Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1197 results about "Pressure rise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

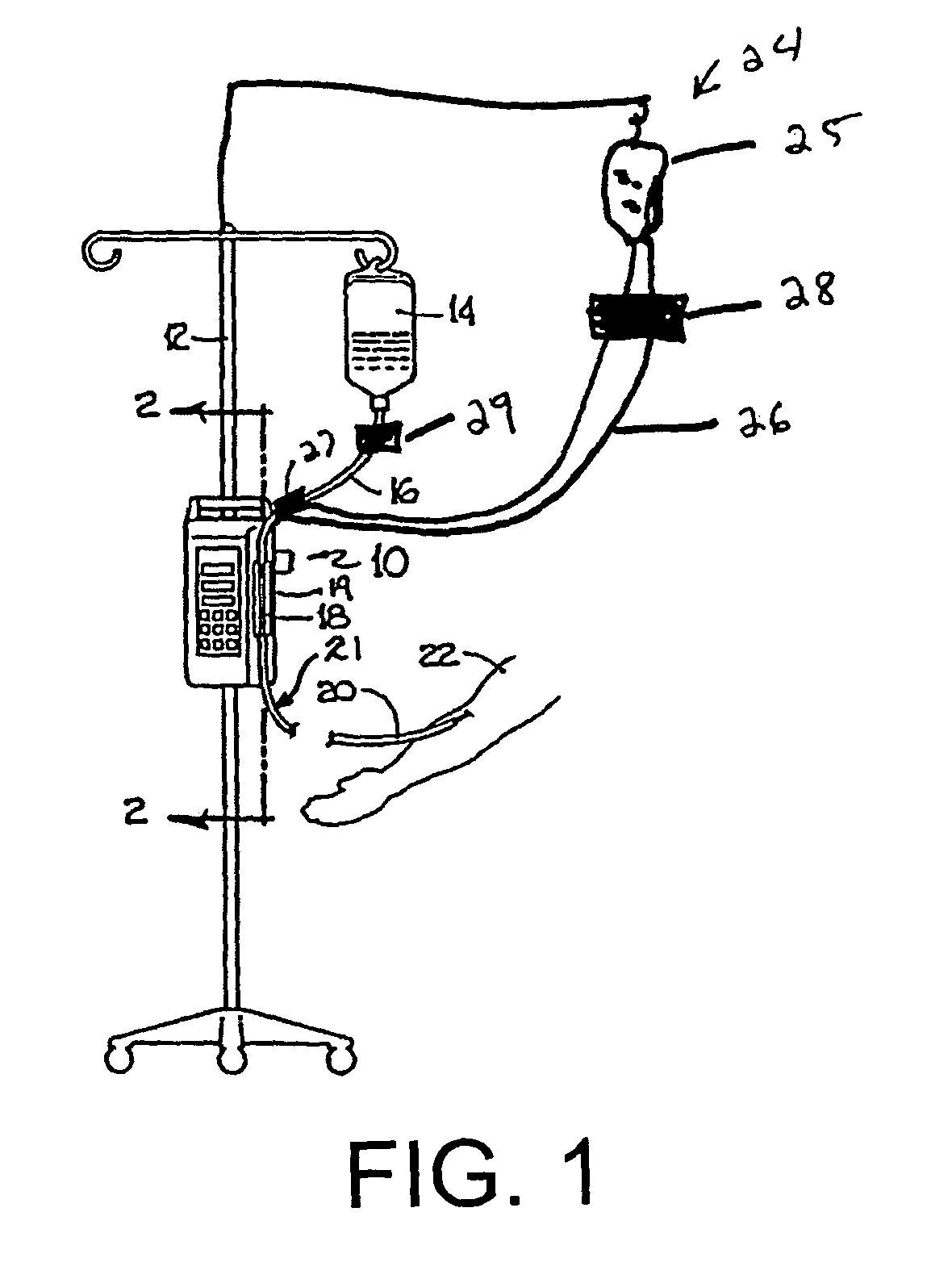

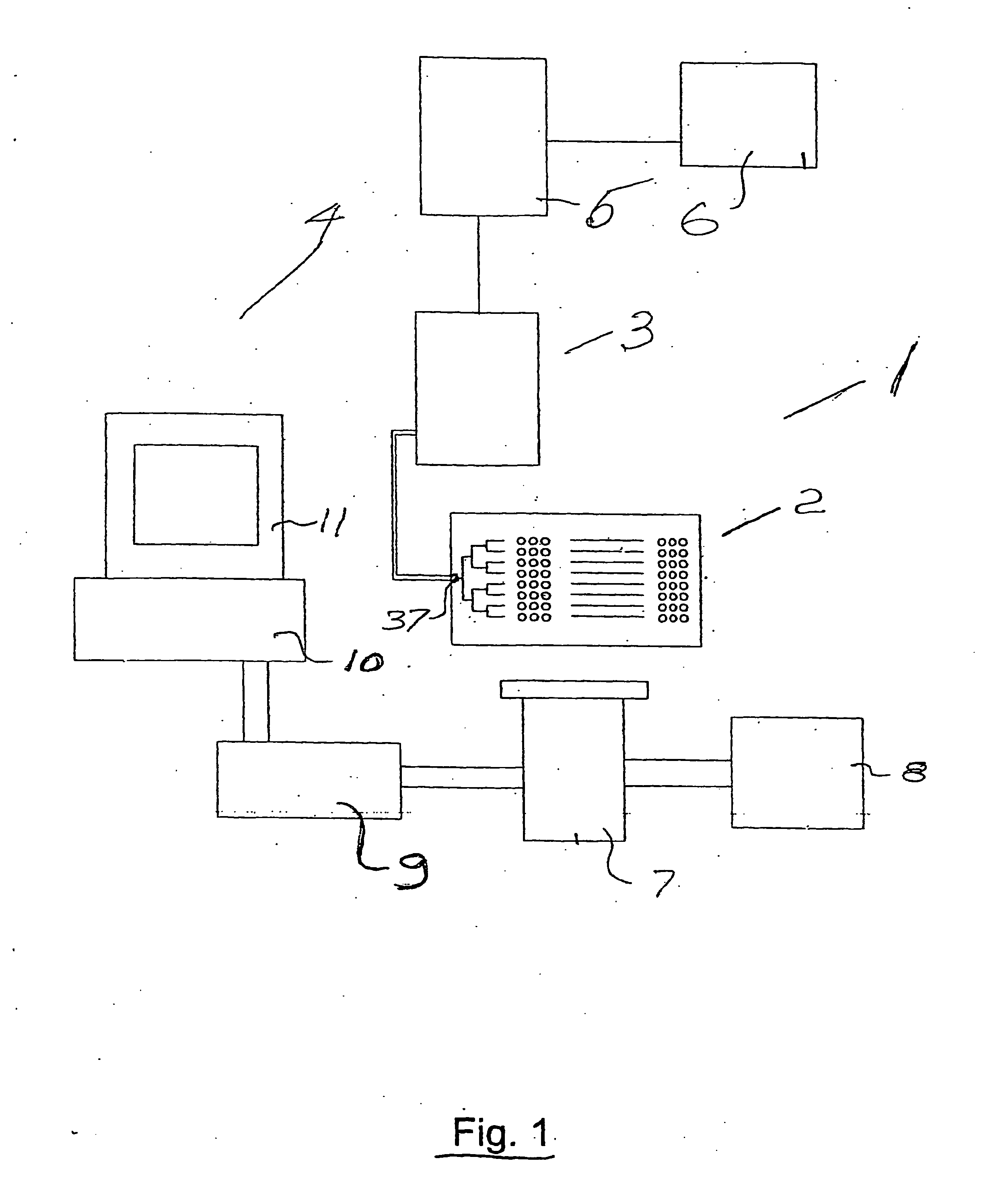

Medication safety enhancement for secondary infusion

ActiveUS20050145010A1Increase the amount of fluidReduce volume capacityMedical devicesFluid pressure measurementDrugPressure rise

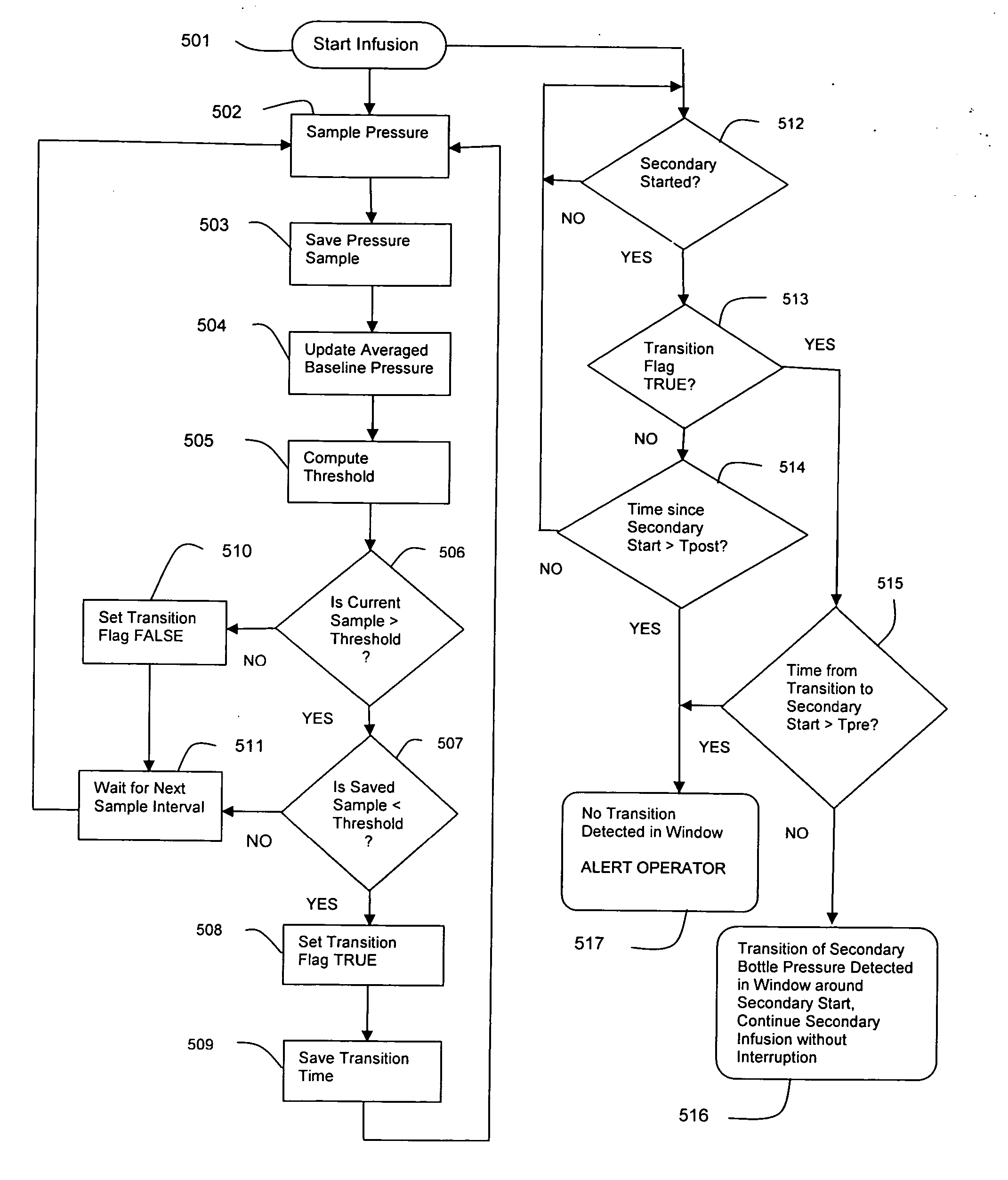

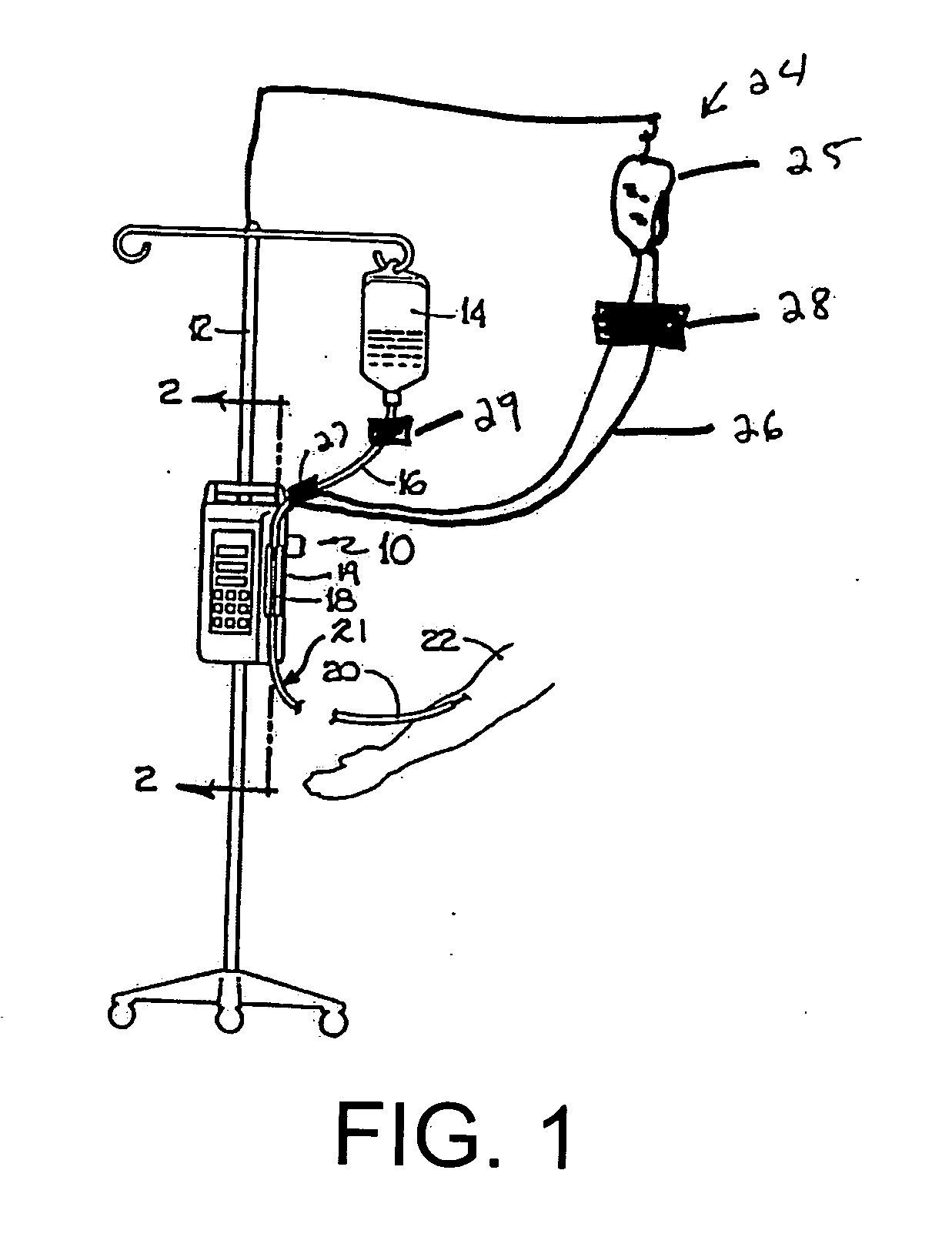

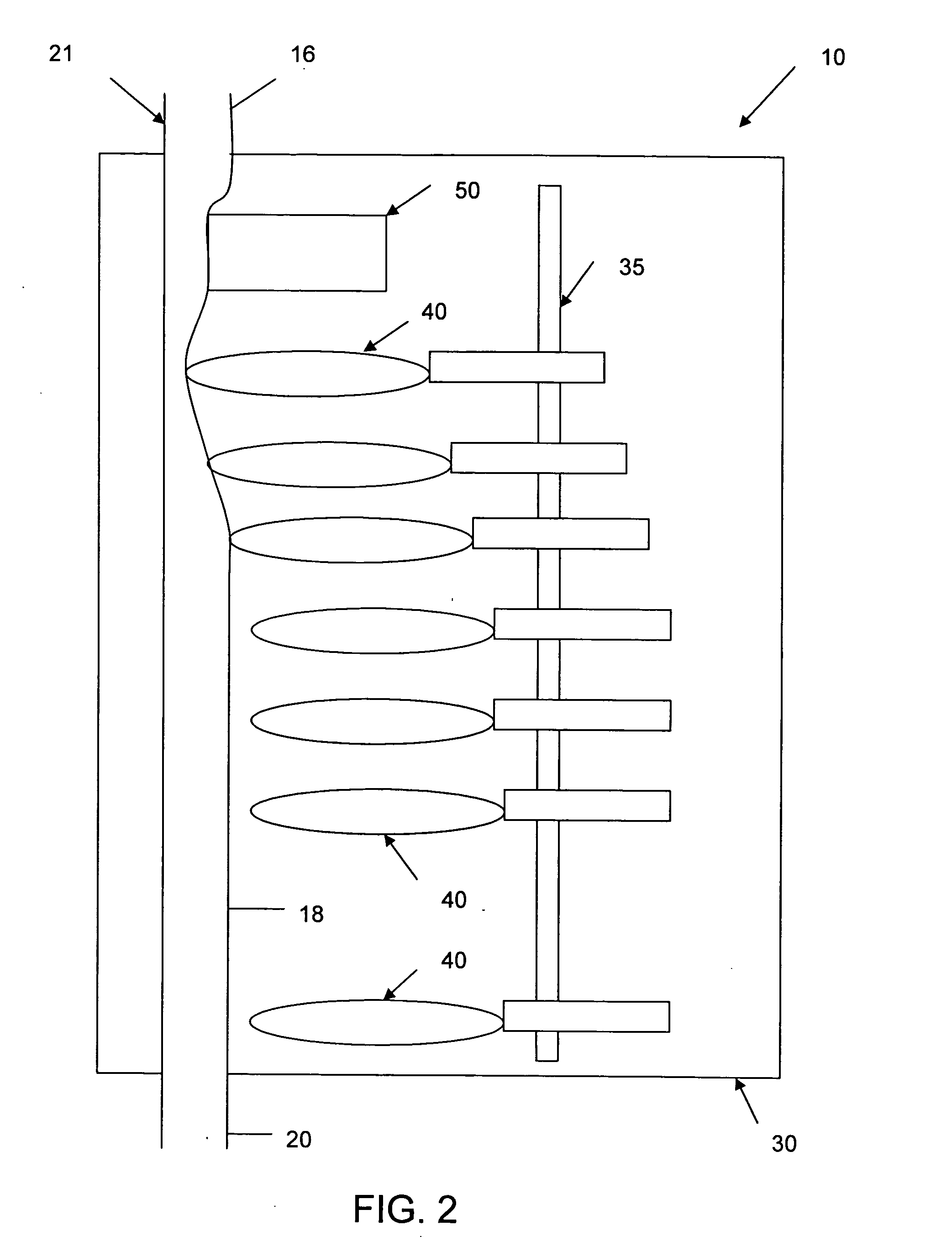

A system and method determine when fluid is not flowing properly from a secondary infusion source during a secondary infusion. The system includes an upstream pressure sensor and a processor programmed to receive signals from the sensor and analyze the signals to determine if secondary fluid flow is proper. The processor samples the output signals from the upstream pressure sensor and analyzes the sampled signals to determine if a pressure rise in the infusion line has occurred when the secondary infusion is initiated. If a pressure rise, indicating that fluid from the secondary container has begun flowing into the infusion line, has not been detected, the processor is programmed to provide a signal indicating that attention should be given to the infusion set up.

