Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

88 results about "Internal Powder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

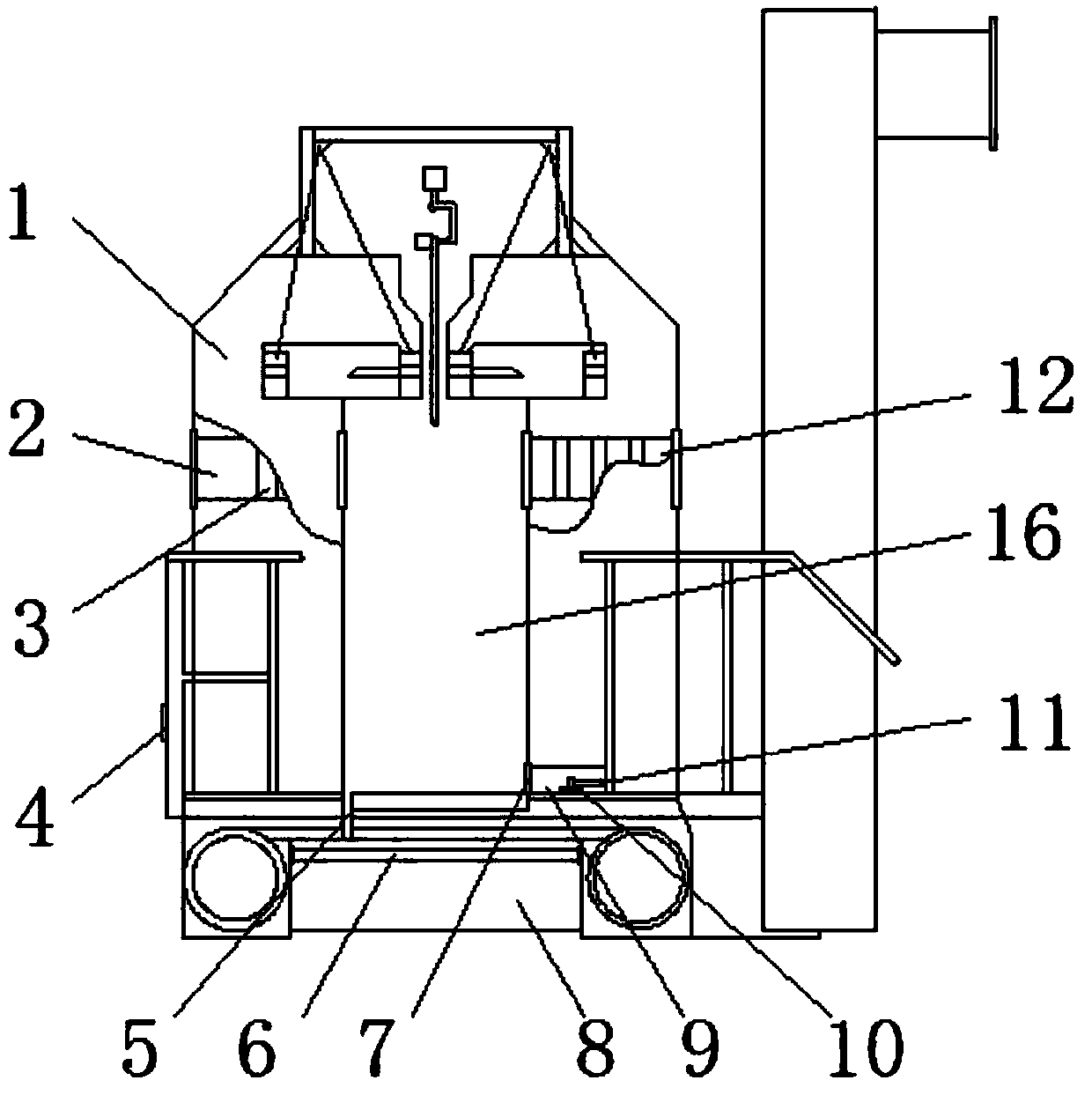

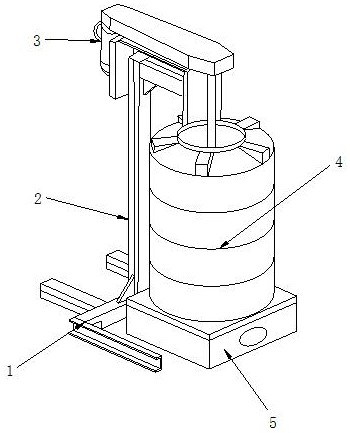

Method and device for manufacturing efficient and high-precision composite additive

ActiveCN104190931AShorten forming timeImprove forming efficiencyIncreasing energy efficiencyLight beamMetal powder

