Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

363 results about "Variable ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-Noise High Efficiency Bias Generation Circuits and Method

ActiveUS20110156819A1Reduce voltageAvoid problemsAmplifier modifications to reduce noise influenceActive element networkLow noiseCapacitance

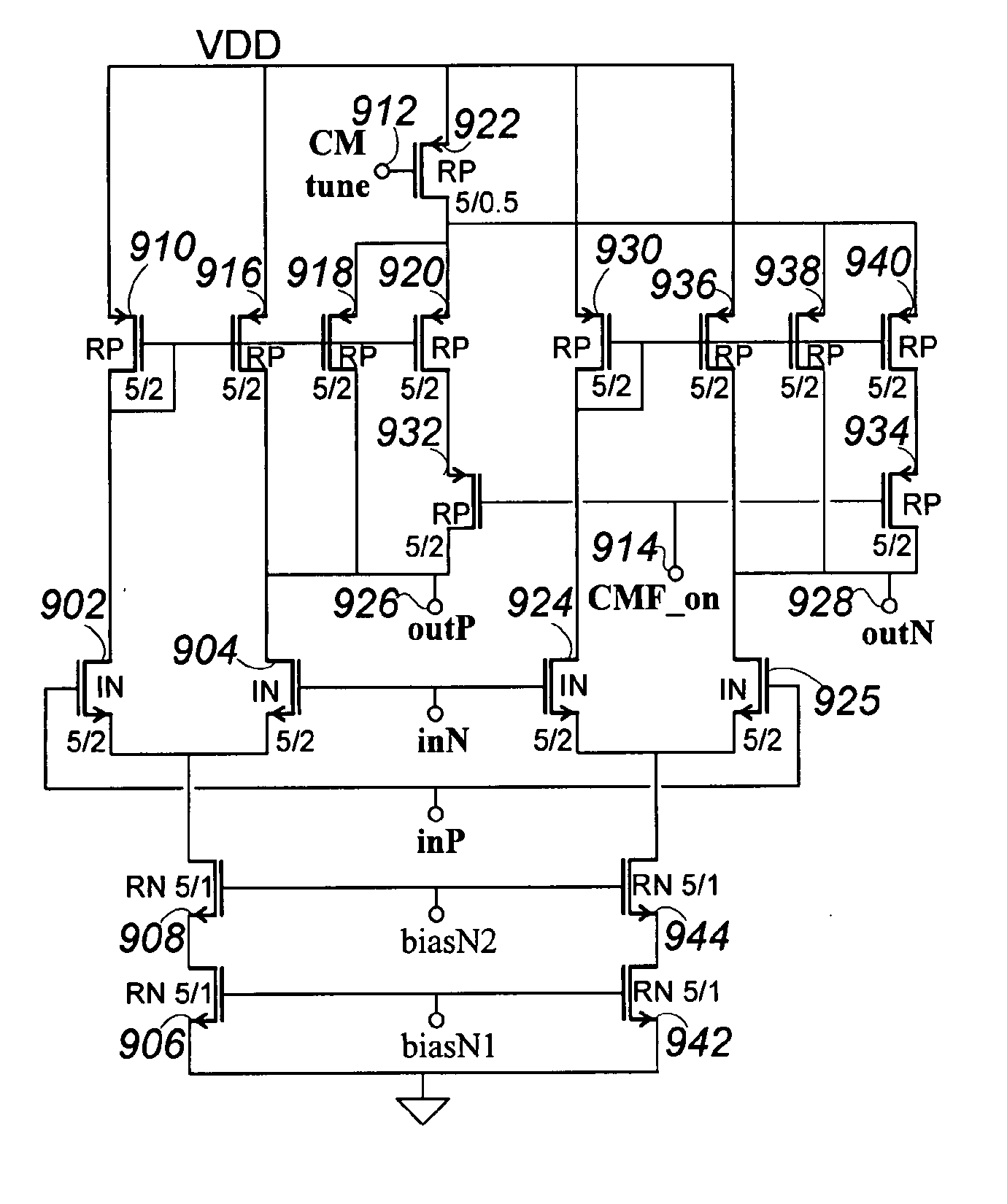

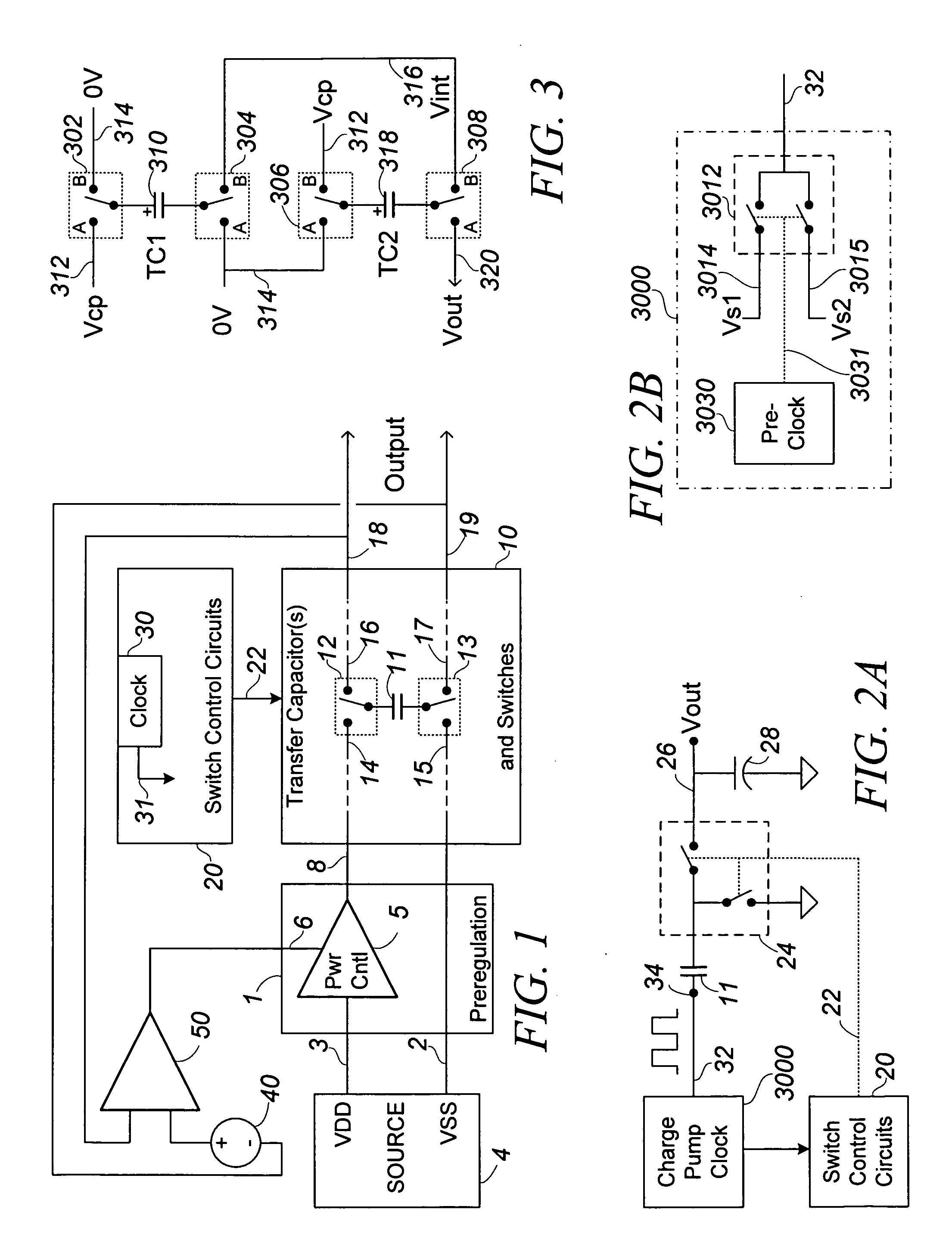

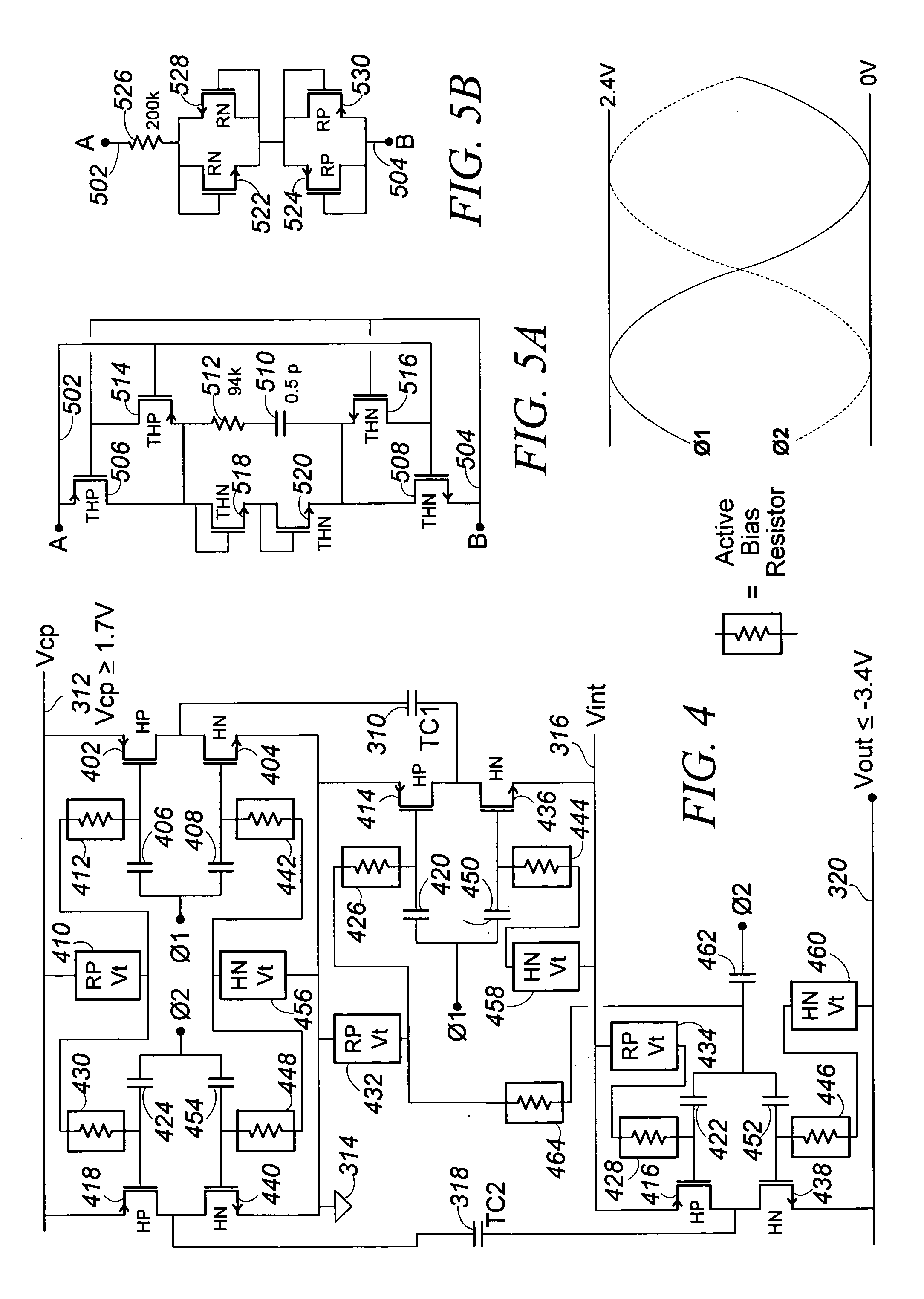

A bias generation method or apparatus defined by any one or any practical combination of numerous features that contribute to low noise and / or high efficiency biasing, including: having a charge pump control clock output with a waveform having limited harmonic content or distortion compared to a sine wave; having a ring oscillator to generating a charge pump clock that includes inverters current limited by cascode devices and achieves substantially rail-to-rail output amplitude; having a differential ring oscillator with optional startup and / or phase locking features to produce two phase outputs suitably matched and in adequate phase opposition; having a ring oscillator of less than five stages generating a charge pump clock; capacitively coupling the clock output(s) to some or all of the charge transfer capacitor switches; biasing an FET, which is capacitively coupled to a drive signal, to a bias voltage via an “active bias resistor” circuit that conducts between output terminals only during portions of a waveform appearing between the terminals, and / or wherein the bias voltage is generated by switching a small capacitance at cycles of said waveform. A charge pump for the bias generation may include a regulating feed back loop including an OTA that is also suitable for other uses, the OTA having a ratio-control input that controls a current mirror ratio in a differential amplifier over a continuous range, and optionally has differential outputs including an inverting output produced by a second differential amplifier that optionally includes a variable ratio current mirror controlled by the same ratio-control input. The ratio-control input may therefore control a common mode voltage of the differential outputs of the OTA. A control loop around the OTA may be configured to control the ratio of one or more variable ratio current mirrors, which may particularly control the output common mode voltage, and may control it such that the inverting output level tracks the non-inverting output level to cause the amplifier to function as a high-gain integrator.

Owner:PSEMI CORP

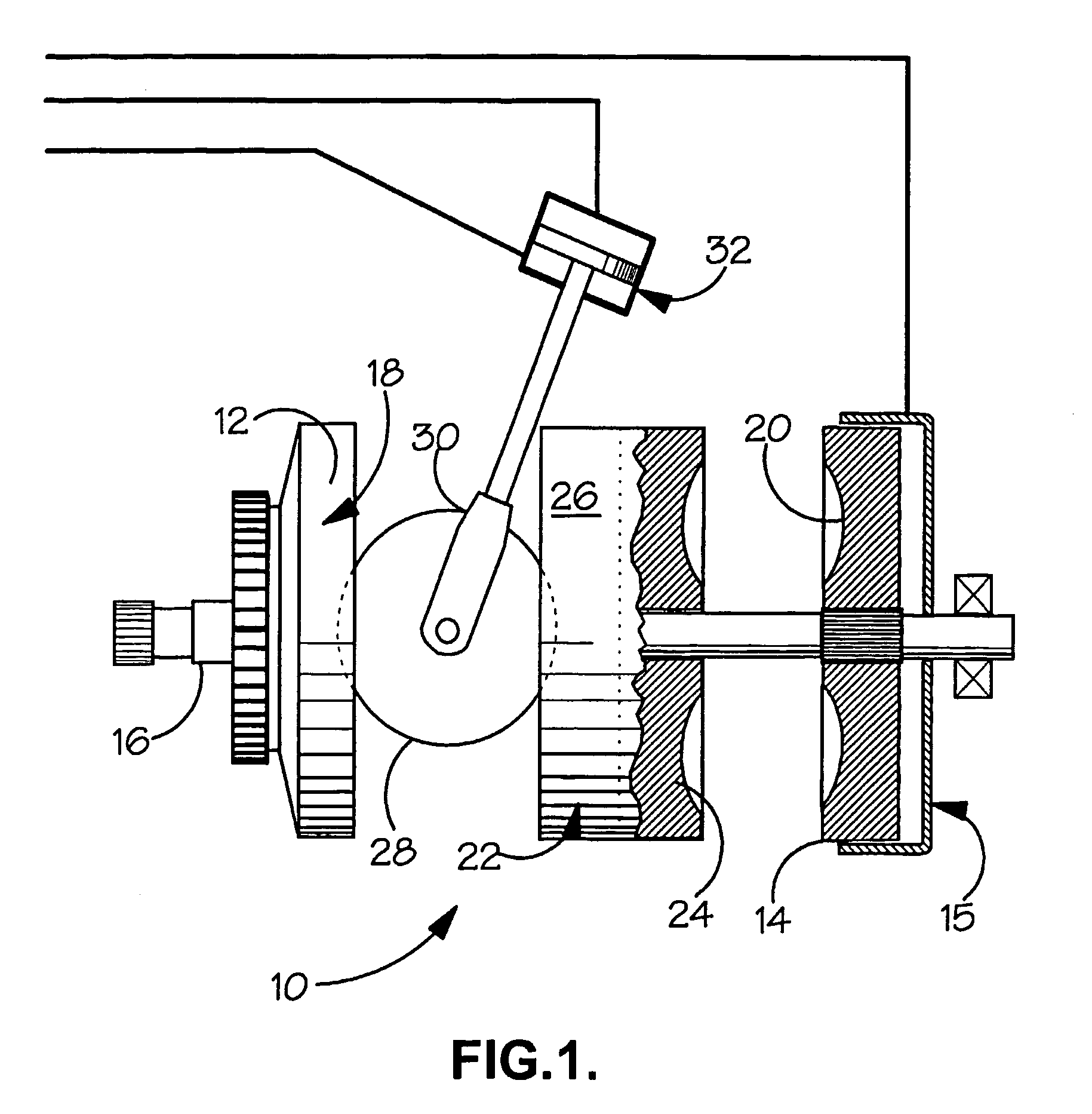

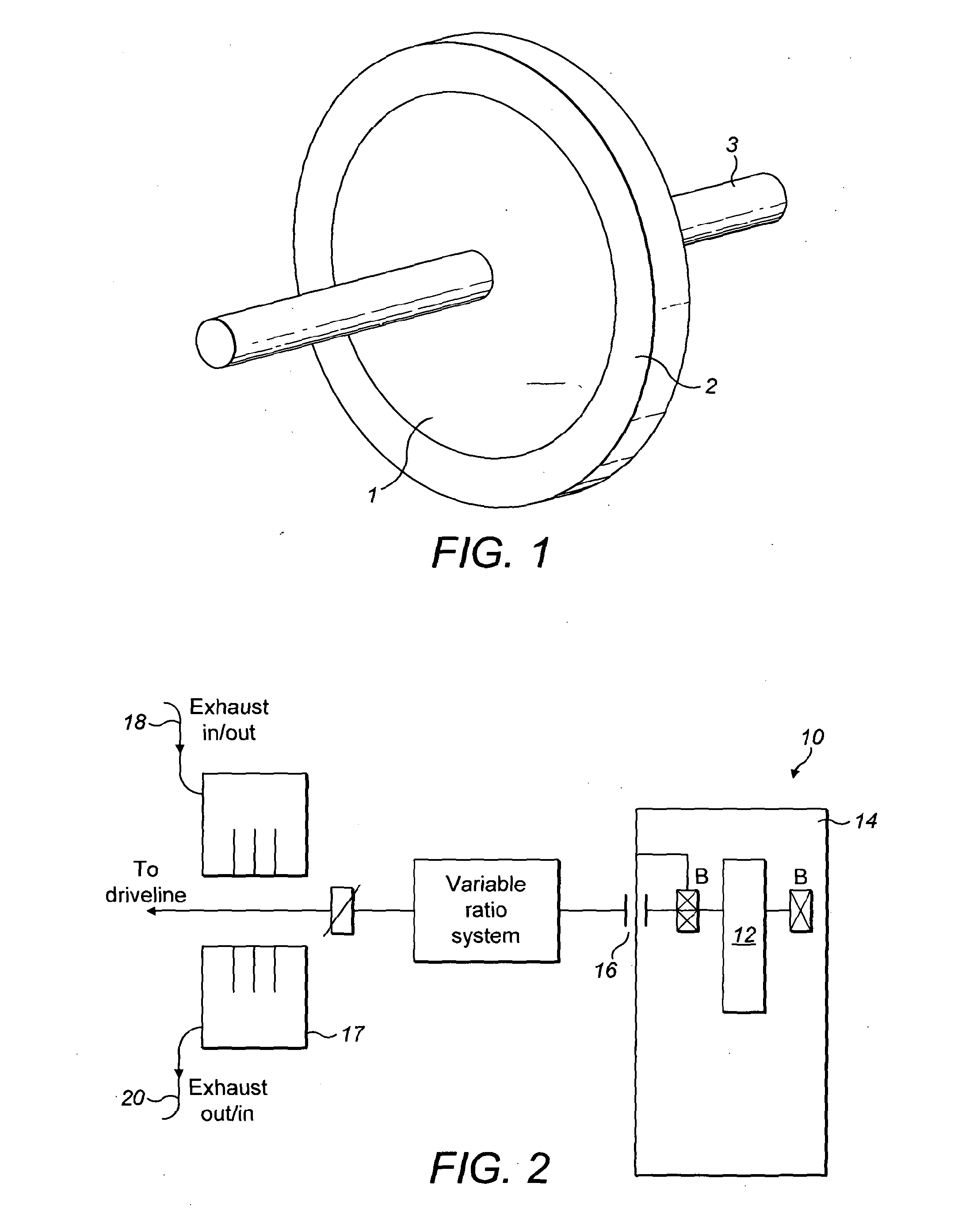

Continuously variable transmission

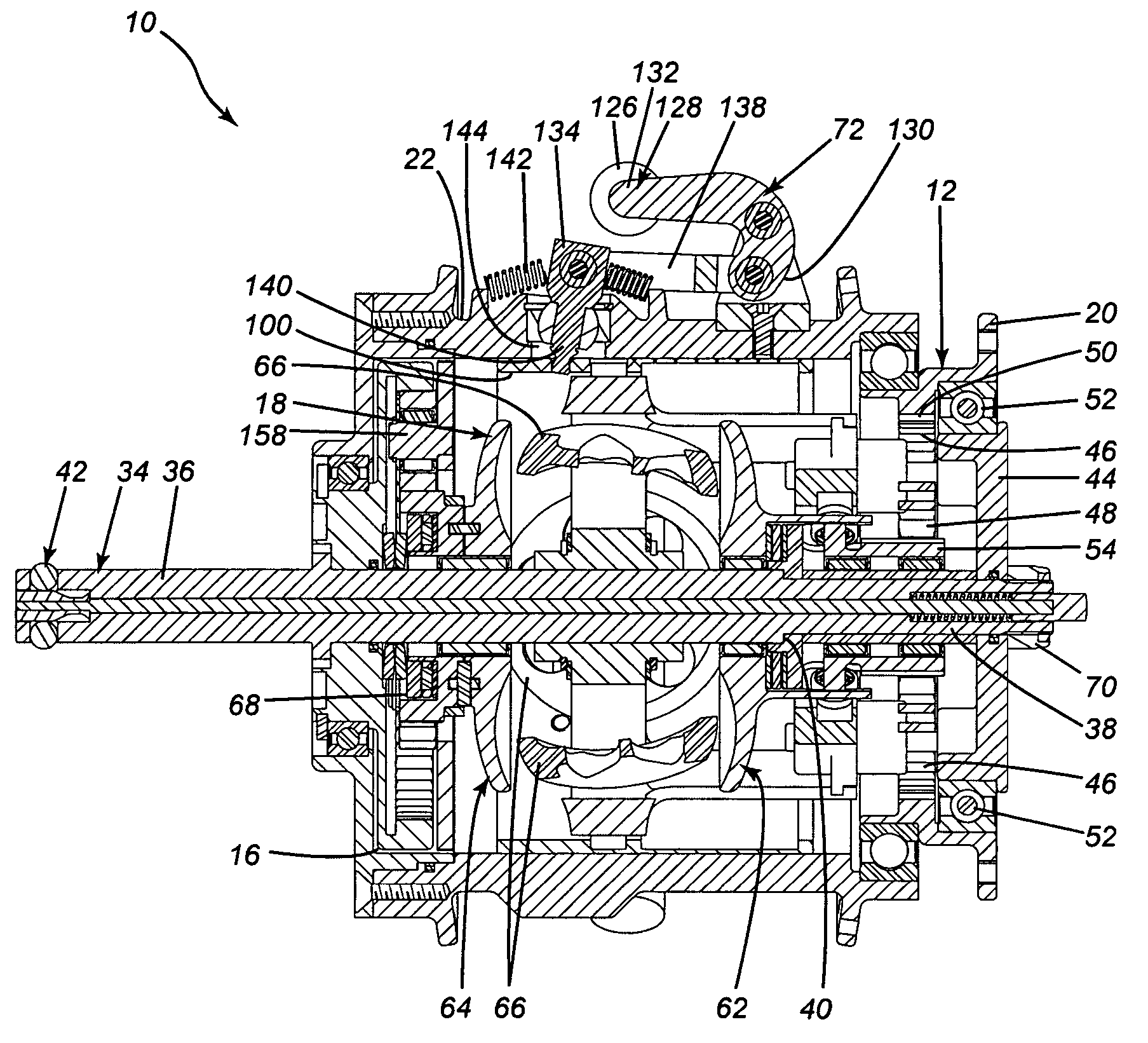

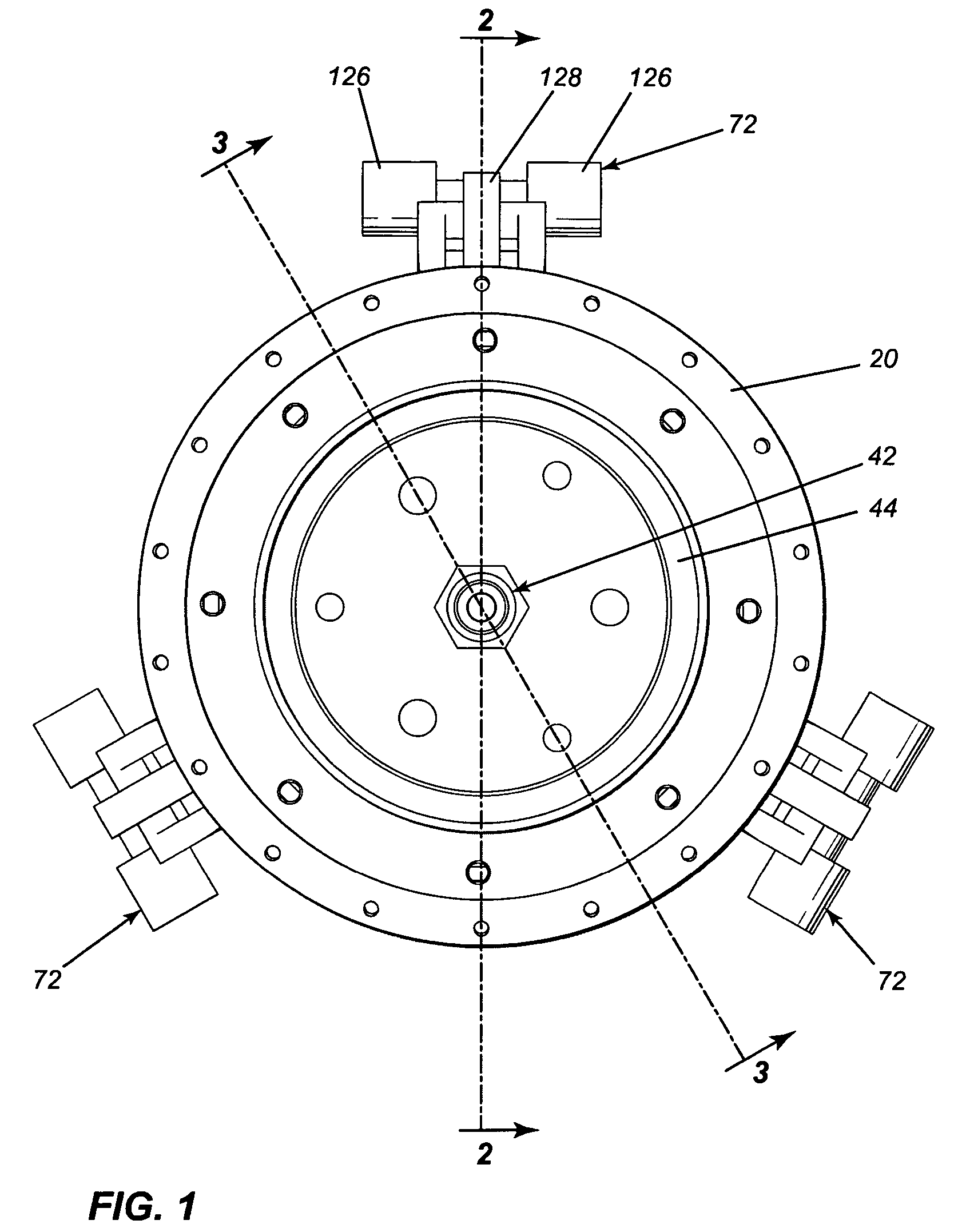

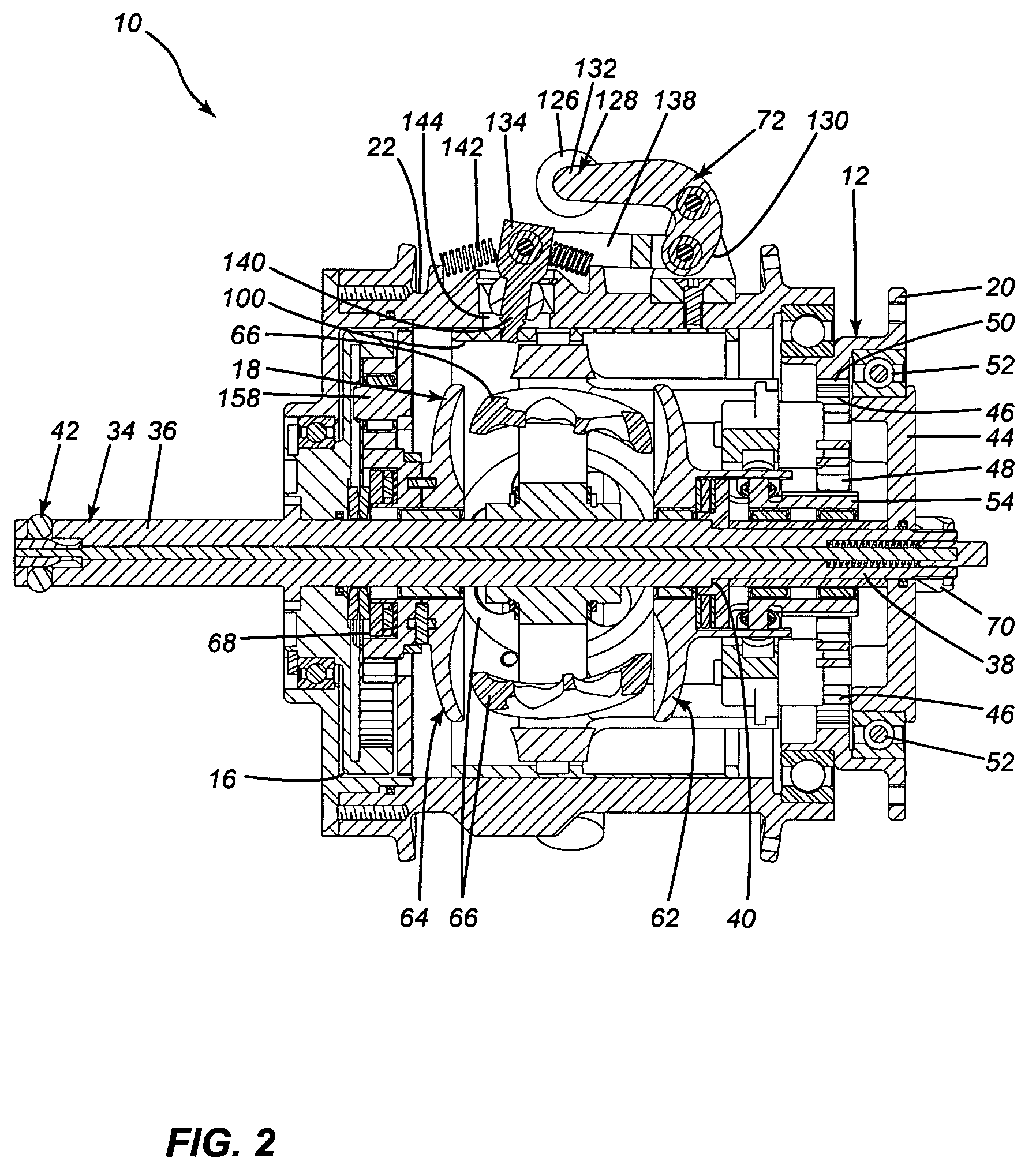

A variable ratio transmission for mechanically coupling an input member to an output member, the variable ratio transmission allowing the conversion of an input rotational motion of the input member into an output rotational motion of the output member, the input rotational motion having an input speed and an input torque and the output rotational motion having an output speed and an output torque. The variable ratio transmission includes a variable ratio transmission assembly mechanically coupled to the input member and to the output member for rotating the output member at the output speed in response to the input member being rotated at the input speed, the variable ratio transmission assembly defining a transmission ratio between the output speed and the input speed, the transmission ratio being variable; and a ratio controller mechanically coupled to the variable ratio transmission assembly and to the input member for automatically adjusting the transmission ratio as a function of the input torque.

Owner:MAHEU PIERRE

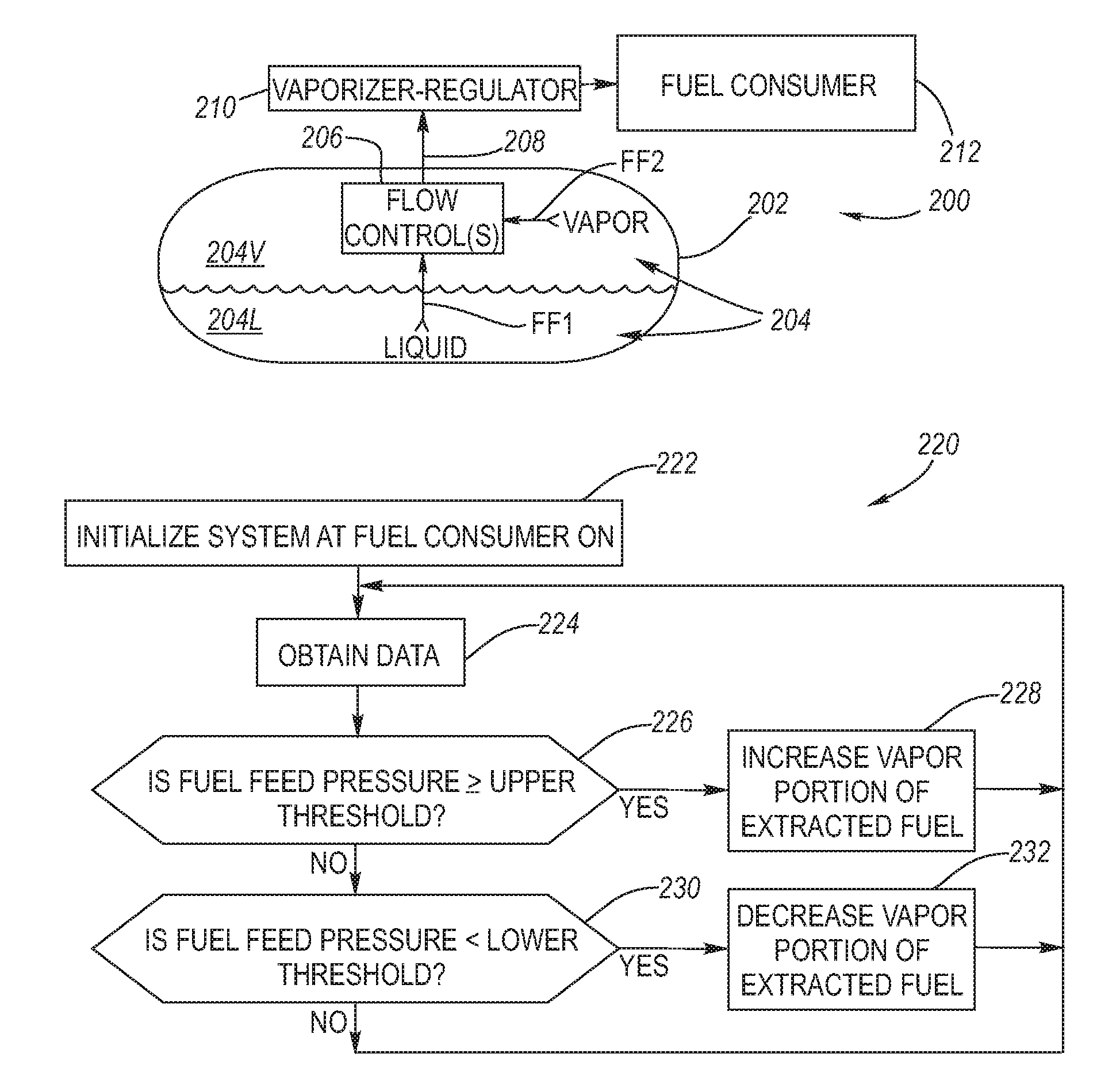

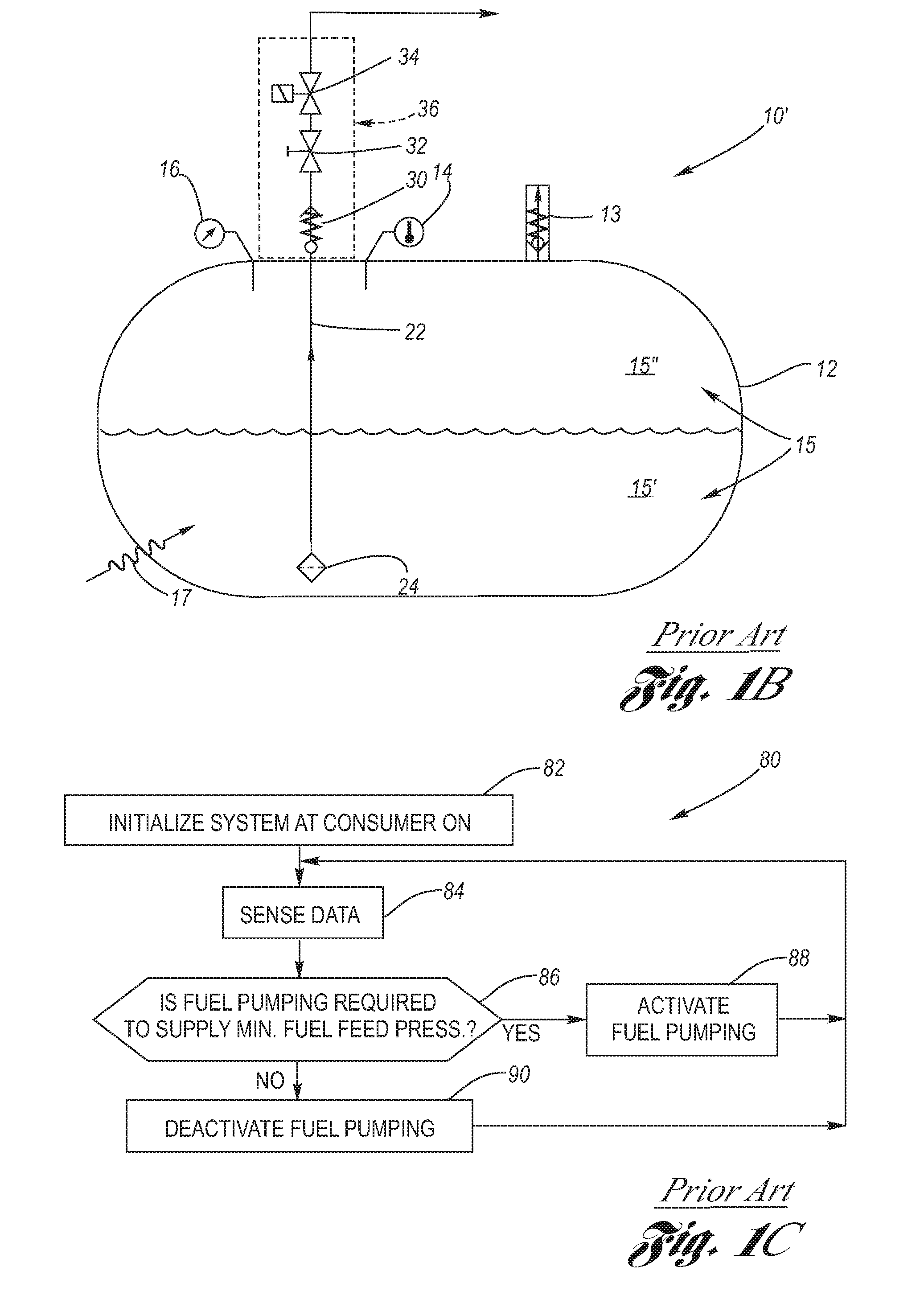

Fuel Tank Temperature and Pressure Management Via Selective Extraction of Liquid Fuel and Fuel Vapor

InactiveUS20120060935A1Low vapor pressureImproved vaporizationElectrical controlInternal combustion piston enginesLiquid fuelFuel vapor

A method and apparatus for managing temperature and pressure of fuel in a fuel tank stored at or near its vapor pressure. In response to fuel feed pressure, a variable ratio of liquid fuel to fuel vapor is extracted from the fuel tank in order to regulate temperature and pressure of the fuel for the purpose of keeping the pressure lower in anticipation of refilling or to assist a vaporizer of the fuel system which is incompletely vaporizing the fuel.

