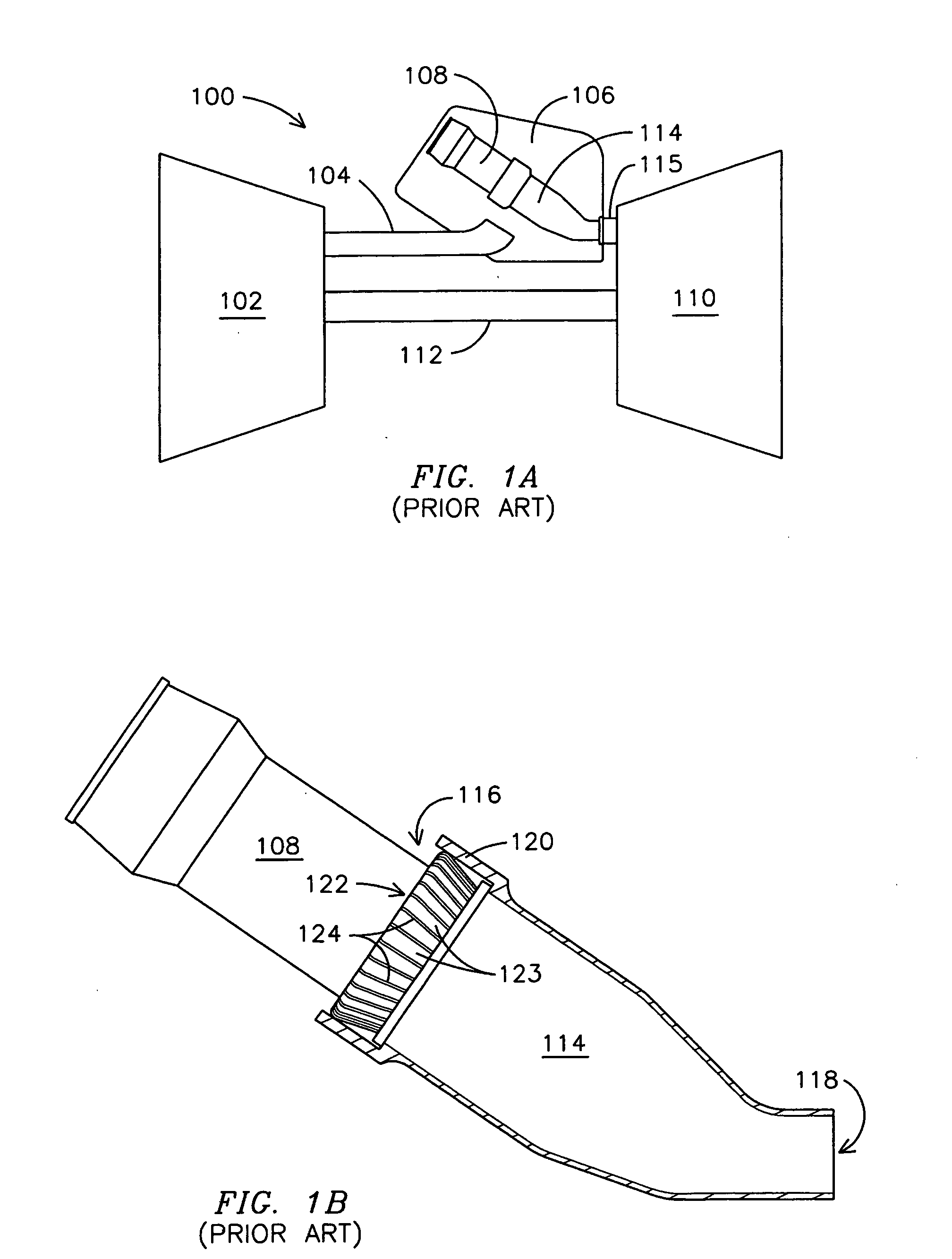

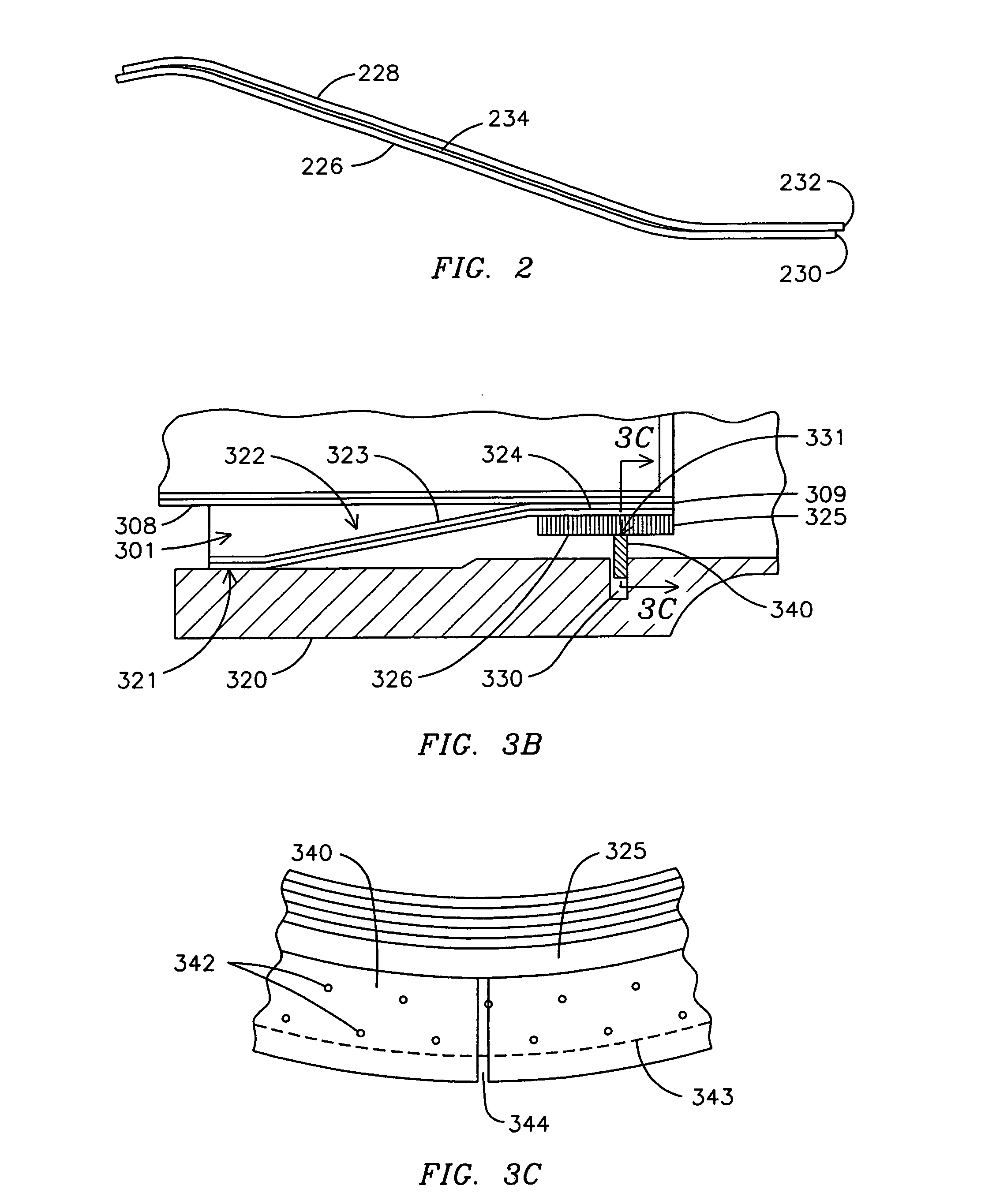

Low leakage spring clip/ring combinations for gas turbine engine

A combustor-to-transition seal (301) includes a spring clip assembly (322, 422, 522) and a first spring metal ring (340, 441) or a ring assembly (440,540) that includes the first spring metal ring (441) and a second spring metal ring (442). Such combustor-to-transition seal (301) provides a first seal (321) and a second seal (331, 531) when at a junction of a combustor (108, 308, 508) and a transition (114, 314, 514). In an embodiment, the first spring metal ring (340) has a plurality of apertures (342) through the ring (340) that provide effusion cooling of the ring (340). The plurality of apertures (342) regulates a flow of cooling fluid to maintain an acceptable temperature of the ring (340). In an alternative embodiment, the second spring metal ring (442) has grooves (446) that regulate a flow of cooling fluid to maintain an acceptable temperature of the ring assembly (440).

Owner:SIEMENS ENERGY INC

Solvating system and sealant for medical use in the middle or inner ear

Owner:MEDTRONIC XOMED INC

Cooling for Combustor Liners with Accelerating Channels

ActiveUS20140096528A1Preventing cross flow degradationIncreased turbulenceContinuous combustion chamberTurbine/propulsion engine coolingCombustorCombustion chamber

A combustor liner which reduces cooling flow to a combustion chamber and augments pressure drop split between impingement holes and effusion holes is disclosed. The combustor liner may further include accelerating channels, trip strips, pedestals, and cone-shaped effusion holes to provide further cooling of the liner. The combustor liner may reduce NOx production and the temperature of the combustion chamber of a gas turbine engine or the like.

Owner:RTX CORP

Noise reducing combustor

ActiveUS20070271926A1Reduce noiseContinuous combustion chamberGas turbine plantsCombustion chamberRadial plane

A combustor having liners with a plurality of angled effusion holes defined therethrough at a first angle with respect to a surface of the liners and at a second angle with respect to a corresponding radial plane. A density of the effusion holes defined in a primary section receiving the fuel nozzles is at least equal to a density of the effusion holes defined in a secondary downstream section.

