Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1832 results about "Tensile testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

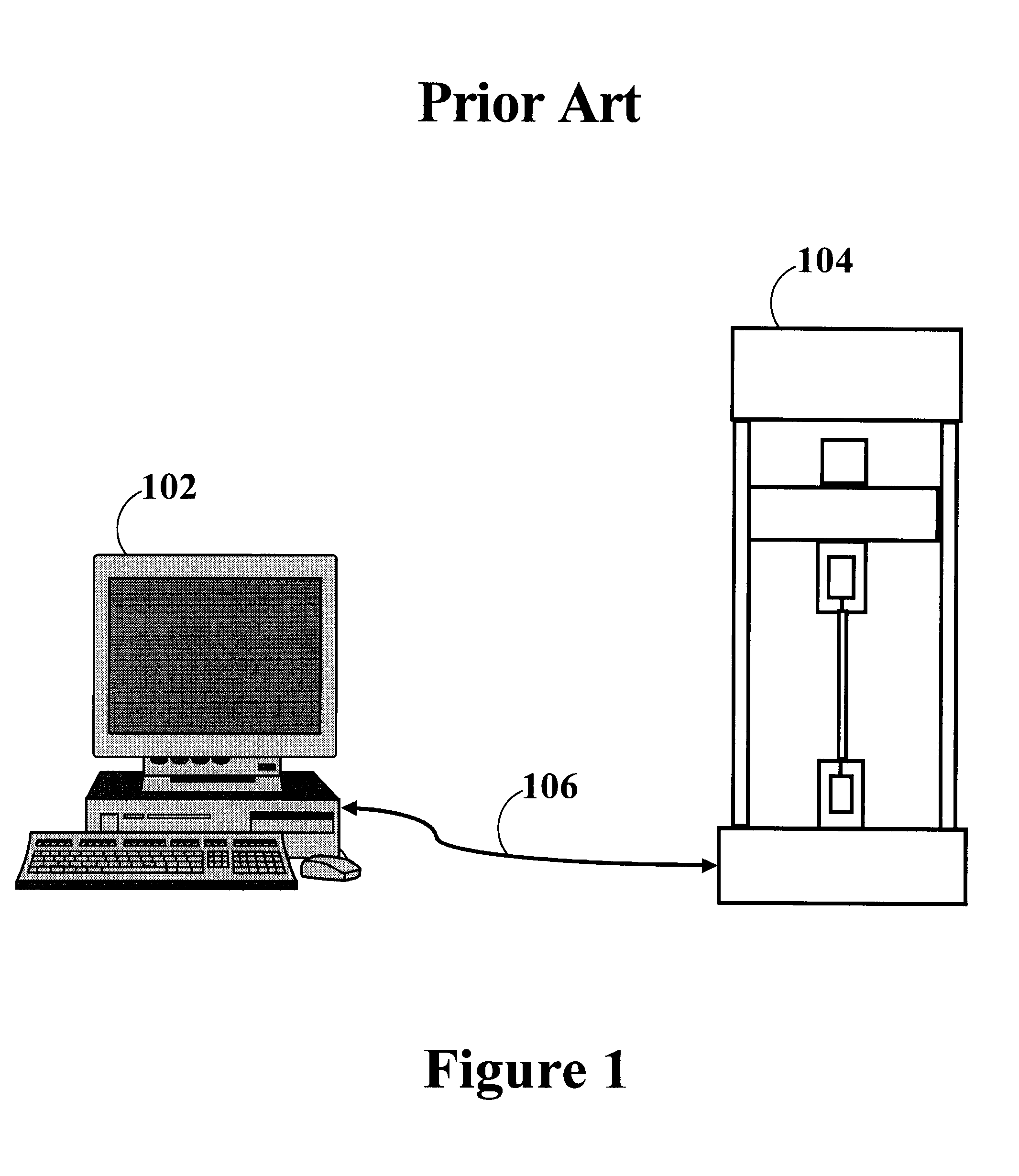

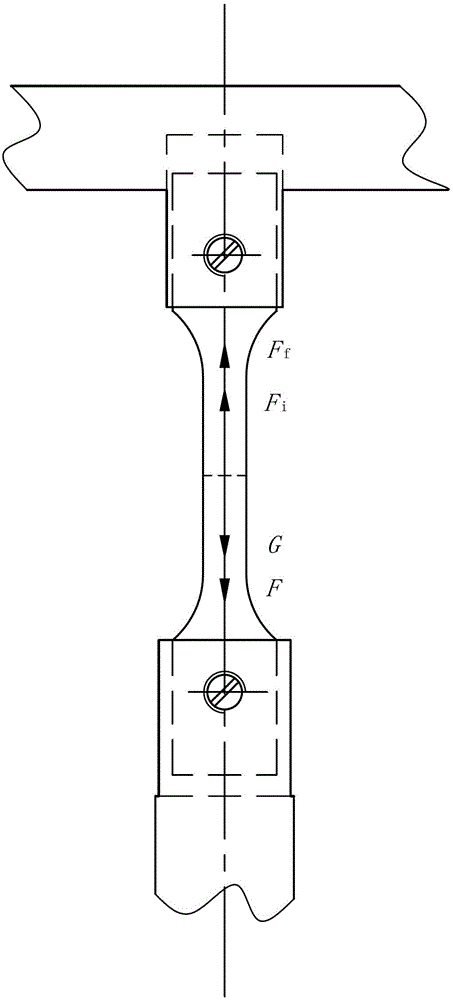

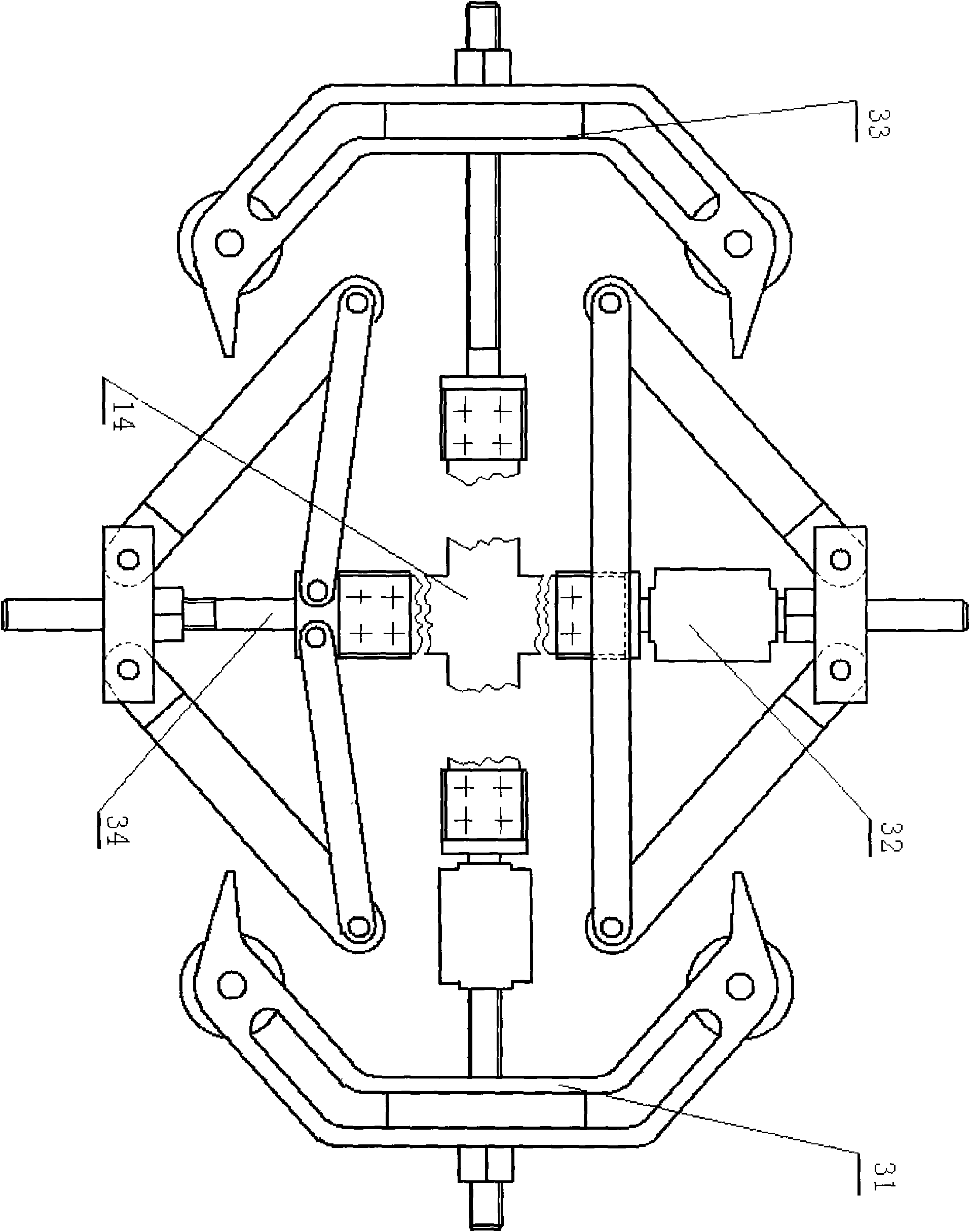

Tensile testing, also known as tension testing, is a fundamental materials science and engineering test in which a sample is subjected to a controlled tension until failure. Properties that are directly measured via a tensile test are ultimate tensile strength, breaking strength, maximum elongation and reduction in area. From these measurements the following properties can also be determined: Young's modulus, Poisson's ratio, yield strength, and strain-hardening characteristics. Uniaxial tensile testing is the most commonly used for obtaining the mechanical characteristics of isotropic materials. Some materials use biaxial tensile testing.

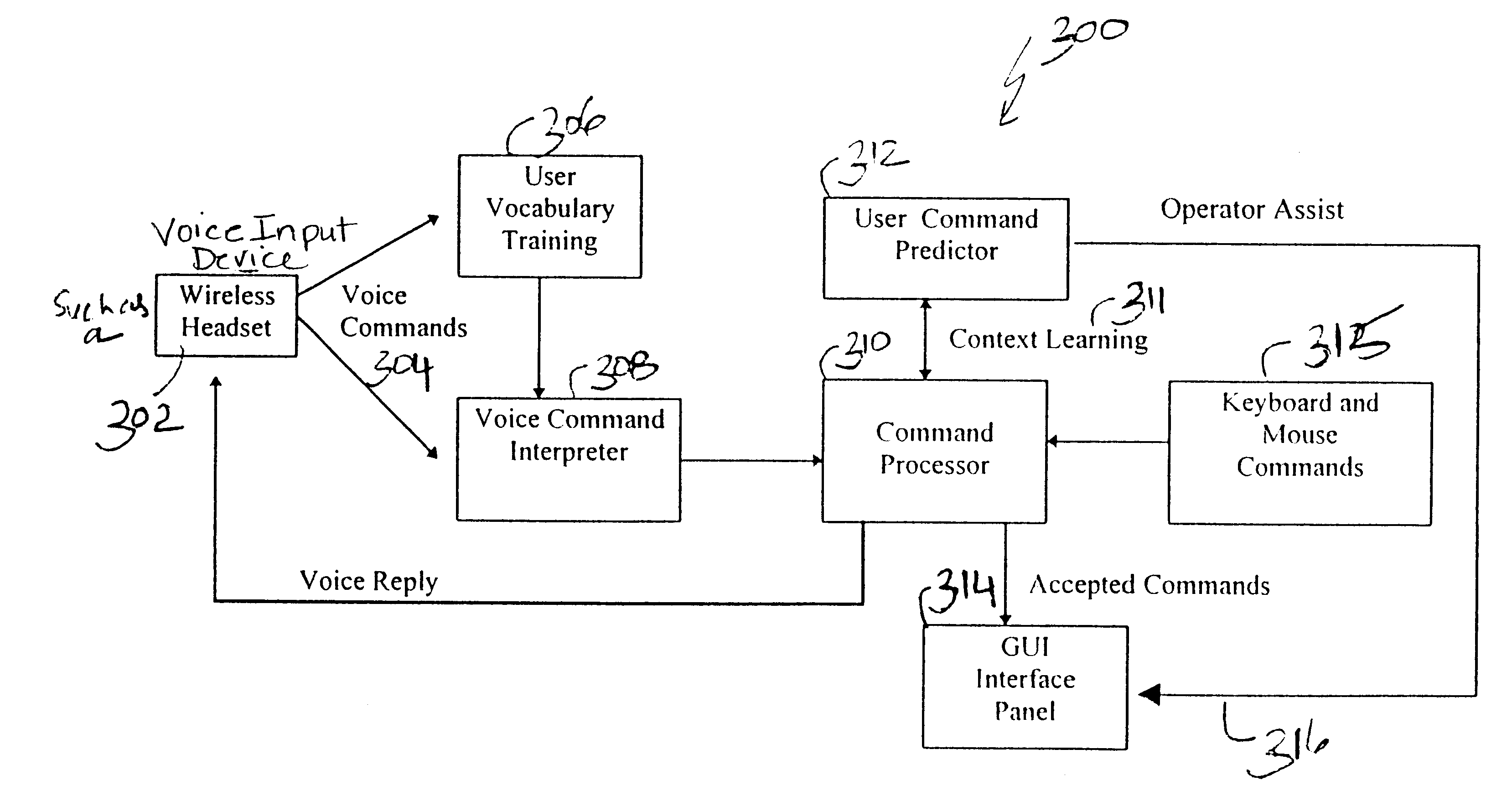

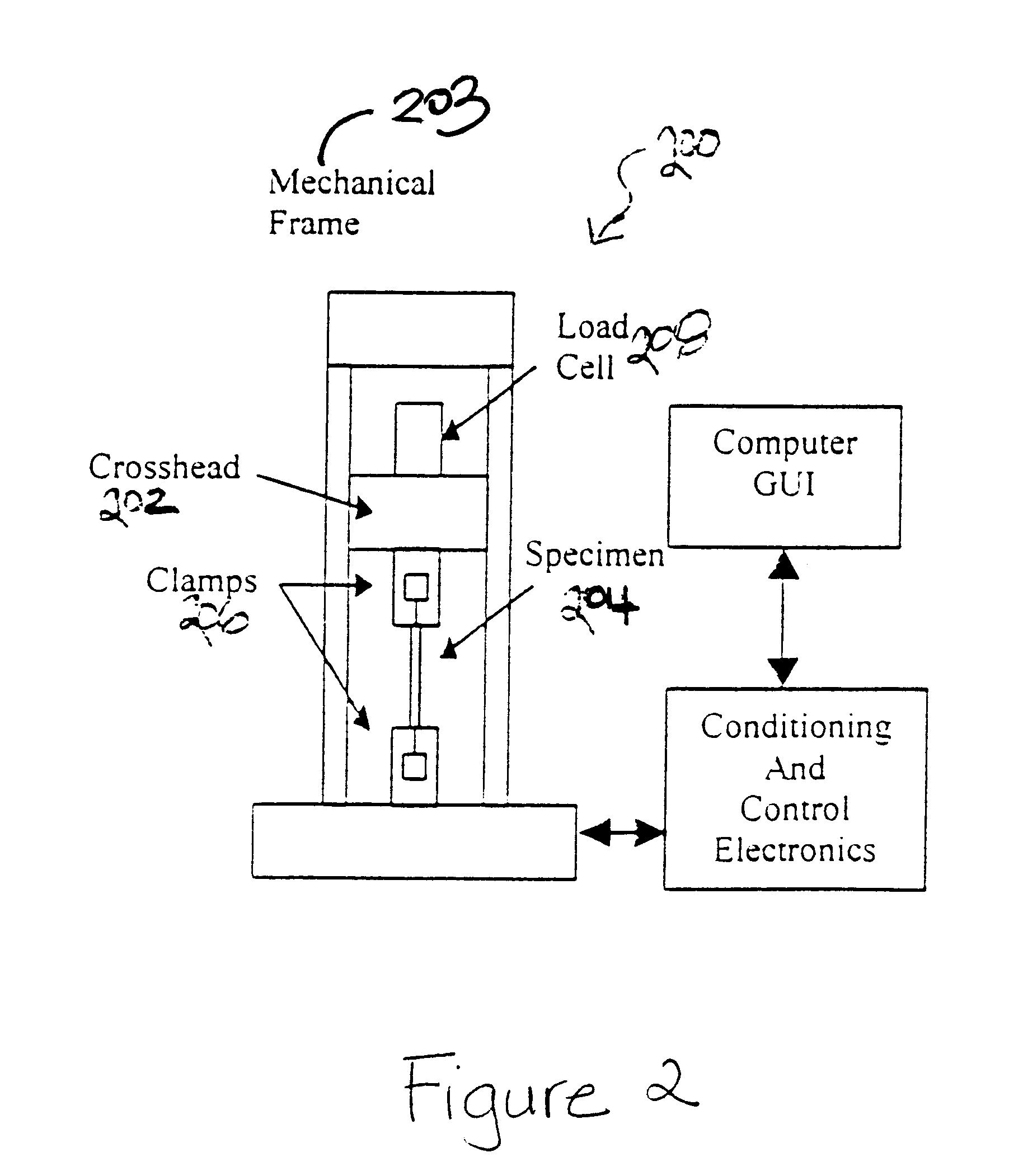

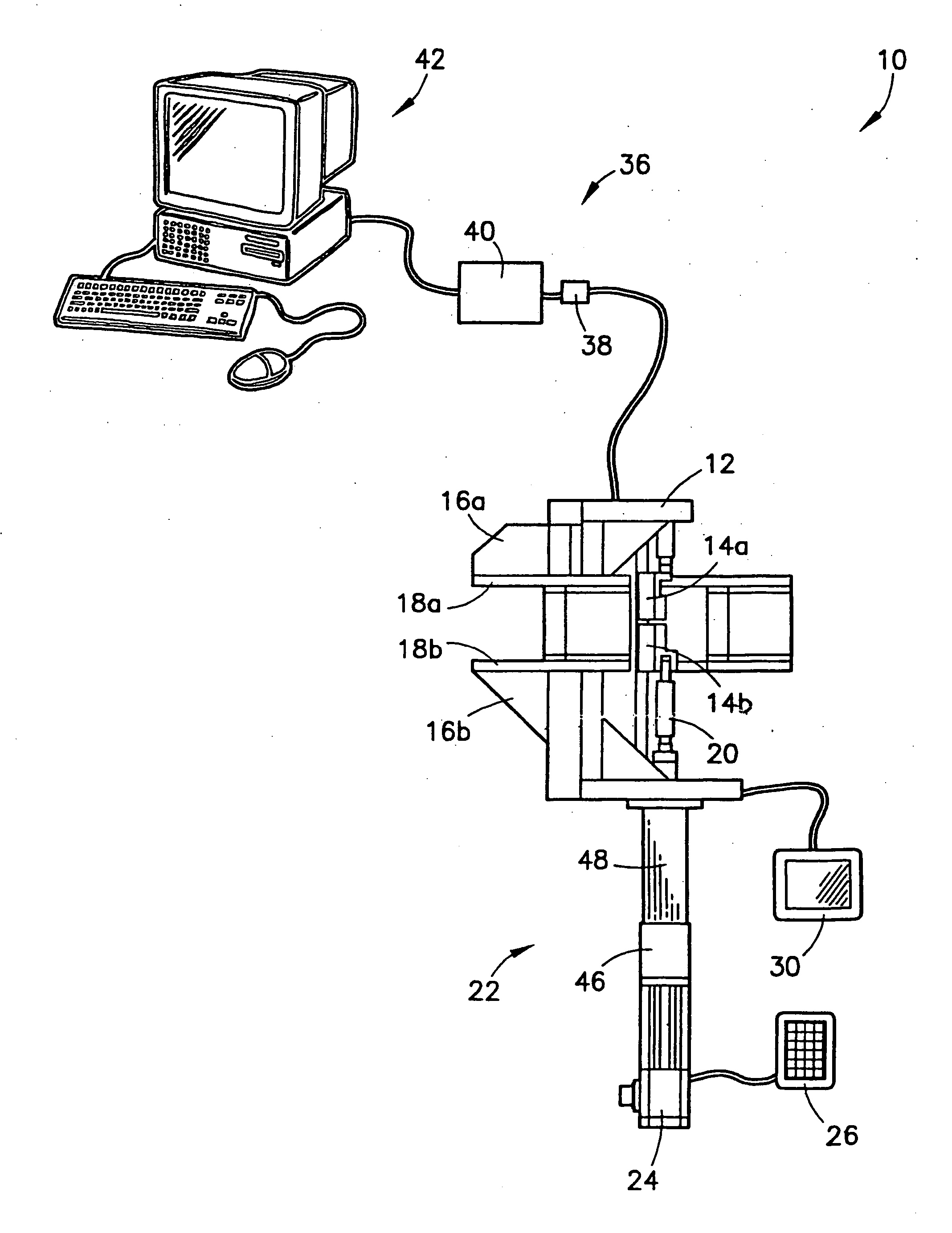

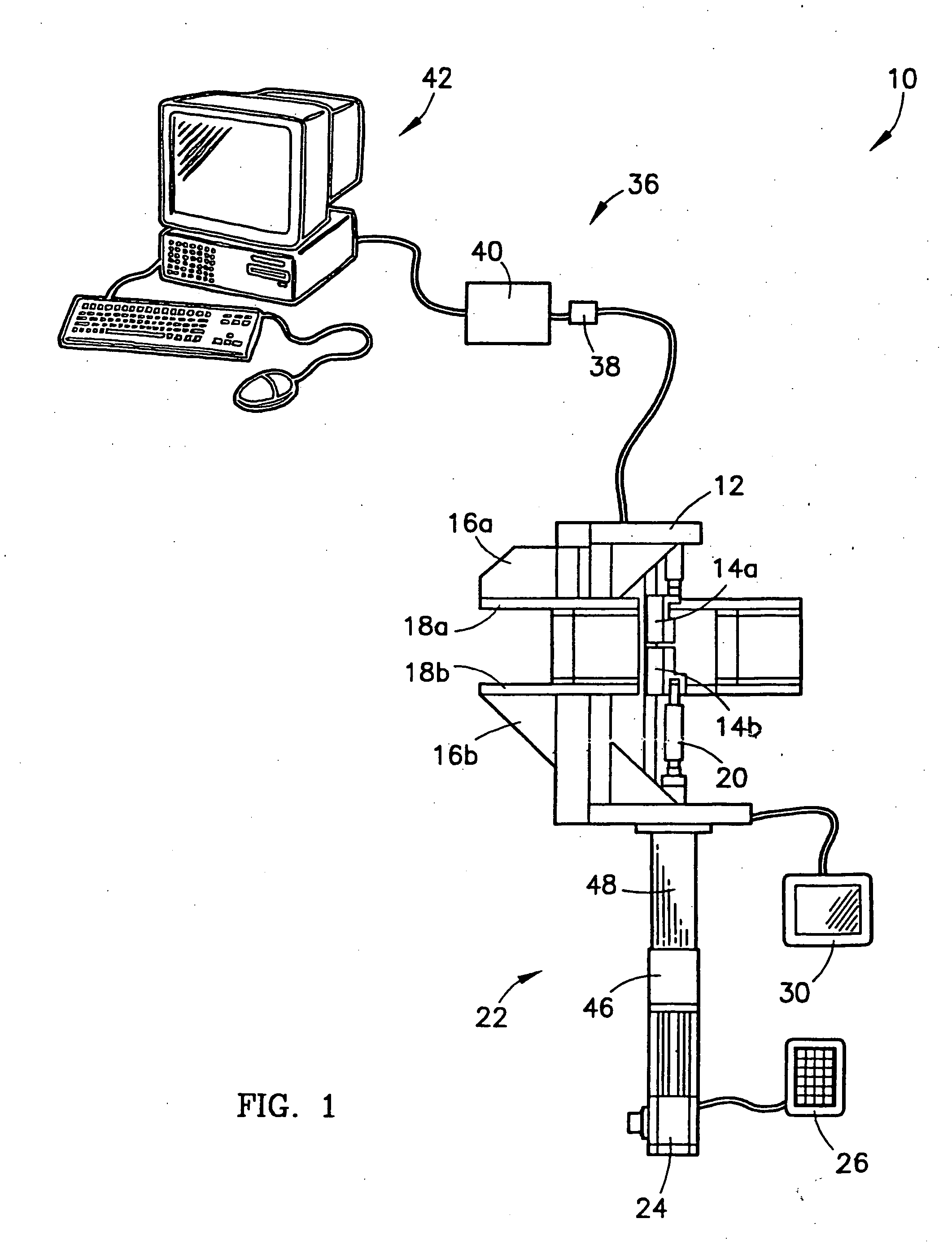

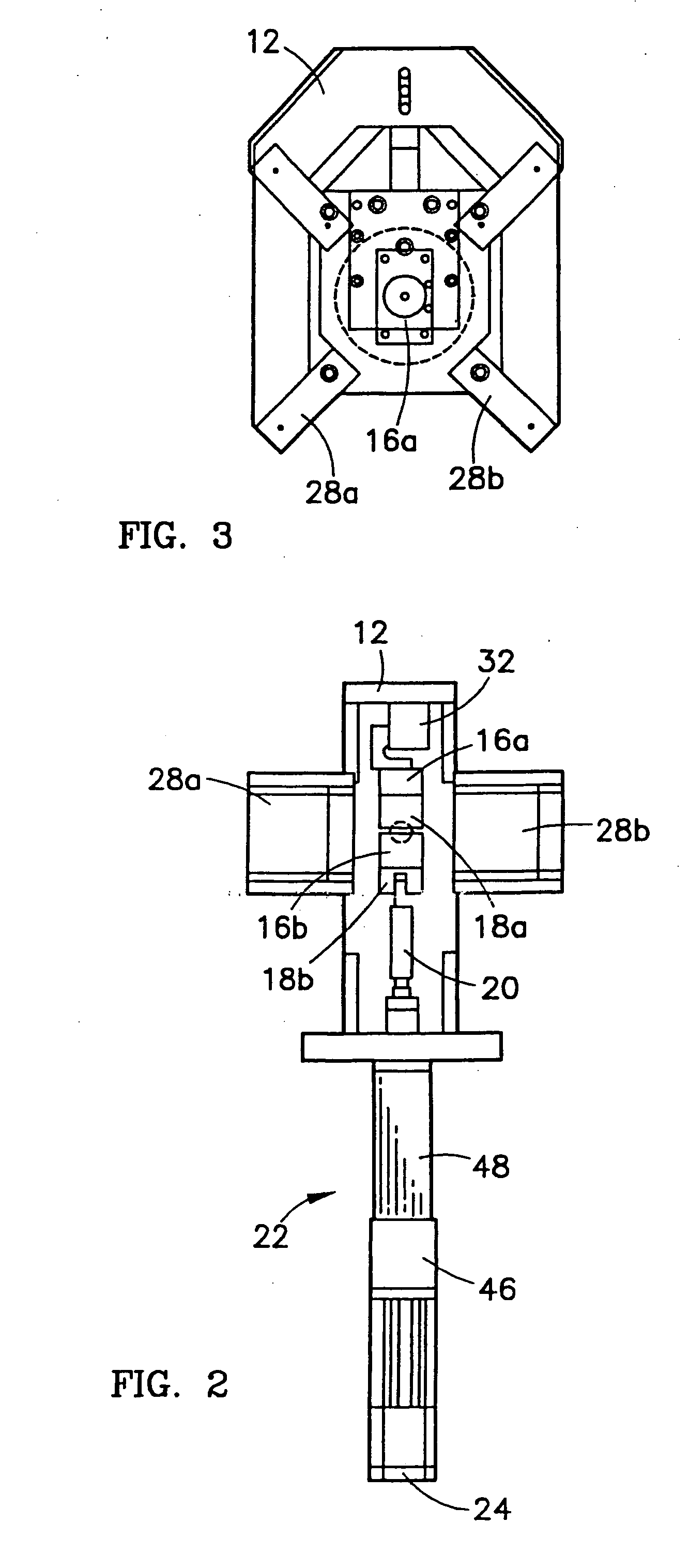

Voice actuation with contextual learning for intelligent machine control

InactiveUS6895380B2Reduce probabilityImprove robustnessFlow propertiesMeasurement arrangements for variableHuman–computer interactionTensile testing

An interactive voice actuated control system for a testing machine such as a tensile testing machine is described. Voice commands are passed through a user-command predictor and integrated with a graphical user interface control panel to allow hands-free operation. The user-command predictor learns operator command patterns on-line and predicts the most likely next action. It assists less experienced operators by recommending the next command, and it adds robustness to the voice command interpreter by verbally asking the operator to repeat unlikely commanded actions. The voice actuated control system applies to industrial machines whose normal operation is characterized by a nonrandom series of commands.

