Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1313results about How to "Simple production equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation of biodegradable thermoplastic starch plastic having high starch content

The invention relates to a production technology of a completely bio-degradable plastic with high starch content. In the technology, natural starch, a plasticizer and other addition agents are blended together, squeezed by a double-screw squeezing machine and manufactured into thermoplastic starch particles. The thermoplastic starch particles are mixed with a blended resin, a compatibilizer, a chemical initiation agent and other addition agents. In the double-screw squeezing machine, the completely bio-degradable plastic with high starch content is manufactured by reactive squeezing. The content of the thermoplastic starch in the prepared completely bio-degradable plastic can achieve 80 percent; the material cost is low; the processing performance is good; the mechanical performance is excellent; in addition, the invention is provided with the completely bio-degradable performance and can be directly used for manufacturing various packaging materials, films, shopping bags and tableware, etc.

Owner:SICHUAN UNIV

High-dietary fiber five-cereal puffing powder and preparation process thereof

The invention relates to high-dietary fiber five-cereal puffing powder and a preparation method, and belongs to the field of food processing. The five-cereal puffing powder comprises the following raw materials: coarse rice powder, wheat meal, oatmeal, millet meal, glutinous corn meal, soybean meal, wheat bran meal, calcium lactate, ferrous gluconate, zinc gluconate, vitamin B1, vitamin B2 and vitamin B6. A method for processing the five-cereal puffing powder comprises the following steps of: screening coarse cereals, grinding, milling, sieving with an 80-mesh sieve, mixing uniformly in a ratio, adjusting the moisture of materials, balancing the moisture, extruding and puffing by using double screws, drying, crushing, and sieving with a 100-mesh sieve, enhancing mineral elements and the vitamins. The high-dietary fiber five-cereal puffing powder has the characteristics that the puffing powder is prepared from natural grain coarse cereals, emulsifying agents and sweeteners are not added, the mineral elements and the vitamins are enhanced, the content of dietary fibers reaches the specified standard of national high-dietary fiber foods, and the puffing powder can be eaten only by being infused by boiling water, so that the high-dietary fiber five-cereal puffing powder is an ideal nutritional and convenient food which is suitable to be eaten by middle and old-aged people.

Owner:HEFEI UNIV OF TECH

Dedicated fertilizer for producing green corn and preparation and application method thereof

ActiveCN101747102ADrain controlIncrease productionFertilising methodsAgriculture gas emission reductionTrace element compositionPhosphate fertilizer

The invention relates to spring maize cultivation, in particular to a dedicated fertilizer for producing green corn and a preparation and an application method thereof.The fertilizer is composed of urine-based nitrogenous fertilizer, phosphate fertilizer, potash fertilizer, medium elements and trace elements; in the preparation method, the solid raw materials with a grain size of 1.5-4.5mm are selected; then the medium elements are added to humic acid or humic acid salt accounting for 60-100% of the mass percent of the medium elements to be mixed; afterwards, trace elements are added and mixed with the mixture, cementing agent is used for pelleting and producing solid raw materials with a grain size of 1.5-4.5mm for standby use; finally, the medium elements and trace elements mixed for pelleting are uniformly mixed with the urine-based nitrogenous fertilizer, phosphate fertilizer and potash fertilizer.The dedicated corn fertilizer is applied to the corn spring sowing as base fertilizer at one time and no after manuring is not needed.The use level of the urea-based nitrogenous fertilizer in the fertilizer of the invention proportion of the urea-based nitrogenous fertilizer in different release periods are set with proportion of the urea-based nitrogenous fertilizer in different release periods according to fertilizer-demanding characteristics on the nitrogenous fertilizer by the corn in different growth periods to form 4-level supply speed of the fertilizer nitrogen, thus remarkably controlling loss of nitrogenous fertilizer.