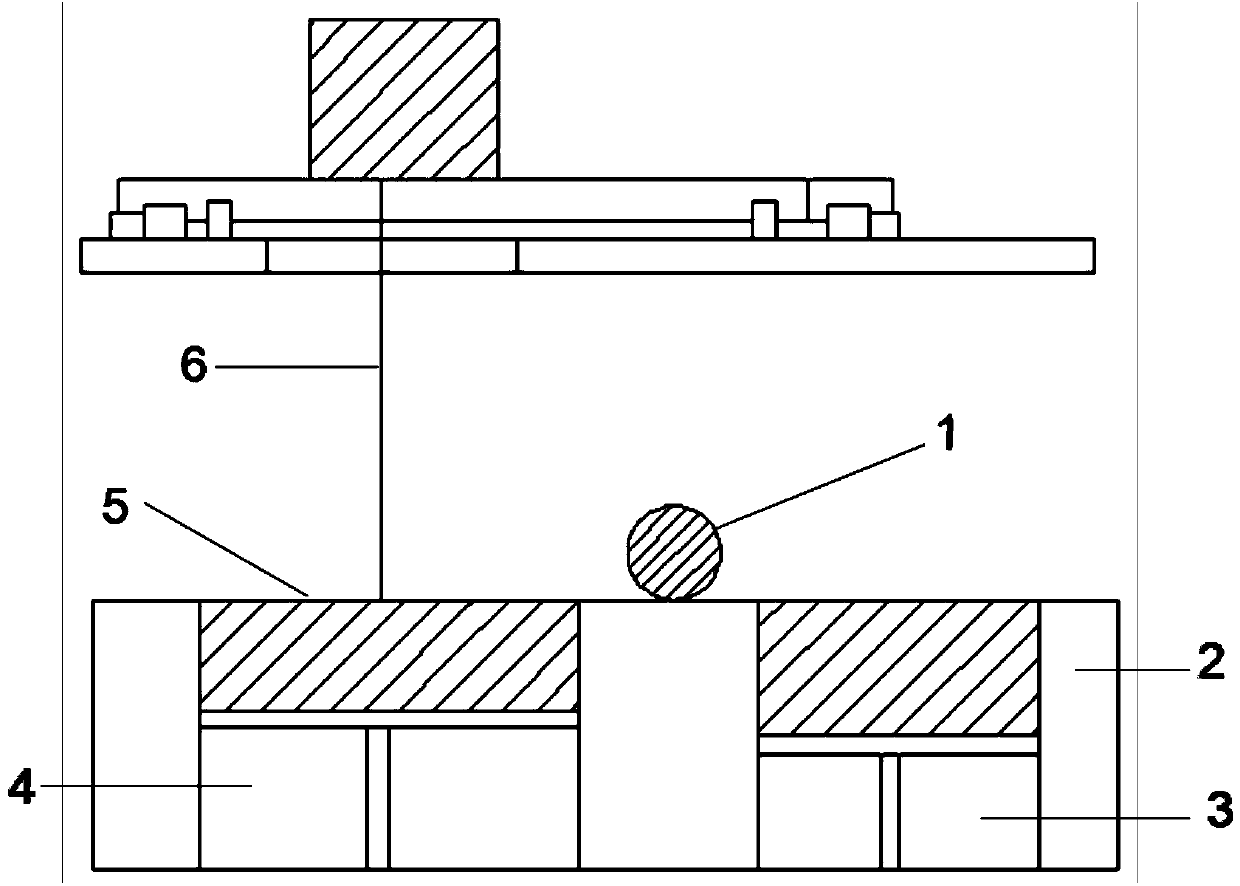

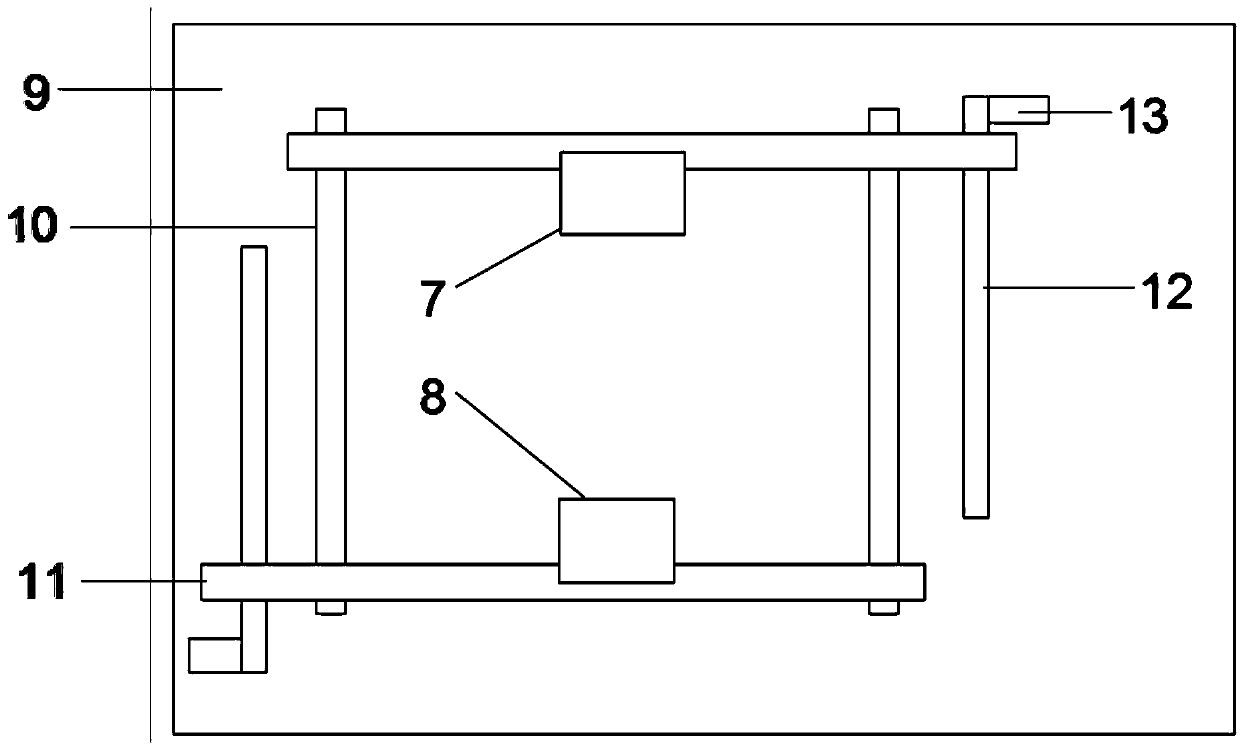

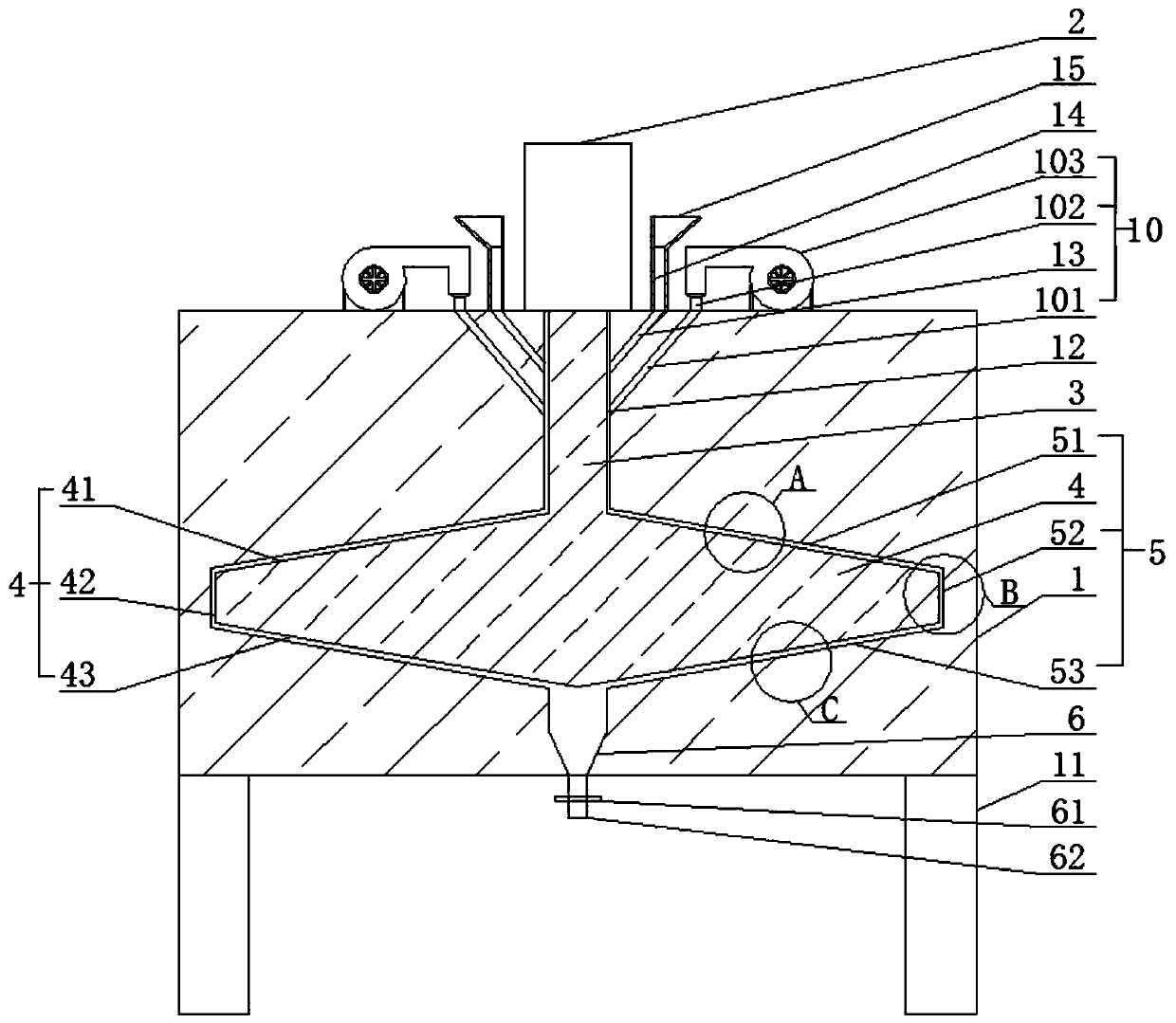

The invention discloses a method and device for manufacturing efficient and high-precision composite additive, and the method and device are achieved through composition of a laser beam and an electron beam. In the process of the action of a high energy beam and metal powder, metal powder of a surface outline is scanned and molten through the laser beam, and the surface of a part has a good surface quality. The electron beam melts the internal powder at a high speed to form a part inner cavity so as to reach the highest forming efficiency. The lower portion of the device comprises a powder laying roller, a workbench, a powder conveying cylinder and a working cylinder. The upper portion of the device comprises an electron beam generating device, a laser beam generating device, a bottom plate, two guide rails, two beams, a synchronous belt wheel and a servo motor. The electron beam generating device and the laser beam generating device are respectively integral and move to the forming area alternately to carry out scanning. By means of the method and device, the defects in the single forming technology can be overcome, and the purposes of reasonably controlling the formed microstructural organization and optimizing the comprehensive performance are achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for increasing yield of molten steel manganese in manganese ore direct-alloying

The invention relates to a method for increasing yield of molten steel manganese in manganese ore direct-alloying and belongs to the technical field of molten steel alloying in steelmaking. The method includes drying, smashing and grinding manganese ore, lime or light-roasted dolomite, anthracite or coke and making into mixture as external powder according to the weight percentage of 50-90% of manganese ore, 0-20% of lime or light-roasted dolomite and 10-30% of anthracite or coke; making core-spun wires by using aluminum or silicone powder accounting for one third or one fourth of the mixture as internal powder, wrapping the internal powder by the external powder so as to form a wrapping layer on the internal powder; feeding the core-spun wires as steel ladle enters in the process of refining. By the method, high yield of manganese is achieved, heating time of a refining furnace is greatly shortened, and power consumption is reduced.

Owner:CENT IRON & STEEL RES INST +1

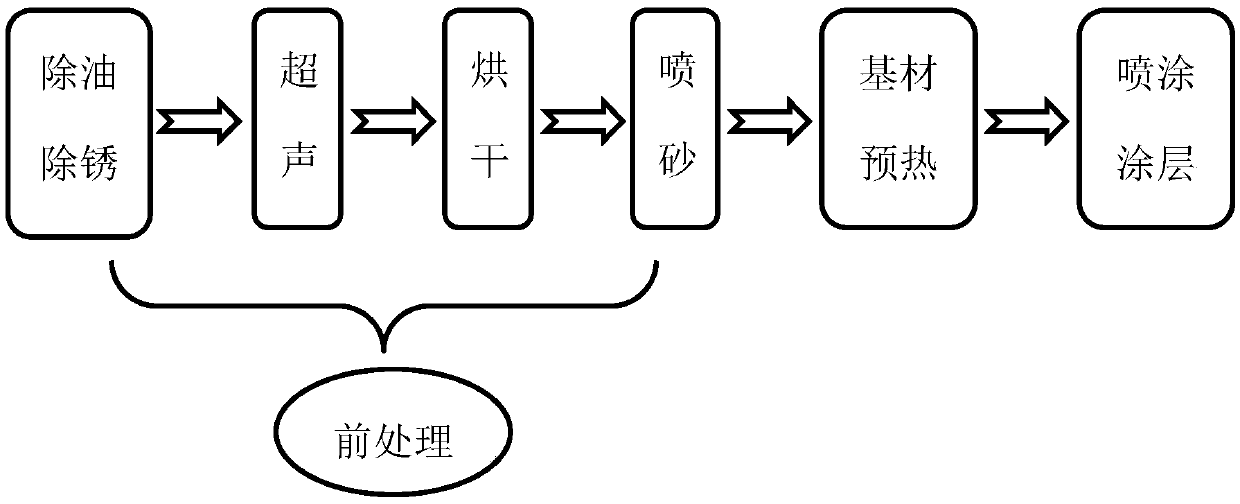

Method for manufacturing high-performance layered thermal barrier coating system

ActiveCN105886994AStable and reliable deposition qualityGood high temperature oxidation resistanceMolten spray coatingEfficient propulsion technologiesPlasma jetSuperalloy

The invention discloses a method for manufacturing a high-performance layered thermal barrier coating system. The method comprises the following steps that firstly, an alloy bonding layer is manufactured on the surface of a matrix; secondly, supersonic plasma jet is used for carrying out surface modification treatment on the alloy bonding layer; and thirdly, a single-layer or multi-layer ceramic material coating is manufactured on the modified surface of the alloy bonding layer, and the thermal barrier coating system is obtained. An internal powder feeding supersonic air plasma spraying method is adopted for obtaining the layered thermal barrier coating system formed by the high-temperature alloy bonding layer and a ceramic surface layer. Compared with a traditional method for manufacturing a thermal barrier coating, the problems that due to technological conversion, the coating manufacturing efficiency is low, and the quality batch stability is poor are effectively avoided, important application value for prolonging the high-temperature service life of the a thermal barrier coating is achieved, wide application prospects are achieved in the national defense sophisticated industry such as aeroturbine engines and heavy duty gas turbines, and huge economic and social benefits are achieved.

