Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1587 results about "Transaxle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A transaxle is a single mechanical device which combines the functions of an automobile's transmission, axle, and differential into one integrated assembly. It can be produced in both manual and automatic versions.

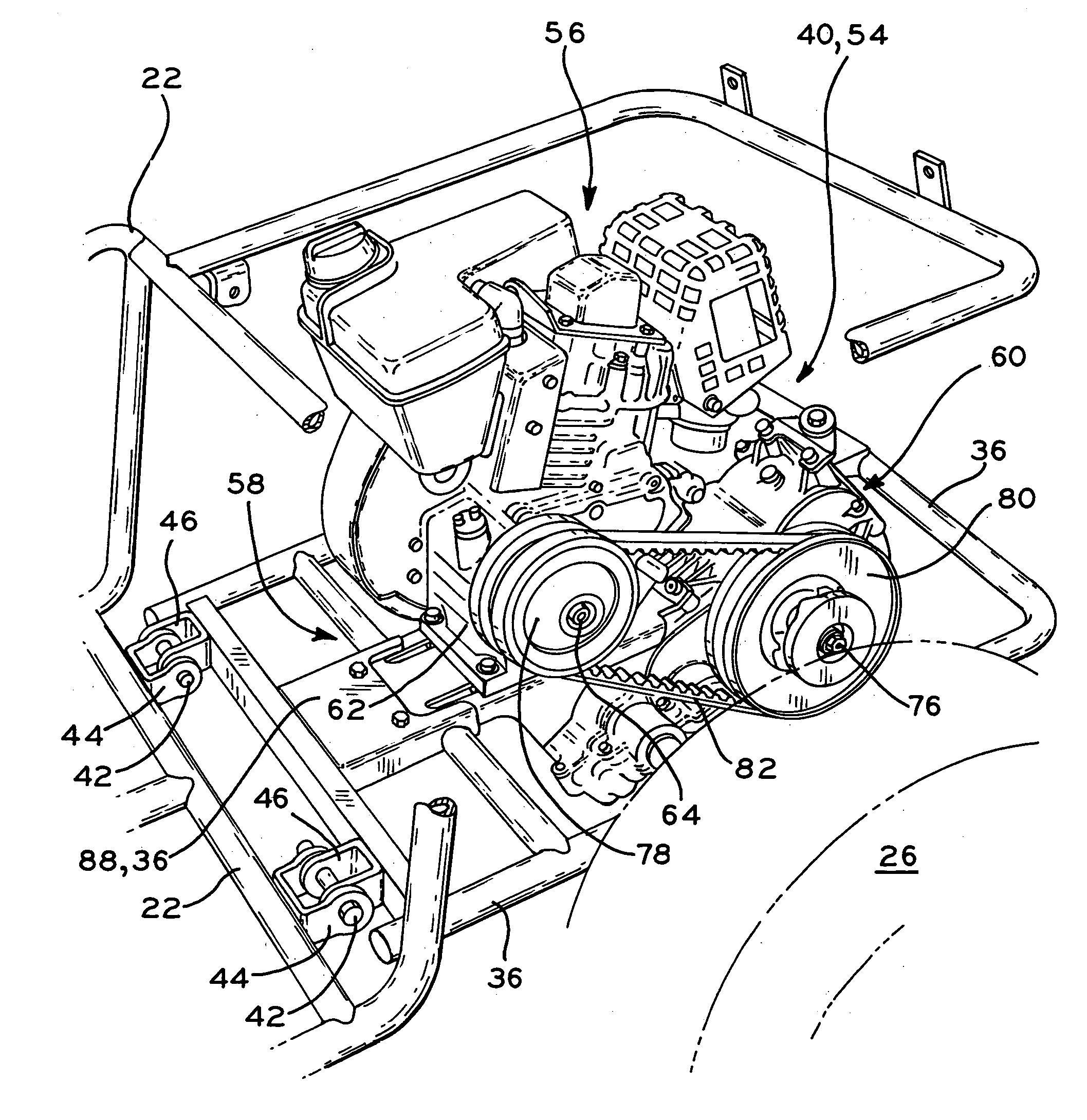

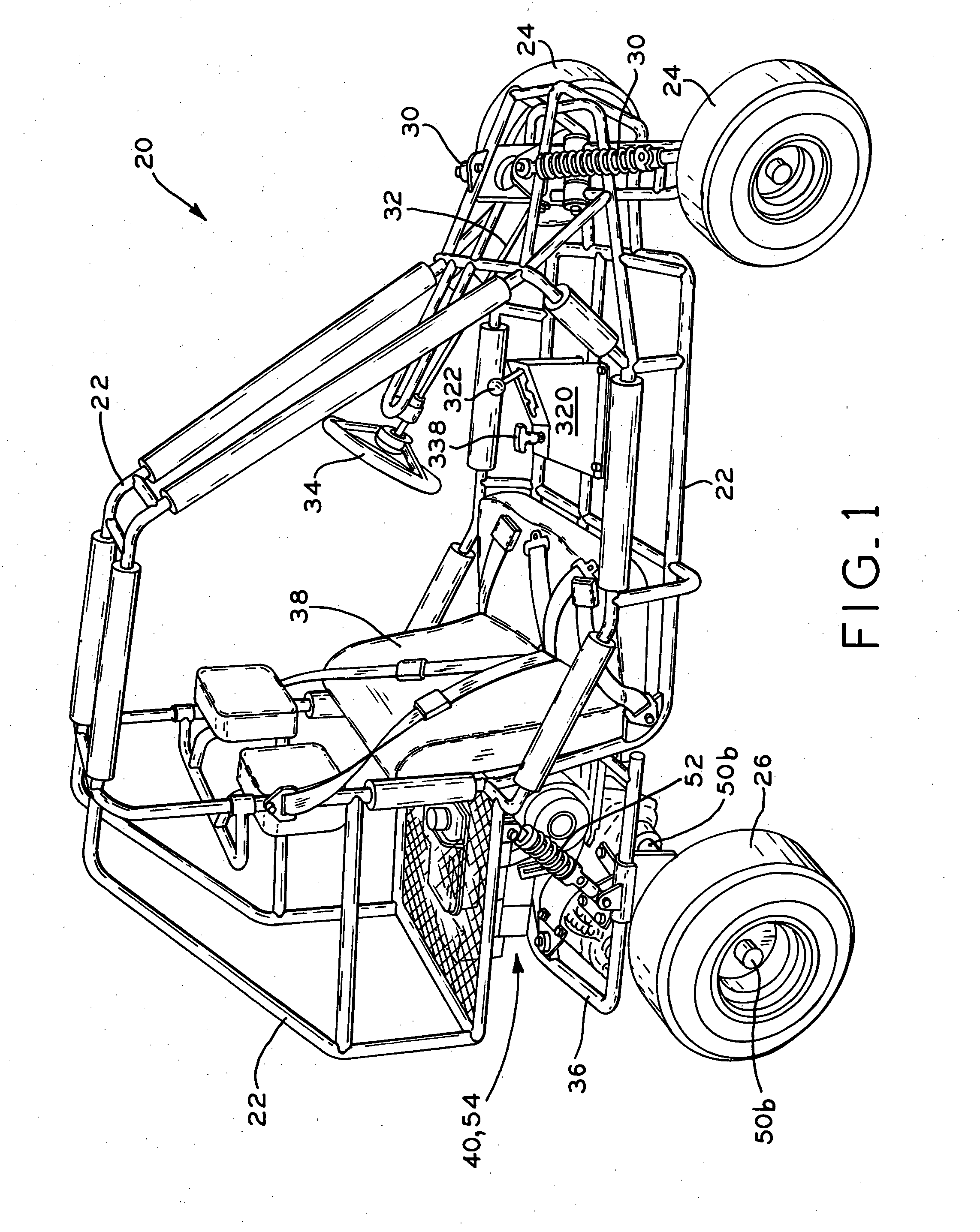

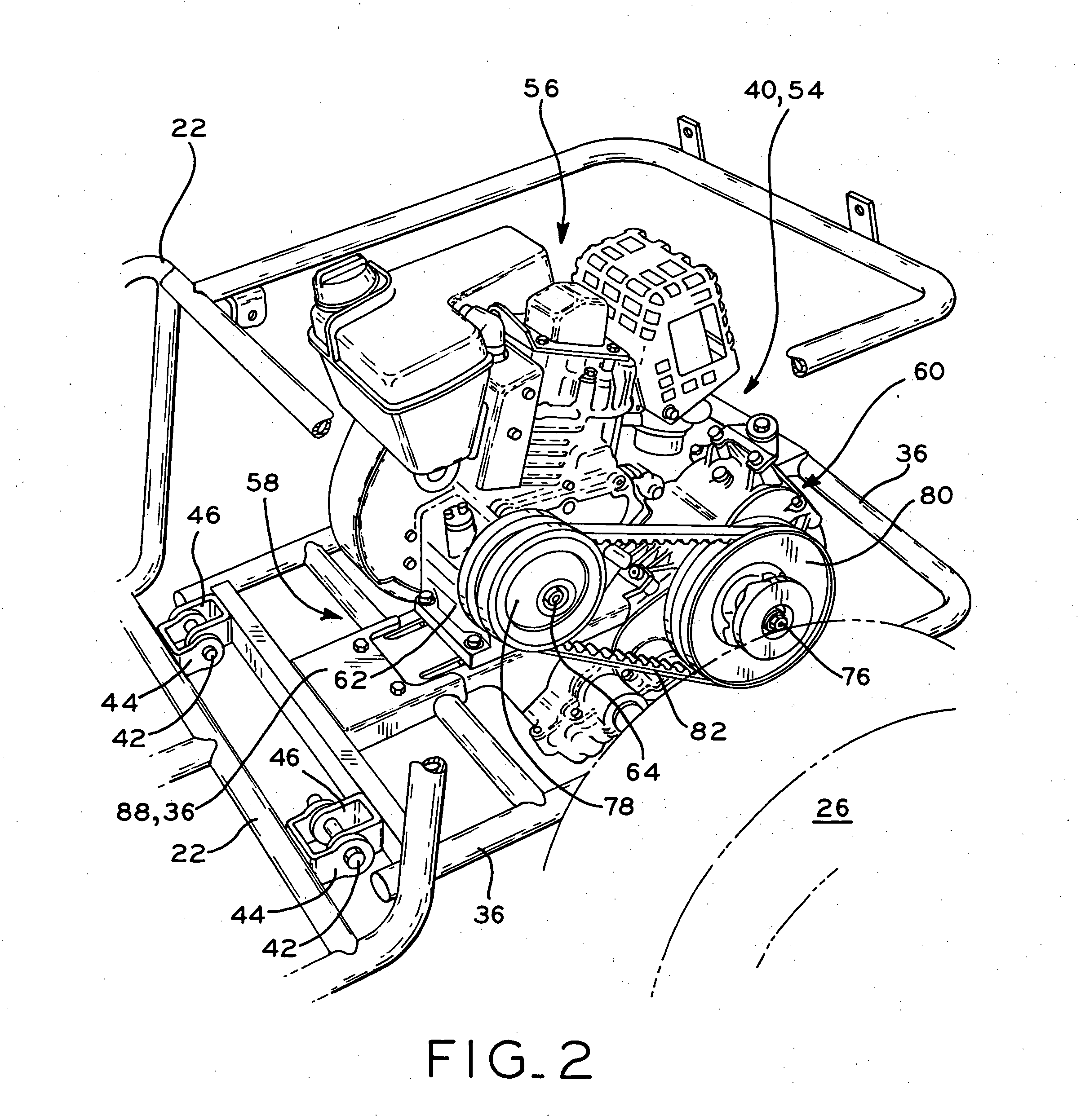

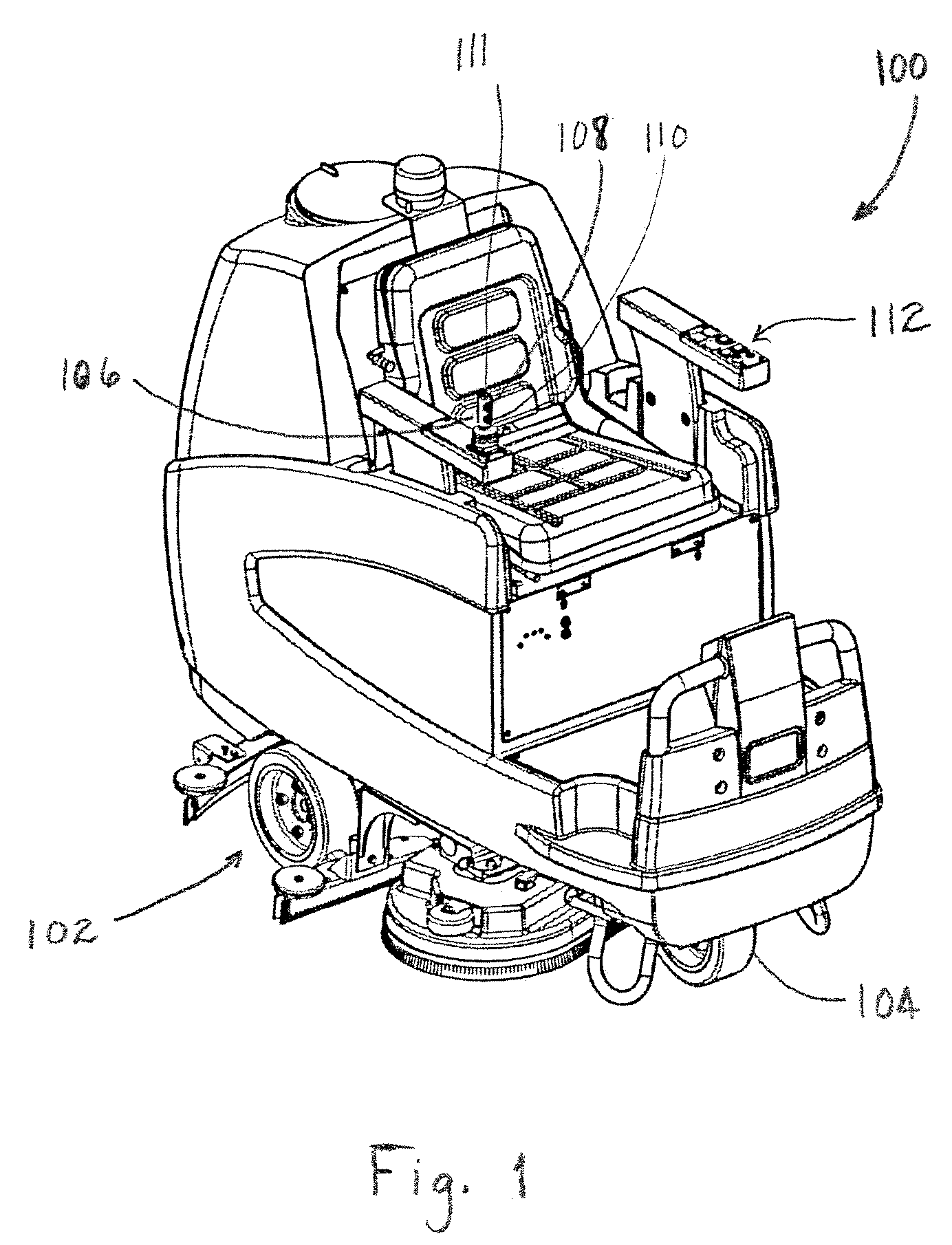

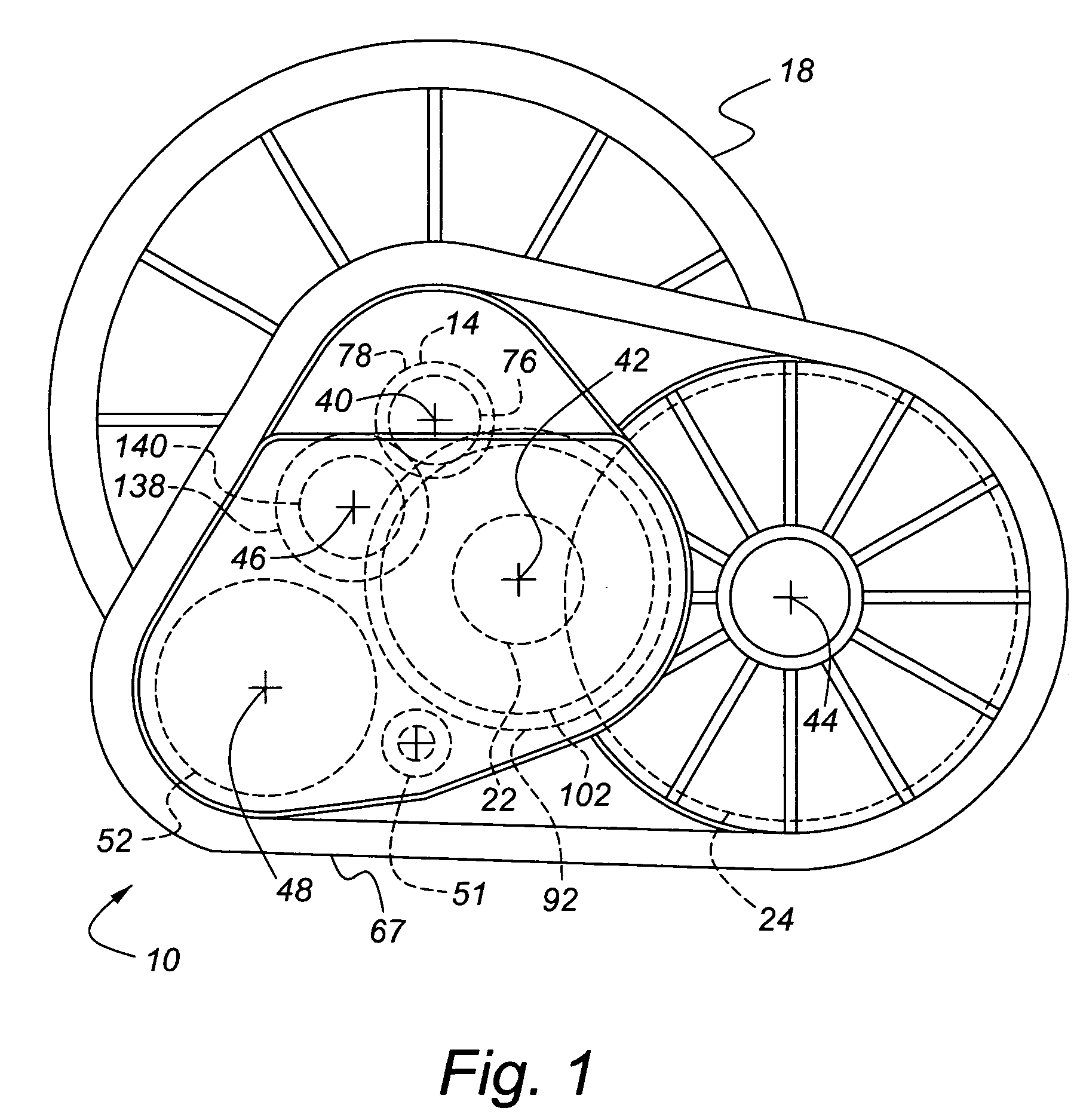

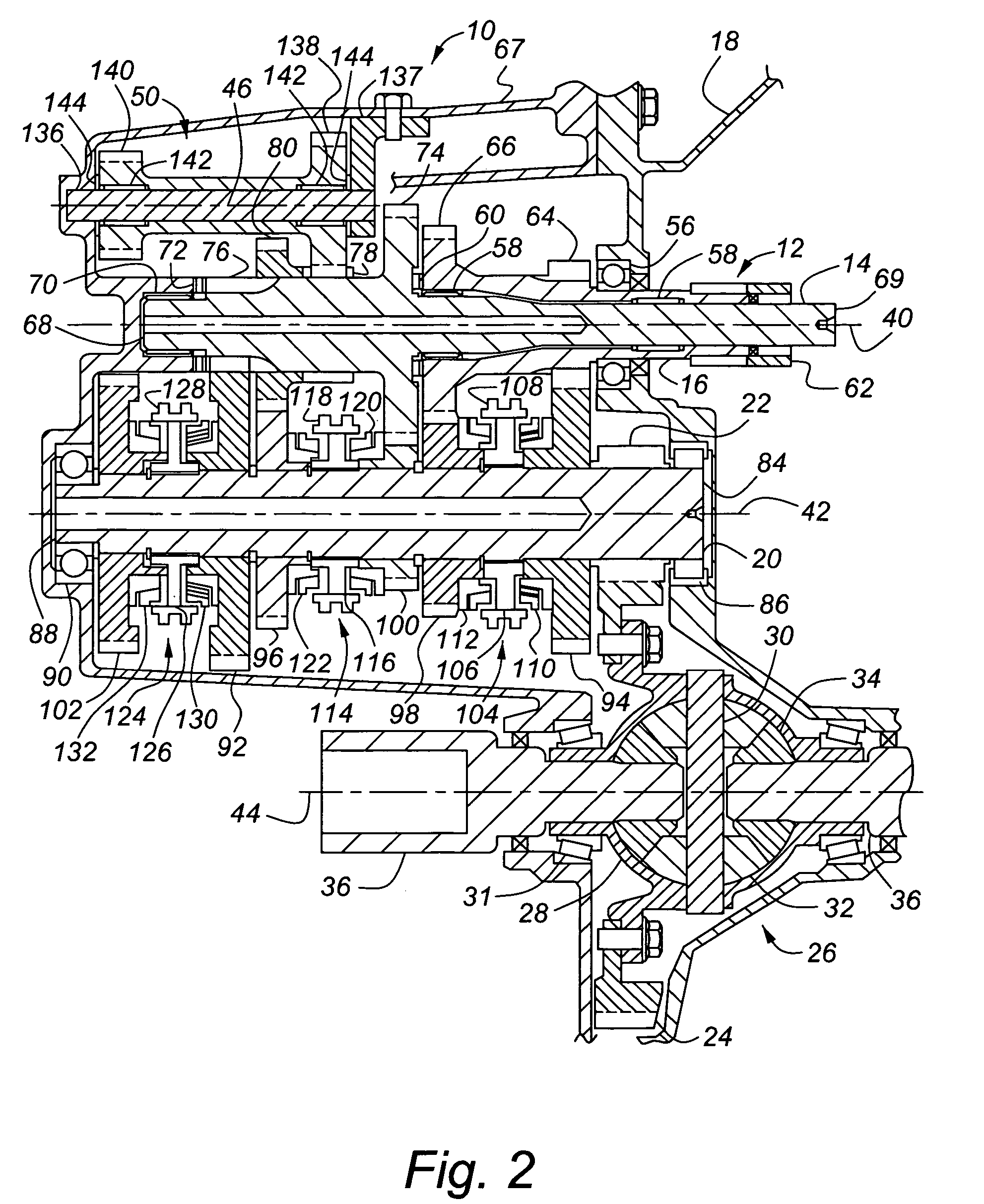

Power train for small recreational vehicle

InactiveUS20050173180A1Easy to installGood adhesionRace vehiclesUnderstructuresTransaxleAutomotive engineering

A small vehicle, such as a go-kart, which includes a power train unit including an engine and a transaxle which are attached to the frame of the vehicle as an integrated component. In this manner, easy installation of the engine and transaxle to the frame of the vehicle is facilitated. An adjustable engine mounting system is provided, which allows fine adjustment of the position of the engine to vary the tension of the belt drive which drivingly couples the engine and the transaxle. The transaxle includes a selective lock-out feature which allows an operator to lock out selected forward or reverse gears to thereby modify or limit the performance characteristics of the go-kart as desired to a particular application. Additionally, the transaxle includes a built-in differential which may be selectively locked out by the operator during running of the vehicle, in order to switch between “differential active” and “differential locked-out” positions.