Owner:锦西天然气化工有限责任公司

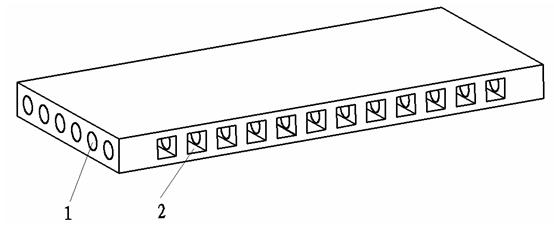

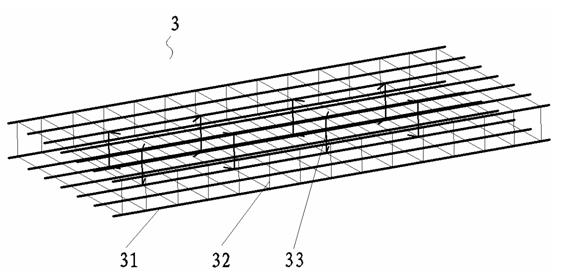

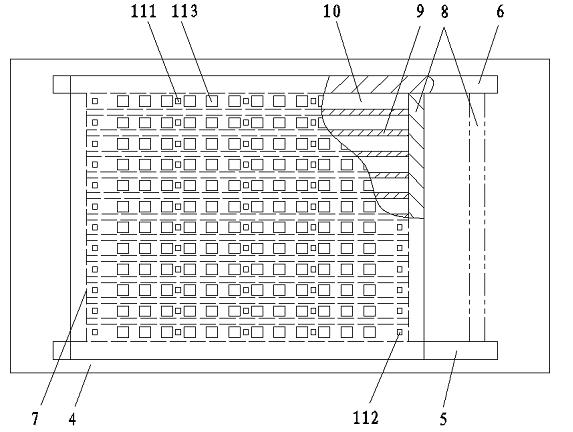

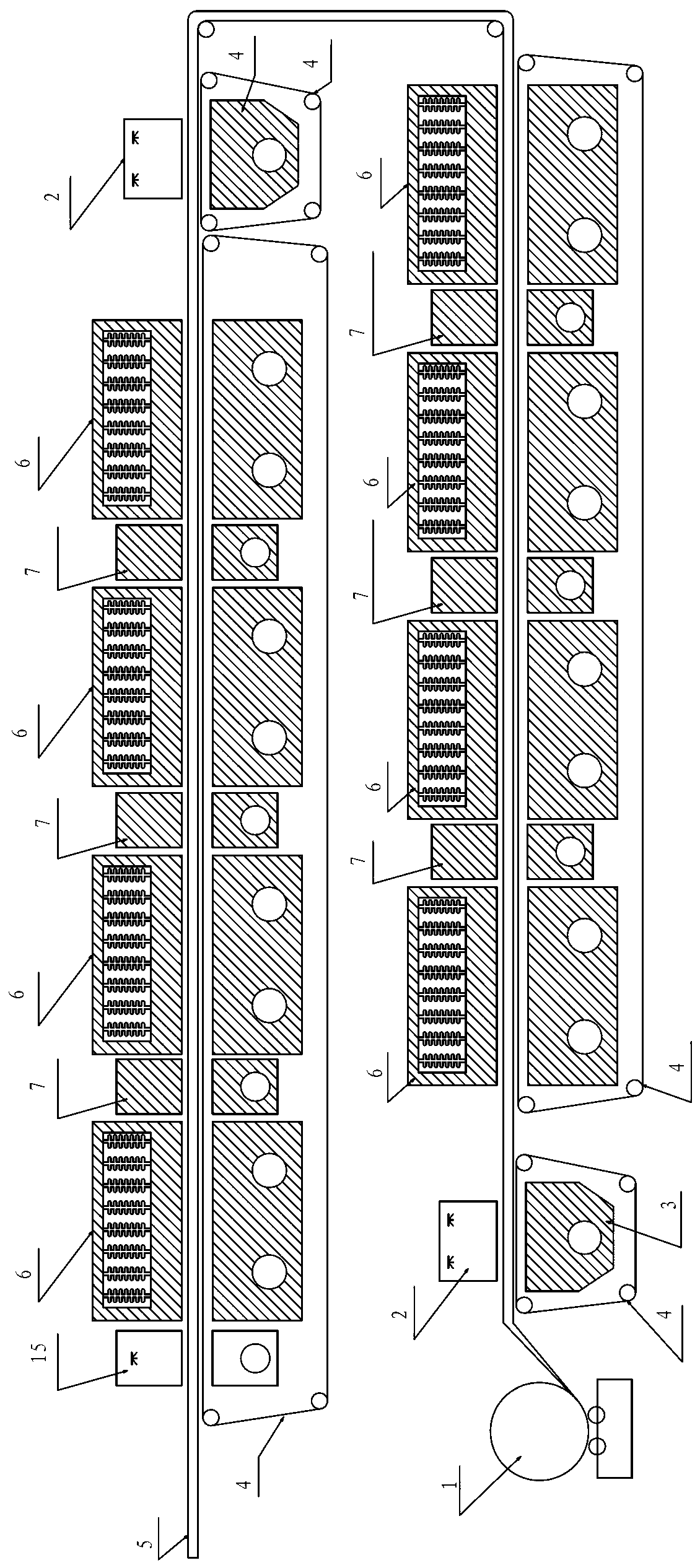

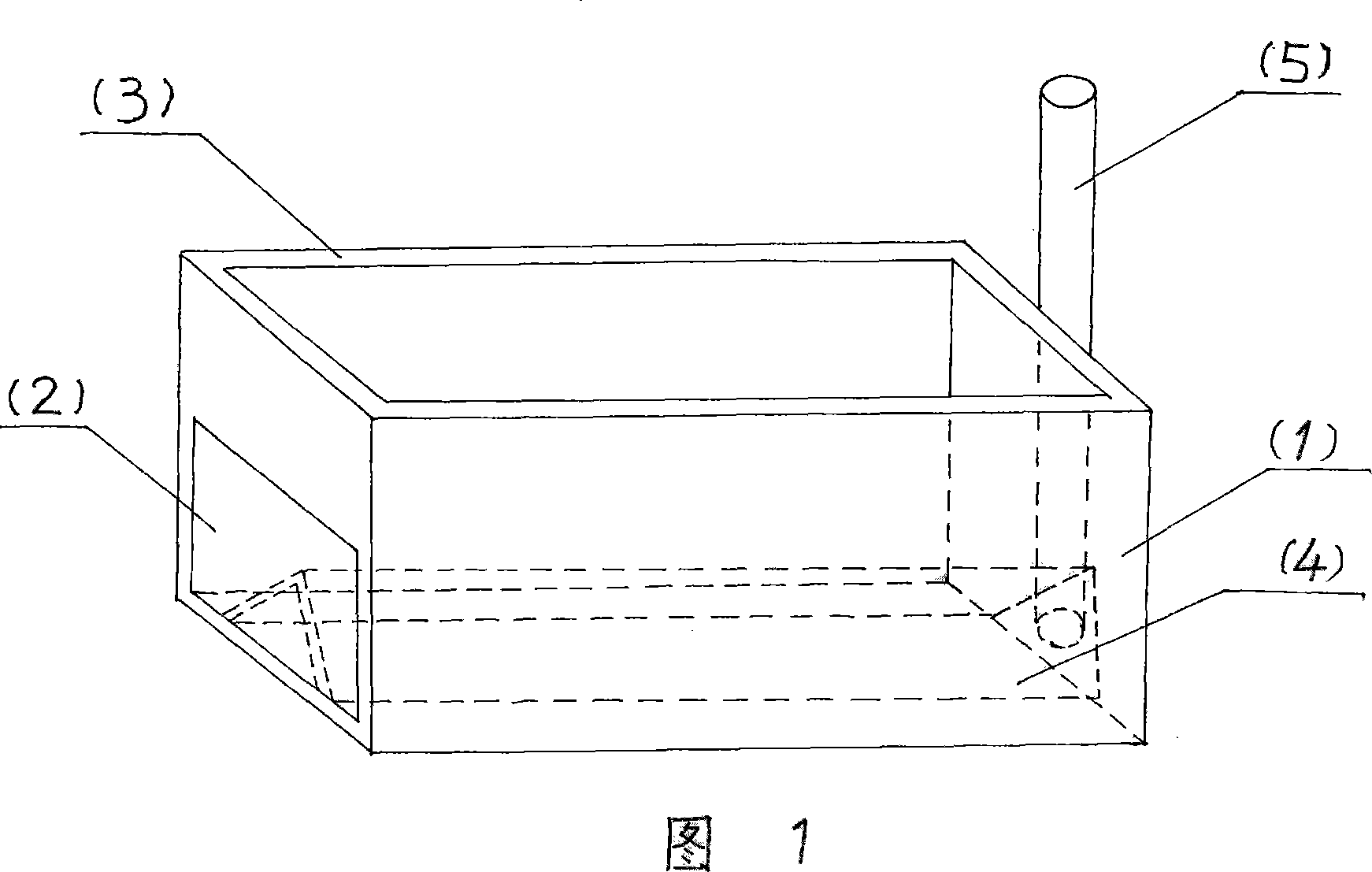

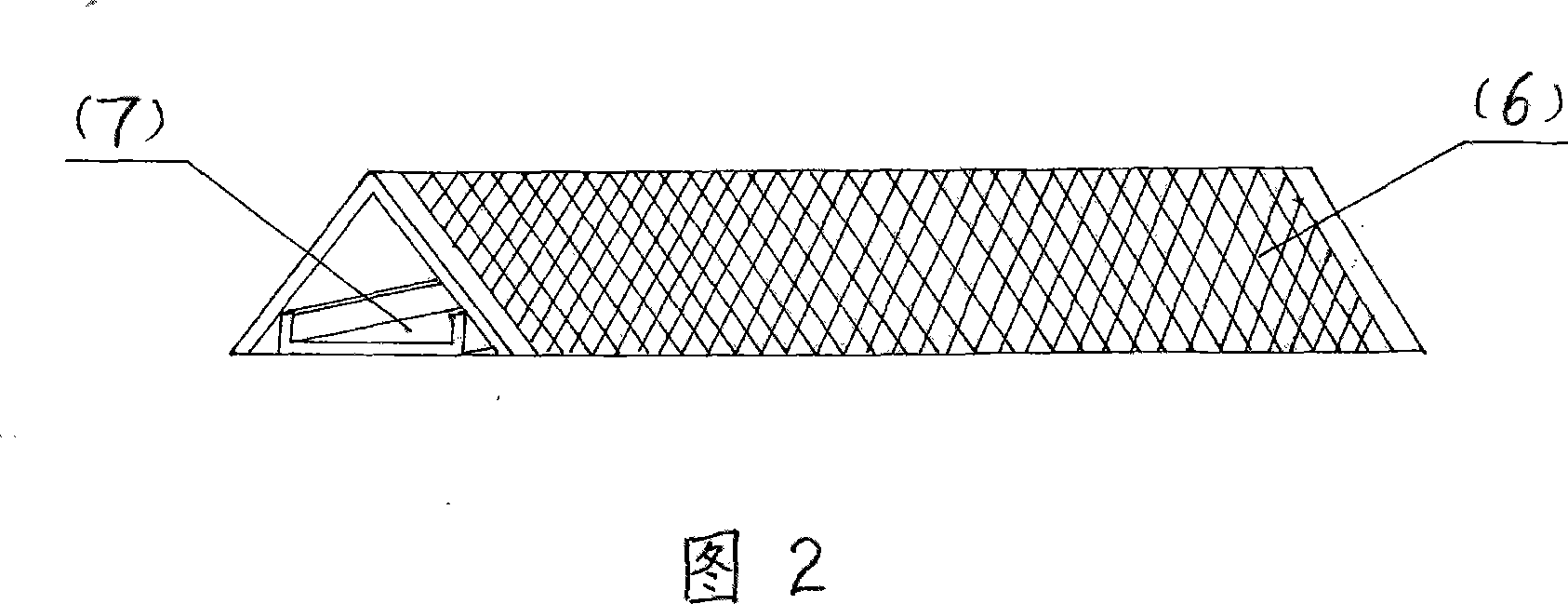

Prefabricated reinforced concrete hollow template internally provided with cross holes and molding and forming device thereof

The invention relates to a prefabricated reinforced concrete hollow template internally provided with cross holes and a molding and forming device of the prefabricated reinforced concrete hollow template. The hollow template is internally provided with longitudinal through holes with round cross sections along the length direction and latitudinal through holes with square cross sections along the width direction, wherein the longitudinal through holes are arrayed parallel one another, the latitudinal through holes are also arrayed parallel one another, and the diameter of each longitudinal through hole is less than the length of the side of each latitudinal through hole. Two large surfaces of the hollow template are flat surfaces formed by molding. A casting mold of the molding and forming device is of a vertical type and provided with one or more mold cavities; each mold cavity is surrounded by a front face plate, a rear face plate, a left side plate and a right side plate; a core tube frame or upper side plate capable of fixing a vertical core tube is arranged on the upper part or above each mold cavity; and the left side plate, the right side plate and the upper side plate are provided with a plurality of horizontal holes and vertical holes respectively. Each surface of the hollow template processed by using the molding and forming device is flat without being polished and subjected to similar treatment. The hollow template is high in strength and good in quality, can be directly used for the construction of a load-bearing wall with few procedures in a short time and can ensure that the load-bearing wall is not easy to shrink and crack.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV

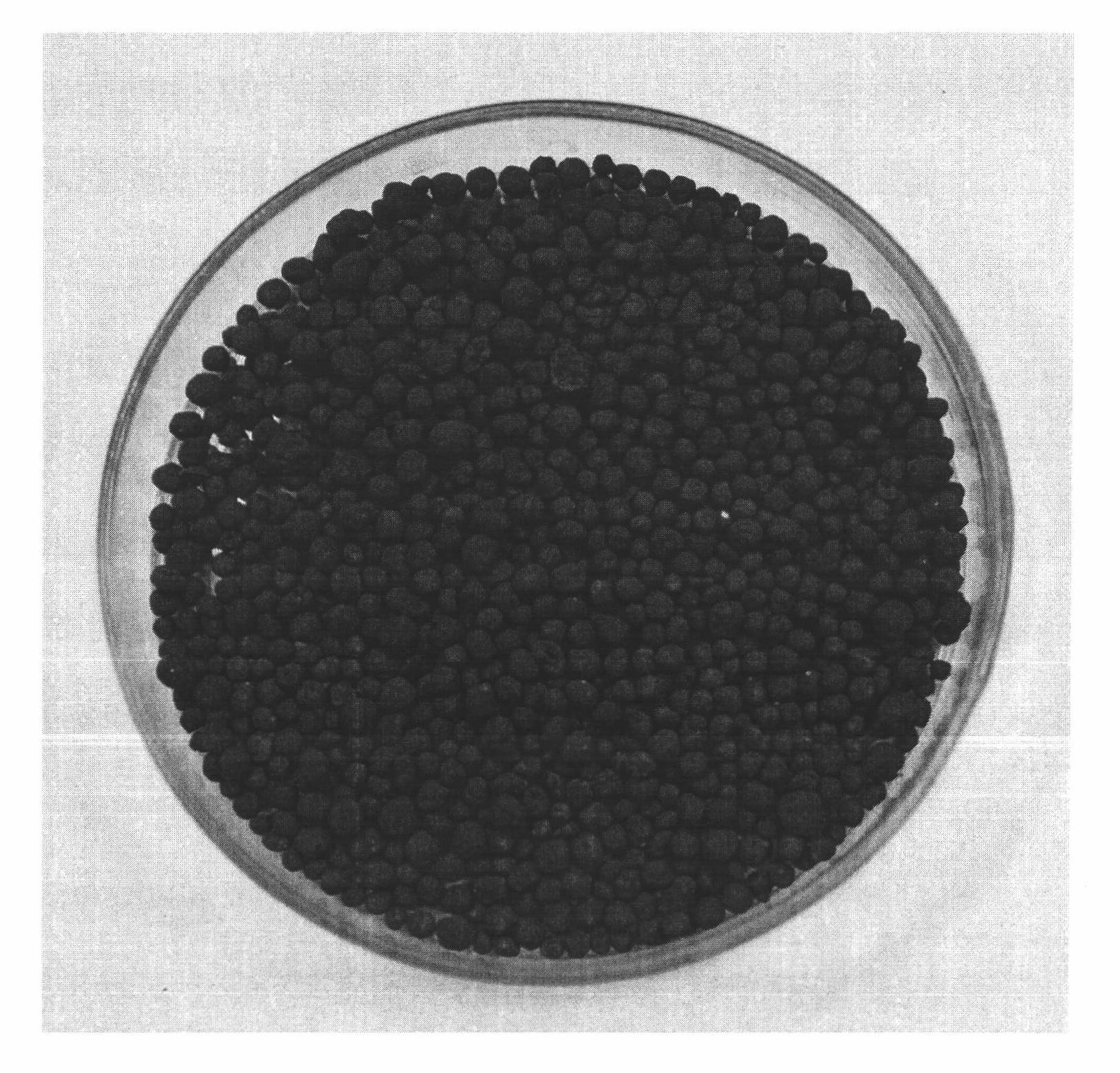

Carbon-base soil improver and preparation method thereof

InactiveCN102174330ASimple production processSimple production equipmentSoil lifting machinesOrganic fertilisersChemistryCarbon black

The invention relates to the crop growing field, particularly relates to a soil improver taking biomass particle carbide discarded in agriculture and forestry as a matrix and a preparation method thereof. The carbon-base soil improver comprises biomass particle charcoal, calcium magnesium phosphate or calcined lime, and binder, and also comprises other fertilizers, such as urea, monoammonium phosphate powder, potassium chloride, zinc sulfate, boricfertilizer, manganese sulfate, ammonium molybdate, ferrous sulfate and copper sulfate and the like. The biomass particle charcoal is a black powdered carbon particle (carbon soot) generated by incomplete combustion of the biomass under hypoxemia condition, has various properties similar with soil humus (acid) and strong ability to absorb and maintain nutrients, such as nitrogen, phosphorus and potassium and the like, and has obvious water retention and moisture preservation effects. The soil improver prepared by the preparation method has the characteristics of soil structure improvement, moisture and fertility preservation, temperature increasing, efficient environmental protection and wide application prospects and the like.

Owner:辽宁金和福农业科技股份有限公司

Biomass activated carbon, preparation method thereof and application thereof in flue gas mercury removal

InactiveCN102515162AReduce manufacturing costReduce pollutionCarbon compoundsDispersed particle separationCarbonizationNitrogen gas

The invention discloses biomass activated carbon, a preparation method thereof and the application thereof in flue gas mercury removal. Ordinary crop straws serve as raw materials, the biomass raw materials are impregnated by activator, i.e. zinc chloride aqueous solution with the concentration being 20 percent to 50 percent for 20 hours to 30 hours; after the impregnated biomass raw materials are carbonized for 1.5 hours to 3 hours at 400DEG C to 700DEG C under the protection of nitrogen and are taken out and naturally cooled, the carbonized biomass raw materials are washed by 5 percent to 15 percent of hydrochloric acid, rinsed by distilled water to neutral and filtered by neutral filter paper, dried and ground in an oven, and finally the biomass activated carbon is finally obtained. According to the biomass activated carbon, the ordinary crop straws serve as the raw materials, not only waste can be changed into valuable, but also the production cost is low. Simultaneously, because the biomass activated carbon can absorb methylene blue and mercury, the biomass activated carbon can be used in the demercuration of coal-fired flue gas, and can mitigate the environmental pollution.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Carbon-based ginseng soil conditioner and preparation method thereof

ActiveCN102604645ASimple production processSimple production equipmentOrganic fertilisersSoil-working methodsEcological environmentPhosphate

The invention relates to the field of agricultural chemistry, in particular relates to a carbon-based ginseng soil conditioner and a preparation method thereof. The carbon-based ginseng soil conditioner comprises biomass particle carbon, wood vinegar and an adhesion agent, and further comprises other fertilizers, such as urea, monoammonium phosphate powder, potassium chloride, zinc sulfate, boric fertilizer, manganese sulfate, ammonium molybdate, ferrous sulfate and copper sulfate. The biomass particle carbon is black carbon powder particles (biomass carbon) generated by incompletely combusting biomasses under a low-oxygen condition and has the advantages of stable property, strong adsorptive capacity and good moisture and fertility preservation effects. The soil conditioner prepared from the biomass particle carbon and the wood vinegar can improve the structure of the soil, optimize a soil ecological environment and improve the utilization efficiency of the fertilizer; when production increasing and synergism of ginsengs can be accelerated, the carbon is effectively stored in the soil, so as to realize agricultural emission reduction; and therefore an application prospect is wide.

Owner:SHENYANG AGRI UNIV

Method for directly preparing honeycomb active carbon from coal

In the preparation of honeycomb active carbon directly with coal, coal powder, emulsified coal tar, water soluble adhesive, lubricant and water are produced into honeycomb active carbon through crushing, compounding, kneading, extruding, drying, carbonizing and activating. The present invention has low cost and simple production apparatus, and the prepared honeycomb active carbon has great specific surface area, high porosity, high resistance to water, acid and alkali, high compression strength, high heat resistance, and easy heat or washing regeneration.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

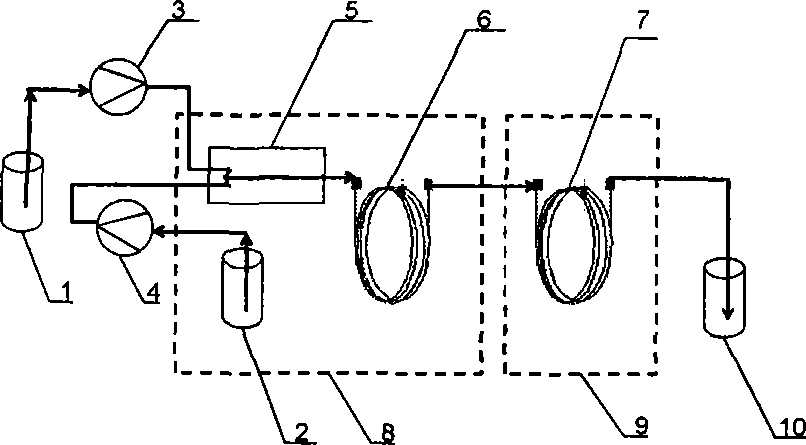

Method of preparing alpha-sulphonic acid fatty acid ester

InactiveCN101508660AImprove securityRelaxed reaction conditionsSulfonic acid preparationState of artReaction temperature

The invention relates to a method for preparing alpha-sulfonic fatty acid ester by sulfonating fatty acid ester, comprising the following steps: injecting the fatty acid ester and a sulfonating agent into a micro-structural reactor (5) and a reactor (6) inside diameter of which is a micro passage respectively, mixing and sulfonating the fatty acid ester and the sulfonating agent, controlling the reaction temperature between 50 and 100 DEG C, and controlling the reaction materials to stay for 1ms to 1s in the micro-structural reactor (5) and stay for 0.5 to 30 minutes in the micro-passage reactor (6); and then injecting the reaction materials into a micro-passage reactor (7), aging the reaction materials at a reaction temperature between 50 and 100 DEG C, and controlling the reaction materials to stay for 0.5 to 30 minutes in the micro-passage reactor to obtain the alpha-sulfonic fatty acid ester. In the method, the novel micro-structural reactor is adopted, the defect of difficult control due to strong reaction heat release in the prior art is overcome, the materials can be mixed evenly, the released reaction heat can be removed in time, the reaction time can be controlled accurately, and the method has the advantages of good sulfonating efficiency, simple and safe operation and good product quality.

