Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2472results about "Gas handling/storage effects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

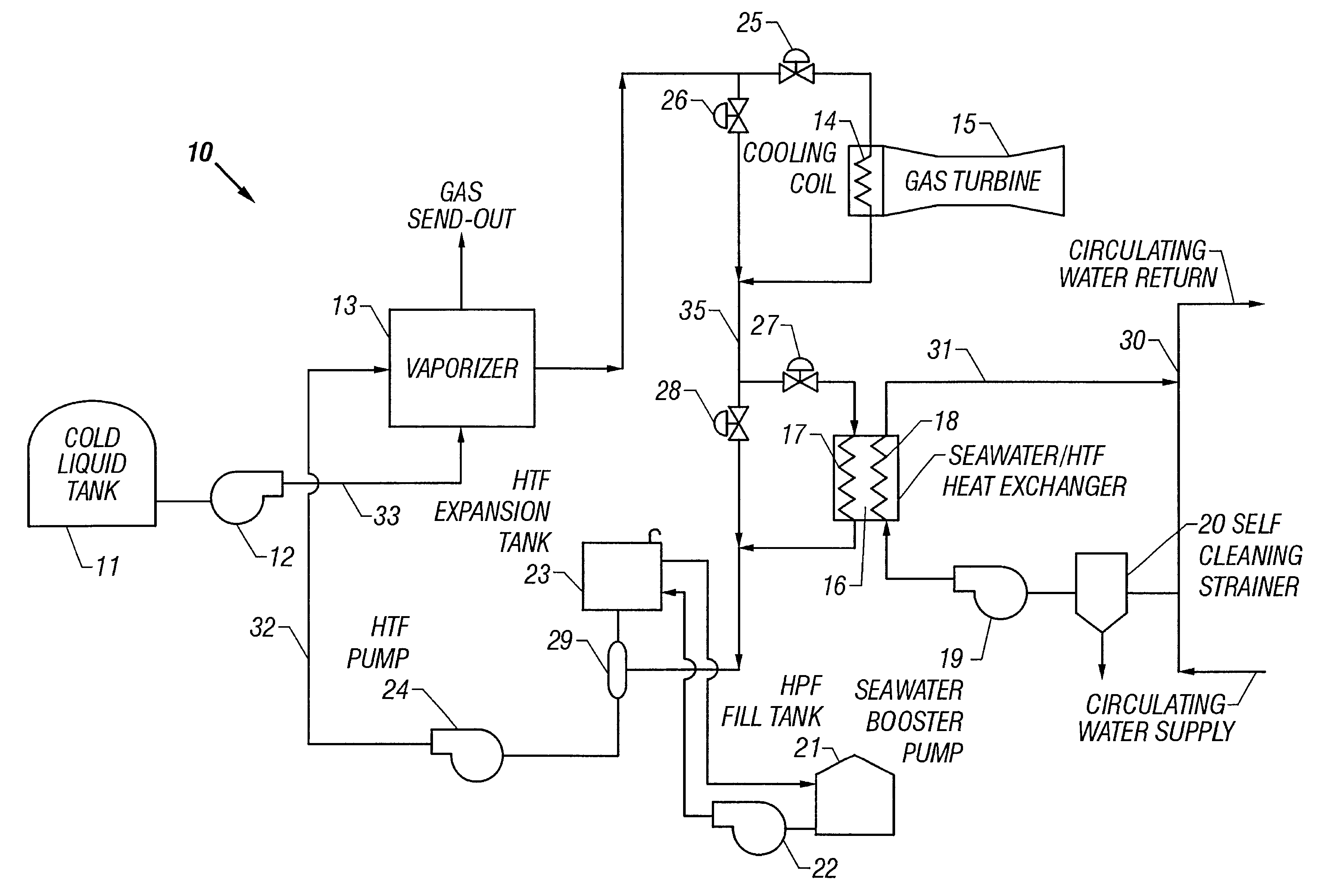

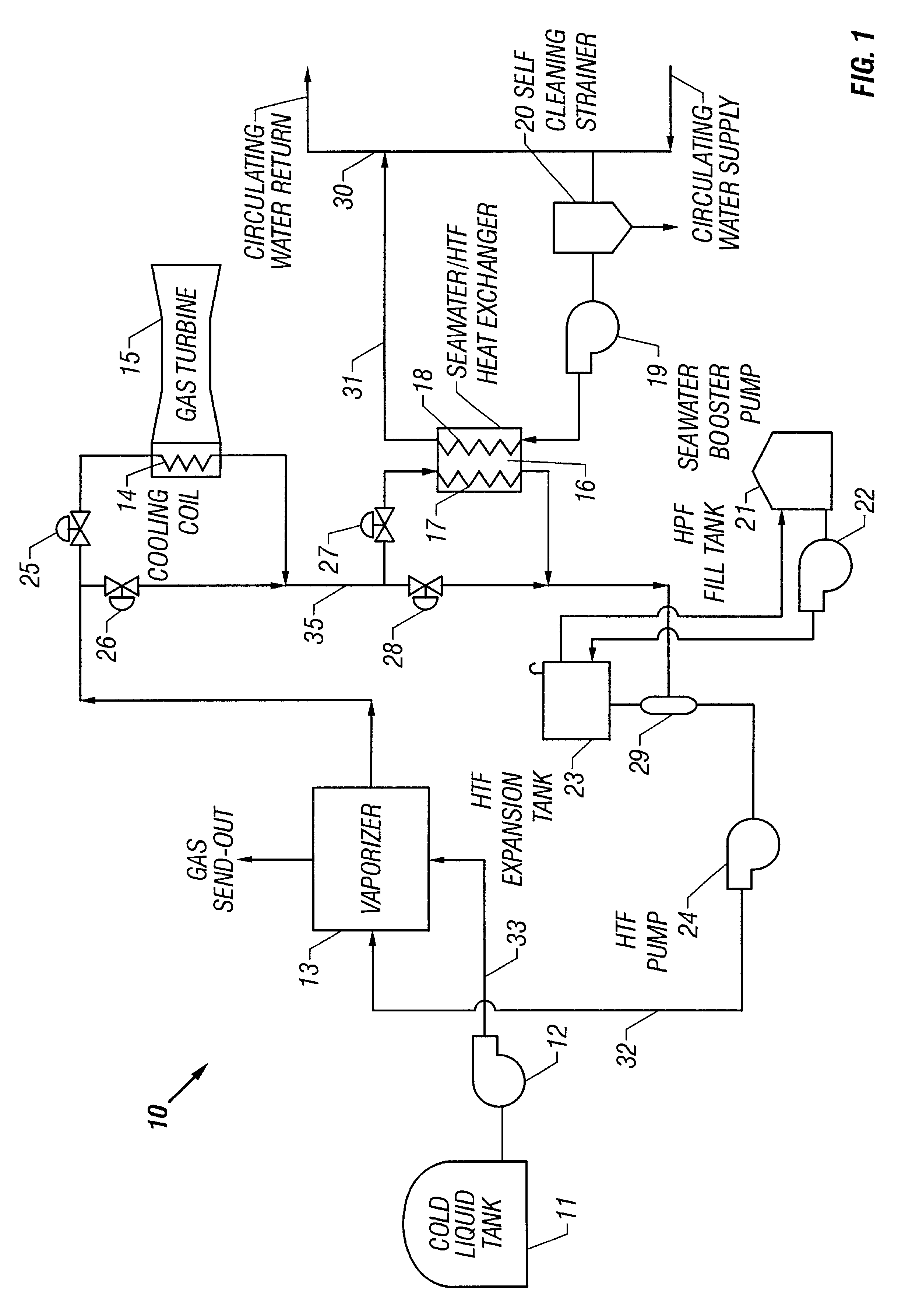

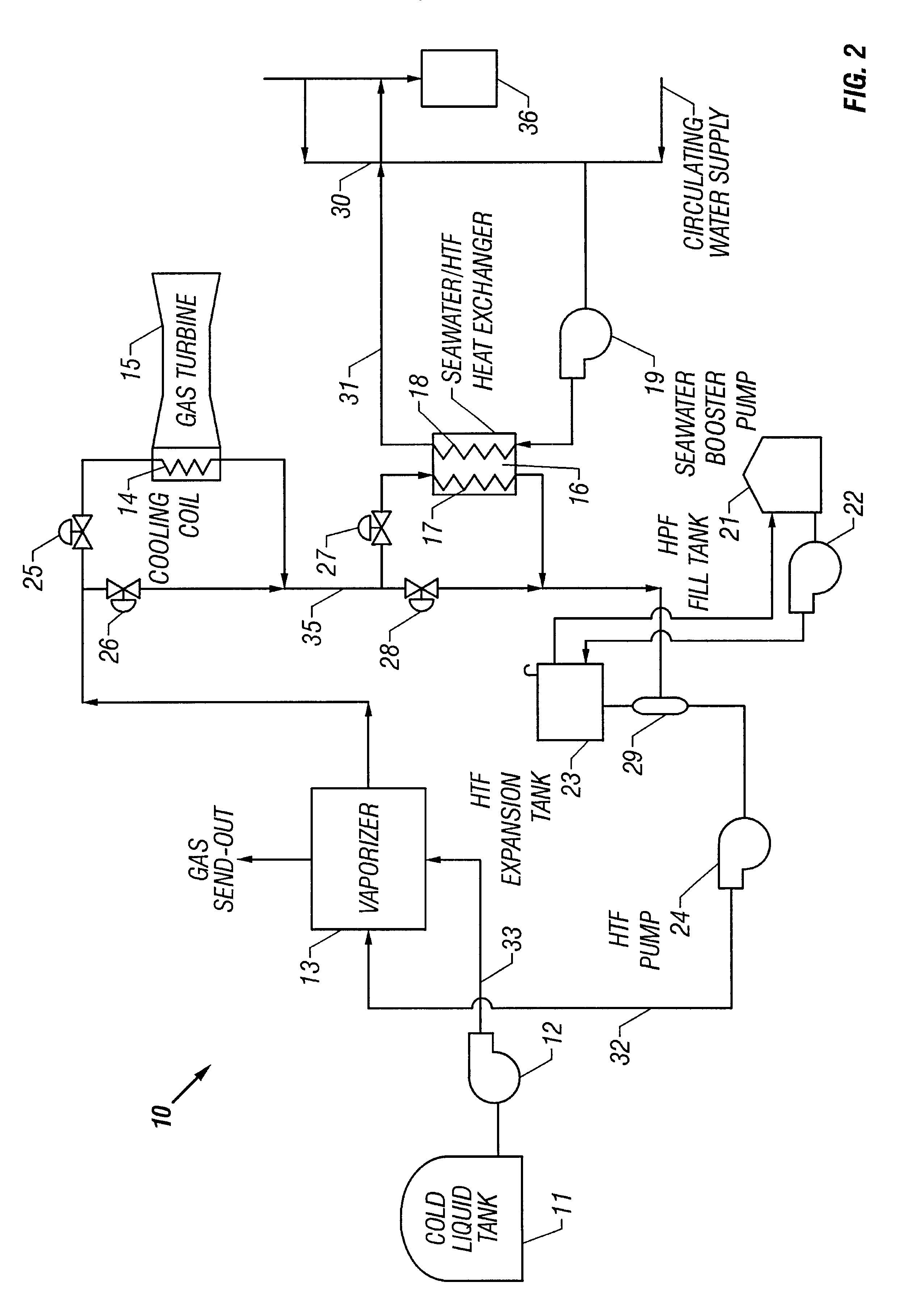

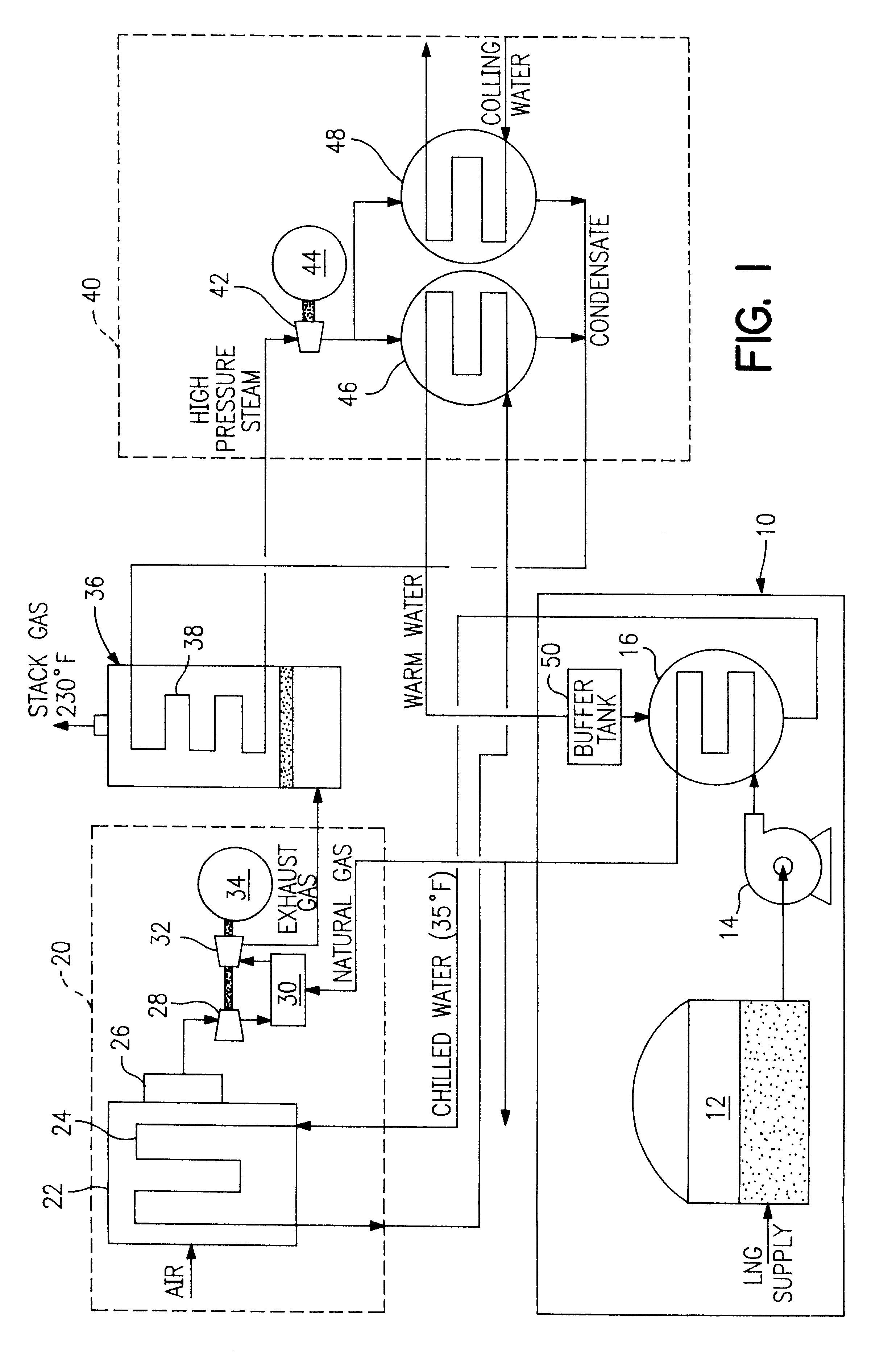

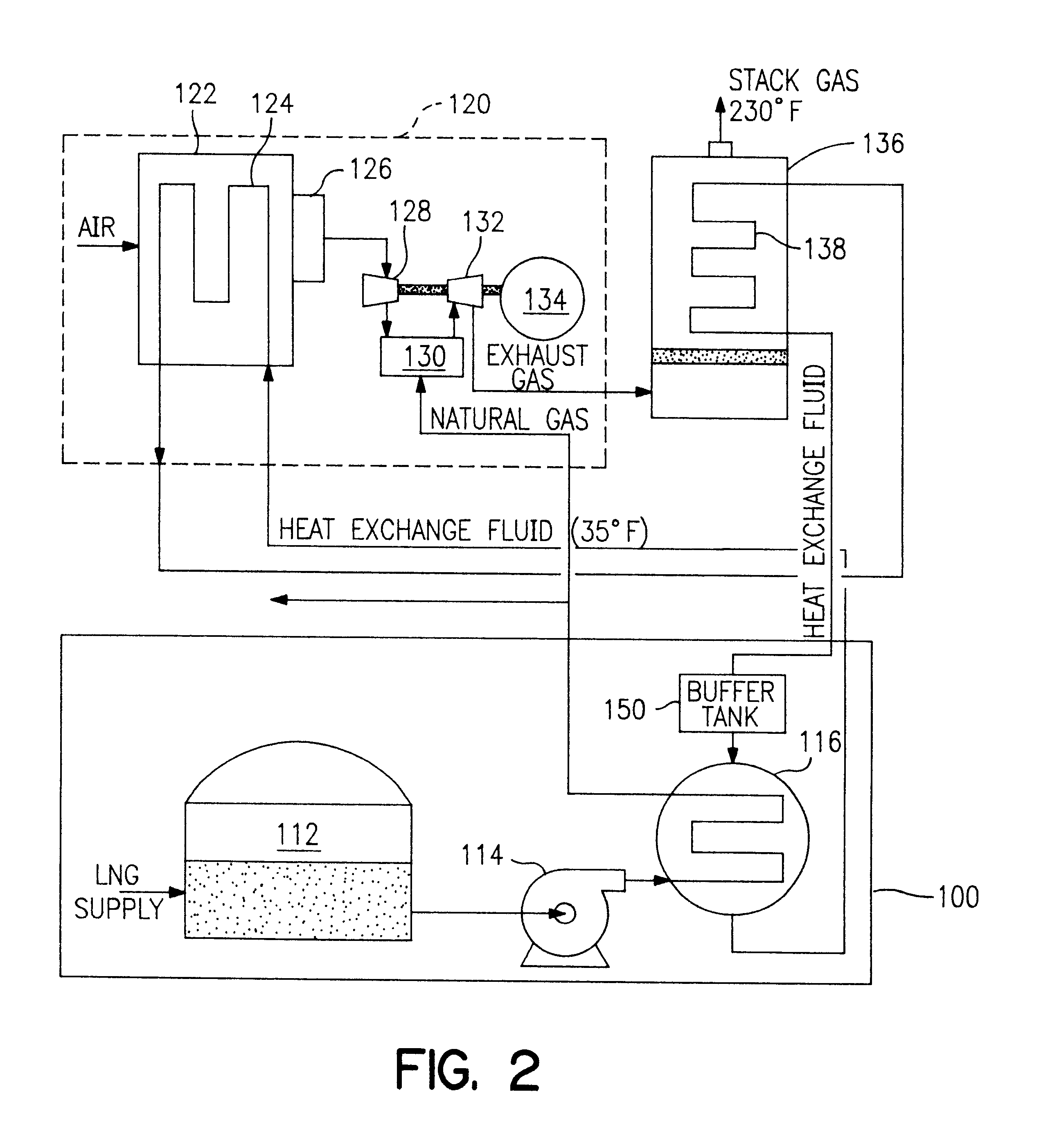

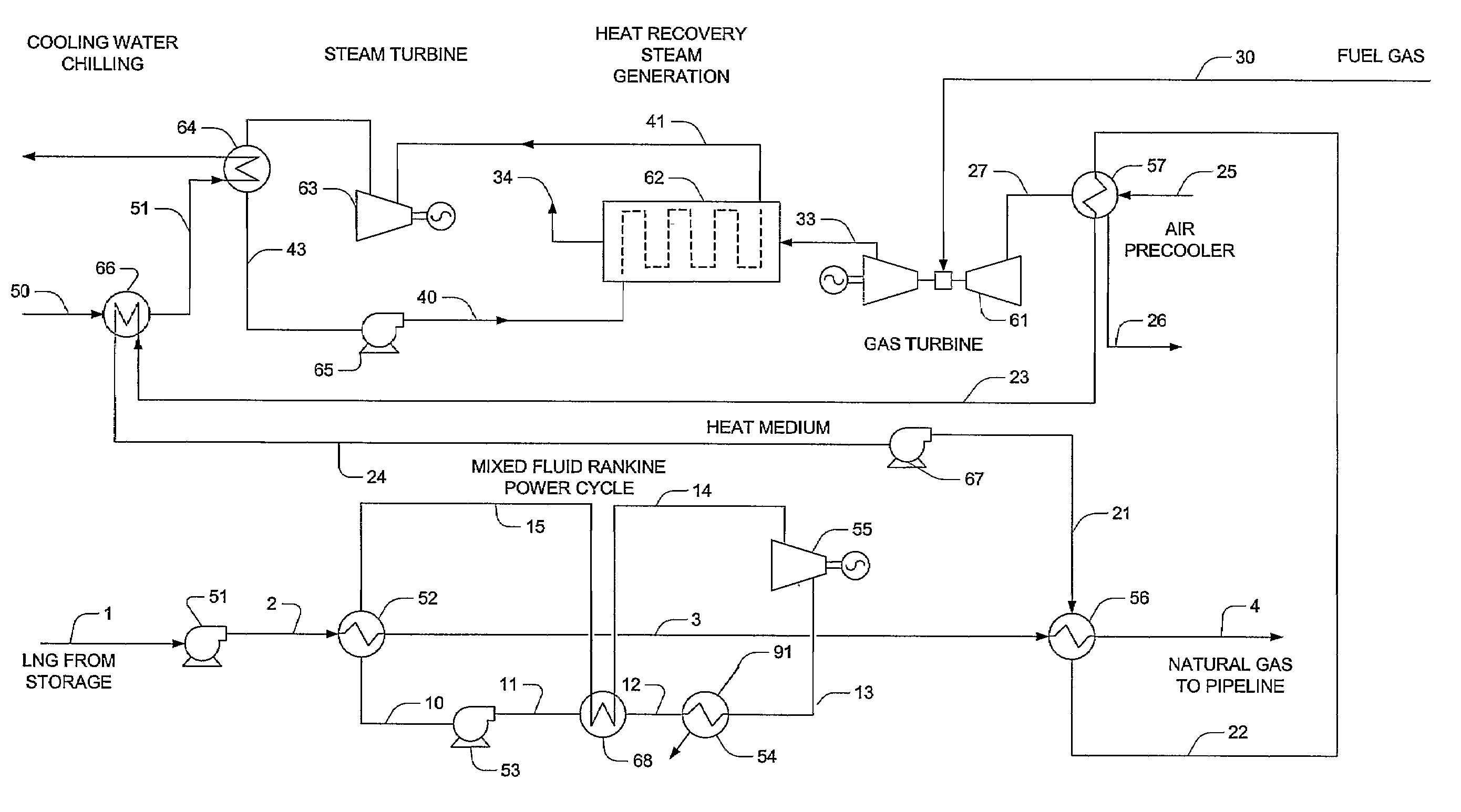

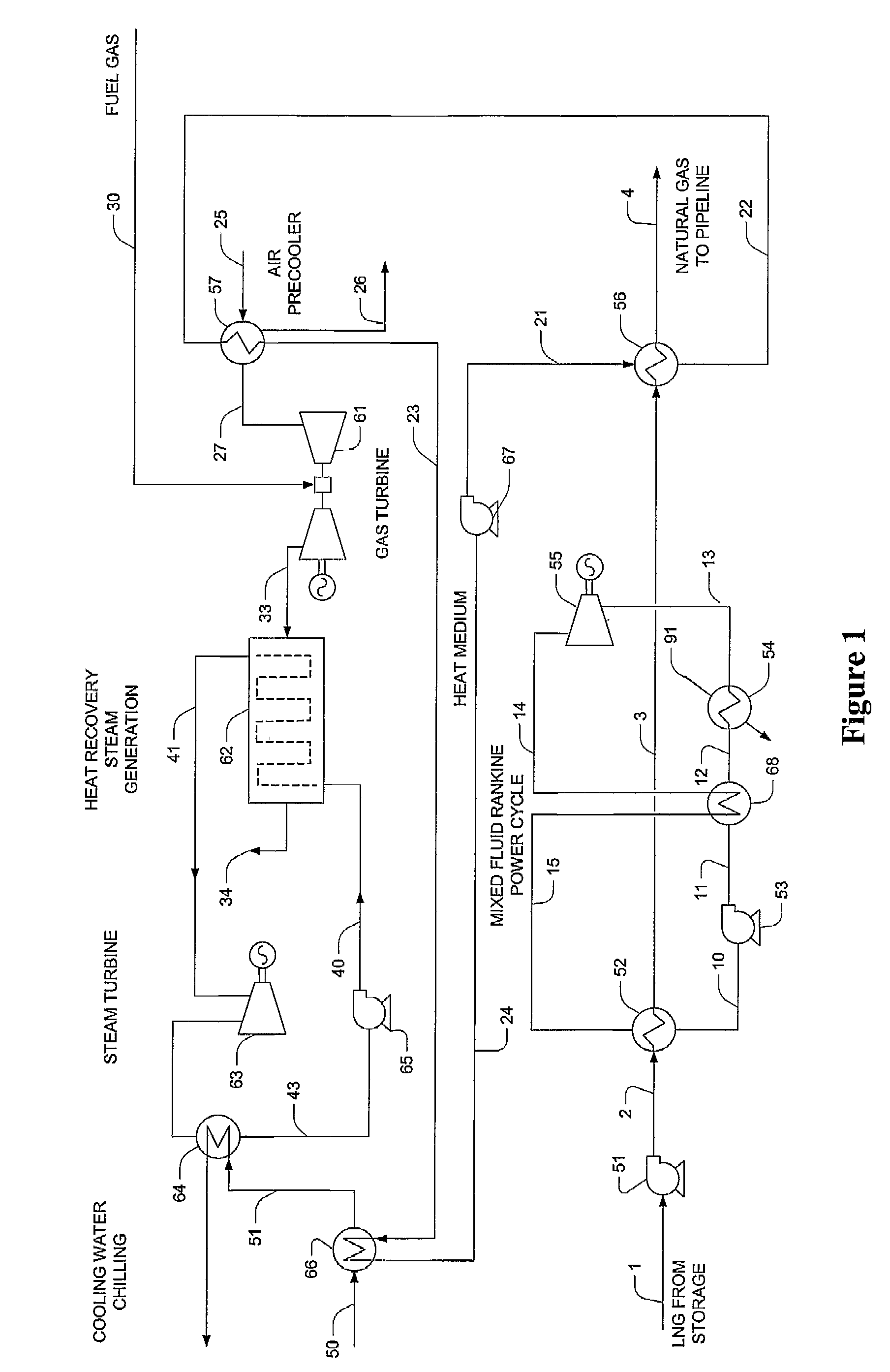

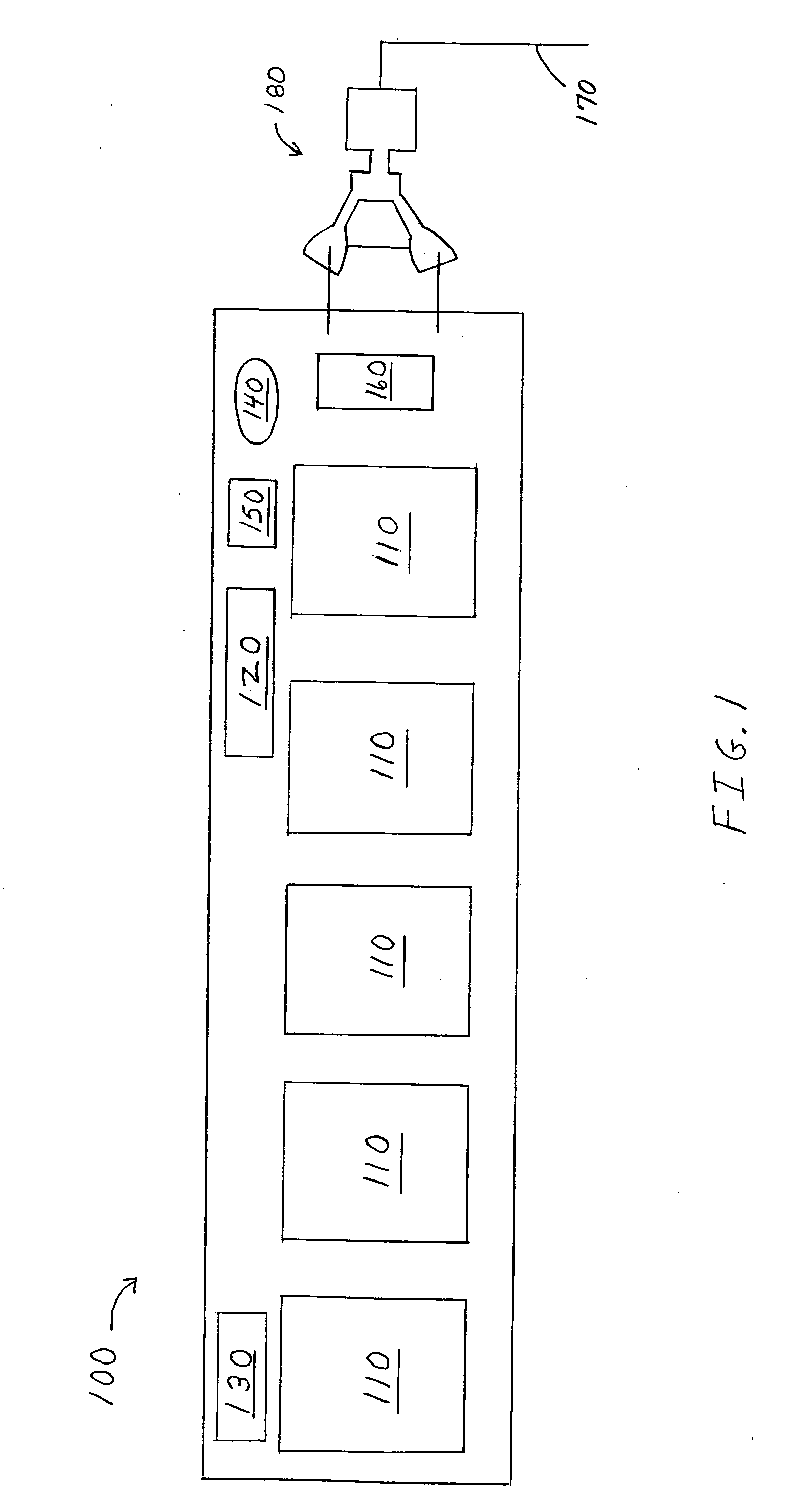

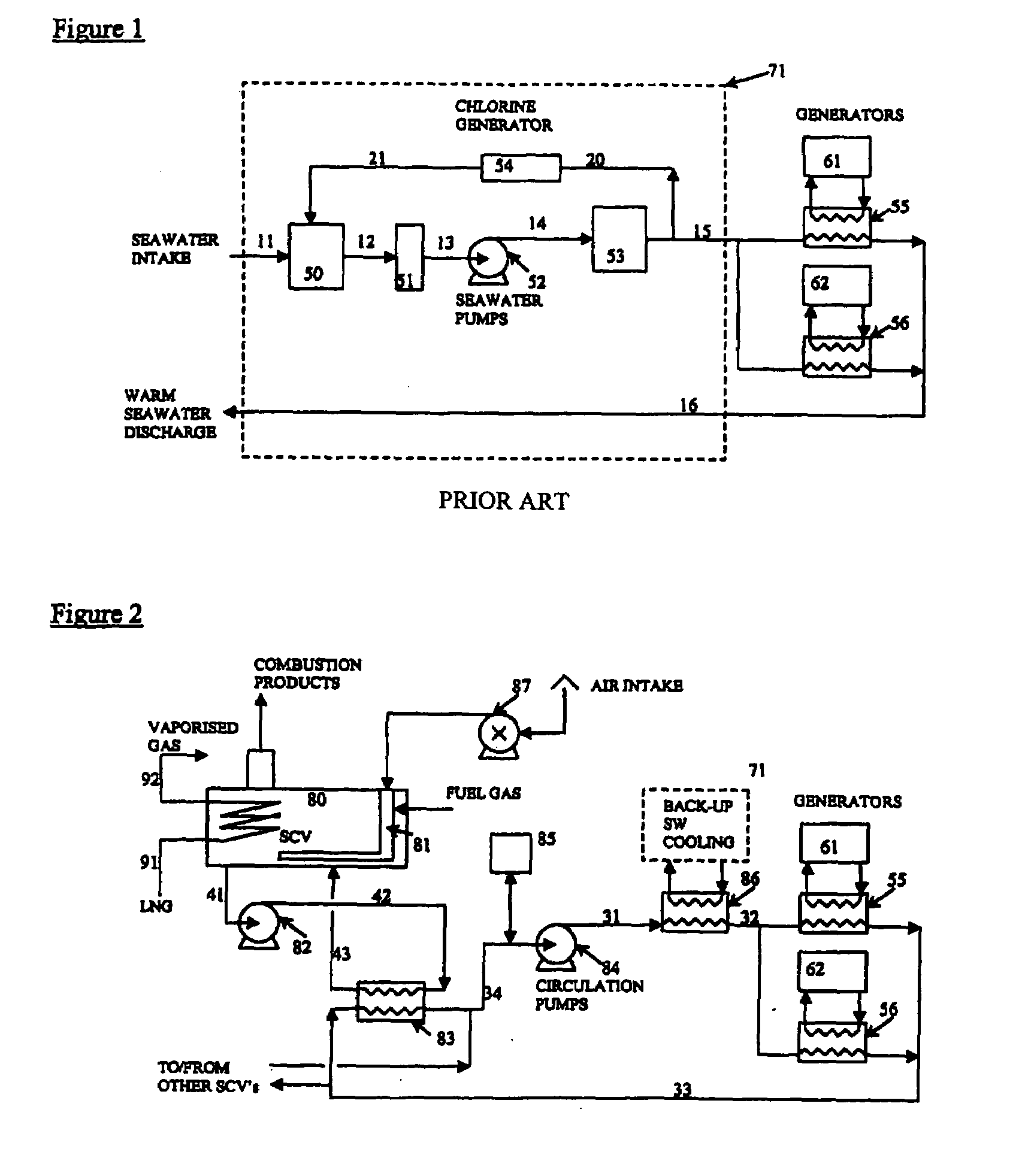

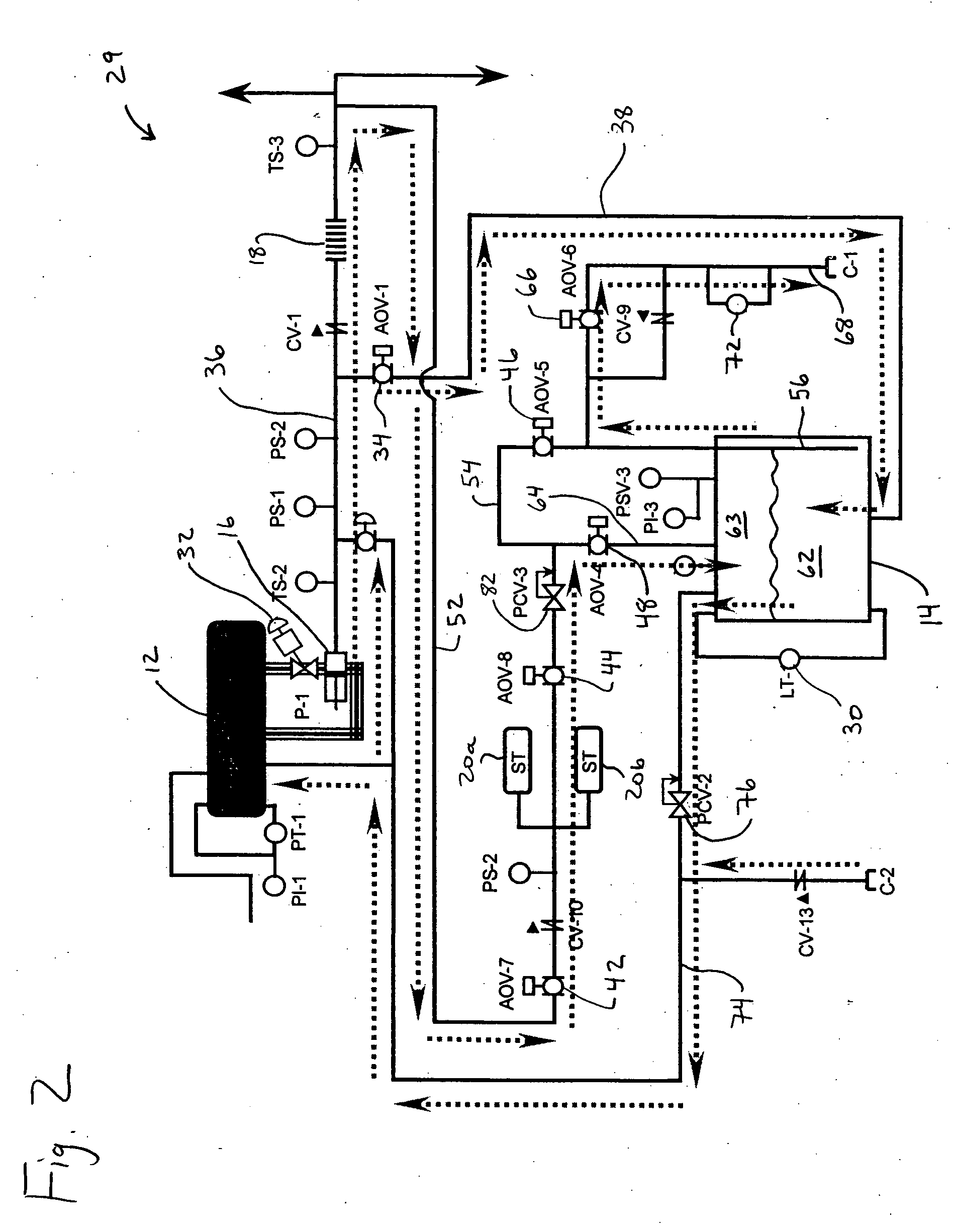

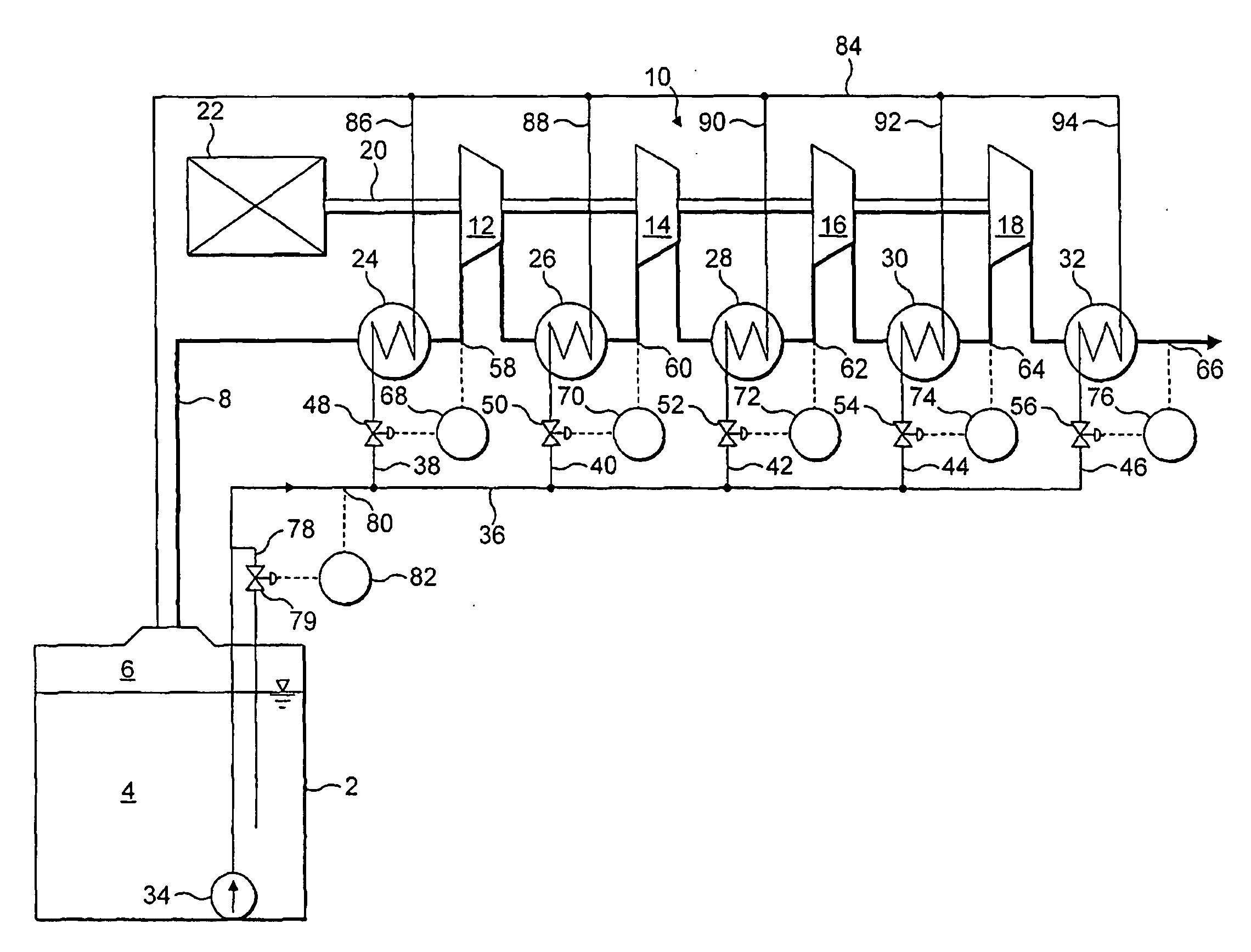

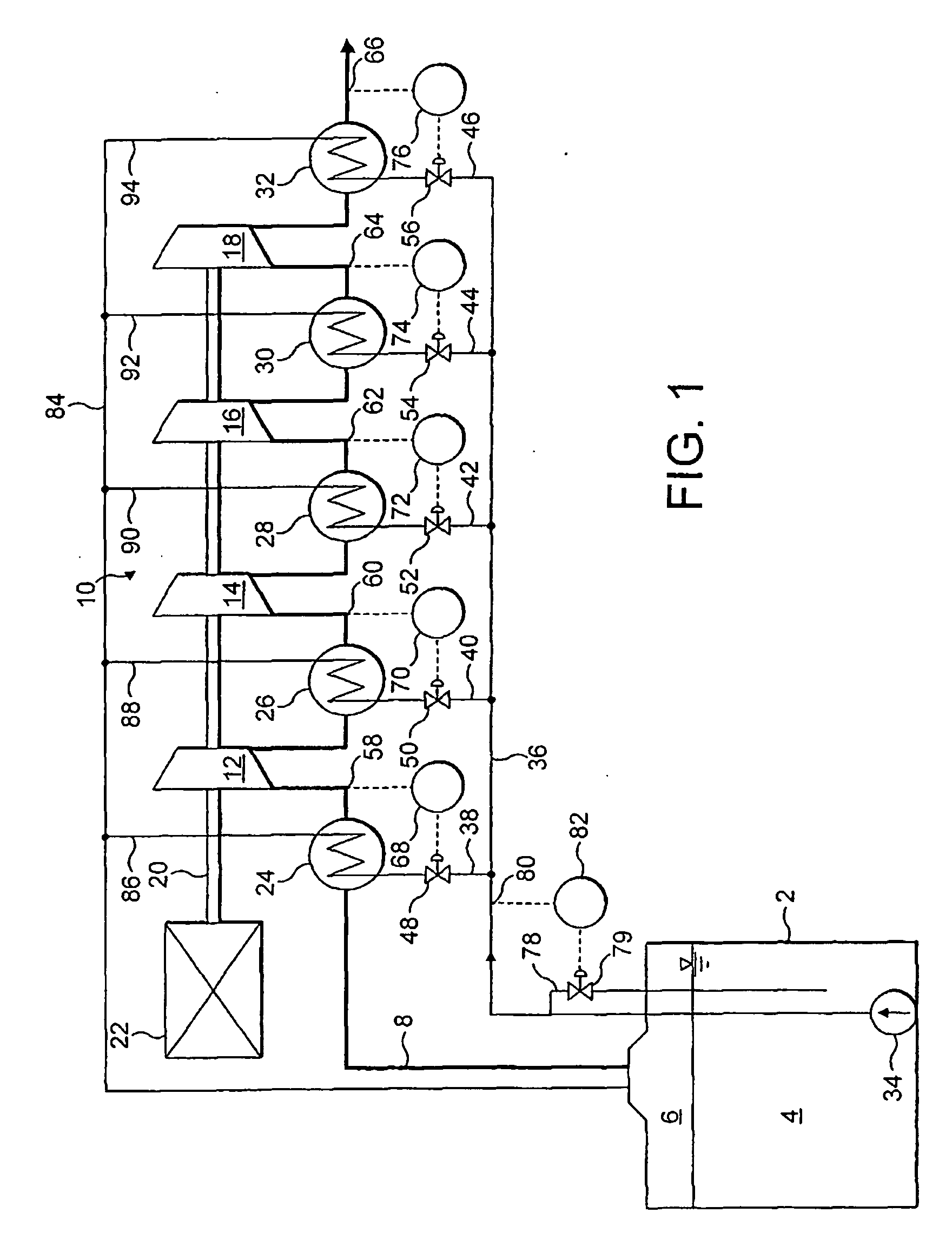

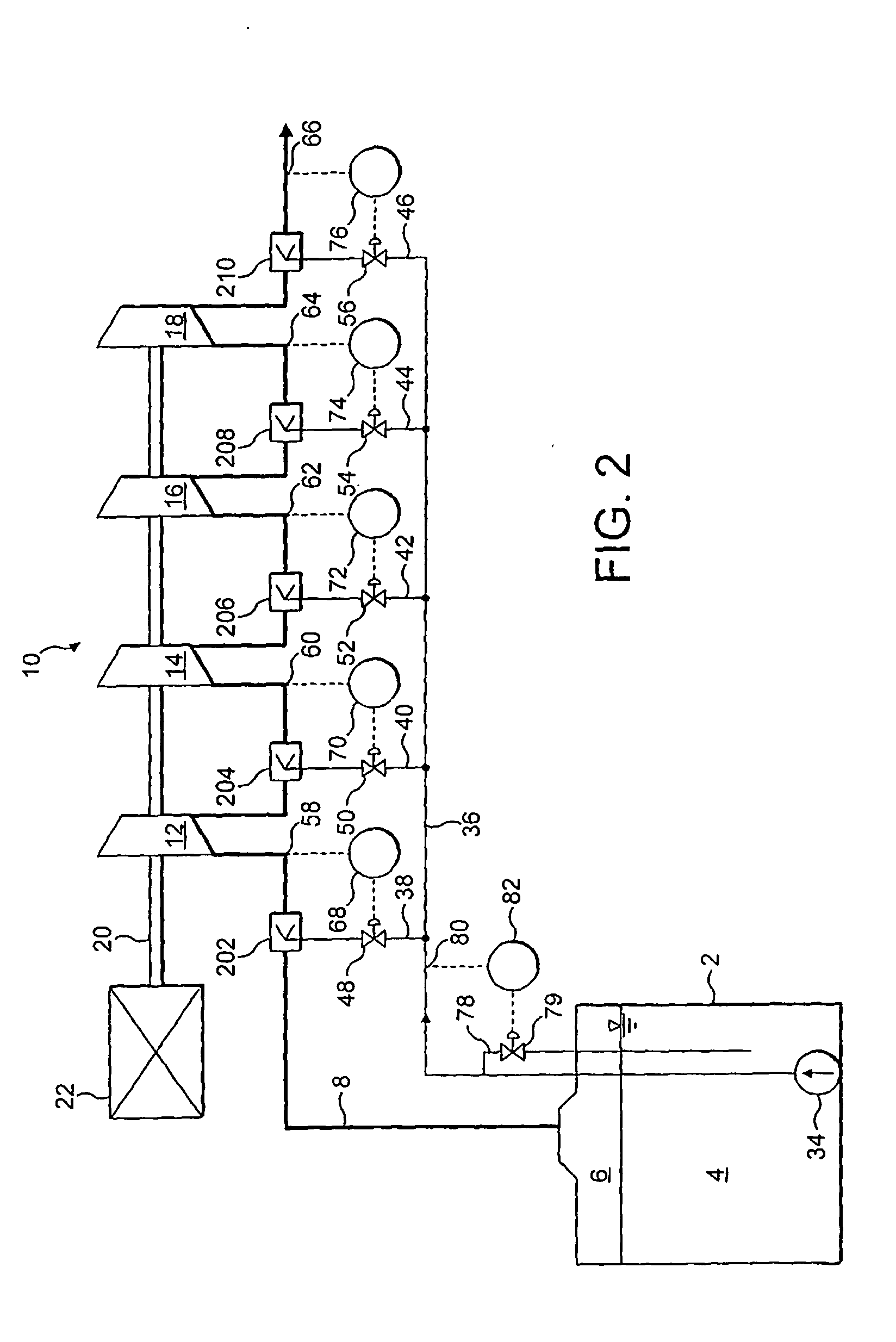

Method and apparatus for vaporizing liquid natural gas in a combined cycle power plant

InactiveUS6367258B1Turbine/propulsion engine coolingTurbine/propulsion fuel heatingPower stationProcess engineering

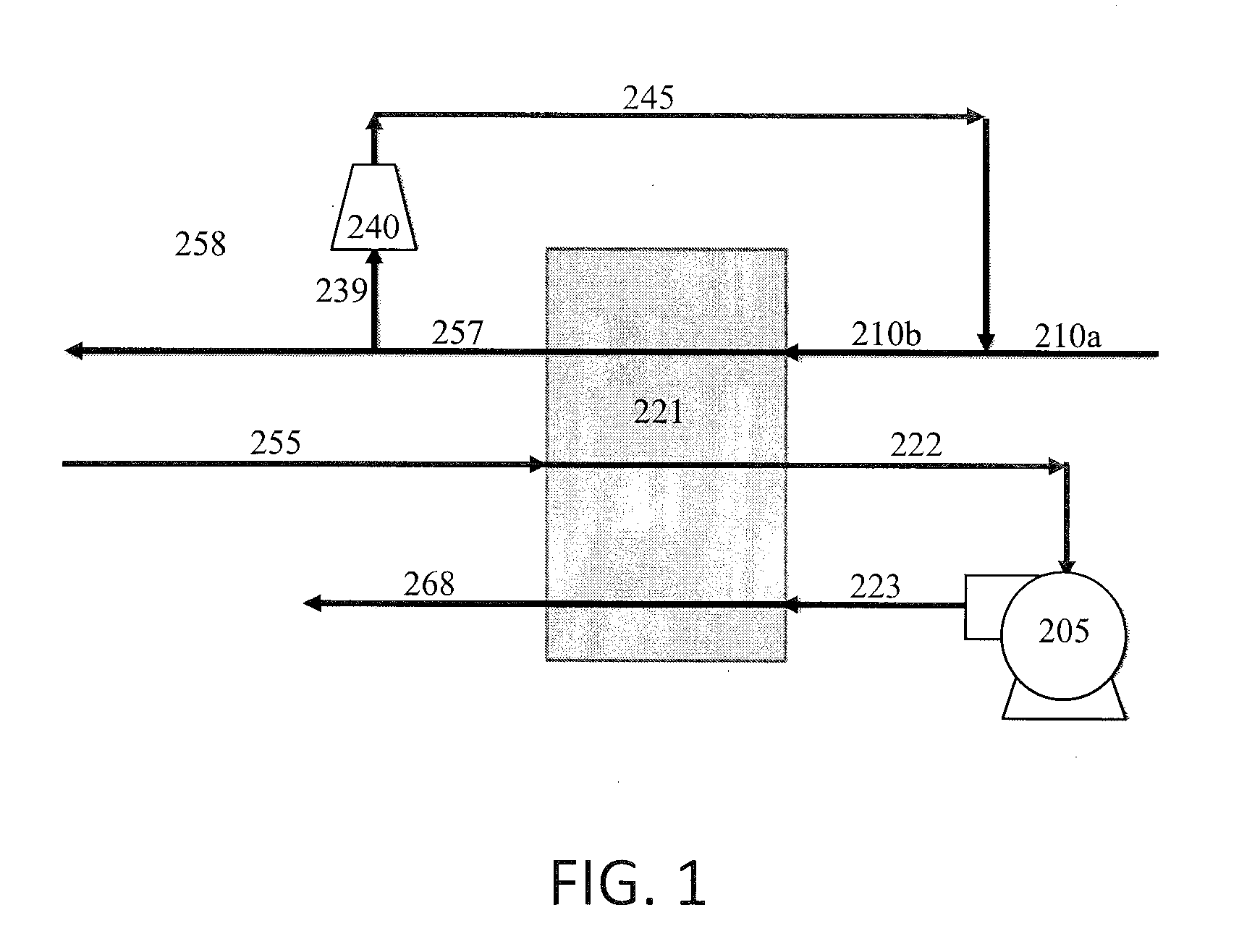

A method and apparatus for increasing the efficiency of a combined cycle generation plant by assisting the vaporization of cold liquid including liquefied natural gas ("LNG") or liquefied petroleum gas (LPG) in a combined cycle power plant. Cold liquid vaporization is assisted by circulating a warm heat transfer fluid to transfer heat to a LNG / LPG vaporizer. The