Owner:TECUMSEH PROD CO

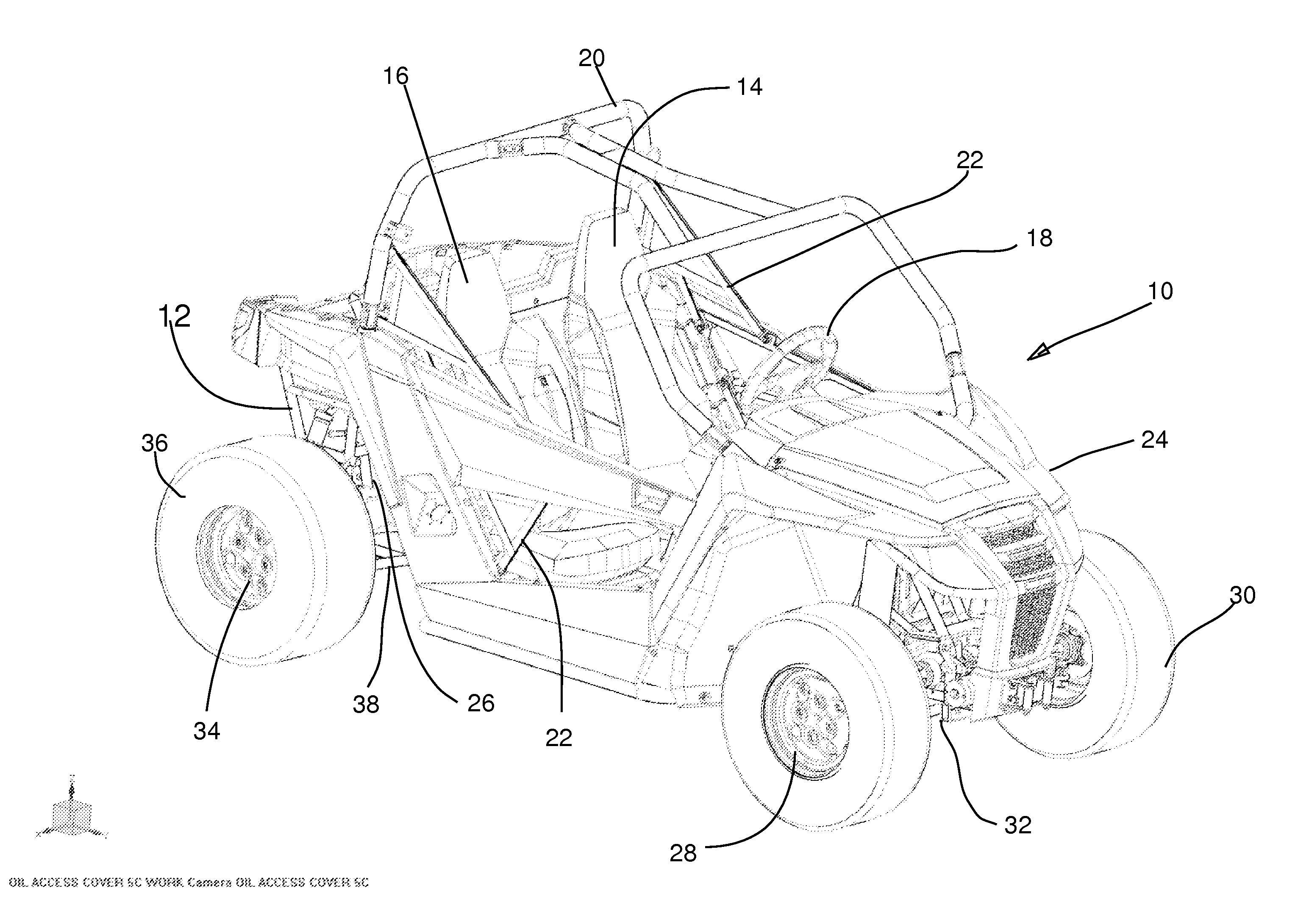

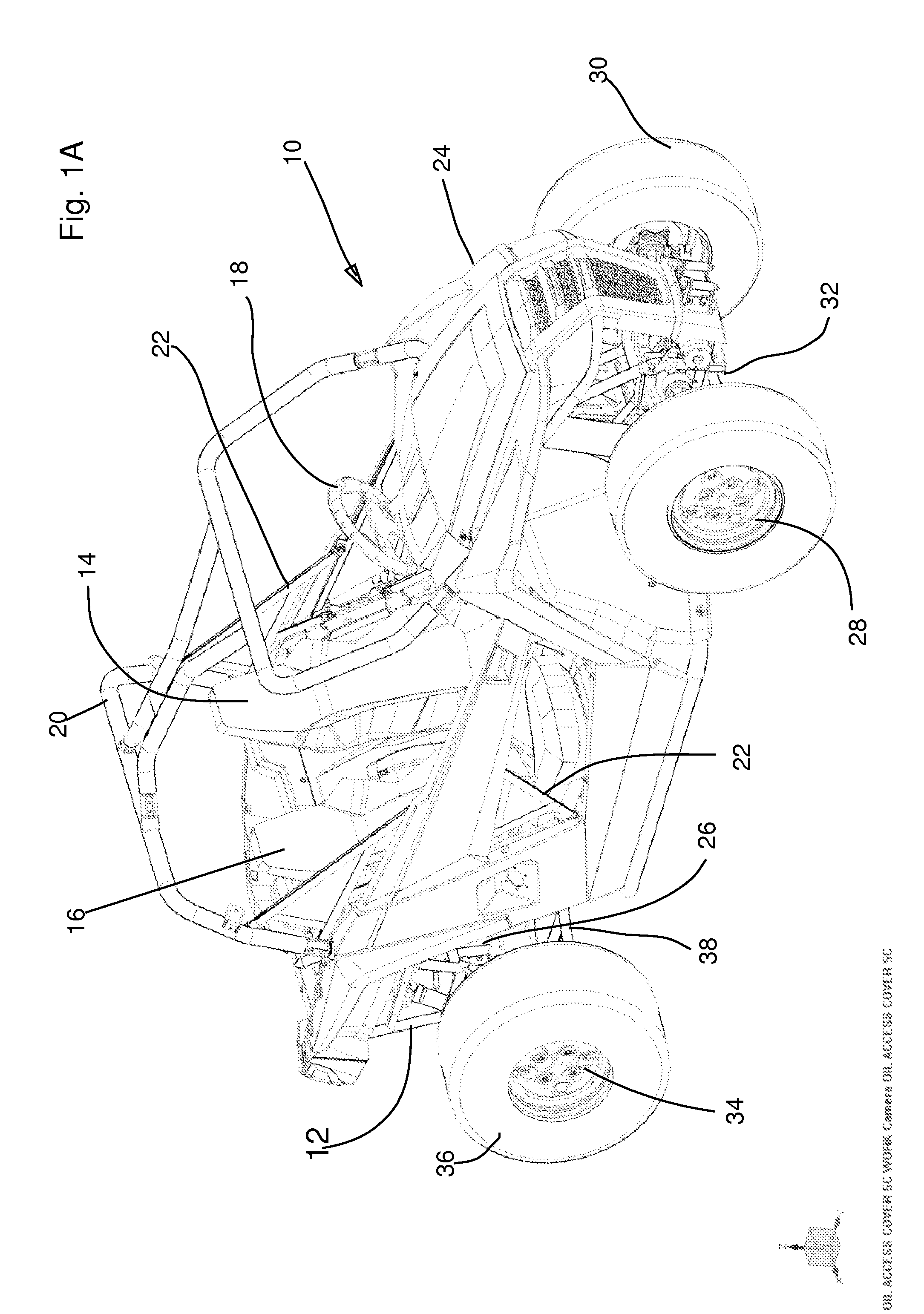

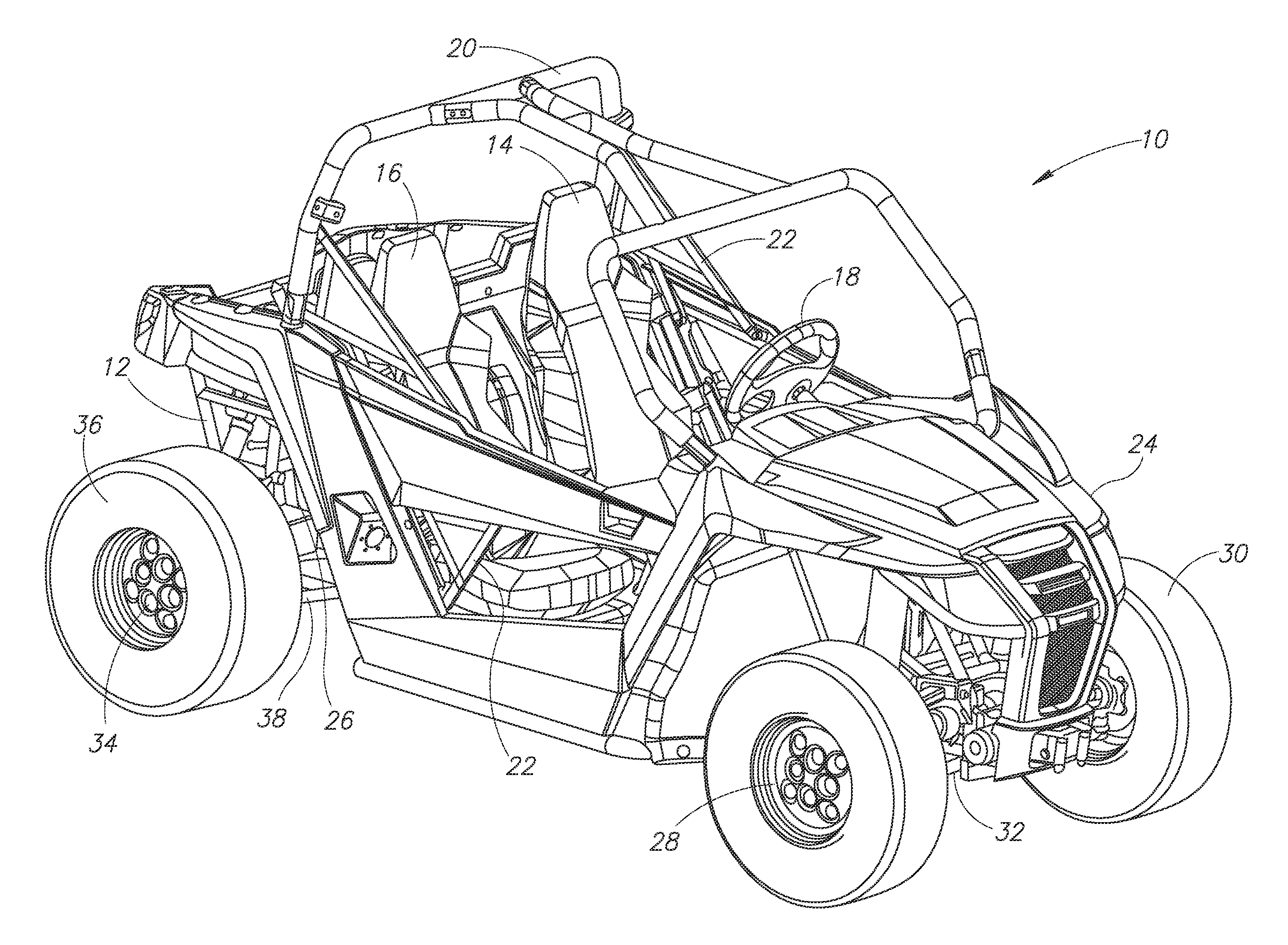

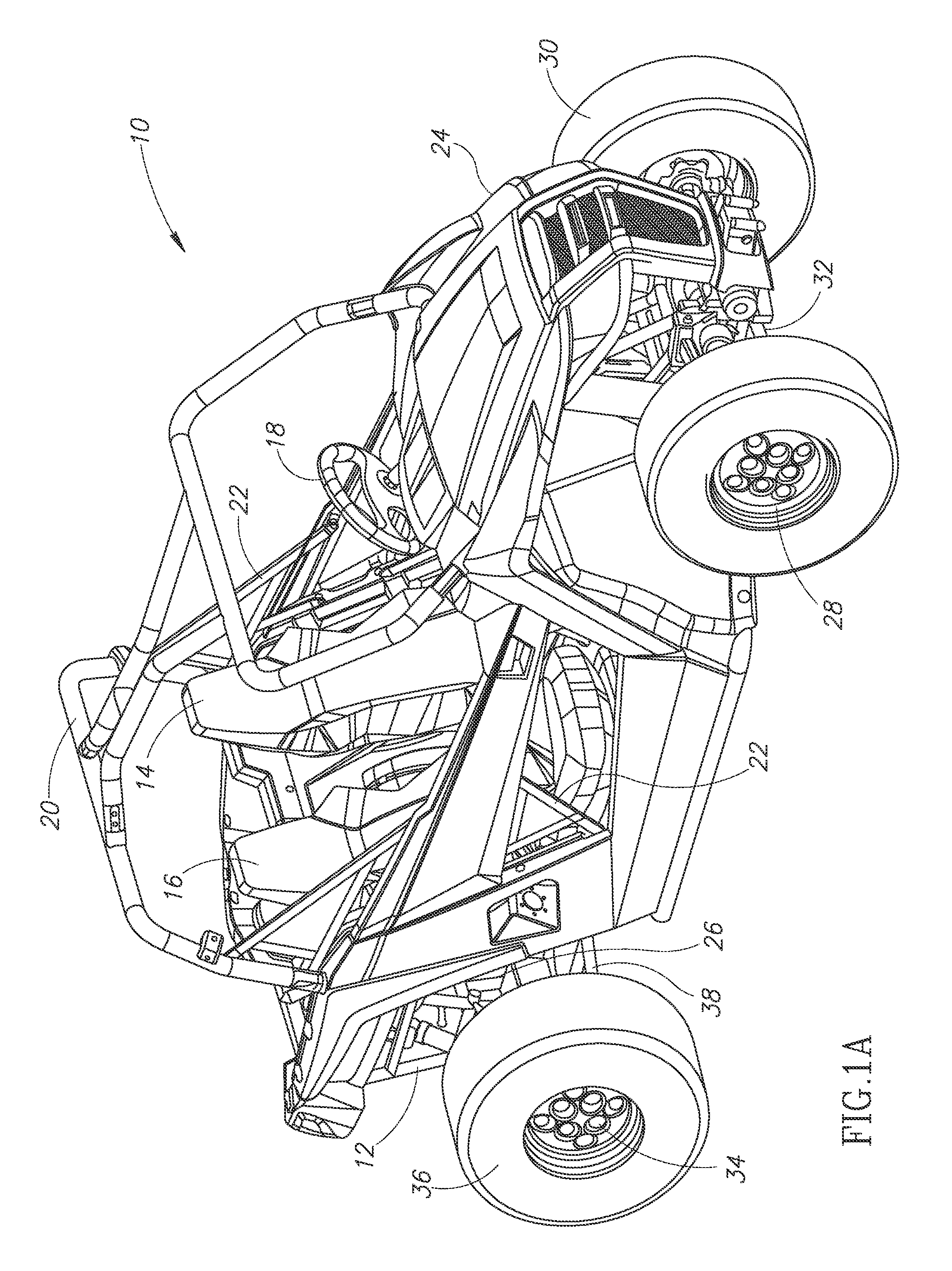

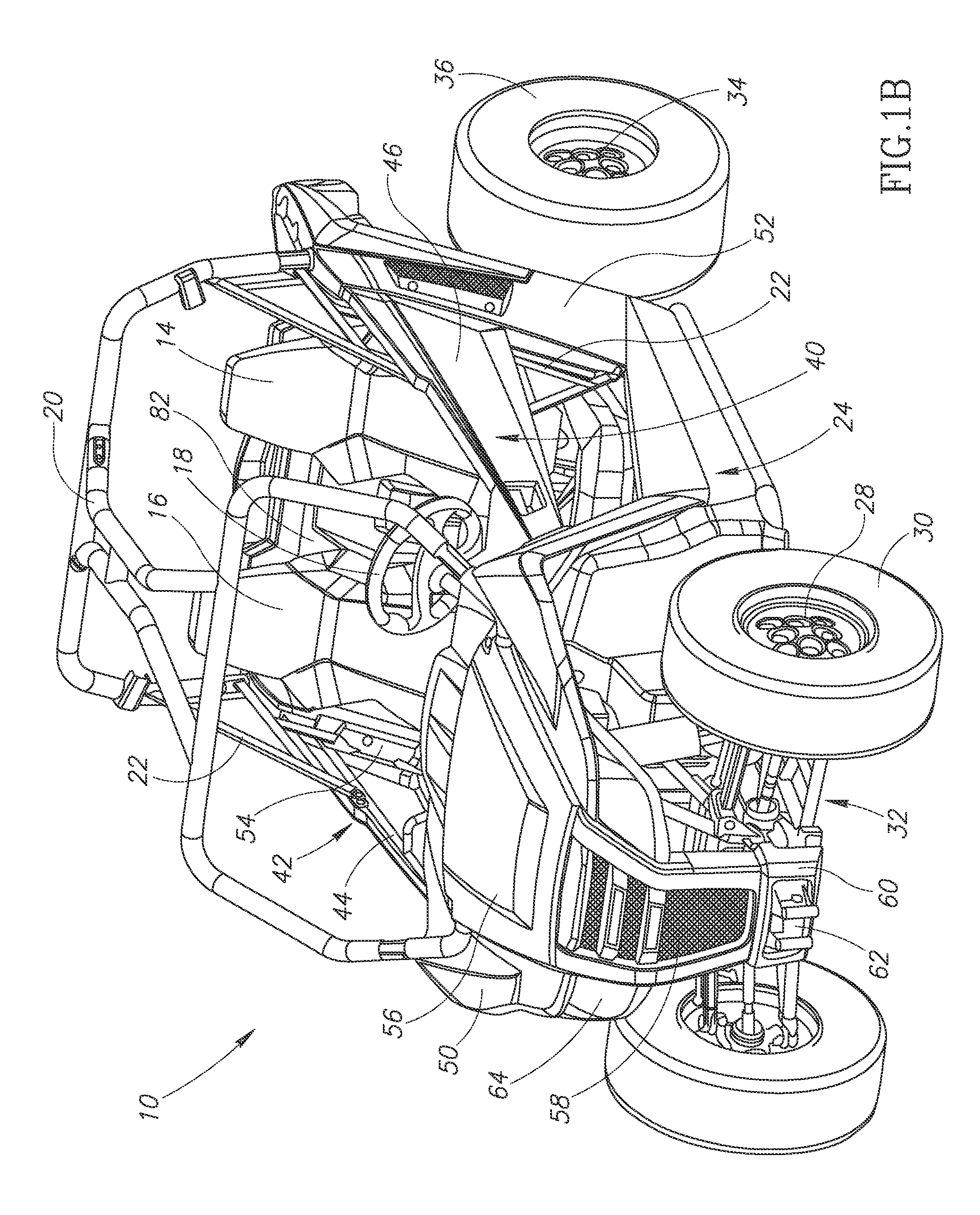

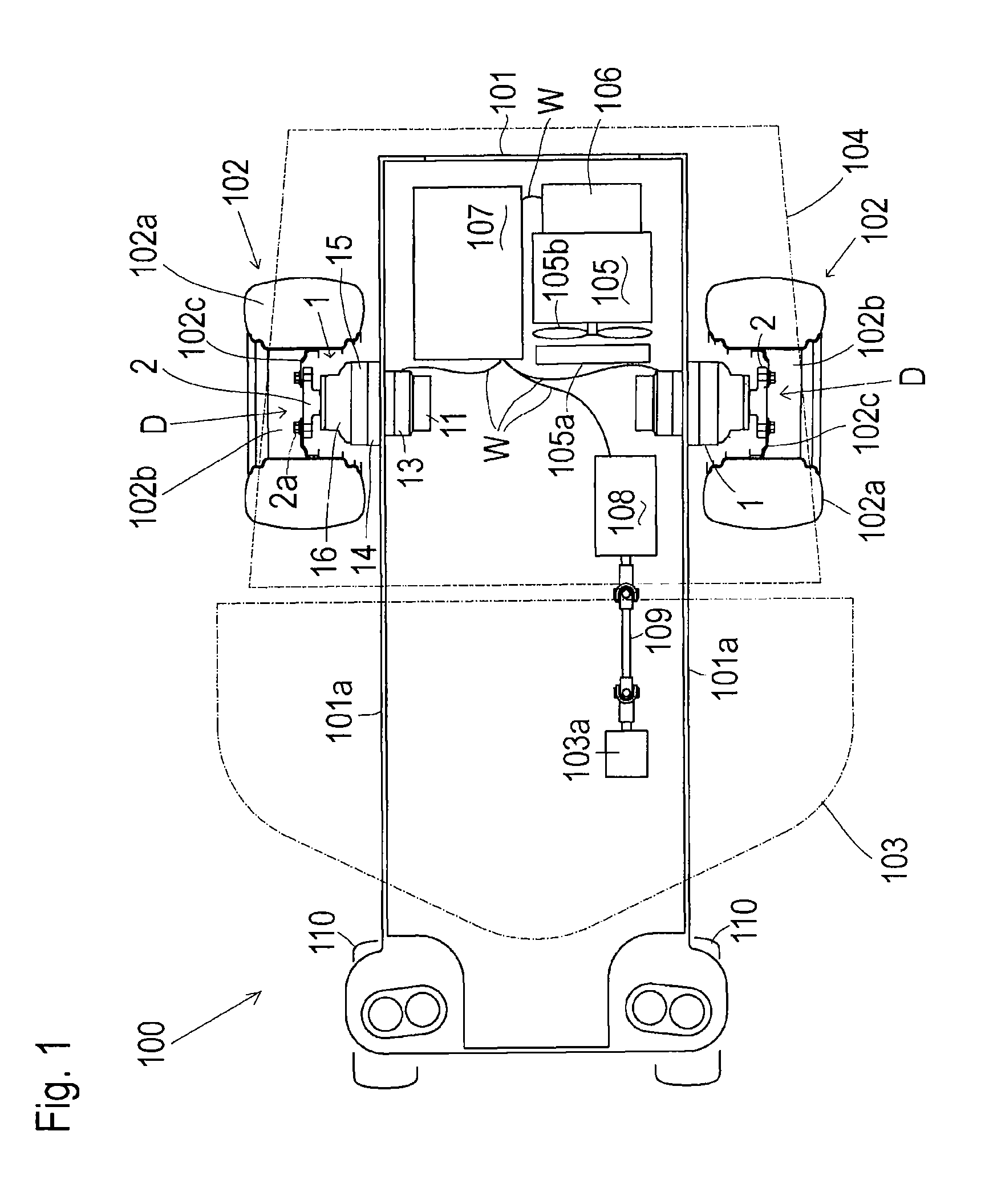

Off-Highway Recreational Vehicle

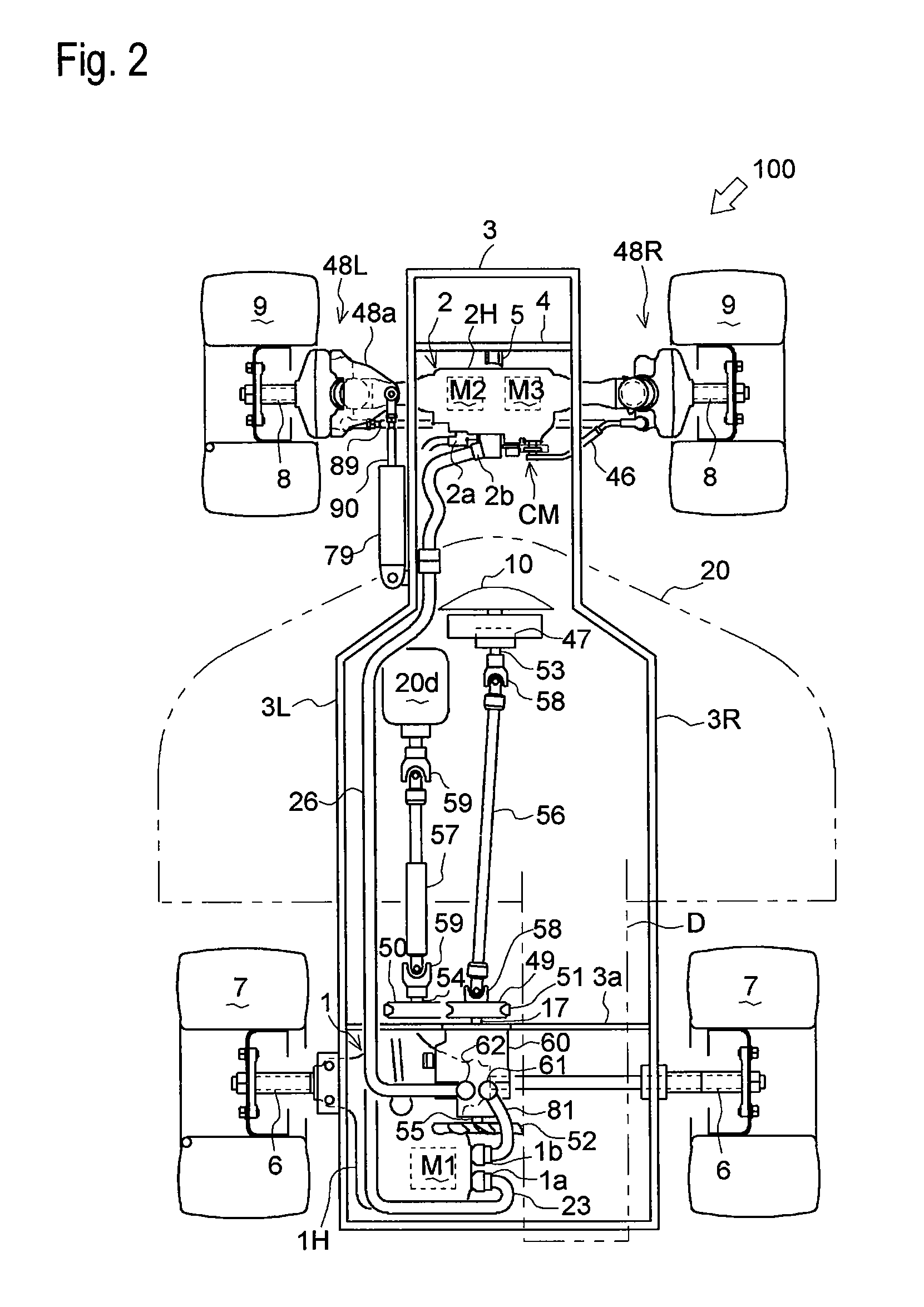

A recreational off-highway vehicle includes side-by-side passenger and driver seats held within a chassis that is approximately 50 inches wide. The seats sit low in the chassis and are covered by a roll cage. Grab handles are positioned on the sides of the passenger seat. Select large round tubing protects the vehicle, while rectangular tubing frames the portions of the vehicle beneath body panels. The vehicle is powered by an engine rearward of the seats that is connected to a transaxle. The engine and transaxle are isolation mounted together with a portion of the air intake assembly. The vehicle is suited for rough terrain travel.

Owner:ARCTIC CAT

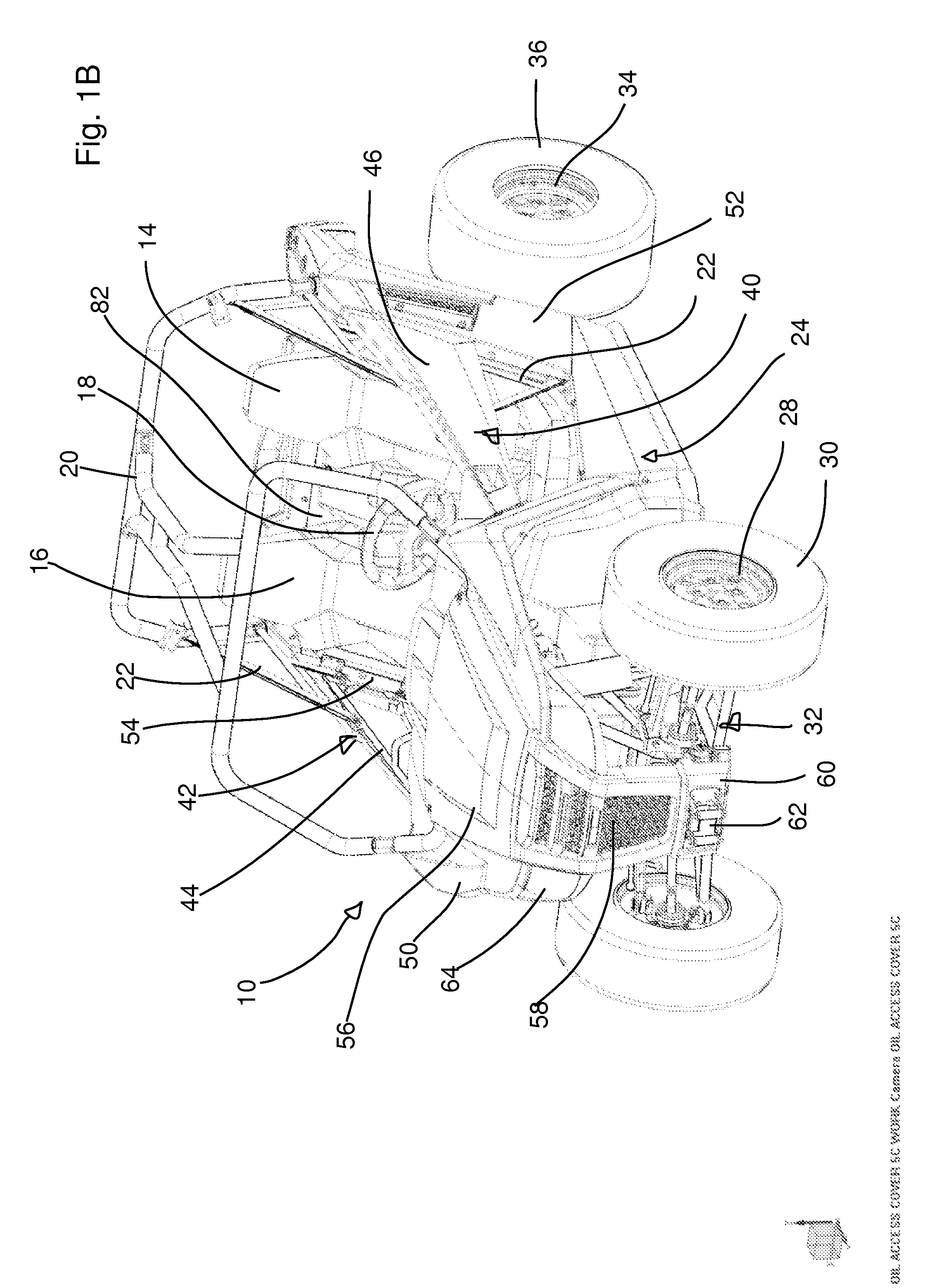

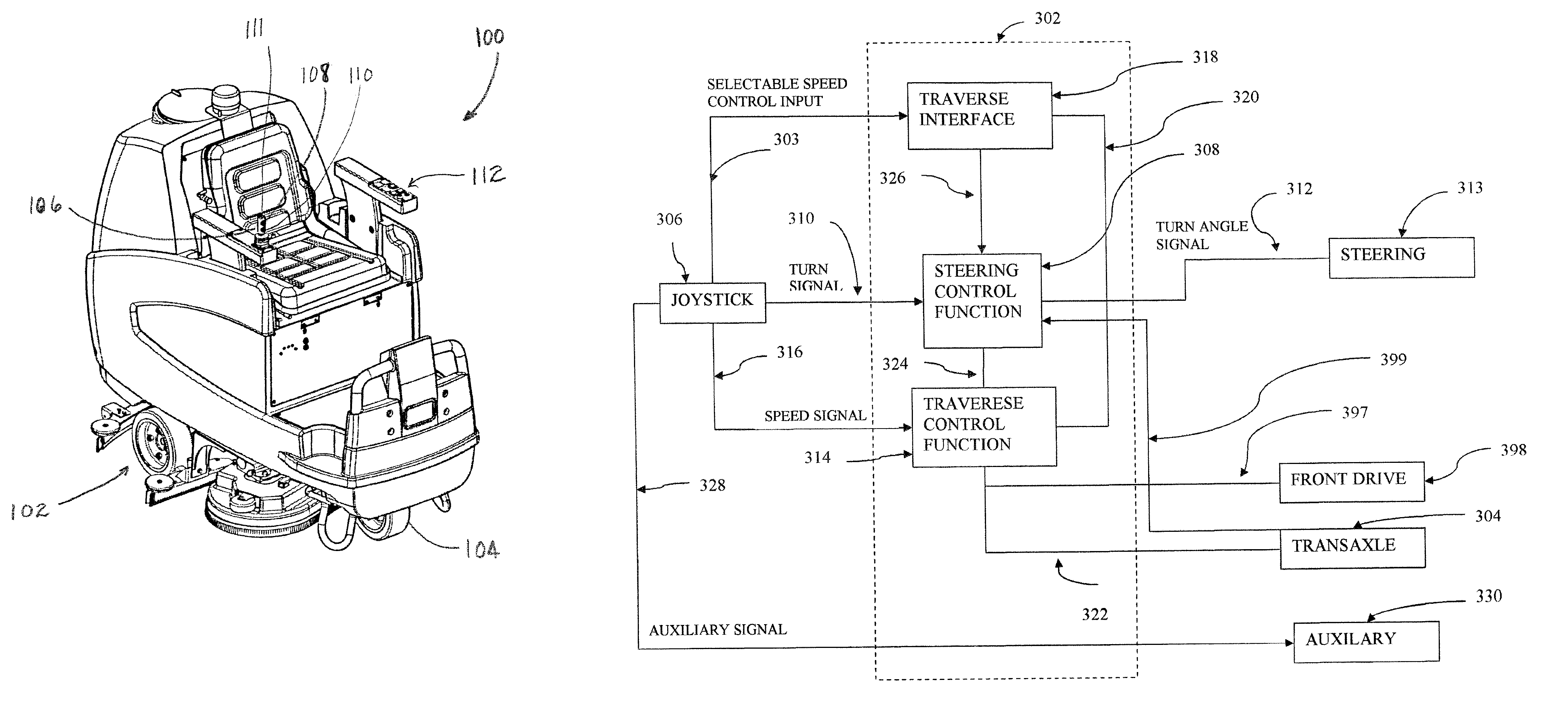

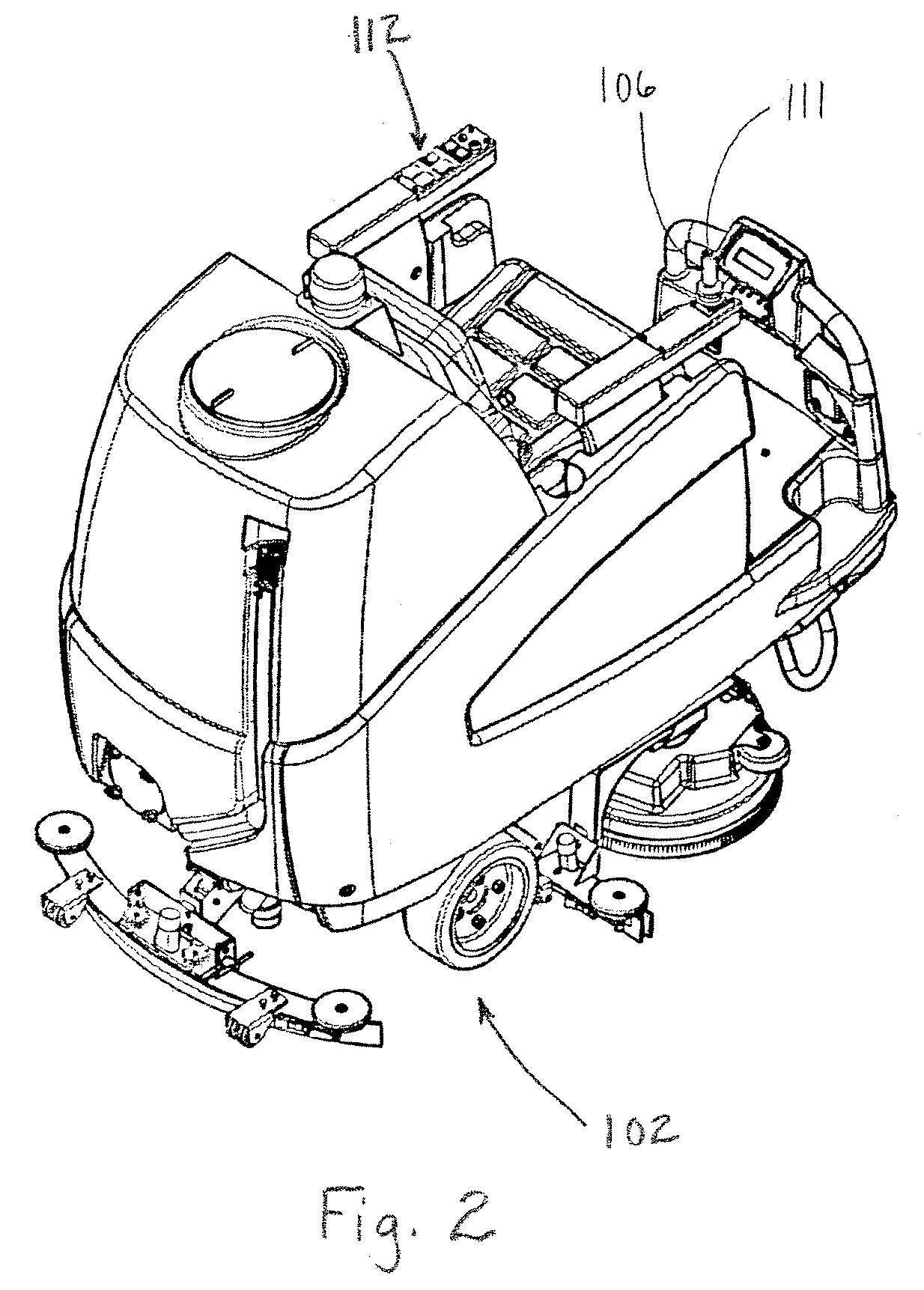

Joystick controlled scrubber

ActiveUS7041029B2Increase awarenessMaintenance safetyMotor/generator/converter stoppersDC motor speed/torque controlTurn angleJoystick