Owner:XI AN JIAOTONG UNIV

Powder feed splitter for hand-held laser powder fusion welding torch

InactiveUS20040016726A1Reduce riskSpeed up the flowLiquid spraying apparatusLaser beam welding apparatusHand heldMaterials processing

A powder feed splitter and a machine using a powder feed splitter, to divide a powder flow into two or more streams in a predictable, adjustable, and reliable manner for use in material processing such as welding. A housing encloses an inlet disk having an inlet regulator preferably a disk, having an inlet tube which may be adjustable radially or laterally with 000respect to the housing. An adjustment mechanism can selectively move the inlet regulator to adjust the powder flow amongst the several powder outlet ports. Funnel-shaped cavities within the housing may have optional gas inlets to enable the introduction of additional gas to the separated powder flow streams. A one-way fit may be present between the interior powder flow splitter and the exterior casing. Smooth interior surfaces through the device prevent turbulence and buildup of powder.

Owner:HONEYWELL INT INC

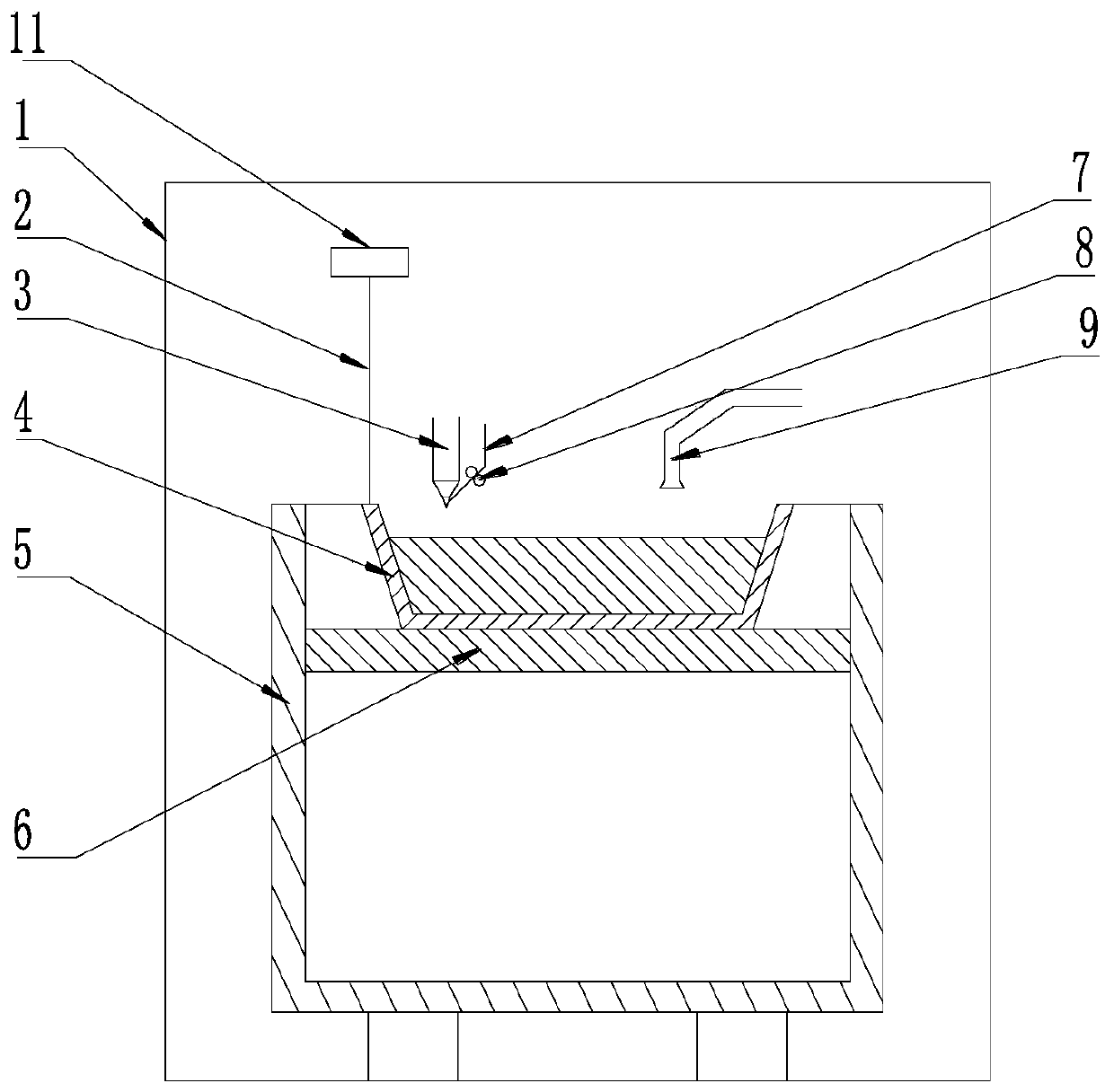

Method for quick additive manufacturing of large-scale bimetal spare parts

ActiveCN109759588AFast printAdditive manufacturing apparatusIncreasing energy efficiencyMulti materialMetal powder

The invention provides a method for quick additive manufacturing of large-scale bimetal spare parts. The technological process of the method mainly comprises the following steps of respectively usinga selecting region laser melting shaping technique and a plasma arc additive manufacturing technique to print an outermost layer and an internal structure of a spare part: after the outermost layer structure in a current circulation is printed through the selecting region laser melting shaping, sucking metal powder in the outline of the outermost layer with an internal powder sucking machine, thenprinting and stuffing the internal structure through plasma arc additive manufacturing, and continuing circulating until printing of the spare part is completed. The method disclosed by the inventionhas the beneficial effects of having the capacity of quickly printing large-scale complex-shape spare parts, having the capacity of quickly printing large-scale spare parts which are high in surfaceaccuracy requirements, and having the capacity of printing multi-material spare parts of which the outermost layer materials and the internal materials are different.

Owner:上海汉邦联航激光科技有限公司

Powder feed splitter for hand-held laser powder fusion welding torch

InactiveUS6894247B2Reduce cloggingSmooth inner surfaceLiquid spraying apparatusLaser beam welding apparatusHand heldMaterials processing

A powder feed splitter and a machine using a powder feed splitter, to divide a powder flow into two or more streams in a predictable, adjustable, and reliable manner for use in material processing such as welding. A housing encloses an inlet disk having an inlet regulator preferably a disk, having an inlet tube which may be adjustable radially or laterally with respect to the housing. An adjustment mechanism can selectively move the inlet regulator to adjust the powder flow amongst the several powder outlet ports. Funnel-shaped cavities within the housing may have optional gas inlets to enable the introduction of additional gas to the separated powder flow streams. A one-way fit may be present between the interior powder flow splitter and the exterior casing. Smooth interior surfaces through the device prevent turbulence and buildup of powder.

Owner:HONEYWELL INT INC

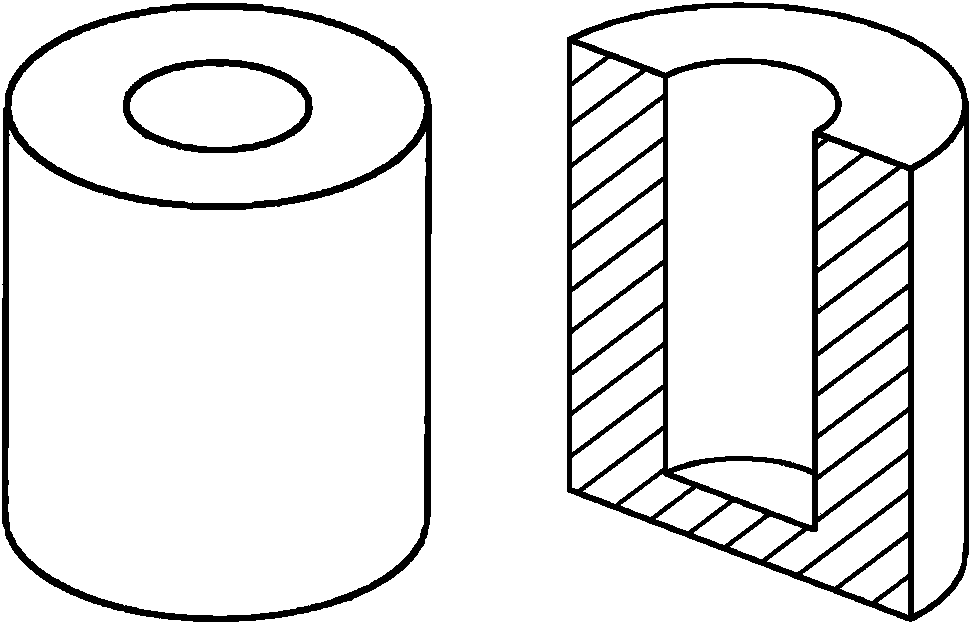

Ultrasonic plasma gun feeding powder internally

The invention discloses an ultrasonic plasma gun feeding powder internally, which is designed by adopting a parameterized structure design method in combination with a numerical simulation technique. The ultrasonic plasma gun mainly comprises a cathode, an anode, a powder feeding air flow channel, and a main air flow channel formed by matching the cathode with the anode. The mechanical compression effect of a nozzle is adjusted by changing the parameter of each pore canal in the internal compression segment and expanding segment of an anode nozzle, so that plasma jet flow in the gun is high in energy density and speed, the thermal efficiency of the gun is increased, and meanwhile the stability of arc voltage is ensured. The internal powder feeding angle is changed to an optimal position, so that heating and acceleration of sprayed powder materials are facilitated, and the problem of blocking of the gun nozzle is solved. The size of the gun is selected on the basis of an advanced computer simulation technology, so that the development period of the gun is shortened greatly, and the design cost is lowered. As proved by results, the novel gun has higher flow field characteristic than an original structure.