Owner:GM GLOBAL TECH OPERATIONS LLC

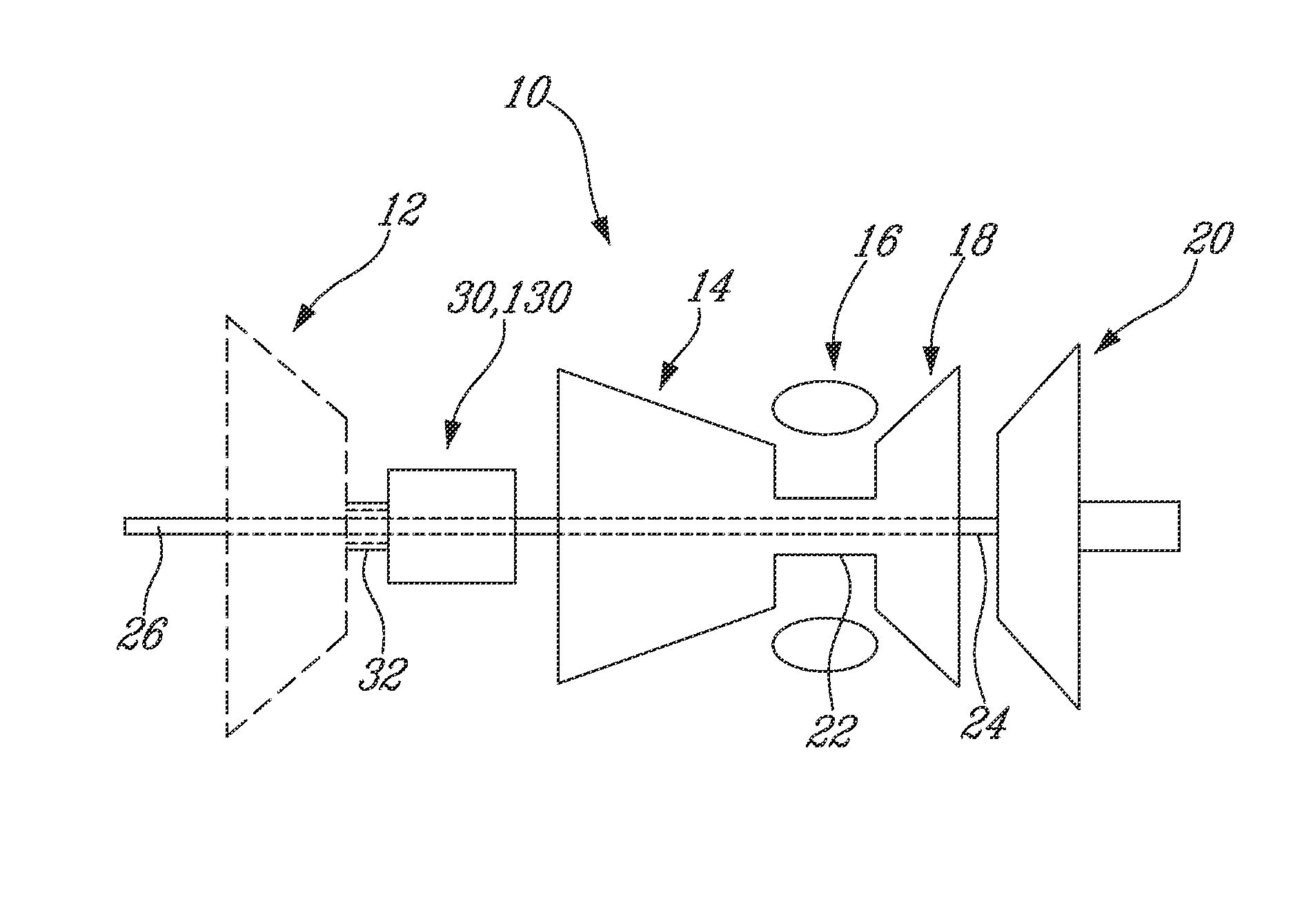

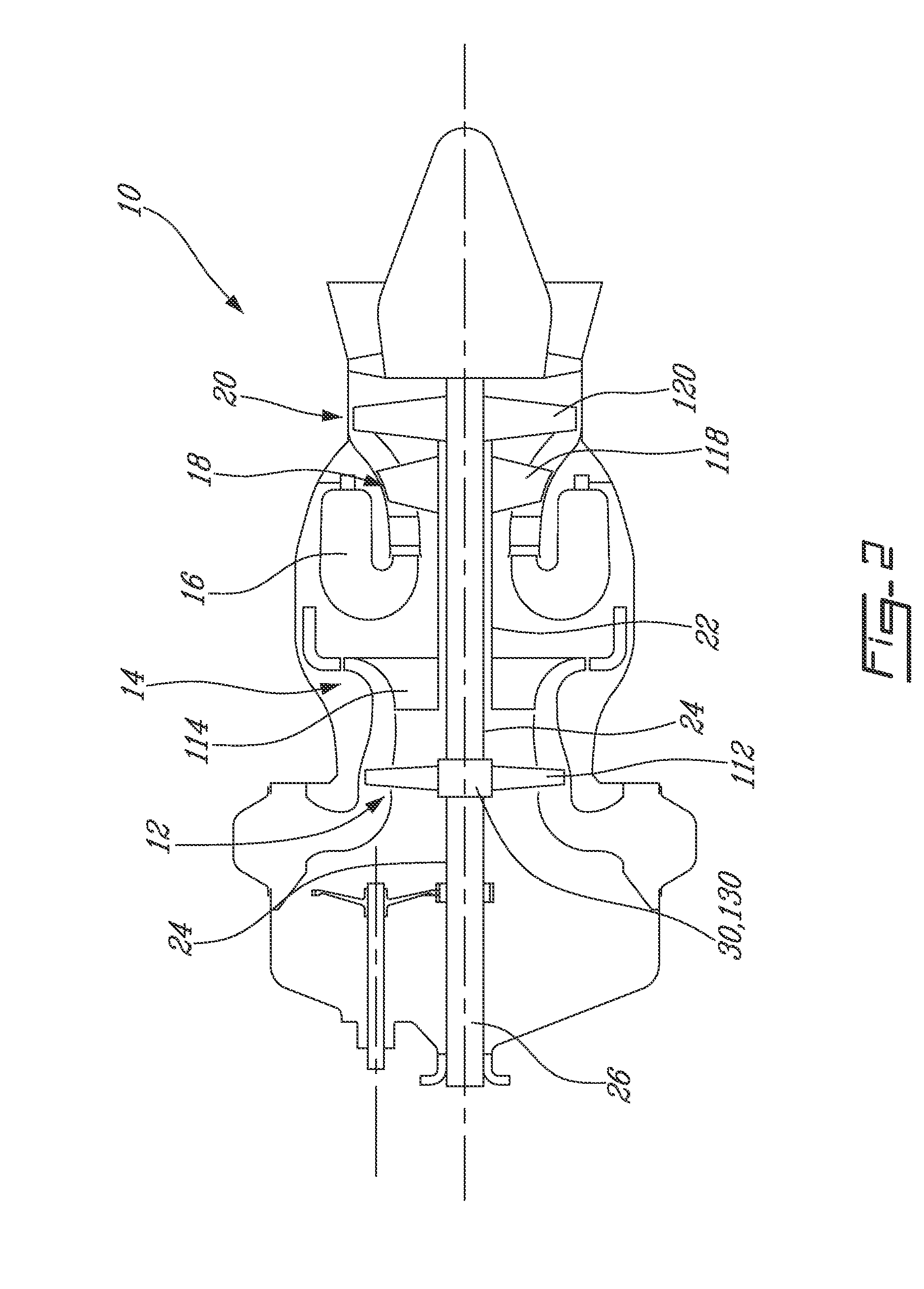

Gas turbine engine with transmission

A multi spool gas turbine engine with a differential having a selectively rotatable member which rotational speed determines a variable ratio between rotational speeds of driven and driving members of the differential. The driven member is engaged to the first spool and a rotatable shaft independent of the other spools (e.g. connected to a compressor rotor) is engaged to the driving member. First and second power transfer devices are engaged to the first spool and the selectively rotatable member, respectively. A circuit interconnects the power transfer devices and allows a power transfer therebetween, and a control unit controls the power being transferred between the power transfer devices. Power can thus be transferred between the first spool and the selectively rotatable member to change the speed ratio between the first spool and the rotatable shaft.

Owner:PRATT & WHITNEY CANADA CORP

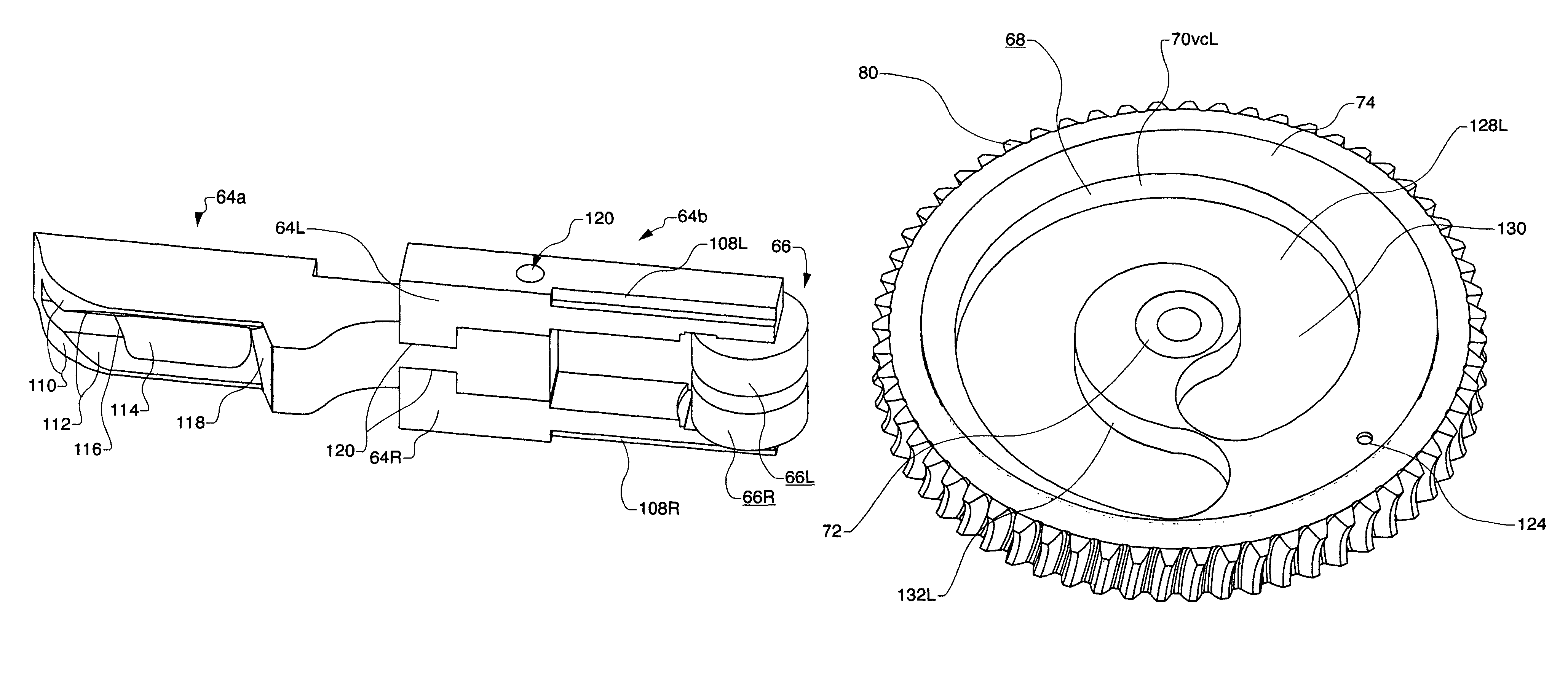

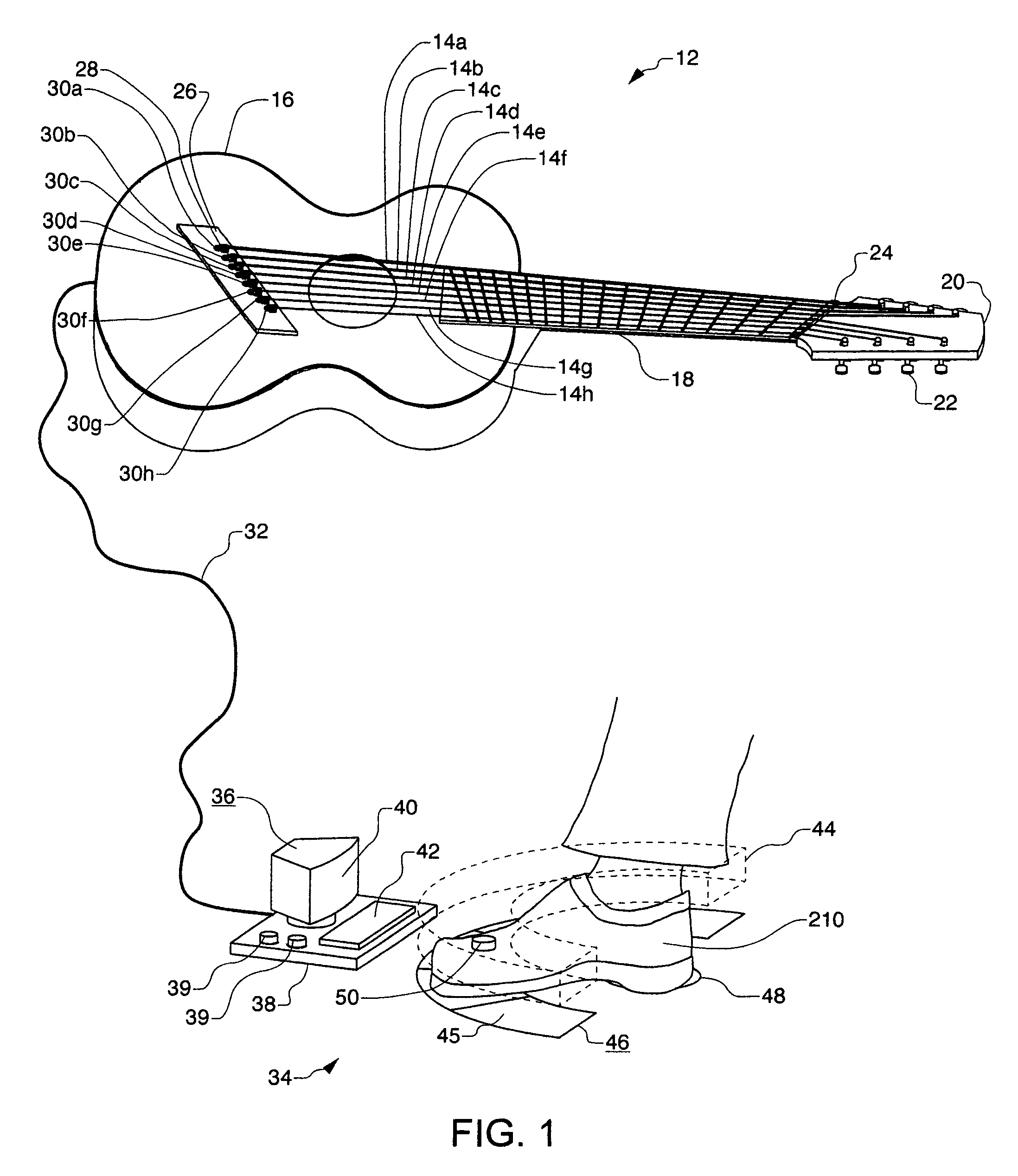

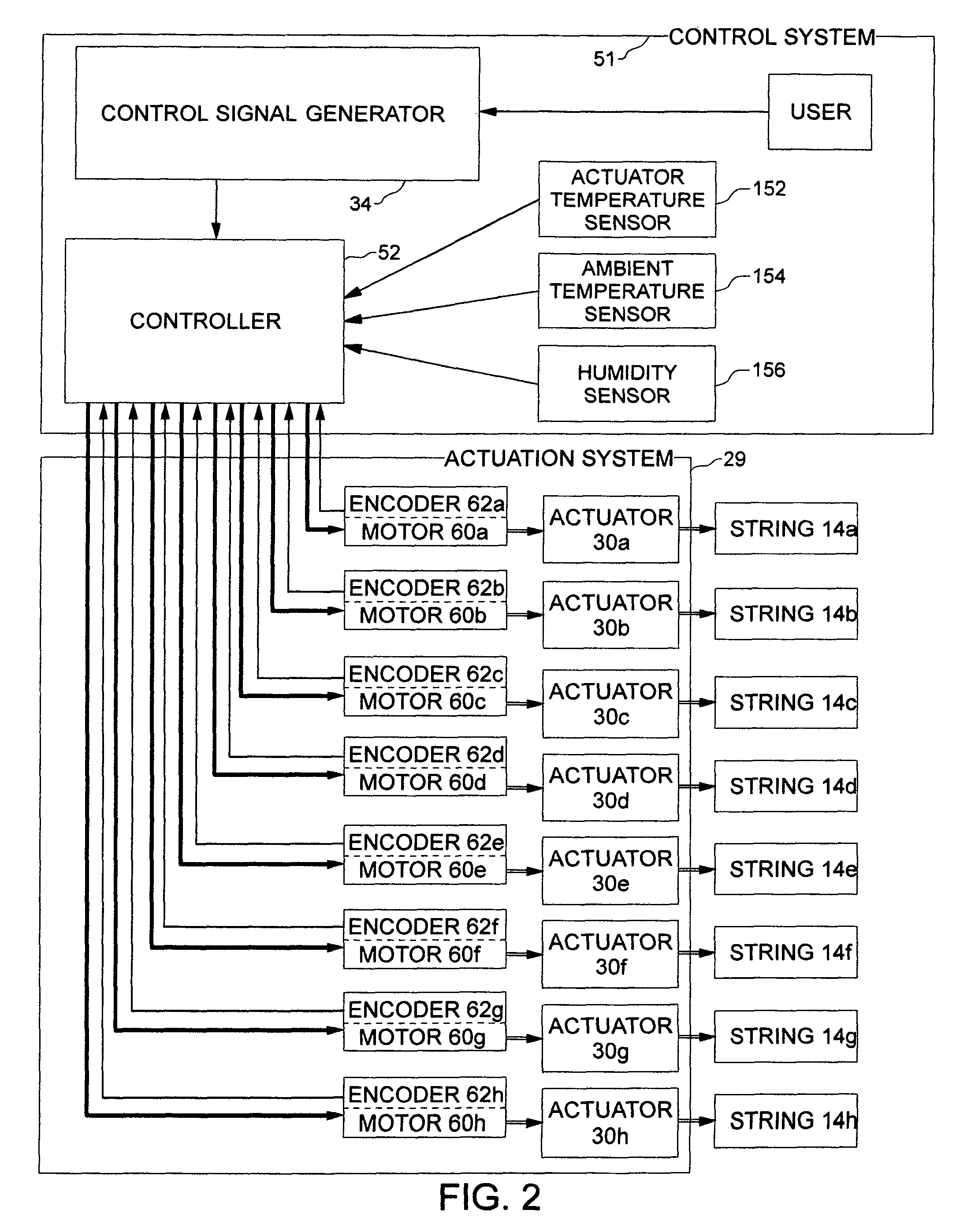

Method and apparatus for string load reduction and real-time pitch alteration on stringed instruments

ActiveUS7935876B1Reduce loadReduces string loadStringed musical instrumentsMusic aidsLoad optimizationControl signal

A method and apparatus for string load reduction and real-time pitch alteration on stringed instruments. A string load is substantially reduced with a camming surface actuator so that the pitch can be rapidly manipulated by an input force which is generated by human power or an electronically controlled motor. Various types of camming surfaces are provided as well as a load optimization calculation which determines the shape of a variable ratio camming surface. Multiple embodiments are described including a constant force pitch alteration device, a motorized control system with pitch compensation and real-time tracking of string pitch to multiple relative input signals, a control signal generator based on real-time position measurement of a control object relative to an electromagnetic radiation sensor, and methods for generating mechanical looping, vibrato, and polyphonic chorus effects which can be automated or dynamically controlled by a user. Other embodiments are described and shown.

Owner:GLISSPHONIC

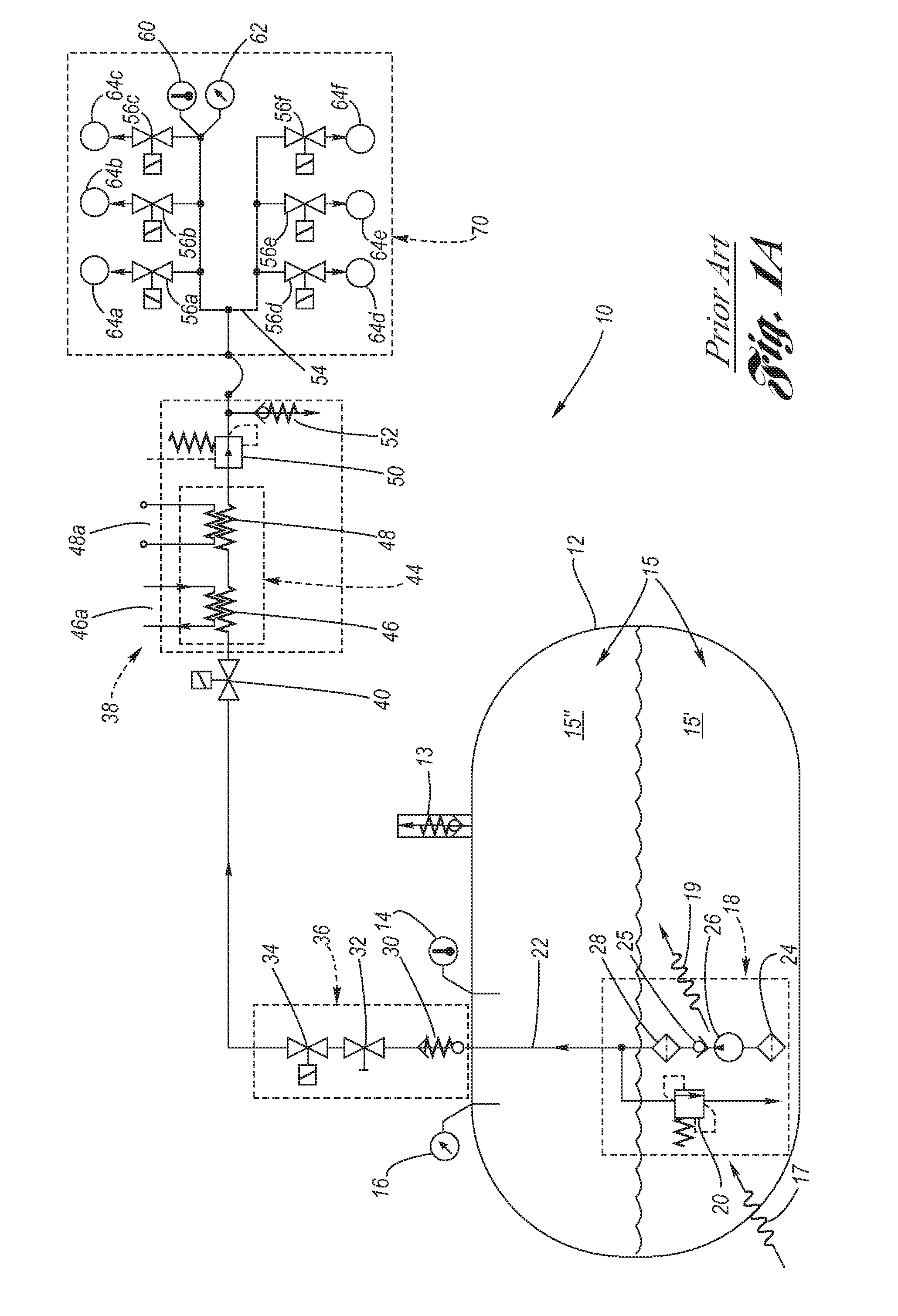

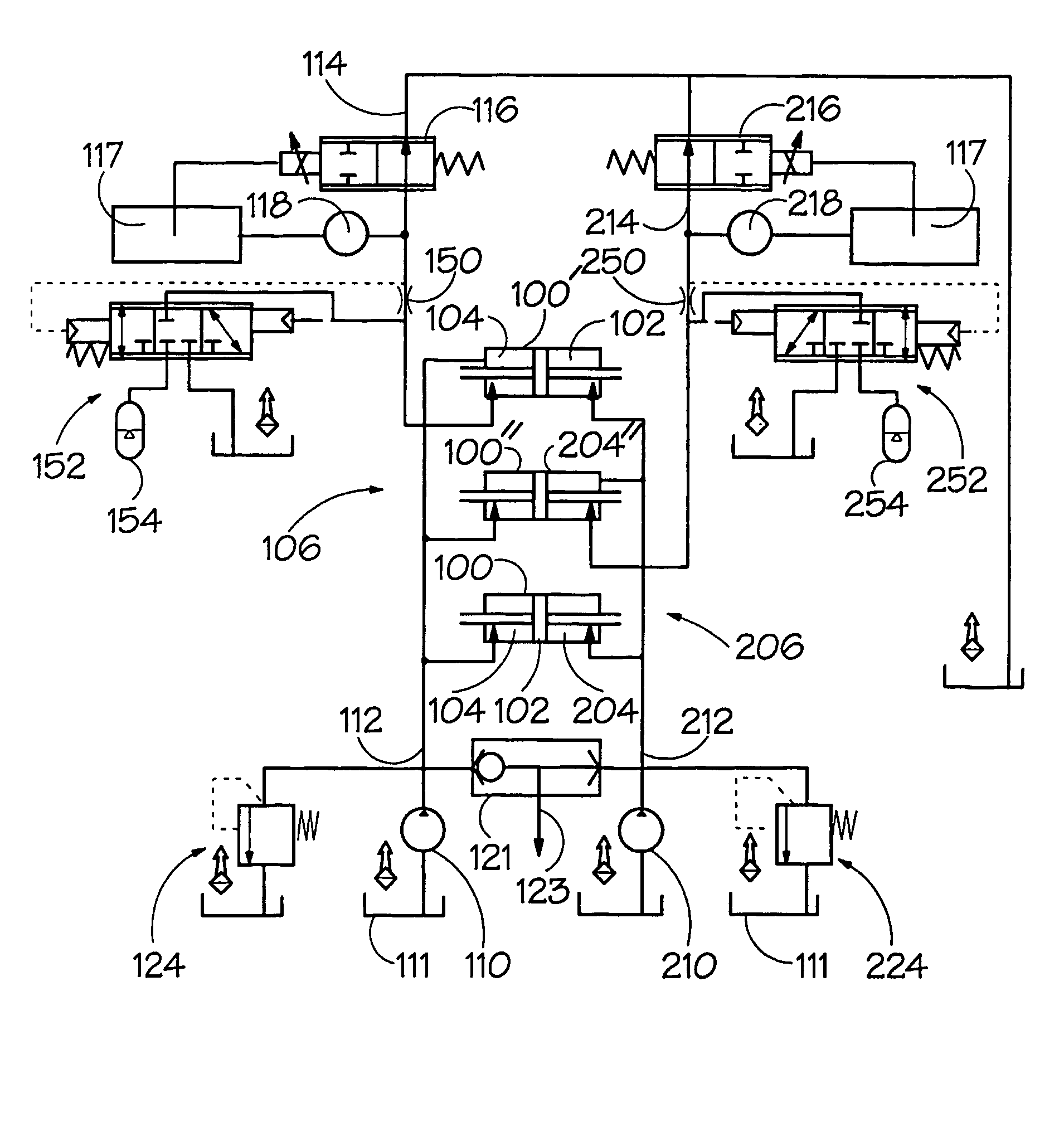

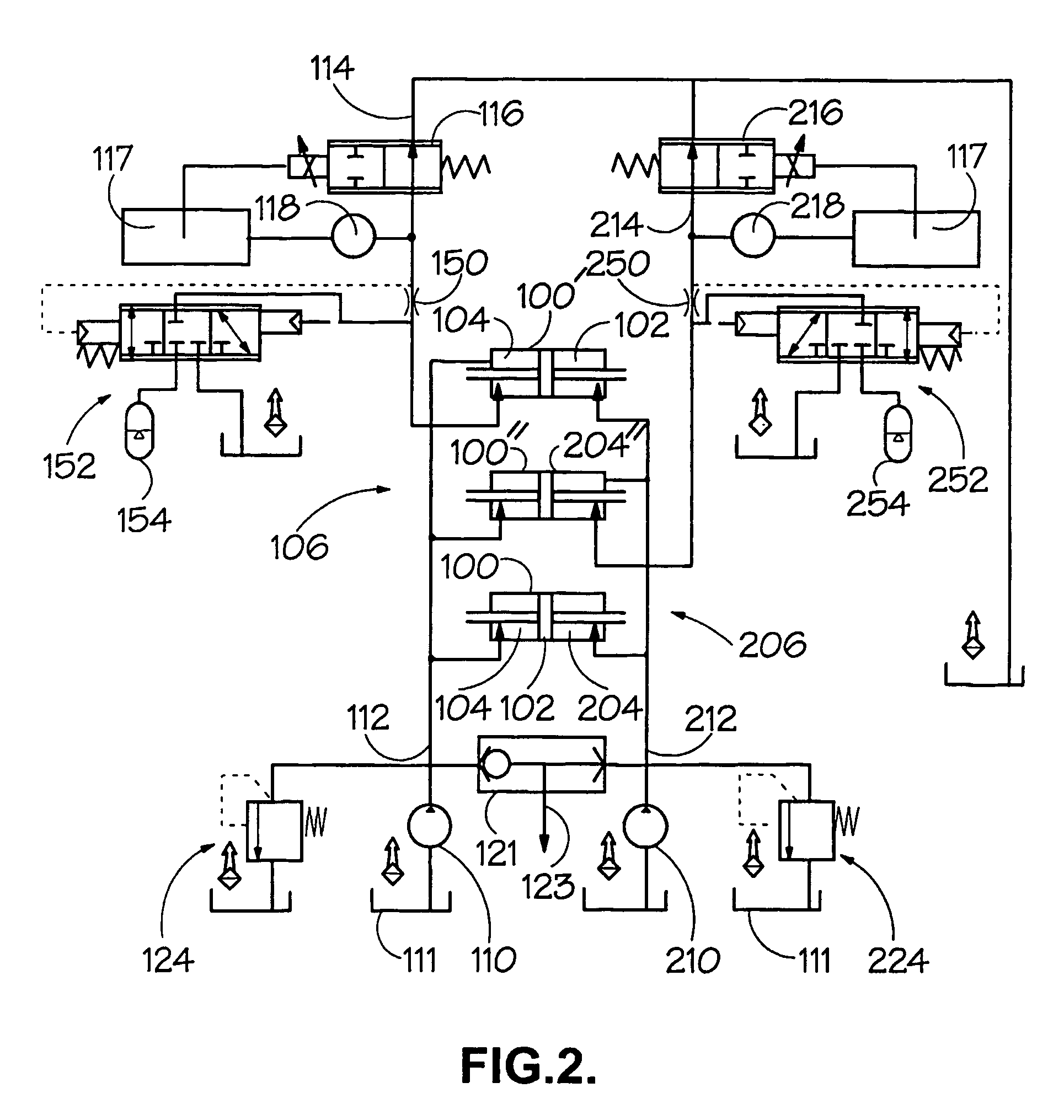

Hydraulic control circuit for a continuously variable transmission

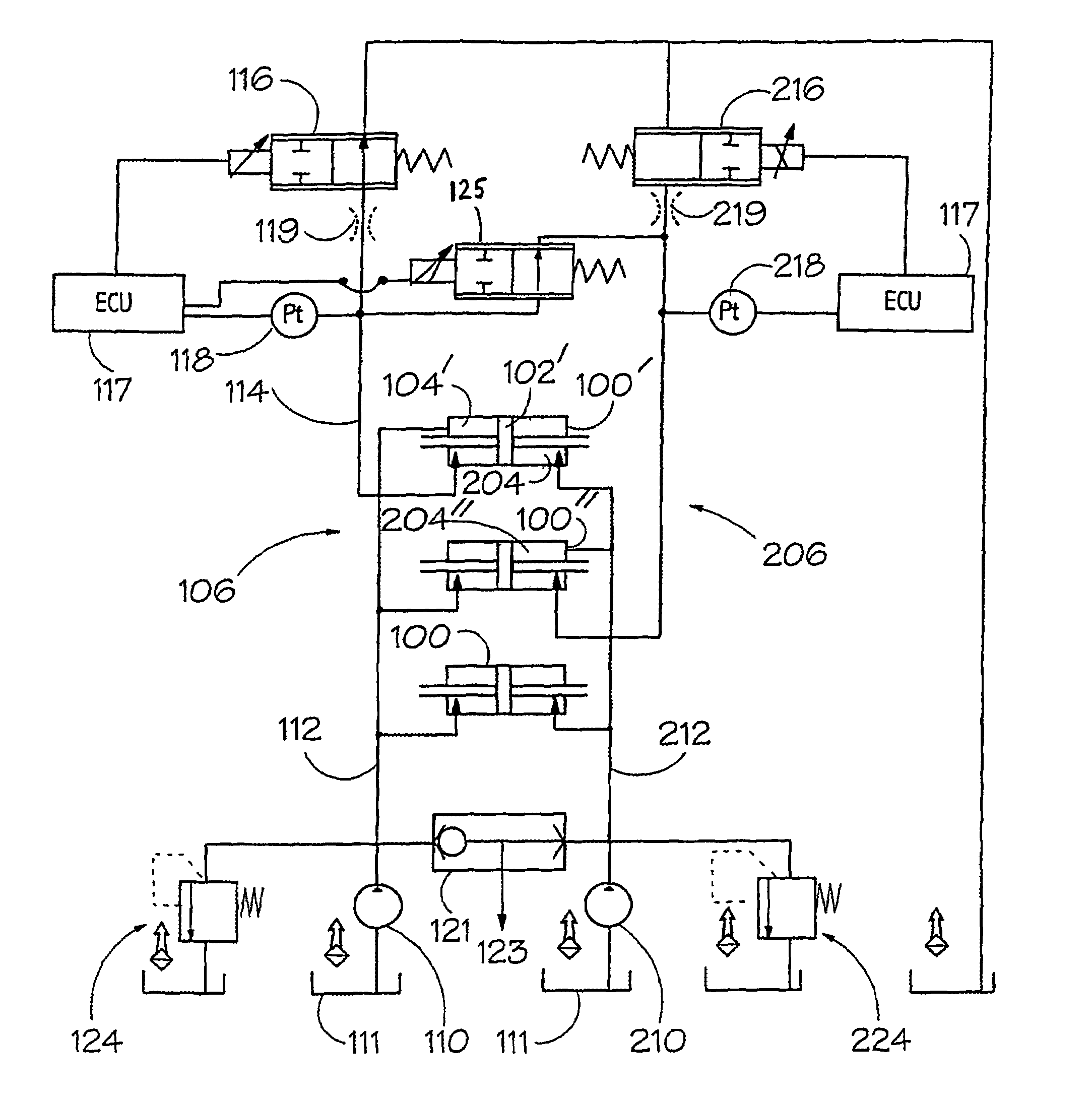

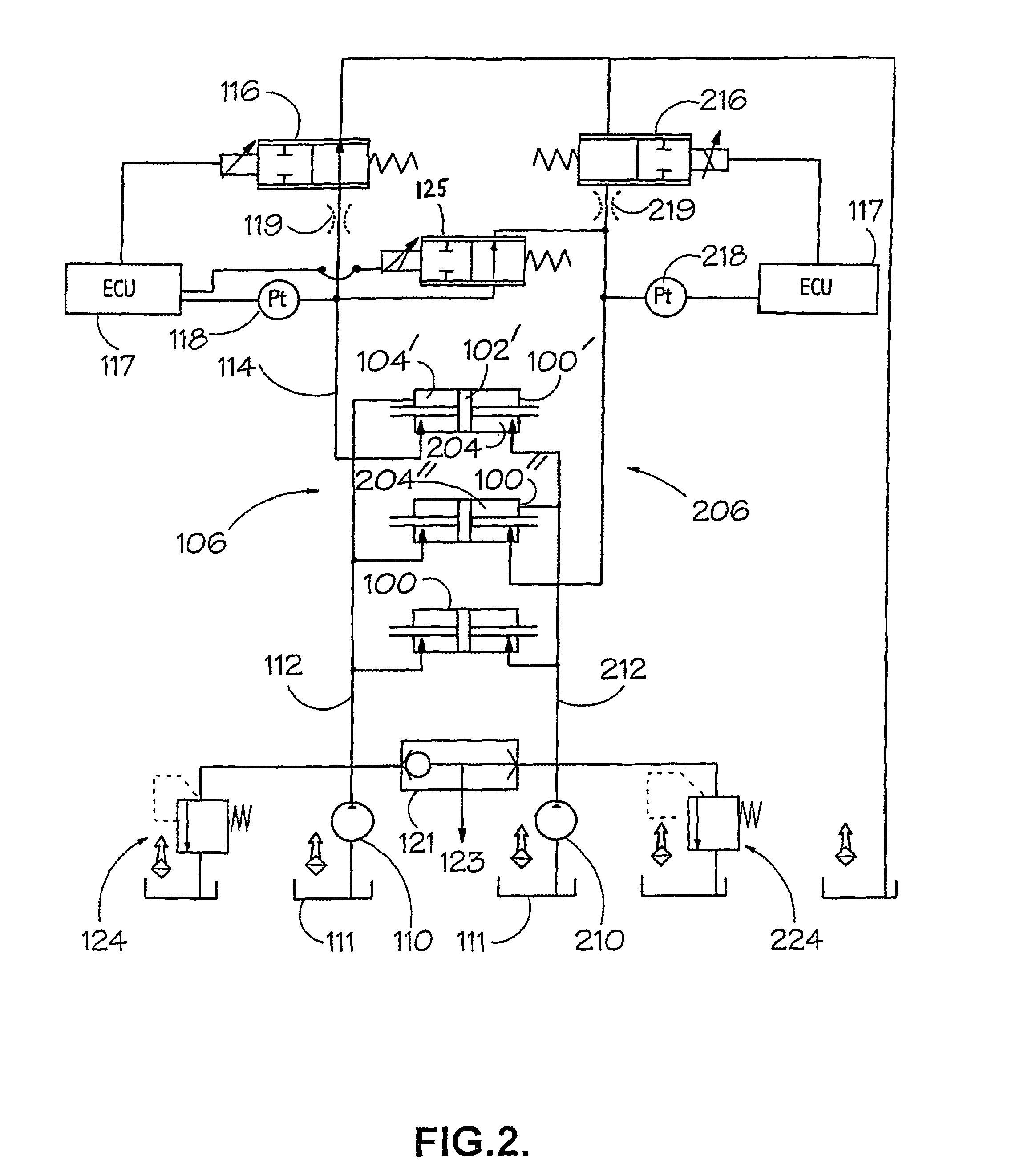

InactiveUS7278951B2Stable controllable operationRapid responseGearing controlEngine controllersTorque transmissionEngineering

A hydraulic control circuit is disclosed for a continuously variable transmission comprising a continuously variable ratio transmission unit (“variator”) 10, the circuit comprising a supply line 106 and means (which may take the form of a pump 110) for providing a flow of pressurised fluid in the supply line, means (which may comprise a pressure control valve 116) for generating a back pressure in the supply line, and at least one connection for feeding fluid from the supply line to a hydraulic actuator 100 acting on a movable torque transmission 23-37 element (which may comprise a roller 28) of the variator 10. The valve means 152 connected to the supply line allows pressure in the supply line to be selectively modified in response to rate of flow in the supply line.