Owner:ELECTRO STANDARDS LAB

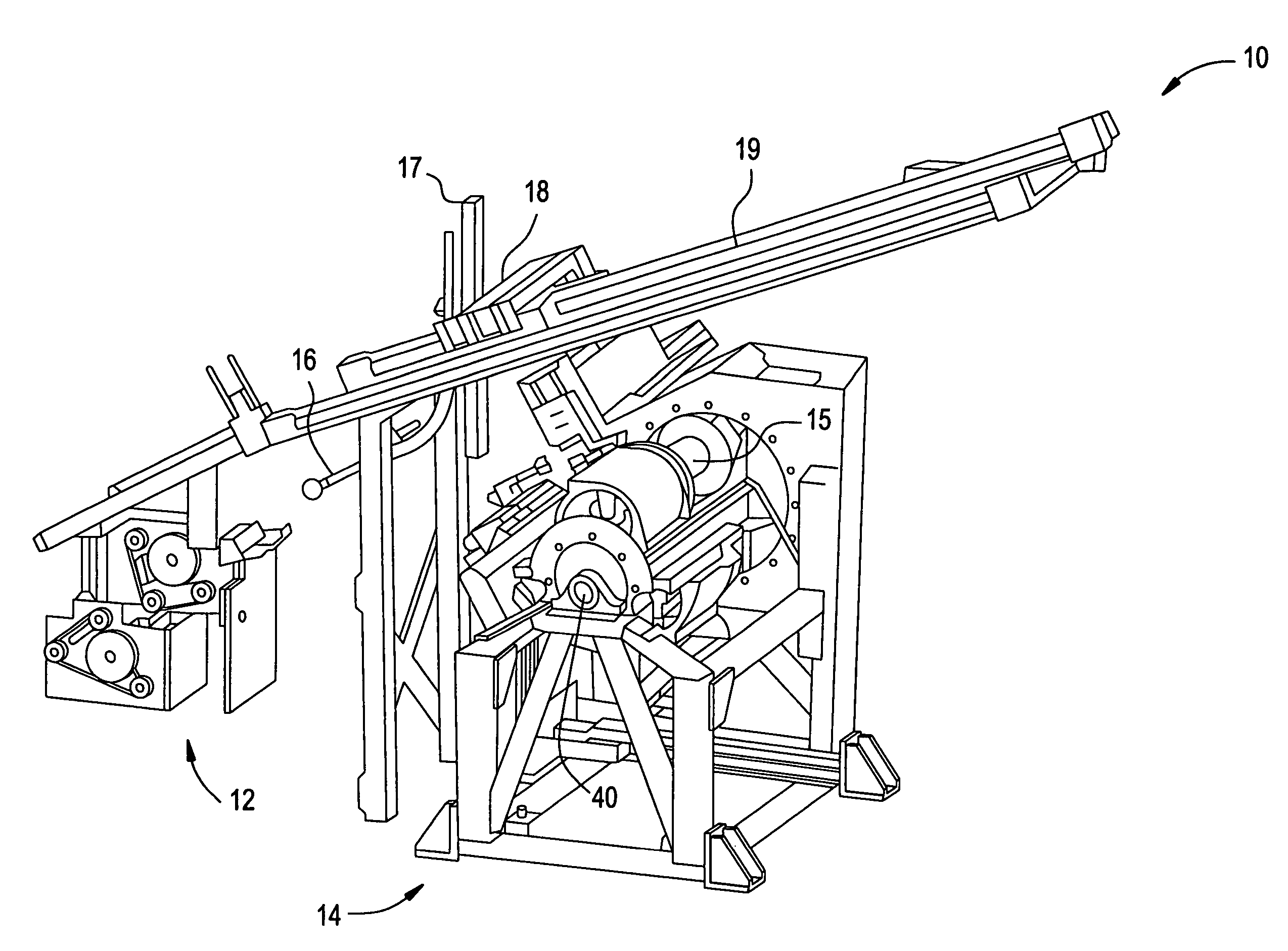

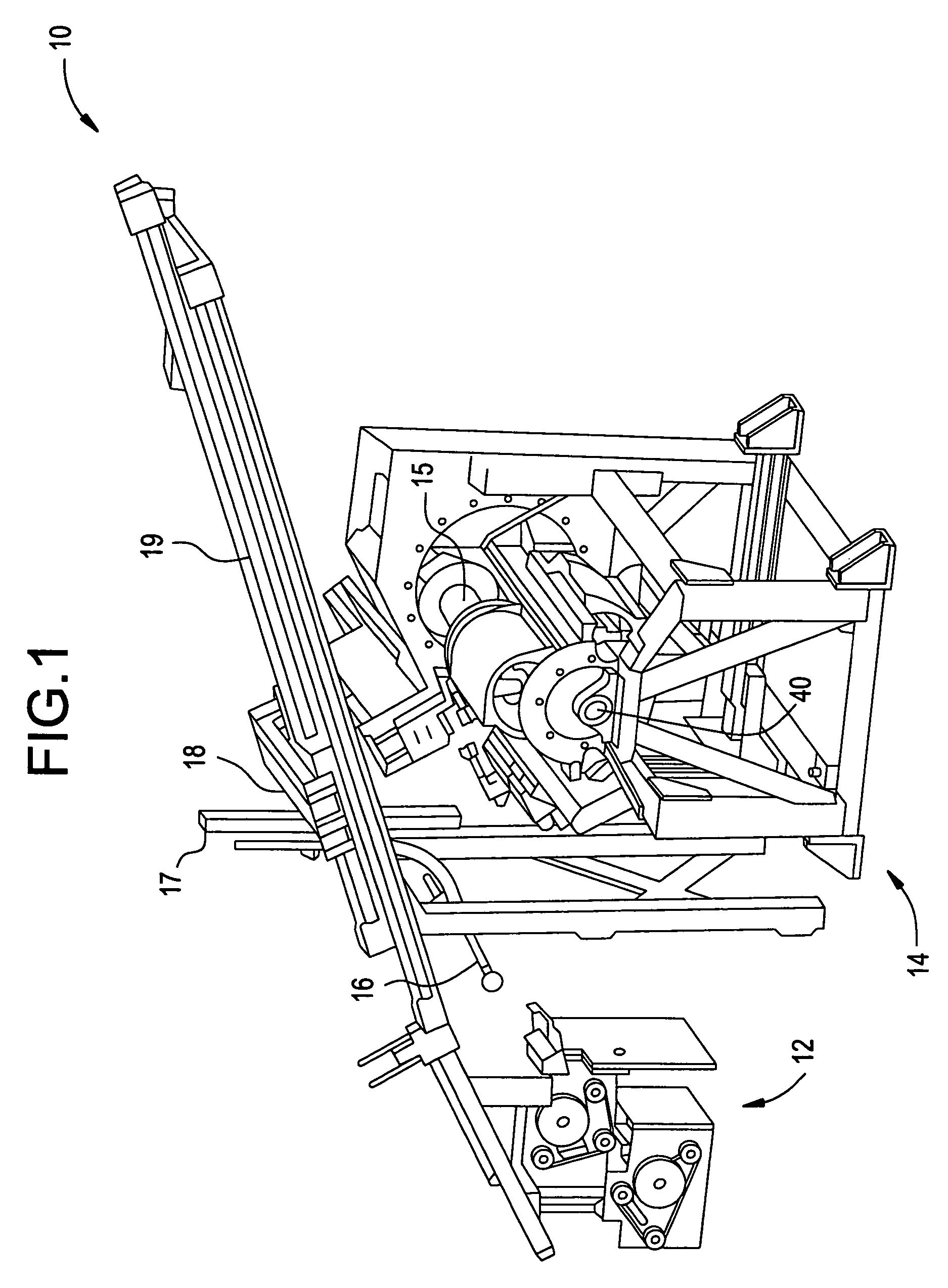

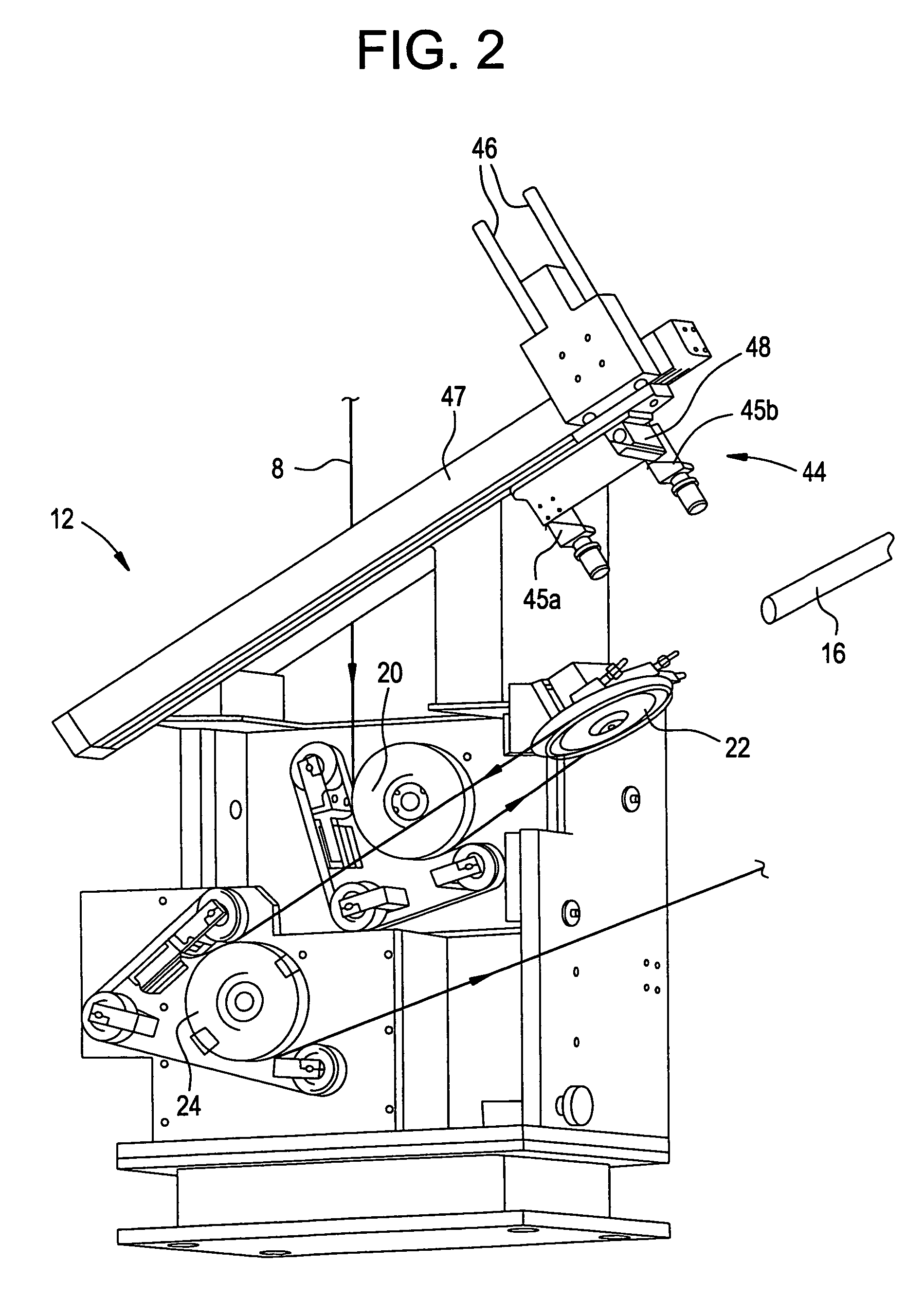

Method and apparatus for tensile testing and rethreading optical fiber during fiber draw

InactiveUS7832675B2Processing speedGlass fibre drawing apparatusFilament handlingFiber drawingTensile testing

A method and apparatus for automatic threading and winding of optical fiber onto various components in a fiber draw system, as well as methods and apparatus for conducting online tensile screening of optical fiber at high speeds. In a preferred embodiment, the fiber is tensile tested during fiber draw and wound directly onto a shipping spool to be shipped to a customer. The tensile stress can be imparted to the fiber during the draw process by feeding the fiber through a screener capstan, which works in conjunction with another capstan to impart the desired tensile stress to the fiber during the draw process. Another aspect is a method and apparatus for threading or rethreading of a moving length of fiber through a fiber draw or fiber testing process, in which fiber is wound onto a spool, comprising activating an aspirator to obtain the fiber at a first location and moving said aspirator in at least two dimensions to thereby move the fiber to a second location and thread the fiber through or onto at least one component in the fiber draw or testing process.

Owner:CORNING INC

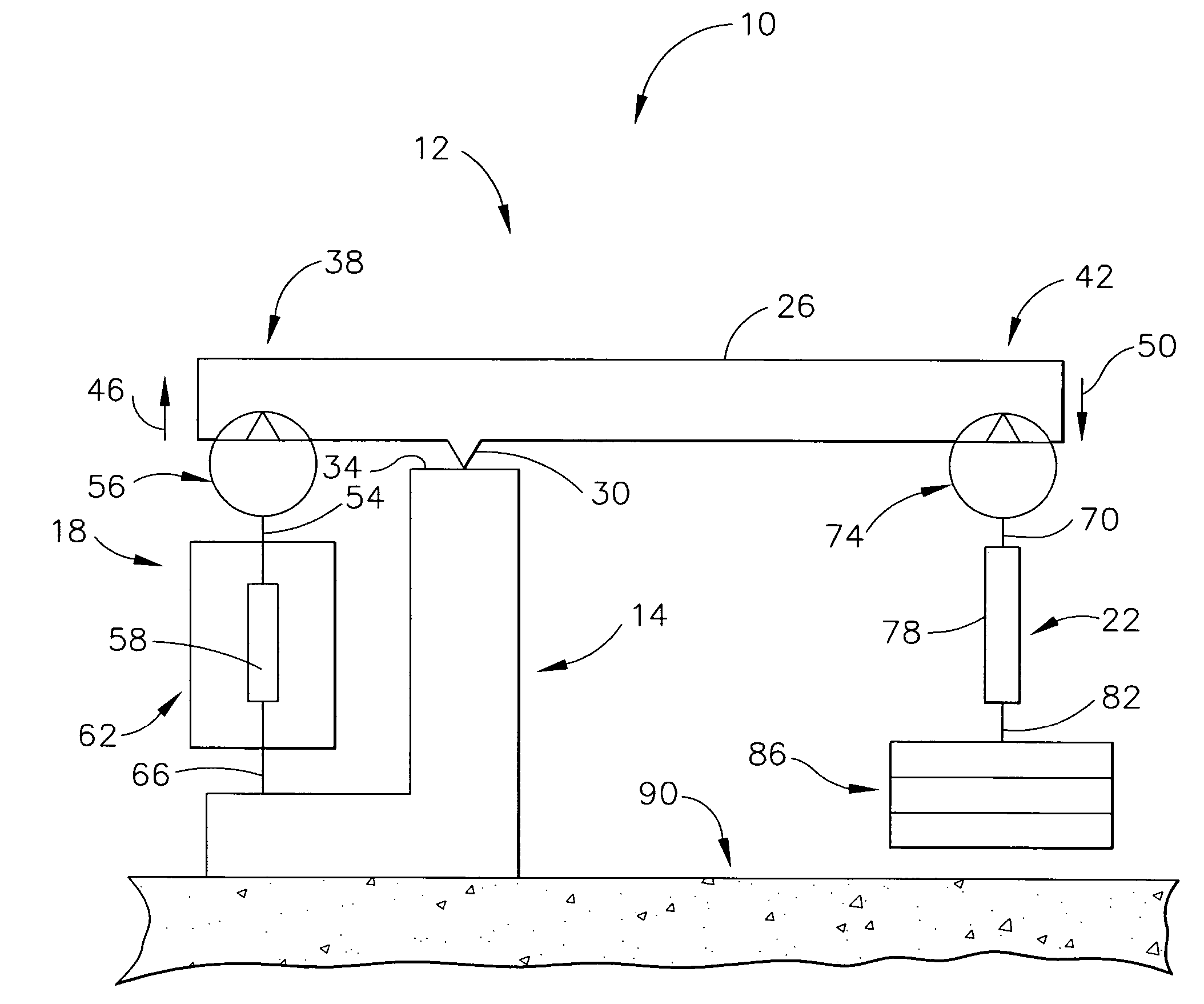

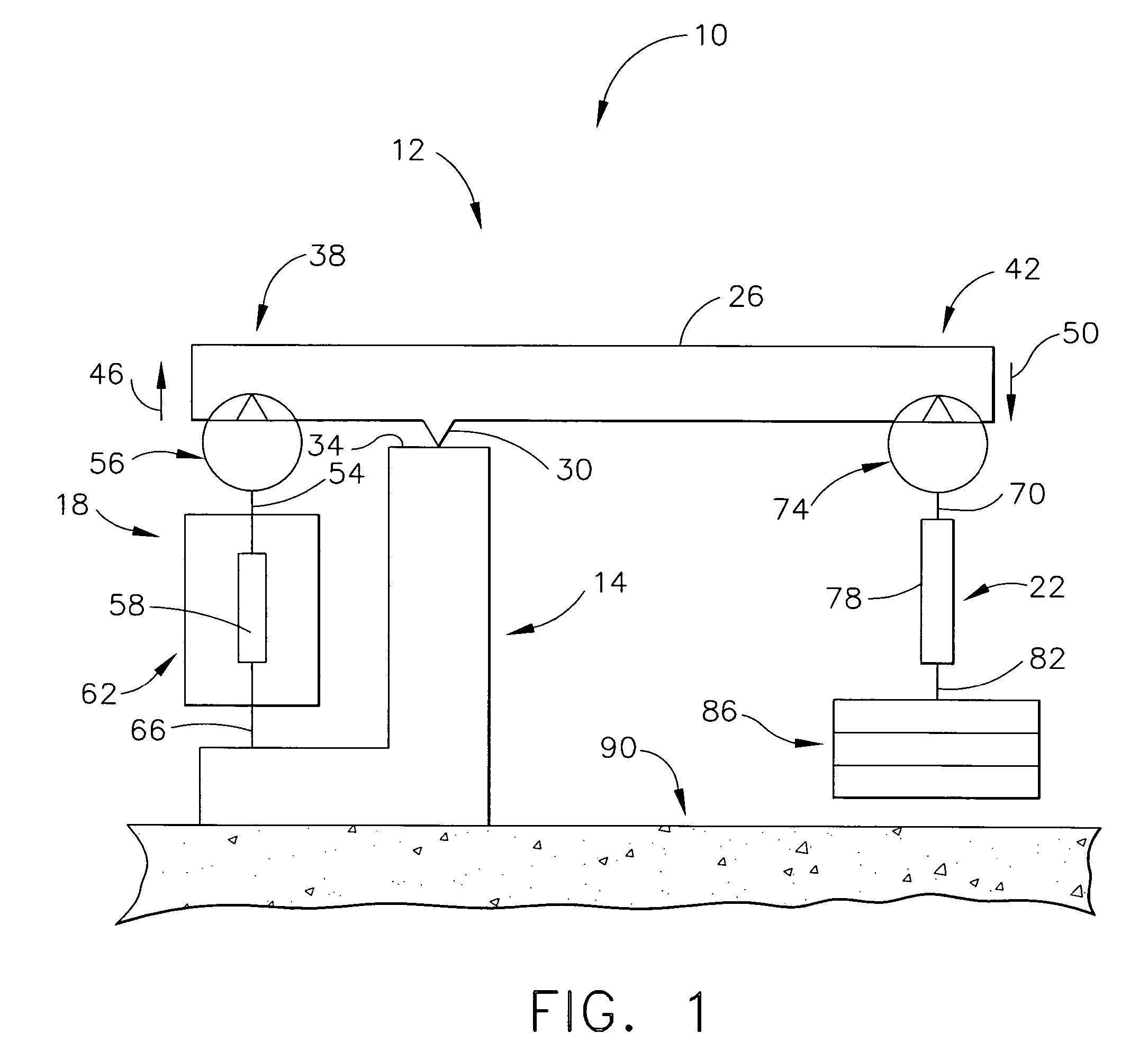

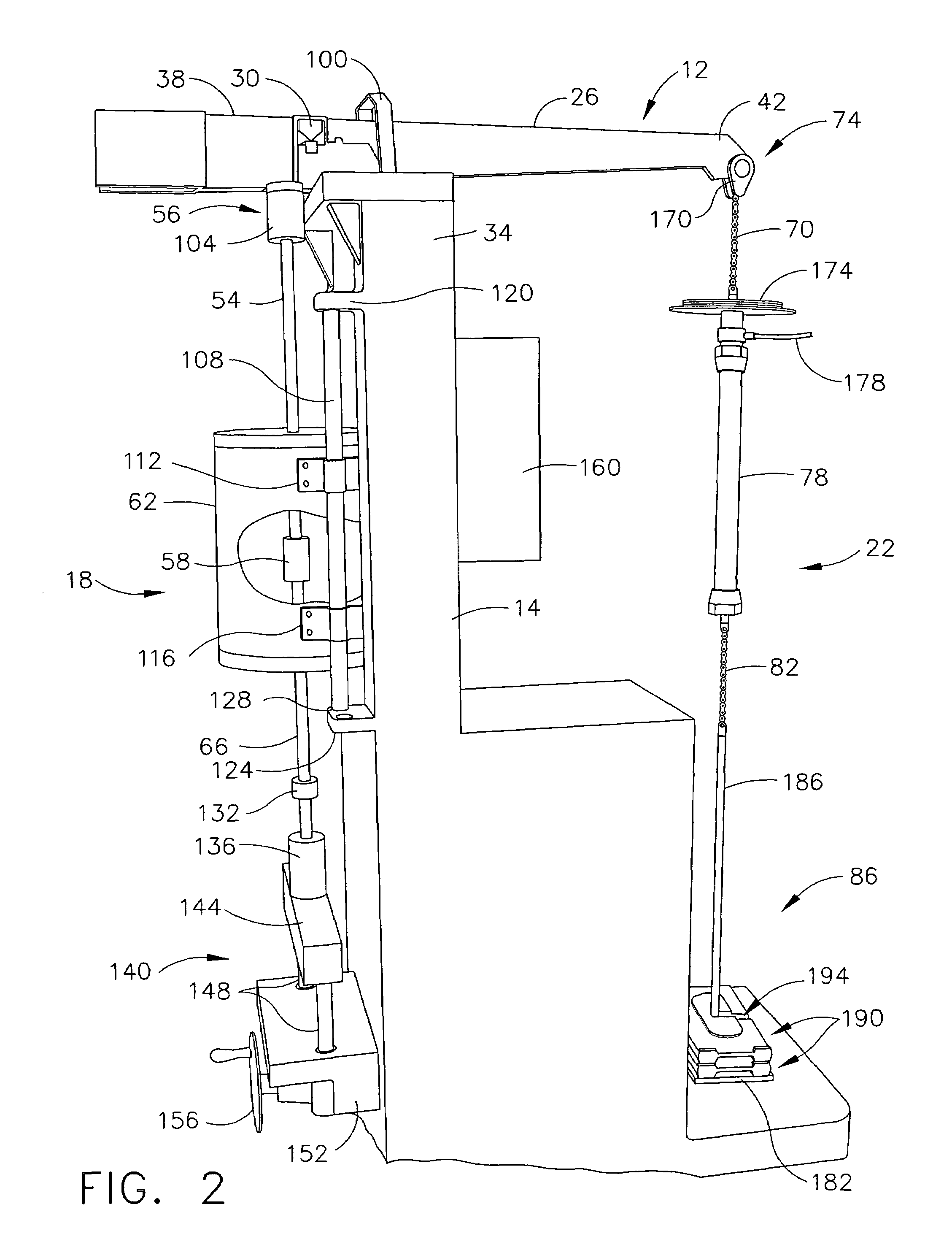

System, apparatus and method for testing under applied and reduced loads

InactiveUS7353715B2Easy maintenanceApply evenlyMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesEngineeringLoad regulation

A system which cyclically applies and reduces a load on a test specimen and which can use an apparatus comprising: (a) a frame; (b) a load adjusting section having a fluidic mechanical muscle that contracts and extends in length to cyclically apply and reduce a load; (c) a load train section frame for subjecting a test specimen to the load; and (d) a lever arm configured to apply and reduce the load from the loading adjusting section to the load train section. The system and apparatus can be used in a method for cyclically applying and reducing a load on a test specimen to thereby subject the test specimen to tensile testing and can also comprise a mechanism for decoupling at least a portion of the load from the test specimen when the load is reduced.

Owner:GENERAL ELECTRIC CO

Microtesting Rig with Variable Compliance Loading Fibers for Measuring Mechanical Properties of Small Specimens

ActiveUS20100186520A1Increase stiffnessIncrease lateral stiffnessFlow propertiesWithdrawing sample devicesFiberSmall specimen

The present invention provides a microtesting rig for measuring mechanical properties of small specimens. The rig includes a microsized specimen positioned on a mounting block, an interchangeable contact tip connected with an actuator and configured for contact with the microsized specimen, and a magnifying imaging system for imaging the microsized specimen. The contact tip may be a fiber platen for compression testing or a fiber grip for tension testing.