Owner:NANJING UNIV OF TECH

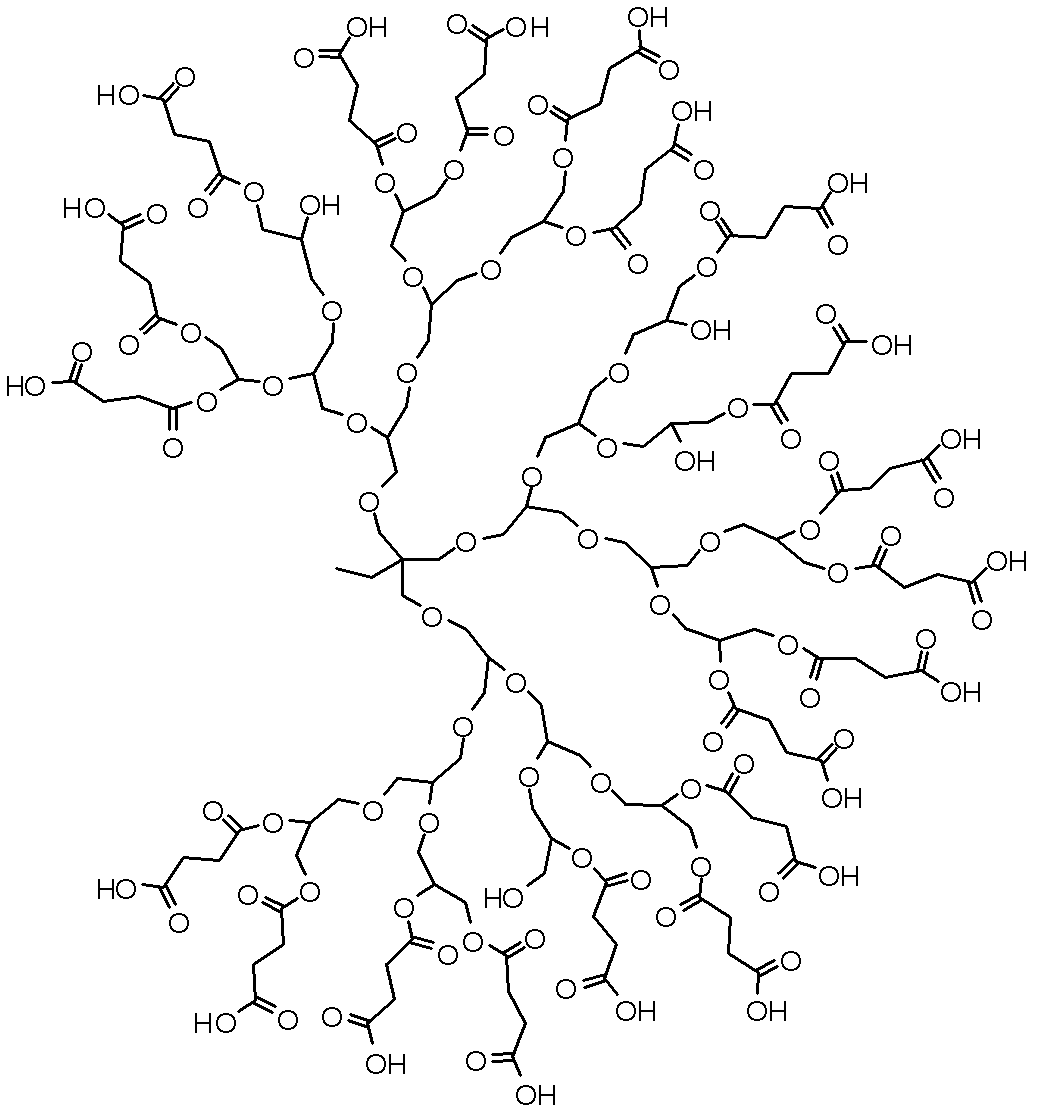

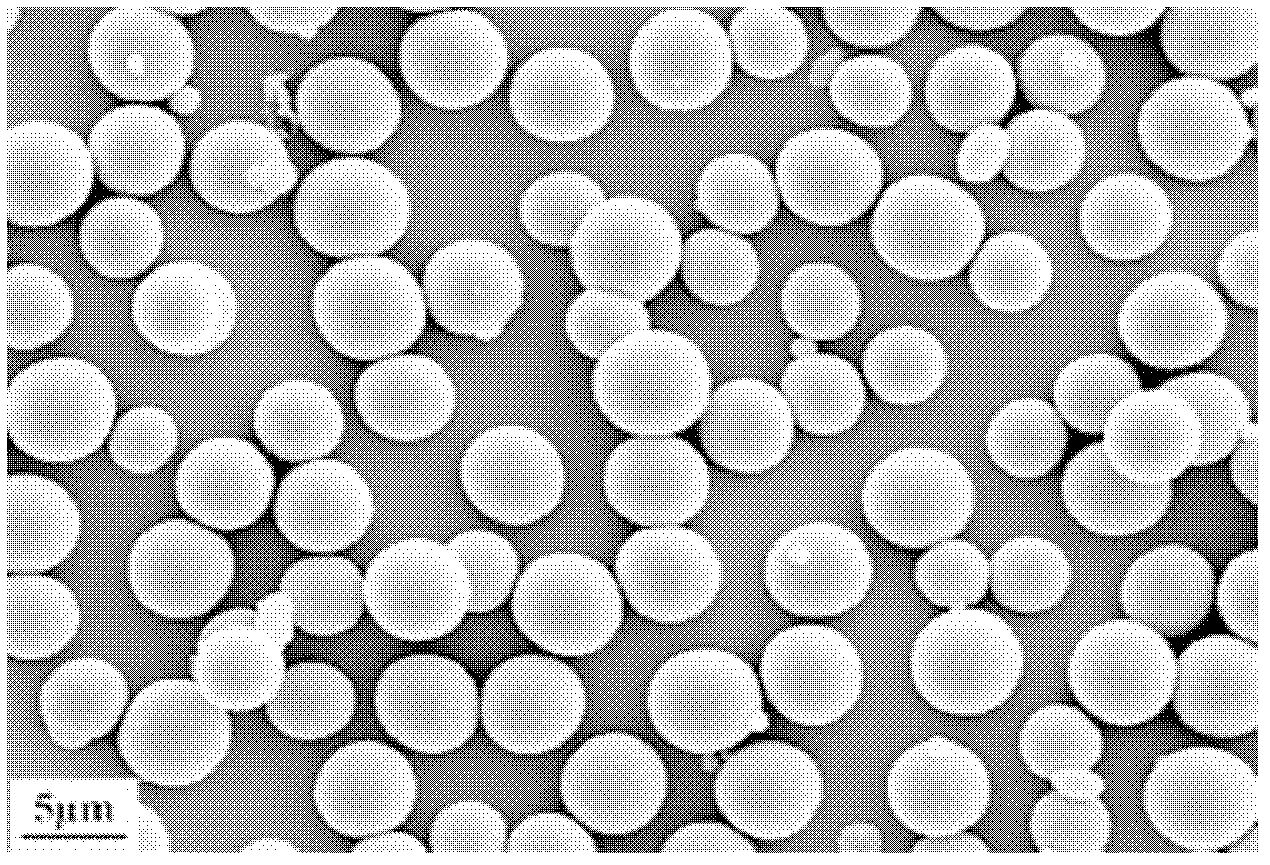

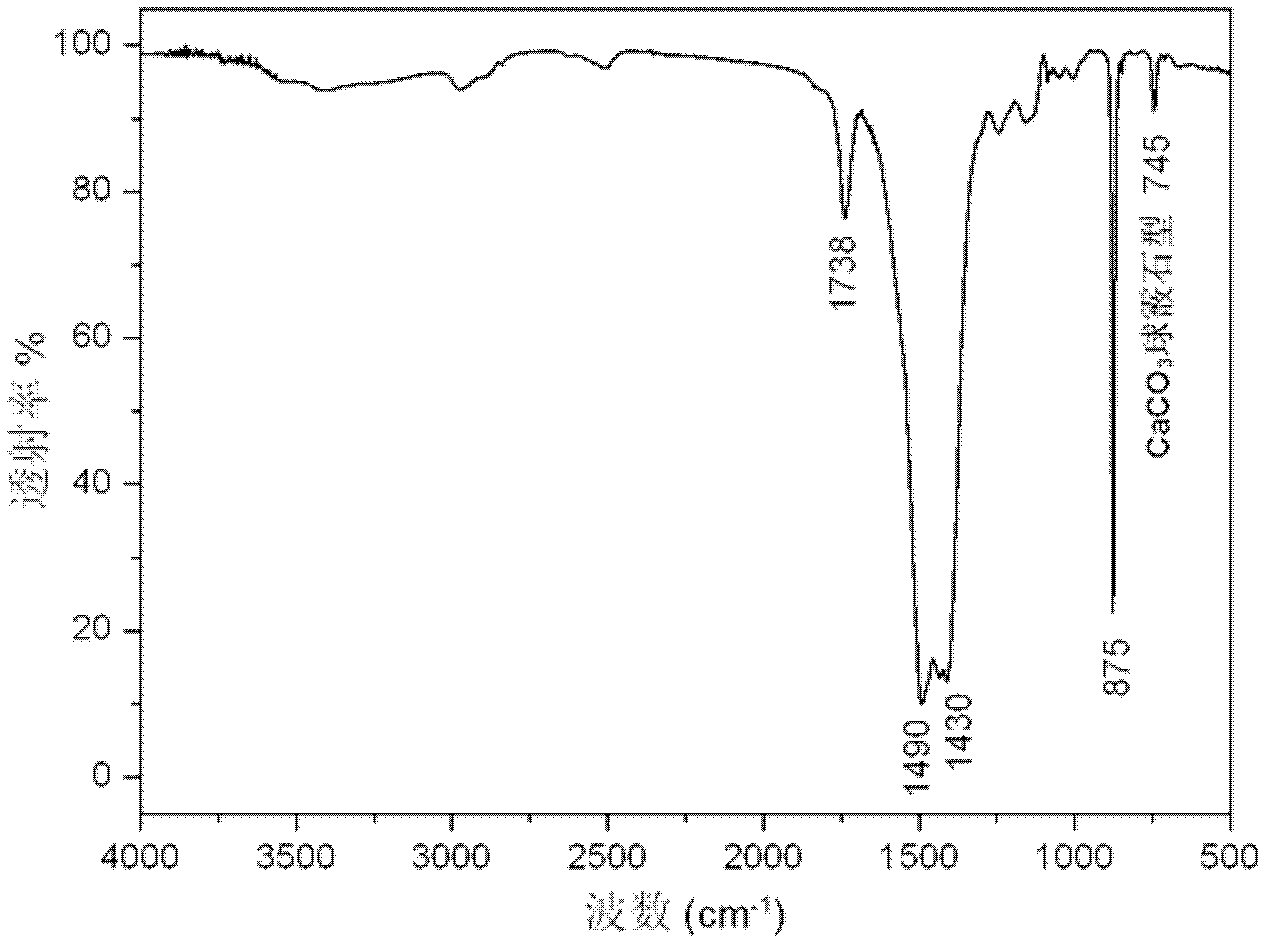

Monodispersed vaterite type calcium carbonate microsphere and preparation method thereof

InactiveCN102583485AIncrease the degree of branchingHigh density of surface functional groupsCalcium/strontium/barium carbonatesBicarbonateCalcium carbonate

The invention relates to a preparation method of a monodispersed vaterite type calcium carbonate microsphere, which comprises the following steps of: (1) preparing a calcium salt aqueous solution with the concentration of 30-150mmol / L, and then, adjusting the pH value of the calcium salt aqueous solution to 8.5-10; (2) preparing a carbonate or hydrocarbonate aqueous solution with the concentration of 30-150mmol / L, and then, adjusting the pH value of the carbonate or hydrocarbonate aqueous solution to 8.5-10; (3) preparing a functional hyperbranched polyglycerol aqueous solution with the concentration of 20-400mg / L, and then, adjusting the pH value of the functional hyperbranched polyglycerol aqueous solution to 8.5-10; (4) mixing and uniformly stirring the carbonate or hydrocarbonate aqueous solution, the calcium salt aqueous solution and the functional hyperbranched polyglycerol aqueous solution at the temperature of 10-35 DEG C, and aging for 1-12h; and (5) centrifuging or filtering the mixed solution, cleaning a sediment, and drying to obtain the monodispersed vaterite type calcium carbonate microsphere. The monodispersed vaterite type calcium carbonate microsphere prepared by using the preparation method provided by the invention has the advantages of uniform particle size, stable crystal form and industrial application value.