Owner:NILFISK

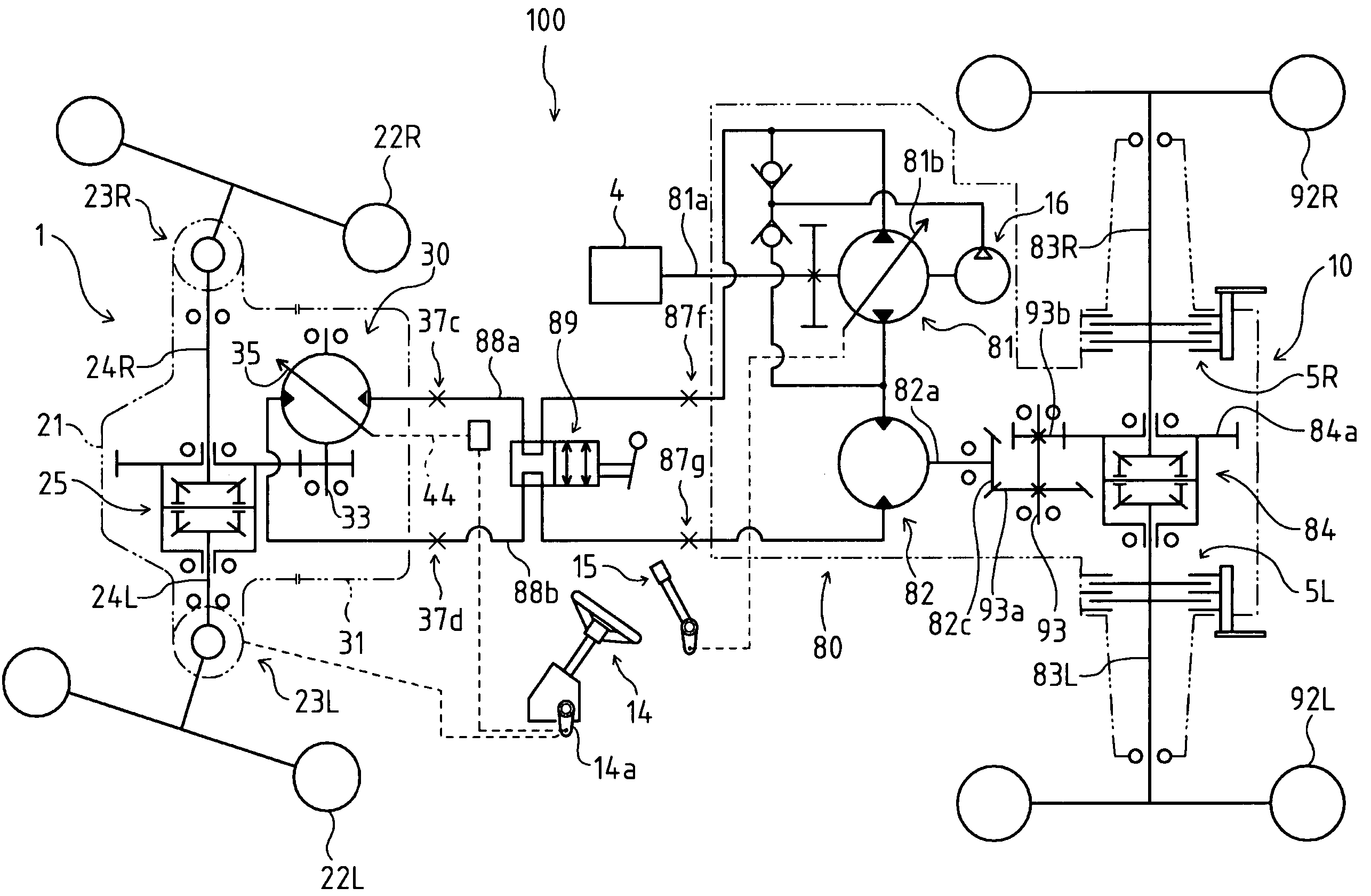

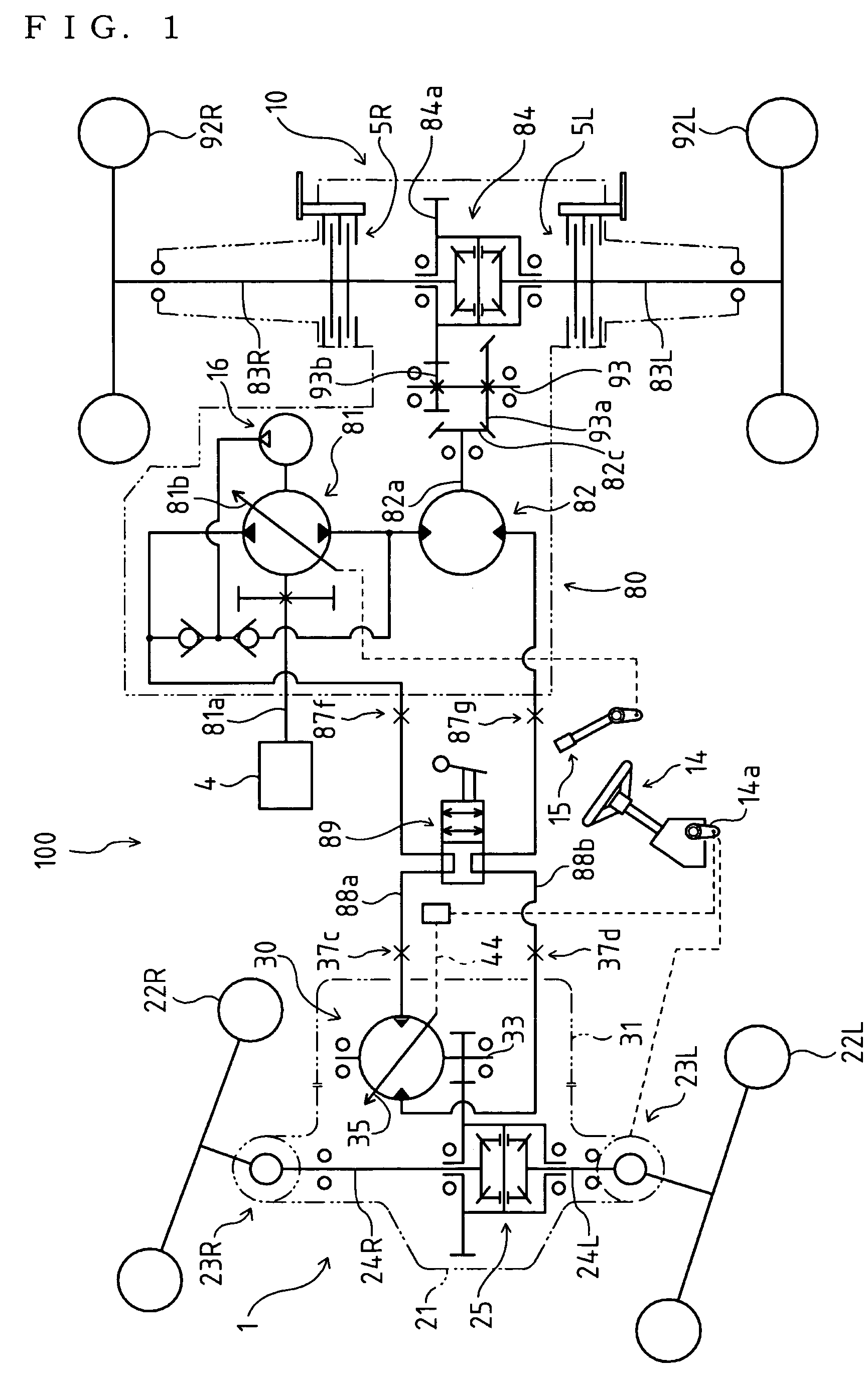

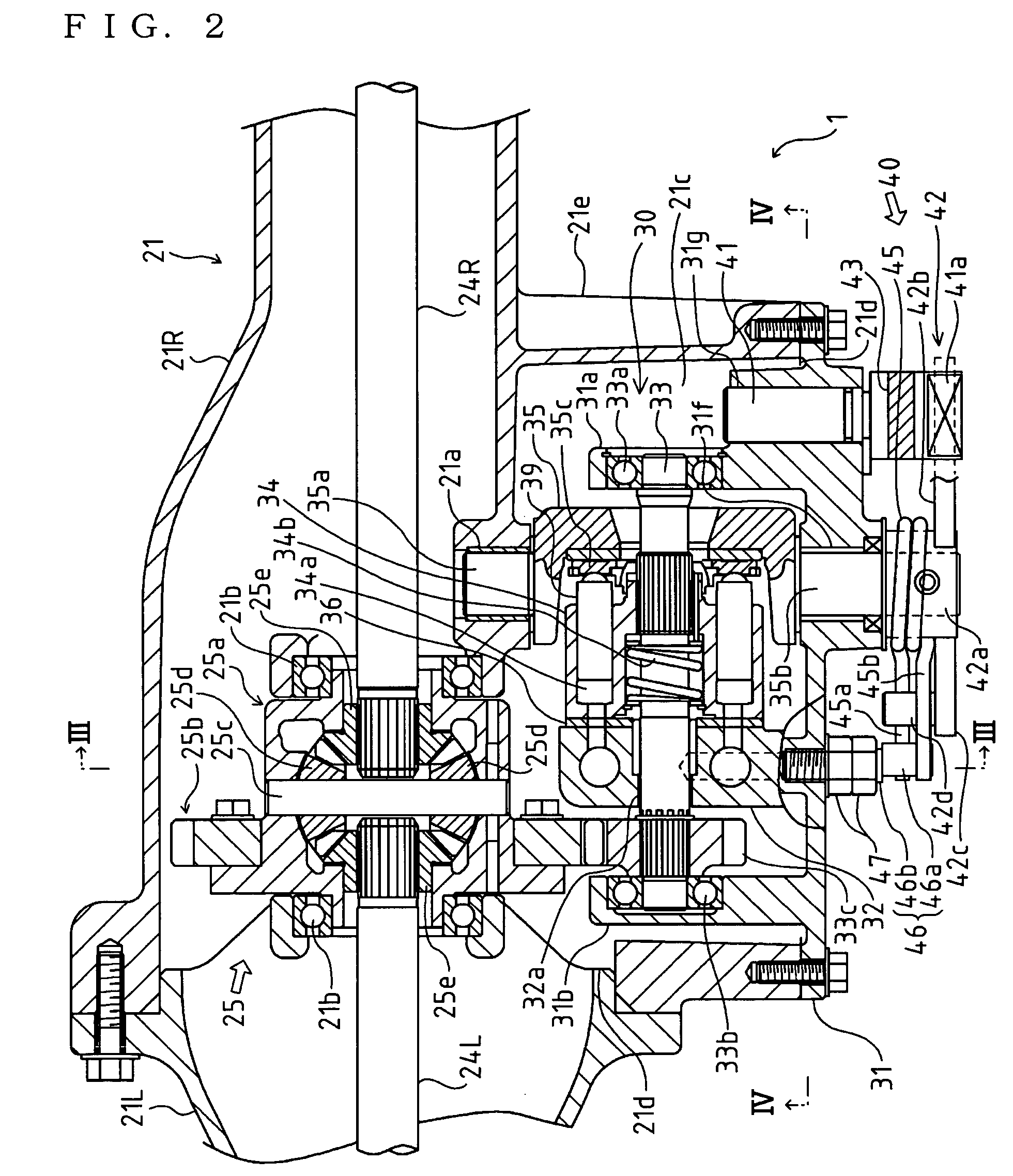

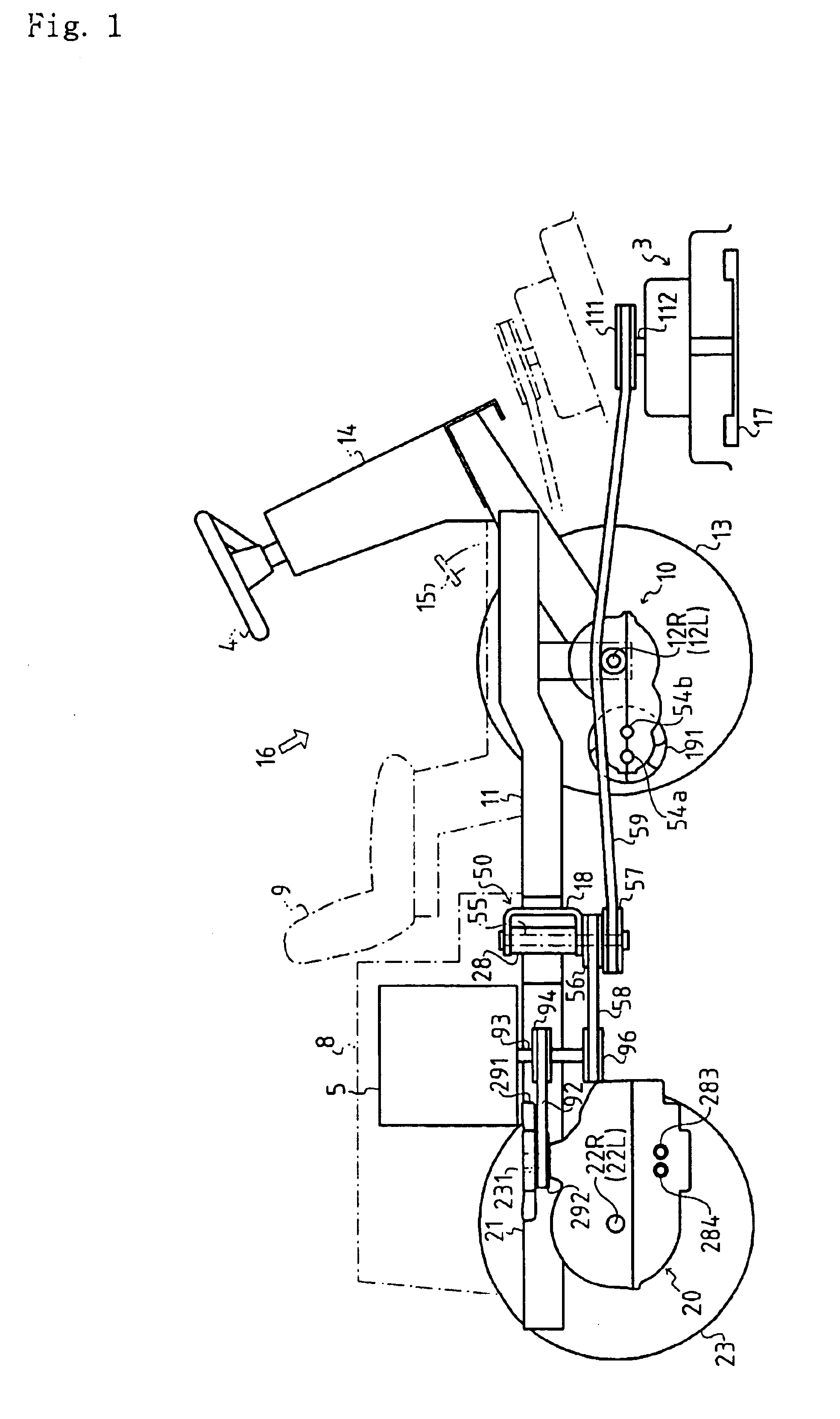

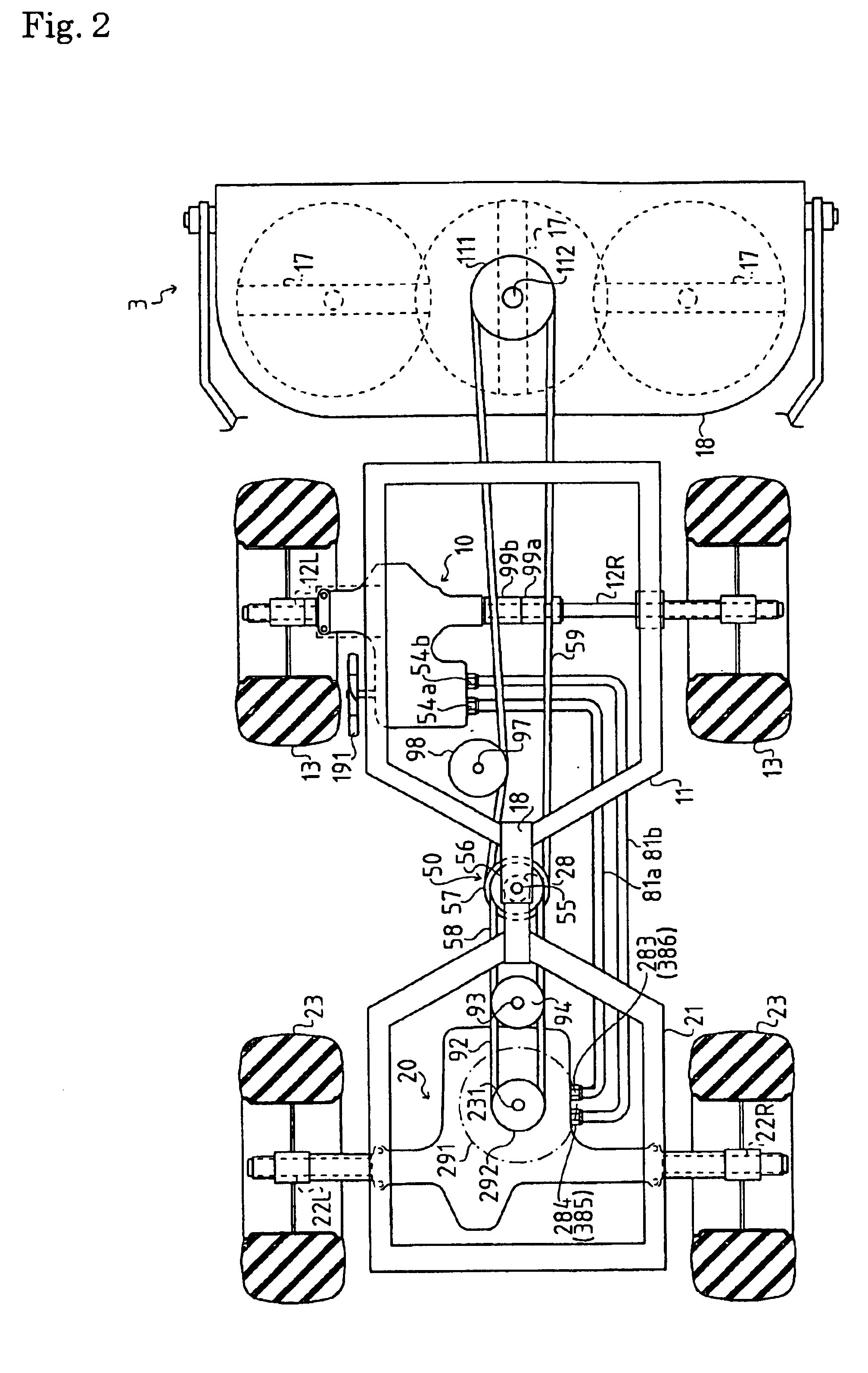

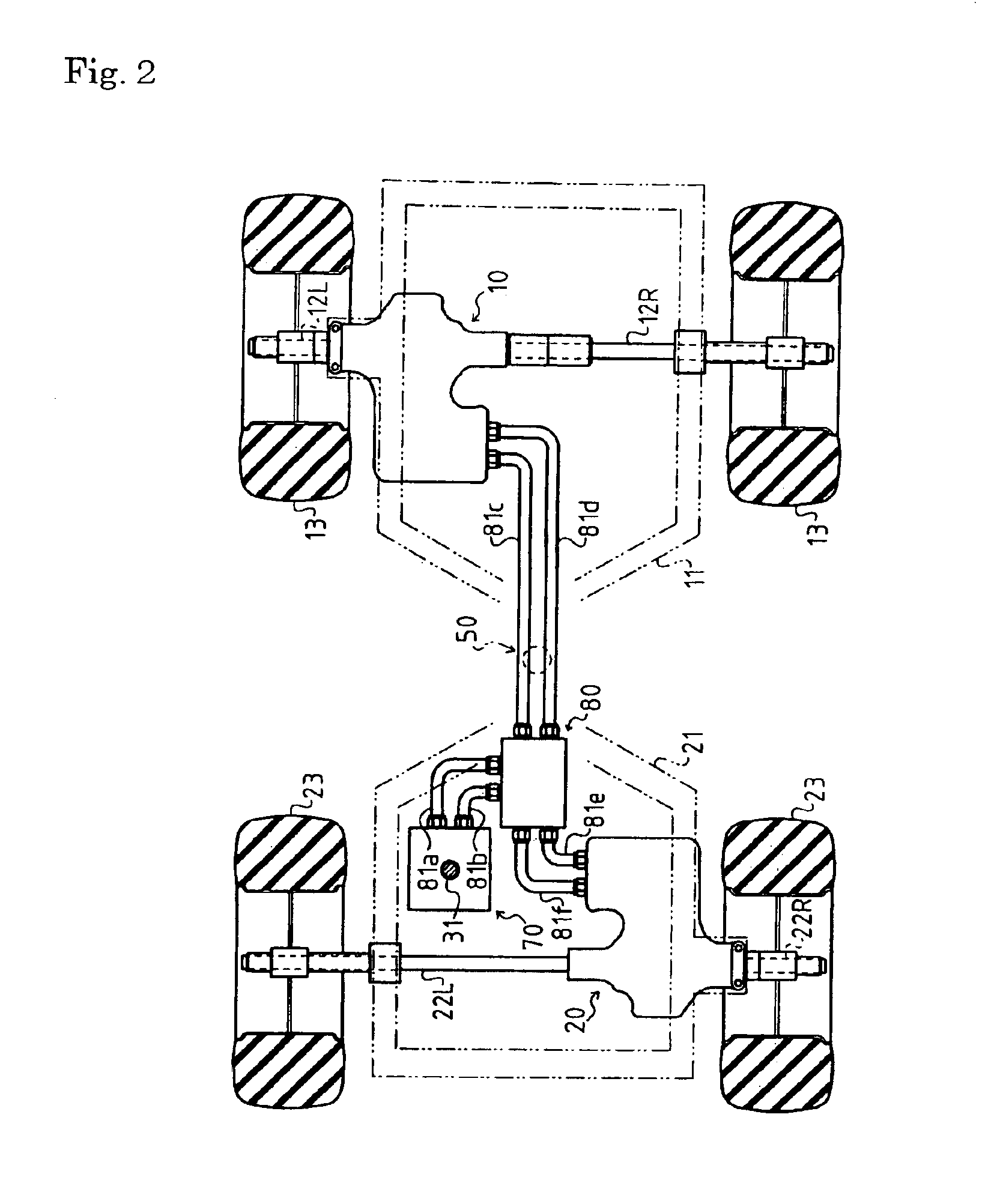

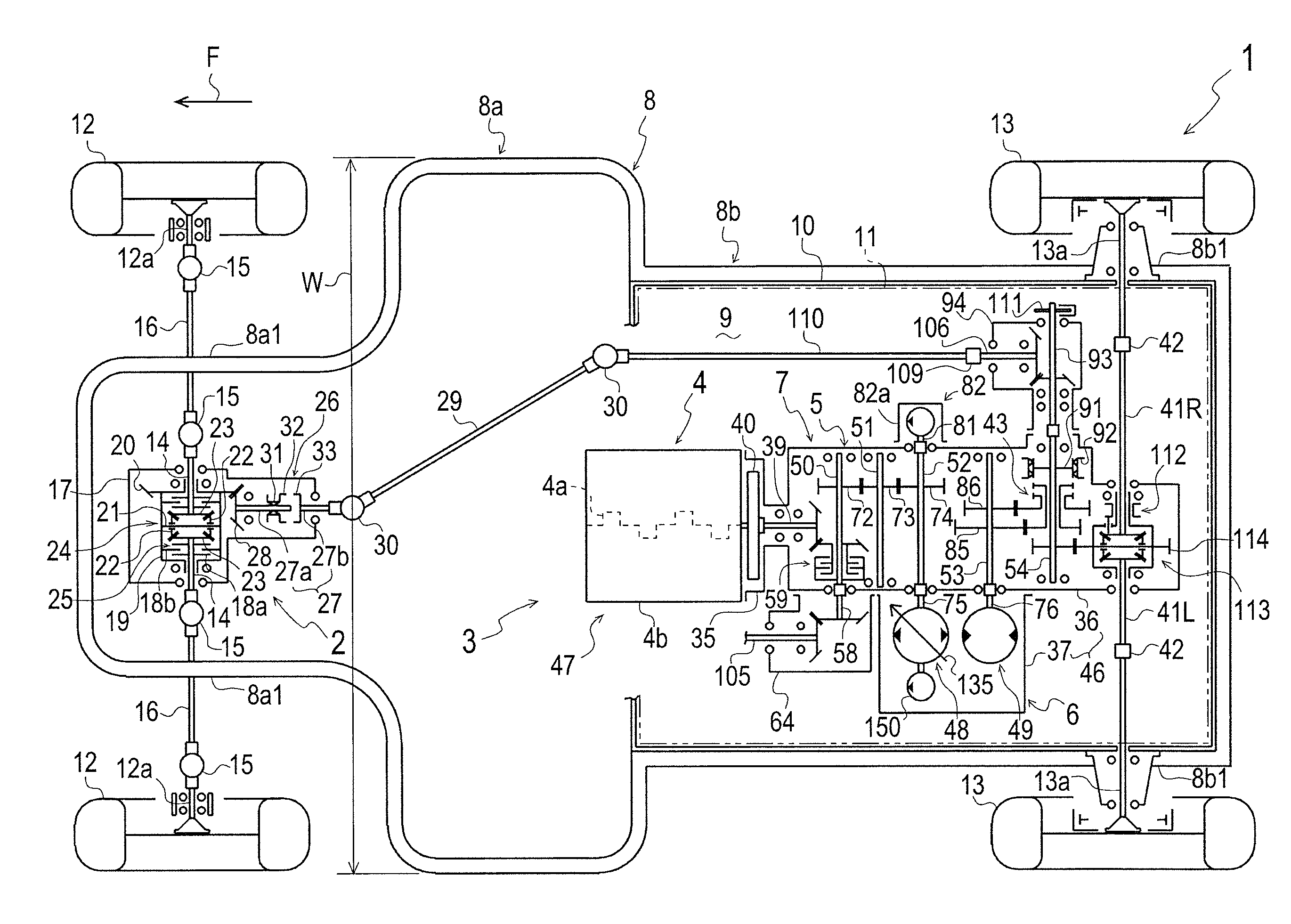

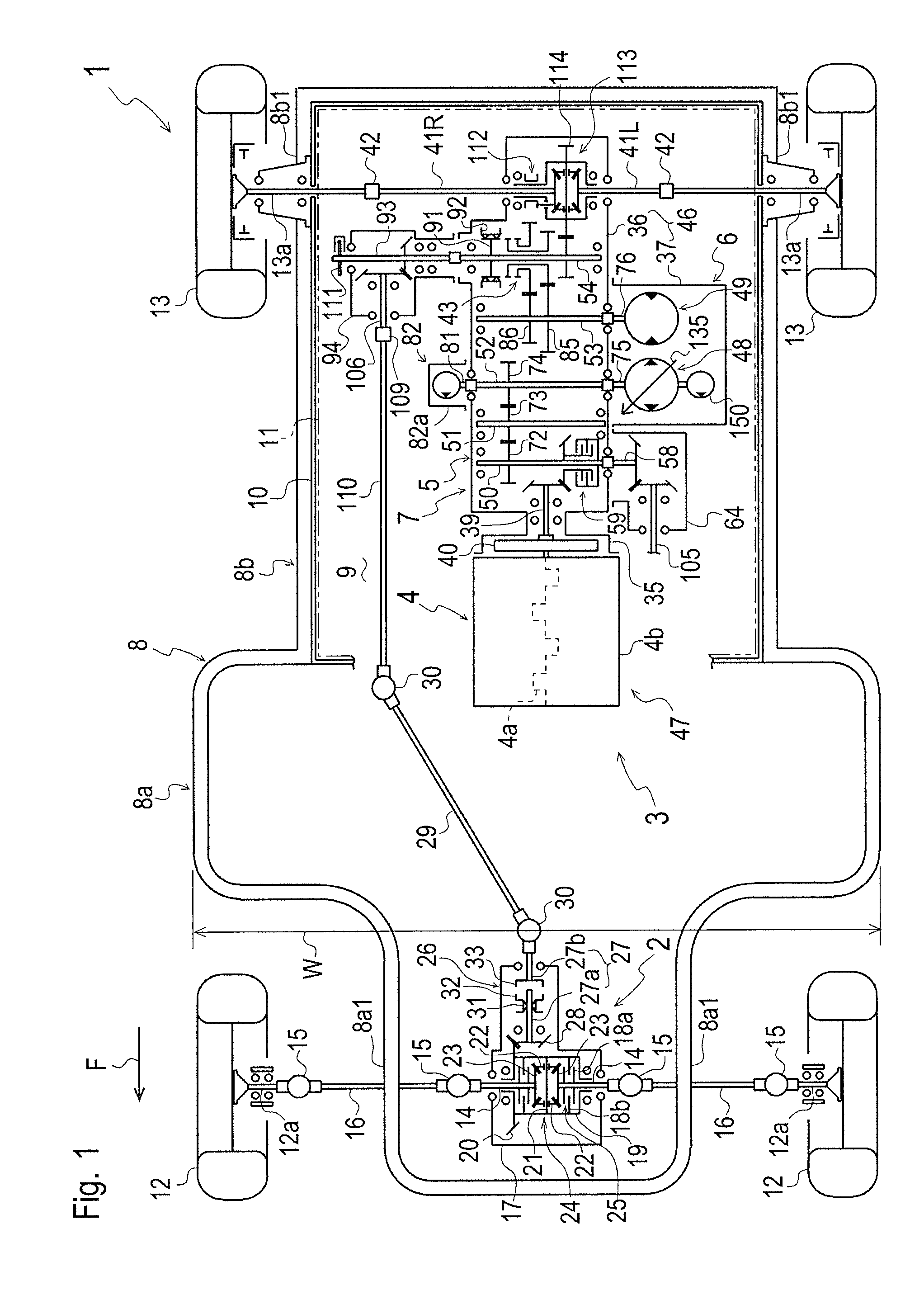

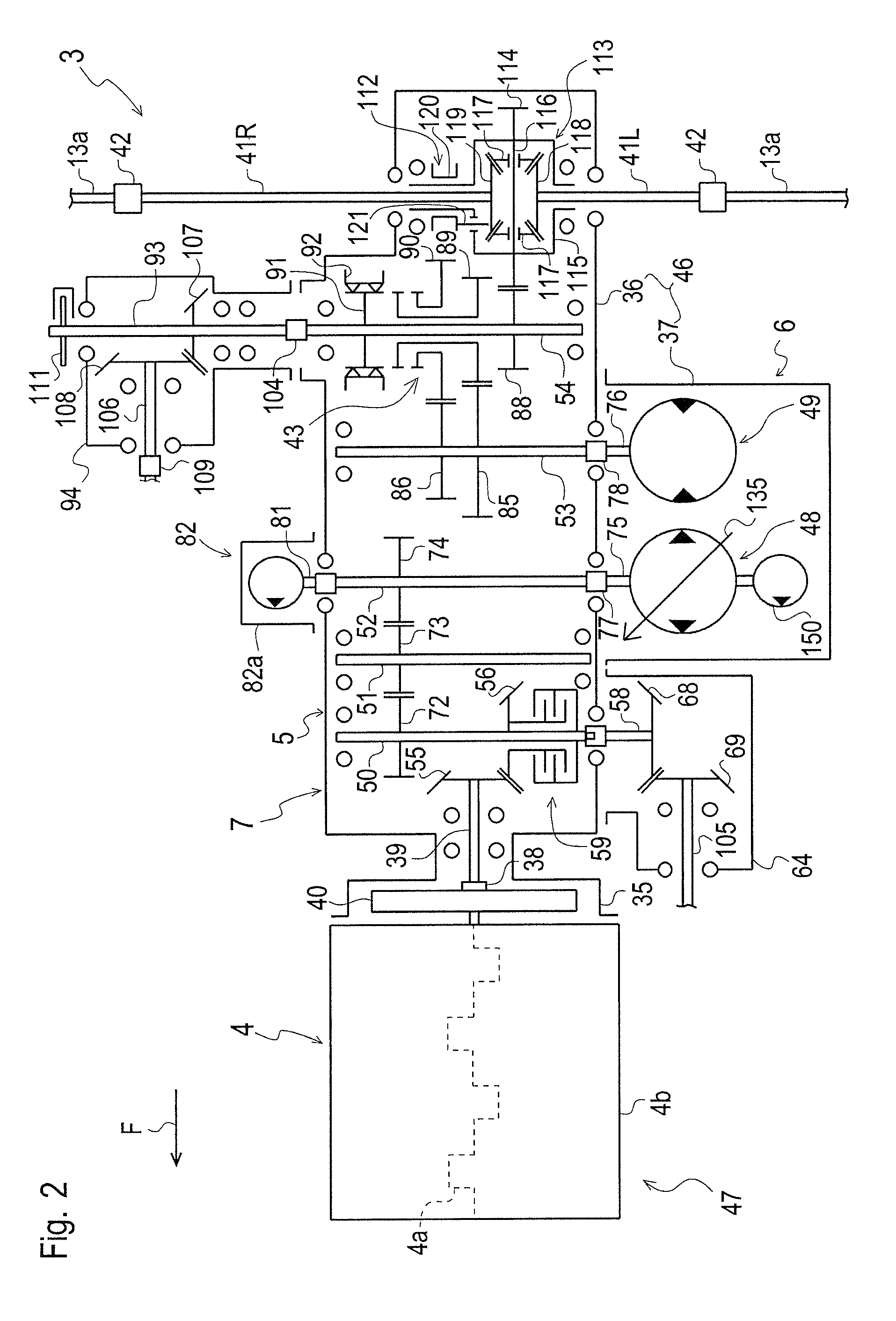

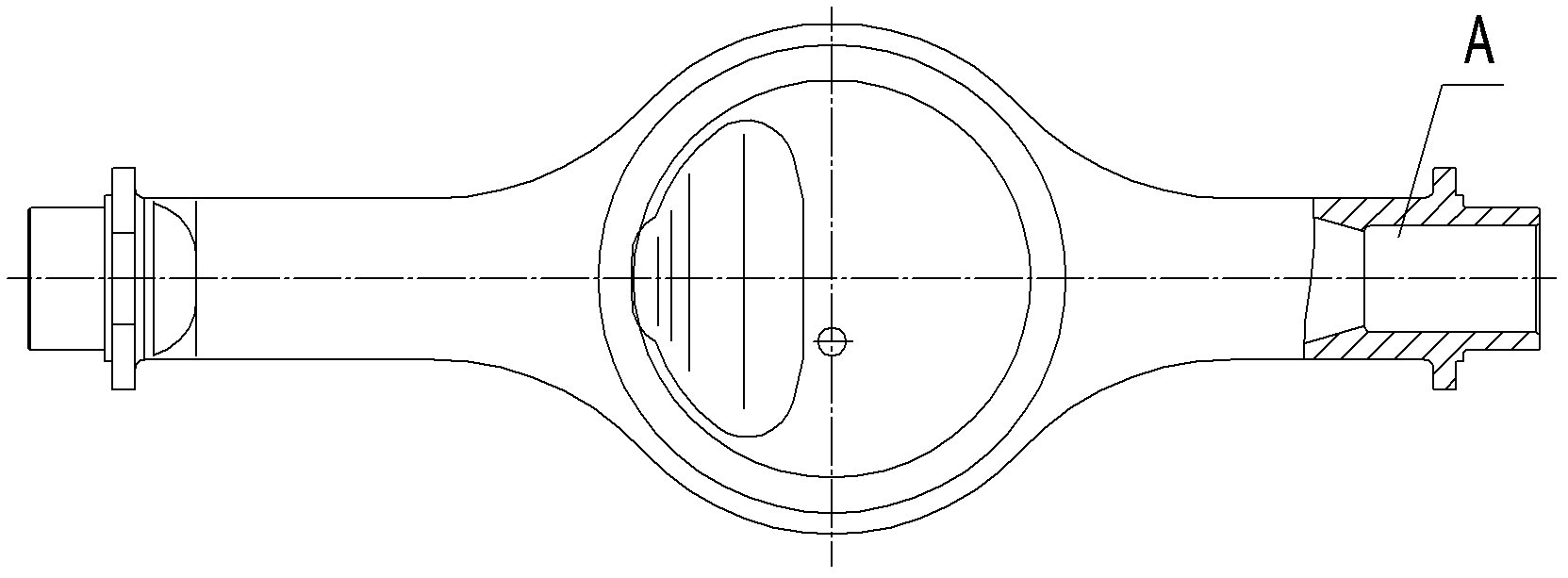

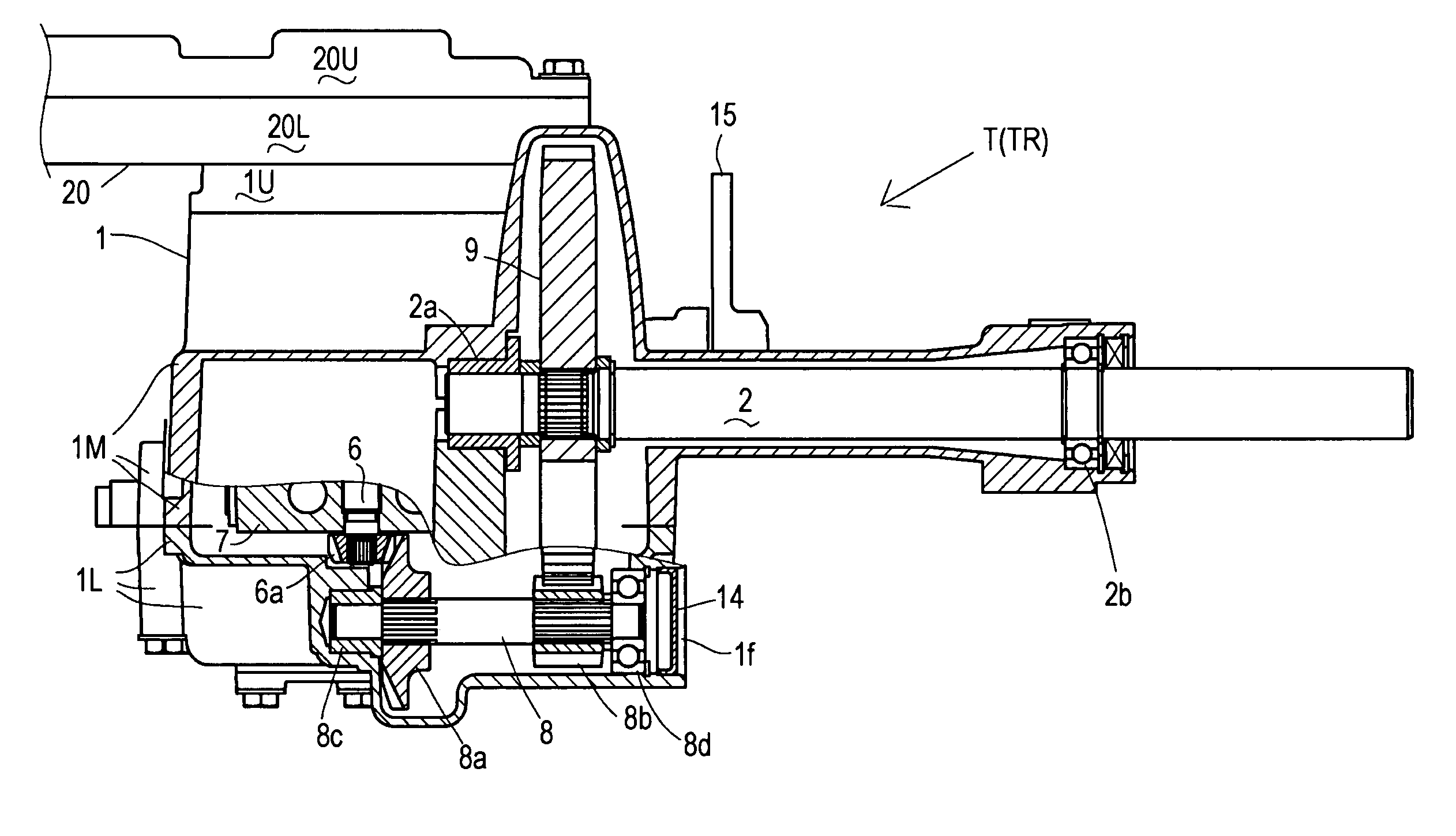

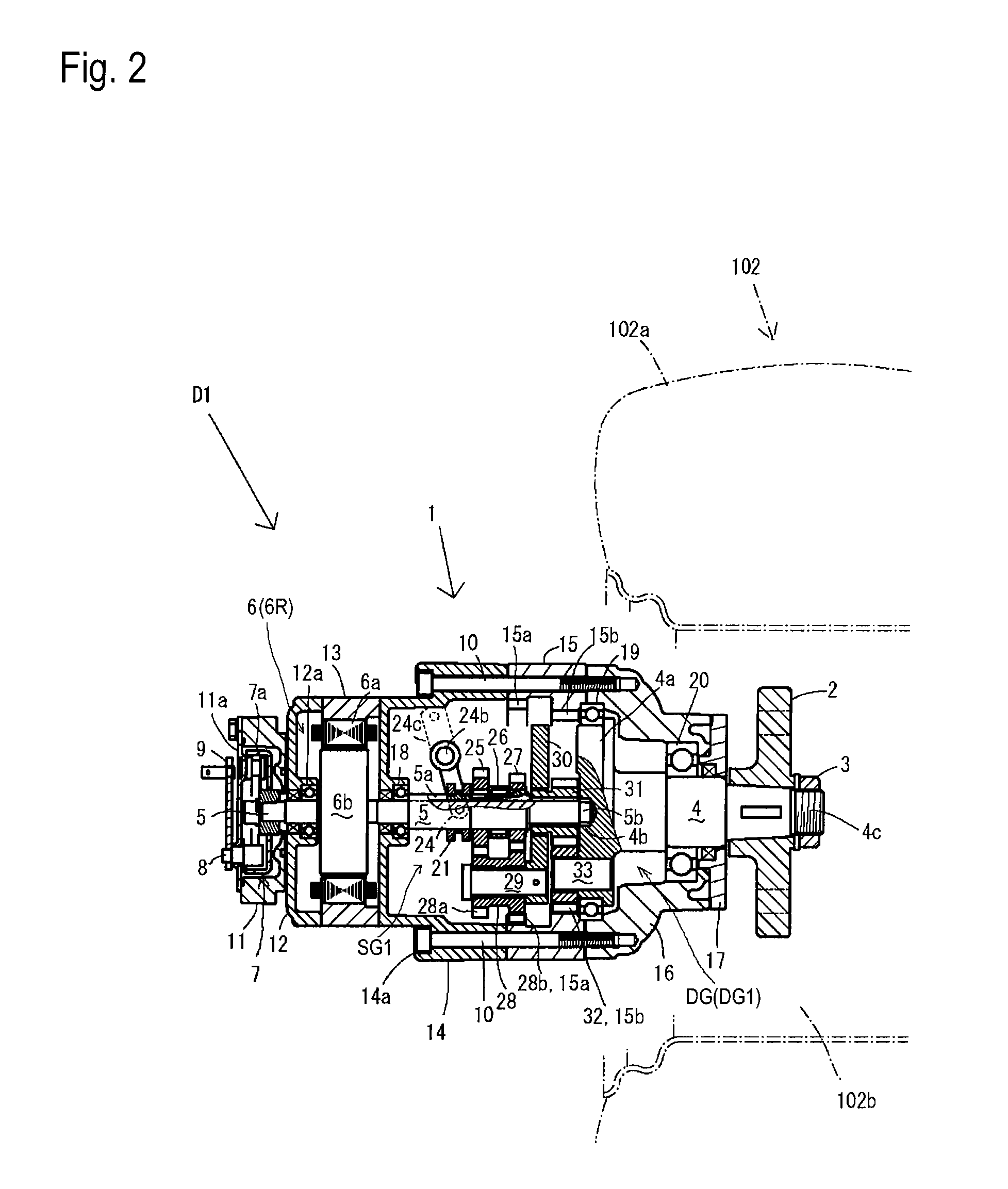

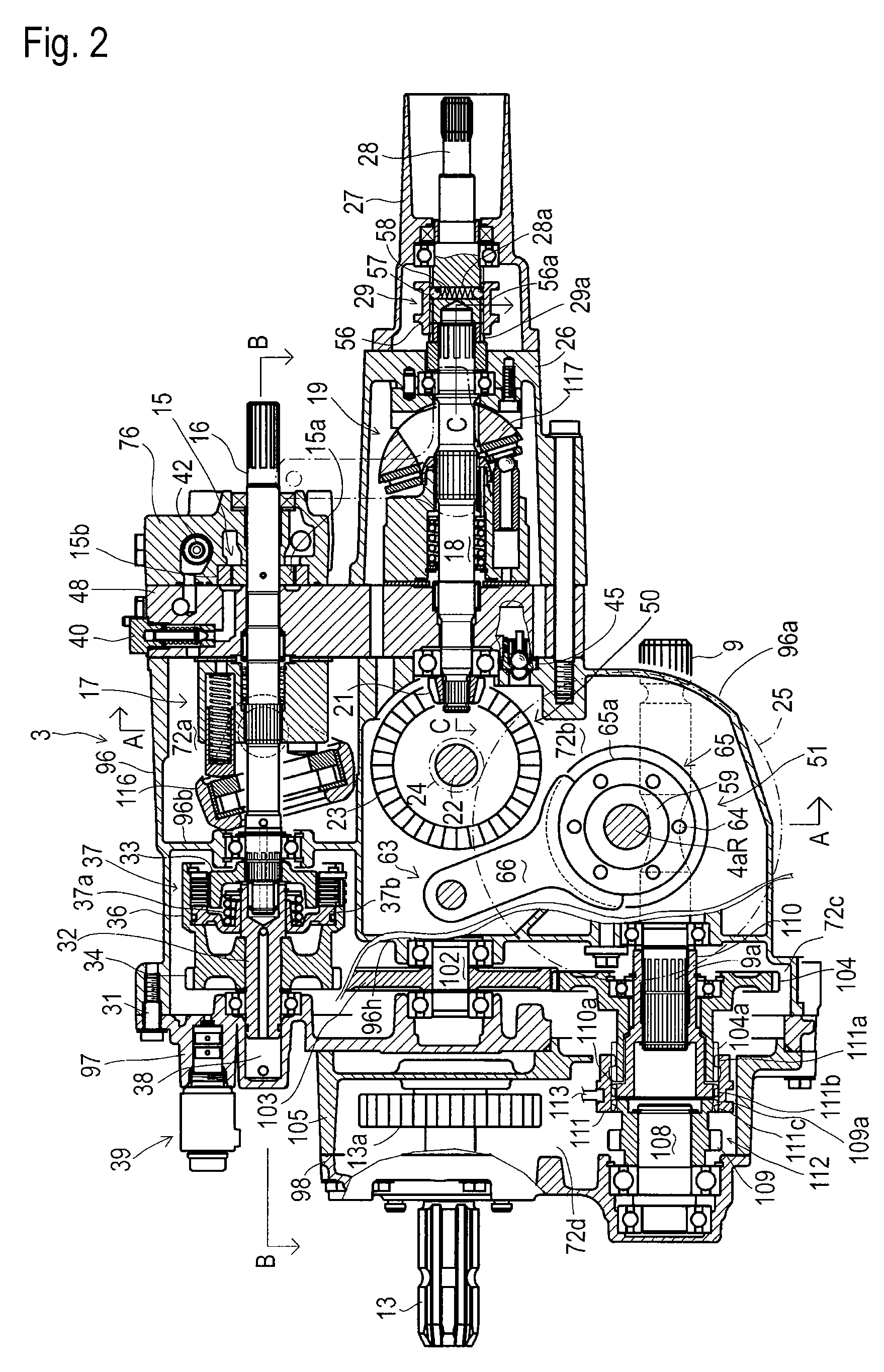

Hydraulic steering transaxle and hydraulic driving vehicle

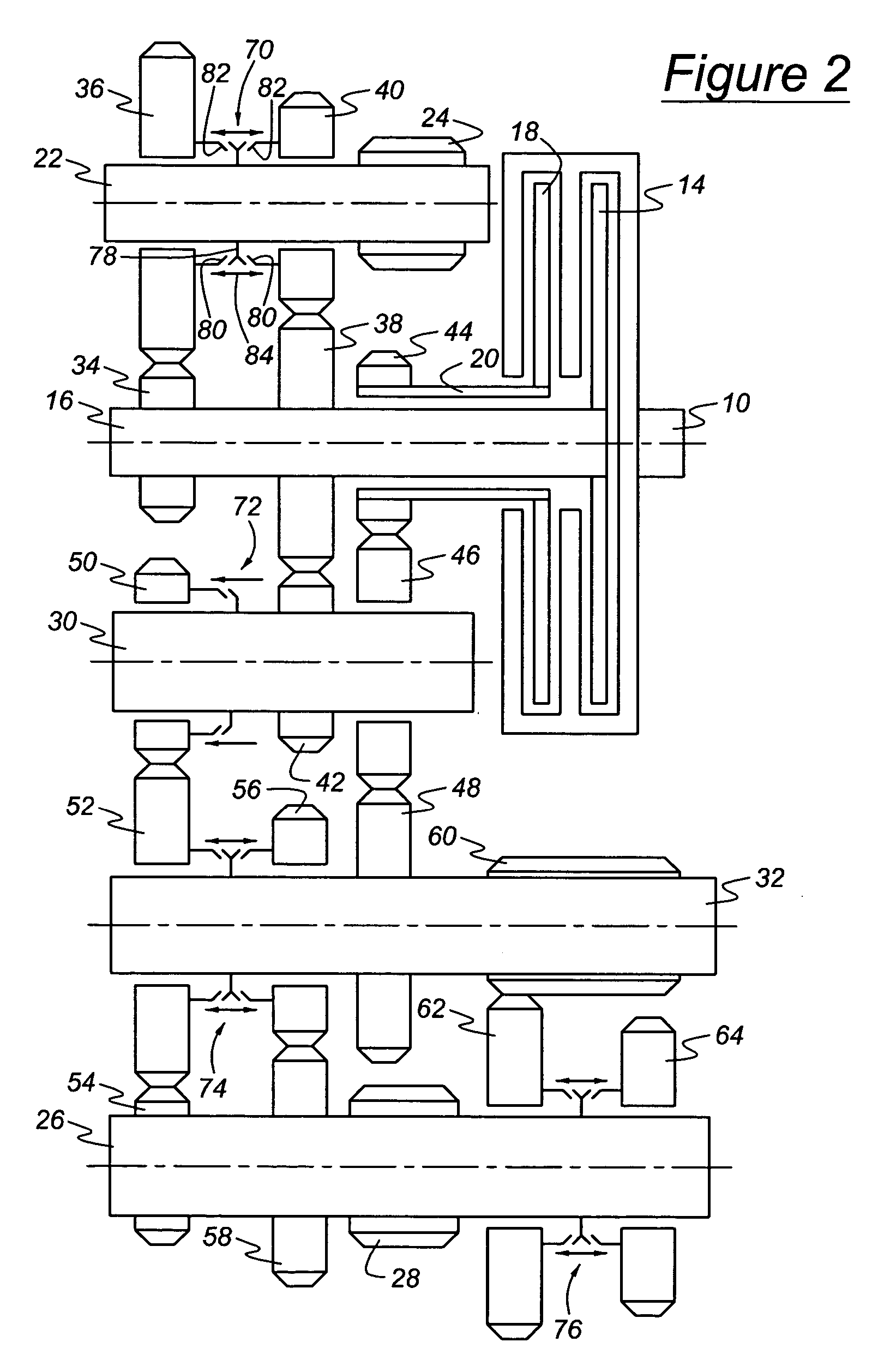

A steering transaxle comprises: left and right drive shafts drivingly connected to respective steerable wheels; a differential gear unit differentially connecting the drive shafts to each other; a transaxle casing having an opening, the transaxle casing incorporating the differential gear unit and the drive shafts; a cover for covering the opening of the transaxle casing; a variable hydraulic motor having a movable swash plate, the hydraulic motor being provided on the inside of the cover; a motor control mechanism for controlling the movable swash plate, the motor control mechanism being provided on the outside of the cover; and a hydraulic oil port for oil supply and delivery to and from the hydraulic motor, the hydraulic oil port being provided on the outside of the cover. The cover, the hydraulic motor with the movable swash plate, the motor control mechanism and the hydraulic oil port constitute an assembly unit, which is detachably attached to the transaxle casing so that, by covering the opening with the cover, the hydraulic motor is disposed in the transaxle casing so as to be drivingly connected to the differential gear unit.

Owner:KANZAKI KOKYUKOKI MFG

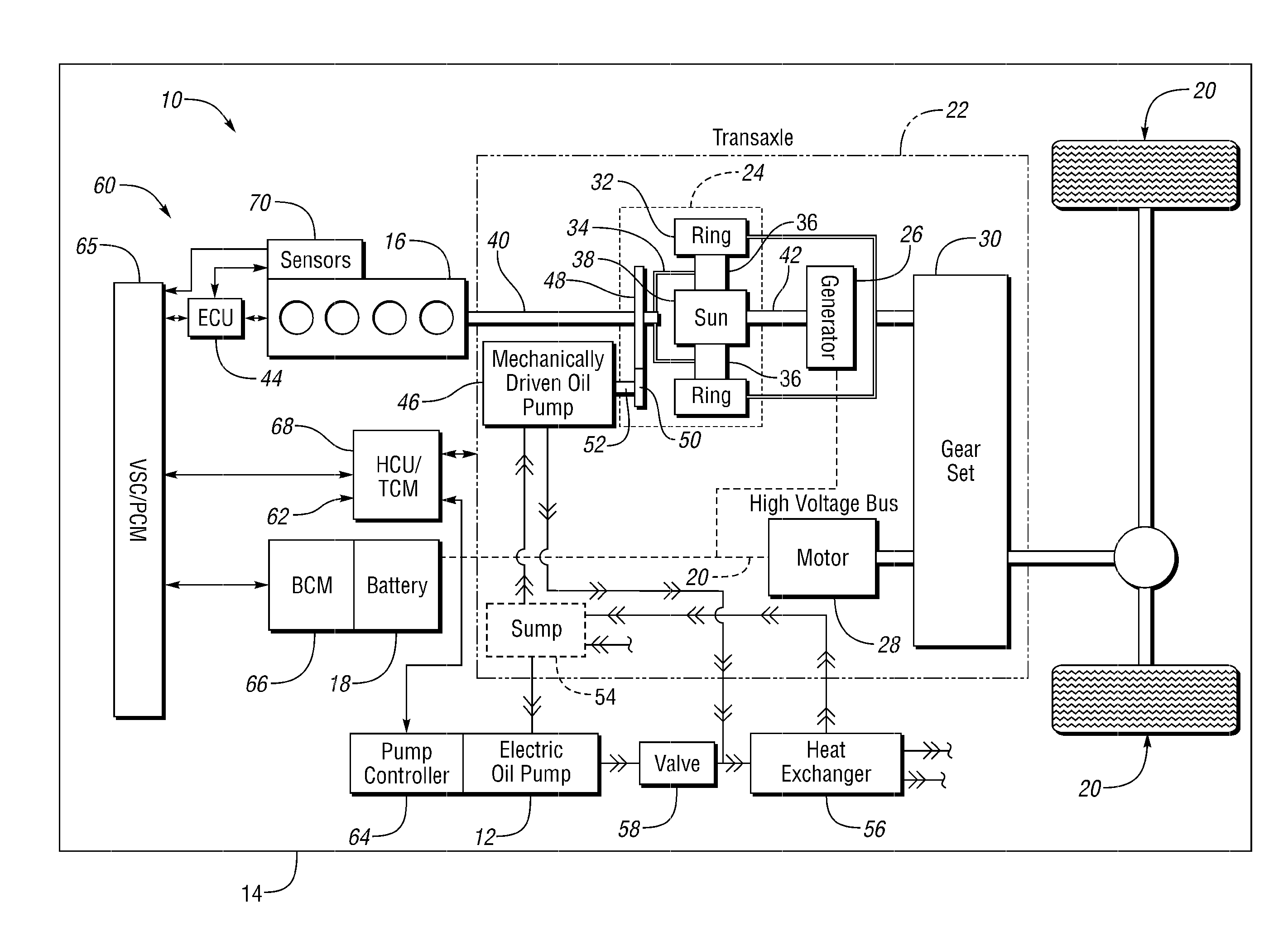

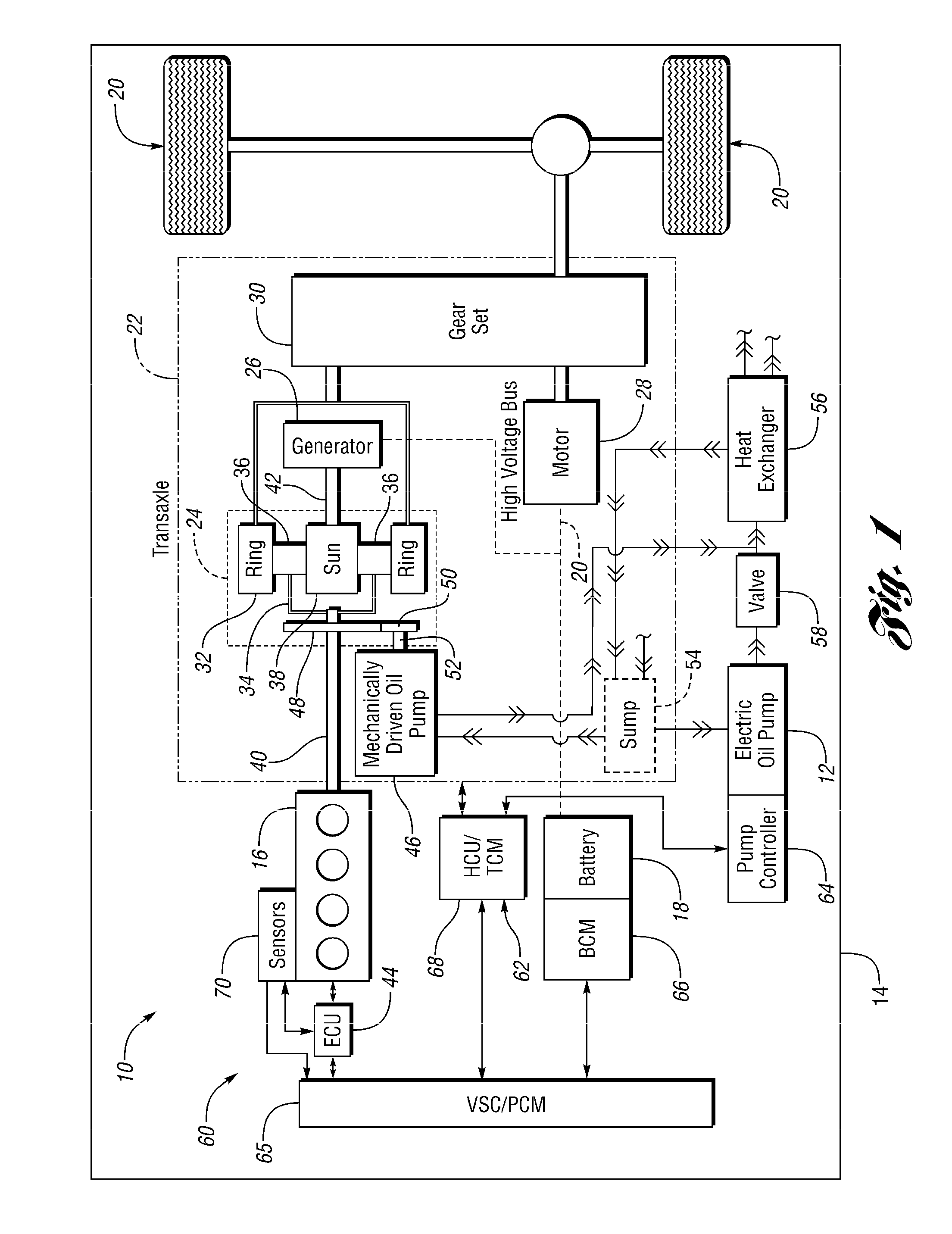

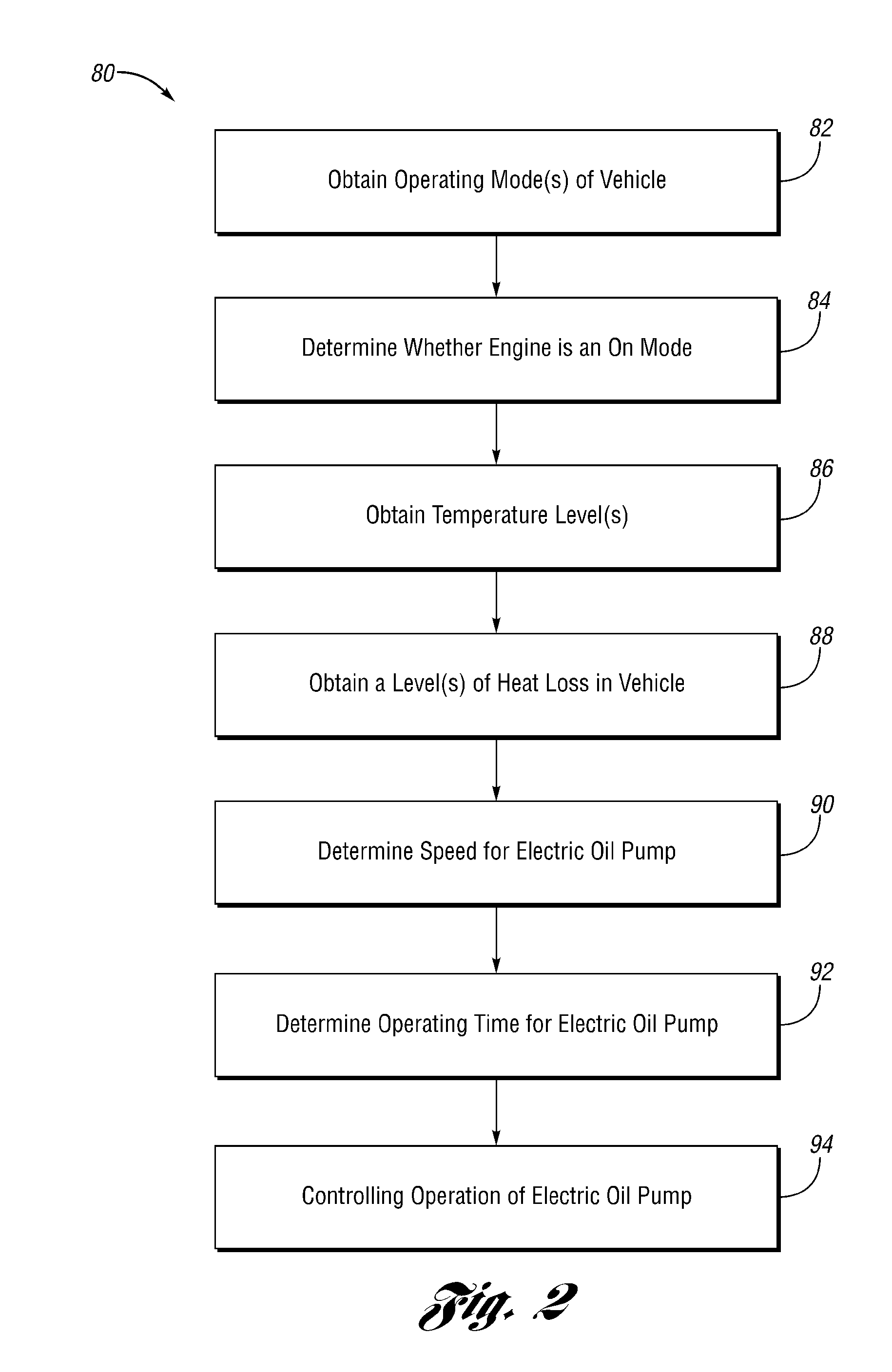

Method And System For Controlling Operation Of An Electric Oil Pump In A Hybrid Electric Vehicle (HEV)

ActiveUS20110166727A1Hybrid vehiclesDigital data processing detailsElectrical batteryHybrid electrical vehicle

A system and method is provided for controlling operation of an electric oil pump in a hybrid electric vehicle (HEV). The HEV includes an engine and a transaxle including an electric motor coupled to a traction battery. A commanded speed for the electric oil pump is determined and whether the engine in the HEV is in an off state is determined. When the engine is in the off state, the electric oil pump is controlled to operate at the commanded speed.

Owner:FORD GLOBAL TECH LLC

Hydraulic transaxle apparatus for a four-wheel driving vehicle and four-wheel driving vehicle using the apparatus

InactiveUS6845837B2Prevent liquid leakageEasy to manufactureFluid couplingsElectric devicesHydraulic pumpArticulated vehicle

An articulated vehicle with a working device has a first frame having a prime mover mounted thereon and supporting a first transaxle apparatus. The first transaxle apparatus includes an input shalt receiving power from the prime mover, a pair of first axles, and a hydrostatic transmission. The hydrostatic transmission comprises a variable hydraulic pump, a first hydraulic motor fluidly connected to the hydraulic pump via a fluid passage, and a housing with a port fluidly connected to the fluid passage. The second transaxle apparatus includes a pair of second axles having different lengths and a second hydraulic motor. The second hydraulic motor is fluidly connected to the port. Proximal ends of the first and second frames with respect to the vehicle are coupled to each other so that the first and second flames are rotatable around a vertical axis relative to each other when steered.

Owner:KANZAKI KOKYUKOKI MFG

Off-highway recreational vehicle

A recreational off-highway vehicle includes side-by-side passenger and driver seats held within a chassis that is approximately 50 inches wide. The seats sit low in the chassis and are covered by a roll cage. Grab handles are positioned on the sides of the passenger seat. Select large round tubing protects the vehicle, while rectangular tubing frames the portions of the vehicle beneath body panels. The vehicle is powered by an engine rearward of the seats that is connected to a transaxle. The engine and transaxle are isolation mounted together with a portion of the air intake assembly. The vehicle is suited for rough terrain travel.

Owner:ARCTIC CAT

Vehicle With Electric Transaxle

ActiveUS20130075183A1Increase torqueSimplified and economized in structureElectric propulsion mountingGearingElectrical batteryEngineering

A vehicle comprises a transaxle, a battery and a load carrying bed. The transaxle includes a casing incorporating a drive train and supporting an axle and includes an electric motor mounted on the casing to drive the axle via the drive train. The battery is provided for supplying electric power to the electric motor. The transaxle and the battery are disposed below the load carrying bed so as to overlap the load carrying bed when viewed in plan.

