Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "Meet design accuracy requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

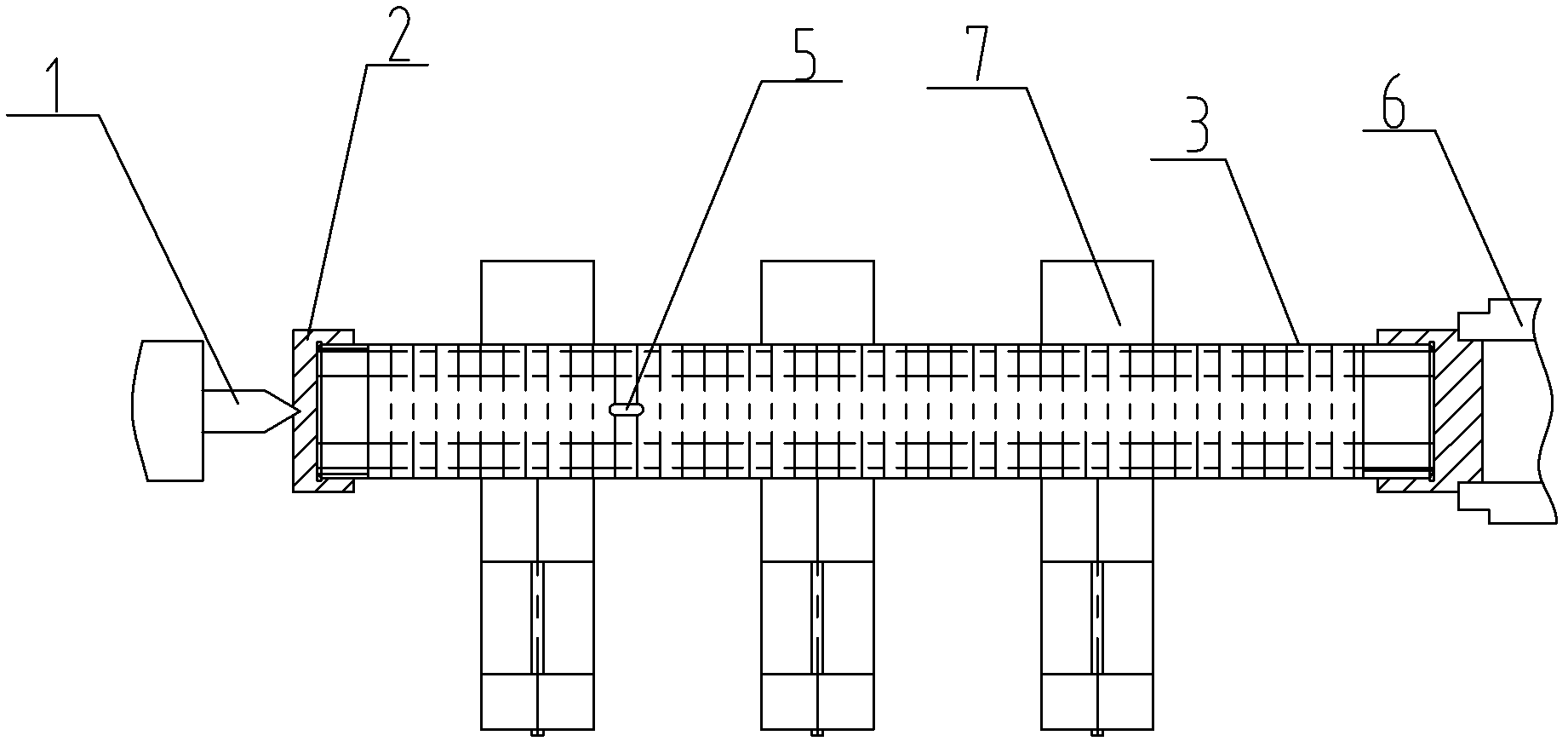

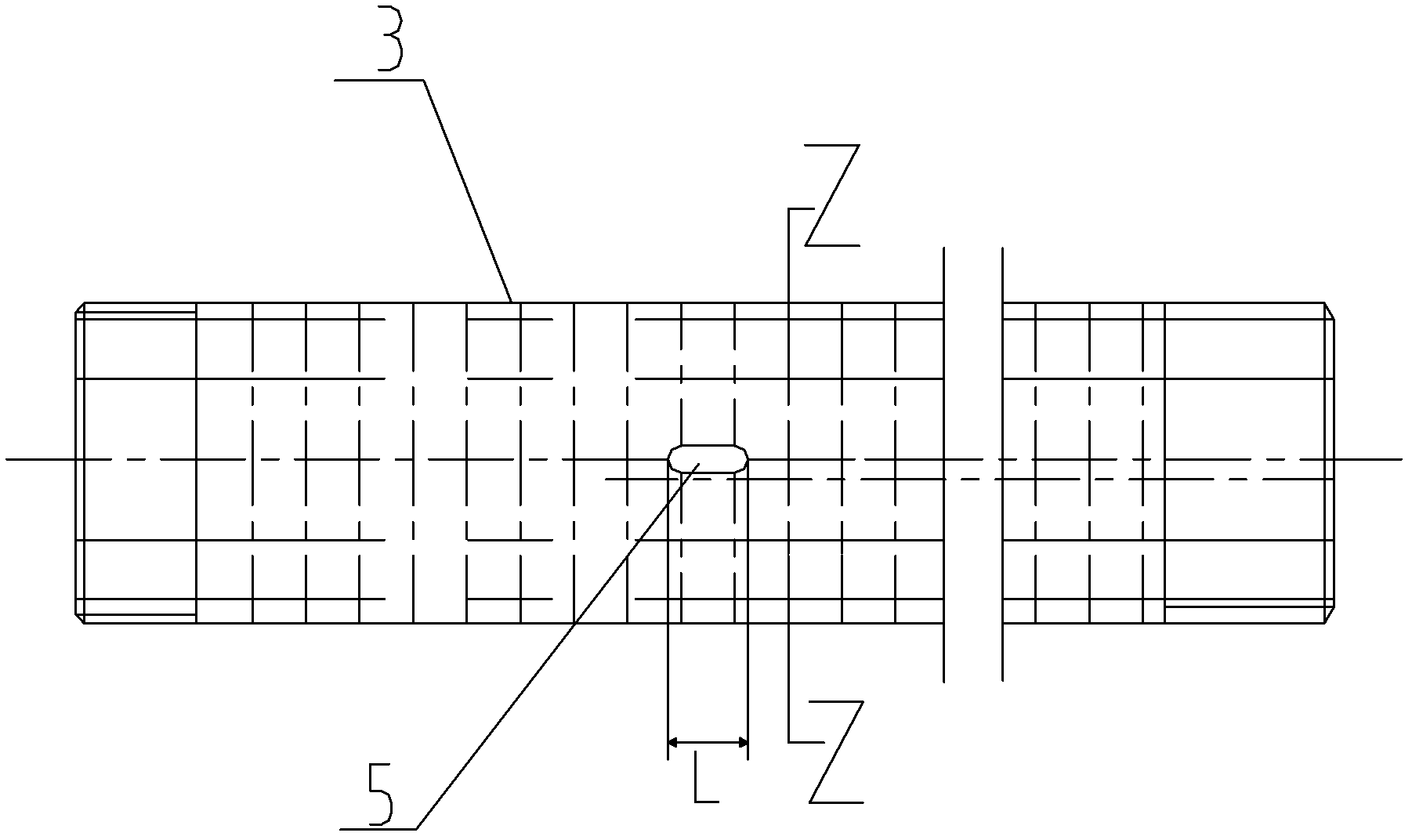

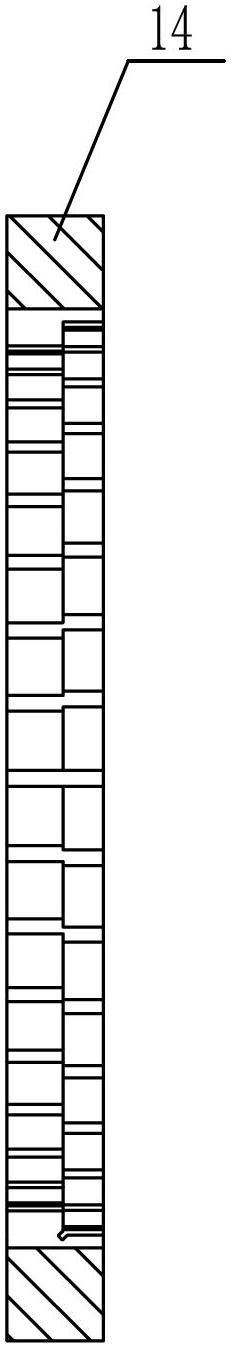

Machining method of porous thin-wall protective tube with large length-diameter ratio

The invention discloses a machining method of a porous thin-wall protective tube with a large length-to-diameter ratio. The method comprises the following steps of: firstly cutting a tube material at a desired length of the protective tube; heating to melt a low-temperature lead / tin alloy material into liquid and then pouring the molten alloy into the inner hole of the tube material; clamping a threaded plug at one end of the tube material by use of a dividing head chuck, compacting a threaded plug at the other end of the tube material by use of a miller center, and straightening and clampingthe two sides of the outer wall of the tube material by use of flat tongs; milling kidney-shaped holes which are uniformly distributed on the wall of the tube material by use of a milling cutter which is mounted on a numerically-controlled milling machine, and milling kidney-shaped holes which are arranged in rows in the axial direction of the tube material; and vertically hanging the tube material subjected to milling, and heating such that the low-temperature lead / tin alloy material is molten and breaks away from the inner hole of the tube material, thus obtaining the porous thin-wall protective tube with large length-to-diameter ratio. The process of machining the porous thin-wall protective tube with large length-to-diameter ratio by the method disclosed in the invention has the advantages that the rate of qualified products is high and is up to above 99%; the machining accuracy is increased and fully meets the design requirement on product accuracy; and the machining efficiency is increased by more than 50%.

Owner:湖北三江航天江北机械工程有限公司

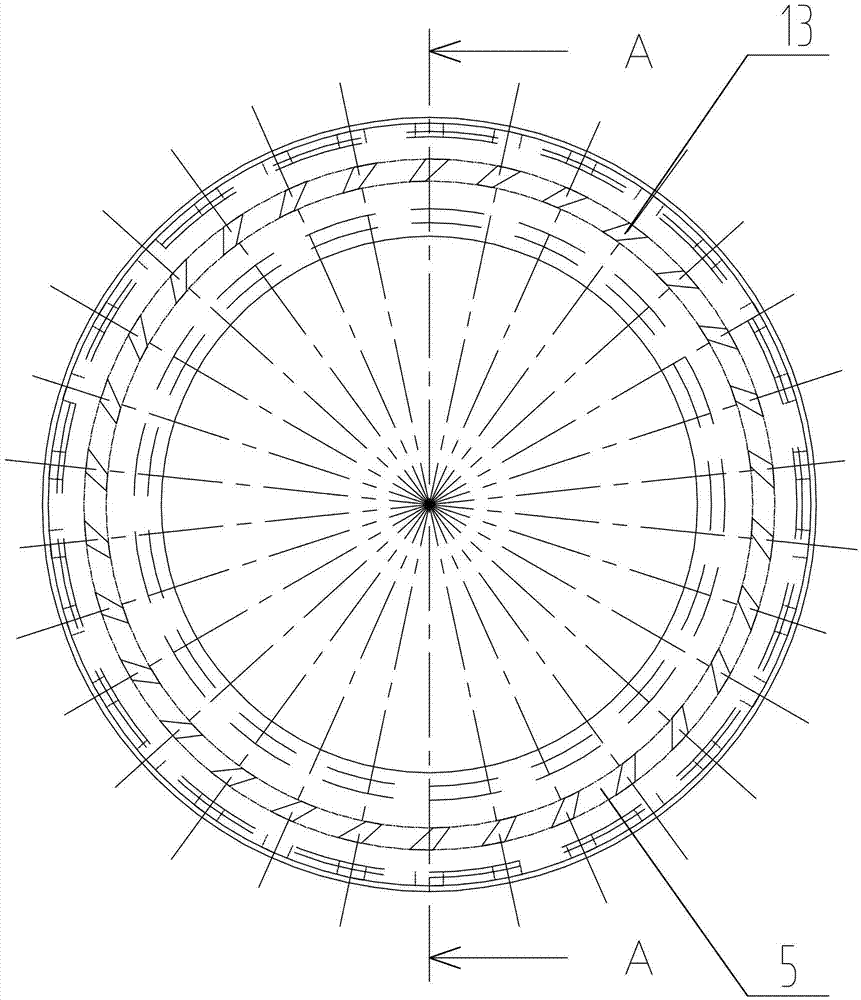

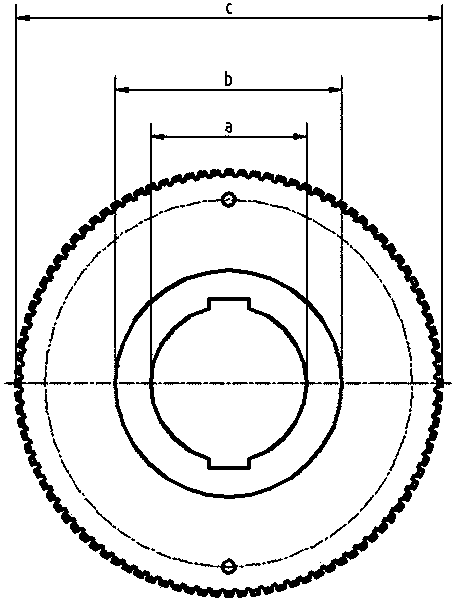

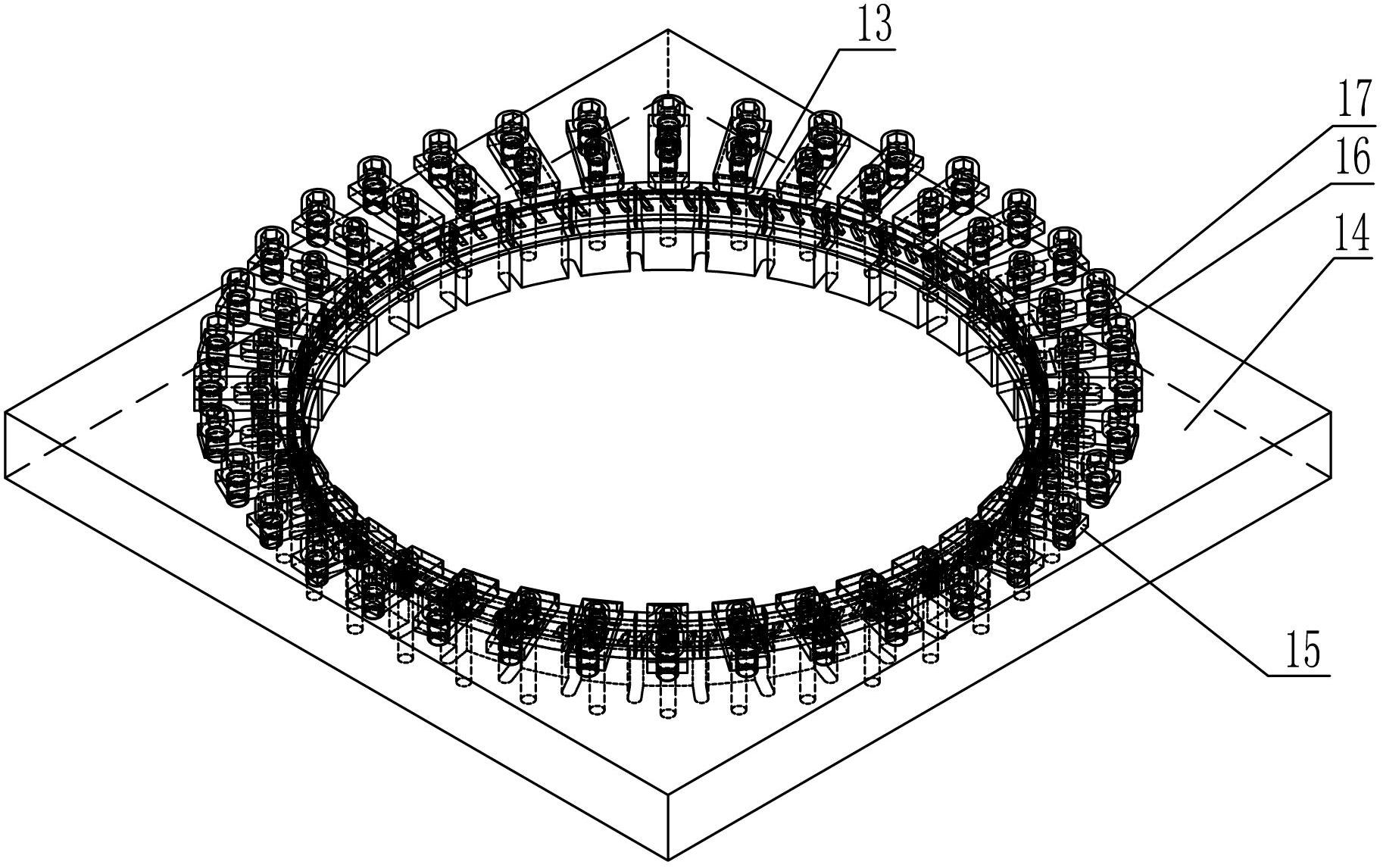

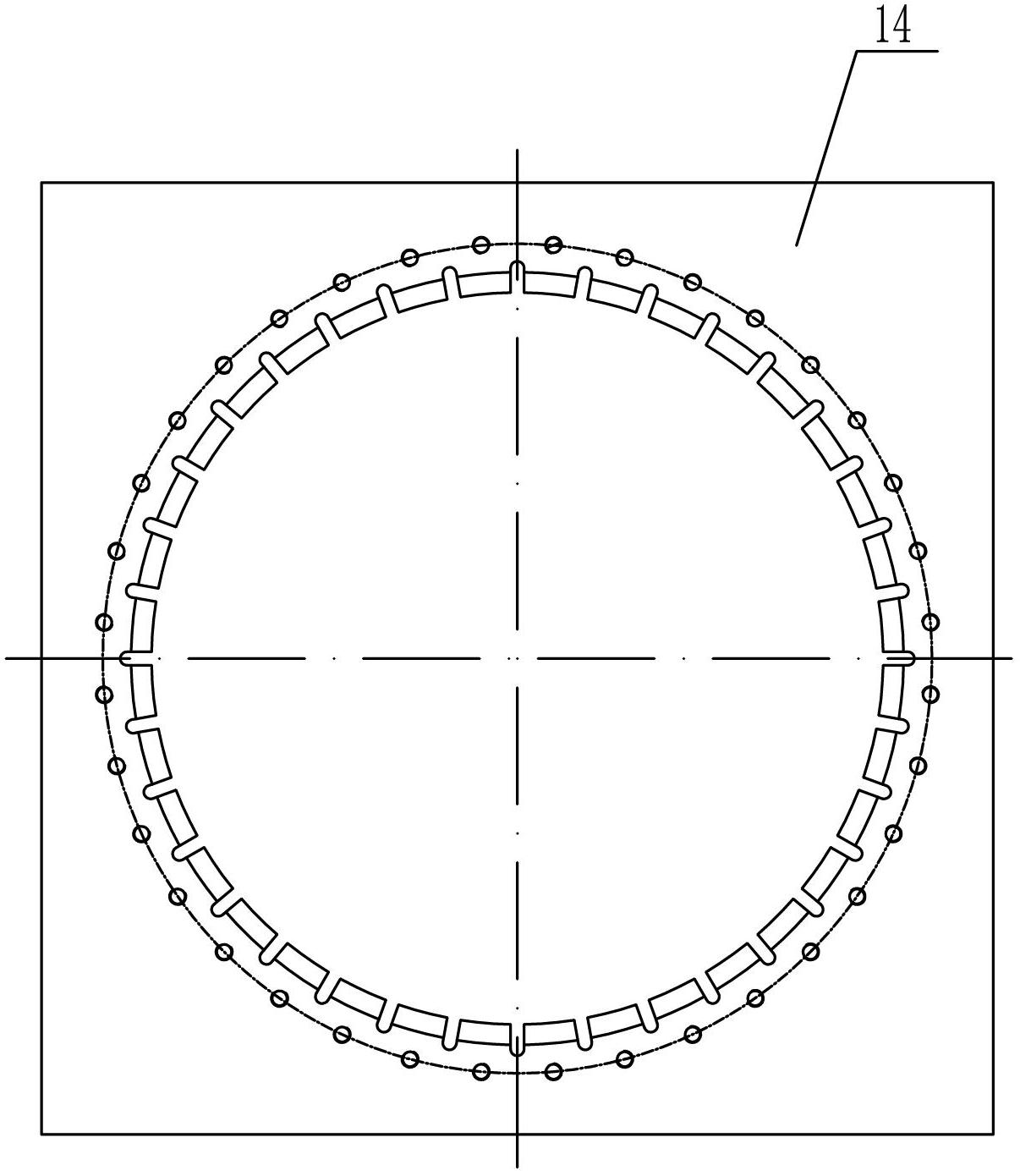

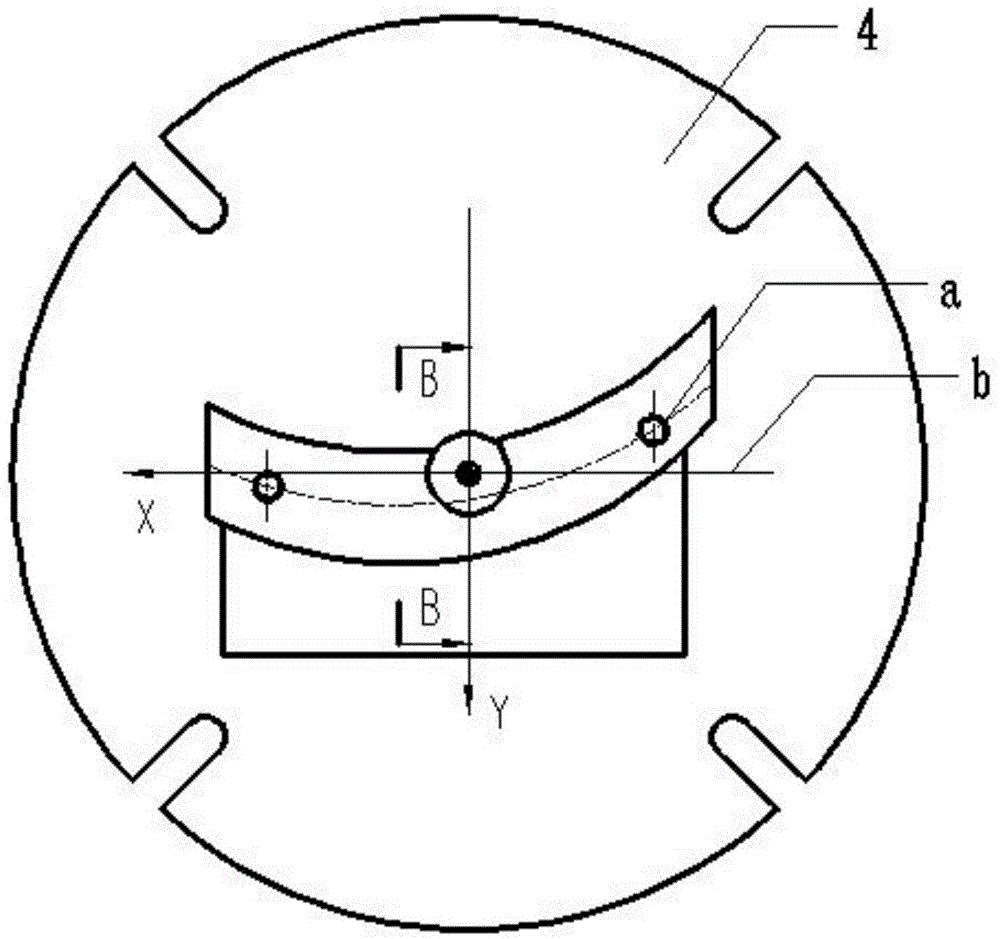

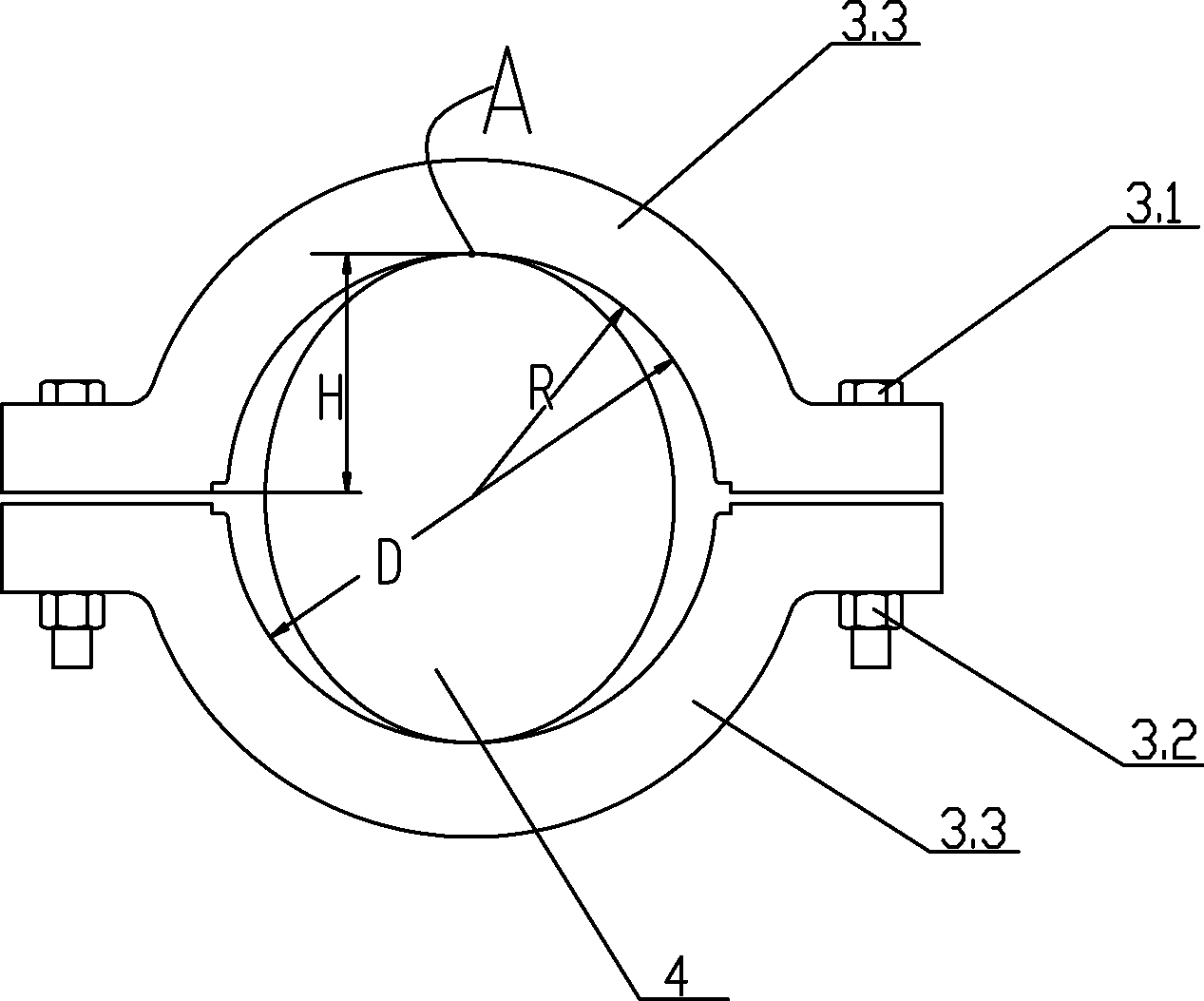

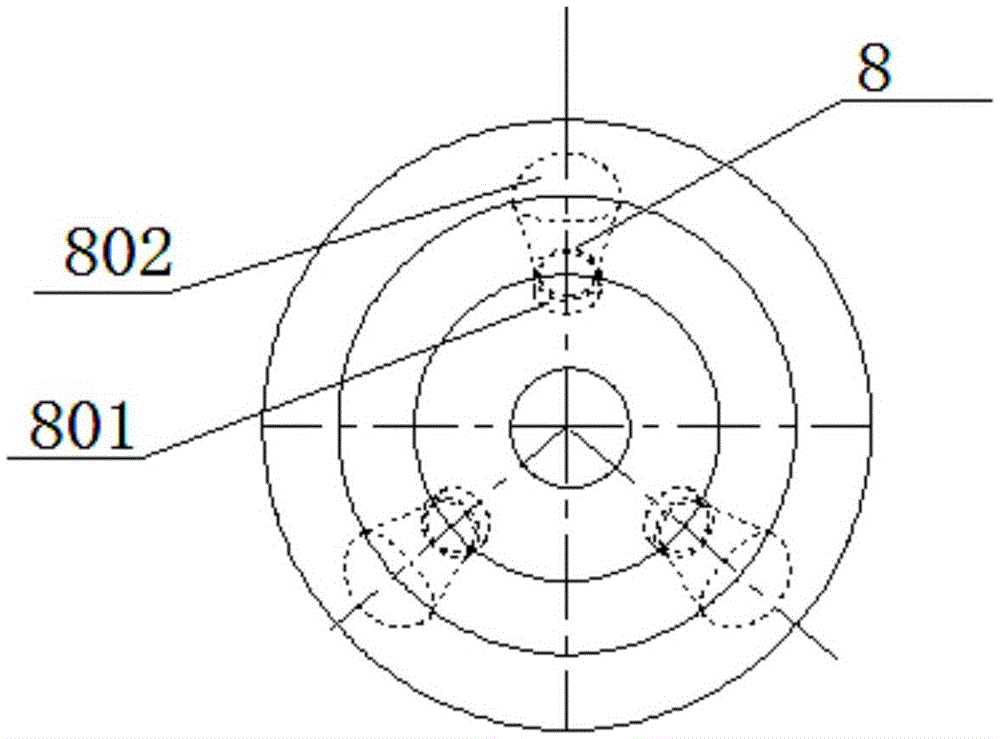

Method for realizing machining of combustion-compression ring bushes by using combustion-compression ring bush cutting clamp

ActiveCN102950479ASmall amount of deformationGuaranteed machining accuracyPositioning apparatusMetal-working holdersCombustionWork in process

The invention discloses a method for realizing the machining of combustion-compression ring bushes by using a combustion-compression ring bush cutting clamp, relating to a machining method for ring parts. The invention aims to solve the problems that because the existing combustion-compression ring bush is a thin-walled workpiece, the existing combustion-compression ring bush is easy to deform in the process of machining, so that the machining quality of the combustion-compression ring bush is affected, and meanwhile, the 30-equated positions of 30 molded holes of a combustion-compression ring bush machined by using the existing machining method are poor in accuracy. The clamp used in the invention comprises a base plate, a turntable, two positioning pins and four pressing plates. The method disclosed by the invention comprises the following steps of: 1, roughly turning an inner hole, an outer circumferential surface and two planes of a blank; 2, relieving stress of a semi-finished combustion-compression ring bush product; 3, carrying out finish turning on an inner hole, an outer circumferential surface and two planes of the semi-finished combustion-compression ring bush product; 4, drawing center position lines of radial holes and molded holes; 5, drilling 30 radial holes with a diameter of 5 mm; and 6, cutting and machining 30 molded holes. The method disclosed by the invention is used for machining combustion-compression ring bushes.