Owner:US SEC THE AIR FORCE THE

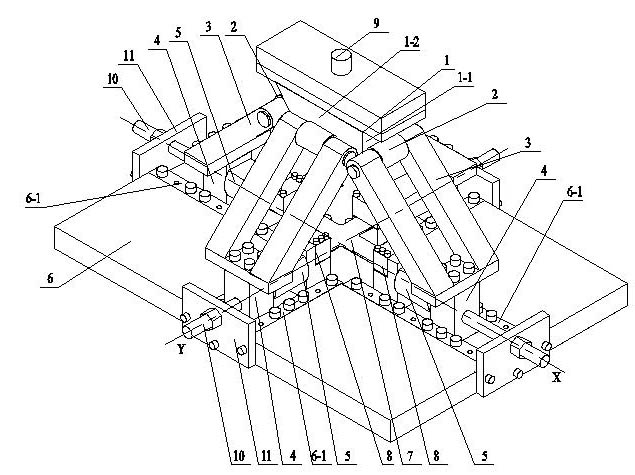

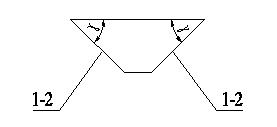

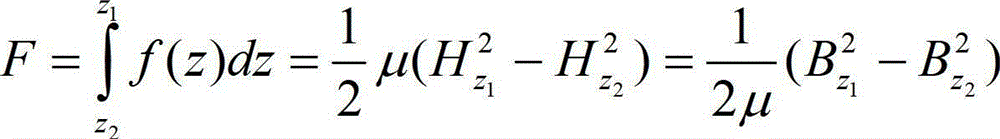

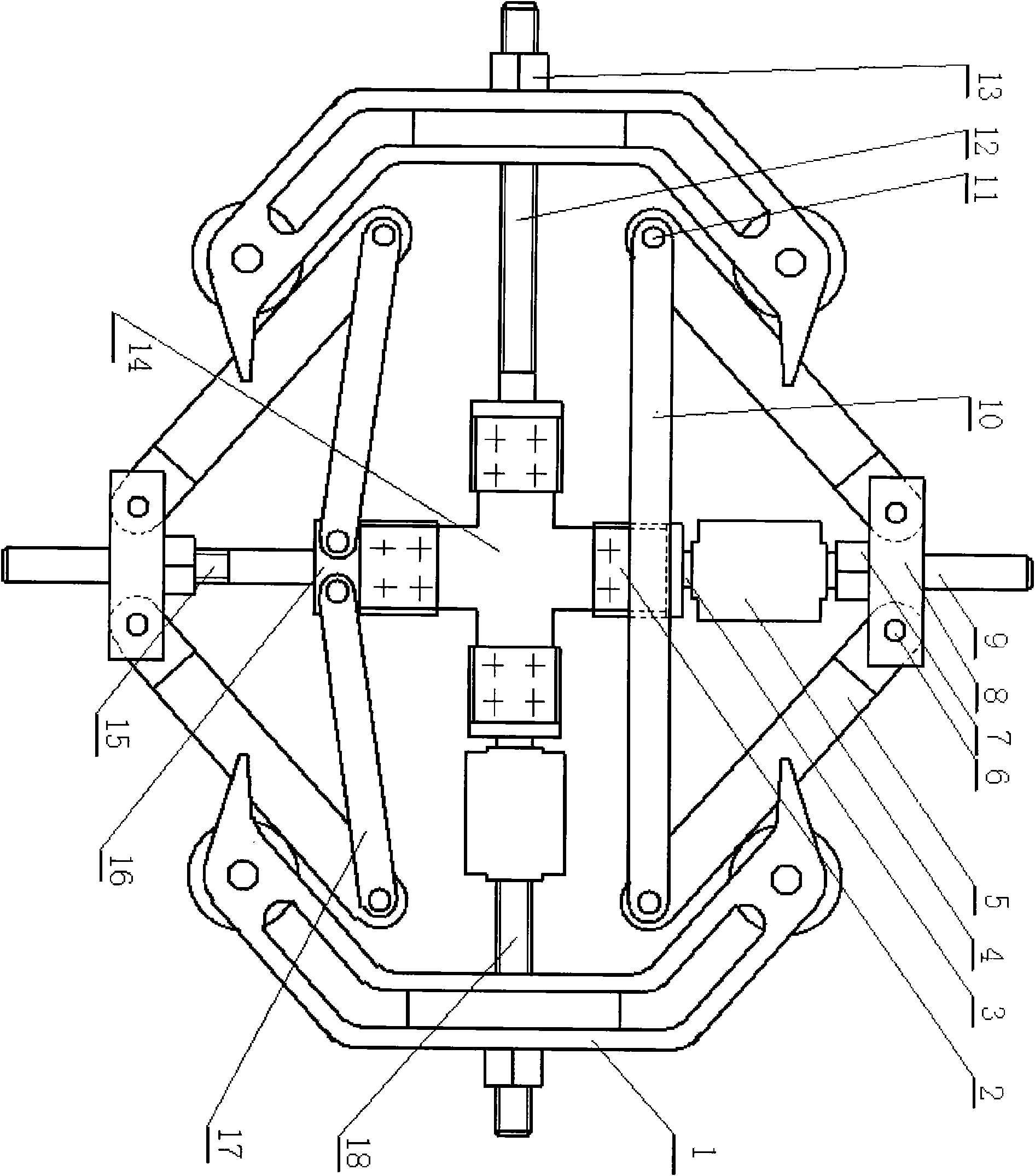

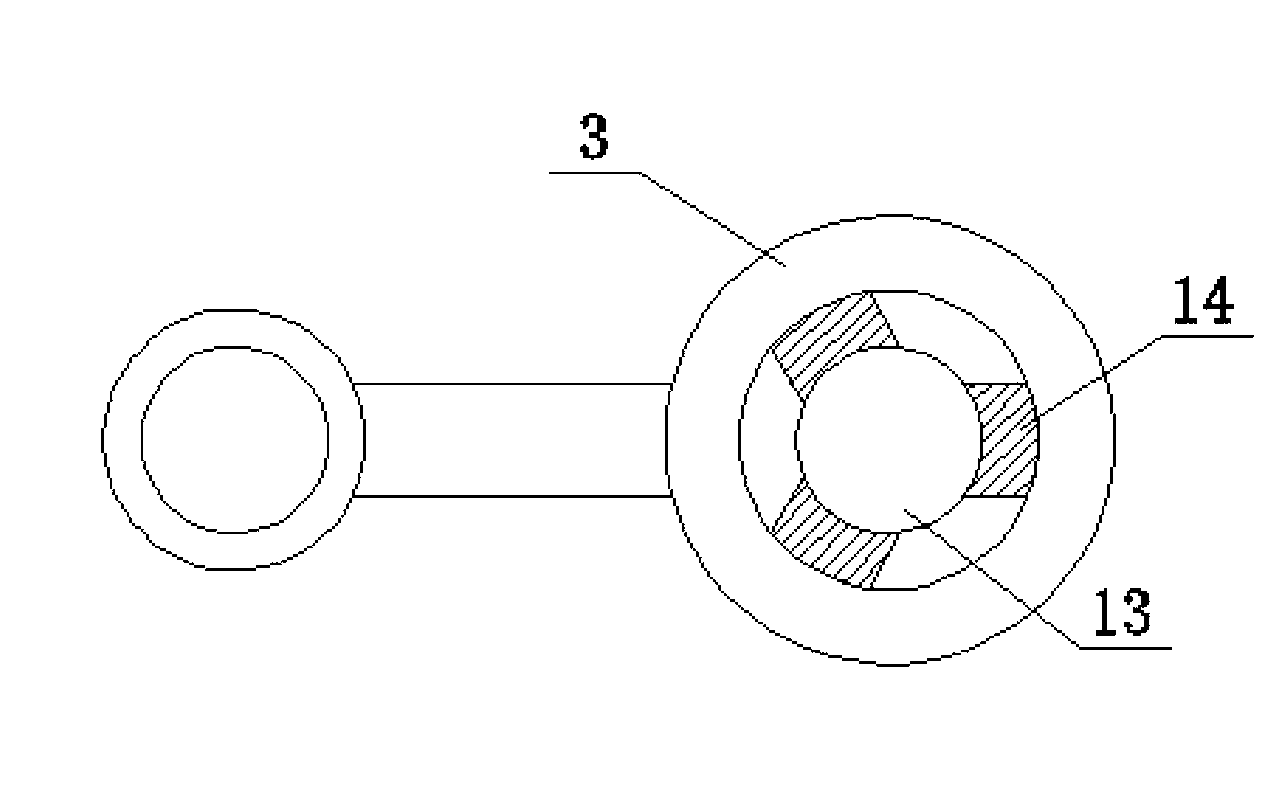

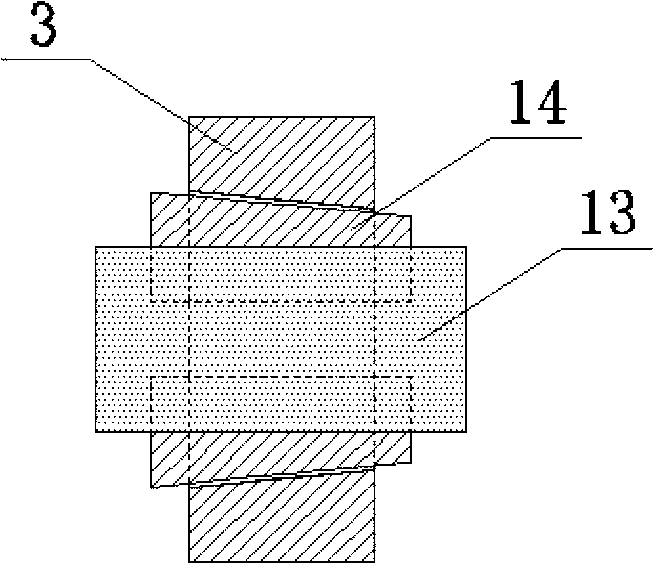

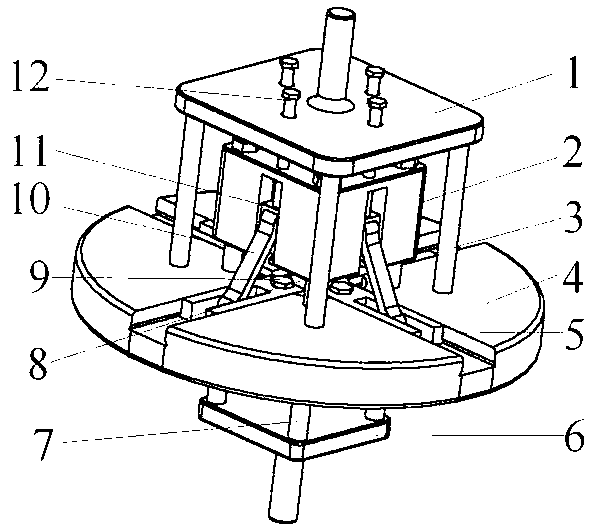

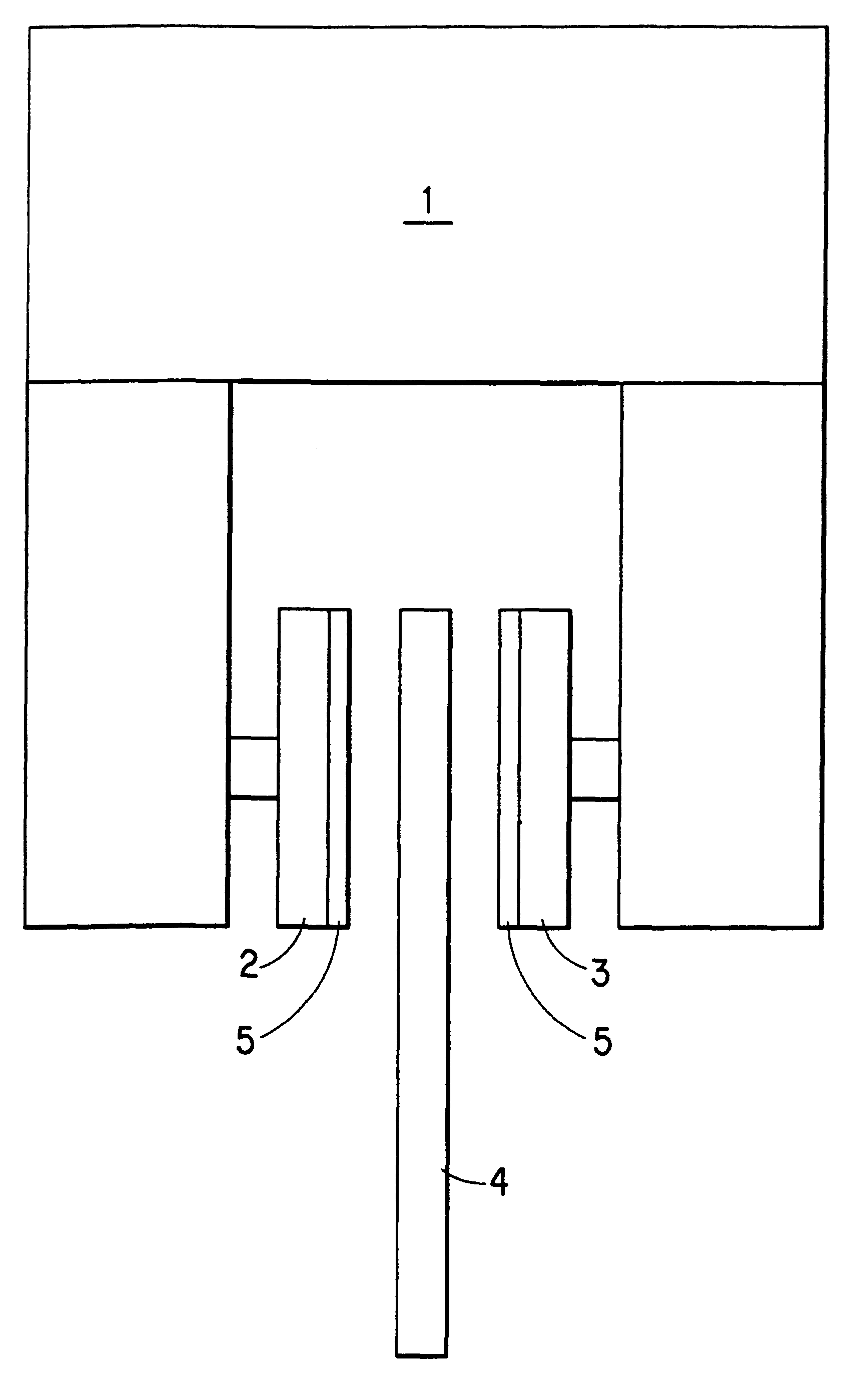

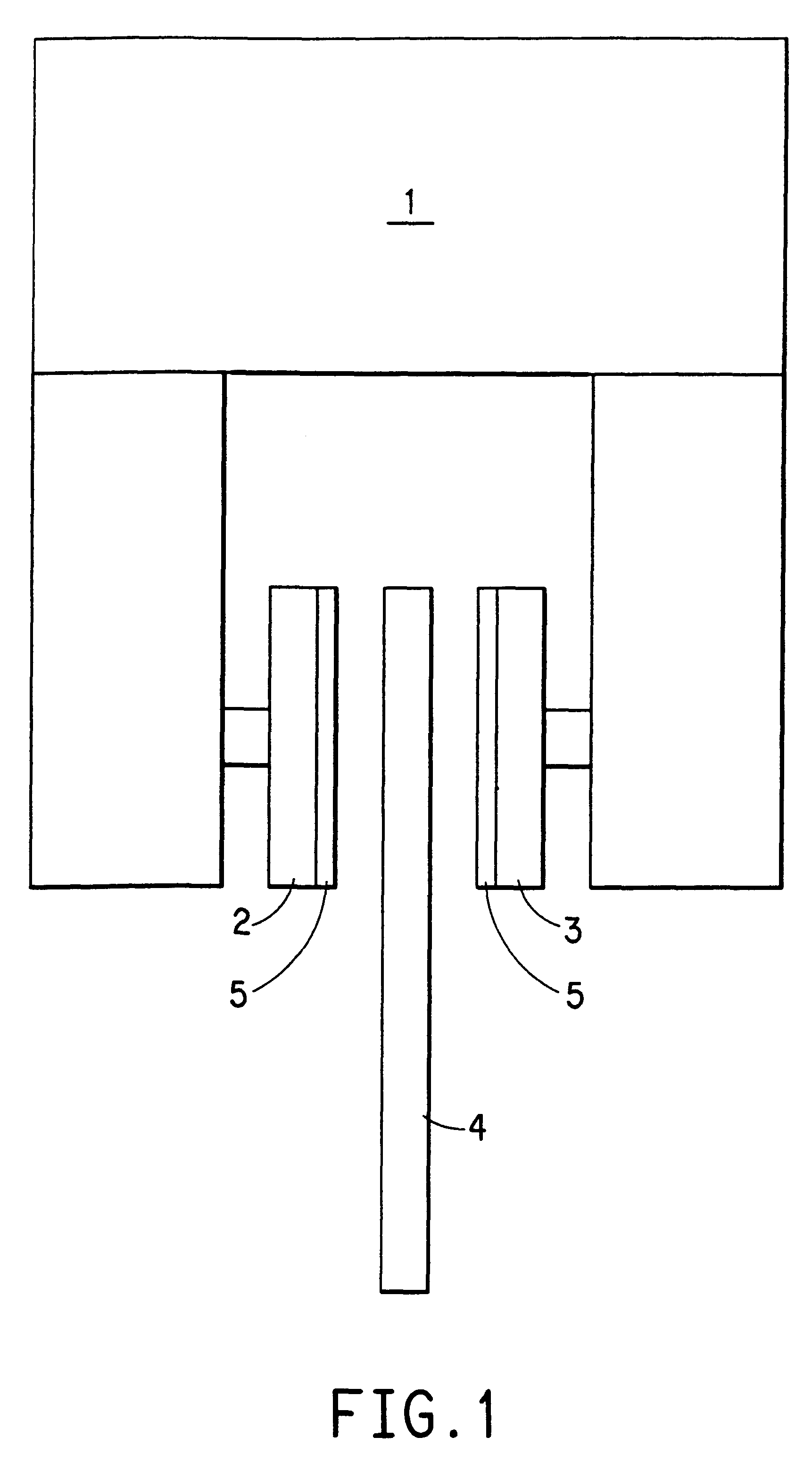

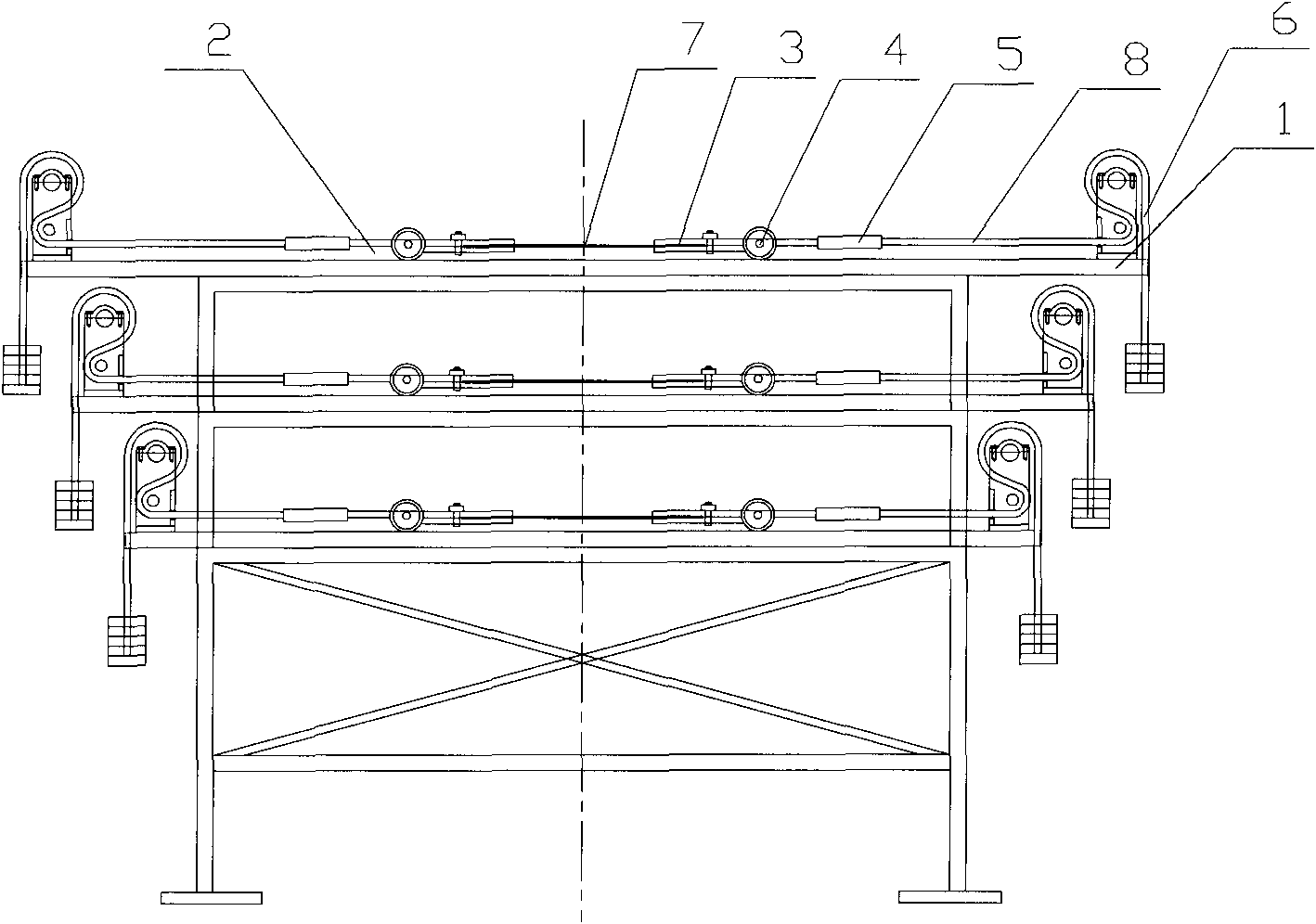

Mechanical biaxial tension tester with variable proportion loading

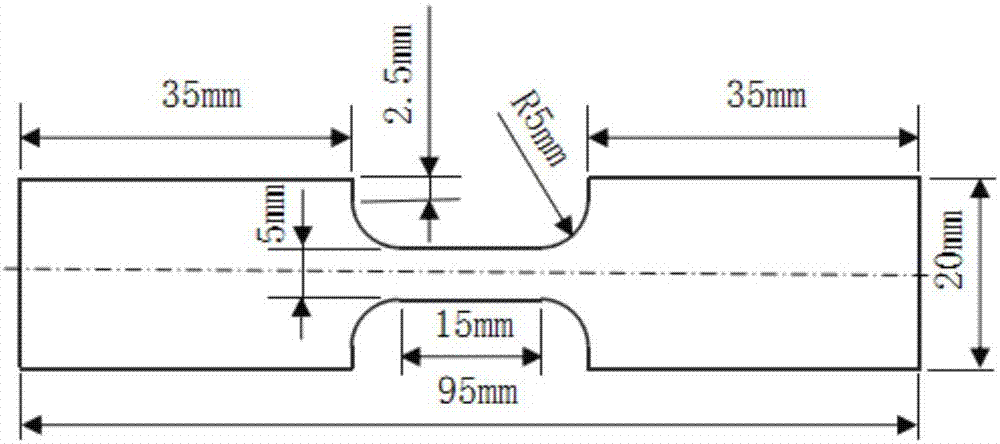

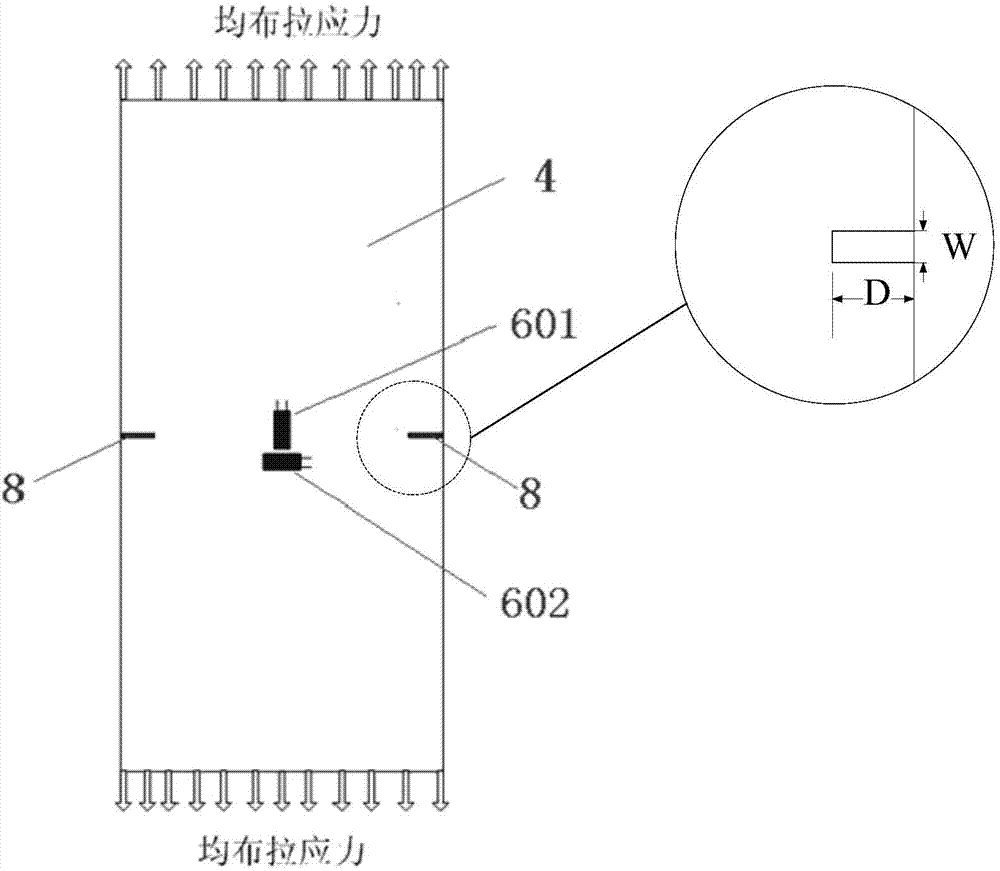

InactiveCN101907538AReduce frictionRatio unchangedMaterial strength using tensile/compressive forcesCruciformTension compression

The invention discloses a mechanical biaxial tension tester with variable proportion loading, relating to a biaxial tension tester. The invention solves the problem that the traditional biaxial tension testing device can not realize variable proportion loading under a complex loading path. In the invention, a slanting slide block is an inverted trapezoidal quadrangular frustum pyramid, a workbench is provided with a cruciform chute, a cruciform test piece is arranged above the cruciform chute, four ends of the cruciform test piece are respectively and fixedly connected with a clamping head, a tension-compression sensor is fixedly connected to the outer end surface of each clamping head, the outer end of each tension-compression sensor is fixedly connected with a horizontal slide block, each horizontal slide block is installed on the workbench, the lower end of each slant beam is fixedly connected with a horizontal slide block, a rolling bearing is installed at the upper end of each slant beam, and each rolling bearing is contacted with a corresponding trapezoidal inclined plane of each slant beam and rolls on the corresponding trapezoidal inclined plane of each slant beam. The invention is suitable for a tension test of the cruciform test piece.

Owner:HARBIN INST OF TECH

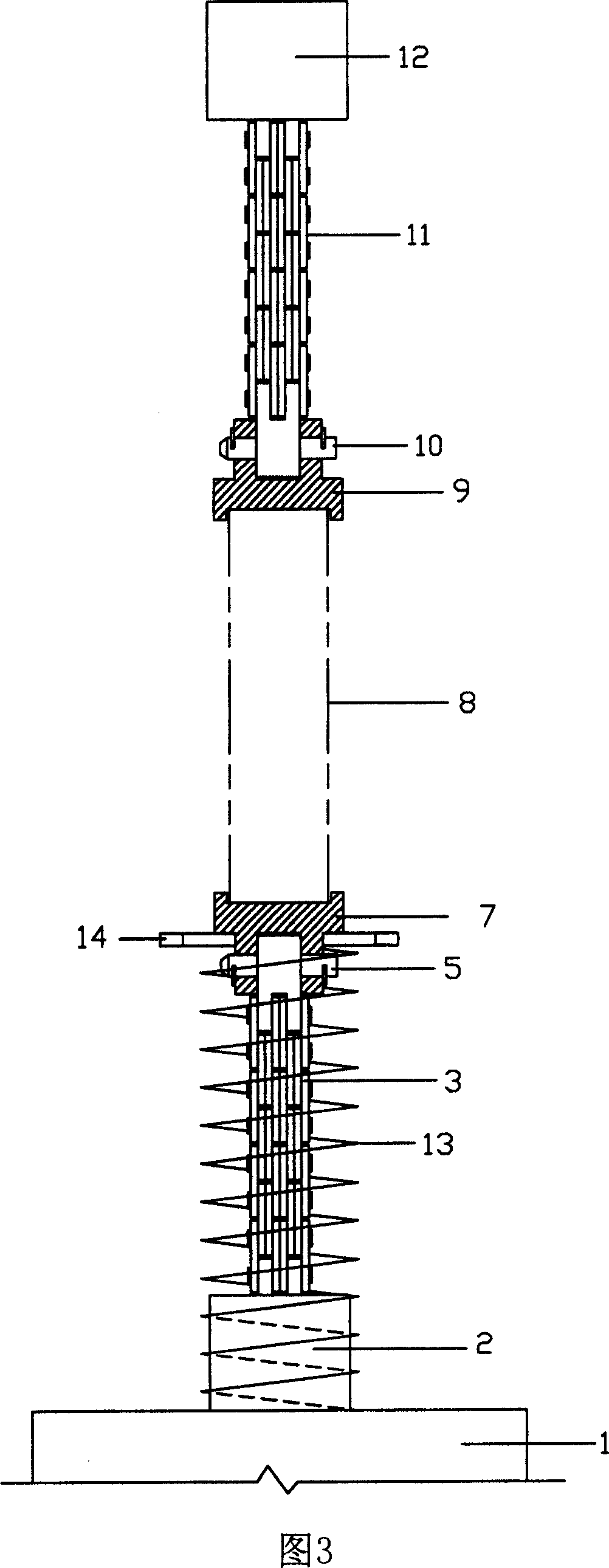

Spring thrust down clamp of direct tensile test

InactiveCN1952643AAvoid sudden destructionSimple structureMaterial strength using tensile/compressive forcesEngineeringTensile testing

Owner:SICHUAN UNIV

Uni-directional stretching test clamp for warm shaping of metal plate

InactiveCN101608988AReduce adverse effectsMaterial strength using tensile/compressive forcesEngineeringHeating furnace

A uni-directional stretching test clamp for warm shaping of a metal plate relates to the technology of testing warm shaping performance of metal plates. The clamp consists of a displacement magnitude leading-out part, a stretching test element positioning and clamping part and a test machine connecting part, and can lead the displacement magnitude of scale distance of a stretching test element with different softness degrees out of a heating furnace so as to provide convenience for accurately measuring the displacement by using an extensometer. After the stretching test element is provided with a clamp, the direction of a loading force and the direction of the length of the stretching test element can be ensured to be on the same line. A cooling device can effectively cool the connecting place between the clamp and a testing machine. The clamp can effectively improve the accuracy of a test result.

Owner:JIANGSU UNIV

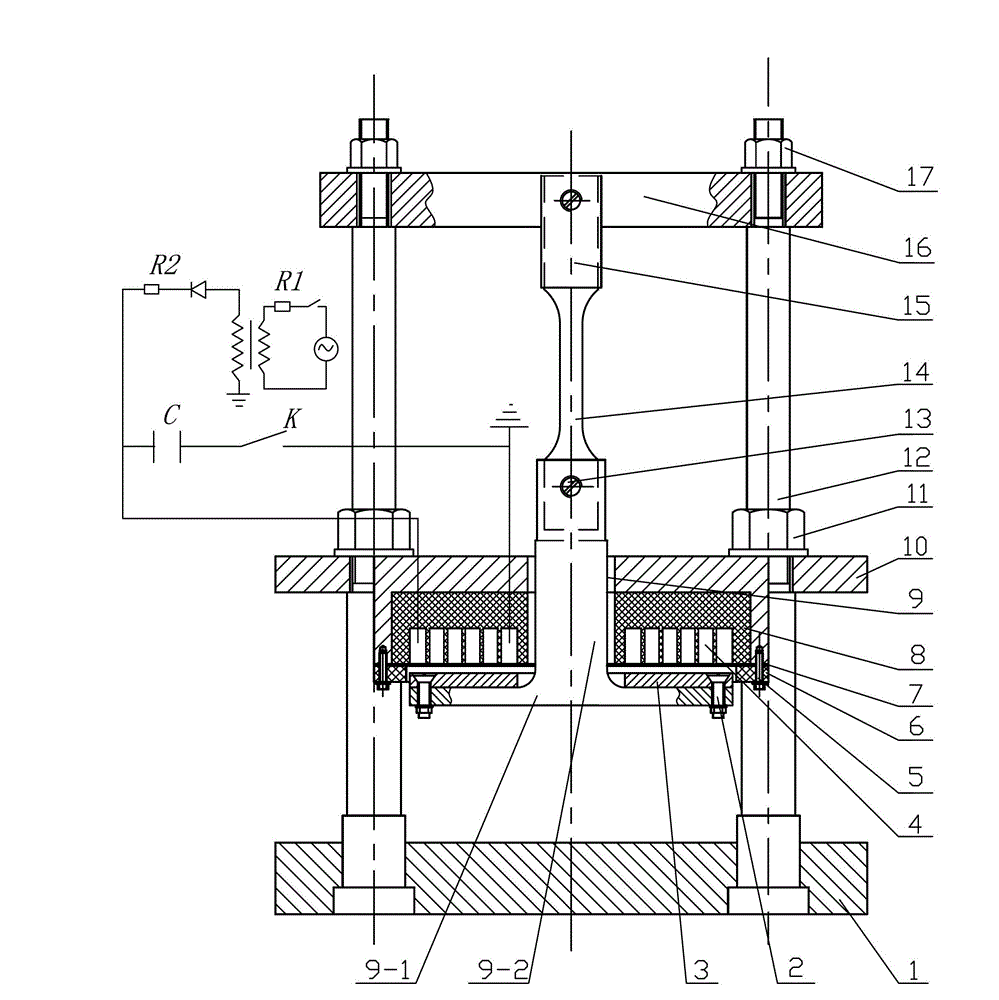

High-speed one-way tensile test device and method

ActiveCN102944474ALow costFew experimental conditionsMaterial strength using tensile/compressive forcesEngineeringHigh pressure

The invention discloses a high-speed one-way tensile test device and method, relates to a one-way tensile test device and method and aims to solve the problems of expensive test equipment and difficulty in obtaining a stress-strain relation curve in research on the constitutive relation of a metal material under the condition of high-speed elongation strain by using a hopkinson bar test. A coil is fixed in a coil supporting sleeve; two pull rods are connected with a bottom plate; the pull rods are detachably connected with the coil supporting sleeve and a sample fixing plate; a rigid coil limiting ring, an insulating partition plate and the coil supporting sleeve are detachably connected; and a drawing die comprises a base and a drawing rod, wherein the drawing rod is fixedly connected with the base, the drawing rod sequentially penetrates out of the coil limiting ring, the insulating partition plate, the coil framework and the coil supporting sleeve, a driving plate is arranged between the base and the rigid coil limiting ring and detachably connected with the base, and leading wires at two ends of the coil are connected with a capacitor bank which is controlled by a high-voltage switch to discharge. The high-speed one-way tensile test device and method are used for carrying out high-speed one-way tensile test on a standard tensile sample.

Owner:HARBIN INST OF TECH

Bidirectional tensile tester

Owner:NORTHWESTERN POLYTECHNICAL UNIV

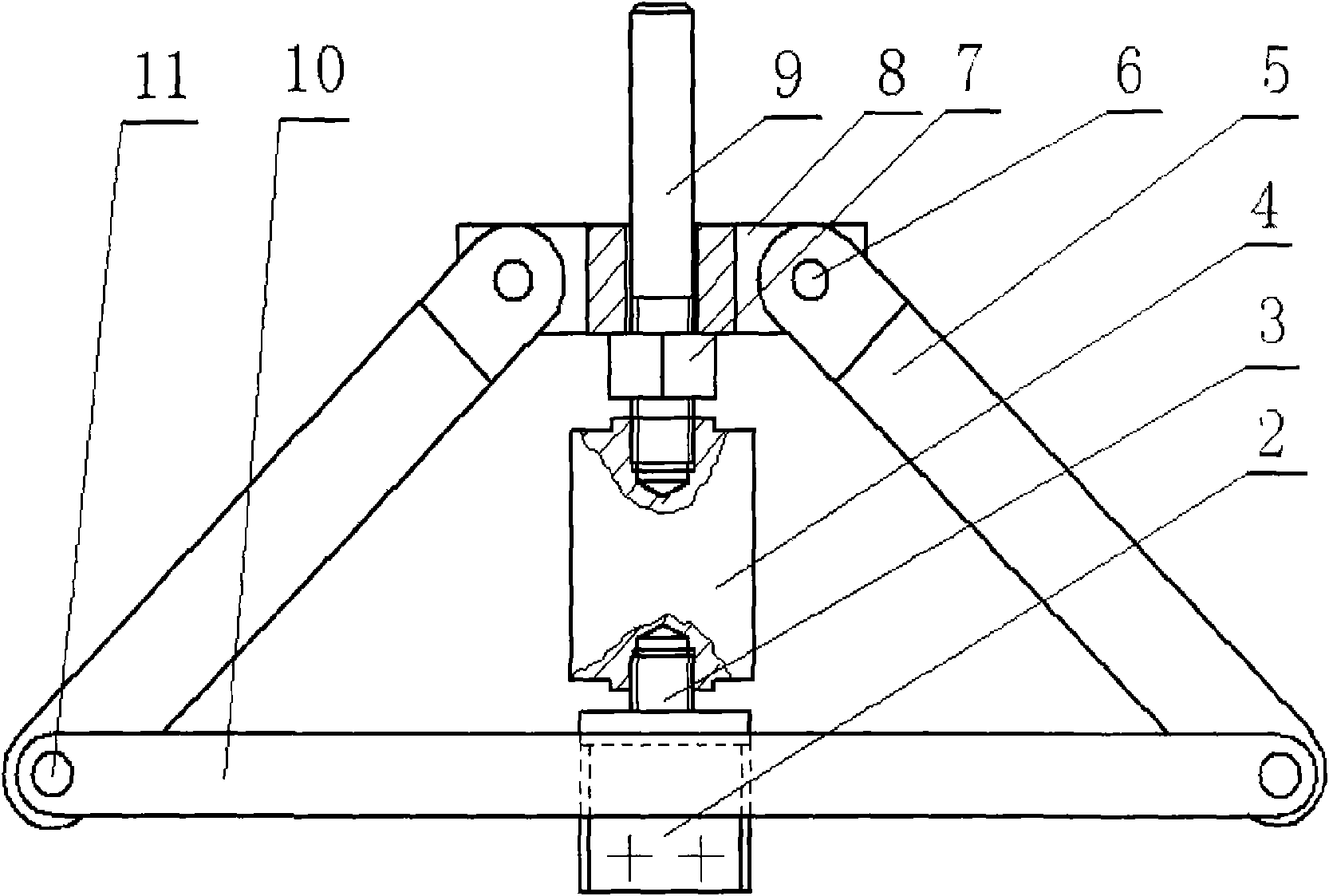

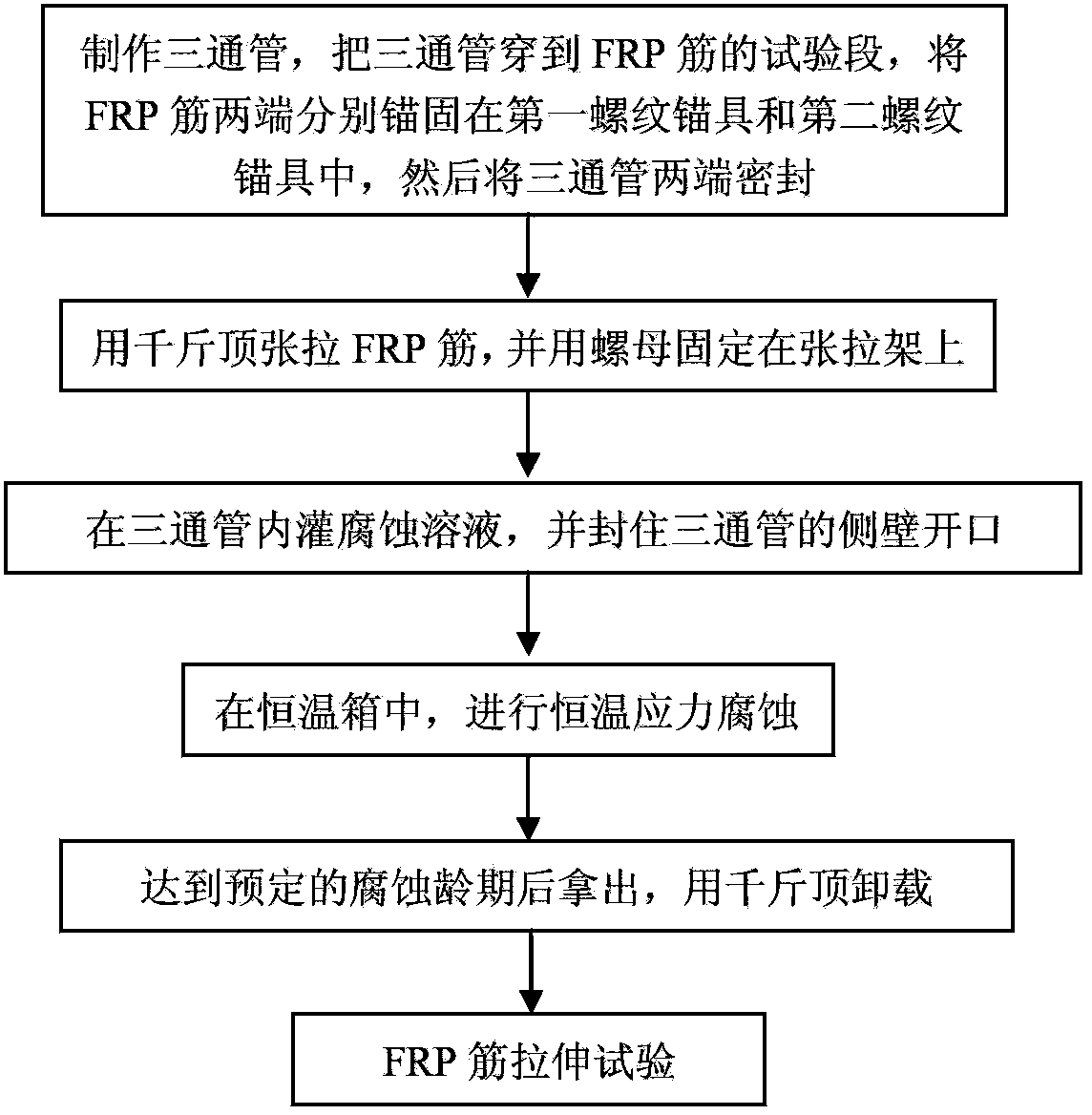

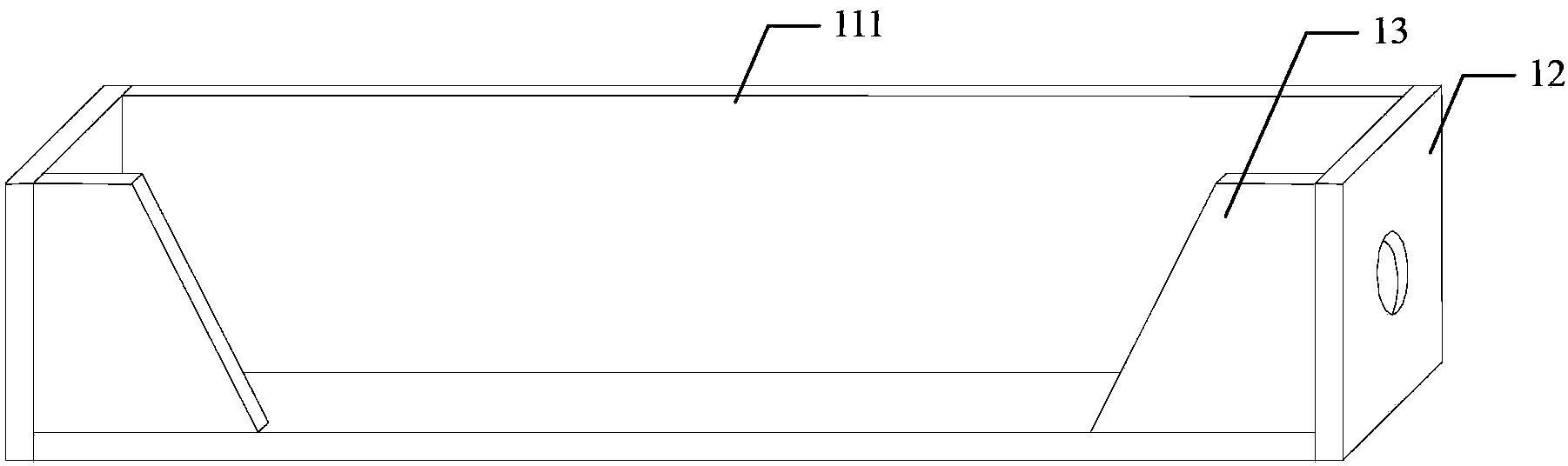

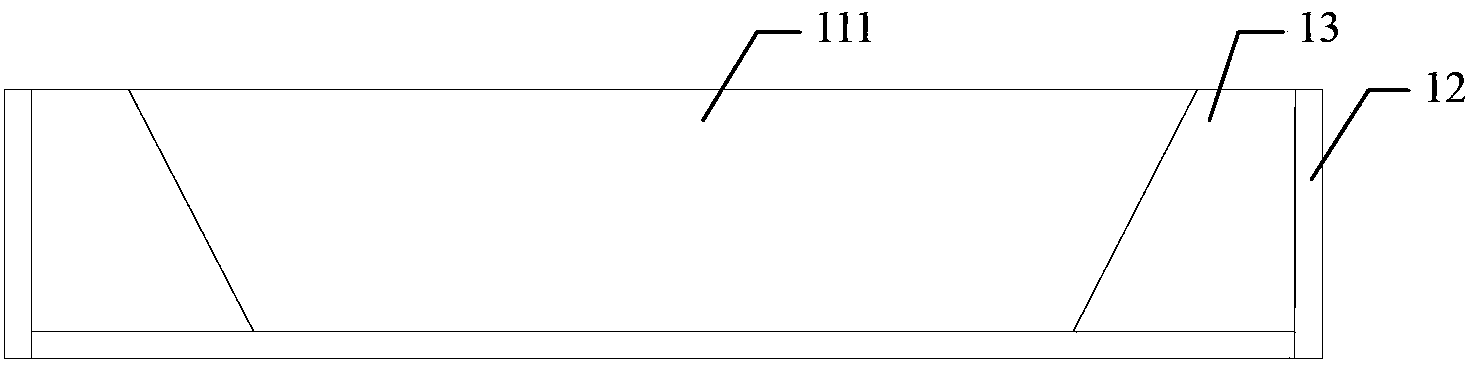

Constant-temperature stress corrosion testing device and method for FRP (fiber reinforced polymer) tendon

