Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

351 results about "Photovoltaic conversion efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

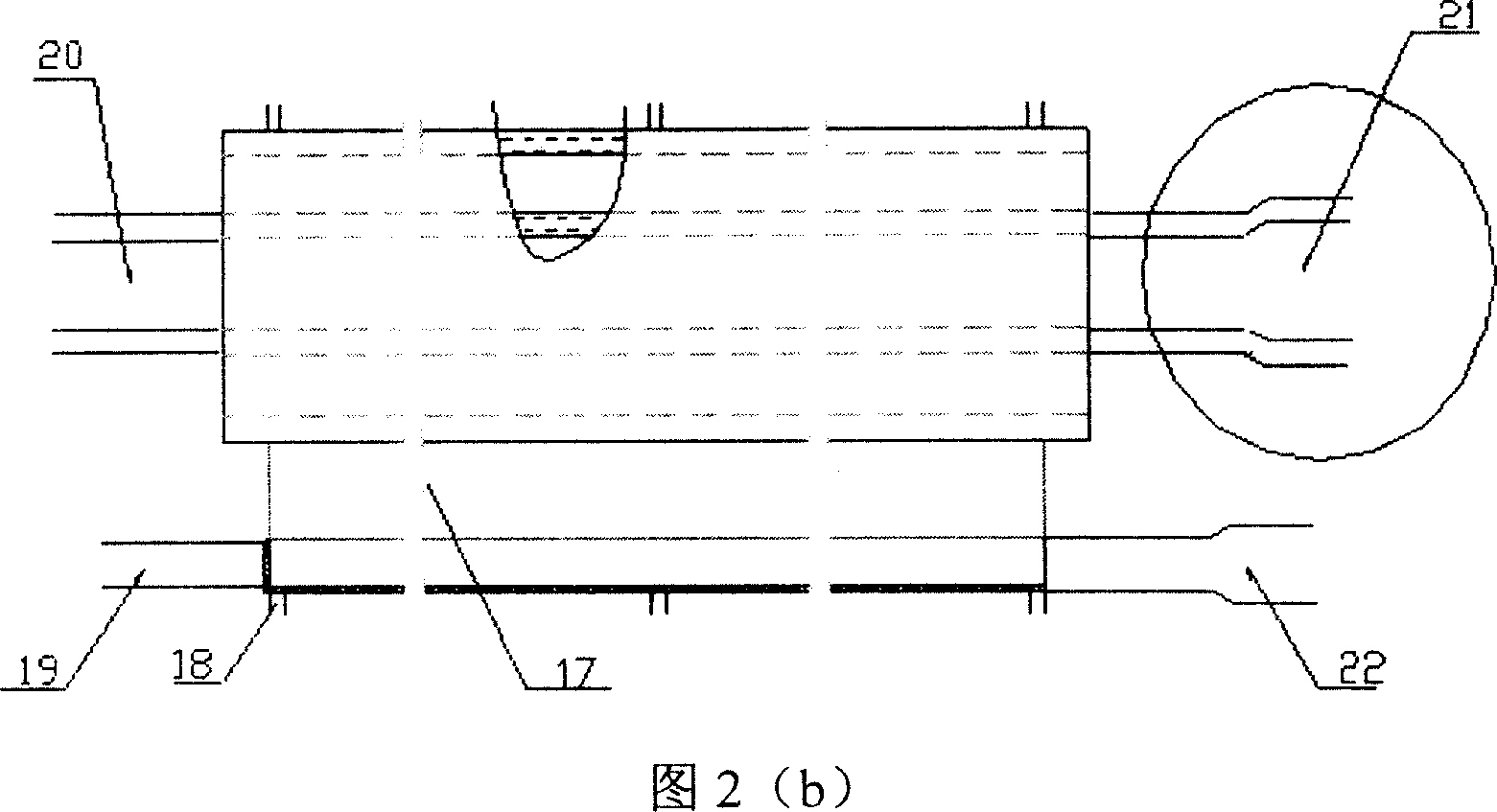

Photovoltaic device and process for producing same

InactiveUS20080196761A1Improve efficiencyHigh levelFinal product manufactureSolid-state devicesProduction rateLength wave

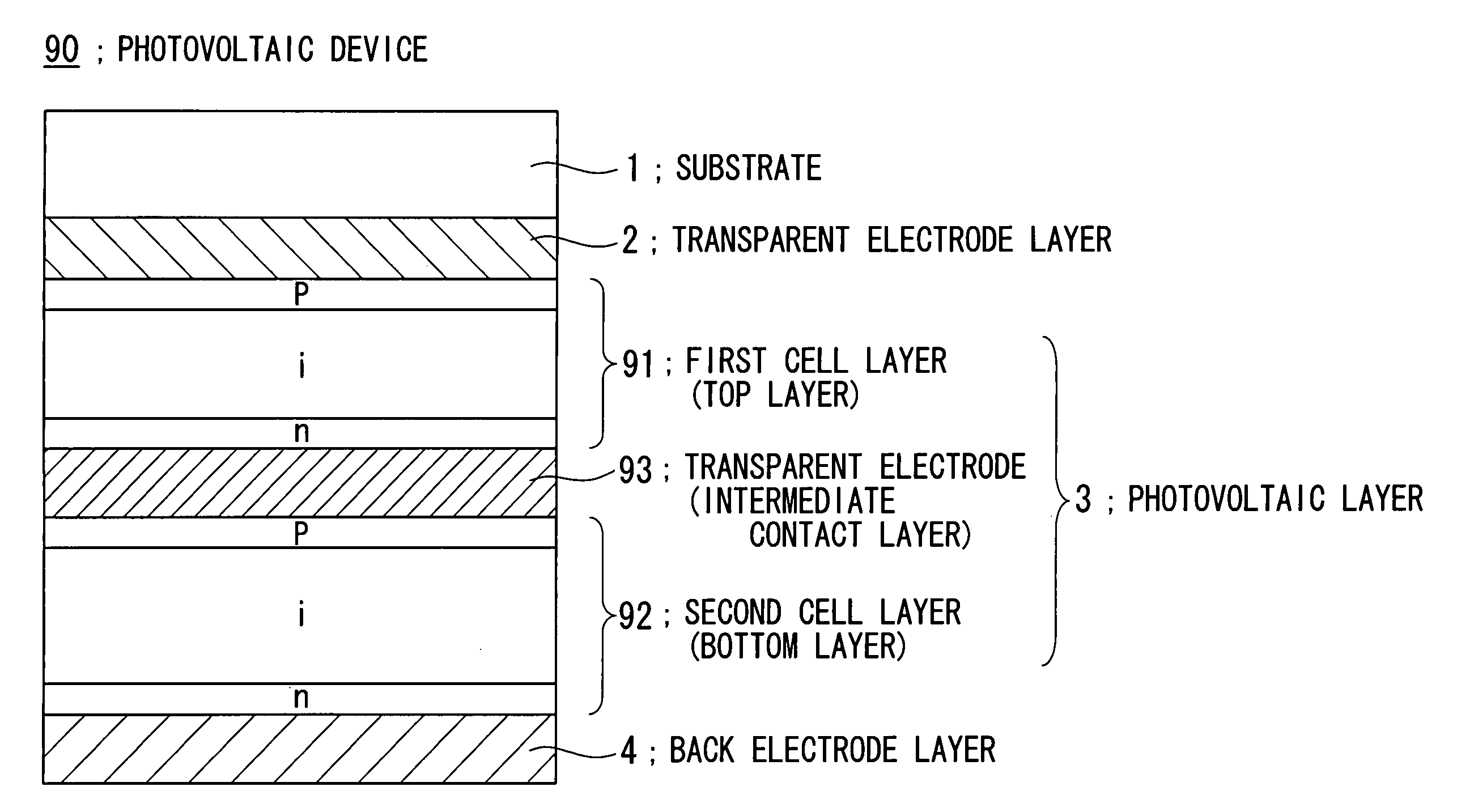

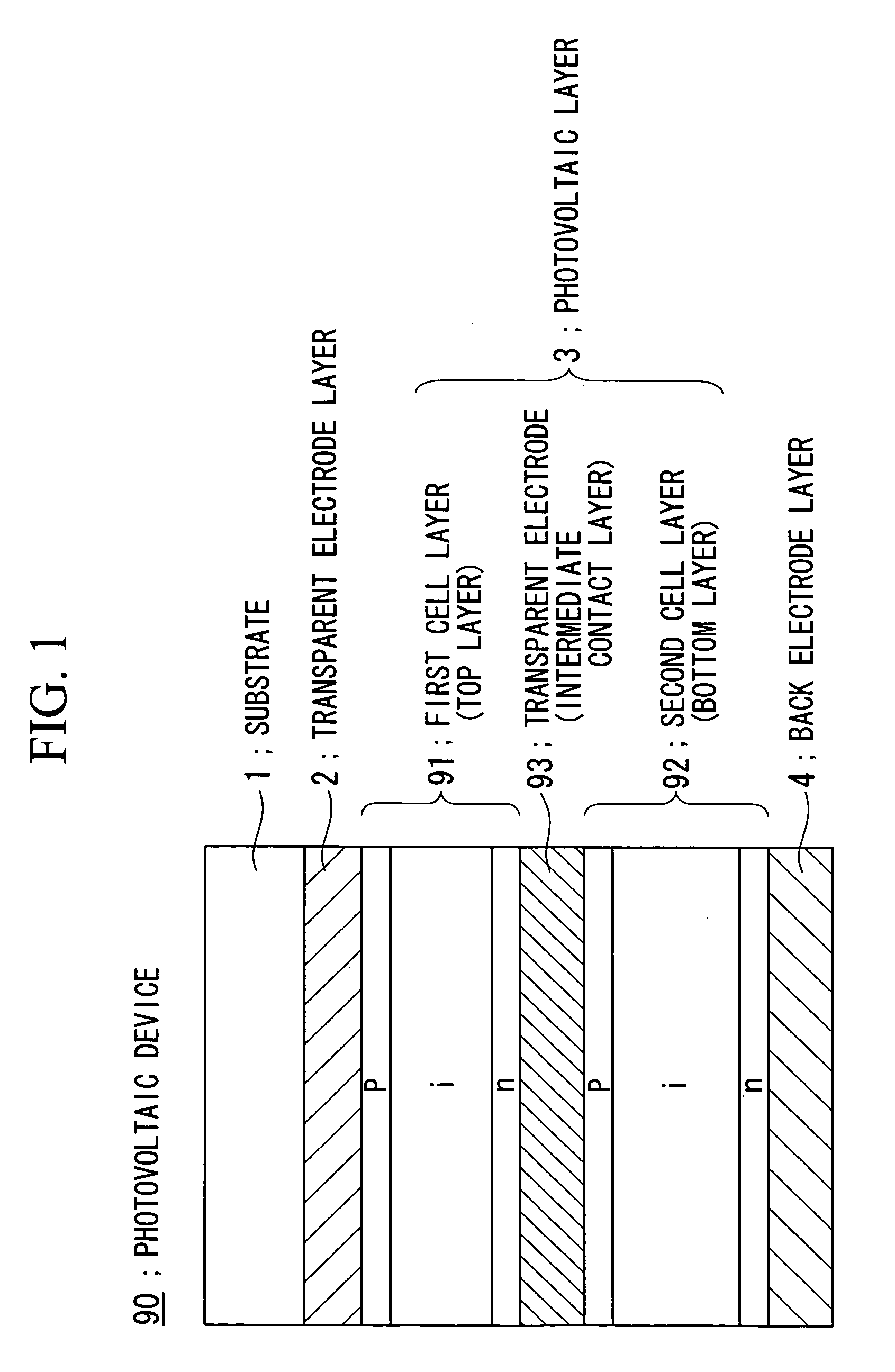

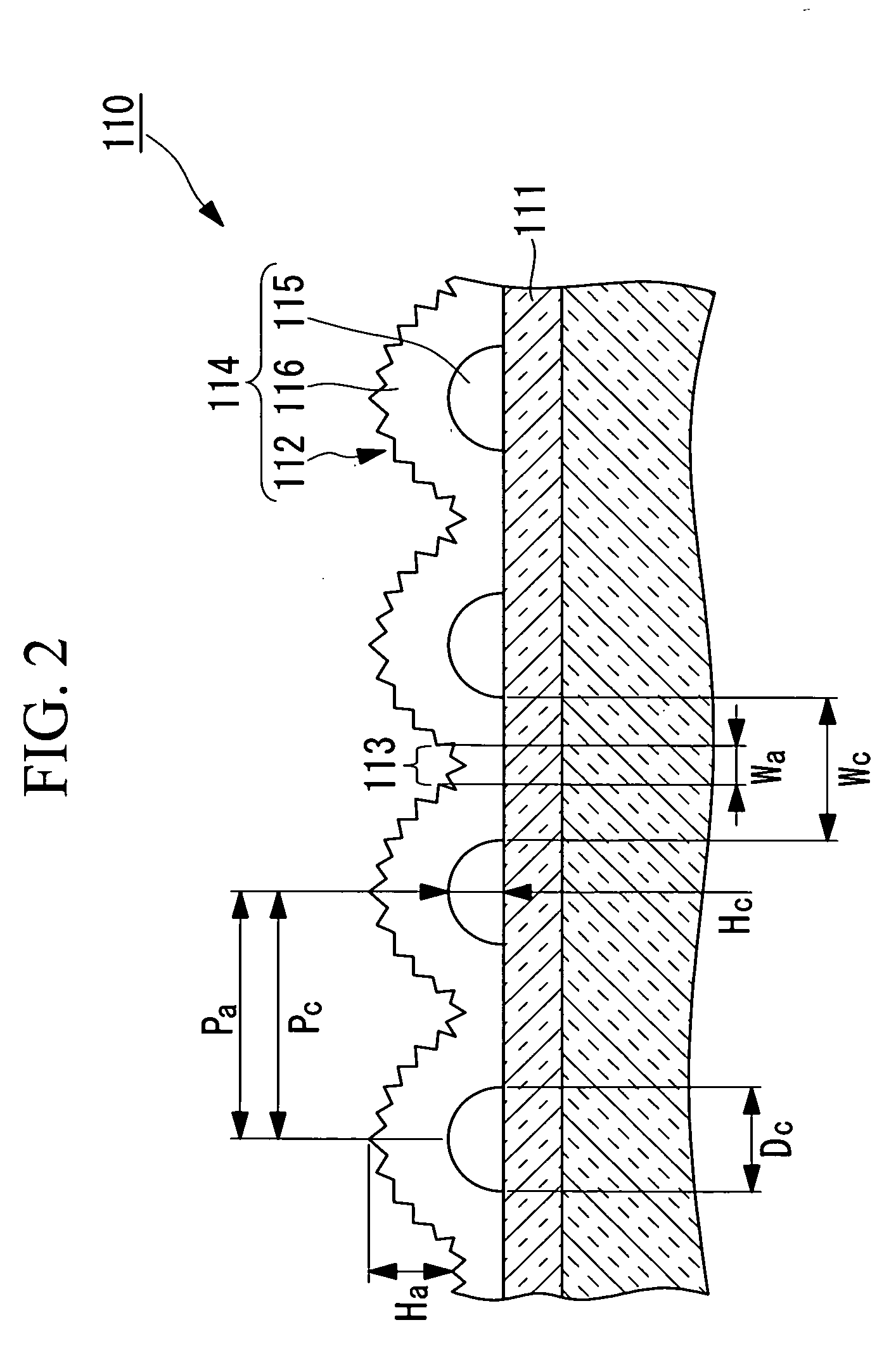

A photovoltaic device and a process for producing the photovoltaic device that combine a high photovoltaic conversion efficiency with a high level of productivity. The photovoltaic device includes at least a transparent electrode-bearing substrate, prepared by providing a transparent electrode layer on a transparent, electrically insulating substrate, and a photovoltaic layer containing mainly crystalline silicon-based semiconductors and a back electrode layer formed sequentially on the transparent electrode layer of the transparent electrode-bearing substrate, wherein the surface of the transparent electrode layer of the transparent electrode-bearing substrate has a shape that contains a mixture of coarse and fine roughness, and exhibits a spectral haze ratio of 20% or greater for wavelengths of from 550 nm to 800 nm, and the photovoltaic layer containing mainly crystalline silicon-based semiconductors has a film thickness of from 1.2 μm to 2 μm, and a Raman ratio of from 3.0 to 8.0.

Owner:MITSUBISHI HEAVY IND LTD

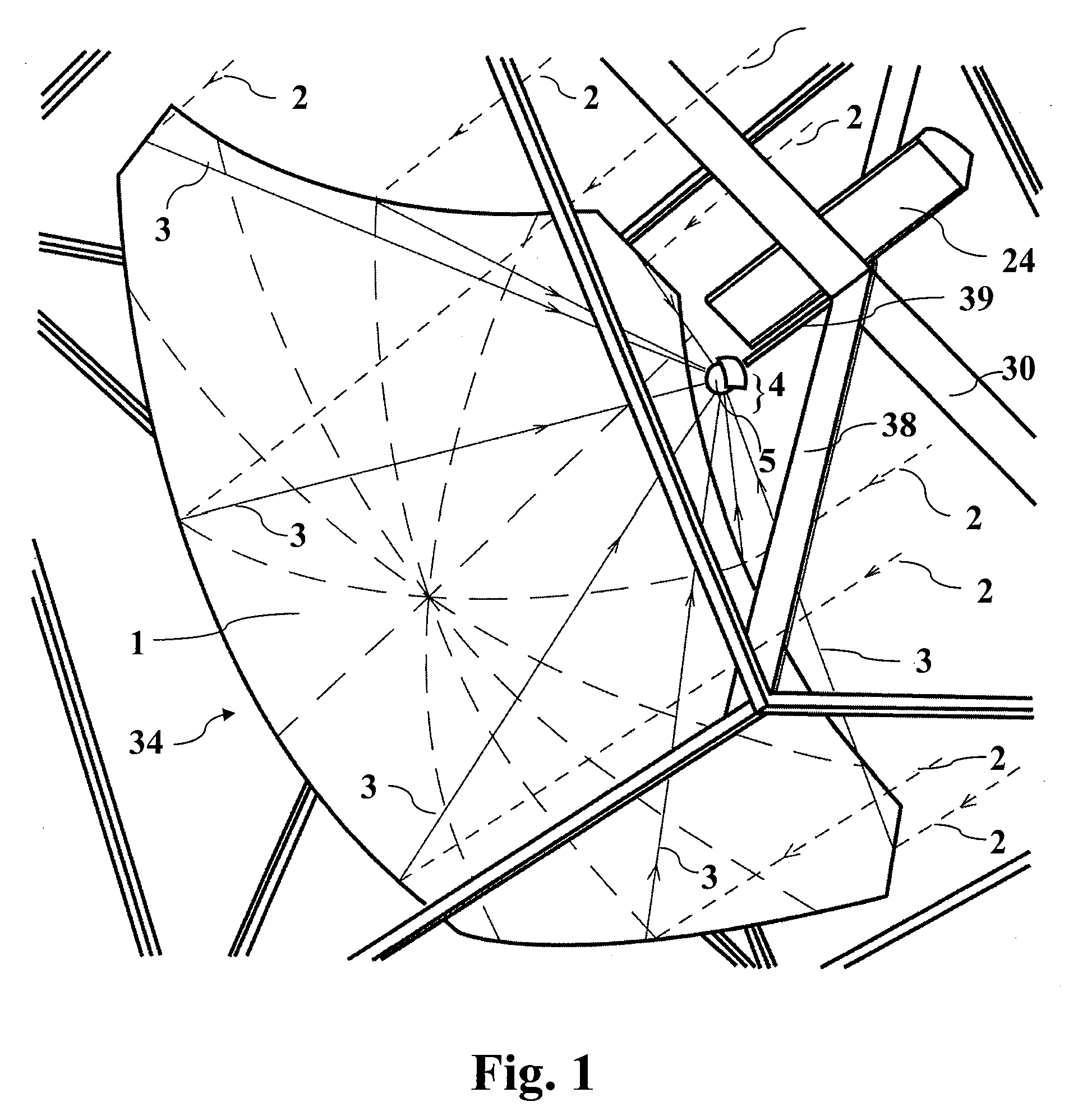

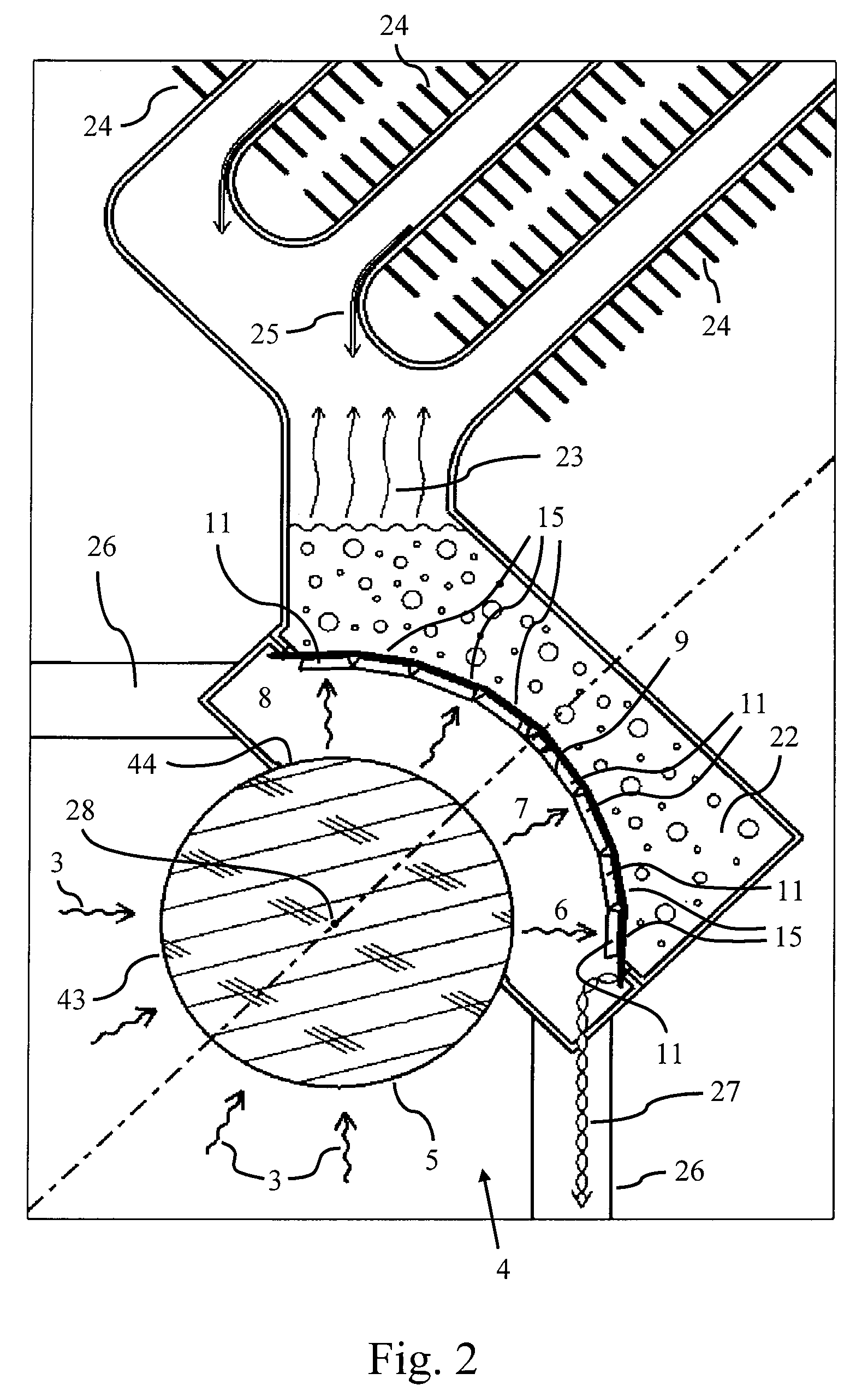

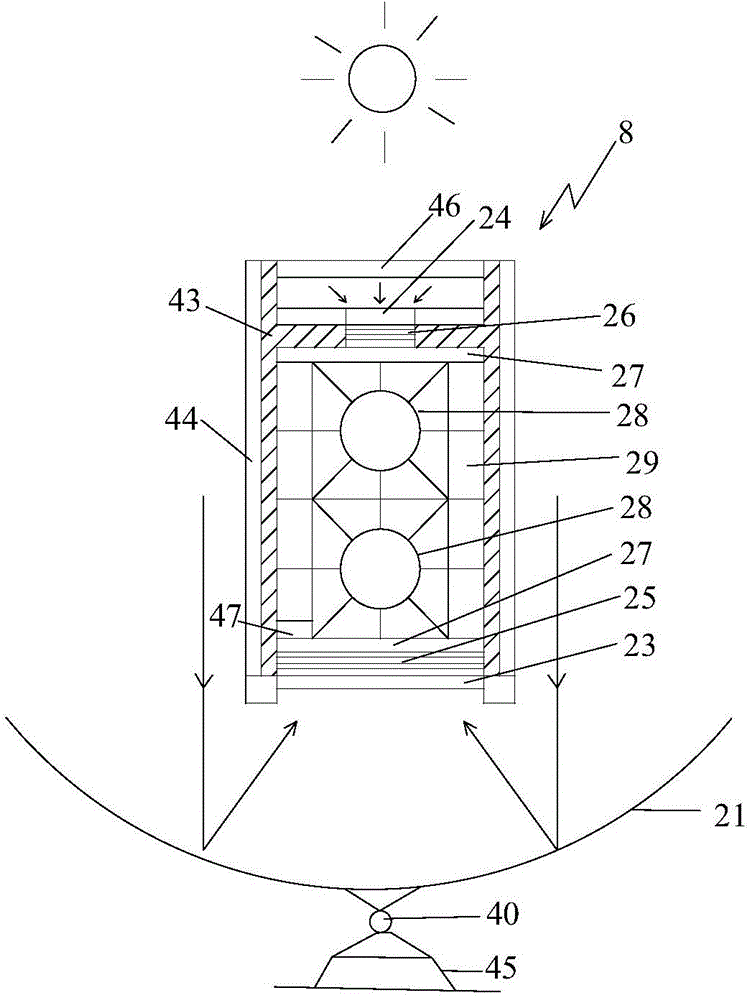

Photovoltaic generator with a spherical imaging lens for use with a paraboloidal solar reflector

ActiveUS20090277498A1Increase surface areaImprove heat transfer performanceSolar heating energySolar heat collector controllersHigh concentrationElectricity