Owner:TOROTRAK (DEV) LTD

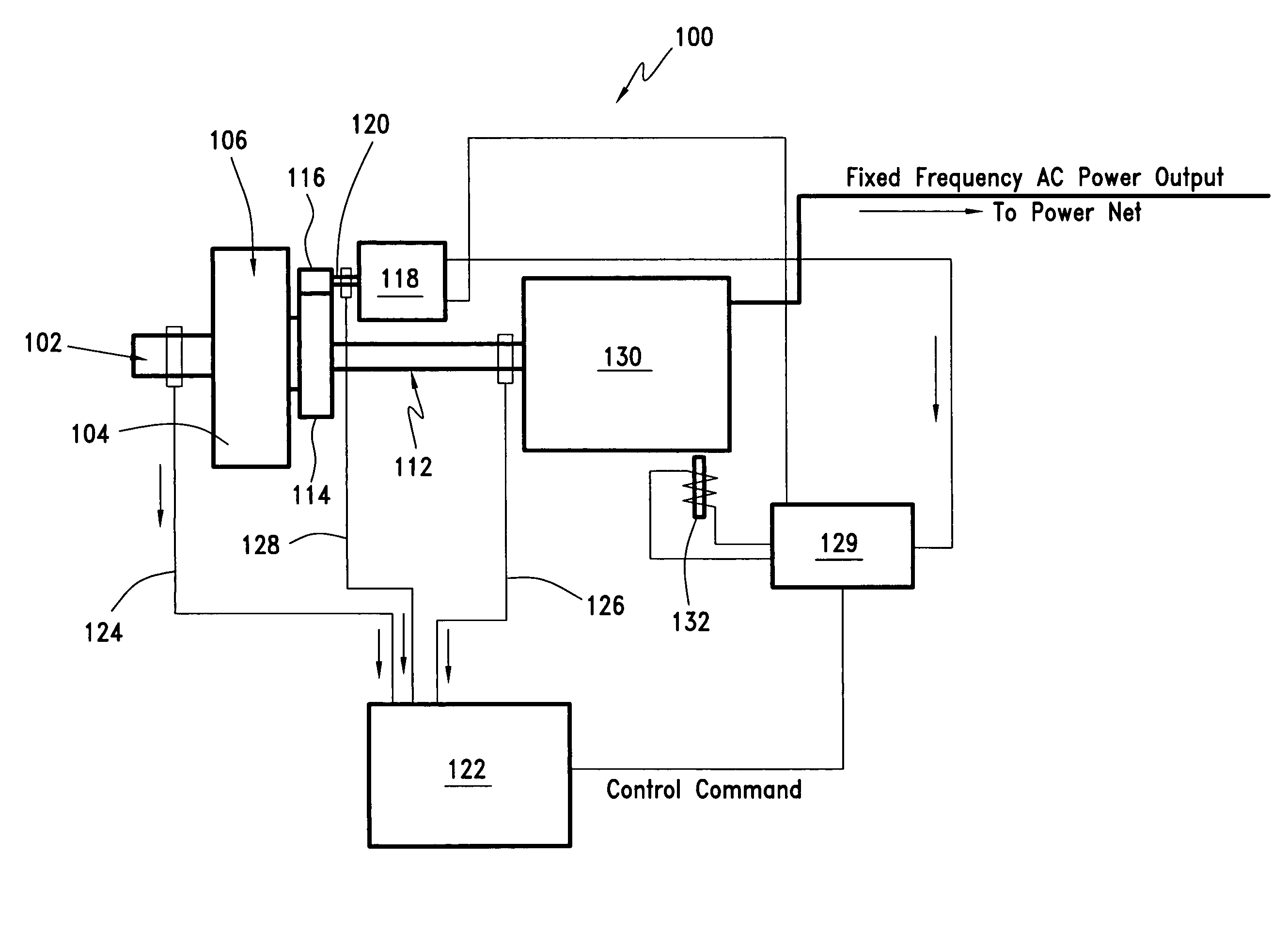

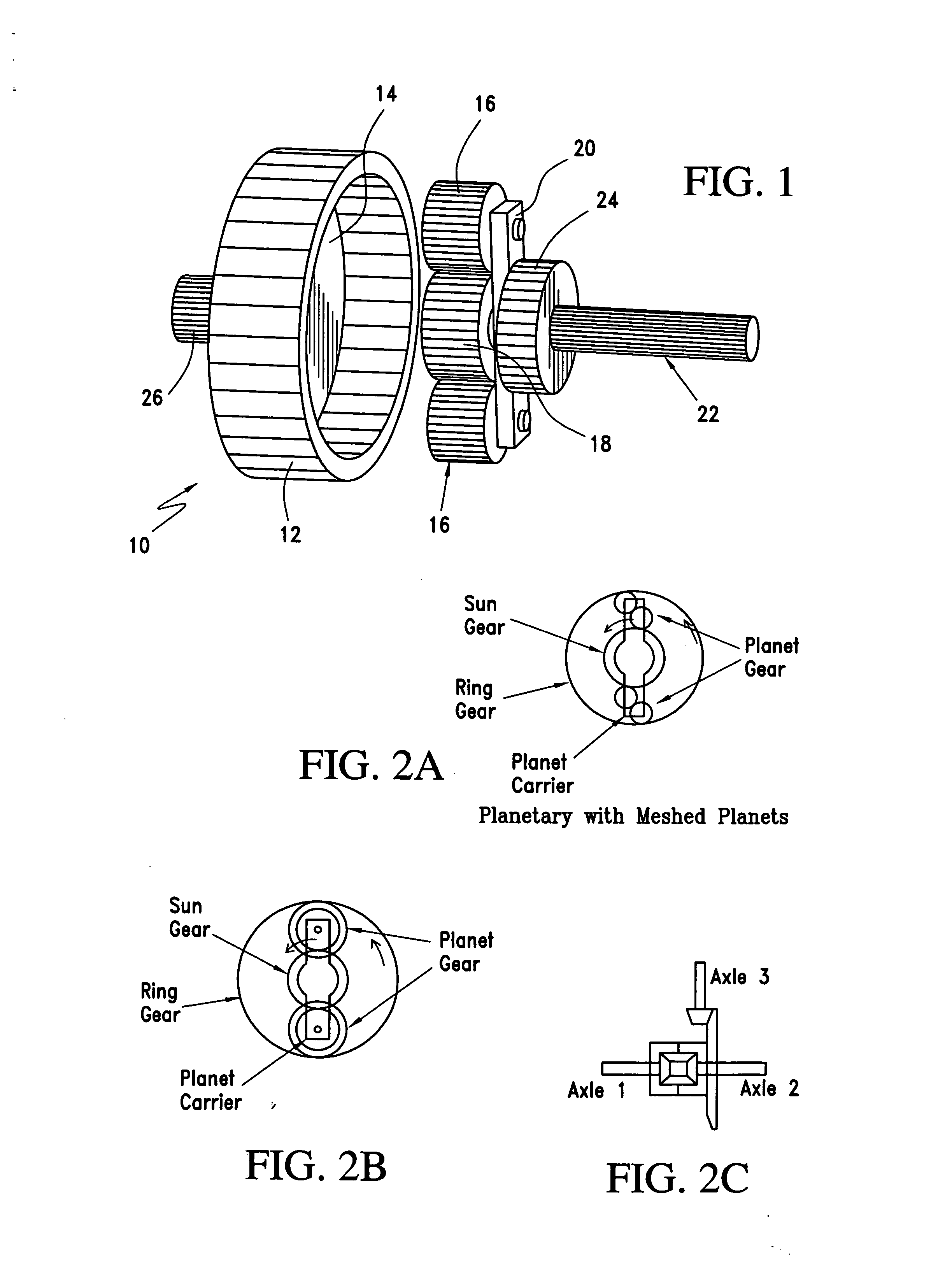

Continuously variable ratio transmission

InactiveUS7115066B1Low efficiencyImprove the level ofEngine fuctionsToothed gearingsEngineeringAC power

A continuously variable ratio transmission including a planetary gear set having a sun gear, a ring gear, and a planet carrier having at least two planet gears carried thereon, a control element including a servogenerator capable of generating electric power, and at least one auxillary field coil adapted to be operatively connected to an output means to influence a power output level and AC power frequency of the output means, the at least one auxillary field coil being powered by the servogenerator and constituting a load to the servogenerator, the speed of the servogenerator being capable of being controlled by the load; and a means for controlling an electrical current to the at least one auxiliary field coil form the servogenerator; where the servogenerator is capable of being driven to produce electrical power by a rotation of one of the sun gear, the ring gear, and the planet carrier.

Owner:LEE PAUL Z

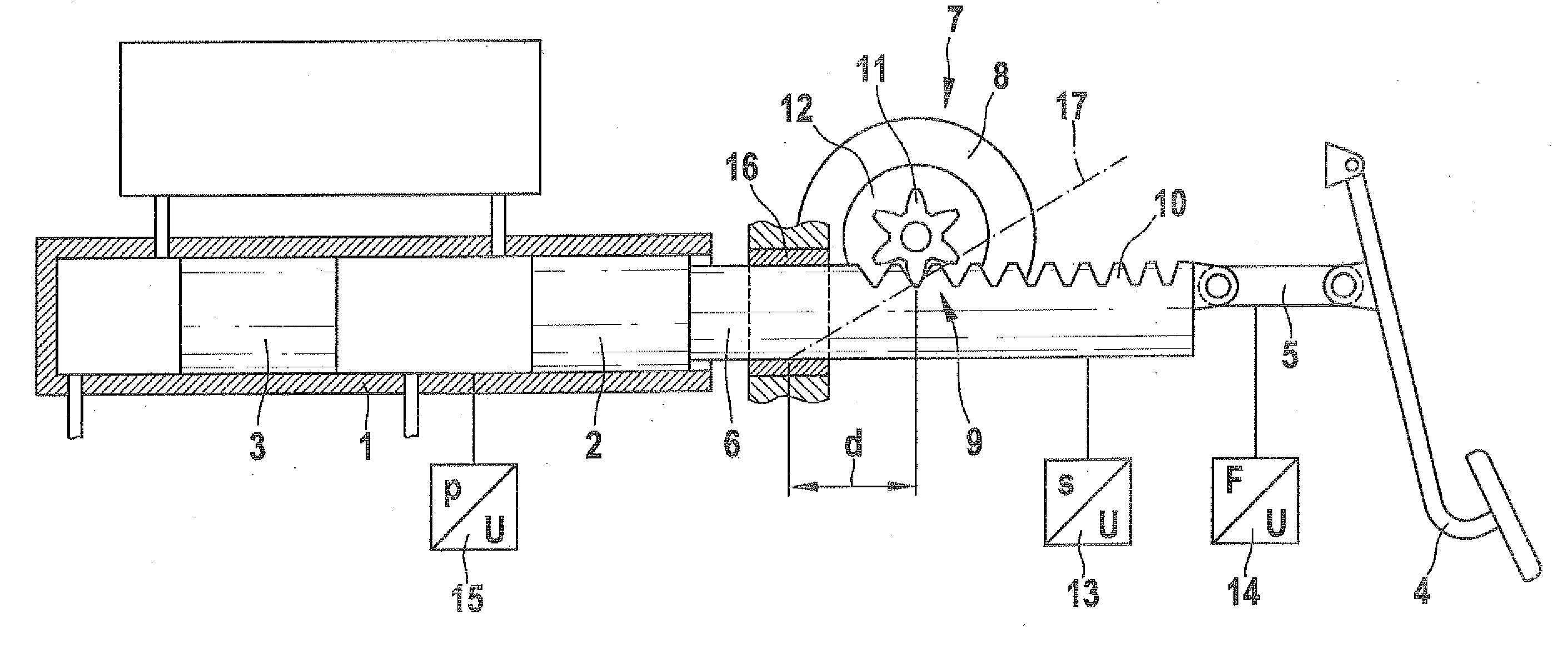

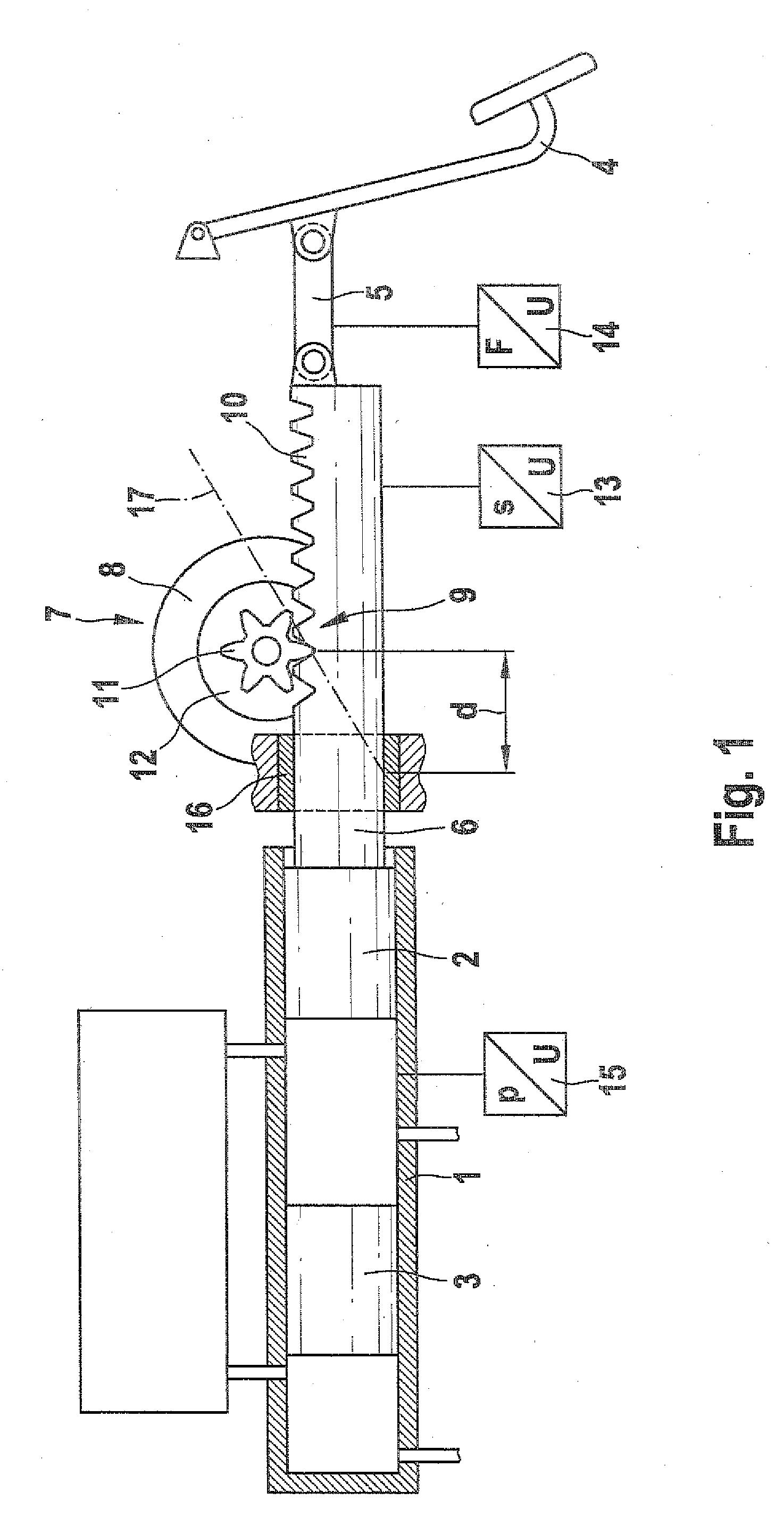

Electromechanical brake booster

InactiveUS20100126167A1Little strengthReduce the risk of injuryBraking action transmissionRotary clutchesFreewheelMaster cylinder

The invention relates to an electromechanical brake booster for a master brake cylinder of a hydraulic vehicle braking system. The invention provides to configure the brake booster such that it preferably includes a switchable freewheel, which enables an actuation of the master brake cylinder without any movement of the electric motor of the brake booster. The invention further provides to configure the brake booster such that it includes a mechanical gear having a variable transmission ratio, which has a high path transmission at the beginning of an actuation of the master brake cylinder, and a force transmission that rises with increasing actuation. A variable gear ratio is possible using a rack and pinion gear, the toothed rack of which has a soothing with a pitch that changes across the length of the toothed rack. A further possibility of a mechanical gear having a variable ratio is a toggle lever mechanism.

Owner:ROBERT BOSCH GMBH

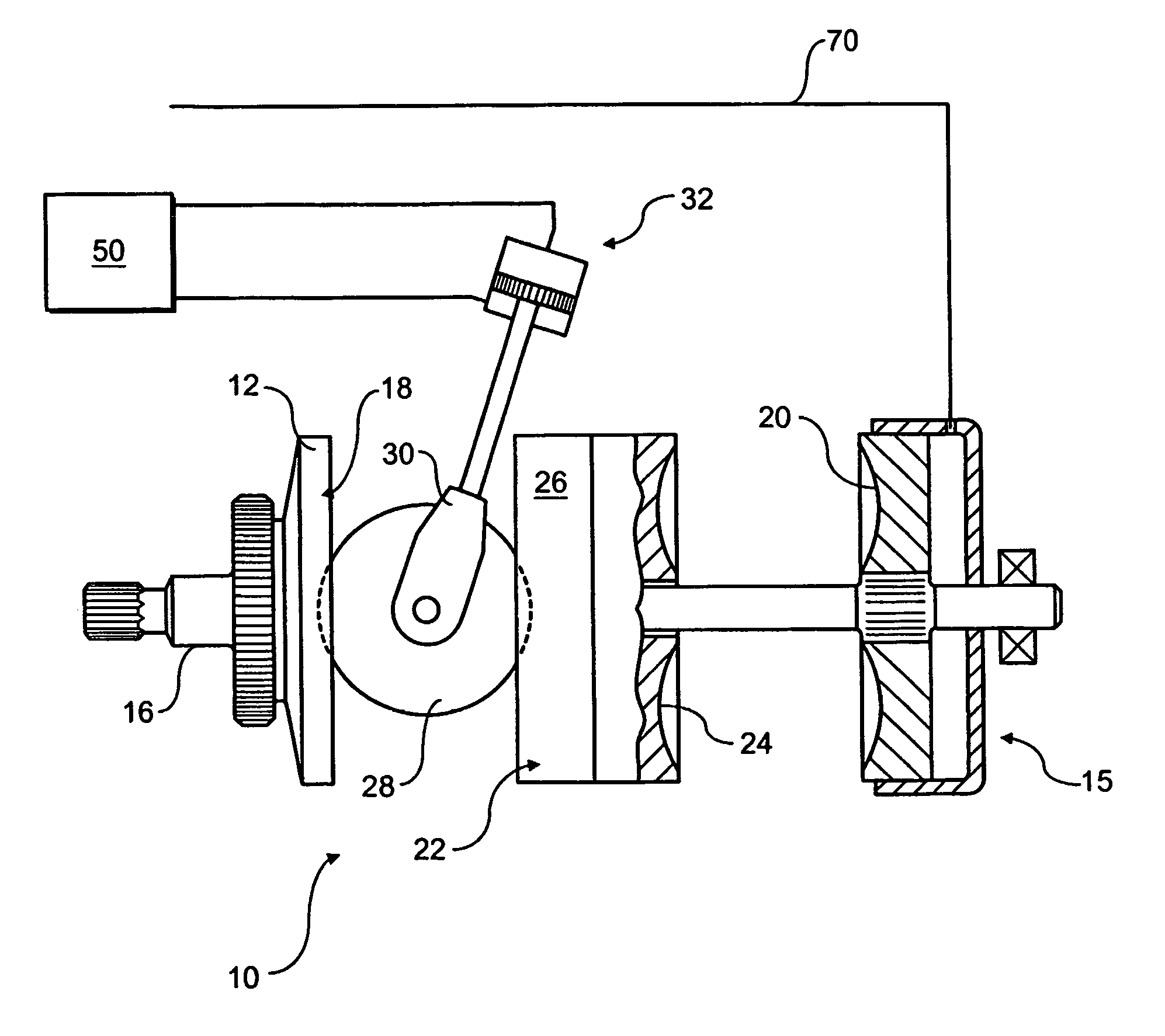

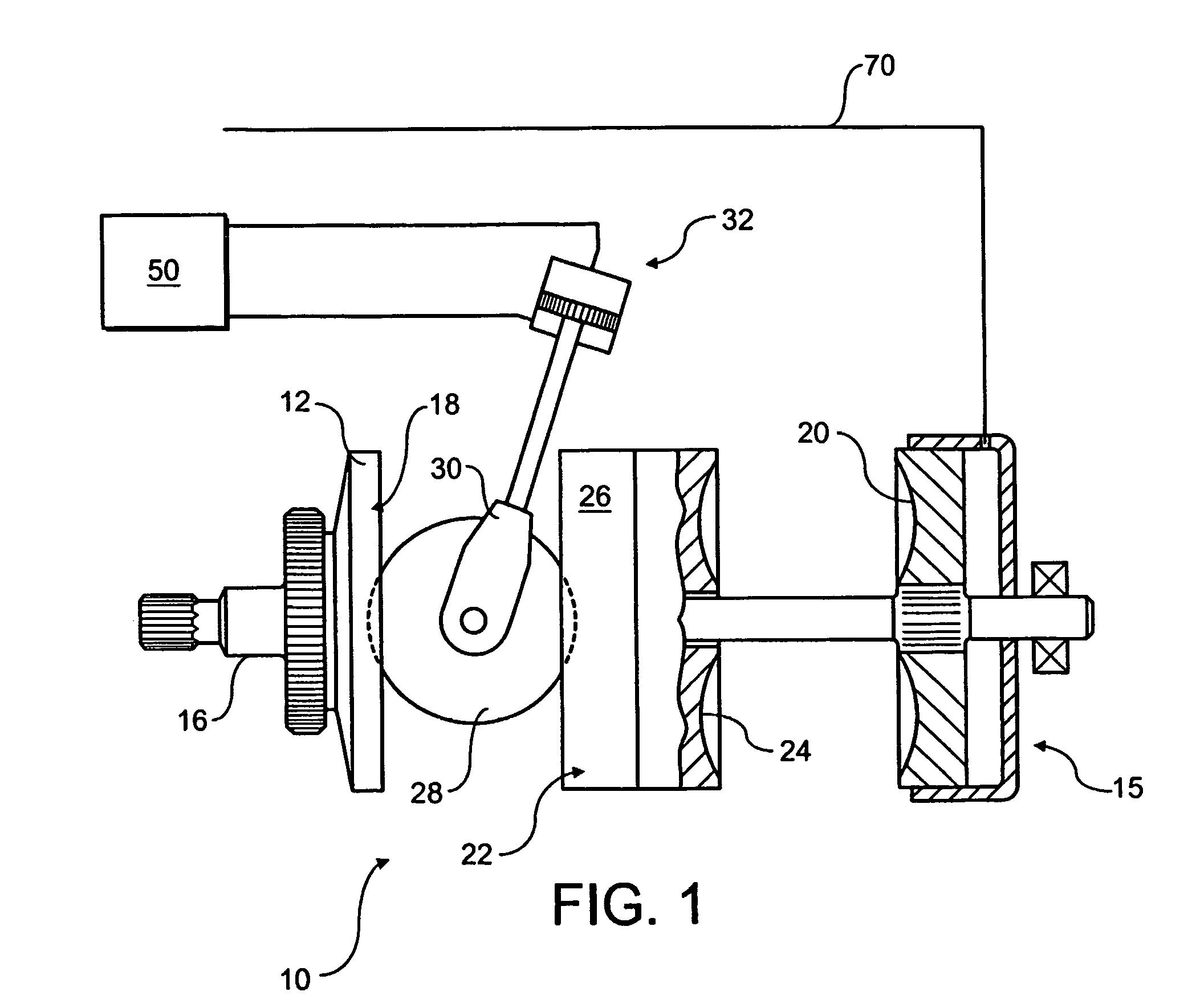

Continuously variable transmission and method of operation thereof

A continuously variable transmission is disclosed comprising a transmission input, a transmission output, and a continuously variable ratio unit (“variator”) arranged to be coupled between the transmission input (205) and output (240) by means of at least one clutch (230,250) thereby to enable transfer of drive between the input and the output at a continuously variable transmission ratio. The variator is connected to a hydraulic control circuit (50) and so subject to a hydraulic control pressure which is adjustable by the control circuit and is also influenced by changes in variator ratio. The variator is constructed and arranged such as to adjust its ratio to provide a variator reaction torque which corresponds to the control pressure. The transmission further comprising means (311,310) for adjusting the torque capacity of the clutch while it is engaged so that by controlling torque loading applied to the variator, the clutch influences the control pressure and the reaction torque.

Owner:ALLISON TRANSMISSION INC

F-69530 Brignais

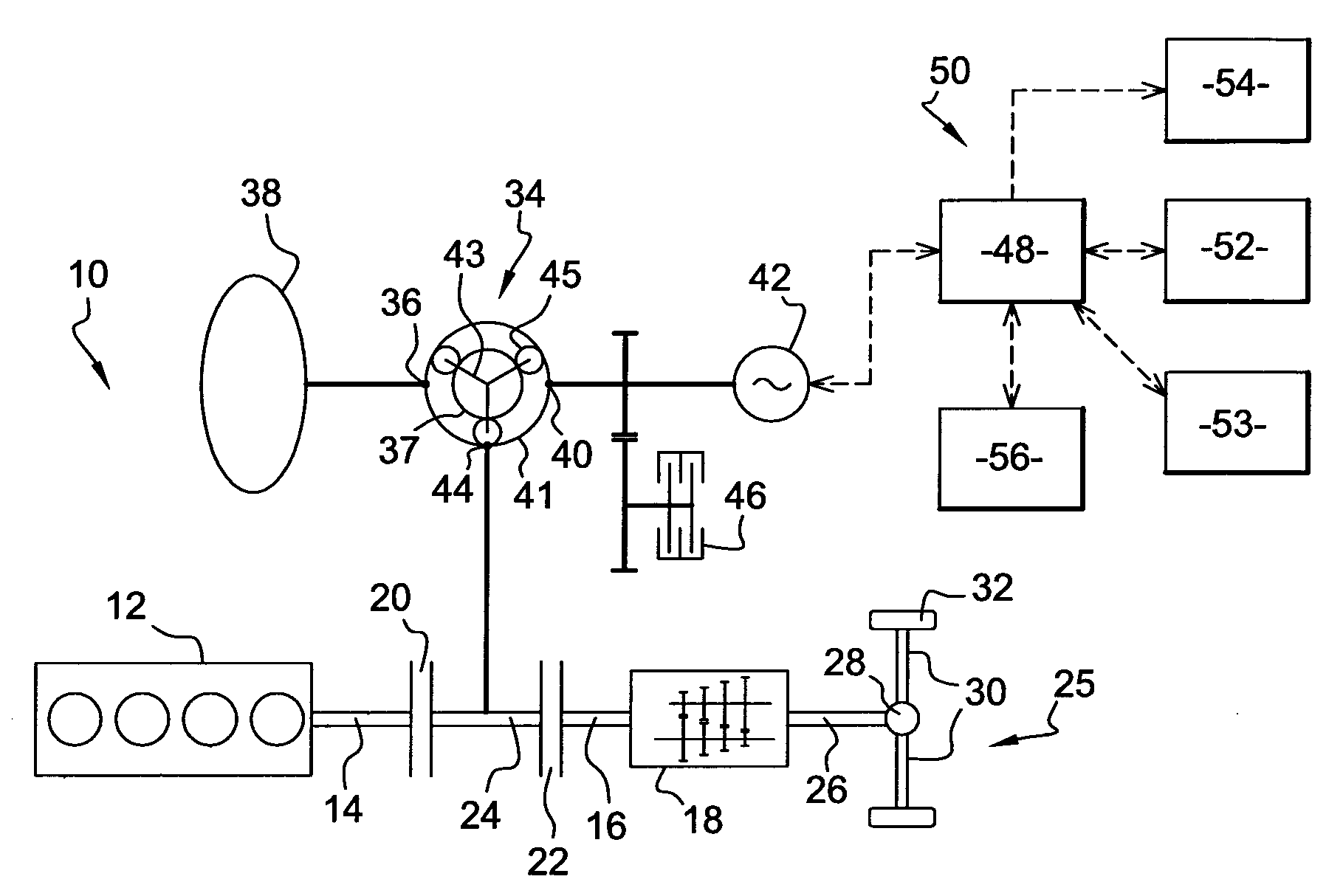

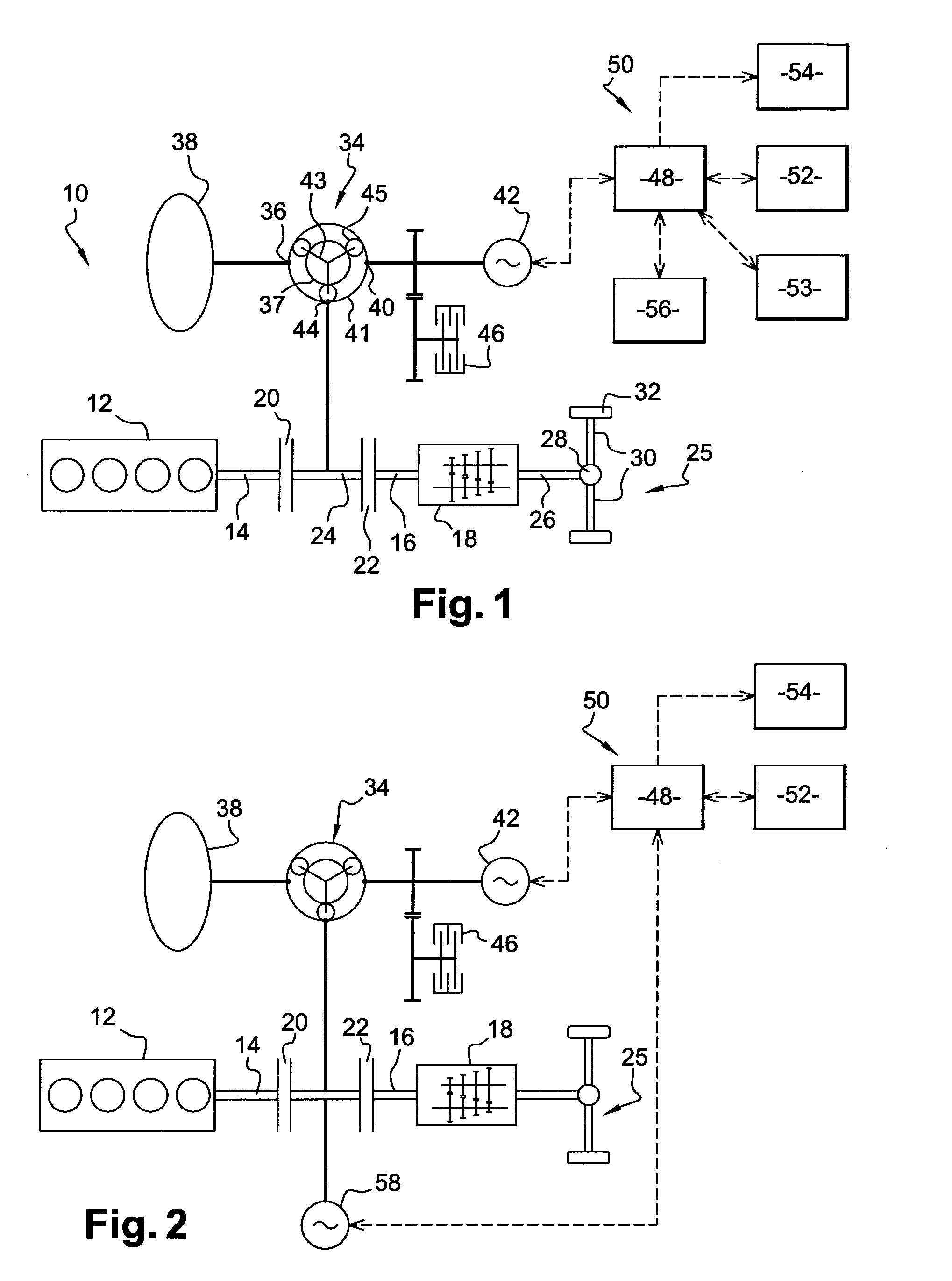

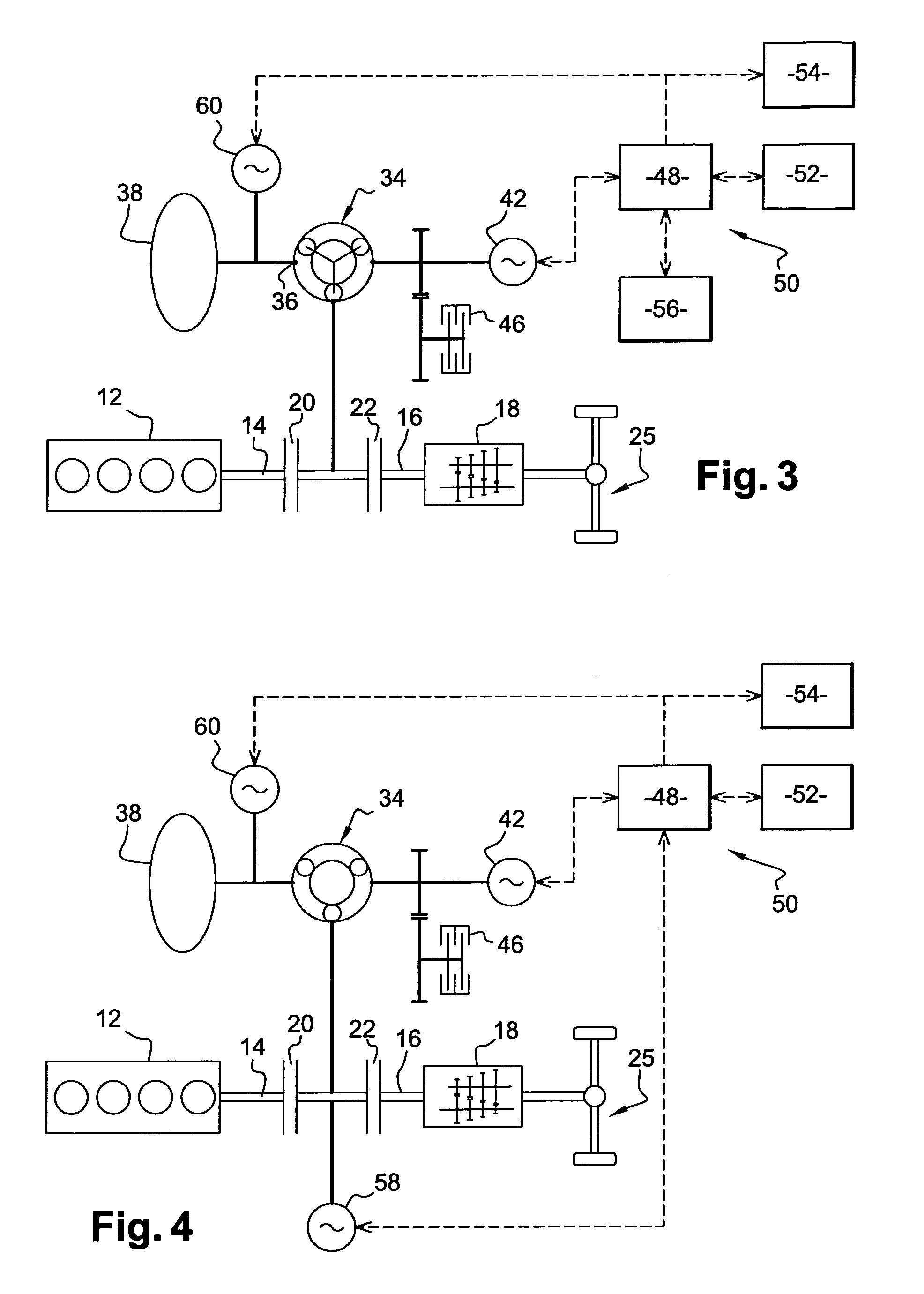

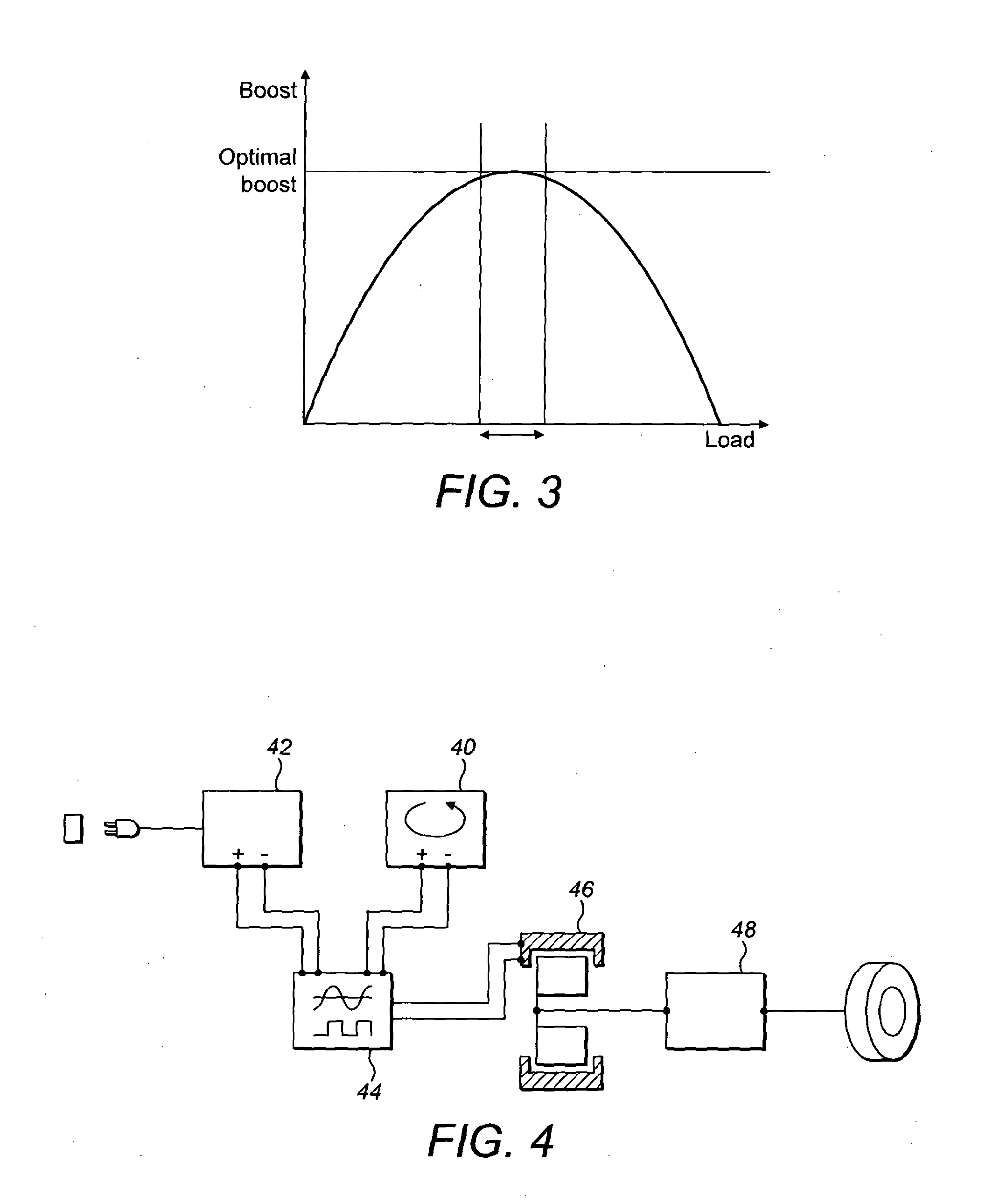

ActiveUS20100184549A1Easy to integrateReduce system sizePlural diverse prime-mover propulsion mountingPropulsion by batteries/cellsPower splitCoupling

A powertrain includes a variable ratio transmission device (having an input shaft coupled to an engine and an output shaft coupled to a driven unit, a three-way power split transmission device including three input / output couplings, a first of which is coupled to a flywheel and a second of which is coupled to an electrical machine. The third input / output coupling of the three way power split transmission device is mechanically coupled to the engine and to the input shaft of the variable ratio transmission device.

