Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

711 results about "Square cross section" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

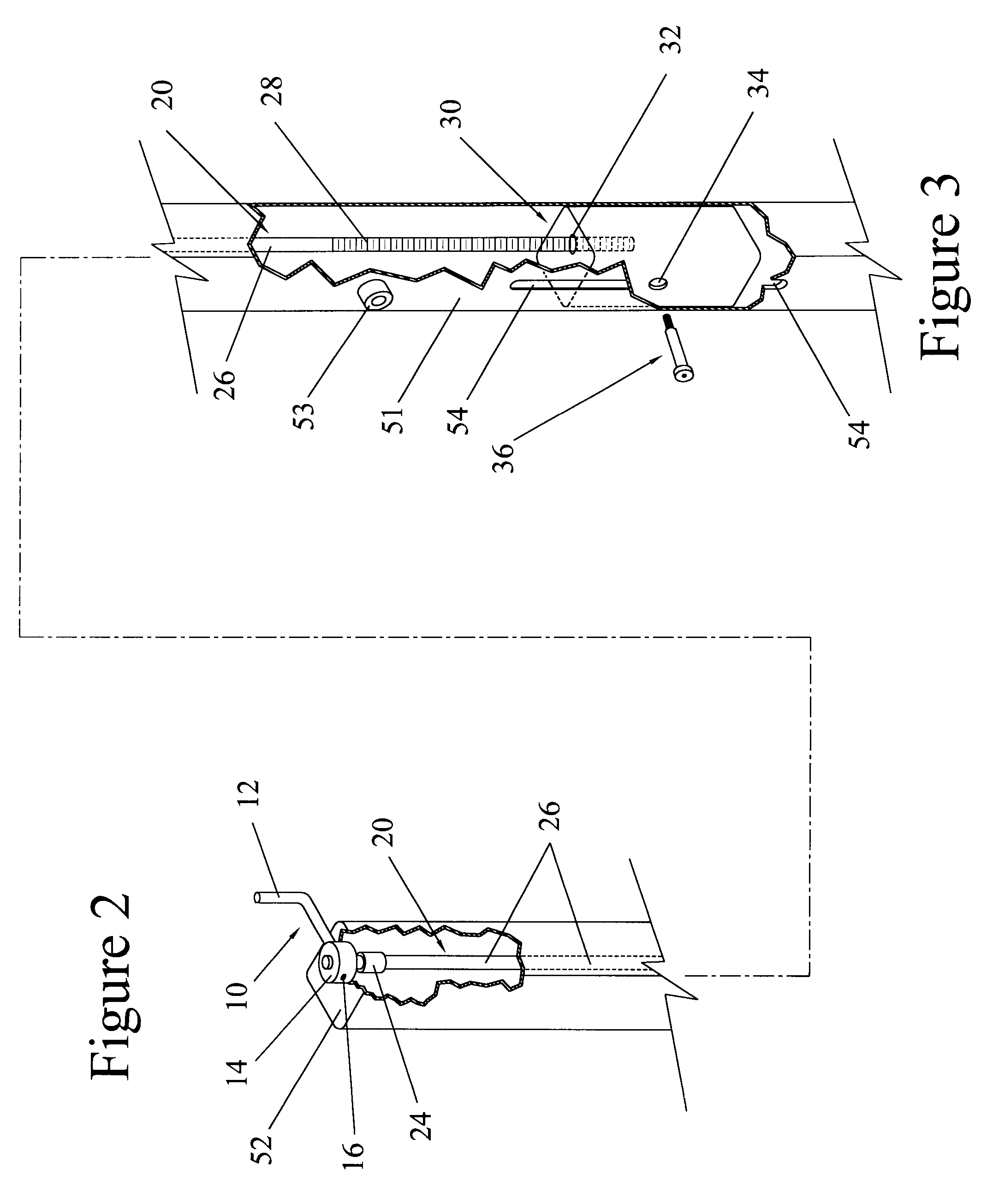

Powdered medication inhaler

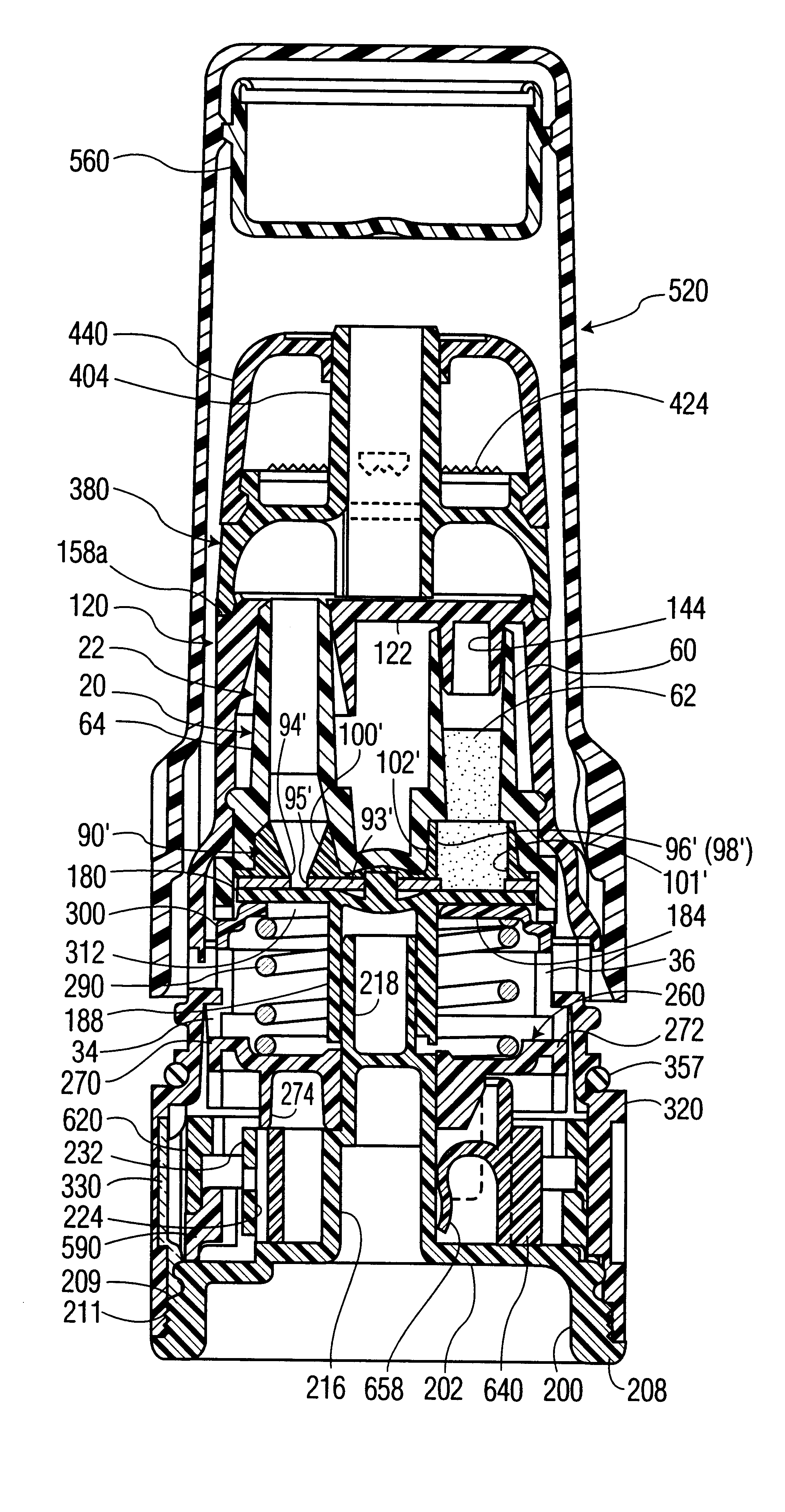

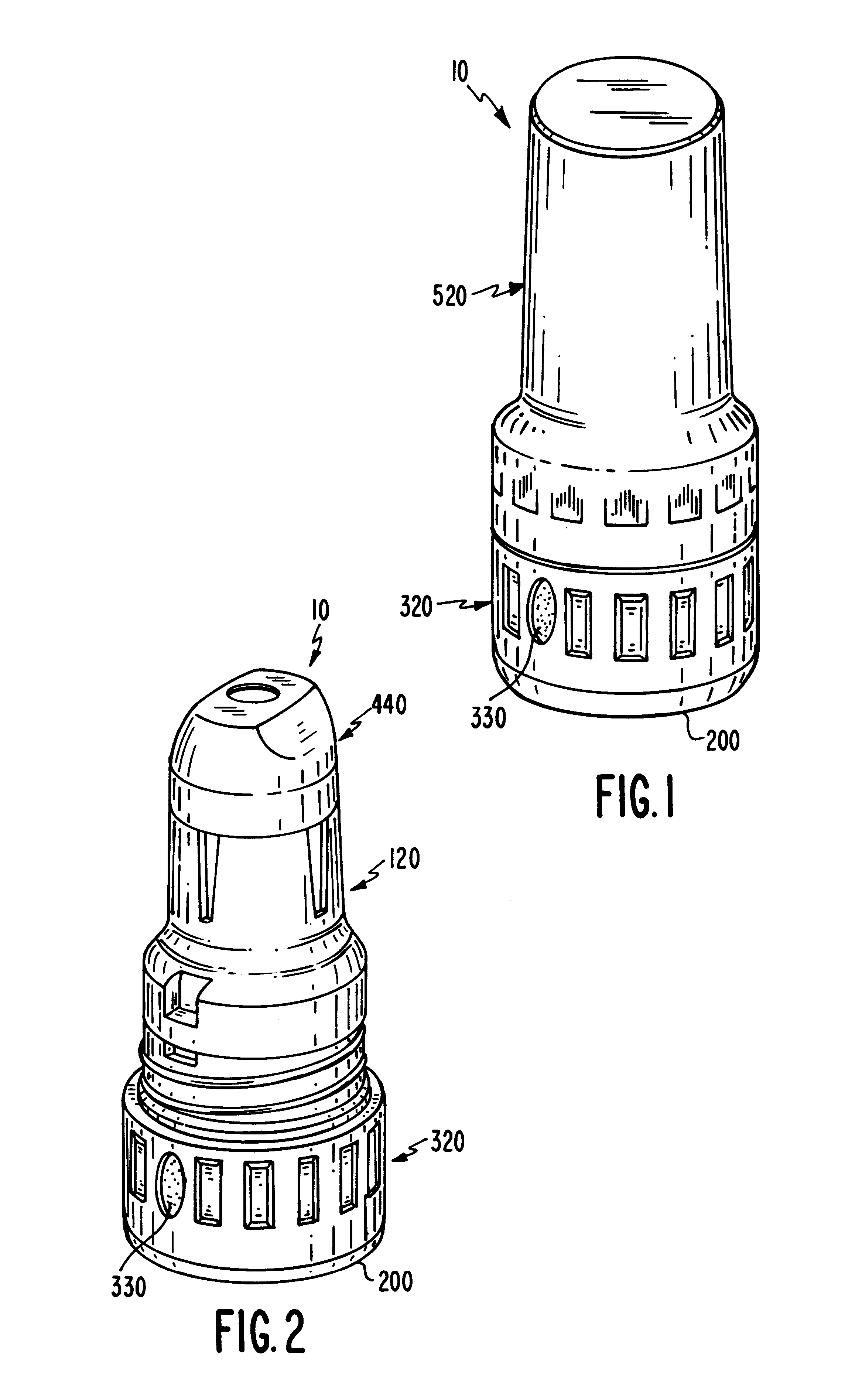

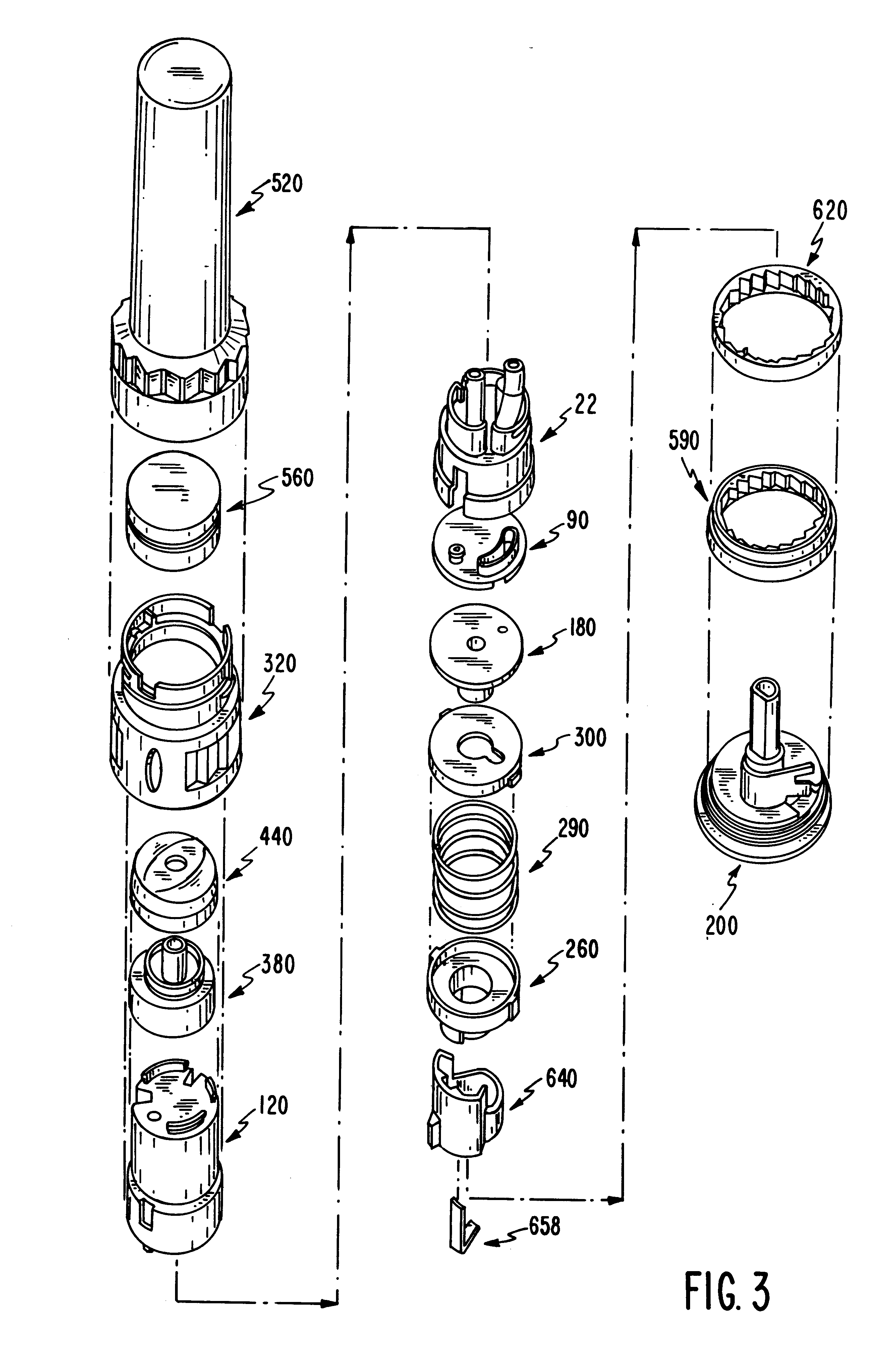

A powder dispenser includes a reservoir body including a supply of powder and an inhalation conduit; a driving body for rotating the reservoir body and including upper recesses and two spring fingers in lower driving recesses thereof; a rotatable metering plate for carrying a metered amount of powder from the supply to the inhalation conduit, and having an underside with ribs; a gas permeable retainer welded to the ribs; a spring biasing the metering plate toward the reservoir body; a nozzle having spiked ribs welded in the upper recesses of the driving body and including a chimney with vertical flutes; an adapter non-rotatably mounted with respect to the metering plate and including two locking recesses for receiving the spring fingers for locking engagement and two helical cam tracks with a square cross-section; a closure cap covering the driving body and including priming ribs biasing the spring fingers out of the locking recesses and engaging with the locking recesses to rotate the driving body, and two cams riding within the cam tracks; a base non-rotatably connected with the metering plate; and a counter rotatably mounted on the base and including rotatable counter rings providing a visual count of the number of doses of powder to be dispensed, and a pawl assembly engaging with gear teeth of the counter rings for rotating the same, the pawl assembly including an outer wall, a pawl and a pawl spring integrally molded as a single piece.

Owner:MERCK SHARP & DOHME CORP

Filter with varying cell channels

InactiveUS6843822B2Increase capacityEfficient and cost-effectiveCombination devicesInternal combustion piston enginesSquare cross sectionHoneycomb structure

Owner:CORNING INC

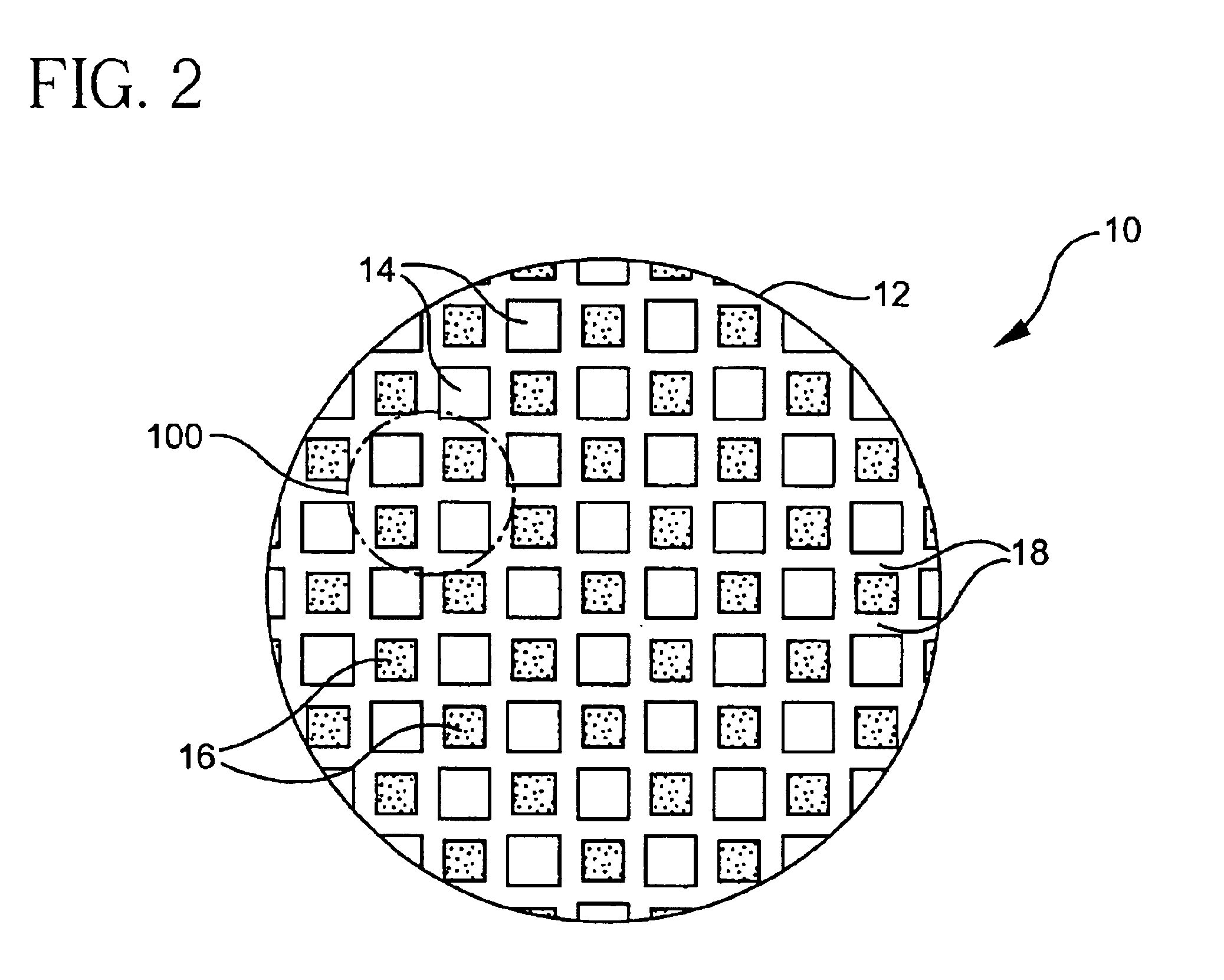

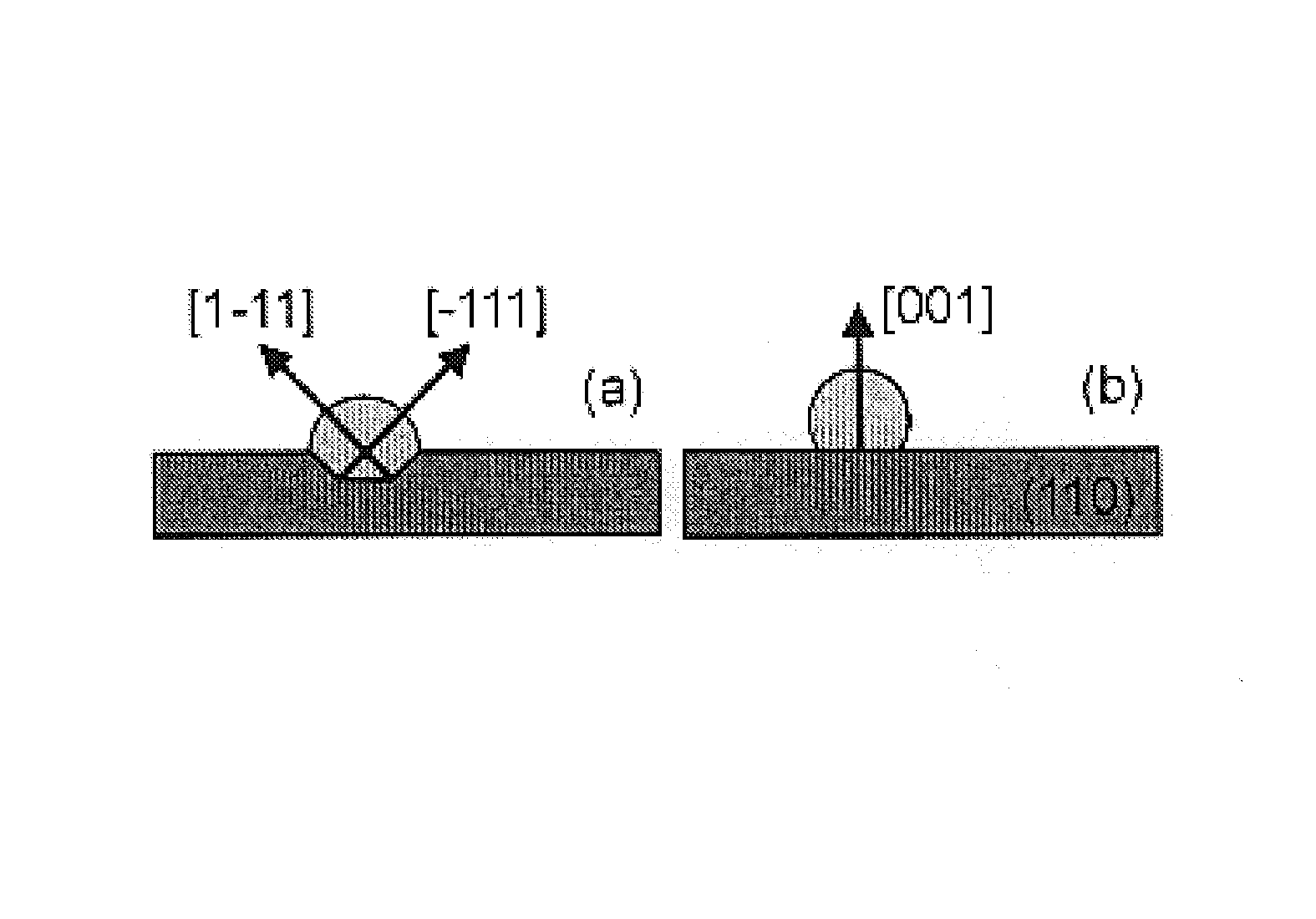

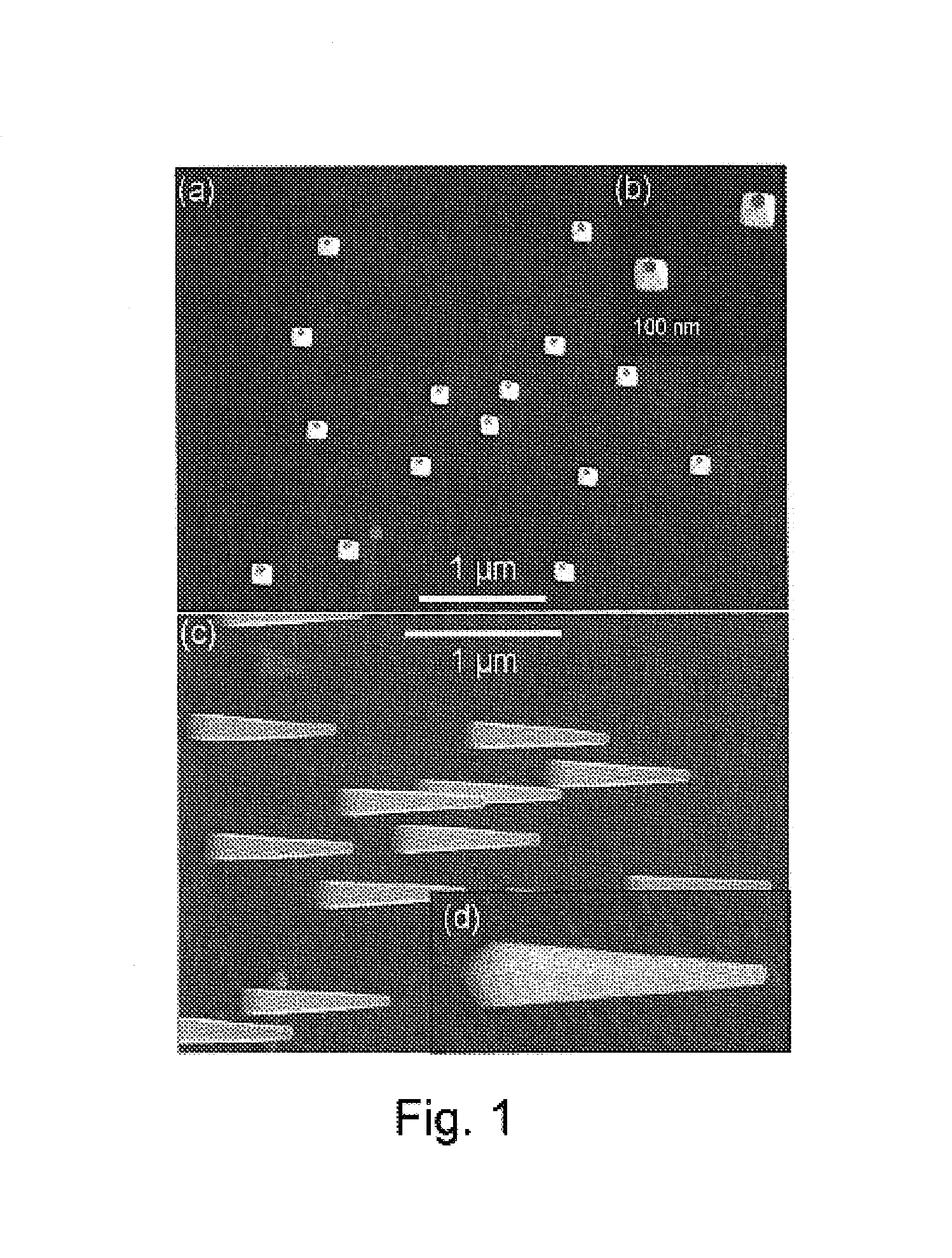

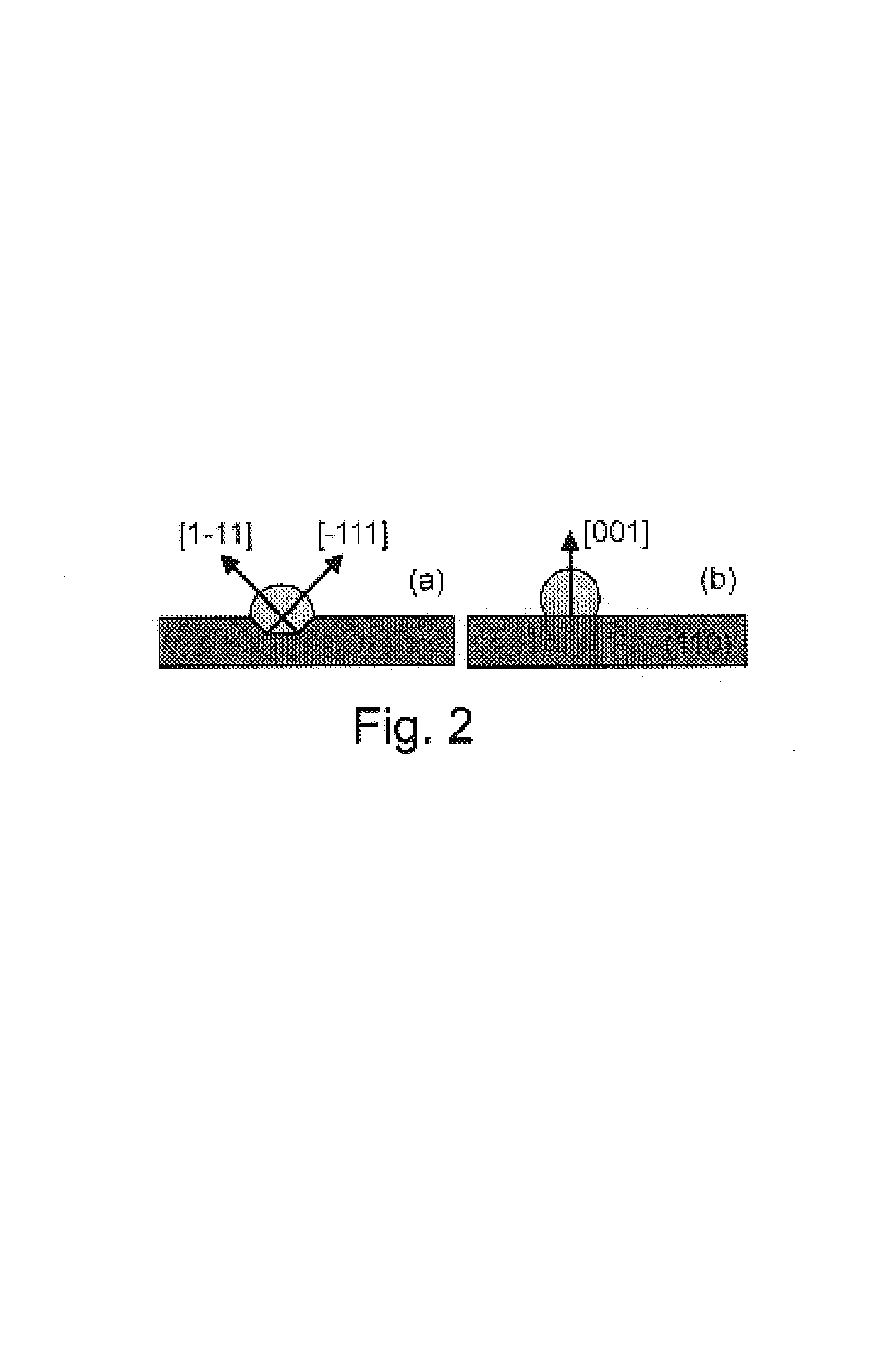

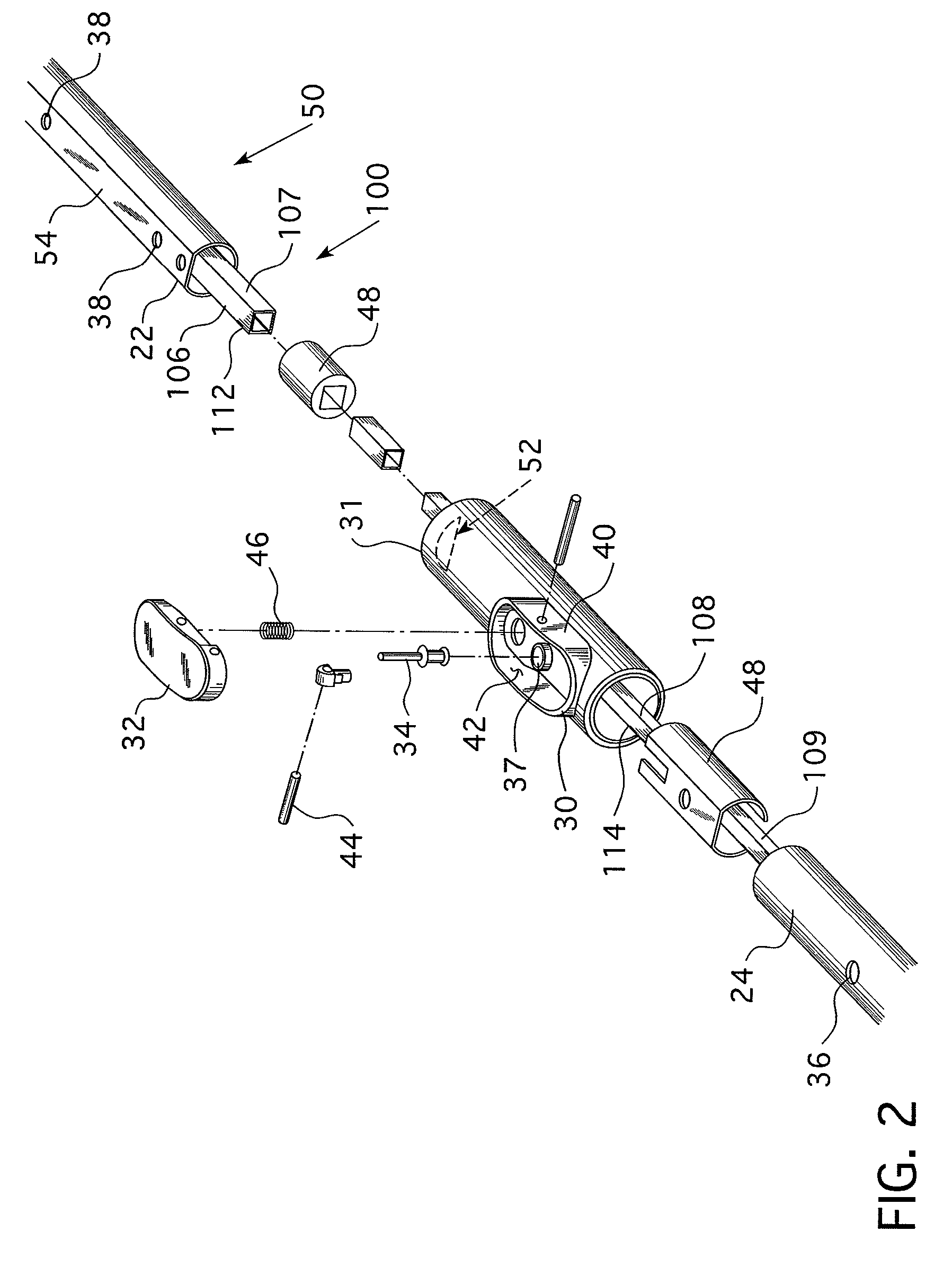

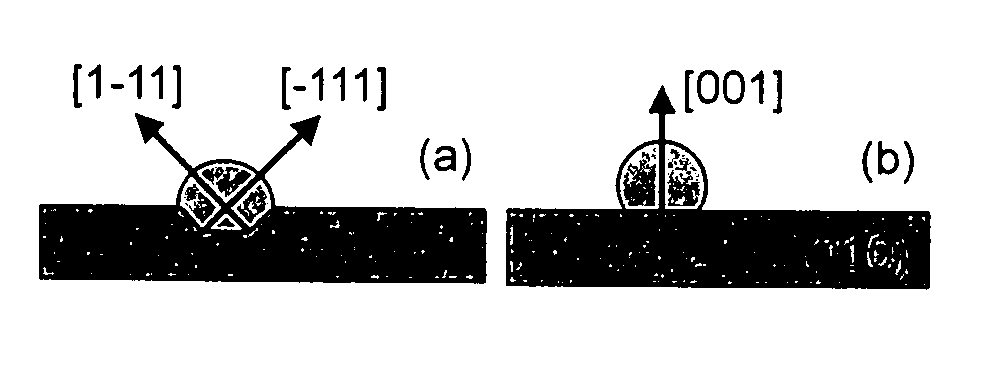

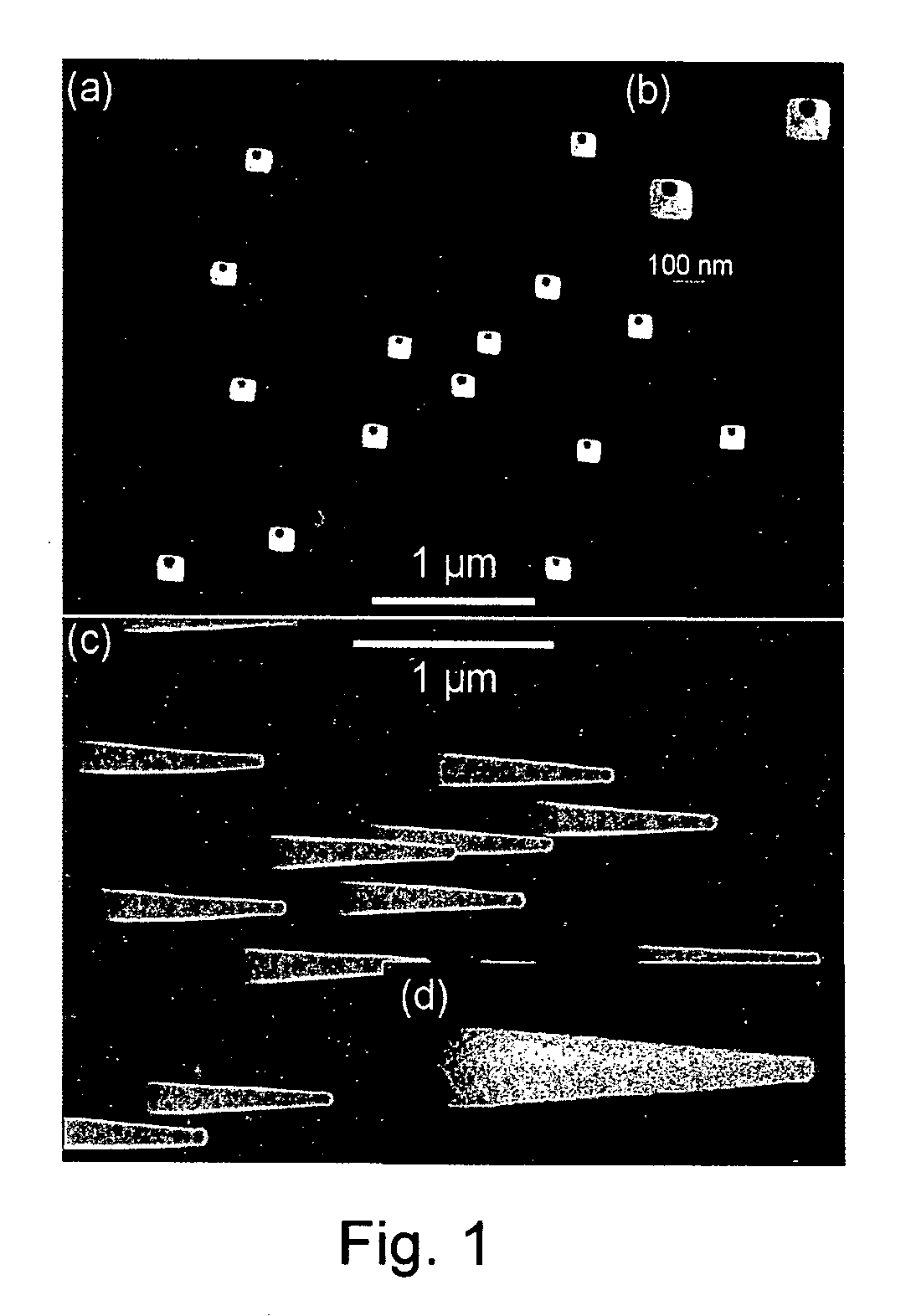

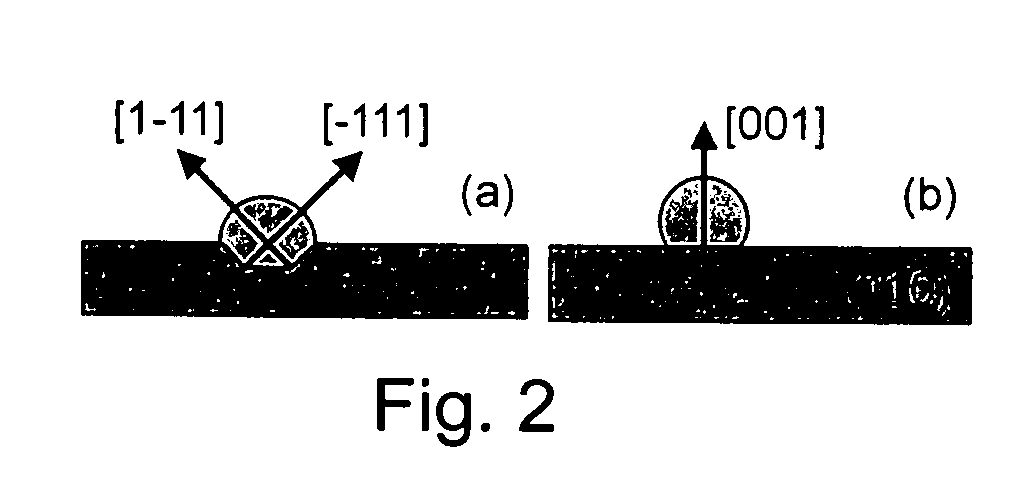

Directionally controlled growth of nanowhiskers

InactiveUS7354850B2Optimized structural formWell-defined surfaceMaterial nanotechnologyPolycrystalline material growthStacking faultOrganic vapor

Nanowhiskers are grown in a non-preferential growth direction by regulation of nucleation conditions to inhibit growth in a preferential direction. In a preferred implementation, <001> III-V semiconductor nanowhiskers are grown on an (001) III-V semiconductor substrate surface by effectively inhibiting growth in the preferential <111>B direction. As one example, <001> InP nano-wires were grown by metal-organic vapor phase epitaxy directly on (001) InP substrates. Characterization by scanning electron microscopy and transmission electron microscopy revealed wires with nearly square cross sections and a perfect zincblende crystalline structure that is free of stacking faults.

