Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

898 results about "Headstock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A headstock or peghead is part of a guitar or similar stringed instrument such as a lute, mandolin, banjo, ukulele and others of the lute lineage. The main function of a headstock is to house the pegs or mechanism that holds the strings at the "head" of the instrument. At the "tail" of the instrument the strings are usually held by a tailpiece or bridge. Machine heads on the headstock are commonly used to tune the instrument by adjusting the tension of strings and, consequentially, the pitch of sound they produce.

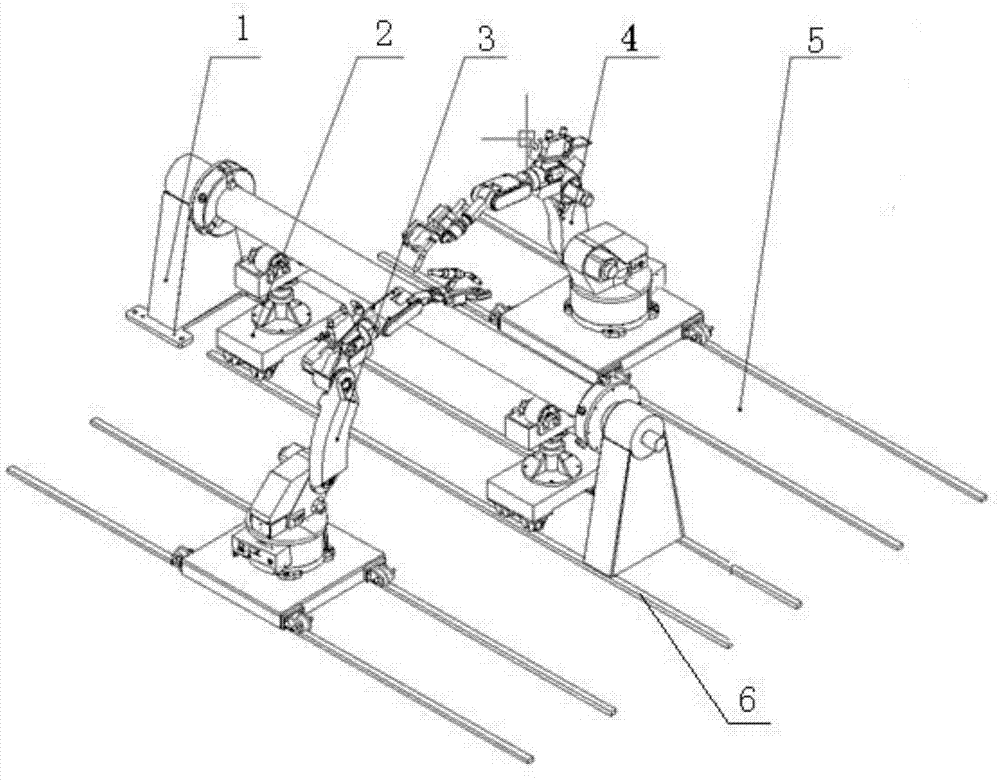

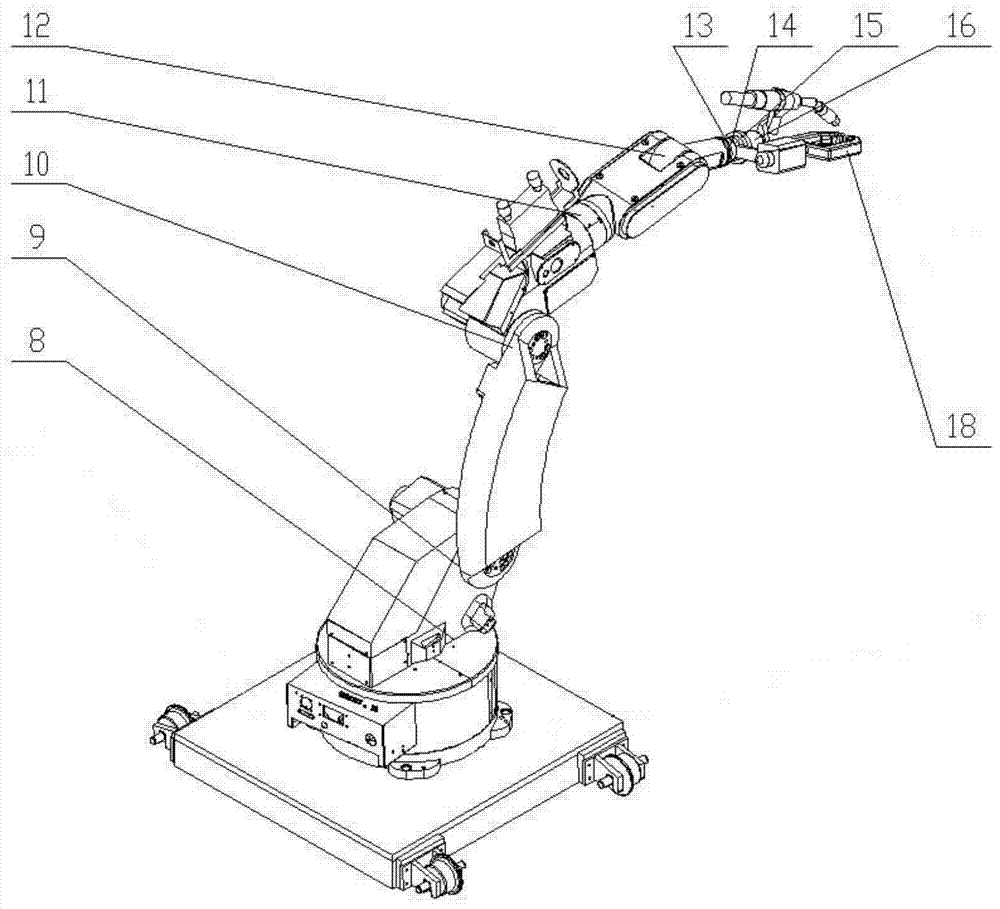

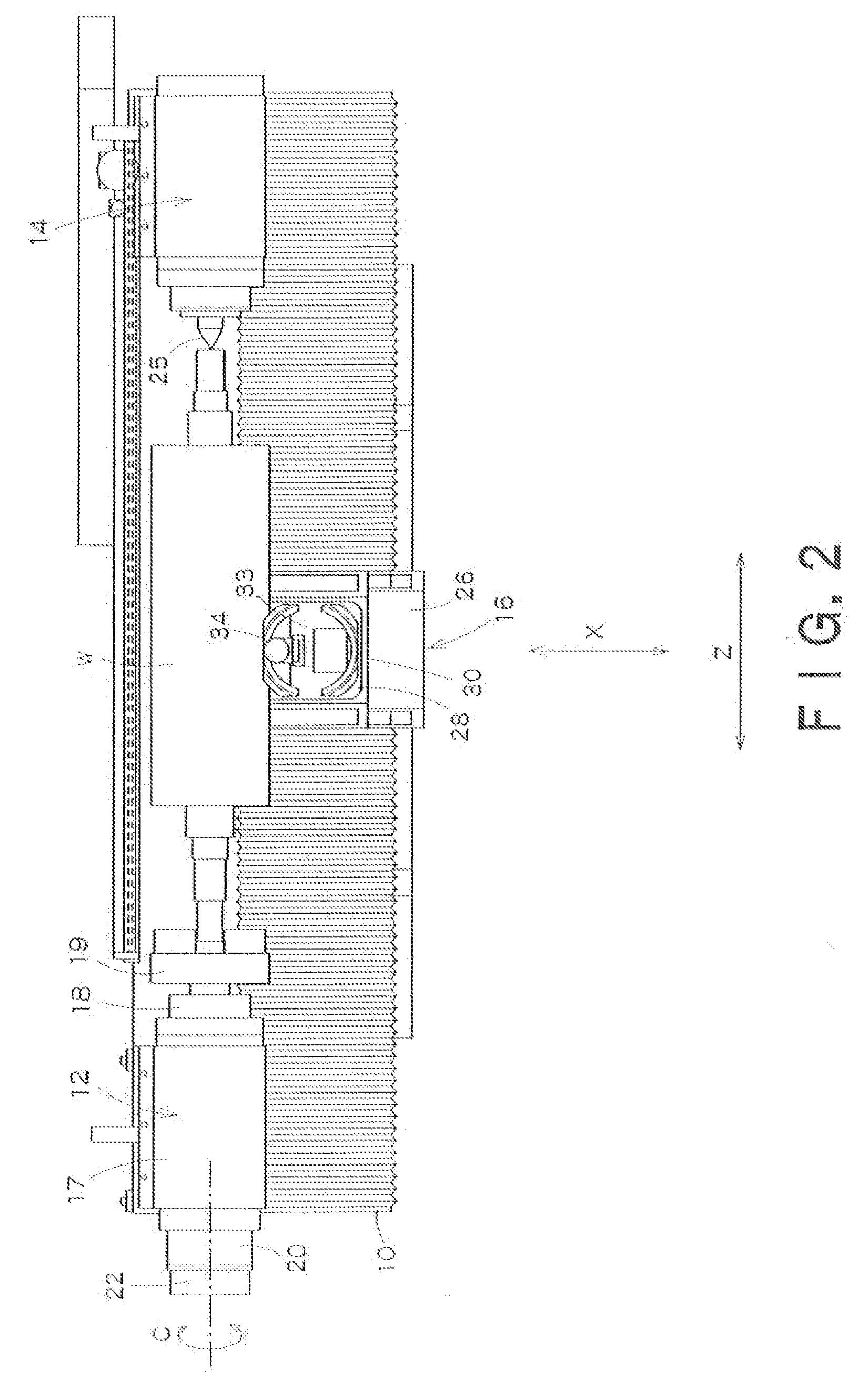

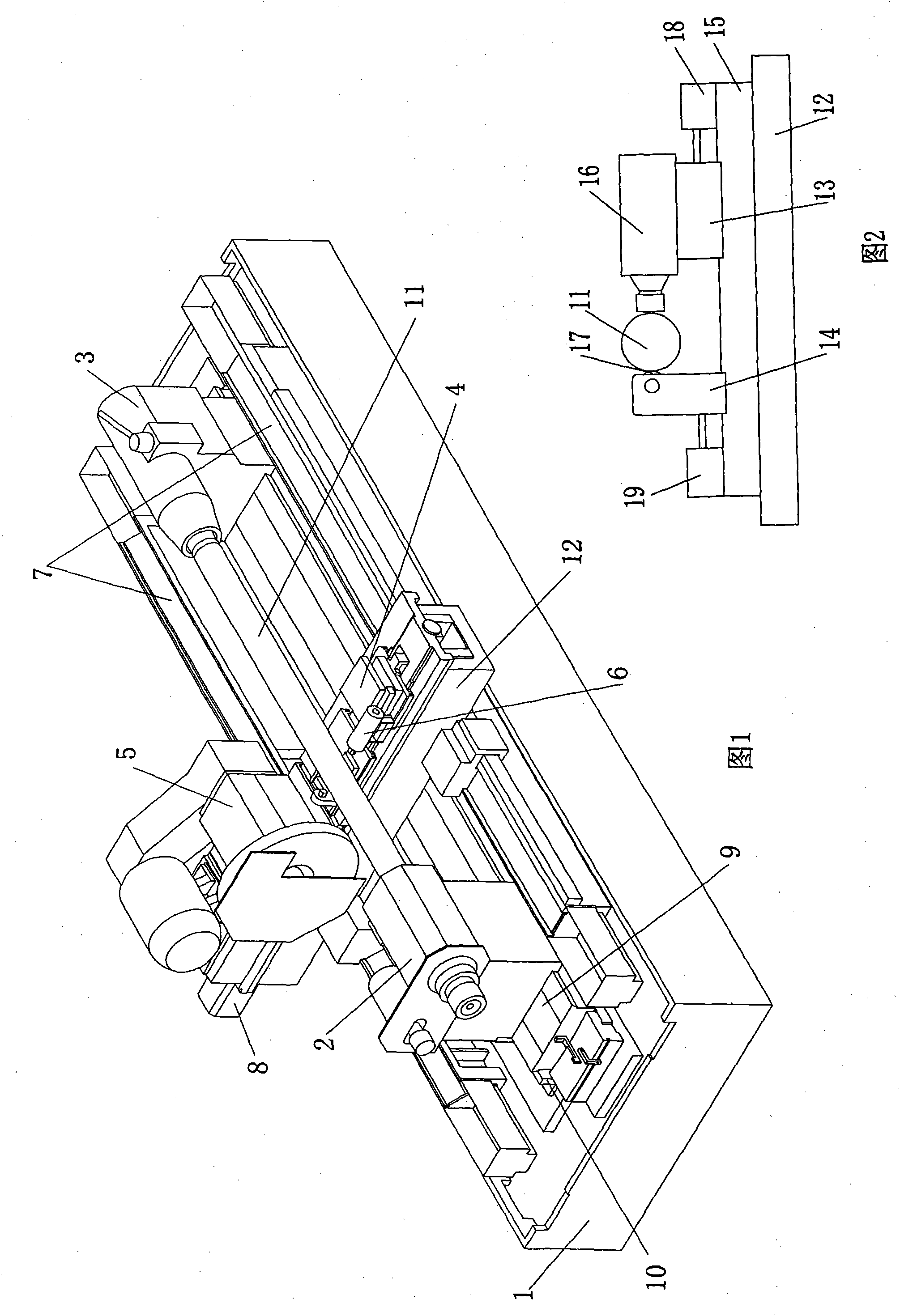

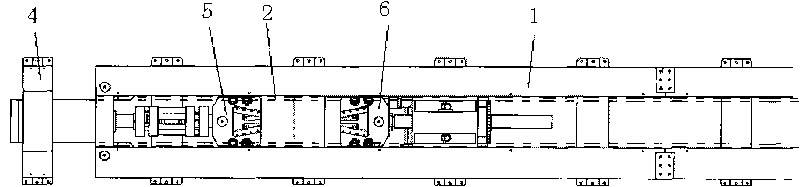

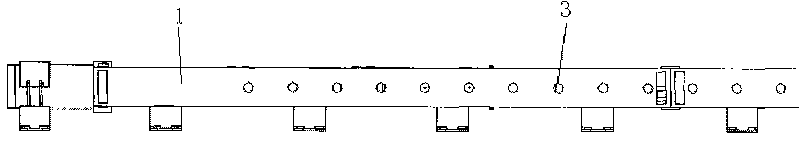

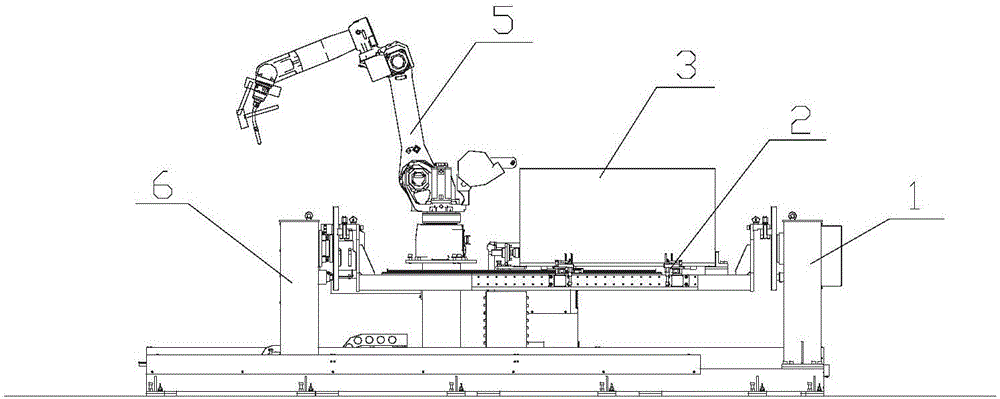

Integrated workstation based on robot cutting, welding and carrying in pipe processing

ActiveCN103567677AImprove processing qualityImprove machining accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSmall footprint

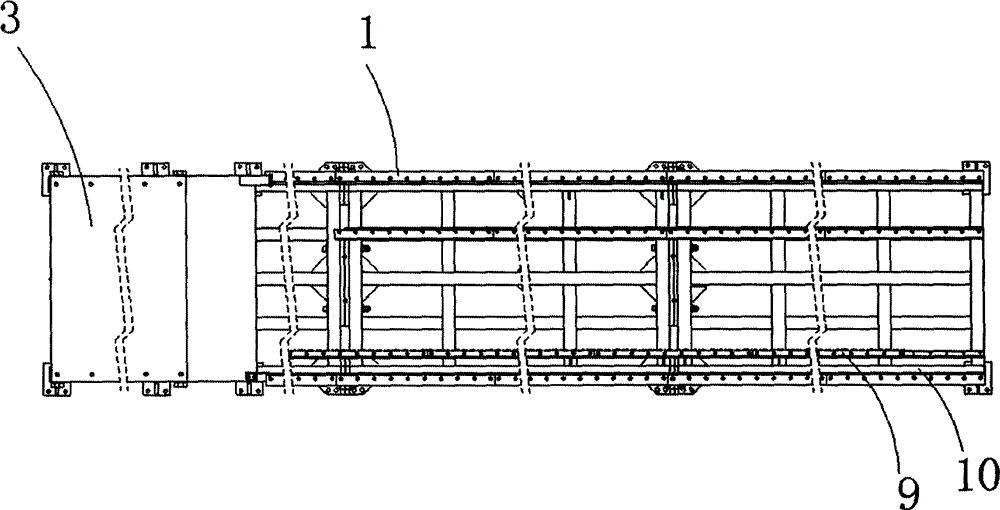

The invention discloses an integrated workstation based on robot cutting, welding and carrying in pipe processing. The integrated workstation comprises a headstock and tailstock position changer, a movable support, a welding robot, a cutting robot, a middle sliding rail and two side sliding rails, wherein the headstock and tailstock position changer comprises a headstock base and a tailstock base; a pipe workpiece is clamped between clamping and fixing devices on the headstock base and the tailstock base; a lifting driving device is installed on a sliding base of the movable support; a roller is installed on the lifting driving device and is tangent with the pipe workpiece; the welding robot and the cutting robot are slidably installed on the two side sliding rails on the two sides of the pipe workpiec respectively to finish carrying, cutting and welding operation and the like. The integrated workstation based on the robot cutting, welding and carrying in pipe processing is an integrated working system, can ensure good consistency in pipe processing, improves the processing quality and the processing precision of the whole pipe workpiece, and is simple in structure, less in equipment and small in occupied area.