Owner:HARBIN TURBINE +1

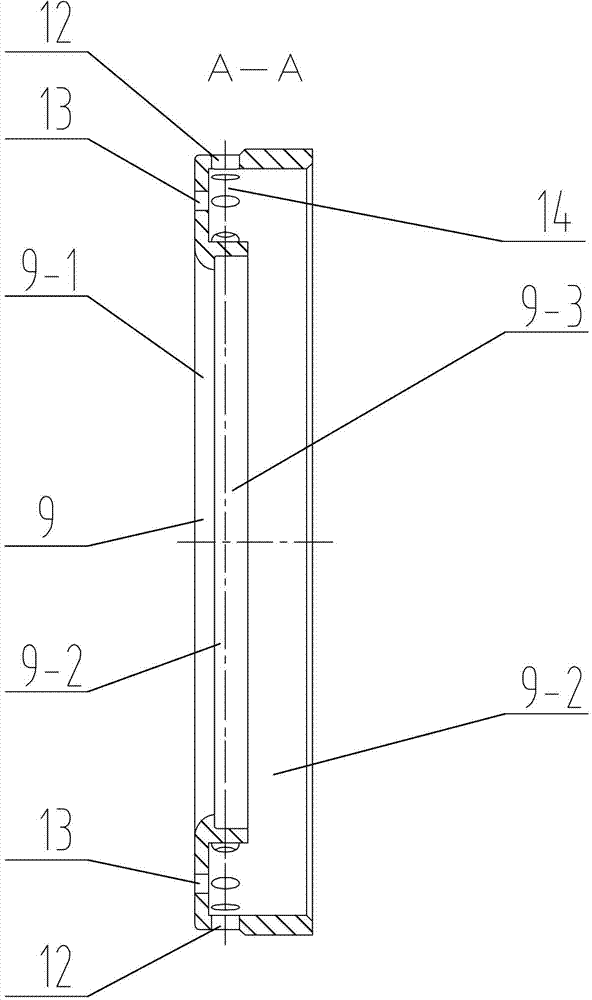

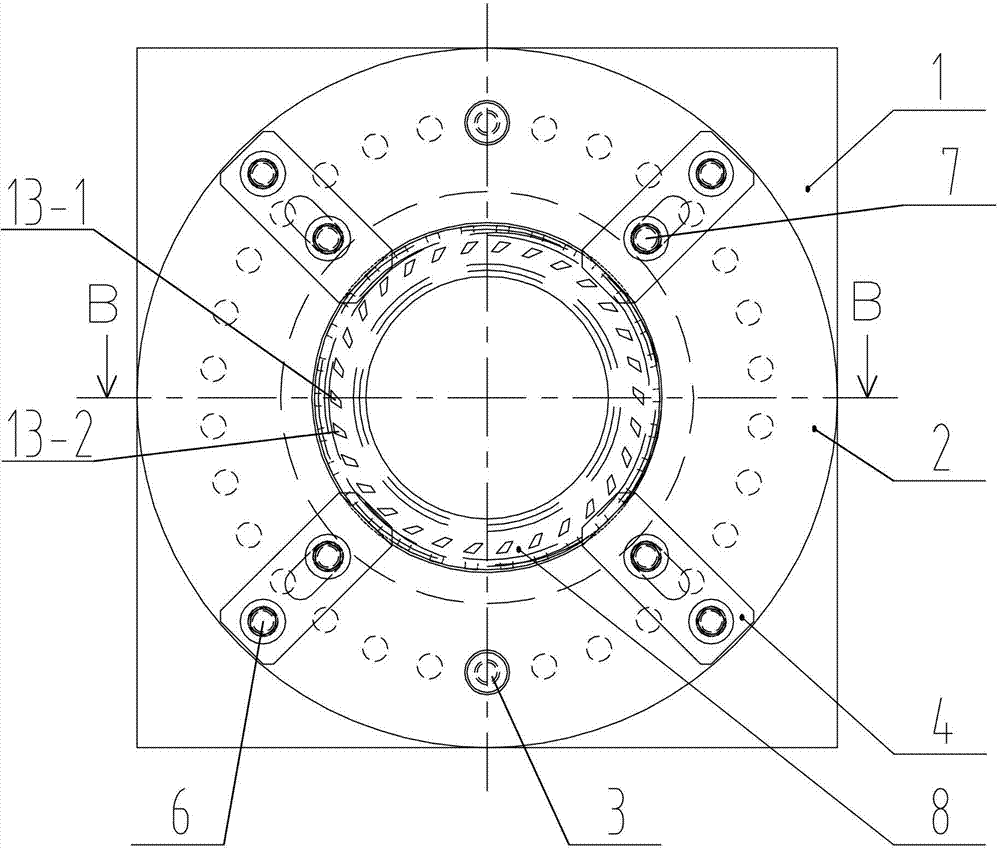

Method for machining circumferential taper holes in irregular spraying pipe casing and composite clamp thereof

ActiveCN103464846AGuaranteed coaxiality requirementsImprove product qualityPositioning apparatusMetal-working holdersMachiningProcessing accuracy

The invention discloses a method for machining circumferential taper holes in an irregular spraying pipe casing and a composite clamp thereof. The method includes the steps of 1) spraying pipe casing rough machining, 2) spraying pipe casing end face plane grinding, 3) spraying pipe casing semi-finish machining, 4) machining of small end taper holes of the spraying pipe casing, 5) machining of outer taper holes of the spraying pipe casing and 6) position accuracy detection of the circumferential taper holes. The special composite clamp is adopted, a strict clamping and alignment method is adopted to machine the taper holes in the spraying pipe casing, machining accuracy is high, and batch quality is stable. Alignment is required to be conducted only when a taper hole at the first position is machined, the following taper holes are machined in a location mode directly by adjusting a location disc, and the machining efficiency is improved. The space size of the taper holes is ensured through the composite clamp, location accuracy is high, and the requirement of products for space size accuracy can be completely met.

Owner:湖北三江航天江北机械工程有限公司

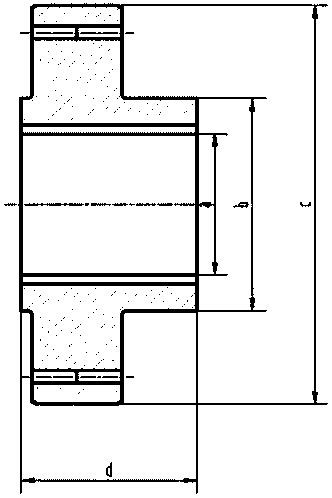

Processing method for nitrided gears

The invention discloses a processing method for nitrided gears which mainly solves the problem of deformation of parts in the course of processing a nitrided gear. The method comprises the following steps: I, rough turning the outer circle and the inner hole; II, performing heat treatment until the HBS reaches 260-300; III, finish turning parts; IV, tinning; V, milling the gear; VI, nitriding; VII, grinding the end surface; VIII, grinding the inner hole; IX, slotting and processing the key groove by utilizing a slotting tool; X, the lathing phi 160 (minus 0.05 / minus 0.20) hub outer circle b to be coaxial with the inner hole a by 0.015 mm, and lathing the two end faces to be perpendicular to the inner hole a by 0.015 mm; XI, grinding the gear tooth form; XII, marking a drilling hole, and finishing nitrided gear processing. The processing method for nitrided gears is used for preparing nitrided gears.

Owner:HARBIN TURBINE

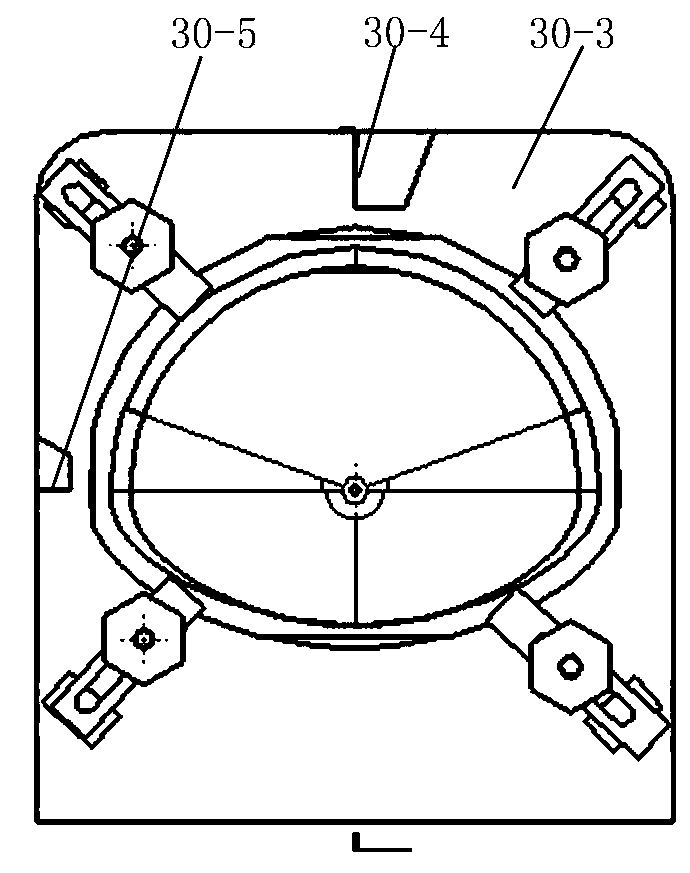

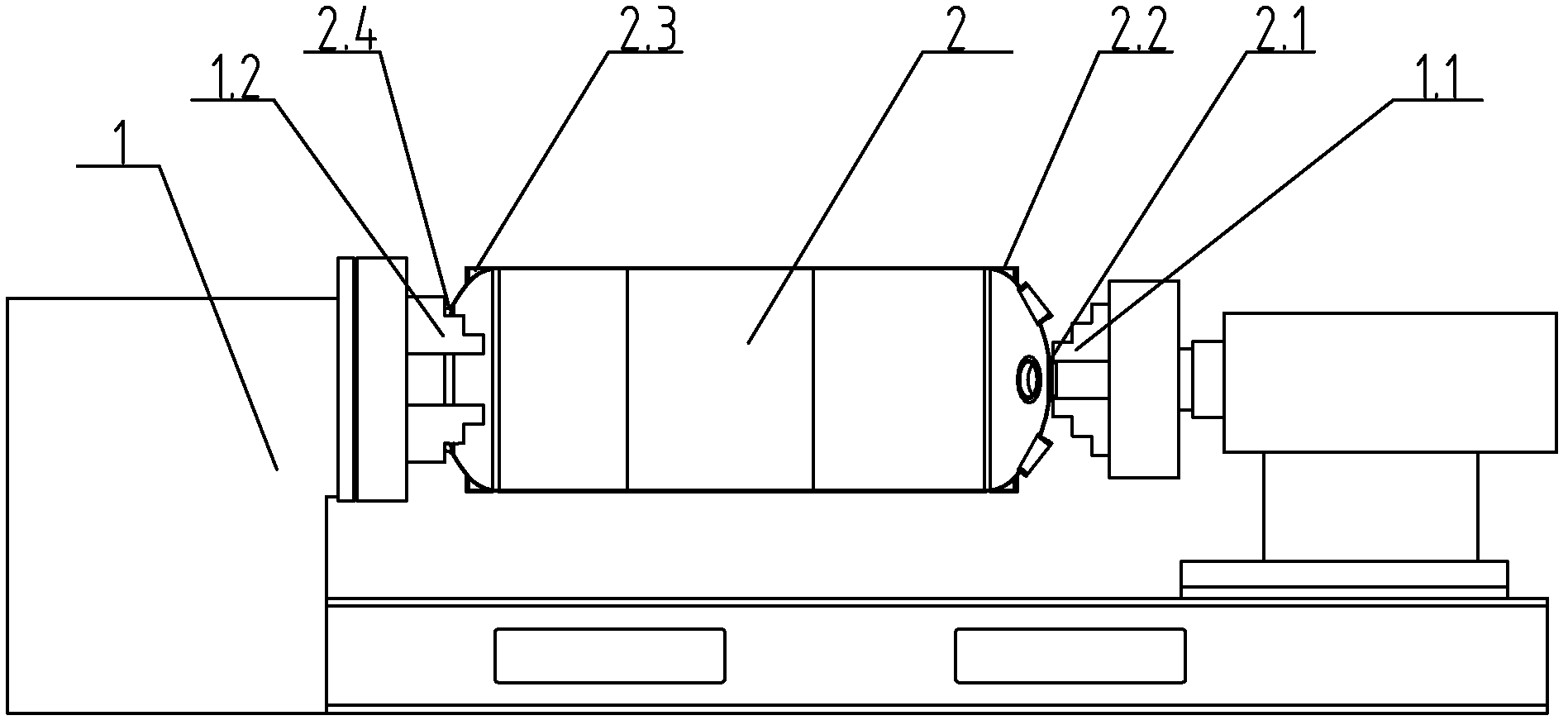

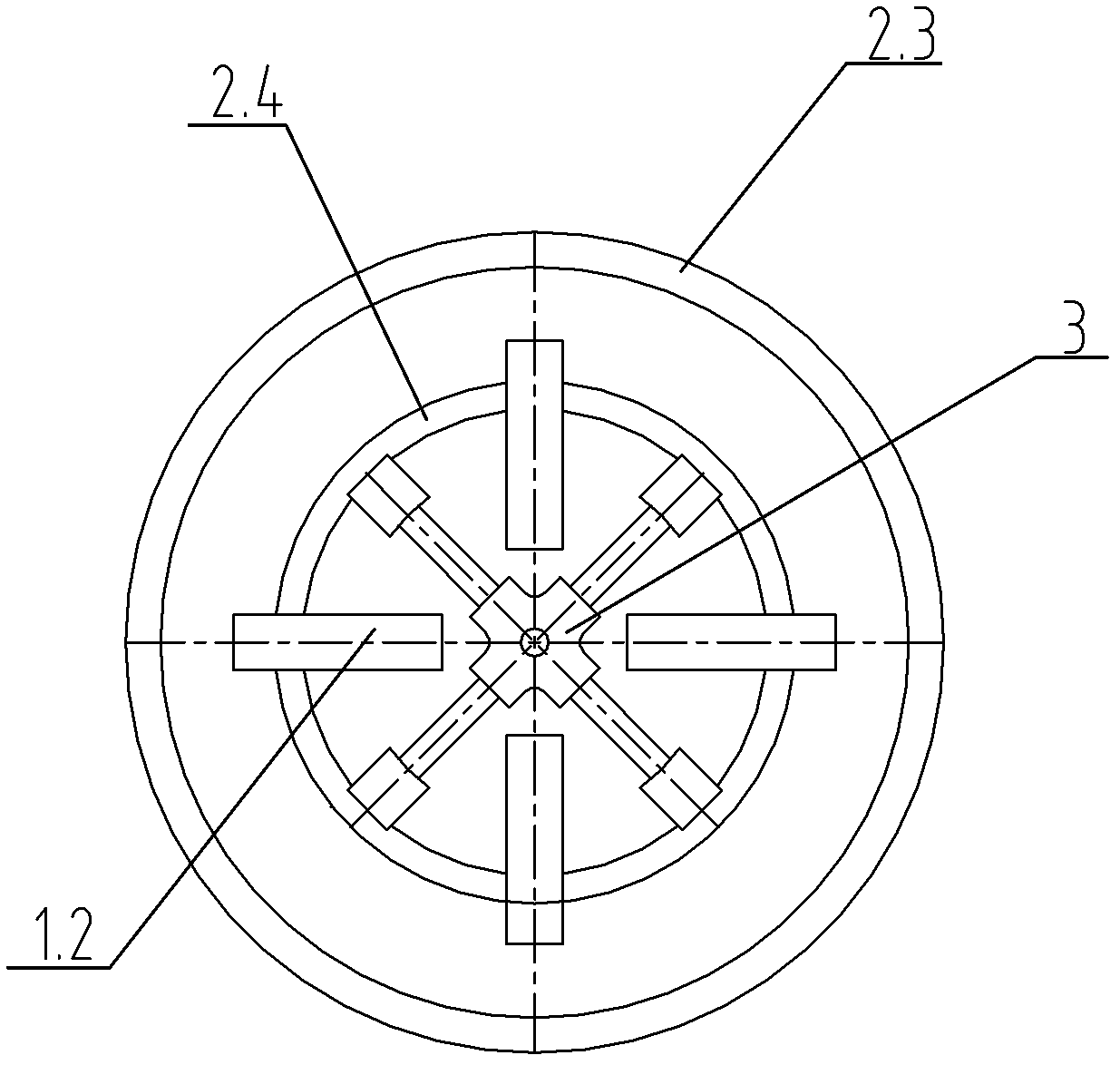

Special-shaped ceramic antenna cover machining device and method

ActiveCN109702605AUnified processing standardsControl machining accuracyRadiating element housingsWorking accessoriesMechanical engineeringEngineering

The invention provides a special-shaped ceramic antenna cover machining device and method. The device comprises a head cone supporting ring, an inner molded surface aligning ring, end face pressing plates and a plurality of outer supporting mechanisms. Each outer supporting mechanism comprises an outer support and an adjusting screw rod, and the inner molded surface aligning ring comprises an insertion end and a fixed end. According to the device and method, the machining reference of an antenna cover is determined through a primary alignment tool, it is guaranteed that the position of a clamping space of the antenna cover in all working procedures is free of deviation, the machining reference is unified, and the machining precision is effectively controlled.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

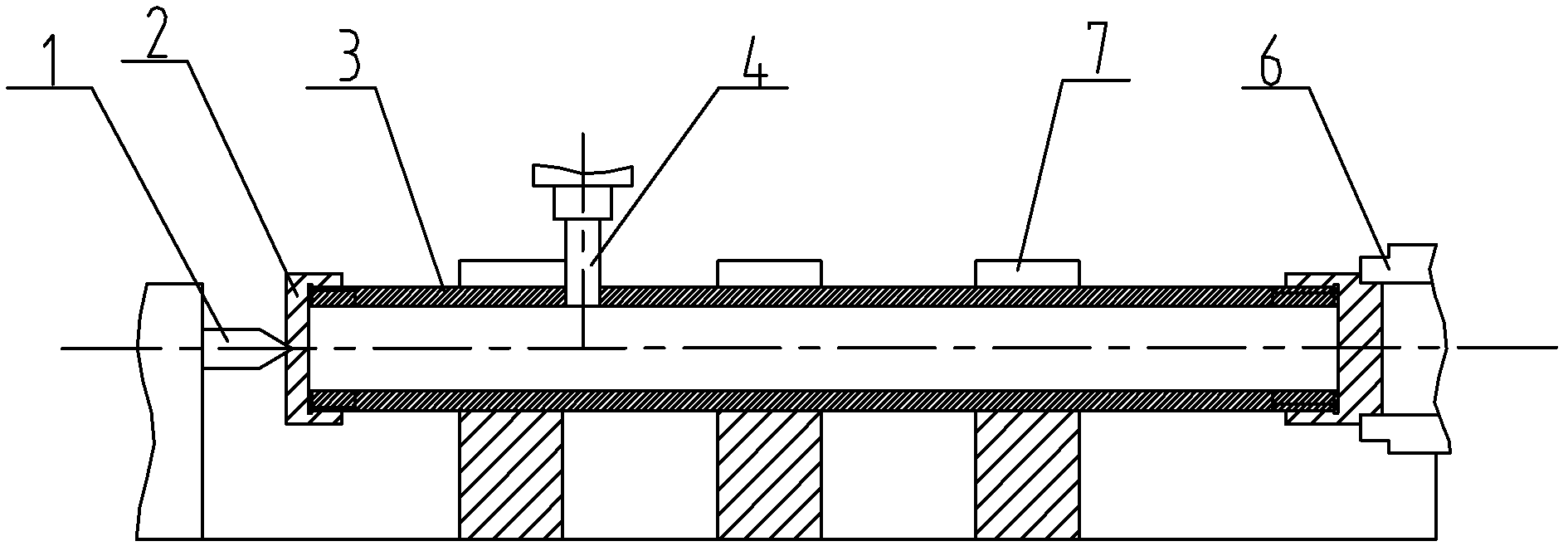

Lathing method of skirt bases of thin-walled high-strength steel rocket hull

InactiveCN102430766AImprove machining accuracyMeet design accuracy requirementsAuxillary equipmentTurning machinesFlight testCombustion chamber

The invention discloses a lathing method of skirt bases of a thin-walled high-strength steel rocket hull. The lathing method comprises the following steps of: 1, clamping a hull and identifying and measuring an alignment part; 2, installing a special support tool; 3, installing, aligning and clamping the hull; and 4, processing the hull: lathing excircles, end faces and inner holes of a front shirt base and a rear shirt base of a rocket combustion chamber hull. By adopting the special support tool and the special clamping and aligning method, the shirt bases of the thin-walled high-strength steel rocket combustion chamber hull are processed with high processing precision, thus requirements of product design precision are completely met. A product made by using the method provided by the invention can be used in a ground test, and can also be used in a flight test and can be delivered to a user for use. The lathing method provided by the invention can be used for processing the shirt bases of the thin-walled high-strength steel rocket hull, and can also be used for processing control of other similar products.