Owner:QUNANO

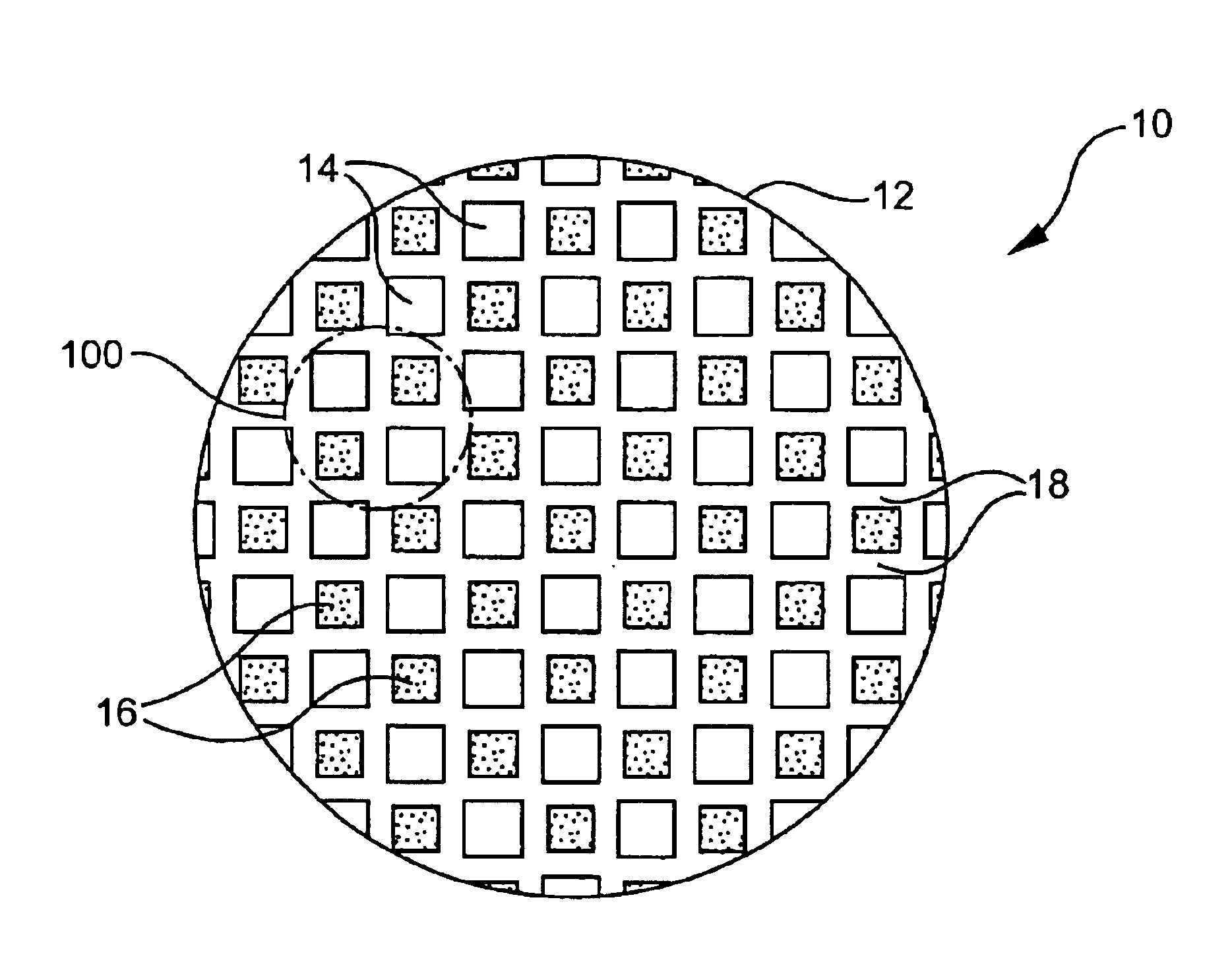

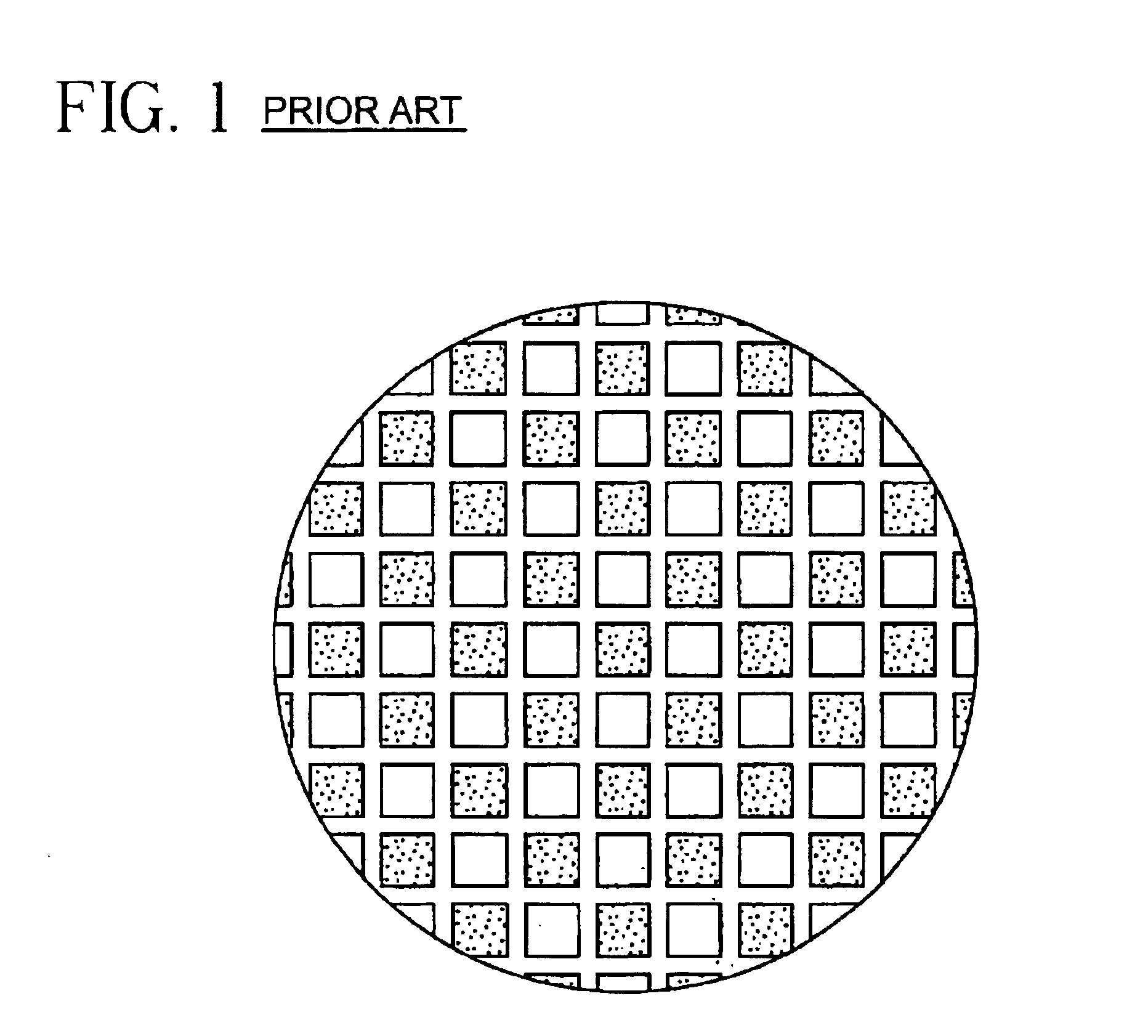

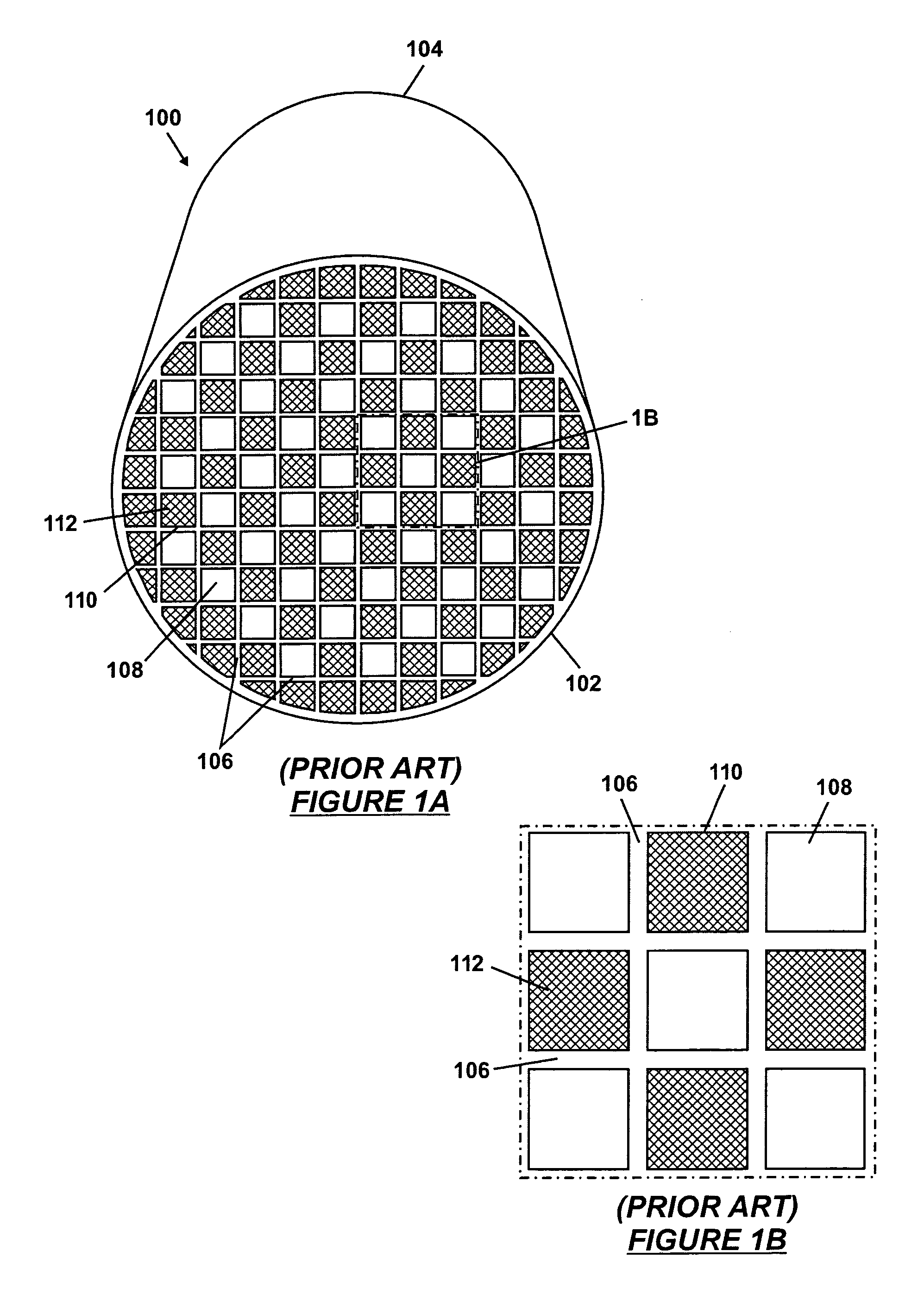

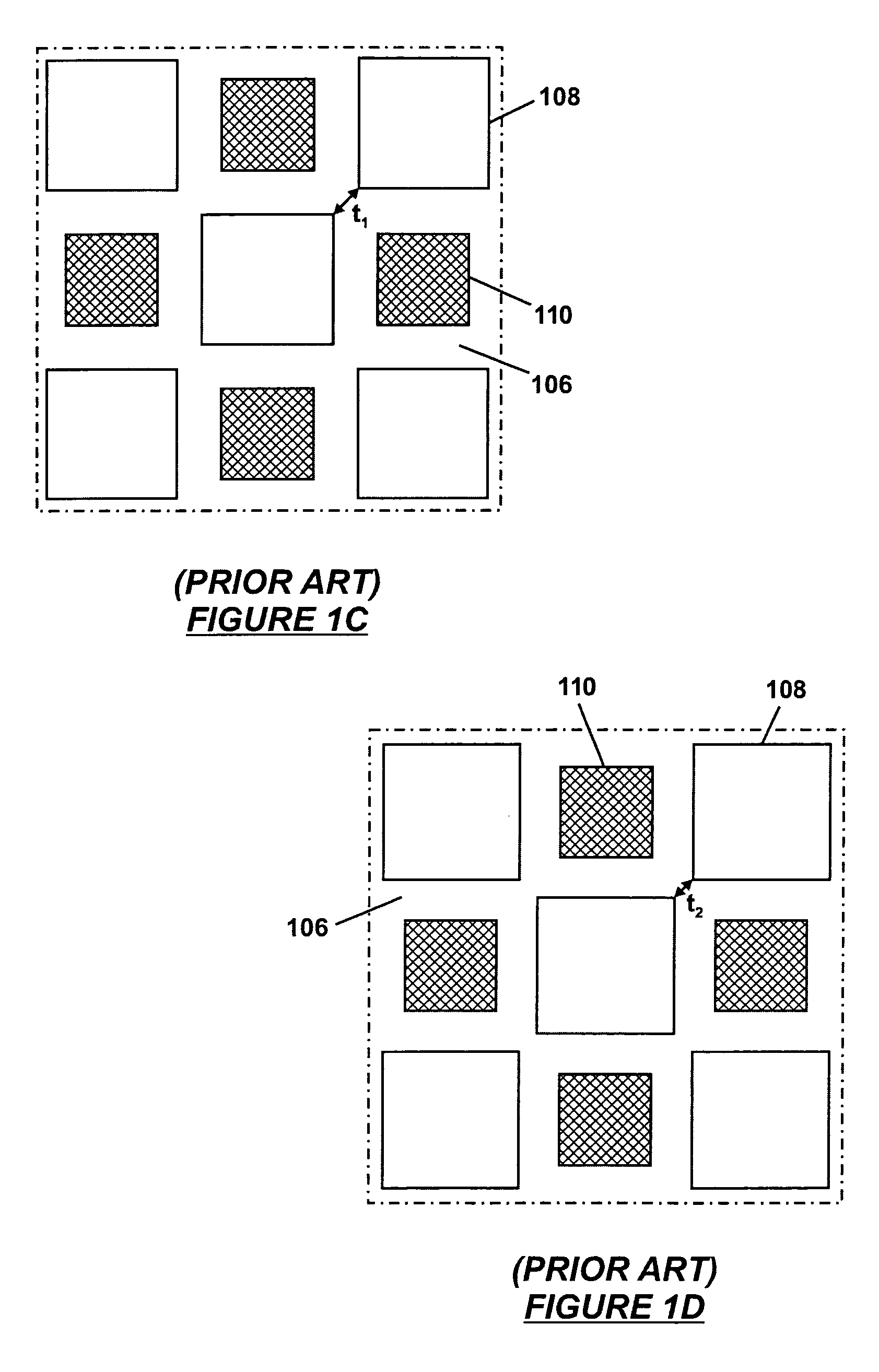

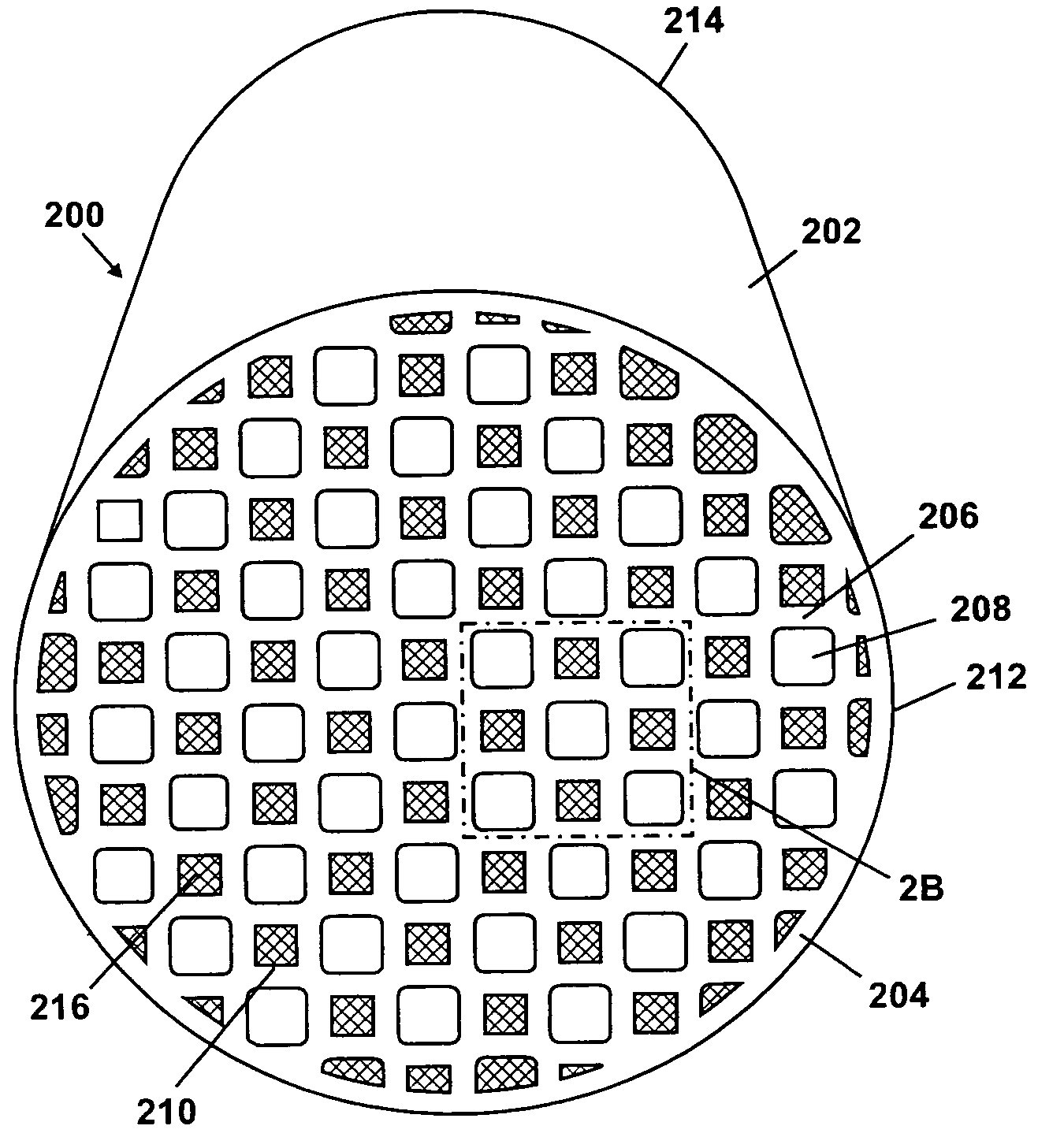

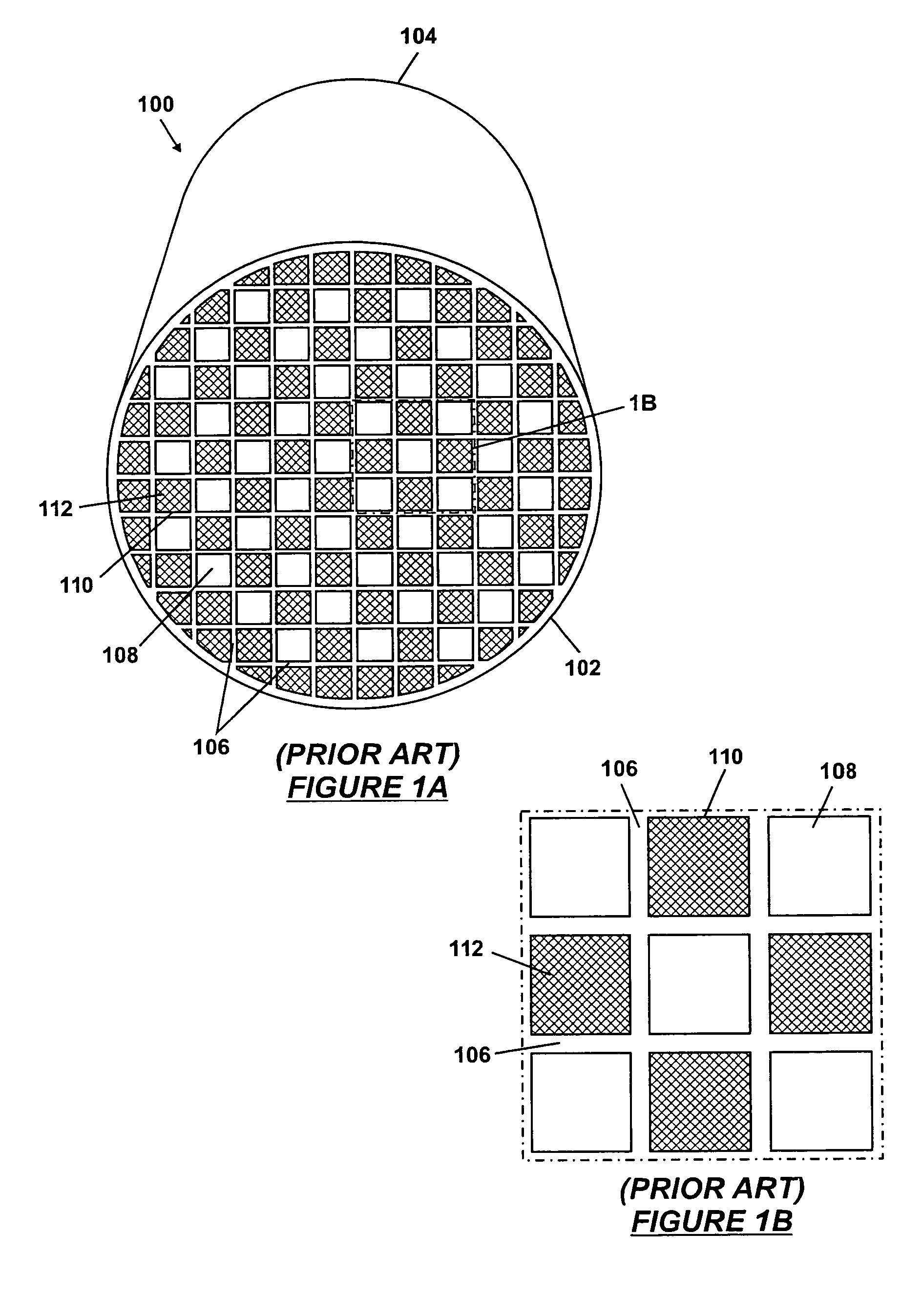

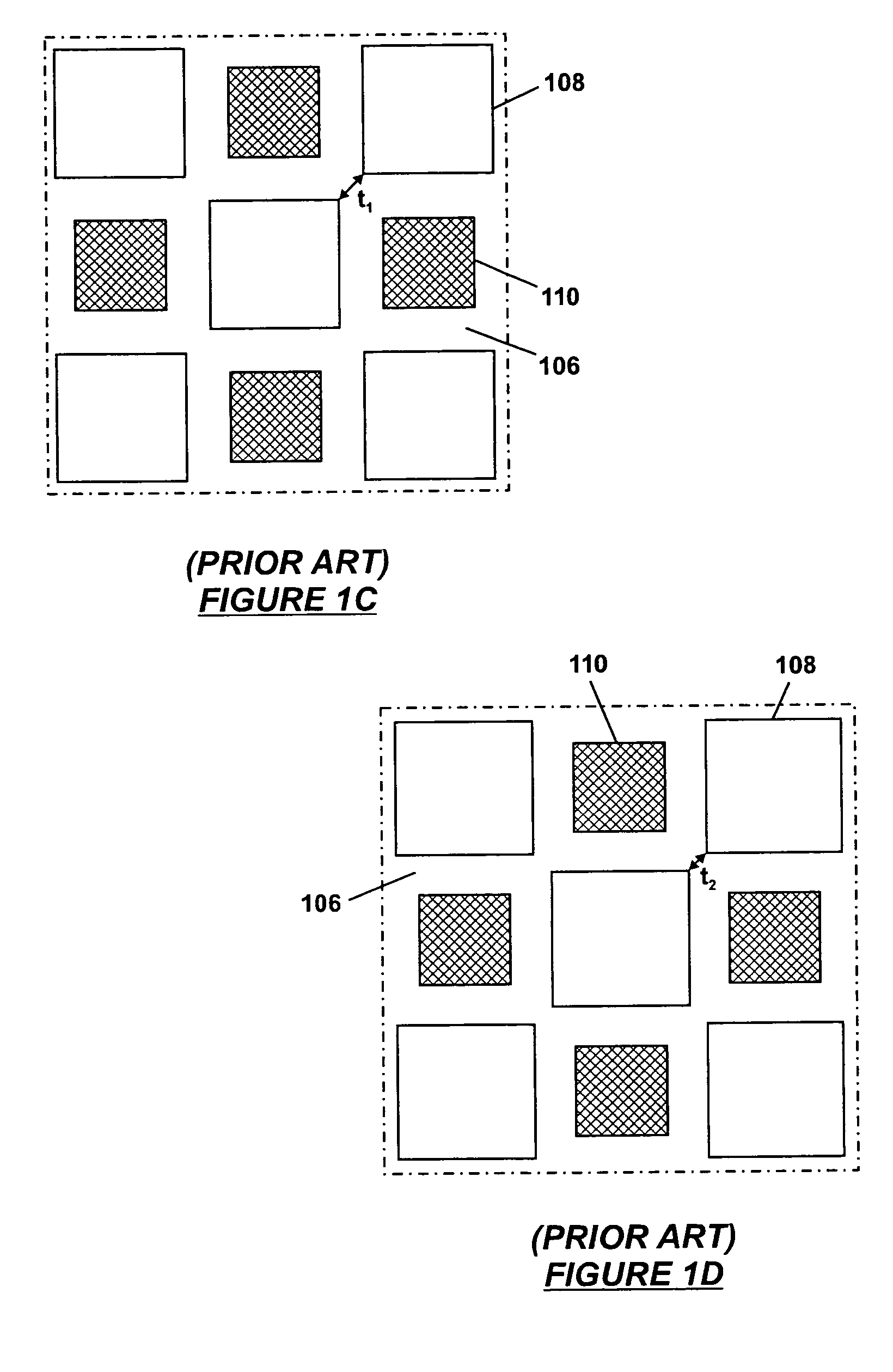

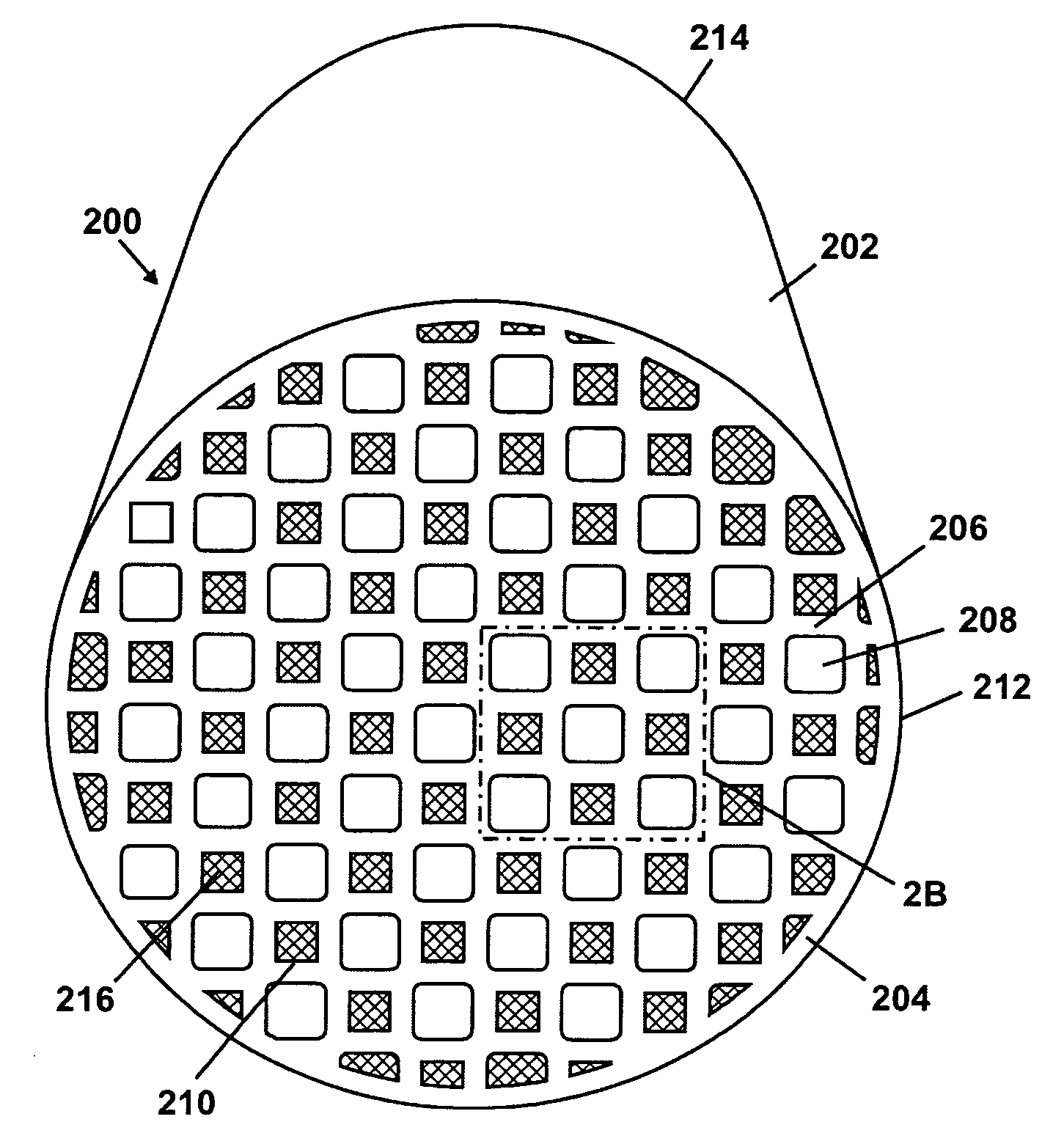

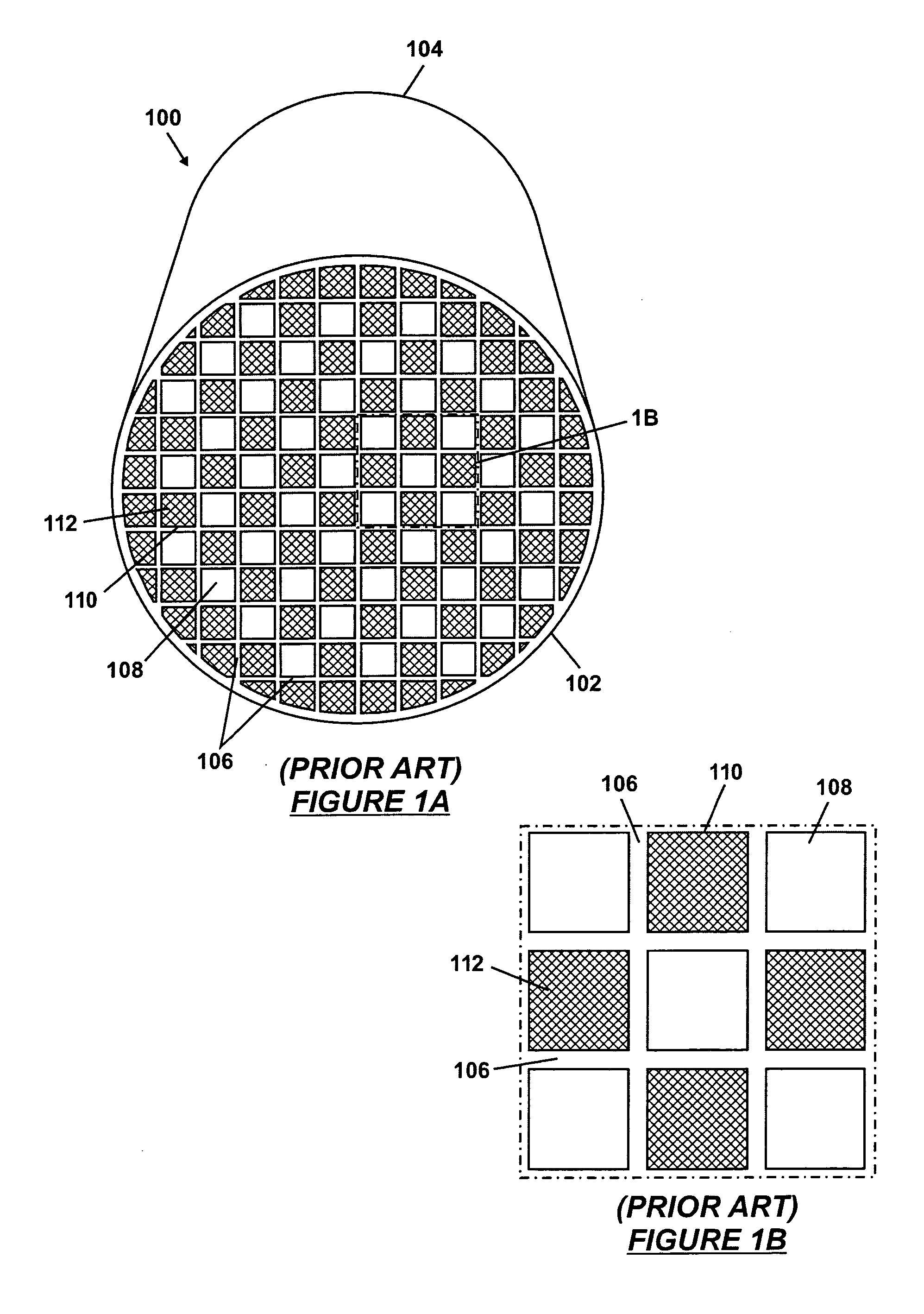

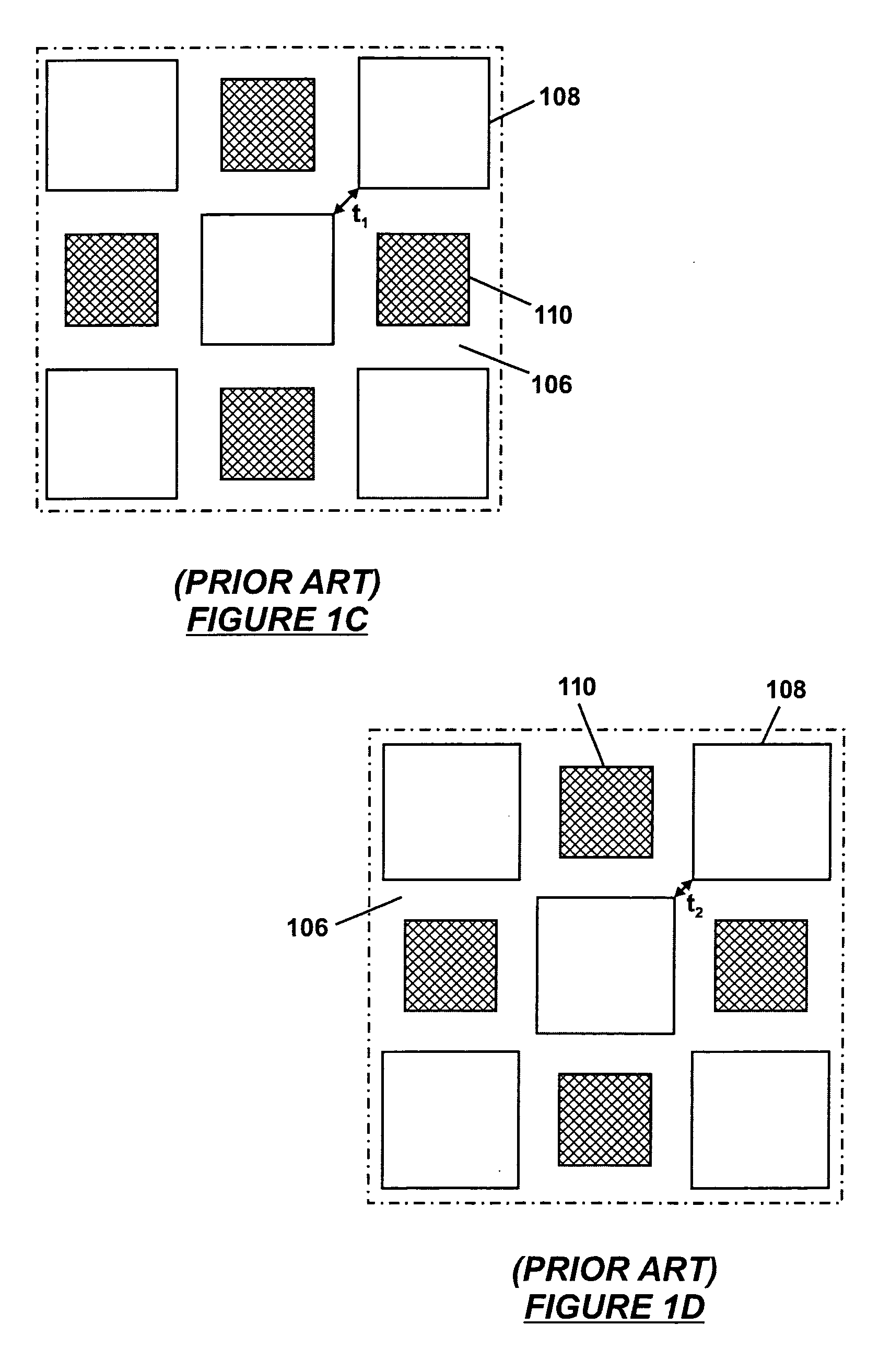

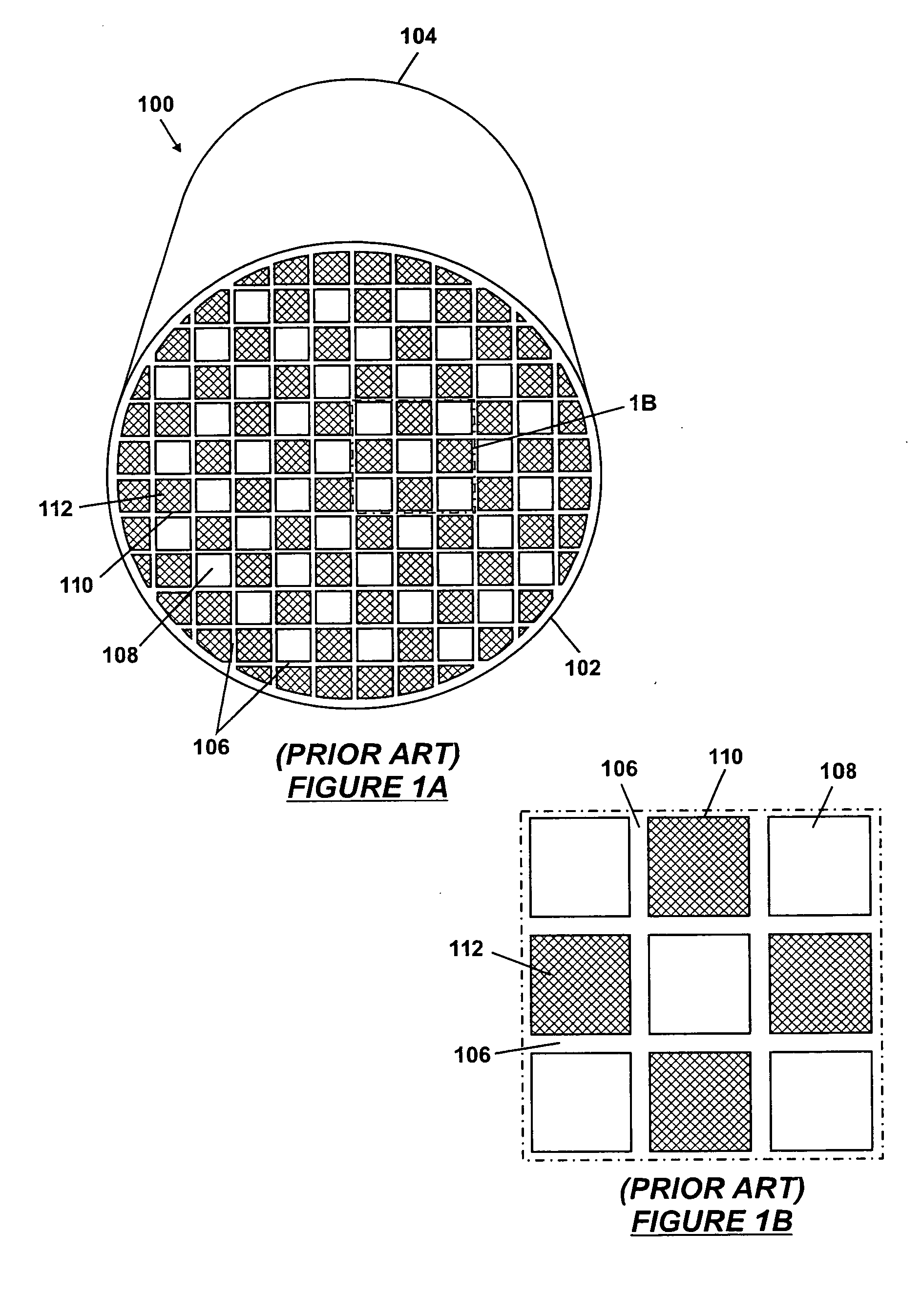

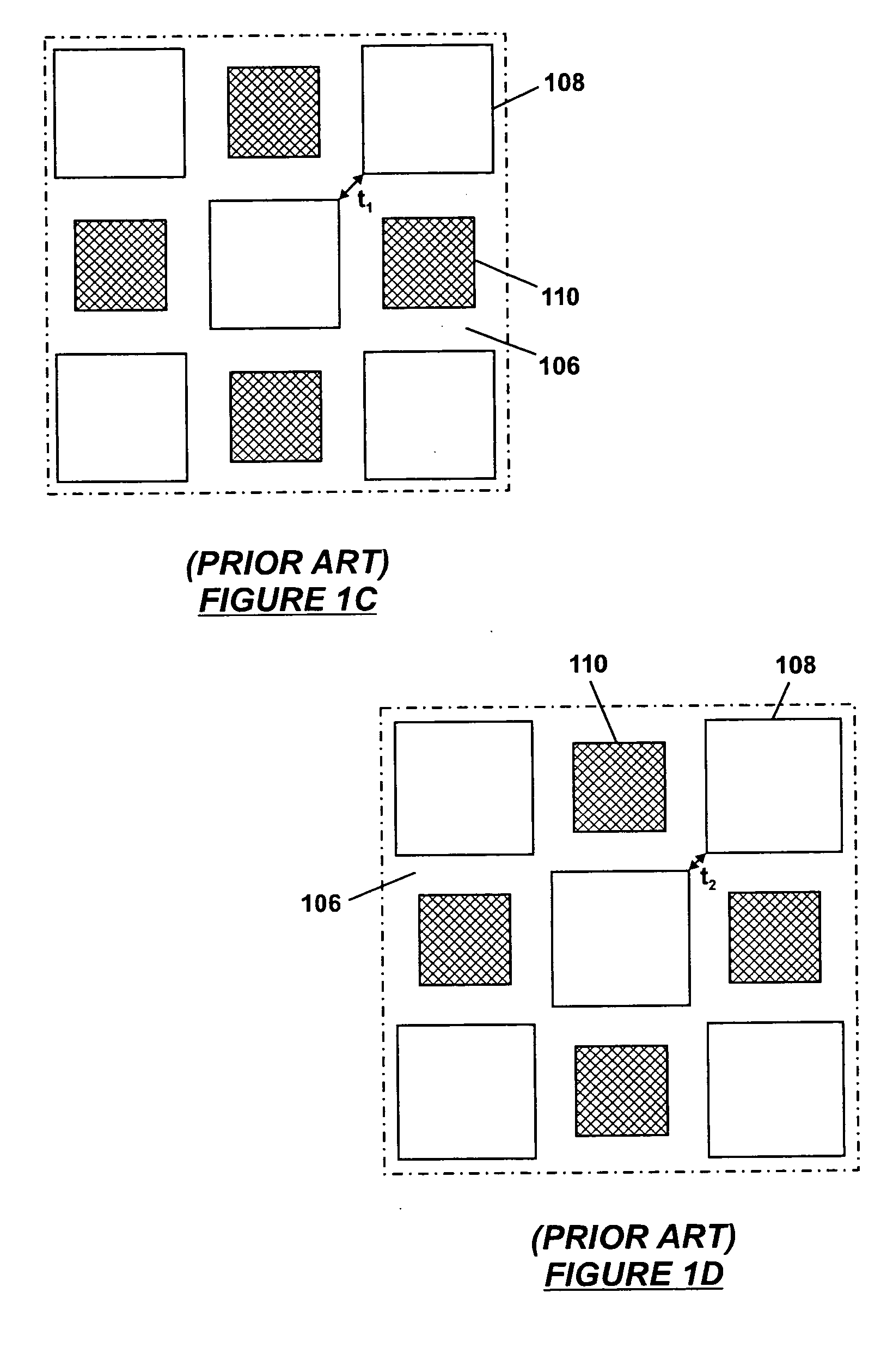

Asymmetric honeycomb wall-flow filter having improved structural strength

InactiveUS7247184B2Combination devicesInternal combustion piston enginesSquare cross sectionHoneycomb

A honeycomb filter includes an array of interconnecting porous walls which define an array of first channels and second channels. The first channels are bordered on their sides by the second channels and have a larger hydraulic diameter than the second channels. The first channels have a square cross-section, with corners of the first channels having a shape such that the thickness of the porous walls adjoining the corners of the first channels is comparable to the thickness of the porous walls adjoining edges of the first and second channels.

Owner:CORNING INC

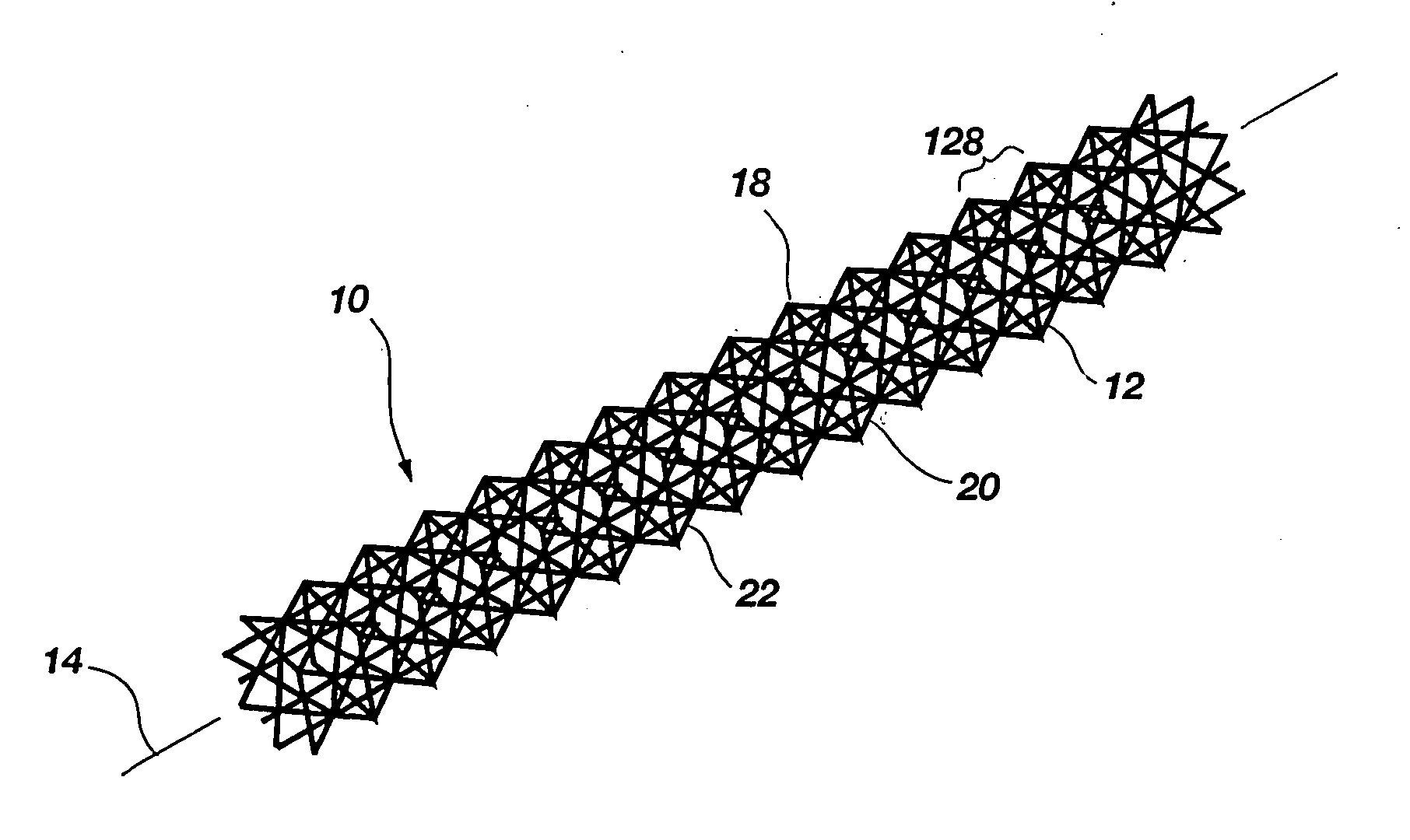

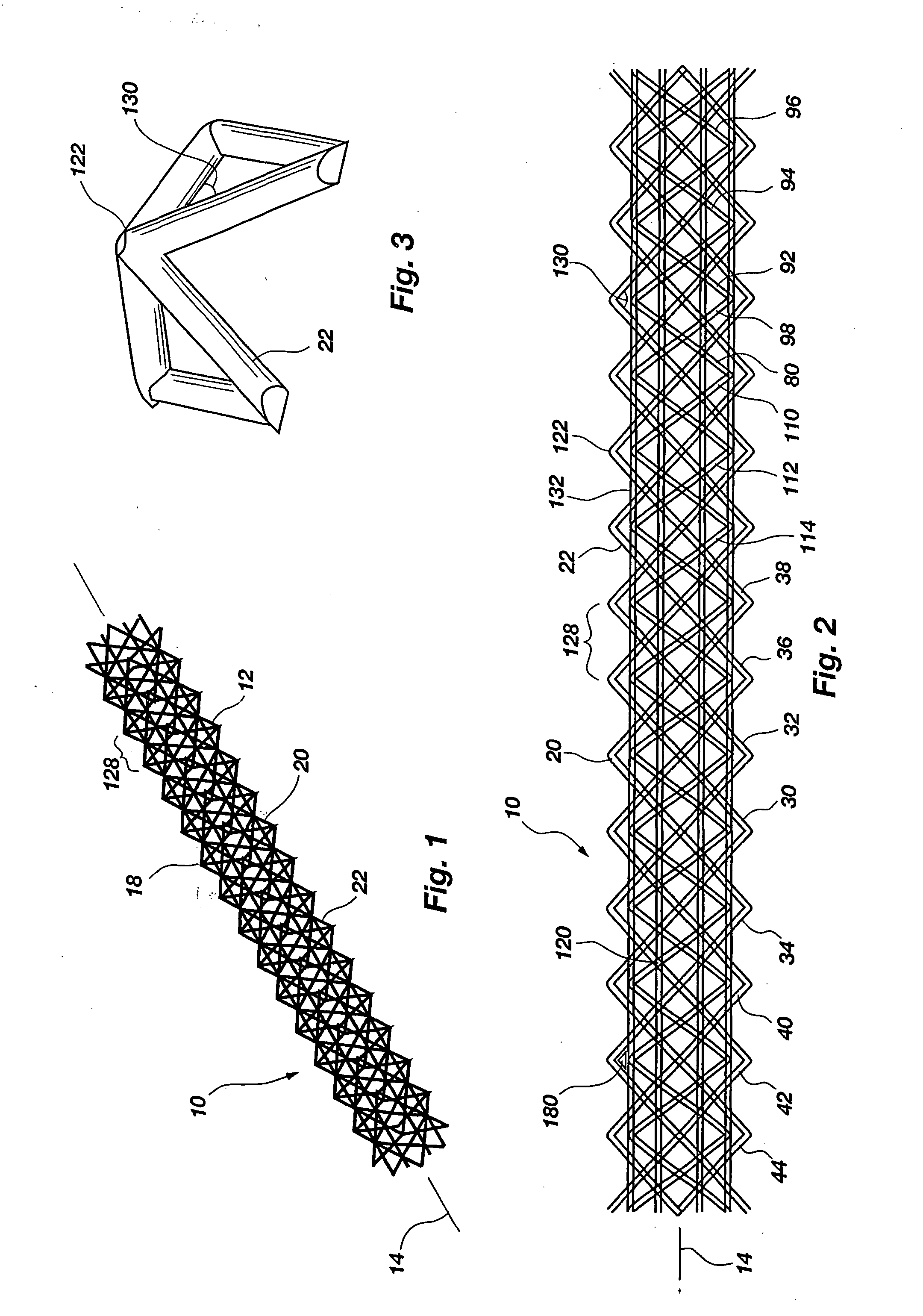

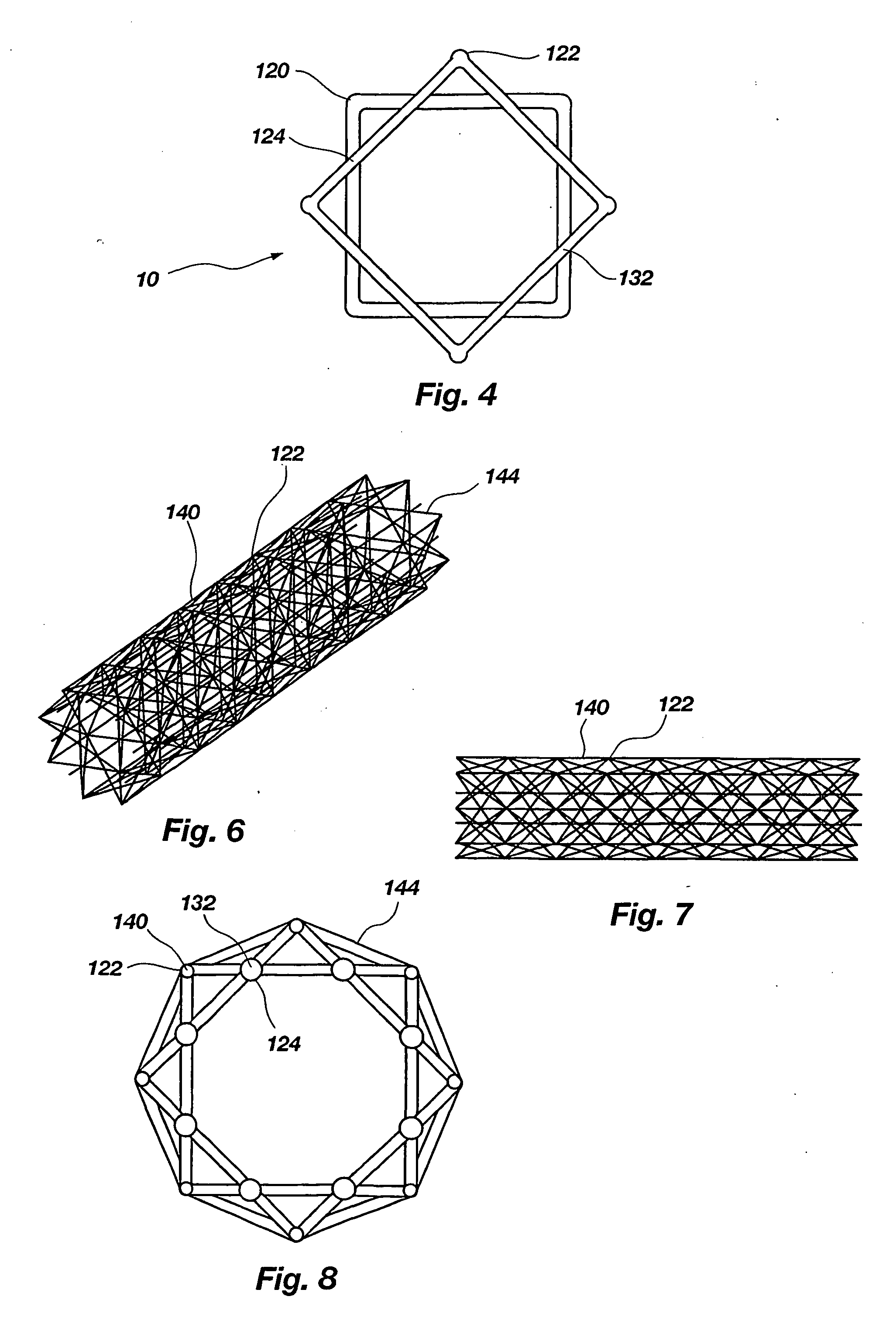

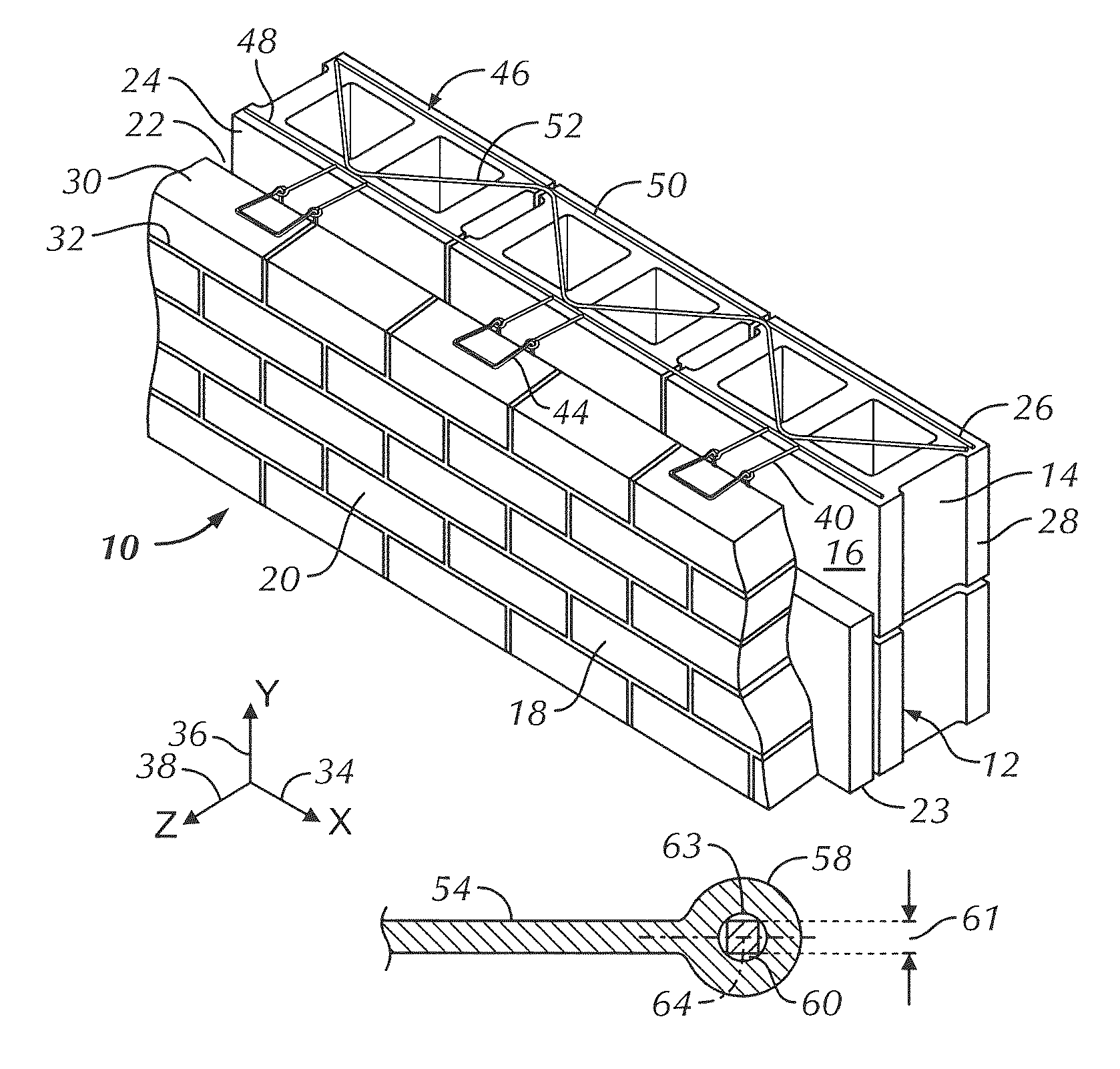

Iso-truss structure

InactiveUS20050115186A1Improved performance characteristicsReduced strengthTravelling sacksTruss-type bridgeSquare cross sectionAngular orientation

An iso-truss structure (10) includes at least two helical components (30, 32) and at least one reverse helical component (34) attached thereto with opposing angular orientations. Each helical and reverse helical component preferably includes at least four elongate, straight segments (22) rigidly connected