Additive manufacturing method for metal part

A technology for metal parts and additive manufacturing, which is applied in the field of composite additive manufacturing of metal parts using arc deposition-laser surface melting, which can solve the problem of poor surface flatness of parts, dimensional accuracy inferior to laser and electron beam additive manufacturing, and surface flatness. Improve the performance, improve the flatness and quality of surface forming, and improve the surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Design the CAD model of the part, and process the model in layers, and then plan the melting deposition path for the specific shape characteristics of each layer after layering;

[0040] (2) The welding wire adopts 316L stainless steel welding wire with a diameter of 1.2mm;

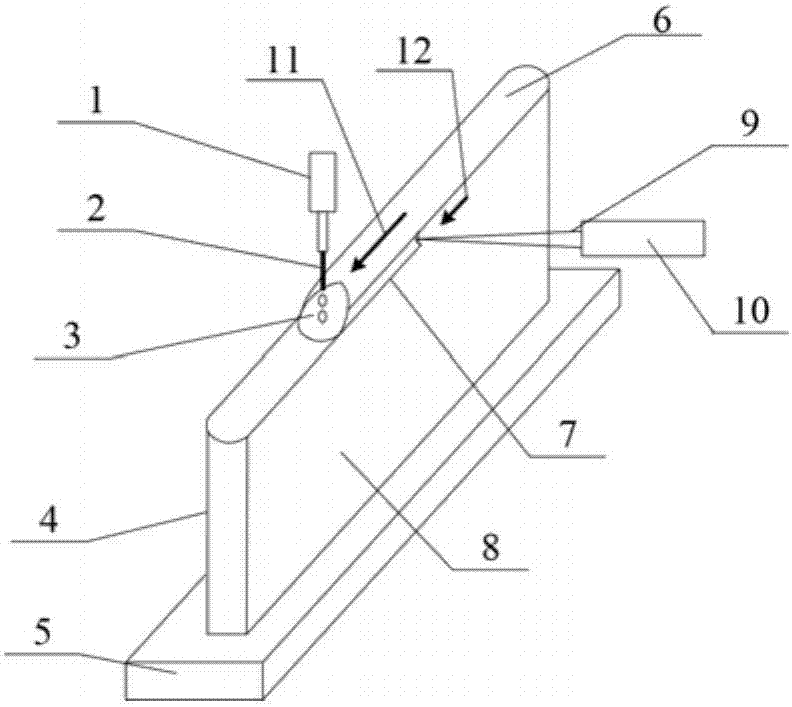

[0041](3) Use a melting electrode arc power supply with a maximum current of 500A for arc additive manufacturing, and place the arc welding torch and substrate in a pure Ar gas-tight box, so that the entire fusion deposition forming process is carried out under the protection of an inert gas (oxygen content ≤ 80ppm), the arc welding torch is melted and deposited according to the planned path, and the side surface of the melted deposition layer is melted by laser at the same time as each layer is melted and deposited. Among them, the arc additive manufacturing parameters are as follows: arc current 300A, arc voltage 28V, arc The scanning speed is 600mm / min, the wire feeding speed is 10m / min, the...

Embodiment 2

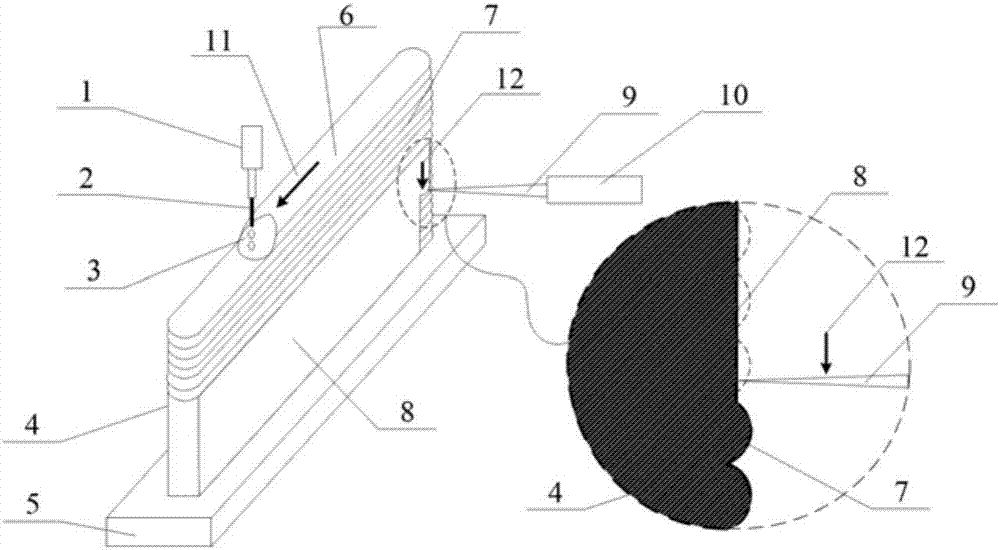

[0043] The difference from Example 1 is that after 10 layers are deposited by arc melting, laser surface melting treatment is carried out on the measured surface, wherein the laser melting parameters are as follows: laser power is 3.5kW, laser scanning speed is 1.5m / min, and the spot is 6mm directly. Road overlap 20%, the schematic diagram of additive manufacturing is as follows figure 2 shown.

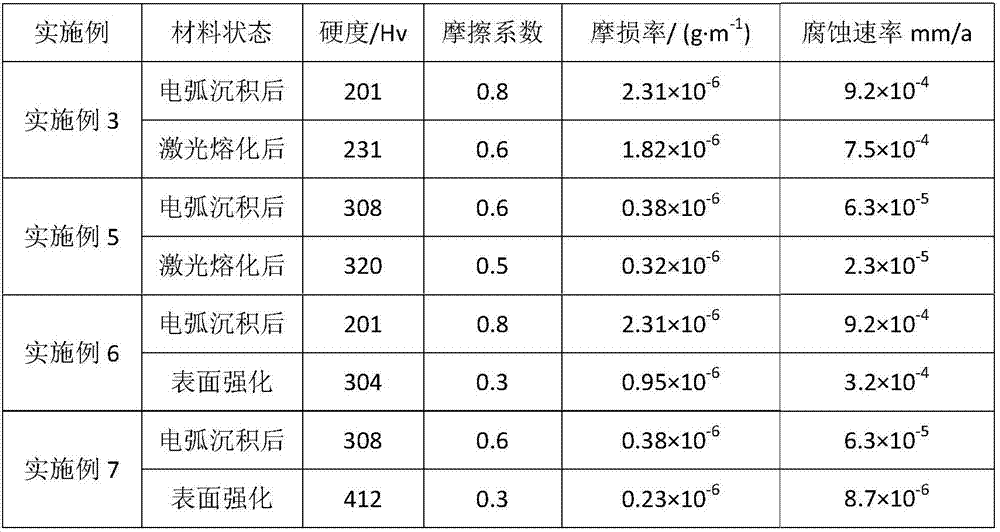

Embodiment 3

[0045] The difference from Embodiment 1 is that after the entire metal part is deposited by arc melting, laser surface melting is performed on the side surface of the part.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com