Owner:湖北三江航天江北机械工程有限公司

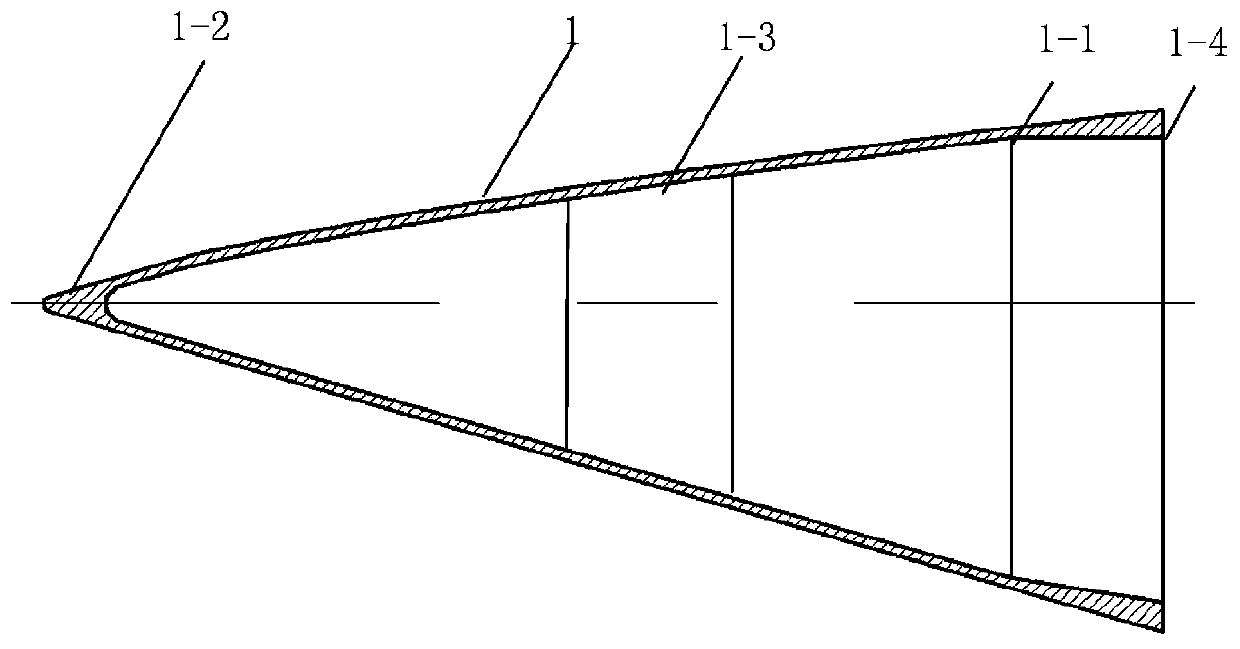

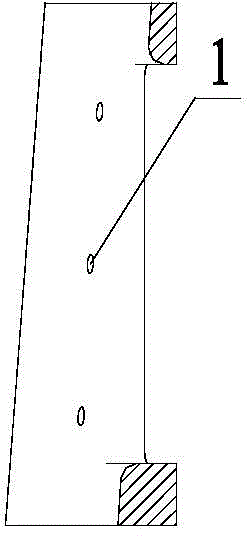

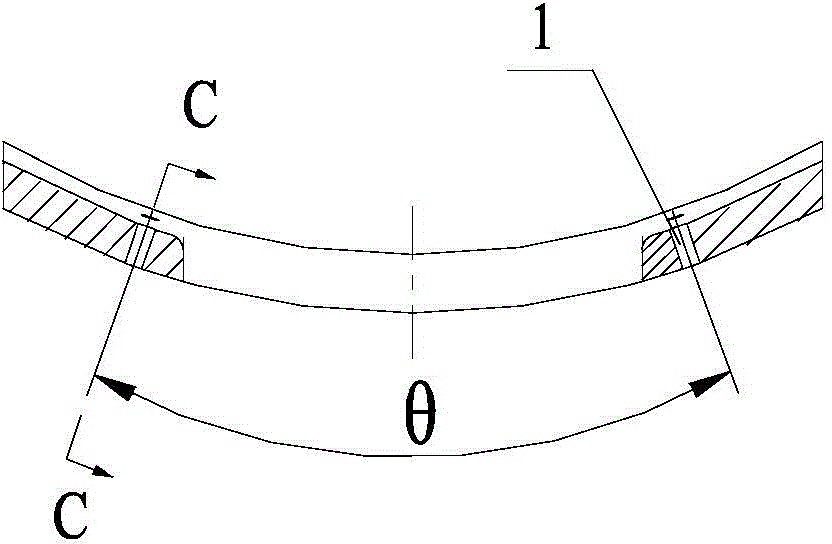

Processing method of nonmetal special-shaped rudder sheet and clamp for processing

InactiveCN102873383AGuaranteed dimensional accuracyGuaranteed surface roughnessMilling equipment detailsPositioning apparatusAbnormal shapedRudder

The invention discloses a processing method of a nonmetal special-shaped rudder sheet and a clamp for processing. The processing method comprises the following steps: 1) designing a nonmetal rudder sheet flat blank according to a product maximum profile dimension; 2) vertically clamping the nonmetal rudder sheet flat blank, symmetrically grinding the two reference surfaces of the nonmetal rudder sheet flat blank; 3) performing rough milling of the profile of the nonmetal rudder sheet flat blank, processing a process chuck for subsequent clamping at a position of a rudderpost; 4) vertically clamping the process chuck, aligning the central planes of the two reference surfaces, performing semi-finish milling of the reference surfaces of the nonmetal rudder sheet flat blank, then performing finish milling one surface to obtain the designed dimension so as to form the rudder sheet; 5) vertically clamping the rudder sheet, performing semi-finish milling of the process chuck to obtain a rudderpost shape; 6) performing finish milling of the rudderpost to obtain the designed dimension so as to finish the processing of the nonmetal special-shaped rudder sheet. With the processing method of the nonmetal special-shaped rudder sheet and the clamp for processing, the processing precision and the form and location tolerance of the nonmetal special-shaped rudder sheet can be effectively ensured.