Owner:NANJING PANDA ELECTRONICS +1

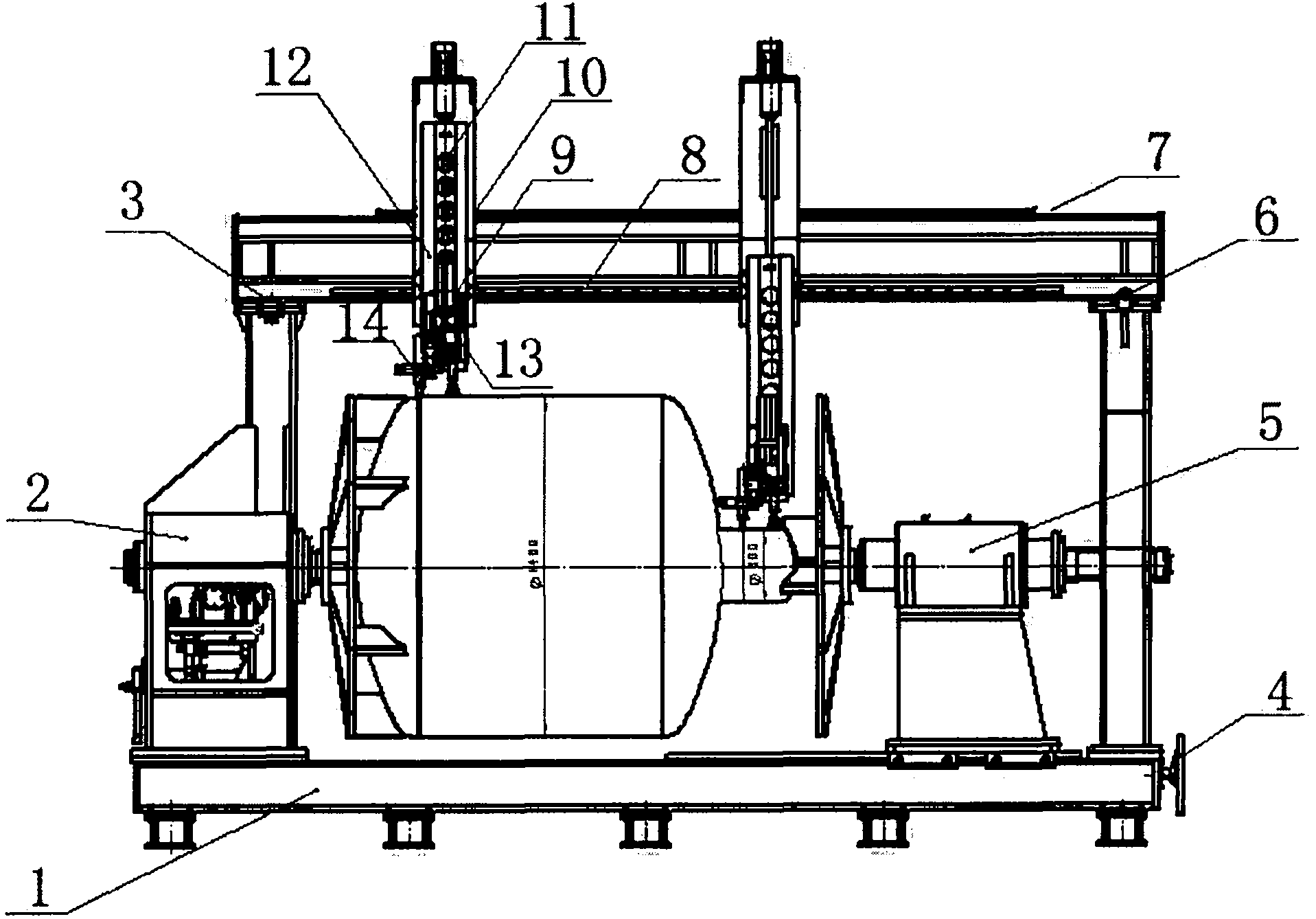

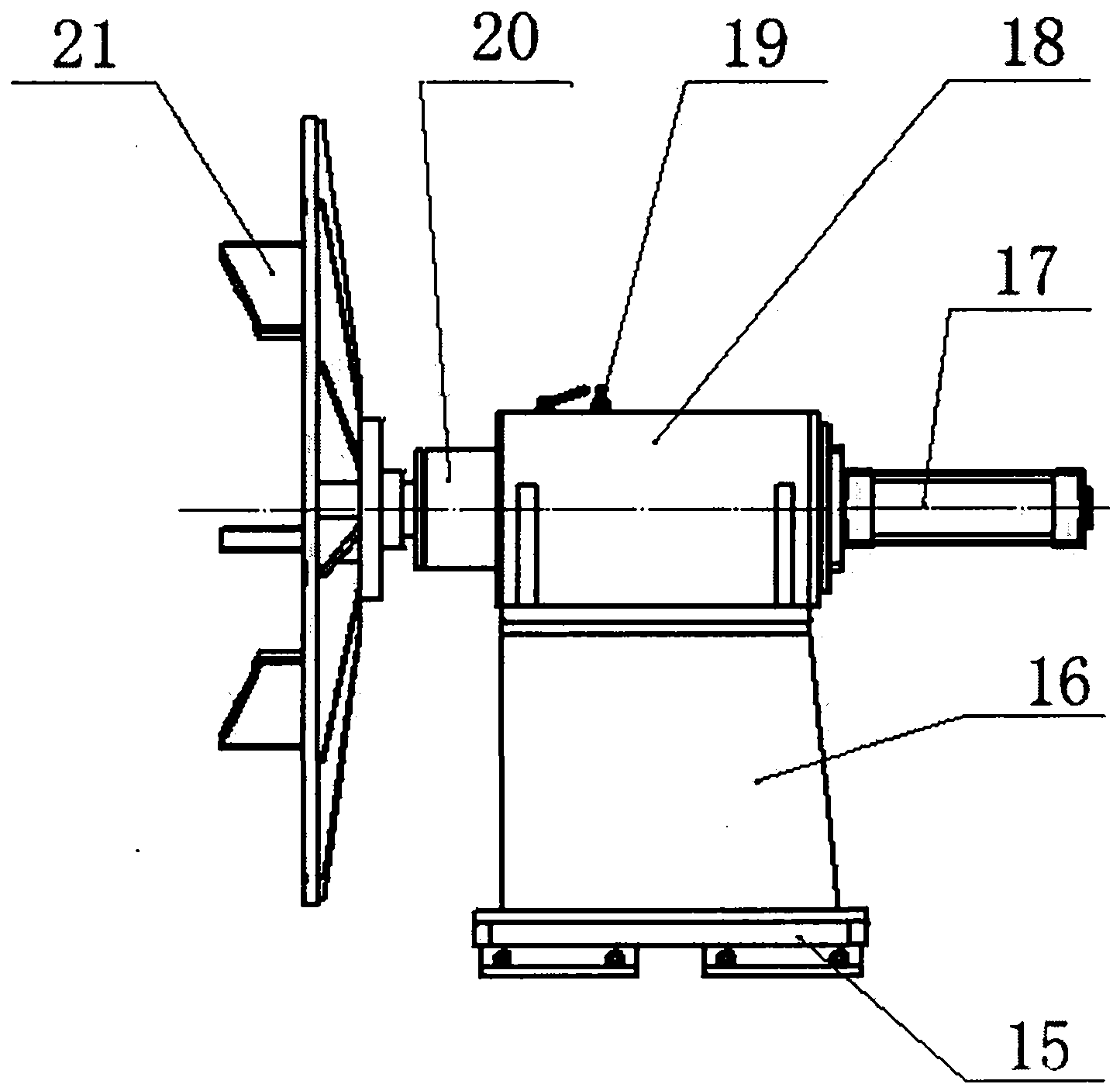

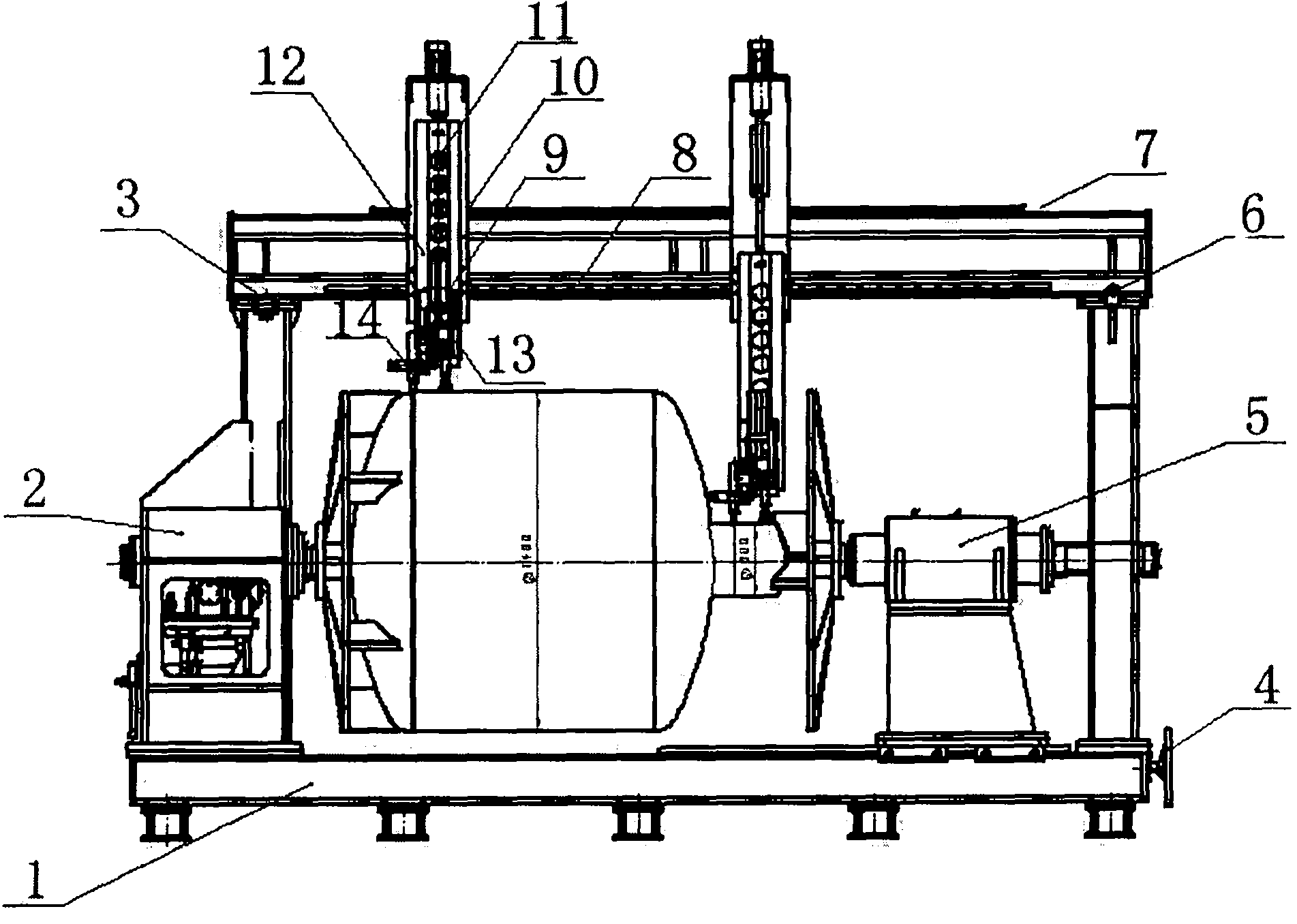

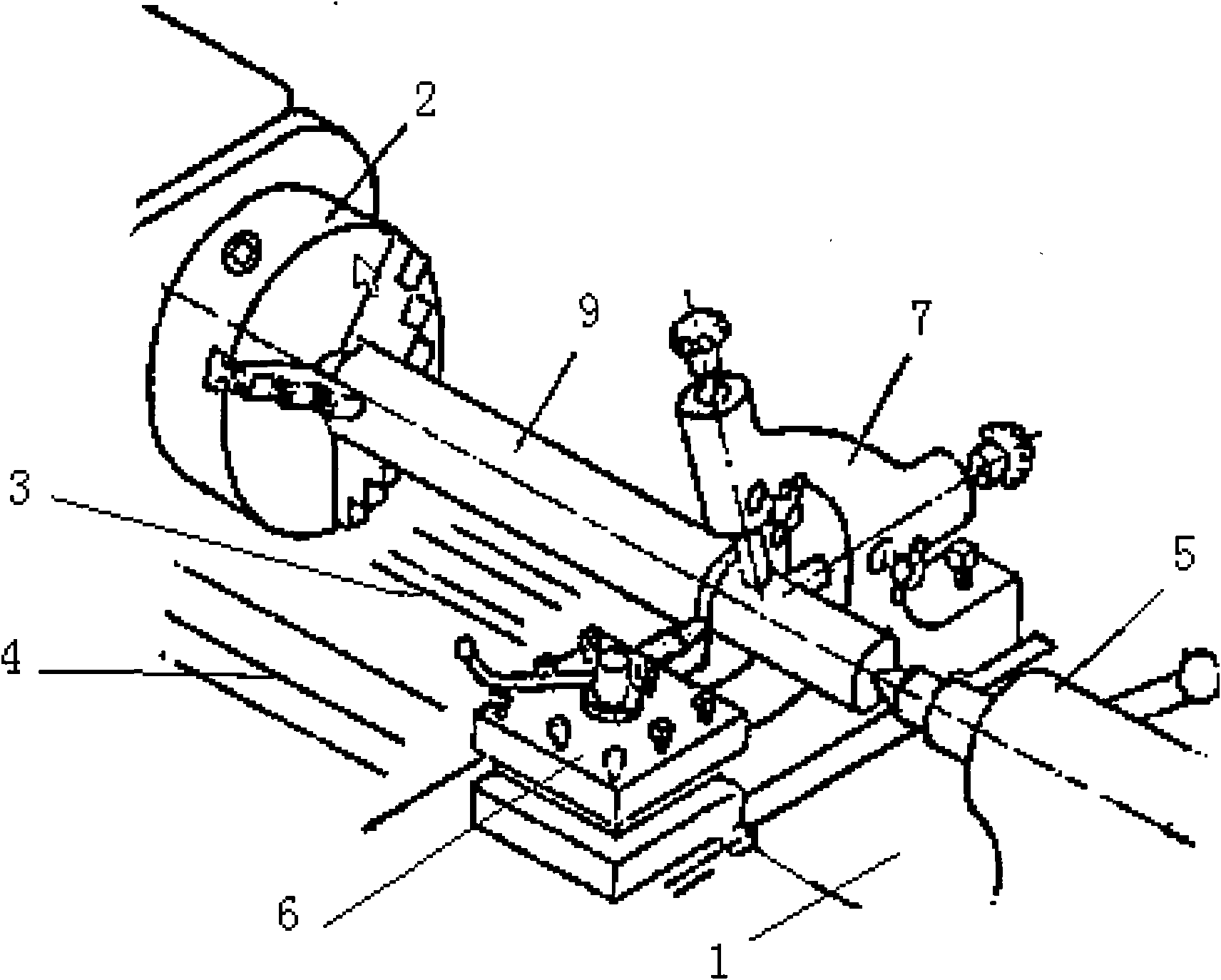

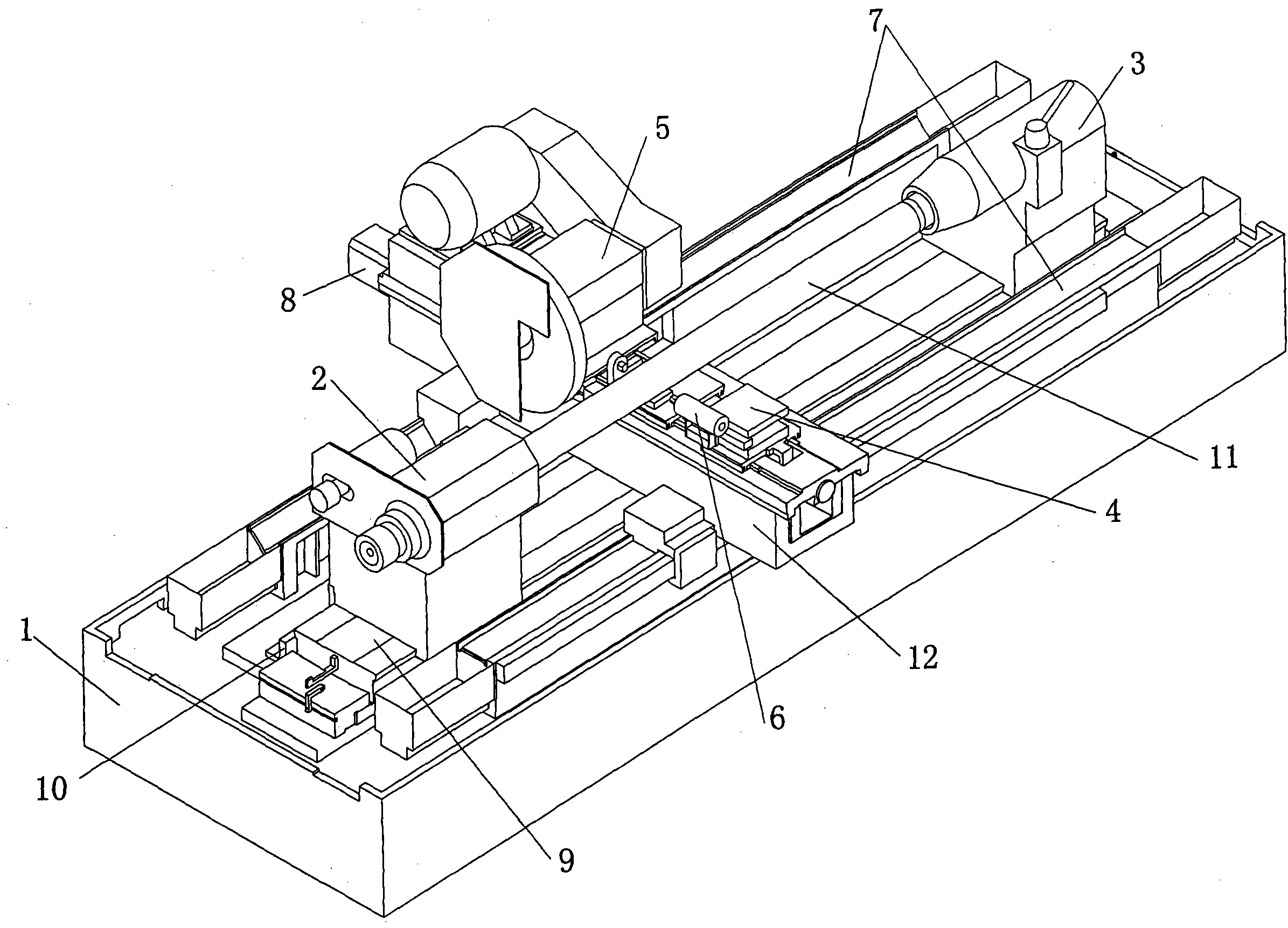

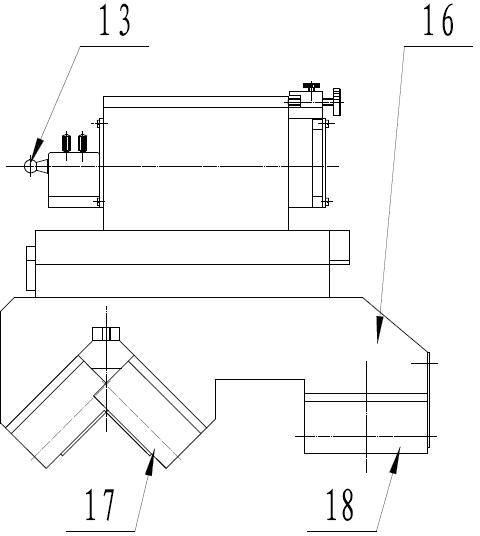

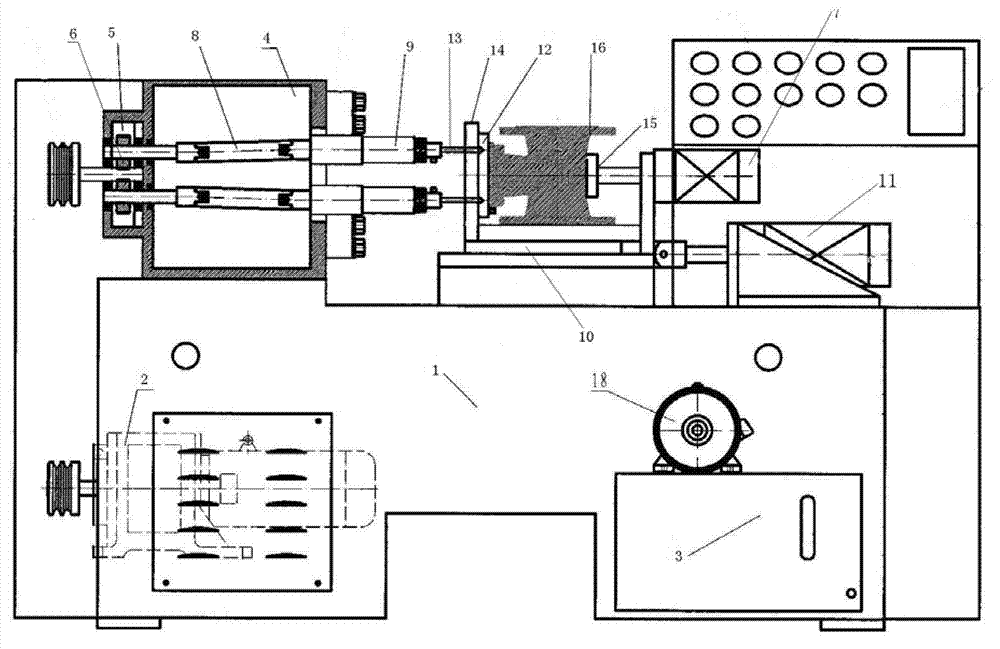

Speed-variable circular and longitudinal seam welder applied to multi-specification tank bodies

InactiveCN101913040ACompact structureEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSeam welding

The invention relates to a welding device, in particular to a circular and longitudinal seam welder special for automatically welding multi-specification tank bodies. The speed-variable circular and longitudinal seam welder applied to the multi-specification tank bodies mainly comprises four parts, namely a bed body (1), a headstock (2), a beam mechanism (12) and a tailstock (5). Compared with the prior art, the circular and longitudinal seam welder has the advantages of adapting to the change of the tank body diameter range of phi300 to 1,400mm and welding linear speed range of 200 to 1,200mm / min, realizing edge sealing and dual circular and longitudinal seam welding of the tank bodies, along with multiple functions, compact structure, convenient operation, high stability and low production cost.

Owner:SHANGHAI HUGONG ELECTRIC WELDING MACHINE MFG

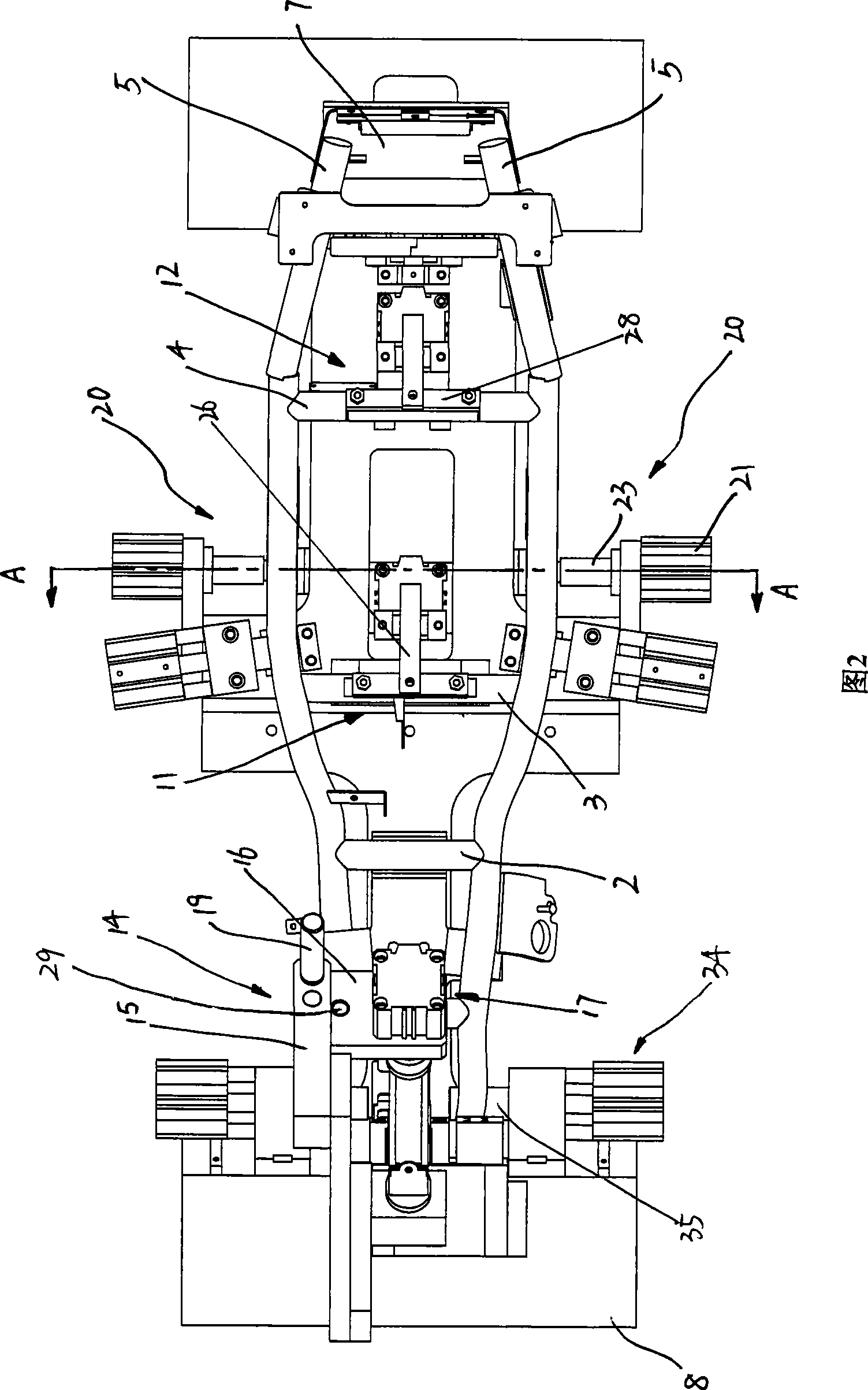

Welding clamp of total vehicle frame

InactiveCN101376200AAvoid displacementHigh precisionWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngineering

The invention relates to a welding fixture of a main chassis, which comprises a pedestal, a plurality of bearing blocks used for bearing welded workpieces and fixedly arranged on the pedestal, and a clamping device arranged on the pedestal with a part propped up against the workpieces to be welded. The clamping device comprises a headstock fixing seat positioned at the front part of the pedestal; a second workpiece table is fixedly arranged at the rear part of the pedestal; and a first workpiece table is also arranged between the headstock fixing seat and the second workpiece table. The welding fixture can rapidly position and fix each component to be welded, thereby improving the accuracy of welding positions, and further improving processing quality; in addition, the invention allows the multi-step welding during the one-time process of clamping, thereby improving processing efficiency.