Owner:CAREFUSION 303 INC

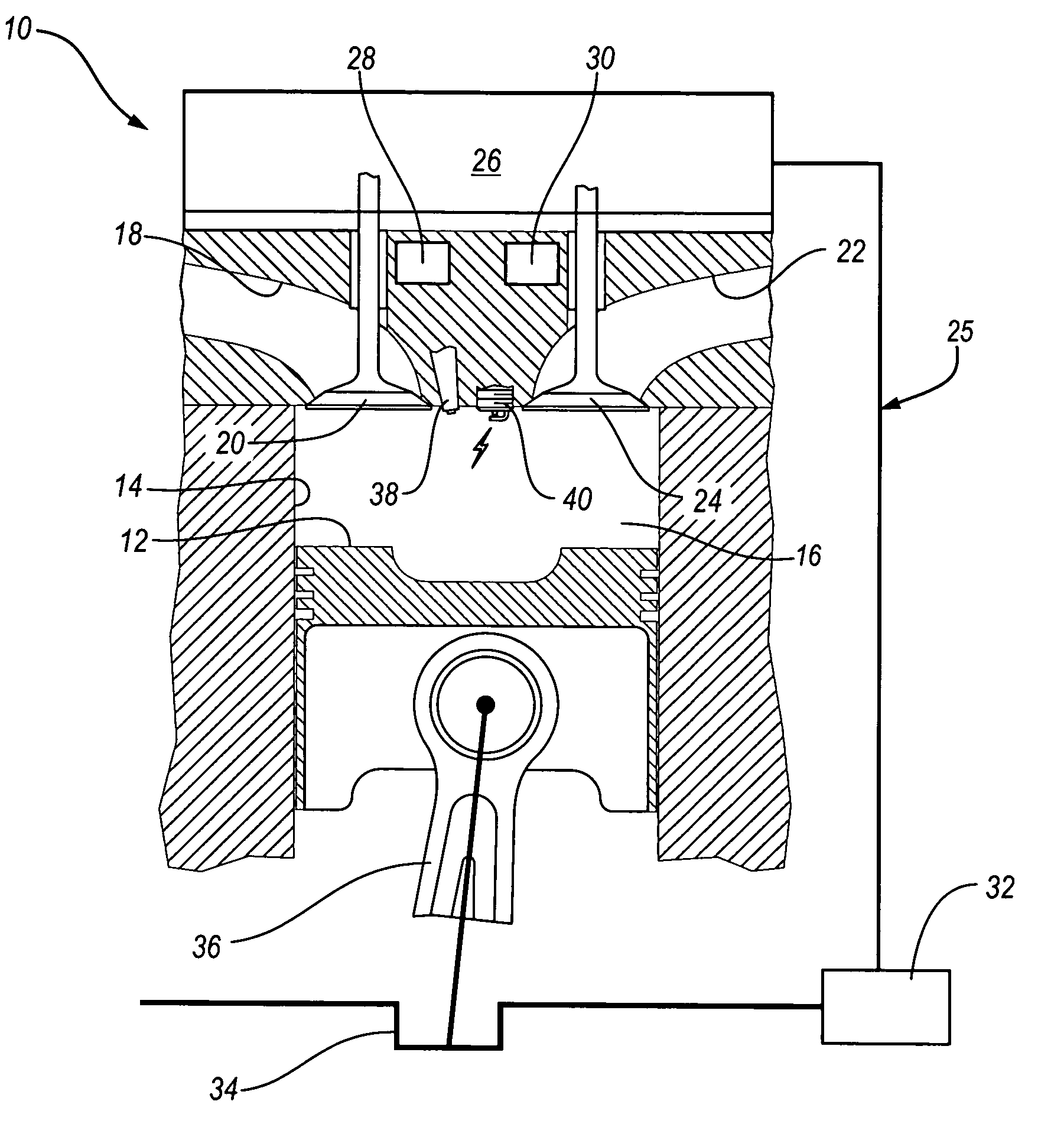

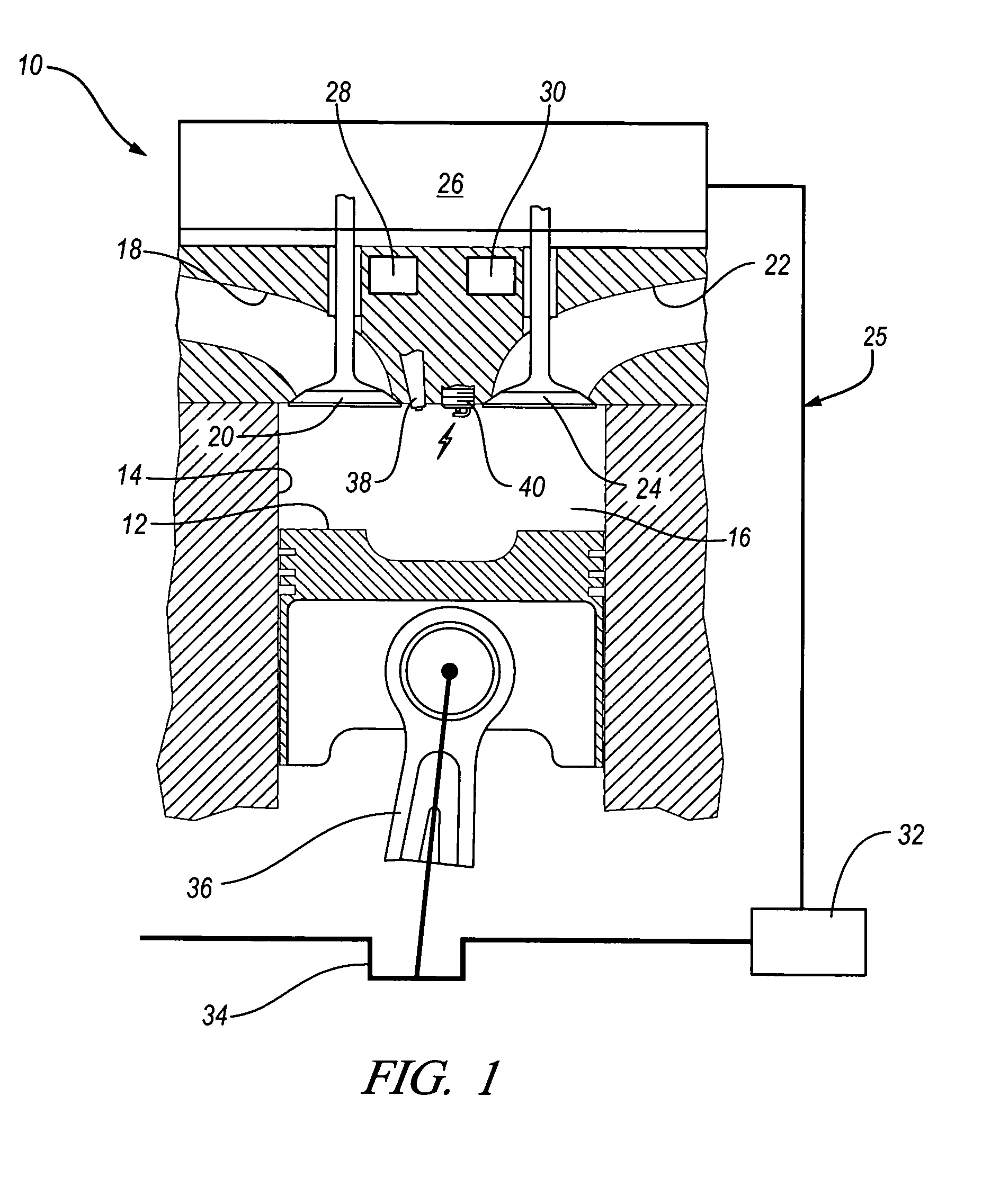

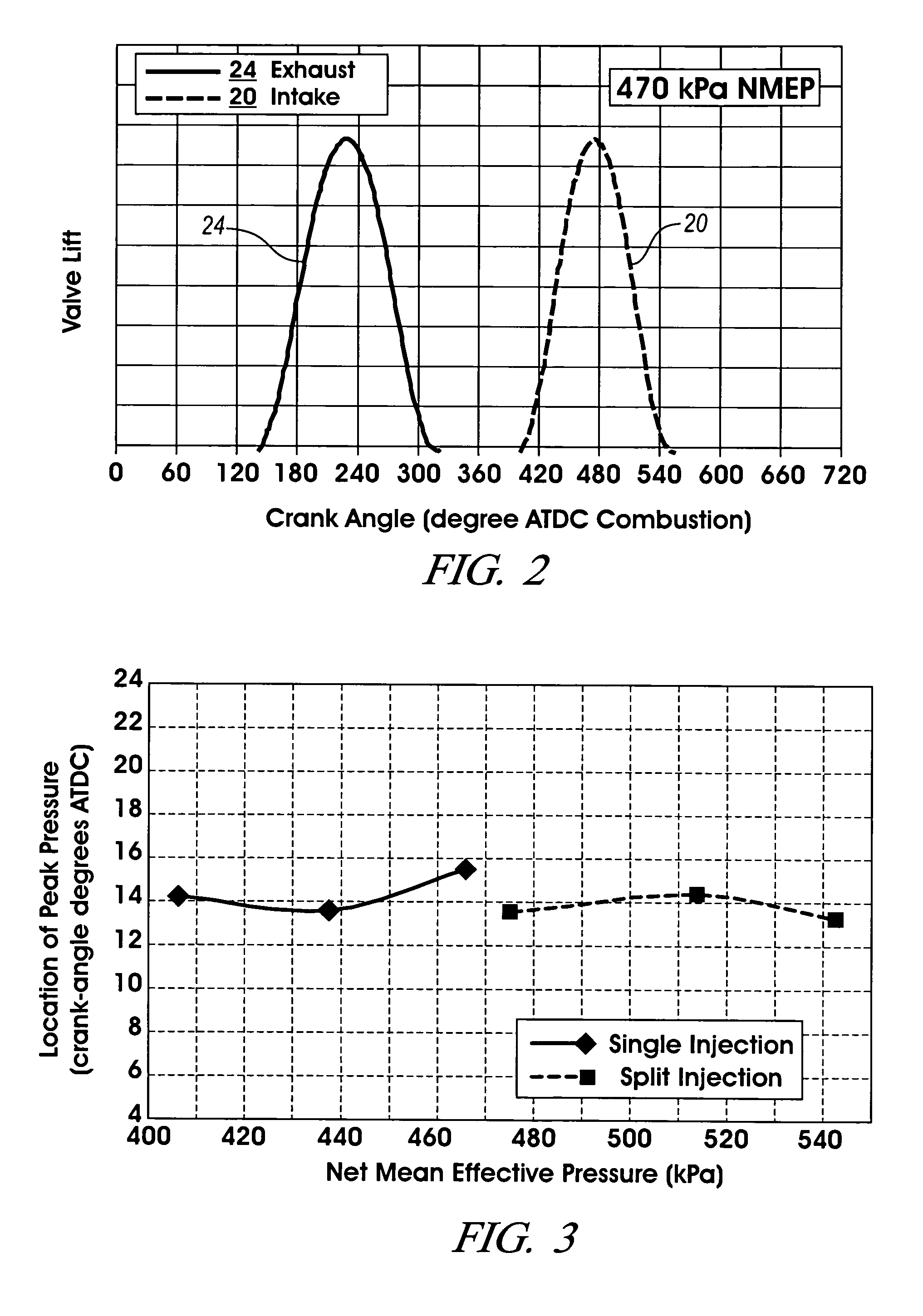

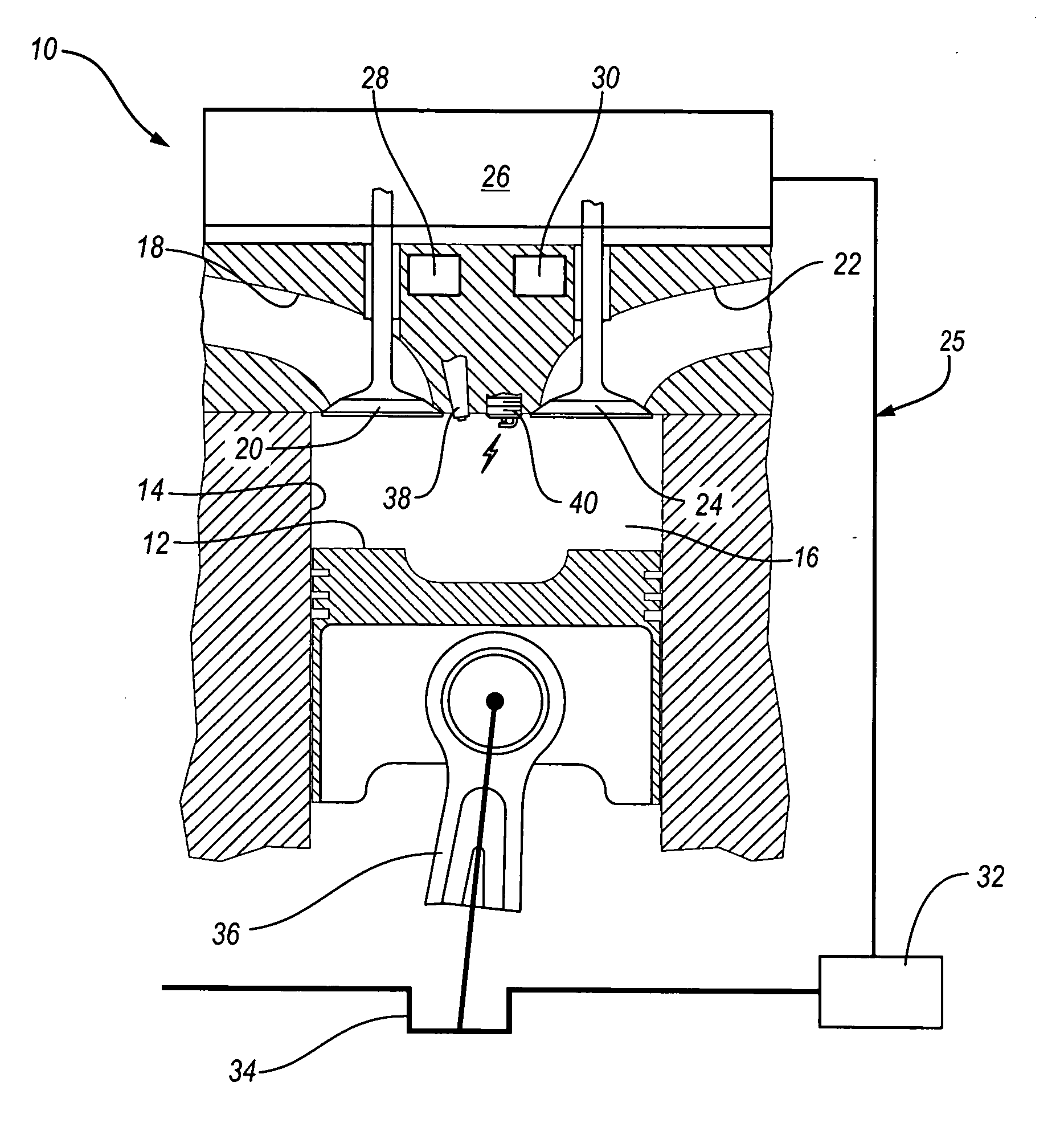

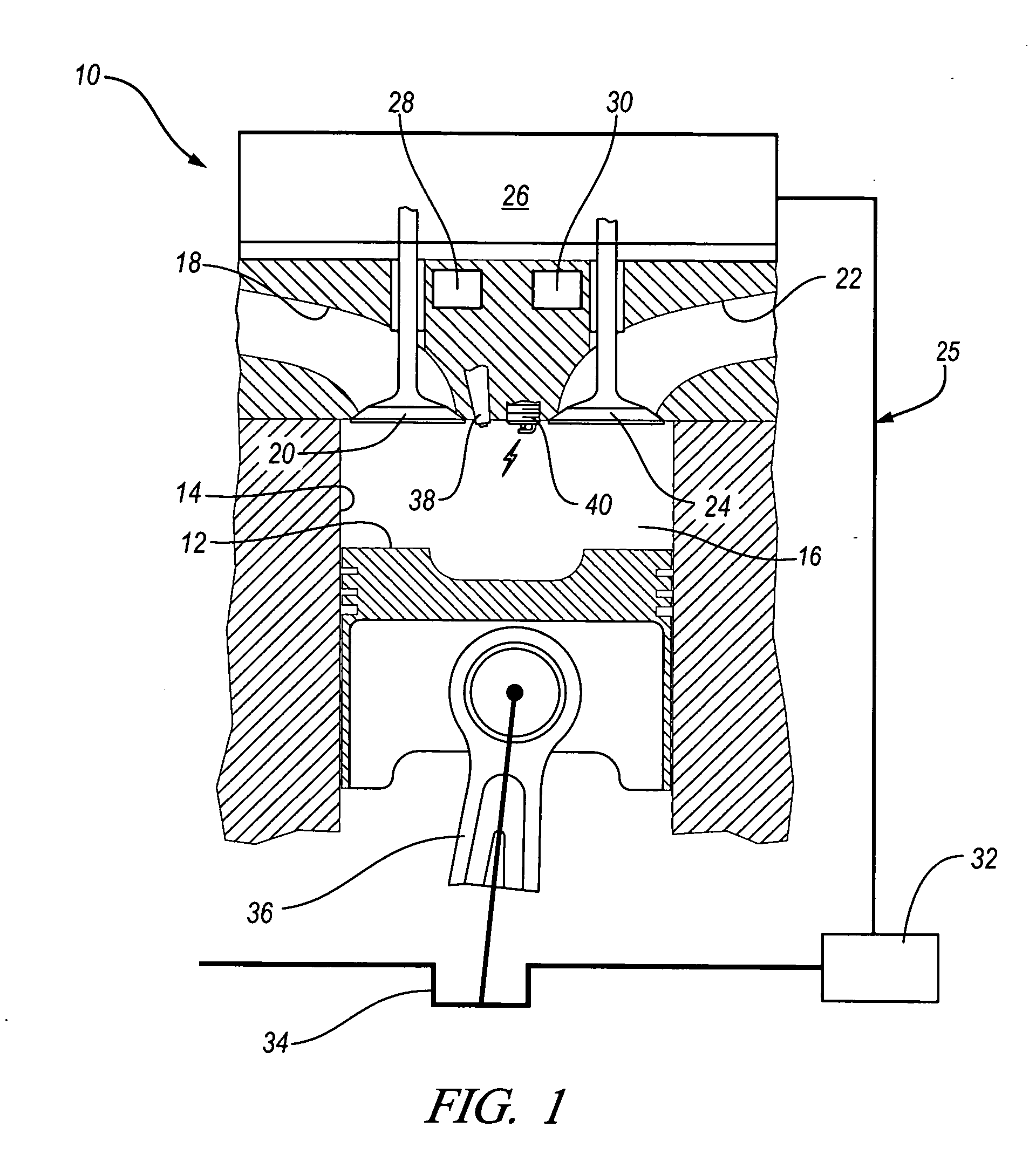

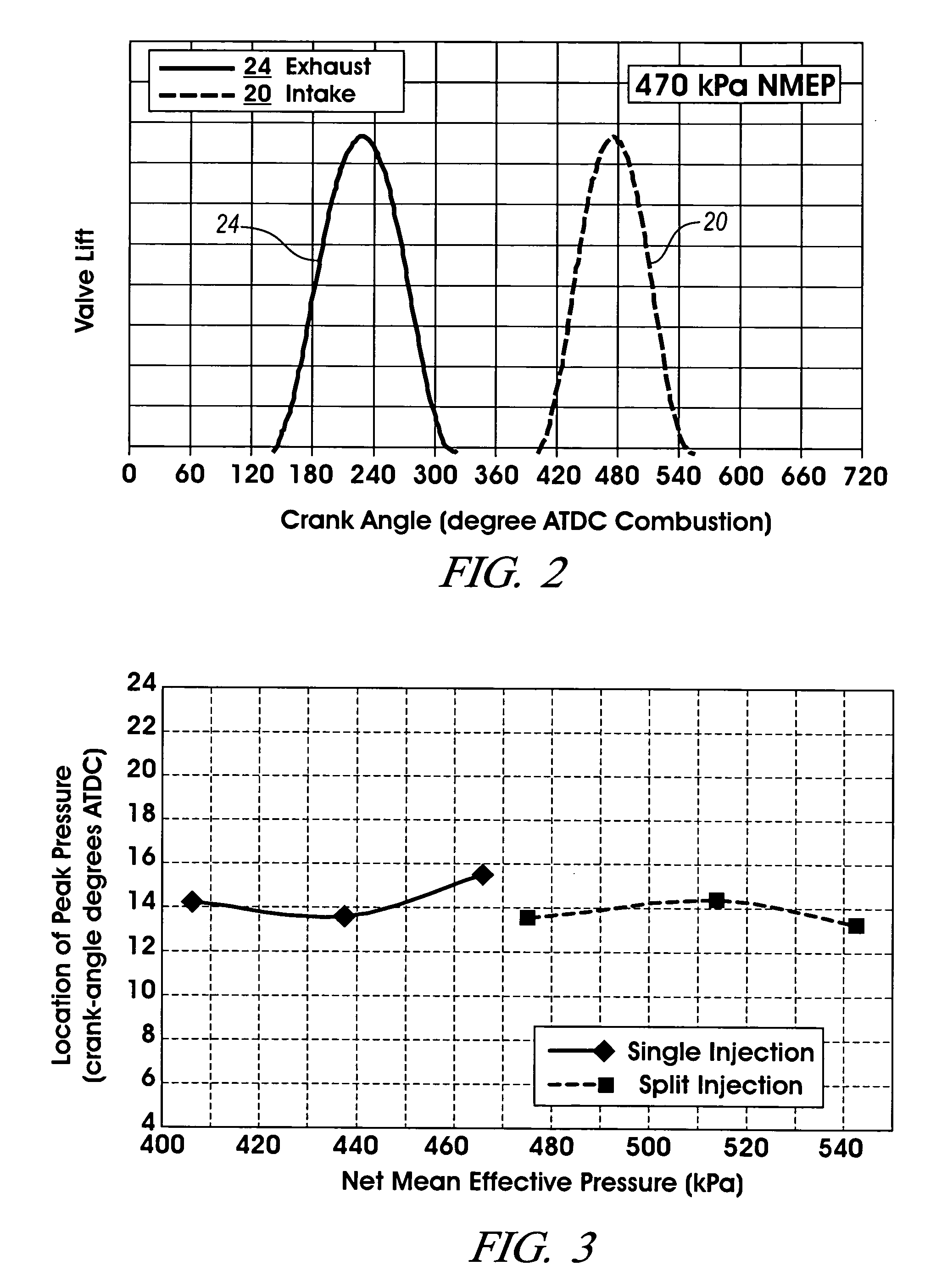

Method for mid load operation of auto-ignition combustion

ActiveUS6994072B2Electrical controlNon-fuel substance addition to fuelPressure riseMultiple injection

A method is disclosed for expanding the mid load operation limit in a four-stroke gasoline direct-injection controlled auto-ignition combustion engine. A system is employed for variably actuating the intake and exhaust valves and for operating the valves with an exhaust re-compression or exhaust re-breathing valve strategy. A spark plug is provided. A fuel injector having multiple injection capability is employed. A first fuel charge is injected into the combustion chamber to form a lean air-fuel mixture. A second fuel charge is injected into the combustion chamber to form a stratified air-fuel mixture having an ignitable mixture located near the spark plug. The ignitable mixture is ignited at the spark gap, thereby causing spark-ignition combustion that causes a sufficient increase in chamber pressure and temperature to trigger auto-ignition of the lean air-fuel mixture, resulting in the obtaining of a higher engine load before a pressure rise rate in the combustion chamber exceeds a prescribed threshold value.

Owner:GM GLOBAL TECH OPERATIONS LLC

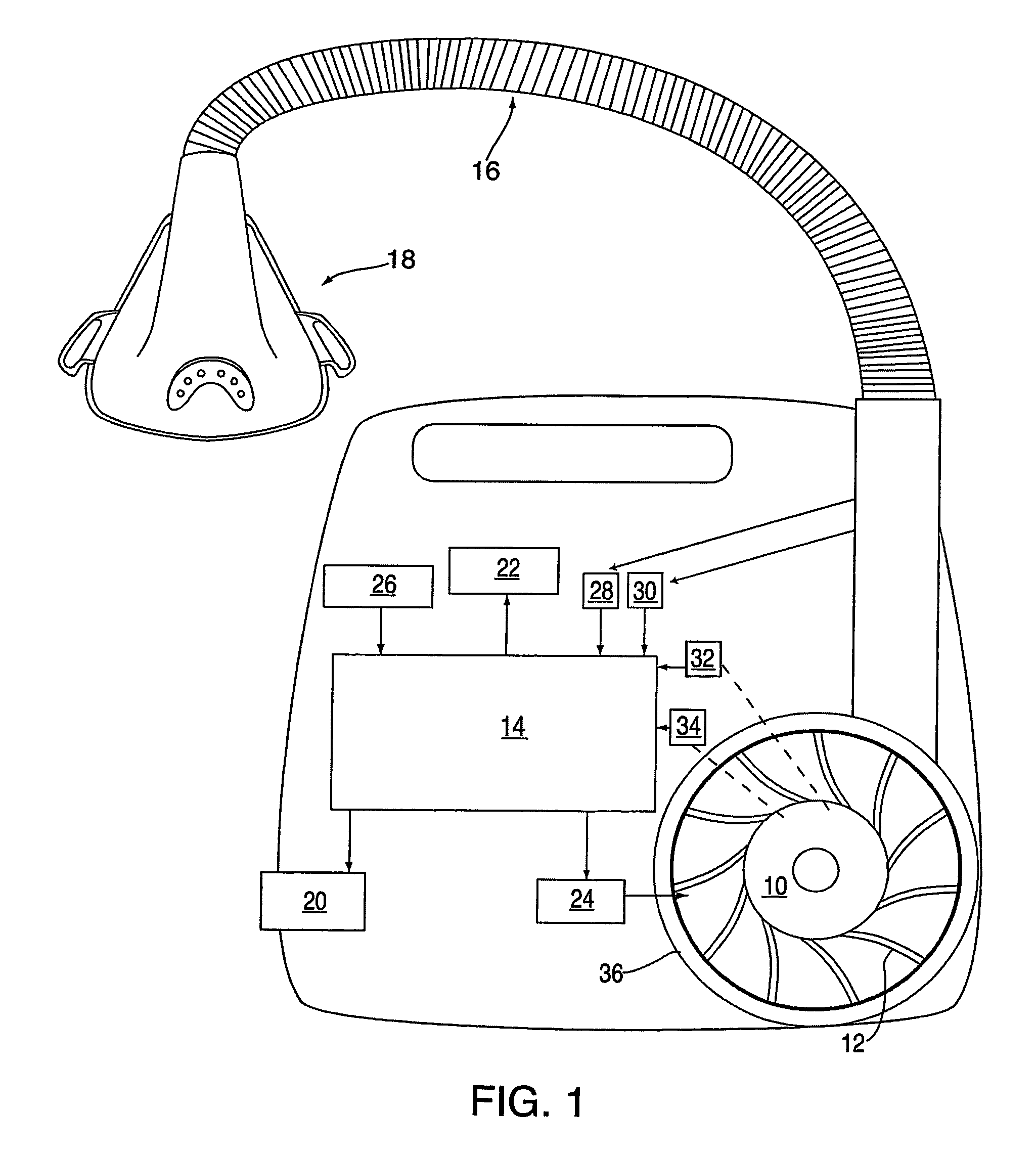

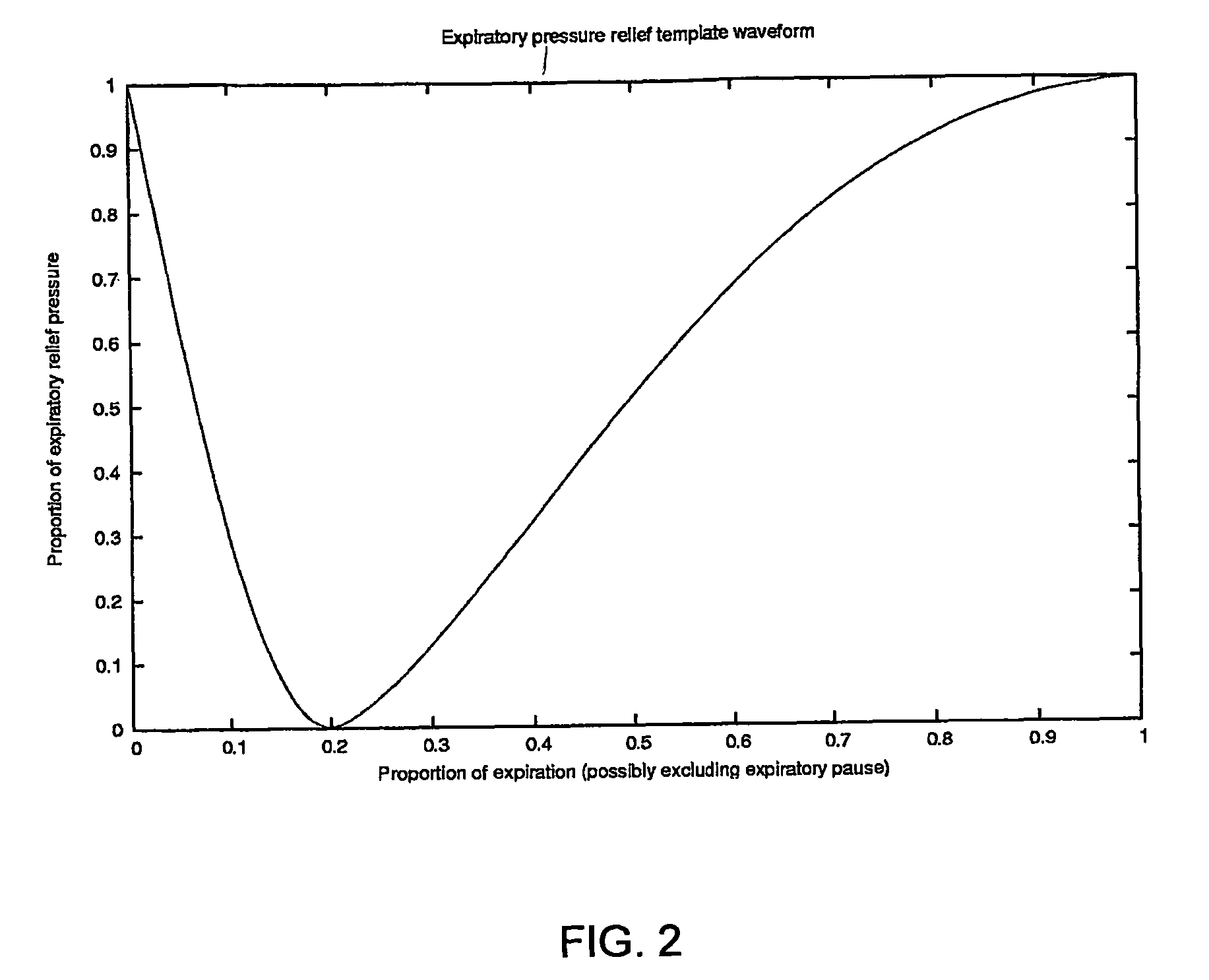

Methods for providing expiratory pressure relief in positive airway pressure therapy

InactiveUS7866318B2Stable changeOperating means/releasing devices for valvesRespiratory masksRespiratory flowExpiration Time

Owner:RESMED LTD

Methods for providing expiratory pressure relief in positive airway pressure therapy

InactiveUS20090020121A1Stable changeOperating means/releasing devices for valvesRespiratory masksExpiration TimePositive airway pressure

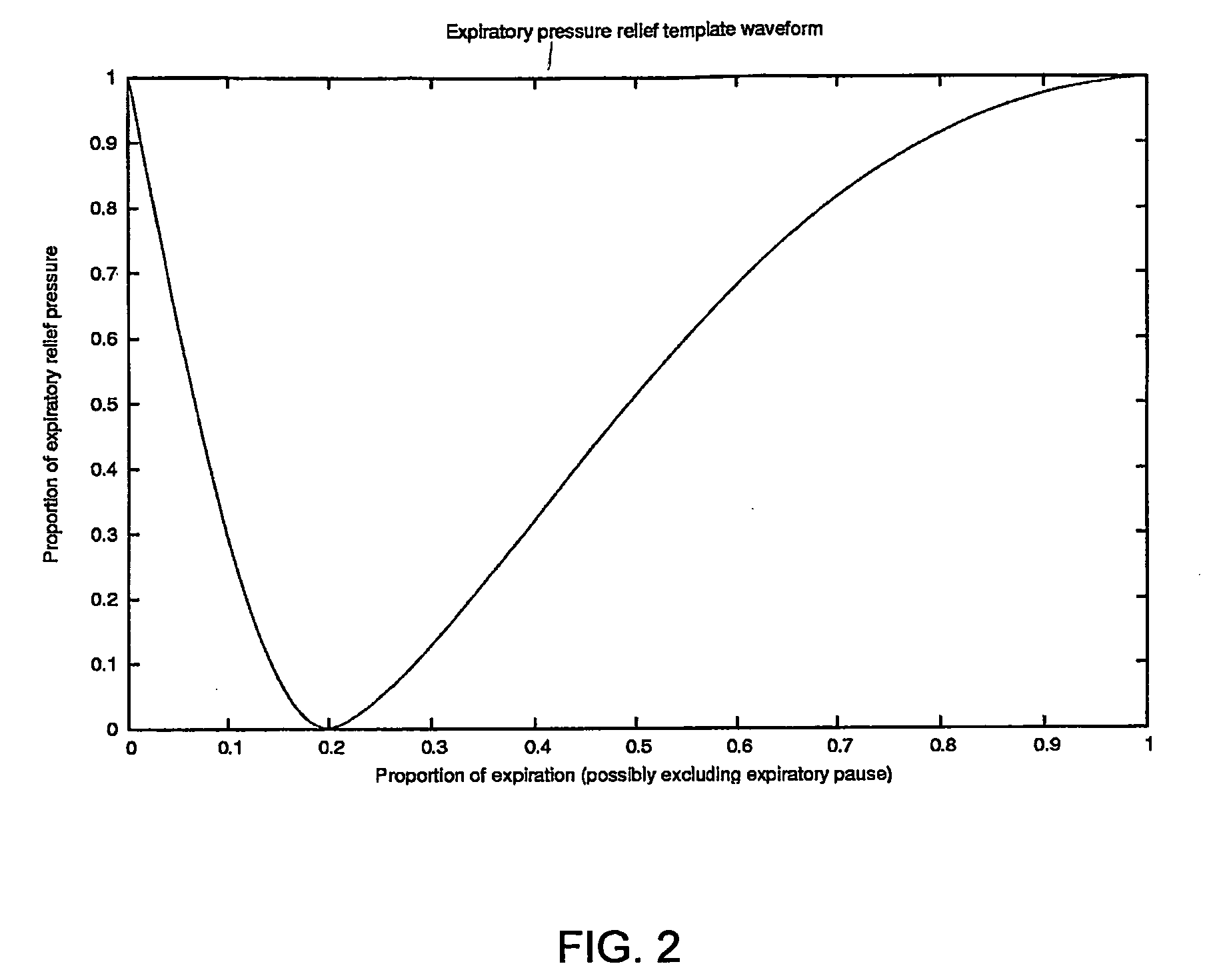

A method of operating a CPAP apparatus in which the interface pressure is controlled to rapidly drop at the start of expiration by an expiratory relief pressure (ERP) that is independent of instantaneous respiratory flow, following which the pressure rises to an inspiratory level at or shortly before the end of expiration, or at the onset of an expiratory pause, if any. The ERP is an increasing function of the inspiratory pressure. The expiratory pressure follows a template that is a function of the expected expiration time, the magnitude of the template being equal to the ERP. The current estimated proportion of expiration is determined by comparing the expiration time of the breath in progress to low-pass filtered expiratory durations measured for a number of the preceding breaths.

Owner:RESMED LTD

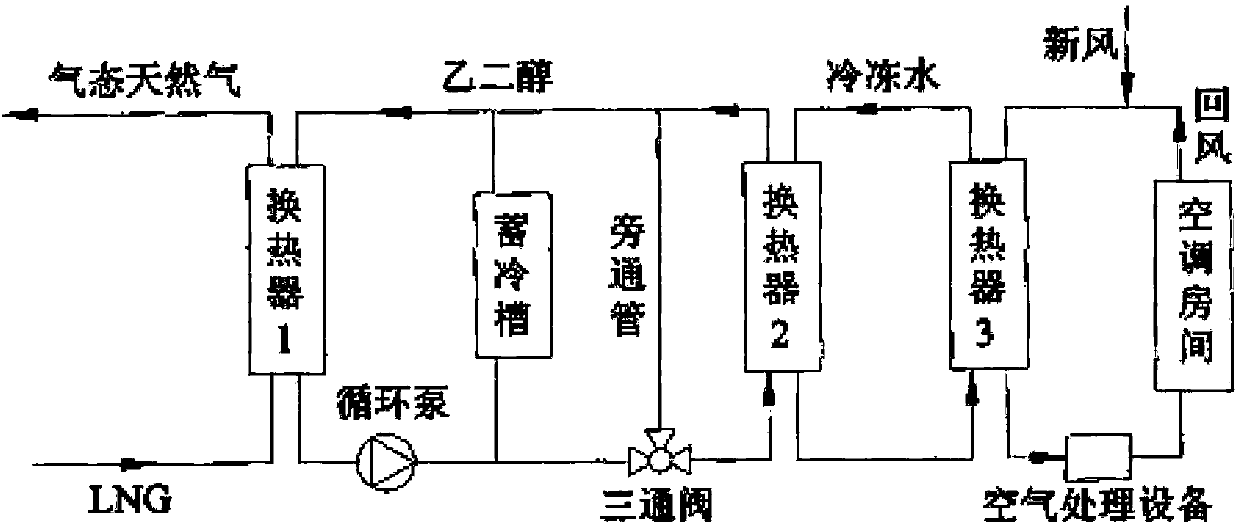

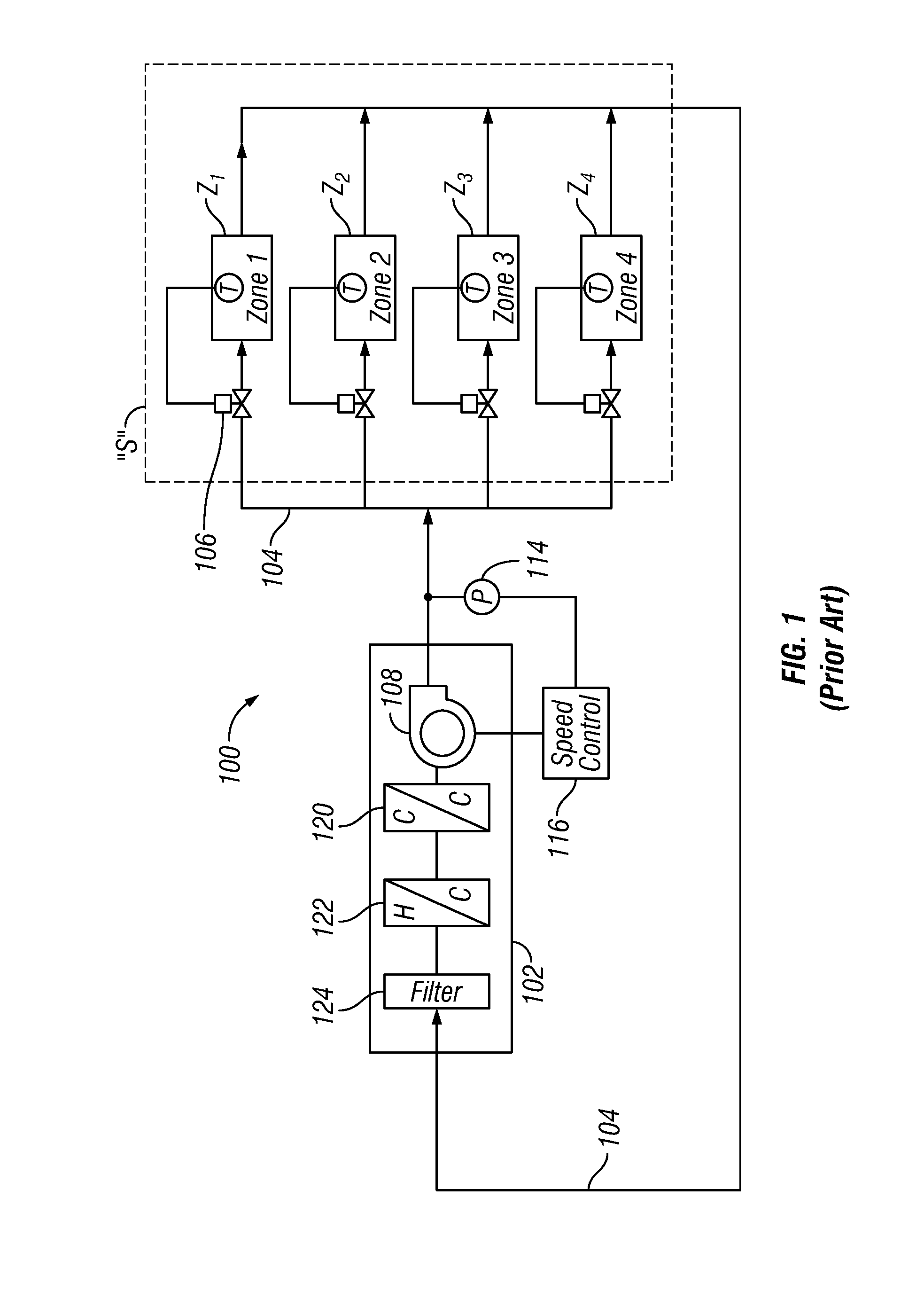

High-efficiency air handler

InactiveUS20030000230A1Lighting and heating apparatusCooling fluid circulationCeiling fanPressure rise

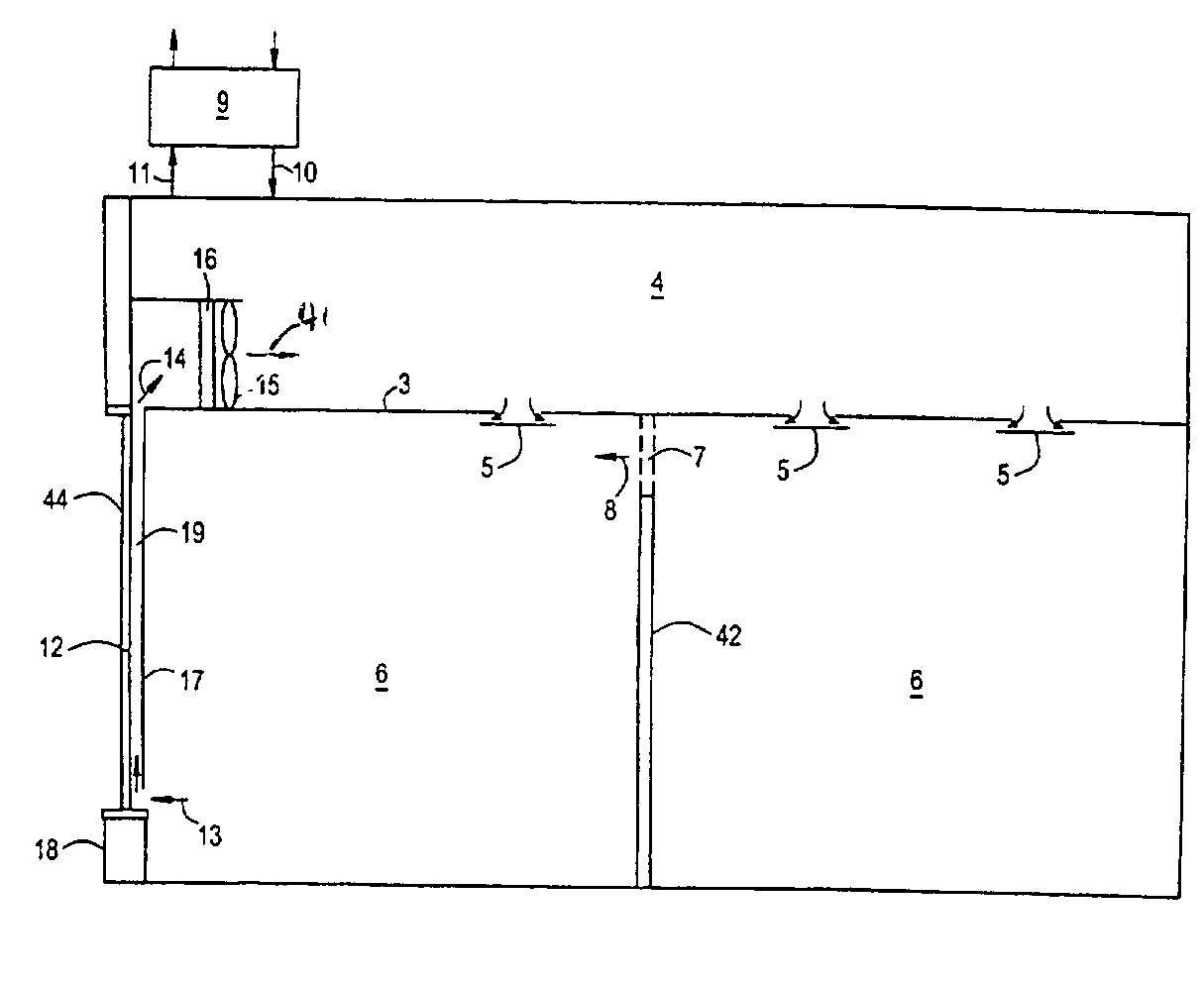

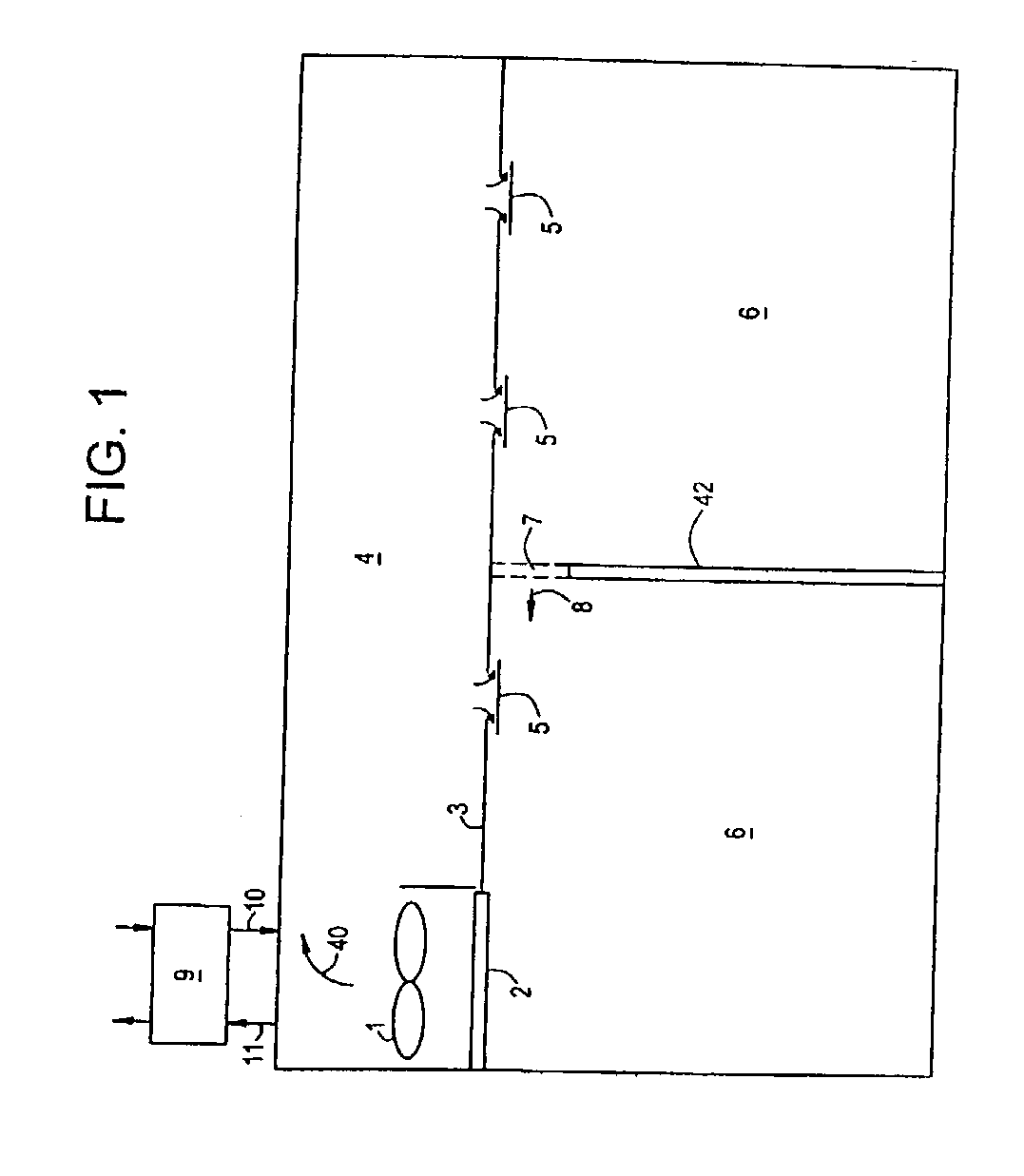

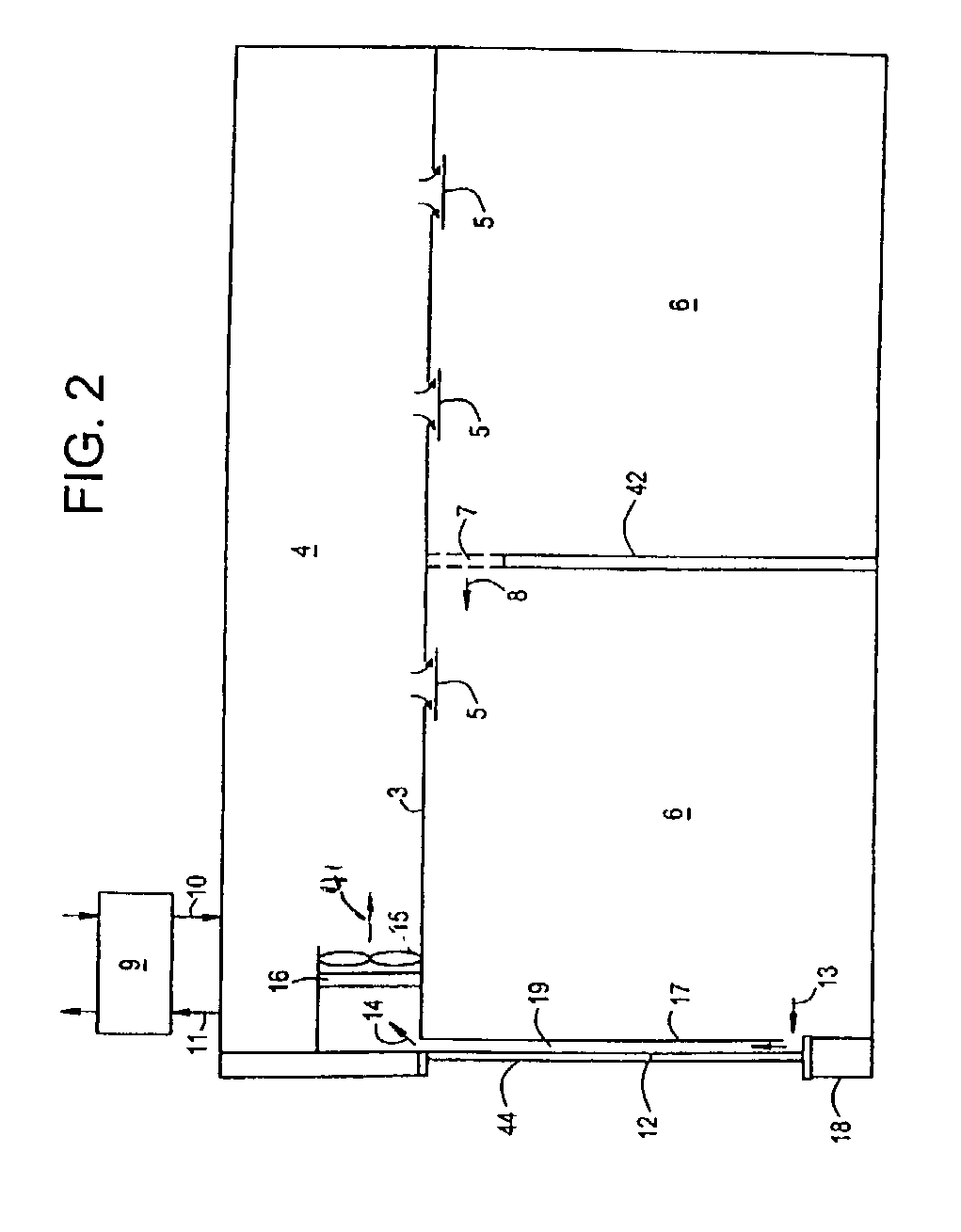

A high-efficiency air handler that is suitable for moving large volumes of air. The air handler comprises a coil and a fan. The total air volume moving through the unit is preferably over about 2000 CFM, with a total fan static pressure rise of less than about 0.5 inches and preferably less than 0.2 inches of water. The fan is preferably a modified ceiling fan with a rotational speed of less than about 450 rpm. The air handler is preferably part of a system where dehumidification and sensible cooling functions are separate. The separate dehumidification allows for much higher supply air temperatures, preferably within about 10° F. of the space temperature. Low-velocity air distribution through a ceiling plenum or a vent into the space allows for very low fan static pressures, which greatly reduces fan energy use compared to conventional ducted systems. The low static pressures and high supply-air temperatures allow the use of existing drop ceiling construction with little modification. The system can also include low-cost thermal storage. Latent thermal storage is in the form of a concentrated liquid desiccant solution. Chilled water storage is another option. The result is a major improvement in energy efficiency and comfort while reducing installed cost and peak electrical demand of the system.

