Mechanical biaxial tension tester with variable proportion loading

A two-way stretching, mechanical technology, applied in the direction of applying stable tension/pressure to test the strength of the material, to achieve the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

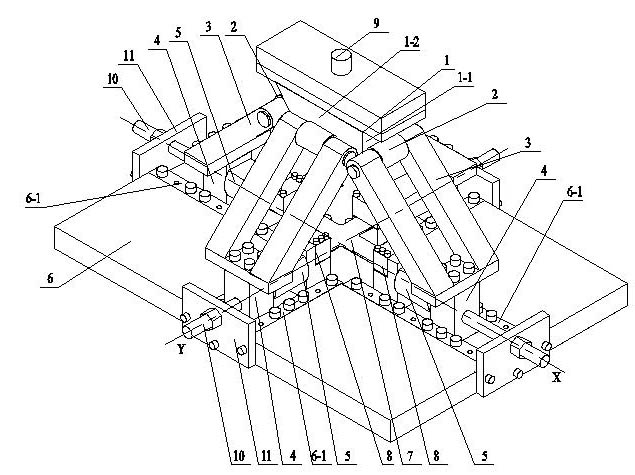

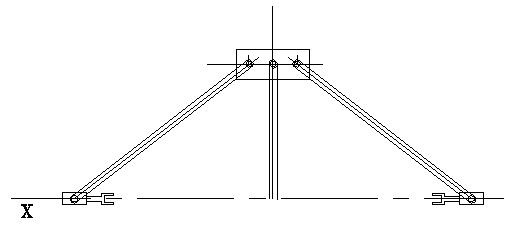

[0008] Specific implementation mode one: combine Figure 1 to Figure 6 Describe this embodiment, the mechanical biaxial tensile tester of variable ratio loading of this embodiment comprises workbench 6, four diagonal struts 3, four tension-compression sensors 5 and four collets 8; The tester also includes an inclined slider 1, four rolling bearings 2 and four horizontal sliders 4. The inclined slider 1 is an inverted trapezoidal quadrangular platform, and the workbench 6 is provided with a cross slide 6-1. The cross-shaped test piece 7 is placed above the cross chute 6-1, and the four ends of the cross-shaped test piece 7 are respectively fixedly connected with a clamp 8, and each clamp 8 is fixedly connected with a tension-compression clamp on the outer end surface of the clamp 8. Sensor 5, the outer end of each tension and pressure sensor 5 is fixedly connected with a horizontal slider 4, each horizontal slider 4 is installed on the workbench 6, and each horizontal slider 4 ...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination figure 2 and image 3 To describe this embodiment, the included angle α between each diagonal brace 3 and the horizontal plane in this embodiment is 45°. With such arrangement, the diagonal brace can well decompose the force to the horizontal direction, and at the same time satisfy the limitation on the moment. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

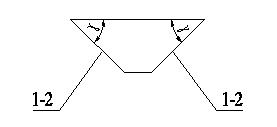

[0011] Specific implementation mode three: combination figure 1 , Figure 4 and Figure 5 Describe this embodiment, the angle β between the trapezoidal inclined surface 1-1 on the left and right sides of the inclined slider 1 of the present embodiment and the upper end surface is 45°, the trapezoidal inclined surface 1-2 on the front and rear sides of the inclined slider 1 and the upper end surface The included angle γ of the end faces is 78°. With such settings, a ratio loading of 8:1 in the X-Y direction is obtained. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com