end to end in a helical configuration forming a single, substantially complete rotation about a common axis (14) forming a first square cross section. The structure may further include at least two rotated helical components (80, 92) and at least one rotated reverse helical component (98) which are rotated with respect to the helical and reverse helical components forming a second square cross section, rotated with respect to the first. The structure may be straight, curved, flexible, or form angles.

Owner:ISOTRUSS IND LLC

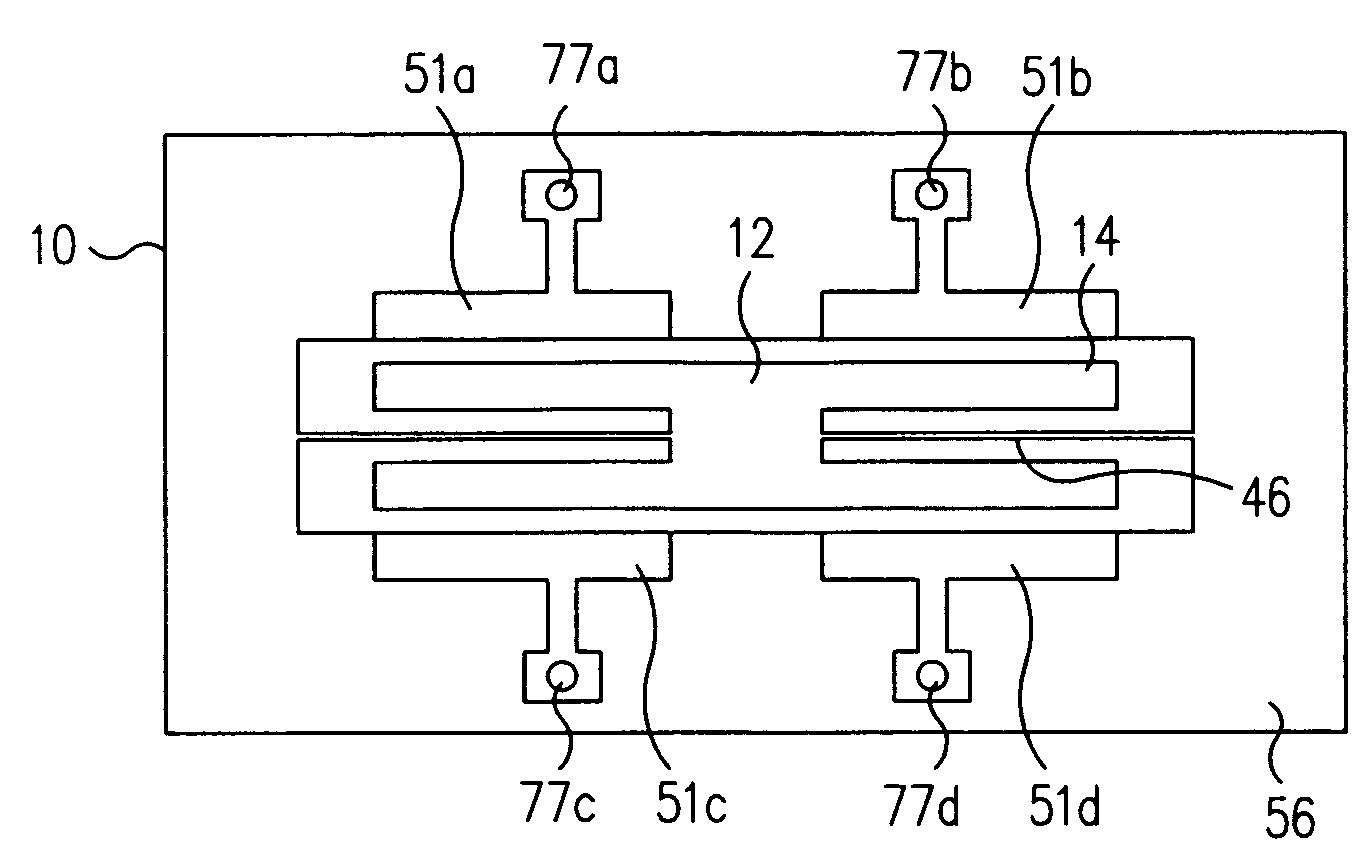

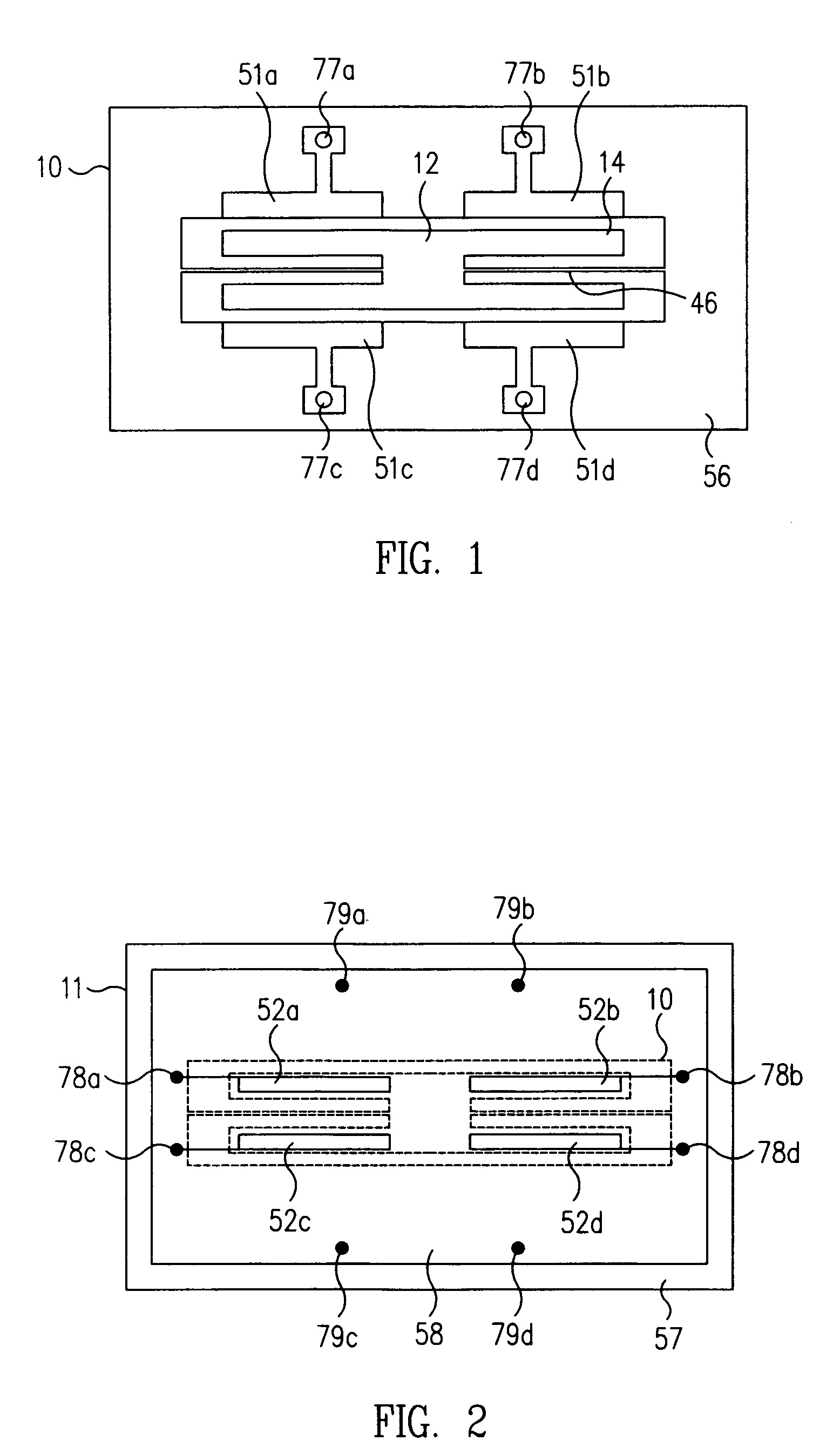

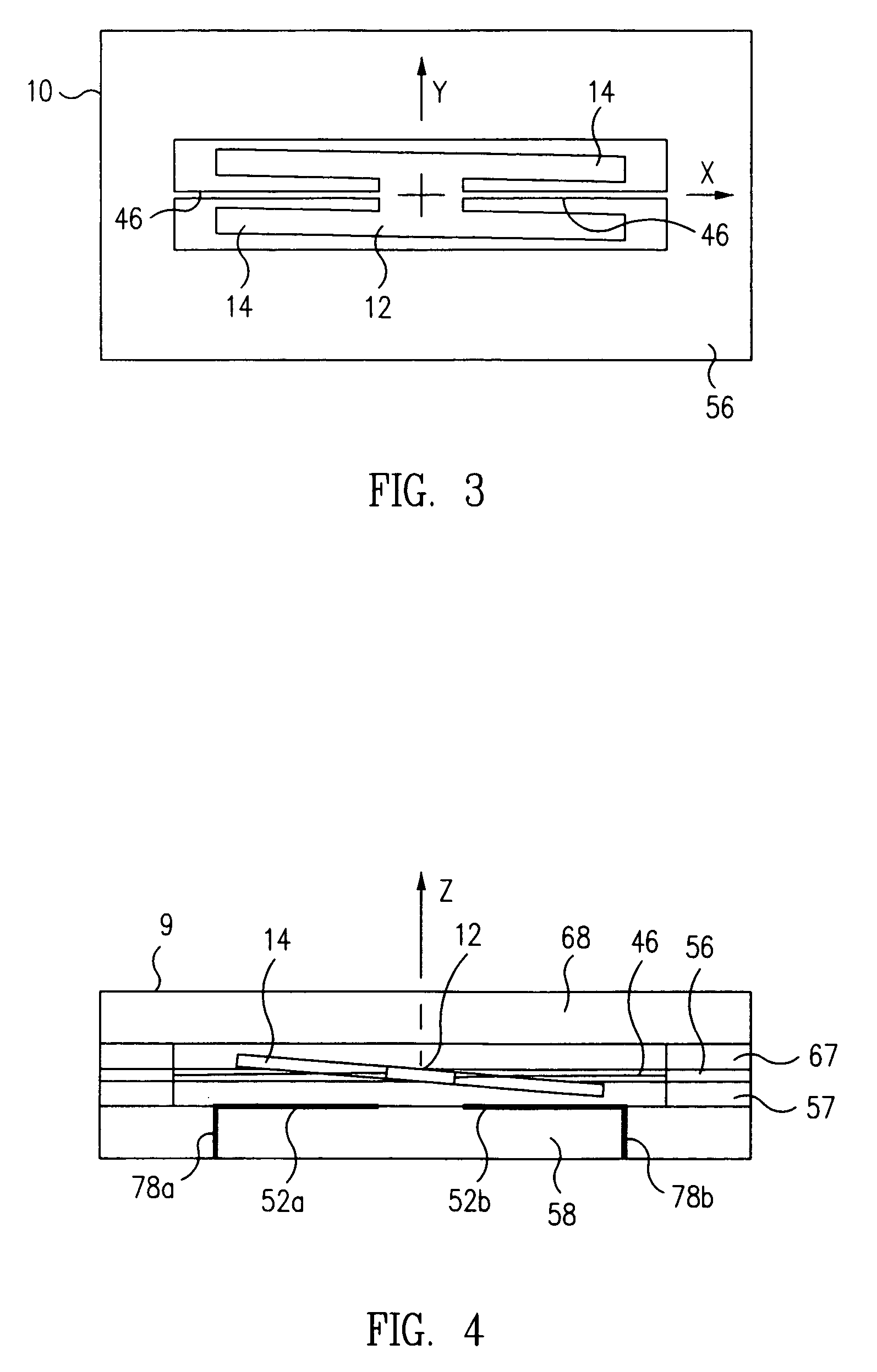

Micro-electromechanical system inertial sensor

InactiveUS7640803B1Easy to manufactureHigh aspect ratioAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsSquare cross sectionAccelerometer

A micro-machined MEMS resonator gyroscope and accelerometer is fabricated from an epilayer semiconductor wafer to incorporate a substantially planar, H-shaped resonator mass suspended from a support plate by two opposed elongated springs that couple to the relatively short crossbar member of the H. The masses are harmonically oscillated relative to the support plate and a baseplate portion, and two orthogonal modes of the structure corresponding to the two nearly degenerate fundamental torsional modes thereof are used for sensing angular rate about one axis, and linear acceleration along two axes, of the sensor. The H-shaped mass advantageously incorporates a relatively high length-to-width aspect ratio, and in one embodiment, the springs may advantageously incorporate either a square cross-section, such that the structure can be tuned to substantially match the fundamental frequencies of the two resonance modes of the structure by removing, e.g., by an etching process, a small amount of material from the upper surfaces of the springs.

