Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

926 results about "High pressure hydrogen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The previous high-pressure hydrogen storage system compressed and stored hydrogen at a pressure of 35 MPa. By compressing hydrogen to an even higher pressure of 70 MPa, about 30% more hydrogen can be stored in the same tank layout space.

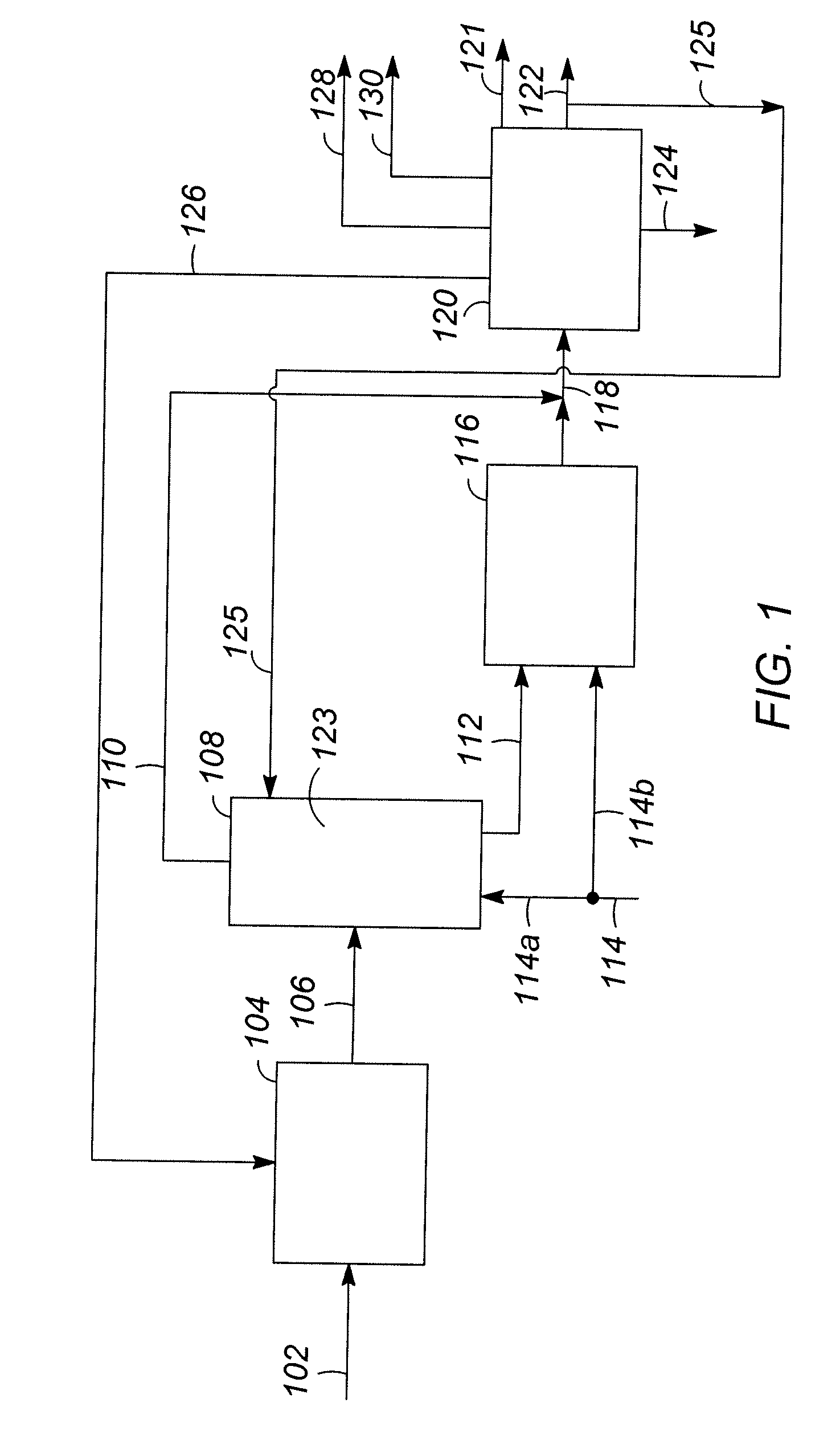

Production of Diesel Fuel from Biorenewable Feedstocks with Selective Separation of Converted Oxygen

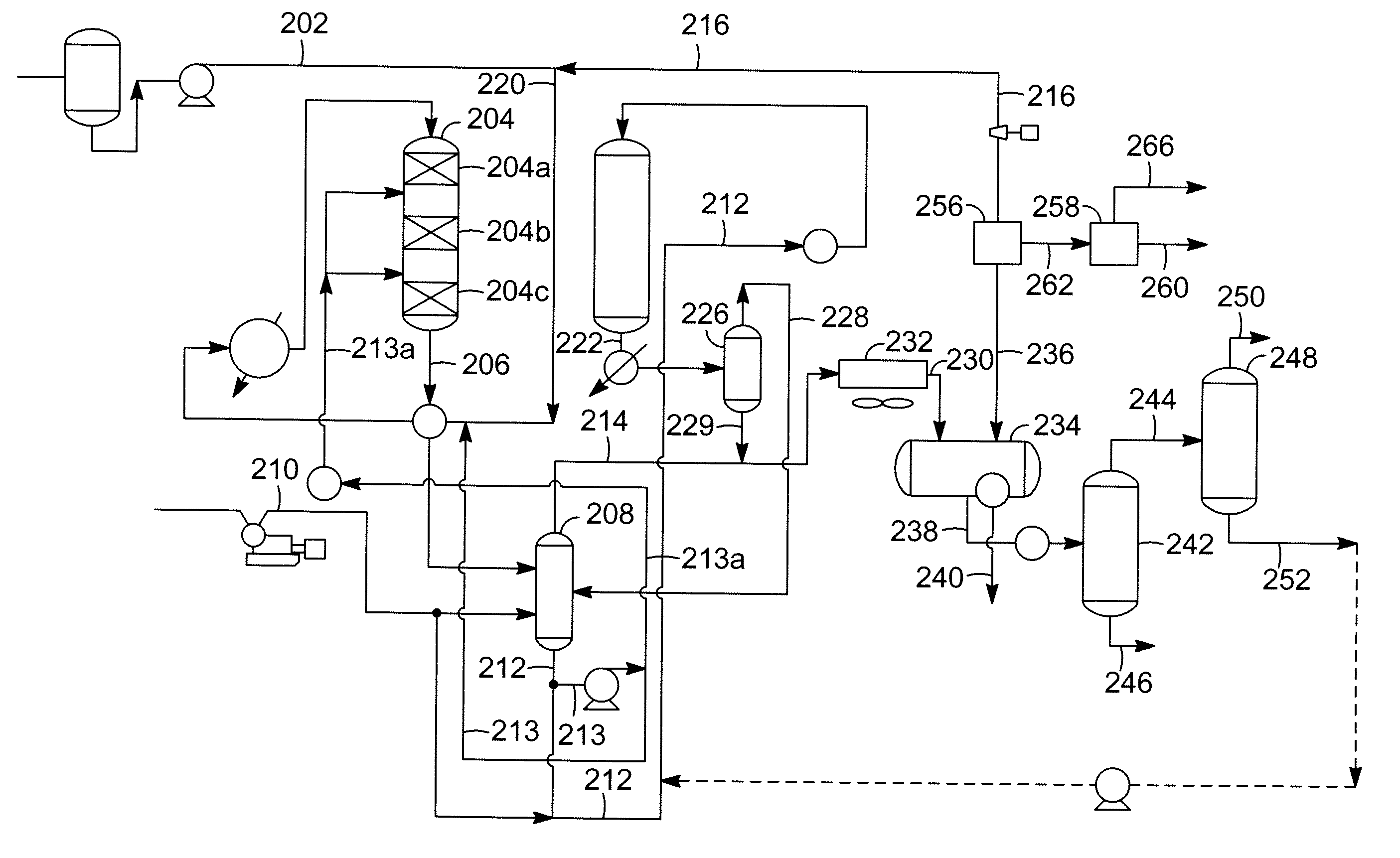

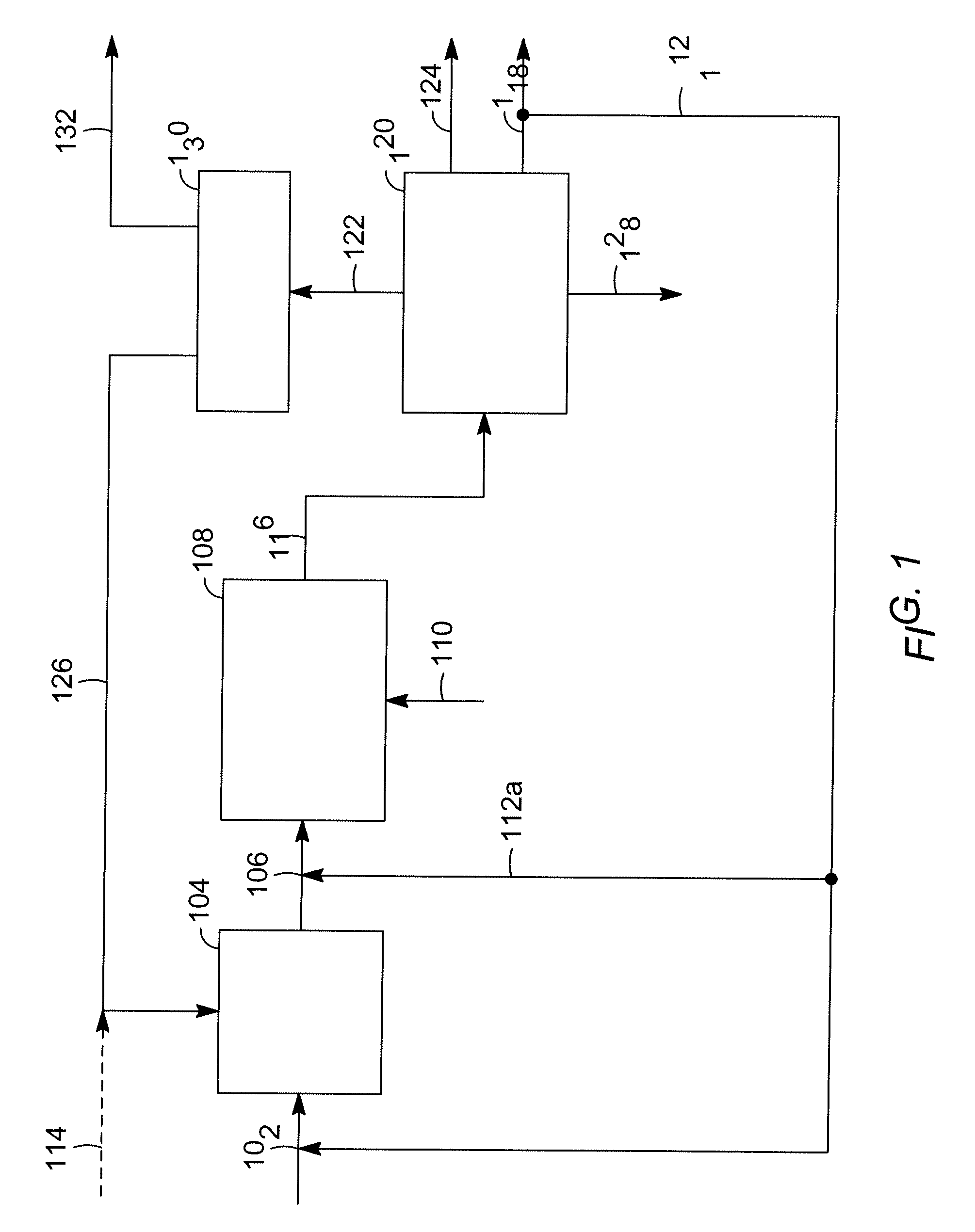

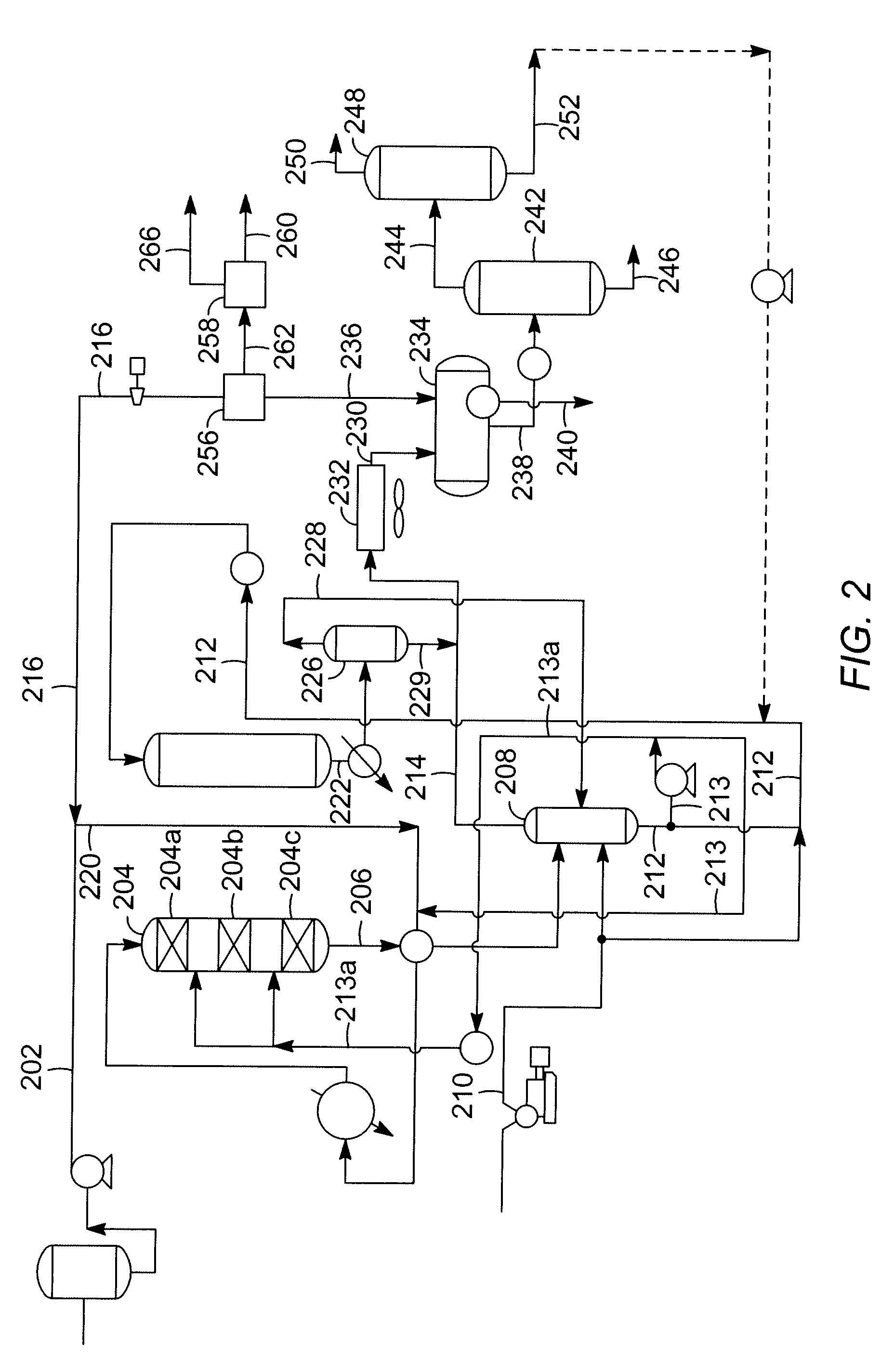

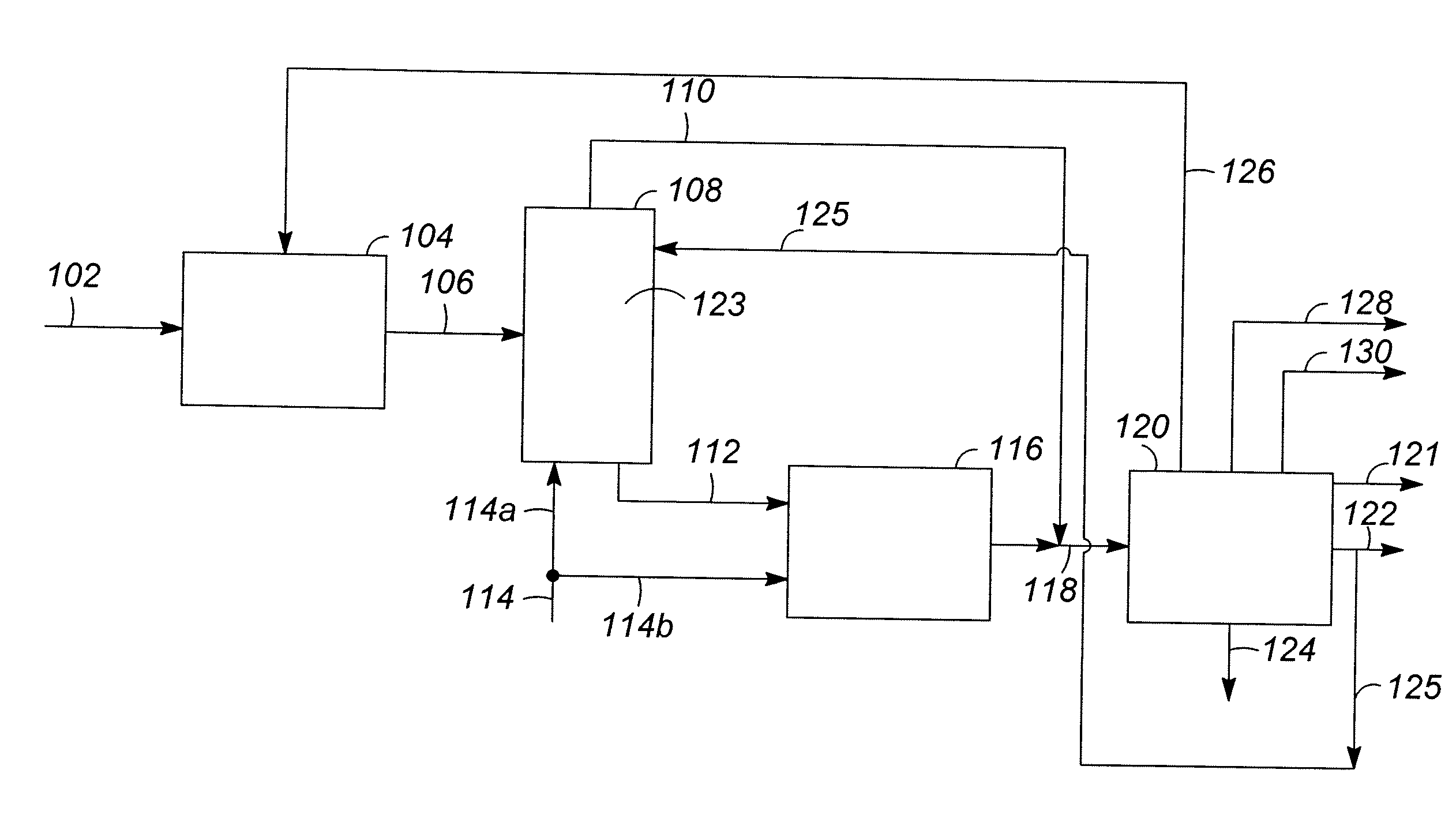

A process has been developed for producing diesel boiling range fuel from renewable feedstocks such as plant and animal fats and oils, the process providing for sulfur management. The process involves catalytically treating a renewable feedstock by hydrogenating and deoxygenating to provide a hydrocarbon fraction useful as a diesel boiling range fuel. The hydrocarbon fraction is isomerized to improve cold flow properties. A selective separation such as a hot high pressure hydrogen stripper is used to remove at least the carbon oxides from the first zone effluent before entering the isomerization zone, and to provide liquid recycle to the treating zone at pressure and temperature. A vapor stream is separated from the isomerization effluent and at least carbon dioxide is removed using at least one selective or flexible amine solution absorber. The resulting hydrogen-rich stream is recycled to the deoxygenation reaction zone

Owner:UOP LLC

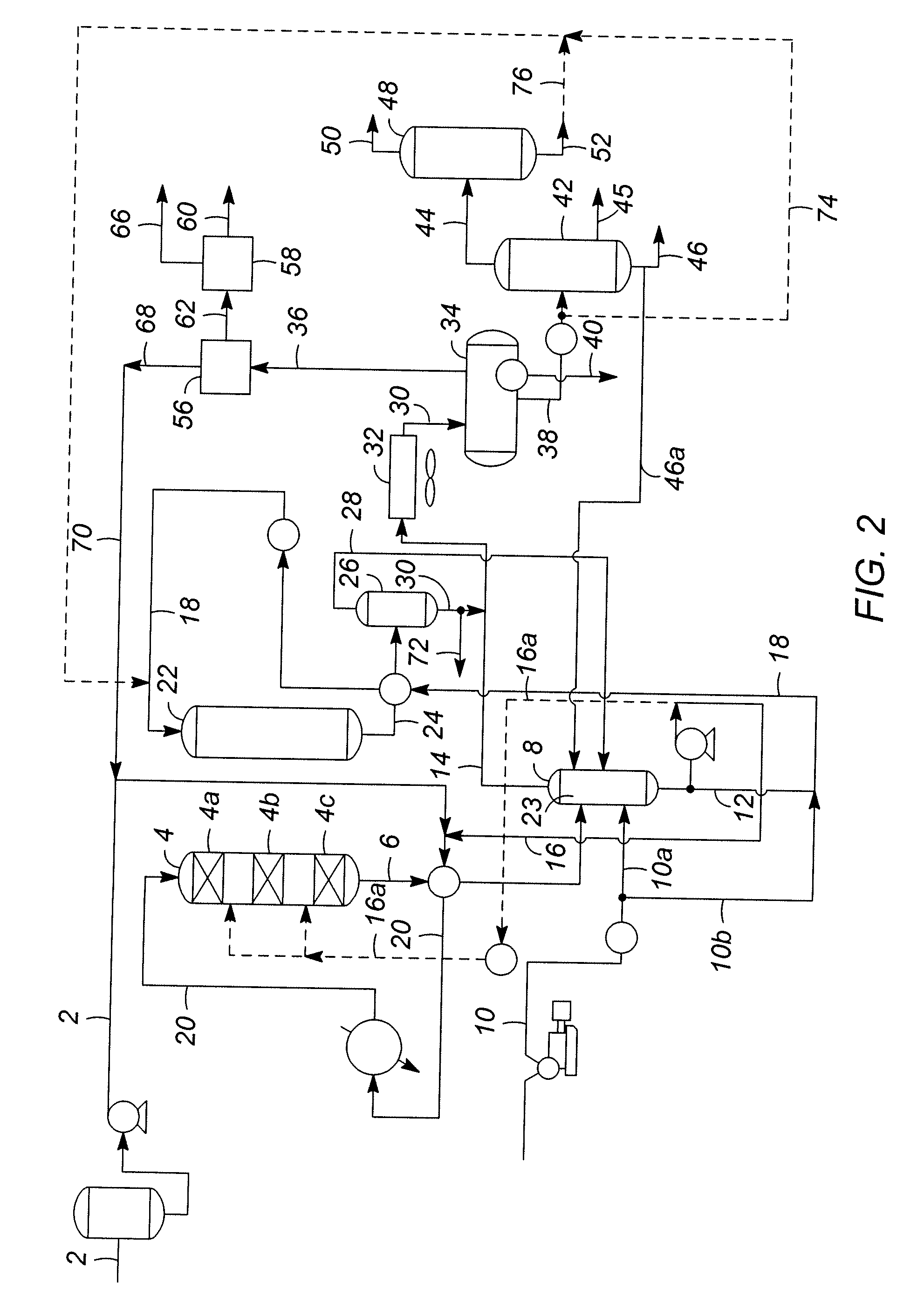

Production of Transportation Fuel from Renewable Feedstocks

ActiveUS20090229172A1Reduce first amountMinimize the numberBiofuelsLiquid hydrocarbon mixture productionNaphthaHigh pressure hydrogen

A process has been developed for producing a diesel boiling point range product and an aviation boiling point range product from renewable feedstocks such as plant and animal oils. The process involves treating a renewable feedstock by hydrogenating and deoxygenating to provide a hydrocarbon fraction which is then isomerized and selectively cracked to form the diesel boiling point range product and the aviation boiling point range product. A portion of the diesel boiling point range product, aviation boiling point range product, naphtha product, LPG, or any combination thereof can be optionally used as a rectification agent in the selective hot high pressure hydrogen stripper to decrease the amount of product carried in the stripper overhead.

Owner:UOP LLC

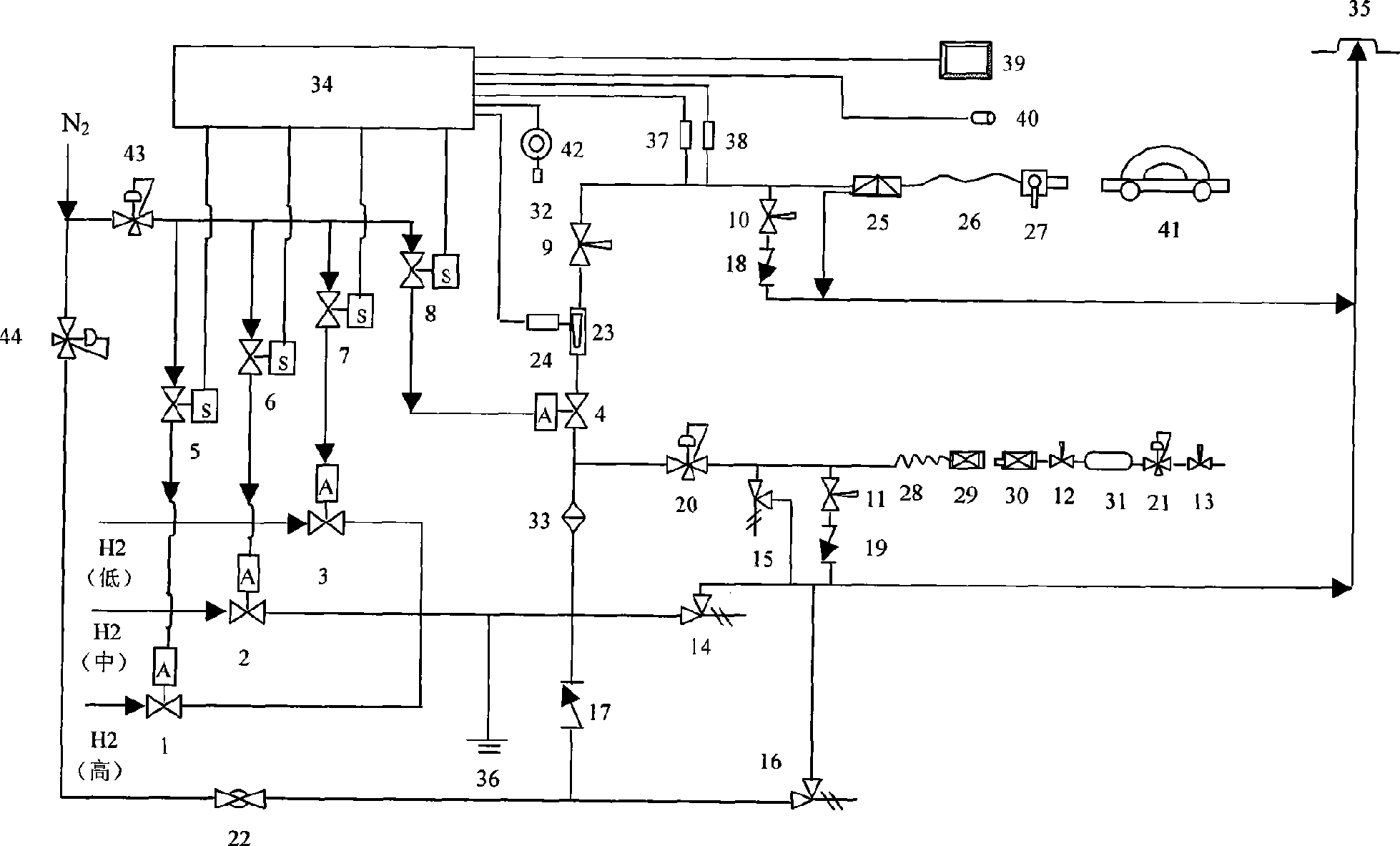

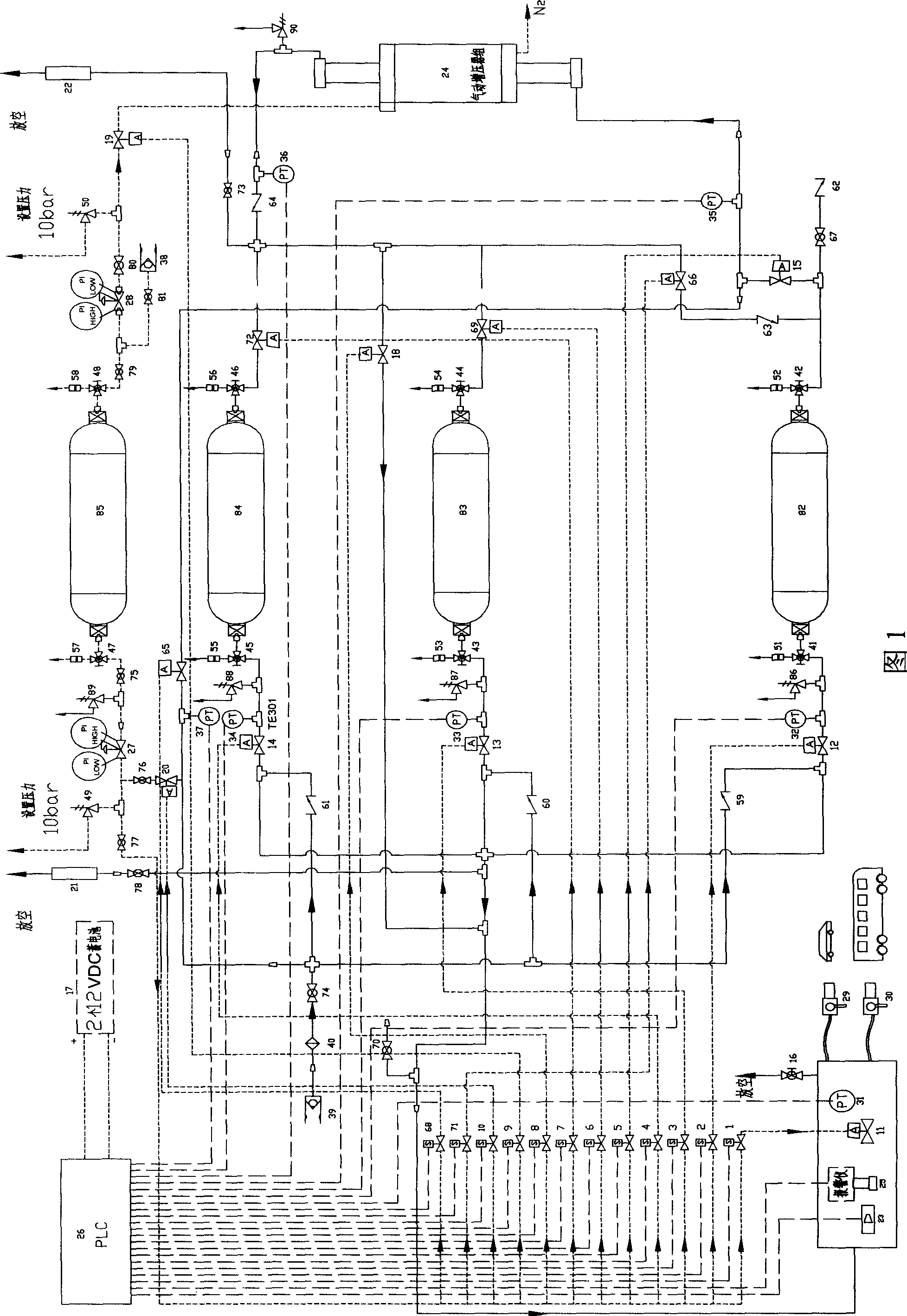

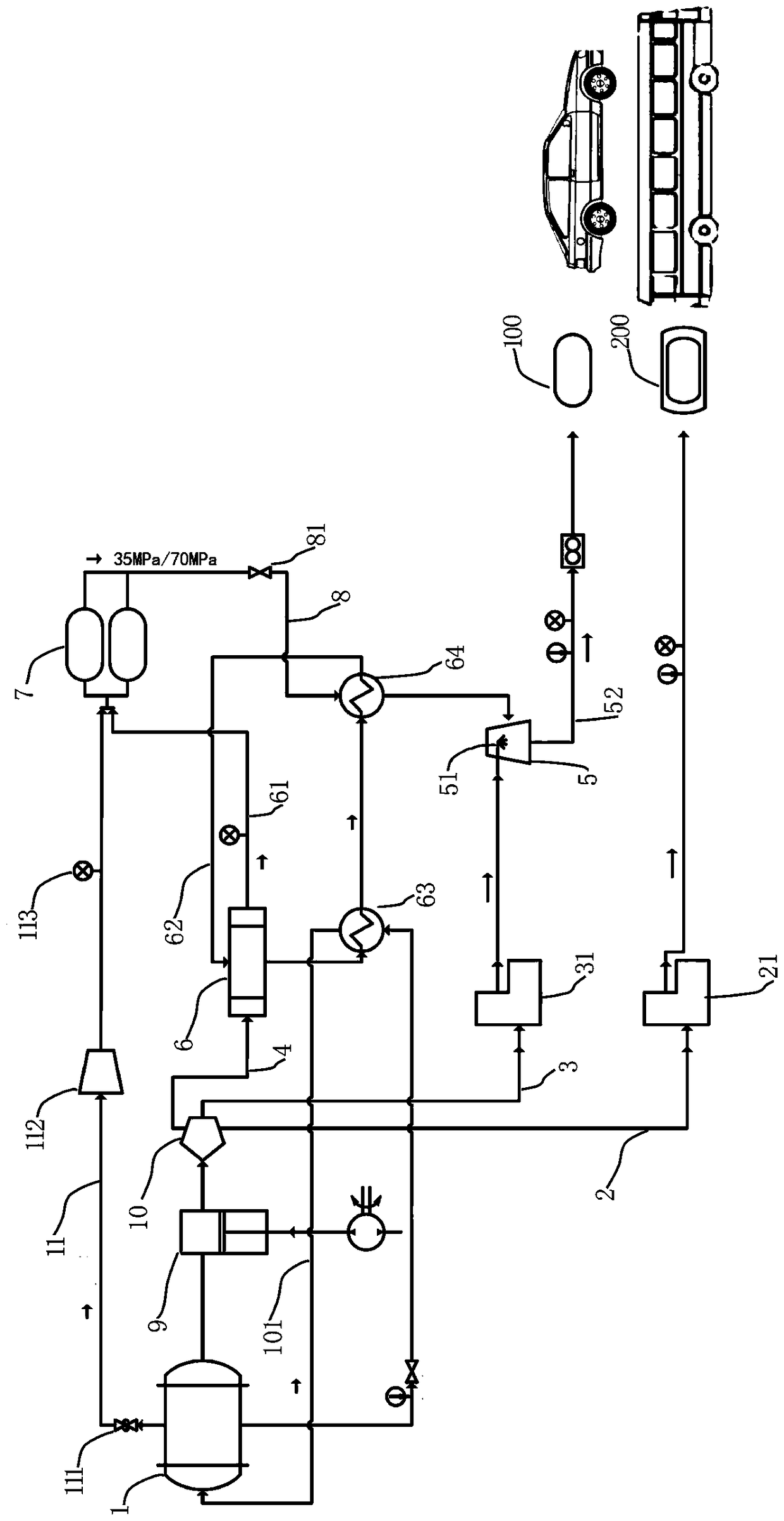

Air entraining system for high-pressure hydrogenation stations

ActiveCN101418908ASimple structureImprove reliabilityContainer filling under pressureFill rateFuel cells