Owner:VOLVO LASTVAGNAR AB

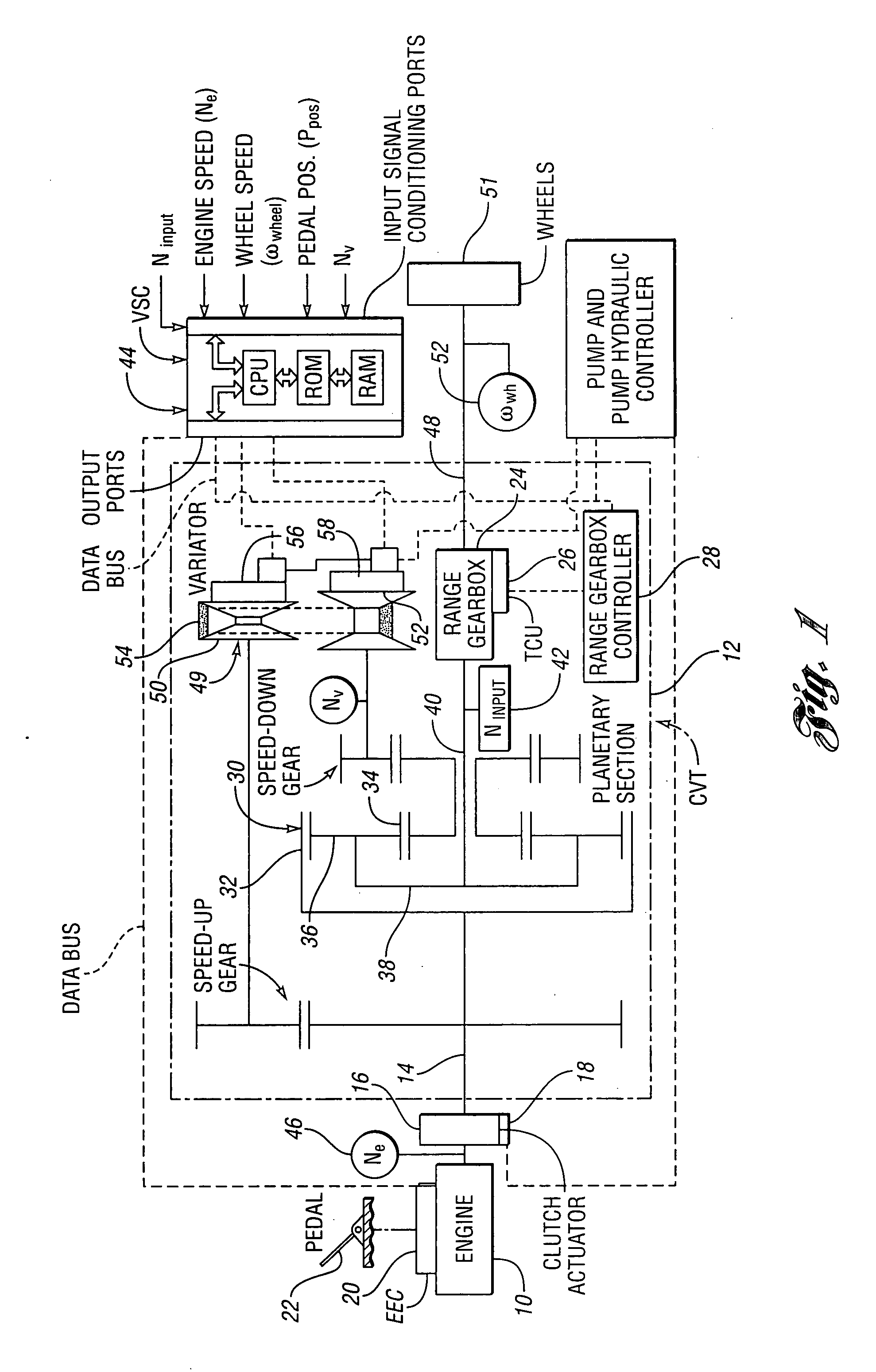

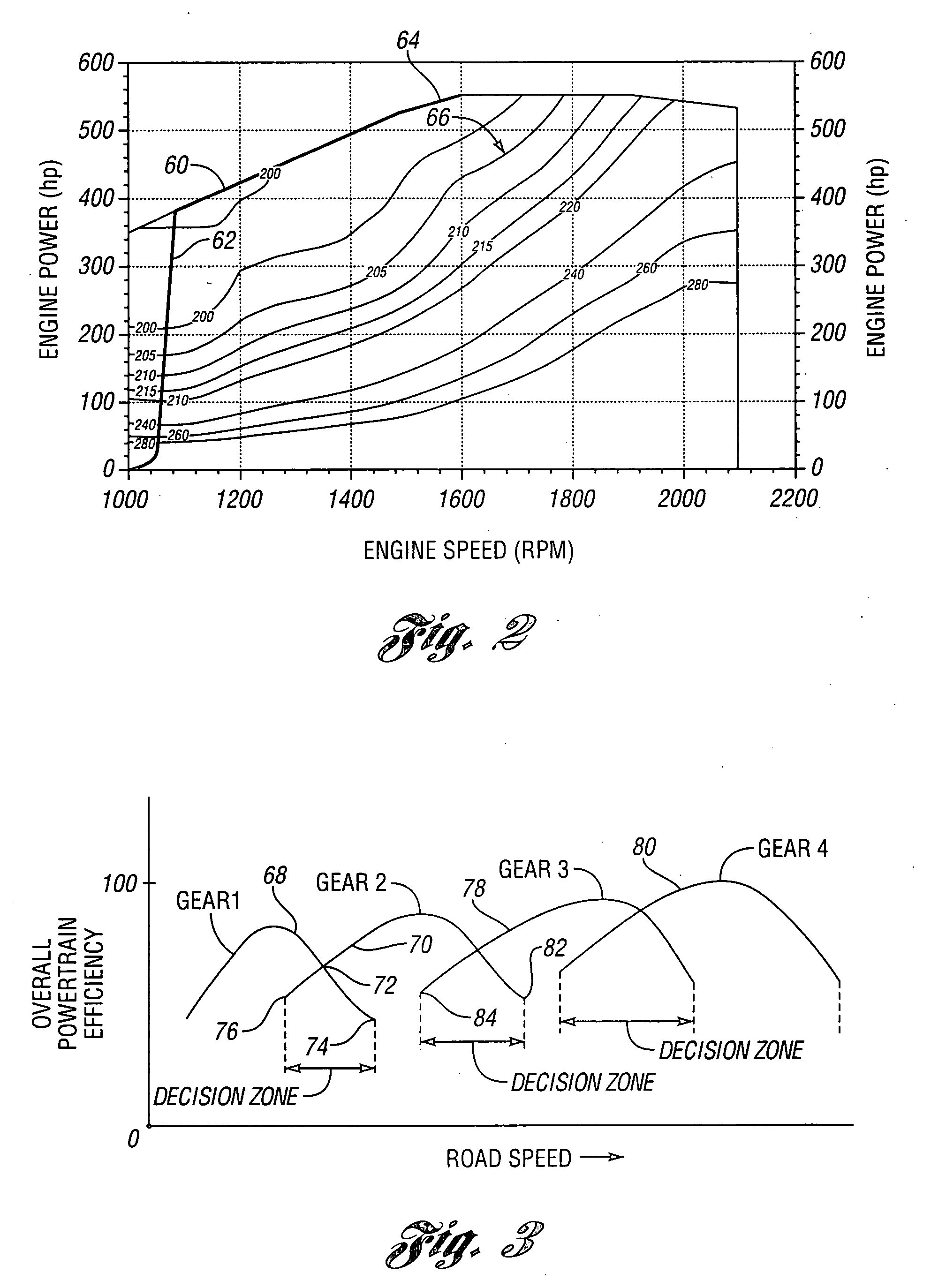

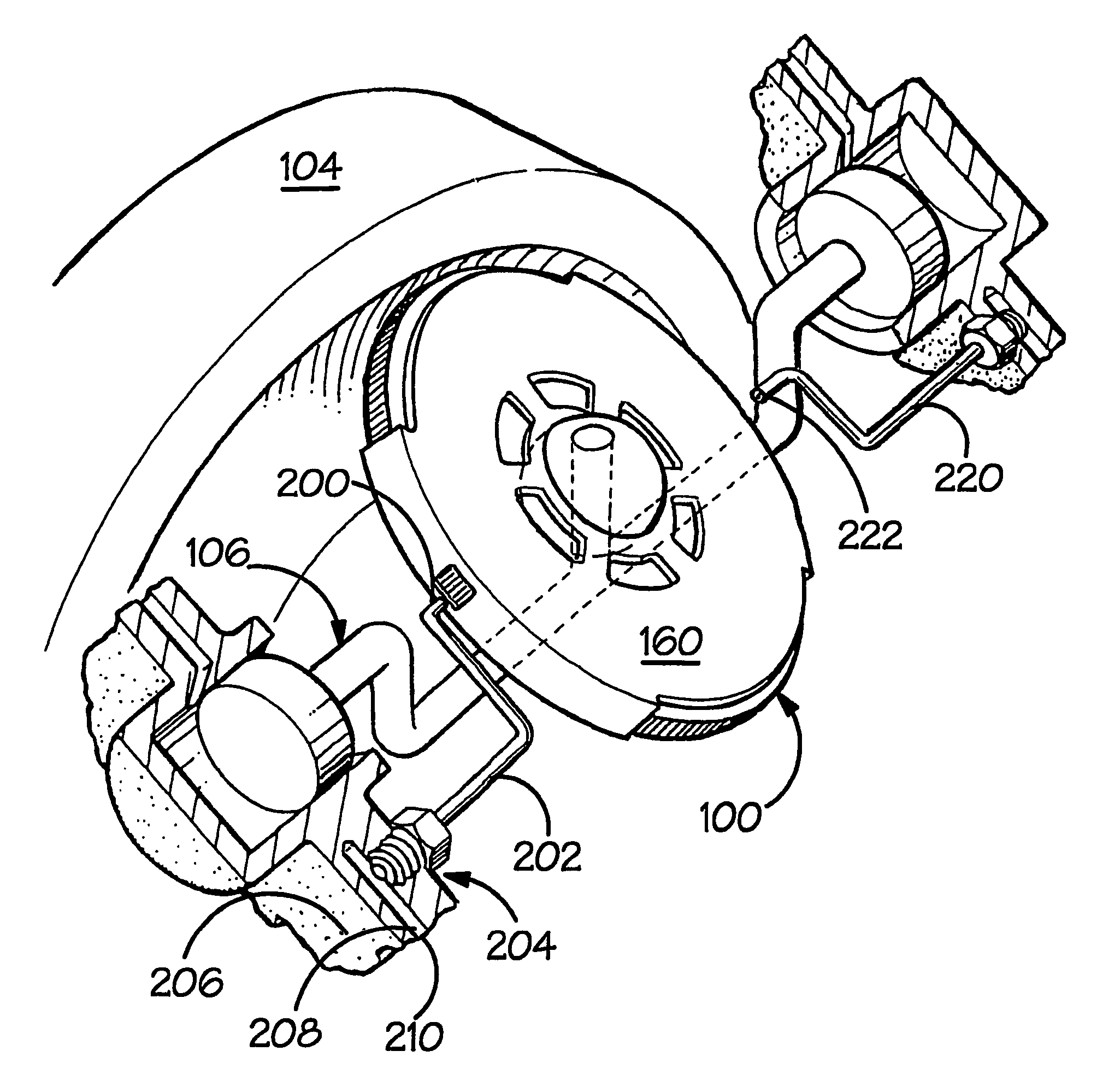

Method for controlling a vehicle powertrain having step ratio gearing and a continuously variable transmission to achieve optimum engine fuel economy

InactiveUS20090105041A1Ignores effectGuaranteed normal transmissionGearingRoad transportPowertrainMotor fuel

A method is disclosed for controlling overall transmission ratios in a vehicle powertrain with an engine, fixed multiple-ratio gearing and infinitely variable ratio components. For a given vehicle speed and for a given vehicle traction wheel horsepower, the fixed multiple-ratio gearing and the infinitely variable ratio components are controlled to operate with an overall ratio that will permit the engine to operate with optimum efficiency.

Owner:EATON INTELLIGENT POWER LIMITED

Fluid supply arrangement for a rolling-traction continuously variable ratio transmission unit

A fluid display arrangement is disclosed for a rolling-traction continuously-variable ratio transmission unit in which drive is transmitted from one race to another by at least one rotating roller whose outer circumference engages the races, the fluid supply arrangement comprising a shroud mounted in proximity to the roller and a fluid supply conduit, and being characterised in that the shroud has an inner surface providing a circumferential portion adjacent the roller's outer circumference and two radially extending portions adjacent respective flanks of the roller, a fluid receiving chamber being thereby defined between the roller and the shroud, and the fluid supply conduit being arranged to deliver fluid into the fluid receiving chamber.

Owner:ALLISON TRANSMISSION INC

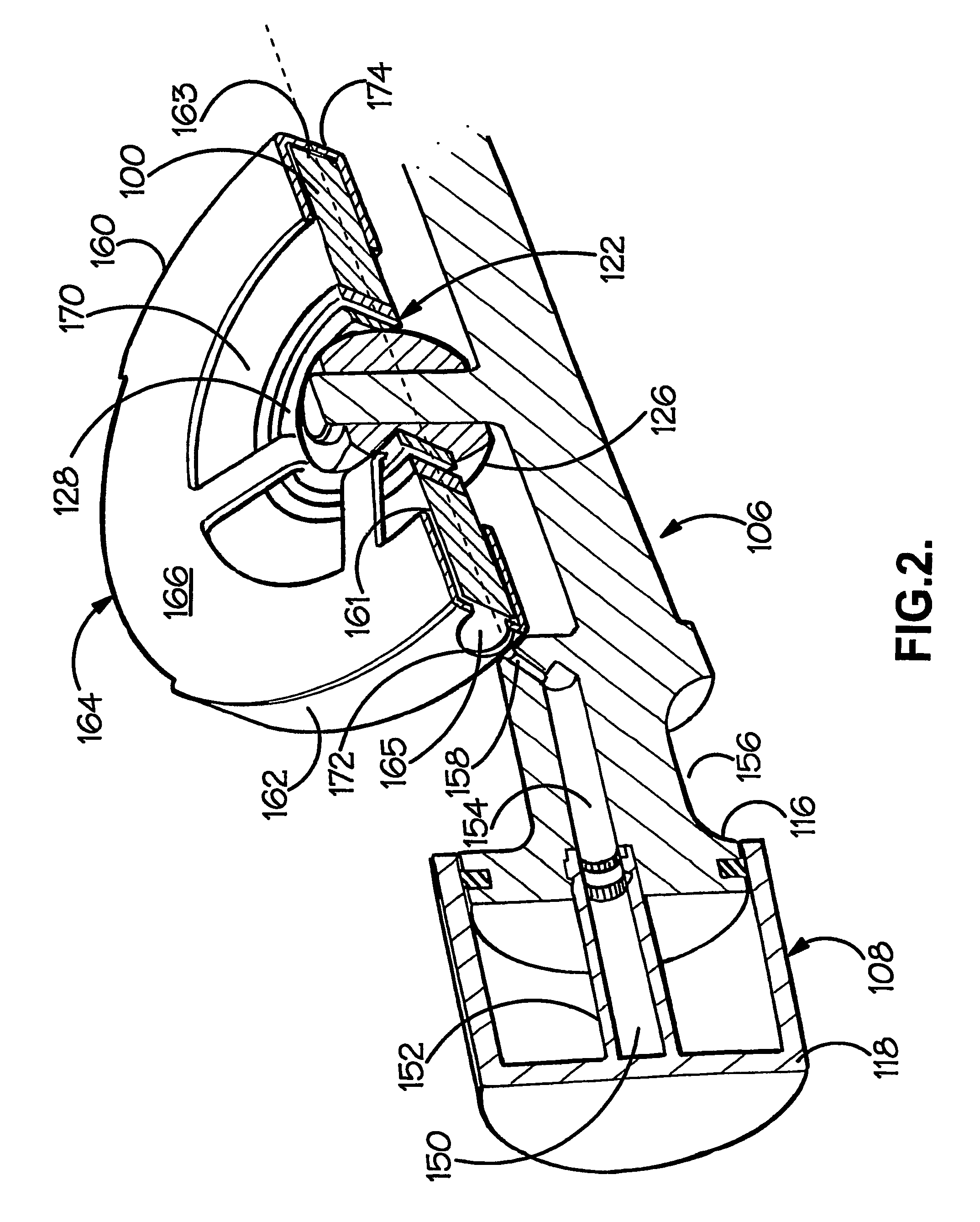

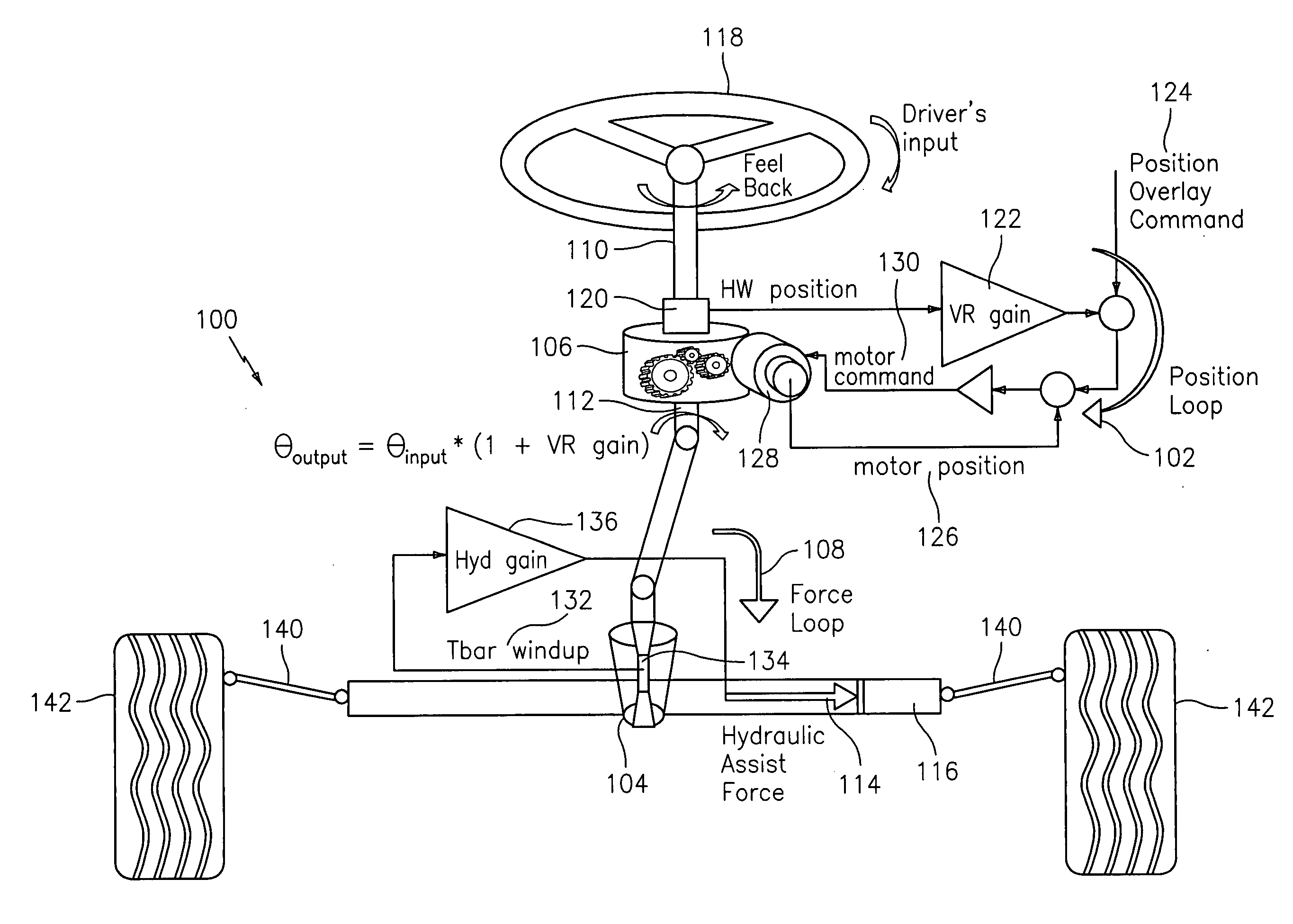

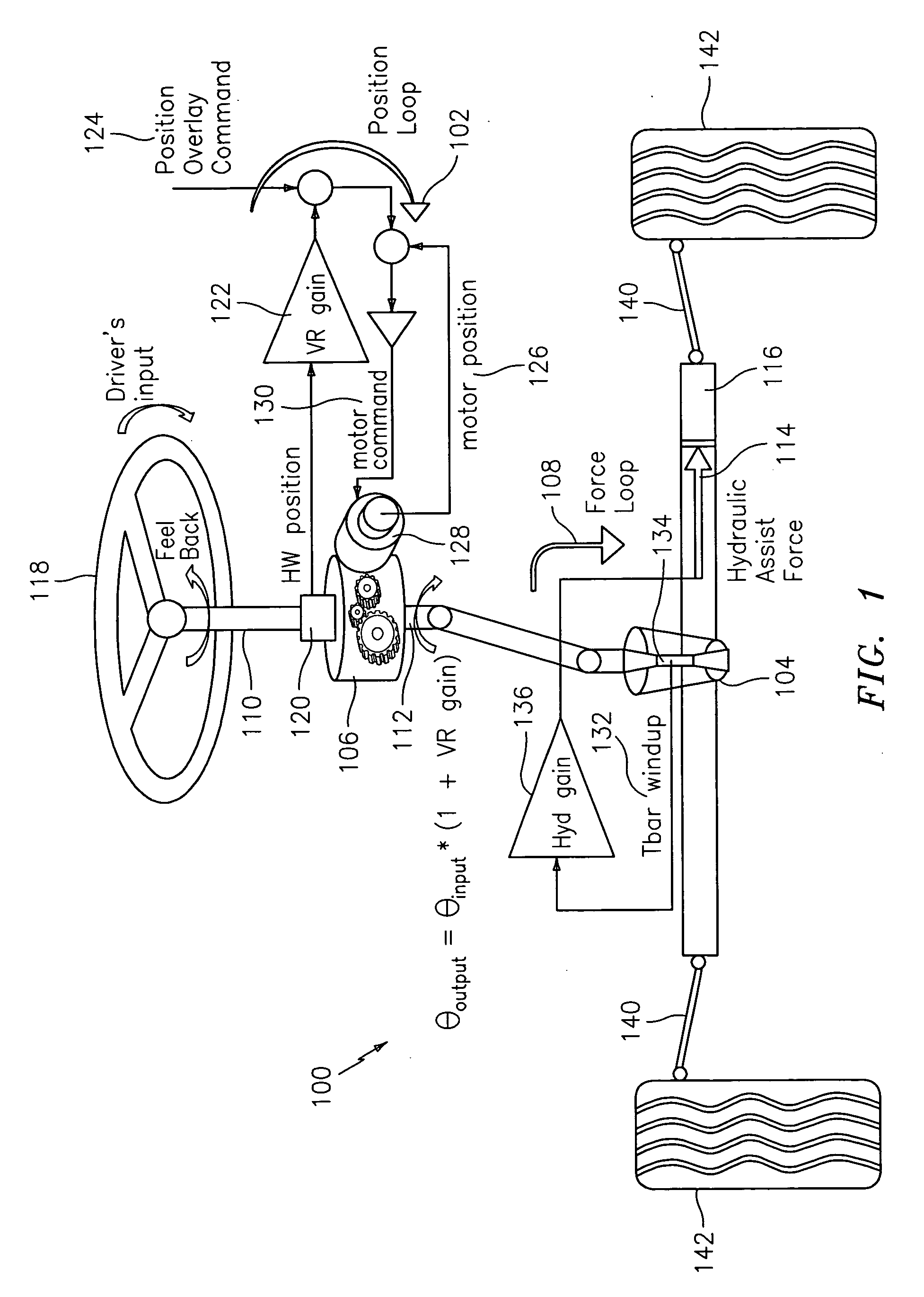

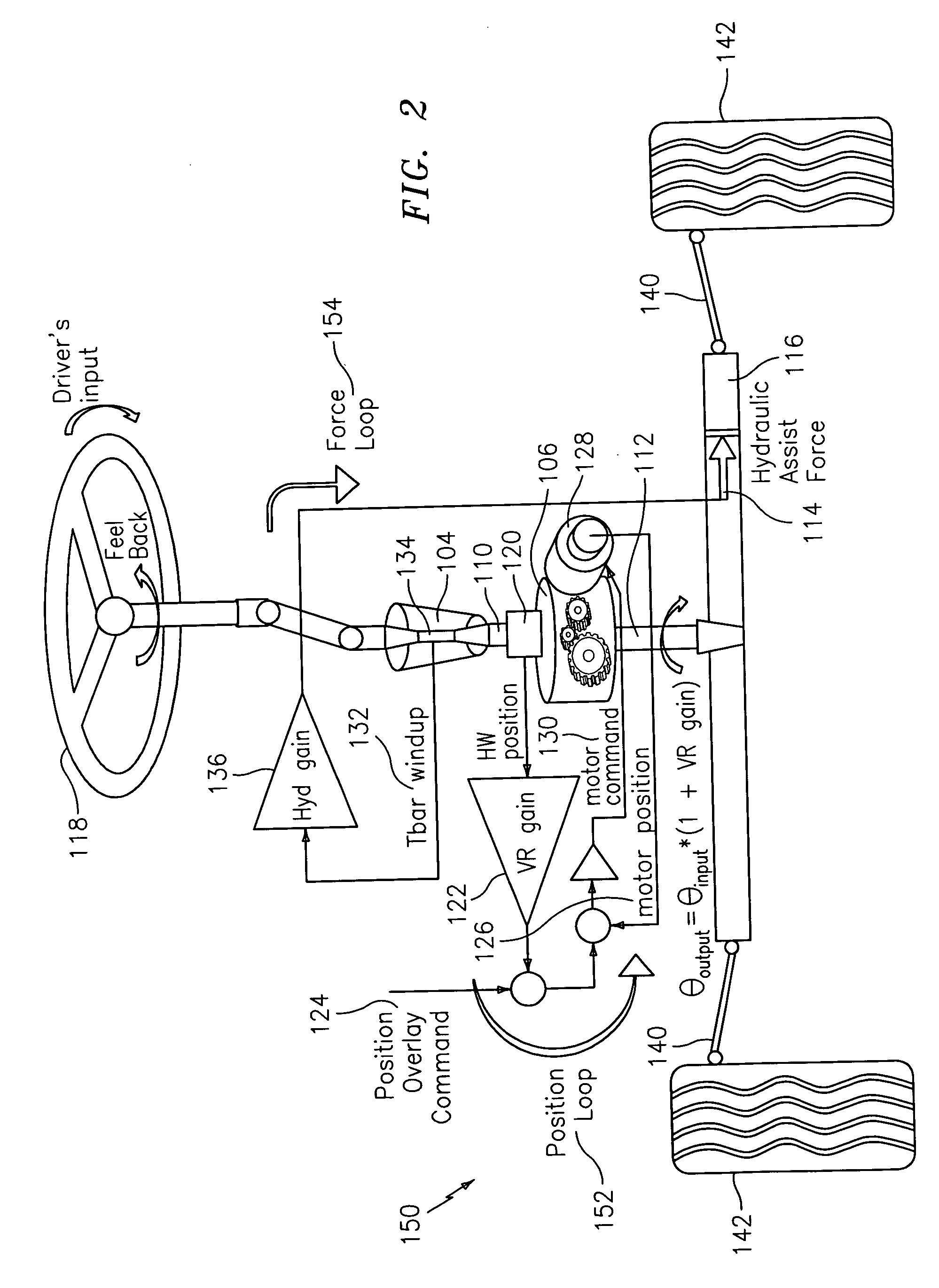

Force and position control for active front steering

A steering system with reduced coupling between a position overlay unit and a torque overlay unit may include a remote valve assembly for controlling a hydraulic assist force or an electric motor for providing torque overlay and electric assist to a rack of a rack and pinion steering system. In one embodiment, the position overlay unit may provide the assist force and the torque overlay unit may provide a motor command signal to the motor of a differential positioned on a steering shaft. In another embodiment, the position overlay unit may provide the motor command signal and the torque overlay unit may provide the assist force. In either embodiment, the position overlay unit may include variable ratio gain that uses a position signal to output a variable ratio command.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

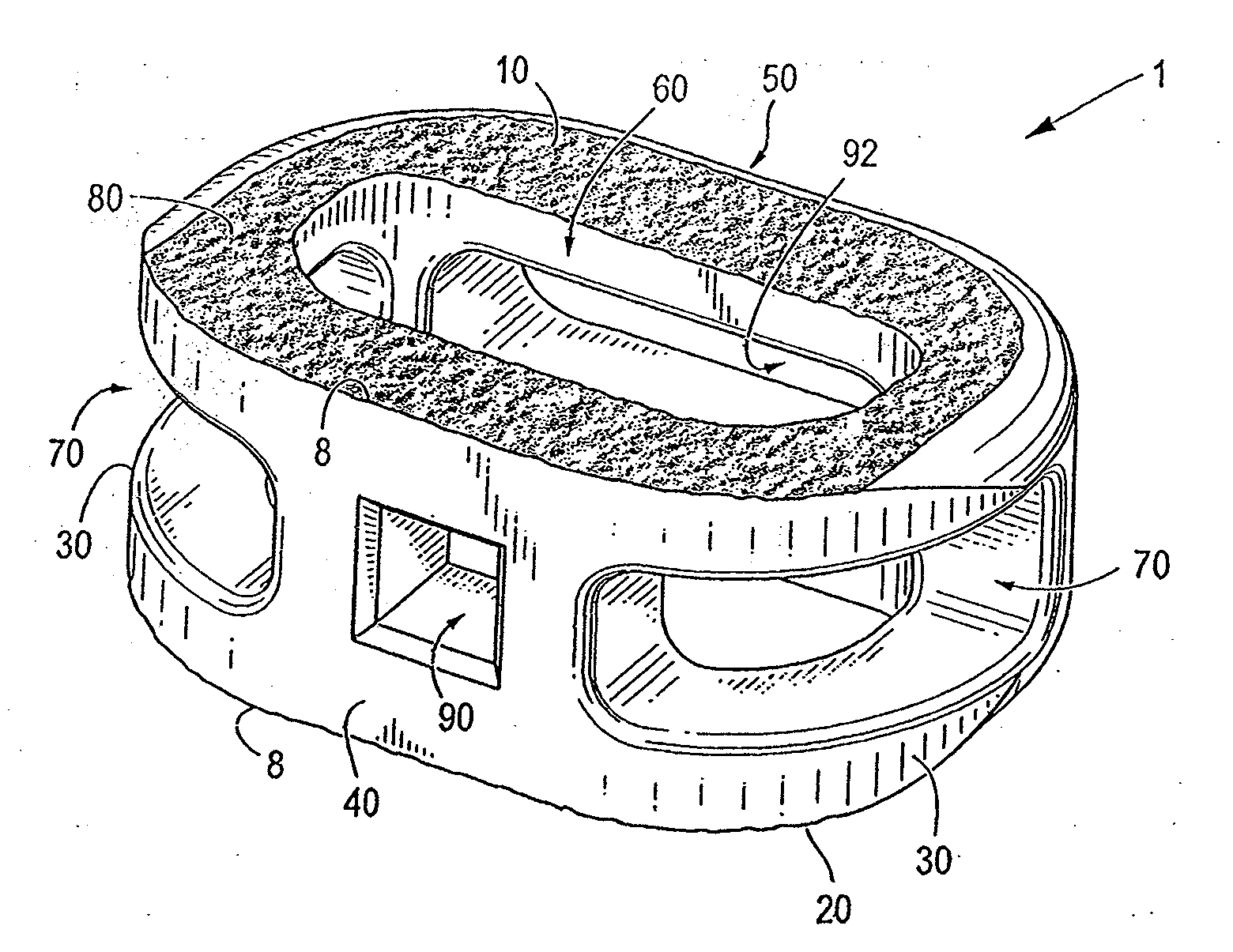

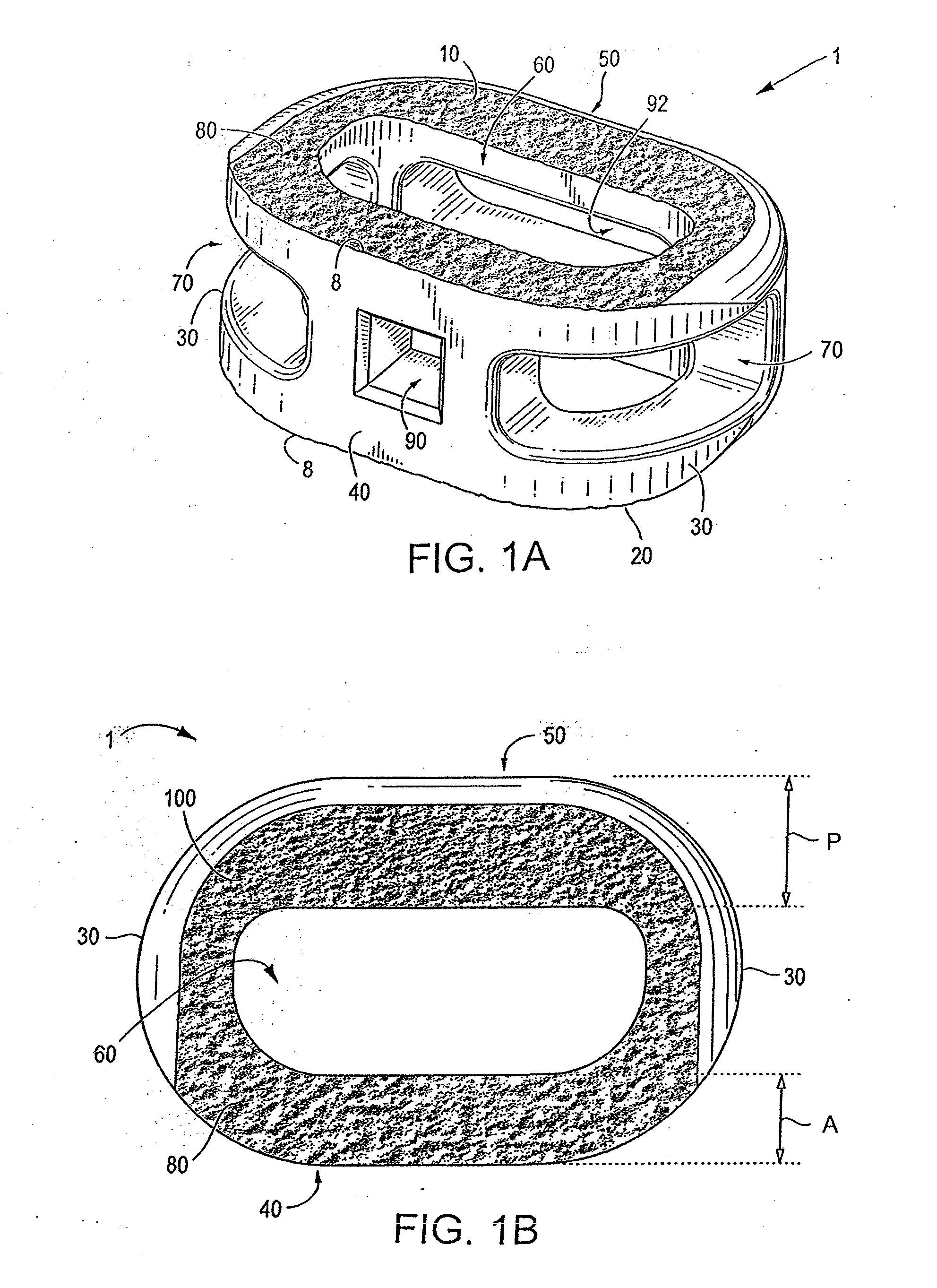

Spinal implant having variable ratios of the integration surface area to the axial passage area

An interbody spinal implant including a body having a top surface, a bottom surface, opposing lateral sides, opposing anterior and posterior portions, and a substantially hollow center in communication with a vertical aperture. The body, vertical aperture, and bone contact surfaces of the implant each have a surface area that may be independently varied to enhance load support and facilitate implant integration with vertebral bone.

Owner:TITAN SPINE

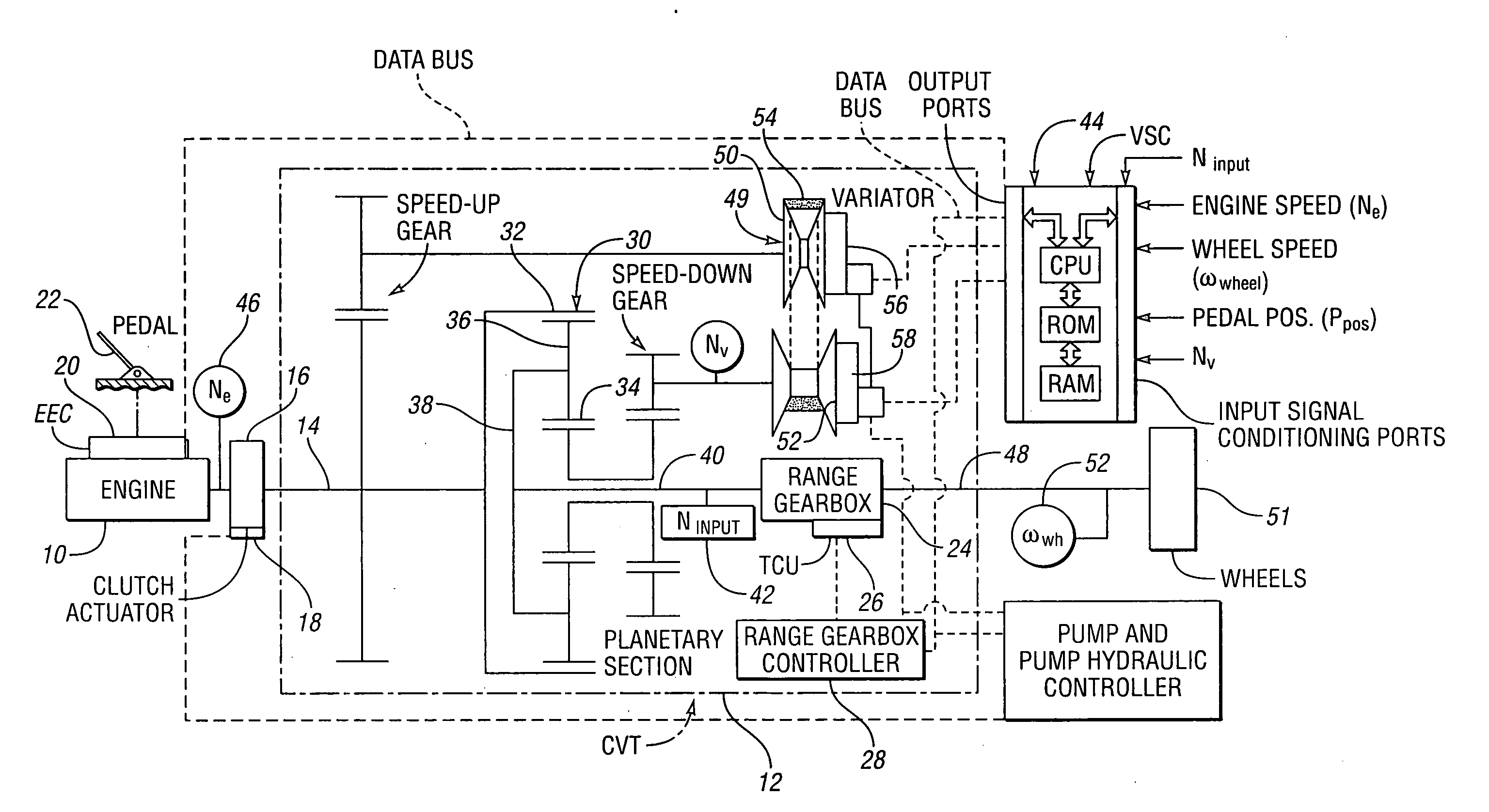

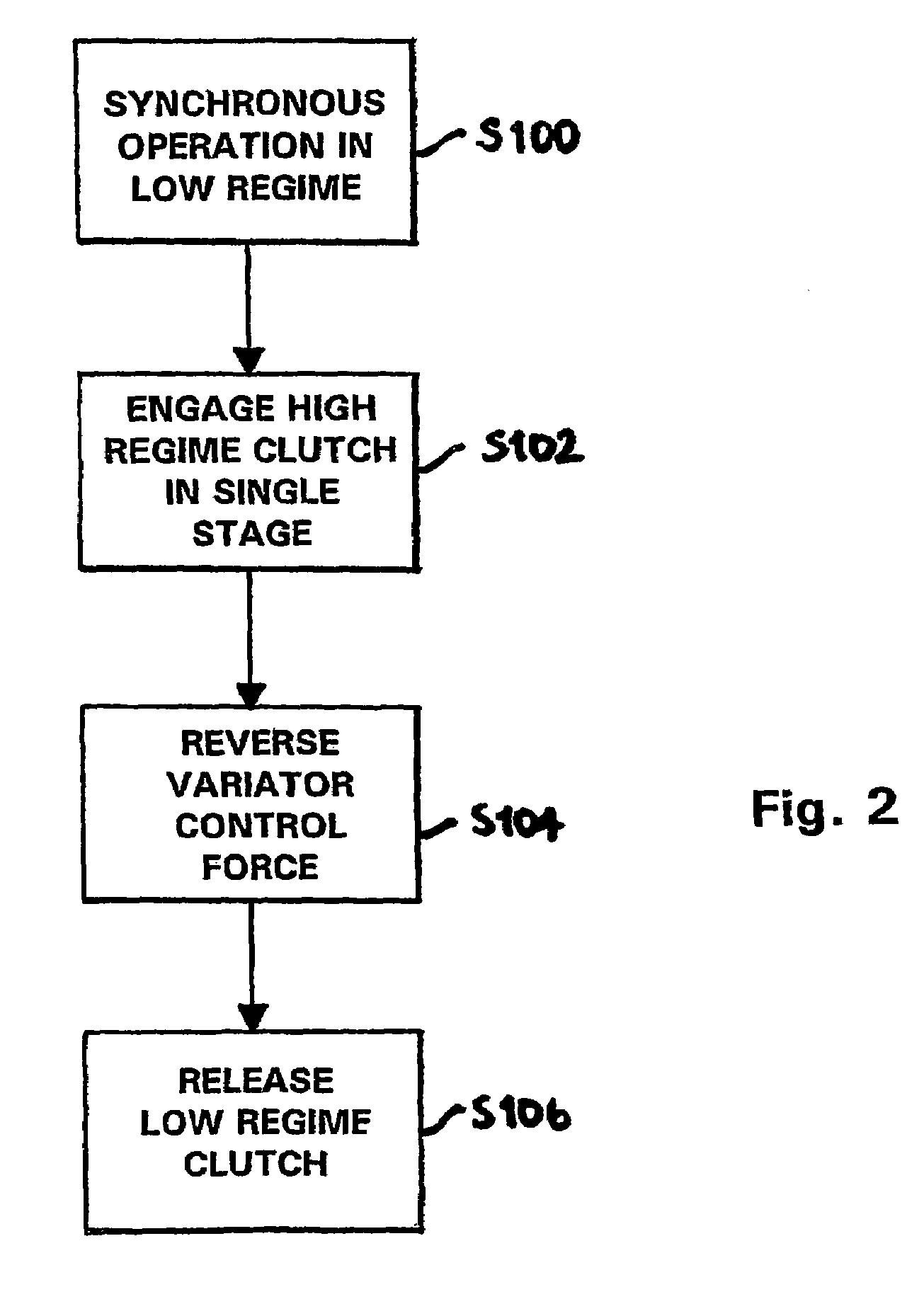

Control system and method for a continuously variable transmission

InactiveUS6979276B2Shorten the timeSacrificing control robustnessMechanical actuated clutchesGearingGear driveSingle stage

A control system for a multi-regime continuously variable ratio transmission system. The system has input and output shafts and a continuously variable ratio transmission unit (“variator”) connected to the input shaft. Also included is a mixing epicyclic gear train with a first input gear coupled to the input shaft, a second input gear connected to the variator output and an output gear driving an output shaft. Fluid-pressure actuated clutches engage the outputs and ratio combinations to operate the CVT in a number of regimes. The control system includes means for engaging the clutch of a new regime, retaining both clutches engaged in a synchronous mode and disengaging the clutch of the old regime. The control system also has means for applying fluid pressure to engage the new regime clutch in a single stage at the maximum available clutch engaging fluid pressure.