Owner:NANCHANG O FILM OPTICAL ELECTRONICS TECH CO LTD

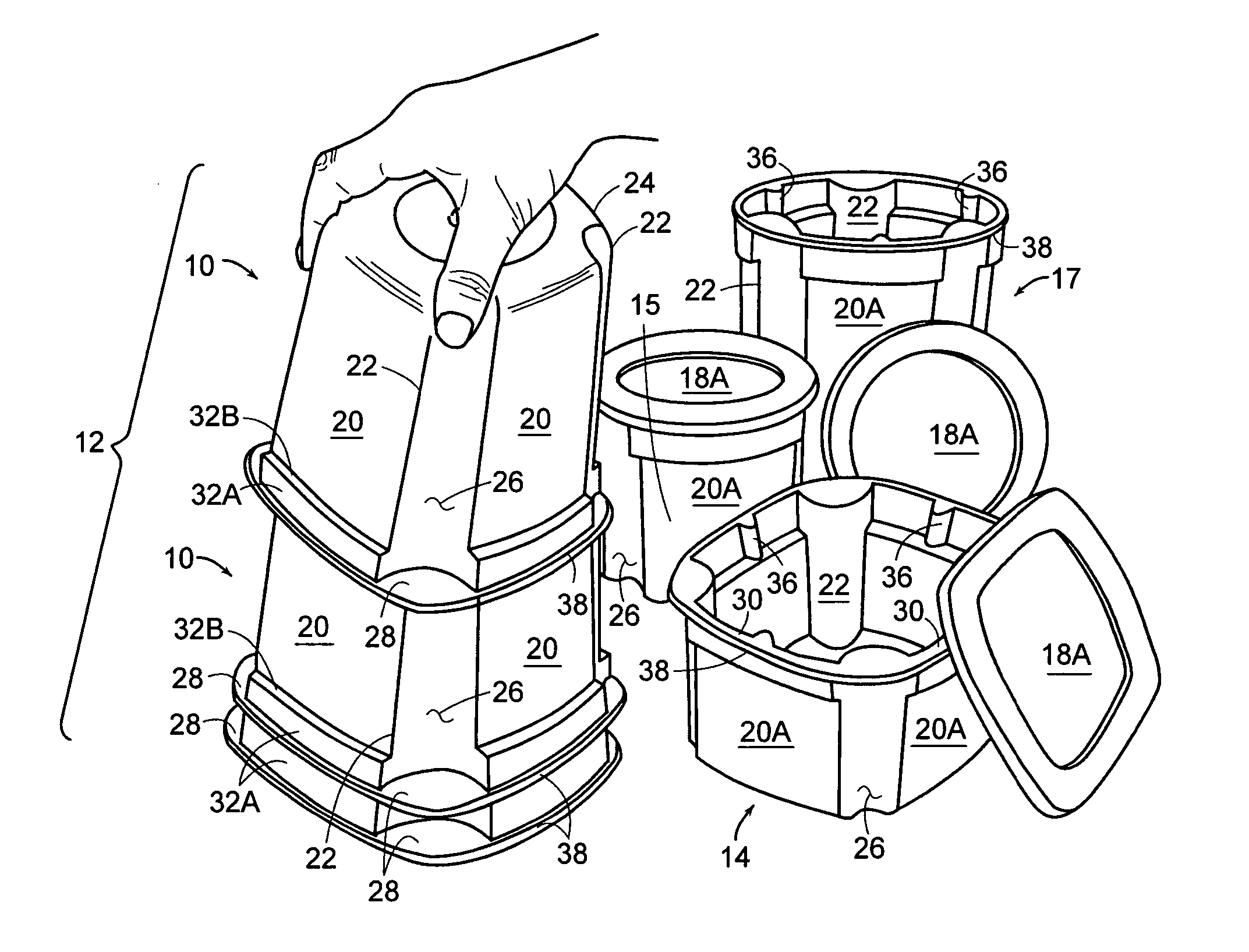

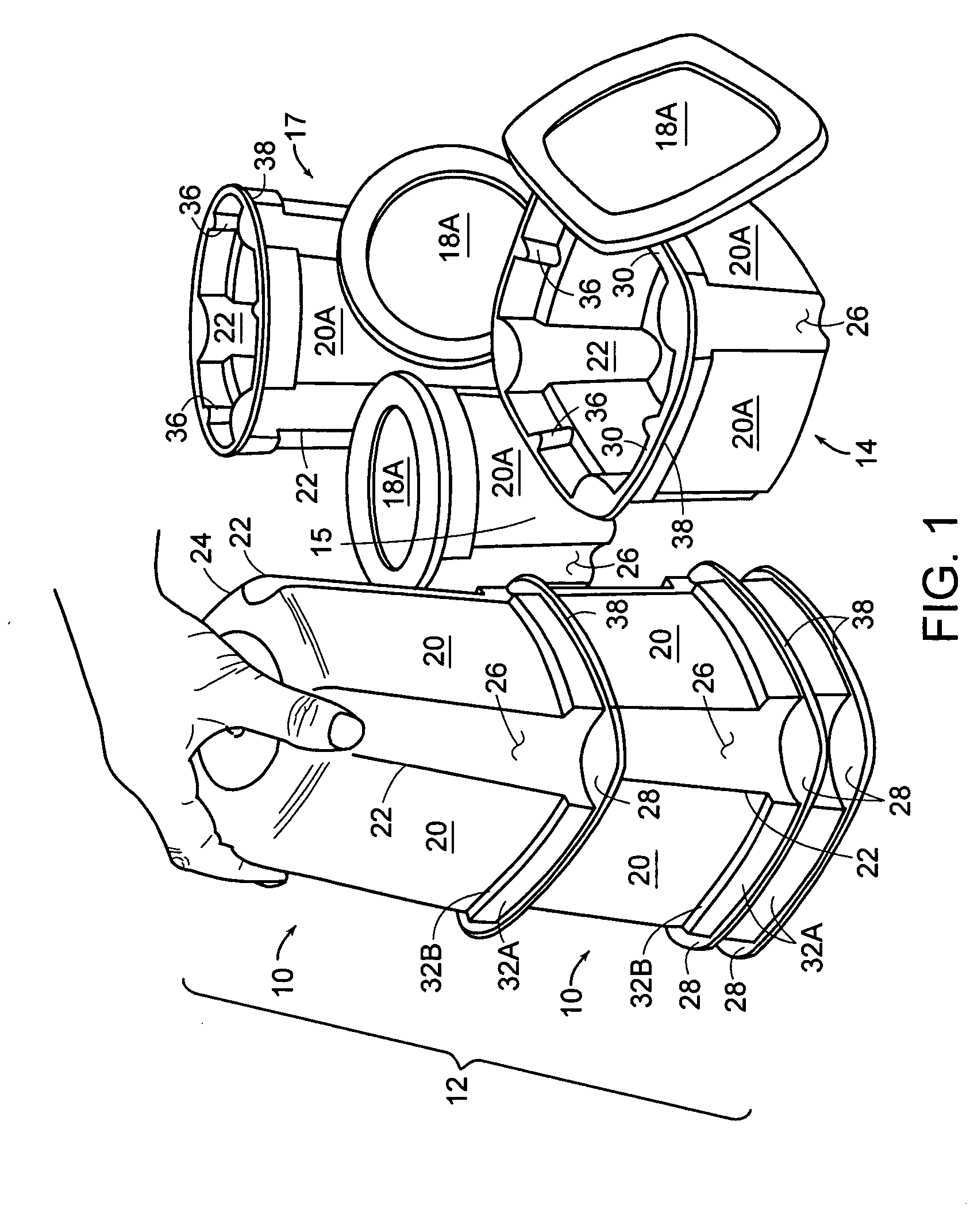

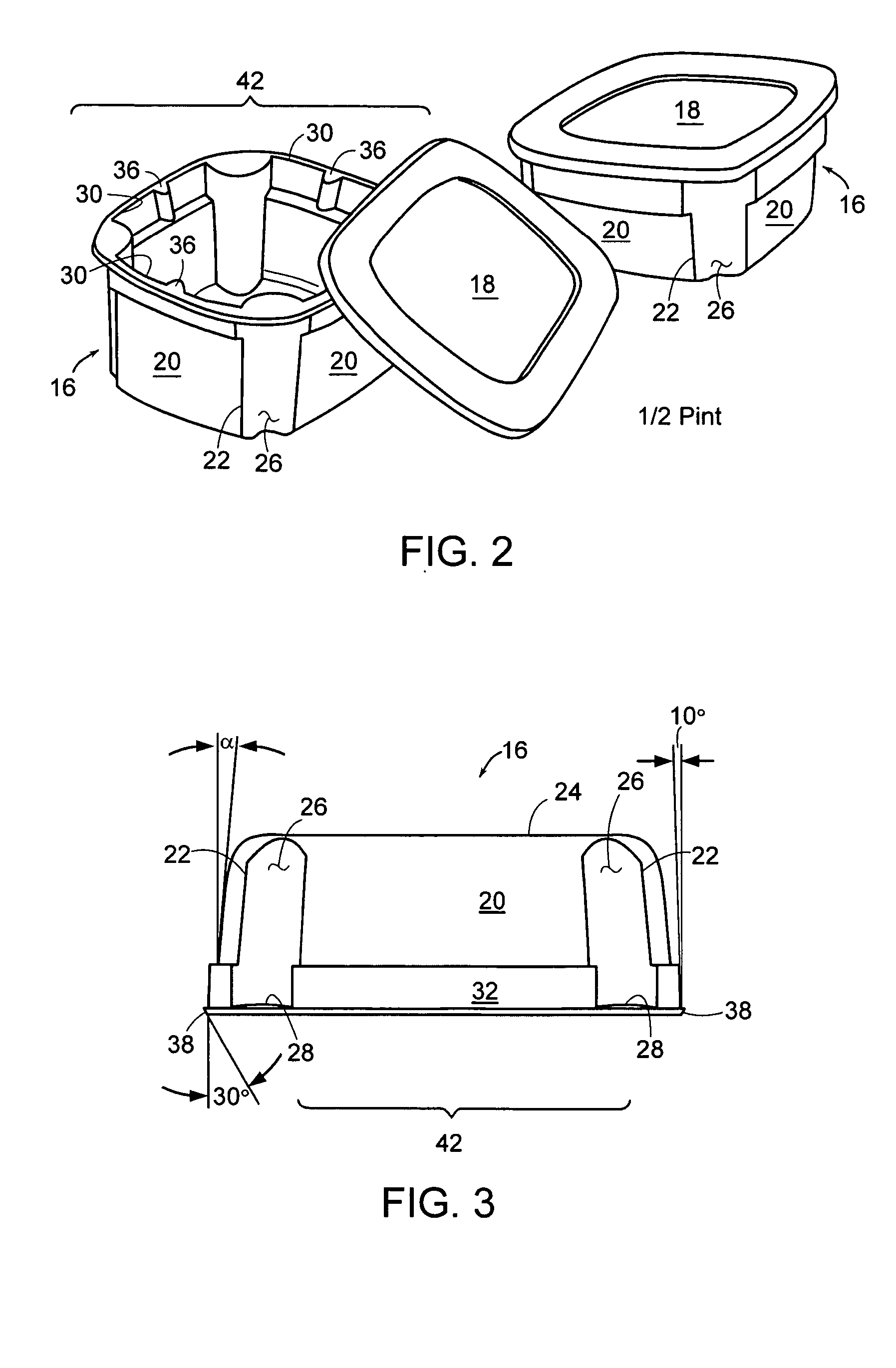

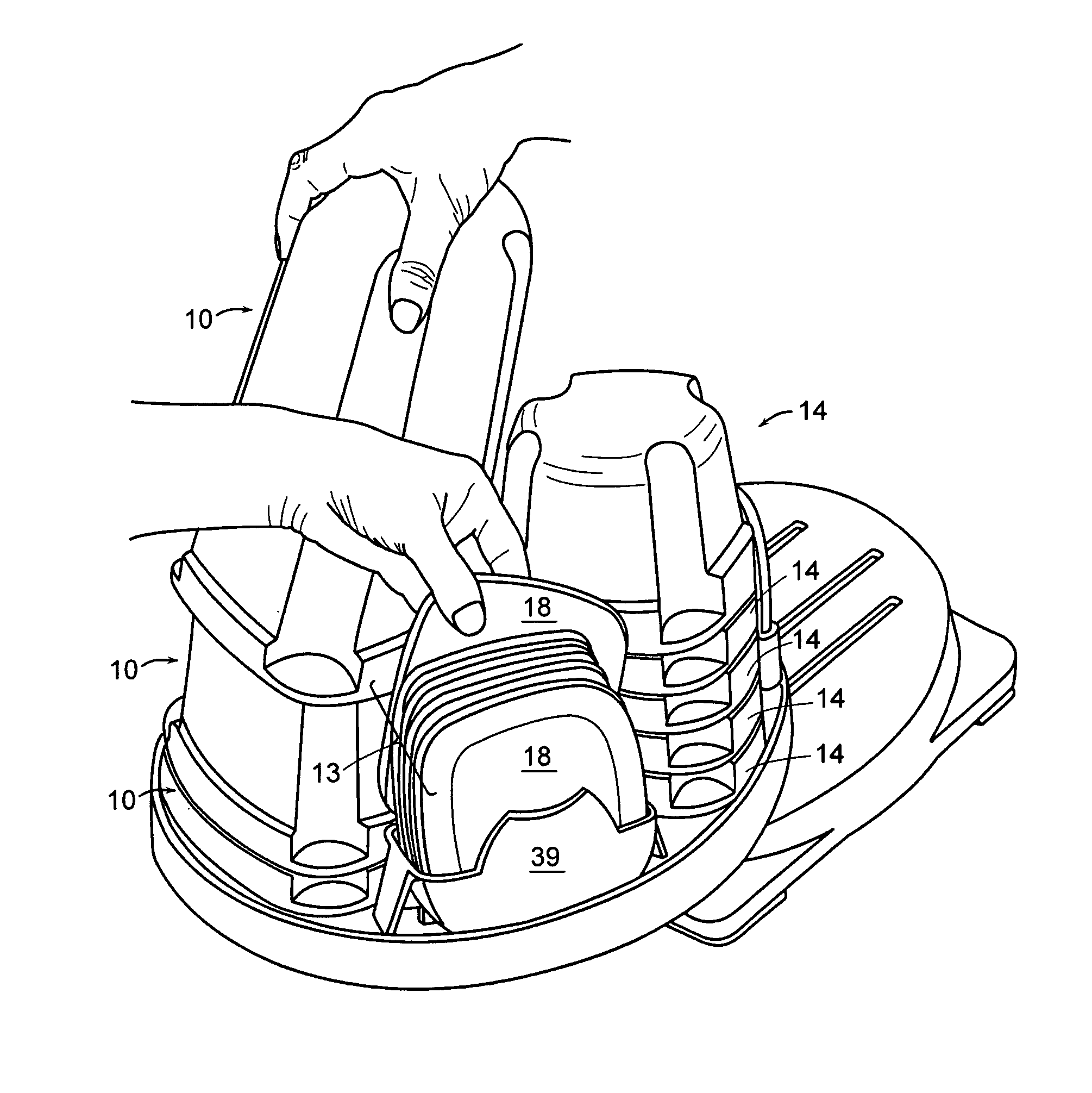

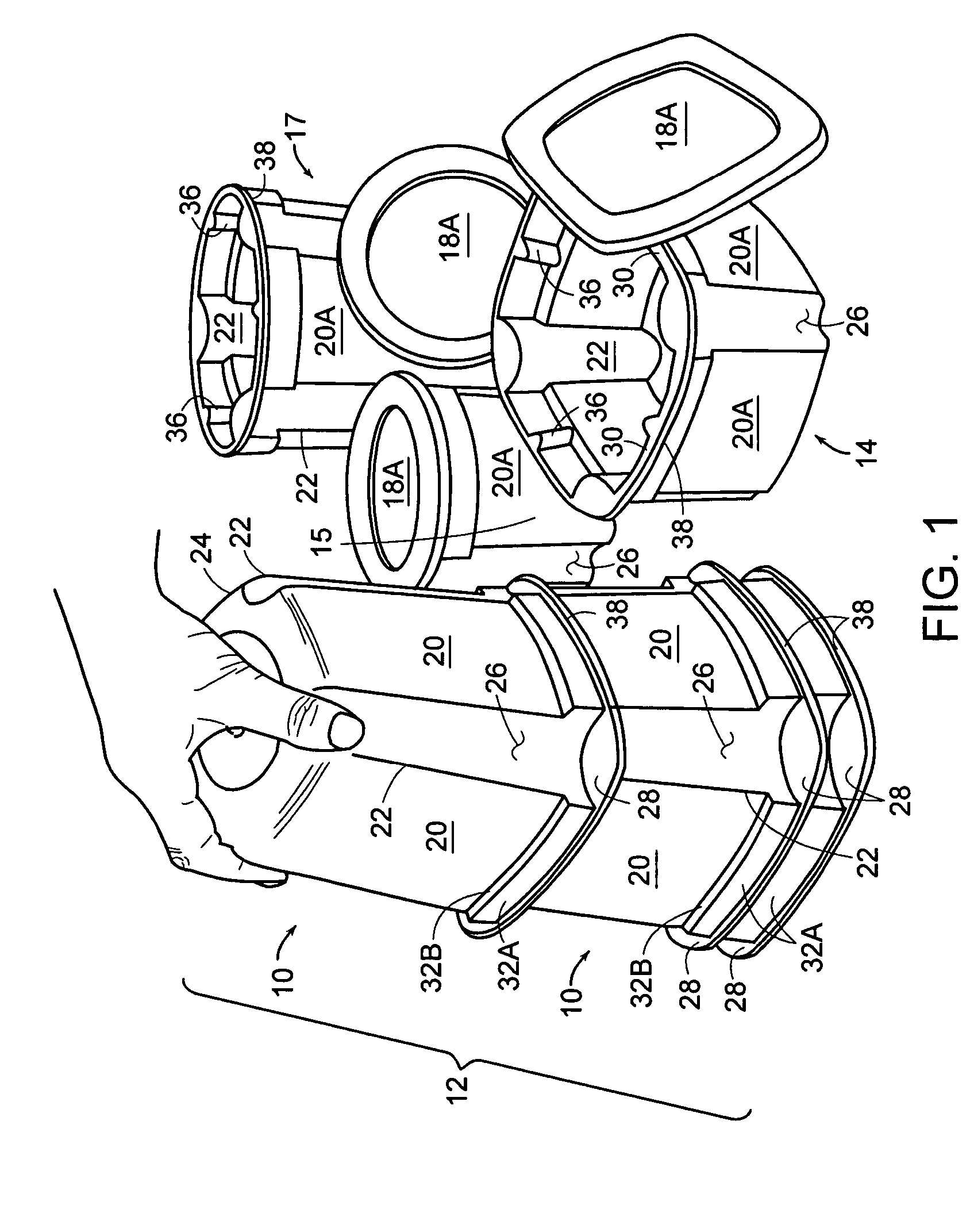

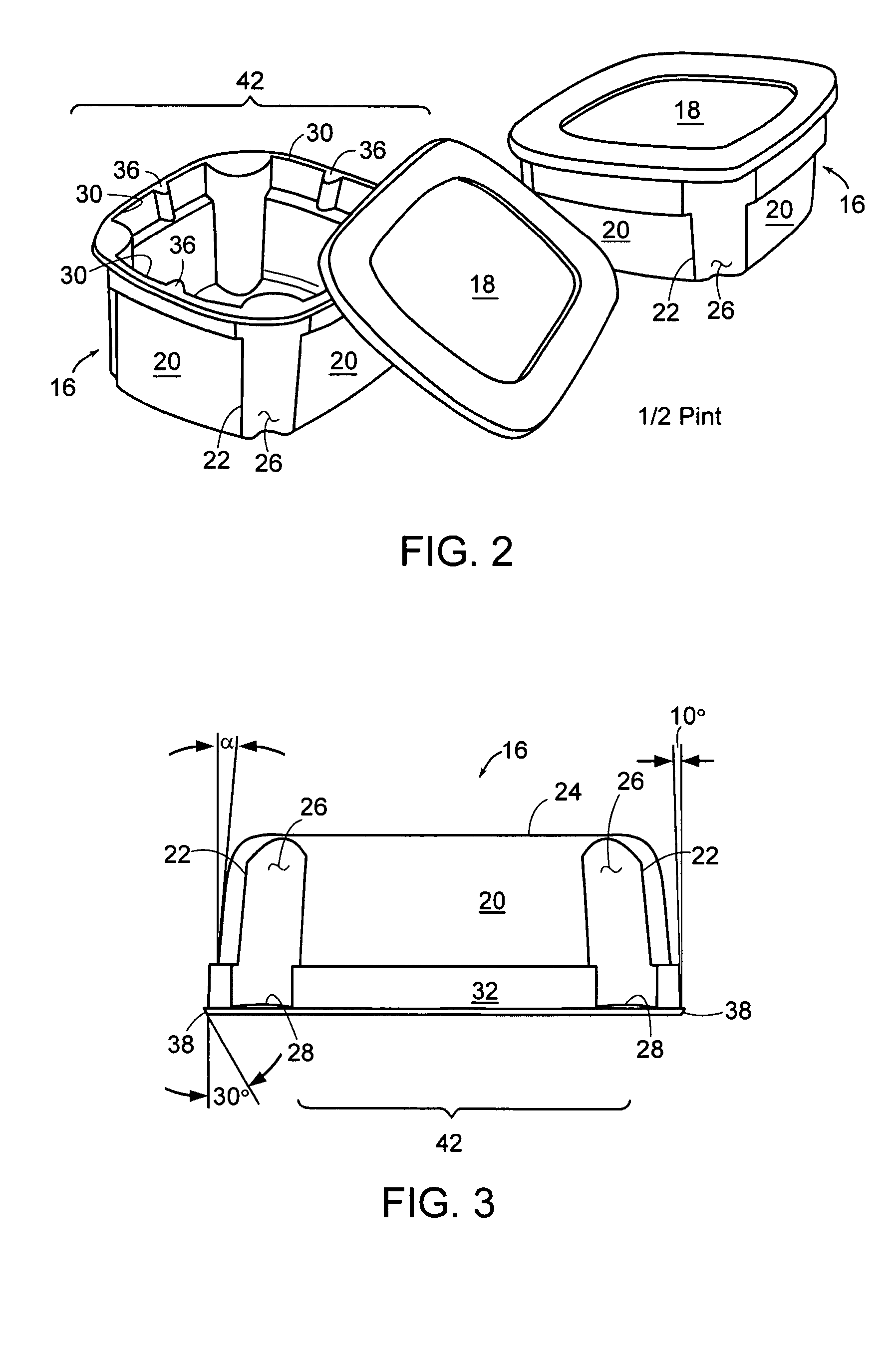

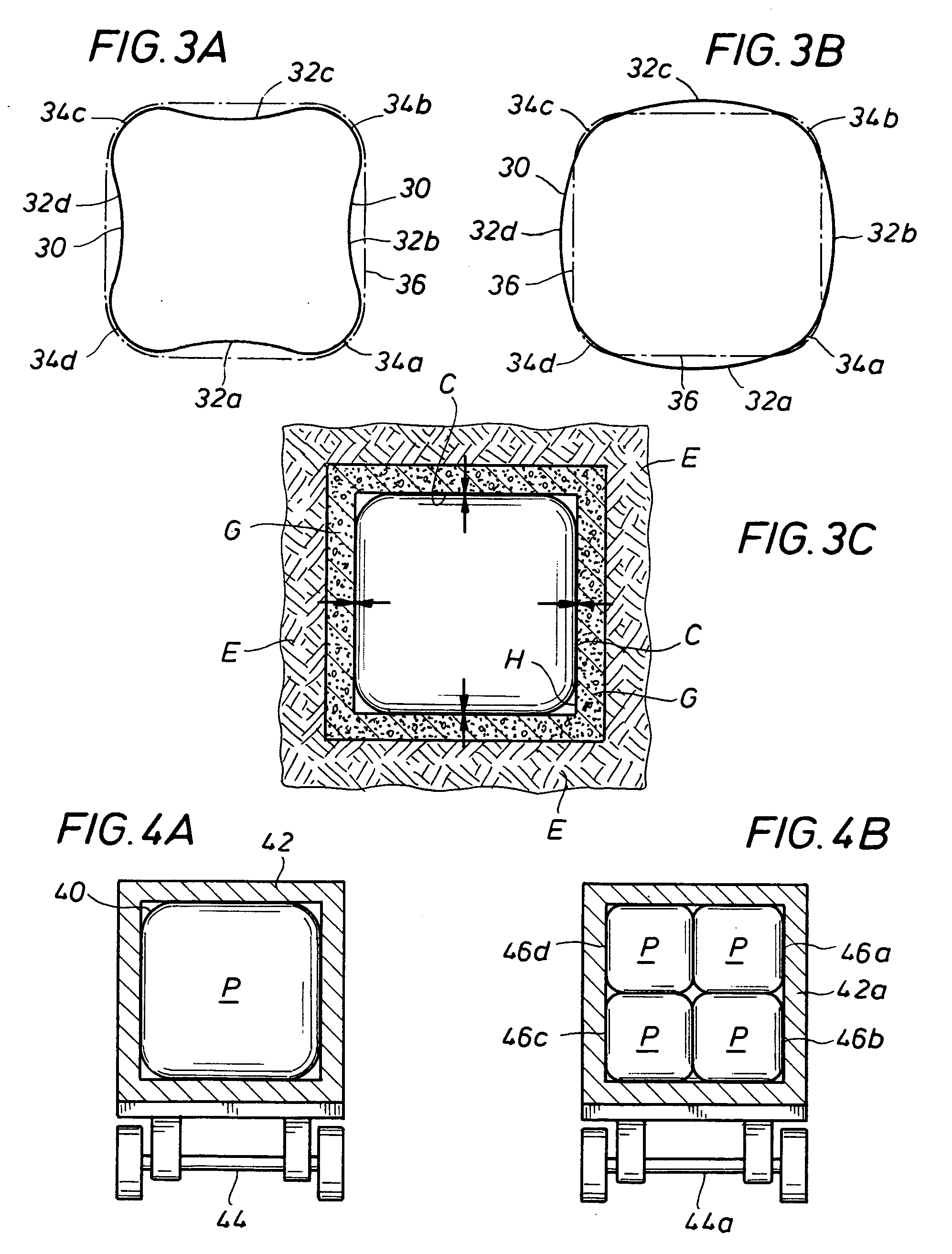

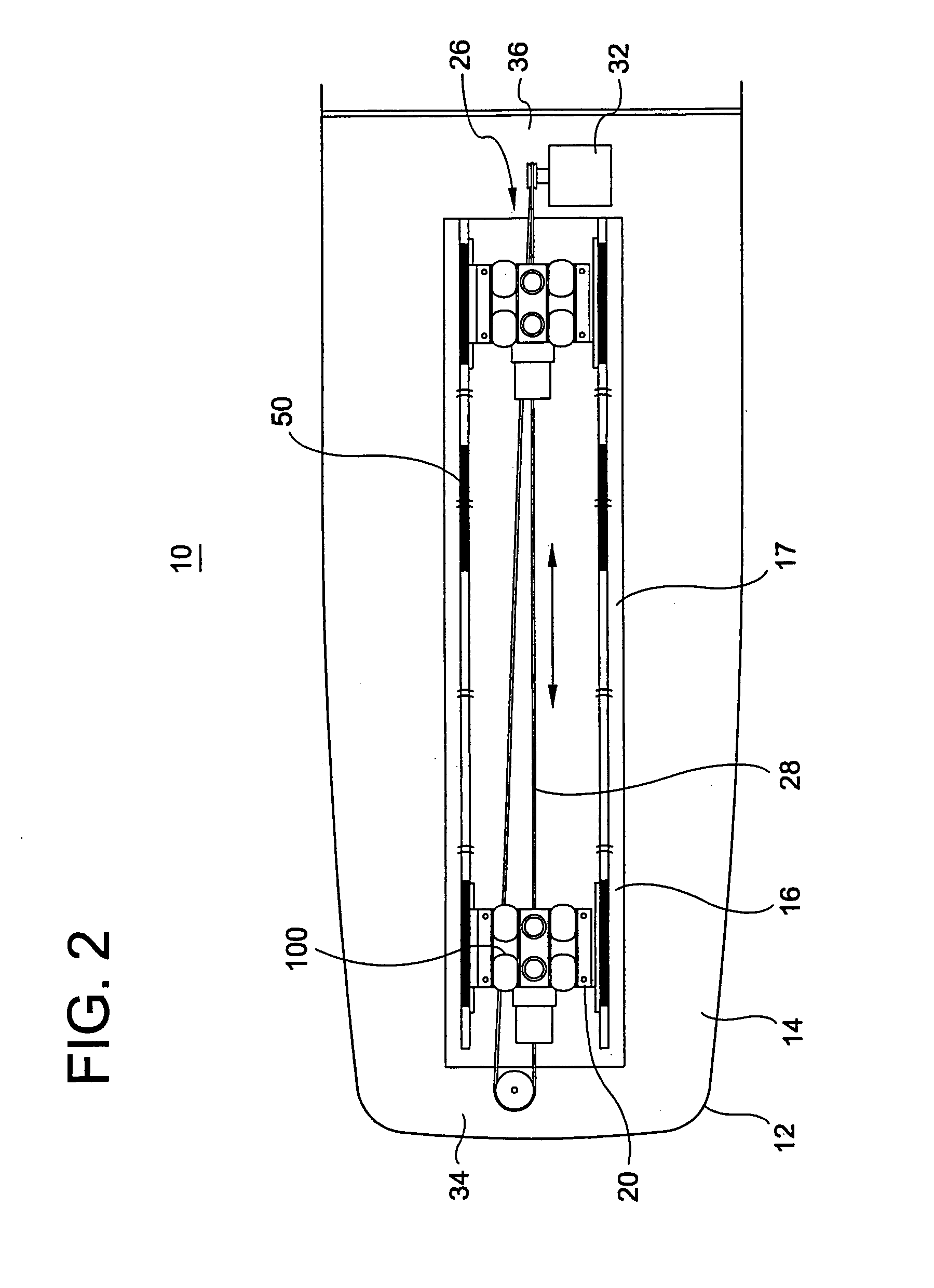

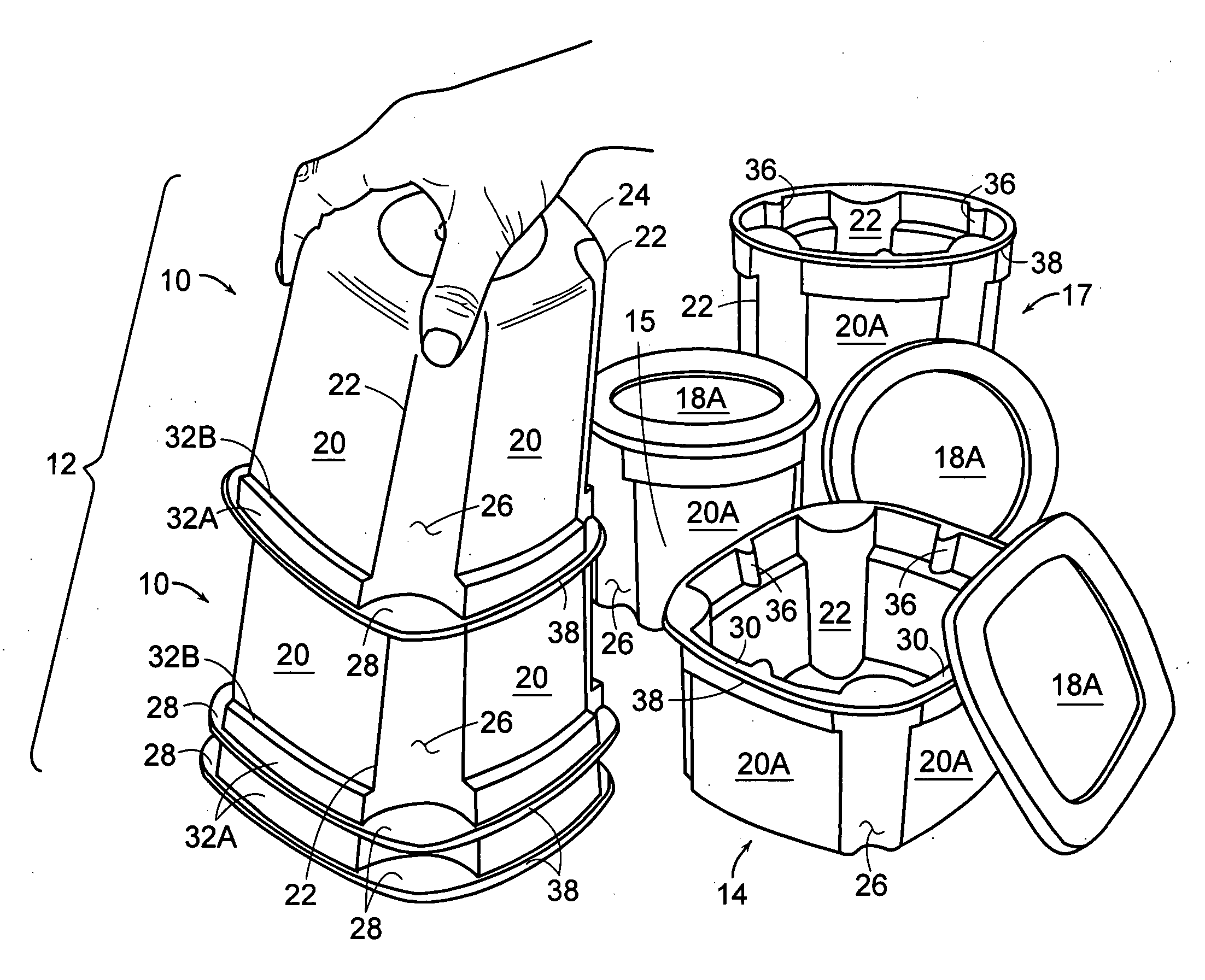

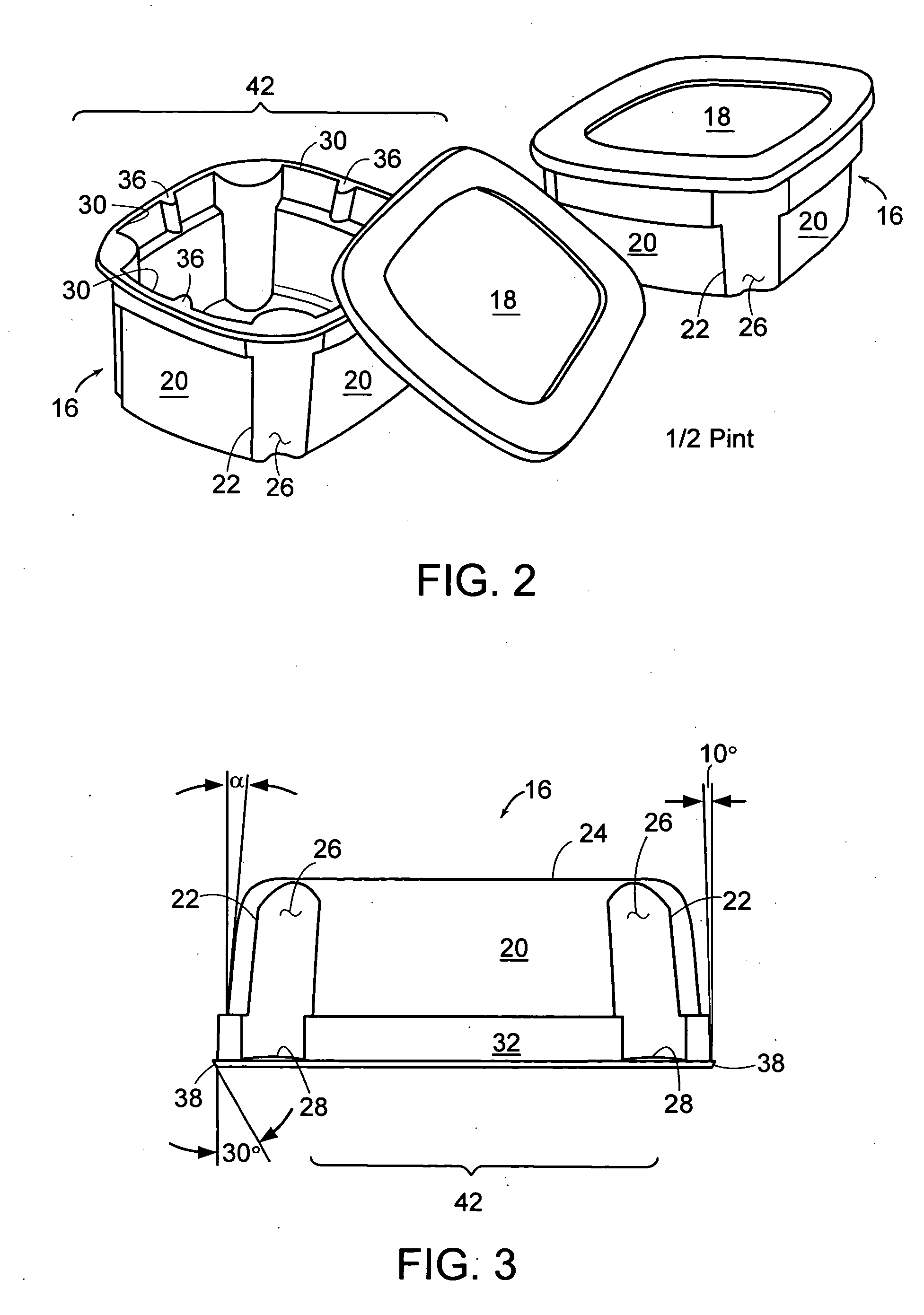

Nestable containers

ActiveUS20050040068A1Simple and safe operationImprove efficiencyBoxesTray containersSquare cross sectionSafe handling

A nestable container designed for efficient storage when the containers is not in use and for safe handling when in use. The container has four outwardly bowed sidewalls flared upwardly from its bottom with each sidewall connected to adjacent sidewalls by an inwardly fluted web to form a essentially square cross section. The webs define finger gripping corners at the edges of the sidewalls that allow the container to gripped better by a user. The containers can be nested with other containers of different sizes without wasting space. The essentially square configuration of the containers also make them easy to pack with or within other containers, that are typically also square or rectangular.

Owner:PALDER SAUL

Nestable containers

InactiveUS7216769B2Simple and safe operationImprove efficiencyBoxesTray containersSquare cross sectionSafe handling

A nestable container designed for efficient storage when the containers is not in use and for safe handling when in use. The container has four outwardly bowed sidewalls flared upwardly from its bottom with each sidewall connected to adjacent sidewalls by an inwardly fluted web to form a essentially square cross section. The webs define finger gripping corners at the edges of the sidewalls that allow the container to gripped better by a user. The containers can be nested with other containers of different sizes without wasting space. The essentially square configuration of the containers also make them easy to pack with or within other containers, that are typically also square or rectangular.

Owner:PALDER SAUL

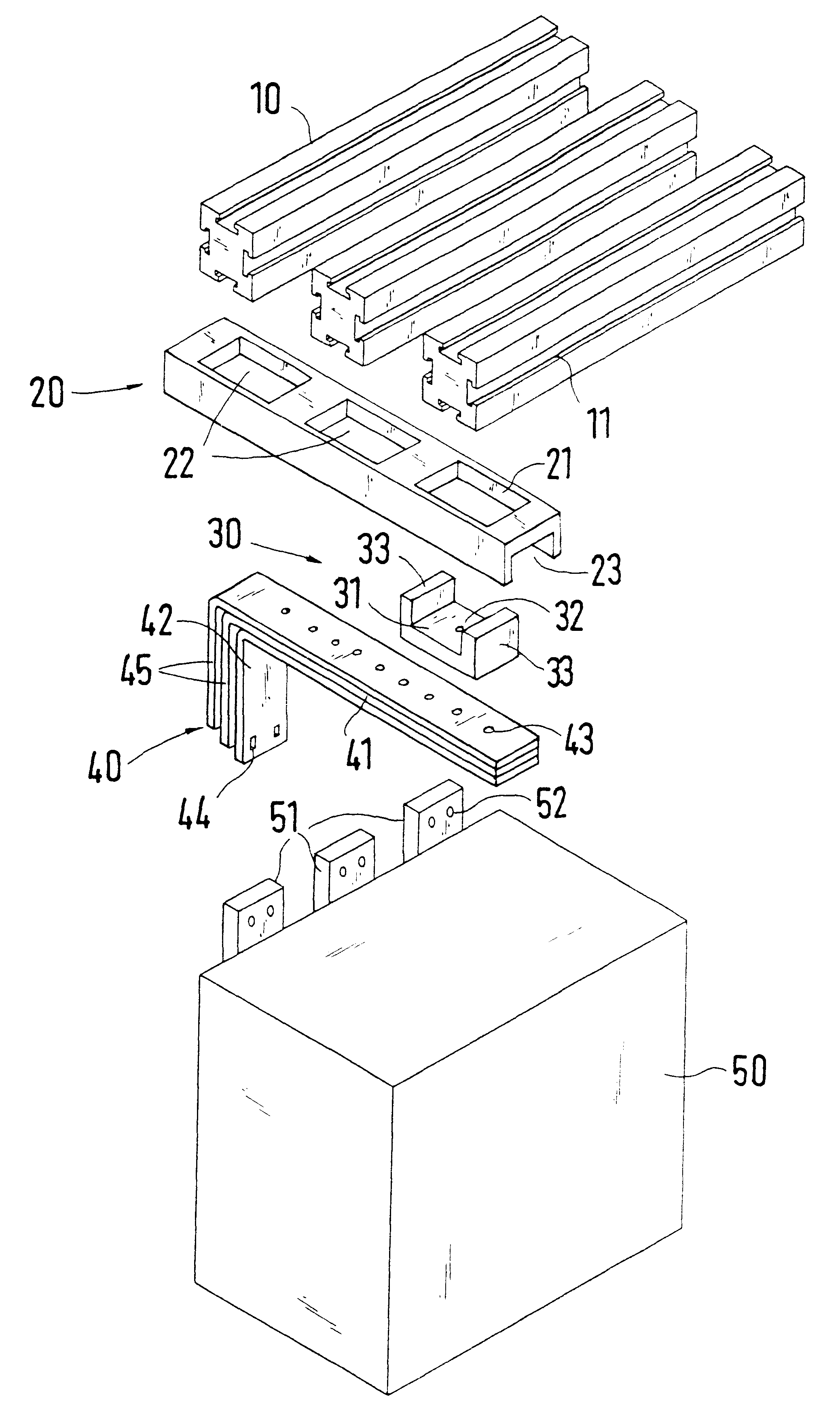

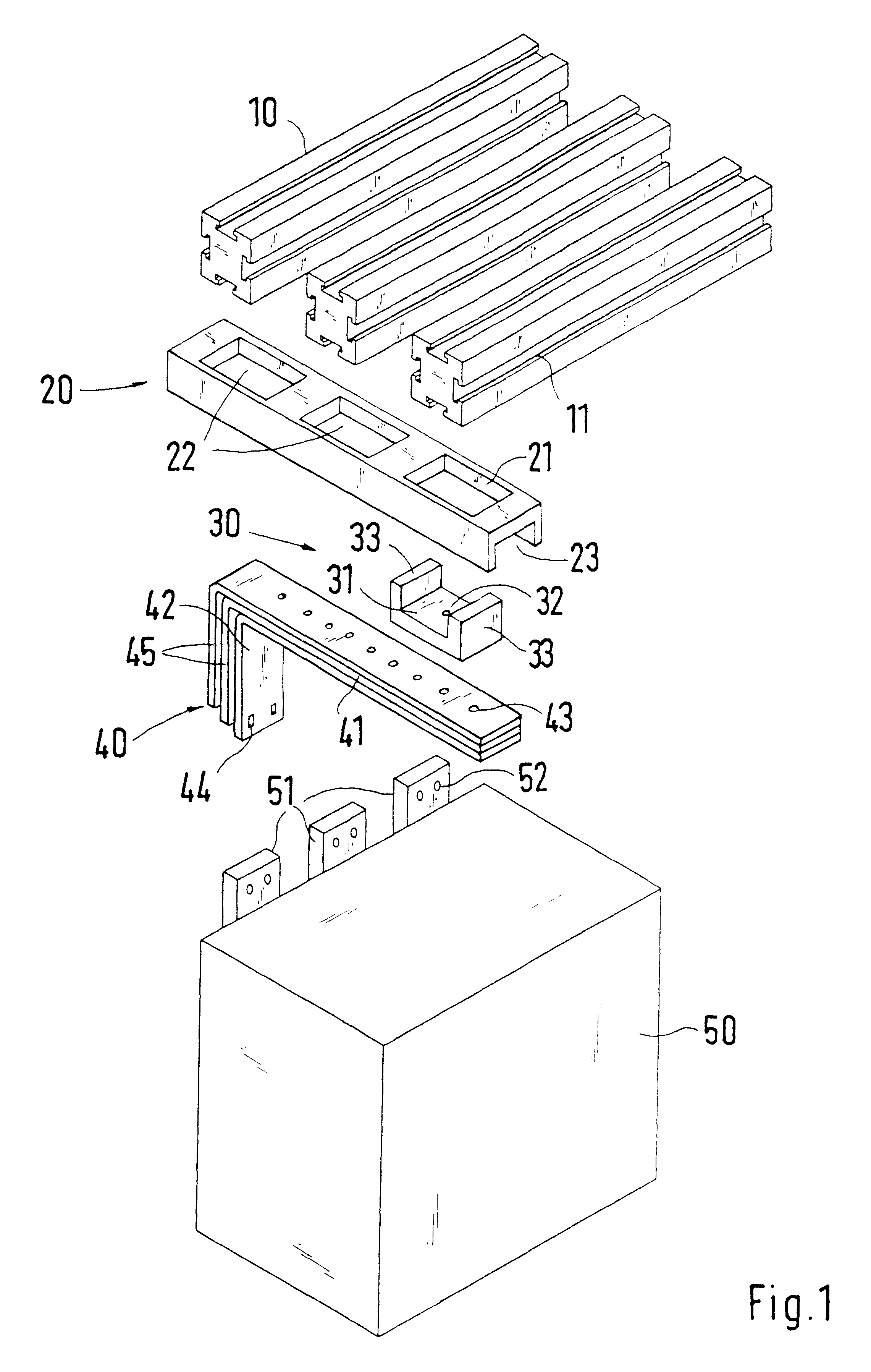

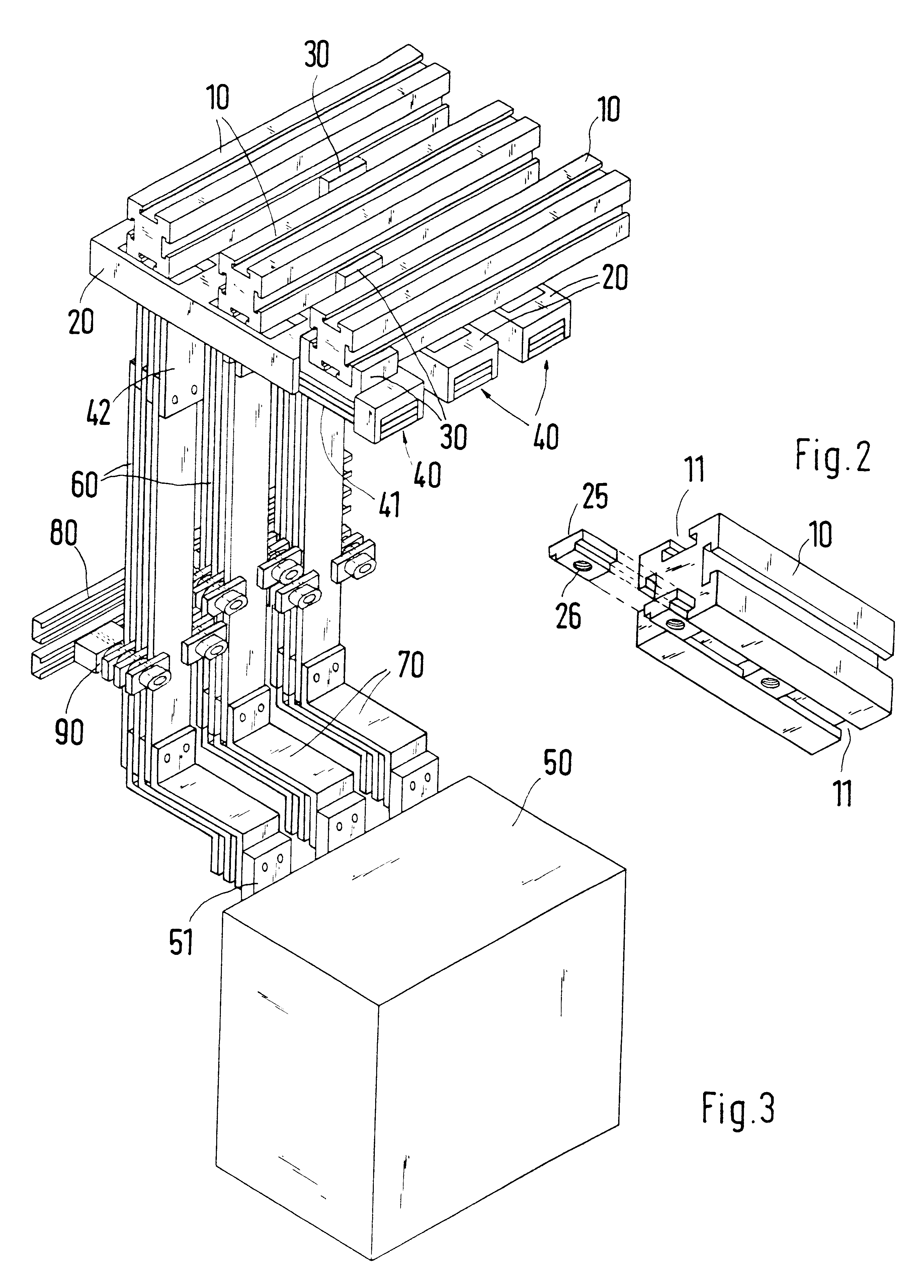

Bus bar system with several bus bars and an installation device with flat connectors

InactiveUS6381122B2Improve insulation performanceAvoid accessBus-bar/wiring layoutsBus-bar installationSquare cross sectionEmbedded system

A bus bar system having several bus bars spaced apart from each other in a first connecting plane and of an essentially square cross section and having T-shaped connecting grooves cut into all outsides for a connection with electrical installation devices having flat connectors in a second connecting plane, which is arranged perpendicular to the first connecting plane. With specially embodied connecting and insulating elements, it is possible to displace the connecting planes of the bus bars and of the flat connectors of the installations device parallel and perpendicular with respect to each other without it being necessary to perform elaborate matching assembly work at the site.