Owner:KOPKO WILLIAM L

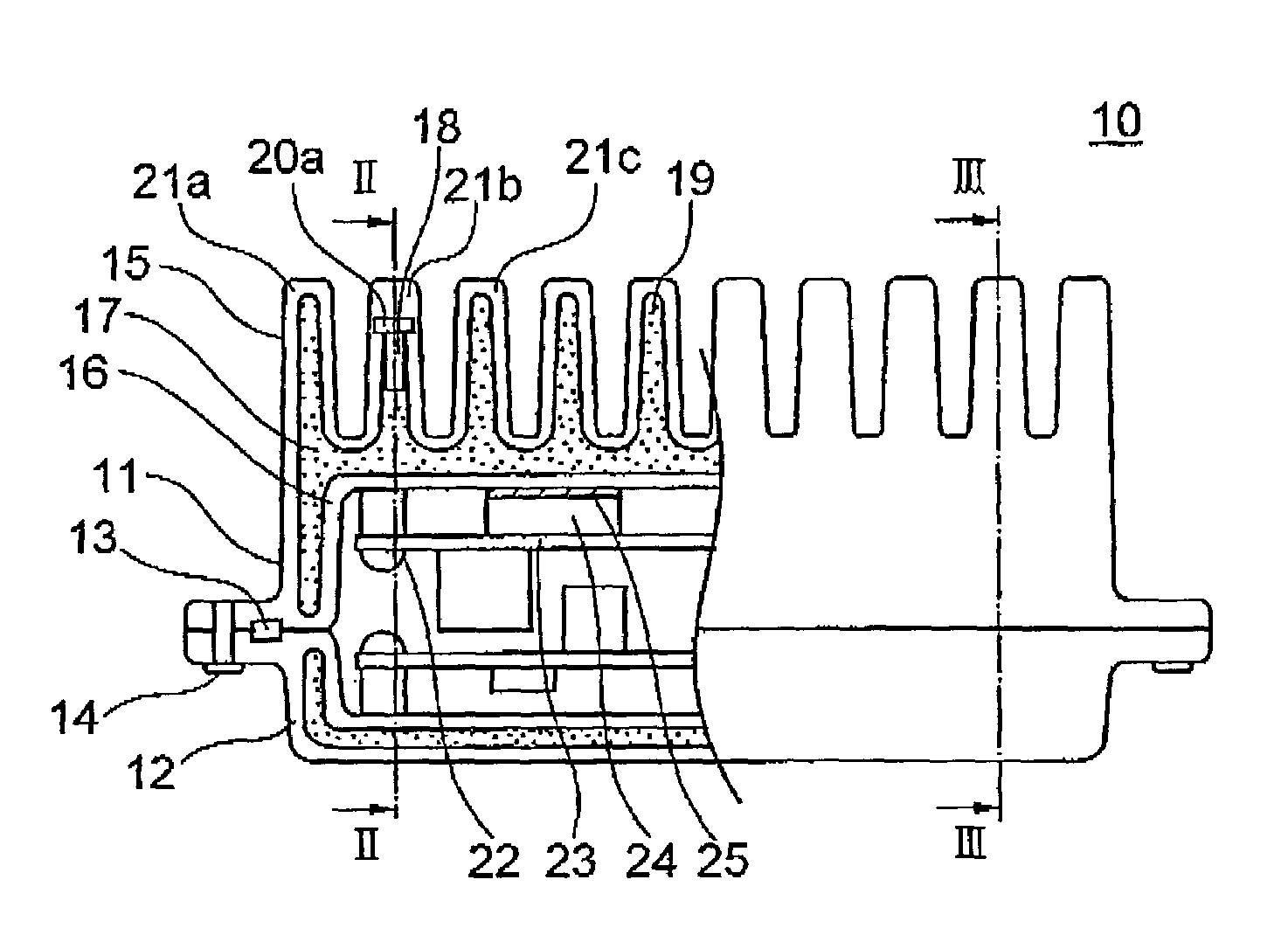

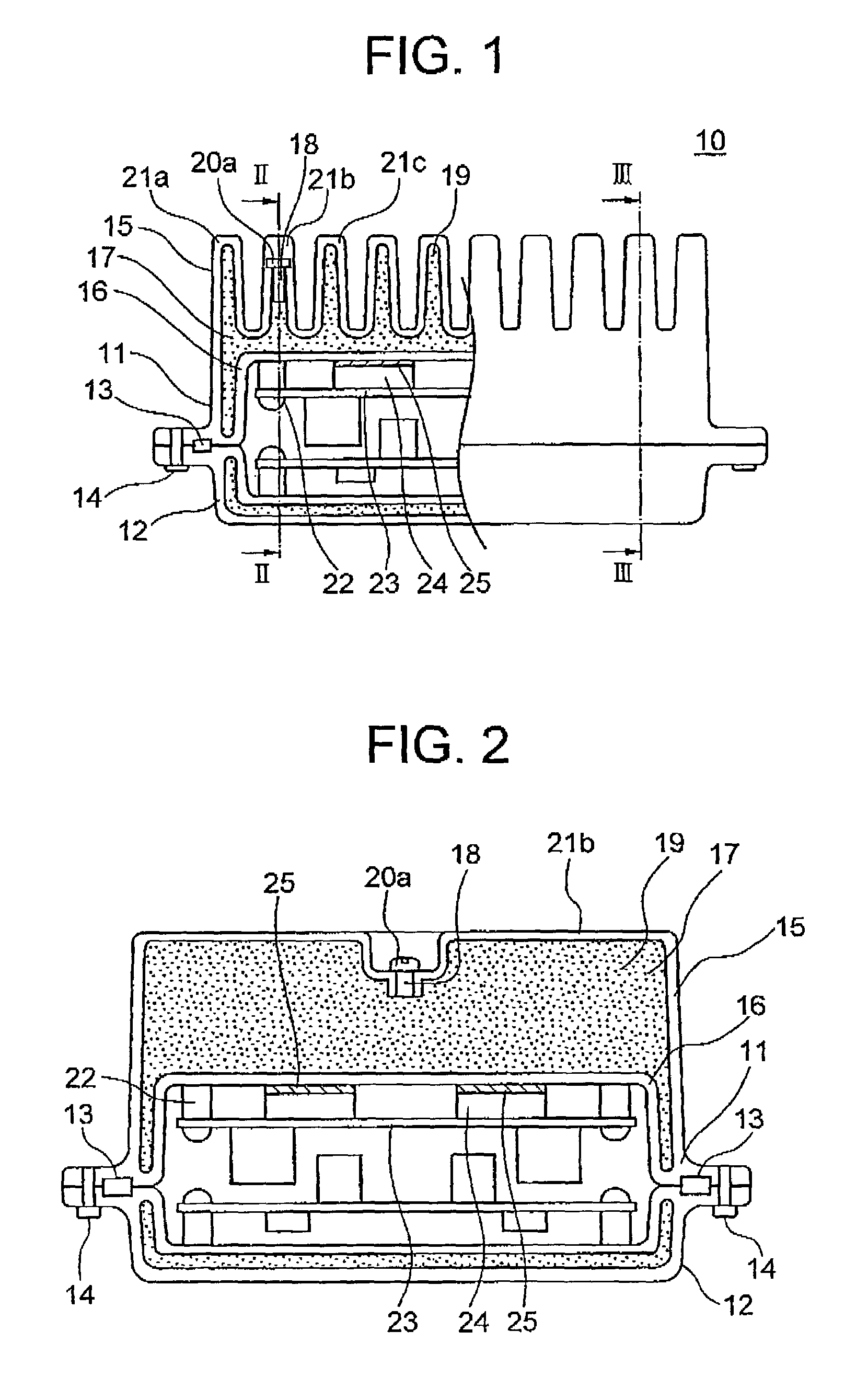

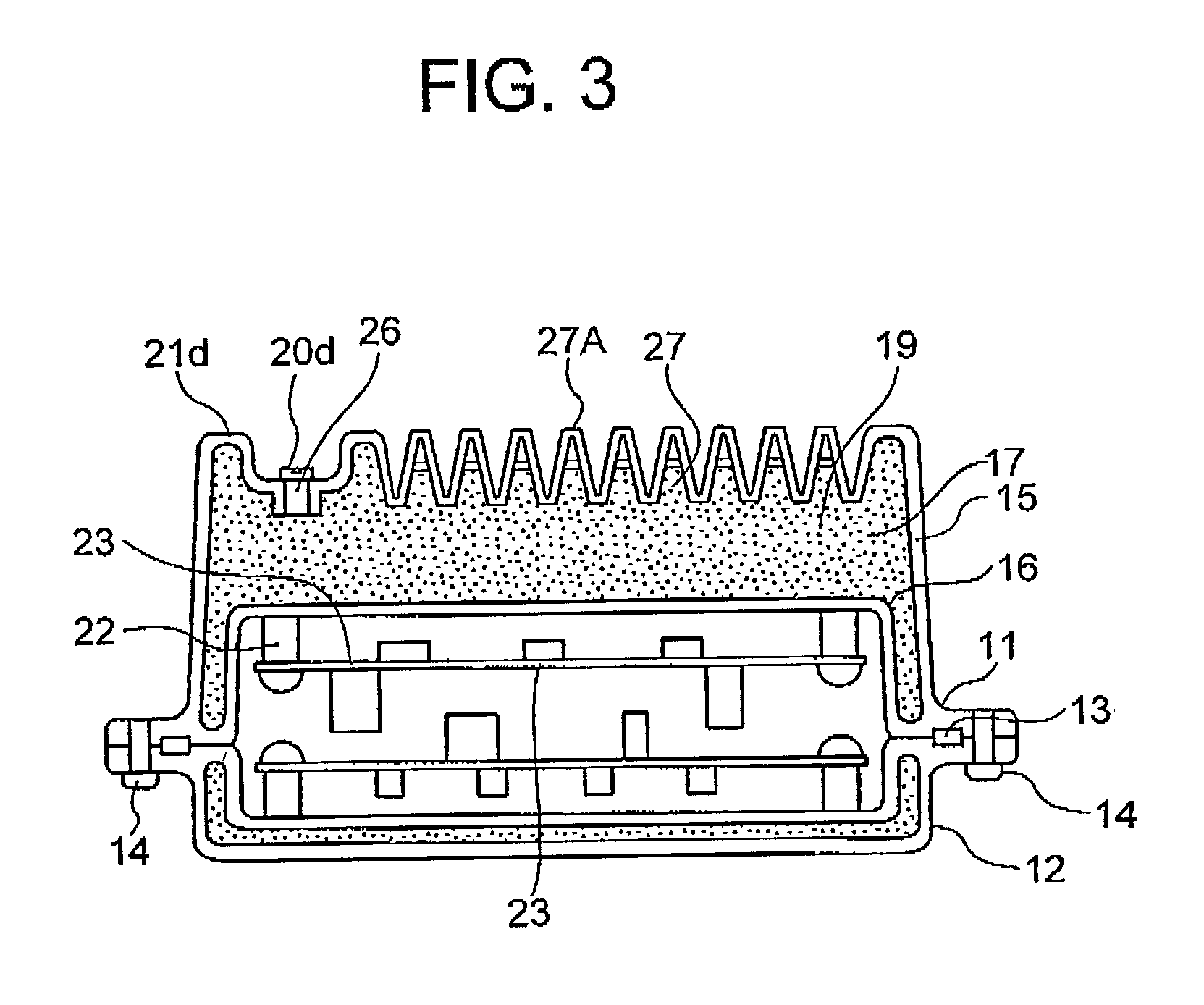

Telecommunication device including a housing having improved heat conductivity

InactiveUS7040383B2Improve Radiation PerformanceImprove propertiesSemiconductor/solid-state device detailsSolid-state devicesPressure riseNatural convection

A telecommunication device includes a housing formed by gas-assist injection molding and having an inner wall, outer wall and a hollow space formed therebetween and receiving therein gas refrigerant. The hollow space has a plurality of vertical channels wherein the gas refrigerant cools the internal of the housing by natural convection within the vertical channels. A movable wall is disposed in the vertical channel for controlling a pressure rise occurring upon a temperature rise.

Owner:NEC CORP

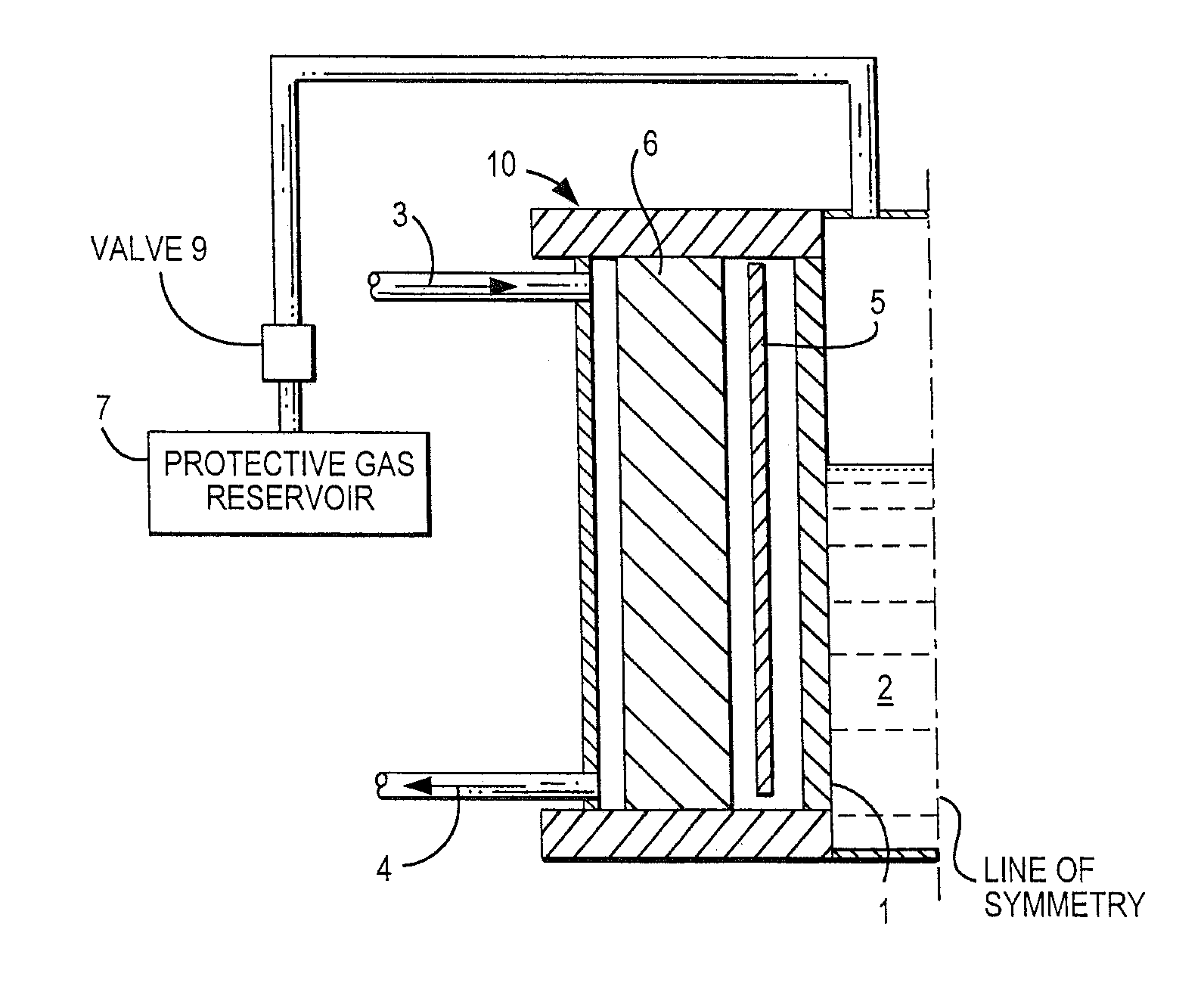

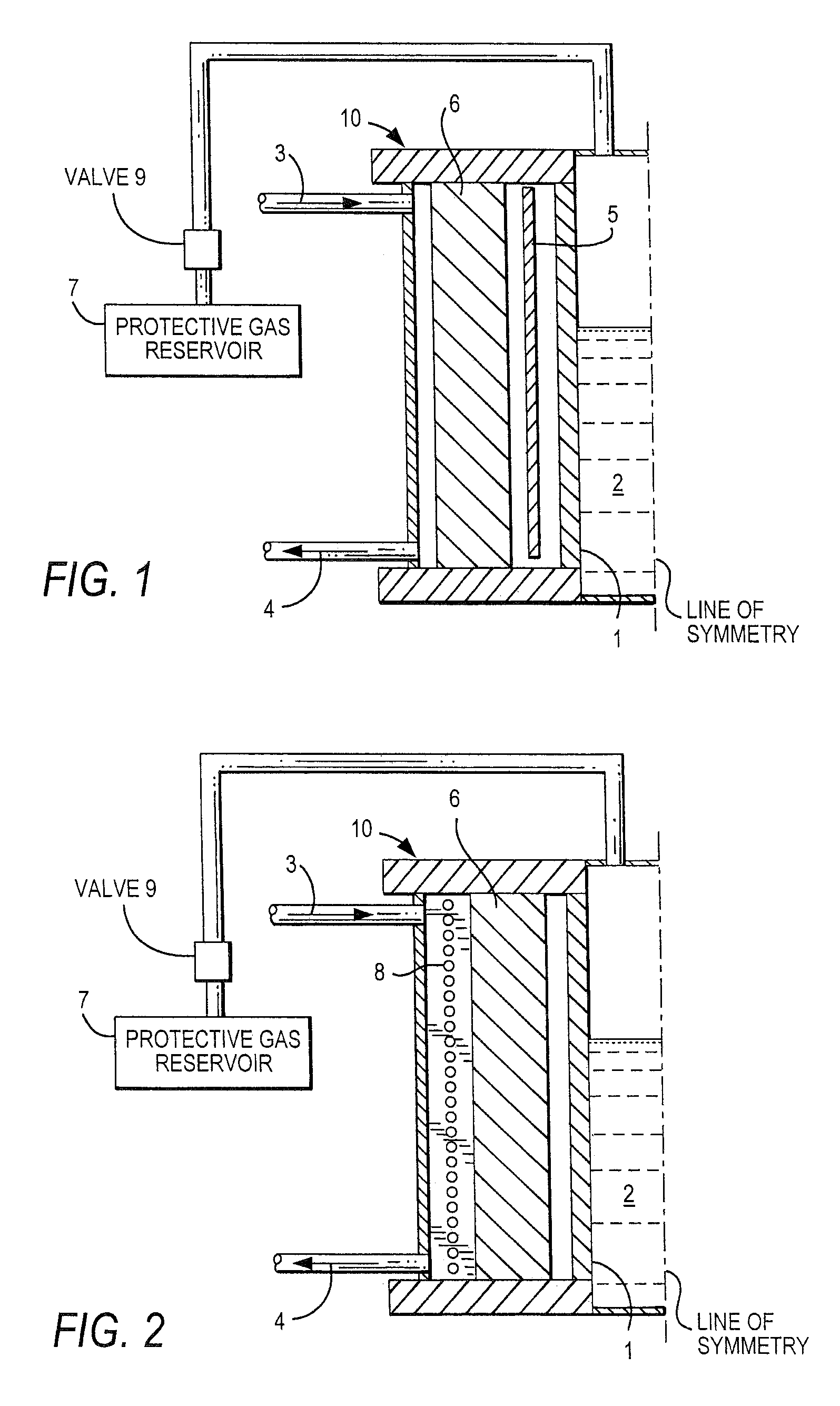

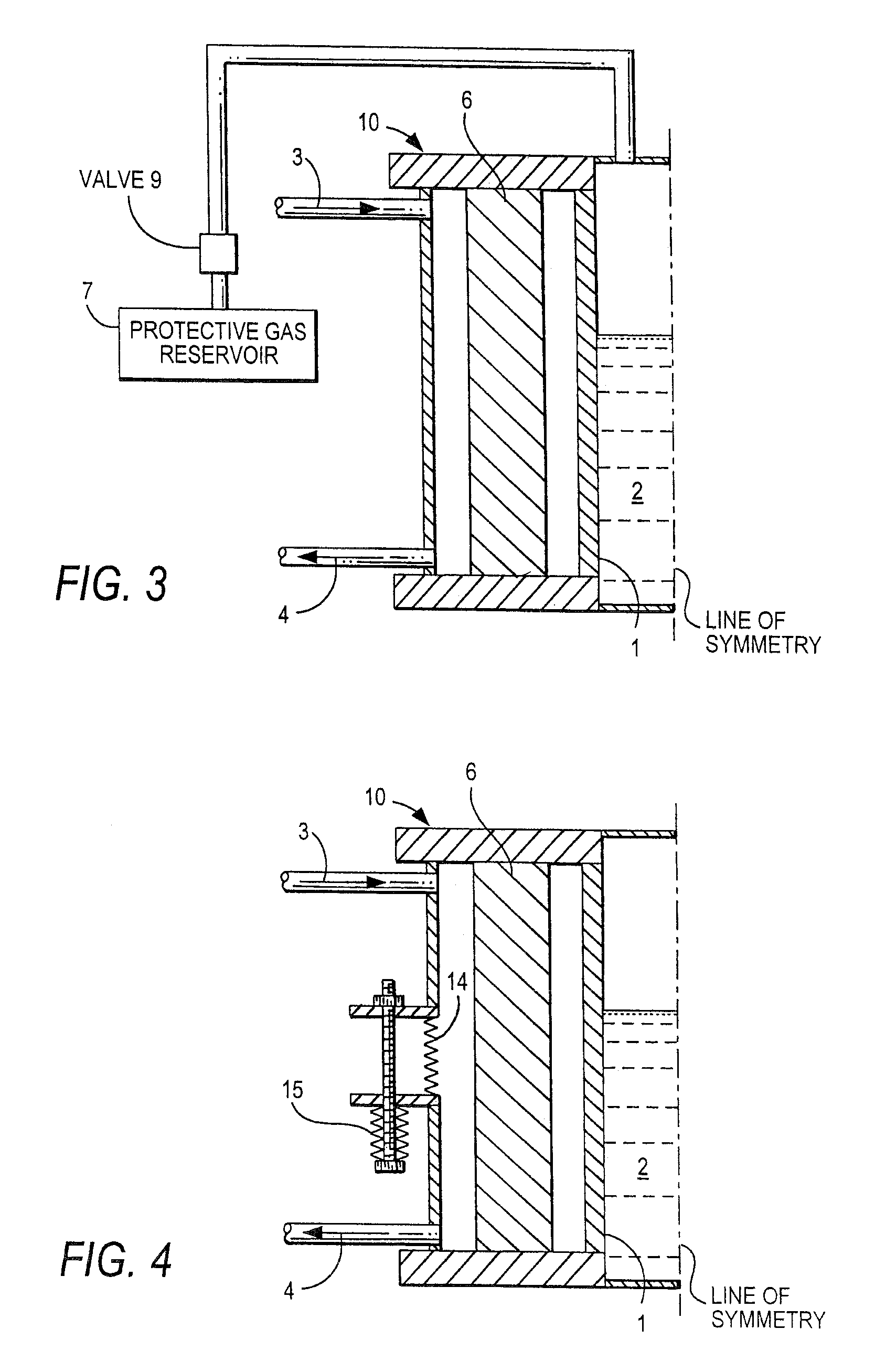

Method and device for refining a glass melt using negative pressure

InactiveUS7231788B2Possible operating costPossible procurement costGlass furnace apparatusGlass blowing apparatusPressure riseShielding gas

The apparatus for reduced-pressure refining of a glass melt includes a refining bank formed so that a reduced pressure is generated by a glass flow in it. The refining bank has a component, which is made from a refractory metal or refractory alloy acting as glass-contact material. The refractory metal or alloy contains molybdenum, tungsten, tantalum, and / or hafnium. The device of the present invention includes a protective gas reservoir for a protective gas and an automatically operating valve connecting the reservoir with the refining bank so that an inner side of the component that would otherwise be exposed when a pressure rise or a falling glass melt column occurs is protected from oxidation by the protective gas. A process for using the device during refining of the glass melt is also part of the invention.

