Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

739 results about "Arc voltage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Define Arc Voltage. It is the voltage that appears across the contacts of the circuit breaker during the arcing period. As soon as the contacts of the circuit breaker separate, an arc is formed. The voltage that appears across the contacts during arcing period is called the arc voltage.

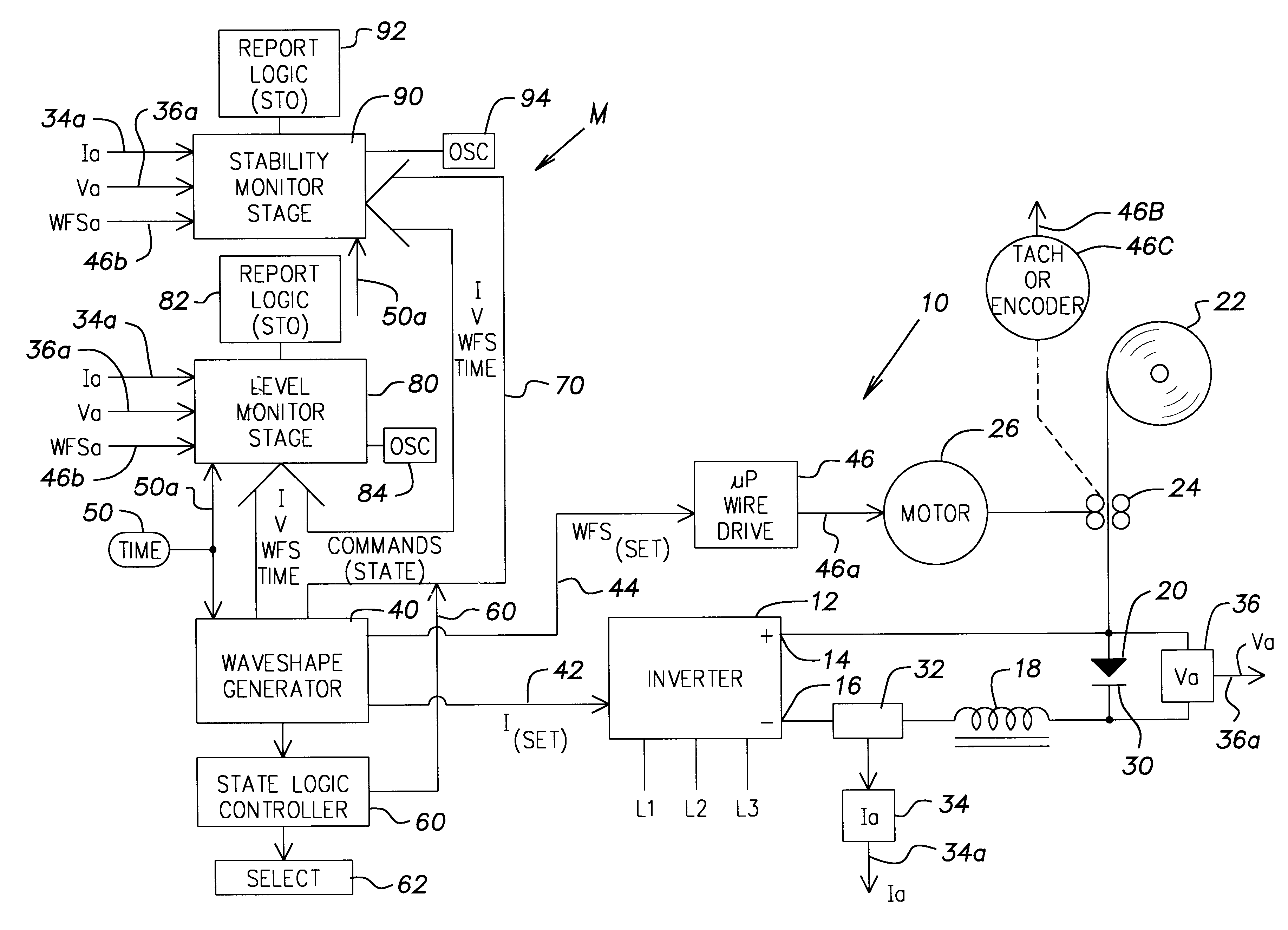

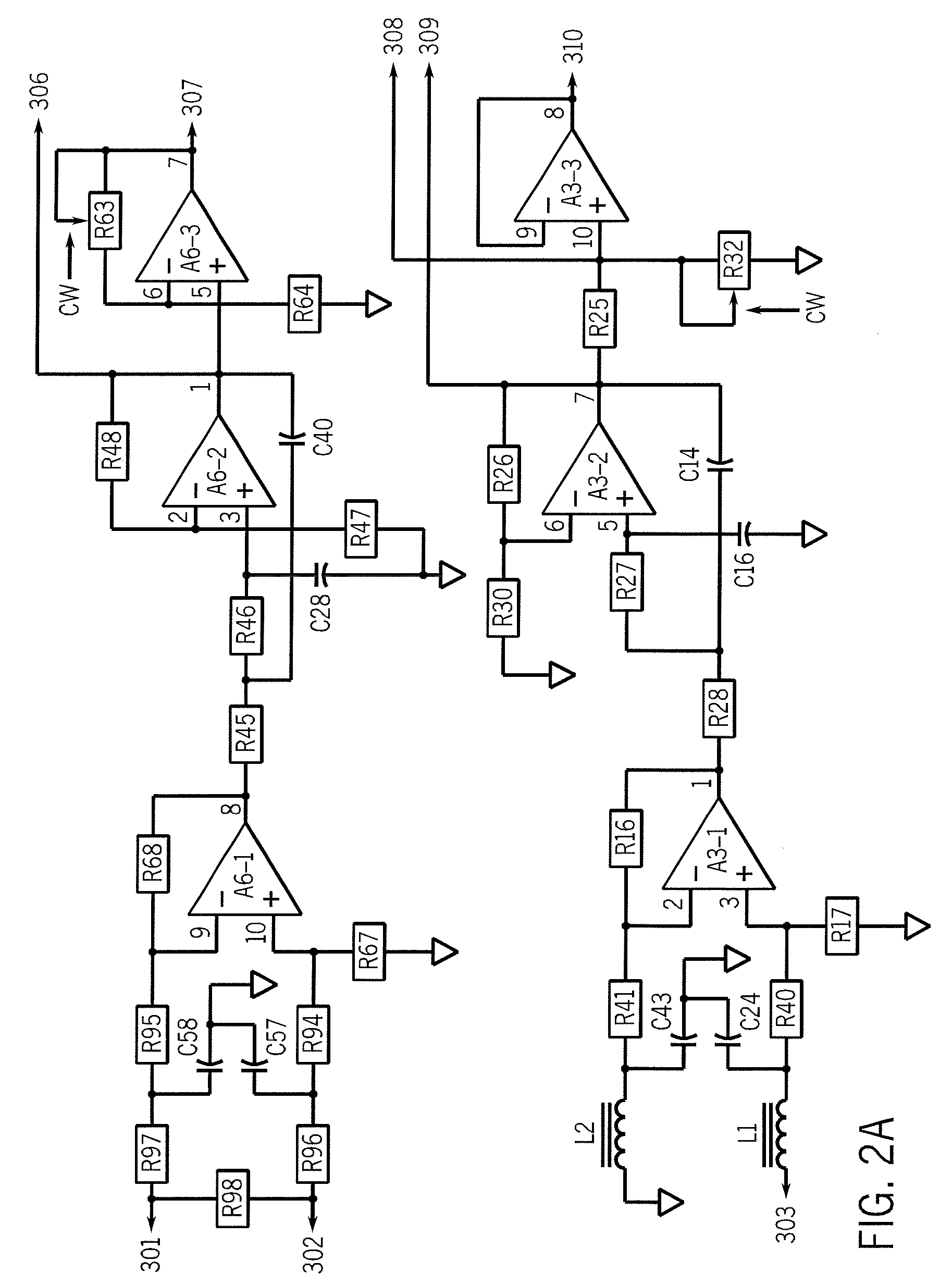

Monitor for electric arc welder

InactiveUS6441342B1Rapid data acquisition rateSufficient memoryArc welding apparatusWave shapeSimulation

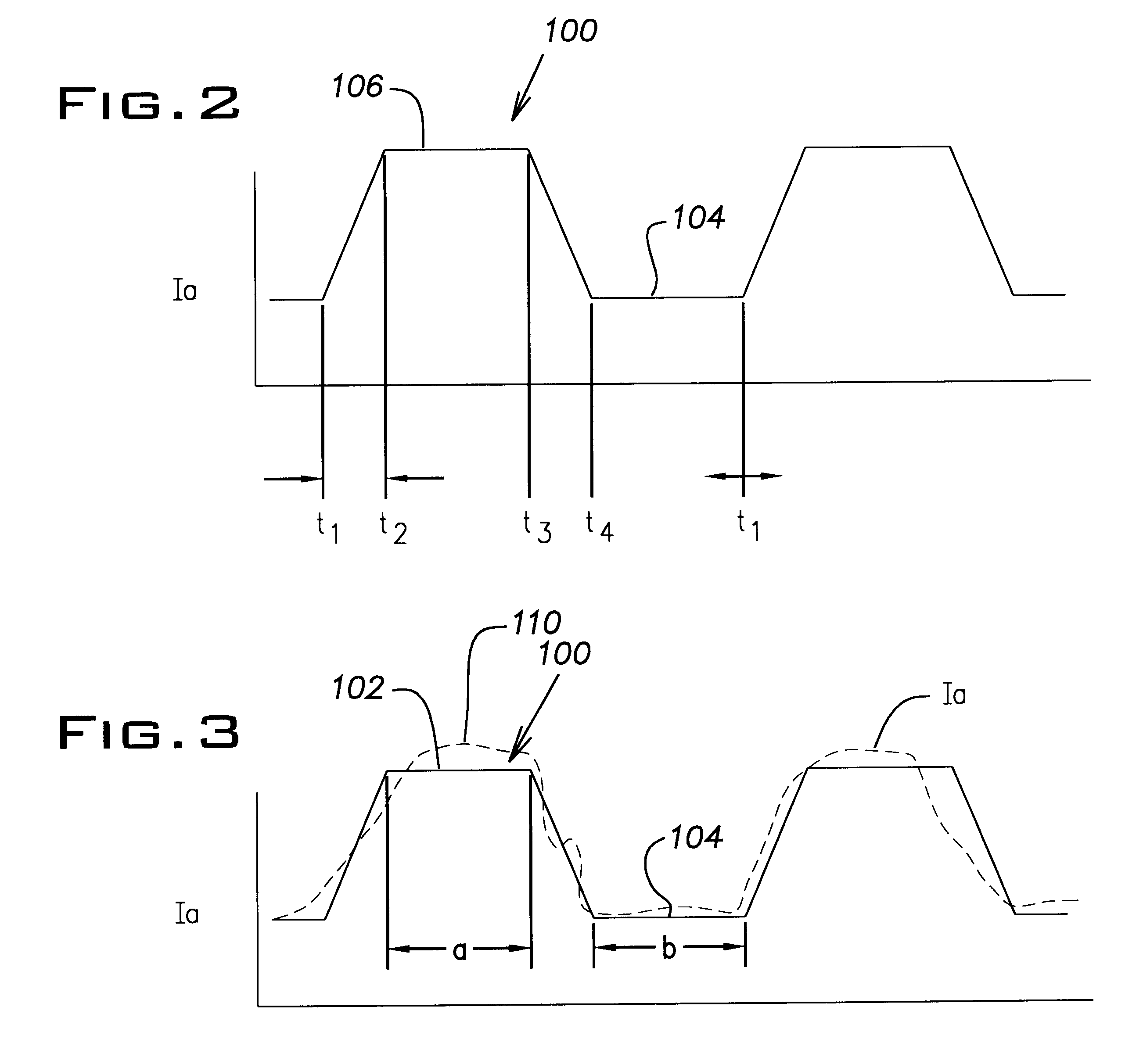

A monitor for an electric arc welder as the welder performs a selected arc welding process by creating actual welding parameters, such as arc current and arc voltage, between an advancing welding wire and a workpiece, where the process involves an arc and is defined by a series of rapidly repeating wave shapes constituting a weld cycle with a cycle time, the wave shapes are each segmented into time states having command signals corresponding to the actual parameters and a time duration. The monitor selects a specific wave shape state, reads one of the actual parameters, compares the actual read parameter with a function of the command signal corresponding to the actual parameter, and uses-the comparison to generate a characteristic of the welding process during the selected state.

