Method and device for manufacturing efficient and high-precision composite additive

A manufacturing method and technology of a generating device are applied in the high-efficiency and high-precision composite material manufacturing method and device, and the high-efficiency and high-precision material manufacturing field to achieve the effects of improving surface quality, shortening forming time, and improving forming efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

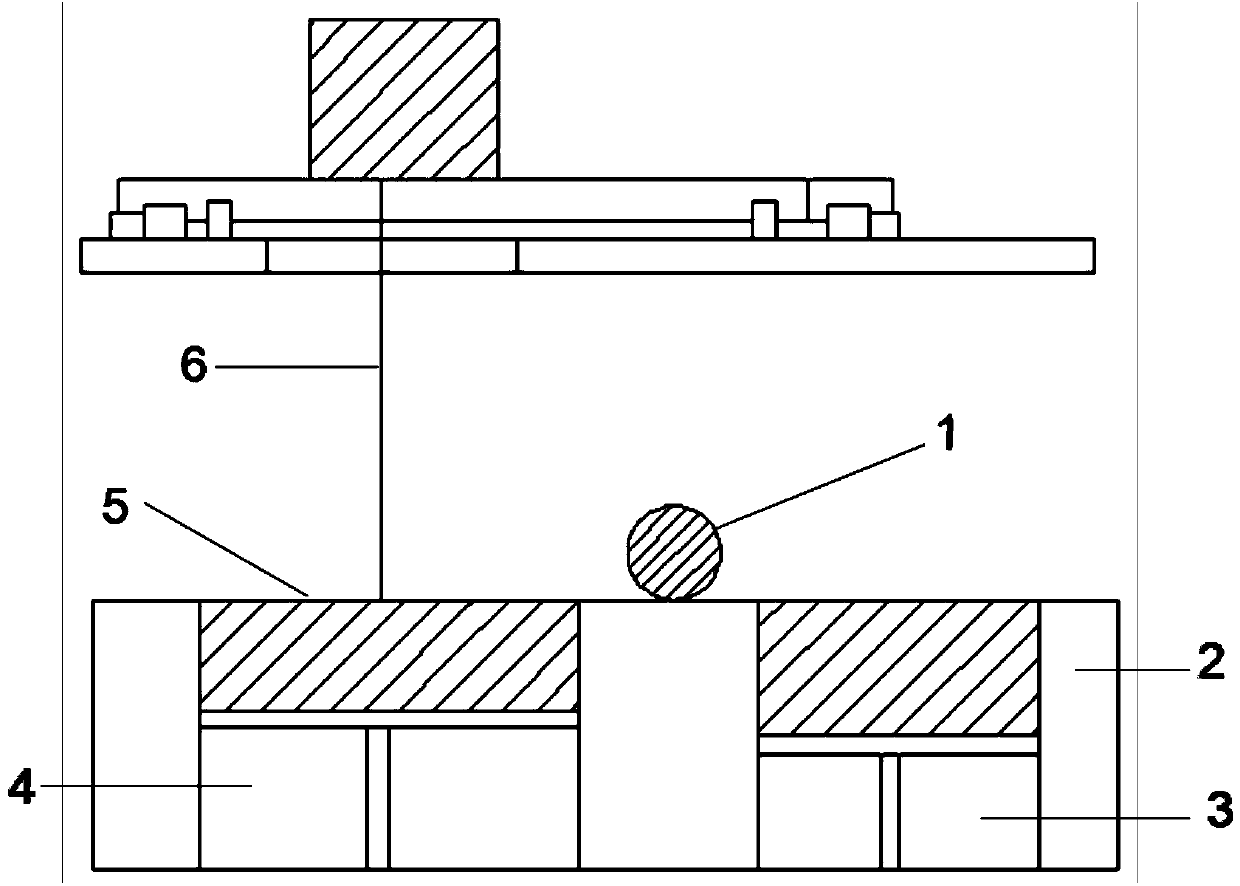

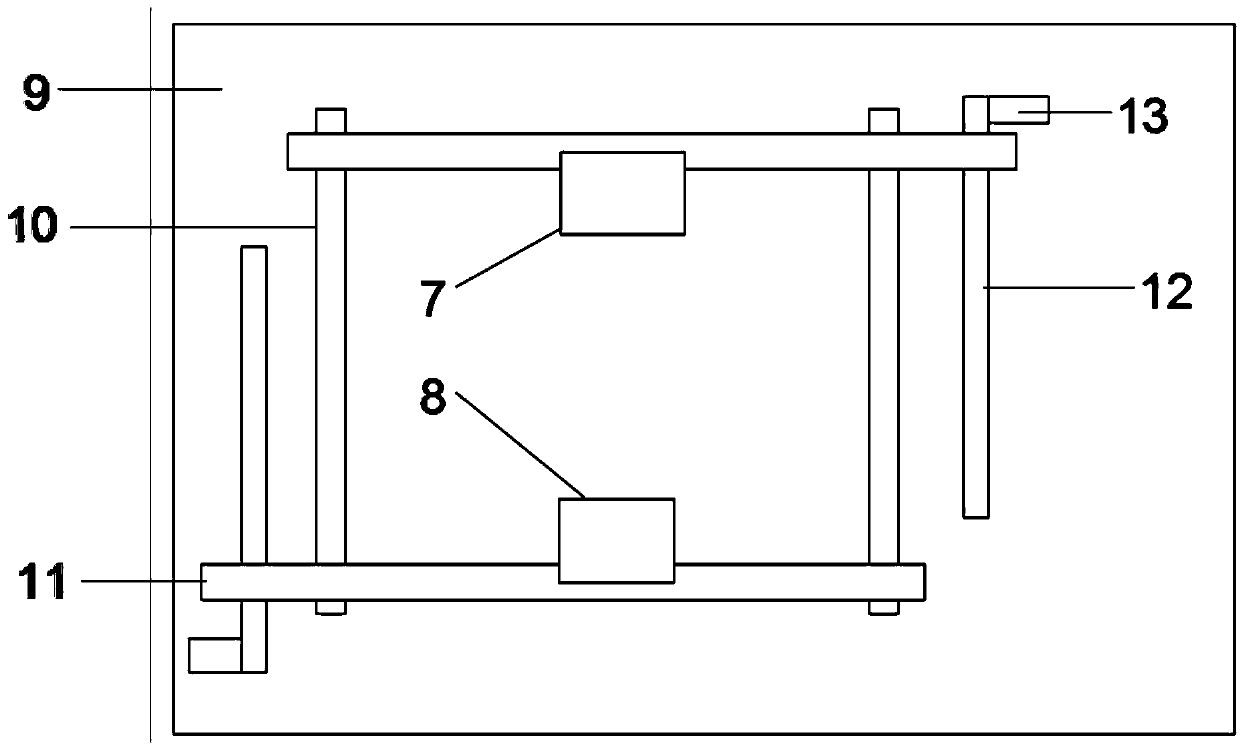

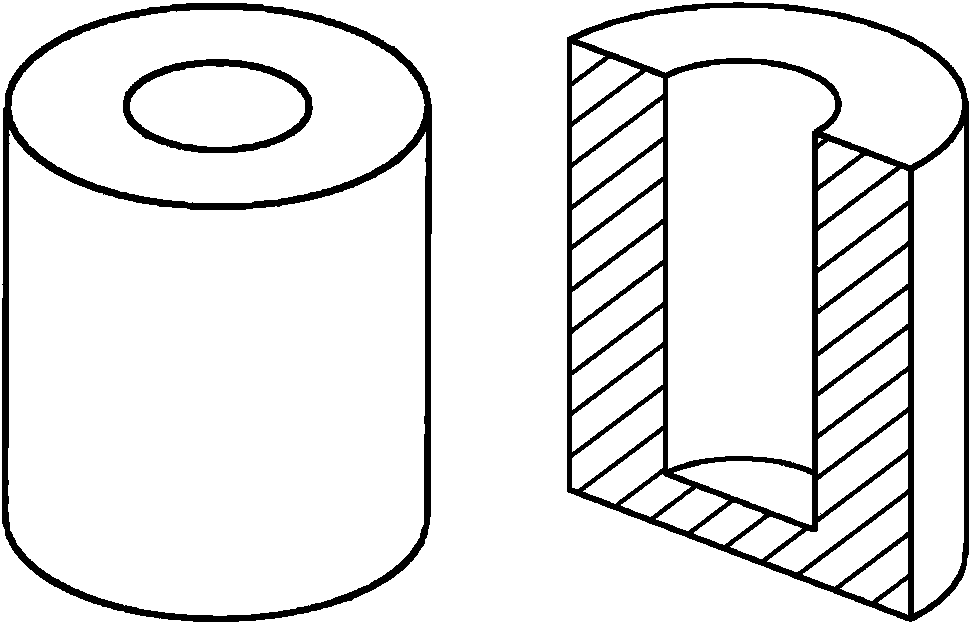

[0040] (1) Put image 3 The surface profile and internal structure of the model shown are divided into three regions, S1, S2, and S3 ( Figure 4 ), control the working range of laser beam and electron beam. The material used is spherical 316L stainless steel powder with a particle size of about 10-100μm.

[0041] (2) Set the powder spreading layer thickness of the device to 0.02mm, SLM scanning single layer powder thickness to 0.02mm, EBM scanning single layer powder thickness to 0.08mm. The forming space of the device is evacuated and a protective gas is introduced.

[0042] (3) A layer of powder is spread on the metal substrate by the powder spreading mechanism, and the thin layer of powder in the S1 area is scanned at a high speed by the small beam current of the electron beam to preheat the powder.

[0043] (4) Control the laser beam generating device to move to the scanning window, the laser beam scans the powder in the S1 area to form a surface contour layer, and the electron...

example 2

[0048] (1) Put image 3 The surface profile and internal structure of the model shown are divided into three regions, S1, S2, and S3 ( Figure 4 ), control the working range of laser beam and electron beam. The material used is spherical Ti6Al4V powder with a particle size of about 10-100μm.

[0049] (2) The thickness of the powder spreading layer of the setting device is 0.02mm, the thickness of the single-layer powder scanned by SLM is 0.02mm, and the thickness of single-layer powder scanned by EBM is 0.5mm. The forming space of the device is evacuated and a protective gas is introduced.

[0050] (3) A layer of powder is spread on the metal substrate by the powder spreading mechanism, and the thin layer of powder in the S1 area is scanned at a high speed by the small beam current of the electron beam to preheat the powder.

[0051] (4) Control the laser beam generating device to move to the scanning window, the laser beam scans the powder in the S1 area to form a surface contour ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com