Owner:湖北三江航天江北机械工程有限公司

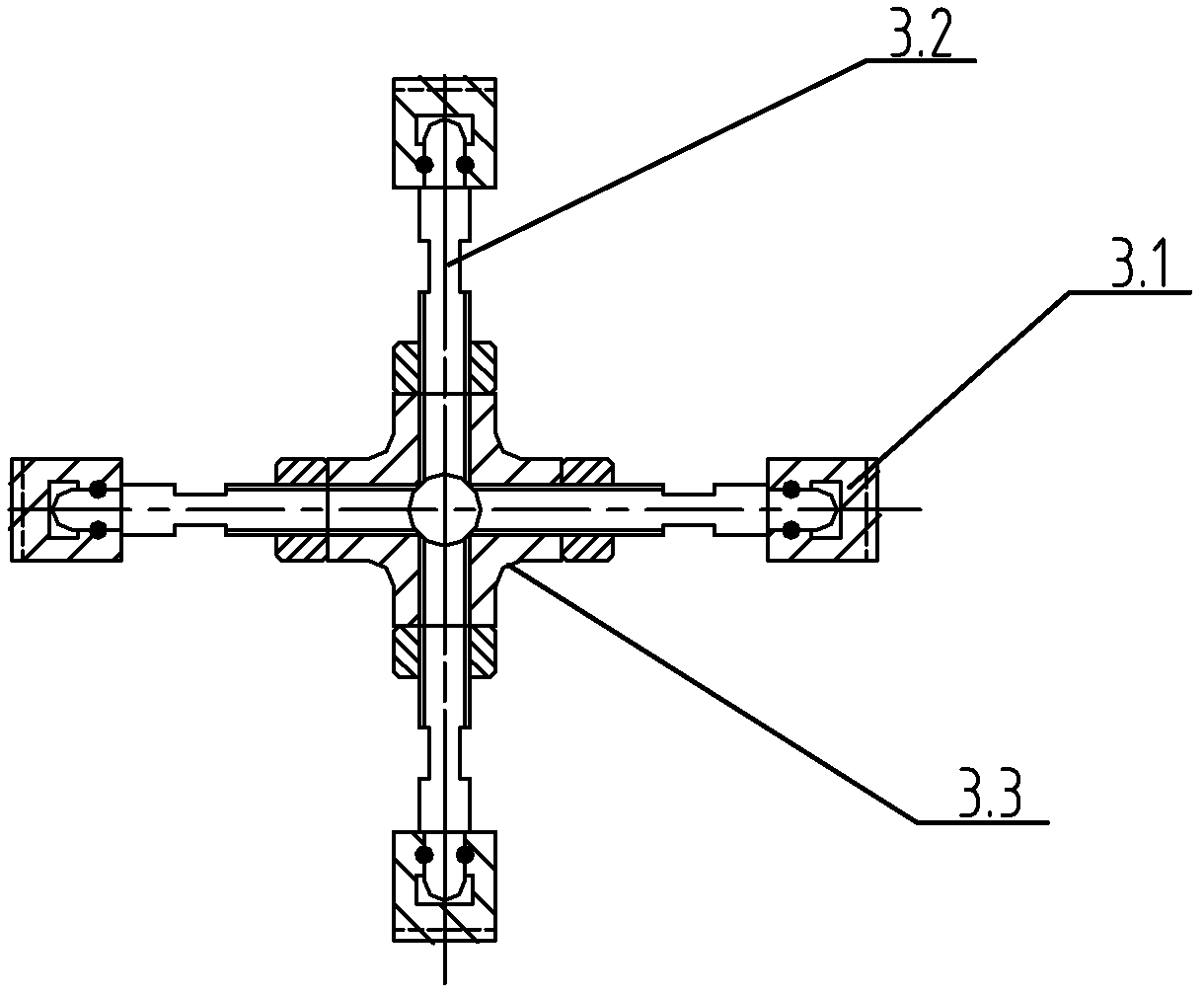

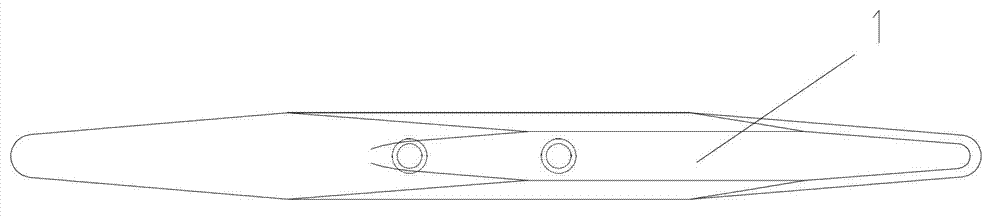

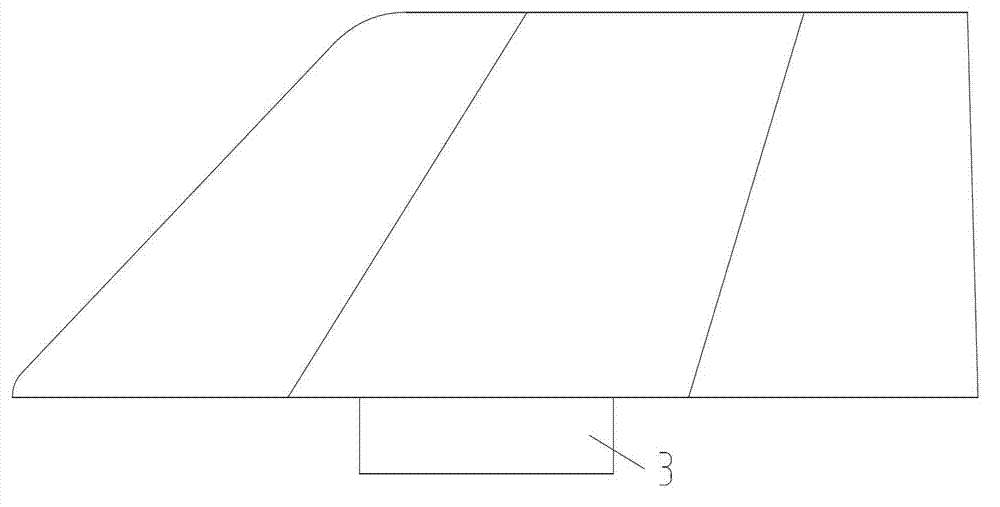

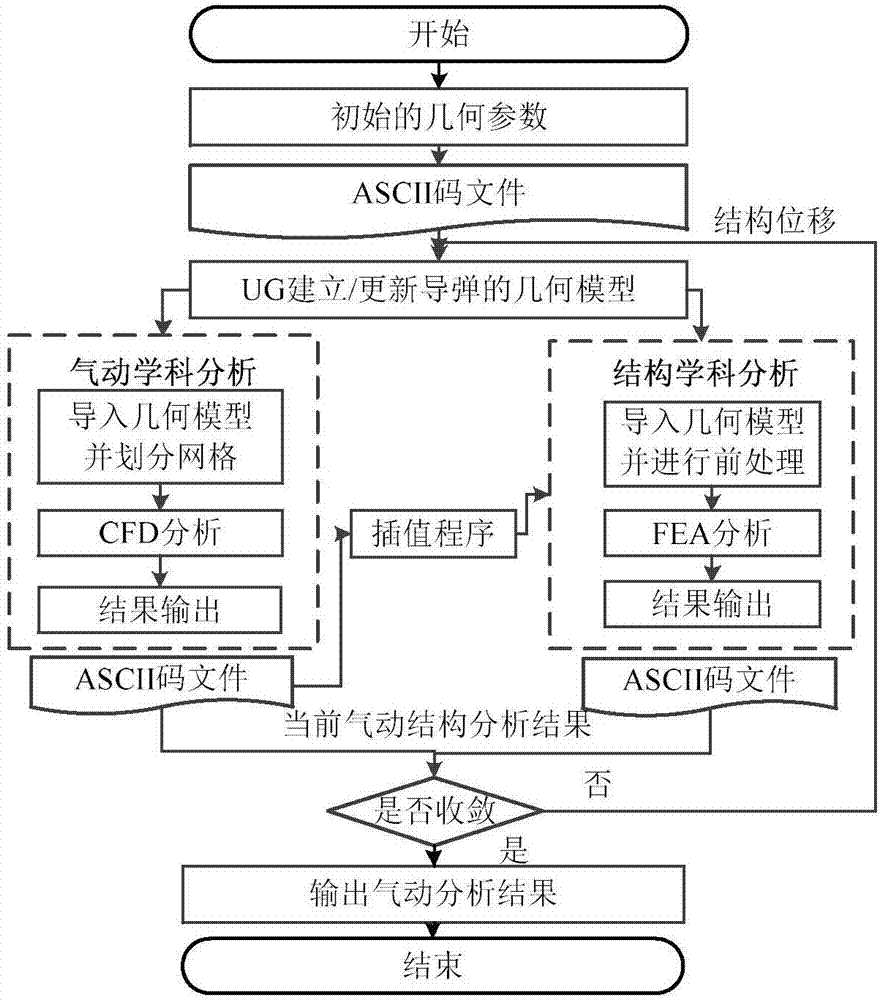

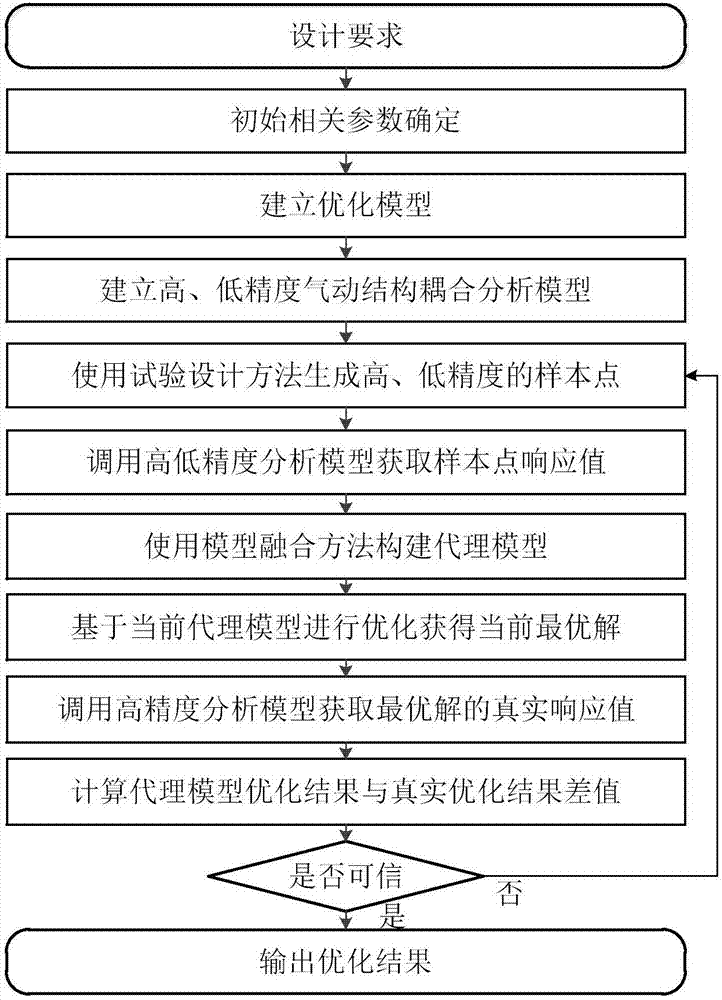

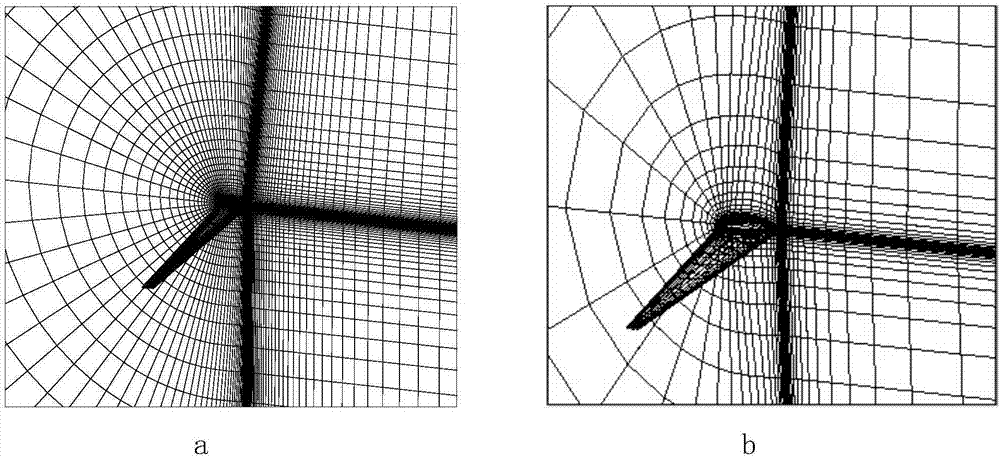

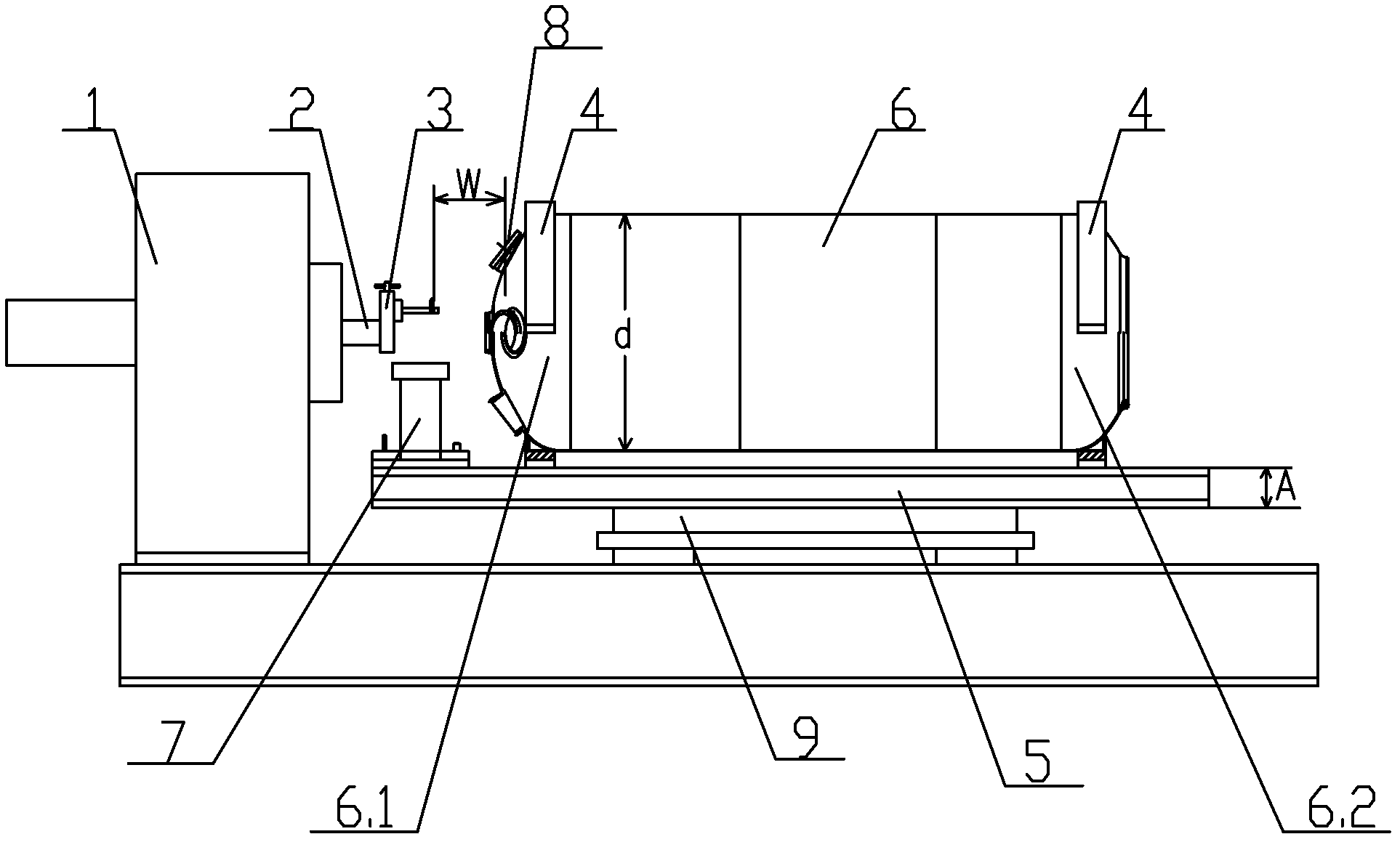

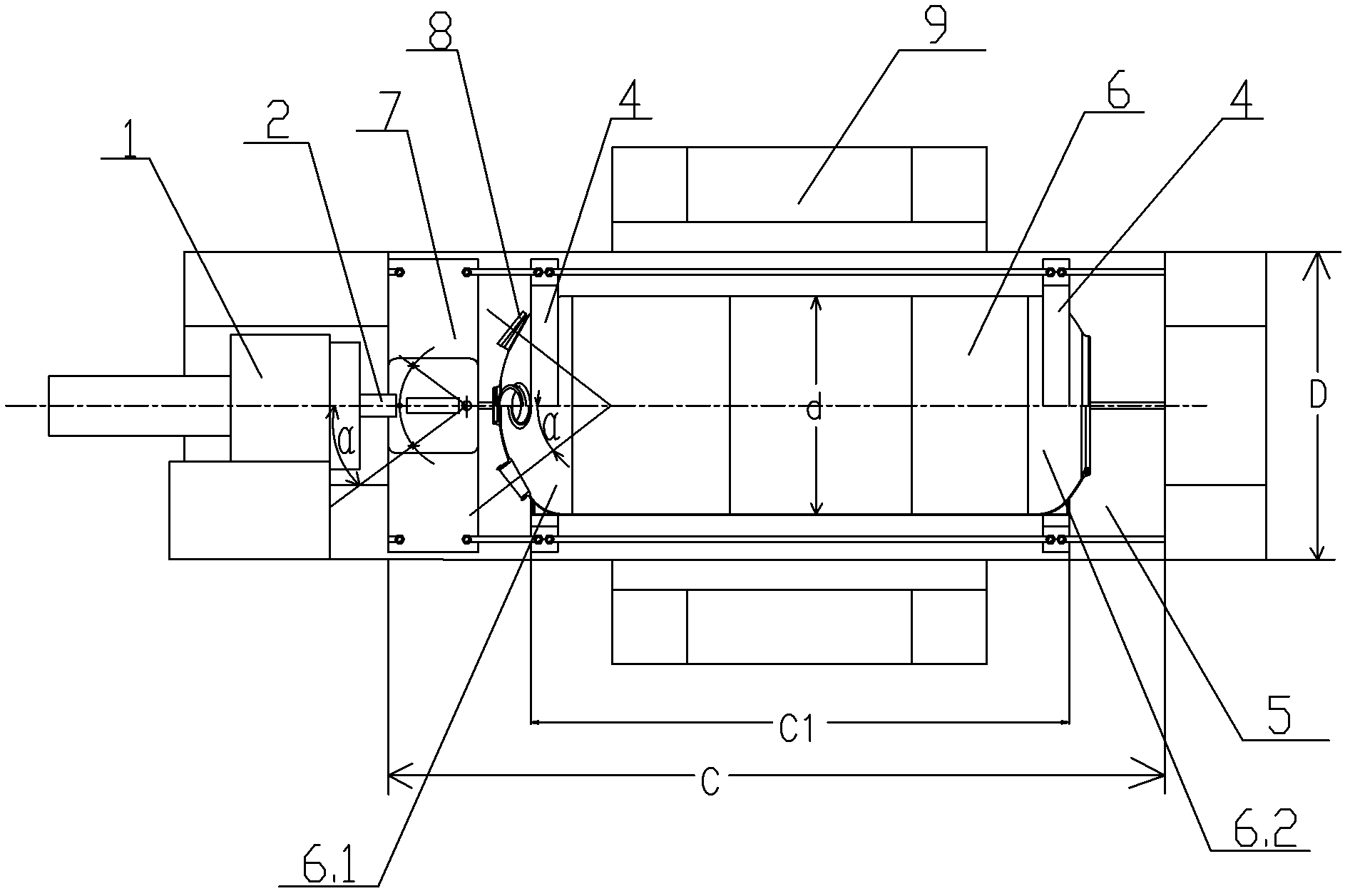

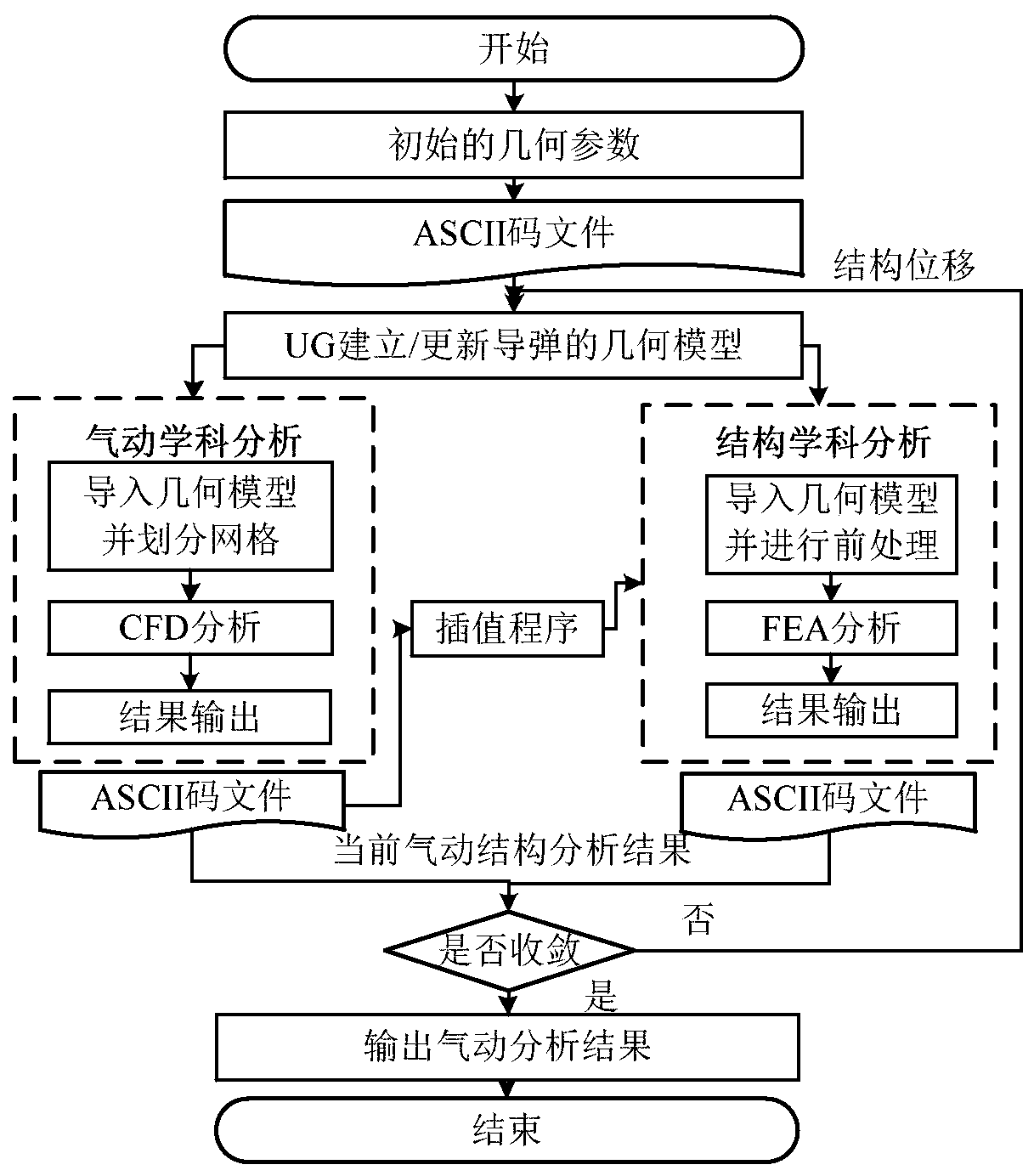

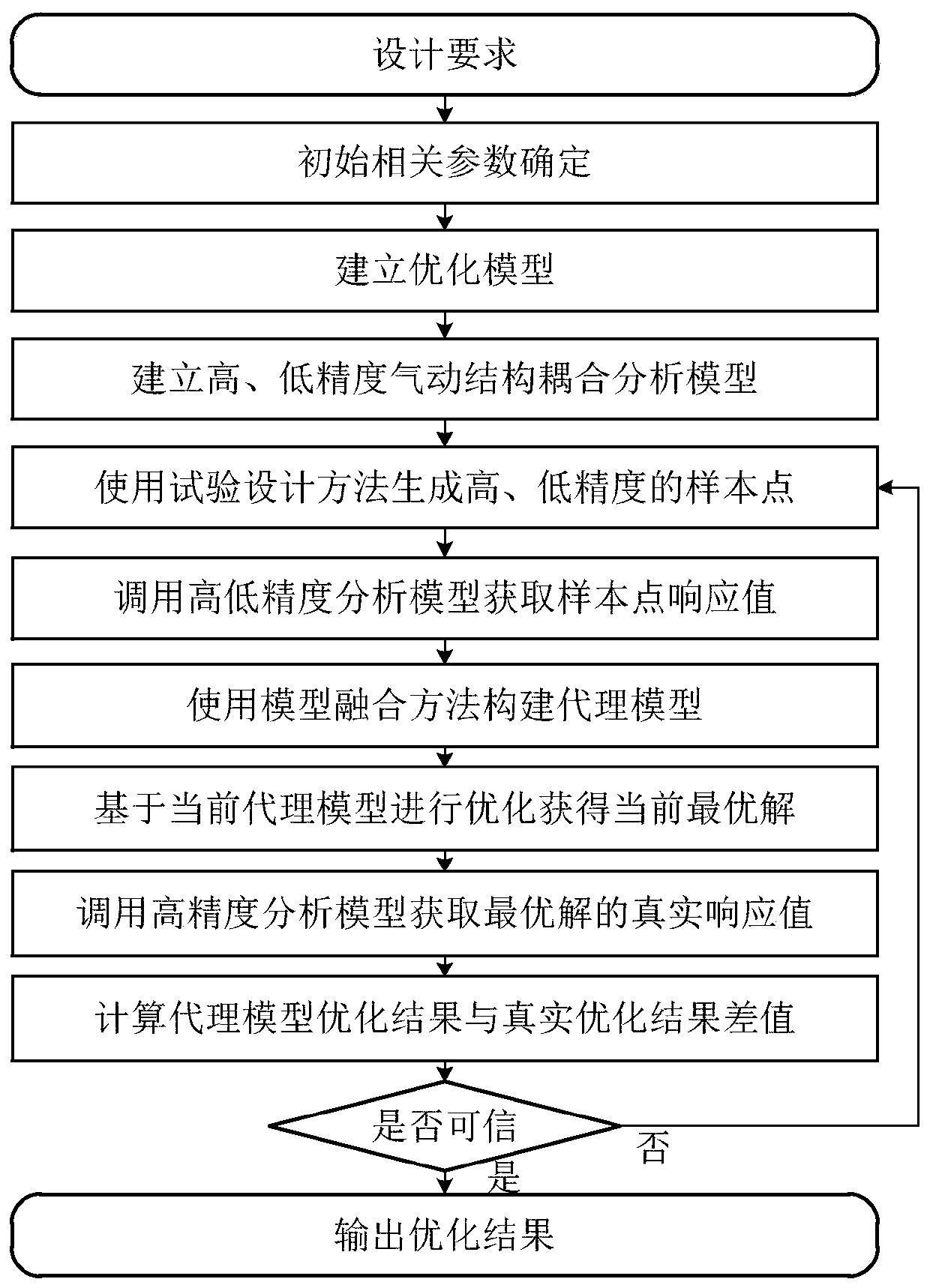

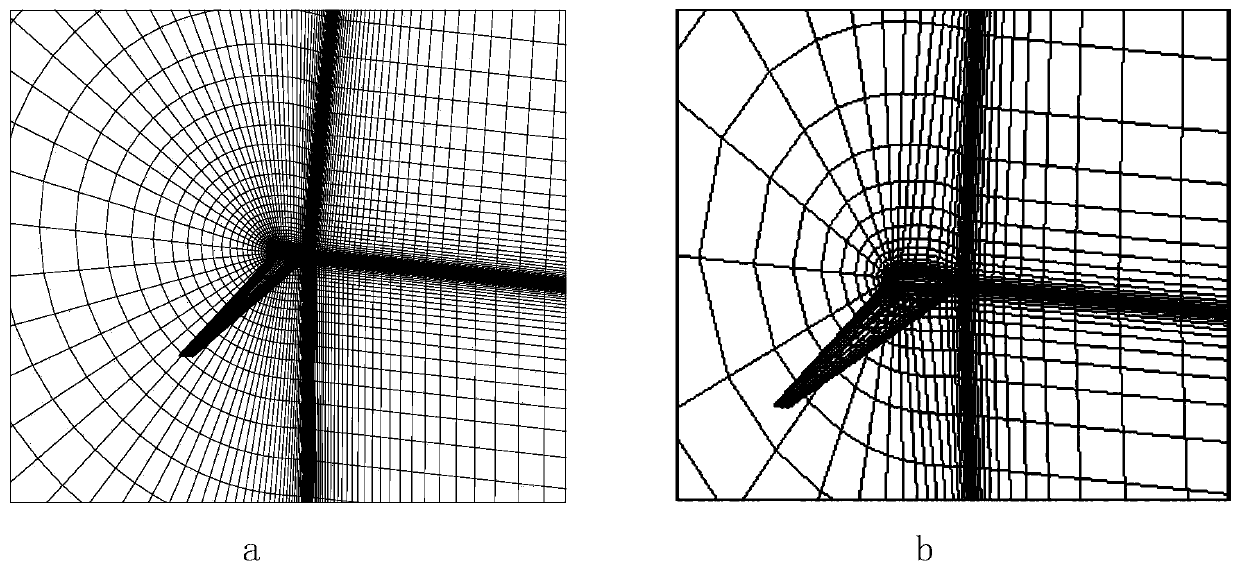

High-aspect-ratio wing optimization design method based on model merging method

ActiveCN107391891AImprove design efficiencyReduce callsGeometric CADSustainable transportationAlgorithmInto-structure

The invention discloses a high-aspect-ratio wing optimization design method based on a model merging method, and belongs to the technical field of overall optimization design of aircraft. The method comprises the steps that a penalty function method is used for processing complex constraints for an optimization model and a system-level optimization model which are optimally divided into structure subjects as needed; a high precision pneumatic structure coupling analysis model and a low precision pneumatic structure coupling analysis model are built through a pneumatic structure coupling modeling technology; high precision sample points and low precision sample points are generated through an experiment design method; high precision sample information and low precision sample information are obtained by calling the high precision pneumatic structure coupling analysis model and the low precision pneumatic structure coupling analysis model respectively and stored; by using the model merging method, the high precision sample information and the low precision sample information are merged to build a surrogate model; optimization solution is conducted based on an optimization method for a current surrogate model, whether the optimization result is credible or not is judged according to a difference value of a true response value of the optimal solution and a surrogate model value based on the model merging method, if not, the step is executed again to rebuild a merging model for optimization solution, if yes, the optimal design result is output, and optimization design is completed.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

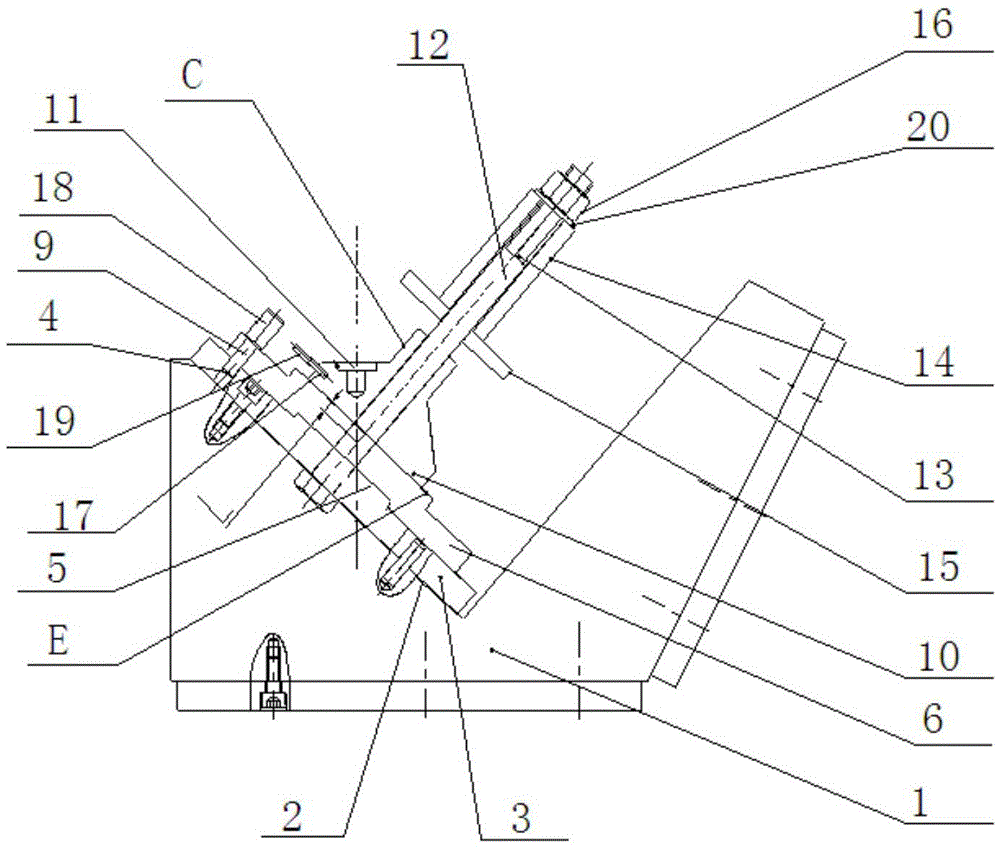

Method for processing back-spraying hole in shell of rocket chamber by using conventional boring machine

InactiveCN102248379ALow costImprove machining accuracyPositioning apparatusMetal-working holdersNumerical controlCombustion chamber

The invention discloses a method for processing a back-spraying hole in a shell of a rocket chamber by using a conventional boring machine. The method comprises the following steps of: (1) aligning and assembling a special tool; (2) aligning and assembling the shell; (3) aligning a space angle of the back-spraying hole; (4) aligning the space location of the back-spraying hole; (5) processing a No.1 back-spraying hole; (6) aligning and processing a No. 3 back-spraying hole; (7) aligning a No.2 back-spraying hole; and (8) aligning and processing No.2 and No.4 back-spraying holes. By adopting aseries of special aligning and clamping tools, the back-spraying holes in the shell of the rocket chamber are processed by using the conventional boring machine, the processing precision is high, andthe requirement for product designing precision is completely met; compared with processing by using an imported high-precision numerical controlled boring machine, the processing by using the methodprovided by the invention has the advantage that the equipment cost is remarkably reduced.