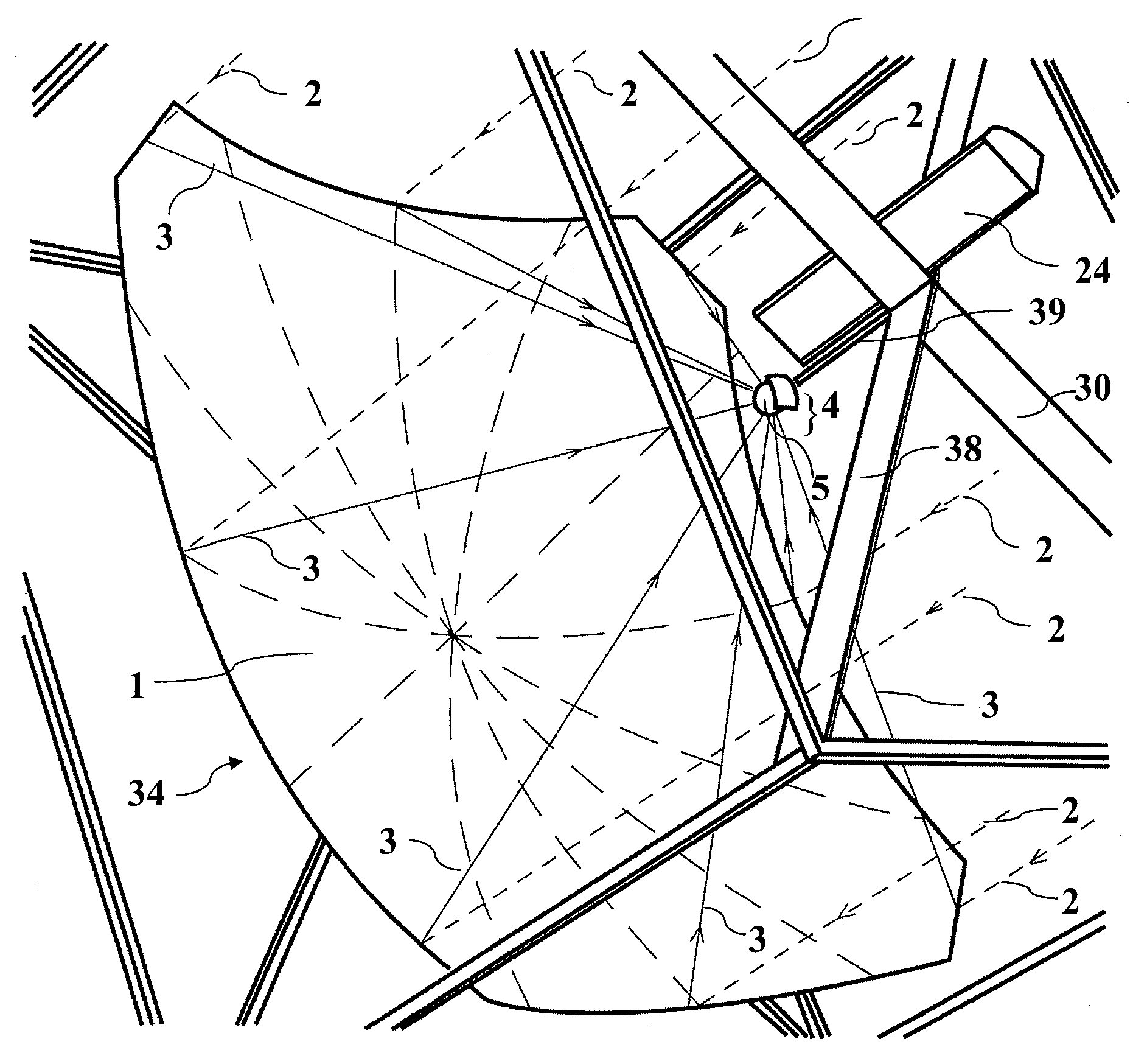

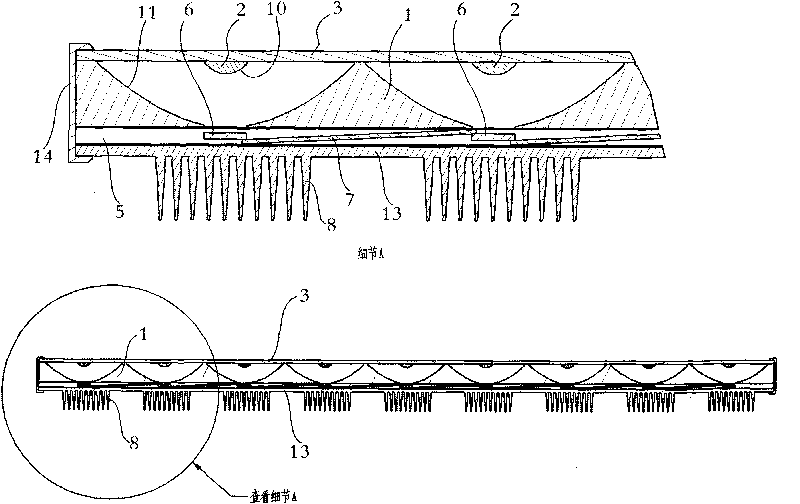

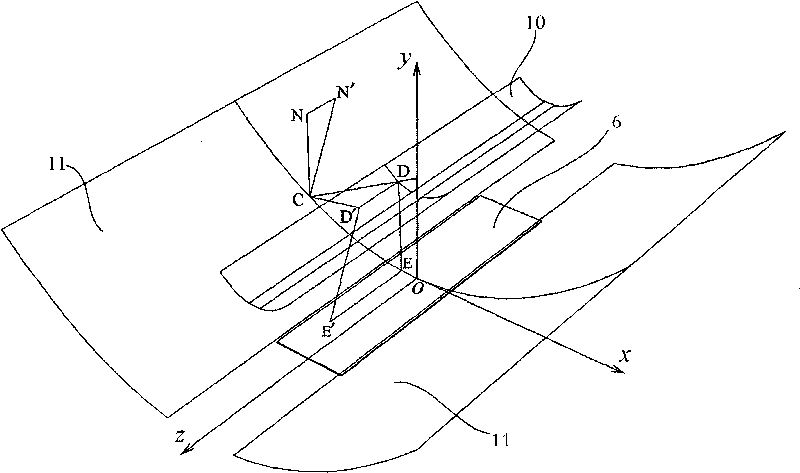

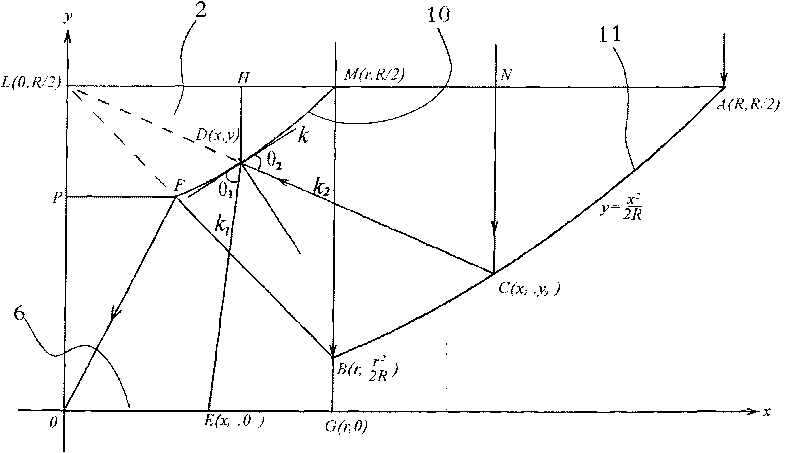

The invention is a generator for photovoltaic conversion of concentrated sunlight into electricity. A generator according to the invention incorporates a plurality of photovoltaic cells and is intended for operation near the focus of a large paraboloidal reflector pointed at the sun. Within the generator, the entering concentrated light is relayed by secondary optics to the cells arranged in a compact, concave array. The light is delivered to the cells at high concentration, consistent with high photovoltaic conversion efficiency and low cell cost per unit power output. Light enters the generator, preferably first through a sealing window, and passes through a field lens, preferably in the form of a full sphere or ball lens centered on the paraboloid focus. This lens forms a concentric, concave and wide-angle image of the primary reflector, where the intensity of the concentrated light is stabilized against changes in the position of concentrated light entering the generator. Receiving the stabilized light are flat photovoltaic cells made in different shapes and sizes and configured in a concave array corresponding to the concave image of a given primary reflector. Photovoltaic cells in a generator are also sized and interconnected so as to provide a single electrical output that remains high and stable, despite aberrations in the light delivered to the generator caused by, for example, mispointing or bending of the primary reflector. In some embodiments, the cells are set back from the image formed by the ball lens, and part of the light is reflected onto each cell small secondary reflectors in the form of mirrors set around its perimeter.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

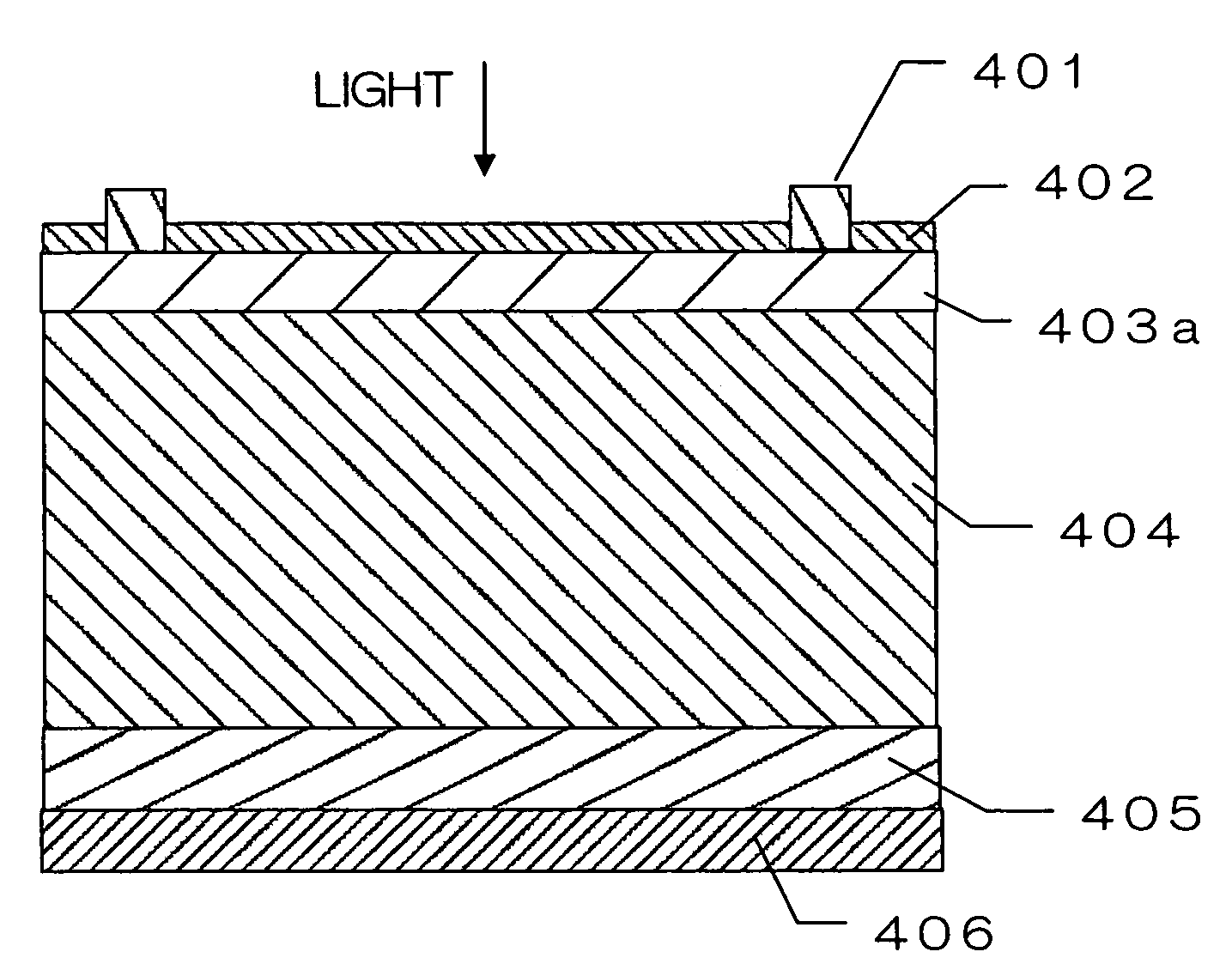

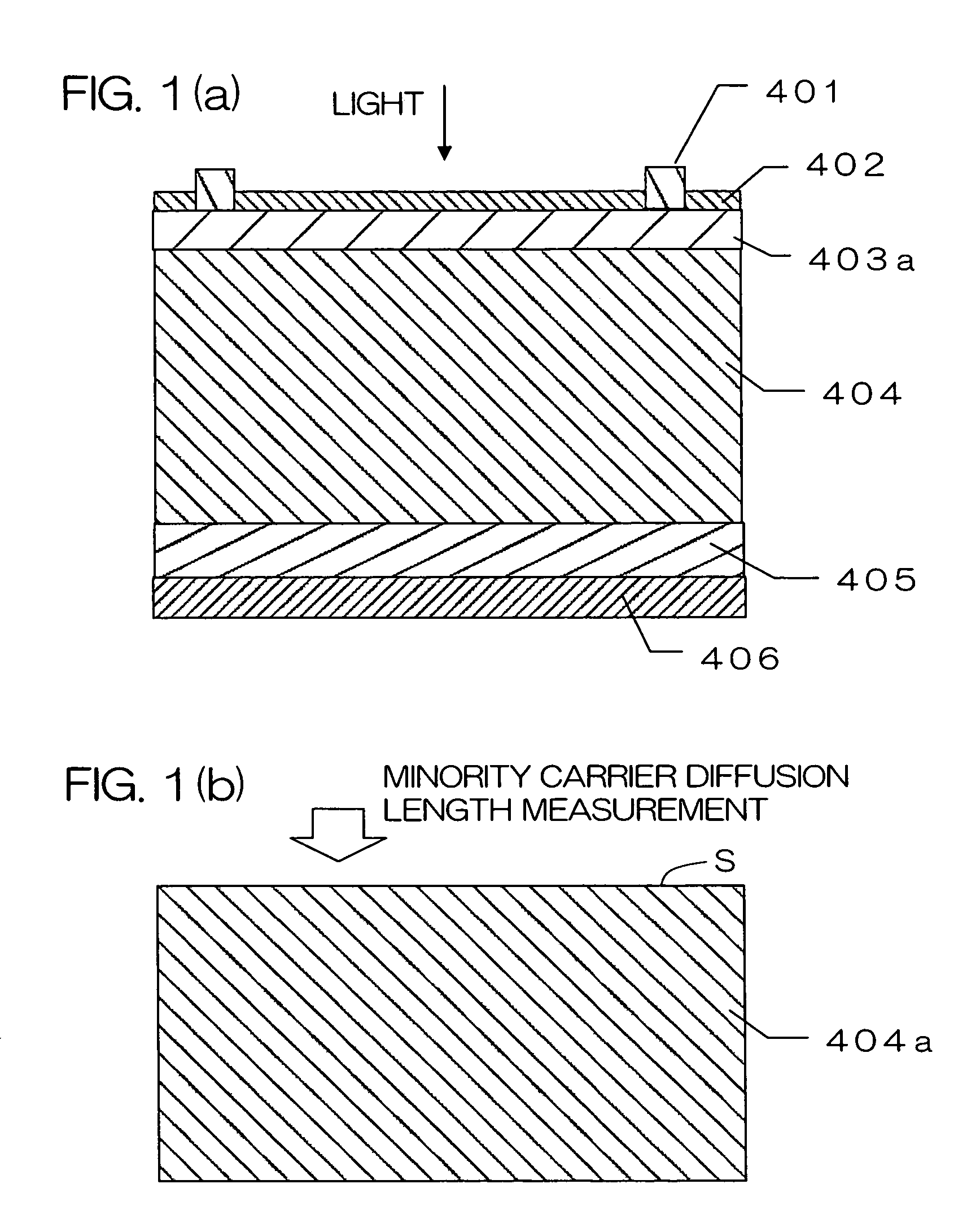

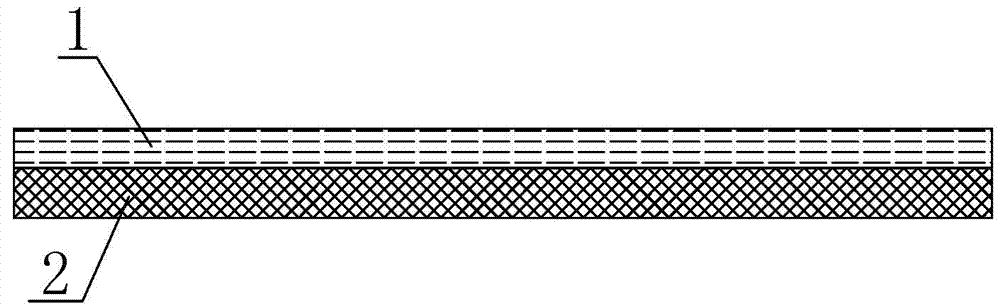

Photovoltaic conversion device and method of manufacturing the device

InactiveUS7317237B2Reduce adverse effectsReduce the number of stepsPolycrystalline material growthFinal product manufactureDiffusionIngot

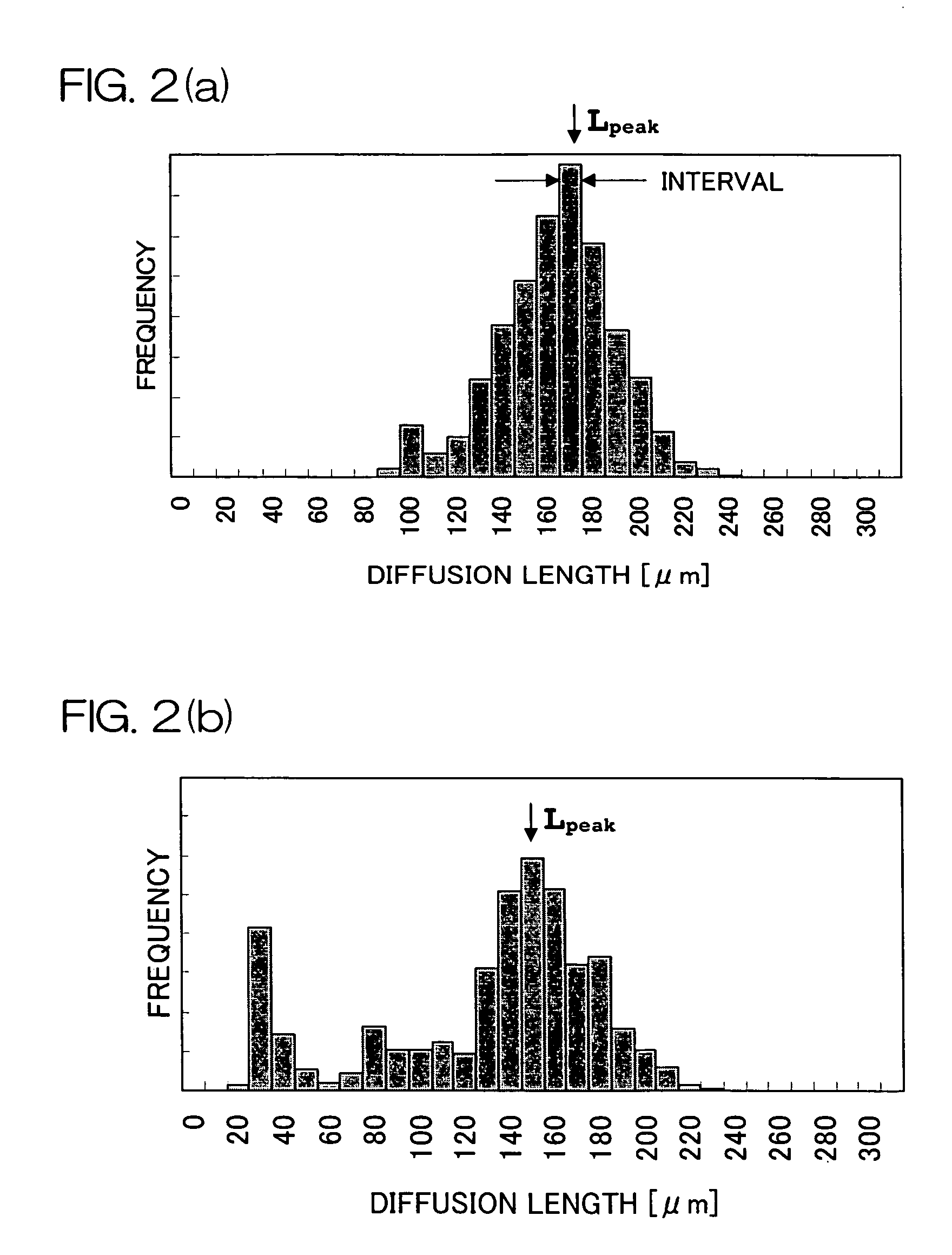

There is disclosed a photovoltaic conversion device constructed using a p-type crystalline silicon substrate 404 doped with boron, which comprises a bulk substrate region 404 , regions other than the bulk substrate region including an n-type region 403 a joining to a light receiving surface of the bulk surface region, a BSF region 405 joining to a back surface of the bulk surface region, wherein with regions other than the bulk substrate region 404 being removed, when a minority carrier diffusion length of the bulk substrate region 404 is measured from the light receiving surface of the bulk surface region, 0.5<(L 1 / Lpeak)is satisfied, where L 1 is a minority carrier diffusion length at an arbitrary measuring area of the light receiving surface of the bulk surface region, and Lpeak is a diffusion length corresponding to a maximum peak on the side of higher diffusion length of a histogram, the histogram being formed from data obtained when a minority carrier diffusion length of the light receiving surface of the bulk surface region is measured at a plurality of measurement areas. This structure can reduce influence of impurities such as Fe, and enhances utilization efficiency of silicon ingots. With this structure, a photovoltaic conversion device with high photovoltaic conversion efficiency can be realized.

Owner:KYOCERA CORP

Solar cell and process for producing solar cell

InactiveUS20050103377A1Avoid reorganizationImprove photovoltaic conversion efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingDopantManufacturing technology

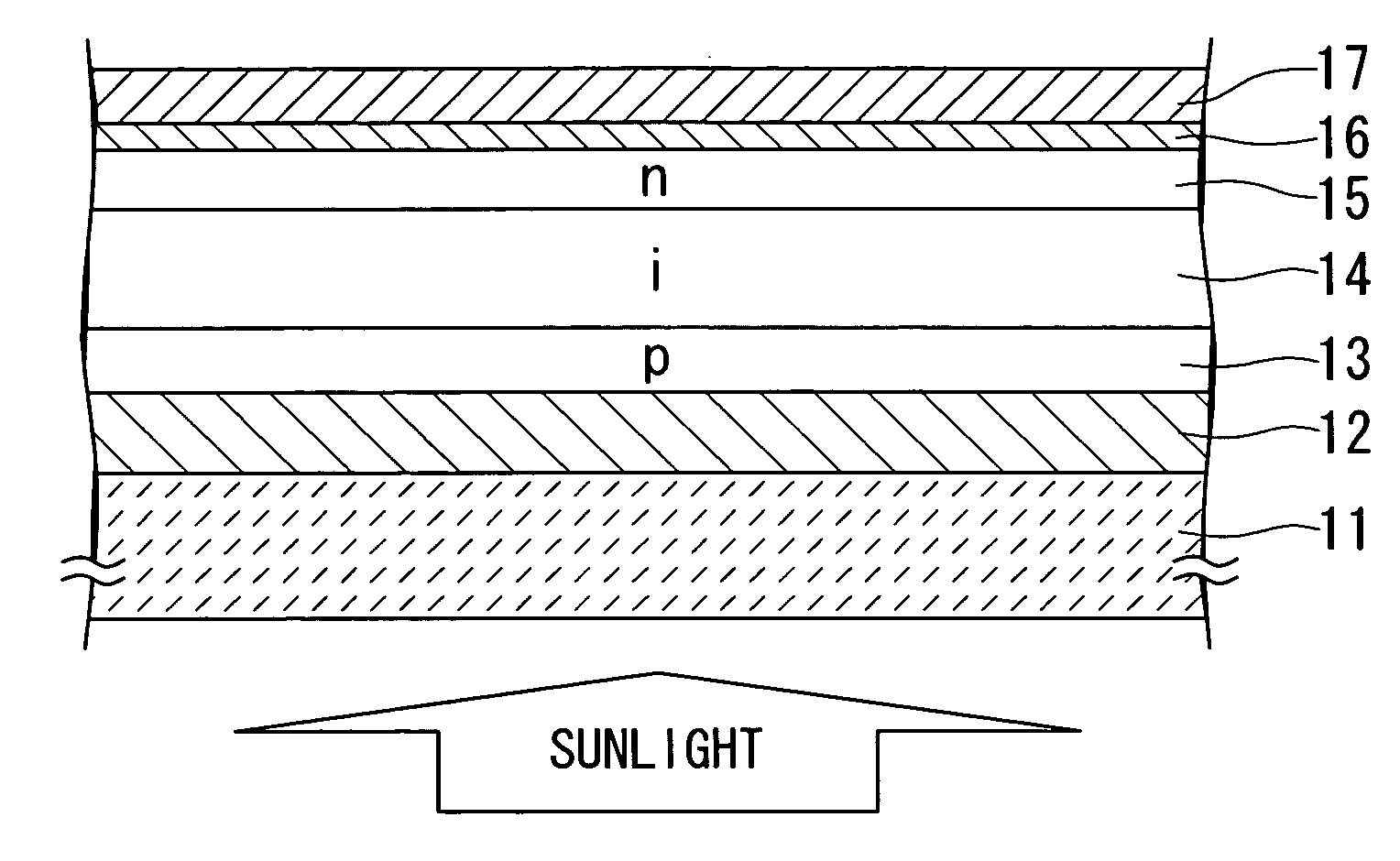

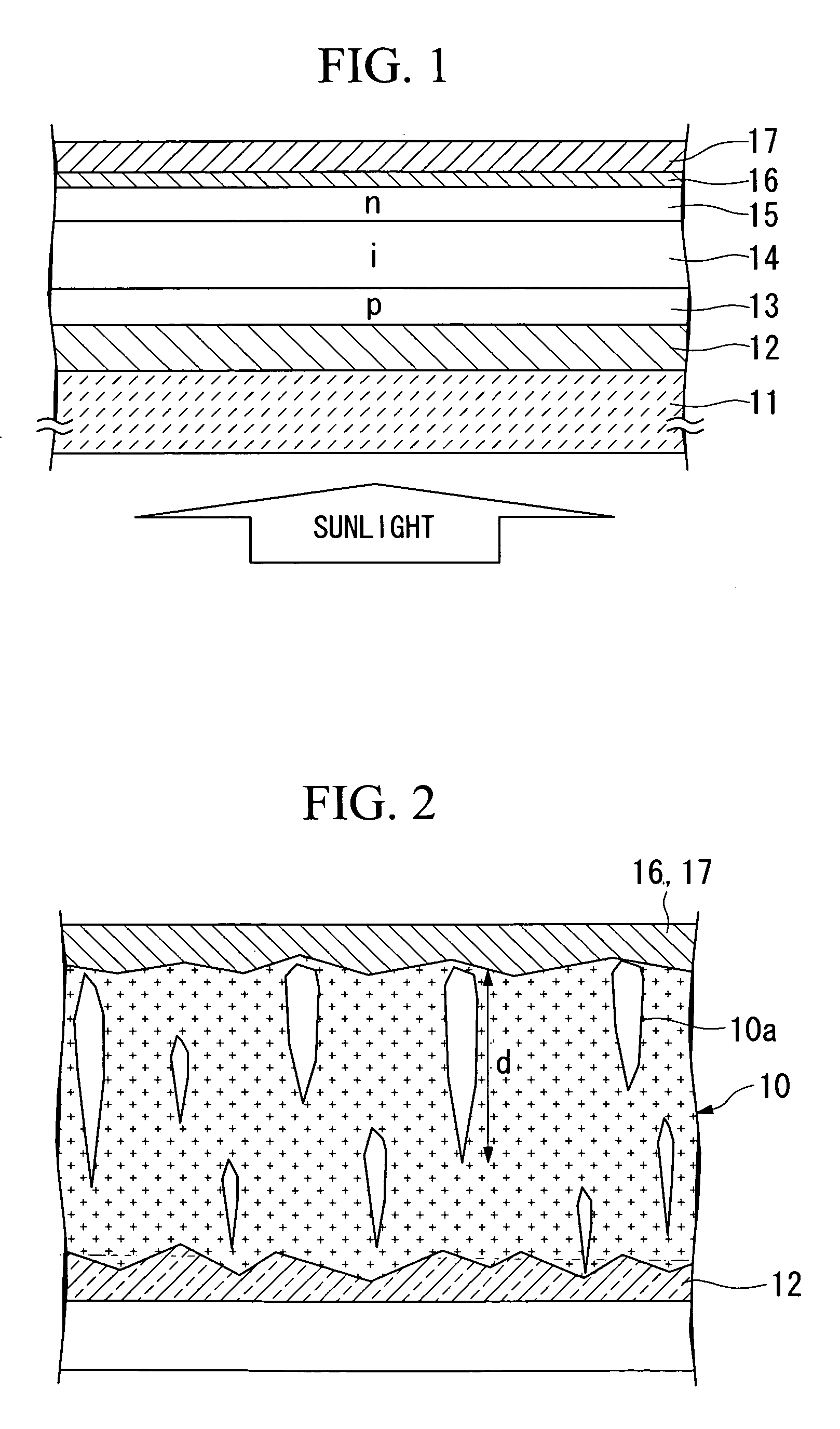

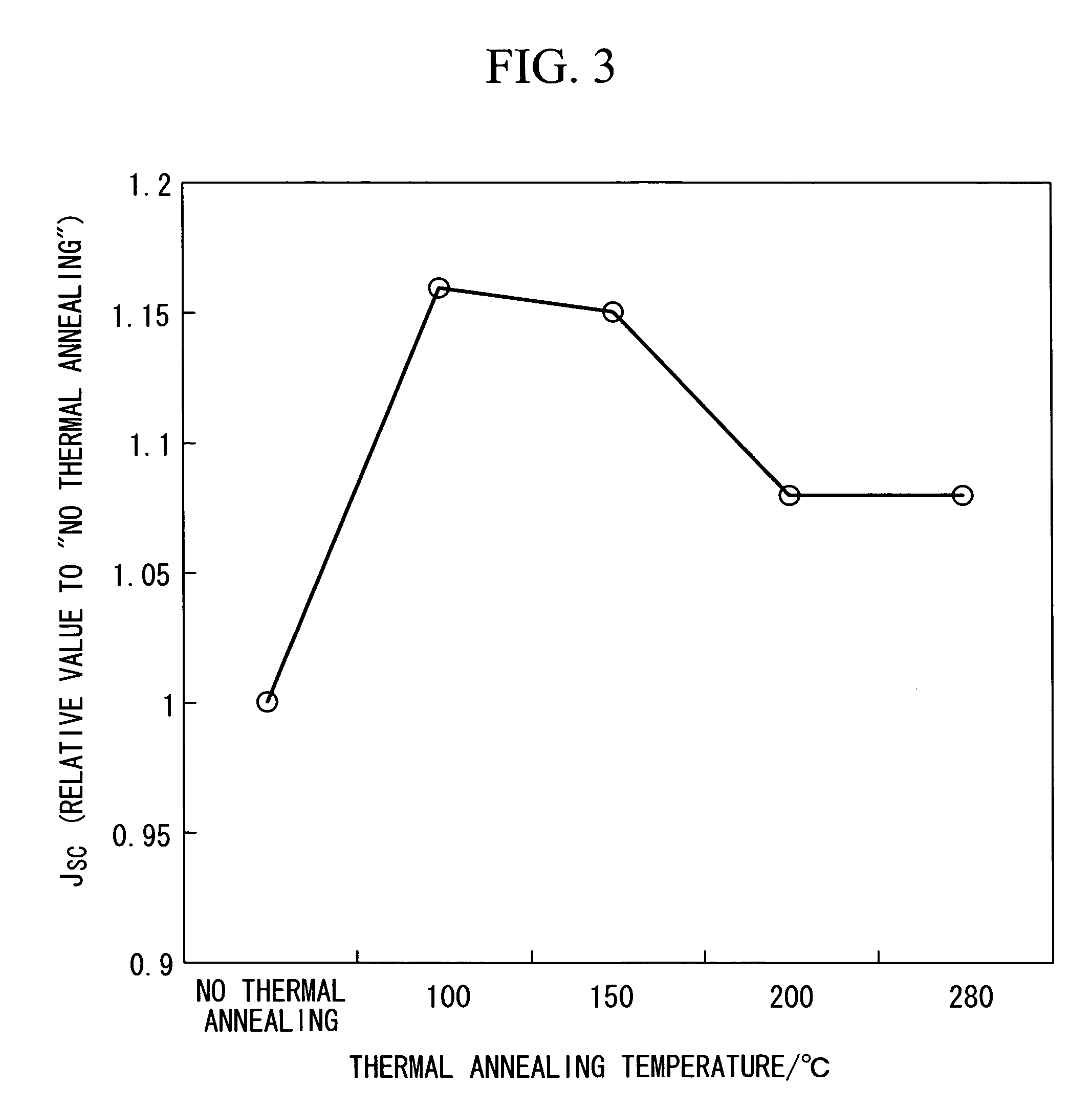

A process for producing a solar cell is provided which can enhance the photovoltaic conversion efficiency by enlarging the grain sizes in the direction of the thickness of an i-layer to reduce grain boundaries, thereby avoiding recombination of carriers and activating the dopant at the same time. A process for producing a solar cell includes depositing at least a first transparent electrode, polycrystalline silicon layers in a PIN structure, and a second electrode in sequence on an electrically insulating substrate, the polycrystalline silicon layers in a PIN structure including a p-type silicon layer, an i-type silicon layer, and an n-type silicon layer, wherein the polycrystalline silicon layers in a PIN structure are formed by: forming a p-type, which is then subjected to thermal annealing; depositing an i-type silicon layer on the p-type silicon layer; and depositing an n-type silicon layer on the i-type silicon layer.