Owner:XI AN JIAOTONG UNIV

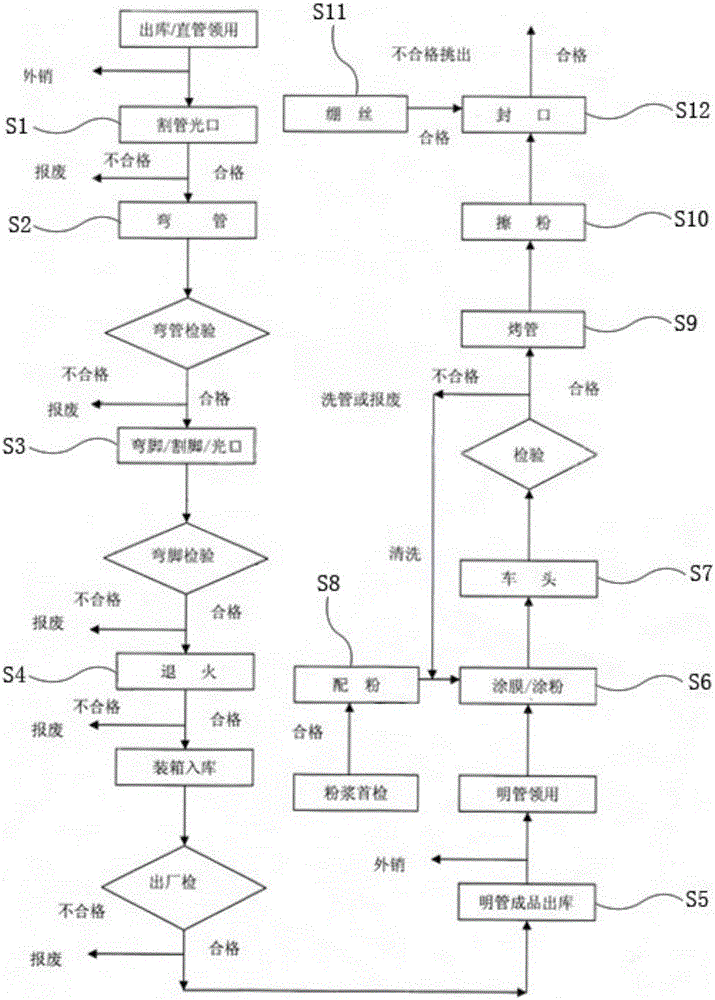

Glass lamp tube processing technology

InactiveCN105140085AStrong light transmissionAvoid wastingLuminescent coatings applicationGlobesCooking & bakingStraight tube

The invention discloses a glass lamp tube processing technology. The technology comprises the following steps of tube cutting and burring, tube bending, pin bending / pin cutting / burring, annealing, exposed tube film coating and powder coating, head lathing, tube baking, powder rubbing and port sealing. Main inspection procedures are arranged after head lathing. When internal powder coating of the exposed tube after head lathing is disqualified through inspection, tube washing or scrapping is performed according to different orders of severity. For example, tube washing is performed if the order of severity is within the repairable scope, then powder distribution is performed again and film coating and powder coating are performed on the repair tube again, the process enters the tube baking procedure and powder rubbing is performed after qualification is proved through inspection, and then wire stretching and port sealing are performed on the lamp tube. A complete production technology procedure is established, all procedures of use of a straight tube, manufacturing of the exposed tube and final completion of the finished lamp tube are coordinated compactly and coherently so that production efficiency of the glass lamp tube is enhanced. Generation of defective products can be eliminated by the inspection procedures arranged between up and down processes, and product percent of pass and transmittance of the glass lamp tube can be substantially enhanced.

Owner:江门市秦粤照明科技有限公司

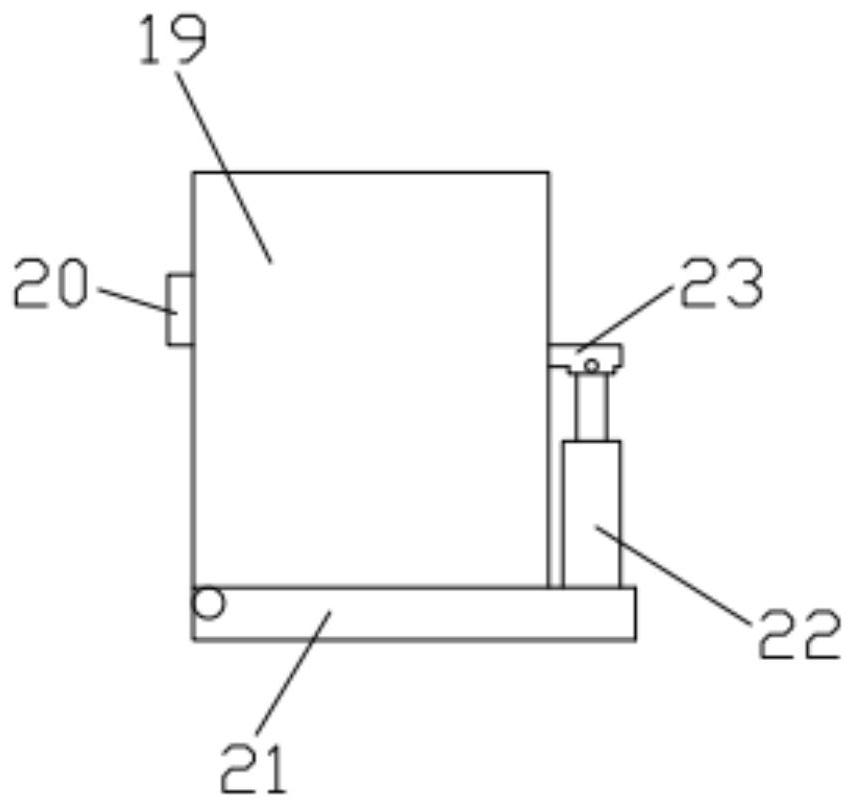

Rotary disc type power coating and curing integrated machine for weld joints of tank

ActiveCN106423674AStable structureImprove quality and efficiencySpraying apparatusPretreated surfacesInternal PowderCoating

The invention relates to a rotary disc type power coating and curing integrated machine for weld joints of a tank. The rotary disc type power coating and curing integrated machine comprises a rotary disc device performing intermittent circumferential motion, a feeding mechanism, a weld joint locating device, a reciprocating internal powder spraying device, a heating mechanism, and a discharge mechanism, wherein the rotary disc device is provided with a discharge end and a feeding end; the rotary disc device comprises a rotatable rotary disc; the rotary disc is provided with a plurality of first sucking parts which are arranged at intervals in the circumferential direction; the feeding mechanism is used for feeding the tank to the rotary disc; the reciprocating internal powder spraying device is used for spraying powder to the weld joints of the inner wall of the tank; the heating mechanism is arranged between a locating mechanism and the discharge end; the heating mechanism is provided with heating parts opposite to the first sucking parts; and the discharge mechanism is used for moving the tank out of the rotary disc, and is arranged at the discharge end. According to the rotary disc type power coating and curing integrated machine for the weld joints of the tank, the production efficiency for repairing and coating the weld joints of the tank is improved, the spraying quality of the weld joints of the tank is improved, integral transportation is facilitated, and the on-site mounting debugging efficiency is improved.