The invention relates to a gas filling system for a high-pressure hydrogen filling station, which comprises a control system, a sampling system, a filling system, an alarm system and a nitrogen purging system, and is the gas filling system which can collect hydrogen sample of the hydrogen filling station and fill high-pressure hydrogen for fuel cell powered vehicles. The gas filling system has the functions of temperature automatic compensation of filling measurement, selectable gas taking procedure in three-stage order, reasonable control of filling rate, alarm of hydrogen leakage and automatic power-down, pulling out prevention and automatic static release in the filling process, overpressure protection of the system, and so on. The sampling points are designed at the tail end of the whole flow of the hydrogen filling station, so that the acquired hydrogen sample can have more representativeness in quality; and through the design of pressure regulation treatment on the high-pressure hydrogen for sampling, the sampling operation is more simple, convenient and quick, and a regular gas sampling steel bottle can also be used together, thereby the sampling cost is low. The gas filling system can improve the gas taking rate of the hydrogen filling station and ensure that the temperature rise of a filled vehicle hydrogen storage tank is strictly controlled within the required temperature range in the quick hydrogen filling process.

Owner:TONGJI UNIV

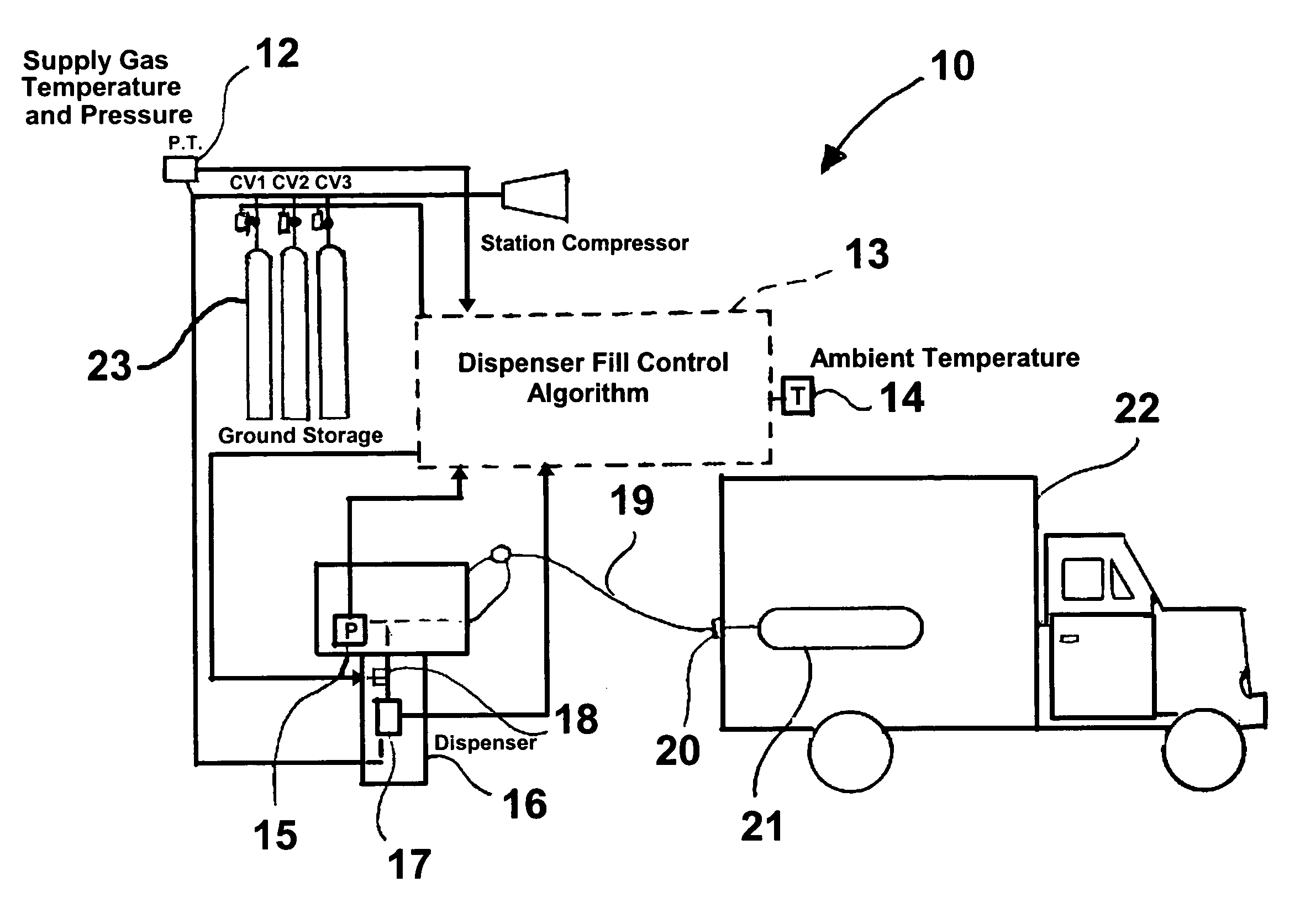

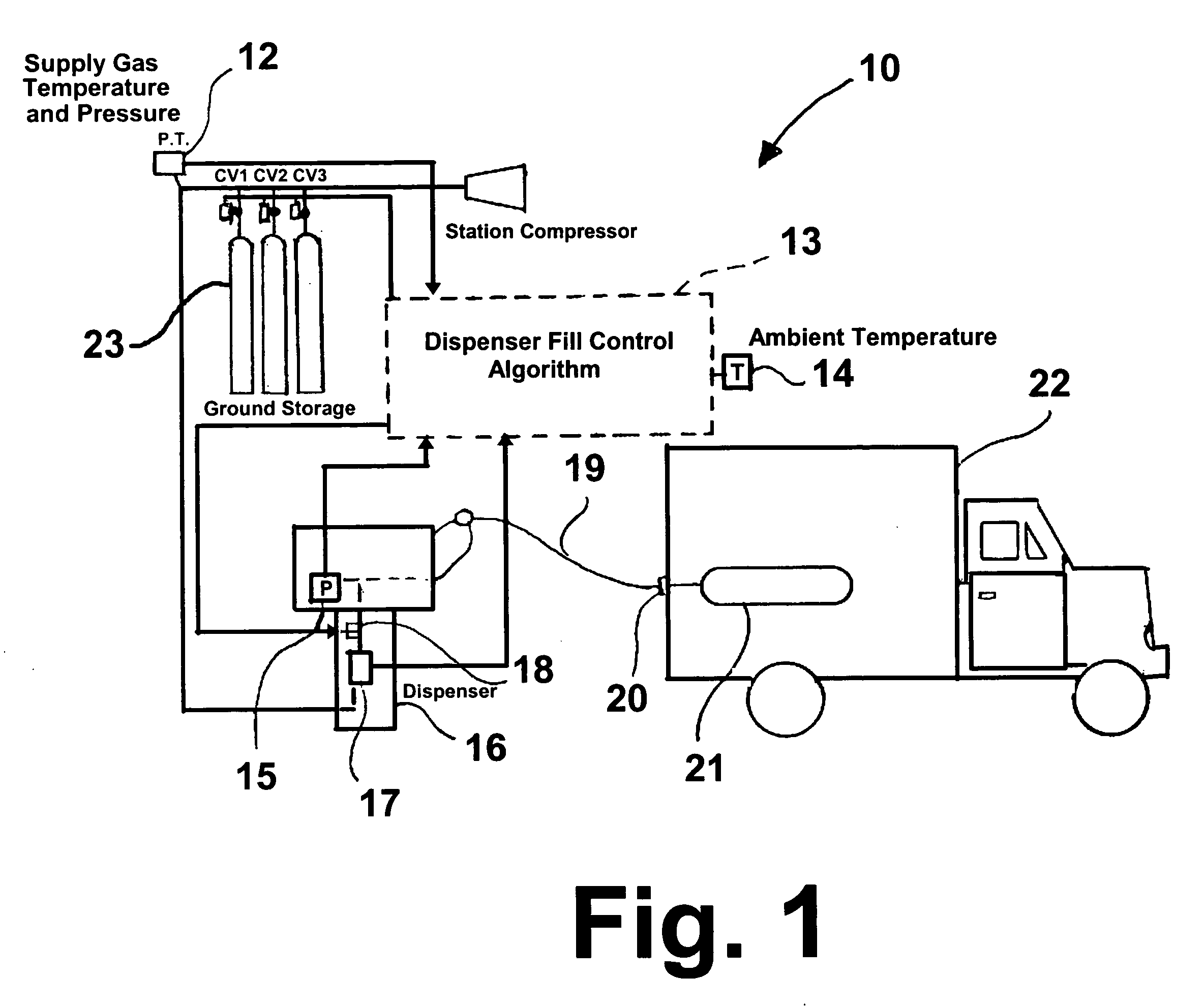

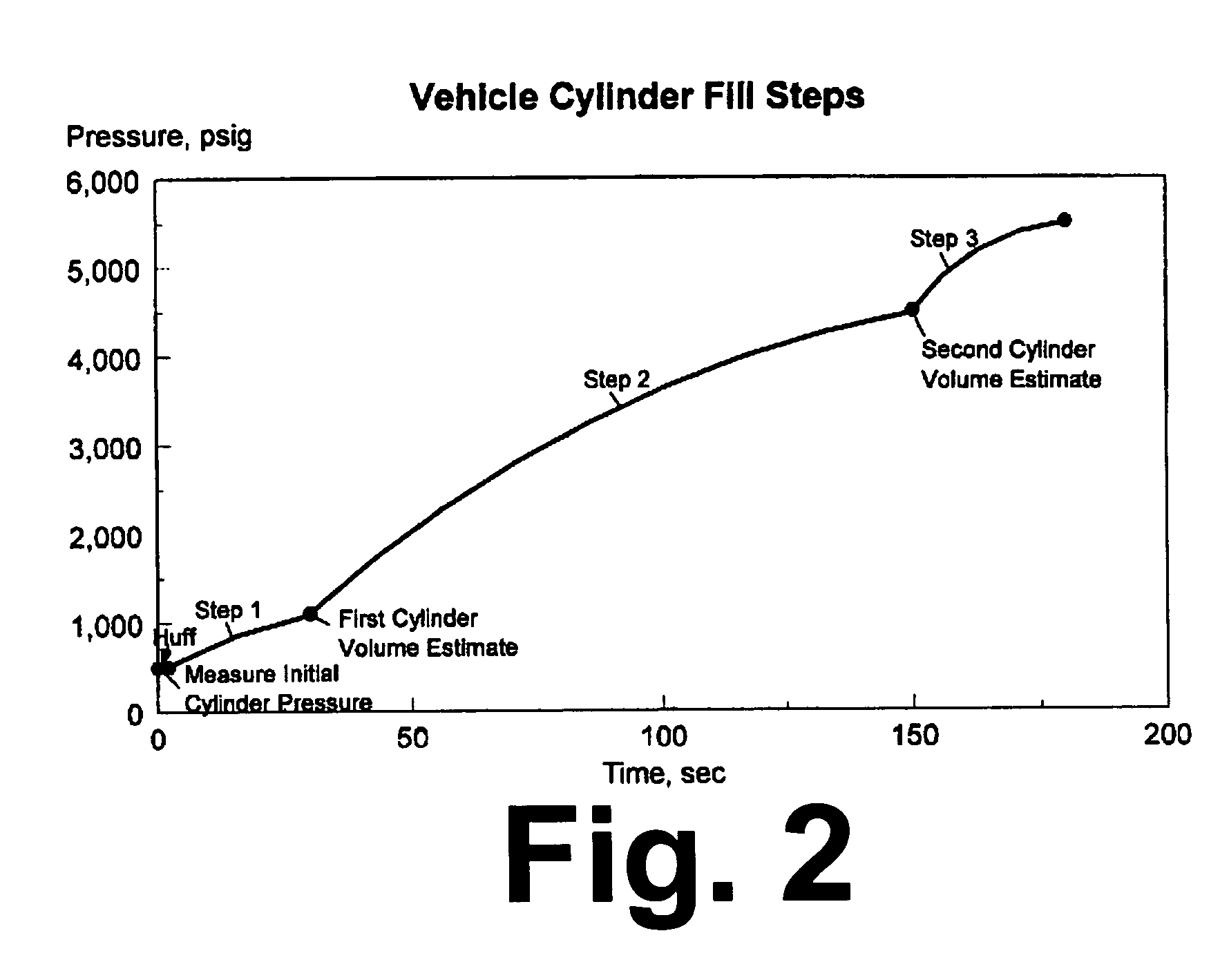

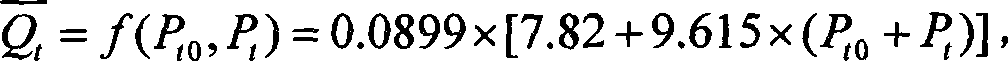

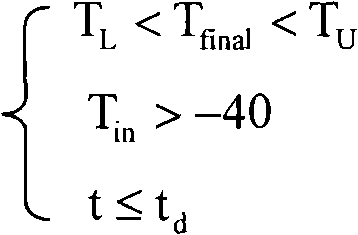

Control method for high-pressure hydrogen vehicle fueling station dispensers

InactiveUS7059364B2Reduces potential for underfillingFast fillGas handling applicationsGas handling/storage effectsHigh pressure hydrogenHigh pressure

A method for quick filling a vehicle hydrogen storage vessel with hydrogen, the key component of which is an algorithm used to control the fill process, which interacts with the hydrogen dispensing apparatus to determine the vehicle hydrogen storage vessel capacity.

Owner:GAS TECH INST

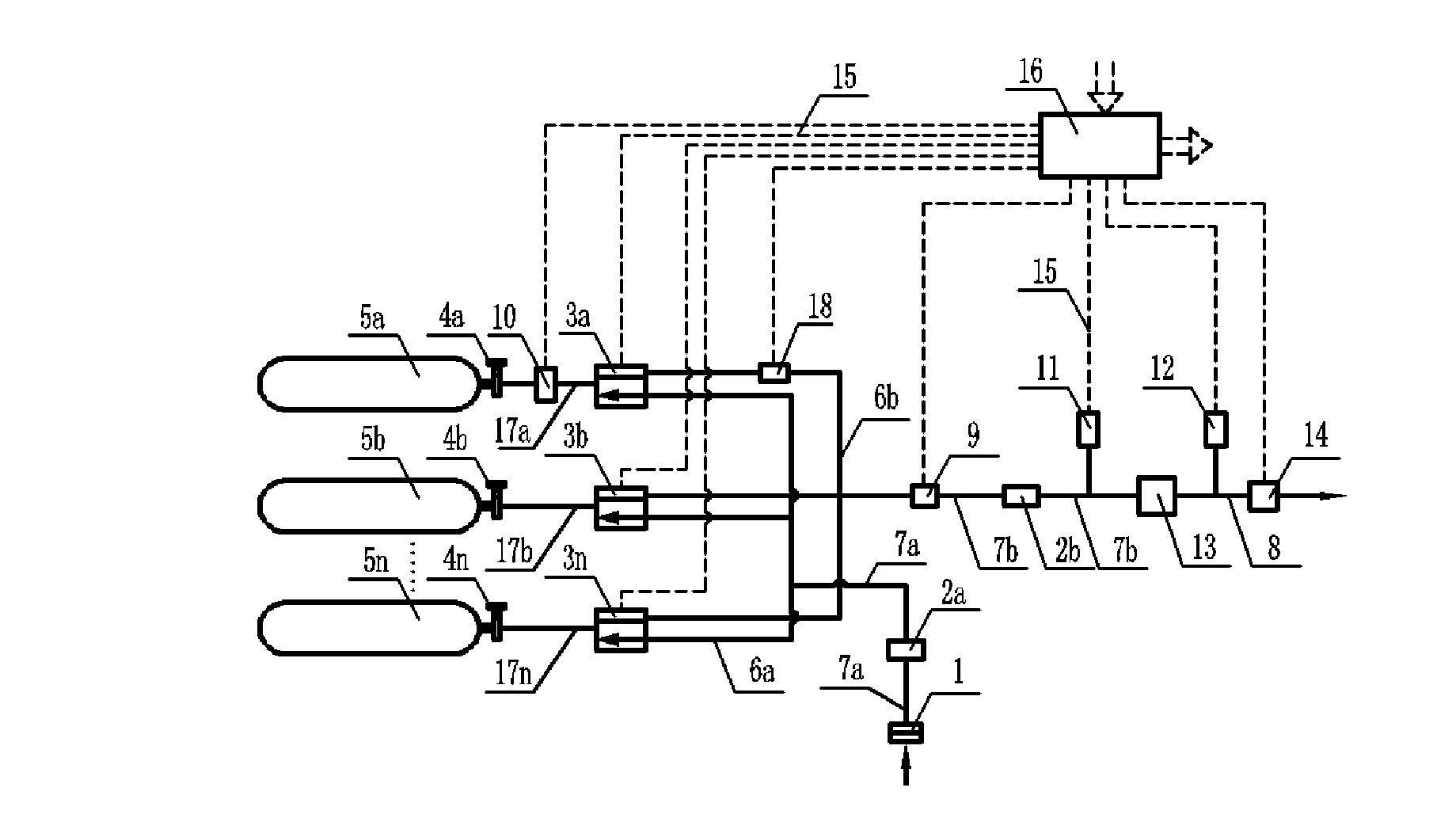

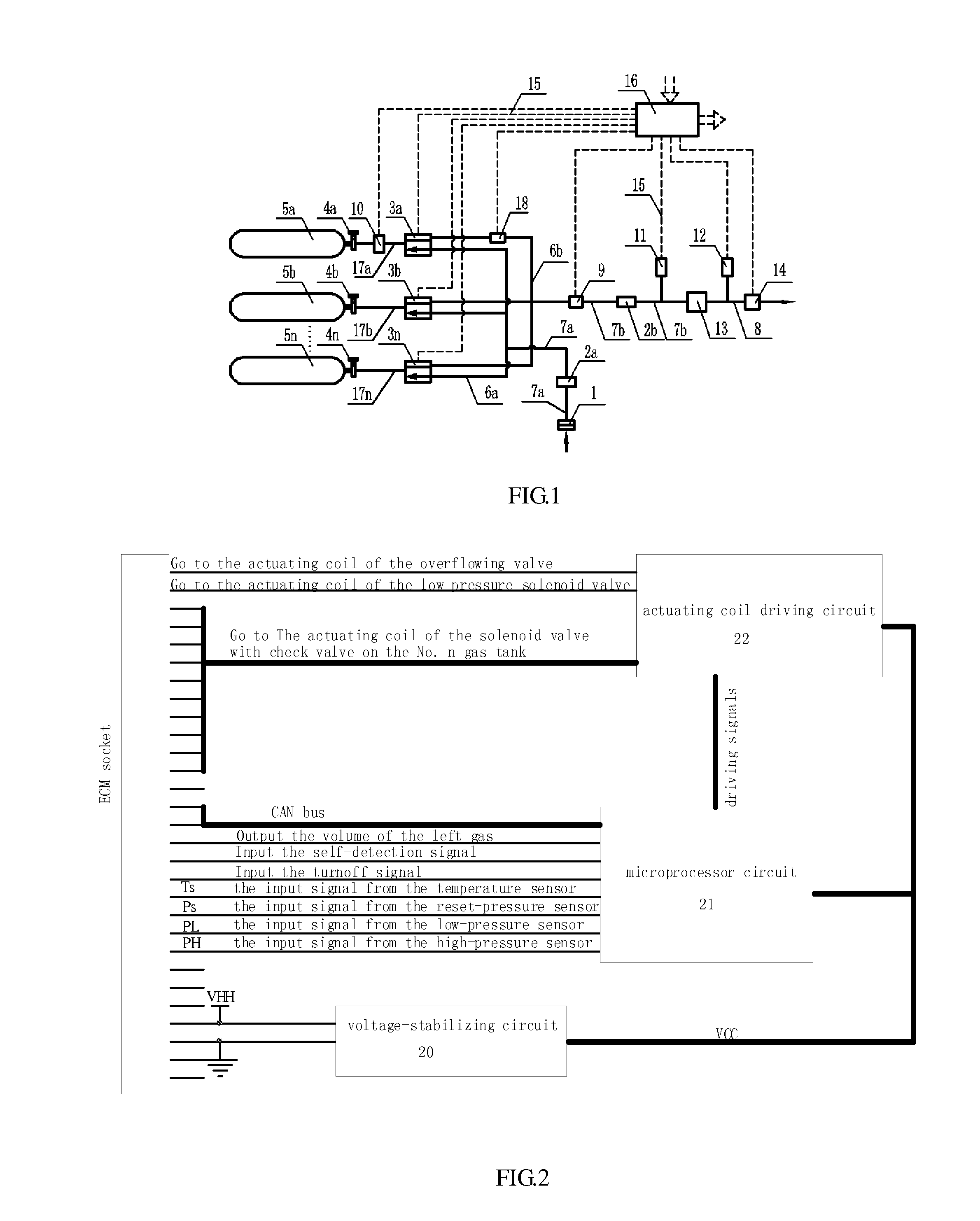

Low consumption and intelligent safe gas-supply system for gas tanks

ActiveUS20100193045A1Simple processImprove reliabilityGas handling applicationsGas handling/storage effectsSolenoid valveHigh pressure hydrogen

A low consumption and intelligent safe gas-supply system for gas tanks comprises: at least two gas tanks and gas tank valves installed on them, charge valves with check valve, at least two gas-filled parallel unit pipes, high-pressure sensor, at least two gas-supply parallel unit pipes, gas-supply main conduit, reset pressure sensor, at least two solenoid valves with check valve, and electronic control module ECM. The invention has the characteristics such as the gas tanks supply gas in sequence, intelligent control, security and reliability for use, low consumption, high display precision for gas volume, decompression transfinite alarm and convenience for installing, use and maintenance etc., and it can be used in the vehicle hydrogen supply system in the fuel cell vehicles or the vehicle compressed natural gas-supply system in the natural gas vehicles, and also the high-pressure hydrogen or natural gas-supply system for gas tanks on the ground.

Owner:BEIJING BOLKEN EQUIP

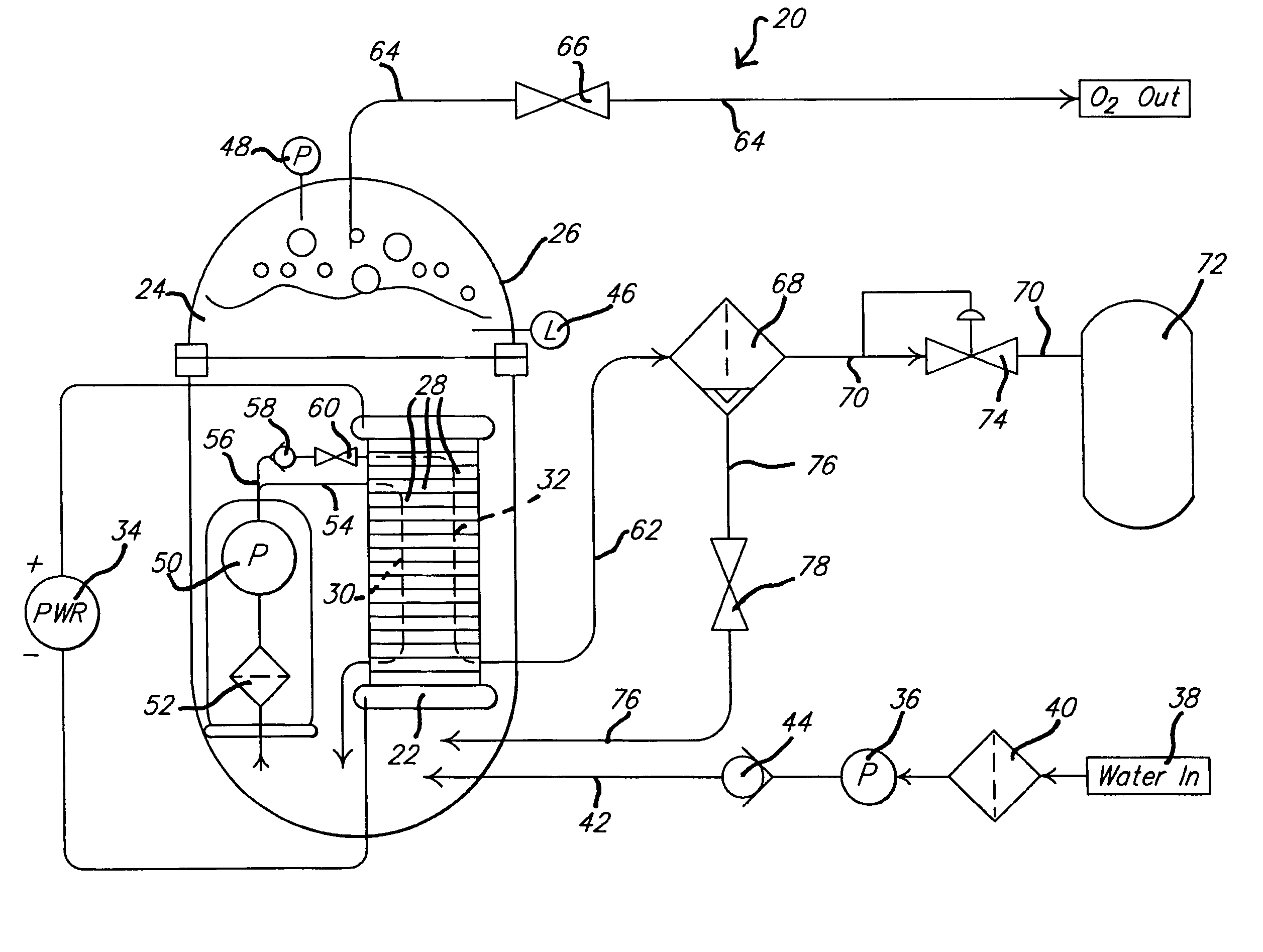

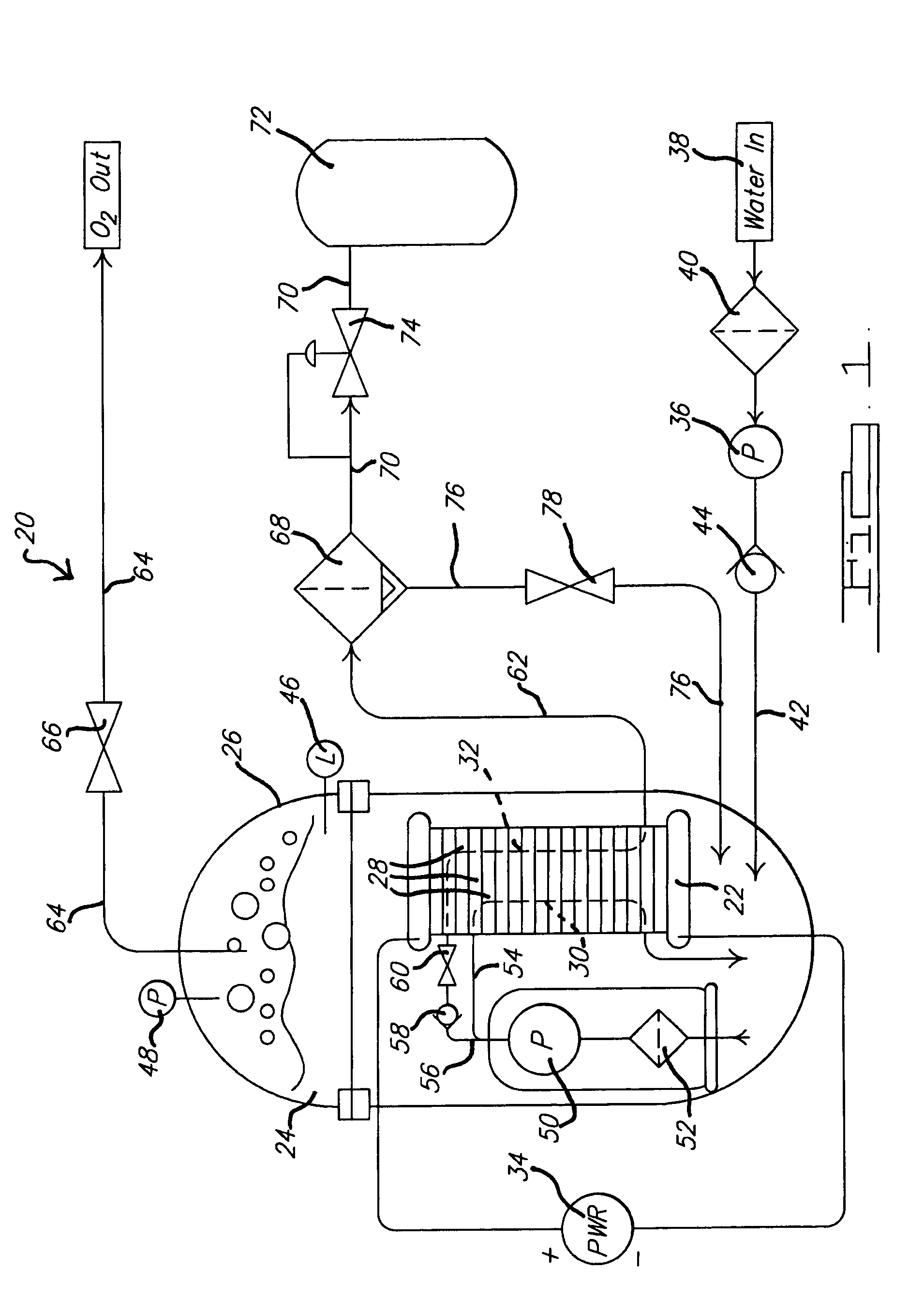

Electrolyzer system to produce gas at high pressure

ActiveUS20050072688A1Increase pressureCellsPhotography auxillary processesElectrolysisHigh pressure hydrogen

An apparatus and method to produce hydrogen gas a high pressure is disclosed. An electrolyzer is located inside a pressure vessel that is pressurized with high pressure water. The high pressure water is provided to both the anode and cathode sides of the electrolyzer by a pump in the pressure vessel Oxygen produced at the high pressure on the anode side of the electrolyzer is vented directly into the pressure vessel while hydrogen produced at the high pressure on the cathode side is routed to a separator and is deadheaded. The high pressure hydrogen is periodically routed from the separator to a storage tank by a pressure regulator.