Owner:MITSUBISHI HEAVY IND LTD

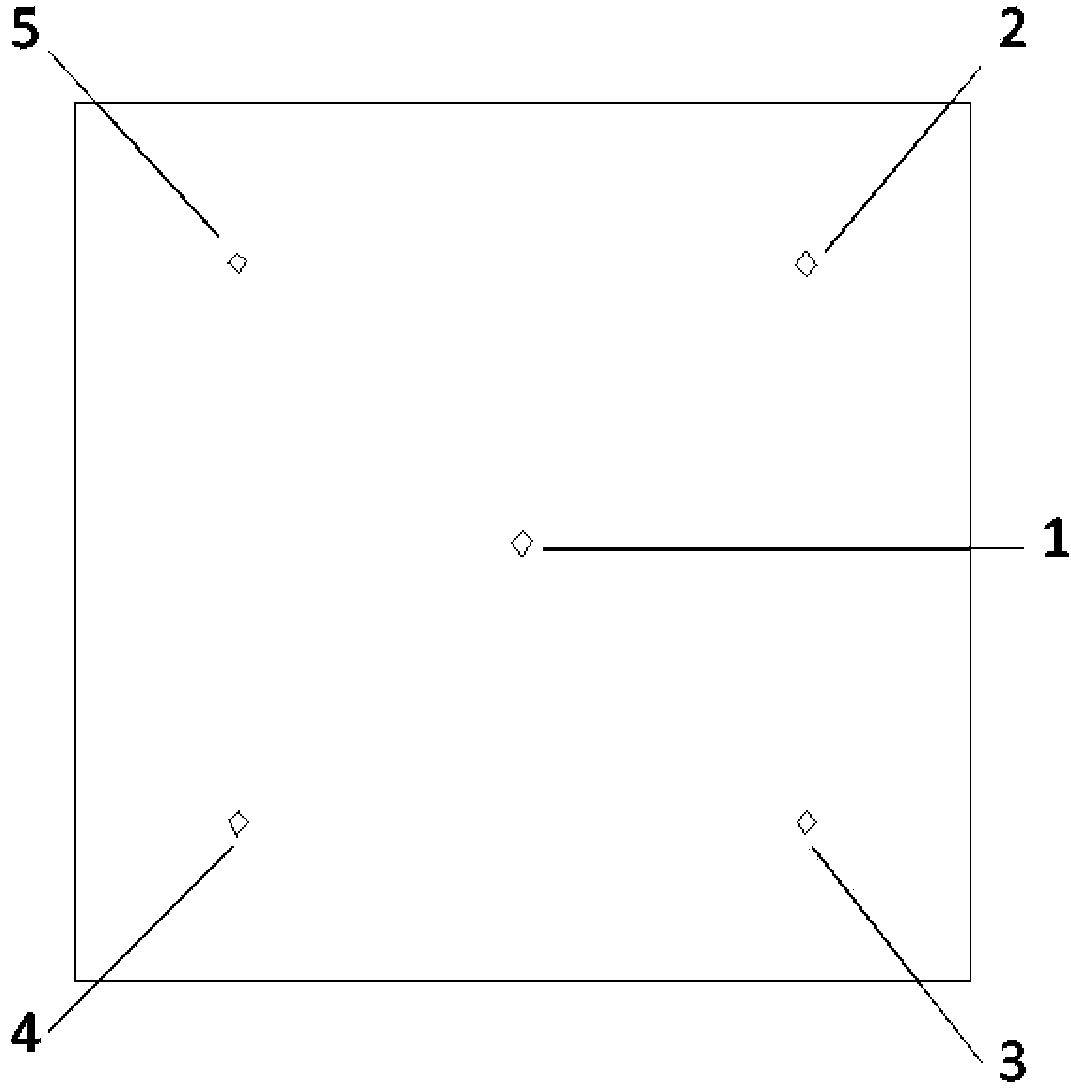

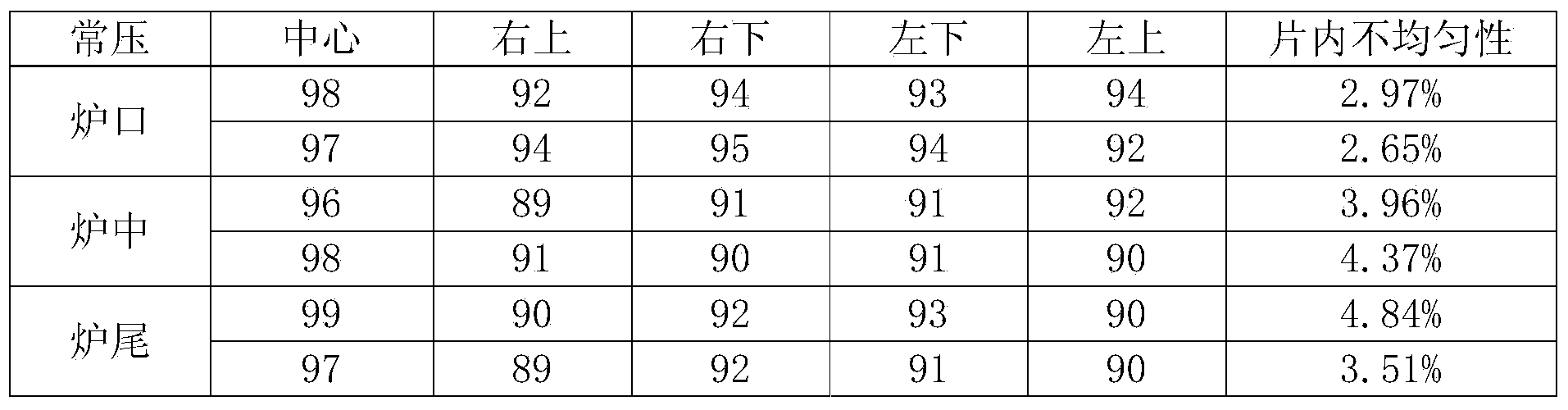

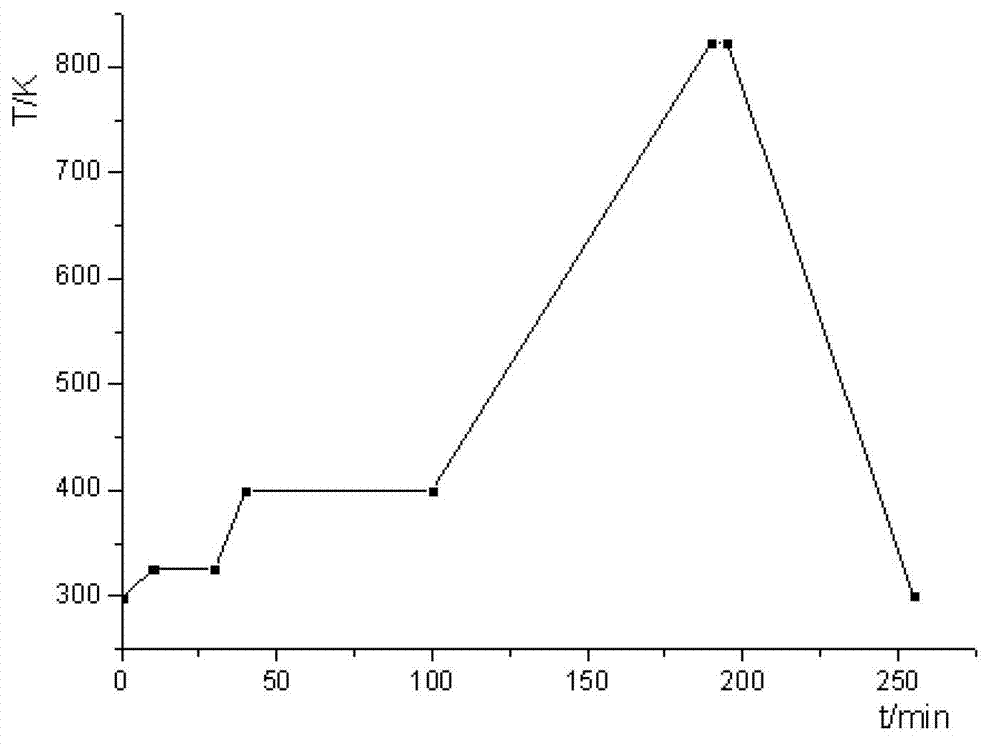

Decompression diffusion technology for manufacturing high-square-resistance battery pieces

ActiveCN104269459ARelieve pressureReduce unevennessFinal product manufactureSemiconductor/solid-state device manufacturingElectrical resistance and conductancePressure rise

The invention discloses a decompression diffusion technology for manufacturing high-square-resistance battery pieces. The technology comprises a constant-temperature decompression process, a pre-oxidation process, a temperature rise process, a deep diffusion process, a phosphorus propulsion process, a post-oxidation treatment process and a temperature drop and pressure rise process. Compared with a constant-pressure diffusion technology, the variable of pressure in the diffusion process is introduced into the decompression diffusion technology, the pressure in a diffusion furnace tube is reduced, meanwhile temperature, time and airflow are adjusted so that the uniformity of the diffusion square resistance can be better, and the photovoltaic conversion efficiency of the manufactured battery pieces can be higher; besides, the yield in unit time of equipment can be increased, and the usage amount of diffusion phosphorus sources is reduced.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

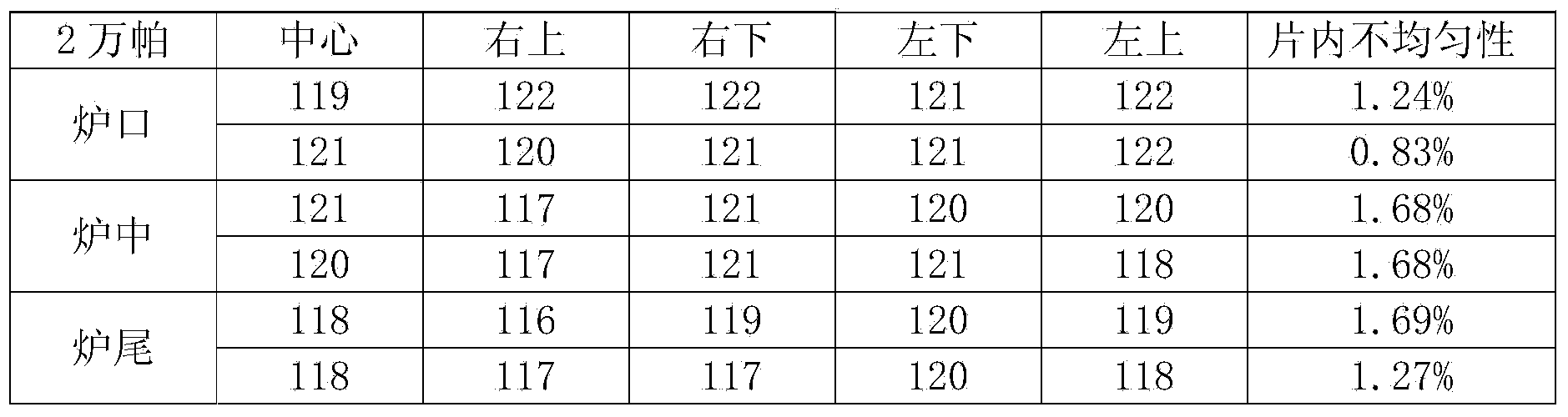

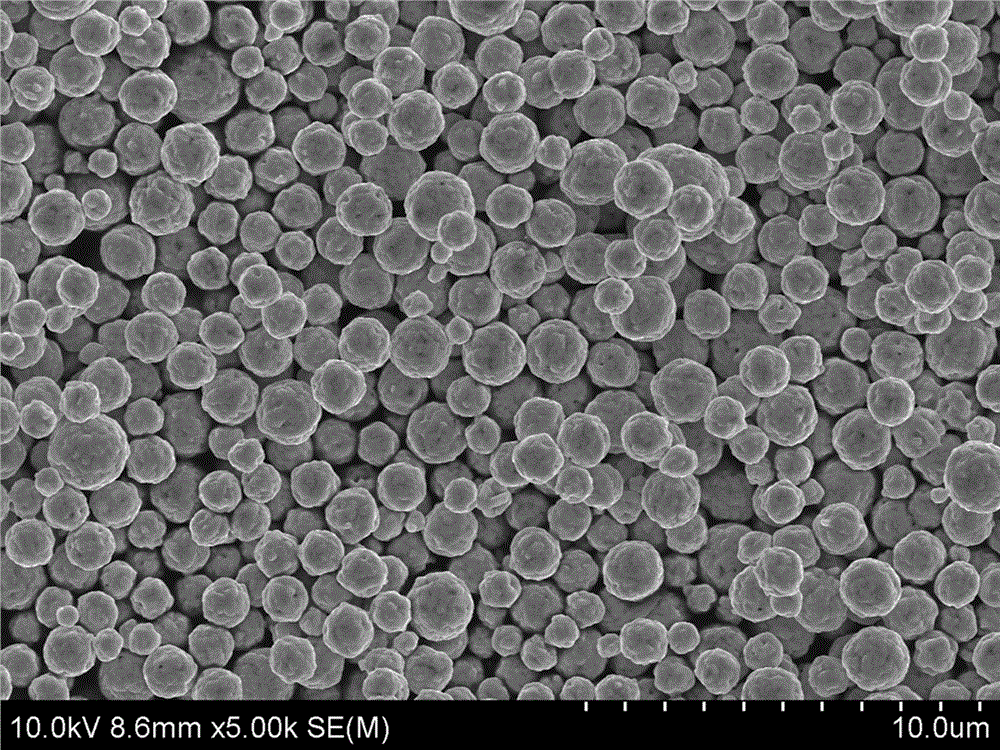

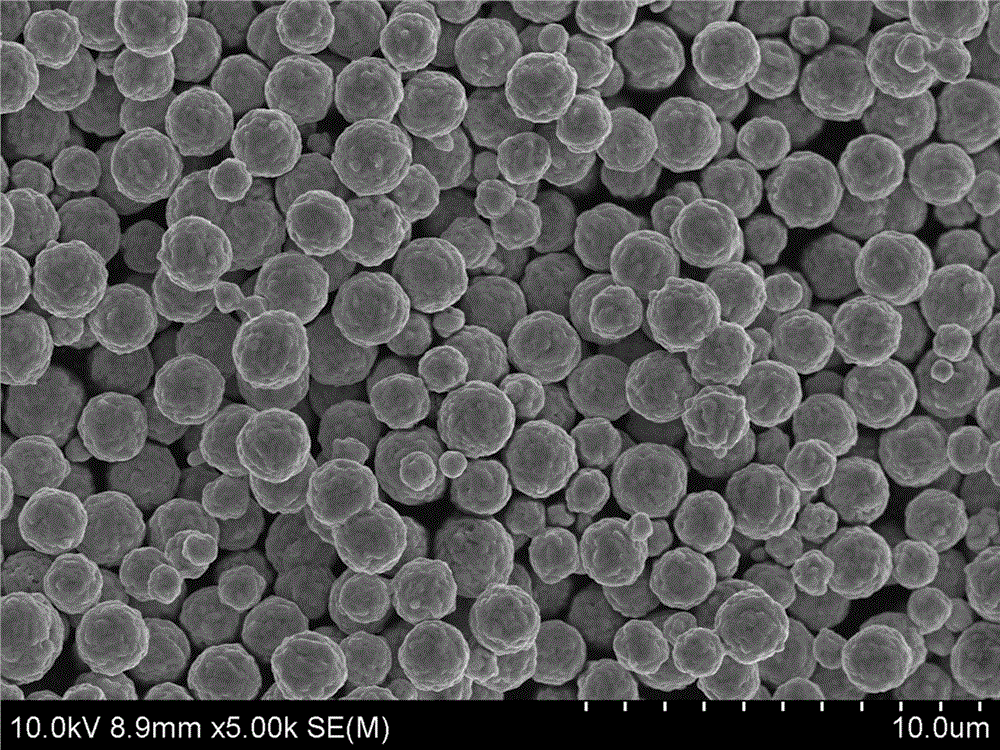

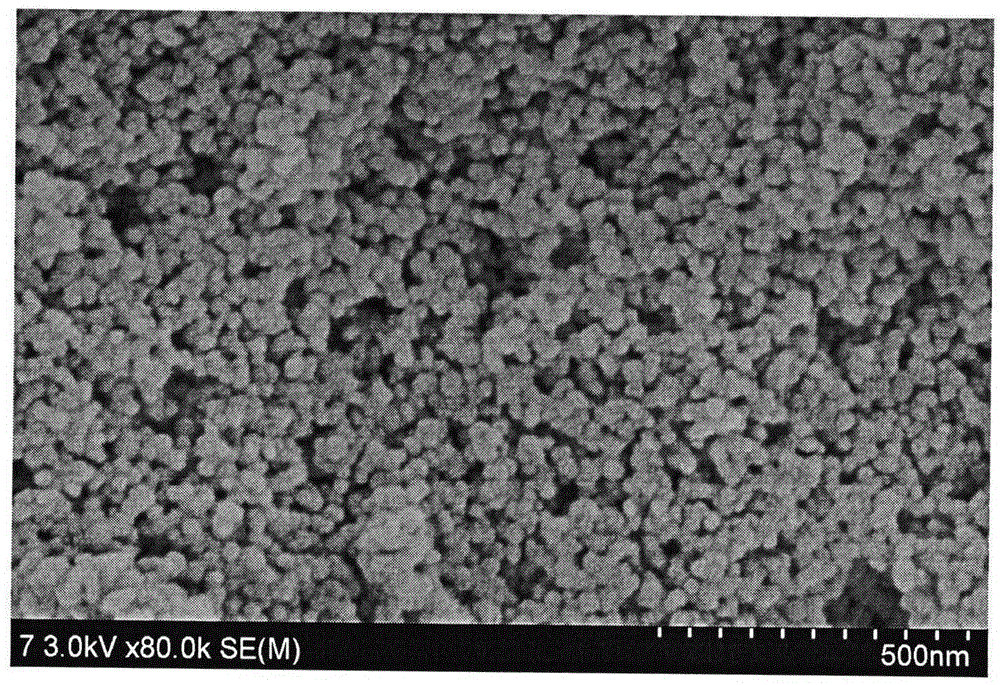

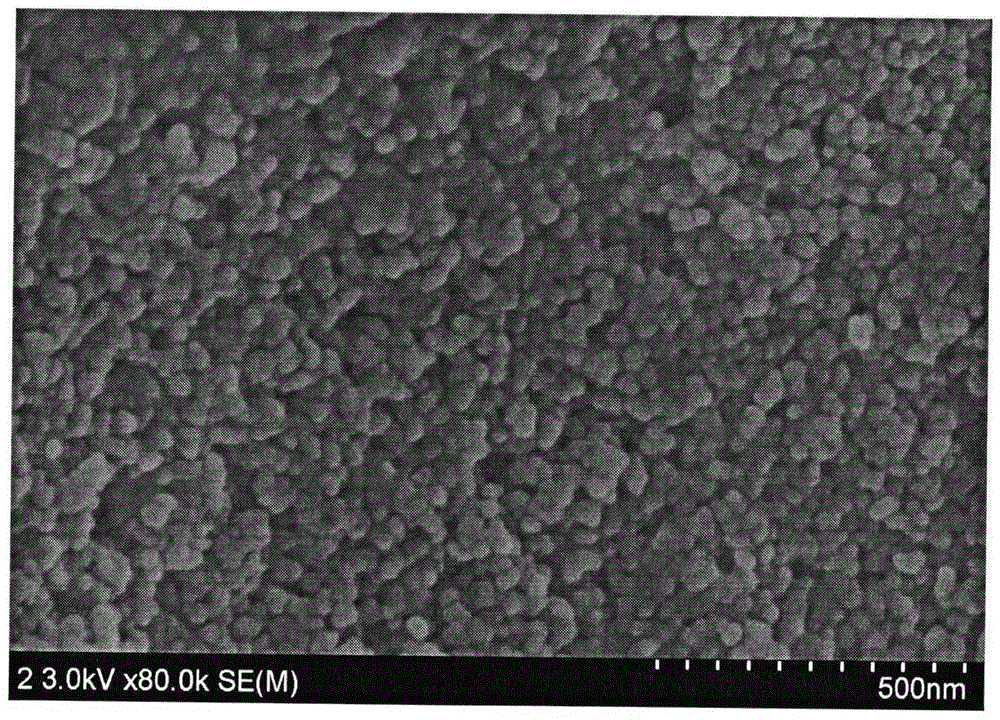

Silver powder for solar cell conductive silver pulp and preparation and application

ActiveCN106513699AEffective size controlGood lookingTransportation and packagingMetal-working apparatusOleic Acid TriglycerideMaterials science

The invention provides silver powder for solar cell conductive silver pulp and preparation and application. A silver nitrate solution is prepared and used as a silver source, and the pH of the silver nitrate solution is adjusted to 1-5 with ammonia water or nitric acid; ascorbic acid of which the mass is 0.6-1.2 times that of the silver nitrate is weighed, an ascorbic acid solution is prepared, and a dispersant is added; a redox reaction is conducted step by step; a part of silver source is quickly added to a redox under heating and stirring, oleic acid is added immediately, then the rest of the silver source is slowly added to the redox dropwise, the pH of the solution is controlled with the nitric acid or the ammonia water in the drop-by-drop adding process, and a reaction is conducted for 30 minutes after drop-by-drop adding is completed; and after the reaction is completed, supernatant is poured out and cleaned three times with deionized water and absolute ethyl alcohol, and then the supernatant is dried for 4 hours at the temperature of 60 DEG C. By the adoption of the method, the silver source is added to the redox step by step, the purpose of step-by-step implementation of silver nucleation and grain growth is achieved, and the oleic acid is added in the drop-by-drop adding process so that the grain size can be controlled effectively, and the silver powder with the narrow grain size distribution range and average grain size is prepared. The silver powder can be used for preparing the solar cell conductive silver pulp, and the high photovoltaic conversion efficiency is achieved.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

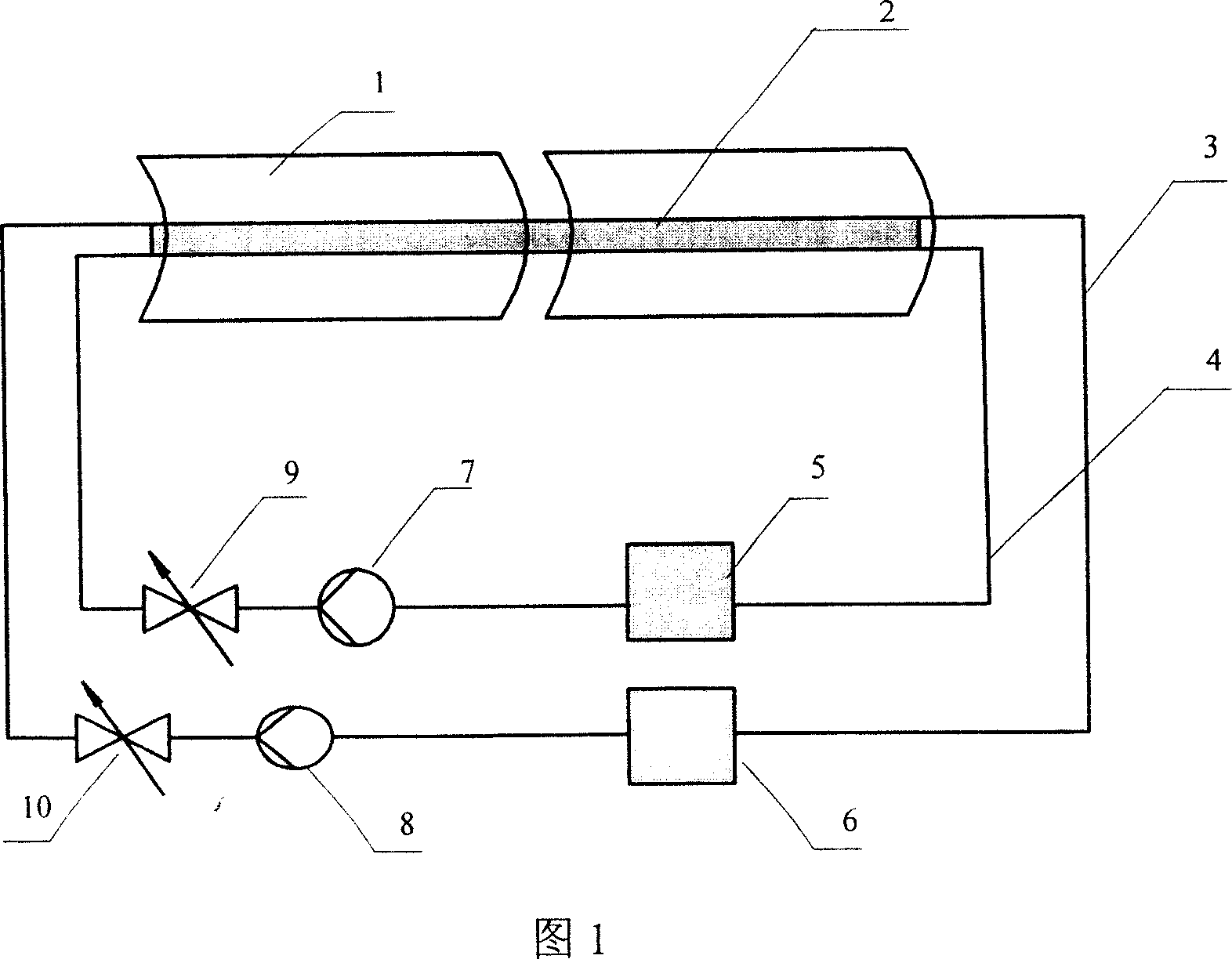

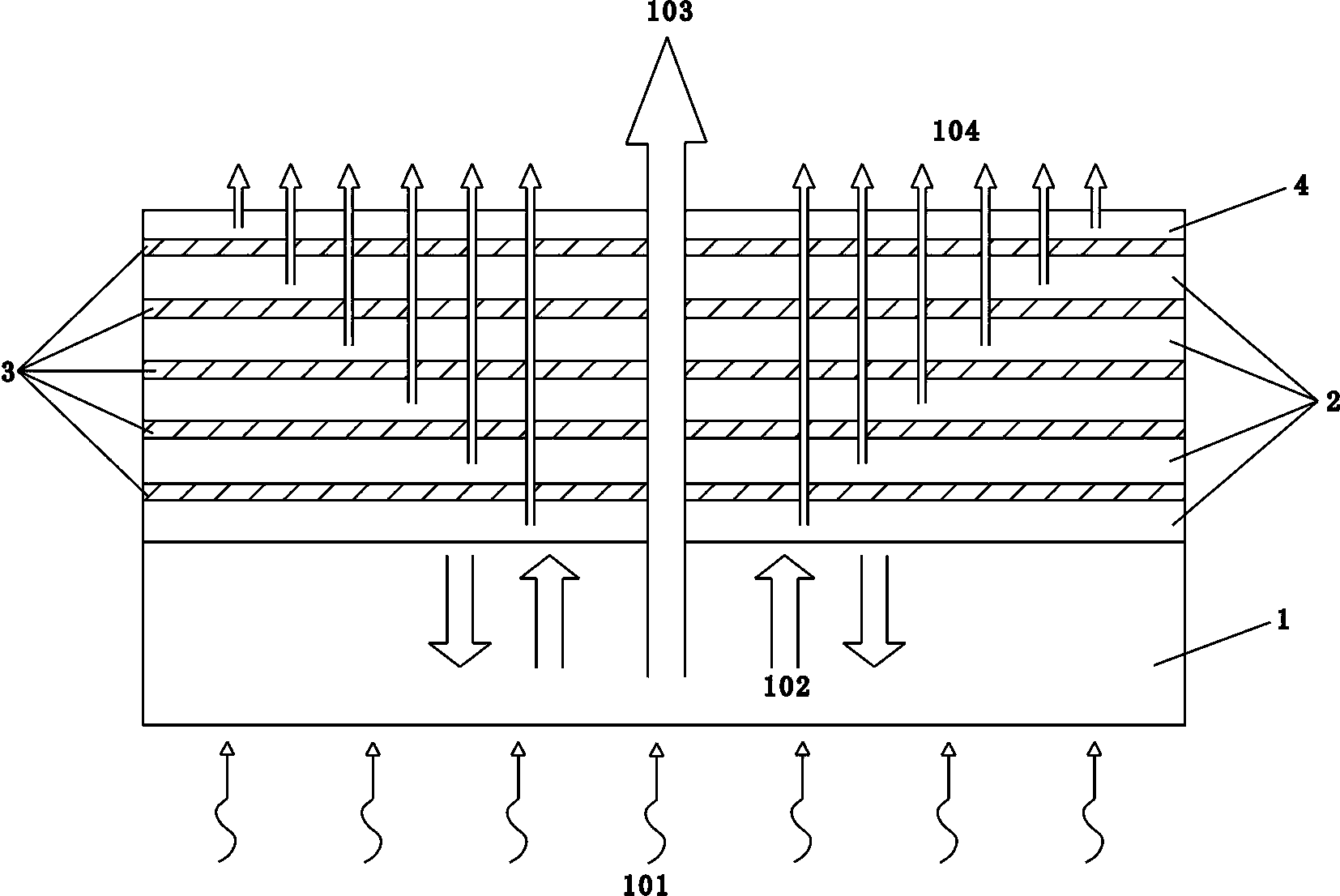

Solar energy light gathering thermo-electric union system

InactiveCN1975282AEfficient use ofReduce lossesSolar heating energySolar heat devicesElectricityPlate heat exchanger

The invention discloses solar united system of concentrate light and pyroelectricity. It has condenser plate and the pyroelectric united device set on condenser zone on the condenser plate. The pyroelectric united device is set with an outer insulating layer of glass, solar cell plate were set under the glass, with cooling conduit which links nano cooling fluid set under the cell plate, the cooling conduit of pyroelectric united device are connected with the cryogenic circulating conduit sequentially installed with cryogenic heat exchanger,cryogenic circulating pump and cryogenic governor valve; the cavity of pyroelectric united device is connected with the high-temperature circulating conduit sequentially installed with high-temperature heat exchanger,high-temperature circulating pump and high-temperature governor valve. The invention complex utilizes the photo electricity and photo-thermal; improve photovoltaic conversion efficiency when the heat is used. The condenser technology reduces the utilization area of photovoltaic battery panels; great reduce the system investment, with a very broad market prospect.