Owner:RITTALWERK RUDOLF LOH GMBH & CO KG

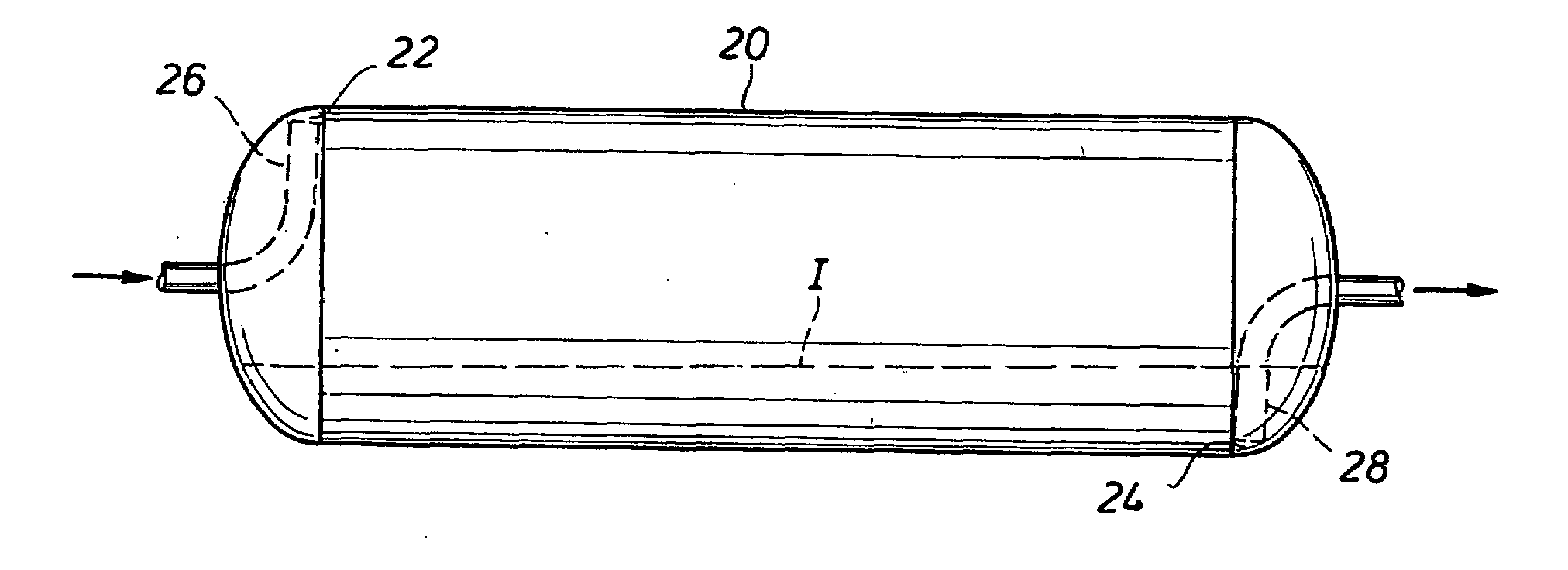

Storing, transporting and handling compressed fluids

ActiveUS20080209918A1Reduce the amount requiredDesired rangeGas handling applicationsGas handling/storage effectsSupporting systemSquare cross section

A container and a method for storage and / or transport of a compressed fluid such as compressed natural gas are provided. The container has a pair of opposing heads and a wall section between the heads, the wall section defining a square cross-section comprising substantially planar sides joined together by rounded corners. The container is designed for the side walls to deflect outwardly while under pressure, but to be supported externally by a support system that restricts outward expansion of the side walls. The support system can be provided as the walls of a cargo hold in a marine or land transport vessel, an ISO shipping container or an underground shaft. Multiple containers can be located side by side in the external support system so that the sides of adjacent containers rest against each other for support while under pressure. In one embodiment, a container comprises an outside tank and a flexible membrane tank inside the outside tank, an annular space being defined in between, where a first fluid is charged into the membrane tank and a second fluid is charged into the annular space in order to discharge the first fluid. In another embodiment, a long tube having a square cross-section is coiled in a support structure and made gas-tight for holding a compressed fluid. The walls of the tube would tend to expand while under pressure, but adjacent coils and the support structure limit the expansion.

Owner:WHITE CHARLES N +1

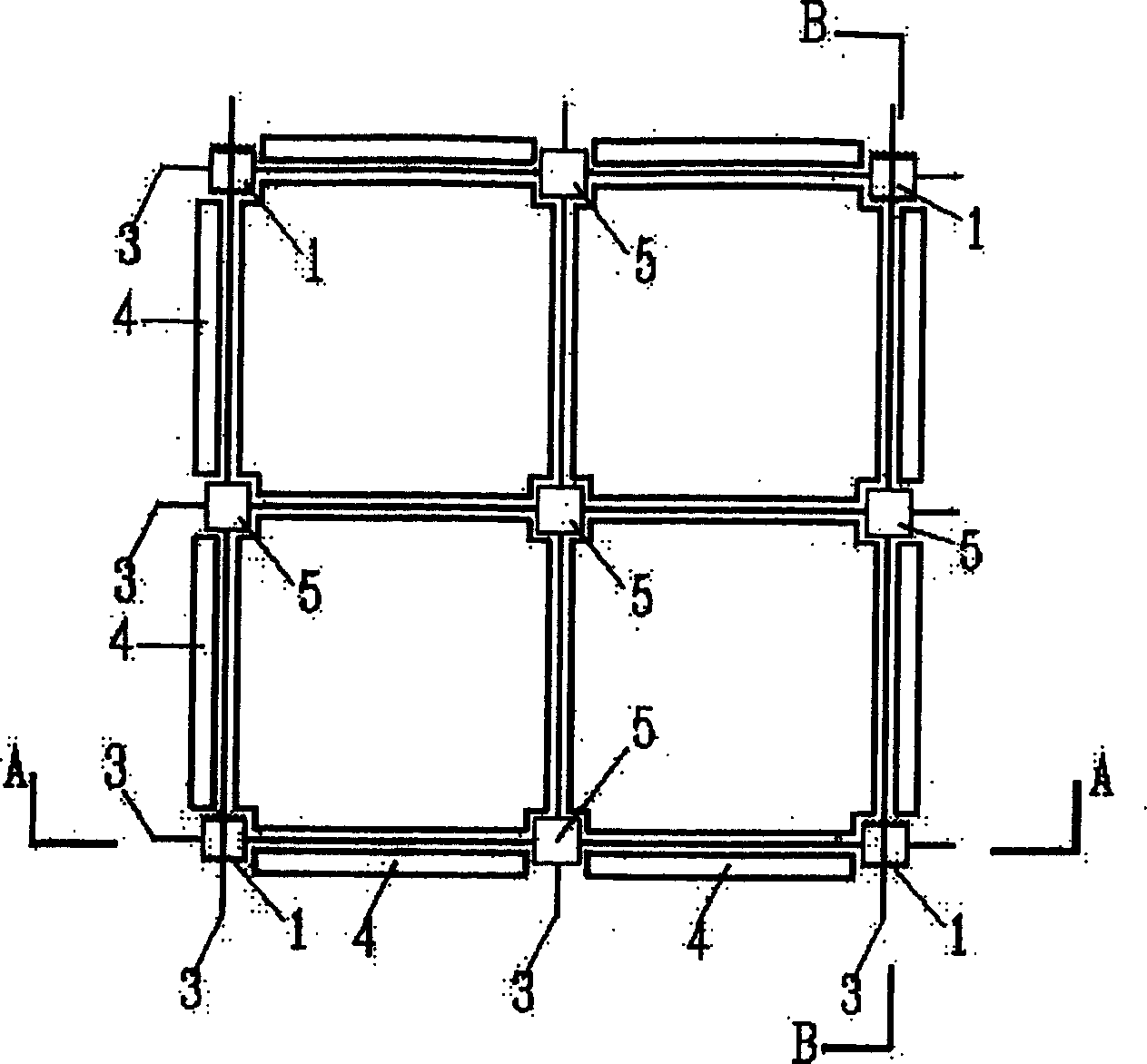

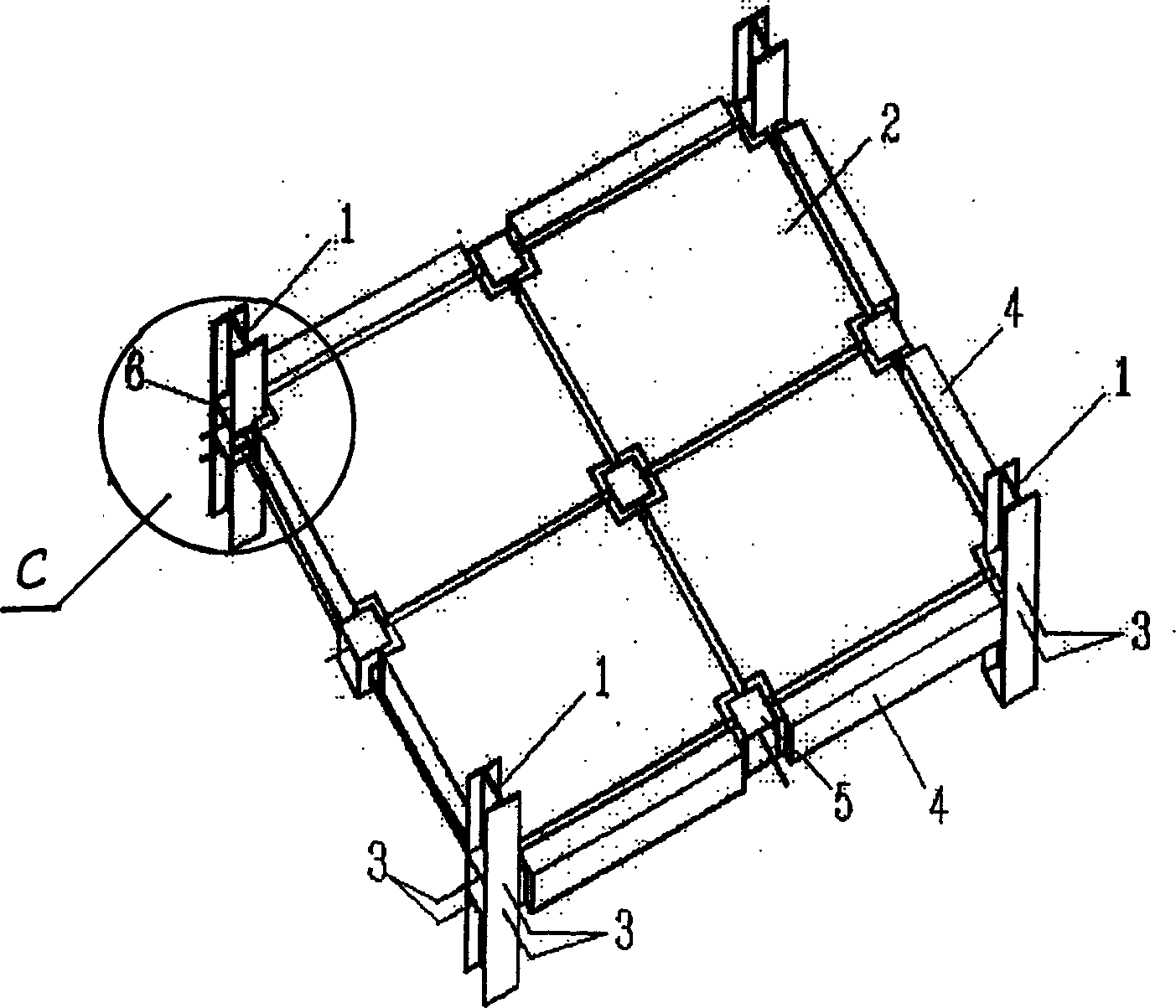

Steel-steel concrete fully prefabricated assembling structure

InactiveCN1554839AEnsure safetyImprove bearing capacityBuilding constructionsHigh strength concreteFloor slab

The fully prefabricated assembled steel-steel concrete structure includes two kinds of assembling forms. The first one is fully prefabricated assembled steel column-steel concrete structure, and its prefabricated steel column consists of H-shaped steel column, reinforcing concrete ribs, supporting steel plate and prestress-shearing force friction nodes with shear resisting strips. The second one is fully prefabricated assembled prefabricated steel pipe-concrete column-steel concrete structure, and the prefabricated steel pipe-concrete column consists of steel pipe with square cross section, micro expanding high strength concrete cast inside the steel pipe and shear resisting strips attached to the outer wall of the steel pipe to form preshearing force-friction type nodes. The present invention has raised antiseismic performance, area utilization, construction efficiency, fireproof performance, low cost and small member size, and is suitable for various buildings.

Owner:KUNMING UNIV OF SCI & TECH

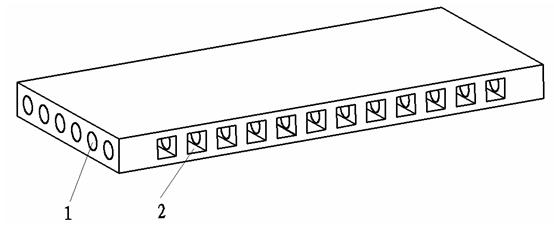

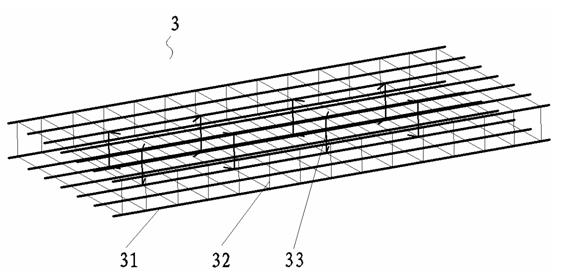

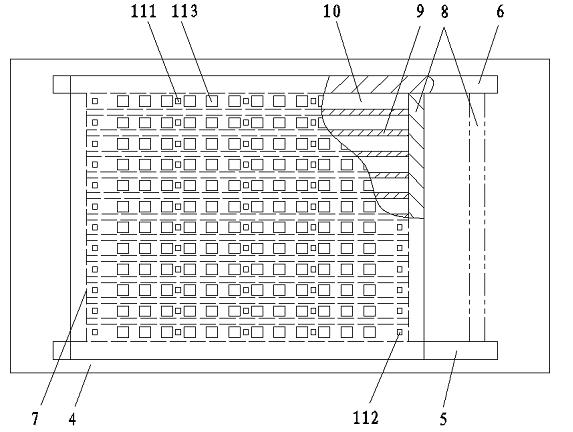

Prefabricated reinforced concrete hollow template internally provided with cross holes and molding and forming device thereof

The invention relates to a prefabricated reinforced concrete hollow template internally provided with cross holes and a molding and forming device of the prefabricated reinforced concrete hollow template. The hollow template is internally provided with longitudinal through holes with round cross sections along the length direction and latitudinal through holes with square cross sections along the width direction, wherein the longitudinal through holes are arrayed parallel one another, the latitudinal through holes are also arrayed parallel one another, and the diameter of each longitudinal through hole is less than the length of the side of each latitudinal through hole. Two large surfaces of the hollow template are flat surfaces formed by molding. A casting mold of the molding and forming device is of a vertical type and provided with one or more mold cavities; each mold cavity is surrounded by a front face plate, a rear face plate, a left side plate and a right side plate; a core tube frame or upper side plate capable of fixing a vertical core tube is arranged on the upper part or above each mold cavity; and the left side plate, the right side plate and the upper side plate are provided with a plurality of horizontal holes and vertical holes respectively. Each surface of the hollow template processed by using the molding and forming device is flat without being polished and subjected to similar treatment. The hollow template is high in strength and good in quality, can be directly used for the construction of a load-bearing wall with few procedures in a short time and can ensure that the load-bearing wall is not easy to shrink and crack.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV

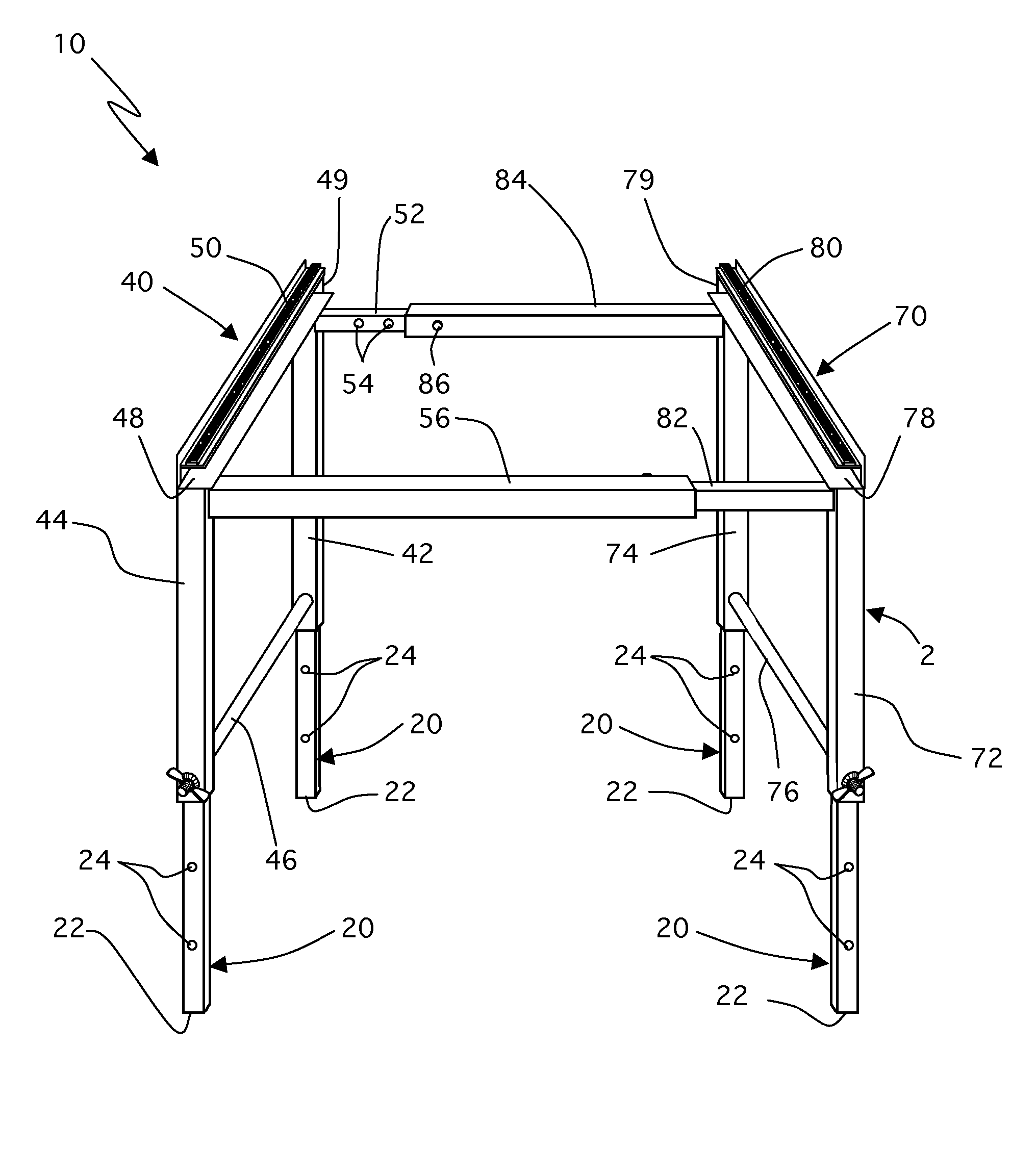

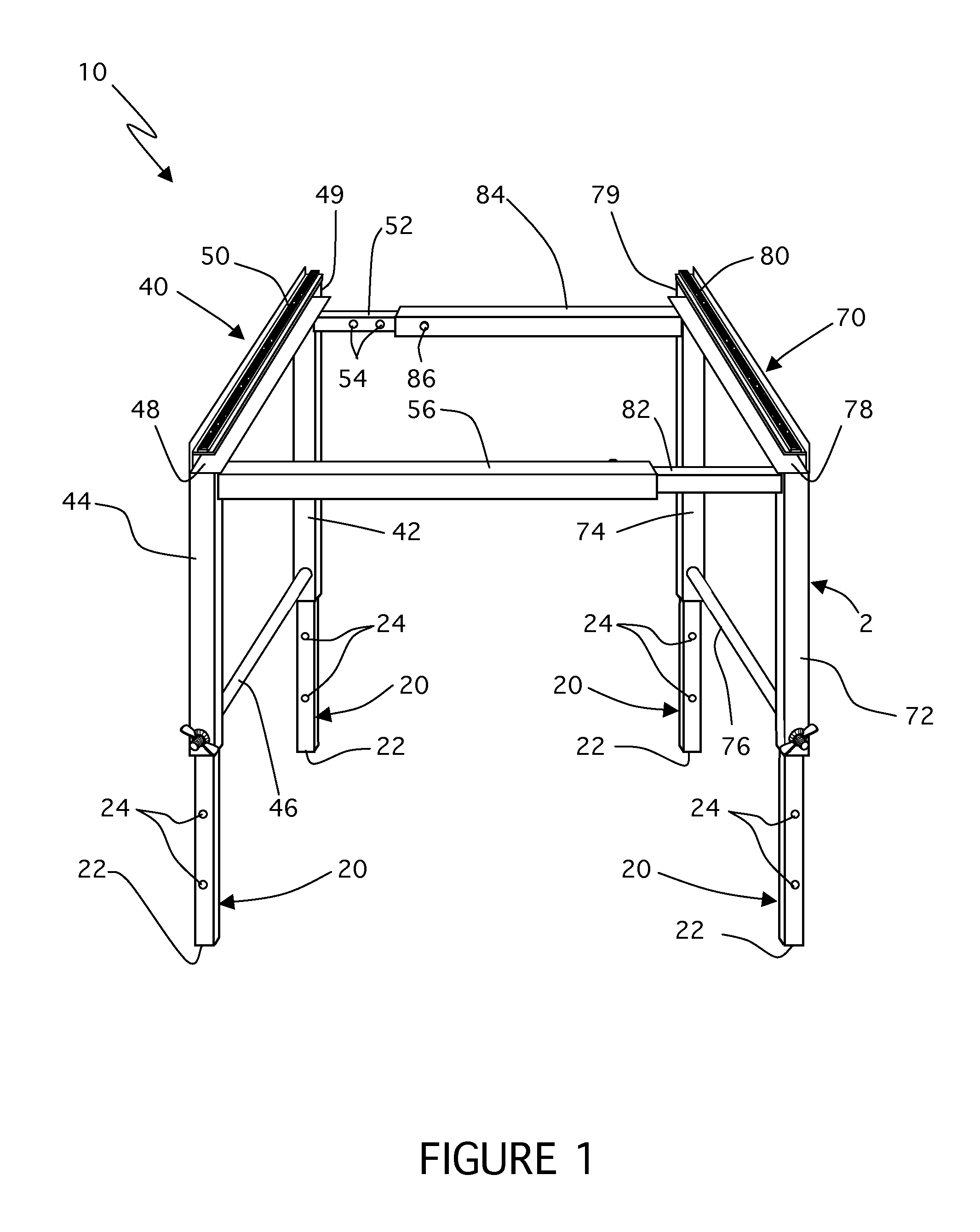

Adjustable air handler stand and filter rack

ActiveUS8348071B1Easy to replaceLighting and heating apparatusSpace heating and ventilation detailsSquare cross sectionAir handler

A base assembly for air handlers having a filter. Four metallic legs each have a distal end. The metallic legs also have first through holes at first predetermined distances from their respective distal ends. The metallic legs have a rectangular or square cross section, and each distal end mounts to a floor. First and second metallic upper frames have vertical extensions to telescopically receive the four metallic legs respectively. The first and second metallic upper frames further have braces member and air filter C-shaped tracks. The first and second metallic upper frames each further have elongated male horizontal arms and elongated female horizontal arms that join whereby the air filter C-shaped tracks face each other to receive a filter.

Owner:JANLERT PEREZ

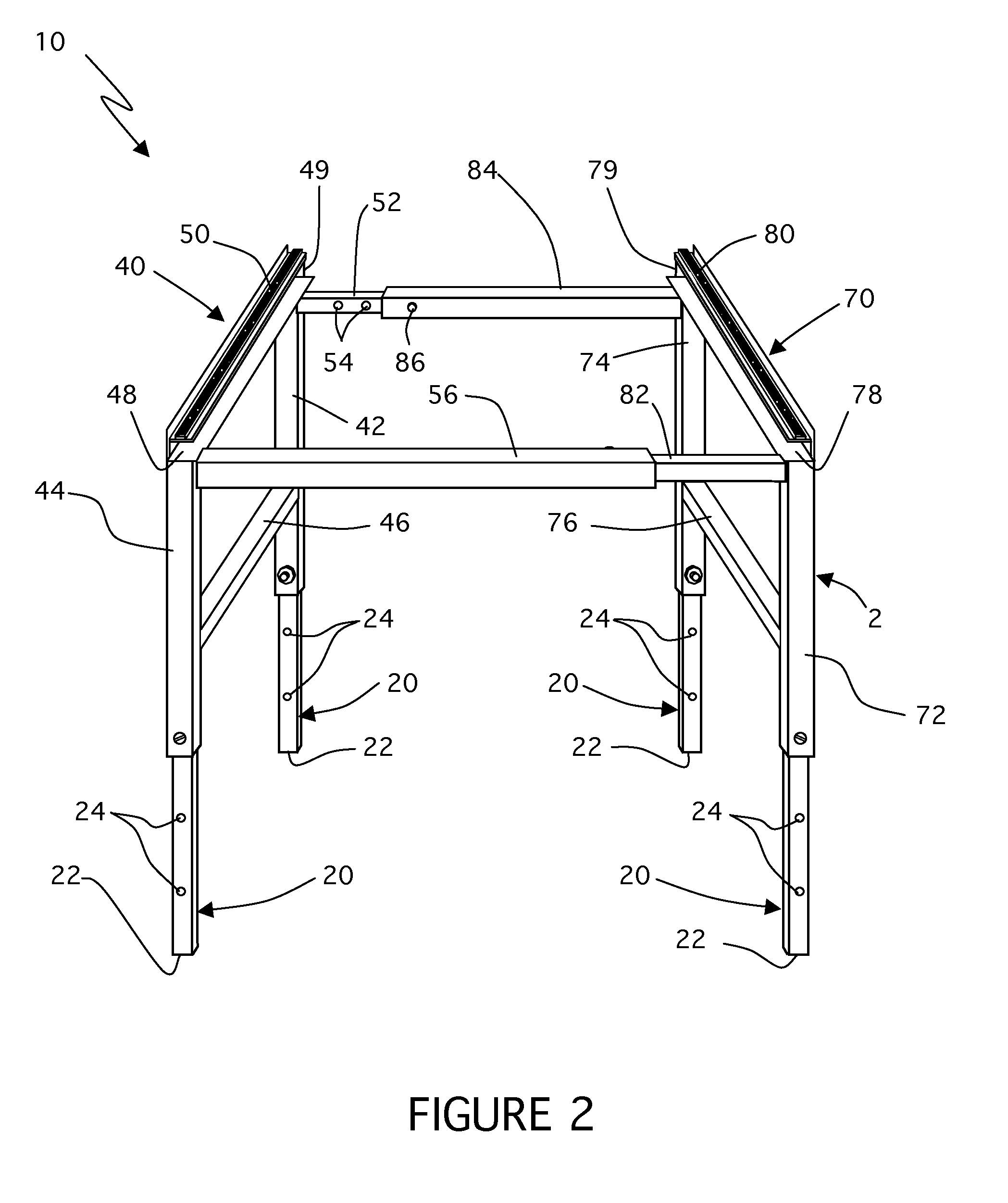

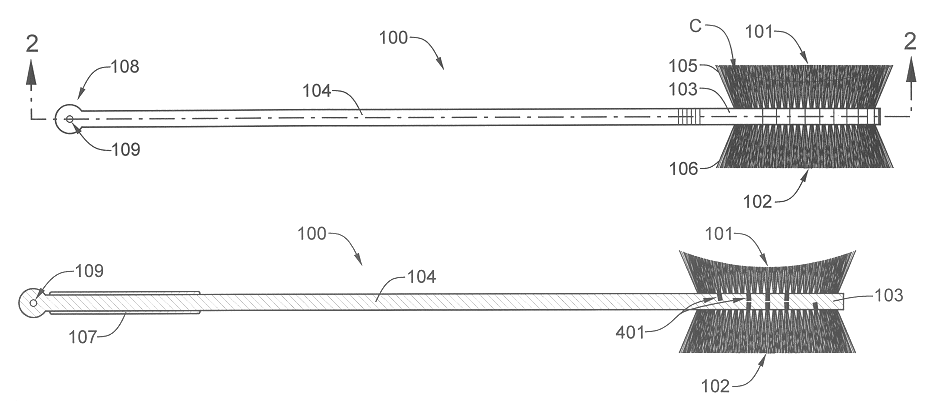

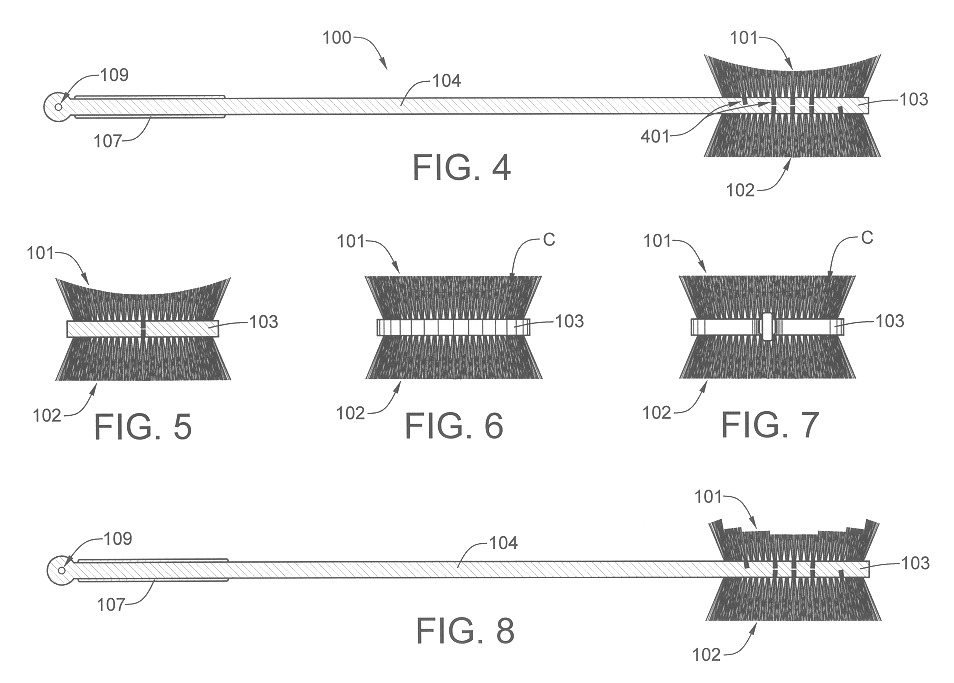

Cleaning brush having back-to-back planar and concave heads

A cleaning brush suitable for use in connection with automotive cleaning tasks, incorporates back-to-back bristle heads at one end of an elongated handle. One of the bristle heads features a concave, or dished, face; the other bristle head has a planar face. The concave brush head is intended for use on tires, and as such, is fabricated from fewer, coarser bristles than is the planar brush head, which is intended for use on wheels and body parts. For a preferred embodiment of the invention, the handle is about 61 cm (24 inches) in length, and includes an elongated portion of square cross section and a flattened, largely disk-shaped portion in which bristles of both heads are imbedded. Optionally, the handle at the end opposite the disk-shaped portion includes an aperture which may be used to hand the brush on a hook.