heat transfer fluid is chilled by LNG / LPG cold liquid vaporization and warmed by heat from a gas turbine. The heat transfer fluid absorbs heat from the air intake of a gas turbine and from a secondary heat transfer fluid circulating in a combined cycle power plant. Chilling the gas turbine air intake densifies the air and increases the gas turbine output. Chilling the steam condenser cooling water increases steam turbine output. The effects of chill recovery is higher output and better efficiency of the combined cycle plant.

Owner:BECHTEL CORP

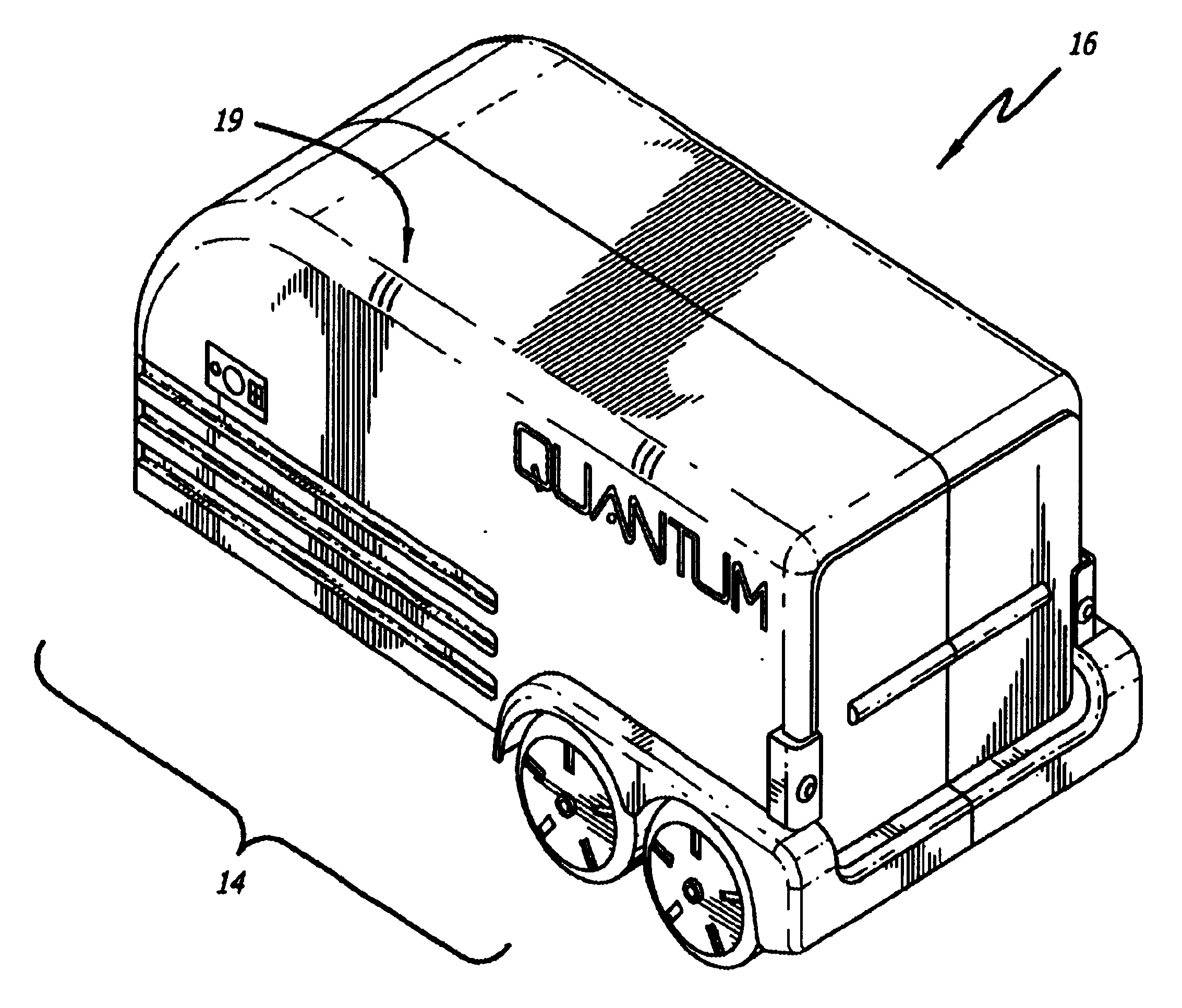

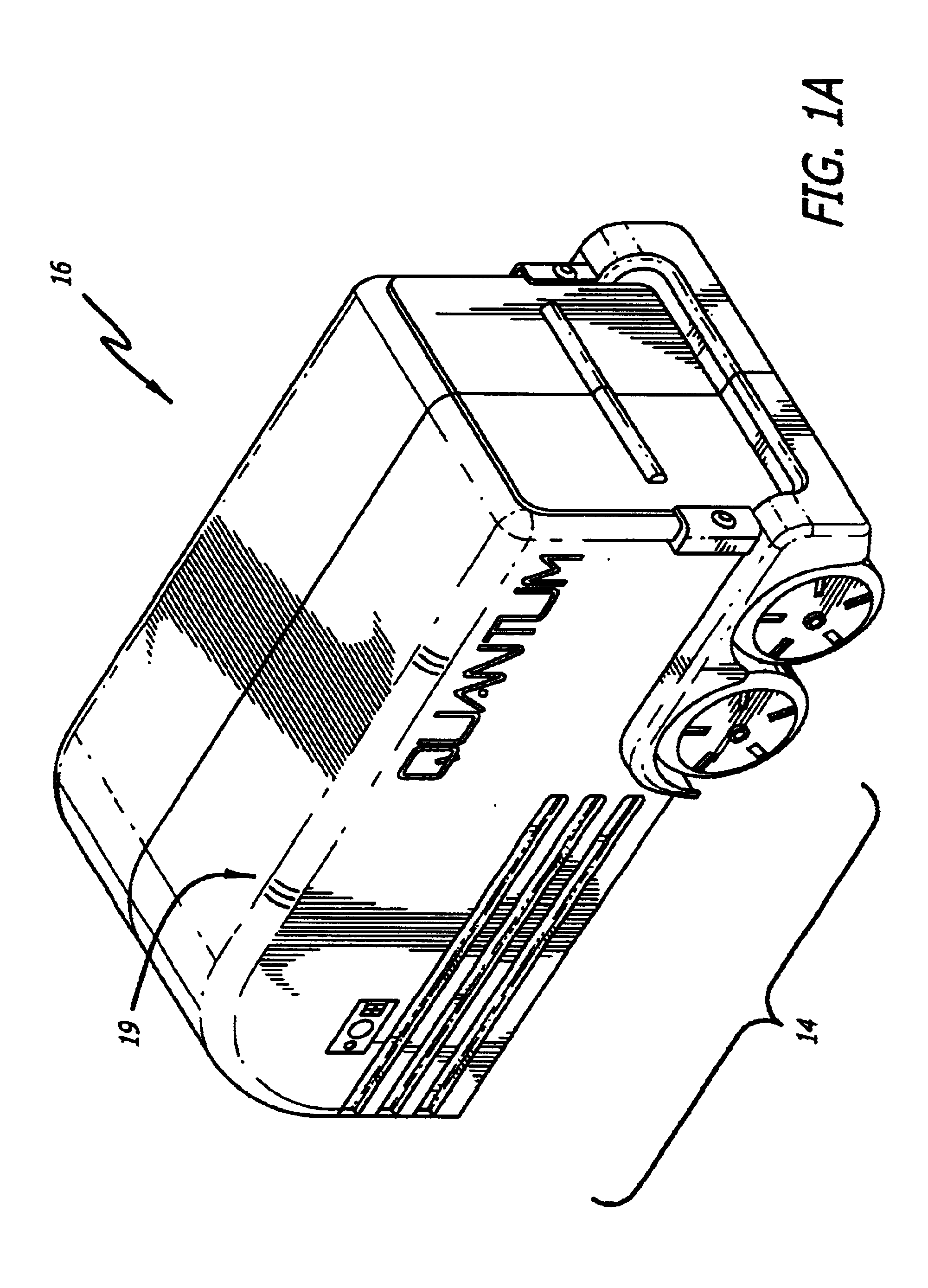

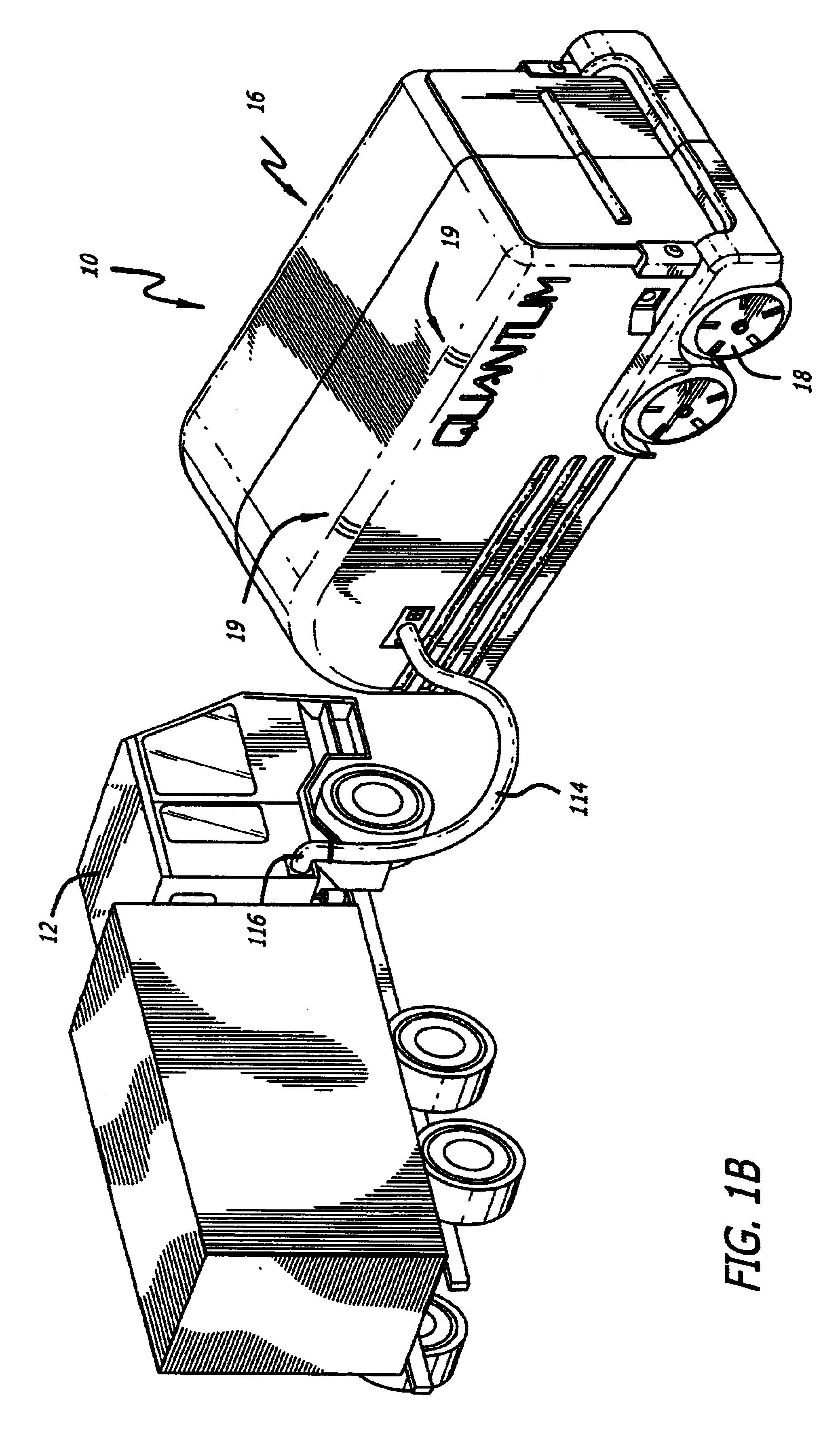

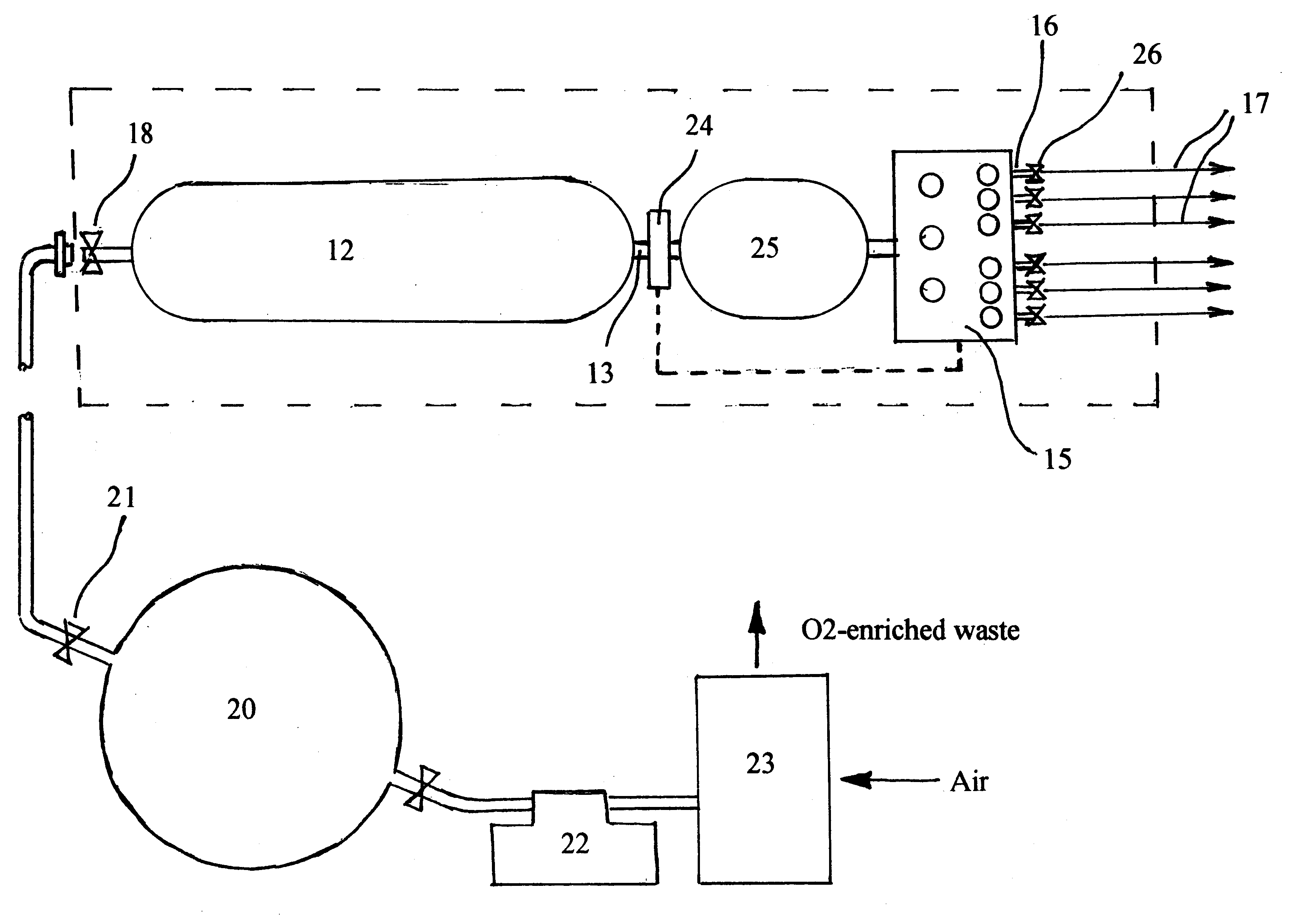

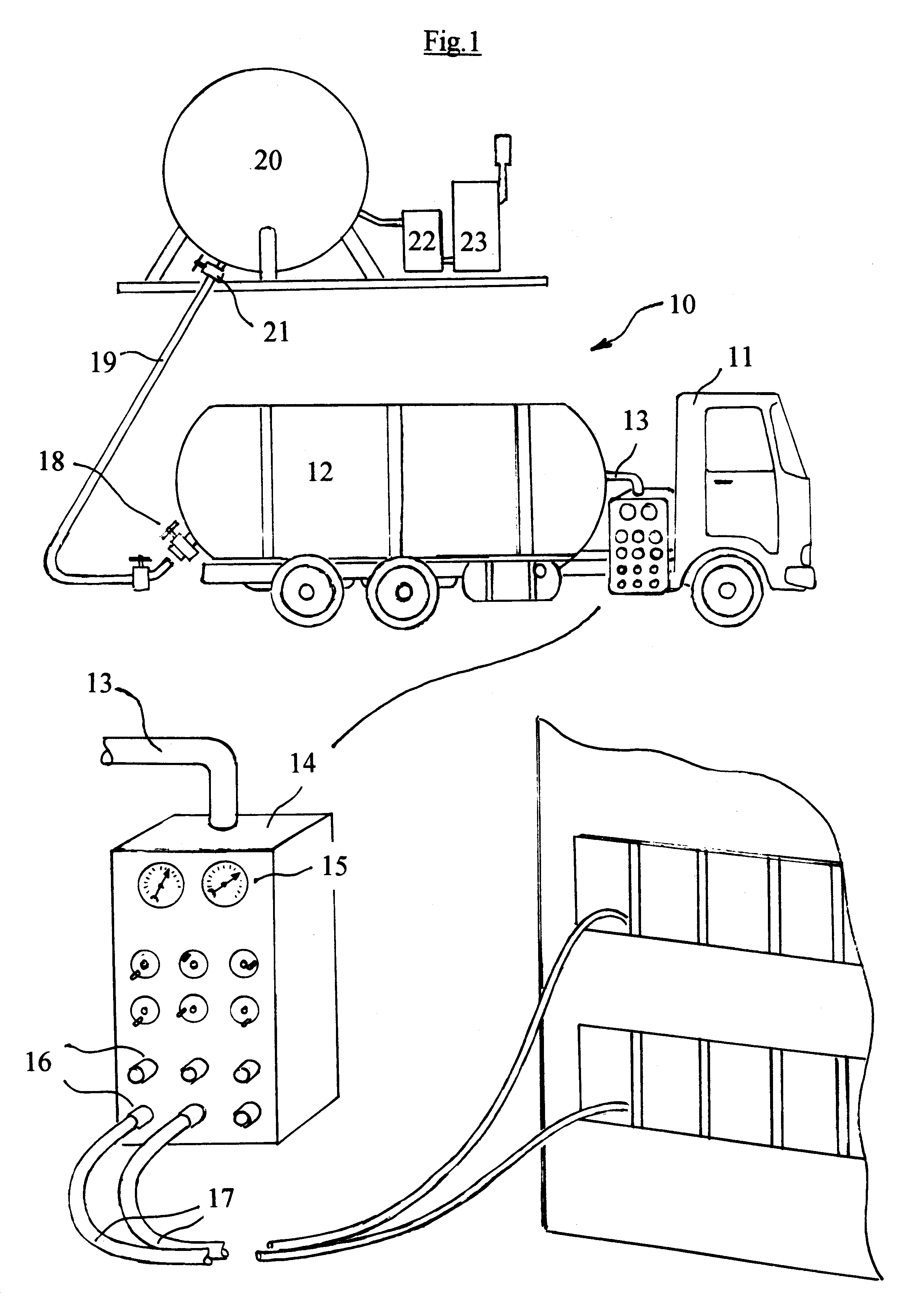

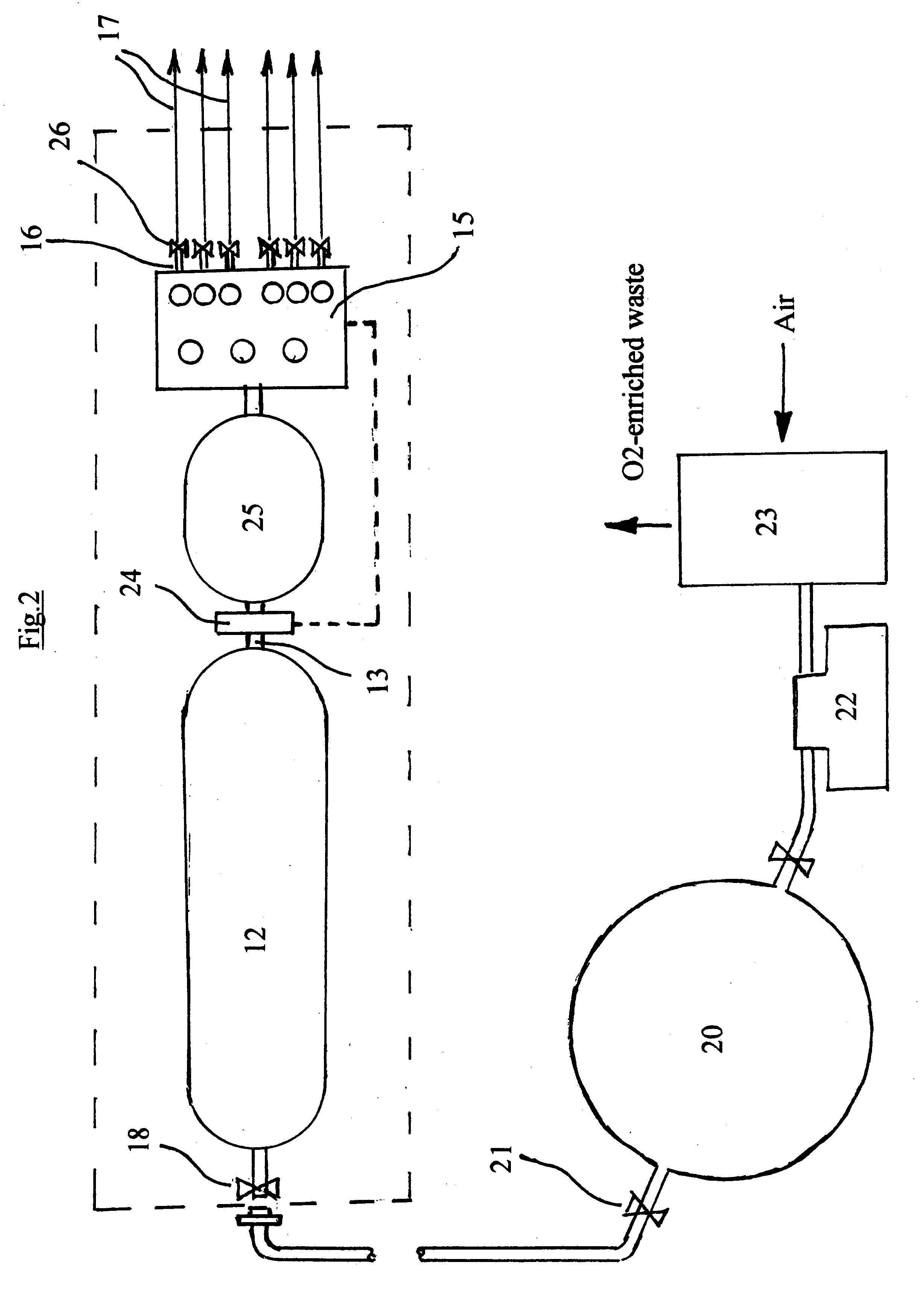

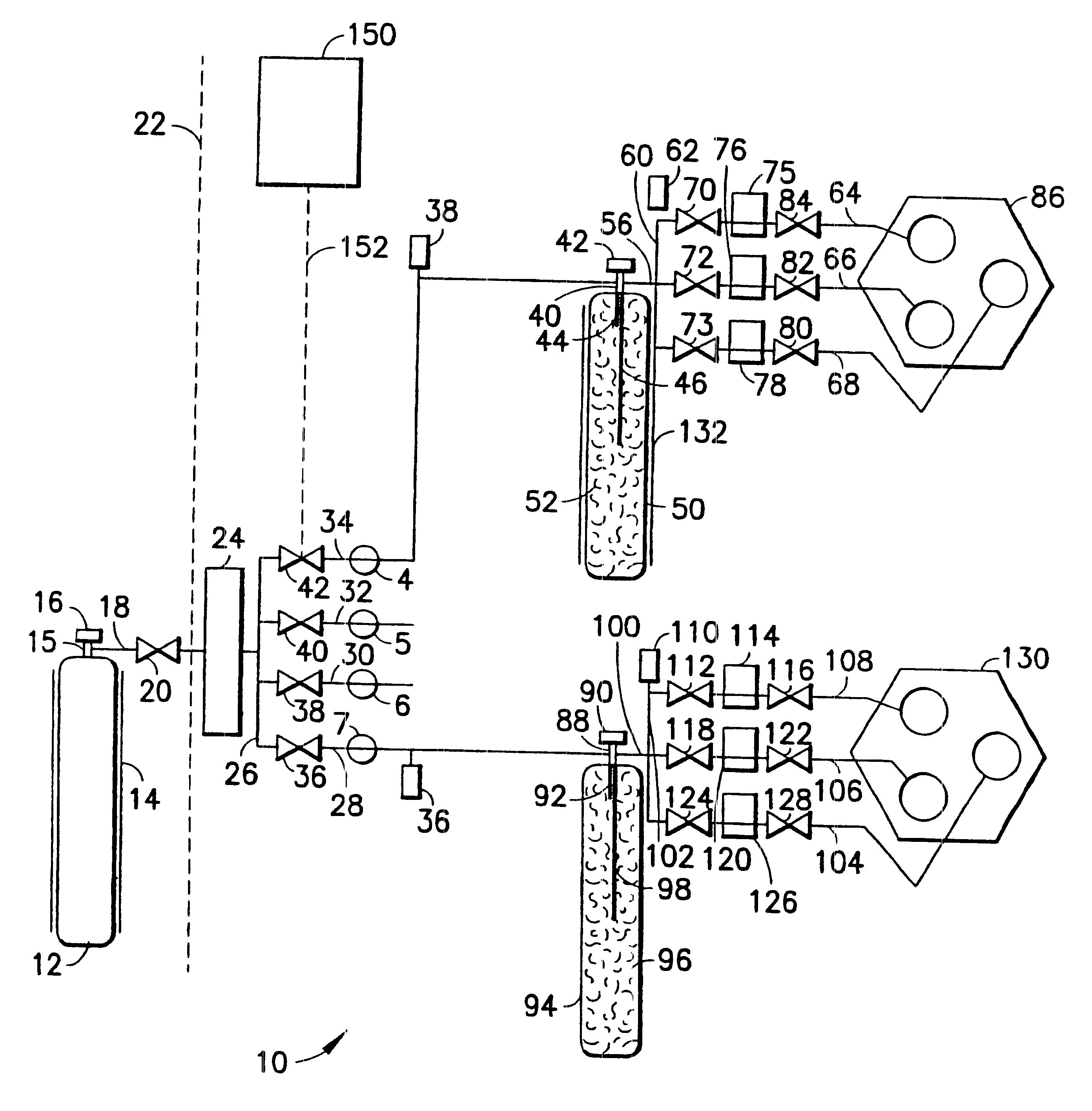

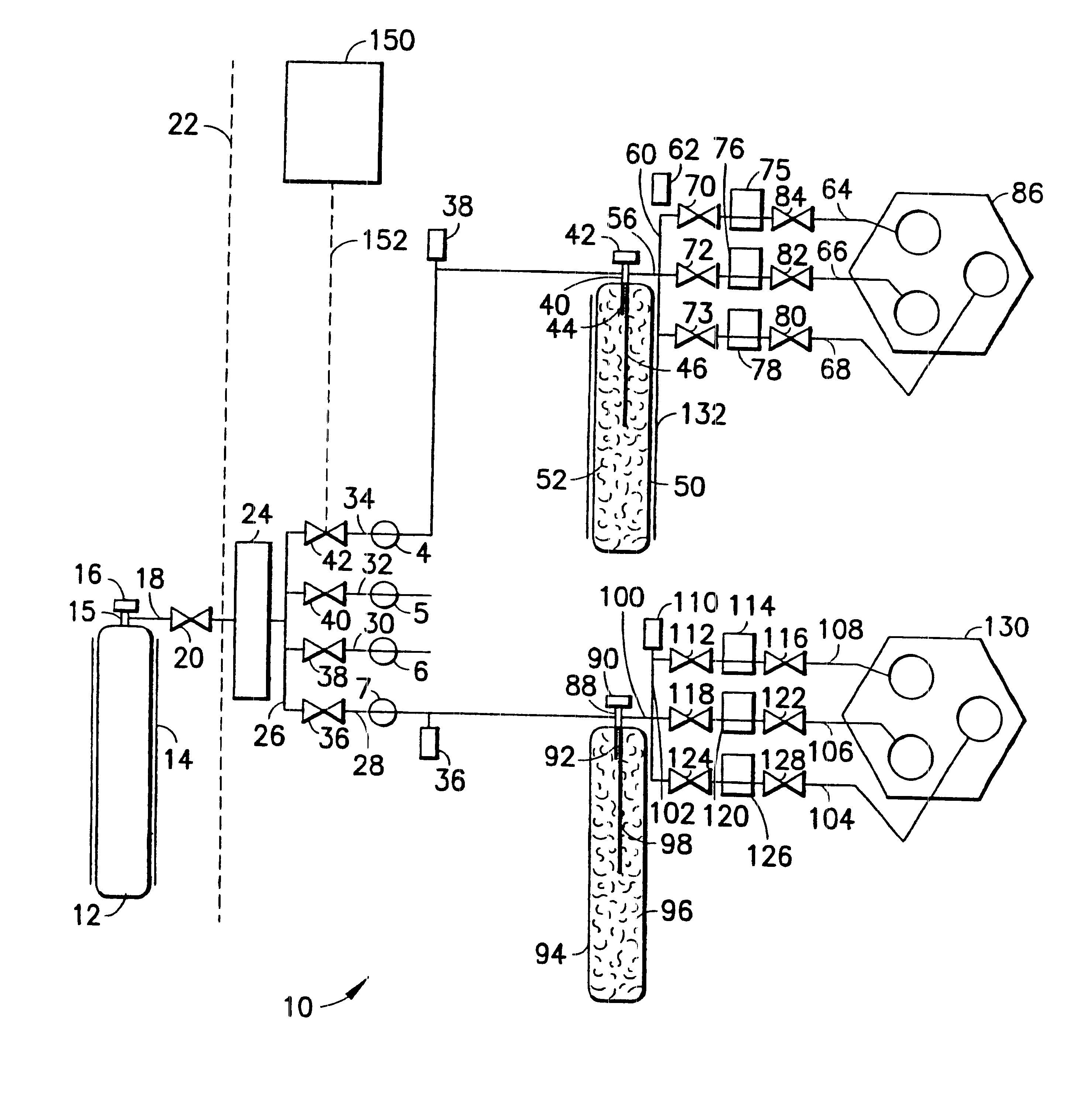

Transportable hydrogen refueling station

InactiveUS6755225B1Easy to monitorReduce riskTank vehiclesGas handling applicationsHigh pressureGaseous hydrogen

A portable hydrogen refueling stations which can dispense gaseous hydrogen from one or more internal high pressure tanks. The refueling station can be refilled with a lower pressure hydrogen gas feed and then compressed for storage within the refueling station.