Owner:ZHEJIANG UNIV

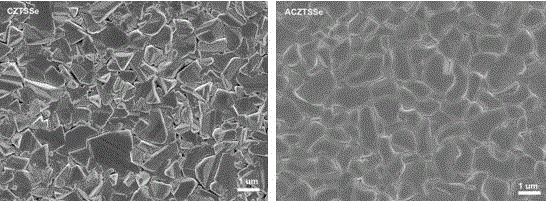

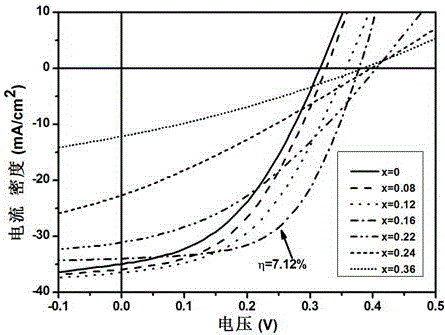

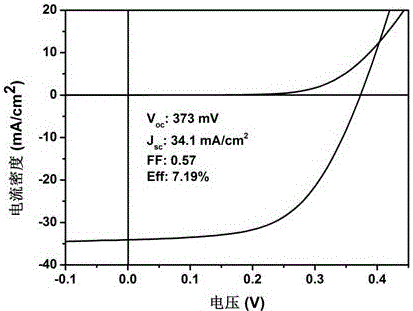

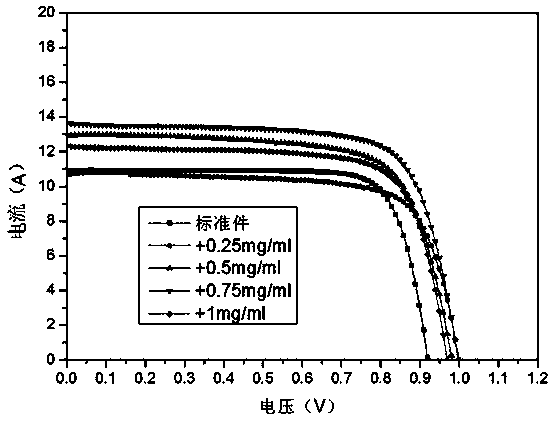

Silver-doped copper zinc tin sulfur selenium light absorption layer film material and application thereof in solar cell

ActiveCN106298995AReduce usageSimple production equipmentFinal product manufacturePhotovoltaic energy generationSulfur containingFilm material

The invention discloses a silver-doped copper zinc tin sulfur selenium light absorption layer film material. The film material is prepared by virtue of the following method: (1) adding 0.07 to 0.13 mol / L of metal copper salt and metal silver salt into an organic solvent, stirring until the metal copper salt and the metal silver salt are completely dissolved, adding 0.03 to 0.07 mol / L of metal tin salt, further stirring until the metal tin salt is dissolved, then adding 0.03 to 0.09 mol / L of metal zinc salt, stirring until the metal zinc salt is completely dissolved, finally adding 2 mol / L of sulfur-containing compound, and stirring until the sulfur-containing compound is completely dissolved to form a stable ACZTS precursor solution; (2) ultrasonically cleaning molybdenum plated glass successively with acetone, absolute ethyl alcohol and deionized water; (3) spin-coating the molybdenum plated glass substrate with the precursor solution, and repeatedly spin-coating and depositing; and (4) after the spin coating is completed, selenizing the sample. The invention also discloses an application of the film material in a solar cell. By doping Ag, the quality of the film can be improved, an open-circuit voltage, a packing factor and photovoltaic conversion efficiency of a device are effectively increased, and the experimental repeatability and stability are also good.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

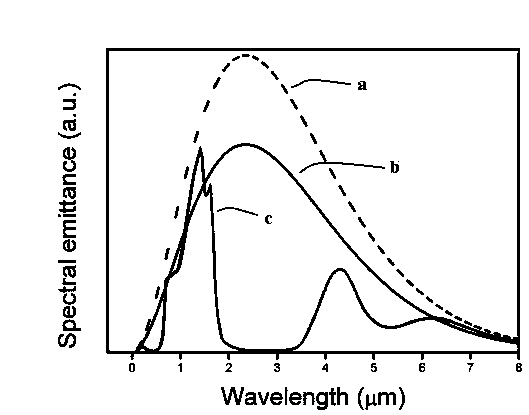

OLED (Organic Light Emitting Diode) display device for integrating solar batteries

ActiveCN103681774ATake advantage ofReduce wasteSolid-state devicesSemiconductor devicesDisplay deviceLength wave

The invention discloses an OLED (Organic Light Emitting Diode) display device for integrating solar batteries. The OLED display device comprises an OLED display screen, and one side of the transparent OLED display screen is also provided with the solar batteries. As the transparent OLED display screen and the solar batteries are combined, the transparency of the OLED display screen can be fully utilized, therefore ambient light can be converted into electrical energy to be utilized or stored, and the energy source is saved. The absorption wavelength of the solar batteries and the absorption wavelength of the transparent OLED display screen are not overlapped, so that the light rays emitted by the transparent OLED display screen are prevented from being absorbed by the solar batteries, almost all the light rays emitted by a pixel region can be emitted out, therefore the electrical energy is fully utilized, and further the energy source is saved. During the working of the transparent OLED display screen, the light rays not overlapped with the absorption wavelength of the transparent OLED display screen can still reach the solar batteries to be absorbed and converted into the electrical energy, so the photovoltaic conversion efficiency is increased.

Owner:BEIJING VISIONOX TECH +1

Large-area polymer solar cell and method for preparing active layer of large-area polymer solar cell

ActiveCN103794729AMeet the needs of industrial productionIncrease the areaLiquid surface applicatorsSolid-state devicesOrganic solventElectron donor

The invention discloses a large-area polymer solar cell and a method for preparing an active layer of the large-area polymer solar cell to solve the technical problems that in the prior art, an active layer prepared through a spin coating process is small in area, can not meet the preparation requirements for a large-area cell module and a series-connection module, and is not suitable for industrial production, and belongs to the technical field of solar cells. The method includes the steps of firstly, dissolving electron donor materials and electron acceptor materials in organic solvents, conducting heating and stirring, and obtaining an evenly-mixed solution; secondly, adding additives to the mixed solution, and obtaining spraying ink of the active layer; thirdly, adding the spraying ink to an ultrasonic spraying instrument, and obtaining the active layer of the polymer solar cell in the spraying process through in-situ atmosphere processing. By means of the method, the active layer of the large-area polymer solar cell can be prepared in the atmosphere environment, and it is ensured that the active layer of the large-area polymer solar cell has high photovoltaic conversion efficiency.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Organic solar battery and preparation method of organic solar battery

ActiveCN103050627AImprove photoelectric conversion efficiencyImprove utilizationFinal product manufactureSolid-state devicesElectronic transmissionOrganic solar cell

The invention relates to an organic solar battery and a preparation method of the organic solar battery. The organic solar battery comprises a positive electrode, a hollow hole transmission layer, an active layer, an electronic transmission layer and a negative electrode, wherein the positive electrode and the negative electrode are transparent electrodes, the active layer comprises an organic donor material, an organic receptor material and quantum dot nanometer particles, and the quantum dot nanometer particles account for 0.1 to 10 weight percent of the active layer. The organic solar battery adopts the technical scheme that the quantum dot nanometer particles with the wavelength emitting spectrum identical to the absorption spectrum of organic semiconductor materials are doped in the active layer, the absorption spectrum of the organic semiconductor materials on sun light is widened, the utilization rate of the organic solar battery on the sun light is enhanced, and the photovoltaic conversion efficiency of the organic solar battery is obviously improved.

Owner:CHINA LUCKY FILM CORP

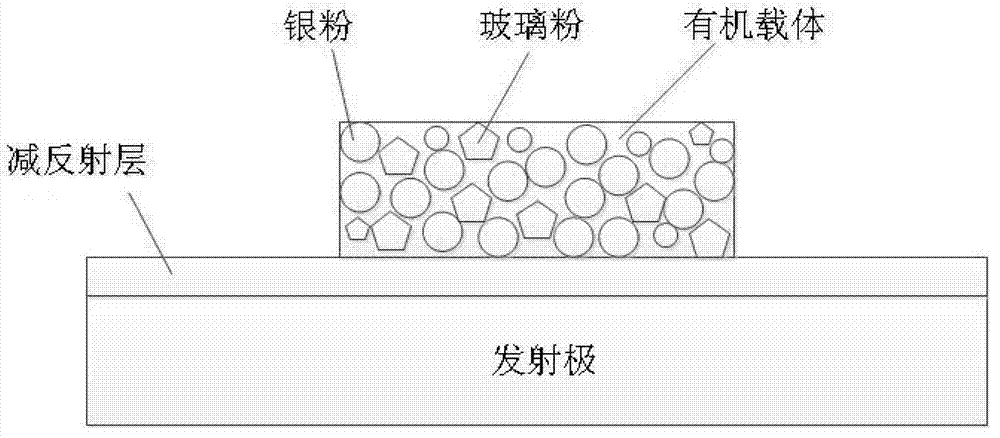

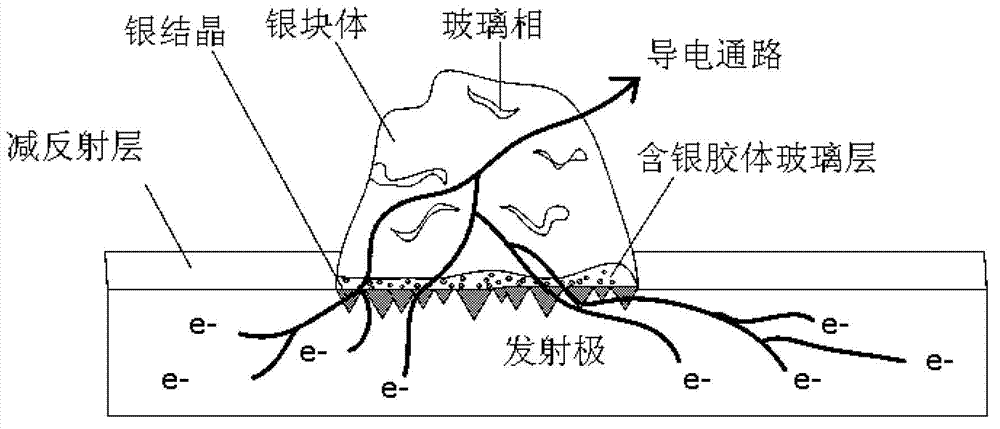

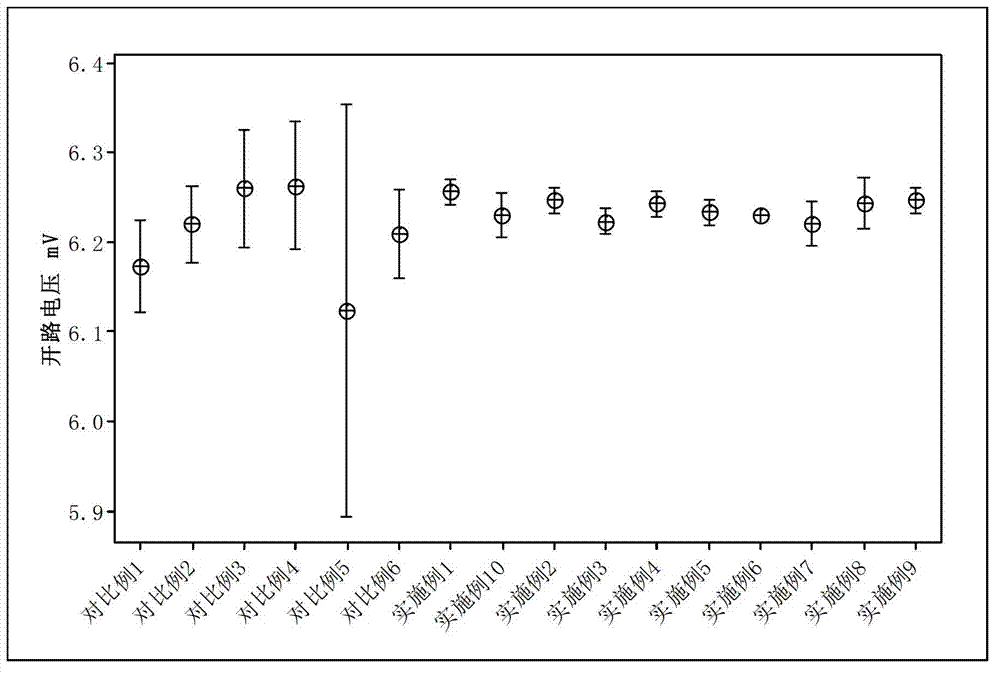

Positive electrode slurry of solar battery and glass powder

ActiveCN102881350AImprove photoelectric conversion efficiencyReduced series resistanceNon-conductive material with dispersed conductive materialPhotovoltaic energy generationElectrical batterySilicon solar cell

Owner:SOLTRIUM ADVANCED MATERIALS TECH LTD SHENZHEN

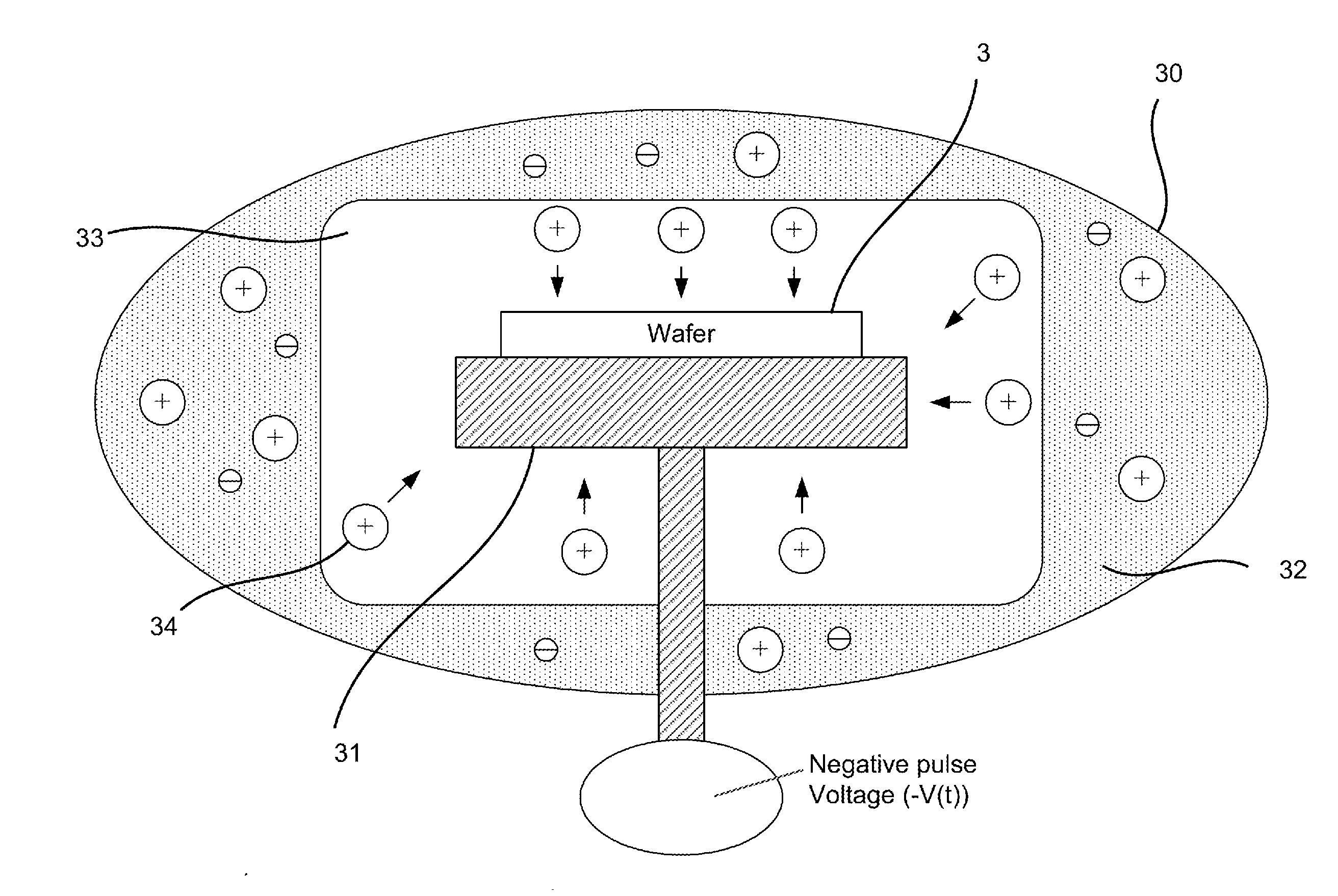

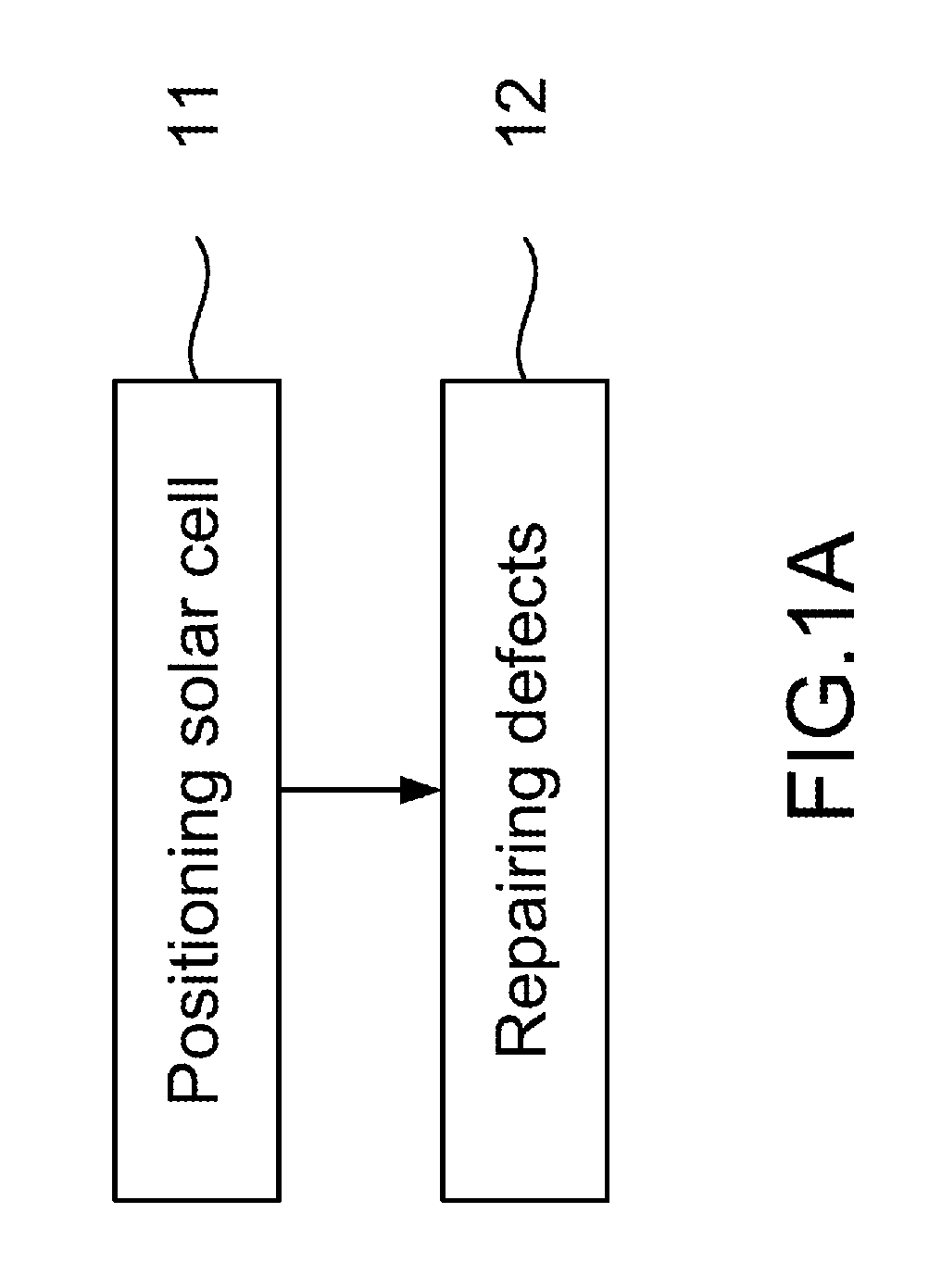

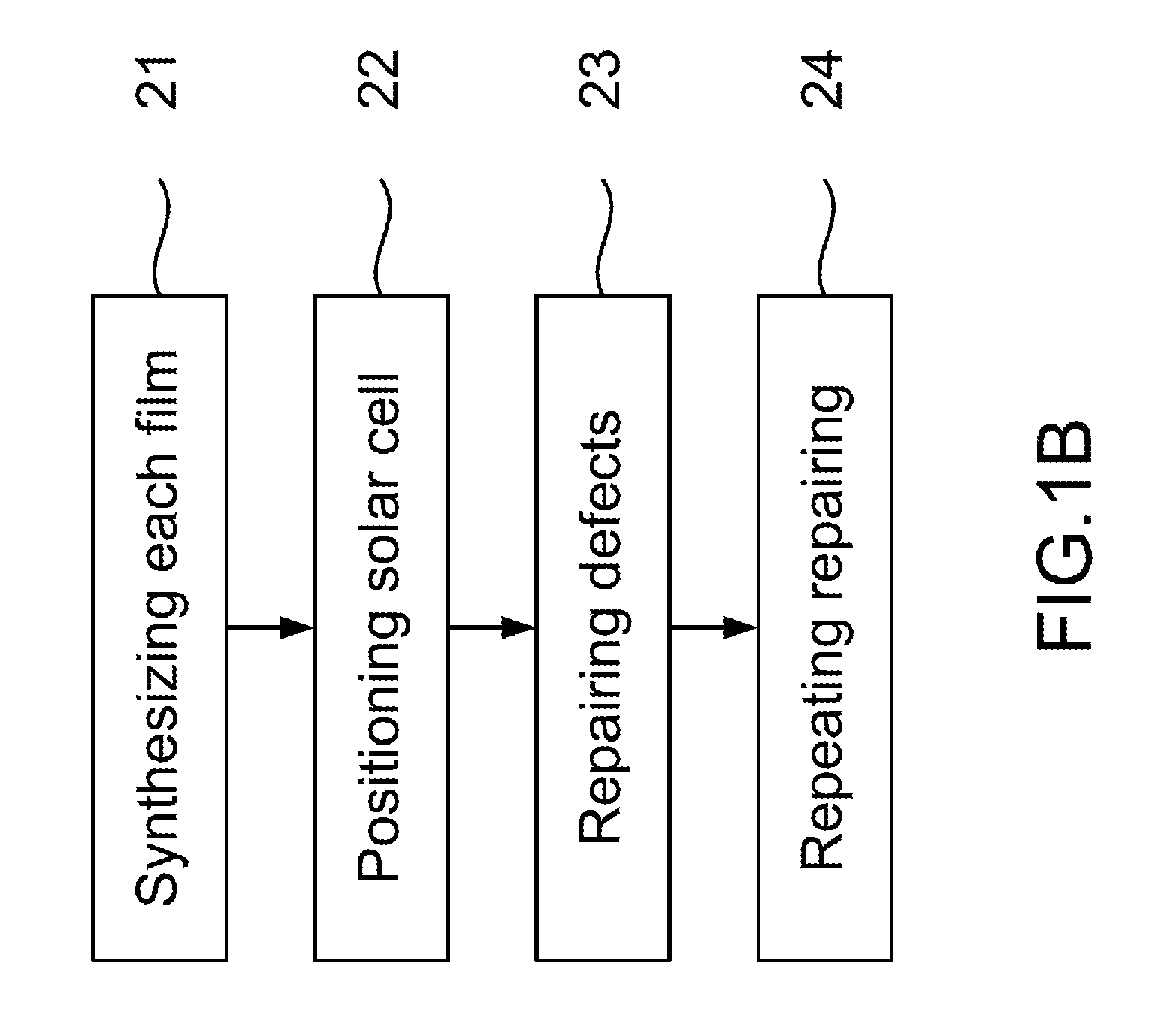

Solar Cell Defect Passivation Method

ActiveUS20110053351A1Improve photovoltaic conversion efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingPlasma-immersion ion implantationPhotovoltaic conversion efficiency

Owner:INST NUCLEAR ENERGY RES ROCAEC

One-dimensional photonic crystal selective radiator

InactiveCN104076530ASimple structureThe preparation method is maturePhotovoltaic energy generationNon-linear opticsPhotonic crystalRare earth ions

The invention provides a one-dimensional photonic crystal selective radiator which comprises a base body material and two types of dielectric materials including multiple periods of erbium-doped silicon dioxide films and silicon films alternatively deposited on the base body material. The base body material is silicon. The first-layer films deposited on the base body material are erbium-doped silicon dioxide films. The one-dimensional photonic crystal selective radiator integrates characteristic radiation of rare earth ions and a spectrum control feature of a photonic crystal to obtain selective radiation characteristic with excellent performance, remarkably improves the photovoltaic conversion efficiency of TPV and STPV systems and further has the advantages of being simple in structure, mature in preparation method and the like.

Owner:SHAOXING UNIVERSITY

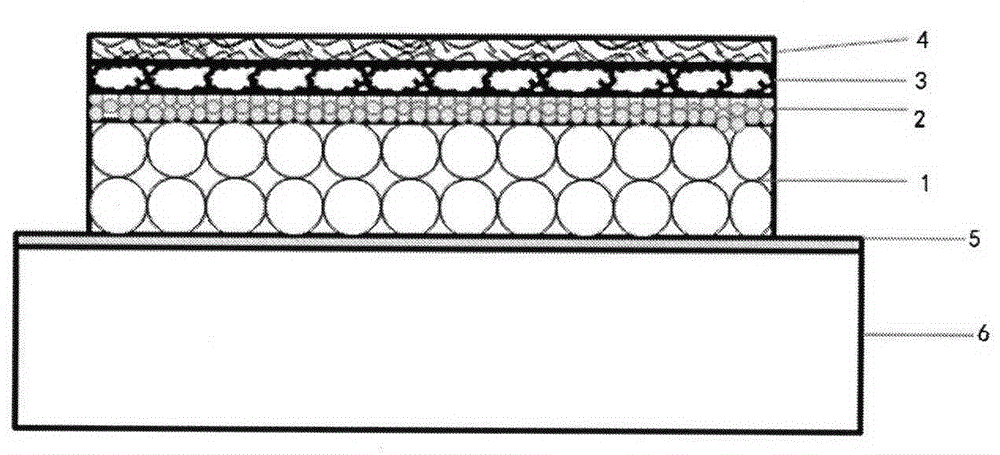

Multi-level hole TiO2/quantum dot/dye lamination thin-film solar cell photo-anode and preparation method thereof

ActiveCN103560009AEasy transferImprove adsorption capacityLight-sensitive devicesState of artQuantum dot

The invention discloses a multi-level hole TiO2 / quantum dot / dye lamination thin-film solar cell photo-anode. A bottom layer is a multi-level hole TiO2 thin film prepared on a transparent conductive substrate. A middle layer is an I-III-VI-group quantum dot thin film. A secondary upper layer is a semiconductor oxide barrier layer. An upmost layer is a dye layer. The invention further discloses a preparation method of the multi-level hole TiO2 / quantum dot / dye lamination thin-film solar cell photo-anode. The method comprises the steps of firstly, preparing the bottom layer, namely the multi-level hole TiO2 thin film, on the conductive substrate, then, preparing the I-III-VI-group quantum dot thin film, namely the middle layer thin film, on the multi-level hole TiO2 thin film by means of the chemical sedimentation method or the continuous ionic adsorption method, then preparing the secondary upper layer, namely the semiconductor oxide barrier layer, on the middle layer, namely the I-III-VI-group quantum dot thin film, by means of the dipping film-drawing method, and finally soaking the lamination layers in a dye solution to obtain the upmost layer, namely the dye layer. Compared with the prior art, the multi-level hole TiO2 / quantum dot / dye lamination thin-film solar cell photo-anode is of the multi-level hole structure, and has the high specific surface area, dispersion and adsorption of dye and an electrolyte are facilitated, sunlight of different spectra is absorbed due to the synergistic effect of the lamination structure, the absorption spectrum range is broadened, and the photovoltaic conversion efficiency of a solar cell is improved.