Owner:NANJING UNIVERSTIY SUZHOU HIGH TECH INST +1

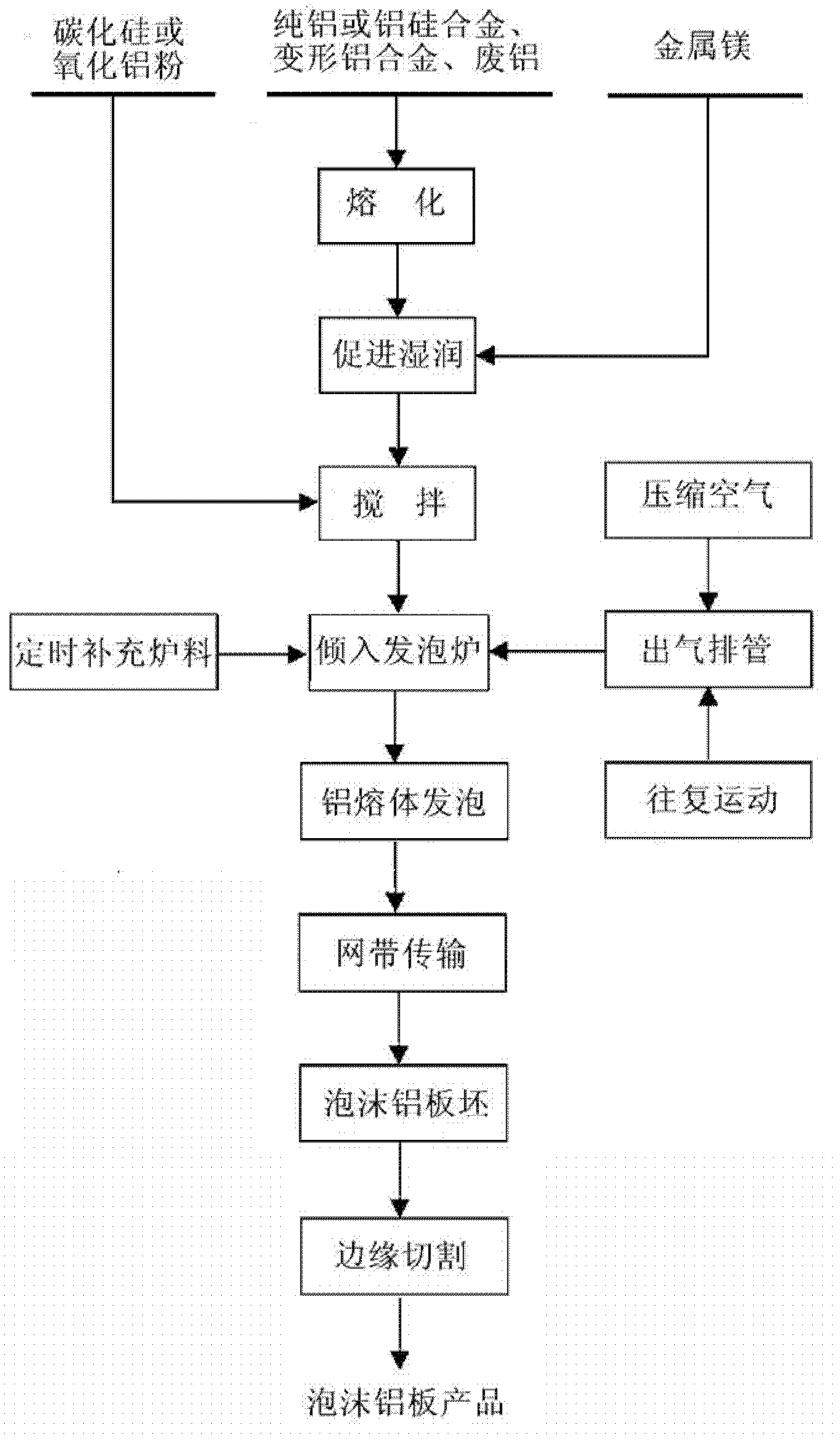

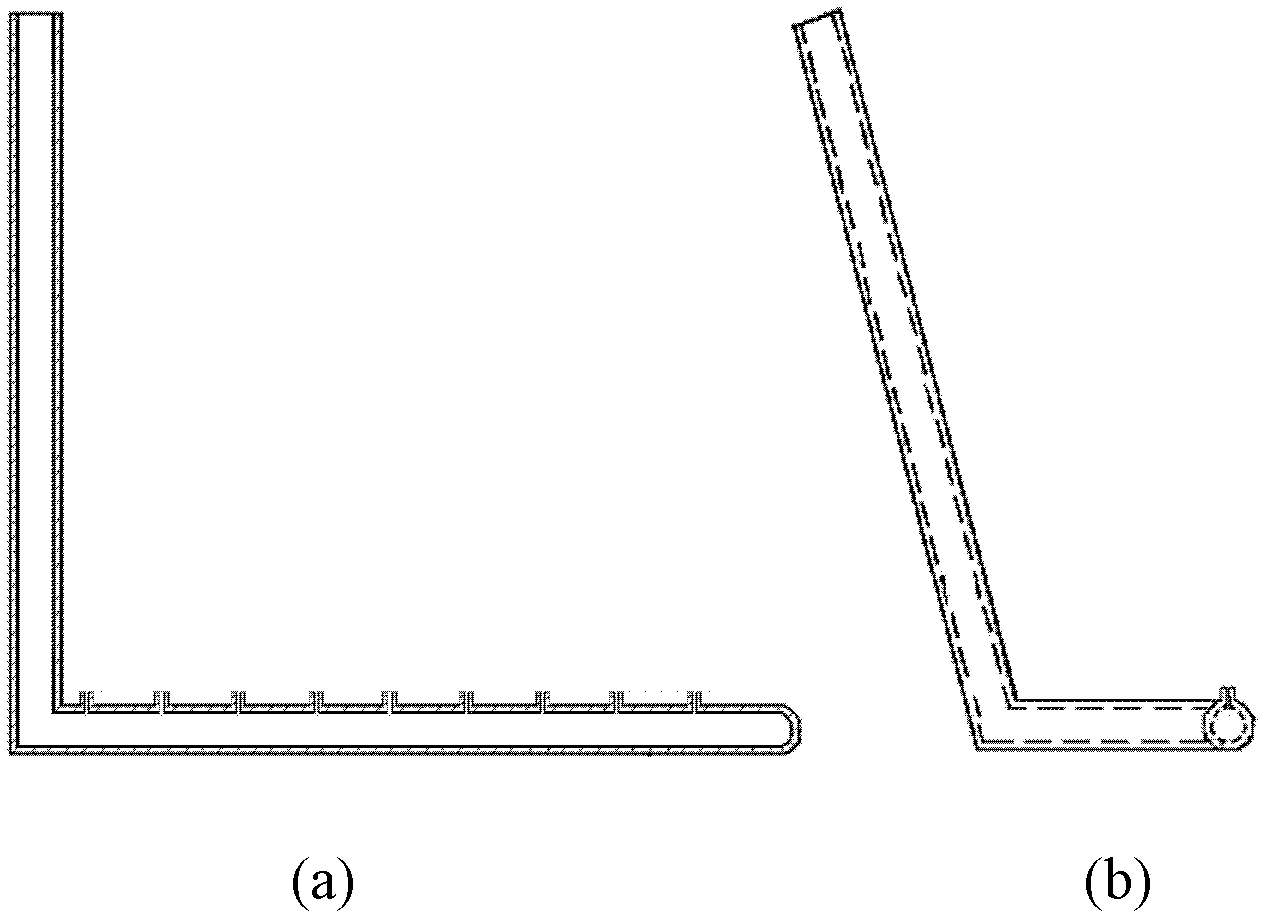

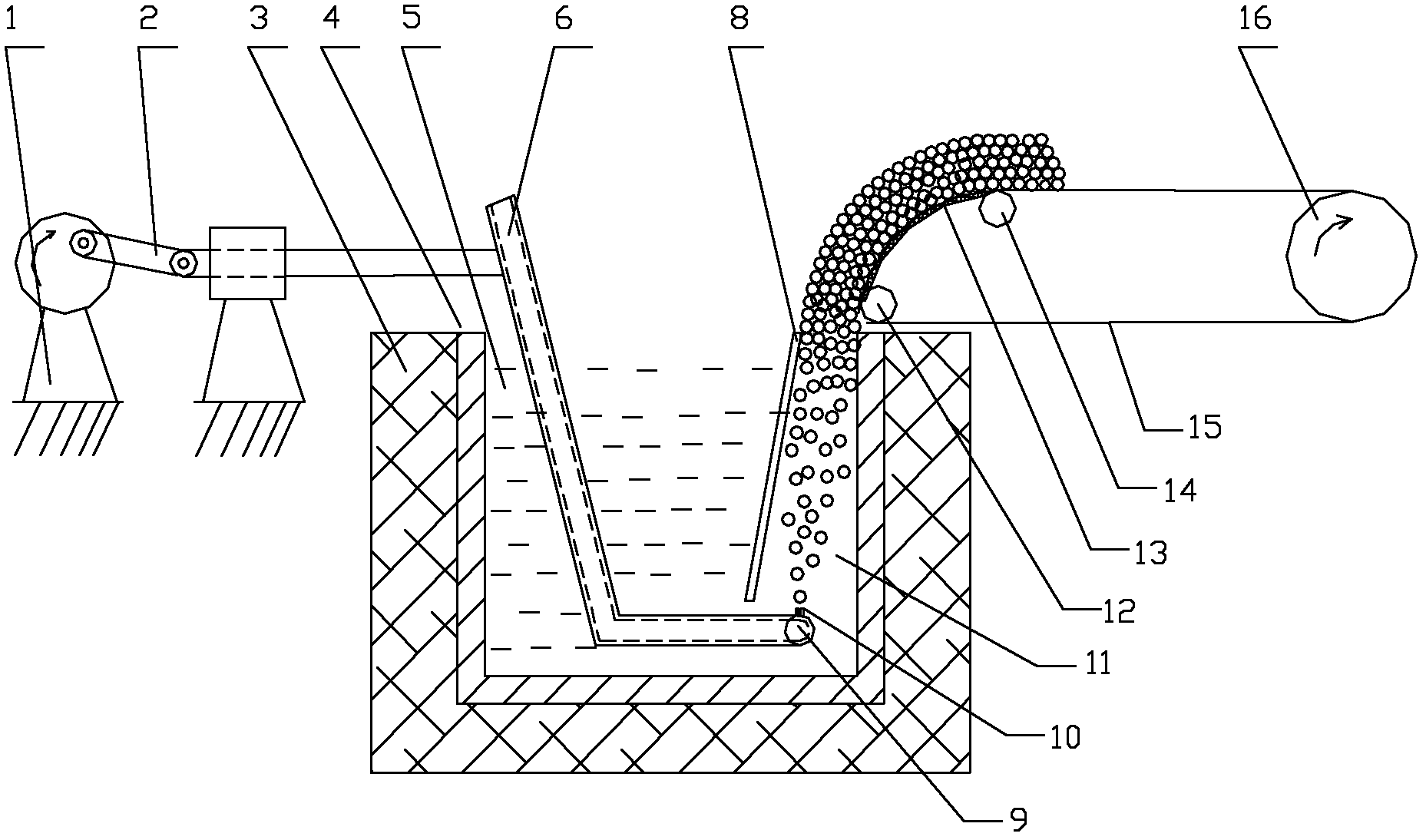

Process and apparatus for continuous production of closed-cell aluminum foam with blowing foaming

The invention relates to a process and an apparatus for continuous production of a closed-cell aluminum foam through blowing foaming. The process comprises the following steps: melting a raw material, adding with a ceramic tackifier and a moistening promoter, stirring to obtain molten aluminum with uniform component, carrying out continuous foaming with the apparatus for the continuous productionof the closed-cell aluminum foam with blowing foaming to obtain a molten aluminum foam with uniform foam size, and controllable density and productivity, and producing a foamed aluminum board by going through a net belt and transmitting with an arc transition mechanism and cutting. The apparatus is characterized in that: a simple crank link mechanism is adopted to realize the reciprocating motion of a horizontal outlet duct, and the arc transition mechanism allows the ascending lifting of the molten aluminum foam to be changed into horizontal transmission. According to the invention, the process and the apparatus are simple, the operation control is accurate, and a purpose that the pore size and the density of foamed aluminum products can be accurately controlled at a high efficiency anda low cost is realized because the foam size of the molten aluminum is adjusted by changing the frequency of the reciprocating motion of the outlet duct, the pressure and the flow of a compressed gasand the diameter of outlet micropores.

Owner:ANHUI NEOFOUND TECH

Method for preparing laminated Co(OH)2 or Co3O4 nano-rod by hydro-thermal method

InactiveCN101544408AEasy to prepareSimple production equipmentNanostructure manufactureCobalt oxides/hydroxidesChemistrySmooth surface

The invention provides a method for preparing a laminated Co(OH)2 and Co3O4 nano-rod by a hydro-thermal method. The method is characterized by taking hydrazine hydrate and sodium phosphate as structure guidance agents to control the appearance, taking cabaltous nitrate as a raw material, and taking the hydrazine hydrate to play roles of a reactant and an antioxidant at the same time. The compositions react for 18 hours under 180 DEG C of hydro thermal to obtain the laminated Co(OH)2 nano-rod; and then, the nano-rod is calcined for 4 hours at 400 DEG C to obtain the Co3O4 nano-rod. The transition process of the laminated Co(OH)2 nano-rod which can be clearly observed by changing reaction time comprises that: firstly, a nano-rod with a smooth surface is generated; then, time is prolonged to grow flakes on the side surface of the nano-rod; and finally, the nano-rod is changed into the laminated nano-rod. The nano-rod or the laminated nano-rod can be acquired by controlling the reaction time, and the laminated nano-rod has larger specific area and is rich in nano-flake periphery on the surface compared with the nano-rod.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