Owner:KANZAKI KOKYUKOKI MFG

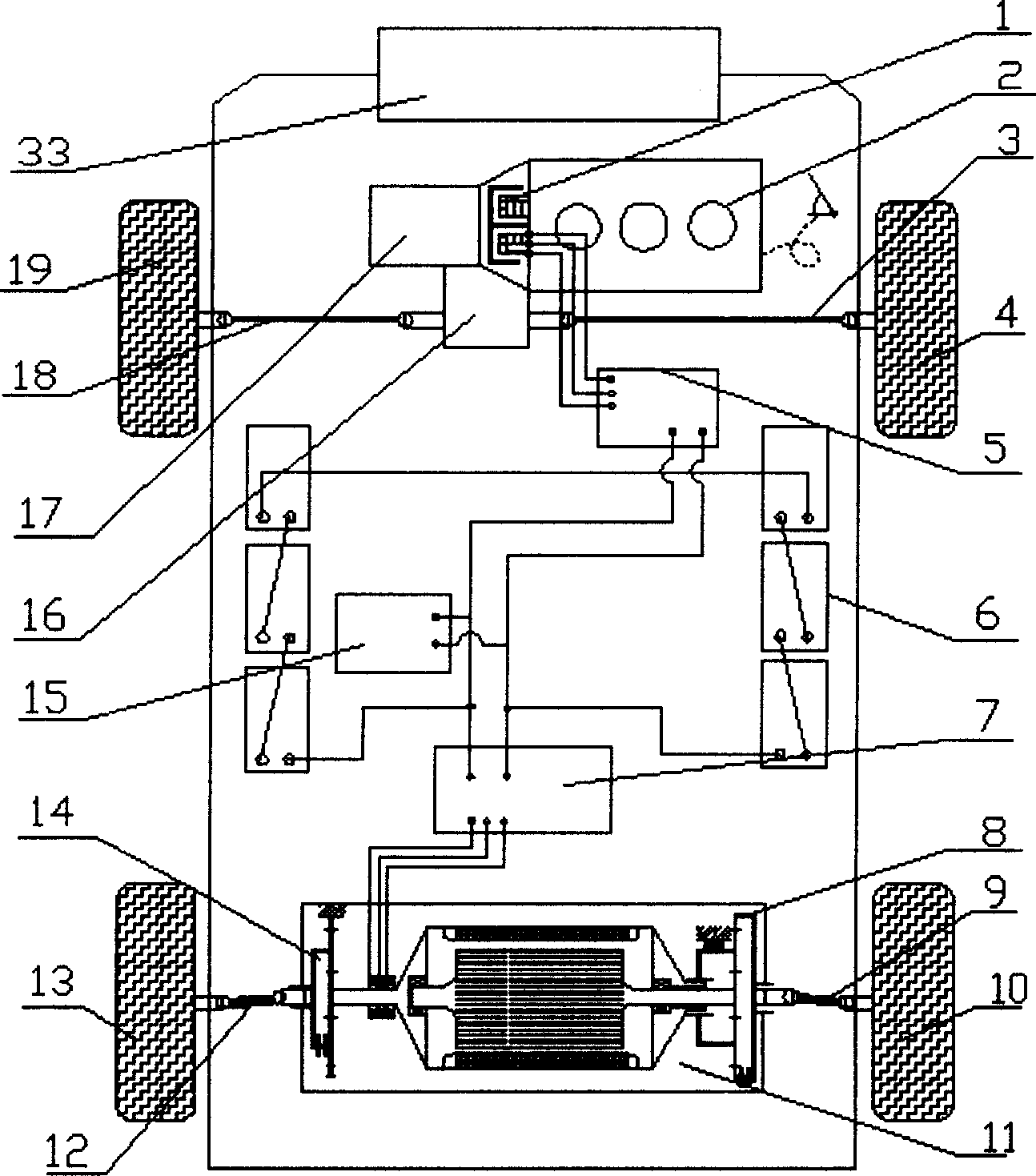

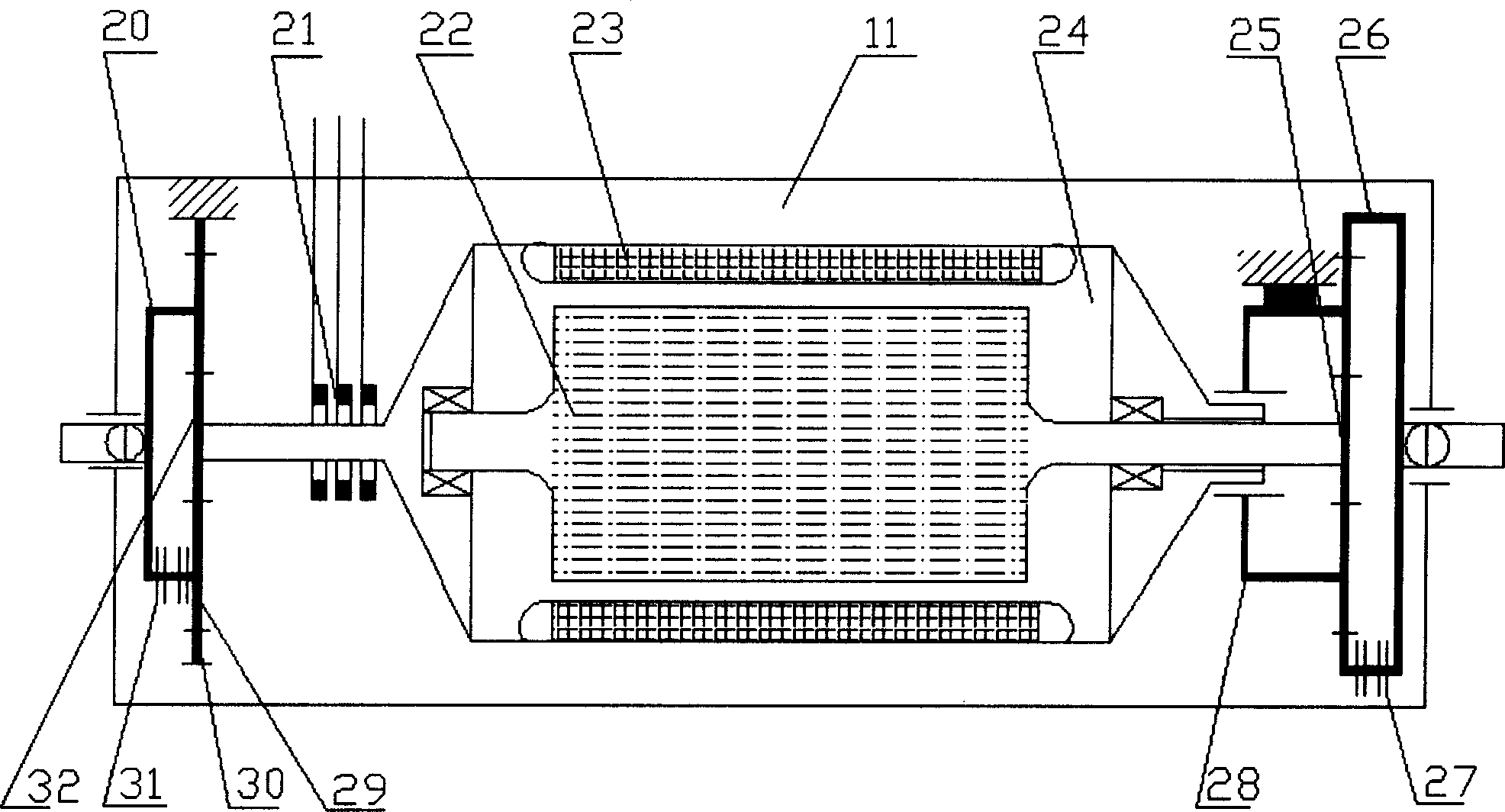

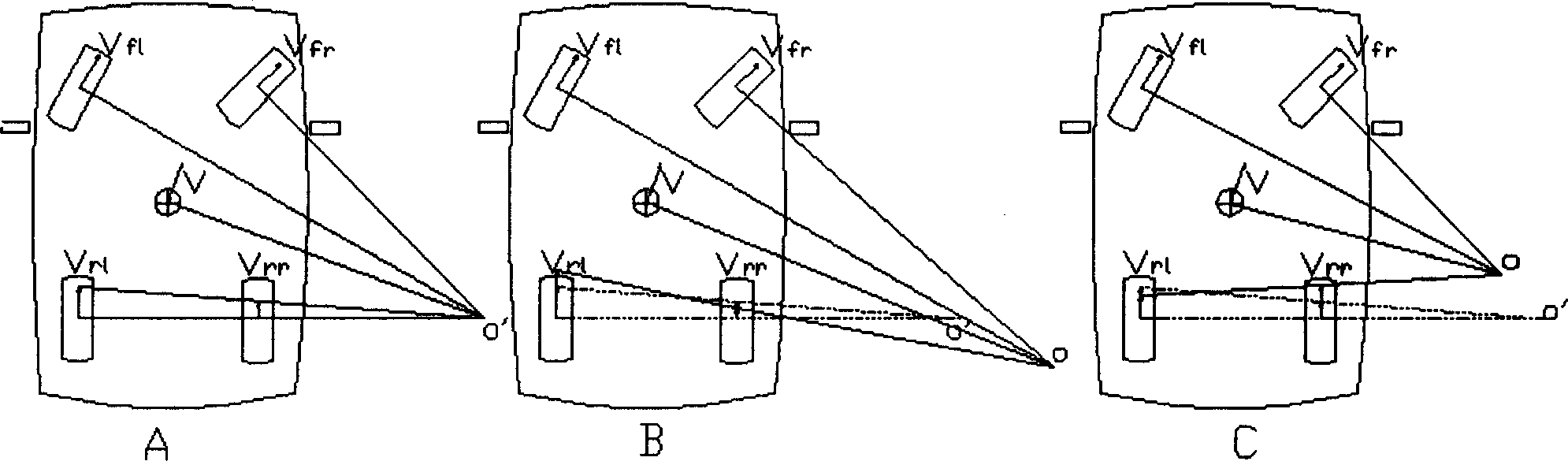

Multiple axle driving system for oil-electricity mixed power automobile

ActiveCN1810557AImprove fuel economyImprove efficiencyHybrid vehiclesSpeed controllerElectricityElectric machine

The multiple axle driving system for mixed power automobile with fuel oil and electric energy as power source includes at least one mechanical driving axle assembly, at least one electric driving axle assembly, one power source assembly, one general controller, one monitoring and communication network system, and one engine and one multifunctional double-rotor motor to drive different axles separately. The double-rotor motor consists of one outer rotor and one inner rotor, the outer rotor is connected to the hub in one side through the reducing mechanism and the versatile transmission mechanism, and the inner rotor is connected to the hub in the other side through the reducing mechanism and the versatile transmission mechanism. The multiple axle driving system integrates the technology and functions of complete mixed power, multiple axle driving, etc. and makes the automobile possess the advantages of easy realization, low cost, raised running smoothness and stability, etc.

Owner:SOUTH CHINA UNIV OF TECH +1

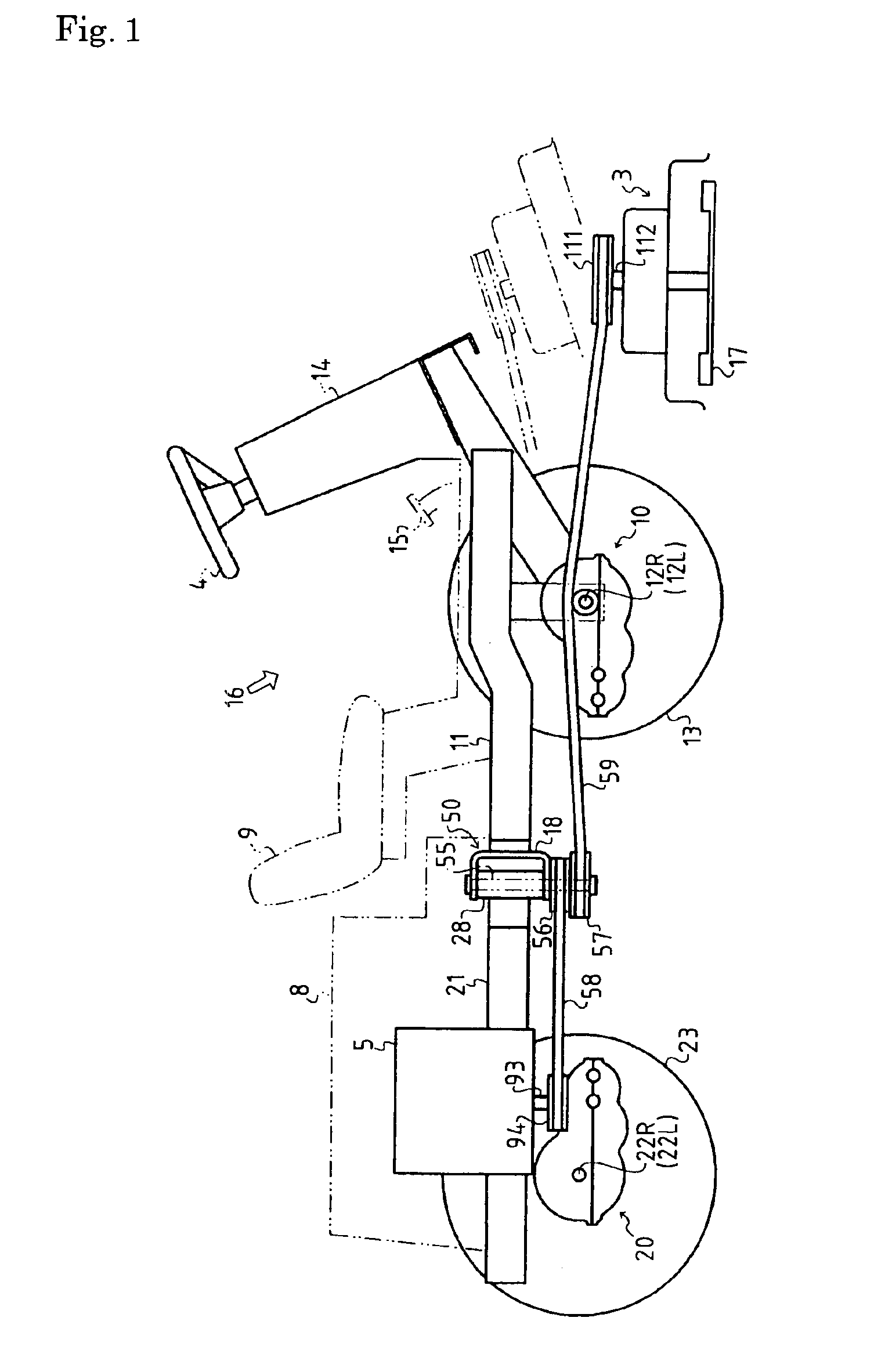

Four wheel-drive vehicle

InactiveUS6889793B2Increase flexibilityConserve costGearing controlLawn-mowersHydraulic motorHydraulic pump

An articulate vehicle comprises a first frame disposed at one of front and rear portions of the vehicle and a second frame disposed at the other of front and rear portions of the vehicle. The first frame supports a first transaxle apparatus supporting a first axle. The second frame supports a second transaxle apparatus supporting a second axle. Proximal ends of the frames with respect to the vehicle are coupled to each other through a coupling part so that the first and second frames are rotatable relative to each other around a vertical axis according to steering operation. An engine is mounted on the first frame. A first hydraulic motor is integrally assembled in the first transaxle apparatus so as to drive the first axle. A working vehicle is equipped at a distal side of the second frame with respect to the vehicle. A second hydraulic motor is integrally assembled in the second transaxle apparatus so as to drive the second axle. A hydraulic pump is mounted on either the first or second frame, drivingly connected to the engine, and fluidly connected to both the first and second hydraulic motors.

Owner:KANZAKI KOKYUKOKI MFG

Dual input automatic transaxle

InactiveUS7272986B2Reduce axial sizeReduce noiseToothed gearingsTransmission elementsPinionControl theory

Owner:FORD GLOBAL TECH LLC

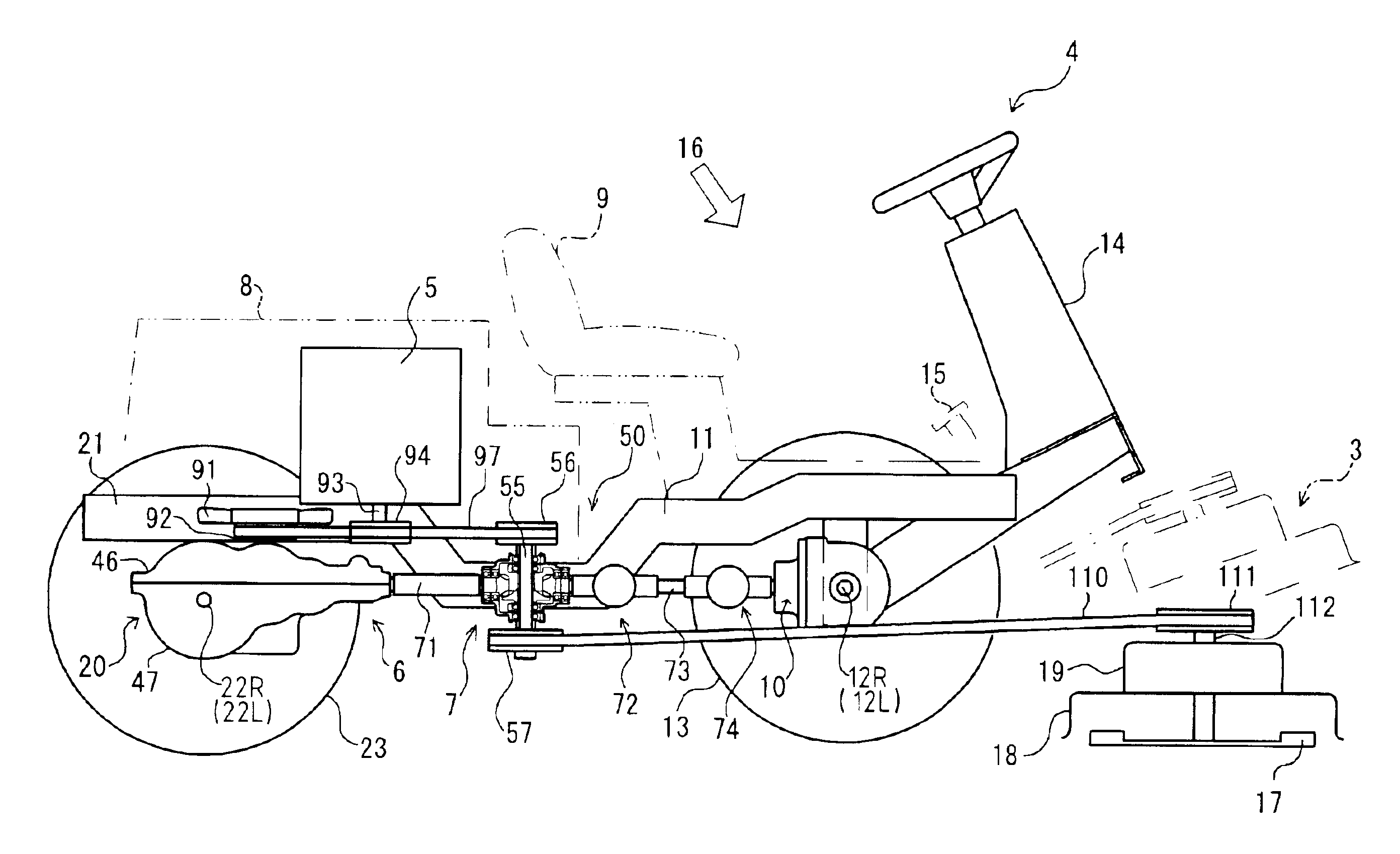

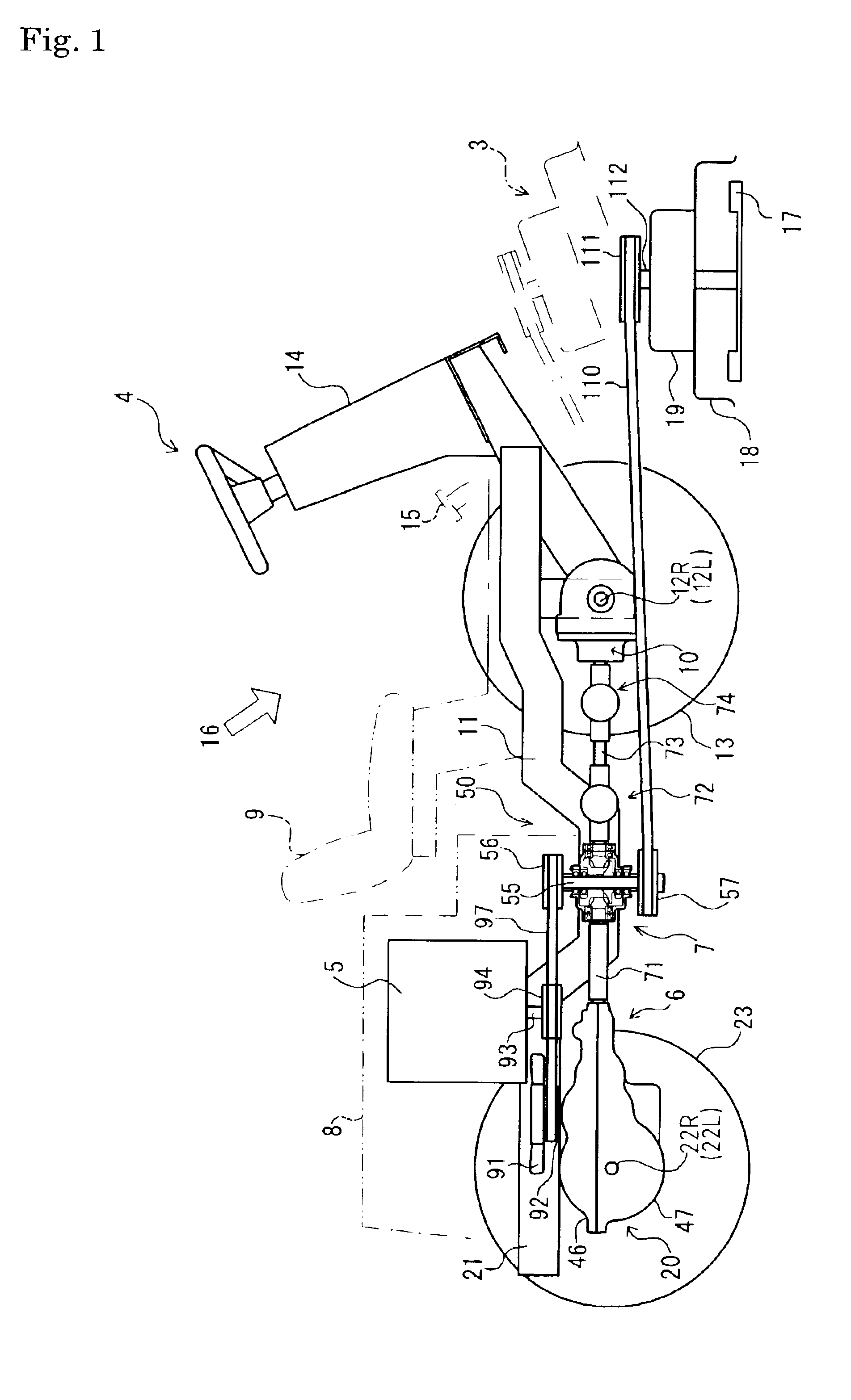

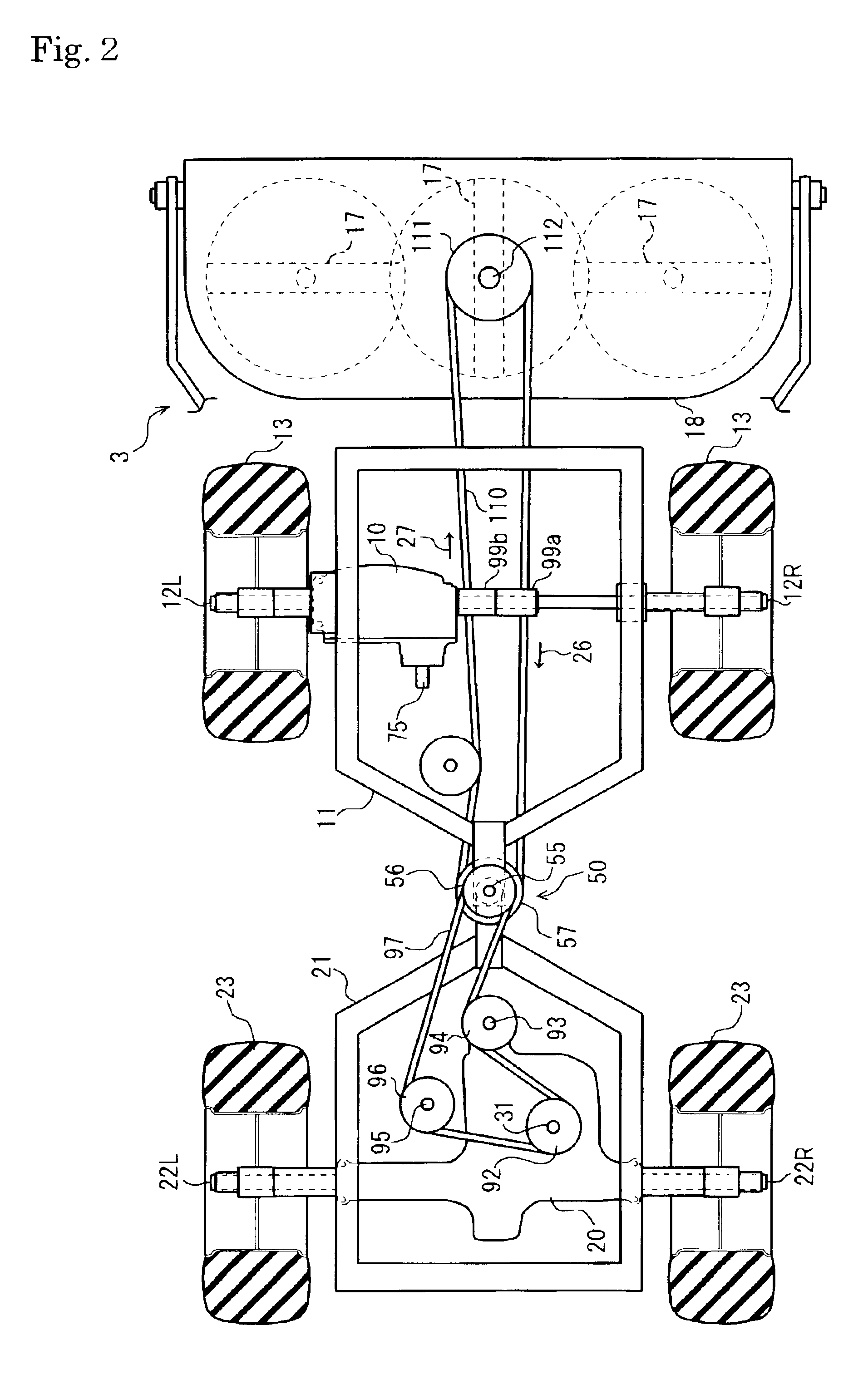

Transaxle and working vehicle equipped with the transaxle

InactiveUS20150306954A1Minimizing vehicleLow costFluid gearingsJet propulsion mountingDrive wheelLongitudinal engine

A transaxle is adaptable to a vehicle equipped with a longitudinal engine including an engine output shaft to be oriented in a longitudinal direction of a vehicle. The transaxle comprises a transmission output shaft to be oriented in a lateral direction of the vehicle so as to be drivingly connected to a drive wheel of the vehicle, a hydrostatic transmission and a mechanical transmission for transmitting power from the engine output shaft to the transmission output shaft, and first and second power take-off shafts for taking off power from the mechanical transmission. The engine is joined to the transaxle so that the engine, the hydrostatic transmission and the mechanical transmission are assembled together. The first and second power take-off shafts are distributed rightward and leftward from the engine.

Owner:KANZAKI KOKYUKOKI MFG

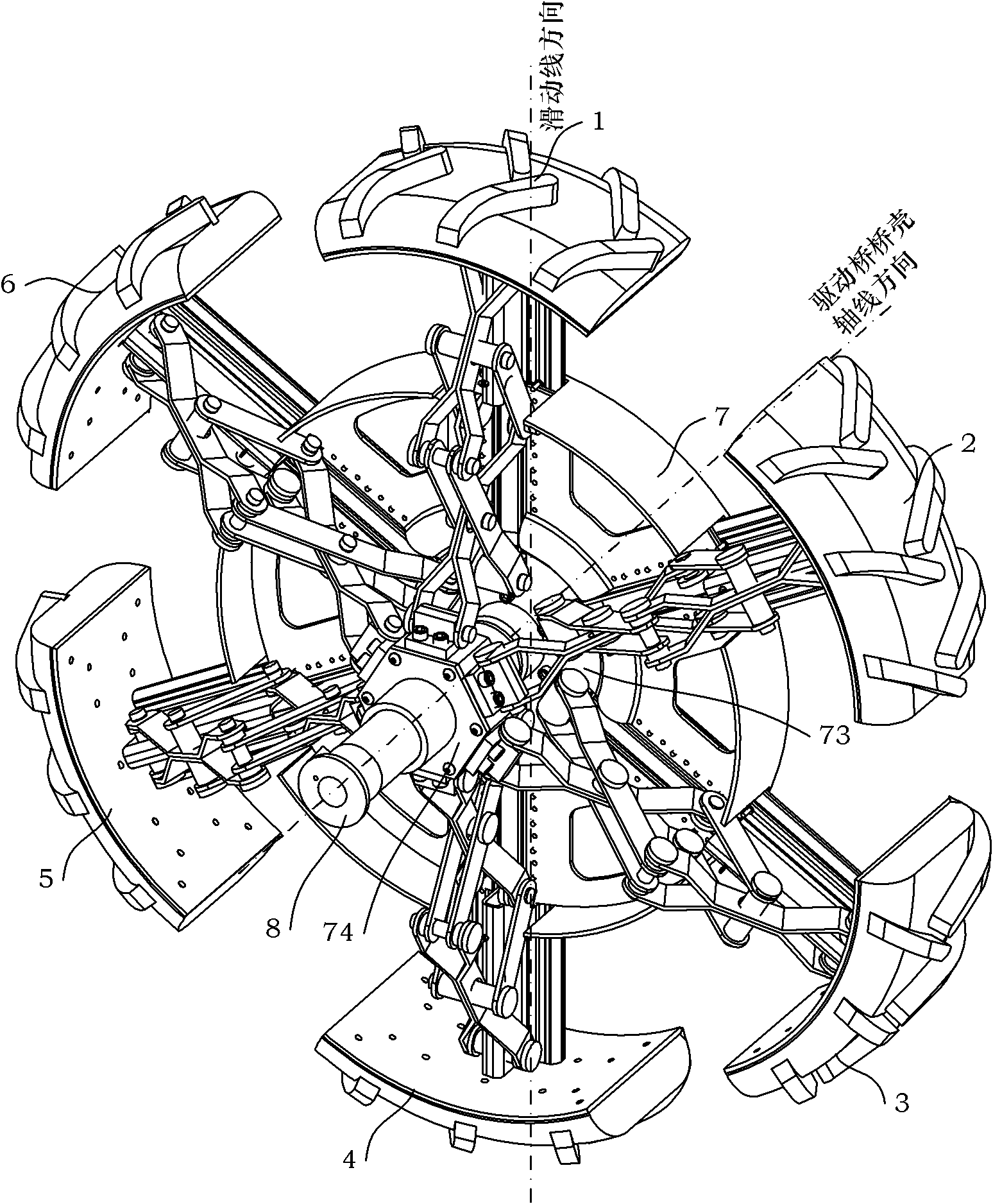

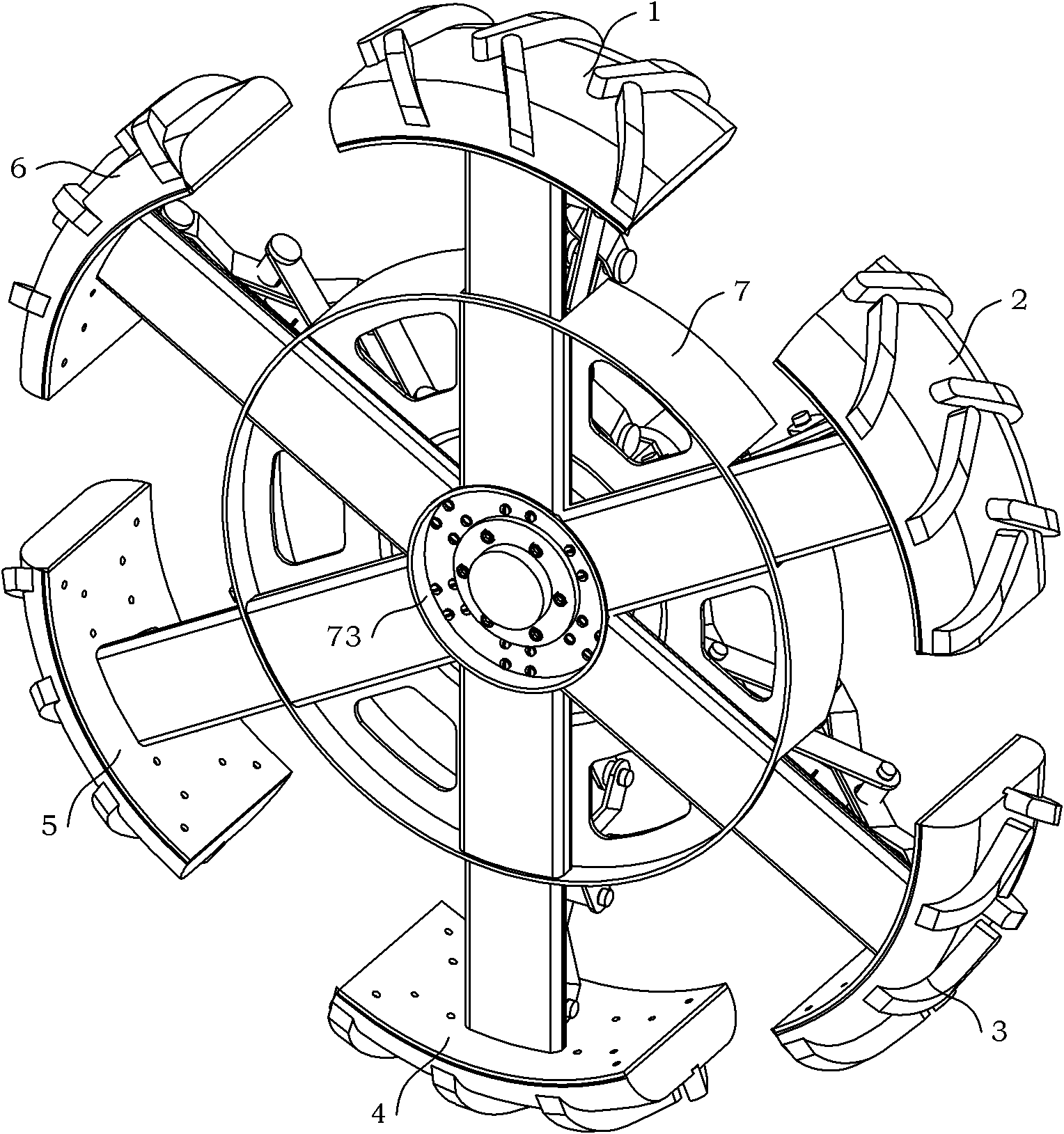

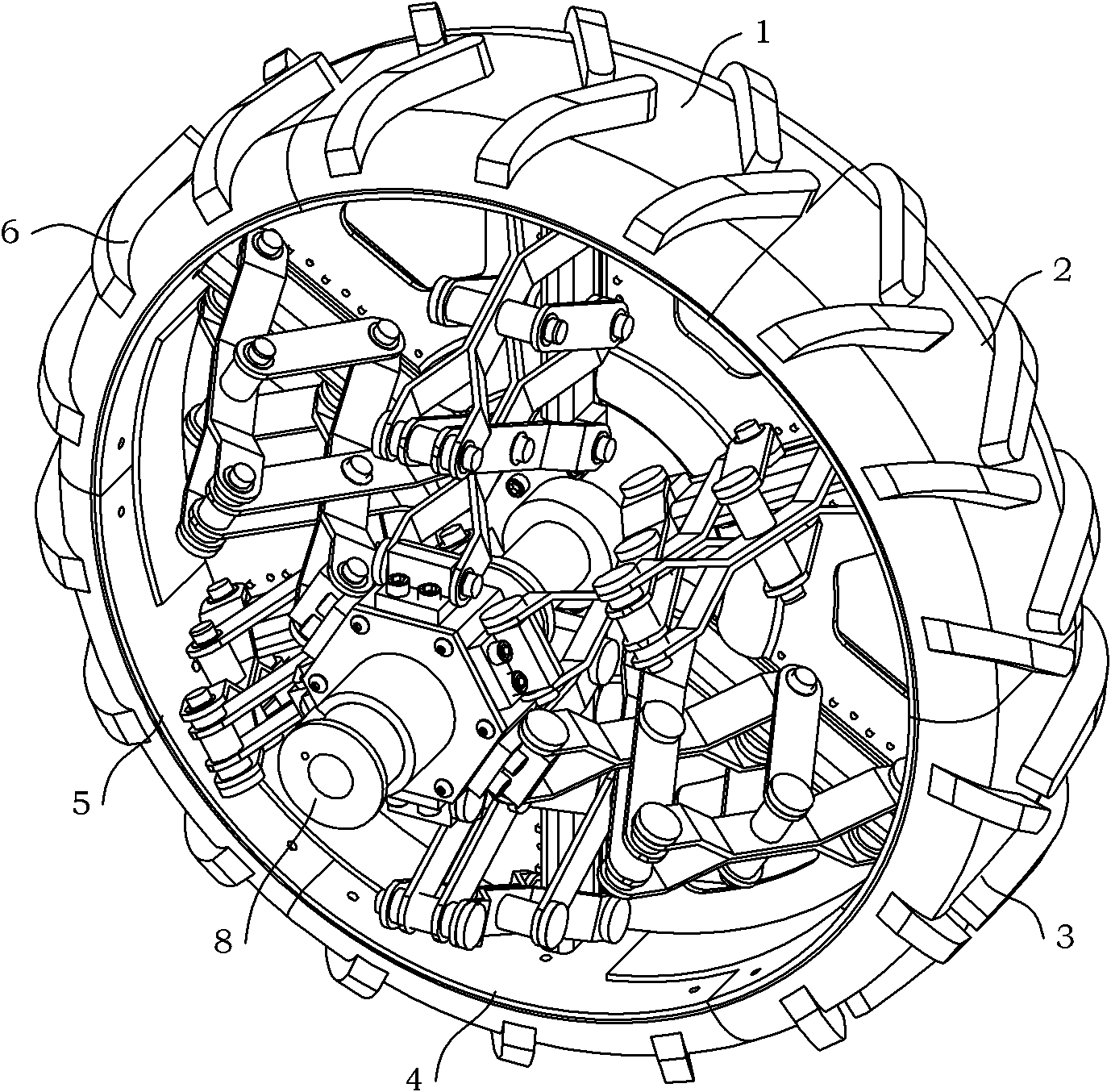

Four-bar linkage wheel carrier suitable for diameter-variable semi-walking wheel

The invention discloses a four-bar linkage wheel carrier suitable for a diameter-variable semi-walking wheel. The four-bar linkage wheel carrier comprises six caster assemblies with the same structure and a hub assembly; upper lifting lugs of the six caster assemblies are respectively arranged on a hydraulic cylinder sleeve, and lower lifting lugs of the six caster assemblies are respectively arranged on a connecting plate; and four link bars are connected by use of pin shafts. Under the condition of hydraulic driving force, the hydraulic cylinder sleeve moves along the axis direction of a drive axle shell, so that the four link bars stretch and shrink; and a slide block moves along the sliding line direction in a slide rail due to stretching and shrinking of the four link bars, so that the wheel provided with the four-bar linkage wheel carrier realizes reducing. When the six caster assemblies are opened or closed, the diameter of the diameter-variable semi-walking wheel is changed.

Owner:BEIHANG UNIV

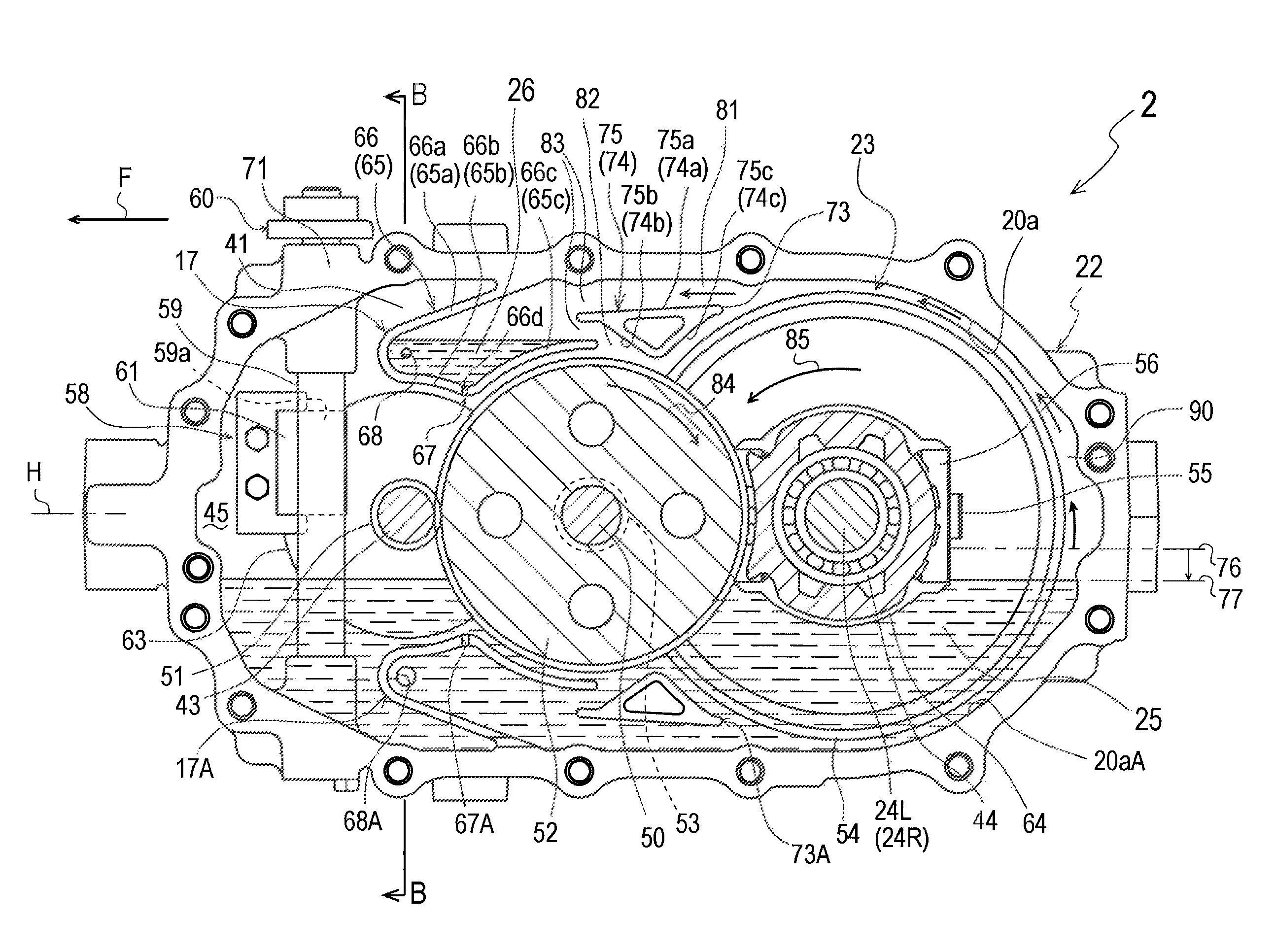

Electric transaxle

ActiveUS8899381B2Low levelEfficient supplyElectric propulsion mountingGear lubrication/coolingTransmitted powerEngineering

An electric transaxle according to the invention comprises a transaxle casing, an electric motor, an axle, a gear mechanism, first and second fluid sumps, and first and second fluid introduction passages. The transaxle casing defines a gear chamber therein. The electric motor includes a motor casing attached to the transaxle casing. The axle is supported by the transaxle casing. The gear mechanism transmits power from the electric motor to the axle. Fluid of the first fluid sump raised by driving the gear mechanism is supplied to the second fluid sump. The first fluid introduction passage introduces the fluid raised from the first fluid sump to the second fluid sump when the axle is rotated in a forward traveling direction. The second fluid introduction passage introduces the fluid raised from the first fluid sump to the second fluid sump when the axle is rotated in a backward traveling direction.