Owner:LINCOLN GLOBAL INC

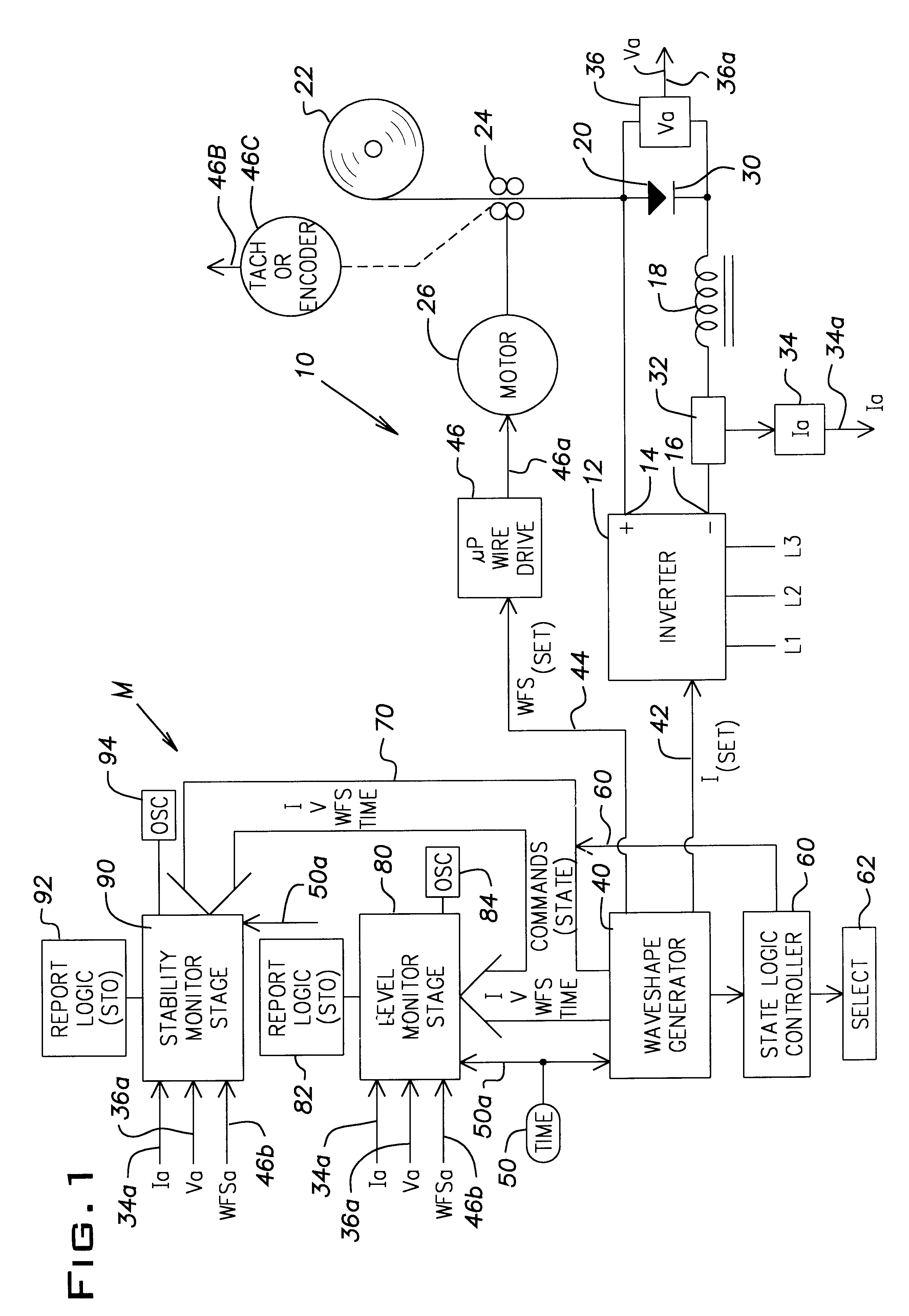

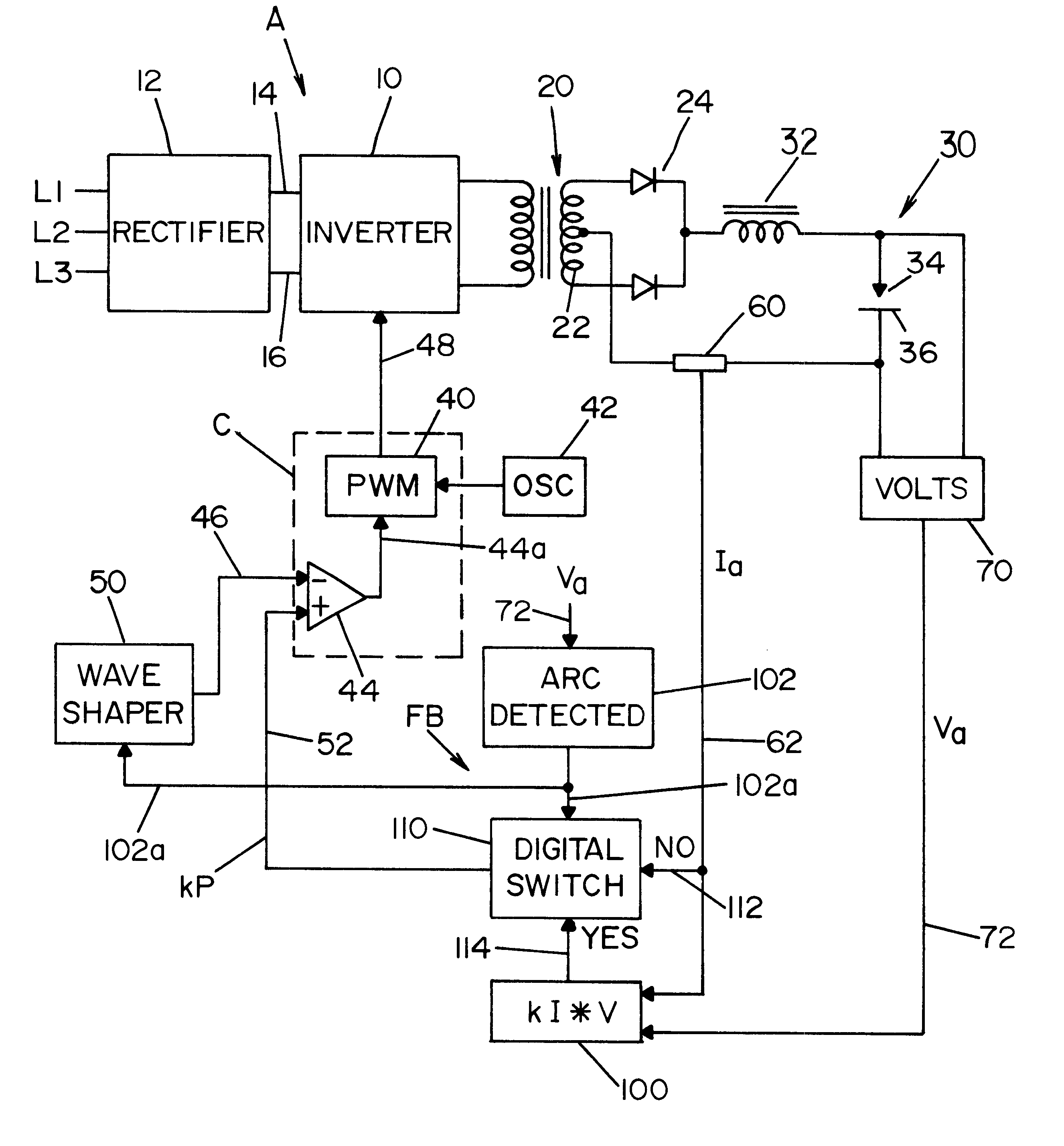

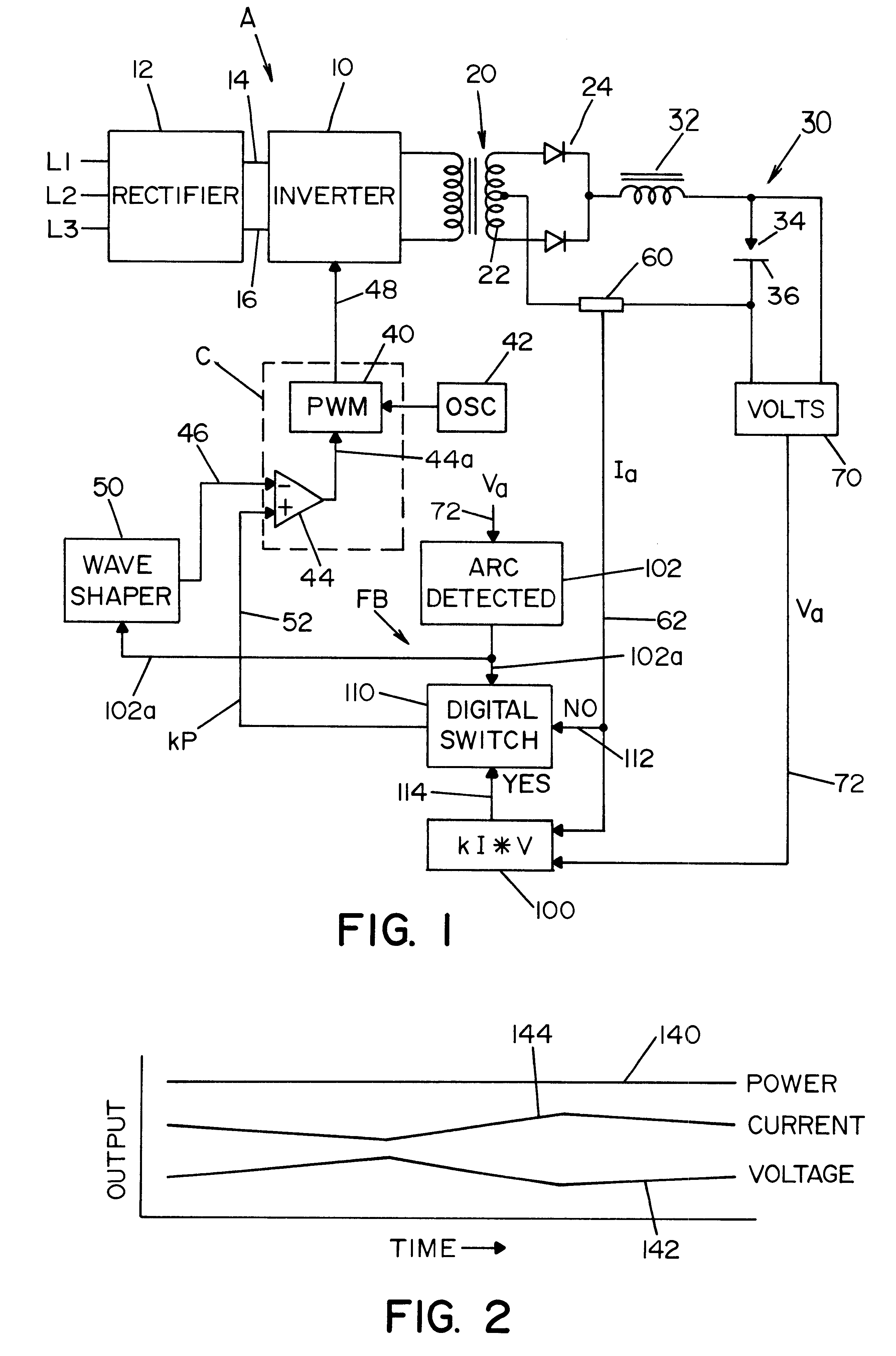

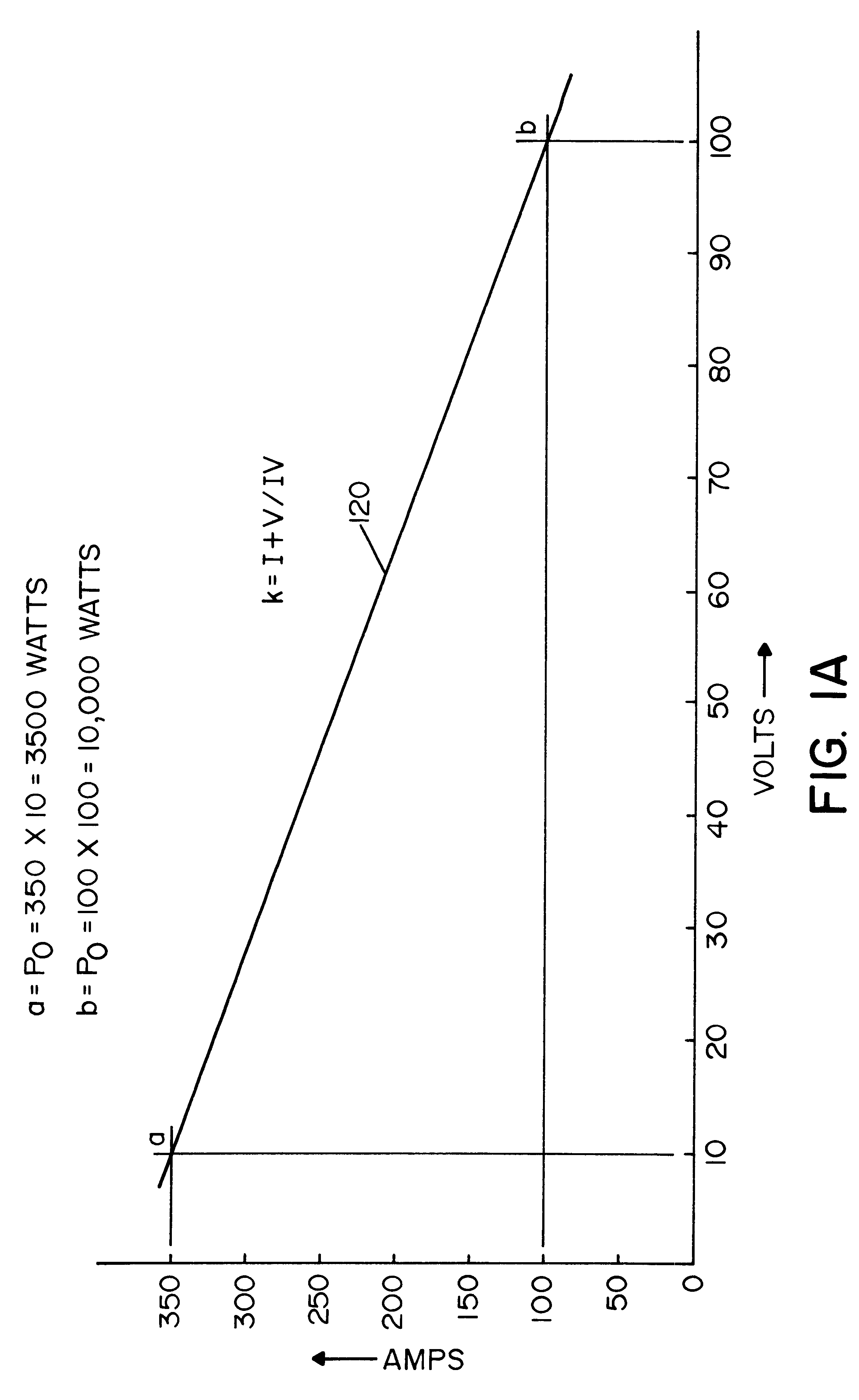

System and method for controlling an electric arc welder

InactiveUS6498321B1Inhibit currentRealize automatic adjustmentArc welding apparatusControl signalControl system

A control system for an electric arc welder performing a welding process between an electrode and a workpiece, which system comprises: a high speed switching type power supply with a controller operated at a switching frequency of at least about 10 kHz with an input current control signal to adjust the output current of the power supply; a first sensor sensing the actual arc voltage; a second sensor sensing the actual arc current; a first circuit for creating a power signal representing the desired real time power level at progressive times during the welding process; a second circuit for creating a function of the sensed actual voltage and the sensed actual current; and a third circuit for adjusting the current control signal in accordance with the difference between the power signal and the function of the actual voltage and current, preferably arc power.