Owner:ALLISON TRANSMISSION INC

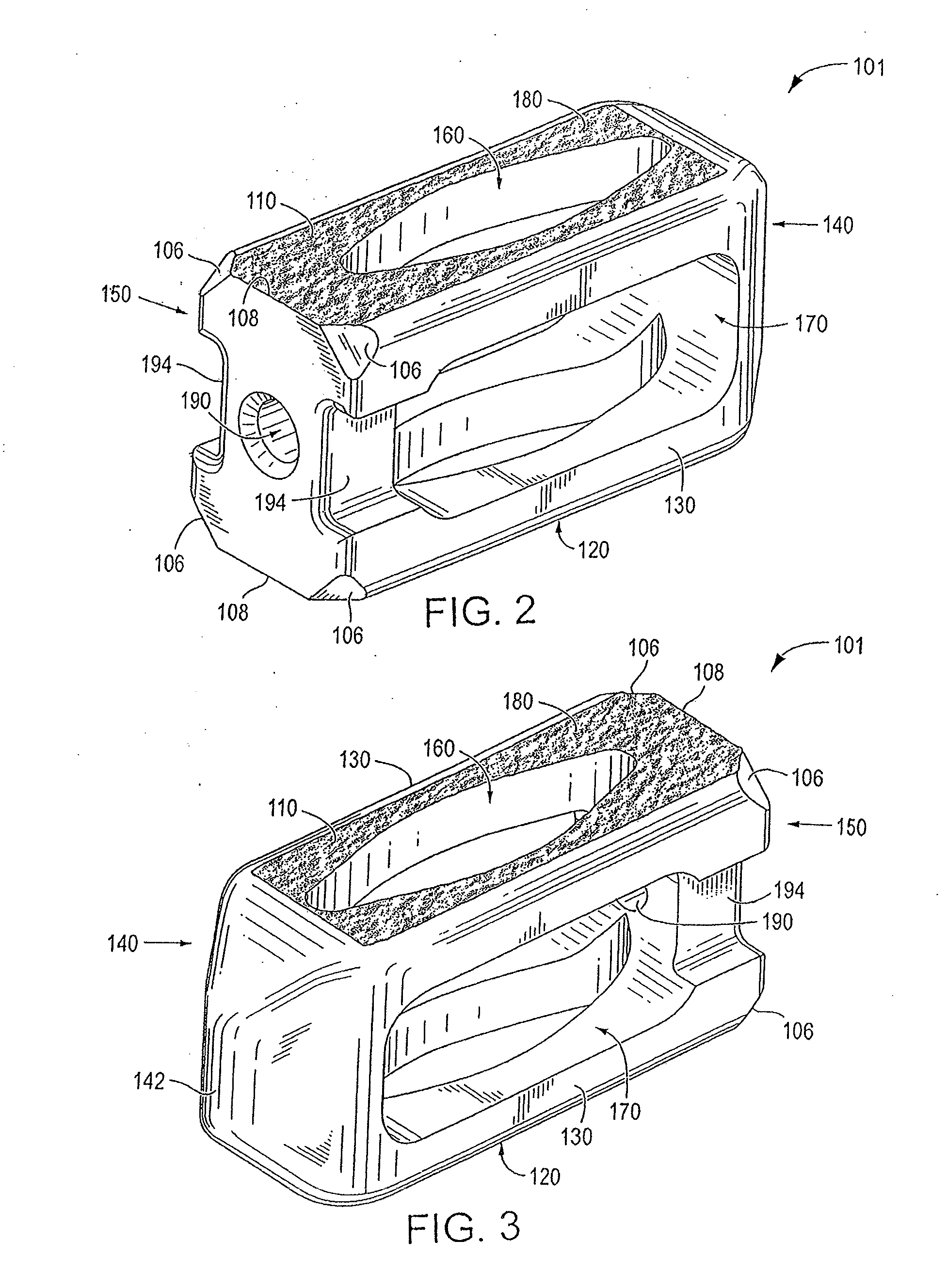

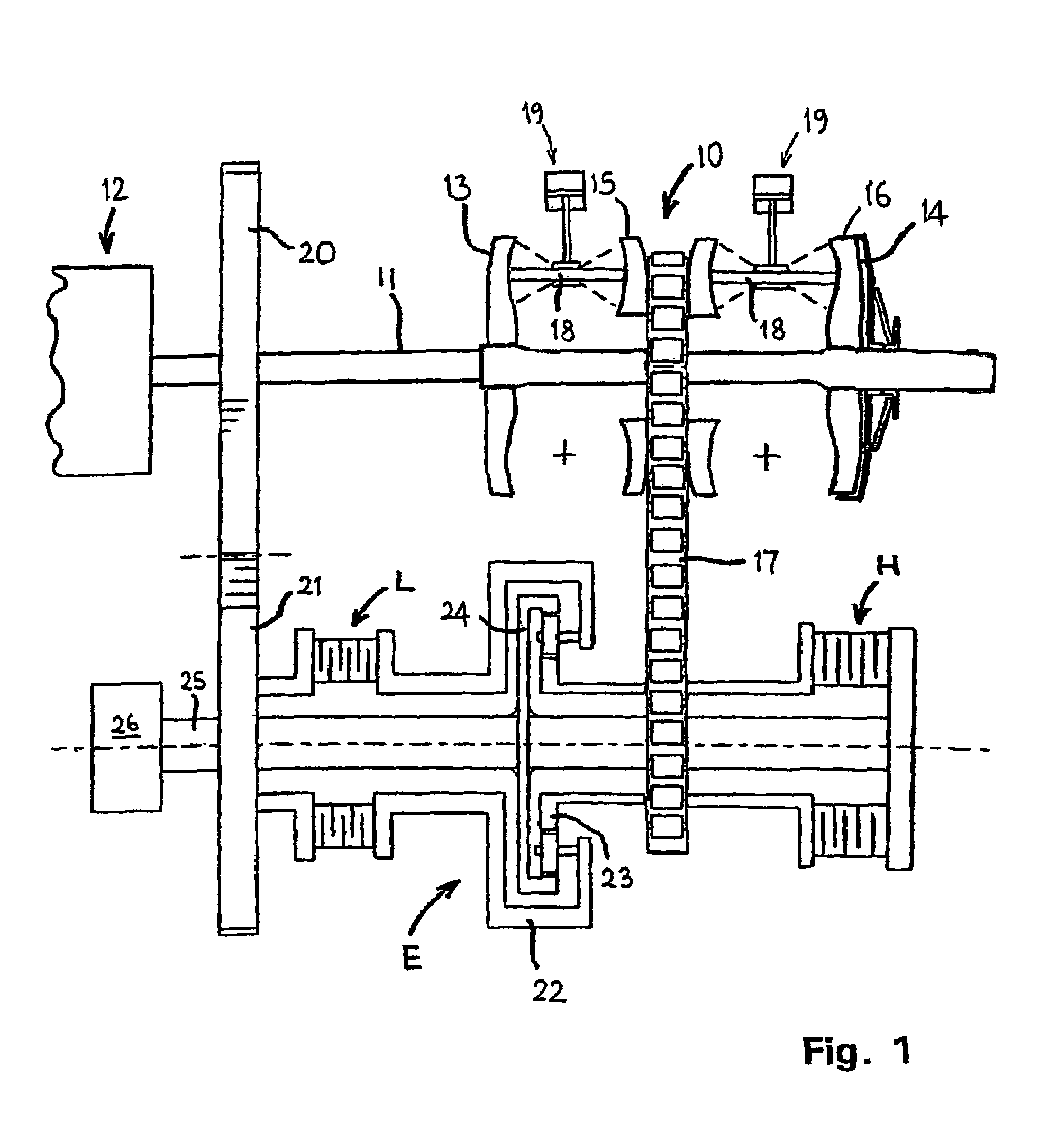

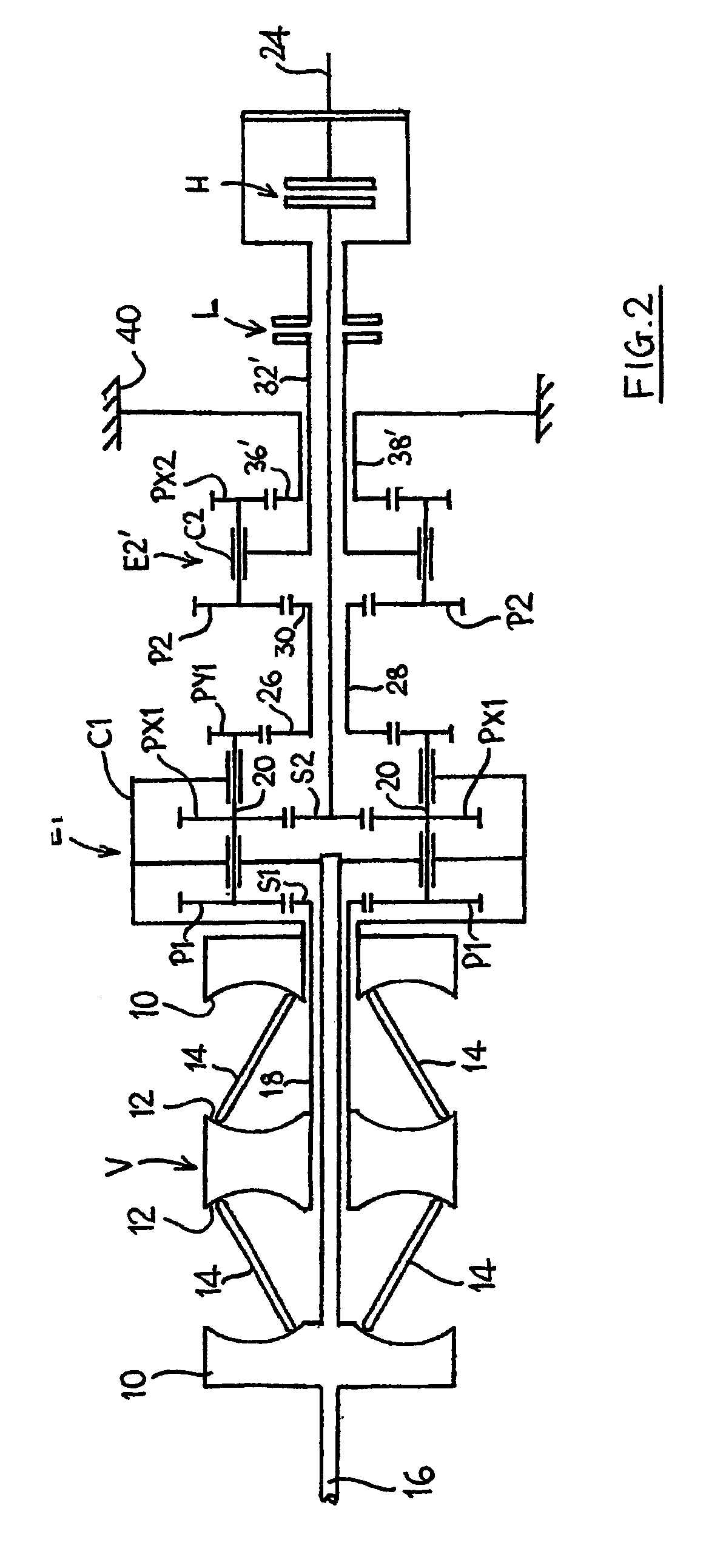

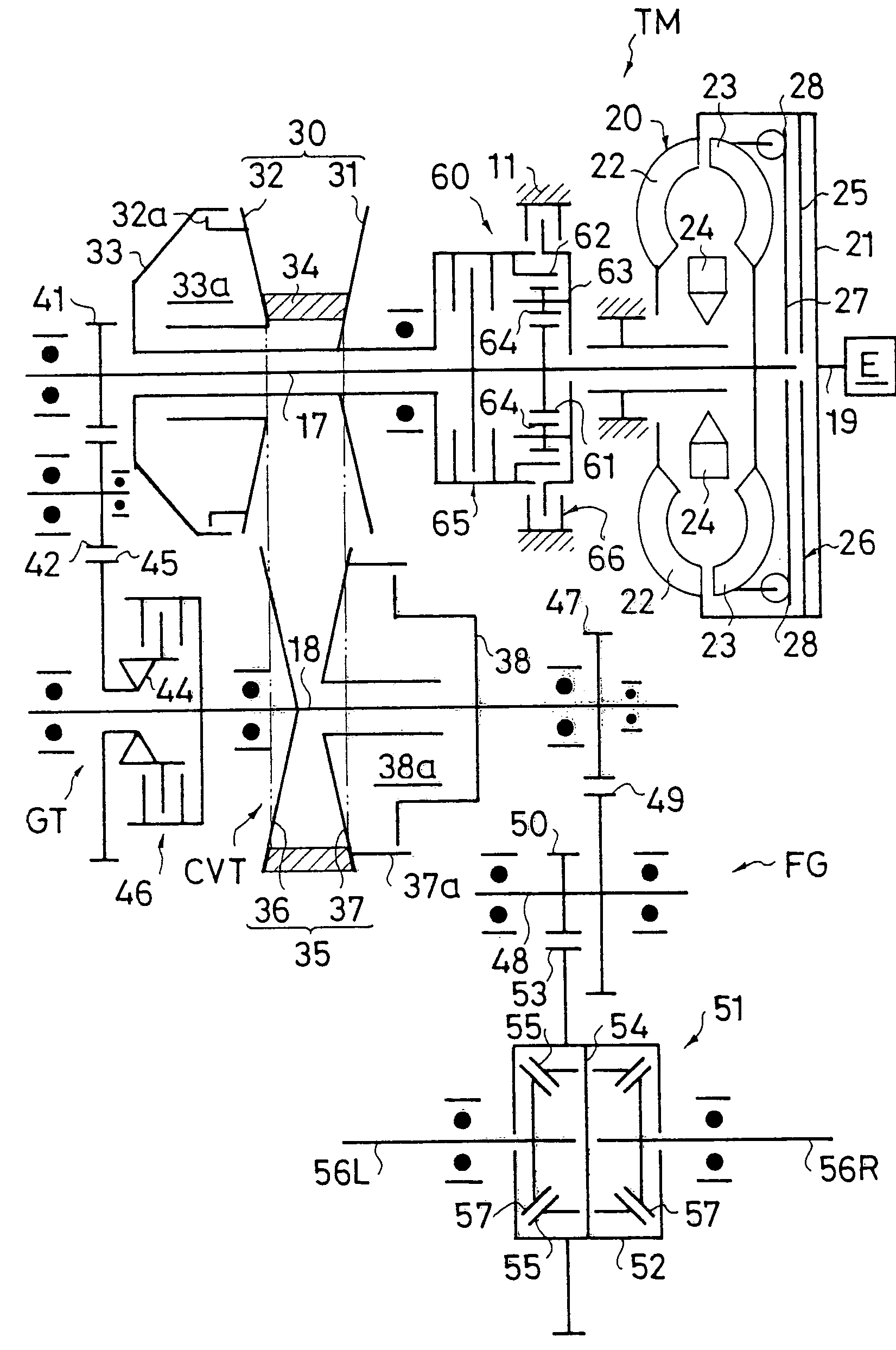

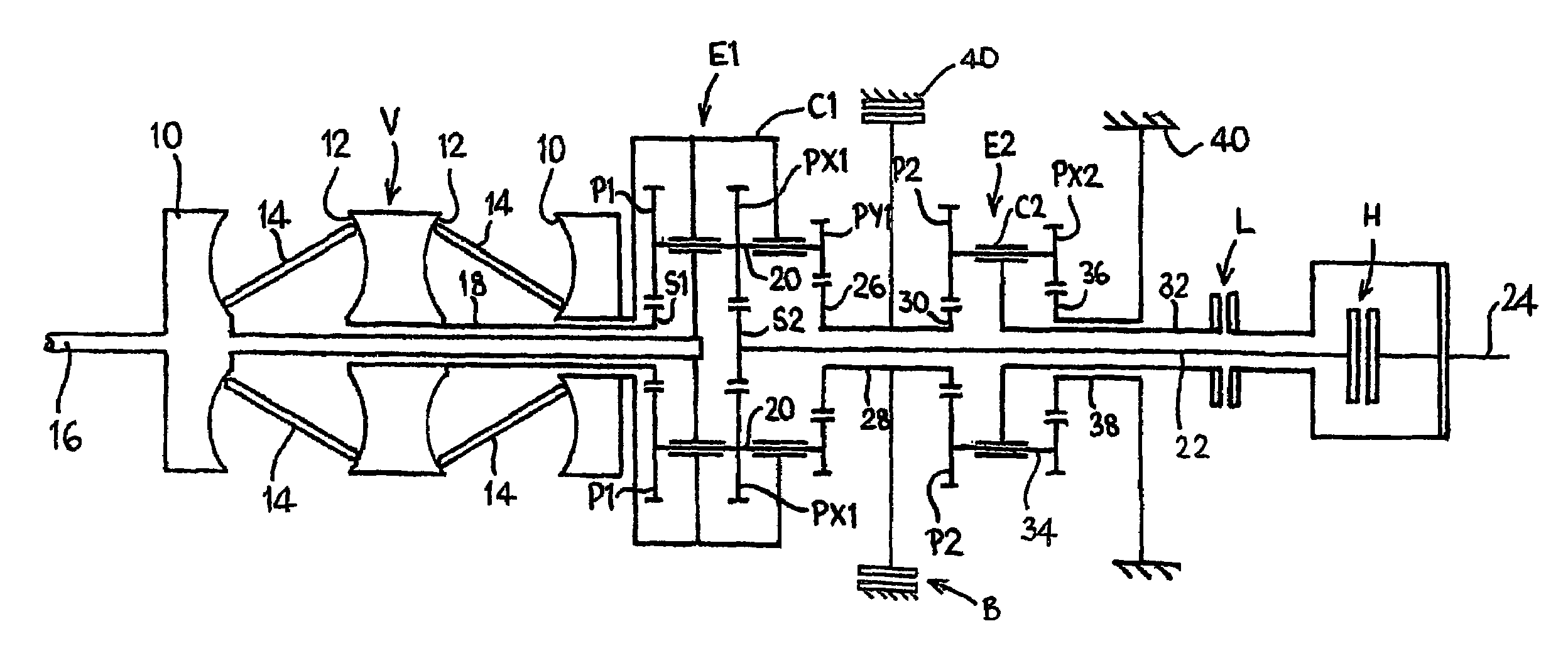

Continuously variable ratio transmission system

A multi-regime continuously variable ratio transmission system has coaxial system input and output shafts (16, 24), a continously variable ratio transmission unit (V) connected coaxially to the system input shaft (16) and having a coaxial variator output shaft (18) and a mixing epicyclic gear train (E1) having an input sun gear (S1) drivably connected to the variator ouput shaft (18), a planet carrier (C1) drivably connected to the system input shaft (16) and a planet gear (P1) mounted on the planet carrier ((C1). The planet gear (P1) drives a first intermediate output shaft (22) arranged coaxially with the system input shaft (16) and selectively connectable to the system output shaft via a first clutch (H) in high-regime operation of the transmission. The planet gear (P1) also provides the input for a second epicyclic gear train (E2) having an output (C2) which is selectively connectable to the system output shaft via a braking element (L) for low-regime operation of the transmission. The arrangement minimises the number of gear meshes, thereby minimising transmission losses and the absence of an annulus in the mixing epicyclic gear train (E1) allows more freedom in the choice of gear sizes, thereby permitting reduced gear speeds.

Owner:TOROTRAK (DEV) LTD

Continuously variable ratio transmission

InactiveUS20060205553A1Improve the level ofLow mechanical efficiencyEngine fuctionsToothed gearingsPower flowEngineering

Owner:LEE PAUL Z

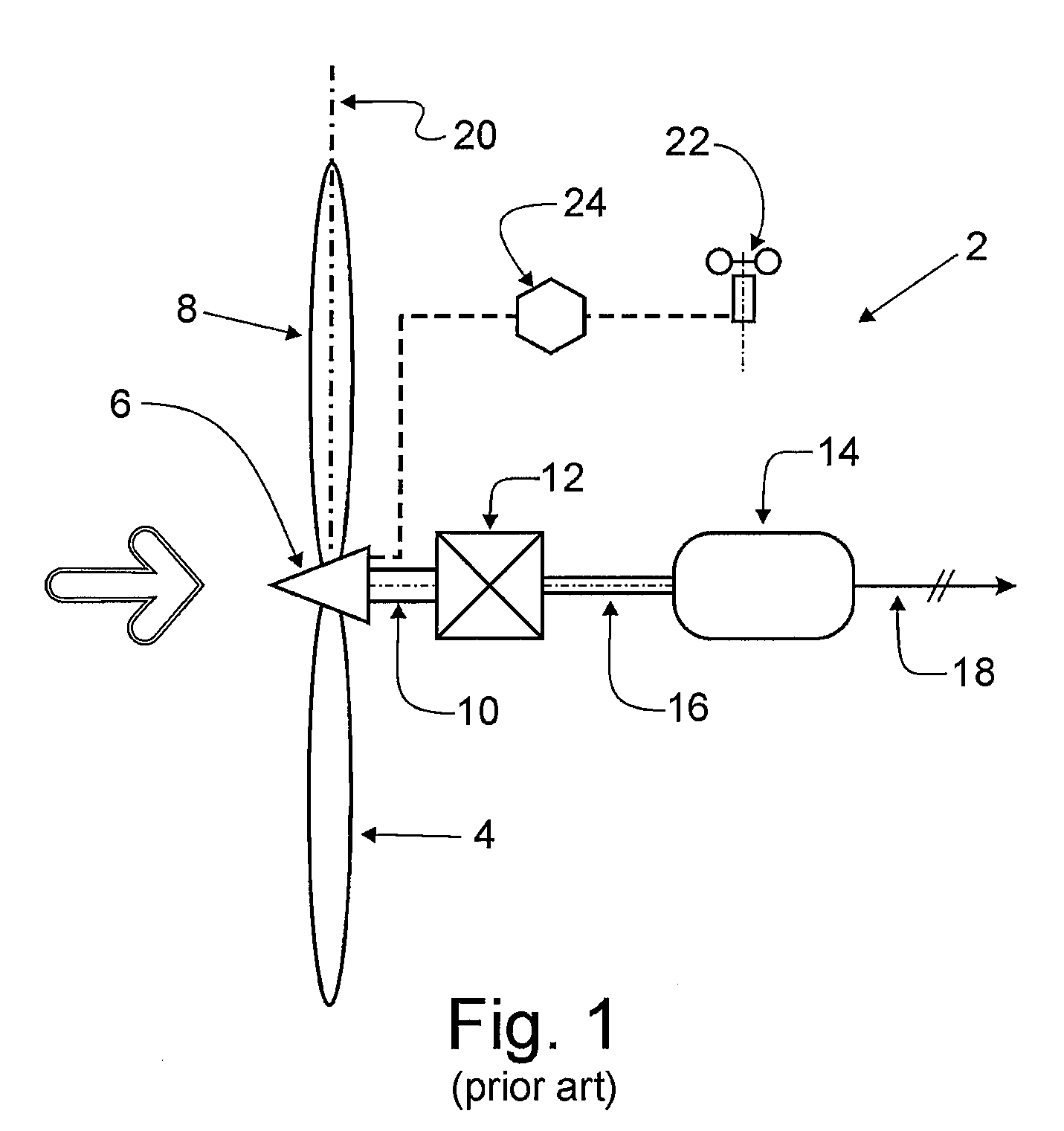

Variable speed wind turbine having a constant speed generator

InactiveUS20100230966A1Limit rotor speedEngine fuctionsWind motor combinationsVariable speed wind turbineMoment of inertia

A variable speed wind turbine including a variable speed rotor, a large constant speed generator, and a small variable speed generator is characterized by a three-shaft variable ratio gearbox connecting the shaft of the rotor with the two generator shafts. The variable ratio gearbox is an epicyclic gearbox which enables the combination of the high performance of a variable speed rotor with the low cost of a large constant speed generator. The torque of the small variable speed generator controls the rotor speed. Variable frequency power conditioning cost is less than that of a prior art variable speed wind turbine, reduced by the ratio of the rated capacity of the small generator to total rated capacity. Also, the small generator enables efficient low wind velocity energy capture. The low rotational inertia of the small variable speed generator further reduces drive train dynamic stress.

Owner:PAVLAK ALEXANDER J

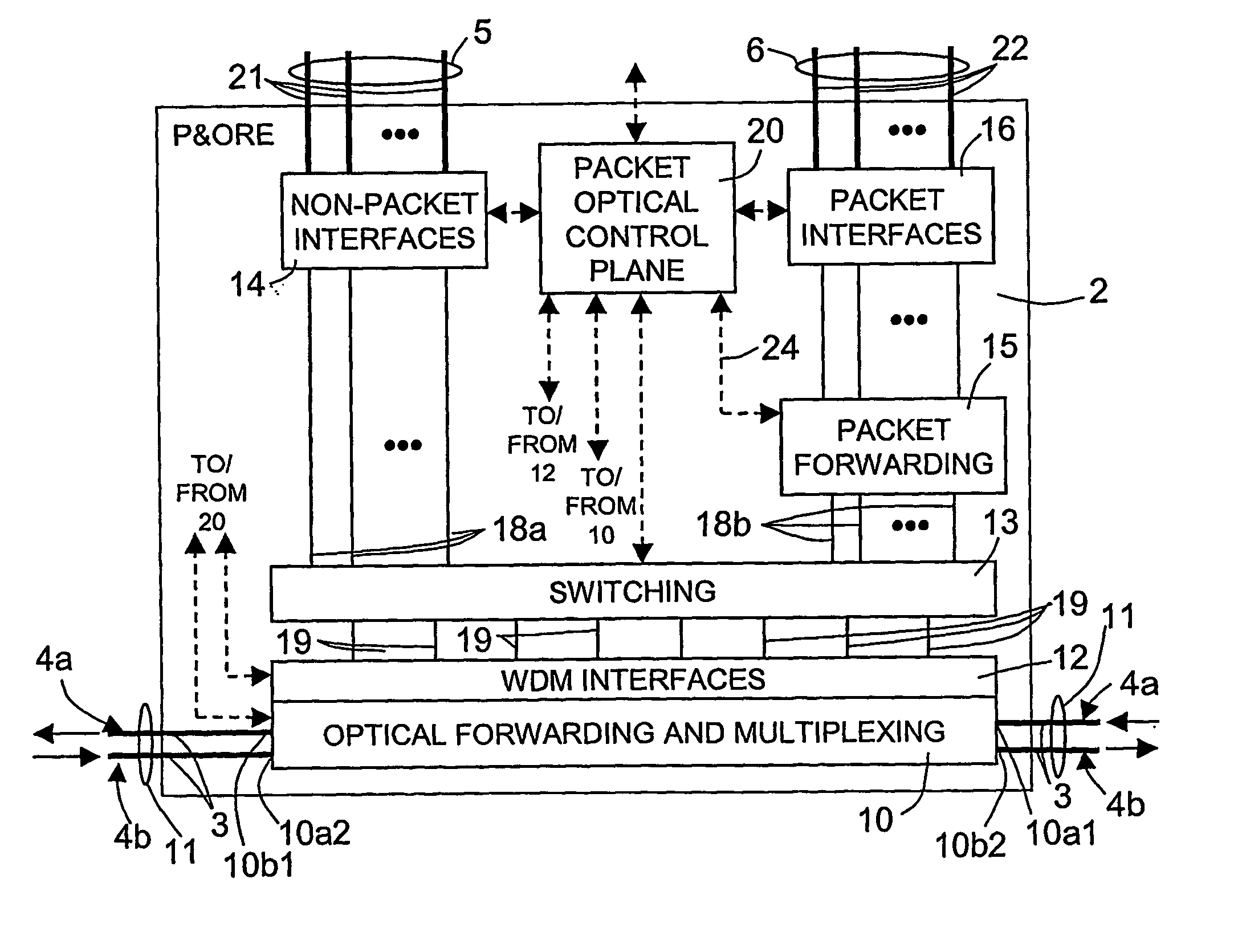

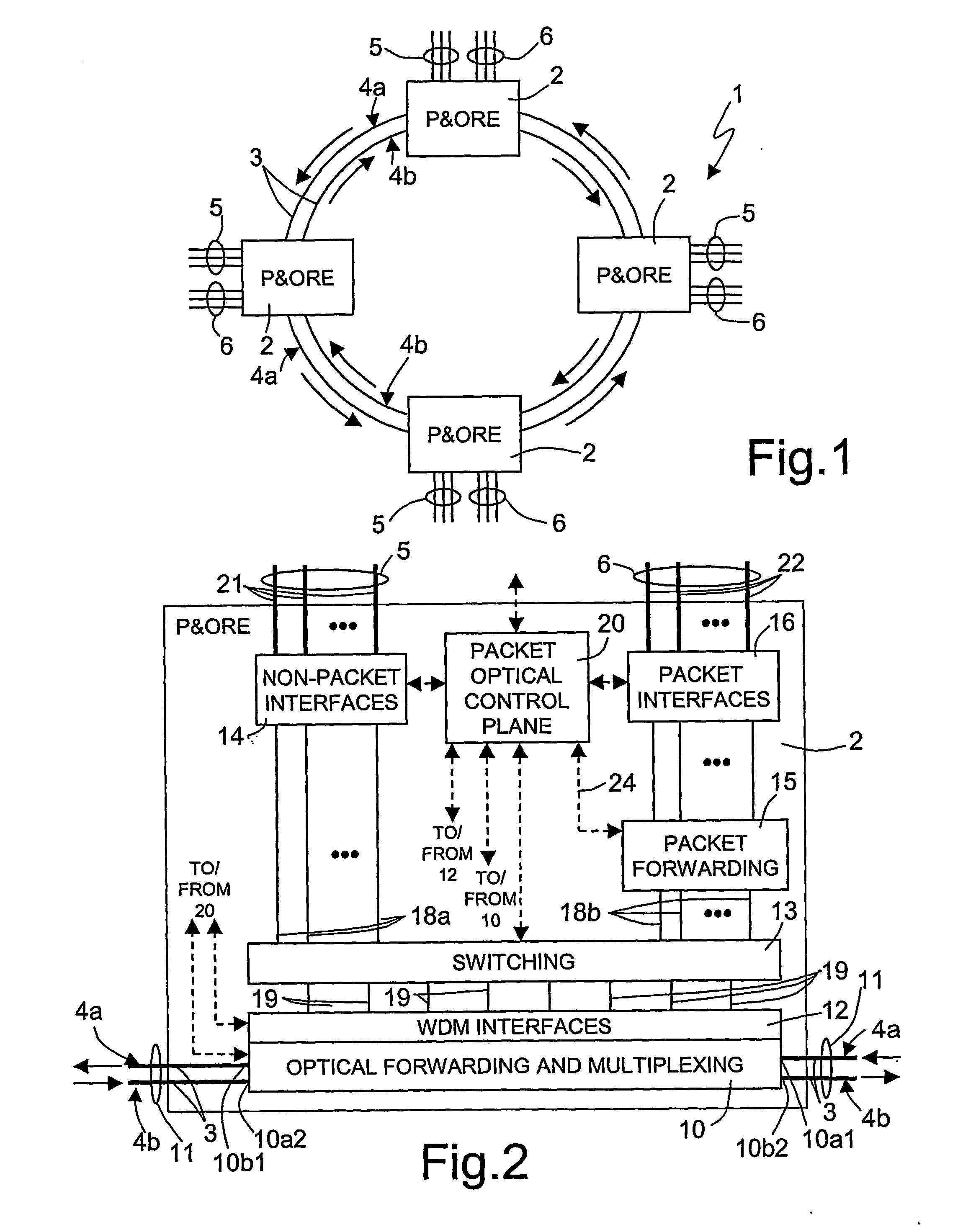

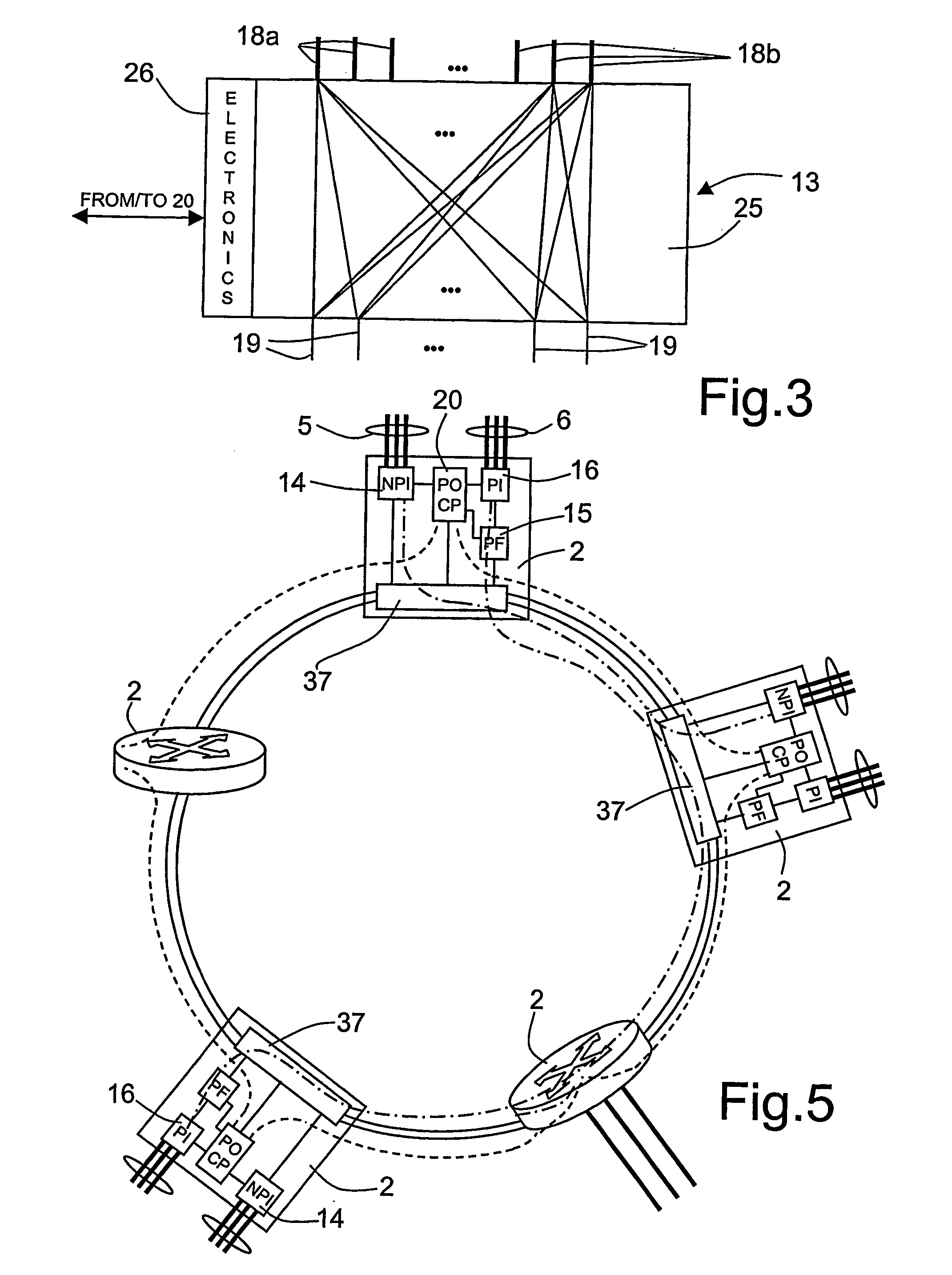

Packet and optical routing equipment and method

InactiveUS20060257143A1Savings in implementationSavings in operationMultiplex system selection arrangementsWavelength-division multiplex systemsMultiplexingElectricity

A packet and optical routing equipment exchanges multiplexed optical signals with other equipment in a network and exchanges branch non-packet and packet signals with client equipment. The entering branch non-packet signals are converted into electric signals by a non-packet interface and supplied directly to an electric switching unit, the entering packet branch signals are converted into electric signals, supplied to a packet forwarding module and routed to the electric switching unit. The electric switching unit switches the electric signals toward a WDM interface that converts them into optical signals at selected wavelengths that are added to the multiplexed optical signals. The entering multiplexed optical signals that should be terminated in the equipment are extracted, converted into electrical signals, and electrically switched toward the non-packet interface or the packet forwarding module according to whether they are of non-packet or of a packet type. The switching unit is of configurable type and may switch a variable ratio of electric non-packet and packet signals according to the traffic requirements.