Owner:KANZAKI KOKYUKOKI MFG

Electric transaxle

ActiveUS20130019707A1Low levelEfficient supplyElectric propulsion mountingGear lubrication/coolingTransmitted powerGear wheel

An electric transaxle according to the invention comprises a transaxle casing, an electric motor, an axle, a gear mechanism, first and second fluid sumps, and first and second fluid introduction passages. The transaxle casing defines a gear chamber therein. The electric motor includes a motor casing attached to the transaxle casing. The axle is supported by the transaxle casing. The gear mechanism transmits power from the electric motor to the axle. Fluid of the first fluid sump raised by driving the gear mechanism is supplied to the second fluid sump. The first fluid introduction passage introduces the fluid raised from the first fluid sump to the second fluid sump when the axle is rotated in a forward traveling direction. The second fluid introduction passage introduces the fluid raised from the first fluid sump to the second fluid sump when the axle is rotated in a backward traveling direction.

Owner:KANZAKI KOKYUKOKI MFG

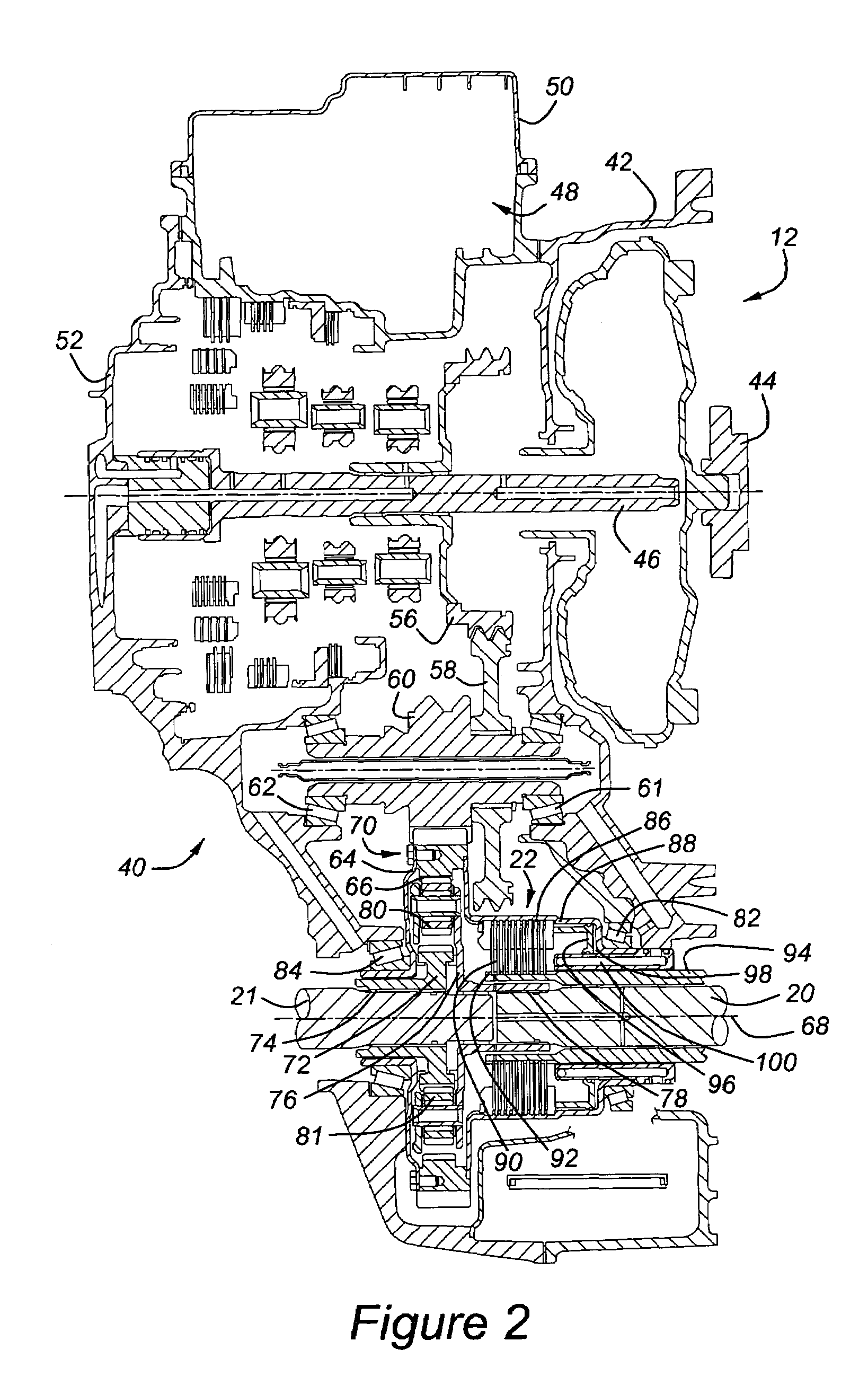

Transaxle unit with integrated power take-off unit and torque coupling device

InactiveUS20060283654A1Minimizes toolingMinimizes manufacturing expenseDifferential gearingsControl devicesHydraulic pumpVariable pressure

A transaxle unit comprises a differential assembly having a differential mechanism, a power take-off unit and a torque-coupling device for selectively restricting differential rotation of a differential mechanism. The torque-coupling device includes a friction clutch assembly for selectively frictionally engaging and disengaging a differential case and one of output axle shafts and a hydraulic clutch actuator. The hydraulic clutch actuator includes a hydraulic pump and a variable pressure relief valve assembly fluidly communicating with the hydraulic pump to selectively control a hydraulic pressure generated by the hydraulic pump. The variable pressure relief valve assembly comprises a valve closure member, a valve seat complementary to the valve closure member and an electro-magnetic actuator for engaging the valve closure member and generating a variable electro-magnetic force urging selectively vary a release pressure of the pressure relief valve assembly based on a magnitude of an electric current supplied to the electro-magnetic actuator.

Owner:DANA AUTOMOTIVE SYST GRP LLC

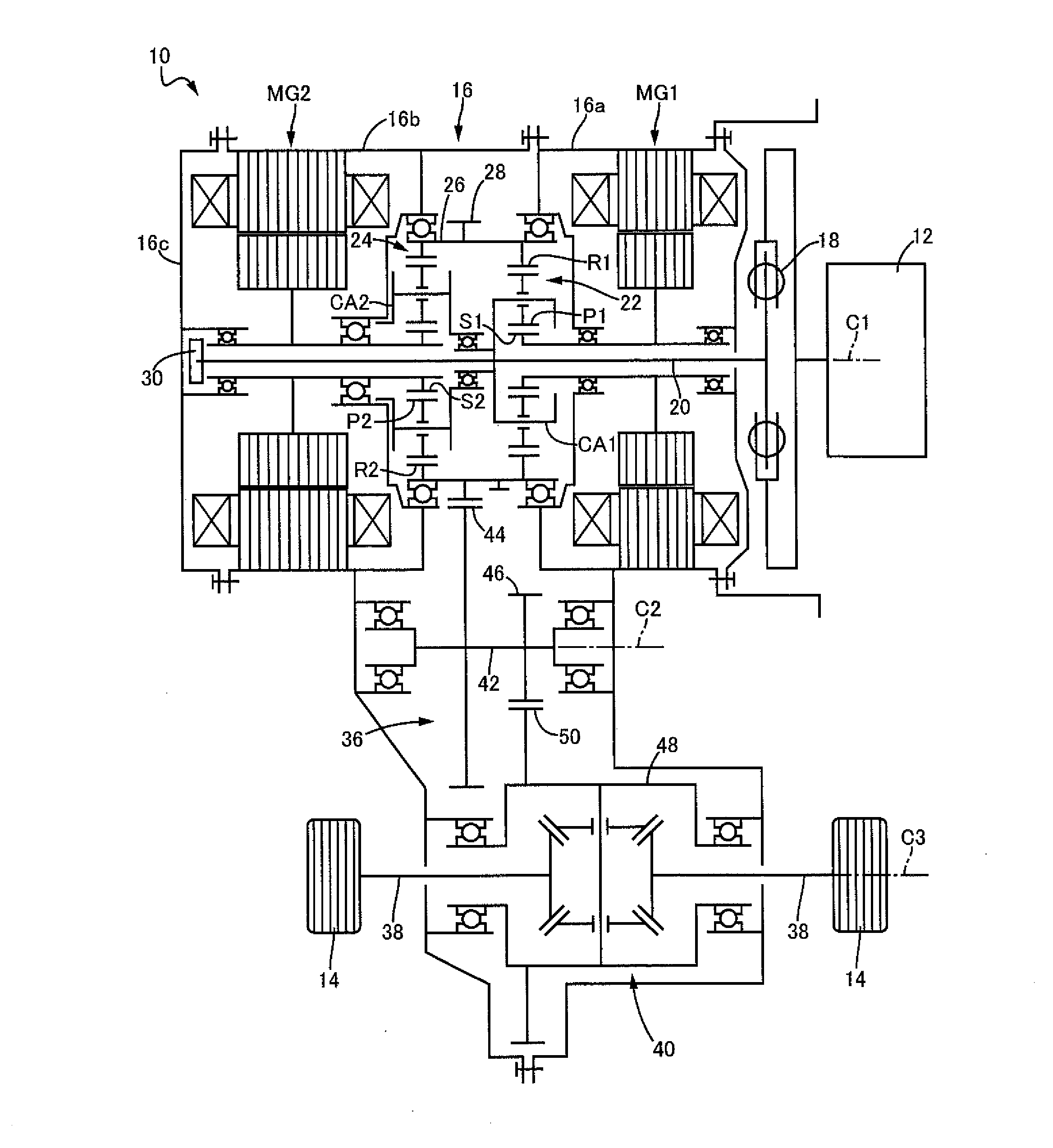

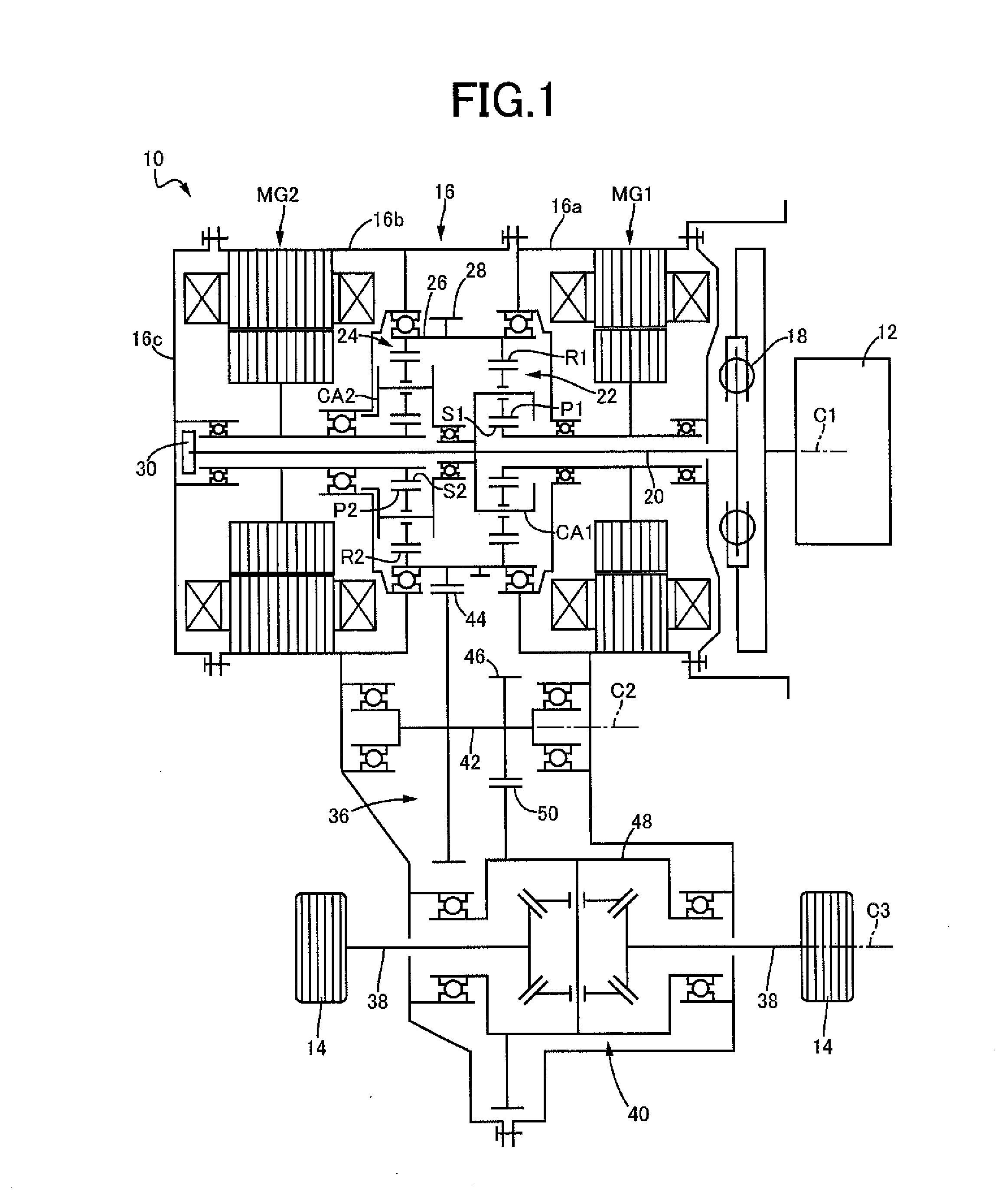

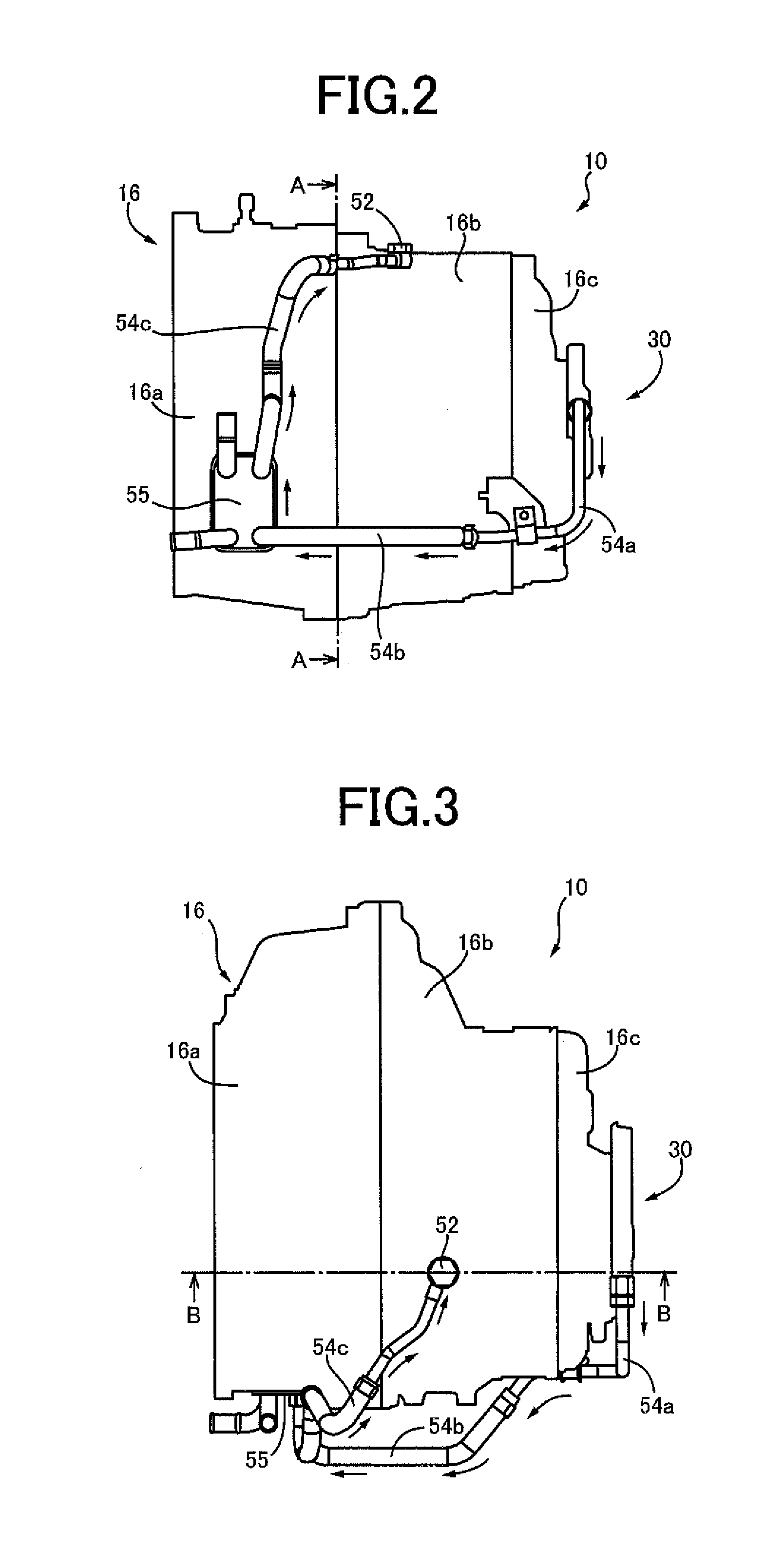

Lubrication device of power transmission device for hybrid vehicle

InactiveUS20140174856A1Supply will become excessiveLow viscosityHybrid vehiclesGear lubrication/coolingHybrid vehicleLubrication

A lubrication device for a hybrid vehicle power transmission device including a gear member, a first electric motor, and a second electric motor within a transaxle case, the lubrication device includes: a first pipe supplying oil forcibly transferred from an oil pump to the second electric motor; an oil passage branched from the first pipe; a first catch tank supplied with oil from the oil passage; a second pipe connected to the first catch tank to supply oil accumulated in the first catch tank to the first electric motor; an oil flow outlet disposed in the first catch tank and located above the second pipe; and a second catch tank disposed vertically beneath the first catch tank to receive oil outflowing from the oil flow outlet.

Owner:TOYOTA JIDOSHA KK

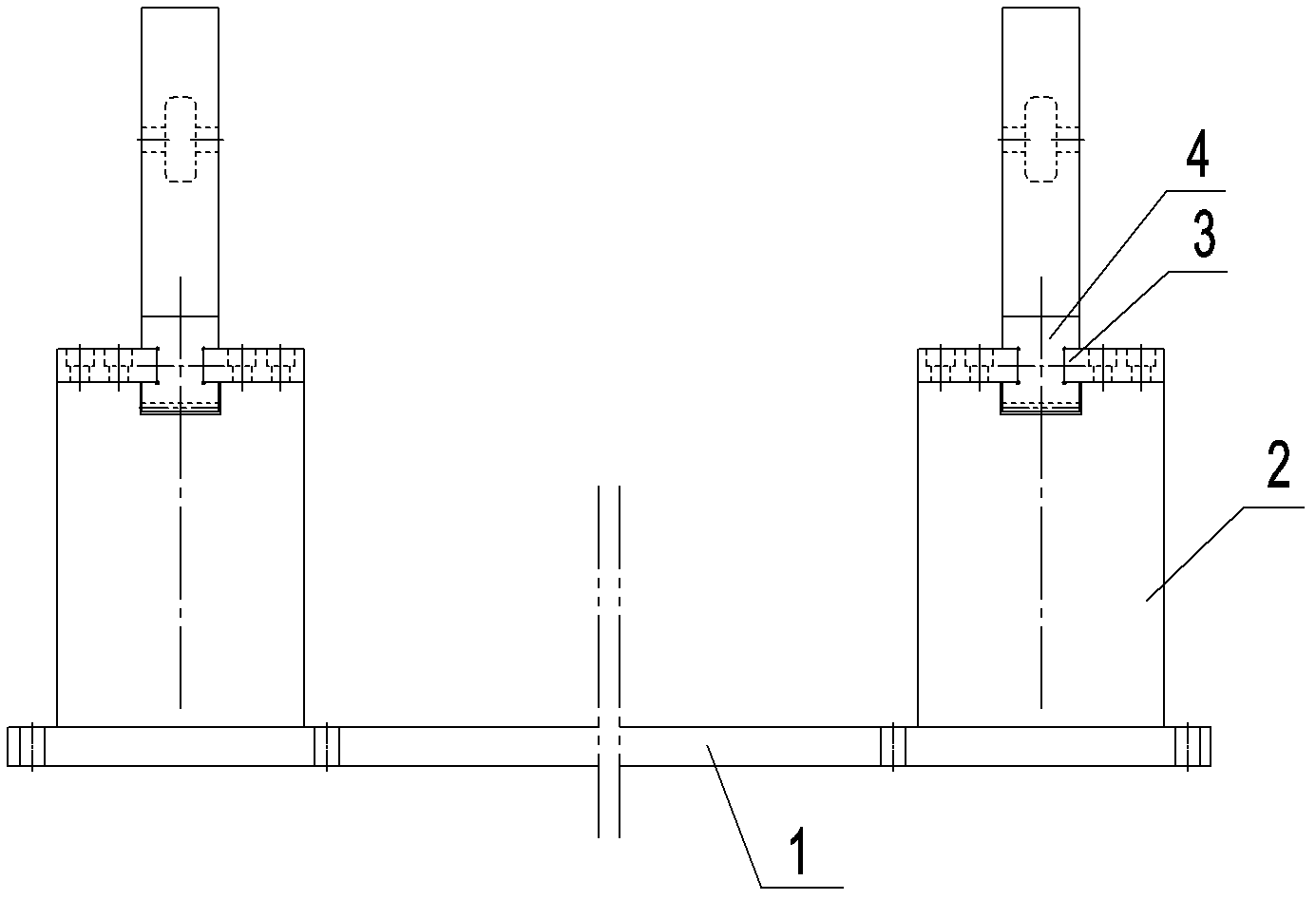

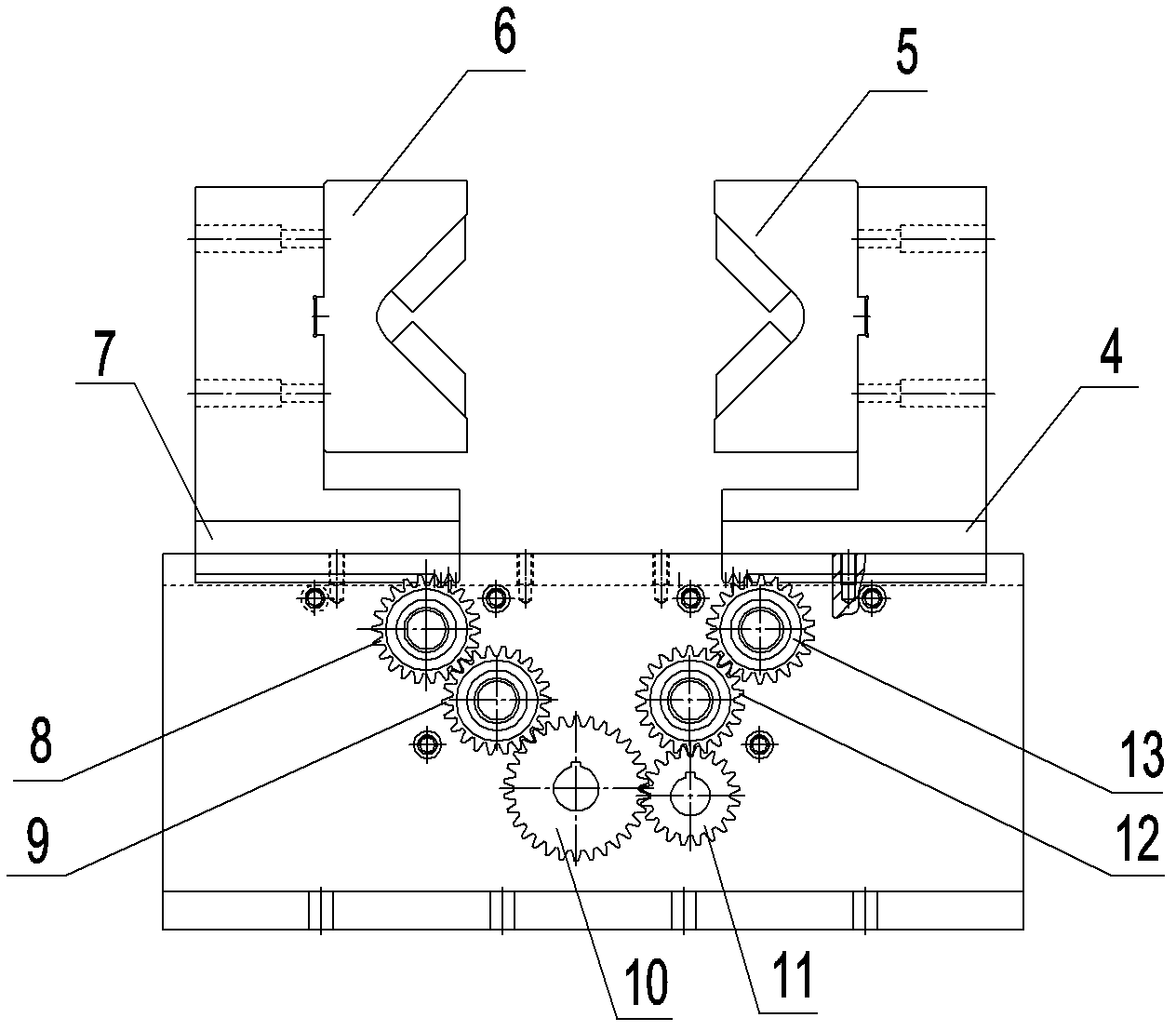

Boring automatic centering clamp of drive axle housing

InactiveCN102581641AGuaranteed machining accuracyImprove work efficiencyPositioning apparatusMetal-working holdersControl theoryMechanical engineering

The invention provides a boring automatic centering clamp of a drive axle housing, relating to a clamp for the mechanical processing field. The boring automatic centering clamp comprises a fixing base, and two sets of clamping positioning devices symmetrically connected to two ends of the fixing base, wherein each set of clamping positioning devices comprises a transmission case, a sliding block I, a sliding block II, a clamping block I and a clamping block II; a slide rail is mounted on the top wall of the transmission case; the sliding block I and the sliding block II are glidingly connected to the slide rail, and protruded on the upper surface of the top wall of the transmission case; the clamping block I is connected to the sliding block I, while the clamping block II is connected to the sliding block II; symmetrically mounted clamping parts having the same shape are concavely arranged in the clamping block I and the clamping block II, respectively; and the transmission case is internally provided with a transmission mechanism for sliding the sliding block I and the sliding block II to reversely move on the lead rail in order to control the clamping block I and the clamping block II to clamp or release the drive axle housing. The boring automatic centering clamp provided by the invention has the advantages of automatically aligning the axes of the sleeve holes at two ends of the drive axle housing, and quickly performing positioning and clamping.

Owner:LIUZHOU CITY LONGCHEN AXLE PARTS MFG

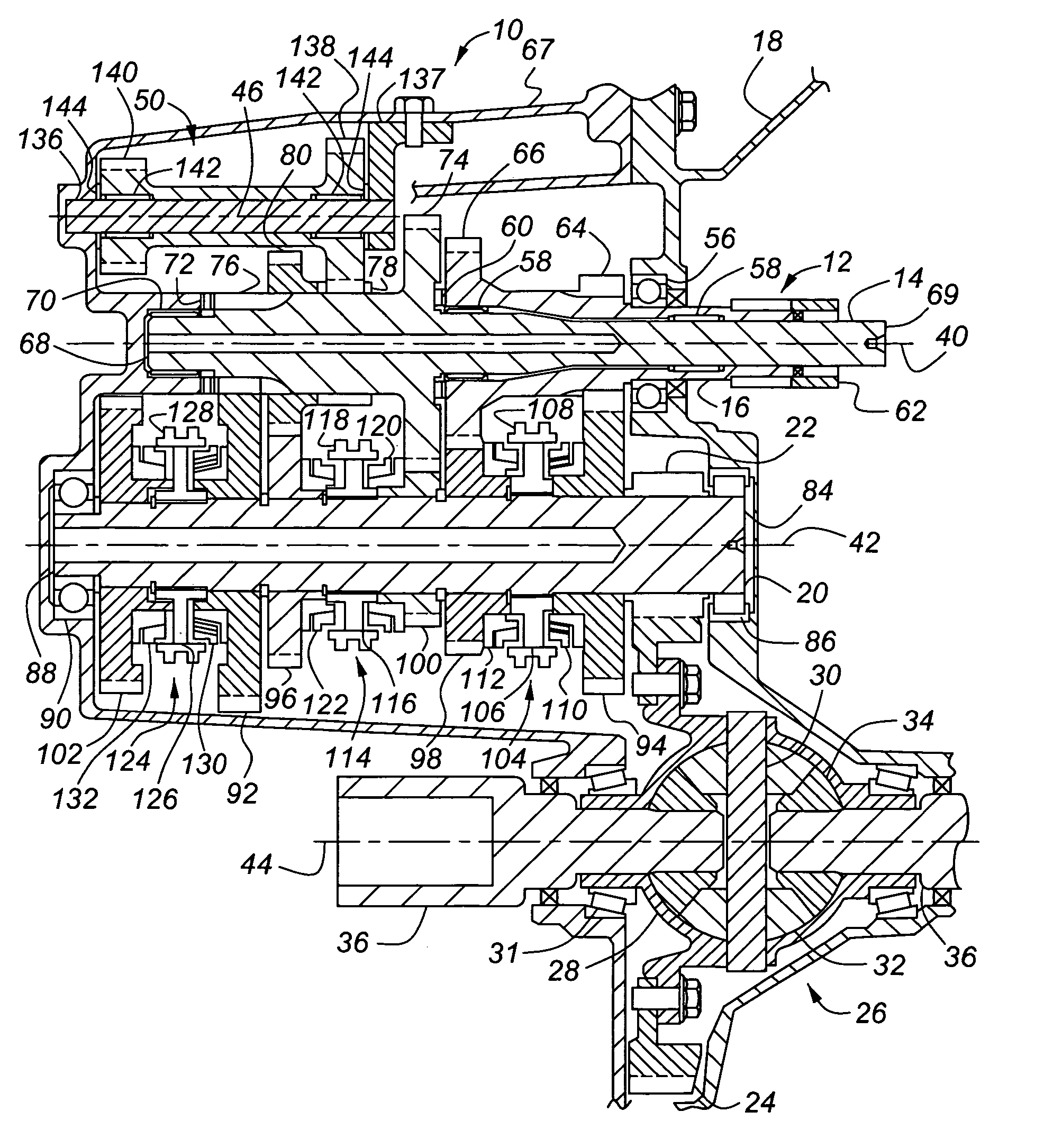

Dual clutch automatic transaxle

InactiveUS7044014B2Shorten the lengthSolve the lack of spaceToothed gearingsTransmission elementsControl theoryLayshaft

A multiple speed transaxle includes first and second input shafts, first and second output shafts, a layshaft, an idler shaft, a first set of selectable torque paths between the first input shaft and first output shaft, a second set of selectable torque paths between the second input shaft and the second output shaft, the second set including the layshaft and idler shaft, and a selectable torque path between the first input shaft and second output shaft including the layshaft and idler shaft.

Owner:FORD GLOBAL TECH LLC

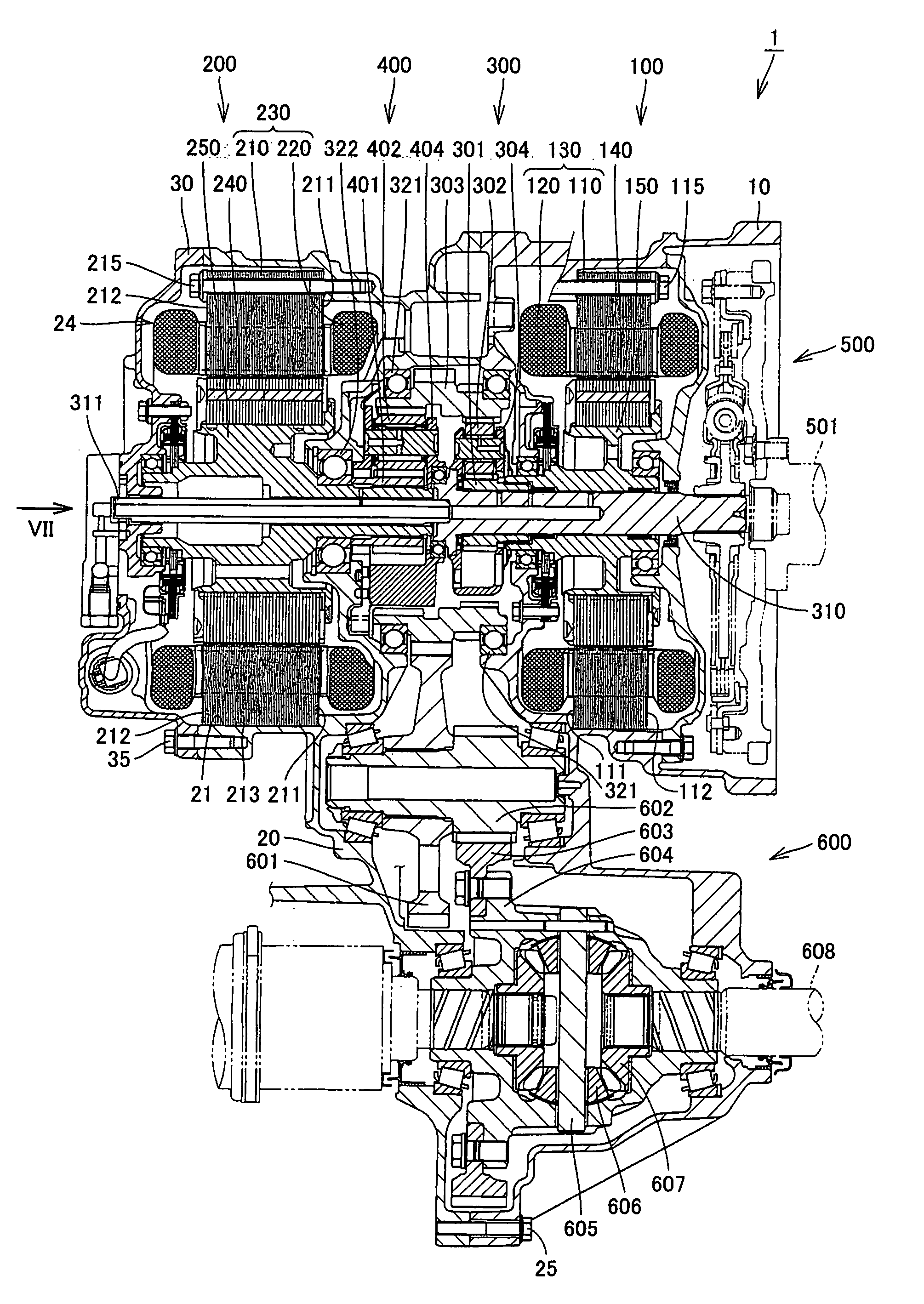

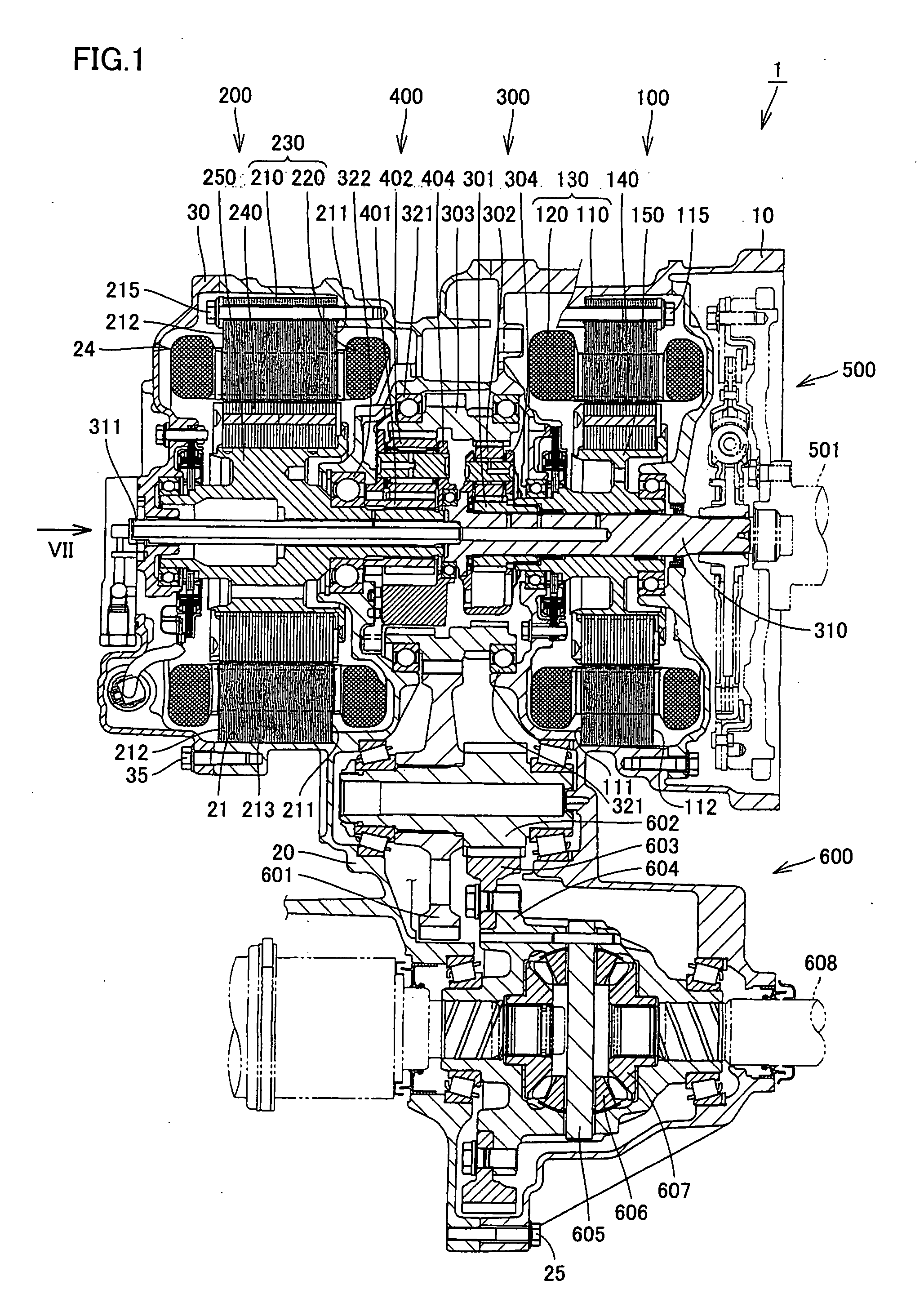

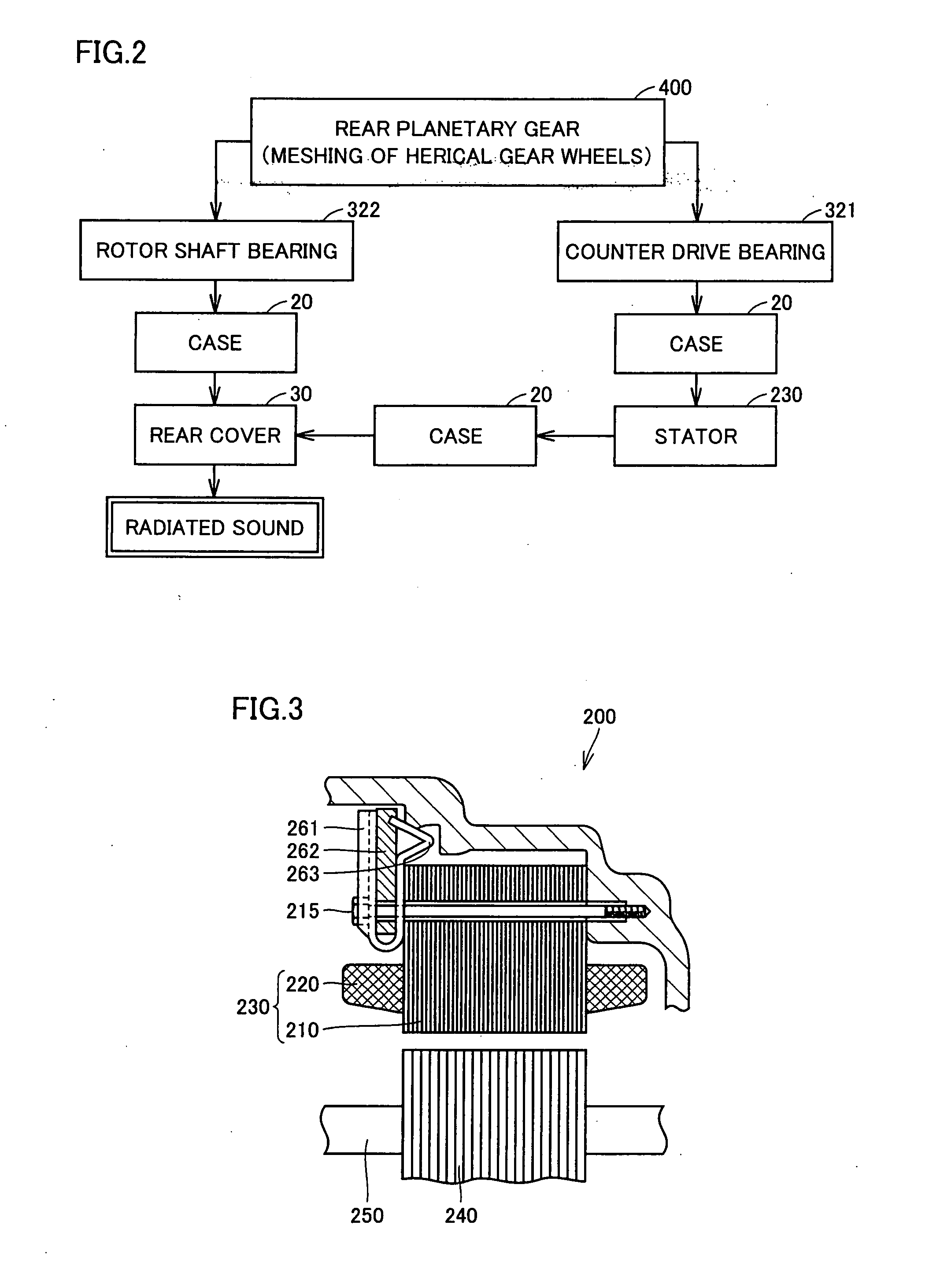

Driving Device With Rotating Electric Machine

InactiveUS20080106163A1Improve appearance qualityAvoid vibrationHybrid vehiclesGear vibration/noise dampingElectric machineGear wheel

A transaxle includes a case having an opening, a second rotating electric machine stored in the opening of the case and having a stators, a rear planetary gear stored in the transaxle case and connected to the second rotating electric machine, a transaxle rear cover sealing the opening and a bolt fixing the second rotating electric machine to the transaxle case. The stator has first and second thrust end faces defining an axial length thereof. The first thrust end face is pressed against an inner surface of the case.