Owner:LINCOLN GLOBAL INC

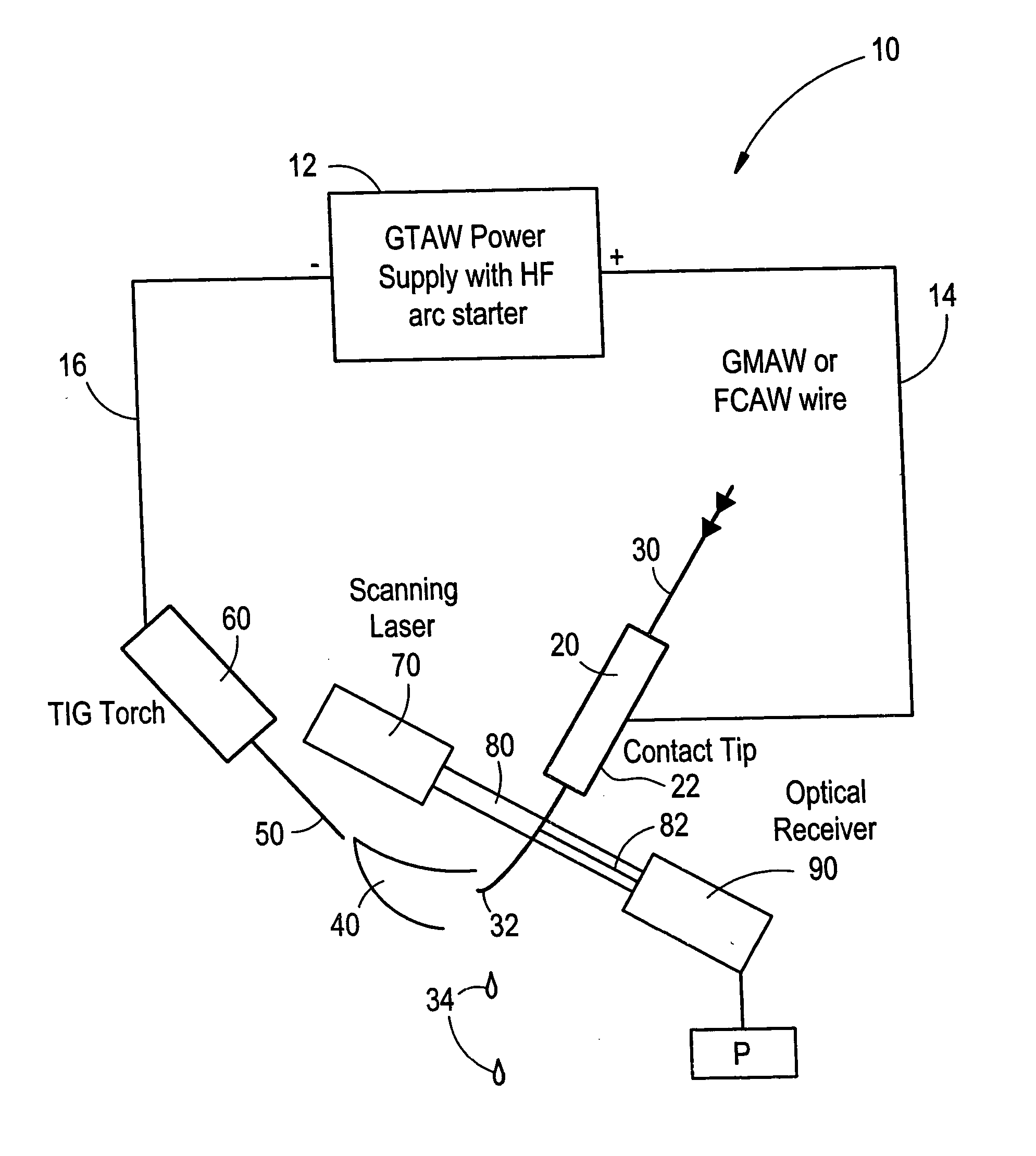

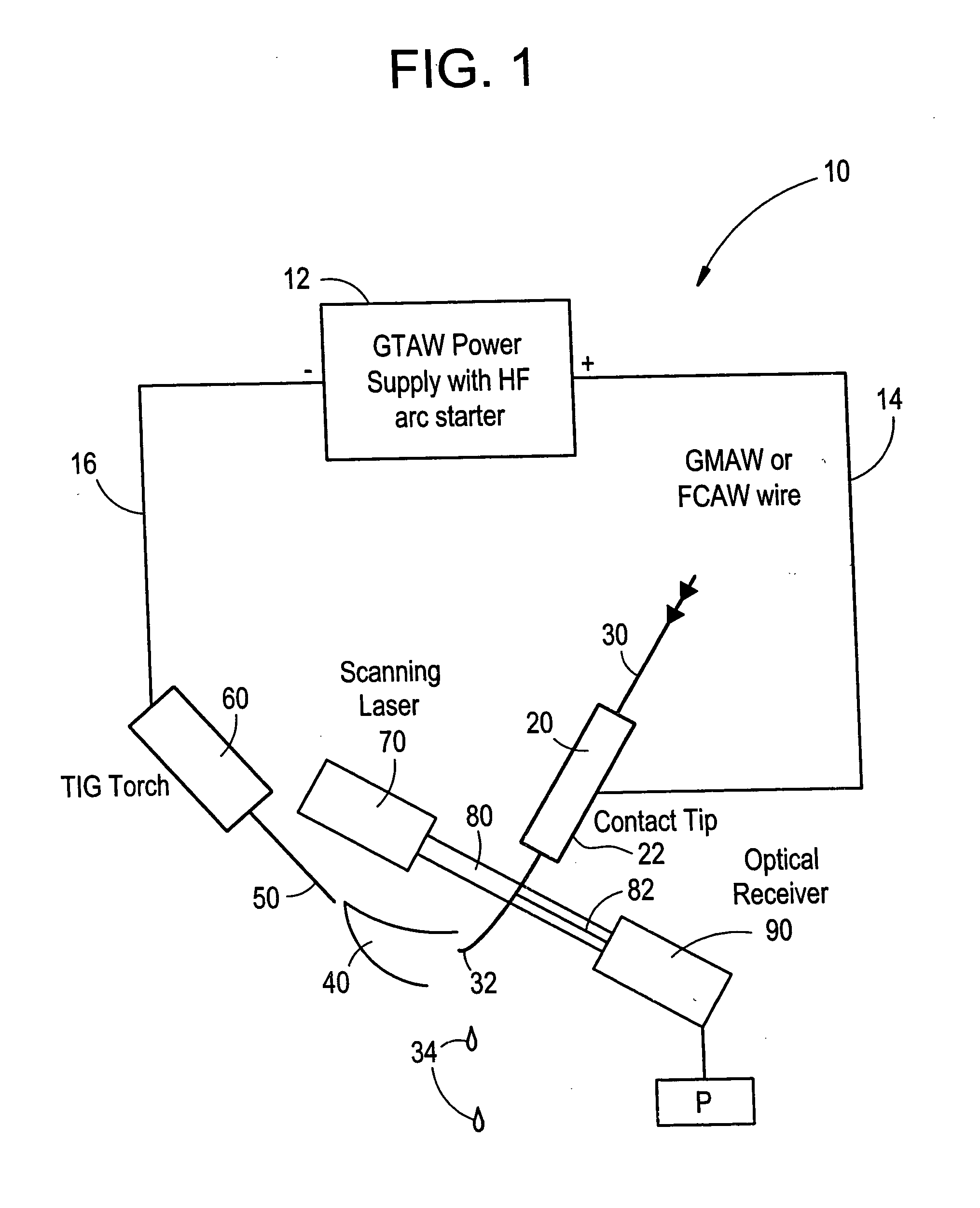

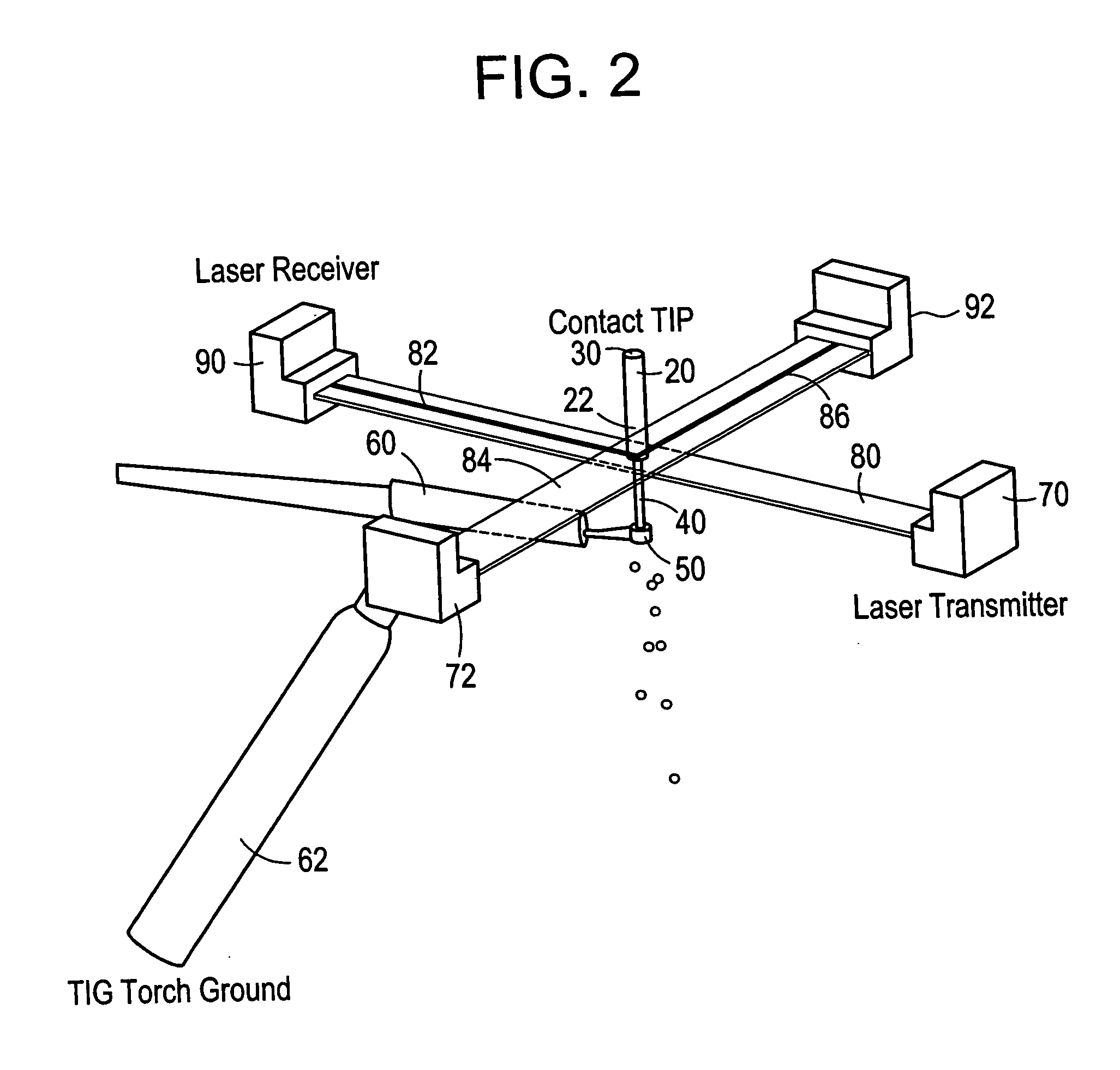

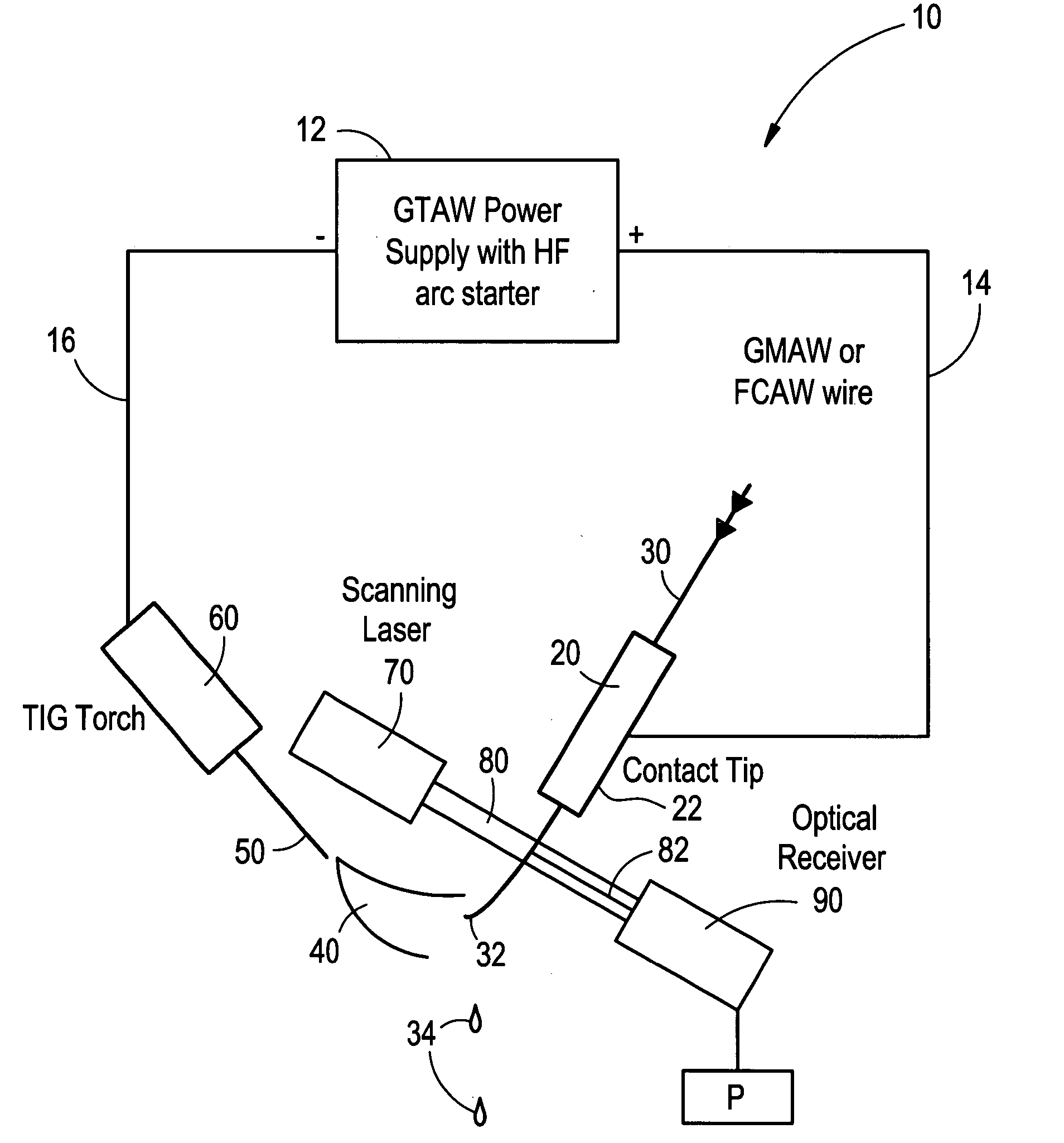

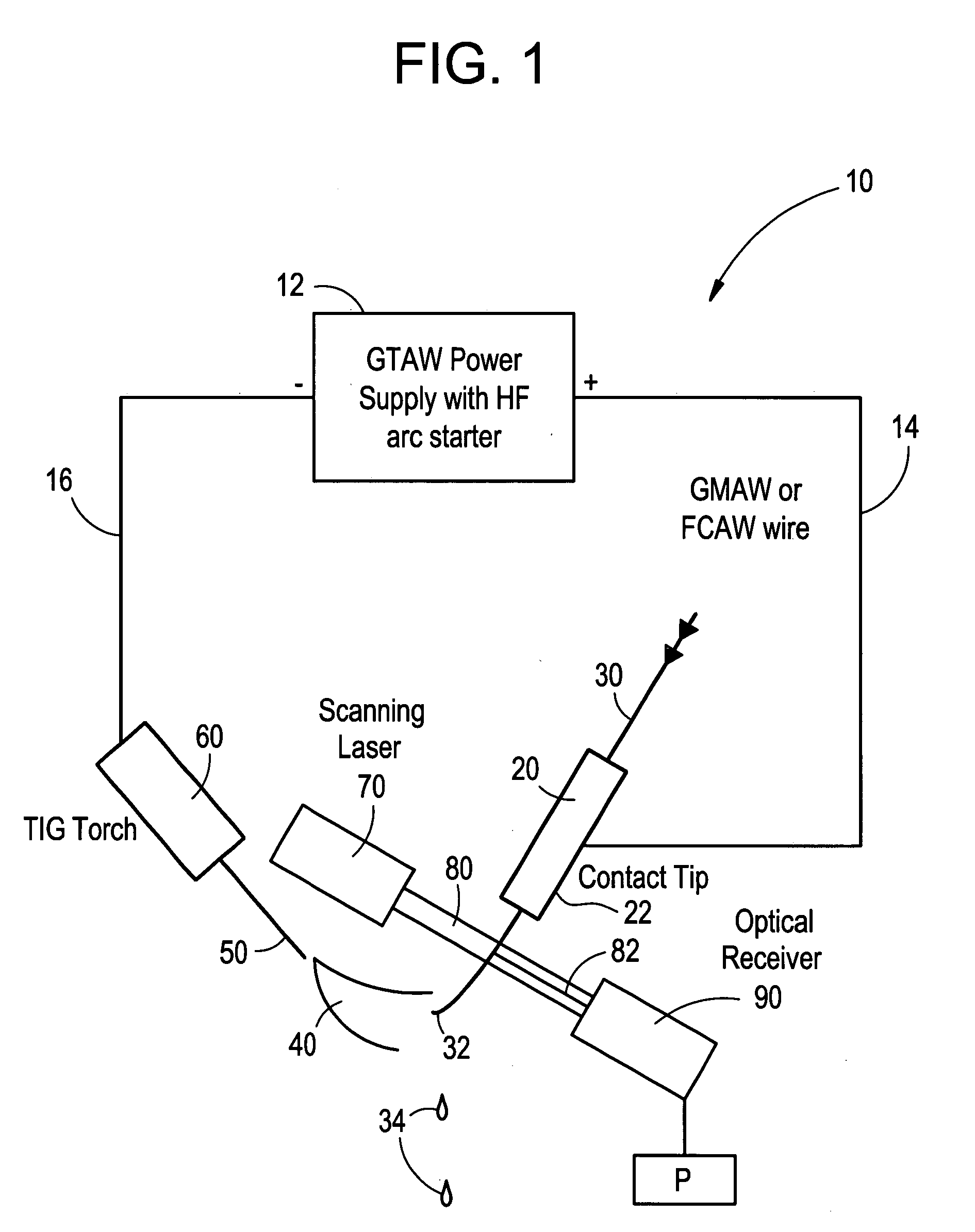

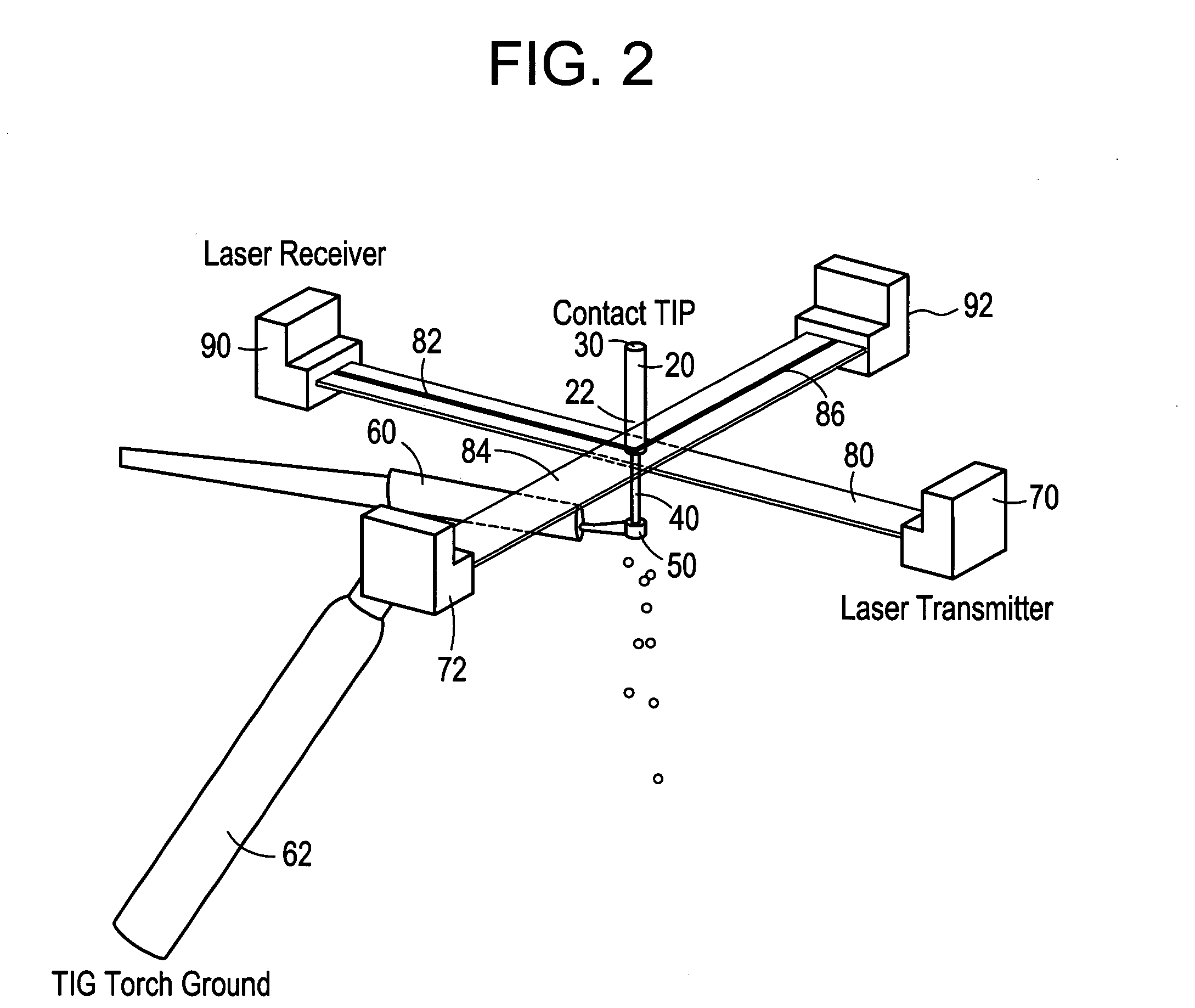

Welding wire positioning system

Owner:LINCOLN GLOBAL INC

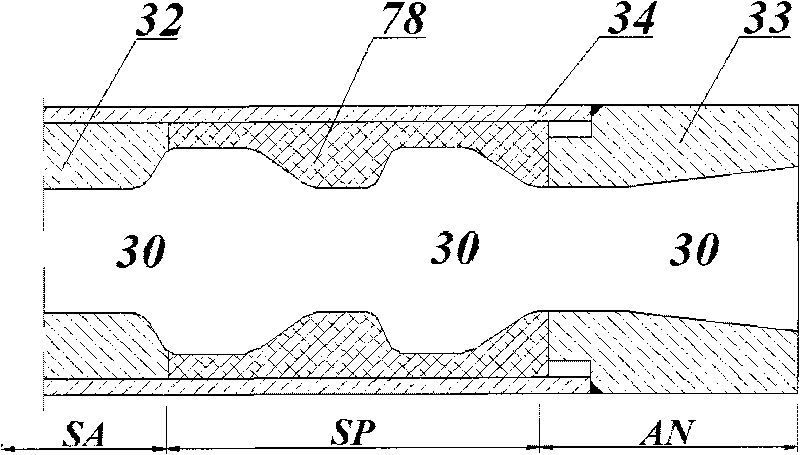

Welding wire positioning system

InactiveUS20050006363A1Minimize wire movementMinimize impactConveyorsArc welding apparatusTransverse planeEngineering

An electrode position detection system for a welder having a laser that is projected in a lateral plane to laterally cross a welding wire at a location below a contact tip of a welding gun and a receiver that receive the laser bean after crossing the welding wire, and a measuring device that determines one or more parameter of the welding wire based on the received laser beam. Arc voltage measurements can also be used to determine one or more parameter of the welding wire.