Owner:广州卓诚智能科技有限公司

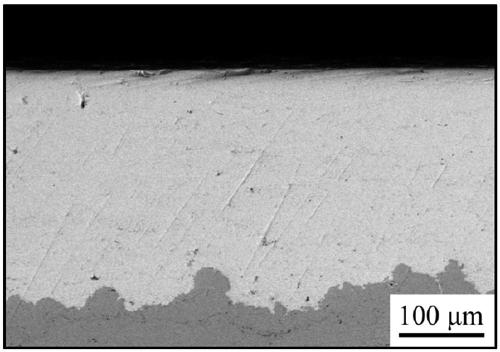

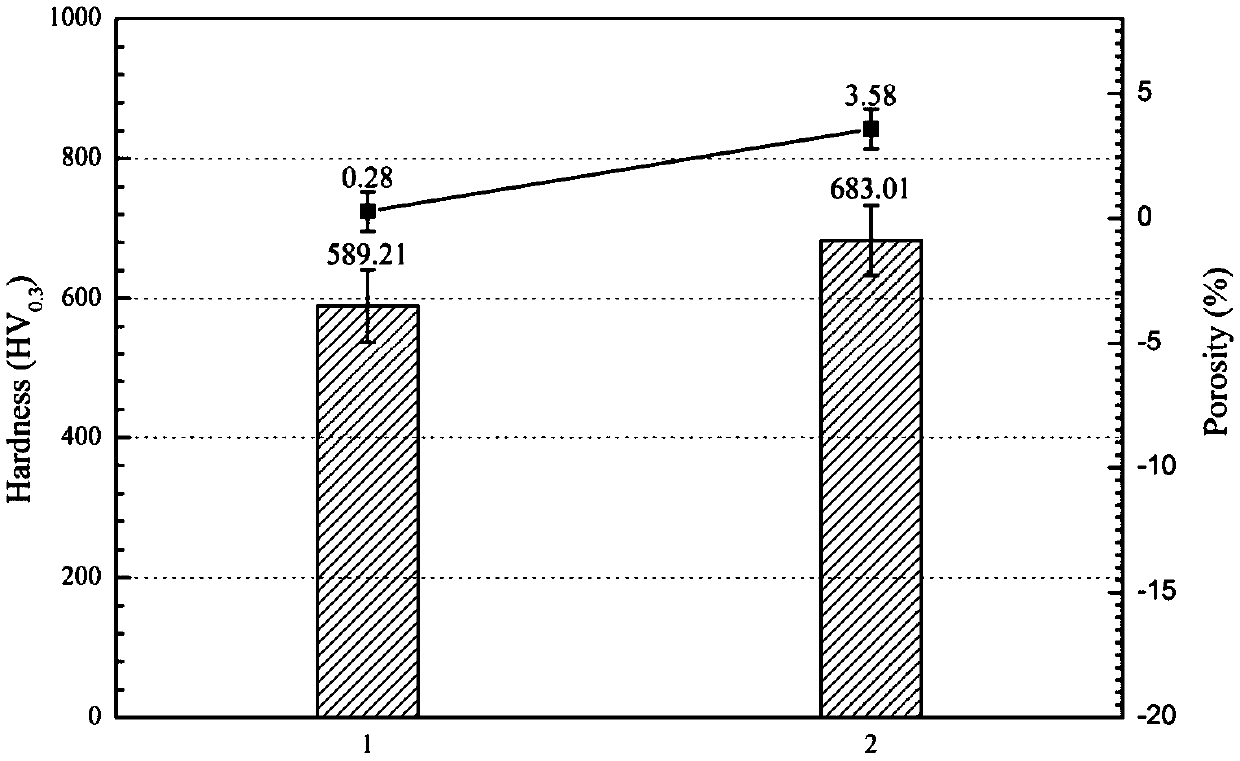

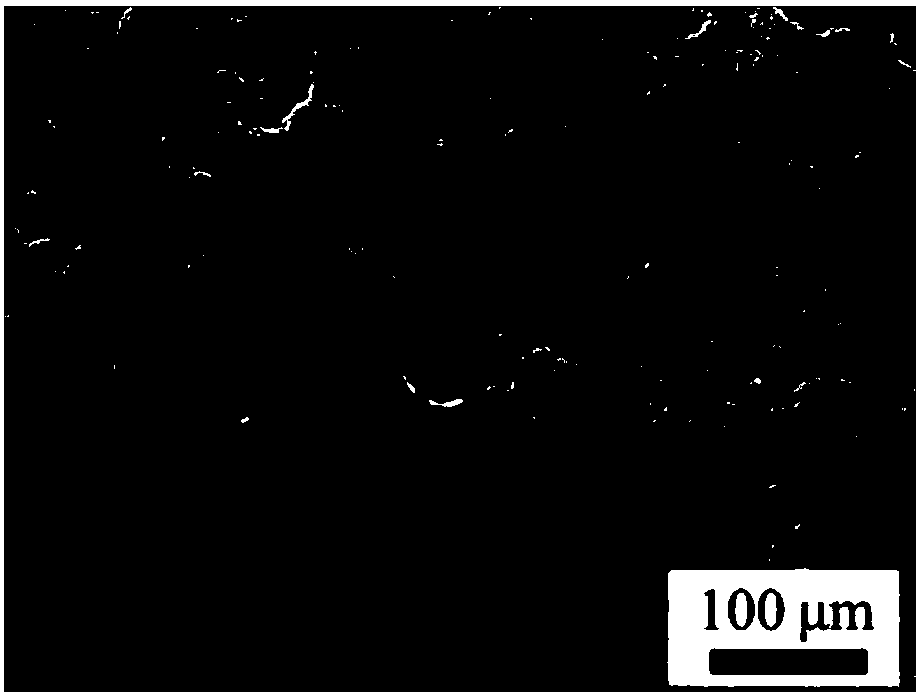

Internal powder feeding type high-energy plasma spraying manufacturing method of refractory metal heavy load wear-proof coating

InactiveCN109518118AImprove densification performanceImprove compactnessMolten spray coatingPorosityThermal spraying

The invention relates to an internal powder feeding type high-energy plasma spraying manufacturing method of a refractory metal heavy load wear-proof coating. Mo powder is used as the raw material ofthe coating, and the coating is obtained on a metal base material by means of an internal powder feeding type high-energy plasma spraying method. By the adoption of the internal powder feeding type high-energy plasma spraying manufacturing method of the refractory metal heavy load wear-proof coating, by means of reasonable thermal spraying technological parameters, the spraying technological process is strictly controlled, so that the porosity of the coating is reduced, the breaking tenacity of the coating is improved, and the comprehensive mechanical property of the coating is greatly improved; the hardness difference between a coated part and a counterpart is small, three-body wear caused under heavy load conditions is avoided, the friction coefficient and wear rate are lowered, the wearresistance is greatly improved, and the service lives of all types of metal parts are effectively prolonged.

Owner:XI AN JIAOTONG UNIV

Sintered body for adsorption, production method therefor, and adsorption device

PendingCN113423500ASmall pressure lossImprove adsorption capacityGas treatmentFatty/oily/floating substances removal devicesActivated carbonPolymer science

The aim is to adsorb a to-be-treated substance in a fluid (7) at high adsorption capacity and with low pressure loss. A sintered body (20) for adsorption according to the present invention is provided with powder adsorbent materials (1a, 1b) and a resin structure (2) which has a void (3) formed so as to have a three-dimensional network-configuration. The powder adsorbent materials (1a, 1b) comprise: a free adsorbent material (1a) that is accommodated within the void (3) in the resin structure (2) so as to be freely movable; and a fixed adsorbent material (1b) that is firmly fixed to a surface (2a) of the resin structure (2) and / or has at least a part thereof embedded inside the resin structure (2). The powder adsorbent materials (1a, 1b) are at least one type selected from among powdered activated carbon, powdered activated white earth, and zeolite.

Owner:AJINOMOTO CO INC +1

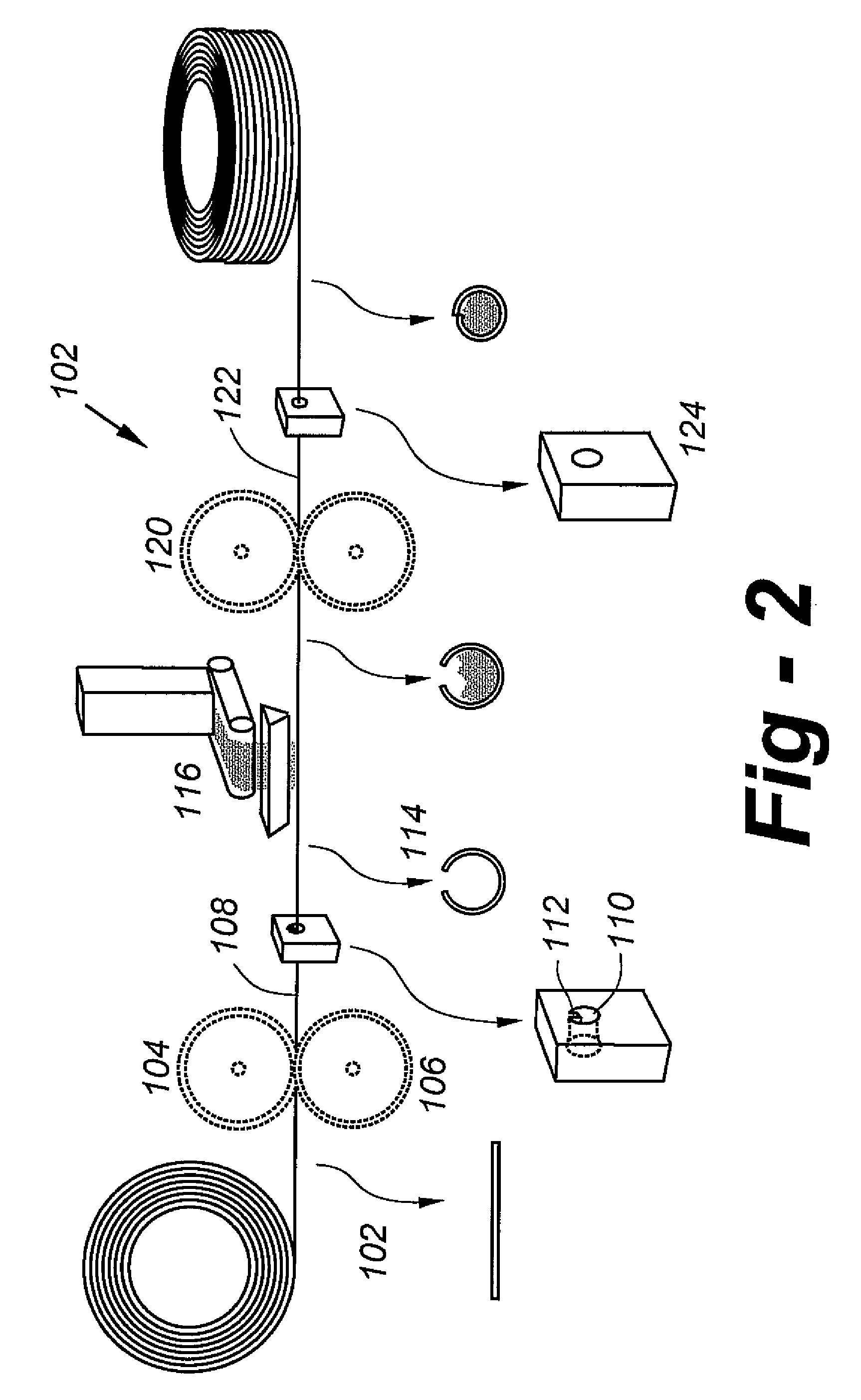

Simplified method and apparatus for making cored wire and other tubular products

InactiveUS20080148796A1Simple processSimple manufacturing methodExtrusion diesWelding/cutting media/materialsEngineeringInternal Powder