Owner:TELECOM ITALIA SPA +1

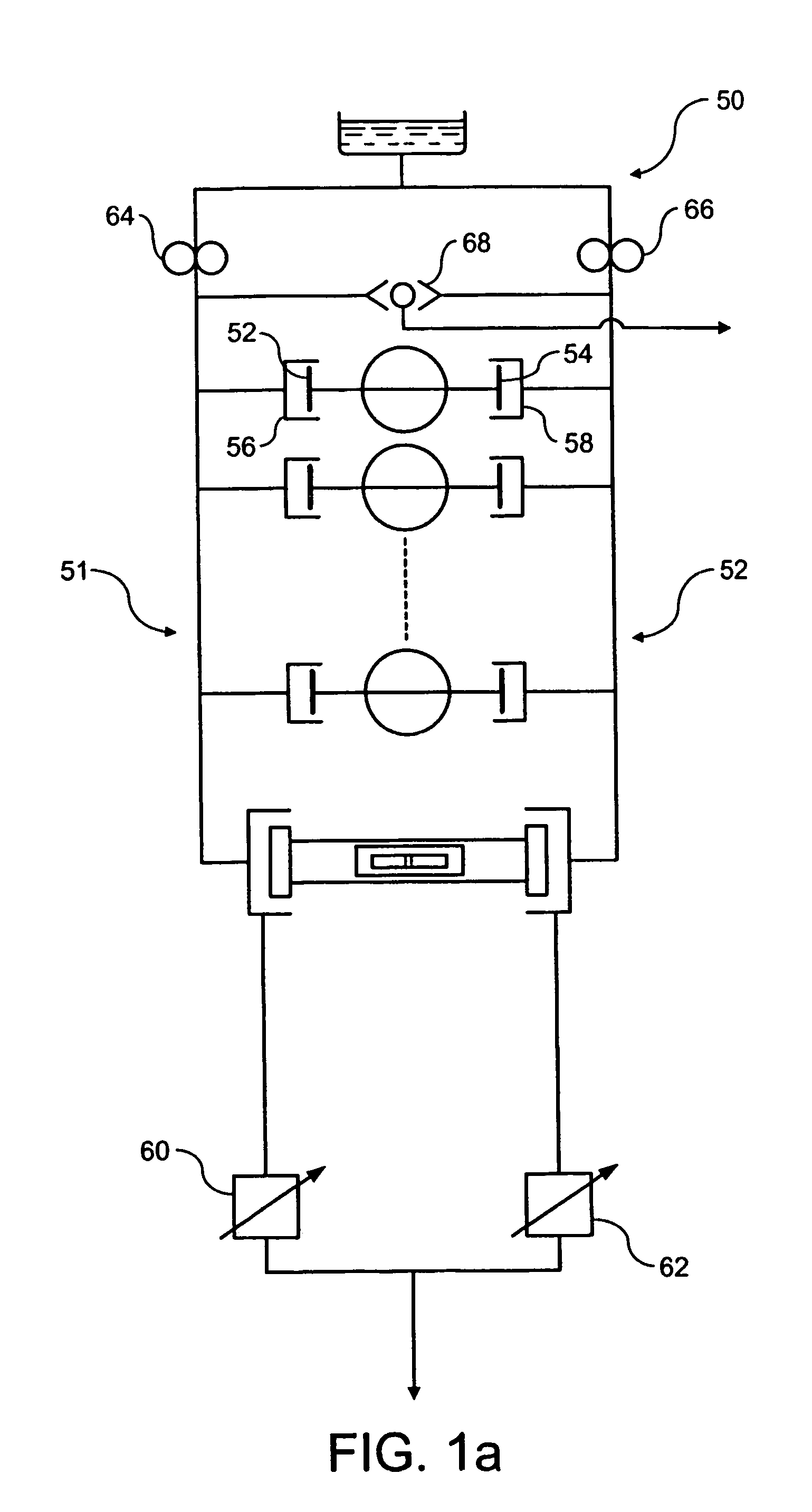

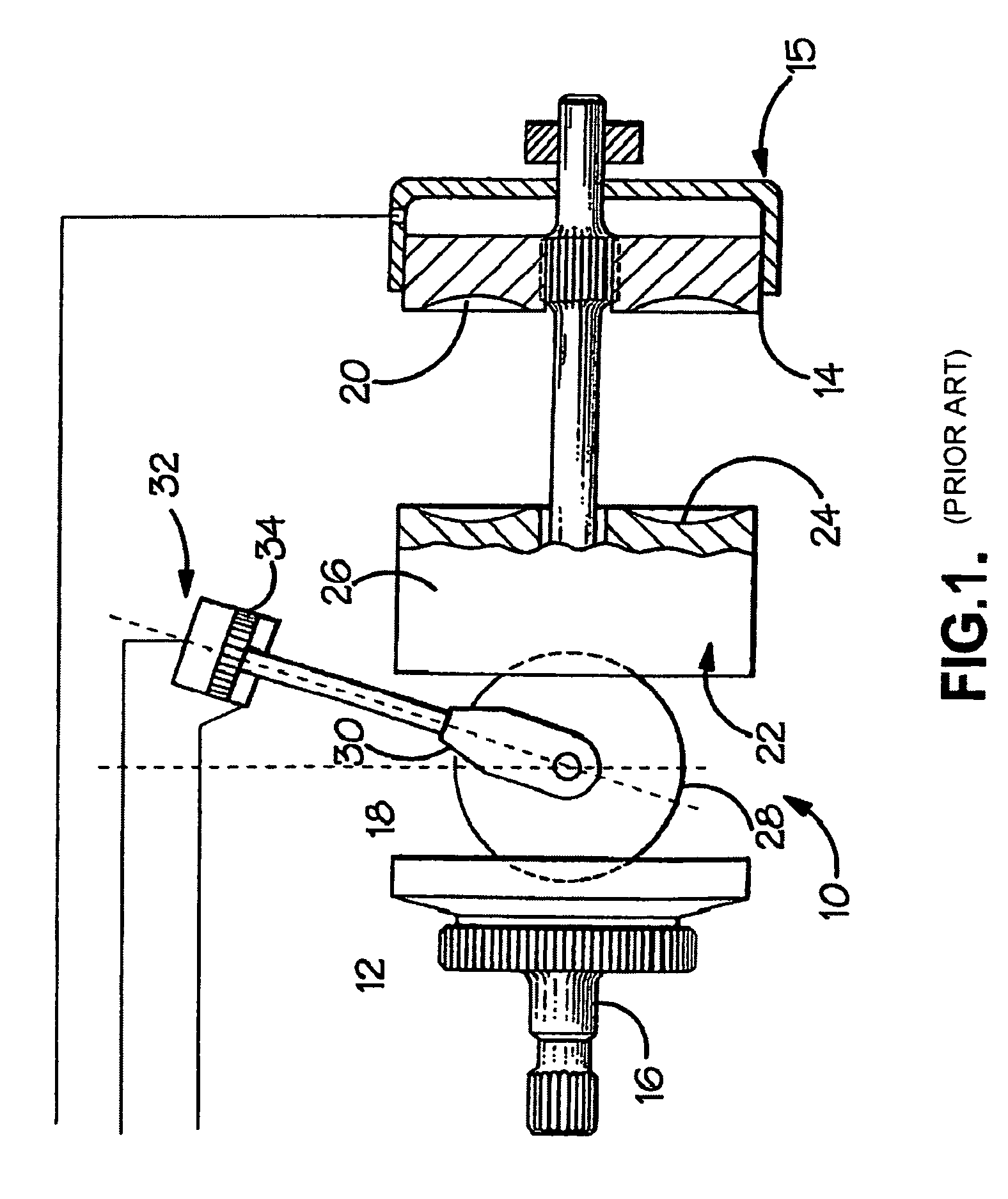

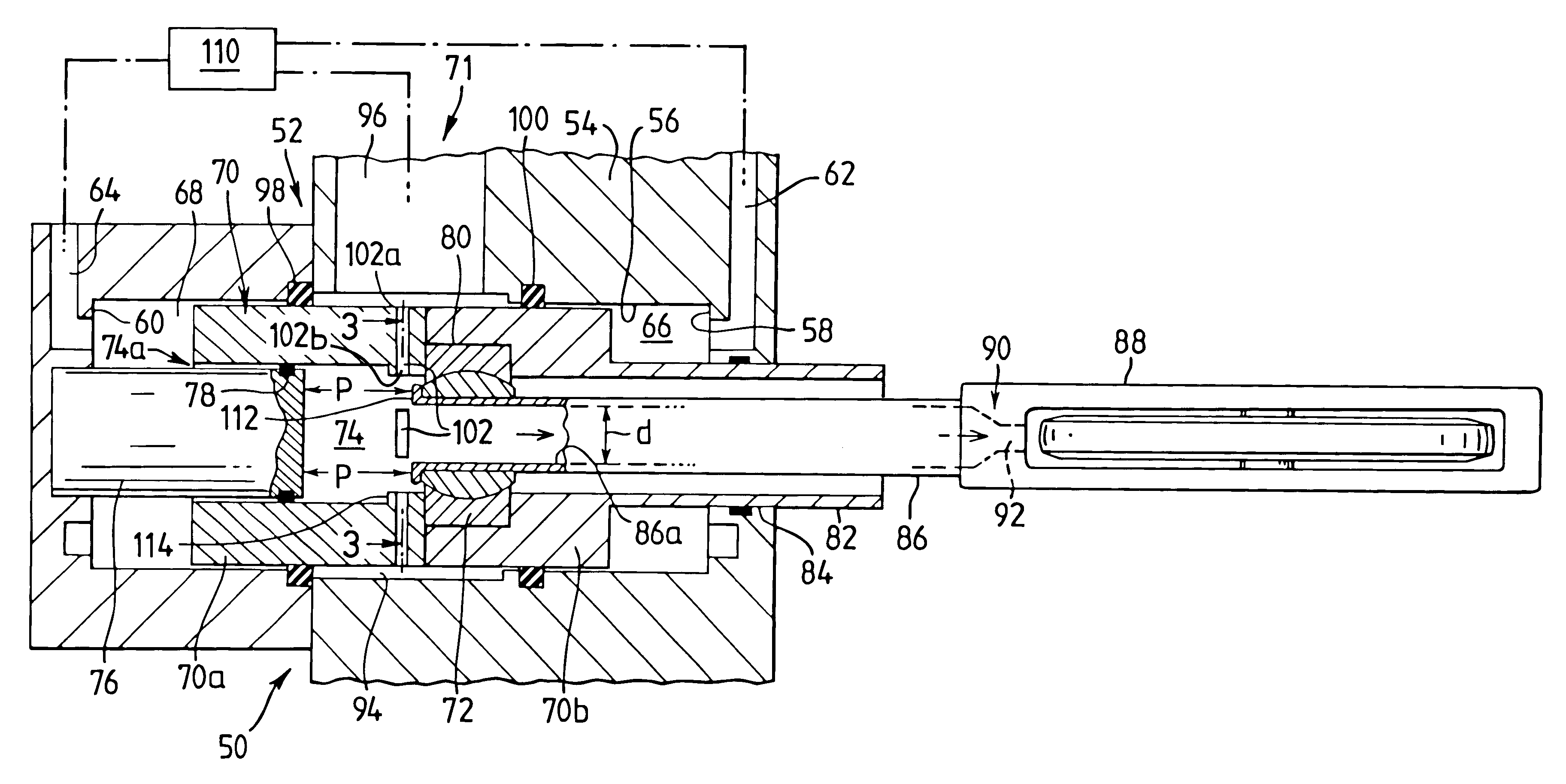

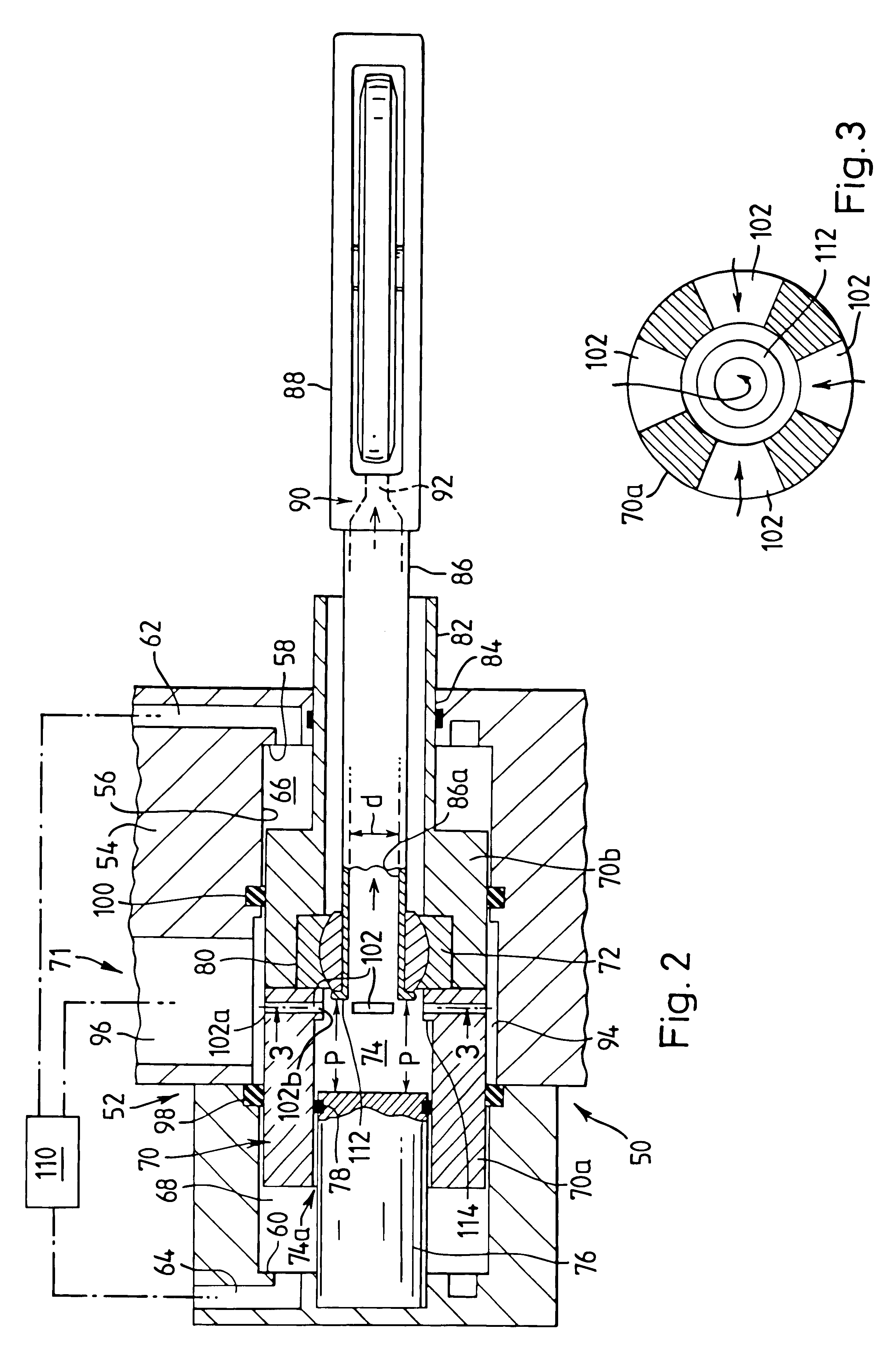

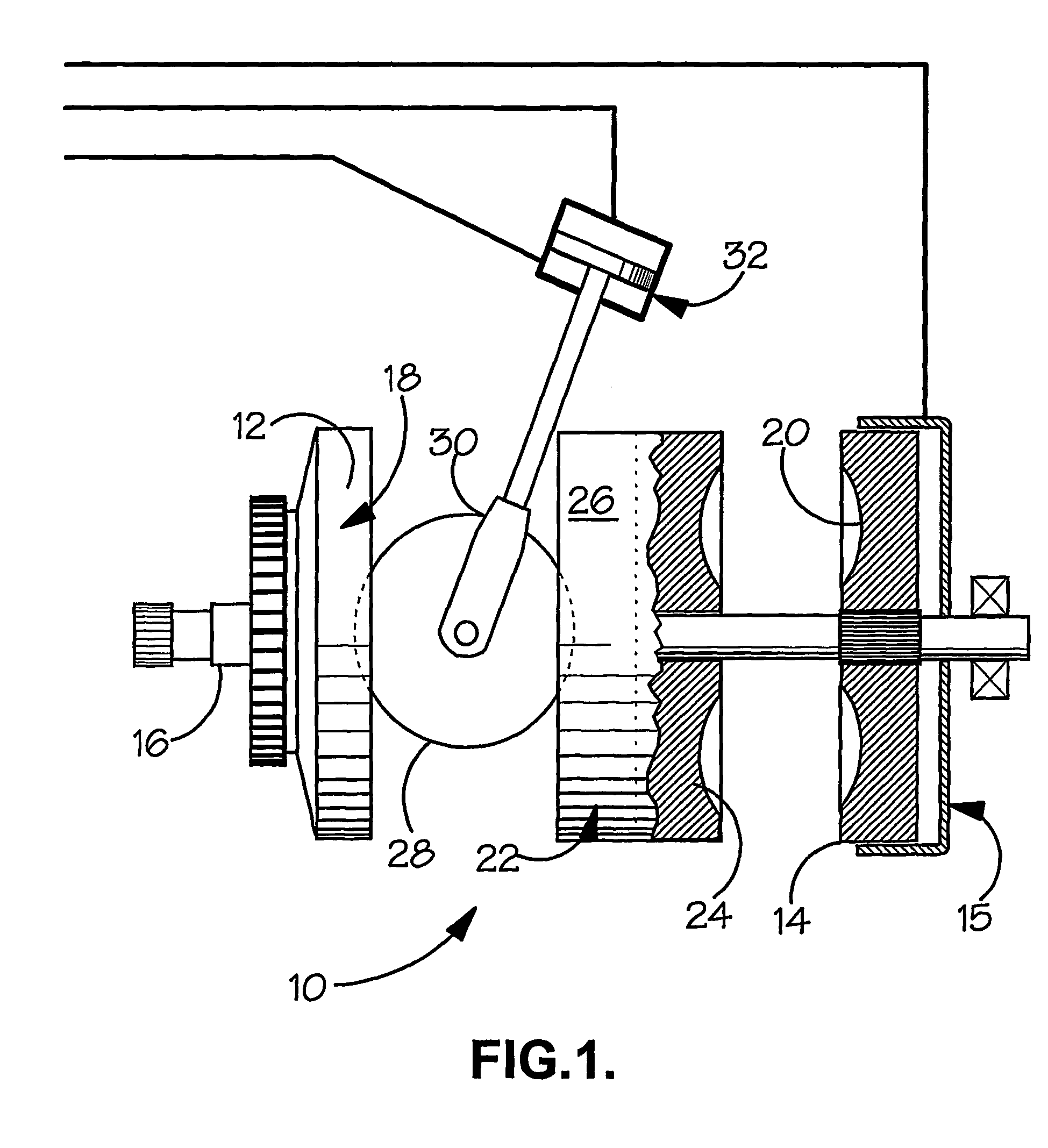

Cooling fluid supply to hydraulically actuated rollers in a continuously-variable-ratio transmission

A roller control unit for a CVT includes a cylinder (54) having a piston (70) positioned therein and operably connected to a roller assembly of said CVT thereby to control its position. The unit includes a lubrication supply which comprises a chamber (94) between the cylinder (54) and piston (70) and one or more radially extending passageways (102) through said piston (70). These passageways are in flow communication with the roller and act to direct cooling fluid to said roller. Radial supply of said lubrication facilitates a reduction in flow losses within the supply.

Owner:ALLISON TRANSMISSION INC

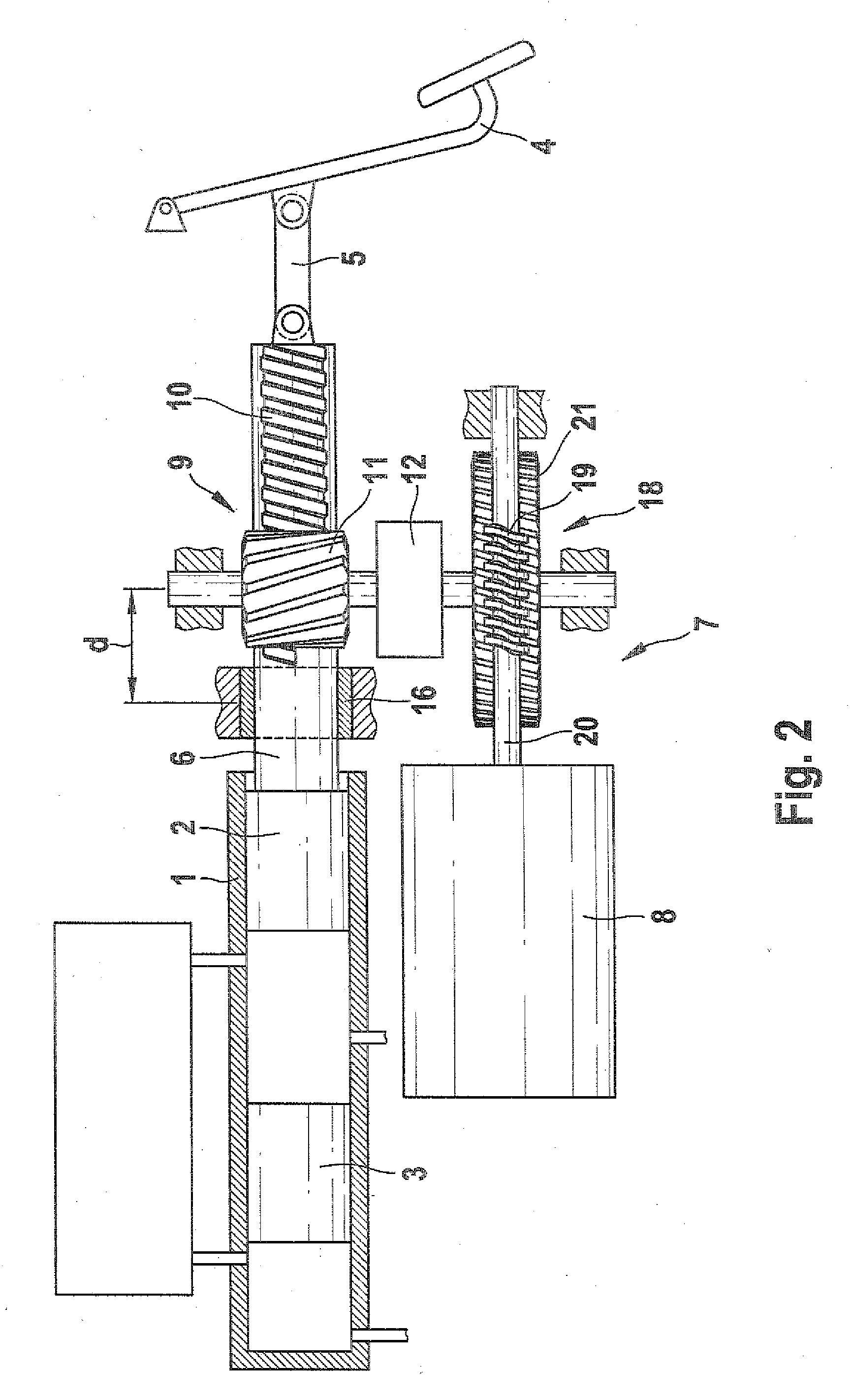

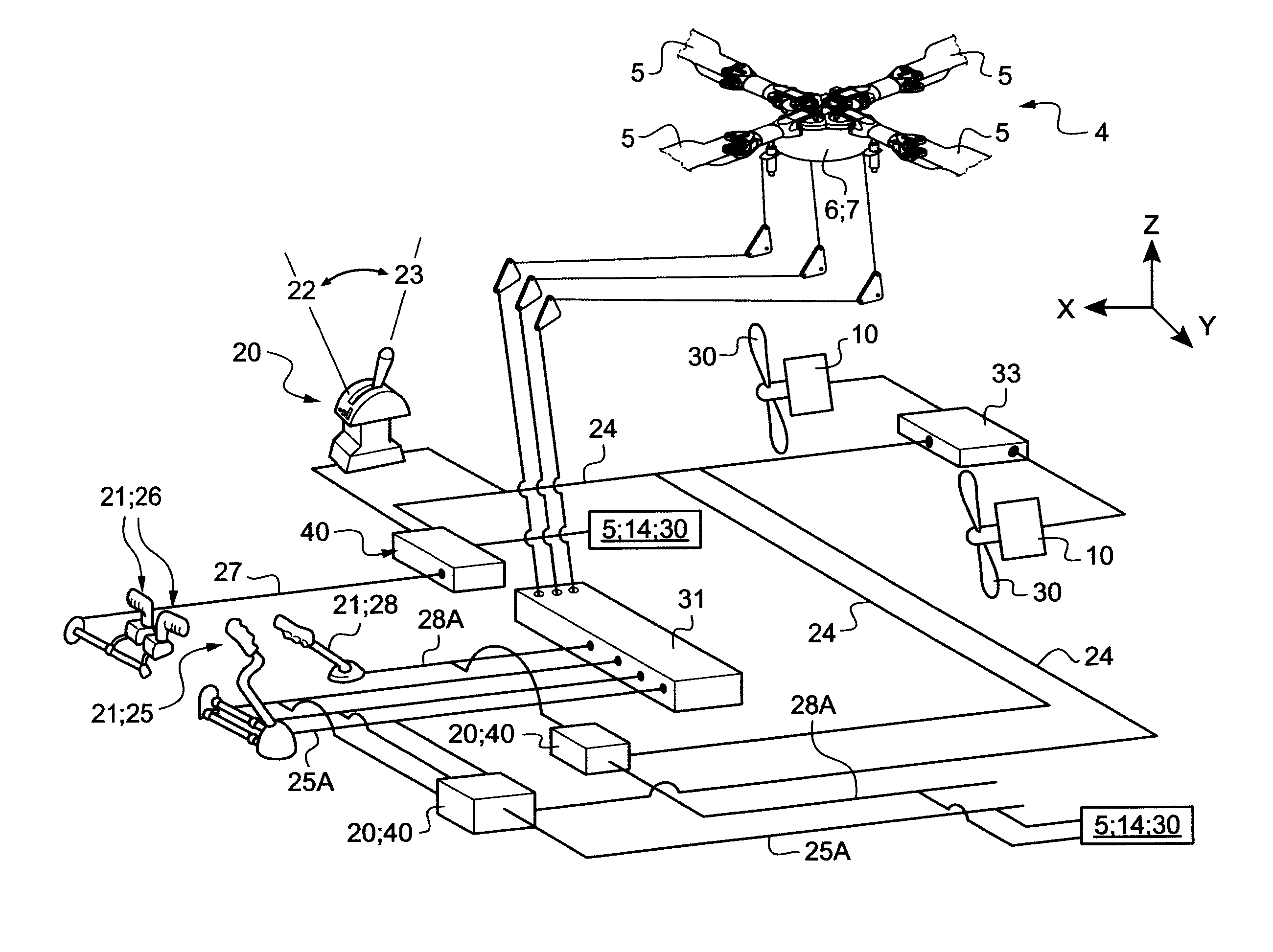

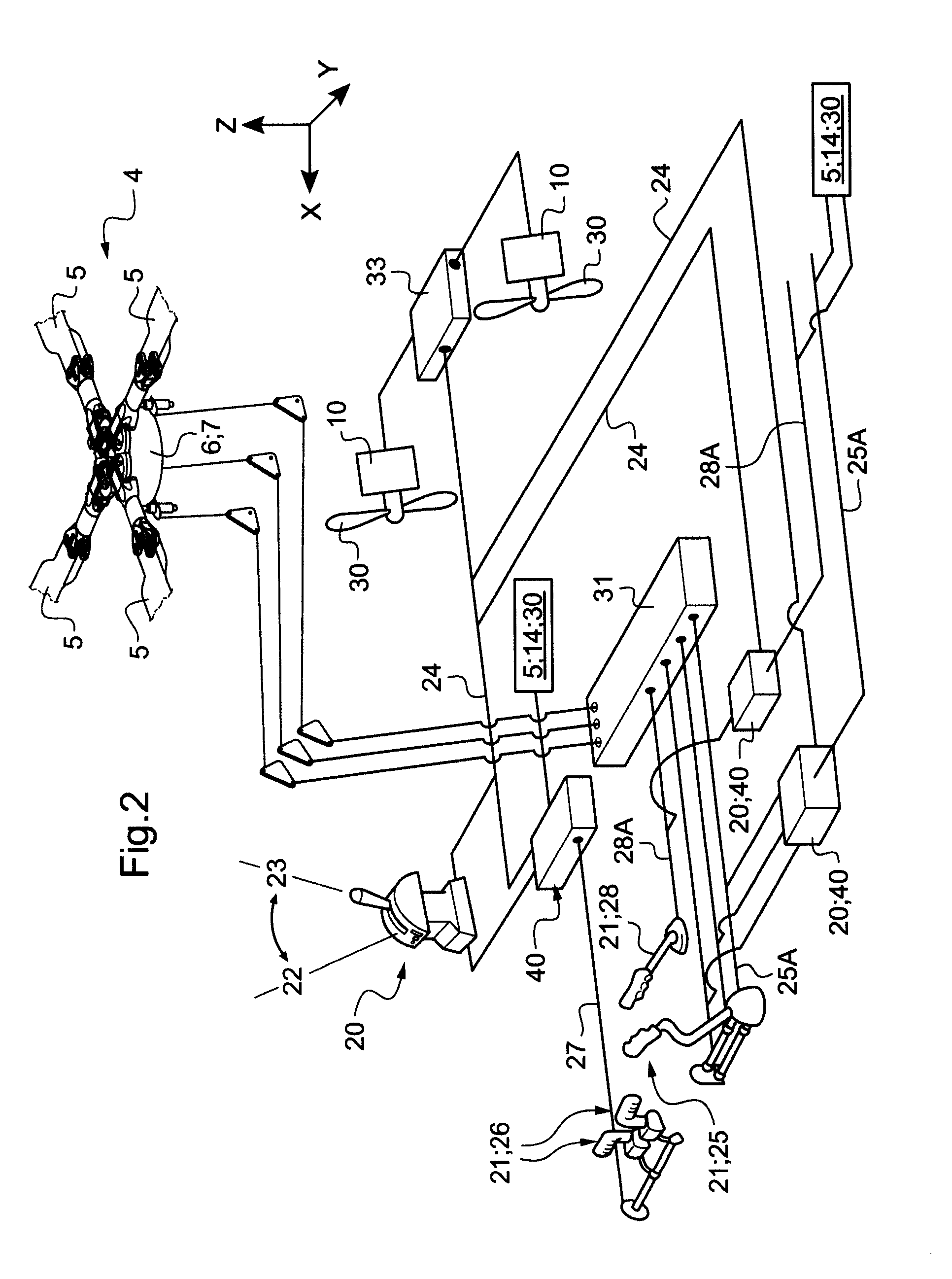

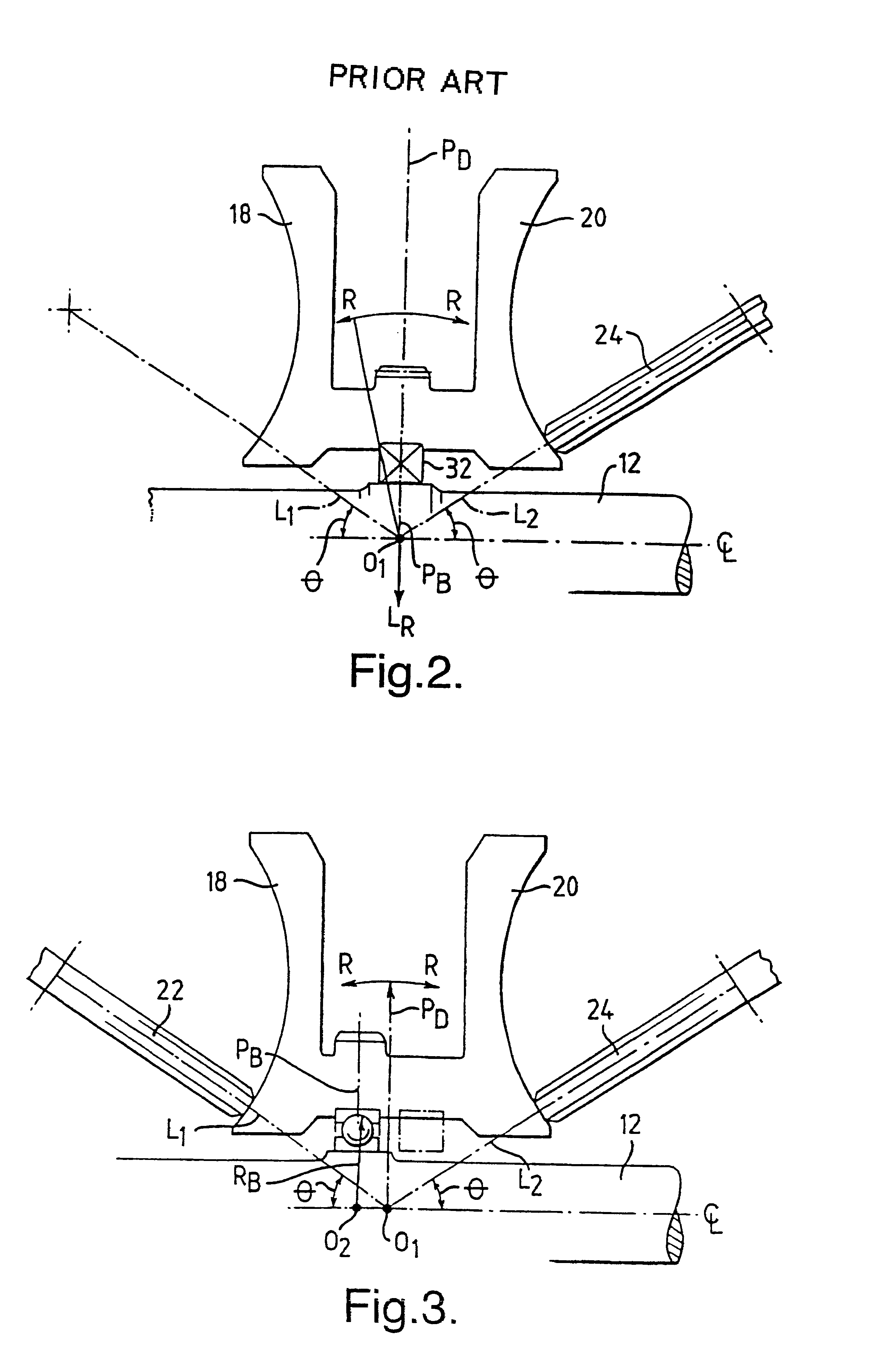

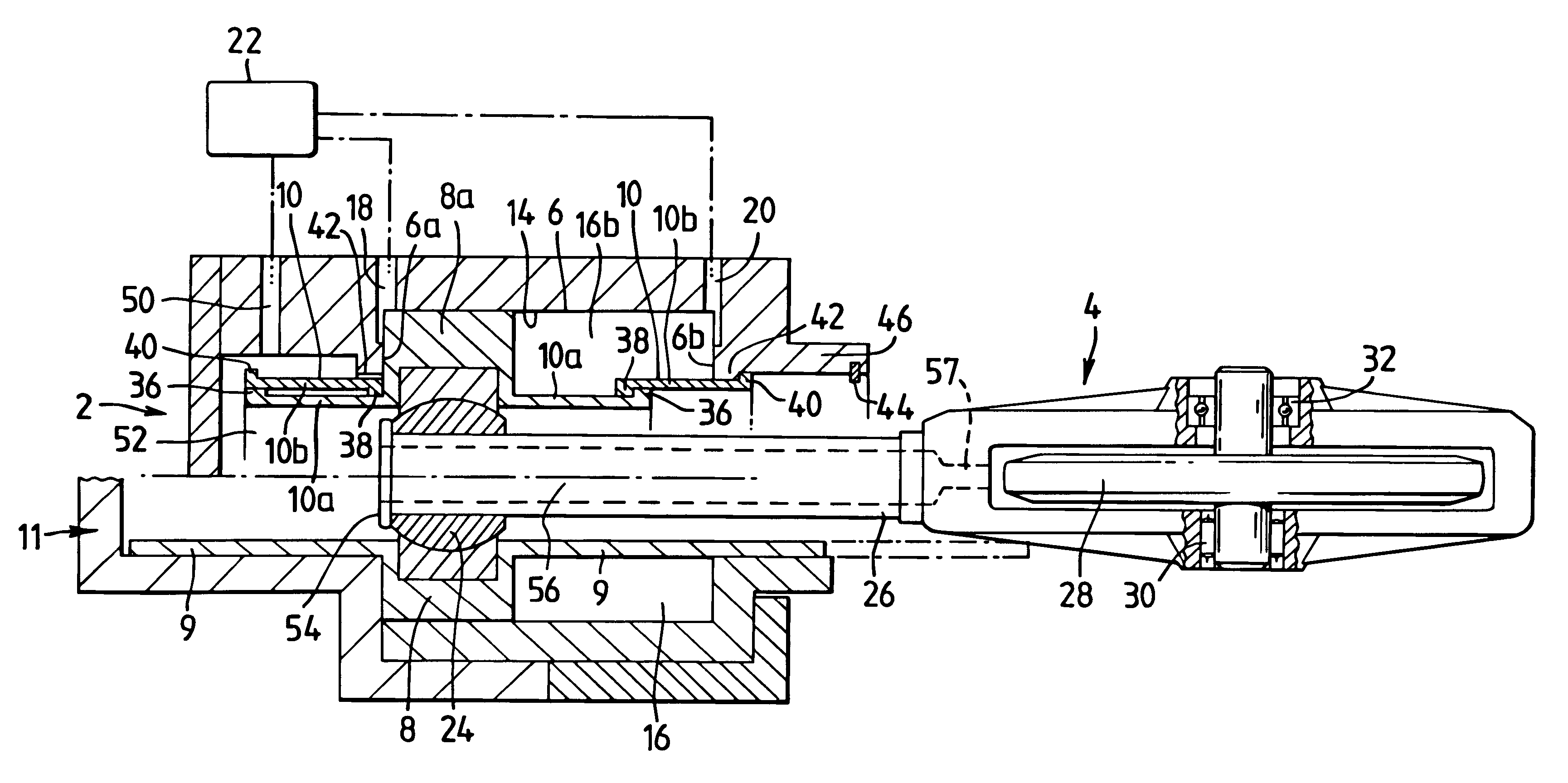

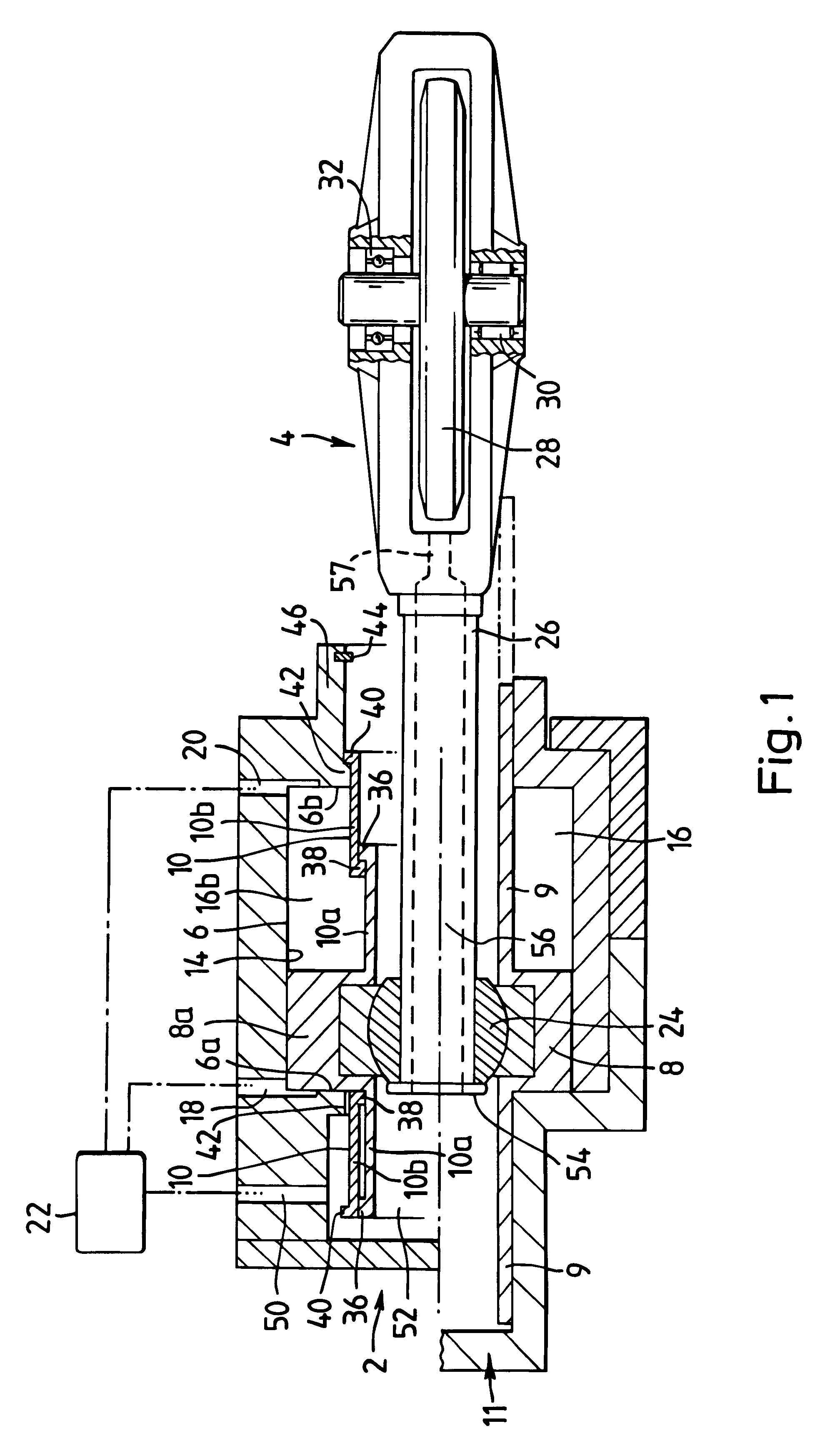

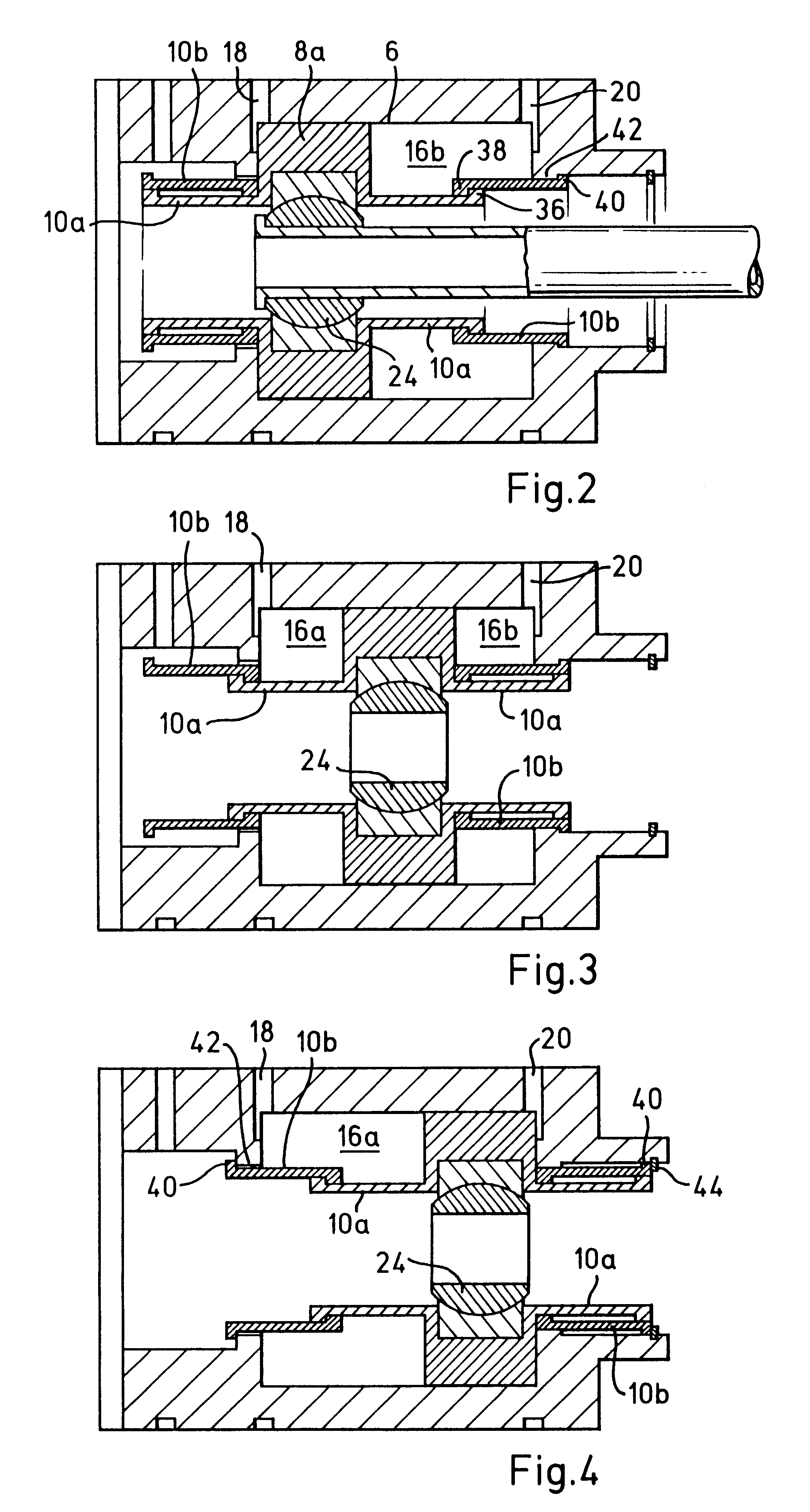

Variable ratio crank for a manual flight control linkage of a rotary wing aircraft

ActiveUS20100308178A1Safer and accurate and more comfortableAvoid damagePropellersPump componentsRotary wingAirplane

The present invention relates to a bellcrank (40) for a flight-attitude-changing linkage (27, 25A, 28A) of the variable gain type. The linkage (27, 25A, 28A) connects a manual flight control device of a rotary wing aircraft (1), e.g. a hybrid helicopter, to at least one airfoil of said aircraft (1) suitable for causing a change in flight attitude. Said bellcrank (40) includes first and second sliders (50, 52). Said first slider (50) is connected to a movable portion (57, 61) of a setpoint flight-attitude-changing linkage (24) that delivers a setpoint, with movements of said linkage causing the gain of said variable-gain linkage (27, 25A, 28A) to be adjusted, which gain is proportional to the position of said movable portion (57, 61).

