Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4906 results about "Machining time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Machining time is the time when a machine is actually processing something. Generally, machining time is the term used when there is a reduction in material or removing some undesirable parts of a material. For example, in a drill press, machining time is when the cutting edge is actually moving forward and making a hole. Machine time is used in other situations, such as when a machine installs screws in a case automatically.

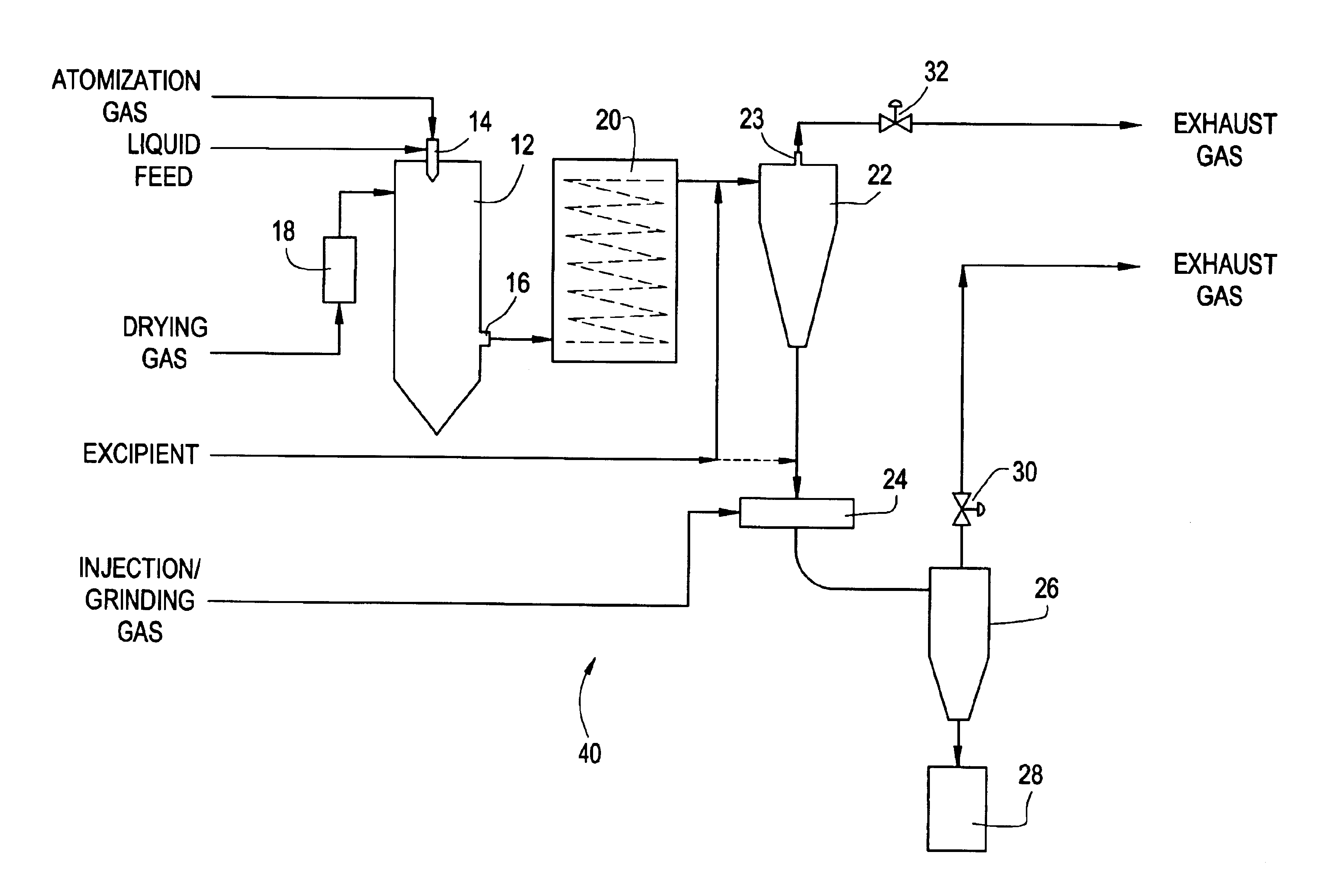

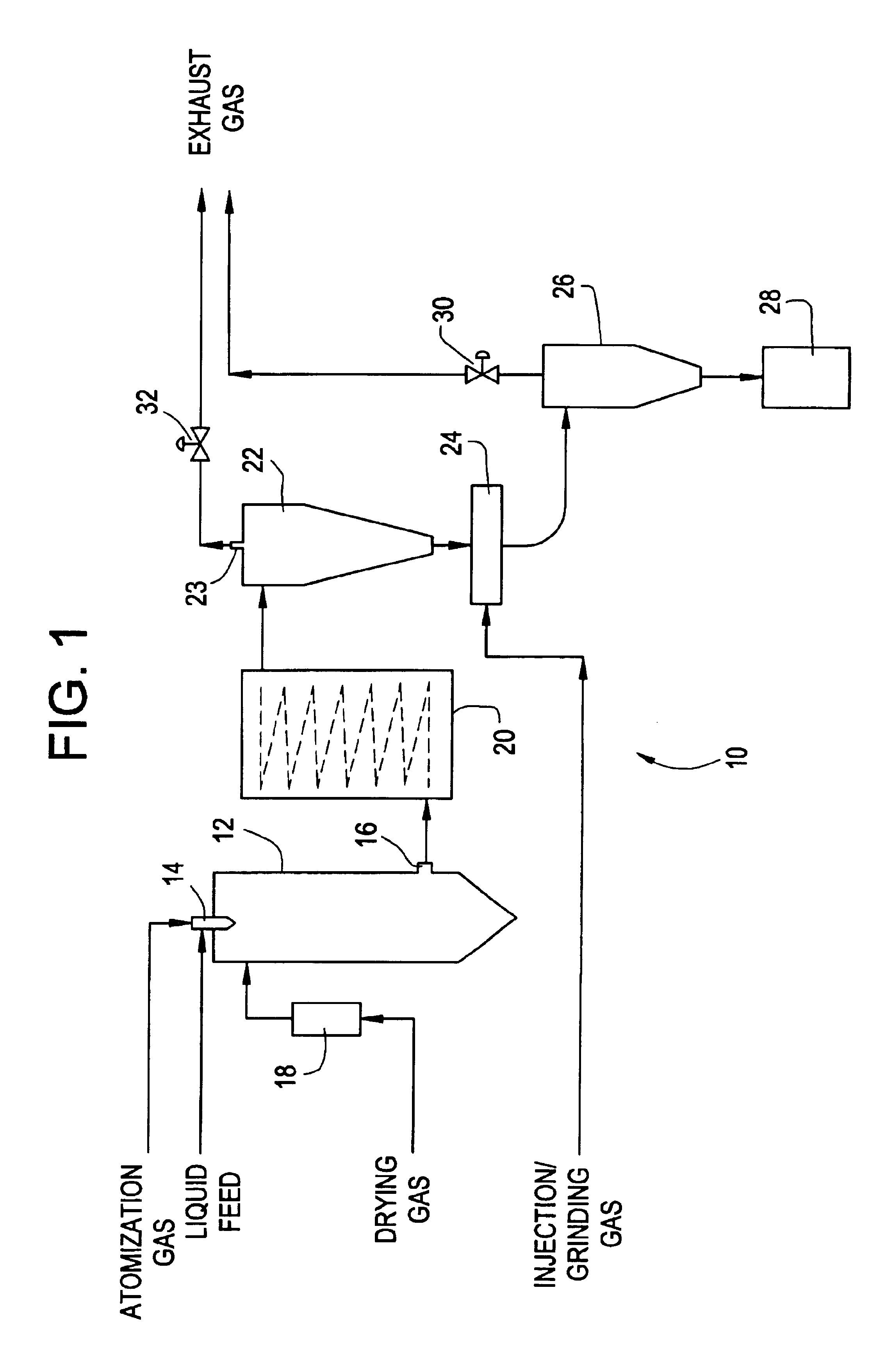

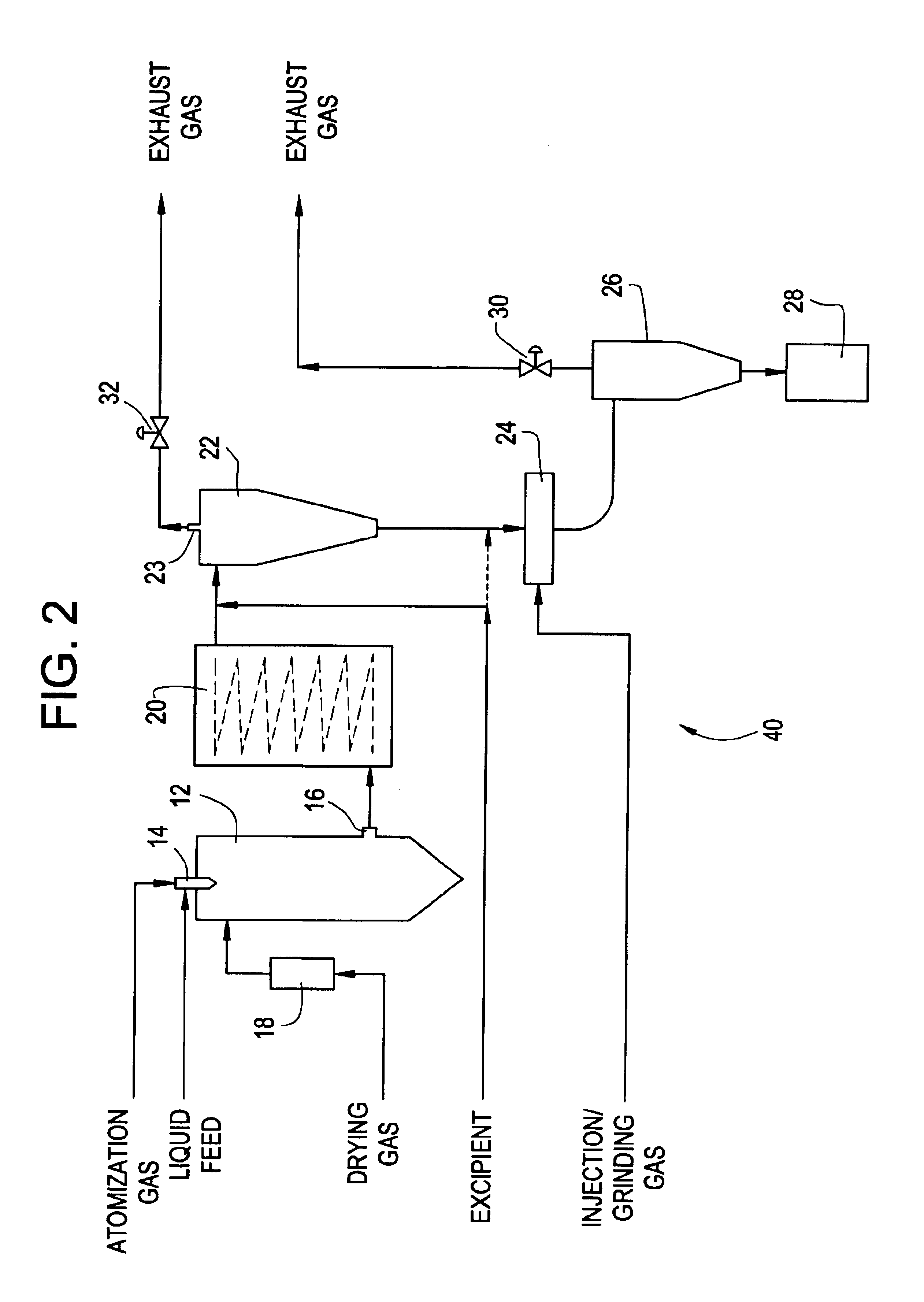

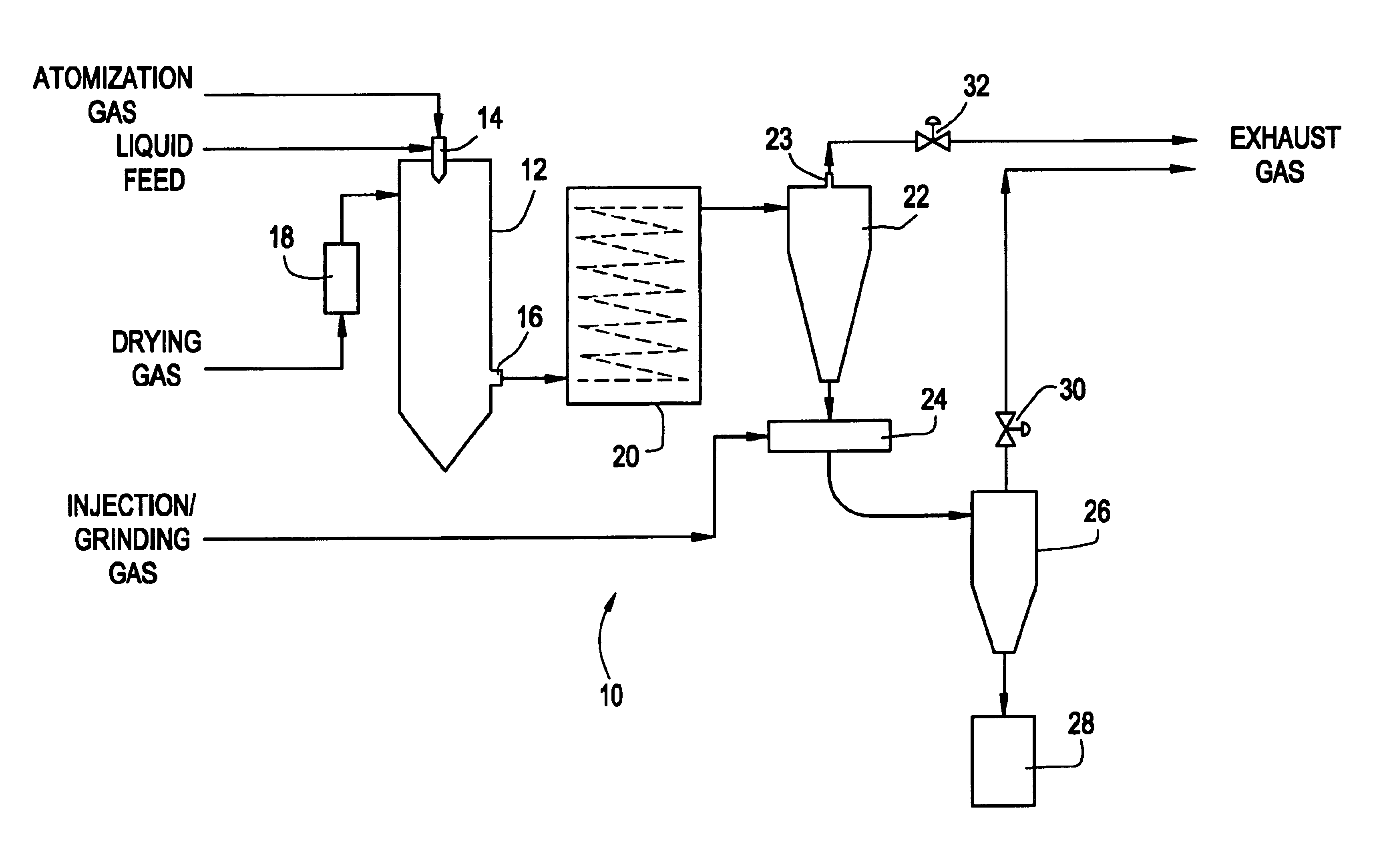

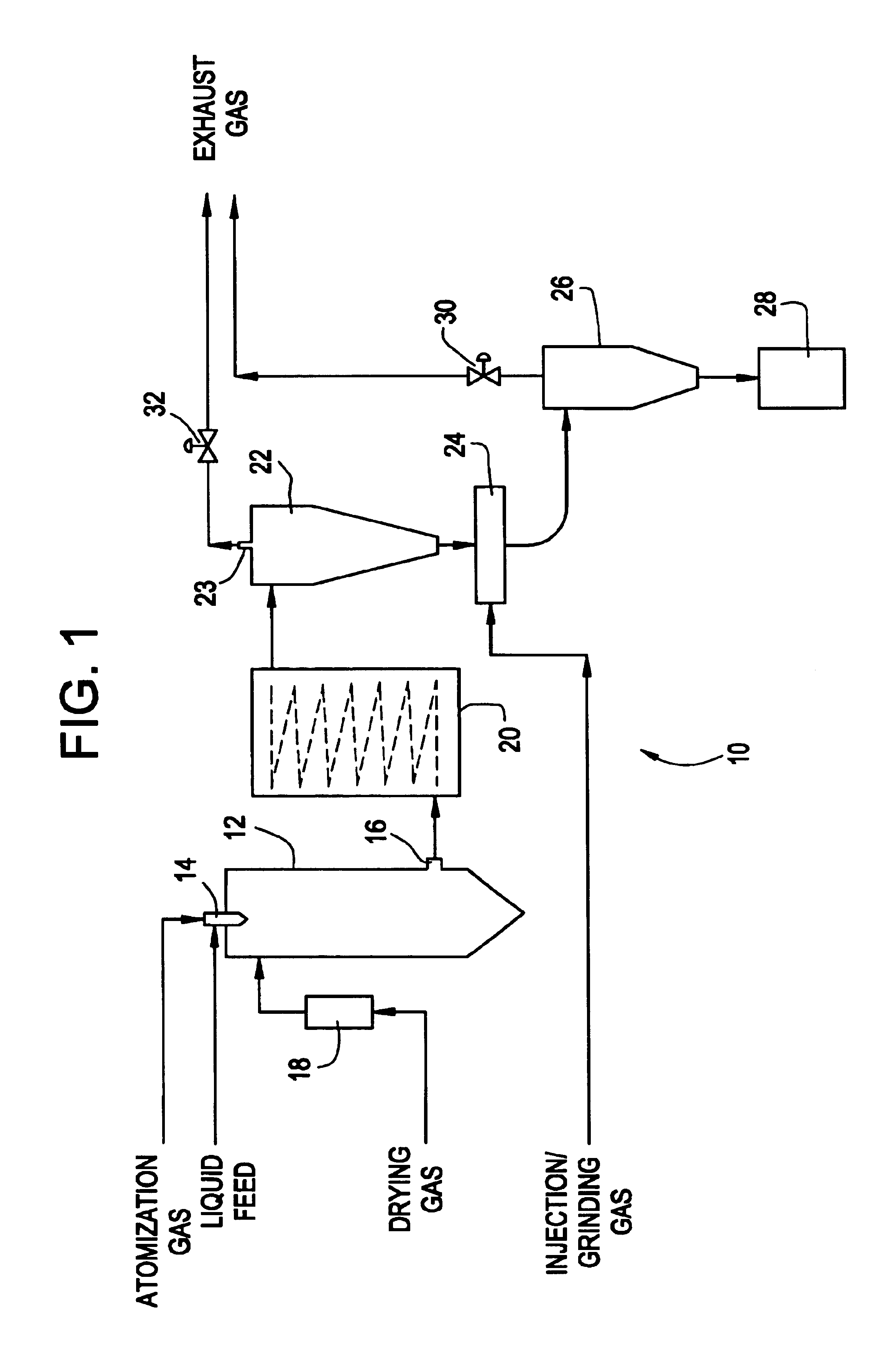

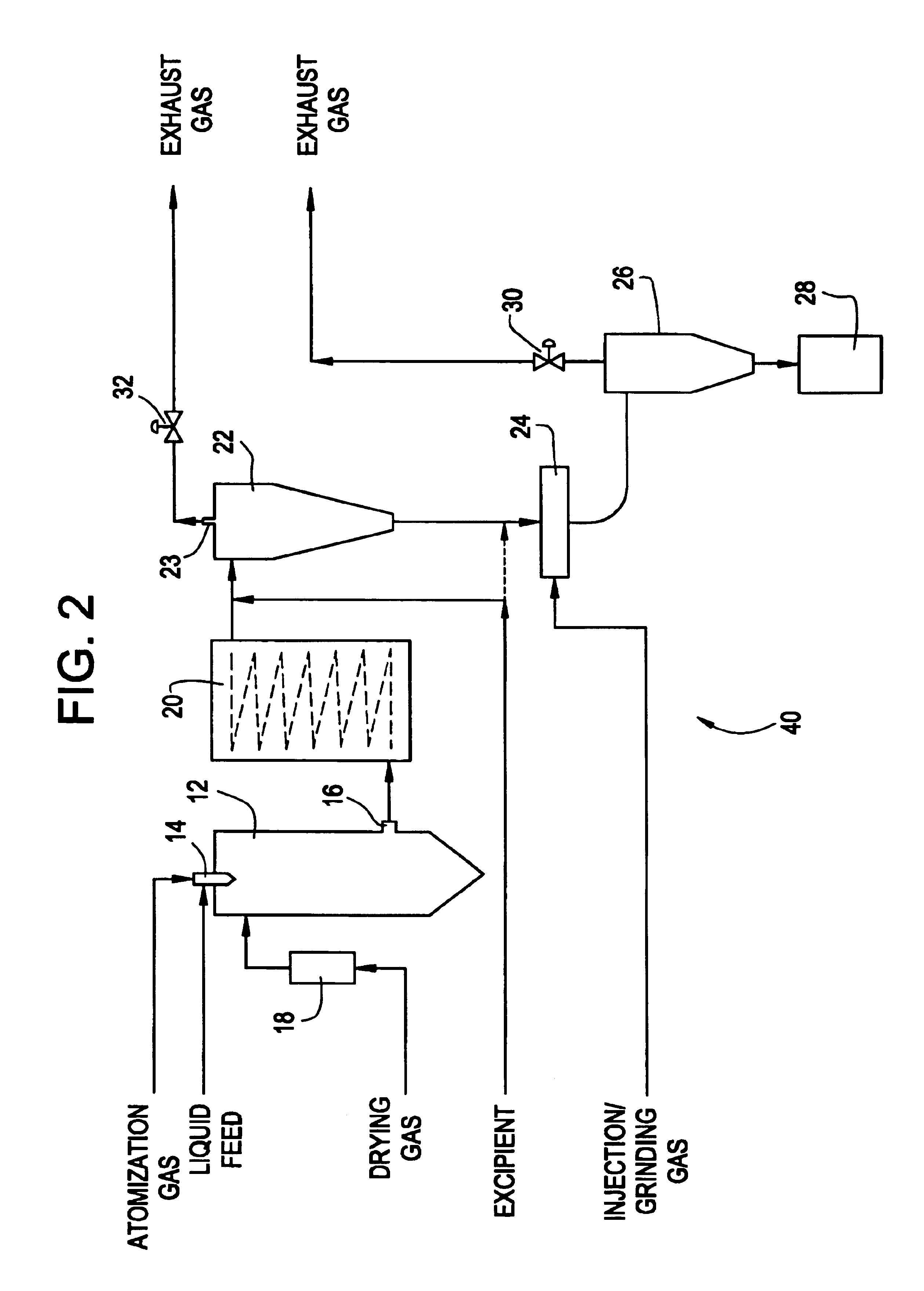

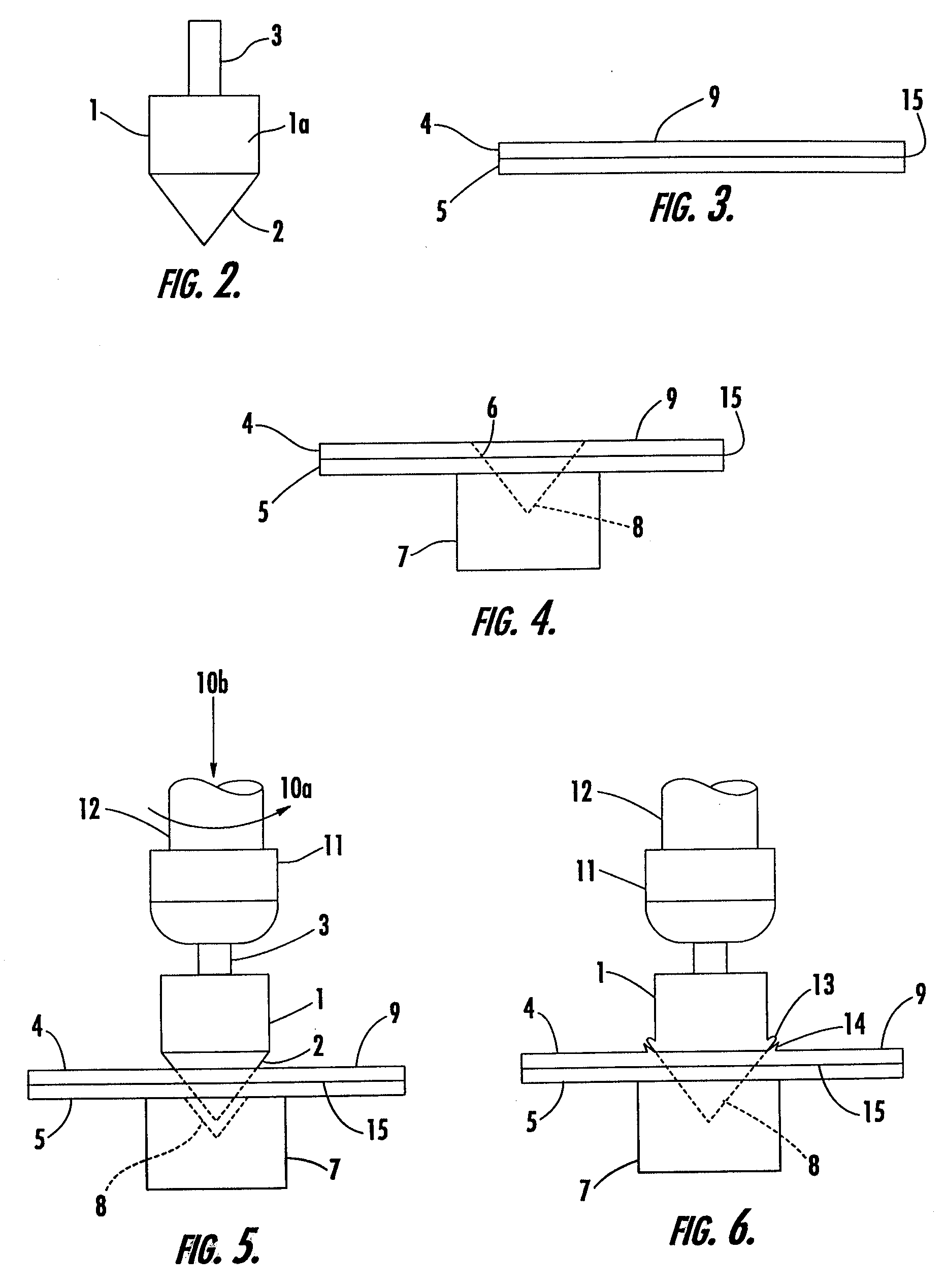

Methods and apparatus for making particles using spray dryer and in-line jet mill

InactiveUS6918991B2Reduce processing timeDrying solid materials with heatGranulation by liquid drop formationPolymer scienceEmulsion

Methods and apparatus are provided for making particles comprising: (a) spraying an emulsion, solution, or suspension, which comprises a solvent and a bulk material (e.g., a pharmaceutical agent), through an atomizer and into a primary drying chamber, having a drying gas flowing therethrough, to form droplets comprising the solvent and bulk material dispersed in the drying gas; (b) evaporating, in the primary drying chamber, at least a portion of the solvent into the drying gas to solidify the droplets and form particles dispersed in drying gas; and (c) flowing the particles and at least a portion of the drying gas through a jet mill to deagglomerate or grind the particles. By coupling spray drying with “in-line” jet milling, a single step process is created from two separate unit operations, and an additional collection step is advantageously eliminated. The one-step, in-line process has further advantages in time and cost of processing.