Owner:TOYOTA JIDOSHA KK

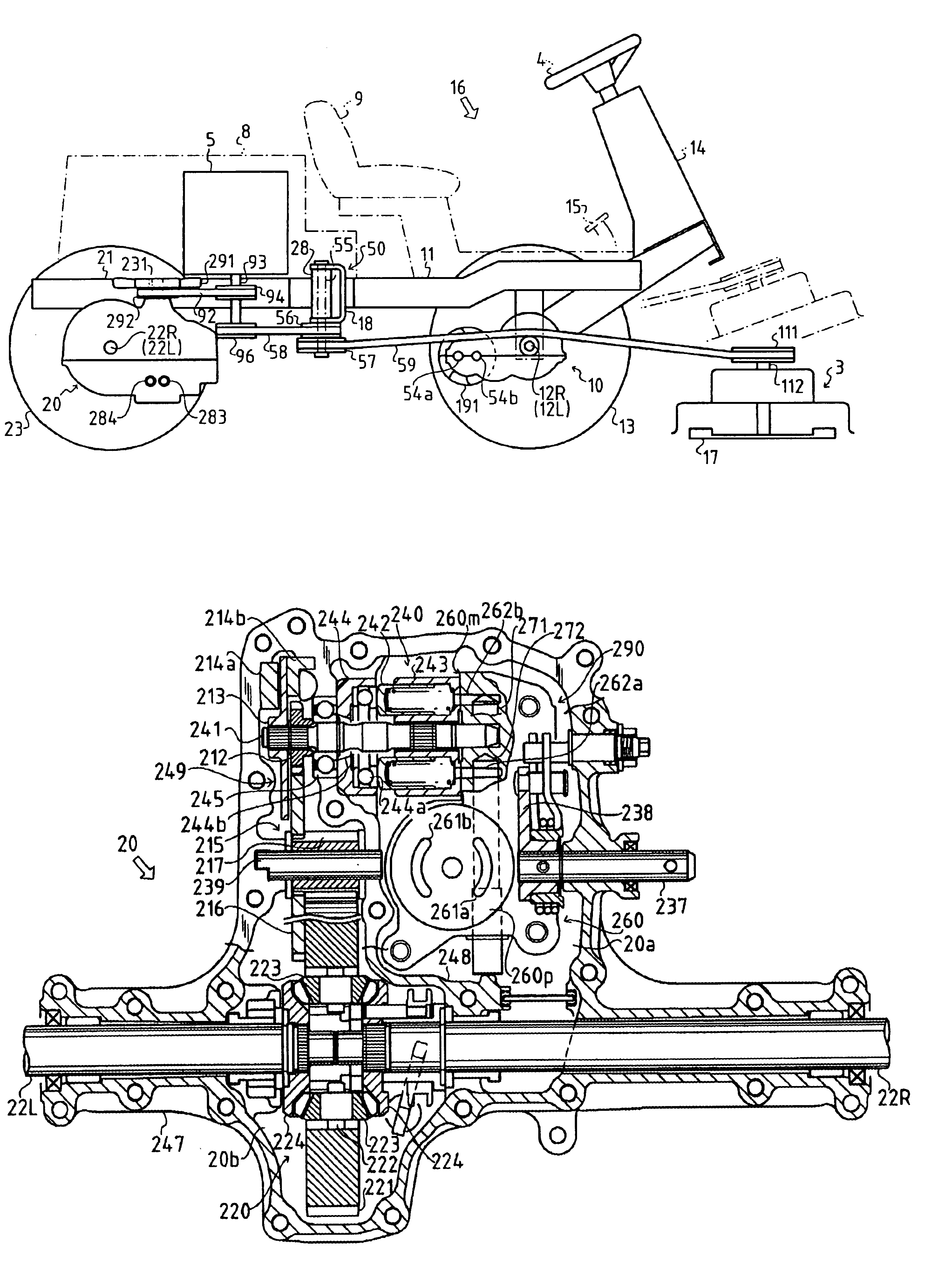

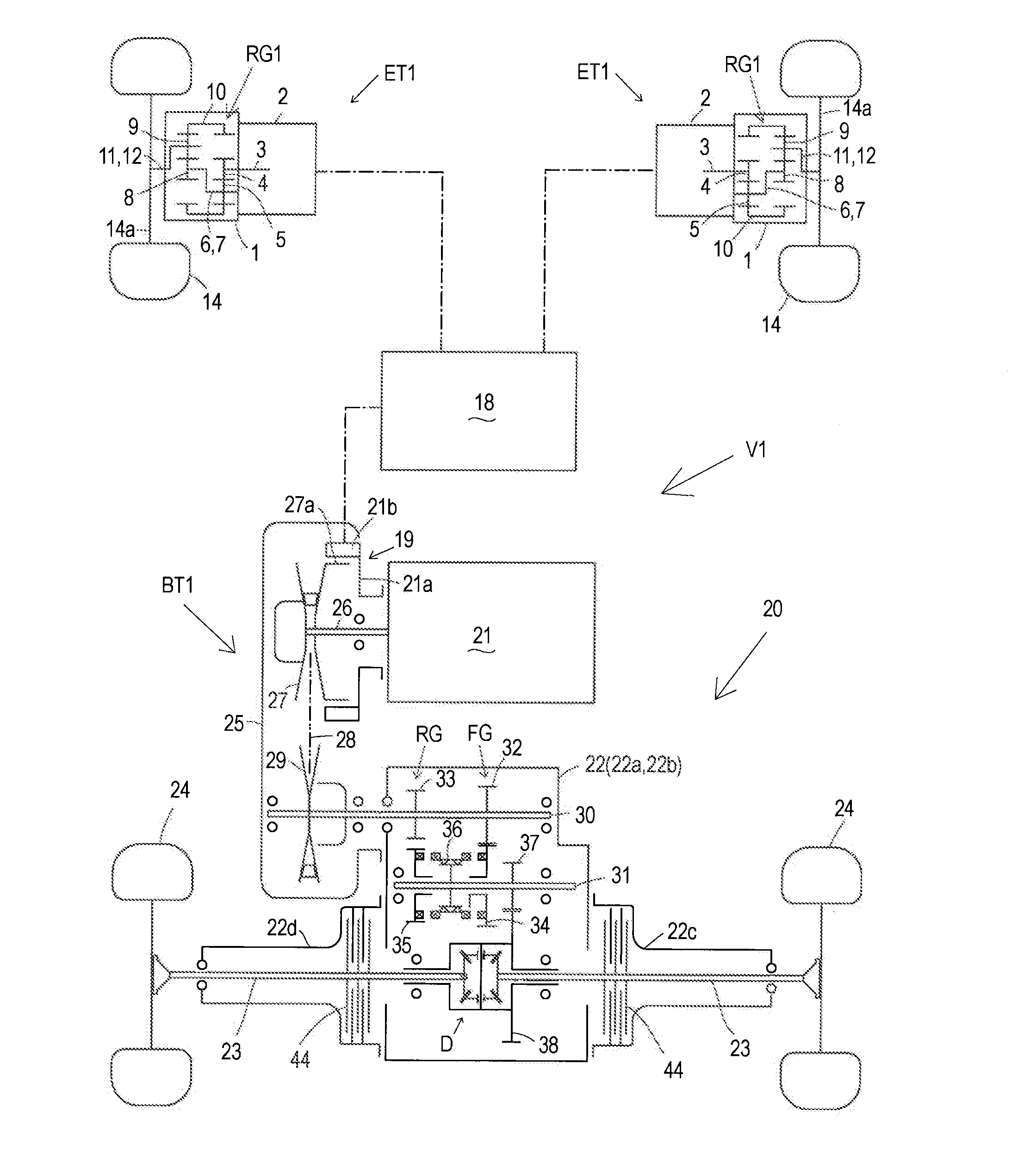

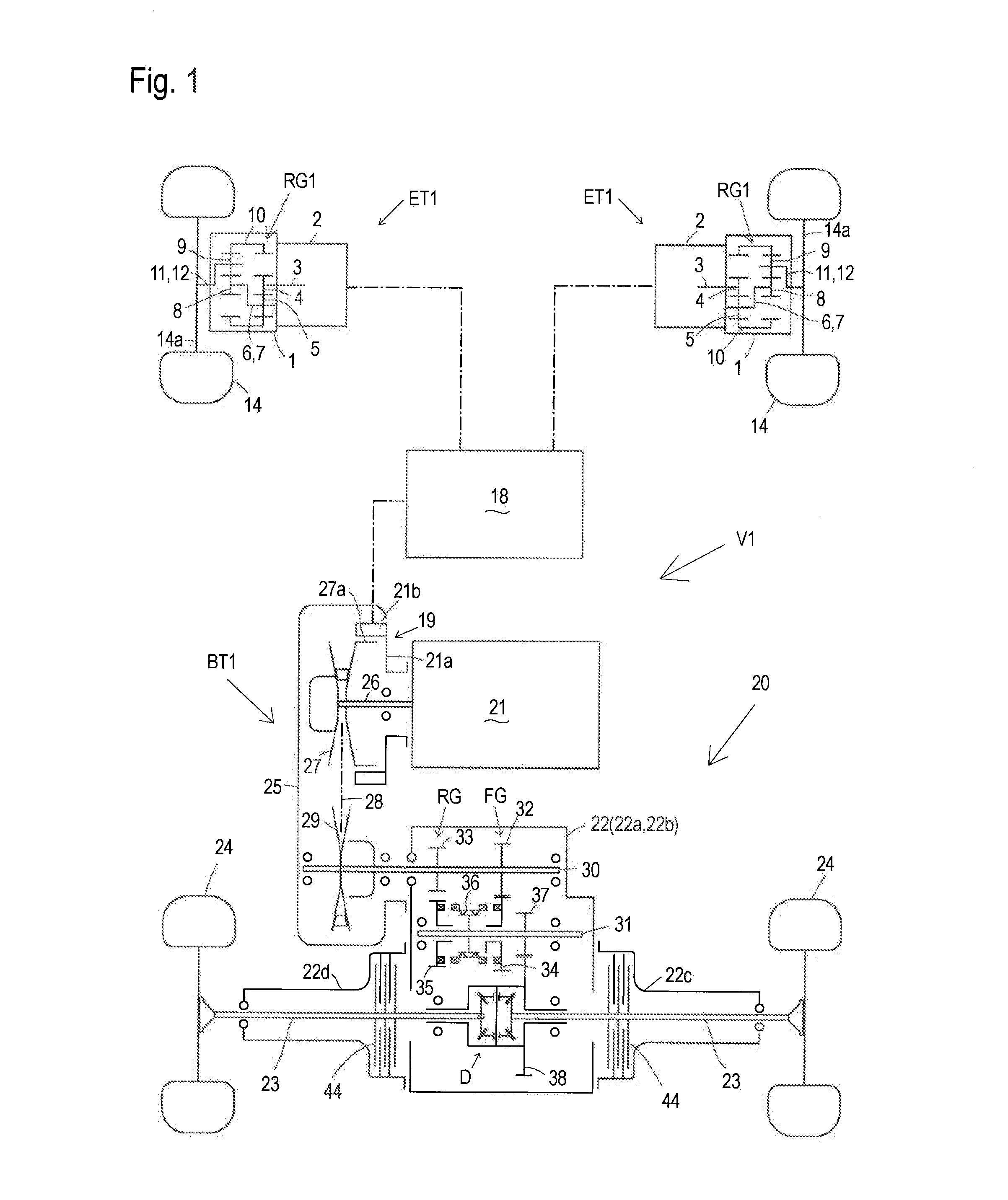

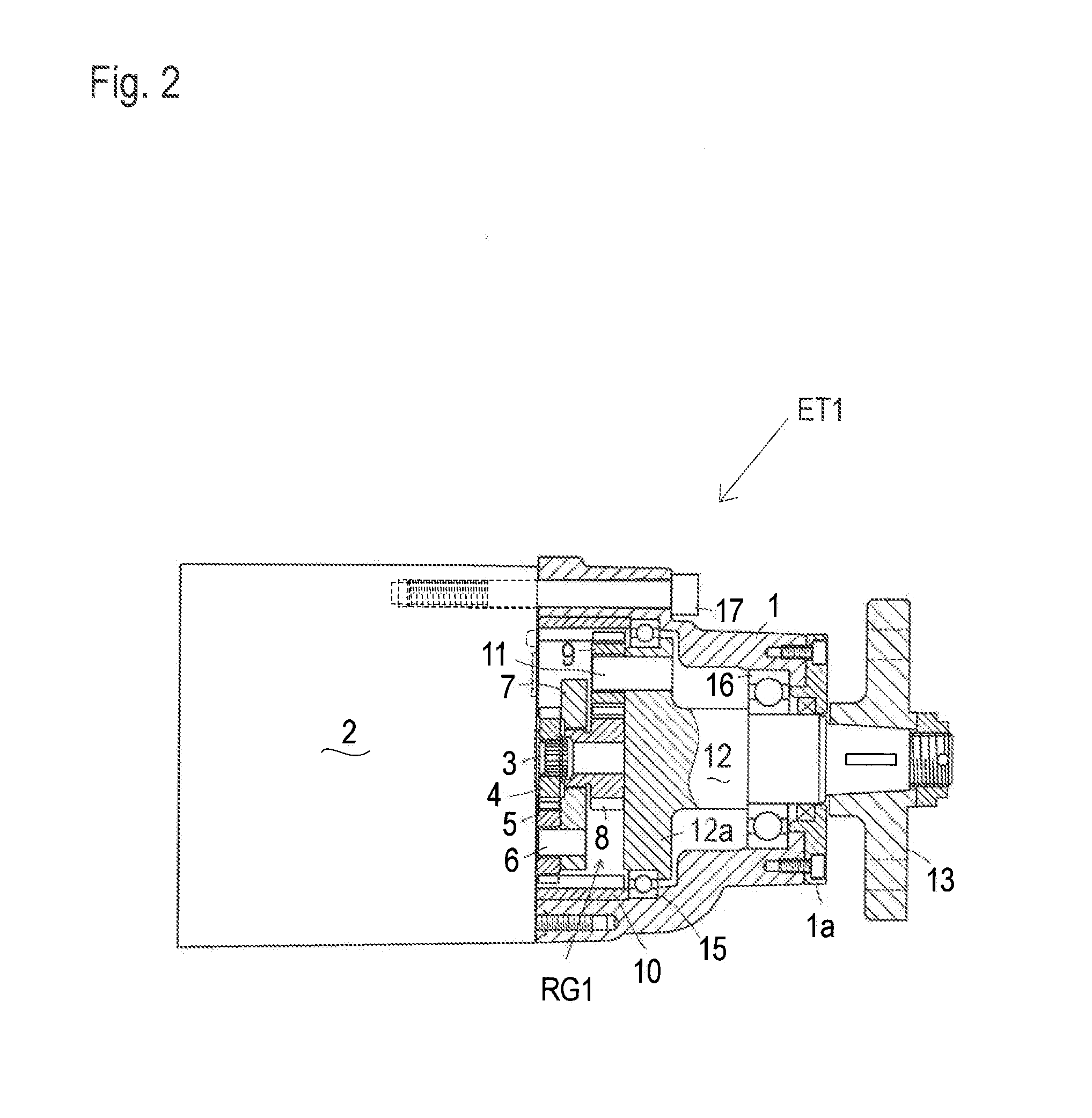

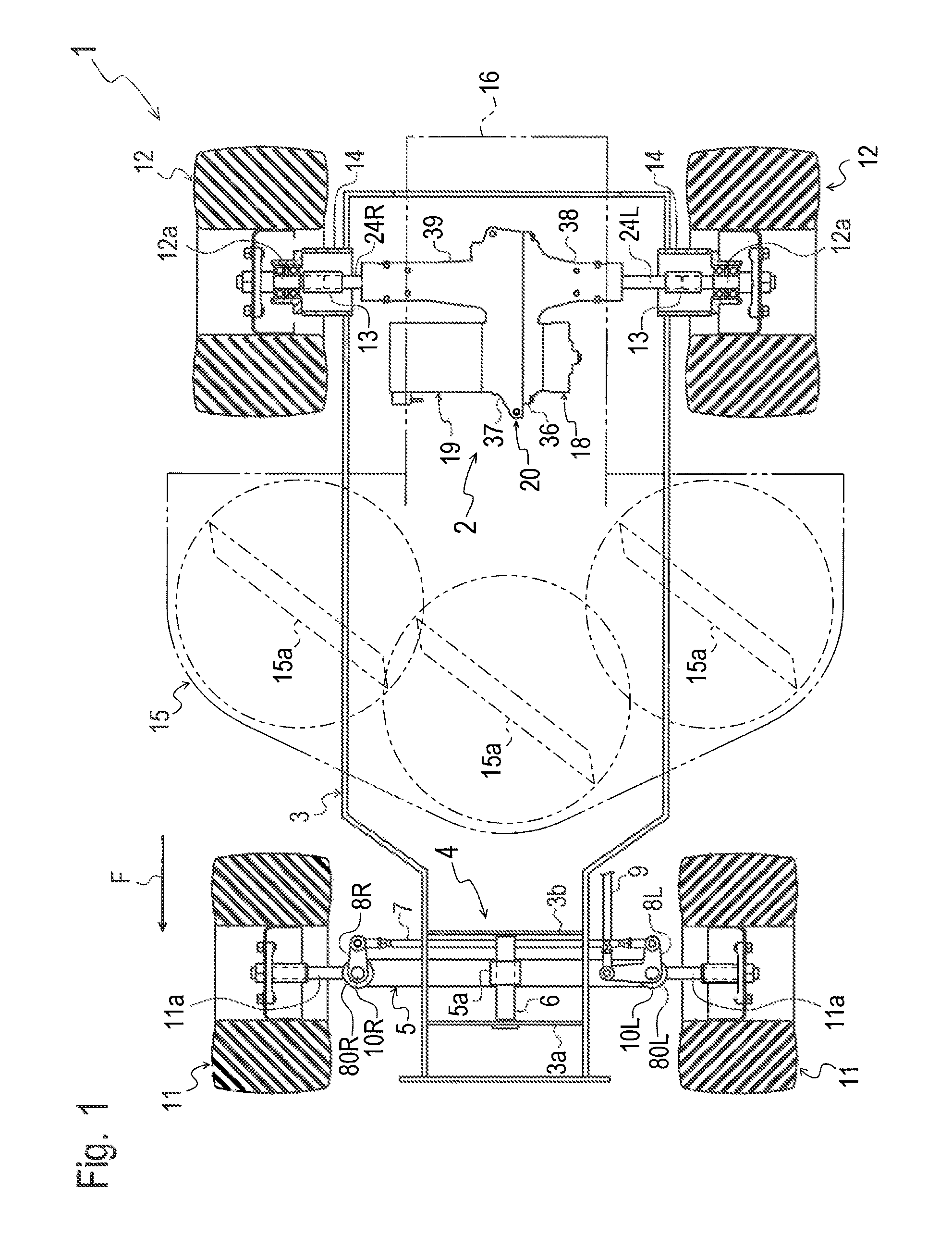

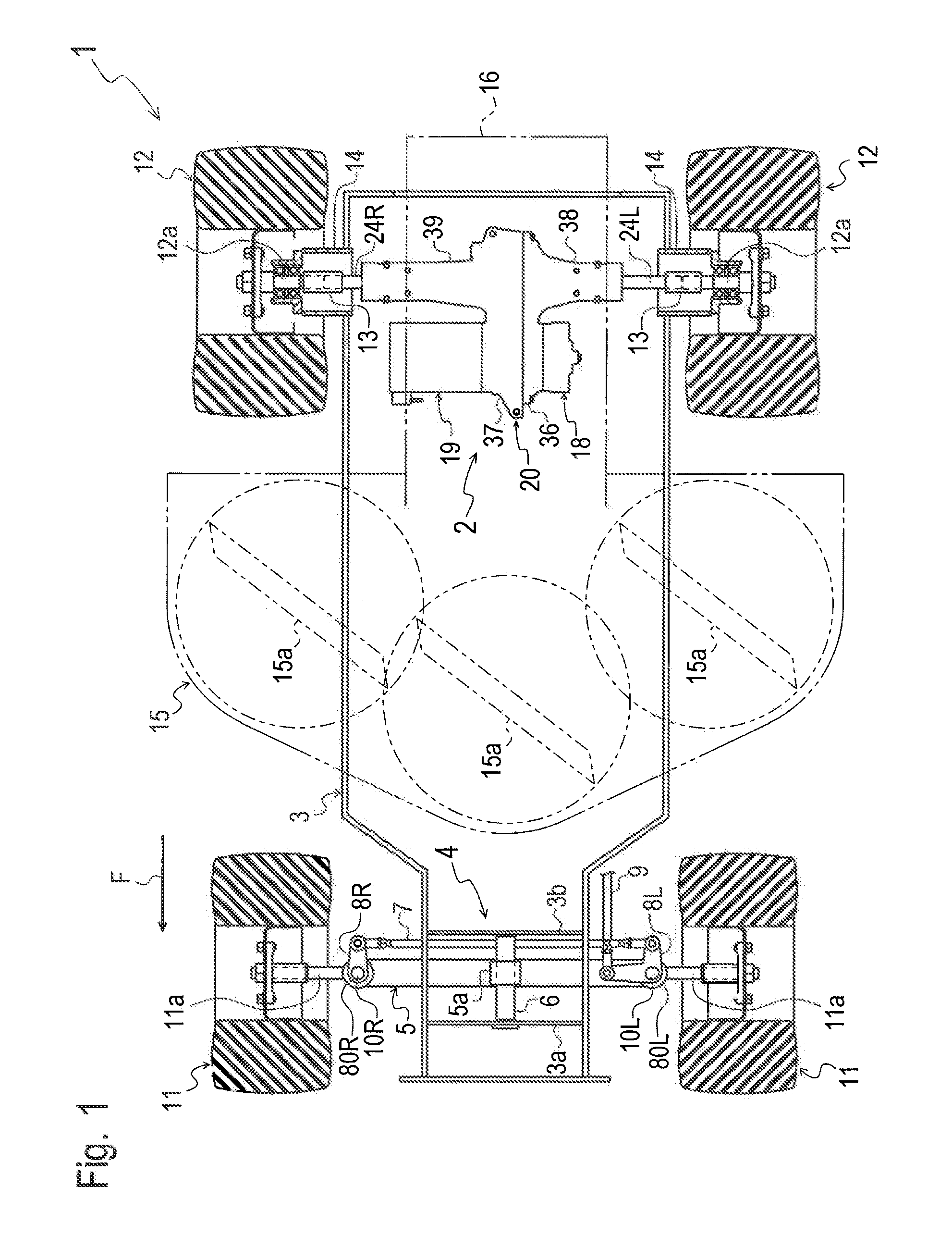

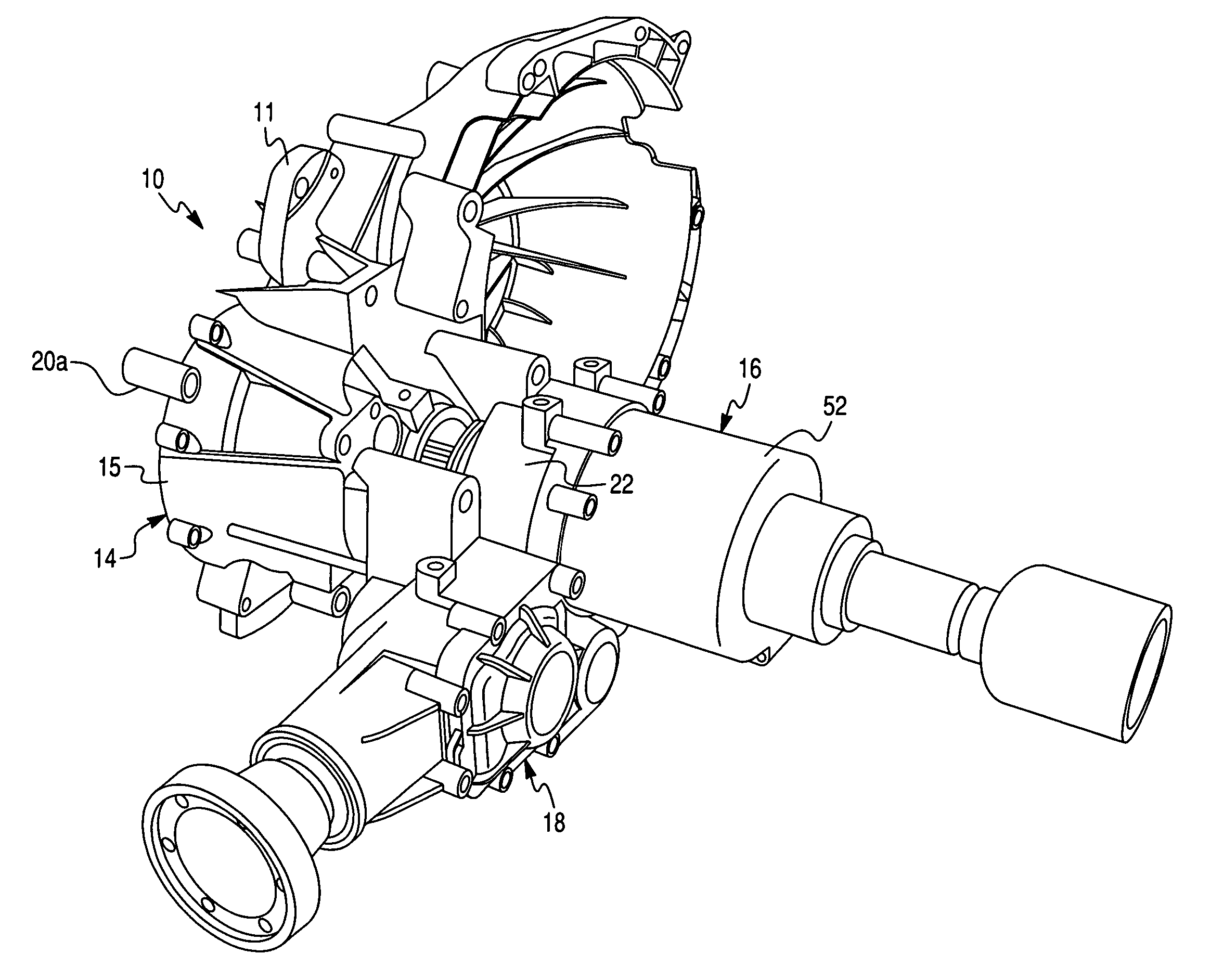

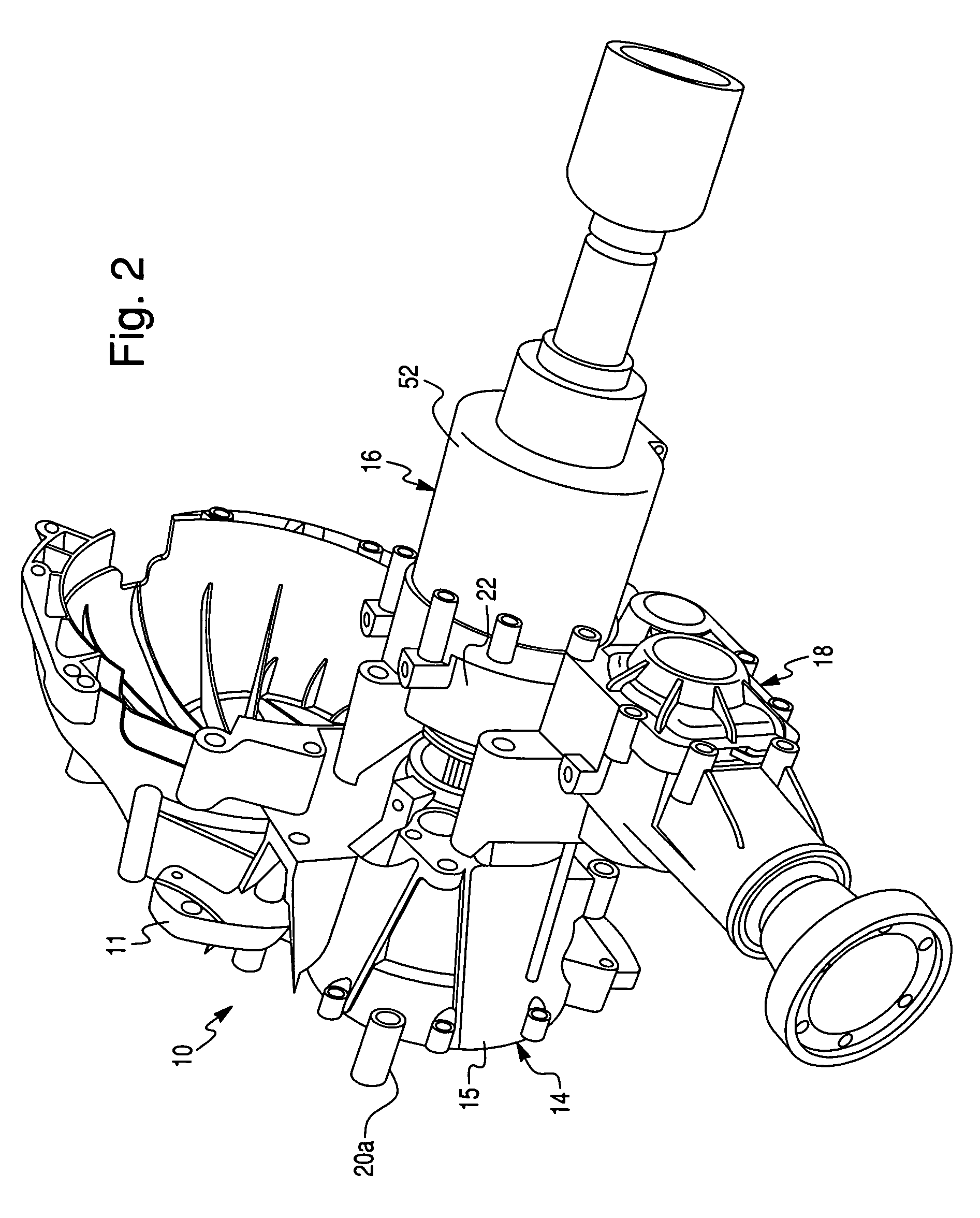

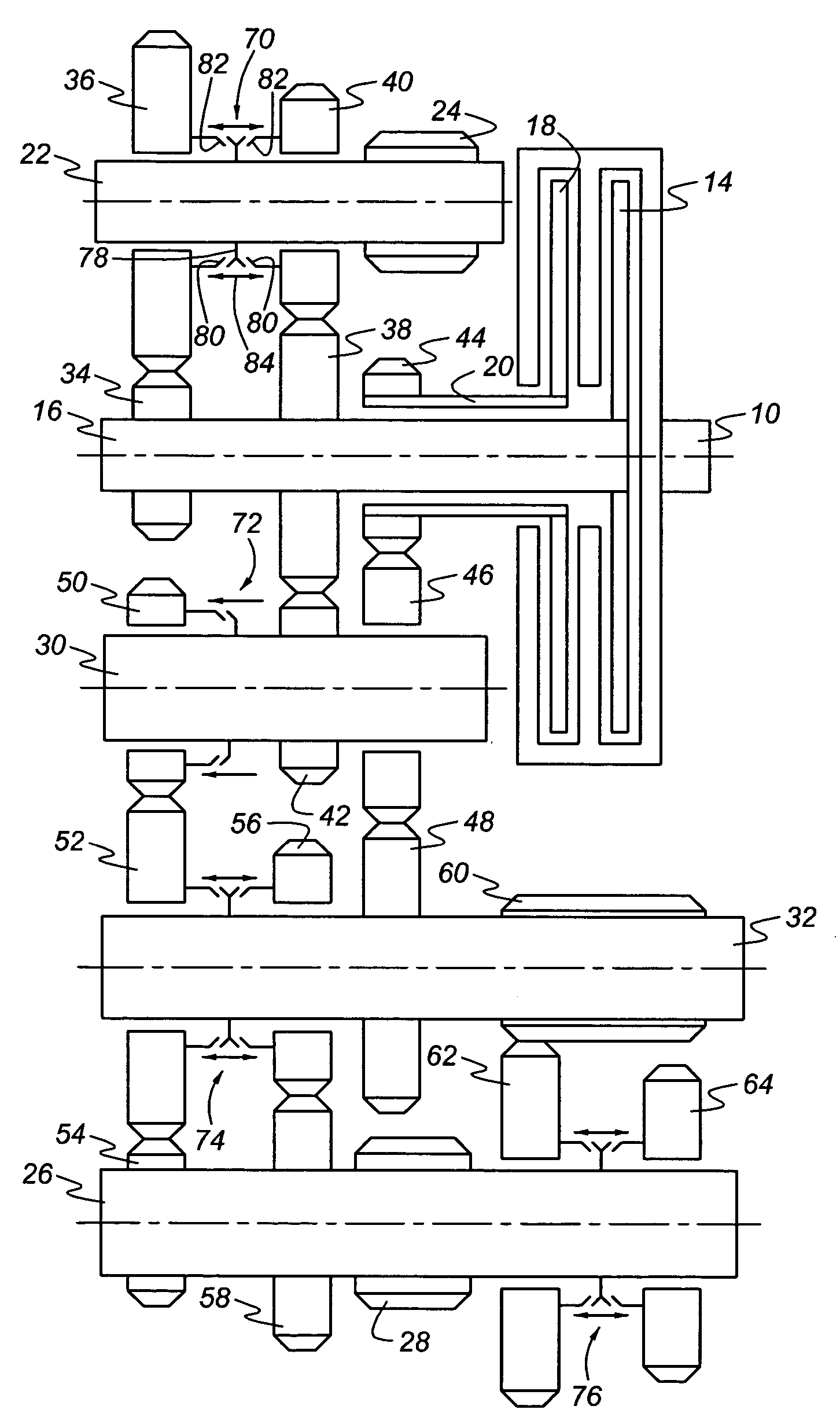

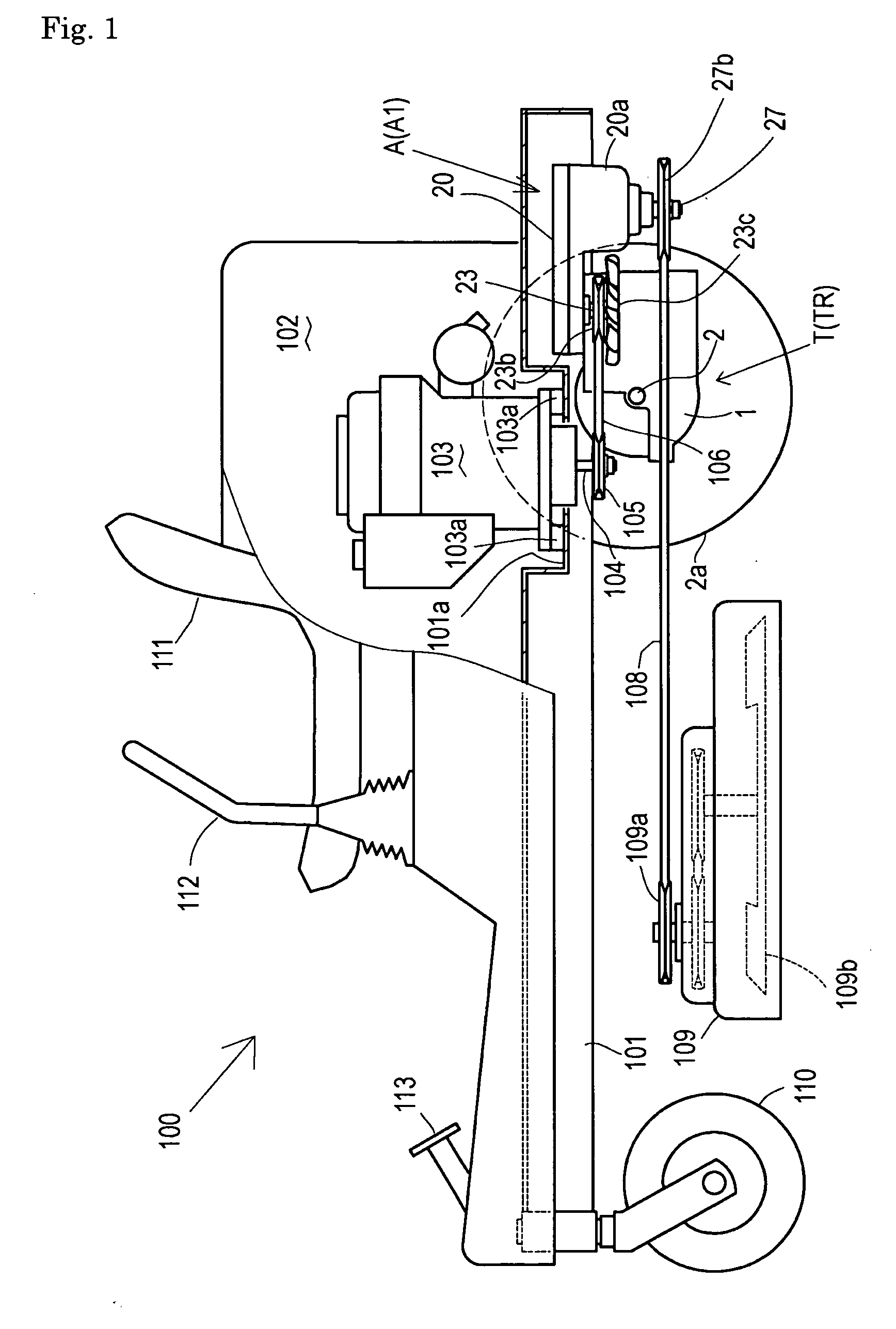

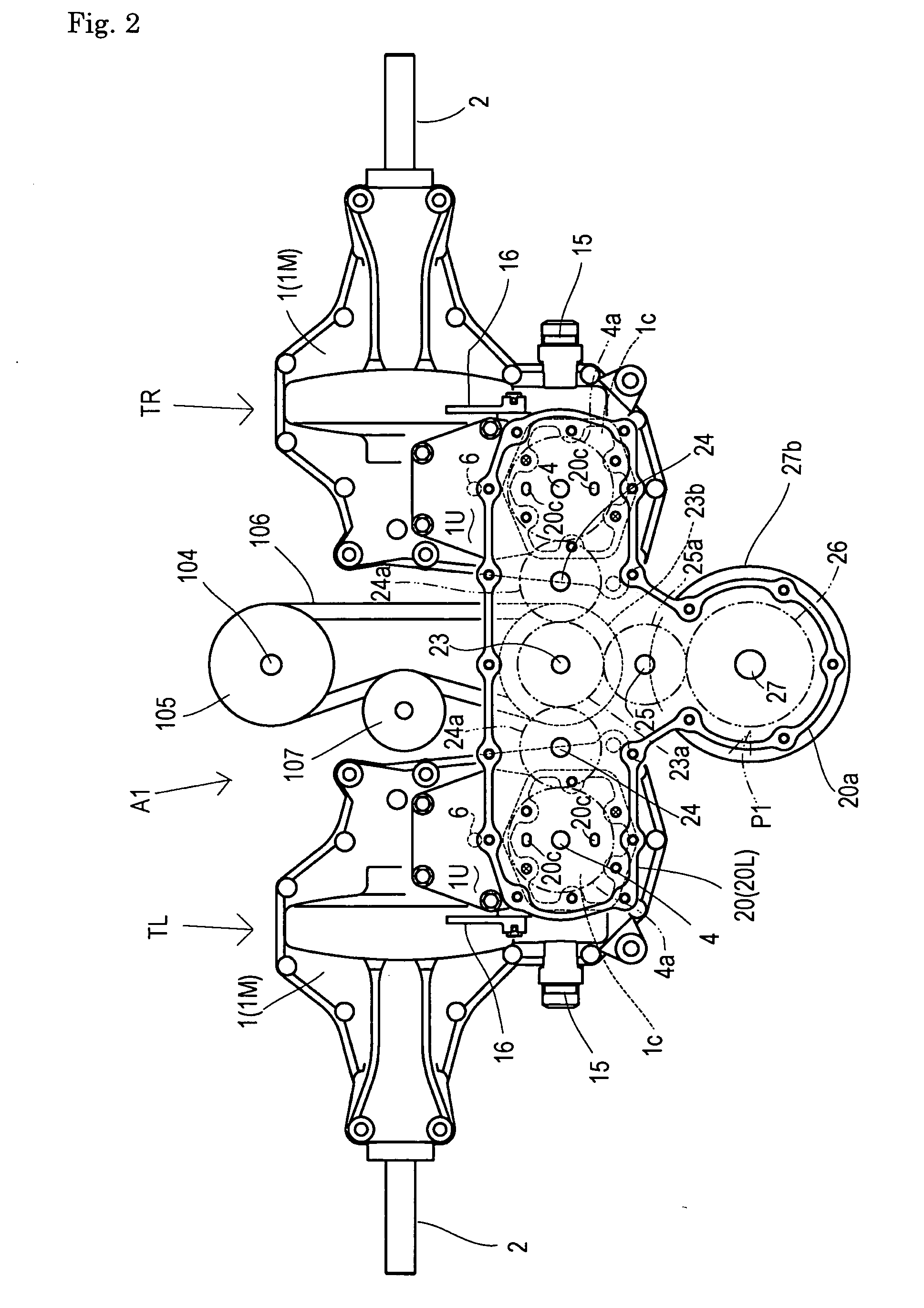

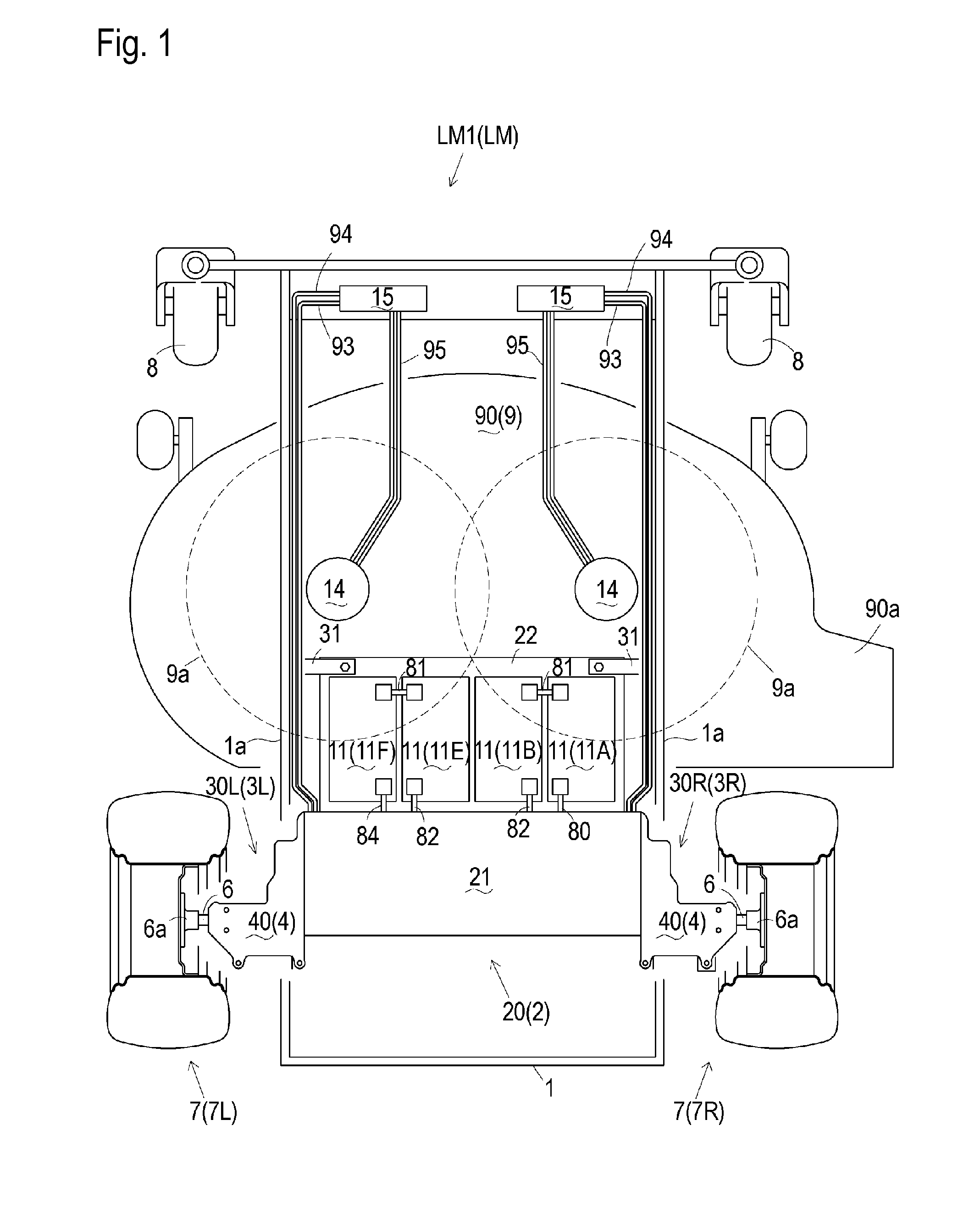

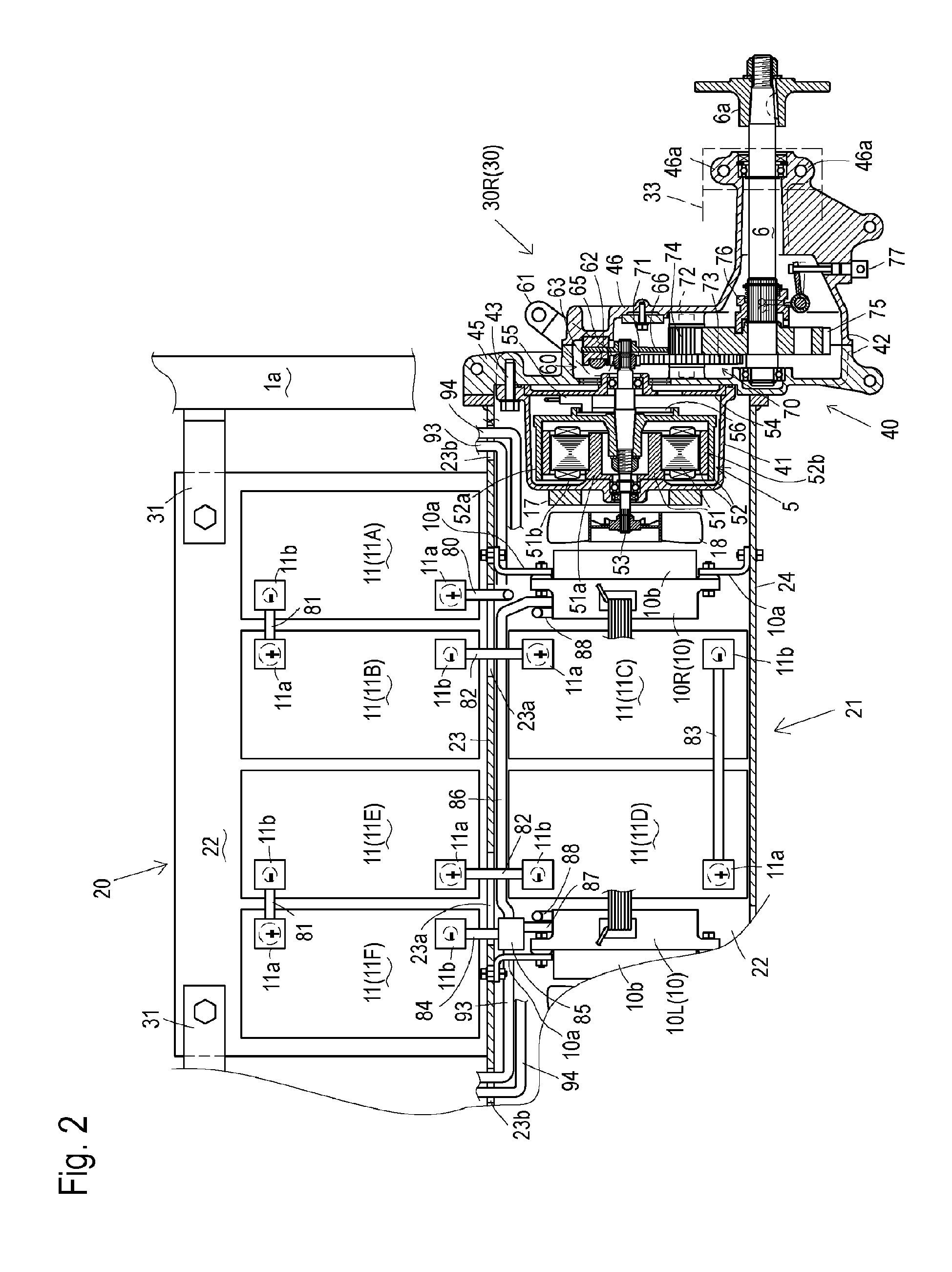

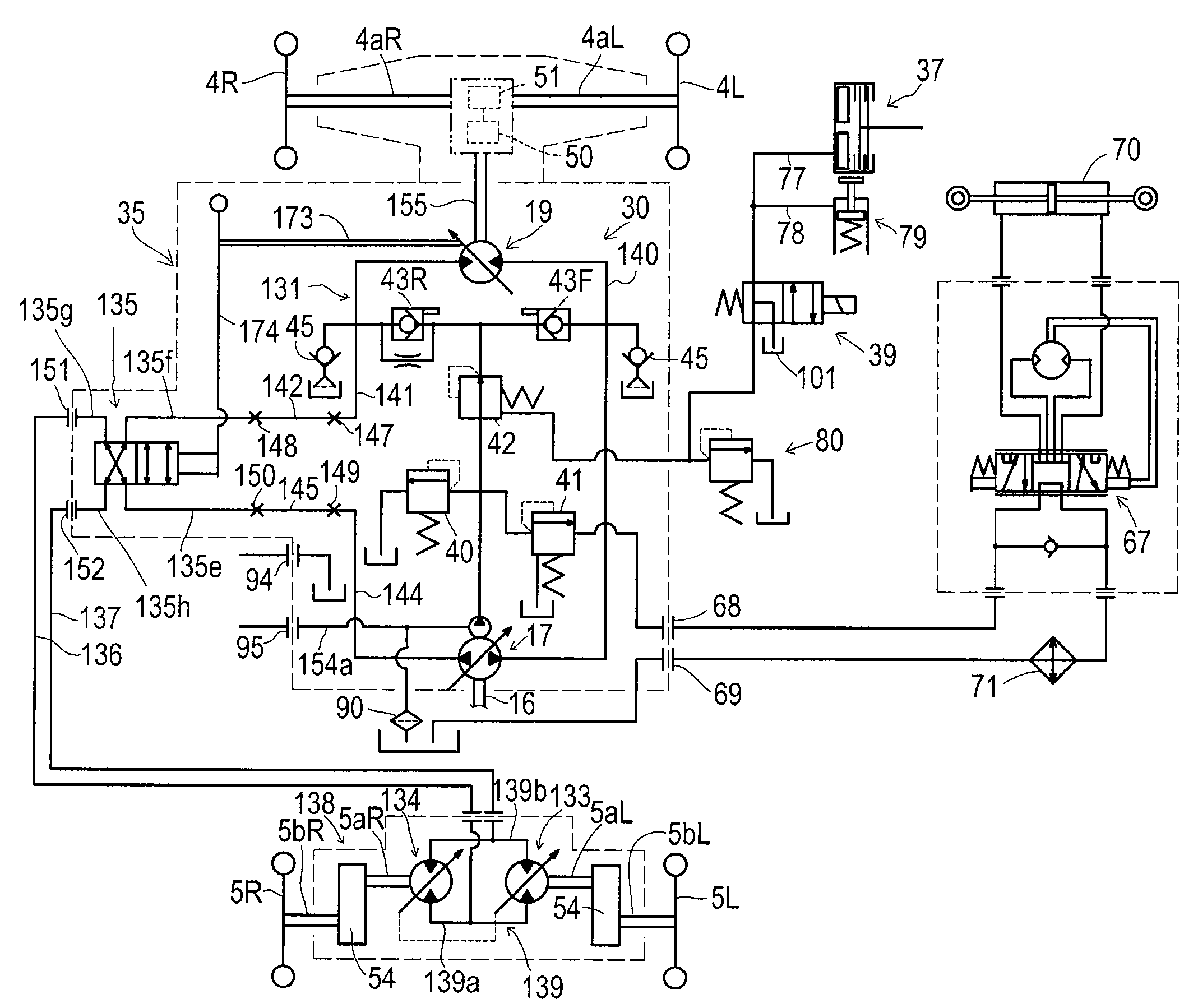

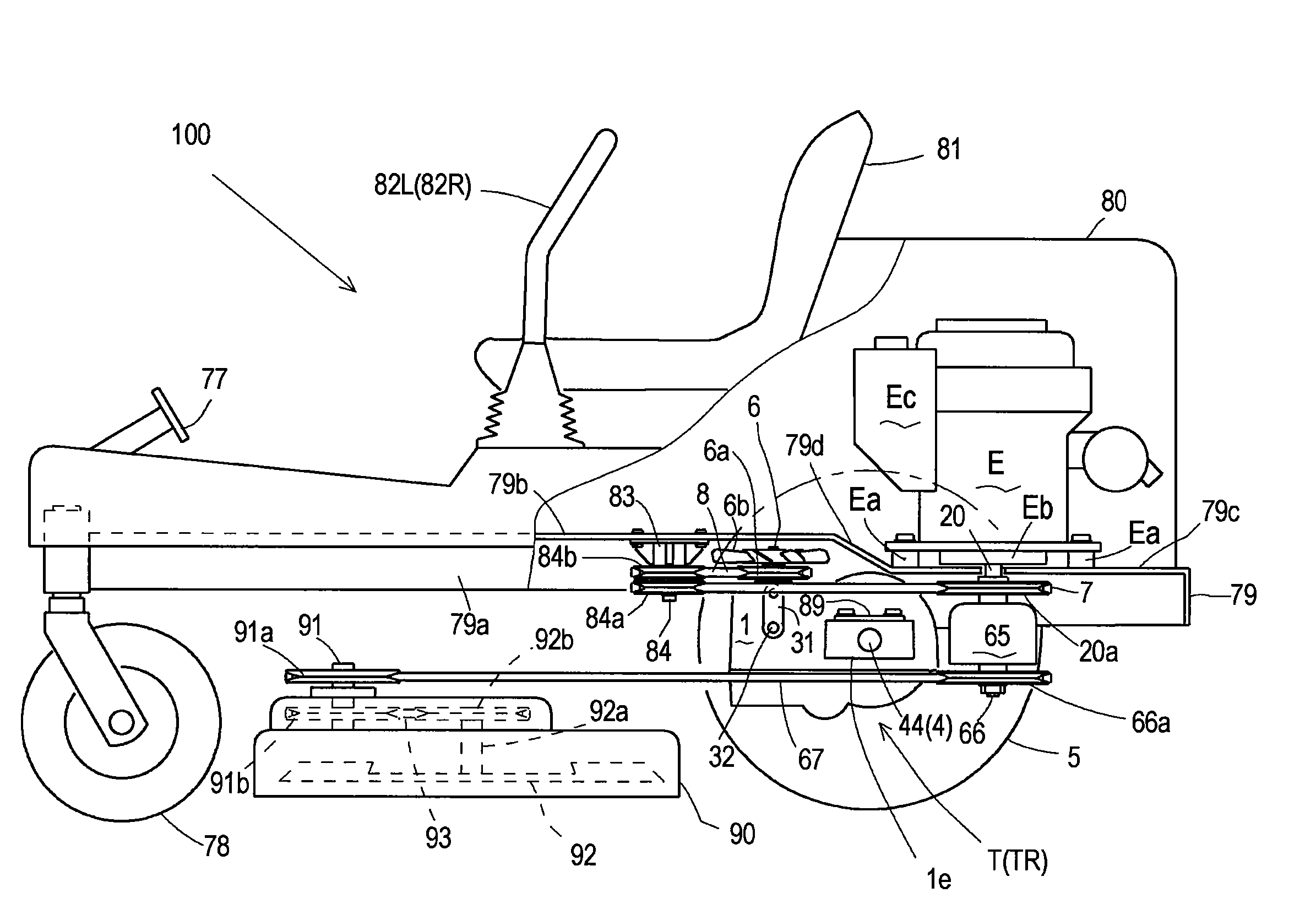

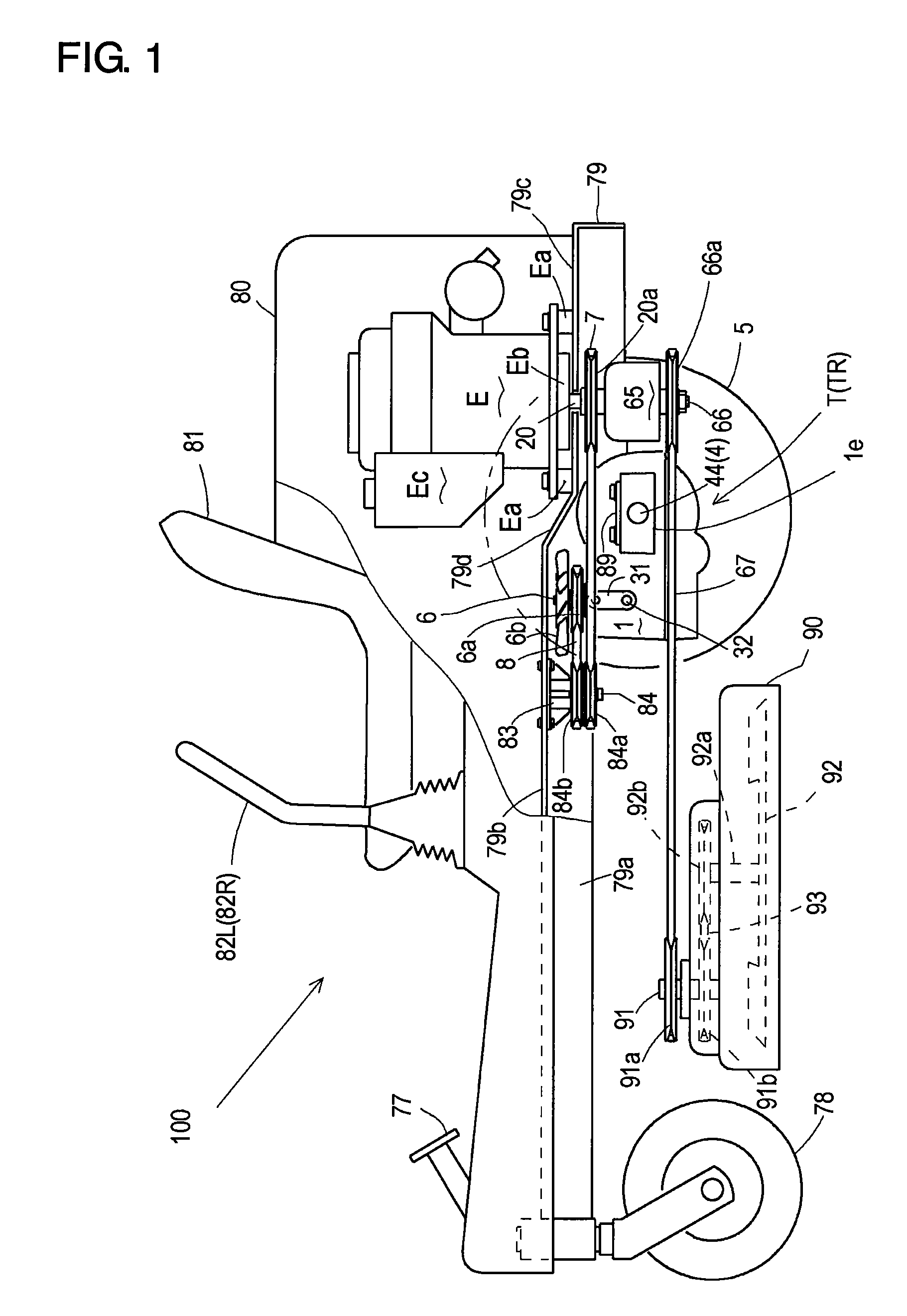

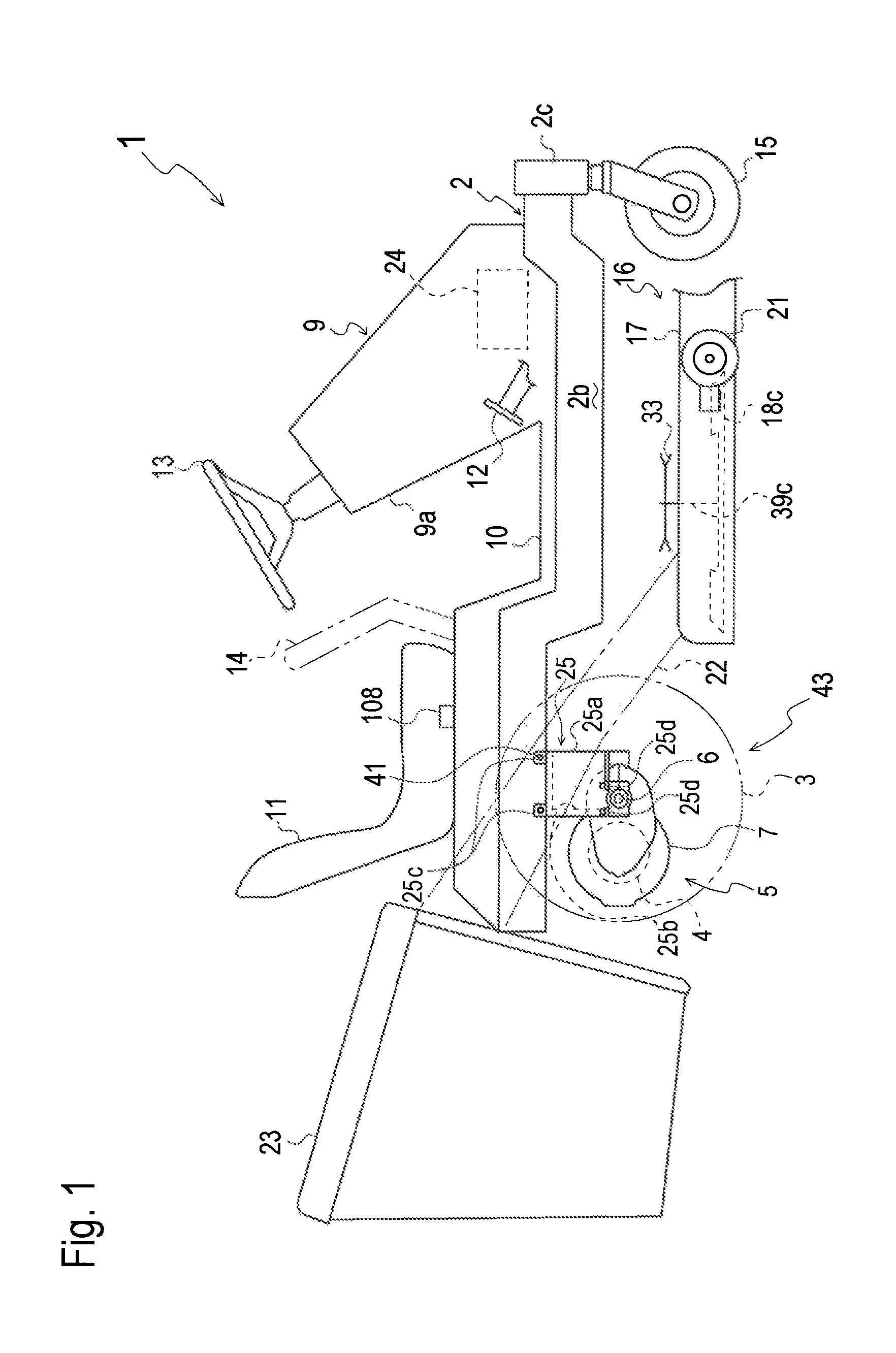

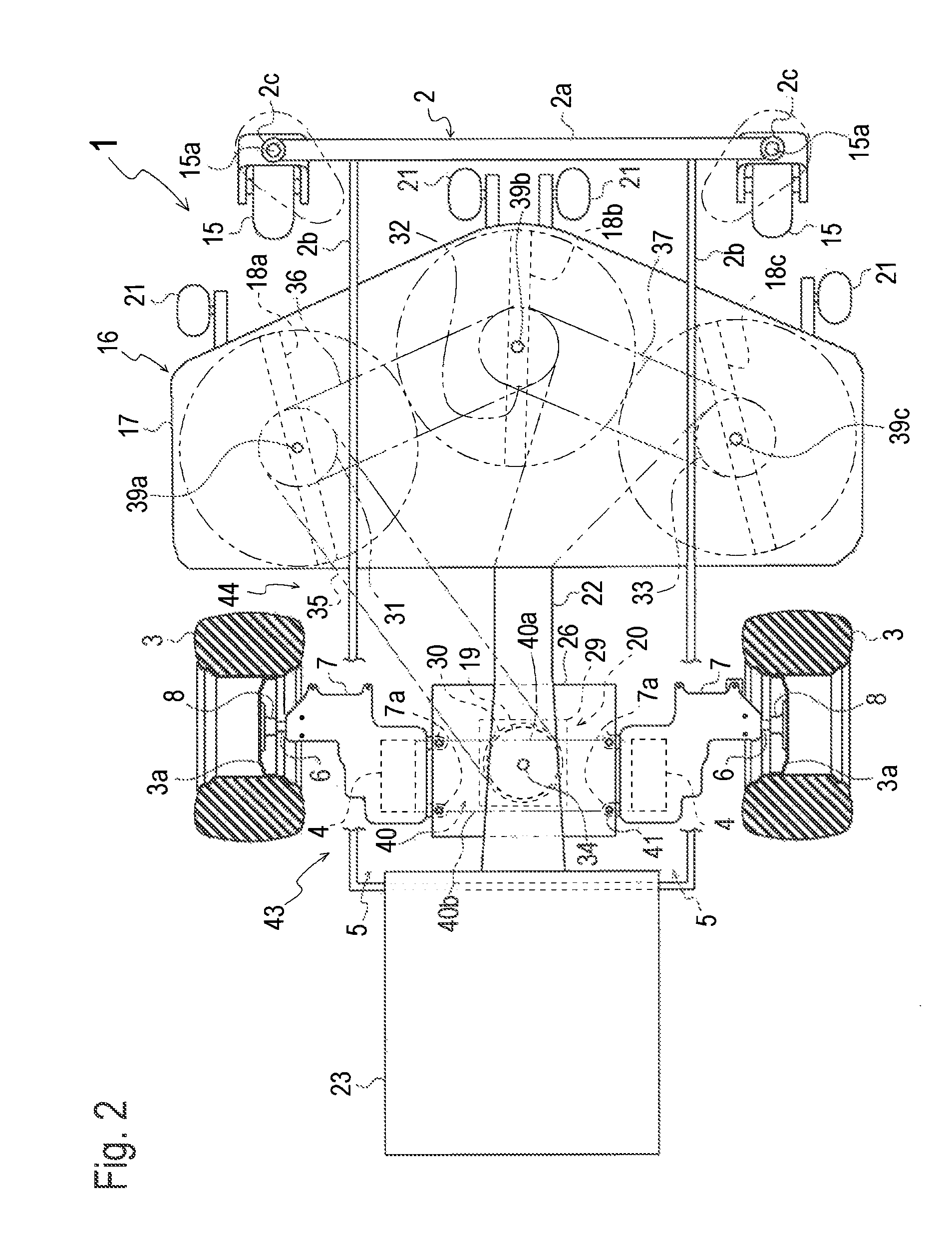

Power transmission apparatus for working vehicle

A power transmission apparatus for a working vehicle according to the present invention comprises: substantially symmetrically disposed first and second transaxles each of which includes an input shaft and a housing supporting a single axle; and a working apparatus driving power take-off device including an input member. A gear casing is spanned between the housings of the respective transaxles. A primary drive shaft is disposed in the gear casing so as to be drivingly connected to a prime mover. A traveling drive train is disposed in the gear casing so as to drivingly connect the primary drive shaft to the input shafts of the respective transaxles. A working apparatus drive train is disposed in the gear casing so as to drivingly connect the primary drive shaft to the input member of the working apparatus driving power take-off device.

Owner:KANZAKI KOKYUKOKI MFG

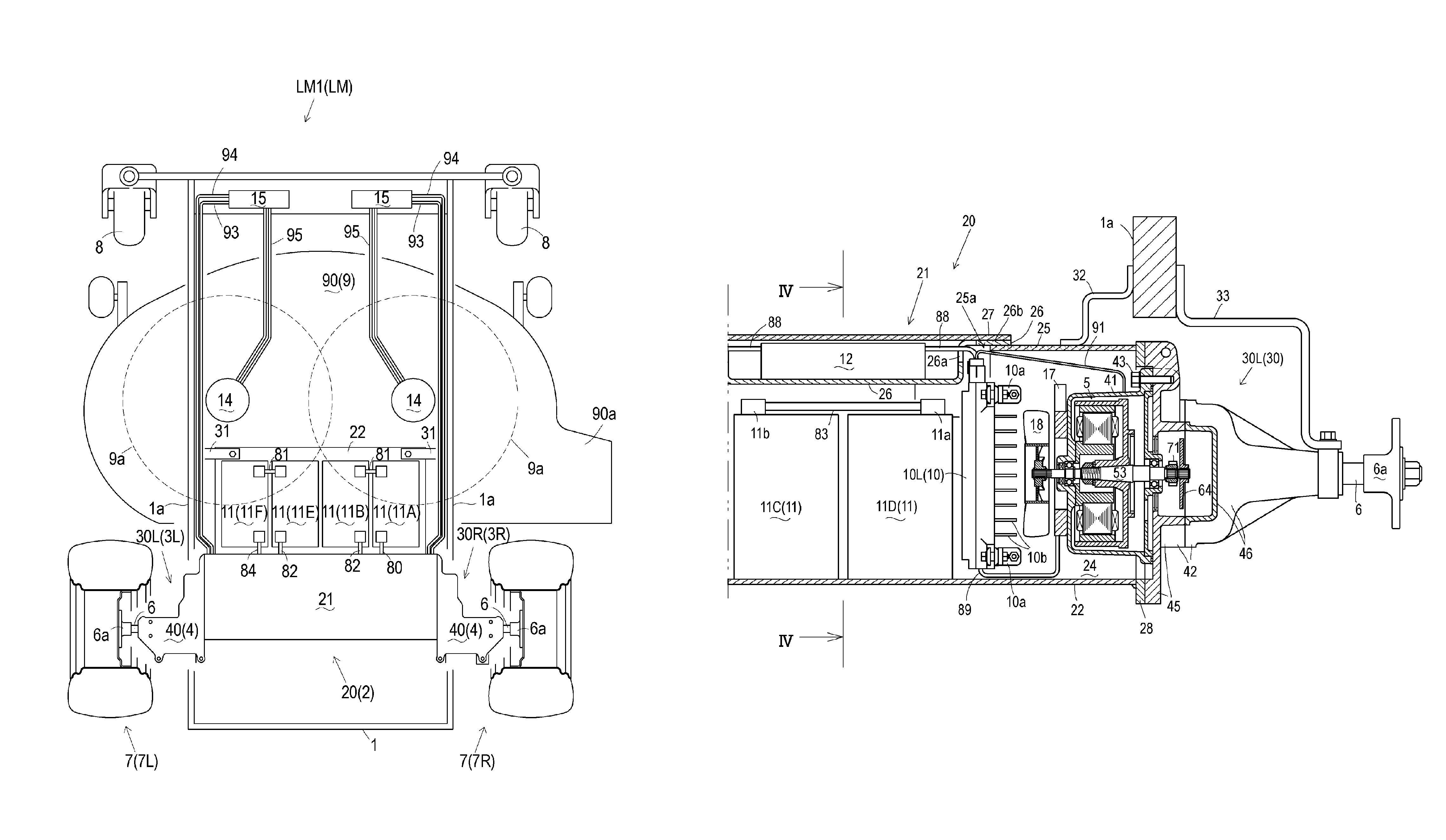

Electric lawn mower having a sub frame supporting transaxles and motor drivers

ActiveUS8240414B2Improve efficiencyLow costAuxillary drivesDigital data processing detailsDrive wheelMotor drive