Owner:GM GLOBAL TECH OPERATIONS LLC

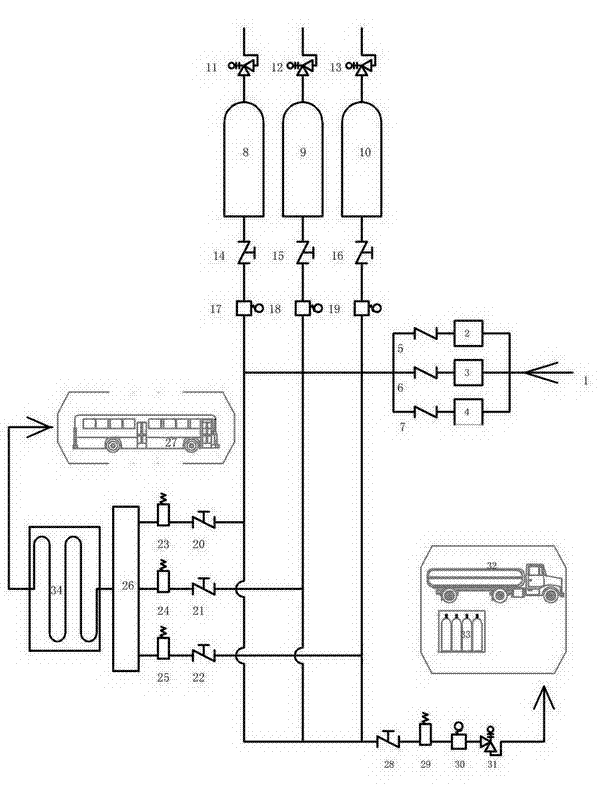

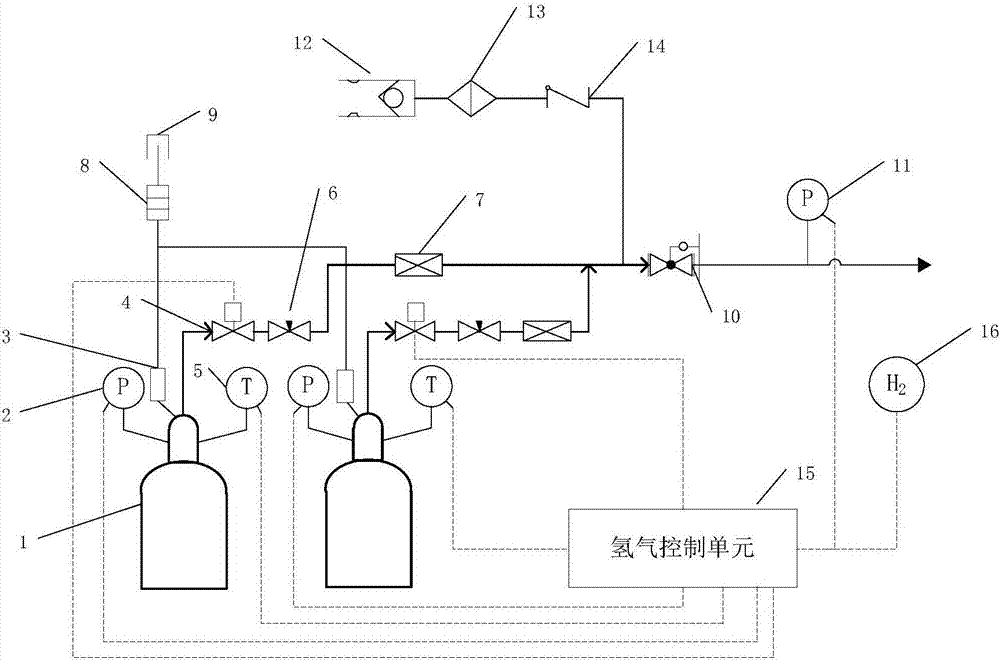

High-pressure hydrogen supply system for exterior hydrogen feeding hydrogenation stations

ActiveCN101418907ASimplified hydrogen supply processLow investment costContainer filling under pressureHigh pressure hydrogenData acquisition

The invention provides a high-pressure hydrogen supply system for an external supplying type hydrogen filling station, which can fill hydrogen fuel for fuel cell powered vehicles. The hydrogen supply system mainly comprises a pipe bundle hydrogen conveying vehicle, a fixed high-pressure hydrogen storage tank group, a parallel multi-compressor pressurizing system, a high-pressure hydrogen filling system, and a data acquiring, processing and safety monitoring system. The high-pressure hydrogen supply system takes the pipe bundle hydrogen conveying vehicle as a part of a hydrogen storage container of the hydrogen filling station and makes the pipe bundle hydrogen conveying vehicle a first stage of the staged hydrogen storage container, adopts the pressurizing system consisting of multiple compressors which are connected in parallel, and introduces the data acquiring, processing and safety monitoring system. The high-pressure hydrogen supply system has the advantages of adjustable hydrogen storage volume, large operation flexibility, cost conservation, convenient maintenance, high service efficiency and so on.

Owner:TONGJI UNIV

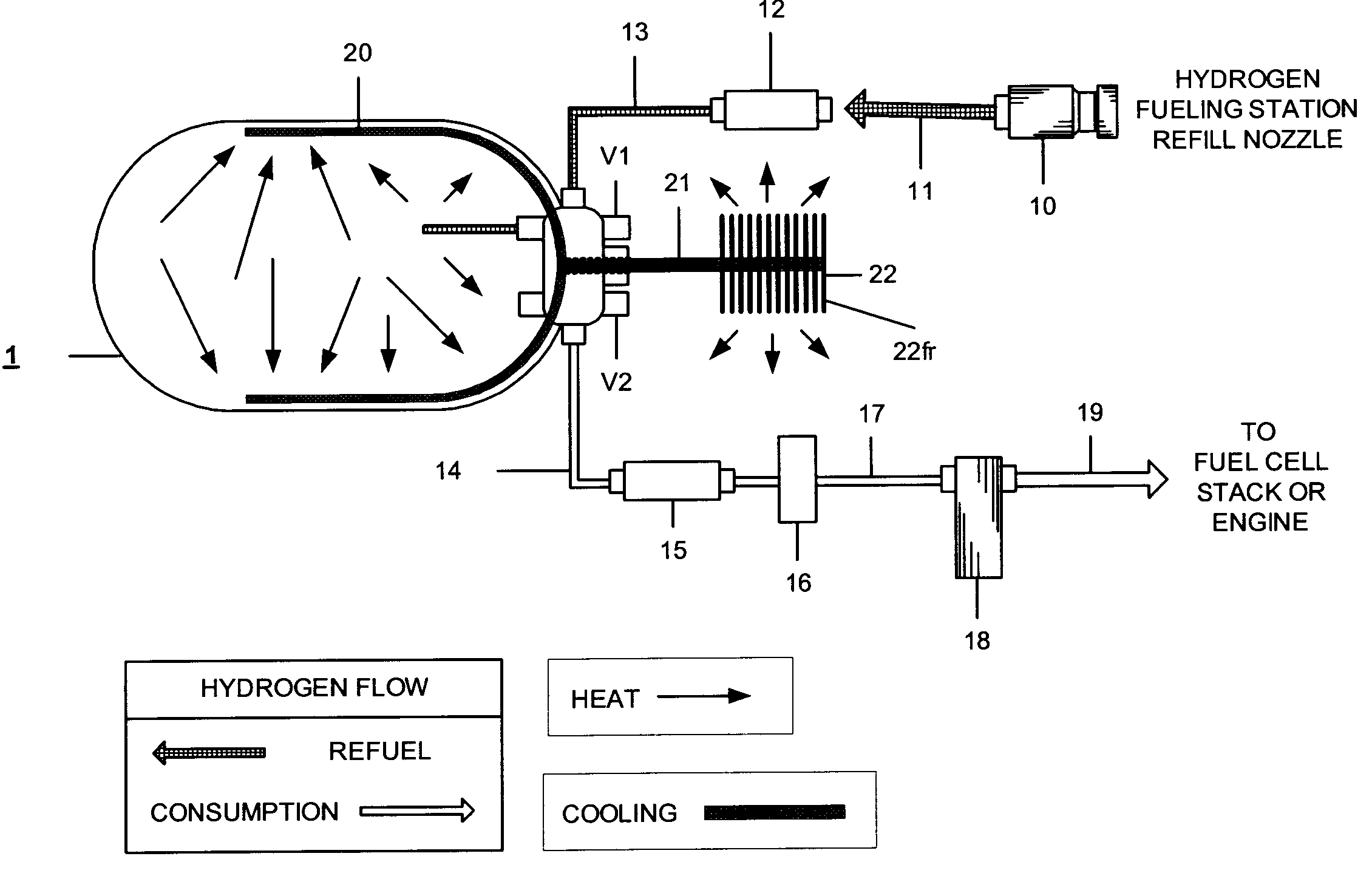

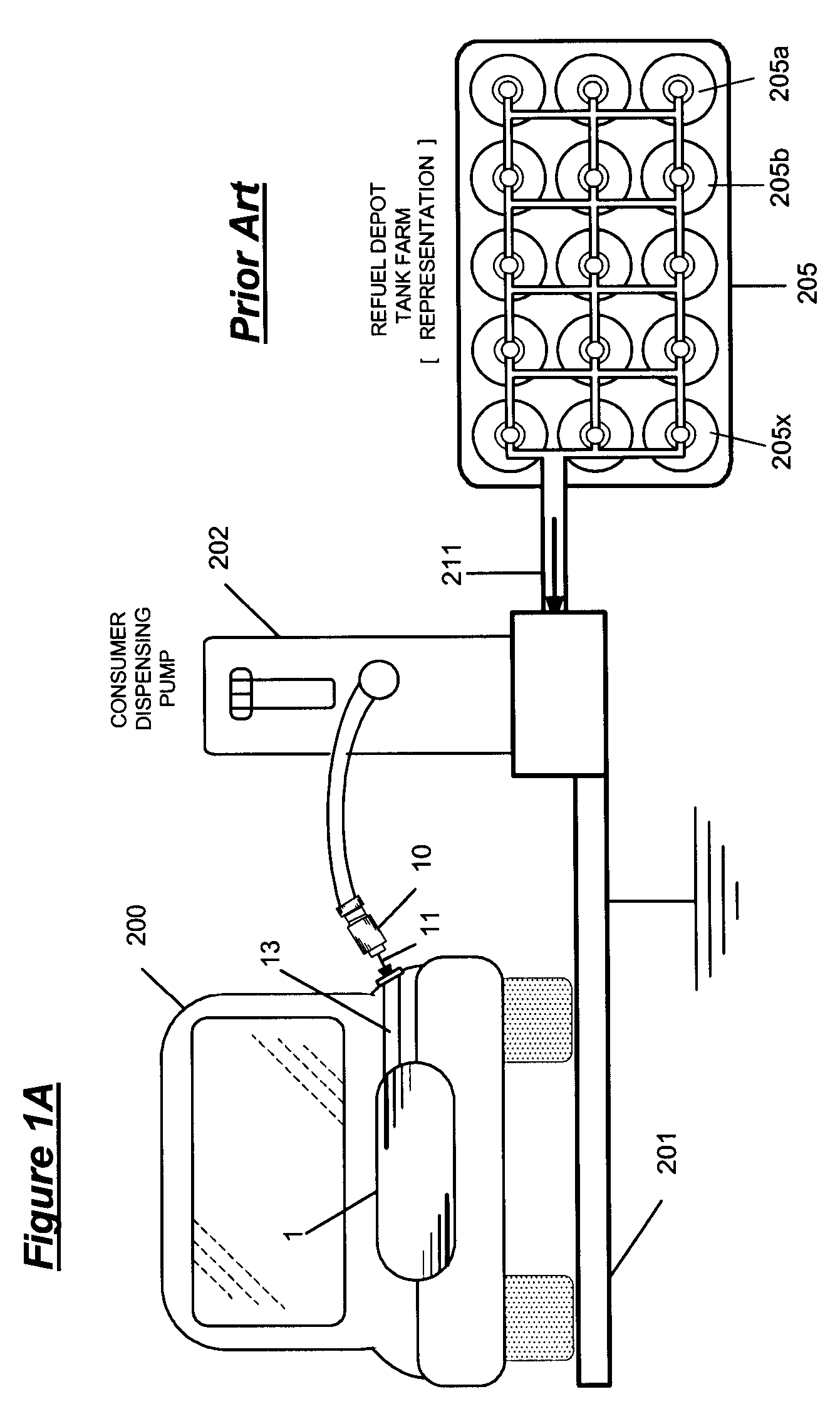

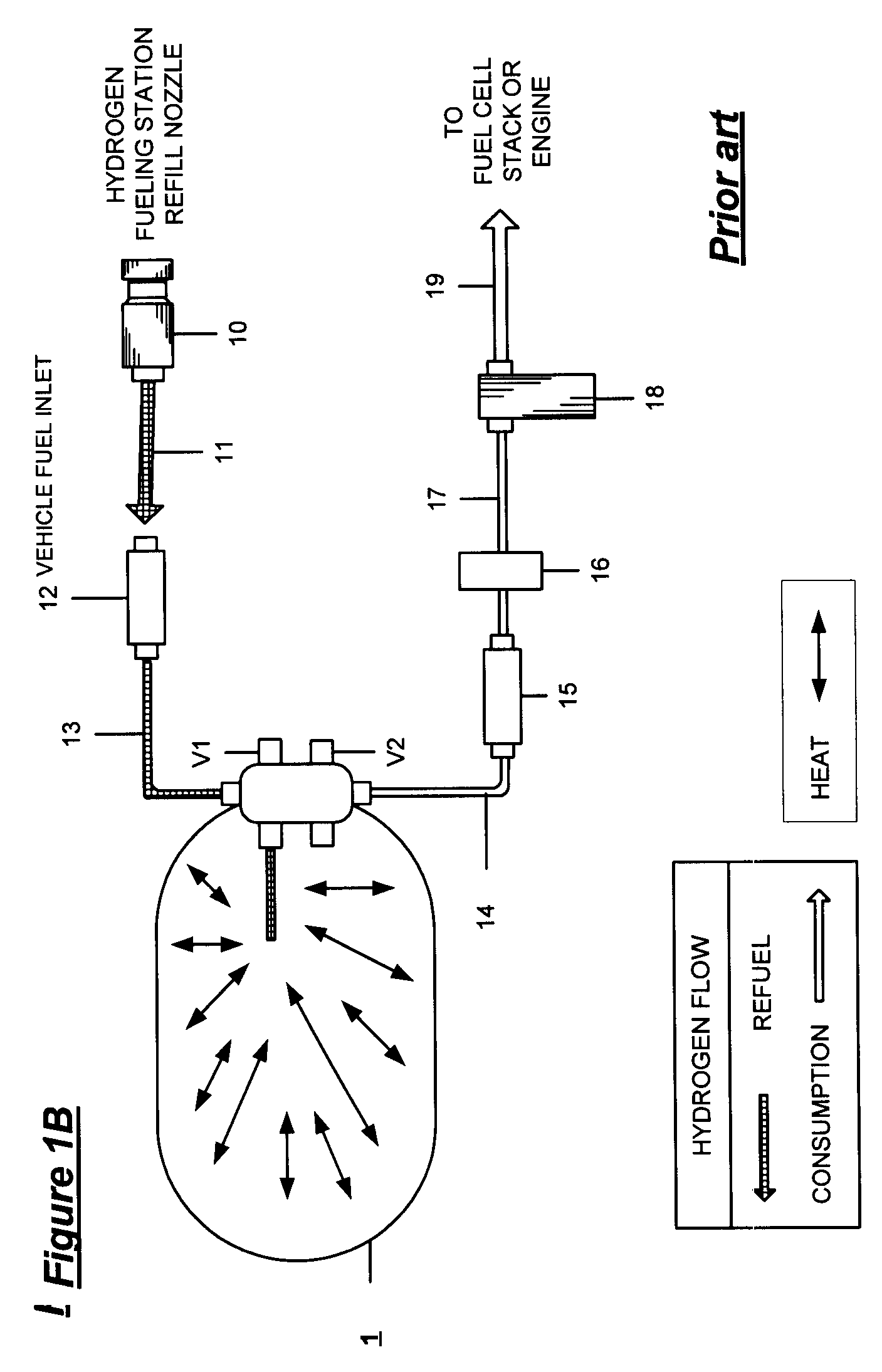

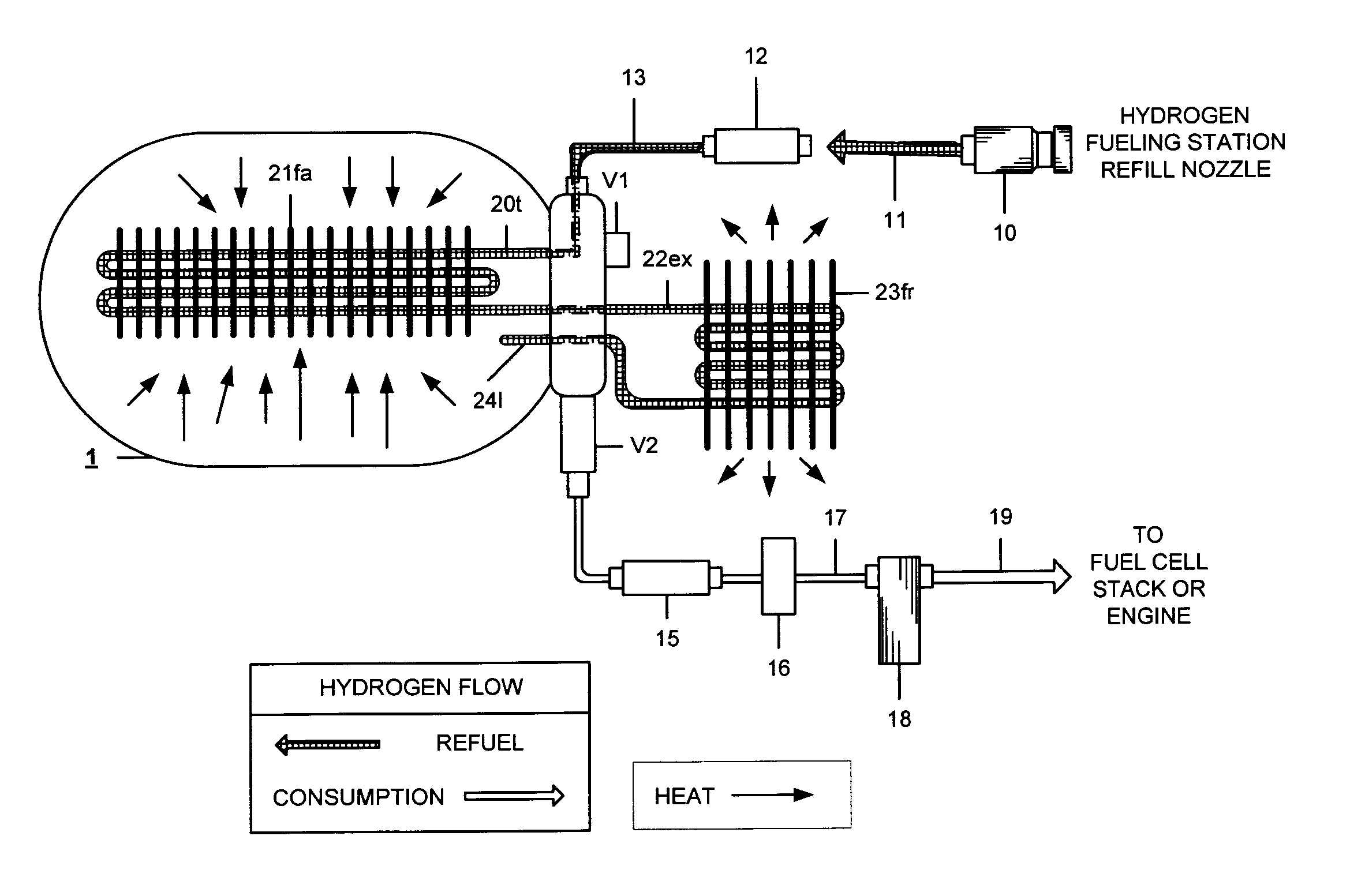

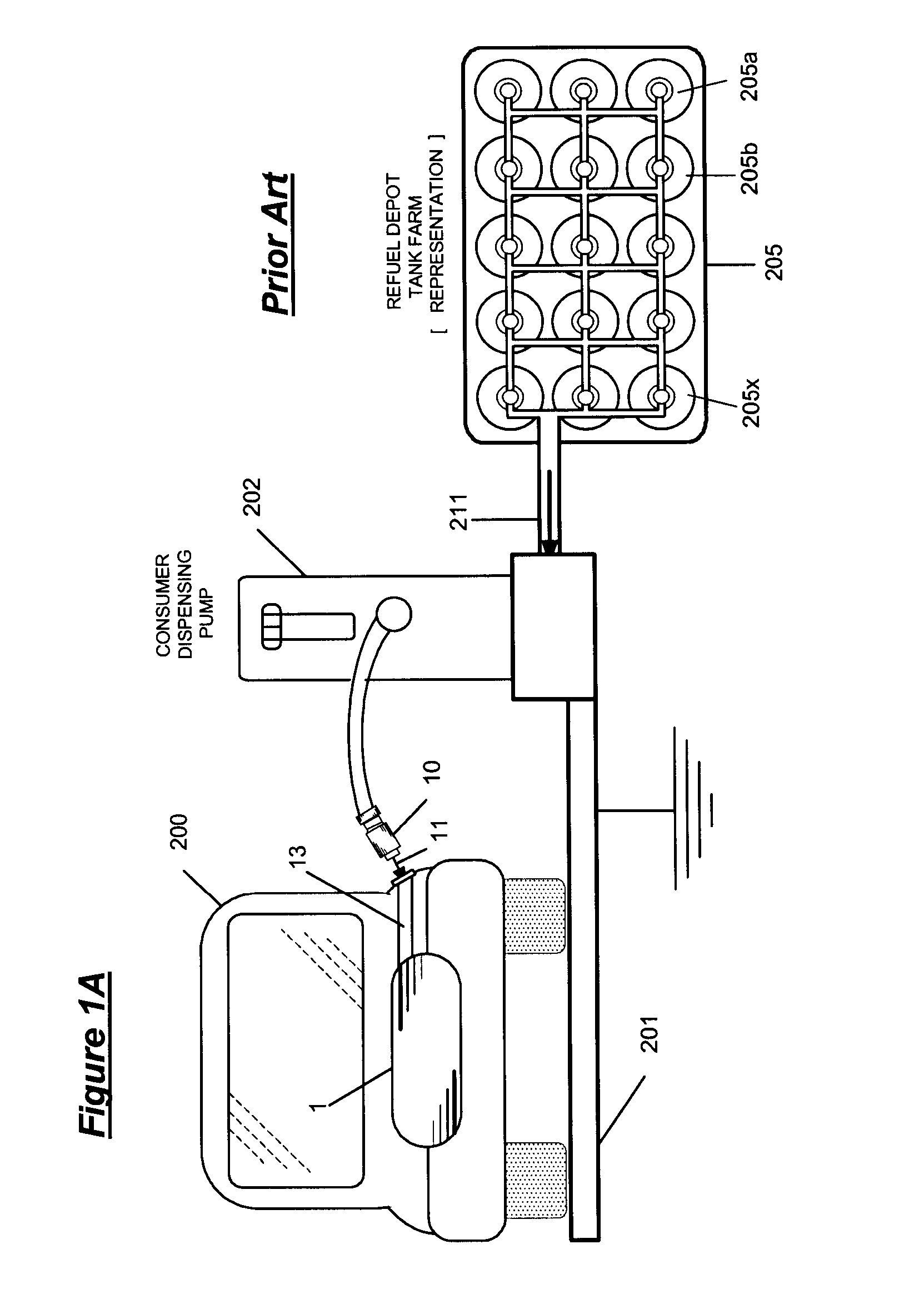

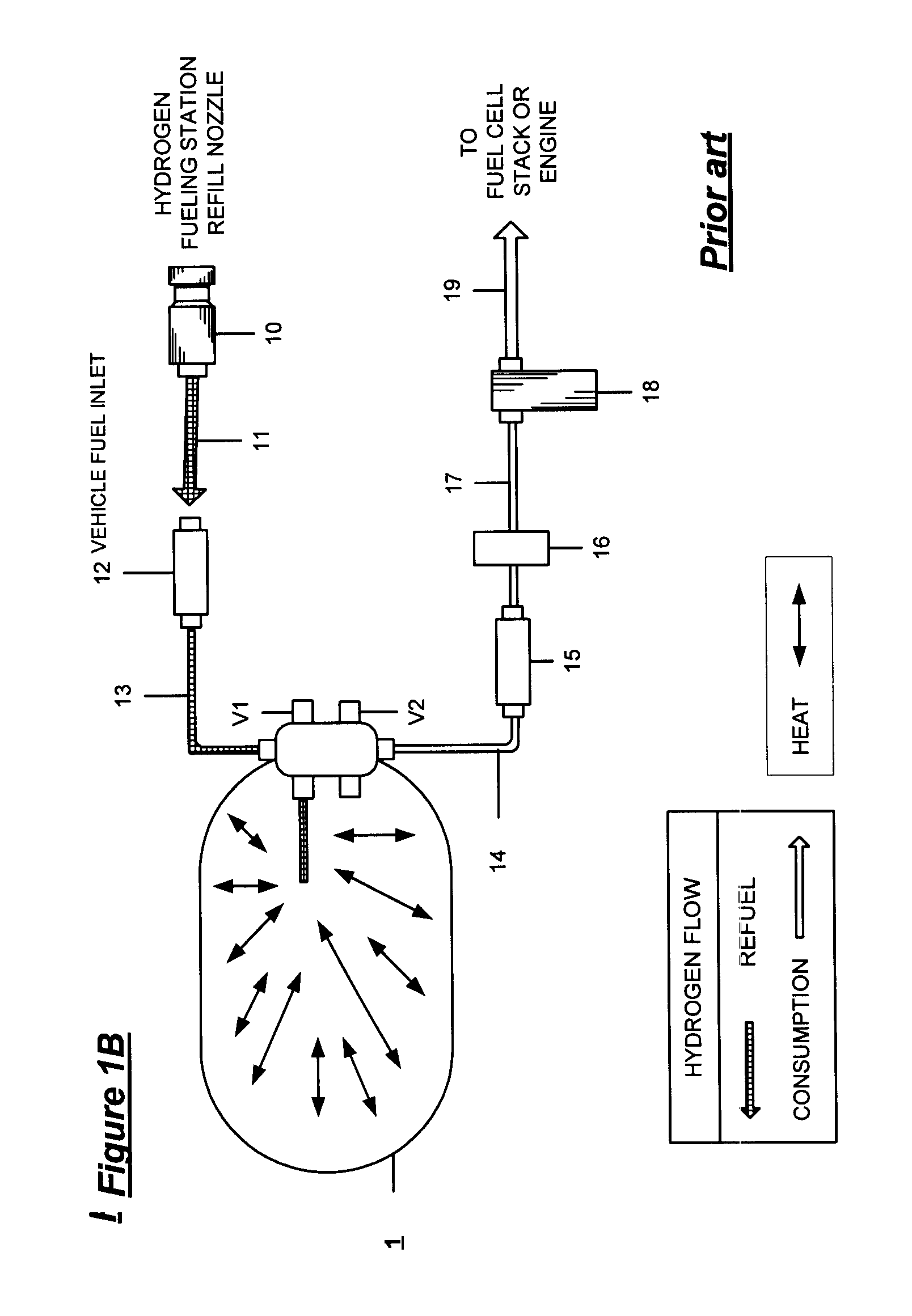

Gas cooling methods for high pressure fuel storage tanks on vehicles powered by compressed natural gas or hydrogen

ActiveUS7377294B2Improve refueling efficiencyIncrease efficiency and refueling capacityGlovesGas handling applicationsThermal energyCompressed natural gas

At a high pressure refuel depot that dispenses high pressure hydrogen or compressed natural gas to vehicles, the thermal energy (heat) generated by the high flow rate of the high pressure refueling gas is evacuated from the on board fuel tank[s] of vehicles eliminating the need for refueling pre treatments such as a slow fill, secondary precooling, and pressure overfill otherwise used to achieve a full vehicle tank refill. In an example, a high pressure fuel depot refilling line is operatively interconnected to an on board vehicle tank having a gas flow circuit wherein the refuel gas itself is circulated within the on board tank to absorb the compression heat of refueling and then to an external radiator before being released into the tank.