Owner:SCHOTT AG

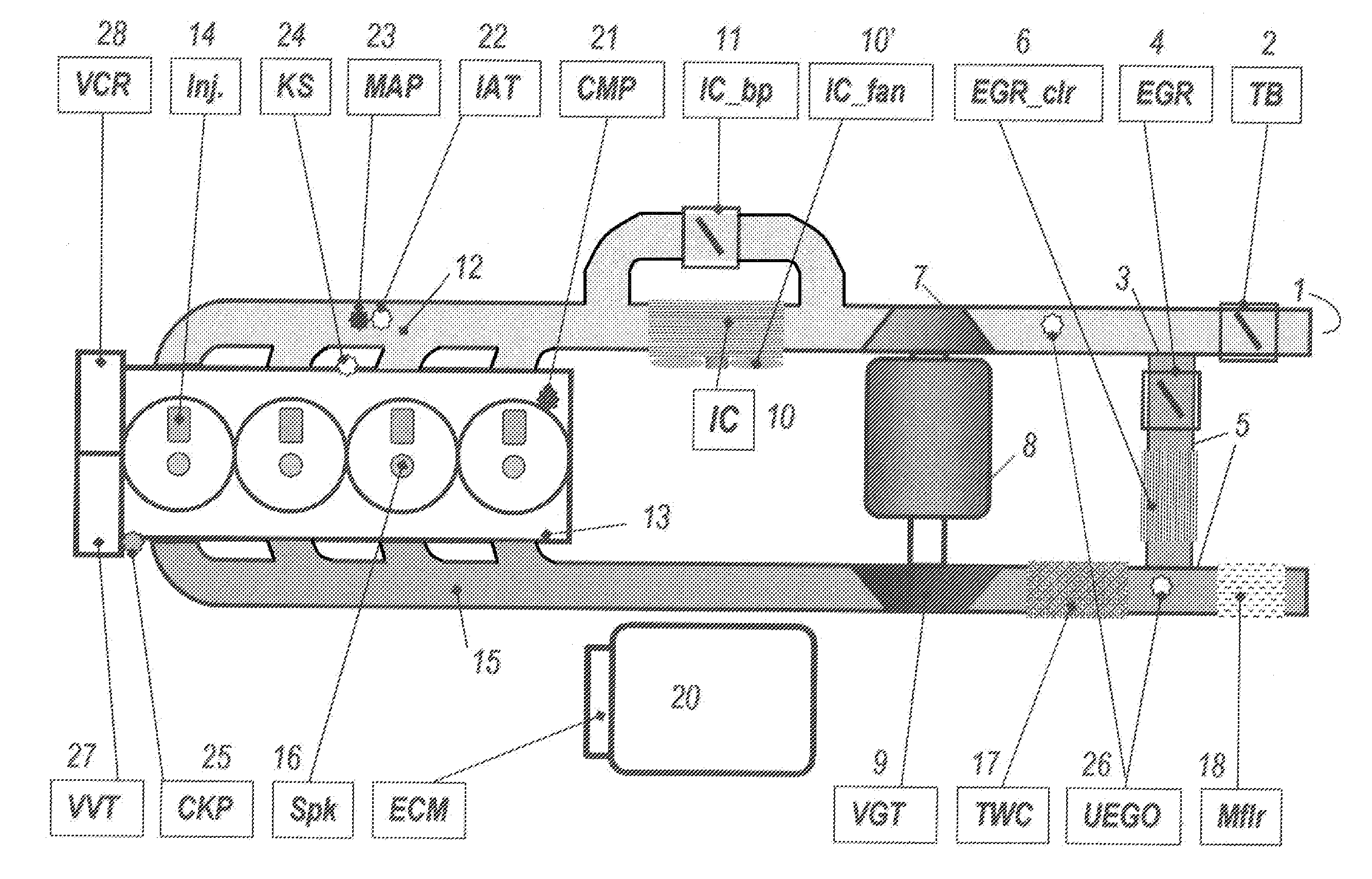

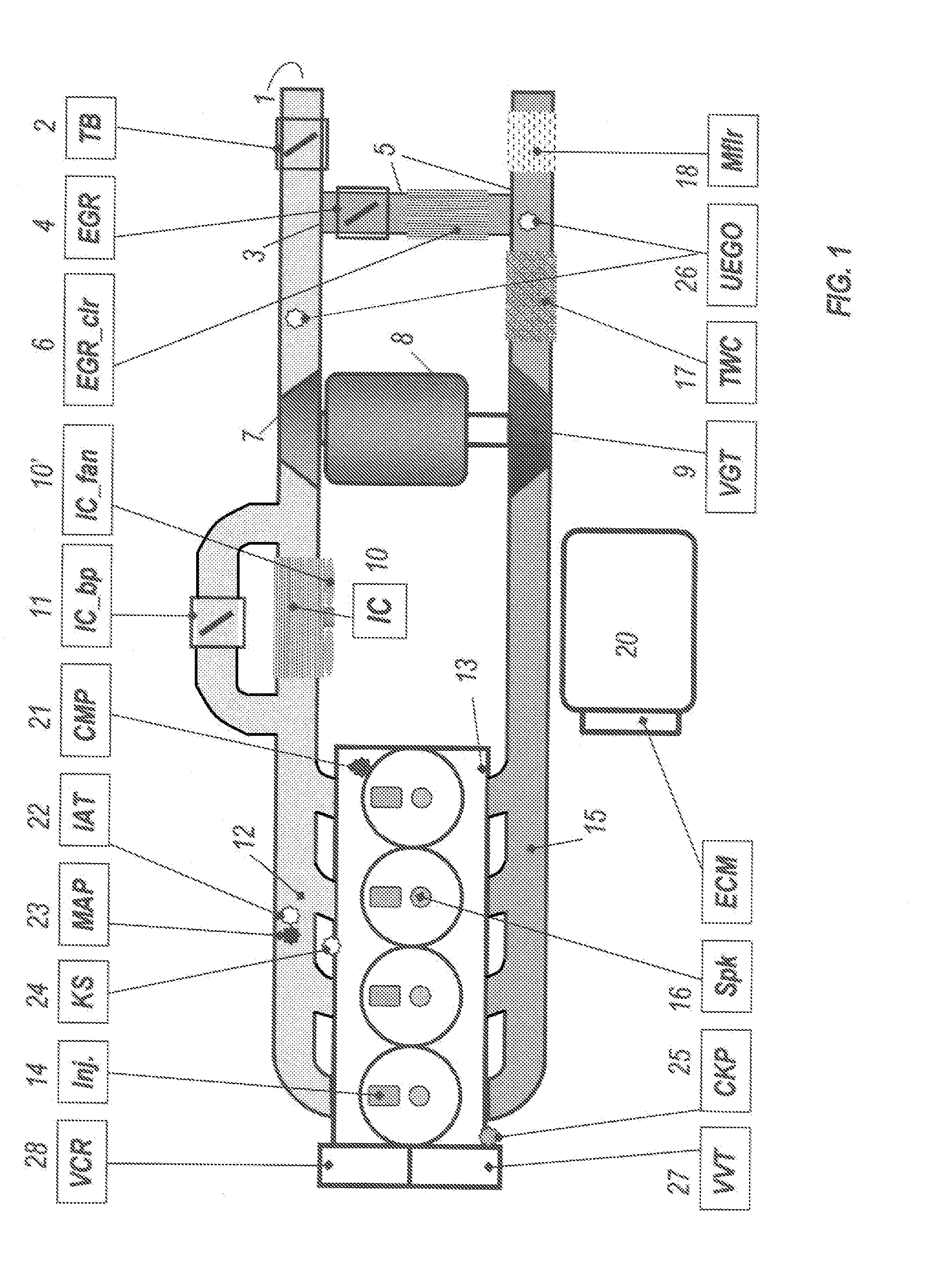

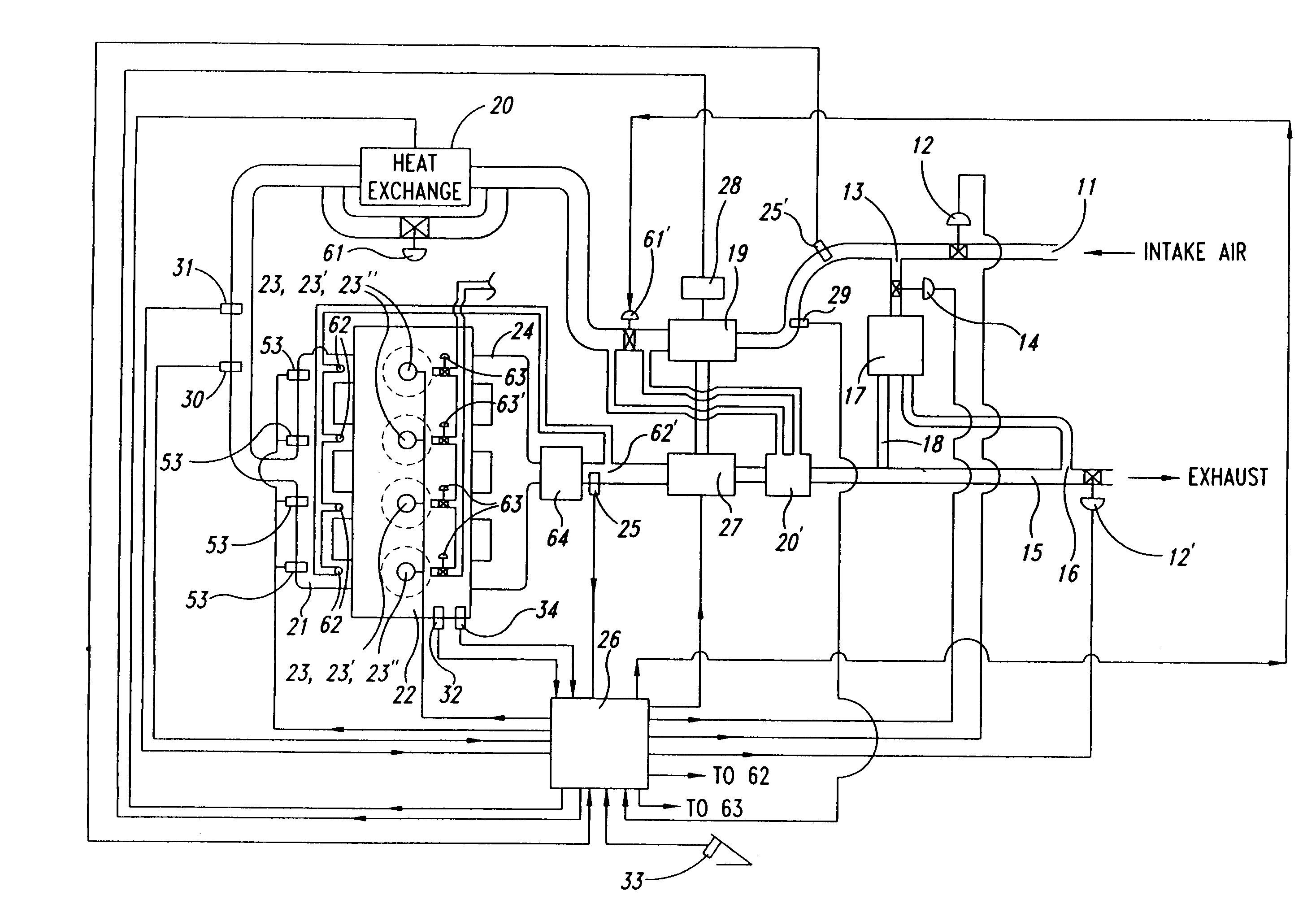

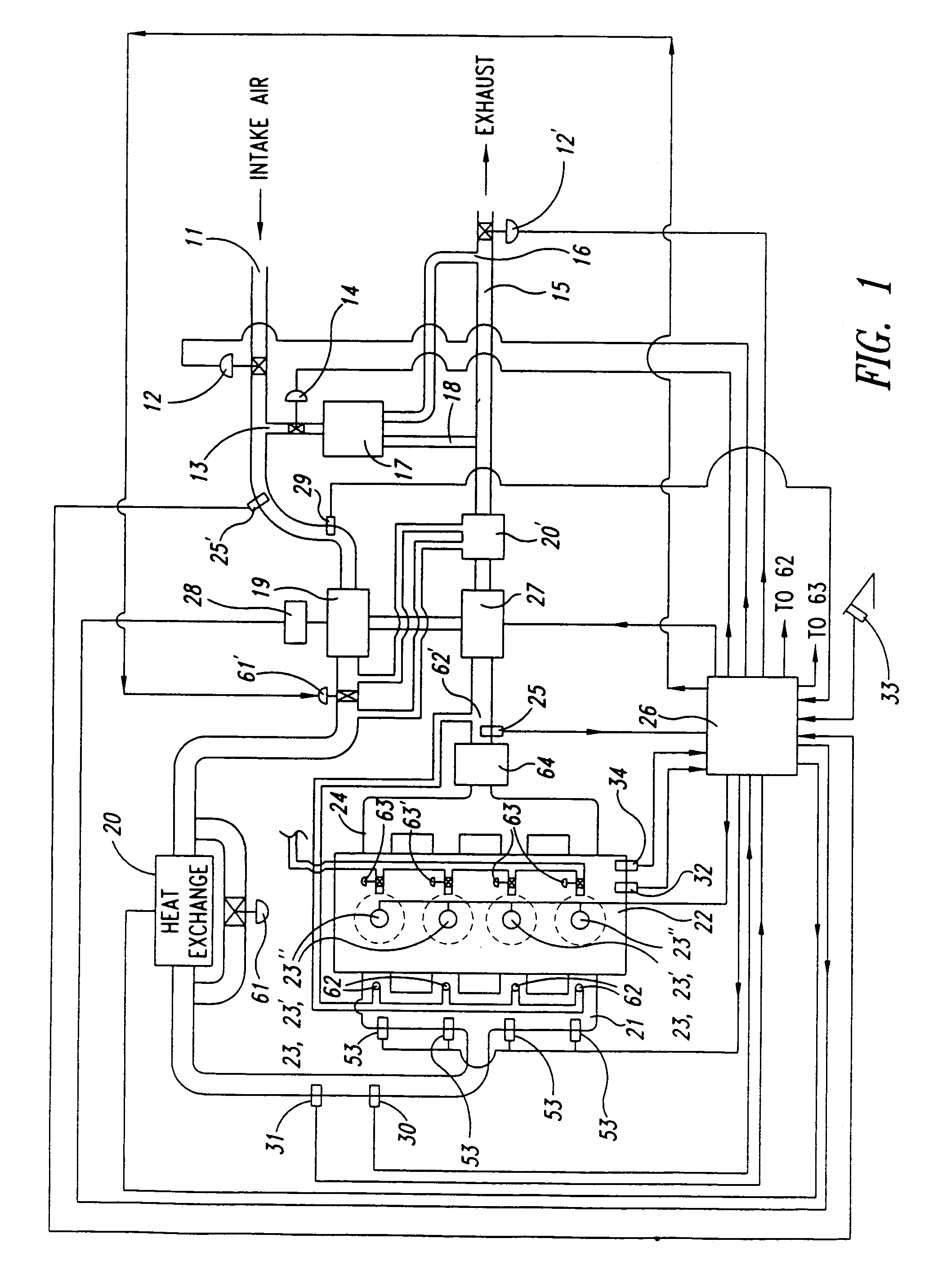

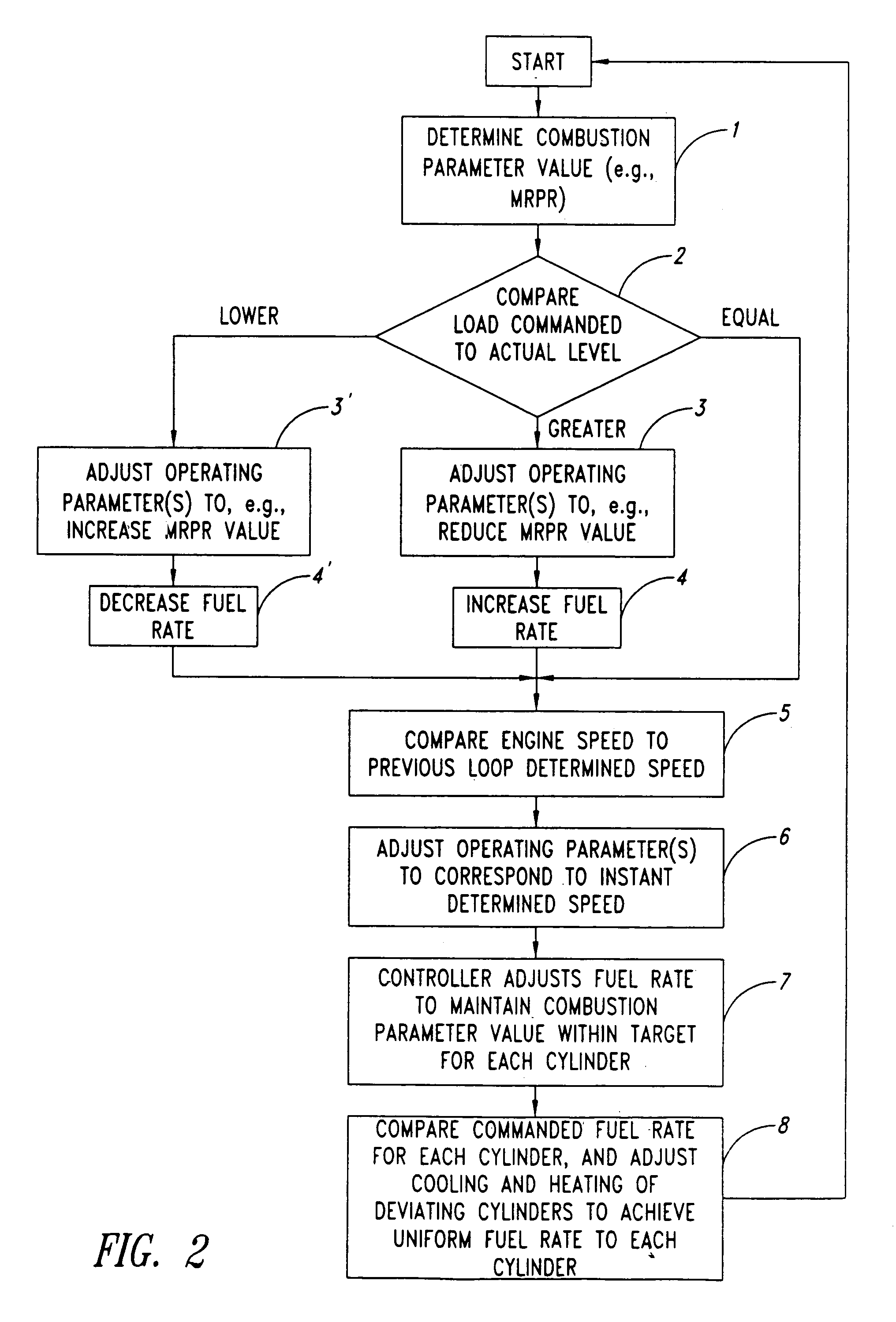

Method and system of transient control for homogeneous charge compression ignition (HCCI) engines

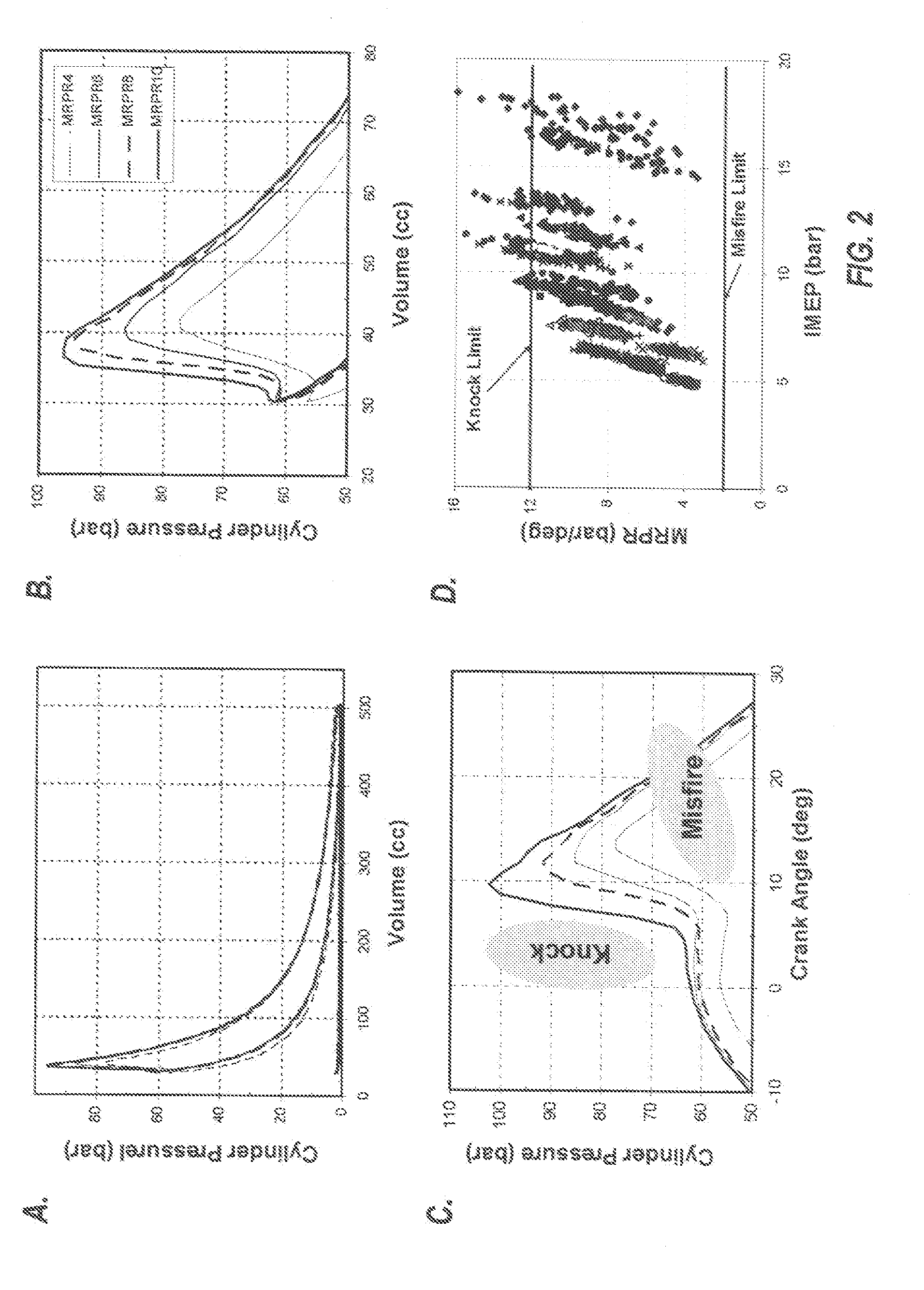

InactiveUS20100031924A1Reduce computing loadRobust engine controlElectrical controlInternal combustion piston enginesApplying knowledgeHcci combustion

A HCCI engine with a model reference adaptive feedback control system maintains stable HCCI combustion during speed / load transitions by: (1) estimating the maximum rate of pressure rise (MRPR), for each cycle, from an extra-cylinder sensor metric, such as a crankshaft dynamics or knock sensor metric, via statistical vector-to-vector correlation; (2) periodically self-tuning the vector-to-vector correlation; (3) applying knowledge base models to guide cycle-to-cycle adjustments of fuel quantity and other engine parameters, to maintain a target MRPR value.

Owner:U S ENVIRONMENTAL PROTECTION AGENCY UNITED STATES OF AMERICA AS REPRESENTED BY THE

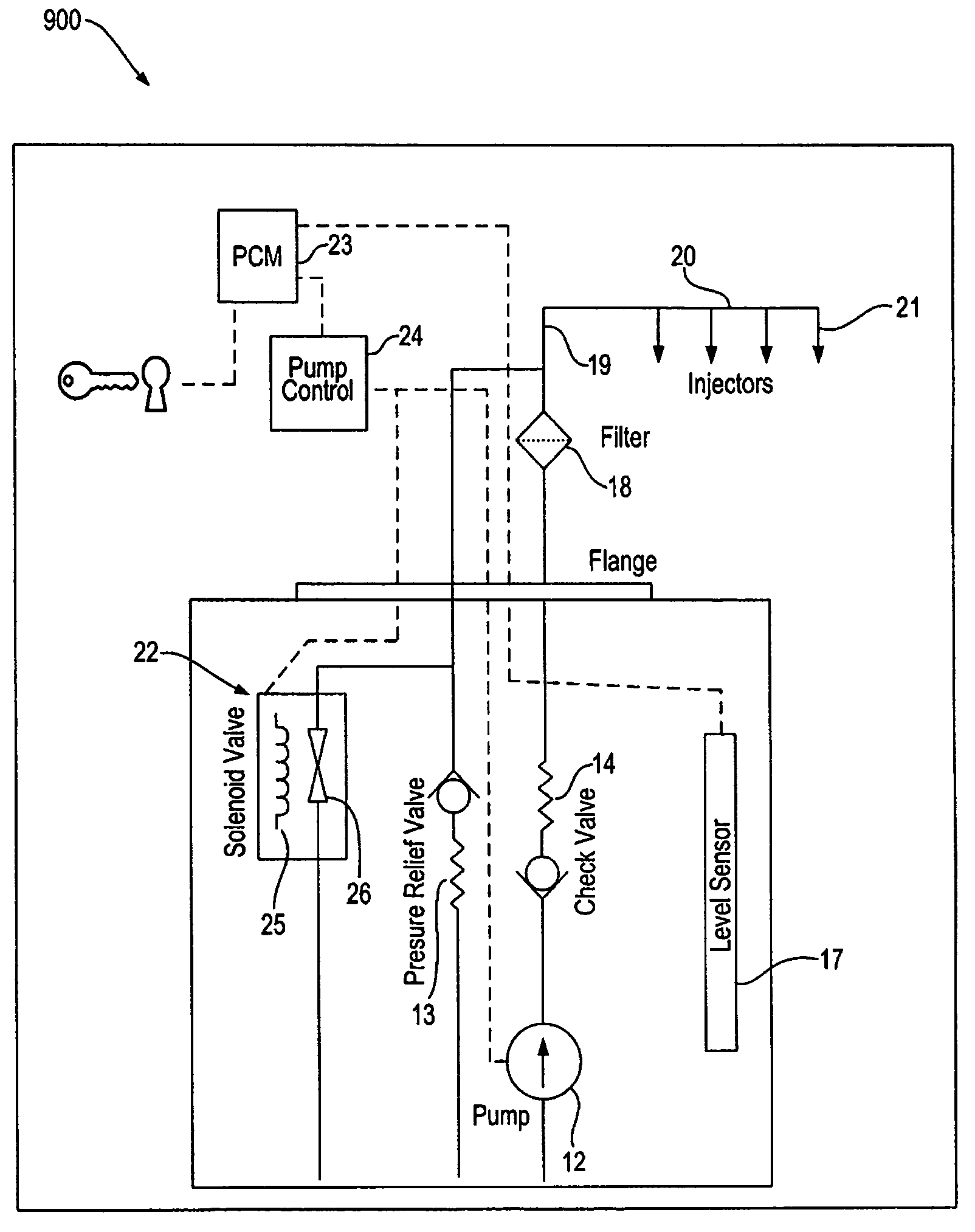

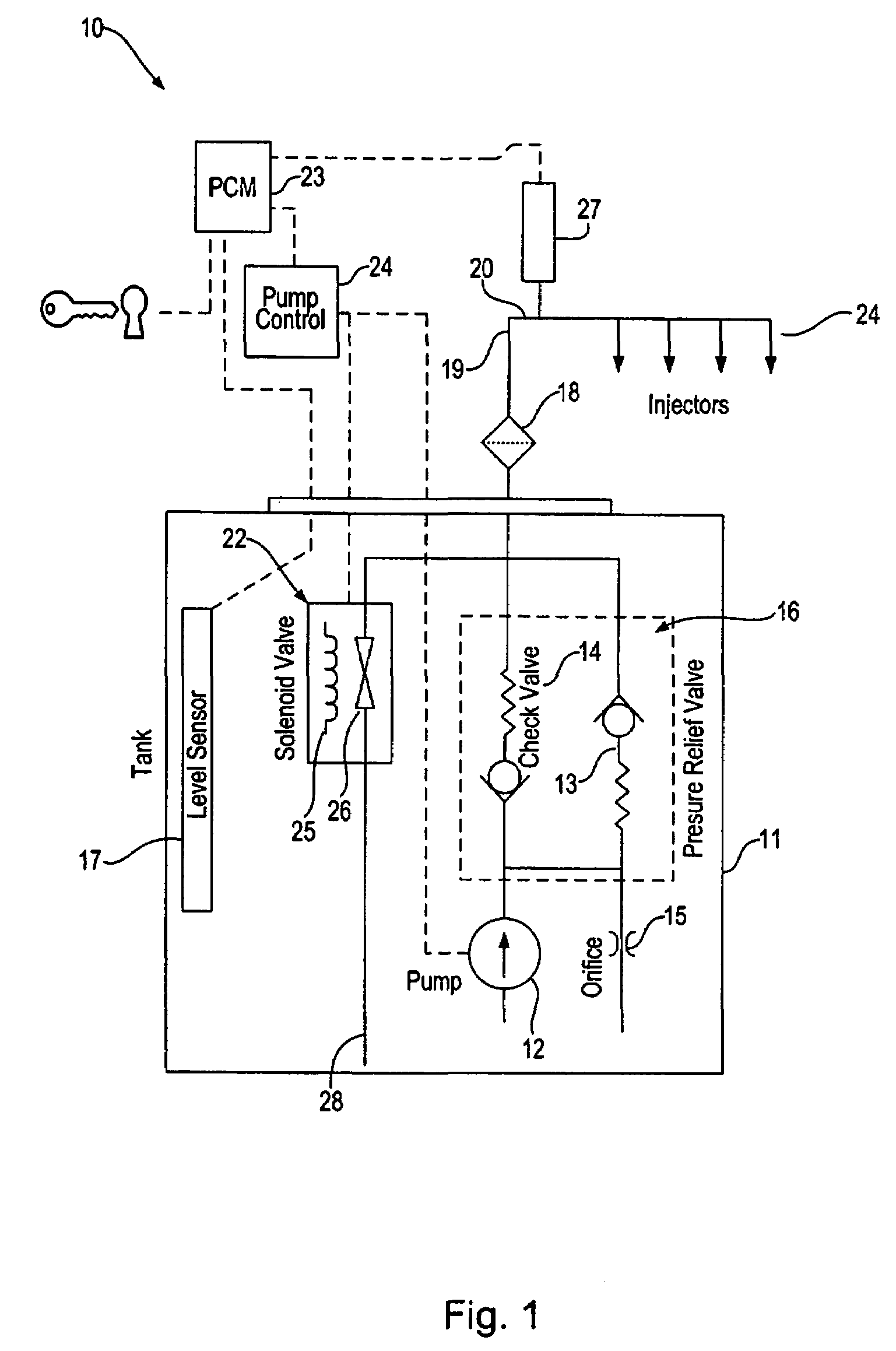

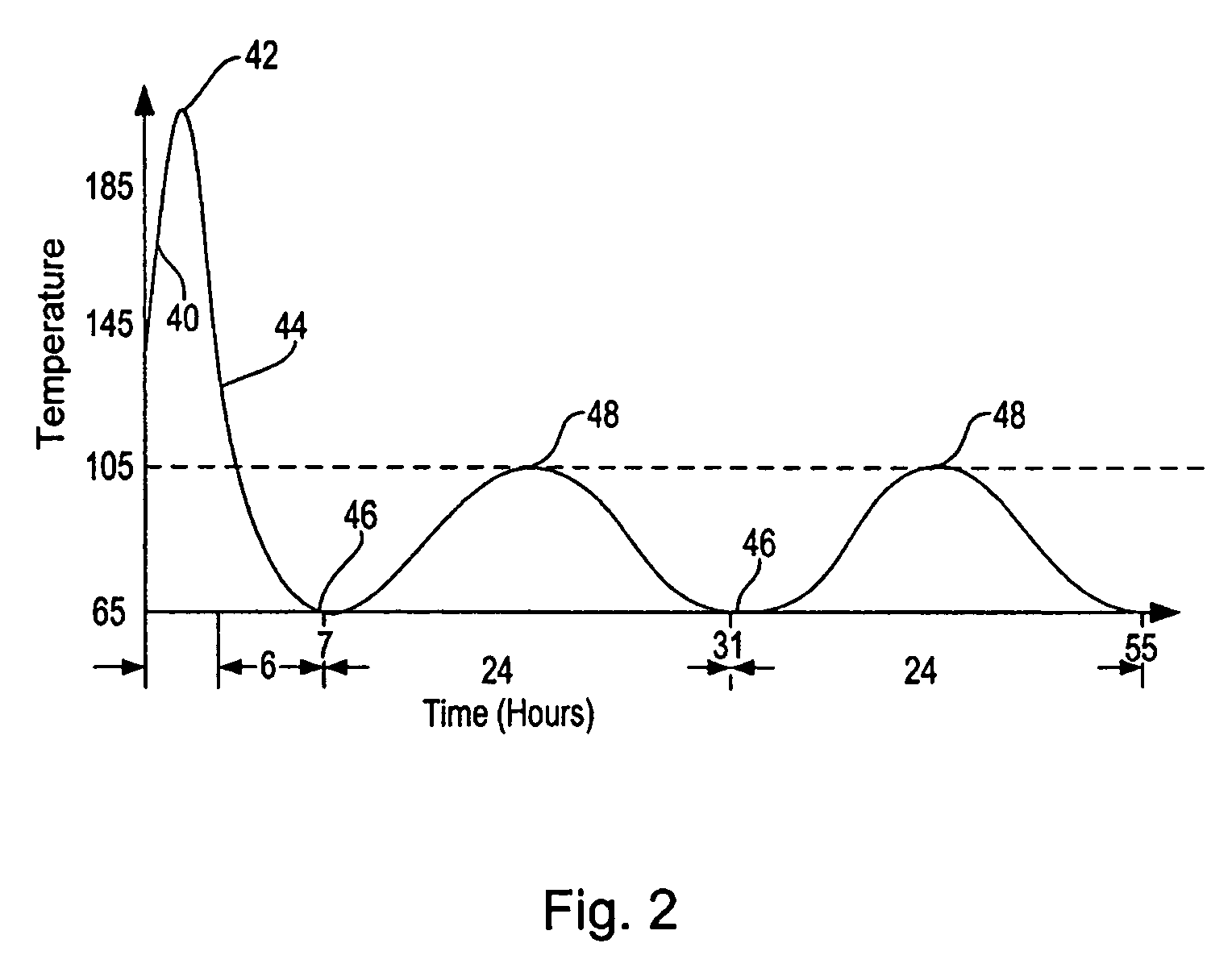

Low evaporative emission fuel system depressurization via solenoid valve

InactiveUS7066152B2Minimizes risingEmission minimizationNon-fuel substance addition to fuelEngine controllersPressure riseSolenoid valve

A fuel delivery system is provided with a fuel solenoid valve to minimize fuel leakage and evaporative emissions during diurnal cycles by preventing pressure buildup as the temperature of the fuel system rises. The fuel solenoid valve is located between a pressurized side of the delivery system and a fuel tank. In one embodiment, the fuel solenoid valve is closed when the engine is running or when the engine is off and the rail is hot. When the fuel rail cools down, the solenoid valve opens to bleed a desired amount of fuel thereby creating a fuel vapor space. Thereafter, during hot soak conditions of the diurnal cycles when the fuel rail is hot again while the engine is off, the pressure will rise due to the thermal expansion of the fuel and the created fuel vapor space minimizes further rising of the fuel pressure. Further, by adjusting the solenoid valve opening time, the pressure rising limit may be set at a desired pressure to minimize injector leakage.