Owner:YANMAR CO LTD +1

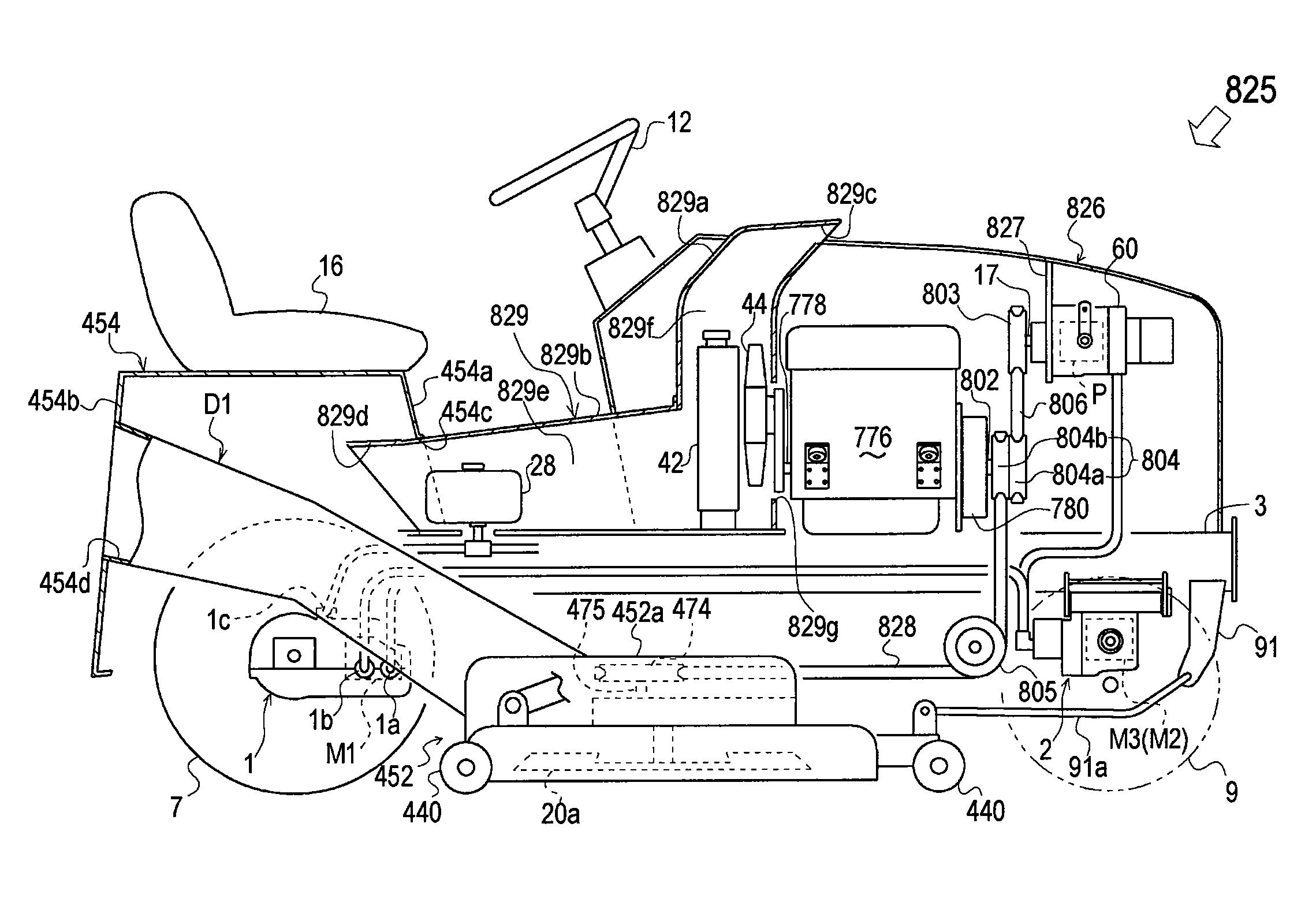

Hydraulic Drive Vehicle with Cooling System

A hydraulic drive vehicle comprises a vehicle frame, a bonnet, a prime mover, a hydraulic transaxle, a seat, a reservoir tank, and a cooling fan and a cooling duct. The bonnet is supported on one of front and rear portions of the vehicle frame, and provided therein with a first space. The prime mover is disposed in the first space. The hydraulic transaxle is driven by the prime mover. The seat is supported on the other of the front and rear portions of the vehicle frame, and is provided therebelow with a second space. The reservoir tank is fluidly connected to the hydraulic transaxle. The cooling fan is driven by the prime mover. The cooling duct is disposed in the second space. The cooling fan and the reservoir tank are disposed in the cooling duct so that the cooling fan cools the reservoir tank. A hydraulic pump for driving the hydraulic transaxle is disposed in the cooling duct so as to be cooled by the cooling fan.

Owner:ISHII NORIHIRO +4

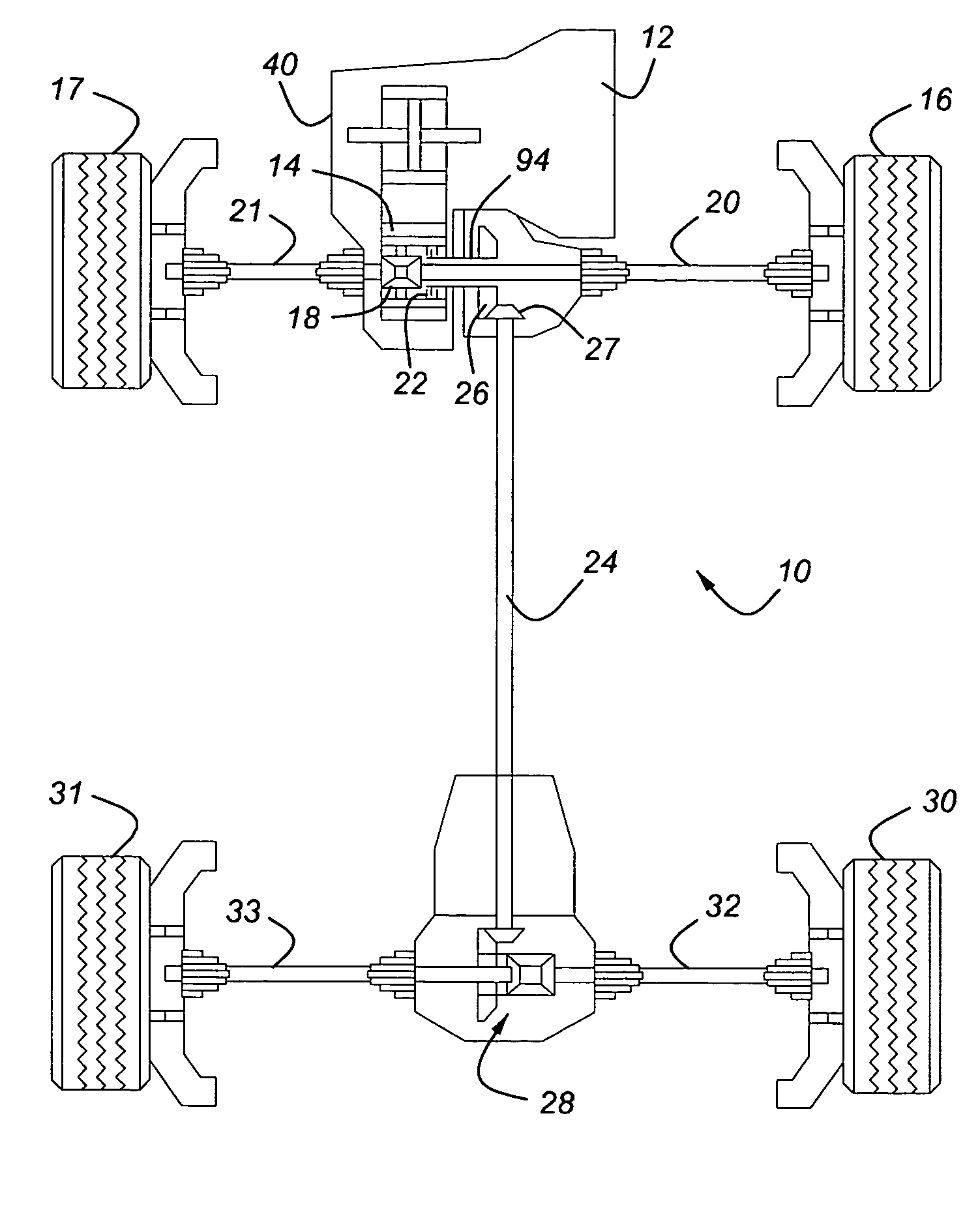

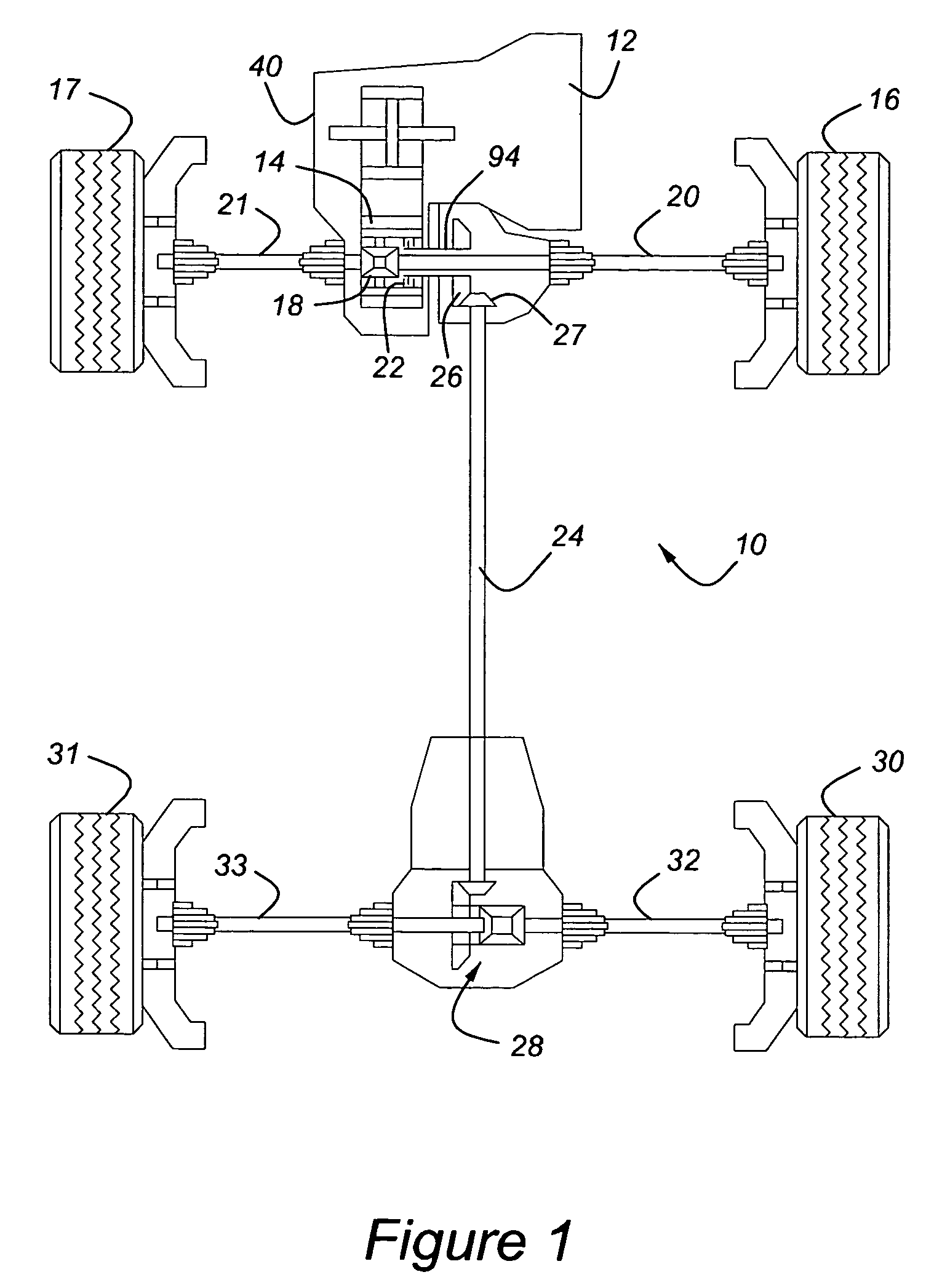

Transaxle having a differential mechanism and on-demand transfer clutch

ActiveUS7309301B2Component can be removedSpace minimizationGearing controlDifferential gearingsDrive wheelControl system

A powertrain for transmitting power to the drive wheels of a vehicle includes a transaxle case containing a transaxle drive mechanism for producing variable ratios of a speed of its output and a speed of its input, a differential mechanism for transmitting power between the output and the wheels of a first set of drive wheel, a transfer clutch secured to the output for transmitting power between the output and the wheels of a second set of drive wheels, and a control system for hydraulically actuating the transfer clutch.