Improved cored-wire fabrication replaces multiple roller pairs with one or more dies. In the preferred embodiment, flat stock is pulled through a single cylindrical die including an upper tab to ensure and orient the formation of a gap to receive internal powders. Once the powders are introduced, a cylindrical die is used for closure though again, one or more rollers may be used between the powder feed and the die used for closing. In the preferred embodiment, however, a single gap-forming die is used before the powder feed, and a single closing die is used after the powder feed, replacing numerous rollers and other moving parts, thereby dramatically simplifying the apparatus and method of manufacture.

Owner:WELD MOLD

Production device for PVC (polyvinyl chloride) plastic film recycling

InactiveCN113199669AReduce workloadImprove crushing effectPlastic recyclingGrain treatmentsPolymer sciencePolyvinyl chloride

The invention relates to a production device for PVC plastic film recycling, and belongs to the technical field of plastic film production. The production device comprises a conveying belt, and a slitting mechanism used for cutting a plastic film is arranged on the conveying belt; a smashing box with an upper opening is arranged at the conveying tail end of the conveying belt, a smashing mechanism used for smashing the cut plastic film is arranged in the smashing box, a discharging port is formed in the bottom of one side of the smashing box, and a discharging mechanism used for discharging internal powder out of the discharging port is arranged at the bottom of the smashing box; and a stirring barrel with an upper opening is arranged on one side of the smashing box, the discharging port is located above the stirring barrel, and a stirring mechanism for stirring the collected powder is arranged in the stirring barrel. According to the production device, leftover materials of the plastic film can be recycled, so that the effect of saving resources is achieved.

Owner:上海盈泰新材料科技有限公司

Treatment process for edge of coated-type alkaline accumulator pole piece and auxiliary edge-covering equipment

ActiveCN102779982AEliminate short circuitEliminate Low Pressure ProblemsAlkaline accumulator electrodesLow voltagePole piece

The invention relates to a treatment process for the edge of a coated-type alkaline accumulator pole piece and auxiliary edge-covering equipment. The process comprises the following steps of: covering an alkali-resistant insulating material having a width of 2-10 mm on the edge of foamed nickel by an automatic edge-covering machine before filling active substances in a cell pole piece preparing raw material namely foamed nickel; and compressing the part of the foamed nickel covered by the alkali-resistant insulating material until the thickness of the part is less than 1.5 mm; and finally filling the active substances in the edge-covered foamed nickel. After the process method is adopted, because the burred edge of the foamed nickel is covered by the smooth insulating material, the edge has no need to be trimmed during the subsequent machining; and because the burred edge of the foamed nickel is covered by the smooth insulating material, the edge cannot be damaged during the subsequent machining for the pole piece, and a powder in the pole piece cannot fall off, so that the problems of short circuit and low voltage caused by the burrs on the edge of the pole piece and the powder falling-off of the edge during the use process of the accumulator are eliminated.

Owner:LIAONING JIUYI ENERGY TECH

Preparation method of wear-resistant anti-friction coating with highly dispersed and distributed lubricating phase

The invention relates to a preparation method of a wear-resistant anti-friction coating with a highly dispersed and distributed lubricating phase. According to the preparation method, powder such as Ni-C, AlSi-polyphenyl ester and NiCr-BN-MoS2 which have the self-lubricating property is used as a raw material, and an internal powder feeding high-energy plasma spraying method is adopted for formingthe wear-resistant anti-friction coating on a metal substrate. According to the preparation method, through reasonable thermal spraying process parameters, the spraying technological process is strictly controlled, the porosity of the coating is reduced, the hardness and the bonding force are improved, the comprehensive mechanical properties are greatly improved, the wear-resisting anti-frictionperformance is obviously optimized, and the work service life of turbomachinery is effectively prolonged.

Owner:XI AN JIAOTONG UNIV +1

Lateral powder feeding head for laser cladding

ActiveCN109295454AWell mixedReduce the ratioMetallic material coating processesVertical planeEngineering

The invention relates to the field of non-traditional machining, in particular to a lateral powder feeding head for laser cladding. The lateral powder feeding head for laser cladding is formed by a left wall, a clapboard, a right wall, a front wall and a back wall, wherein the clapboard divides the powder feeding head into an independent cavity I and an independent cavity II with two rectangular cross sections; the lower ends of the two independent cavities are reduced to form two rectangular powder nozzle I and powder nozzle II; the end surfaces of the powder nozzle I and the powder nozzle IIare located on the same vertical plane; the independent cavity I and the independent cavity II feed powder through carrier gases and have the same internal powder feeding pressure; the powder nozzleI and the powder nozzle II spray various powder at the same time, the powder is radiated and melted through a laser beam so as to arrive at the surface of a workpiece, and the covering areas of the sprayed powder arriving at the surface of the workpiece coincide exactly; the cross section of the laser beam is in a rectangular shape, and the shape and the size of the laser beam and the shape and the size of the powder arriving at the surface of the workpiece are identical and coincide in positions; and the laser beam is firstly acted on the powder sprayed through the powder nozzle I and the powder nozzle II and is then acted on the surface of the workpiece.

Owner:JIANGSU UNIV

Manufacturing technique for split type carbon powder box

InactiveCN105278290AIncrease productivityReduce manufacturing costElectrographic process apparatusWorking environmentMaterials science

The invention discloses a manufacturing technique for a split type carbon powder box and aims to provide a manufacturing technique for a split type carbon powder box, wherein the manufacturing technique has low labor cost, good working environment and capability of providing high product quality. The manufacturing technique comprises the following steps: (1) assembling internal powder cabin accessories; (2) welding a surface cover; (3) assembling a powder feeding roller and sealing; (4) pasting a developing roller sealing element and assembling a developing roller; (5) assembling a gear set and a side cover; and (6) filling the powder. The manufacturing technique for the split type carbon powder box is applied to the technical field of production of split type carbon powder boxes.

Owner:ZHUHAI GREE MEIDA TECH

Simplified method and apparatus for making cored wire and other tubular products

InactiveUS7950126B2Simple manufacturing methodExtrusion diesWelding/cutting media/materialsEngineeringInternal Powder