Owner:LINCOLN GLOBAL INC

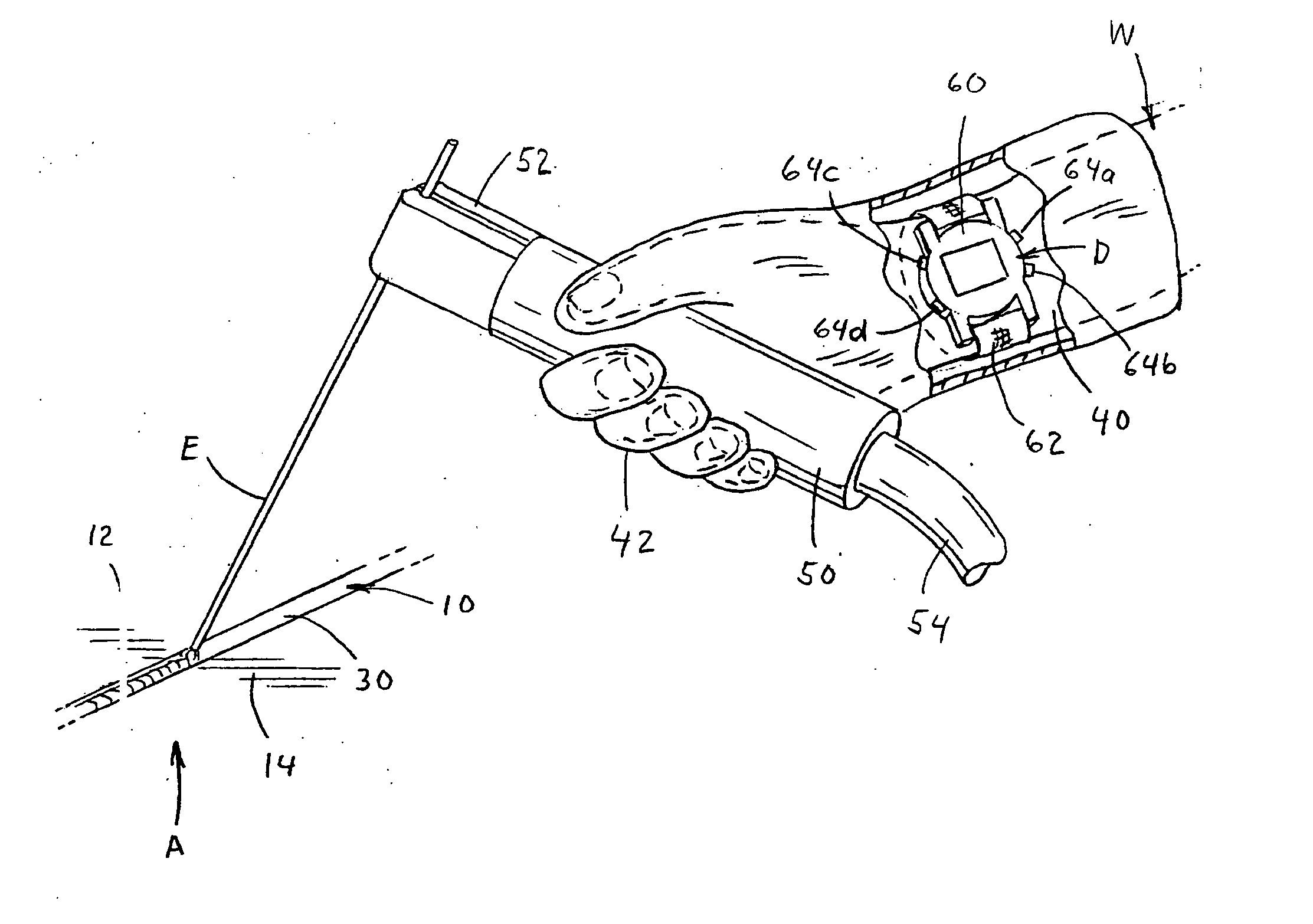

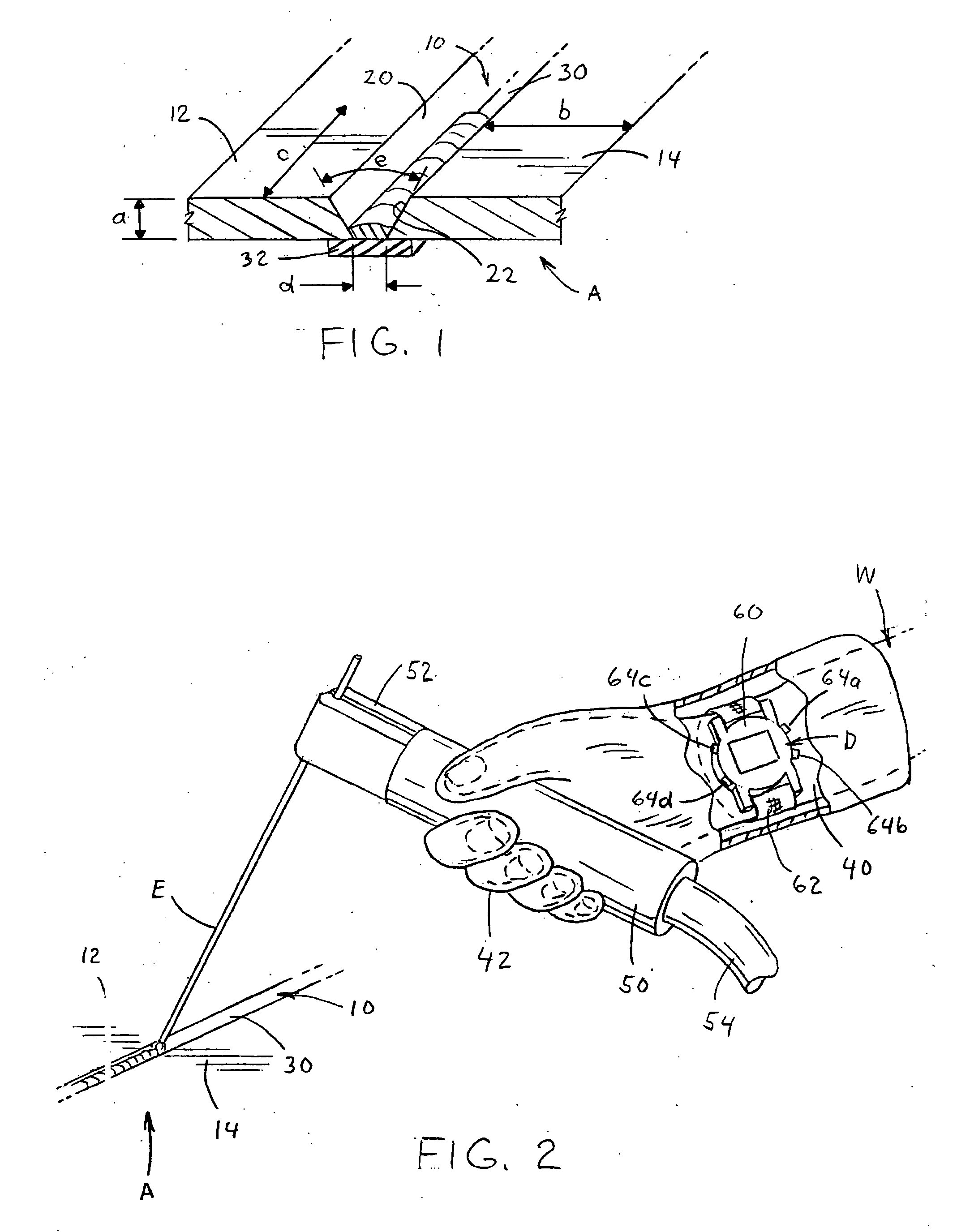

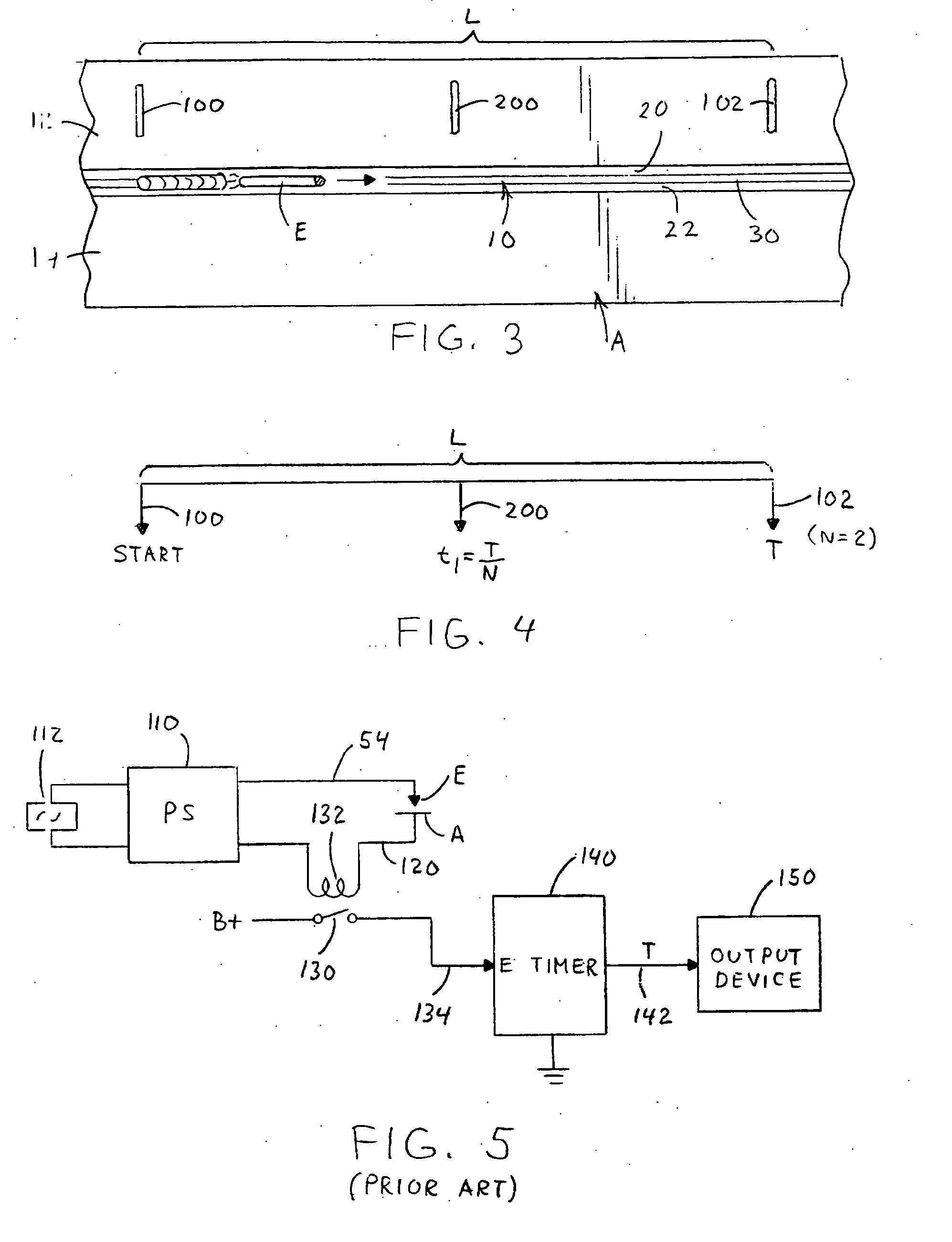

Method of pacing travel speed

InactiveUS20070114215A1Arc welding apparatusWelding/cutting media/materialsEngineeringElectrical current

A method of pacing a desired travel speed of a manual arc welding process performed by a welder for depositing weld metal on a workpiece and along a test groove with a given test length defined by a visible start location and a visual end location using a specified amount of energy distributed generally uniformly in the groove between the locations. The method comprises providing a power source with output leads and an arc current and an arc voltage; setting the output welding power of the power source; providing a consumable welding wire; connecting the output leads across the welding wire and the workpiece; determining the time T for the wire to traverse the test length to consume the specific amount of energy; marking the groove with a visible indicia spaced from the start location a given distance; associating a programmable haptic device with an exposed body part of the welder where the device has a tactile alarm activated after a programmed time t from start of the haptic device, which time t is coordinated with the given distance to give the desired travel speed; starting the haptic device when the operator commences welding at the start location and employs a manual rate of travel; and, changing the manual rate of travel according to the relationship of the wire to the indicia when the tactile alarm is activated.

Owner:LINCOLN GLOBAL INC

Electric arc welder and method for controlling the welding process of the welder

An operating system is provided for an electric arc welder including a high switching speed inverter power source for creating an arc voltage and arc current between an electrode and a workpiece. This operating system regulating the arc voltage to provide a voltage with a slope by using an error circuit to create an error output and having a first input with a signal representing the set voltage and a second input representing the sum of the actual arc voltage and the actual arc current multiplied by a slope constant. A DSP program reduces the error output by adjusting the voltage output of the inverter power source to change the actual arc voltage. The slope constant is in the range of 0-10%.

Owner:LINCOLN GLOBAL INC

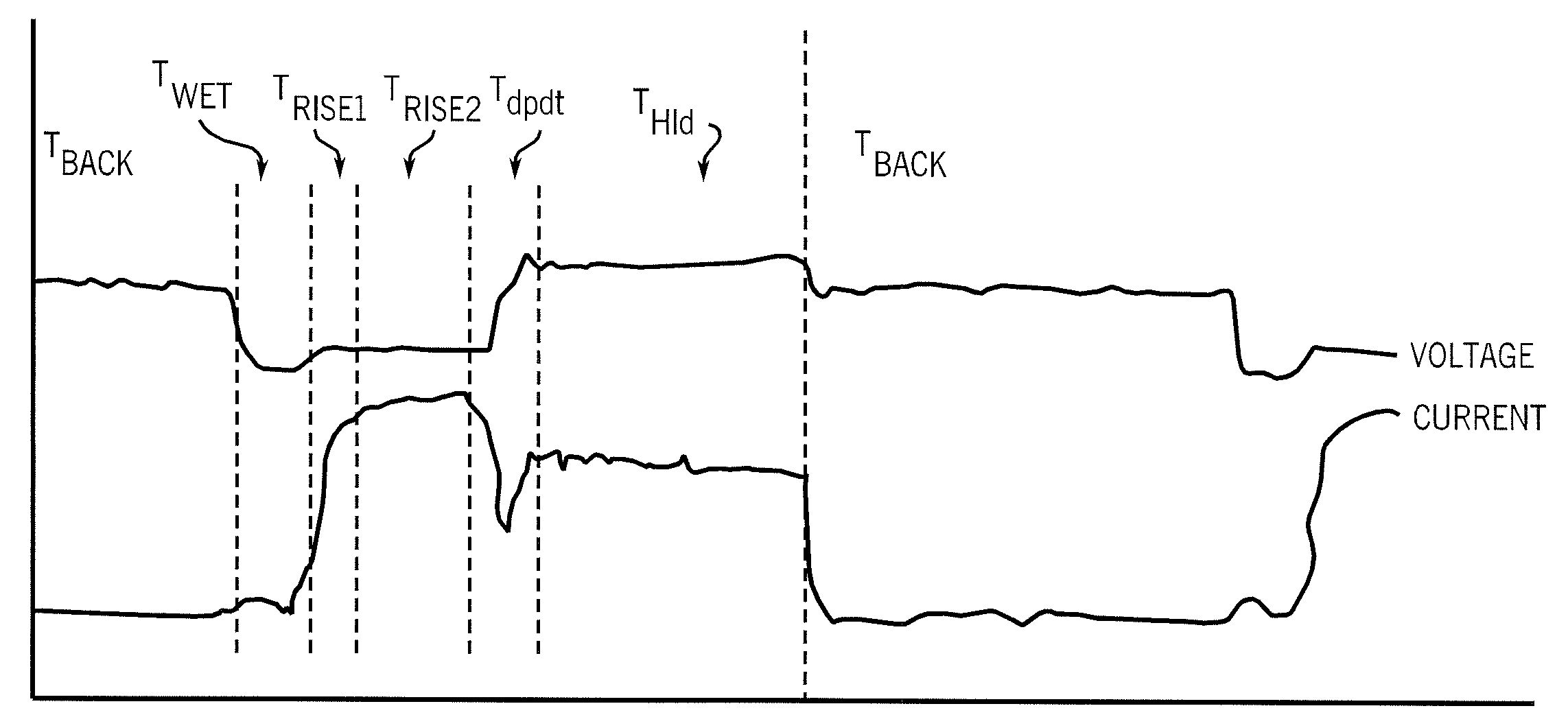

Method and apparatus for welding

A short circuit arc welding system is disposed. The control scheme uses a current command signal to drive the output current. The command signal is comprised of a long-term current command that sets the long-term current command level and a real-time or short-by-short current command. Arc voltage feedback is used to determine if the desired arc length is present and to adjust the long-term command. The short-by-short current command is derived from real-time arc current feedback and is used to control the burn-off rate by an instantaneous, or short-by-short, adjustment of the current command. A function of the time derivative of arc power, less the time derivative of arc current, is used to detect, in real time, when the short is about to clear. A stop algorithm is employed that monitors the arc on a short-by-short basis. When the process is ending a very low current level is provided to avoid forming a ball. However, if a short is created, (indicated by a drop in arc voltage) after the low current level, a burst of energy is provided to clear of burn off the short. After the short is cleared, very low current is again provided to avoid forming a large ball. This is repeated until the wire stops and the process ends.

Owner:ILLINOIS TOOL WORKS INC

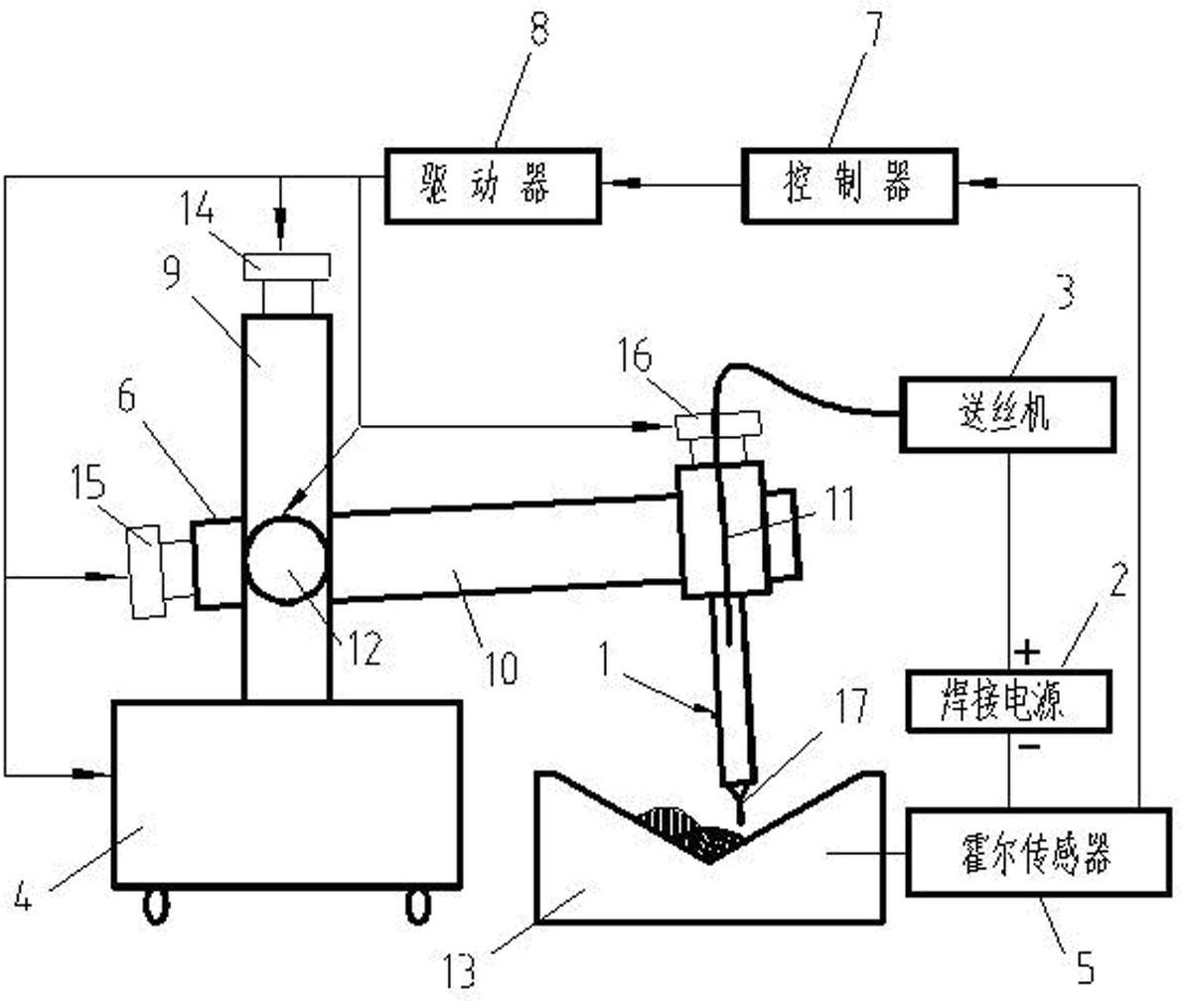

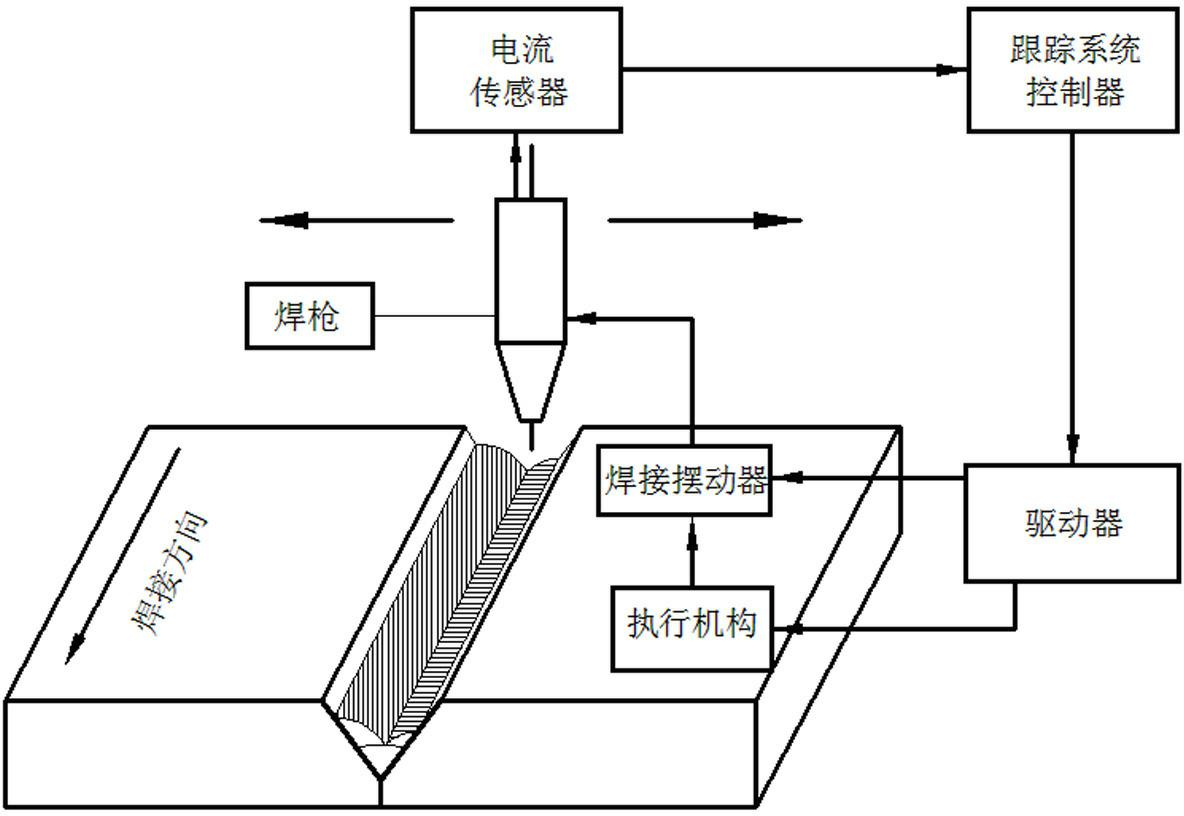

Swing arc-based multi-layer and multi-channel weld tracking system and identification method thereof

InactiveCN102615390AHigh precisionGuaranteed uptimeArc welding apparatusWelding power supplyCurrent sensor

Owner:XIANGTAN UNIV

Method of controlling a welding process and controller therefor

A controller and method for adjusting an output welding parameter of a D.C. electric arc welder for controlling a welding process wherein a welding wire is advanced toward a workpiece while an arc voltage is applied across the advancing wire and the workpiece, the control and method comprise measuring the rate of spatter events and then adjusting the output parameter to maintain the measured rate of spatter events at a selected rate in the range of 10-30 spatter events per second.