Owner:庄添财

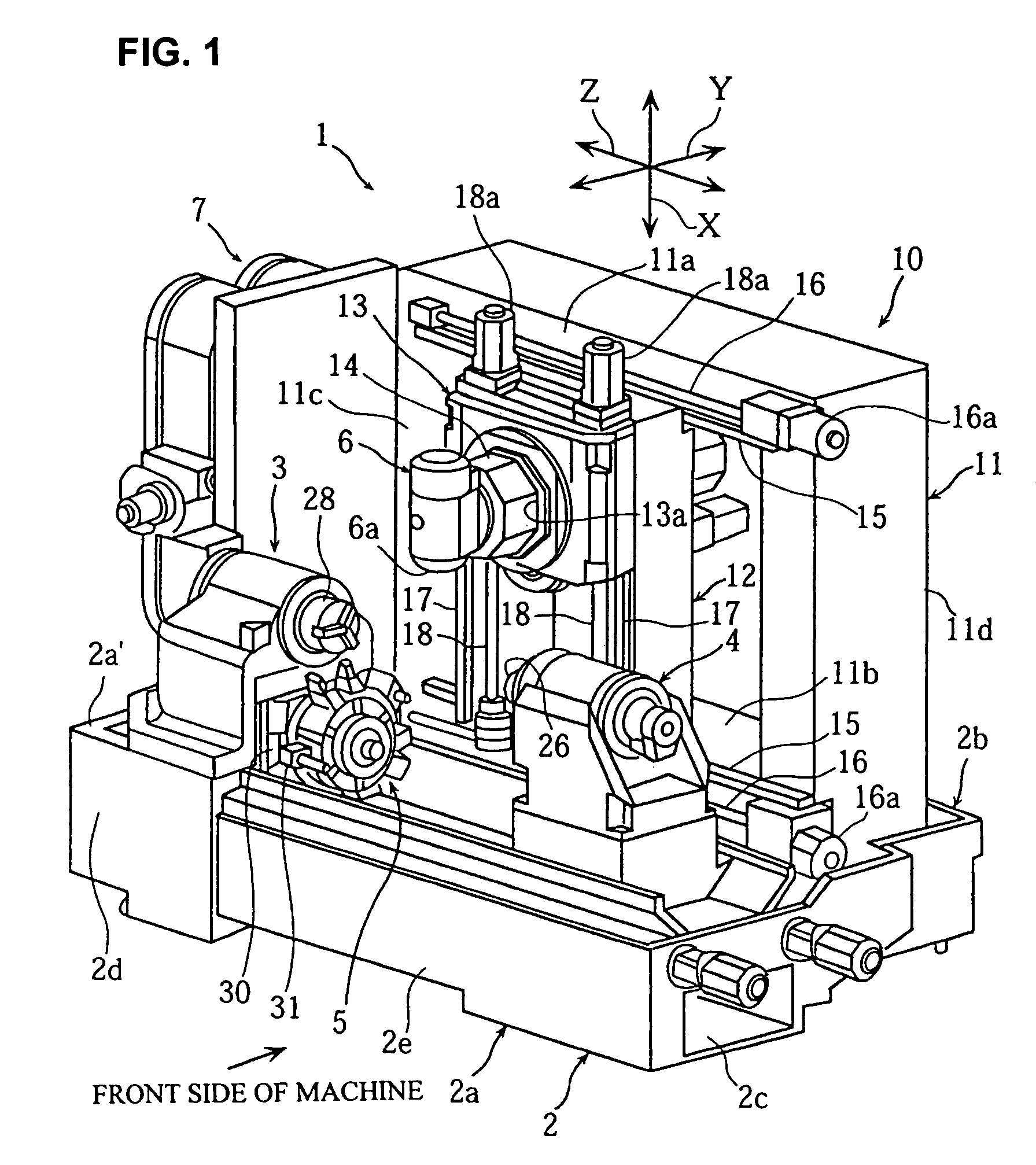

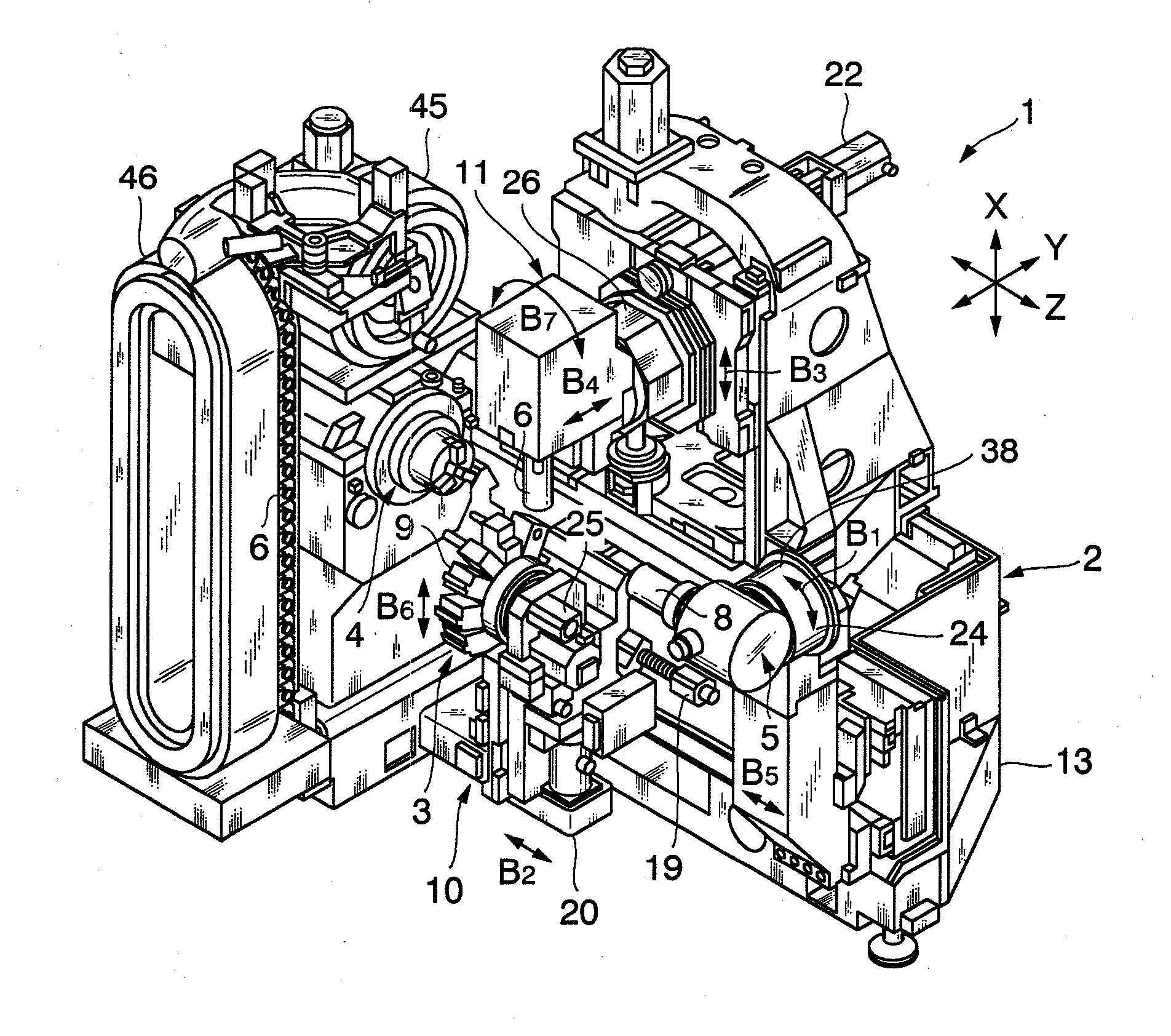

Machine tool

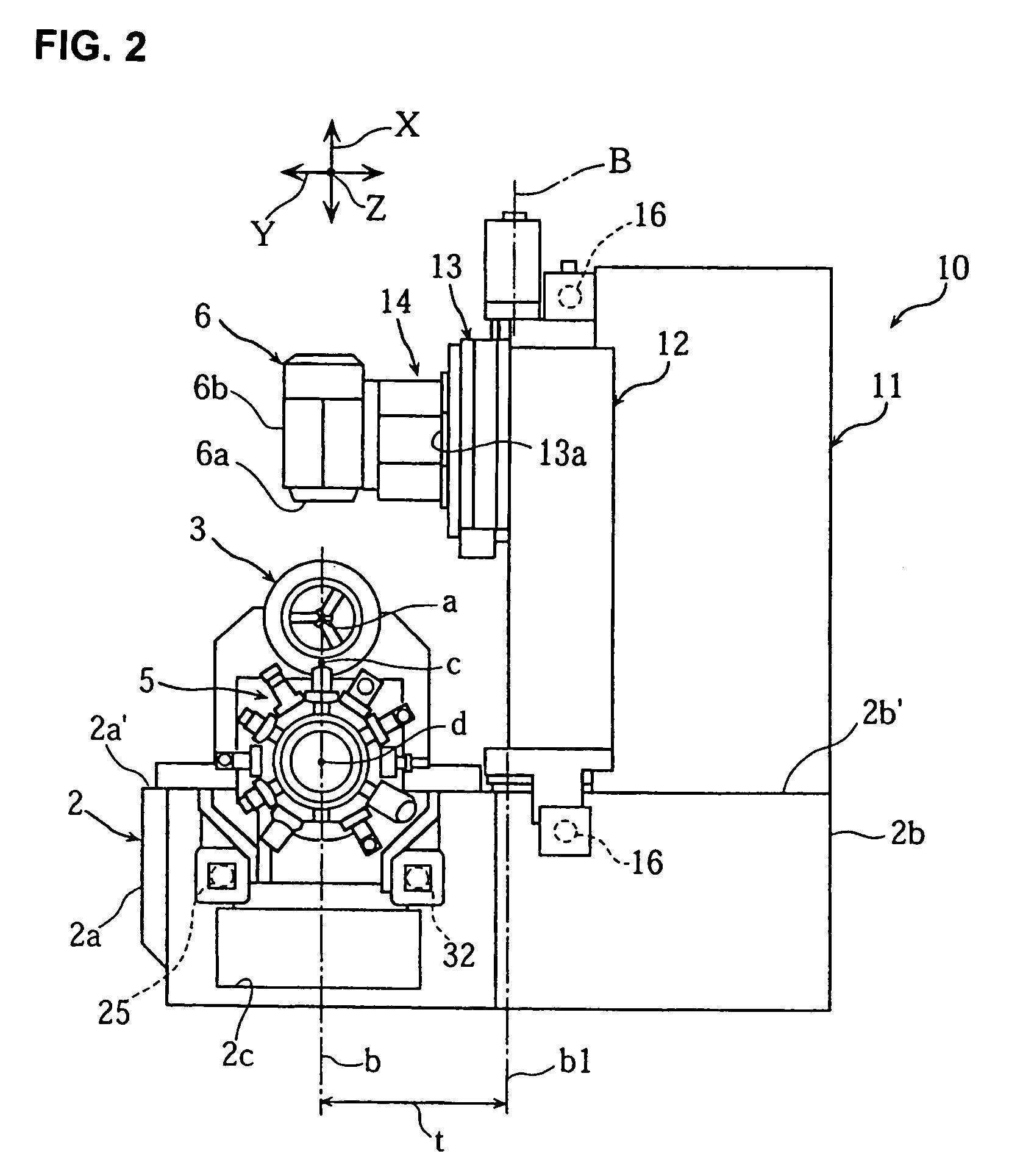

InactiveUS7266871B2Improve support stiffnessImprove machining accuracyAutomatic/semiautomatic turning machinesTurning toolsEngineeringHeadstock

To provide a machine tool in which supporting stiffness of a tool post is increased, thereby enabling improvement in machining accuracy. When seen in a Z-axis direction, a tool post 5 includes: a supporting member 30 having a pair of left and right leg parts 30a, 30a and an upper beam part 30b coupling at least upper ends of the both leg parts 30a with each other; and a turret 31 to whose outer circumferential portion a plurality of tools are attached. The supporting member 30 is supported to be movable in a Z-axis direction between a first and a second spindle headstock 3, 4, and the turret 31 is supported to be movable in an X-axis direction by turret guide rails 33, 33 which are disposed on front faces of the left and right leg parts 30a, 30a.

Owner:DMG MORI CO LTD

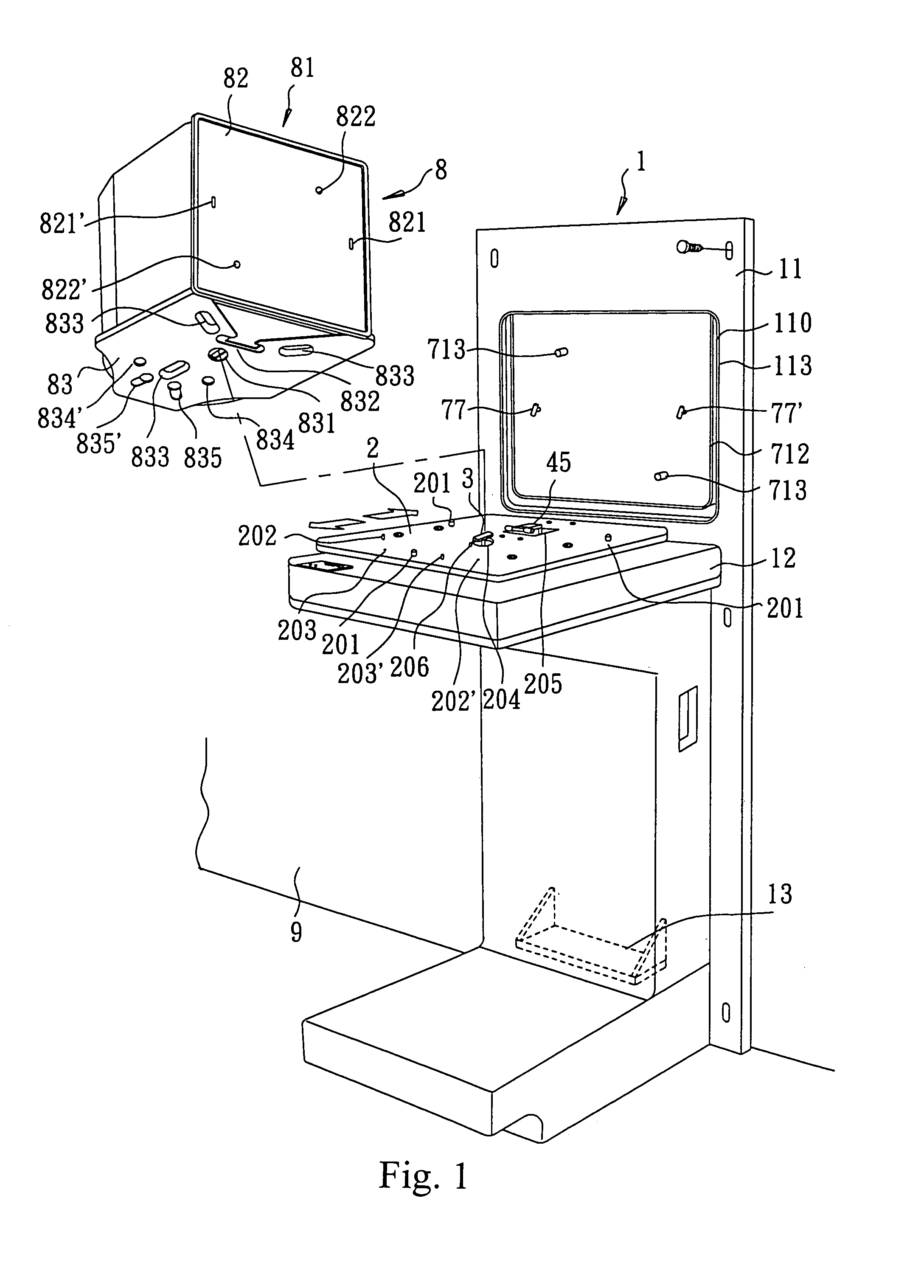

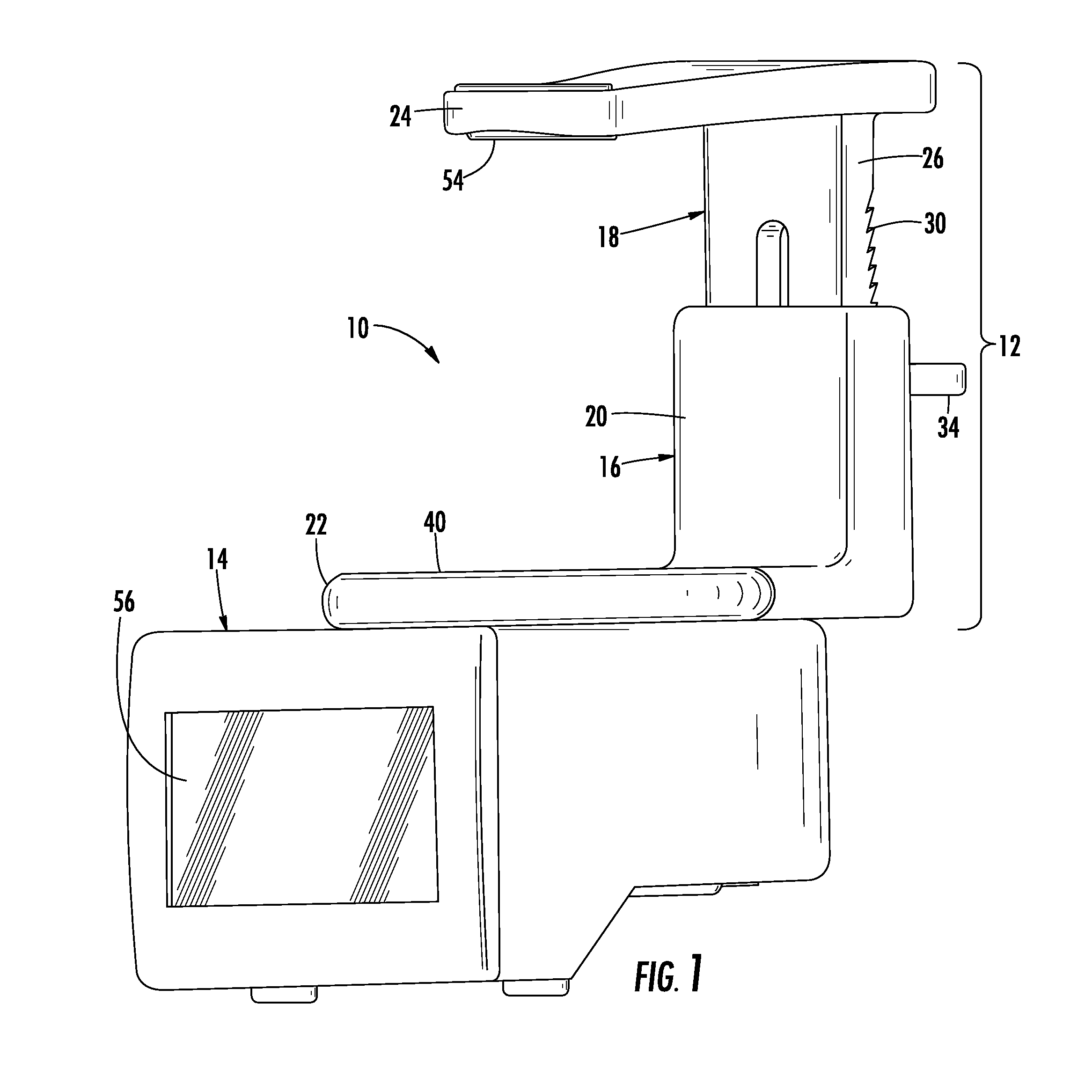

Front-opening unified pod auto-loading structure

InactiveUS6896470B1Avoid pollutionEliminate the problemSemiconductor/solid-state device manufacturingArticle unpackingHeadstockAutomation

The invention includes mainly a machine base, a carrier, a sliding control mechanism, a latch mechanism, a horizontal shifting mechanism, and a lifting mechanism. The FOUP (front-opening unified pod) is put on the carrier and latched by a locking plate of the latch at an accurate position. The carrier moves forwardly to tightly engage the FOUP to a gate on an access at a backboard of the machine base, and thus a cover of the FOUP is opened by a headstock gear at the back of the gate then carried backwardly away from the FOUP by the horizontal shifting mechanism and lowered by the lifting mechanism. Reversely, the cover is closed on the FOUP. As such, the cover is loaded and opened automatically, as well as in closed, which can be a part of automation and prevents wafers from contamination.