Owner:WELD MOLD

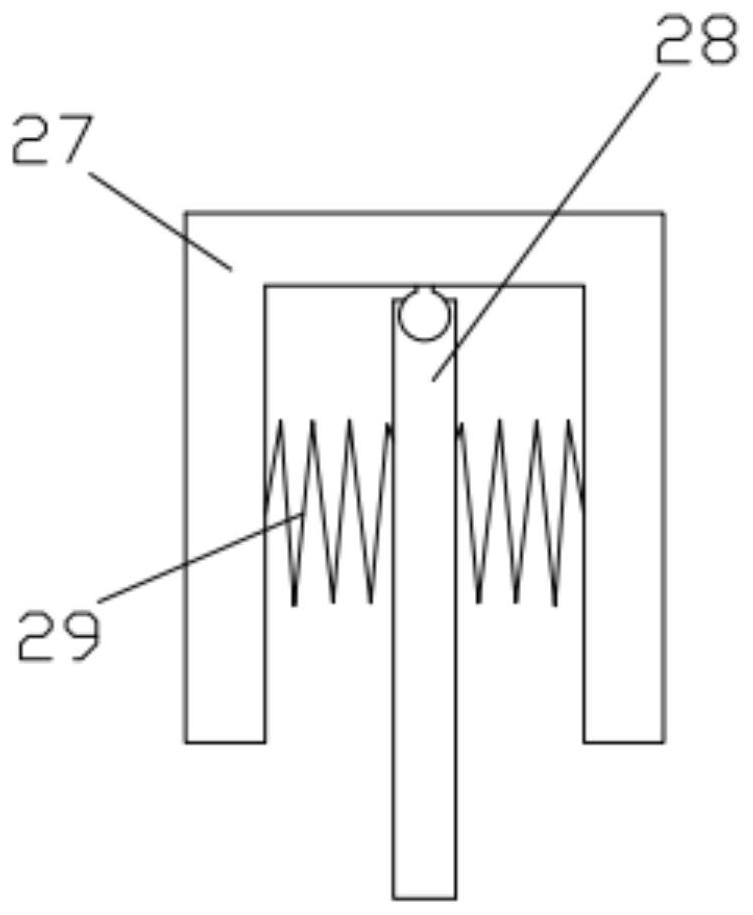

Internal powder machine

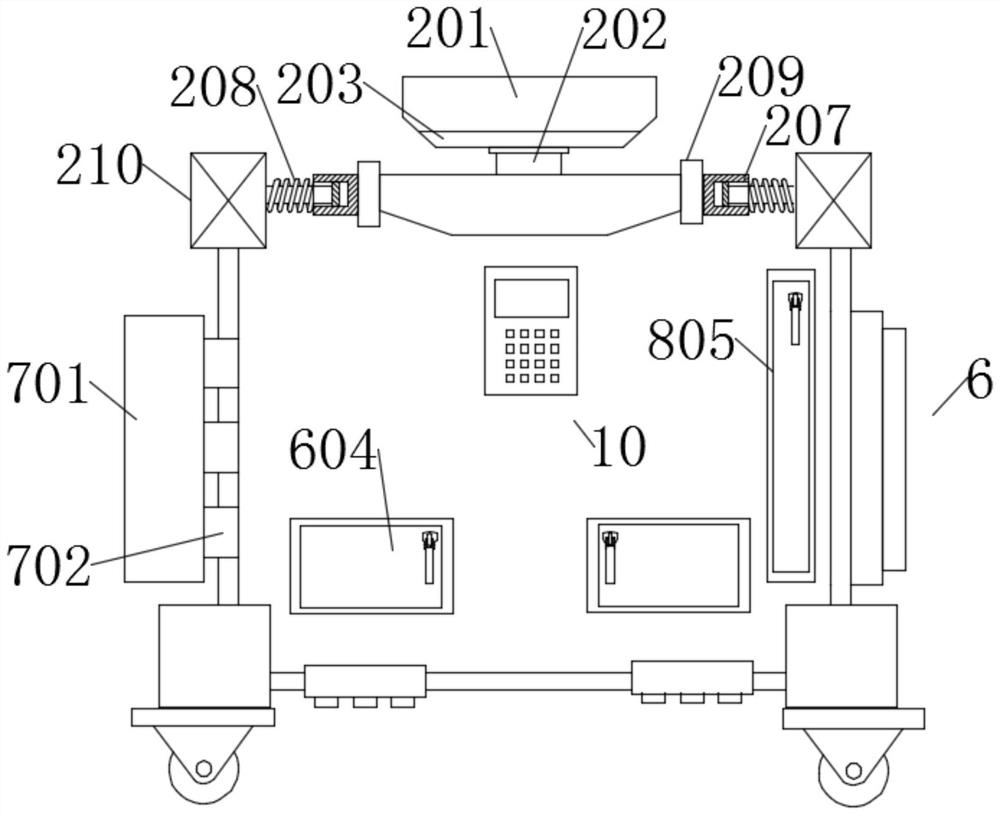

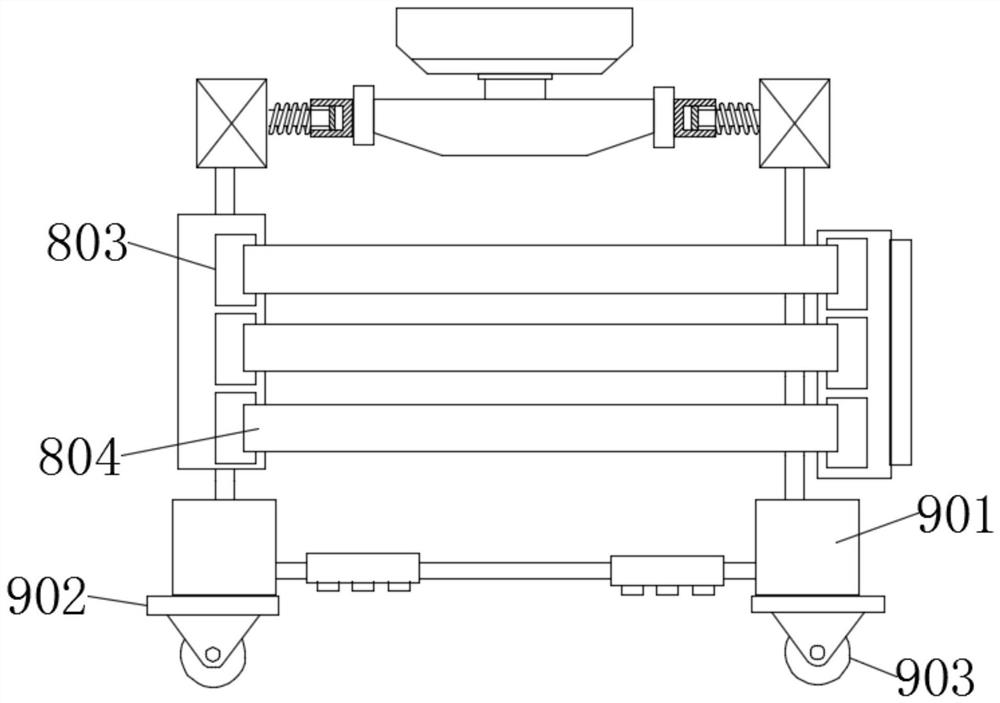

ActiveCN113620058AEasy to adjustImprove work efficiencyLarge containersBulk conveyorsVibration amplitudeEngineering

The invention relates to the technical field of powder conveying equipment, in particular to an internal powder machine. The machine comprises a rack, an upper plate, a vacuum processor mounting frame, a hopper, a vacuum processor component, a vibrator, a vibrating disc component and a discharging groove, wherein the vibrating disc component driven by the vibrator is arranged at the discharging end of the hopper; the discharging groove is formed in the discharging end of the vibration disc component and located above the vacuum processor component; the vacuum processor mounting rack is arranged on the rack; the vacuum processor component is arranged on the vacuum processor mounting frame and comprises a threaded rod; and the threaded rod is made of ceramic materials. The vibrator and the vibration disc component are arranged, the vibration frequency of the vibrator is controlled through a digital controller, and the vibration amplitude is convenient to adjust; a spiral frame is arranged in the vibration disc, powder cannot be blocky, particles are easily crushed into powder through vibration, and the powder is conveyed uniformly; and a powder outlet nozzle descends in an inclined mode, powder conveying is stable and uniform without accumulation, and the working efficiency of the internal powder machine is improved.

Owner:漳州迈邦自动化设备有限公司

Spraying room for quick color changing equipment

The invention discloses a spraying room for quick color changing equipment. The spraying room comprises a spraying room body, a ventilation opening, an electrostatic filter layer and an air outlet, wherein a spraying cavity is arranged on the middle position inside the spraying room body; the ventilation opening is formed in one side of the spraying cavity; the air outlet is formed in the other side of the spraying cavity; the filter layer is arranged inside the ventilation opening; a filter element is arranged at the other side inside the air outlet; and a fan is arranged at the other side inside the air outlet. The spraying room realizes cleaning for powder inside the spraying cavity through an electric telescopic pole and a brush; the spraying cavity communicates with a powder recyclingcavity through a powder leaking slot, so that powder conveniently enters the powder recycling cavity for being recycled and utilized for a second time; an electrostatic filter layer can adsorb lightparticles, namely dust, in powder, so that dust impurities are prevented from being mixed into the powder to affect spraying quality; and secondary screening processing does not need to manually perform, so that the spraying room is simple in structure and is reasonable in design.

Owner:湖南三五二环保科技有限公司

Capsule internal powder conveying and screening device and using method thereof

ActiveCN113798164AReduce the proportion of deliquescence cakingAchieve decompositionSievingScreeningCakingInternal Powder

The invention discloses a capsule internal powder conveying and screening device and a using method thereof, and relates to the technical field of capsule internal powder conveying and screening. The capsule internal powder conveying and screening device comprises a screening barrel and a screening mechanism; the top end of the outer wall of the screening barrel is provided with a feeding opening, and the opening part of the feeding opening is provided with a feeding pipe, a discharging opening is formed in the right side wall of the screening barrel, a material guiding pipe is obliquely and downwards arranged at an opening of the discharging opening, the screening mechanism is located in the screening barrel and installed at the discharging opening, the screening mechanism comprises a supporting plate, and the supporting plate is flush with the material guiding pipe and fixedly arranged at the opening of the discharging opening; and multiple rubber partition plates which are evenly distributed at intervals are vertically fixed to the upper end of the supporting plate. A stirring mechanism is used for pre-stirring capsule particles fed into the screening barrel, and meanwhile, an L-shaped heating plate is used for preheating the lifted capsule powder, damp caking is avoided, the screening mechanism is used for screening and crushing the large-particle caked capsule powder, and the deliquescent capsule particles are decomposed, and complete guiding-out is achieved.

Owner:安徽城市药业股份有限公司

PTA refining condensate recovery device

ActiveCN111939688AQuick squirtEject fasterCombination devicesUsing liquid separation agentWater storageStructural engineering

The invention provides a PTA refining condensate recovery device, which comprises a main body; an impurity removing mechanism; a filtering mechanism; a collection mechanism; a control mechanism, wherein the control mechanism comprises a sliding groove, a fixing block, an air pipe, a fixing funnel, an extrusion plate, a fixing rod, a floating ball and a supporting rod, the interior of the sliding groove is slidably connected with the extrusion plate with the semicircular side wall, and the supporting rod is slidably connected with the interior of the air pipe and the interior of the collectingmechanism; a condensation mechanism; a water storage mechanism; and a flushing mechanism, wherein the flushing mechanismv comprises a hose, a water inlet pipe, a pressing rod, a piston, a fixing ball,an air inlet pipe, spray heads and a coil pipe, the spray heads are installed at the top end of the coil pipe at equal intervals, the piston with the inclined top end is slidably connected to the interior of the fixing ball, and the piston is slidably connected to one end of the air inlet pipe. According to the invention, the PTA refining condensate recovery device has the advantages that condensate is added into the washing tower, water cost is reduced, and powder in the washing tower is convenient to clean.