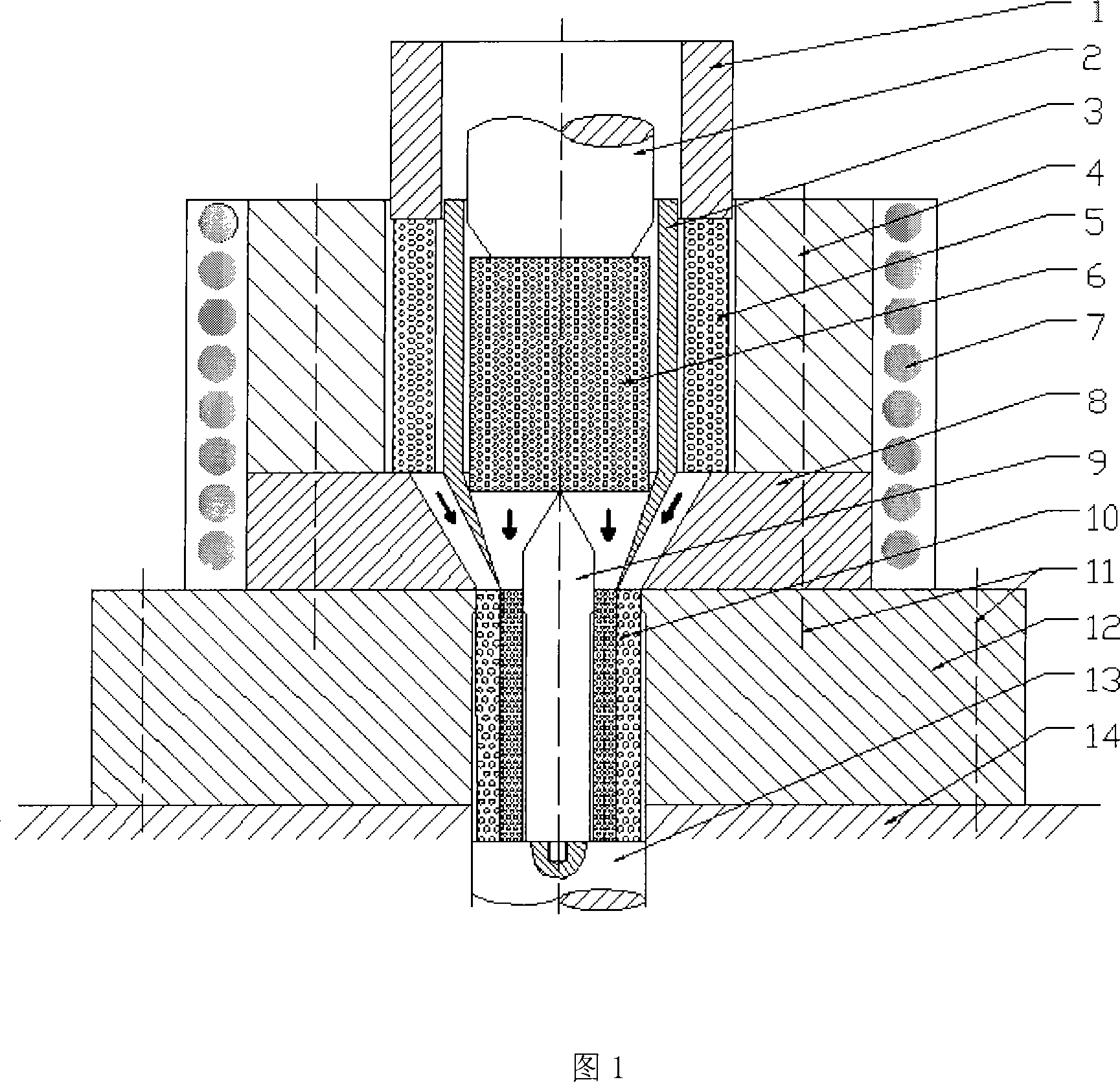

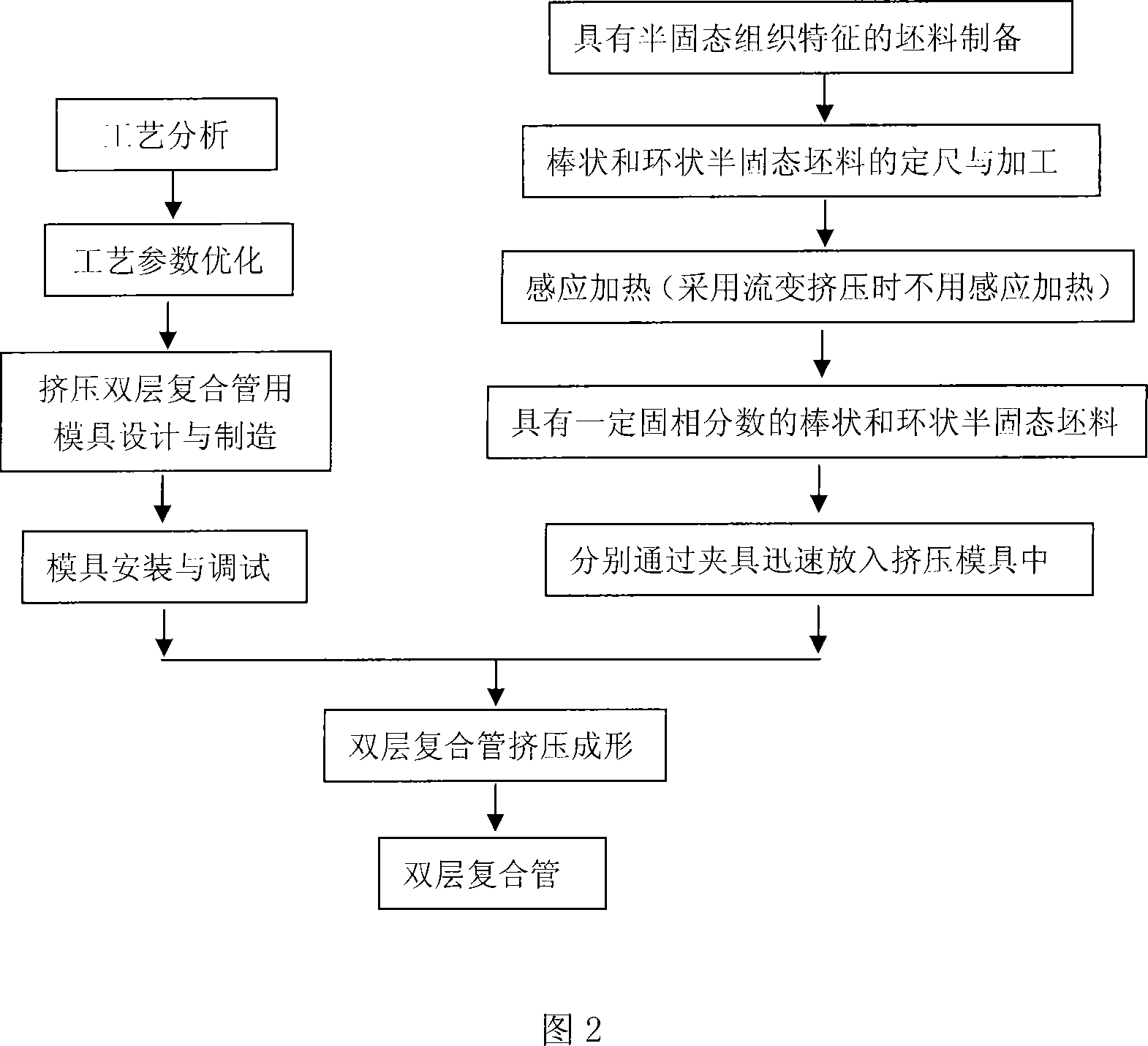

Semi-solid multi-blank extruding process and apparatus for forming double-layer composite pipe

InactiveCN101020201AReduce consumptionImprove product qualityExtrusion diesExtrusion control devicesTemperature controlControl system

The present invention relates to semi-solid forming technology, and is especially semi-solid multi-blank extruding process and apparatus for forming double-layer composite pipe. The technological process includes the following steps: pre-heating the mold to 200-300 deg.c and establishing temperature control system, setting the induction heated blank into the extruding mold, and extruding at regulated speed and stroke to obtain the required composite pipe. The new extruding process for making composite pipe has short procedure, low power consumption and high product quality.

Owner:TSINGHUA UNIV

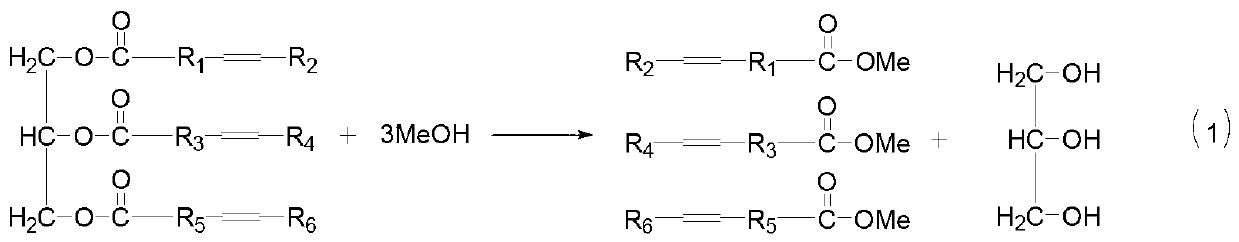

Method for preparing epoxidized fatty acid methyl ester with microreactor one-step method

ActiveCN102993133AImprove product qualityHigh epoxidation yieldOrganic chemistryDouble bondFatty acid methyl ester

The invention discloses a method for preparing epoxidized fatty acid methyl ester with microreactor one-step method, comprising the following steps: injecting oil and fat, low-carbon alcohol and basic catalyst in a first microstructure reactor of a microchannel modularized reaction device, wherein the mole ratio of oil and fat to low-carbon alcohol is 1:11-17, and remaining for 3-10 min at the temperature of 65-85 DEG C; mixing outlet material of the first microstructure reactor with hydrogen peroxide, organic acid, acidic catalyst and stabilizing agent in a second microstructure reactor of the microchannel modularized reaction device, wherein the mole ratio of number of double bonds in organic acid to number of double bonds in oil and fat is 11-17:1, and remaining 1-5 min at the temperature of 65-95 DEG C; guiding the outlet material of the first microstructure reactor in a separator, standing for demixing to remove aqueous solution at lower layer; washing an organic phase at the upper layer with water till the pH is 6.5-7.5; and drying to obtain epoxidized fatty acid methyl ester.

Owner:NANJING UNIV OF TECH

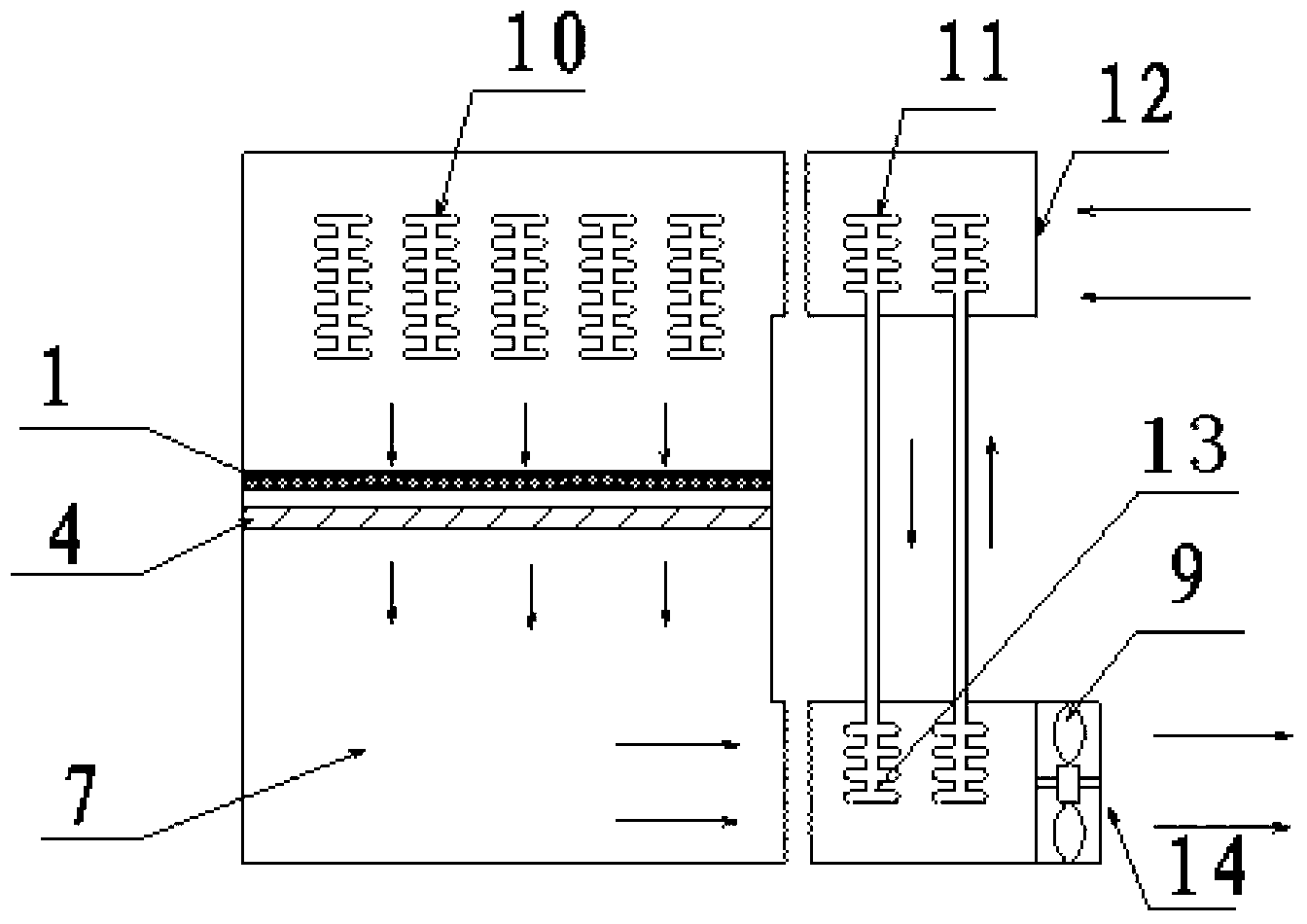

Method for preparing high-performance polycarboxylate superplasticizer via heat resource-free process

The invention discloses a method for preparing high-performance polycarboxylate superplasticizer via a heat resource-free process, and the method comprises the following steps of 1) adding unsaturated polyoxyethylene ether and water in certain proportion into a reaction still and stirring for dissolution, 2) adding oxidizing agent water solution at 5-30 DEG C at one time and stirring, and 3) respectively dropping mixed solution of accelerant and chain transfer agent in proper proportion and comonomer in 2-4h, after the dropping, curing for 1.5h, and finally adding alkaline modifier for neutralization so as to obtain the polycarboxylate superplasticizer. The method is simple in process and the prepared polycarboxylate superplasticizer has high dispersing performance in low amount of admixture. By using the heat resource-free process, the step of heating is decreased, so that the production is more simple and convenient, the cost is lower, the environmental-friendly property is provided and the energy consumption is decreased.