Owner:IND TECH RES INST

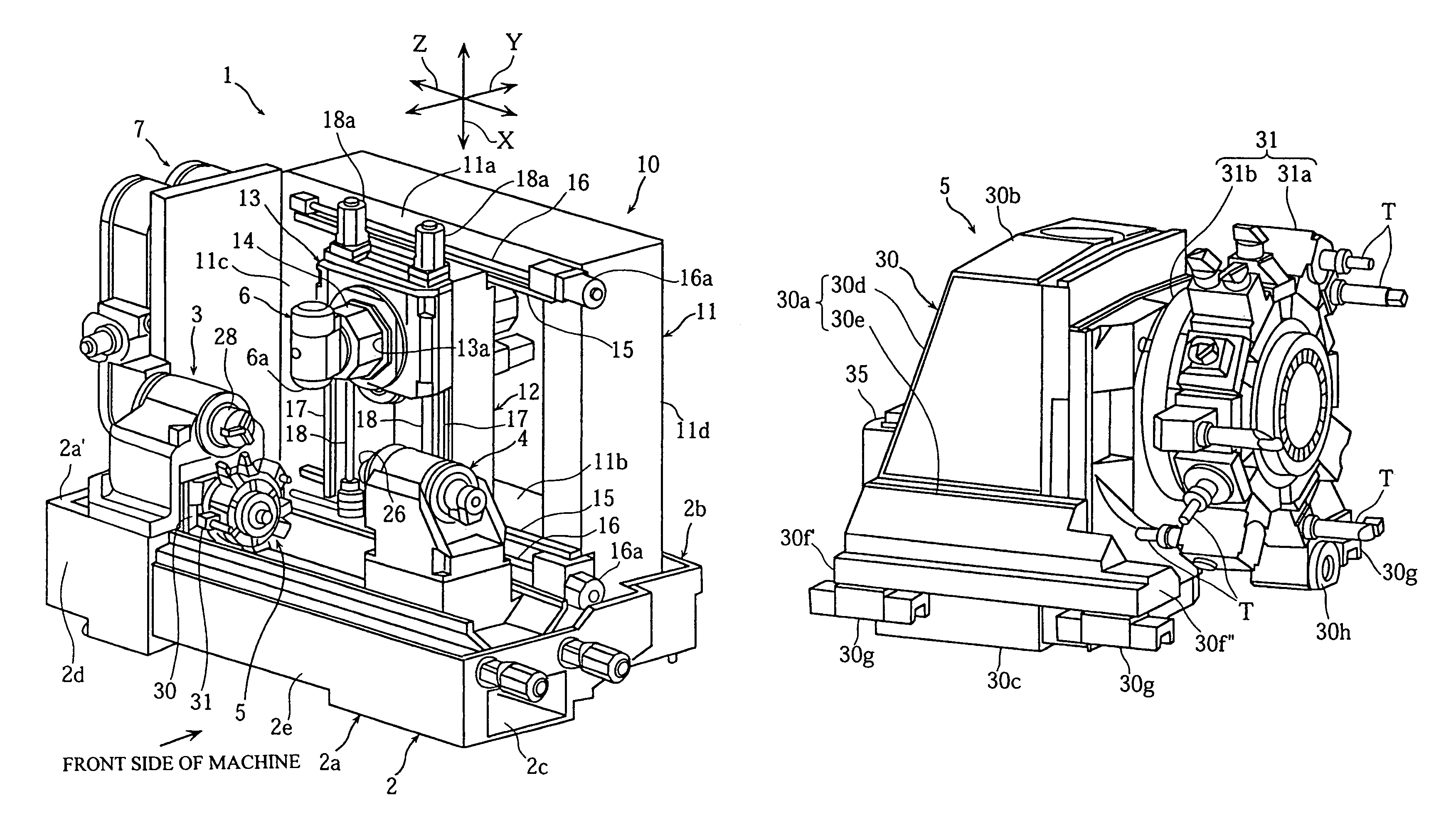

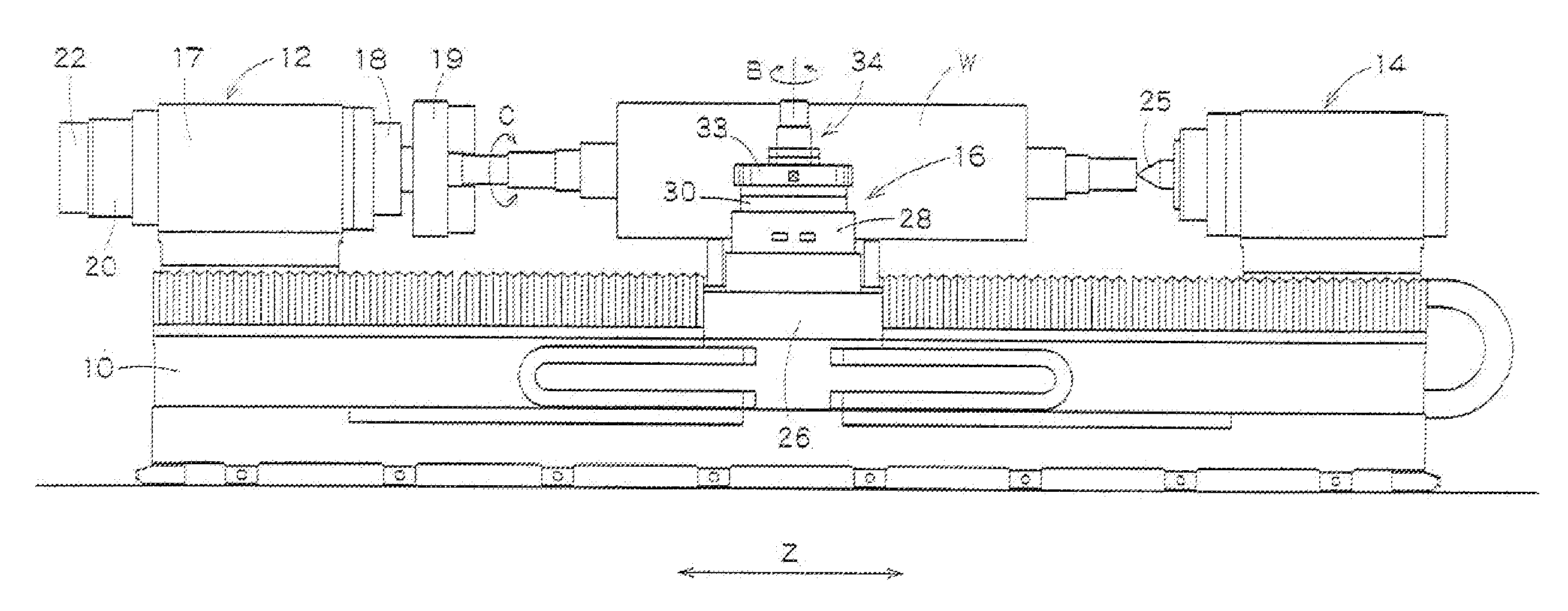

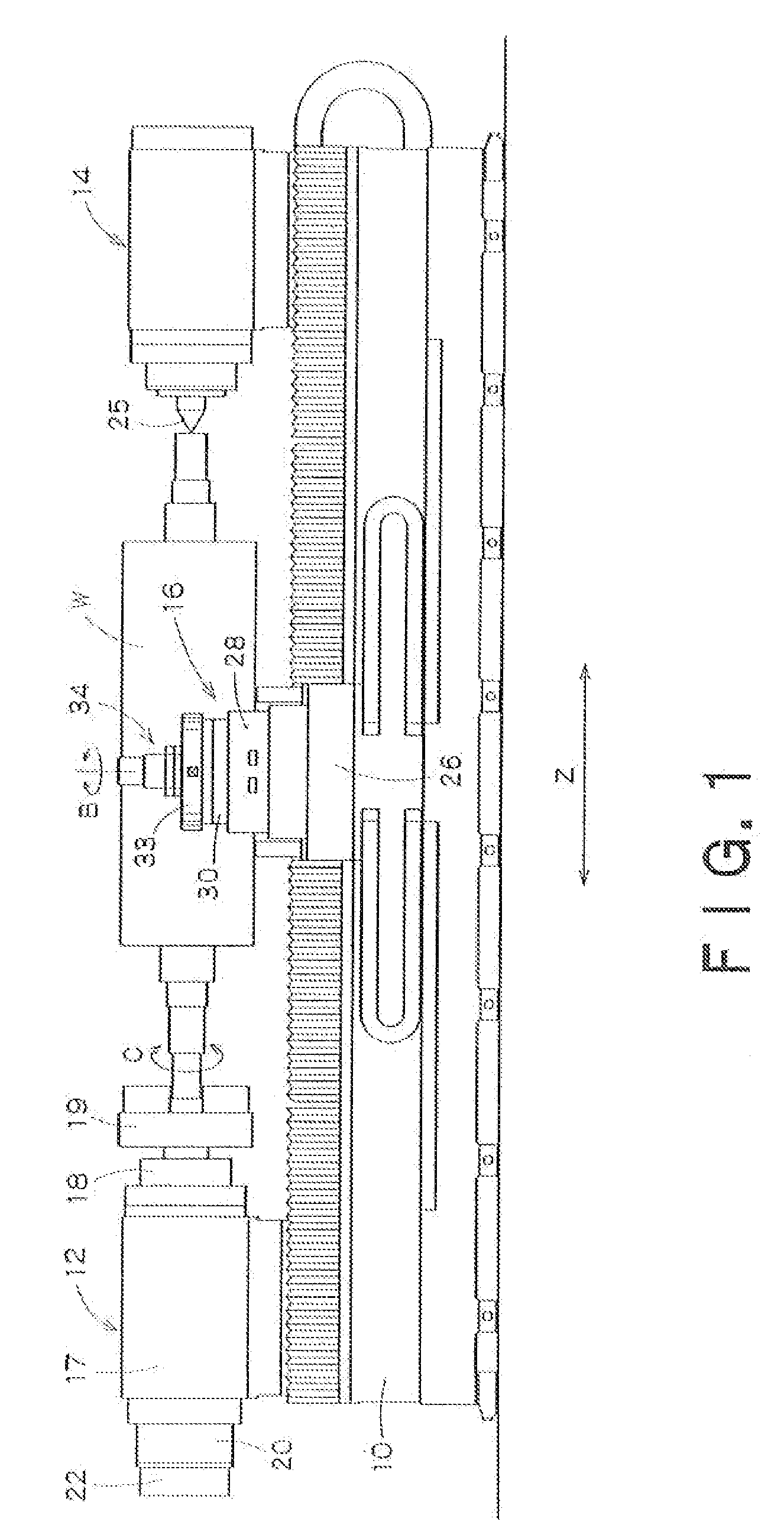

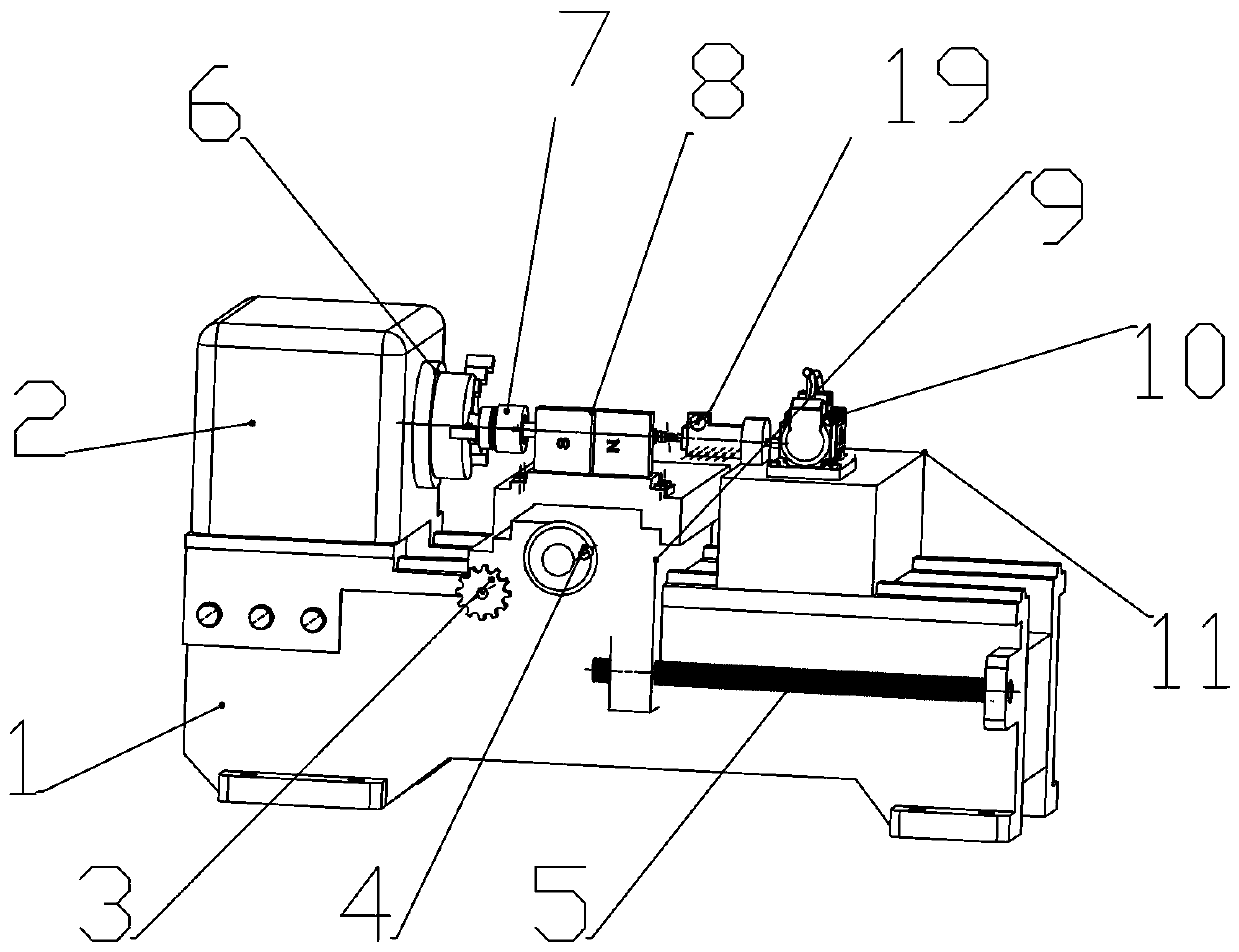

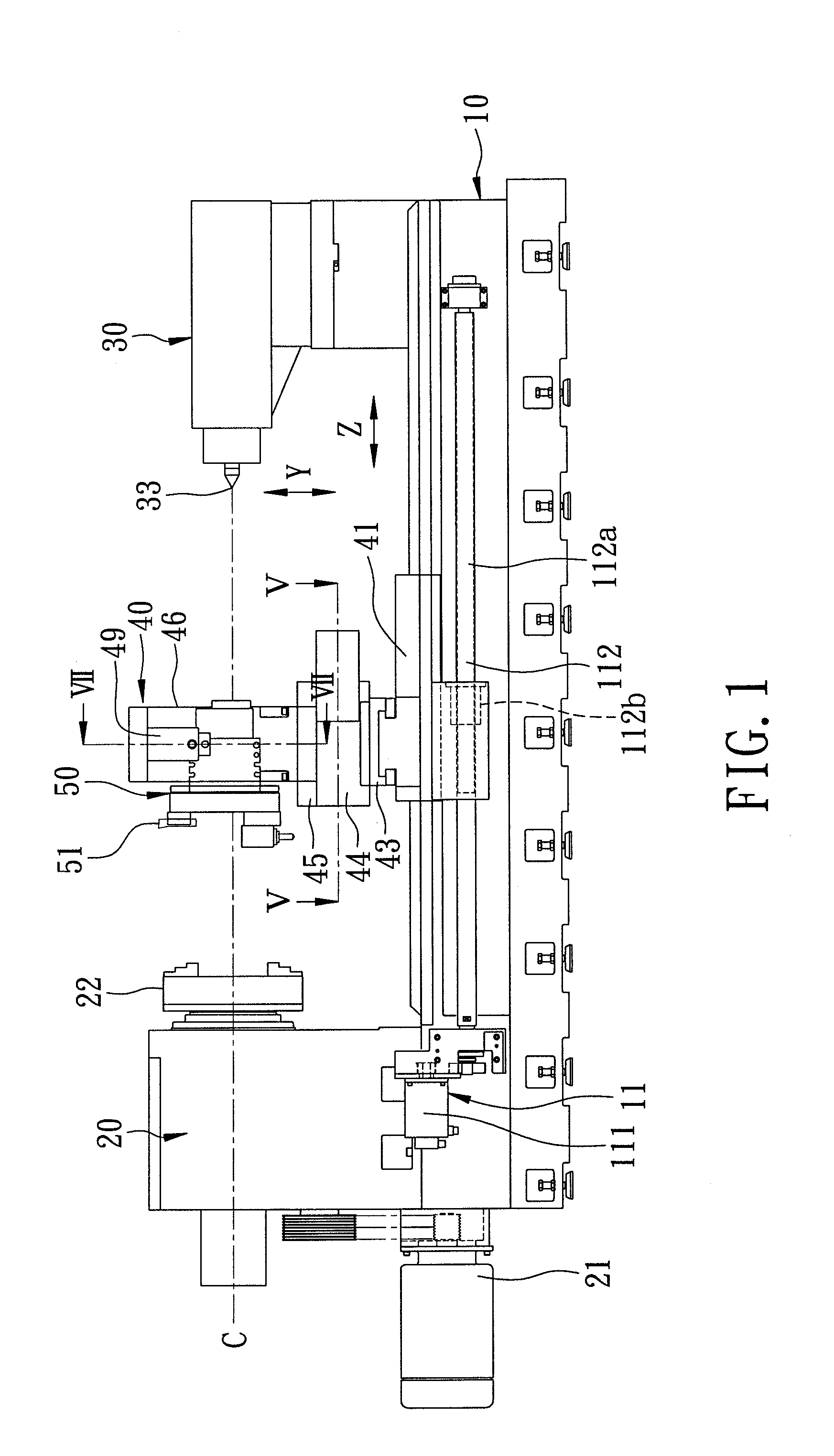

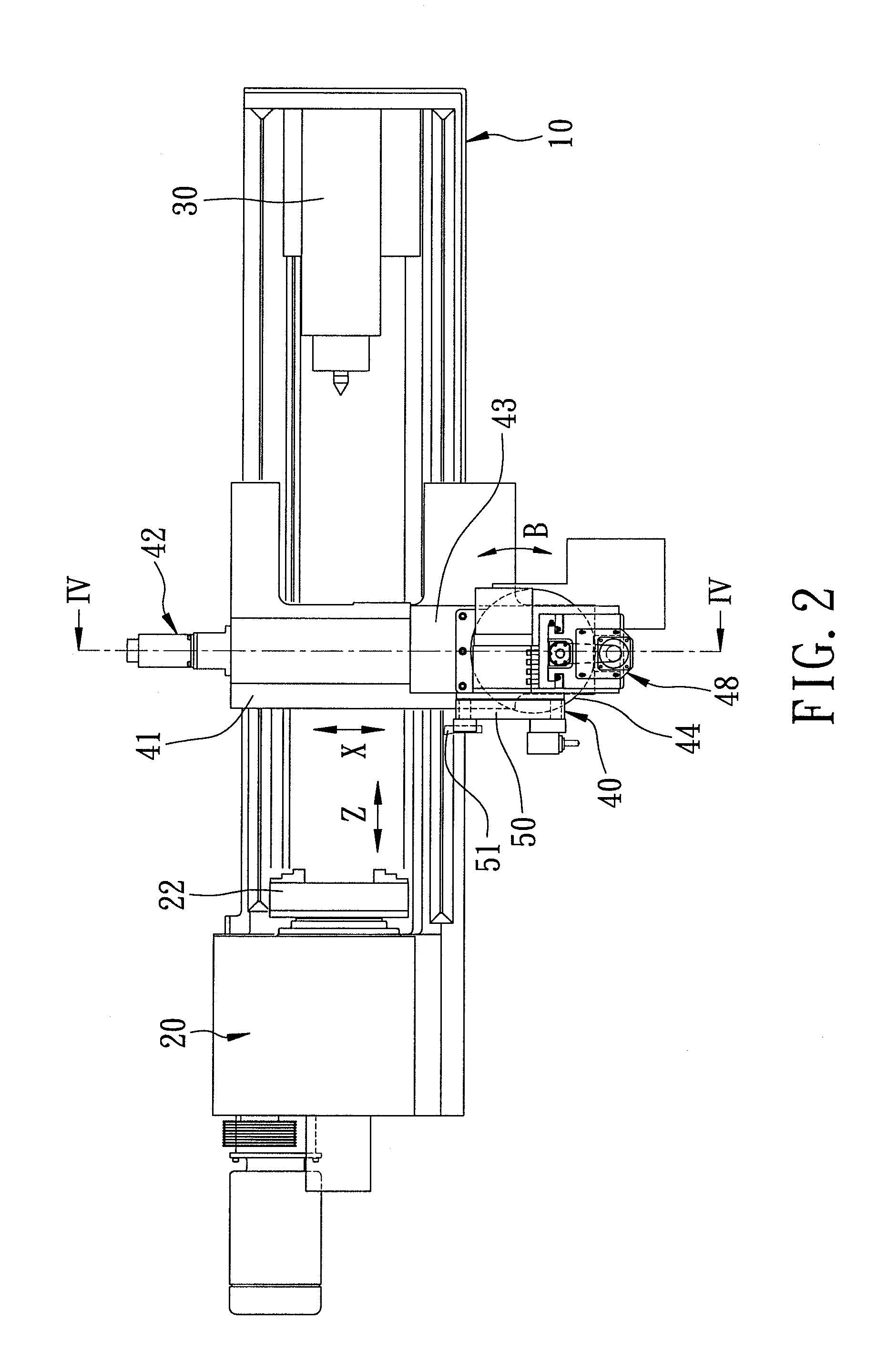

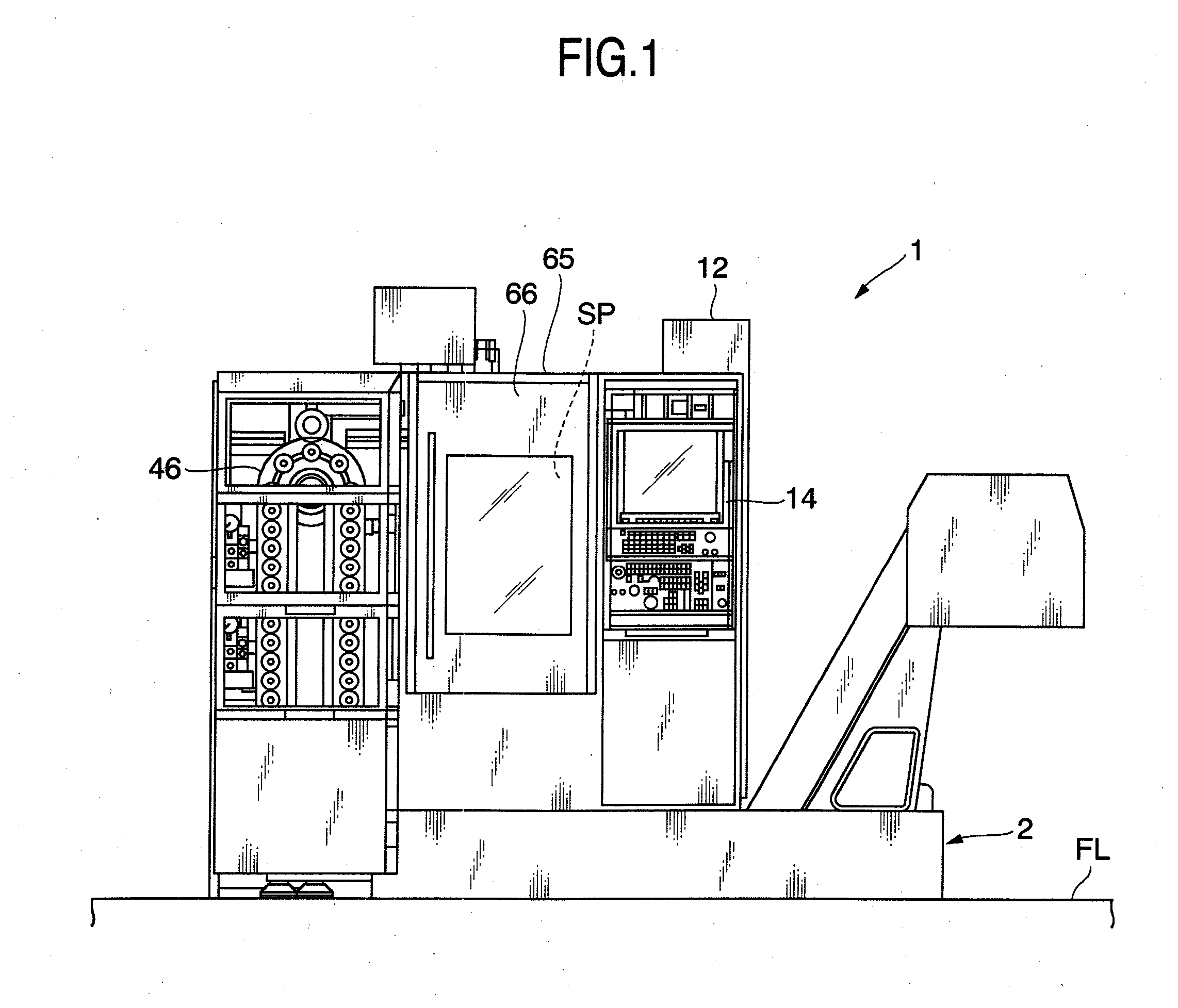

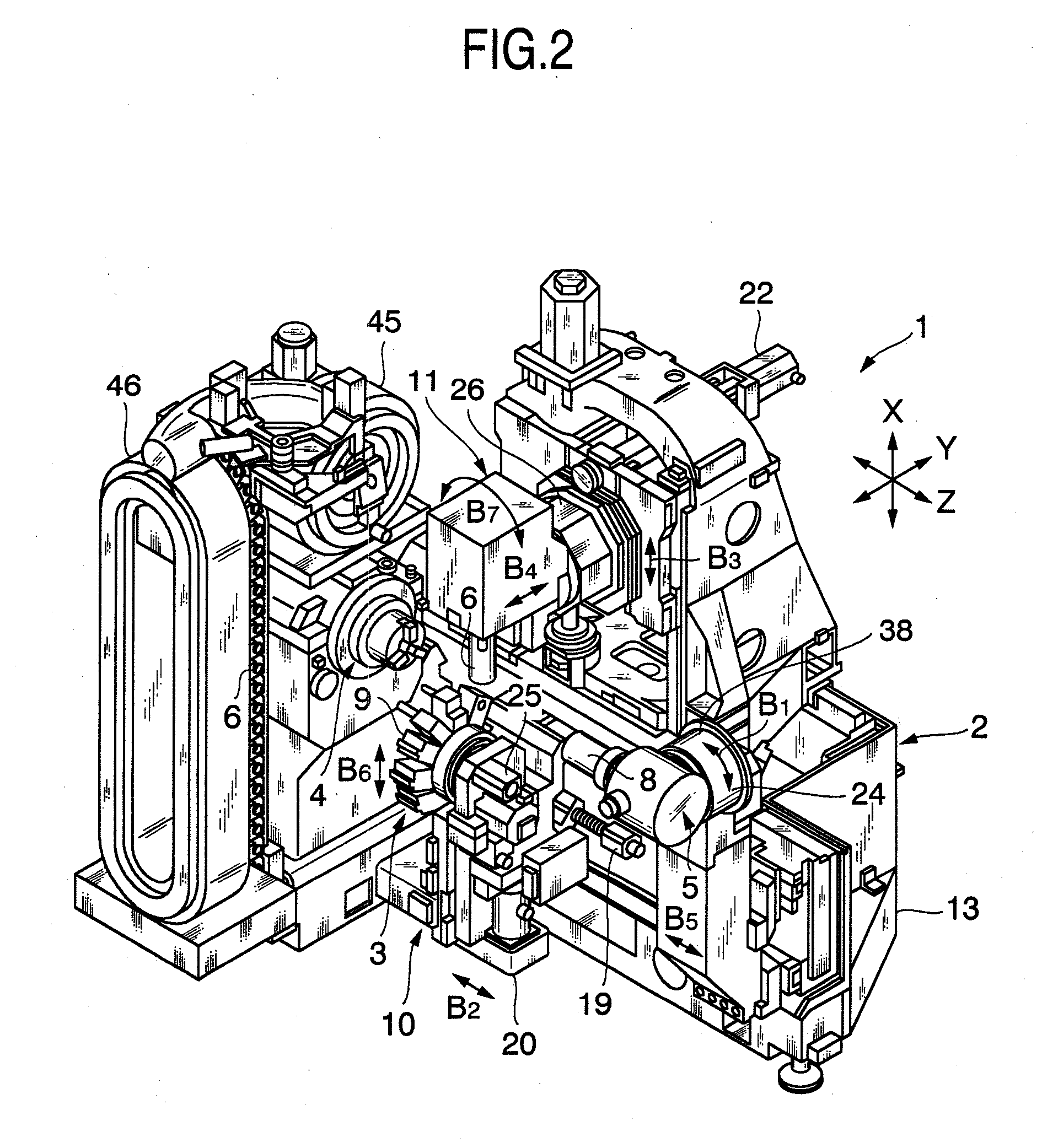

Precision roll turning lathe

ActiveUS20070251360A1High precision machiningAvoid low machining accuracyAutomatic/semiautomatic turning machinesPropelling pencilsTransverse grooveHeadstock

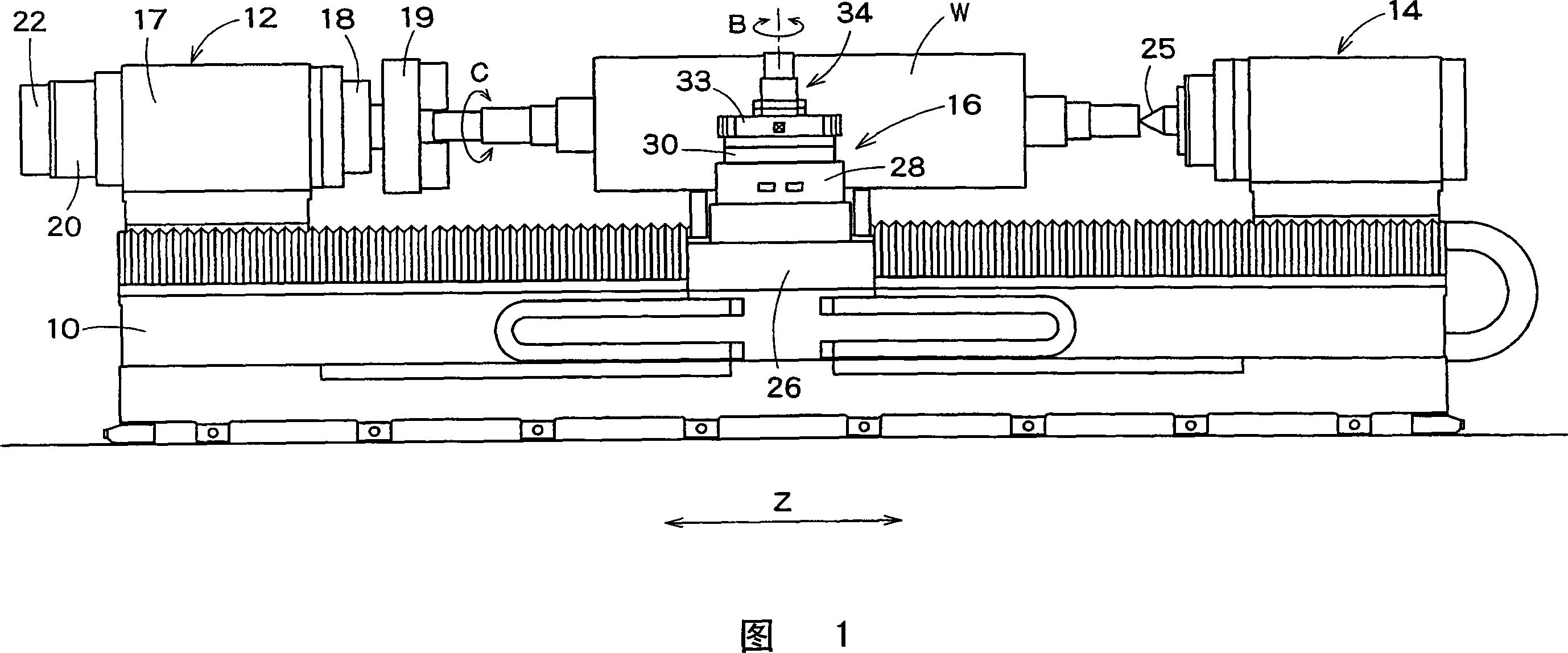

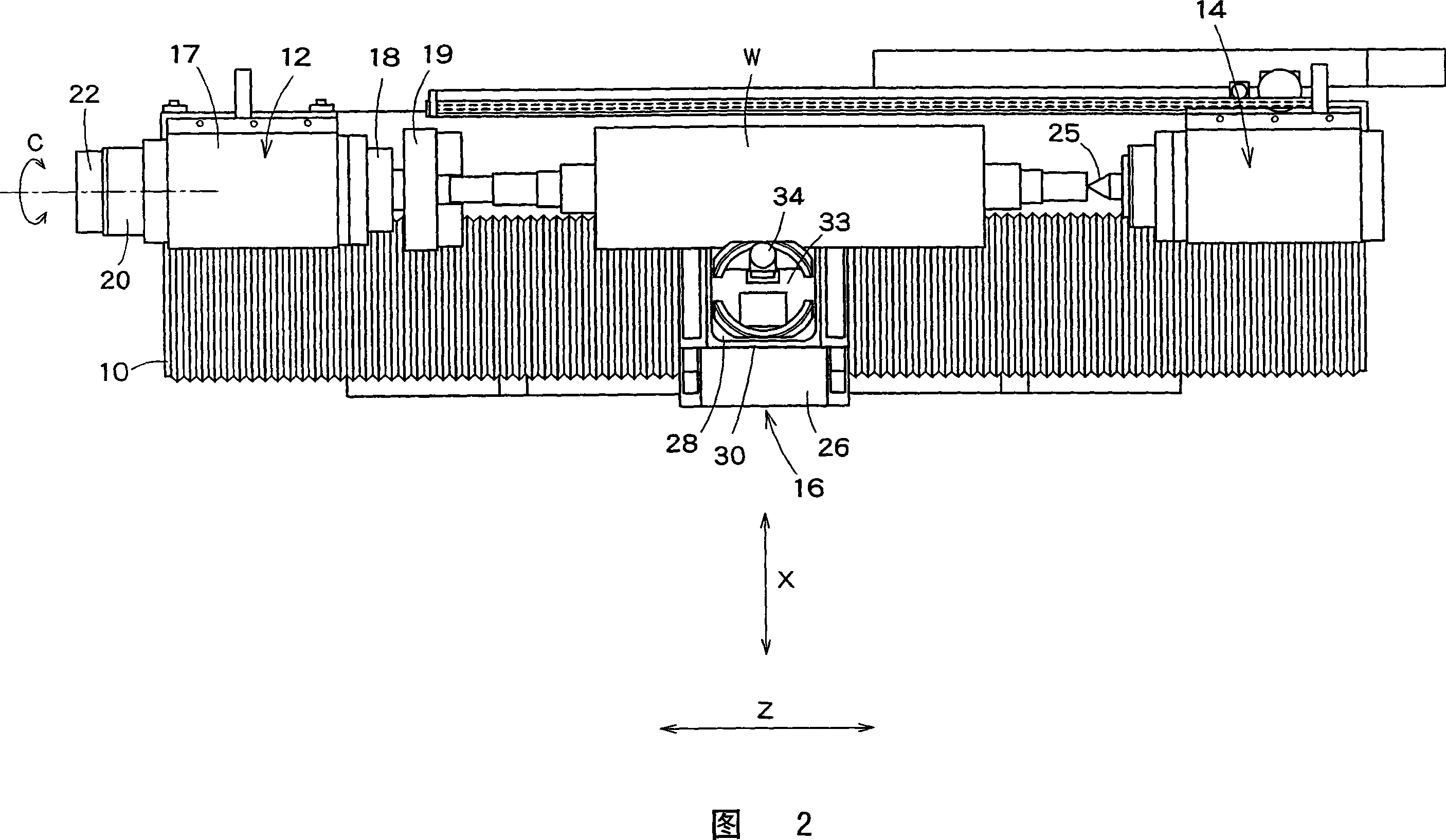

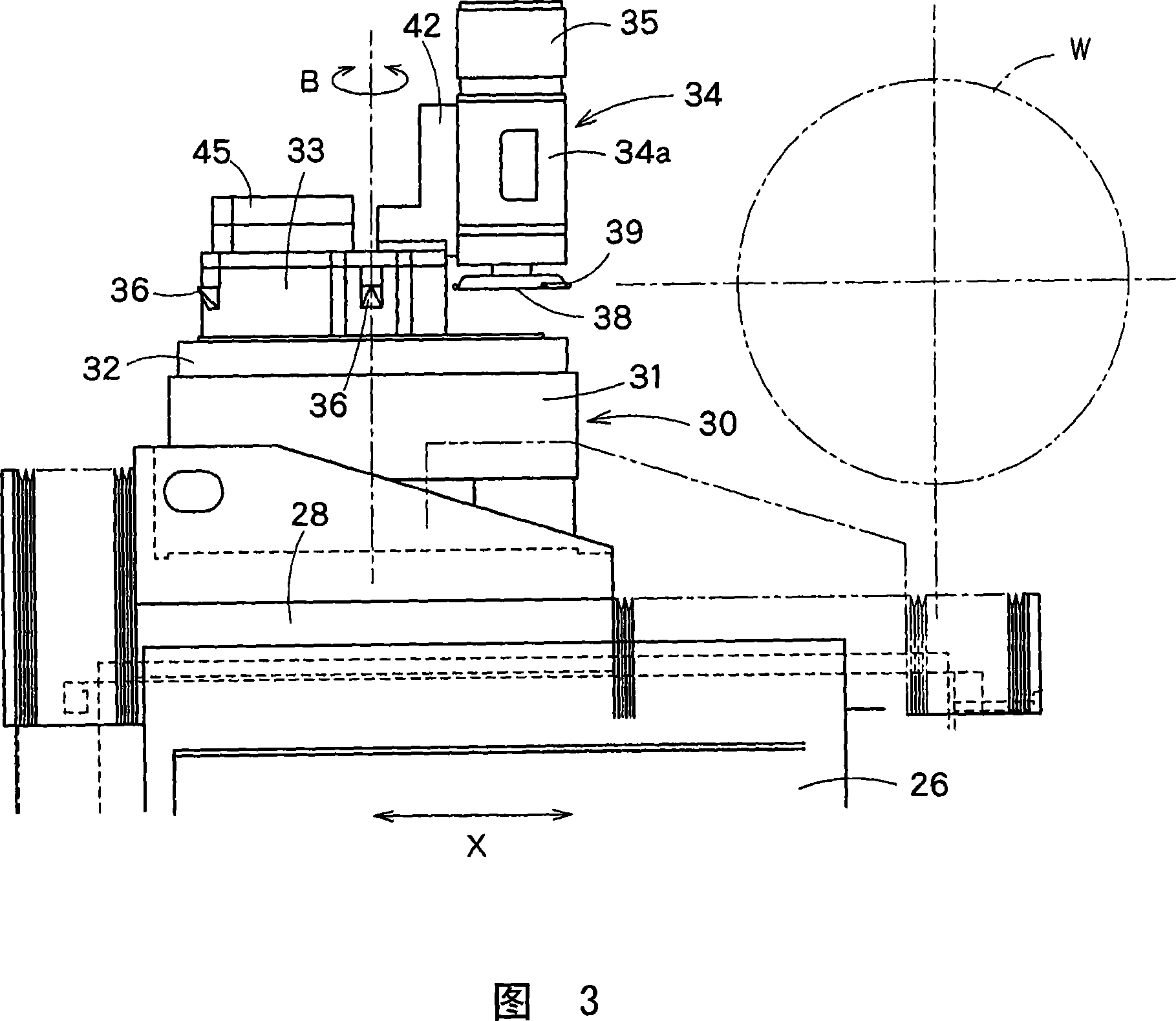

There is provided a precision roll turning lathe which can not only machine with high precision circumferential transverse grooves in the peripheral surface of a roll but can also machine with high precision longitudinal grooves in the peripheral surface. The precision roll turning lathe includes: a bed 10; a headstock 12, mounted on the bed 10, for rotating a roll-shaped workpiece while holding one end of the workpiece by means of a chuck, said headstock having an indexing axis (C axis) for performing circumferential indexing of the workpiece; a tail stock 14, mounted on the bed 10 and disposed opposite the headstock 12, for rotatably supporting the other end of the workpiece; a carriage 16 including a saddle 26 mounted on the bed 10 movably in the longitudinal direction (Z-axis direction) of the workpiece, and a table 28 mounted on the saddle 26 movably in a direction (X-axis direction) perpendicular to the longitudinal direction of the workpiece; a tool swivel 30 mounted on the table 28 and having an indexing axis (B axis); a tool post 33 mounted on the tool swivel 30 and having a plurality of cutting tools 36 attached thereto; and a fly cutter spindle device 34 mounted to the tool post 34 and having a cutter spindle for rotating a fly cutter 39.