Owner:LINCOLN GLOBAL INC

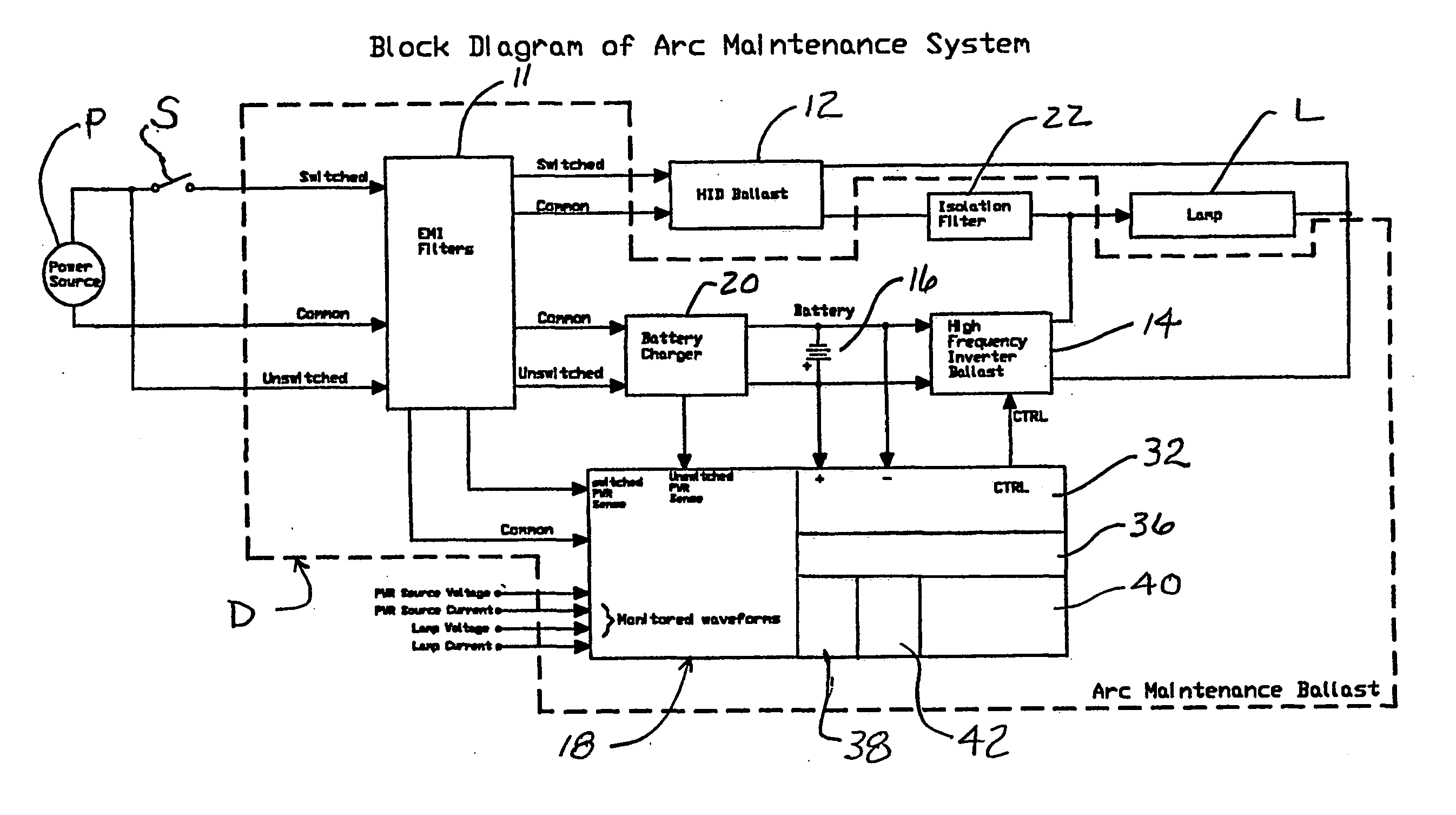

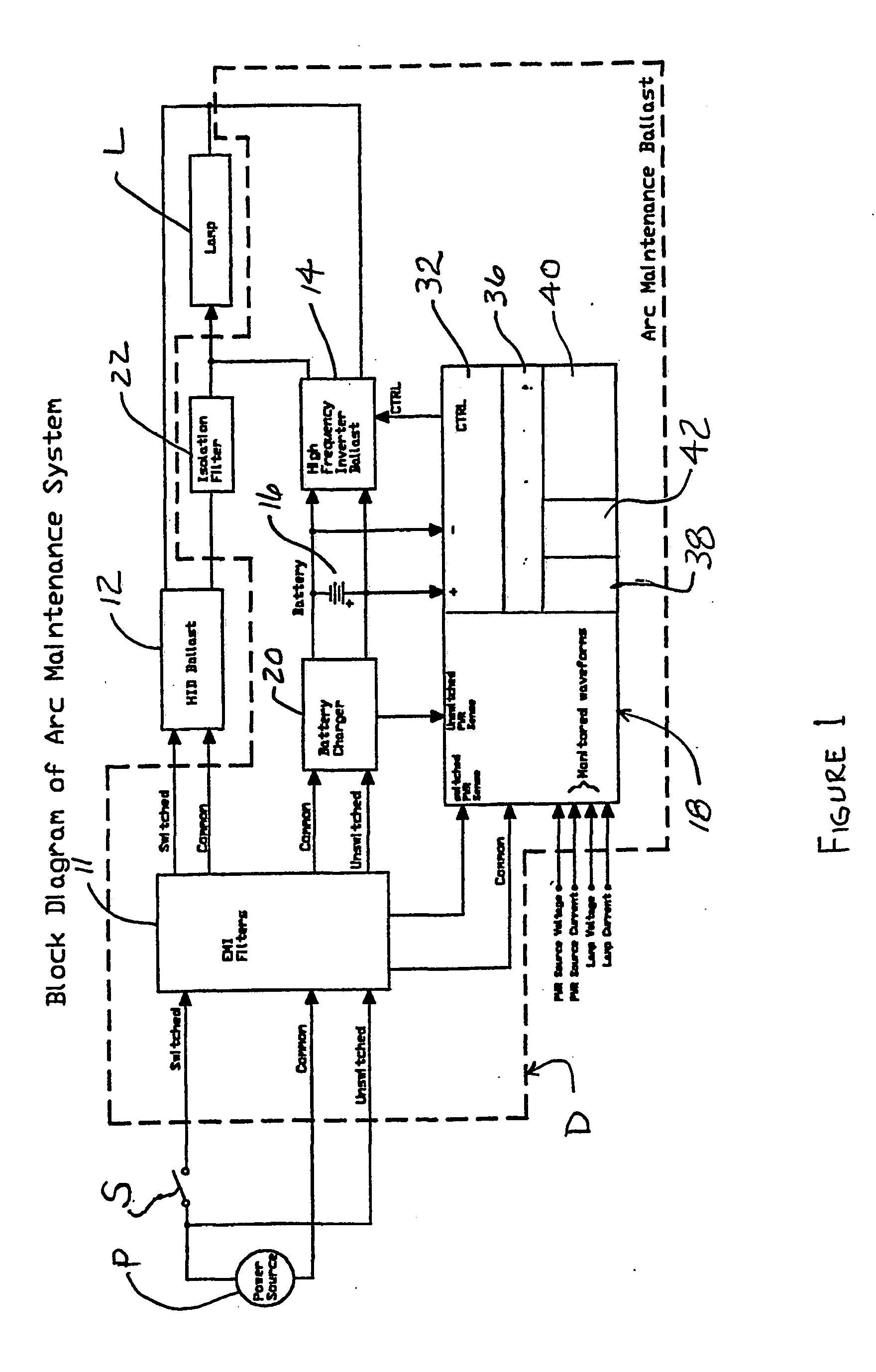

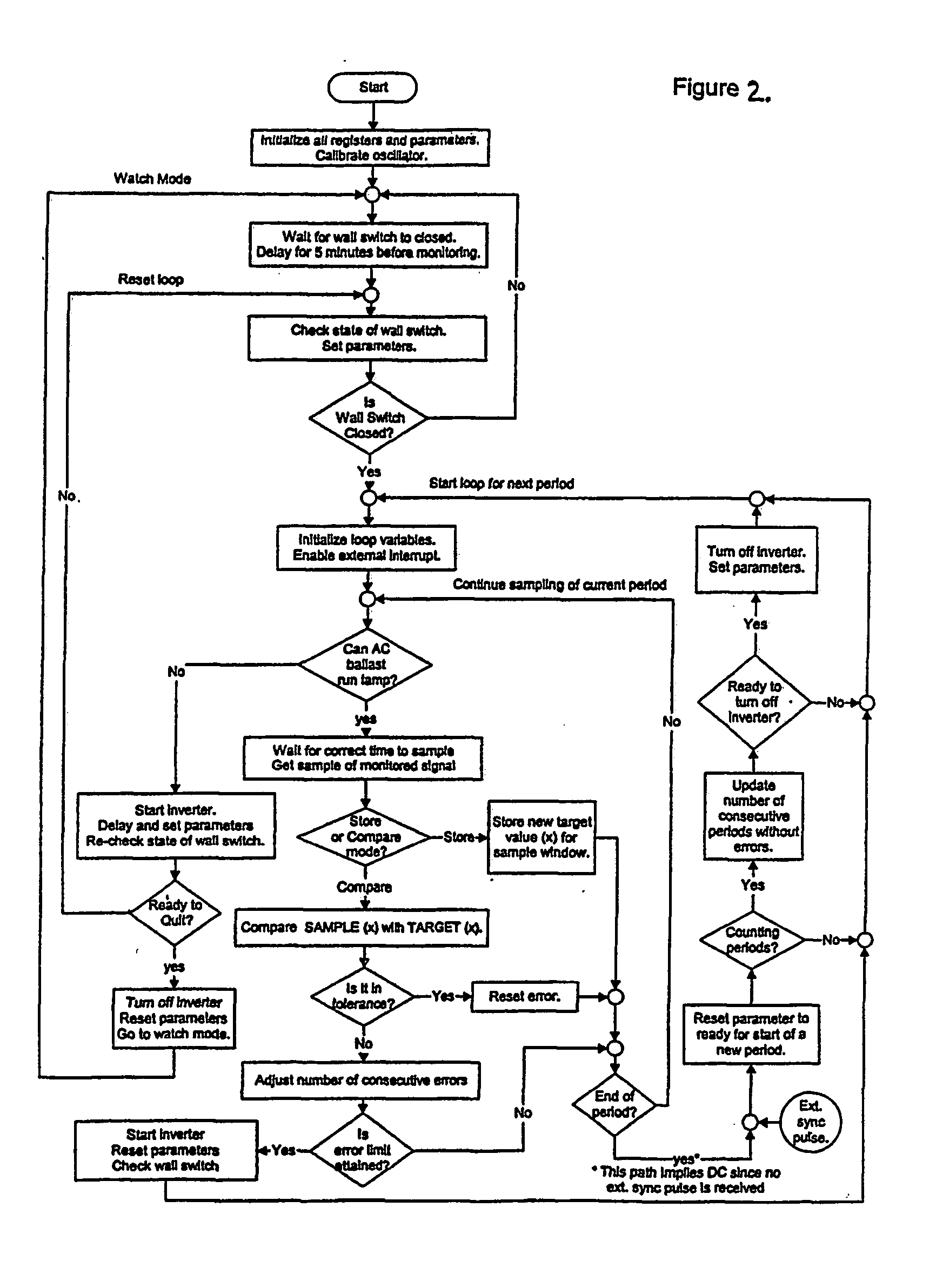

Arc maintenance device for high density discharge lamps including an adaptive wave form monitor

InactiveUS20050258765A1Electric light circuit arrangementGas discharge lamp usageInstabilityEngineering

A supplemental arc maintenance electrical supply for a high density discharge (HID) lamp (L) for applying a high frequency supplemental arc voltage to maintain the arc during a period of unstable or intermittent AC supply in addition to or in lieu of the voltage or current being supplied to the lamp by the HID ballast (12). AC supply instability is identified in less time than the unstable or intermittent power will cause the lamp to arc to extingish and energize a supplemental arc maintenance electrical supply to maintain the arc of the lamp during the period of instability or interruption, so long as its internal, rechargeable battery is operational. The monitoring system (18) also recognizes the re-establishment of a stable (as by being a persistently repeating cycle but not necessarily a sinusoidal AC supply) repeating electrical power supply which is also of sufficient energy level to maintain operation of the HID lamp.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV +1

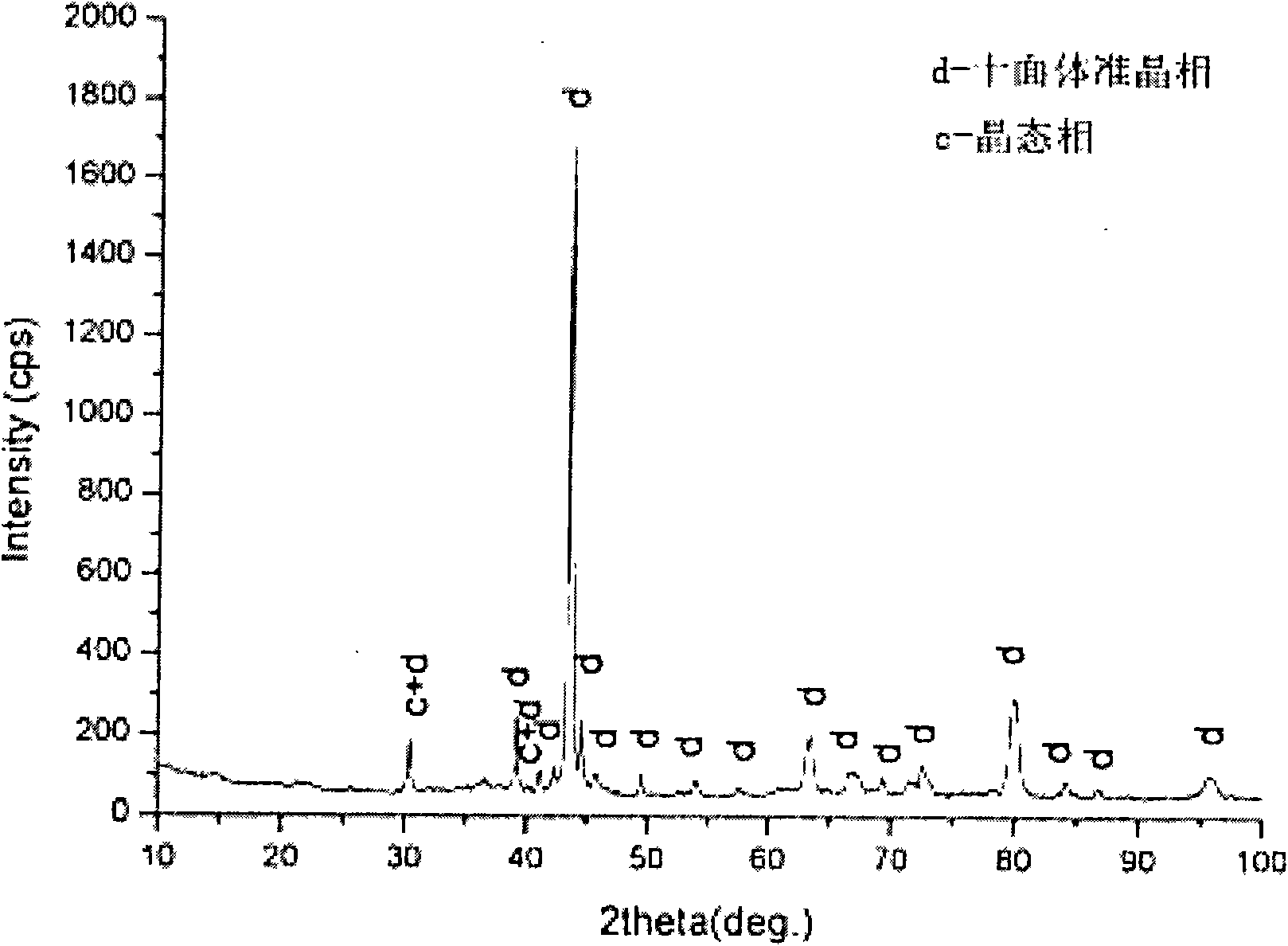

Non-stick pan coating layer and preparation method thereof

The invention provides a non-stick pan coating layer and a preparation method thereof. The coating layer comprises Al-Cu-Fe-Cr-B quasicrystalline alloy which has components as follows by the atomic percentage: 70-90 of Al, 1-15 of Cu, 5-15 of Fe, 5-15 of Cr, and the balance of B and unavoidable impurity. The method comprises the specific steps as follows: (1) smelting alloy materials with a spraying device at a temperature of 900-1100 DEG C to prepare alloy powder; (2) spraying the alloy coating layer on a boiler basal body with a plasma spraying device, with a main gas feed rate of 65 L / min, a secondary gas feed rate of 20-30 L / min, an arc current of 550-590A, an arc voltage of 45-60V, a powder delivering amount of 10-15 g / min, and a coating layer thickness of about 100-200 micro. At a cooking temperature, the invention has the advantages of stable chemical property, large rigidness, lower cost than Teflon or organic silicon, low surface friction coefficient, and the like.

Owner:鞠汉清

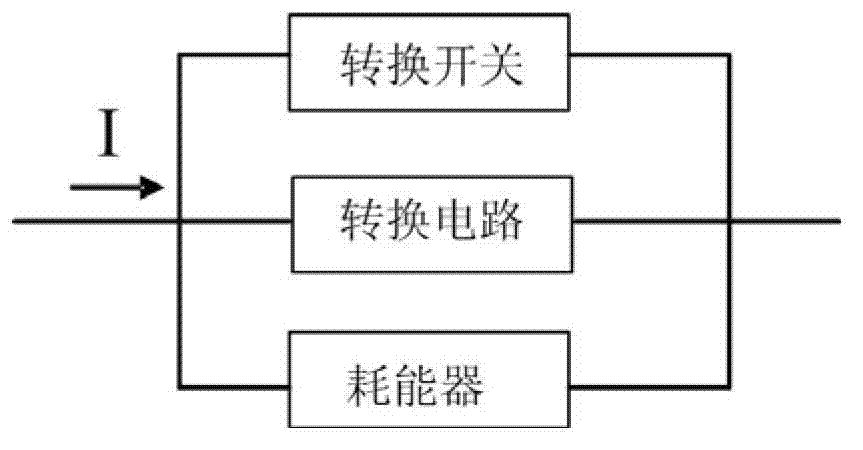

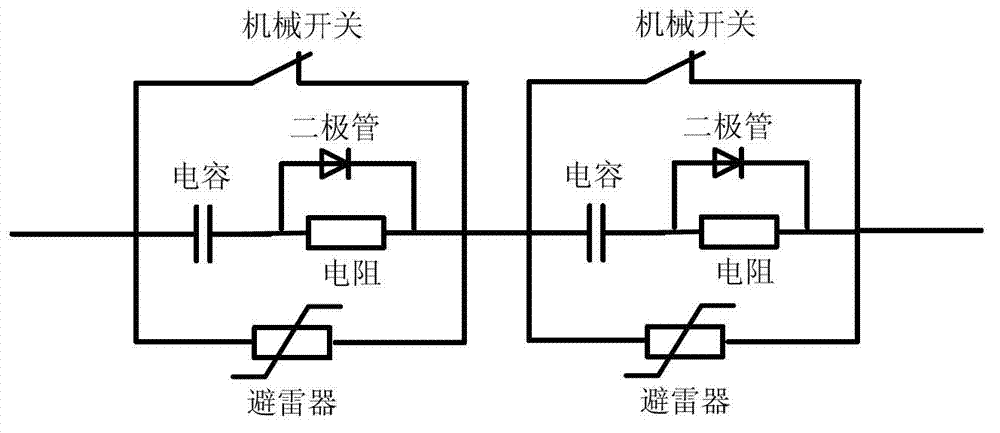

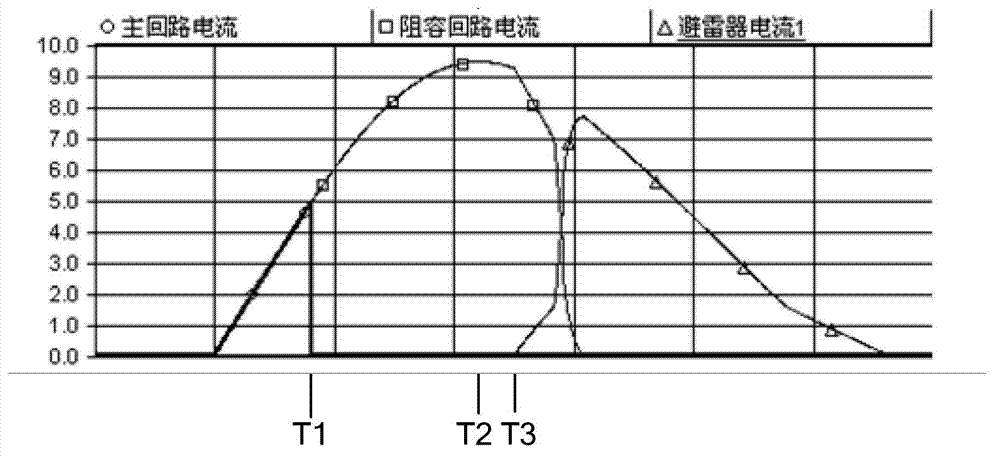

Series capacitor type high-voltage direct current breaker and control method thereof

ActiveCN103117528ARealize no arc breakingMeet the demand for fast cut-off fault currentEmergency protective arrangements for automatic disconnectionHigh-voltage direct currentTypes of capacitor

The invention relates to a series capacitor type high-voltage direct current breaker and a control method thereof. The breaker comprises direct current breaker units which are connected in series, and each direct current breaker unit comprises a change-over switch, a switching circuit and an energy consumption device which are connected in parallel. The change-over switch adopts a mechanical switch, and the switching circuit adopts a resistance capacitance branch circuit, and the energy consumption device adopts a lightning arrester. The high-voltage direct current breaker is connected with a control circuit, and the mechanical switch detects failure current and acts at the T1moment, and transfers the failure current into the resistance capacitance branch circuit. The failure current charges a capacitor, and controls switching-on and switching-off of the mechanical switch. Before the mechanical switch witches off at the T2 moment, charging voltage on two ends of the capacitor throughout is lower than arcing voltage at fractures of the mechanical switch. When the voltage on two ends of the capacitor reaches operation voltage of the lightning arrester, the control circuit controls the lightning arrester to act at the T3 moment so that energy can be released from the lightning arrester. According to the series capacitor type high-voltage direct current breaker and the control method thereof, the mechanical switch does not have electric arc, non-arc breaking off is realized, energy is released through utilization of the lightning arrester, quick extinguishing of the electric arc is realized, and the failure current is cut off.