Owner:HONDA MOTOR CO LTD

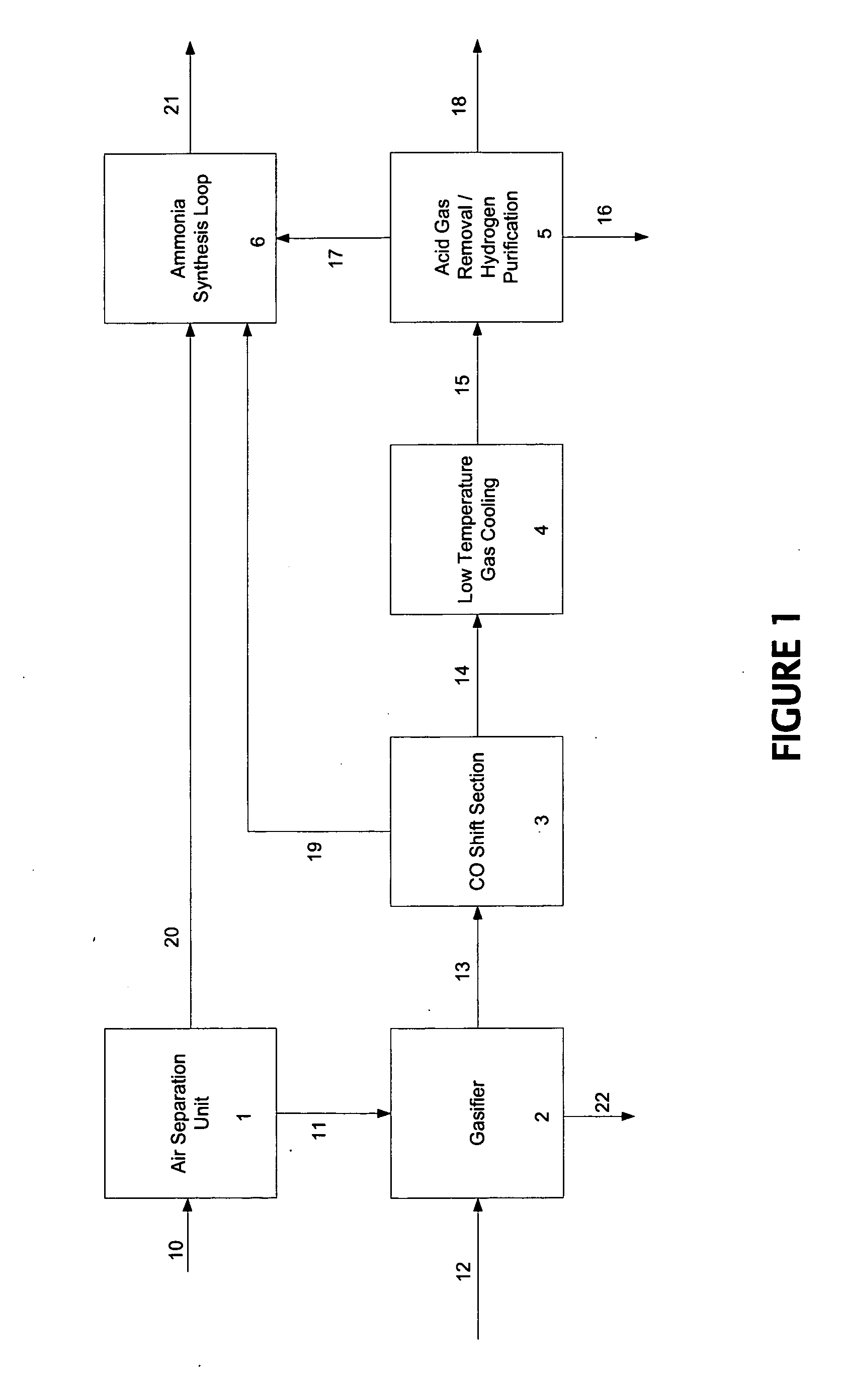

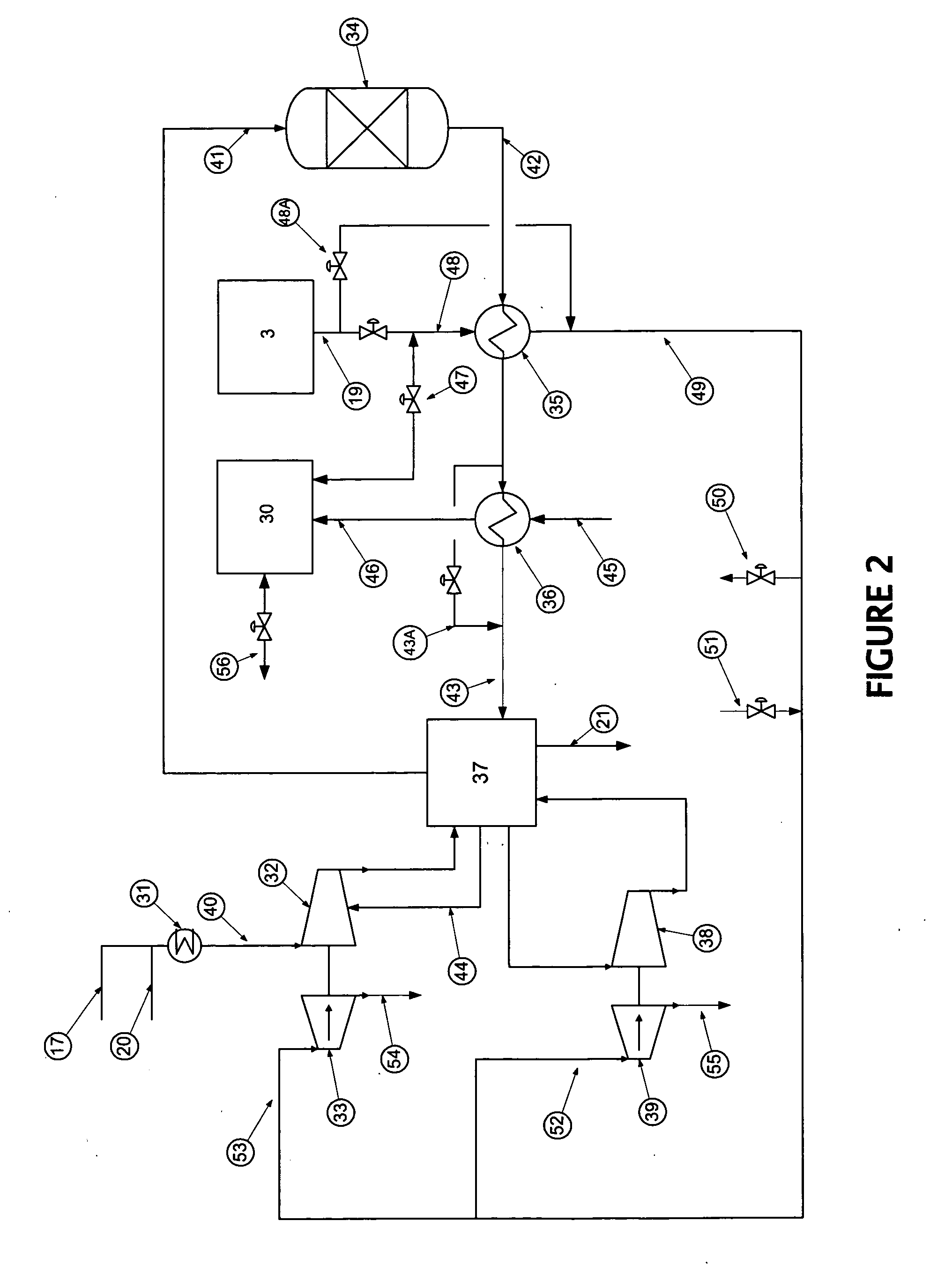

Integration of gasification and ammonia production

A method and system are described for making ammonia using hydrogen from a gasification process and for integrating the steam systems of the two processes. The gasification process provides high-pressure, purified hydrogen and high-pressure, saturated steam. The high pressure hydrogen lowers the overall compression requirement for the ammonia process. In addition, the high-pressure, saturated steam can be converted into superheated steam by recovering heat from ammonia synthesis and used to power steam turbines for compression and refrigeration needs.

Owner:EASTMAN CHEM CO

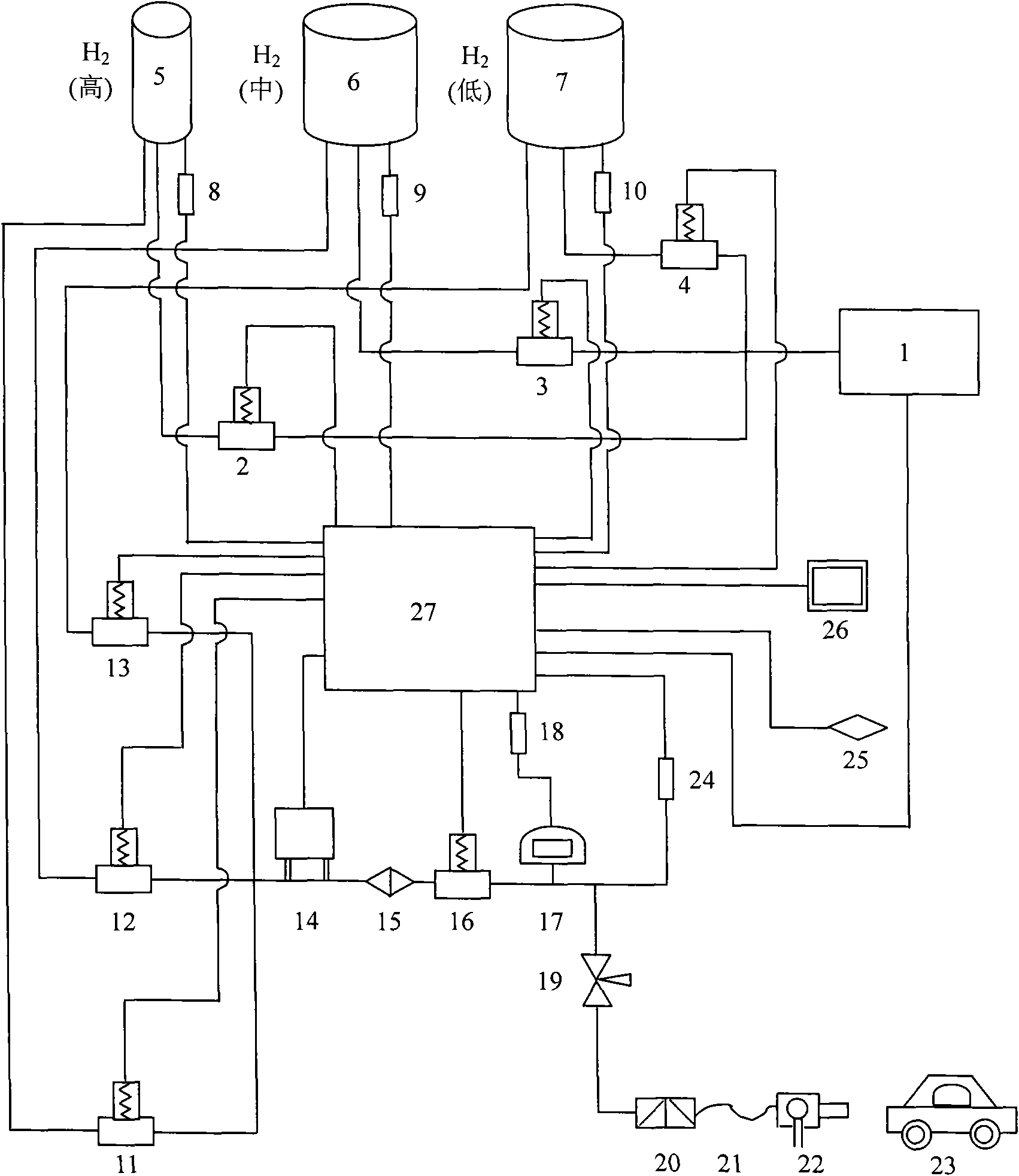

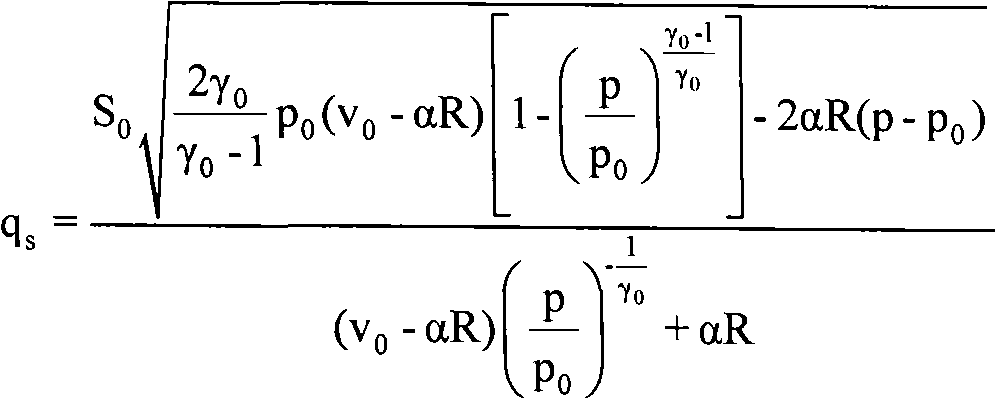

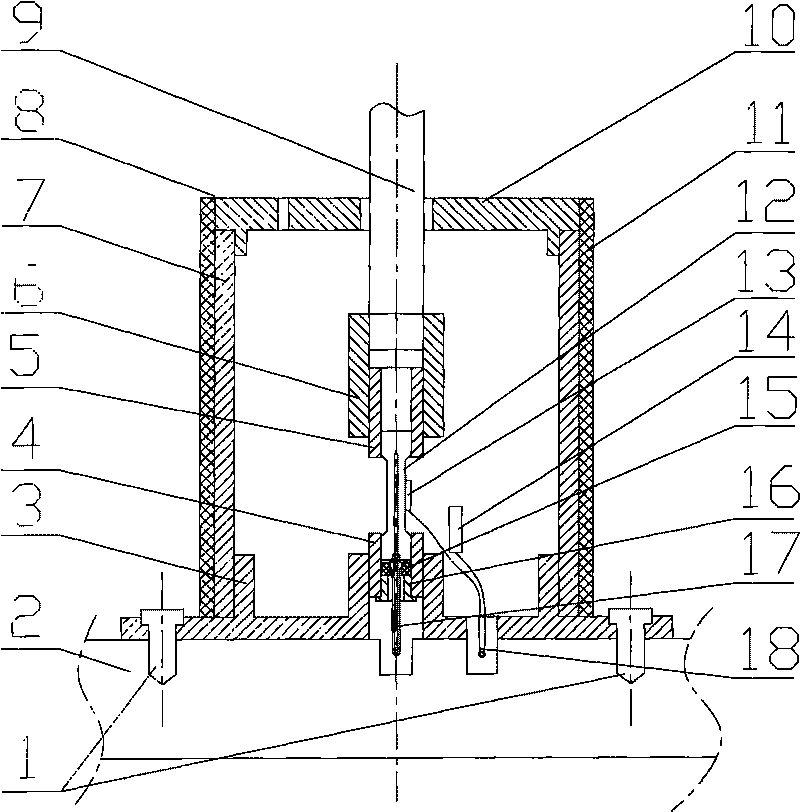

Hydrogen refueling station hydrogen optimizing filling method based on temperature rise and energy consumption control and system thereof

ActiveCN101832467AReduce energy consumptionLow energy operationContainer discharging methodsContainer filling under pressureNew energyProgrammable logic controller

The invention relates to the field of renewable, clean and environment-friendly new energy, aiming at providing a hydrogen refueling station hydrogen optimizing filling method based on temperature rise and energy consumption control and a system thereof. The method comprises the steps of: establishing a database arranged inside a programmable logic controller (PLC), and using the database to record the corresponding relationship between the corresponding filling initial condition and the opening value of a needle valve; according to the filling initial condition, using the PLC to inquire the opening value of the needle valve when hydrogen storage tanks with different pressure levels are used for taking gas; and according to the data inquired by the PLC, arranging the needle valve at the corresponding demarcated position, and carrying out the filling operation. The invention can run at the lower power consumption of a cooling device, ensures the temperature of a vehicle hydrogen storage container to be strictly controlled within the required range, and remarkably shortens the filling time, thus leading the whole system to effectively, safely and reliably fill high pressure hydrogen, and having the advantages of high gas taking efficiency, low power consumption and the like.

Owner:ZHEJIANG UNIV

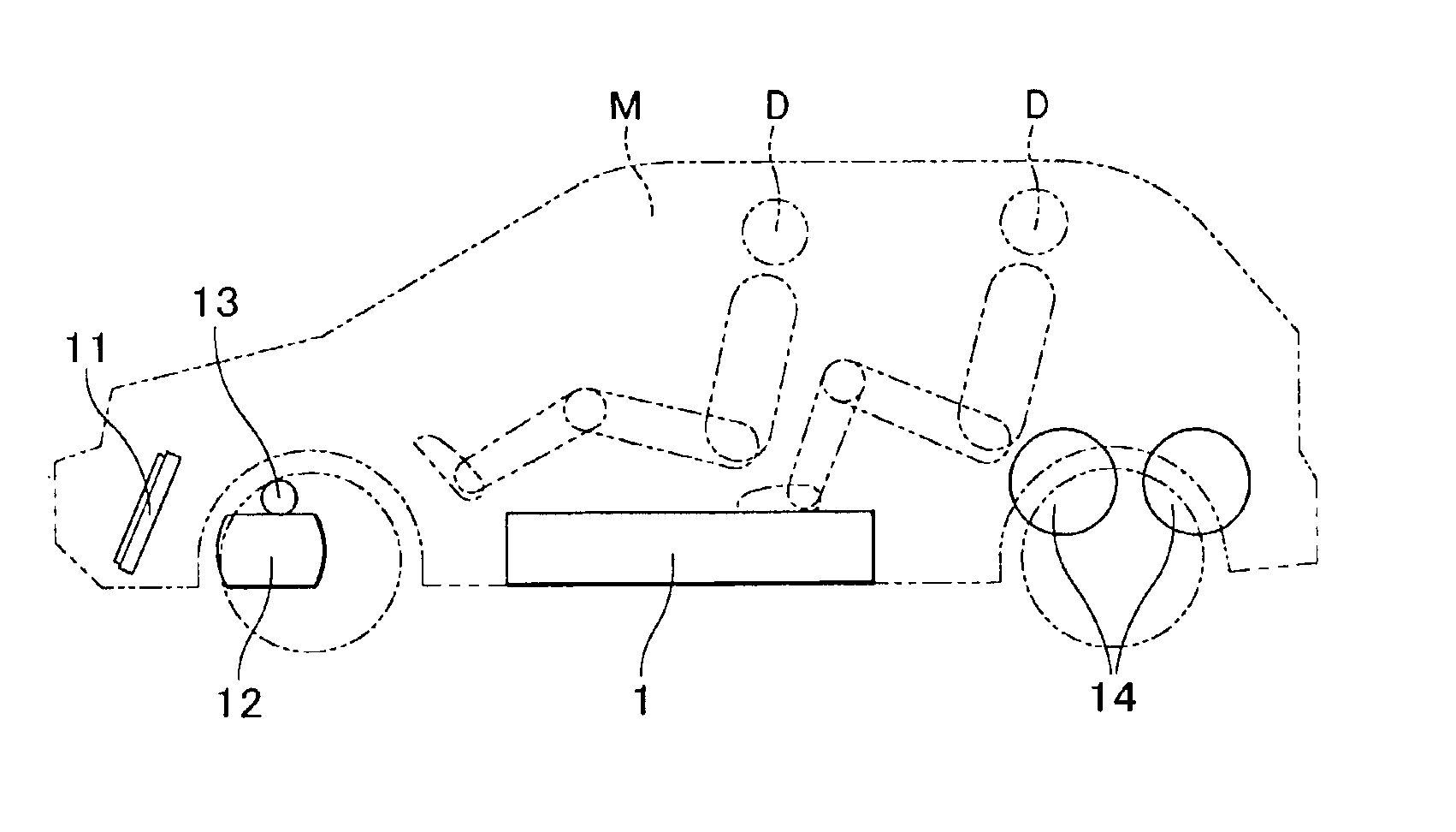

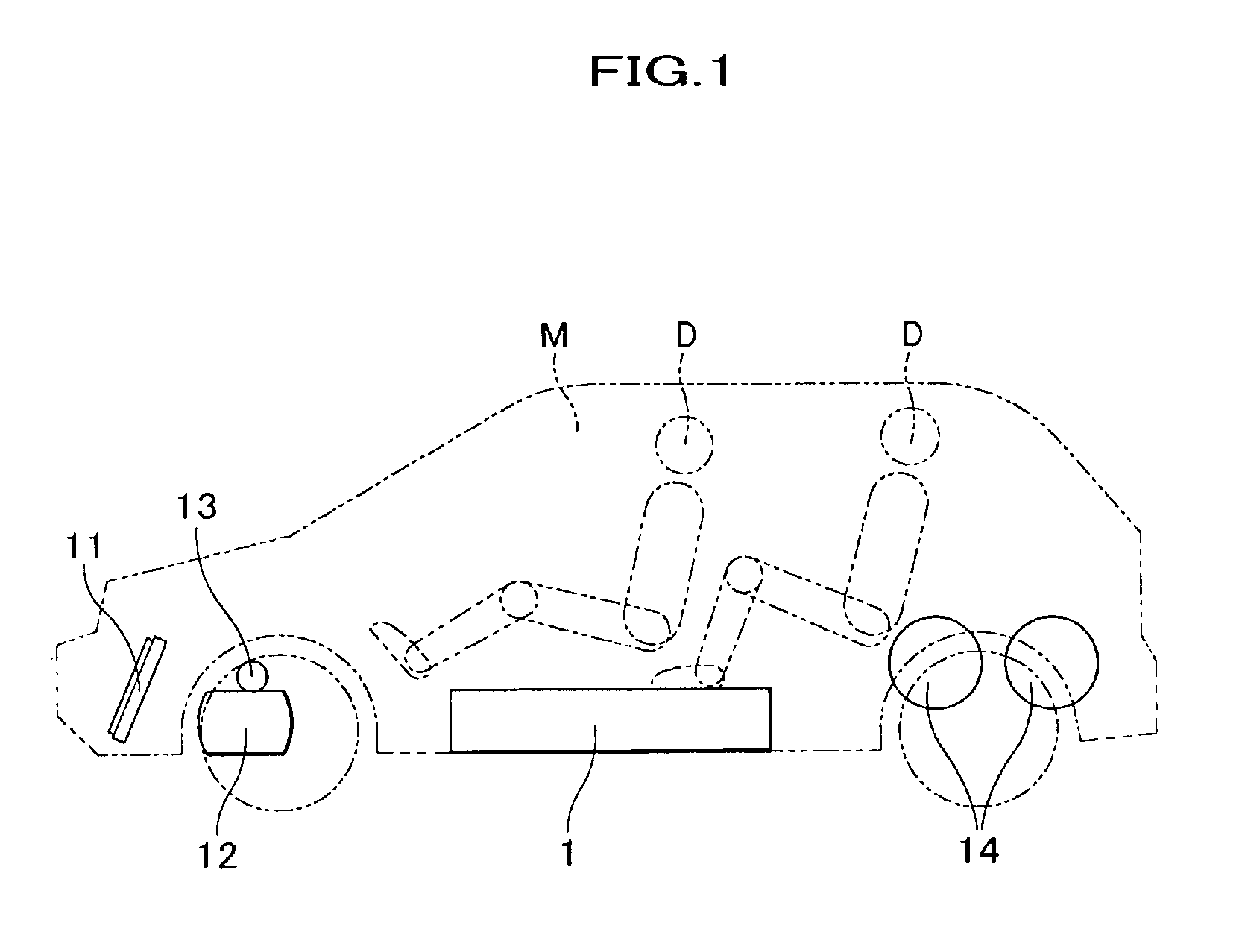

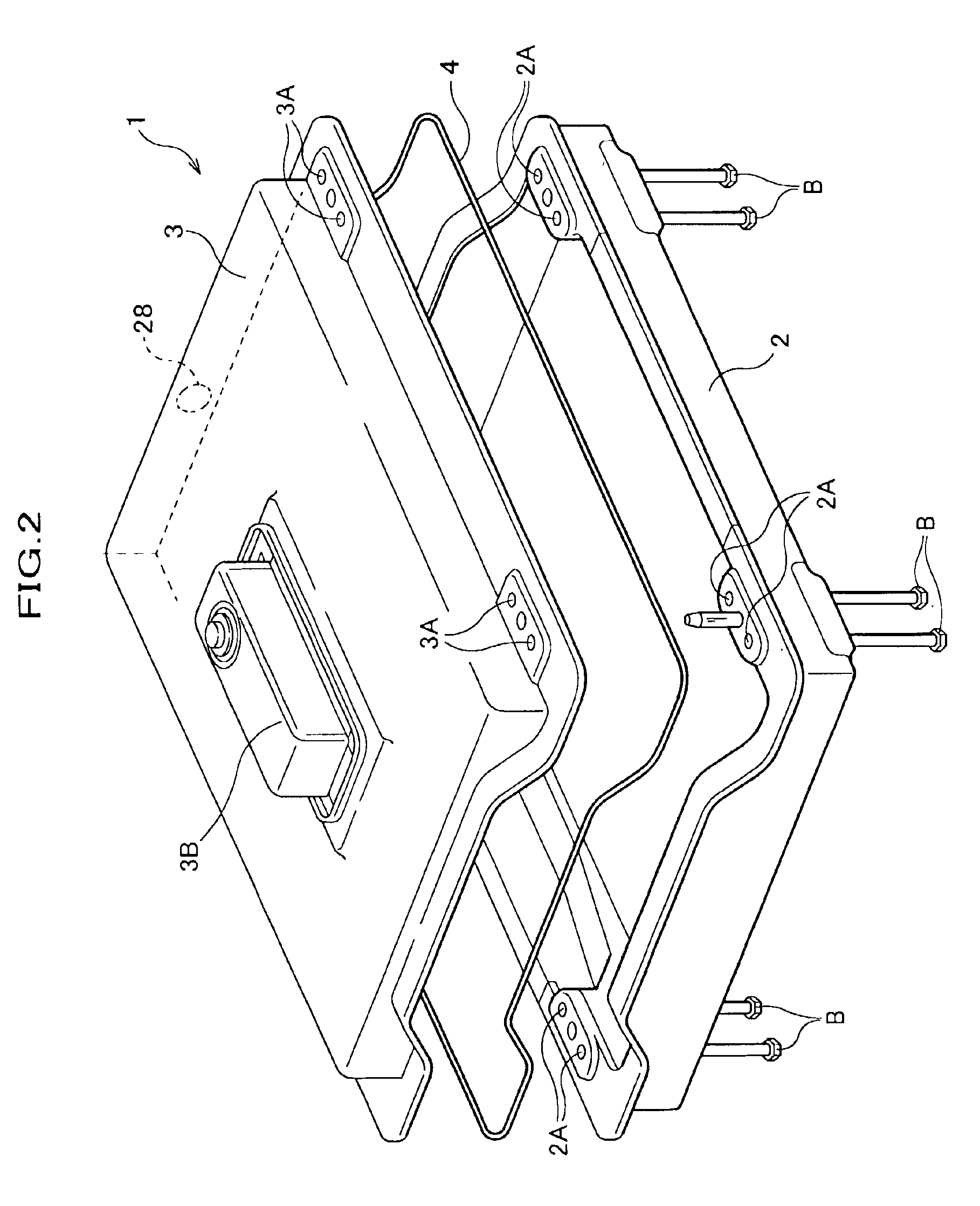

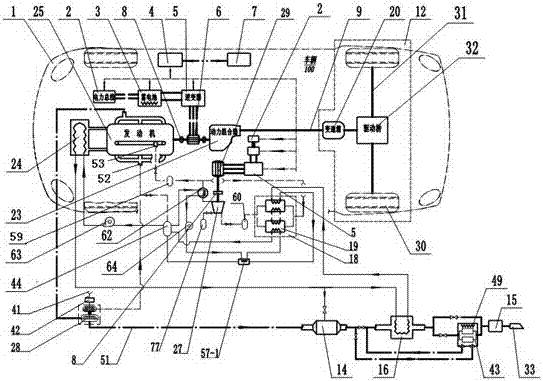

Fuel cell electric vehicle and a fuel cell system box

InactiveUS6874588B2Not easy to damageImprove vehicle stabilityReactant parameters controlInternal combustion piston enginesFuel cellsHigh pressure hydrogen

The vehicle M which is a fuel cell loading type electric vehicle includes a fuel cell 30, thermoregulator 20 to adjust the temperature of the fuel cell 30; humidifier 40 to supply moisture to the fuel cell; and the high-pressure hydrogen containers 14 and 14, which is filled up with hydrogen. The thermoregulator 20, a fuel cell 30, the humidifier 40, and the high-pressure hydrogen containers 14 and 14 are disposed covering from the front position to the back position of the vehicle, and arranged in the longitudinal direction of the vehicle in this order. Even when there is a collision of vehicles etc., equipment of the fuel cell system, especially a fuel cell is protected from being damaged and also the space of a vehicle compartment or a load room is fully secured, and further, behavior stability etc. is good.