Owner:TOSHIBA MASCH CO LTD

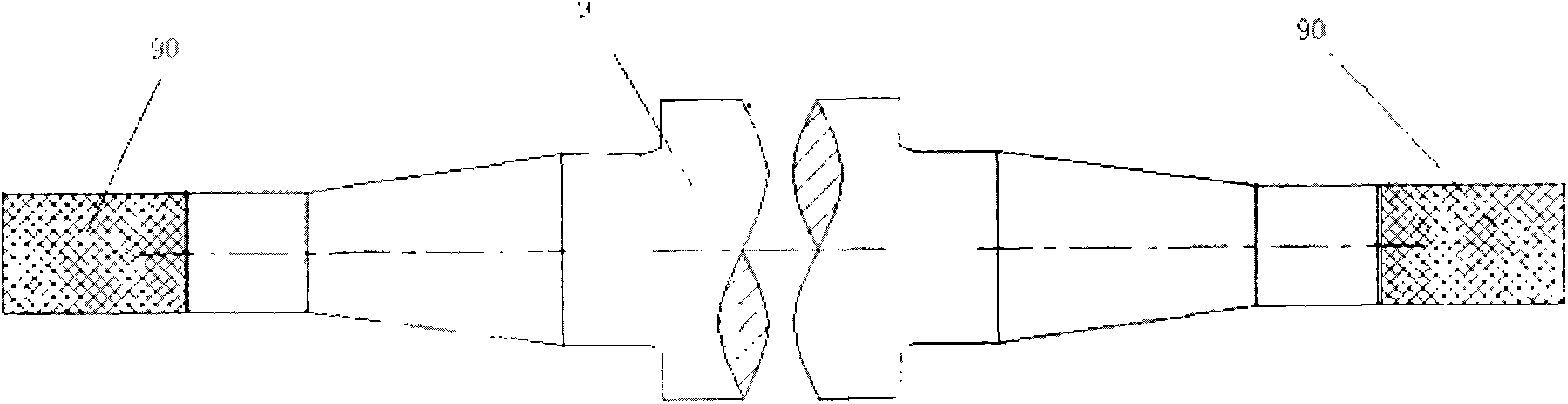

Machine tool and method for machining over-long diameter ratio shaft exceeding machine tool standard

InactiveCN101574743AIncrease profitIncrease travelLarge fixed membersTurning machinesFinialLongest Diameter

The invention discloses a machine tool and a method for machining an over-long diameter ratio shaft exceeding the machine tool standard. The method comprises the following steps: firstly, leaving a section of chuck dock with an effective length respectively at two ends of a workpiece in advance, and drilling central holes on two end surfaces of the workpiece; secondly clamping one end of the workpiece on a chuck of a headstock, and supporting the other end by a finial on a tailstock; thirdly, coarsely turning the excircle of each section of the workpiece, and reversing the workpiece for turning when a knife rest feeds to the tail end of a knife rest lead rail; fourthly, finely turning the excircle of each section of the workpiece, and reversing and clamping the workpiece for turning when the knife rest feeds to the tail end of the knife rest lead rail; and finally, milling the chuck docks at the two ends and the chamfer angle on a boring lathe, a milling machine or other machine tools. The machine tool and the method for machining an over-long diameter ratio shaft exceeding the machine tool standard achieve the purpose of machining long-shaft parts over 15 m on a common machine tool for machining long shaft parts, thereby reducing the production cost.

Owner:SHANGHAI HEAVY MACHINERY PLANT

Precision roll turning lathe

ActiveCN101062543AHigh precision machiningSuppress feverPropelling pencilsWorkpiecesMilling cutterTransverse groove

There is provided a precision roll turning lathe includes: a bed 10; a headstock 12, mounted on the bed 10, for rotating a roll-shaped workpiece while holding one end of the workpiece by means of a chuck, said headstock having an indexing axis (C axis) for performing circumferential indexing of the workpiece; a tail stock 14, mounted on the bed 10 and disposed opposite the headstock 12, for rotatably supporting the other end of the workpiece; a carriage 16 including a saddle 26 mounted on the bed 10 movably in the longitudinal direction (Z-axis direction) of the workpiece, and a table 28 mounted on the saddle 26 movably in a direction (X-axis direction) perpendicular to the longitudinal direction of the workpiece; a tool swivel 30 mounted on the table 28 and having an indexing axis (B axis); a tool post 33 mounted on the tool swivel 30 and having a plurality of cutting tools 36 attached thereto; and a fly cutter spindle device 34 mounted to the tool post 33. The precision roll turning lathe can not only machine with high precision circumferential transverse grooves in the peripheral surface of a roll but can also machine with high precision longitudinal grooves in the peripheral surface.

Owner:TOSHIBA MASCH CO LTD

Shaft-like workpiece multi-operation composite processing machine tool

InactiveCN101890640AReduce surface roughnessGuaranteed machining accuracyFeeding apparatusOther manufacturing equipments/toolsUltrasonic machiningSurface roughness

The invention provides a shaft-like workpiece multi-operation composite processing machine tool, which comprises a machine tool body, a worktable, a headstock, a tailstock, a saddle, turning fixture, a milling device and an ultrasonic processing device, wherein the machine tool body is provided with two longitudinal guide rails, the saddle is arranged on the two longitudinal guide rails of the machine tool body, a screw feeding mechanism is arranged on the machine tool body, and the saddle is connected with the screw feeding mechanism; the worktable is arranged on the machine tool body and between the two longitudinal guide rails, and the headstock and the tailstock are arranged at two ends of the worktable respectively; and the turning fixture, the milling device and the ultrasonic processing device are all arranged on the saddle of the guide rails. In the invention, through one time of clamping, the three functions required for processing shaft-like workpieces, namely turning, milling and ultrasonic surface processing, can be completed, a milling or turning device can be used to meet the requirements on dimensional tolerance, shape tolerance and the like of parts, and the ultrasonic processing device can be used to complete reducing surface roughness of the parts.

Owner:赵显华

Fully-automatic grinder

InactiveCN103962901AHigh degree of automationReduce labor intensityRevolution surface grinding machinesGrinding feed controlNumerical controlMulti machine

The invention relates to a fully-automatic grinder comprising a base, a workbench, a headstock, a tailstock, a grinding wheel mechanism, a feeding and discharging manipulator, an automatic feeding mechanism, an automatic discharging mechanism and a numerical control device. A chuck and a centre are arranged on opposite faces of the headstock and the tailstock respectively and concentrically. The feeding and discharging manipulator comprises a taking pneumatic gripper, a taking cylinder, a putting pneumatic gripper, a putting cylinder, a guide slide fixing frame, a ball screw, a linear guide rail and a guide rail bracket, the taking pneumatic gripper, the taking cylinder, the putting pneumatic gripper and the putting cylinder are all mounted on the guide slide fixing frame, the taking pneumatic gripper and the putting pneumatic gripper are arranged at an included angle forward and backward and arranged parallelly leftward and rightward, and the guide slide fixing frame is in sliding fit with the ball screw and the linear guide rail. The grinder is high in automation degree, the whole process of feeding, discharging, clamping, machining, on-line measurement and the like of workpieces is completed automatically through the numerical control device, one-man multi-machine operation can be realized, production efficiency and production quality are improved, and labor intensity and production cost of workers are lowered.

Owner:JIAHE TOOLS

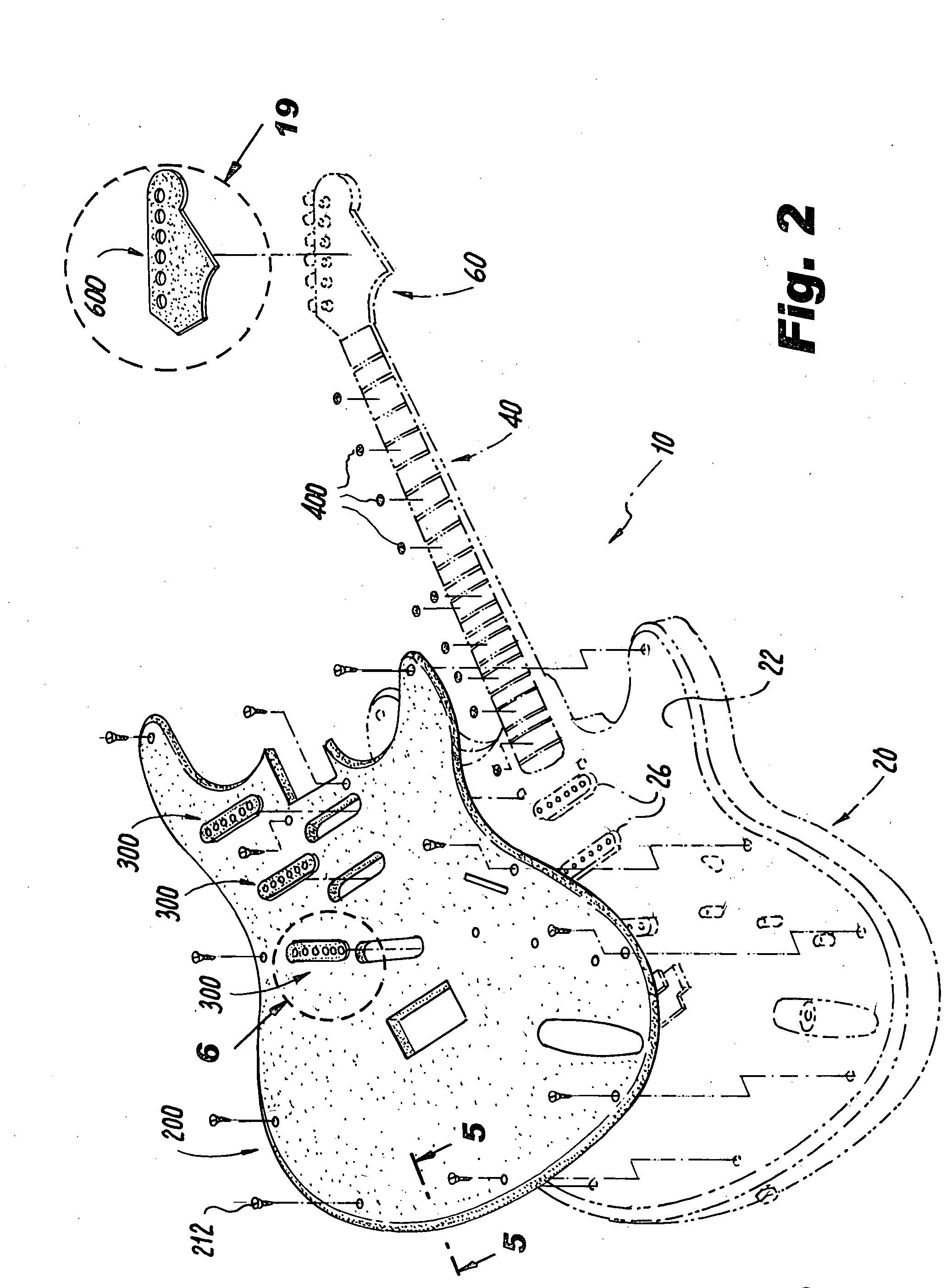

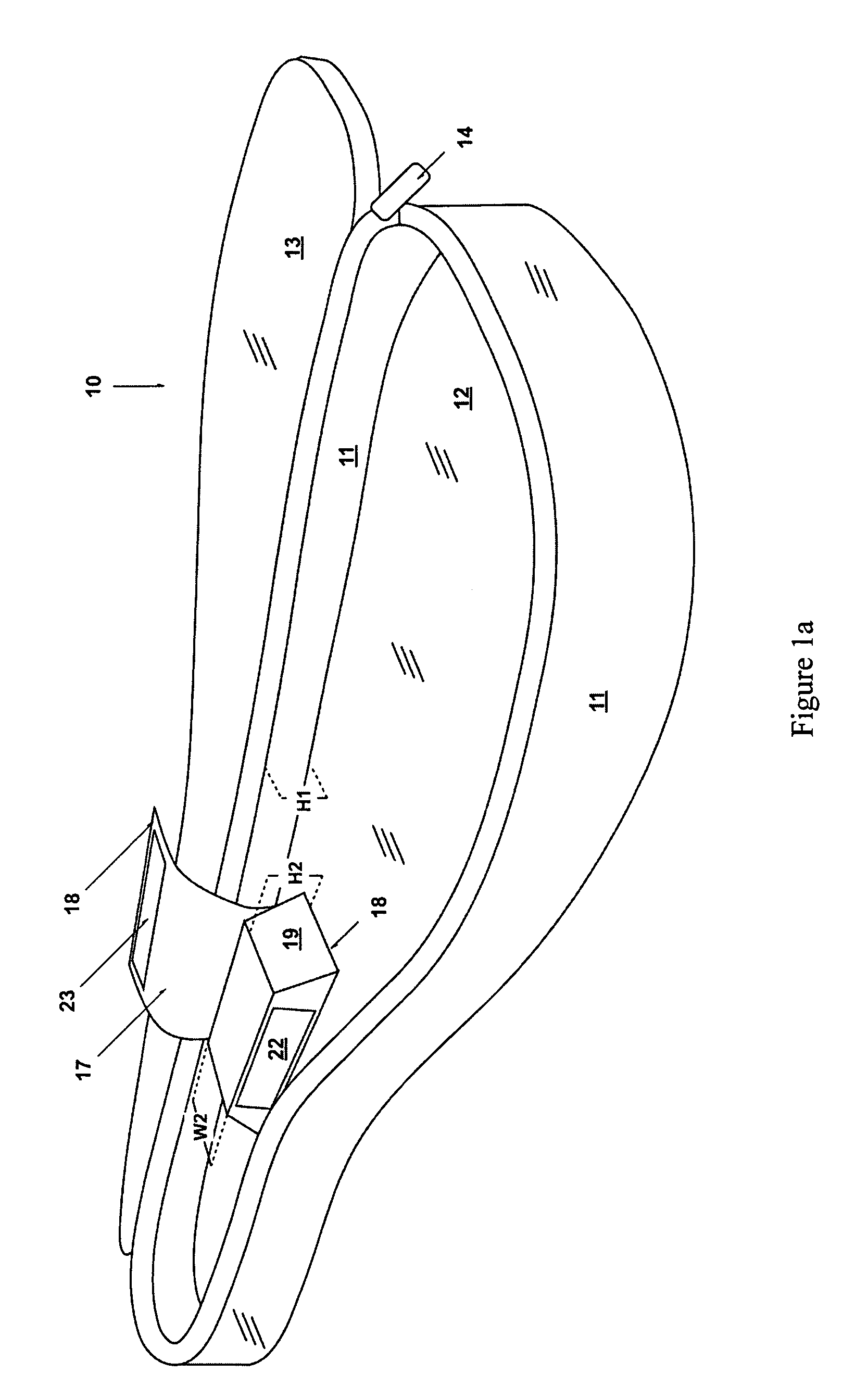

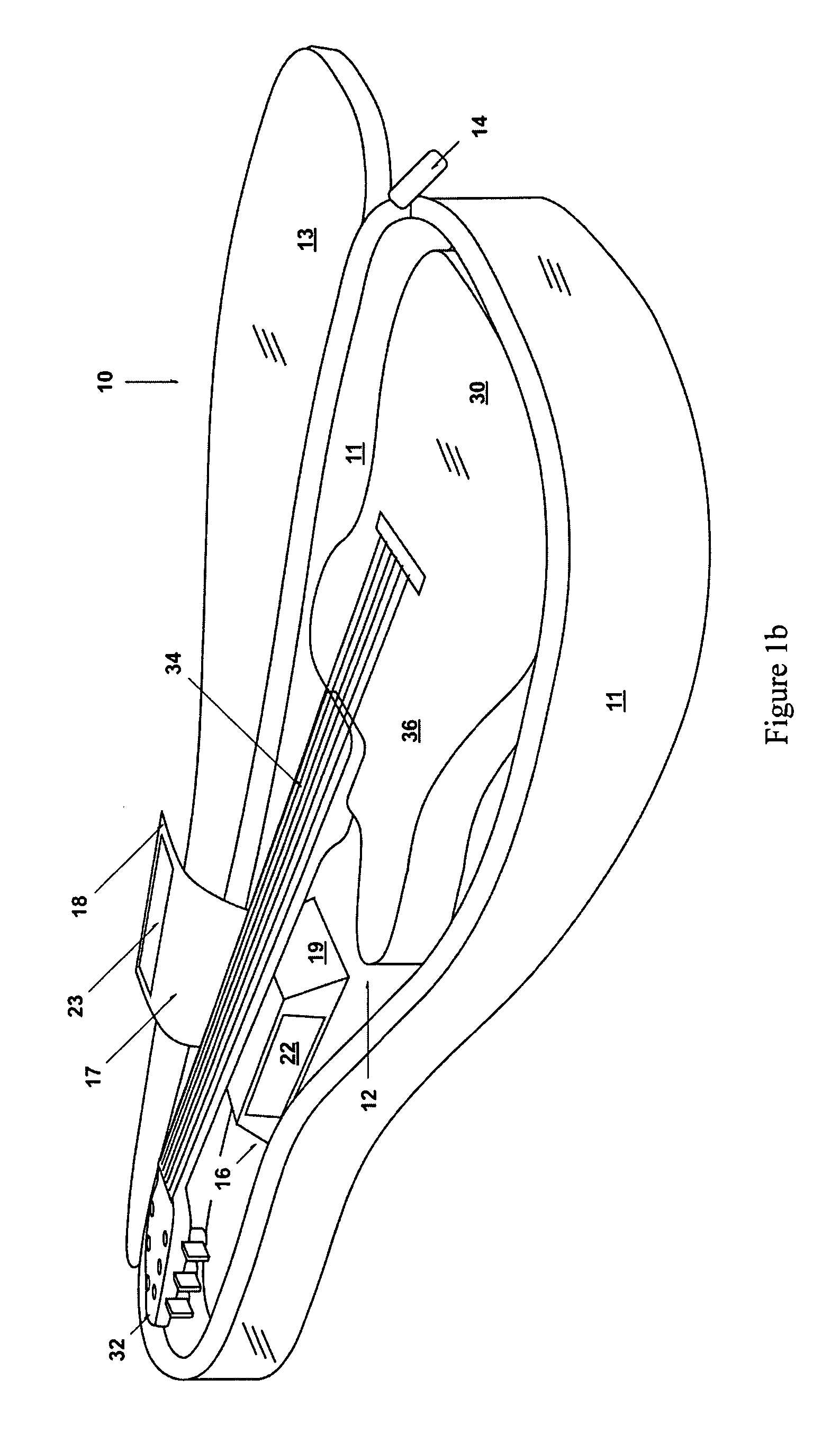

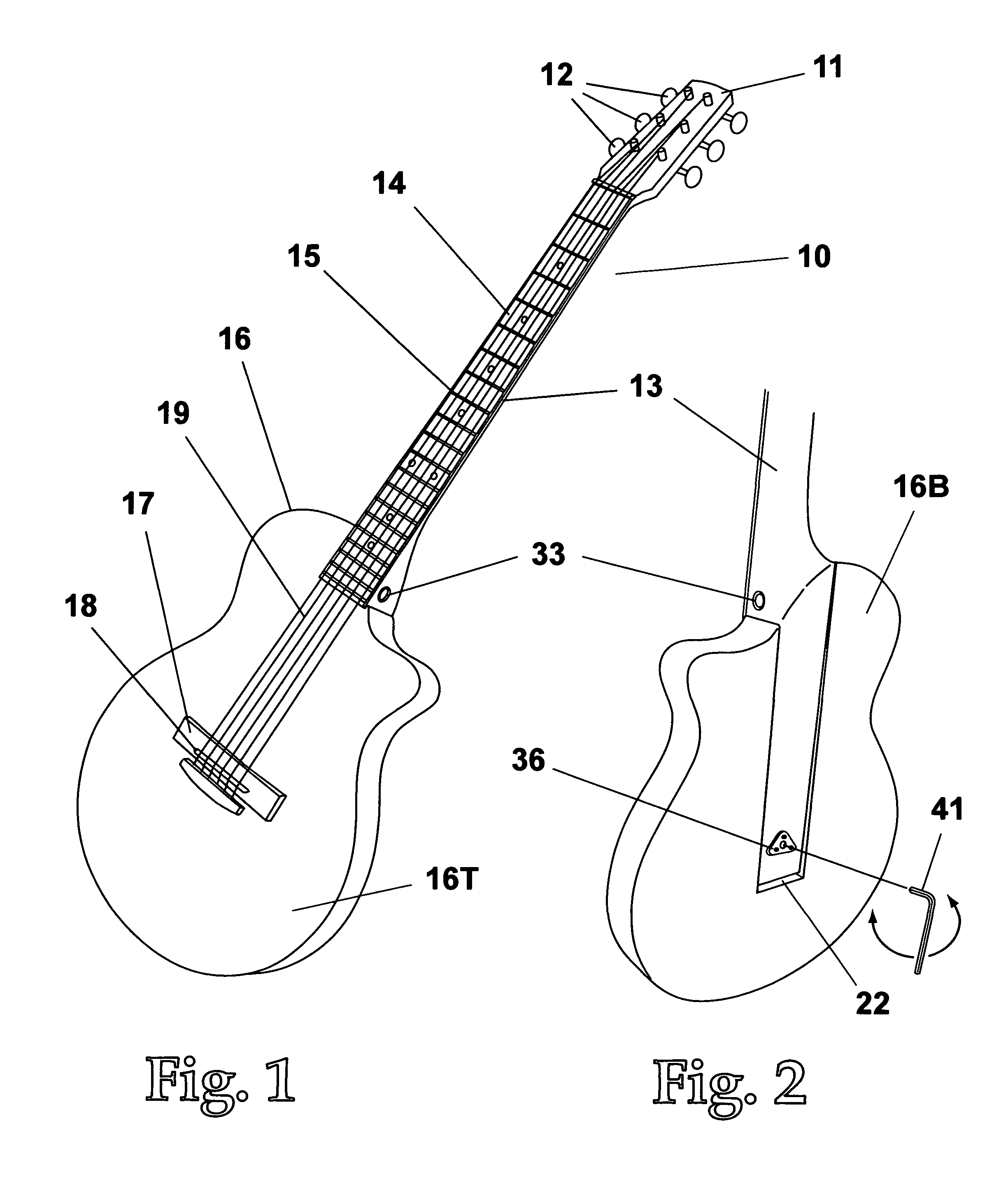

Interchangeable decorative covers for guitar components

An interchangeable cover covers the front viewable face of a body and / or a headstock of a guitar. The removable cover has an outline corresponding to an outline of the front face of the guitar body and / or headstock. Fasteners are provided along a periphery of each removable cover to attach each respective cover to the front viewable face of the body and or headstock of the guitar. The covers may have decorative apertures filled with a replaceable decorative insert, such as one or more pieces of mosaic inlay, a rastered image engraved on a rear portion thereof, multiple apertures with replaceable decorative inserts with different design features or a strip light embedded in the face of the body, with the cover being transparent over an area above the strip light. Preferably the periphery of each cover has a rounded and polished edge.