Owner:FORD GLOBAL TECH LLC

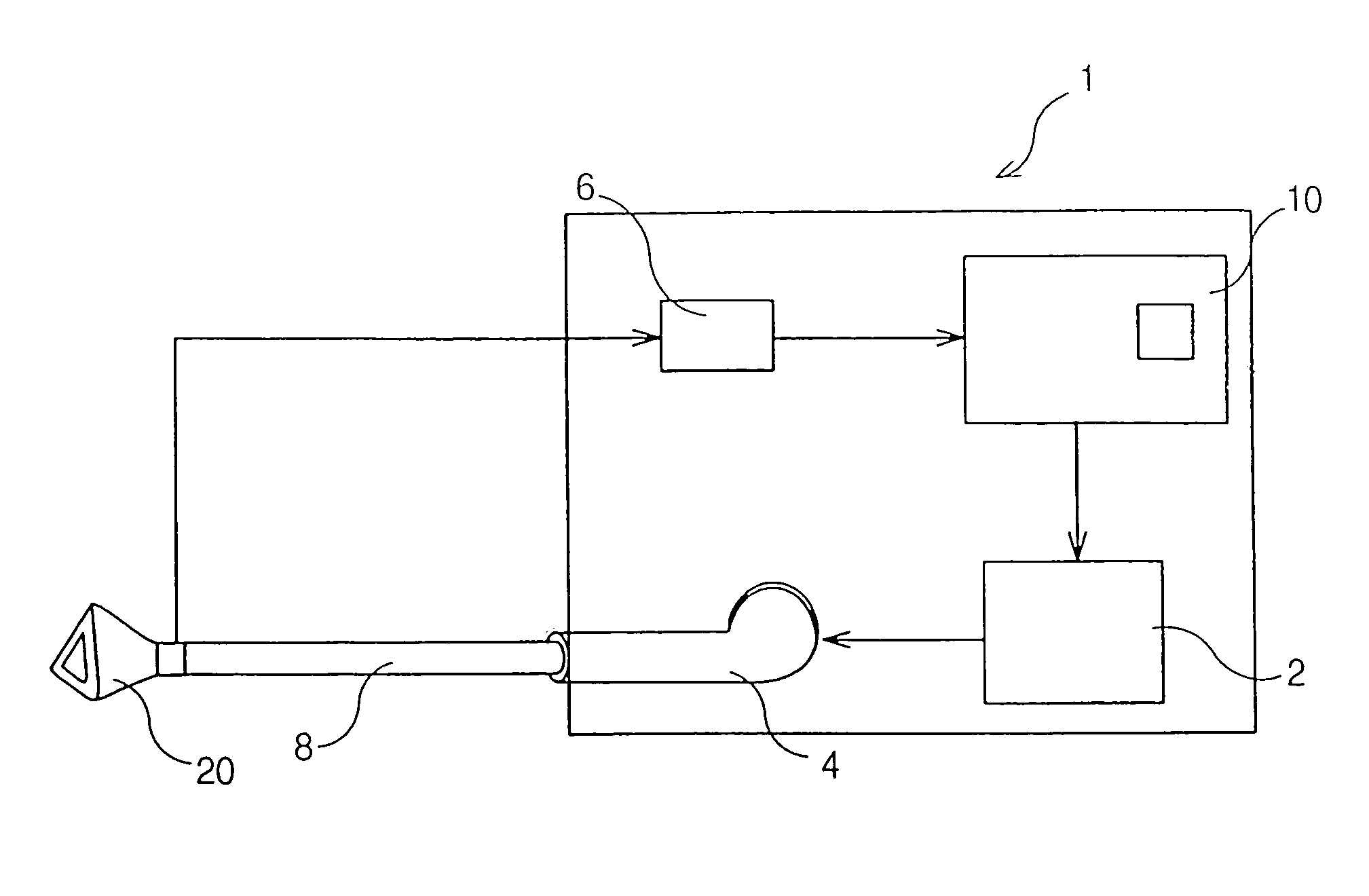

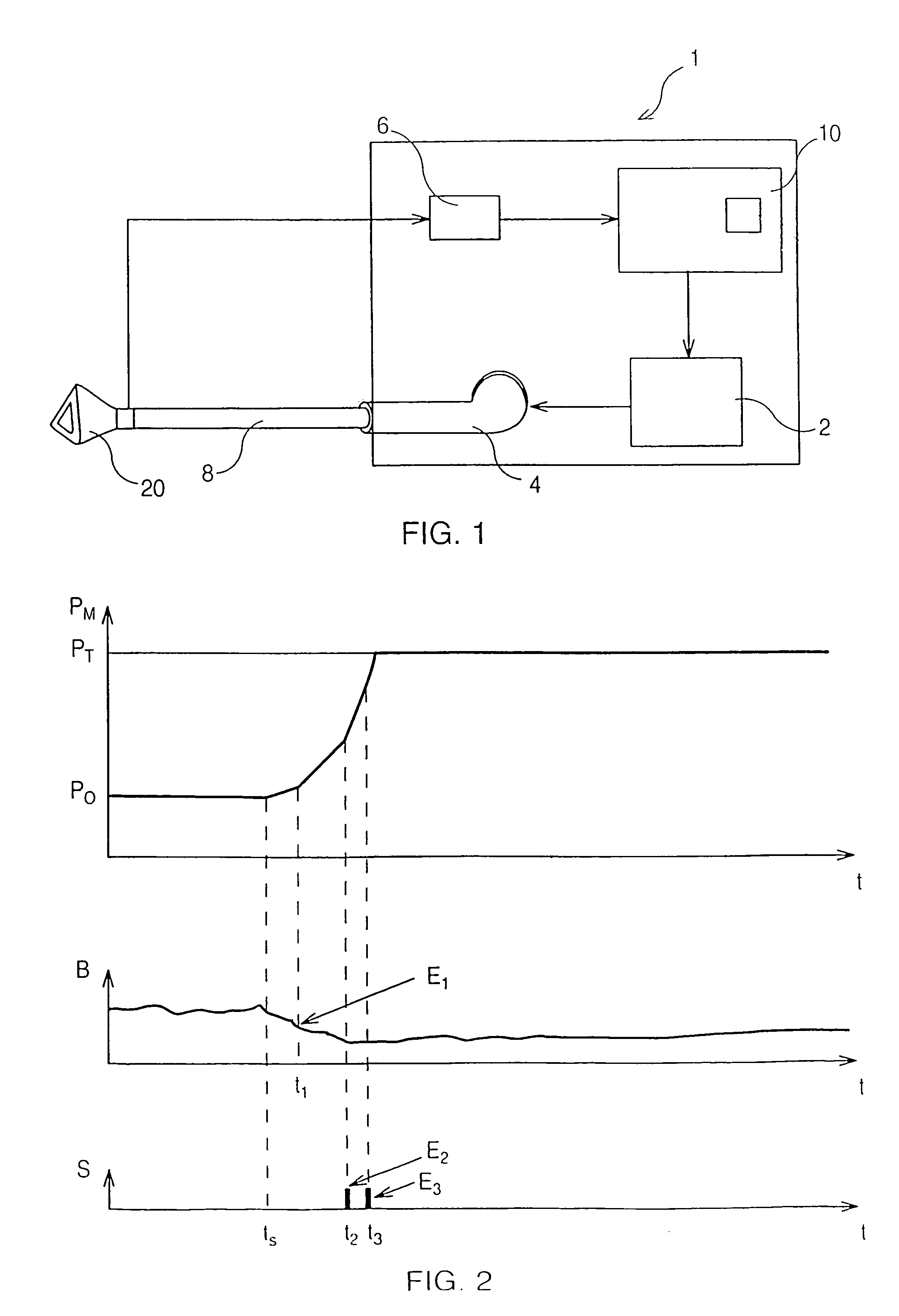

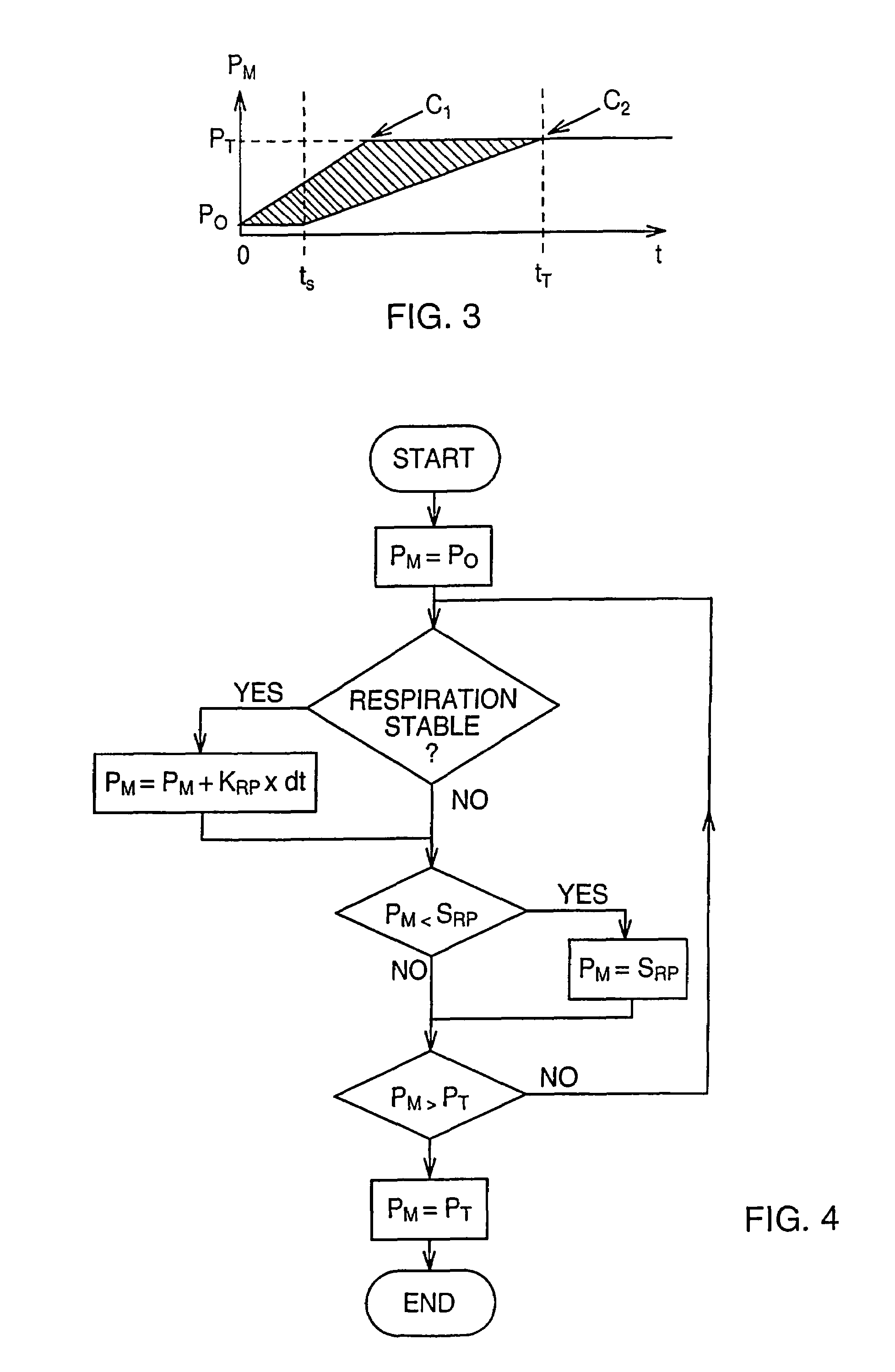

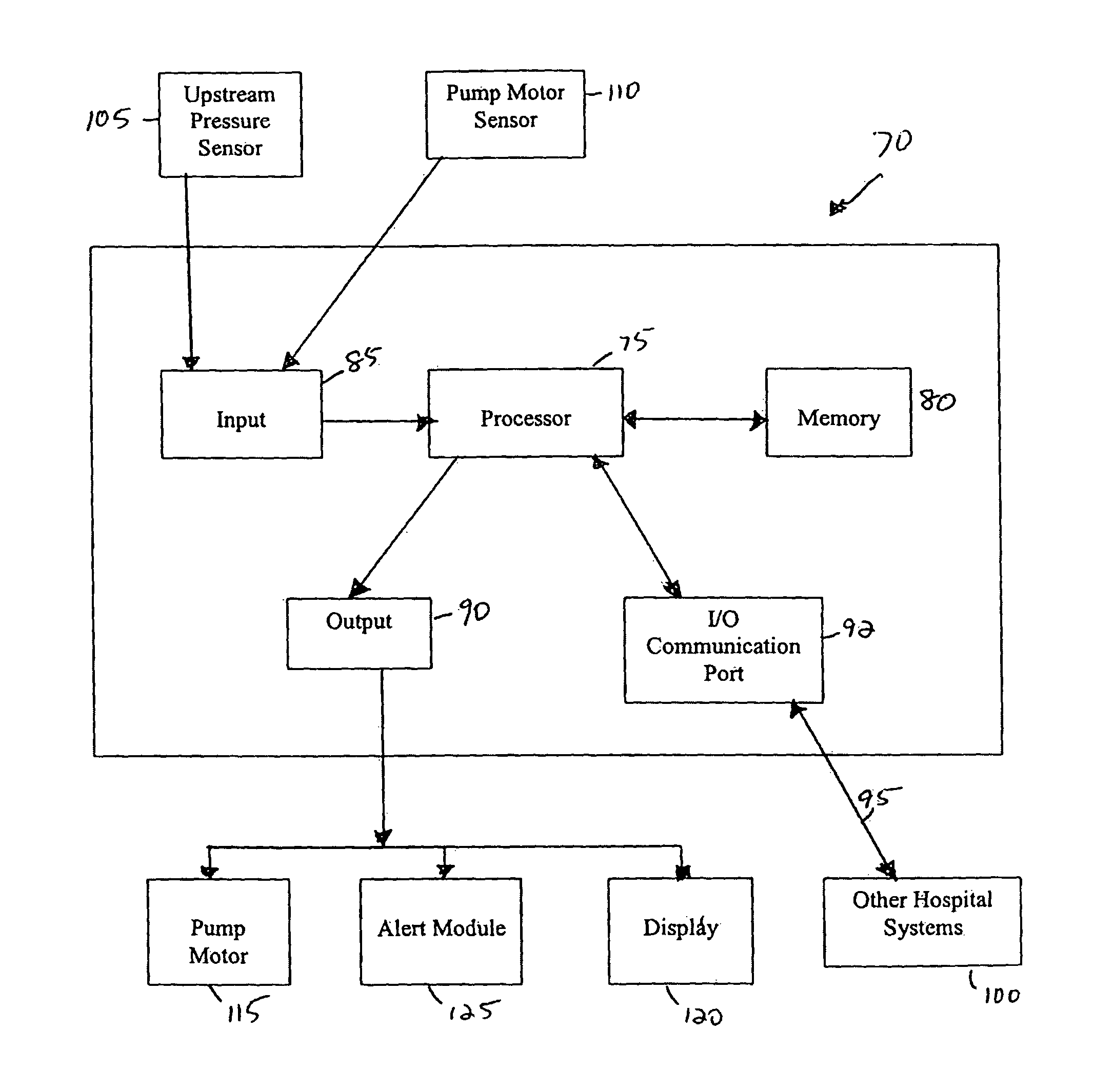

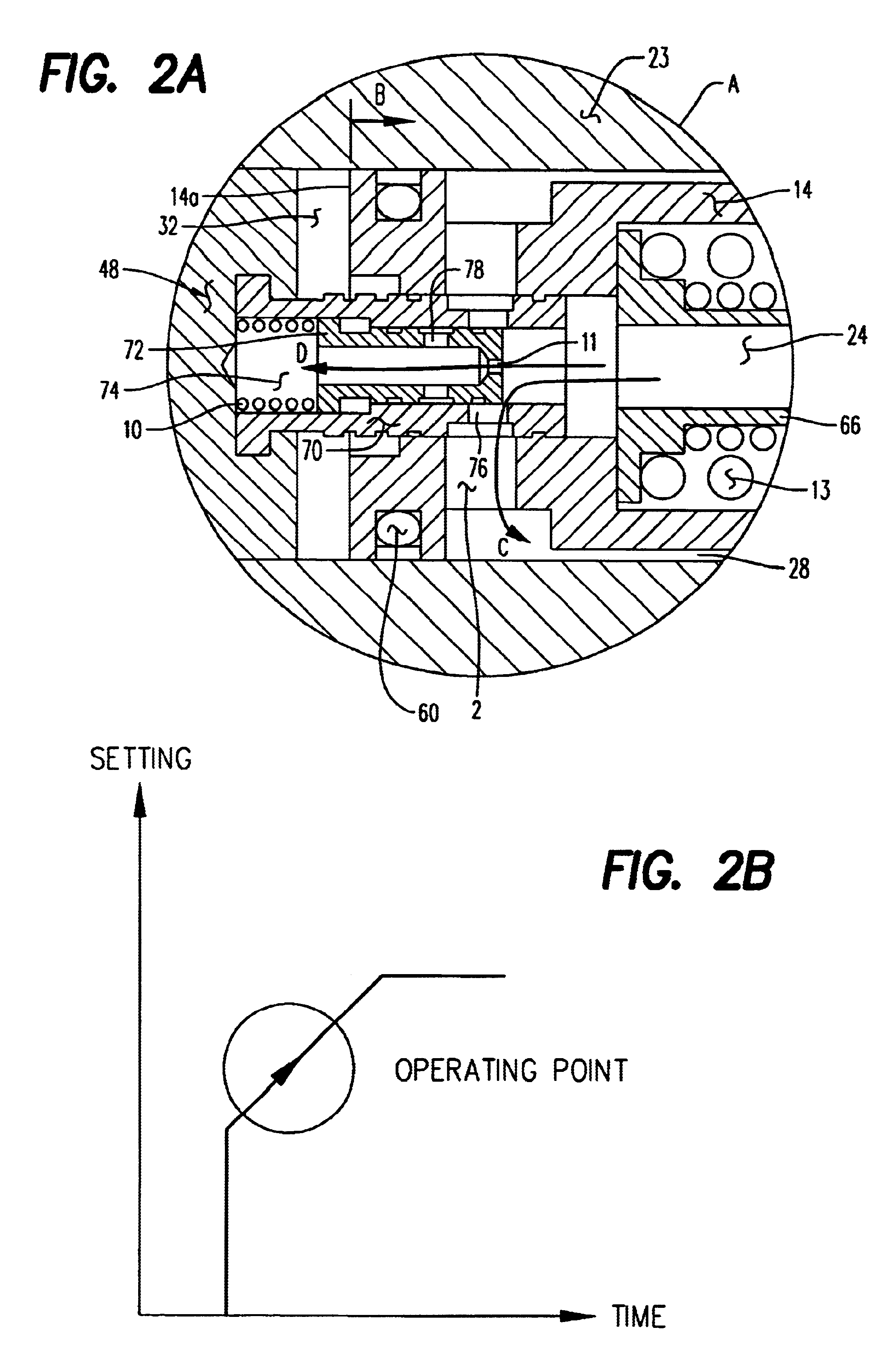

Apparatus to assist a patient's breathing with a variable ramp period to rise to treatment pressure

ActiveUS7500481B2RespiratorsOperating means/releasing devices for valvesPressure riseComputer module

An apparatus (1) to assist a patient's respiration by delivering air to a patient through a mask (20), including a ramp module (10) connected to a control unit (2) to provide the control unit with a pressure value PM at mask (20), so that when apparatus (1) starts functioning, the pressure progressively rises until it reaches a treatment pressure PTi, the apparatus further including a comparator connected to ramp module (10), at least one device for detecting the patient's breathing parameters and sending them to the comparator, so that the comparator can determine whether an event (E1, E2 or E3) occurs in patient's breathing and to send the corresponding data to ramp module (10) which provides control unit (2) with a pressure value PM that will speed up with respect of time, so that the pressure rise at patient's mask (20) is accelerated.

Owner:KONINKLJIJKE PHILIPS NV

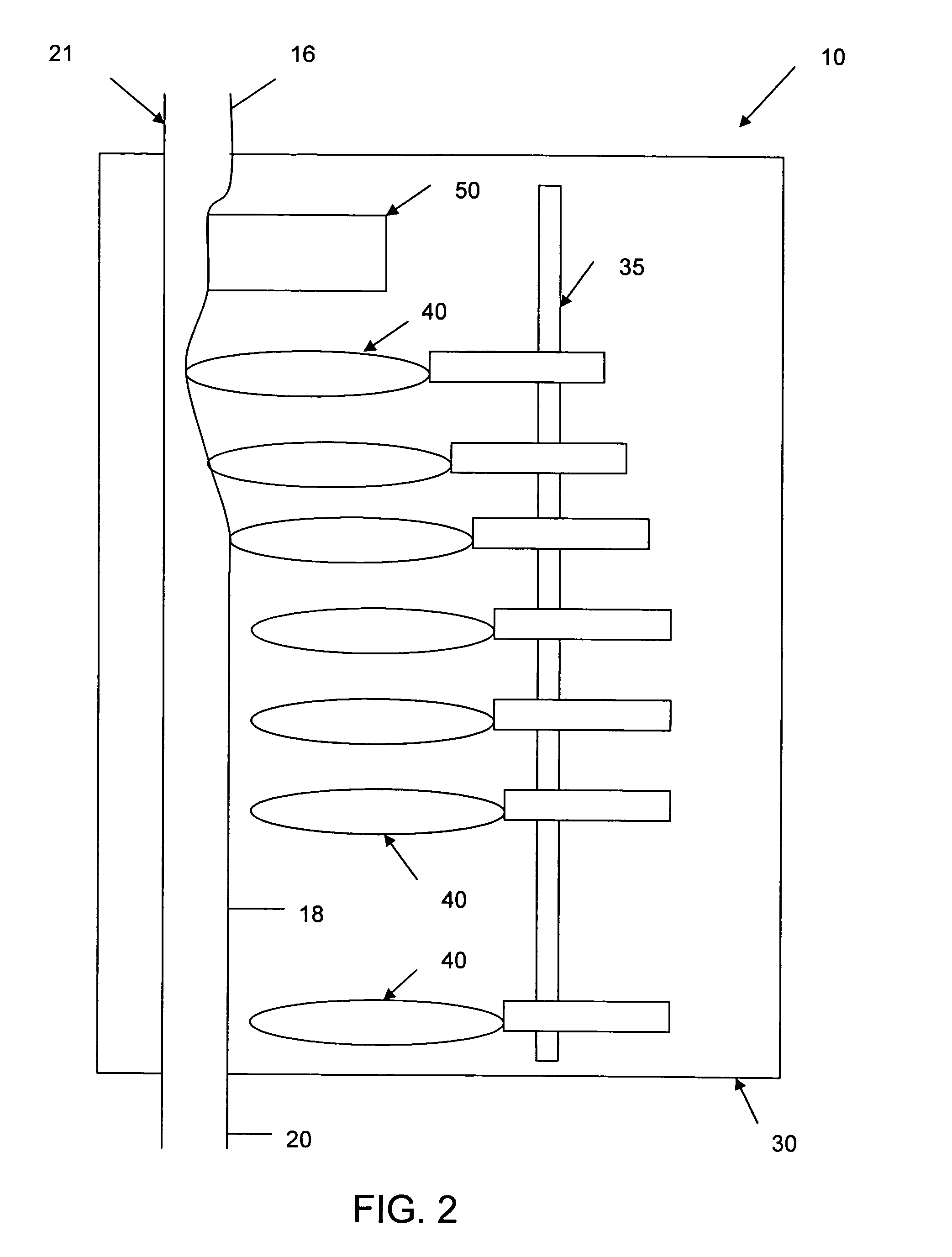

Medication safety enhancement for secondary infusion

ActiveUS8672875B2High sensitivityUse minimizedMedical devicesFluid pressure measurementPressure riseInfusion set

A system and method determine when fluid is not flowing properly from a secondary infusion source during a secondary infusion. The system includes an upstream pressure sensor and a processor programmed to receive signals from the sensor and analyze the signals to determine if secondary fluid flow is proper. The processor samples the output signals from the upstream pressure sensor and analyzes the sampled signals to determine if a pressure rise in the infusion line has occurred when the secondary infusion is initiated. If a pressure rise, indicating that fluid from the secondary container has begun flowing into the infusion line, has not been detected, the processor is programmed to provide a signal indicating that attention should be given to the infusion set up.

Owner:CAREFUSION 303 INC

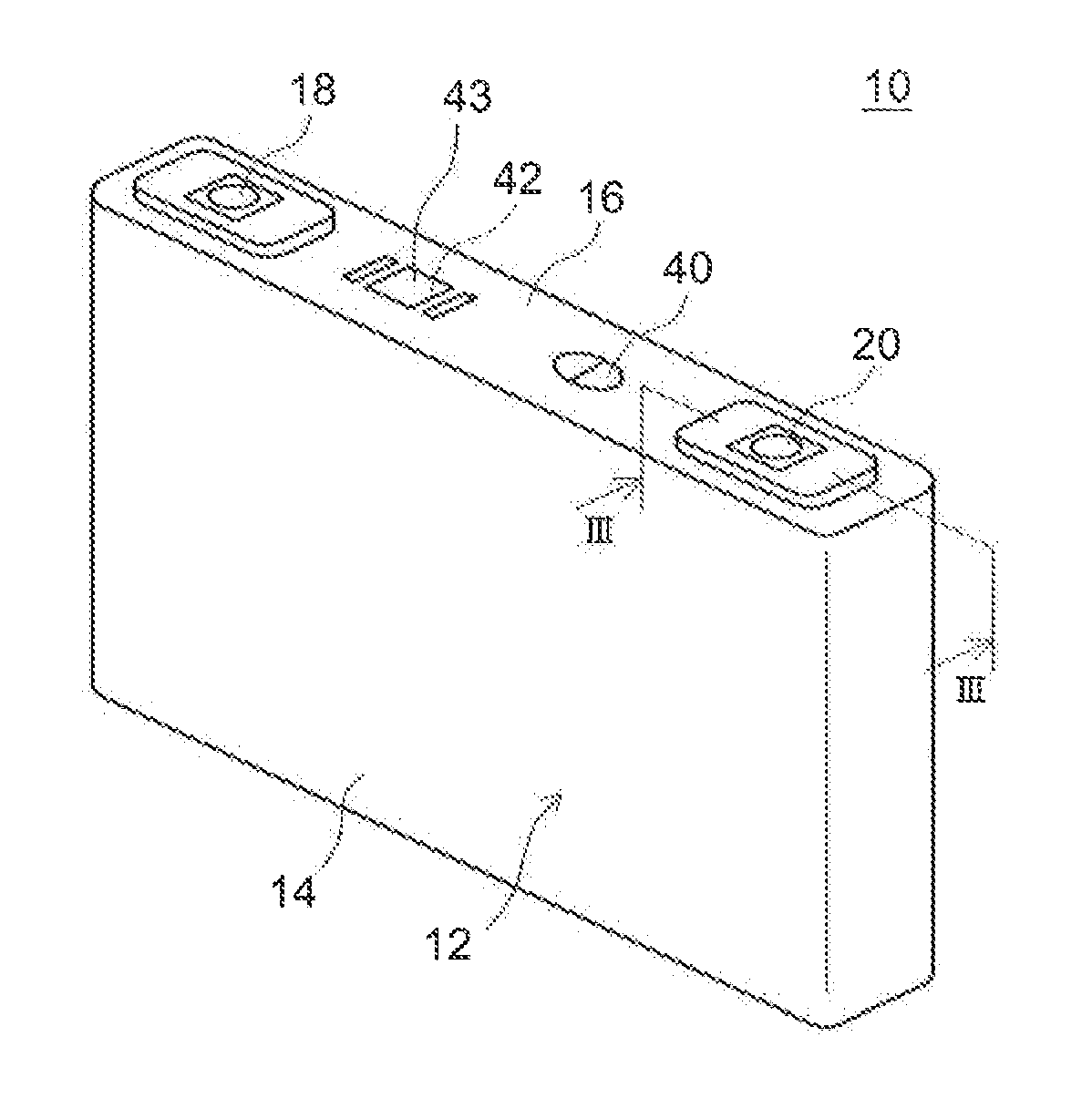

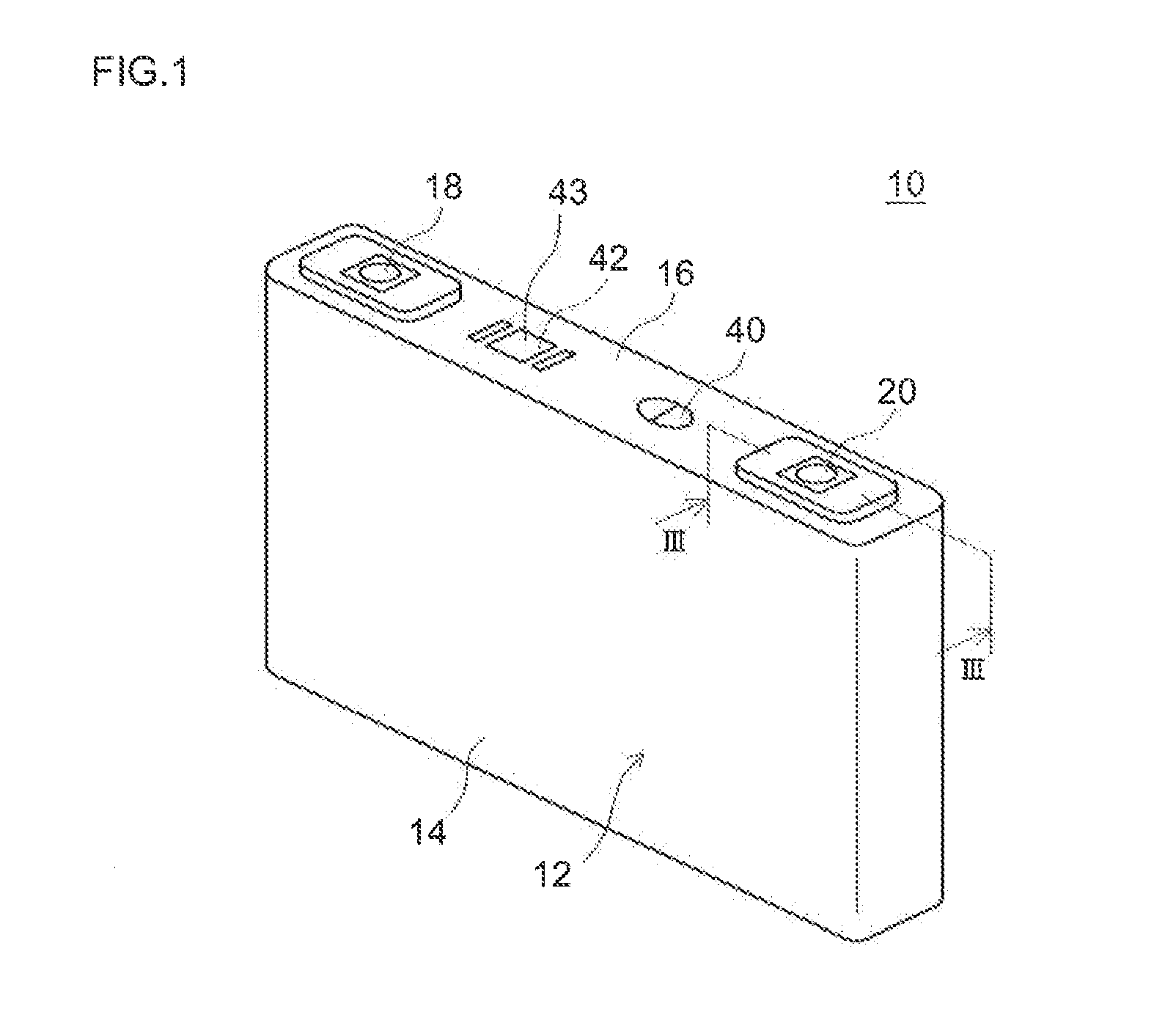

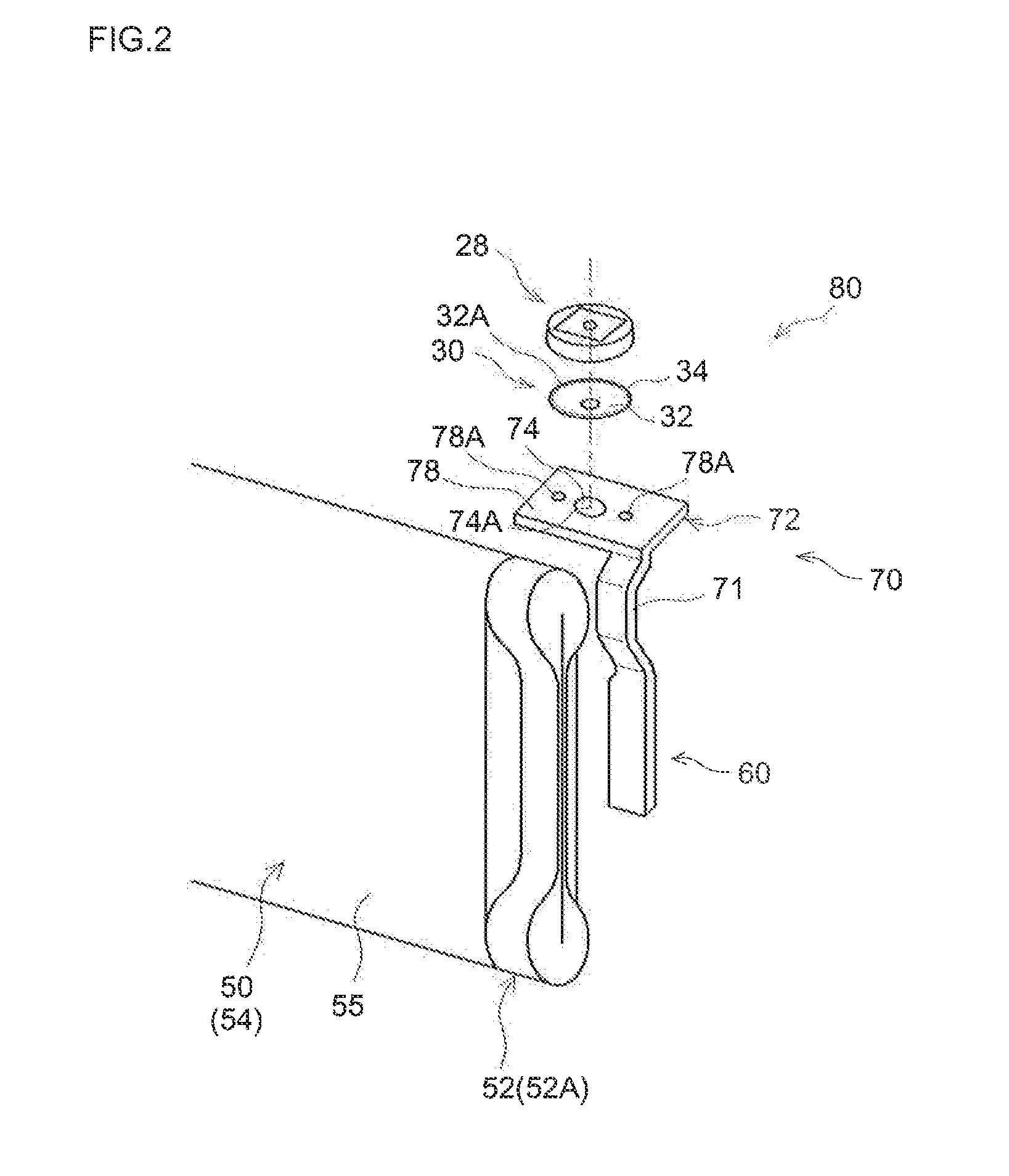

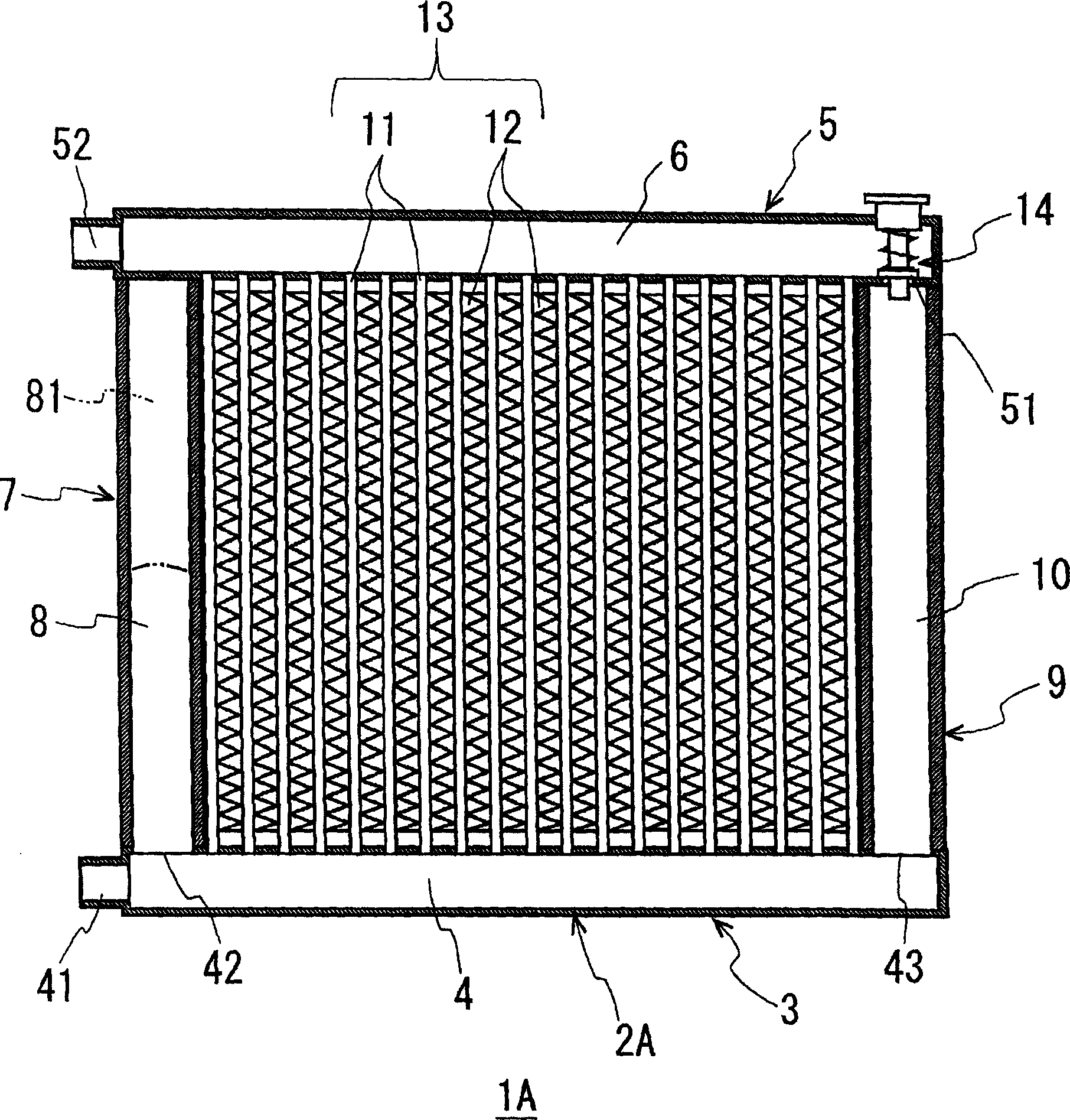

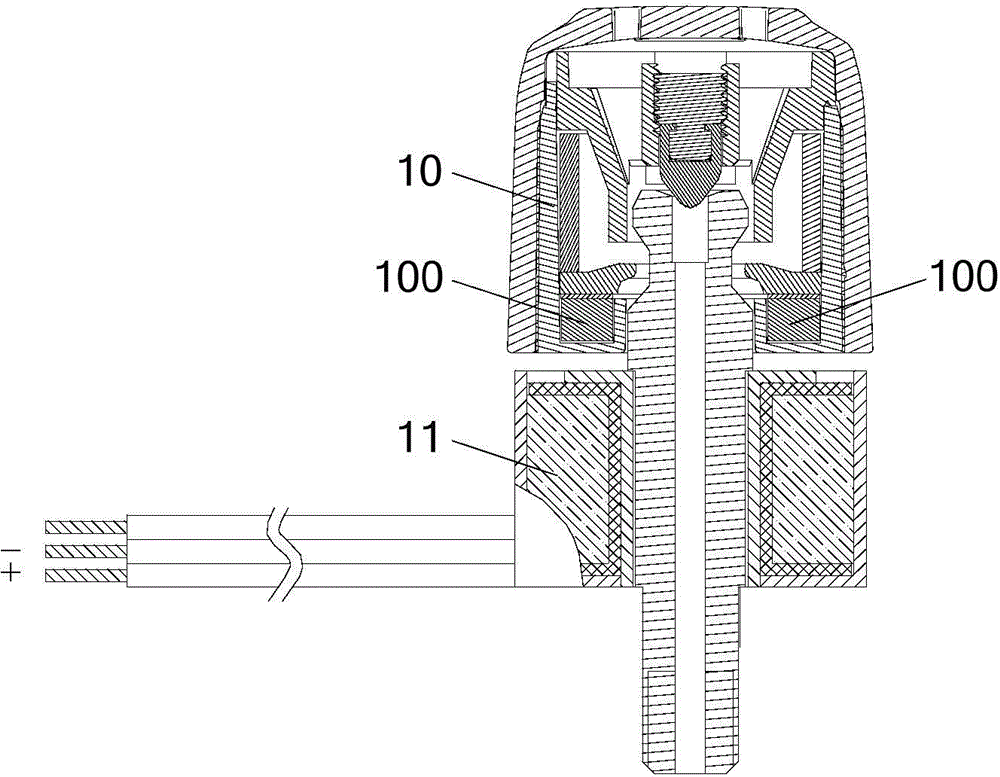

Sealed secondary battery

ActiveUS20150171411A1Rapid disconnectionSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsPressure riseEngineering

There is provided a sealed secondary battery whose current-blocking system yields little change in the actuation pressure even on long-term use. The sealed secondary battery comprises a current-blocking system 80 that is actuated by a pressure rise inside a battery case 12 to disconnect conduction path between an electrode and an electrode terminal. Current-blocking system 80 comprises a pressure-sensitive member having a pressure-sensitive deformable portion 32 that deforms from a first state via snap-through deformation to a second state upon a pressure rise inside battery case 12, and is configured to disconnect the conduction path by snap-through deformation of pressure-sensitive deformable portion 30.

Owner:TOYOTA JIDOSHA KK

Method for mid load operation of auto-ignition combustion

ActiveUS20060005804A1Easy loadingElectrical controlNon-fuel substance addition to fuelPressure riseMultiple injection

A method is disclosed for expanding the mid load operation limit in a four-stroke gasoline direct-injection controlled auto-ignition combustion engine. A system is employed for variably actuating the intake and exhaust valves and for operating the valves with an exhaust re-compression or exhaust re-breathing valve strategy. A spark plug is provided. A fuel injector having multiple injection capability is employed. A first fuel charge is injected into the combustion chamber to form a lean air-fuel mixture. A second fuel charge is injected into the combustion chamber to form a stratified air-fuel mixture having an ignitable mixture located near the spark plug. The ignitable mixture is ignited at the spark gap, thereby causing spark-ignition combustion that causes a sufficient increase in chamber pressure and temperature to trigger auto-ignition of the lean air-fuel mixture, resulting in the obtaining of a higher engine load before a pressure rise rate in the combustion chamber exceeds a prescribed threshold value.