Owner:QUANTUM FUEL SYST TECH WORLDWIDE INC

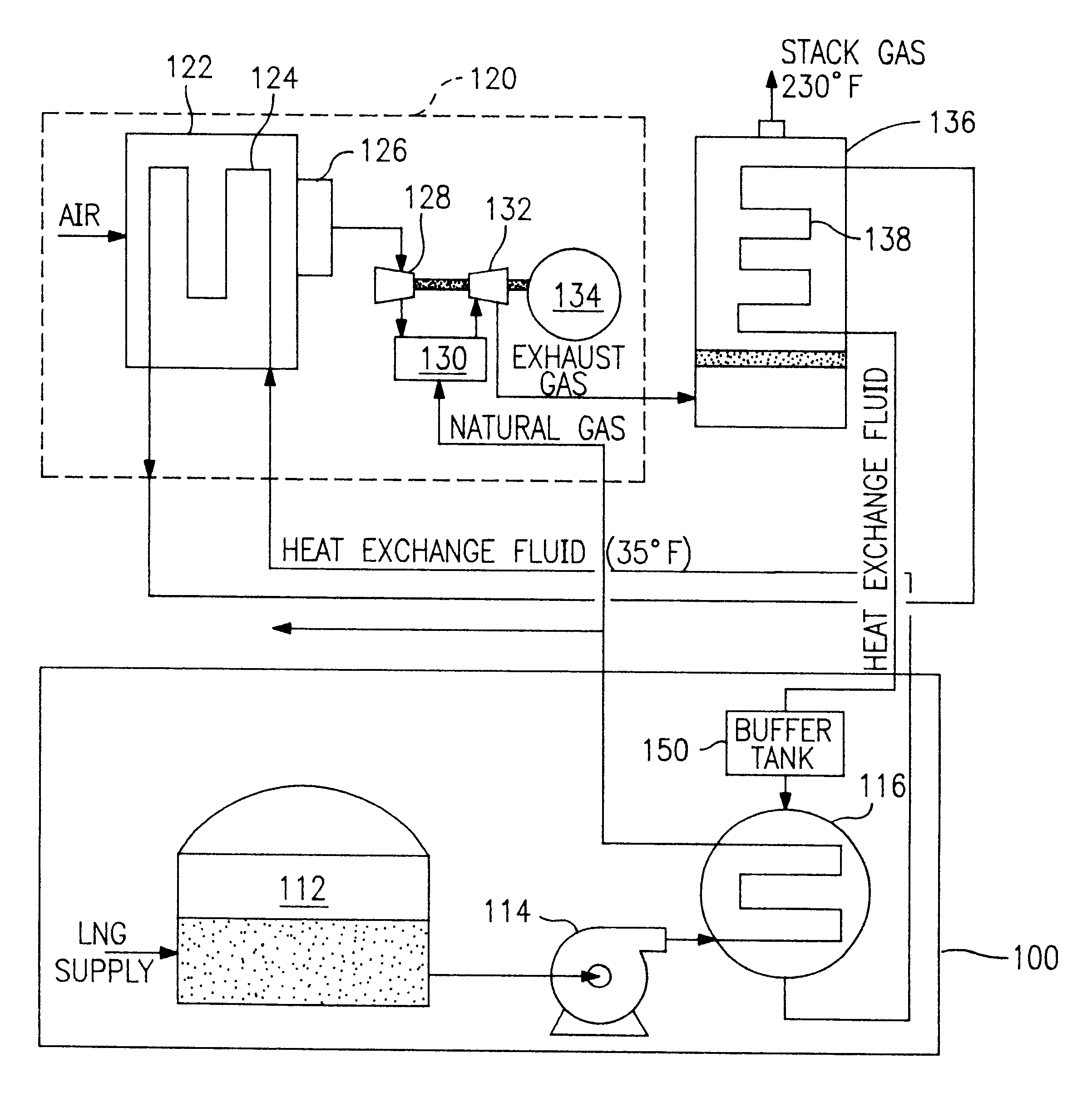

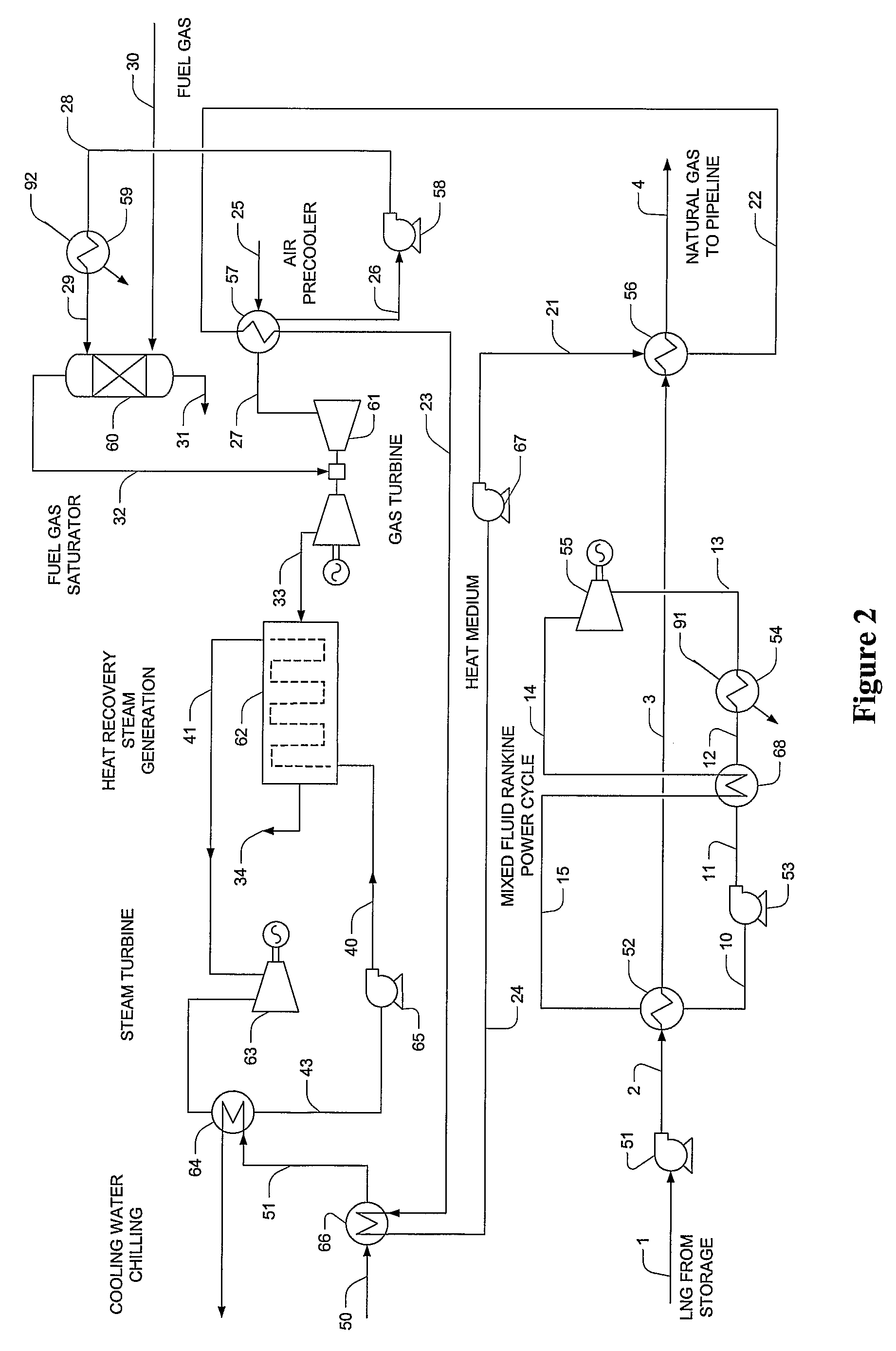

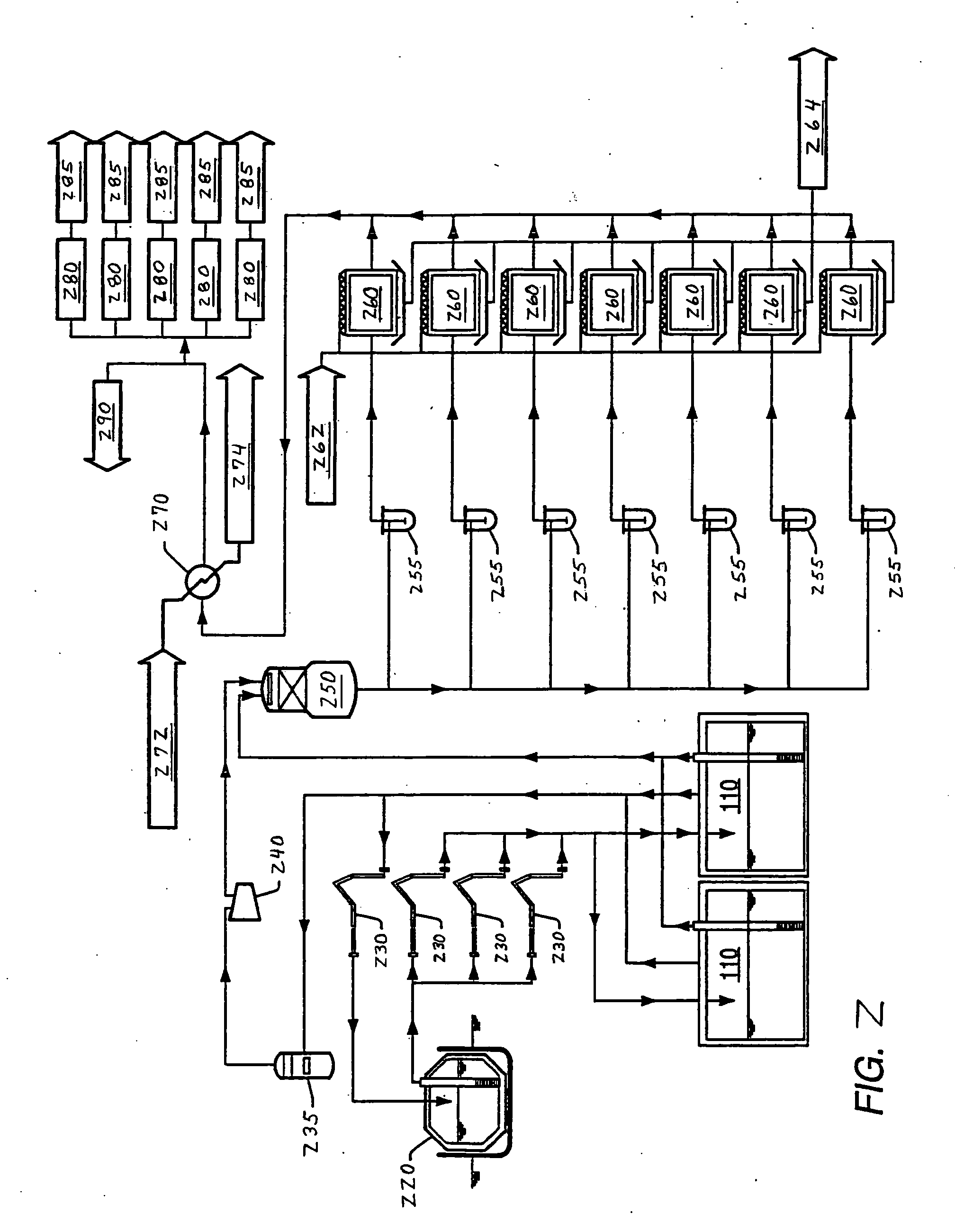

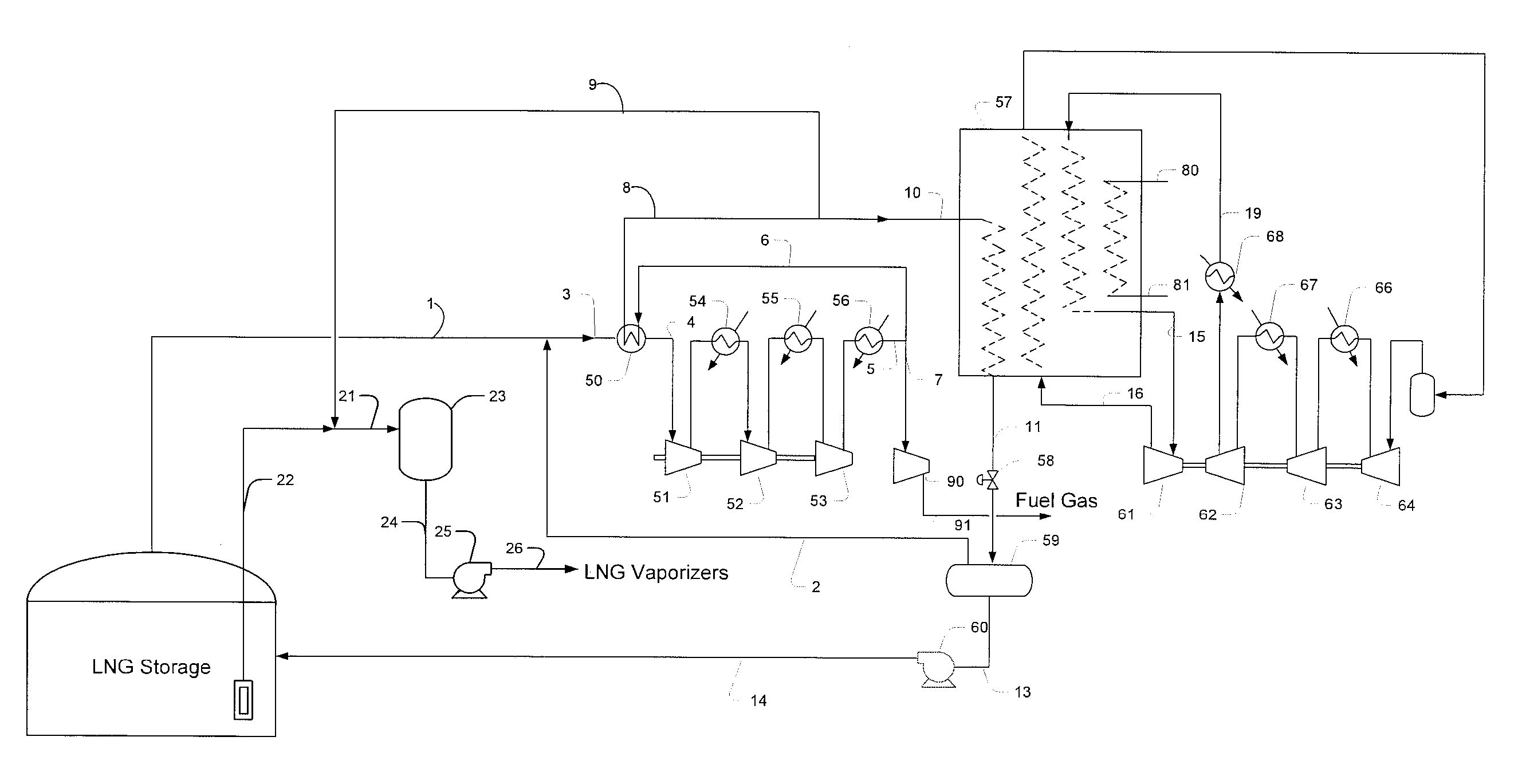

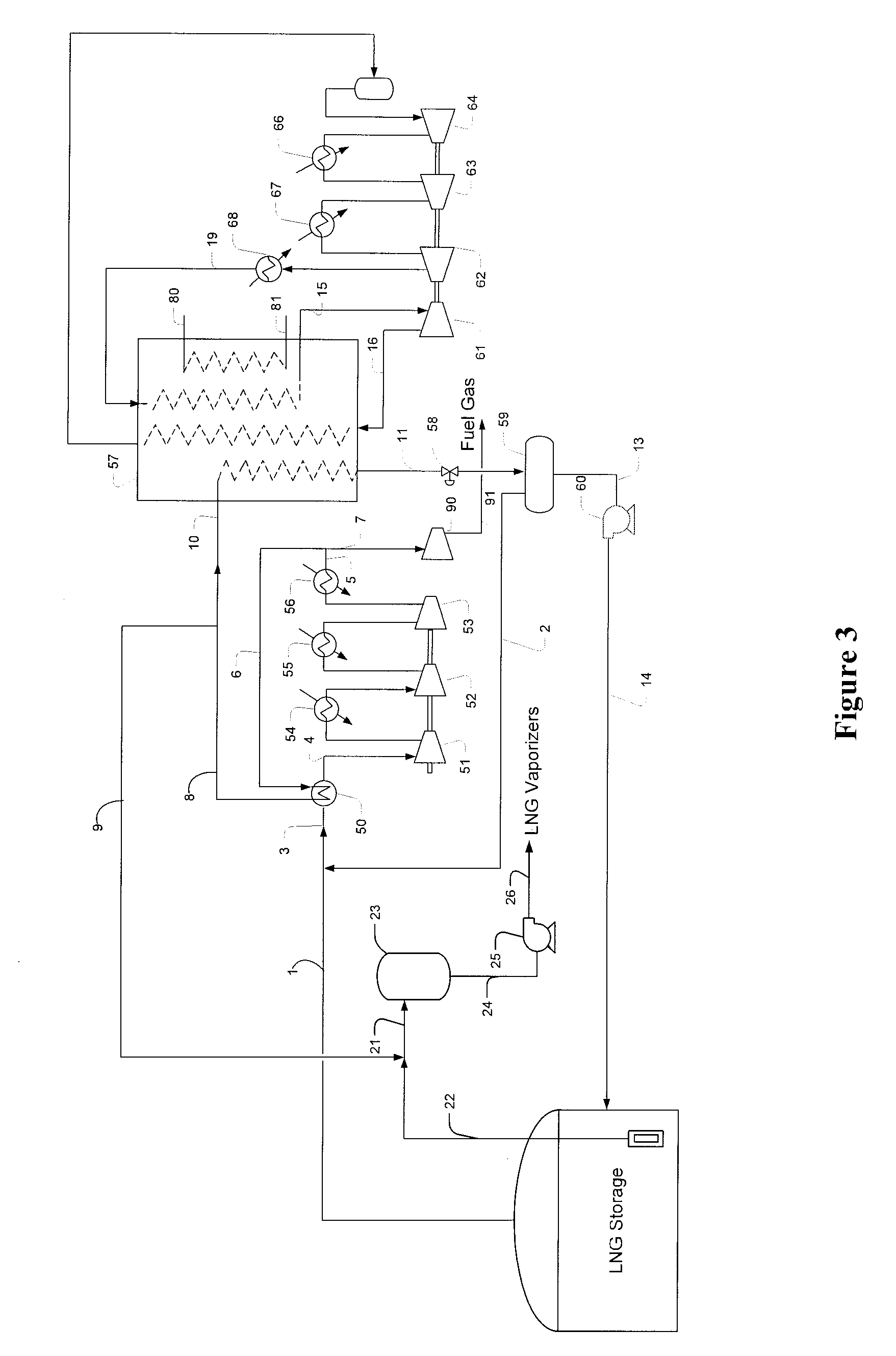

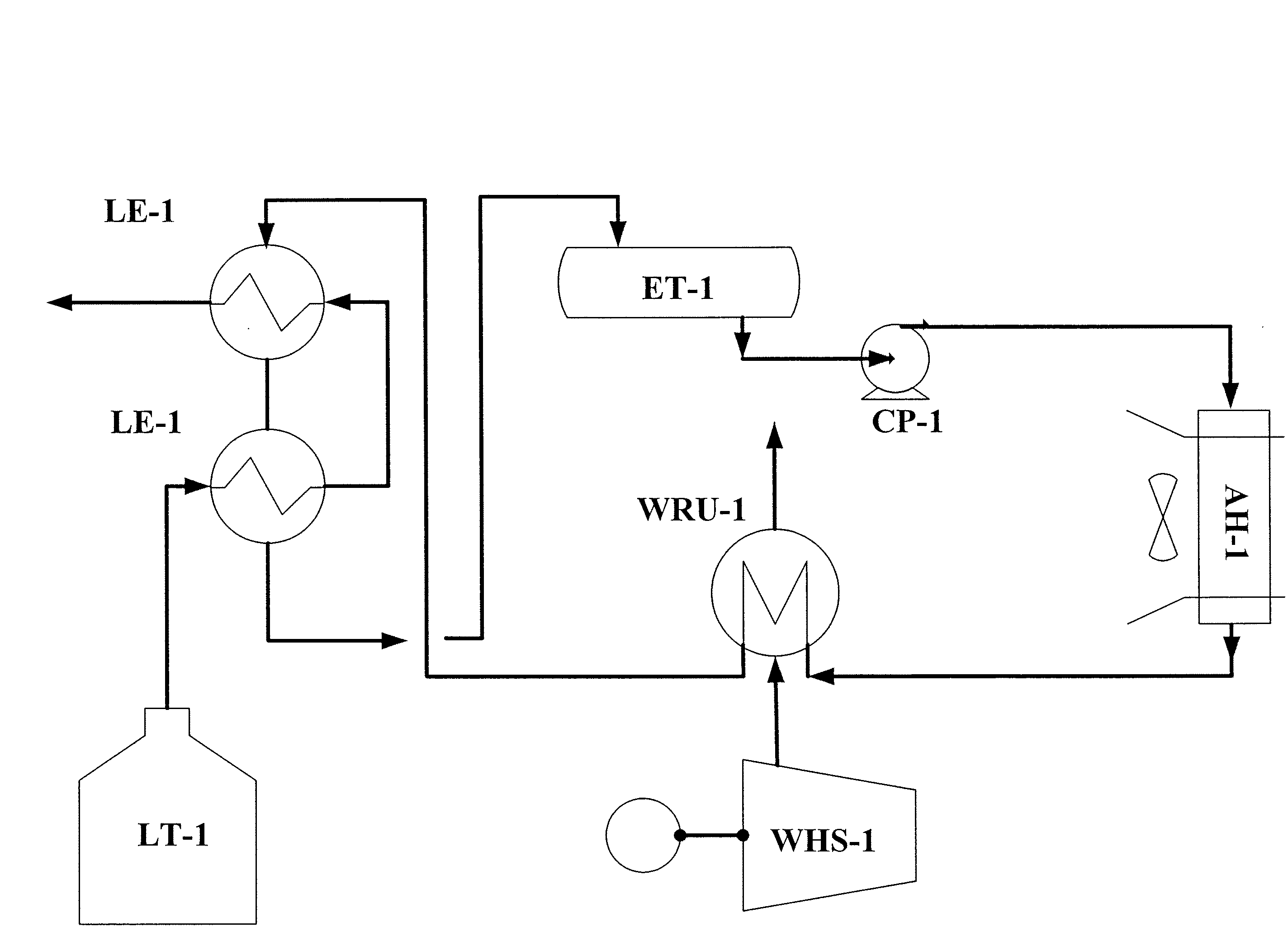

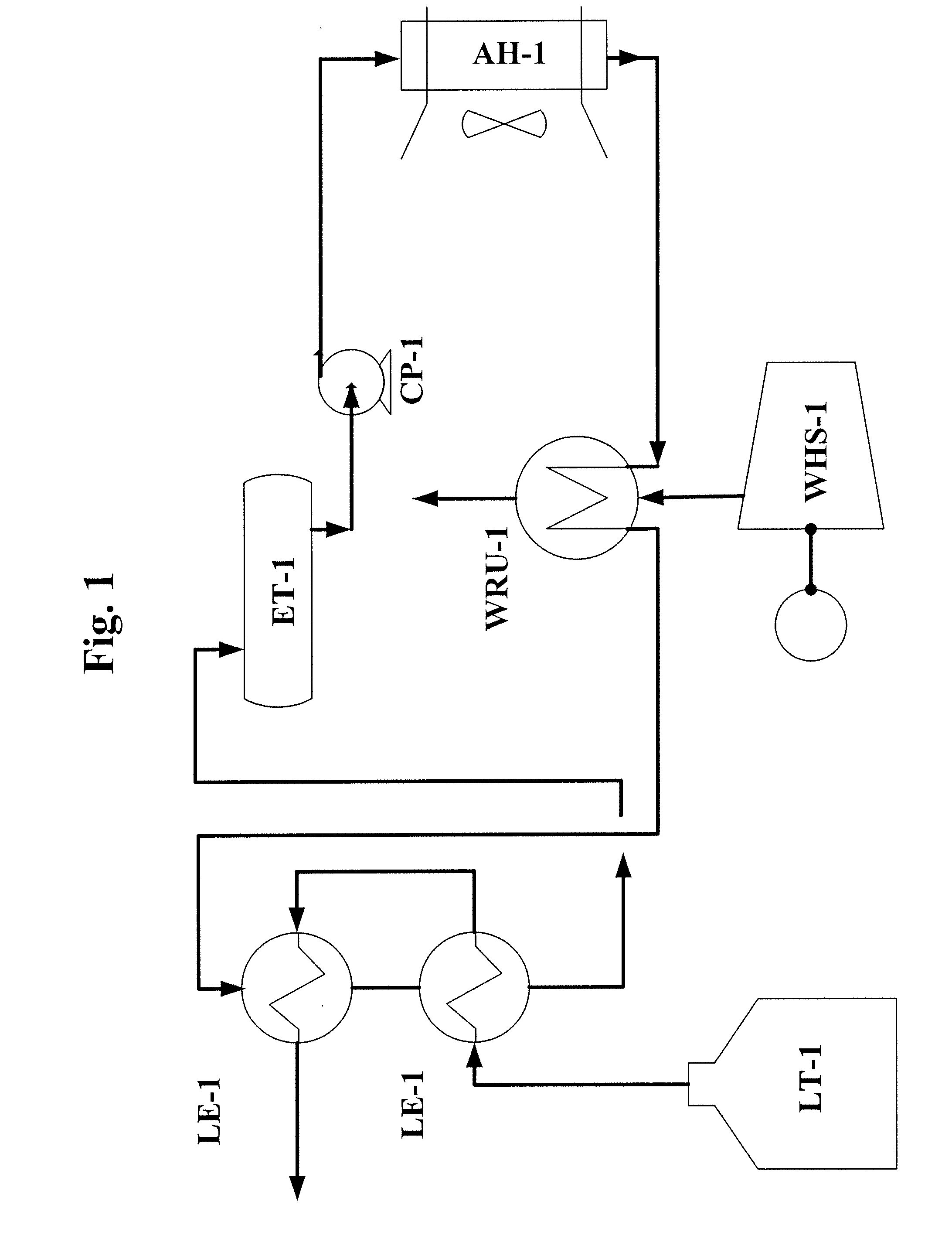

Liquified natural gas (LNG) fueled combined cycle power plant and a (LNG) fueled gas turbine plant

InactiveUS6374591B1Improve efficiencyParts are smallGas handling applicationsGas turbine plantsCombustion chamberPower station

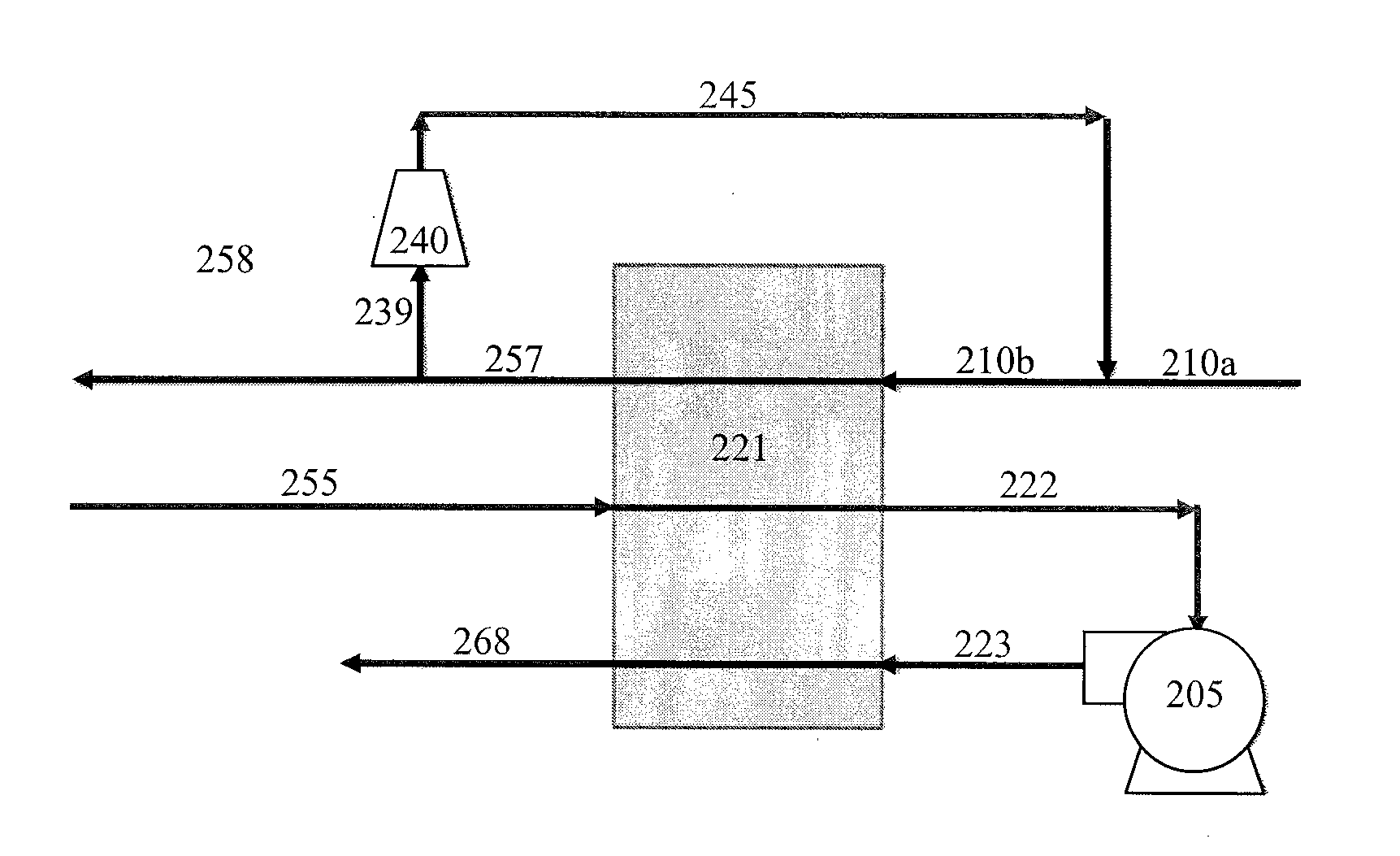

A process and system which improves the capacity and efficiency of a power plant. A LNG supply system fuels the plant. Gasified LNG in a combustor mixes with the air from an air compressor to provide the hot combustion gas for a gas turbine. The expanding LNG is used to chill a heat exchange fluid, e.g. water, which heat exchange fluid cools and densifies the intake air for the air compressor. Subsequently, the heat exchange fluid is used in another heat exchange step and is then re-chilled and recycled to cool and densify the intake air.

Owner:SUEZ LNG NA

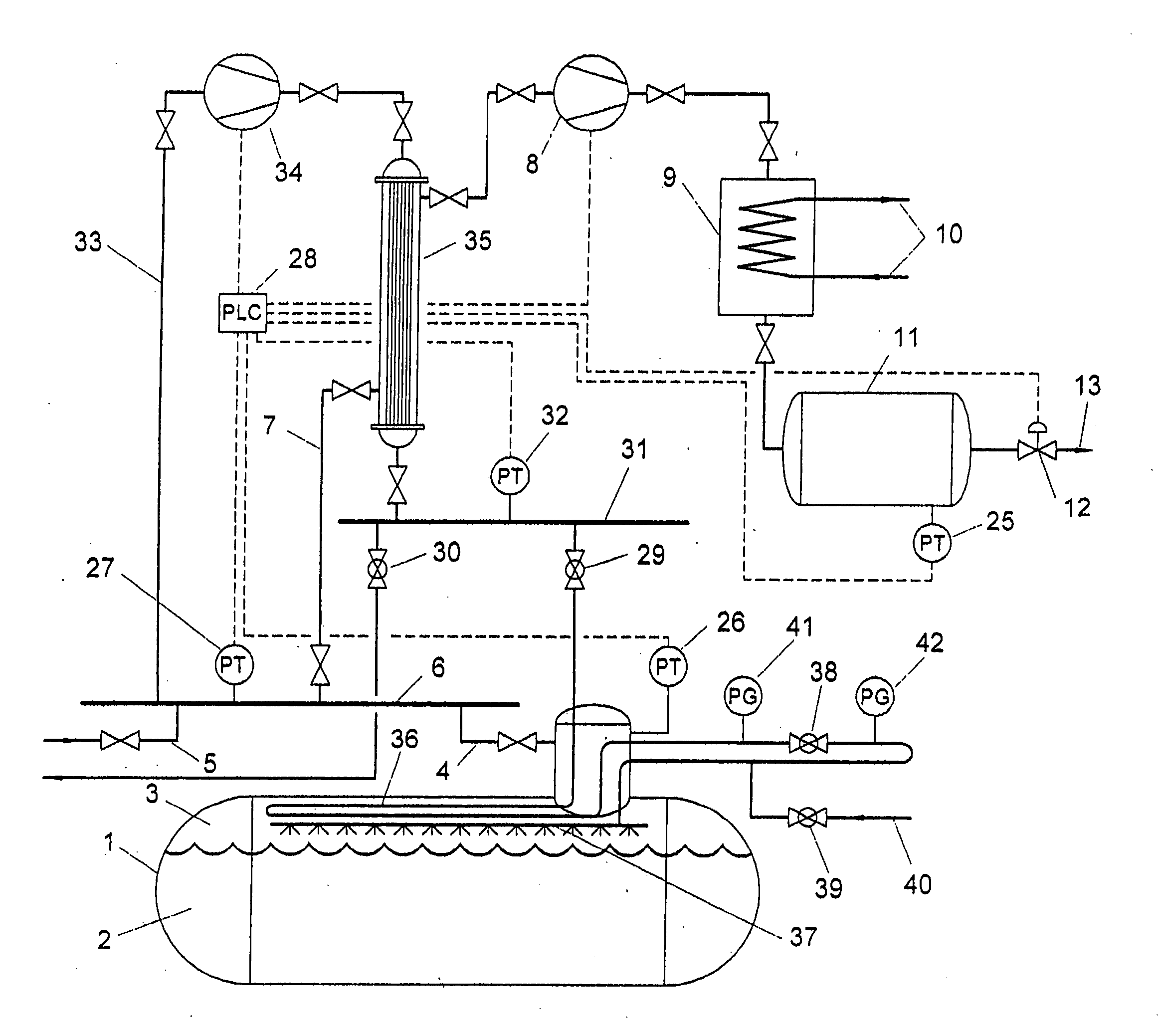

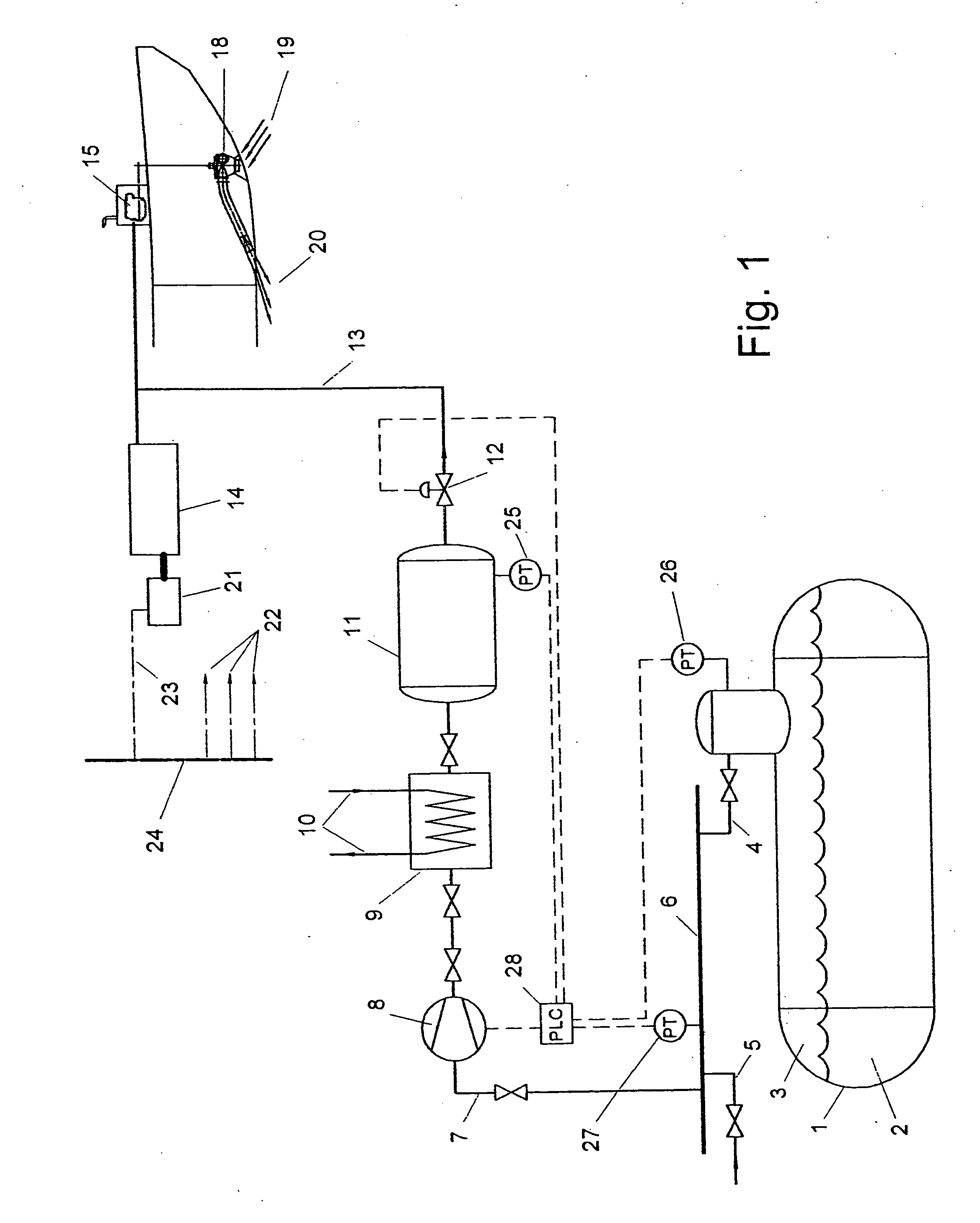

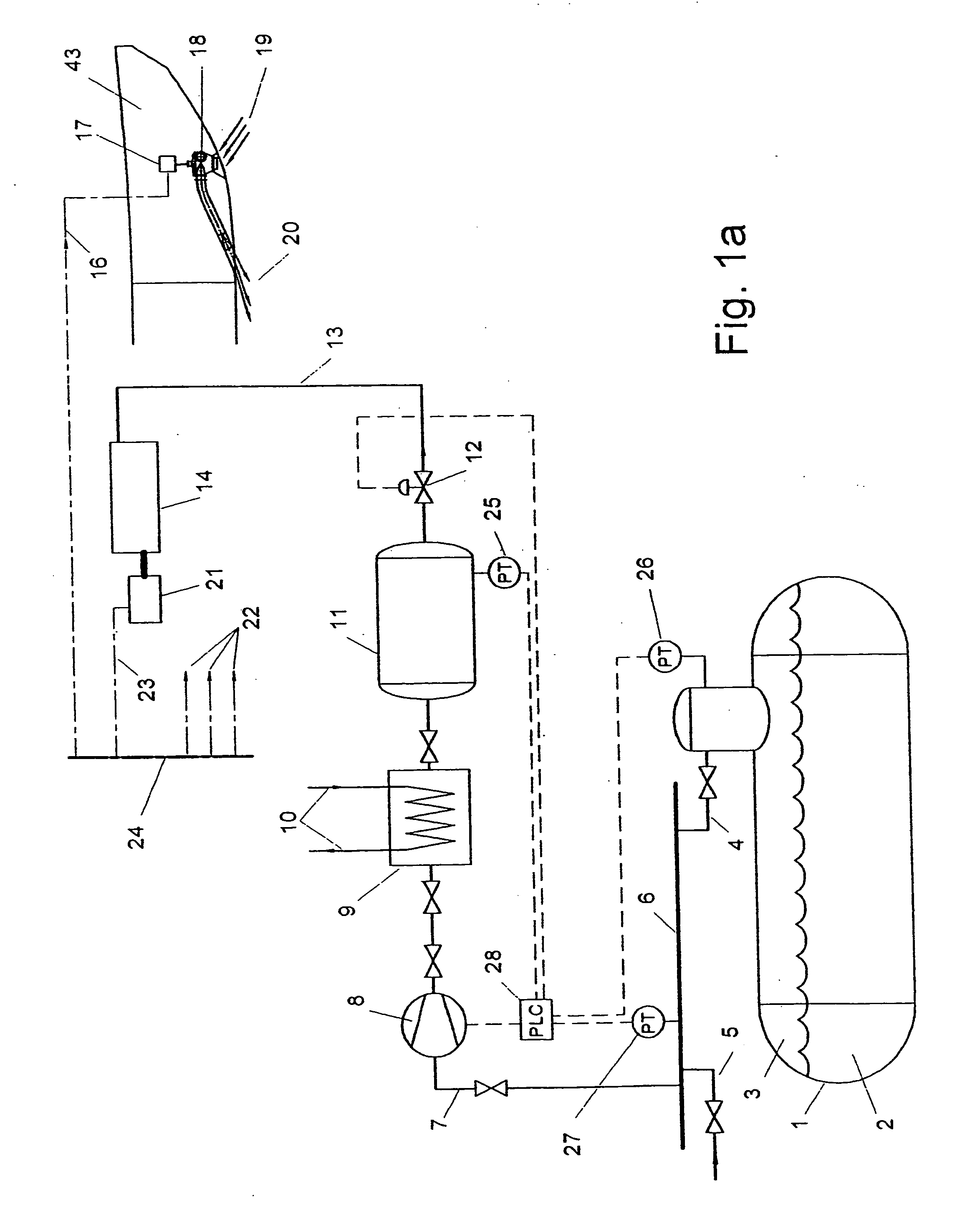

System and process for transporting LNG by non-self-propelled marine LNG carrier

Marine LNG carrier and method of operating the marine LNG carrier. The LNG carrier carries LNG in at least one tank. Gas composed of evaporated LNG within the at least one tank is removed. The gas is fed to at least one gas consuming prime mover of the LNG carrier. Power is provided with the at least one gas consuming prime mover. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:ARGENT MARINE MANAGEMENT