Owner:湖北三江航天江北机械工程有限公司

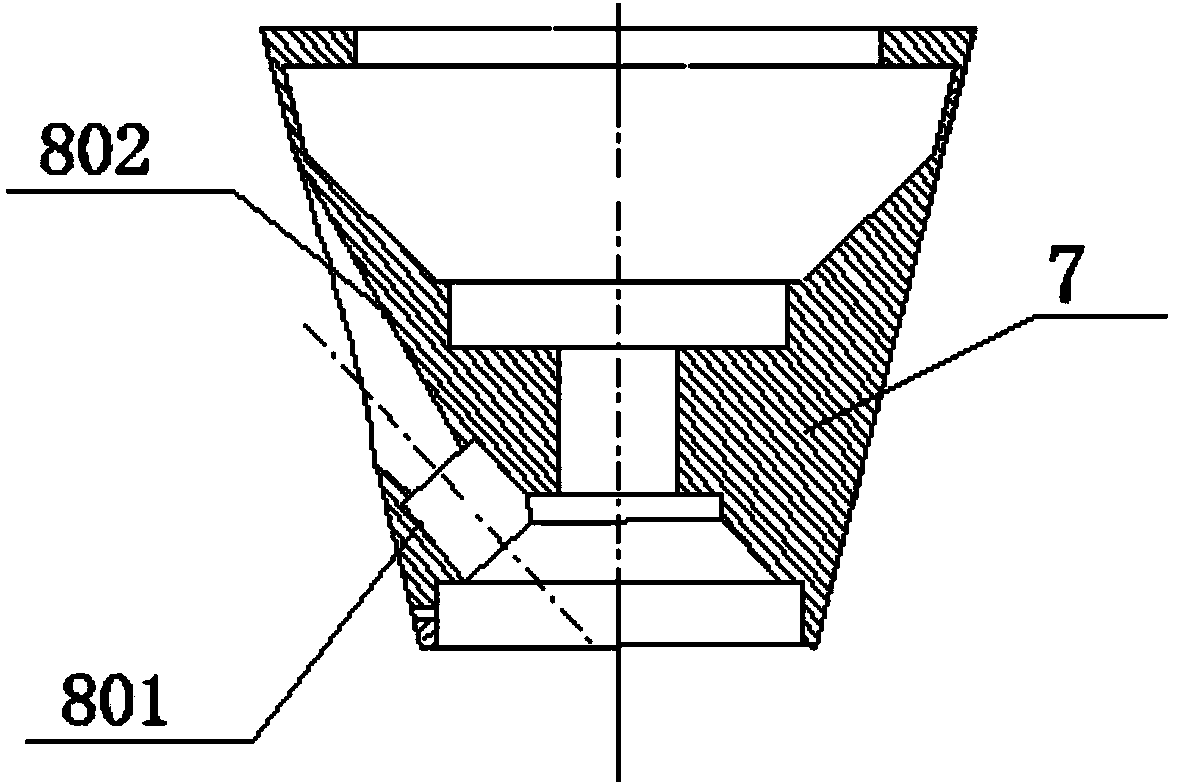

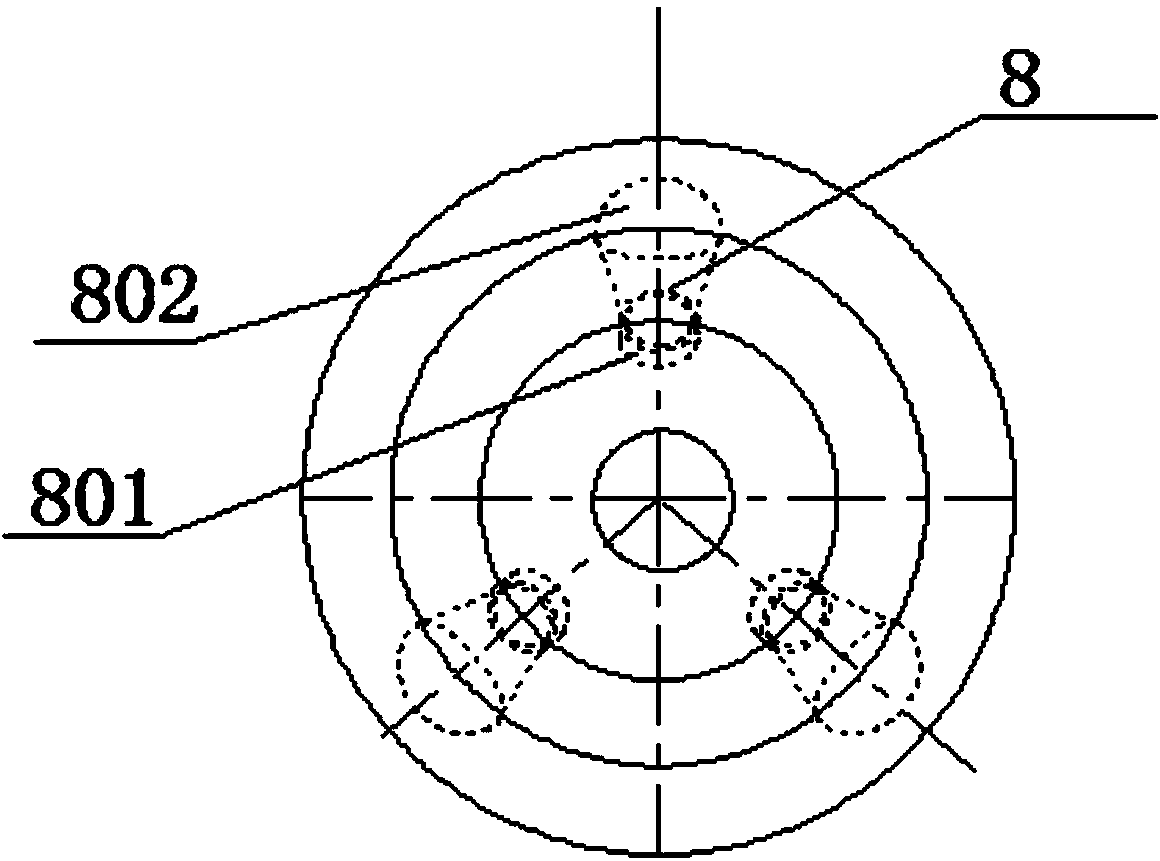

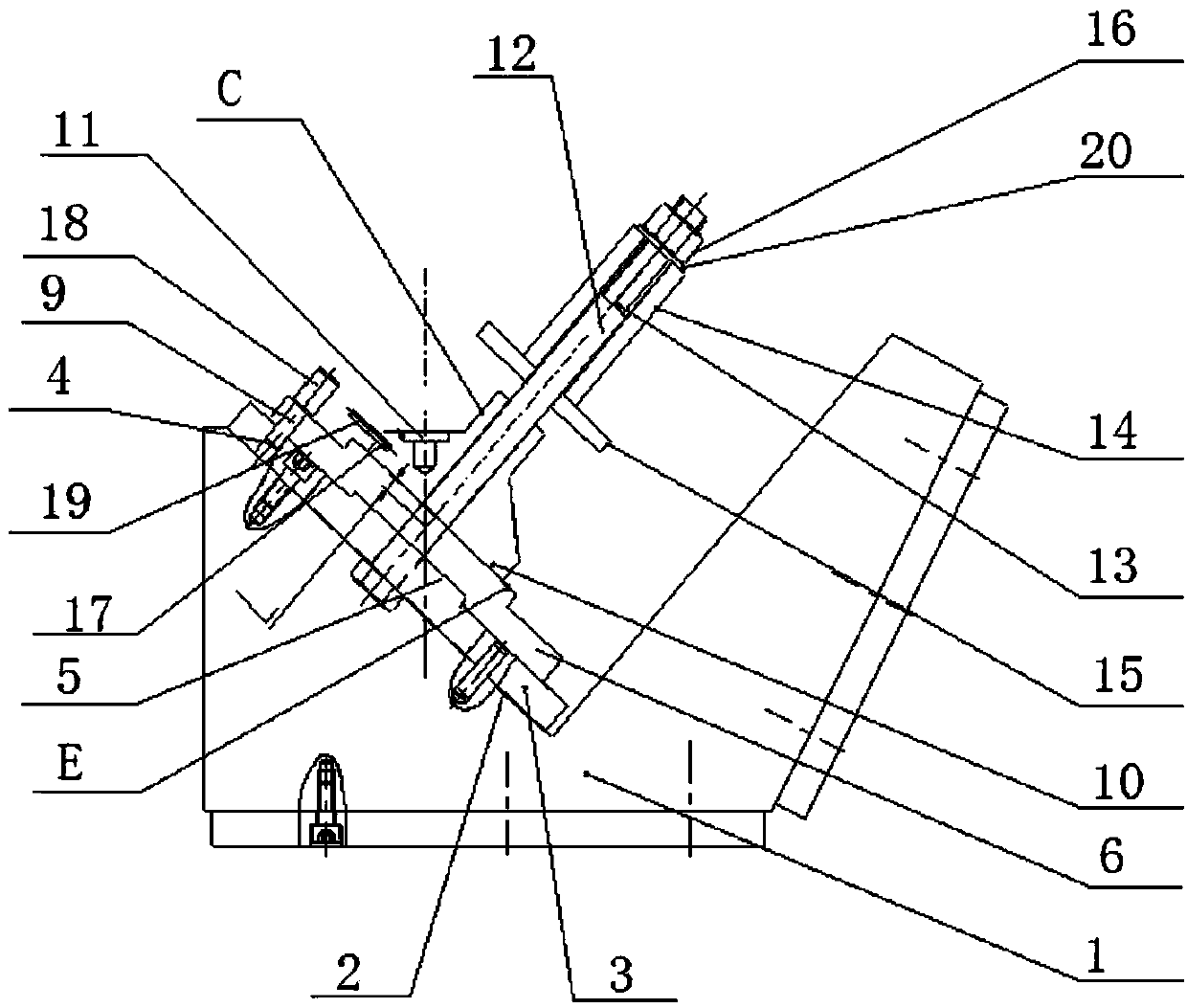

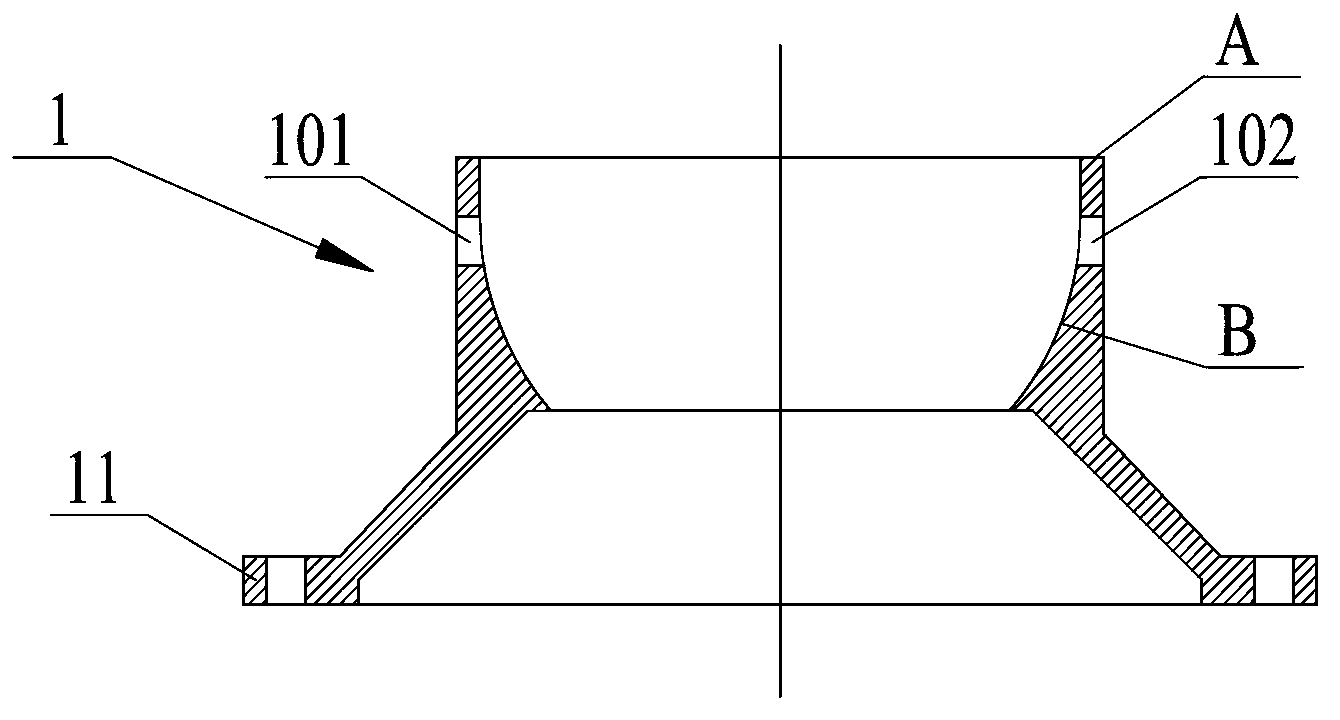

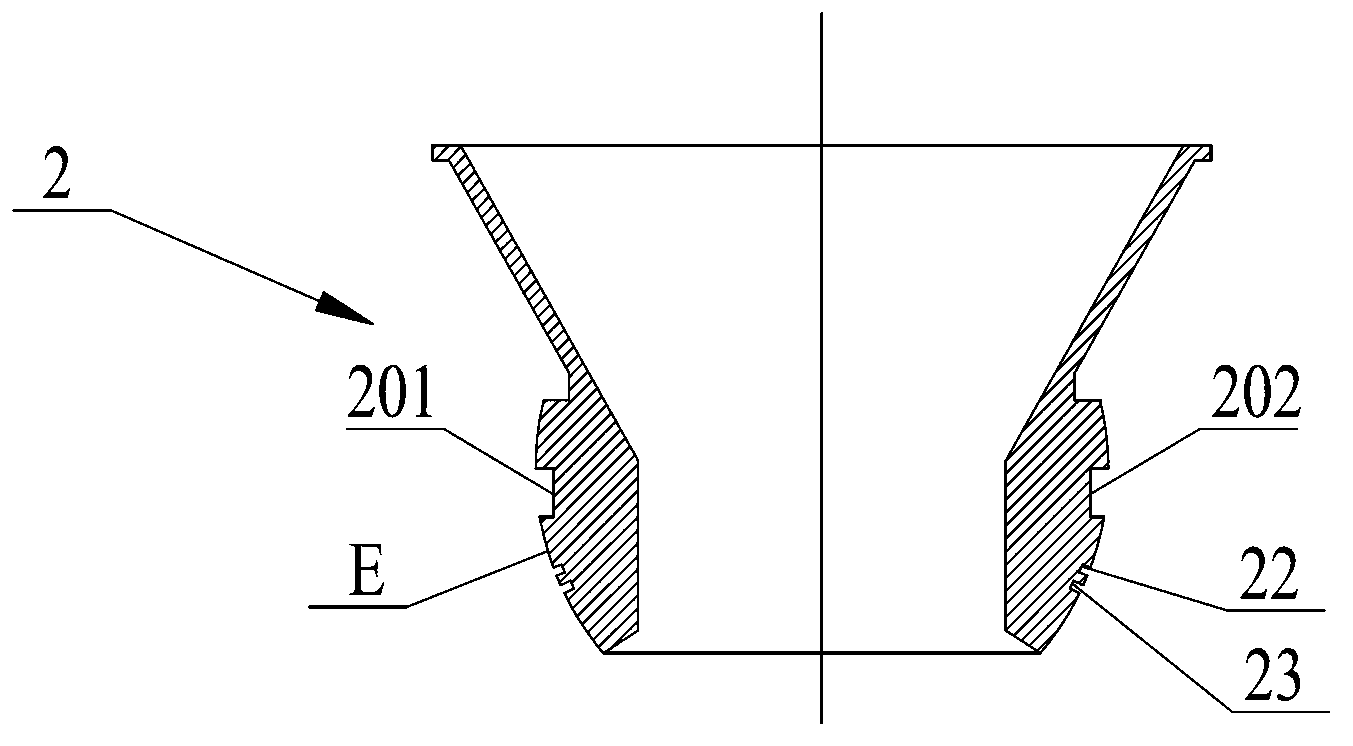

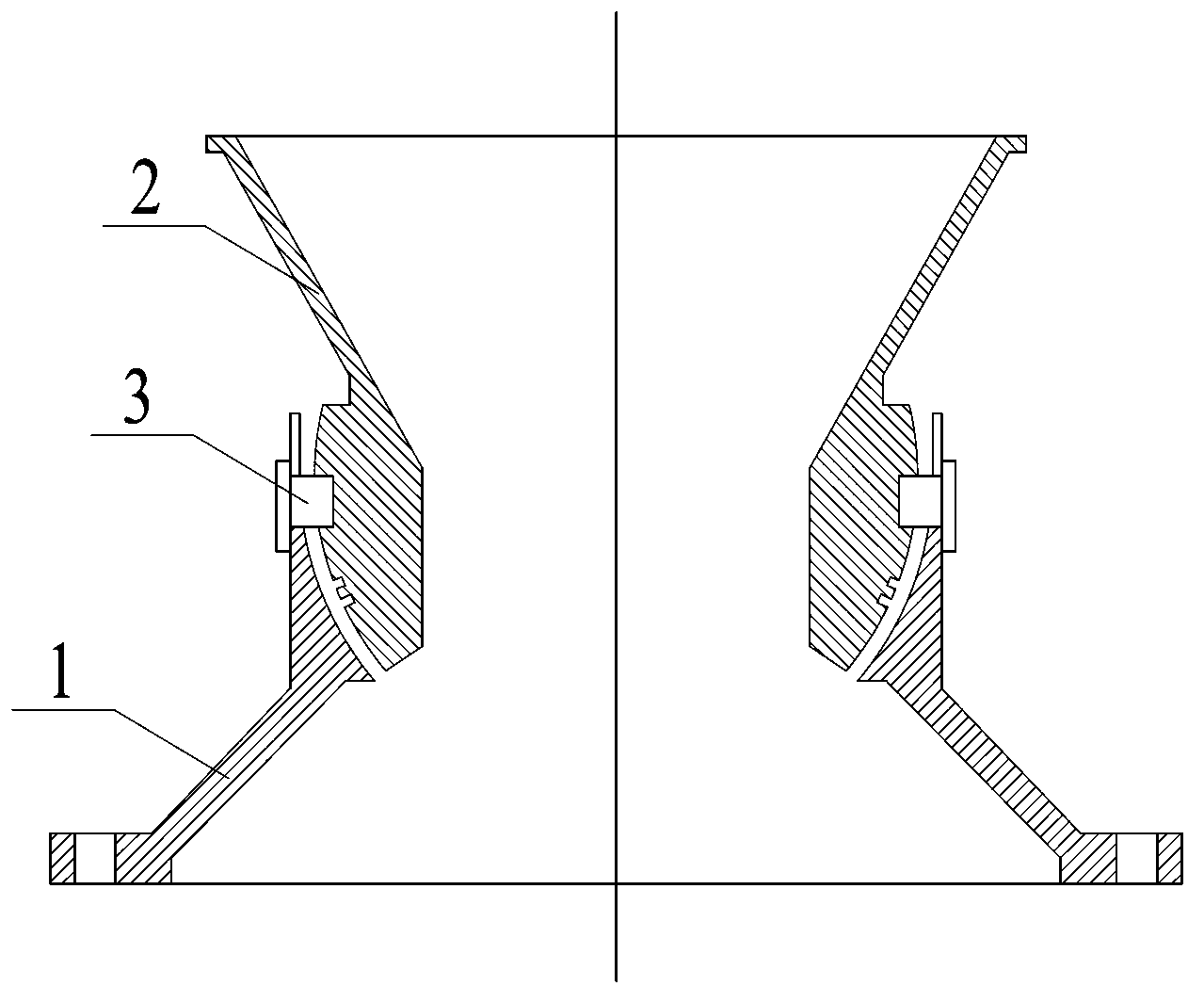

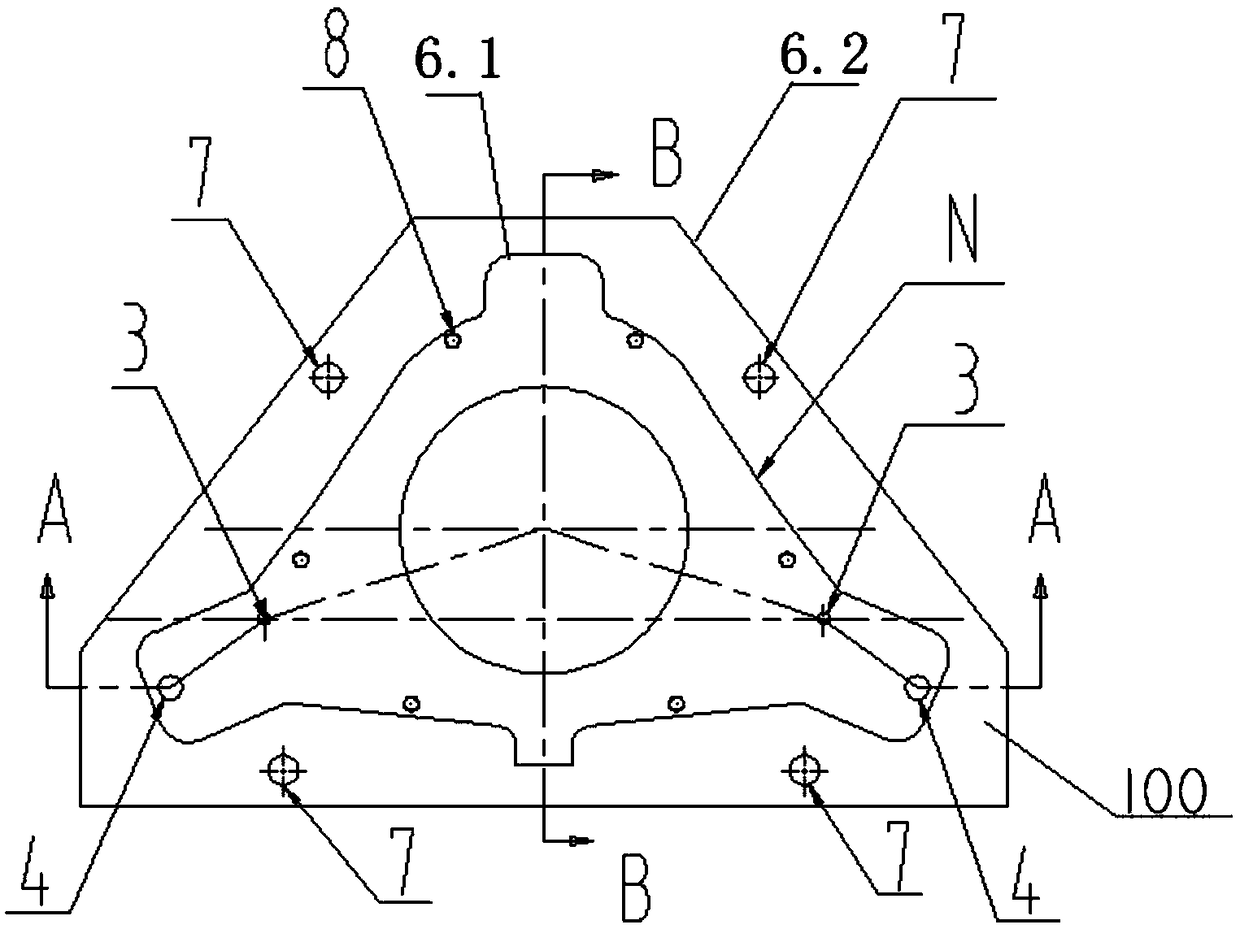

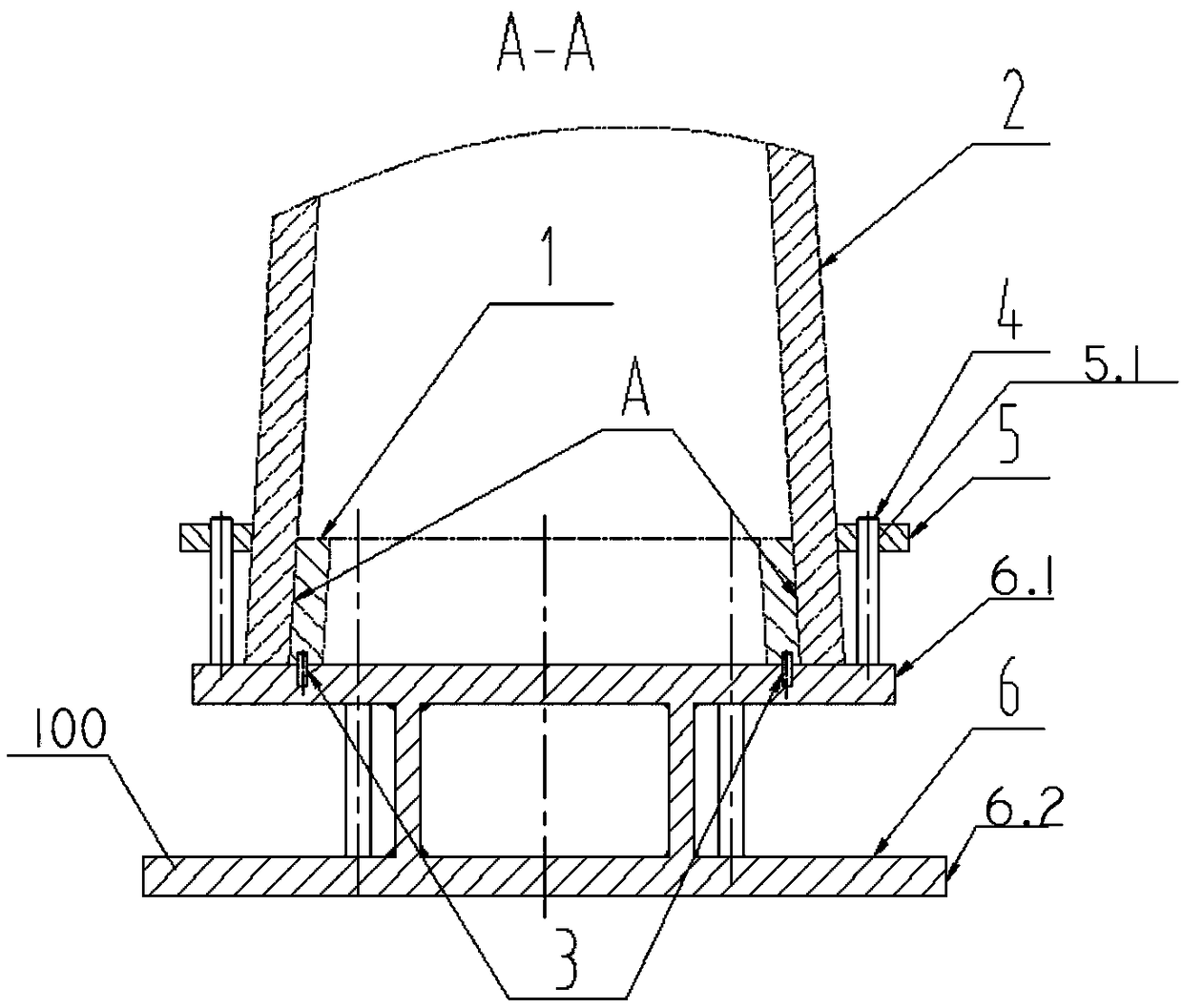

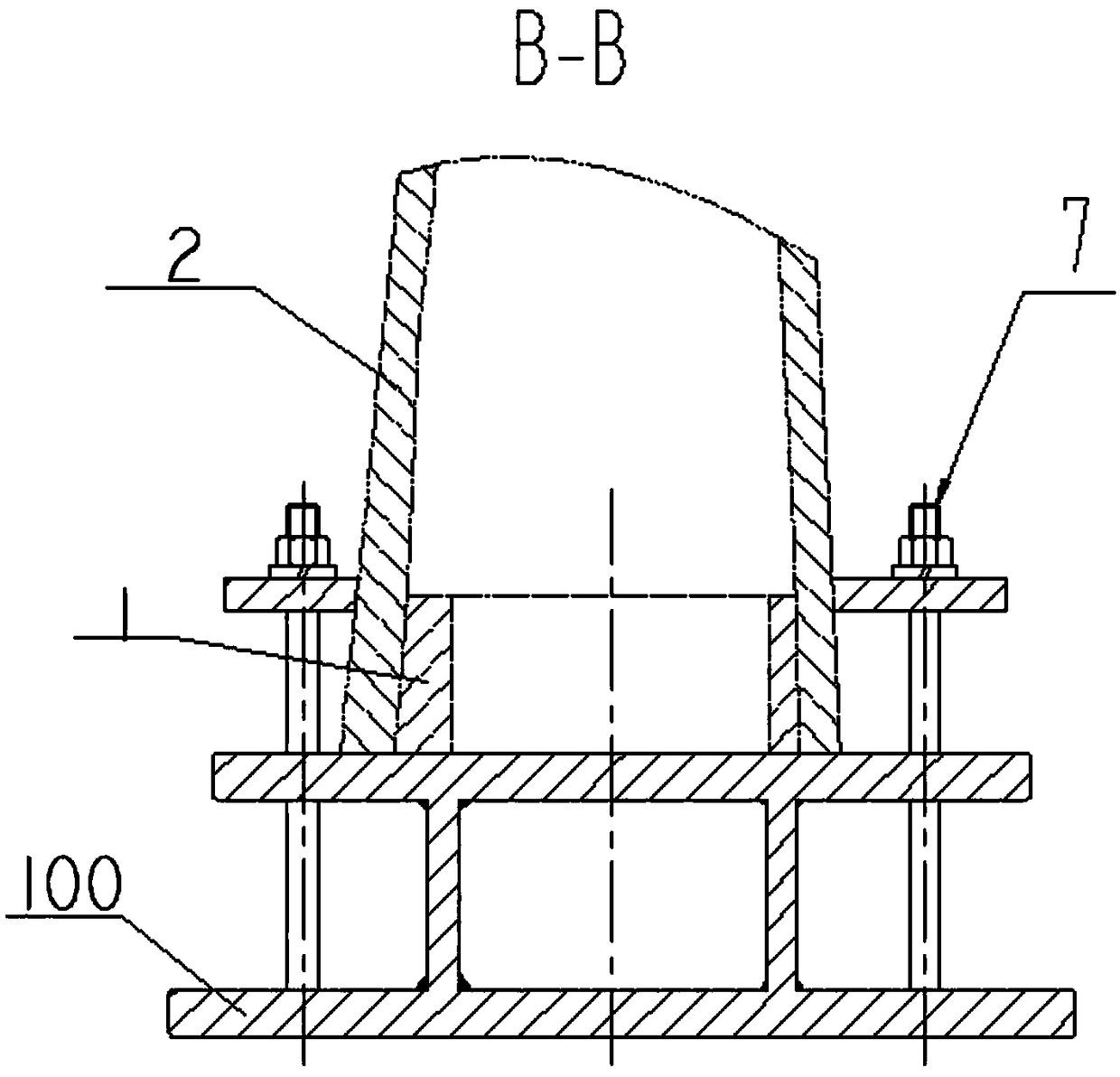

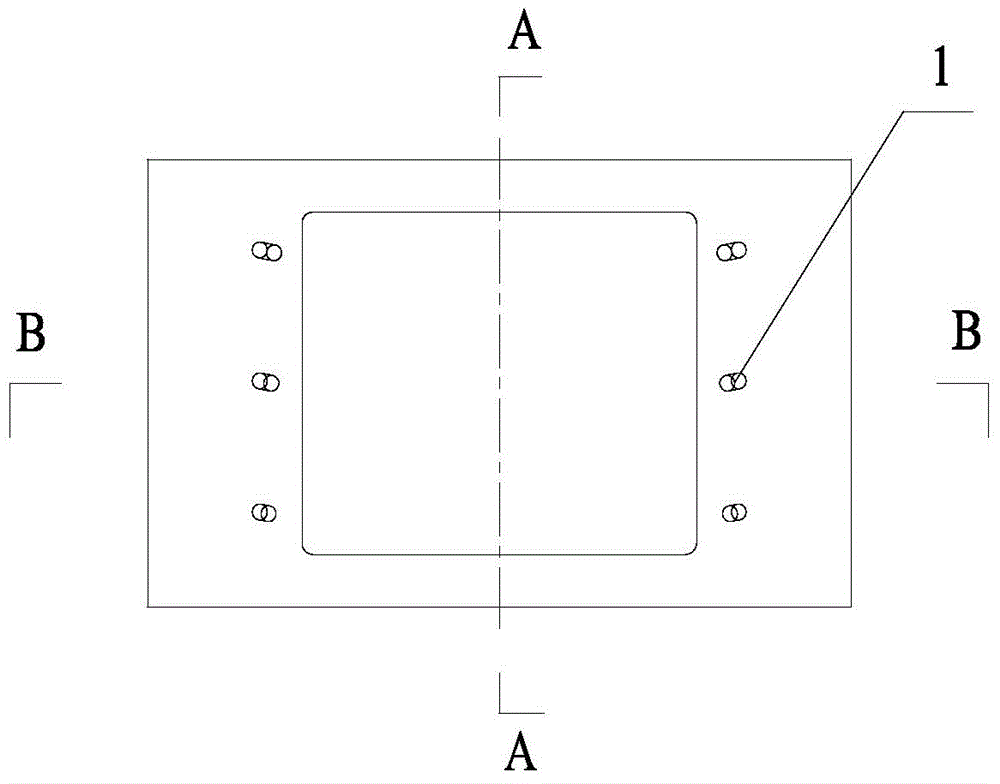

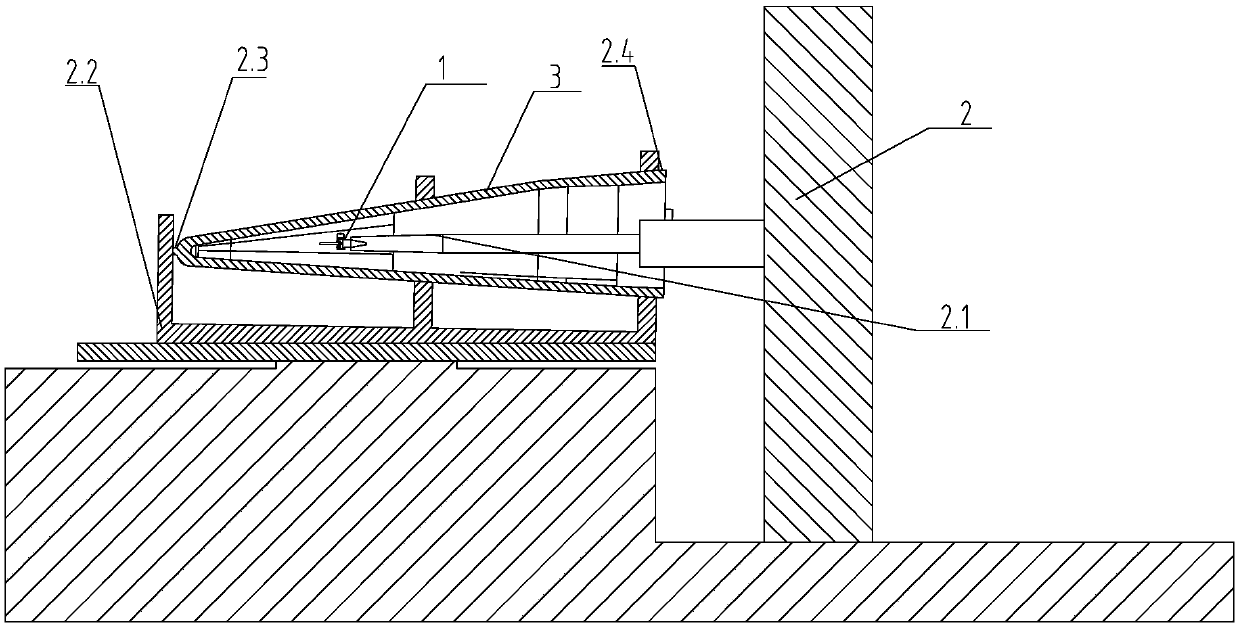

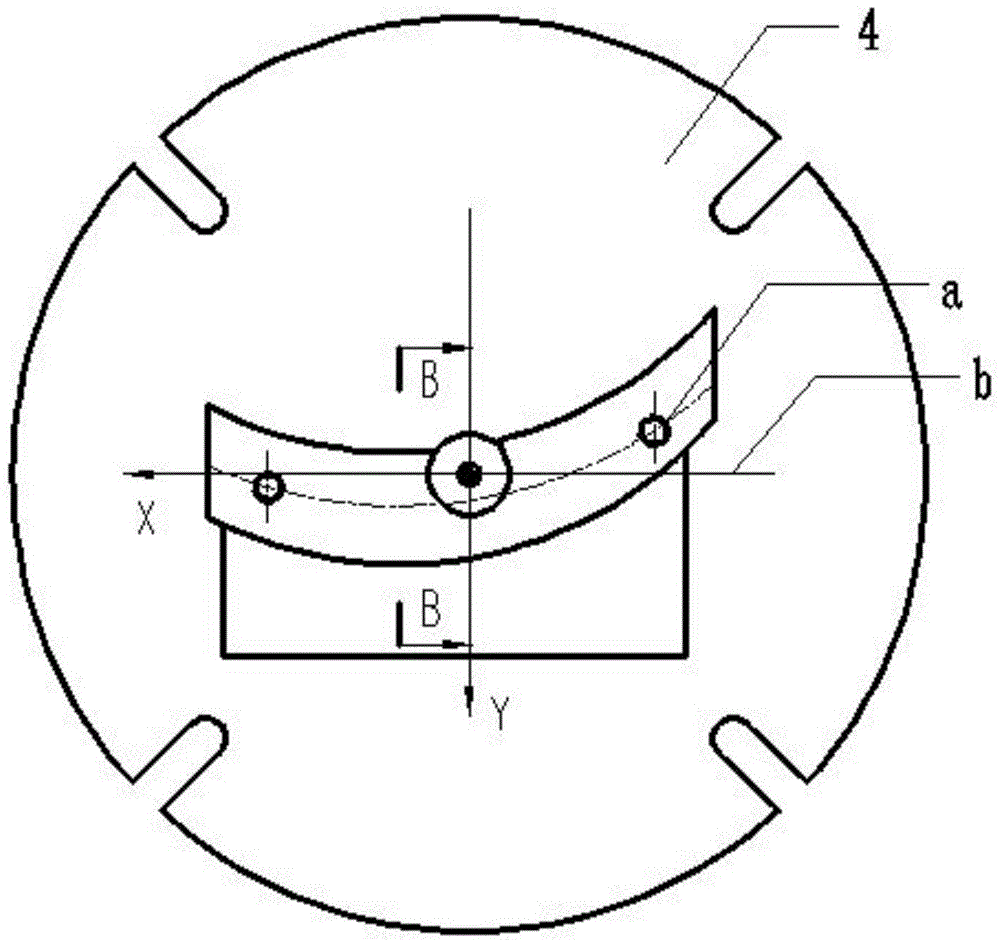

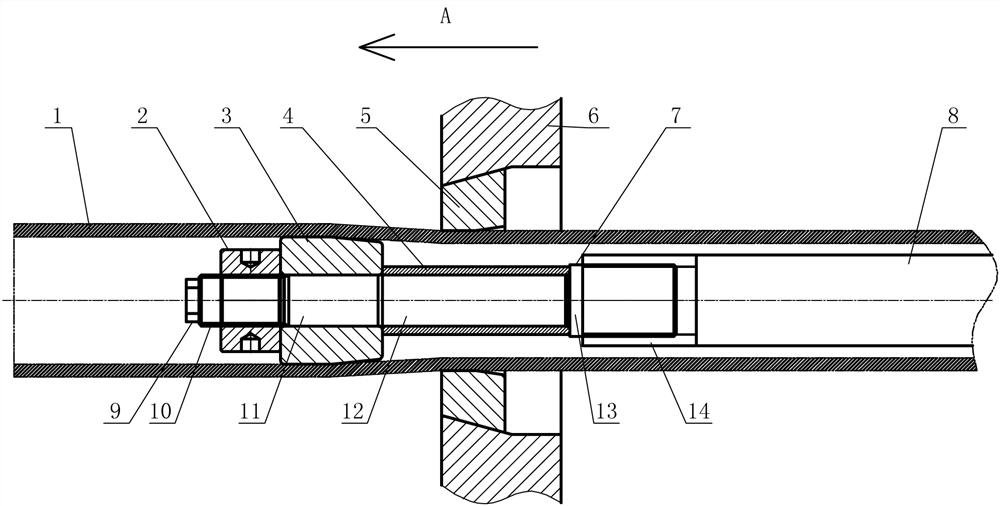

Combined milling method of shell body of bearing ball socket swing nozzle and fixture thereof

ActiveCN103252619AUniform spherical clearanceReduce scrap ratePositioning apparatusMetal-working holdersEngineeringFlange

The invention discloses a combined milling method of a shell body of a bearing ball socket swing nozzle and a fixture of the shell body of the bearing ball socket swing nozzle. The milling method comprises the following steps: mounting and machining a fixed nozzle shell body, machining a movable nozzle shell body in a matching mode, carrying out combined milling, and carrying out machining to remove the locating boss at the lower end of the blank of the movable nozzle shell body. The fixture achieving the milling method comprises a flange bottom plate, a central rod is arranged in the center of the flange bottom plate, a supporting ring is arranged on the lower portion of the central rod in a coaxial and sleeved mode, the bottom portion of the supporting ring is fixedly connected with the flange bottom plate, a flange used for placing the blank of the movable nozzle shell body is arranged on the inner wall of the top portion of the supporting ring, and a movable pressing plate used for pressing the blank of the movable nozzle shell body is arranged on the upper portion of the central rod in a sleeved mode. The bearing ball socket swing nozzles manufactured through the combined milling method and the fixture pass through the checking of multiple times ground tests, product quality completely meet design requirements. The combined milling method of the shell body of the bearing ball socket swing nozzle and the fixture can not only be used for processing the shell body of the bearing ball socket swing nozzle, but also be used for processing control of other similar combination products.

Owner:湖北三江航天江北机械工程有限公司

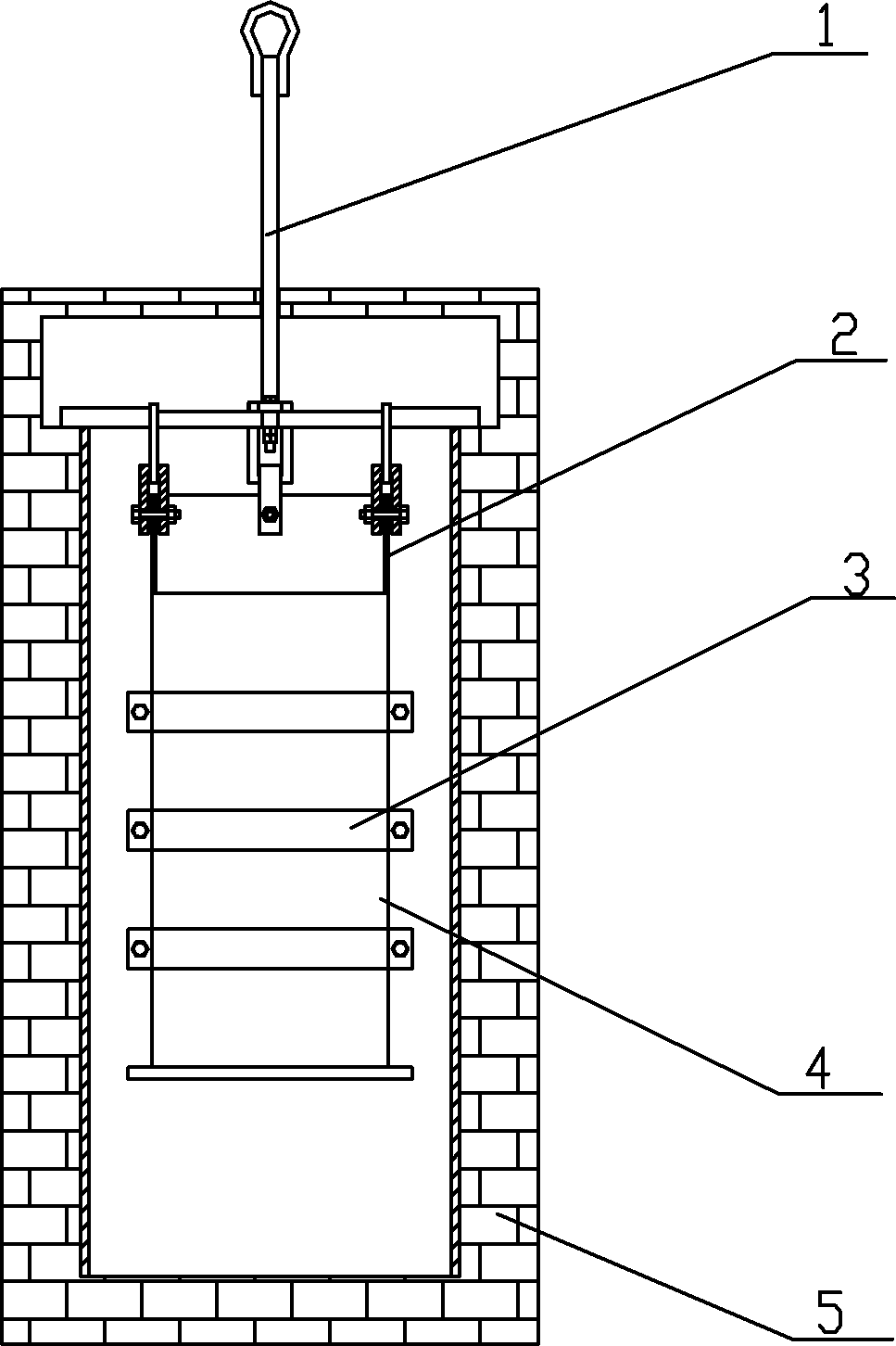

Construction method of ballastless tracks of tunnel group of heavy haul railway

ActiveCN110541329AAdvanced technologyHigh precisionBallastwayRailway track constructionRailway tunnelRebar

The invention relates to a construction technology of a heavy haul railway, specifically relates to a construction method of ballastless tracks of a tunnel group of a heavy haul railway. According tothe characteristics of high requirement on the construction precision of a ballastless track bed and difficulty in control in the construction of the ballastless tracks, the principle of near laying and convenience in precision control is adopted; a double-block sleeper is hung and placed to a position to be laid near a construction track bed plate; after key processes of steel bar binding, trackpanel assembly, comprehensive grounding, track coarse adjustment and the like are carried out, the geometric dimension of the tracks is finely adjusted by using a track inspection trolley measuring system, so that the design precision requirement is met, and finally, the track bed concrete is poured for one-step forming. The technology has the characteristics of being simple and convenient to operate, safe, practical, accurate in track geometric dimension, quick to position and the like.