Owner:GM GLOBAL TECH OPERATIONS LLC

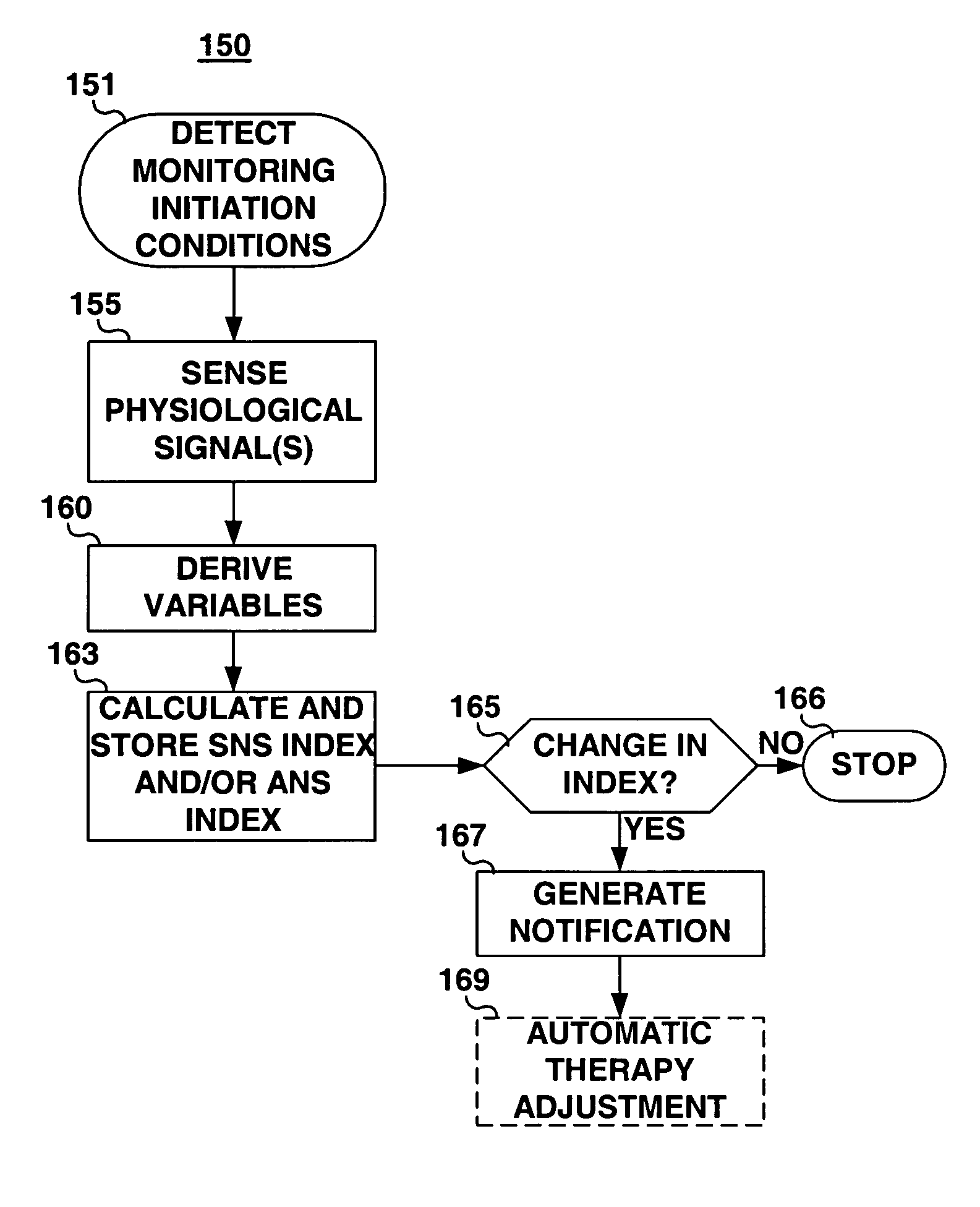

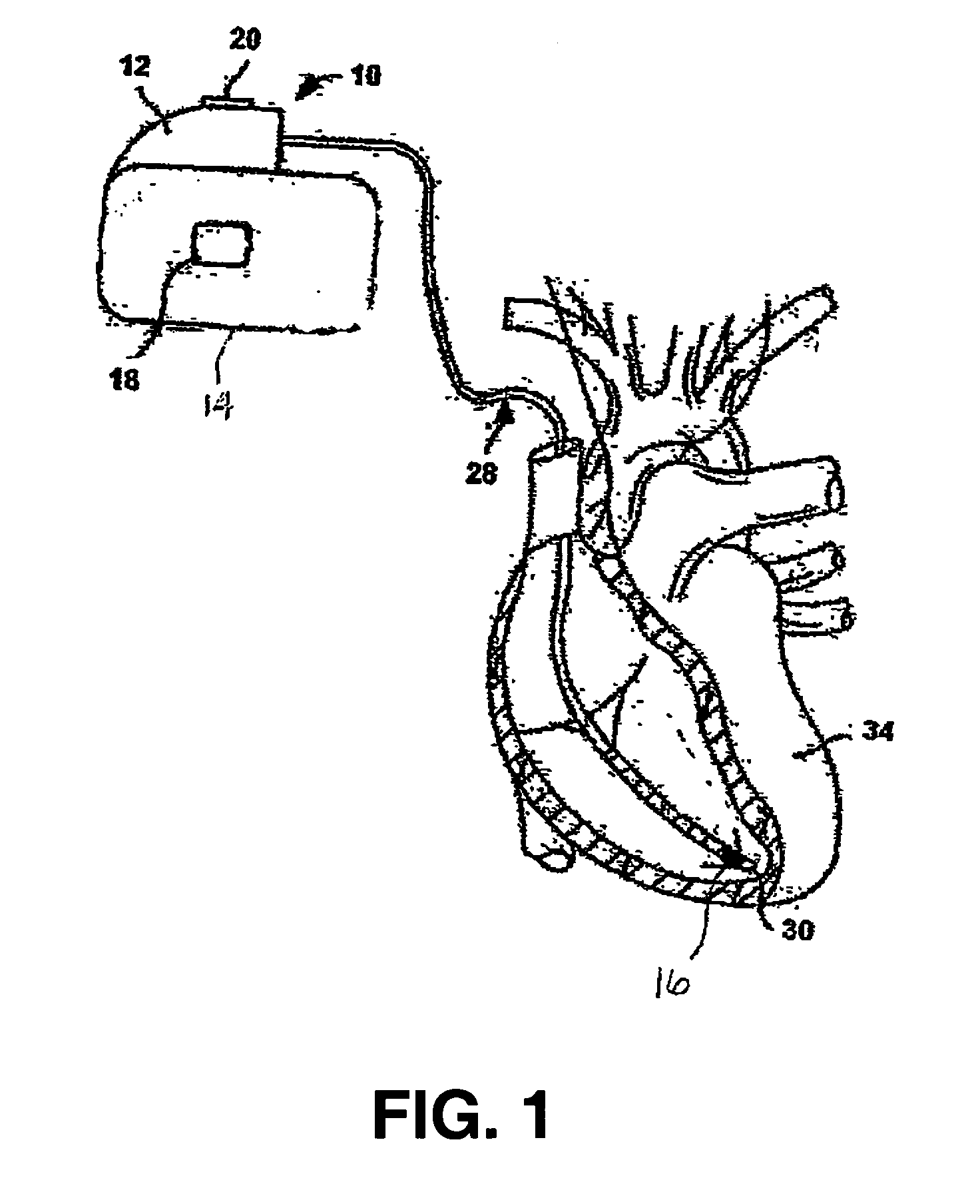

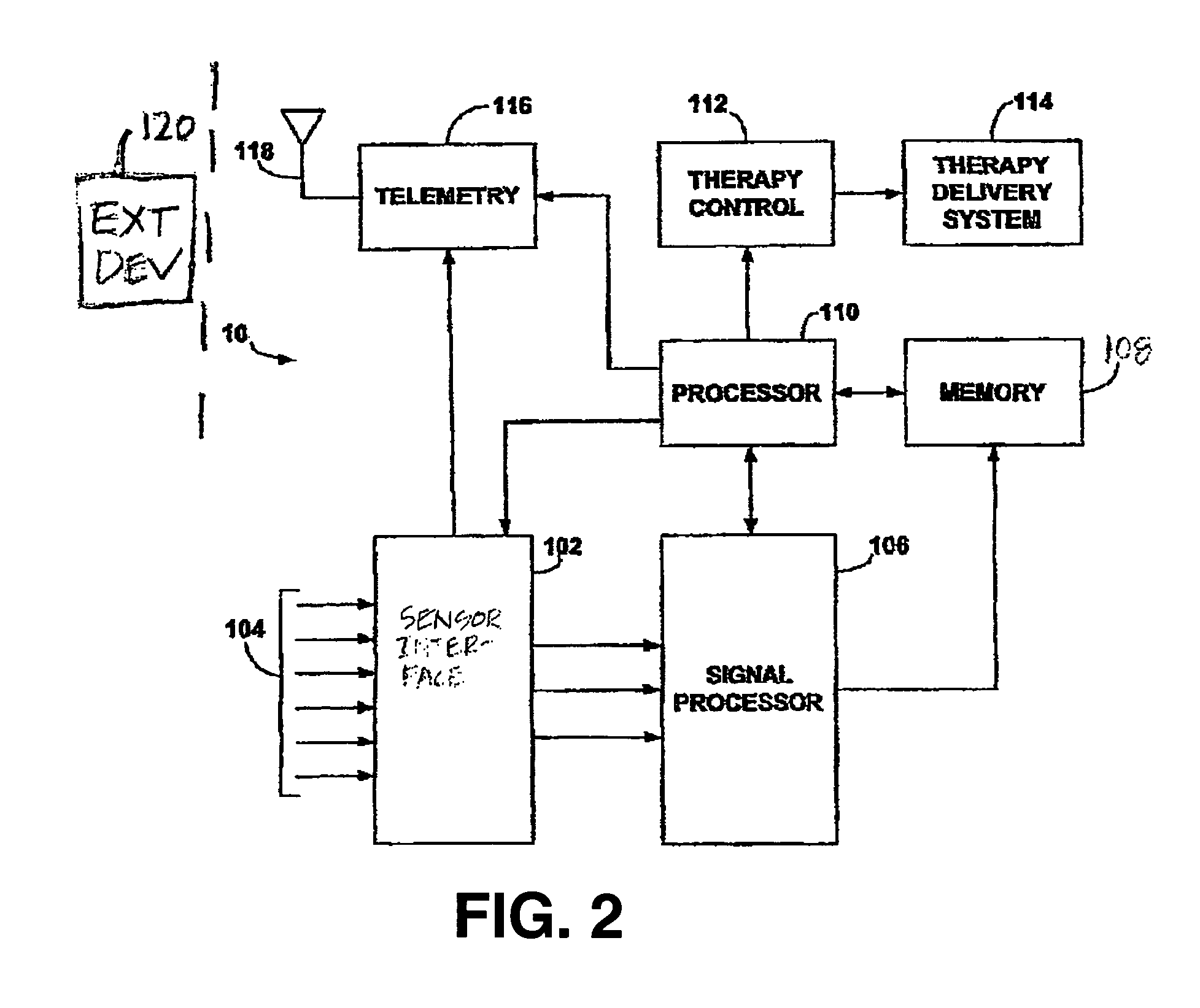

Method and apparatus to provide diagnostic index and therapy regulated by subject's autonomic nervous system

Owner:MEDTRONIC INC

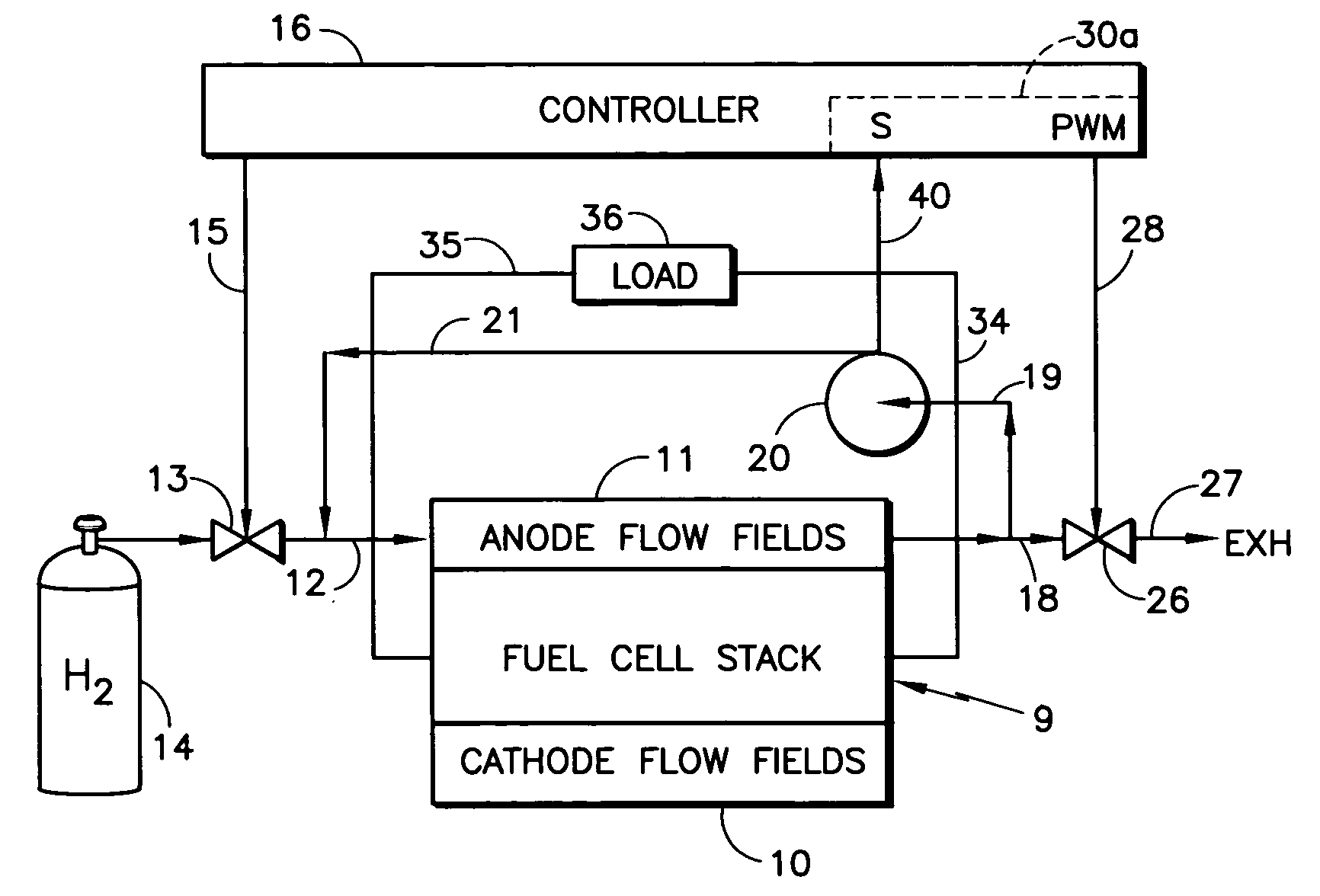

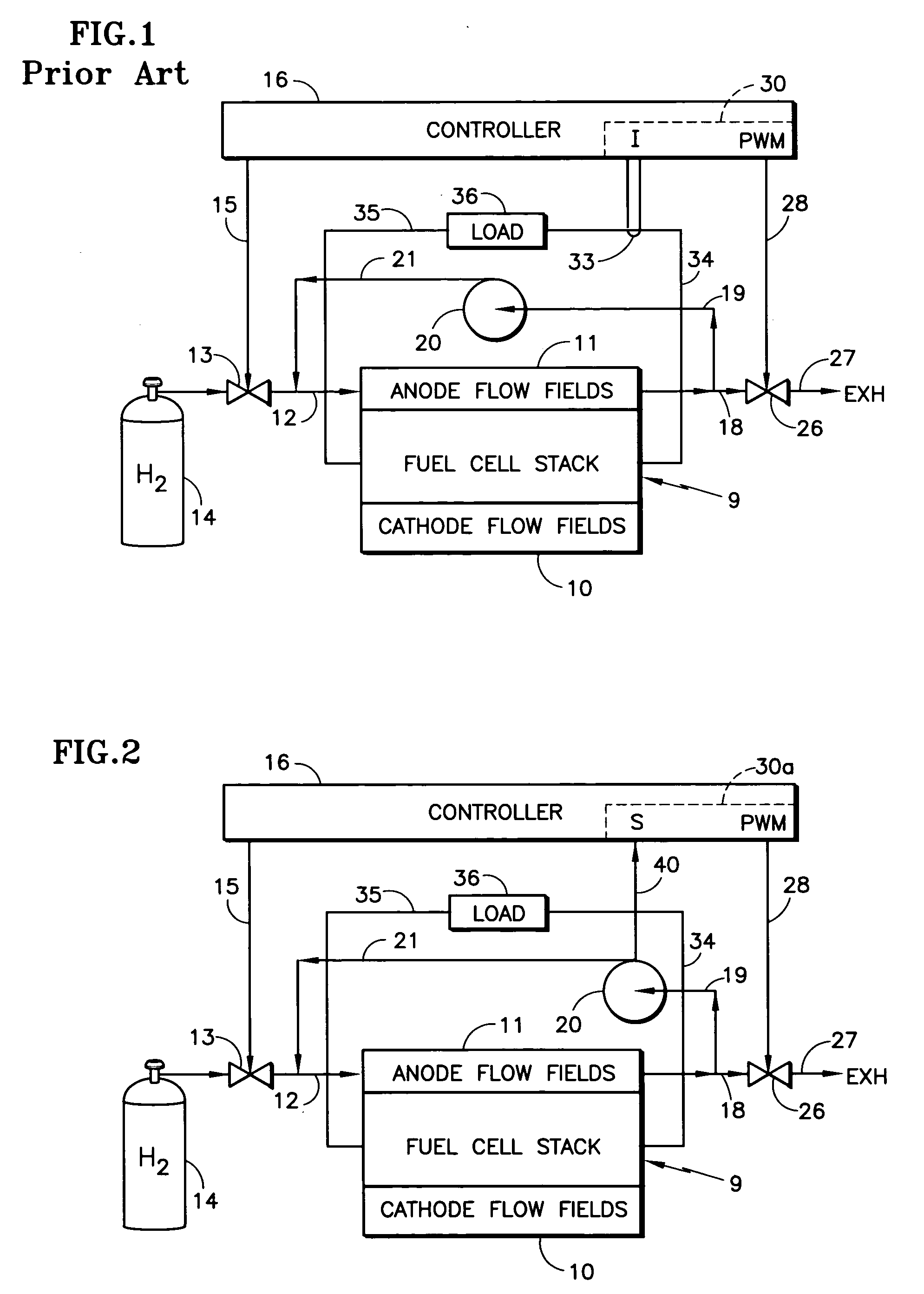

Controlling fuel cell fuel purge in response to recycle fuel blower operating conditions

InactiveUS20060003204A1Easy to controlImproved startup and shutdownFuel cell heat exchangeFuel cells groupingPressure riseFuel cells

A fuel cell power plant fuel purge valve (26) is controlled in response to a parameter (40, 40a) of a fuel recycle blower which is indicative (20) of the recycle fuel impelled thereby, either alone or together with load current (33), pressure rise of the blower (50, 51), and temperature of the fuel recycle gas (44), to provide a pulse width modulation-control signal (28) controlling the purge valve.

Owner:INT FUEL CELLS

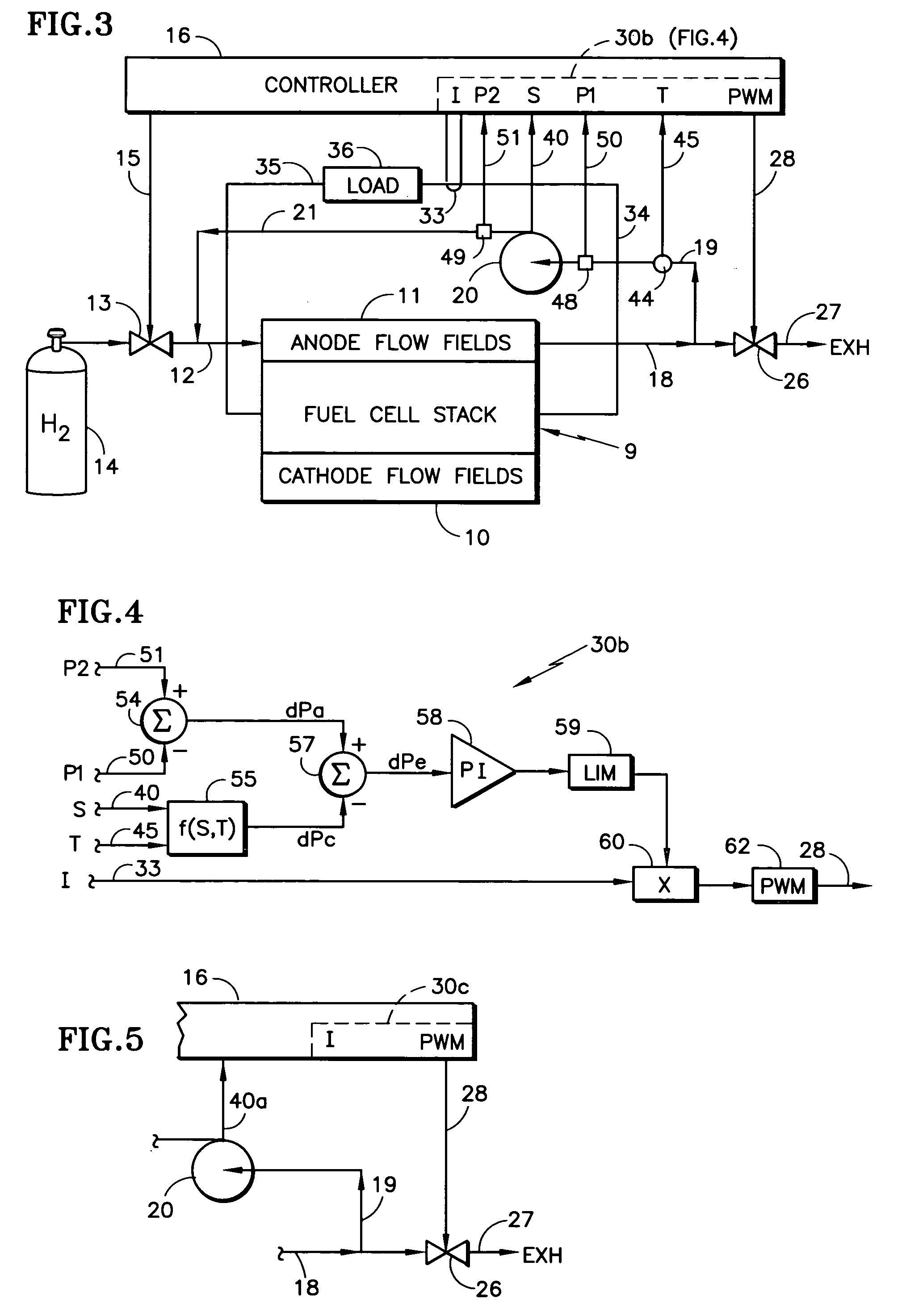

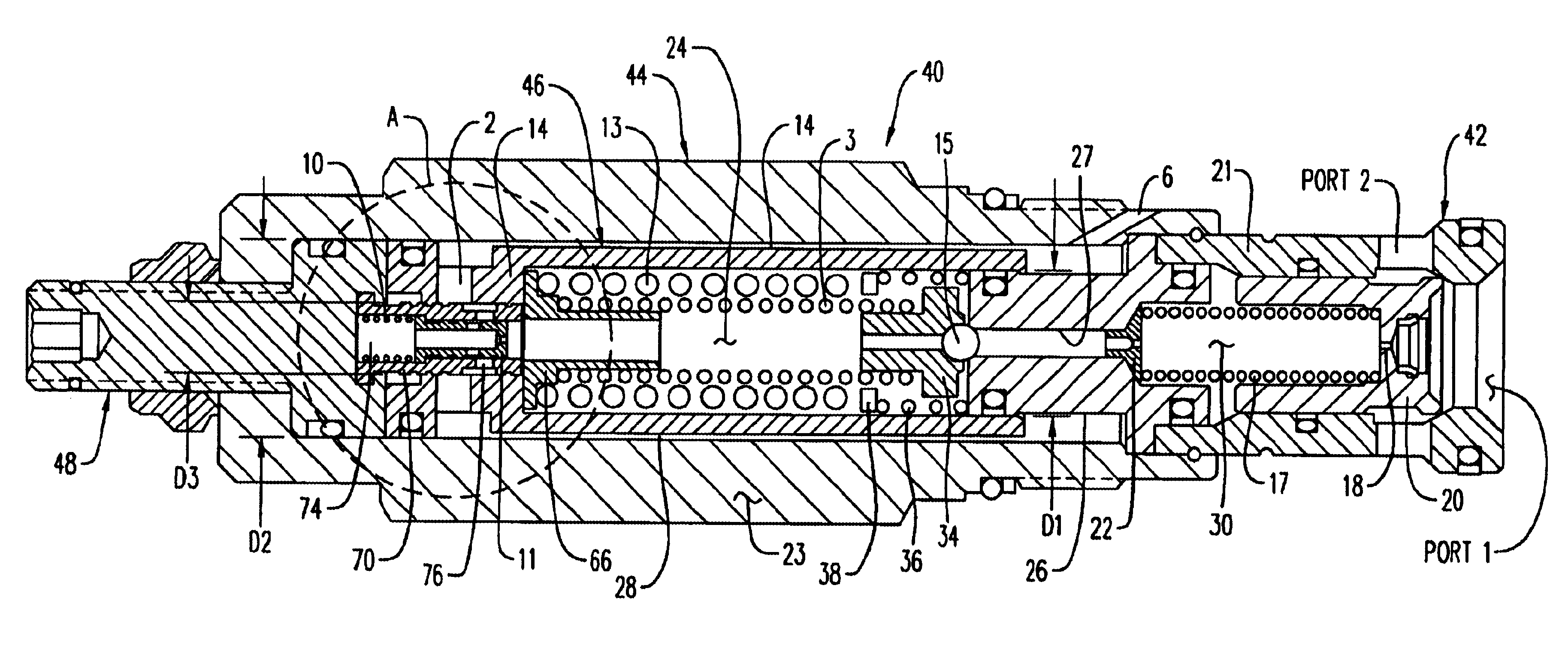

Pilot operated pressure valve

InactiveUS6640830B2Eliminates excessive system pressure spikesControl rateOperating means/releasing devices for valvesEqualizing valvesPressure riseSystem pressure

A pilot operated pressure valve which limits the rate of start-up pressure rise ("soft start-up") and substantially eliminates excessive system pressure spikes. The valve includes an inlet, a hollow cylindrical main body sealingly connected at one end thereof to the inlet, a pilot chamber having a sleeve slidably mounted within the main body and an operating pressure adjustment connected to another end of the main body adjacent another end of the pilot chamber for varying the threshold operating pressure of the valve. A main chamber receives pressurized fluid metered through a main orifice and discharges pressurized fluid through a damping orifice when the main chamber is filled and fluid inlet pressure exceeds the inlet threshold pressure which is just sufficient to open a spring biased pilot ball downstream of the damping orifice. An exit port upstream of the main orifice will open for discharging pressurized fluid from the valve back to a supply tank when inlet pressure exceeds the maximum operating pressure setting of the valve. Pressurized fluid is also metered from the pilot chamber into a pressure compensated priority flow control valve arrangement including an adjust chamber to automatically vary the operating pressure of the valve in "soft start-up" fashion by selectively discharging pressurized fluid from the pilot chamber and / or the adjust chamber in modulated fashion when fluid pressure reaches the threshold operating pressure.

Owner:SUN HYDRAULICS

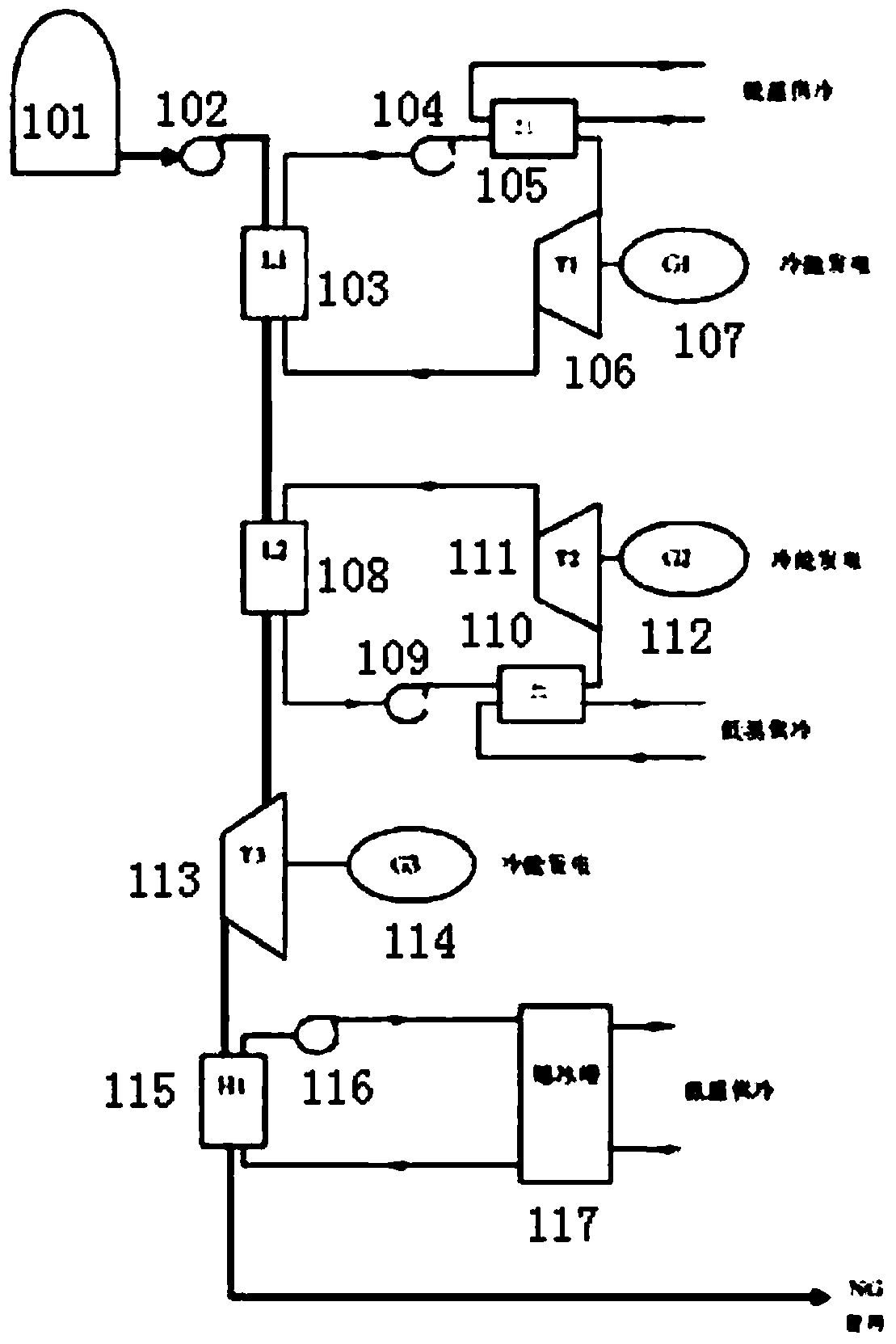

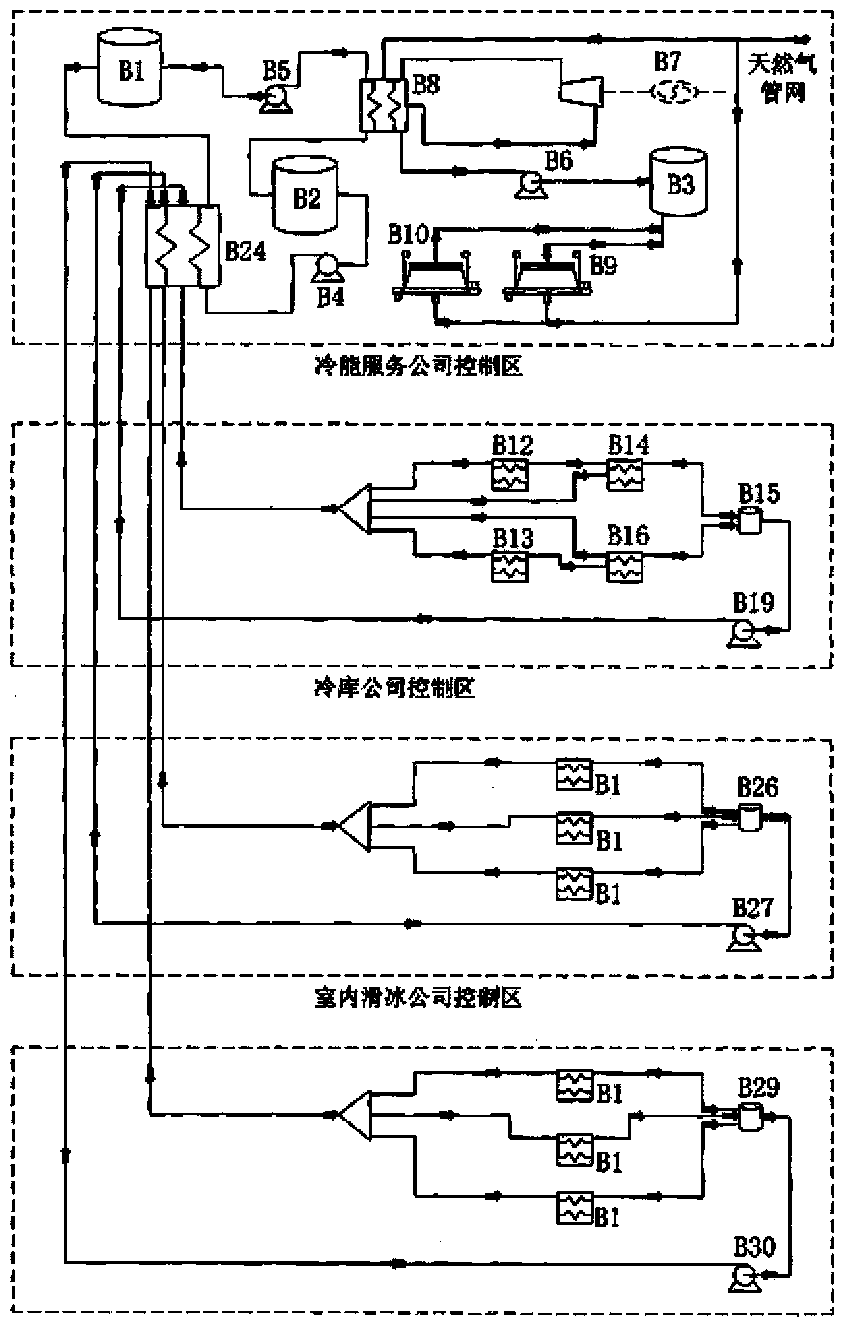

Two-stage expansion power generation device and method for recovering liquefied natural gas cold energy

InactiveCN103362579AImprove cold energy utilization efficiencyReduce heat transfer temperature differenceSteam engine plantsPressure riseMulti stream

The invention relates to a two-stage expansion power generation device and method for recovering liquefied natural gas cold energy. LNG enters a first runner of a multi-stream cryogenic heat exchanger for vaporization and temperature rise after passing through an LNG pump for pressure rise; high-pressure working medium gas outputs electric power after entering a first-stage turbine expander for expansion, the working medium gas is divided into two parts, the first part enters a second runner of a plate-fin multi-stream cryogenic heat exchanger to absorb the LNG cold energy and become liquid through condensation, and then a pump is used for pressurization; the second part enters a second-stage turbine expander for expansion after passing through a second heat exchanger, enters a third runner of the plate-fin multi-stream cryogenic heat exchanger to become liquid through condensation, enters a fourth runner after being pressurized through the pump, converges with the first part of the working medium gas, conducts heat exchange with a refrigerant after the convergence, and then returns to an inlet of the first-stage turbine expander after conducting heat exchange with the environment and / or absorbing industrial waste heat to finish the circulation. Power output by the first-stage turbine expander and power output by the second-stage turbine expander are both used for generating the electric power. According to the two-stage expansion power generation device and method for recovering the liquefied natural gas cold energy, ethylene or ethane is used as the working medium, the LNG cold energy and the waste heat are recovered for power generation, and the two-stage expansion power generation device and method can be widely applied to power generation through utilization of the liquefied natural gas cold energy.