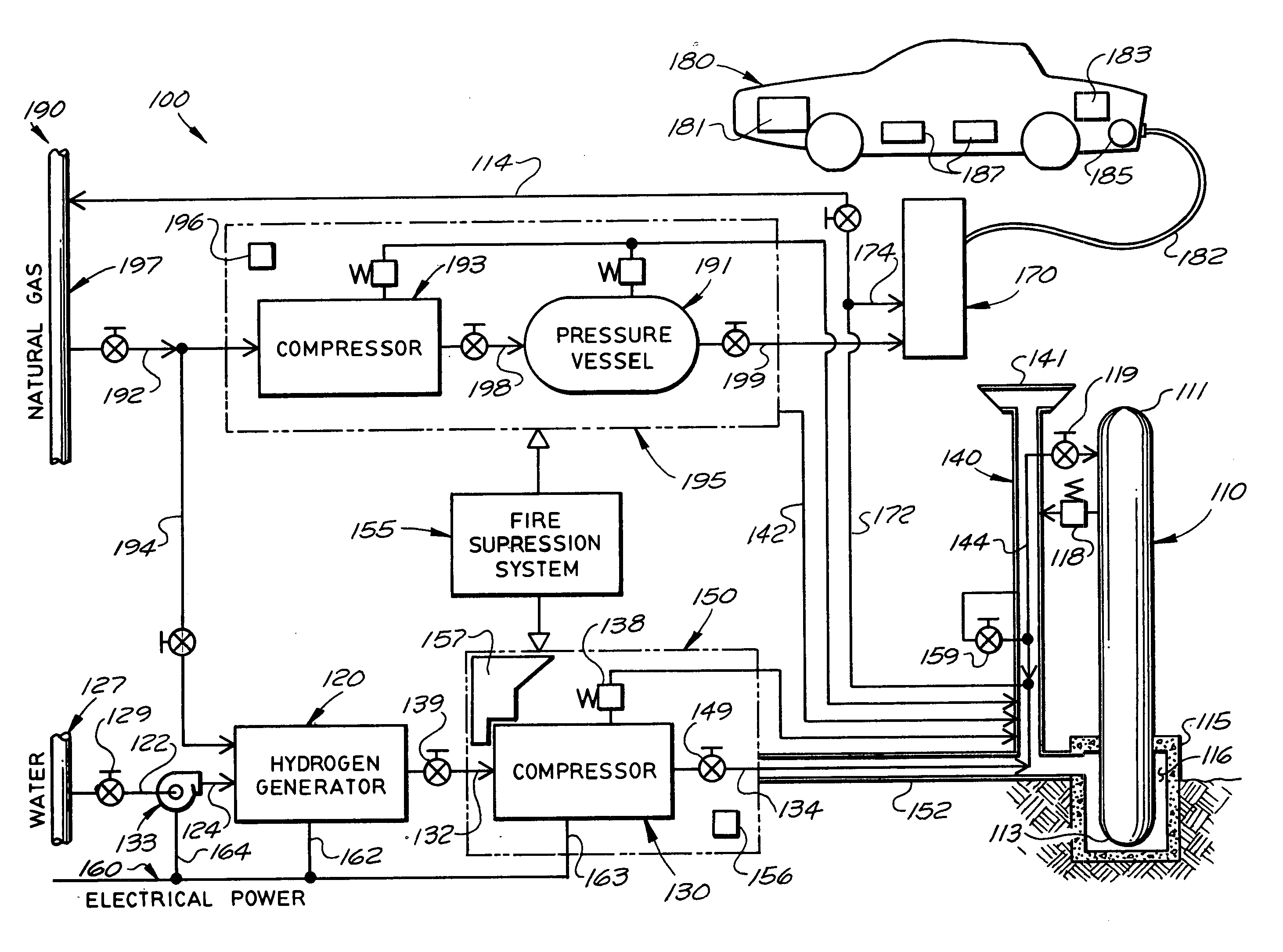

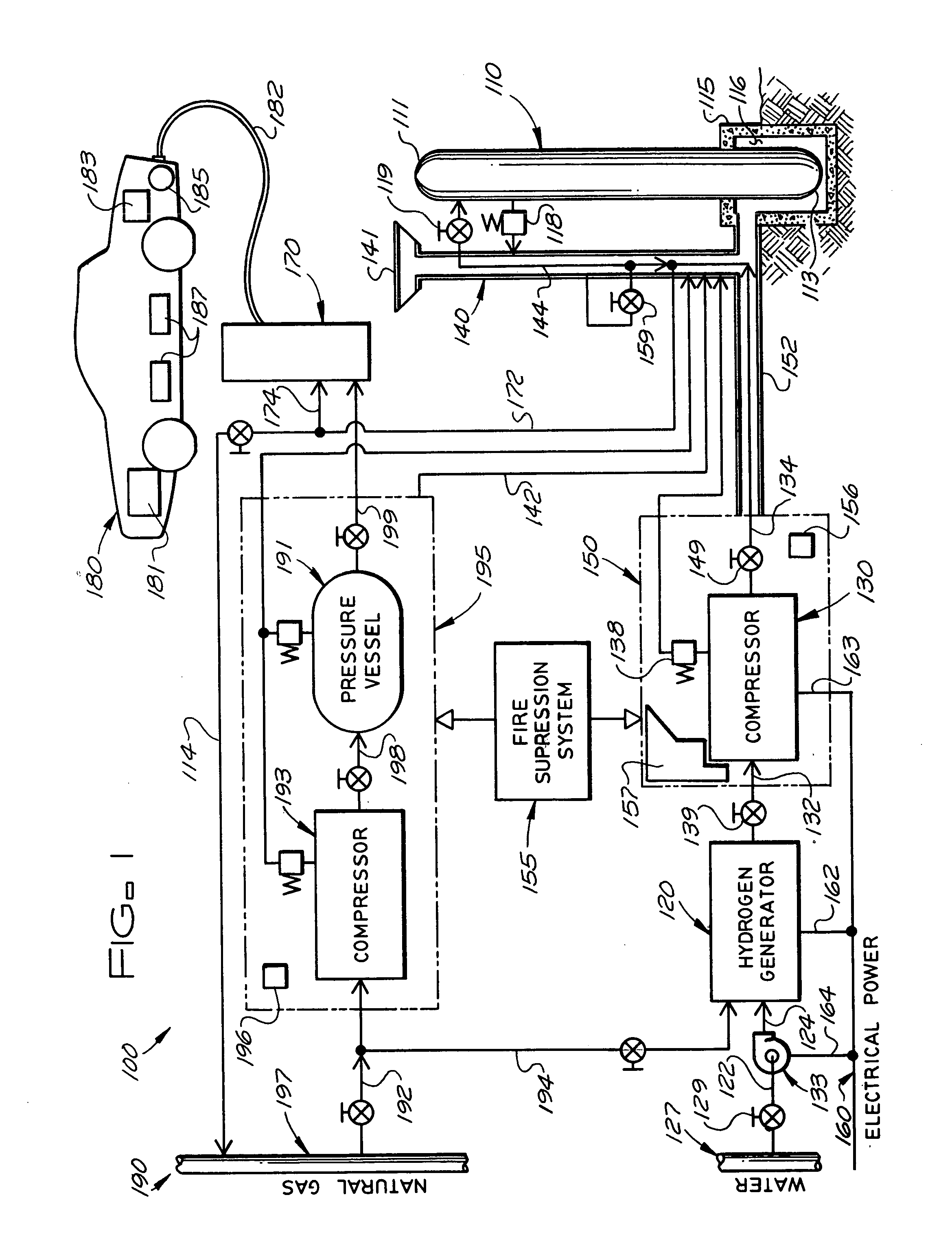

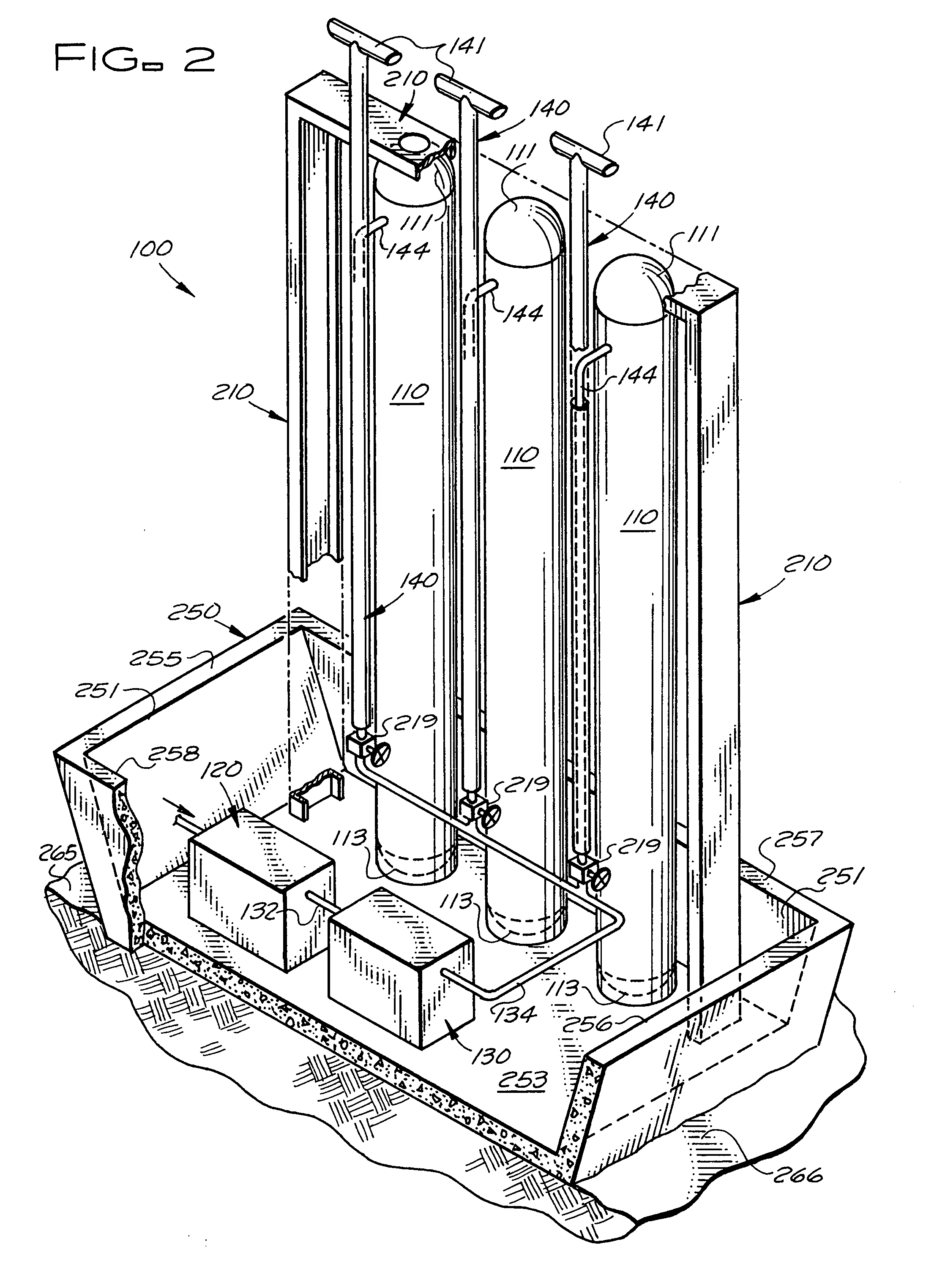

Hydrogen handling or dispensing system

InactiveUS20050000802A1Avoid burnsCheap manufacturingLiquid fillingGas handling applicationsHydrogenHuman life

Systems for handling and / or dispensing hydrogen or a mixture of fuels containing hydrogen gas including refueling stations for hydrogen-powered vehicles. Pure hydrogen or various mixtures ratios of hydrogen and CNG may be dispensed. Hydrogen handling equipment may include a hydrogen generator, a pressurizing apparatus or compressor, pressure vessels, piping, valves, vent pipes, and / or a dispenser. Substantially vertical orientation of pressure vessels may reduce the amount of land required and facilitate installation in urban environments. Pressurization may take place before hydrogen generation to reduce the power required for pressurization. Safety features include enclosures and surrounding walls that lean away from the equipment. Any leaking hydrogen, fires, or explosions may be contained and / or directed upward, protecting human life and property. Systems may be shop assembled and certified.

Owner:ARIZONA PUBLIC SERVICE

Configurations and methods for power generation with integrated LNG regasification

Owner:FLUOR TECH CORP

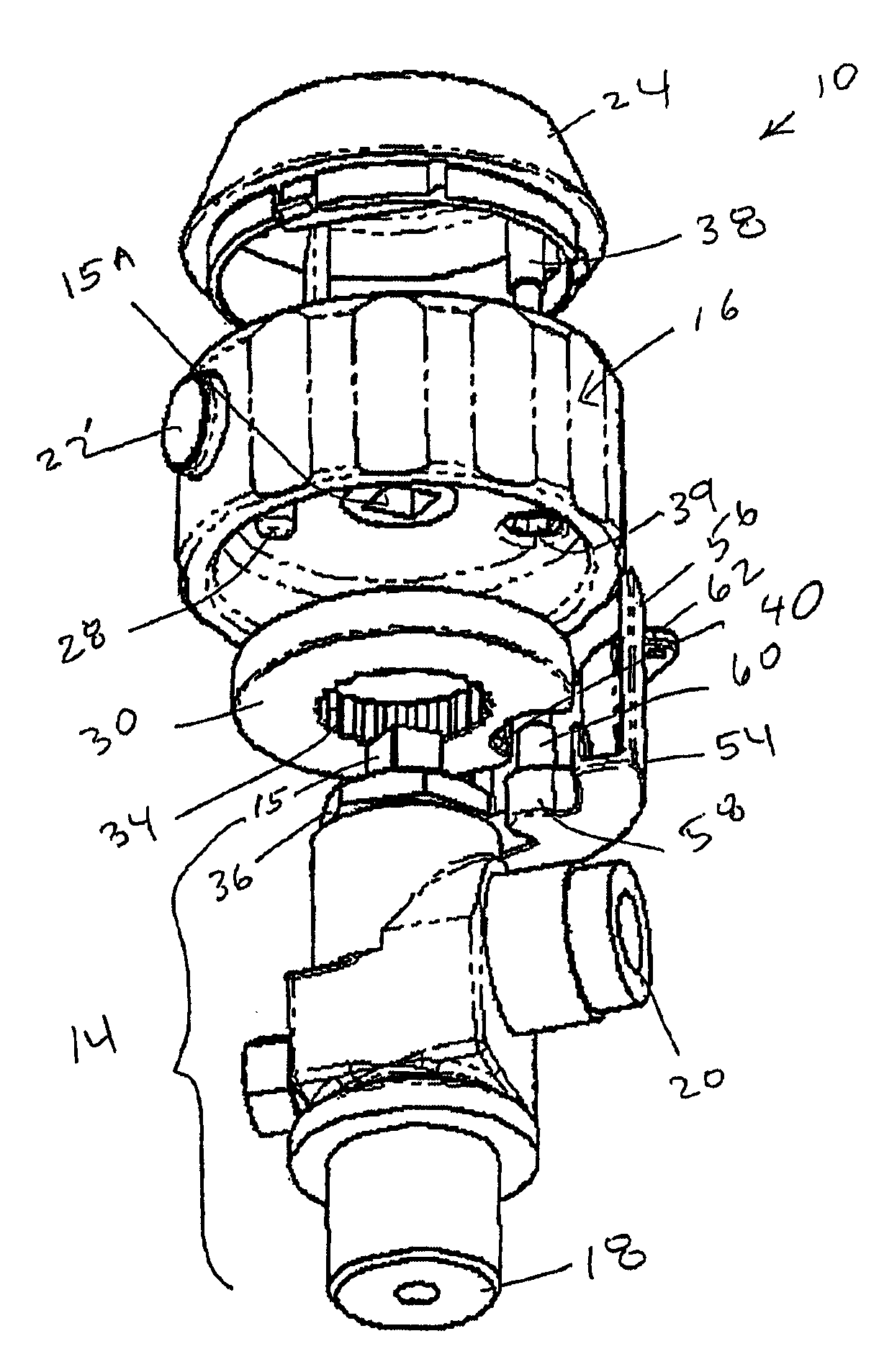

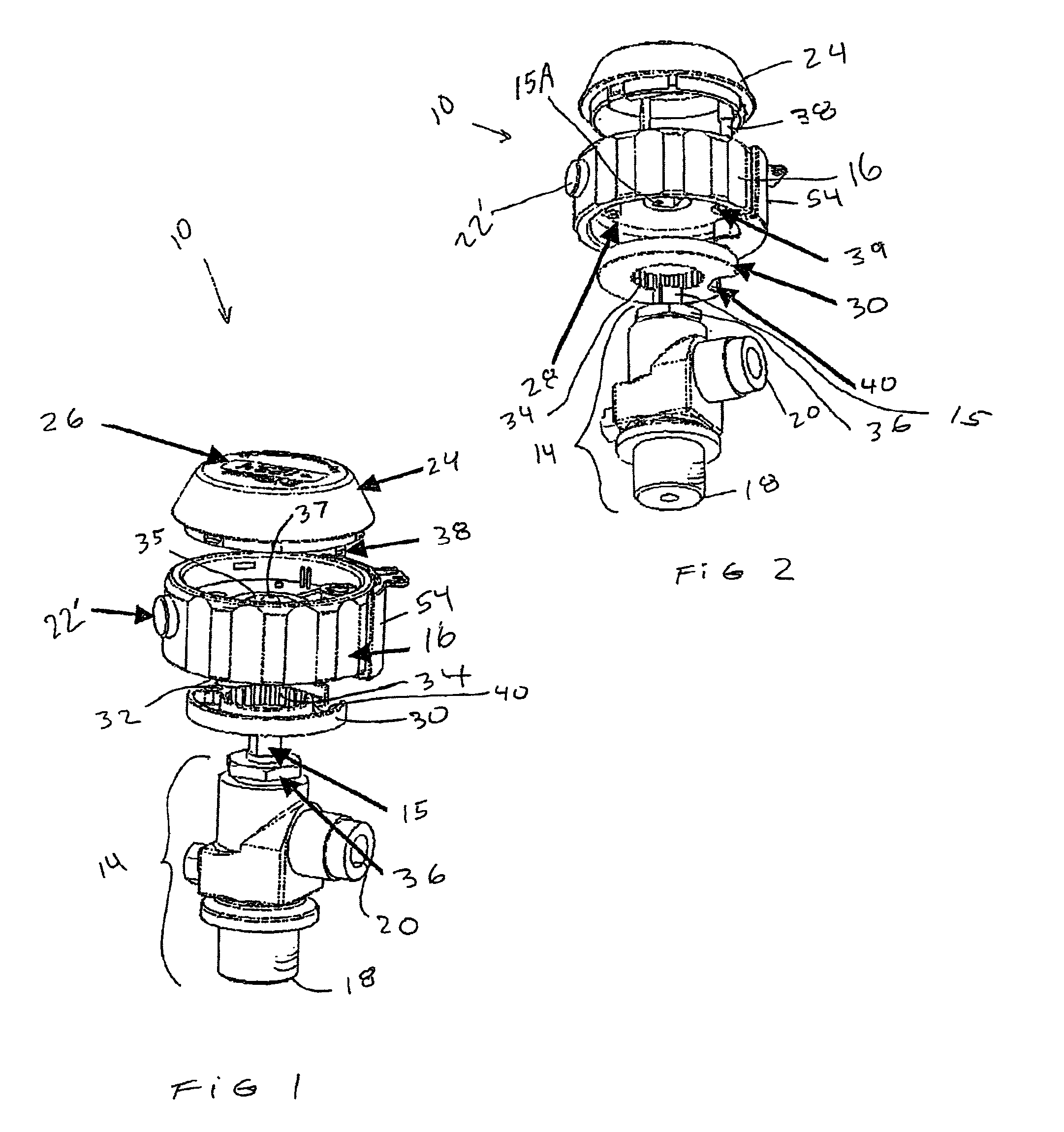

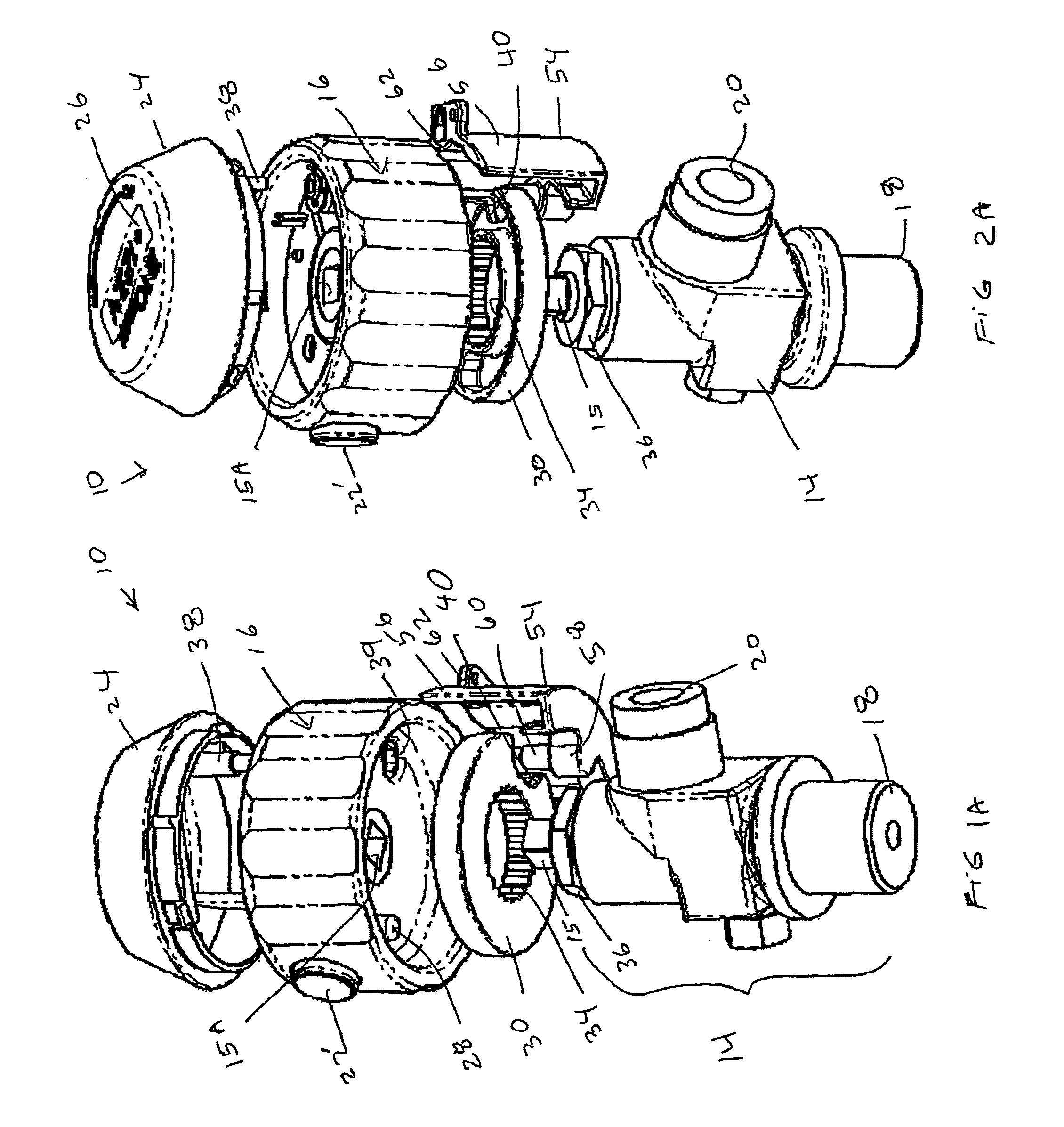

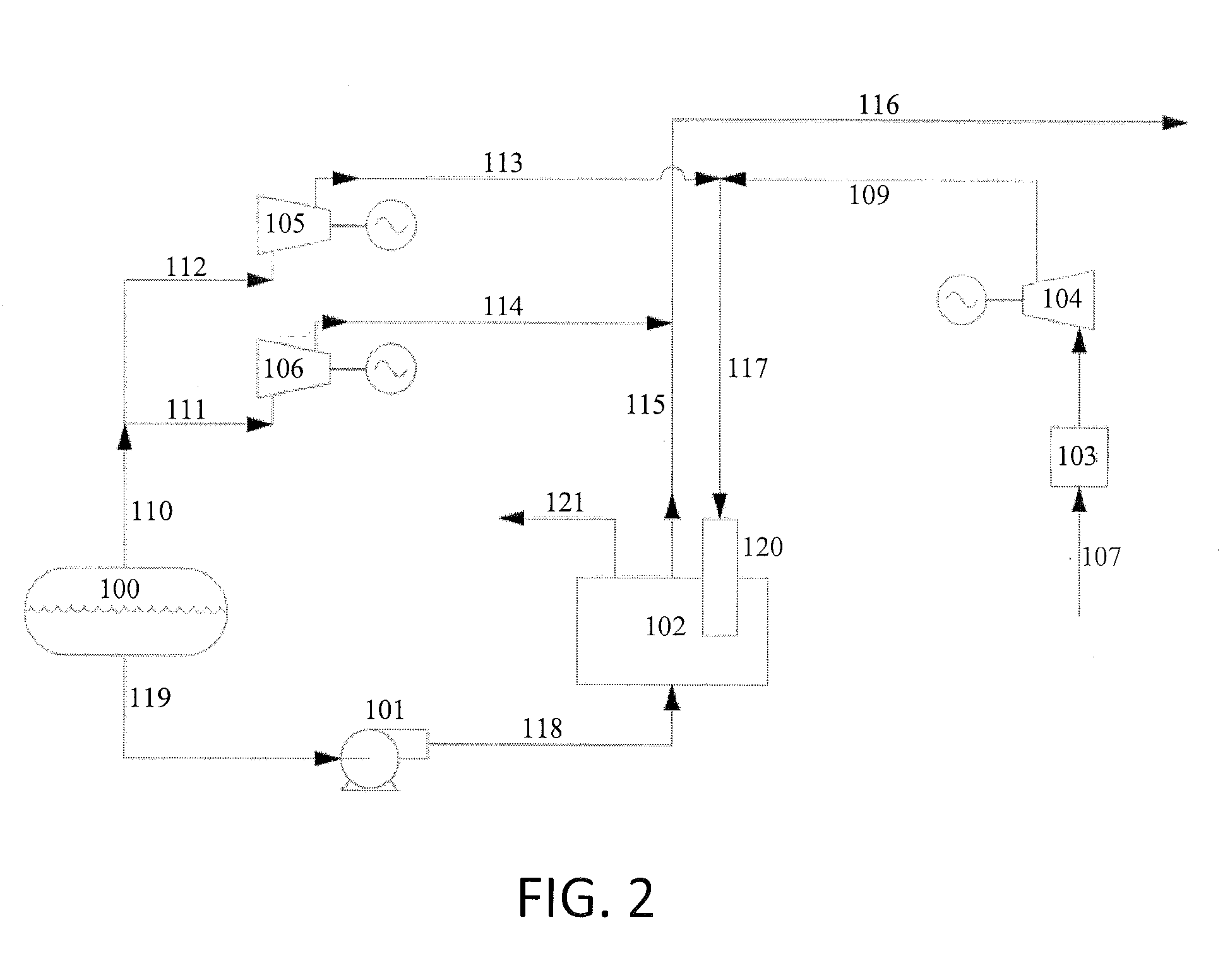

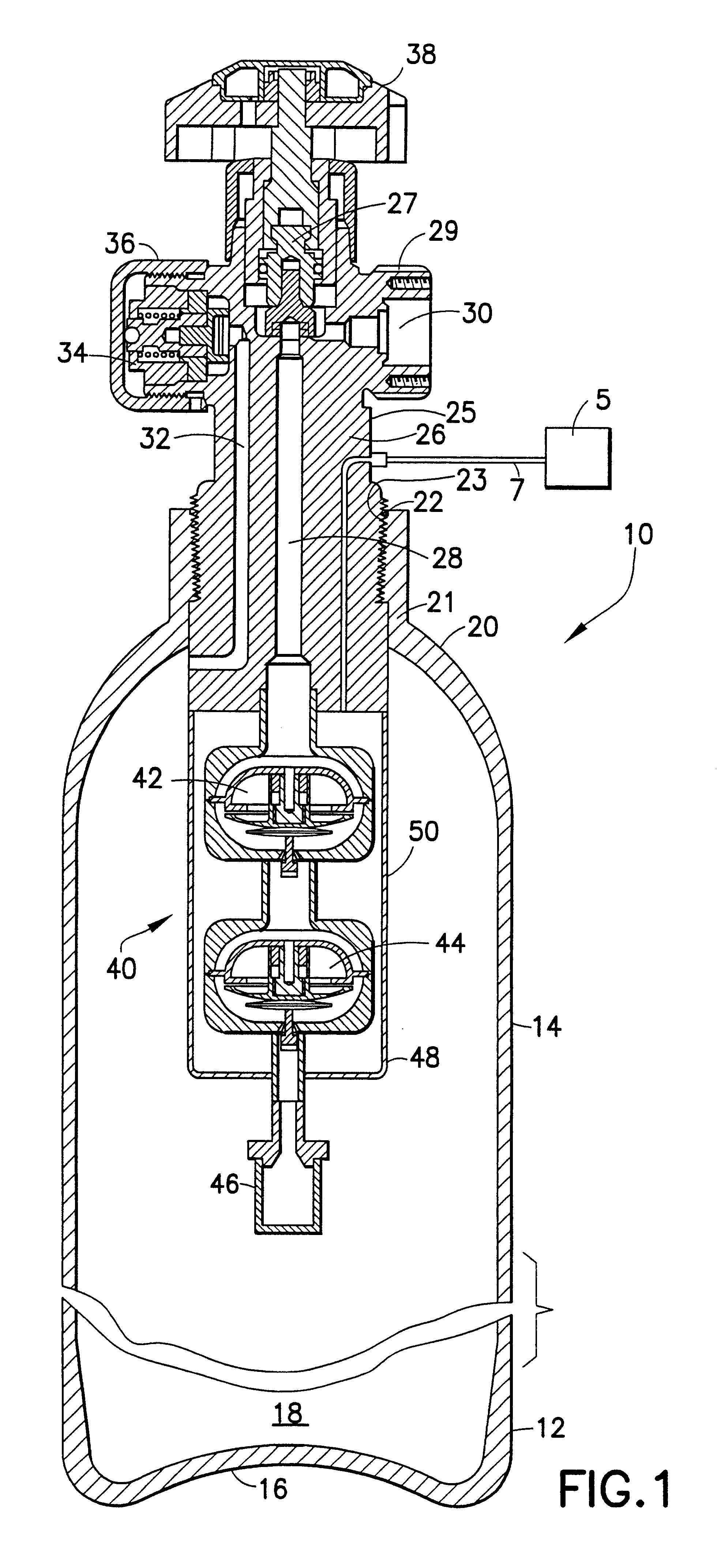

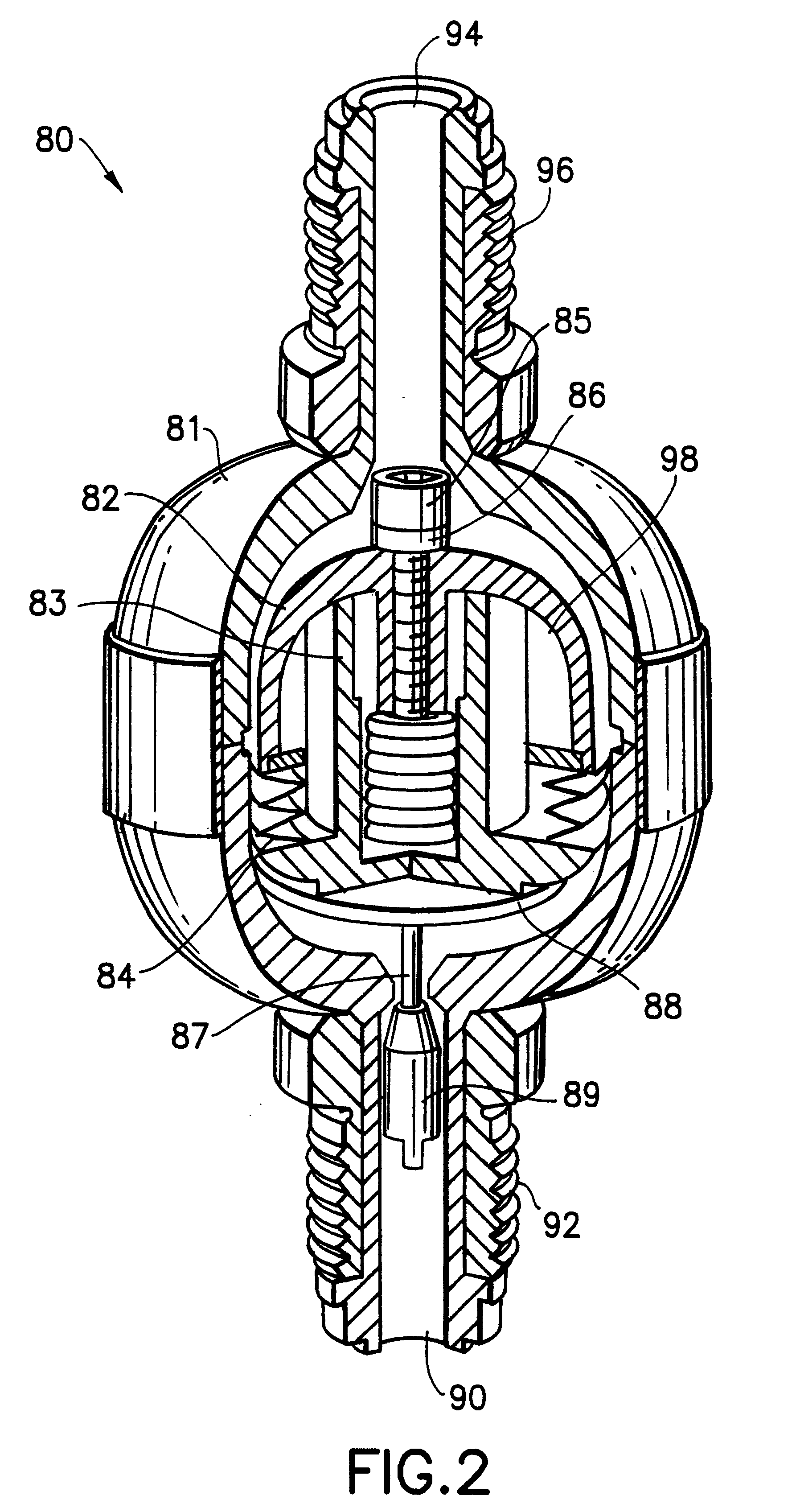

Valve with smart handle

A valve with a smart handle including a memory module to log relevant data. A sensor on the handle determines when the valve is open, and this triggers the start of timers and recording of the “open” event in a log in the memory module. When the valve is closed, the sensor triggers stopping of the timers and recording of the “closed” event in the log. The timer information is used to calculate the duration of the time “open” event, and this, together with the actual date and time of the opening and closing of the valve are recorded in the log. Other relevant information, such as cylinder fill date, cylinder I.D. number, batch number, and patient name or account number may also be logged in the memory module. The log of the events and the corresponding dates and times may be used to prepare invoices for billing gas treatments, for inventory control, and for other record-keeping and control functions.