Owner:ACUSPHERE INC

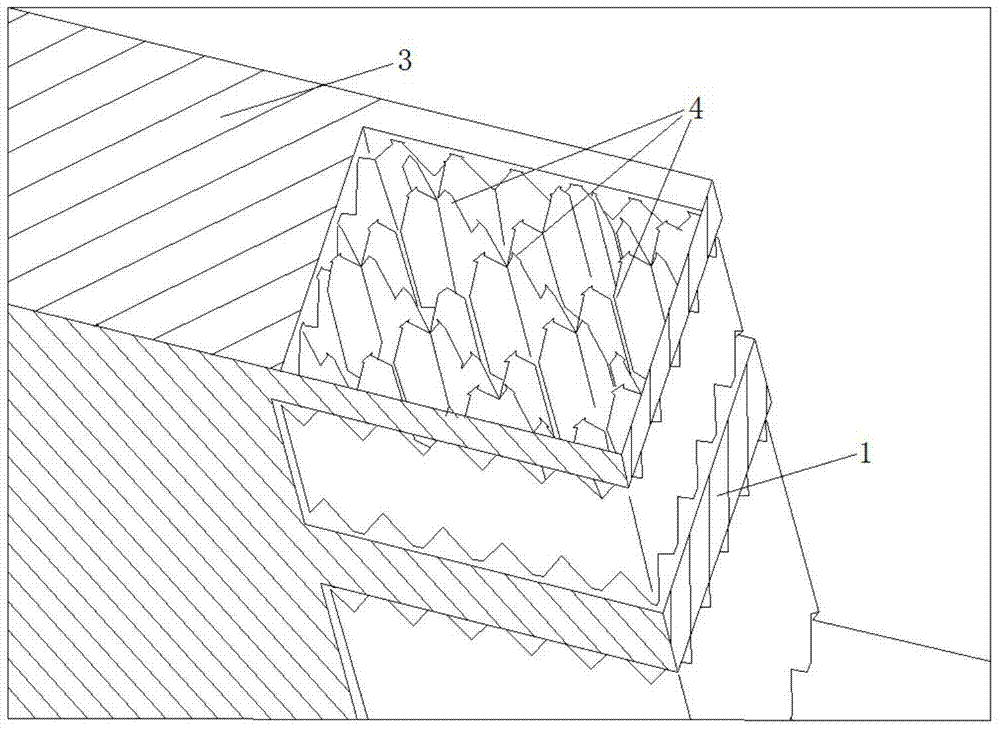

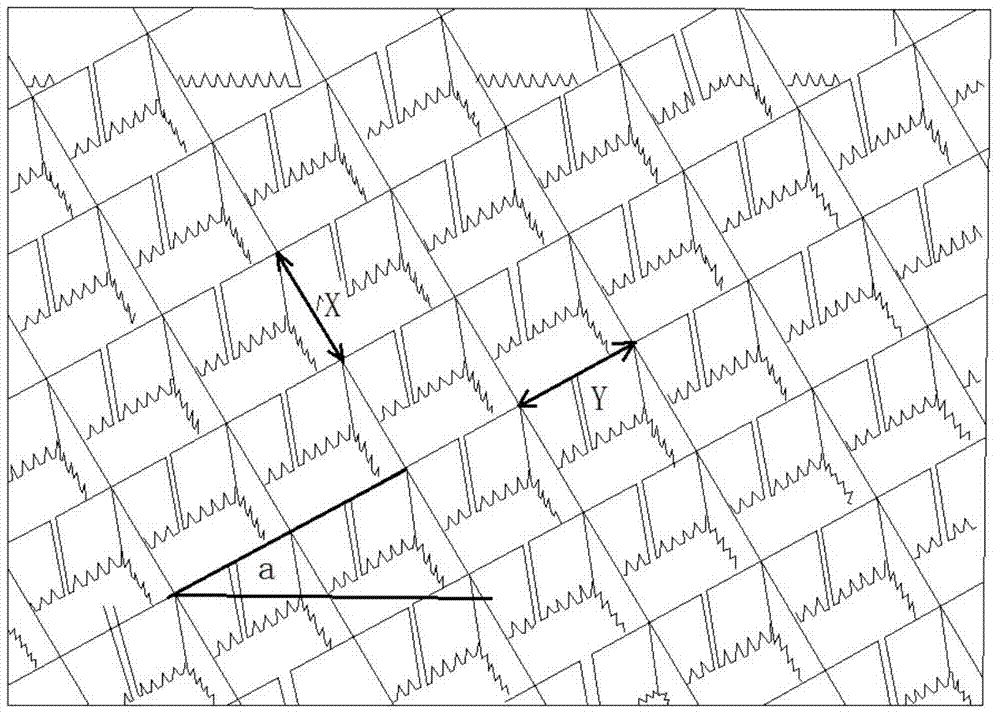

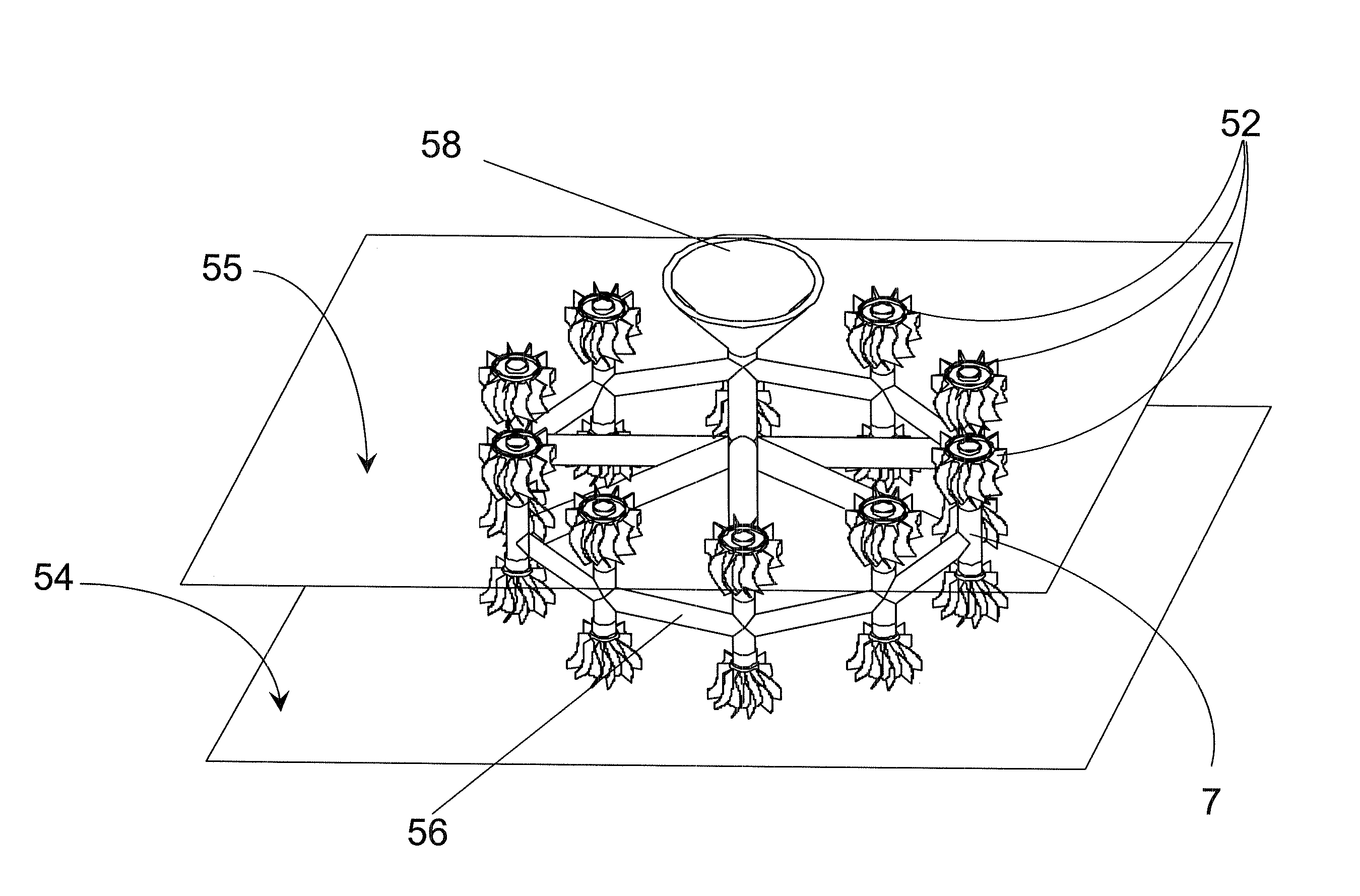

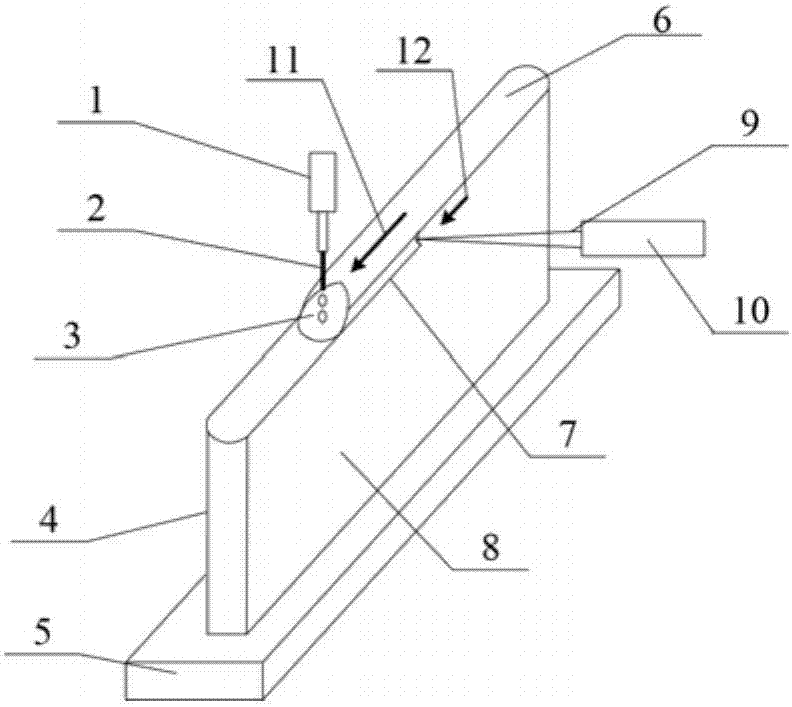

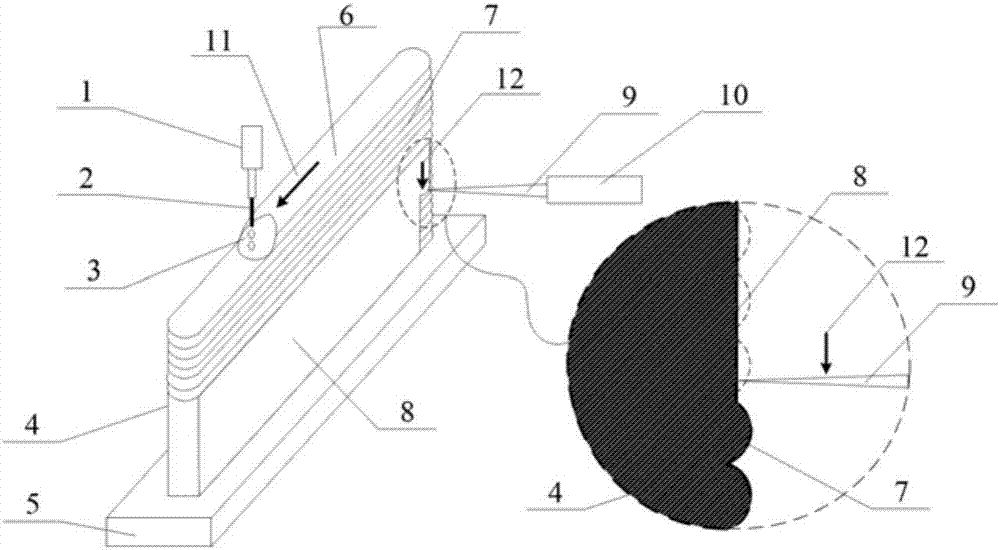

Design method of easily-removable support structure for SLM-manufactured metal parts

ActiveCN103920877AThe process is easy to realizeGenerate easyIncreasing energy efficiencySelective laser meltingSurface roughness

A design method of an easily-removable support structure for SLM-manufactured metal parts is applied to the design of supports for the structures such as suspended planes and surfaces in the process of producing metal parts by SLM (selective laser melting), so that the surfaces can be formed, and stability of the structures on the surfaces and forming quality can meet the technical requirements. A meshed thin-walled structure support is designed by the design method; a saw-toothed structure is designed at the connection of a support and a solid body. The meshed thin-walled structure support has the advantages that weight of the support and even consumption of powder are decreased; forming strength of the support suspended surfaces is met, and the support is easy to remove by mechanical methods; manufacturing time of the support is shortened, and efficiency is improved. The saw-toothed structure has the advantages that strength of the connection of the support with the solid body is decreased, and the influence of many supports upon the surface quality of the formed surfaces after removal is avoided. The support structure is easy to impellent and to produce and is easy to remove during the post-treatment process, the surface roughness of the support faces can be minimized, and the design method is suitable for mass production.

Owner:BEIJING UNIV OF TECH

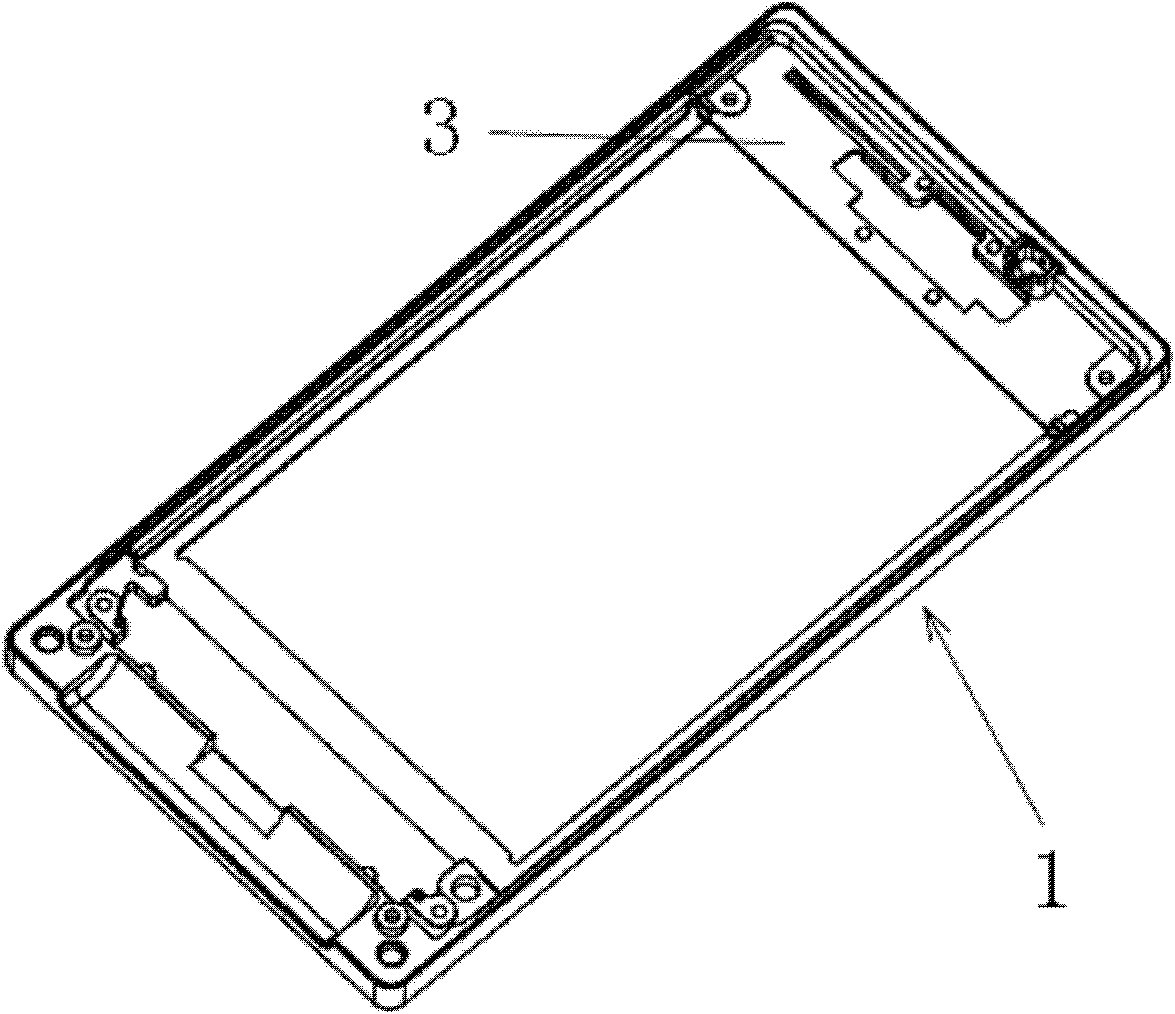

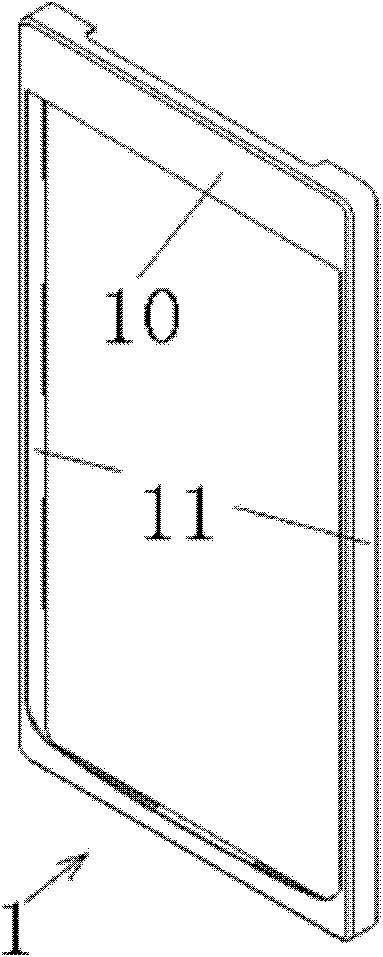

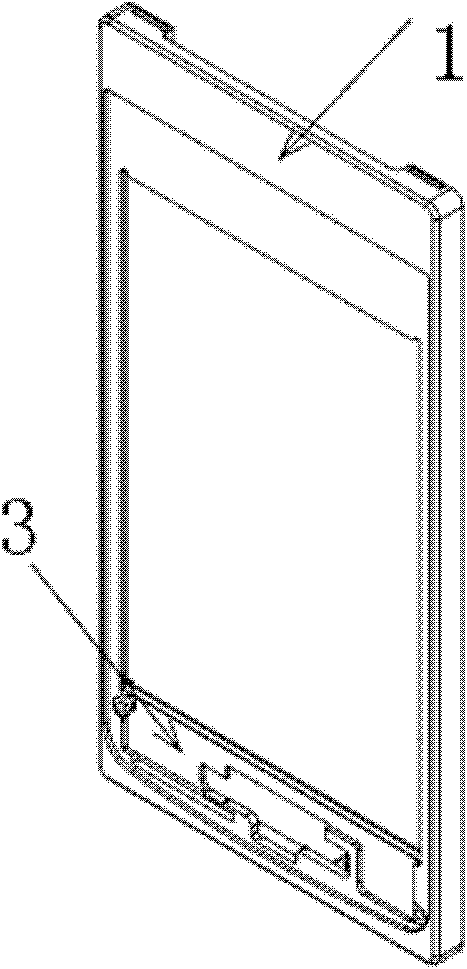

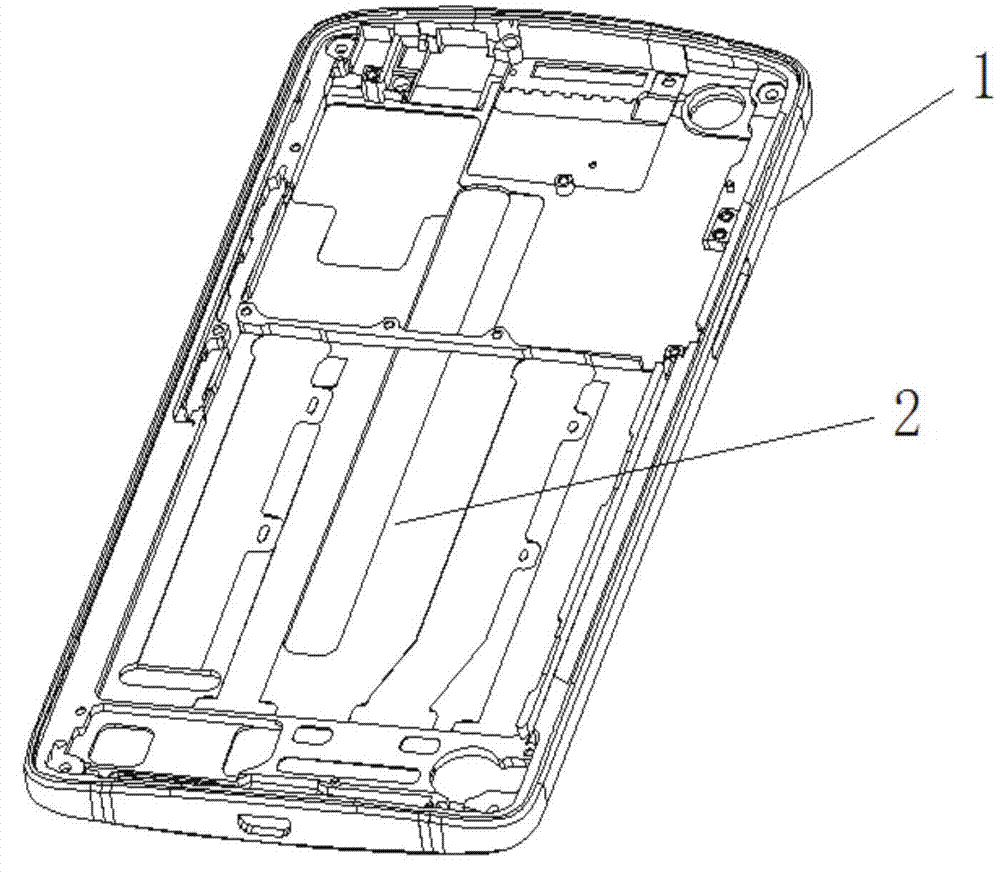

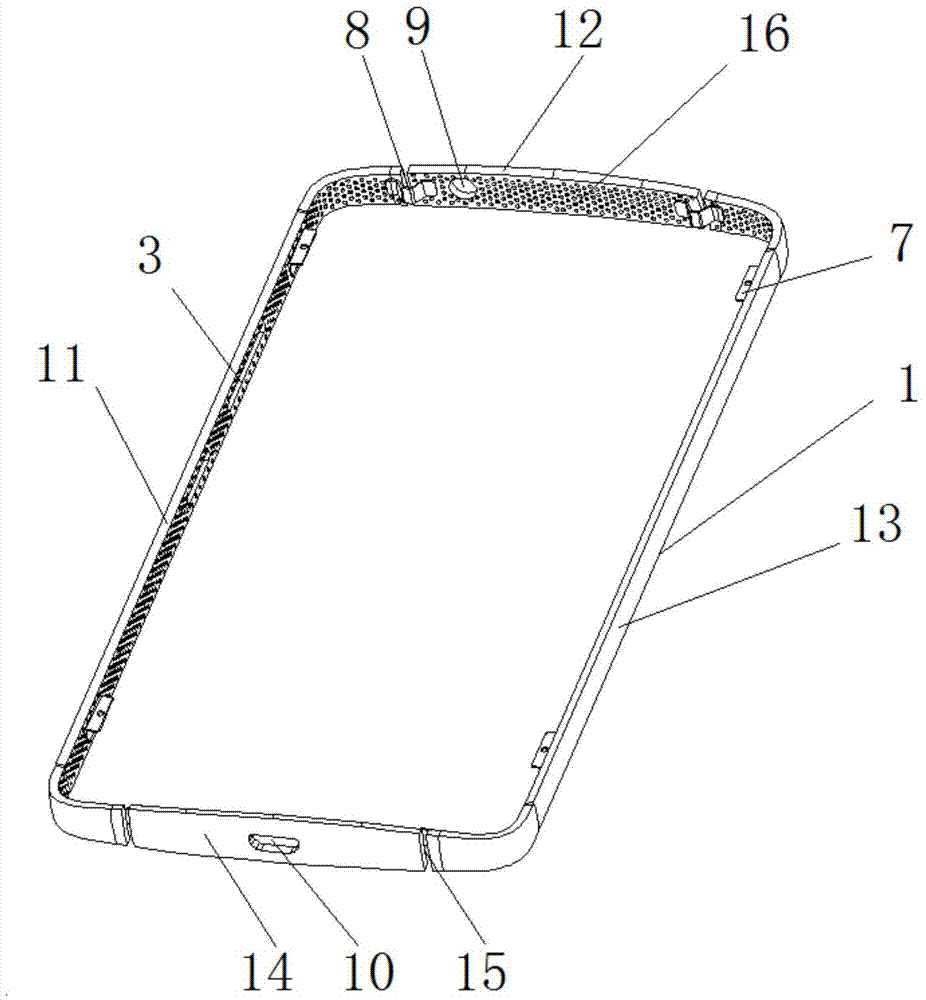

Mobile phone shell and machining method thereof

InactiveCN102811264AGuaranteed Appearance RequirementsLow costTelephone set constructionsMetal layered productsDie castingEngineering

Owner:李树忠 +1

Methods and apparatus for making particles using spray dryer and in-line jet mill

InactiveUS6921458B2Reduce processing timeDrying solid materials with heatGranulation by liquid drop formationPolymer scienceEmulsion

Methods and apparatus are provided for making particles comprising: (a) spraying an emulsion, solution, or suspension, which comprises a solvent and a bulk material (e.g., a pharmaceutical agent), through an atomizer and into a primary drying chamber, having a drying gas flowing therethrough, to form droplets comprising the solvent and bulk material dispersed in the drying gas; (b) evaporating, in the primary drying chamber, at least a portion of the solvent into the drying gas to solidify the droplets and form particles dispersed in drying gas; and (c) flowing the particles and at least a portion of the drying gas through a jet mill to deagglomerate or grind the particles. By coupling spray drying with “in-line” jet milling, a single step process is created from two separate unit operations, and an additional collection step is advantageously eliminated. The one-step, in-line process has further advantages in time and cost of processing.