Owner:REISS STUART +1

Cylinder type workpiece code word machine

A cylindrical workpiece coding machine, the body is built with a motor and its gearbox, the body is obliquely installed with an adjustable bracket, the width adjustable hopper is installed on the adjustable bracket, the width adjustable hopper is connected to a curved material channel, the width The front end of the adjustable hopper is equipped with a puller mechanism, the front side of the fuselage is fixed with the headstock, the headstock supports the main shaft, the gearbox drives the main shaft, the front end of the main shaft is fixed with rollers, and at least one font box is fixed around the rollers, and the characters and patterns are embedded in the font box Among them, a cam is installed on one side of the font box, and a special-shaped backing plate mechanism is fixed on the other side of the front side of the fuselage. The frame is installed on the adjustment bracket, and when the main shaft rotates, the cam drives the feeding frame, the material pulling drive frame contacts and moves with the feeding frame, and the material pulling drive frame contacts and pulls the material pulling mechanism. The handwriting it engraves is neat and clear, and the production efficiency is high.

Owner:李钢放

Insulator horizontal tensile testing machine

ActiveCN101706394AAdjustable distanceEasy to adjust the distanceMaterial strength using tensile/compressive forcesLocking mechanismControl system

The invention relates to an insulator horizontal tensile testing machine, which comprises a working platform, wherein a rail is arranged on the working platform; the rail is provided with a headstock and a tailstock; the side wall of the working platform is provided with a plurality of through pin holes; the tailstock comprises a traveling mechanism, locking mechanisms and a fine adjustment mechanism, and is provided with a travel switch; the traveling mechanism comprises a driving motor, and an output end of the driving motor drives a pulley block through a middle transmission mechanism; the locking mechanisms are divided into two groups and are symmetrically arranged on two sides of the tailstock, each group of the locking mechanisms comprises a locking motor, an output end of the locking motor is connected with a transverse screw rod, a sliding block provided with a plug pin is inserted on the screw rod, and the position of the plug pin corresponds to the through pin holes; and the fine adjustment mechanism comprises a fine adjustment motor, an output end of the fine adjustment motor is connected with a rotating wheel, a longitudinally arranged screw rod is inserted on the rotating wheel, and the front end of the screw rod is connected with a tailstock clamp. The insulator horizontal tensile testing machine is also provided with a loading cylinder which is controlled by a remote measurement and control system. The insulator horizontal tensile testing machine adopts the movable tailstock, and has macro-movements, positioning and micro-adjustments so that the distance between the headstock and the tailstock on the working platform is convenient to adjust to adapt to tensile tests of insulators with different lengths.

Owner:CHINA ELECTRIC POWER RES INST +1

Cases for the protection of stringed musical instruments

ActiveUS7687701B1Reduce riskAvoid damageOther accessoriesContainer/bottle contructionEngineeringHeadstock

Cases for the protection of stringed musical instruments having a bottom, a sidewall of a predetermined height extending from the bottom and a cover which is hingedly connected to the sidewall and which can be closed and secured with an appropriate fastener are described herein. The cases include a semi-rigid neck-brace having a height approximately the same as the inner height of the sidewall and being affixed to the bottom. The cases further include at least one retaining band that may be used to releasably secure the instrument neck to the neck-brace. Instrument damage may be prevented in the event of a sideways or backward fall, in at least part, because the neck-brace suspends the headstock between the bottom, sidewall and cover of the case and thereby prevents it from making contact.

Owner:MONO CREATORS

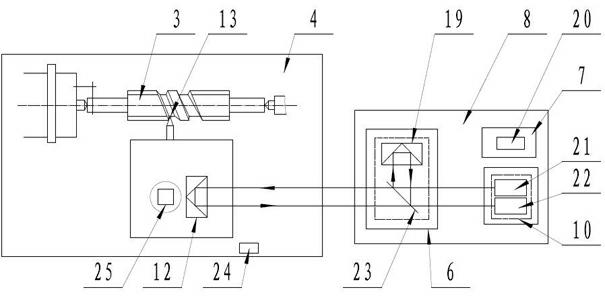

Dynamic measuring device for worm helix error and pitch error

InactiveCN102322824AStrong self-resetting abilityIncrease stiffnessUsing optical meansHelical lineGrating

The invention discloses a dynamic measuring device for worm helix errors and pitch errors, which comprises a headstock, a measuring table, a worm to be measured, a machine bed, a tailstock, an interference mirror, a compensator, a laser support, a computer, a laser head, a flat-V-shaped guide rail, a movable pyramid reflecting mirror, a measuring head, a circular grating system, an axial feed transmission assembly and the like. The circular grating system in the headstock and the worm to be measured are driven by the axial feed transmission assembly to realize synchronous rotation. When the worm to be measured rotates, the measuring table is dragged to move on the guide rail through the measuring head. The laser support supports the laser head, the interference mirror and the compensator. The movable pyramid reflecting mirror is fixedly arranged on the measuring table and moves along with the measuring table relative to the laser support. Since the entire instrument is provided with compensation units for temperature, environment and the like, the measuring accuracy is further improved. By using the measuring device, the automatic and dynamic high-accuracy measurement of the helix errors, pitch deviations and accumulated pitch errors of the worm with precision being or above third grade can be realized.

Owner:NANJING UNIV OF SCI & TECH

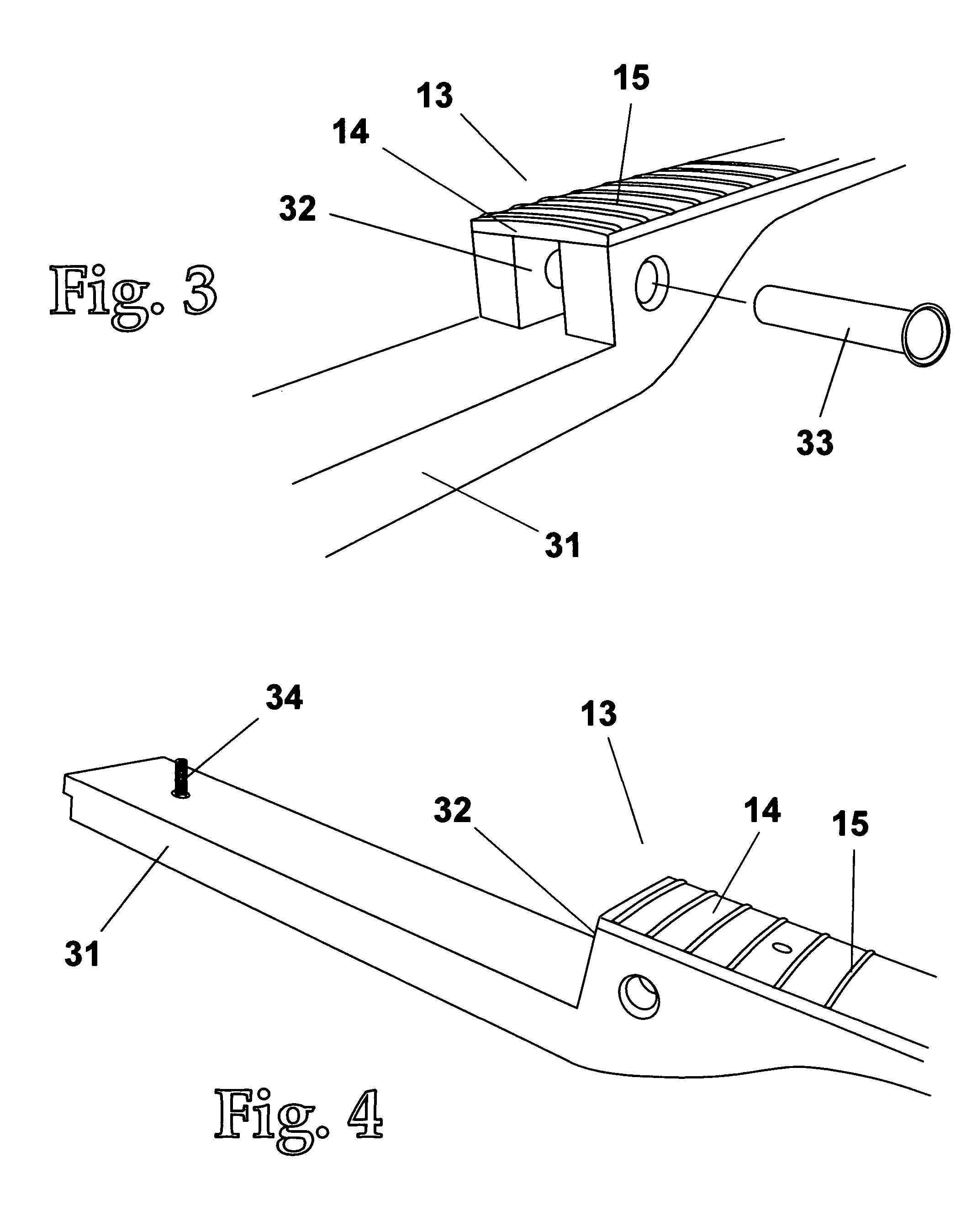

Stringed instrument string action adjustment

A stringed musical instrument comprises: a headstock with tuners; a neck having a fingerboard, and a neck extension; a body having a top, a back, a longitudinal recess in the back for receipt of the neck extension and a bridge with a saddle secured to the body; and, one or more strings stretched from the headstock over the neck and fingerboard and over a portion of the top of the body to contact points on the bridge saddle. The instrument is further provided with a pivotal mount for mounting the neck to the body and a string action adjustment member for moving the neck lower extended end within the body longitudinal recess and thereby the position of the neck relative to the body, whereby the height of the strings are adjusted relative to the neck and its fingerboard.

Owner:BABICZ JEFFREY T

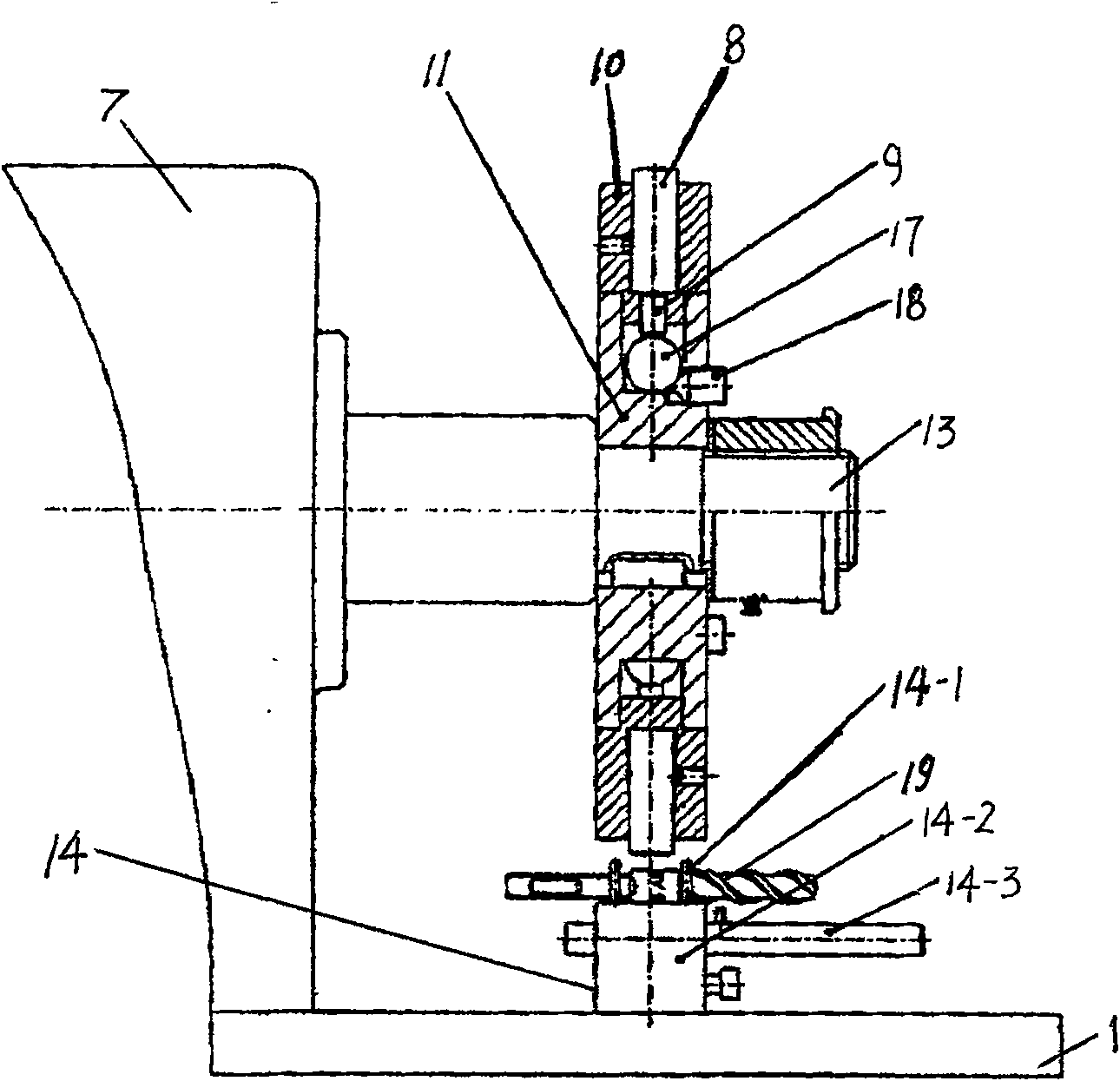

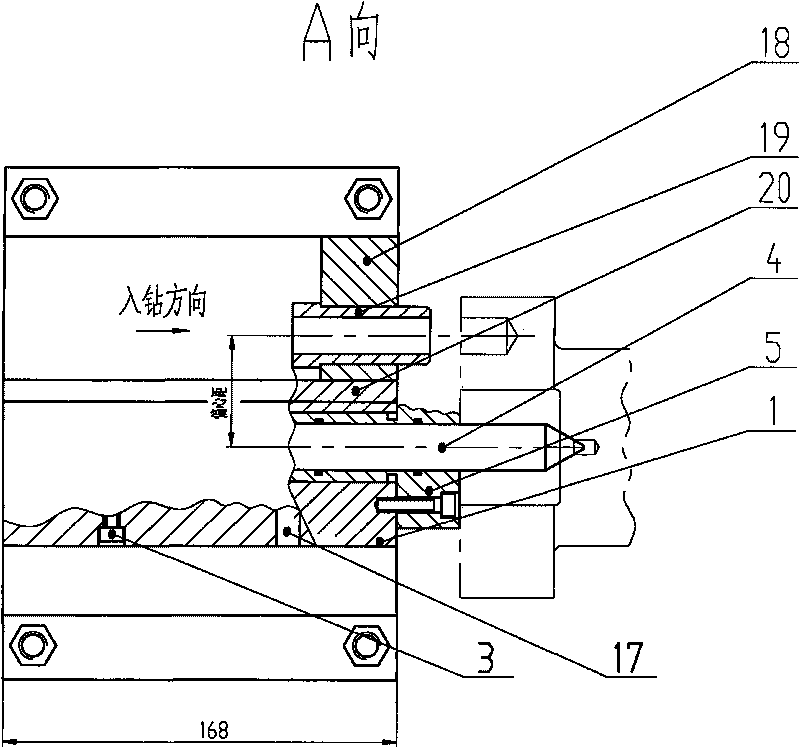

Horizontal drilling device

InactiveCN103192108AEasy to operateHigh speedDrill jigsBoring/drilling machinesGear wheelUniversal joint

Owner:QINGYANG HENGYUAN MACHINERY MFG

Polishing device for inner surface of straight pipe

ActiveCN107745326ACompact structureImprove general performanceEdge grinding machinesPolishing machinesStraight tubeMagnetic poles

The invention belongs to the technical field of polishing of the inner surfaces of straight pipes and particularly relates to a polishing device for the inner surface of a straight pipe. The polishingdevice comprises an overall machine tool frame and a three-jaw chuck arranged on the overall machine tool frame; and the overall machine tool frame comprises a tool body and further comprises a spindle box, a lead screw and a tailstock which are arranged on the tool body. The polishing device is characterized in that a clamping machining part, a guiding part and a magnetic pole part are arrangedon the overall machine tool frame. The polishing device is compact in structure, high in universality, easy to operate and convenient to mount; a magnetic pole chain is mounted, grinding particles arefully utilized to polish the straight pipe which is long and small in inner diameter, and the effect is better especially for a magnetic conductive straight pipe; and compared with a traditional modeof additionally arranging an auxiliary magnetic pole, according to the polishing device, leftward-rightward moving of the magnetic pole chain can be controlled, and the inner surface of a workpiece can be polished thoroughly.

Owner:UNIV OF SCI & TECH LIAONING

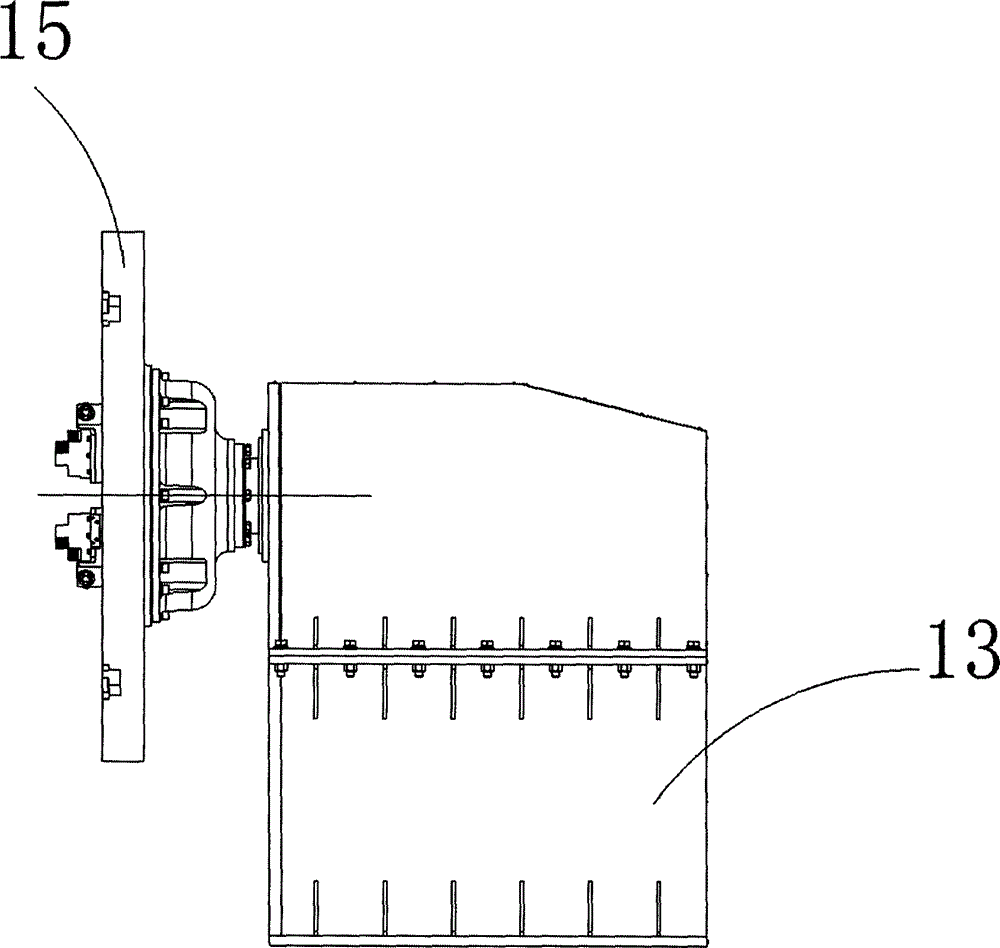

Box robot welding system

ActiveCN106425254AAchieve weldingAchieve coverageWelding/cutting auxillary devicesAuxillary welding devicesLinear motionControl theory

The invention relates to a robot welding system, in particular to a box robot welding system. The box robot welding system comprises a positioner headstock, a tool clamp, a robot sliding table walking mechanism, a robot welding system body, a positioner tail frame and a positioner base. The positioner headstock and the positioner tail frame are mounted on the positioner base. The positioner tail frame can move in the direction close to or away from the positioner headstock. The two ends of the tool clamp are connected with the positioner headstock and the positioner tail frame through fast connecting devices correspondingly. The robot sliding table walking mechanism is arranged on one side of the positioner base. The robot welding system body is arranged on the robot sliding table walking mechanism. According to the box robot welding system, the servo drive sliding table walking mechanism can do X-axis linear motion, and positioner and workpiece rotation and a robot welding gun are matched for achieving welding in various angles.

Owner:斯图加特航空自动化(青岛)有限公司

Synchronous control device of hydraulic headstock gear

InactiveCN101033758AReduce manufacturing costHigh synchronization accuracyBarrages/weirsServomotorsAutomatic controlClosed loop

The invention relates to hydraulic start-stop technique field, particularly a control device of high degree of accuracy synchronization hydraulic start-stop machine. The hydraulic can auto controls double-cylinder synchronous operation in start-stop progress of anchor gate. It has a hydraulic and an electricity control device. The hydraulic control device makeup with an oil pump electric engine group, two rectified speed control value group and a by-pass cut-away gate gurgle value group. The electricity control system makeup with a gate opening-detection device and a PLC. The invention use synchronous closed loop program combine the coarse adjustment of rectified speed control value group and gate gurgle of by-pass cut-away gate gurgle value group. It makes high degree of accuracy synchronization of two fluid cylinders and low cost of hydraulic start-stop machine.

Owner:CHANGZHOU HYDRAULIC COMPLETE EQUIP

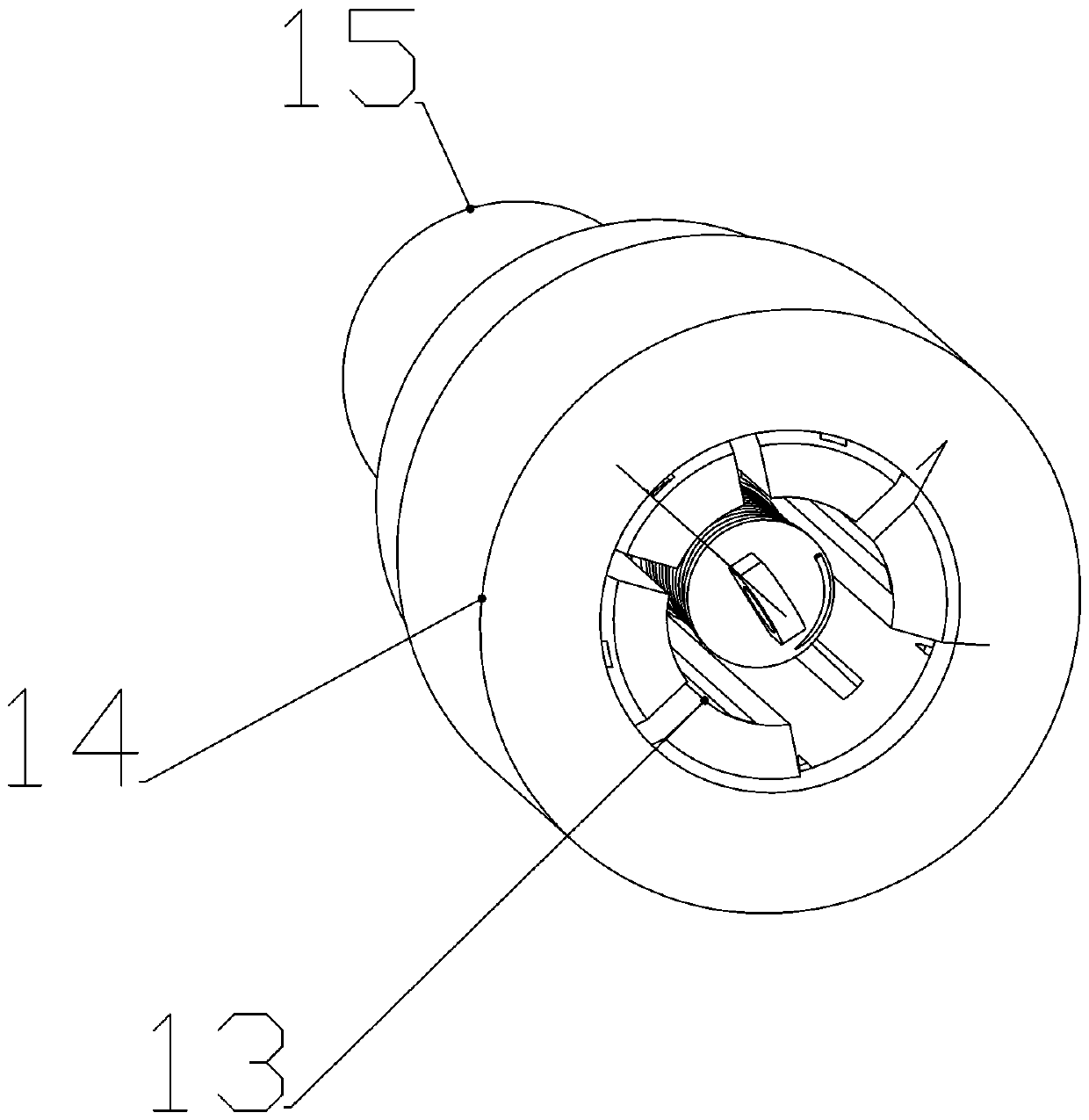

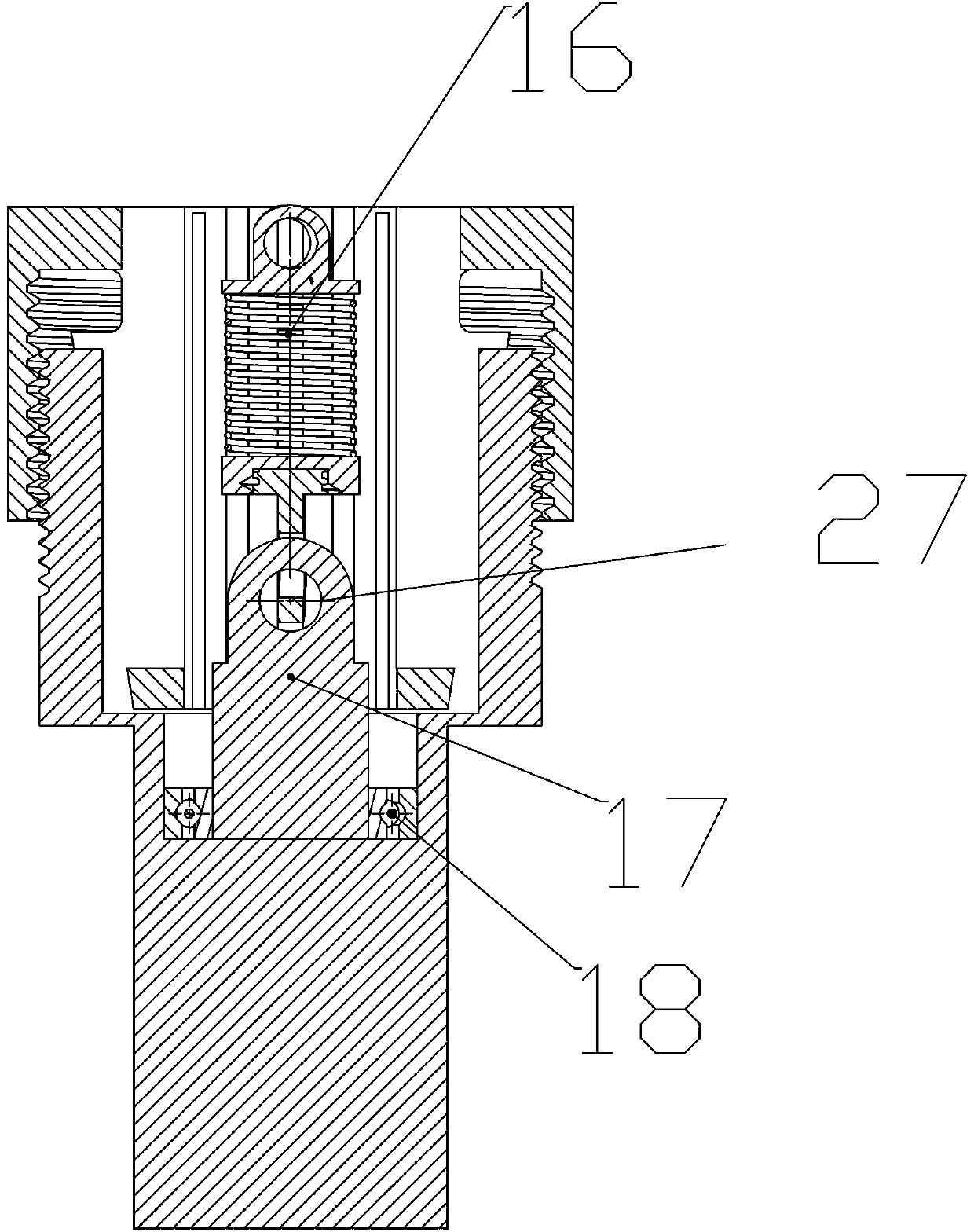

High-efficiency dial linking machine

ActiveCN102953234AStable structureGuaranteed uptimeLubrication/cooling devicesSewing-machine control devicesElectric machineryEngineering