Owner:HONDA MOTOR CO LTD

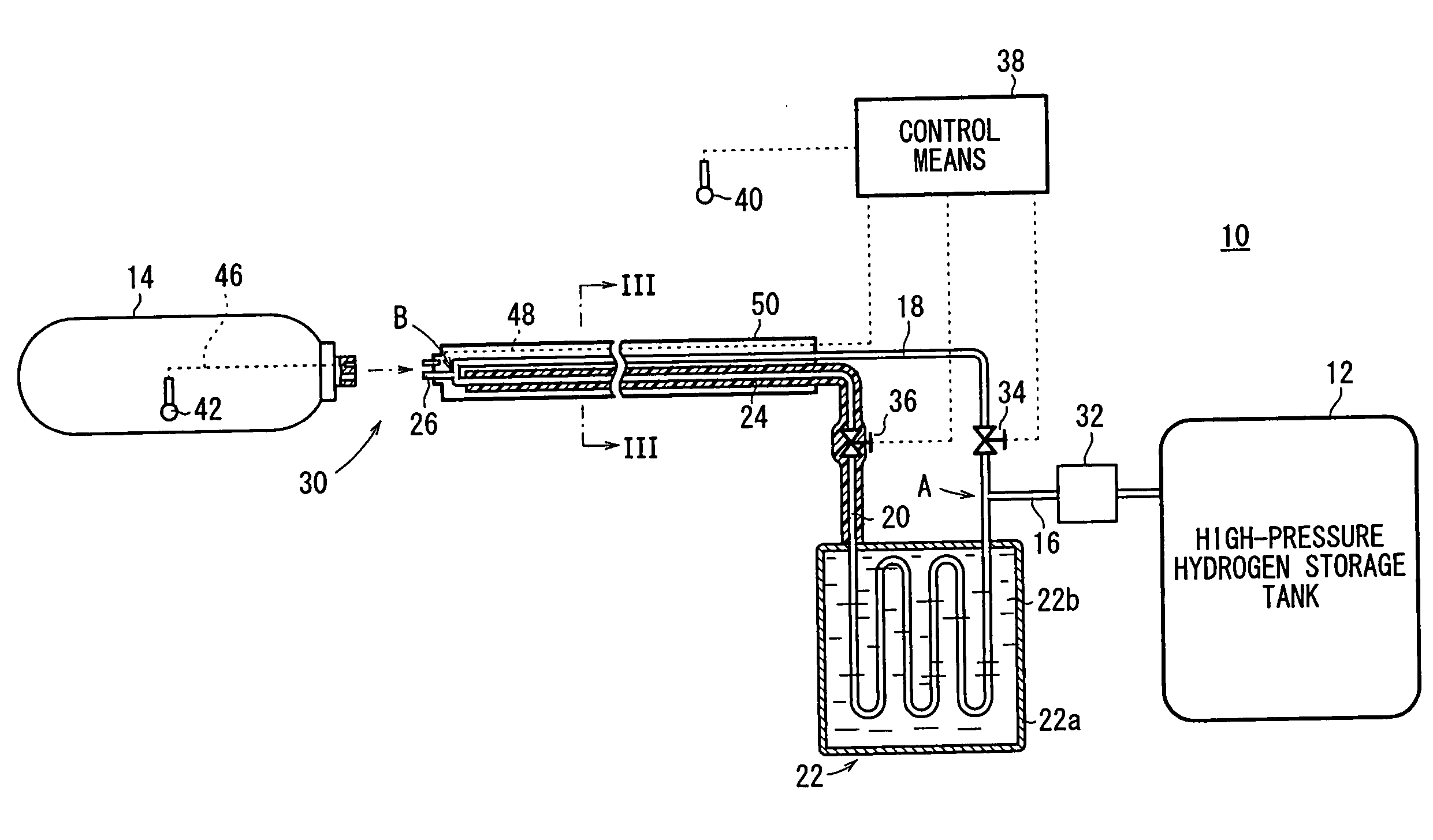

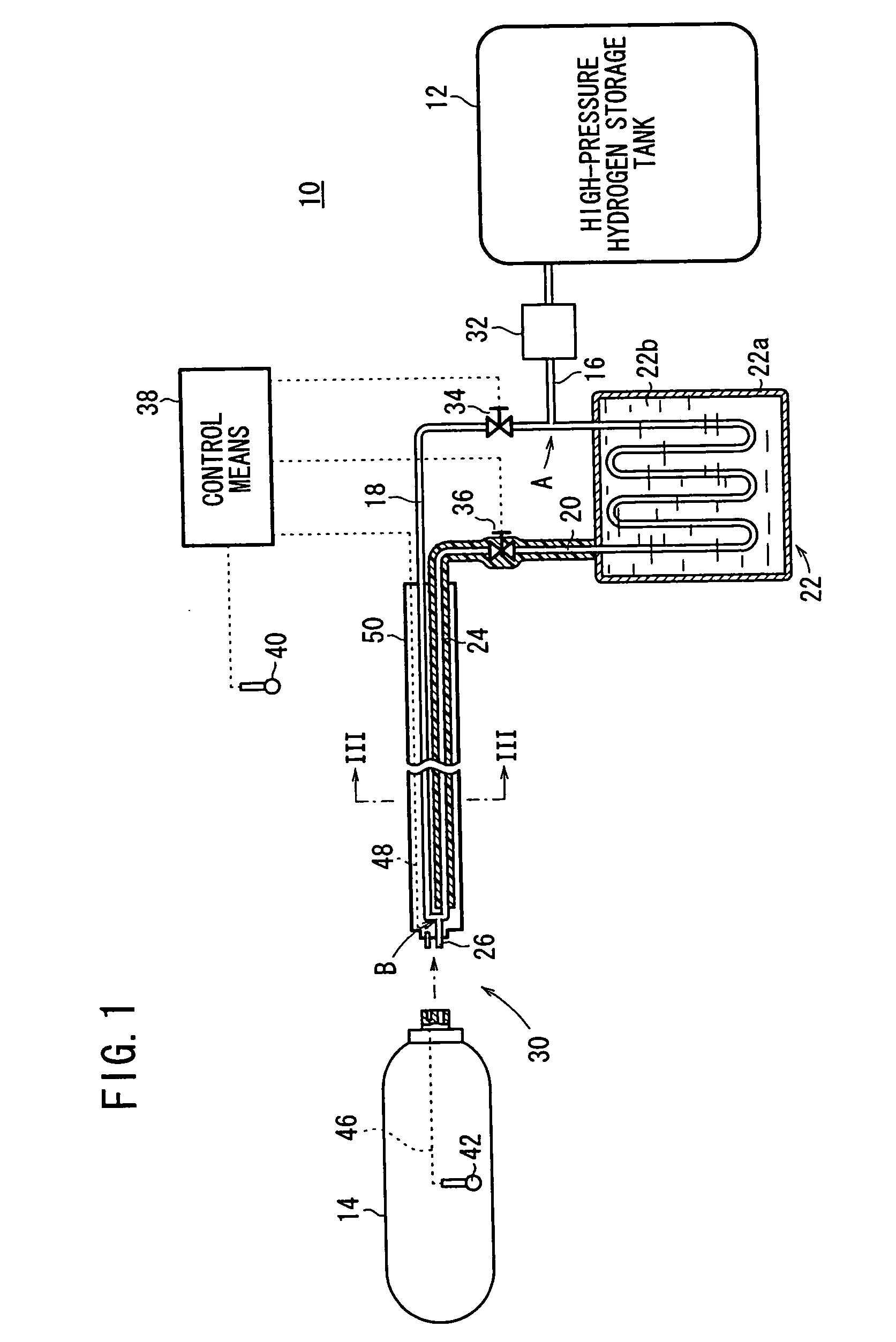

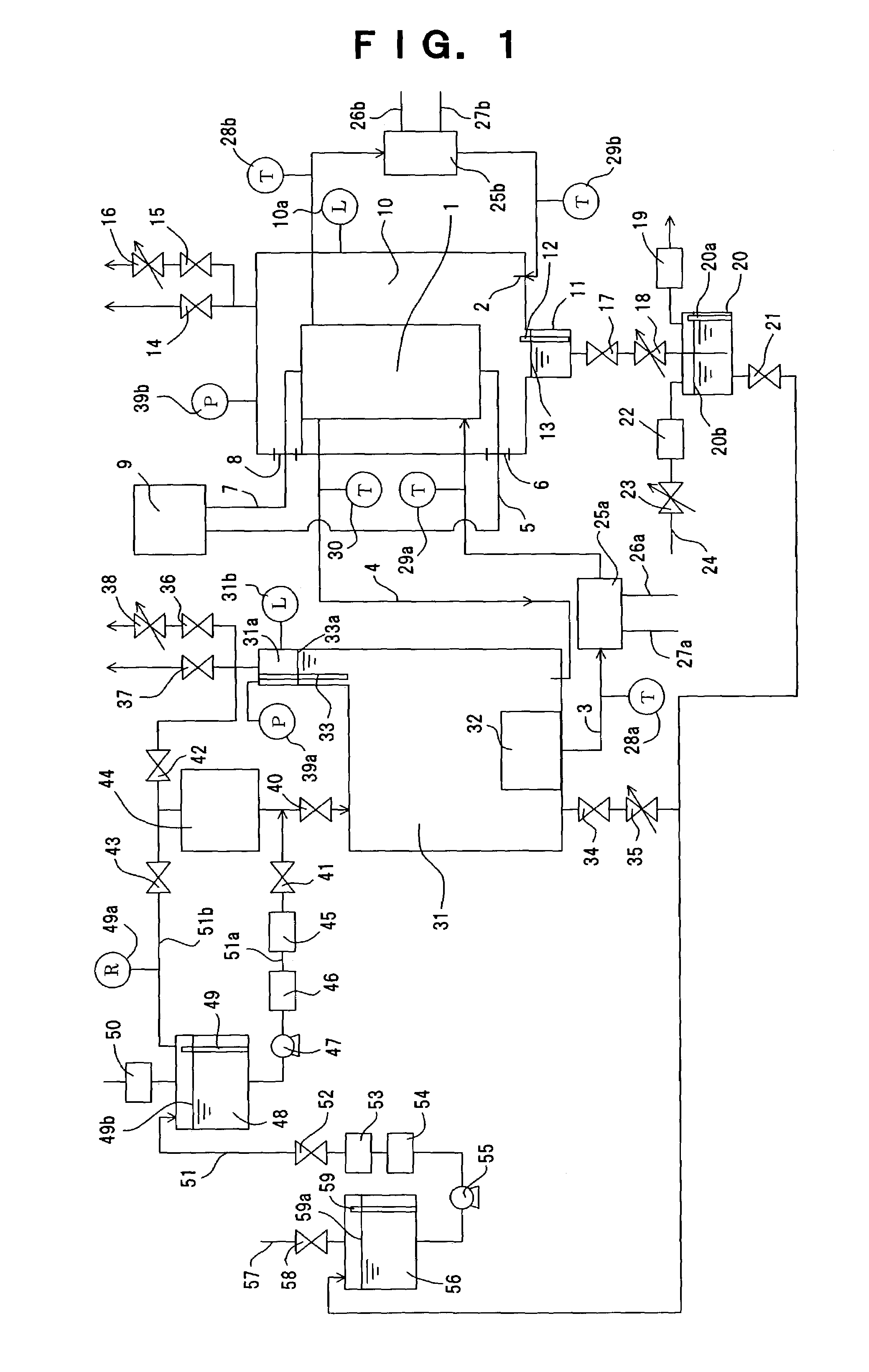

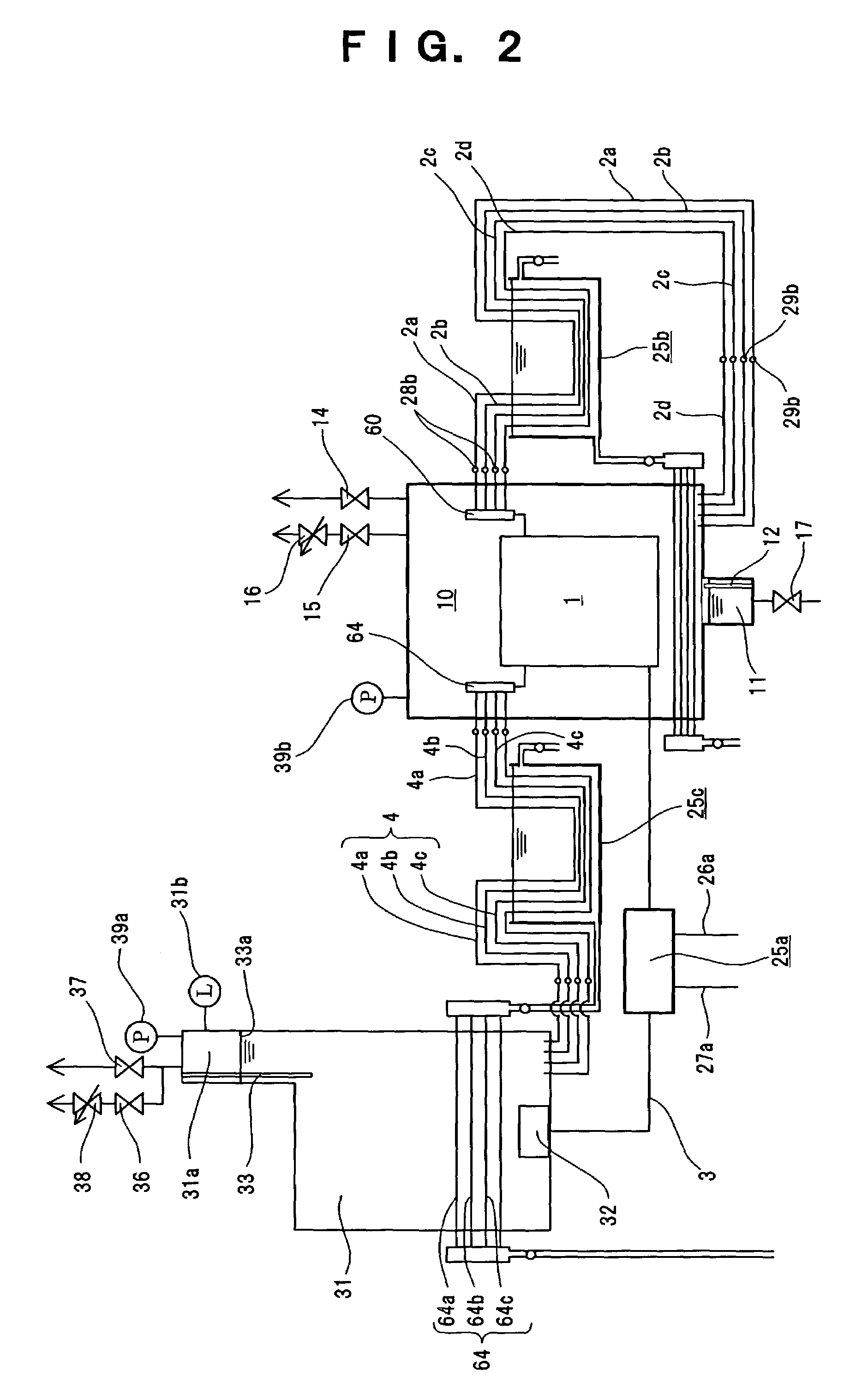

Apparatus for and method of filling hydrogen tank with hydrogen

InactiveUS20070257043A1Fast fillSuppresses temperature changesLarge containersGas handling/storage effectsHigh pressure hydrogenAtmospheric temperature

An hydrogen tank filling apparatus includes a first hydrogen supply pipe for supplying hydrogen substantially at an atmospheric temperature from a high-pressure hydrogen storage tank to a hydrogen tank, a second hydrogen supply pipe for supplying cooled hydrogen from the high-pressure hydrogen storage tank to the hydrogen tank, and an internal tank temperature measuring unit for measuring the temperature inside the hydrogen tank. The first hydrogen supply pipe and the second hydrogen supply pipe are selectively switched by a control unit, depending on changes in the temperature inside the hydrogen tank.

Owner:HONDA MOTOR CO LTD

Gas Cooling Methods for High Pressure Fuel Storage Tanks on Vehicles Powered by Compressed Natural Gas or Hydrogen

ActiveUS20070000016A1Reduce energy lossImprove refueling efficiencyGlovesGas handling applicationsThermal energyCompressed natural gas

At a high pressure hydrogen or compressed natural gas vehicle refuel depot, the thermal energy (heat) generated by from the high flow rate of the high pressure refueling gas is evacuated from the on board fuel tank[s] of consumer vehicles eliminating the need for refueling pre treatments such as a slow fill, secondary precooling, and pressure overfill otherwise used to achieve a full vehicle tank refill. In an example, a high pressure fuel depot refilling line is operatively interconnected to an on board vehicle tank having a gas flow circuit wherein the refuel gas itself is circulated within the on board tank to absorb the compression heat of refueling and then to an external radiator before being released into the tank.

Owner:HONDA MOTOR CO LTD

System and method for rapid hydrogen filling

InactiveCN103244825AImprove securityReduce temperature risePipeline systemsContainer filling under pressureGas cylinderHigh pressure hydrogen

The invention provides a system and a method capable of achieving balanced pressure-reducing rapid hydrogen filling by three storage tanks with hydrogen of any sources. The system comprises a hydrogen compression device, hydrogen storage devices and a hydrogen filling device. Hydrogen prepared by any methods is compressed via the hydrogen compression device and then is stored in the high-pressure hydrogen storage devices, and a hydrogen outlet of each hydrogen storage device is directly connected to a hydrogen dispenser or an industrial hydrogen cylinder filling system. A set of pressure-reducing balanced filling system is shared during automobile hydrogen (hydrogen for the energy purpose) filling and cylinder filling (industrial hydrogen). A pressure-reducing valve is not arranged in the system, so that pipe resistance of the system is lower, and filling rate is higher. Besides, a pre-cooling device is added to the system, so that temperature rise of a filling container is lower.

Owner:BEIJING JONTON HYDROGEN TECH

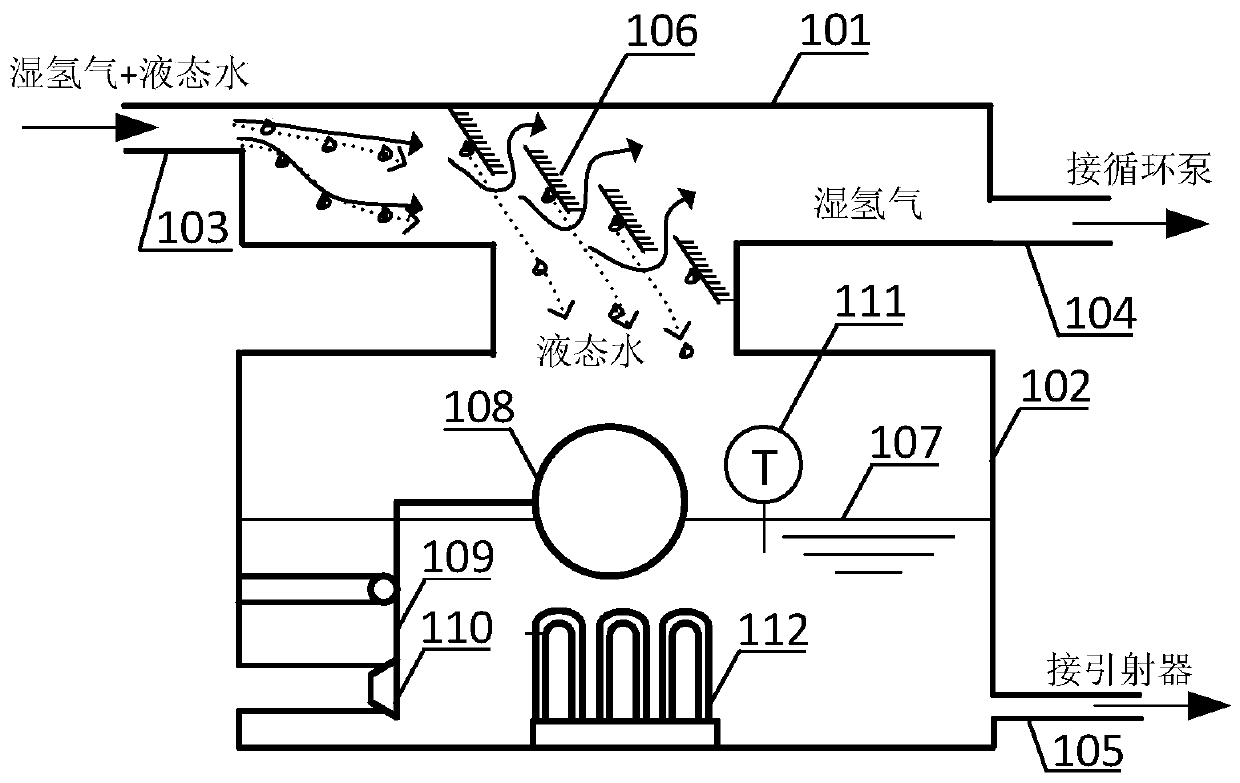

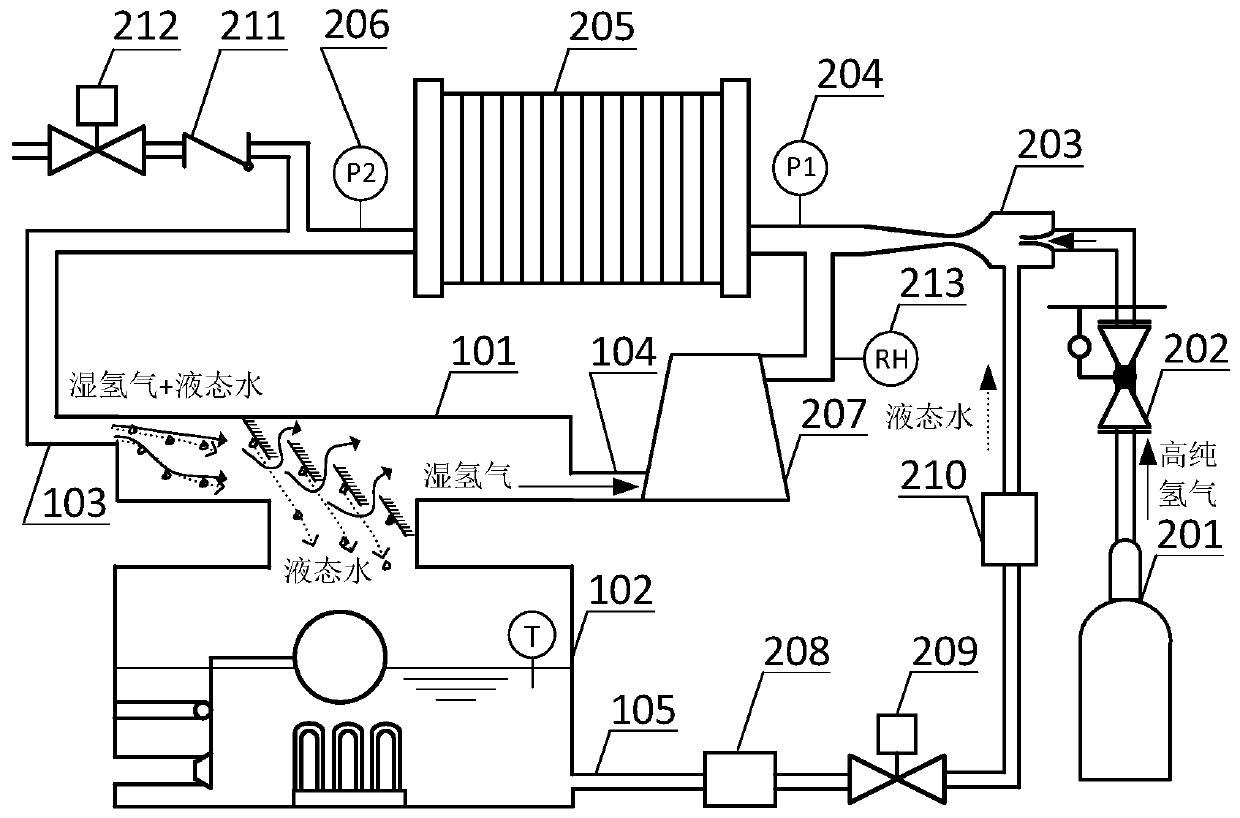

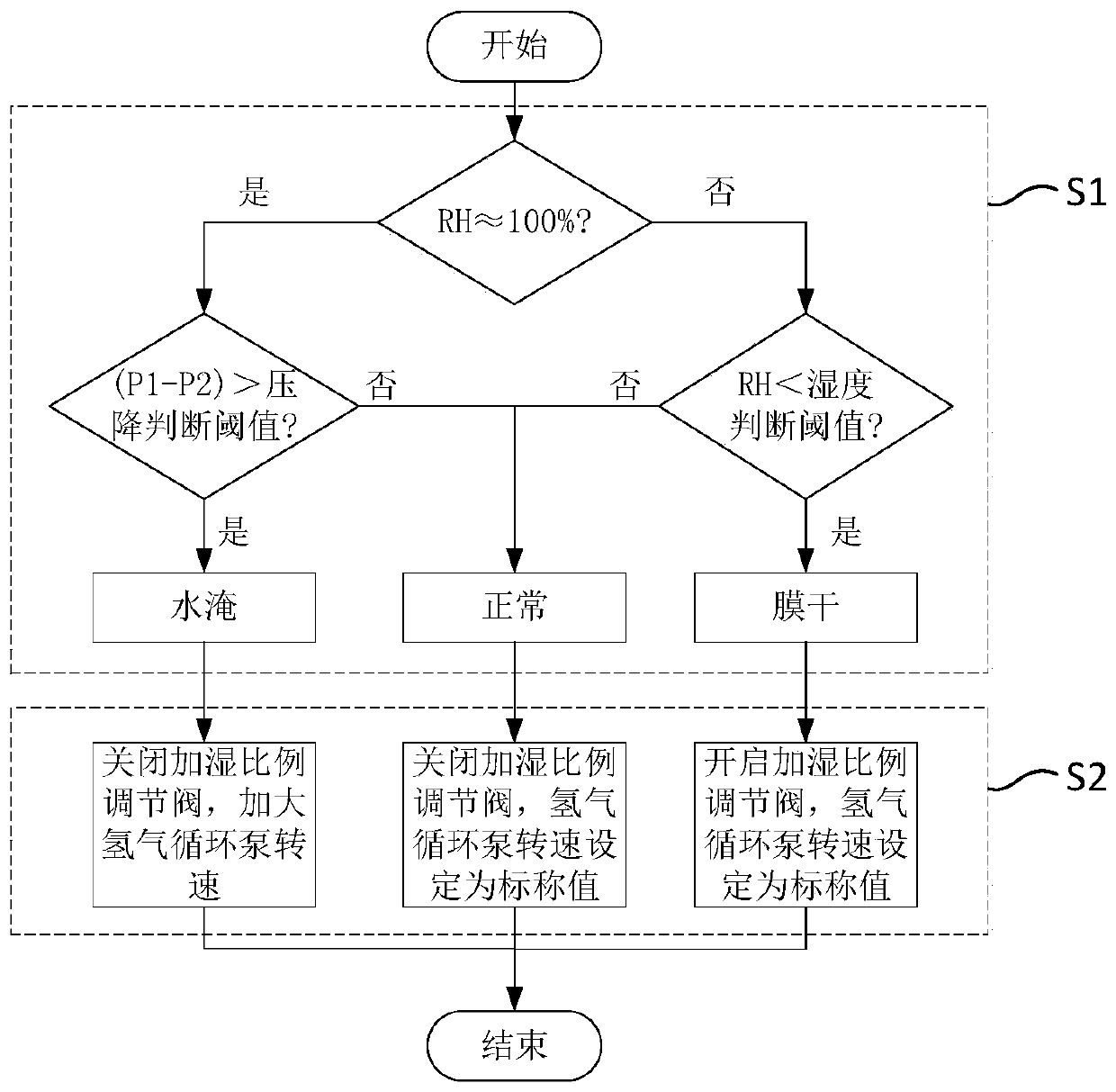

Fuel cell anode water management system and control method

ActiveCN111063916AImprove environmental adaptabilityIncrease power consumptionFuel cell heat exchangeAtomizer nozzleLiquid water

The invention discloses a fuel cell anode water management system and a control method, and belongs to the technical field of proton exchange membrane fuel cells. Aiming at the problem of anode watermanagement in the operation process of a proton exchange membrane fuel cell, the scheme provided by the invention can realize two functions of water removal and humidification, and liquid water separated from a baffle in a gas-water separation device in the water removal process is stored and supplemented to an ejector when the fuel cell membrane is dry and needs to be humidified. Liquid water inthe electric pile tail gas is fully recycled, so that the environmental adaptability of a humidifying system to a water shortage condition and a low-temperature condition is improved. Liquid water issucked into a mixing chamber through high-pressure hydrogen and the ejector, and extra system power consumption increased by humidifying devices such as an atomizing nozzle and an ultrasonic atomizeris avoided.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

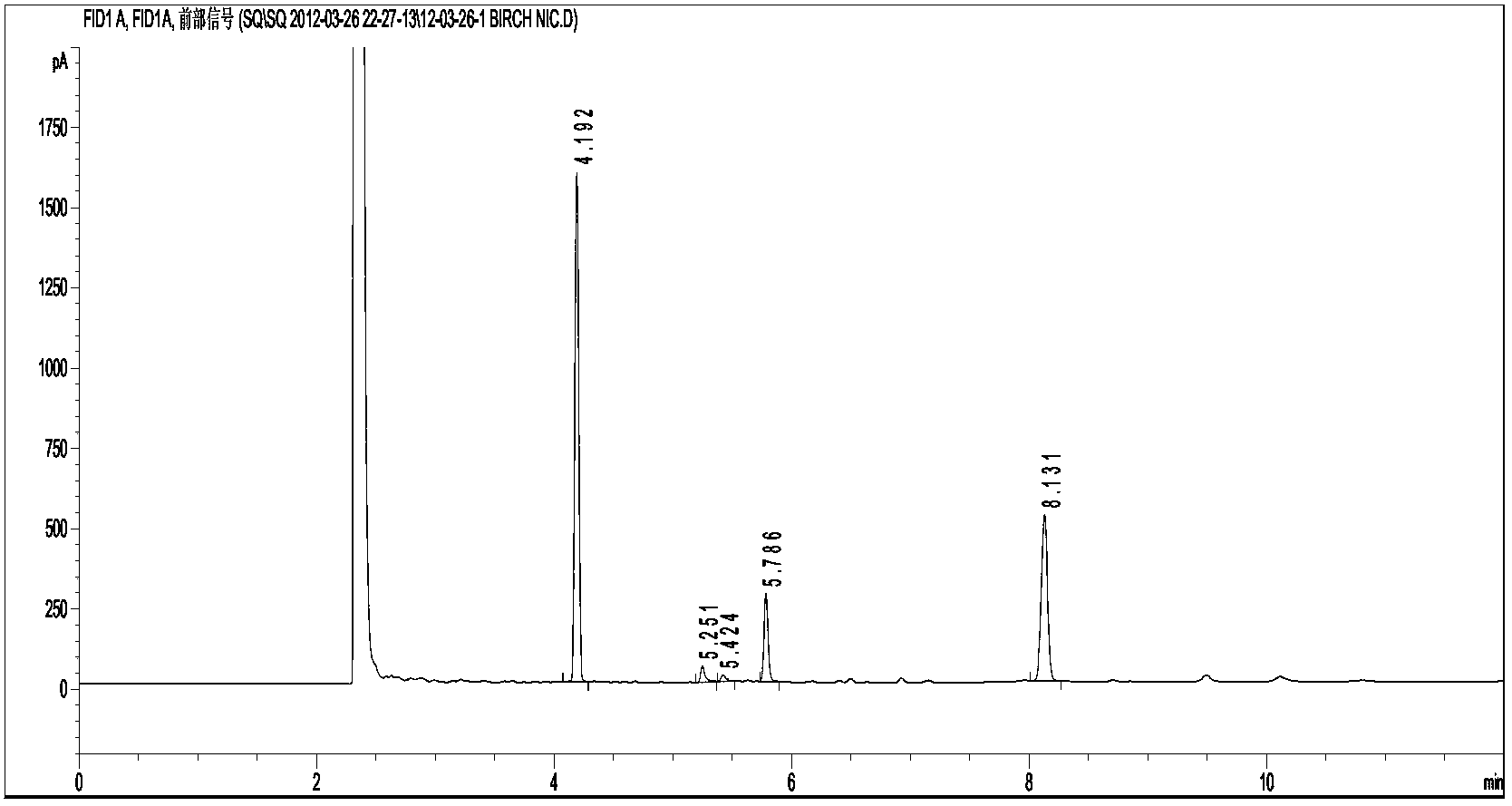

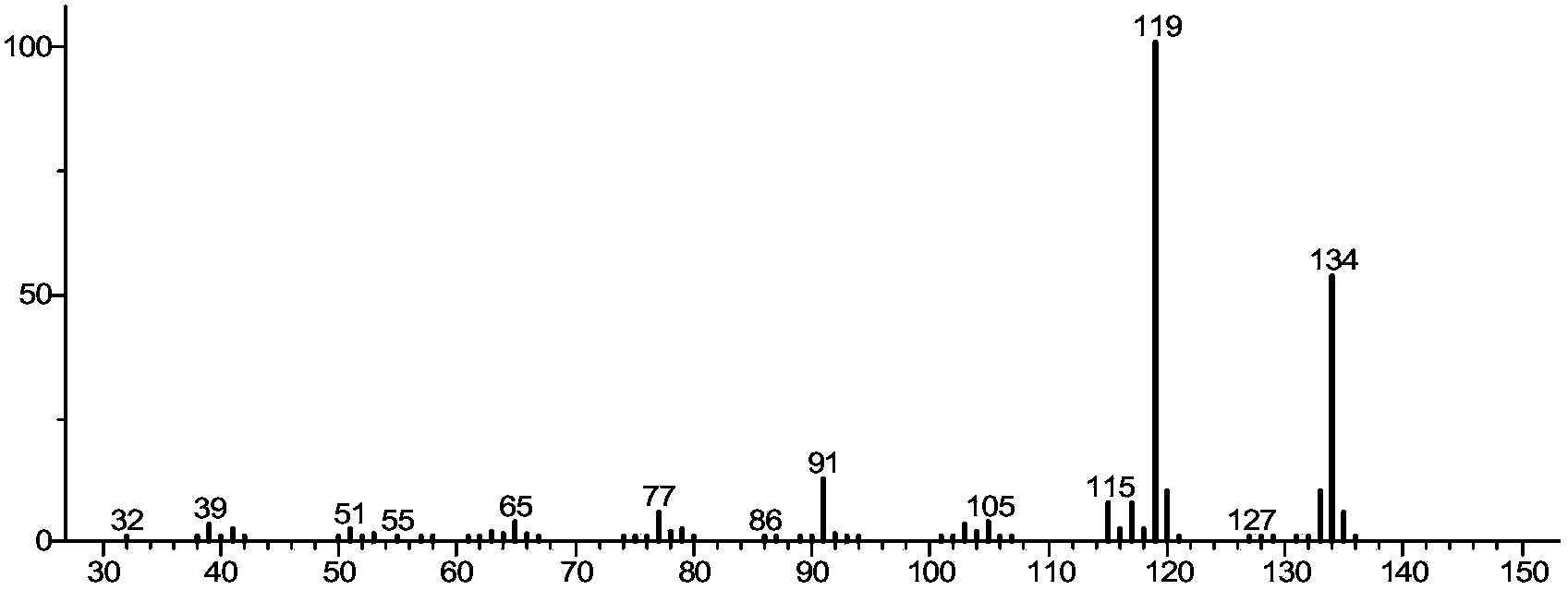

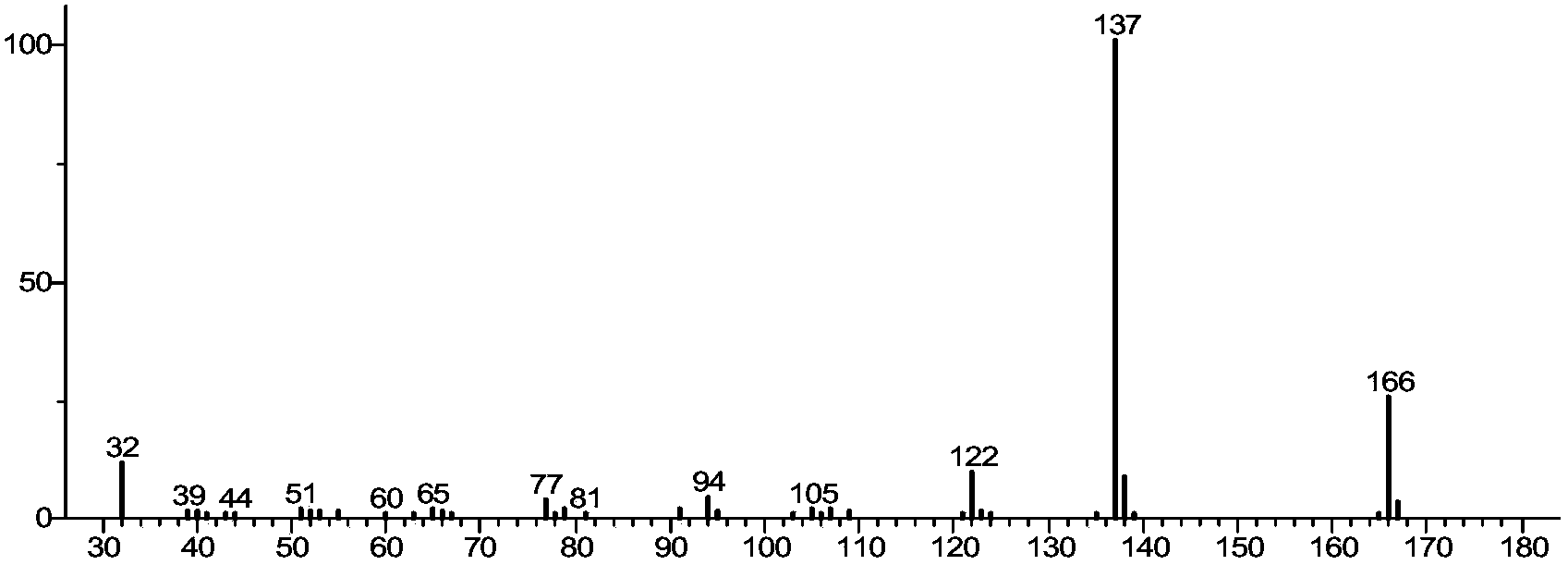

Method for depolymerizing lignin into aromatic compounds under conditions of no additional hydrogen

