Method for realizing machining of combustion-compression ring bushes by using combustion-compression ring bush cutting clamp

A processing method and ring sleeve technology, which is applied in the processing field of ring parts, can solve the problems of affecting the processing quality of the fuel pressure ring sleeve, poor precision of the fuel pressure ring sleeve, and easy deformation, so as to achieve clear and complete processing steps and ensure processing accuracy , the effect of preventing stress deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

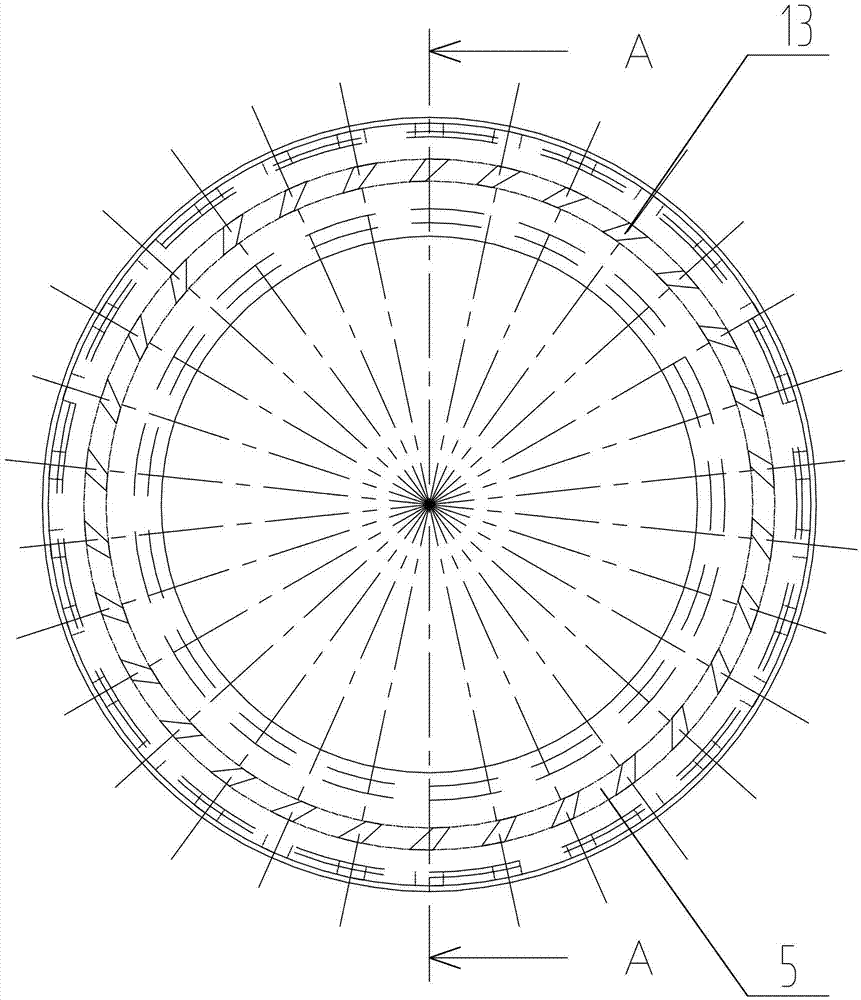

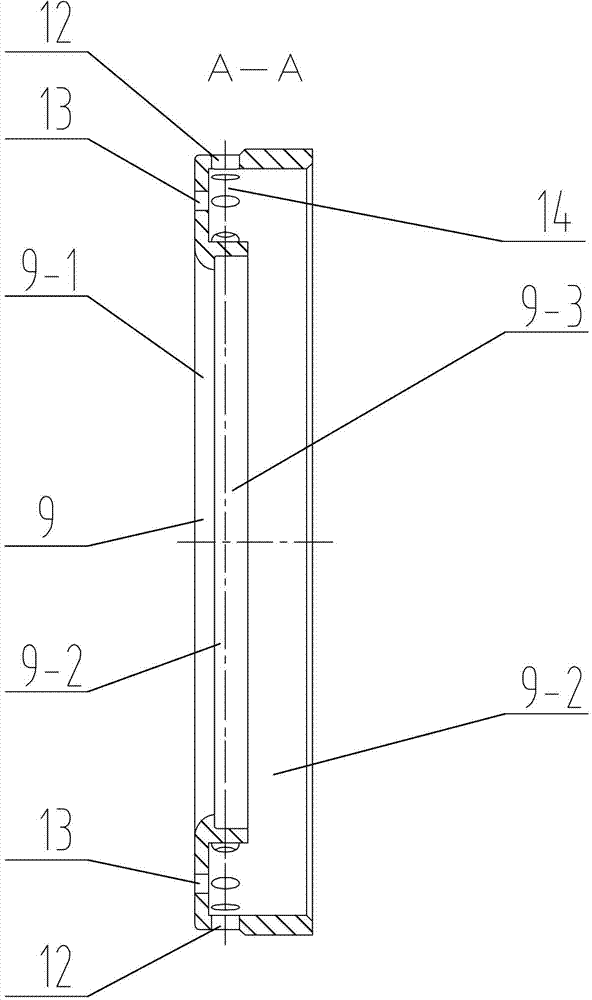

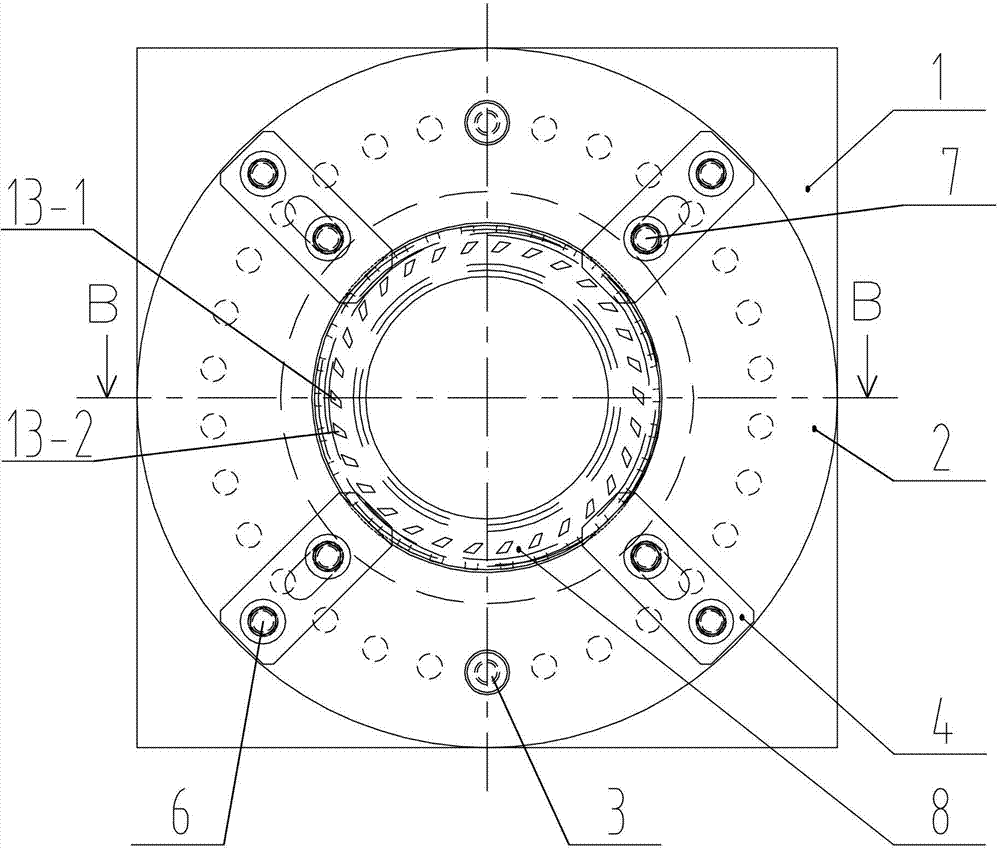

[0017] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 and Figure 15 To illustrate this embodiment, the fuel pressure ring sleeve cutting jig used in the processing method of the fuel pressure ring sleeve in this embodiment includes a bottom plate 1, a turntable 2, two positioning pins 3 and four pressure plates 4, and the turntable 2 is located at Between the bottom plate 1 and the pressure plate 4, the center of the top surface of the turntable 2 is processed with a turntable counterbore 2-1, and the center of the bottom surface of the turntable 2 is processed with an outer boss 2-2, and the turntable counterbore 2-1 and the outer convex The table 2-2 is coaxially arranged, the aperture of the counterbore 2-1 of the turntable is 140mm, the shape of the outer boss 2-2 is cylindrical, and the outer diam...

specific Embodiment approach 2