Owner:FORD GLOBAL TECH LLC

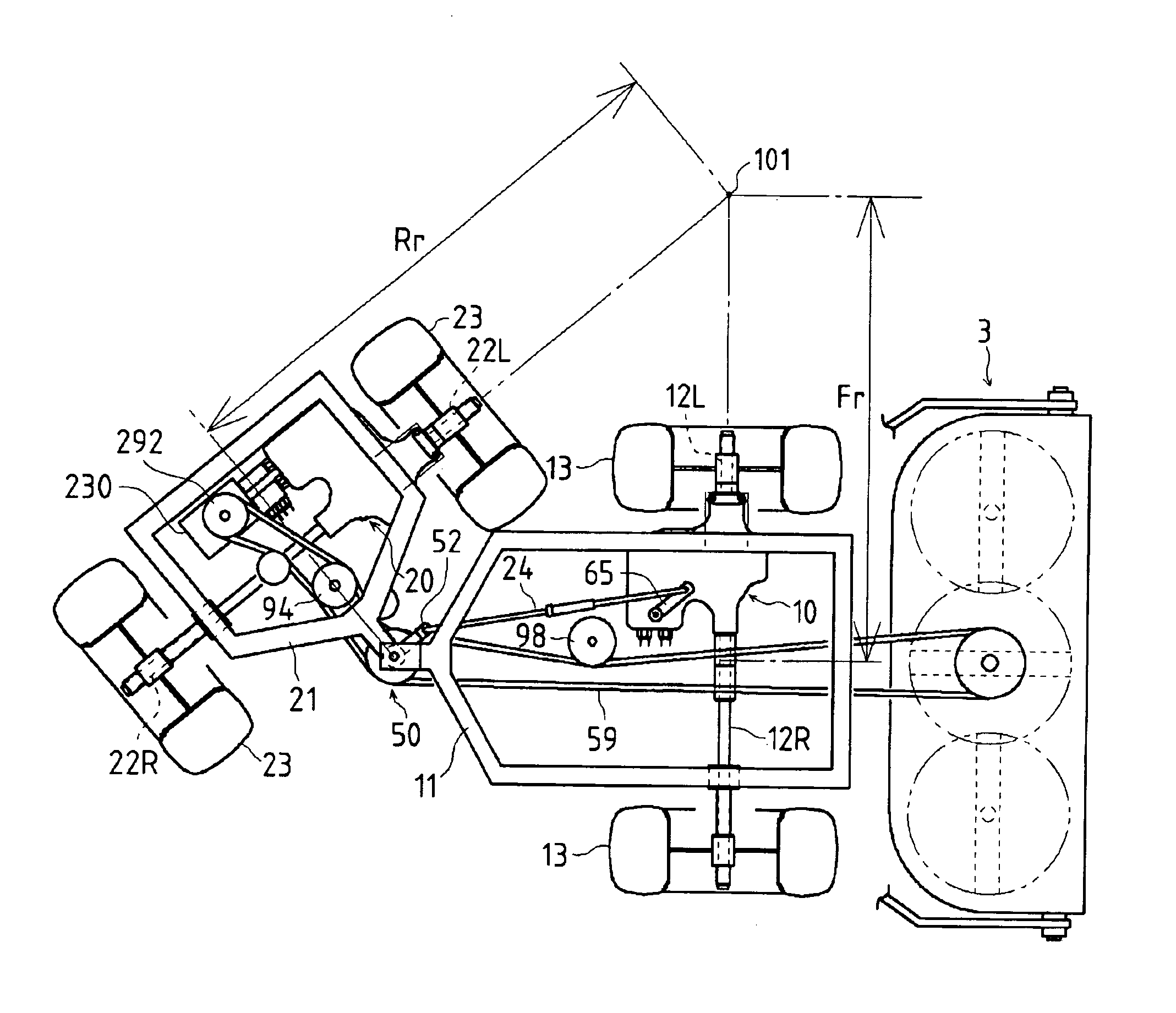

Transaxle apparatus and four-wheel driving working vehicle using the apparatus

InactiveUS6902017B2Improve workabilityAuxillary drivesFluid couplingsArticulated vehiclePower take-off

An articulate vehicle has first and second frames, which are coupled to each other at proximal ends thereof with respect to the vehicle through a coupling part so as to be relatively rotatable around a vertical axis according to steering operation. The first and second frames are distributed at front and rear portions of the vehicle. The first frame supports a first transaxle apparatus having first axles, and the second frame supports a second transaxle apparatus having a pair of second axles. A gearbox is disposed near the coupling part and provided with a pair of mutually drivingly connected horizontal shafts which are variable in relative angles thereof around the vertical axis according to steering operation. One of the horizontal shafts is drivingly connected to a power take-off shaft for extracting output power of a speed-changing arrangement in the first transaxle apparatus. The other of the horizontal shafts is drivingly connected to an input shaft of the second transaxle apparatus. The vehicle is provided with a rotor having a rotary axis disposed on the vertical axis so as to output power from a prime mover to a working device.

Owner:KANZAKI KOKYUKOKI MFG

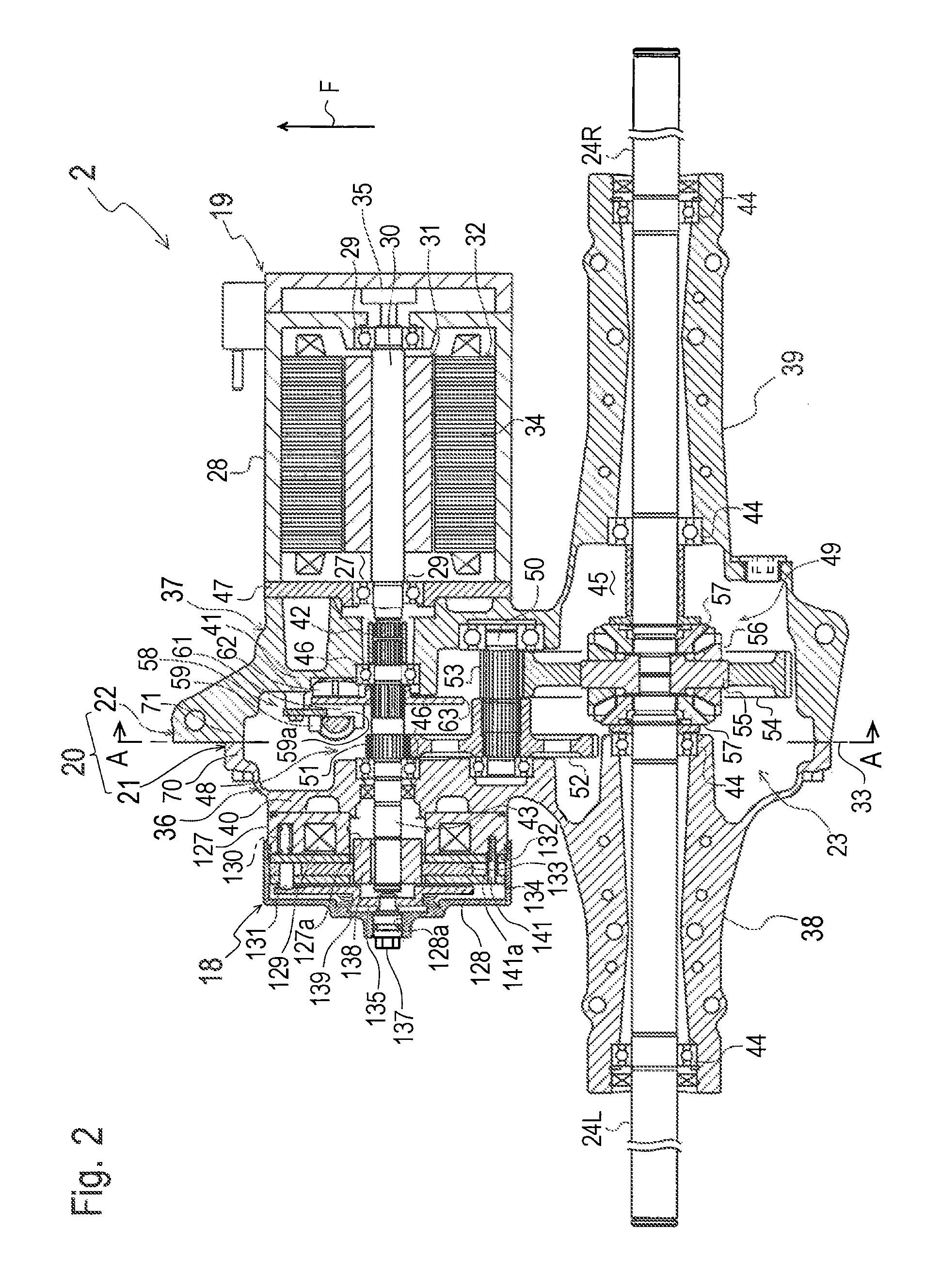

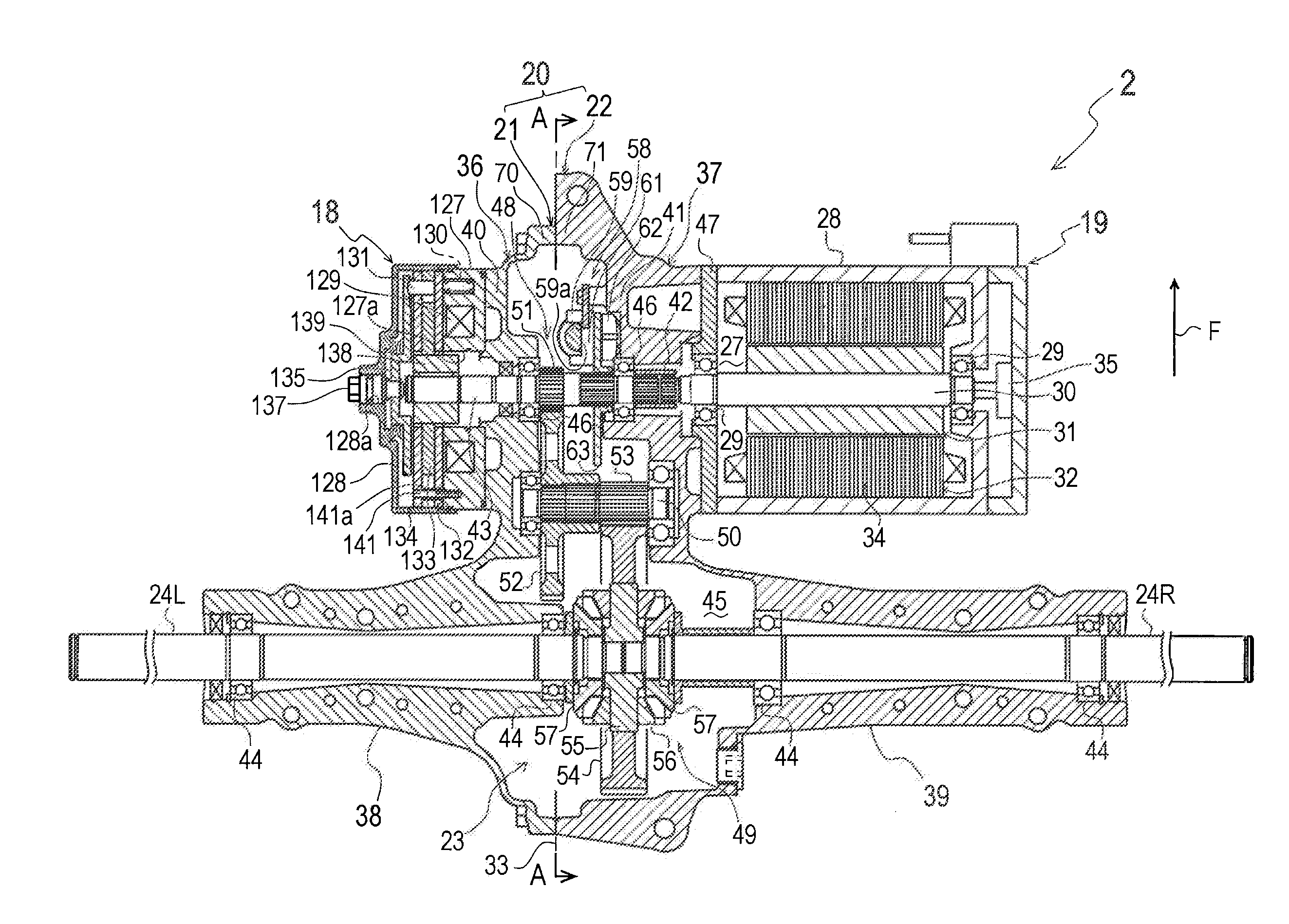

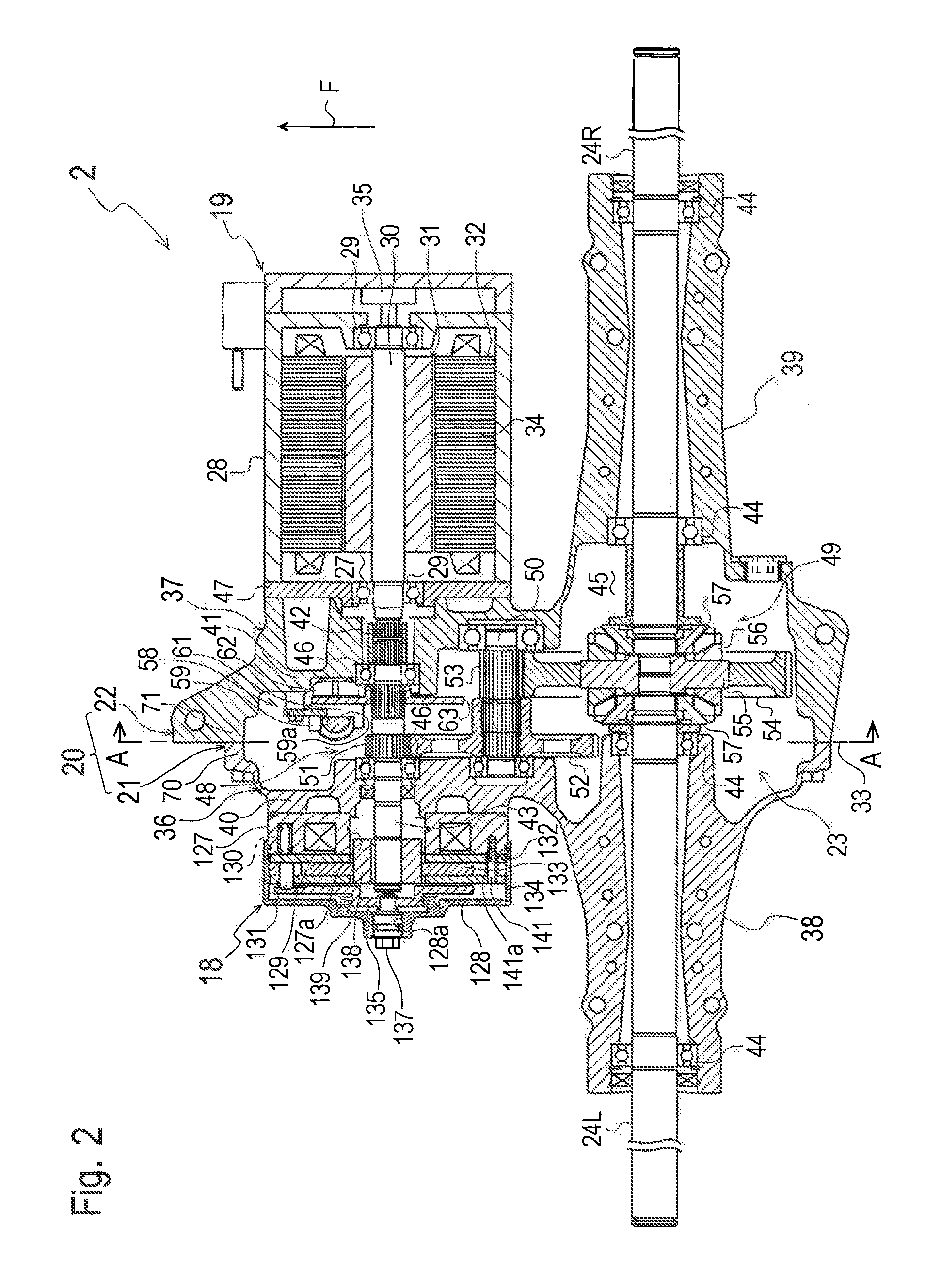

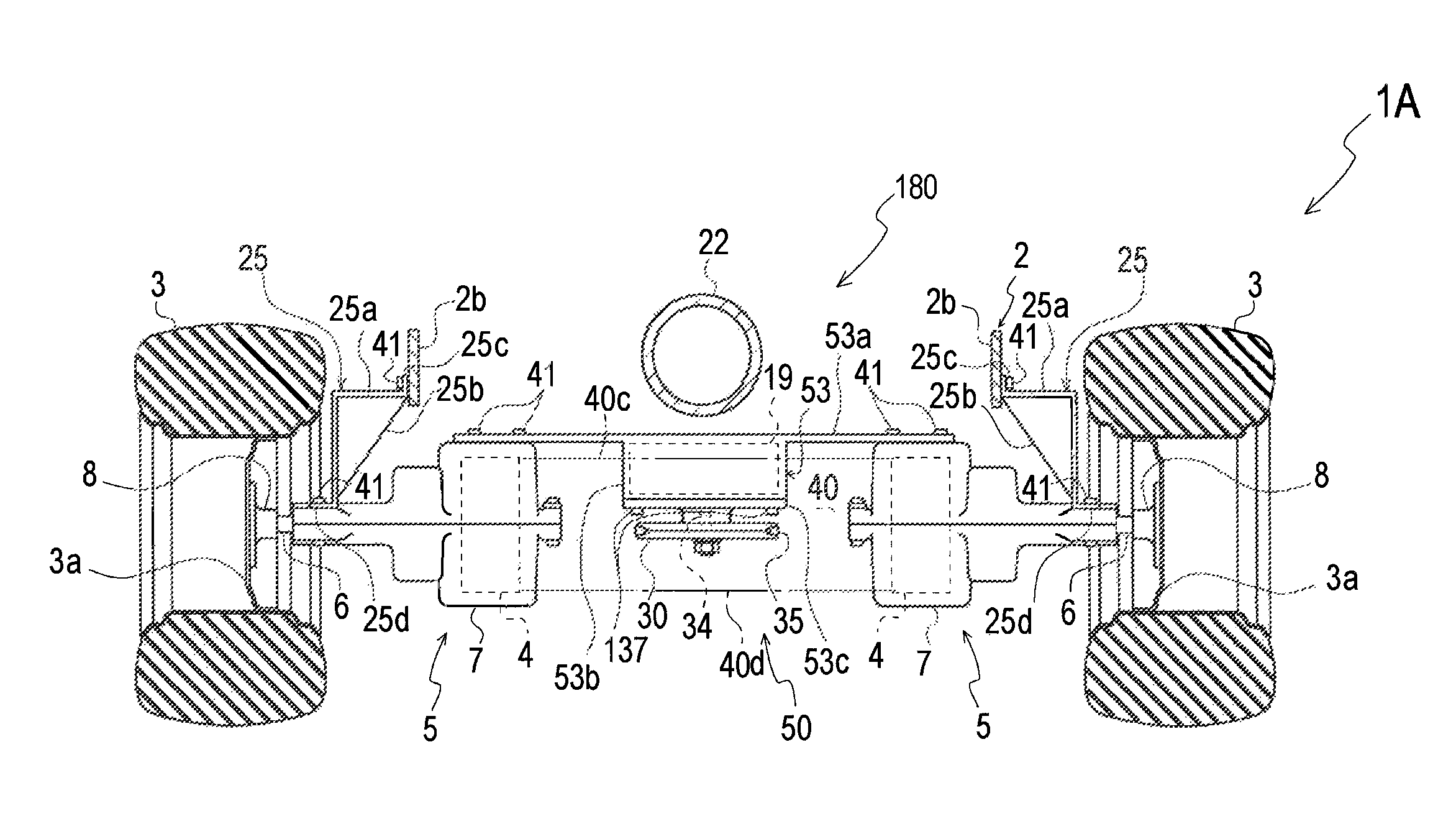

Transaxle

ActiveUS8424625B2Reduce componentsLow costAuxillary drivesPlural diverse prime-mover propulsion mountingEngineeringControl theory

A transaxle includes an axle and a multiple motor generator unit for driving the axle. The multiple motor generator unit includes a common rotor shaft drivingly connected to the axle, armature windings serving as a first stator and a second stator aligned opposite each other in the axial direction of the rotor shaft, a common rotor member fixed on the rotor shaft, and permanent magnets provided on the common rotor member so as to serve as a first rotor facing the first stator, and as a second rotor facing the second stator. The first stator and the first rotor constitute a first motor generator. The second stator and the second rotor constitute the second motor generator. A total motor output torque of the first and second motor generators for rotating the rotor member and the rotor shaft can be changed in correspondence to a load applied from the axle to the rotor shaft.

Owner:KANZAKI KOKYUKOKI MFG

Hydrostatic transaxle

InactiveUS7503172B2Reduce in quantityEasy to assembleFluid couplingsGearing controlHydraulic motorHydraulic pump

Owner:KANZAKI KOKYUKOKI MFG

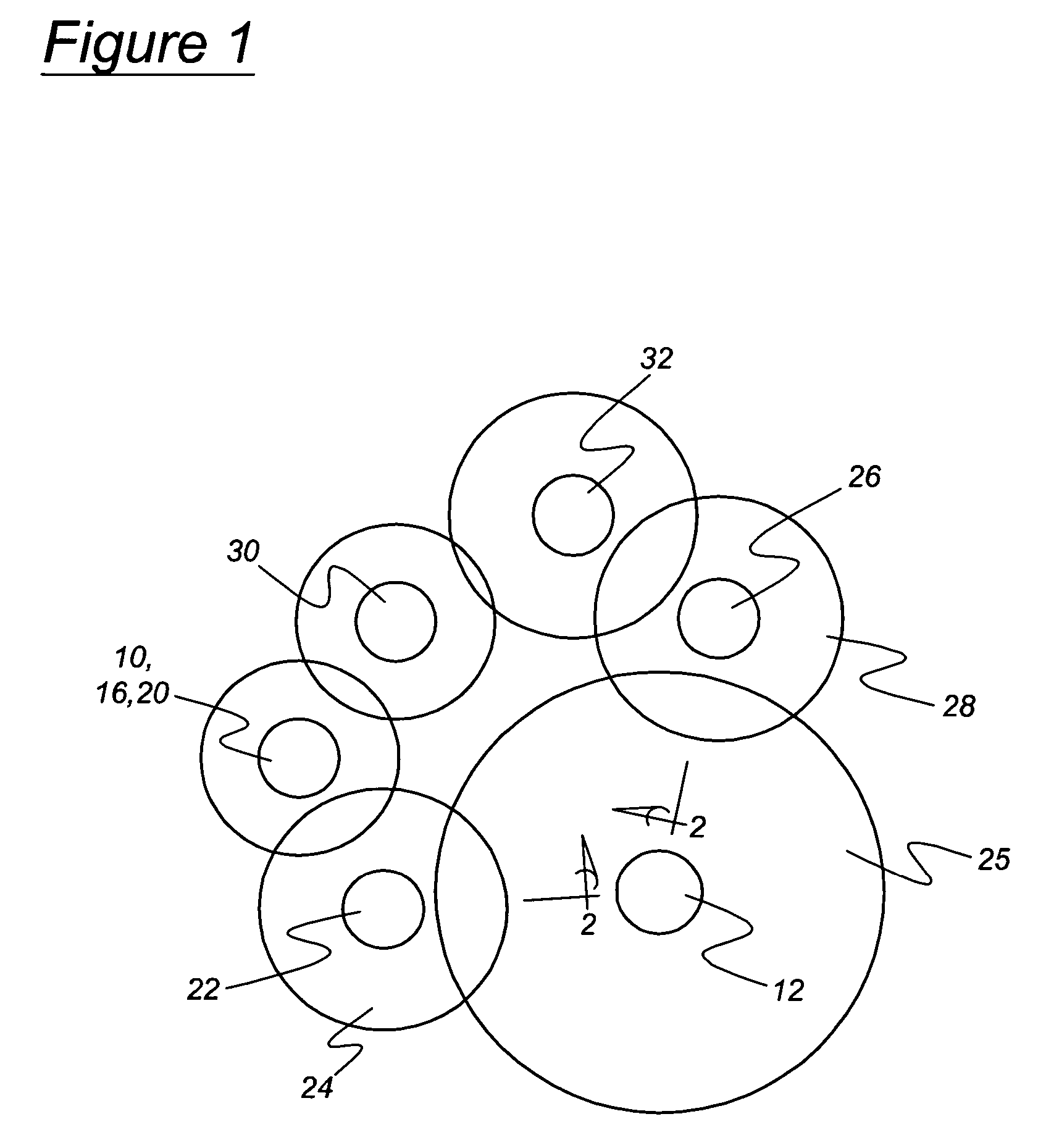

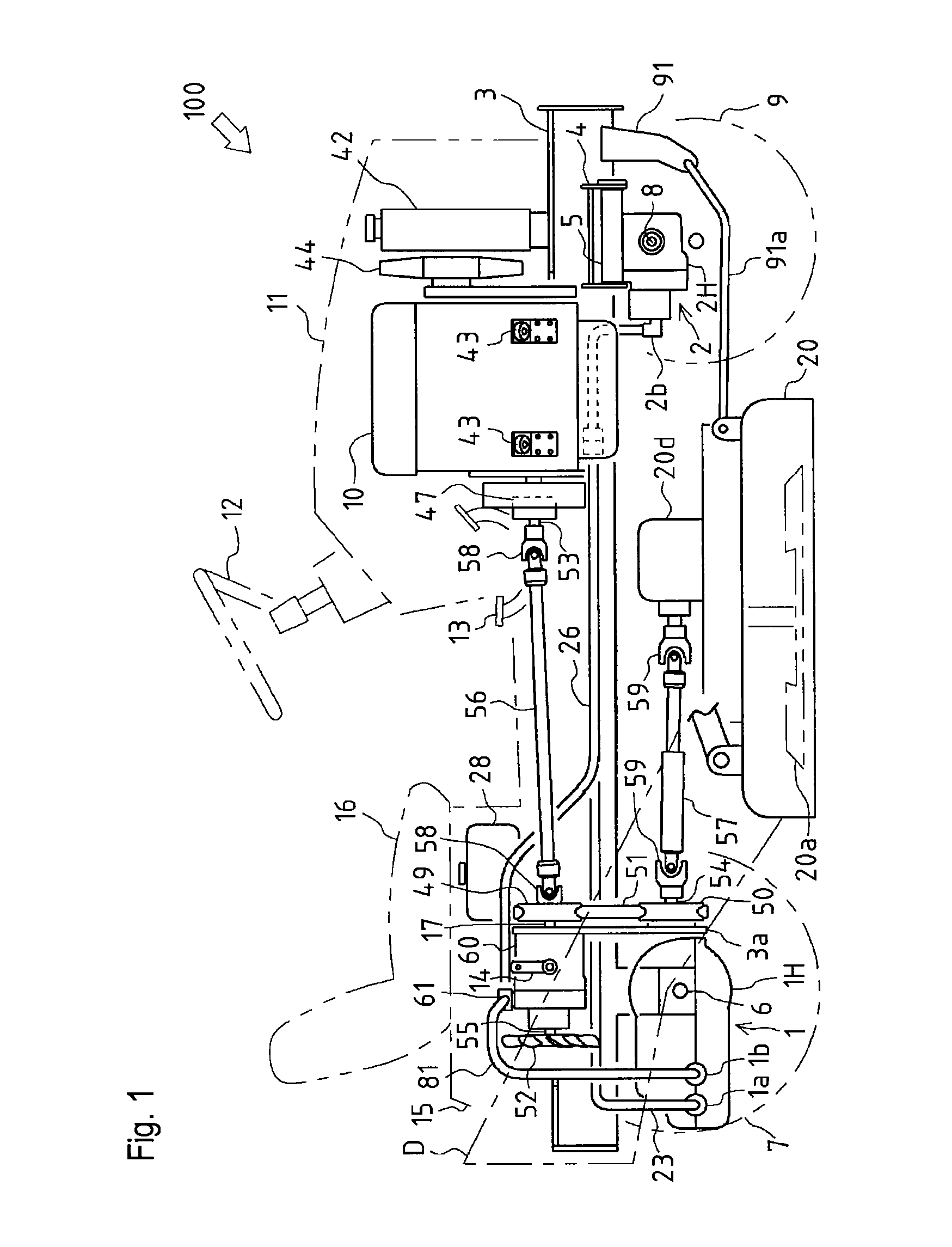

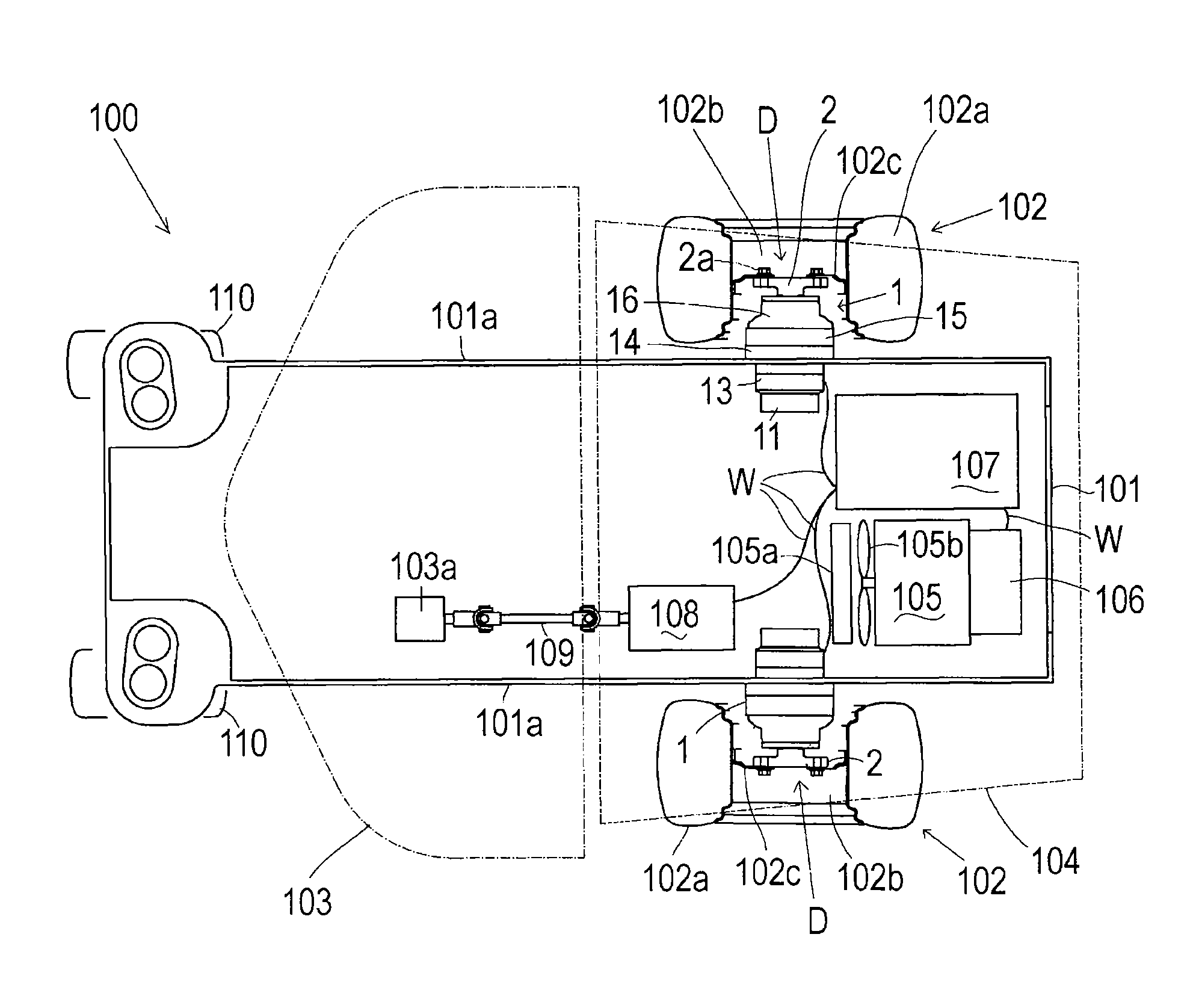

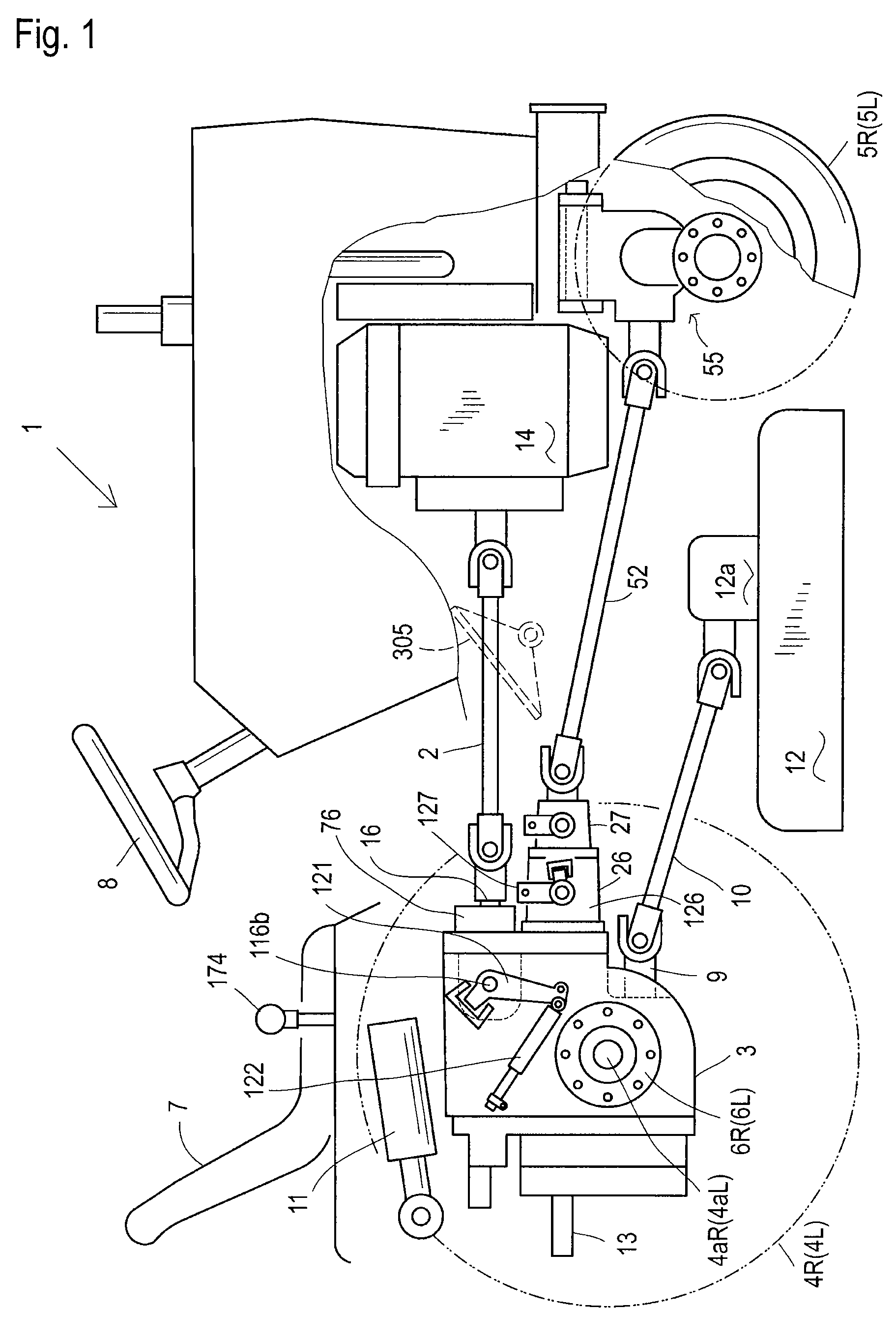

Power Transmission System and Vehicle With It

ActiveUS20070151222A1Low costReduce the number of partsMowersSteering linkagesDrive wheelVehicle frame

A working vehicle comprises: a vehicle frame; a prime mover mounted on an upper surface of a first portion of the vehicle frame; a pair of left and right transaxles juxtaposed below the vehicle frame, the left and right transaxles having respective single axles so as to individually and reversibly rotatably driving left and right drive wheels; a working device disposed below the vehicle frame; an output shaft of the prime mover extended downward from the first portion of the vehicle frame; a traveling belt transmission disposed below the vehicle frame and extended from the output shaft to the pair of left and right transaxles; a working belt transmission disposed below the vehicle frame and extended from the output shaft to the working device; a counter shaft for the traveling belt transmission extended downward from a second portion of the vehicle frame; and a pair of upper and lower pulleys provided on the counter shaft, wherein a belt looped over the lower pulley is extended from the output shaft of the prime mover, and a belt looped over the upper pulley is extended to the left and right transaxles.

Owner:KANZAKI KOKYUKOKI MFG

Bearing having thermal compensating capability

InactiveUS20090080824A1Low costLess complex to assembleRoller bearingsGearboxesThermal expansionAlloy

A roller bearing for use in transmission cases (1) made from aluminum alloy or other lightweight materials where the transmission contains a steel shaft (2) which is supported in the case on two directly mounted tapered roller bearings (8,9) so that the two bearings (8,9) confine the shaft (2) both radially and axially. To compensate for the differences in expansion and contraction between the case and the steel shaft (2) as the transmission or transaxle experiences variations in temperature, a race (20) of at least one of the bearings is fitted with a compensating ring (34) having a coefficient of thermal expansion greater than that of the case (1) or shaft (2). As a consequence, the bearings operate at a generally uniform setting over a wide range of temperature variations.

Owner:THE TIMKEN CO

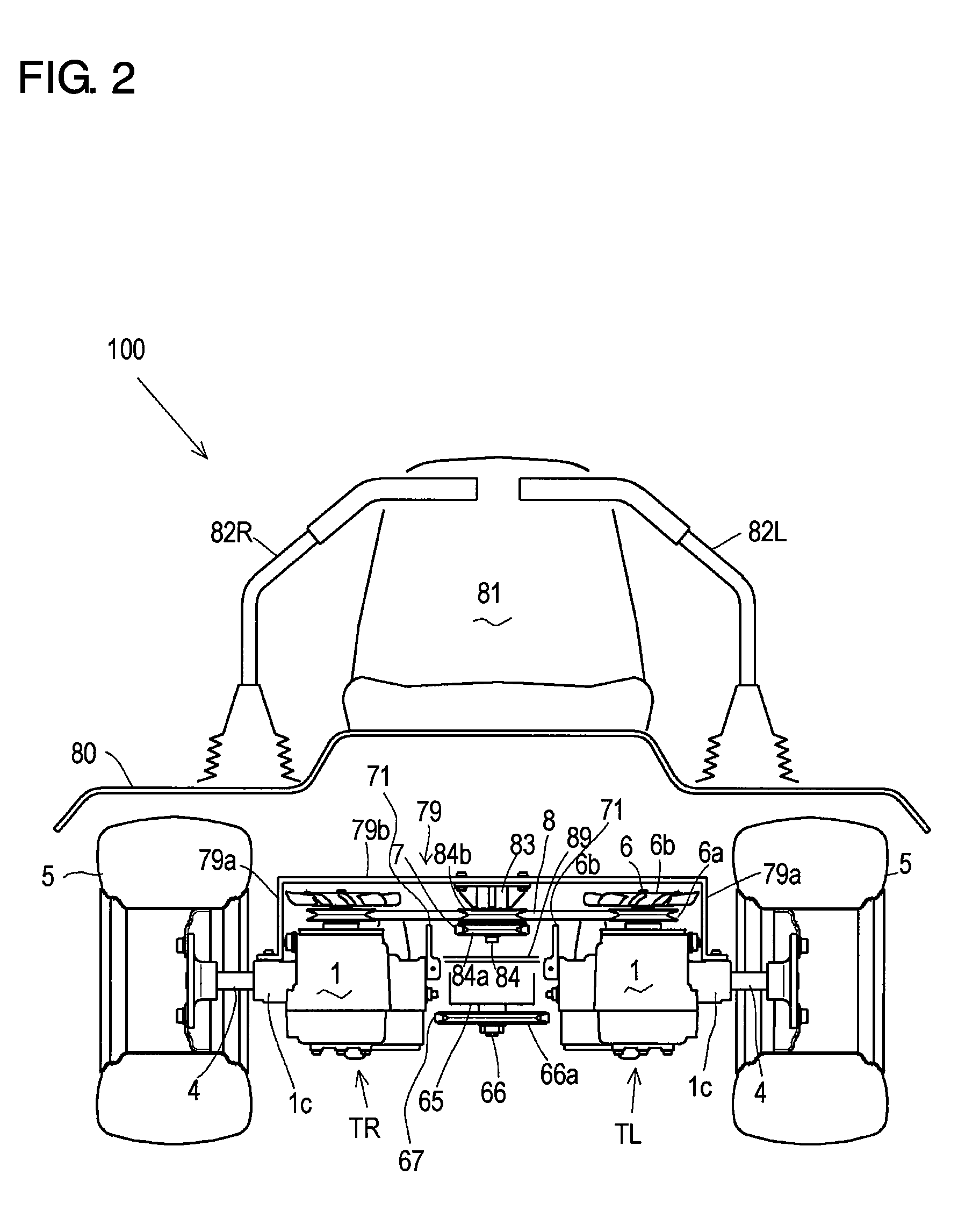

Electric zero-turn working vehicle

An electric zero-turn working vehicle comprises a vehicle body frame, right and left drive wheels, right and left first electric motors for driving the respective right and left drive wheels, a transaxle including at least one of the right and left first electric motors, a working implement, and a second electric motor for driving the working implement. The right and left first electric motors have a space therebetween. The transaxle is supported by the vehicle body frame and is disposed below the vehicle body frame. At least a part of the second electric motor is disposed in the space between the right and left first electric motors.

Owner:KANZAKI KOKYUKOKI MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com