Owner:CHINA EPRI ELECTRIC POWER ENG CO LTD +1

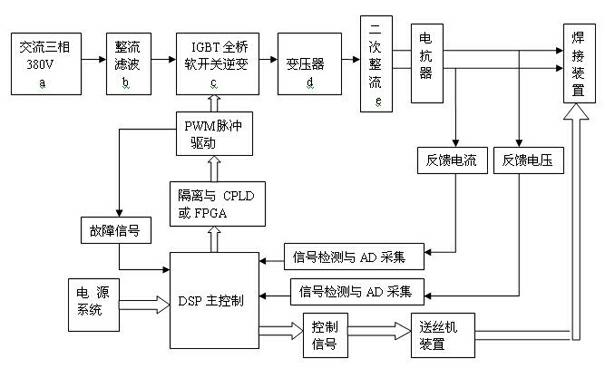

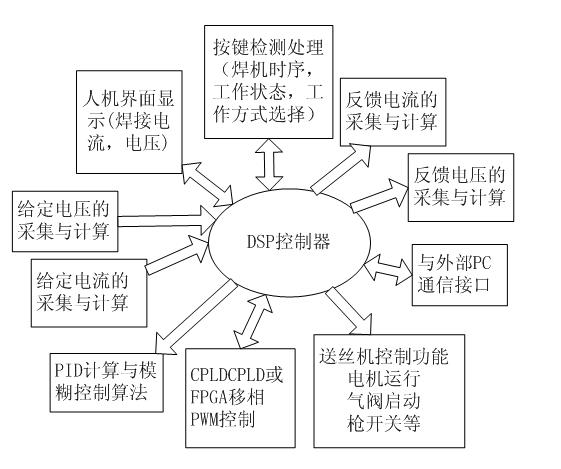

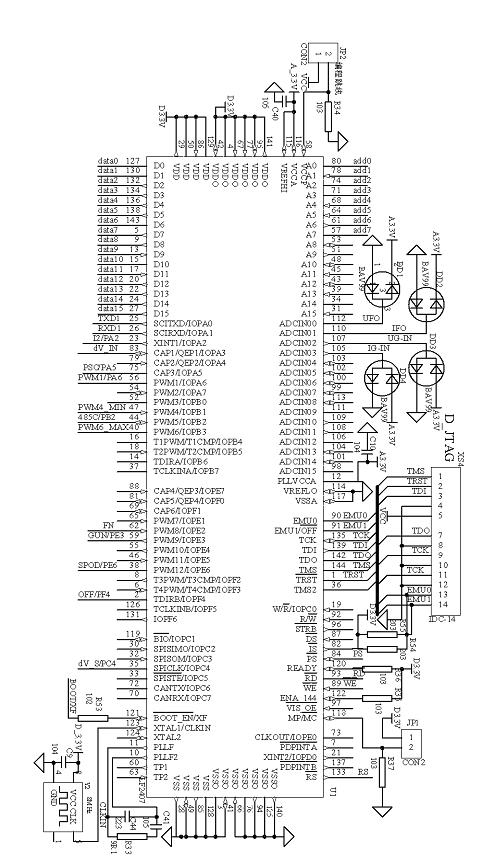

Multifunctional digitized welding machine

InactiveCN102350569ABeautiful shapeImprove dynamic response performanceArc welding apparatusFull bridgeTransformer

The invention relates to a multifunctional digitized welding machine, which comprises a full-bridge type inversion main circuit, a control circuit and a soft switch PWM (Pulse-Width Modulation) driving circuit, wherein the full-bridge type inversion main circuit is composed of an IGBT (Insulated Gate Bipolar Translator); the soft switch PWM driving circuit of a symmetric carrier is based on a CPLD (Complex Programmable Logic Device) or FPGA (Field Programmable Gate Array); the inversion main circuit comprises a rectifying filtering module, an IGBT full-bridge inversion module, a main transformer and a secondary rectifying filtering module; the control circuit comprises a DSP (Digital Signal Processor) control processor, a manual idle-dropping circuit, a regulating, detecting and sampling circuit for a feedback current and voltage signal outputted by the welding machine, a collecting and setting circuit for a feeding speed and given voltage of the welding machine, a display circuit for an interface and parameter of an external keyboard and a communication circuit connected to a PC (Personal Computer); the regulating, detecting and sampling circuit for the feedback current and voltage signal outputted by the welding machine comprises a Hall voltage sensor for detecting a feedback arc voltage outputted by the welding machine and a Hall current sensor for detecting an output current of the welding machine; and the collecting and setting circuit for the feeding speed and given voltage of the welding machine comprises a collecting circuit for a given voltage and given current, namely the feeding speed, on a panel of a feeder.

Owner:PANDA ELECTRONICS GROUP +2

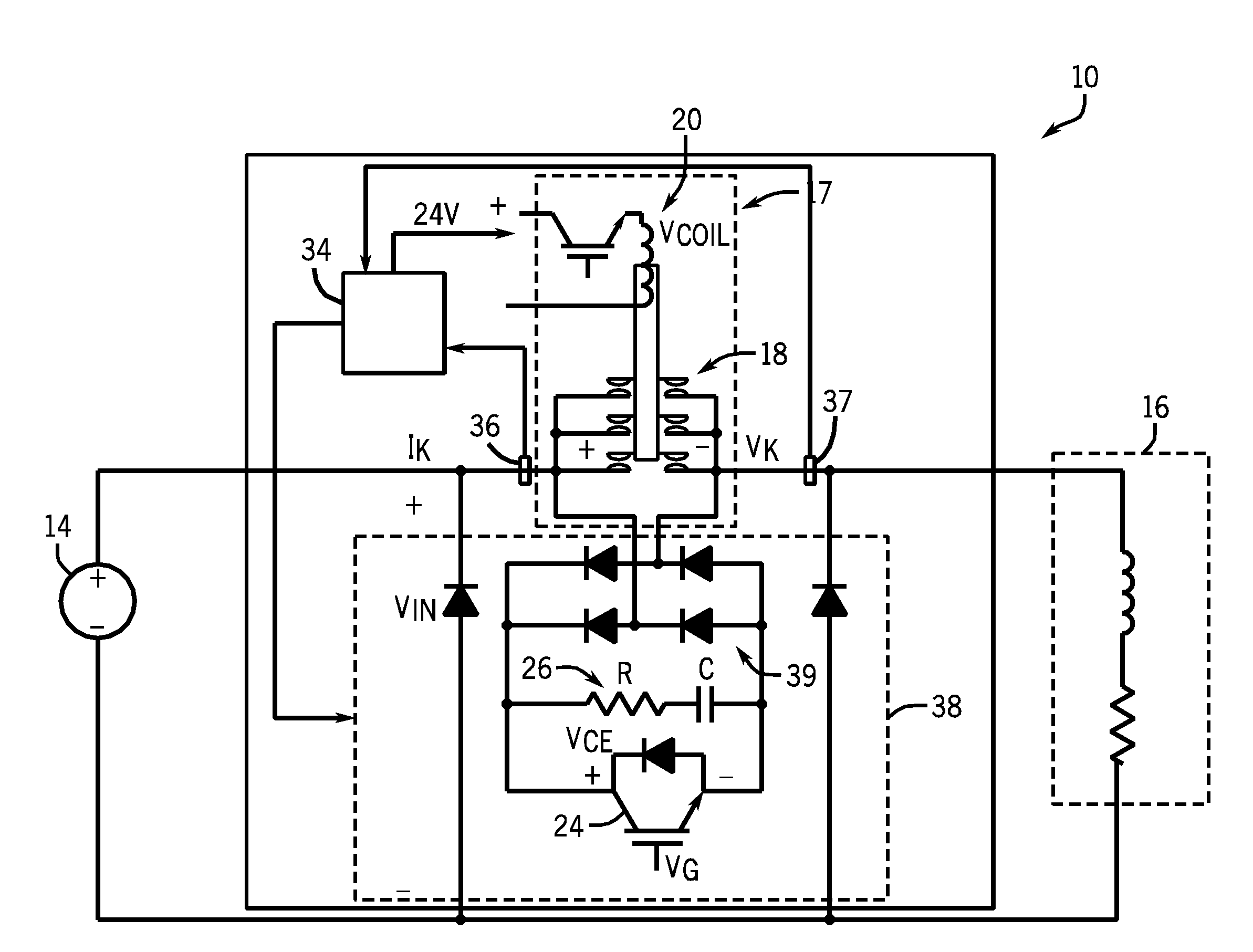

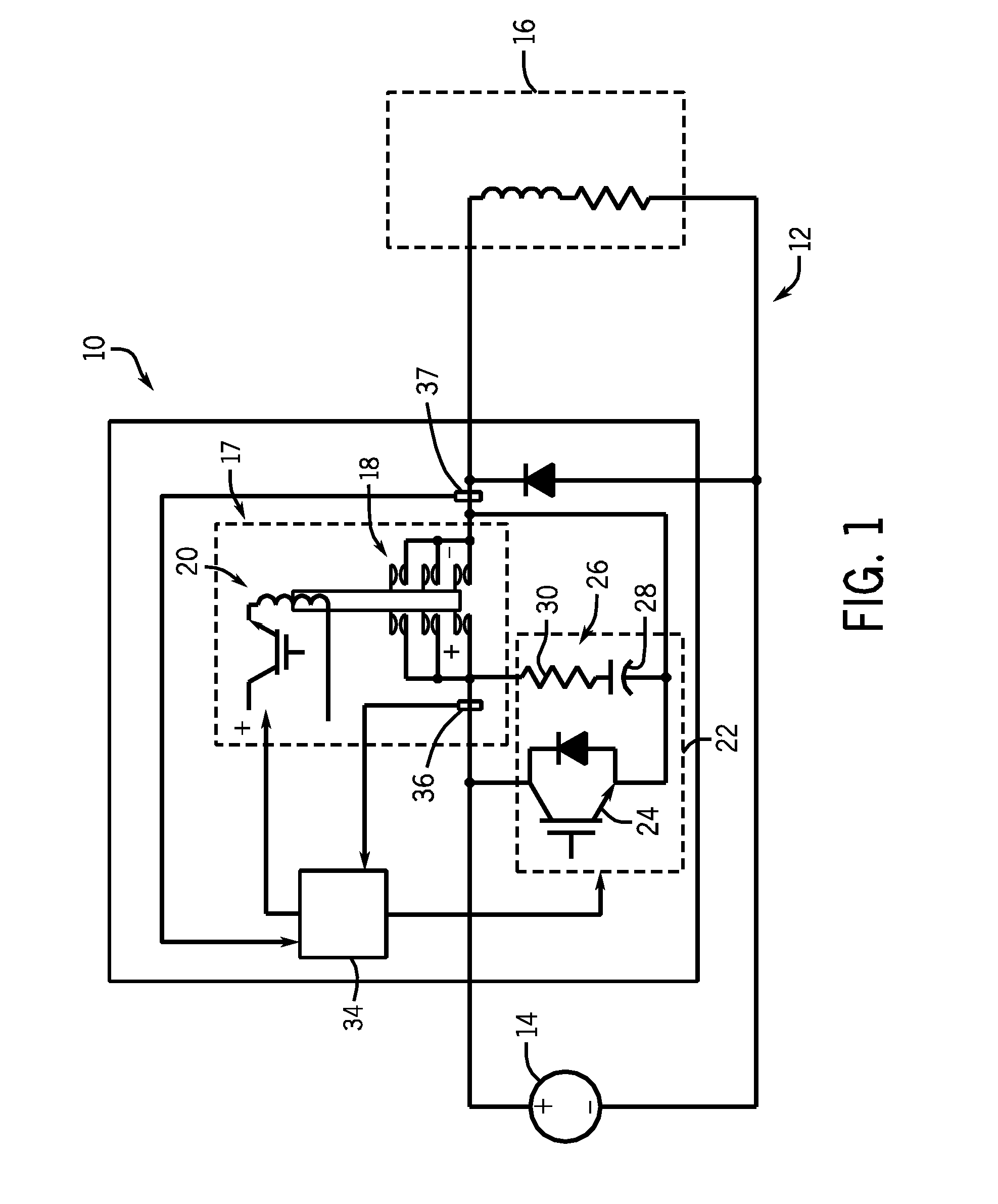

Hybrid bi-directional DC contactor and method of controlling thereof

A hybrid DC contactor includes contacts that provide a first current path between a DC power source and a load, an electromagnetic coil to position the contacts, a semiconductor switch in parallel with contacts that, when turned on, provides a second parallel current path that diverts current away from the contacts when the main contacts are being opened in either direction. A controller is provided to terminate power to the electromagnetic coil to open the contacts, detect an arc voltage across the contacts as the contacts open, provide a gate signal to the semiconductor switch to pulse the switch on for a pre-determined period of time to route current to the semiconductor switch, measure a current through the contacts and, if current is present through the contacts, then provide another gate signal to the semiconductor switch to pulse the switch on again so as to route current thereto.

Owner:EATON CORP

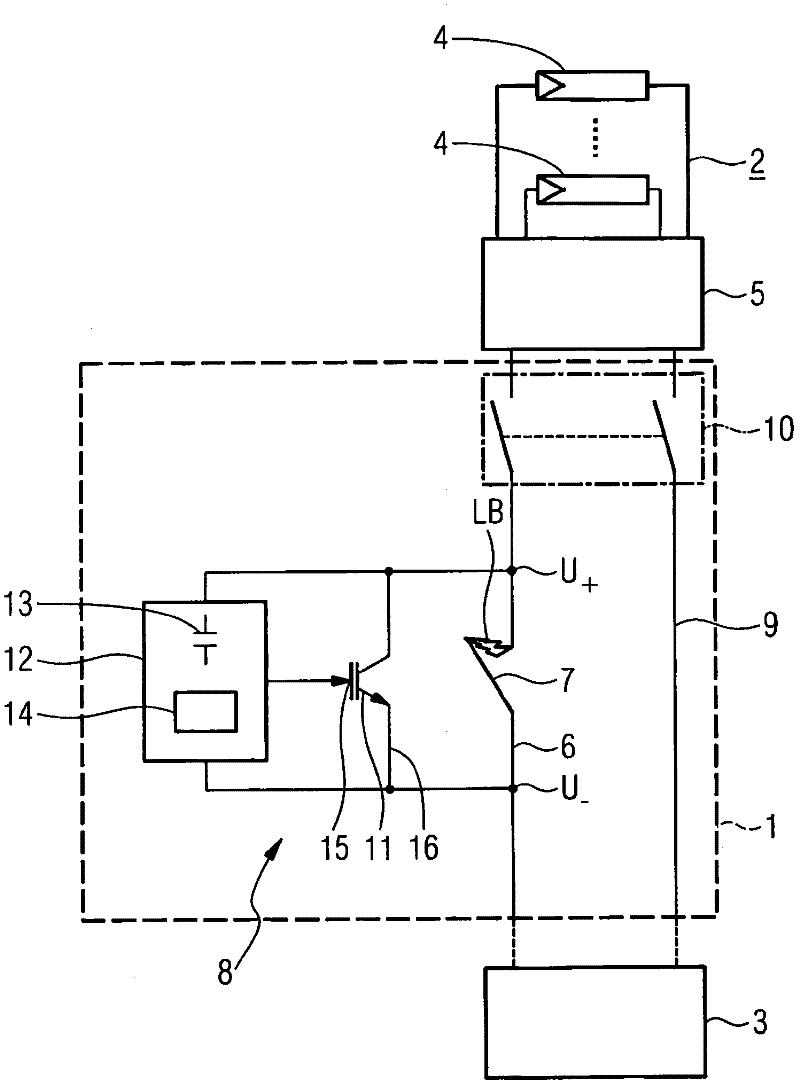

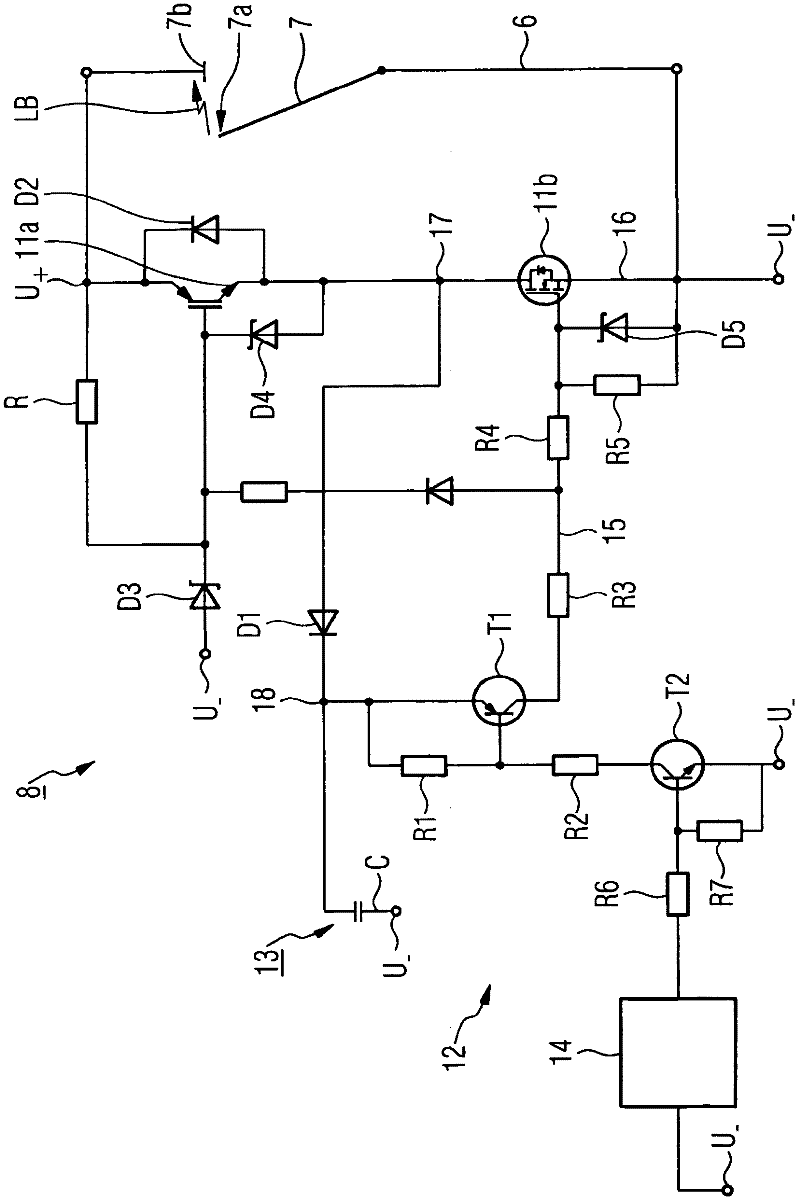

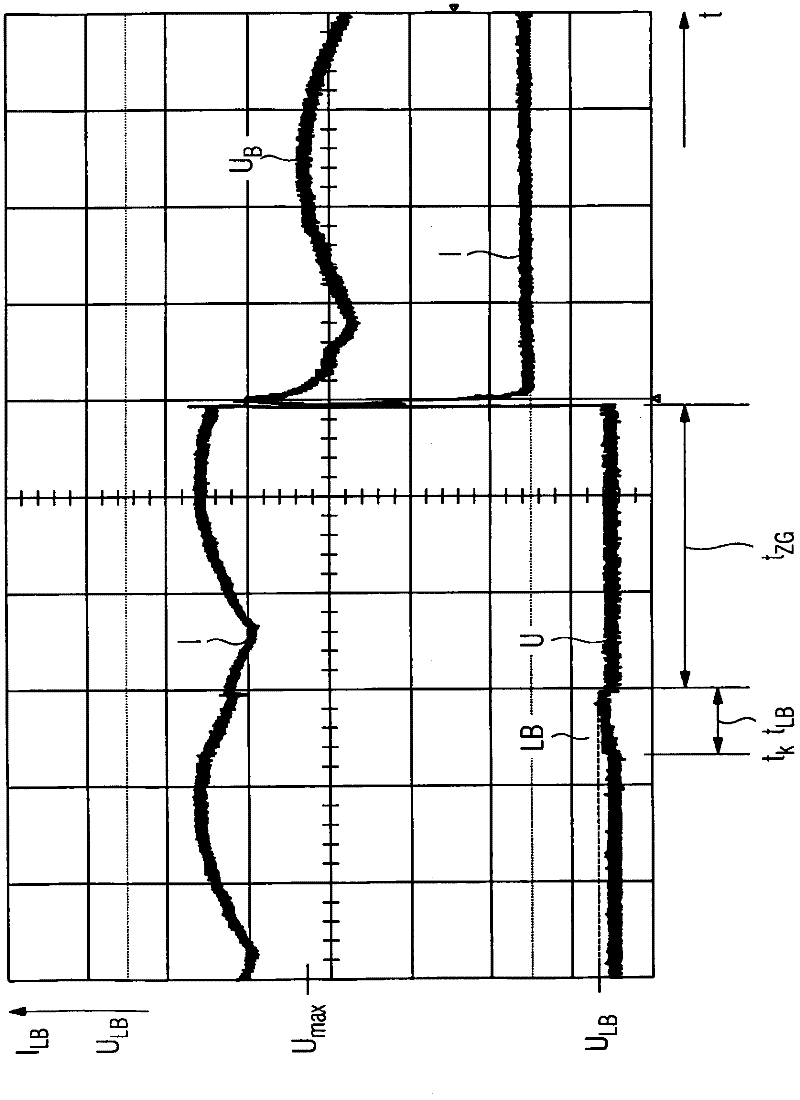

Switch disconnector for galvanic direct current interruption

ActiveCN102349124ACut offHigh-tension/heavy-dress switchesAir-break switchesPhotovoltaic generatorEngineering

The invention relates to a disconnecting apparatus (1) for direct current interruption between a direct current source (2) and an electrical device (3), in particular between a photovoltaic generator and an inverter, with a current-conducting mechanical switching contact (7a, 7b) and with semiconductor electronics (8) connected in parallel with the switching contact (7a, 7b). The semiconductor electronics (8) are non-conducting when the switching contact (7a, 7b) is closed, wherein a control input (15) of the semiconductor electronics (8) is wired with the switching contact (7a, 7b) in such a way that, when the switching contact (7a, 7b) opens, an arc voltage (ULB)generated as a result of an arc (LB) via the switching contact (7a, 7b) switches the semiconductor electronics (8) to be conducting.