Owner:SHIJIAZHUANG TIEDAO UNIV

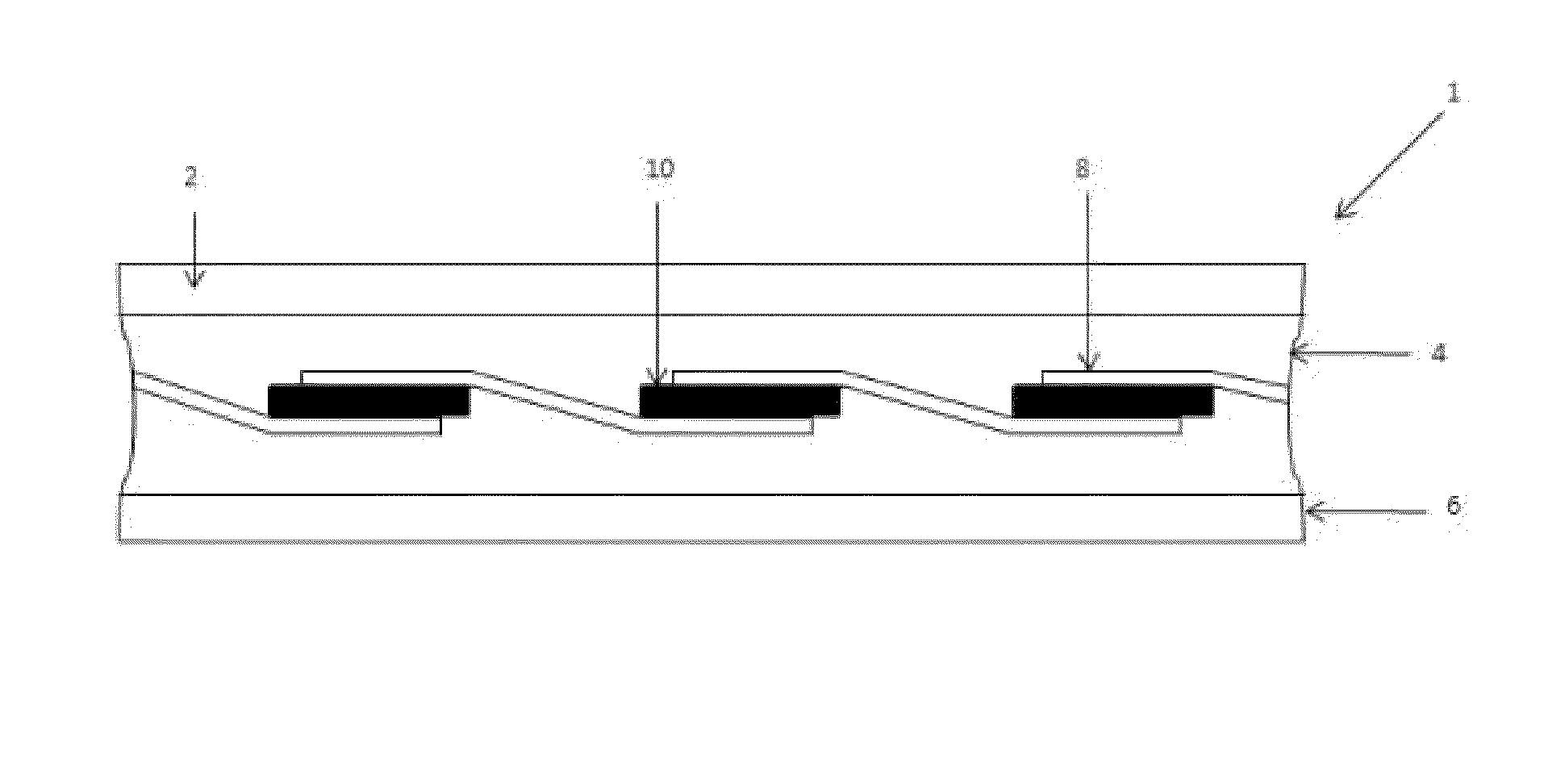

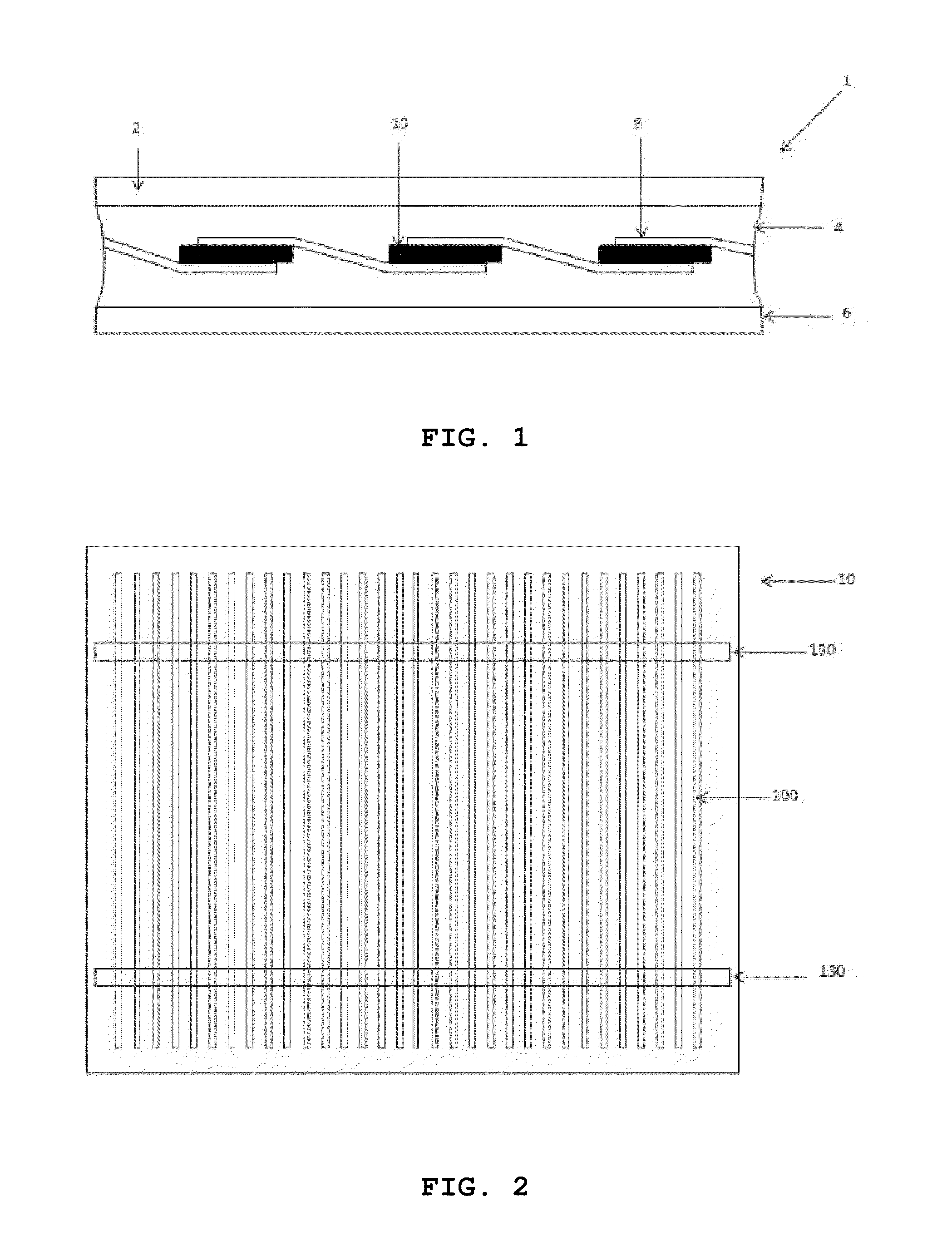

Silicon solar cell module using conductive npaste as electrode and method for manufacturing same

InactiveUS20150004740A1Reduce the required powerDecrease in electric currentPV power plantsSemiconductor/solid-state device manufacturingSilver pasteConductive paste

The present invention relates to a silicon solar cell module comprising electrodes formed from conductive paste. In the invention, front electrode finger lines and front electrode bus bars are separately formed. The front electrode finger lines are formed by printing a silver paste and calcining the printed silver paste at high temperature, and rear electrode bus bars and front electrode bus bars are formed from an inexpensive lower-temperature conductive paste including a buffer and a curing agent having reducing power, whereby the expensive silver paste is replaced with the inexpensive low-temperature conductive paste, thereby reducing the production cost. Because the front electrode bus bars formed from the conductive paste do not come into contact with the silicon substrate, the area of contact between the silicon substrate and the front electrode is reduced, and thus the decrease in electric current caused by the recombination of electrons and holes resulting from this contact is inhibited, thereby increasing the photovoltaic conversion efficiency of the cell. Also, when the conductive paste is used, the rear electrode and front electrode bus bars are calcined at low temperature, and thus the occurrence of cracks in the silicon substrate is reduced, thereby preventing a decrease in the photovoltaic conversion efficiency of the silicon solar cell and increasing the yield of the cell.

Owner:GENS ENG

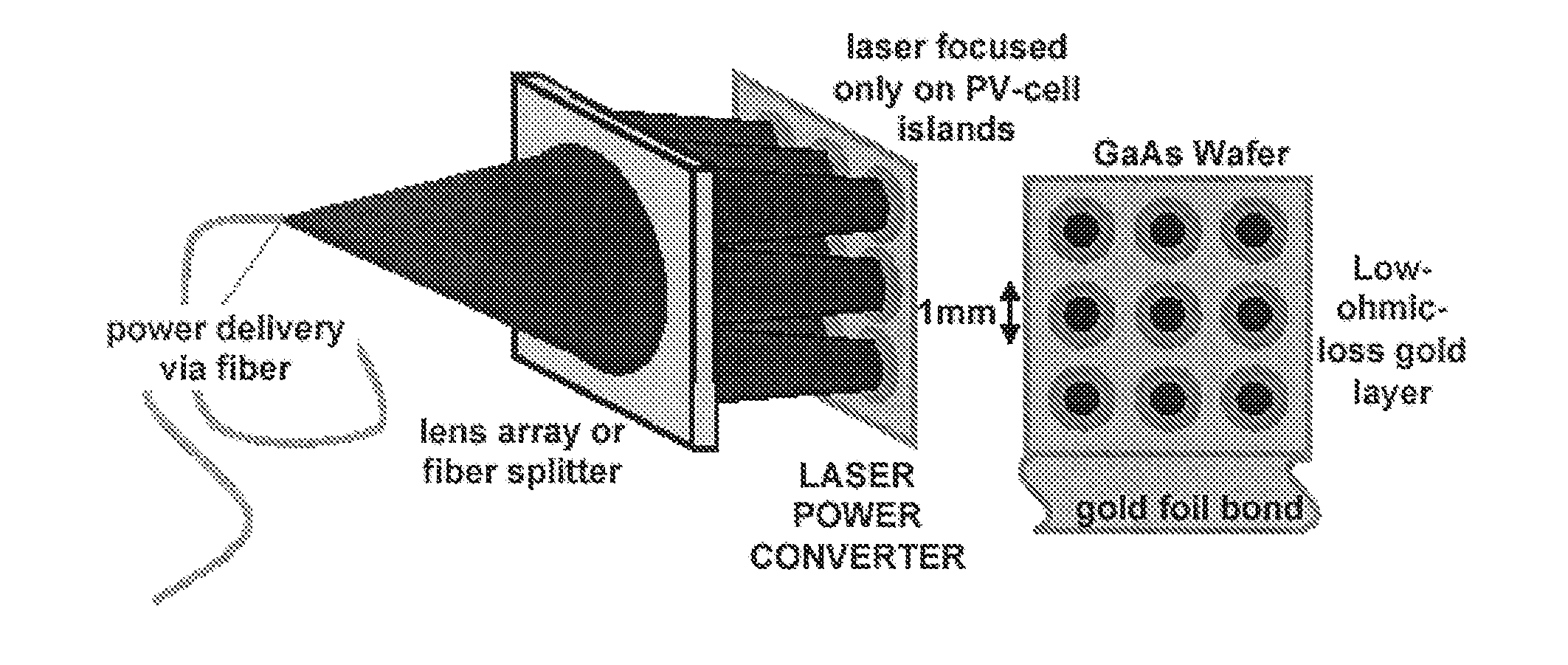

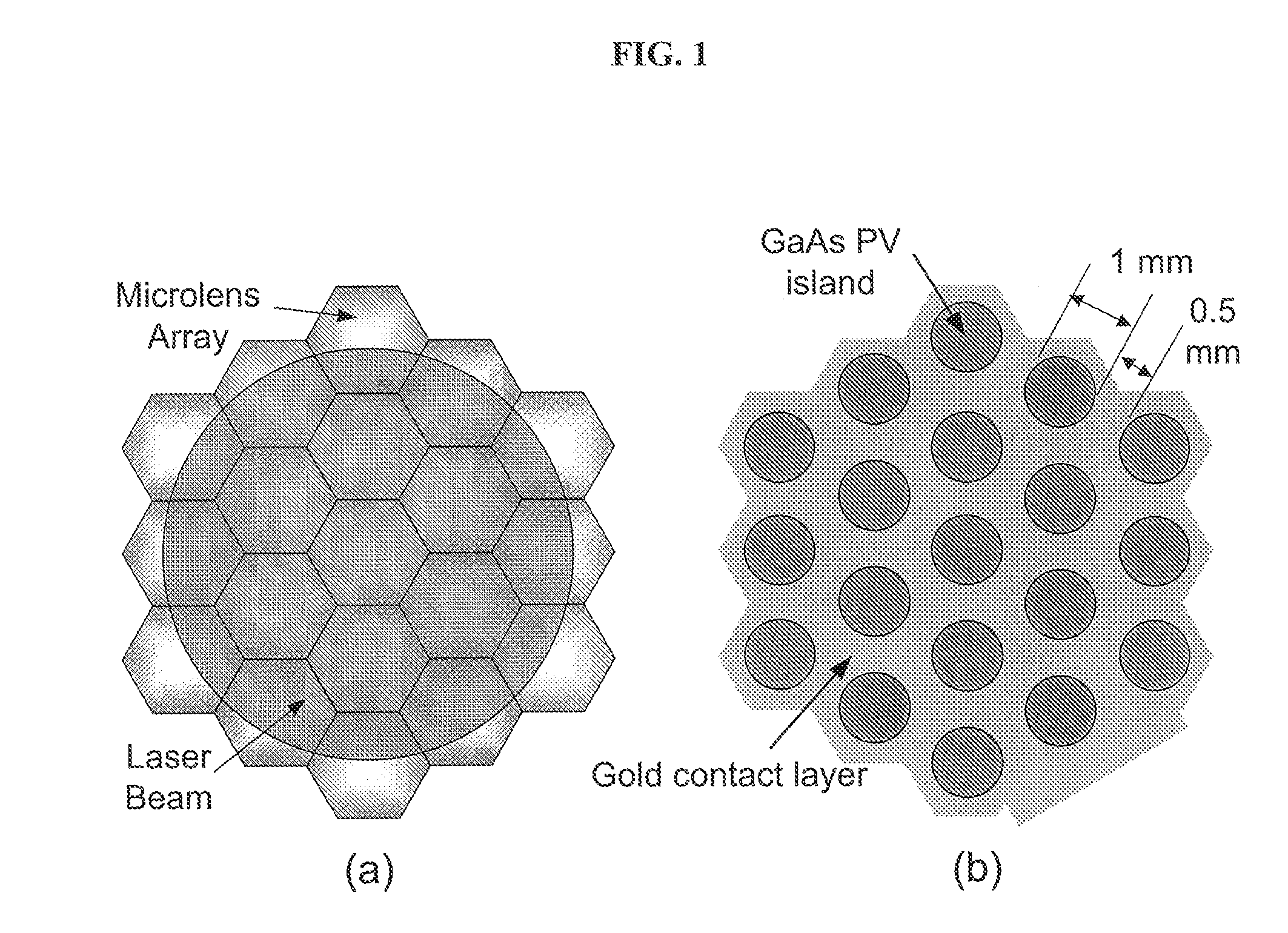

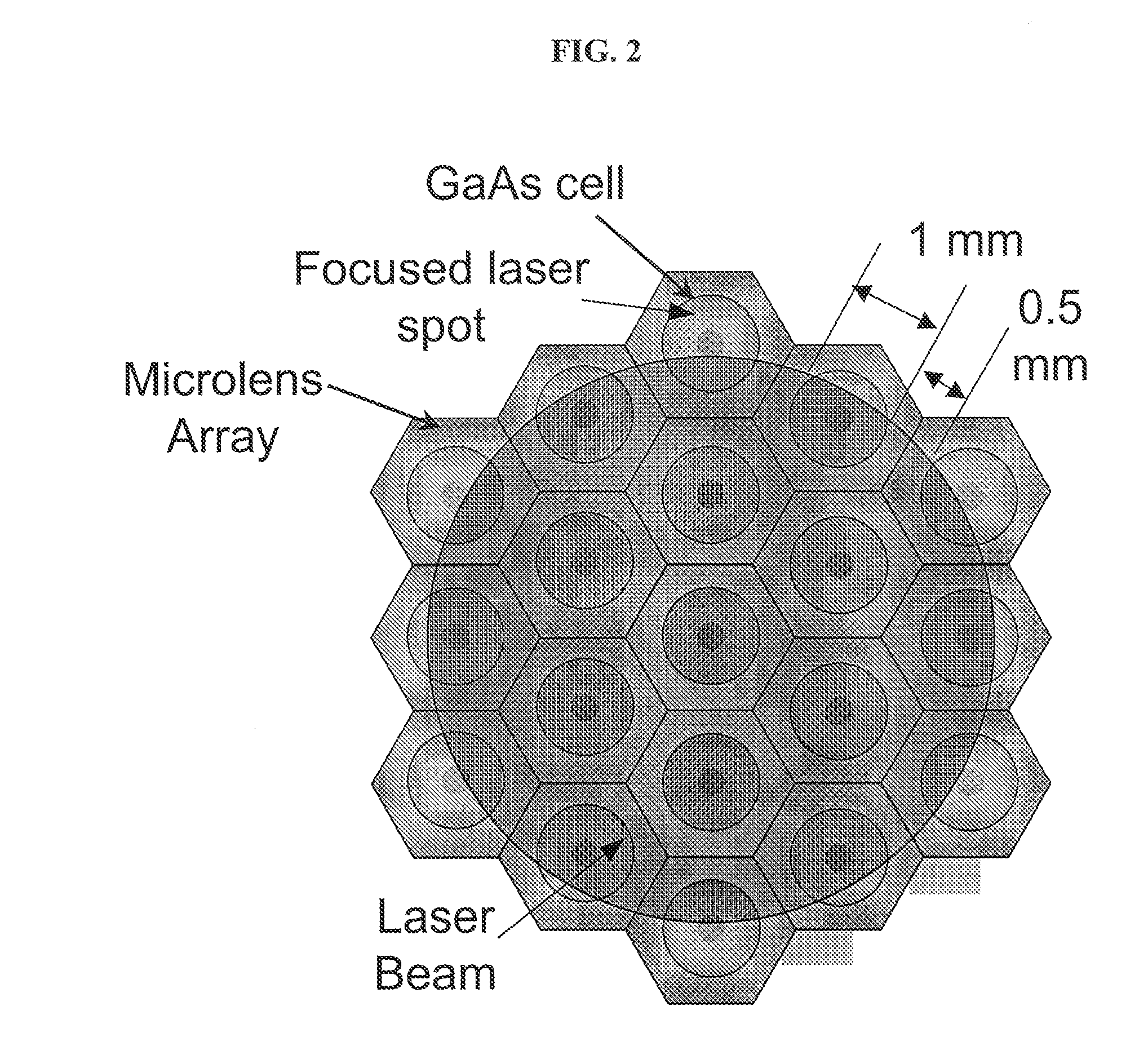

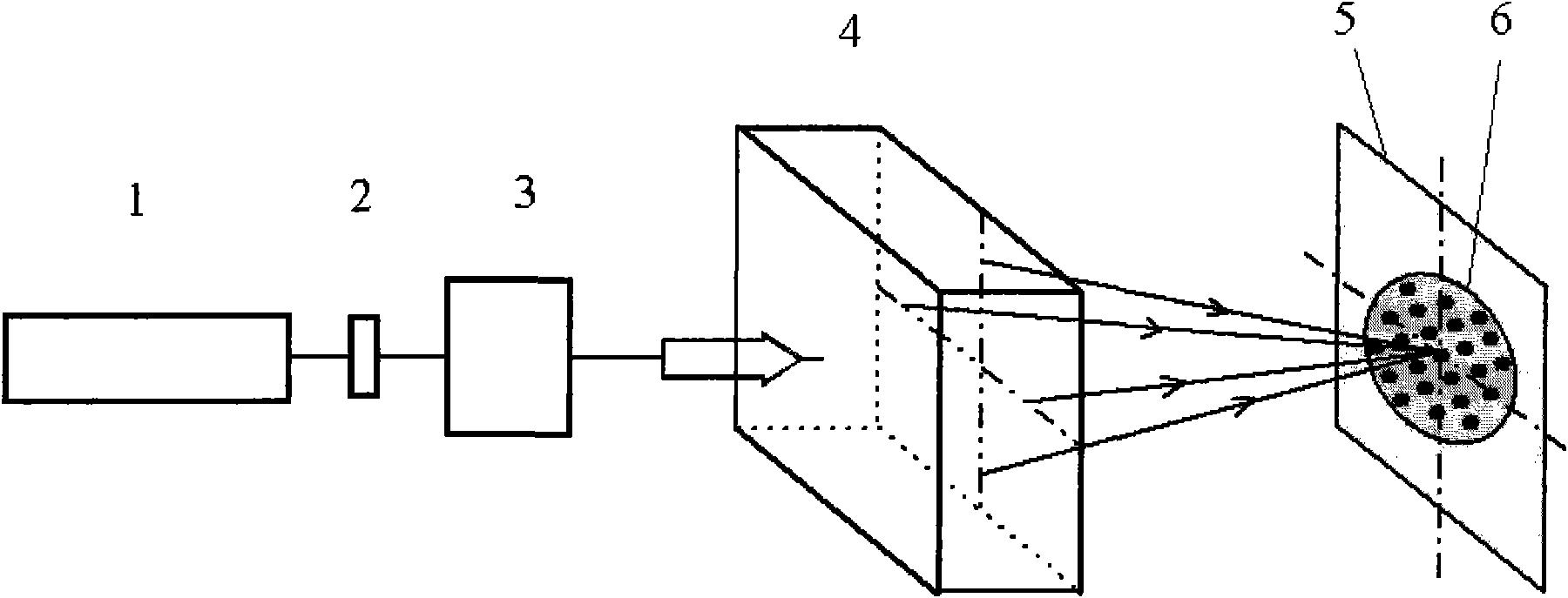

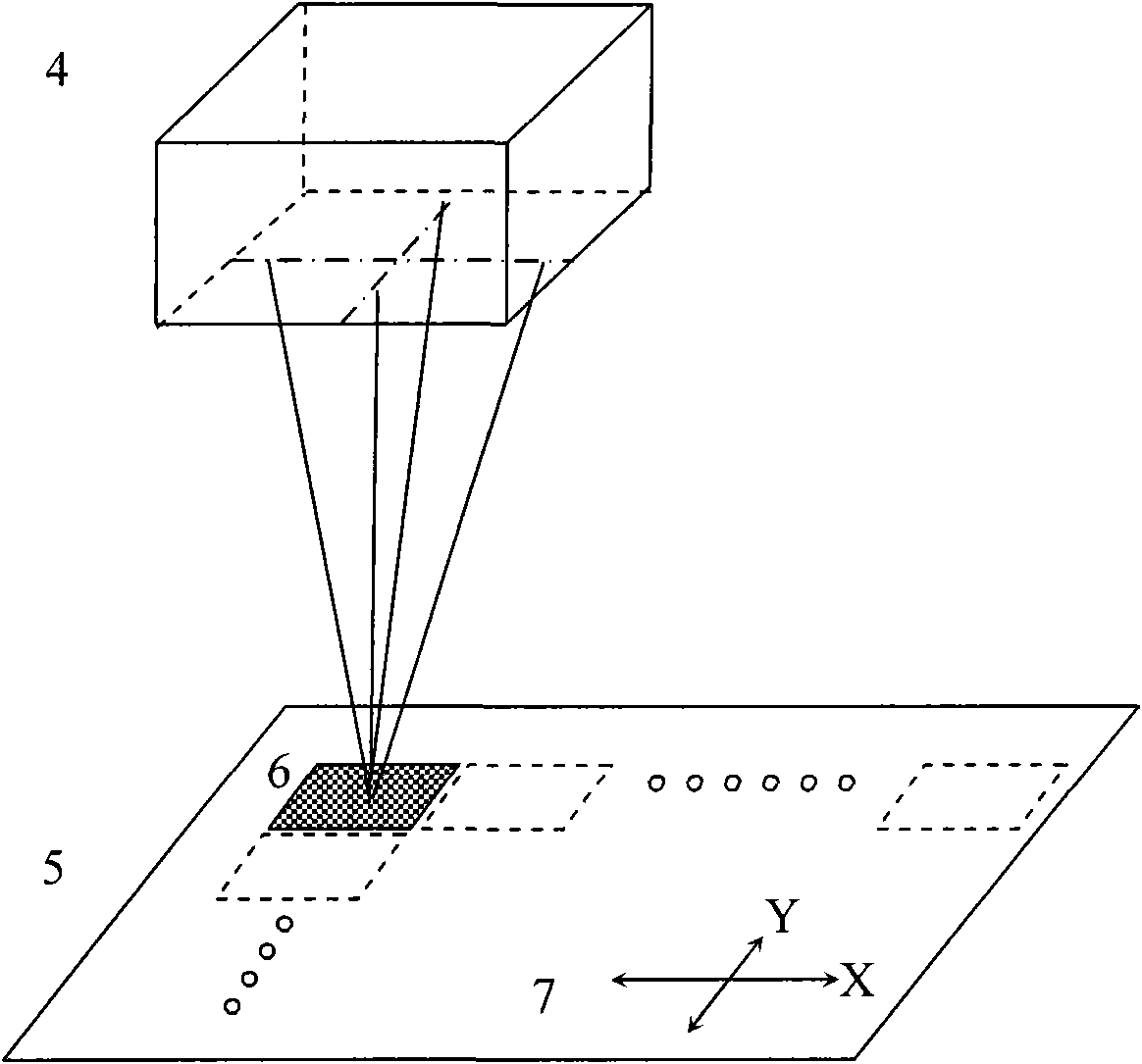

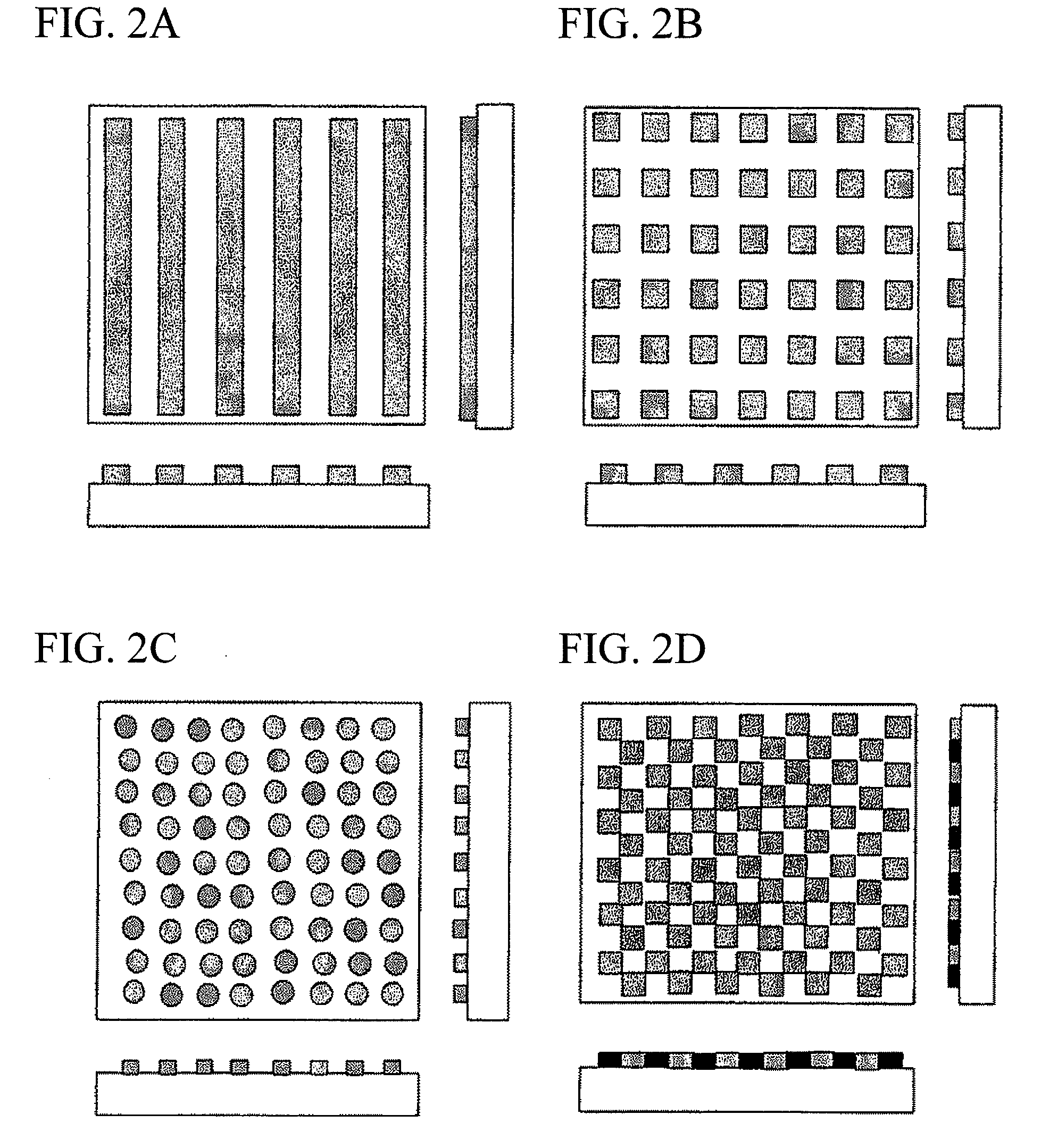

Pixelated photovoltaic array method and apparatus

InactiveUS20100116318A1Improve device efficiencyImprove photovoltaic conversion efficiencyPV power plantsPhotovoltaic energy generationOptical powerLight beam

The present invention comprises a method and apparatus to increase the efficiency of photovoltaic conversion of light into electrical power and to achieve operation at higher optical power and therefore higher electrical power. Preferred embodiments increase the efficiency of photovoltaic power conversion of any source of a beam of photons by spatially dividing the beams into a plurality of individual beamlets, each beamlet focusing on an active photovoltaic region. The preferred architecture of the apparatus of the invention comprises spatially separated photovoltaic cells to substantially match the pattern of the spatially separated plurality of beamlets. Preferred embodiments result in a significant reduction in ohmic losses and current shunting, thereby increasing photovoltaic conversion efficiencies.