Owner:ACUSPHERE INC

Joining of structural members by friction plug welding

InactiveUS20030201306A1Cost effectiveEfficiently joinedWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingEngineering

Abstract of the Disclosure The method of manufacturing a structural assembly includes positioning a first structural member at least partially adjacent a second structural member to define an interface therebetween and inserting a rotating plug into the first and second structural members at the interface to thereby join the first structural member to the second structural member. The resulting friction plug weld provides a relatively strong joint between the structural members, requires less forming and machining time, and is compatible with single-sided tooling. Additionally, the friction plug weld is compatible with other joining methods, such as friction stir welding.

Owner:THE BOEING CO

Processing method of aluminum alloy thin-wall cylindrical part

The invention discloses a processing method of an aluminum alloy thin-wall cylindrical part. The method comprises the following steps of blanking, tool selection, rough machining, excircle semi-finish machining, aging treatment, internal-hole semi-finish machining, internal-hole finish machining, excircle finish machining and the like. According to the method, as a special clamp is adopted to guarantee clamping precision, the clamping deformation is reduced and the internal stress of part processing is eliminated; moreover, the method is simple to operate; for a workpiece, procedures of keeping a technological chuck and removing the technological chuck are omitted, so that the material and the processing time are saved; meanwhile, the aluminum alloy thin-wall cylindrical part processed by using the method is stable in quality, low in processing cost and high in efficiency; in addition, the influence that a product generates deformation due to directly suffering three-point clamping force can also be avoided, the rotation heat stress deformation and the pressure damage can be reduced, the flexible deformation of the tools can be reduced, the raw material consumption of the product can be reduced, and the qualification rate and the production efficiency of the workpiece can be improved; moreover, the processing cost can be lowered.

Owner:贵州凯星液力传动机械有限公司

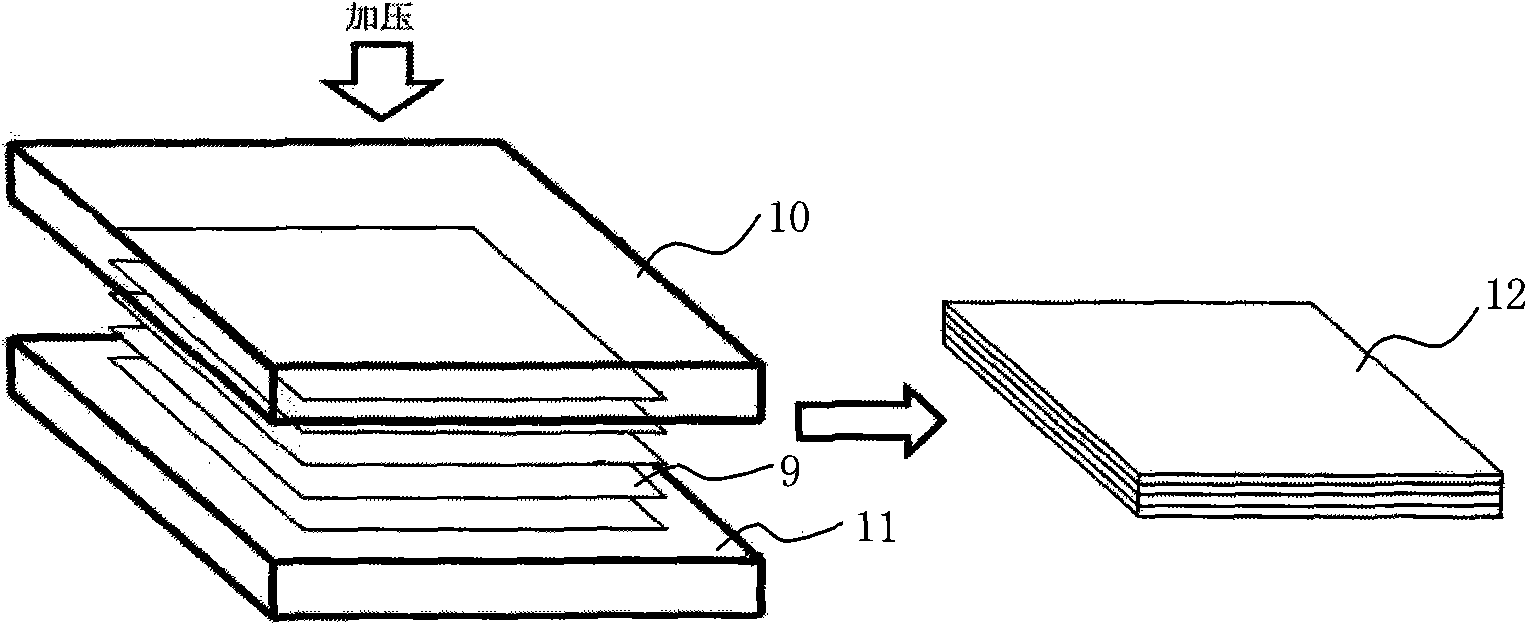

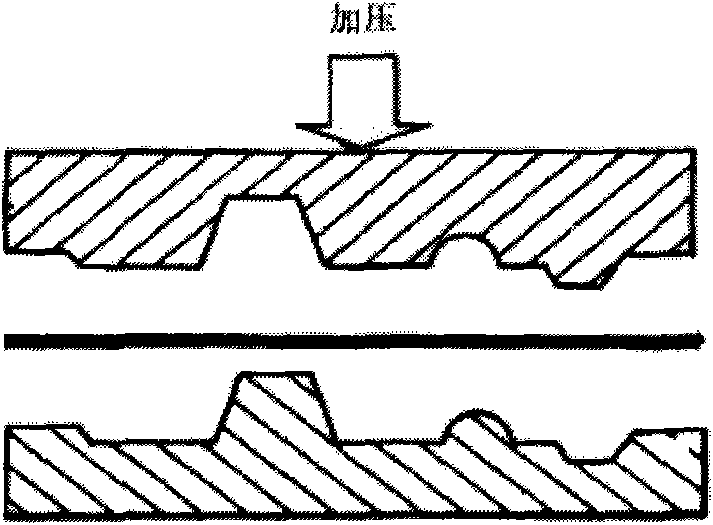

Thermoplastic resin-based carbon fiber composite and preparation method thereof

The invention discloses a thermoplastic resin-based carbon fiber composite and a preparation method thereof. The thermoplastic resin-based carbon fiber composite comprises the following components in percentage by volume: 50 to 70 percent of carbon fibers and 30 to 50 percent of thermoplastic resin. In the preparation method, according to rheological properties of the thermoplastic resin, the thermoplastic resin-based carbon fiber composite with good interface binding property is prepared by utilizing hot-roller hot-pressing continuous equipment and adjusting process conditions such as machining temperature, machining pressure, machining time and the like. Compared with the prior art, the thermoplastic resin-based carbon fiber composite has the advantages of simple structure, good interface binding property, high impact resistance and recycling property; and the preparation method can realize the uniform distribution of the carbon fibers and the thermoplastic resin and ensure the carbon fibers are immersed by the thermoplastic resin completely, so that the defect of the conventional method is overcome.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

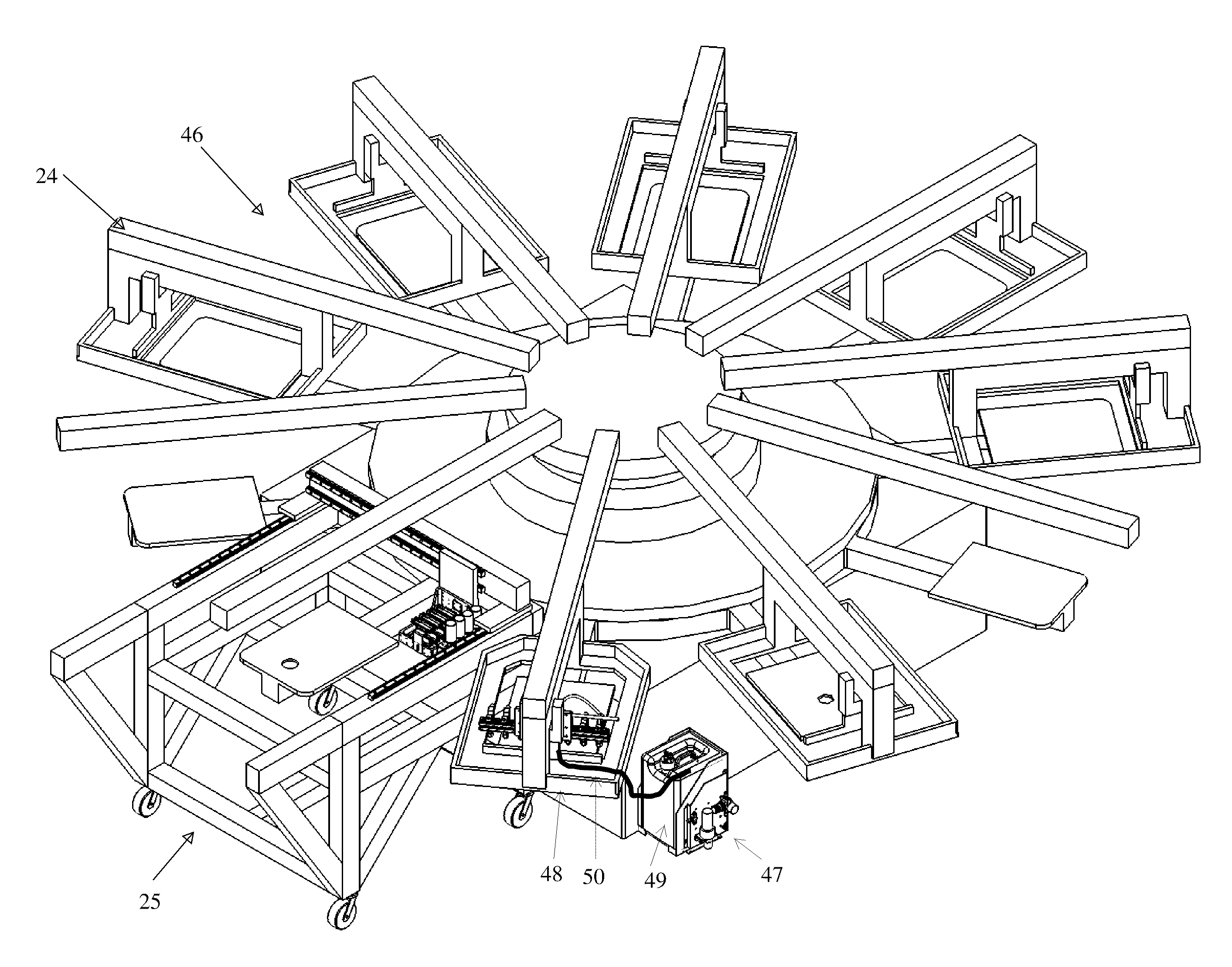

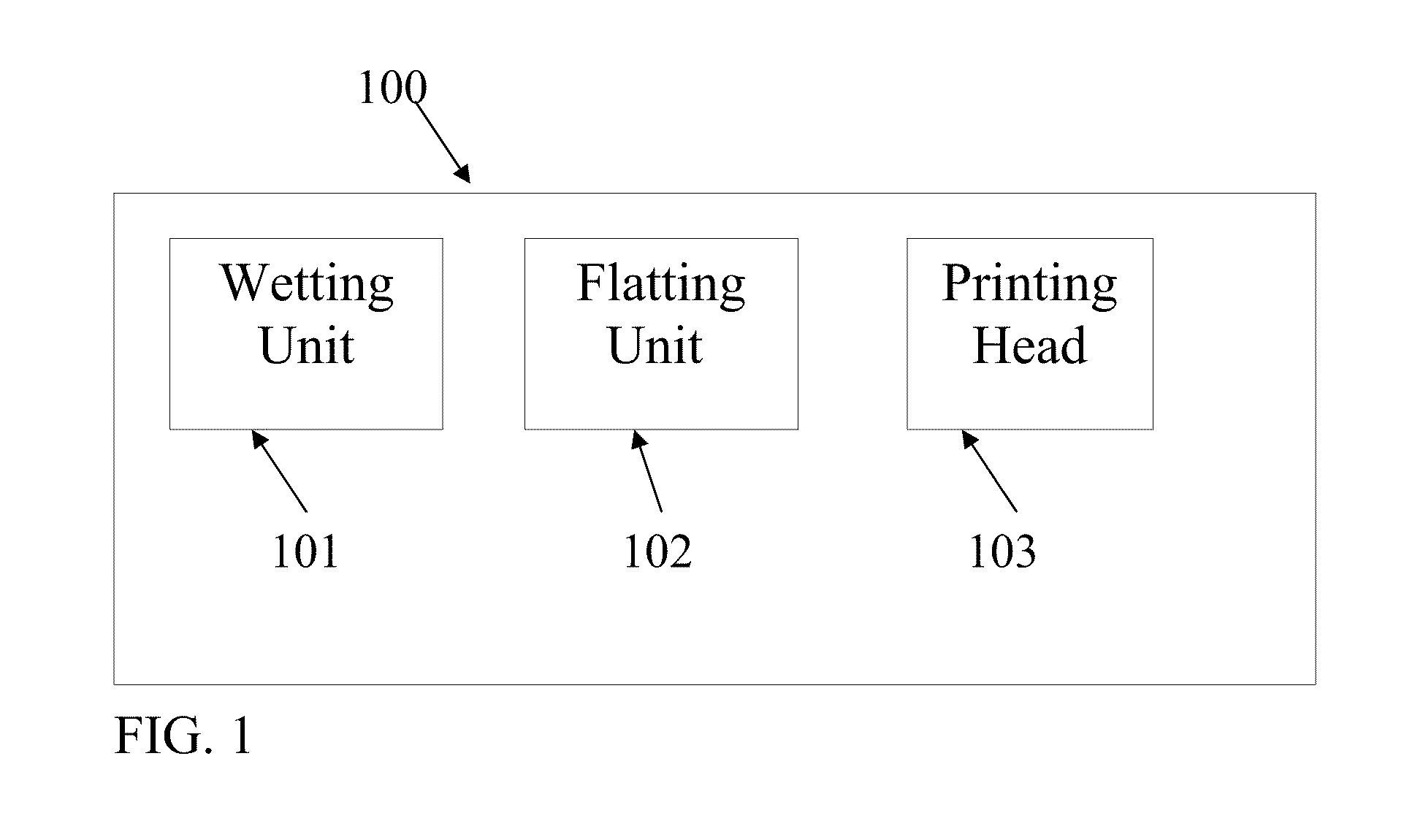

Inkjet compositions and processes for stretchable substrates

ActiveUS20110032304A1Suitable for useLess fluidInking apparatusMeasurement apparatus componentsColor imageFilm-forming agent

Novel inkjet ink compositions for forming an image in a form of an elastic film attached to a surface of a stretchable and / or flexible substrate and processes utilizing same for inkjet printing color images on various substrates such as colored and absorptive or impregnable stretchable materials, which are characterized by heightened efficiency in process time, ink and energy consumption, as well as products having durable, wash-fast and abrasion-fast images printed thereon by the process, are disclosed. The novel ink compositions comprise a first part, which contains a property-adjusting agent and a carrier, and a second part which contains an emulsified property-sensitive proto-elastomeric film-forming agent, a colorant and a carrier, such that the second part congeals upon contact with the property-adjusting agent. The second part is digitally applied to the substrate less than 1 second following the application of the first part to the substrate.

Owner:KORNIT DIGITAL LTD

Steel tube rust removal device with automatic paint spraying function

ActiveCN104084872AGuaranteed SprayingAvoid harmPolishing machinesRevolution surface grinding machinesMotor drivePhysical health

Provided is a steel tube rust removal device with the automatic paint spraying function. When a control cabinet controls the whole device to operate, a second motor drives a steel tube to rotate while driving a rotary clamping base to rotate, rust removal and polishing are carried out on the inner wall and the outer wall of the steel tube at the same time through an inner wire wheel, an inner polishing wheel, an outer wire wheel and an outer polishing wheel, and a rack and a gear of a first motor are in transmission to control a first paint can, the outer wire wheel and the outer polishing wheel to move horizontally to carry out rust removal, polishing and paint spraying on the outer wall of the whole steel tube evenly, wherein the outer wire wheel and the outer polishing wheel are installed on the first paint can. Meanwhile, a screw rod is driven by a guide wheel and a third motor to rightwards rotate and move, and the rotation direction of the screw rod is opposite to the rotation direction of the steel tube. By means of rust removal and polishing carried out through the inner wire wheel and the inner polishing wheel, spraying on the inner wall of the steel tube through an inner spray gun is ensured. By means of the automatic rust removal and spraying device, harm to physical health of staff by rust and dust is avoided. Meanwhile, due to timely spraying, later corrosion and manpower resource waste caused when the machining time of the steel tube is too long can be prevented.

Owner:广州市南粤钢管有限公司

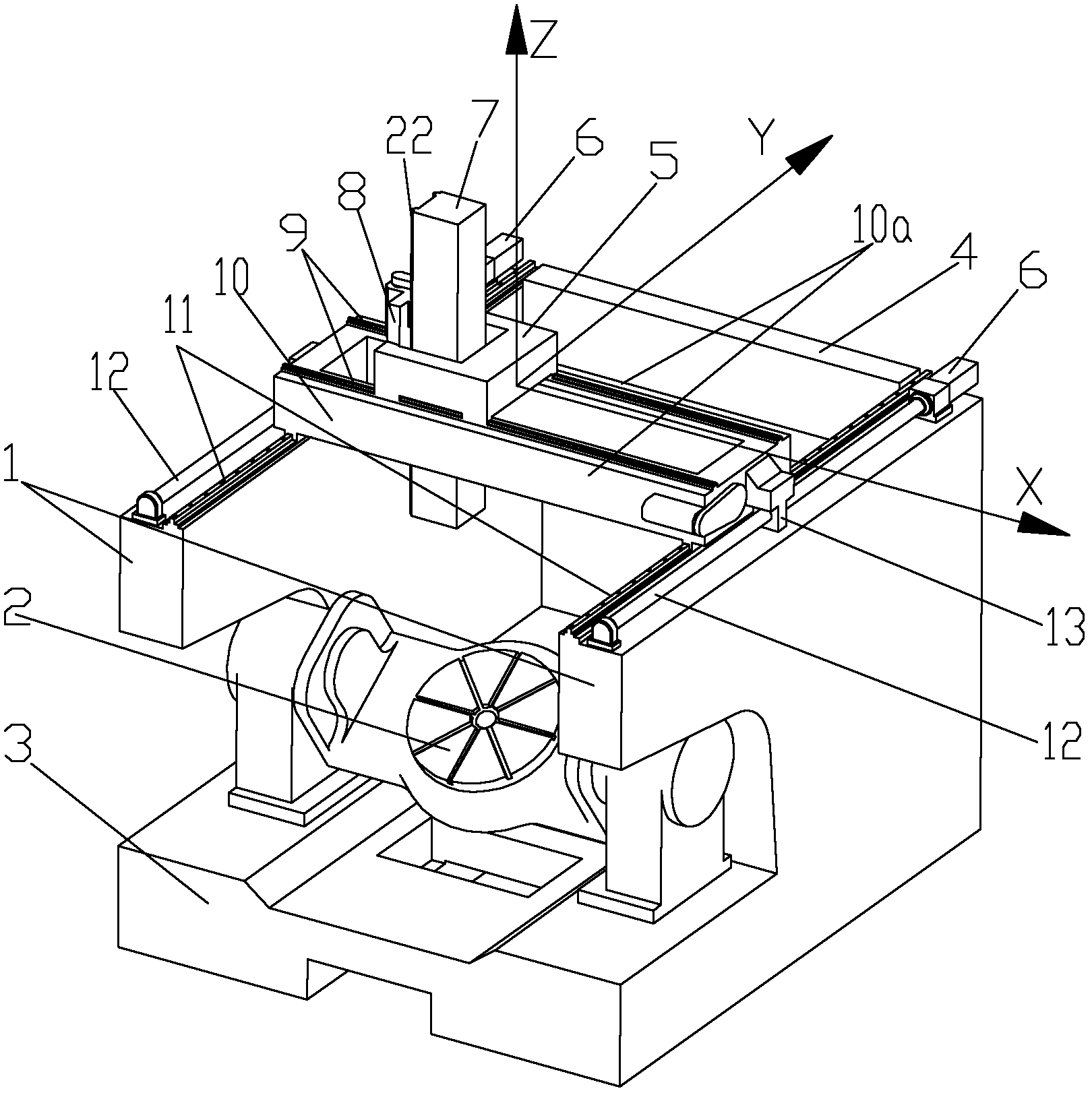

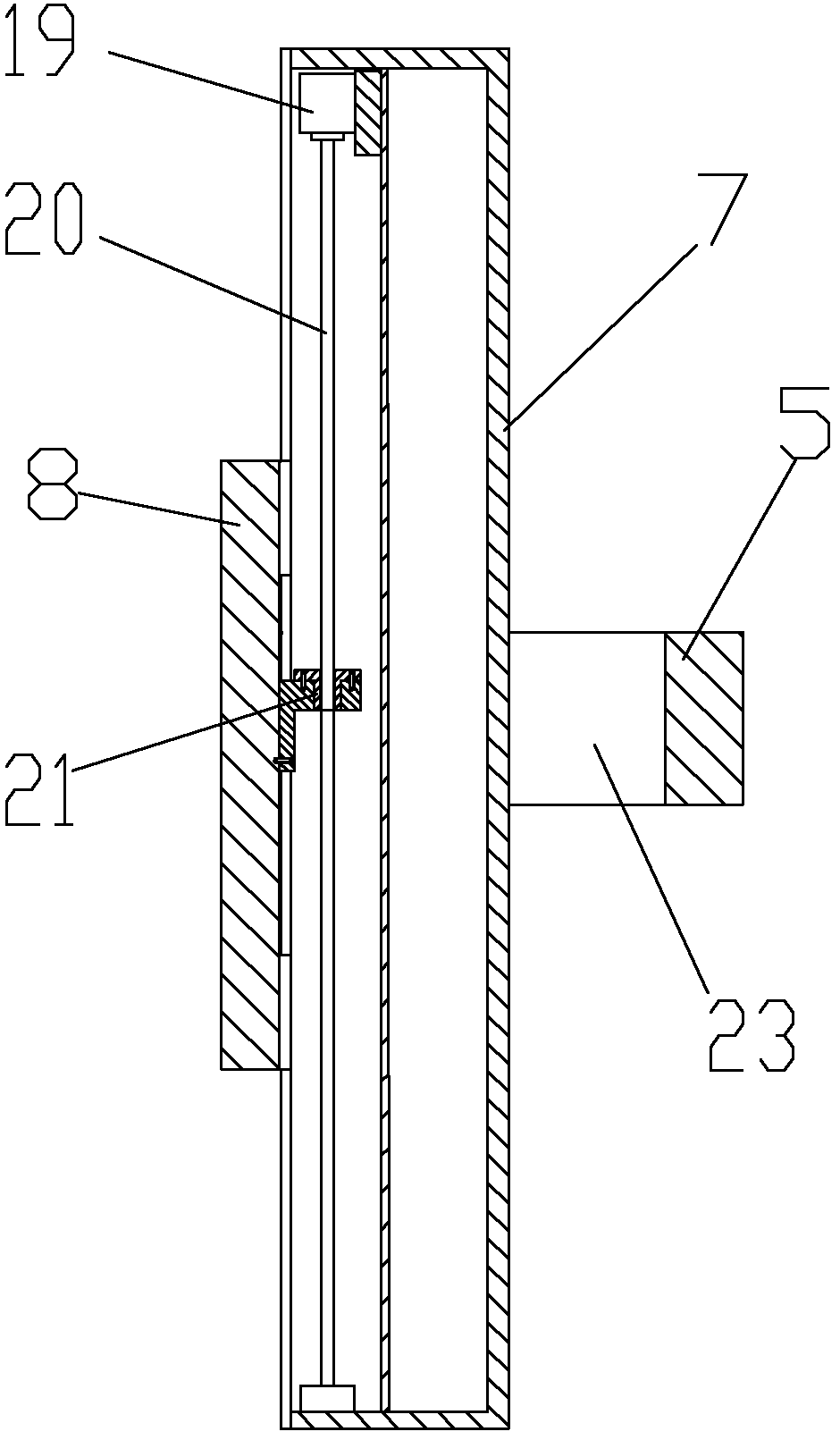

Small high-speed five-axis linkage machine tool

InactiveCN102632422AGuaranteed stabilitySmall sizeMachine tool componentsFeeding apparatusBridge typeEngineering

The invention discloses a small high-speed five-axis linkage machine tool, which comprises a foundation structure, a spindle box component and a cradle type worktable. The spindle box component is supported on the foundation structure, and a crossbeam with a frame-shaped structure is arranged on two upright columns to form a bridge-type portal structure. The torque bearing capacity of the crossbeam is improved, the small high-speed five-axis linkage machine tool has all advantages of a five-axis linkage machine tool in the prior art, and carries identical machining reacting force, the volume of a structural part is reduced, and the weight of the structural part is greatly lightened; a spindle box is positioned between two transverse rods of the frame-shaped crossbeam, overturning moment is eliminated, and the stability of the machine tool can be guaranteed; in addition, sizes of various components are greatly reduced on the premise of identical machining capacity, and the stroke of the machine tool can be large in the design; and by the aid of the structure, the machining precision is greatly improved, the machining range is greatly expanded, better dynamic characteristics and higher feeding speed and higher cutting speed can be realized, cutting and machining time is greatly shortened, better surface machining quality is obtained, and machining efficiency is enhanced.