InactiveCN103376222ASimple structureEasy to manufactureMaterial strength using tensile/compressive forcesTemperature stressFiber

The invention discloses a constant-temperature stress corrosion testing device and method for an FRP (fiber reinforced polymer) tendon. The device comprises a stretch-draw frame, threaded anchors, a three-way pipe, a spring, a counter force frame, a lifting jack, a force sensor and a stretch-draw anchor rod. Certain stretch-draw stress is applied to the FRP tendon by utilizing the stretch-draw frame, the counter force frame, the lifting jack and the force sensor, and the FRP tendon is fixed by a nut, and the stress loss is compensated by the compression spring, and the constant stress level can be kept for a long time. A corrosion solution soaking environment is provided through a method that a corrosion solution is filled into a home-made PVC pipe device fixed in the middle of the FRP tendon, so that the FRP tendon is in the corrosion solution soaking environment for a long time. After the corrosion solution is filled completely and the prestress is stretched and drawn, the whole stretch-draw frame for stretching and drawing the FRP tendon is put into a constant-temperature constant-humidity test box so as to guarantee the long-term constant-temperature environment. After the constant-temperature corrosion, the device is unloaded through the steps the same with the stretch-draw step, the FRP tendon is taken down for a stretch test. The method comprises the following steps of: anchoring the FRP tendon, fixing through stretching and drawing, corroding at constant temperature, unloading and carrying out the stretch-draw test.

Owner:SOUTHEAST UNIV

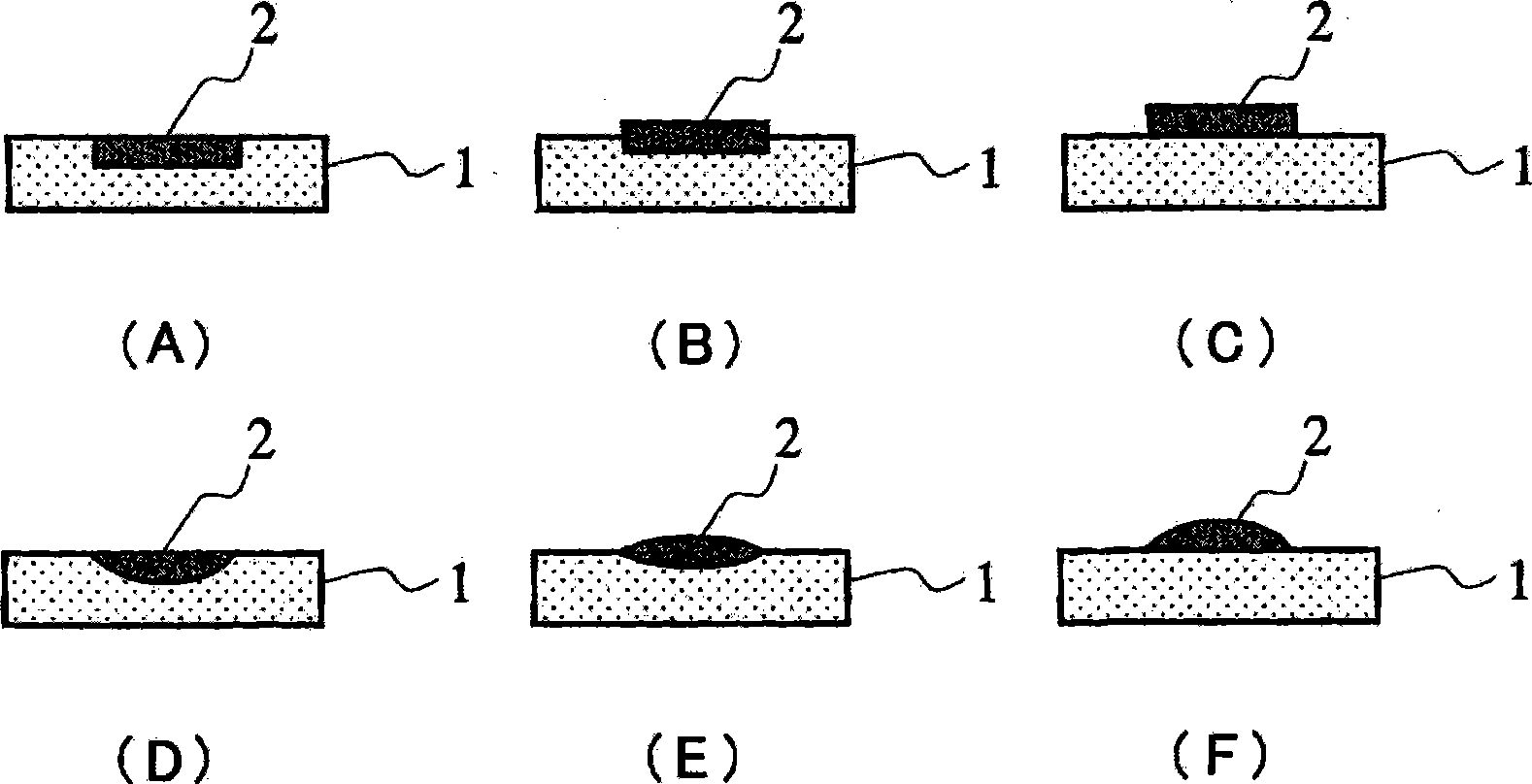

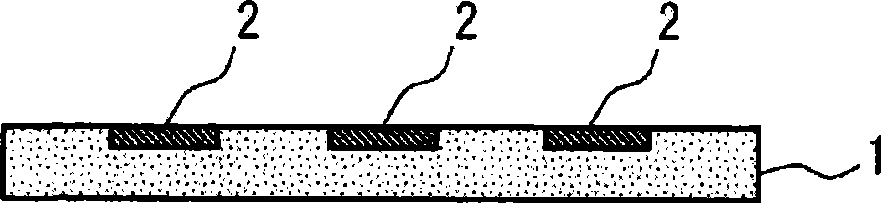

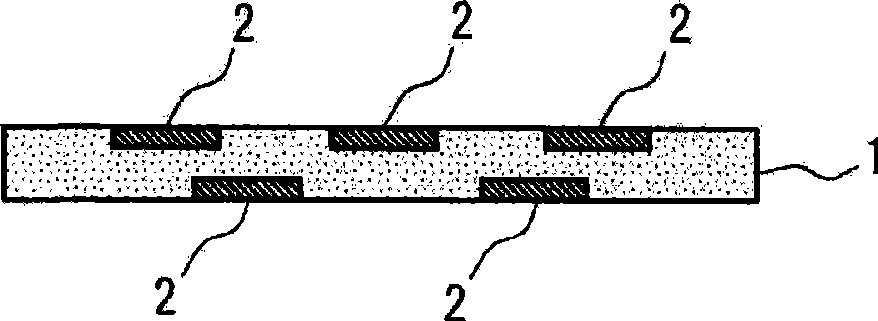

Porous film and multilayer assembly using the same

InactiveCN101384425ASmall widthImprove adhesionLayered productsPrinted circuit manufactureAdhesive beltPorous layer

To provide a porous-film layered product which has excellent porousness, has flexibility, and is excellent in handleability and formability; and a process for producing the layered product. [MEANS FOR SOLVING PROBLEMS] The porous-film layered product comprises a base and, superposed on at least one side thereof, a porous layer having many fine interconnecting pores having an average pore diameter of 0.01-10 [mu]m, and is characterized by suffering no interfacial separation between the base and the porous layer when examined in a tape peeling test by the following method. Tape peeling test A 24 mm-wide masking tape [Film Masking Tape No. 603(#25)] manufactured by Teraoka Seisakusho Co., Ltd. is applied to the surface of the porous layer of the porous-film layered product and press-bonded thereto with a roller having a diameter of 30 mm and a load of 200 gf. Thereafter, this sample is subjected to a T-peel test with a tensile tester at a peeling rate of 50 mm / min.

Owner:DAICEL CHEM IND LTD

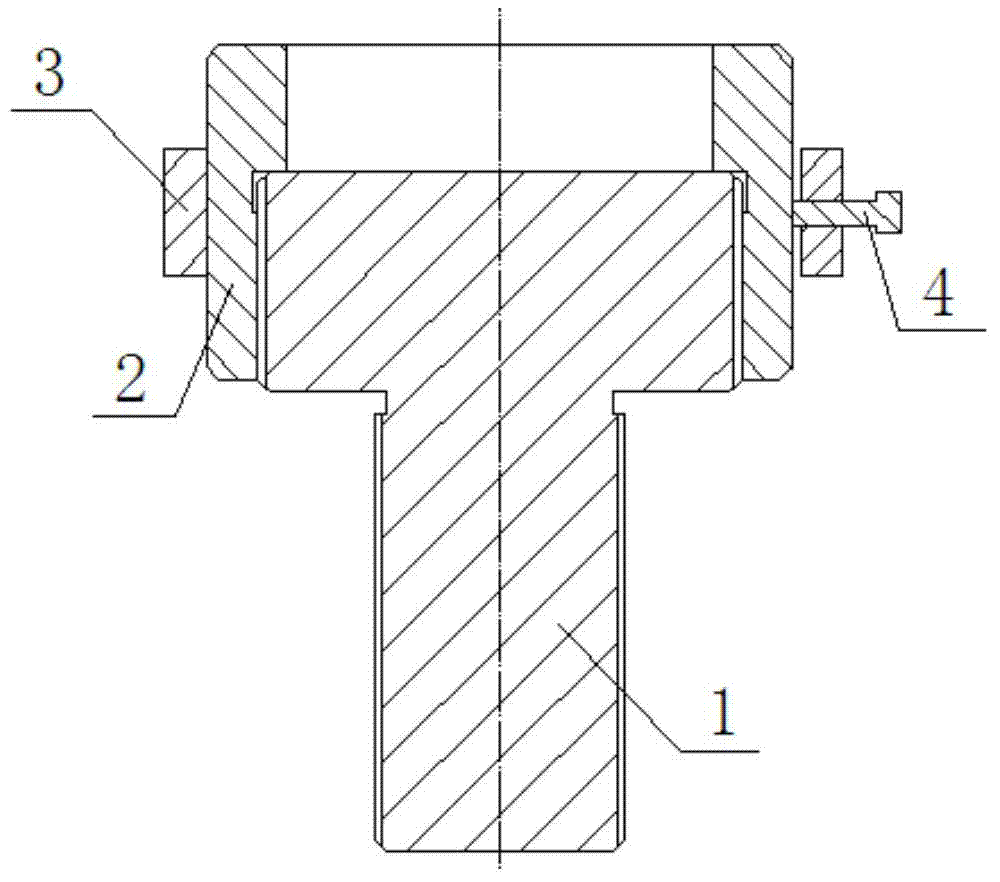

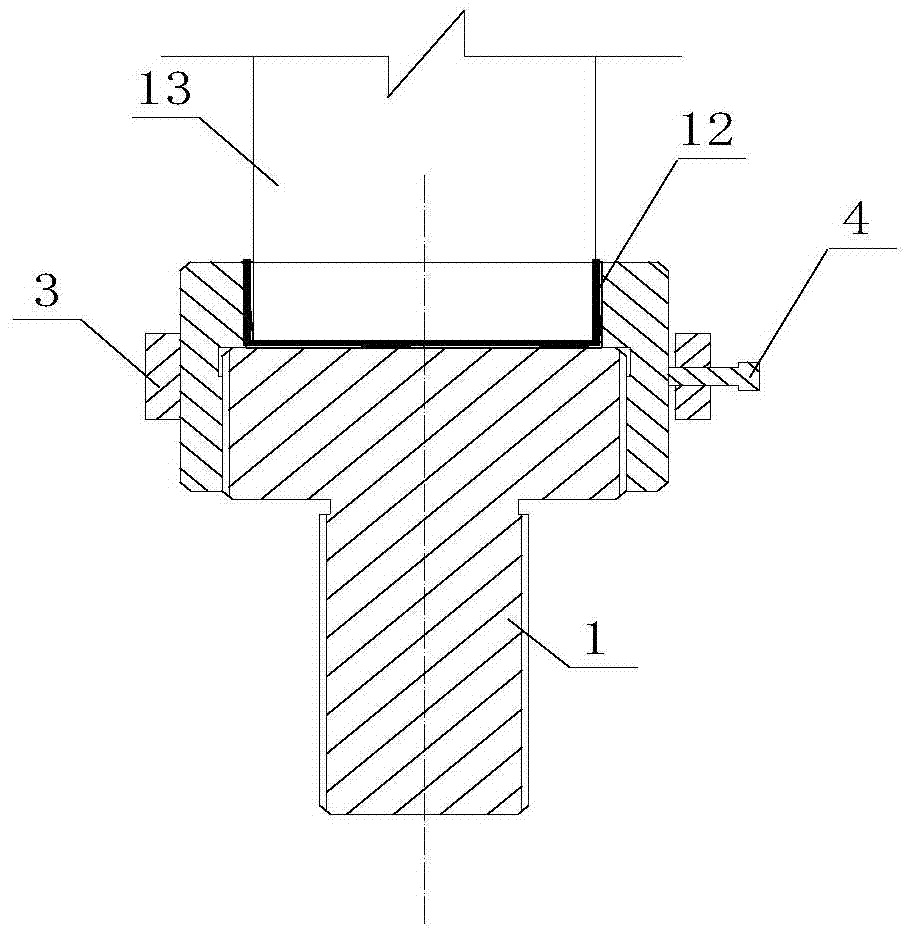

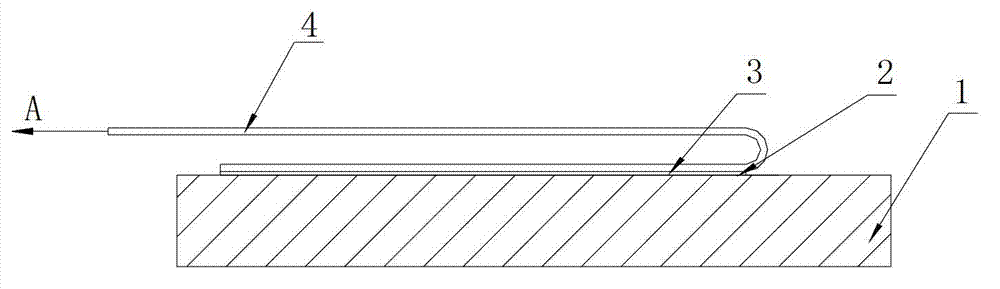

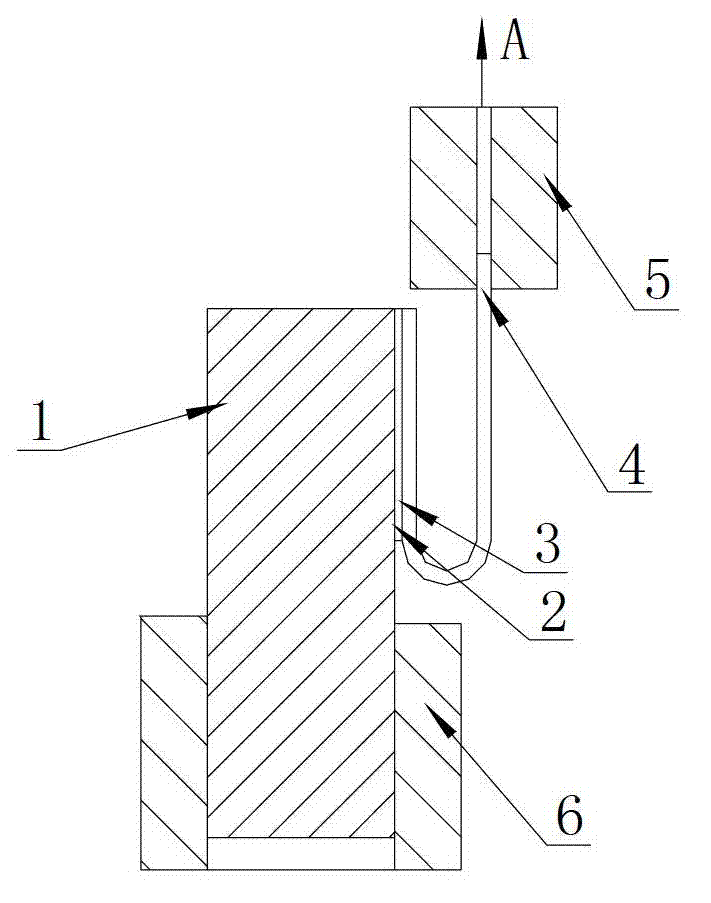

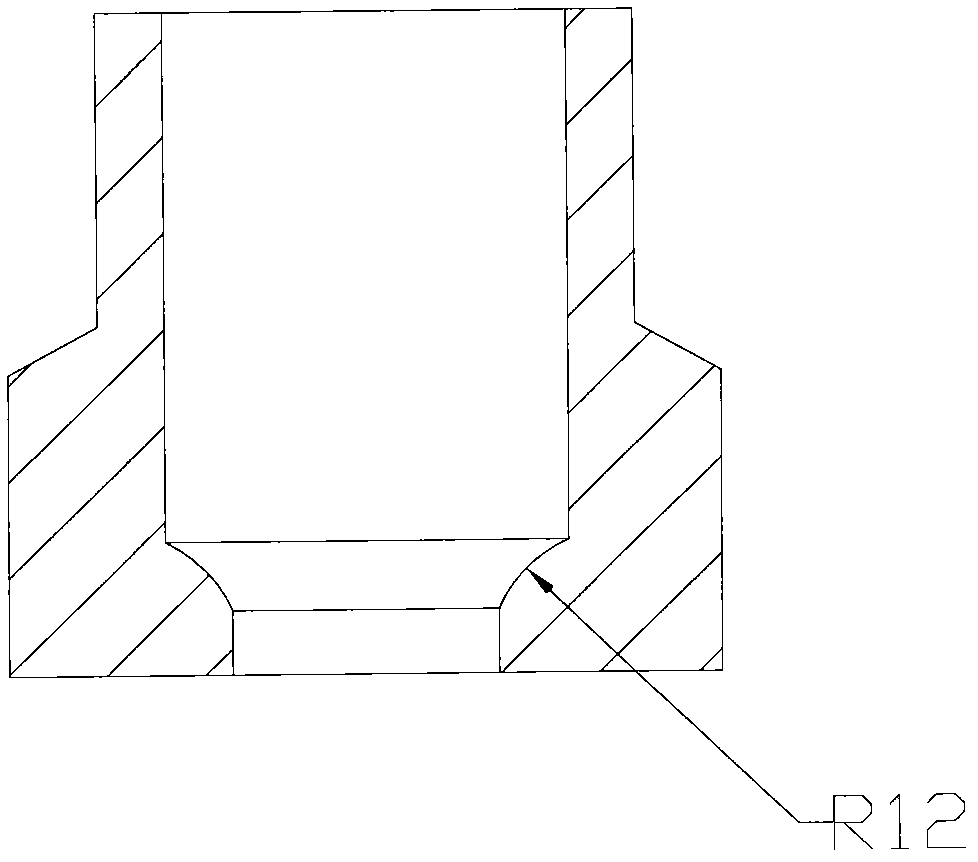

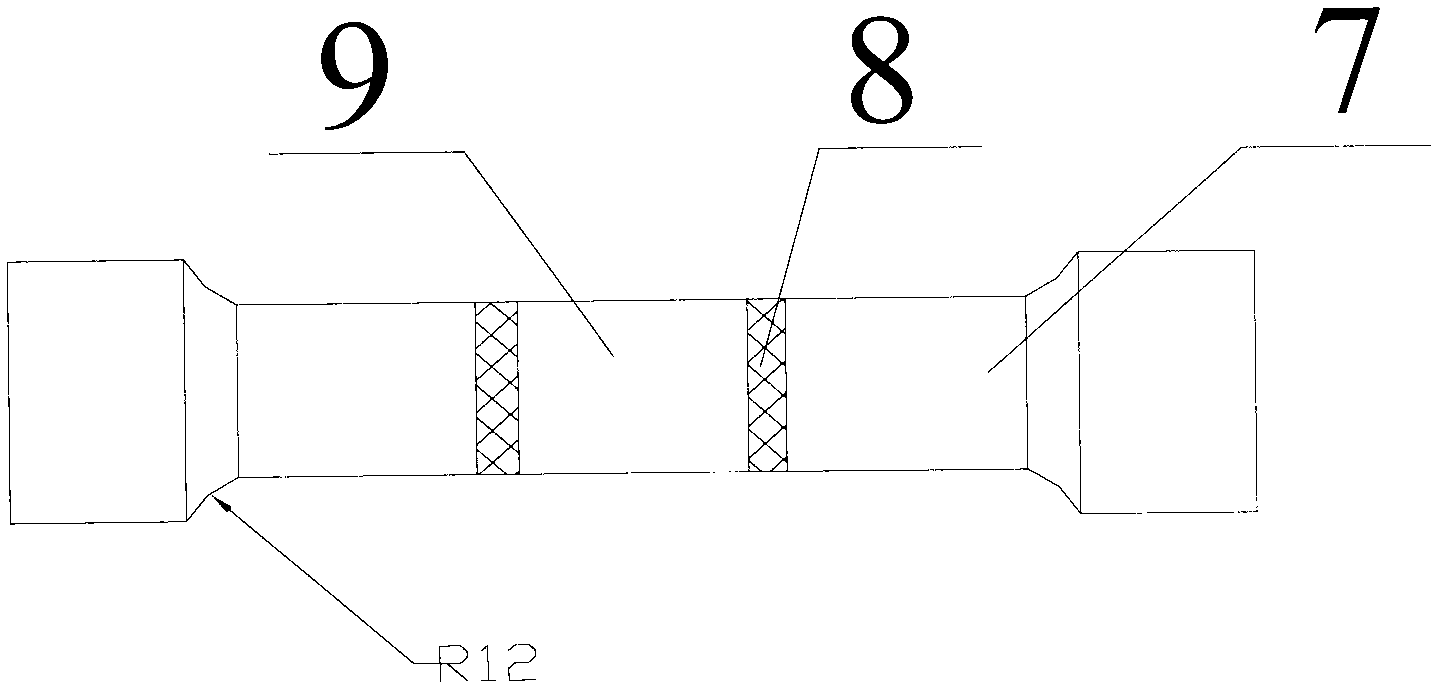

Sleeve-spliced rock direct tensile test device and method

ActiveCN103543066AImprove tensile capacityReduce eccentricityMaterial strength using tensile/compressive forcesEconomic benefitsHigh intensity

The invention discloses a sleeve-spliced rock direct tensile test device and method. The test device comprises a sleeve assembly, a splicing device and a tensile positioning device which are matched, wherein sleeves is adhered to end faces and a part of sides of a rock test piece, the tension capacity of the end part of the test piece is effectively improved through increasing the adhered area of the end parts of the test piece, and thus the purpose of performing a high-strength rock tensile test is reached. The test device is simple in structure, convenient to dismantle, and easy to operate, and is simple and convenient. The test device and method are easy to popularize and has a wide application prospect and remarkable economic benefit.

Owner:SHANDONG UNIV

Test method for performing rock direct stretching by using axial centering positioning device

ActiveCN103323329AObvious technical advantagesAccurate testing of tensile strengthMaterial strength using tensile/compressive forcesTensile strainStress–strain curve

The invention discloses a test method for performing rock direct stretching by using an axial centering positioning device. The positioning device comprises an adhesion centering positioning device and a stretching centering positioning device which are matched with each other. The adhesion centering positioning device is used for eliminating the eccentricity caused by the adhesion of a test piece; the stretching centering positioning device is used for eliminating the eccentricity generated in the test piece stretching process; the tensile strength and the ultimate tensile strain and a tensile stress-strain curve of a rock can be accurately tested by using a direct stretching test method. The device is simple in structure, convenient to operate and easy to assemble and disassemble; the problem about the eccentricity when the rock test piece is adhered and stretched is solved; the test method can accurately test the tensile strength of the rock and also can effectively test the ultimate tensile strain and the tensile stress-strain curve of the rock.

Owner:SHANDONG UNIV

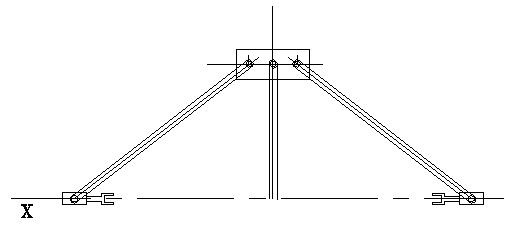

Biaxial tension test device for testing performance of sheet metal

InactiveCN102706731ASimple structureEasy maintenanceUsing optical meansStrength propertiesSoftware engineeringEngineering

The invention discloses a biaxial tension test device for testing the performance of sheet metal. The biaxial tension test device comprises an upper connecting structure, a lower connecting structure, a proportion adjusting mechanism, a fixture slide block mechanism and connecting rods. The biaxial tension test device with a simple pure mechanical structure is easy to maintain and mount, requires a relatively low cost and can effectively achieve a biaxial tension goal; besides, the loading proportion in two mutually vertical directions is convenient to adjust, and each connecting bolt can be adjusted to be horizontal with a chassis, so as to guarantee that specimens are in horizontal positions; and the biaxial tension test device has relatively high test accuracy and can effectively control failure time of the specimens.

Owner:HENAN POLYTECHNIC UNIV

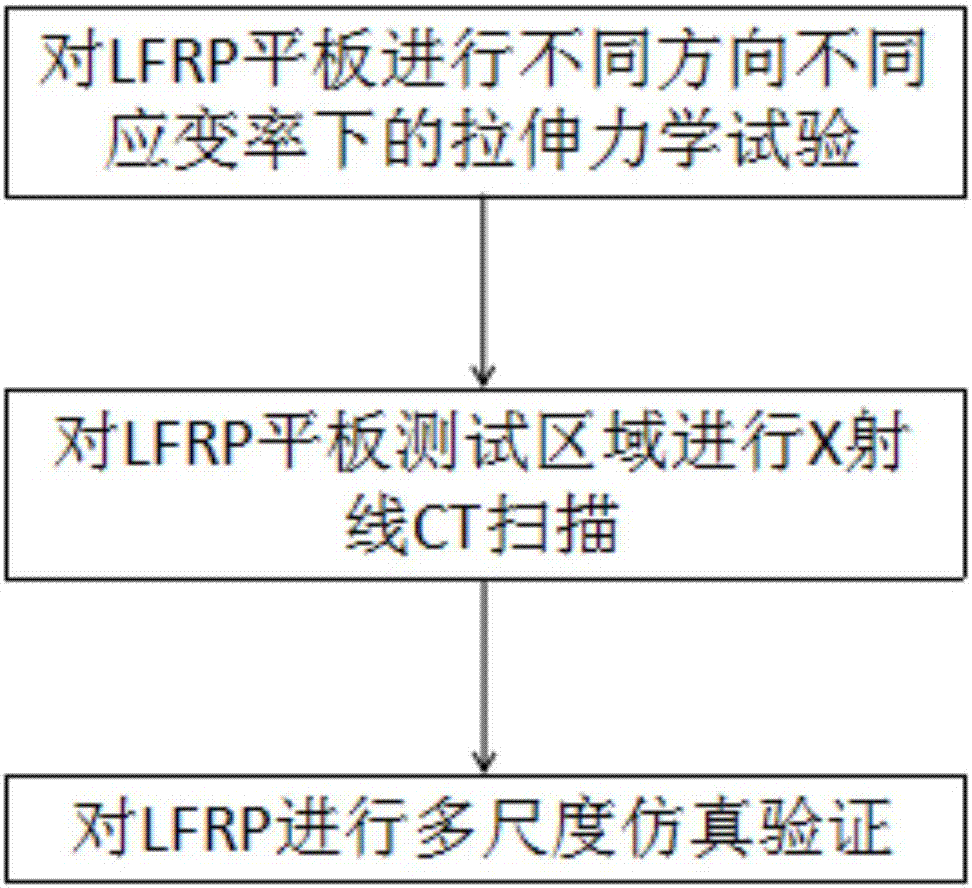

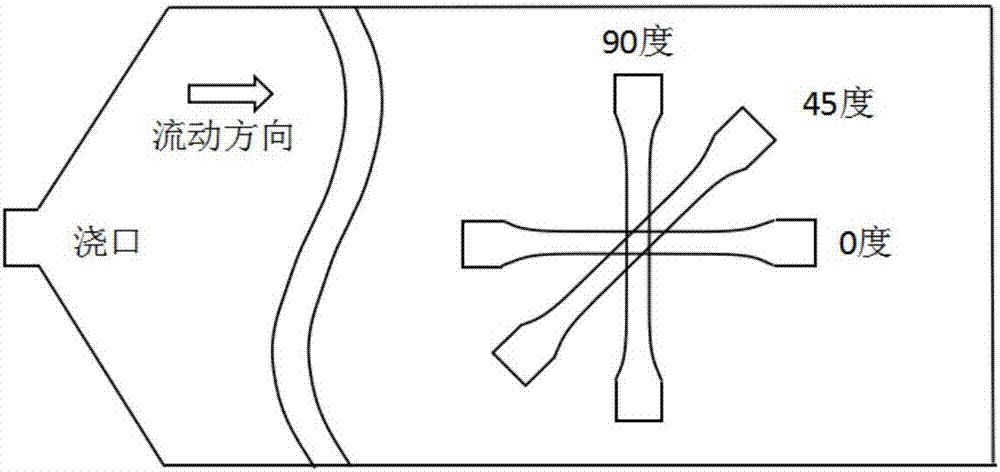

Long fiber reinforced thermoplastic composite material multi-scale simulation method

InactiveCN107356478ALow imaging resolutionRequires minimizationMaterial strength using tensile/compressive forcesMaterial analysis by transmitting radiationElement modelX-ray

The invention discloses a long fiber reinforced thermoplastic composite material multi-scale simulation method to solve the problem of difficult accurate simulation of long fiber reinforced thermoplastic composite material in simulation because of strain rate effect and anisotropic mechanical properties. The method includes the steps of: 1. conducting tensile test on an LFRP plate under different directions and different strain rates; 2. performing x-ray CT scanning on an LFRP plate test area; and 3) carrying out multi-scale simulation verification on the LFRP plate: 1) viscoelastic-viscoplastic material model and failure; and 2) simulation verification: using ABAQUS software and Digimat software coupling to establish a simulation finite element model, conducting simulating calculation of tensile test under three strain rates, wherein 0.001s<-1> and 1s<-1> adopt implicit algorithm, and 100s<-1> adopts display algorithm; fixing one end of the finite element sample model, and applying load to the other end along the length direction, and comparing all the mechanical characteristic curves obtained by simulating calculation with test data.