Owner:CHINA RAILWAY SIXTH GROUP +2

Method for assembling special-shaped curved radome cover body and connecting ring

ActiveCN108994360ARealize the assemblySolving Assembly ChallengesMaterial gluingMilling equipment detailsAdhesiveEngineering

The invention discloses a method for assembling a special-shaped curved radome cover body and a connecting ring. The method comprises the following steps: 1) matching the connecting ring with a milling: fixing the connecting ring on an assembly fixture and positioning, matching a milling according to the actual size of the inner curved surface of the cover body, and machining the outer curved surface of the connecting ring, in which the cover body and the connecting ring are subjected to trial assembly until the outer curved surface of the connecting ring meets the fit clearance requirements;2) radome assembly: uniformly brushing and applying an adhesive onto the assembly surface of the outer curved surface of the connecting ring and the inner curved surface of the cover body, lifting thecover body with a cover body spreader, aligning an open end of the cover body with the connecting ring, slowly loading the cover body onto the connecting ring, and then fixing the cover body and positioning to fit the cover body in place. By adopting the method, not only is the assembly precision of the cover body and the connecting ring is ensured, but also the difficulty of matching milling andmachining on the assembly surface of the cover body and the connecting ring is reduced.

Owner:湖北三江航天江北机械工程有限公司

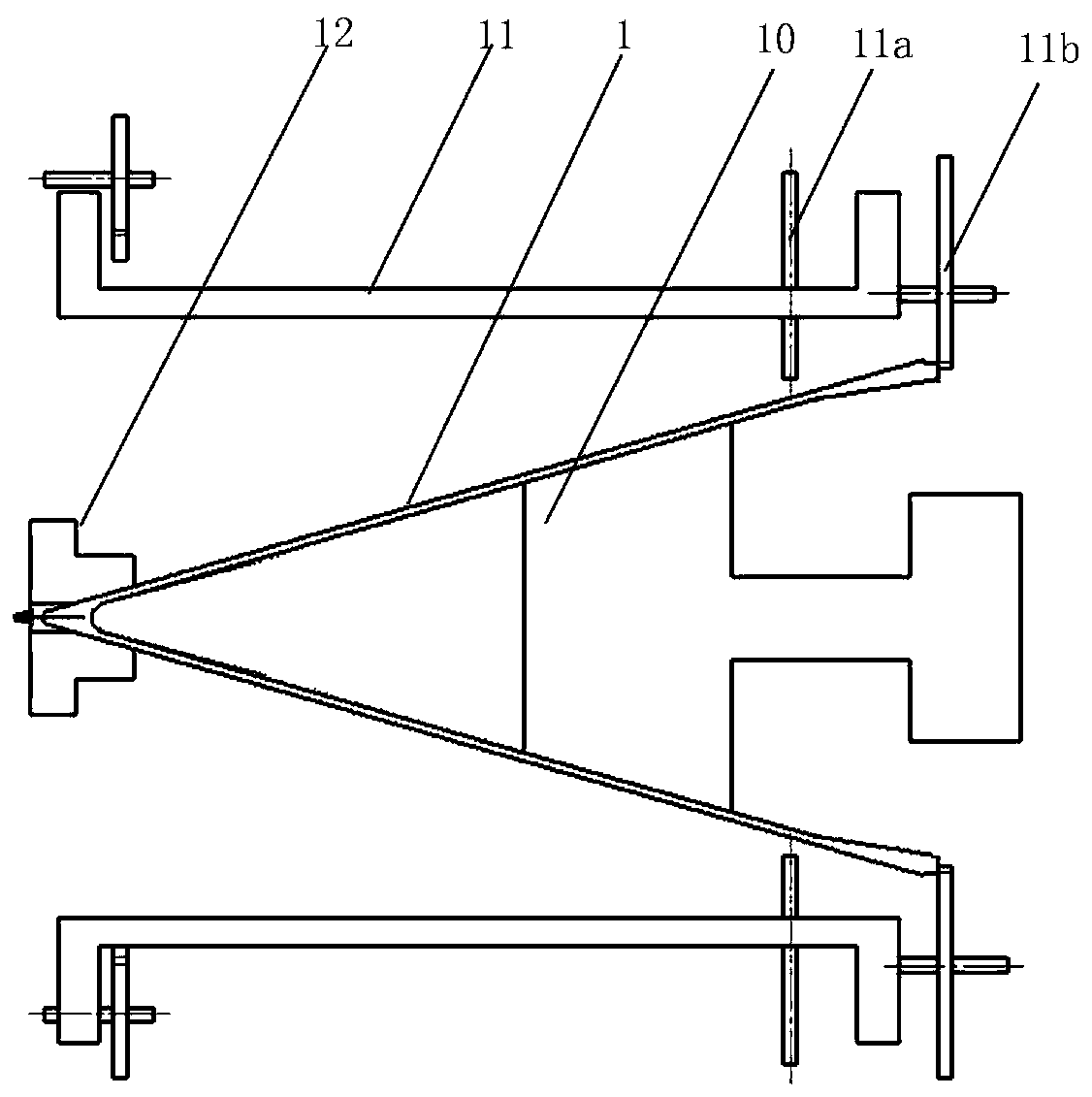

Method for processing three dimensional spatial structure assembly hole of antenna housing through special drilling rig

The invention discloses a method for processing a three dimensional spatial structure assembly hole of an antenna housing through a special drilling rig. The method for processing the three dimensional spatial structure assembly hole of the antenna housing through the special drilling rig includes that milling an outer conical molded surface, an inner conical molded surface and false bosses in sequence, wherein the angle between the outer lateral surfaces of the false bosses at the two sides is equal to the angle between the central lines of two rows of pre-processing assembly holes of the special drilling rig. The processing for the three dimensional spatial structure assembly hole of the antenna housing through the special drilling rig is realized through the false bosses, the processing difficulty is lowered, the production efficiency is improved, and the precision of the assembly hole is guaranteed; the assembly hole processing precision is high, and the product design precision requirement is completely satisfied.

Owner:湖北三江航天江北机械工程有限公司

Drilling bit assembly, drilling device and drilling method

InactiveCN107971511AAvoids the problem of not being able to fit in existing through-holesRealize steering punchingBoring/drilling componentsBoring/drilling machinesDrill bitPetroleum engineering

The invention provides a drilling bit assembly, a drilling device and a drilling method and belongs to the technical field of processing. The drilling bit assembly comprises a drill bit, a drill rod,a transmission part and an installing part. The drill bit is fixedly connected with the installing part and is installed on the drill rod through the installing part. The drill bit is perpendicular tothe axis of the drill rod. The transmission part is used for enabling the installing part to rotate. According to the drilling bit assembly provided by the embodiment of the invention, the drill bitis perpendicular to the axial direction of the drill rod and is installed on a rotary head, and the extending direction of the drill rod is changed. When drilling is conducted in an existing hole, thedrill rod can extend into the existing hole in the axial direction of the existing hole, the installing part is driven by the transmission part to rotate, thus the drill bit is driven to drill in thedirection perpendicular to the axis of the drill rod, and the problems that the total length of the drill bit, the drill rod and the like is larger than the diameter of the existing hole, the drill bit and the drill rod cannot be installed in the existing through hole in the radial direction of the existing hole, and thus drilling cannot be achieved are solved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Processing method for inner ring arc section of guide vane

ActiveCN102672416AReduce distortionGuaranteed machining accuracyPositioning apparatusMetal-working holdersComputer engineeringGas compressor

The invention relates to a processing method for an inner arc section, in particular to a processing method for an inner ring arc section of a guide vane of a gas compressor unit, and aims to solve the problem of low processing precision in the existing processing method for the inner ring arc section of the guide vane of the gas compressor unit. The processing method mainly includes: step one, rough-turning the inner hole, the outer circle, the front and the rear end surfaces of the inner ring arc section; step two, relieving stress of the inner ring arc section after the rough turning; step three, finish-turning the inner hole, the outer circle, the front and the rear end surfaces of the inner ring arc section; step four, cutting and fixing each arc section; step five, scribing and drilling threading holes; and step six, performing cutting process on shroud holes of each arc section. The processing method is applied to the process of the inner ring arc section of the guide vane of the gas compressor unit.

Owner:HARBIN TURBINE

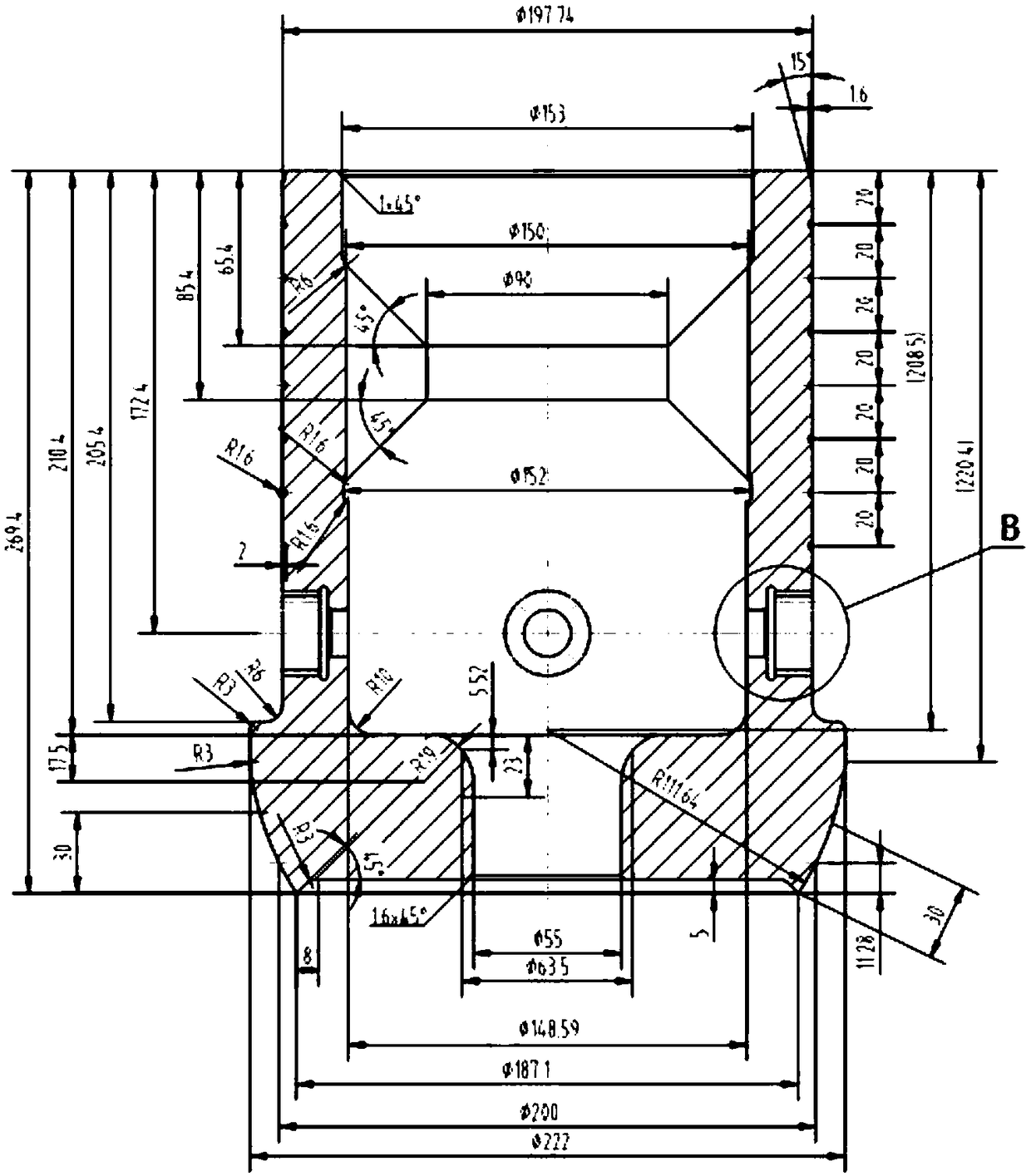

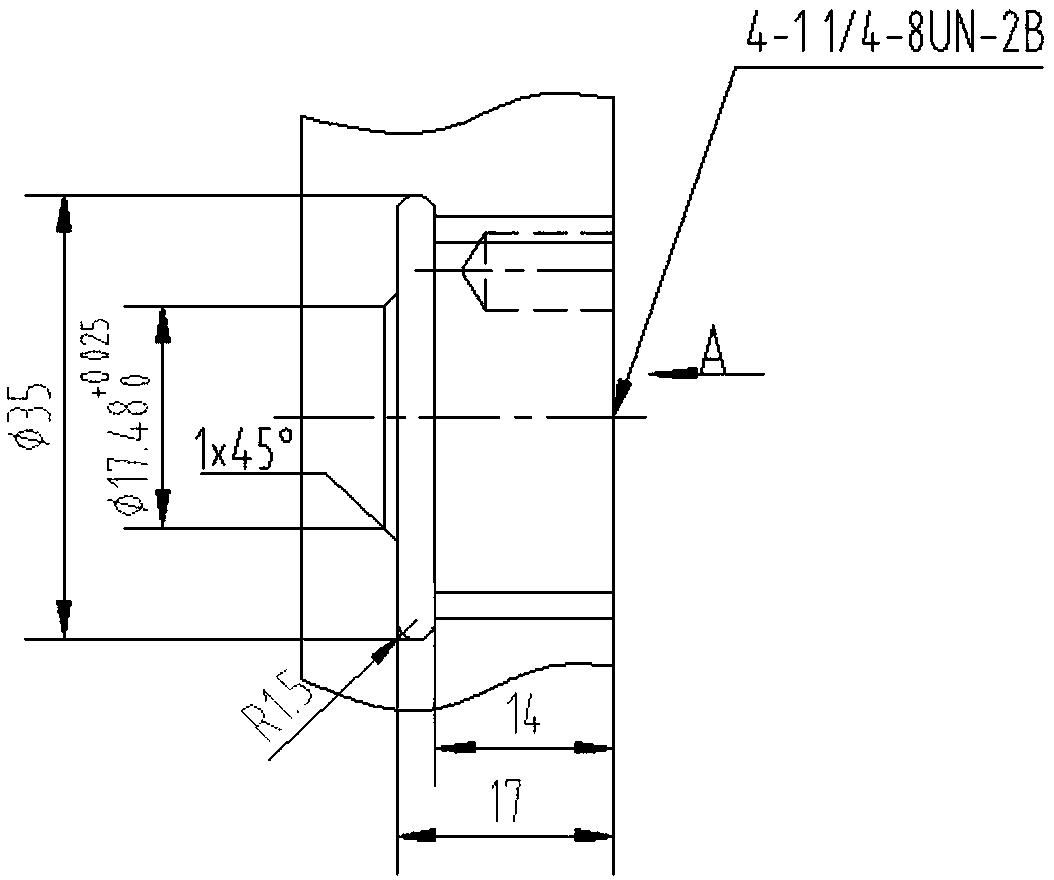

Machining method for valve disc of regulating valve

The invention discloses a machining method for a valve disc of a regulating valve and relates to a machining method for a valve disc of a regulating valve. The problem that the quality of valve discsof regulating valves is poor through existing processes is solved. The method comprises the steps that firstly, a blank is forged; secondly, an inner hole and an outer circle are turned roughly; thirdly, tempering stress relief treatment is conducted; fourthly, all parts of a machined part subjected to heat treatment is turned finely; fifthly, a groove is machined; sixthly, drilling is conducted;seventhly, tinning is conducted; eighthly, a quasi-inner hole and a quasi-outer circle are turned; ninthly, nitriding treatment is conducted; and tenthly, a quasi 4-11 / 4-8 UN screw hole is drilled bya bench worker, a quasi phi 17.48, phi 35 hole is drilled, a 4-phi 6 hole is drilled, and machining of the valve disc of the regulating valve is completed. The method is used for preparing the valve disc of the regulating valve.

Owner:HARBIN TURBINE

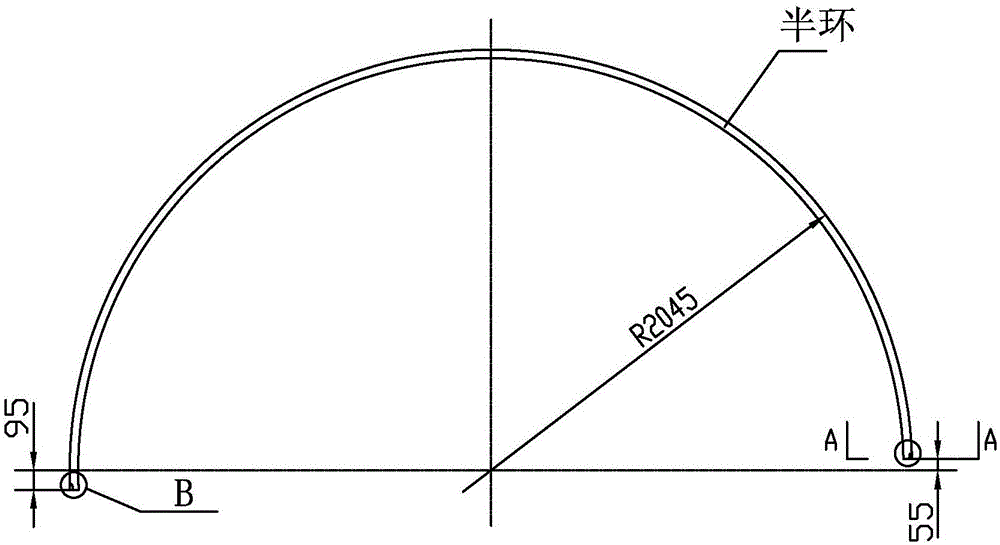

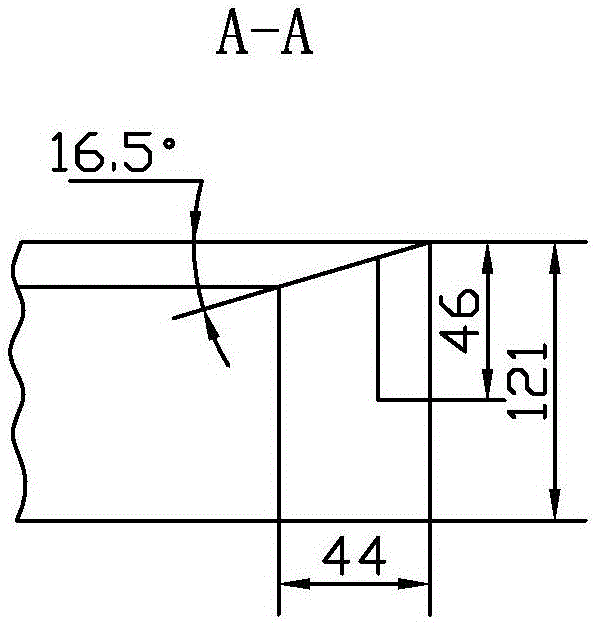

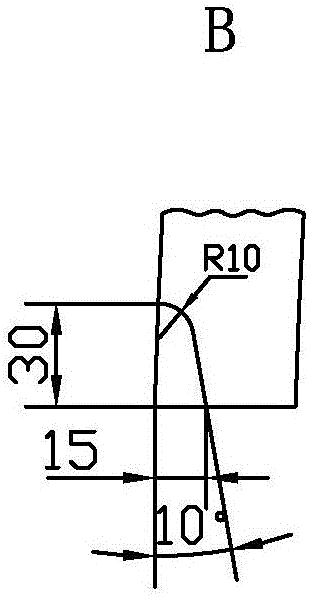

Nuclear power semi-ring machining method

The invention belongs to the field of machining and relates to a machining method, in particular to a nuclear power semi-ring machining method. The problems that according to an existing technological scheme, the machining precision of a nuclear power semi-ring cannot be guaranteed, the working difficulty is increased for subsequent welding, and the welding quality is lowered are solved. The machining method specifically comprises the steps that firstly, a semi-ring blank is formed through casting; secondly, the surface of the semi-ring is turned by 121 mm on a vertical lathe, and the two planes are turned to 122 mm; thirdly, an inner hole, the outer circle line and two end face lines are marked on the semi-ring, and a line is marked in the position 55 mm away from the right side according to the dimension of 95 mm; fourthly, the two end faces of the semi-ring are milled on a boring mill, and the two end faces of the semi-ring are machined according to the dimension of 95mm; fifthly, the standard inner hole of the semi-ring is turned on the vertical lathe, and the volume of the outer circle is 3-5 mm; sixthly, tie bars are welded to the semi-ring in a matched mode by a bench worker; and seventhly, the tie bars are welded through electric welding.