The invention relates to a method for depolymerizing lignin into aromatic compounds under the conditions of no additional hydrogen. According to the method, biomass-base alcohol compound reformation hydrogen production reaction and lignin hydrodepolymerization reaction are combined; and in the reaction process, the biomass-base alcohol compounds are subjected to in-situ reformation hydrogen production, and meanwhile, the hydrogen is used for hydroepolymerizing lignin. The lignin is selectively cracked into C6-C9 aromatic compounds of phenolic group, guaiacol group, lilac group or other derivatives under the action of the catalyst. The conversion rate of the raw materials is up to higher than 50%, and the content of the guaiacol-group and lilac-group aromatic compounds in the cracked product can reach higher than 90%. The method uses the hydrogen prepared by biomass-base alcohol in-situ reformation as the hydrogen source, and avoids using high-pressure hydrogen in the preparation route; and thus, the method has the characteristics of high safety coefficient in the reaction process, high yield of the aromatic compounds, and mild reaction conditions.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

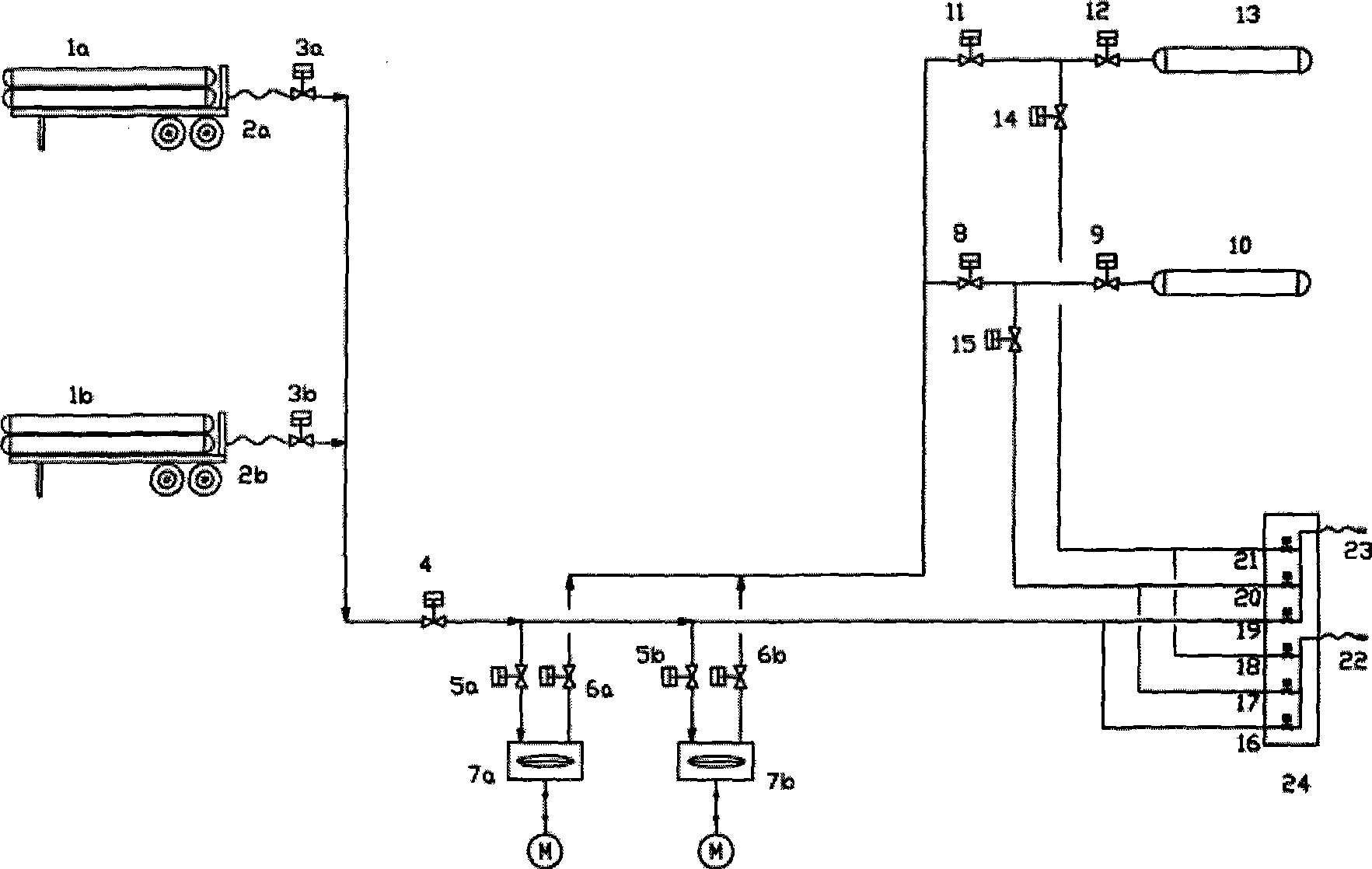

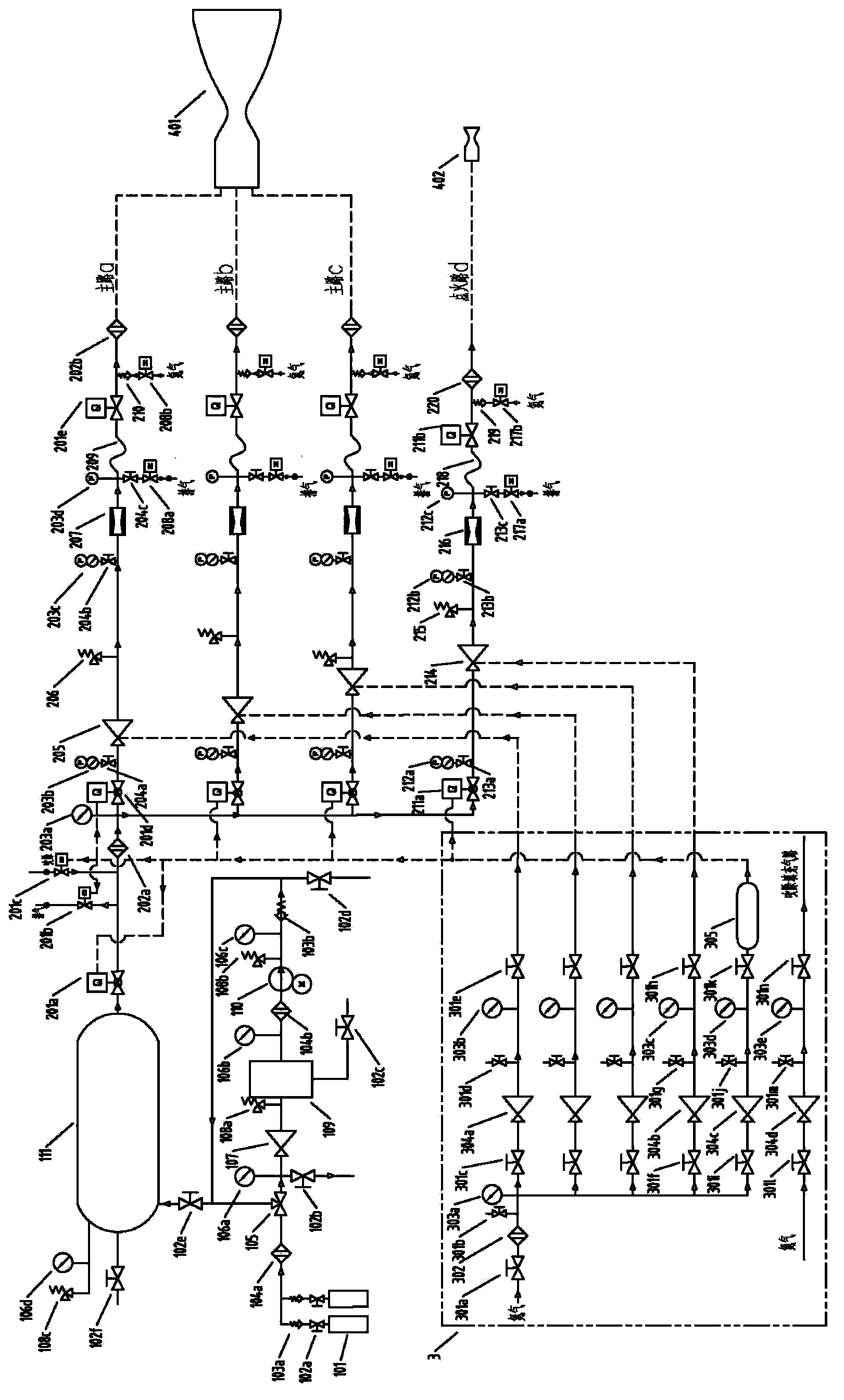

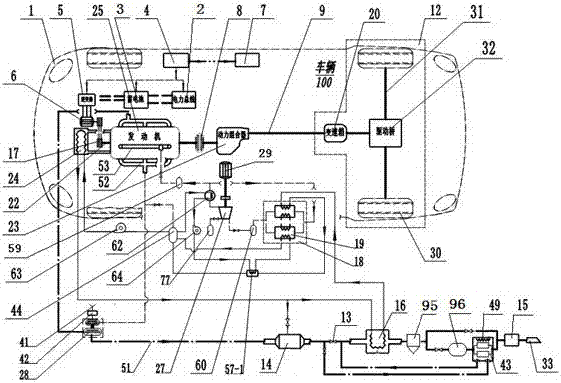

Fuel supplying system for liquid-propellant rocket engine test

ActiveCN103411775AMeet the needs of using other mediaTake advantage ofEngine testingGas cylinderHigh pressure hydrogen

The invention discloses a fuel supplying system for a liquid-propellant rocket engine test. The fuel supplying system for the liquid-propellant rocket engine test comprises a hydrogen source system, a hydrogen conveying pipeline system and a gas distribution platform system. The hydrogen source system comprises a large high-pressure gas storage tank, a high-pressure gas cylinder, a filter, a manual adjusting and pressure reducing device, a hydrogen pump and a pipeline. The hydrogen conveying system comprises three main paths and an ignition path d, wherein the three main paths are respectively the main path a, the main path b and the main path c. The gas distribution platform system comprises three main path branch paths, an ignition path branch path, a fifth branch path and a blowdown filling gas path. The three main path branch paths are respectively the main path branch path a, the main path branch path b and the main path branch path c. According to the fuel supplying system for the liquid-propellant rocket engine test, the principle that low-pressure hydrogen and high-pressure hydrogen are used in an isolated mode is utilized, the high-pressure hydrogen is directly filled into the high-pressure gas cylinder and the low-pressure hydrogen goes through a certain pressure reducing and boosting device to have high pressure and is continuously filled into the high-pressure gas cylinder. Leftover media in the hydrogen cylinder are fully utilized and the utilization rate is improved.

Owner:BEIHANG UNIV

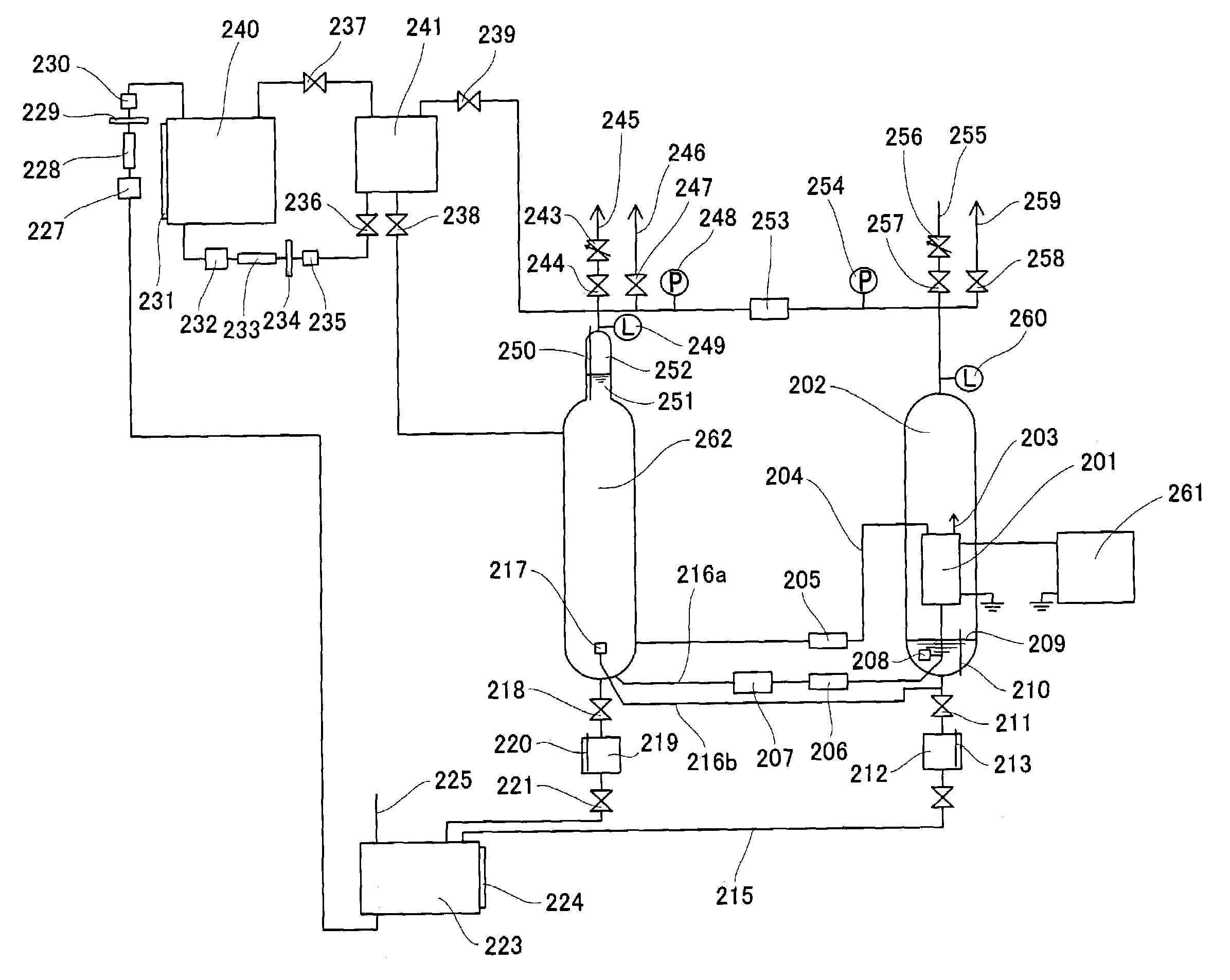

System and method for generating high pressure hydrogen

InactiveUS7048839B2Generate efficientlyStably and safely generatedCellsEnergy inputWater useElectrical battery

The invention provides a system and a method for generating high pressure hydrogen that is able to efficiently and safely generate hydrogen by only the electrolysis of water even when using electric power generated by a frequently varying natural energy, such as sunlight, without using any compressors. The system comprises an electrolysis cell using polyelectrolyte membranes, particularly a double-polarity multi-layered type electrolysis cell having a specified structure disposed in a vessel for storing generated hydrogen, preferably for storing cooled hydrogen under a high pressure hydrogen atmosphere. High pressure hydrogen is generated by electrolysis of pure water using the electrolysis cell by suppressing the pressure applied to the cell to a pressure below the pressure resistance of the cell using a differential pressure sensor and pressure controller.

Owner:HARADA HIROYUKI

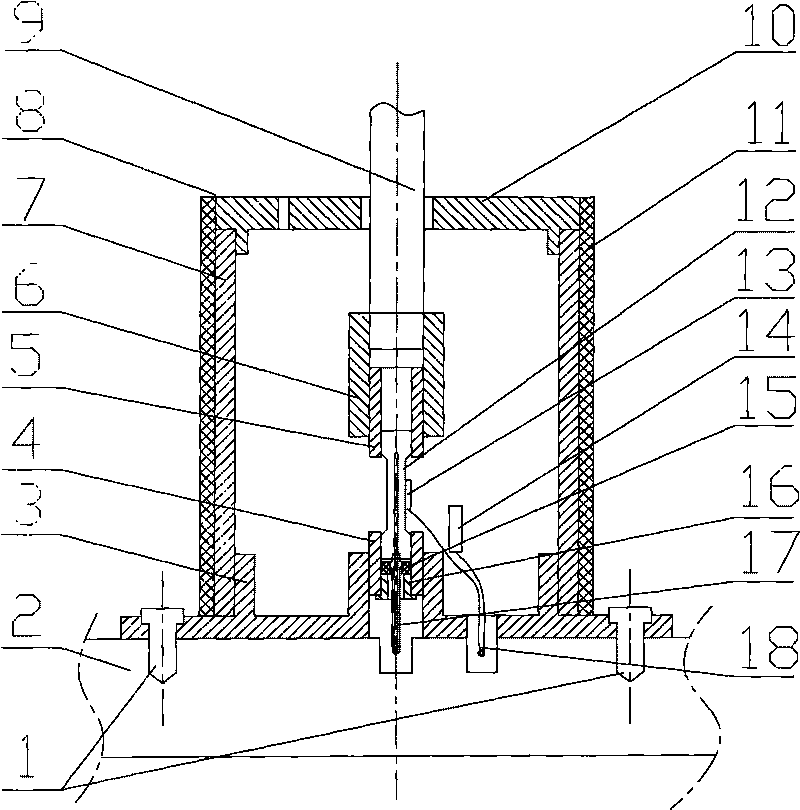

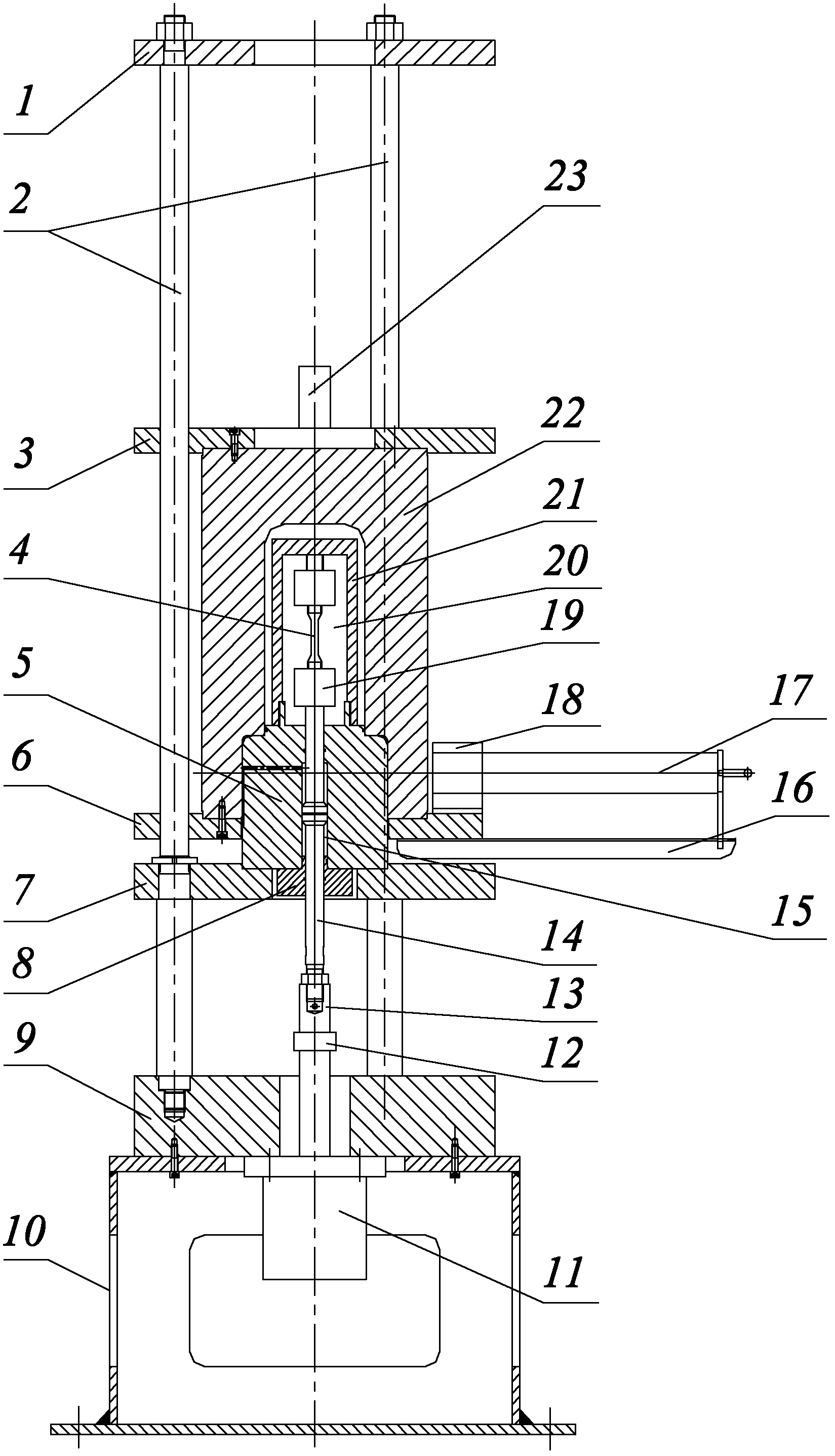

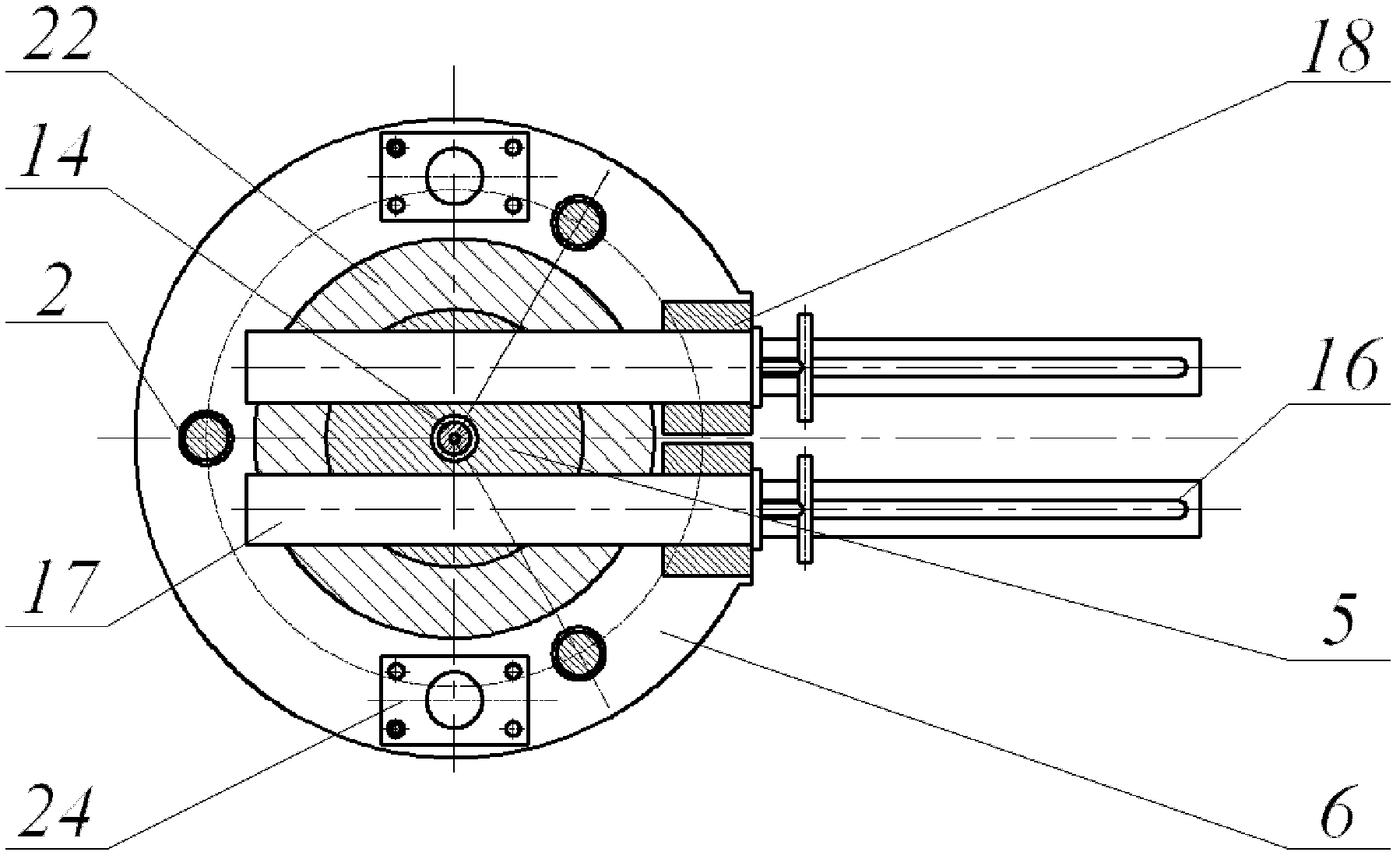

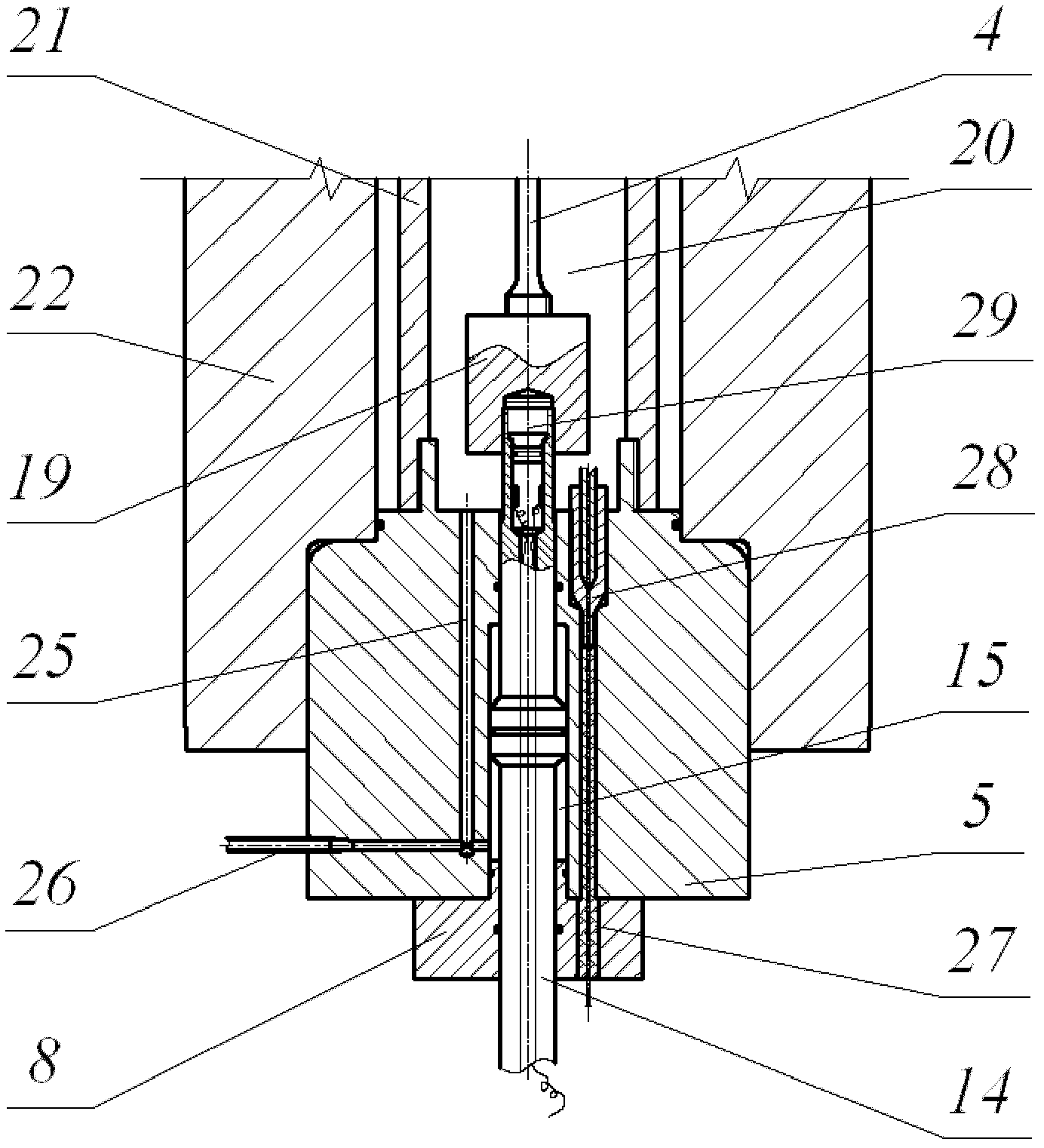

Device for measuring hydrogen embritllement sensitivity of materials in low-temperature environment

InactiveCN101706395AFix security issuesReduce experiment costsMaterial strength using tensile/compressive forcesMeasurement deviceHigh pressure hydrogen

The invention discloses a device for measuring hydrogen embritllement sensitivity of materials in a low-temperature environment, consisting of an experiment table base 2, an experiment box 8, a stress application shaft 9, a sample clamping part, a hydrogen charging interconnecting piece and a temperature measuring and adjusting device 18, wherein the sample clamping part consists of a loading clamp A5, a loading clamp B6 and a fixed clamp 4 and is arranged in the experiment box 8; the stress application shaft 9 passes through the center of the experiment box 8 from the upper part, the lower part of the stress application shaft 9 is coaxially connected with the upper part of a sample 12 through the ample clamping part, the hydrogen charging interconnecting piece passes through the center of the experiment box through the lower part, and the upper part of the hydrogen charging interconnecting piece is coaxially connected with the lower part of the sample 12 through threads; and the temperature measuring and adjusting device 18 is arranged in the experiment box 8. The device is used for measuring the change of mechanical property of the materials in a high-pressure hydrogen charging environment; no high pressure cavity is used and only a low temperature environment is provided in the cavity, so the experiment process is extremely safe and the problem of potential safe hazard caused by the high pressure cavity used in the traditional hydrogen charging experiment can be solved.