Owner:VENTEK +1

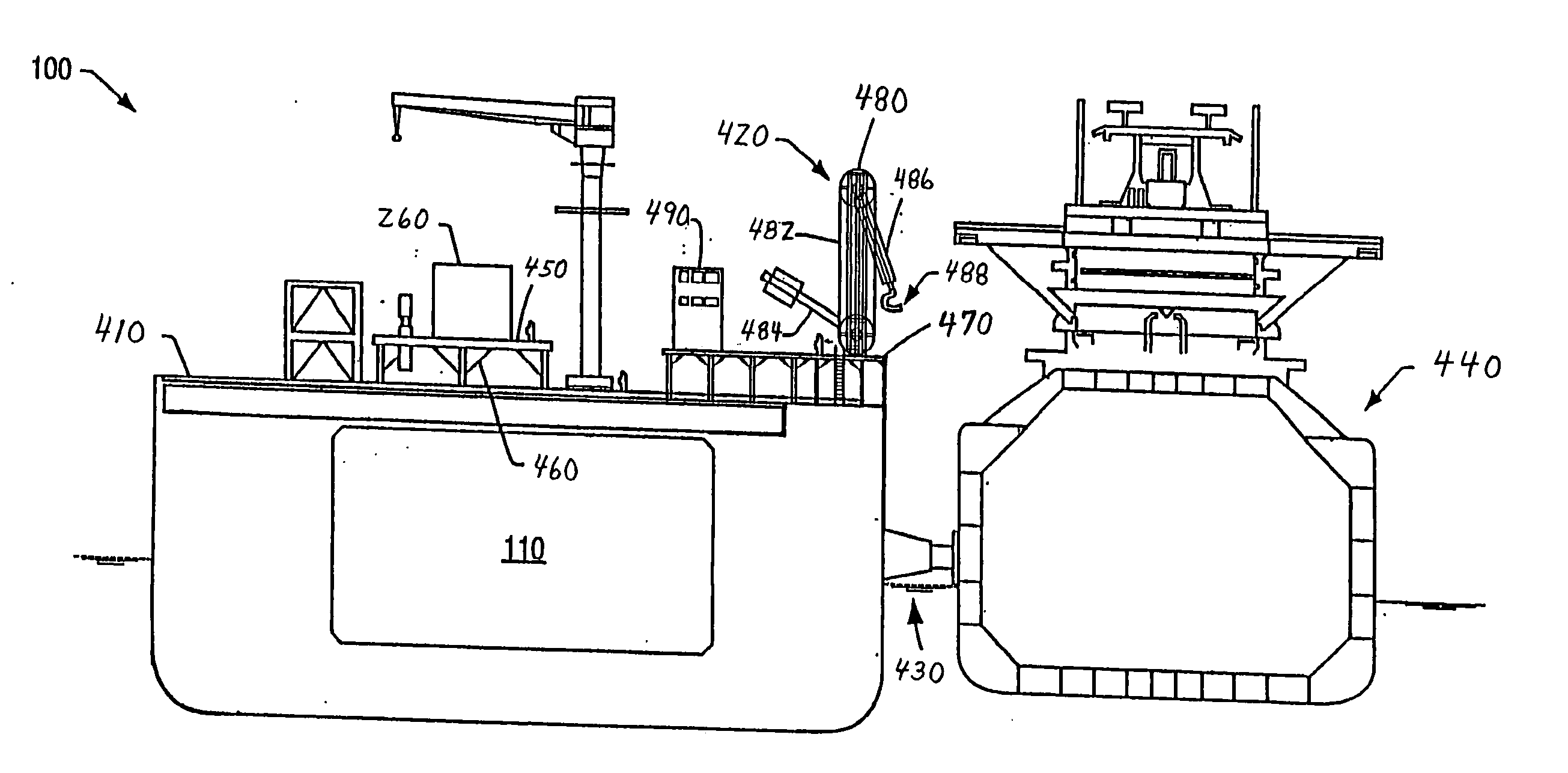

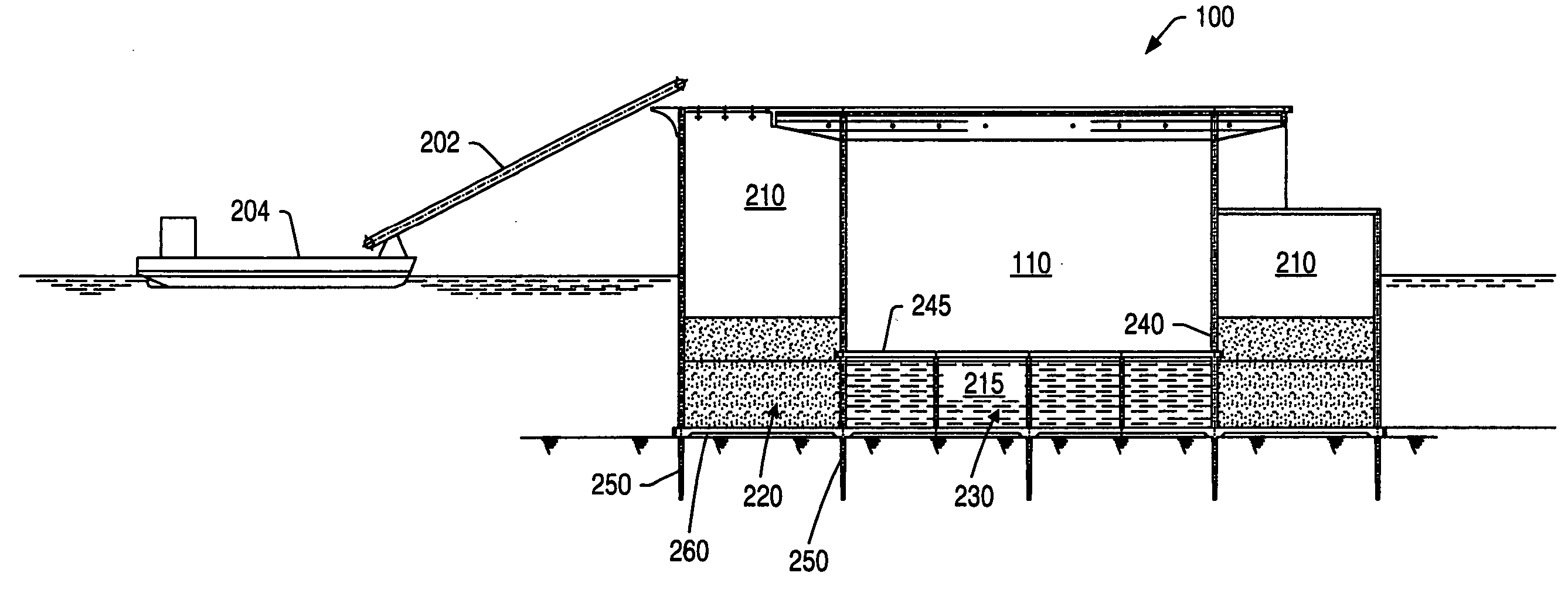

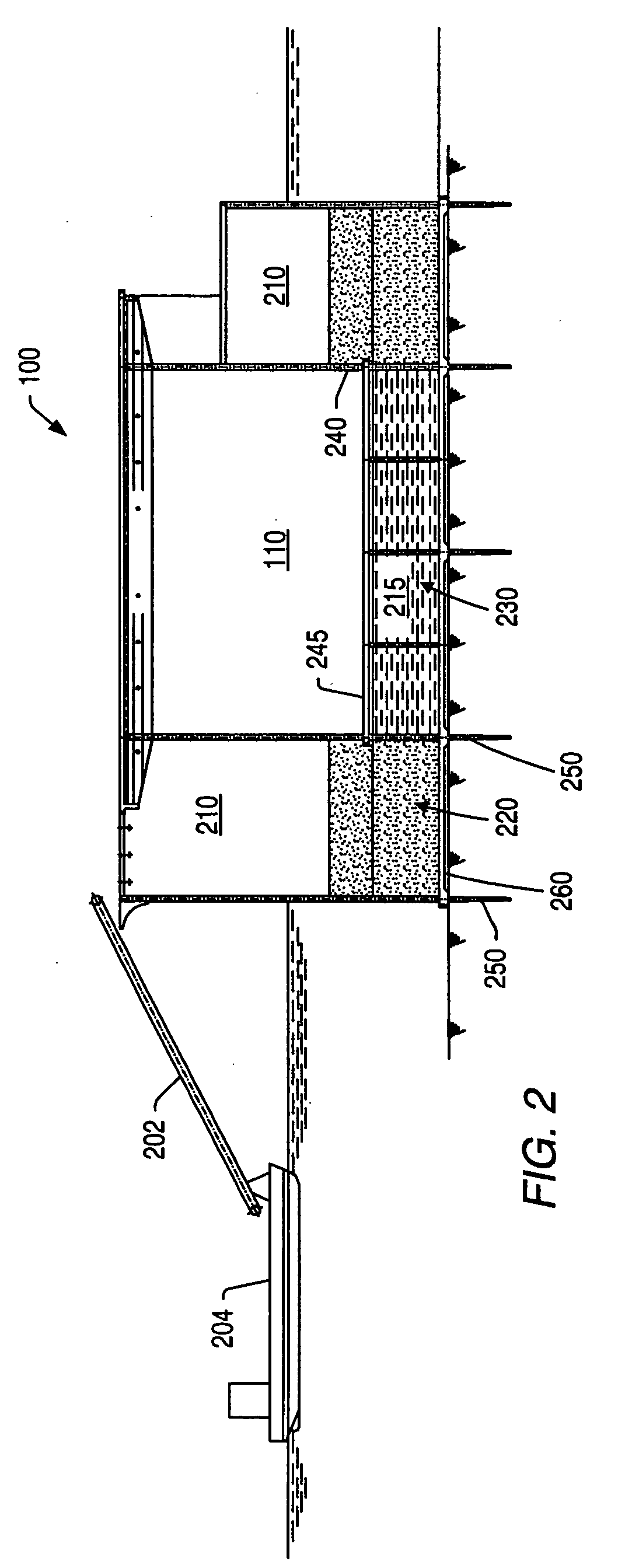

Liquefied natural gas floating storage regasification unit

InactiveUS20060156744A1Reduce the amount requiredProvide protectionGas handling applicationsGas handling/storage effectsMooring systemMarine engineering

An offshore liquefied natural gas floating storage regasification unit that may receive, store, and process liquefied natural gas from carriers. A floating storage regasification unit may include transfer equipment to offload liquefied natural gas from a carrier, a first mooring system to provide for mooring of a floating storage regasification unit at a location in a body of water, a second mooring system to provide for mooring a carrier to the floating storage regasification unit, and combinations thereof. A portion of the floating storage regasification unit may be composed of a double-hull containment structure.

Owner:SHELL OIL CO

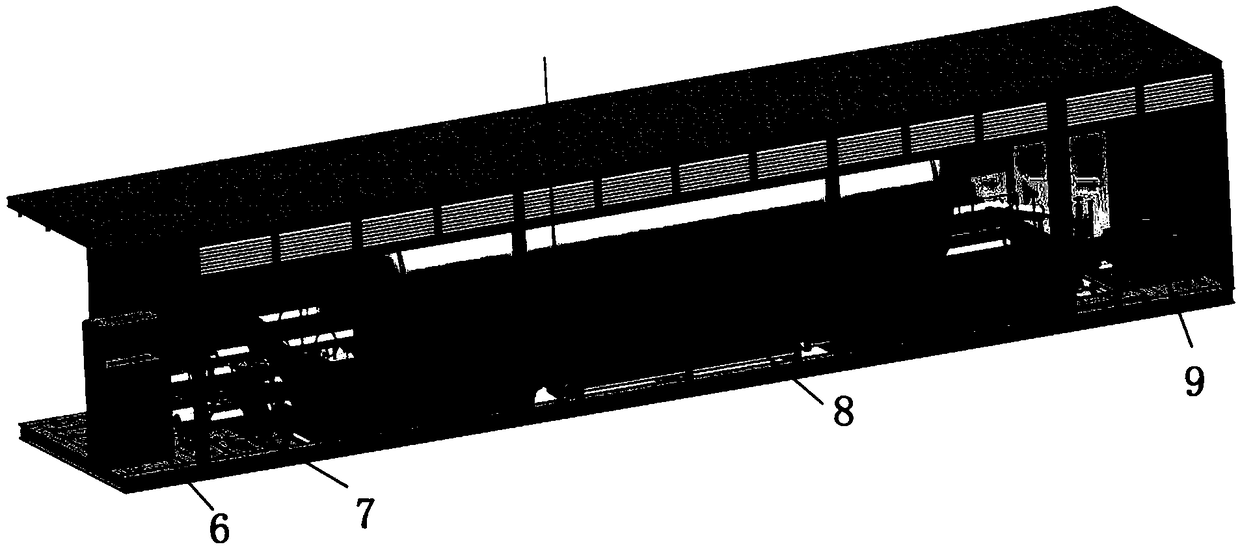

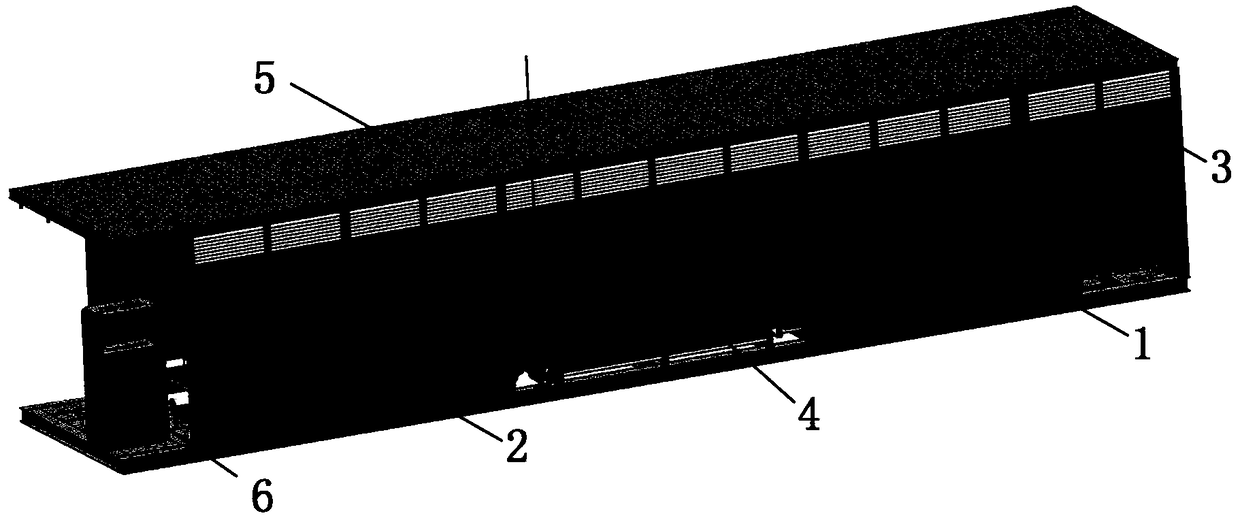

LNG/L-CNG skid-mounted gas station

PendingCN109027662AFunction increaseShort construction periodVessel mounting detailsVessel geometry/arrangement/sizeEngineeringIndustry standard

The invention discloses a LNG / L-CNG skid-mounted gas station. The LNG / L-CNG skid-mounted gas station comprises a first sled base, a second sled base, a LNG pump sled, a low-temperature storage tank, aL-CNG pump sled and a gas filling machine; the L-CNG pump sled is arranged on the first sled base; the low-temperature storage tank, the L-CNG pump sled and the gas filling machine are integrated onthe second sled base in sequence; an unloading table is additionally arranged at the end, near the gas filling machine, of the second sled base; the end, near the low-temperature storage tank, of thesecond sled base is movably connected with the first sled base; the low-temperature storage tank discharges liquid by the head and tail ends; fences are arranged on two sides of the first sled base and the second sled base; the first sled base is connected with the end, near the low-temperature storage tank, of the second sled base; top cover plates are arranged at the tops of the fences; and thehorizontal plane of the top cover plates is higher than the horizontal plane of the top of the low-temperature storage tank. The LNG / L-CNG skid-mounted gas station has the following beneficial effects: through high integration degree, the country and industry standards are met, and the functions of an integrated gas station are expanded; and through the mode of discharging the liquid by the head and tail ends of the low-temperature storage tank, the generation of BOG is greatly reduced, and the liquid outlet speed is accelerated.

Owner:JEREH OIL & GAS ENG

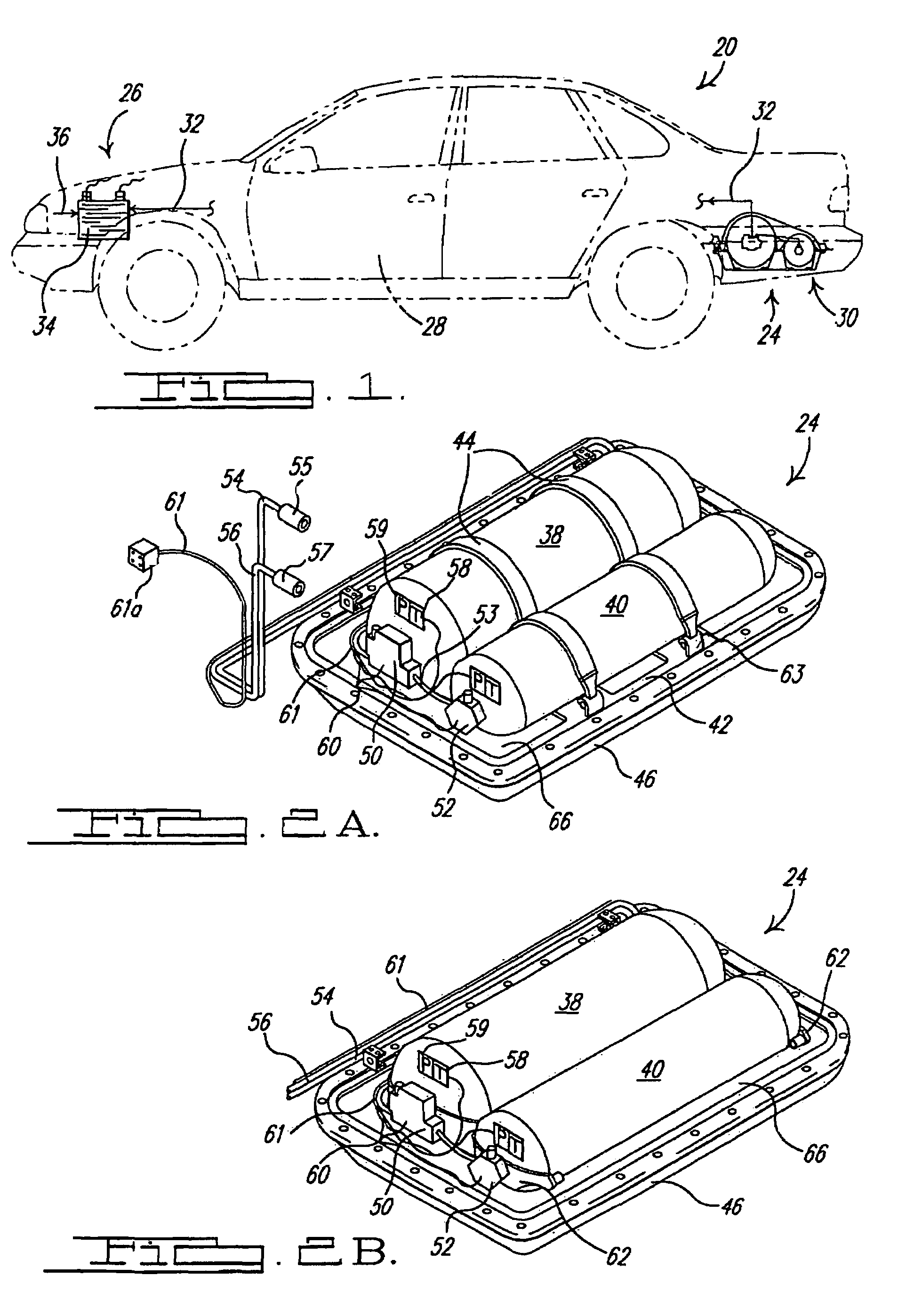

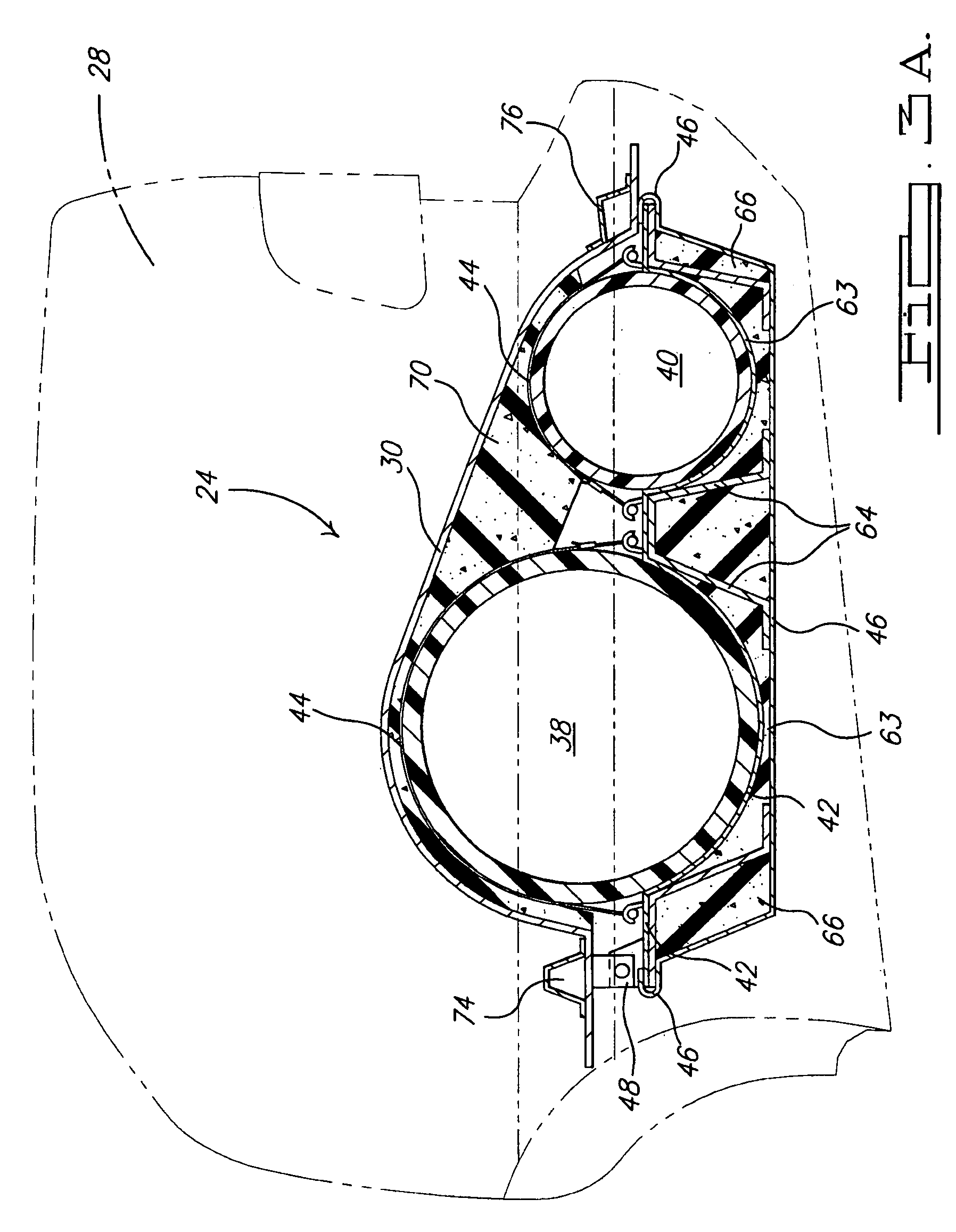

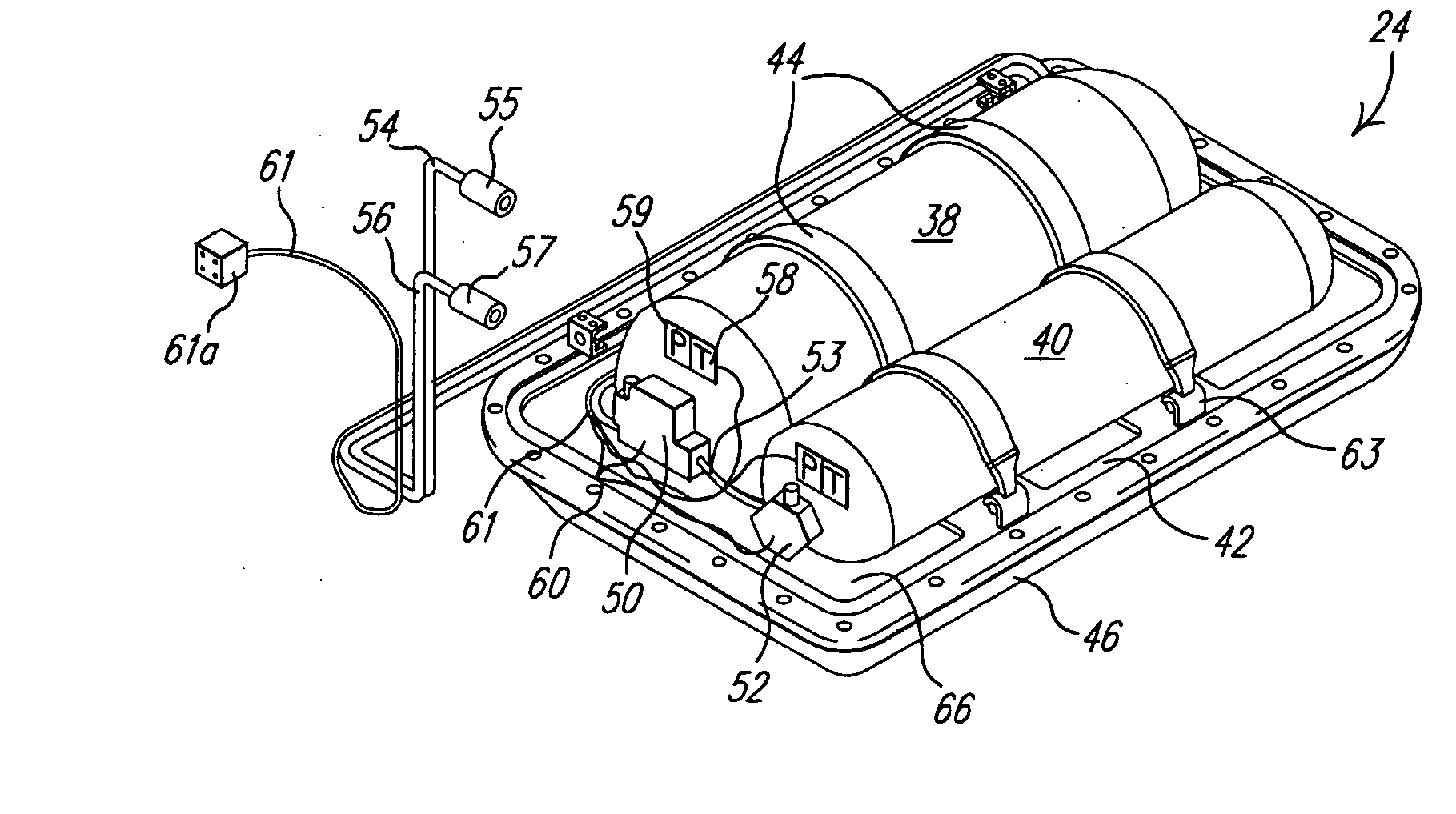

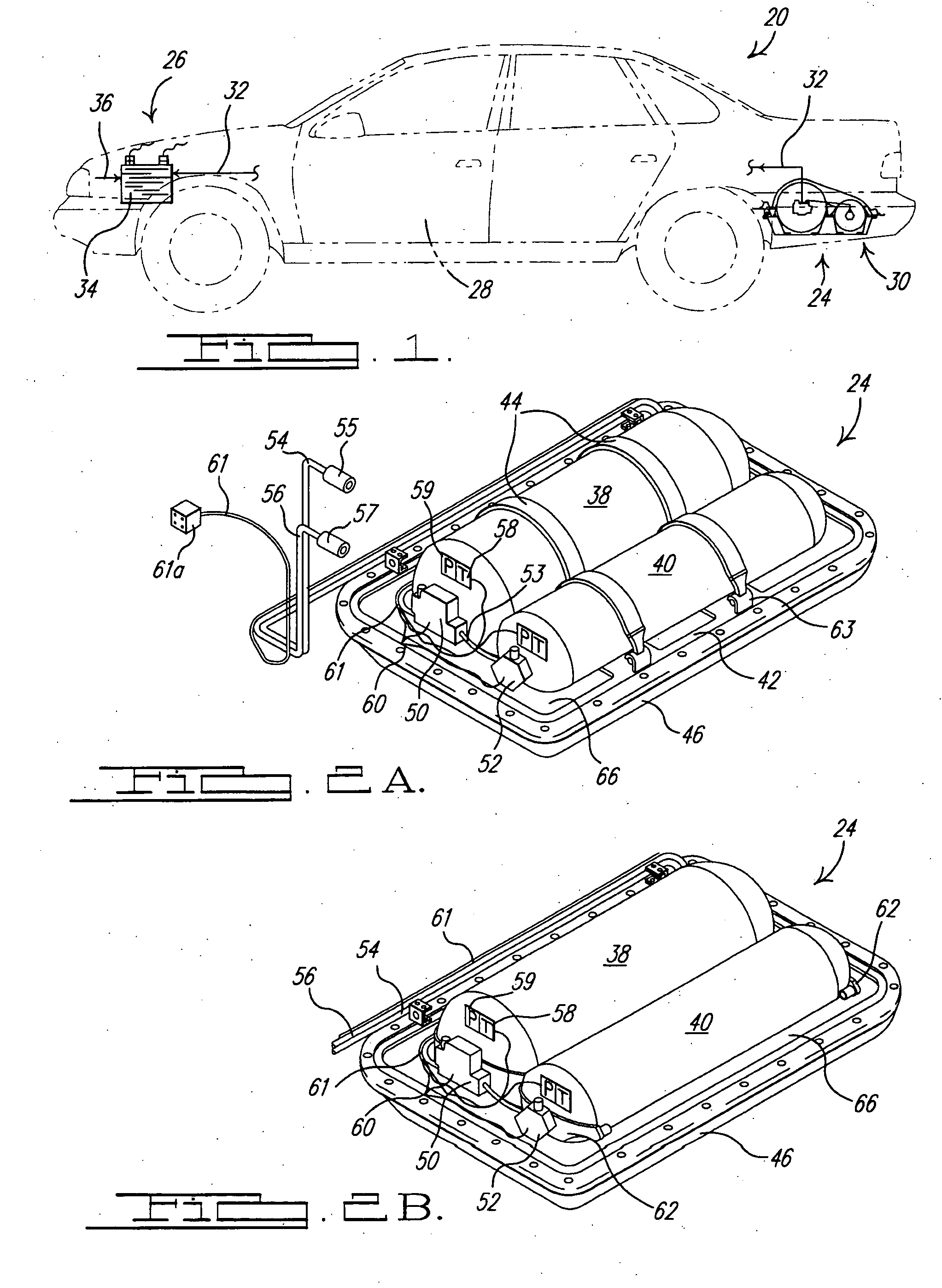

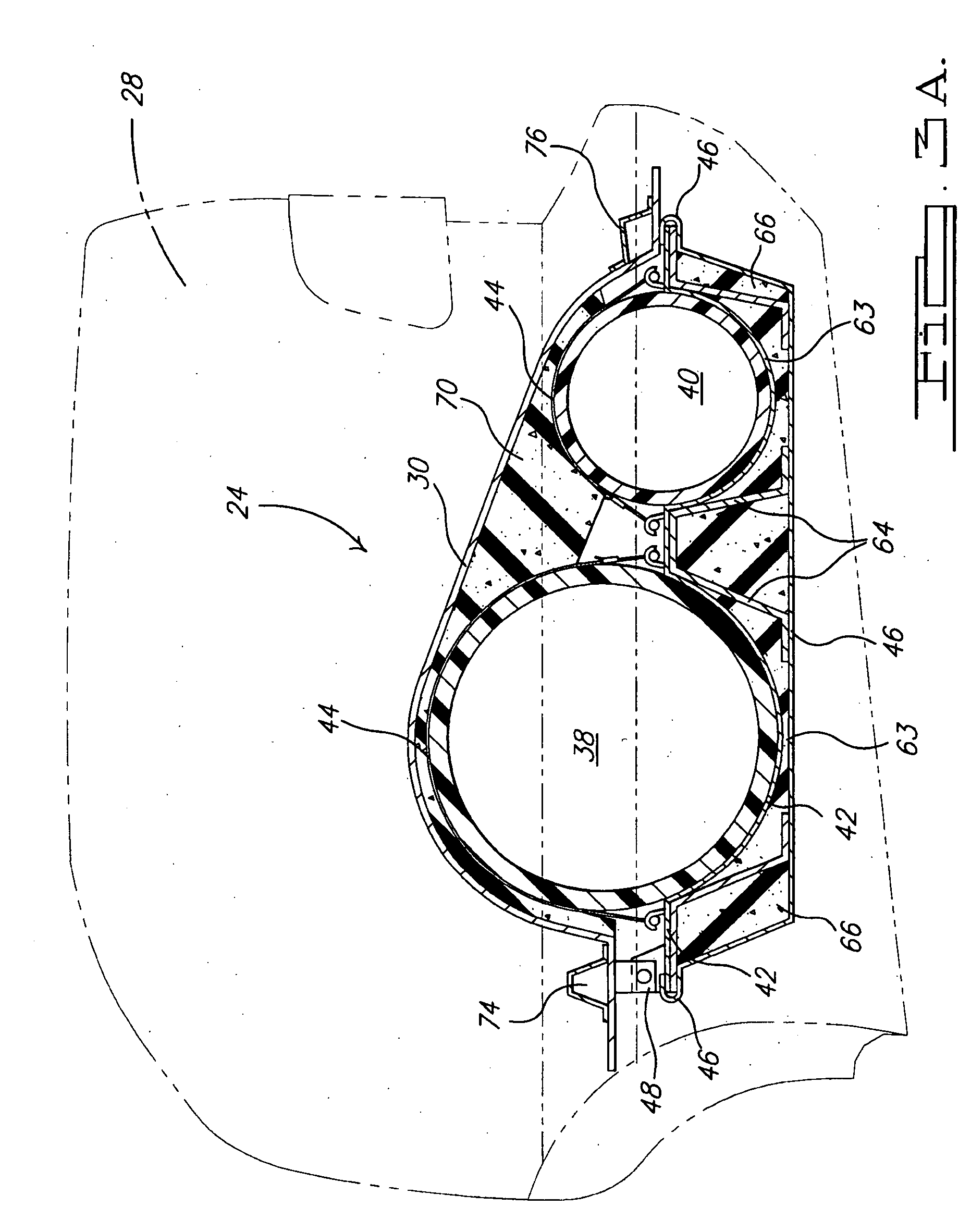

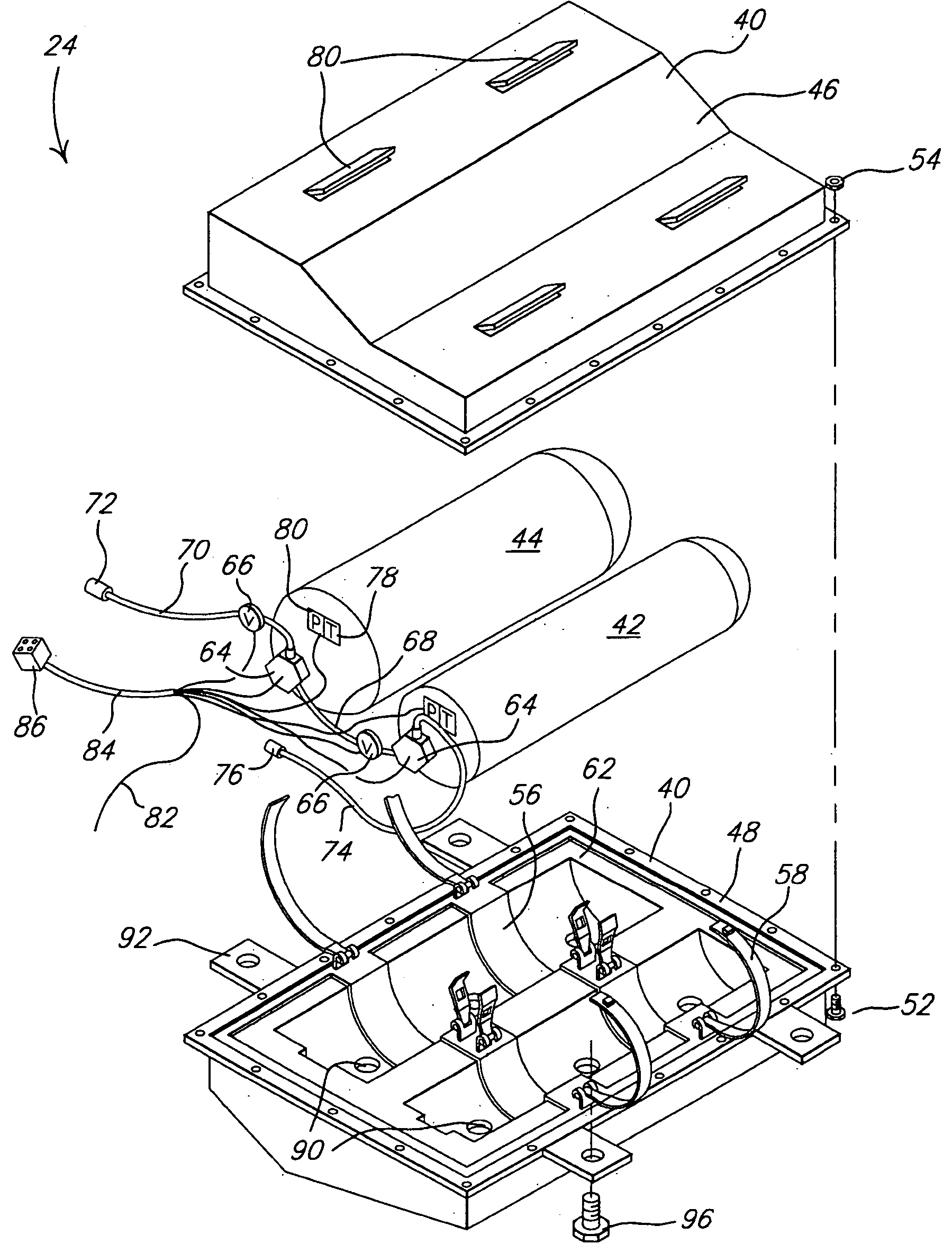

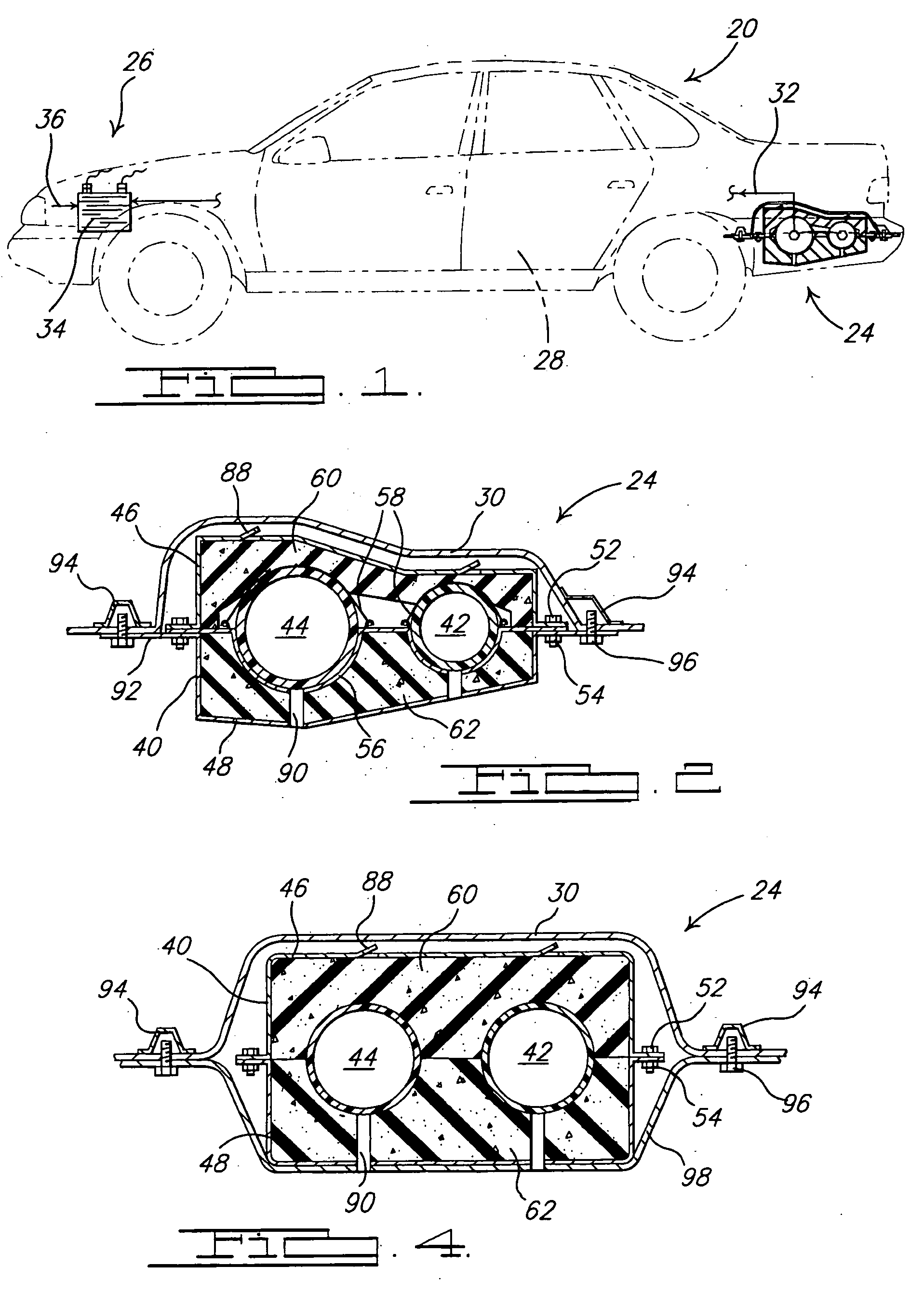

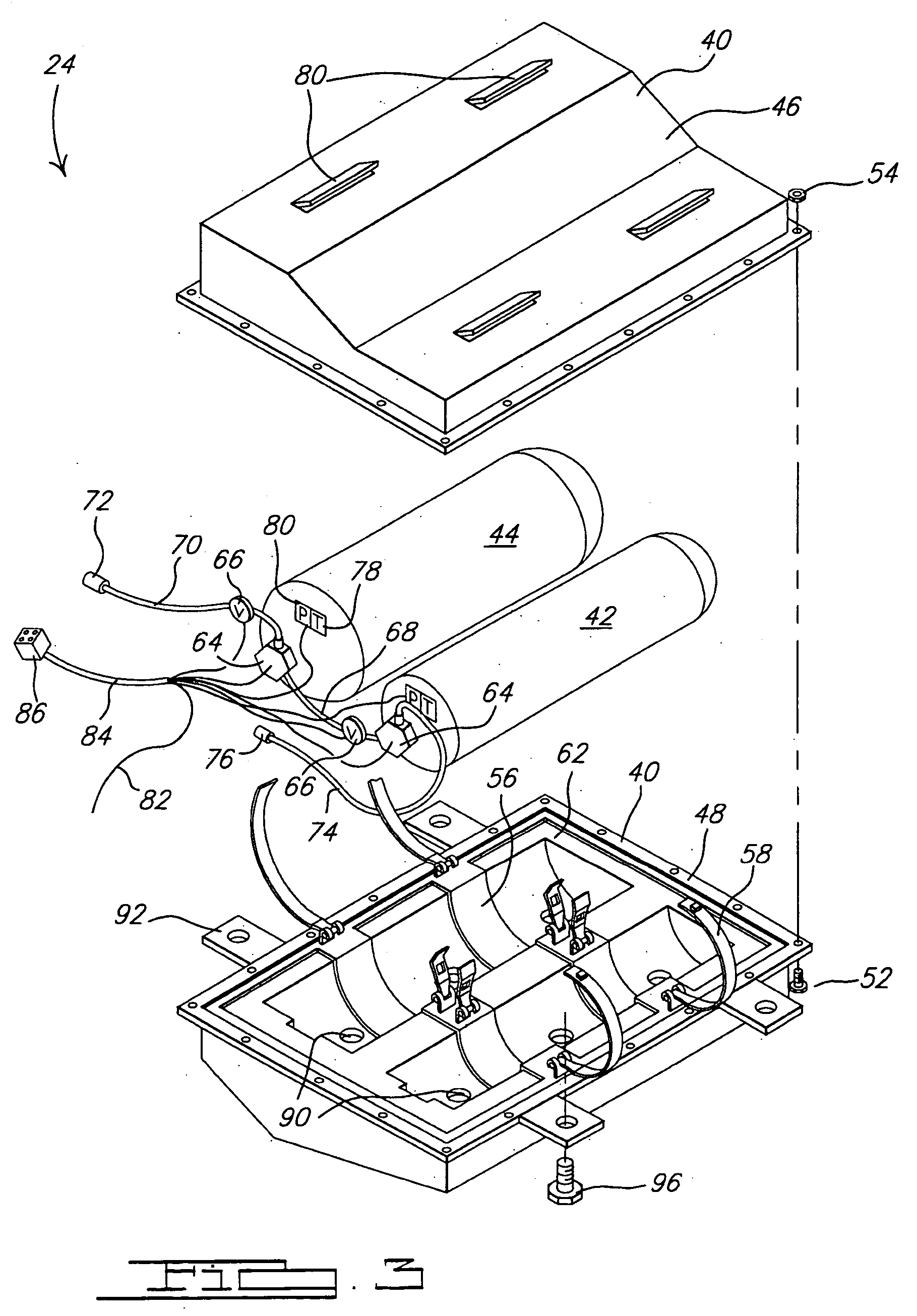

Modular fuel storage system for a vehicle

A gaseous fuel storage system for a vehicle is disclosed. The fuel storage system can be installed as a modular unit in the vehicle. The fuel storage system is pivotable relative to the vehicle to allow easy accessibility to the storage tanks without requiring the storage tanks to be unmounted from the vehicle. The fuel storage system also provides protection for the storage tanks through the use of shielding and energy absorbing material.