Owner:HENRIE JAMES L

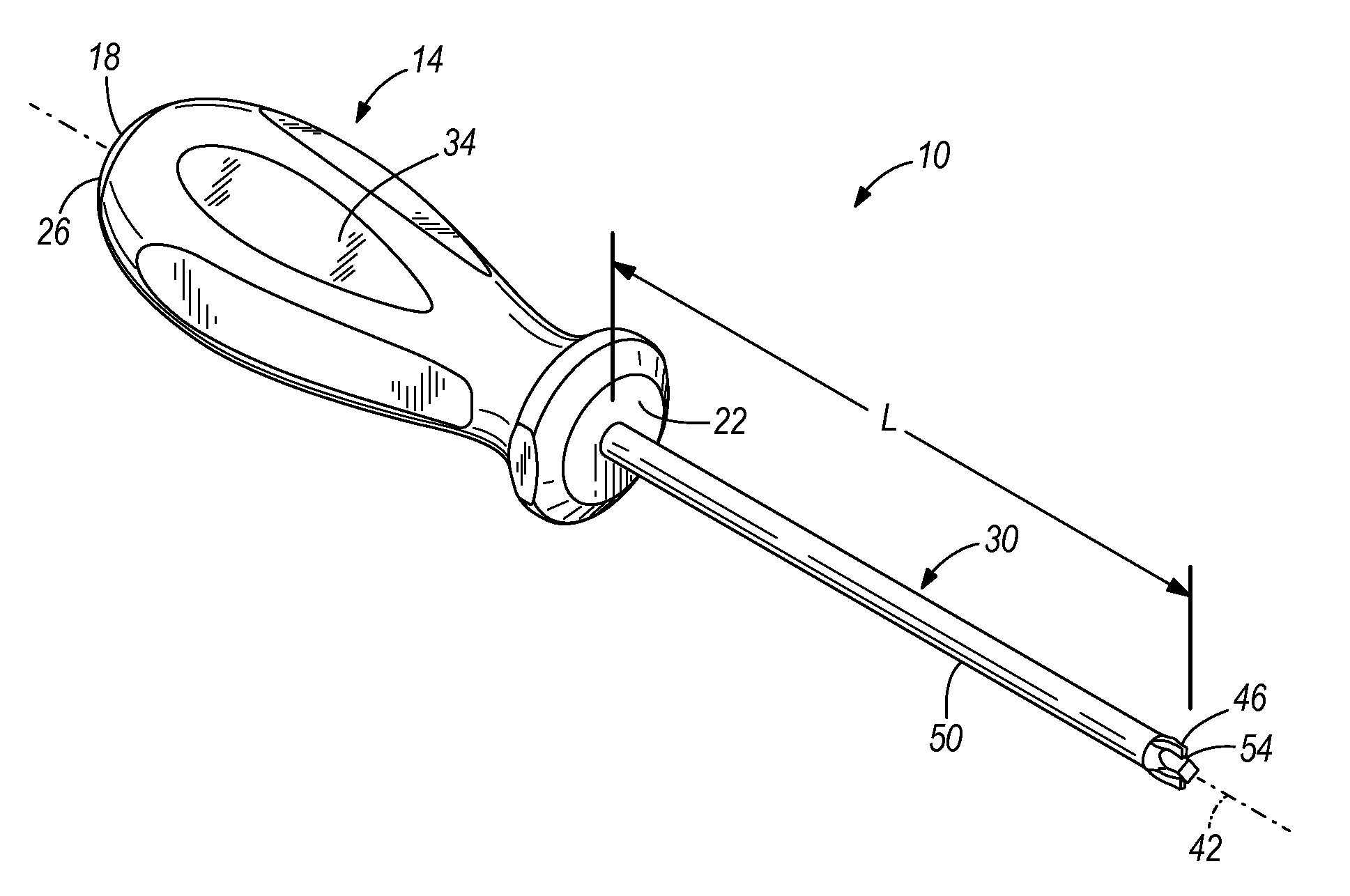

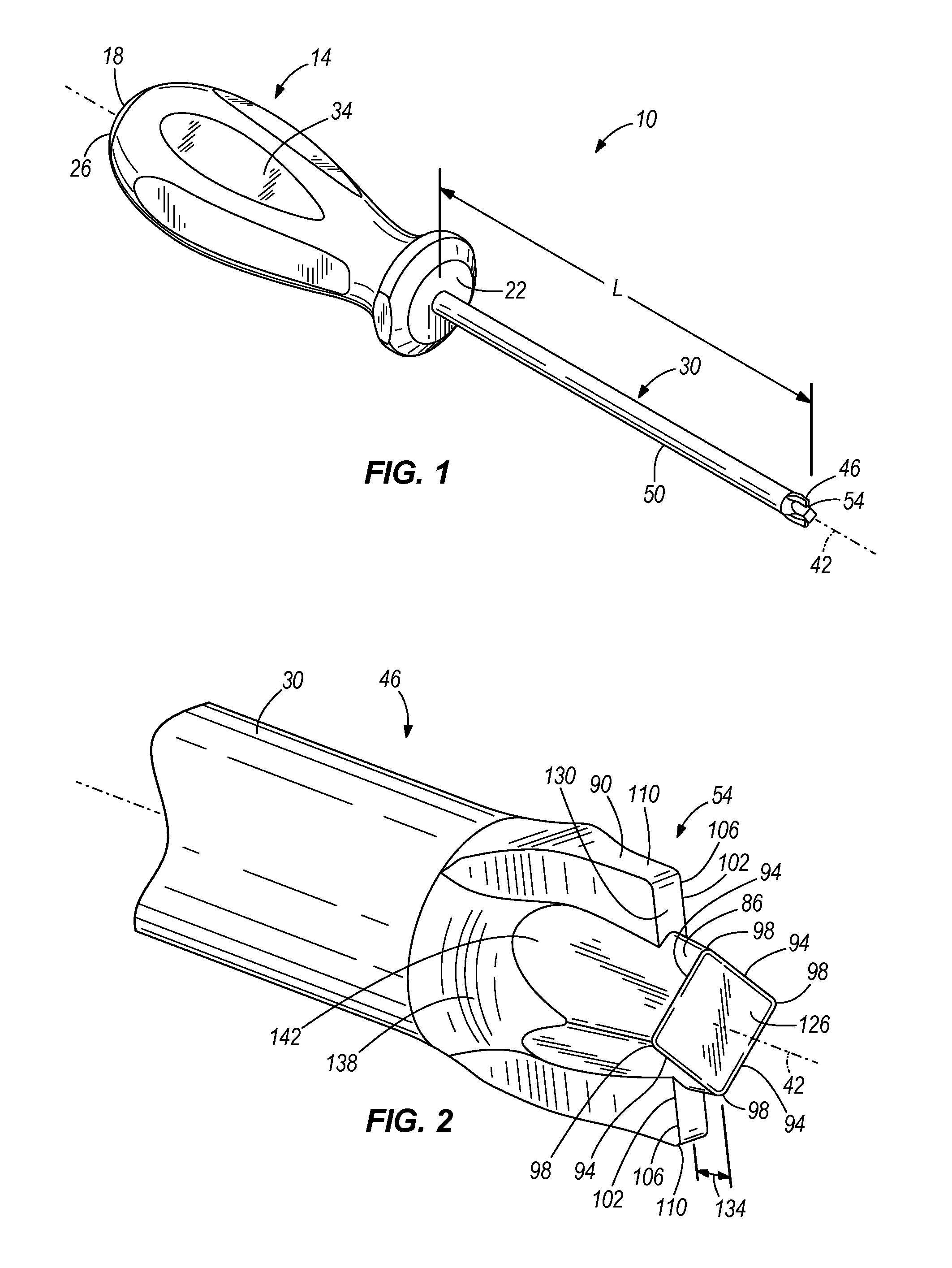

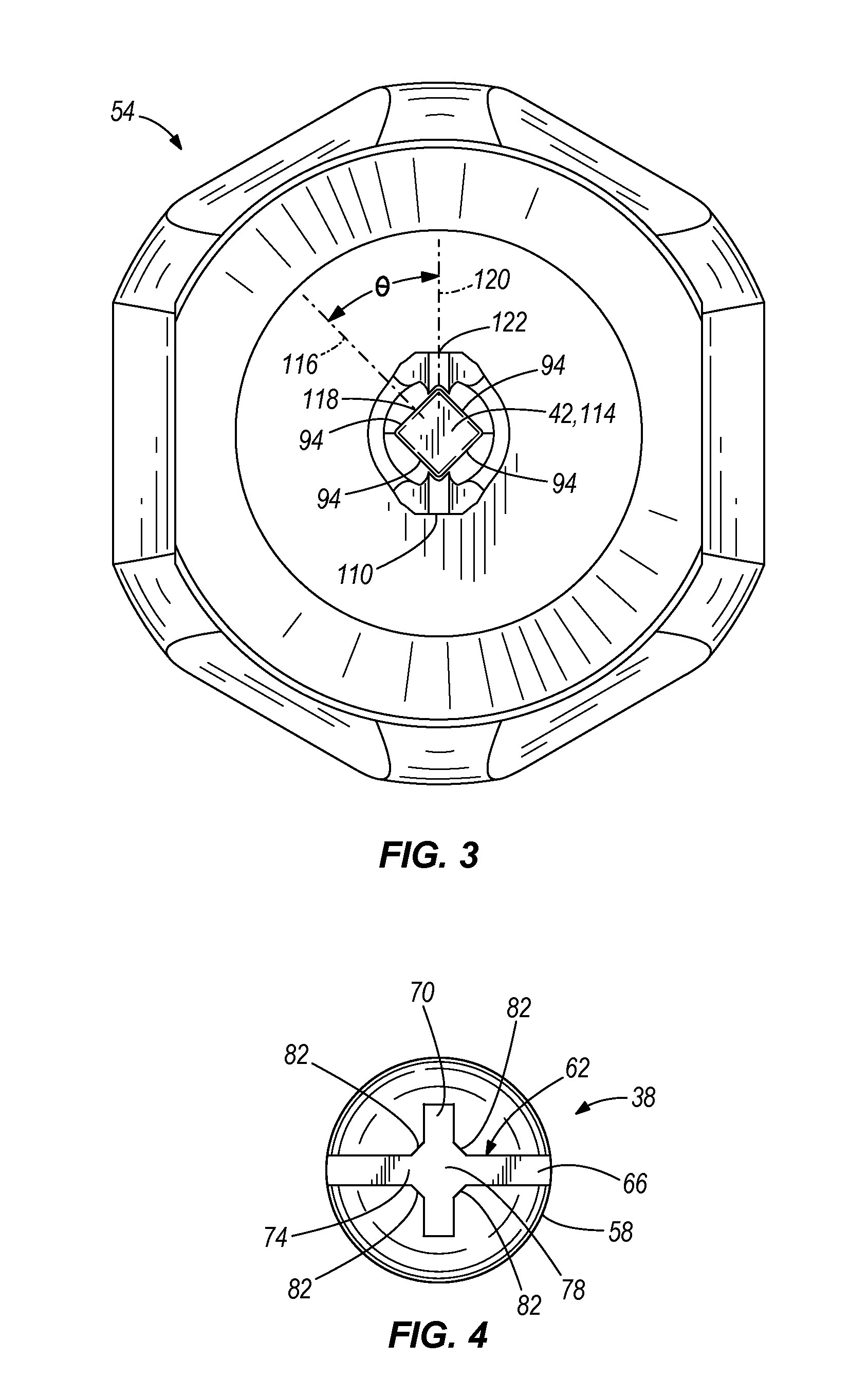

Screwdriver

A driver tool configured to engage and drive the head of a threaded fastener includes a shank defining a longitudinal axis. The shank has a mating end and a driver end. A driver head is coupled to the shank adjacent the driver end. The driver head includes a first driving portion having a substantially square cross section normal to the axis and a geometric center along the axis. The first driving portion includes four walls and a corner at an intersection of adjacent walls such that the first driving portion includes a first corner, a second corner, a third corner opposite the first corner, and a fourth corner opposite the second corner. The driver head further includes a second driving portion including a first flange extending radially outward from the first driving portion and a second flange extending radially outward from the first driving portion. The second flange is opposite the first flange, and each of the flanges includes an end wall having a midpoint. A plane passing through the first corner and the third corner of the first driving portion passes through the midpoints of the end walls of the second driving portion.

Owner:MILWAUKEE ELECTRIC TOOL CORP

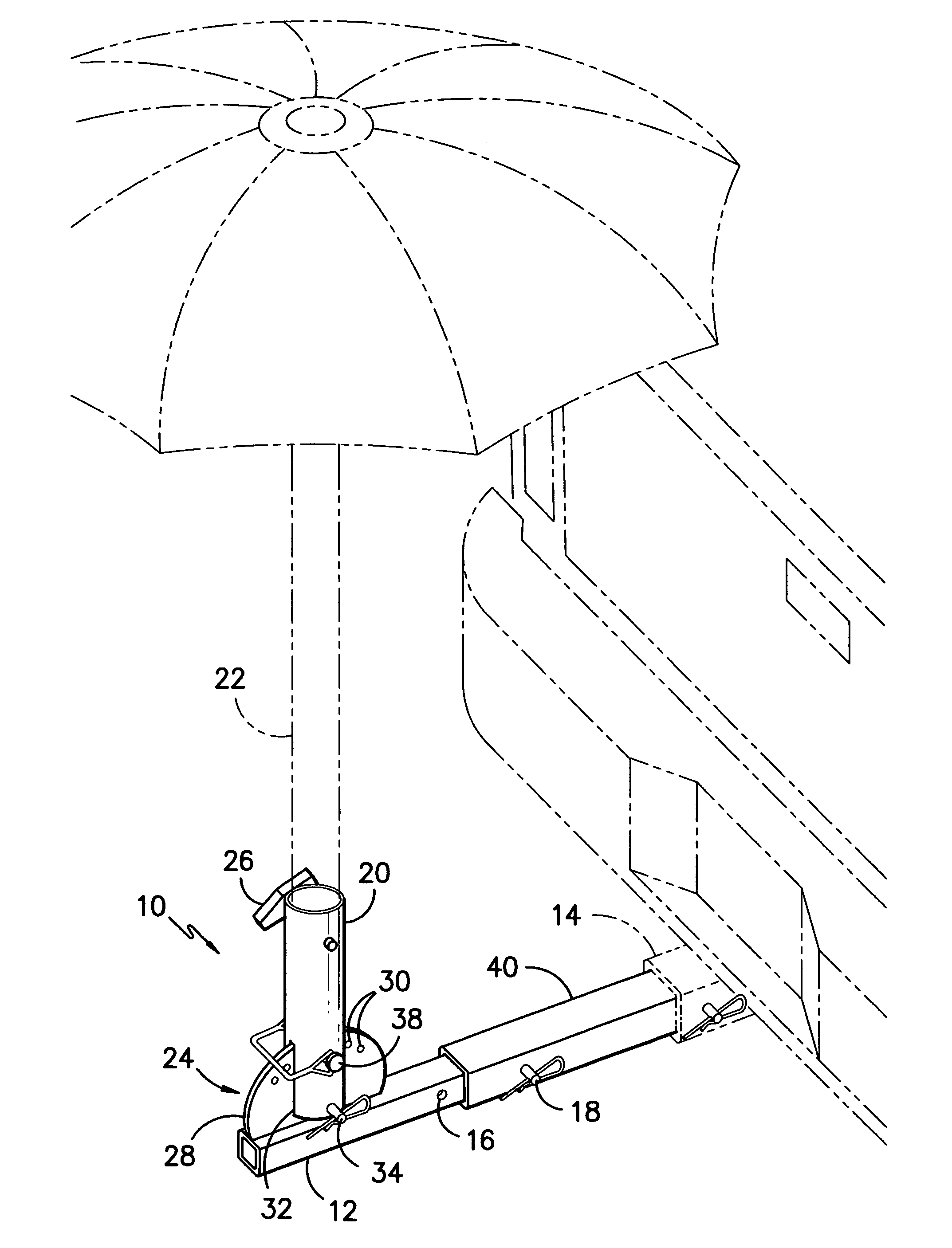

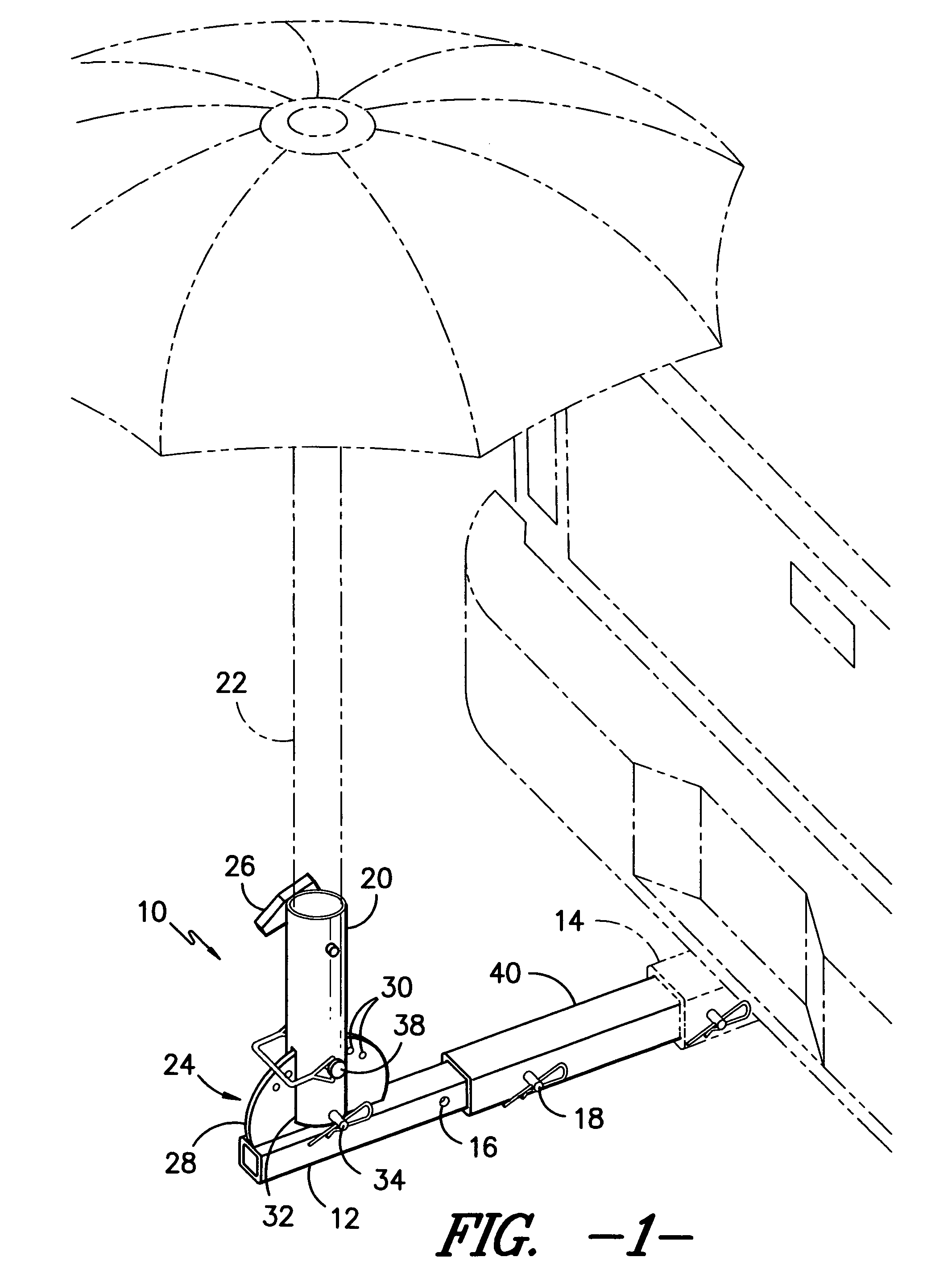

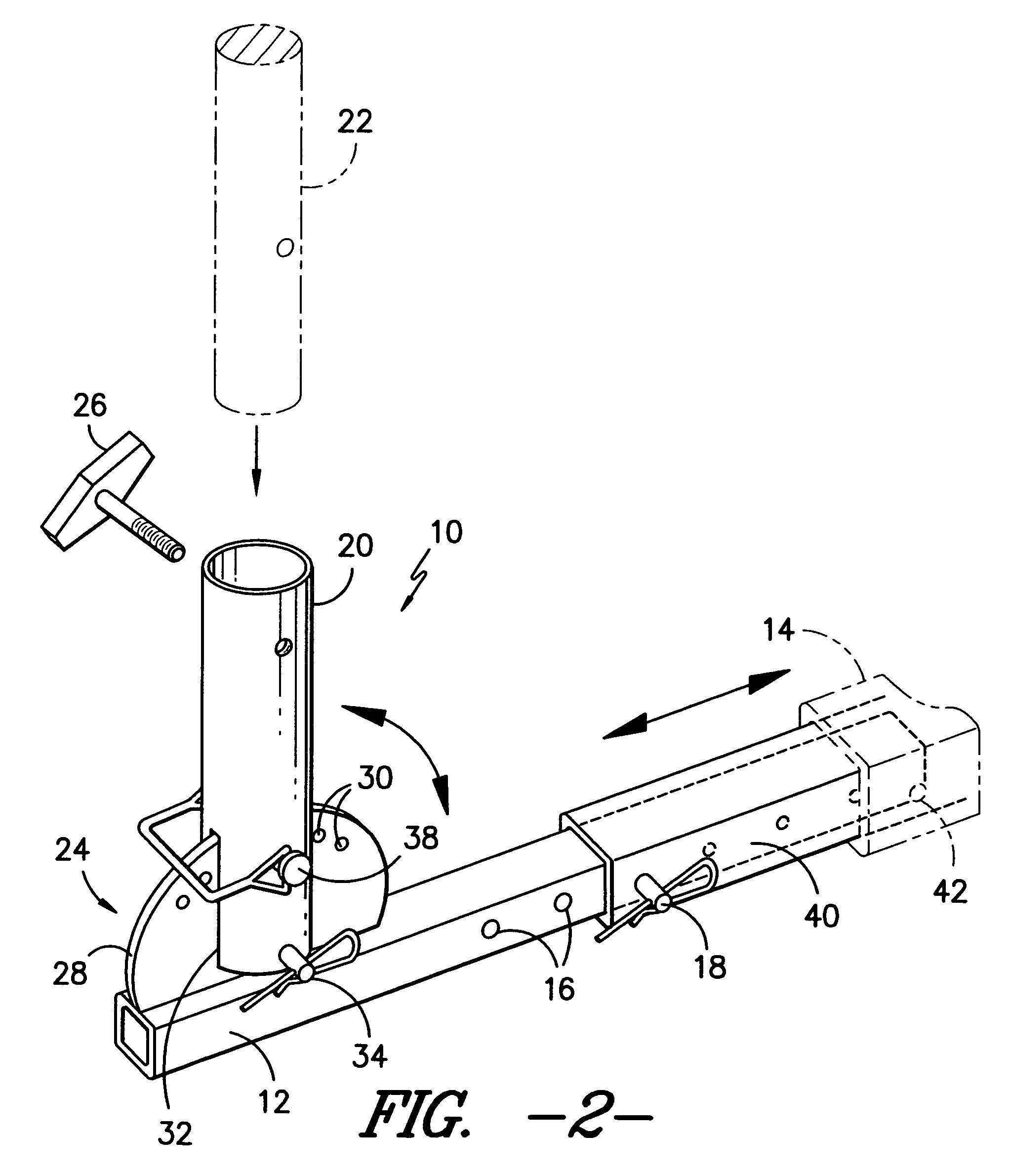

Adjustable trailer hitch mount for an umbrella

InactiveUS7819128B2Increase distanceDesired lengthWalking sticksUmbrellasSquare cross sectionScrew position

The trailer hitch mount for an umbrella includes a square cross-section shaft that is adapted to slide into a standard sleeve-style trailer hitch receiver that is currently available on many vehicles. The shaft includes a series of holes along the sides thereof to receive a pin in order to secure the shaft to the trailer hitch receiver in a telescopic relationship. The series of holes allows the shaft length to be adjusted, so that the distance between the trailer hitch receiver and the opposed end of the shaft may be shortened or lengthened, as desired. The shaft includes two ends, one of which slides into the trailer hitch receiver, and the other end includes a hollow pivoting cylindrical tube that is used to receive the bottom end of an umbrella pole. The pivoting tube includes adjustment means, so that the pivoting tube may be tilted to a desired angle and secured in that position. For travel or storage purposes, the pivoting tube may be folded down and secured into a compact position parallel with the shaft. At an upper end of the pivoting tube is receiving and securing means for the umbrella pole. The umbrella pole, in a preferred embodiment, slides into the hollow pivoting tube and a hand screw positioned on the side of the pivoting tube at its upper end may be tightened against the umbrella pole and secured thereby.

Owner:CLARK SCOTTY OBRIAN +1

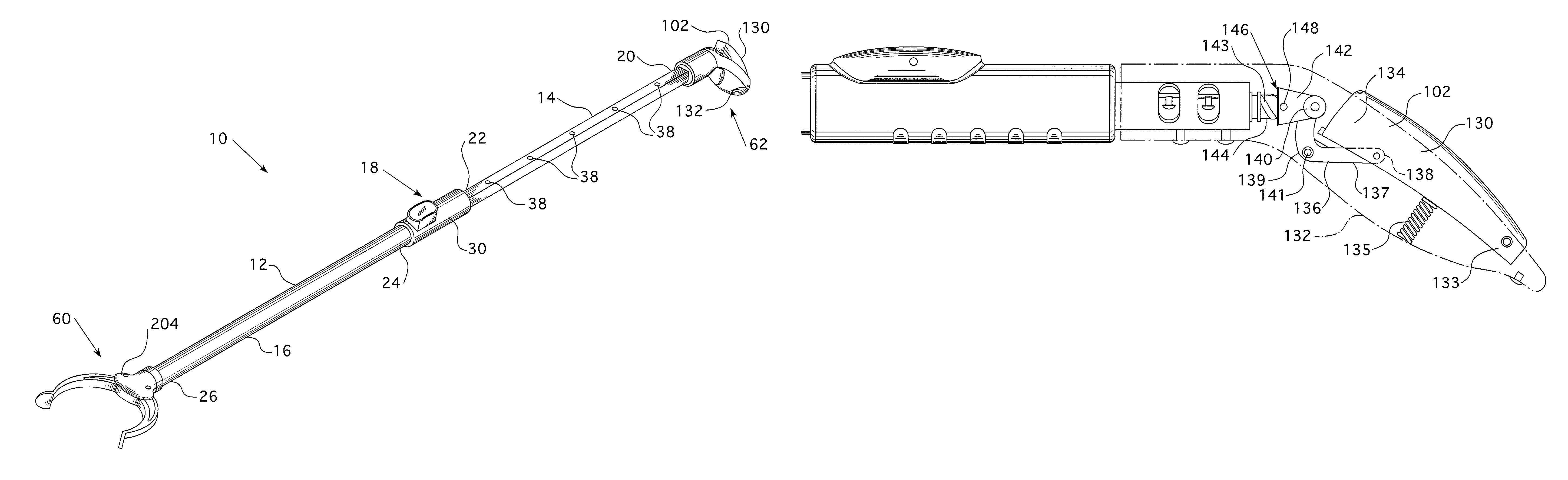

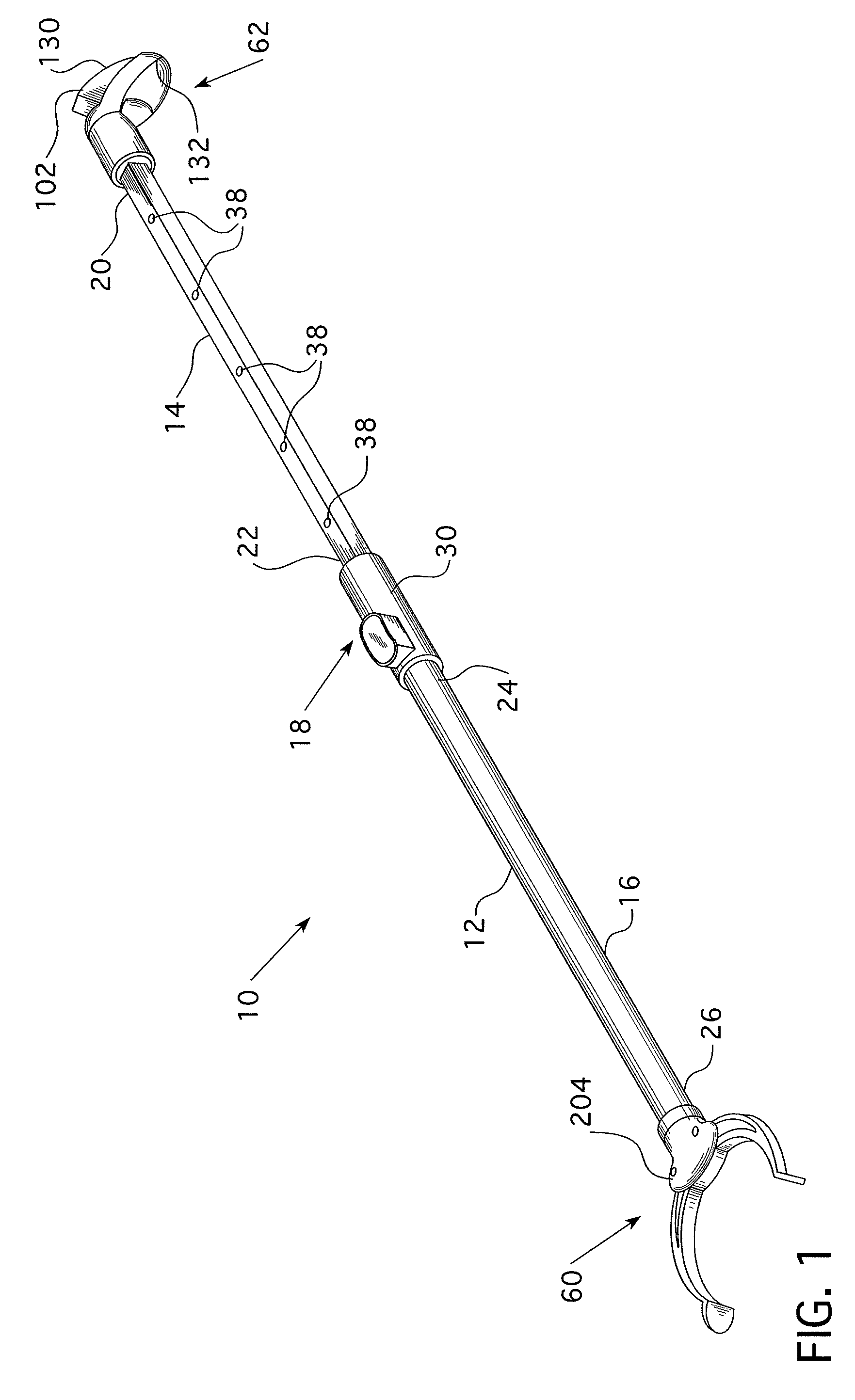

Extendable reaching tool

InactiveUS8061751B2InexpensiveEasy to assembleControlling membersMechanical apparatusSquare cross sectionDrive shaft

An extendable tool having an internal drive assembly is disclosed. The extendable components of the internal drive assembly are two, or more, telescoping drive shafts each having an alignment structure. The alignment structure ensures that the drive shafts generally maintain their circumferential alignment relative to each other, i.e. the shafts rotate together and maintain their orientation, while allowing the drive shafts to slide axially relative to each other. In one embodiment the drive shafts have a non-circular cross-section, and more preferably, a square cross-section. Each inner drive shaft has a cross-sectional area that is slightly smaller than the next larger outer drive shaft. Thus, the drive shafts may slide axially relative to each other. However, when the drive shafts are rotated, the non-circular shape causes the inner drive shaft and the larger outer drive shaft to engage each other and rotate together.

Owner:IAMS

Directionally controlled growth of nanowhiskers

InactiveUS20060019470A1Well-defined surfaceReduce the temperatureMaterial nanotechnologyPolycrystalline material growthNanowireStacking fault

Nanowhiskers are grown in a non-preferential growth direction by regulation of nucleation conditions to inhibit growth in a preferential direction. In a preferred implementation, <001> III-V semiconductor nanowhiskers are grown on an (001) III-V semiconductor substrate surface by effectively inhibiting growth in the preferential <111>B direction. As one example, <001> InP nano-wires were grown by metal-organic vapor phase epitaxy directly on (001) InP substrates. Characterization by scanning electron microscopy and transmission electron microscopy revealed wires with nearly square cross sections and a perfect zincblende crystalline structure that is free of stacking faults.

Owner:QUNANO

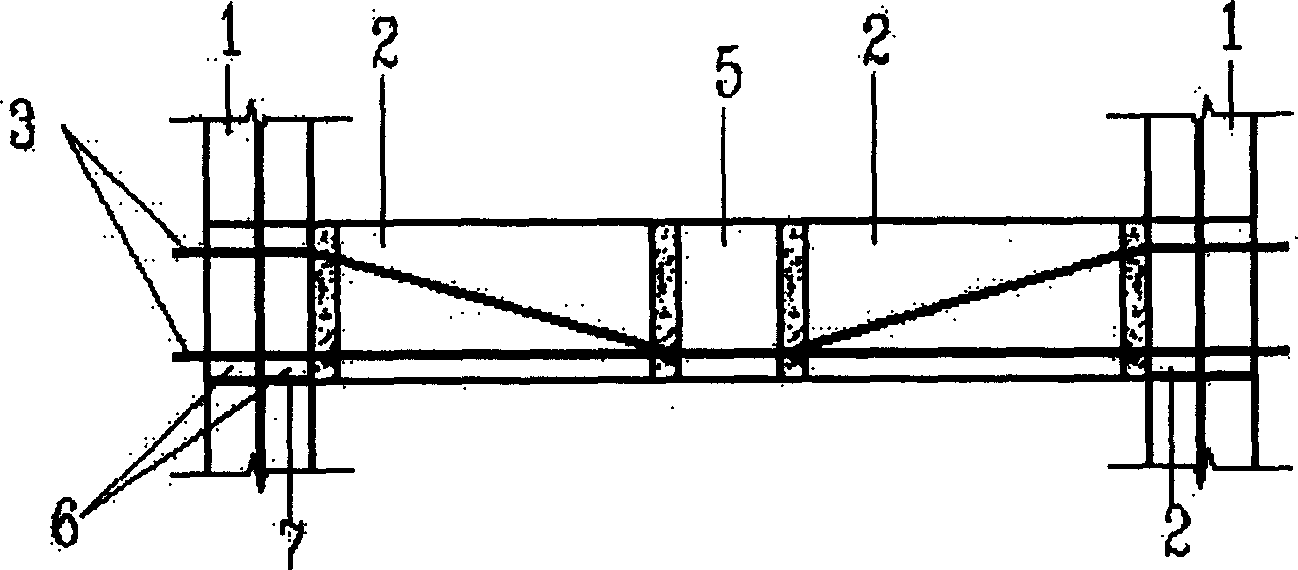

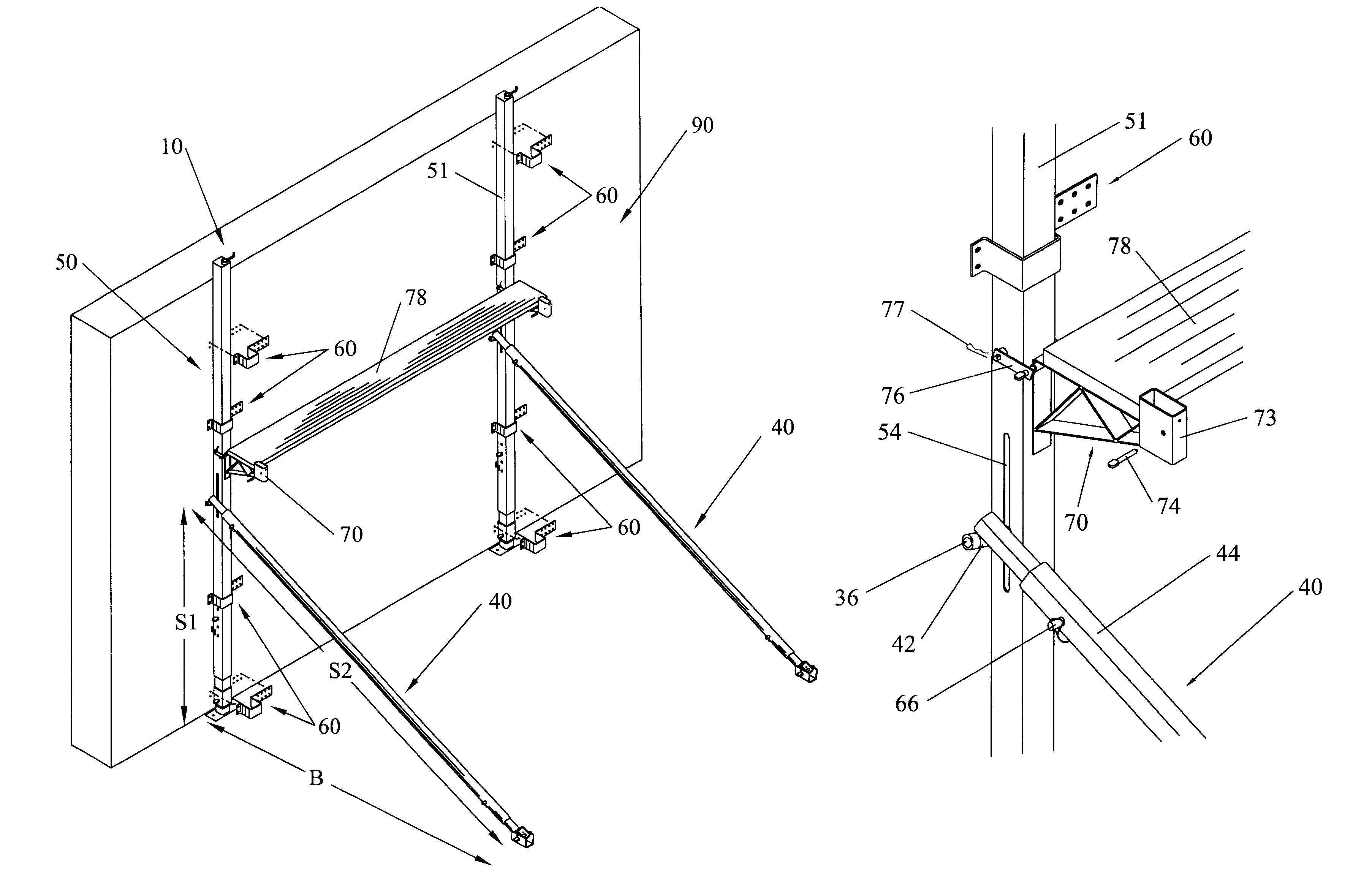

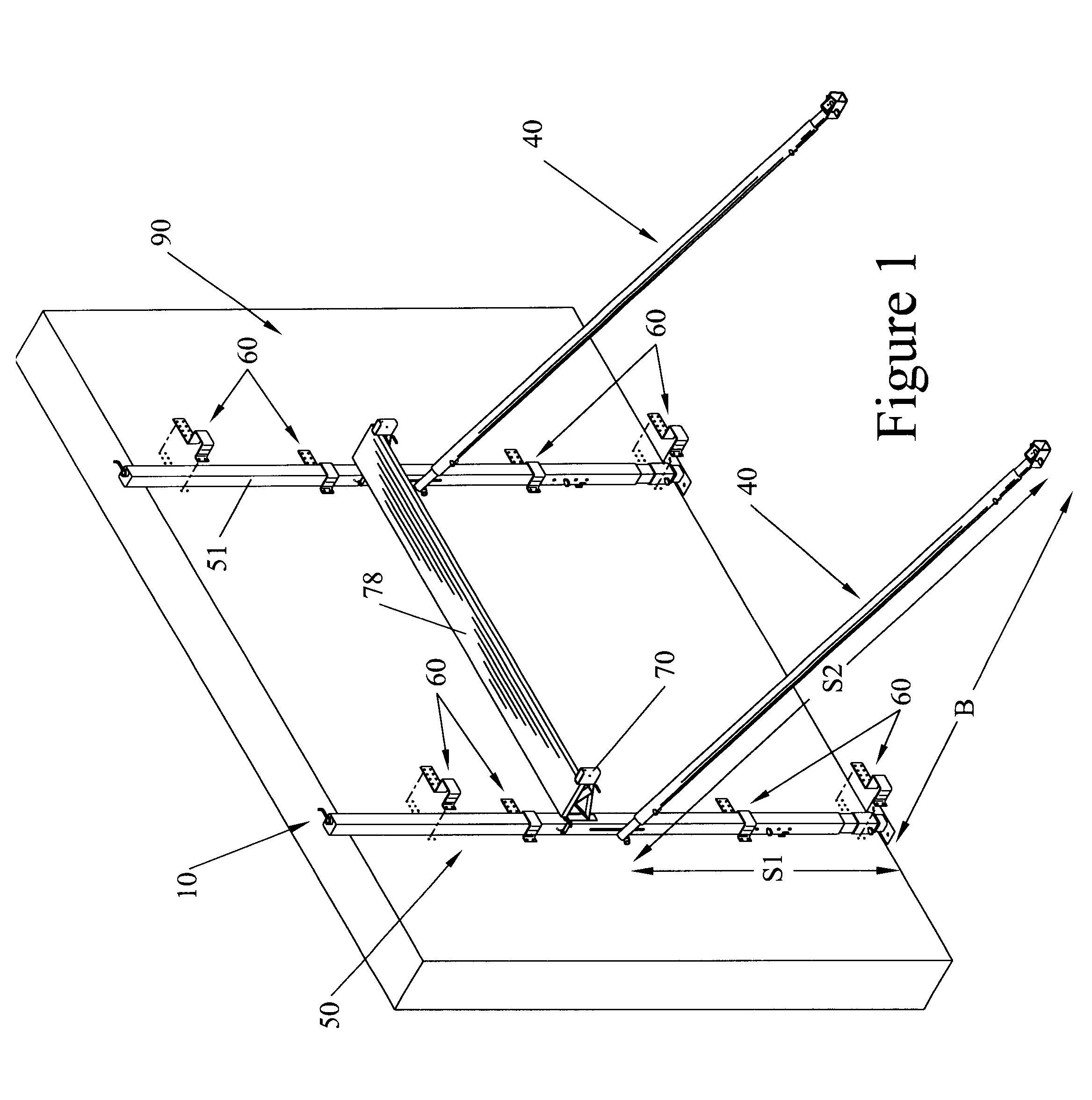

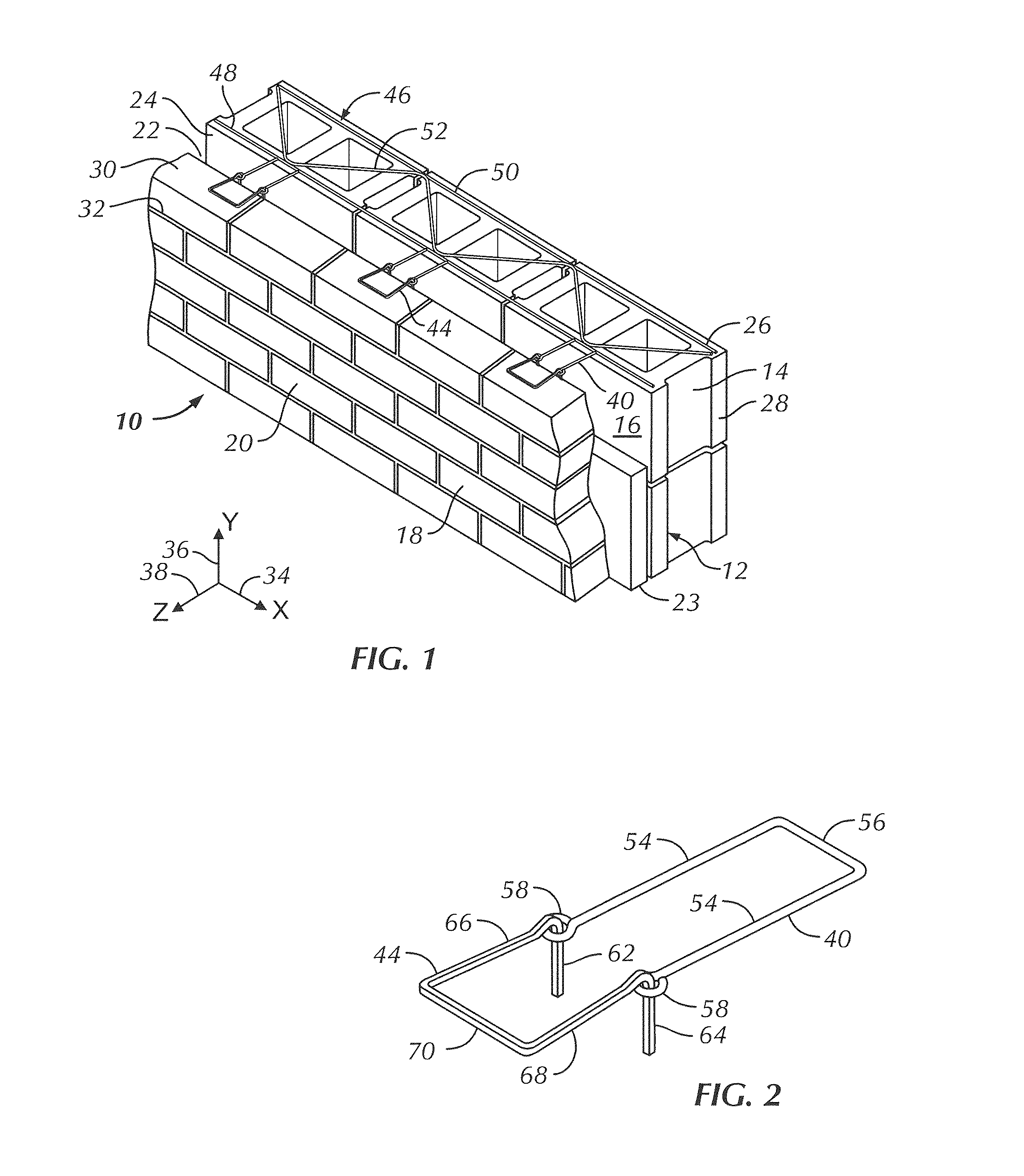

Adjustable scaffold used with concrete-receiving forms

InactiveUS6550188B2Rigid enoughEasy to moveStands/trestlesTowersSquare cross sectionExpanded polystyrene

Walls of expanded polystyrene, concrete-receiving forms (referred to as insulated or insulating concrete forms or ICFs) need to be vertical while they are being filled with concrete and while the concrete is curing. An apparatus with a vertical member and a brace member is such that one person can erect it and use it to adjust walls of ICFs so as to be vertical or plumb. The apparatus is capable of being readily used with the forms of any manufacturer by being provided with asymmetrical brackets for detachably attaching the vertical member to a wall firmly, but not rigidly. The apparatus provides a support for a platform, or scaffold, for a person to stand on while guiding the concrete pouring and while plumbing the wall. The vertical member extends upward from the ground and is held firmly against the wall with asymmetrical brackets. The brace member extends from the vertical member at a pivot with the other end of the brace member attached to the ground or floor. A lead screw in the vertical member is used to change the height of the pivot and thus slightly, and adjustably, tilt the vertical member into or out of the wall so as to cause the wall to be vertical. The vertical member and the brace member are preferably adjustable in length, however neither member changes length a noticeable amount while being used to cause the wall to be vertical. The members are preferably made of sections of square cross section, steel tubing that may be nested together.

