Boring automatic centering clamp of drive axle housing

A self-centering, drive axle housing technology, applied in boring/drilling, clamping, positioning devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

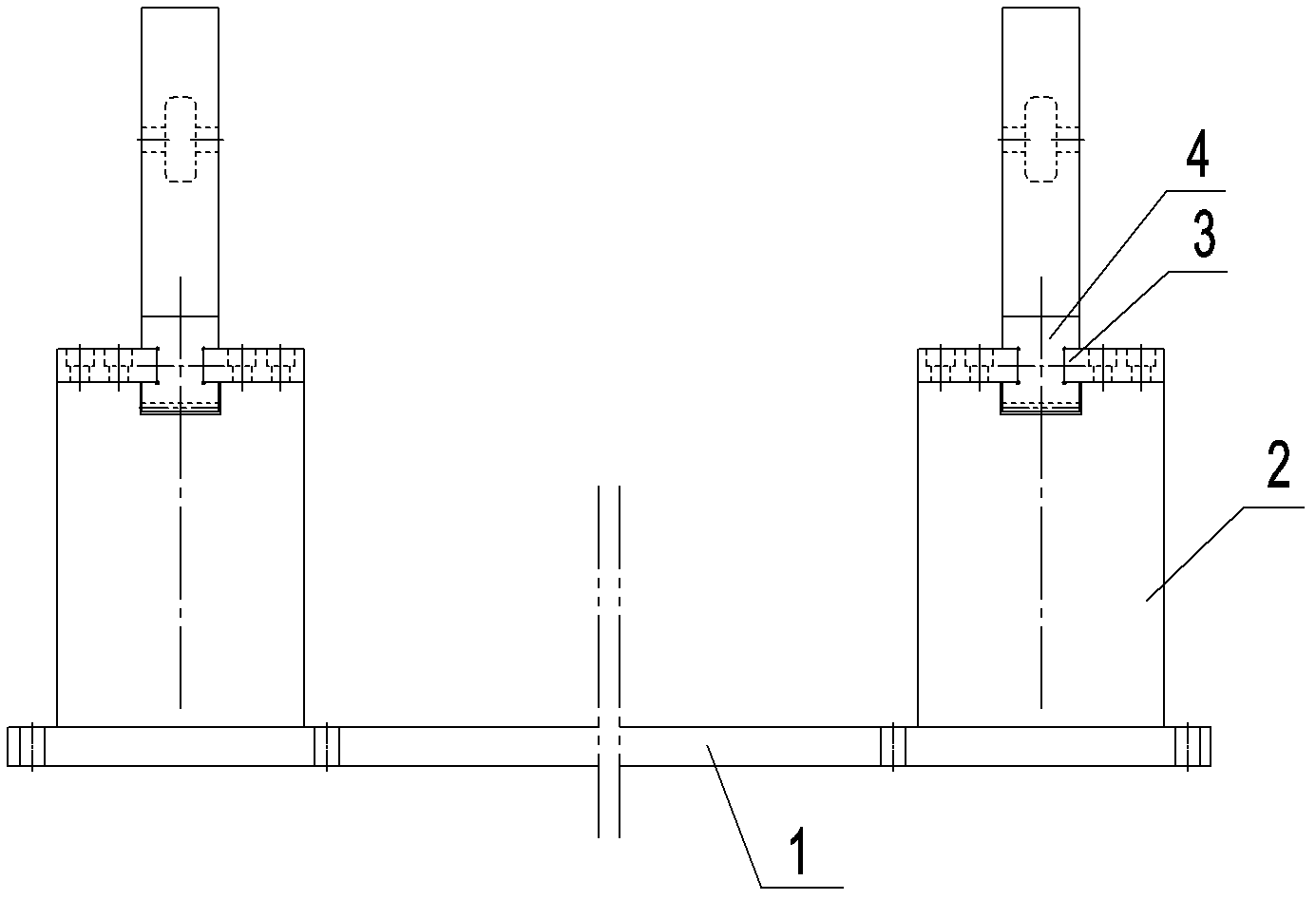

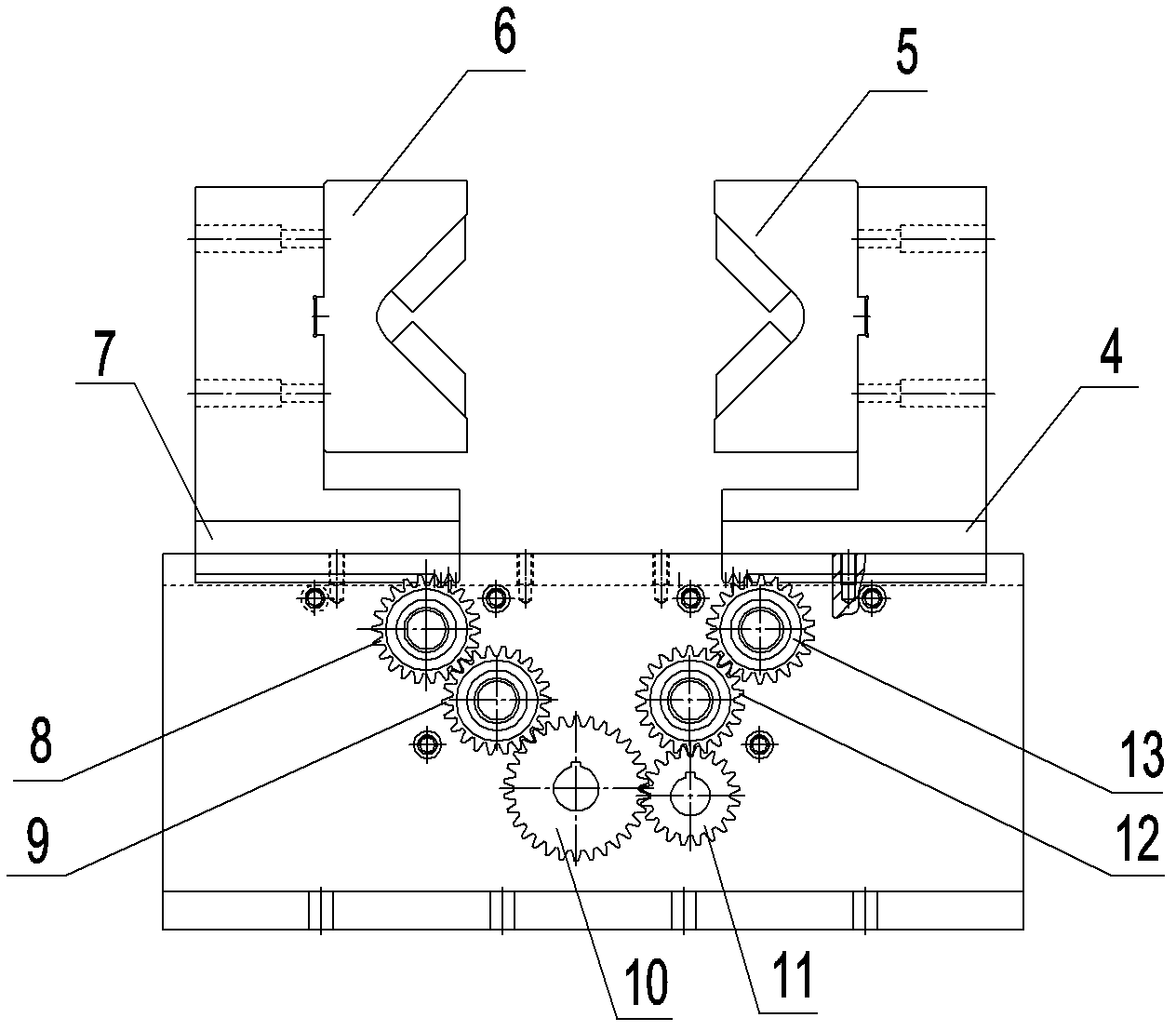

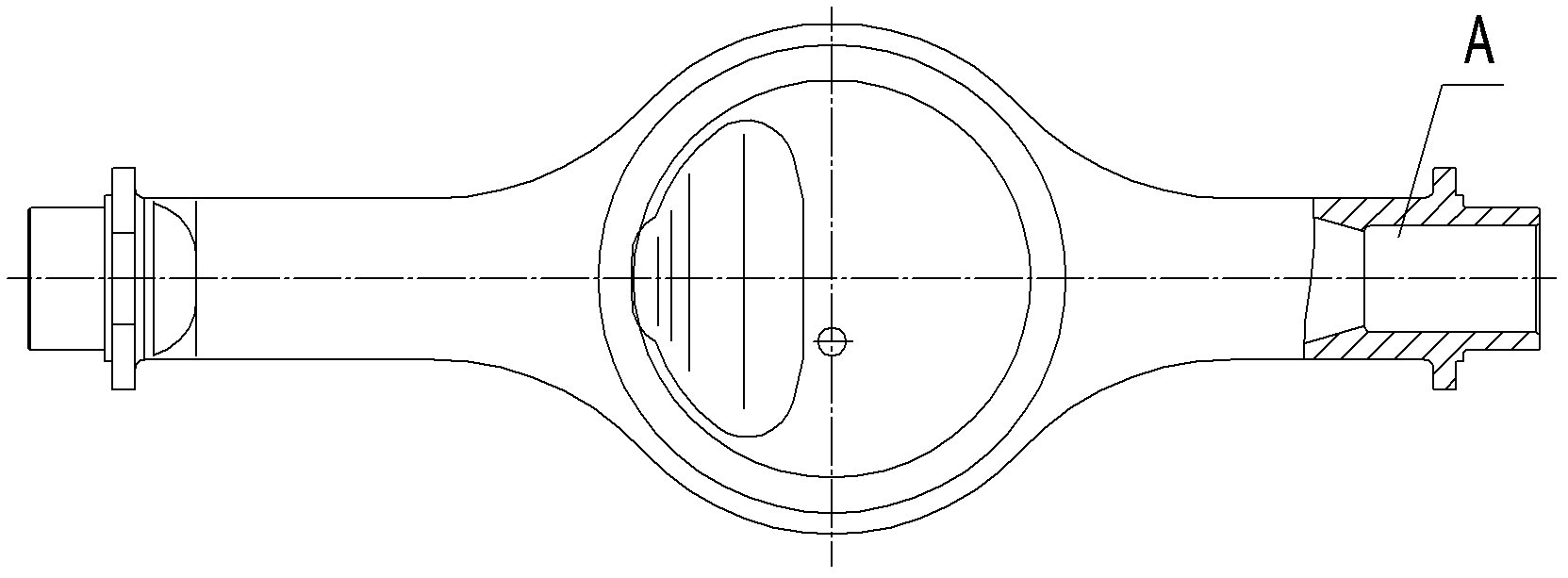

[0018] Such as figure 1 , figure 2 As shown, the automatic centering jig of the drive axle case boring hole of the present invention includes a fixed base 1 and clamping and positioning devices respectively connected to the two ends of the fixed base 1, and two sets of clamping and positioning devices are symmetrically arranged on the fixed base 1 at both ends.

[0019] Each set of clamping and positioning device includes transmission box 2, slide block I4, slide block II7, clamping block I5 and clamping block II6, the top wall of transmission box 2 is provided with slide rail 3, and slide block I4 and slide block II7 can be respectively Slidingly connected to the slide rail 3 and protruding from the upper surface of the top wall of the transmission box 2, the clamping block Ⅰ5 is connected to the sliding block Ⅰ4, the clamping block Ⅱ6 is connected to the sliding block Ⅱ7, the clamping block Ⅰ5 and the clamping block Ⅱ6 The inner sides are respectively recessed with clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com