Owner:NORTH CHINA INST OF SCI & TECH

Methods of operation for controlled temperature combustion engines using gasoline-like fuel, particularly multicylinder homogenous charge compression ignition (HCCI) engines

InactiveUS7025042B2Stable and efficient and low emissionElectrical controlNon-fuel substance addition to fuelPressure riseHcci combustion

Owner:ENVIRONMENTAL PROTECTION AGENCY US

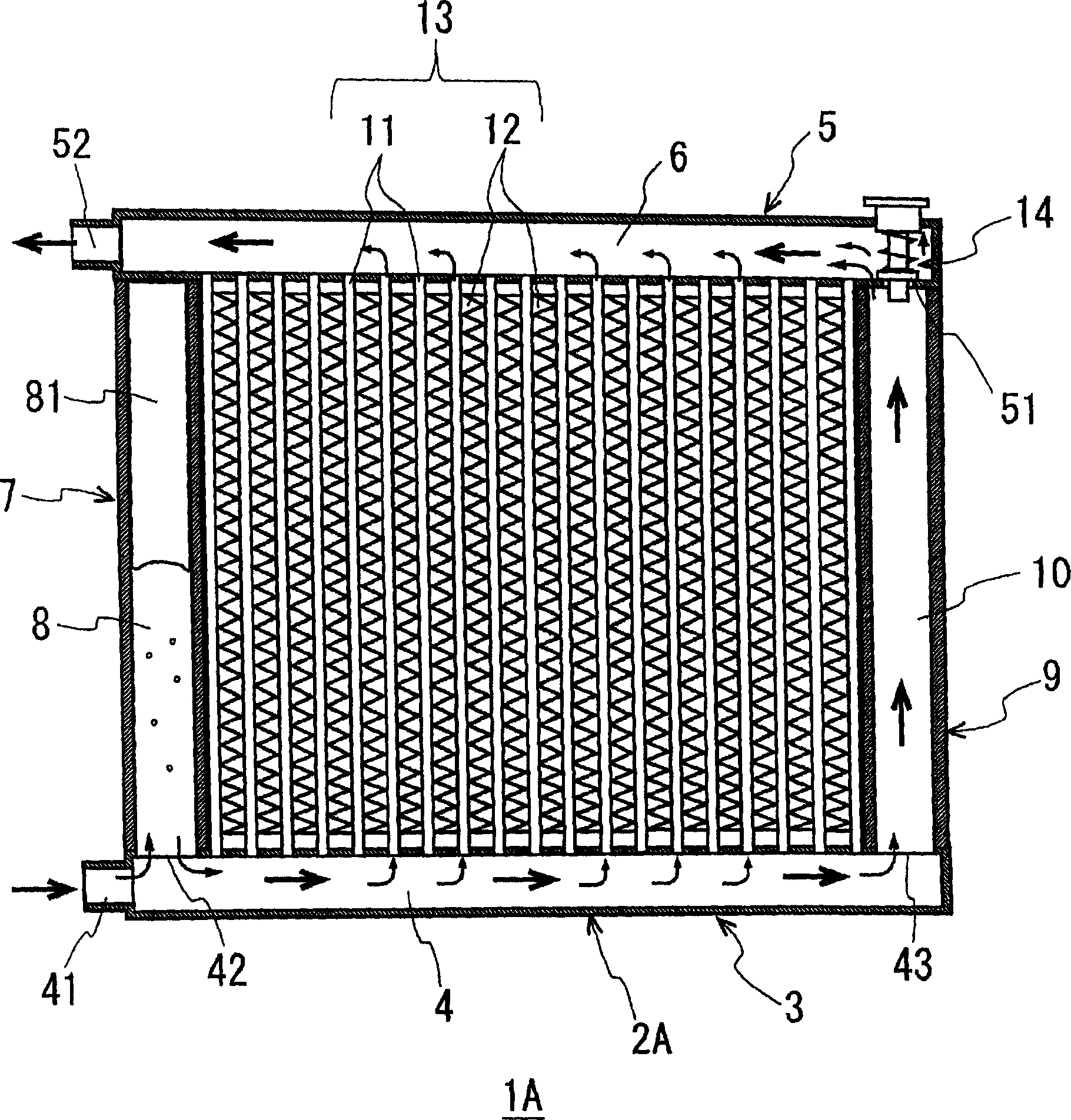

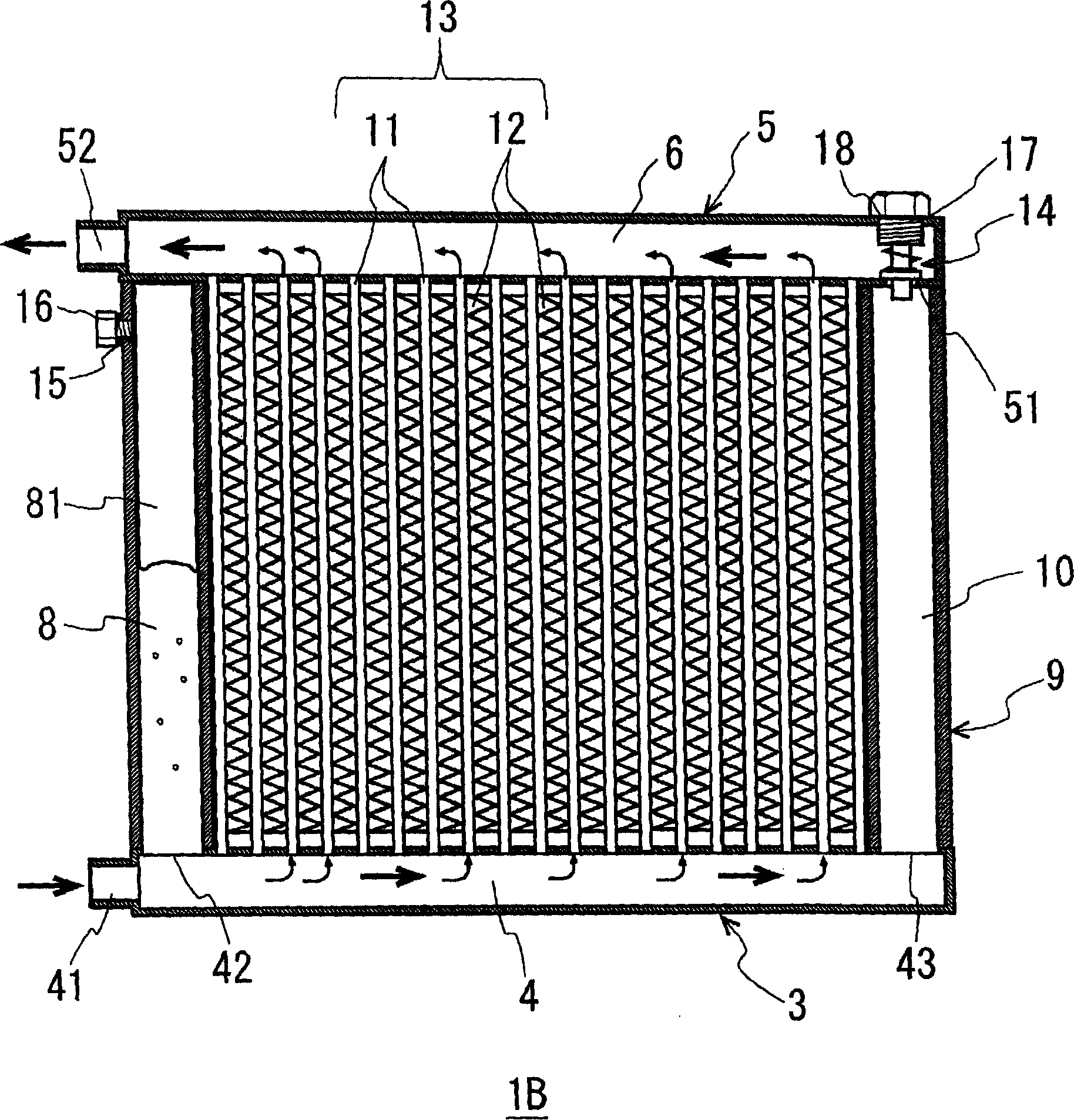

Working oil cooler

ActiveCN1916431AIncrease pressureEasy to adjustSoil-shifting machines/dredgersFluid-pressure actuator componentsPressure riseEngineering

A cooler of working oil is prepared as forming said cooler by connecting multiple heat conduction tubes in parallel way to form heat radiation unit, setting formed cooler between inlet chamber at lead in port of working oil sent from oil pressure device and outlet chamber at send out port of working oil sent from oil pressure device, connecting buffer chamber with air storage unit through to inlet chamber for utilizing air in air storage unit to absorb pulsation and pressure rise of working oil at inlet chamber in order to cool working oil stably.

Owner:SHINTAKESHI IND

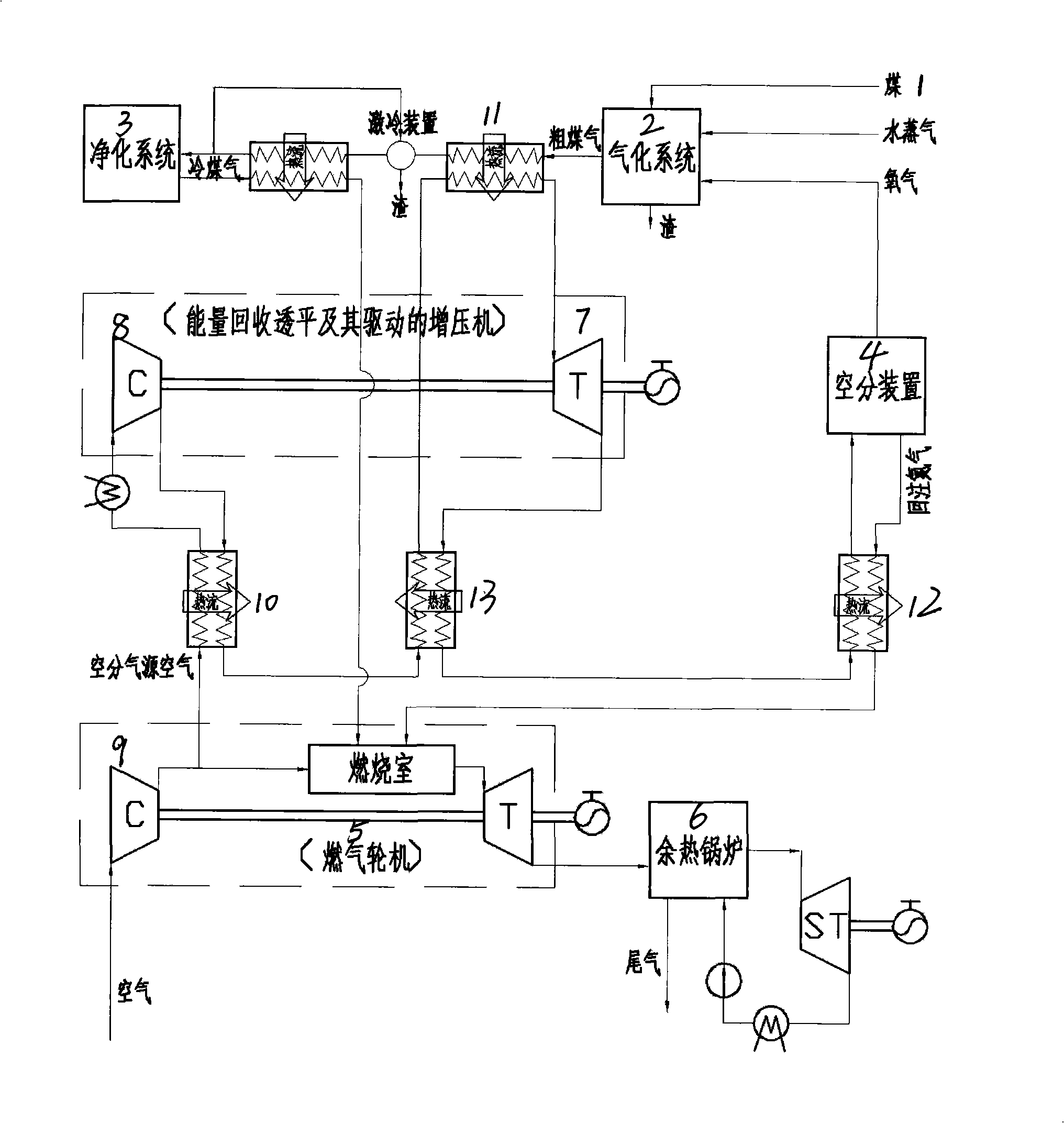

Energy conversion and recovering method of coal gasification supercharging association circulating power generation system

ActiveCN101270689AImprove work efficiencyAchieve recyclingSolidificationLiquefactionThermal energyPressure rise

The invention relates to a method of energy transformation and recovery of a combined cycle generating system of gasified pressure rise. The method comprises two parts, which are the process of gasifying and purifying coal and gas-vapor combined cycle generating process. Coal gas and high-pressure air are mixed and burnt in a combustion chamber and the produced gas with high temperature and pressure drive an expansion machine to do working, thus providing impetus to a gas booster and an electric generator. Sufficient raw material of air provided by gas turbine system is used as working fluid. The working fluid undergoes the processes of heat exchange and heat control, pressurization, repeated reheat and gradual heating up and the heat of high temperature coal gas is obtained from the outlet of a gasification device, thus making the temperature of the working fluid high enough. And a pressurization wheel is dragged and generates electricity by the turbine expansion action of energy recovery. Afterwards, the procedure of heat exchange and temperature control is practiced. At last, the air with proper pressure and temperature is transported to an air segregating unit that comprises a coal gasification device, a purifying device and a gas-vapor combined cycle generation device. In addition, an energy recovery turbine and a gas compressor and a plurality of heat exchangers driven by the energy recovery turbine are added. The method has the characteristics of easy and reliable practice and simple device structure. Moreover, the method can increase working efficiency of heat recovery turbine and output power, so the generating efficiency of IGCC system is raised by 3 percent, thus achieving the effects of saving energy and reducing consumption.

Owner:杭州杭氧透平机械有限公司

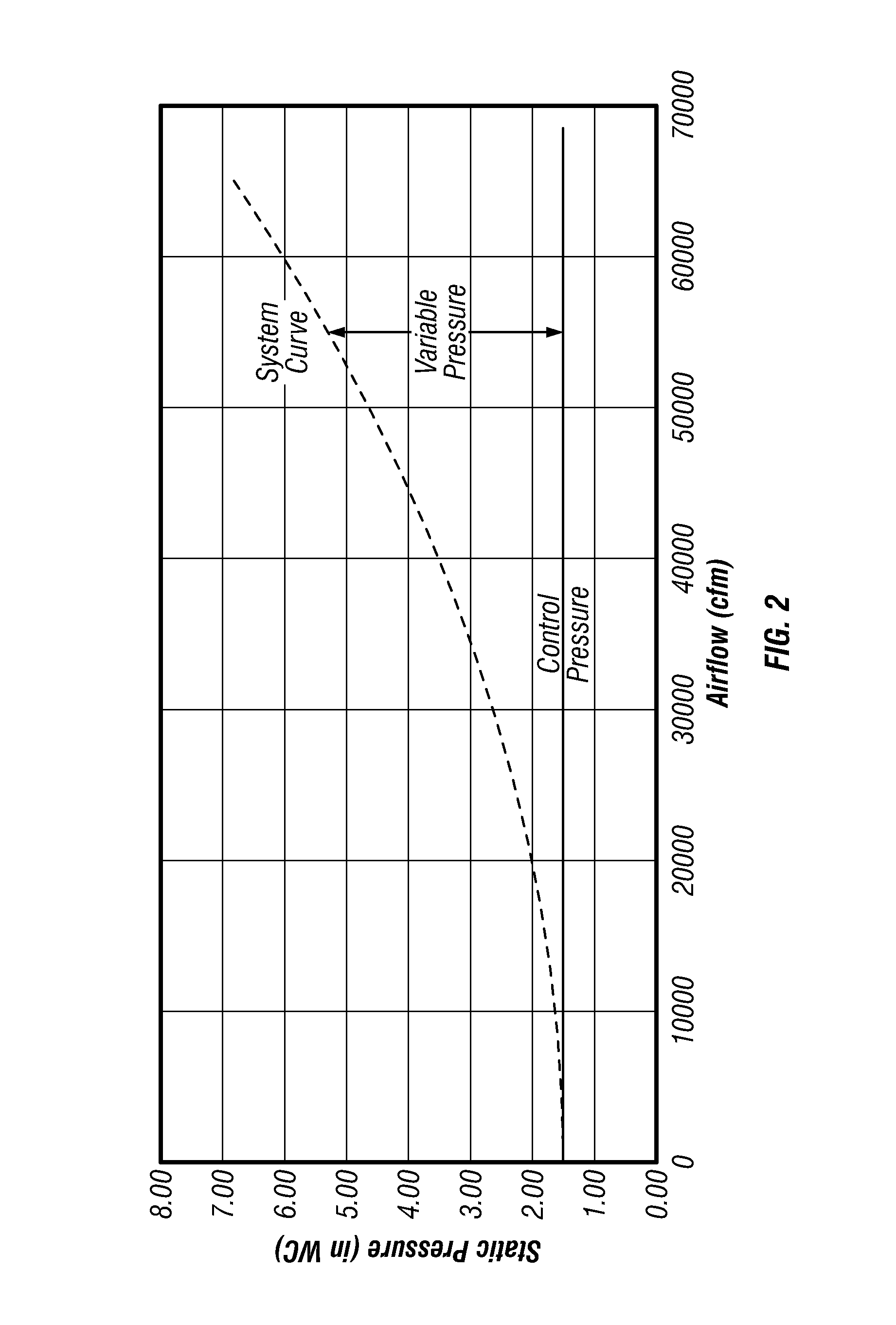

Fan system comprising fan array with surge control

A fan system for a variable air volume heating and / or air conditioning unit comprising a fan array with a control system to eliminate surge at low operating flows and to maximize operating range. The fan control system includes a fan pressure sensor for determining the pressure rise across the fan array and a fan airflow sensor for determining the total airflow generated by the fan array. A surge controller is programmed to constantly monitor the calculated surge pressure as the fan speed control is modulating the fan speed in response to user demands. As airflow increases or decreases in response to changes in fan speed, so will the calculated surge pressure. The surge control turn fans on and off to ensure that the operating fans are running in their optimum fan speed ranges. Thus, the fans in the fan array are prevented from reaching the surge point.

Owner:CLIMATECRAFT INC

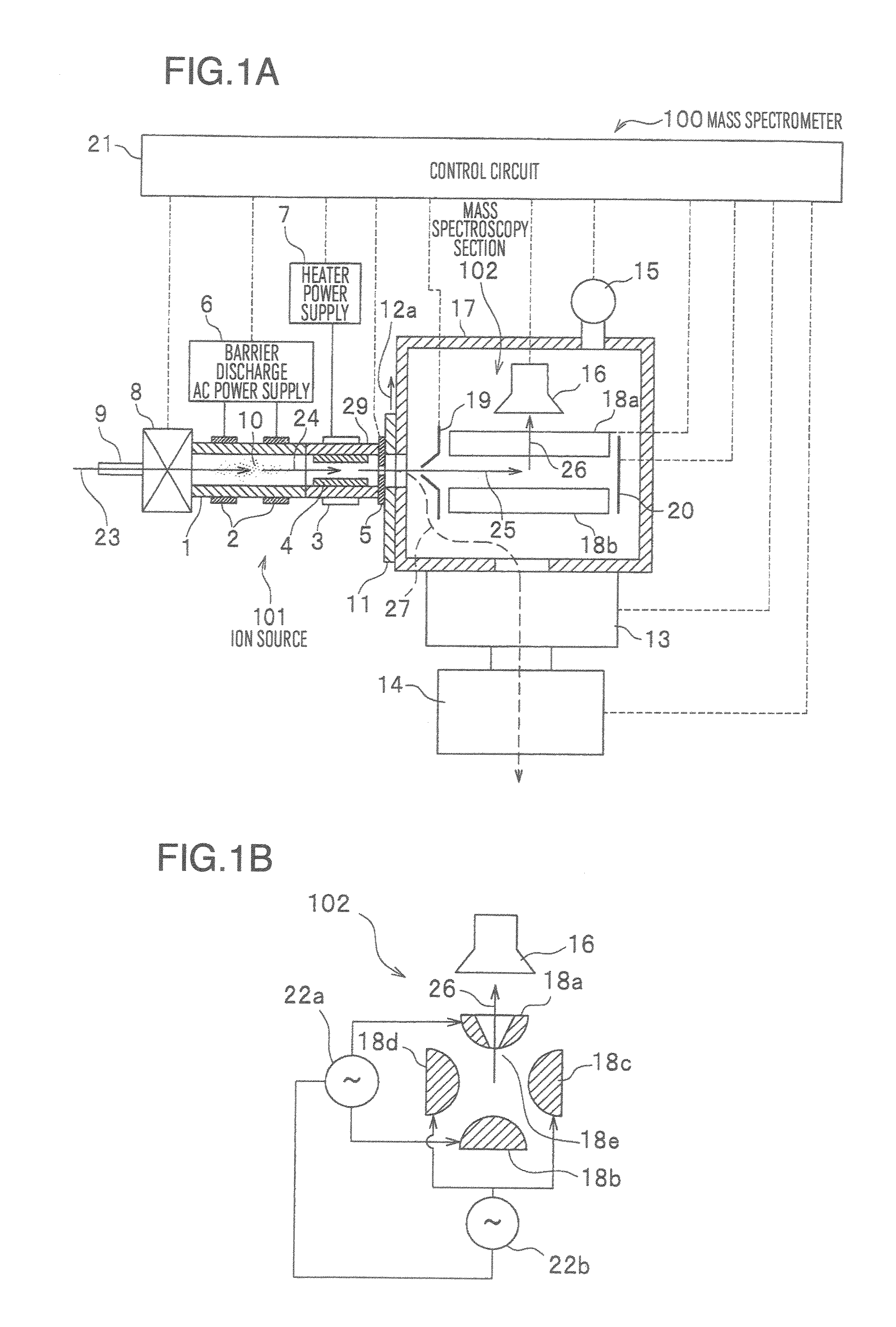

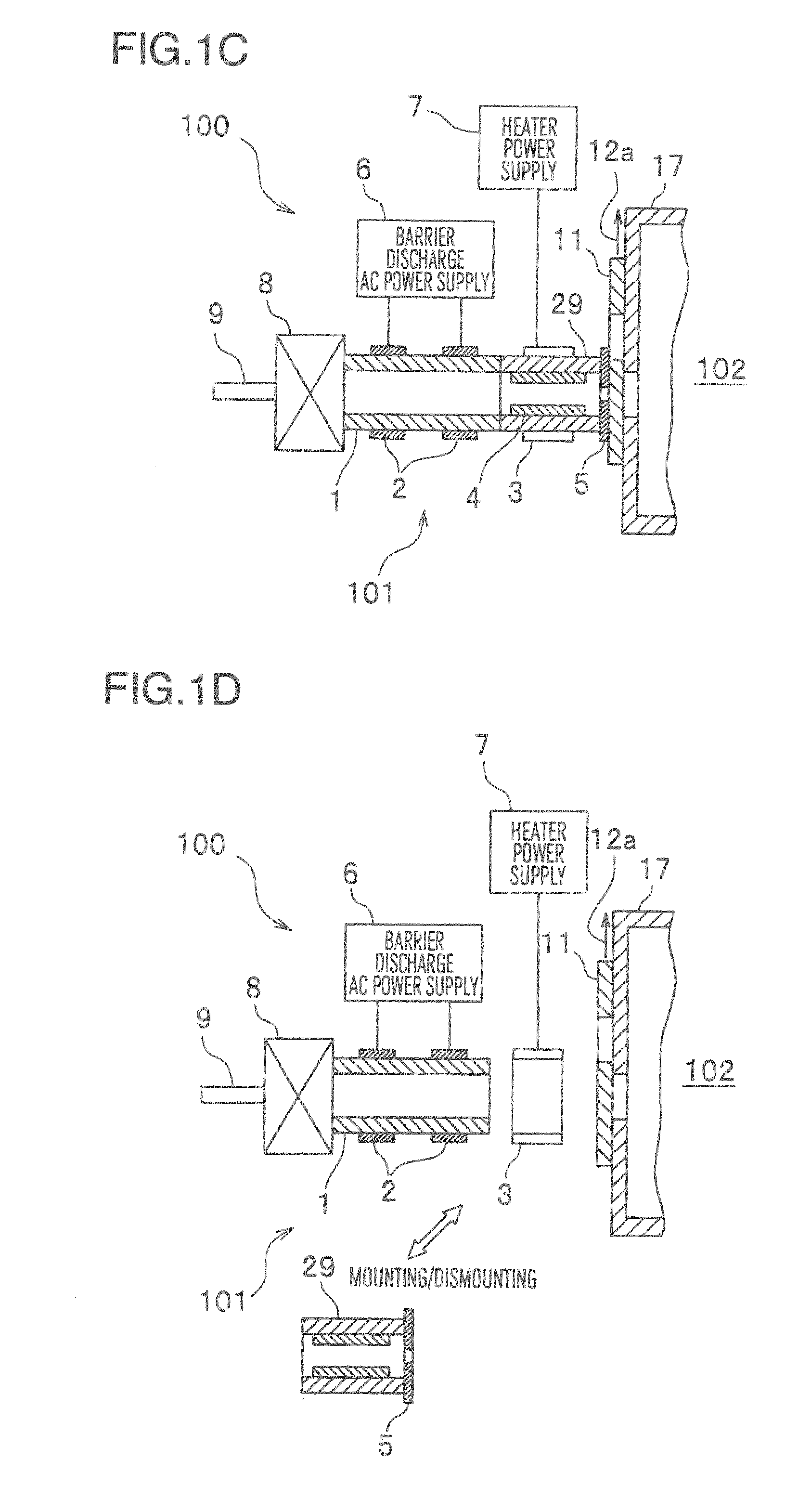

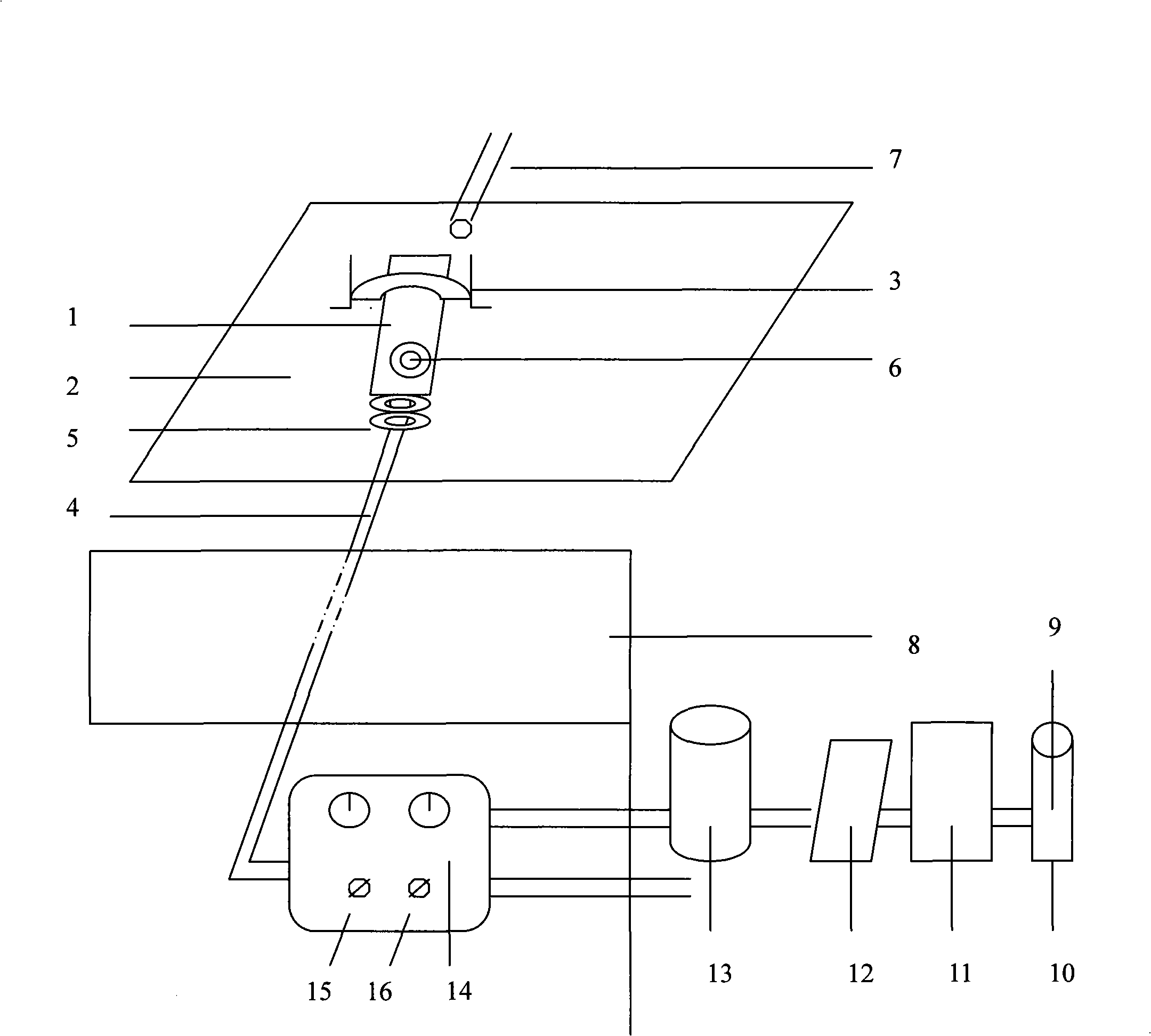

Mass spectrometer

ActiveUS20120112061A1Small sizeReduce weightSamples introduction/extractionMiniaturised spectrometersPressure riseInternal pressure

A mass spectrometer of reduced size and weight is provided which is capable to conduct highly accurate mass spectroscopy. The mass spectrometer includes an ion source adapted to ionize gas flowing in from outside in order to ionize a measurement sample and a mass spectroscopy section for separating the ionized measurement sample. The ion source has its interior reduced in pressure by differential pumping from the mass spectroscopy section and ionizes the gas when the interior pressure rises as it inhales the gas, and the mass spectroscopy section separates the ionized measurement sample when its interior pressure falls after inhale of the gas. The mass spectrometer may further include a restriction device for suppressing a flow rate of the gas the ion source inhales and an open / close device for opening and closing a flow of the gas the ion source inhales.

Owner:HITACHI HIGH-TECH CORP

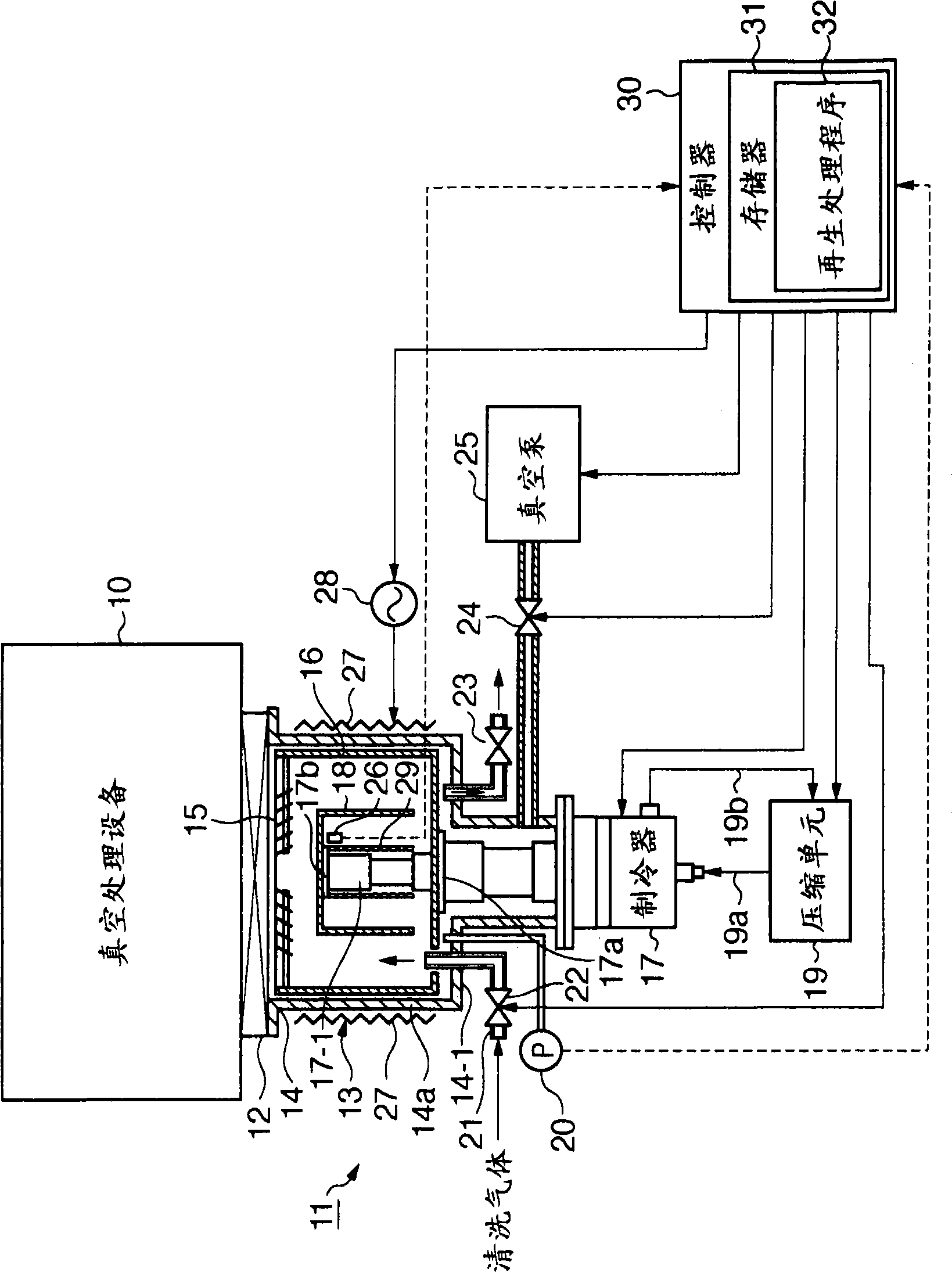

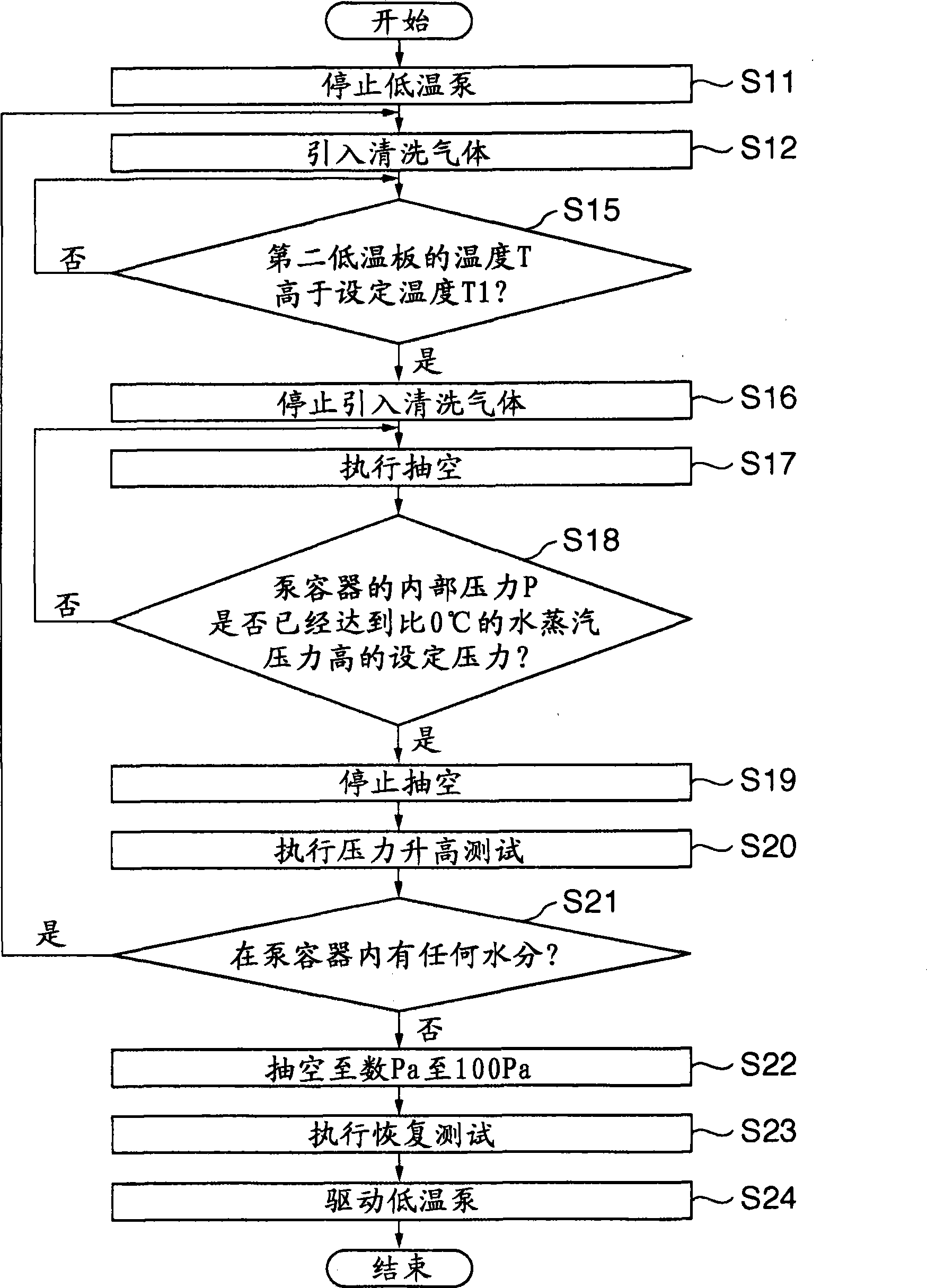

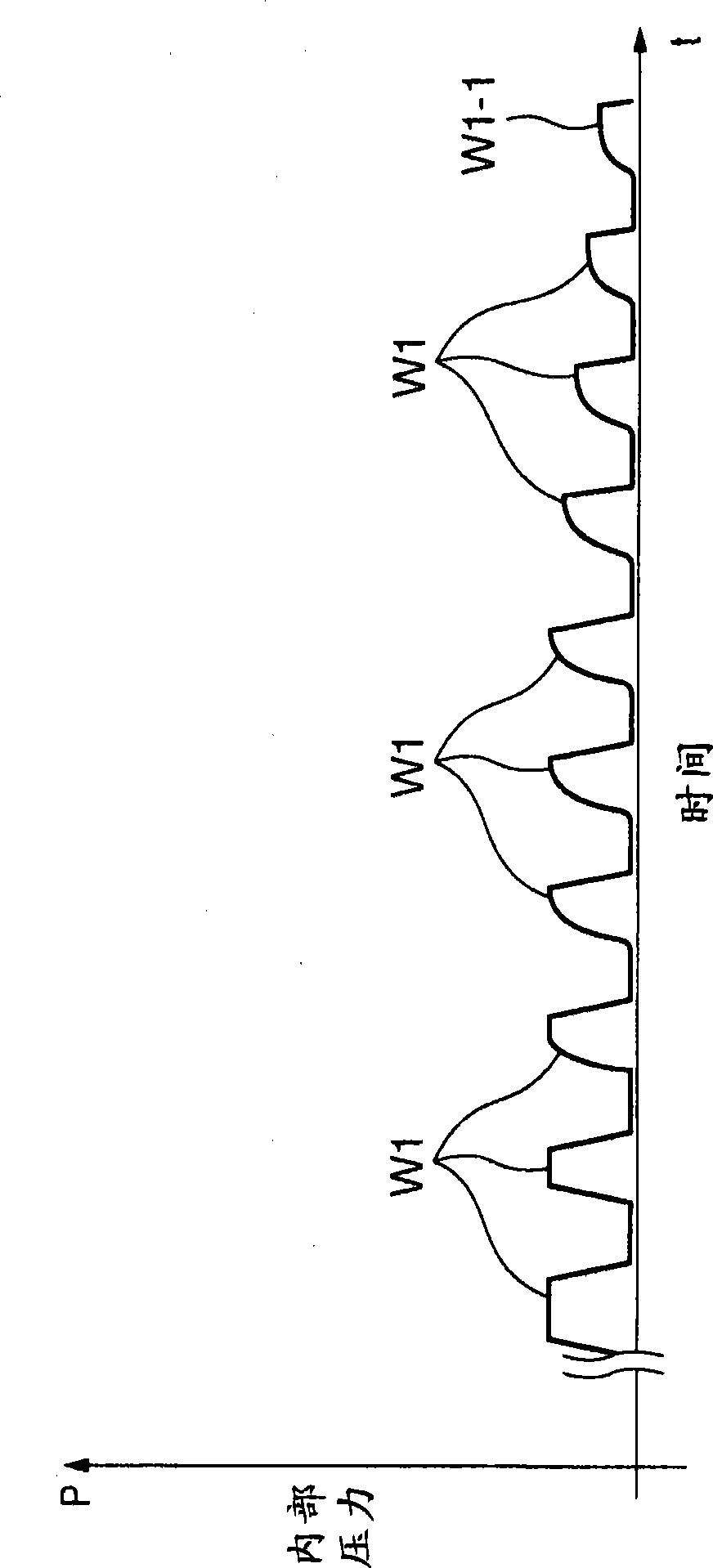

Cryopump, cryopump unit, vacuum processing apparatus including cryopump unit, and cryopump regeneration method