Owner:JILIN UNIV

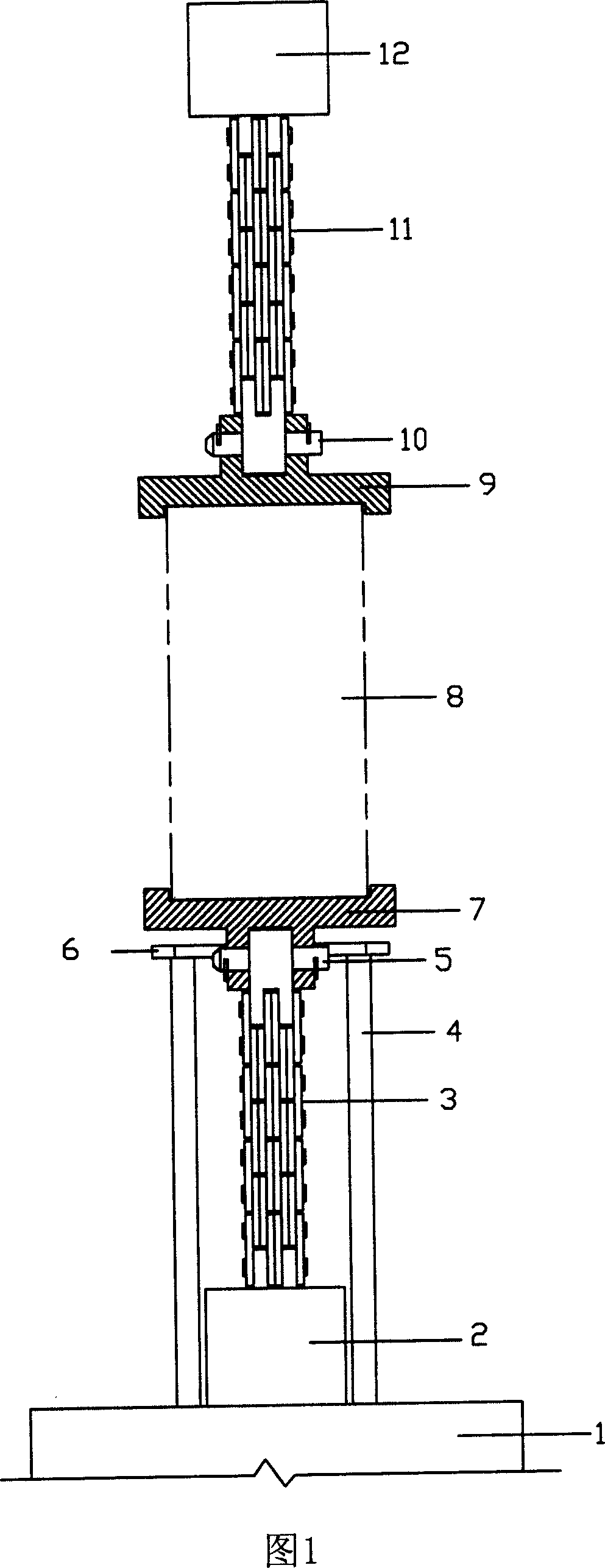

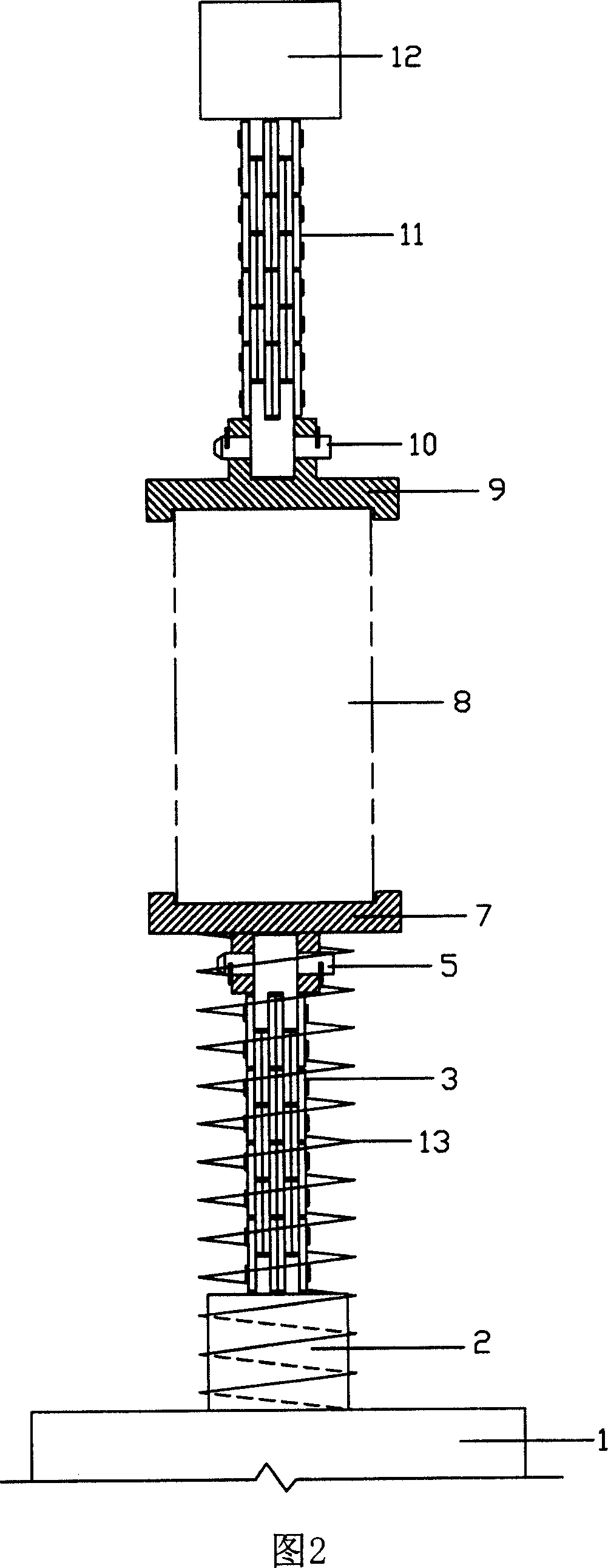

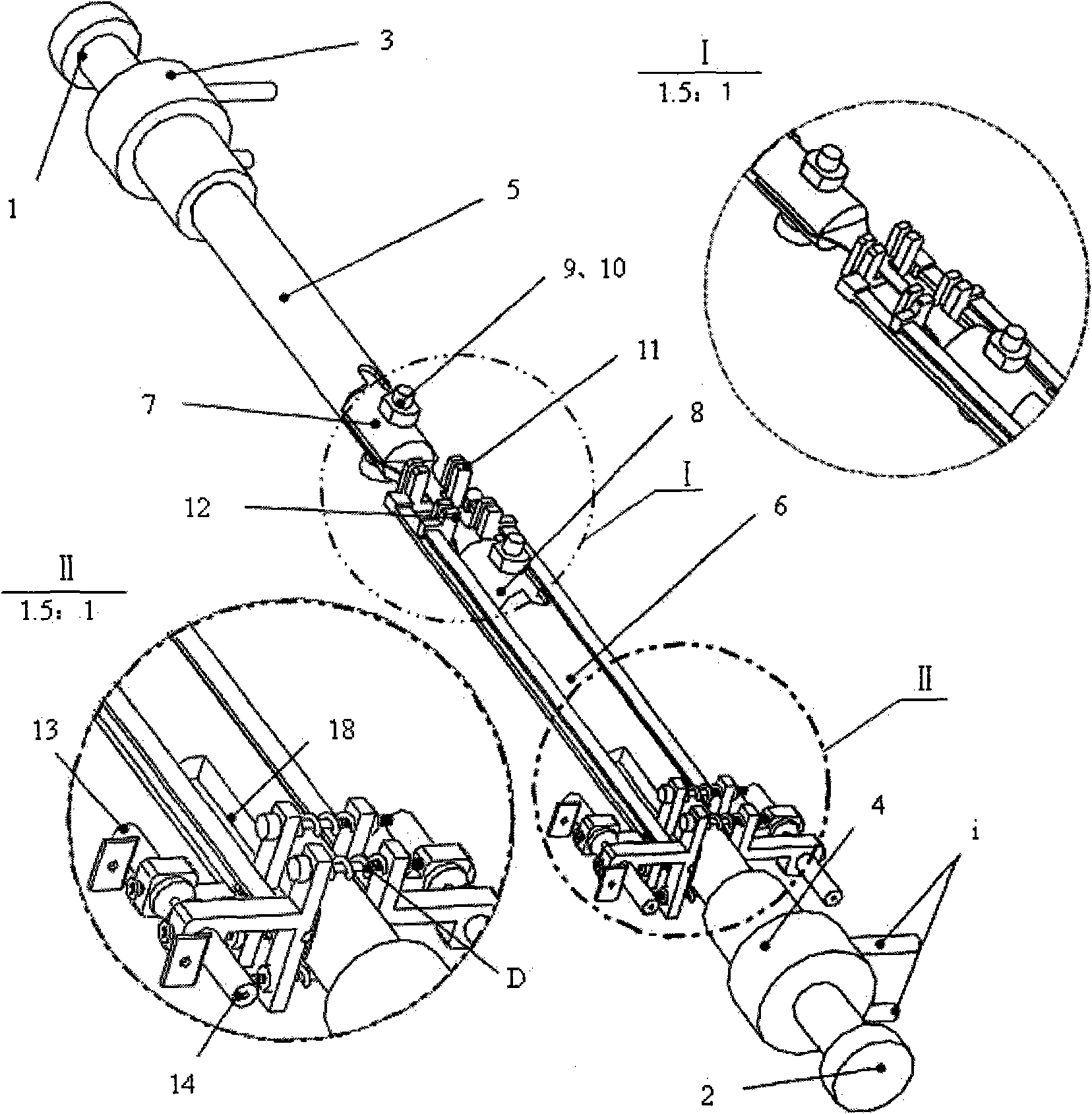

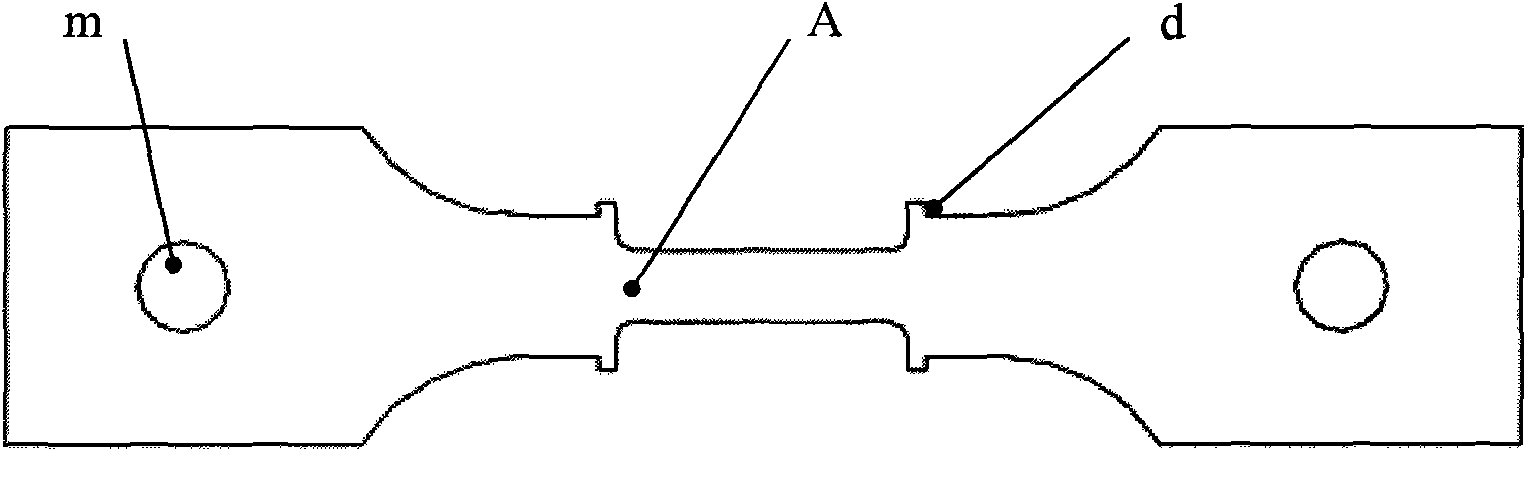

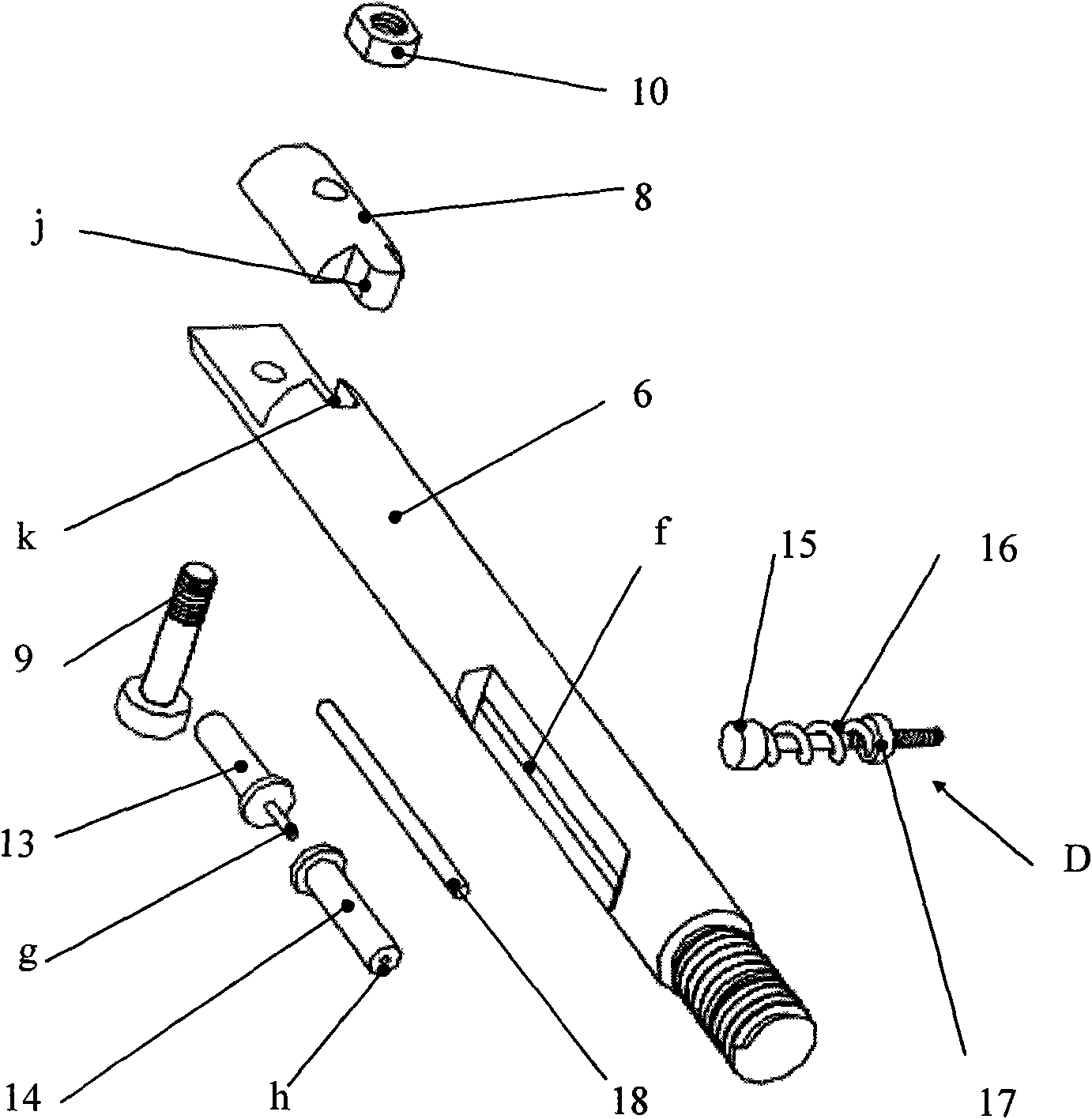

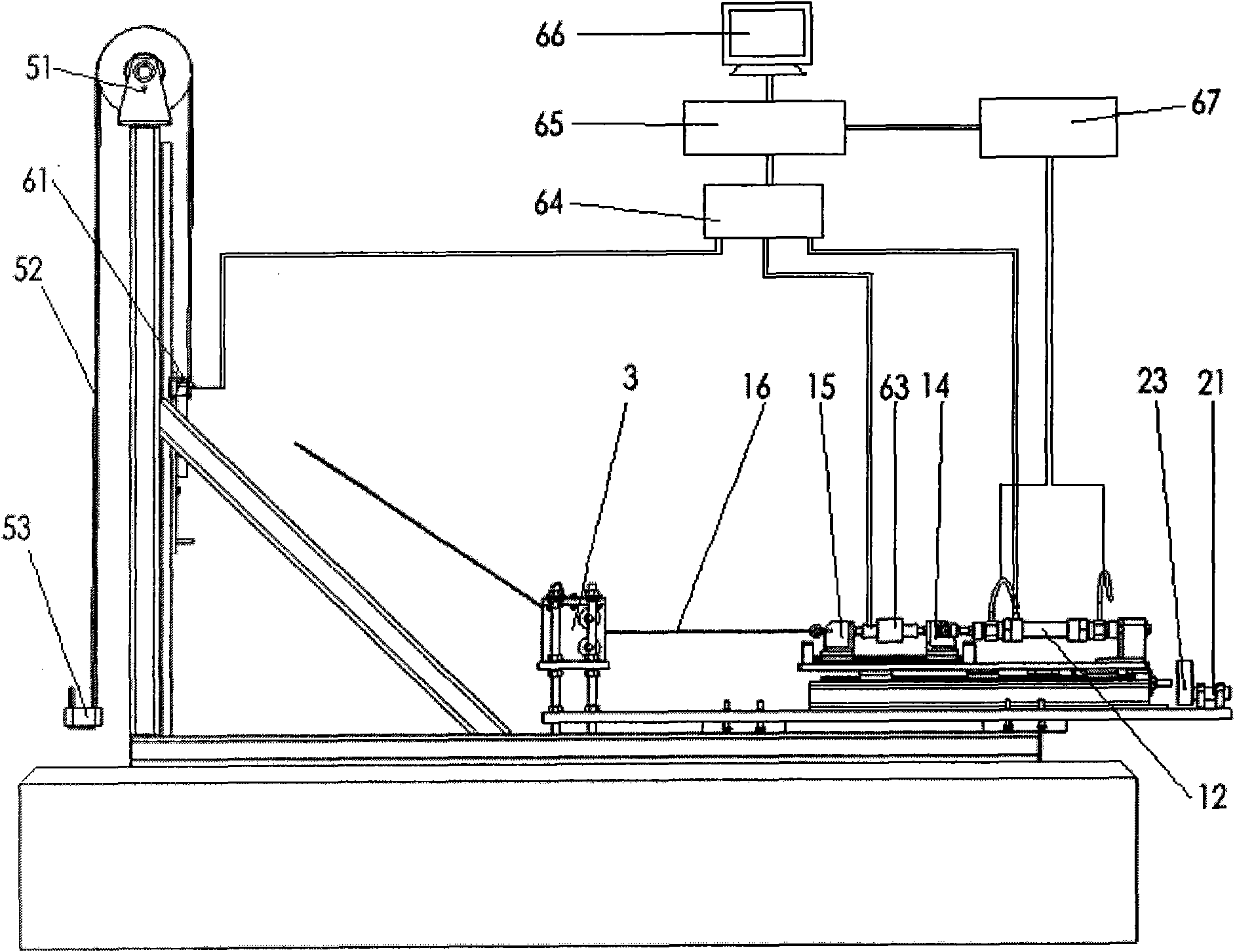

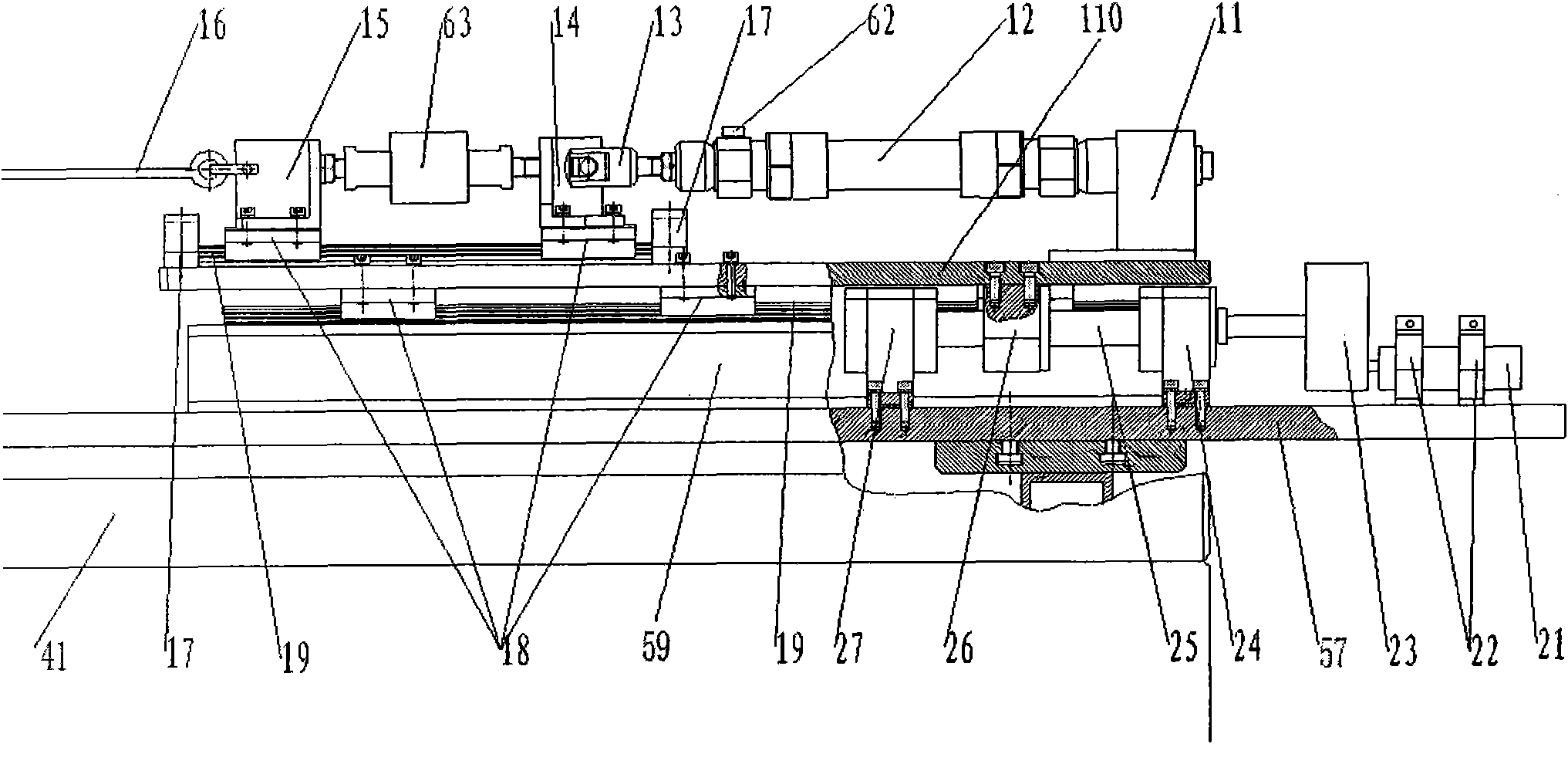

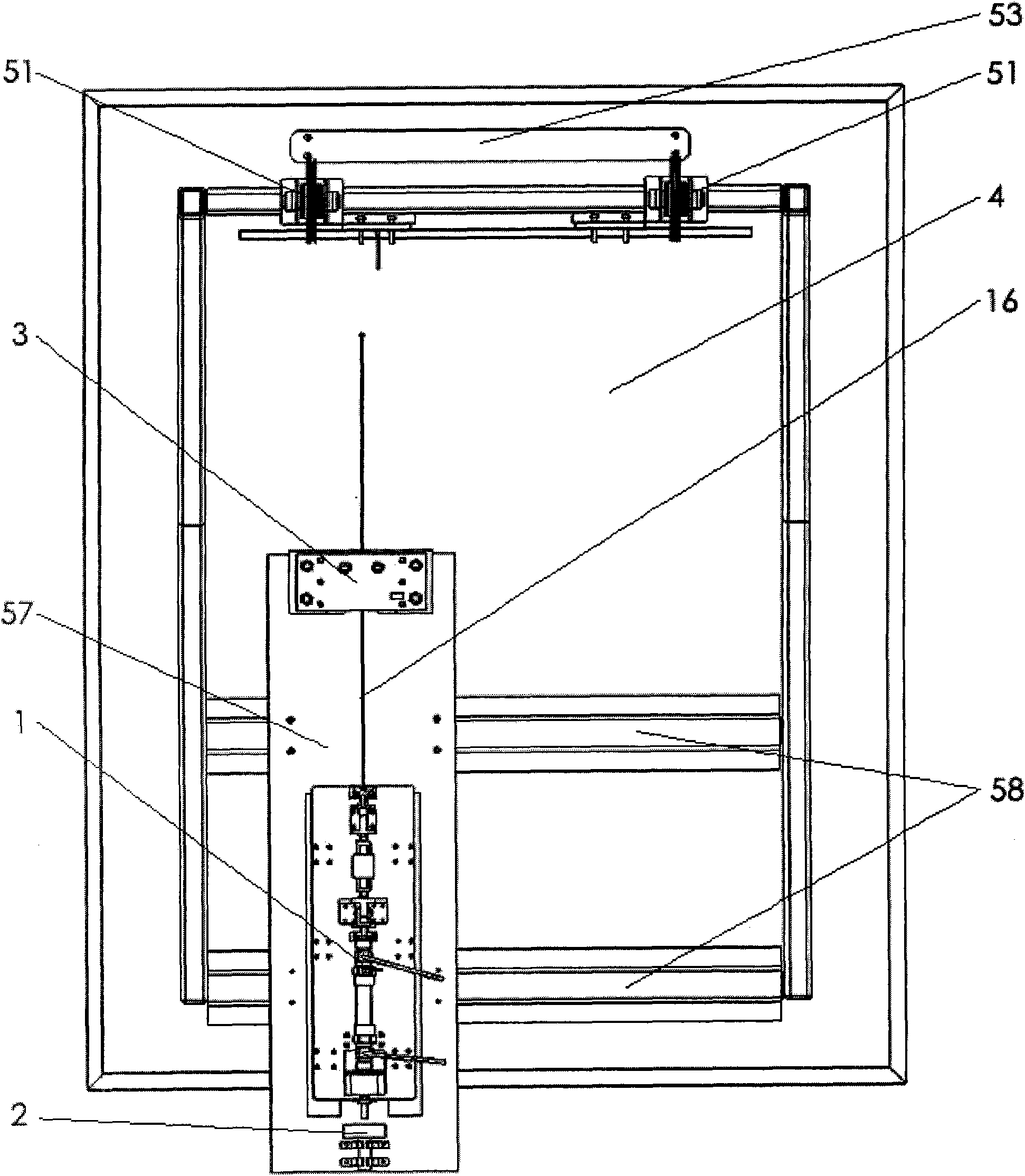

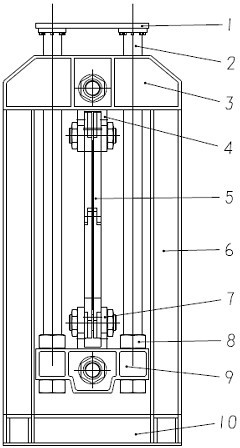

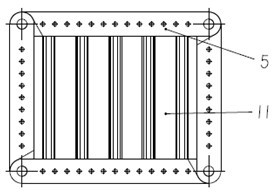

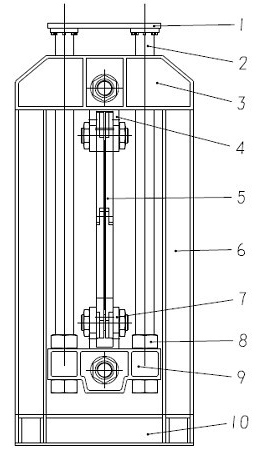

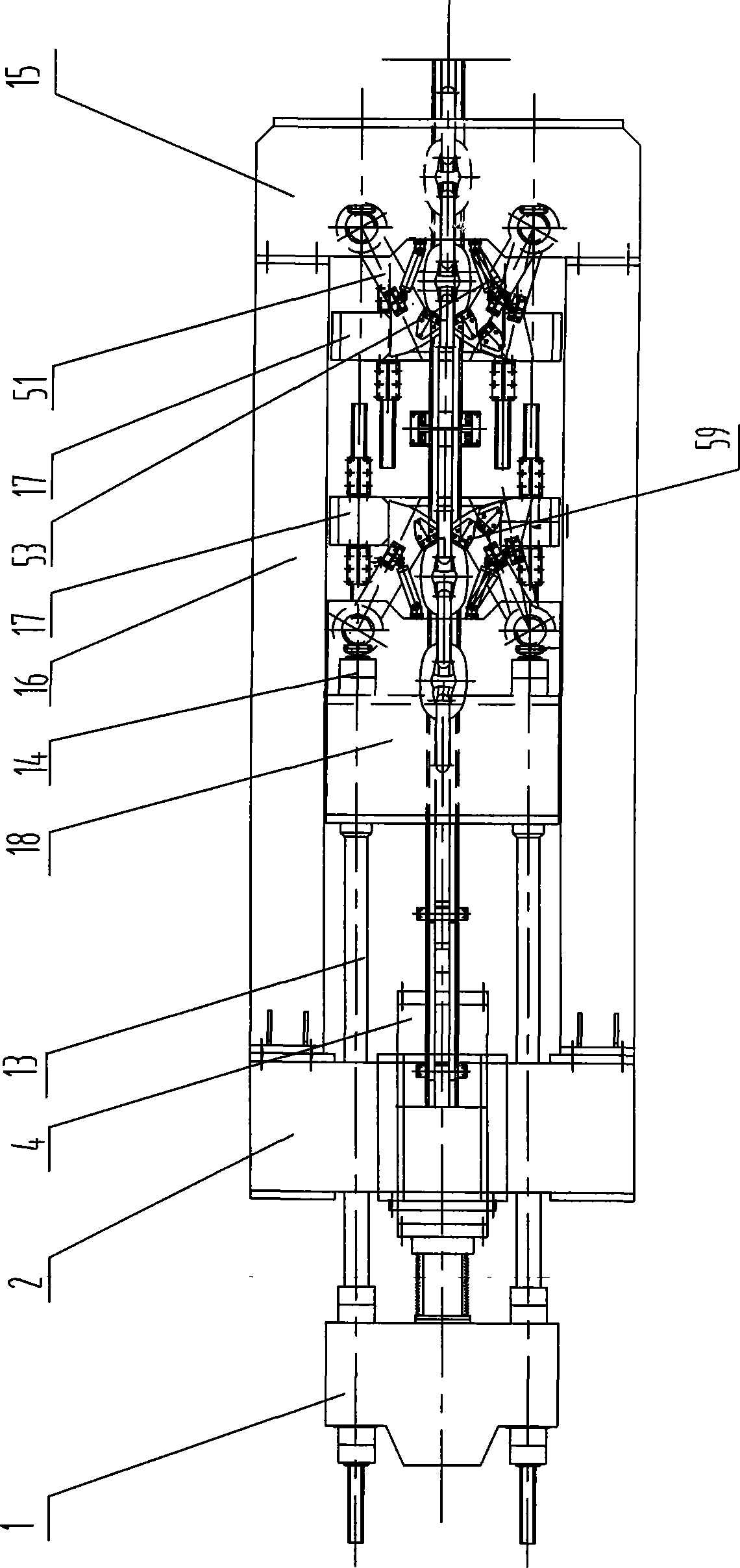

Fatigue testing machine applied to tension test piece and method thereof

InactiveCN101957290AMaximum average displacementMaximum peak displacementMaterial strength using tensile/compressive forcesMechanical componentsPull force

The invention discloses a fatigue testing machine applied to a tension test piece. The fatigue testing machine is mainly used for a tensile test and a tensile fatigue test for mechanical components. The testing machine comprises a fatigue force application mechanism, a pretightening force mechanism, a straightening roller mechanism, a test fixing frame, an auxiliary mechanism and a control system. A power system of the fatigue testing machine comprises the fatigue force application mechanism and the pretightening force mechanism; the tensile force output by the power system is redirected by the straightening roller mechanism and is transmitted to the tension test piece; and the fatigue force application mechanism, the pretightening force mechanism, the straightening roller mechanism and the auxiliary mechanism of the fatigue testing machine are arranged on the test fixing frame. The fatigue testing machine has the advantages of adopting hybrid pneumatic and electric power as the power system of the fatigue testing machine, mastering numerous parameters including the maximum average displacement, the minimum average displacement, peak displacement, the maximum average tension, minimum average tension, minimum fatigue tension, frequency, accumulated test times, accumulated test time and the like, and providing a basis for optimization design of the tension test piece.