Owner:ELLENBERGER POENSGEN

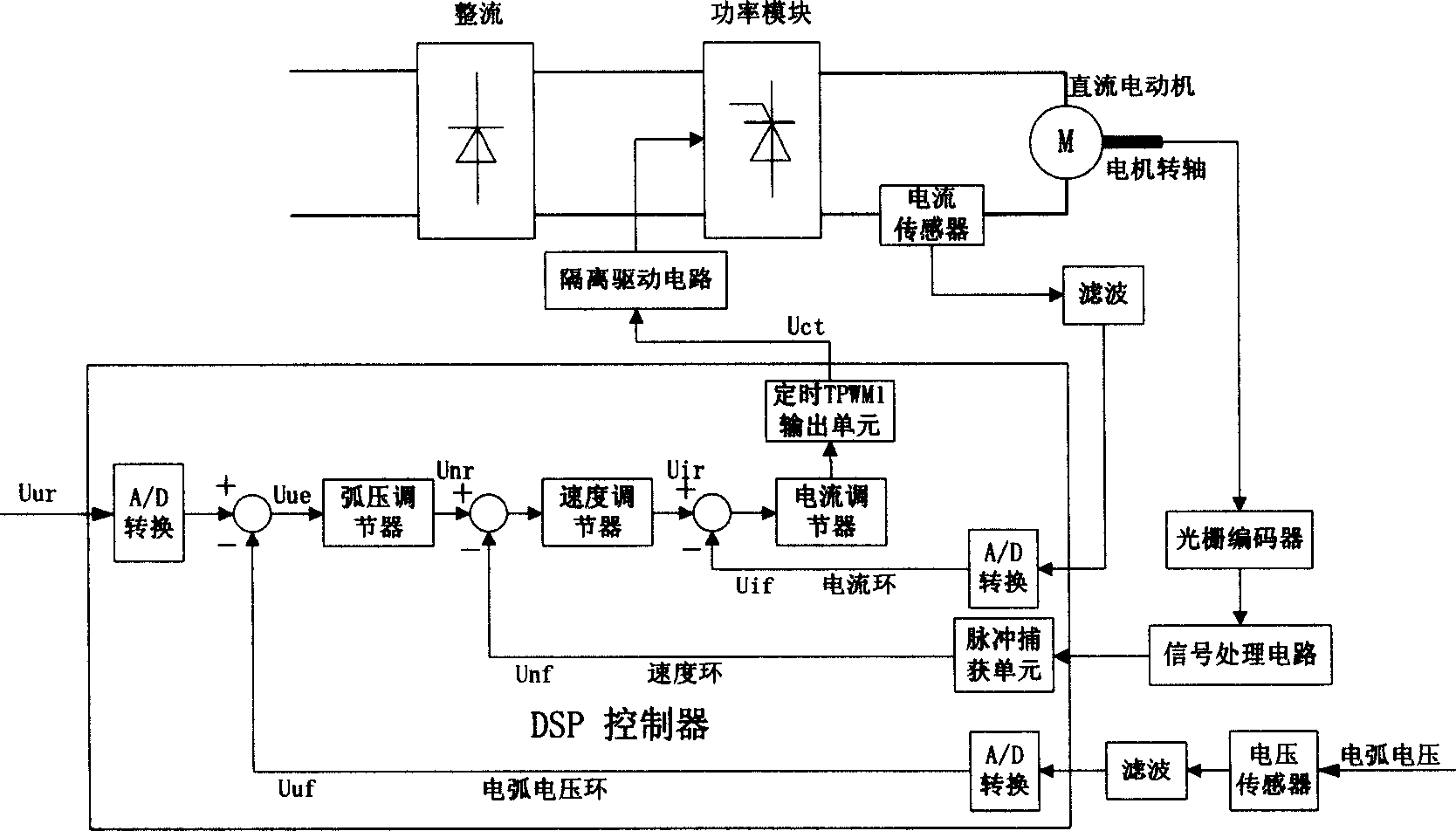

Full-digital speed change control method for wire feeding for submerged arc welding

InactiveCN1634676ARealize full digital controlFlexible adjustmentArc welding apparatusLoop controlControl signal

This invention relates to whole digital buried arc welding varying wire feed control method, which adopts series three-loop control structure with inner one as current ring, second ring as rotary speed ring and outer ring as arc voltage ring with one adjustor in each ring for arc voltage, rotation speed and current. It adopts high speed digit signals processor as central control part to form whole digital DC servo motor control system whose all control strategies area realized by software and the hardware completes digital trigger function and signal process function.

Owner:SHANGHAI JIAO TONG UNIV

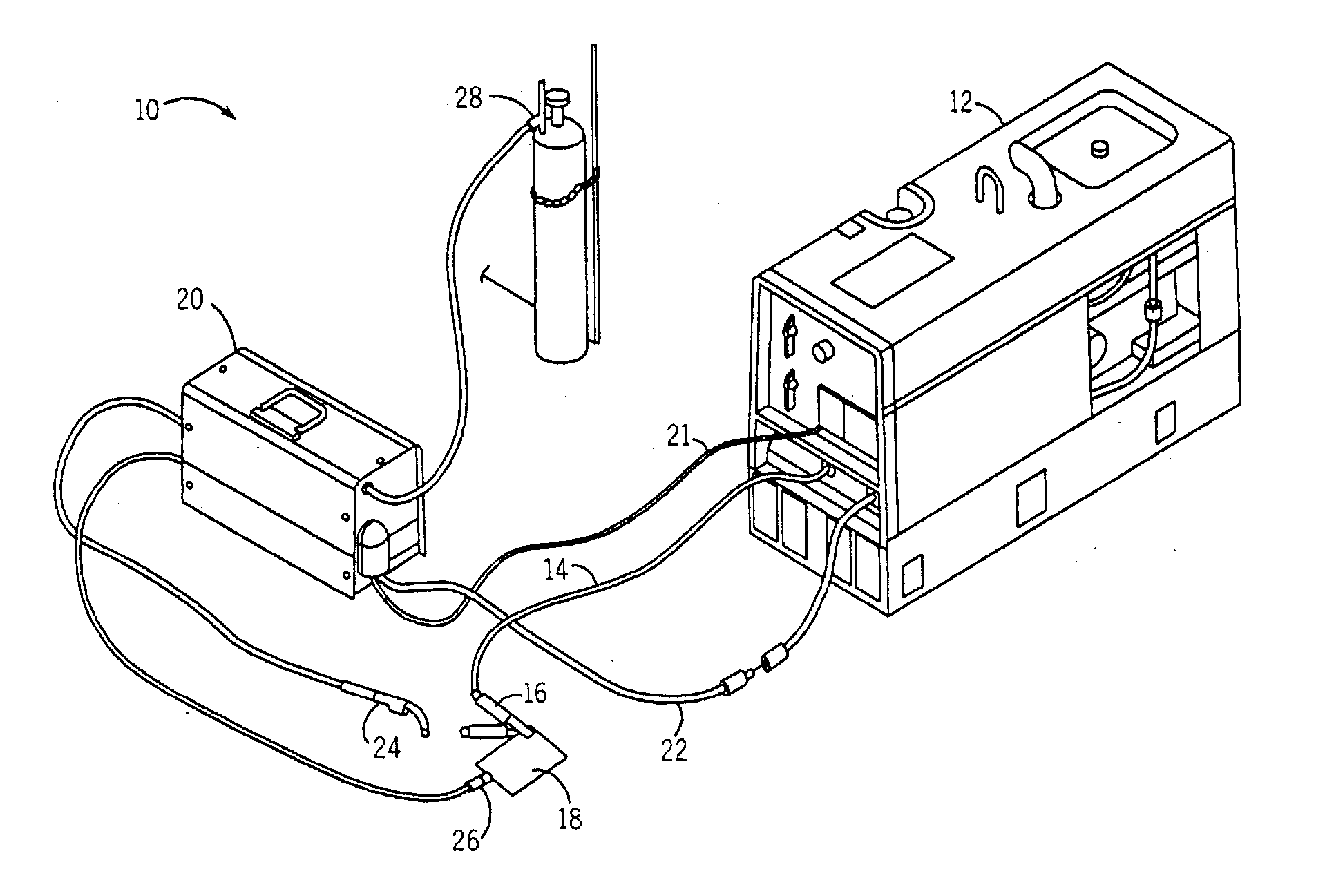

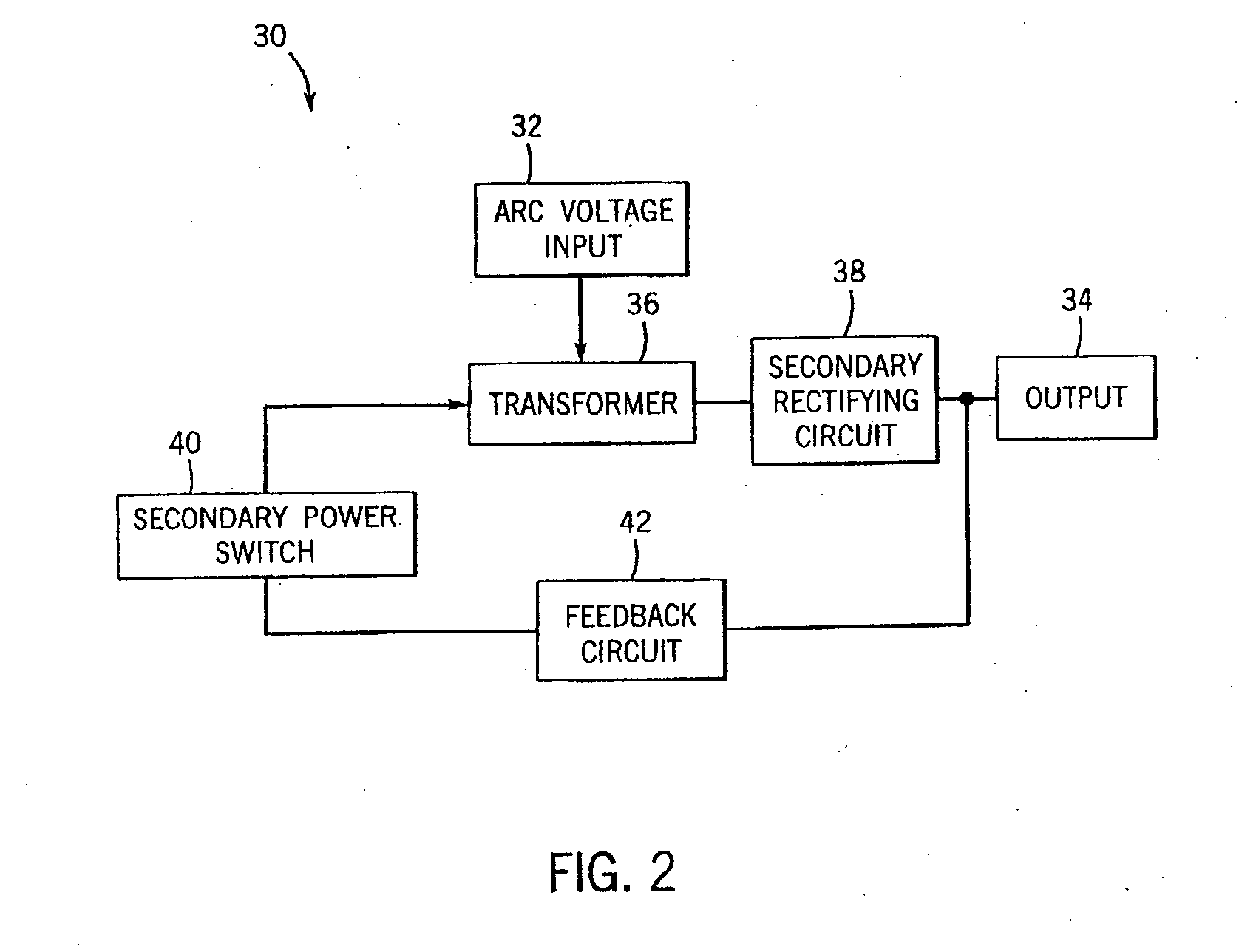

Wire feeder operable with lower minimum input voltage requirement

The present invention is directed to a power supply that maintains power supply to a plurality of electronic components of a welding system when an arc voltage falls below approximately 15 volts. The invention includes a power supply having a secondary supply circuit that improves the operable range of the power supply by maintaining power to components of a welding system when the arc voltage at a weld is greater than or equal to approximately 10 volts. As a result, the operable range of the power supply is no longer limited by the arc voltage. The invention includes a secondary power supply circuit having a power switch that when activated causes a buildup of energy in the transformer assembly whereupon deactivation of the power switch in the magnetic core is exhausted such that power supply is maintained. The power switch regulates the transformer assembly such that sufficient secondary power is provided if the input voltage to the transformer is as low as approximately 10 volts.

Owner:ILLINOIS TOOL WORKS INC

Method for detecting stability of gas tungsten arc welding (GTAW) additive manufacturing process based on arc voltage feedback

InactiveCN106363275AImprove stabilityLess susceptible to interferenceArc welding apparatusData acquisitionEngineering

The invention provides a method for detecting the stability of the gas tungsten arc welding (GTAW) additive manufacturing process based on arc voltage feedback. The method comprises the steps that the stability of the process is reflected through the arc length, the arc length is indirectly fed back though arc voltage, and the initial position of a GTAW gun on a substrate is adjusted; in the forming process of a first layer, a voltage sensor is matched with a data acquisition card to obtain a variation signal of the arc voltage along a forming path; the arc voltage is converted into the arc length according to a calibration relationship, a variation signal of the arc length along a forming path is obtained, and a second layer, a third layer until the n layer are formed, so that a variation signal of the n layer arc length along a forming path is obtained; and if the arc length is within a certain range, it is judged that the forming process is stable. According to the method for detecting the stability of the GTAW additive manufacturing process based on arc voltage feedback, the purpose of real-time detection of the stability of the GTAW additive manufacturing process is effectively achieved, and the detection process is easy to operate, high in stability, not prone to being interfered by intense arc light, high in calculation speed, capable of achieving automation easily and suitable for engineering application of real-time site detection.

Owner:SOUTHWEST JIAOTONG UNIV

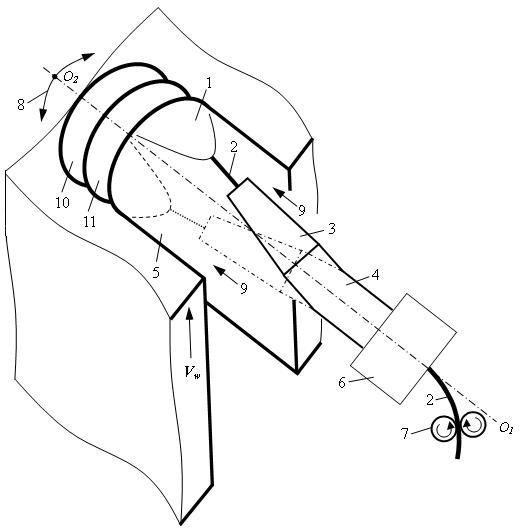

Shaking arc narrow gap melting electrode gas shielded vertical welding method

The invention discloses a rocking-arc narrow-gap vertical gas metal arc welding method comprising the following steps of: assembling metal-piece thick plates into an I-shaped vertical groove to be welded having a gap within a range of 12-15 mm; according to the gap of the groove to be welded and the difference of weld joint passes, firstly selecting a gas protection way, setting an arc rocking frequency, an arc rocking amplitude, arc side wall retention time, an average arc current of pulse welding, an average arc voltage, a welding speed and the dry extension of a welding wire, and selectinga slightly bent conductive rod with an appropriate bending angle; moving a welding torch integrally upwards or downwards in the vertical direction at the welding speed, thereby realizing vertical andautomatic rocking-arc narrow-gap gas metal arc welding in such a manner of single-pass multi-layer welding per layer in a state where a weld joint is freely formed. The method of the invention does not need to form a large welding groove and does not require a forced forming device; besides, the welding device is simple, the welding efficiency is high, the weld joint is formed beautifully, and the performance of the welded joint is good.

Owner:JIANGSU UNIV OF SCI & TECH

Method for arc welding with melting electrode

InactiveUS6313437B1Satisfactory fillingReduce heatArc welding apparatusWelding power supplyEngineering

The present invention relates to a method of controlling a welding power source and the associated wire feed arrangement intended for arc welding operations that employ a consumable electrode, to ensure crater filling at the end of the welding operation by means of fading of the arc voltage and of the wire feed rate, respectively. More particularly the invention relates to a method comprising arc voltage reduction at the onset of the end of the welding operation for a period that is considerably briefer than the total fading time, during which the arc voltage is reduced to a value below the value at which it is possible to weld during continuous welding and advancement in the joint with otherwise unchanged welding parameters, followed by a further reduction to a final value of arc voltage and fading of the wire feed rate simultaneously with the arc voltage fading to a final value of the wire feed rate.