InactiveCN101469689AAccurate observationShort regeneration timePumpsPositive-displacement liquid enginesInternal pressurePressure rise

Owner:CANON ANELVA CORP

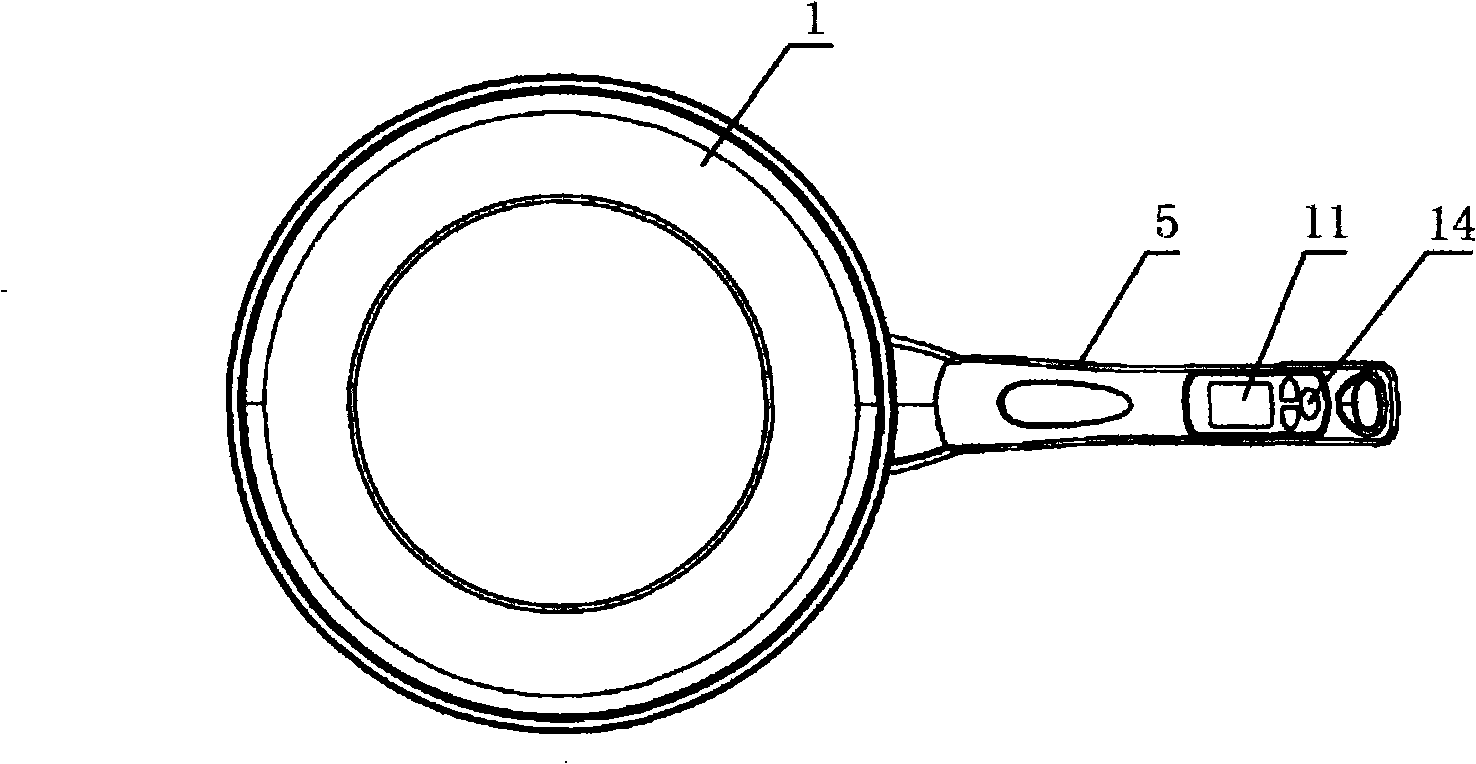

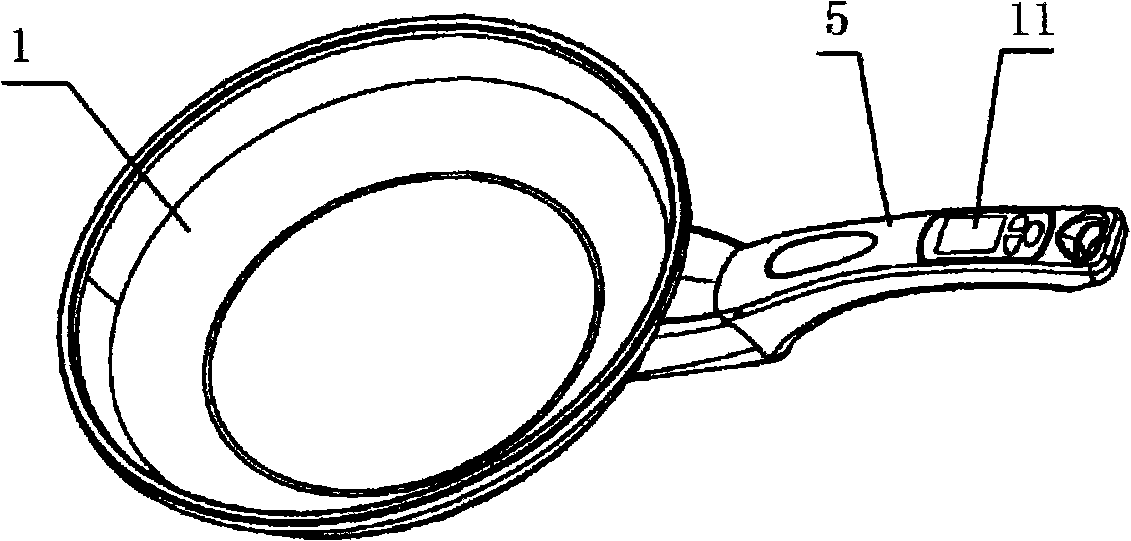

Semiconductor chilling plate thermo-electric generation electronic temperature measurement pan

The invention discloses an electronic thermometric pan with the function of electric generation by temperature differences of a semiconductor refrigeration piece, which mainly consists of a pan body, a handle, a temperature difference power generating system and a thermometric system. The temperature difference power generating system comprises the semiconductor refrigeration piece, a pressure-rising and voltage-stabilizing electronic component and an electric energy storage device. The thermometric system consists of a temperature sensor, a microprocessor, a circuit board and a liquid crystal piece. The temperature sensor is directly arranged at the bottom part of the pan body and the circuit board is arranged in a cavity of the handle. A cavity of the joint of the handle and the pan body is internally provided with the semiconductor refrigeration piece that is in contact with the pan body. The other surface of the semiconductor refrigeration piece is in close contact with a metal radiator. The temperature difference power generating system, the thermometric system and the liquid crystal piece are respectively connected with the circuit board. By utilizing cooking residual heat to generate power, the electronic thermometric pan of the invention realizes the temperature measurement for the bottom of the pan without battery drive, thereby not only becoming a healthy, hygienic and safe cook utensil, but also meeting the requirements of the times of environmental protection and economy; furthermore, the electronic thermometric pan of the invention also has convenient and reliable use, thereby having quite broad application prospect.

Owner:MINGLE DEV (SHENZHEN) CO LTD

Shale gas horizontal well proppant in-crack shielding and temporary plugging staged fracturing process

ActiveCN106223922ASolve complex problems such as inability to downloadStable and reliable perforationFluid removalPressure riseSand blasting

The invention discloses a shale gas horizontal well proppant in-crack shielding and temporary plugging staged fracturing process. The process includes following steps: lowering a continuous oil pipe and a sand blasting perforation tool a layer section needing fracturing modification, performing multi-cluster perforation, and lifting up the continuous oil pipe and the perforation tool; setting highest safe pumping pressure on the ground, and conducting main fracturing to promote a reservoir to generate a size crack; after injection liquid quantity reaches 1600-1800m3, pumping a proppant section plug for temporary plugging; after the section plug used for sand filling enters a stratum hole, lowering injection displacement until a sand plug completely enters a stratum; if shaft pressure rises to the highest safe pumping pressure set on the ground, showing that shielding and plugging are successful; lowering the continuous oil pipe for multi-cluster perforation and main fracturing of the next section until fracturing of all sections is completed. Multi-cluster sand blasting perforation of the continuous oil pipe is combined with in-crack sand filling temporary plugging staged fracturing, so that the complex problems that a mechanical bridge plug and a perforation tool cannot be lowered due to casing deformation and hole shrinkage and the like can be solved effectively.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

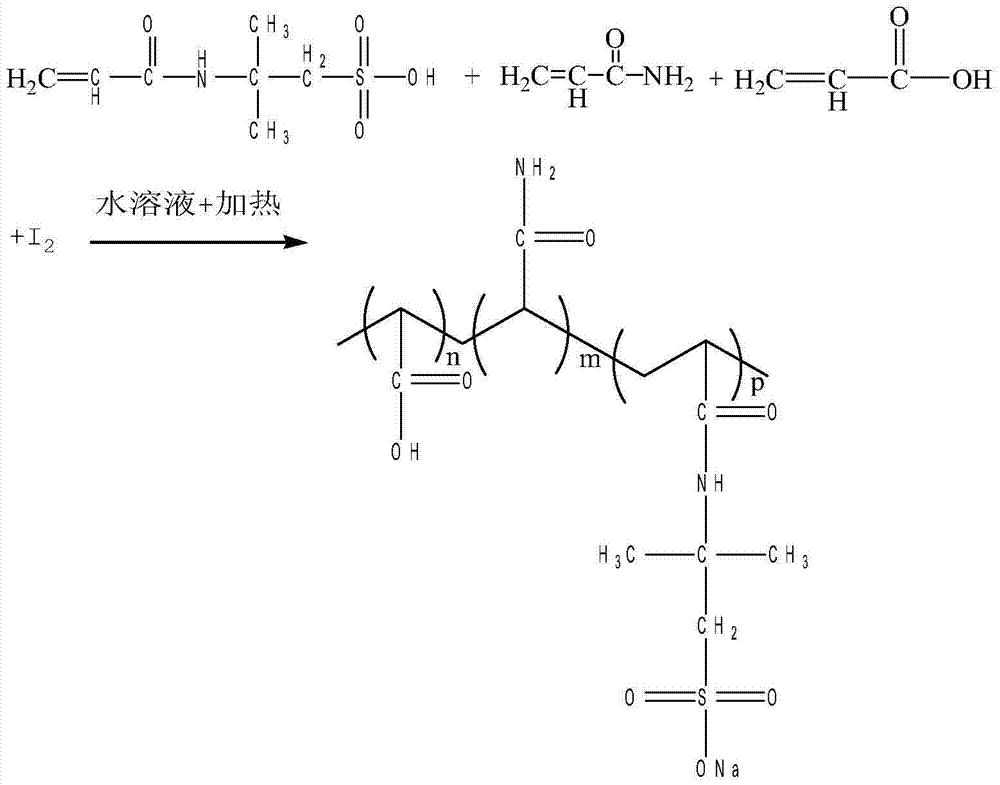

Slow-expansion water-absorbable salt-resistant gel particle, and preparation and applications thereof

InactiveCN104513341ASimple and fast operationLow costDrilling compositionSalt resistancePressure rise

The invention relates to a slow-expansion water-absorbable salt-resistant gel particle, and preparation and applications thereof. The gel particle relates to crosslinked gel having a net structure and formed by reactions of following raw materials: A), an acrylamide monomer, B) acrylic acid, C) a crosslinking agent, D) a salt-resistant crosslinking agent, E) an initiator that is persulfate, F) a reinforcing agent, G) a pH value conditioning agent, H) a foaming agent and I) water. The gel particle is a gel particle modifying and flooding agent having slow expansion performance, strong water absorption performance and salt resistance. The gel particle slowly absorbs water and expands when encountering water, and along with construction, the gel particle blocks, in the deep stratum, cracks or large pores and channels, thus adjusting water absorption profiles, diverting liquid streams, reducing inert areas in oil deposits, increasing production of oil of an oil well, and achieving a function of increasing the oil recovery rate of the oil deposits. The gel particle is low in expansion in construction processes, so that pressure rise is small, and the gel particle is suitable for profile control of a water injection well having low permeability and high water injection pressure.

Owner:PETROCHINA CO LTD

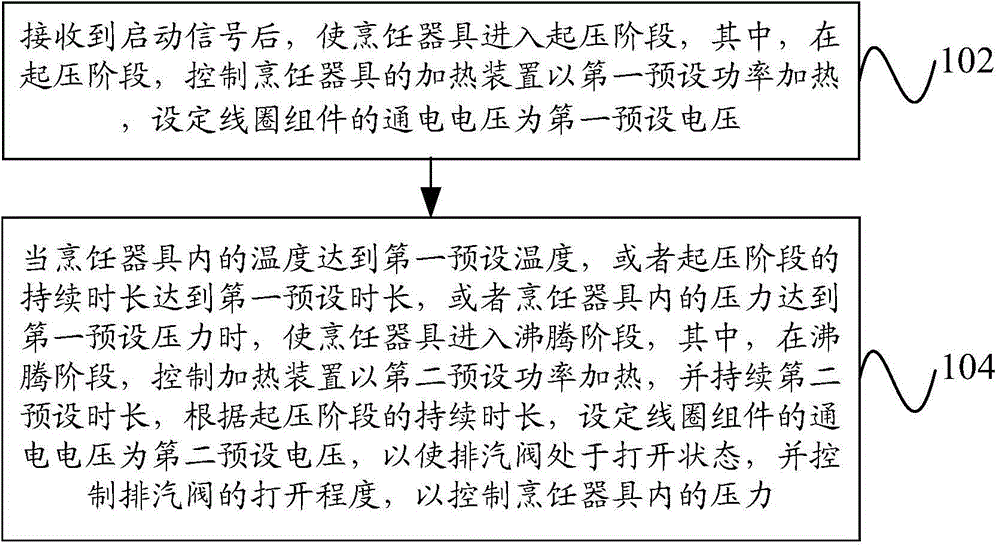

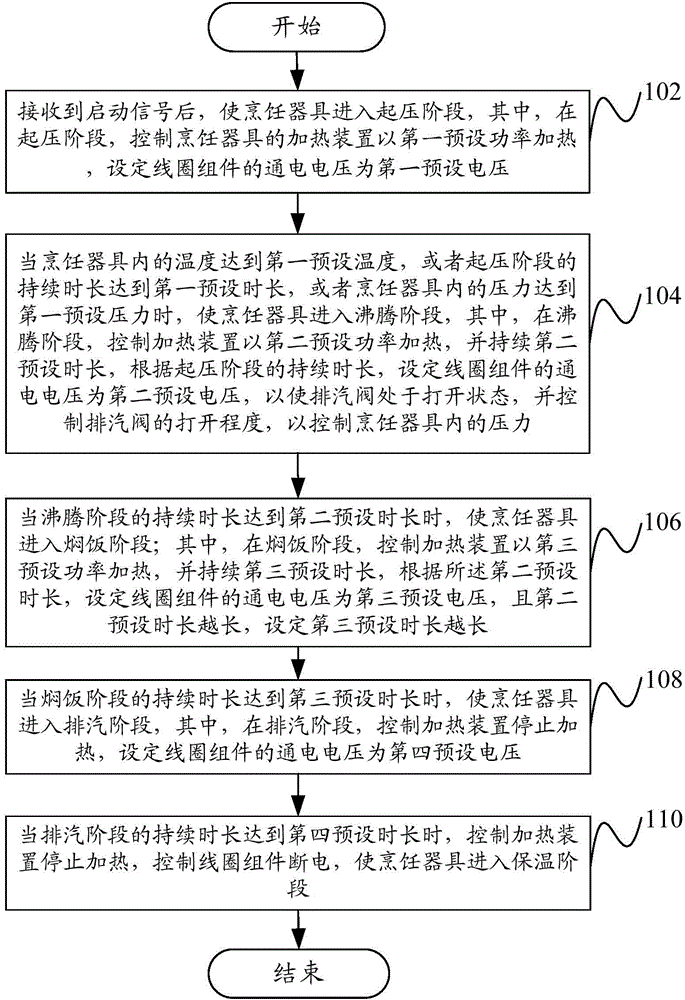

Control method, control device and cooking utensil

The invention provides a control method, a control device and a cooking utensil. The control method includes the steps that after a starting signal is received, the cooking utensil enters a pressure rising stage; a heating device is controlled to perform heating at first preset powder, and the electrification voltage of a coil assembly is set as first preset voltage; when the temperature in the cooking utensil reaches a first preset temperature, or the duration of the pressure rising stage reaches first preset duration, or the pressure in the cooking utensil reaches first preset pressure, the cooking utensil enters a boiling stage; the heating device is controlled to perform heating at second preset power and continues heating for second preset duration, the electrification voltage of the coil assembly is set as second preset voltage according to the duration of the pressure rising stage, and a steam exhaust valve is switched on with the switching-on degree of the steam exhaust valve controlled so as to control the pressure in the cooking utensil. By means of the control method, the electrification voltage of the coil assembly in the boiling stage is dynamically adjusted according to the duration of the pressure rising stage to ensure that an optimum boiling stirring effect can be achieved when a large or medium or small amount of food is cooked.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

Calibration apparatus and method for ultra-high pressure safety valve

ActiveCN101403657ASimple structureEasy to operateDetection of fluid at leakage pointMeasurement of fluid loss/gain ratePressure riseUltra high pressure

The invention relates to an ultra-high pressure safety-valve test apparatus and a corresponding test method. The apparatus adopts a U-shaped bolt to fix the ultra-high pressure safety-valve on a work platform and the output flange of the ultra-high pressure safety-valve is arranged upward; an ultra-high pressure flange is connected with an ultra-high pressure tube and the ultra-high pressure safety-valve; an air-supply is compressed through an air bottle firstly by a compressor and secondly by an ultra-high pressure pump and then is charged into an accumulator; the purified water is injected into the valve cavity through the outlet flange of the ultra-high pressure safety-valve and the video monitor device is arranged well and the position is adjusted well; a safety shielding wall is adopted to separate the operation zone from the test apparatus zone; after all are ready, a back-up valve on a control table carries out the operations of pressure-rising and pressure-preserving step by step according to the set pressure percentage and sealing test pressure and the opening pressure and the sealing capability of the safety-valve are assessed according to the leakage rate of bubbles from the outlet. The ultra-high pressure safety-vale test apparatus is provided with simple structure, economical and practical capability, high operablity and sensitive and reliable testing performance and solves the actual problems in the ultra-high pressure safety-valve testing field of our country.

Owner:南京金创有色金属科技发展有限公司

Assay assembly

InactiveUS20070077547A1Improve throughputReduce gas volumeBioreactor/fermenter combinationsBiological substance pretreatmentsBiological cellPressure rise

A cell based assay assembly includes a biochip assembly, a liquid delivery unit and detection and recording equipment is used for conducting an assay on a biological cell as it is delivered through the biochip assembly. The biochip assembly includes a plurality of separate biochips each comprising a microchannel with input and output ports, separate reservoir wells are provided on the biochip assembly and are periodically connected to the liquid delivery unit by removable separate disclosed transfer conduits. The input and output ports of the biochip are also periodically connected to the delivery unit by the conduit. The liquid delivery unit includes a liquid link assembly and a positive displacement pump such as a syringe pump. The liquid link assembly includes pressure compressible means which acts to smooth out pressure rises by initially contacting and then expanding to in turn dispense a steady liquid delivery output below 10μ per minute.

Owner:TRINITY COLLEGE DUBLIN

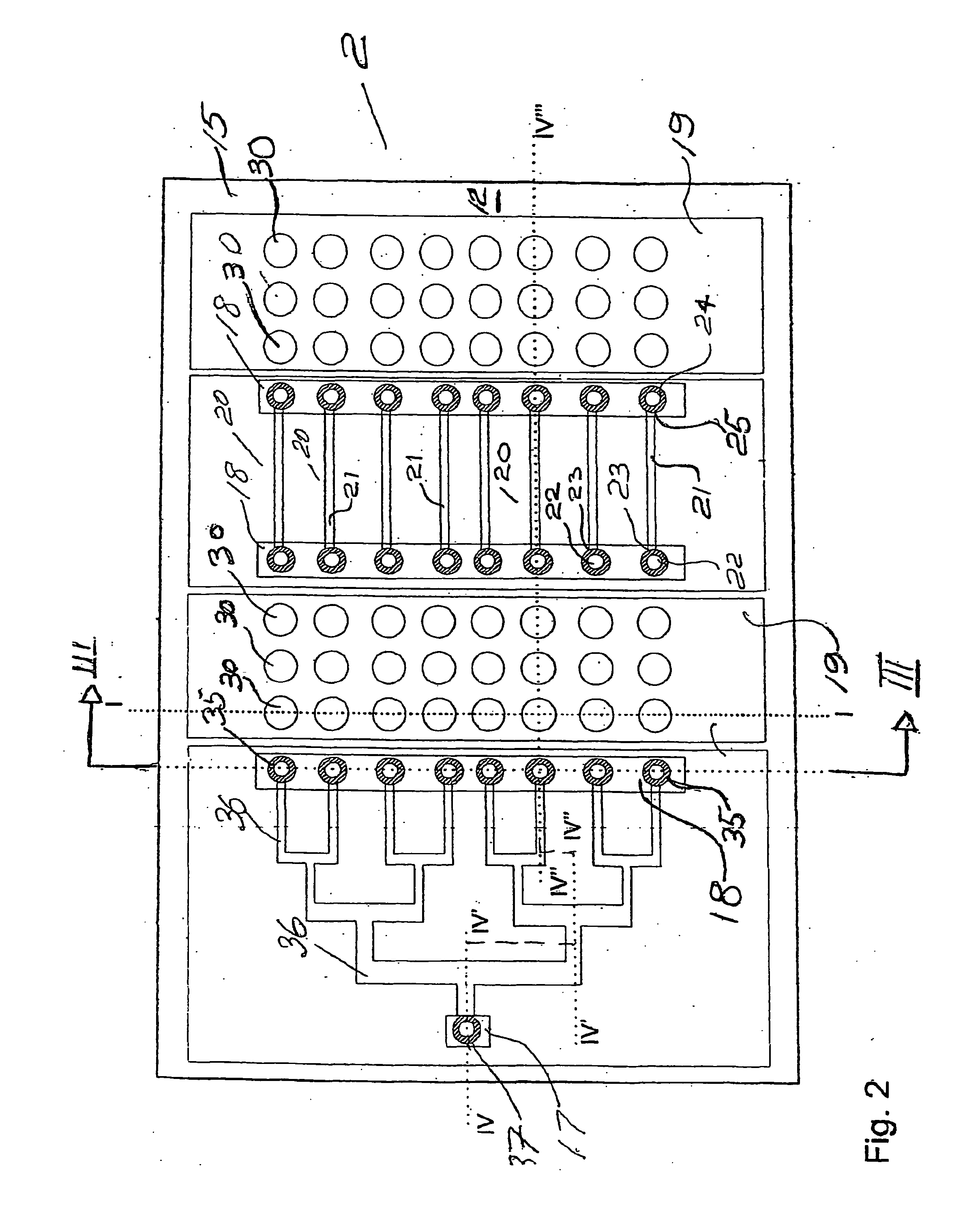

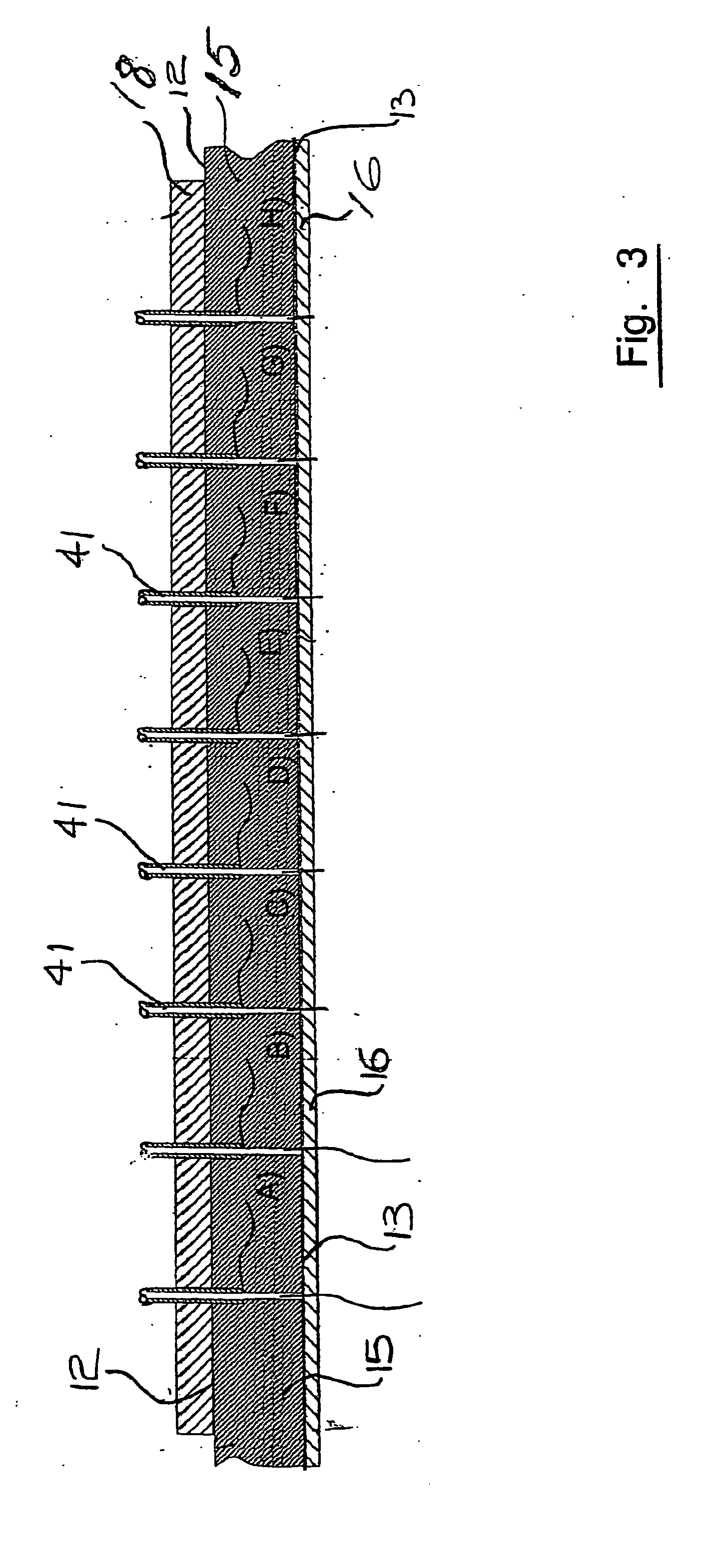

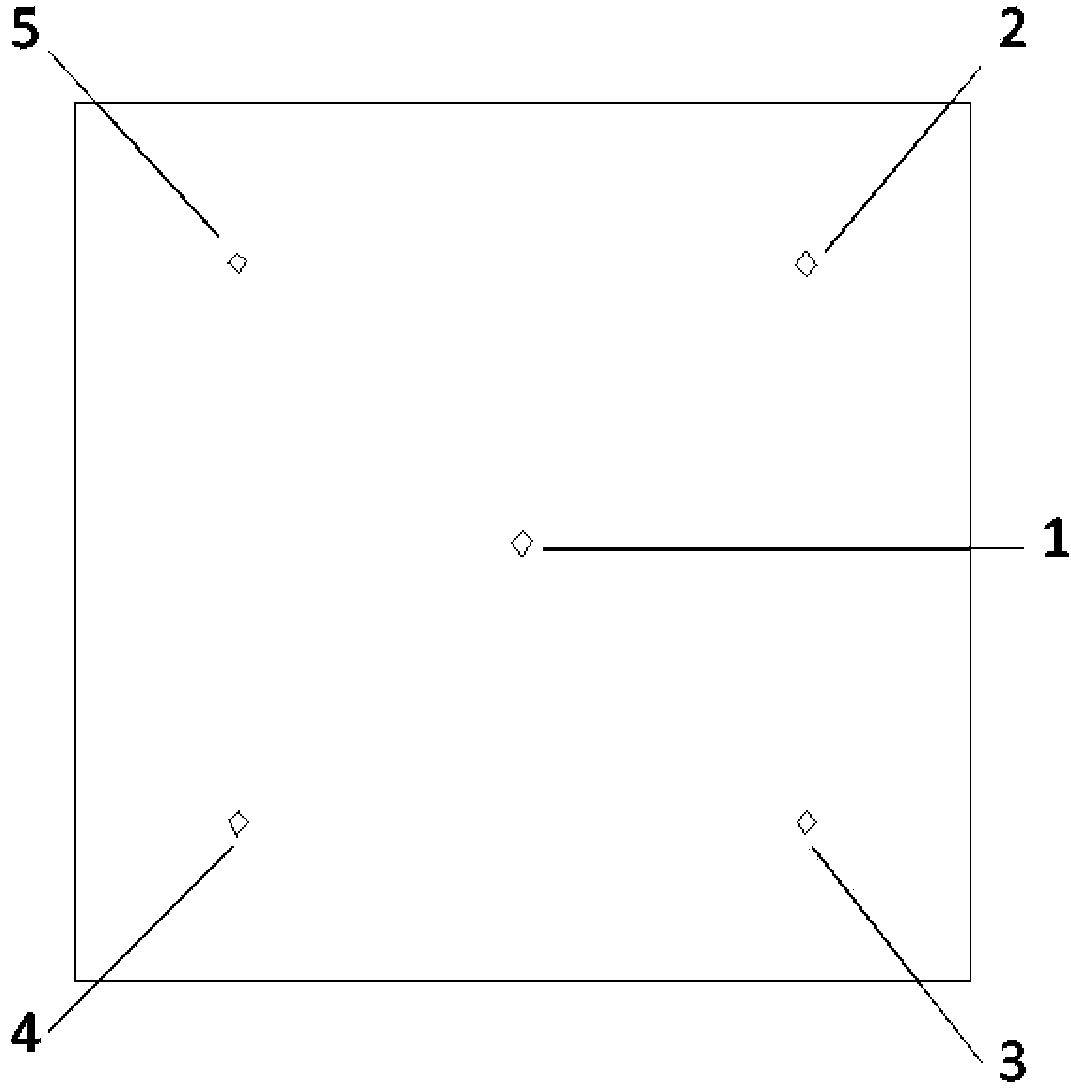

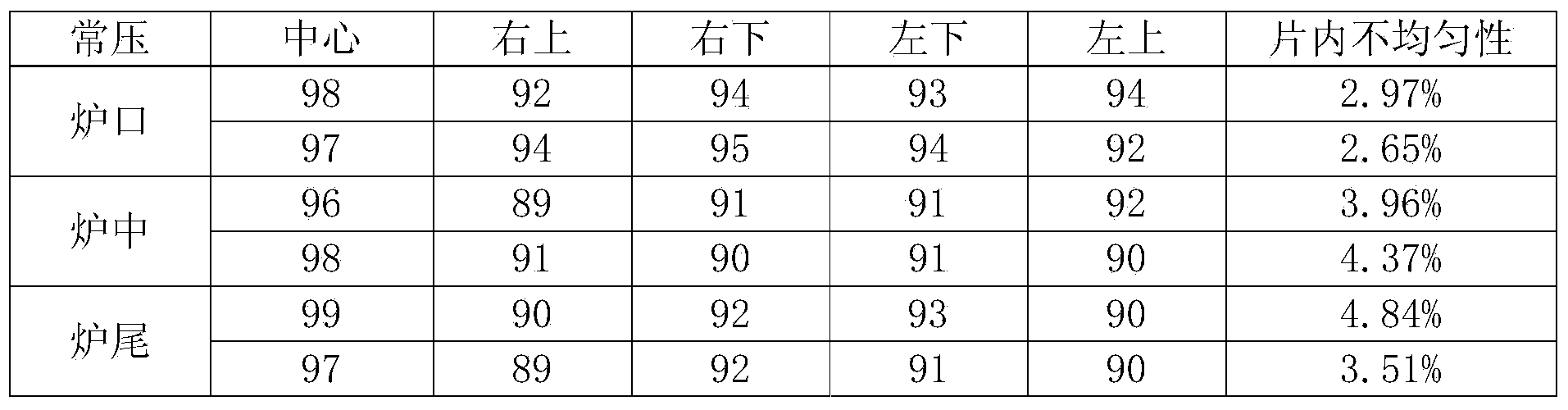

Decompression diffusion technology for manufacturing high-square-resistance battery pieces

ActiveCN104269459ARelieve pressureReduce unevennessFinal product manufactureSemiconductor/solid-state device manufacturingElectrical resistance and conductancePressure rise

The invention discloses a decompression diffusion technology for manufacturing high-square-resistance battery pieces. The technology comprises a constant-temperature decompression process, a pre-oxidation process, a temperature rise process, a deep diffusion process, a phosphorus propulsion process, a post-oxidation treatment process and a temperature drop and pressure rise process. Compared with a constant-pressure diffusion technology, the variable of pressure in the diffusion process is introduced into the decompression diffusion technology, the pressure in a diffusion furnace tube is reduced, meanwhile temperature, time and airflow are adjusted so that the uniformity of the diffusion square resistance can be better, and the photovoltaic conversion efficiency of the manufactured battery pieces can be higher; besides, the yield in unit time of equipment can be increased, and the usage amount of diffusion phosphorus sources is reduced.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com