Owner:ZHEJIANG UNIV

Method for measuring adhesive force of lithium ion battery pole piece coating

ActiveCN102788746AEasy to measureGood repeatabilityUsing mechanical meansMaterial analysisElectrical batteryPole piece

The invention discloses a method for measuring the adhesive force of a lithium ion battery pole piece coating, comprising the following steps: taking a test base plate, bonding a layer of a transparent adhesive tape on the surface of the test base plate, bonding a layer of a double faced adhesive tape on the adhesive-free surface of the transparent adhesive tape, bonding the other adhesive surface of the double faced adhesive tape onto the coating of a pole piece to be tested by pressing, and reserving an unbonded part at one end in the length direction of the pole piece; clamping the reserved unbonded part by a stretch chuck of a stretch testing machine, bending the pole piece in the length direction of the pole piece and stretching, after peeling the coating of the pole piece to be tested, reading the adhesive force value of the pole piece coating. According to the invention, without changing the technological conditions and process flow of the battery manufacturing technique, the adhesive force value of the pole piece coating can be conveniently measured with small error and good repeatability, and the invention provides the design and manufacturing process of batteries with a reliable basis.

Owner:中创新航科技(江苏)有限公司

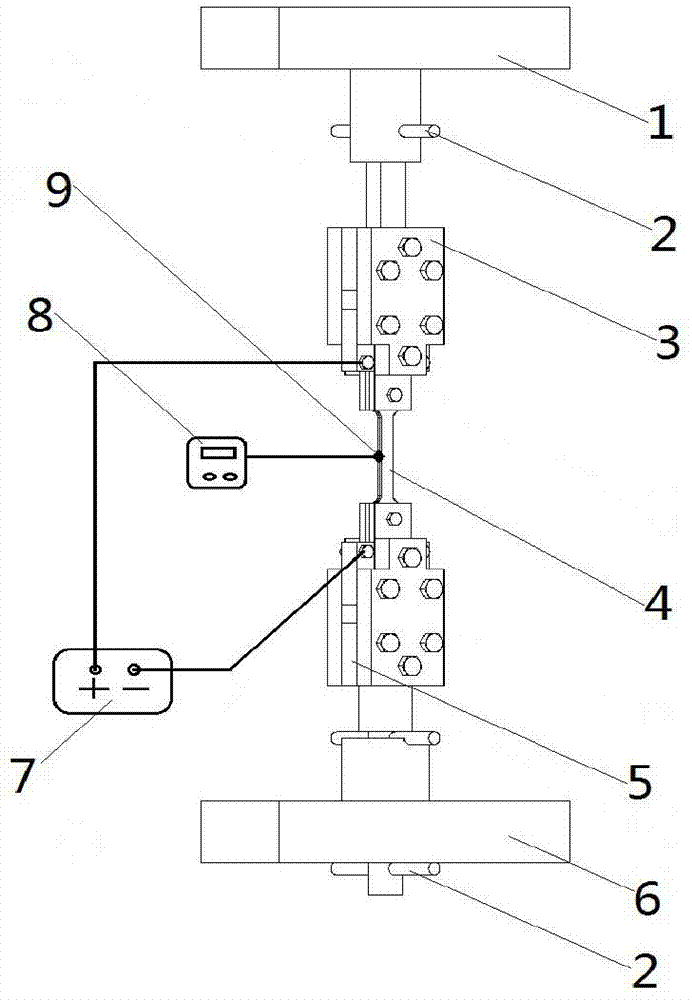

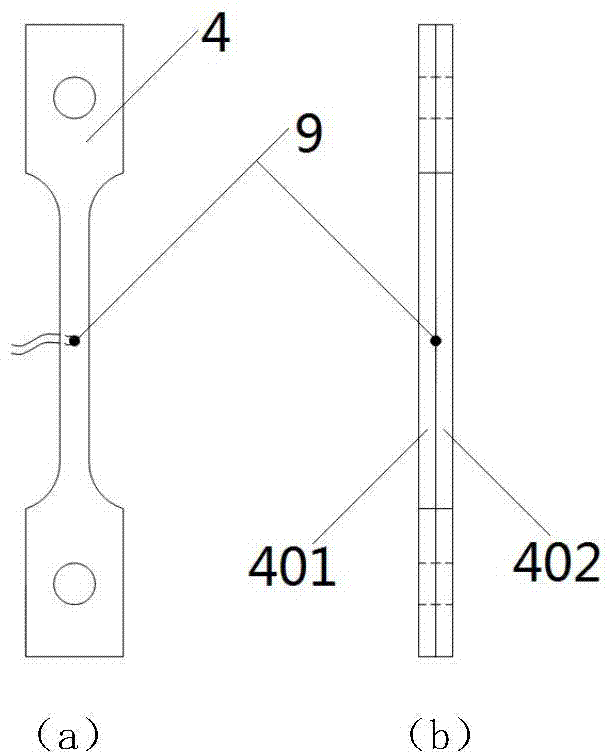

Temperature measurement method for electrified tensile test piece and tensile test device

InactiveCN104515707ASimple structureEasy to fixPreparing sample for investigationMaterial strength using tensile/compressive forcesRoom temperatureEngineering

The invention discloses a temperature measurement method for electrified tensile test pieces and a tensile test device. An electronic universal testing machine with an insulating chuck is used for finishing an electrified unidirectional tensile test of metal test pieces and real-time measurement on the temperatures of the test pieces through thermocouple matching. The method comprises the steps: firstly spraying a protective agent to each of the test pieces to carry out anti-oxidization treatment; after the surface protective coating layers are naturally dried at a room temperature, performing insulating treatment on a thermocouple, clamping the two unidirectional tensile test pieces by the insulating chuck of the electronic universal testing machine, clamping the thermocouple between the two test pieces to ensure that the temperature measured by the thermocouple is the real temperatures of the center positions of the test pieces, electrifying a direct current power supply to heat the test pieces, and measuring the temperatures of the test pieces in real time by a thermocouple temperature measurer; after the test pieces reach the stable temperatures, switching on the electronic universal testing machine to carry out the unidirectional tensile test on the test pieces. Therefore, accurate temperature measurement on the unidirectional tensile test pieces can be guaranteed; furthermore, the test device is simple in structure, short in manufacturing period and low in cost.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

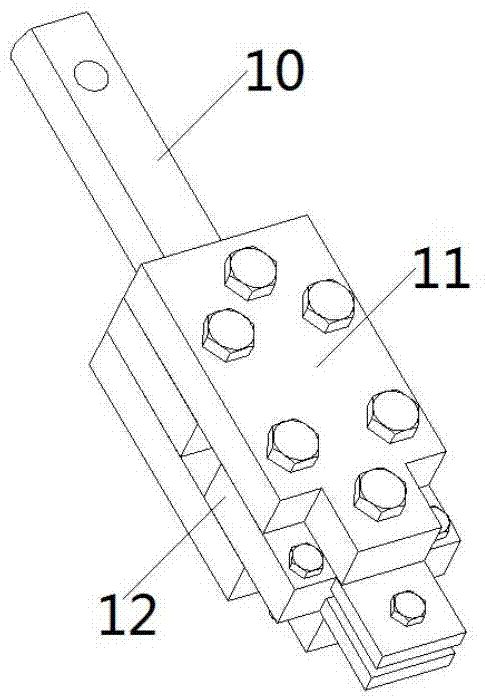

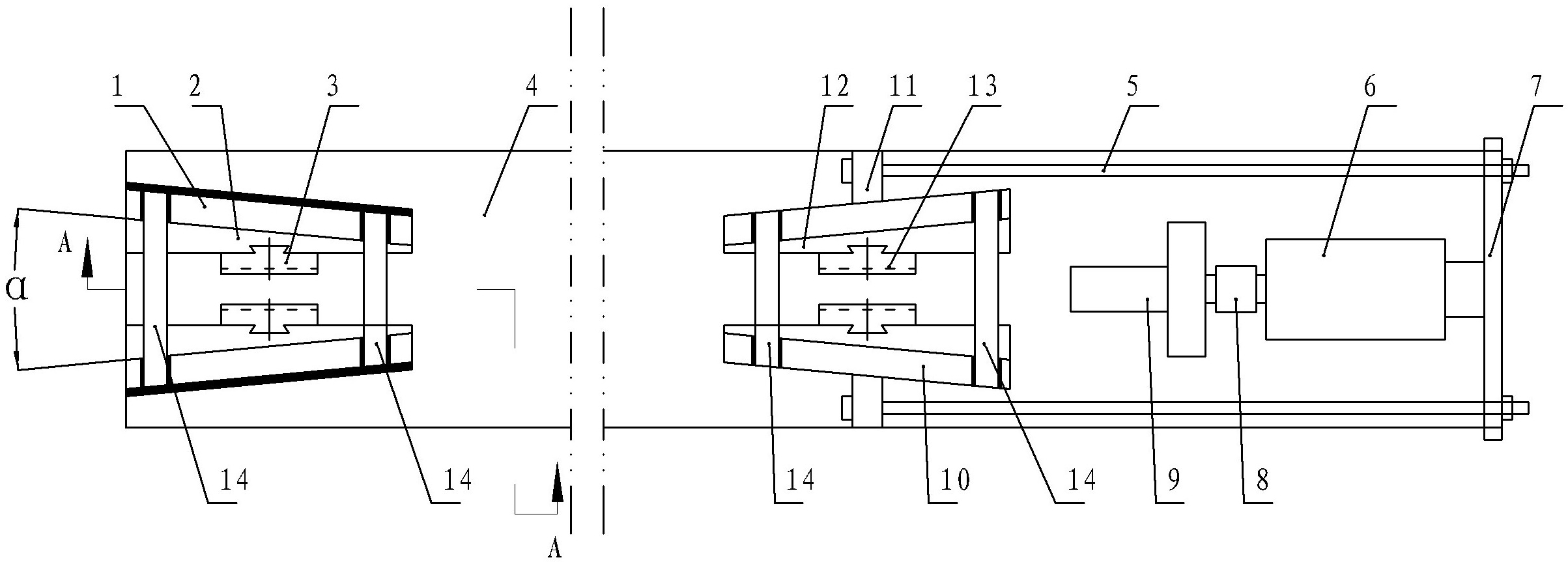

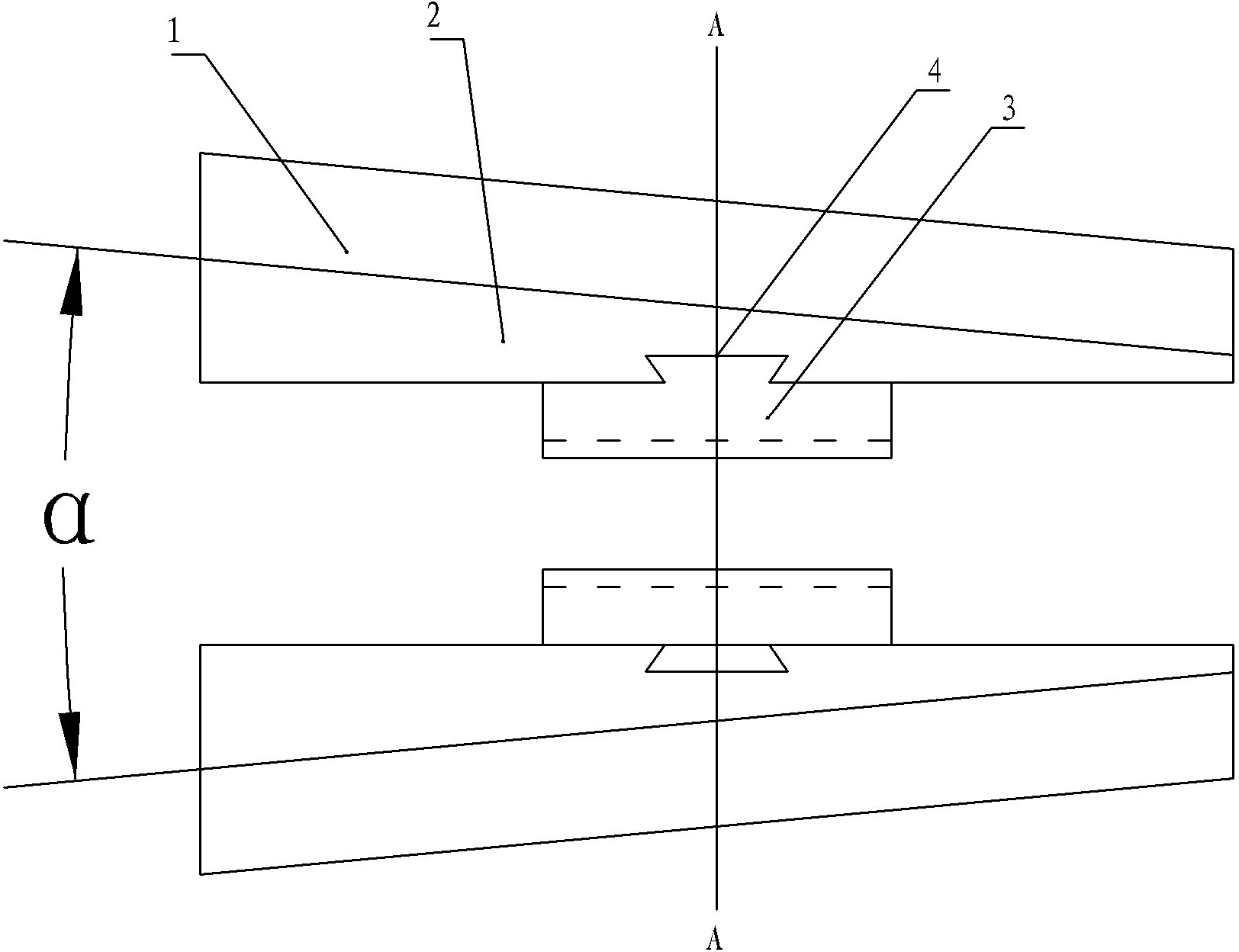

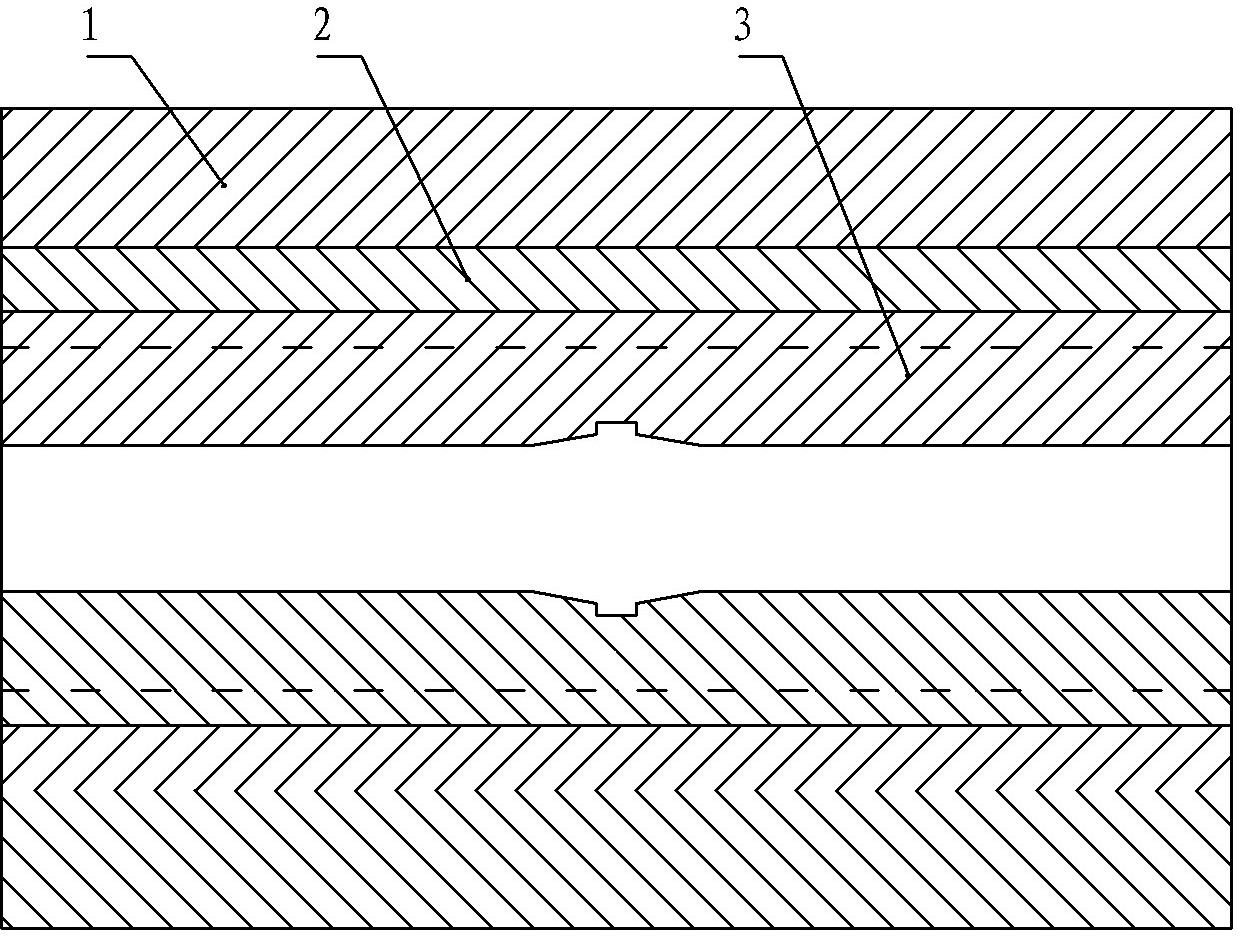

Steel wire rope tensile fixture and horizontal steel wire rope tensile testing machine thereof

ActiveCN102323144ARealize breaking testLarge clamping forceMaterial strength using tensile/compressive forcesEngineeringSlide plate

The invention discloses a steel wire rope tensile fixture and a horizontal steel wire rope tensile testing machine thereof. The steel wire rope tensile fixture comprises frame bodies, wedged sliding plates and friction blocks which are arranged symmetrically, wherein each frame body comprises two vertical plates of which the inner surfaces are arranged by forming an included angle alpha; the inclination angle of each wedged sliding plate is matched with the included angle alpha; the inner surface of each wedge sliding plate is connected with each friction block through a vertical dovetail groove structure; the included angle alpha is more than or equal to 13 degrees and less than or equal to 23 degrees; and the width L of each friction block is 190-340 millimeters. The horizontal steel wire rope tensile testing machine comprises a pressure sensor, a power device, a fixed steel wire rope tensile fixture and a movable steel wire rope tensile fixture, wherein the pressure sensor is arranged horizontally; the fixed steel wire rope tensile fixture comprises an upper fixture; and the power device is connected with the movable steel wire rope tensile fixture through a pull rod. The horizontal steel wire rope tensile testing machine has a simple structure, and is convenient to operate; the horizontal steel wire rope tensile testing machine is only required to be fixed on the ground, and the operation of the entire test process can be completed by one person, so that the labor intensity of detection test can be reduced greatly; and compared with the conventional testing machine, the horizontal steel wire rope tensile testing machine has the advantages of energy-saving test process, safety, environmental friendliness, mobility, low manufacturing cost and low test cost.

Owner:河南省煤科院检测技术有限公司

Composite coated jaw faces

Clamp or grip faces used in fiber / fabric tensile testing instruments are coated with an aramid-epoxy composite, thus allowing high-strength fiber / fabric samples to be tested with greater reproducibility at lower applied pressure and without clamp or grip face scarring.

Owner:EI DU PONT DE NEMOURS & CO

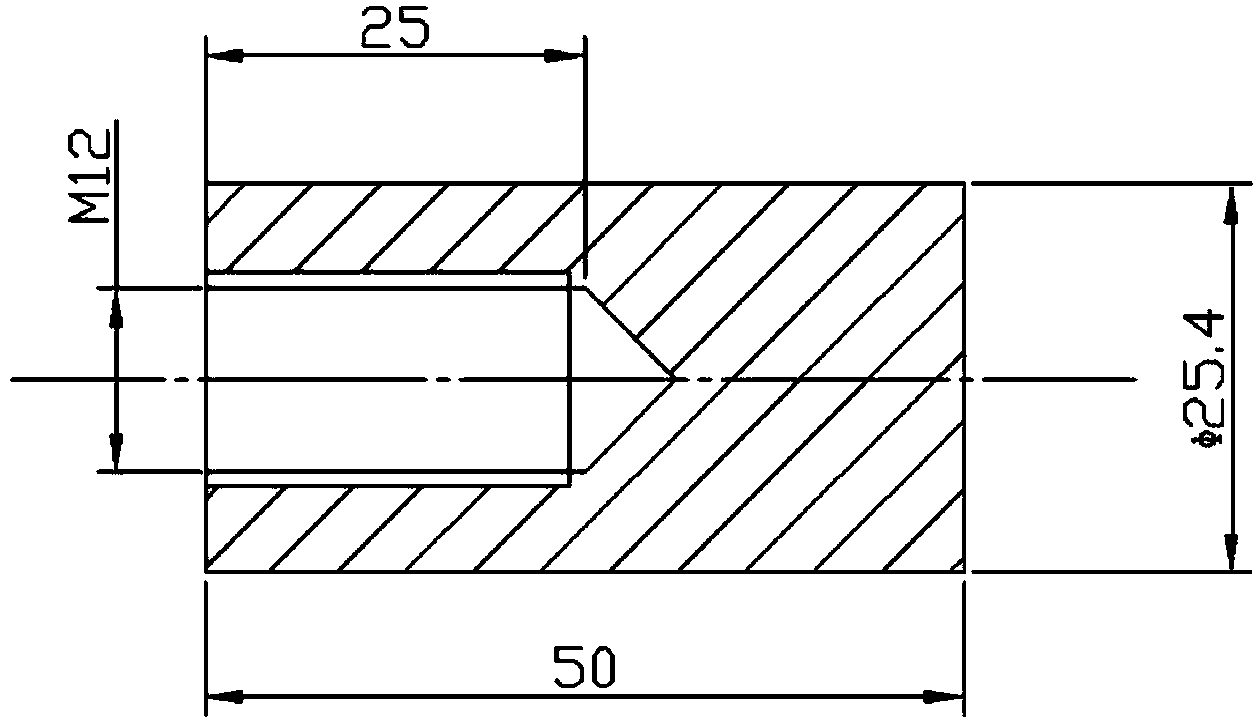

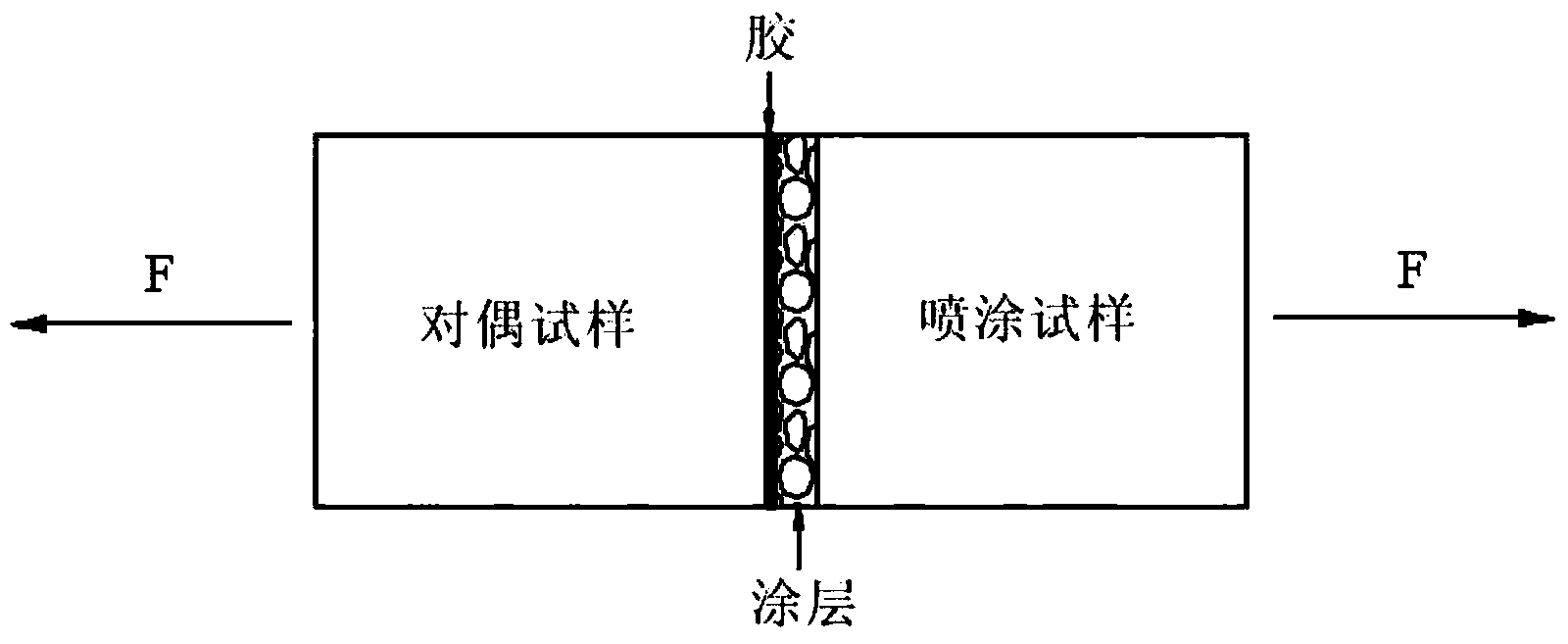

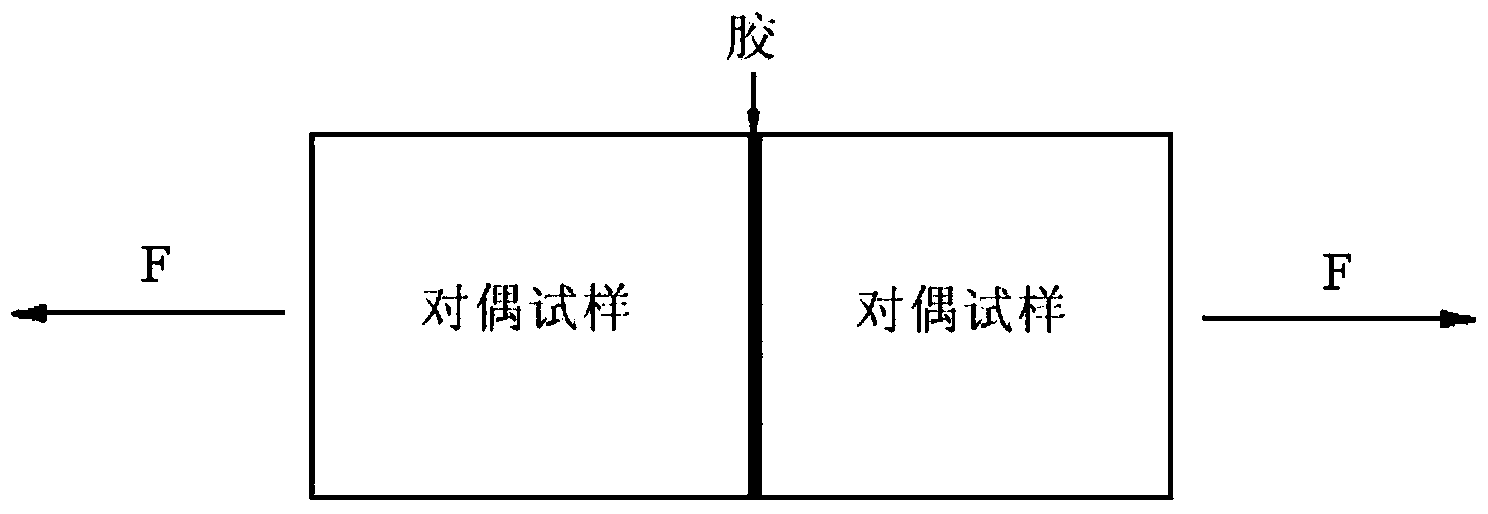

Method for testing elasticity moduli of coatings

InactiveCN103528885AAccurately measure the elastic modulus valueEasy to makePreparing sample for investigationMaterial strength using tensile/compressive forcesUltrasonic testingTensile testing

The invention provides a method for testing elasticity moduli of coatings. Coatings are deposited on surfaces of matrix samples and are boned with dual samples by using high-strength glue; load displacement curves of boned samples are tested by using a tensile testing machine; and the curves are compared with a tensile testing result of a sample formed by bonding two matrix samples with deposition layers, so that elasticity modulus values perpendicular to the surface directions of the coatings during tensile processes of the coatings are obtained. The method makes up various disadvantages of a conventional surface coating testing technology. The advantages are as follows: a bending method can only be used for testing coating elasticity moduli parallel to the surface directions; and an indentation method is only can be used for testing local mechanical properties of the coatings and complexity of an ultrasonic testing method. The technical requirement for testing the elasticity moduli perpendicular to the surface directions of the coatings conveniently and reliably can be met. The method is applicable to measurement of indexes of elasticity moduli perpendicular to the surface directions of various surface coatings.