Owner:GM GLOBAL TECH OPERATIONS LLC

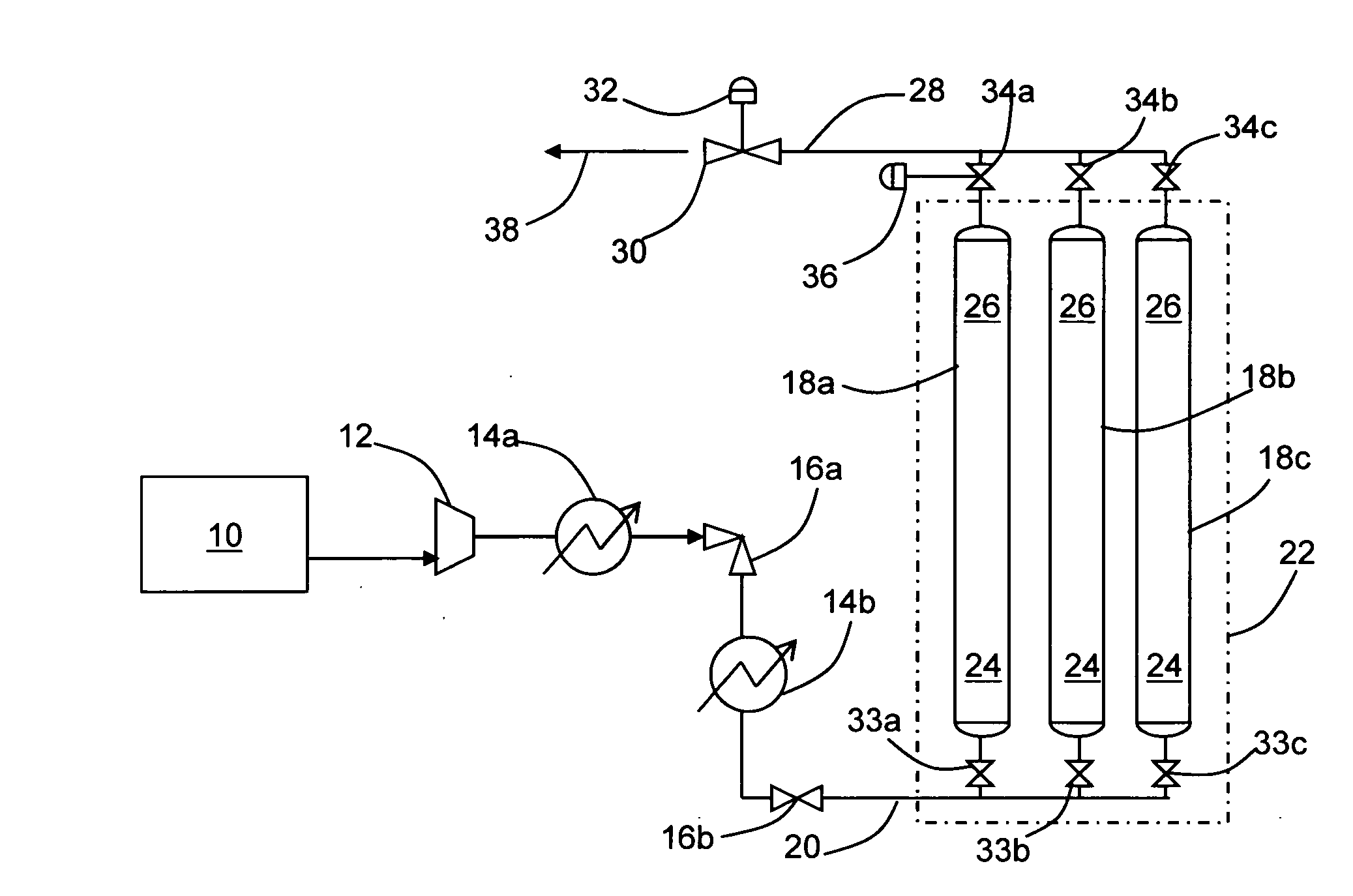

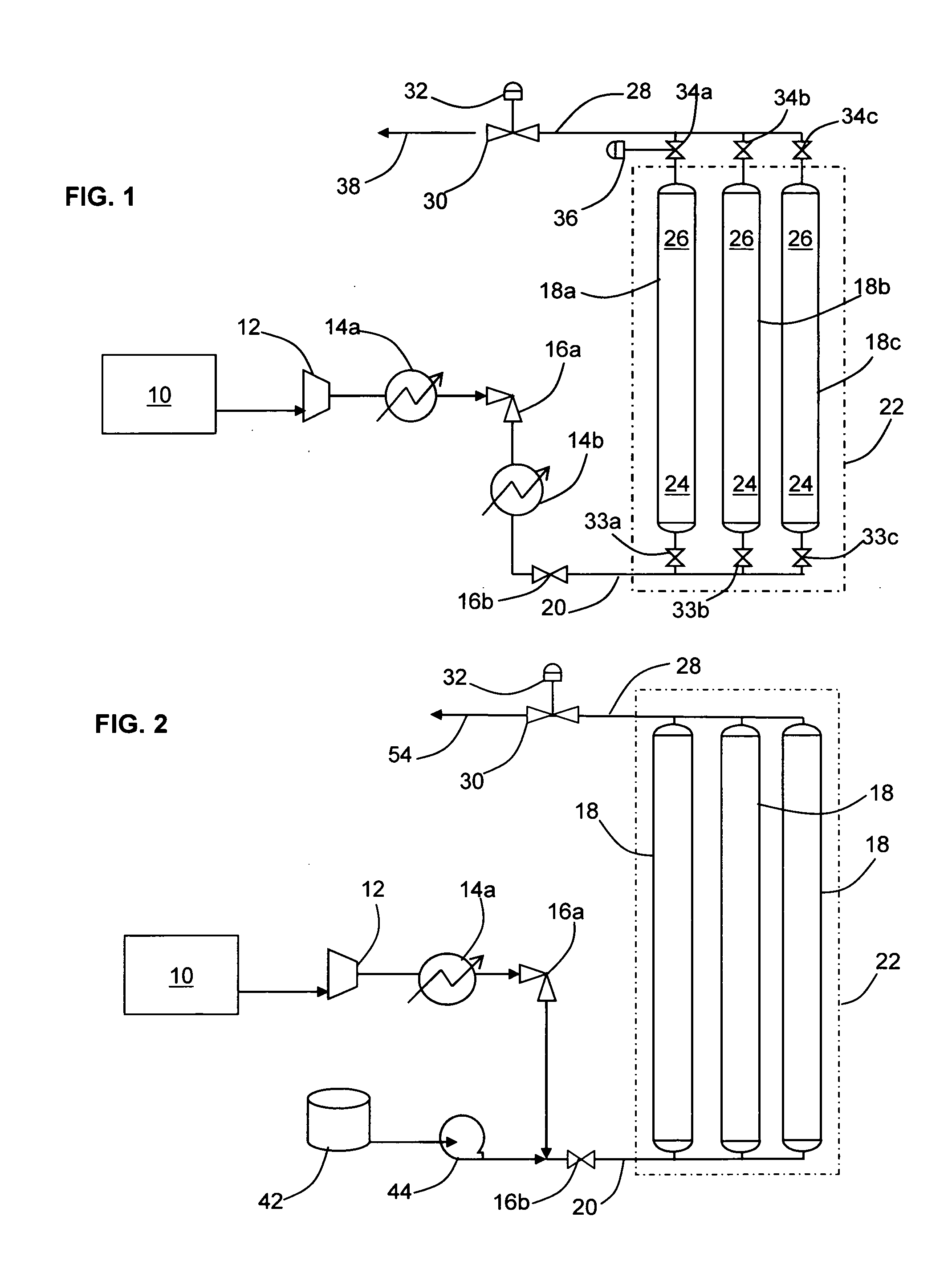

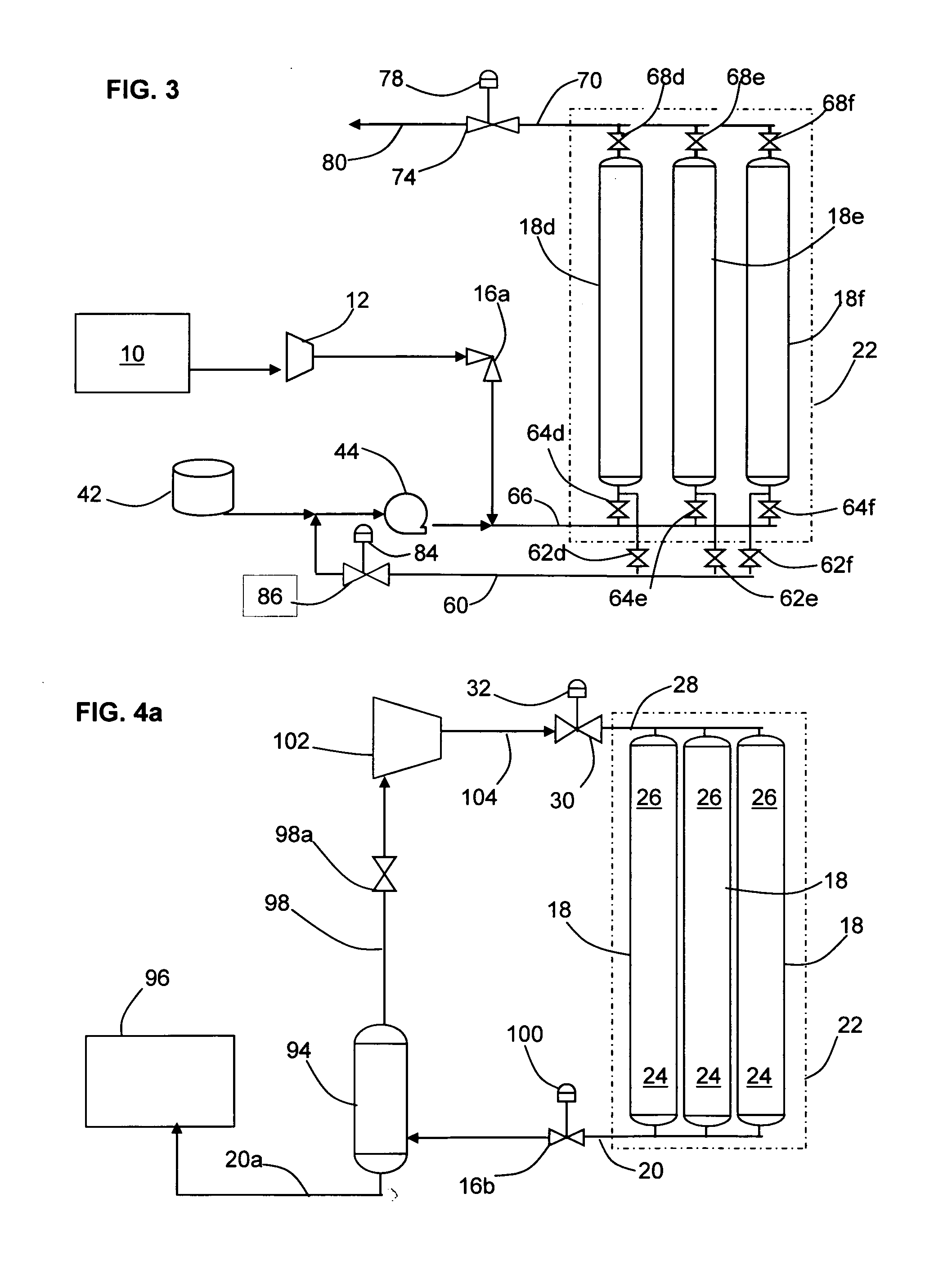

Apparatus and method for flowing compressed fluids into and out of containment

ActiveUS20080209916A1Adjustable temperatureGas handling applicationsGas handling/storage effectsChemical compositionCompressed fluid

Methods for loading a compressed fluid, such as natural gas, into and discharging the compressed fluid out of containment are provided. The compressed fluid is injected into a bottom portion of a container system for storage and / or transport until a target pressure is reached after which gas is withdrawn from an upper portion of the container system at a rate to maintain the target pressure while the compressed fluid is injected in the bottom portion. The compressed fluid is cooled through an expansion valve and by refrigerated chillers or by injecting a cold liquid of the same chemical composition as the compressed fluid, such as liquid natural gas, into the compressed fluid prior to injection into the container system. Withdrawal or discharge from the container system to a receiving facility begins with blow down from the bottom portion of the container system without a displacement fluid and continues until pressure falls below an acceptable differential pressure. The discharge stream is passed through a separator and a light gas from the separator is pressurized and injected into an upper portion of the container system to drive the compressed fluid out the bottom. The light gas is pressurized using either a compressor or a heated tank system, where two vessels operate in parallel, trapping and heating the light gas and then discharging to the container system from one while filling the other and alternating the operation between the two.

Owner:WHITE CHARLES N +1

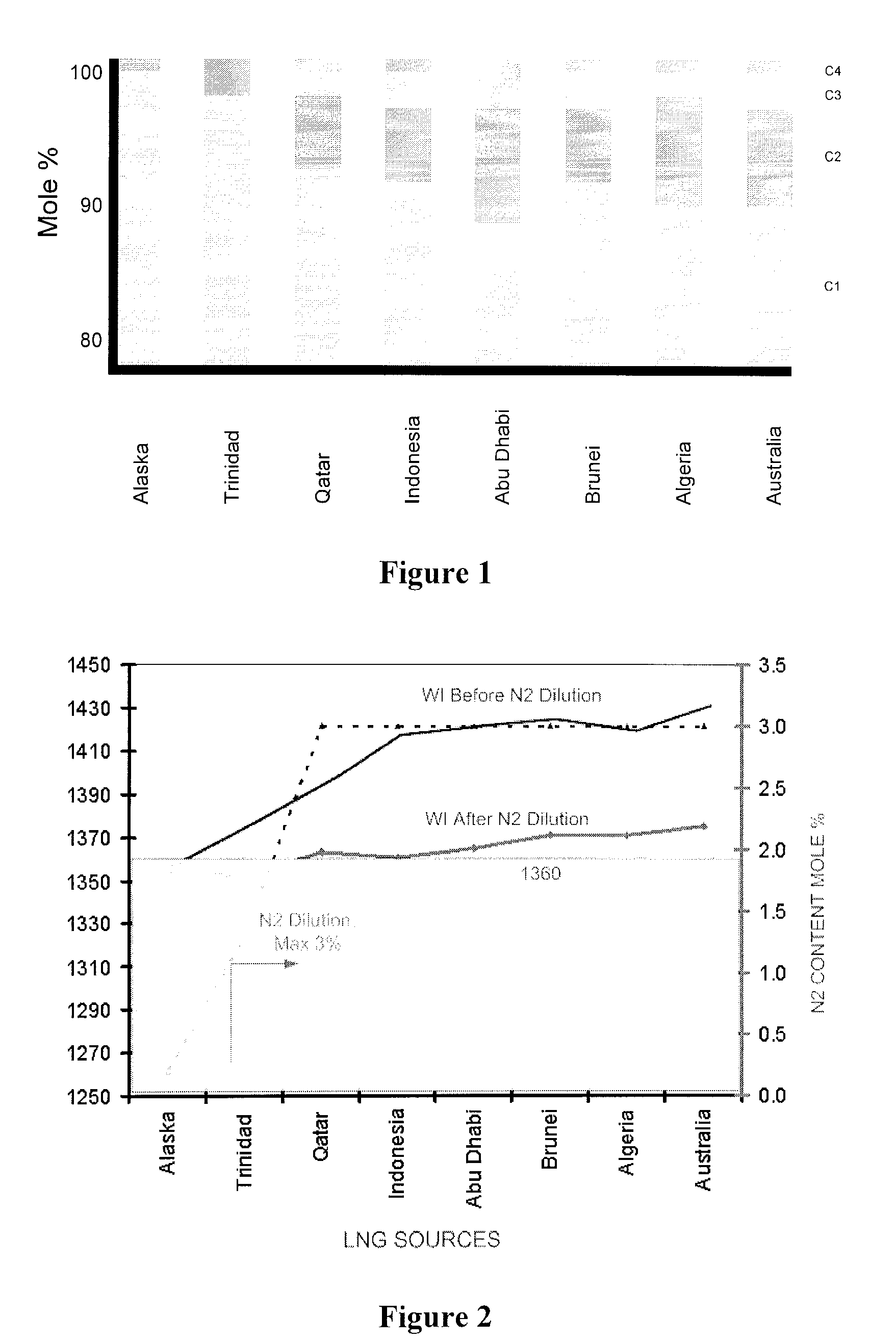

Methods and Configurations of Boil-off Gas Handling in LNG Regasification Terminals

InactiveUS20110056238A1Stable storage tank pressure controlStable controlSolidificationLiquefactionProcess engineeringWobbe index

A LNG storage and regasification plant includes a reliquefaction unit in which boil-off vapors from the storage tanks are re liquefied and recycled back to the LNG storage tanks for tank pressure and Wobbe index control. Preferably, LNG cold is used for reliquefaction and operational flexibility is achieved by feeding a portion of the pressurized boil-off gas to a fuel gas header and / or to be recondensed by the sendout LNG.

Owner:FLUOR TECH CORP

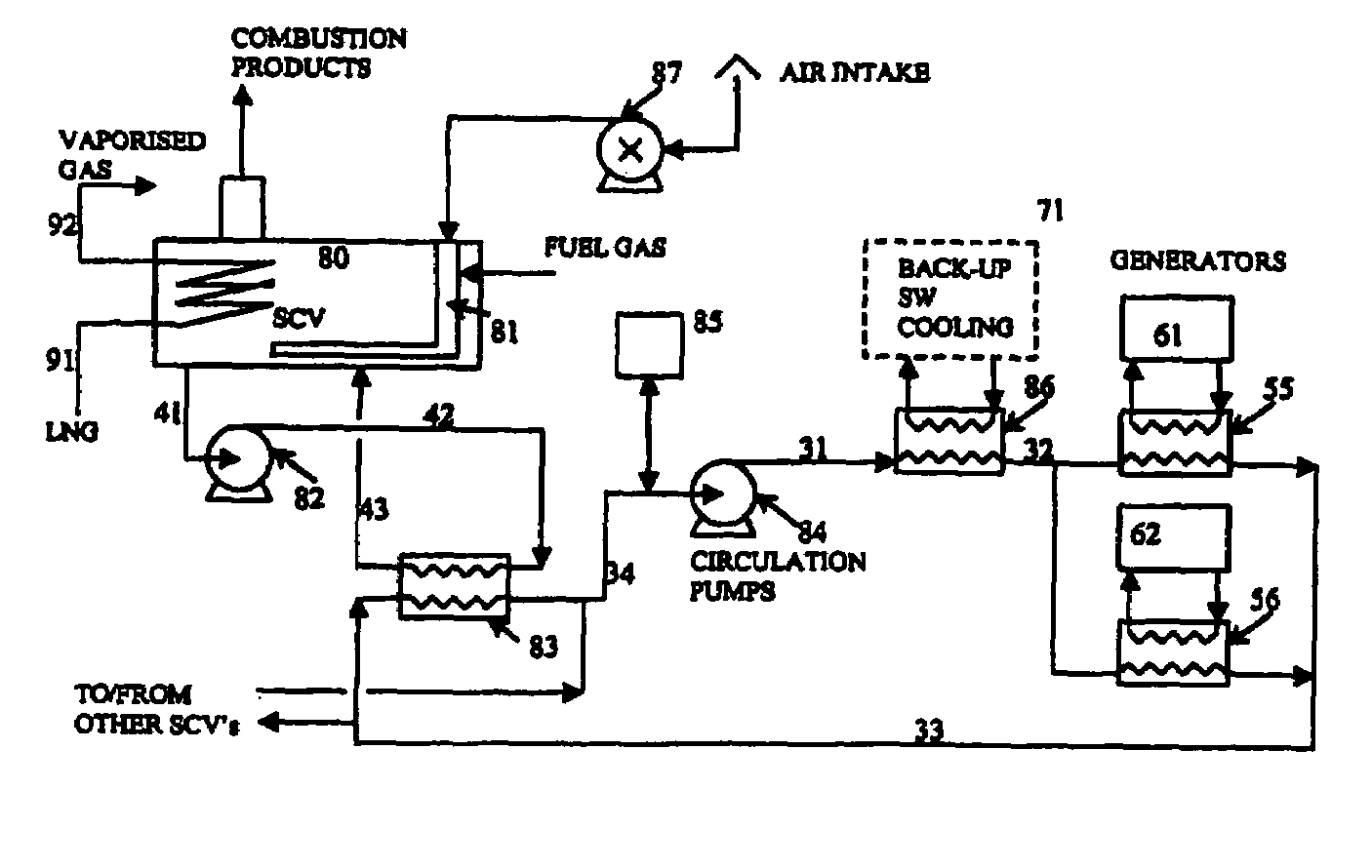

Heat recovery system

InactiveUS20080047280A1Easy to replenishReduce and even eliminateGas handling/storage effectsFluid transferredClosed loopEngineering

A heat recovery system comprising: an LNG warmer; at least one item of equipment requiring cooling and thereby generating waste heat; a heat exchanger arranged to provide heat exchange between the LNG warmer and the waste heat, whereby said waste heat can be used to provide warming for the LNG; wherein said heat exchanger is a closed loop heat exchange means, whereby the heat exchange fluids in said heat exchanger are substantially retained within the heat exchanger during operation of the system. This enables the system to be operated offshore without needing to use the surrounding seawater to provide cooling for the waste heat from the equipment.

Owner:BHP BILLITON INNOVATION PTY LTD

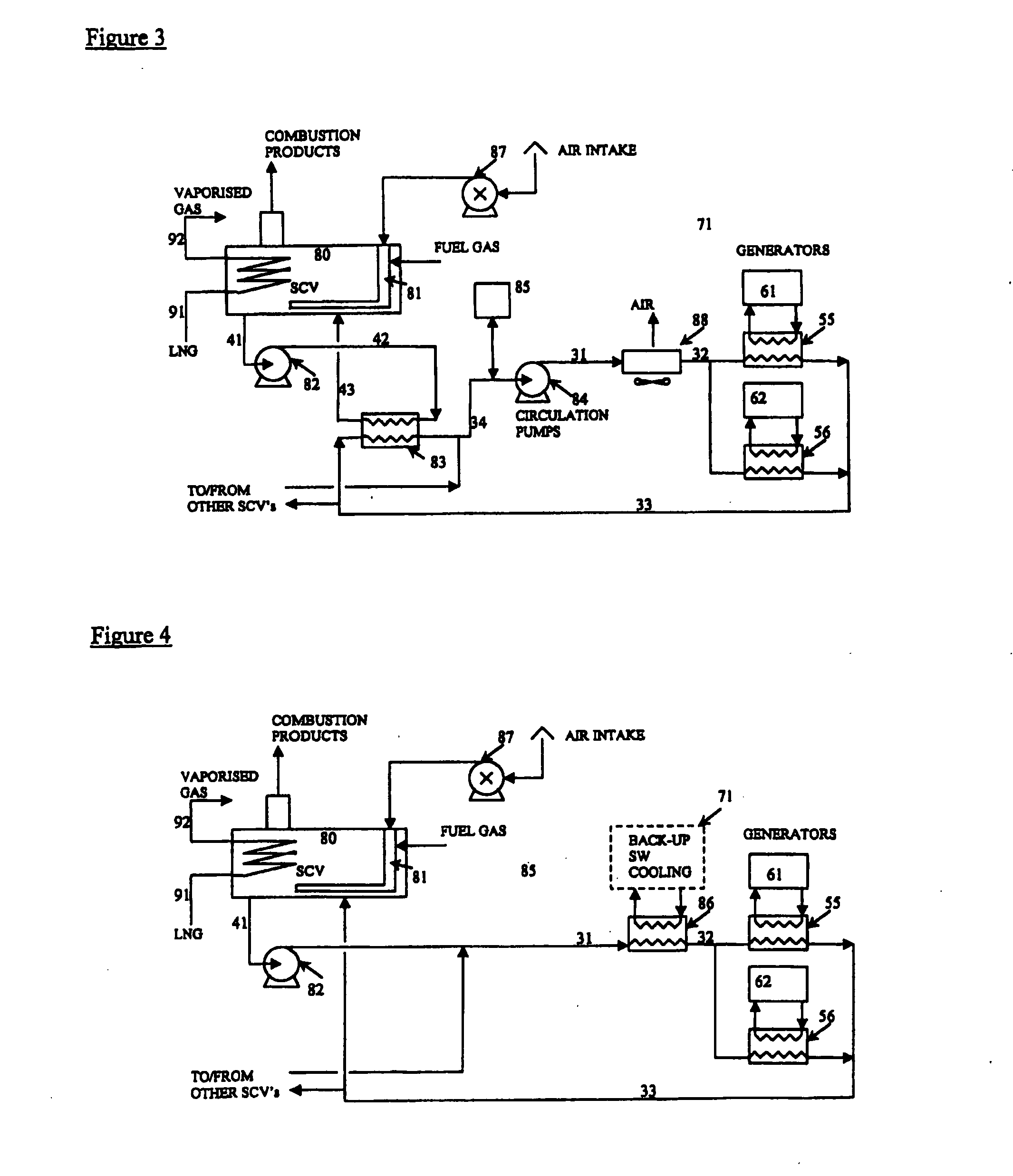

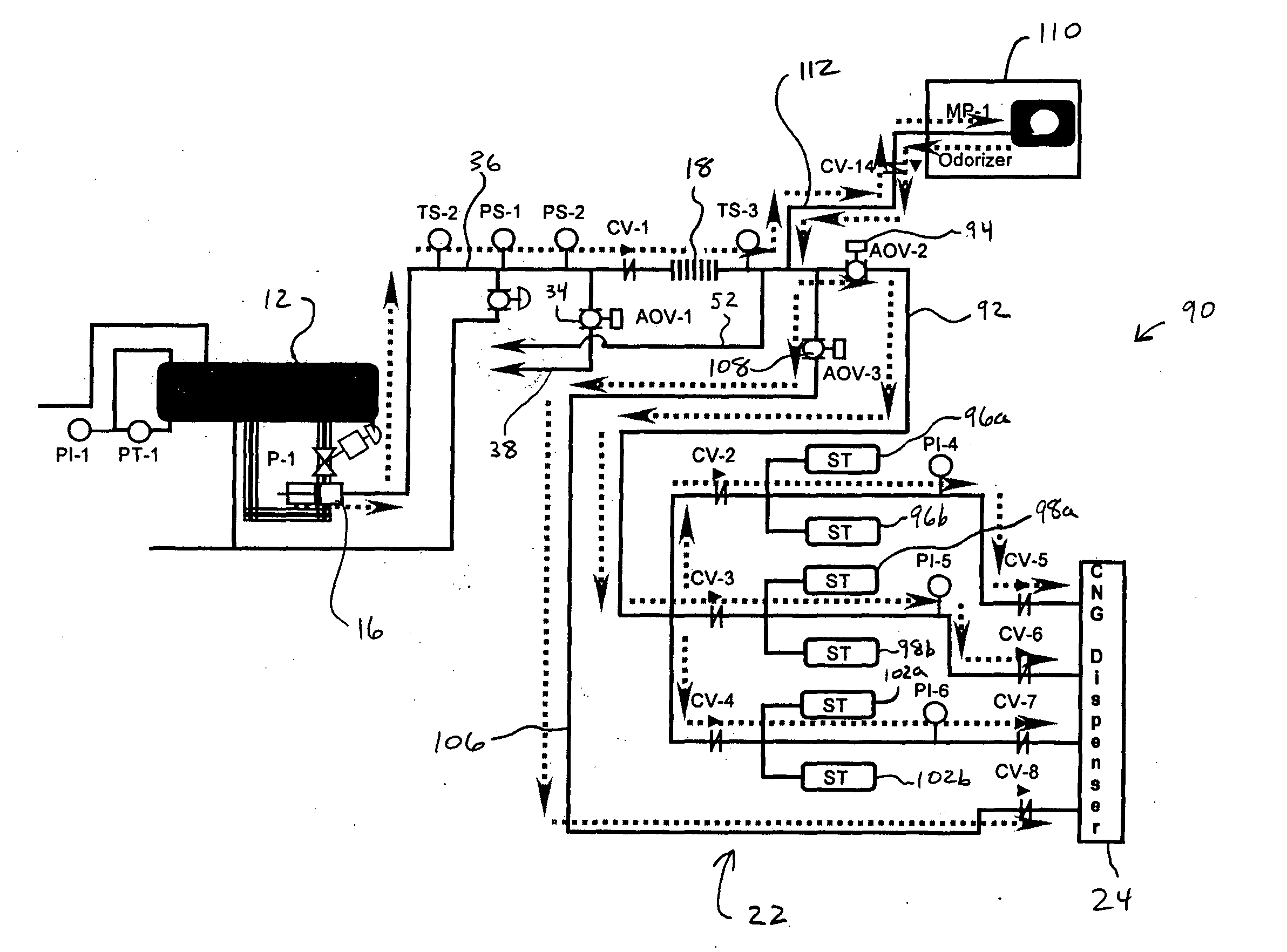

Liquid and compressed natural gas dispensing system

InactiveUS20050016185A1Distribute quicklyEliminate timeGas handling applicationsGas handling/storage effectsCompressed natural gasProcess engineering

A system dispenses both liquid natural gas (LNG) and compressed natural gas (CNG). A bulk tank contains a supply of LNG which is pumped to a smaller storage tank. After the storage tank is refilled, LNG from the bulk tank is pumped to a vaporizer so that CNG is produced. The CNG may be routed to the LNG in the storage tank to condition it. It is also used to recharge a pressurizing cylinder that is placed in communication with the head space of the storage tank when it is desired to rapidly dispense LNG to a vehicle. A bank of cascaded storage cylinders alternatively may receive CNG from the vaporizer for later dispensing through the system CNG dispenser. The CNG from the vaporizer may also be dispensed directly via the system CNG dispenser.

Owner:CHART INC

Ecological Liquefied Natural Gas (LNG) Vaporizer System

InactiveUS20080178611A1Gas handling applicationsGas handling/storage effectsProcess engineeringAmbient air

An approach is provided for vaporizing liquefied natural gas (LNG). A system utilizing closed circulation of a heat transfer medium heated by ambient air and waste heat from a waste heat source vaporizes the LNG.

Owner:AMEC FOSTER WHEELER USA CORP

Liquefied natural gas structure

InactiveUS20050115248A1Easy transferProvide protectionGas handling/storage effectsSolid materialMarine engineeringTower

An offshore liquefied natural gas structure may receive, store, and process liquefied natural gas from carriers. A structure may be a gravity base structure. A structure may include a system of ballast storage areas, transfer equipment to offload liquefied natural gas from a carrier, docking equipment to allow direct mooring with carriers, platforms to elevate equipment, water intake systems to provide water to the structure, wave deflectors, and / or projections extending from a bottom of the structure. A portion of the structure may be composed of lightweight concrete. Pipelines may be coupled to the structure to export processed natural gas onshore. Living quarters, flare towers, and export line metering equipment may be included on the structure.