Owner:EUROCOPTER

Hydraulic control circuit for a continuously variable transmission

InactiveUS7056261B2Reduce the degree of openingRapid ratio changeGearing controlEngine controllersHydraulic circuitTorque transmission

A hydraulic circuit for a continuously variable transmission having a continuously variable ratio unit that is controlled by at least one hydraulic actuator acting on a movable torque transmission element. The actuator has opposed first and second working chambers. The circuit includes first and second flow lines that are connected to two respective actuator working chambers. The lines feed fluid thereto and therefrom A pressurized supply of fluid urges fluid flow through the flow lines. A variable control valve is incorporated in both flow lines. Each valve generates an adjustable back pressure therein. A further valve is connected between the two flow lines. The further valve has a variable opening and is located upstream of the variable control valve. Opening of the further valve enables flow fluid from one flow line to the other to reduce pressure difference between the lines.

Owner:TOROTRAK (DEV) LTD

Vehicular transmission

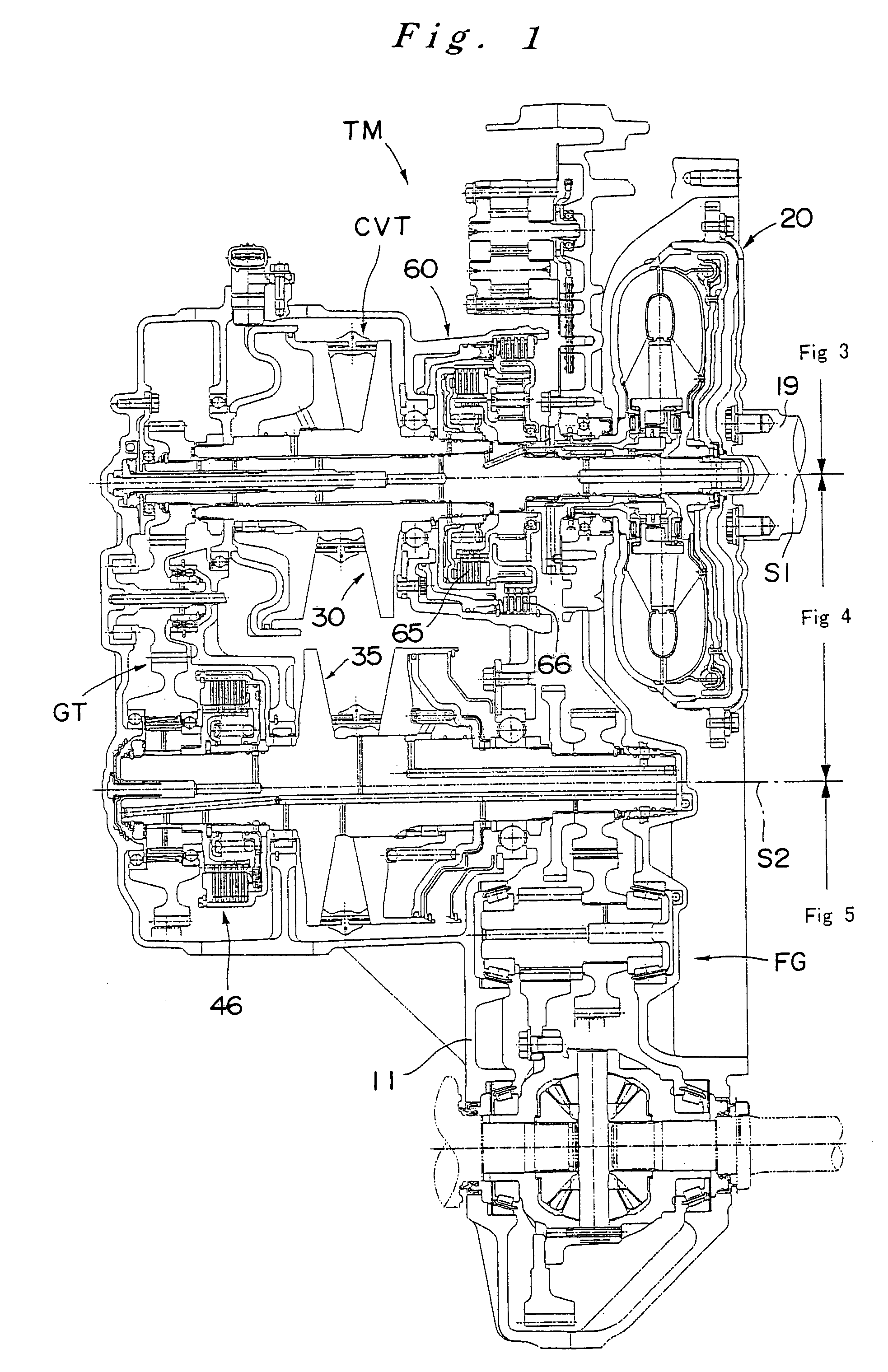

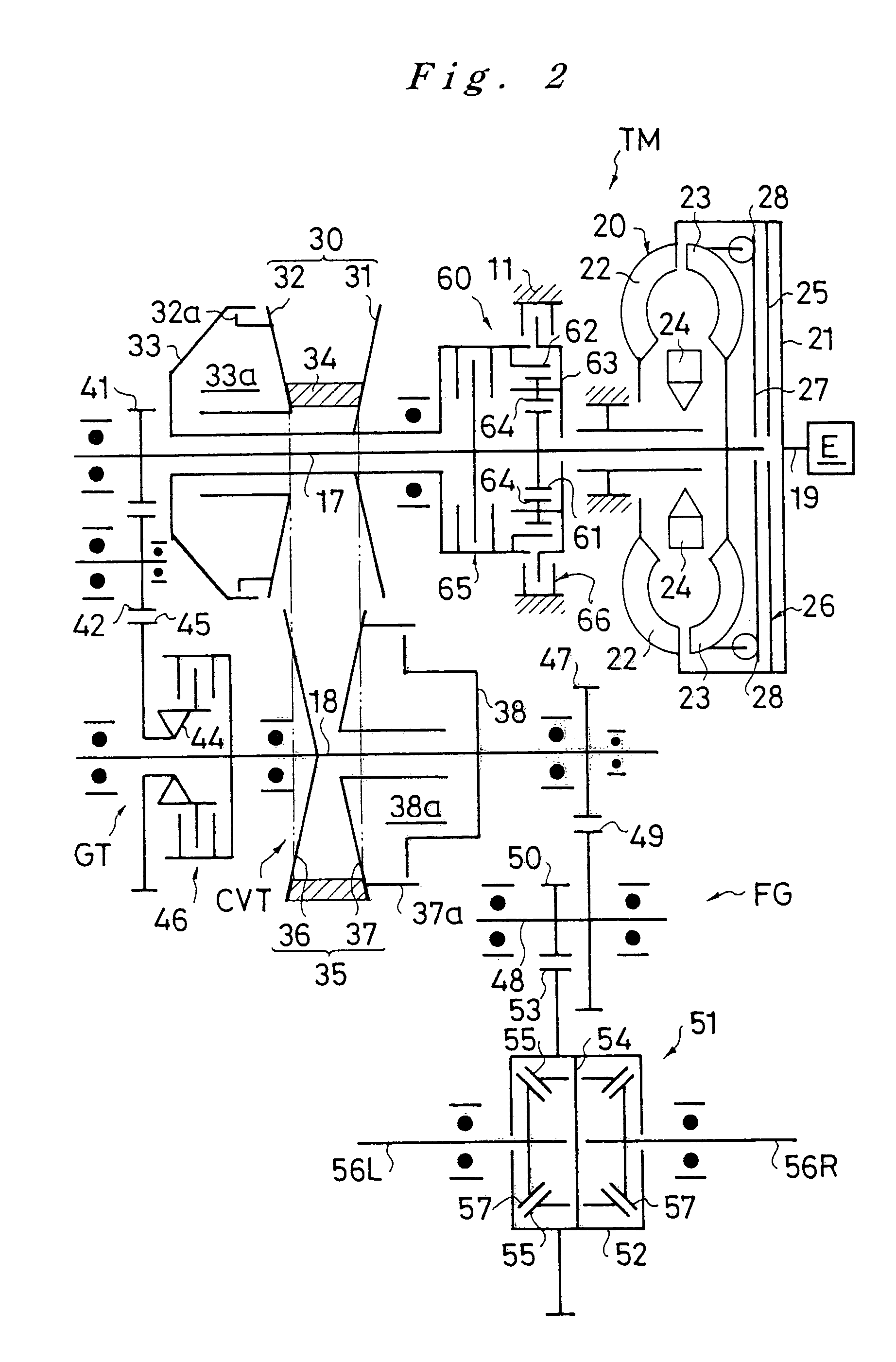

A transmission equipped with a continuously variable ratio-change mechanism CVT and a LOW rotational transmission mechanism GT, which are disposed parallel with each other, comprises a forward clutch 65 and a reverse brake 66, which are used to set a power transmission through the continuously variable ratio-change mechanism, a LOW clutch 46, which is used to set a power transmission through the LOW rotational transmission mechanism, and a control unit ECU and a hydraulic control valve HV, which control the engagement of the clutches and the brake. When the transmission is switched from its neutral mode to its in-gear mode, at first, the forward clutch 65 is brought gradually into engagement, and then it is released before the LOW clutch 46 is brought into engagement in a squat control.

Owner:HONDA MOTOR CO LTD

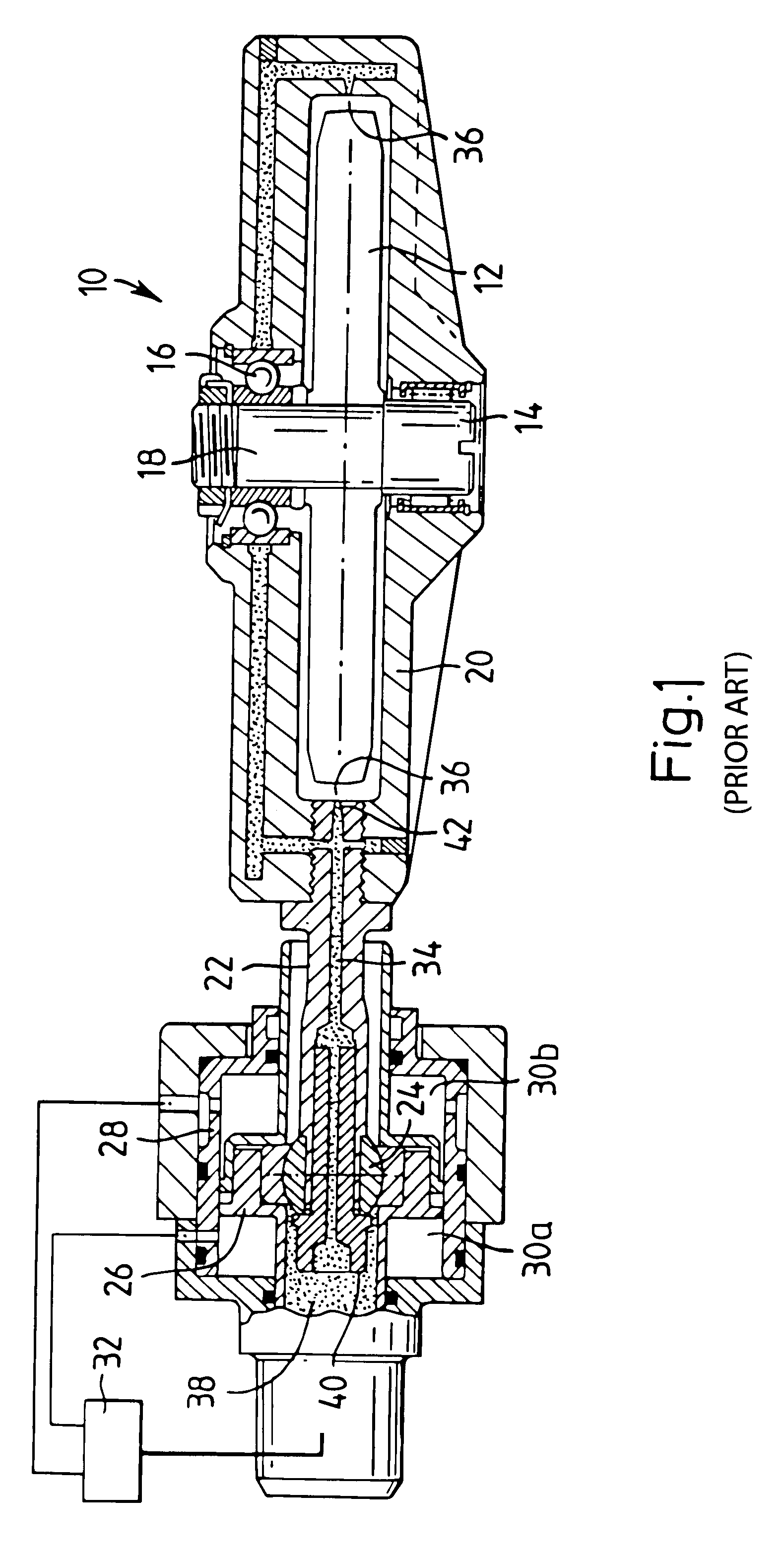

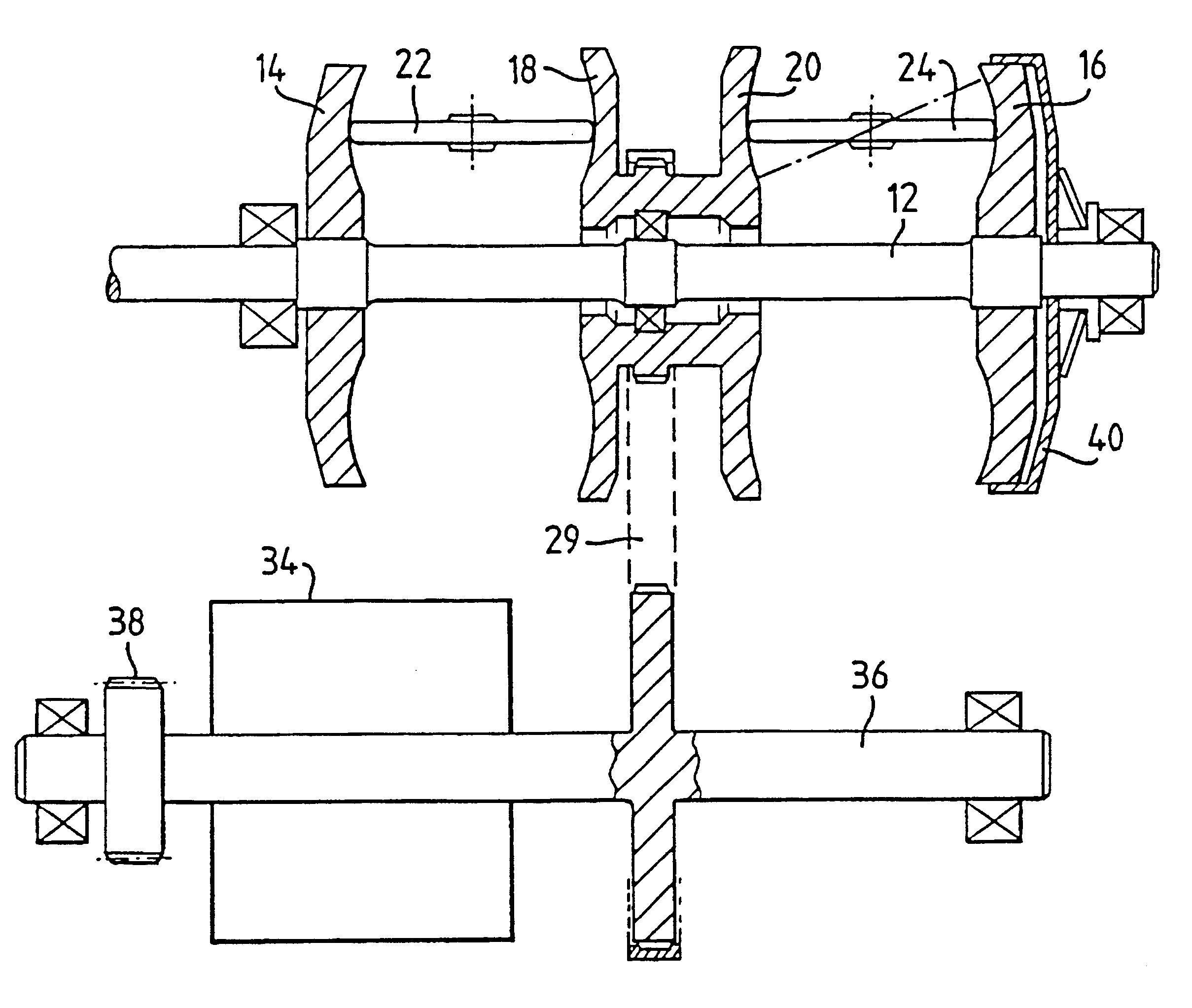

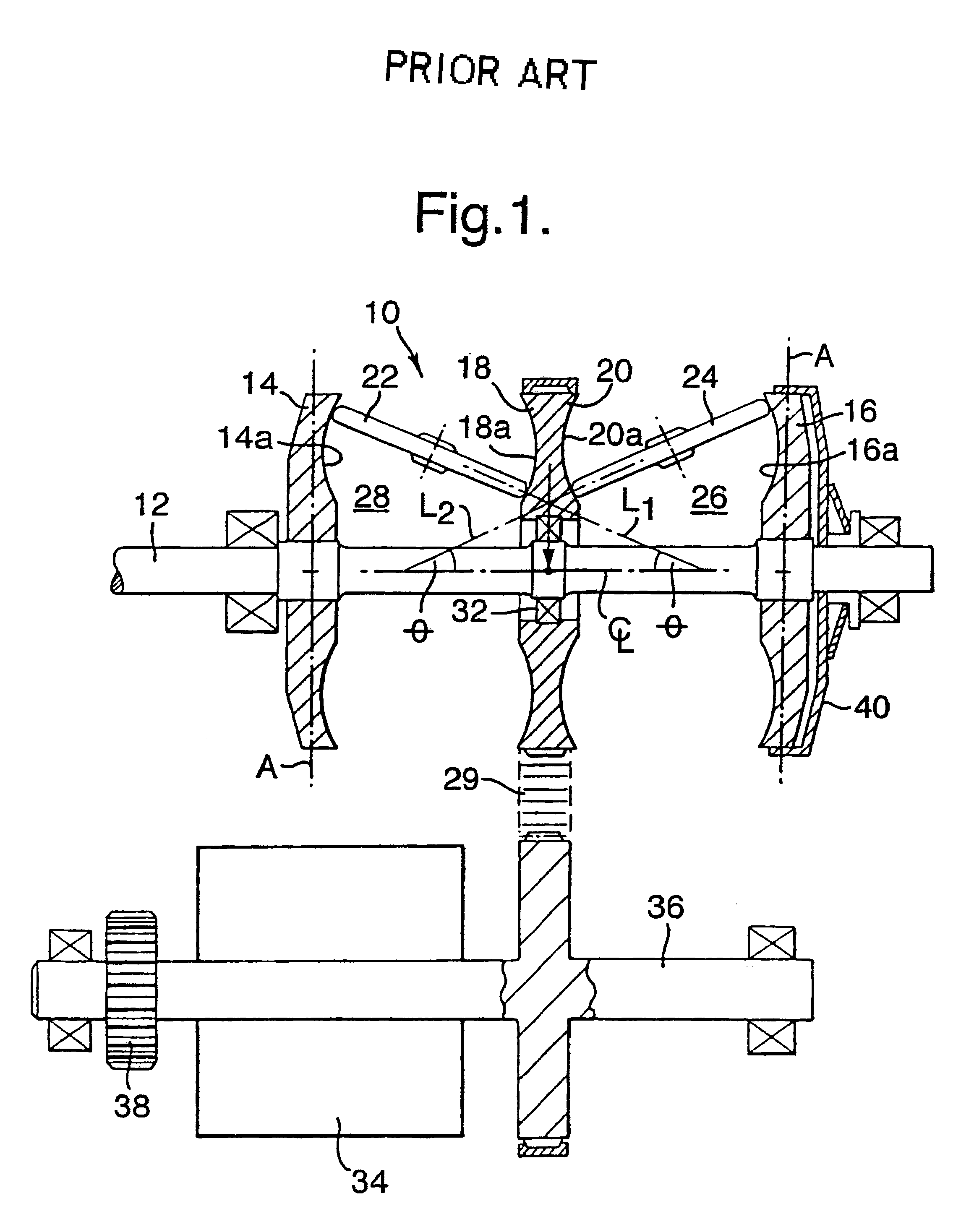

Bearing support for infinitely-variable-ratio transmission output discs

A variator transmission apparatus (10) comprises an input shaft (12), one or more input discs (14, 16) mounted on the shaft for rotation therewith, one or more inner discs (18, 20), the input and output discs defining between them one or more toroidal cavities, a plurality of rollers (22, 24) located within the one or more cavities for transmitting rotation from the outer disc(s) (14, 16) to the inner disc(s) in which means are provided for preventing the end load locking the inner discs (18, 20) to the shaft (12).

Owner:TOROTRAK (DEV) LTD

Roller control unit for a continuously-variable-ratio transmission

A roller control unit (2) for a continuously-variable-ratio transmission includes a cylinder (6) having a cylinder wall and an end wall; and a piston (8), within the cylinder (6) and to which the roller assembly (4) is connected for movement therewith, said unit includes an axially extending shroud (10) of variable length extending between the piston (8) and the end wall, thereby to define in combination with the piston (8) and cylinder (6) a chamber (16) for receiving hydraulic fluid, and in which the shroud (10) comprises a telescopic shroud which in a first position of the piston (8) is extended and in a second position of the piston (8) is retracted.

Owner:TOROTRAK (DEV) LTD

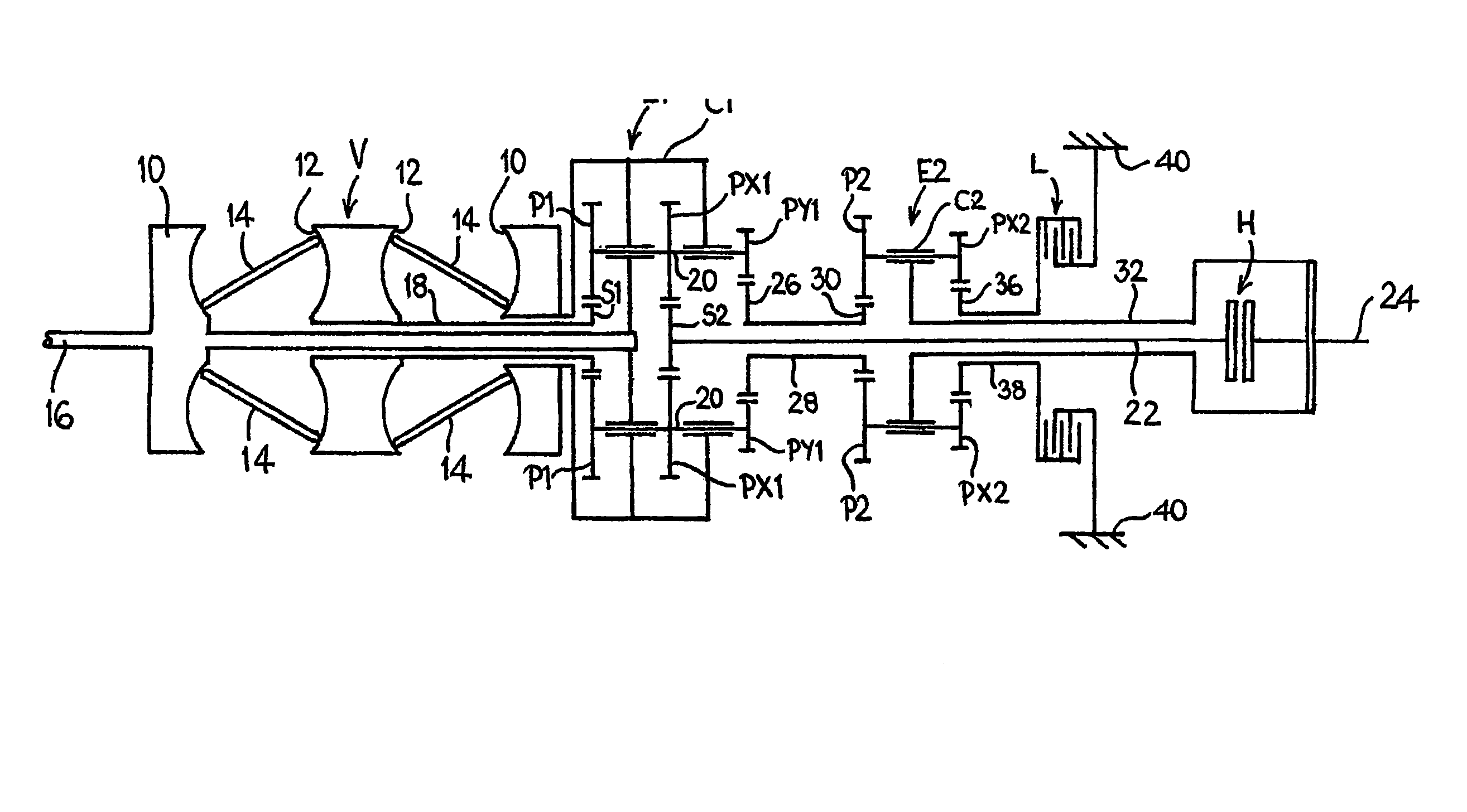

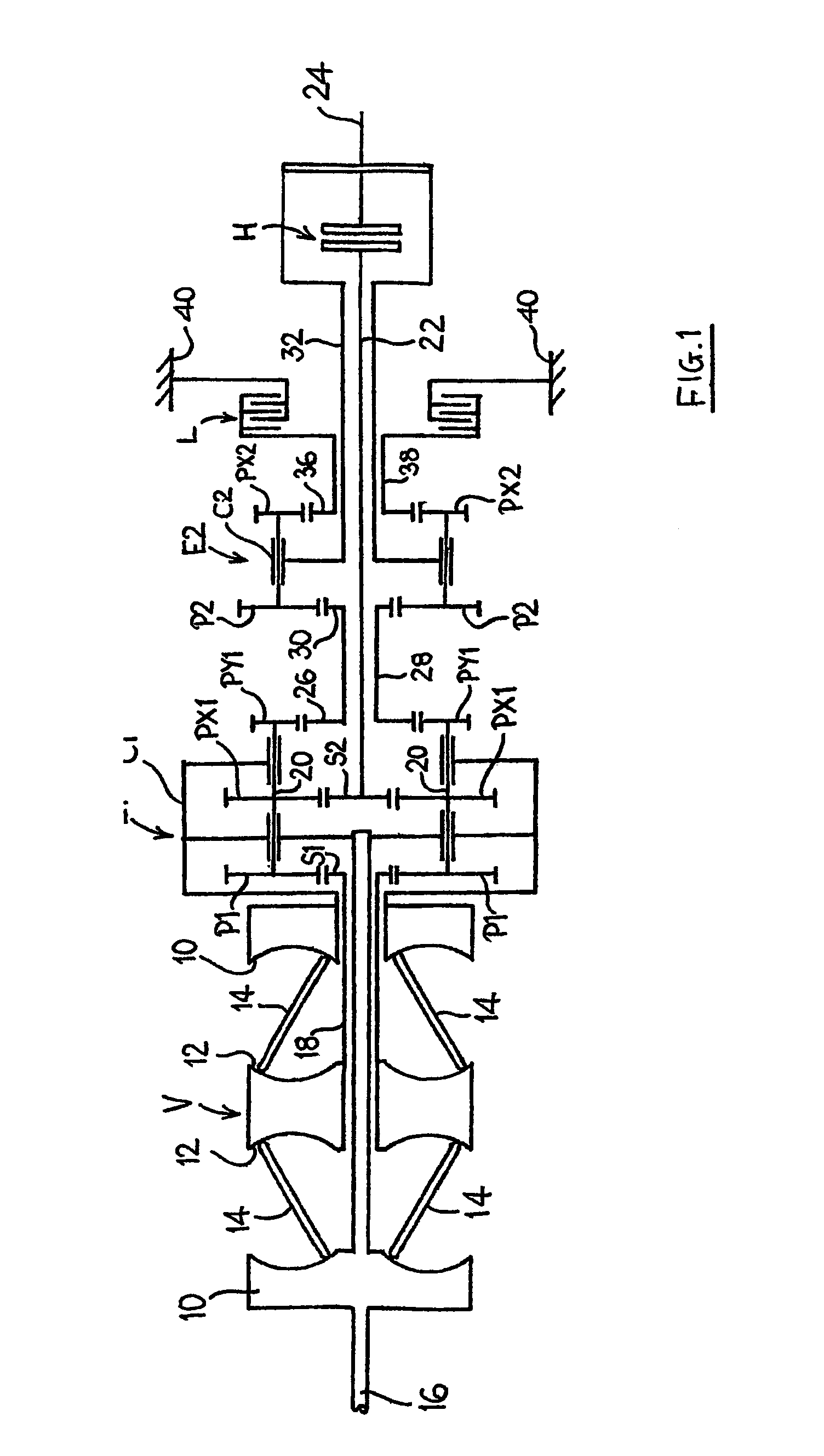

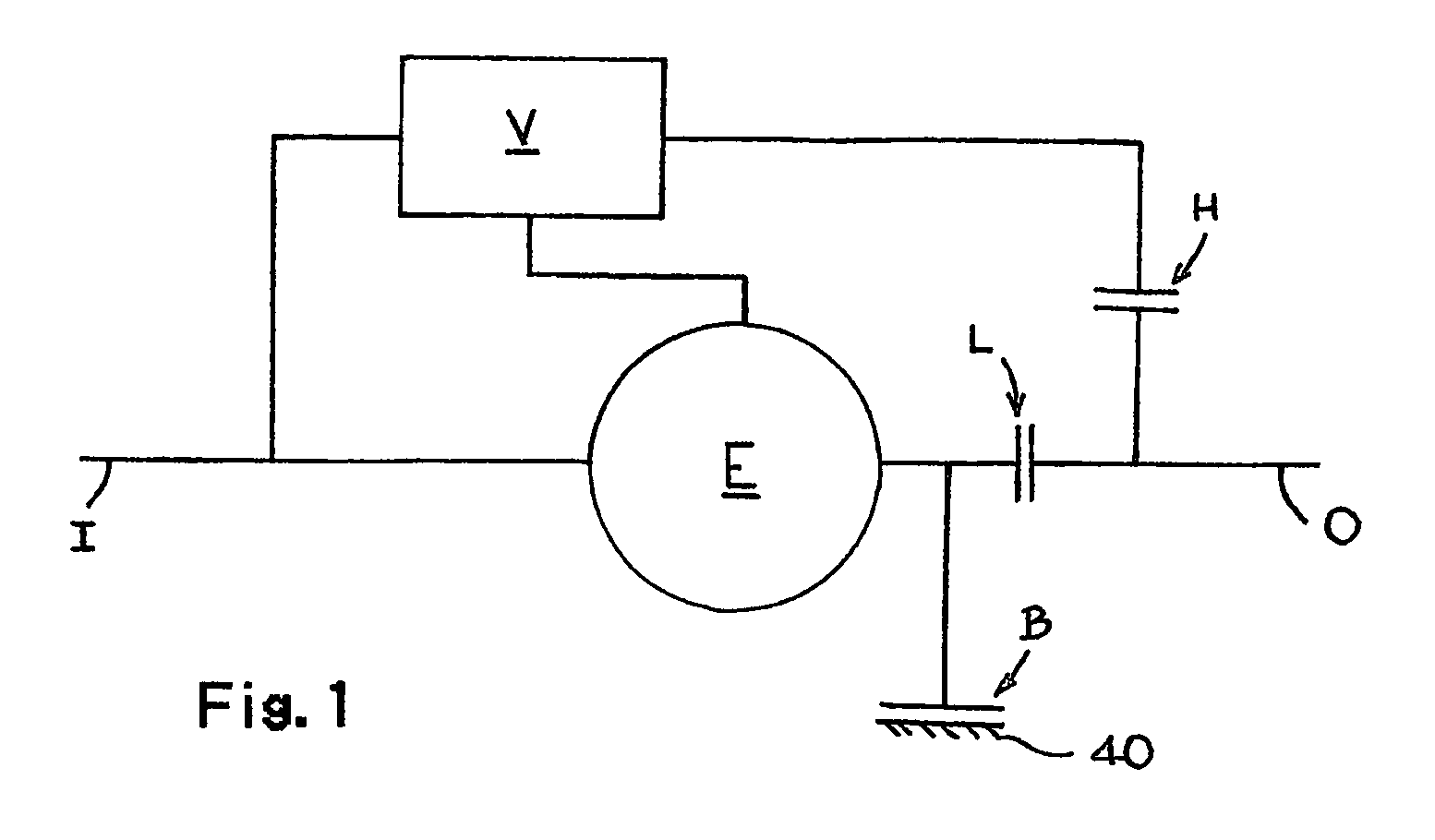

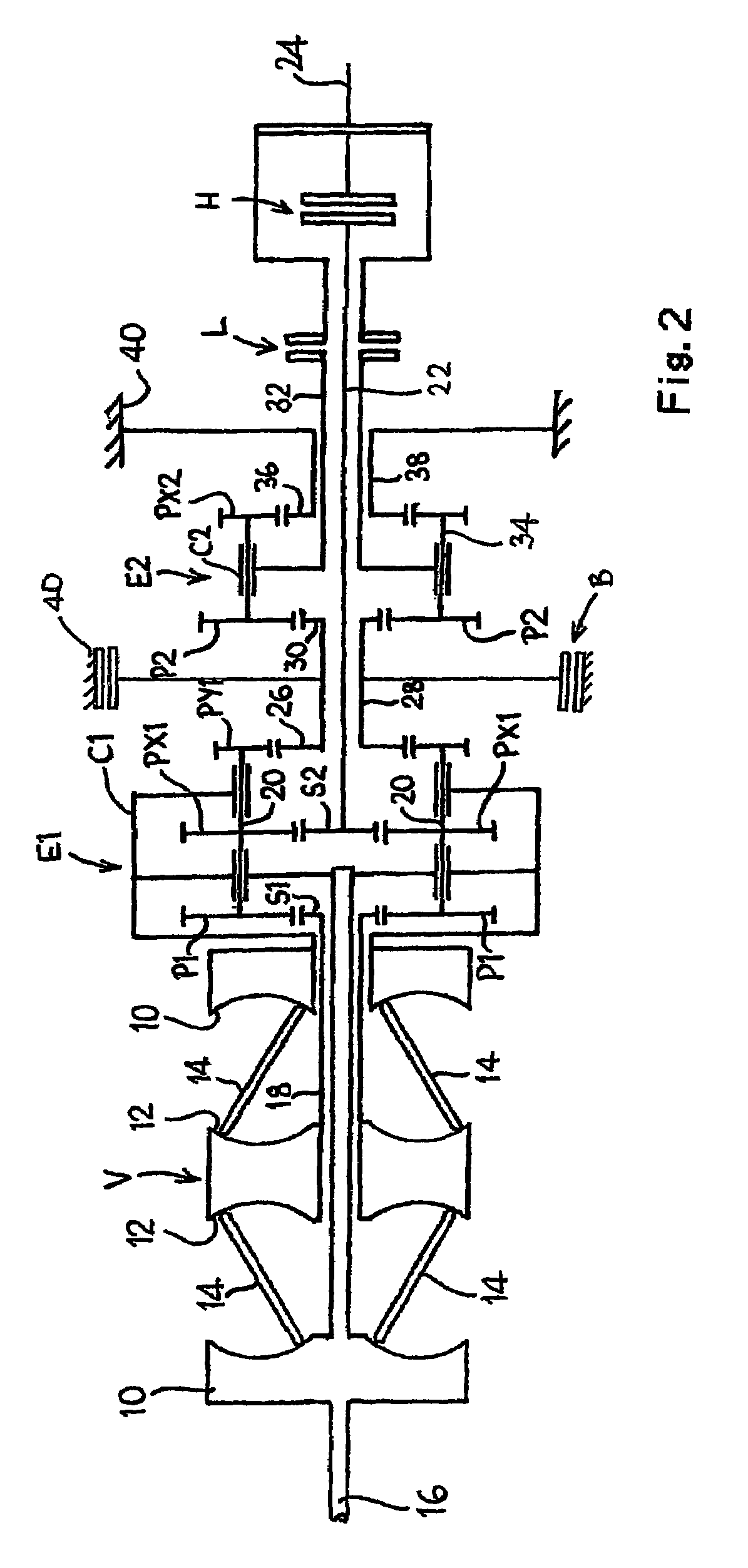

Continuously variable ratio transmission system

ActiveUS7530916B2Improve economyAvoid a slight reduction in the top speed of the vehicleGearingGear wheelGear train

A multiple-regime continuously variable ratio transmission system has a system input shaft (I), a system output shaft (0) and a continuously variable ratio transmission unit (variator) connected to the system input shaft and having a variator output shaft. A first mixing epicyclec gear train (P1) having inputs drivably connected to the variator output shaft (V) and the system input shaft via a first clutch (H) and a second mixing epicyclic gear train having inputs drivably connected to the variator output shaft and the system input shaft has an output (28) connected to a third epicyclic gear train (E2) having an output which is selectively connectable to the to the system output shaft via a first braking element (L). A second braking element (B) is adapted to lock the output (28) of the second mixing epicyclic gear train in a stationary position.