Owner:BOLINGER DAVID N +1

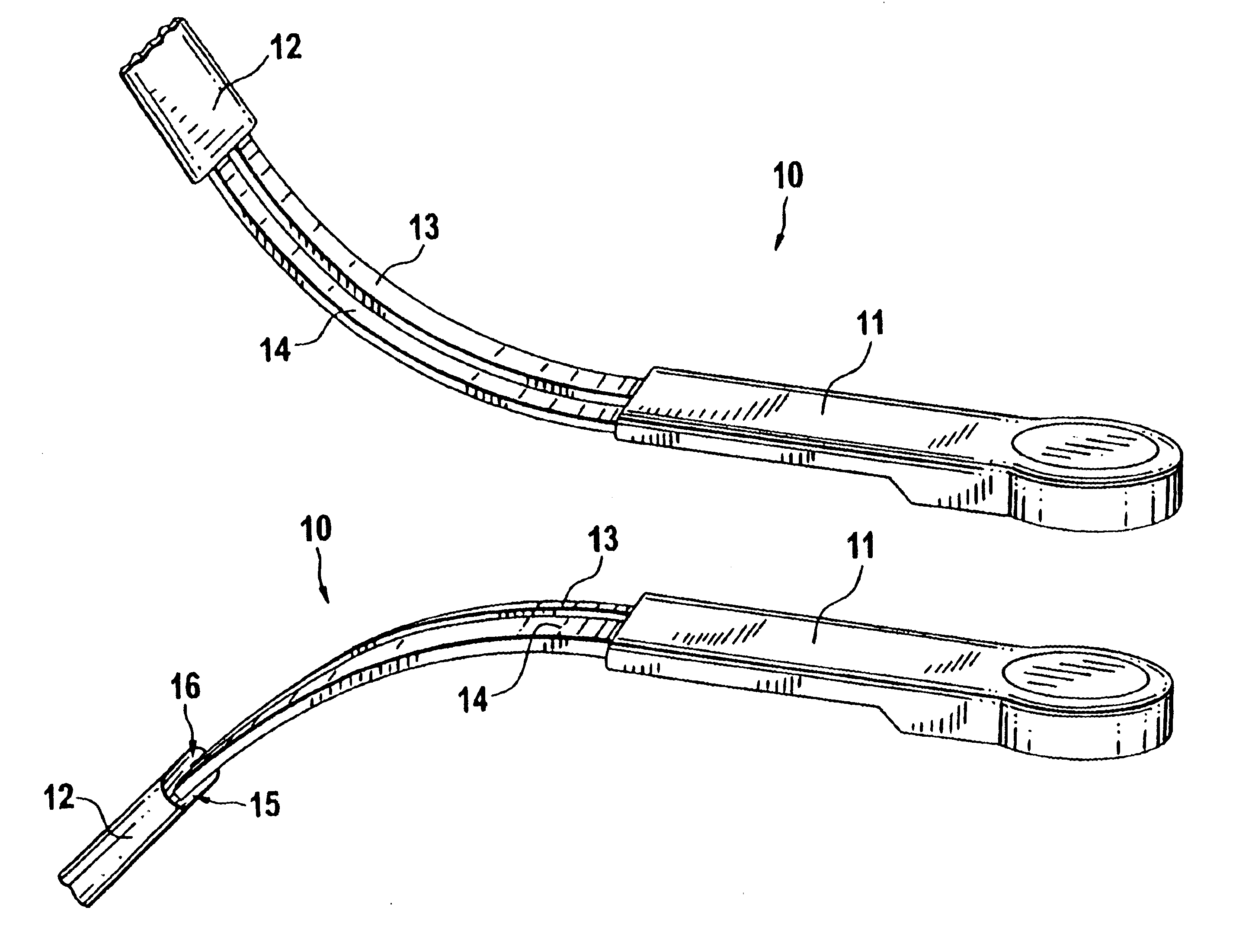

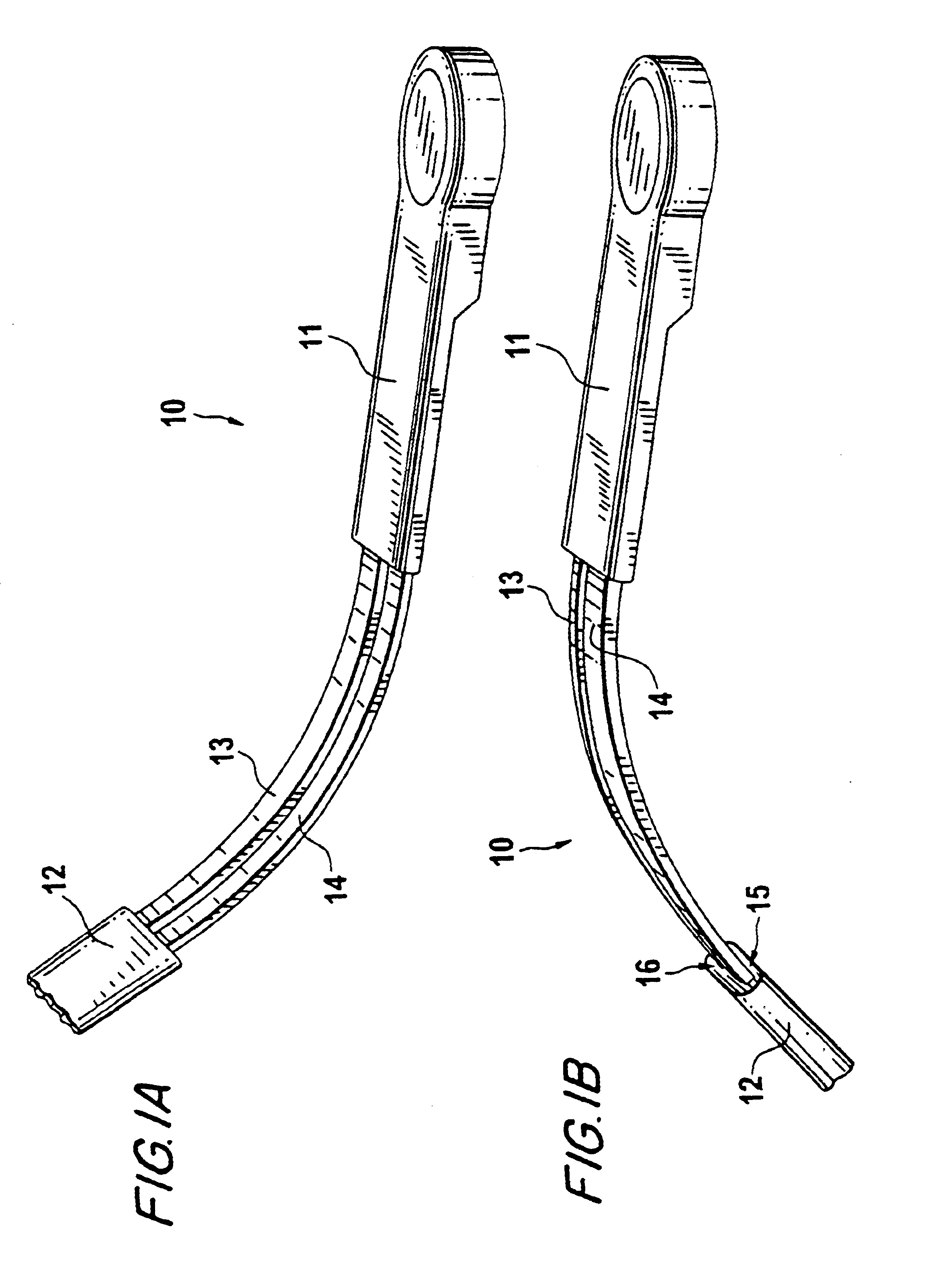

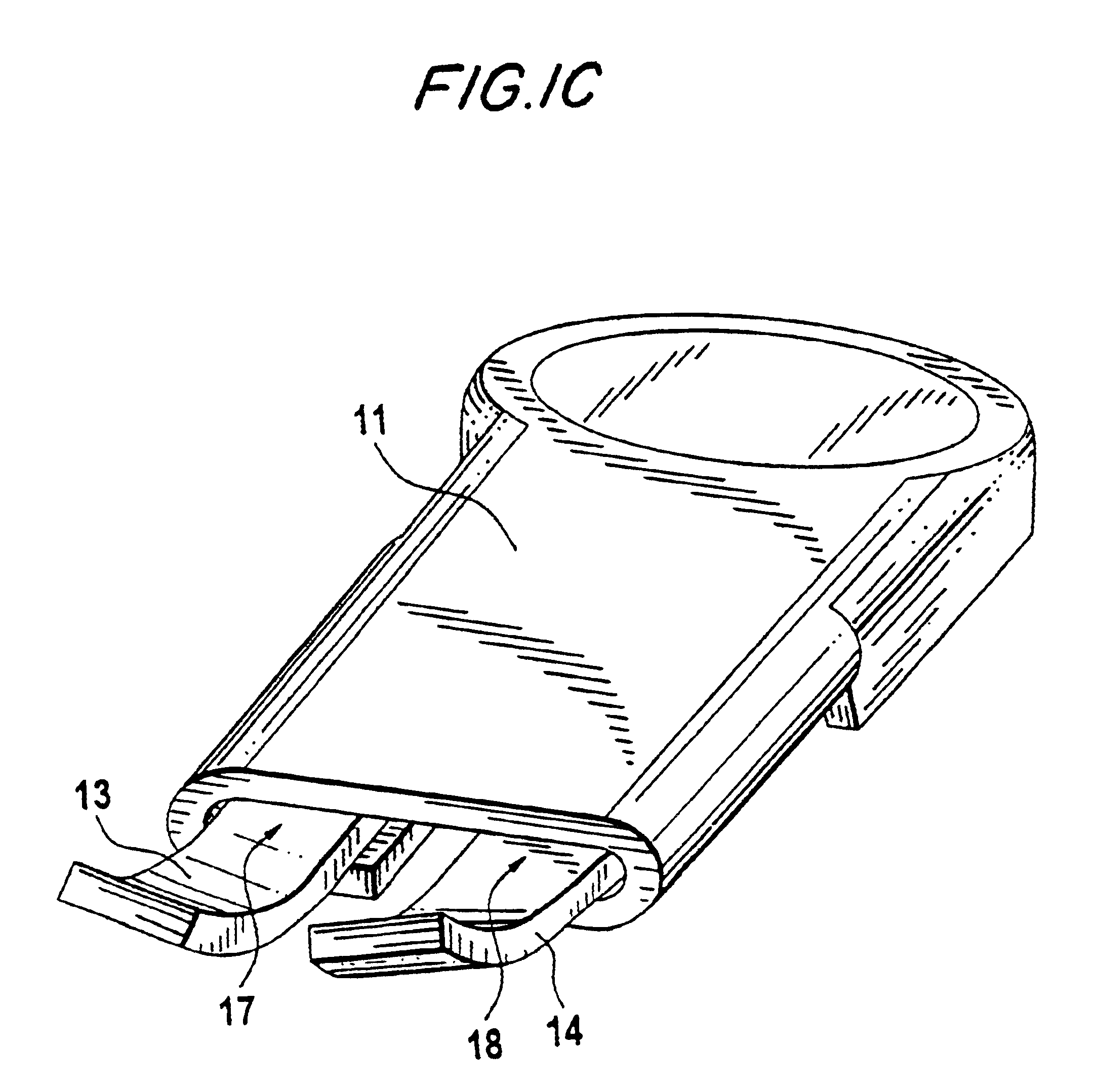

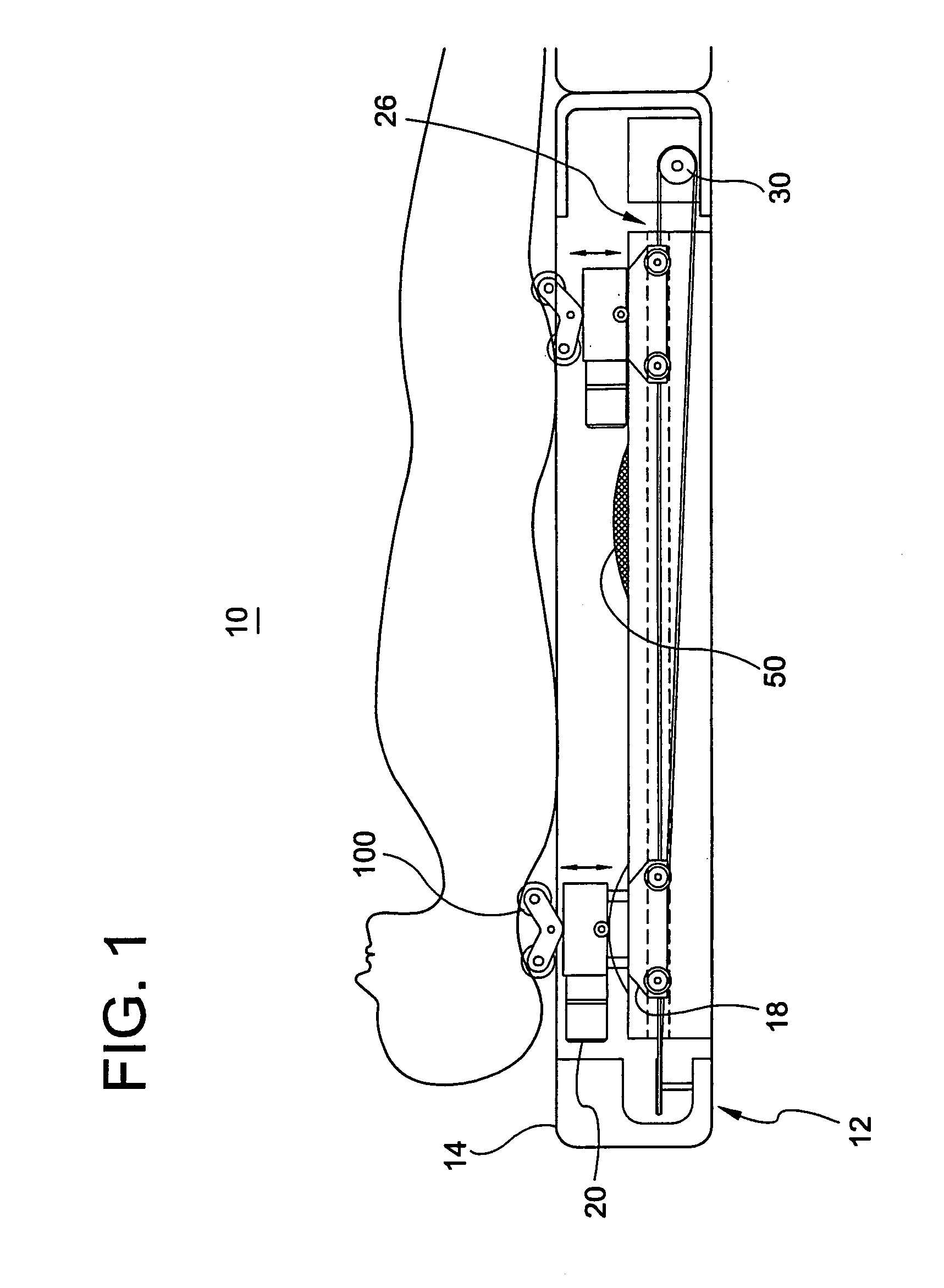

Windshield wiper device

Owner:ROBERT BOSCH GMBH

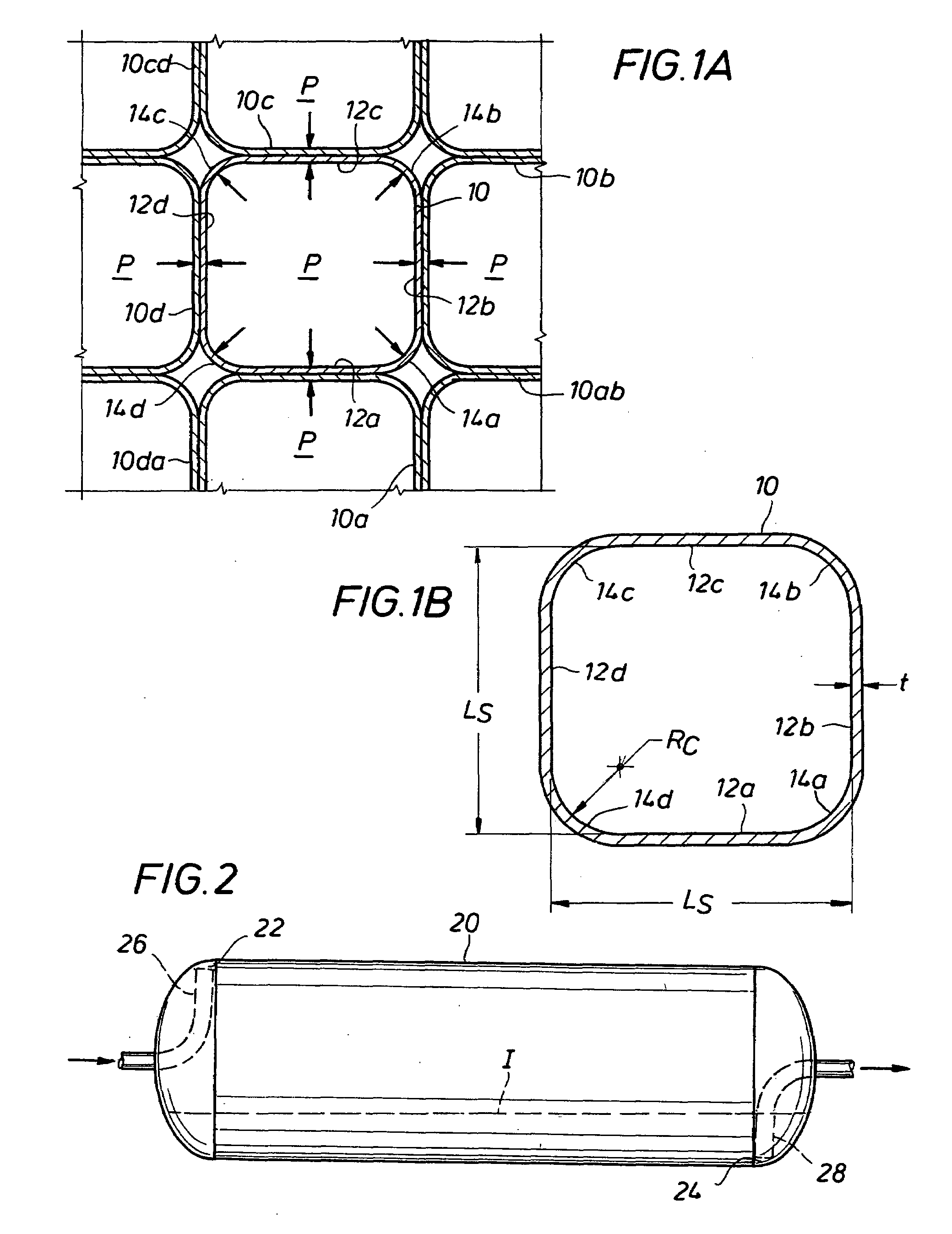

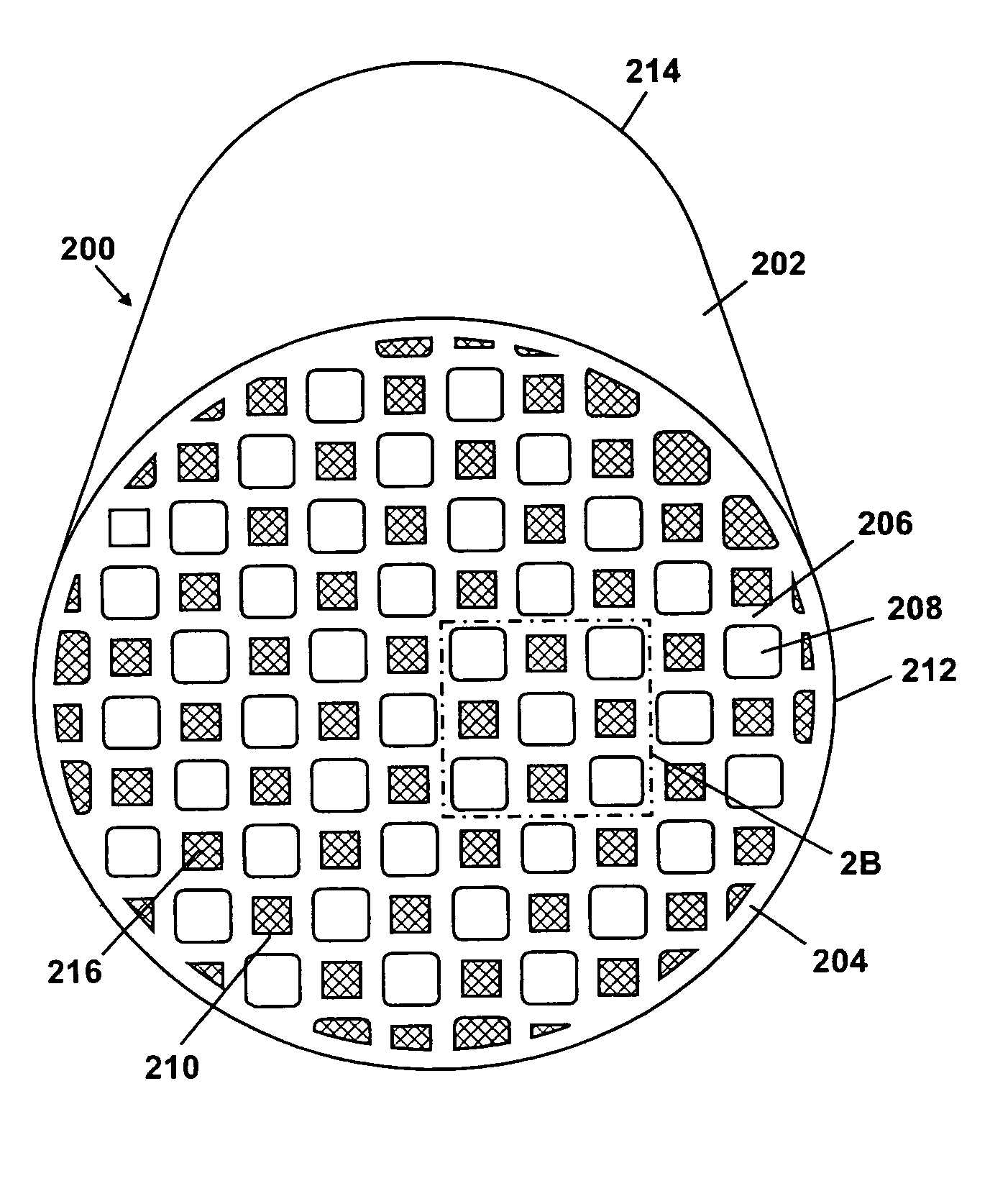

Asymmetric honeycomb wall-flow filter having improved structural strength

InactiveUS7601194B2Combination devicesInternal combustion piston enginesSquare cross sectionHoneycomb

A honeycomb filter includes an array of interconnecting porous walls which define an array of first channels and second channels. The first channels are bordered on their sides by the second channels and have a larger hydraulic diameter than the second channels. The first channels have a square cross-section, with corners of the first channels having a shape, such as a bevel or fillet, such that the thickness, t3, of the porous walls adjoining the corners of the first channels is comparable to the thickness, t4, of the porous walls adjoining edges of the first and second channels. Embodiments having a corner fillet with a radius, Rc, are also disclosed. Embodiments wherein 0.30 t4≦Rc≦1.0 t4 exhibit combinations of low wall pressure drop and low thermal stress.

Owner:CORNING INC

Asymmetric honeycomb wall-flow filter having improved structural strength

ActiveUS20050066639A1Increase the cross-sectional areaUniform widthCombination devicesInternal combustion piston enginesSquare cross sectionHoneycomb

Owner:CORNING INC

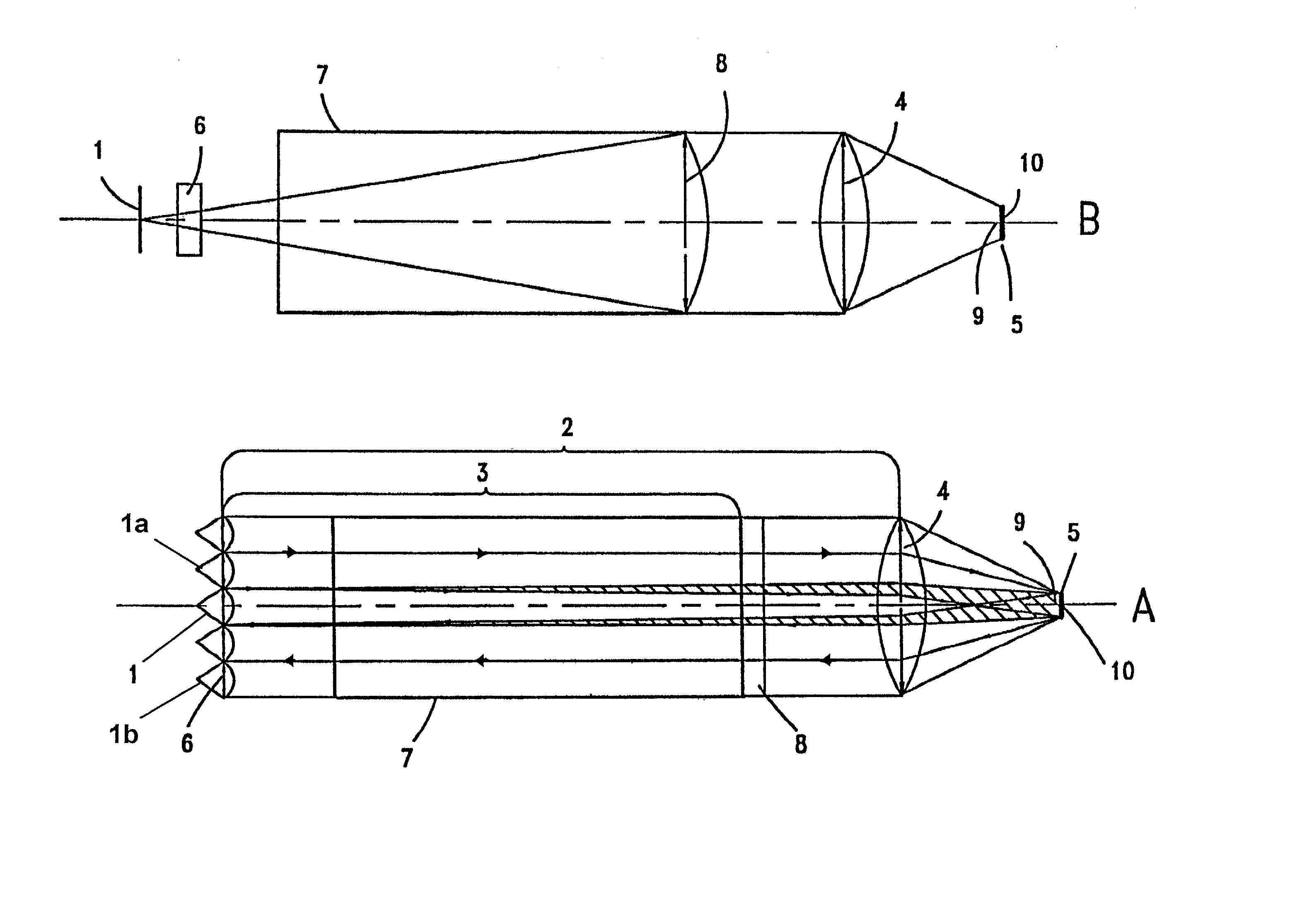

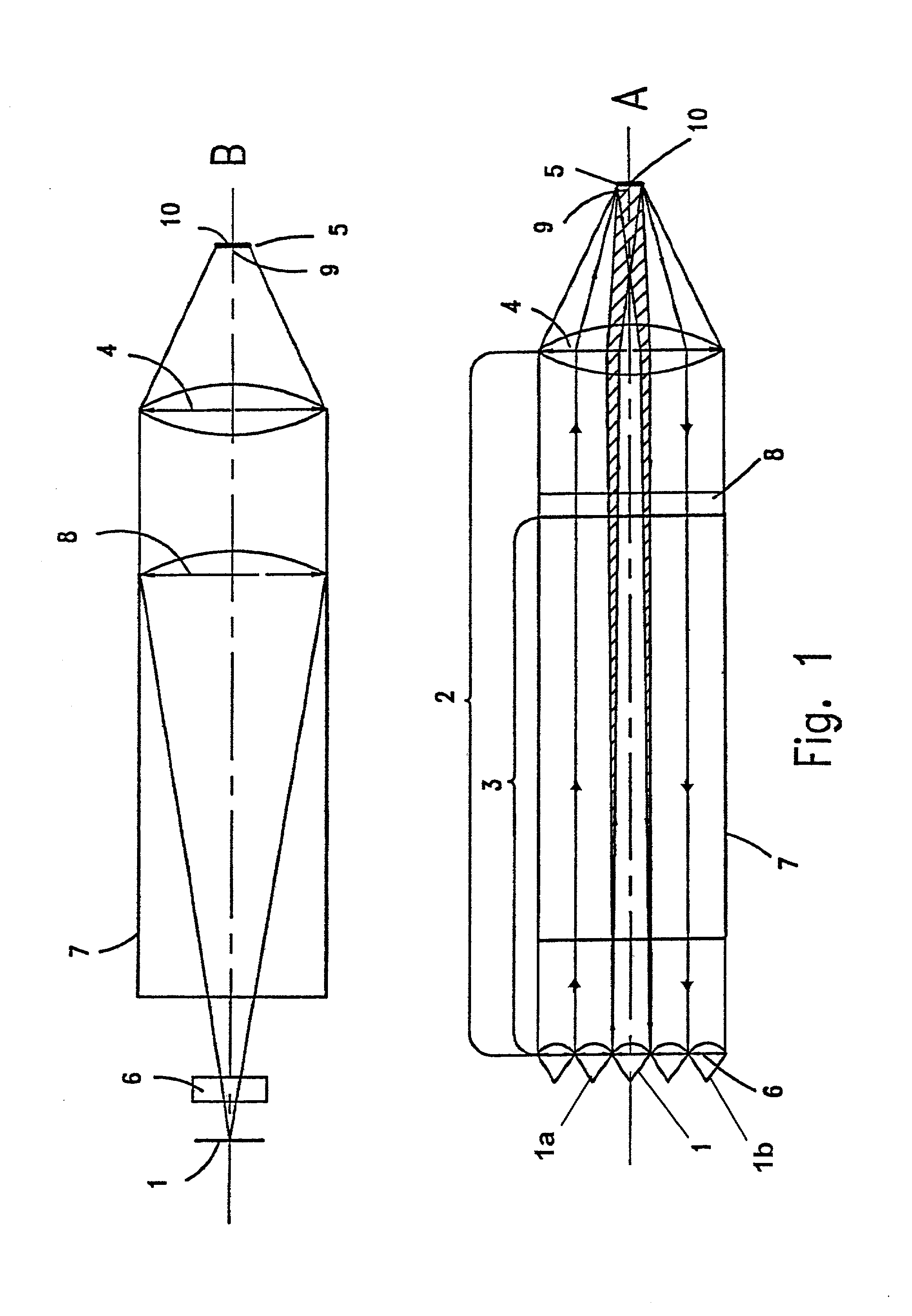

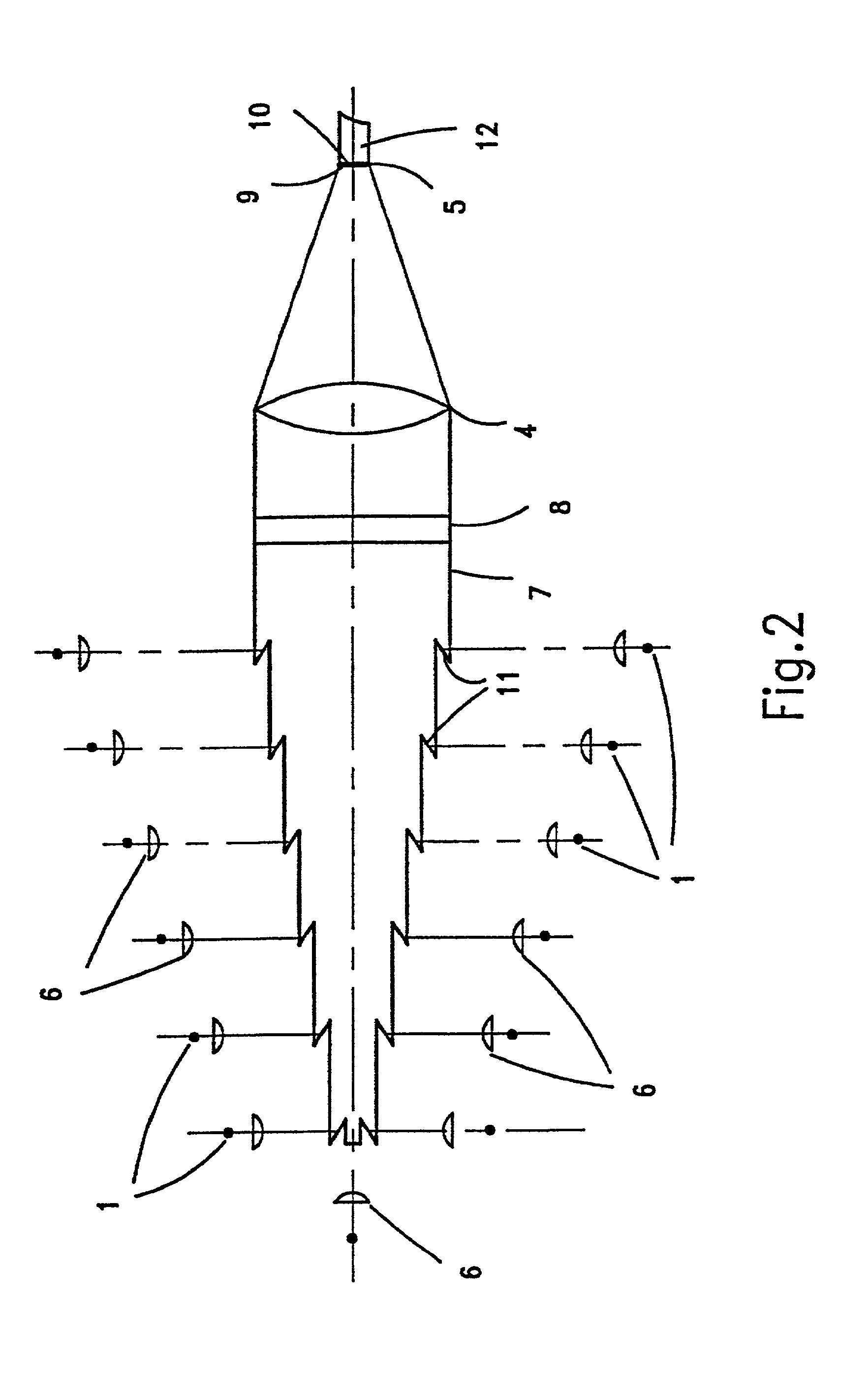

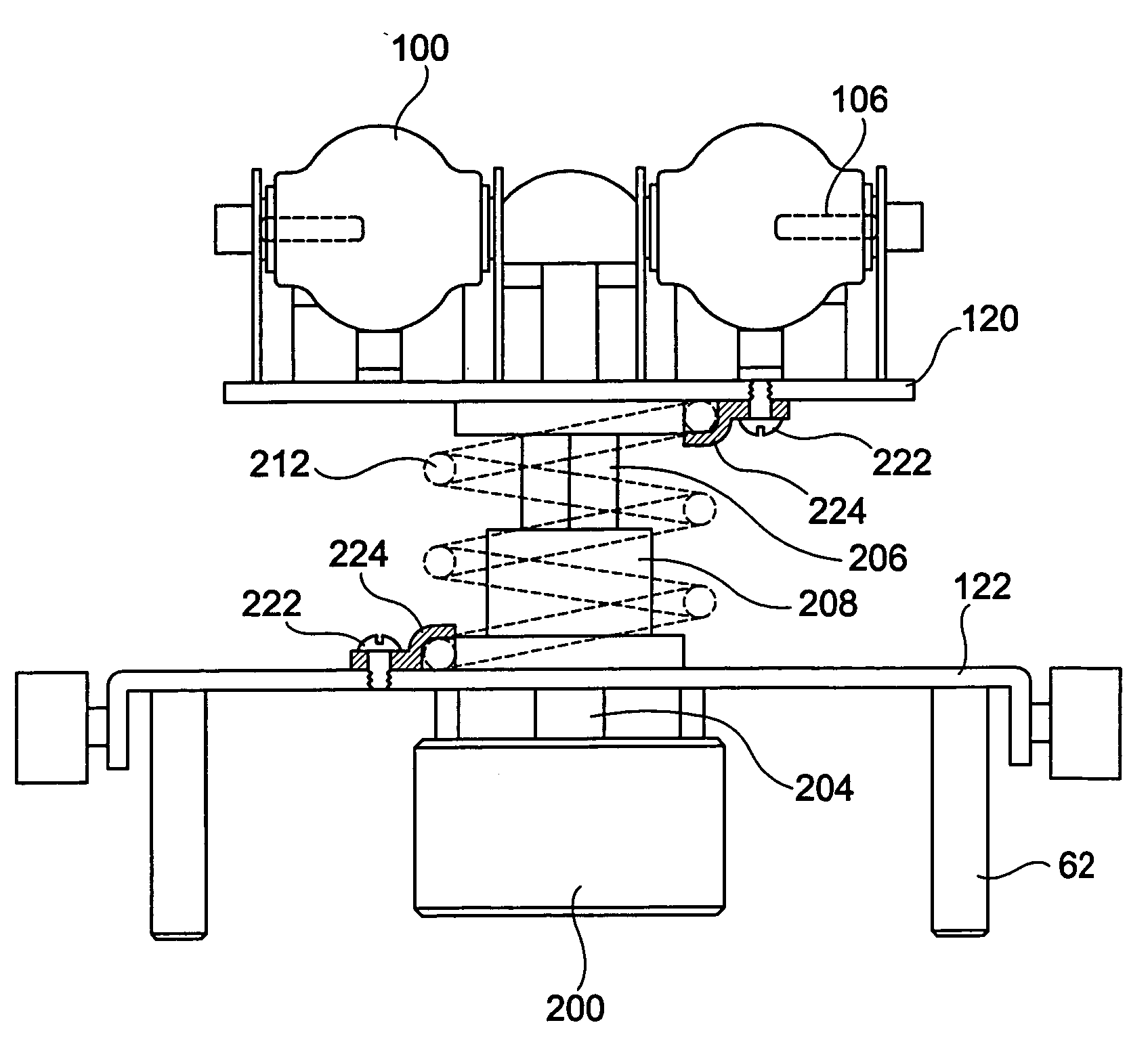

Method and apparatus for unifying light beams

InactiveUS20020051360A1High yieldReduce disagreementPoint-like light sourcePortable electric lightingSquare cross sectionLight energy

A light unifier, which comprises a plurality of light sources, particularly laser diodes, emitting parallel light beams of a rectangular cross-section, for focusing the light energy of all the beams onto a target area through beam-shaping means, which comprises transverse collimators, means for juxtaposing the emitted beams to form a unified beam, a longitudinal collimator for longitudinally collimating the unified beam, and means for focusing it onto the target area. The light beams have a transverse and a longitudinal divergence and the ratio of the transverse divergence to the longitudinal divergence is higher than 1. The transverse collimators are placed at such a distance from the sources that, at the point at which the beams reach them, the sum of the short sides of the beams is equal to the long side of each of them at the point at which they reach the longitudinal collimator. The number of light sources is such as to permit to obtain a unified beam that has a square cross-section and the same divergence on all its sides. Two groups of laser diodes may be arranged in parallel or mutually perpendicular planes and the unified beams produced by them are focused together onto the target area.