Owner:PRATT & WHITNEY CANADA CORP

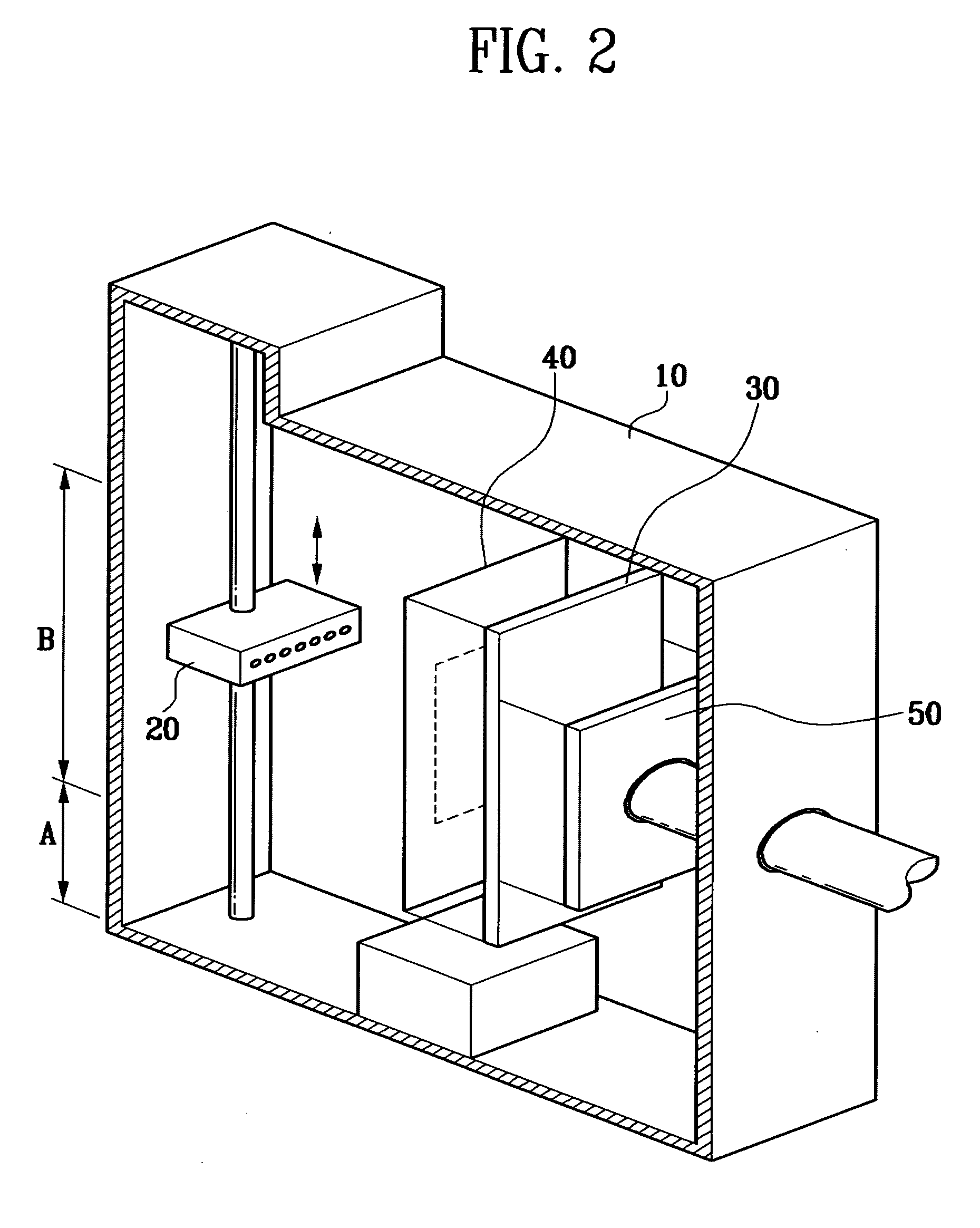

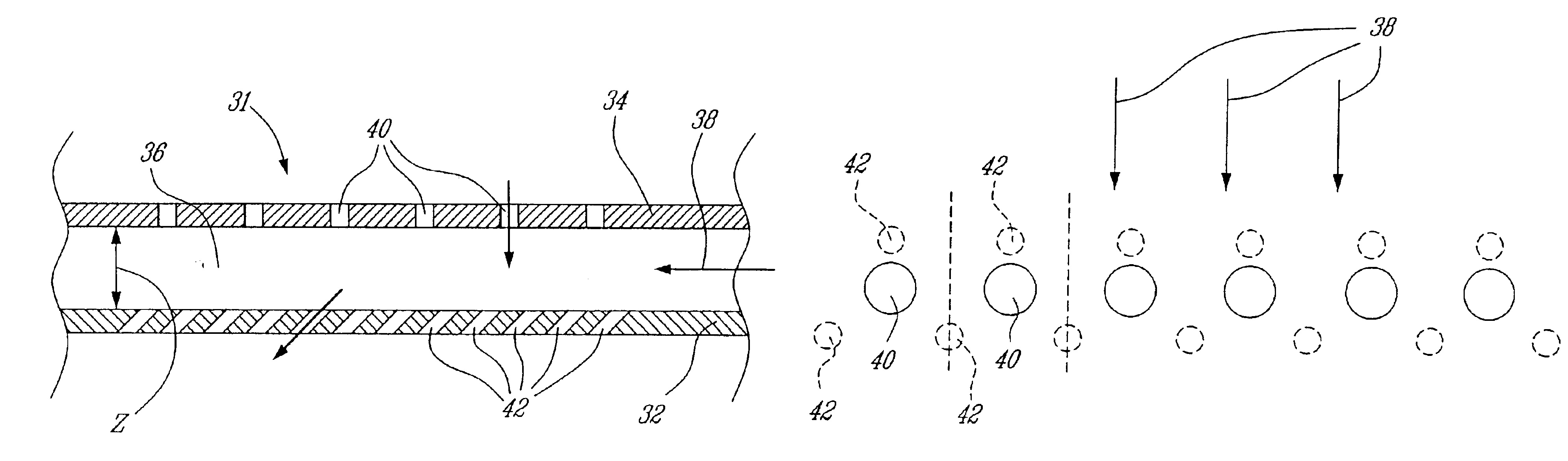

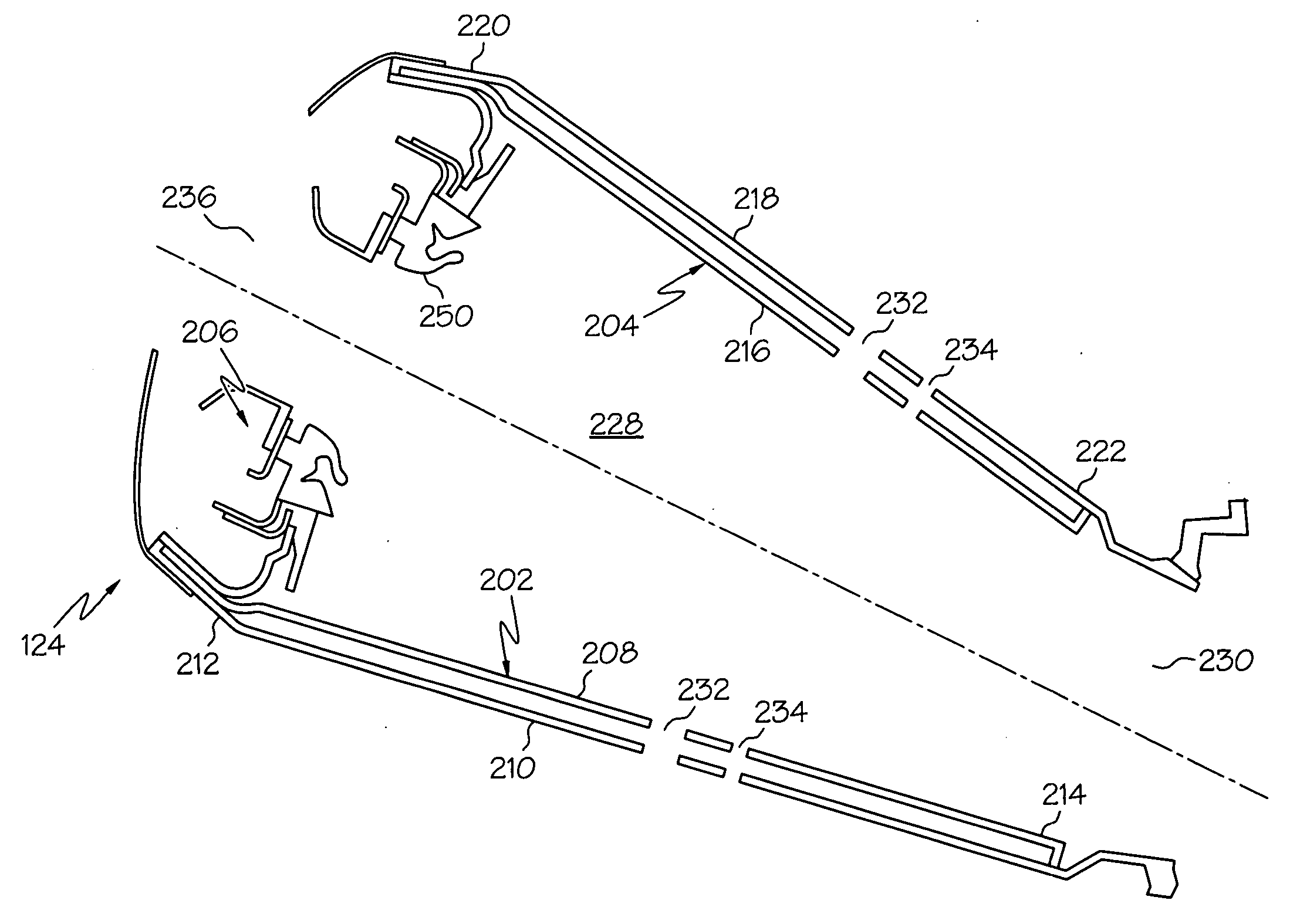

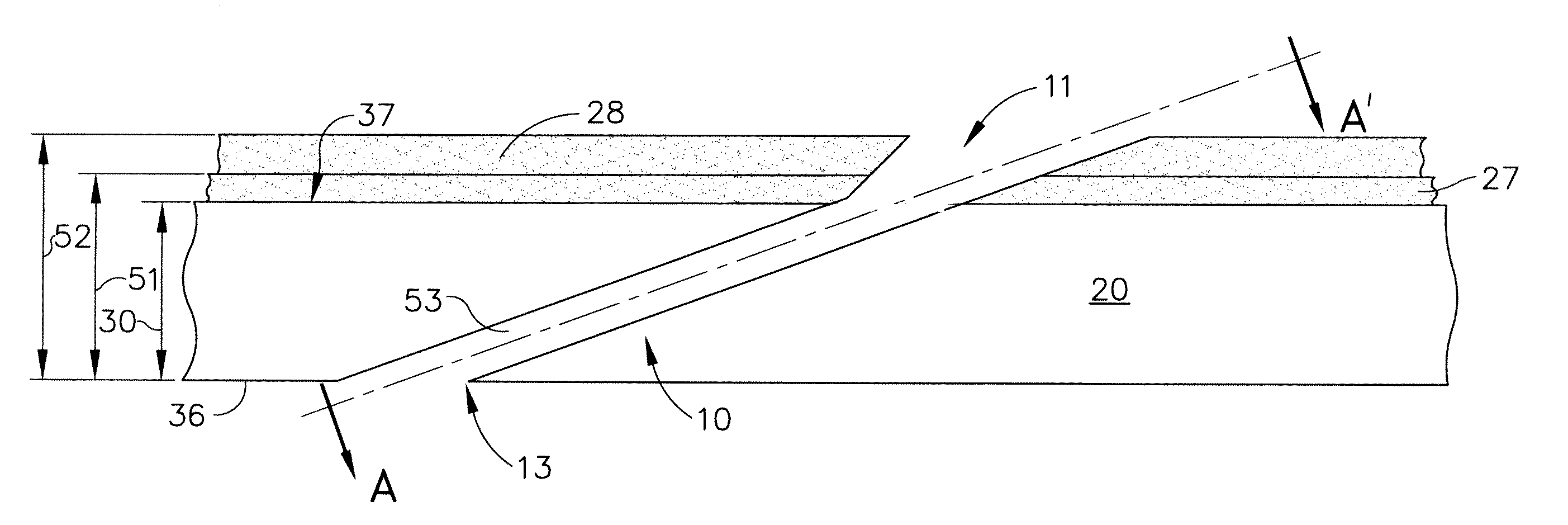

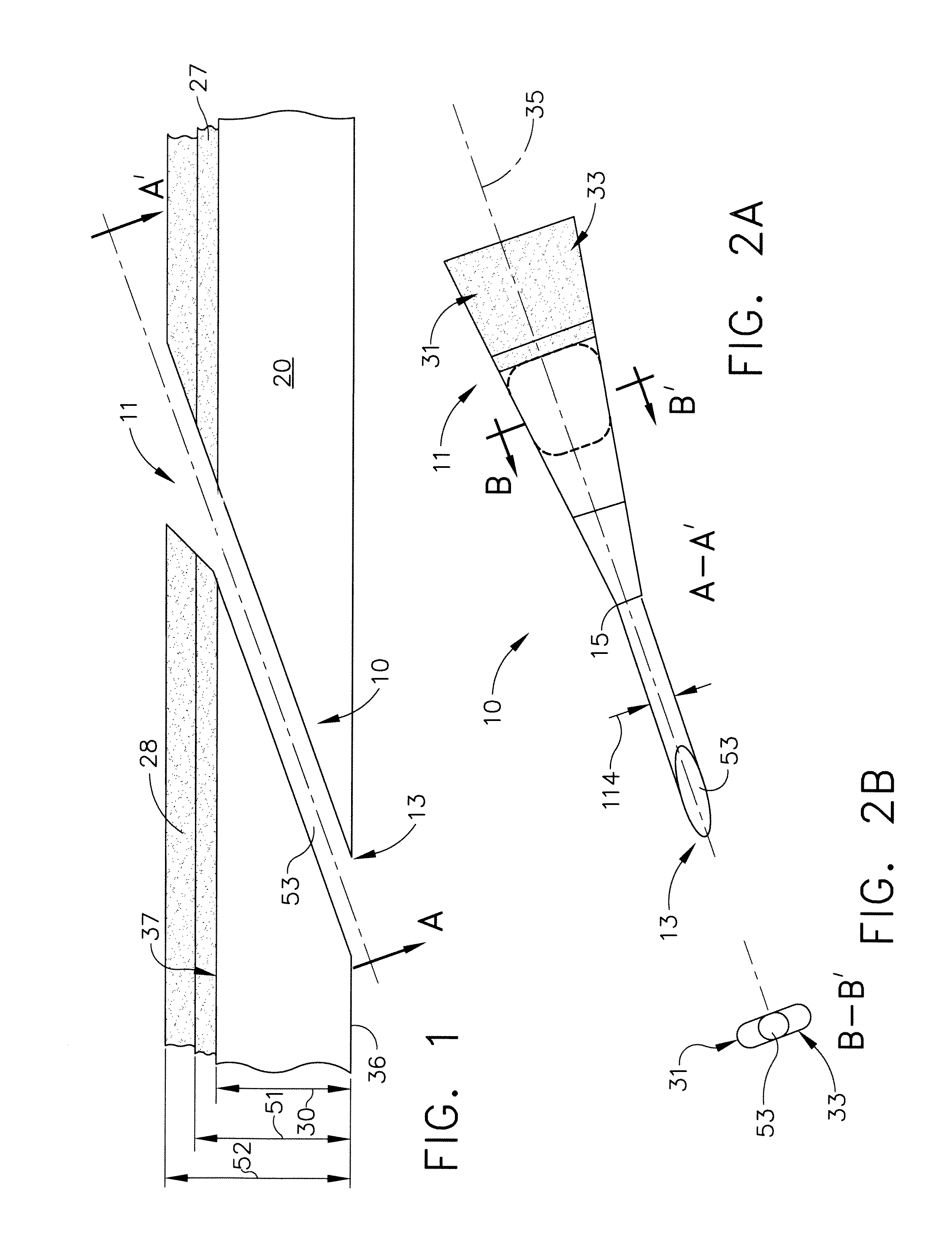

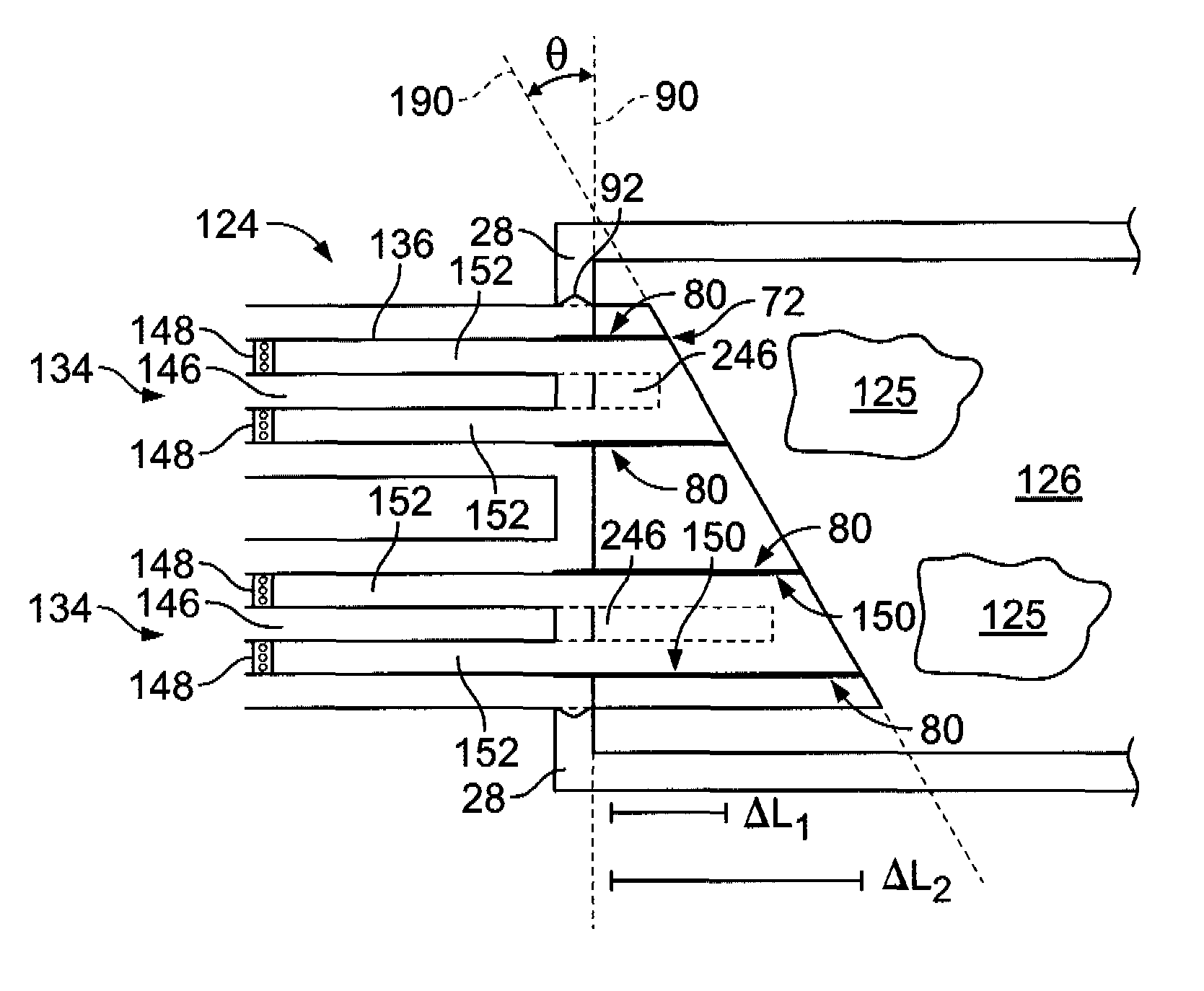