Owner:ESAB AB

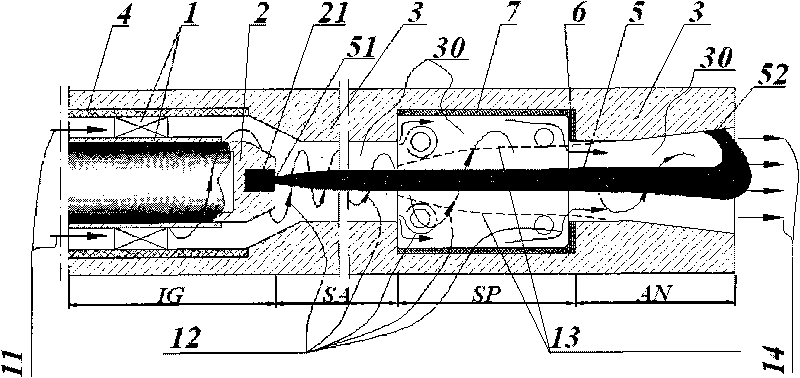

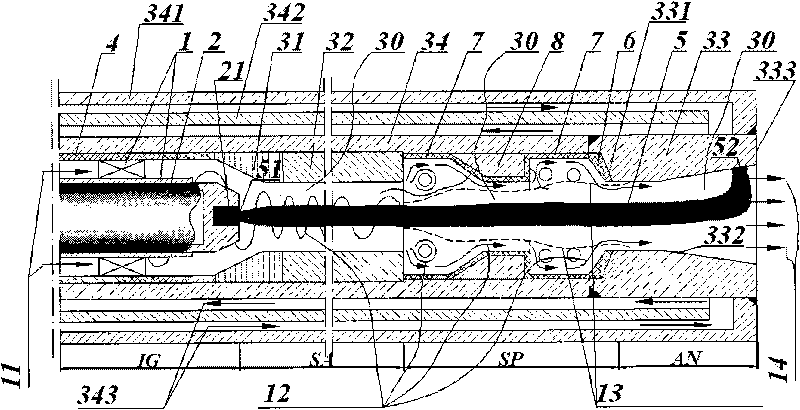

Anode for non-transferred arc plasma torch and plasma torch

The invention relates to an anode for an arc plasma torch and a non-transferred arc plasma torch with the anode. The anode comprises a stable arc section and an anode nozzle section which have evenly varied diameters, a burble section which is connected with the two sections and is provided with a groove with increasing diameter, wherein an insulating material is filled in the burble section. The plasma torch comprises a swirler, a cathode, the anode and a cathode-anode isolation sleeve which are arranged coaxially. Working gas flows into the stable arc section by rotation of the swirler, and restricts arc in an axle center position stably; the burble section ensures that air flow generates high frequency turbulence to drive an arc stream to swing in high frequency randomly and constantly impacts the inlet side of the anode nozzle; and the anode arc root moves quickly under the action of high speed air flow. The non-transferred arc plasma torch can obviously improve the arc voltage, the jump frequency and the moving speed of the anode arc root, reduces heat consumption, has the characteristics of high power, low electrode loss rate, high heat conversion efficiency, wide operation parameter range, small arc voltage fluctuation and the like, and is particularly suitable for gas heating.

Owner:UNIV OF SCI & TECH OF CHINA +1

Coupling double line down distance measuring method using six-phase system new phase mode transformation

ActiveCN101252275ASmall time windowHigh precisionEmergency protective circuit arrangementsFault locationFiltrationElectric power system

Disclosed is a fault distance measurement method for a coupled double loop line through mode transformation of a six-phase system, belonging to the technical field of relay protection for an electric power system. In the method, a mode transformation matrix suitable for the loop lines is deduced from the fact that a single module is capable of reflecting the new mode transformation matrix of a common three-phase system according to the relationship between the impedance matrix of the common three-phrase system and the impedance matrix of the system of the double loop lines within the same tower. The invention provides a time domain fault locating method for double loop line based on new mode transformation. The method fabricates the criterion for distance measurement by making use of the transfer characteristics of the arc voltage and current under certain module. The method is characterized in that the measurement is carried out in time domain, the needed time window is short and the method avoids wave filtration; with the method of least square, the distance measurement precision is improved and the distance measurement precision is free from the influences from transition resistance, fault type and impedance change of the opposite system. A large number of electromagnetic transient simulation results show that the method is highly precise.

Owner:KUNMING UNIV OF SCI & TECH

Same tower double back transmission line fault distance measuring time domain method using single end current flow

InactiveCN101252274AReliable methodOvercoming the Effects of ImpedanceEmergency protective circuit arrangementsFault locationFiltrationElectric power system

Disclosed is a fault distance time domain detection method based on magnitude of single end current for a double power transmission lines within the same tower, belonging to the technical field of relay protection for electric power system. In the method, the coupled double transmission lines are decoupled into a same directional component and an reverse directional component, and the voltage and the current at the fault point are worked out according to the voltages at the two ends of the reverse directional component, and the fault distance measurement can be realized according to the transfer characteristics of the arc voltage current. Making the best use of the characteristics of a reverse network, the method measures the distance based on that the reverse network are irrelative to the impedance of the system, and only uses time domain single end current to measure the fault distance; the method is simple and overcomes the influence from the impedance of the reverse system in the past. Since the time domain method is dispensed with wave filtration, the required data window in small. A large number of numeral simulation results show that the method is effective and reliable.

Owner:KUNMING UNIV OF SCI & TECH

Wire feeder operable with lower mininum input voltage requirement

The present invention is directed to a power supply that maintains power supply to a plurality of electronic components of a welding system when an arc voltage falls below approximately 15 volts. The invention includes a power supply having a secondary supply circuit that improves the operable range of the power supply by maintaining power to components of a welding system when the arc voltage at a weld is greater than or equal to approximately 10 volts. As a result, the operable range of the power supply is no longer limited by the arc voltage. The invention includes a secondary power supply circuit having a power switch that when activated causes a buildup of energy in the transformer assembly whereupon deactivation of the power switch in the magnetic core is exhausted such that power supply is maintained. The power switch regulates the transformer assembly such that sufficient secondary power is provided if the input voltage to the transformer is as low as approximately 10 volts.

Owner:ILLINOIS TOOL WORKS INC

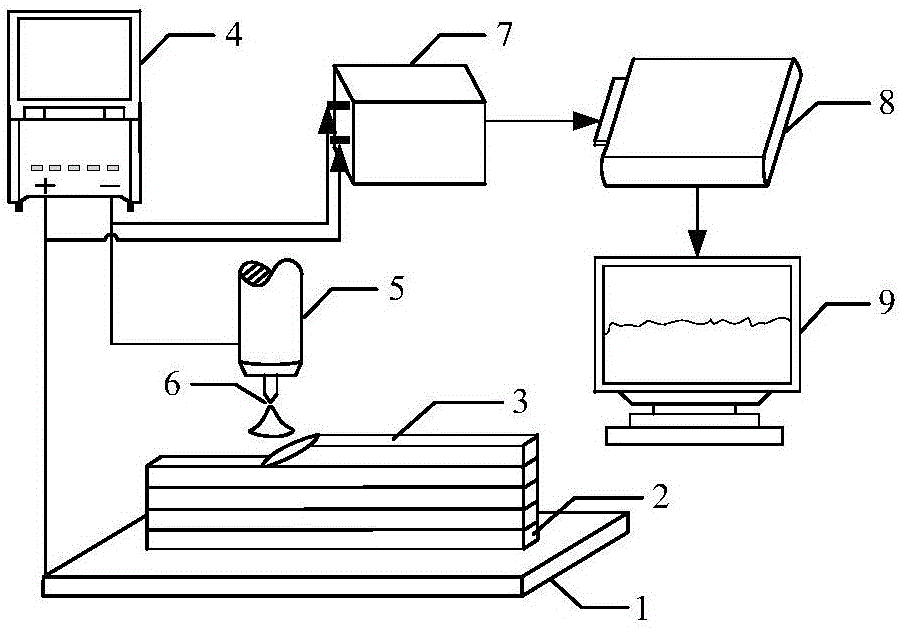

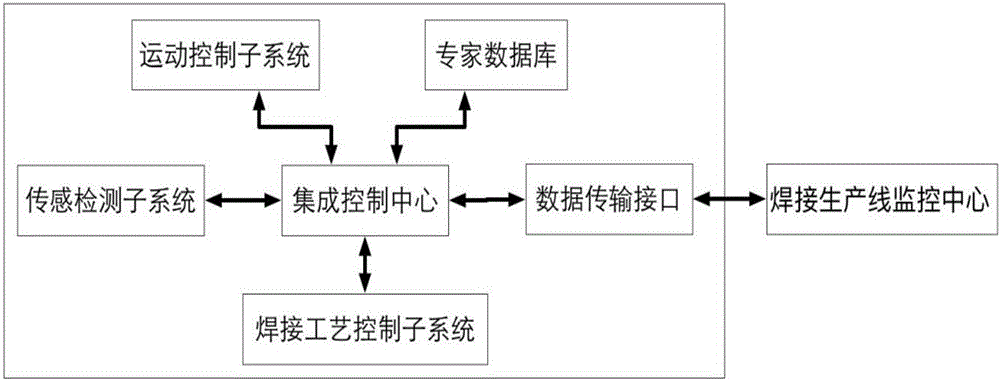

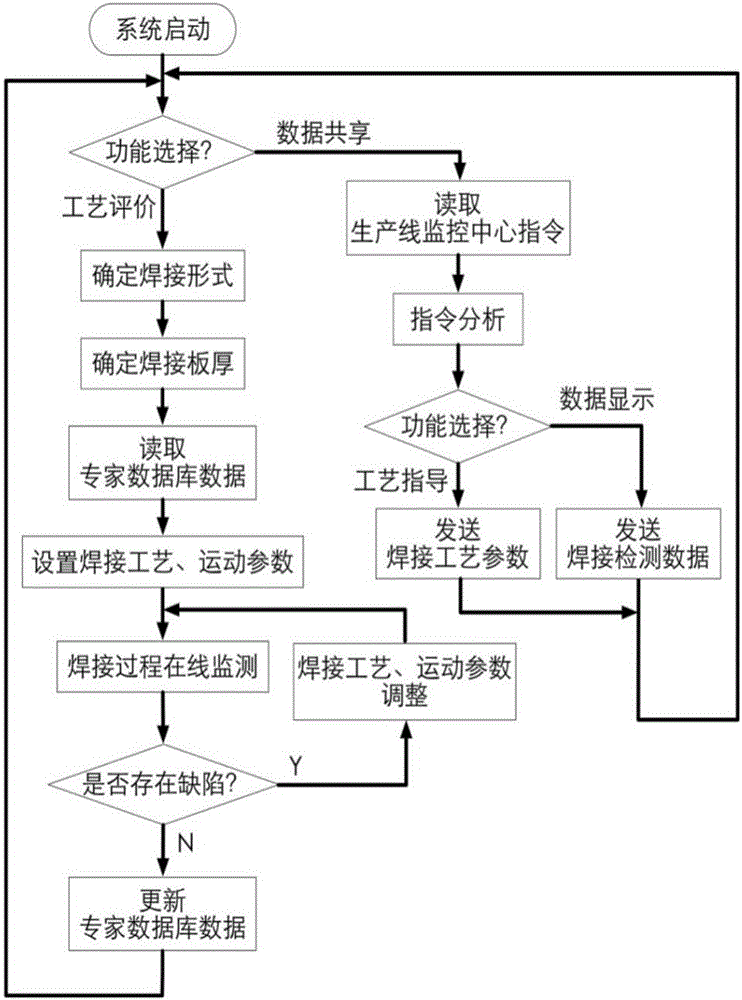

On-line monitoring system and method for weld pool dynamic process

ActiveCN105855743ARealize optimal adjustmentImplement automatic trackingWelding apparatusData informationWeld seam

The invention discloses an on-line monitoring system and method for a weld pool dynamic process. The on-line monitoring system for the weld pool dynamic process comprises an integrated control center, a sensing detection subsystem, a motion control subsystem, an expert database, a welding process control subsystem and a data transmission interface. The integrated control center is used for receiving data information, sending motion control instructions, welding process control instructions and data and reading instructions. The sensing detection subsystem is used for acquiring weld pool image information, process information, acoustical signals and temperature. The motion control subsystem is used for accomplishing weld seam tracking, welding gun height adjustment and speed control. The expert database is used for storing welding process control parameters, motion control parameters and sensing detection information. The welding process control subsystem is used for achieving control on welding current, arc voltage and speed. The data transmission interface is used for achieving data communication. The on-line monitoring method adopts the monitoring system to carry out on-line monitoring. The on-line monitoring system and the on-line monitoring method for the weld pool dynamic process have the advantages of being high in reliability, highly integrated in function and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Boron-containing dopant compositions, systems and methods of use thereof for improving ion beam current and performance during boron ion implantation

ActiveUS20150248992A1Quality improvementExtended source lifeHydrogenOther chemical processesIon implantationHydrogen ion

A novel composition, system and method thereof for improving beam current during boron ion implantation are provided. The boron ion implant process involves utilizing B2H6, BF3 and H2 at specific ranges of concentrations. The B2H6 is selected to have an ionization cross-section higher than that of the BF3 at an operating arc voltage of an ion source utilized during generation and implantation of active hydrogen ions species. The hydrogen allows higher levels of B2H6 to be introduced into the BF3 without reduction in F ion scavenging. The active boron ions produce an improved beam current characterized by maintaining or increasing the beam current level without incurring degradation of the ion source when compared to a beam current generated from conventional boron precursor materials.

Owner:PRAXAIR TECH INC

Monitor for electric arc welding machine

A monitor for an electric arc welder as the welder performs a selected arc welding process by creating actual welding parameters, such as arc current and arc voltage, between an advancing welding wire and a workpiece, where the process involves an arc and is defined by a series of rapidly repeating wave shapes constituting a weld cycle with a cycle time, the wave shapes are each segmented into time states having command signals corresponding to the actual parameters and a time duration. The monitor selects a specific wave shape state, reads one of the actual parameters, compares the actual read parameter with a function of the command signal corresponding to the actual parameter, and uses the comparison to generate a characteristic of the welding process during the selected state. <IMAGE>

Owner:LINCOLN GLOBAL INC

Three-dimensional weld seam tracking system and method based on visual and arc-pressure sensing

ActiveCN108637435AAvoid interferenceReduce sizeImage enhancementImage analysisImage transferSimulation

The invention discloses a three-dimensional weld seam tracking system and method based on visual and arc-pressure sensing. The system comprises an image acquisition and processing module, an arc pressure sensing module and a robot control module; and the image acquisition module is used for shooting an arc, a molten pool and a weld image in the welding process, the image is transmitted to an industrial personal computer, and the industrial personal computer calculates and obtains a welding deviation through an image processing algorithm. The arc pressure sensing module is used for collecting arc voltage values in the welding process and transmitting the arc-pressure value to the industrial personal computer, the industrial personal computer keeps the stability of the arc length in the welding process according to the arc-pressure-arc length relation, and the effect of height direction control is achieved. The robot control module is used for robot movement deviation correction and welding gun posture control.

Owner:GUANGDONG FUWEIDE WELDING

Multiple-cathode central-axis anode arc plasma generator

Provided is a multiple-cathode central-axis anode arc plasma generator. The multiple-cathode central-axis anode arc plasma generator is of a central-axis column anode structure, three or more than three cathodes are annularly and evenly arranged around an anode column, the anode and the cathodes are mounted and fixed on the same base and are mutually insulated, the base is provided with a water channel, an electricity channel and a gas channel, the outer surface of the column anode is relatively insulated, only a head portion close to an outlet is bared and conductive, thus an electric field is formed between the anode and the cathodes, the whole generator is in the shape of a sealed water-cooled barrel, one end of the generator is provided with a plasma outlet (nozzle), and the nozzle is used for carrying out mechanical compression on arc plasmas. The arc plasmas generated by the plasma generator are stable and concentrated, plasma arcs with the properties of high arc voltage, low current, laminar flow and long beam can be generated, the service life of the anode and the service life of the cathodes are long, the total power of the system is large, and working efficiency is stable and high.

Owner:CHENGDU PLASMAJET SCI & TECH

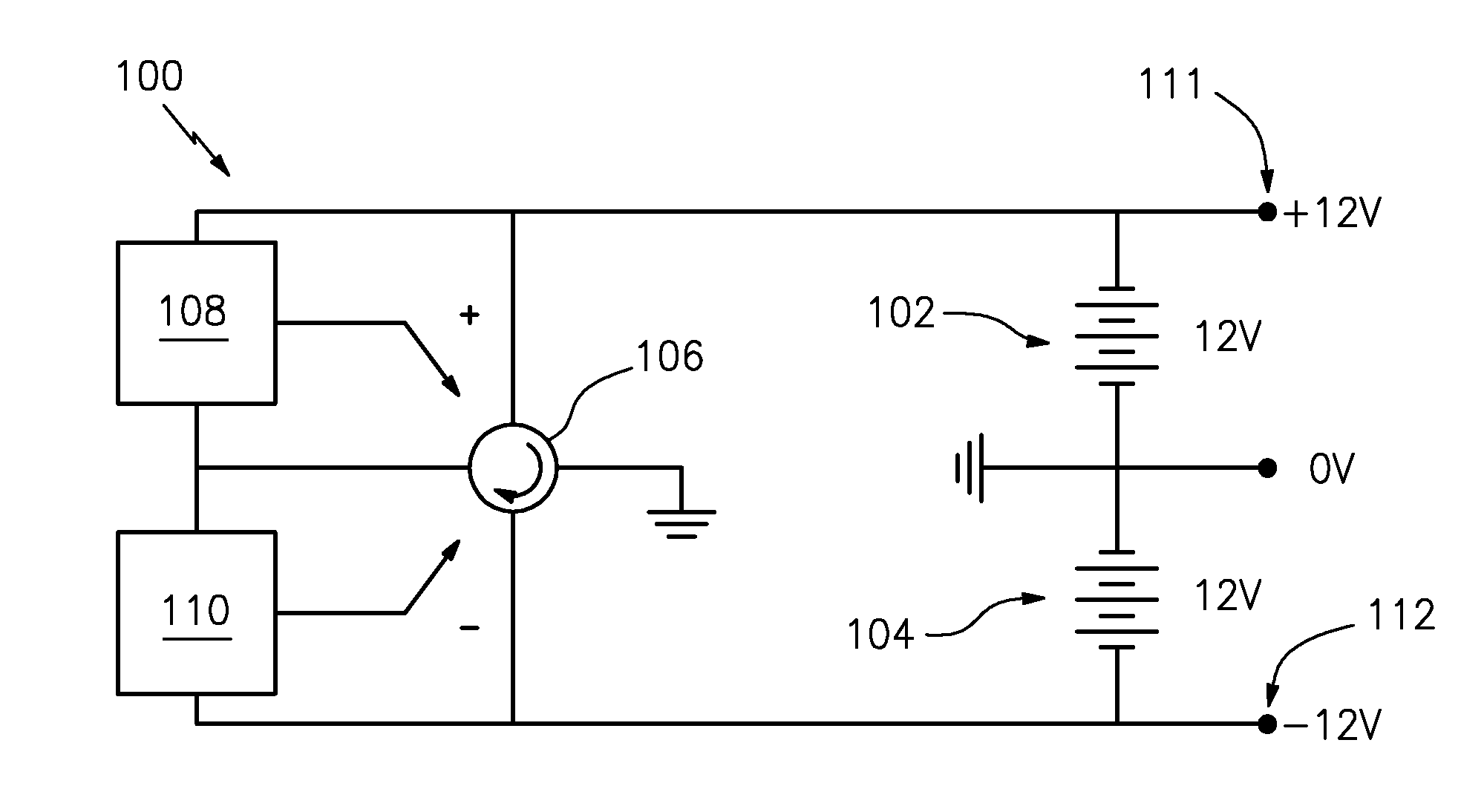

Automotive bipolar electrical system

InactiveUS20120200242A1Mass productionBatteries circuit arrangementsElectric devicesAlternatorElectrical battery

Applicant has disclosed a method and apparatus for a bipolar automotive electrical system. In the preferred “apparatus” embodiment, Applicant's bipolar electrical system comprises: two (e.g., 12 V) batteries of equal, but opposite voltage (e.g., +12 V, −12 V), with bipolar outputs; an alternator, responsive to the batteries, which controls electrical charge to the batteries individually; an automotive DC motor connected by a single lead wire to the bipolar outputs from the batteries; and, wherein the reversible motor is run off the bipolar output without the need for any intervening devices between the bipolar command outputs and the motors. Alternatively, the alternator can inherently charge the batteries sequentially with the lowest voltage battery being addressed first. This approach allows heavy loads to be powered by 24 V or 48 V DC, yet the arc voltage to ground is still only 12 V or 24 V DC.

Owner:GRADY JOHN K

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com