Owner:ALLISON TRANSMISSION INC

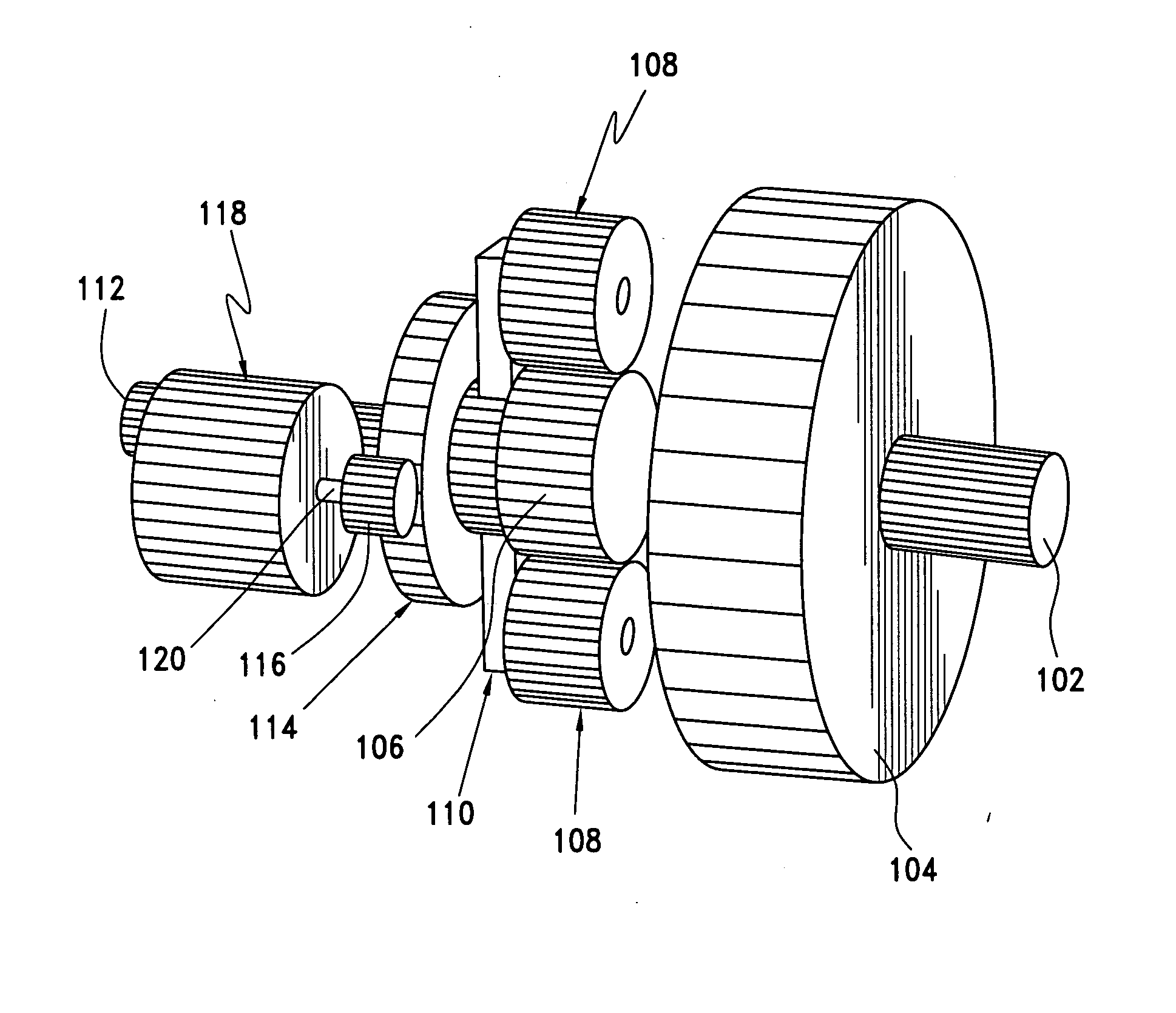

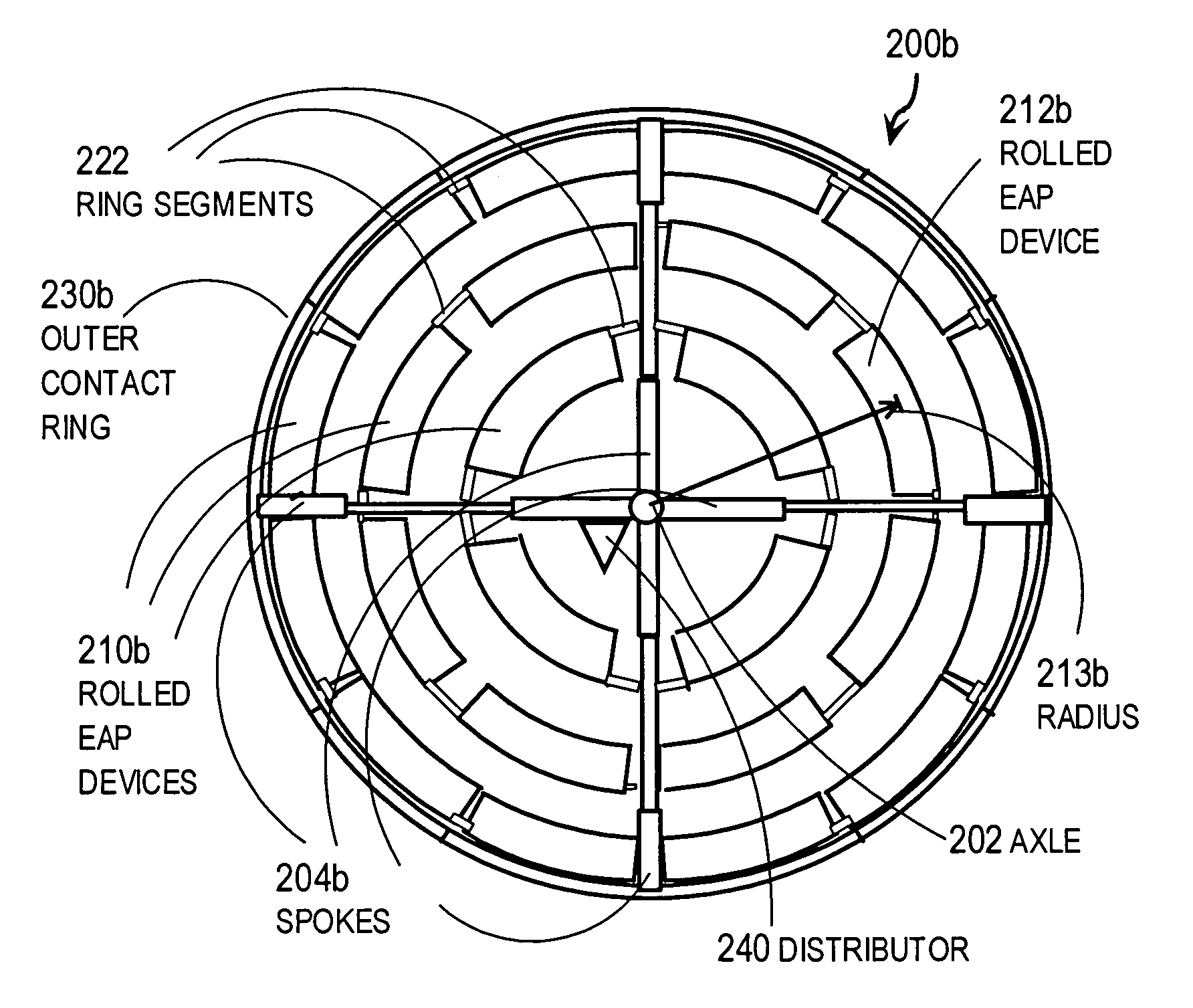

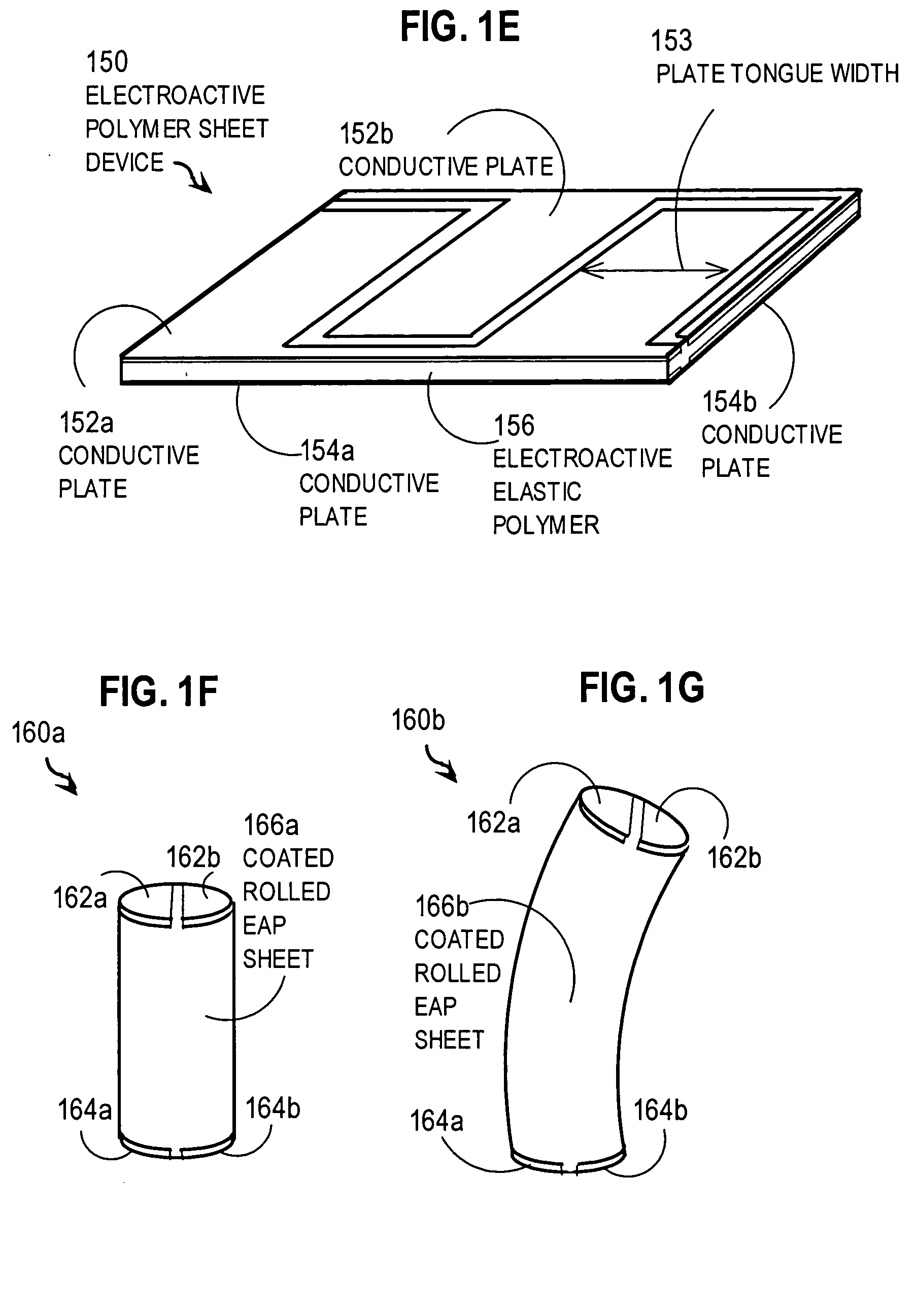

Variable ratio transmission elements for motor drive shafts

ActiveUS7075213B2Piezoelectric/electrostriction/magnetostriction machinesSemiconductor/solid-state device manufacturingMotor driveVariable ratio

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

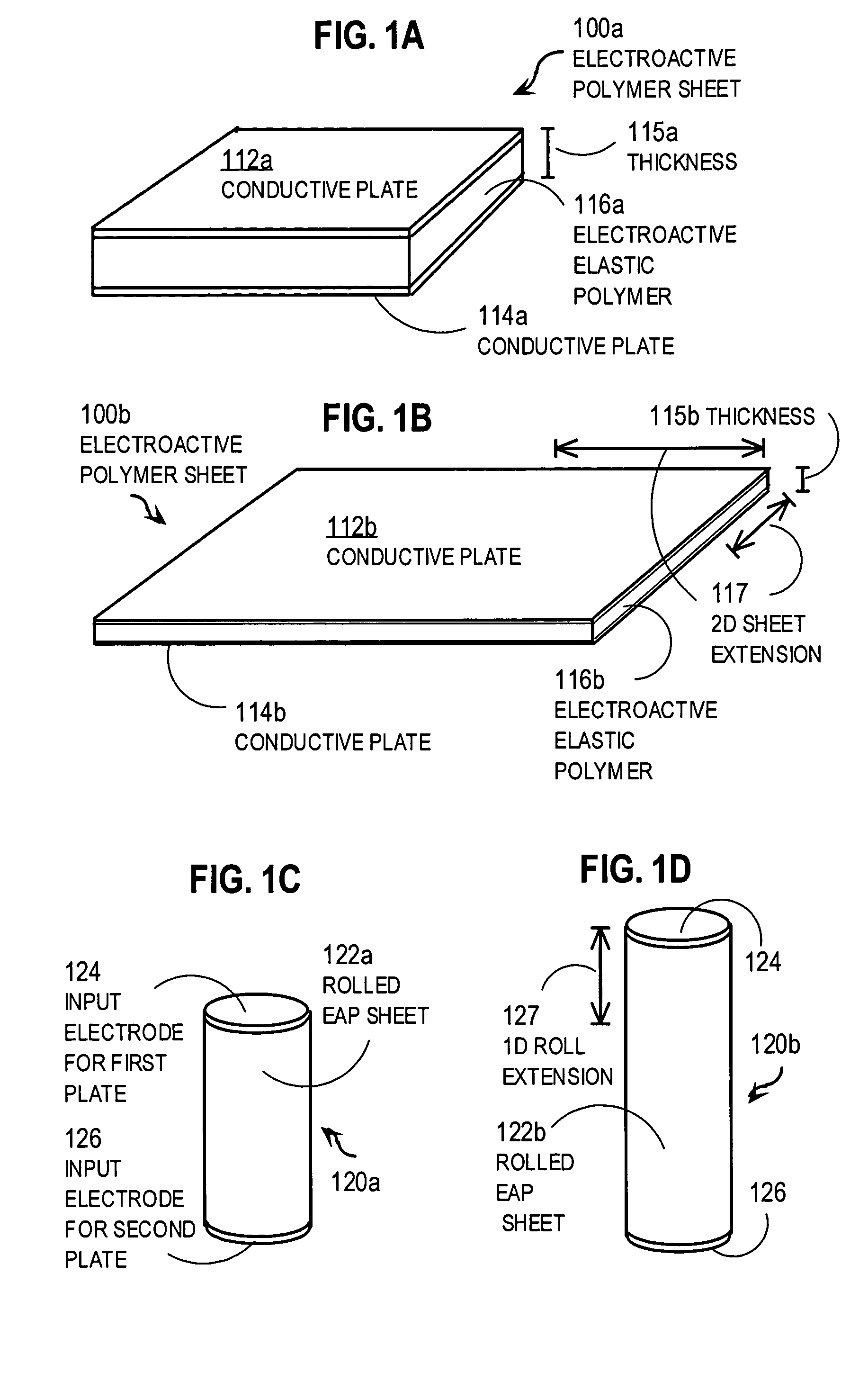

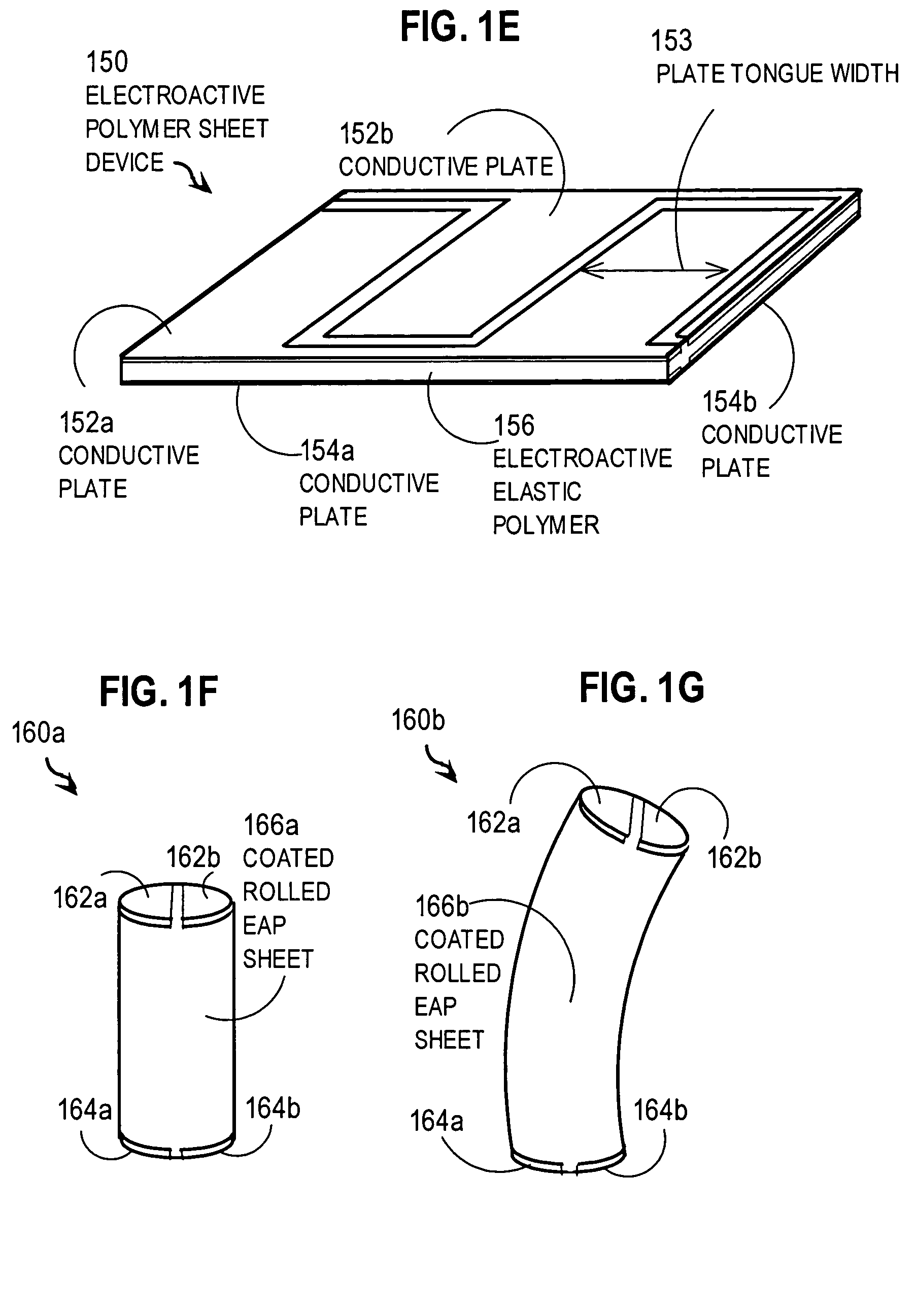

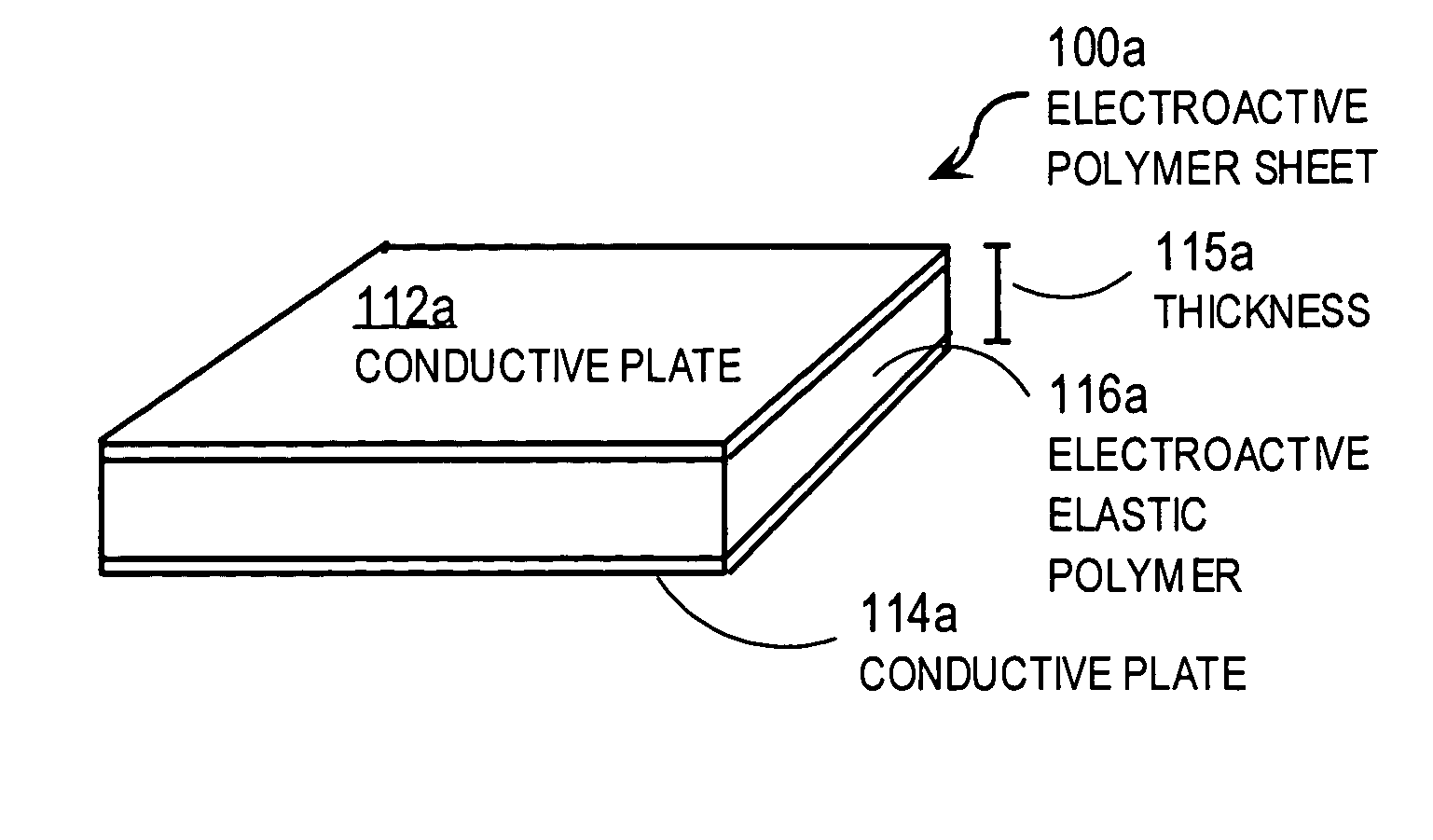

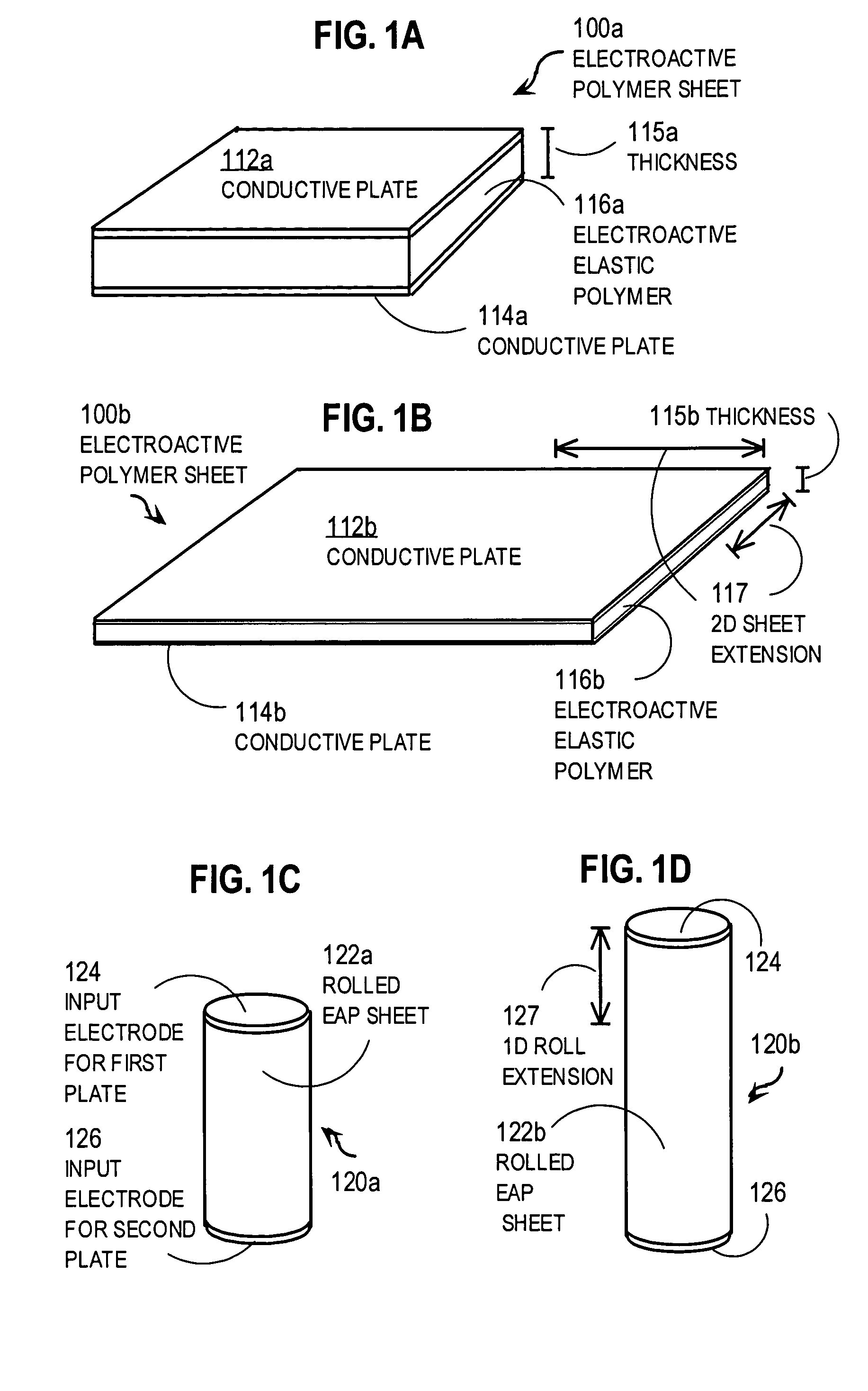

Variable ratio transmission elements for motor drive shafts

ActiveUS20050162049A1Increase radiusImprove the circumferencePiezoelectric/electrostriction/magnetostriction machinesSemiconductor/solid-state device manufacturingMotor driveEngineering

A motor transmission element includes an axle, an expandable circumferential component and multiple rolled electroactive polymer (EAP) devices. The circumferential component is located at a contact radius from the axle for connection to a different rotating body and is mechanically connected to the axle. The rolled EAP devices are mechanically connected to the circumferential component and the axle. Each rolled EAP device has a pair of input electrodes and is configured to deform substantively parallel to a roll longitudinal axis upon application of a voltage difference. Deformation of a rolled EAP device causes a change in the contact radius. A voltage difference that expands the rolled EAP device increases the contact radius, and thereby the circumference of the transmission element. By varying the voltage, a continuously variable ratio can be achieved between a rate of rotation of the transmission element and a rate of rotation of the second body.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

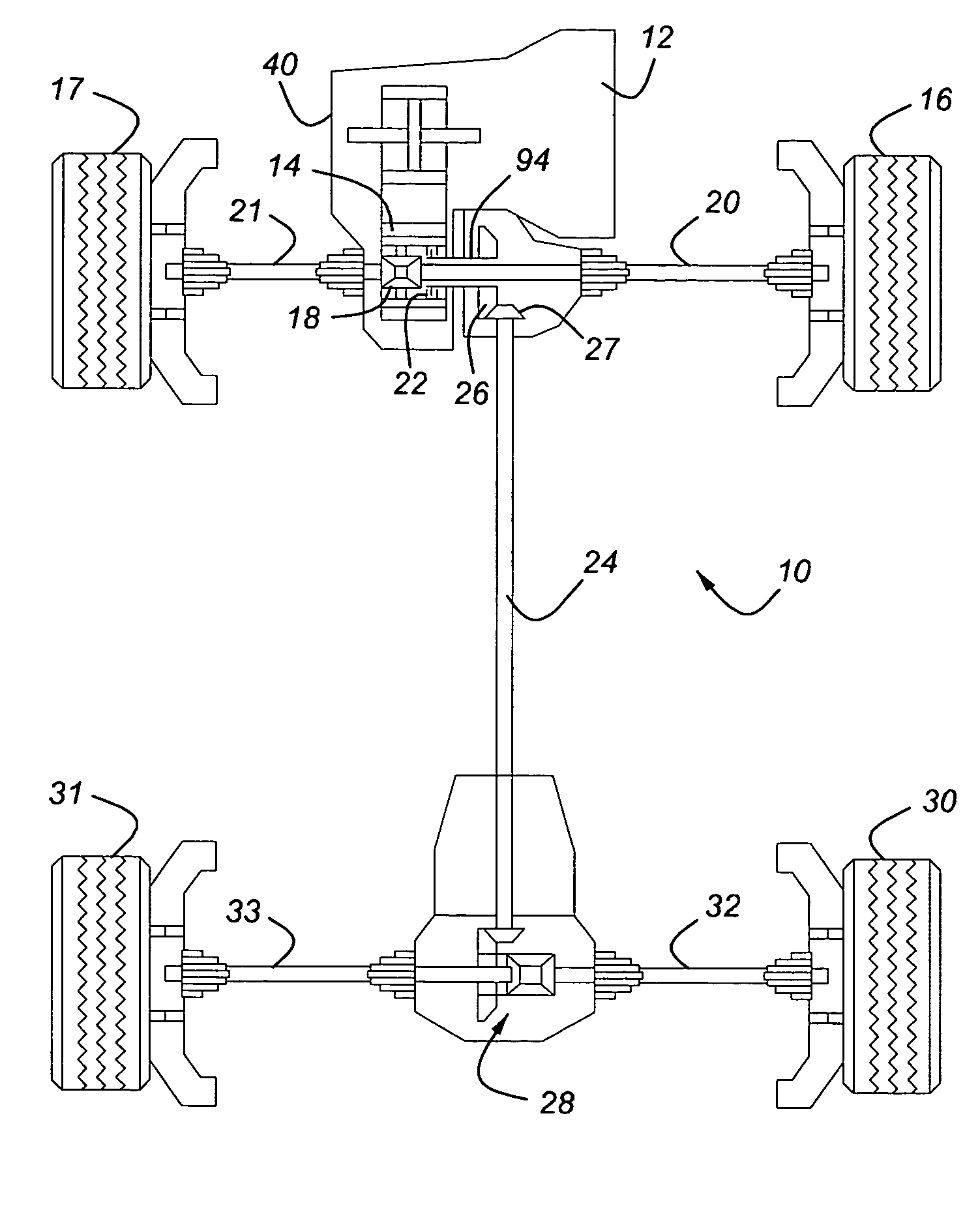

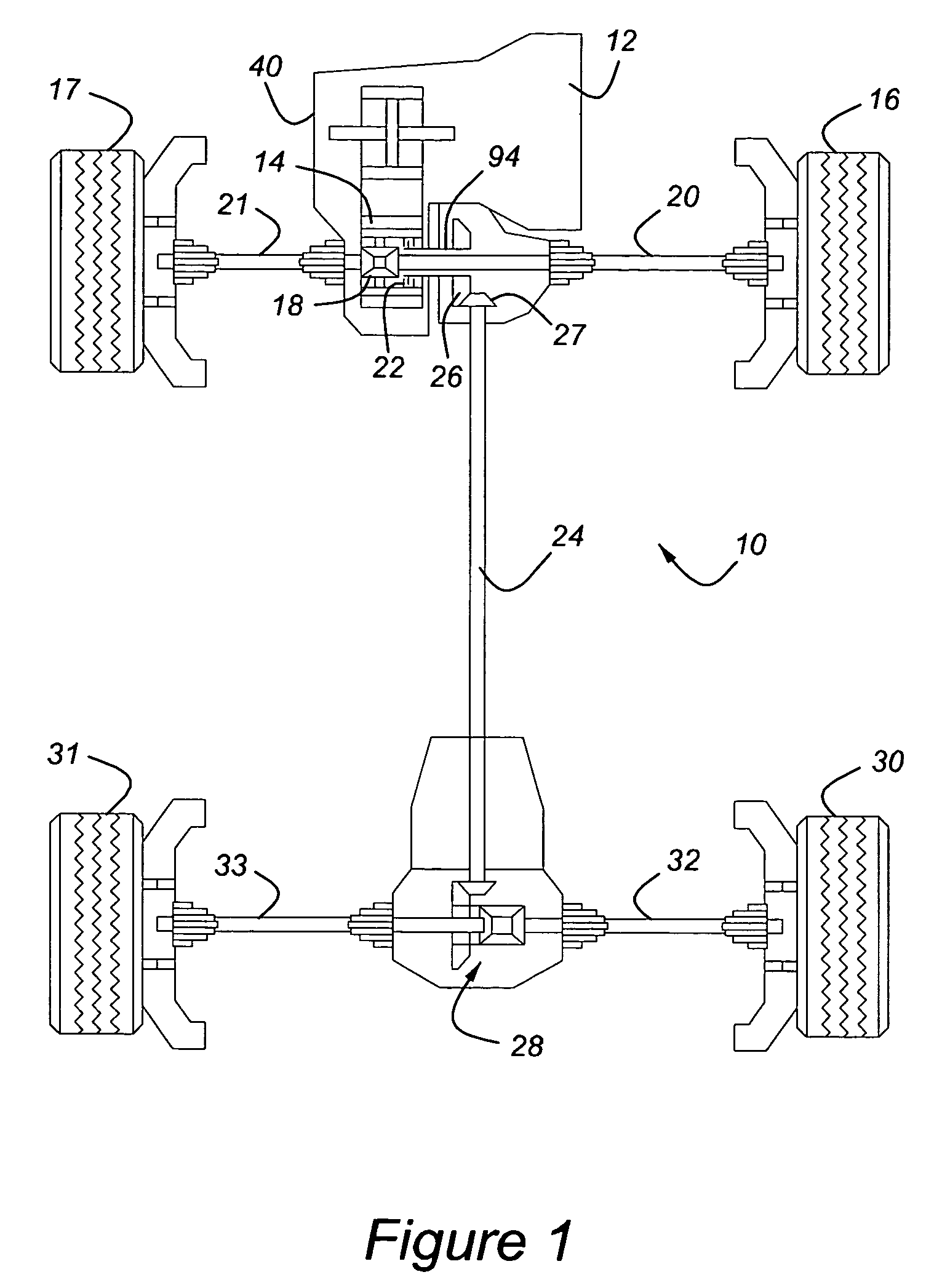

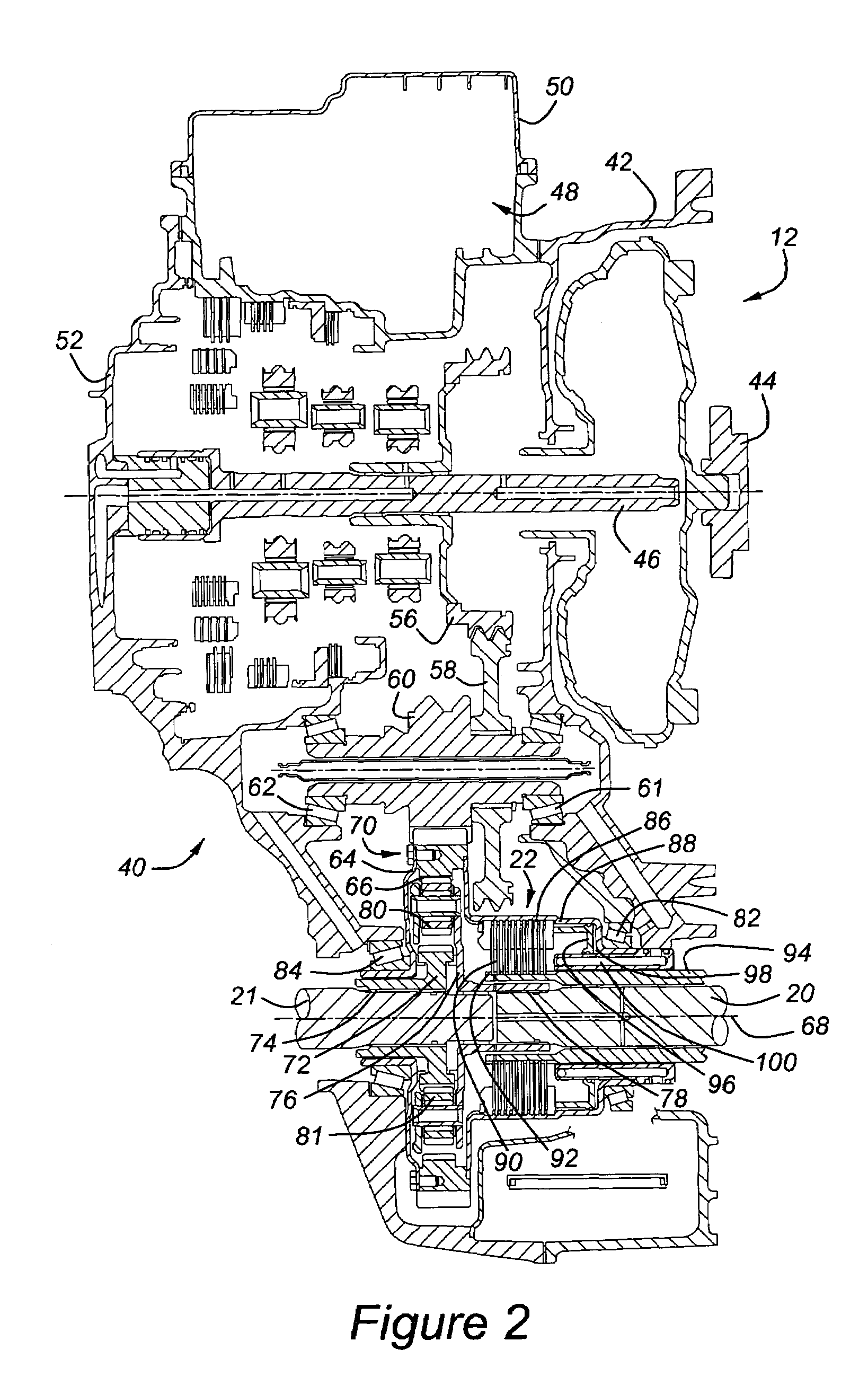

Transaxle having a differential mechanism and on-demand transfer clutch

ActiveUS7309301B2Component can be removedSpace minimizationGearing controlDifferential gearingsDrive wheelControl system

A powertrain for transmitting power to the drive wheels of a vehicle includes a transaxle case containing a transaxle drive mechanism for producing variable ratios of a speed of its output and a speed of its input, a differential mechanism for transmitting power between the output and the wheels of a first set of drive wheel, a transfer clutch secured to the output for transmitting power between the output and the wheels of a second set of drive wheels, and a control system for hydraulically actuating the transfer clutch.

Owner:FORD GLOBAL TECH LLC

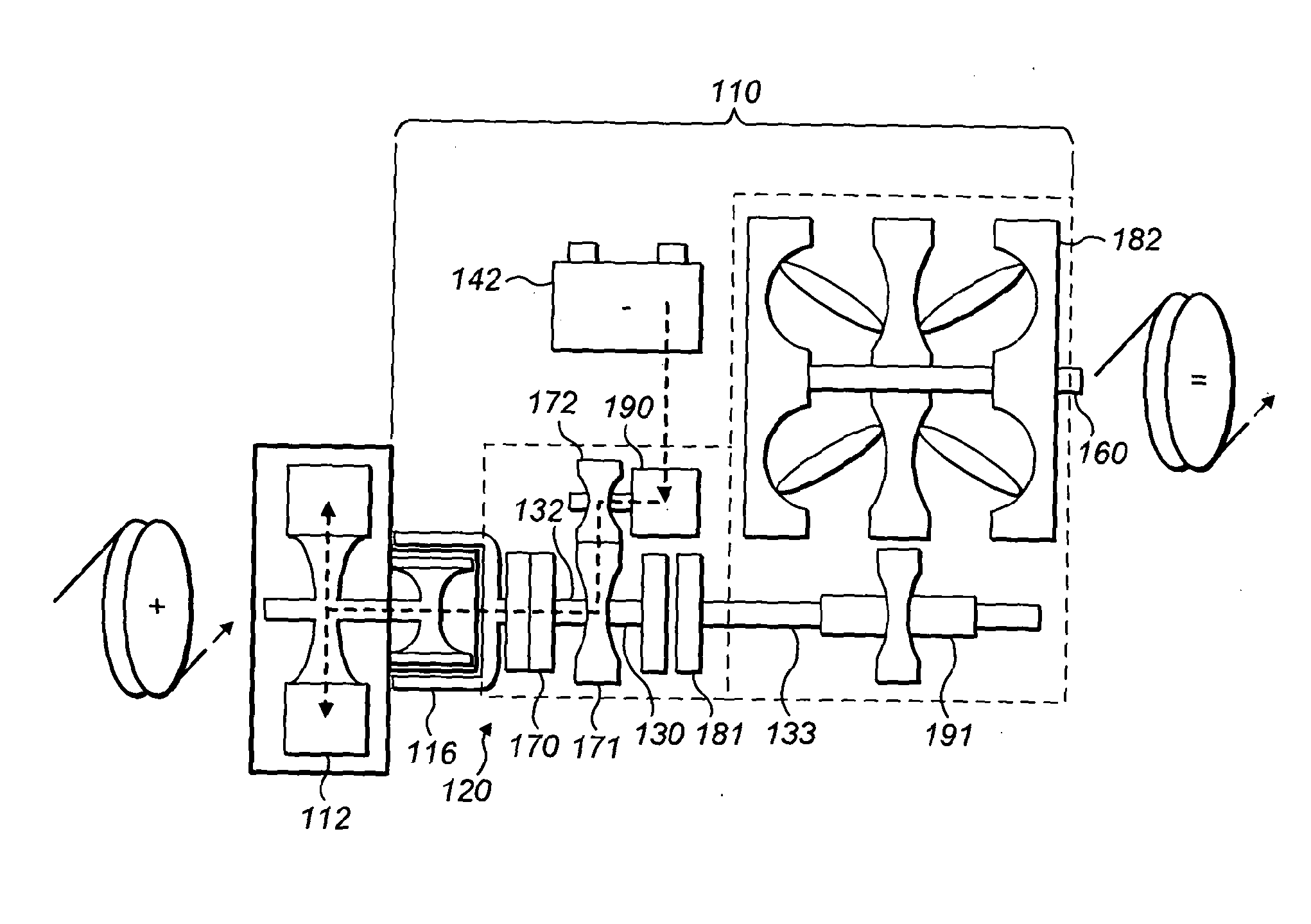

Energy storage system

InactiveUS20140103761A1Improve efficiencySuppress chargingHybrid vehiclesDynamo-electric brakes/clutchesCouplingMechanical energy

An apparatus is provided comprising a flywheel (112) for storing kinetic energy and an electrical machine (190) mechanically coupled to the flywheel and arranged for conversion between mechanical and electrical energy. The apparatus is arranged for transferring energy between the flywheel and a vehicle transmission via a variable ratio transmission (182). The electrical machine is coupled to the flywheel via a disconnect clutch which comprises a magnetic coupling (116).

Owner:RICARDO UK LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com