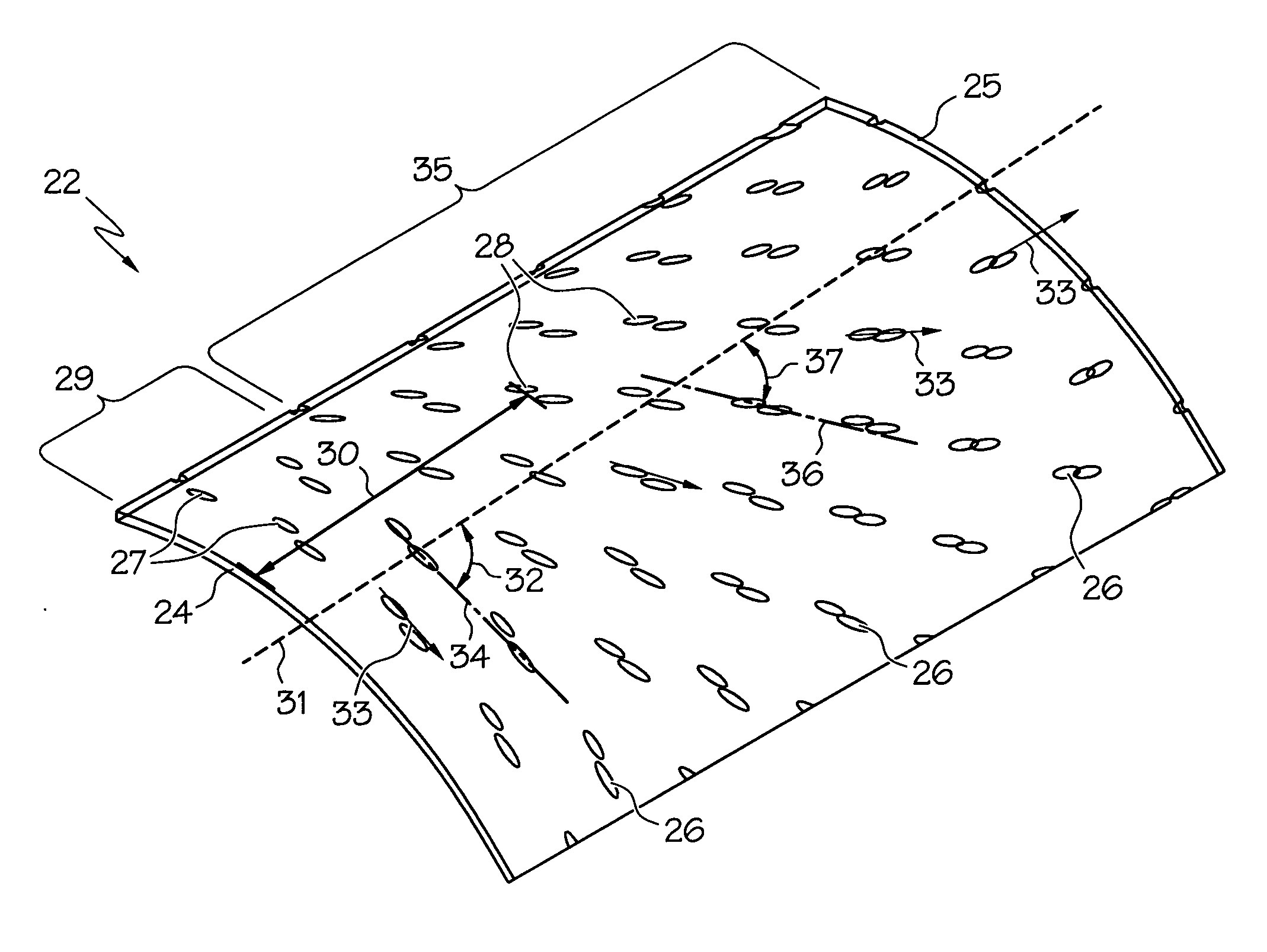

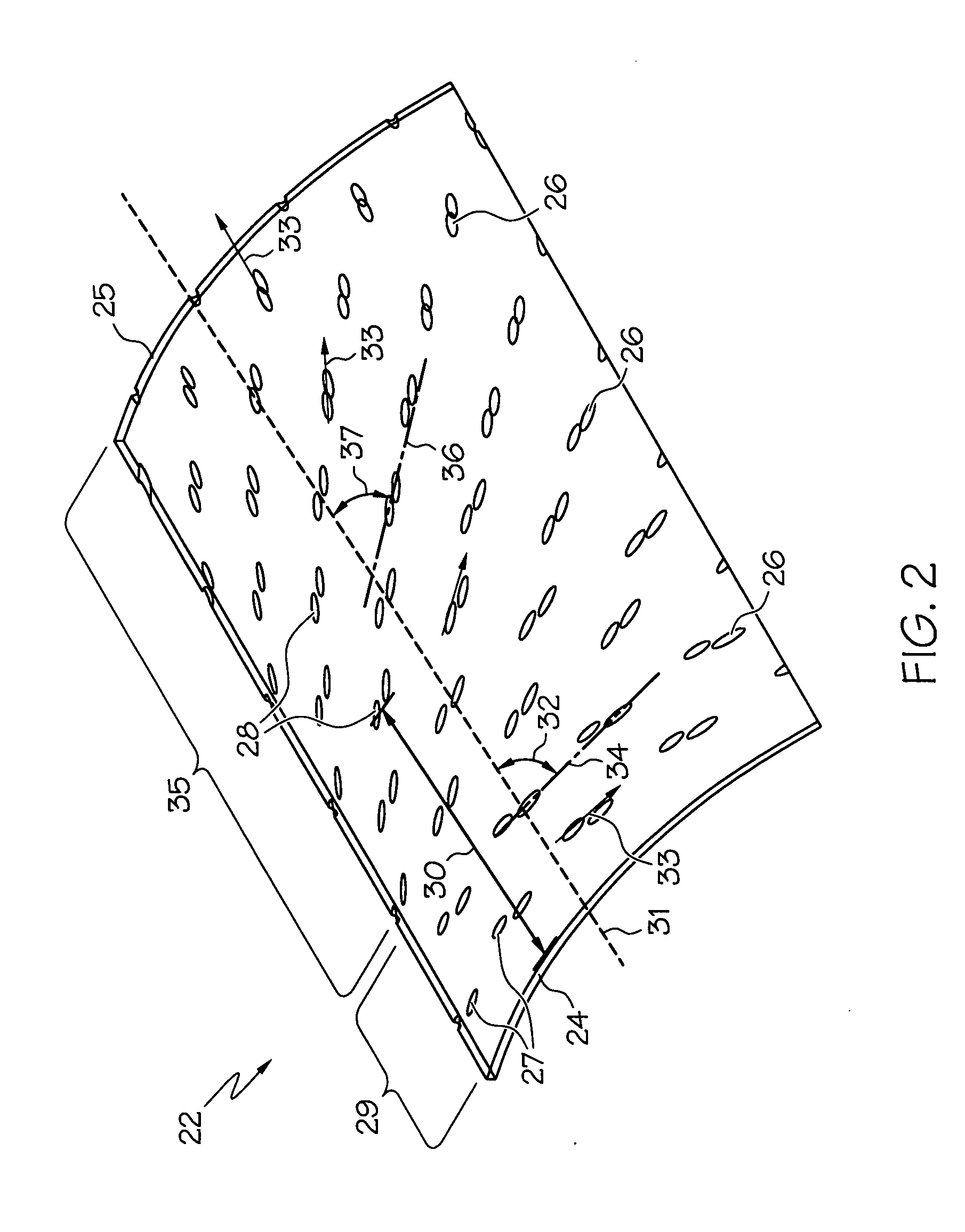

Film effectiveness enhancement using tangential effusion

InactiveUS20060037323A1Improve film propertiesContinuous combustion chamberEfficient propulsion technologiesCombustorEffusion

Film effectiveness enhancement is provided by a plurality of tangentially angled effusion holes in a combustor liner. The effusion holes positioned in the initial flow region at the start of the panel have a tangential angle between about 75° and about 90° to the combustor axis. The tangential angle of the effusion holes positioned downstream from the initial flow region is gradually reduced to a value corresponding to the bulk swirl of the combustor internal flow or to zero so that the effusion hole orientation at the end of the panel corresponds to that of convention effusion.