Owner:SHELL OIL CO

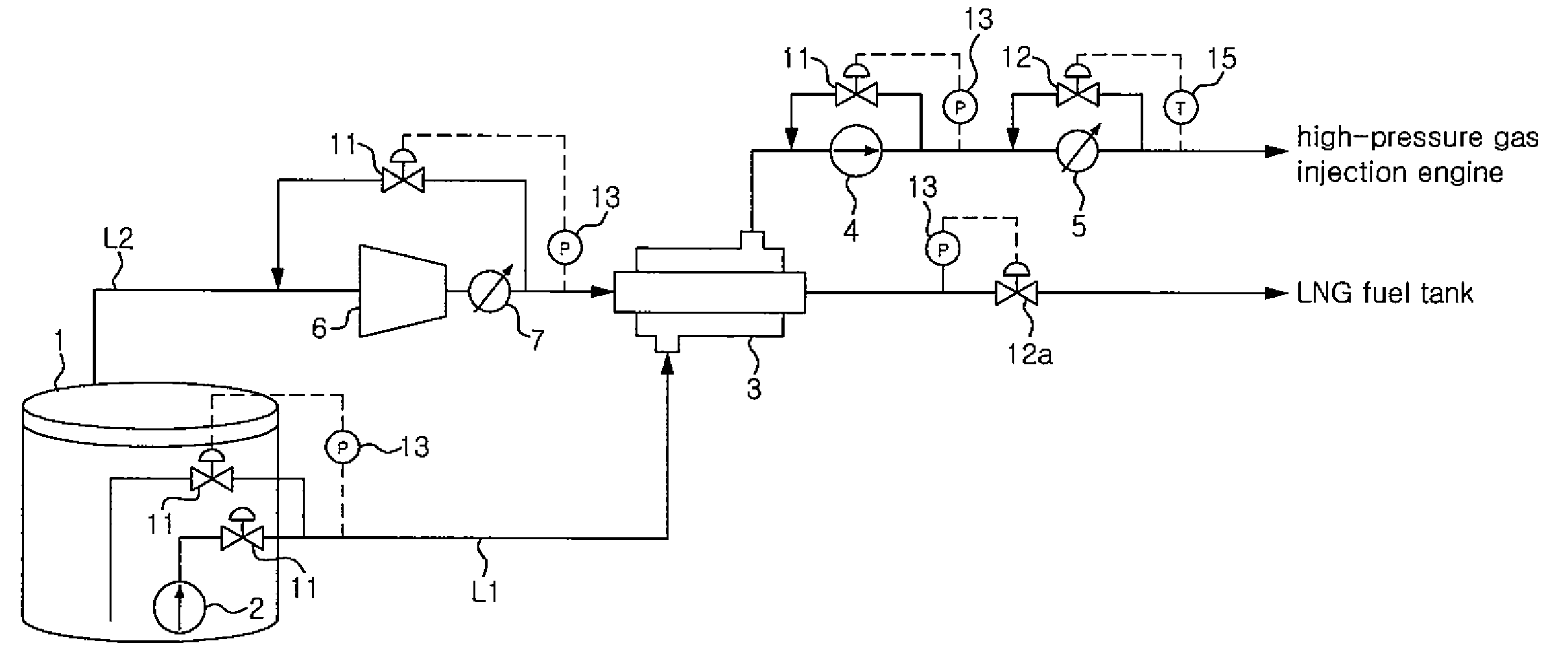

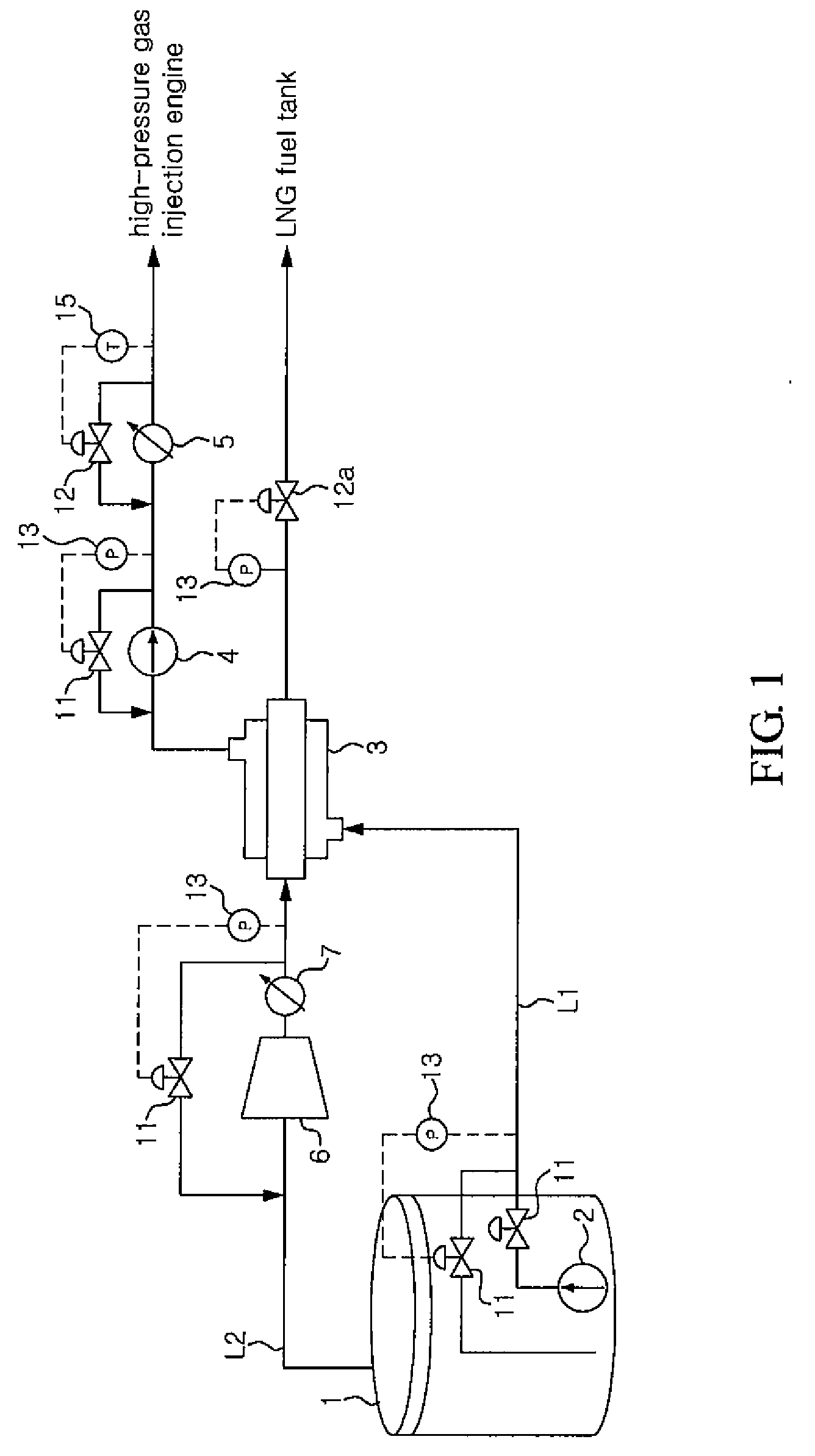

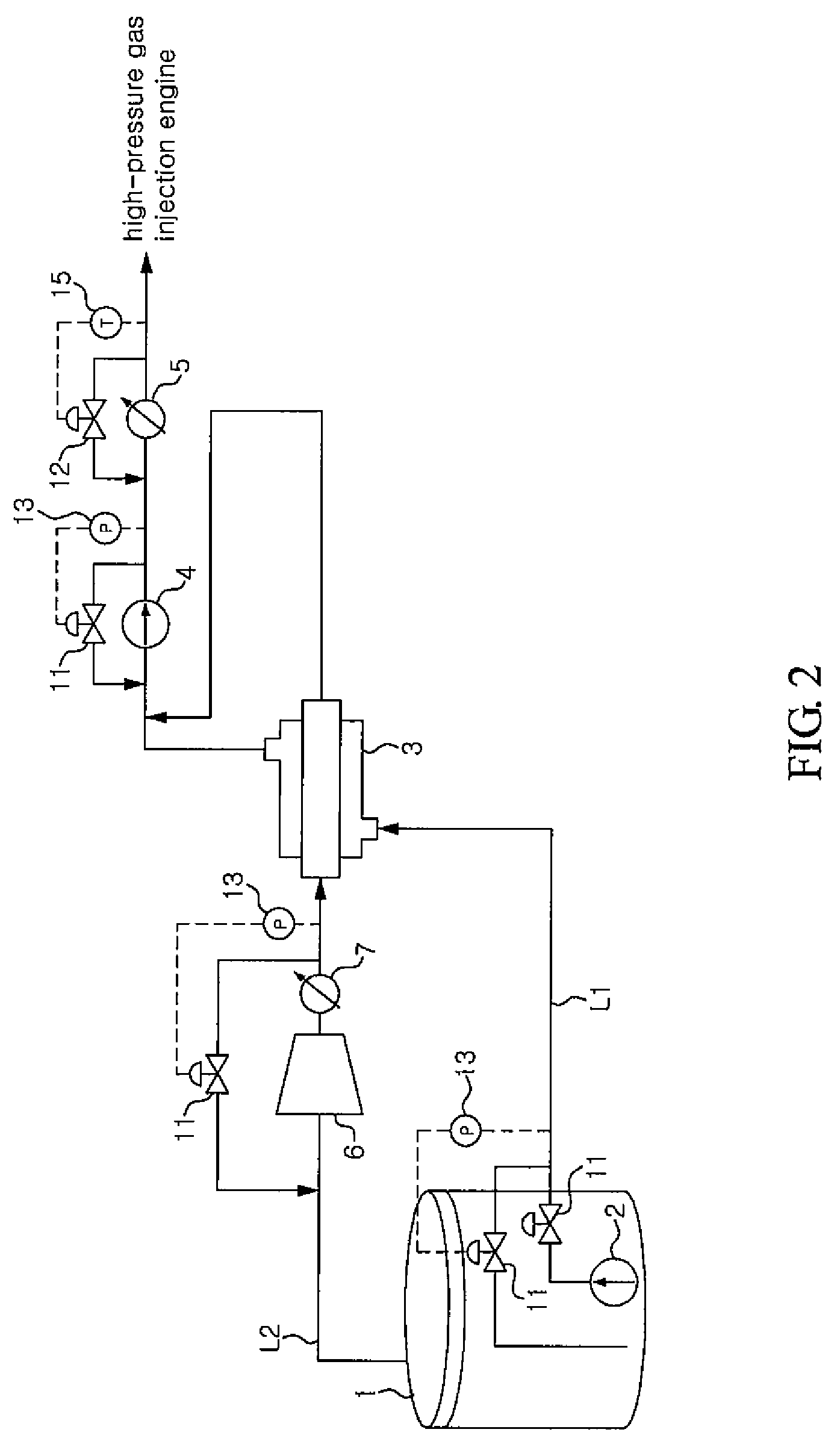

Fuel gas supply system and method of a ship

InactiveUS20080276627A1Prevent excessive pressure increaseSimple configurationInternal combustion piston enginesContainer filling methodsFuel tankProduct gas

A fuel gas supply system of a ship is provided for supplying fuel gas to a high-pressure gas injection engine of the ship, wherein the ship has an LNG fuel tank for storing LNG as fuel and LNG is extracted from an LNG fuel tank of the ship, compressed at a high pressure, gasified, and then supplied to the high-pressure gas injection engine.

Owner:DAEWOO SHIPBUILDING & MARINE ENG CO LTD

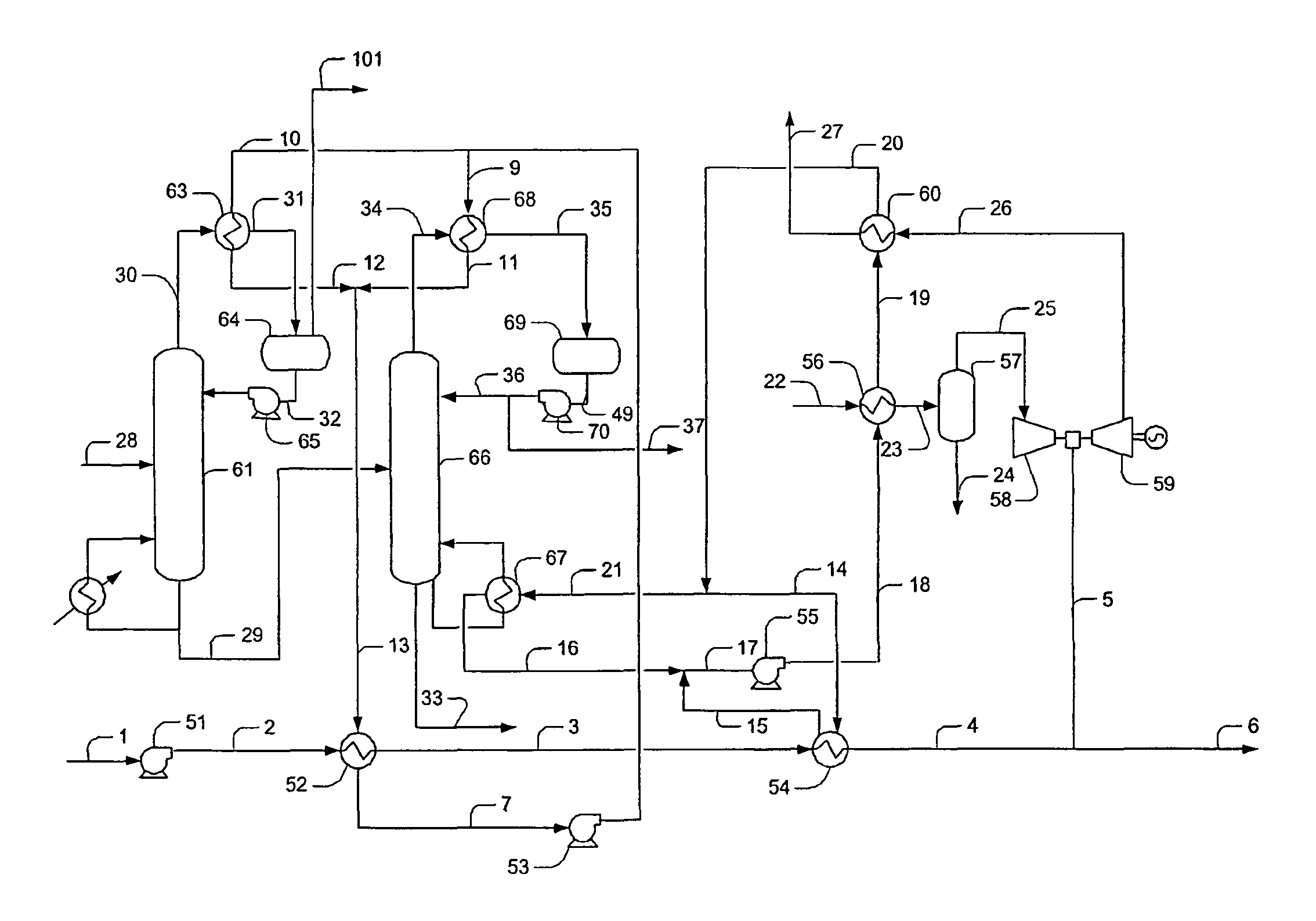

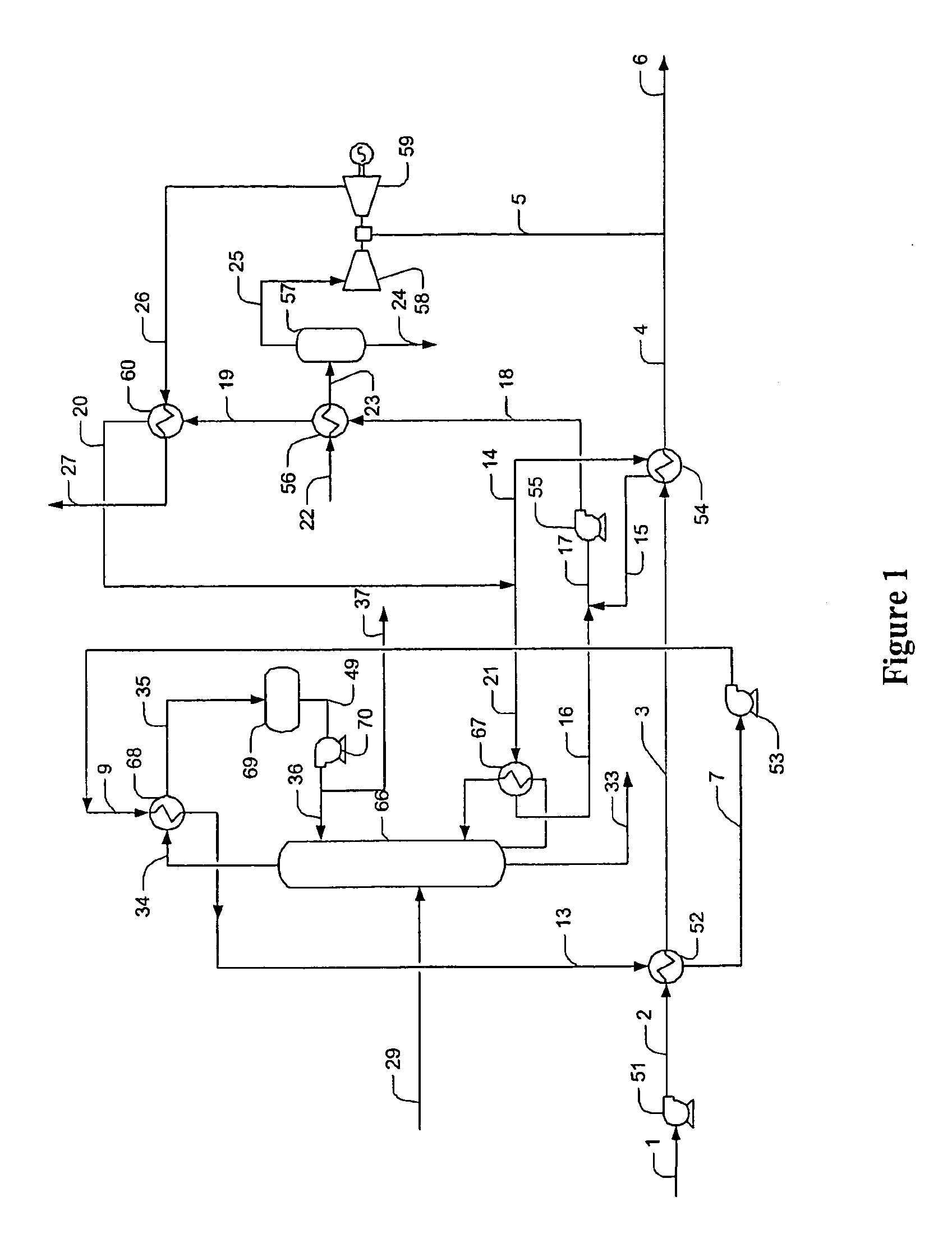

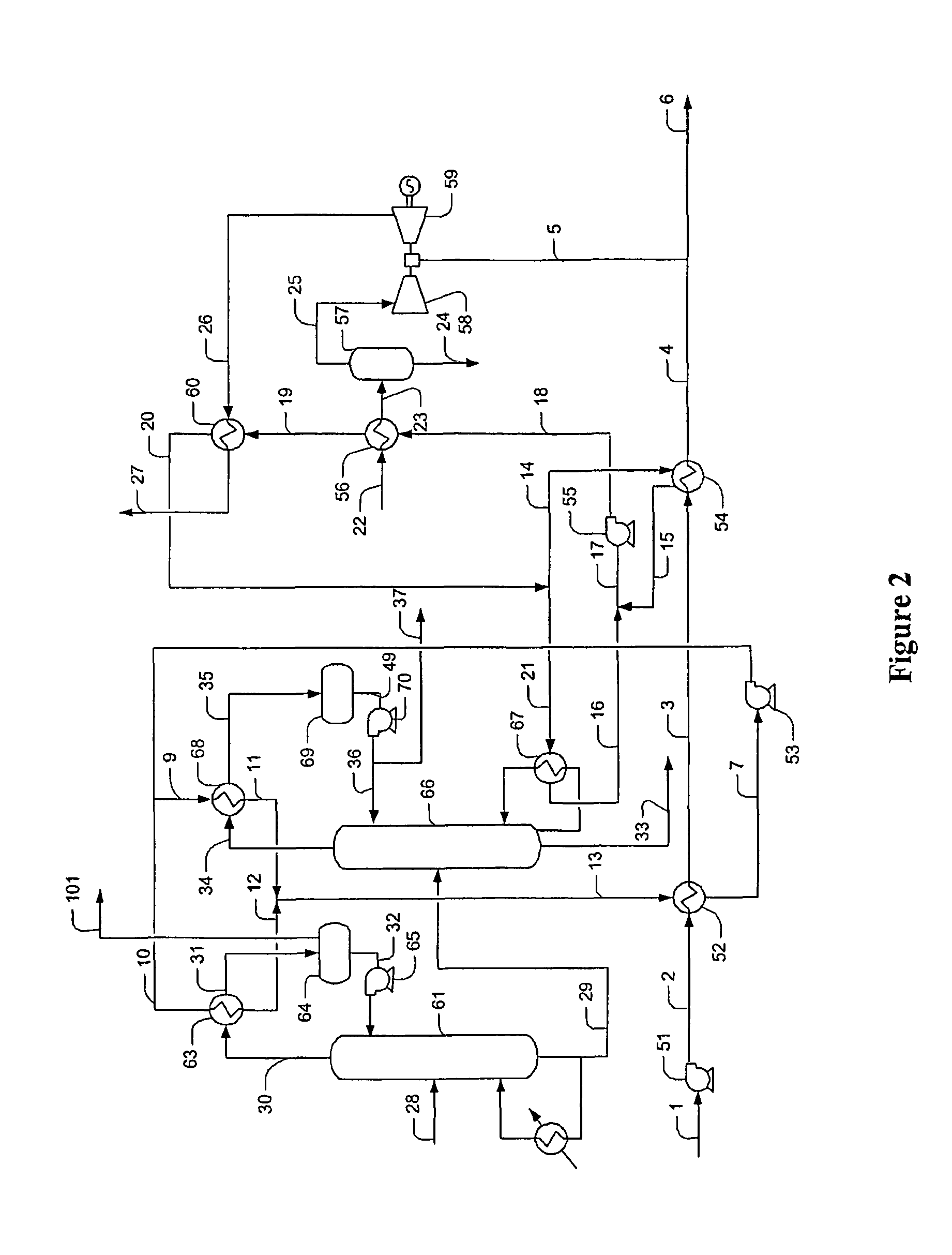

Integration of LNG regasification with refinery and power generation

Contemplated plants thermally integrate operation of a refinery component, and most preferably of a hydrocarbon splitter with LNG regasification to provide refrigeration duty and with a power cycle to provide the reboiler duty of the component. It should be noted that such configurations advantageously allow operation of the splitter at a reduced temperature and at reduced pressure, thereby increasing separation efficiency, while the power output is boosted using air intake chilling. Most notably, such process advantages are achieved by satisfying the heating duty of LNG regasification.

Owner:FLUOR TECH CORP

Modular fuel storage system for a vehicle

A gaseous fuel storage system for a vehicle is disclosed. The fuel storage system can be installed as a modular unit in the vehicle. The fuel storage system is pivotable relative to the vehicle to allow easy accessibility to the storage tanks without requiring the storage tanks to be unmounted from the vehicle. The fuel storage system also provides protection for the storage tanks through the use of shielding and energy absorbing material.

Owner:GM GLOBAL TECH OPERATIONS LLC

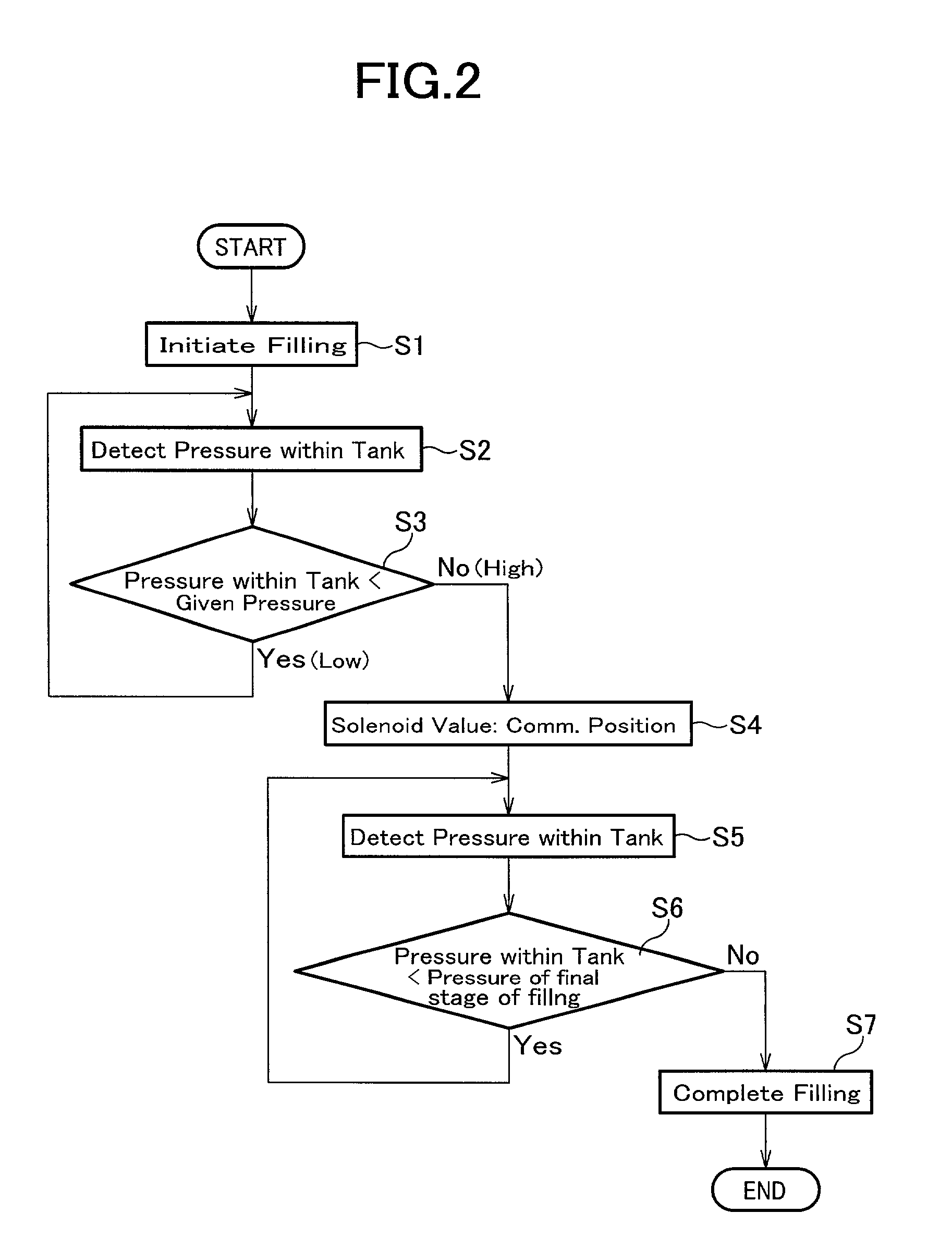

Apparatus and process for rapidly filling with hydrogen

InactiveUS20020014277A1Increase heatIncrease rangeLiquid fillingGas handling applicationsFilling rateDelayed time

An apparatus for rapidly filling a hydrogen tank with a hydrogen gas comprises a hydrogen source; a hydrogen tank; a passage which connects the hydrogen source and said hydrogen tank; and a mechanism for varying the hydrogen-filling rate. The mechanism for varying the hydrogen-filling rate changes the hydrogen-filling rate depending upon the pressure within said hydrogen tank. The apparatus can suppress heat generation at the initial filling stage where the temperature is easily increased. Also, even if it takes longer time for increasing the pressure within the hydrogen tank at the initial filling state, the delayed time can be caught up and, the apparatus and the process of the present invention can totally attain a rapidly filling with hydrogen.

Owner:HONDA MOTOR CO LTD

Compressor

InactiveUS20080008602A1Reduce consumptionSmall sizeAuxillariesContainer filling methodsEngineeringControl valves

A rotary liquefied natural gas boil-off compressor has a series of compression stages. A gas passage passes through the series of compression stages. The gas passage extends through and is in heat exchange relationship with cooling means in the form of indirect heat exchangers. Each of the heat exchangers is cooled by LNG supplied from a pipeline. Flow control valves are provided for controlling the flow of LNG to the heat exchangers respectively. The valves are controlled in response to temperature sensors respectively, so as to maintain the inlet temperature of each of the compression stages at a chosen sub-ambient temperature or between chosen sub-ambient temperature limits.

Owner:THE BOC GRP PLC

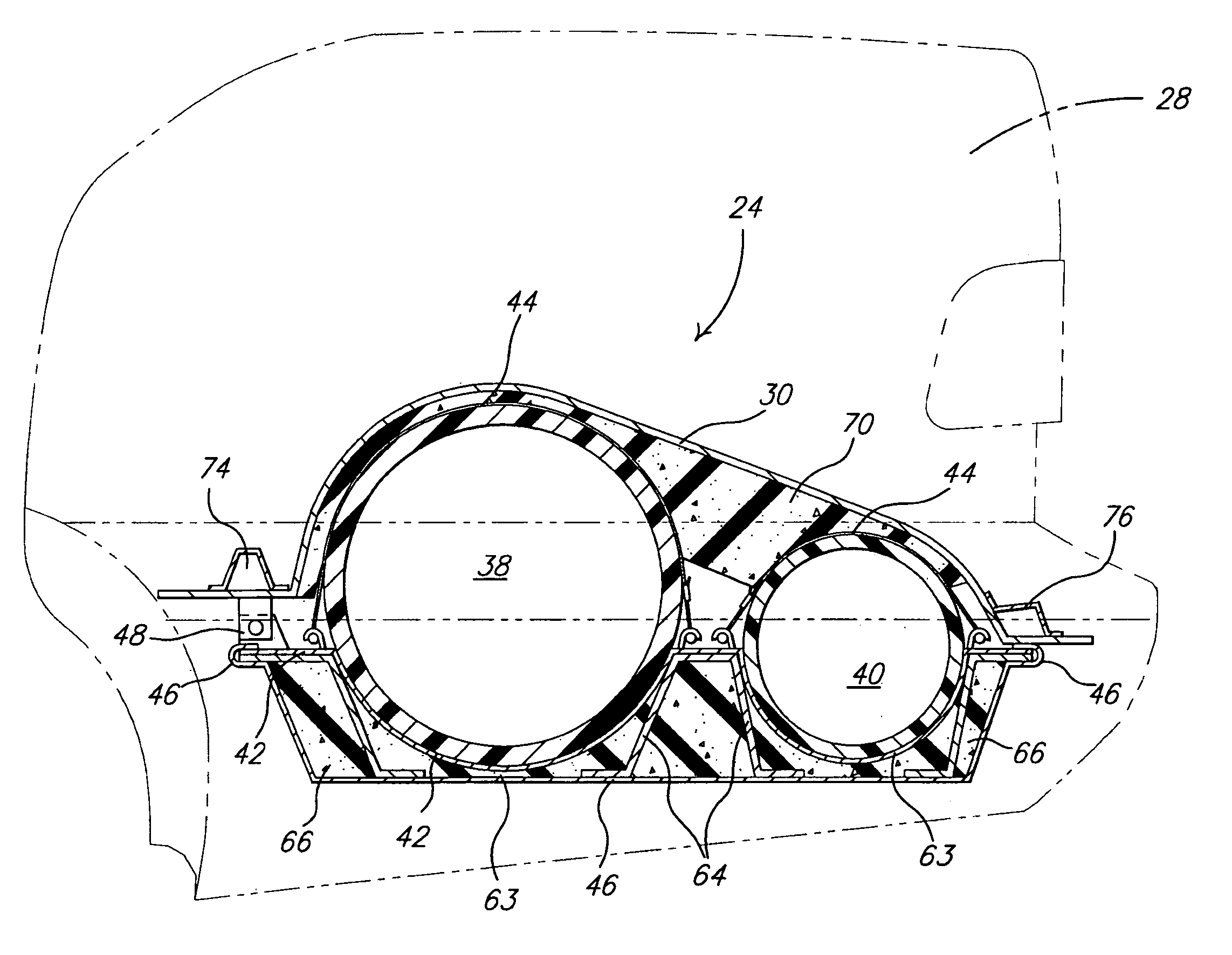

Container for gas storage tanks in a vehicle

ActiveUS20060032532A1Maximize available spaceEasy to disassembleContainer filling methodsGas handling/storage effectsPressure regulatorVALVE PORT

A container for gas storage tanks in a vehicle is disclosed as part of a fuel storage system. The container is dimensioned to include one or more storage tanks along with a flow control device, such as a pressure regulator or automatic valve. The container does not form a fluid-tight containment around the storage tank and includes one or more ventilation openings to allow a gas within the container to be vented therefrom. There is also one or more drain openings in the container to allow liquid within the container to be drained therefrom.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

Mobile firefighting systems with breathable hypoxic fire extinguishing compositions for human occupied environments

Mobile fire-fighting systems and a method of producing breathable fire-suppression compositions are provided for extinguishing fires in buildings, and other human occupied structures, being also effective in suppressing fires under ruins of collapsed buildings. The systems employ a transportable high-pressure container having the breathable composition or nitrogen gas, or a liquid nitrogen container, vaporizer and a mixing chamber, wherein a vaporized nitrogen gas is mixed with an ambient air in order to produce said breathable fire-suppression composition. Refilling stations are provided for refilling the mobile systems with said composition, nitrogen gas or liquid nitrogen, all being generated at site from the ambient air. The method of producing said composition at a fire site employs mixing of nitrogen gas with ambient air or, alternatively, vaporizing of liquid nitrogen in necessary quantities and mixing it with ambient air in provided proportions. A method of delivery of the breathable fire-suppressive composition inside a building on fire is provided as well. The systems are also suitable for installation as a stationary fire-suppression system for a building or other structure. A breathable fire-suppression composition is provided for use in said mobile systems, said composition having an oxygen content below 16% or from 10% to 12% for the majority of civil applications.

Owner:FIREPASS CORP

Fluid distribution system and process, and semiconductor fabrication facility utilizing same

A fluid distribution system for supplying a gas to a process facility such as a semiconductor manufacturing plant. The system includes a main fluid supply vessel coupled by flow circuitry to a local sorbent-containing supply vessel from which fluid, e.g., low pressure compressed gas, is dispensed to a fluid-consuming unit, e.g., a semiconductor manufacturing tool. A fluid pressure regulator is disposed in the flow circuitry or the main liquid supply vessel and ensures that the gas flowed to the fluid-consuming unit is at desired pressure. The system and associated method are particularly suited to the supply and utilization of liquefied compressed gases such as trimethylsilane, arsine, phosphine, and dichlorosilane.

Owner:ENTEGRIS INC

Integrated LNG gasification and power production cycle

ActiveUS20130104525A1Improve efficiencyLow costSolidificationLiquefactionCombustorProcess engineering

The present disclosure provides an integrated power generating system and method and liquefied natural gas (LNG) vaporization system and method. More particularly, heat from a CO2 containing stream from the power generating system and method can be used to heat the LNG for re-gasification as gaseous CO2 from CO2 containing stream is liquefied. The liquefied CO2 can be captured and / or recycled back to a combustor in the power generating system and method.

Owner:8 RIVERS CAPTTAL LLC

Fluid storage and dispensing system featuring externally adjustable regulator assembly for high flow dispensing

InactiveUS6360546B1CostPerformanceContainer filling methodsGas handling applicationsEngineeringAtmospheric pressure

A fluid storage and dispensing system including a fluid storage and dispensing vessel enclosing an interior volume for holding a fluid. The vessel includes a fluid discharge port for discharging fluid from the vessel. A pressure regulating element in the interior volume of the fluid storage and dispensing vessel is arranged to flow fluid therethrough to the fluid discharge port at a set pressure for dispensing thereof. A controller external of the fluid storage and dispensing vessel is arranged to transmit a control input into the vessel to cause the pressure regulating element to change the set pressure of the fluid flowed from the pressure regulating element to the fluid discharge port. By such arrangement, the respective storage and dispensing operations can have differing regulator set point pressures, as for example a subatmospheric pressure set point for storage and a super atmospheric pressure set point for dispensing.

Owner:ADVANCED TECH MATERIALS INC

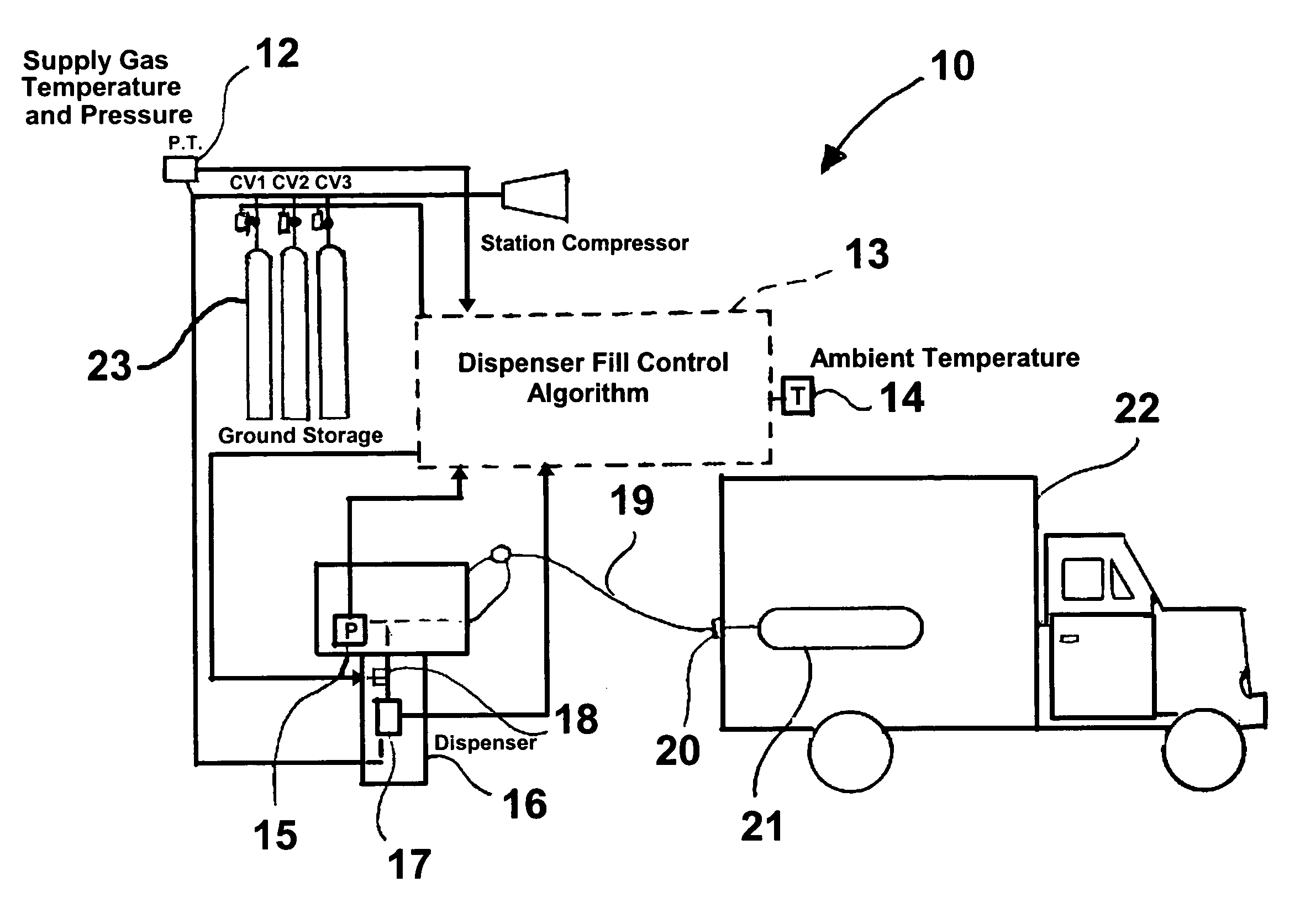

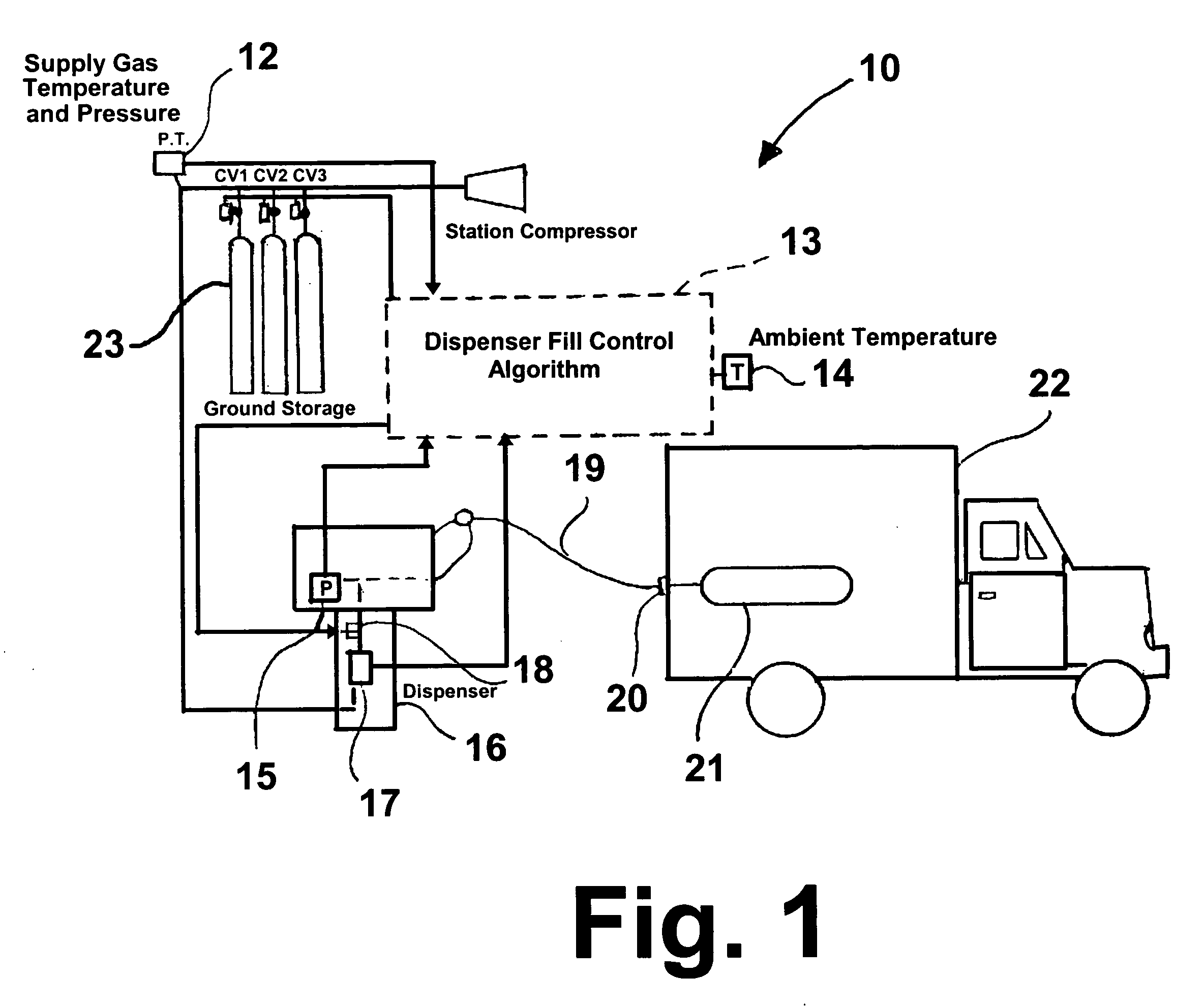

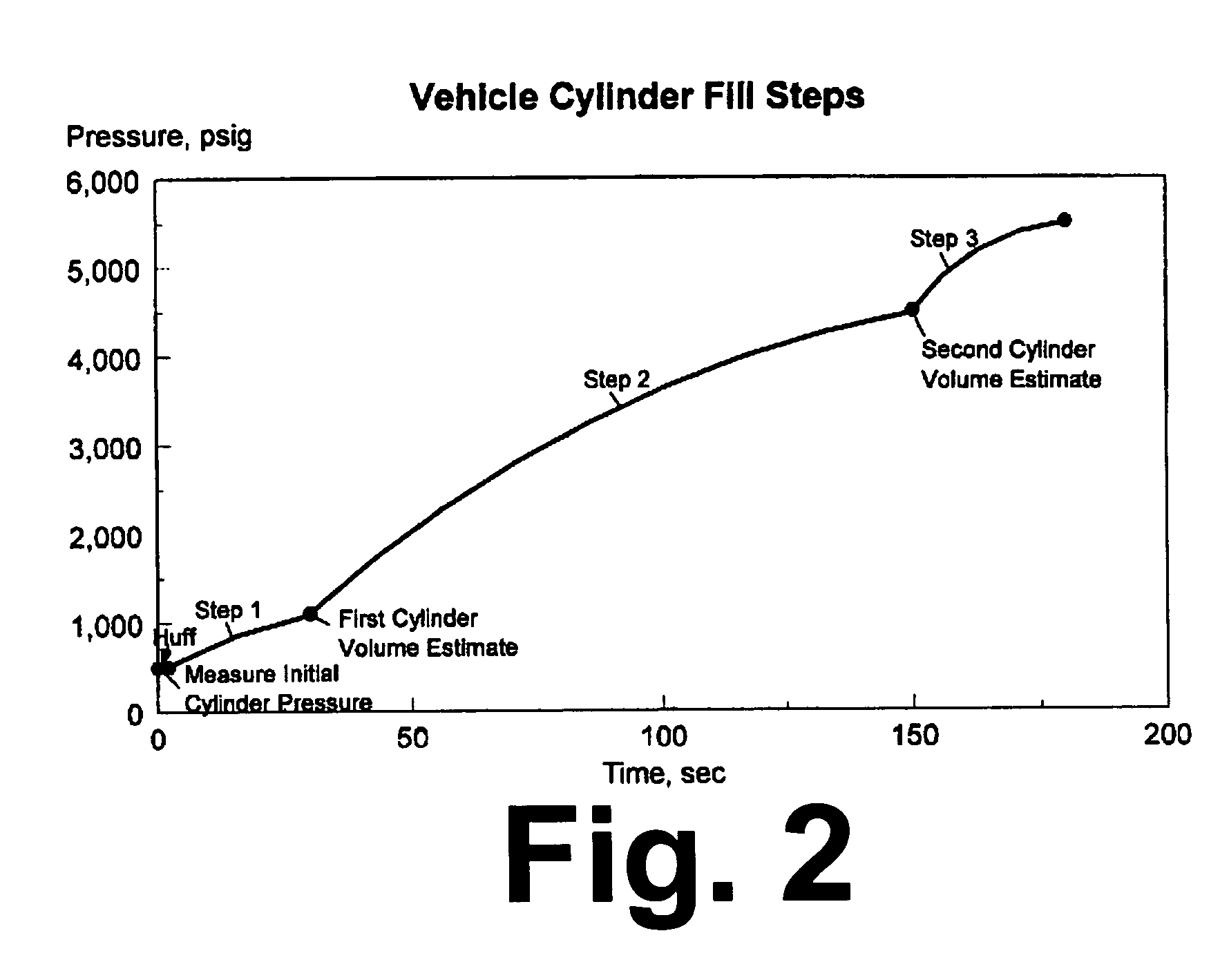

Control method for high-pressure hydrogen vehicle fueling station dispensers

InactiveUS7059364B2Reduces potential for underfillingFast fillGas handling applicationsGas handling/storage effectsHigh pressure hydrogenHigh pressure

A method for quick filling a vehicle hydrogen storage vessel with hydrogen, the key component of which is an algorithm used to control the fill process, which interacts with the hydrogen dispensing apparatus to determine the vehicle hydrogen storage vessel capacity.

