Processing method for inner ring arc section of guide vane

A processing method and technology of guide vanes, which are applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of low processing accuracy, achieve the effect of improving processing quality, ensuring accuracy requirements, and ensuring processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

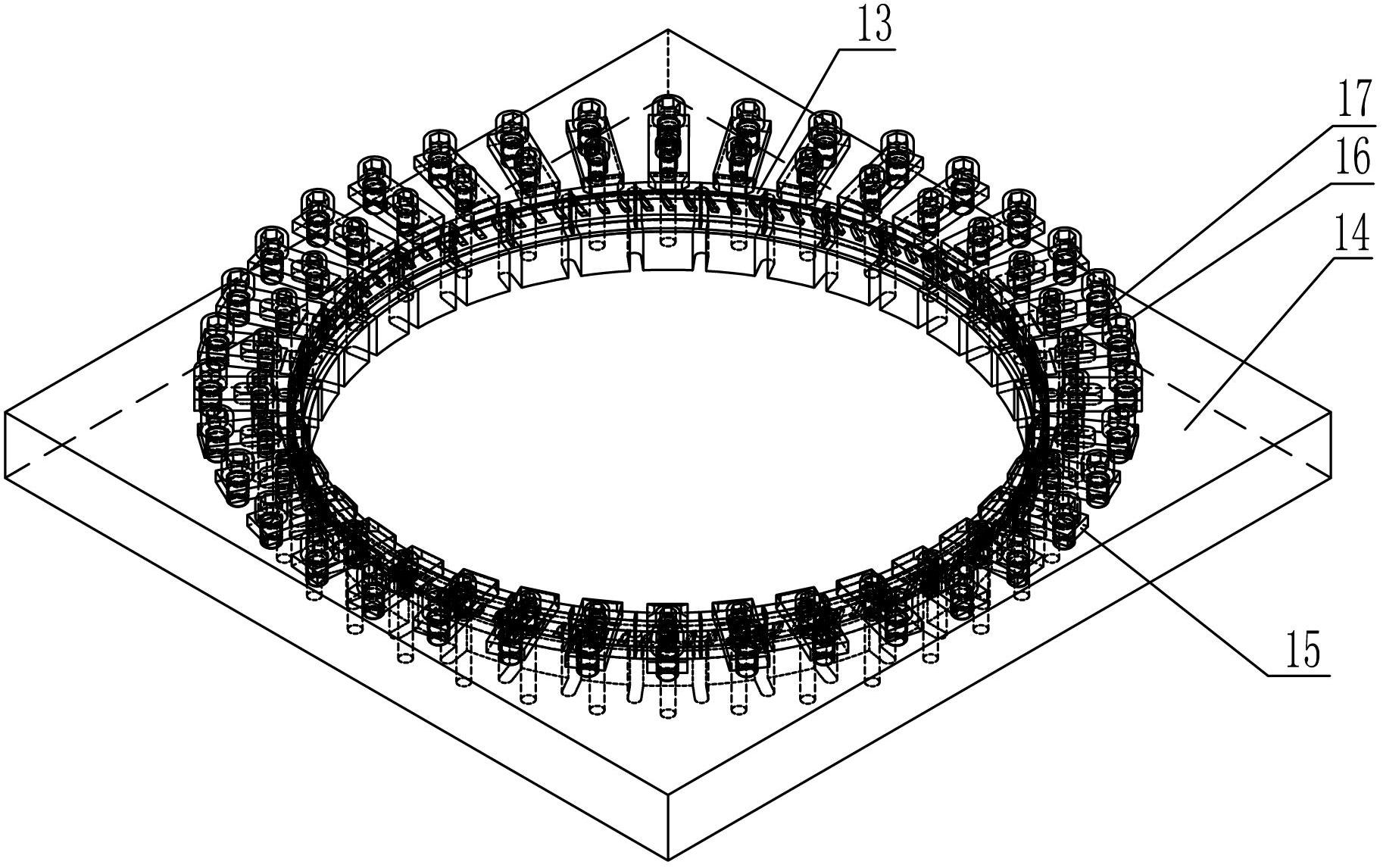

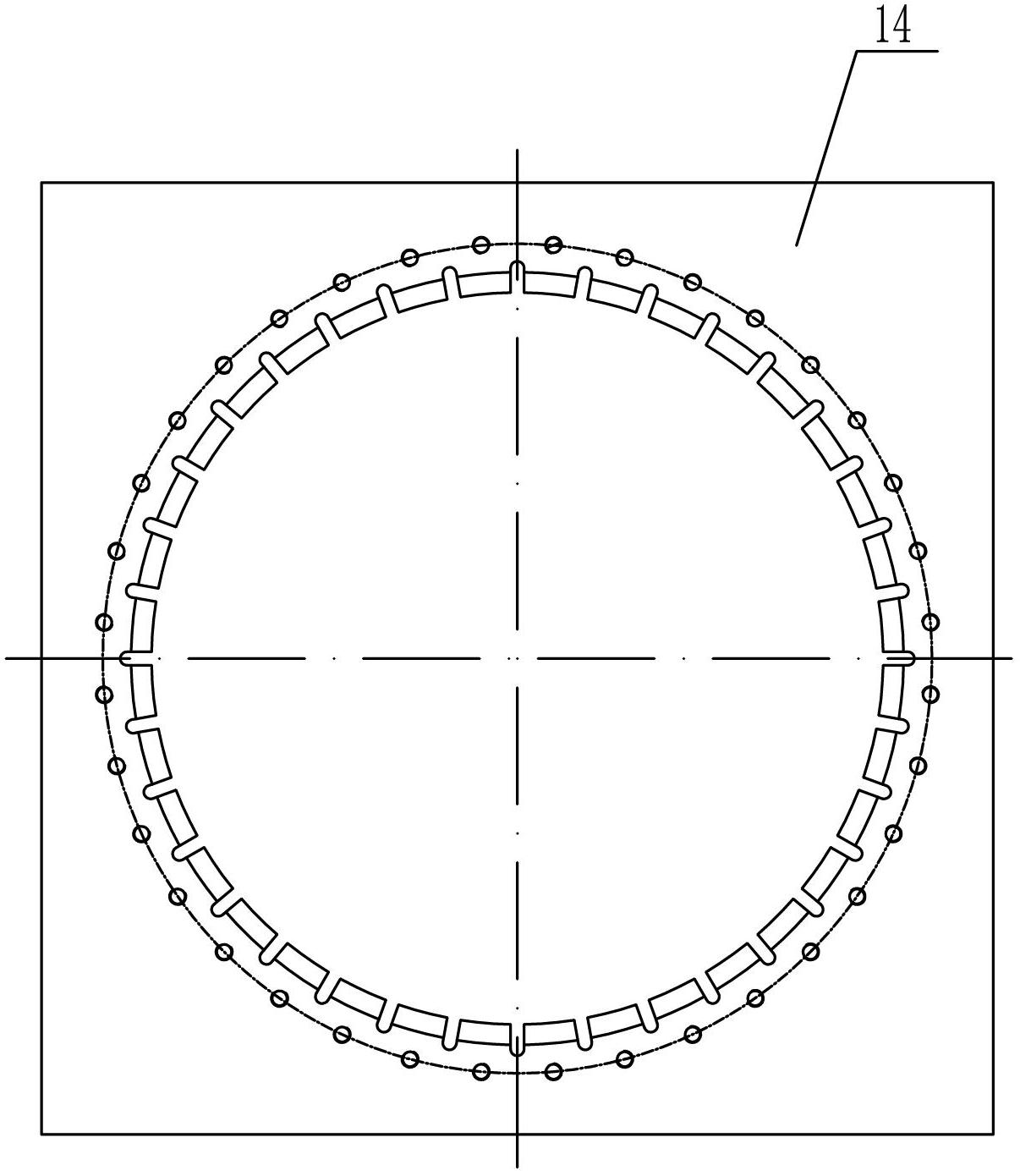

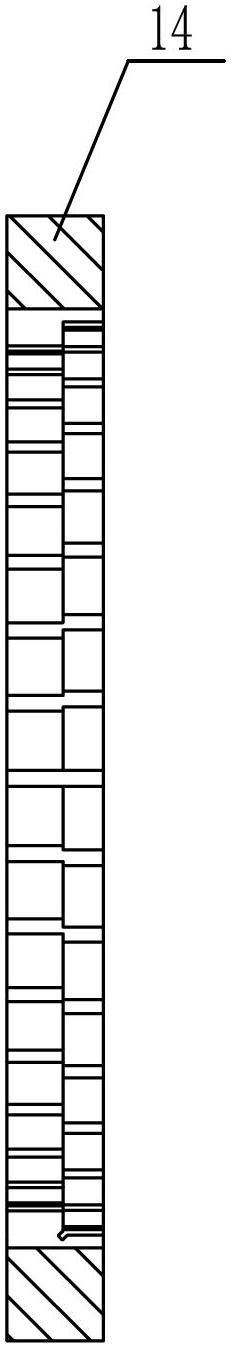

[0013] Specific implementation mode one: combine Figure 1-Figure 16 Describe this embodiment, the concrete steps of a kind of guide vane inner ring arc section processing method of this embodiment are:

[0014] Step 1. Rough turning the inner hole, outer circle and upper and lower end faces of the arc section 13 of the inner ring: the inner hole and the outer circle are all loaded with 1.5 mm, and the upper and lower end faces are given 1 mm. The cutting parameters are: the speed is 56r / min-64r / min, The feed rate is 0.2mm / r-0.4mm / r, and the cutting depth is 1.5mm.

[0015] Step 2: Stress-relieving treatment of the inner ring arc section 13 after rough turning. The specific process of stress treatment is as follows: first, heat the rough turning inner ring arc section 13 to 500°C-650°C, then keep it warm for 2 hours, and finally cool down slowly with the furnace to 200°C-300°C.

[0016] Step 3: Finish turning the inner hole, outer circle and upper and lower end faces of the ...

specific Embodiment approach 2

[0023] Embodiment 2: In step 1 of this embodiment, the rotational speed of the inner hole, the outer circle and the upper and lower end surfaces of the inner ring arc section 13 of the rough turning is 60r / min, and the feed rate is 0.3mm / r. Such setting meets the design requirements and actual needs. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0024] Embodiment 3: In step 2 of this embodiment, the inner ring arc section 13 of the rough car is heated to 575° C., then kept for 2 hours, and finally cooled slowly to 250° C. with the furnace. With such setting, the temperature control is reasonable, and the stress in rough turning can be effectively released. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com