Owner:KZJ NEW MATERIALS GROUP CO LTD

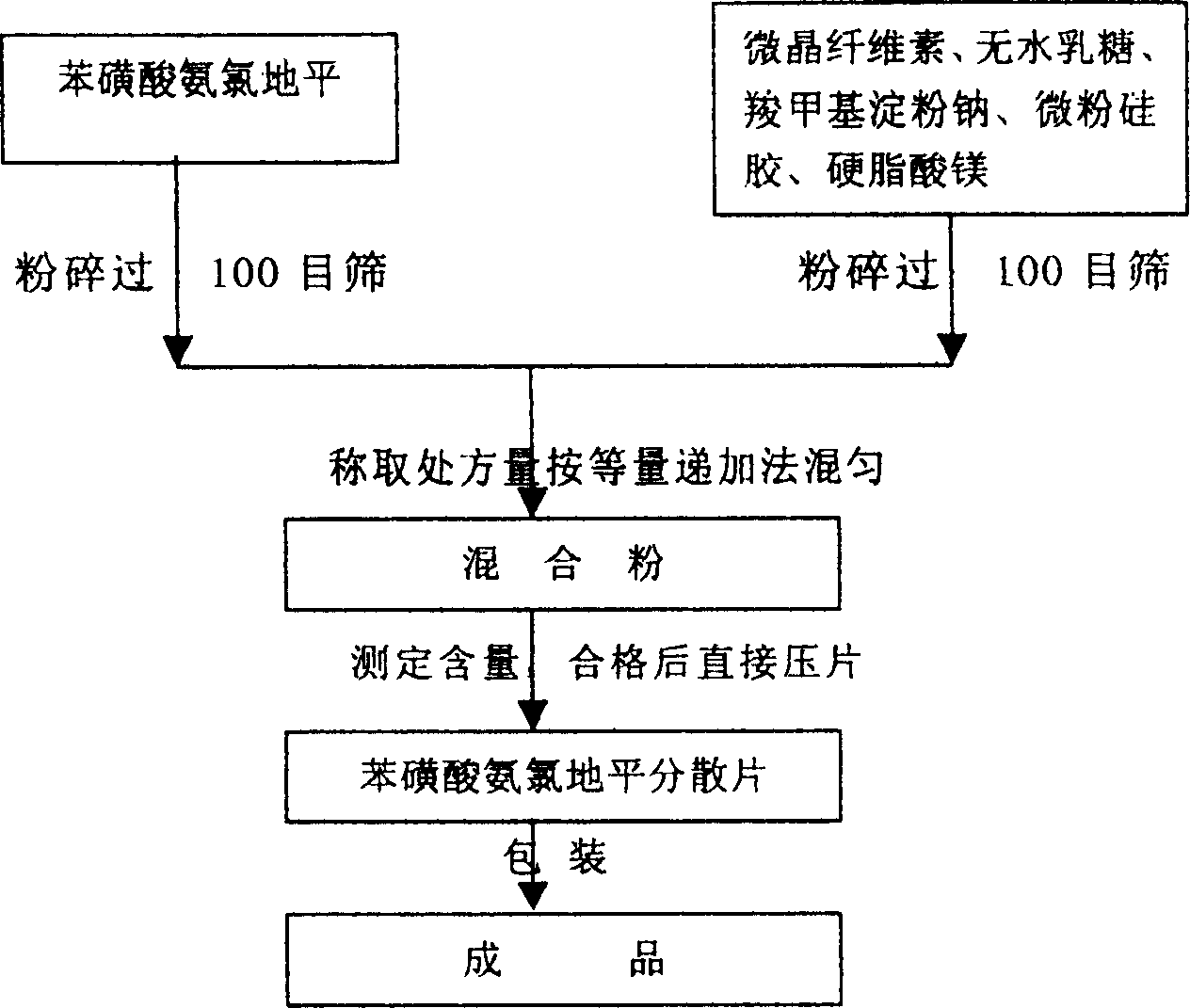

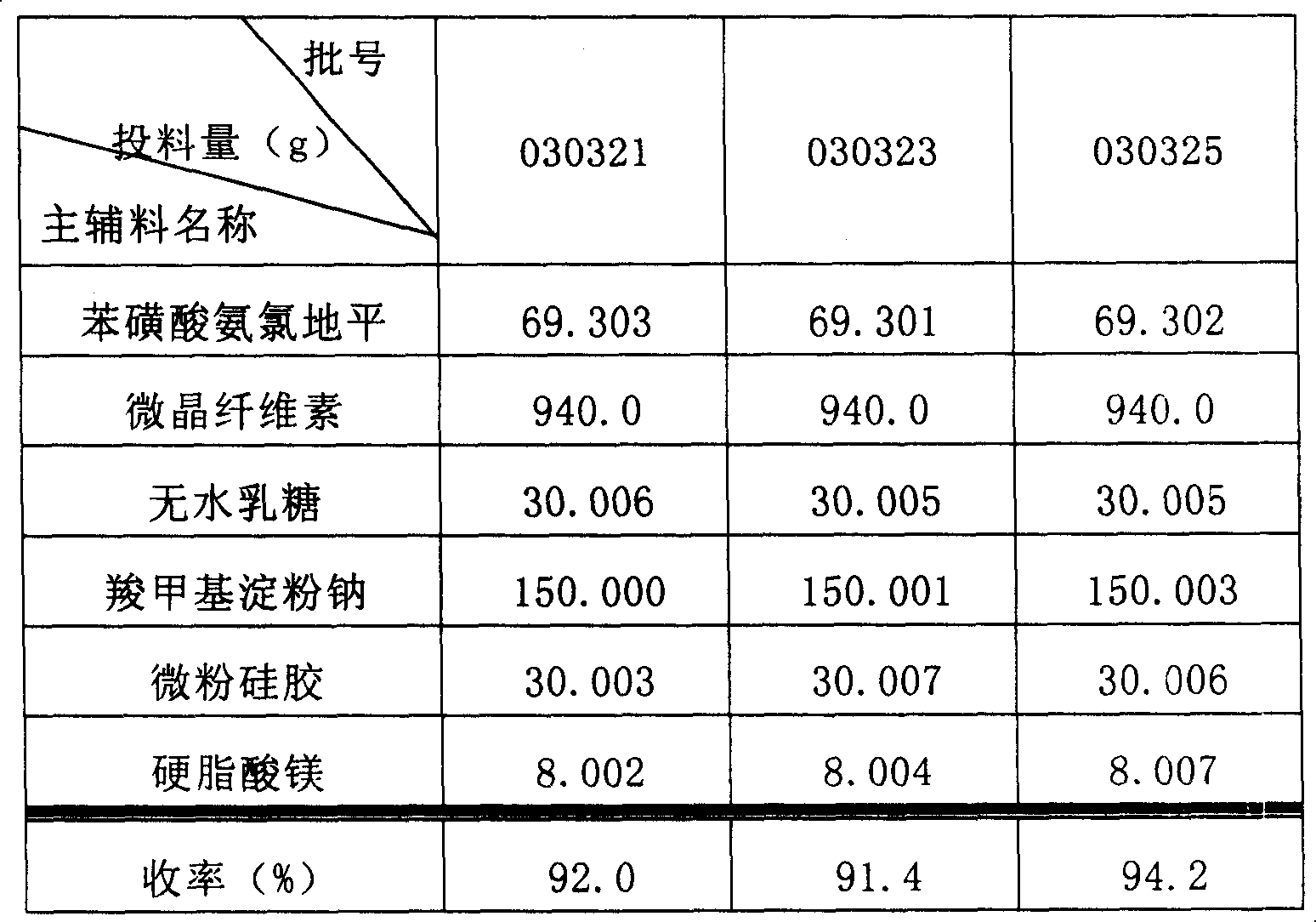

Phenylsulfonic acid amido chloro diping dispersion tablet and its preparation method

InactiveCN1686121AEasy to takeTake fastOrganic active ingredientsPill deliveryCarboxymethyl starchAmlodipine besilate

A dispersing table of amlodipine benzosulfonate for treating hypertension is proportionally prepared from amlodipine benzosulfonate, microcrystalline cellulose, anhydrous lactose, carboxymethyl starch sodium, micropowdered silica gel, and magnesium stearate.

Owner:YUNNAN BAIYAO GRP HEALTH PROD CO LTD

Method for producing phosphorus building gypsum by phosphorous gypsum

The invention discloses a method for producing phosphorus building gypsum by phosphorous gypsum. The method is characterized by comprising the following steps of drying industrial residual phosphorous gypsum by a pneumatic drier to a state that water content is smaller than 5%; sending the dried phosphorous gypsum to a steam jet mill, grinding the industrial residual phosphorous gypsum by the steam jet mill and dewatering, collecting the grinded phosphorous gypsum by a dust collector and cooling the phosphorous gypsum to obtain the phosphorus building gypsum, wherein the power medium of the steam jet mill is superheated steam; a frequency of a powder concentrator is 10 Hz-40 Hz; the temperature of the superheated steam is 250 DEG C-300 DEG C; and a pressure of the superheated steam is 0.7 MPa-1.2 MPa. In the method, the industrial residual phosphorous gypsum is used as a raw material; the superheated steam generated by industrial waste heat is used as a power for the steam jet mill to prepare the phosphorus building gypsum. The method has the characteristics of wide available raw materials, simple production equipment, high yield, low cost, large-scale production, etc. The prepared phosphorus building gypsum can be used for preparing building functional mortar and producing gypsum boards and building blocks, and has strong practicality.

Owner:SOUTHWEAT UNIV OF SCI & TECH

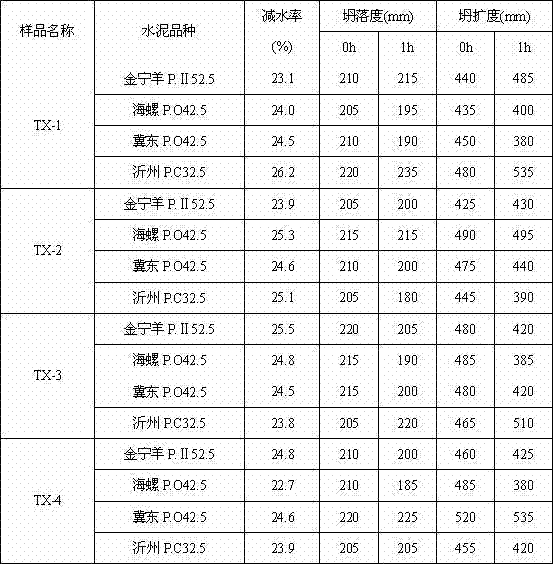

Mud content inhibitor for concrete doped with polycarboxylic acid type water reducer and preparation method and application method of mud content inhibitor

The invention relates to the field of concrete additives and specifically relates to a mud content inhibitor for concrete doped with a polycarboxylic acid type water reducer and a preparation method and an application method of the mud content inhibitor. The mud content inhibitor is prepared by the following raw materials of, by weight, 20%-30% of mud dispersion components, 0.5%-5% of mud adsorption components, 0.5%-5% of ion complexation exchange components and the balance water. The preparation method includes firstly, uniformly stirring water and the mud dispersion components, and adding and uniformly stirring the mud adsorption components and the ion complexation exchange components. The application method includes that the usage amount of the mud content inhibitor is 2-5 wt. % of that of the polycarboxylic acid type water reducer. By means of the mud content inhibitor, the liquidity and the slump-retaining performance of the concrete can be increased, the viscosity of the concrete is reduced, the work state of the concrete can be improved, the adsorption quantity of high valence metal ions to the polycarboxylic acid type water reducer can be reduced, and the performance of the concrete doped with the polycarboxylic acid type water reducer is guaranteed.

Owner:山东华伟银凯建材科技股份有限公司

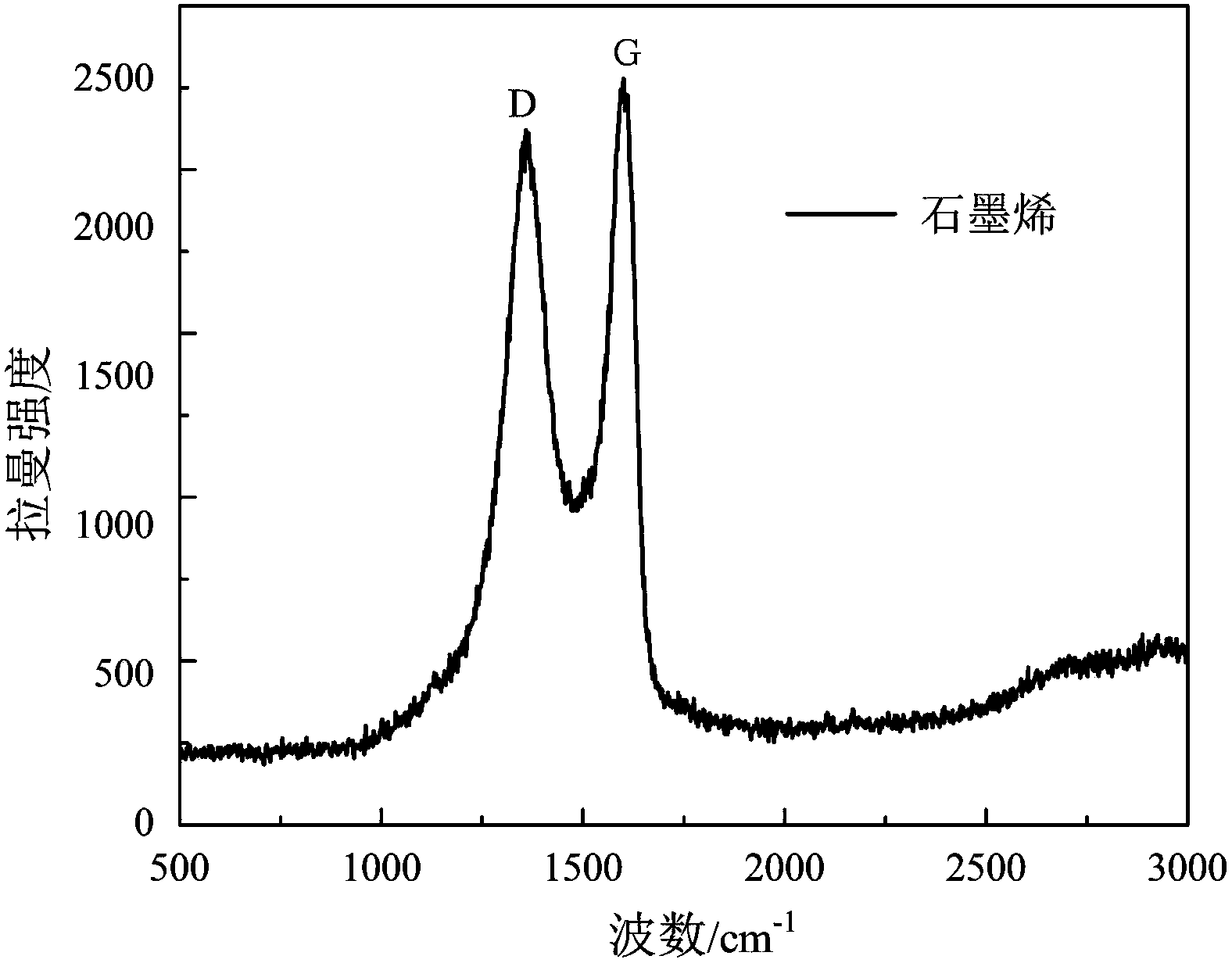

Method for preparing graphene powder by using dry process

InactiveCN103922330AReduce defectsImprove conductivityGrapheneBulk chemical productionSupercapacitorDry ice