Owner:NANJING UNIV OF TECH

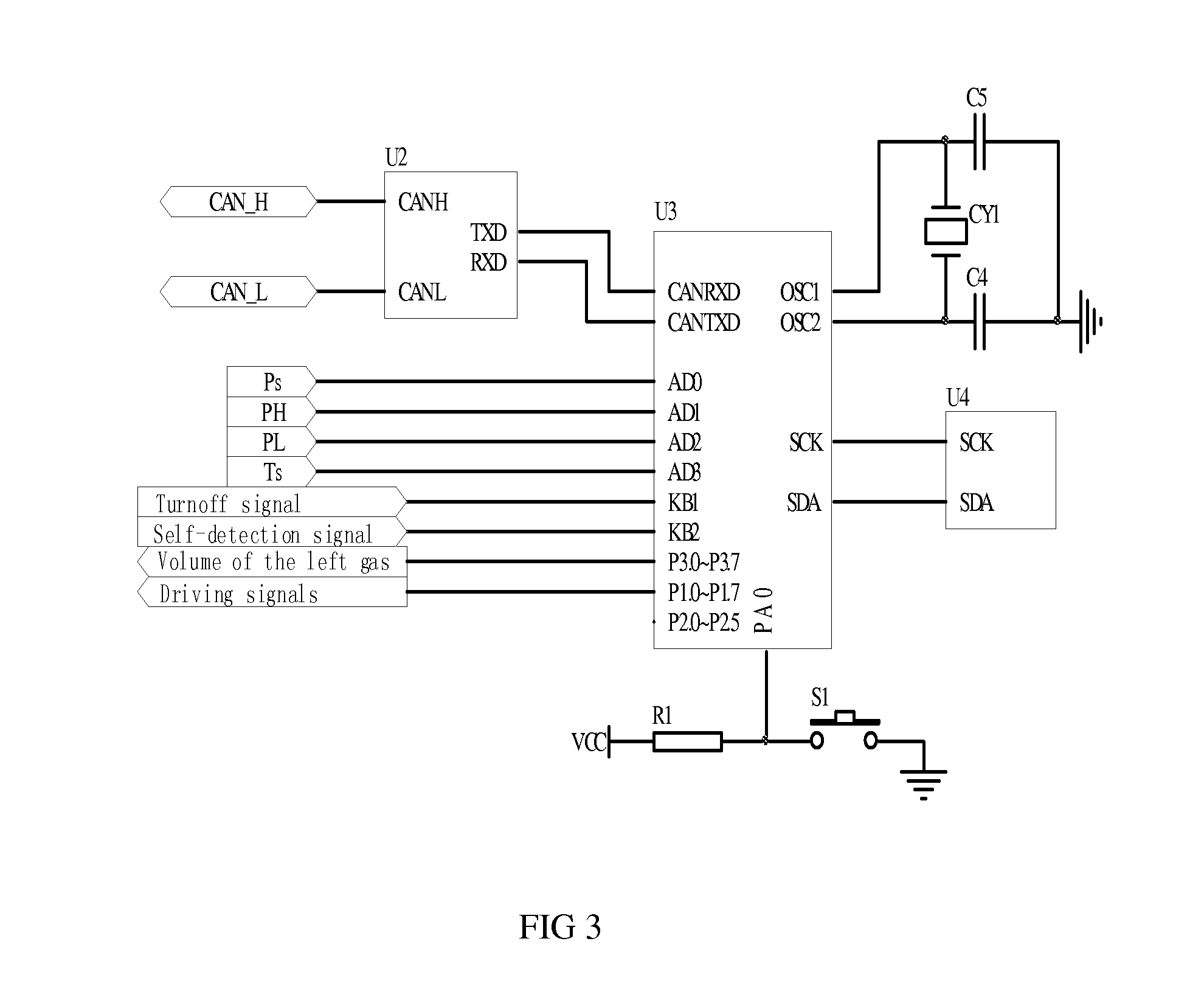

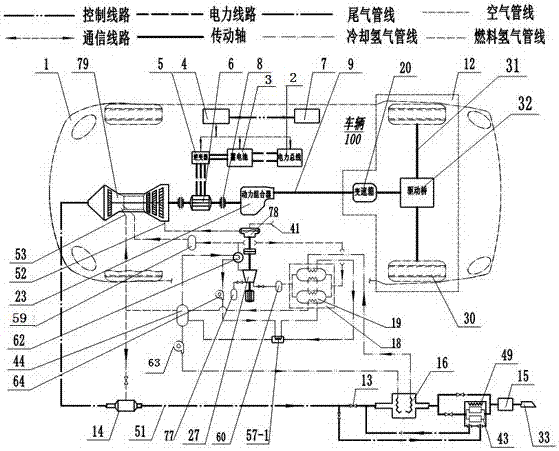

Hydrogen management system of vehicle-mounted fuel cell

PendingCN106876749AAchieve hydrogenation controlRealize hydrogen supply controlFuel cell auxillariesGas cylinderHydrogen storage system

The invention relates to a hydrogen management system of a vehicle-mounted fuel cell. The hydrogen management system comprises a hydrogen control unit (15), and a hydrogen bottle electromagnetic valve (4), a hydrogen bottle pressure sensor (2), a temperature sensor (5) and a hydrogen concentration sensor (16) which are connected with the hydrogen control unit (15) separately; the hydrogen bottle electromagnetic valve (4), the hydrogen bottle pressure sensor (2) and the temperature sensor (5) are connected with a vehicle-mounted high-pressure hydrogen bottle (1) separately; a probe of the hydrogen concentration sensor (16) is arranged in the environment above the high-pressure hydrogen bottle (1); and the hydrogen control unit (15) is in communication connection with a vehicle-mounted fuel cell controller through CAN. Compared with the prior art, the functions of hydrogen adding control, hydrogen supplying control, safety detection and the like of a vehicle-mounted hydrogen storage system can be realized, cable connection between systems is reduced, and signal missing in a signal transmission process and risk of high probability of interference are lowered.

Owner:TONGJI UNIV

Efficient hydrogen energy vehicle power system for purifying ambient air

ActiveCN106915235AReduce consumptionIncrease motivationHybrid vehiclesInternal combustion piston enginesPower combinerEngineering

The invention relates to an efficient hydrogen energy vehicle power system with an ambient air purifying function. The efficient hydrogen energy vehicle power system comprises a drive system, a gas turbine, a high pressure hydrogen storage tank, a hydrogen compression unit, a hydrogen gas surge tank, an inverter, an electric-power generator, an expander, a storage battery and an exhaust gas treating and discharging system. The high pressure hydrogen storage tank is connected to an inlet of the expander, one path of an outlet of the expander is connected to a hydrogen inlet through a cold capacity recovery device and the hydrogen gas surge tank, and the other path is connected to the inlet of the expander through a hydrogen compression unit and an intermediate tank. A power combiner is connected with the gas turbine and / or the electric-power generator, according to the technical scheme, the gas turbine is replaced with a hydrogen fuel engine, and the power combiner is connected with the drive system through a drive shaft. According to the efficient hydrogen energy vehicle power system with the ambient air purifying function, the gas turbine is combined with the electric-power generator, so that work efficiency of the hydrogen energy vehicle power system is improved. By recycling of exhaust gas heat, air pollution is reduced, and the natural environment can be protected easily.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

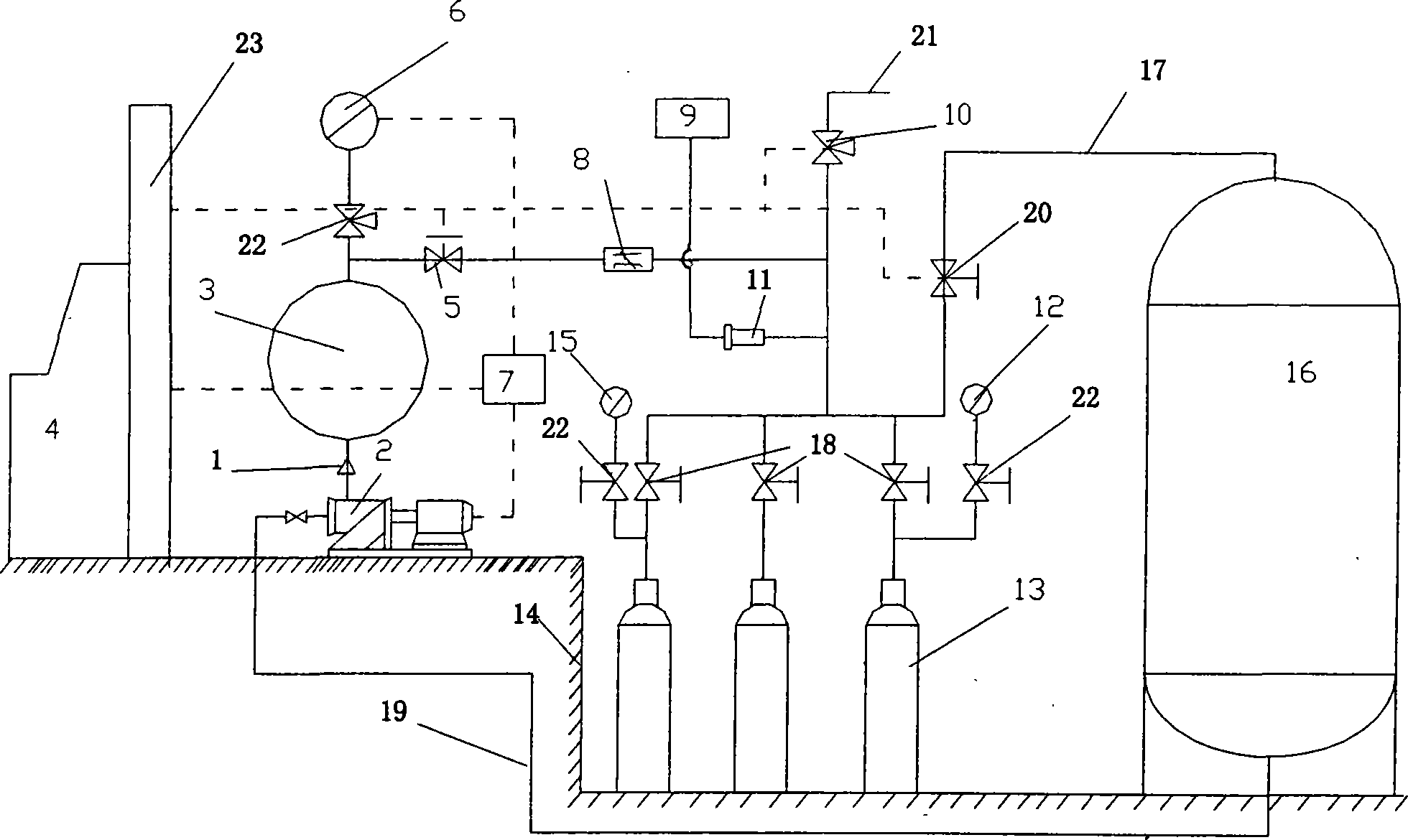

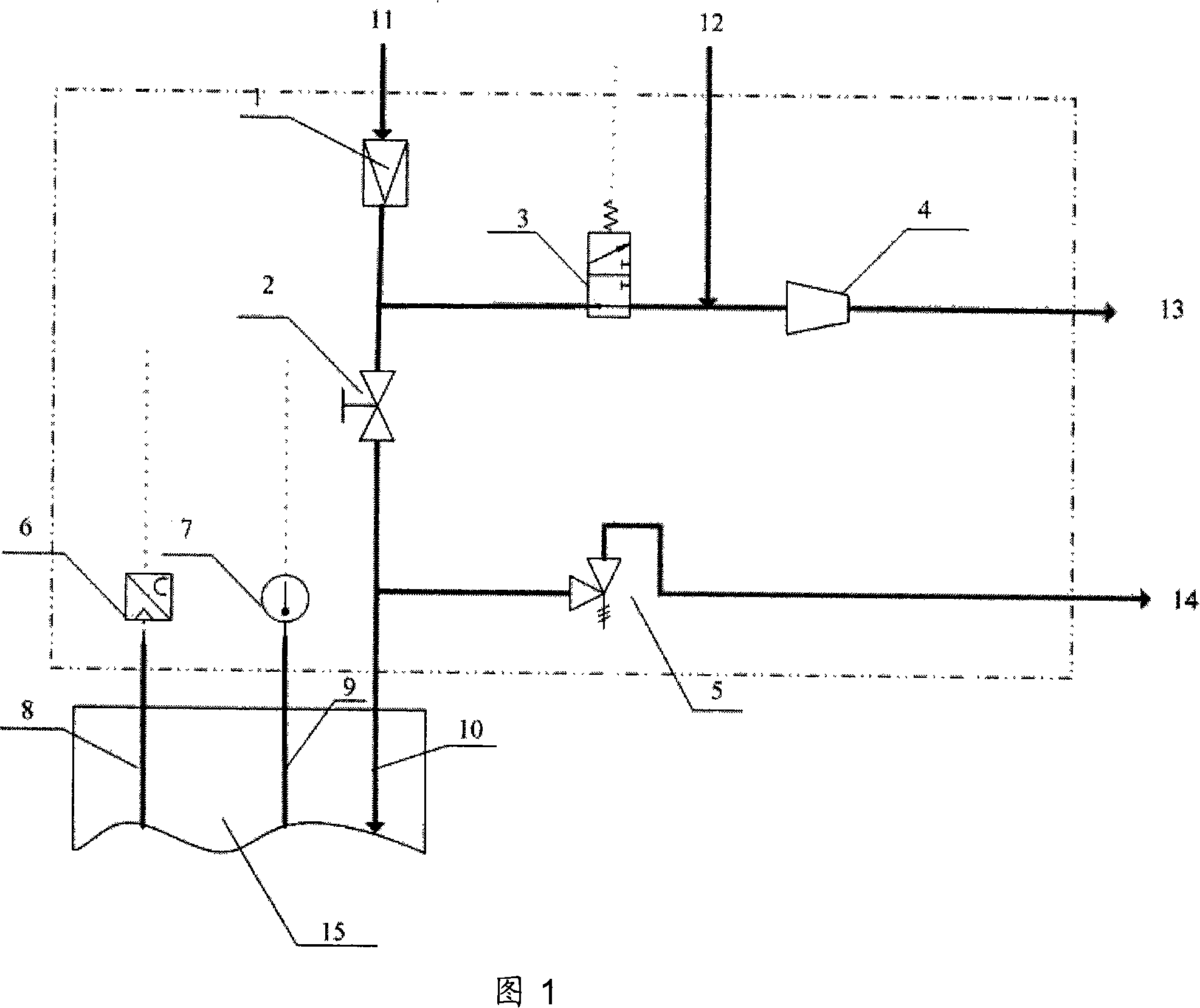

Hydrogen storing container hydrogen environment fatigue test system

InactiveCN101236138ANo pollution in the processReduce mistakesMaterial strength using tensile/compressive forcesStructural/machines measurementElectricityPilot system

The invention discloses a hydrogen container hydrogen environment fatigue test system. One end of a high pressure hydrogen container is respectively communicated with a test container and a low pressure hydrogen container through an explosion protection pressure reducing valve, a flow regulating control valve, a first normal open stop valve and a test container depressurizing valve; the low pressure hydrogen container is communicated with the other end of the high pressure hydrogen container through a booster pump; a pressure sensor and a cycle recording device are arranged between the first normal open stop valve and an atmospheric valve; the normal open stop valve, a pressure display and a standard pressure gauge are arranged between the test container and the normal open stop valve; one path of an automatic control system operation console is respectively electrically connected with the booster pump and the pressure gauge through an excessive pressure controller; the other path of the automatic control system operation console is electrically connected with the atmospheric valve and the test container depressurizing valve. The high pressure hydrogen in the high pressure container is charged into the test container through the explosion protection pressure reducing valve and the flow regulating control valve, the explosion protection pressure reducing valve is closed when a set pressure is reached, the test container depressurizing valve is opened after maintaining the pressure for a while, and the hydrogen is depressurized into the low pressure container to complete a fatigue test cycle.

Owner:ZHEJIANG UNIV

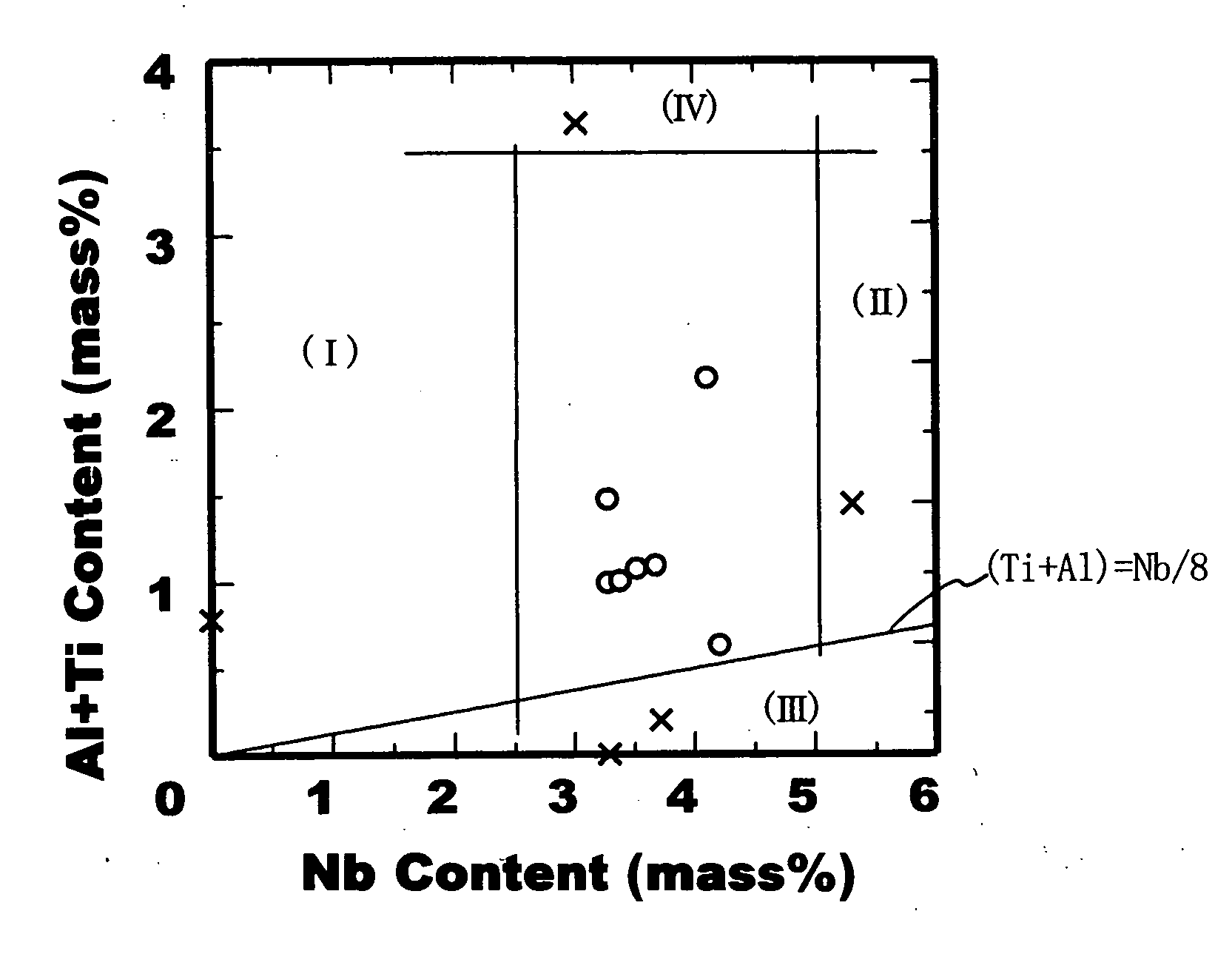

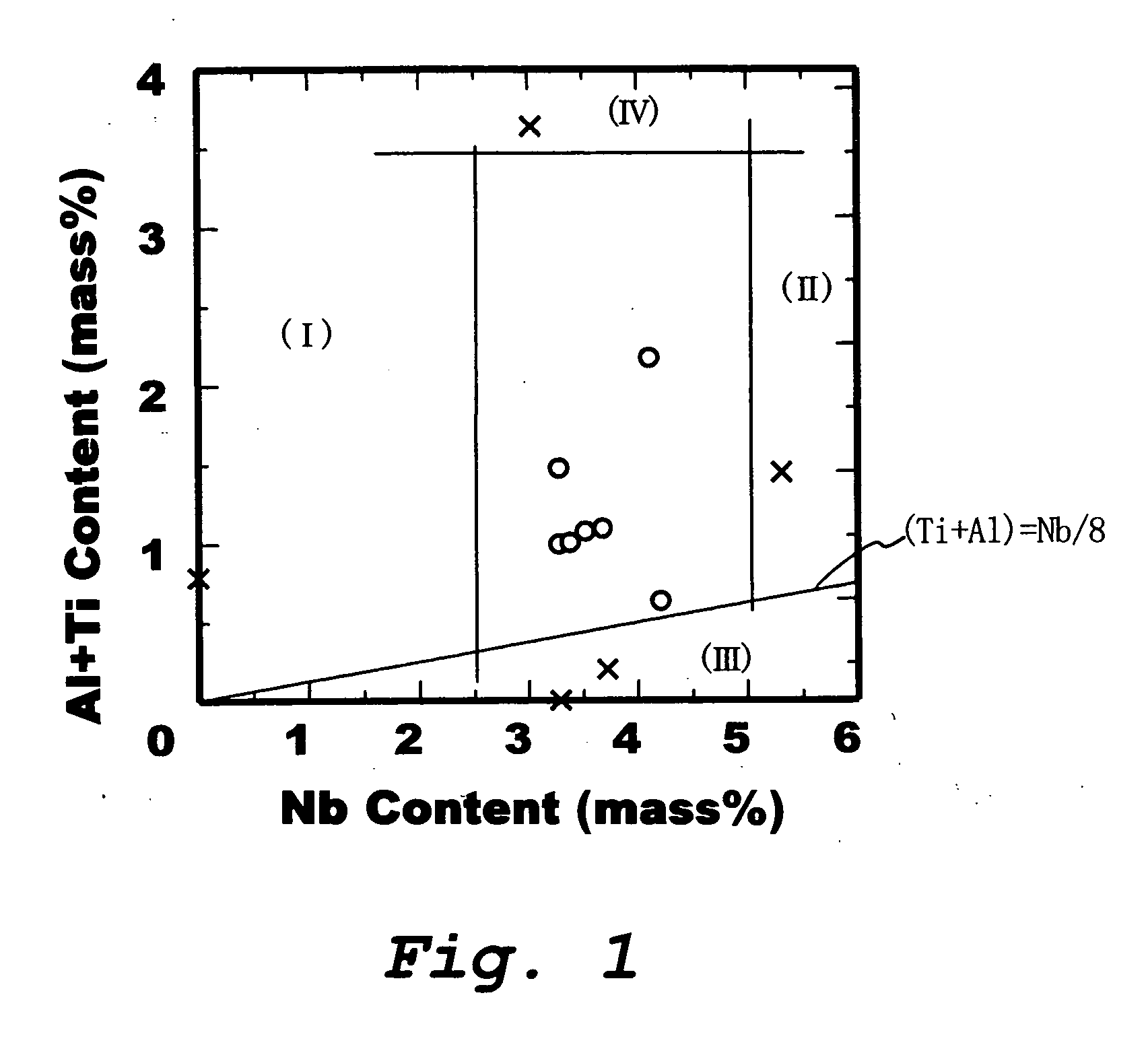

Welded joint made of an austenitic steel

InactiveUS20060191606A1High strengthIncrease resistanceArc welding apparatusMachines/enginesChemical compositionHigh pressure hydrogen

A weld joint having a base material and a weld metal both of an austenitic steel, wherein the weld metal has a chemical composition, in mass %, that C: 0.04% or less, Si: 1.0% or less, Mn: 3% or less, P: 0.02% or less, S: 0.005% or less, Cr: 15 to 25%, Ni: 30% or more, Mo: 10% or less, Nb: 2.5 to 5%, Al: 3.0% or less, Ti: 0.5% or less, and the balance: Fe and inevitable impurities, the contents of Al and Ti satisfying the following: (Ti+Al)>Nb / 8. The weld joint is a high strength austenitic steel weld joint which exhibits excellent toughness at a low temperature and excellent resistance to hydrogen embrittlement, which are required for a piping and a vessel for high pressure hydrogen, particularly also in a welded zone.

Owner:NIPPON STEEL CORP

Hydrogenation substation

InactiveCN101387370AReduce construction costsShort cycleContainer filling under pressureNoise removalControl system

The invention relates to a sub-station of a hydrogenation station, which can provide services of charging and unloading hydrogen fuels for a fuel battery automobile. The sub-station of the hydrogenation station comprises a traction headstock, a semi-trailer, and an integral skidded part detachably fixed on the semi-trailer, wherein the skidded part is formed by connecting a hydrogen loading system, a high pressure hydrogen-storing system, a hydrogen pressurizing system, a hydrogen unloading system, a high pressure hydrogen charging system, a control system and an auxiliary system. By a compressor for fixing the hydrogenation station, high pressure hydrogen loading capacity of the sub-station is greatly improved, and the compressor is saved so that the sub-station has the advantages of low cost, noise removal, reduced size, simplified operation and maintenance and intensified maneuverability. The self-prepared pressurizing system of the sub-station can greatly improve yield of the hydrogen, and the unloading system can securely unload the vehicle high pressure hydrogen to the sub-station when the fuel battery automobile has a fault. The sub-station of the hydrogenation station can be independently used as an apparatus for charging the hydrogen fuels of the fuel battery automobile, and is more suitable to combine the fixed hydrogenation station to form a high pressure hydrogen charging network with flexible maneuver.