Owner:SOLODOVNIKOV VLADIMIR VADIMOVICH +1

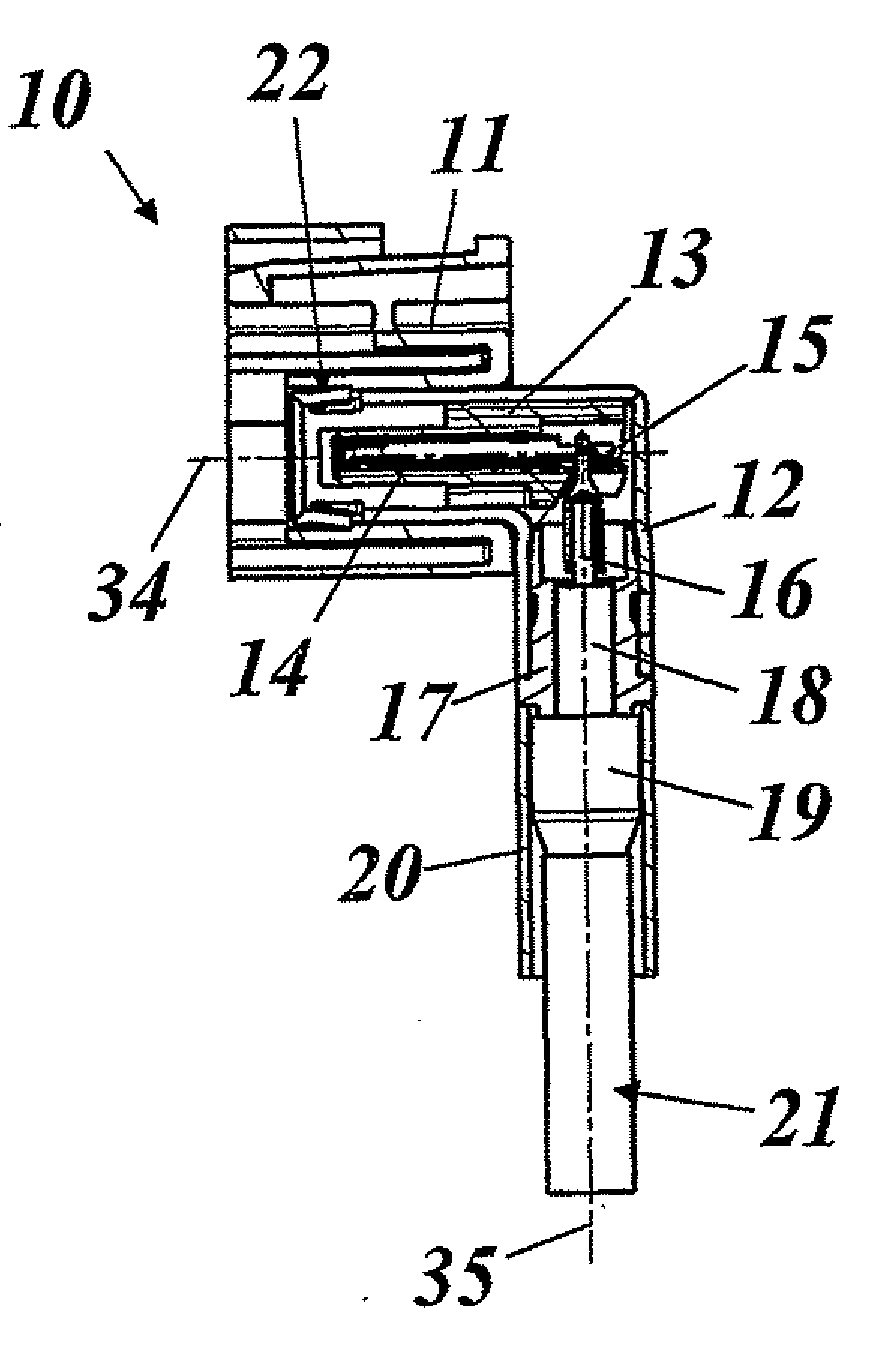

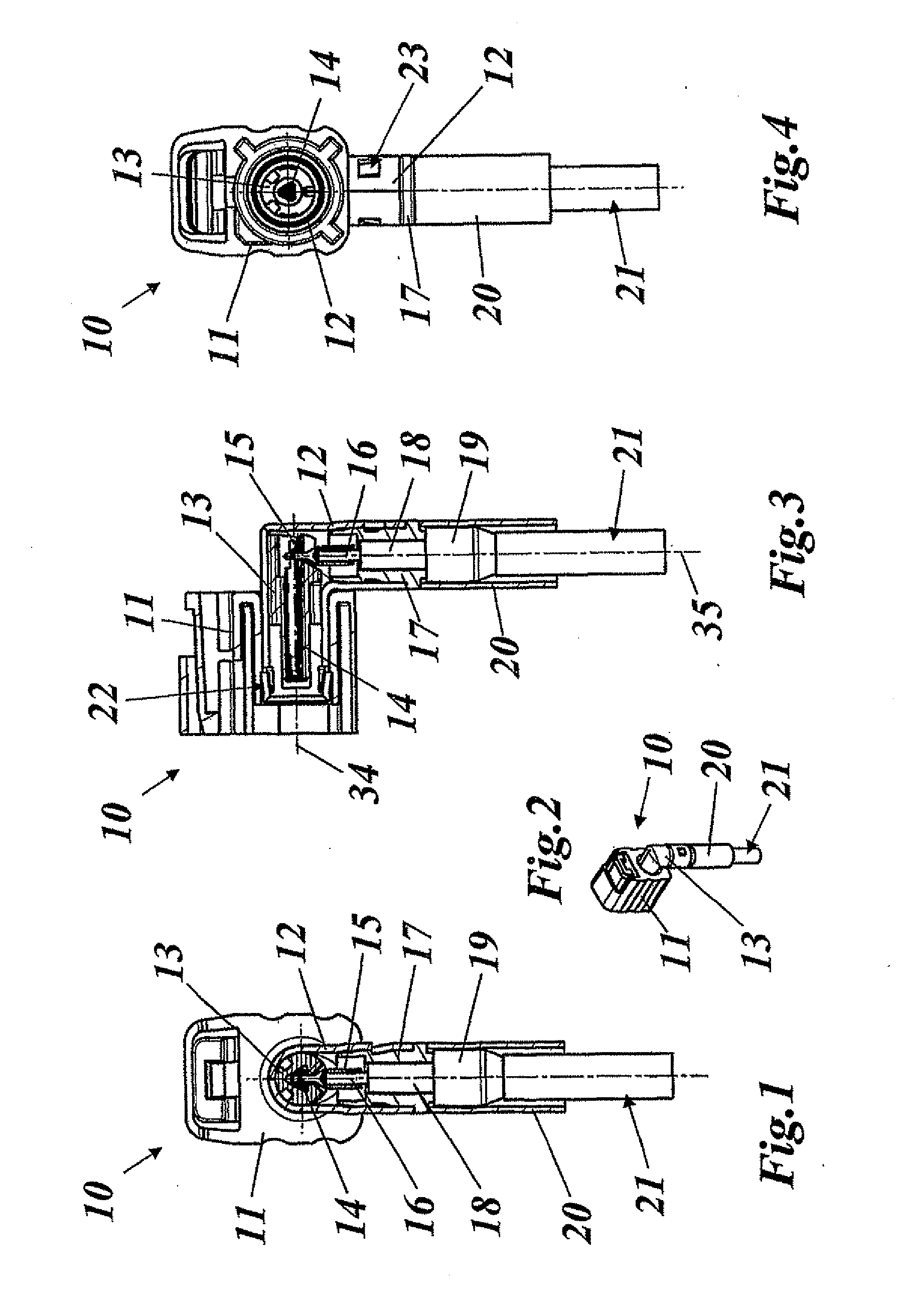

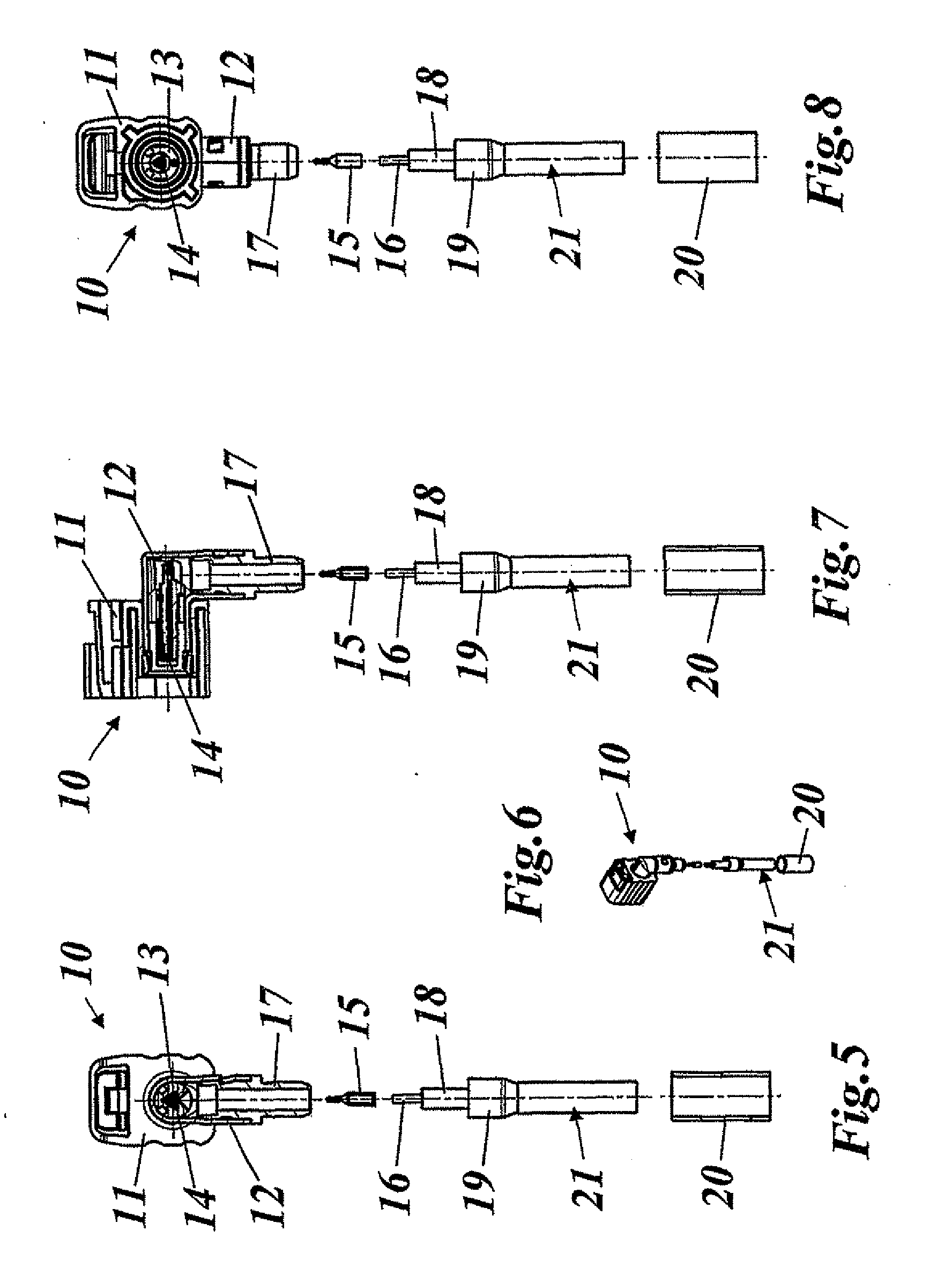

Bent-Back Plug-Type Connector for Coaxial Cables

InactiveUS20090017678A1Reliable and long-lasting connectionEasy to assembleContact member manufacturingVehicle connectorsSquare cross sectionElectrical conductor

A bent-back plug-type connector for coaxial cables includes a bent-back outer conductor having a first conductor section which extends along a plug axis and a second conductor section which adjoins the first conductor section and is arranged at an angle with respect thereto, as well as a first inner conductor, which is arranged concentrically and insulated in the first conductor section, and a second inner conductor, which is arranged concentrically and insulated in the second conductor section and is detachably connected to the first inner conductor in the corner region of the bent-back outer conductor. With such a plug-type connector, simpler fitting, a secure and permanent connection and simpler and more cost-effective production are achieved by virtue of the fact that the first inner conductor has a square cross section, and the fact that an opening is provided in the first inner conductor.

Owner:HUBERSUHNER AG

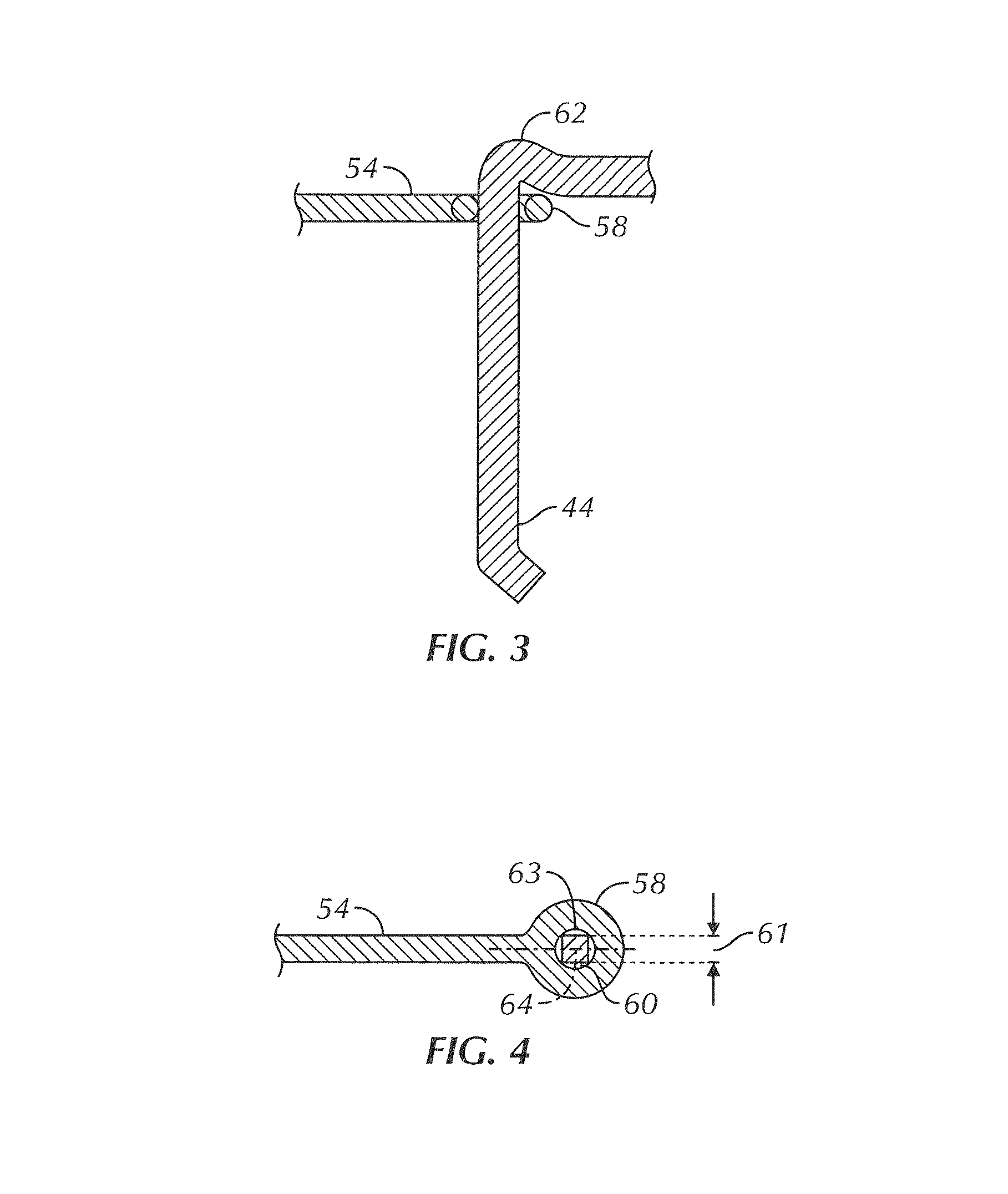

High-strength rectangular wire veneer tie and anchoring systems utilizing the same

ActiveUS8833003B1Easy to installIncrease volumetric occupancyProtective buildings/sheltersShock proofingSquare cross sectionSingle plate

A high-strength rectangular pintle veneer tie and cavity wall anchoring system employing the same is disclosed. The rectangular wire formative construct optionally includes a square cross-section that provides greater volumetric occupancy than that of a similar diameter circular wire formative. The interengaging portions and insertion portion are optionally compressed for greater strength and the rectangular shaped interengaging portion provides a locking interconnection within the anchor precluding significant movement lateral with or normal to the inner wythe.

Owner:HOHMANN & BARNARD INC

Asymmetric honeycomb wall-flow filter having improved structural strength

InactiveUS20050166562A1Internal combustion piston enginesDispersed particle filtrationSquare cross sectionHoneycomb

A honeycomb filter includes an array of interconnecting porous walls which define an array of first channels and second channels. The first channels are bordered on their sides by the second channels and have a larger hydraulic diameter than the second channels. The first channels have a square cross-section, with corners of the first channels having a shape, such as a bevel or fillet, such that the thickness, t3, of the porous walls adjoining the corners of the first channels is comparable to the thickness, t4, of the porous walls adjoining edges of the first and second channels. Embodiments having a corner fillet with a radius, Rc, are also disclosed. Embodiments wherein 0.30 t4≦Rc≦1.0 t4 exhibit combinations of low wall pressure drop and low thermal stress.

Owner:CORNING INC

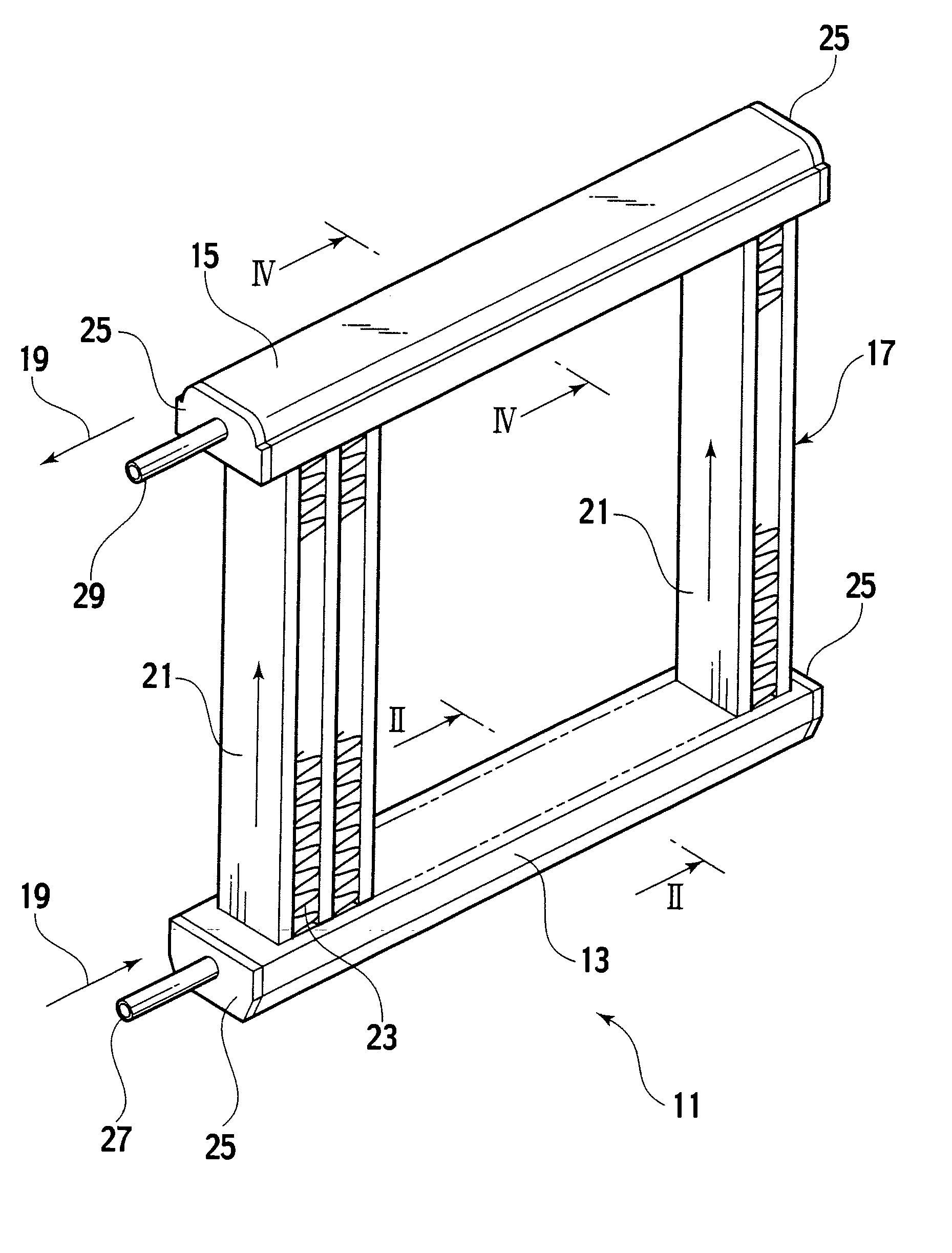

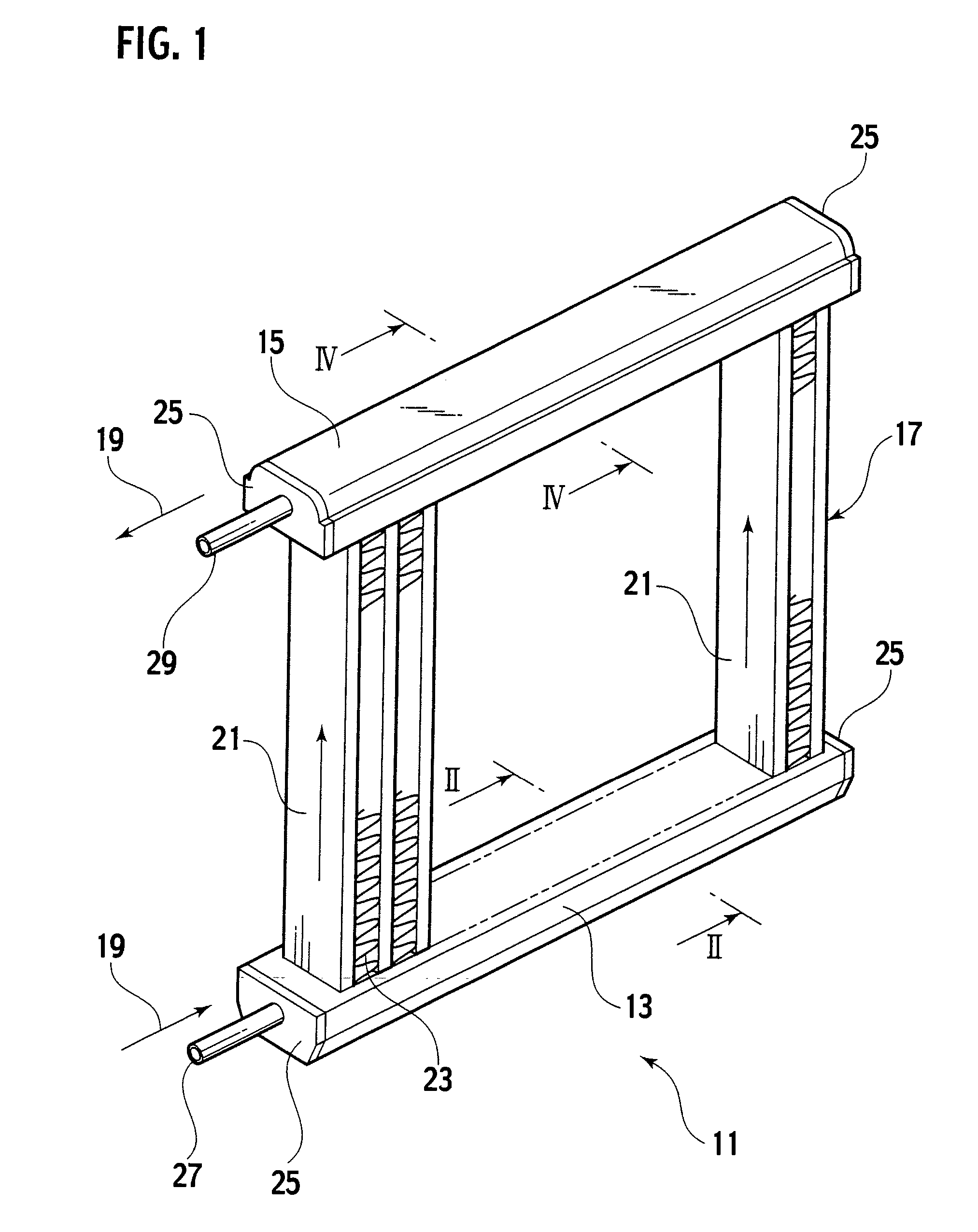

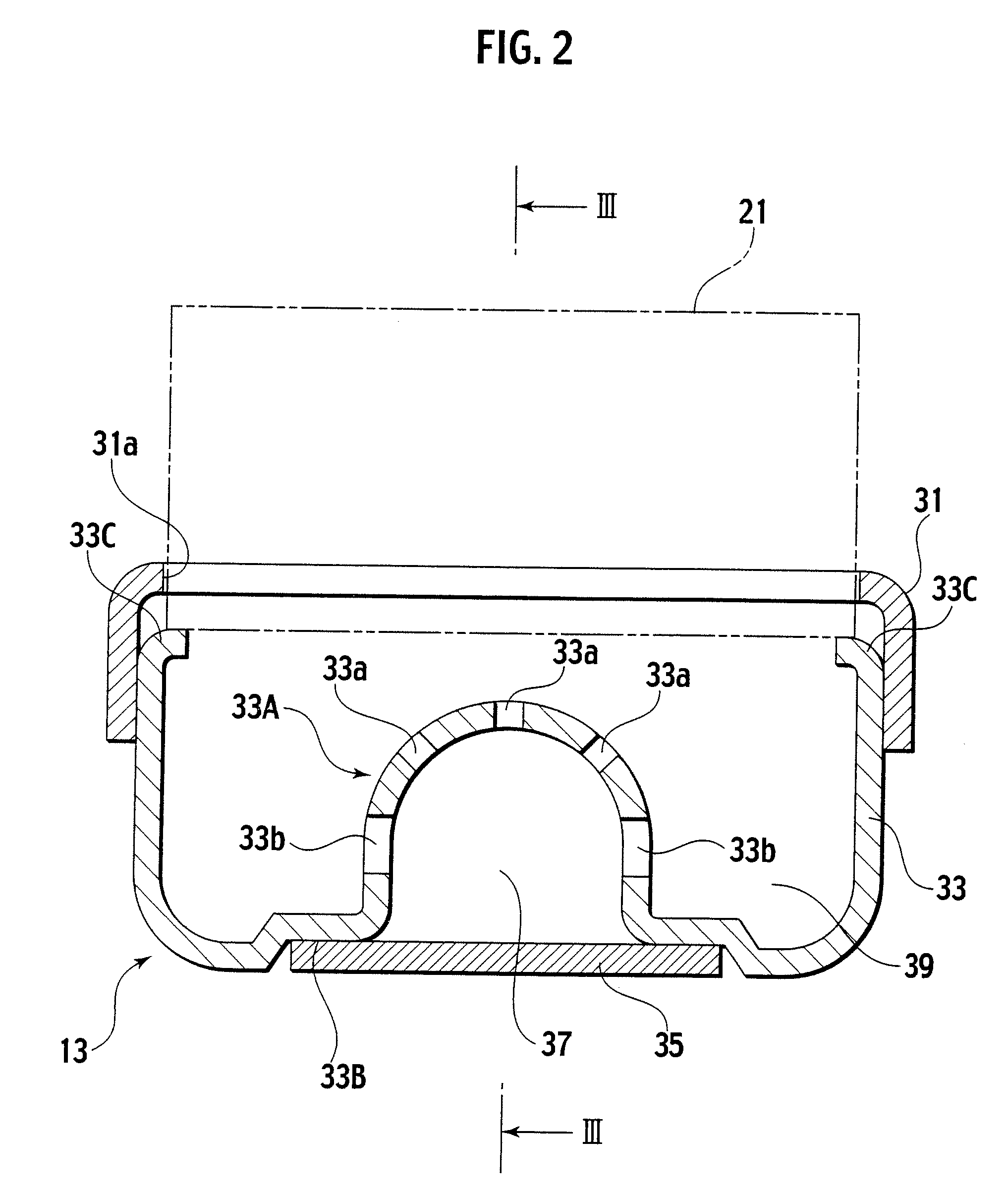

Header Tank for Heat Exchanger

InactiveUS20070256821A1Lower component costsPrevents reduction of distribution efficiencyEvaporators/condensersHeat exchanger casingsSquare cross sectionFuel tank

A header tank for a heat exchanger includes tank forming sections that are joined into a tubular shape with a substantially square cross-section. The header tank has a refrigerant low path formed inside the tank forming sections include a tank upper section (31) in which tube insertion holes (31a) for connecting tubes of a heat exchanger core are formed. The tank lower section (33) having a substantially U-shaped refrigerant split-flow groove (33A) that has, in its longitudinal direction, communication holes (33a, 33b) for the refrigerant. The tank forming sections include a plate section (35) for closing an opening of the refrigerant split-flow groove (33A) to form a refrigerant split-flow path (37) inside the tank lower section.

Owner:CALSONIC KANSEI CORP

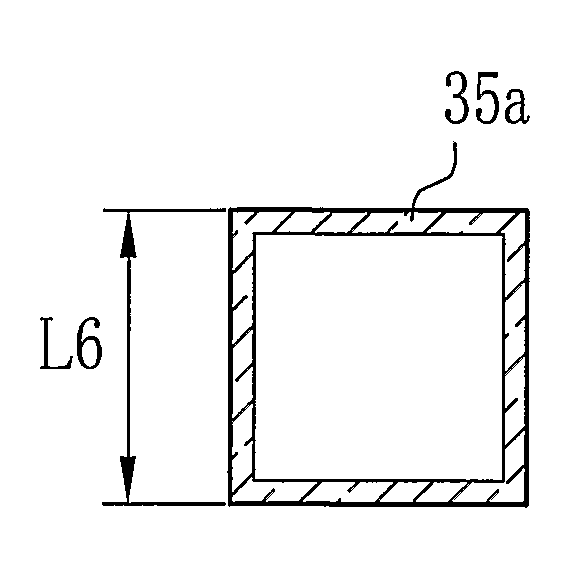

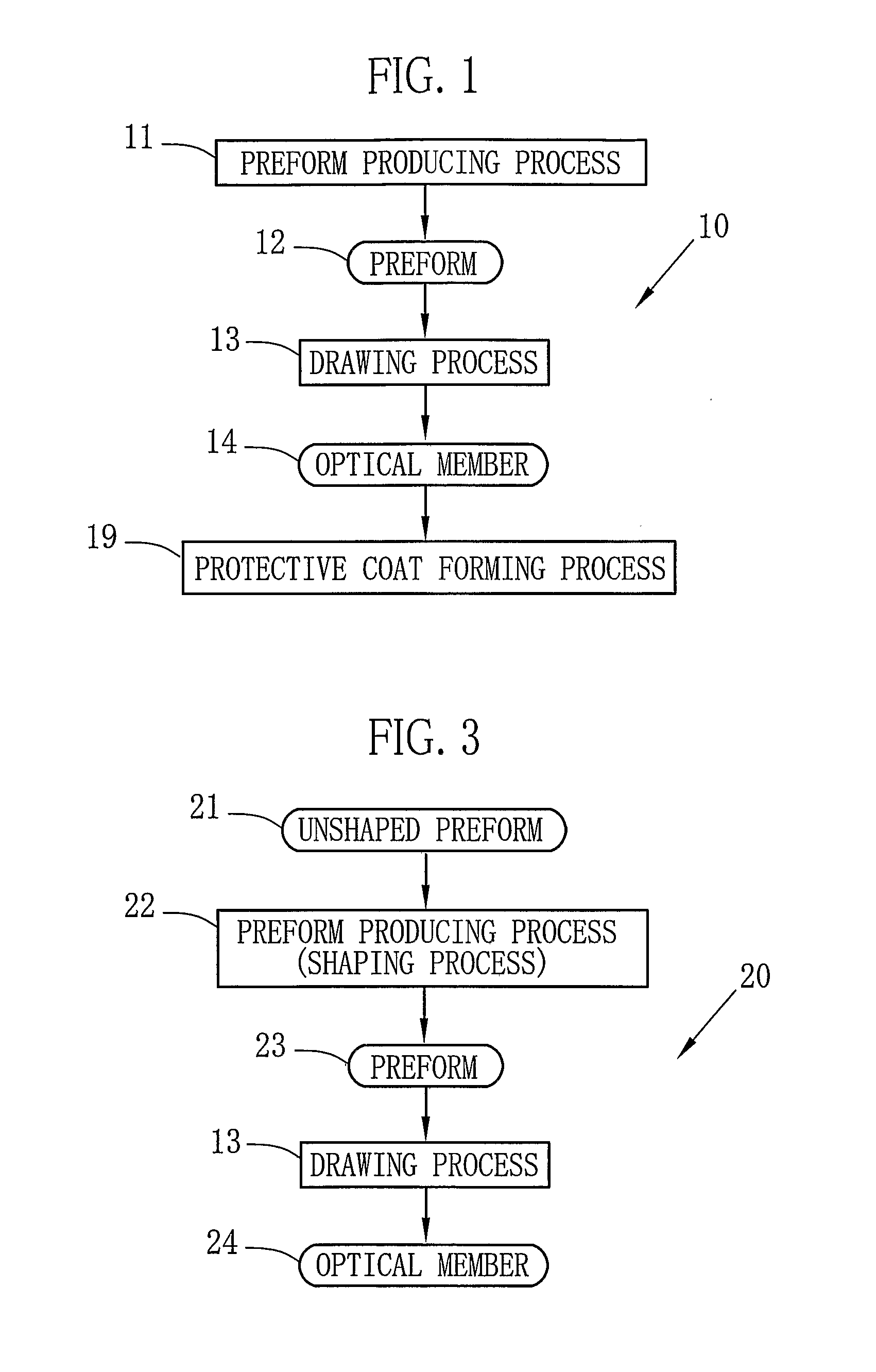

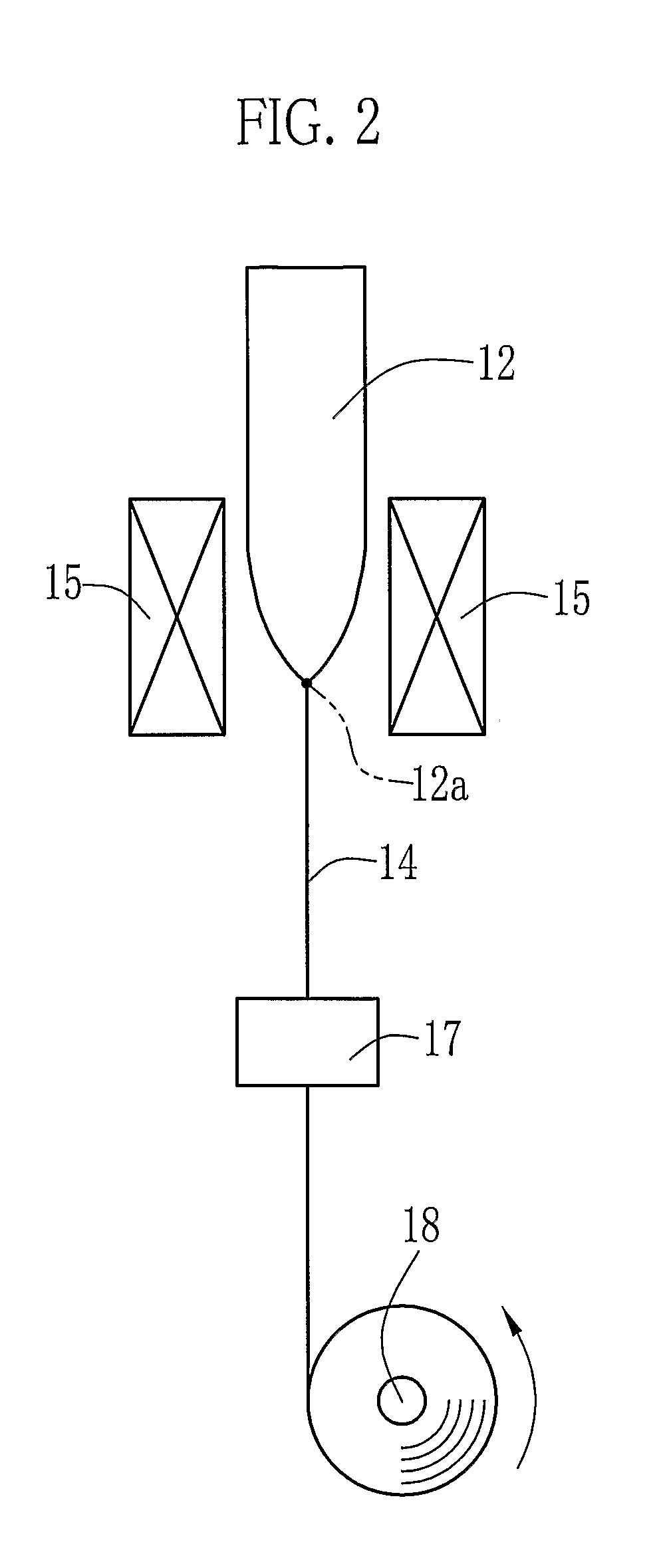

Plastic Optical Member and Producing Method Thereof

InactiveUS20080205840A1Easy to produceSimple structureOptical fibre with multilayer core/claddingOptical articlesSquare cross sectionMelt extrusion

A clad pipe (70) is produced by heating PVDF to 180° C., and then this PVDF being extruded from a melt-extrusion device. The clad pipe (70) has a square cross-section whose sides L1 are 20 mm length, and in a center thereof, there is a square hole. In the square hole, a core (72) mainly includes PMMA is formed. Accordingly, a preform (12) having a clad (71) of PVDF and the core (72) of PMMA is obtained. The preform (12) is heat-soften-drawn at 210° C. A drawing ratio is 1600. Finally, an optical member (14) having a 0.5 mm square cross-section is obtained.

Owner:FUJIFILM CORP

Lie-down massager

InactiveUS7081098B2Good treatment effectImprove reliabilityChiropractic devicesEye exercisersSquare cross sectionReciprocating motion

A lie-down massager includes a base frame having a top panel, a rider provided below the top panel of the base frame, a guide member movably engaged between the base frame and the rider to enable the rider to make a horizontally reciprocal movement relative to the base frame, massage bumps that move vertically along an elongated top opening of the elongated top panel of the base frame, and a lifter that holds the massage bumps and adjusts the height of the massage bumps. The lifter includes a top plate, a bottom plate, a fluid operated cylinder fixed to the bottom plate, and a spring fixed between the top plate and the bottom plate. The fluid operated cylinder has a cylinder shaft that is moved by pressurized fluid overcoming the force of the spring, and a guide shaft and a guide bearing that have a square cross section.

Owner:SHIM 30 SIMON K

Nestable containers

InactiveUS20060011626A1Simple and safe operationImprove efficiencyBoxesSquare cross sectionEngineering

A nestable container designed for efficient storage when the containers is not in use and for safe handling when in use. The container has four outwardly bowed sidewalls flared upwardly from its bottom with each sidewall connected to adjacent sidewalls by an inwardly fluted web to form a essentially square cross section. The webs define finger gripping corners at the edges of the sidewalls that allow the container to gripped better by a user. The containers can be nested with other containers of different sizes without wasting space. The essentially square configuration of the containers also make them easy to pack with or within other containers, that are typically also square or rectangular.

Owner:PALDER SAUL

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com