Owner:CHONGQING UNIV

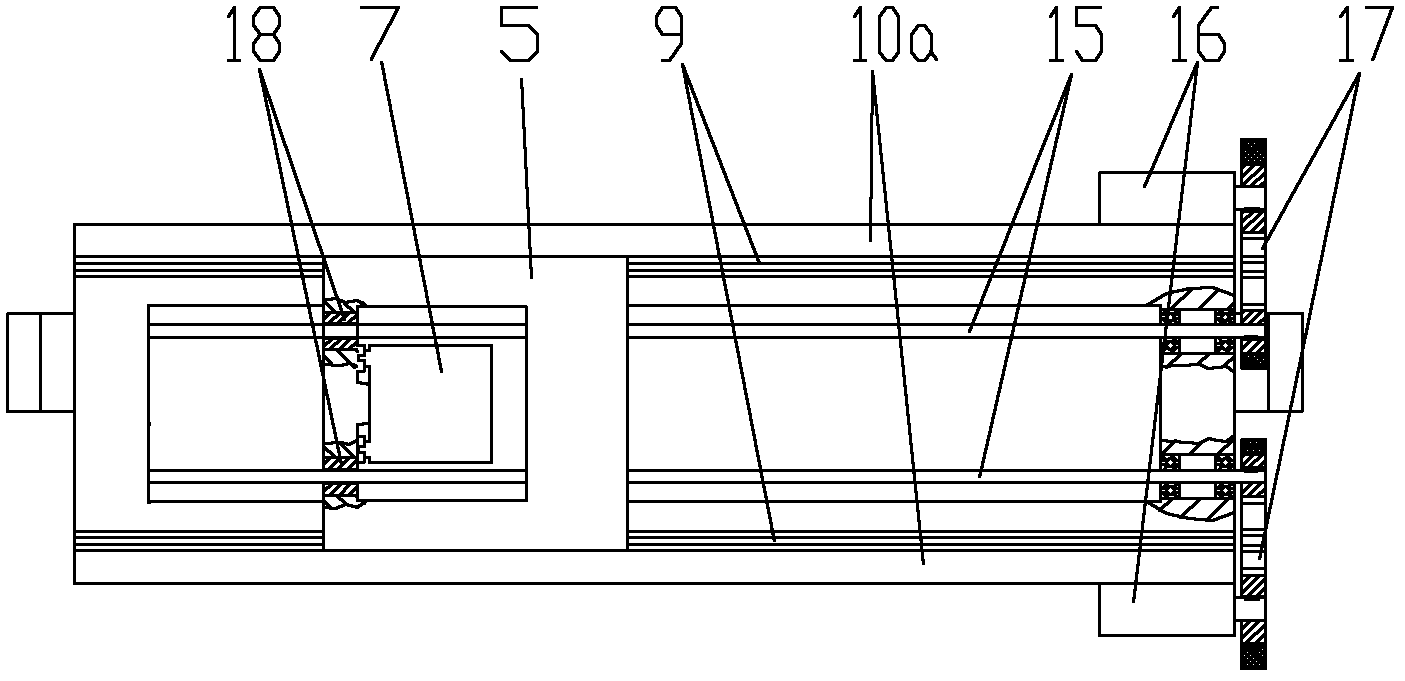

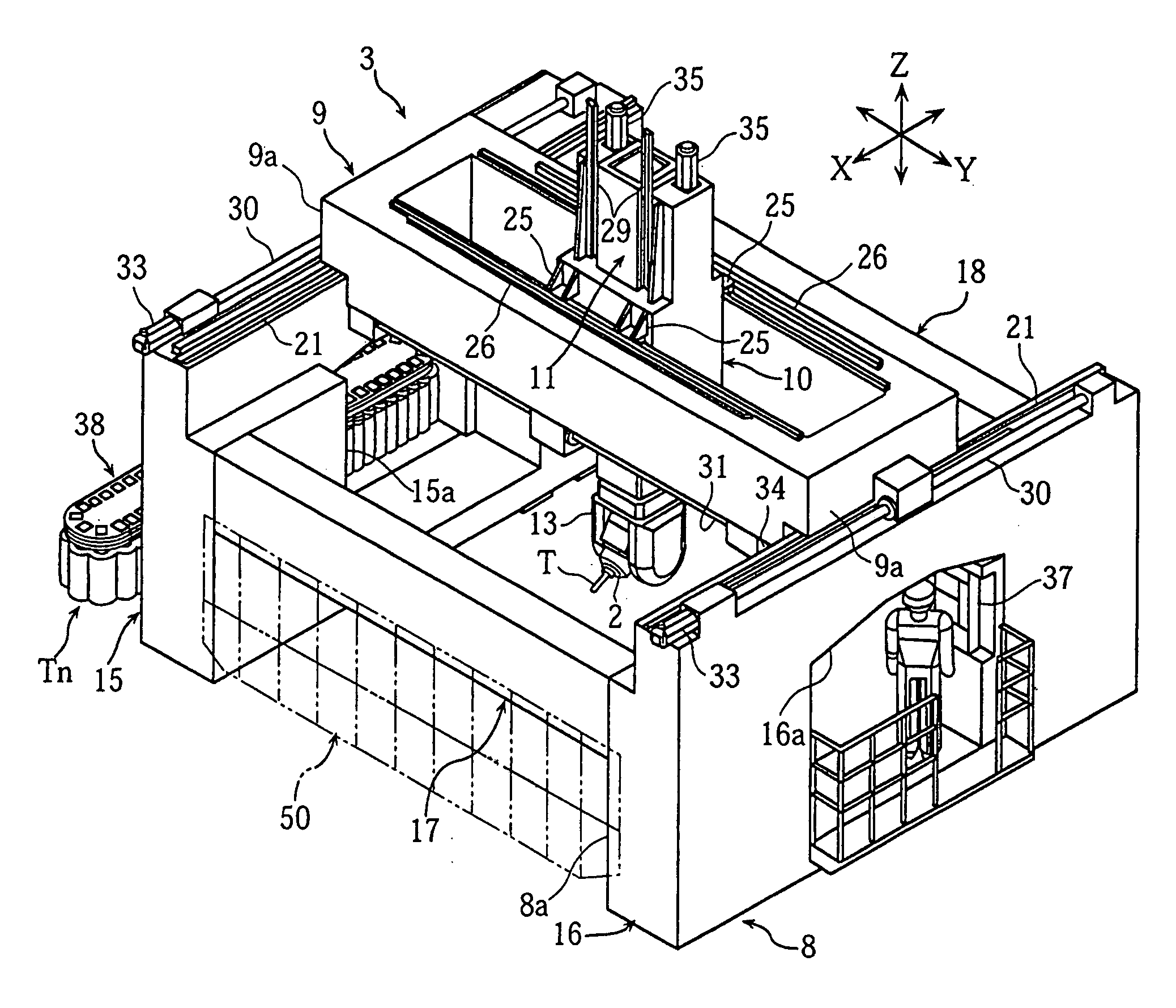

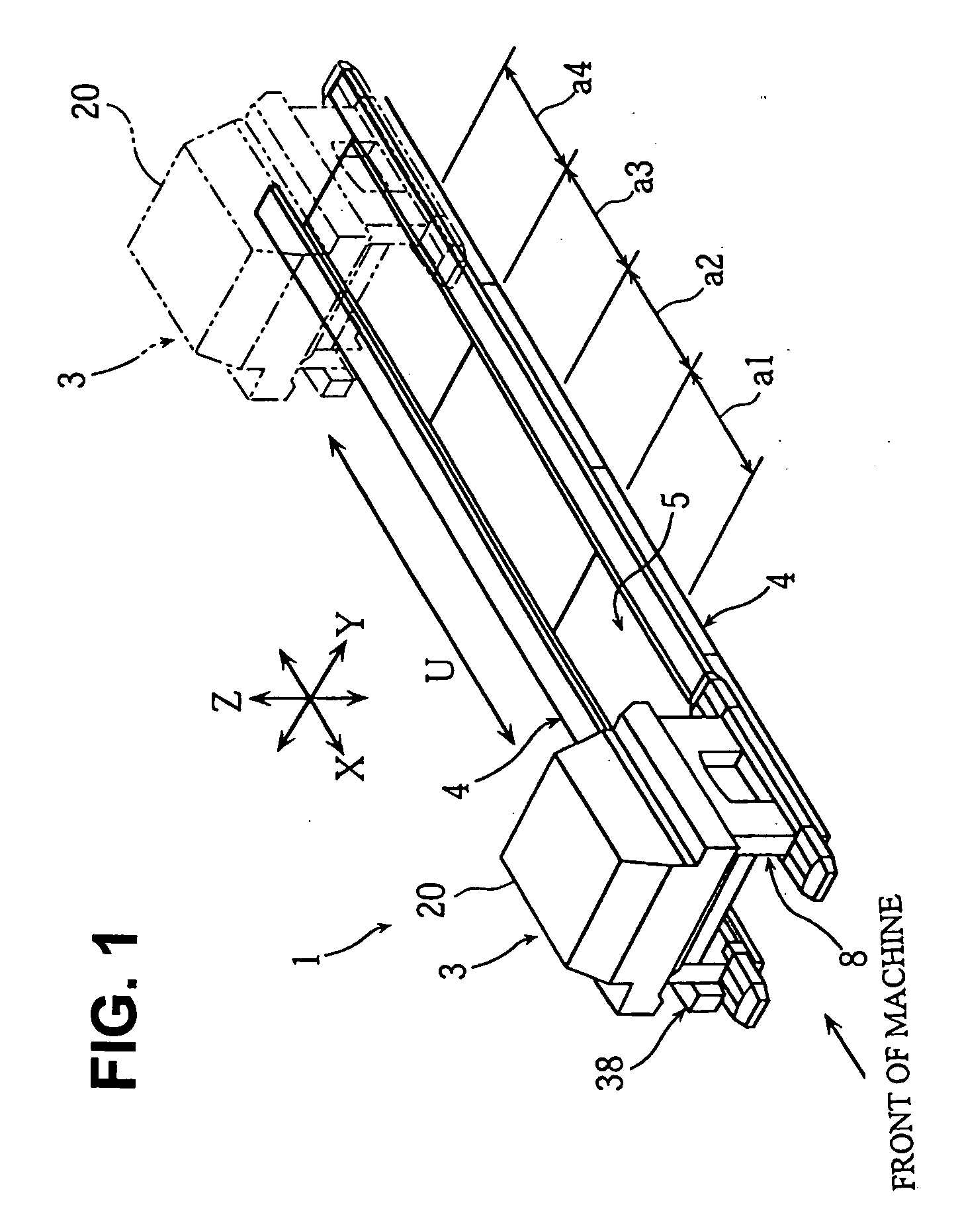

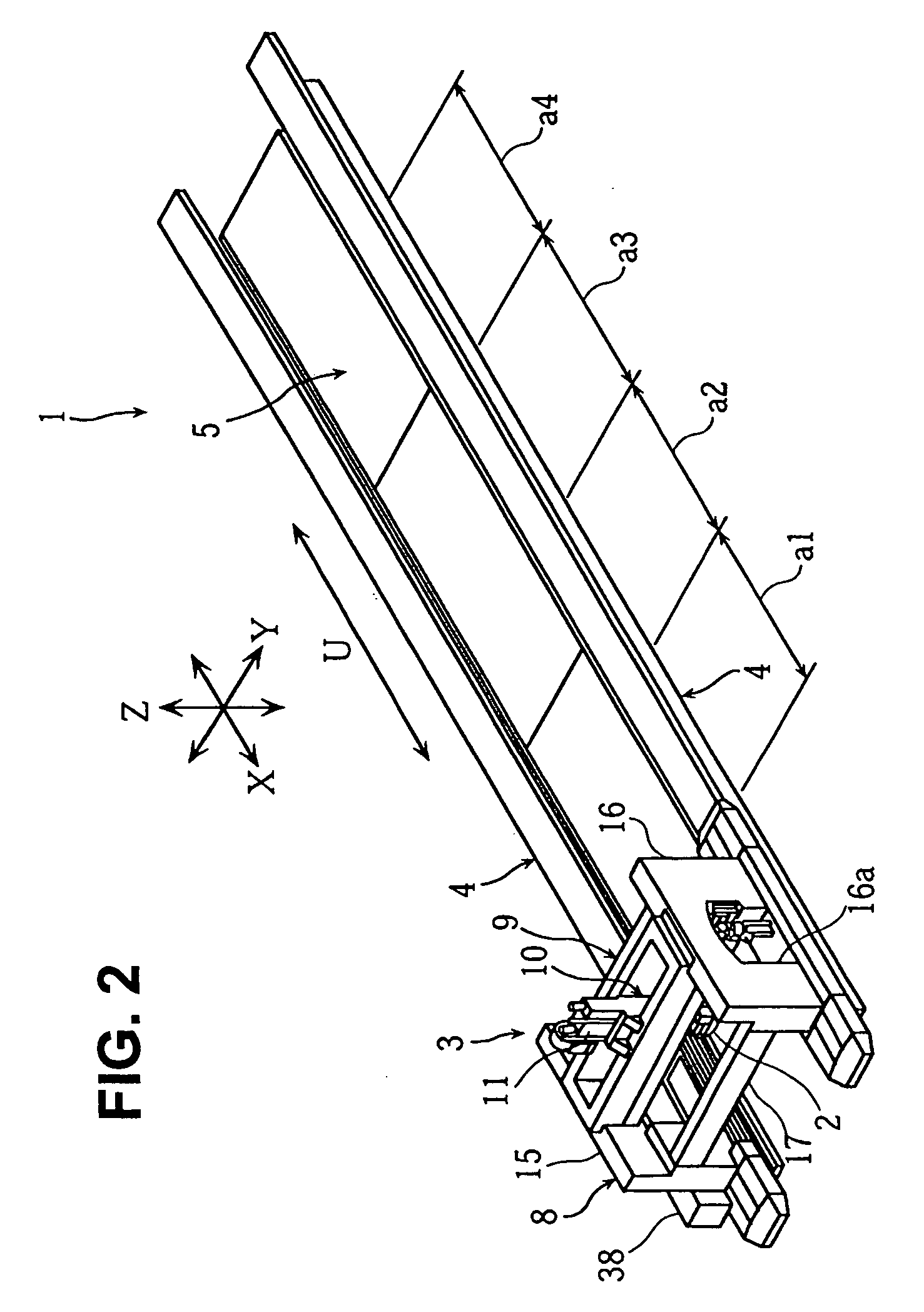

Machine tool

The present invention provides a machine tool realizing high-speed movement of a spindle and thus reducing the machining time without any increase in size of the whole machine. A machining unit 3 by which a spindle 2 with a tool T attached thereto is supported to be relatively movable in X-axis, Y-axis, and Z-axis directions is mounted on a long bed 4 having a plurality of machining areas a1 to a4 arranged in one direction, and the machining unit 3 is movable in the arrangement direction of the machining areas.

Owner:DMG MORI CO LTD

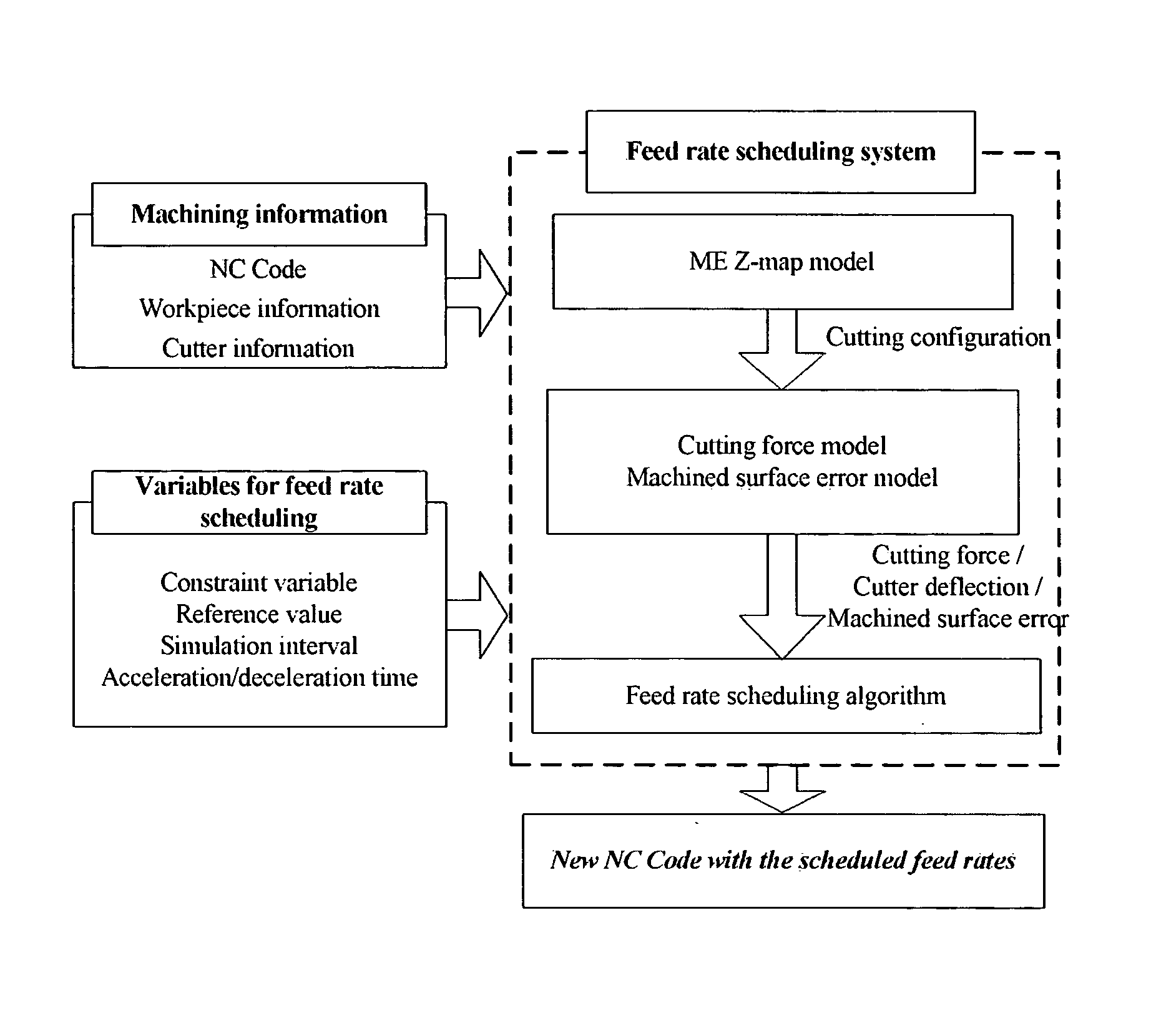

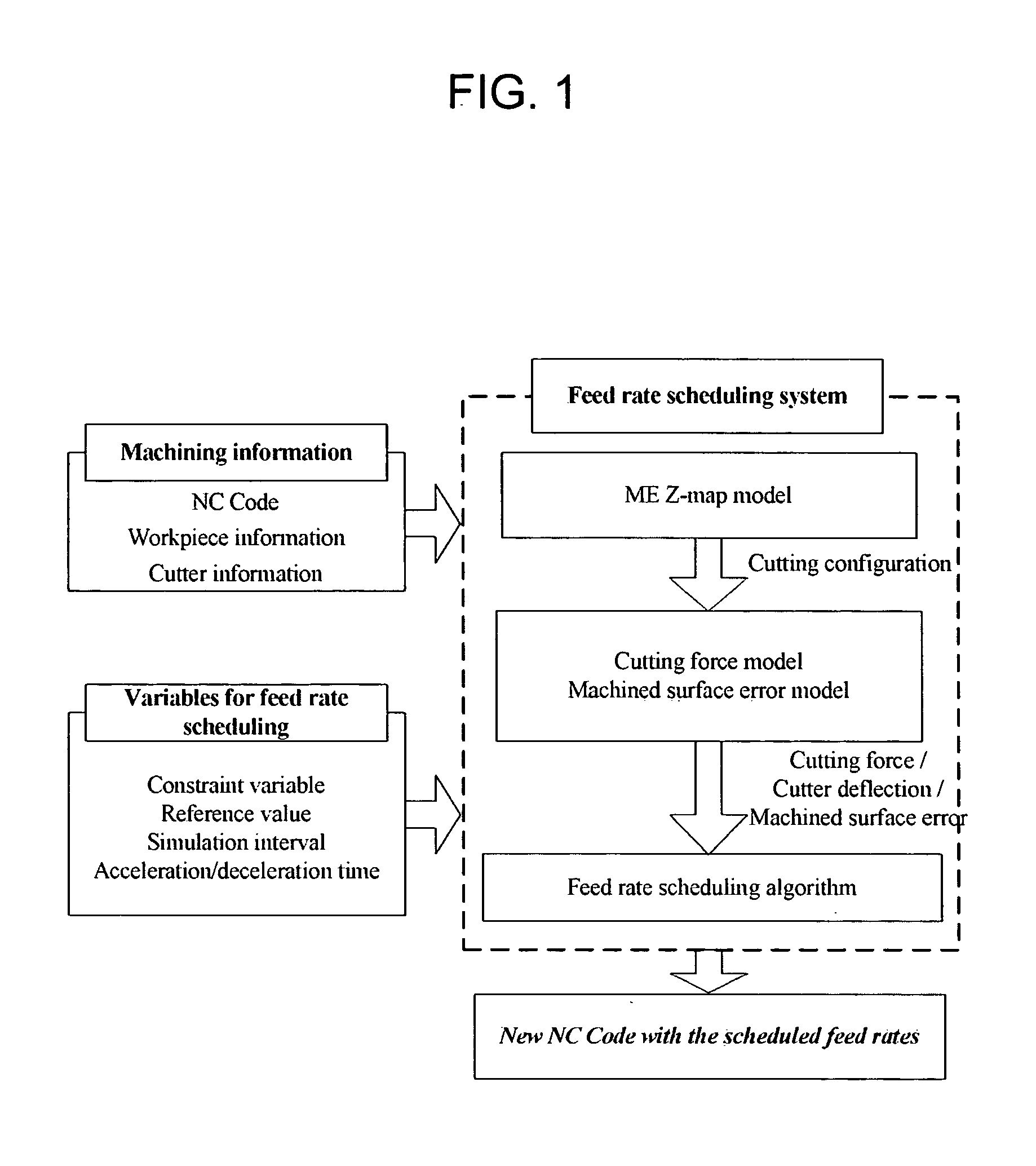

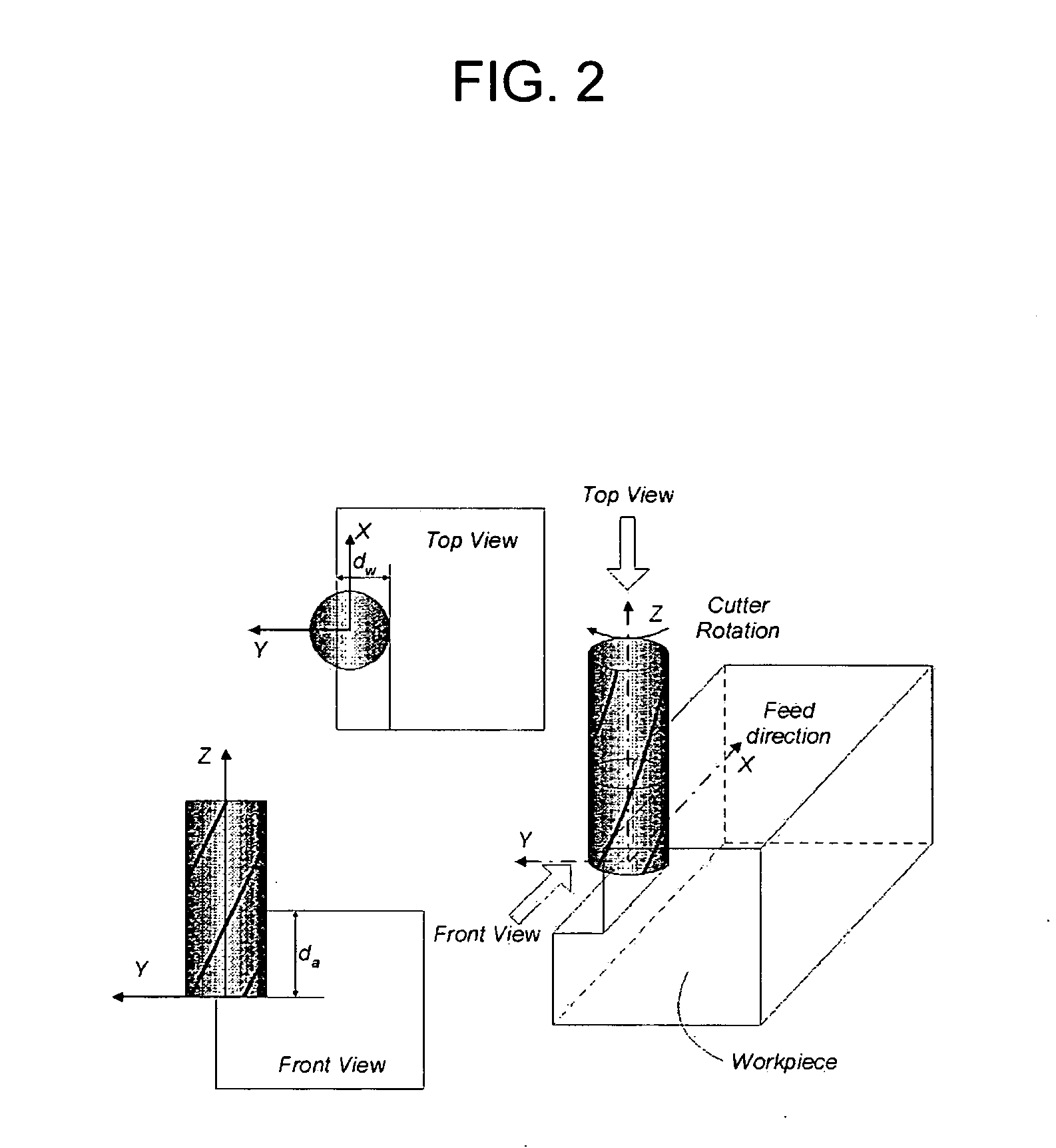

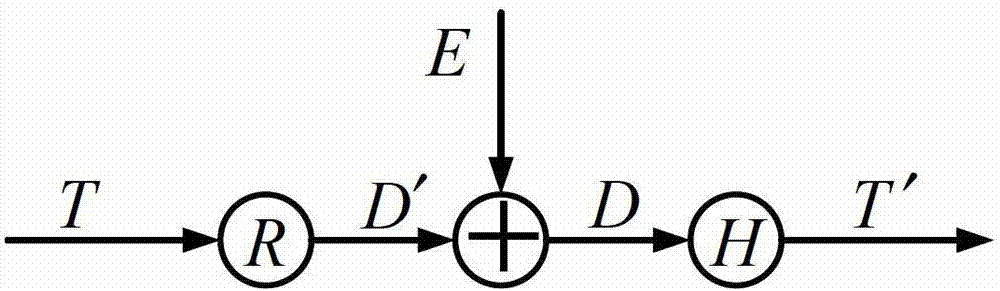

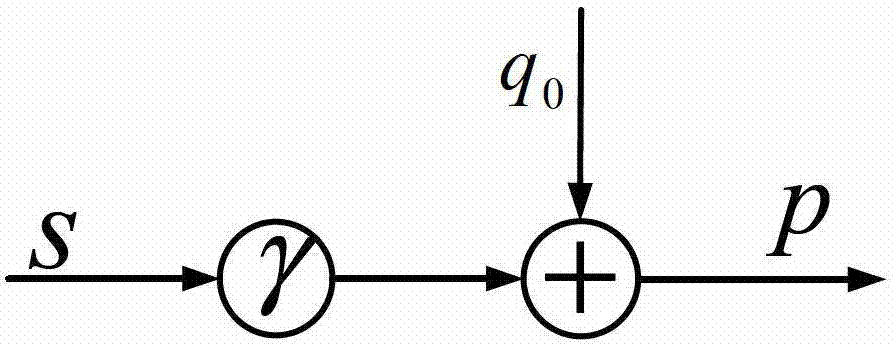

Off-line feed rate scheduling for reduction of machining time and enhancement of machining accuracy in CNC machining

InactiveUS20050113963A1Improve machining precisionIncrease productivityComputation using non-denominational number representationNumerical controlMachined surfaceSpecific rotation

An off-line feed rate scheduling method of a CNC machining process includes selecting a constraint variable and inputting a reference value related to the constraint variable; estimating a cutting configuration where a maximum constraint variable value (CVV) occurs through ME Z-map modeling; receiving the estimated cutting configuration and estimating a specific rotation angle (φs) where the maximum constraint variable value occurs through constraint variable modeling; calculating a feed rate that satisfies the reference value of the constraint variable at the estimated specific rotation angle; and applying the calculated feed rate to the NC code. Cutting force or machined surface error may be selected as a constraint variable depending on machining conditions.