Owner:TONGJI UNIV

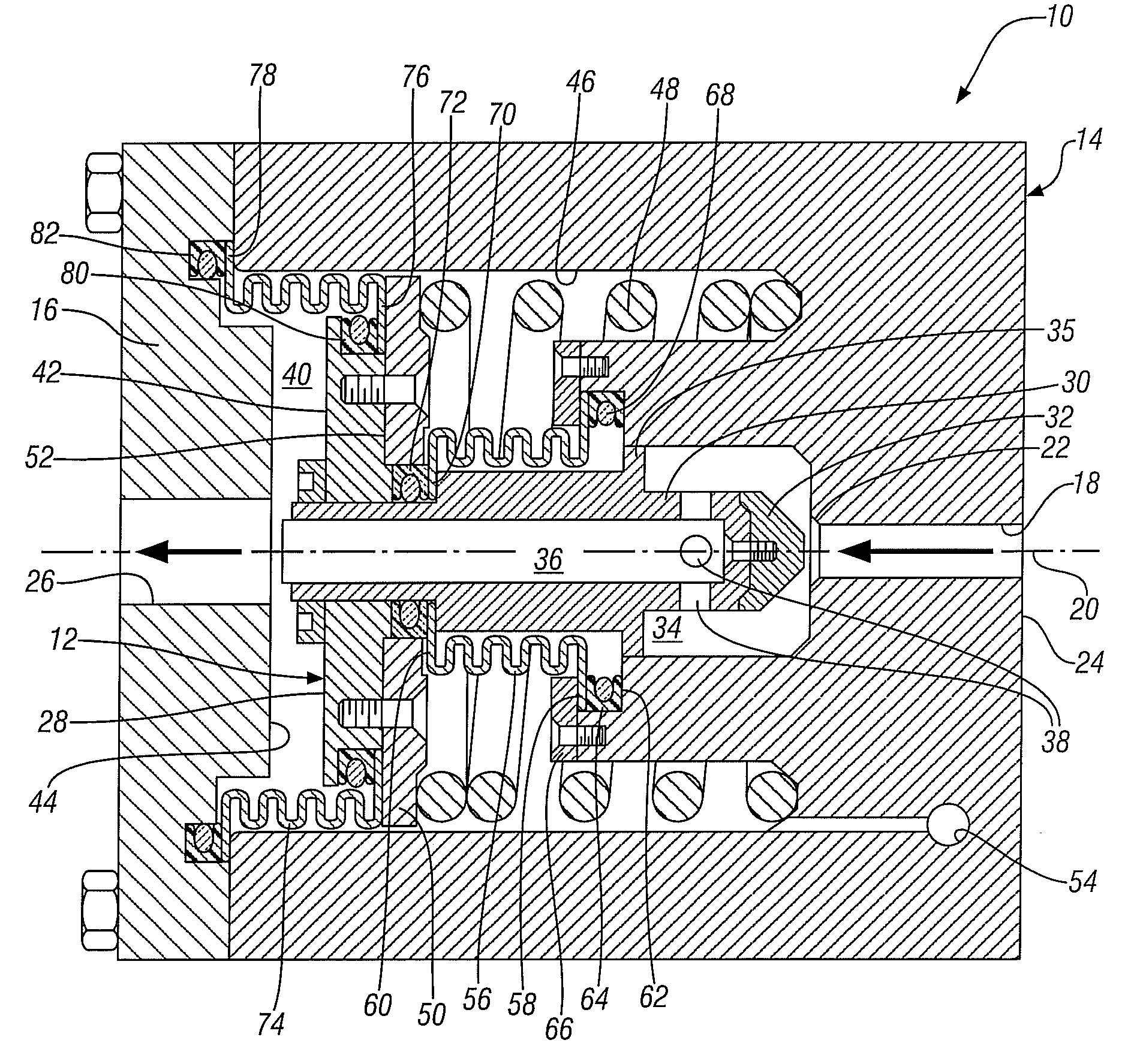

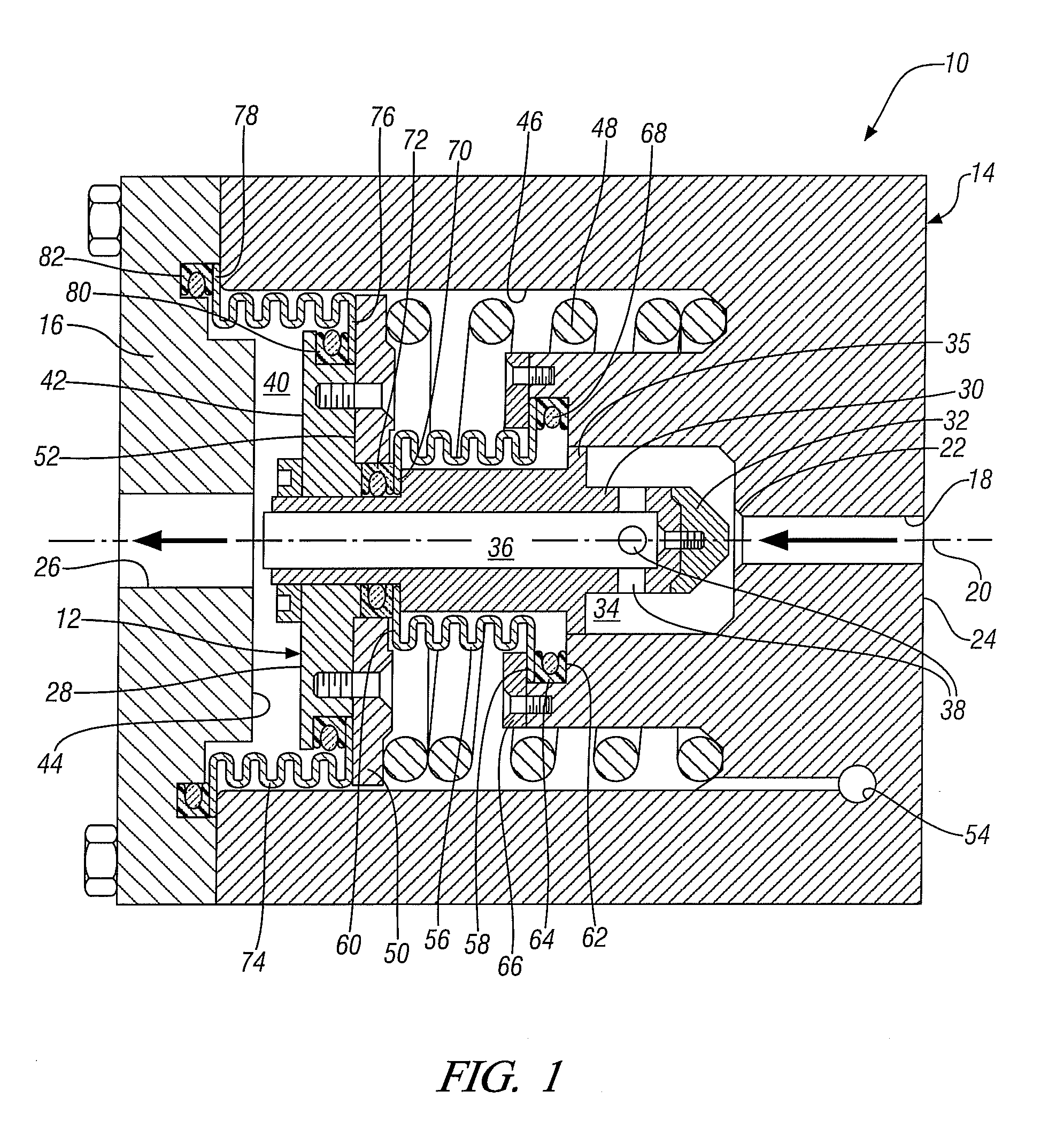

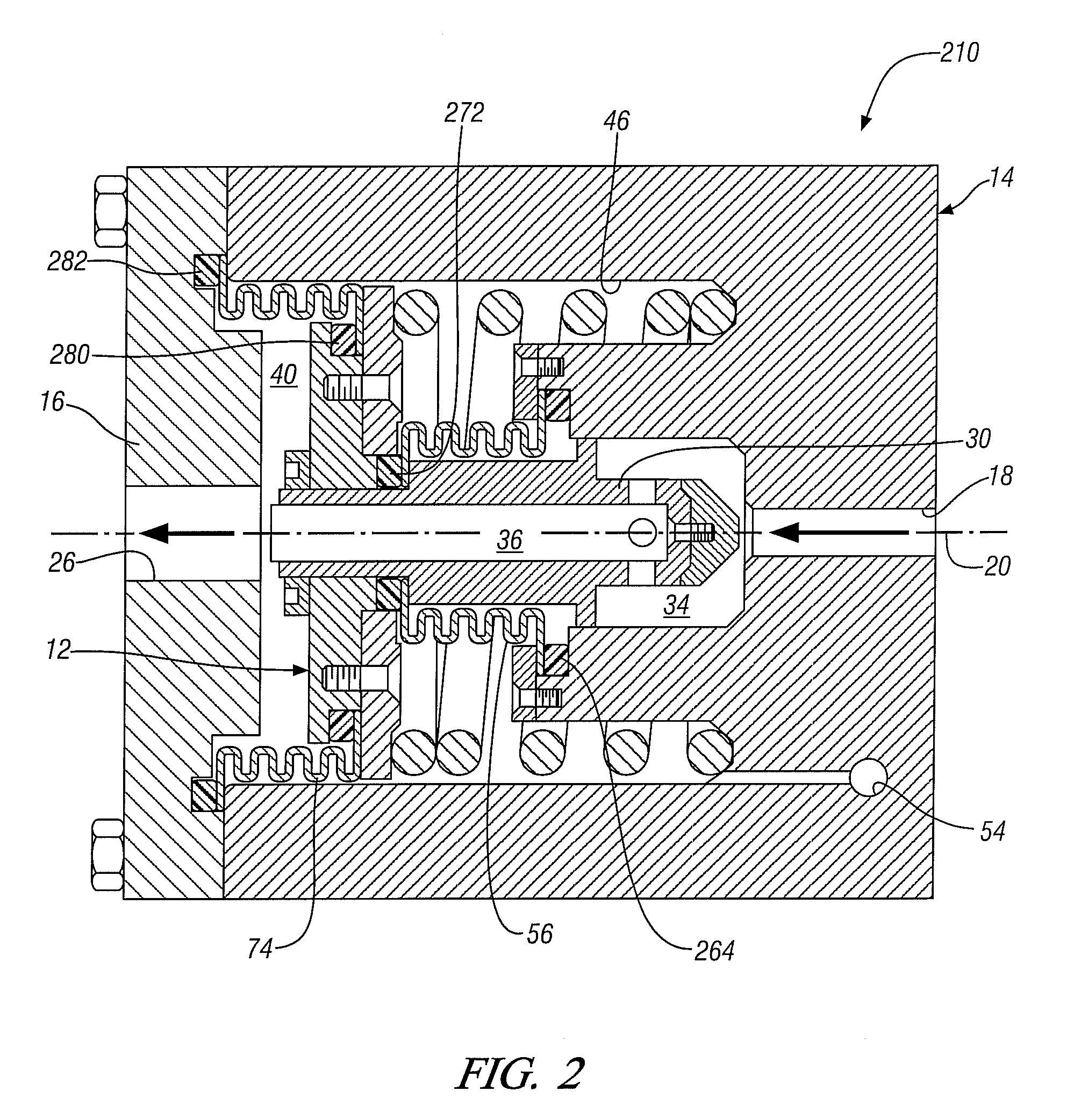

Hydrogen supply pressure regulator

InactiveUS20090242043A1Prevent leakageReduce frictionOperating means/releasing devices for valvesReactant parameters controlHydrogen pressureHigh pressure hydrogen

Hydrogen gas flow from high pressure storage to a lower pressure hydrogen-using device is managed using one or more axial flow pressure regulators comprising a cup-shaped housing with an inlet for high pressure hydrogen gas at one end of the flow axis and a closure with a low pressure hydrogen outlet at the other end of the flow axis. A piston head with a piston stem are aligned on the flow axis and a hydrogen flow passage is formed up the stem and through the piston head to the hydrogen flow outlet. One or more combinations of a corrugated tubular bellows (or like expansive sealing vessel) with static seals attaching one bellows end to the piston stem or head and the other bellows end to the housing or closure are used to accommodate axial movement of the piston while isolating and containing hydrogen gas flow from a high pressure chamber at a flow entrance to the piston stem to a low hydrogen pressure chamber at the piston head and closure outlet.

Owner:GM GLOBAL TECH OPERATIONS LLC

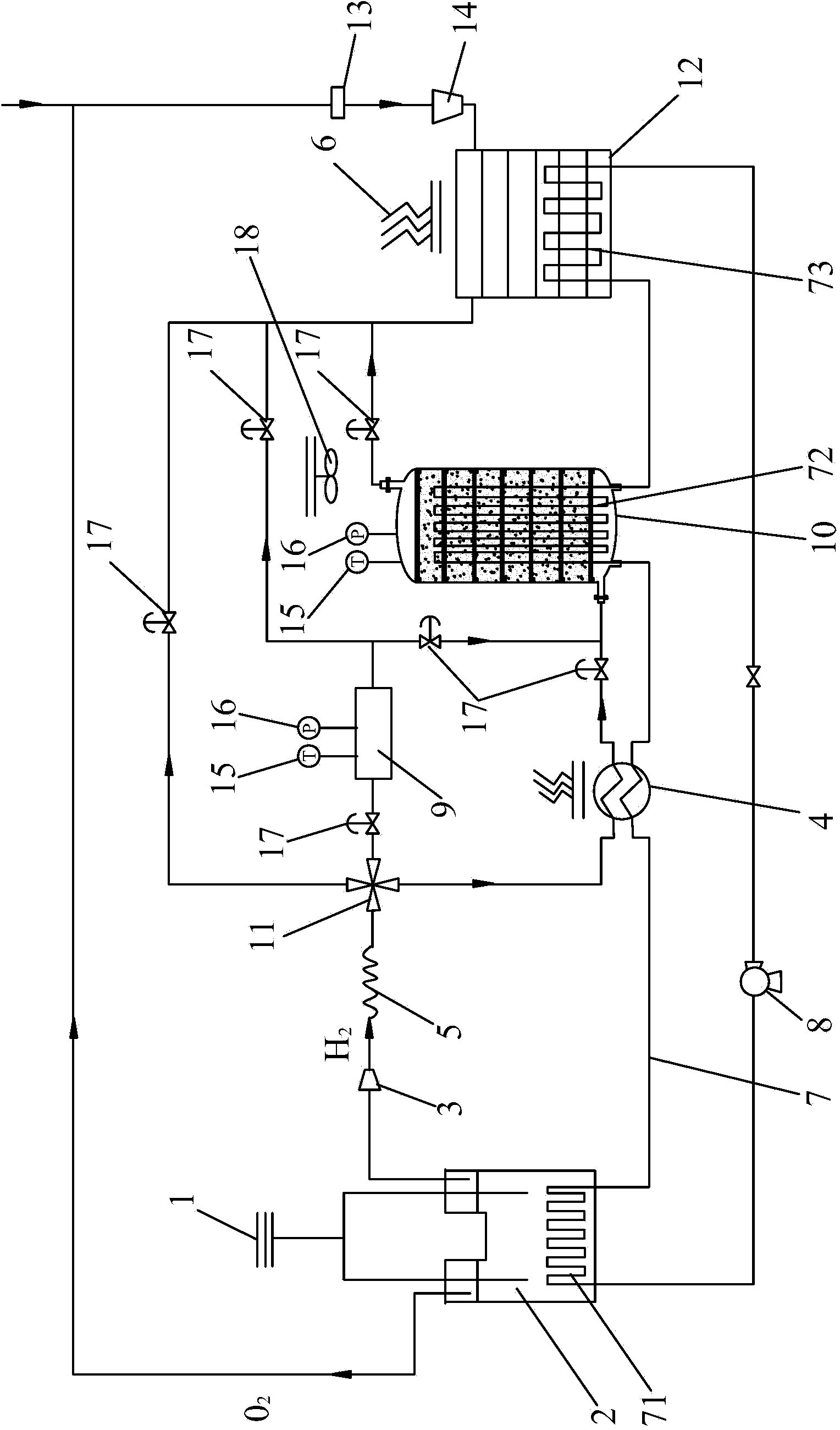

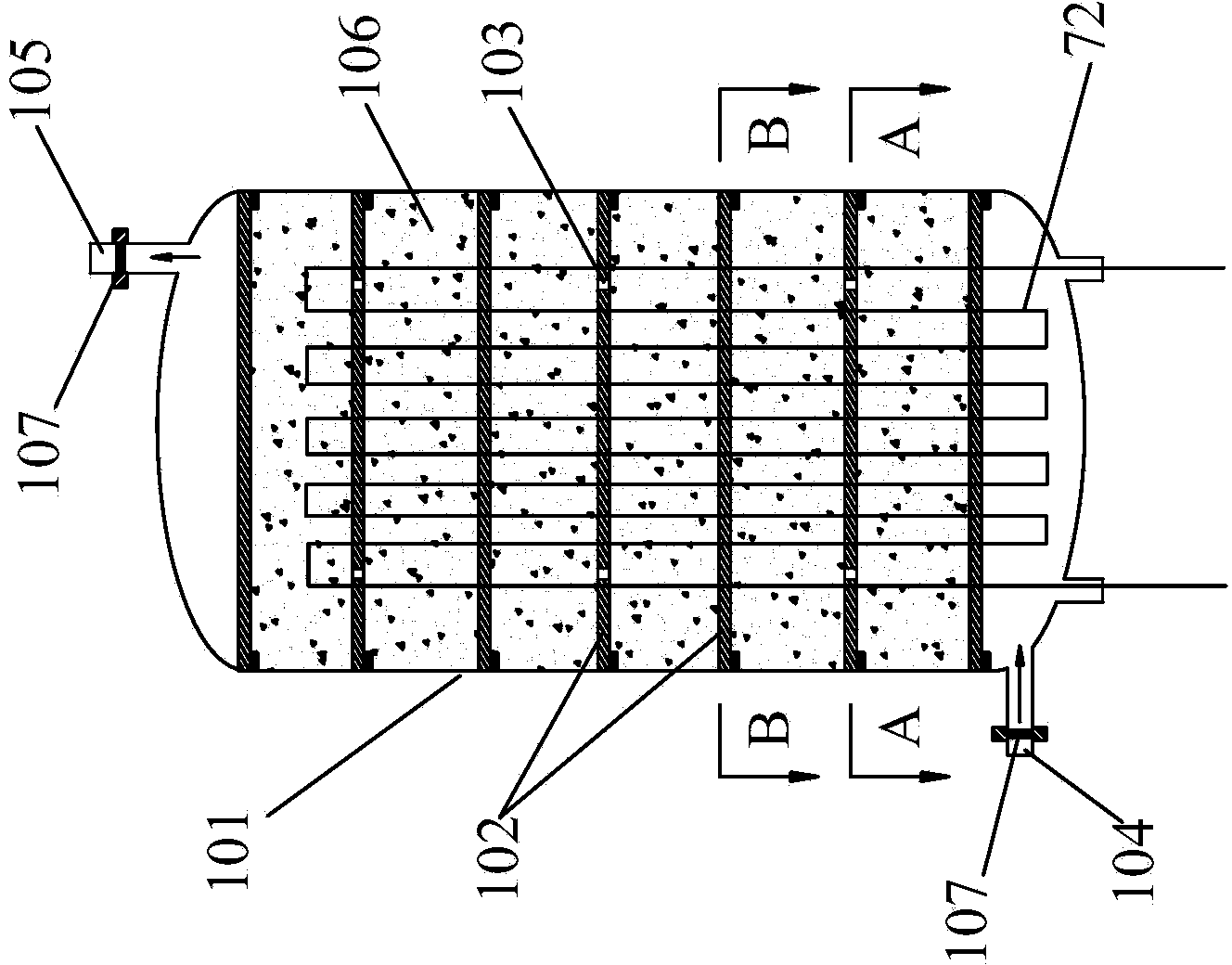

Integrated type hydrogen energy preparation, storage and cyclic utilization equipment

ActiveCN104037434AImprove the efficiency of hydrogen productionTransfer in timeReactant parameters controlFuel cell usageElectrolysisDesorption

The invention discloses integrated type hydrogen energy preparation, storage and cyclic utilization equipment. The integrated type hydrogen energy preparation, storage and cyclic utilization equipment mainly comprises a solar power generation light source, a water electrolysis hydrogen production device, a high-pressure hydrogen storage buffering tank, a metal hydride hydrogen storage tank and a hydrogen fuel cell device, which are connected by a multi-channel control valve and related pipelines, and a thermal medium circulating pipe system is arranged; the thermal medium circulating pipe system is provided with a first heat exchanger, a second heat exchanger and a third head exchanger, which are serially connected with one another to form a circulating loop, the first heat exchanger is arranged inside the solar power generation light source, the second heat exchanger is a arranged inside the metal hydride hydrogen storage tank, the third head exchanger is arranged inside the hydrogen fuel cell device, and a medium circulating pump and a medium electric heater are arranged on the circulating loop of the thermal medium circulating pipe system respectively. The integrated type hydrogen energy preparation, storage and cyclic utilization equipment is simple in structure, low in cost, good in hydrogen storage and desorption effect, high in hydrogen energy cyclic utilization rate and stable and safe to operate, and is particularly suitable for hydrogen fuel energy-saving automobiles and portable mobile equipment using hydrogen fuel power supply.

Owner:ZHONGYING CHANGJIANG INTERNATIONAL NEW ENERGY INVESTMENT CO LTD

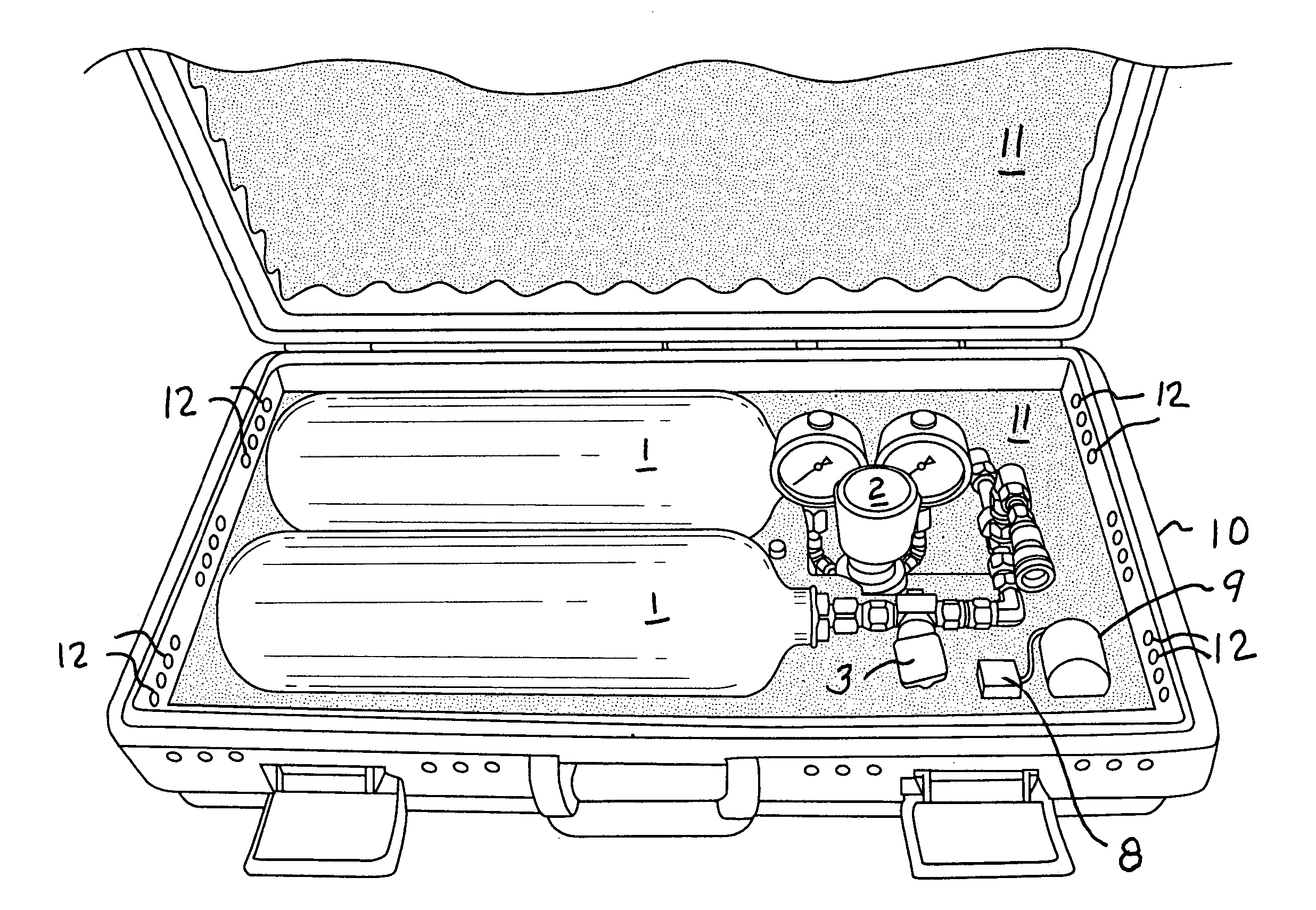

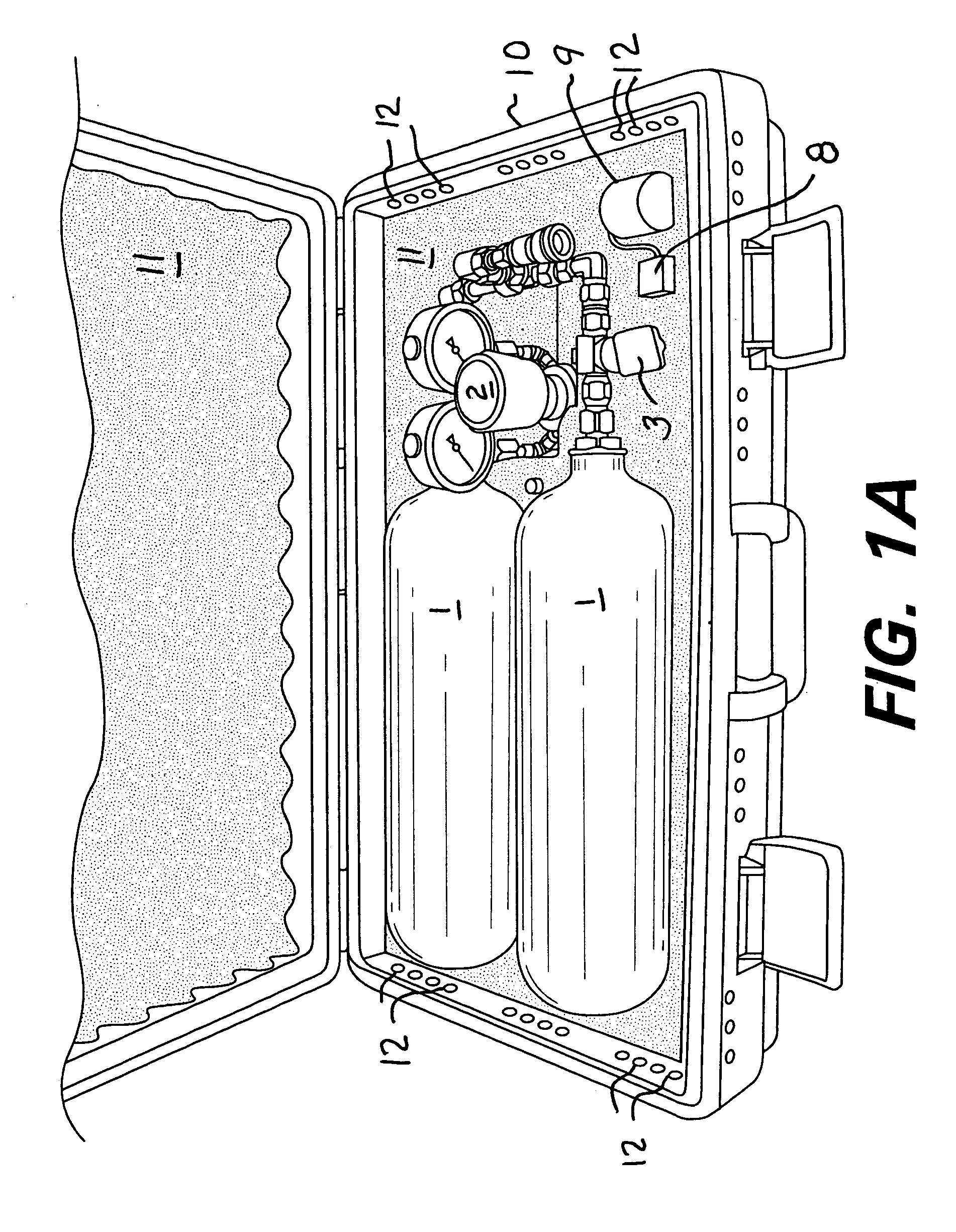

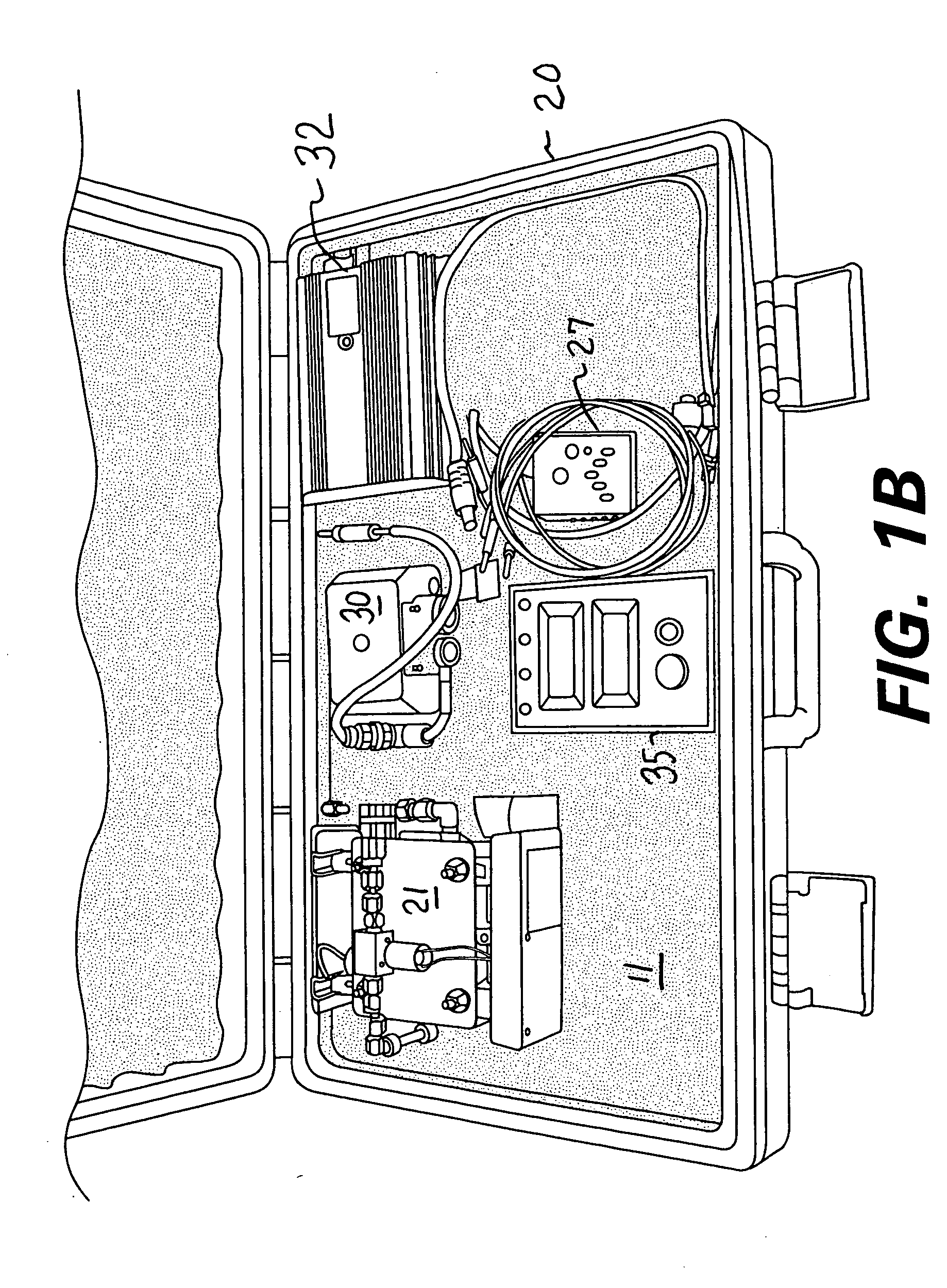

Portable fuel cell power supply

InactiveUS20050202292A1Reactant parameters controlFuel cells groupingMetallic materialsHigh pressure

A portable proton exchange membrane fuel cell power supply system has a high pressure hydrogen gas supply that is provided from hydrogen storage cylinders that are enclosed in a case that has through holes for ventilation to prevent hydrogen gas concentrations from reaching explosive levels. Enclosed in a second case are a fuel cell stack, control unit, variable speed air compressor and power inverter. The cases incorporate lightweight, high-strength non-metallic materials and foam insulation to render the contents shock resistant. In operation a hydrogen gas connection line is made to extend between the hydrogen cylinders and the fuel cell that is connected through quick disconnect valves. The compressor is also connected to the fuel cell through a quick disconnect valve. Start up of the fuel cell is accomplished with a battery supplying power to the compressor while hydrogen gas is supplied at the same time.

Owner:RICHARDS WILLIAM R +2

Mixed filling system applied to hydrogen filling station of liquid hydrogen

PendingCN108561749AIncreased hydrogen storage capacityIncreased fill volume requirementsGas handling/storage effectsFluid transferredHigh pressure hydrogenLiquid hydrogen

The invention discloses a mixed filling system applied to a hydrogen filling station of liquid hydrogen. The mixed filling system comprises a liquid hydrogen filling unit and a high-pressure hydrogengas filling unit which are connected with a liquid hydrogen storage pot for the station, wherein a first liquid hydrogen conveying pipe in the liquid hydrogen filling unit can be communicated with theliquid hydrogen storage pot for the station through a liquid hydrogen pump; an output end of the first liquid hydrogen conveying pipe is used for connecting a liquid hydrogen filling gun; the high-pressure hydrogen gas filling unit comprises a second liquid hydrogen conveying pipe and a third liquid hydrogen conveying pipe which can be communicated with the liquid hydrogen storage pot for the station through the liquid hydrogen pump; the second liquid hydrogen conveying pipe is communicated with a spraying nozzle in a gas-liquid mixer; the third liquid hydrogen conveying pipe is communicatedwith a vaporizer; a gas output pipe on the vaporizer is communicated with a high-pressure hydrogen gas hydrogen storage bottle; a storage bottle output pipeline of an output end of the high-pressure hydrogen gas hydrogen storage bottle is communicated to the gas-liquid mixer; a hydrogen gas output pipe of the output end of the gas-liquid mixer is used for being connected with a high-pressure hydrogen gas filling gun. The mixed filling system has the advantages that a hydrogen filling form is effectively increased and the liquid hydrogen capability is greatly improved.

Owner:ZHANGJIAGANG RES INST OF HYDROGEN ENERGY CO LTD

Testing machine for testing the durability of materials in a high-pressure hydrogen environment

ActiveCN102297807AAvoid interferenceMaterial strength using tensile/compressive forcesEngineeringHigh pressure

The invention relates to the field of material mechanical property testing equipment development, and aims to provide a tester for testing durability of a material under a high-pressure hydrogen environment. The tester comprises a main machine and a high-pressure hydrogen environment box; only one side of the environment box is provided with an opening, and a sealing seat is hermetically jointed with the box at the opening of the box through a pin; a loading rod with a piston is arranged in a central through hole of the sealing seat; at least two sealing elements jointed to the sealing seat are arranged on the loading rod, and the piston is positioned between the two sealing elements; at one side close to the internal opening of the through hole, the space between the piston and the sealing element is communicated with the external atmosphere; and the through hole space between the other side of the piston and the sealing element forms a balance cavity, and the balance cavity is communicated with the cavity of the box through a hydrogen passage in the sealing seat. According to the tester, balance of gas thrust of the loading rod is realized by using air pressure in the high-pressure testing cavity; and a load sensitive element for directly measuring the load of a test sample is arranged in the loading rod, so that the interference of the high-pressure sealing elements to the load measurement precision is avoided.

Owner:ZHEJIANG UNIV

High-pressure hydrogen storing bottle combined valve

InactiveCN101140051AGuaranteed to workIncrease effective storage spaceVessel mounting detailsContainer filling methodsGas cylinderBottle

The invention relates to a combination valve for a high-pressure hydrogen storage cylinder, which comprises a charging check valve, a manual stop valve, an electromagnetic valve, a pressure reducing adjusting valve and a safe pressure releasing device; wherein a gas flue of a charging inlet of the hydrogen storage cylinder is provided with the check valve and the manual stop valve, a gas supply flue is educed between the two valves and supplies gas outwards through the electromagnetic valve and the pressure reducing adjusting valve; a pressure releasing gas flue is educed between the manual stop valve and the gas flue connected into the combination and releases pressure outwards through the safe pressure releasing device. As a cylinder valve is provided with the pressure reducing adjusting, considering the integration of the cylinder valve and the mensurability and output controllability of the gas, the invention can implement the low-pressure output; therefore, a gas supply output system has the very high safe reliability and simultaneously can be used as a main valve of a hydrogen storage cylinder group; other gas cylinders of the hydrogen storage cylinder group can supply gas outwards after pressure reduction through the main valve.

Owner:徐焕恩

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com