The invention belongs to the technical field of nanometer material preparation and particularly relates to a method for preparing graphene powder by using a dry process. The method comprises the steps of firstly, carrying out microwave heat treatment on graphite to form pre-expanded graphite; placing pre-expanded graphite into a high-pressure-resistant peeling reactor, and adding dry ice or liquid nitrogen to peel at high pressure and high speed to obtain graphene. The method for preparing the graphene powder is simple in production equipment, few in process flow, free of oxidation reduction and subsequent acid treatment processes, environment-friendly and suitable for large-scale production; the prepared graphene powder is few in defect, good in conductivity and suitable for the application fields such as supercapacitors, sensors, sea water desalination and the like.

Owner:NANJING XINYUE MATERIAL SCI & TECH +1

Water hyacinth biological manure

InactiveCN1583679AImprove qualityNutritional diversityClimate change adaptationExcrement fertilisersPotassiumNitrogen

An organic biofertilizer is prepared from the excrement and urine of animals, water hyacinth, and duckwed and / or straw (stalk) and / or saw dust through proportional mixing and fermenting. It is rich in N,P,K and other necessary elements.

Owner:尚韬

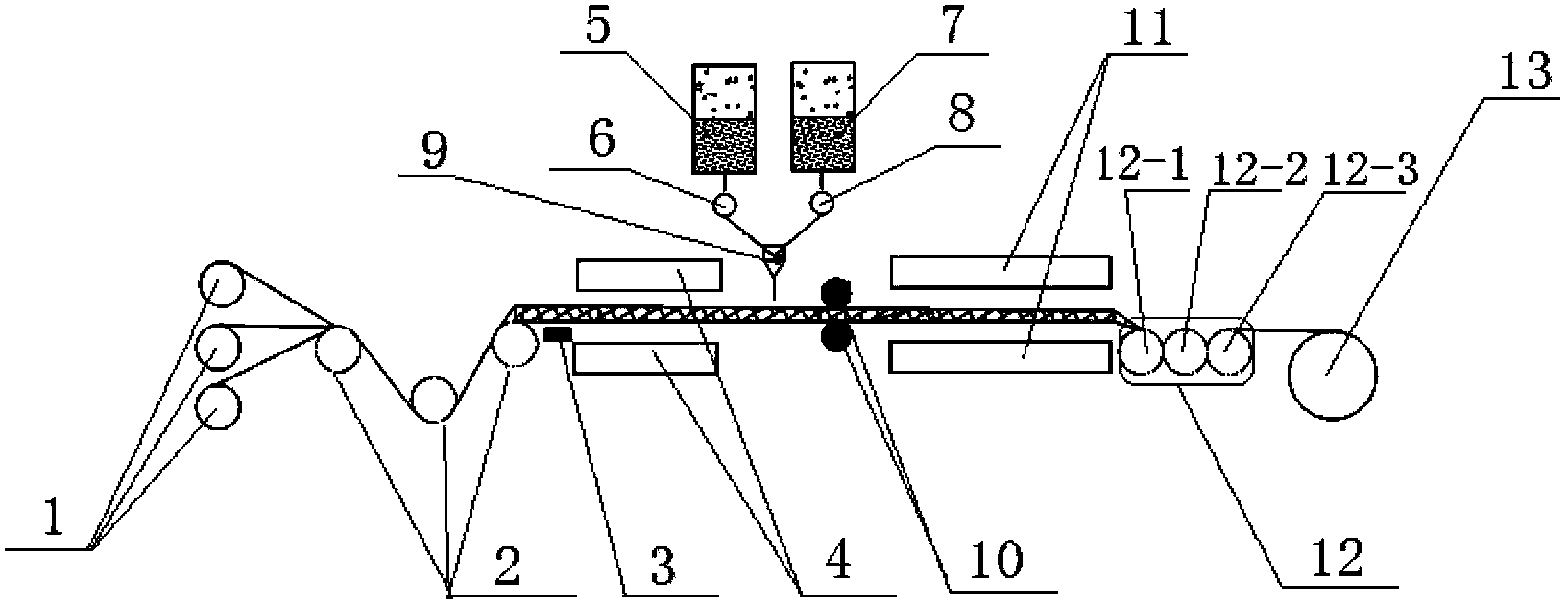

Method for manufacturing tobacco sheet taking substrate as carrier through dry paper making method

A method for manufacturing tobacco sheet taking substrate as a carrier through a dry paper making method comprises the following steps: spraying slurry onto the right side of the substrate through a high pressure spraying method, and meanwhile carrying out negative pressure suction across a wire belt to the reverse side of the substrate; then sending the substrate into an oven and carrying out medium temperature baking and humidity discharging under the condition that the temperature of the substrate is 55 DEG to 70 DEG, and enabling hot air inside the oven to flow directional from the right surface of the substrate to the reverse surface of the substrate to carry out humidity discharging; sequentially, carrying out normal temperature humidity discharging treatment; setting medium temperature baking and humidity discharging time and the normal temperature baking and humidity discharging alternatively; and repeating the steps on the reverse side of the substrate, namely a tobacco sheet is prepared. The substrate is prepared by that scattered material is evenly paved and absorbed onto a formation fabric for dry paper making to form a fiber thin layer under the vacuumpumping of a vacuum air pumping device under the formation fabric, and carrying out antistatic-electricity treatment; and spraying adhesion agent onto a fiber thin layer, under the combination of mist spraying and vacuum take-off on sprayed back surface; and finally carrying out drying.

Owner:CHINA TOBACCO HUNAN INDAL CORP +1

Green preparation method of slow-release polycarboxylic-acid high-performance water reducing agent

The invention relates to a green preparation method of a slow-release polycarboxylic-acid high-performance water reducing agent, which comprises the following steps: firstly, dissolving unsaturated polyethenoxy ether in water, adding an oxidant solution, and evenly stirring; then, respectively and dropwisely adding a reducer / chain-transfer agent mixed solution and a comonomer solution, and polymerizing; and finally, adding an alkaline regulator to neutralize and age the solution, thereby obtaining the slow-release polycarboxylic-acid high-performance water reducing agent. In the invention, hydrogen on the terminal hydroxyl group of the original unsaturated polyethenoxy ether is substituted by an allyl group containing unsaturated bond, so that the terminal group of methoxypolyethylene glycol is converted from the original active hydroxyl group into the inert methoxy group at present; and thus, the byproducts of the copolymerization product are greatly reduced, and the molecular weight distribution is narrow, so that the synthesized water reducing agent has the advantages of high water reduction rate and slump resistance. The redox system with low activation energy is used for initiating the monomer copolymerization, so that the polymerization can be implemented at normal temperature, thereby implementing the production of the product by a no heat source method, simplifying the production equipment and lowering the energy consumption and cost.

Owner:NANJING RUIDI HIGH TECH

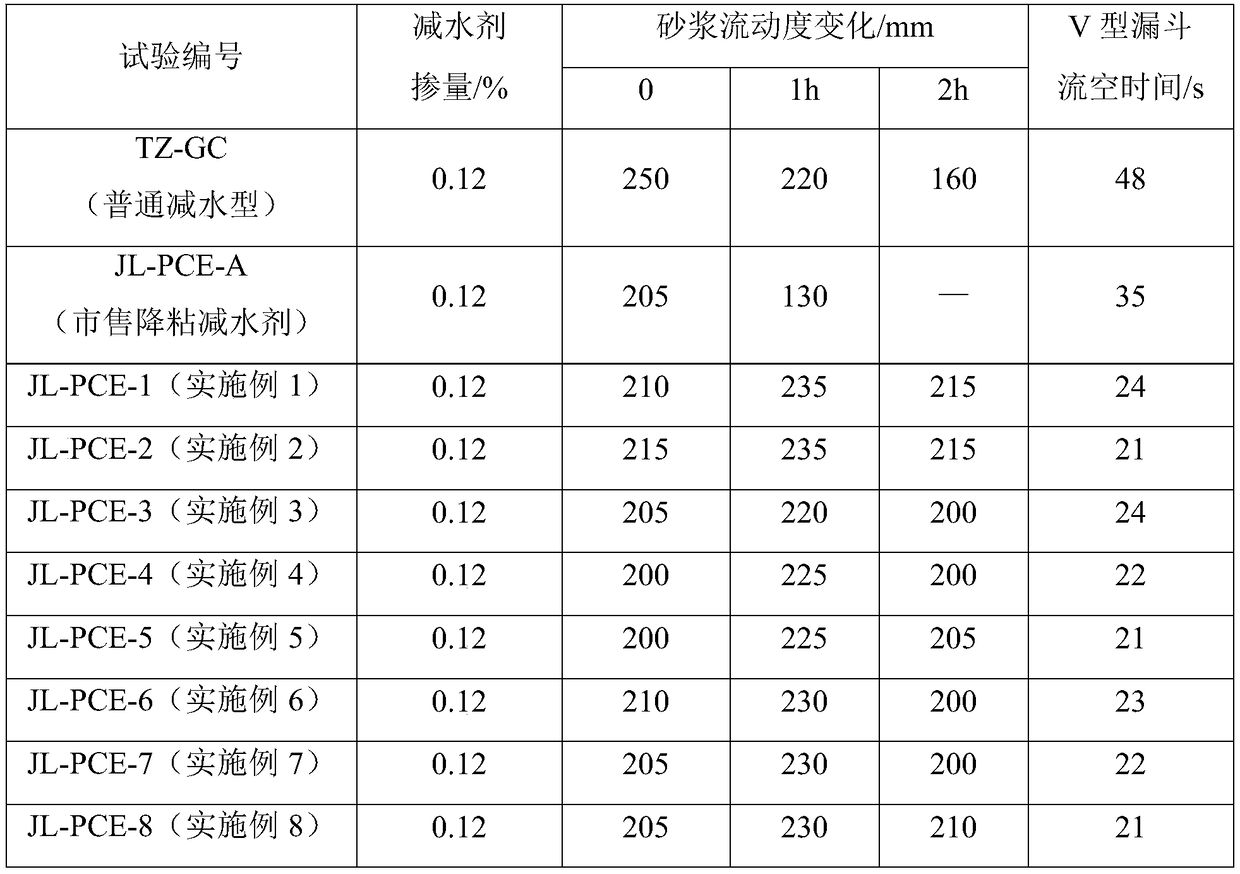

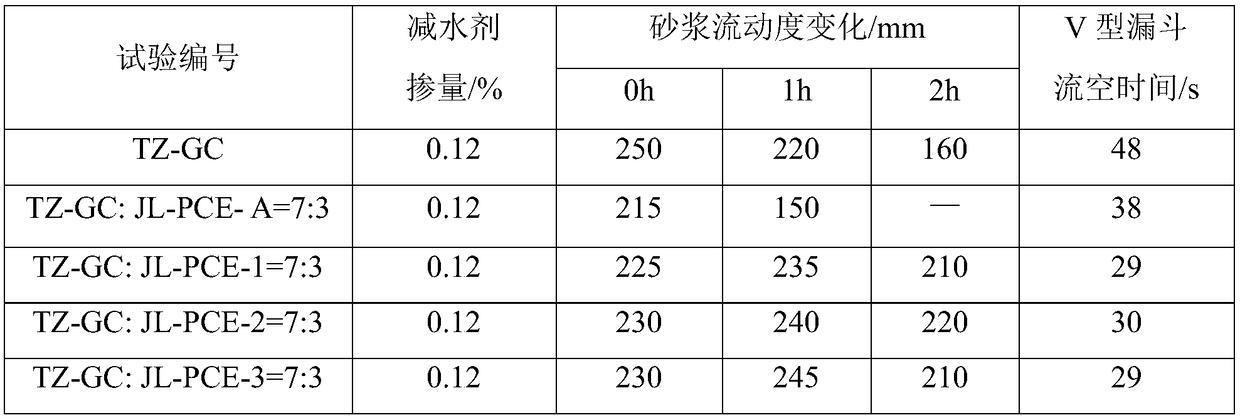

Polycarboxylic water reducer with viscosity reducing and slump retaining functions, and preparation method thereof

InactiveCN109021181AReduce the hydrophilic-lipophilic balanceReduce generationHigh strength concreteWork performance

The invention discloses a polycarboxylic water reducer with viscosity reducing and slump retaining functions, and a preparation method thereof, and belongs to the technical field of building materials. The polycarboxylic water reducer is prepared through the following steps: free radical polymerization of an unsaturated polyether monomer I, an unsaturated block modified polyether monomer II, an unsaturated carboxylic acid monomer, an unsaturated carboxylic acid alkyl ester, an unsaturated phosphate ester monomer, a chain transfer agent, an oxidant, a reducing agent and deionized water in an aqueous solution at 15-30 DEG C, addition of an alkali solution to adjust the pH value, and water supplementation. The water reducer can meet the requirements of the water-reducing and slump-retaining performances of high-strength concrete, and also can greatly reduce the viscosity of the concrete and significantly improve the working performances of the high-strength concrete, so the problems of fast slump loss and excessive viscosity of existing polycarboxylic water reducers are solved. The preparation method can be carried out at normal temperature without a heat source, so the preparation method has the advantages of simple production device, reasonable process, simplicity in operation, high production efficiency, and suitableness for industrial production and promotion.