Owner:POSTECH ACAD IND FOUND

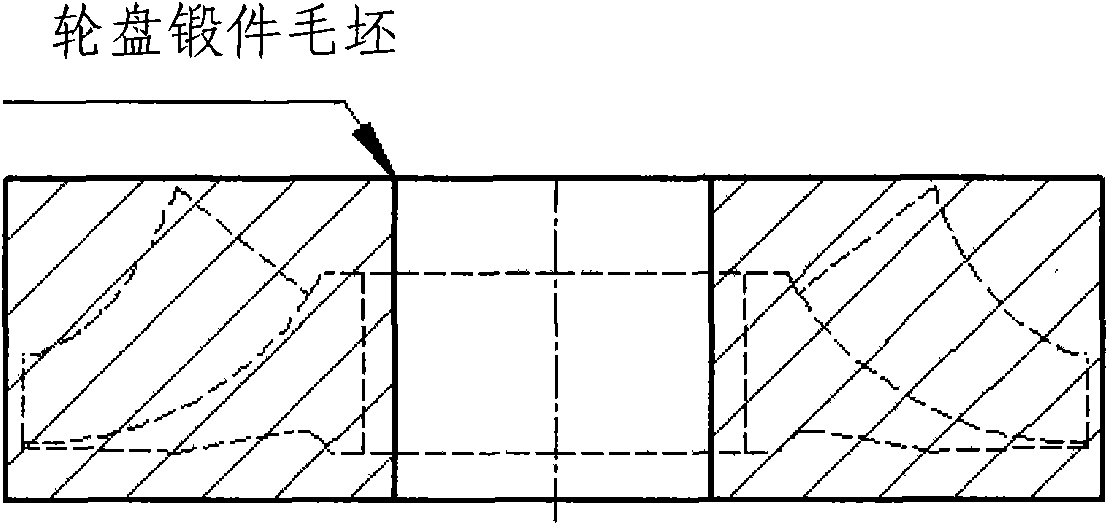

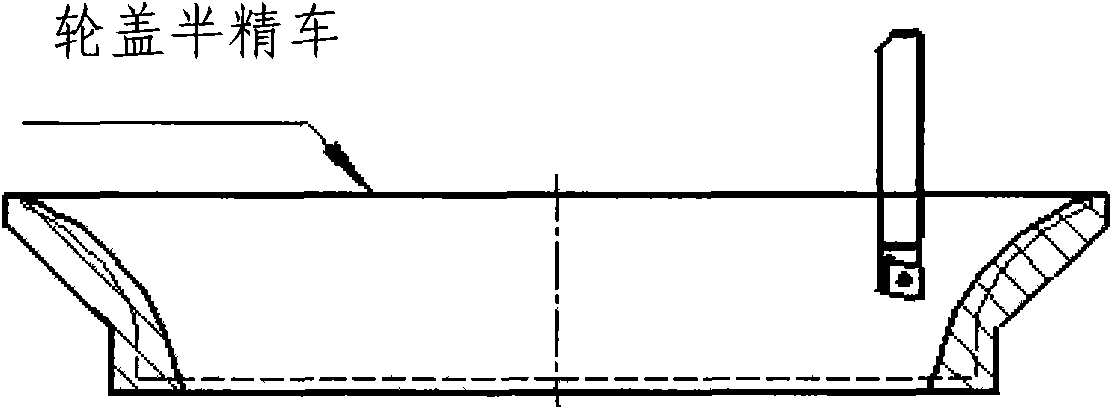

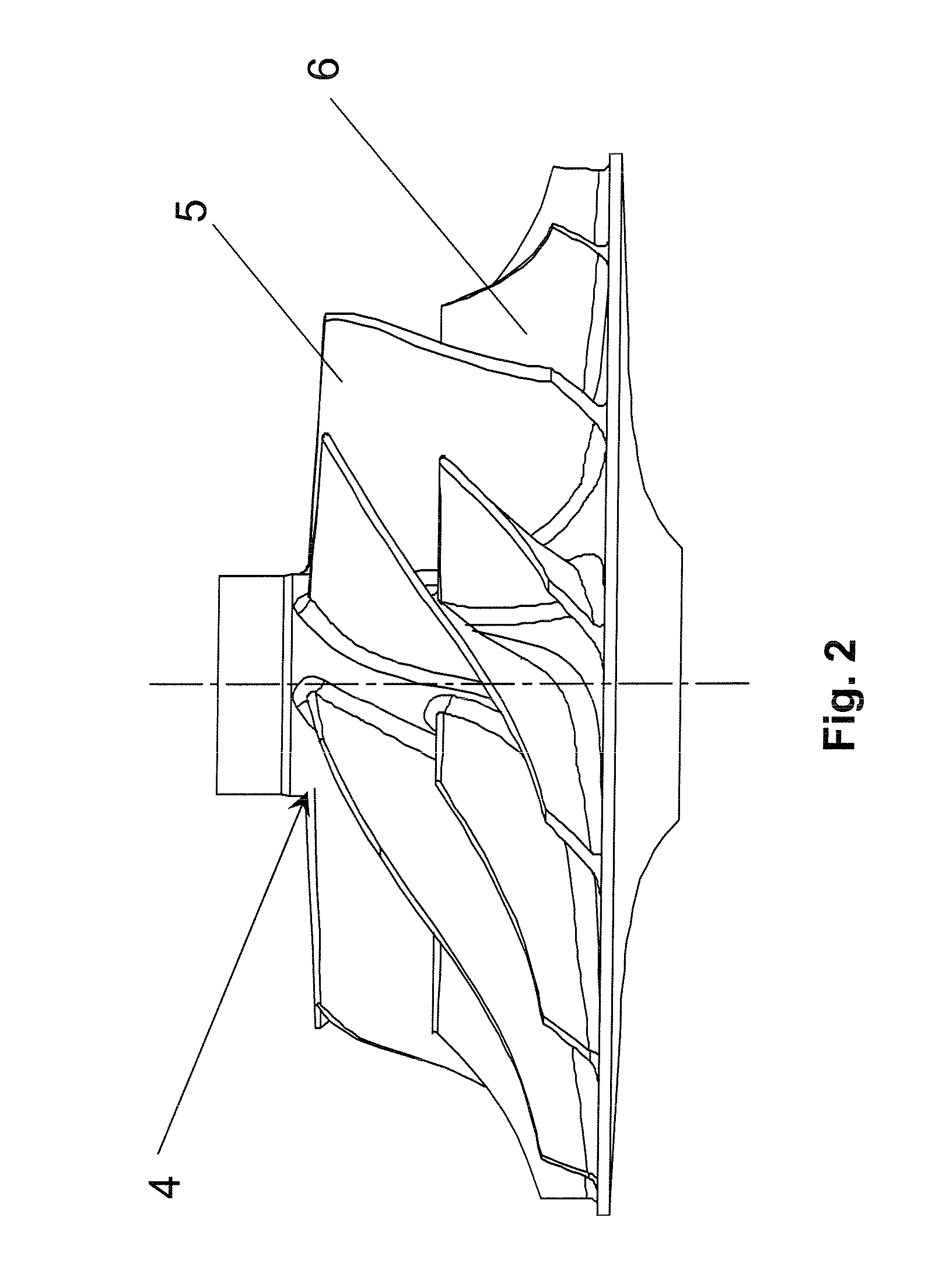

Machining method of three-dimensional closed impeller

ActiveCN102091919ASave raw materialsReduce manufacturing costMilling equipment detailsNumerical controlImpeller

The invention relates to a machining process of an impeller of a compressor, in particular to a machining method of a three-dimensional closed impeller, which is to clamp a semi-finish turned forge piece on a five-axis linked computer numerical control machining center to perform closed channel overall milling including drilling, coarse machining, semi-precision machining, back chipping and finish machining to mill the entire impeller and impeller channels. Compared with the conventional welding method, the machining method has the advantages that: the raw materials are saved and production cost is reduced as only one entire forge piece blank is used; the working efficiency is improved greatly because fewer machining process procedures are adopted and machining speed is high; the machining quality is high as quality defects caused by thermal deformation and welding are avoided; the machined impeller has high strength and high corrosion resistance; and the machining time of the impeller is reduced and the life index of a tool is improved because the flow the overall milling machining method is optimized according to the material, structure, specification and technical requirements of the workpiece and an applicable tool is configured according to different machining process procedures.

Owner:SHENYANG BLOWER WORKS GROUP CORP +1

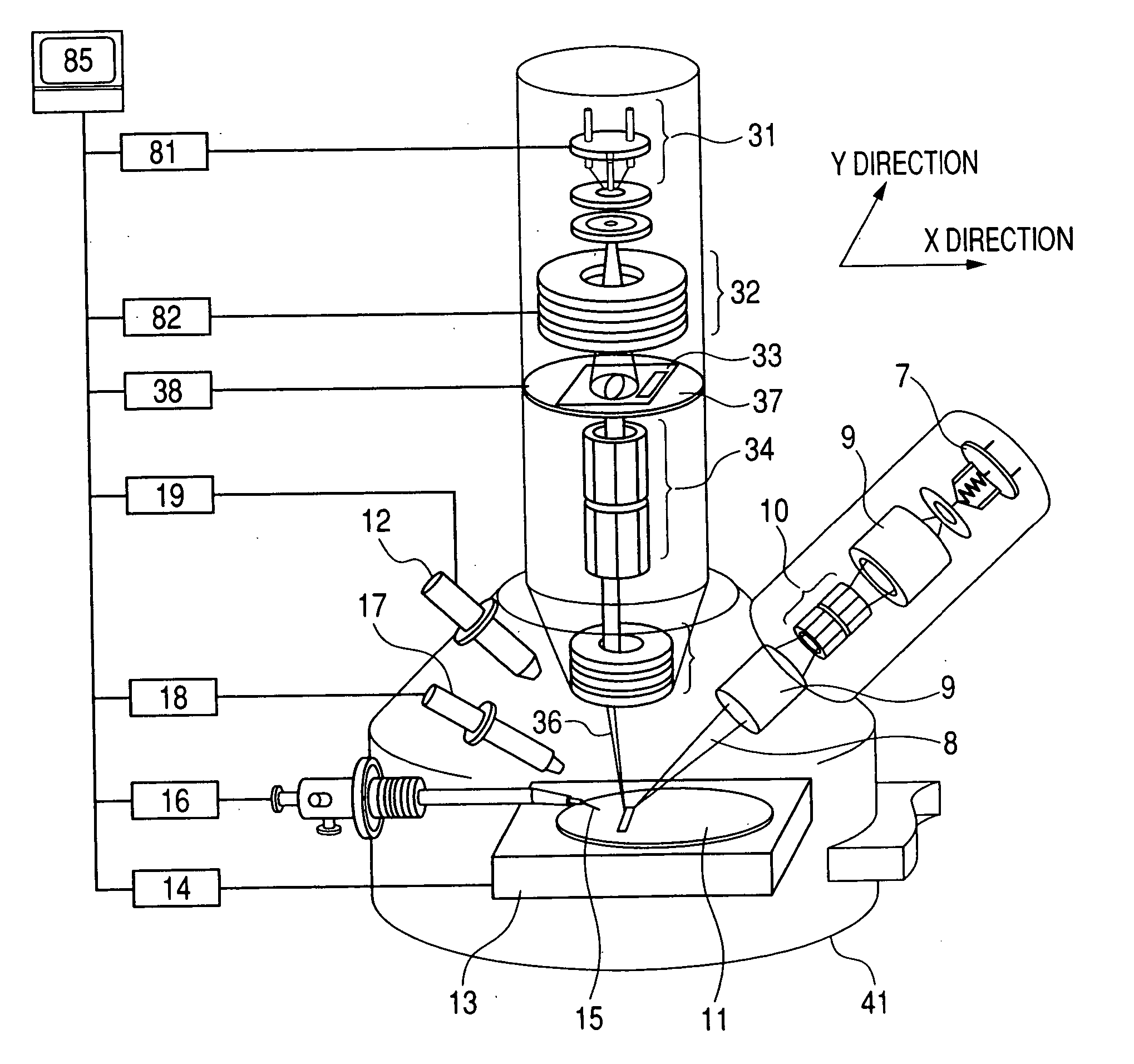

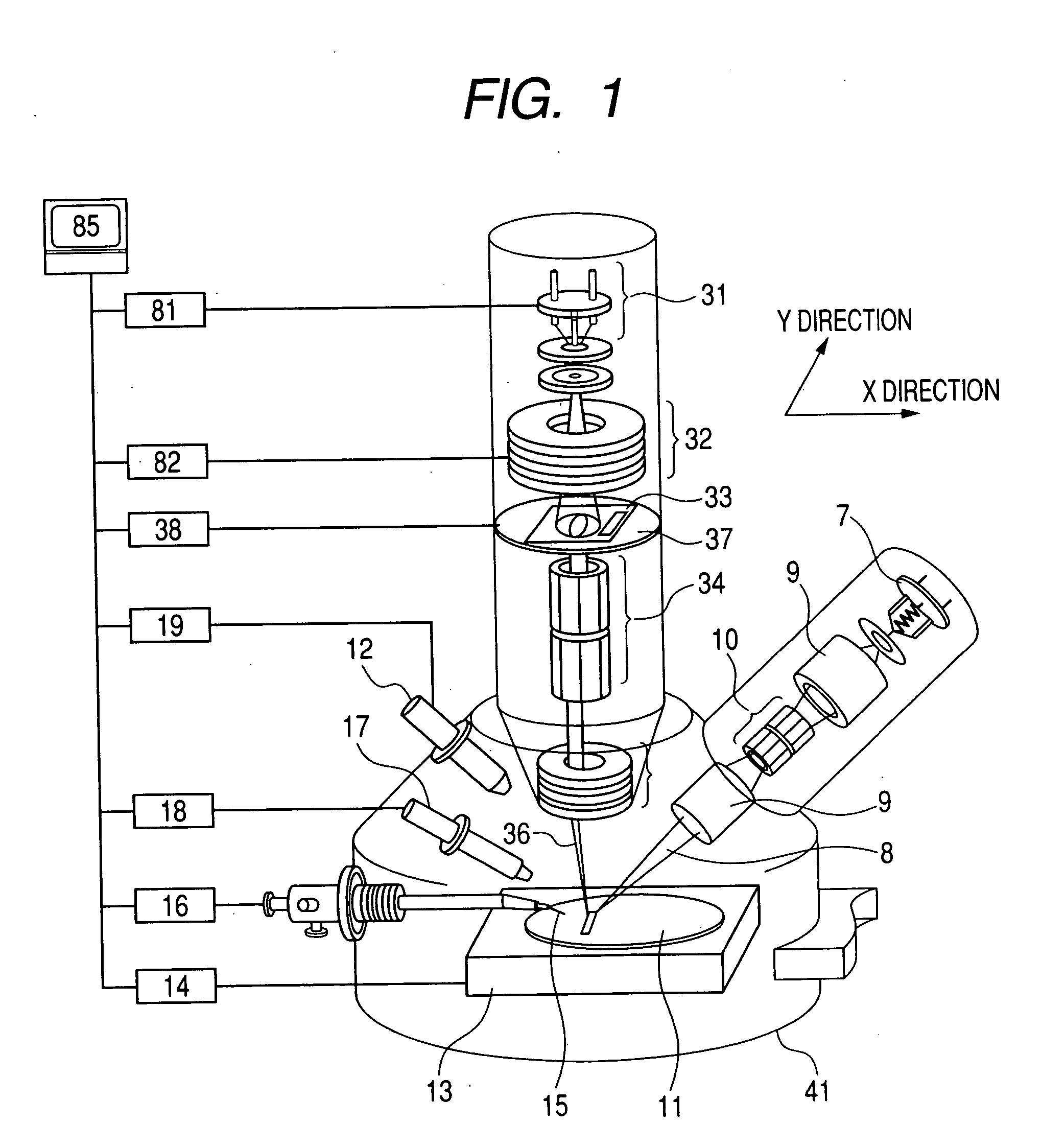

Ion beam system and machining method

InactiveUS20060065854A1Short timeReduce manufacturing costPreparing sample for investigationIon beam tubesMachining systemAnalysis method

There is a machining method which shortens a cross-section forming time by an ion beam, a machining method which shortens a machining time for separating a micro sample from a wafer, and an ion beam machining system. The ion beam machining system has a vacuum container containing a duoplasmatron, non-axially symmetric ion beam lens and stencil mask, wherein a micro sample is removed from a sample by an argon ion beam having a steep beam profile in a direction perpendicular to the cross-section. The cross-section observations for wafer inspection / defect analysis used in device manufacture can be obtained in a short time. Further, there is a inspection / analysis method which does not cause defects even if a sample is removed and a wafer is returned to the process.

Owner:HITACHI HIGH-TECH CORP

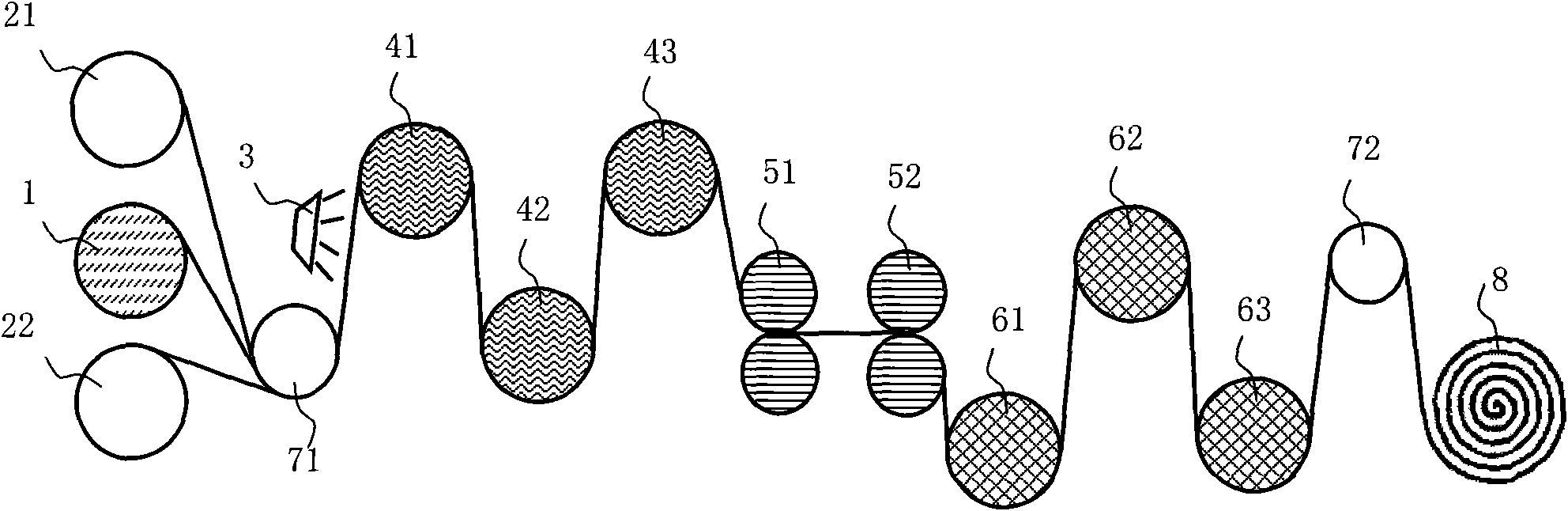

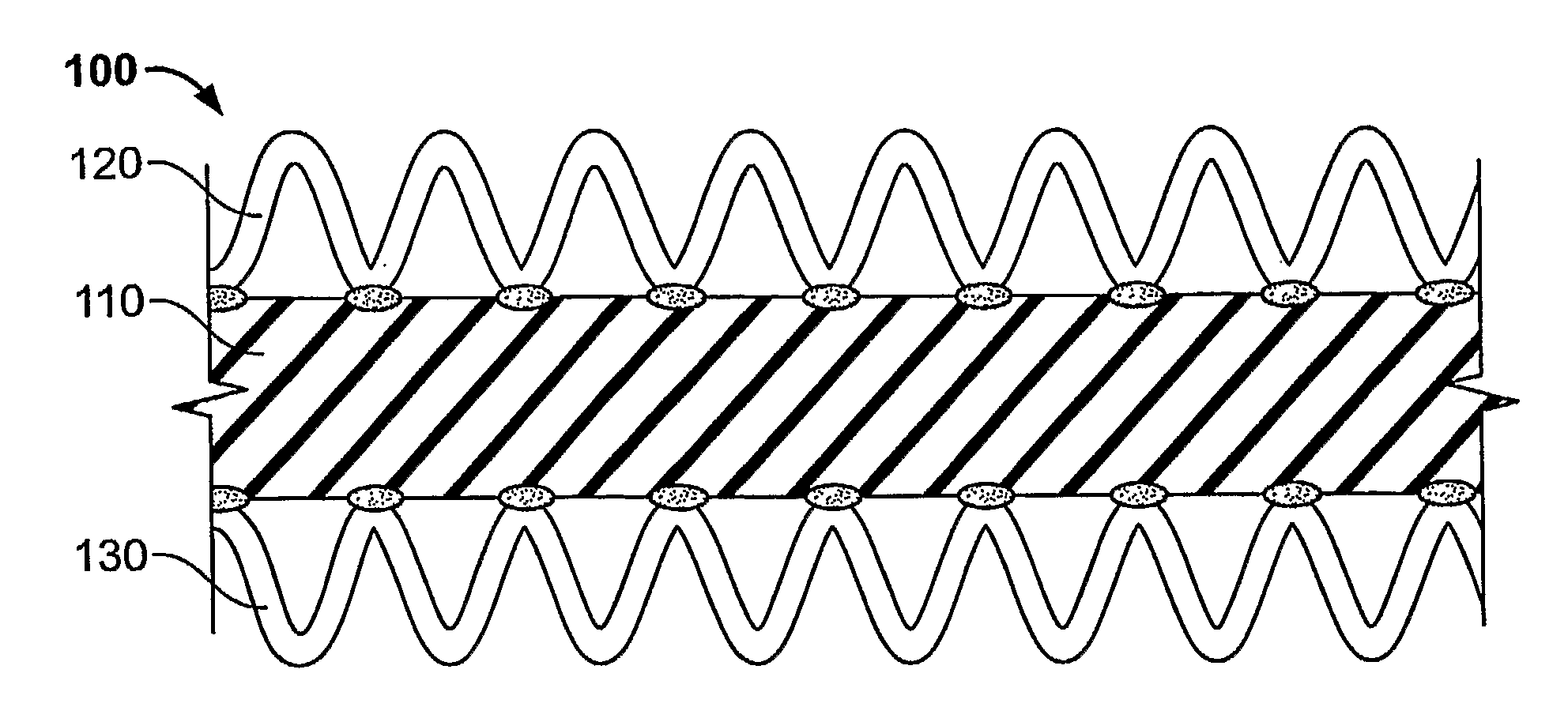

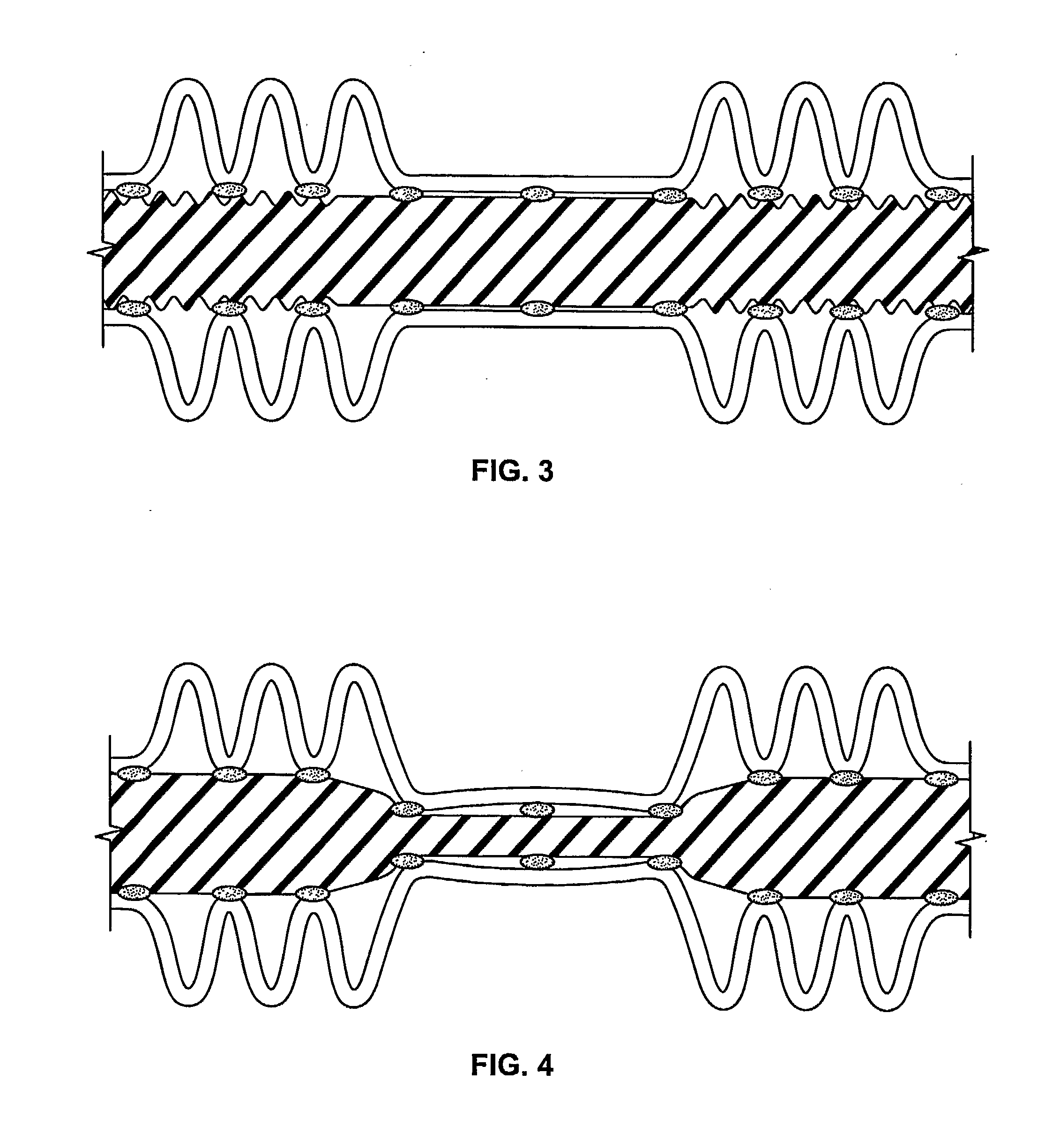

Elastic laminates

InactiveUS20100285286A1Lamination ancillary operationsLayered product treatmentEngineeringMachining time

The presently described technology provides one or more types of low cost elastic laminates with improved elasticity via stretching of an elastic layer, a non-woven layer, or the overall laminate that achieves reduced processing time and cost, can be utilized in a variety of end-user applications, and further provides self-warning capability to end-users of potential film and / or laminate overstretch. The described elastic laminates have at least one elastic layer and at least two non-woven layers, in which the elastic layers has at least one inelastic region formed via heating, incremental stretching, severing, or bonding. Additionally, heat shrink laminates having improved elasticity and compatibility with various laminate components are also described. Processes and systems for the manufacture of the described elastic laminates are also provided.