Owner:HARBIN TURBINE

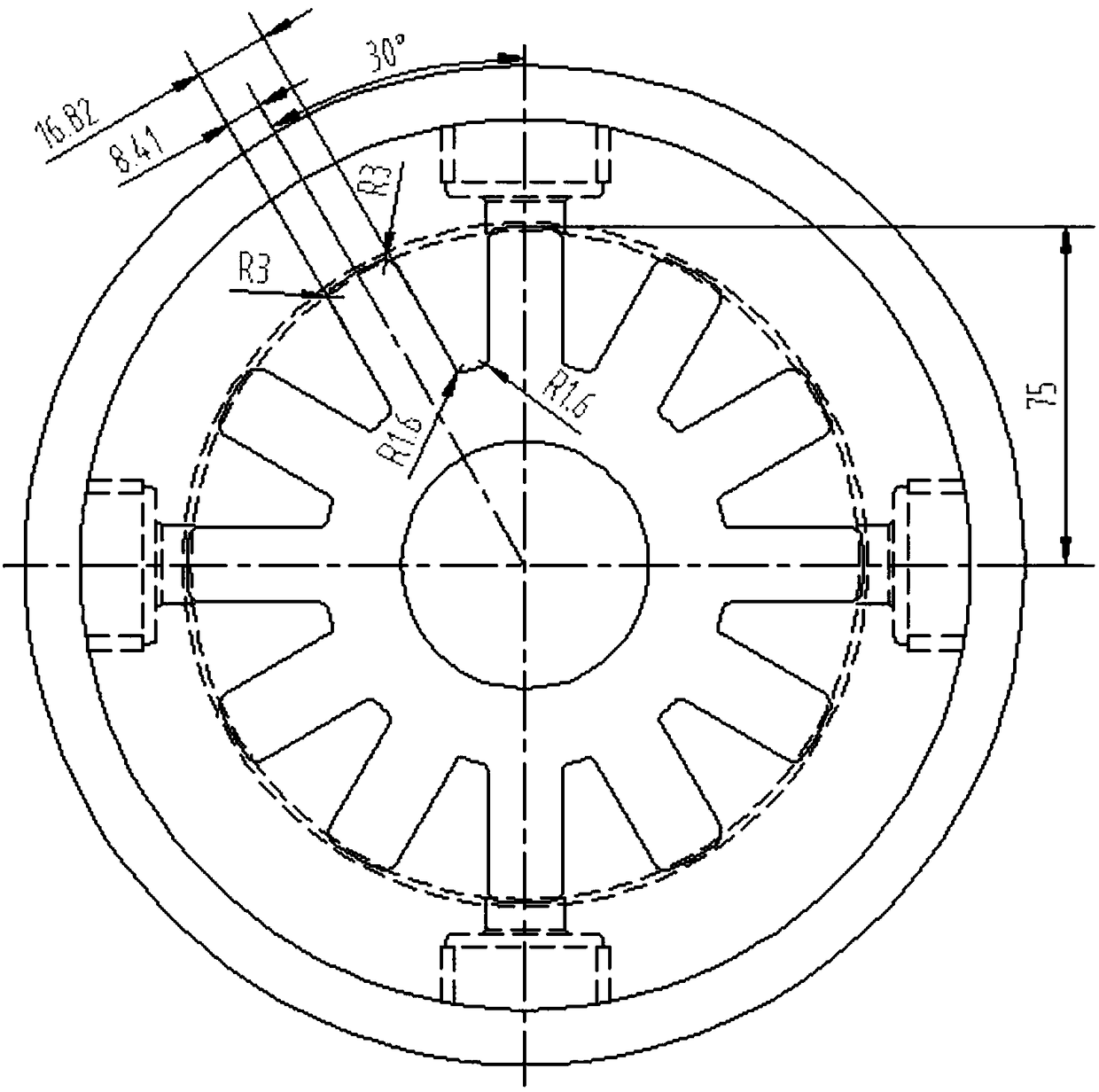

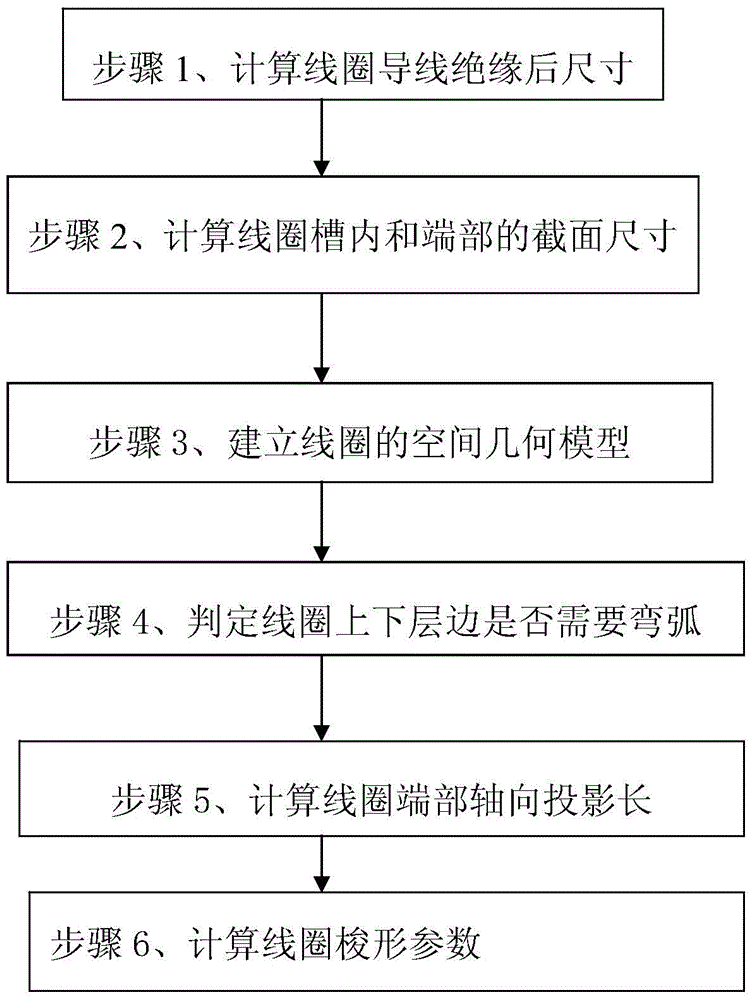

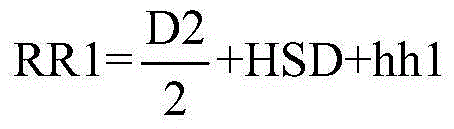

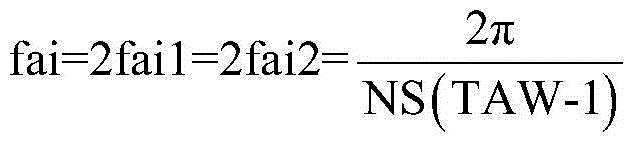

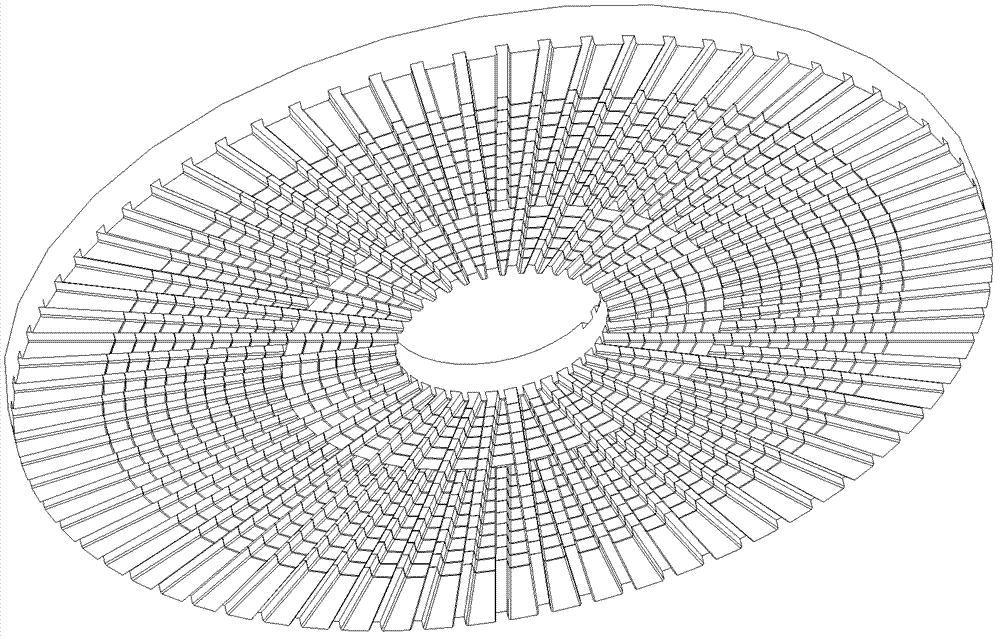

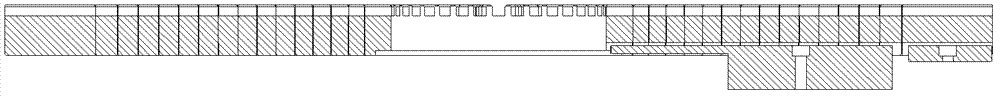

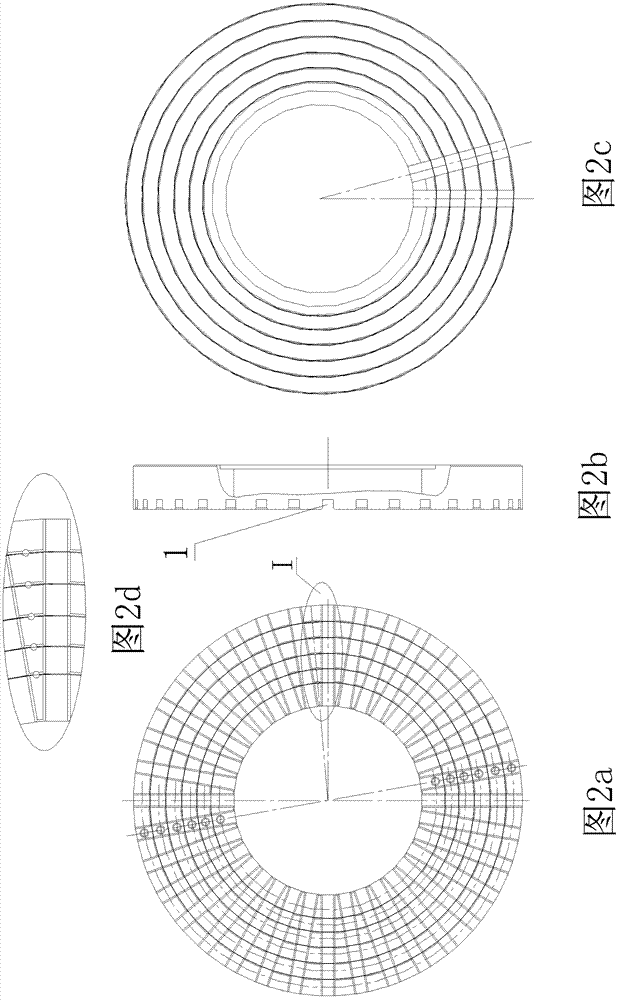

Method for calculating alternating-current motor stator winding coil parameters

ActiveCN104965948AGuaranteed clearanceGuaranteed upSpecial data processing applicationsWire gaugeEngineering

The invention relates to a method for calculating alternating-current motor stator winding coil parameters. The method comprises the following steps of: step 1, calculating the size of an insulated coil wire; step 2, calculating the section size of the end part and the interior of a coil groove and verifying residual space in the groove; step 2, calculating the section size of the end part and the interior of a coil groove and verifying residual space in the groove; step 3, creating a space geometric model of a coil; step 4, judging whether upper and lower edges of the coil need to be subjected to arc bending; step 5, calculating the axial projection length of the end part of the coil, the arc length of the bevel edge of the end part of the coil, the length of a central line of a straight-line part of the coil, the center distance of bent arcs at two ends of the straight-line part of the coil, and the mean turn of the coil; and step 6, calculating shuttle-shaped parameters of the coil. During coil section calculation, the situation of parallel winding of different wire gauges is considered, so that the design scheme of different winding wire gauges can be satisfied; and the space geometric model is adopted, so that pure formulation of a calculation process is realized, computer programming realization is convenient, and the consumption of winding wires is reduced.

Owner:XIANGTAN ELECTRIC MFG CORP LTD

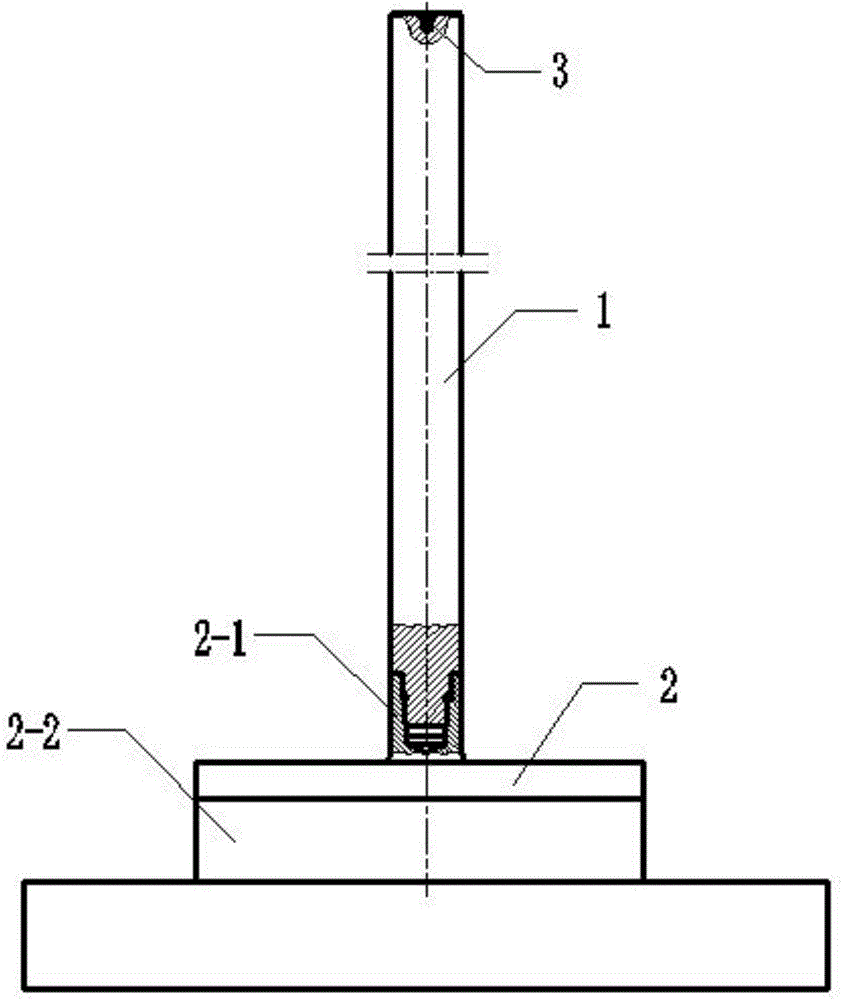

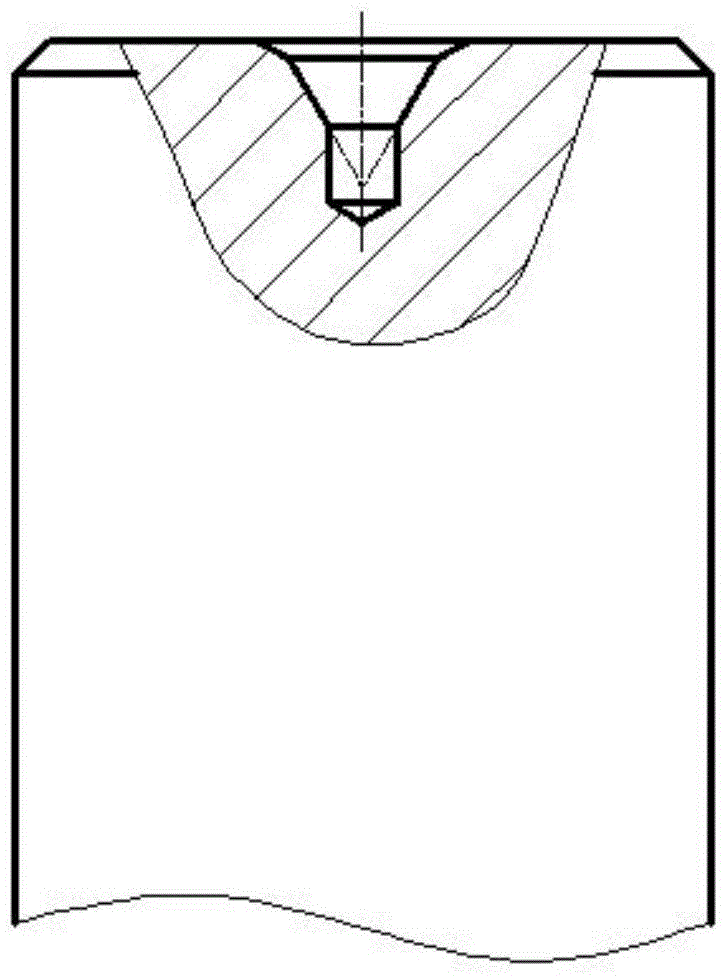

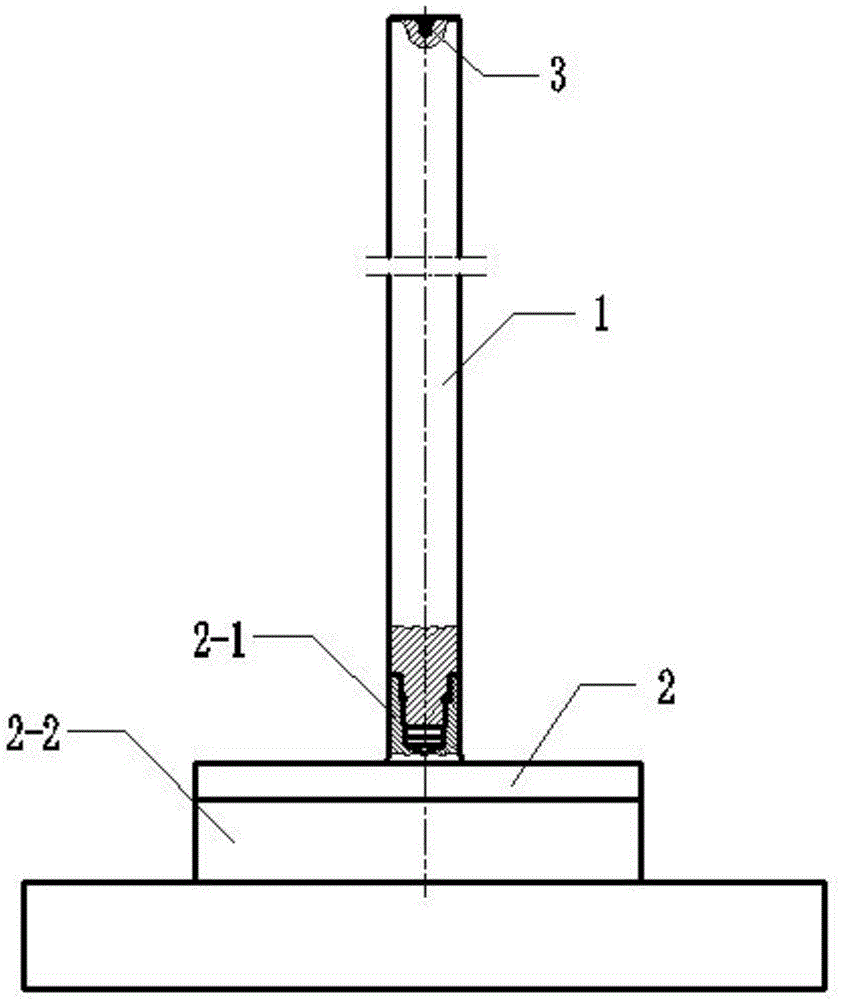

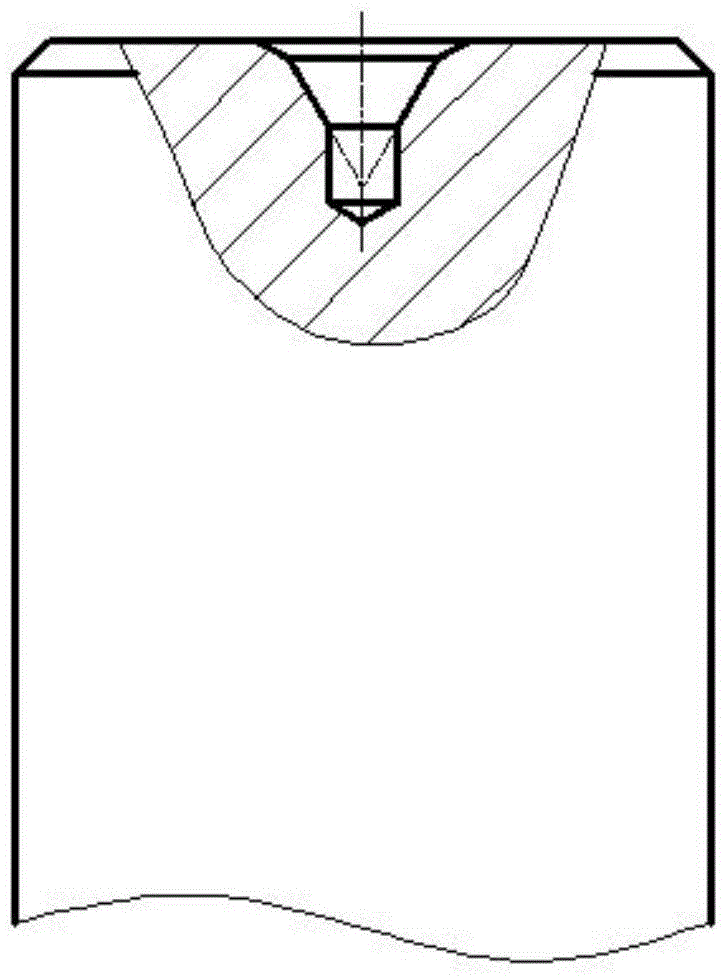

Deep blind hole housing body rapid measurement device and measurement and compensation machining methods

ActiveCN107914185AImprove machining accuracyMeet design accuracy requirementsMeasurement/indication equipmentsOther manufacturing equipments/toolsMeasurement deviceMachine tool control

The invention discloses a deep blind hole housing body rapid measurement device and measurement and compensation machining methods. The device comprises a base, wherein the base is arranged to be coaxial with a machine tool main shaft. The rear end of the base is embedded into the machine tool main shaft. The front end of the base is provided with a mounting cover. A cavity structure is formed bythe mounting cover at the front end of the base. An electric conduction plate is arranged at the front end of an inner cavity of the mounting cover. The middle of the mounting cover and the middle ofthe electric conduction plate are each provided with a through hole, wherein the through holes allow a probe to penetrate. The rear end of the probe penetrates the mounting cover and the electric conduction plate and extends into a moving plate, wherein the moving plate is mounted in the inner cavity of the mounting cover. The front end face of the moving plate is attached to the rear end face ofthe electric conduction plate. The rear end of the moving plate is provided with a spring. A spring locating table is arranged in the middle of the base. One end of the spring is connected with the rear end of the moving plate, and the other end of the spring is connected with the spring locating table. The electric conduction plate and the moving plate are in series connection with a diode through wires. The output end of the diode is connected with a machine tool control circuit. According to the deep blind hole housing body rapid measurement device and the measurement and compensation machining methods, rapid measurement of a housing body is achieved through a photoelectric measurement device; and the compensation machining method is achieved through post-processing of measurement data.

Owner:湖北三江航天江北机械工程有限公司

Fuel measurement sensor layout optimization method for aircraft fuel tank

ActiveCN108595792AOptimize layoutMeet design accuracy requirementsDesign optimisation/simulationConstraint-based CADFuel tankAirplane

The invention discloses a fuel measurement sensor layout optimization method for an aircraft fuel tank. The method comprises the steps of generating an initialized arrangement region of the fuel tank;dividing different fuel surface attitude angles; screening out sensor installation wire sets meeting bottom and top non-measurable fuel capacity constraints under the different fuel surface attitudeangles; combining the sensor installation wire sets accordingly, and arranging the combined sensor installation wire sets according to the quantities from small to large, thereby obtaining different quantities of sensor installation wire combinations; and traversing different sensor installation wire combinations, performing continuity judgment and attitude error judgment on the sensor installation wire combinations, and selecting the minimal quantity of the sensor installation wire combinations meeting continuity constraints and attitude error constraints as a fuel capacity sensor layout optimization result. According to the method, an optimal sensor layout can be obtained on the basis of meeting design precision requirements; and meanwhile, sensors arranged by designers can be subjectedto design precision verification, thereby ensuring the sensors to meet the design requirements.

Owner:XI AN JIAOTONG UNIV

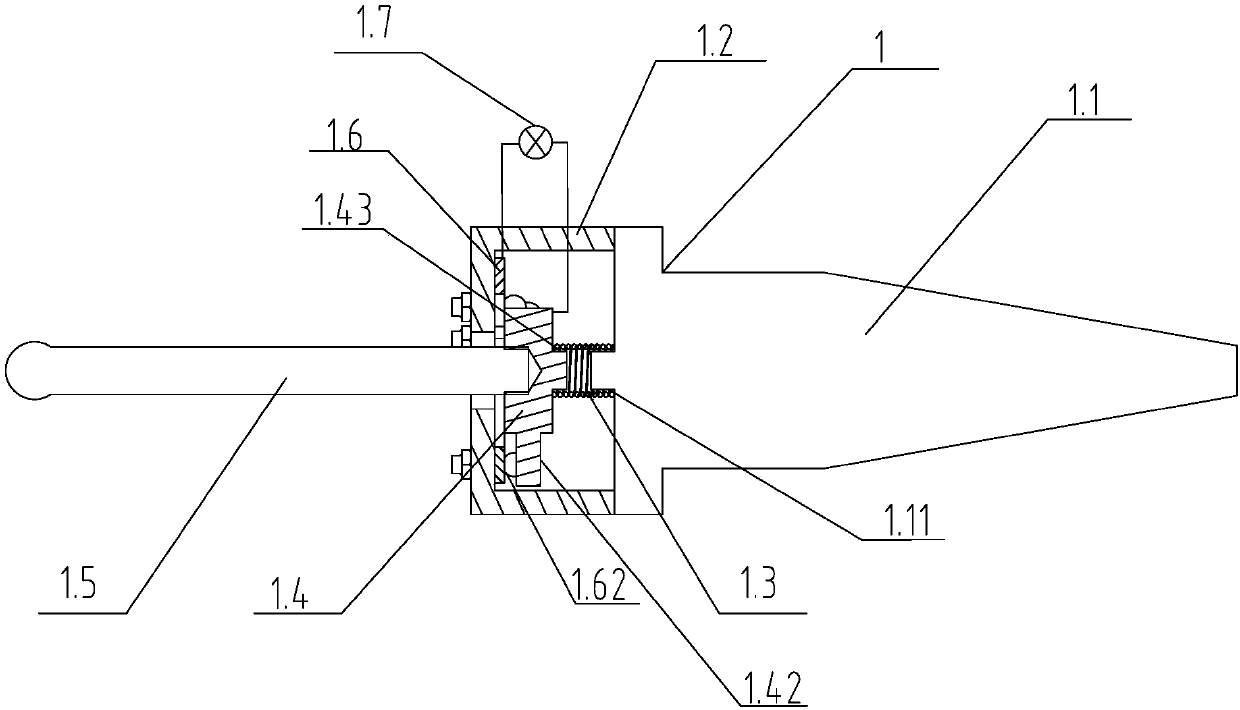

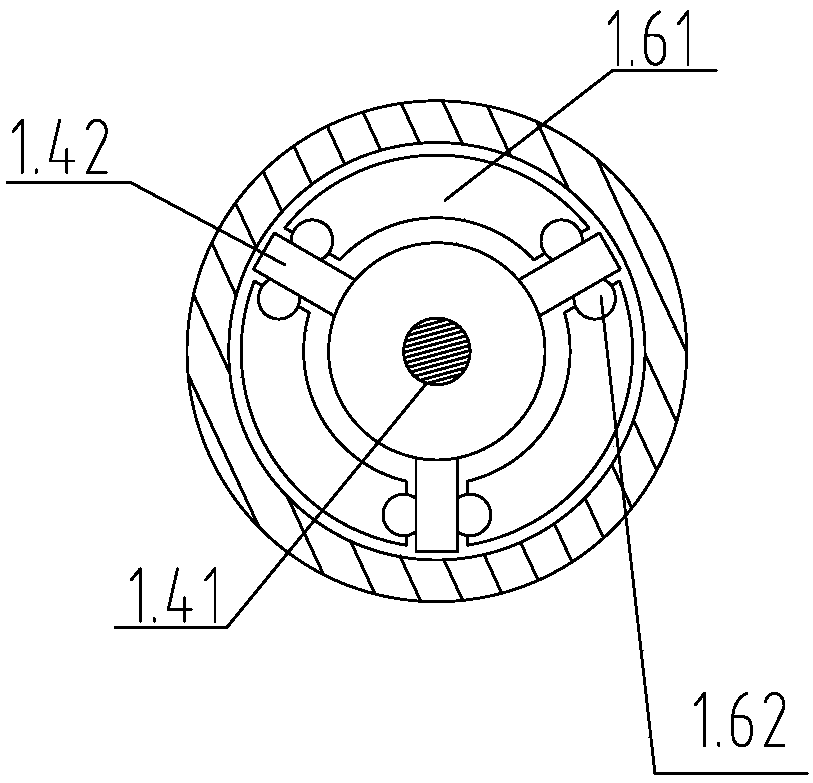

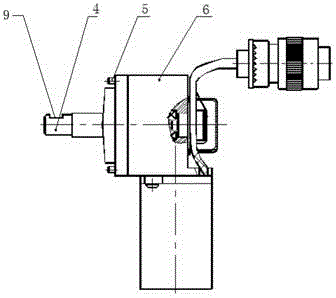

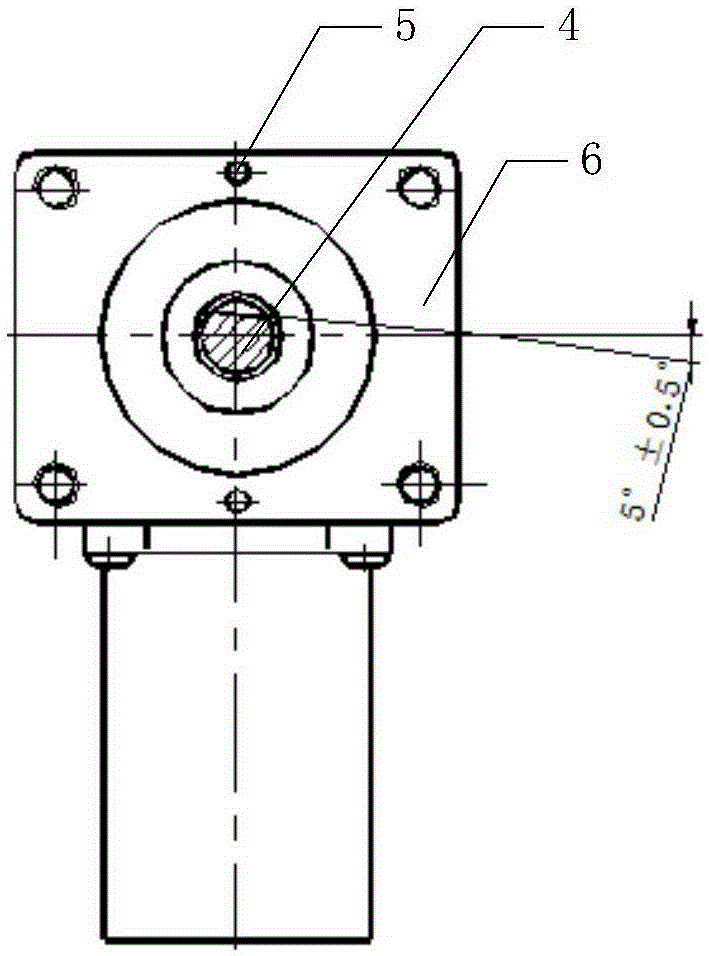

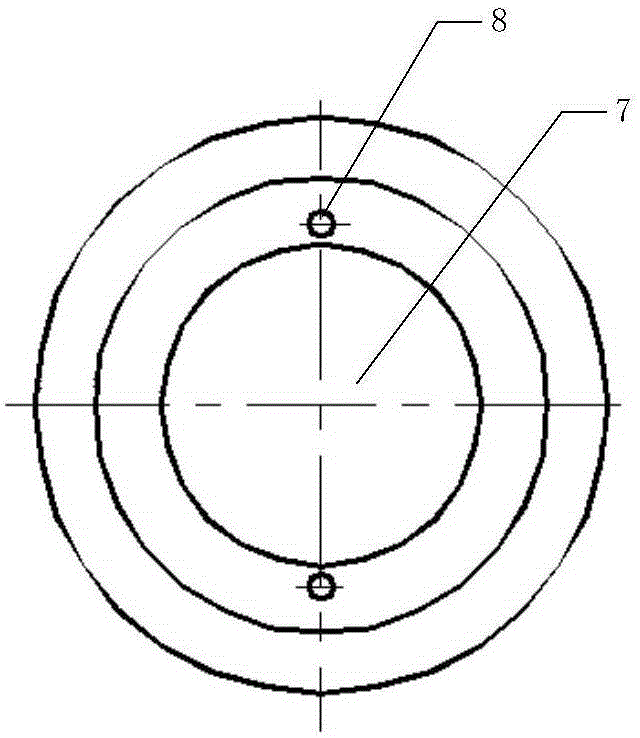

Adjustment detection device for initial position of small-stress-plane output shaft of steering engine

InactiveCN106610255ASolve precise positioningEasy to operateMechanical measuring arrangementsControl theoryMeasurement precision

The invention relates to an adjustment detection device for the initial position of a small-stress-plane output shaft of a steering engine, and belongs to the technical field of steering engine control. The device comprises a reference calibration disc 1, a prolonged pointer 2, and a self-screwing bolt 3. The position of the reference calibration disc 1 is achieved through two pins 5 of the steering engine, and the reference calibration disc 1 is disposed on the steering engine. When a stress plane 9 of the output shaft of the steering engine is sleeved by a central rectangular through hole of the prolonged pointer 2, the upper plane of the central rectangular through hole of the prolonged pointer 2 is enabled to be attached to the stress plane 9 of the output shaft of the steering engine, and the self-screwing bolt 3 is screwed, thereby enabling the output shaft 4 of the steering engine and the prolonged pointer 2 to be integrated into one body, and loading a small voltage to enable the output shaft 4 of the steering engine to slowly rotate to a required position. The device provided by the invention solves a problem that the small-stress-plane of an electric steering engine needs to be located precisely, is simple in operation, is convenient to use, and greatly improves the work efficiency and measurement precision.