Owner:HRL LAB

Manufacture system of anti-reflection structure on surface of solar cell and manufacture method thereof

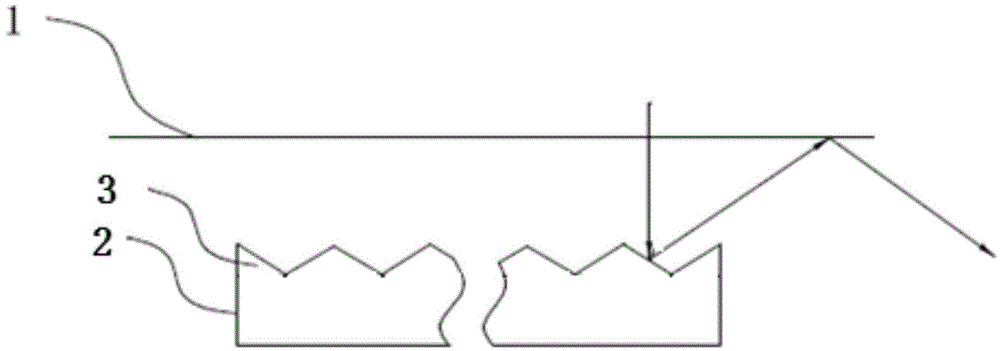

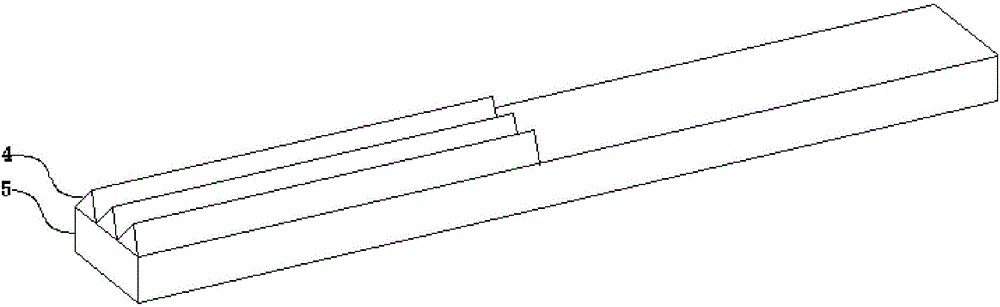

InactiveCN101924166ALithographic feature size adjustablePromote absorptionFinal product manufactureSemiconductor devicesFine structureEngineering

The invention relates to a manufacture system of an anti-reflection structure on the surface of a solar cell and a manufacture method thereof, which is characterized in that a plurality of coherent laser beams are combined by a laser interference lithography system to modulate the light intensity distribution in an interference field; the material surface of a photovoltaic cell device is ablated with redistributed laser energy after modulation; and micro or nano-stage dense hole and column relief structures are generated in a large-area range so as to reduce the reflectivity, enhance the light absorption and improve the photovoltaic conversion efficiency. Lacking of external materials, the anti-reflection fine structure generated on the substrate surface by using the method is more stableand durable, and the cycle and the size of the structure can be adjusted by adjusting the incidence angle of the interference lithography system so that the received wavelength has better pertinence and has the advantage of good working band controllability.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI +2

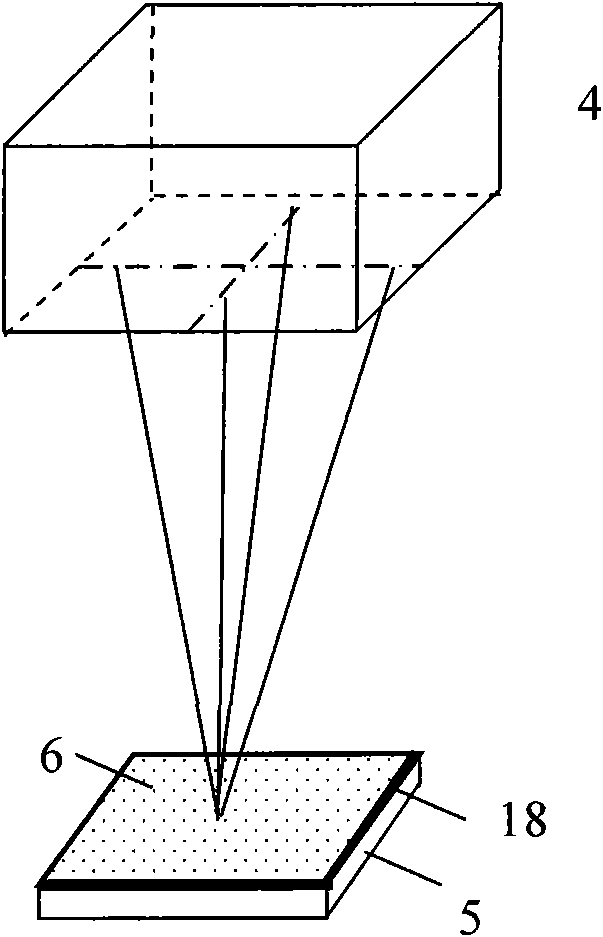

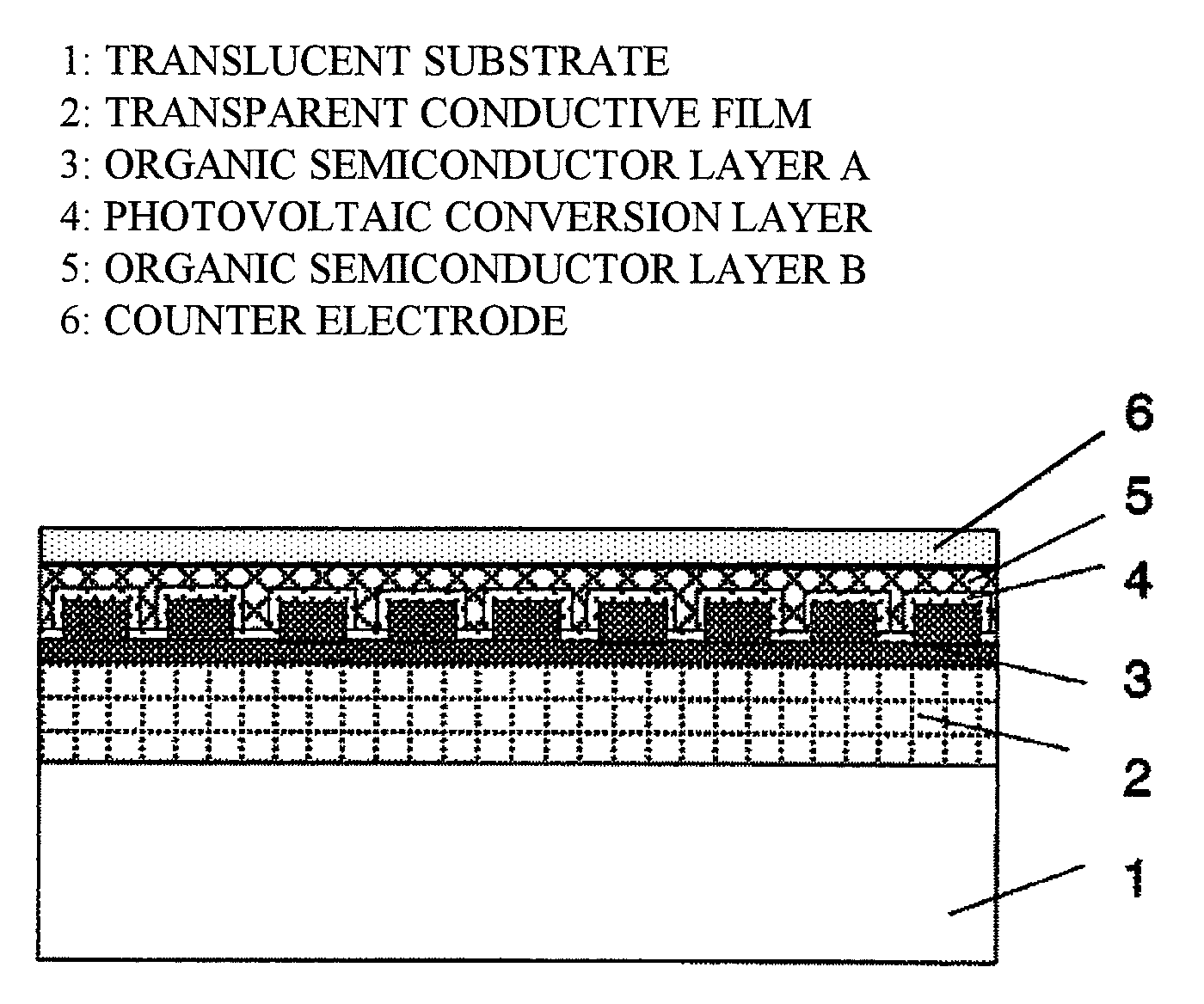

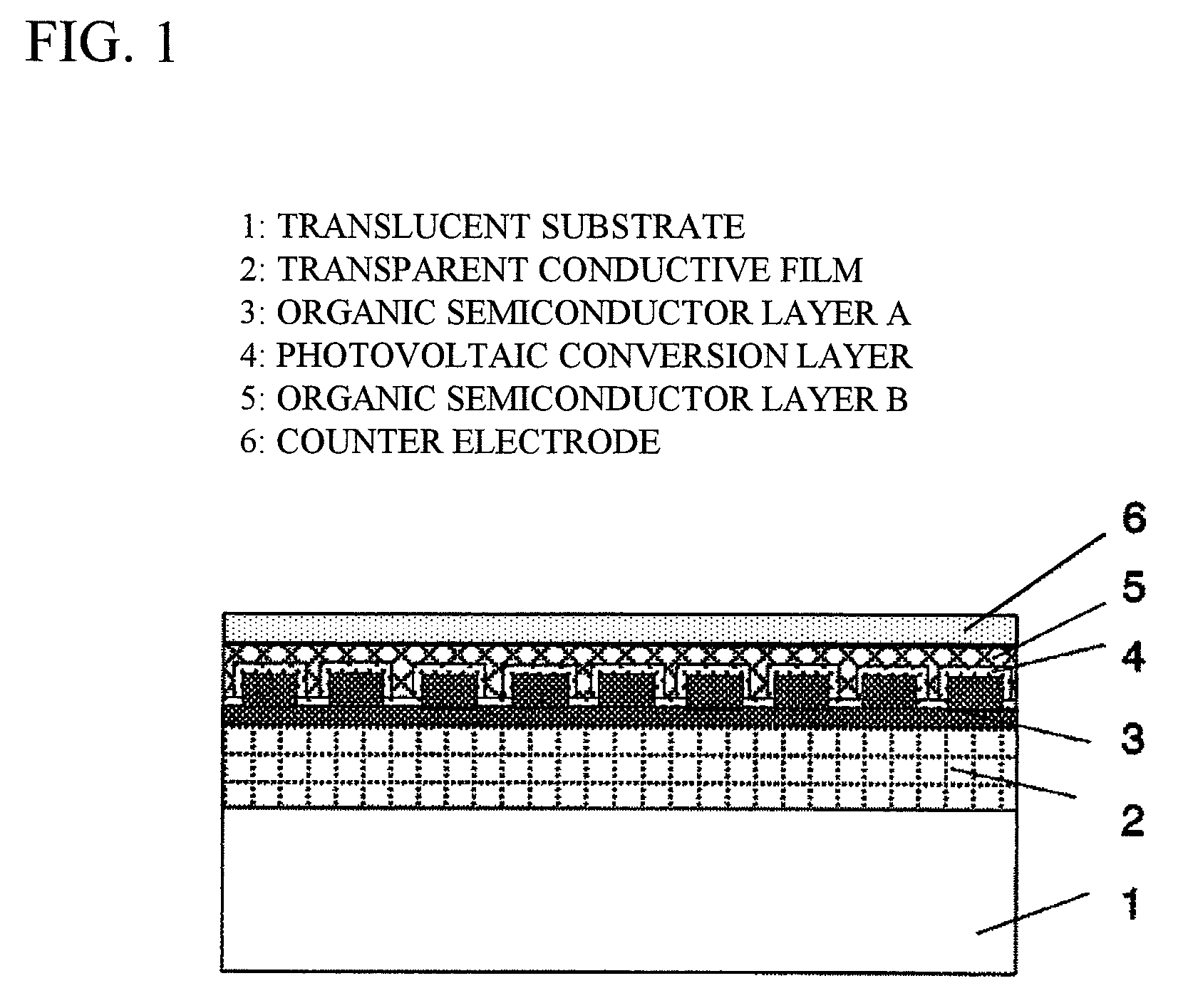

Photovoltaic Cells and Manufacture Method

InactiveUS20090084442A1Improve photovoltaic conversion efficiencyInhibit currentFinal product manufactureNanoinformaticsLight CellEngineering

The present invention provides photovoltaic cells that stably increase photovoltaic conversion efficiency while restraining current leakage. The photovoltaic cells of the present invention include a transparent conductive layer formed on a light-permeable substrate, an organic semiconductor layer A covering the surface of the transparent conductive layer, a photovoltaic conversion layer in contact with the organic semiconductor layer, an organic semiconductor layer B in contact with the photovoltaic conversion layer, and a counter electrode in contact with the organic semiconductor layer B. In the photovoltaic cells, a patterned indented interlayer is formed at the interface between the organic semiconductor layer A and the photovoltaic conversion layer. With the patterned indented interlayer at the interface between the organic semiconductor layer A and the photovoltaic conversion layer, the interface between the organic semiconductor layer A and the photovoltaic conversion layer has a specific surface area 1.5 to 10 times as large as the interface between the transparent conductive layer and the organic semiconductor layer A.

Owner:HITACHI LTD

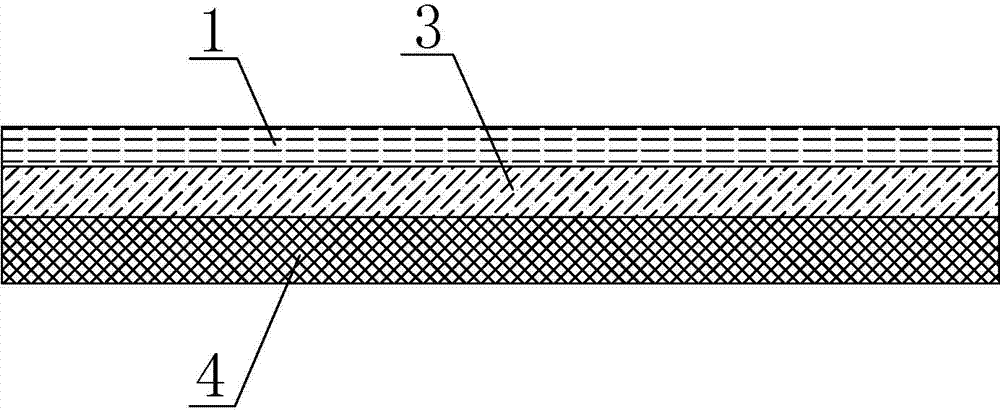

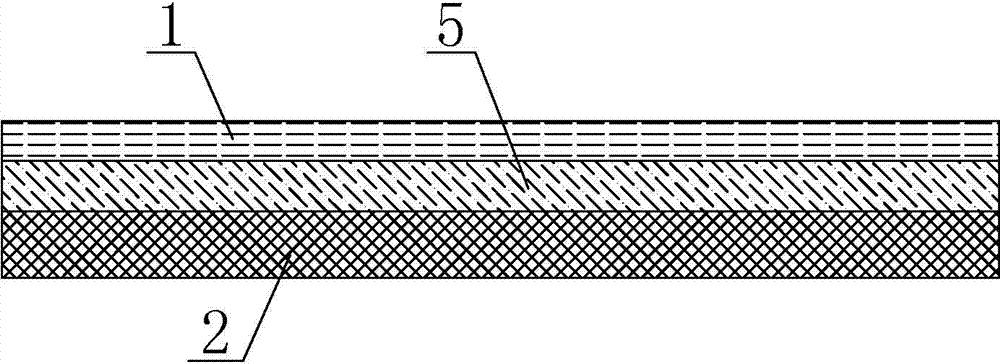

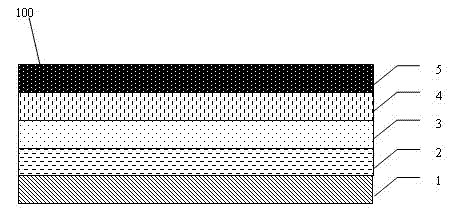

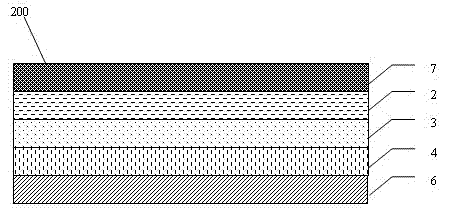

Perovskite solar cell based on PVA modified hole transport layer

ActiveCN108832002AImprove surface wettabilityQuality improvementSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellOptoelectronics

The invention discloses a perovskite solar cell based on a PVA modified hole transport layer. The perovskite solar cell comprises a lower transparent electrode layer and an upper electrode layer, wherein five functional layers are clamped between the lower transparent electrode layer and the upper electrode layer; the five functional layers comprise a hole transport layer, a PVA interface modification layer, a perovskite active layer, an electron transfer layer and a buffer layer from bottom to top in sequence; and the hole transport layer, the PVA interface modification layer, the perovskiteactive layer and the electron transfer layer are prepared into a film through a low-temperature solution method. The thin film is prepared by using the low-temperature solution method, the technological conditions are reasonably controlled, and the PVA modification layer is added between a PEDOT:PSS layer and a perovskite layer, the perovskite surface wettability is improved effectively, the holetransport efficiency is improved, the perovskite thin film is obtained continuously and uniformly, the quality of a perovskite absorbed layer is improved, and the obtained perovskite solar cell is high in photovoltaic conversion efficiency and high in stability.