Owner:PLIANT LLC

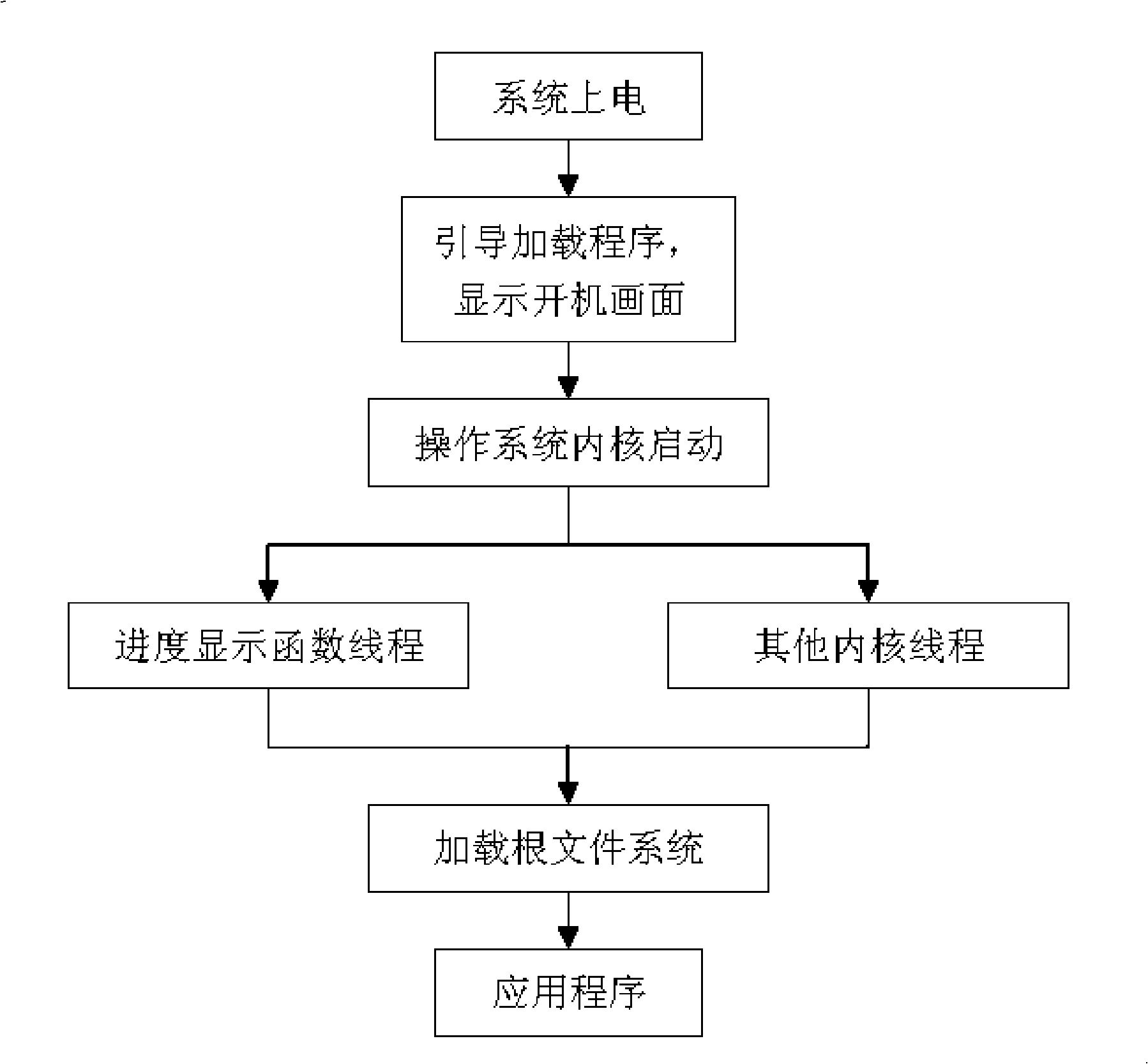

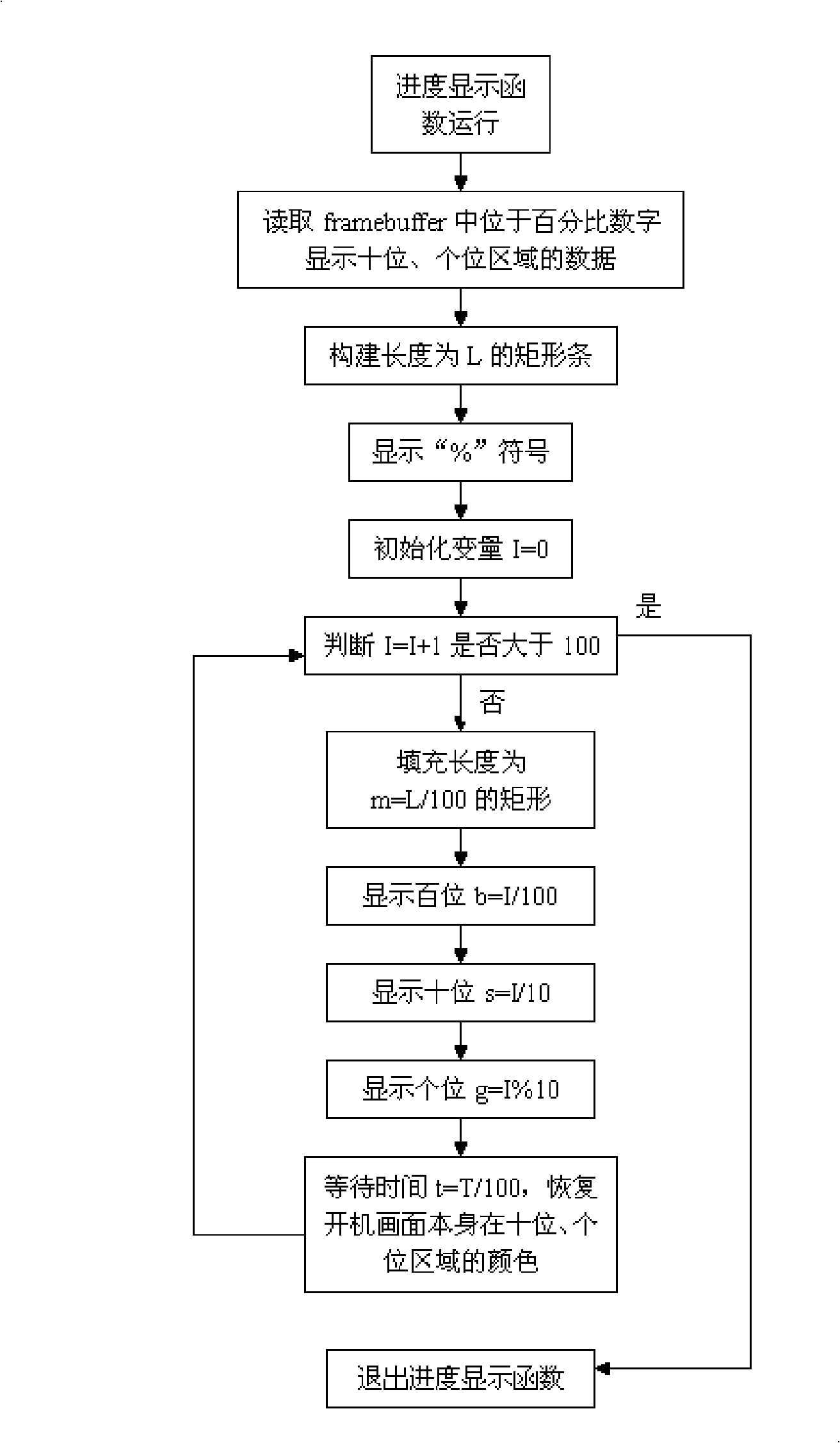

Method for displaying starting up progress of embedded device

InactiveCN101526905AImprove experienceAvoid blurHardware monitoringProgram loading/initiatingOperational systemProgress bar

The invention relates to the technique for displaying a startup picture of an embedded device and solves the problems that in the process of starting up the embedded device, latency time is long and nod feedback is displayed on the screen and provides a method for displaying starting up progress of the embedded device. The technical proposal is: the method is characterized by comprising the following steps: a. electrifying the system, starting up a boot loader program, invocating a display function to display the startup picture; b. starting up operating system nucleus, establishing a kernel thread and invocating a progress display function; c. operating the progress display function, displaying corresponding progress bars and percentage number according to available machine time; d. completing system startup and withdrawing the progress display function; the invention has the beneficial effects of offering convenience to the users and being applicable to embedded devices.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

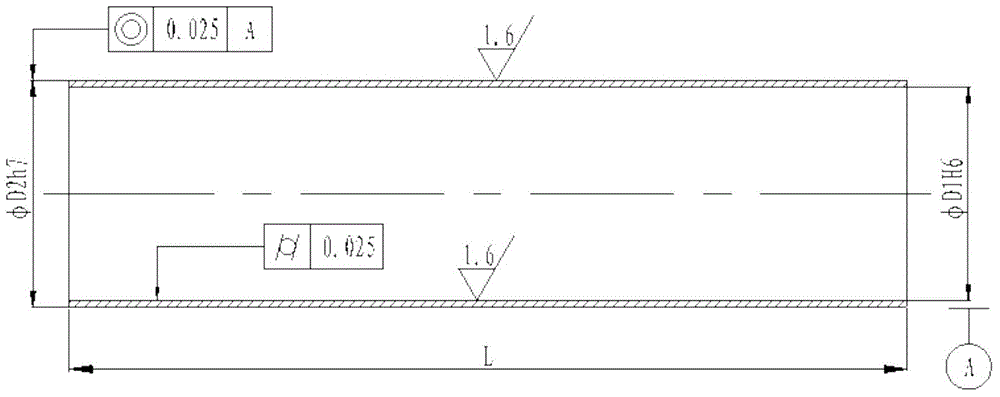

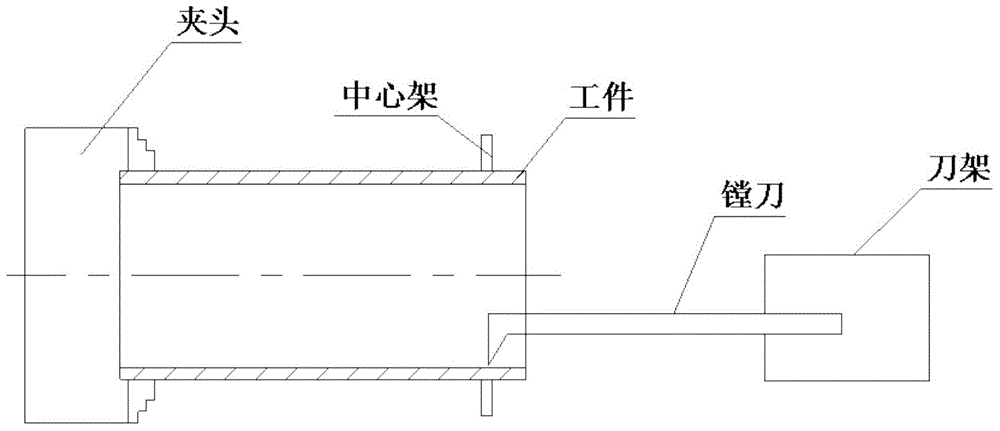

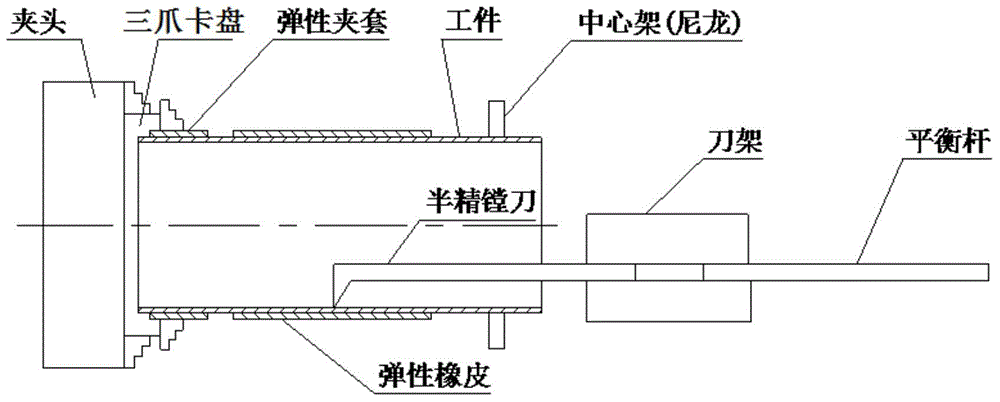

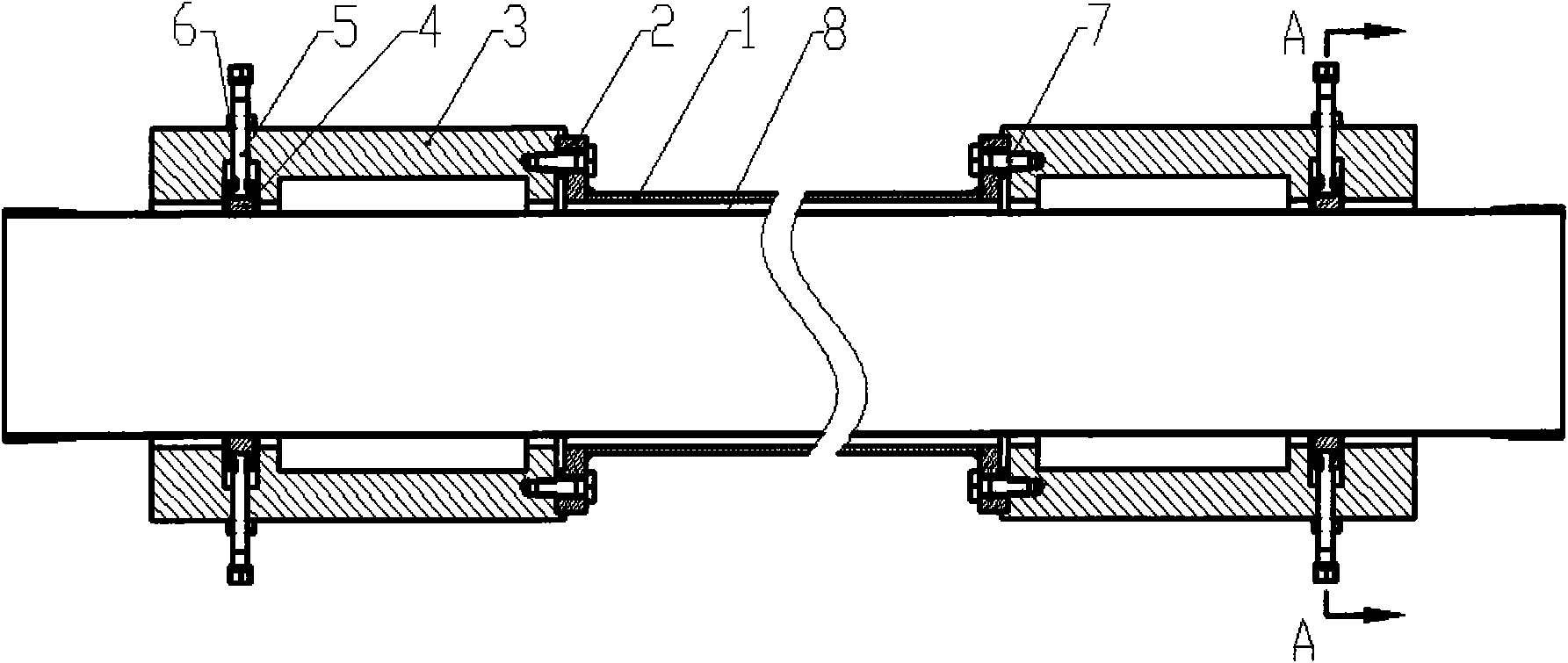

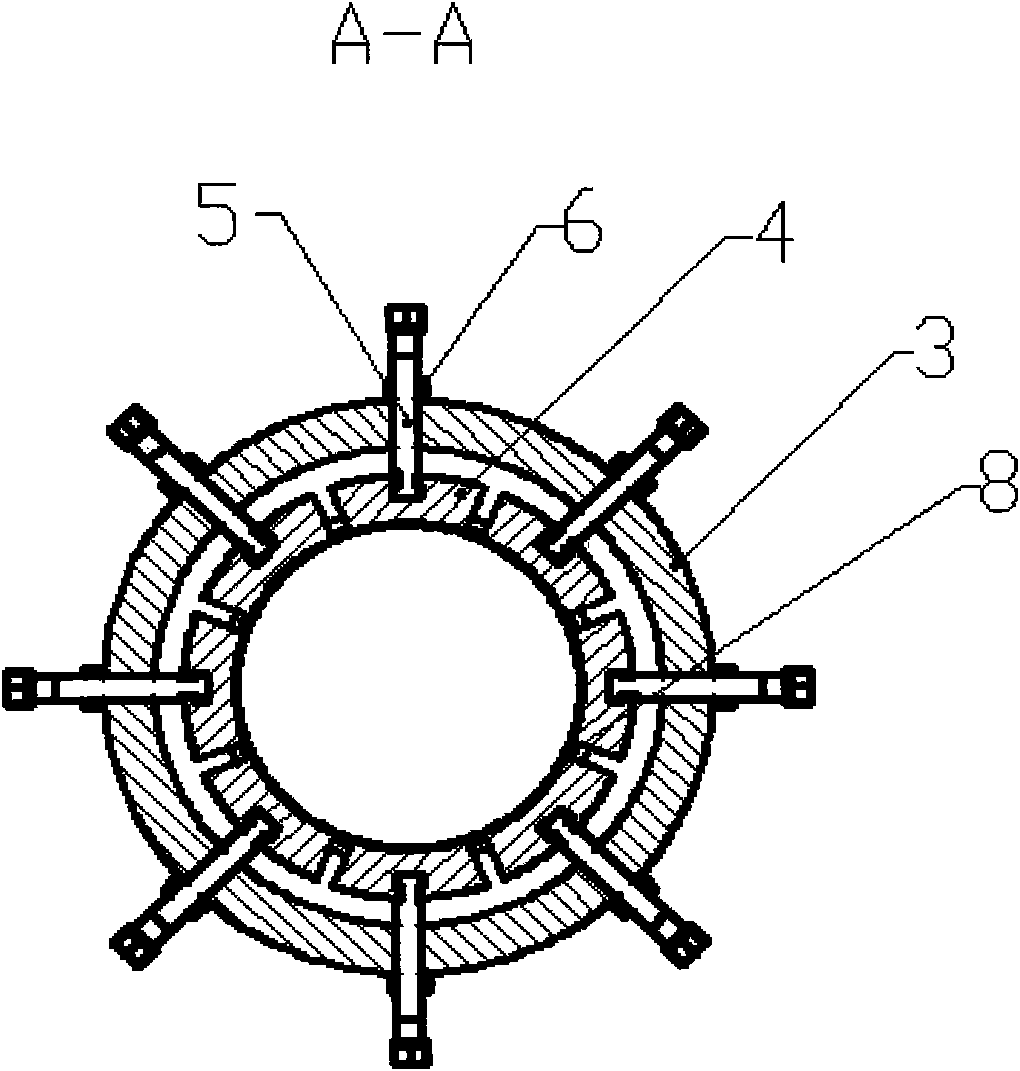

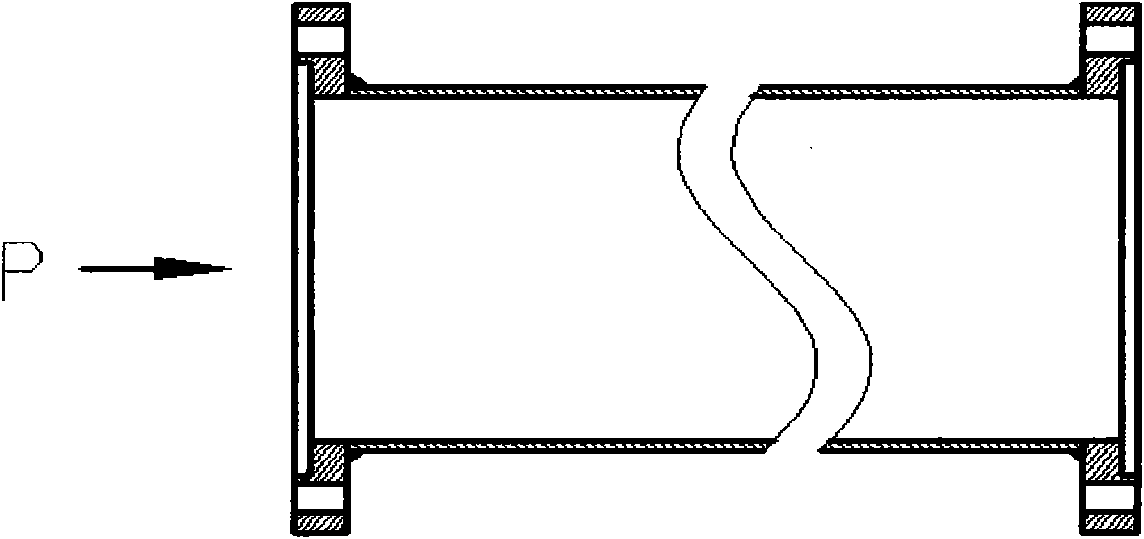

Processing method and technological equipment for cylindrical thin and long thin-walled workpiece

InactiveCN102049695AReduce distortionReduce the impact of machining accuracyAuxillary equipmentPositioning apparatusBall bearingEngineering

The invention relates to a processing method and technological equipment for a cylindrical thin and long thin-walled workpiece, which comprises positioning technological equipment and aligning technological equipment, wherein the positioning technological equipment consists of a connecting cylinder, a connecting flange, a positioning cylinder, a compression block, a compression screw, a stop nut and a connection screw; and the aligning technological equipment consists of an aligning technological equipment bottom plate, a bearing pedestal, a core shaft and a ball bearing. The processing method of the invention comprises a processing method suitable for manual operation of ordinary lathe and a processing method for operation of a hydraulic clamping center rest. The invention has the advantages that the deformation of the cylindrical thin and long thin-walled workpiece brought by clamping can be effectively reduced, the influence of workpiece clamping force on the workpiece processing precision is reduced, the processing quality is improved, the processing procedure is simplified, the processing time is shortened, the processing efficiency is improved, the high-quality product rate reaches 100%, the cost is saved at the same time, and the effect in batch production is more obvious.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

Vacuum evanescent die casting process

InactiveCN102974762AHigh precisionNo uneven wall thicknessFoundry mouldsFoundry coresModel compositionAfter treatment

The invention discloses an evanescent die process. The evanescent die process is characterized by comprising the following steps of: selecting foaming plastic beads, manufacturing a model; enabling the beads to expand to be in a certain size through hot water pre-frothing, steam pre-frothing and vacuum pre-frothing, curing and frothing forming; clustering model composition, coating a model; vibrating and shaping; pouring and displacing; and cooling and cleaning, wherein the full mold casting ramoff is simple, a casting piece can be hoisted out when a sand box is inclined or can be directed hoisted out form the sand box, the casting piece and dried sand are naturally separated, and the separated dried sand is reused after treatment. According to the process, a die is not required to be taken out, and a parting plane and a sand core are not required, and thus the casting piece has no flash, no burrs and no pattern tapers, and the dimension error caused by core combination is reduced; and compared with the conventional sand casting method, for the evanescent die process, the 40%-50% machining time is reduced.

Owner:CHANGTU COUNTY JIPAI MACHINERY CASTING

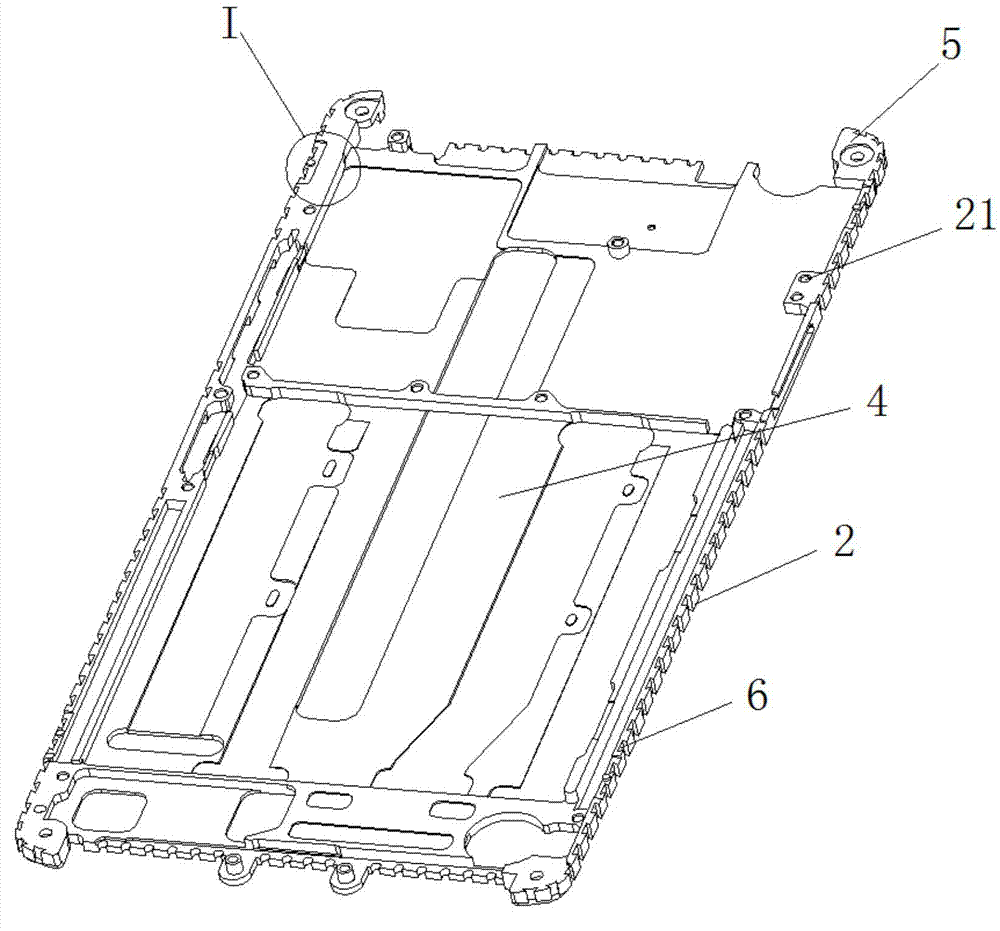

Mobile electronic product metal middle frame and processing technique thereof

InactiveCN104853549AHigh hardnessAvoid breakingCasings/cabinets/drawers detailsMetal casingsManufacturing technologyEngineering

The present invention relates to the technical field of mobile electronic product housing manufacturing, and especially relates to a mobile electronic product metal middle frame. The mobile electronic product metal middle frame comprises a side frame and a middle board, wherein the middle board is internally installed inside the side frame; the side frame comprises a first side wall, a second side wall, a third side wall and a fourth side wall which are arranged in turn; a plurality of key holes are disposed on the first side wall; the middle board comprises a middle board body and arc-shaped plates arranged at two ends of the middle board body; and a plurality of dovetail grooves are formed in the outer wall of the middle board. Through the above structure, the hardness is raised, and the structure is not easy to damage and is attractive and elegant in appearance. The present invention also relates to a processing technique for manufacturing the above mobile electronic product metal middle frame. The technique is little in processing time, and the processing time is saved.