Owner:浙江独山能源有限公司

Multi-stage sieving device for pastry powder

The invention discloses a multi-stage sieving device for pastry powder. The multi-stage sieving device comprises a base, a sieving cylinder and a powder receiving assembly, wherein the sieving cylinder is rotationally connected to the base; the sieving cylinder is obliquely arranged and comprises a first-stage sieving part, a second-stage sieving part and a third-stage sieving part; the head of the first-stage sieving part is connected to a feeding hopper; the powder receiving assembly is matched with the sieving cylinder; the powder receiving assembly comprises position-limiting plates and receiving boxes arranged between the position-limiting plates; and the receiving boxes can be drawn and pulled to move relative to the base. Compared with the prior art, the multi-stage sieving device for the pastry powder achieves rotary sieving through the arrangement of the sieving cylinder, and enables the internal powder to move in the process, thereby avoiding the situation that sieving holes are blocked due to mutual bonding of the powder, and achieving a good sieving effect. Moreover, through the arrangement of the first-stage sieving part, the second-stage sieving part and the third-stage sieving part, the powder of different particle sizes can be sieved out at the same time, so that the sieving efficiency is greatly improved.

Owner:徐州恒星面业有限公司

Inclinable food processing stirrer

InactiveCN112138571AAvoid unqualifiedRotary stirring mixersTransportation and packagingBiotechnologyFood material

The invention discloses an inclinable food processing stirrer. The inclinable food processing stirrer structurally comprises a base, a support, a stirrer body, a stirring barrel and an inclined discharging port, the top face of the base is welded to the bottom face of the support, the bottom face of the stirrer body is fixedly installed on the top face of the support, the top of the stirring barrel is fixedly connected with one side of the stirrer body, and the top of the inclined discharging port communicates with the bottom of the stirring barrel; by means of the rotatable and obliquely-distributed adhesive beater provided with the multiple beating knives, an outer layer shell of caked flour in food raw materials is crushed, internal powder is shaken off again, and meanwhile the raw materials dispersed into the outer wall through centrifugal force and accumulated are scraped off through the wall scraping knives; the raw materials are returned to the stirring position and mixed; the situation that the processed biscuits are unqualified due to flour caking is avoided, and meanwhile, the problem that too many flour blocks which are not uniformly stirred are attached to the interiorof the outer wall due to centrifugal force is thoroughly avoided.

Owner:广州畅新生物科技有限公司

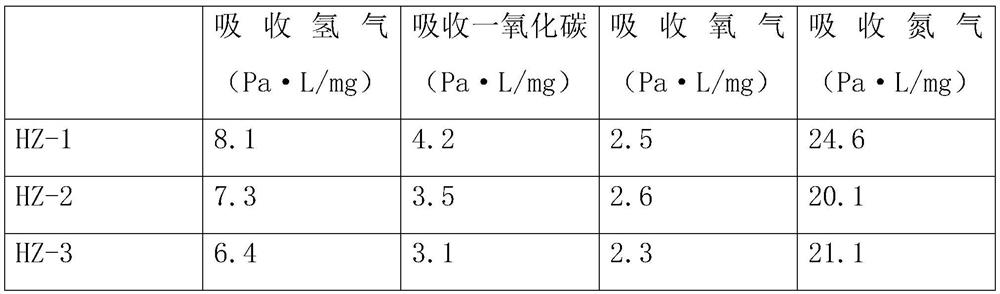

Normal-temperature vacuum getter and preparation method thereof

ActiveCN113134279AEasy to useEnvironmental protectionDispersed particle separationWater vaporNitrogen gas

The invention discloses a normal-temperature vacuum getter and a preparation method thereof, and relates to the technical field of getters, the normal-temperature vacuum getter comprises an outer airtight tube shell and internal powder; wherein the outer-layer airtight tube shell is one of a glass tube shell and a metal tube shell; the internal powder is one or more of silicon dioxide powder, aluminum oxide powder, zeolite powder, graphite powder and montmorillonite powder. The normal-temperature vacuum getter can effectively avoid performance degradation of the getter in the VIP production operation process, does not need to be activated, has a good absorption effect on nitrogen, oxygen, water vapor, hydrogen, carbon dioxide and the like, and is safe and environmentally friendly.

Owner:三河市华臻新材料有限公司

Energy-saving grinding equipment special for deodorant stone added with stone missile powder

The invention discloses energy-saving grinding equipment special for deodorant stone added with stone missile powder. The energy-saving grinding equipment is characterized in that a shell, a grindingmotor, a rotating shaft and a grinding block are included; and a first grinding bulge, a second grinding bulge and a third grinding bulge are fixedly arranged on the grinding block and a grinding cavity. A multi-section grinding mode is adopted, the mode that the first grinding bulge, the second grinding bulge and the third grinding bulge are matched is adopted, grinding is delicate, and the effect is good; and an air blowing device is specially arranged, thus internal powder flowability can be improved, grinding is sufficient, and the effect is good.

Owner:宝盈联华(厦门)生物科技有限公司

Powder storage equipment for powder metallurgy

ActiveCN113996784AReasonable designKeep drySievingScreeningStructural engineeringProcess engineering

The invention discloses powder storage equipment for powder metallurgy. The equipment comprises a shell, a feeding device is installed above the middle of the shell, a storage bin is arranged in the shell, a circulating drying device used in cooperation with the storage bin is arranged in the middle of the shell, a stirring device used in cooperation with the circulating drying device is further installed in the storage bin, the left side and the right side of the bottom of the storage bin are each provided with a discharging device, the left side and the right side of the bottom of the shell are each provided with a supporting assembly, and a control device is further electrically installed outside the shell. The feeding device in the equipment can conduct double screening before powder storage, and meanwhile, the circulating drying device can conduct circulating flow drying on the interior of the storage bin so as to avoid that in the drying process, the drying effect of internal materials is not uniform and humidity steps are formed. The stirring device is matched for stirring and mixing the internal powder, the drying effect is further improved, the drying efficiency is improved, and the storage is facilitated.

Owner:安徽九华富康冶金材料有限公司

A method for preparing a high-performance layered thermal barrier coating system

ActiveCN105886994BStable and reliable deposition qualityGood high temperature oxidation resistanceMolten spray coatingEfficient propulsion technologiesPlasma jetSuperalloy

The invention discloses a method for manufacturing a high-performance layered thermal barrier coating system. The method comprises the following steps that firstly, an alloy bonding layer is manufactured on the surface of a matrix; secondly, supersonic plasma jet is used for carrying out surface modification treatment on the alloy bonding layer; and thirdly, a single-layer or multi-layer ceramic material coating is manufactured on the modified surface of the alloy bonding layer, and the thermal barrier coating system is obtained. An internal powder feeding supersonic air plasma spraying method is adopted for obtaining the layered thermal barrier coating system formed by the high-temperature alloy bonding layer and a ceramic surface layer. Compared with a traditional method for manufacturing a thermal barrier coating, the problems that due to technological conversion, the coating manufacturing efficiency is low, and the quality batch stability is poor are effectively avoided, important application value for prolonging the high-temperature service life of the a thermal barrier coating is achieved, wide application prospects are achieved in the national defense sophisticated industry such as aeroturbine engines and heavy duty gas turbines, and huge economic and social benefits are achieved.

Owner:XI AN JIAOTONG UNIV

A high heat input gas-electric vertical welding gas-shielded flux-cored wire based on grain refinement mechanism

ActiveCN109128573BPromote high melting point interstitial phaseNucleation refinementWelding/cutting media/materialsSoldering mediaLithium oxideMagnetite

A high heat input gas-electric vertical welding gas-shielded flux-cored wire based on a grain refinement mechanism, including a flux-cored wire sheath and its inner drug powder, wherein the flux-cored wire sheath is made of low-carbon steel cold-rolled steel strip, which The mass percentage of the composition is: C<0.06%, Si<0.3%, Mn<0.8%, P<0.02%, S<0.01%, and the balance is Fe and unavoidable impurities; the mass percentage of the composition of the powder is: titanium dioxide Or one or both of rutile: 1-5%, quartz sand: 2-6%, feldspar: 3-8%, magnetite: 1-5%, lithium oxide, sodium oxide or potassium oxide One or more: 2-5%, low-carbon ferromanganese: 10-15%, aluminum powder: 3-8%, titanium iron: 3-8%, nickel powder: 2-6%, rare earth silicon: 2- 6%, magnesium powder: 1-3%, and the rest is reduced iron powder; and the powder accounts for 15-20% of the total mass of the flux-cored wire. The welding wire of the invention can be used for gas-electric vertical welding of thick steel plate with large heat input of 100kJ / cm-300kJ / cm.

Owner:BAOSHAN IRON & STEEL CO LTD

A powder spreading device for full-color powder 3D printing

ActiveCN110978507BConvenient supplementImprove compactnessManufacturing enclosures3D object support structuresBall screwElectric machinery

The invention discloses a powder spreading device for full-color powder 3D printing. The pushing assembly for material compaction and the powder spreading assembly for spreading. The storage assembly includes a storage box for storing powder materials, two sets of feeding pipes for feeding, and a set for cutting off or connecting discharge. The electric gate valve and the material guide pipe for discharge, the moving assembly includes a support frame for support, two sets of chutes and two sets of sliders for guiding and limiting, and a forward and reverse drive for driving A motor and a ball screw used to connect with the material storage box, the pushing assembly includes an electric push rod for providing power, a briquetting block for compacting the powder material, and several pushing rods for pushing the material. The invention conveniently realizes loosening of the powder material and extrusion after injection, avoids material blocking and enhances the compactness of the powder material inside the printing tank.

Owner:安徽薄荷三维科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com