Owner:GAS TECH INST

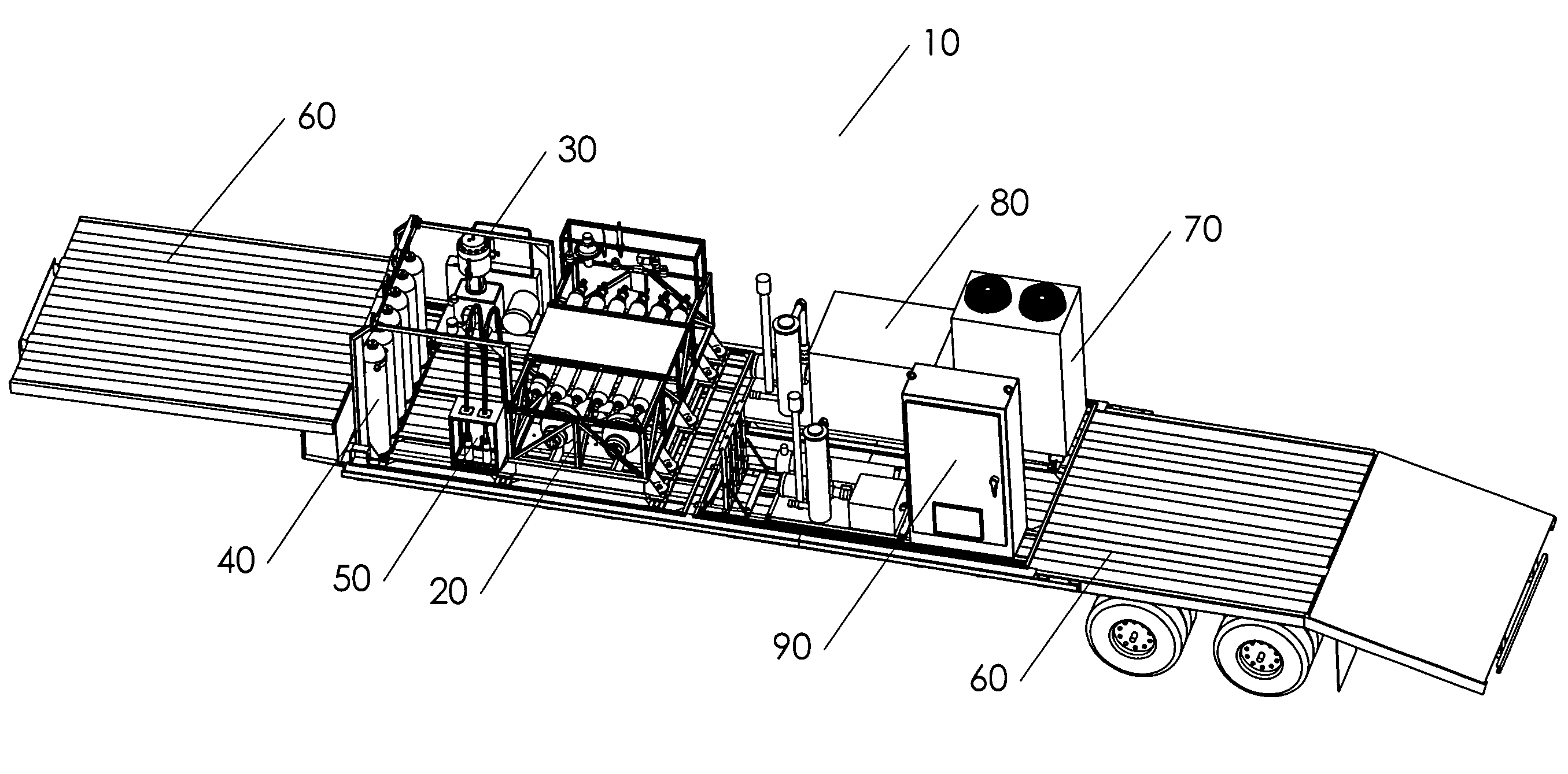

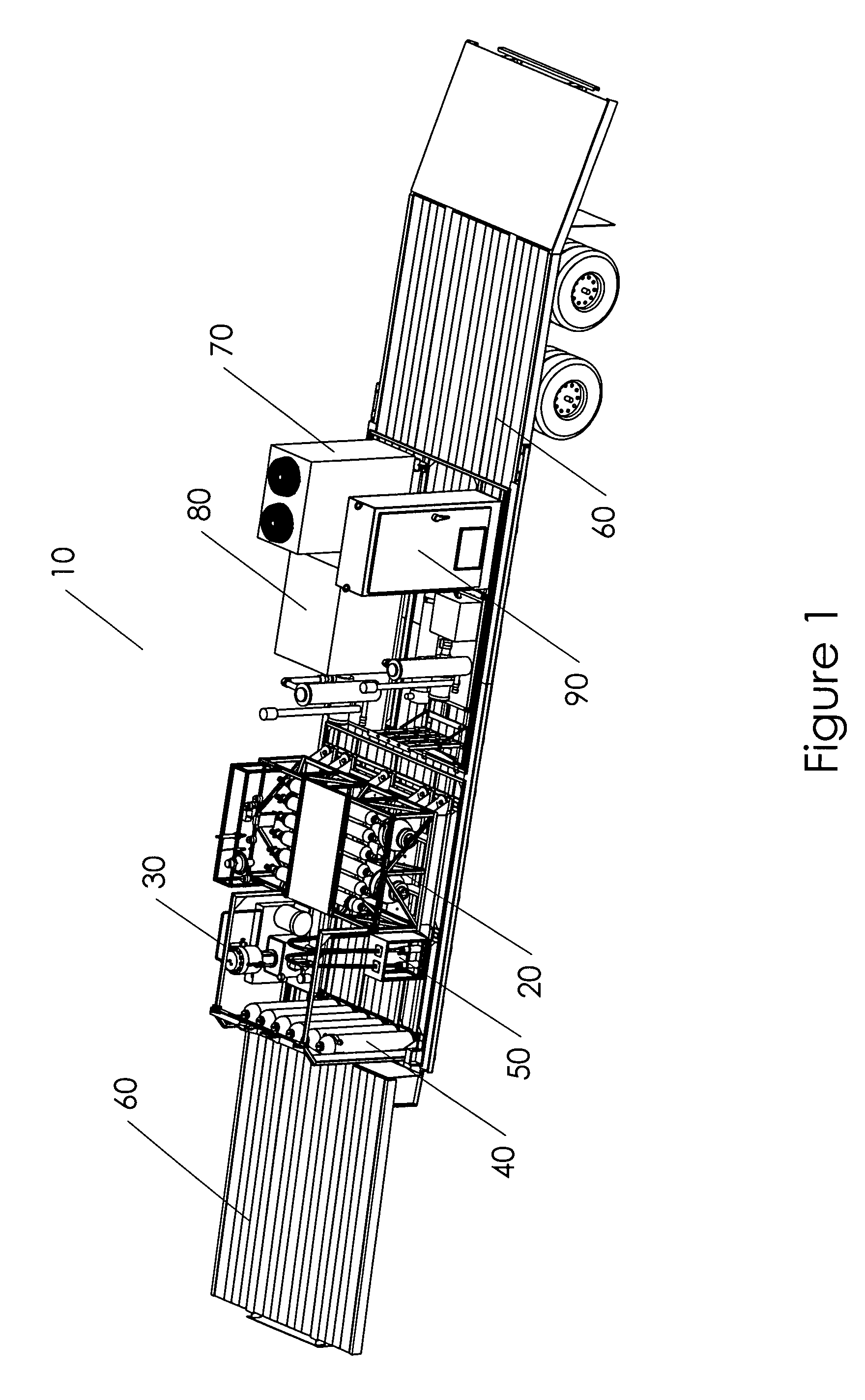

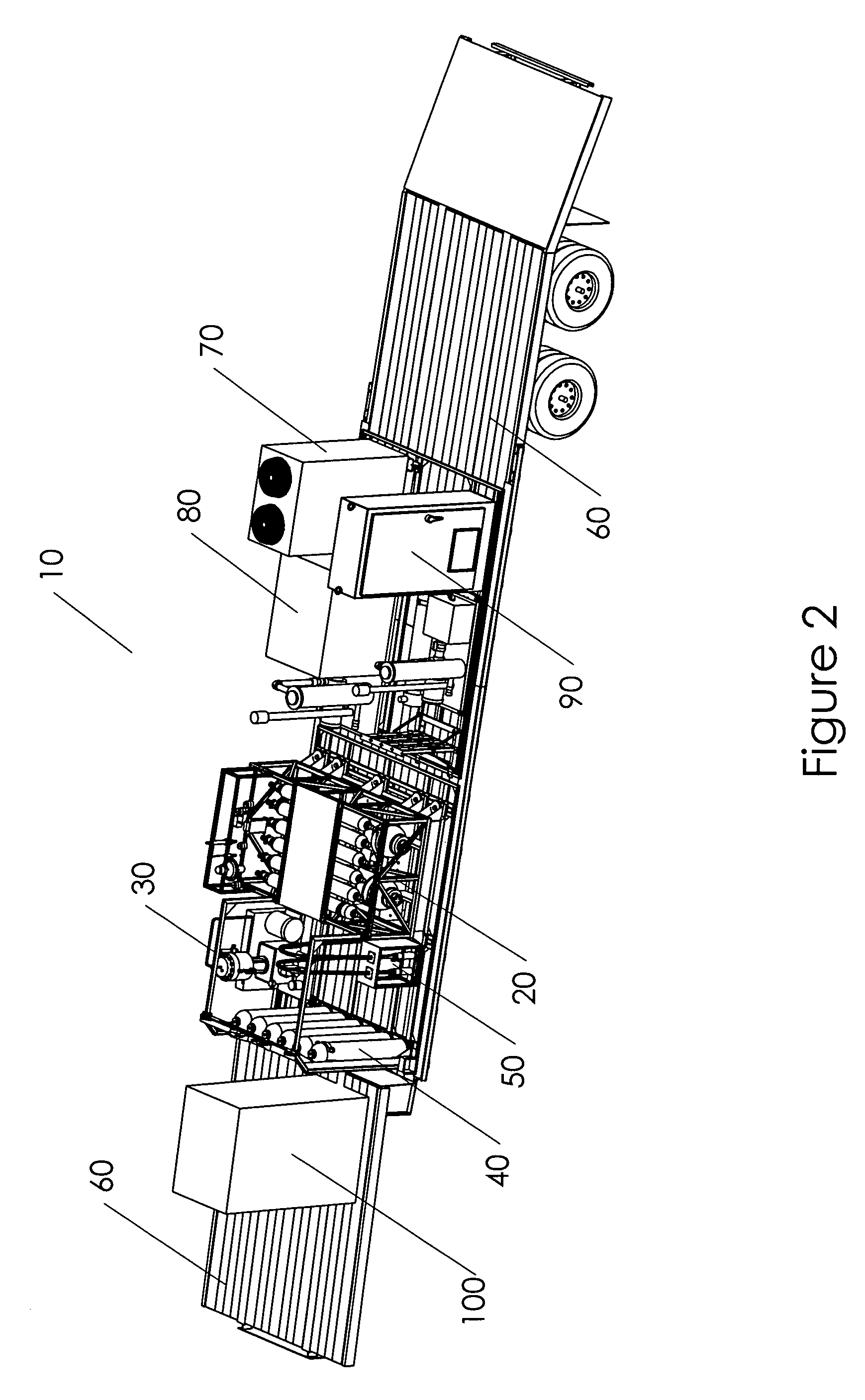

Mobile hydrogen delivery system

A mobile hydrogen delivery system for delivering a compressed stream of hydrogen at pressures up to 15000 psig. The mobile hydrogen delivery system includes a hydrogen compression system, a gaseous hydrogen storage system, and a delivery system for supplying hydrogen to end users. A mobile platform supports the hydrogen compression system, the gaseous hydrogen storage system, and the dispensing system. The mobile platform may be any platform, such as a trailer, capable of being pulled, pushed, or supported by any type of vehicle, such a truck, train, boat, tractor, etc.

Owner:HARNYSS IP LLC +1

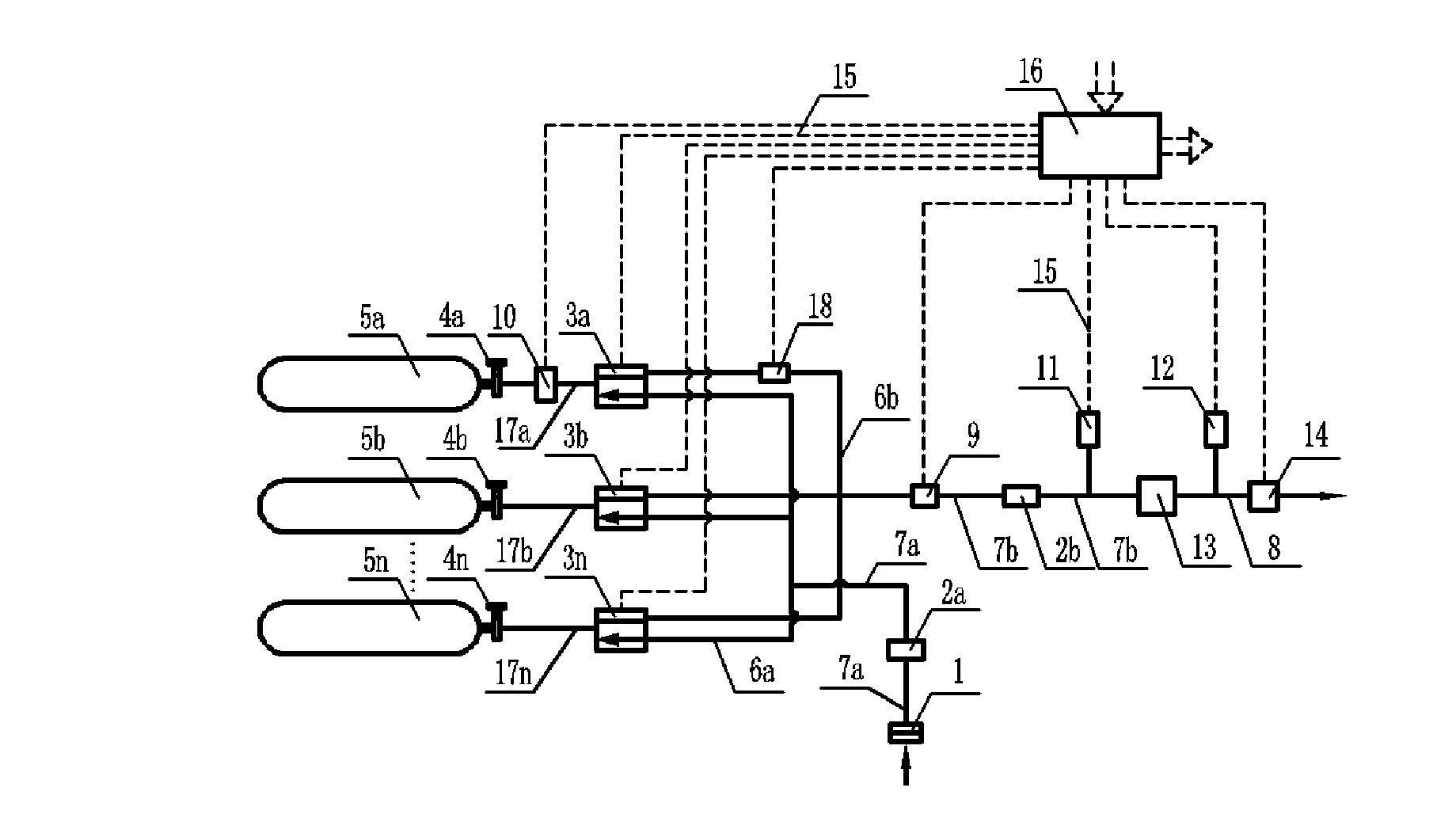

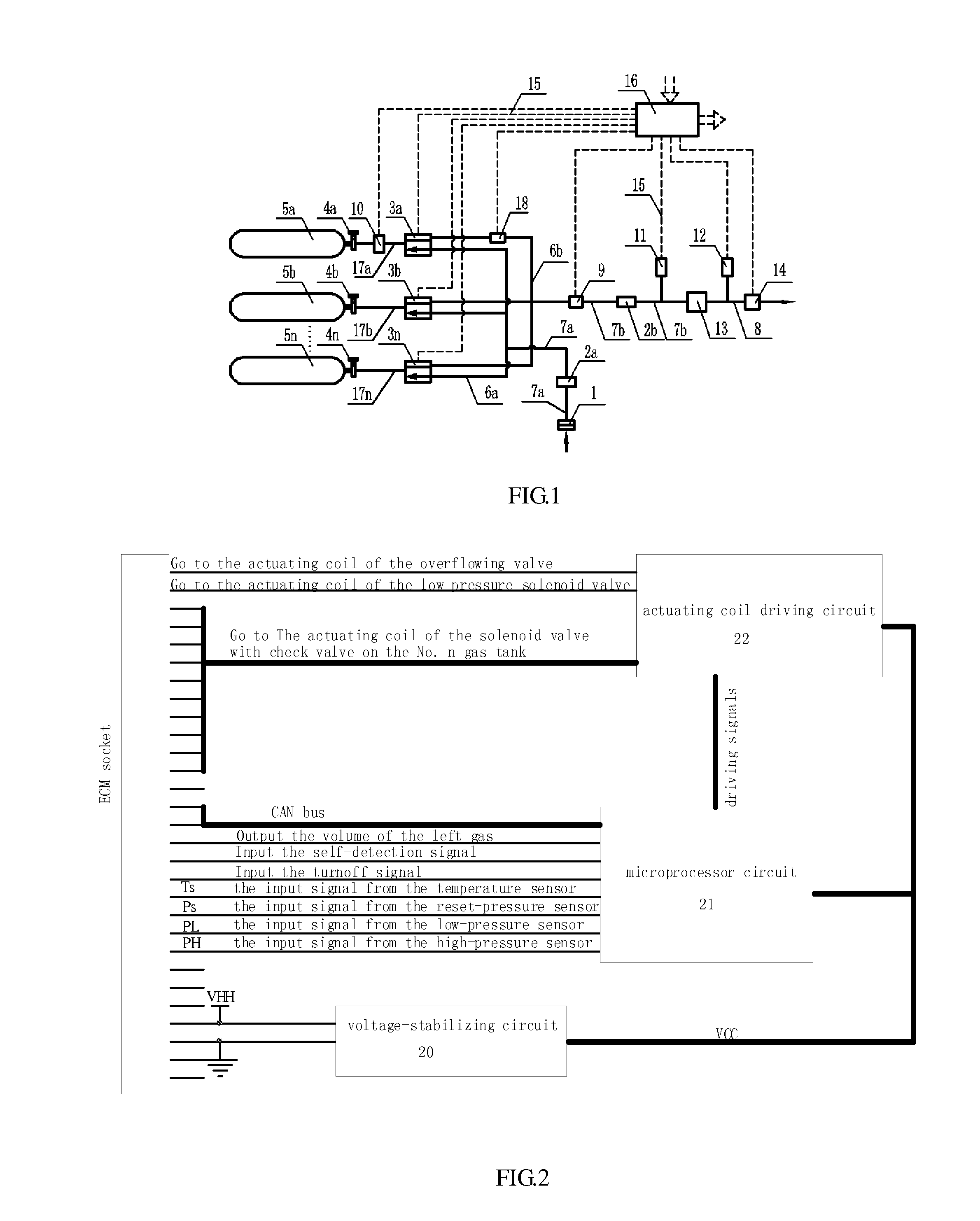

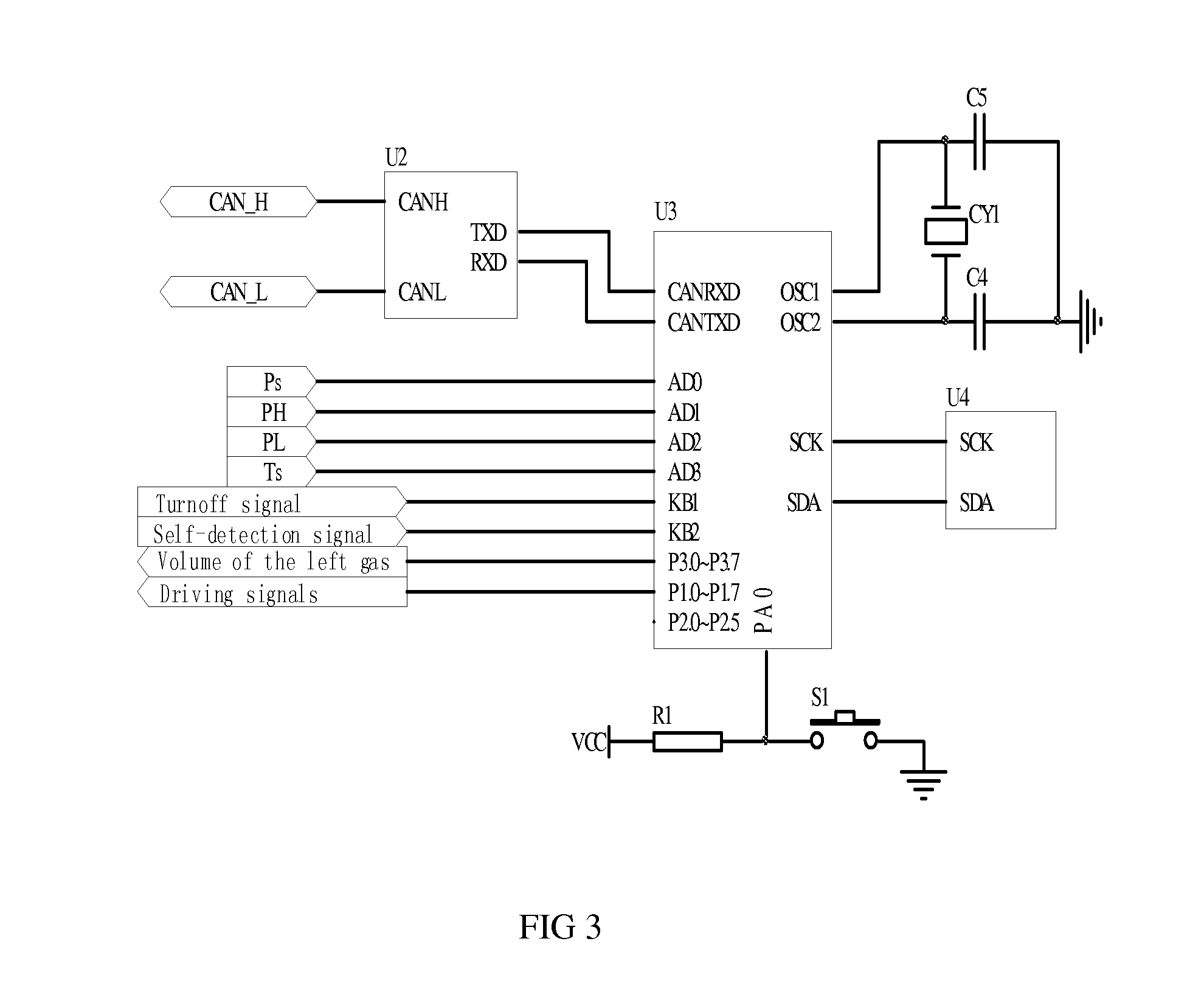

Low consumption and intelligent safe gas-supply system for gas tanks

ActiveUS20100193045A1Simple processImprove reliabilityGas handling applicationsGas handling/storage effectsSolenoid valveHigh pressure hydrogen

A low consumption and intelligent safe gas-supply system for gas tanks comprises: at least two gas tanks and gas tank valves installed on them, charge valves with check valve, at least two gas-filled parallel unit pipes, high-pressure sensor, at least two gas-supply parallel unit pipes, gas-supply main conduit, reset pressure sensor, at least two solenoid valves with check valve, and electronic control module ECM. The invention has the characteristics such as the gas tanks supply gas in sequence, intelligent control, security and reliability for use, low consumption, high display precision for gas volume, decompression transfinite alarm and convenience for installing, use and maintenance etc., and it can be used in the vehicle hydrogen supply system in the fuel cell vehicles or the vehicle compressed natural gas-supply system in the natural gas vehicles, and also the high-pressure hydrogen or natural gas-supply system for gas tanks on the ground.

Owner:BEIJING BOLKEN EQUIP

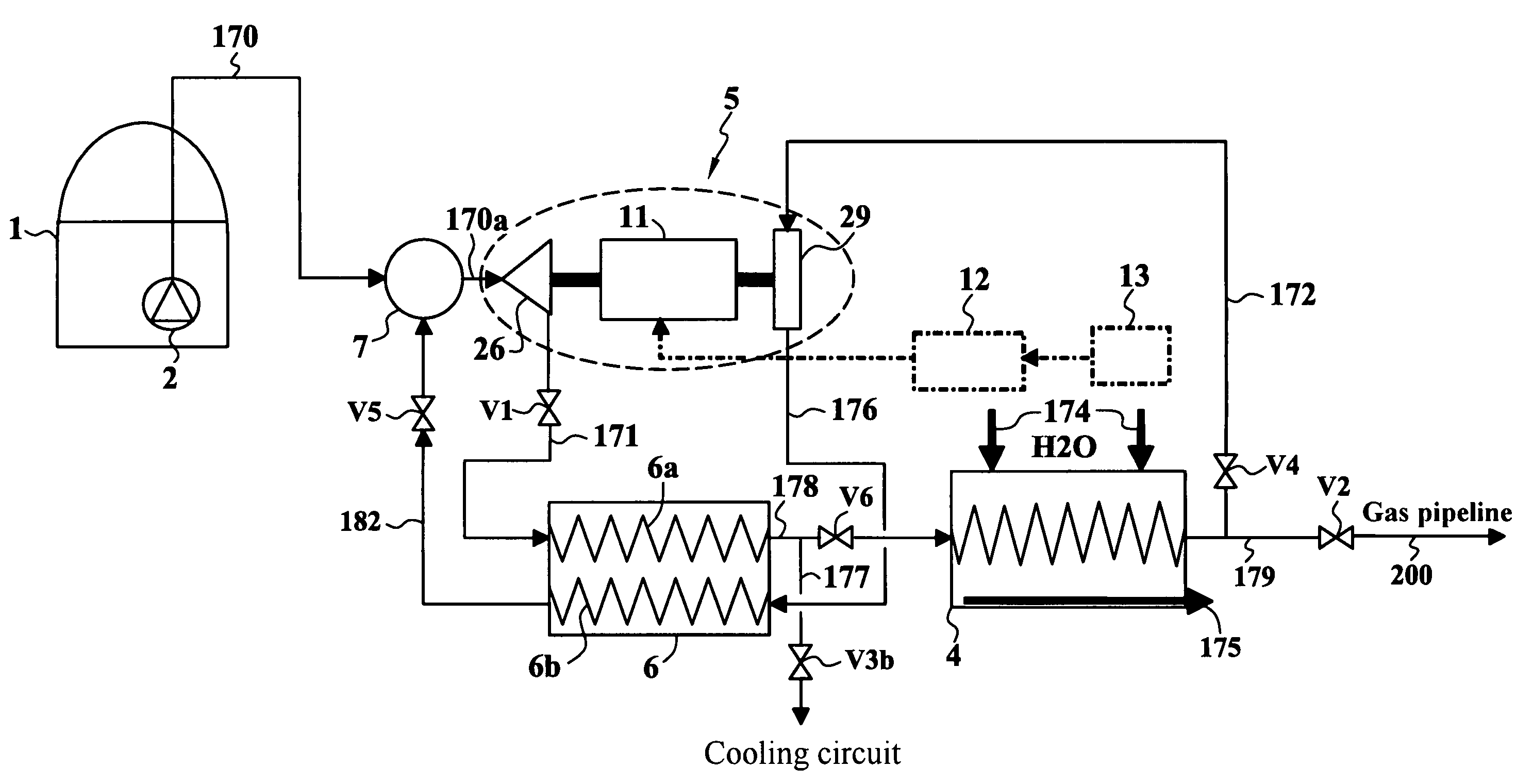

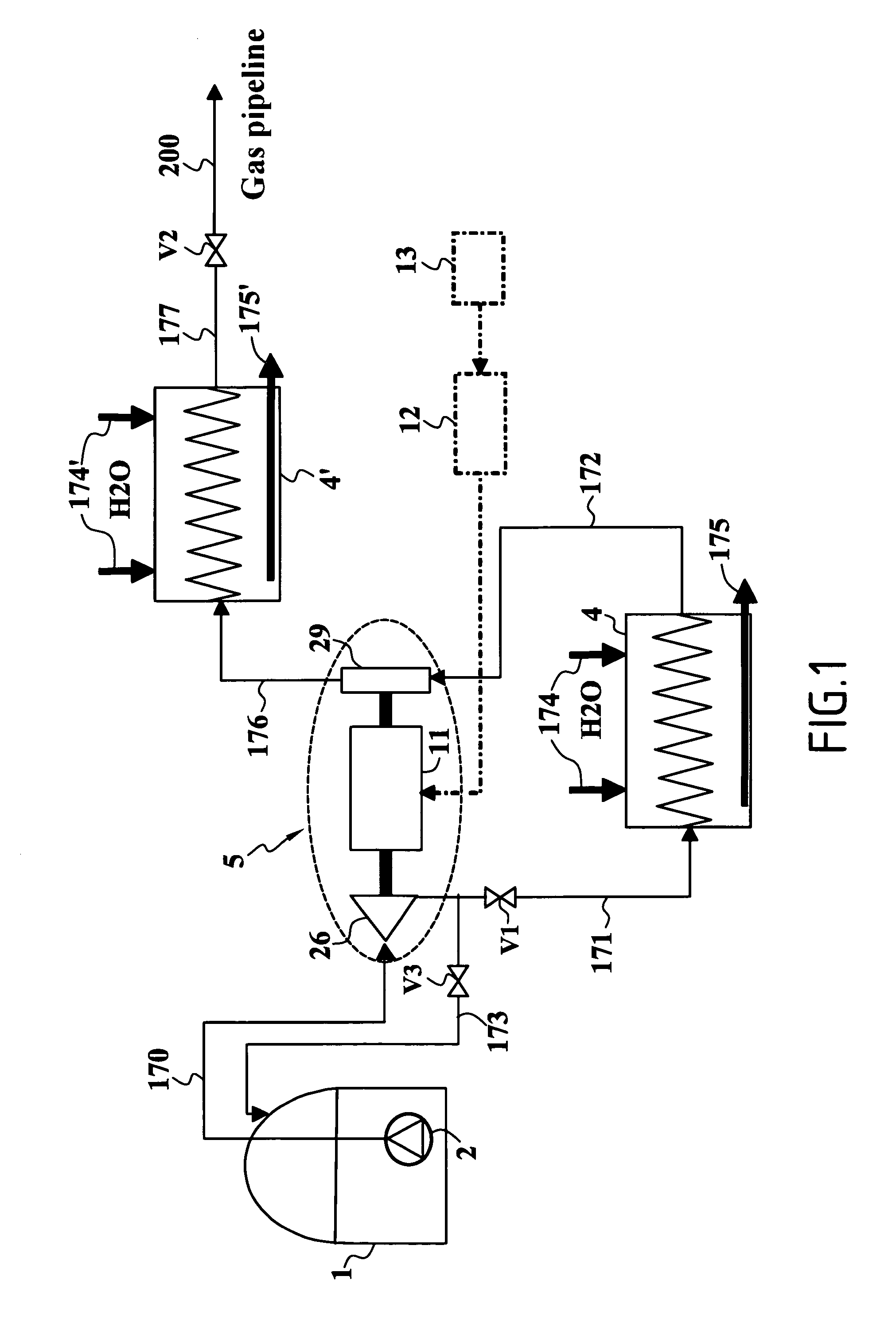

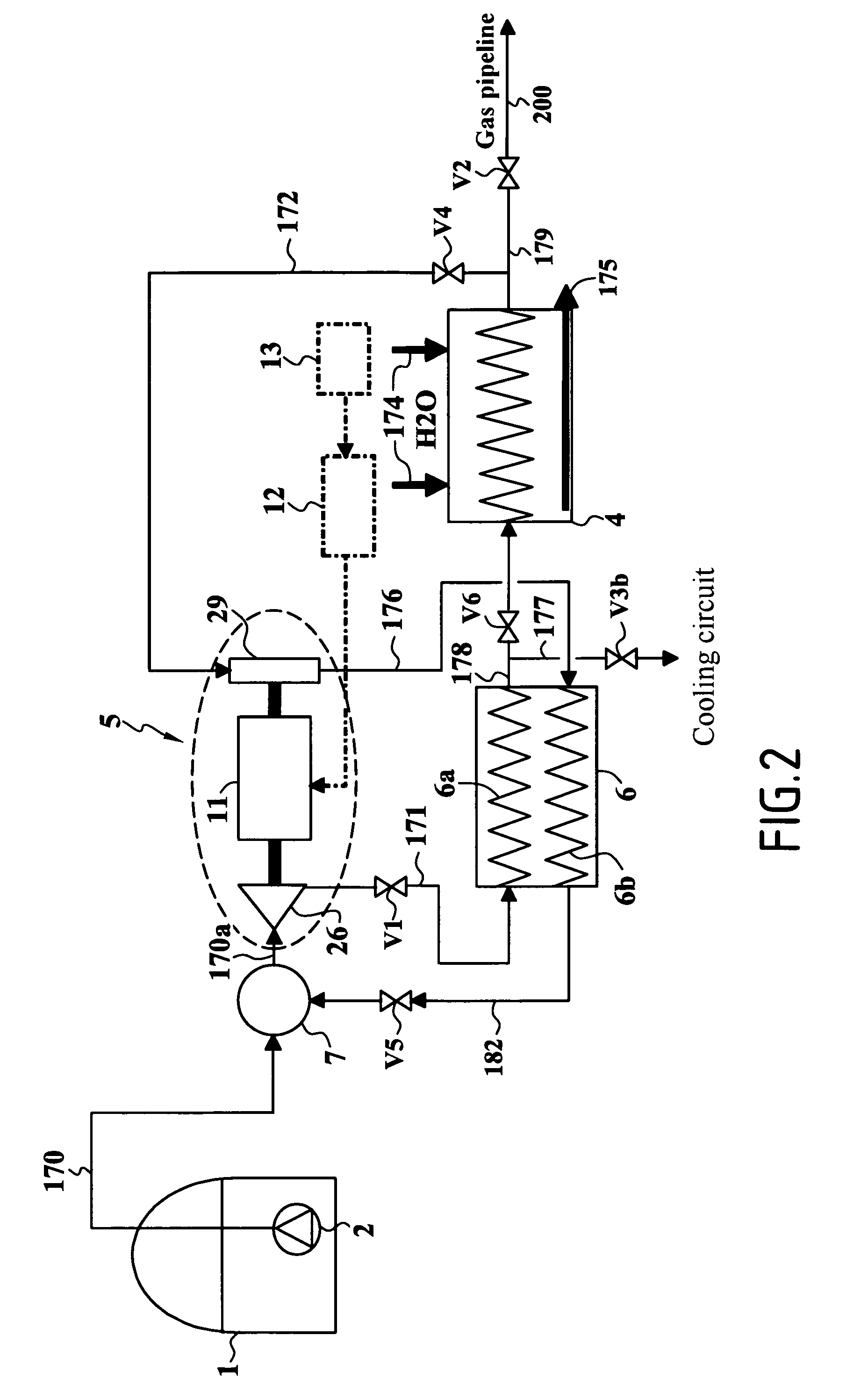

Compression-evaporation system for liquefied gas

InactiveUS7406830B2Reduce and even eliminate consumptionGas handling applicationsGas handling/storage effectsEvaporationEngineering

The compressor-evaporator system for liquefied gas contained in a tank comprises, in addition to a deice for evaporation by heat exchange with a liquid and devices for conditioning and transferring gas to a pipeline, a motor-driven turbopump comprising a rotary assembly of high bending stiffness on a common shaft line, with at least one high pressure pump, a turbine, and a central electrical machine capable of being used in motor mode or in generator mode. The rotary assembly of the motor-driven turbopump is adapted to present a high speed of rotation, greater than 12,000 rpm, while remaining outside ranges for exciting critical speeds in rotation. All of the internal portions of the motor-driven turbopump are immersed in a cryogenic fluid that is the same as the liquefied gas contained in the tank. The internal cavities of the motor-driven turbopump that are under different thermodynamic conditions are separated by contactless dynamic seals. Electronic power circuits connected to an electricity network control the central electrical machine in motor mode or generator mode.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com