Owner:HARBIN JIANCHENG GRP

Driving disc clamp detection measuring tool during machining of steam turbine blades and machining method thereof

ActiveCN104551862ASimple processing methodSave material costMeasurement/indication equipmentsSteam turbine bladeMachining time

The invention relates to a measuring tool and a machining method thereof, particularly to a driving disc clamp detection measuring tool during machining of steam turbine blades and a machining method thereof. The driving disc clamp detection measuring tool during machining of the steam turbine blades and the machining method thereof are used for solving the problems of machining difficulty and low working precision of existing central measuring tools. The driving disc clamp detection measuring tool during machining of the steam turbine blades comprises an extension bar and a measuring tool body; the blade root portion at the lower end of the measuring tool body is identical in size and shape to the root of a blade to be simulated; the cylindrical boss of the measuring tool body is provided with a threaded hole, and the extension bar is connected with the cylindrical boss of the measuring tool body through threads. The machining method of the driving disc clamp detection measuring tool during machining of the steam turbine blades comprises, firstly, rough-milling out the measuring tool body and the extension bar, and performing quenched-tempered heat treatment on the measuring tool body and the extension bar; secondly, drilling out the threaded hold inside the cylindrical boss, and turning out the external threads of the extension bar; lastly, preforming finish turning after the measuring tool body and the extension bar are assembled to complete machining of the central measuring tool. According to the driving disc clamp detection measuring tool during machining of the steam turbine blades, the extension bar and the measuring tool body are of an assembly type structure, so that the machining time can be saved, and a locating degree within 0.03 mm can be reached.

Owner:HARBIN TURBINE

Processing method for bed die ferrules

InactiveCN102350621BReduce or eliminate deformation factorsIncrease profitMetal working apparatusEngineeringRoughcast

The invention relates to a processing method for bed die ferrules. The processing method is characterized by comprising the following steps of: grouping all ferrules according to the number of oil tanks, wherein each group of ferrules form one aggregate and each aggregate is processed with one blank; conducting rough processing, semi-refined processing and thermal treatment between the rough processing and semi-refined processing; drilling threading holes for line cutting and completing processing of other hole-shaped elements; conducting quenching thermal treatment; conducting finish processing of end surface of a disc, and carrying out qualitative thermal treatment; and cutting the disc into single pieces with a line cutting method. The processing method has the advantages of eliminating the quenching deformation of single parts, controlling the out-of-roundness of each single part to be within 0.07 and meeting the design precision requirement by adopting a multi-piece integrated processing manner, as well as removing repeatedly complicated processing procedures of single parts, reducing cutting quantity, improving the utilization rate of materials to 70% from original 30%, and further saving a great quantity of raw materials. In addition, the complicated tuning processing can be omitted, local process flows can be adjusted at any time according to change of production fieldconditions so as to be adapted to the needs of modern production.

Owner:天津市进口精密设备新技术发展公司

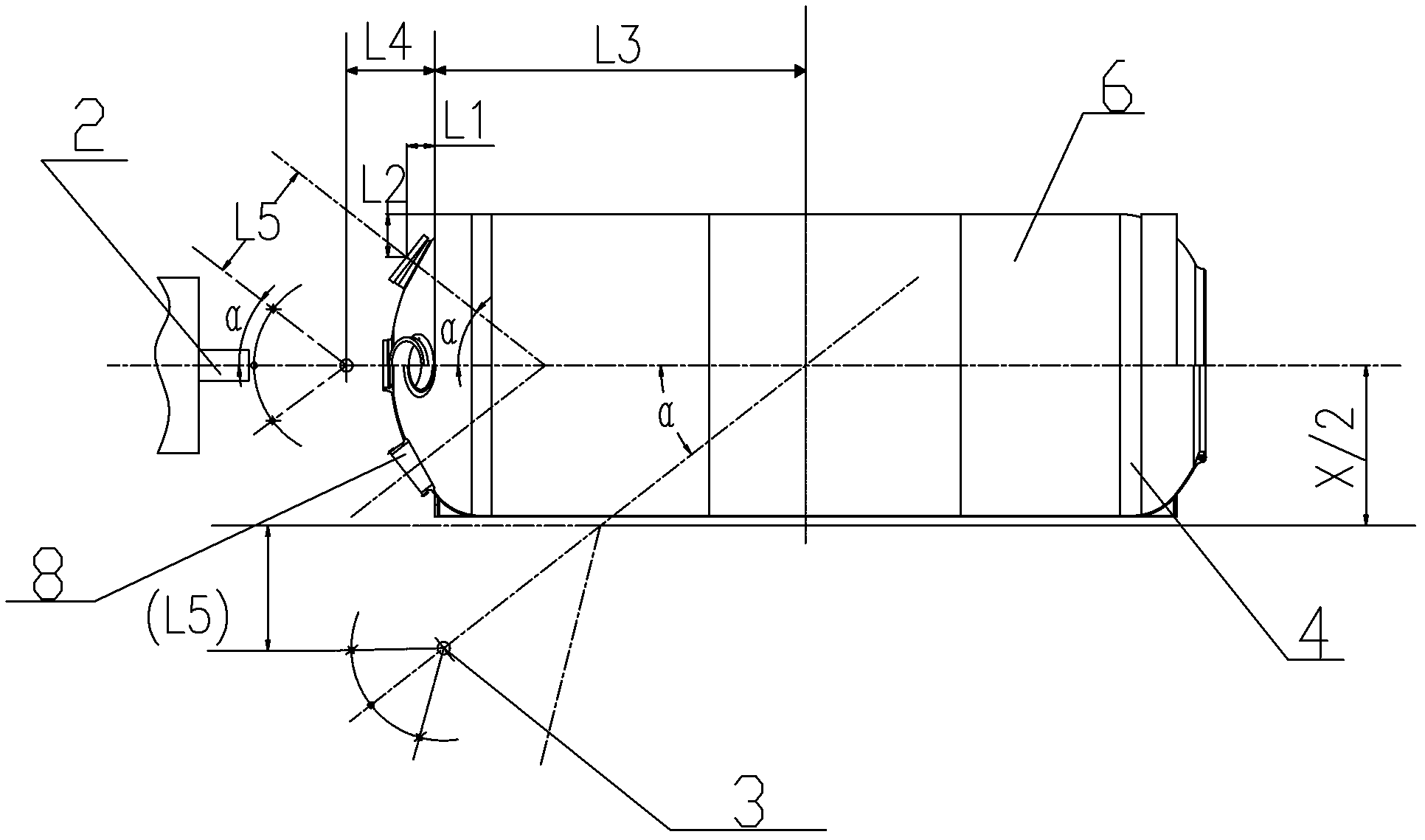

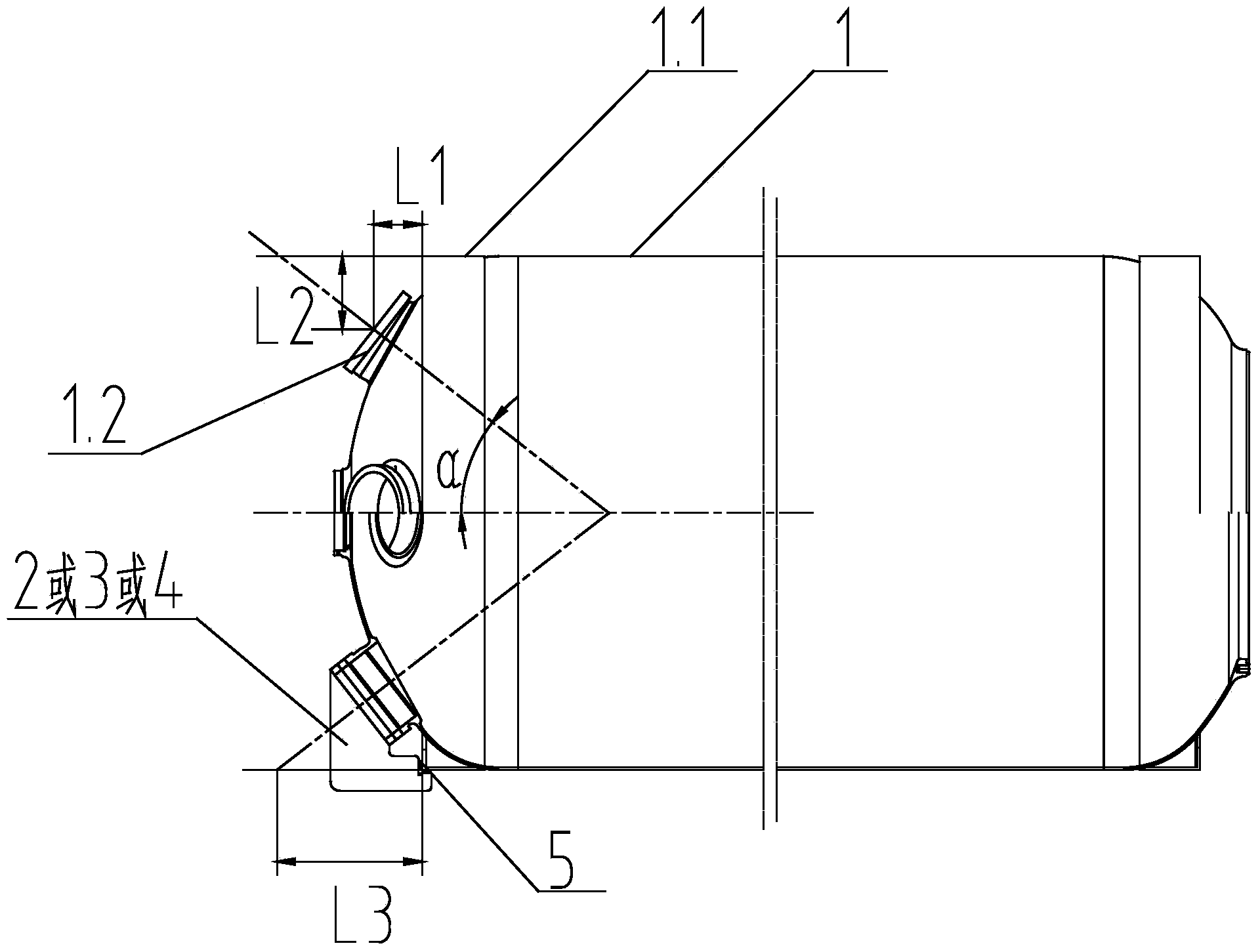

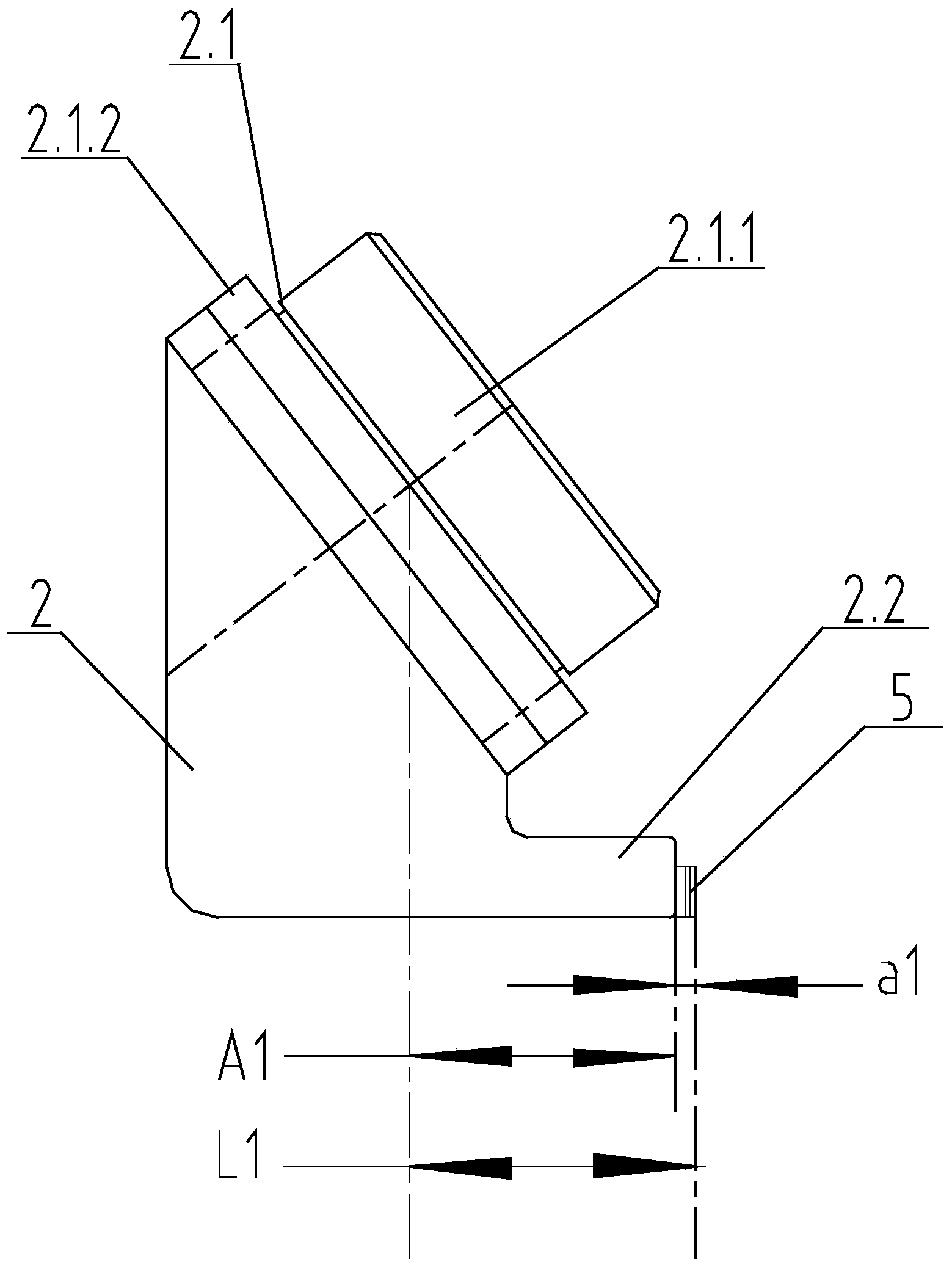

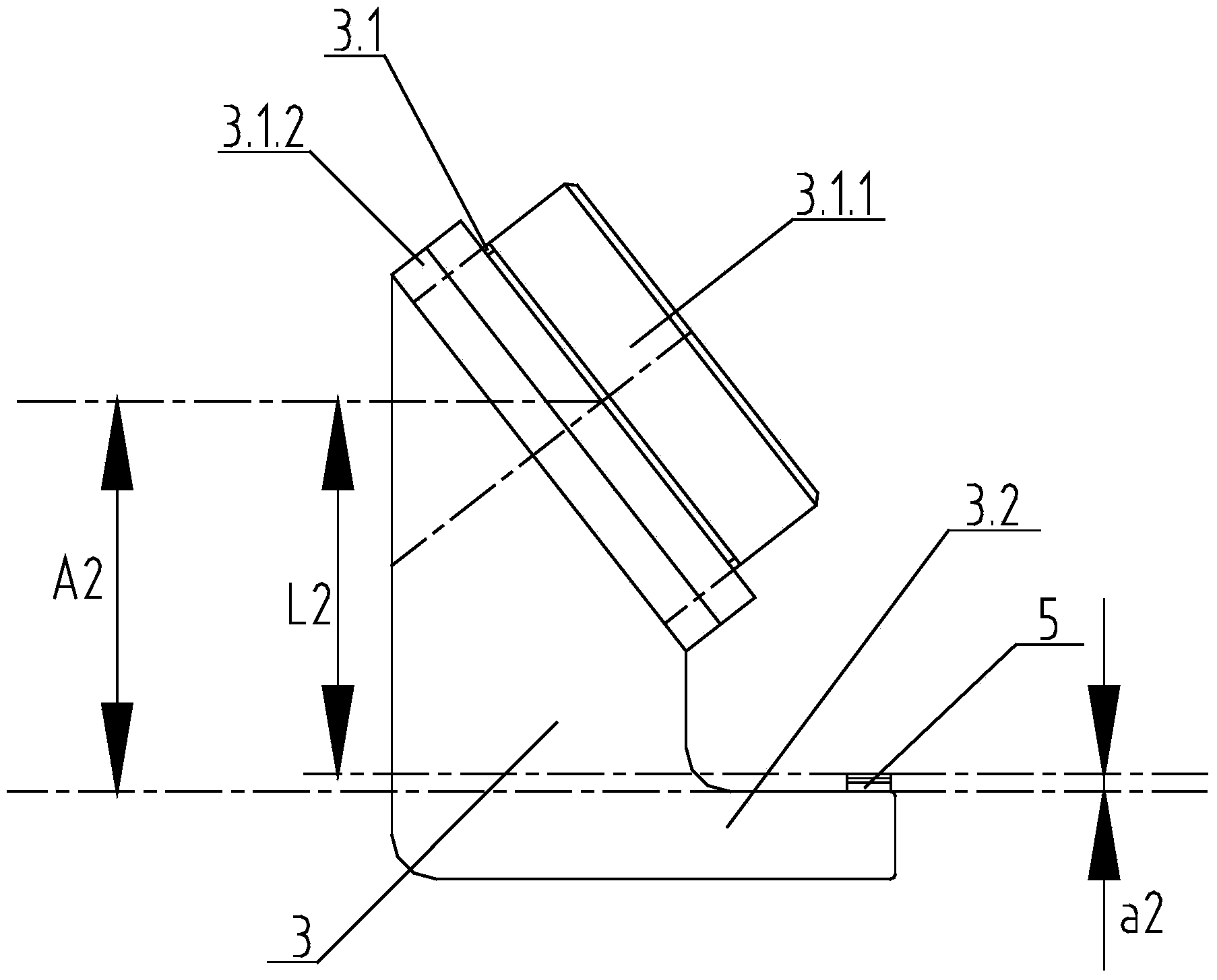

Method for measuring reversely-spraying hole of rocket chamber shell and special devices

ActiveCN103557761ARealize measurementEasy to measureAngles/taper measurementsCombustion chamberEngineering

The invention discloses a method for measuring a reversely-spraying hole of a rocket chamber shell and special devices. The distance L1 from the end face of a front hem base on the rocket chamber shell to the center of the end face of an outlet of the reversely-spraying hole is measured through a first special measuring clamp and a standard block gauge; the distance L2 from the outer circle of the front hem base to the center of the end face of the outlet of the reversely-spraying hole is measured through a second special measuring clamp and a standard block gauge; the distance L3 from the end face of the front hem base to the intersection point of an axis extension line of the reversely-spraying hole and an outer circle extension line of the front hem base is measured through a third special measuring clamp and a standard block gauge; the space angle alpha of the reversely-spraying hole satisfies the equation that alpha = arctg L2 / (L3-L1). According to the method for measuring the reversely-spraying hole of the rocket chamber shell and the special devices, a detection device which is high in price, strict in environment requirement and high in accuracy is not needed, and the special measuring clamps and the standard block gauges are adopted, so that the size and the angle of the space position of the reversely-spraying hole of the rocket chamber shell are measured accurately. According to the method for measuring the reversely-spraying hole of the rocket chamber shell and the special devices, measurement is convenient and rapid, the detection accuracy is high, and the requirement for accuracy of product design can be fully satisfied.

Owner:AEROSPACE SCI & IND KET TECH CO LTD

Method for controlling accuracy of shape of ultrahigh-strength steel thin-wall cylinder

ActiveCN102416414BHigh shape accuracyMeet design accuracy requirementsFurnace typesHeat treatment furnacesRamjetCombustion chamber

The invention discloses a method for controlling accuracy of the shape of an ultrahigh-strength steel thin-wall cylinder. The method comprises the following steps of: 1) detecting the appearance of a cylinder; 2) mounting a special shape correction clamp; 3) tempering for stable shape; 4) discharging and cooling; 5) removing the special shape correction clamp and detecting the appearance; and 6) performing repeated shape correction. In the method, after a cylinder shell is quenched, the special shape correction clamp performs shape correction of the cylinder shell, and then the corrected shape is stabilized by tempering. The shape accuracy of the obtained cylinder shell is relatively high, and the requirement on the product design accuracy is completely met, wherein after the shape correction, the linearity error is not greater than 2.5 mm, and difference between large and small diameters is not greater than 1.5 mm. The processing method disclosed by the invention can be applied to the shape accuracy control on the cylinder shell of a secondary combustion chamber of a solid rocket ramjet.

Owner:湖北三江航天江北机械工程有限公司

Composite Fixture for Machining Circumferential Taper Hole of Special-shaped Nozzle Shell

ActiveCN103464846BGuaranteed coaxiality requirementsImprove product qualityPositioning apparatusMetal-working holdersDetentAgricultural engineering

The invention discloses a method for processing a circumferential taper hole of a special-shaped nozzle casing and a composite fixture thereof. The method includes: 1) rough machining of the nozzle casing; 2) flat grinding of the end surface of the nozzle casing; 3) the nozzle casing body semi-finishing; 4) Small end taper hole processing of the nozzle casing; 5) Outer taper taper hole processing of the nozzle casing; 6) Position accuracy detection of the circumferential taper hole. The invention adopts special composite fixtures, strict clamping and alignment methods to process the taper hole of the nozzle shell, high machining accuracy, and stable batch quality; during processing, alignment and tool alignment only need to be performed when processing the first taper hole , the follow-up taper hole is directly processed by adjusting the positioning plate, and the processing efficiency is improved; the space size of the taper hole is guaranteed by the composite fixture, and the positioning accuracy is high, which fully meets the product space dimension accuracy requirements.

Owner:湖北三江航天江北机械工程有限公司

An Optimal Design Method for Large Aspect Ratio Wing Based on Model Fusion Method

ActiveCN107391891BImprove design efficiencyReduce callsGeometric CADSustainable transportationAnalytic modelAlgorithm

The invention discloses a high-aspect-ratio wing optimization design method based on a model merging method, and belongs to the technical field of overall optimization design of aircraft. The method comprises the steps that a penalty function method is used for processing complex constraints for an optimization model and a system-level optimization model which are optimally divided into structure subjects as needed; a high precision pneumatic structure coupling analysis model and a low precision pneumatic structure coupling analysis model are built through a pneumatic structure coupling modeling technology; high precision sample points and low precision sample points are generated through an experiment design method; high precision sample information and low precision sample information are obtained by calling the high precision pneumatic structure coupling analysis model and the low precision pneumatic structure coupling analysis model respectively and stored; by using the model merging method, the high precision sample information and the low precision sample information are merged to build a surrogate model; optimization solution is conducted based on an optimization method for a current surrogate model, whether the optimization result is credible or not is judged according to a difference value of a true response value of the optimal solution and a surrogate model value based on the model merging method, if not, the step is executed again to rebuild a merging model for optimization solution, if yes, the optimal design result is output, and optimization design is completed.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

An initial alignment device, processing device and processing method for a special-shaped ceramic radome

ActiveCN109702605BUnified processing standardsReduce machining accuracyRadiating element housingsWorking accessoriesStructural engineeringRadome

The invention provides a special-shaped ceramic antenna cover machining device and method. The device comprises a head cone supporting ring, an inner molded surface aligning ring, end face pressing plates and a plurality of outer supporting mechanisms. Each outer supporting mechanism comprises an outer support and an adjusting screw rod, and the inner molded surface aligning ring comprises an insertion end and a fixed end. According to the device and method, the machining reference of an antenna cover is determined through a primary alignment tool, it is guaranteed that the position of a clamping space of the antenna cover in all working procedures is free of deviation, the machining reference is unified, and the machining precision is effectively controlled.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

The processing method of the central measuring tool for detecting the driving disc fixture when processing the steam turbine blade

ActiveCN104551862BSimple processing methodSave material costMeasurement/indication equipmentsSteam turbine bladeEngineering

The invention relates to a measuring tool and a machining method thereof, particularly to a driving disc clamp detection measuring tool during machining of steam turbine blades and a machining method thereof. The driving disc clamp detection measuring tool during machining of the steam turbine blades and the machining method thereof are used for solving the problems of machining difficulty and low working precision of existing central measuring tools. The driving disc clamp detection measuring tool during machining of the steam turbine blades comprises an extension bar and a measuring tool body; the blade root portion at the lower end of the measuring tool body is identical in size and shape to the root of a blade to be simulated; the cylindrical boss of the measuring tool body is provided with a threaded hole, and the extension bar is connected with the cylindrical boss of the measuring tool body through threads. The machining method of the driving disc clamp detection measuring tool during machining of the steam turbine blades comprises, firstly, rough-milling out the measuring tool body and the extension bar, and performing quenched-tempered heat treatment on the measuring tool body and the extension bar; secondly, drilling out the threaded hold inside the cylindrical boss, and turning out the external threads of the extension bar; lastly, preforming finish turning after the measuring tool body and the extension bar are assembled to complete machining of the central measuring tool. According to the driving disc clamp detection measuring tool during machining of the steam turbine blades, the extension bar and the measuring tool body are of an assembly type structure, so that the machining time can be saved, and a locating degree within 0.03 mm can be reached.

Owner:HARBIN TURBINE

Cold-drawing finishing device and process

PendingCN111957758ASave resourcesGuaranteed finishing effect and qualityDrawing mandrelsDrawing diesDimensional precisionManufacturing engineering

Owner:宜昌中南精密钢管有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com