Owner:TIANJIN UNIV

Tensile-shear test loading device with flight structure

InactiveCN102607940AAchieve shearMaterial strength using tensile/compressive forcesAviationEngineering

The invention relates to a test loading device, in particular to a tensile-shear test loading device with a flight structure. Compression bars are arranged between stand columns, the upper ends of the compression bars are extended to form an upper beam, a compression plate is arranged on the top ends of the stand columns, a lower beam is arranged on the bottom ends of the stand columns, an upper cross type joint is arranged between the compression bars on the bottom end of the upper beam, a lower cross type joint is arranged on the upper end of the lower beam between the compression bars; and a fixture is arranged between the upper cross type joint and the lower cross type joint. The test loading device provided by the invention can be used for converting pressure of a compression tester into tensile of a test piece or realizing shear force of the test piece through the action of the fixture, and can be used for a tensile or shear test of stiffened wall plates and similar structures without being provided with a special large loading tensile testing machine independently.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

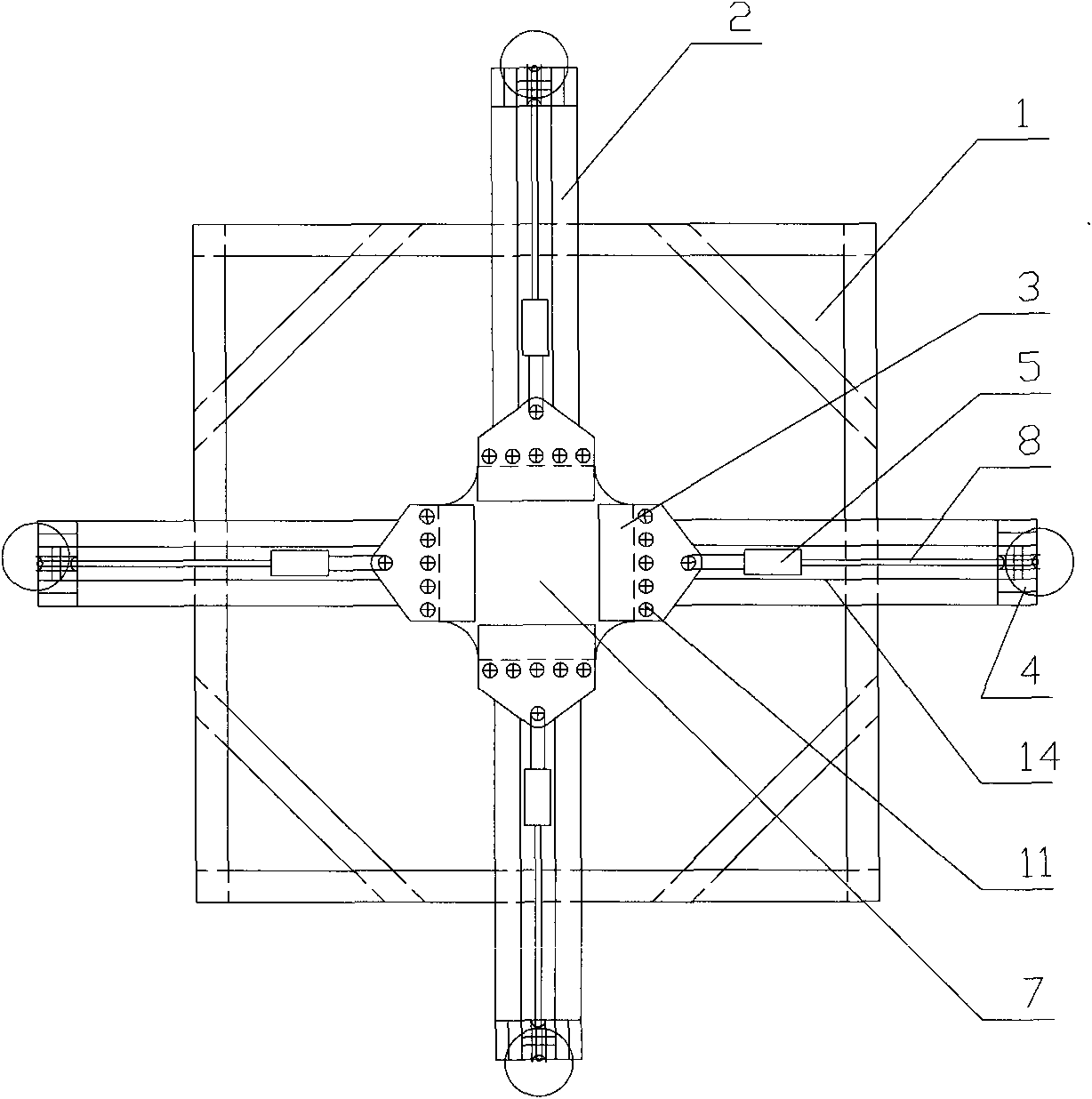

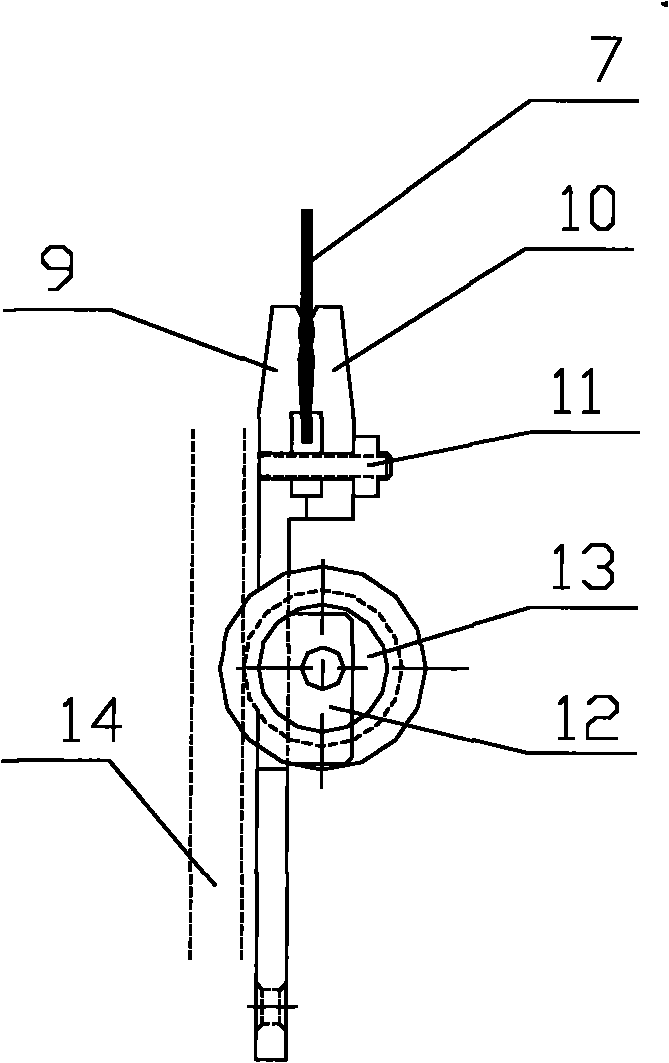

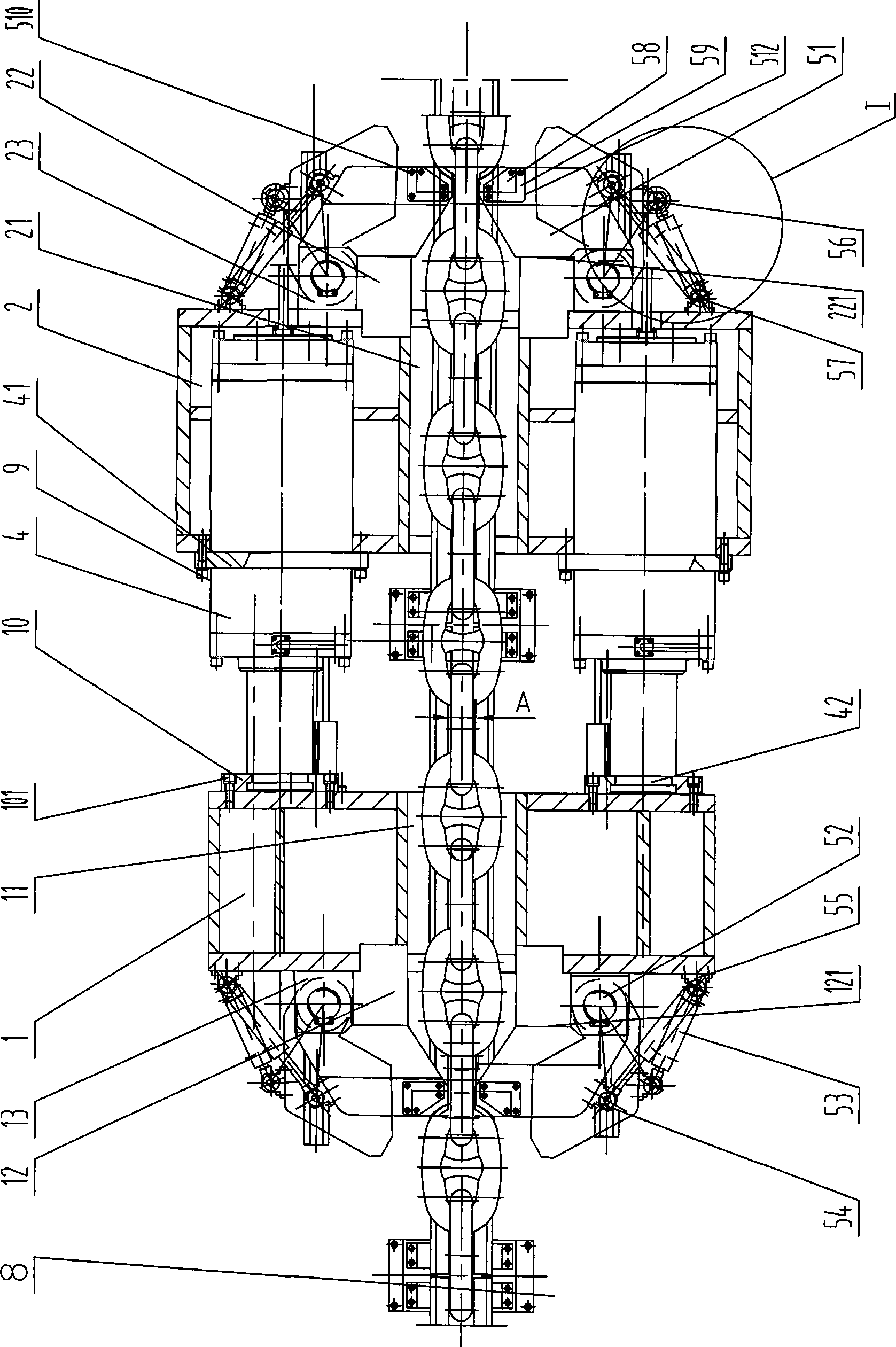

Geosynthetic biaxial tension creep tester

InactiveCN101776553ASolve the problem of long time-consuming and low efficiency of creep testImprove long-term stabilityMaterial strength using tensile/compressive forcesEngineeringGeosynthetics

The invention provides a geosynthetic biaxial tension creep tester. The tester comprises a main frame platform and a cross-shaped tensile testing device arranged on the main frame platform, wherein the cross-shaped tensile testing device comprises four groups of clamping devices, four groups of guiding devices, four groups of displacement sensors and four force-applying devices; the clamping devices are used to clamp the four edges of a test-piece placed in the middle of the cross-shaped tensile testing device and separately connected with the four force-applying devices arranged at the four ends of the cross-shaped tensile testing device through steel cables; the four groups of clamping devices can slide to the force-applying devices separately along the four groups of guiding devices; and the displacement sensors are separately arranged between the clamping devices and the force-applying devices. The geosynthetic biaxial tension creep tester of the invention can be used to perform creep test in any complex stress-strain loading path under the action of biaxial tensile loading, and compared with the easy uniaxial tension test, the creep test is more similar to the actual stress-strain state in engineers.

Owner:HOHAI UNIV

Fixture for tensile bonding strength test of solid propellant and coating

InactiveCN102323143AOvercome the problem of breakingSolve the problem of easy slipping and "pull off"Strength propertiesTest sampleEngineering

The invention discloses a fixture for tensile bonding strength test of solid propellant and coating, belonging to the field of test of explosive performance. The fixture comprises two sets of fixtures which are used symmetrically and have the same structure. Before test, the two ends of a propellant test sample are bonded on the small-diameter end faces of two coating test sample joints through a test adhesive respectively; two connecting rods are correspondingly and fixedly connected to pull rods on both sides of a tensile testing machine; two fixing seats are in threaded connection with the connecting rods; and the large-diameter ends of the two test sample joints and a limiting groove are fixed in corresponding fixing seats through two compression nuts in cooperation with two pairs of semicircular wristlets. According to the fixture, the problems of easy damage to the surface of the test sample and easy slippage and looseness of the test sample during low-temperature test, existing in the conventional tensile test fixture, are solved. Meanwhile, the test fixture has the advantages of simple structure, light weight, small size, convenience for clamping, high centering accuracy and the like.

Owner:XIAN MODERN CHEM RES INST

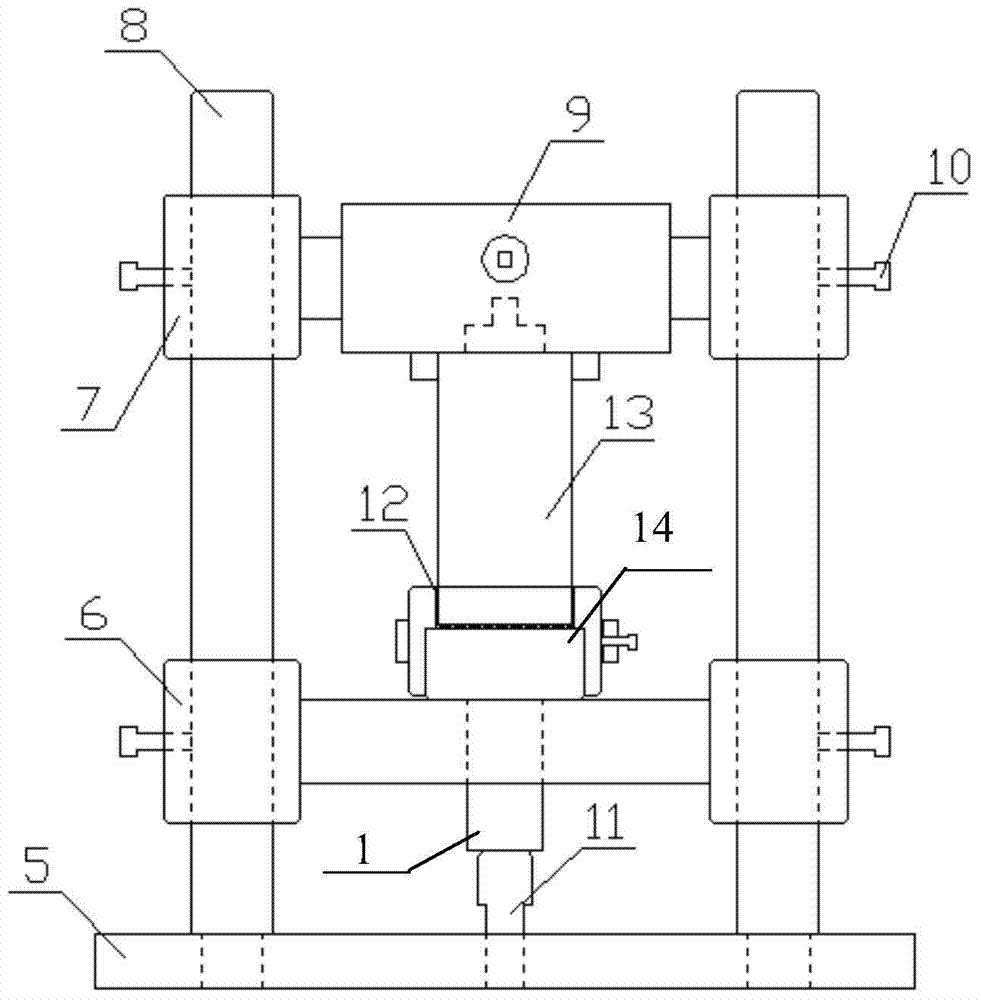

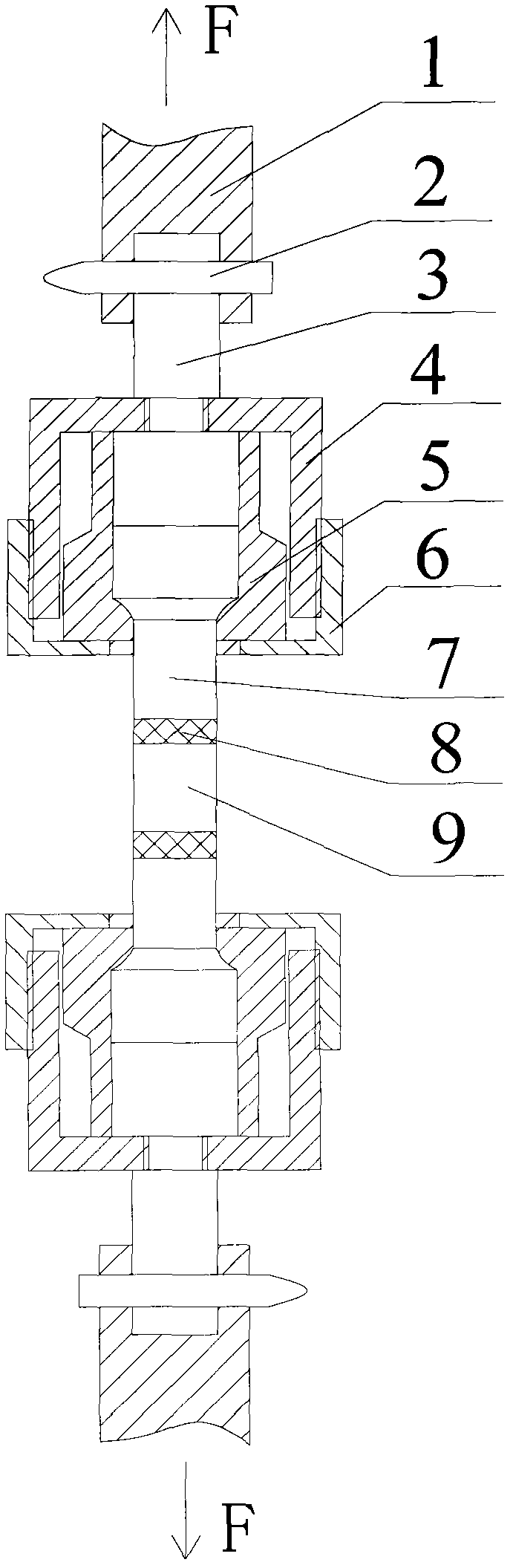

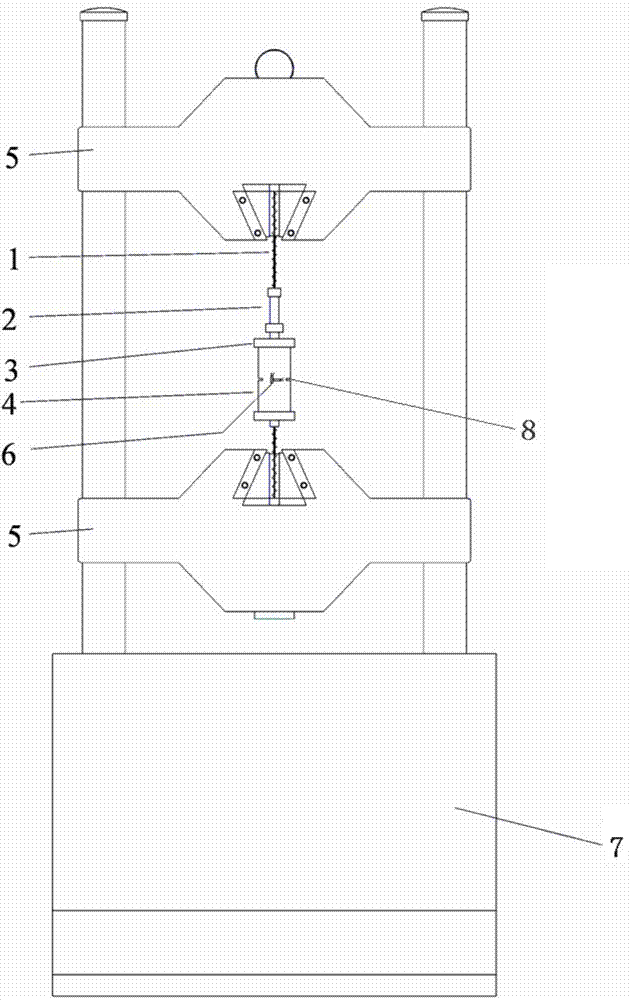

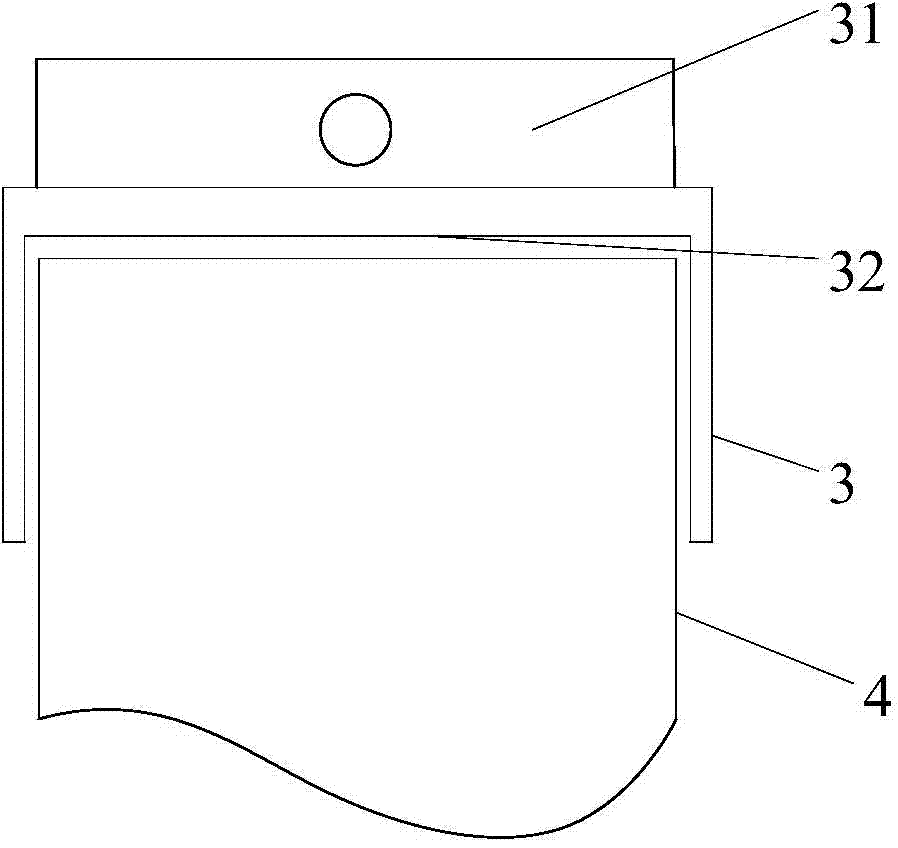

System and method for measuring direct tensile strength and deformation of rock

InactiveCN103674707AAccurately measure deformation dataTroubleshooting Stretch FailuresMaterial strength using tensile/compressive forcesElectrical/magnetic solid deformation measurementStress concentrationRock sample

The invention provides a system and a method for measuring direct tensile strength and deformation of rock by using manual kerfs. The system comprises test loading equipment, a rock sample, metal sleeve caps, a flexible connecting mechanism and a tensile load sensor, wherein the rock sample is cylindrical, two kerfs are symmetrically cut in two sides of the middle position of the rock sample, and the kerf directions are the radial direction of the sample; and an upper metal sleeve cap and a lower metal sleeve cap are arranged at two ends of the rock sample respectively, the upper metal sleeve cap is connected with an upper clamp clamping opening of the test loading equipment through the flexible connecting mechanism and the tensile load sensor sequentially, and the lower metal sleeve cap is connected with a lower clamp clamping opening of the test loading equipment 7 through the flexible connecting mechanism. According to the technical scheme, the defects that the rock sample is prone to bend or produce torsion stress in a direct tensile test are overcome, at the same time, the situation that tensile fracture is not produced during fracture due to the end stress concentration effect of the rock sample is avoided, and the rock tensile strength and the axial and radial deformation of the rock in a stretching process can be accurately and effectively measured.

Owner:UNIV OF SCI & TECH BEIJING

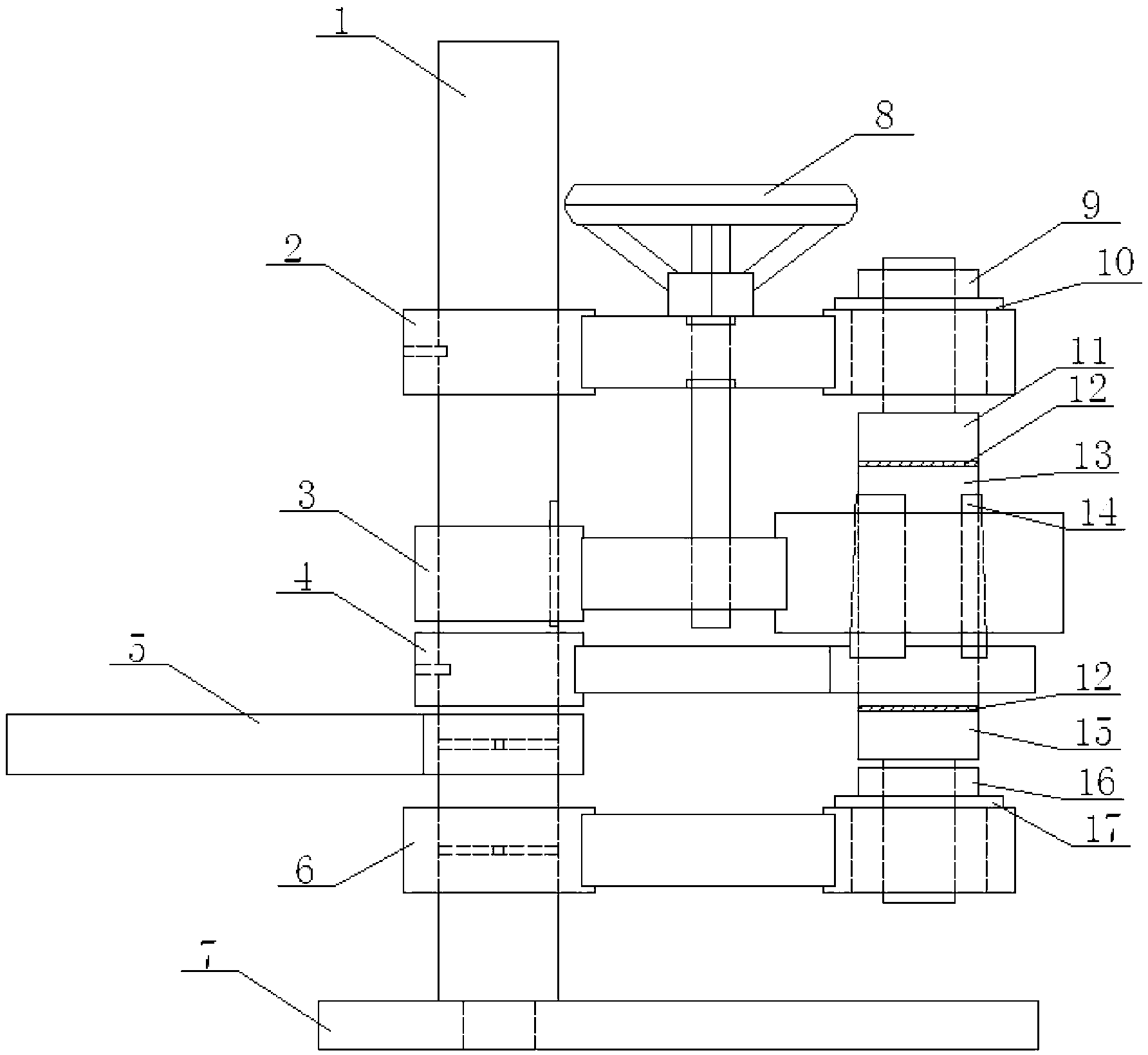

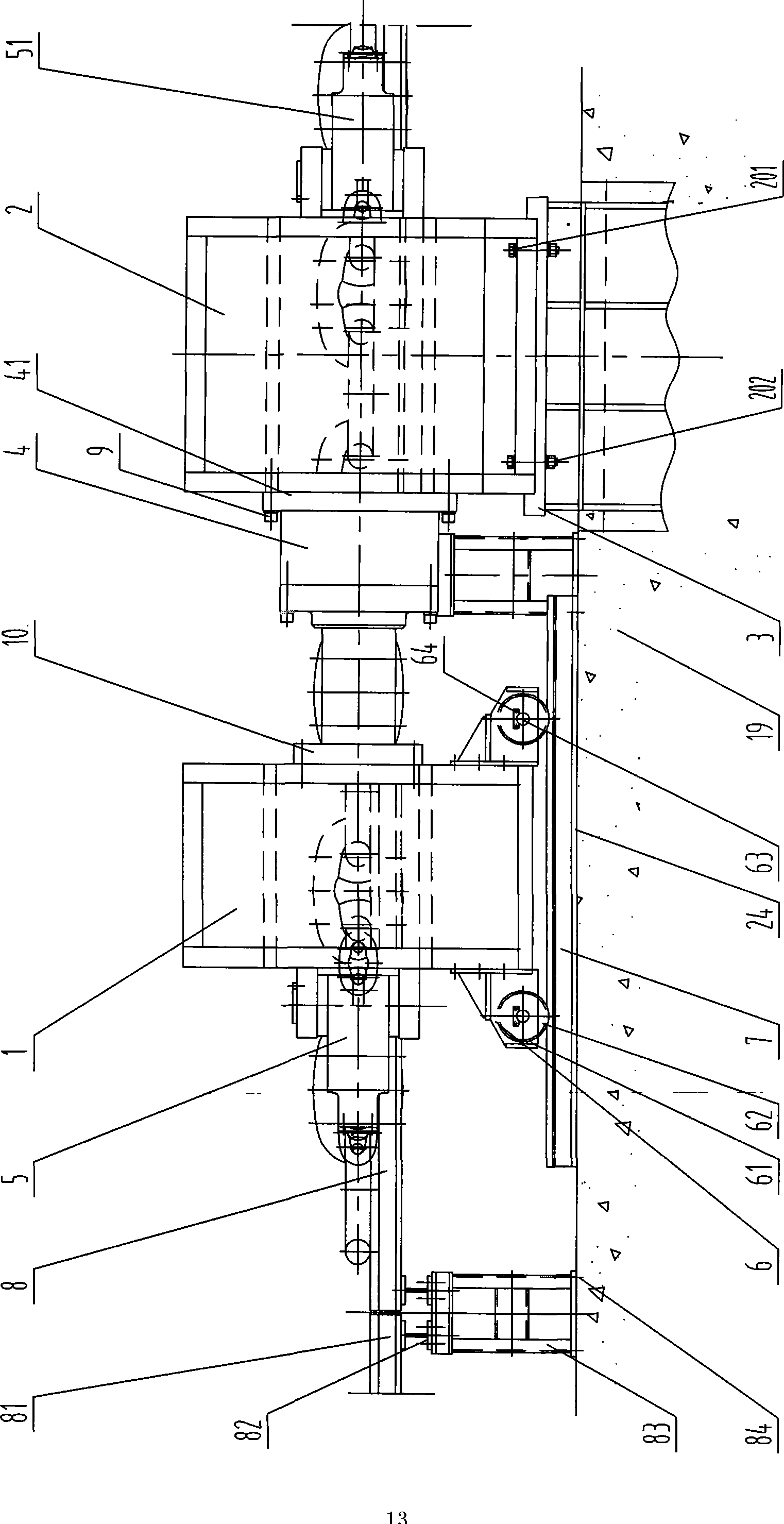

Loading apparatus for chain cable tensile testing machine

InactiveCN101498632ASolve the problem that the tension test cannot be performed on the mooring anchor chain of the offshore oil platform with a length of hundreds to thousands of metersSolve the problem of pull testMaterial strength using tensile/compressive forcesMobile deviceTensile testing

The invention discloses a charger of an anchor chain tension tester, which comprises a movable cross beam, a fixed cross beam, a fixed cross beam base, load oil cylinders, anchor chain link clamping devices and mobile devices, wherein the fixed cross beam base is buried in a concrete foundation, the lower side of the fixed cross beam is fixedly connected with the fixed cross beam base; the two load oil cylinders are symmetrically arranged in the fixed cross beam along the length direction of the fixed cross beam, and piston rod heads of the load oil cylinders are respectively fixedly connected with the rear side of the movable cross beam by symmetrically arranged pairing flanges; the mobile devices are arranged in pair between the top surface of a railway and the lower side of the movable cross beam; and the anchor chain link clamping devices are respectively arranged at the front side of the movable cross beam and the rear side of the fixed cross beam. The invention can perform the tension test on offshore oil platform mooring anchors with the length of several hundred meters or several thousand meters, reduces the manufacture cost of the charger, extends the length of the tested anchor chain link, reduces the test frequency and enhances the work efficiency.