Owner:NANJING UNIV OF POSTS & TELECOMM

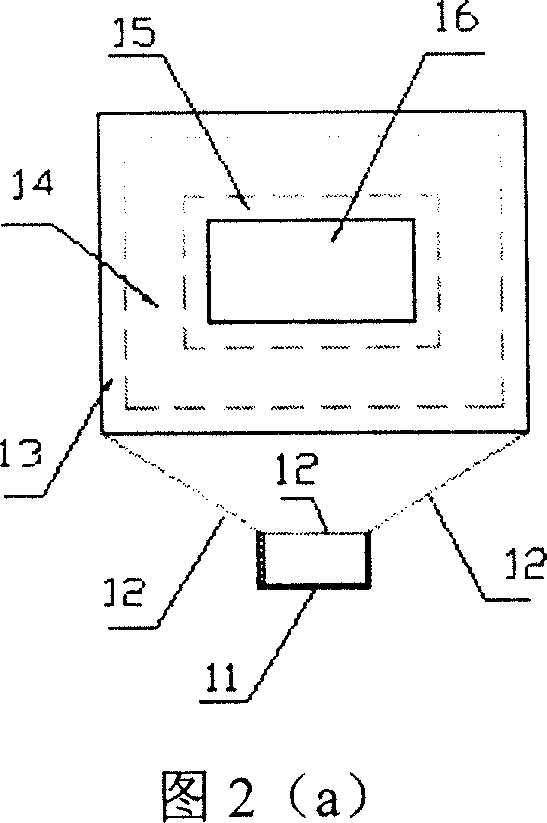

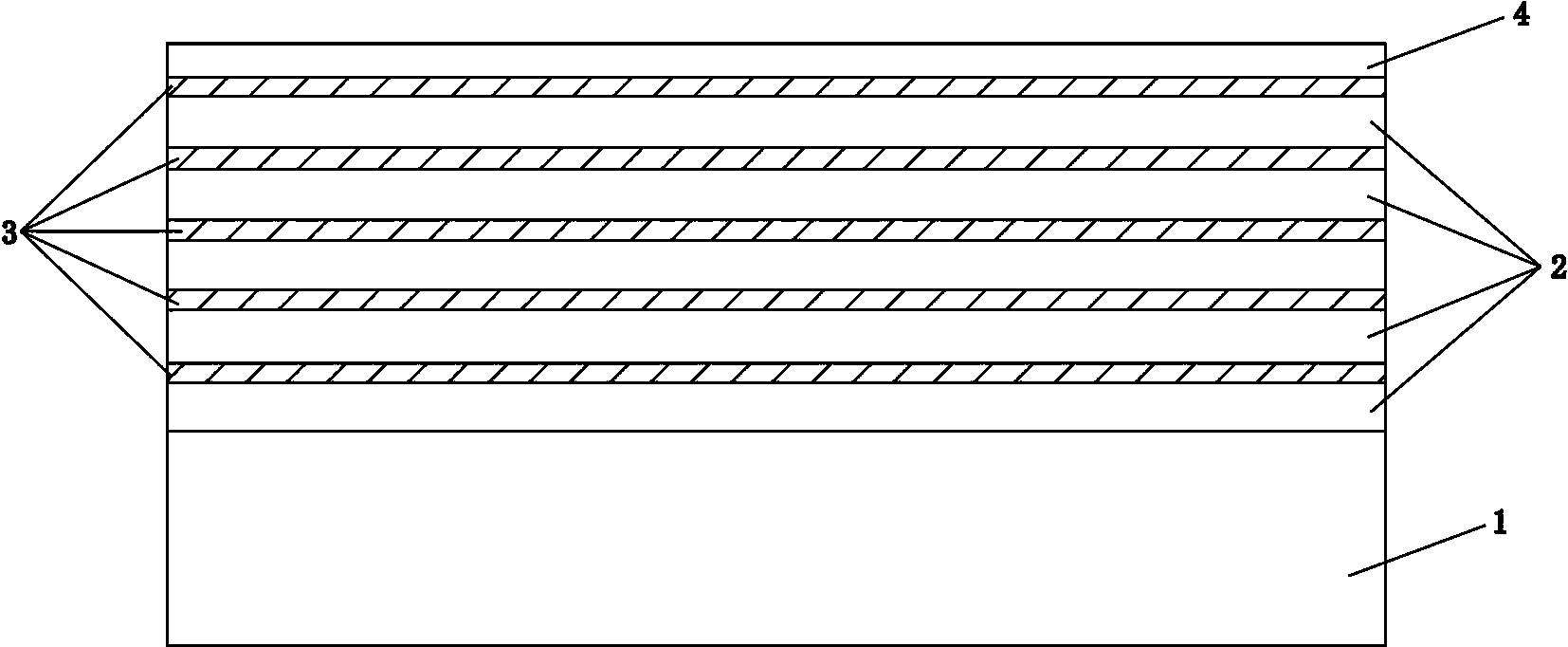

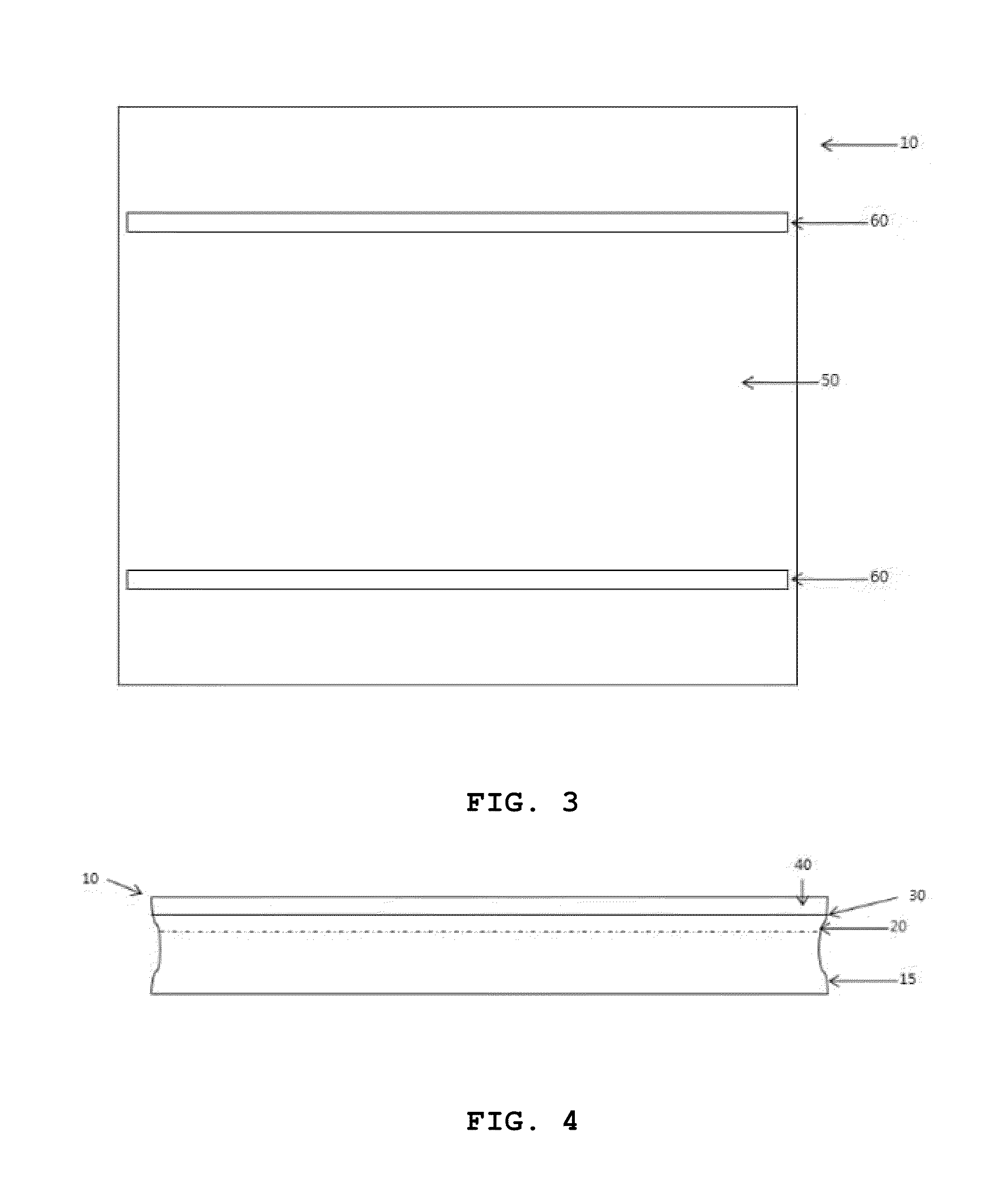

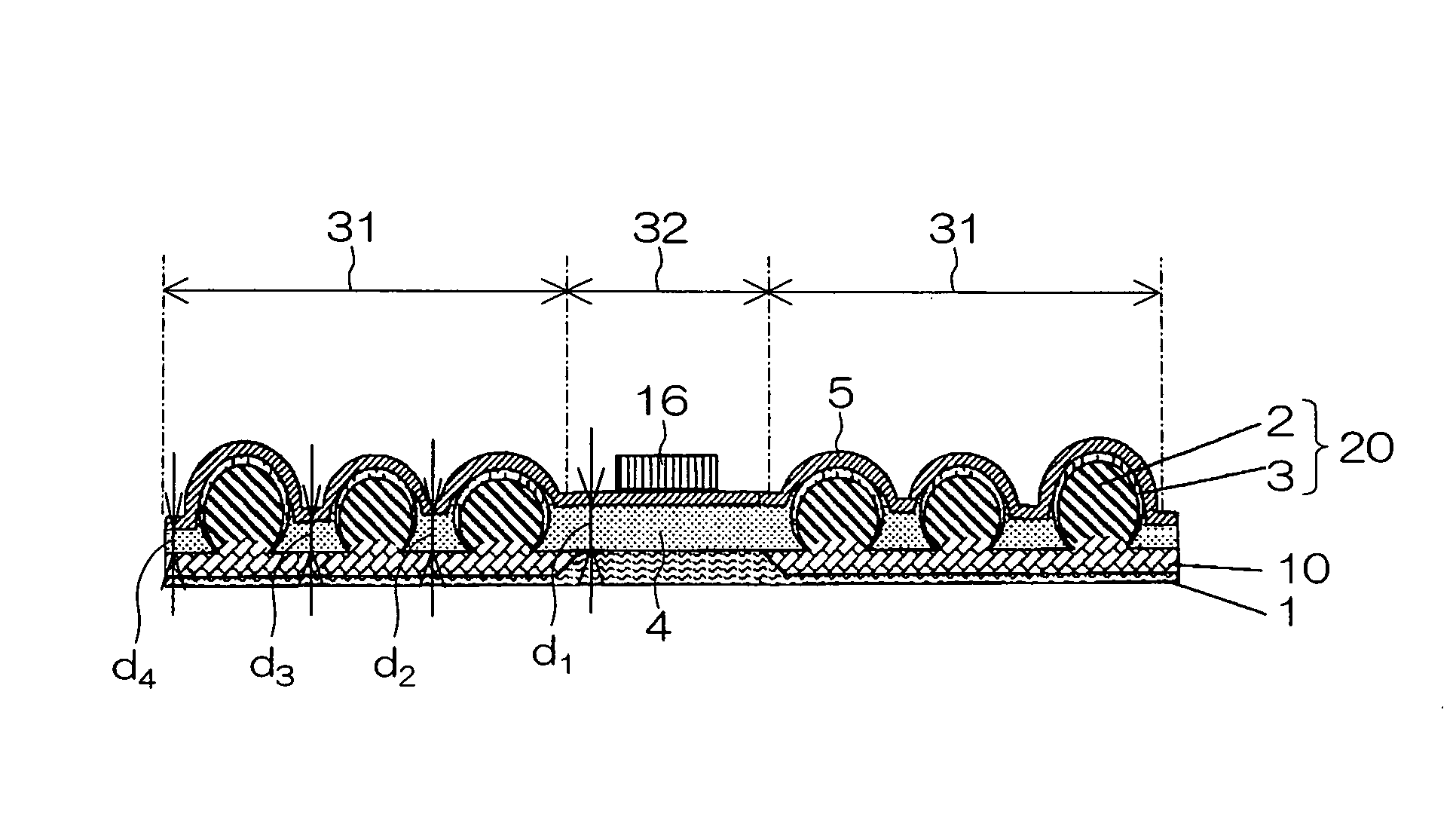

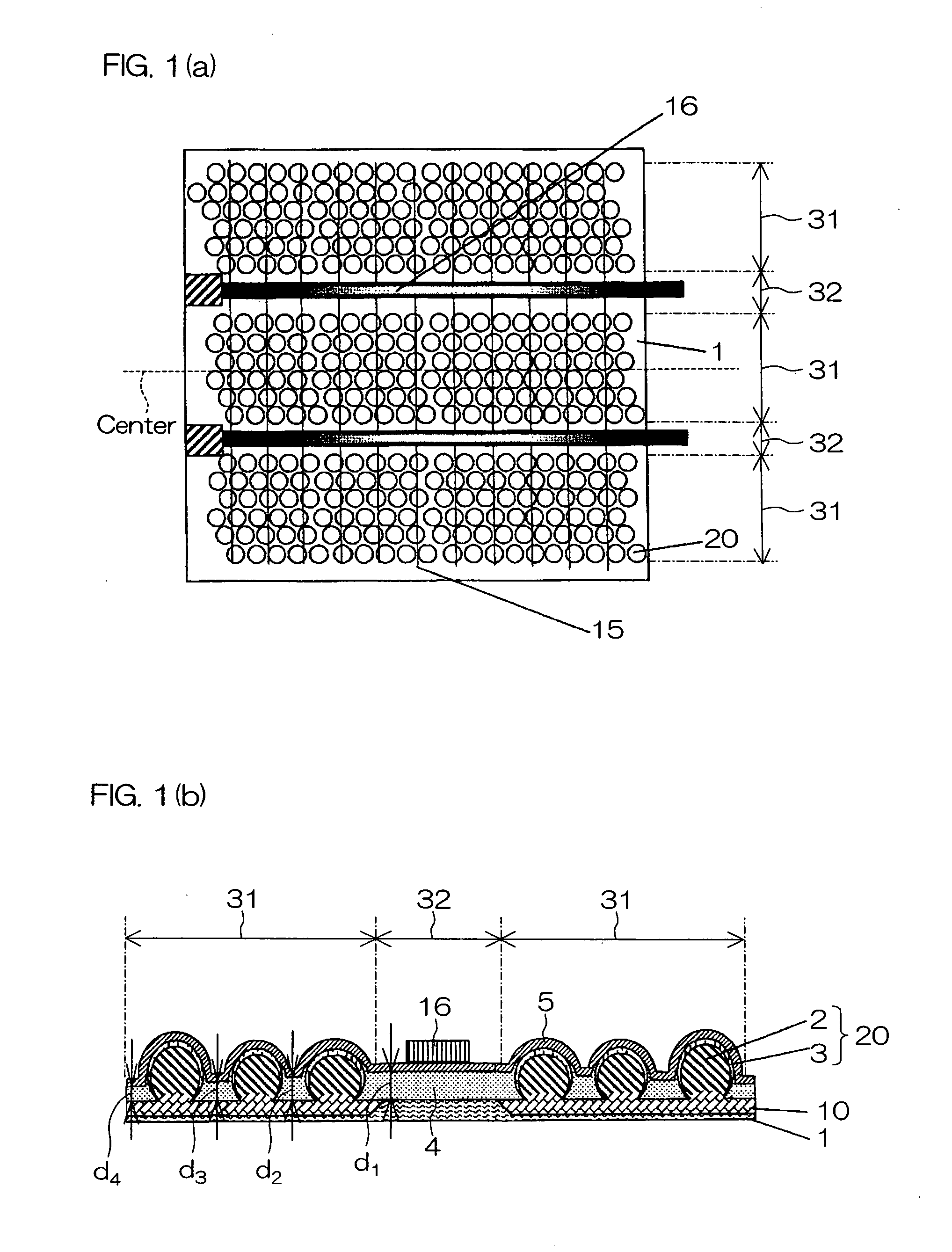

Photovoltaic conversion device, its manufacturing method and solar energy system

InactiveUS20050205126A1High photovoltaic conversion efficiencyStability GuaranteePV power plantsSolid-state devicesEngineeringPhotocurrent

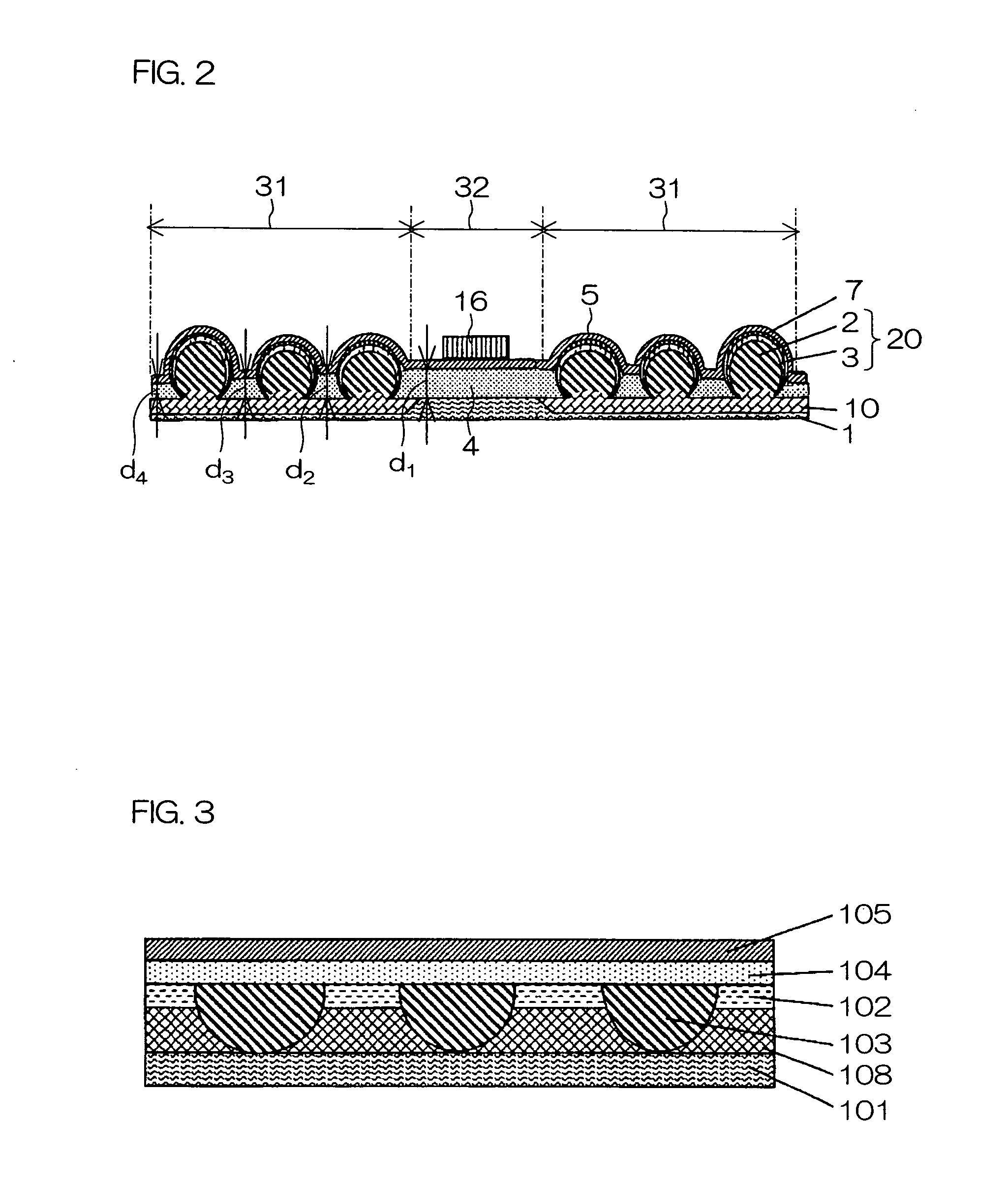

A photovoltaic conversion device has a substrate 1 as a lower electrode having a first region 31 and a second region 32 adjacent to the first region, a lot of semiconductor particles 20 joined to the first region 31, an insulator 4 formed between the semiconductor particles 20 on the substrate 1 in the first region 31 and on the substrate 1 in the second region 32, a transparent conductive layer 5 as an upper electrode formed so as to cover the upper part of the semiconductor particles 20 in the first region 31 and the insulator 4 in the first region 31, and a collecting electrode formed of a finger electrode 15 arranged on the transparent conductive layer 5 in the first region 31 and a bus bar electrode 16 which is arranged in the second region 32 and connected to the finger electrode 15. By making the thickness of the insulator 4 in the second region 32 larger than that of the insulator 4 in the first region, even if generated photocurrents concentrate on the bus bar electrode 16, insulating properties between the substrate 1 and the transparent conductive layer 5 can be ensured stably, thereby to achieve high photovoltaic conversion efficiency.

Owner:KYOCERA CORP

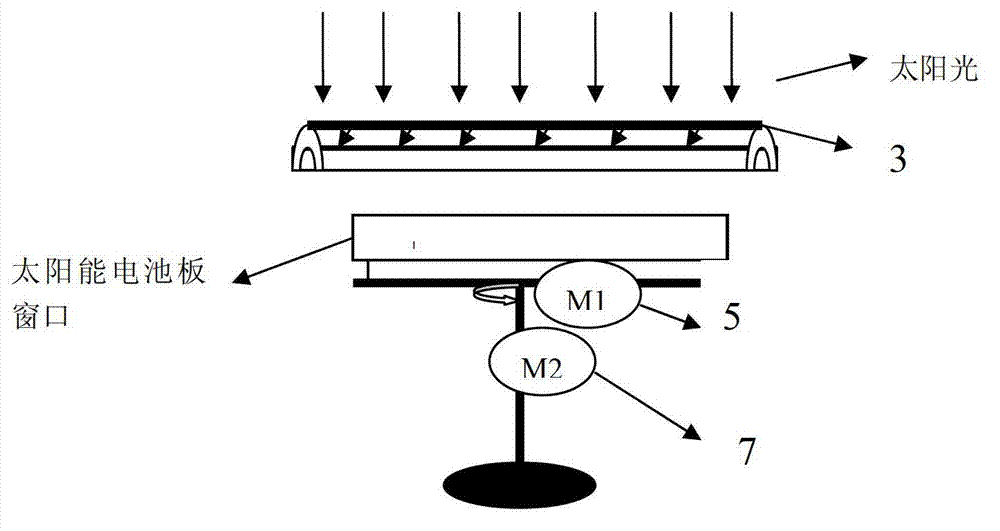

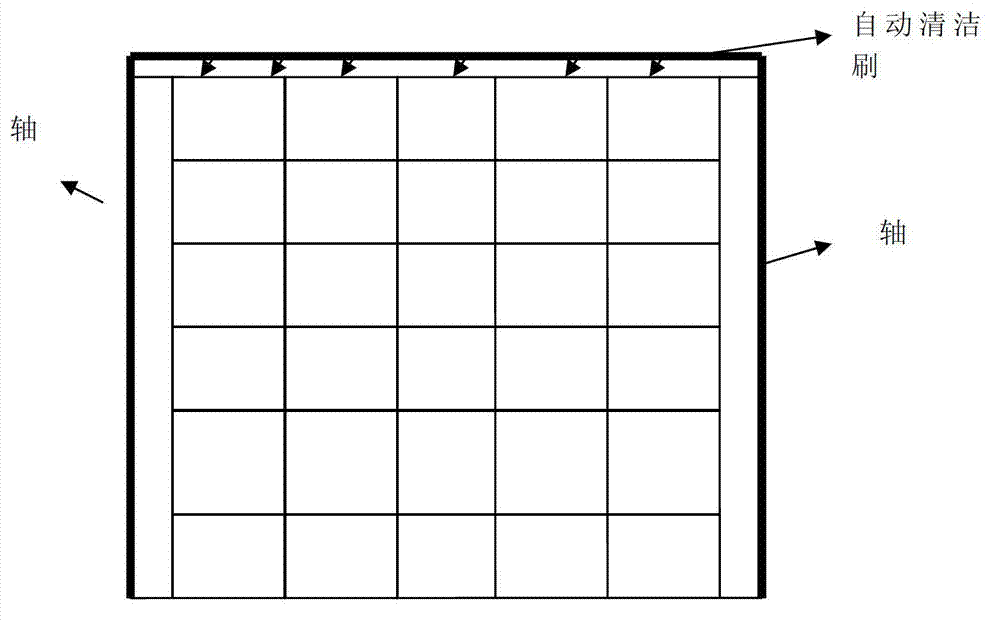

Window surface self-cleaning device of solar cell panel system

InactiveCN102832259ASelf-cleaning hasUniform light receivingPhotovoltaicsCleaning using toolsCells panelTemperature resistance

The invention relates to a window surface self-cleaning device of a solar cell panel system. The window surface self-cleaning device is characterized in that (1) a nano diamond thin film is prepared at a solar cell window; (2) the nano diamond thin film has high temperature resistance and corrosivity resistance; (3) the film prepared by diamond grains of nano grade has the self-cleaning function; (4) fixing shafts for fixing a cleaning brush are added at the two sides of the solar cell panel system which can track for 180 degrees at both the longitude and latitude; when the solar cell panel is rotated to a certain angle, the cleaning brush drops downwards automatically when a sliding force of the cleaning brush is larger than a friction force; the cell panel is swept during the automatic falling process so as to remove the soil and dust covering on the window. The cleaning brush and the cleaning characteristics of the diamond thin film ensure that the soil from the wind cannot stay at the solar photovoltaic electroplate window from two aspects, thereby solving the realistic problem that the solar photovoltaic conversion efficiency is reduced as the window is covered by the soil from the wind.

Owner:BEIFANG UNIV OF NATITIES

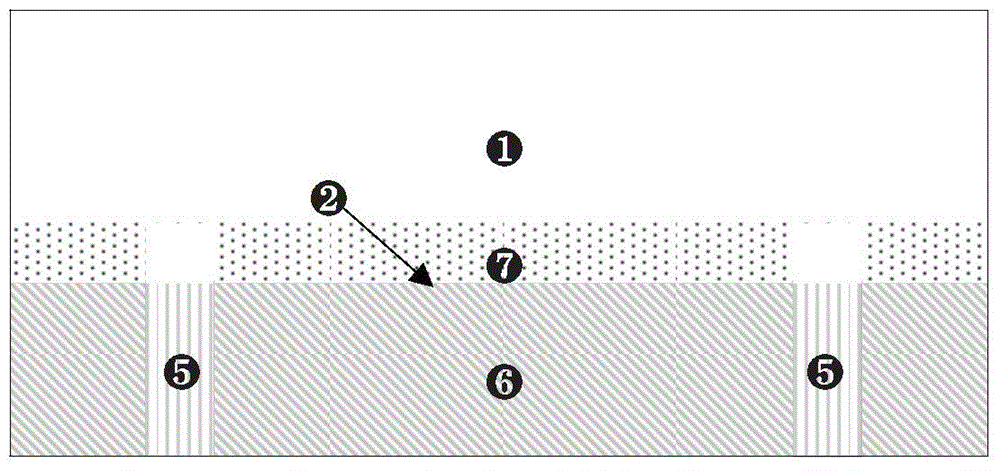

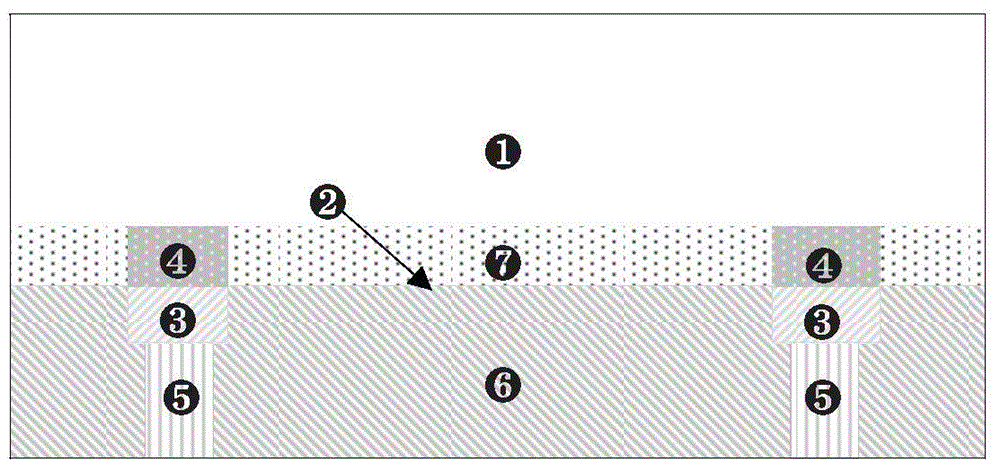

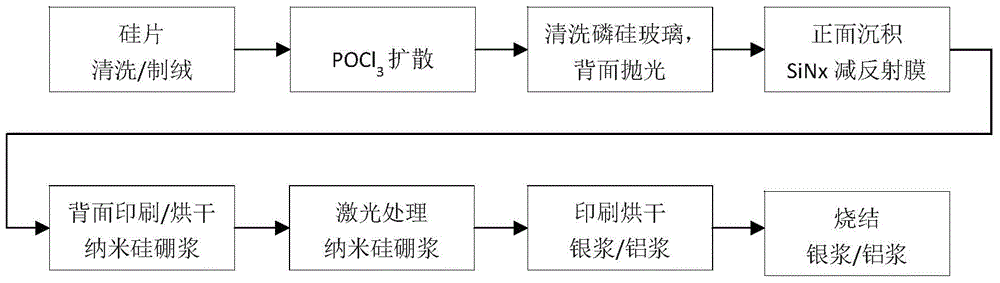

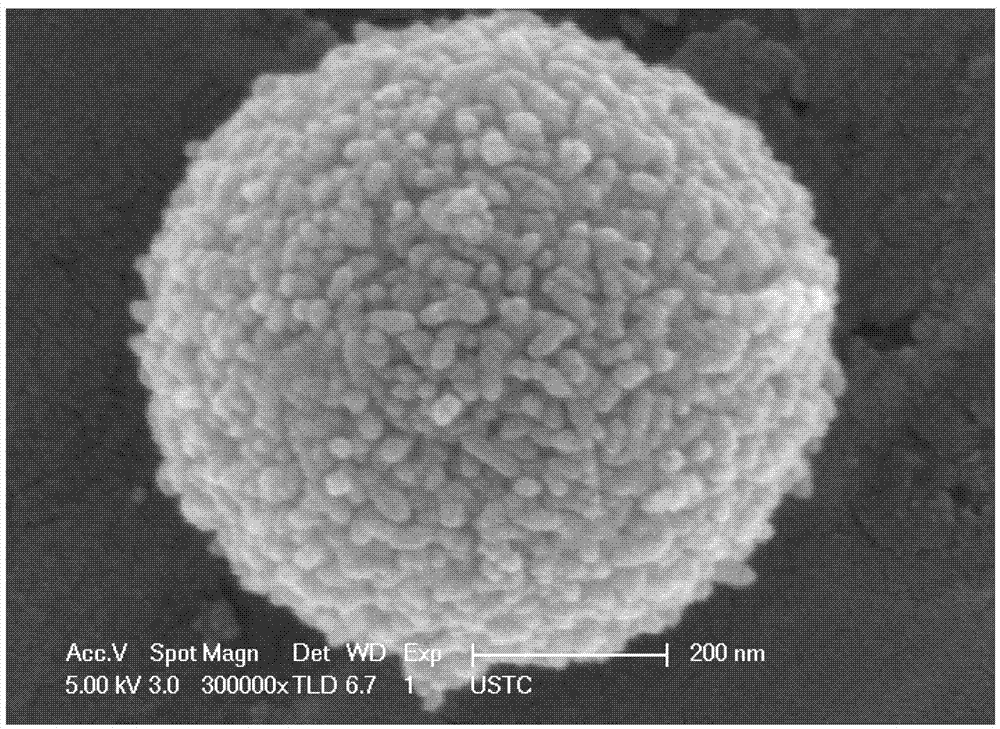

Nano silicon boron slurry and method for preparing solar cell with the same

InactiveCN104617164AImprove efficiencyReduce contact resistanceFinal product manufacturePhotovoltaic energy generationNano siliconGrating

The invention discloses nano silicon boron slurry and a method for preparing N type composite emitter and an improved P type solar cell with the nano silicon boron slurry. The nano silicon boron slurry is used as a carrier, and local boron adulteration of the grating line coverage area of the solar cell back through laser or high-temperature treatment can be realized. The method is combined with the aluminum paste sintering process to prepare an N-type composite emitter cell when an N type cell is produced so that the problems that the ordinary aluminum paste sintering process only forms emitters in the aluminum paste coverage area and the emitters in the silver grating line coverage area are not continuous can be solved, and the photovoltaic conversion efficiency of the N type aluminum emitter cell is improved. The method is combined with the original aluminum paste sintering process to prepare the improved P type cell when the P type cell is produced so that the problems that the original P type cell only forms a back surface field in the aluminum slurry coverage area and the back surface field in the silver grating line coverage area is not continuous can be solved.