The invention discloses a high-efficiency dial linking machine. The high-efficiency dial linking machine comprises a headstock, a speed-regulating unit, a case and a dial; the headstock comprises a box, a box cover, a gear assembly and an adjusting handle, wherein the box cover is mounted on the top of the box, the gear assembly is mounted in the box, the adjusting handle is linked with the gear assembly, and the gear assembly comprises a first gear assembly and a second gear assembly which are respectively provided with a first helical gear and a second helical gear and are engaged with each other; the speed-regulating unit is linked with the gear assembly through a transmission by being matched with a motor; the case comprises a mounting bracket, an upper shield and a lower shield, and the upper shield and the lower shield are jointly formed into an automatic oil filling device; a helical tooth drive unit, a cam drive mechanism linked with the helical tooth drive unit, a striping unit, a push rod drive mechanism and a dividing unit linked with the cam drive mechanism are mounted in the case, wherein the helical tooth drive unit is linked with the gear assembly through a synchronous drive mechanism; and a debuggable counterweight is mounted on the dividing unit. The high-efficiency dial linking machine has the advantages of stable and smooth operation, good sewing quality, long service life and the like.

Owner:东莞市缝神机械设备有限公司

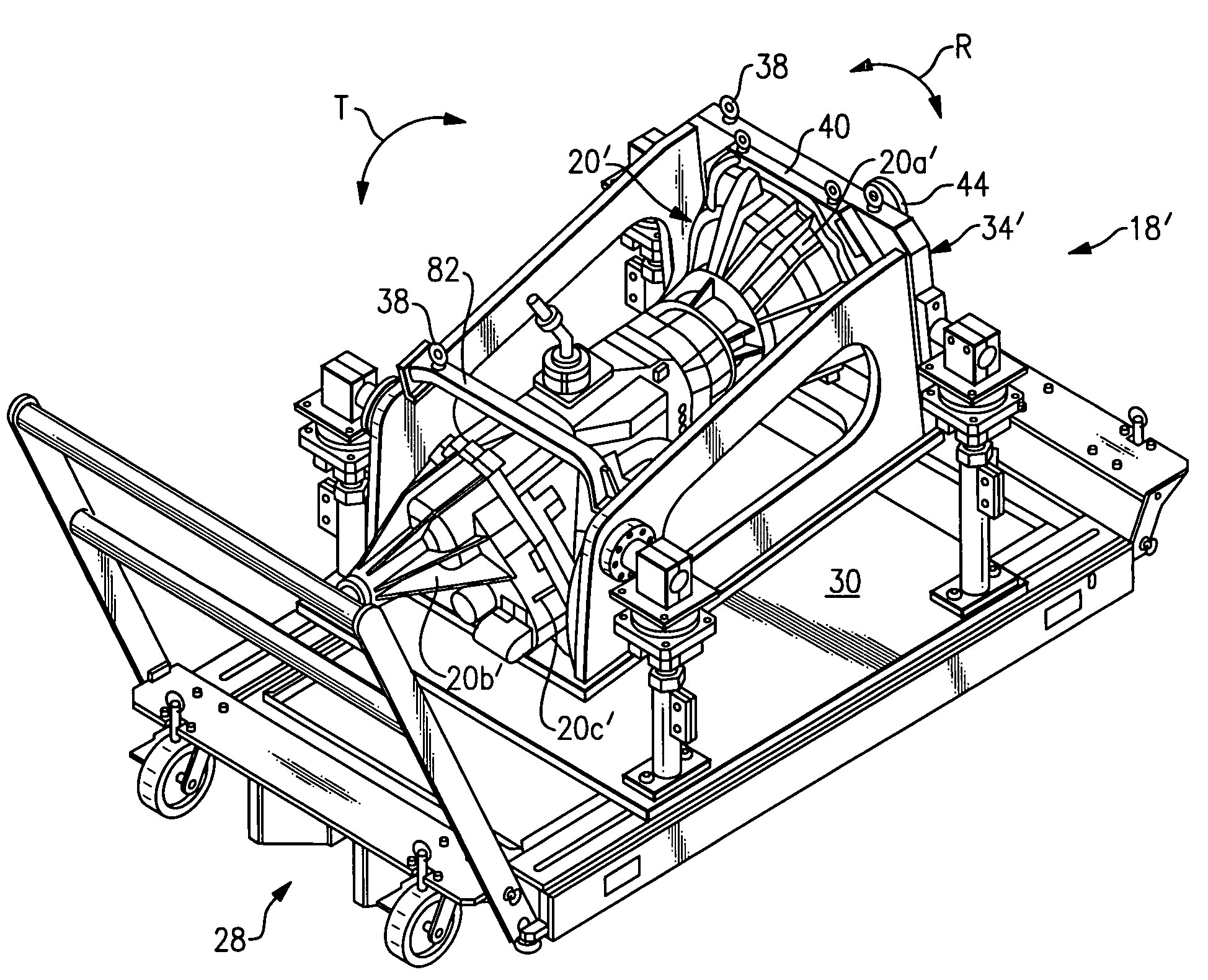

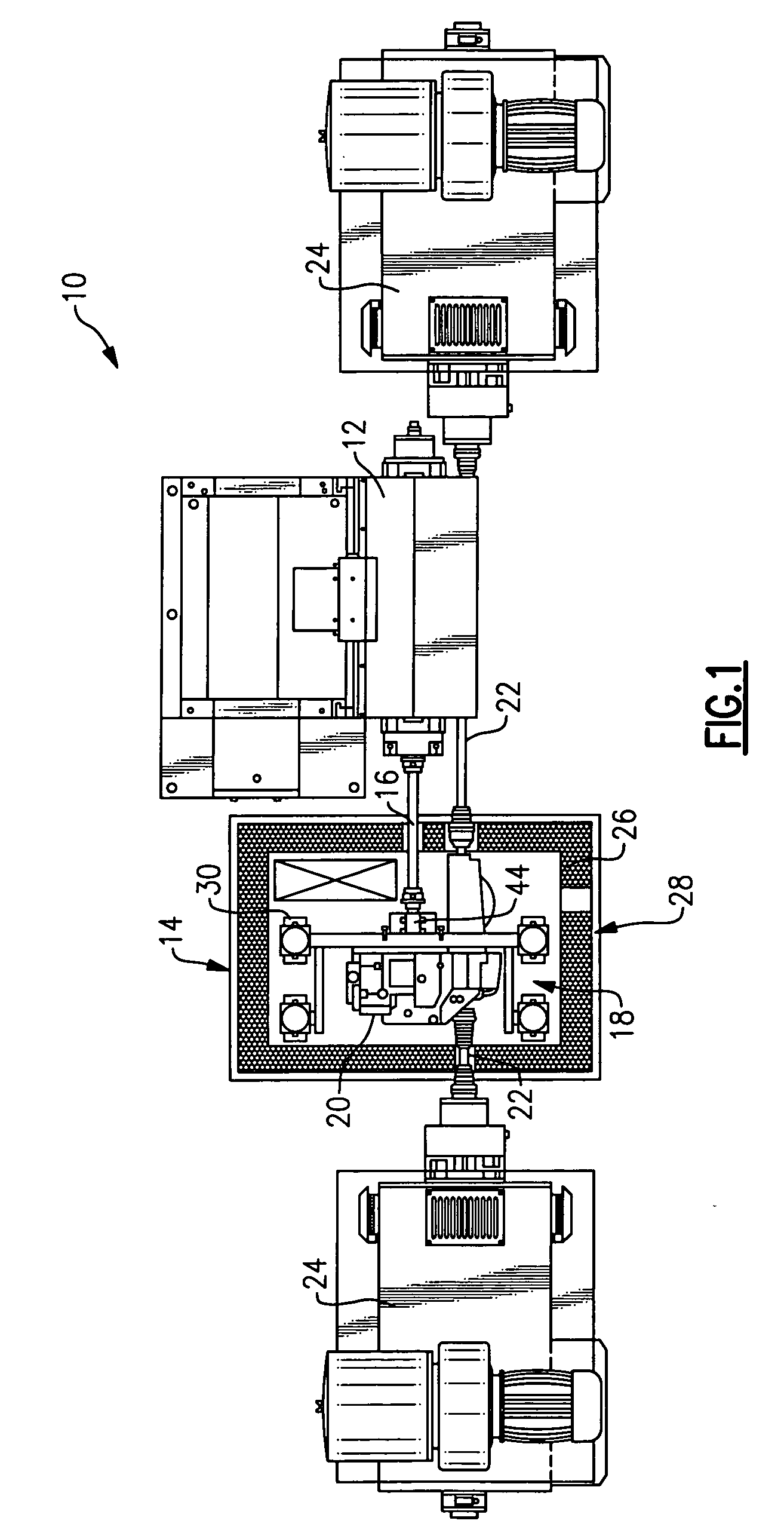

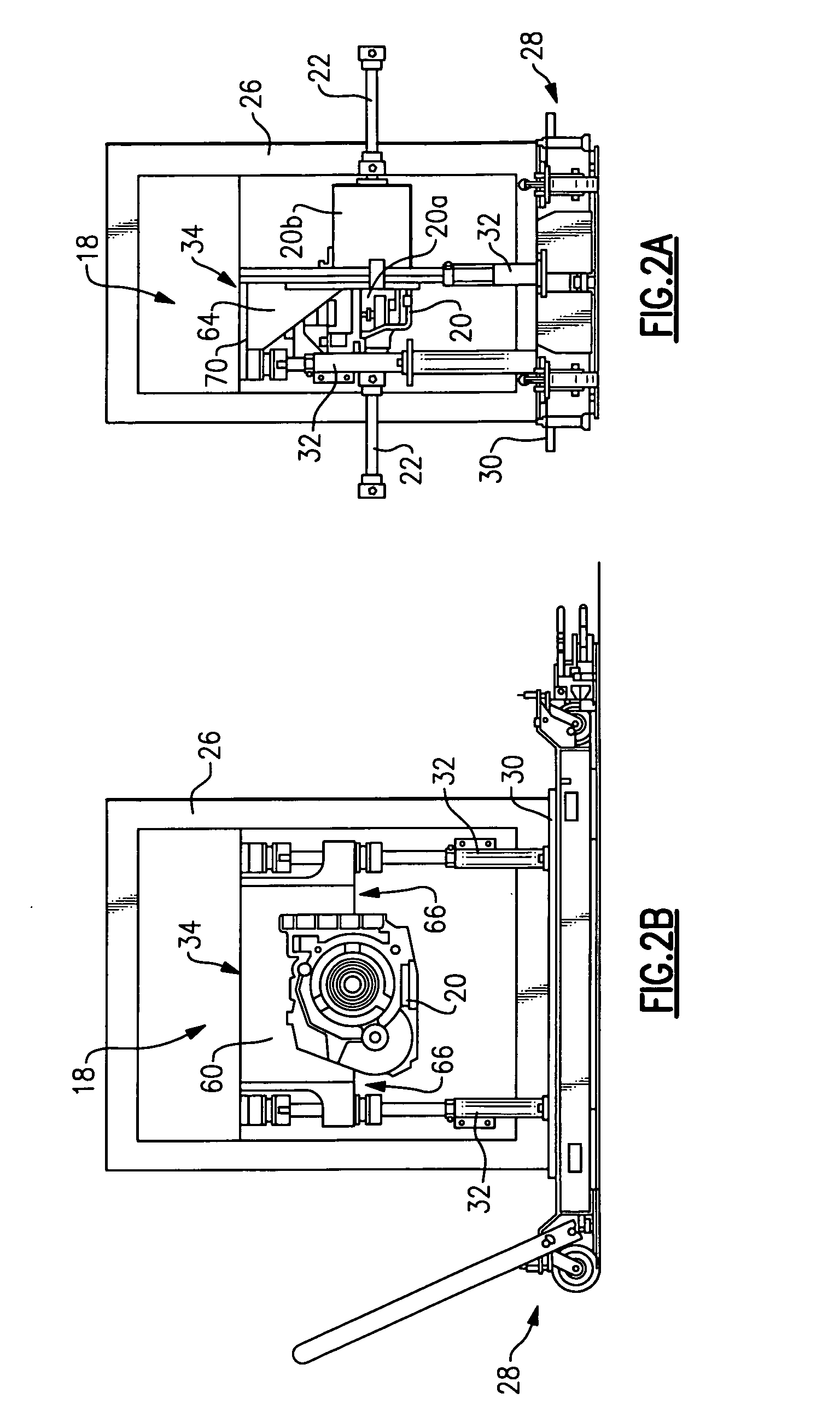

Transmission headstock for test stands

InactiveUS20080126889A1Extension of timeMachine gearing/transmission testingError detection/correctionHeadstockAutomotive engineering

A mobile test unit for testing a powertrain component such as a transmission is used in a test cell. A test unit includes a movable, generally horizontal base plate, and a frame spaced from the base plate. A headstock is secured to the frame for supporting the transmission. An adjustable support, which is arranged on each of four corners of the frame in the example embodiment, interconnects the frame to the base plate. The adjustable supports are movable in a vertical direction, in one example, between multiple positions to achieve a desired orientation relative to the base plate. In particular, the orientation of the frame is adjusted to obtain a desired rotational and / or tilt angle that corresponds to a rotational and / or tilt angle of the transmission when installed into a vehicle. The transmission can be installed onto the test unit, and the test unit can be moved into and out of a test cell. The example test unit is capable of replicating the orientation of the transmission when installed in a vehicle to provide more representative test data. Furthermore, the adjustments to the test unit can be done outside of a test cell to increase the time during which the test cell can be utilized.

Owner:AVL TEST SYST

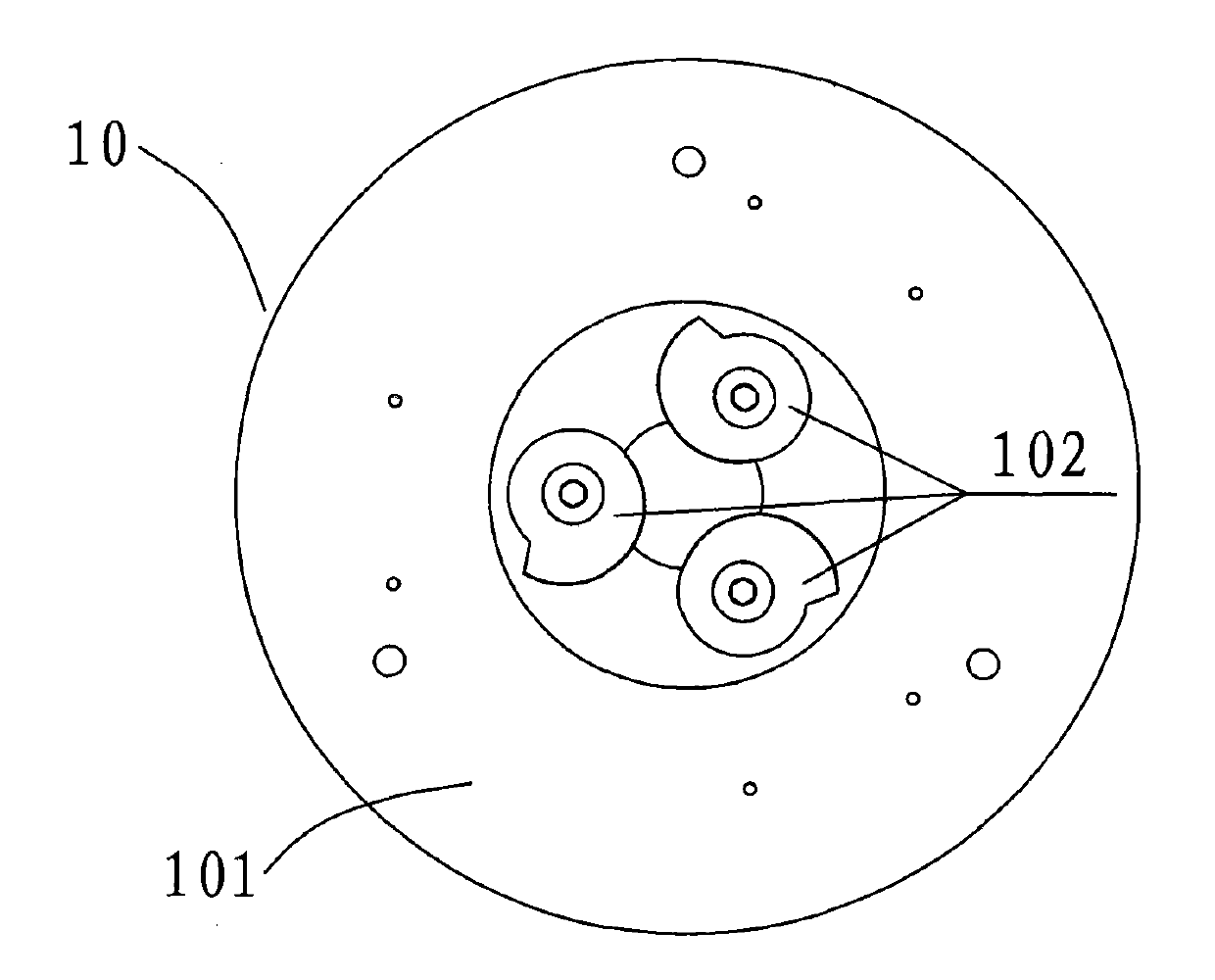

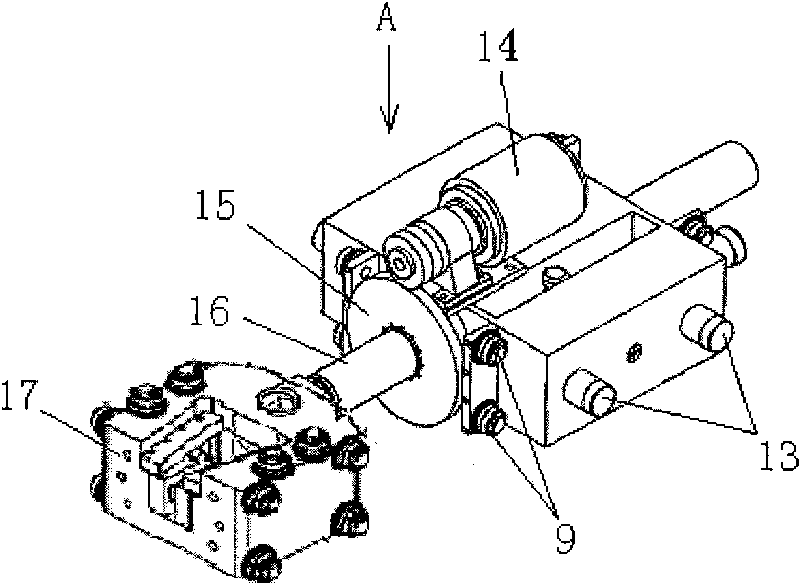

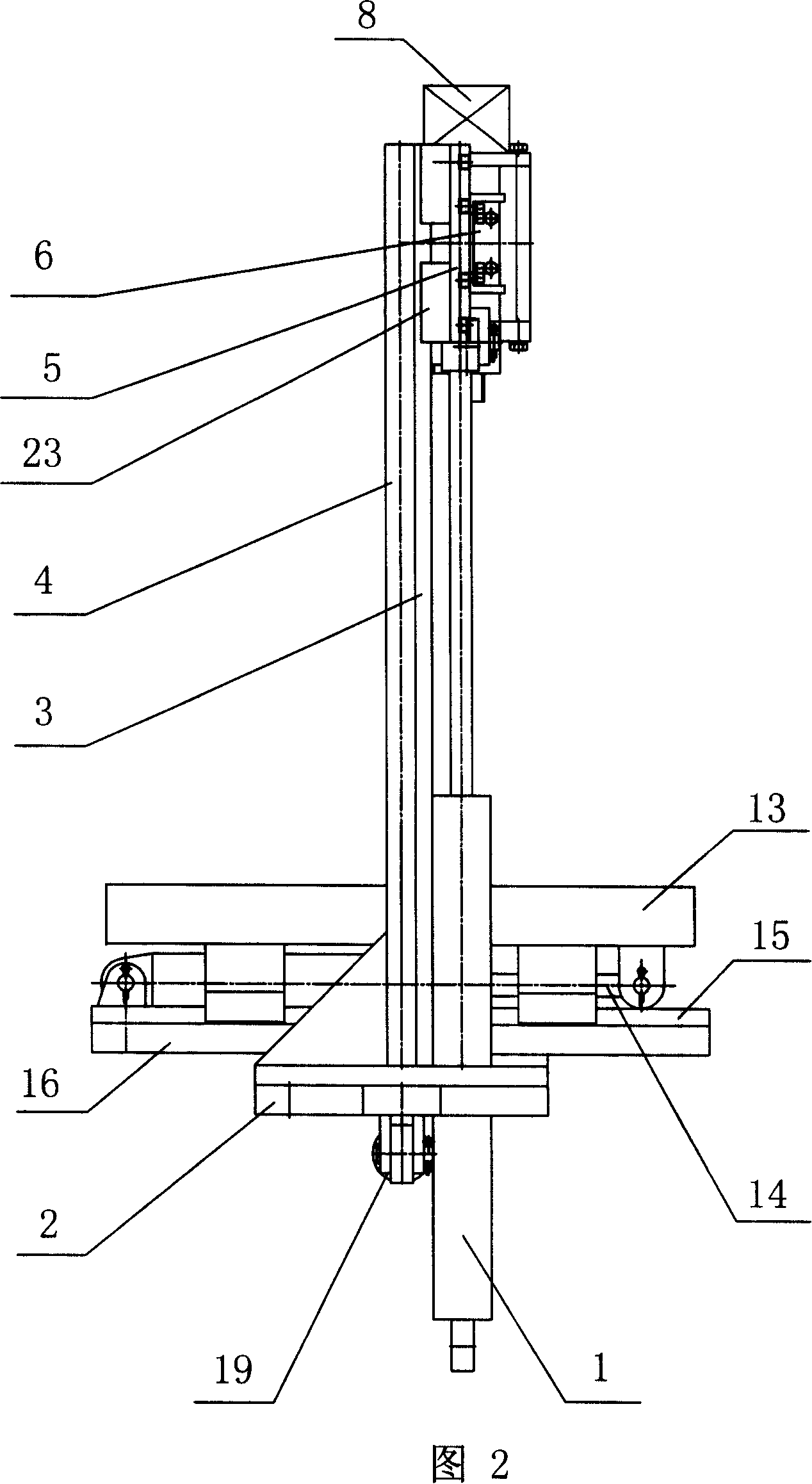

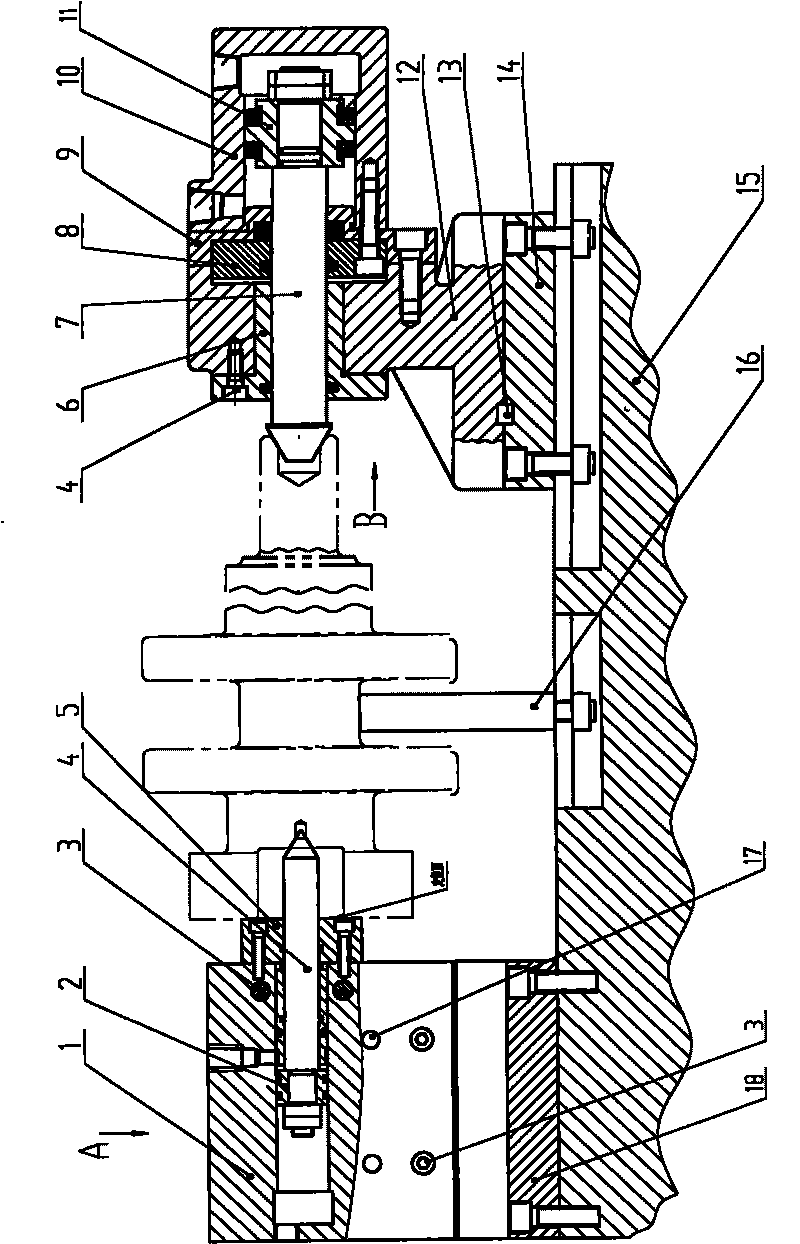

Multifunction friction wear testing machine

InactiveCN101021466AScientific experiment dataExperimental data is reliableStructural/machines measurementUsing mechanical meansHydraulic cylinderHydraulic motor