Owner:HONEYWELL INT INC

Secondary Fuel Delivery System

ActiveUS20090071159A1Reduce the impactAvoid heat dissipation difficultiesTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustionEffusion

A secondary fuel delivery system for delivering a secondary stream of fuel and / or diluent to a secondary combustion zone located in the transition piece of a combustion engine, downstream of the engine primary combustion region is disclosed. The system includes a manifold formed integral to, and surrounding a portion of, the transition piece, a manifold inlet port, and a collection of injection nozzles. A flowsleeve augments fuel / diluent flow velocity and improves the system cooling effectiveness. Passive cooling elements, including effusion cooling holes located within the transition boundary and thermal-stress-dissipating gaps that resist thermal stress accumulation, provide supplemental heat dissipation in key areas. The system delivers a secondary fuel / diluent mixture to a secondary combustion zone located along the length of the transition piece, while reducing the impact of elevated vibration levels found within the transition piece and avoiding the heat dissipation difficulties often associated with traditional vibration reduction methods.

Owner:SIEMENS ENERGY INC

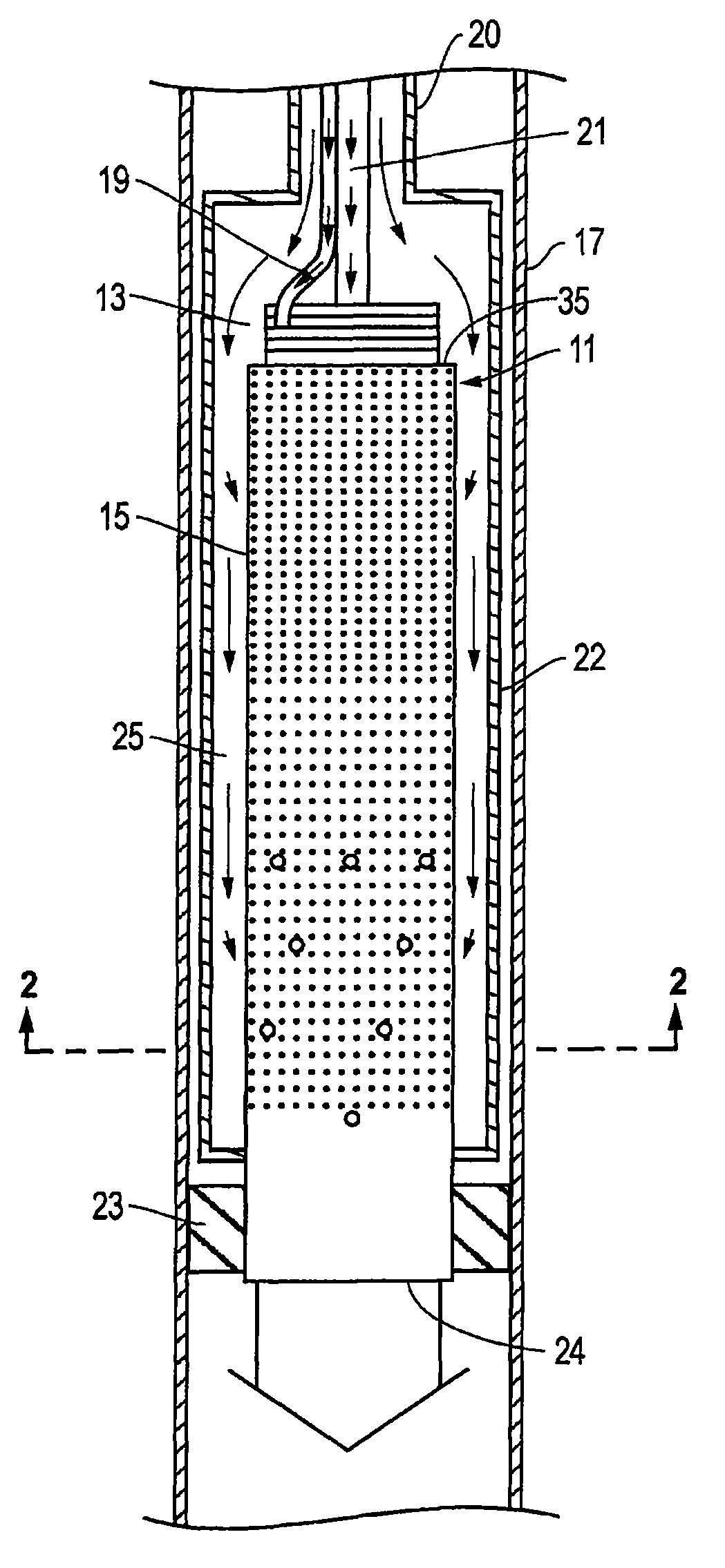

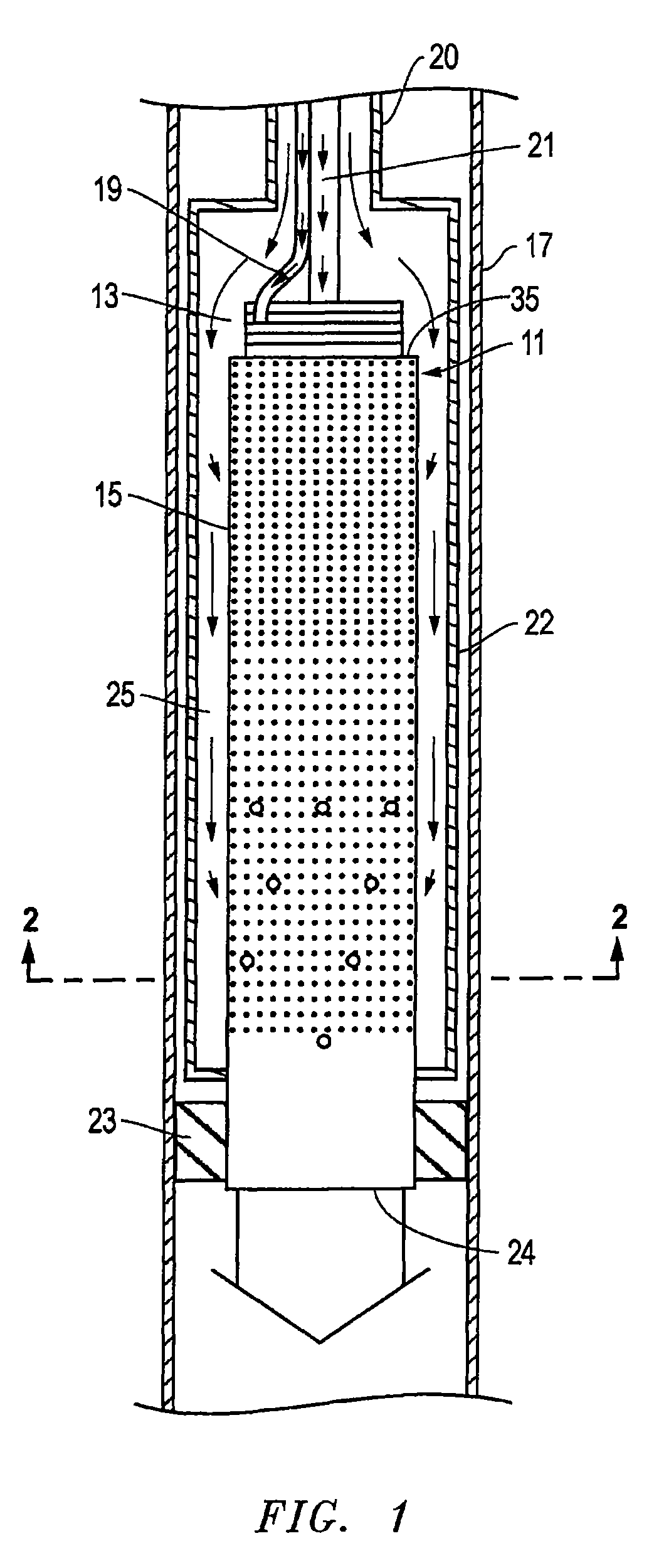

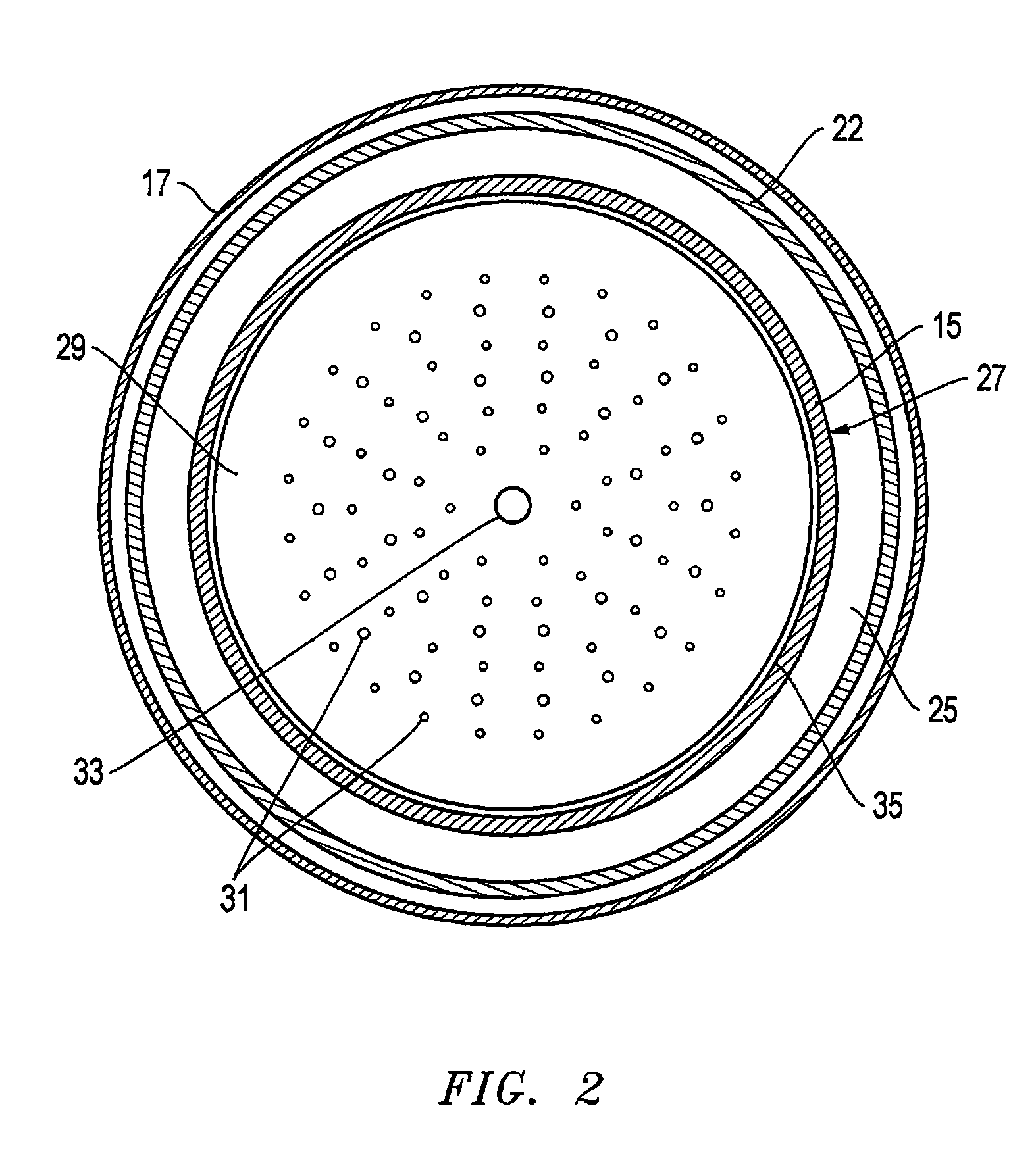

System, method and apparatus for hydrogen-oxygen burner in downhole steam generator

A downhole burner for a steam generator includes an injector and a cooling liner. Steam enters the burner through holes in the cooling liner. Combustion occurring within the cooling liner heats the steam and increases its quality and may superheat it. The heated, high-quality steam and combustion products exit the burner and enter an oil-bearing formation to upgrade and improve the mobility of heavy crude oils held in the formation. The injector includes a face plate, a cover plate, an oxidizer distribution manifold plate, and a fuel distribution manifold plate. The cooling liner has an effusion cooling section and effusion cooling and jet mixing section. The effusion cooling section includes effusion holes for injecting steam along the cooling liner surface to protect the liner. The effusion cooling and jet mixing section has both effusion holes and mixing holes for injecting steam further toward central portions of the burner.

Owner:WORLD ENERGY SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com