Owner:苏州金瑞晨科技有限公司

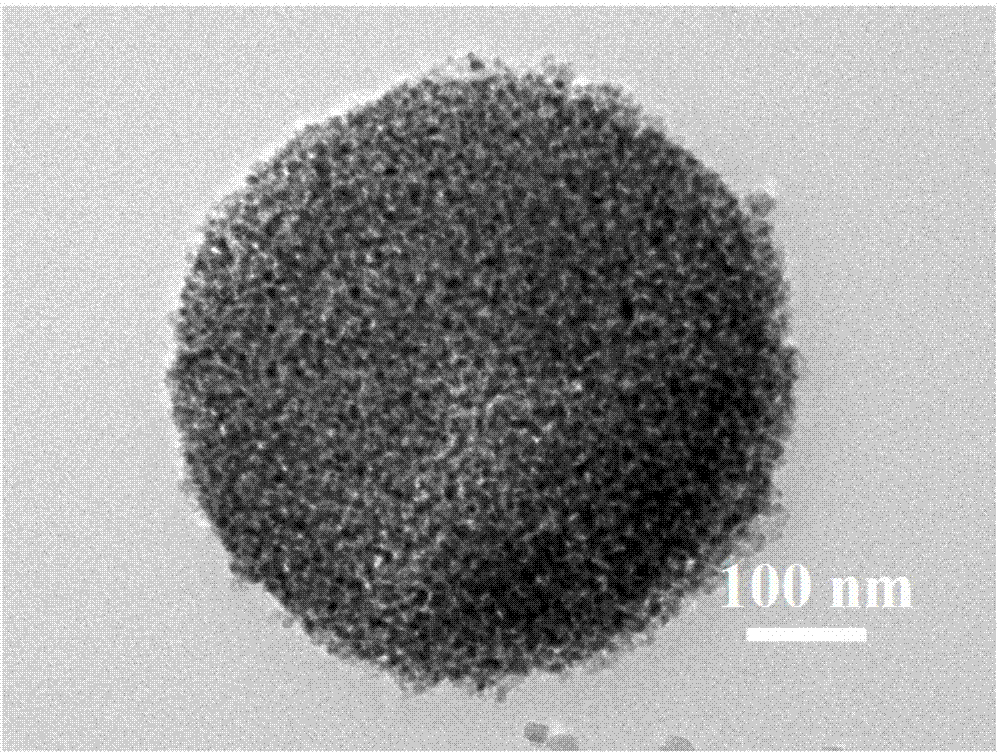

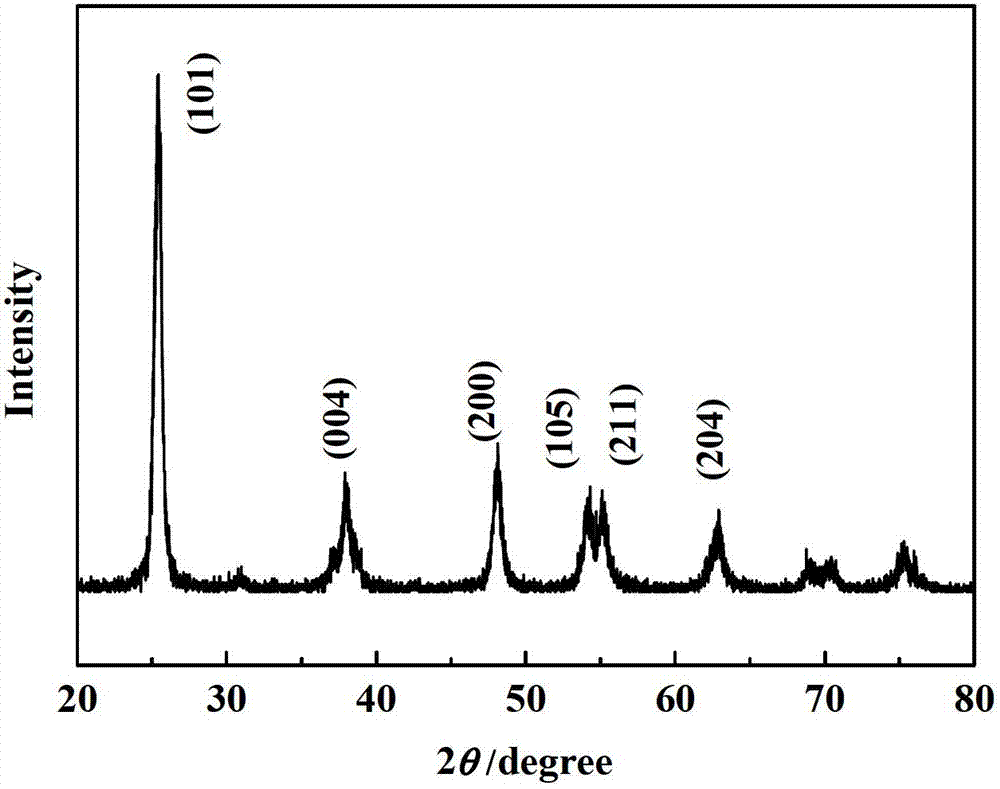

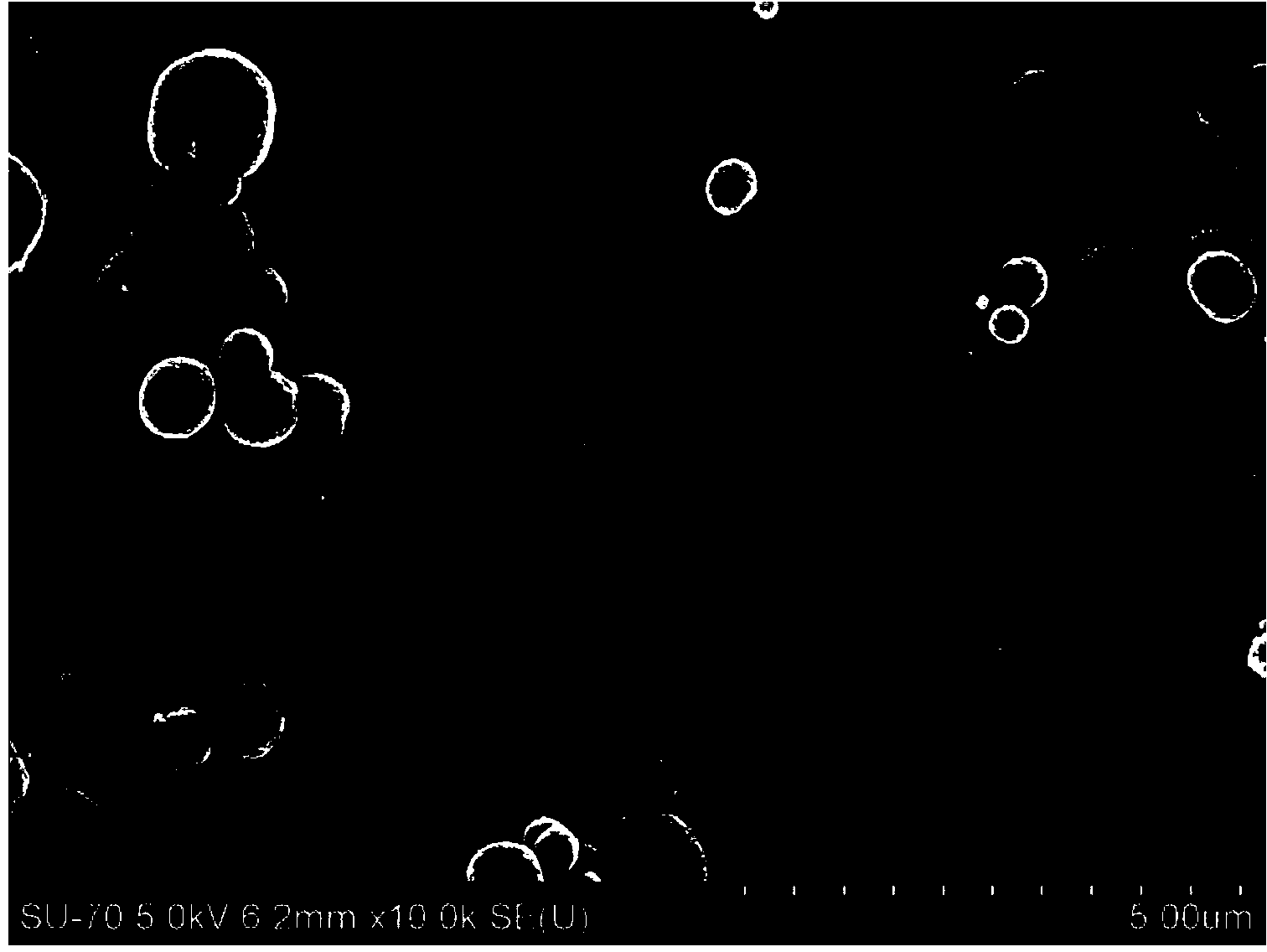

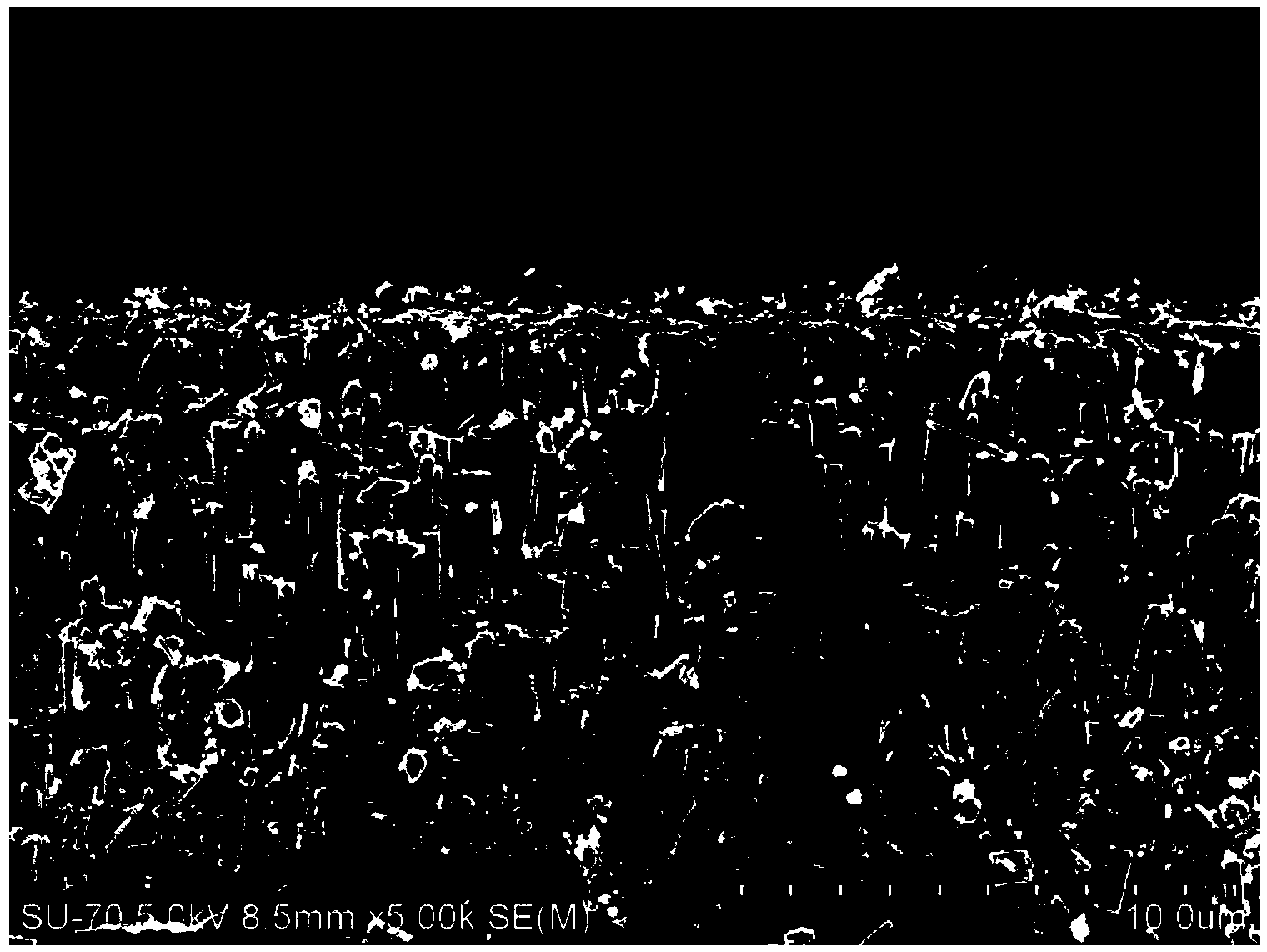

Porous submicron sphere, porous film electrode and preparation method and application in dye sensitized solar cells thereof

InactiveCN102774885AIncrease profitIncrease collection rateLight-sensitive devicesTitanium dioxideElectronic transmissionElectron

The invention discloses a porous submicron sphere, a porous film electrode and a preparation method and the application in dye sensitized solar cells thereof. The submicron sphere is in a porous structure formed by nano TiO2 particles, the pore diameter ranges from 5nm to 50nm, the grain diameter of the TiO2 particles ranges from 10nm to 100nm, the diameter of the submicron sphere ranges from 150nm to 1000nm, and the BET specific surface area is controlled to range from 80m2 / g to 200m2 / g. The porous submicron sphere formed by titanium dioxide nano particles is in a distribution of monodisperse and wide-diameter, and the structure is large in specific surface area, higher in scattering capacity to visible lights and quicker in electronic transmission performance inside the sphere, so that the porous film electrode has larger light scattering capacity and dye adsorption capacity. When the porous submicron sphere and the porous film electrode are applied to fields of photocatalysis and photovoltaic conversion, light use ratio and electron collection rate can be increased, and the dye sensitized solar cells can obtain higher photovoltaic conversion efficiency and save TiO2 usage.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Dye-sensitized solar cell and preparation method of ZnO composite photo-anode of dye-sensitized solar cell

ActiveCN103730260AHigh specific surface areaEase of industrial productionLight-sensitive devicesFinal product manufactureElectronic transmissionElectrical battery

The invention discloses a preparation method of a ZnO composite photo-anode of a dye-sensitized solar cell. The preparation method includes the steps of firstly, growing a ZnO nanometer wire array on a conductive substrate, and then growing and filling ZnO nanometer particles in situ in gaps between nanometer wires. By means of the preparation method, the specific area of the ZnO composite photo-anode is enlarged, and therefore the photovoltaic conversion efficiency of the photo-electrode is remarkably improved; meanwhile, the nanometer wires grow in a specific direction perpendicular to the substrate, and therefore the electronic transmission speed can be increased. In addition, the preparation method is easy to operate, free of sintering, short in response time when the nanometer particles grow in the gaps of the ZnO nanometer wire array, capable of reducing cost and beneficial to industrial production of the photo-anode. Due to the advantages of the photo-anode of the dye-sensitized solar cell, the dye-sensitized solar cell with the ZnO composite photo-anode can be widely applied to the solar cell field.

Owner:SHENZHEN UNIV

Reflective light-gathering solar photovoltaic electricity-generating component

InactiveCN101702598AUniform radiation intensityLow costPhotovoltaicsPhotovoltaic energy generationOptoelectronicsPhotovoltaic conversion efficiency

The invention discloses a reflective light-gathering solar photovoltaic electricity-generating component, which comprises a primary reflector, a secondary reflector, a transparent protective cover plate, photovoltaic cells, a conductive connecting line, a radiator base plate and a frame. The primary reflector thereon is provided with more than one group of trough parabolic reflecting mirror surfaces, one trough parabolic reflecting mirror surface is correspondingly provided with a secondary reflector, and each secondary reflector thereon is provided with a strip curved reflecting mirror surface, and the bottom of each trough parabolic reflecting mirror surface is corresponding to a photovoltaic cell. The strip curved reflecting mirror surfaces and the trough parabolic reflecting mirror surfaces are matched and used for forming light-gathering illumination with the same radiation strength on the surfaces of the photovoltaic cells, so as to improve the photovoltaic conversion efficiency of ordinary photovoltaic cells of unit area, even obtain higher fold of light-gathering ratio, and reach the purpose of using less photovoltaic cells under the condition of given power, so that the total cost of a photovoltaic electricity-generating system is reduced.

Owner:新疆维吾尔自治区新能源研究所

Preparation method of hollow microsphere silicon dioxide (SiO2) antireflection film

InactiveCN103074620AMore obvious than the surface effectImprove transmittanceSolid/suspension decomposition chemical coatingMicrosphereSolar battery

The invention relates to a preparation method of a hollow microsphere silicon dioxide (SiO2) antireflection film, and the method comprises the following steps of preparing the SiO2 sol with concentration of 0.02mol / L to 0.8mol / L, placing nucleating agent into the SiO2 sol under a stirring condition, then adding stabilizer, and stirring and homogenizing the mixture to form the sol. The nucleating agent is polyelectrolyte with number-average molecular weight of the nucleating agent of 2000 to 5000, mutually soluble with water and easy to decompose under the temperature of less than 300 DEG C, and the stabilizer is N, N - dimethyl formamide and N, N - dimethylacetamide. The sol is used for coating a film on a clean glass substrate, after the coated film is dried at the temperature of 70 to 150 DEG C, the coated film is heated to 300 to 500 DEG C to be thermally treated, the heat preserving time is not less than 0.1h, and the SiO2 antireflection film can be obtained. The prepared SiO2 film can reduce the reflection rate of the sunlight, so that the transmission rate of the sunlight can be improved, the photovoltaic conversion efficiency of a solar battery can be effectively increased, and the method is simple, low in cost and remarkable in economic benefit.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

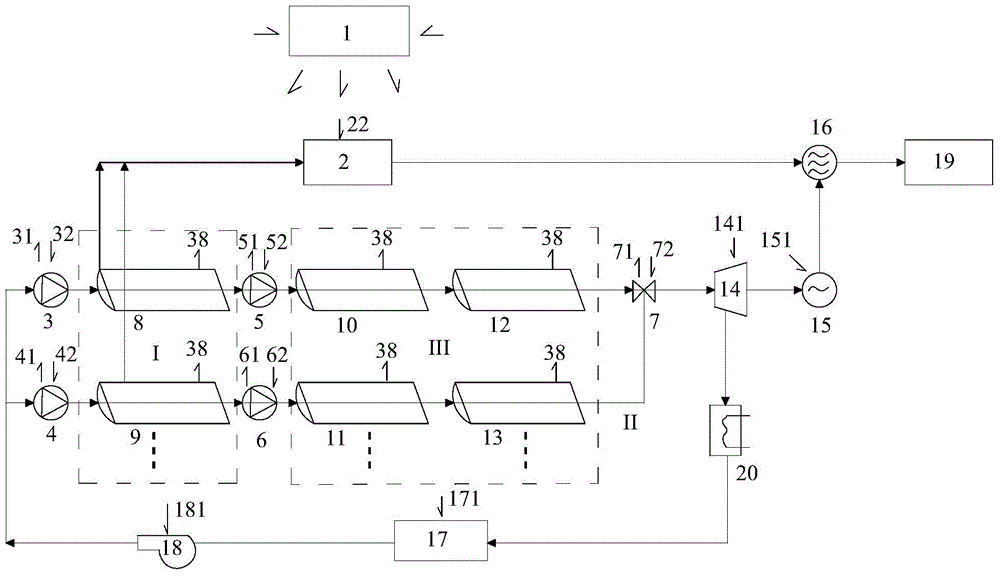

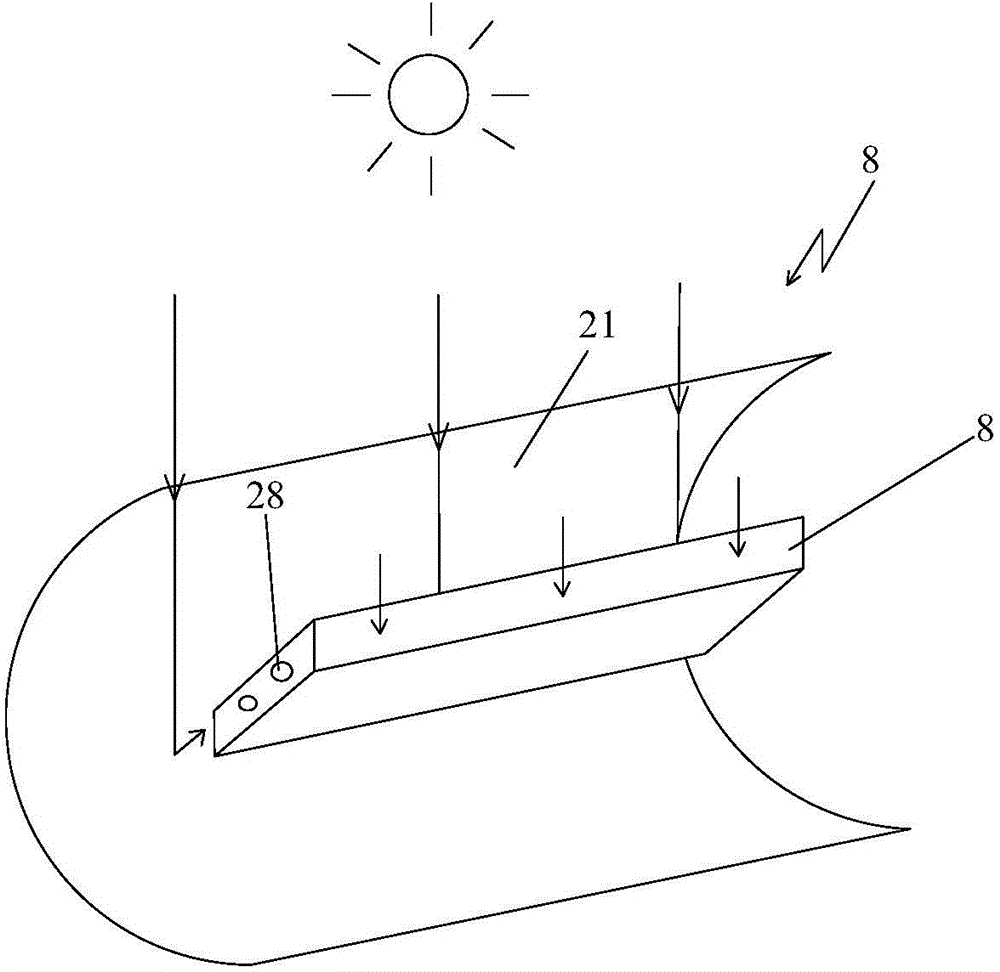

Solar dual condensing photovoltaic and photo-thermal integrated power generation system

InactiveCN104811122APlay a role in heat dissipation and coolingImprove the efficiency of solar power generationFrom solar energyPV power plantsEngineeringSolar power

The invention relates to a solar dual condensing photovoltaic and photo-thermal integrated power generation system. The system comprises a dual condensing photovoltaic generator component, a dual condensing photo-thermal power generation device and a grid-connected inverter, wherein the dual condensing photovoltaic generator component comprises a single or multiple dual condensing photovoltaic generators or photovoltaic cell panels combined in parallel to output generated power; the dual condensing photo-thermal power generation device comprises a dual condensing heat collector component, an engine, a generator, a working medium condenser, a working medium storage tank and a working medium pressure pump; the dual condensing photovoltaic generator is connected with the dual condensing heat collector through a working medium control valve. According to the provided solar dual condensing photovoltaic and photo-thermal integrated power generation system, the problem of scatter of solar energy utilization can be solved, the solar photovoltaic conversion efficiency can be comprehensively improved, the high efficiency and the stability of the solar power generation system can be maintained, the using amounts of a photoelectric silicon material and a non-silicon material can be greatly reduced, and the cost of solar power generation can be effectively reduced.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Compound type embossing photovoltaic welding strip and machining method thereof

ActiveCN104485365AReduce manufacturing costReduce processing costsFinal product manufacturePhotovoltaic energy generationEngineeringCopper

The invention provides a compound type embossing photovoltaic welding strip. The compound type embossing photovoltaic welding strip comprises a strip-shaped conductive substrate which is welded with a main grid line of a solar cell plate; a plurality of specially-shaped metal wires capable of reflecting light are put on one side of the upper surface of the strip-shaped conductive substrate; the lengths of the specially-shaped metal wires are not greater than the maximum length of the solar cell plate. Furthermore, the specially-shaped metal wires have sections which are shaped like isosceles triangles with top angles being greater than 90 degrees; furthermore, the sections of the specially-shaped metal wires are semicircular; furthermore, the specially-shaped metal wires are parallelly arranged on the strip-shaped conductive substrate; furthermore, the specially-shaped metal wires are made of pure copper or pure silver; if the specially-shaped metal wires are made of pure copper, a layer of soldering tin is plated on the outer surface of each specially-shaped metal wire. The invention also discloses a machining method for combining the compound type embossing photovoltaic welding strip with solar cells through serially welding machining. According to the compound type embossing photovoltaic welding strip, the strength for welding the photovoltaic welding strip with back electrodes of the solar cells can be improved; meanwhile, the photovoltaic conversion efficiency is improved.

Owner:WUXI SUNTECH POWER CO LTD

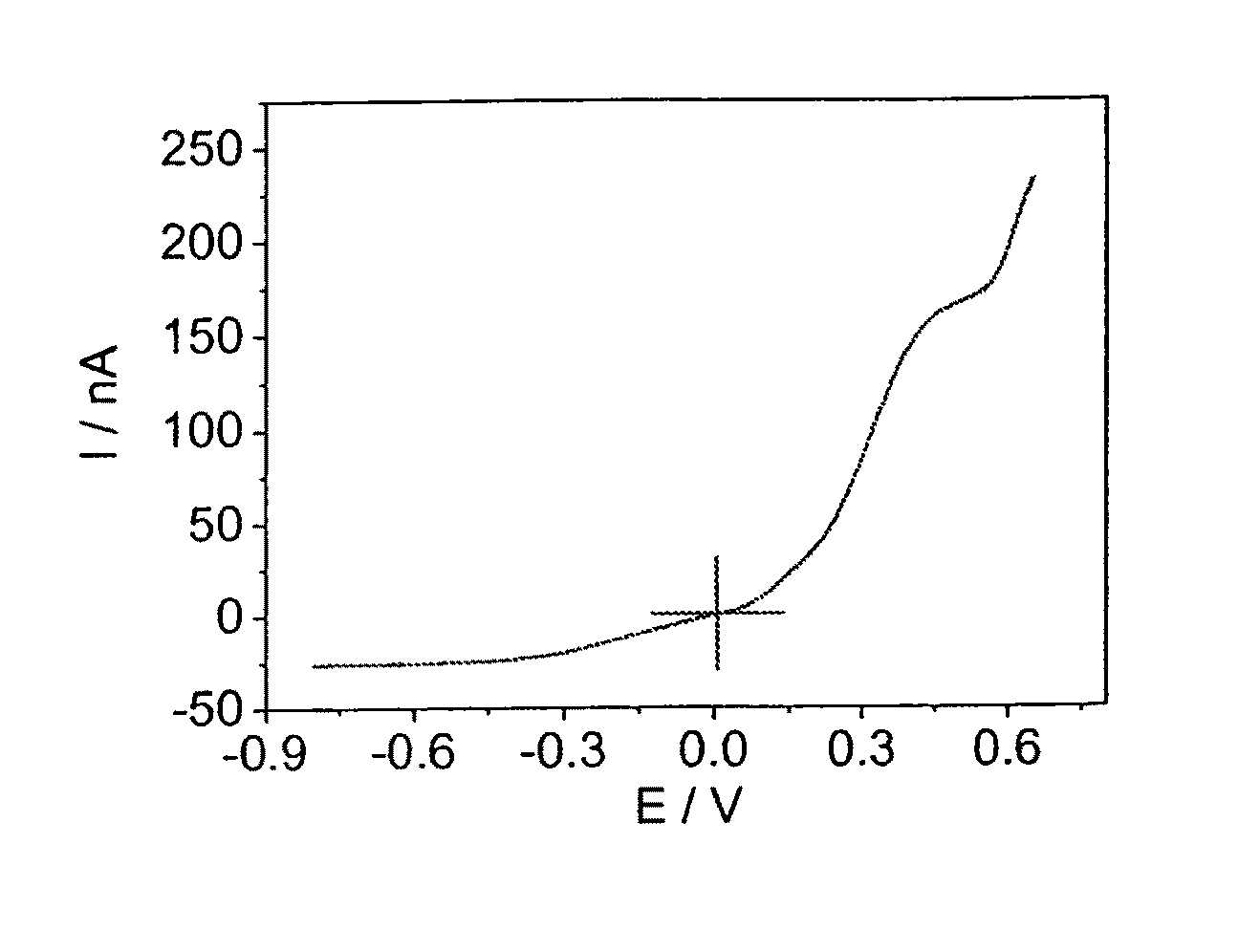

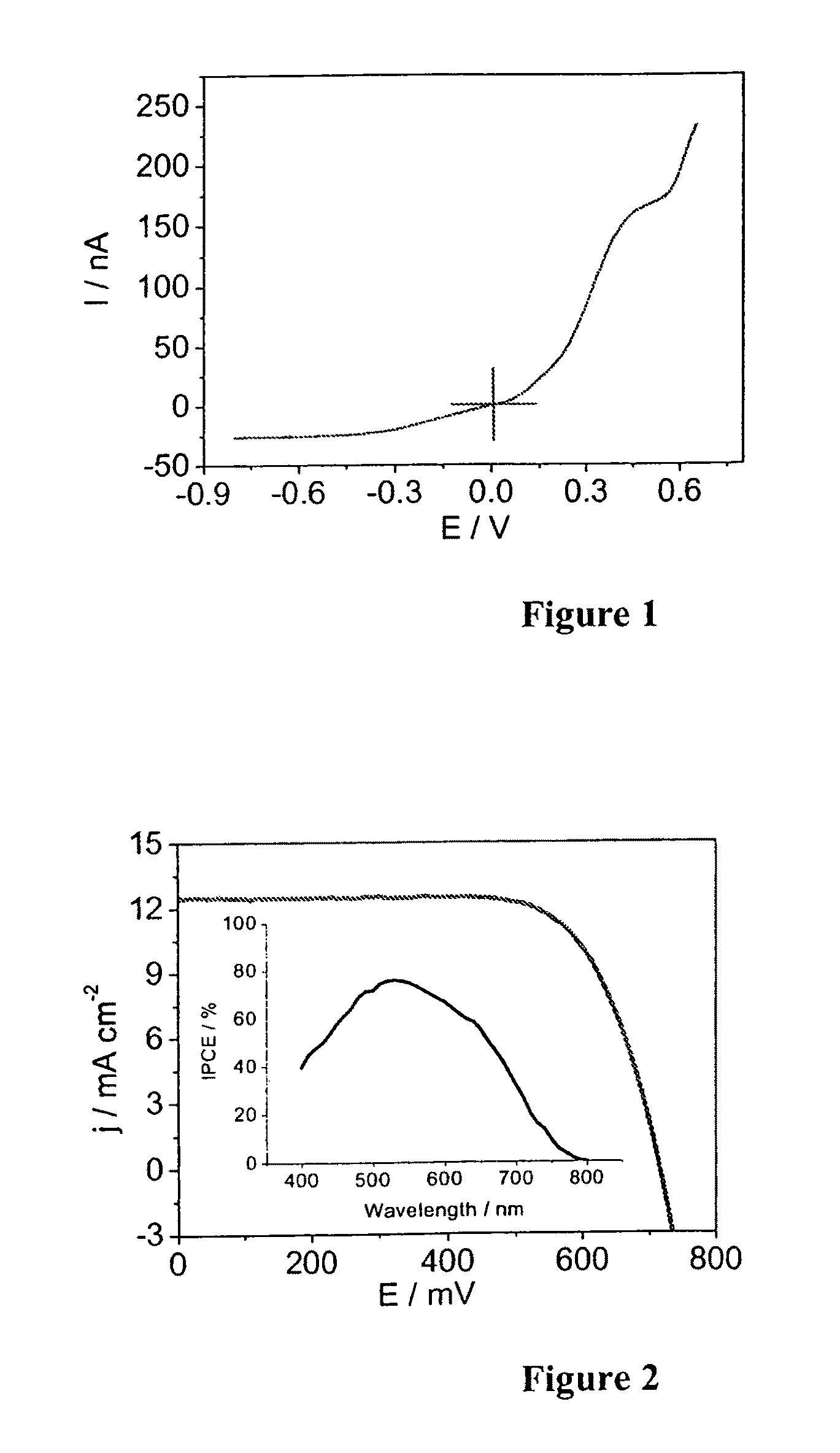

Ionic liquid electrolyte

InactiveUS8114318B2Improve performanceImprove stabilityLiquid organic insulatorsElectrolytic capacitorsSolventElectrochemistry

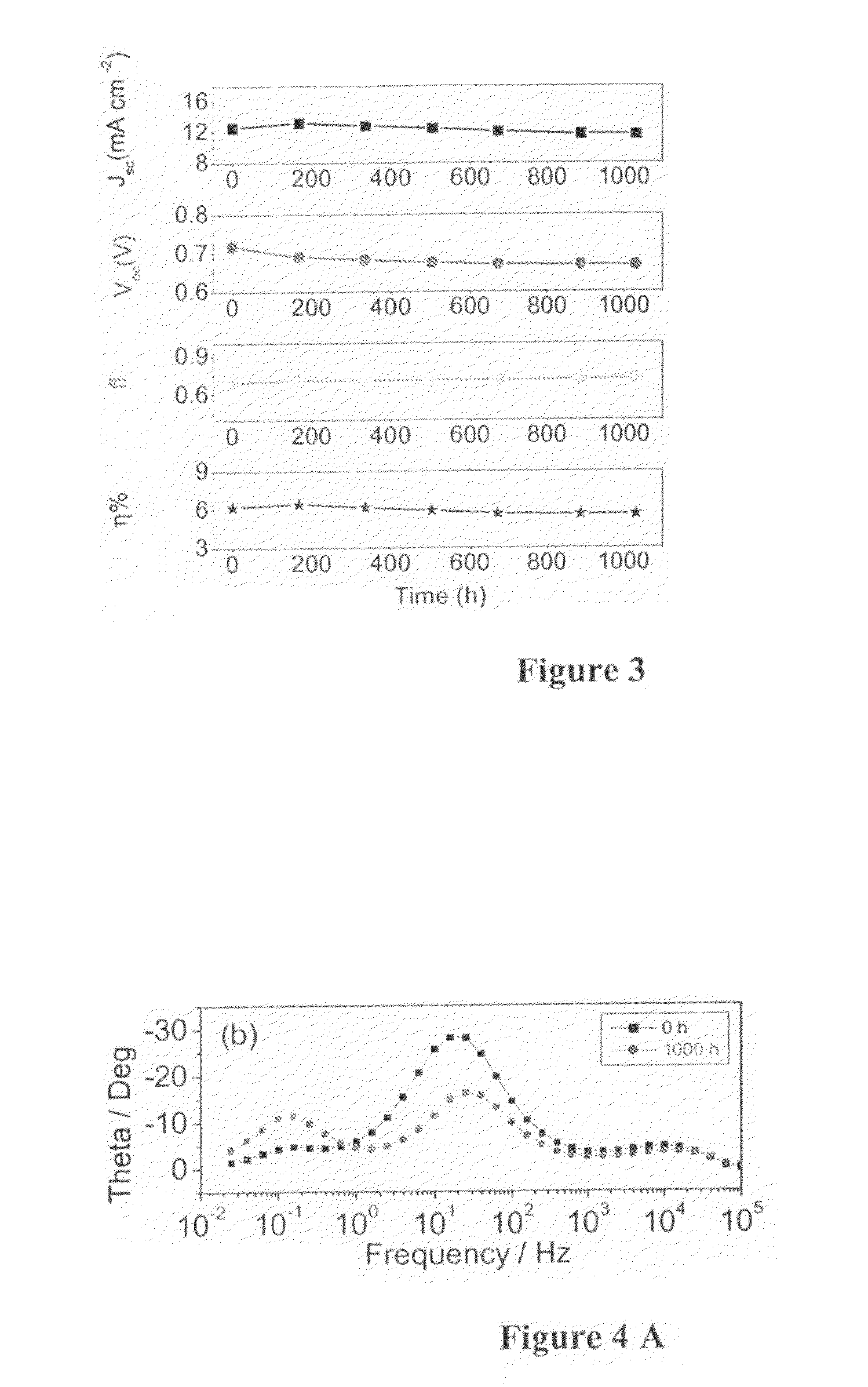

The present invention relates to electrolytes comprising tetracyanoborate and an organic cation as components of electrolytes in electrochemical and / or optoelectronic devices, in particular solar cells. This ionic liquid has low viscosity and can be used as electrolyte in the absence of a solvent. Importantly, the ionic liquid remains stable in solar cells even after prolonged thermal stress at 80° C. for 1000 hours. Photovoltaic conversion efficiency remained stable and keeping more than 90% of the initial value.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com