Owner:AOJIE HARDWARE JIANGSU

Combination machining method for removing high-frequency errors in optical elements

ActiveCN102848287AImprove high frequency errorOptical surface grinding machinesEngineeringSpectral density

The invention discloses a combination machining method for removing high-frequency errors in optical elements. The combination machining method includes measuring surface shape errors of an optical element to be machined by an interferometer, carrying out PSD (power spectral density) analysis, and determining distribution characteristics of the medium and high-frequency errors on the basis of a DSD curve; acquiring an optimized removal function model according to predetermined machining time and machining precision, and acquiring an amplitude spectral line of a removal function; acquiring cut-off frequency of the removal function according to the amplitude spectral line; machining by a magneto-rheological finishing process if correctable medium and high-frequency errors with the frequency lower than the cut-off frequency exist according to the frequency distribution of the medium and high-frequency errors; and machining by a computer controlled optical surfacing process if uncorrectable medium and high-frequency errors with the frequency higher than the cut-off frequency exist according to the frequency distribution of the medium and high-frequency errors. By the combination machining method, technical advantages of MRF (magneto-rheological finishing) and technical advantages of CCOS (computer controlled optical surfacing) can be sufficiently combined, efficient uniform convergence of all-band errors of the optical element can be realized, and performance of the optical element is effectively improved.

Owner:NAT UNIV OF DEFENSE TECH

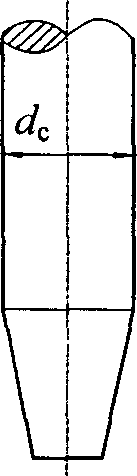

Drum taper tool and method for side milling complex cambered centrifugal impeller using drum taper tool

InactiveCN1413790AShort track lengthEasy to correct interferenceMilling cuttersMilling equipment detailsImpellerMachining time

A conic drum-shaped cutting tool and its feed pitch, feed step length and method for calculating the position of cutting tool are disclosed. Its cutting part is a rotary surface. Its generating line is an arc with radius R. Its advantages are high productivity, high rigidity and high rotation flexibility. A method for laternally milling a centrifugal blade wheel with complex curved surface with the said cutting tool is also disclosed, which features less number of tracings, short tracing and high productivity.

Owner:XI AN JIAOTONG UNIV

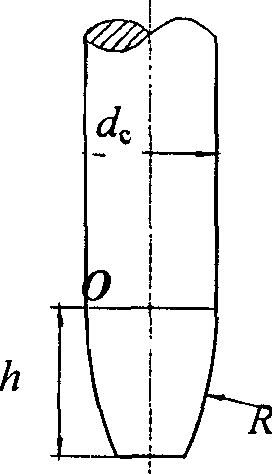

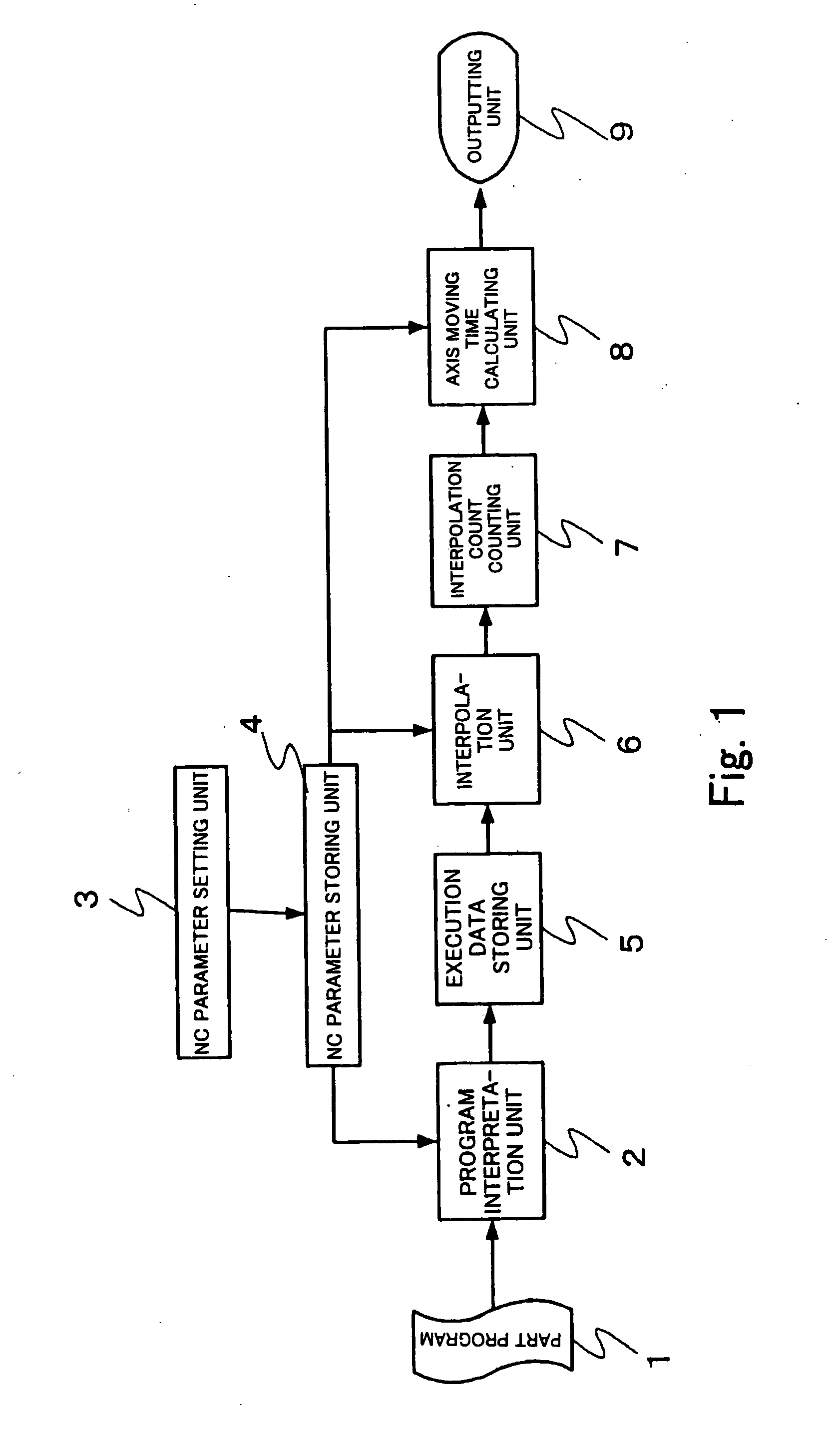

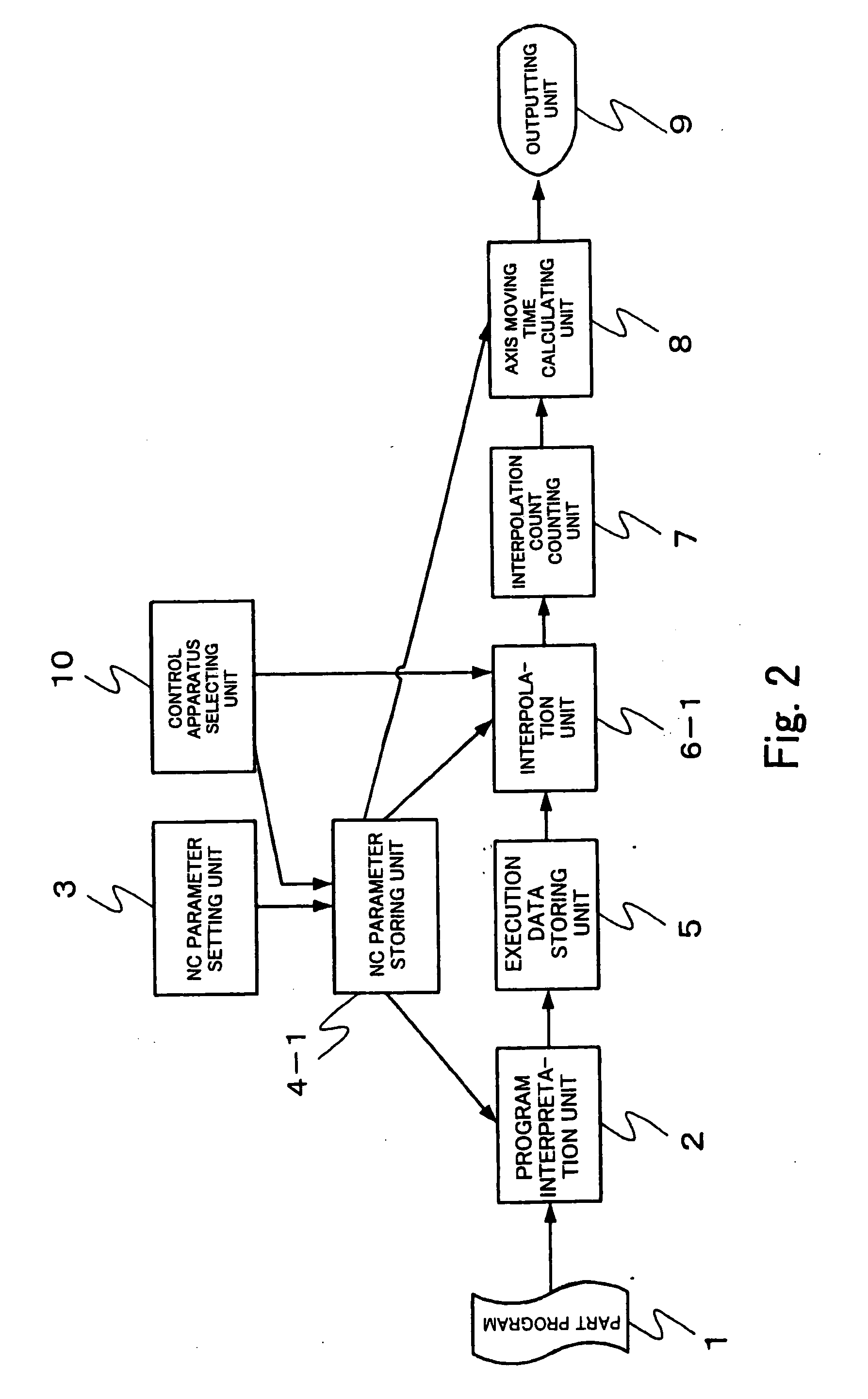

Machining time calculating apparatus

ActiveUS20050228533A1Accurate calculationHigh precisionProgramme-controlled manipulatorTime indicationNumerical controlComputer architecture

A structure having a parameter storing unit which stores a parameter to be used when a numeric control apparatus drives and controls the numeric control machine tool, a program interpretation unit which reads a part program to generate machining data for each block, an interpolation unit which interpolates a movement path instructed in an axis moving instruction referring to a parameter stored in the parameter storing unit and using an interpolation algorithm which is identical to a driving and controlling interpolation algorithm of the numeric control apparatus, an interpolation count counting unit which counts an interpolation count in the movement path, and an axis moving time calculating unit which multiplies an interpolation cycle when the numeric control apparatus drives and controls the numeric control machine tool and the counted interpolation count to calculate an axis moving time.

Owner:OKUMA CORP

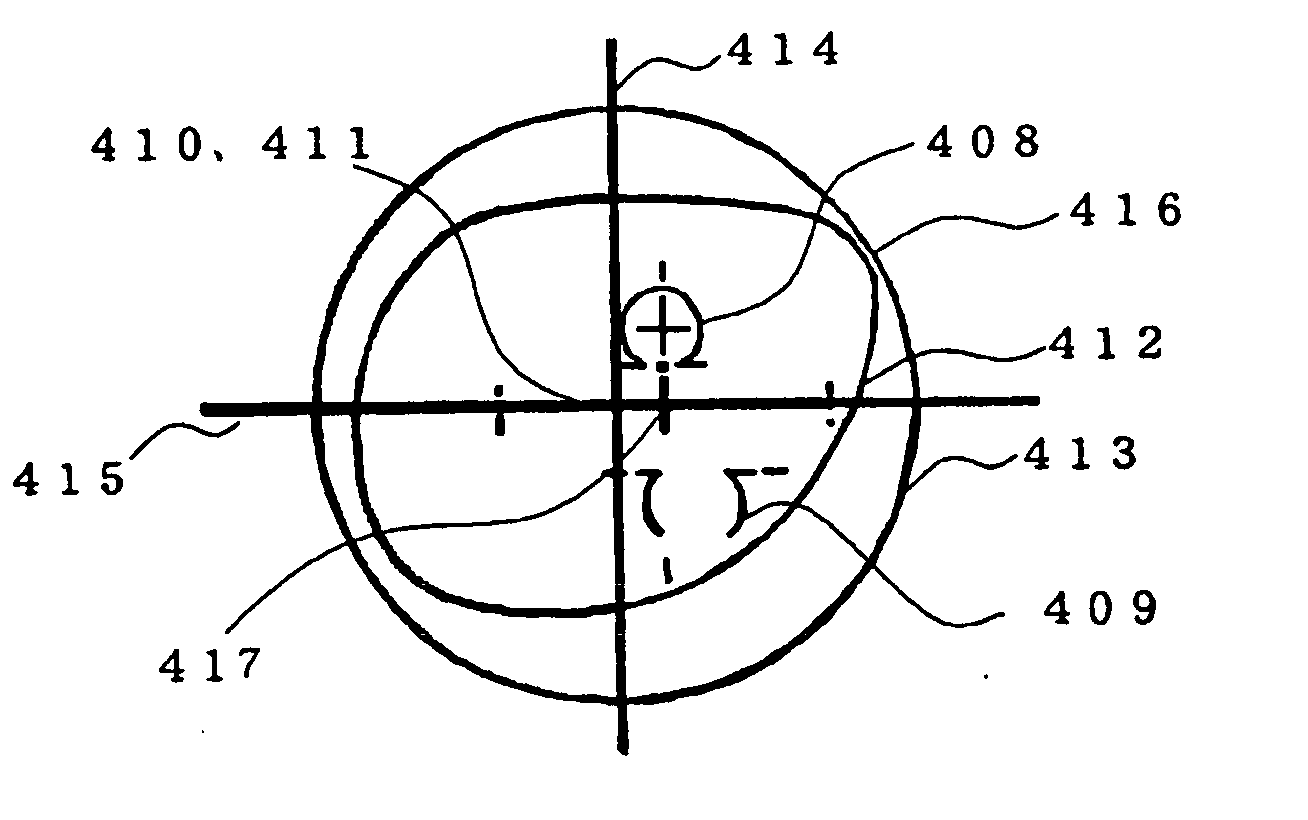

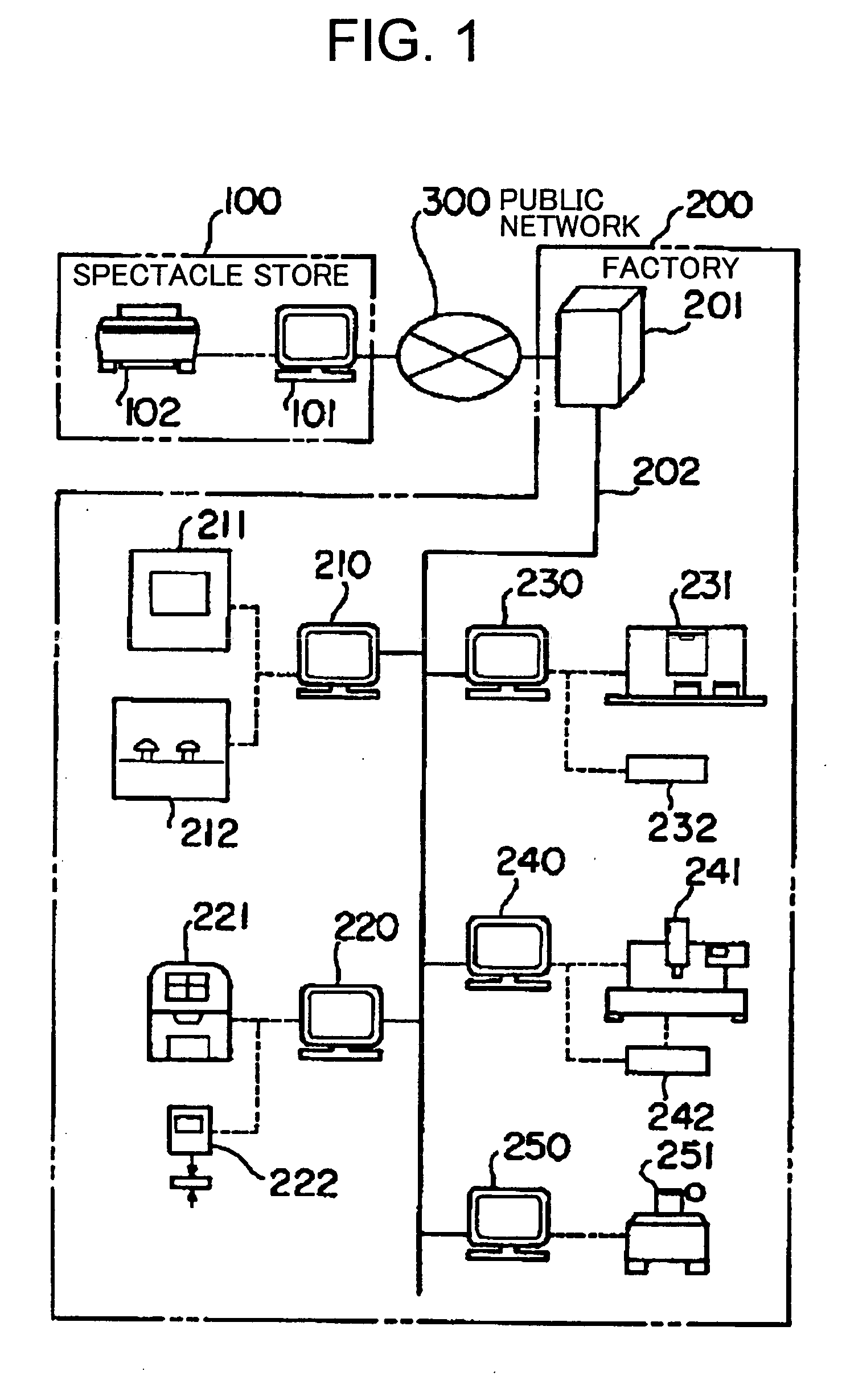

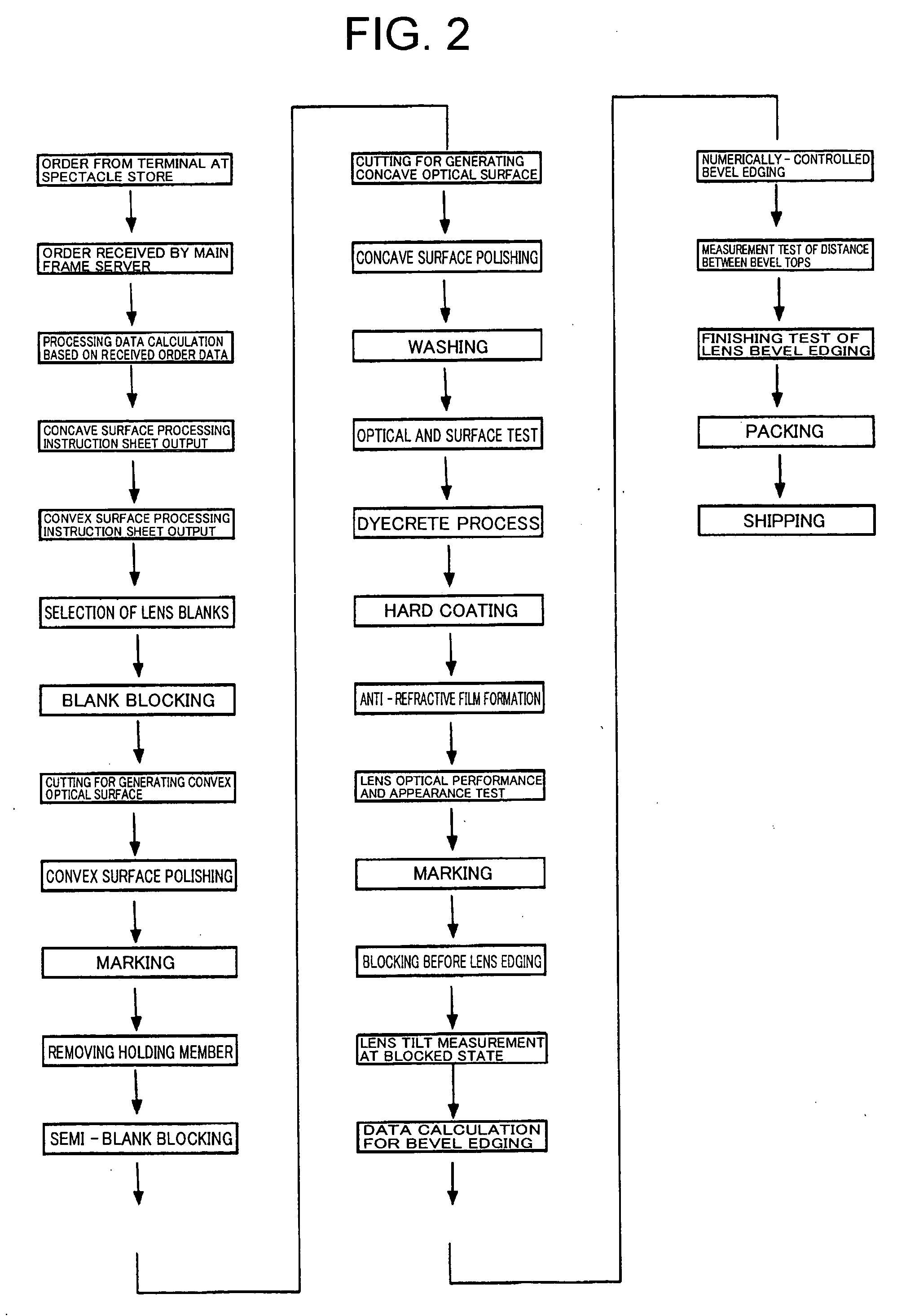

Spectacle lens manufacturing method and spectacle lens manufacturing system

InactiveUS20060189255A1Reduce wasteFast preparationEdge grinding machinesPolishing machinesNumerical controlPlastic materials

Aims to reduce the types of blanks such as a semi-finished lens blank, materials, and processing time. A spectacle lens design device 201 disposed at a factory 200 on a manufacturing side and a lens processing device connected thereto block an applicable semi-finished lens blank or lens blank so that a reference surface thereof tilts at a predetermined angle using a numerical-control curve generator based on order information sent from an order terminal 101 disposed at an spectacle store 100 on a order-placement side, and form both surfaces of a plastic material so that a geometric center of an edge shape positions at a center of a circle of a circular lens to thereby satisfy an optical specification of the spectacle lens-related to the order, and next, the circular lens is processed to have the edge shape of the spectacle lens-related to the order to thereby obtain the spectacle lens-related to the order.

Owner:HOYA CORP

Method for rapid generation of multiple investment cast parts such as turbine or compressor wheels

ActiveUS20100006252A1Remove capital expenditureReduce processing timeAdditive manufacturing apparatusFoundry mouldsInvestment castingRefractory

The process for investment casting of complex shapes has historically had 6 basic steps in it. Depending upon the path taken, these discrete steps have been reduced to either 5 steps, or to 2 steps, discarding the unwanted steps. Instead of having to generate the shape of each sacrificial pattern, the process generates either(A) a male tree containing a plurality of sacrificial patterns, already on their runners, onto which a mold shell can be formed, or,(B) a female shell, made of a refractory material, and forming internally the outside surfaces of the plurality of patterns and runners.This process removes both capital expenditure for tooling and process time by up to 90%. By removing several lengthy, time-dependant steps from the process the part cost and lead time are reduced.