[0028] Specific implementation mode two: combination image 3 , Figure 4 and Figure 5 Describe this embodiment, the fuel pressure ring sleeve cutting fixture in this embodiment also includes four support screws 6, the second threaded hole 4-1 is processed on the pressure plate 4, and the outer thread of the second threaded hole 4-1 The diameter is 12 mm, and the support screw 6 is detachably connected with the pressure plate 4 through the second threaded hole 4 - 1 on the pressure plate 4 . The setting of the supporting screw 6 can achieve a better supporting effect, which is more conducive to realizing the purpose of the present invention. Other method steps are the same as those in the first embodiment.

specific Embodiment approach 3

[0029] Specific implementation mode three: combination image 3 , Figure 4 and Figure 5 Describe this embodiment, the fuel pressure ring sleeve cutting fixture in this embodiment also includes four clamping screws 7, the pressure plate 4 is processed with a waist hole 4-2, and the clamping screws 7 pass through the pressure plate 4 in turn The upper waist hole 4-2 and the first threaded hole 2-4 of the turntable 2 detachably connect the pressing plate 4 to the turntable 2. The clamping screw 7 is set because in the specific processing process, the clamping force of the clamping screw 7 can be adjusted according to workpieces of different sizes, so that the clamping effect is better, and its operation is flexible and adjustable; the waist hole 4- 2 is R6.25 waist hole, R6.25 waist hole means that the fillet radius on both sides of the waist hole is 6.25mm. Other method steps are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com