Owner:JIANGSU UNIV OF SCI & TECH

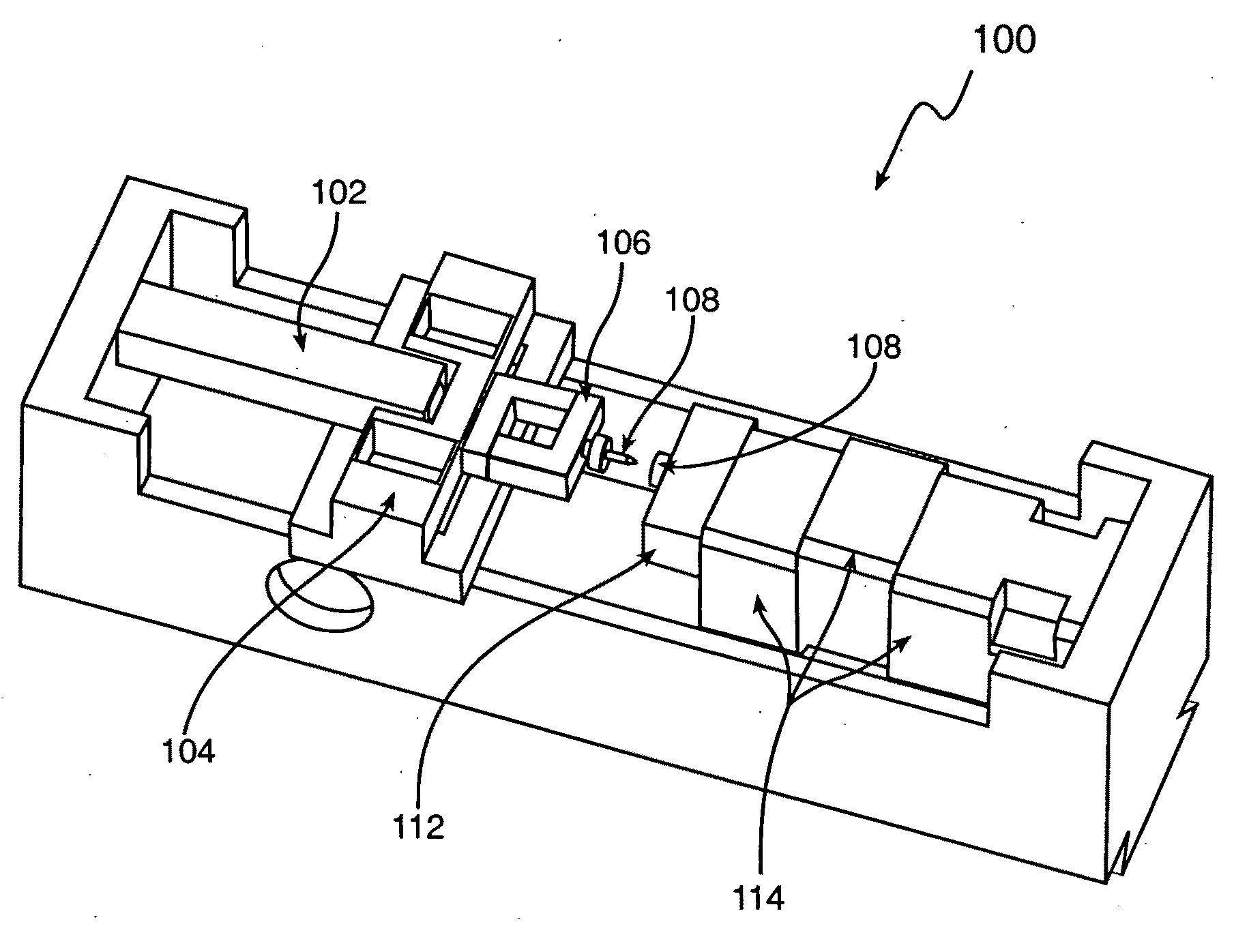

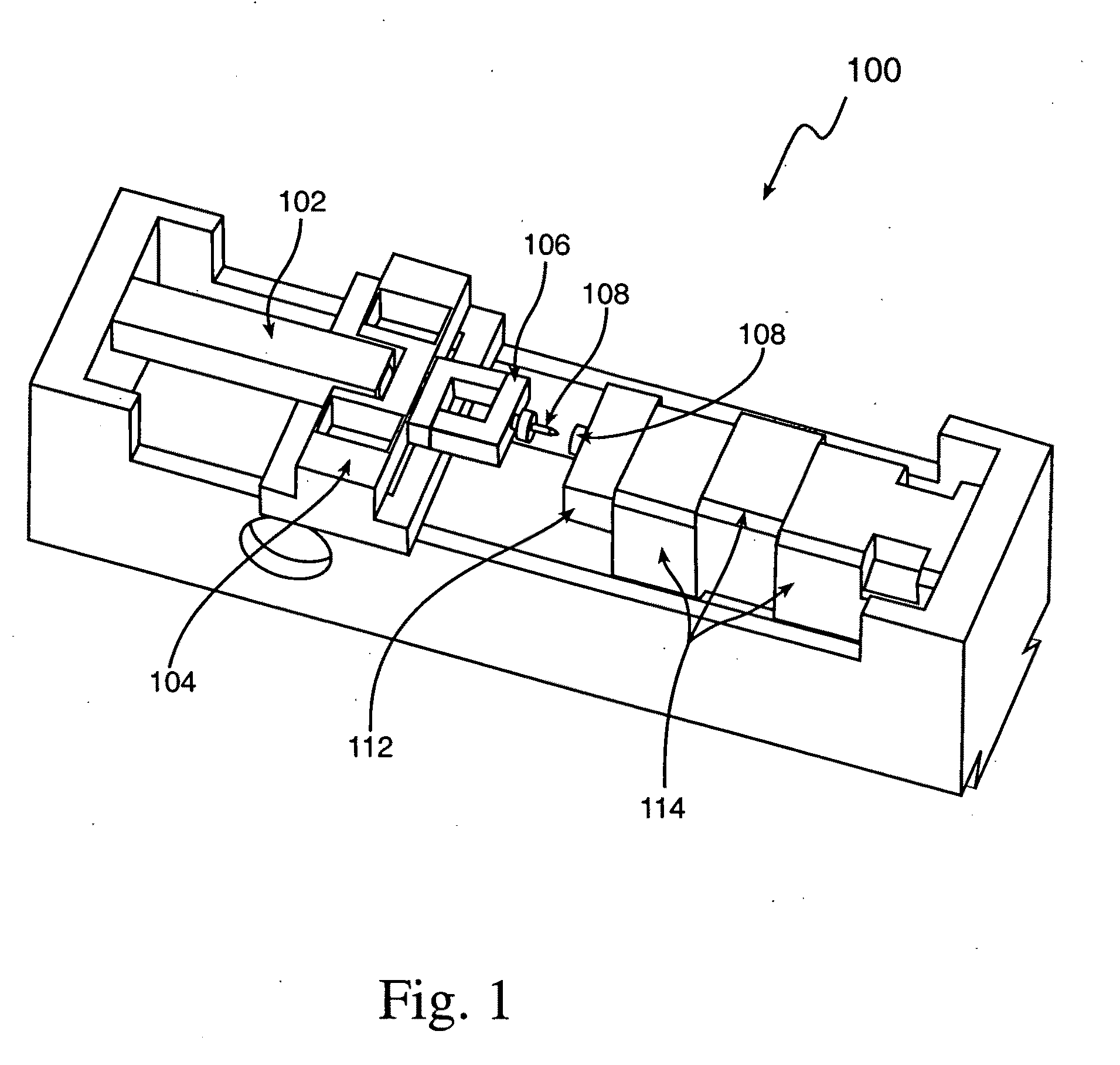

Micro-tensile testing system

InactiveUS20060096385A1Error minimizationMinimize measurement errorForce measurement by measuring optical property variationMaterial strength using tensile/compressive forcesCyclic testMicrometer

A micro-tensile testing system providing a stand-alone test platform for testing and reporting physical or engineering properties of test samples of materials having thicknesses of approximately between 0.002 inch and 0.030 inch, including, for example, LiGA engineered materials. The testing system is able to perform a variety of static, dynamic, and cyclic tests. The testing system includes a rigid frame and adjustable gripping supports to minimize measurement errors due to deflection or bending under load; serrated grips for securing the extremely small test sample; high-speed laser scan micrometers for obtaining accurate results; and test software for controlling the testing procedure and reporting results.

Owner:HONEYWELL FED MFG & TECHNOLOGI

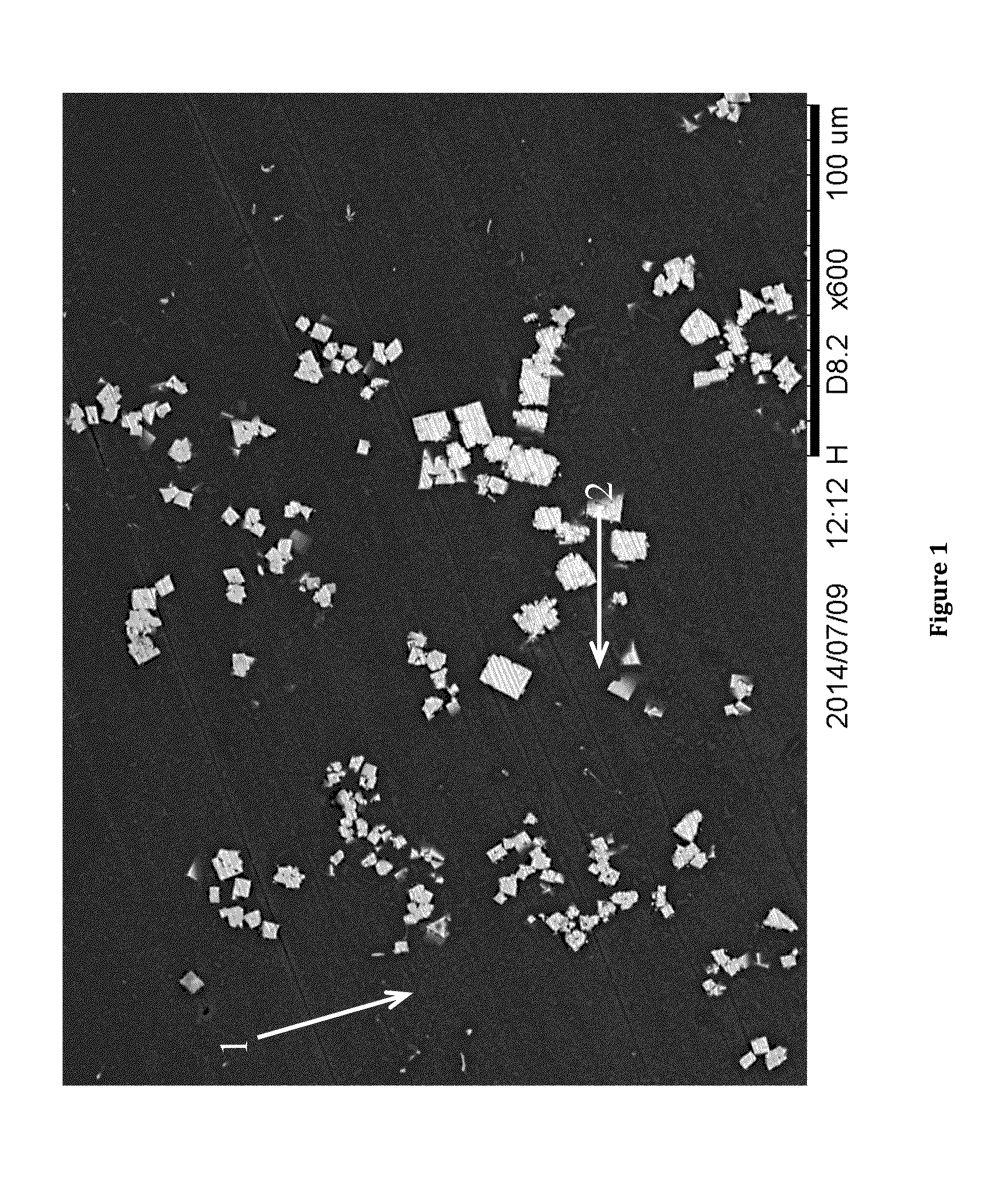

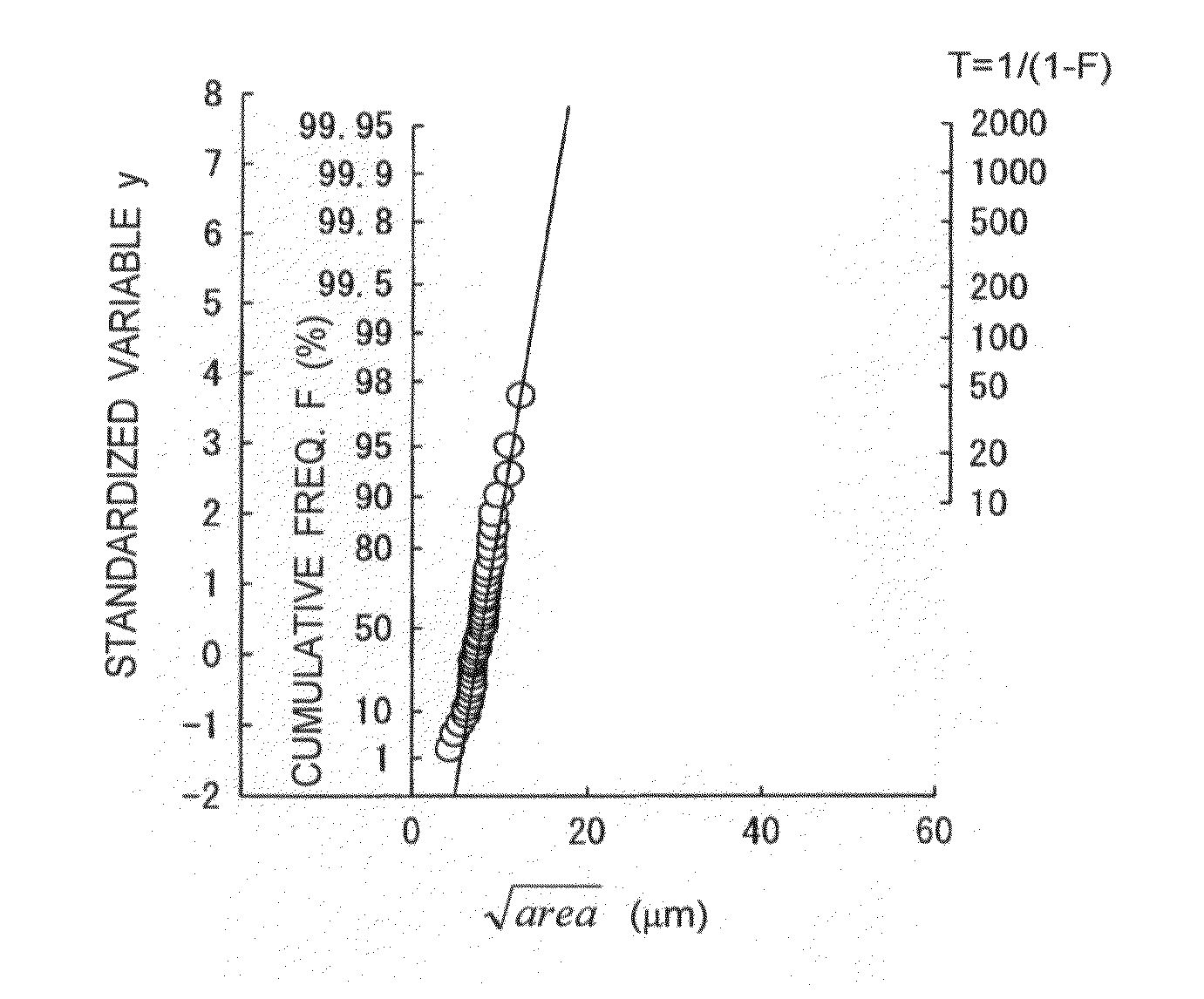

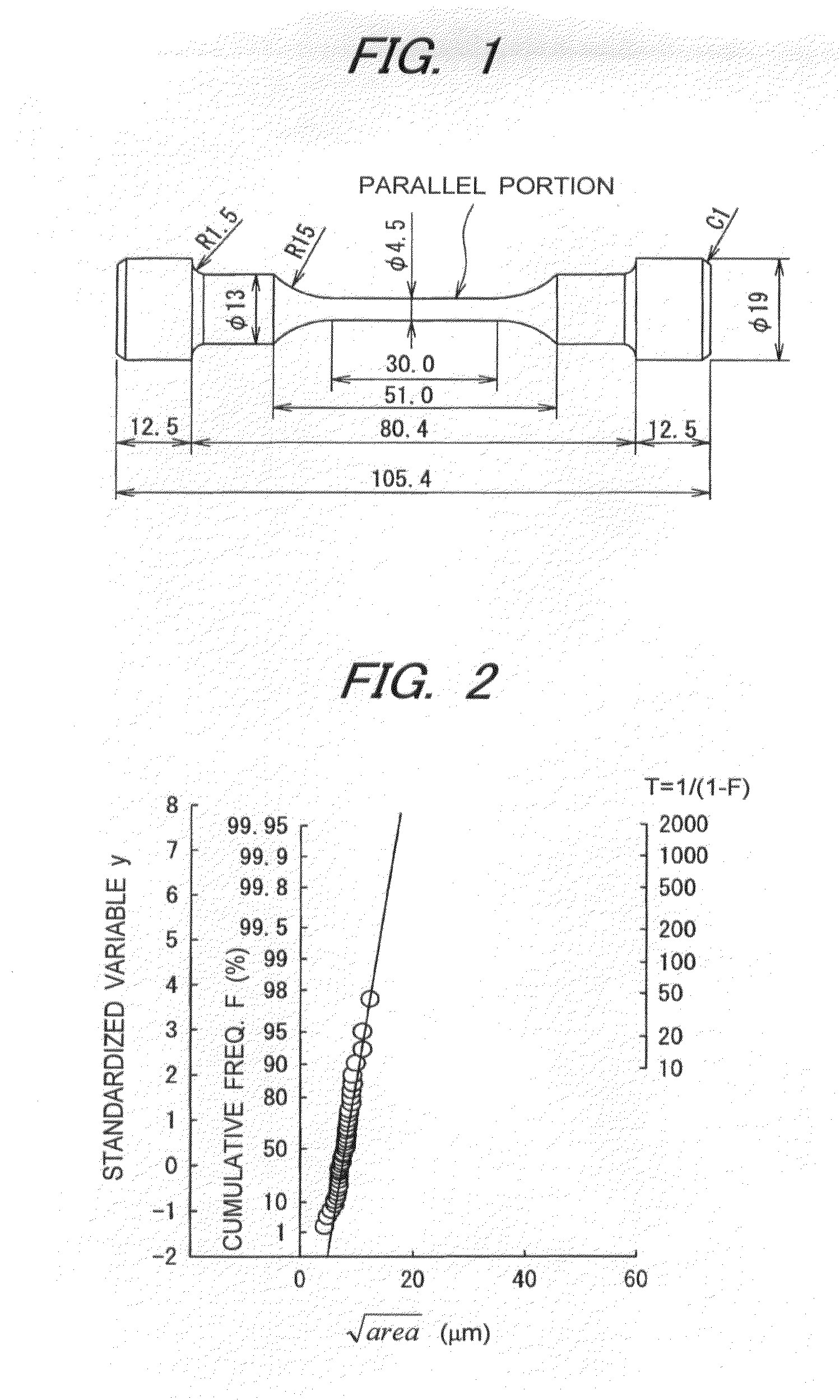

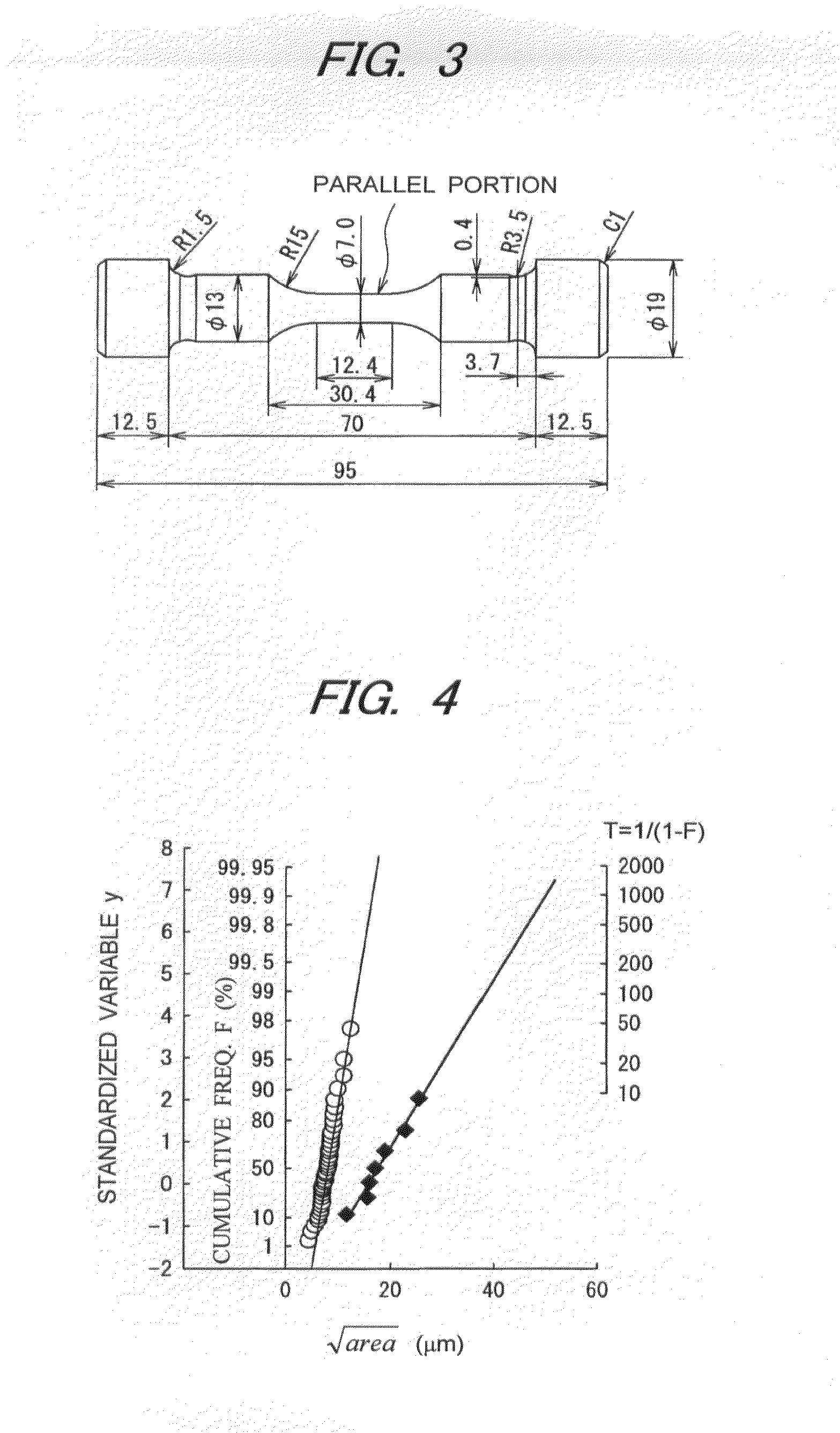

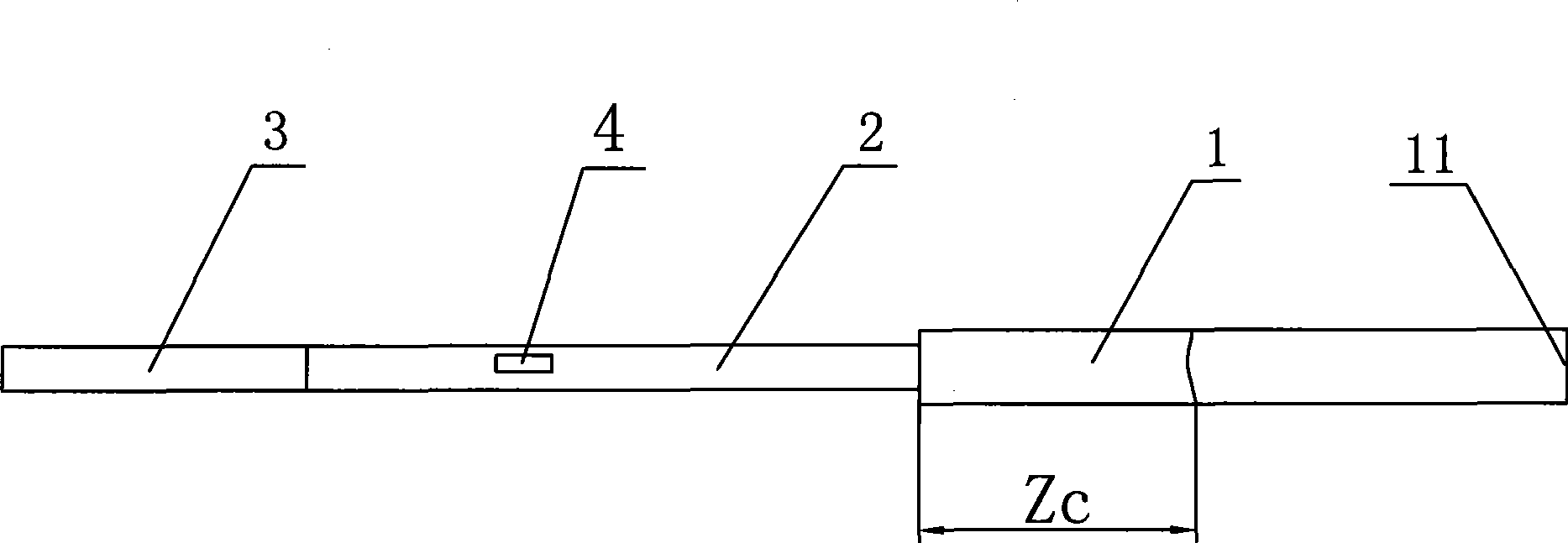

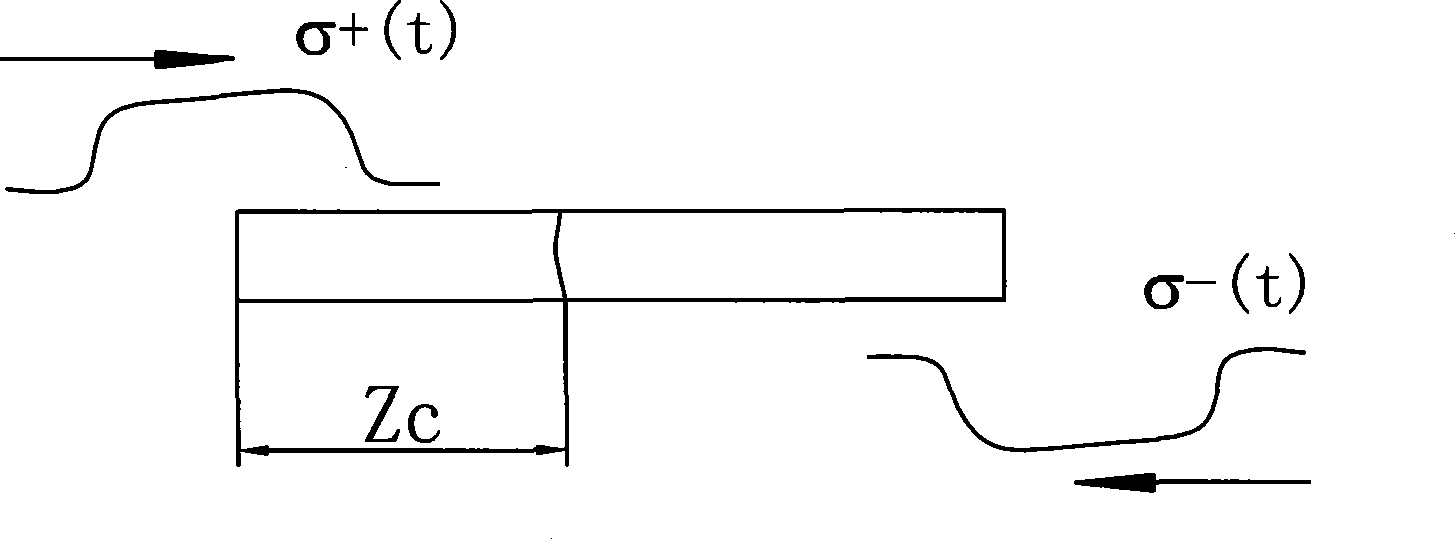

Inclusion rating method

ActiveUS20120024077A1Convenient and speedy inclusion rating methodCarry-out stablyMaterial strength using tensile/compressive forcesTesting metalsHydrogenNon-metallic inclusions

An inclusion rating method includes carrying out a tensile test on a test specimen, which is made of a metallic material and charged with a hydrogen, to cause a fracture originating from a nonmetallic inclusion affected by the hydrogen in the test specimen, identifying a type of the nonmetallic inclusion, measuring a size of the nonmetallic inclusion, and evaluating a cleanliness of the metallic material by obtaining a distribution function of the size of the nonmetallic inclusion.

Owner:NSK LTD +1

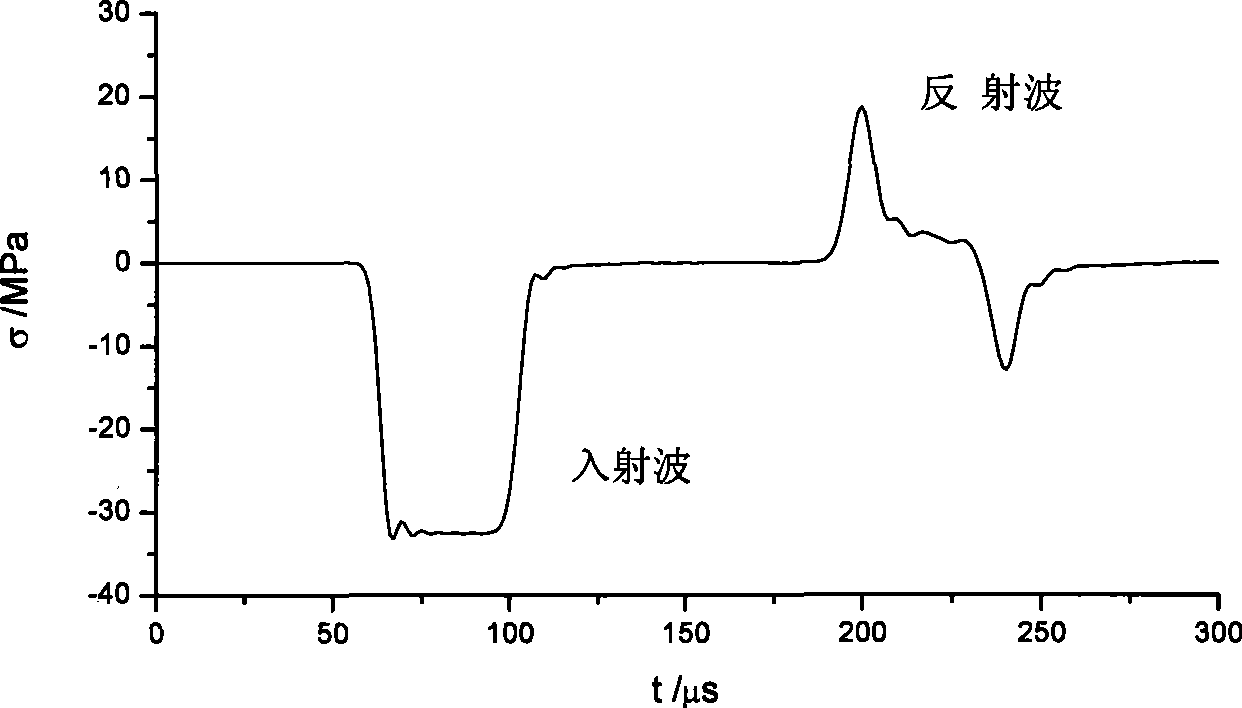

One-dimensional lamination crack tension test method based on Hopkinson principle

InactiveCN101482472AEffectiveUniform stressStrength propertiesExperimental researchImpedance matching

The invention discloses an one-dimensional lamination crack drawing test method based on the Hopkinson principle, Advantages: because the incident rod and the rod shaped test piece completely or approximately satisfies the impedance match condition, the one-dimensional lamination crack drawing test of large size test piece can be performed based on the Hopkinson compressed rod; in the polyphase brittle material (such as concrete) impact characteristic experiment research field, the method can be applied for the dynamic experiment and research to the concrete containing large sized aggregate accordance with engineering reality, in order to cause the test result to have macroscopic validity; and the length of the rod shape test piece satisfies the condition: Ls=2L(impact rod)C(impact rod)Cs, the lamination drawing crack approximately occurs in the middle of the test piece, thereby, the stress adequation on the section of the test piece is ensured.

Owner:NINGBO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com