Owner:SICHUAN TONGZHOU CHEM TECH

Continuous fiber fabric reinforced thermoplastic polyurethane composite material and preparation method thereof

InactiveCN103570961AMake up for the shortcomings of high melt viscosity and poor melt fluiditySolve viscosityPorosityPolyurethane elastomer

The invention relates to a continuous fiber fabric reinforced thermoplastic polyurethane composite material and a preparation method thereof. The composite material is prepared by heating, curing and cooling a continuous fiber reinforced fabric which is steeped in thermoplastic polyurethane elastomer reaction liquid, wherein the continuous fiber reinforced fabric is selected from one or more of organic fibers, metal fibers or inorganic fibers, and the thermoplastic polyurethane elastomer reaction liquid is formed by polymerizing a polyether component and an isocyanate component. Compared with the prior art, the continuous fiber fabric reinforced thermoplastic polyurethane composite material prepared by using the continuous fiber reinforced fabric as a reinforcing material and a thermoplastic polyurethane elastomer as a reinforced matrix has the advantages of good steeping, low porosity, adjustable thickness, high glass fiber content and the like. The preparation method has the advantages that the production line is simple, equipment can realize the high-efficient continuous production, no environmental pollution is caused in the production process and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

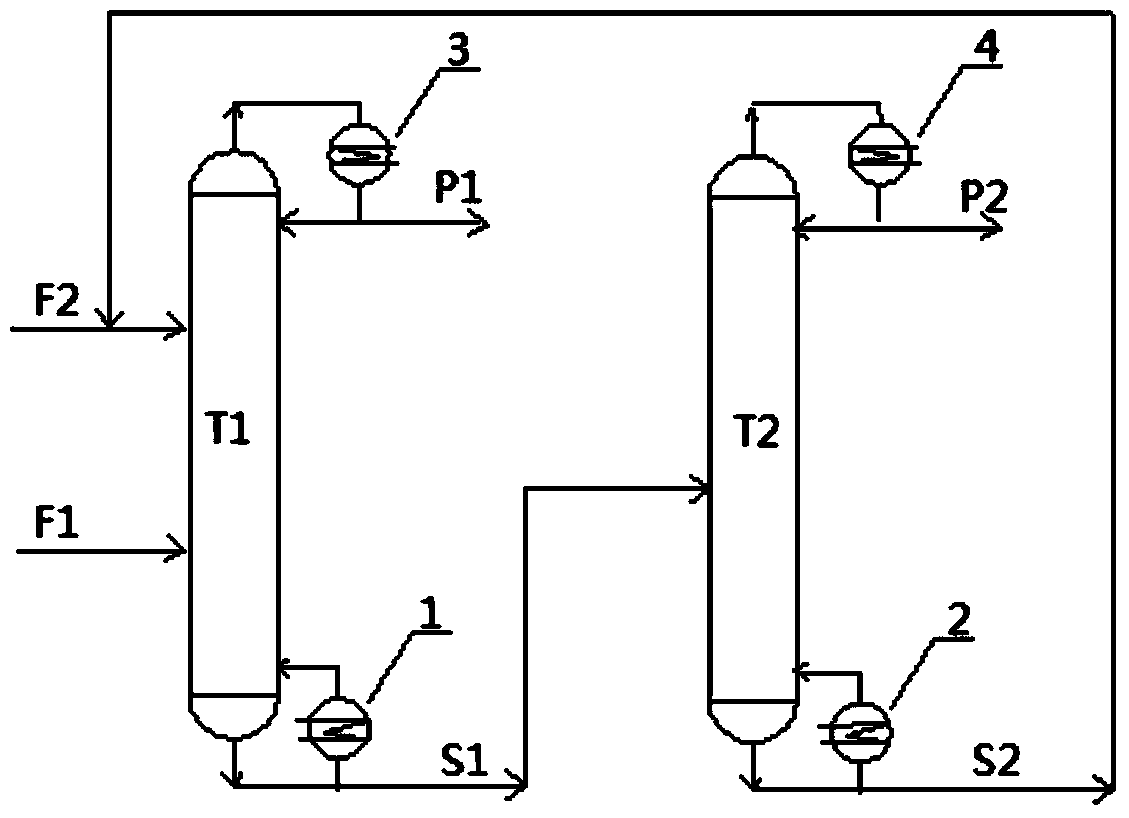

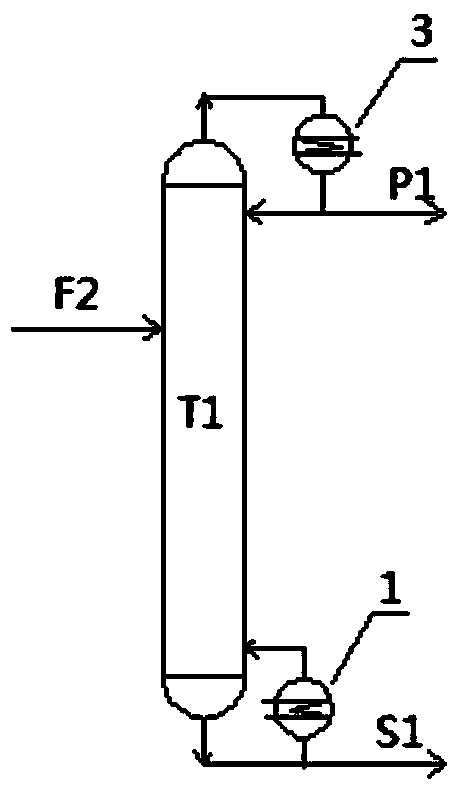

Method for separating ethyl acetate-ethyl alcohol compound

InactiveCN103467286AReduce dosageEasy to recycleOrganic compound preparationCarboxylic acid esters preparationExtractive distillationEthyl acetate

The invention provides a method for separating ethyl acetate-ethyl alcohol, which comprises the following steps: adopting ethyl acetate-ethyl alcohol compound in any proportion as a raw material, taking ionic liquid or a double solvent composed of ionic liquid and an organic solvent as an extraction agent, and extracting ethyl acetate and ethyl alcohol in sequence after the raw material goes through an extractive distillation stage and an extraction agent recycle stage, wherein the extraction agent is used circularly after being extracted in the recycle stage. Compared with the prior art, the new method has the advantages that the energy can be conserved by more than 40%, the environment pollution can be avoided, the product purity is high, the industrialization is facilitated, the equipment cost is low, and the economic benefit is good.

Owner:TIANJIN CLEANTECH TECH

Special carbon-base slow release fertilizer for corn and preparation method thereof

ActiveCN101054327AIncrease profitReduce leachingAgriculture gas emission reductionUrea compound fertilisersIncreased fertilitySoil humus

An environmental protection type high efficiency corn special charcoal base slow-release fertilizer of the invention is a long-action compound fertilizer using organic corn cob particle charcoal as substrate material, corn cob particle charcoal are black charcoal powder particles (carbon black) of anaerobic incomplete combustion corn cob, which has a plurality of functions similar to soil humus (acid), has very strong adsorption and nutrient and moisture reserving capacity, also can stimulate crop growth, has good slow-release performance for N, P, K, the prepared disposable slow-release fertilizer can be used for complete growth and development of corn, and has advantages of increasing fertility of farmland, improvement soil structure and high efficiency environmental protection, has wide application prospect.

Owner:辽宁金和福农业科技股份有限公司

Process for preparing carbon nano tube film through electrophoresis deposition

InactiveCN1570220AShort preparation cycleControl thicknessElectrophoretic coatingsHigh volume manufacturingElectrophoresis

A method for electrophoretic deposition preparation of the carbon nanotube film belongs to the field of the nano materials technology. The preparing method comprises the following steps: purification treatment and face finish for the carbon nanotube, the formation of the carbon nanotube stable suspension, electrophoretic deposition for the carbon nanotube film, film drying, and second electrophoretic deposition. The invention has the advantages of simple production equipment, rapid film forming speed, controllable film thickness, and unlimited substrate shape.

Owner:TSINGHUA UNIV

Method for preparing extruding physical foaming polypropylene bead granule

The invention discloses a preparation method of an extrusion physical foaming polypropylene bead; the method is as follows: an injector port is arranged at the middle of a machine barrel of a screw extruder, a machine head is provided with a bushing type neck ring mold and a die surface chip cutter, polypropylene foaming material and addition agents are added into the screw extruder, alkane foaming agent is injected into the machine barrel from the injector port, the proportion by weight between the polypropylene foaming material and the alkane foaming agent is 10-25%, the pressure of the neck ring mold is controlled to be 5-30MPa, and the temperature of the neck ring mold is 110-150 DEG C, thus leading the cut material to generate foams when the material enters the atmosphere, and then the product is obtained after cooling and drying. The method of the invention has the advantages of continuous extrusion of the polypropylene foaming beads, low energy consumption, little environmental pollution due to the adoption of the alkane foaming agent, low residue of foaming agent in the foaming bead and high foaming rate.

Owner:浙江华江科技股份有限公司

Production process of high-count and high-density long stapled cotton shirt fabric

ActiveCN105671727AImprove permeabilityImprove wear resistanceSucessive textile treatmentsDry-cleaning apparatus for textilesYarnHigh density

The invention relates to a production process of a high-count and high-density long stapled cotton shirt fabric. The finished product fabric is prepared from long stapled cotton yarns sequentially by processes of slashing, weaving, singeing, desizing, boiling-off, cold pad batch dyeing, liquid ammonia mercerized finishing, moist-cure anti-crease finishing and preshrinking, and the long stapled cotton yarns adopt 140s / 2 celo compact-spun GIZA45 long stapled cotton yarns and are woven into twill weaves. According to the production process provided by the invention, the long stapled cotton yarns are used as raw materials; technologies of cold pad batch dyeing, liquid ammonia mercerized finishing and moist-cure anti-crease finishing are combined; the energy-saving environmental-friendly high-count and high-density shirt fabric is developed; the high-count and high-density long stapled cotton shirt fabric has soft and comfortable hand feeling, fine and soft gloss and excellent wear comfort, mode-holding nature and anti-crease property and can be free of ironing; the comprehensive technology of the product reaches the domestic advanced level; the high-count and high-density long stapled cotton shirt fabric has wide market prospect and social and economic benefits; meanwhile, the energy-saving environmental-friendly fabric production process reduces pollution to the environment and makes a contribution to development of a cleaning fabric processing technology and social sustainable development.

Owner:FUJIAN SEPTWOLVES IND

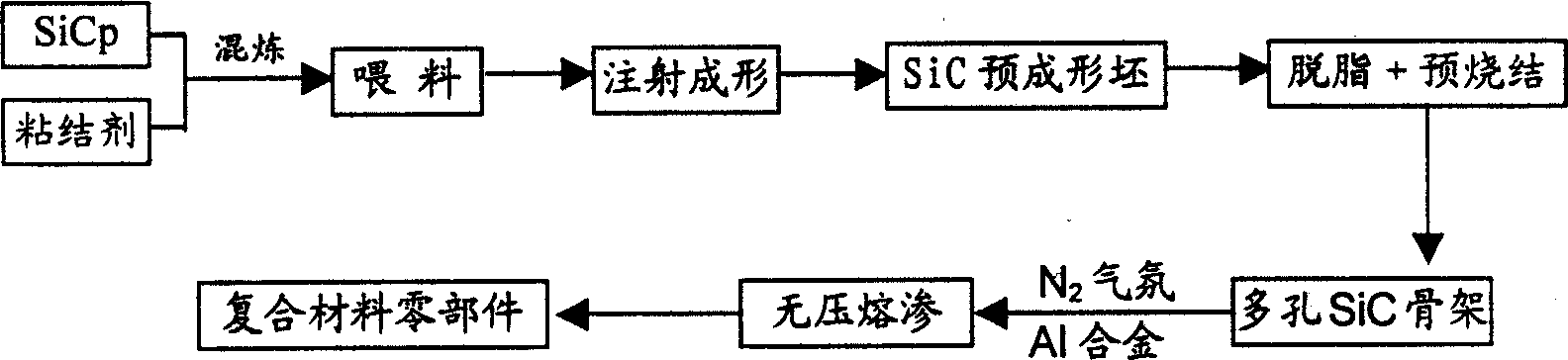

Method for producing high-volume fractional silicon-carbide particle reinforced aluminium-base composite material member

A technology for preparing the silicon carbide particles reinforced Al-based workpiece (SiCp / Al) with high volume fraction includes such steps as proportionally mixing SiC particles with paraffin wax based multi-polymer adhesive, stirring, granulating, injection moulding, thermal defatting in solvent, presintering at 1000-1150 deg.C, and osmosizing the molten Al alloy into SiC skeleton at 1100-1200 deg.C in N2 atmosphere.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com