Owner:BORGWARNER INC

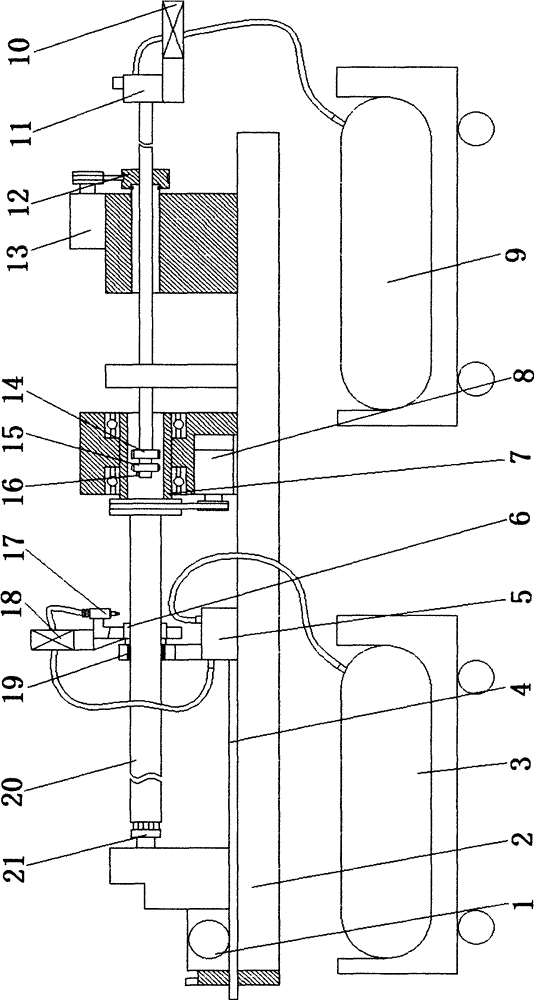

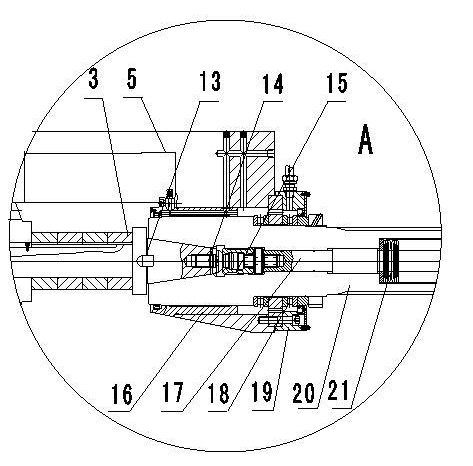

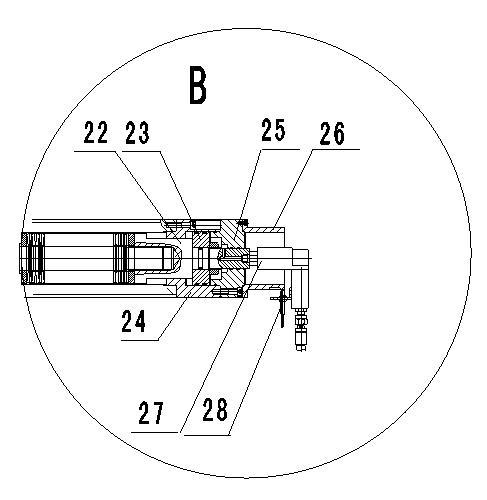

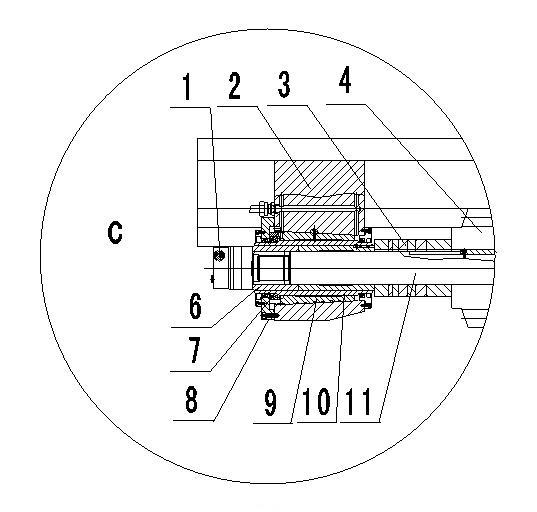

Main shaft device for numerical controlled gear hobbing machine

ActiveCN102059408AHigh precisionImprove work efficiencyGear-cutting machinesGear teethNumerical controlHobbing

The invention discloses a main shaft device for a numerical controlled gear hobbing machine. The main shaft device comprises a cutter bar assembly, a cutter bar assembly clamping mechanism and a cutter changing mechanism, wherein the cutter bar assembly comprises a cutter bar, a hobbing cutter, a cutter regulating pad, an axle sleeve, a locking nut and a cutter bar blind rivet; the cutter bar assembly clamping mechanism consists of a square key and a claw assembly; and the cutter changing mechanism consists of a pull rod, a piston rod, a disc-shaped spring, a hydro-cylinder body, a flange plate, a bracket, a rotary joint and a spacing switch. The main shaft device has the advantages that: a hydrostatic bearing is arranged in the main shaft structure of the high-accuracy numerical controlled gear hobbing machine, so the main shaft device can constantly work under a heavy-load cutting condition; a main shaft has high accuracy and good accuracy retaining ability; and the cutter bar assembly with the hobbing cutter is arranged and set outside a machine in a cutter workshop; the cutter bar assembly is subjected to whole cutter changing on the gear hobbing machine; and the setting assisting time of the hobbing cutter does not occupy the total part machining time of a machine tool, so the whole machine tool has high working efficiency.

Owner:齐重数控装备股份有限公司

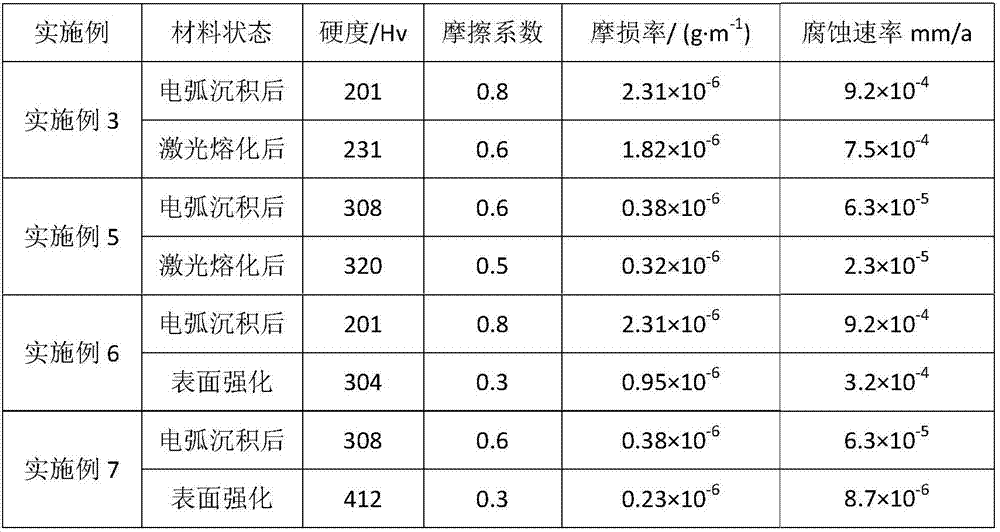

Additive manufacturing method for metal part

InactiveCN107470619AHigh surface hardnessImprove wear resistanceAdditive manufacturing apparatusArc welding apparatusHardnessPath plan

The invention discloses an additive manufacturing method for a metal part. The additive manufacturing method comprises the following steps of: (1) designing a CAD model according to the outline dimension of a metal part, performing layering processing on the model, and performing melting deposition path planning according to the specific appearance features of each layer subjected to layering processing; (2) preparing a material which is the same with the part in components into powder or a welding wire; (3) performing melting deposition on powder or the welding wire according to the planned path on a base plate through an electric-arc heat source; and (4) lifting a processing head by height of a deposition layer after melting deposition, repeating the step (3) to perform layer-by-layer melting deposition until a needed shape dimension of the metal part is reached. The method further comprises a step of performing laser melting on the surface of the melting deposition layer by laser or performing laser melting to generate a composite reinforcing layer. The additive manufacturing method disclosed by the invention effectively improves surface forming flatness and quality of the metal part, and reduces follow-up processing time and cost; and meanwhile, surface hardness, wear resistance and corrosion resistance of the metal part are also remarkably improved.

Owner:北京煜鼎增材制造研究院股份有限公司

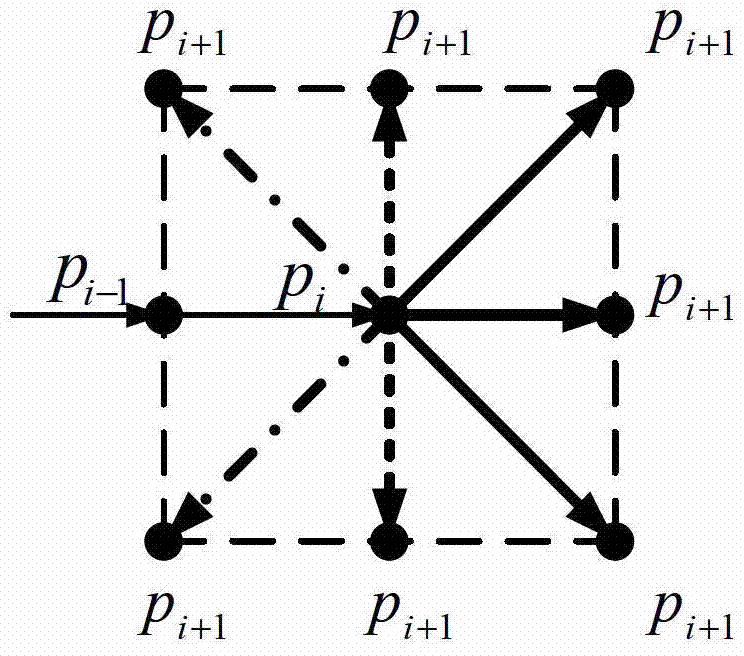

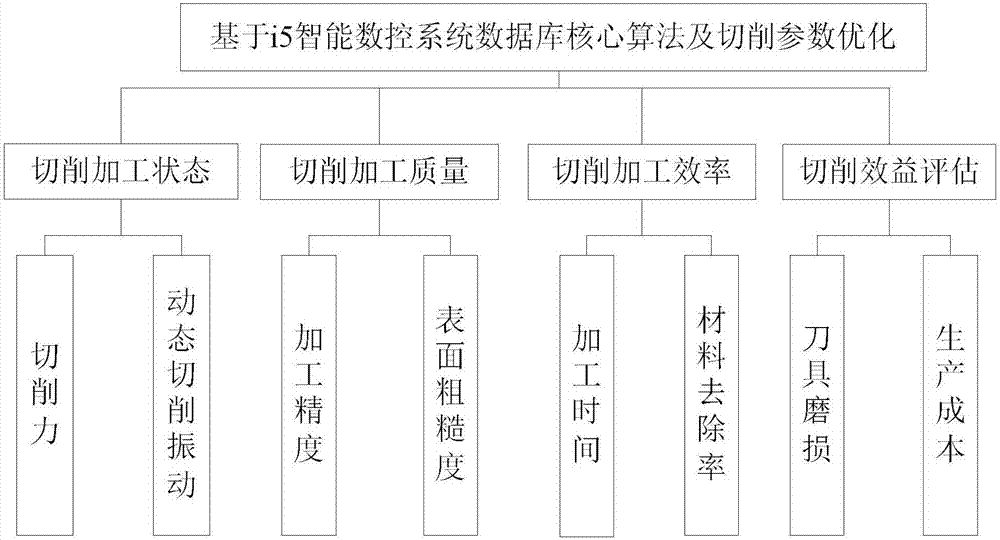

Multi-target cutting data generation algorithm and cutting parameter optimization method of numerical control machine tool

ActiveCN107976956AMeet special processing requirementsGood cutting parametersProgramme controlComputer controlMaterial removalSurface roughness

The present invention relates to a multi-target cutting data generation algorithm and cutting parameter optimization method of a numerical control machine tool. The core algorithms of a database comprise calculation of cutting processing states such as cutting force and dynamic cutting vibration, and calculation of load conditions such as cutting power and main shaft torque, processing quality such as processing precision and surface roughness, processing efficiency information such as processing time and material removal rate and benefit assessment such as cutter wearing and production cost.Cutting parameters are optimized according to a calculation result to improve the usage rate and part processing efficiency of a machine tool. A cutting database algorithm developed aiming at a numerical control lathe and numerical control turning center is integrated on a domestic I5 intelligent numerical control system platform to allow machine tool users to conveniently call and select cuttingparameters according to concrete processing demands and to predetermine cutting effects, which are likely to generate, before actual cutting.

Owner:SHENYANG MASCH TOOL CO LTD

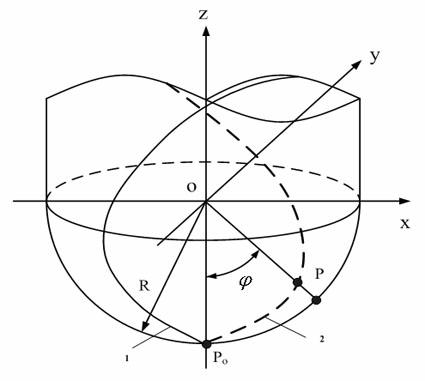

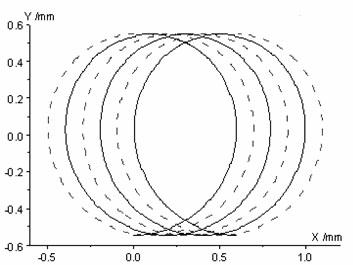

Modeling method for milling surface appearance of workpiece

The invention discloses a modeling method for milling the surface appearance of a workpiece, belonging to the field of digital milling. The modeling method comprises the steps of carrying out dispersing treatment on the cutting edge of a ball-end mill according to cutting movement locus of a milling cutter; establishing infinitesimal cutting locus equation of the cutting edge of the ball-end mill, wherein the surface appearance of the cutting locus equation is formed by the outermost side locus in the established locus equation; determining corresponding cutter turning angle range for milling the outermost side locus by judging the cutting infinitesimal position angle range corresponding to the outermost side locus; calculating corresponding milling time for milling the locus by combining with angular rotation speed obtained through a cutter spindle rotation speed; and obtaining the outermost side milling locus through a helical lag angle at the cutting infinitesimal position, thus obtaining the surface appearance of the milling workpiece. The modeling method can solve the generation problem on the surface appearance of the workpiece in milling process.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

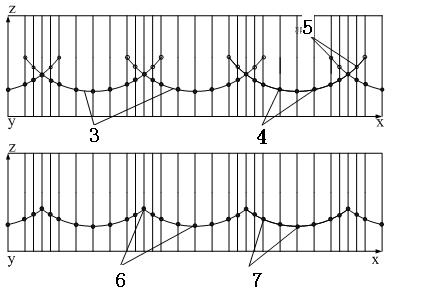

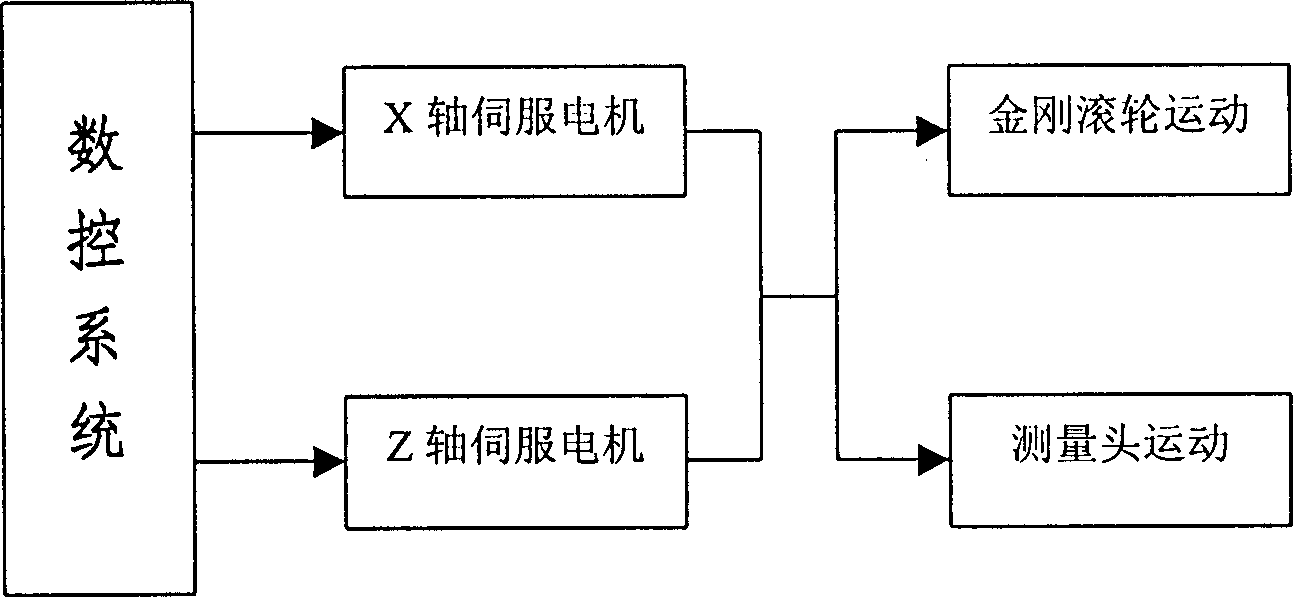

In-situ trimming method for shaping abrasive wheel

InactiveCN1453103AReduce wasteful processing timeImprove grinding accuracyAbrasive surface conditioning devicesGear wheelEngineering

The present invention features that one digitally controlled grinding wheel corrector is used in in-situ measurement and data processing to judge the work state, determine the correcting curve and create the correcting program automatically. The trimming process includes the following steps: the machine tool to control the shaping abrasive wheel to move in X direction to grind gear; to set the measuring head locate in gear measuring position and contact with the base circle; to control the measuring head to move along the ideal involute locus by means of the interpolation of the X-servo motor and the Z-servo motor to obtain the data; to evaluate the gear tooth shape error; and to control the grinding wheel to trim. The said method reduces the idle machining time and raise the grinding precision, and is suitable for machining gear and spline shaft.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

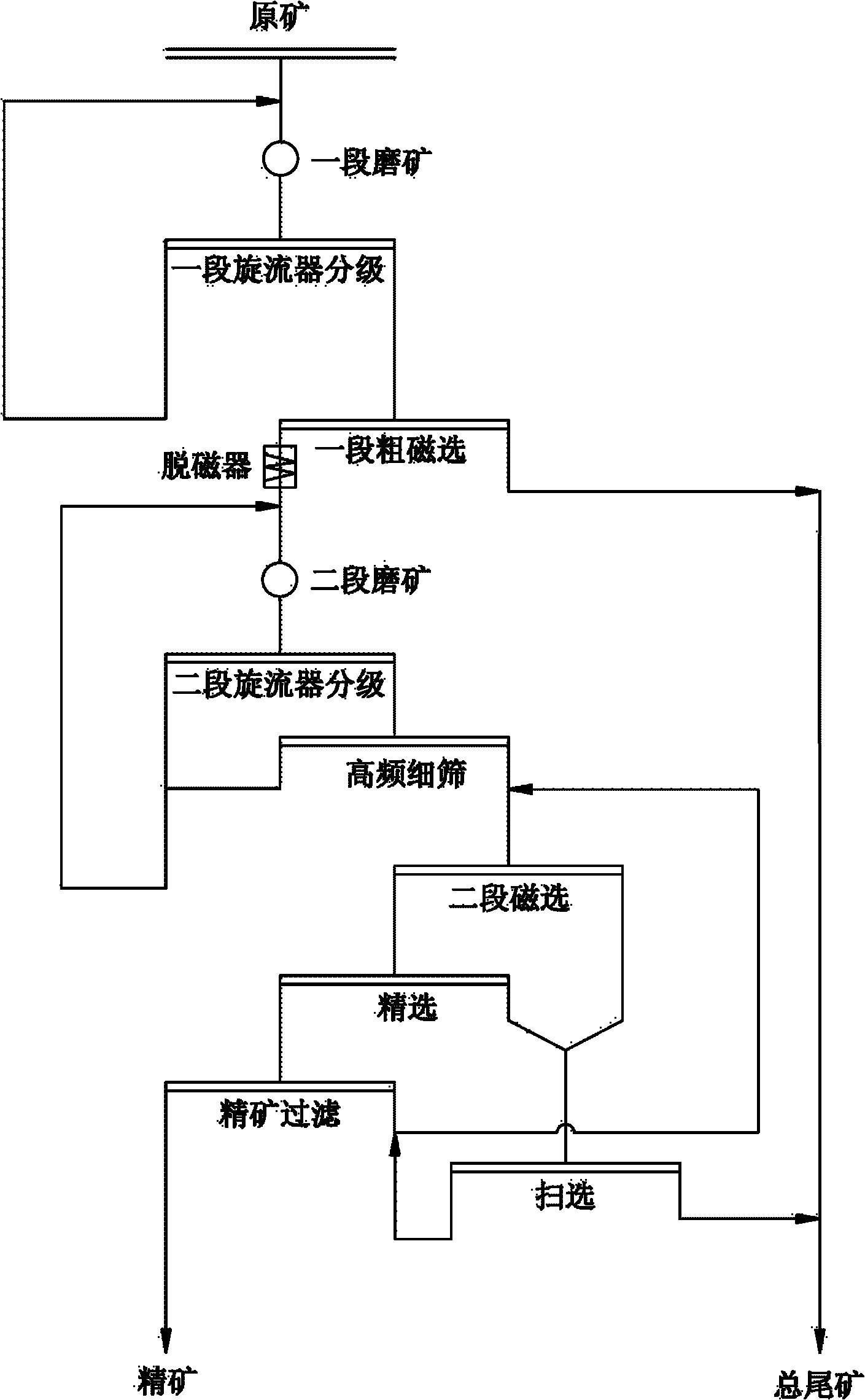

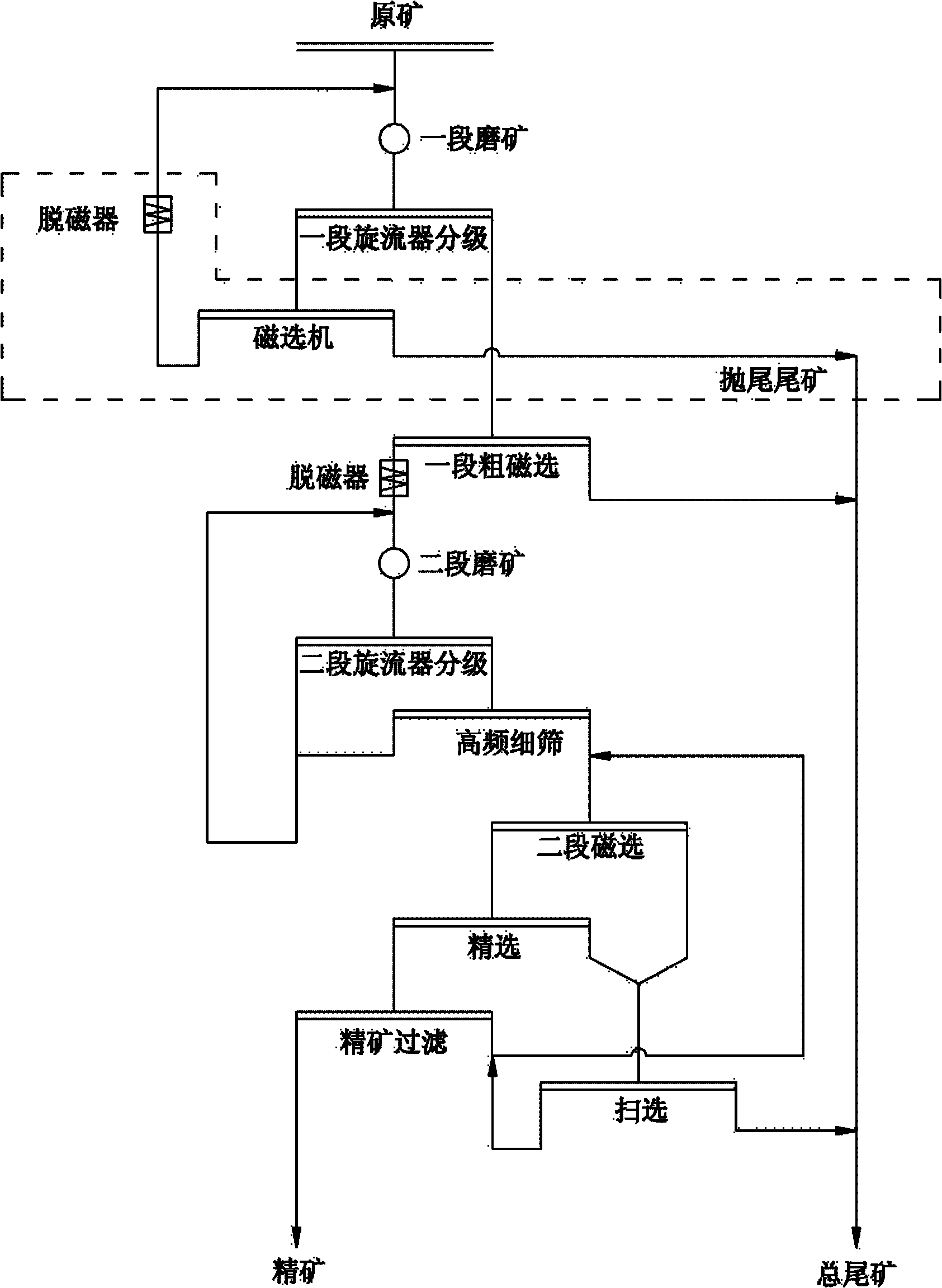

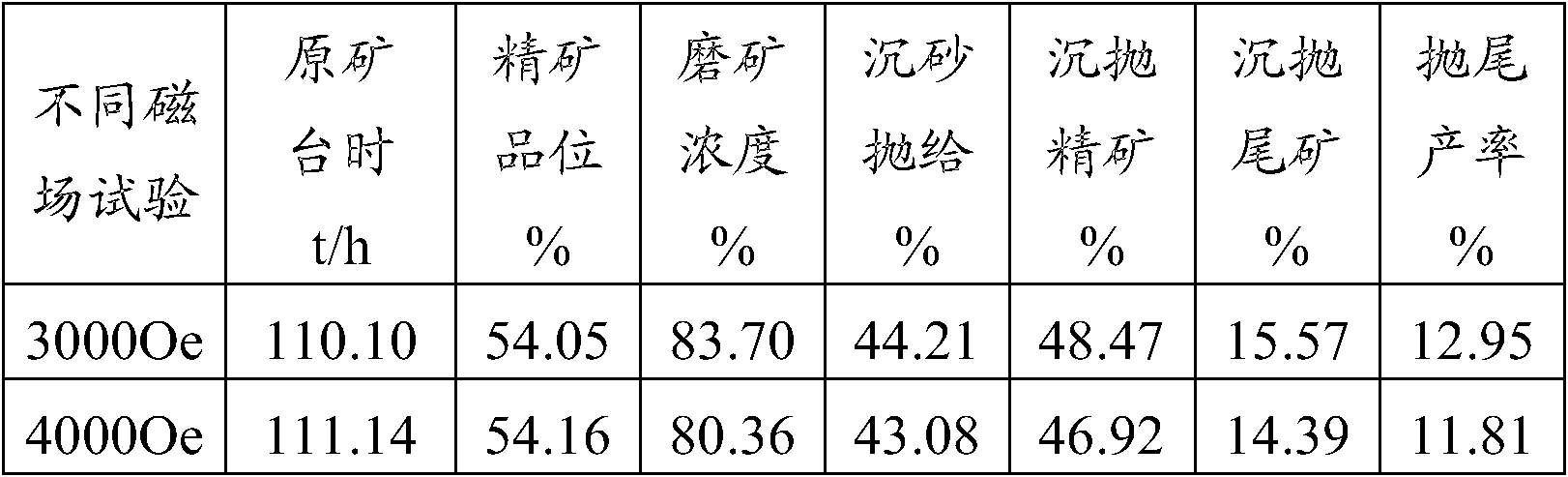

Mineral separation method for vanadium-titanium magnetite ores

The invention discloses a mineral separation method for vanadium-titanium magnetite ores. The mineral separation method comprises the following steps of: conveying raw vanadium-titanium magnetite ores to a primary grinding stage; conveying the crushed vanadium-titanium magnetite ores to a primary swirler for classification; conveying deposited sand of the primary swirler to a magnetic separator for magnetic separation, demagnetizing primary tail-ground refined ores subjected to magnetic separation, and returning to the primary grinding stage for grinding again, wherein the tail-ground tailings subjected to magnetic separation are final tailings; and sequentially performing primary rough magnetic separation, secondary grinding, secondary swirler classification, high-frequency fine screening classification, secondary magnetic separation, fine separation, sweeping, filtration and dehydration on overflowed ores of the primary swirler so as to obtain the vanadium-titanium magnetite ores and the final tailings. Compared with the prior art, the treatment capacity and the yield of a vanadium-titanium magnetite ore mineral separation system are improved, the raw ore machine time and the fine ore machine time are prolonged, and great economic benefit can be obtained.

Owner:PANGANG GRP MINING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com