The invention relates to an experimental device to detect and analyze wearing of superhard tool. It is a multifunctional rubbing-wearing experimental machine. It is characterized in that: it contains first hydraulic cylinder (1), soleplate (2), first guide (3), upright column (4), gliding block joint plate (5), crossbeam (6), torque sensor (7), hydraulic motor (8), headstock (9), principle axis (10), rotary transducer (11), workbench (13), third hydraulic cylinder (14), third guide (15), slip board (16), second guide (17), second hydraulic cylinder (19) and first pressure sensor (20). Set (20) in (1) and rotate speed measuring flag on principle axis of hole in (11). (11) and (9) are connected. (7) is composed of a twist bar (28) and two torque meter pressure sensors (29). The invention can realize drilling, sawing and milling of tool, test torque, drilling speed and infix pressure parameters of superhard tool during working.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

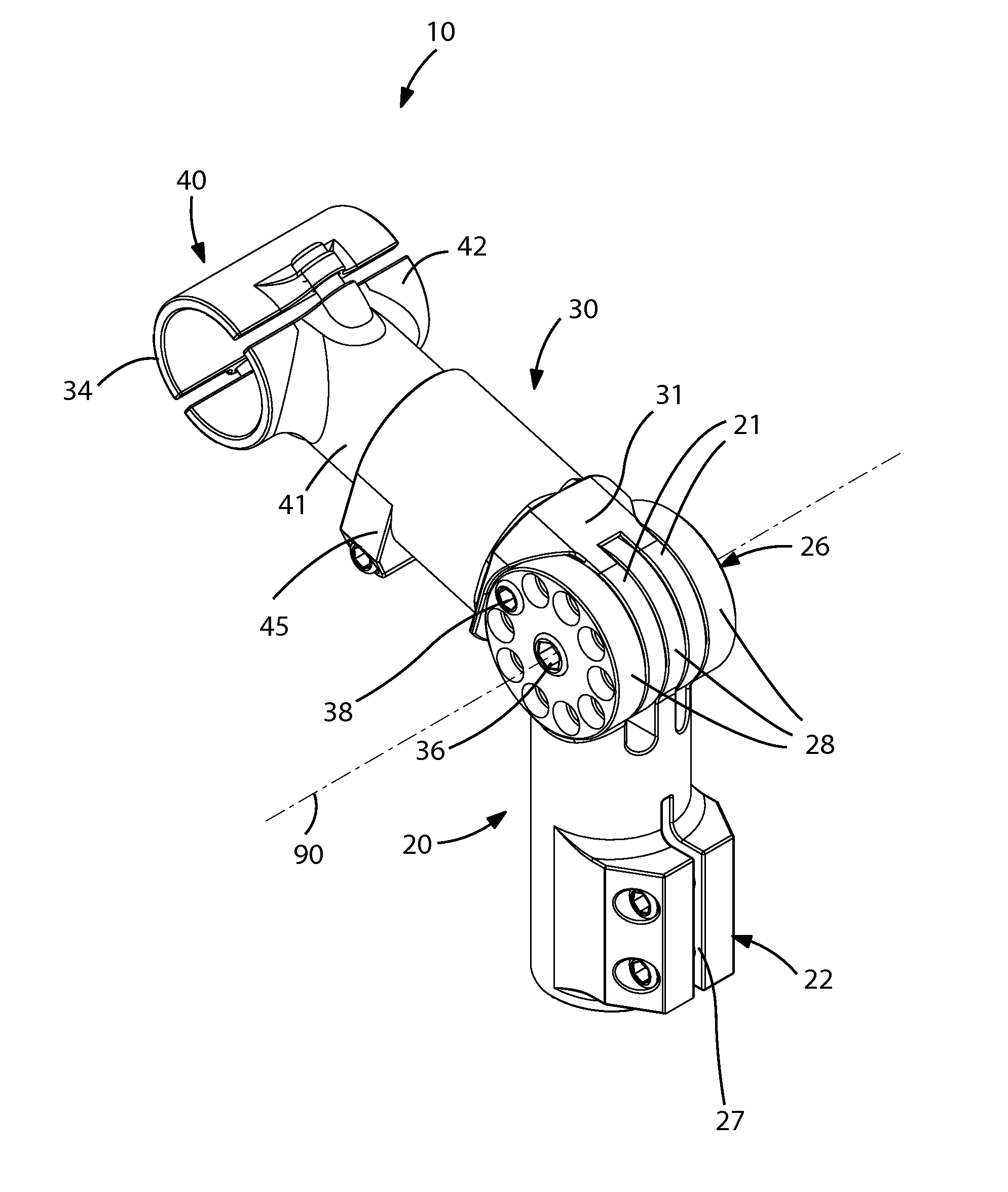

Adjustable bicycle handle bar adapter and associated method

ActiveUS8550484B1Improve gripIncrease friction areaFoot-driven leversWheel based transmissionEngineeringPivot joint

A bicycle headstock assembly may include a lower member adapted to be attached to a steering rod of the bicycle, and an upper member adjustably connected to the lower member. A pivot joint may be formed at a connection of the lower and upper members respectively. A handle bar clamp may be connected to the upper member and extending away therefrom. A primary fastener may pass through a first location of the pivot joint while an auxiliary fastener may pass through a second location of the pivot joint respectively. In this way, the primary and auxiliary fasteners may cooperate to permit the upper member to selectively pivot and lock at alternate positions relative to the lower member.

Owner:DRAPER RICHARD

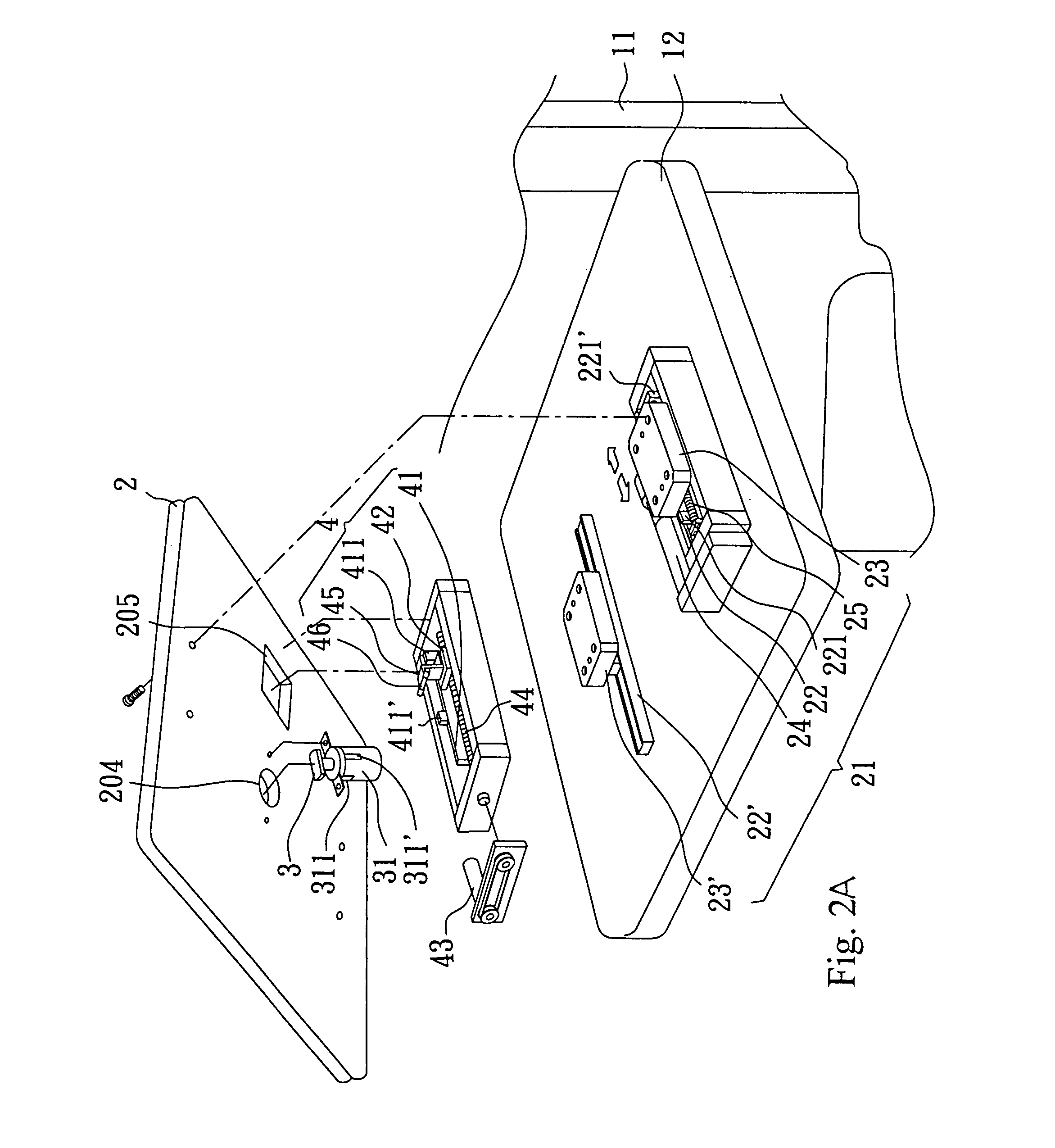

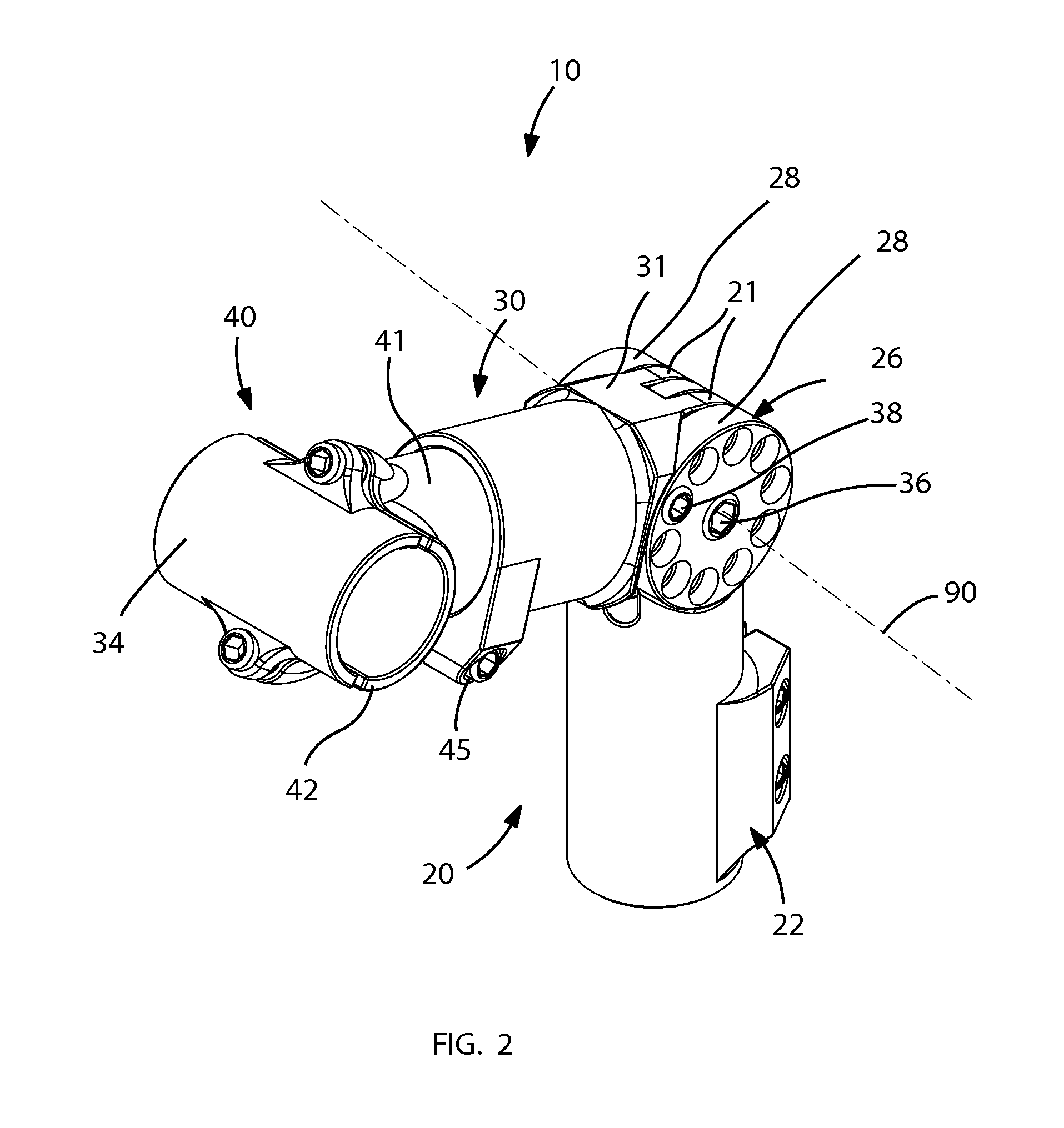

Tool holding device for a five-axis lathe

InactiveUS20100288090A1Complicated geometric shapeReduce setup timeAutomatic/semiautomatic turning machinesTool holdersTool bitEngineering

A tool holding device is disposed between a headstock unit and a tailstock unit of a five-axis lathe, and includes a saddle driven to move longitudinally, a cross-slide riding on the saddle and driven to move transversely, a turntable platform disposed on a base mount that is disposed on the cross-slide and driven to revolve about an upright axis, and a tool post mounted on a base rest that is disposed on the turntable platform and driven to move uprightly. An indexable turret is disposed on the tool post for holding tool bits such that the five-axis lathe can perform movements about five axes to machine a workpiece so as to obtain a complicated geometric shape, thereby reducing setup time and errors and increasing production.

Owner:WEY YII CORP

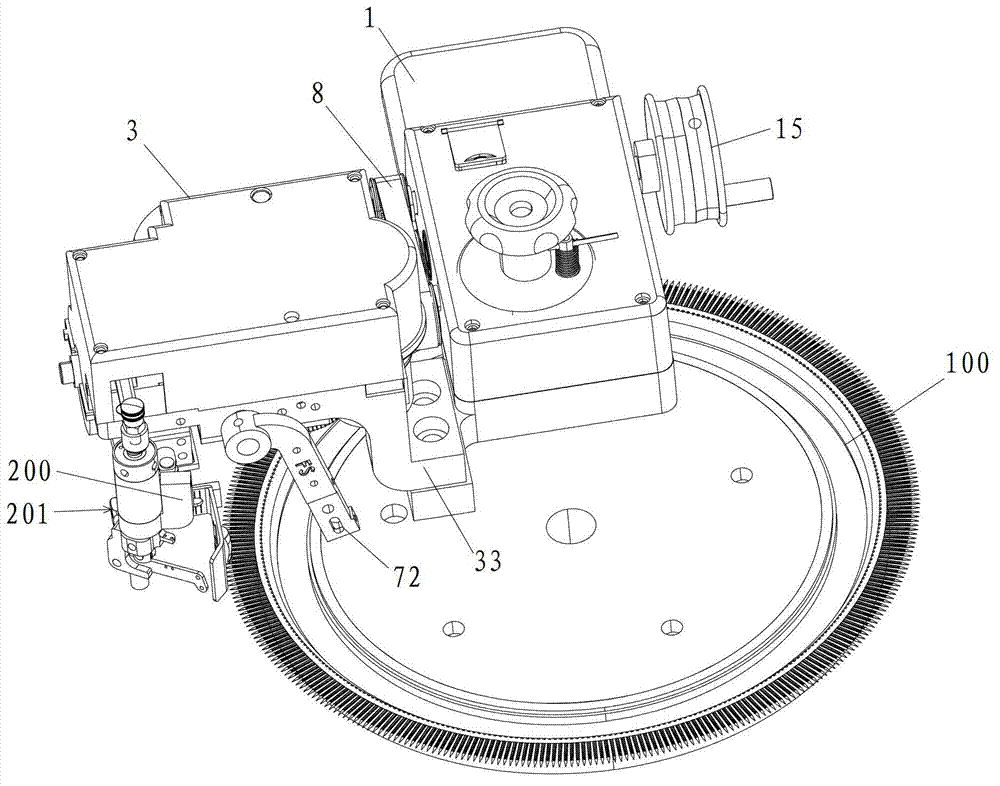

Assembly welding system for cone-shaped pipe circumferential weld

InactiveCN105397345ACompact structureRealize mechanized productionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringTailstock

The invention discloses a welding system, in particular to an assembly welding system for cone-shaped pipe circumferential welds. A headstock locking machine is arranged on a headstock installing plate. The right end of a base is provided with a tailstock locking machine, a gantry external pressure tool is arranged on the base, and the two ends of the gantry external pressure tool are provided with rolling wheel bracket machines respectively. An overturn railway is provided with an overturn feeding machine. The tailstock locking machine, the gantry external pressure tool, the rolling wheel bracket machines and the overturn feeding machine are connected with a drag chain. The upper portions of the headstock locking machine and the tailstock locking machine are provided with flange hoisting systems respectively, and the flange hoisting systems are distributed correspondingly to the rolling wheel bracket machines. The assembly welding system for the cone-shaped pipe circumferential welds is compact in structure, manual press-button operating is achieved, and feeding and centering are completed electrically; mechanized production is achieved, efficiency is greatly improved, labor intensity is reduced, production quality is ensured, and human factors are decreased; the assembly welding system is convenient to operate, high in speed, stable and high in efficiency.

Owner:HANGZHOU XINCHENGXIANG ELECTROMECHANICAL TECH

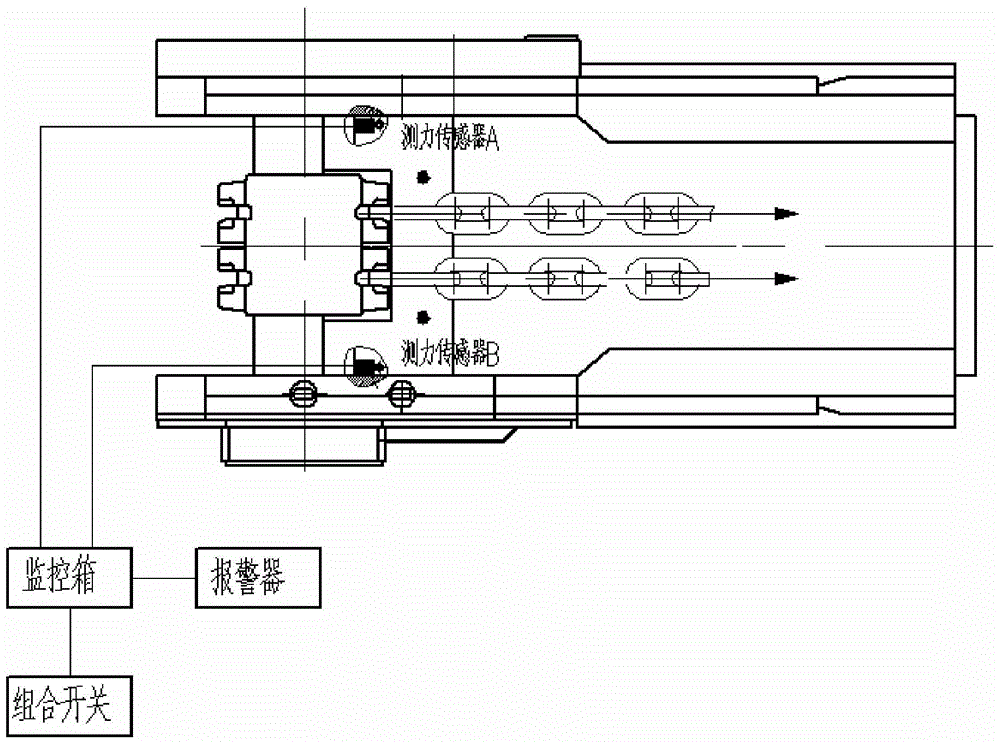

Broken chain monitor device and method for coal face scraper conveyer

InactiveCN104444227AMonitor and control operating conditions in real timeTimelyControl devices for conveyorsElectric machinerySprocket

The invention relates to a broken chain monitor device and method for a coal face scraper conveyer. The device is characterized by comprising pressure load sensors installed on two arc blocks of a headstock of the scraper conveyer, so that pressure signals between each arc block and a bearing pedestal of a chain wheel shaft set are measured in the working process of the scraper conveyer, the pressure load sensors are connected with a PLC in a monitor case of the scraper conveyer, and the PLC is also connected with a head motor and a tail motor of the scraper conveyer through a combined switch. It is proved on trial that by adoption of the monitor method, the pressure signals between each arc block and the bearing pedestal of the chain wheel shaft set can be measured in the working process of the scraper conveyer according to the pressure load sensors installed on the two arc blocks of the headstock, so that the operating situation of a chain is monitored and controlled in real time.

Owner:NINGXIA TIANDI BENNIU IND GRP

Crankshaft flange eccentric hole clamp for drill

InactiveCN101758396AReasonable structureEasy to assemblePositioning apparatusMetal-working holdersHeadstockCrankshaft

The invention relates to a crankshaft flange eccentric hole clamp for a drill, which comprises a clamp body, a positioning column, a headstock mechanism and a tailstock mechanism. In the headstock mechanism, a headstock oil cylinder is fixed on a fixed support with bolts and positioning pins; the fixed support is fixed on the clamp body; a guide sleeve is installed on the headstock oil cylinder; one end of a piston rod is provided with a piston, the other end of the piston rod passes through the guide sleeve and is installed in the hole of the headstock oil cylinder; and the conic section of the front of the piston rod is pushed into the central hole of the big end of a crankshaft. In the tailstock mechanism, a tip guide sleeve is installed on a tailstock; the tailstock is connected with and installed on a subplate by keys; the subplate is connected with and installed on the clamp body by radial keys; one end of the tailstock piston rod is provided with a piston, the other end of the tailstock piston rod is installed in the hole of the tailstock by a fixing flange, a connecting flange and the tip guide sleeve, and the conic part of the front end of the tailstock piston rod is pushed into the small end of the crankshaft. The invention has the advantages of reasonable structure, convenient assembly, low production cost, high universality, and oil hole drilling high efficiency and is suitable for processing various crankshaft flange eccentric holes.

Owner:TIANRUN IND TECH CO LTD

Ratcheted Mounting Bracket for Tuner

Owner:D'ADDARIO

Machine tool for turning operations

ActiveUS20100282037A1Increase profitSmooth outAutomatic/semiautomatic turning machinesTailstocks/centresEngineeringMulti axis

A multi-axis turning center for turning operations includes a machine body, a tool rest means for holding a tool, a first headstock for holding a workpiece, and a second headstock disposed in confronting relation to the first headstock, for holding a workpiece. The second headstock has a front chuck and a rear chuck for gripping respective workpieces. The second headstock performs a workpiece changing function by swiveling about a central axis. The multi-axis turning center is capable of automatically changing the workpieces by itself while it is carrying out a machining process, without the need for a workpiece changer. The multi-axis turning center does not need to stop its machining process for changing workpieces, resulting in an increase in the utilization ratio thereof.

Owner:DMG MORI CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com